Patents

Literature

2287 results about "Soldering process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Procedures for Soldering Soldering is a joining process wherein coalescence is produced by heating below 800°F, using a non-ferrous filler metal with a melting point below that of the base metal.

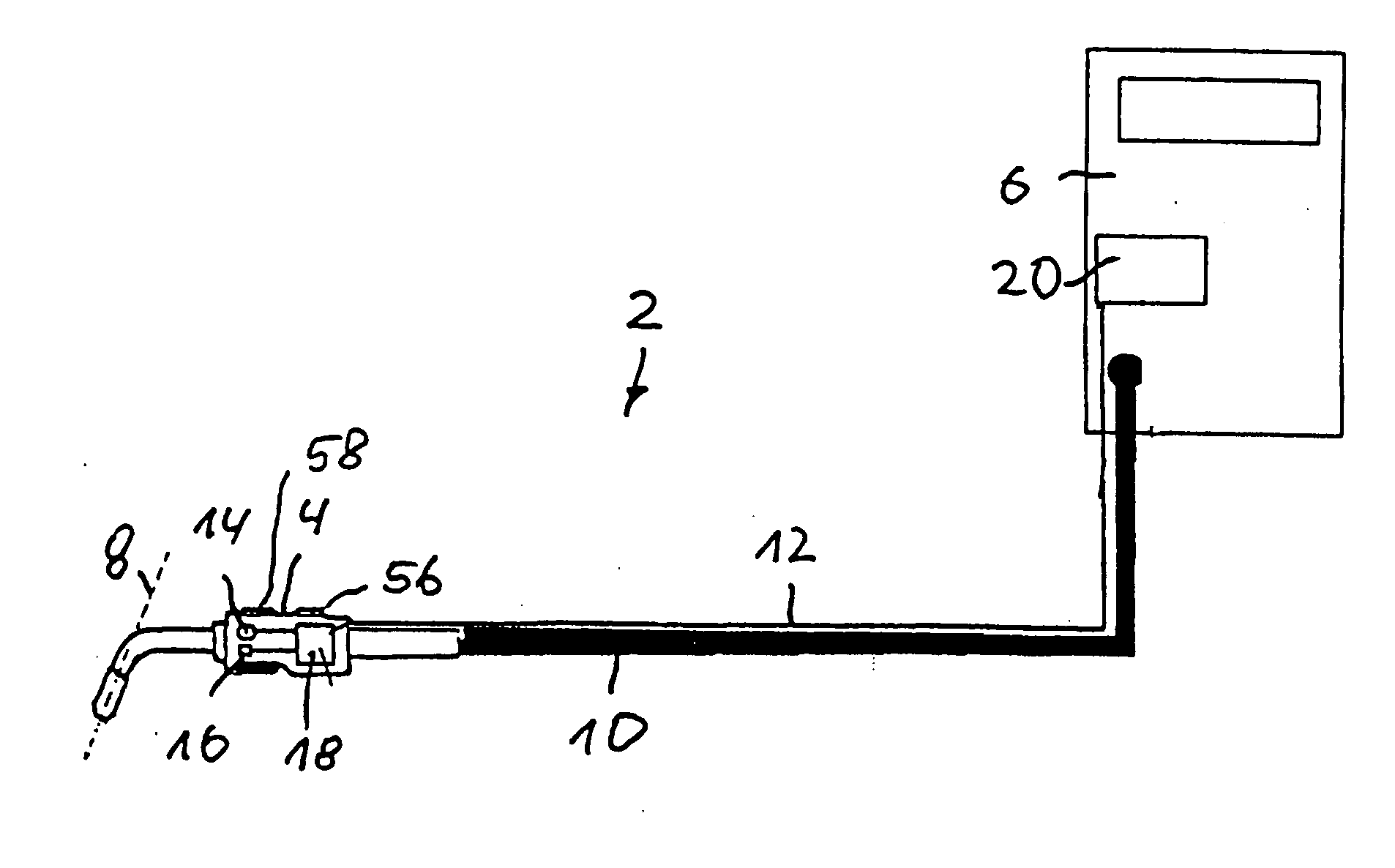

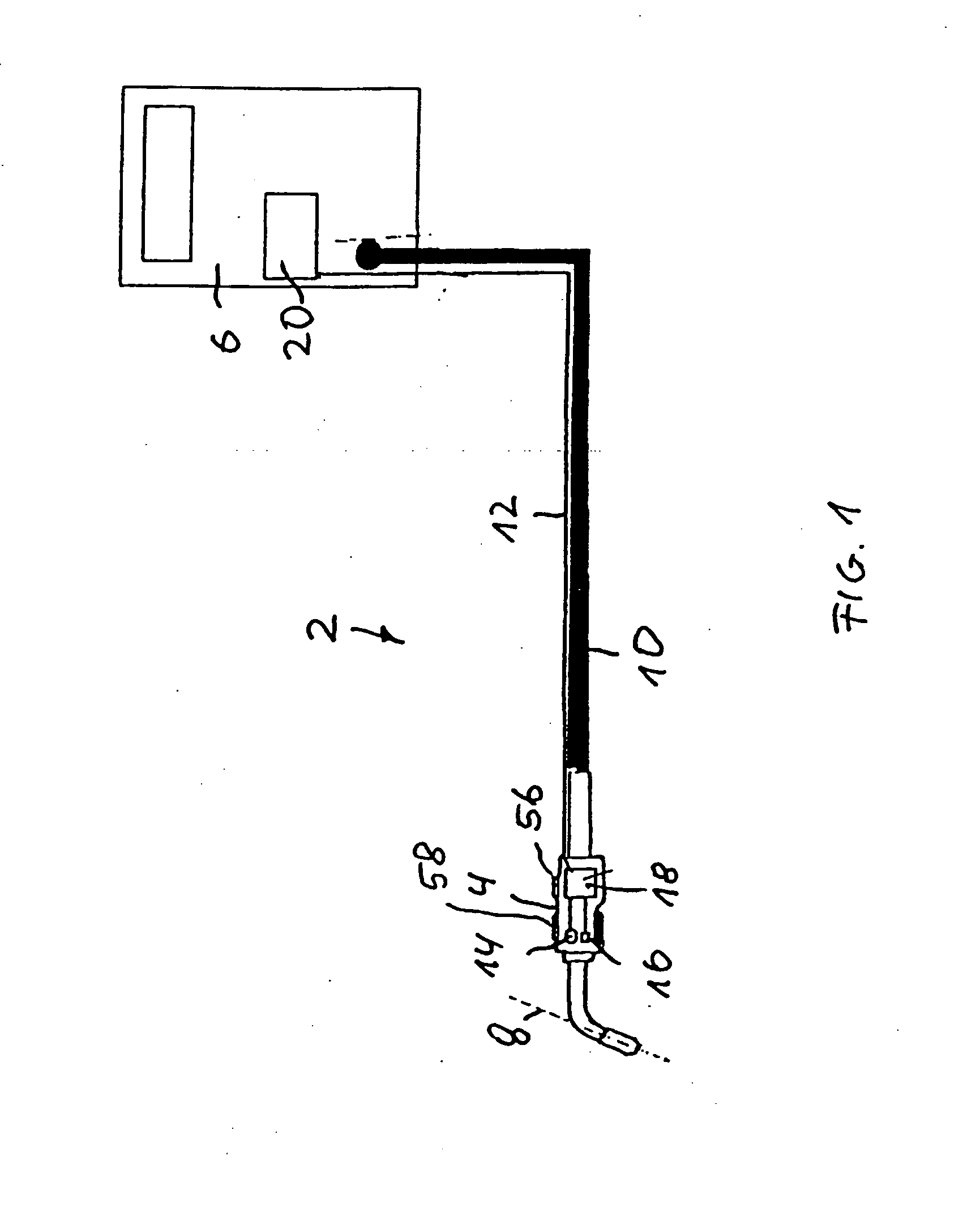

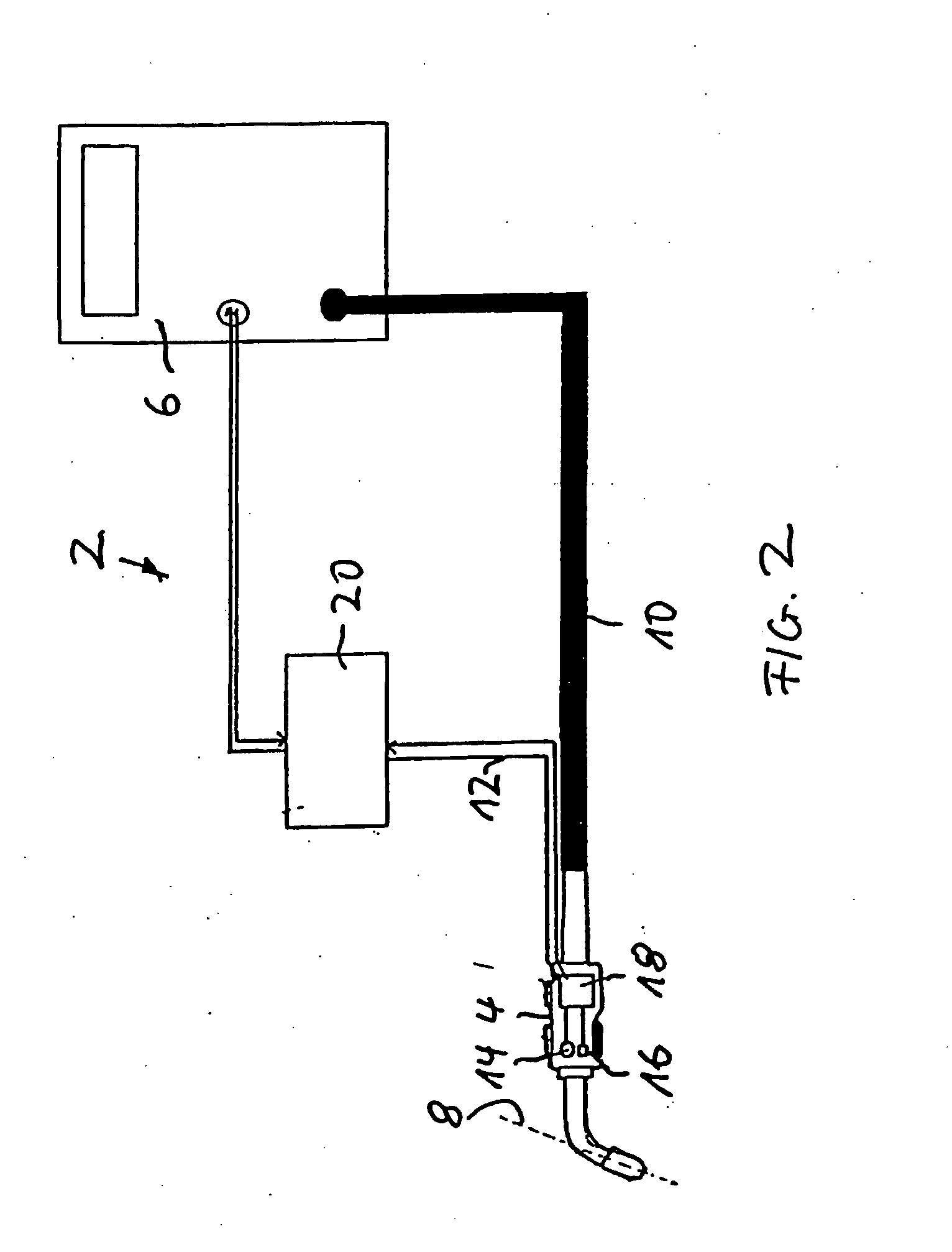

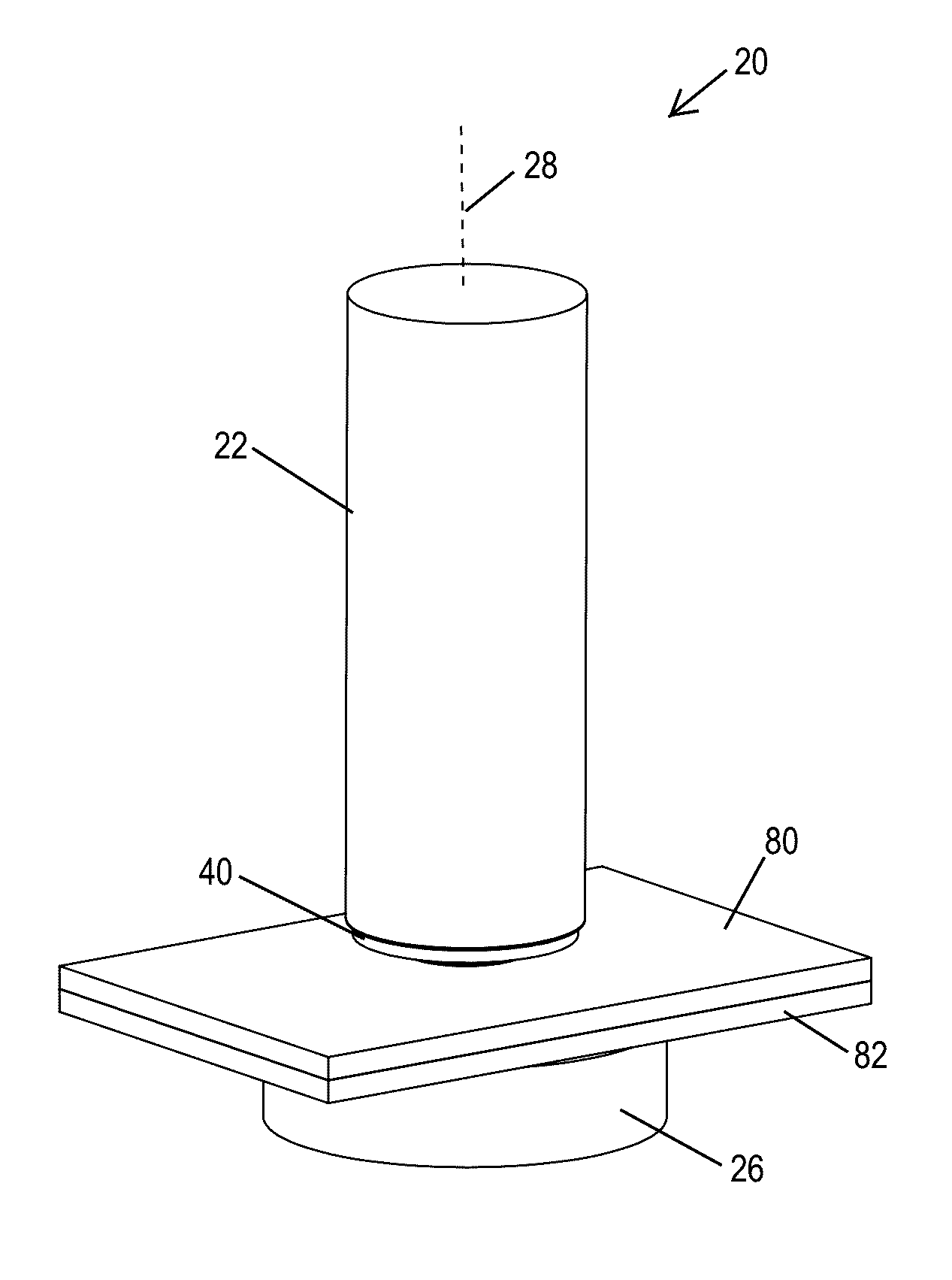

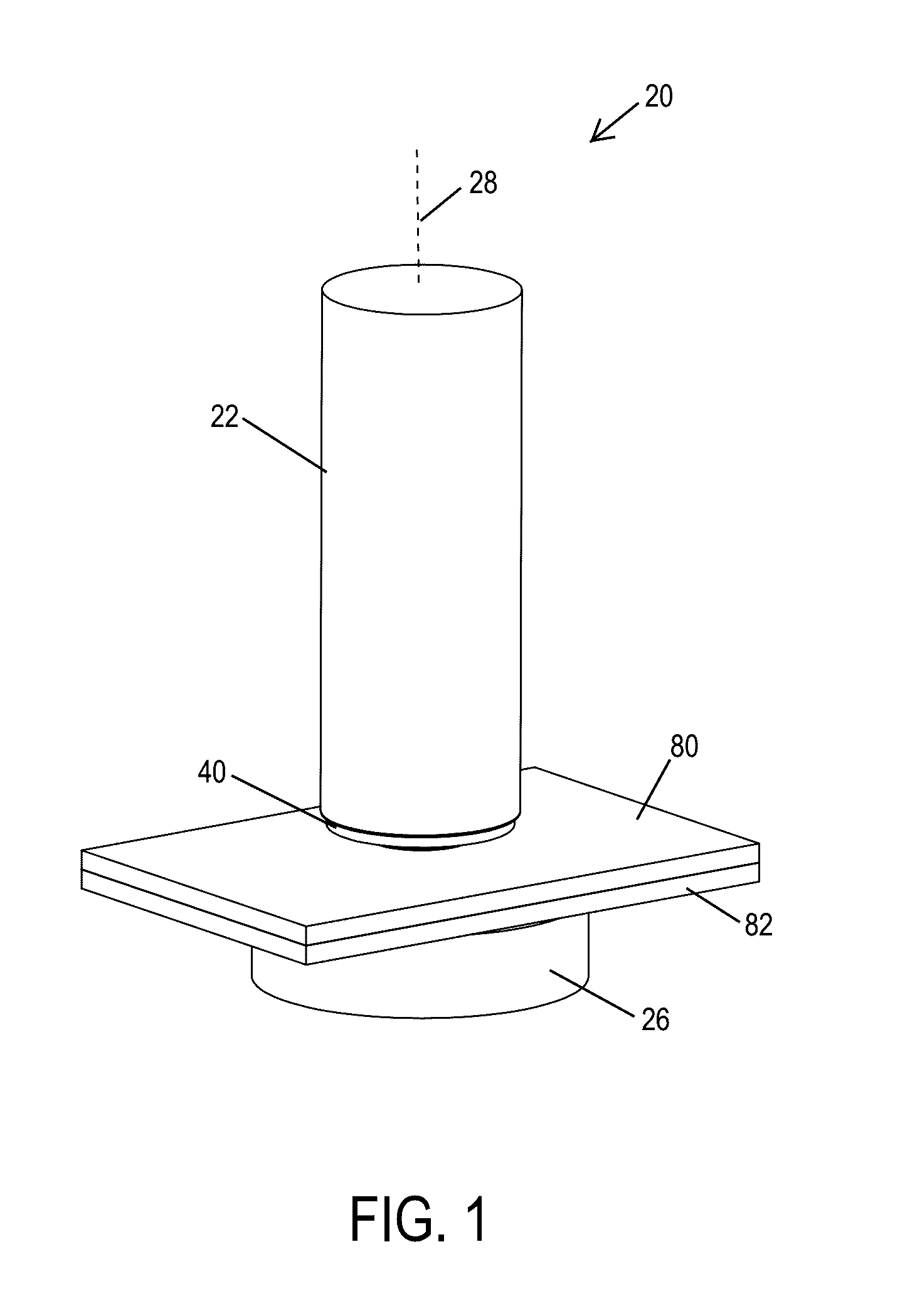

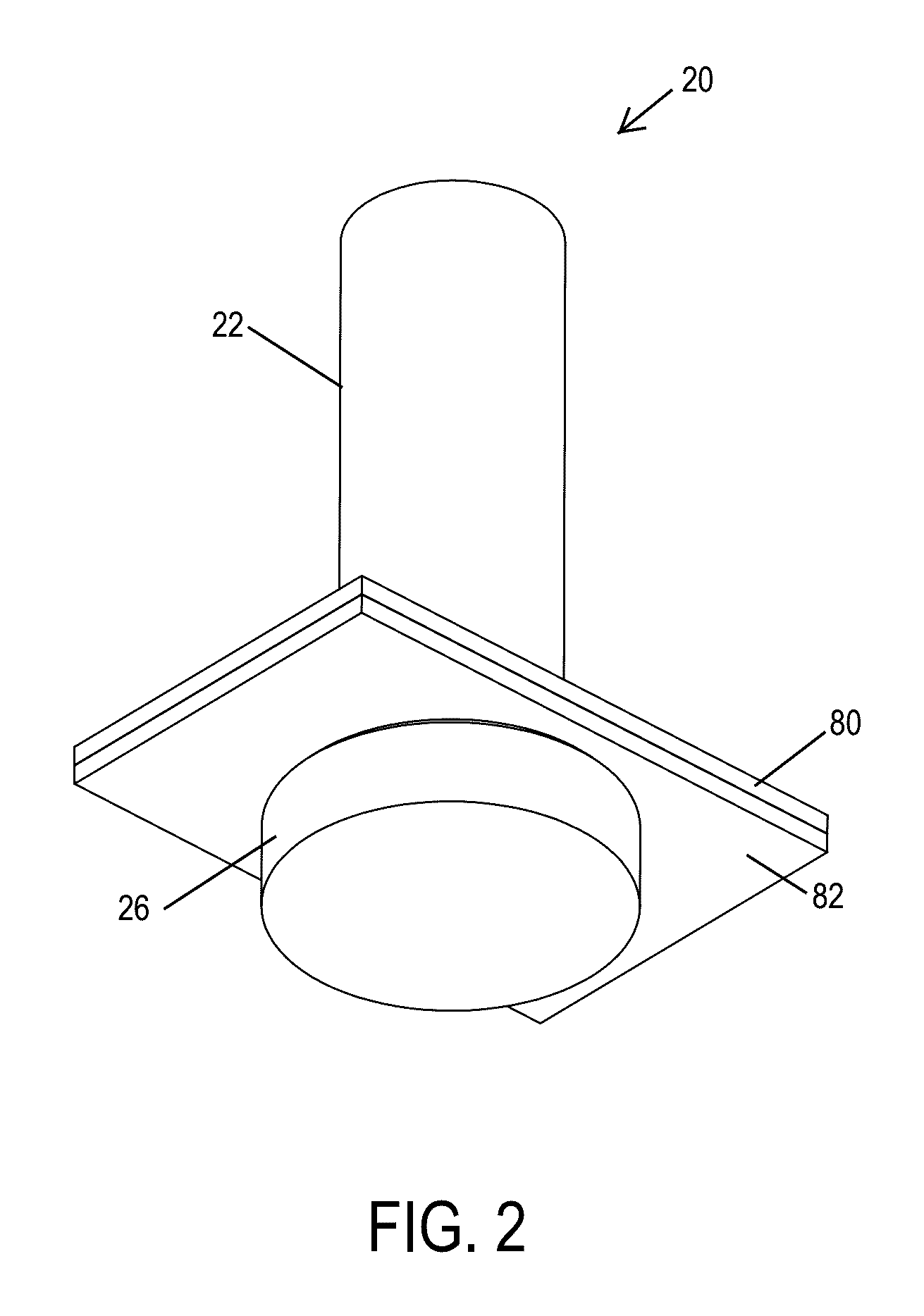

Device for carrying out a joint, separation, or suface treatment process, particularly a welding process

InactiveUS20070187378A1Easy and comfortable to operateImprove welding qualityWelding/cutting auxillary devicesArc welding apparatusEngineeringSoldering process

Owner:DRITTE PATENTPORTFOLIO BET GMBH & CO KG

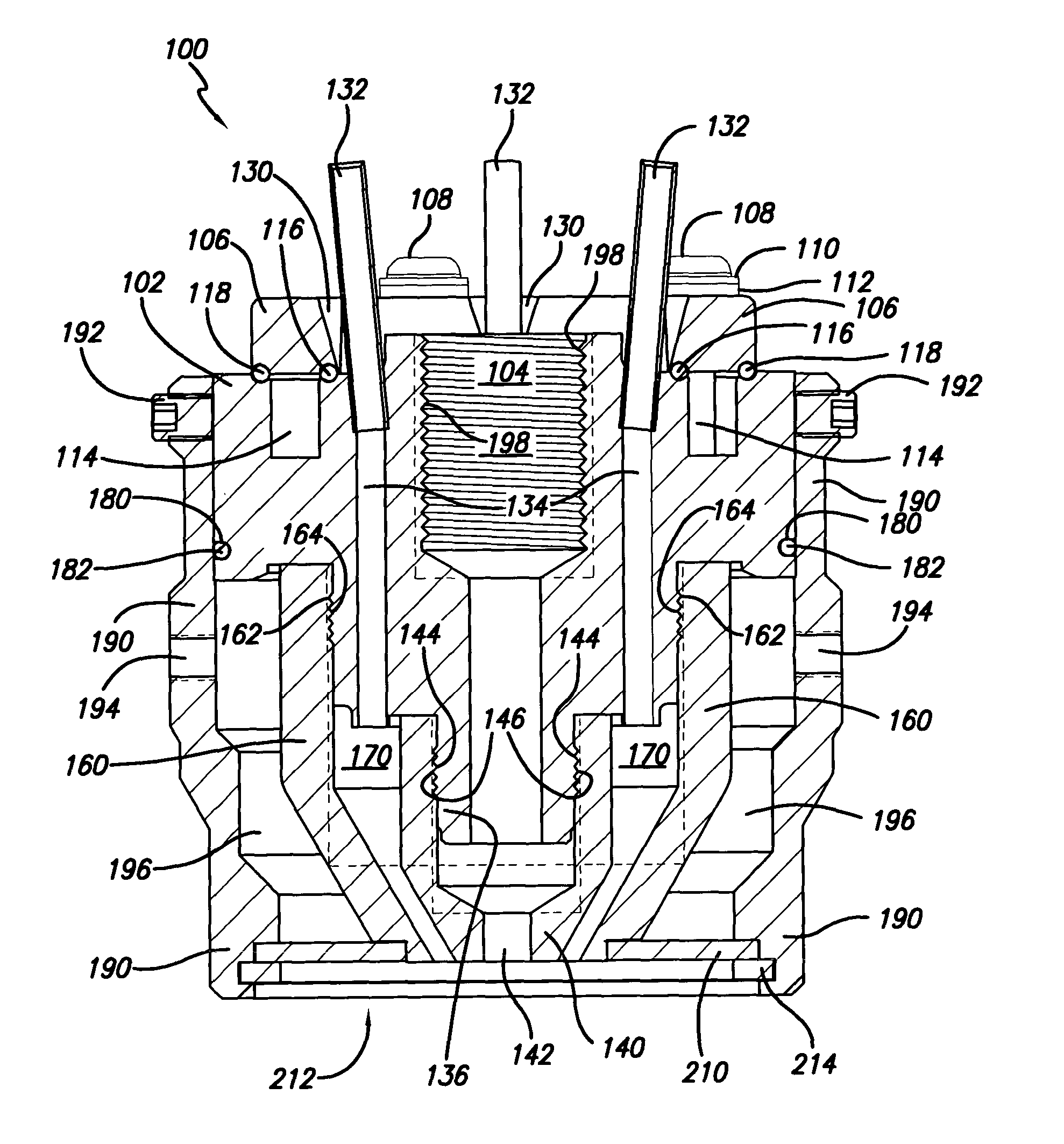

Coaxial nozzle design for laser cladding/welding process

InactiveUS20050056628A1Reliably-symmetric powder flowLong-term useLaser beam welding apparatusLaser NozzleShielding gas

A laser nozzle for use in a laser powder fusion (LPF) welding process provides longer service life and ease of maintenance. Eliminating the use of laser nozzle inserts, the laser nozzle uses an inner tip that is less subject to damage from the welding process. The laser beam travels down an open central passage to exit out the inner tip in focused alignment with a conical powder flow stream ending in a point generally coincident with the laser beam. The powder supply travels through a passage that is generally coaxial to the central laser passage. A circumscribing passage for inert shielding gas or the like is coincidentally coaxial with both the laser powder flow channel and the central laser channel. Coolant is circulated through a main body portion of the nozzle in order to keep the entire assembly cool. Both the laser and the flow of powder may be adjusted according to operating preferences. A porous shielding cover prevents ejecta and other materials from entering into the shielding gas flow channel. The entire assembly is easily constructed from readily available materials and is easily disassembled for cleaning. Reassembly is also easily achieved in order to enable rapid refurbishment and reconstitution of an optimal LPF welding nozzle.

Owner:HONEYWELL INT INC

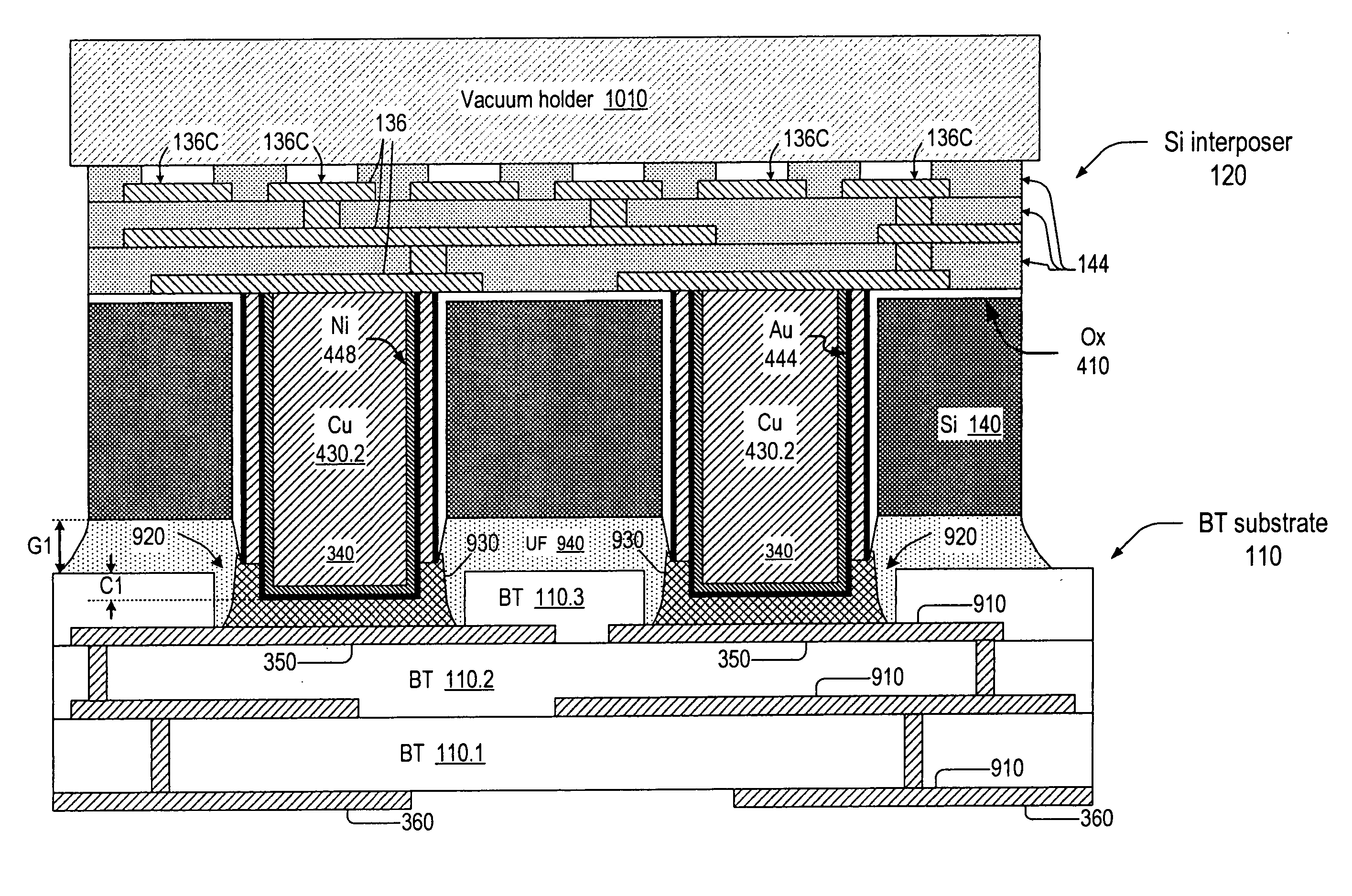

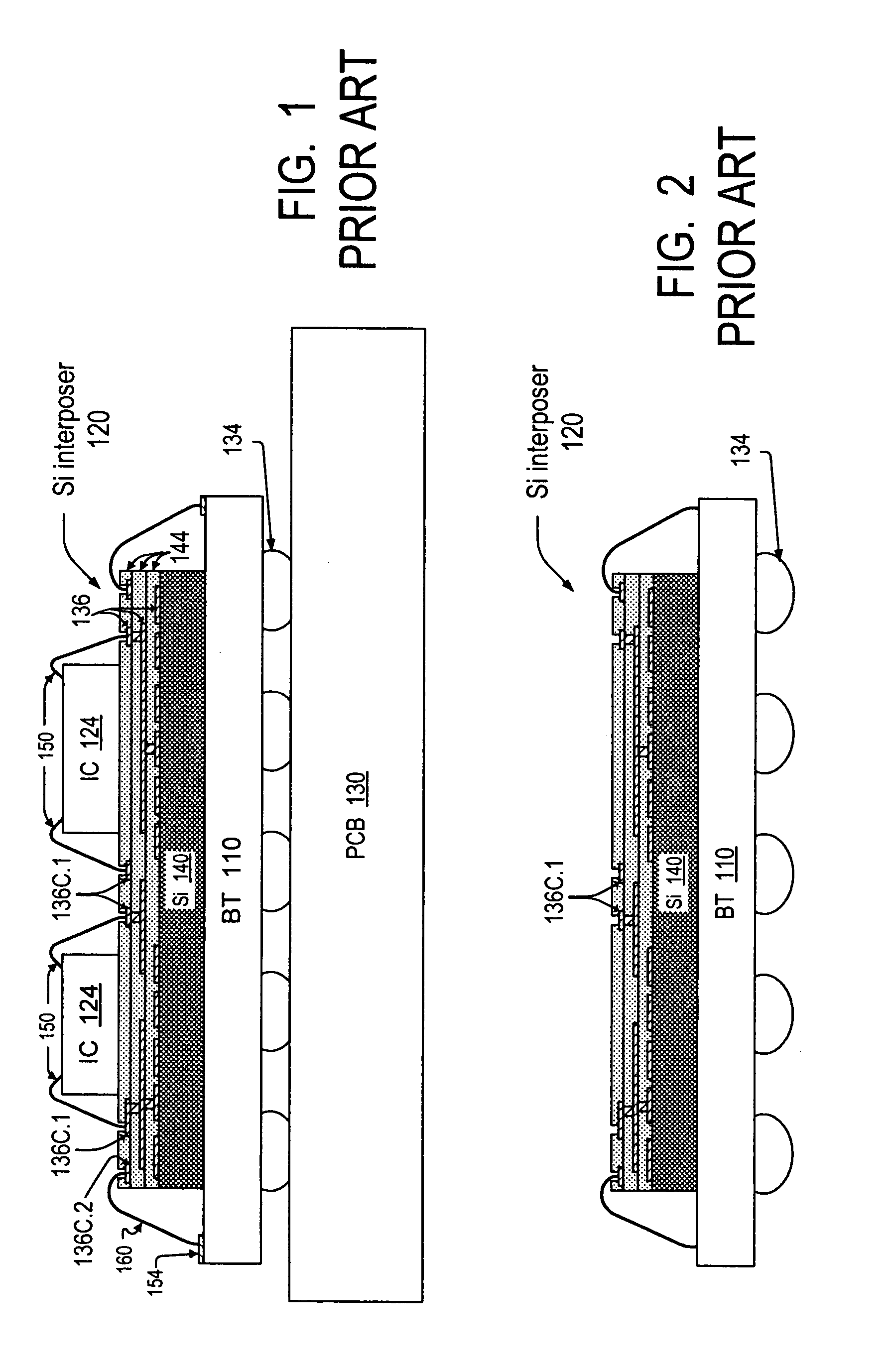

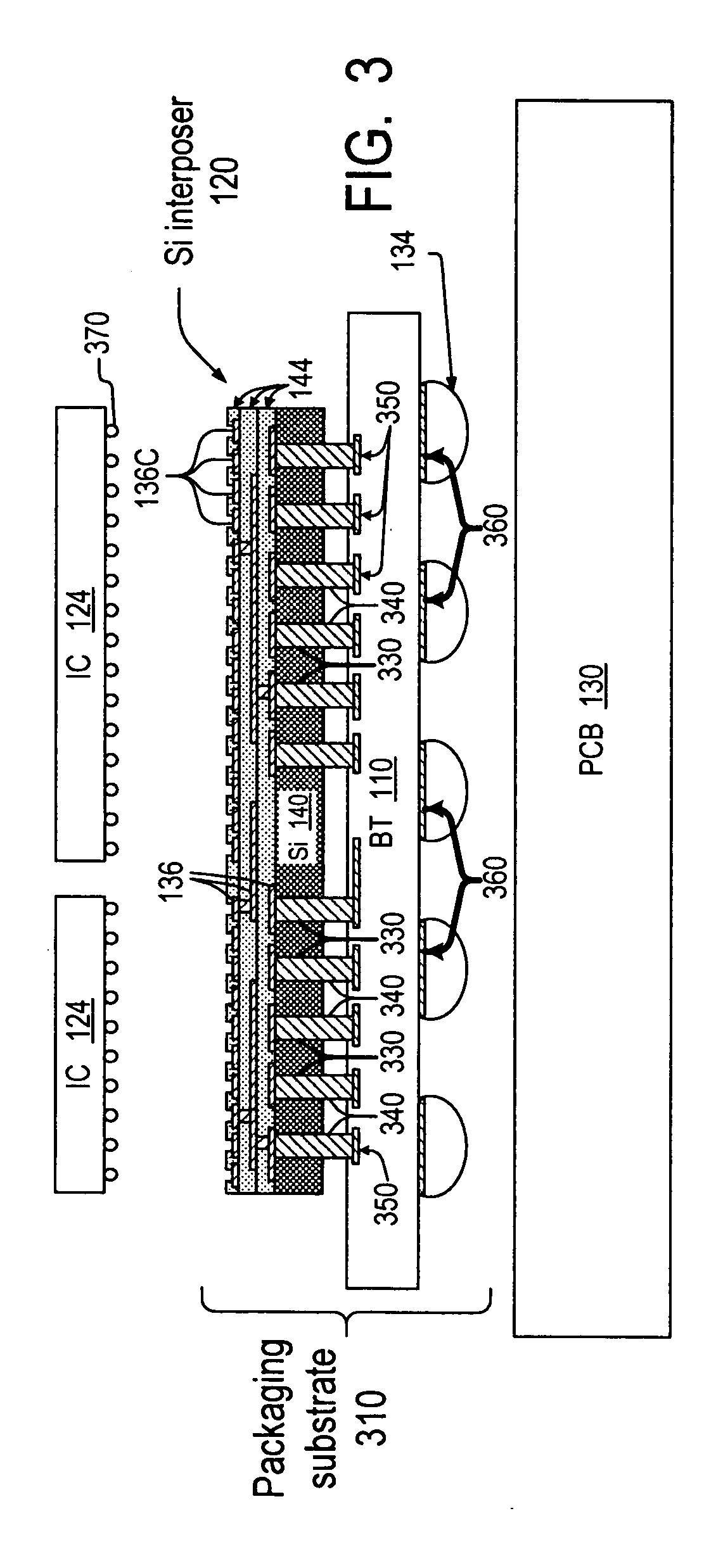

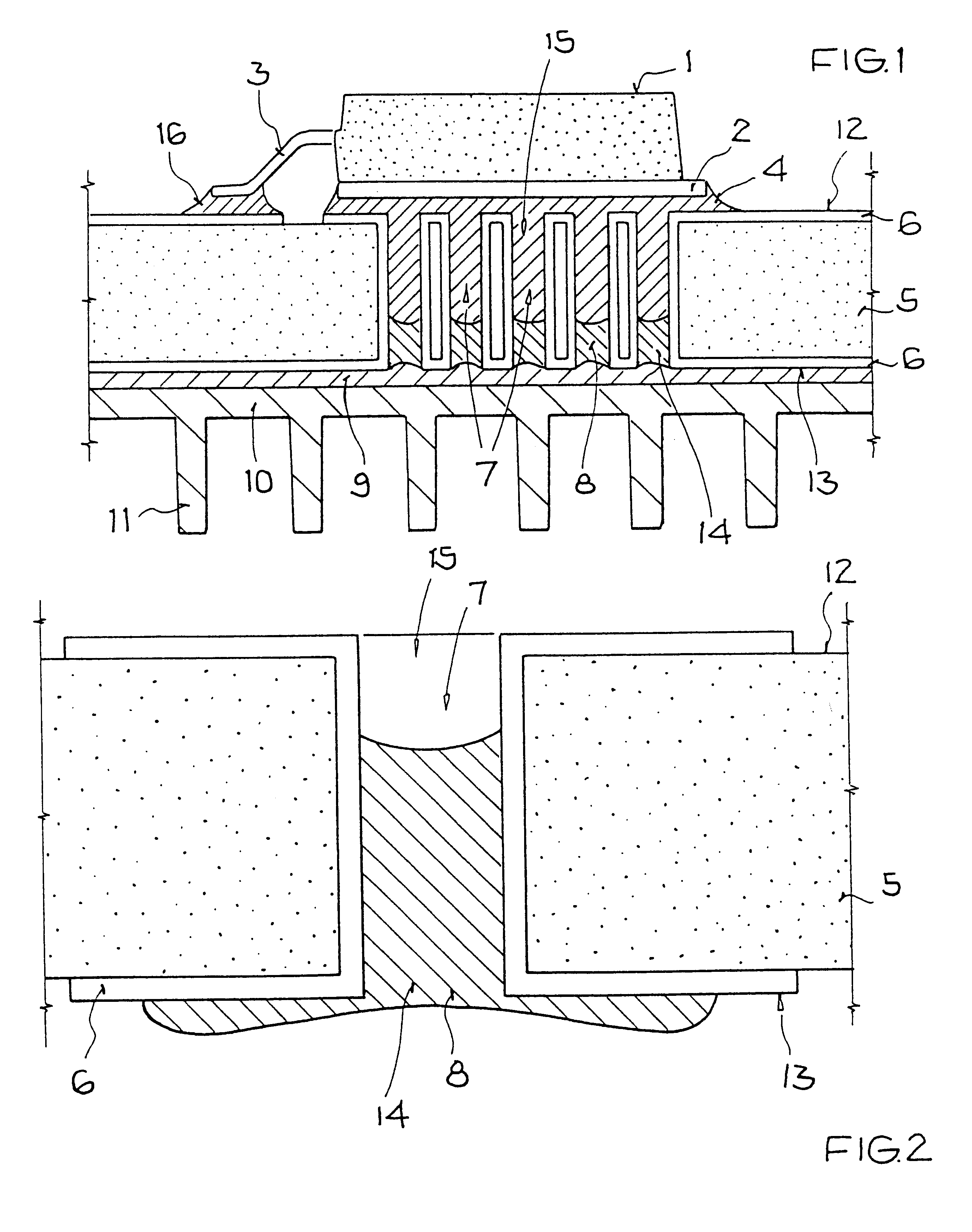

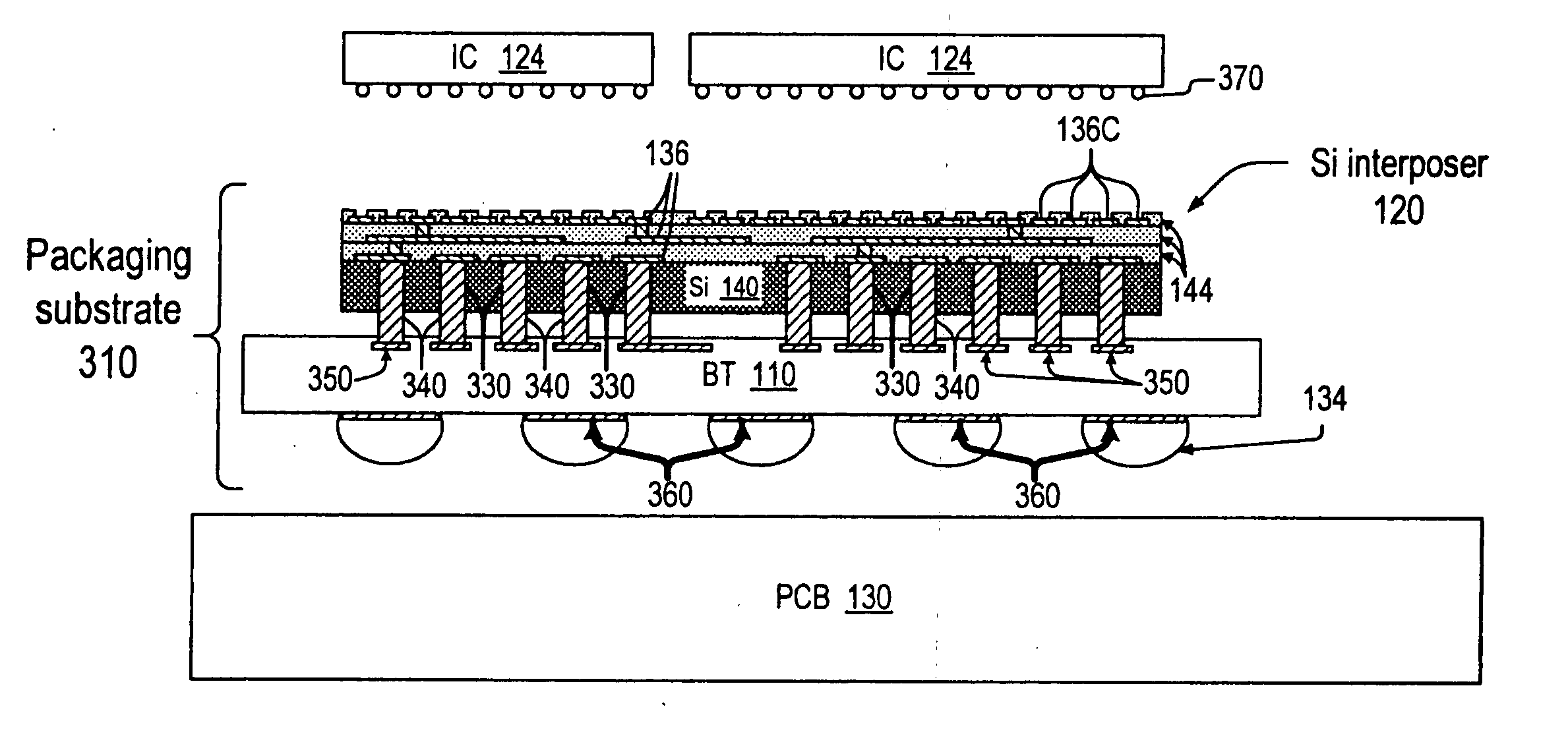

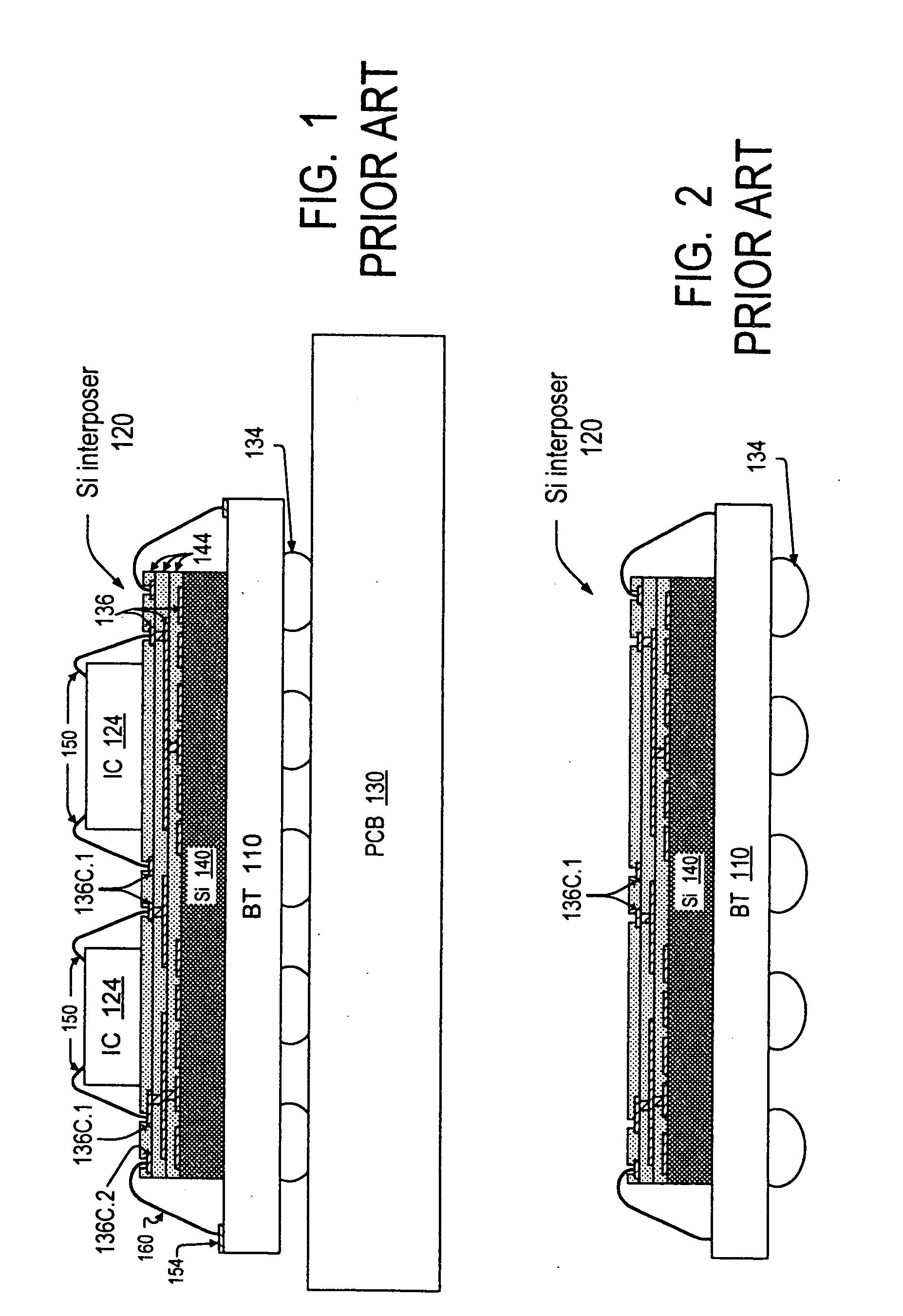

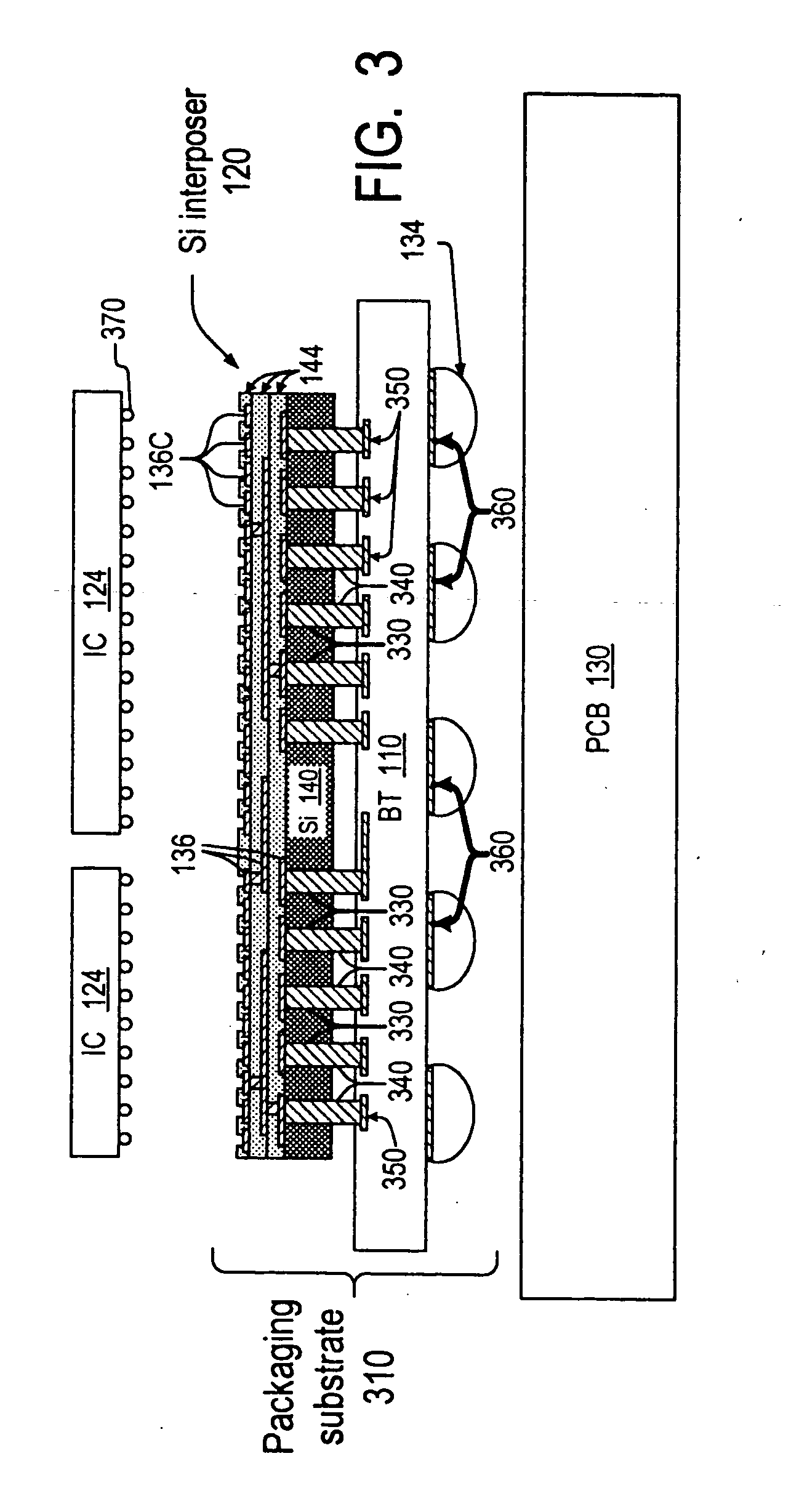

Packaging substrates for integrated circuits and soldering methods

ActiveUS20050133930A1Raise solder melting temperatureEasy maintenancePrinted circuit assemblingSemiconductor/solid-state device detailsContact padInterposer

A packaging substrate (310) includes a semiconductor interposer (120) and at least one other intermediate substrate (110), e.g. a BT substrate. The semiconductor interposer has first contact pads (136C) attachable to dies (124) above the interposer, and second contact pads (340) attachable to circuitry below the interposer. Through vias (330) are made in the semiconductor substrate (140) of the interposer (120). Conductive paths going through the through vias connect the first contact pads (136C) to the second contact pads (340). The dies (124) are attached to the interposer after the attachment of the interposer to the BT substrate. In sequential soldering operations, the solder hierarchy is maintained by dissolving some material (e.g. copper) in the solder during soldering to raise the solder's melting temperature. For example, all of the solders may initially have the same melting temperature, but each solder's melting temperature is increased during soldering to prevent the solder from melting in the subsequent soldering operations.

Owner:INVENSAS CORP

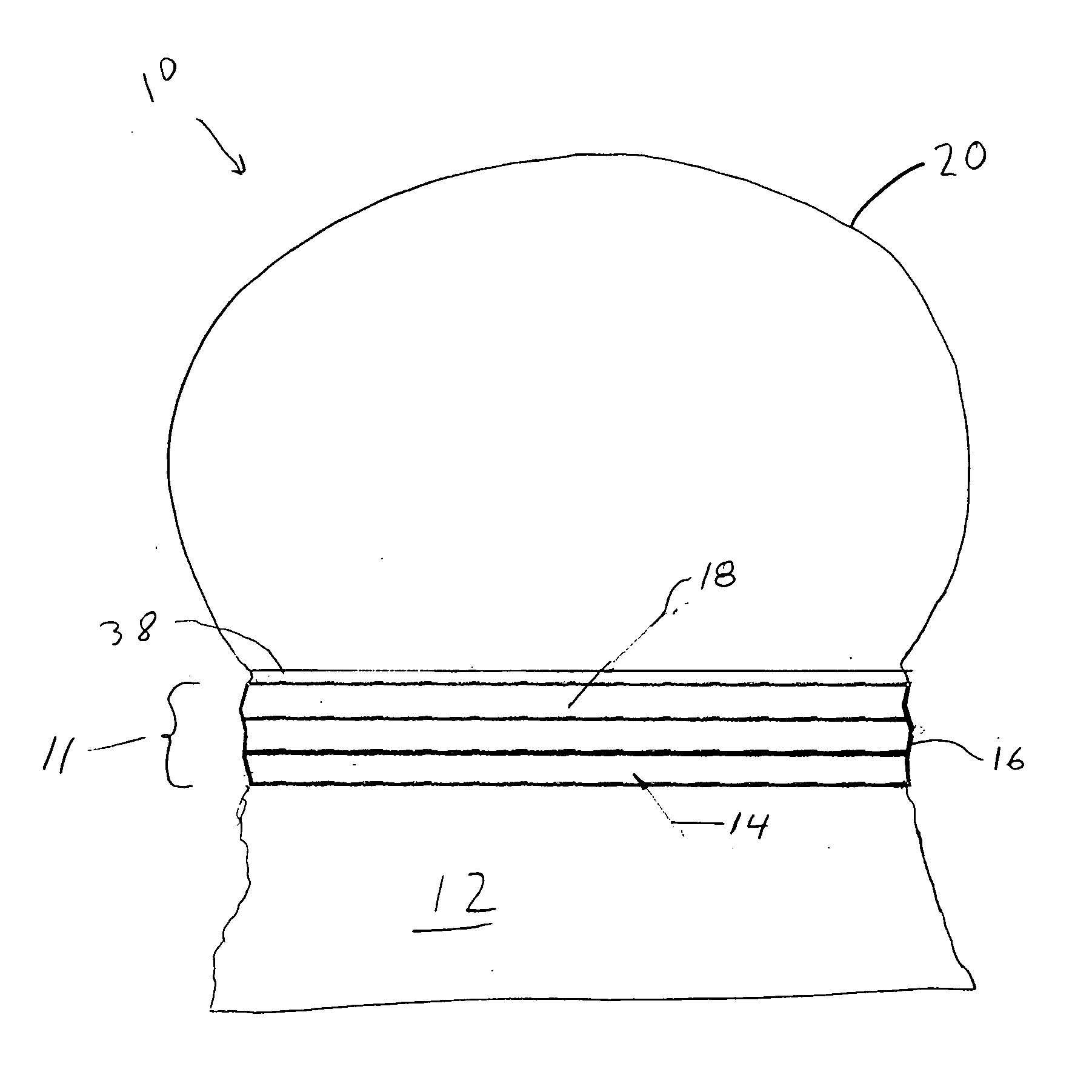

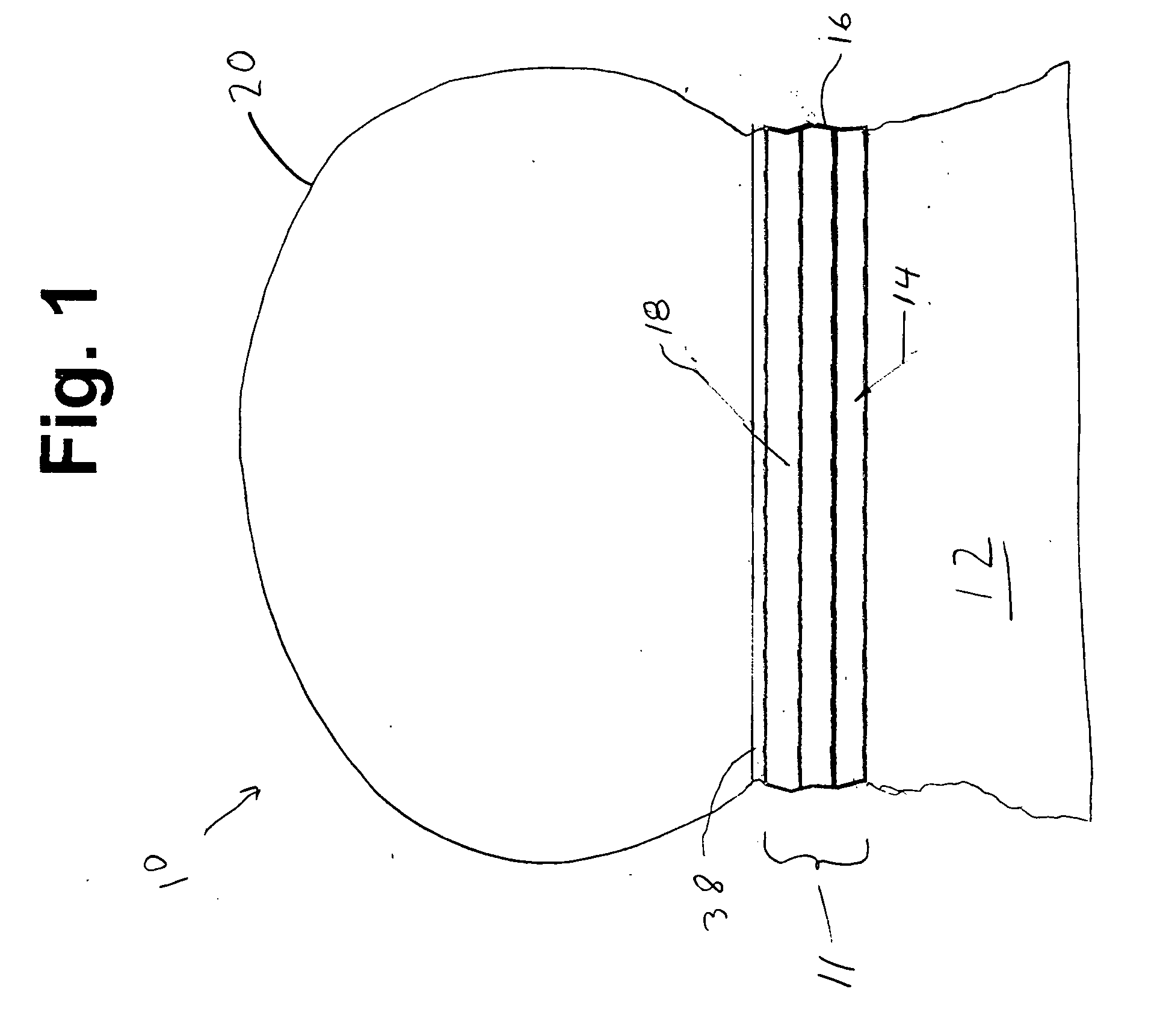

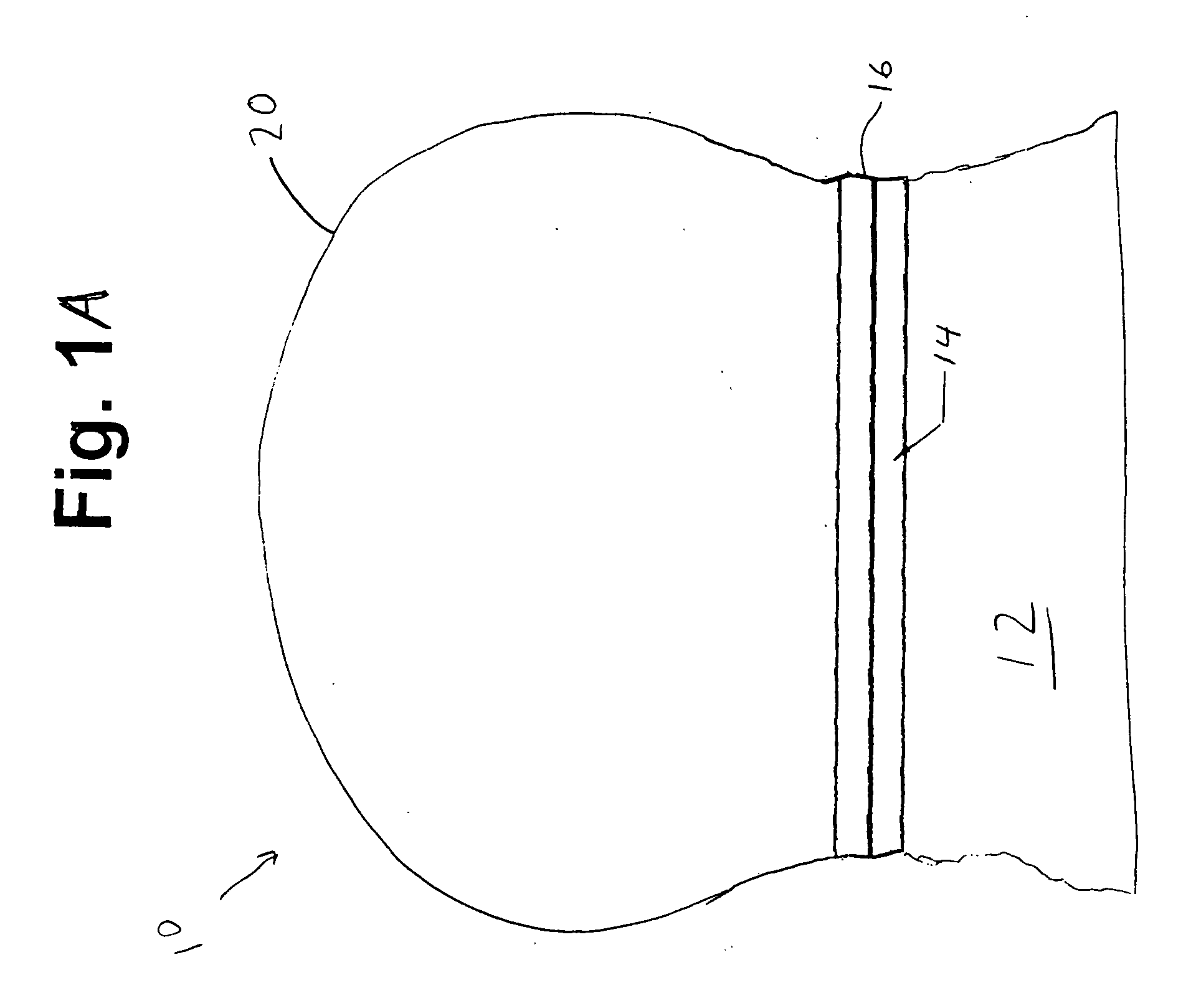

Interconnections for flip-chip using lead-free solders and having reaction barrier layers

InactiveUS20050224966A1Soft errorCost-effectivePrinted circuit assemblingSemiconductor/solid-state device detailsFlip chip interconnectSolder ball

An interconnection structure suitable for flip-chip attachment of microelectronic device chips to packages, comprising a two, three or four layer ball-limiting composition including an adhesion / reaction barrier layer, and having a solder wettable layer reactive with components of a tin-containing lead free solder, so that the solderable layer can be totally consumed during soldering, but a barrier layer remains after being placed in contact with the lead free solder during soldering. One or more lead-free solder balls is selectively situated on the solder wetting layer, the lead-free solder balls comprising tin as a predominant component and one or more alloying components.

Owner:ULTRATECH INT INC

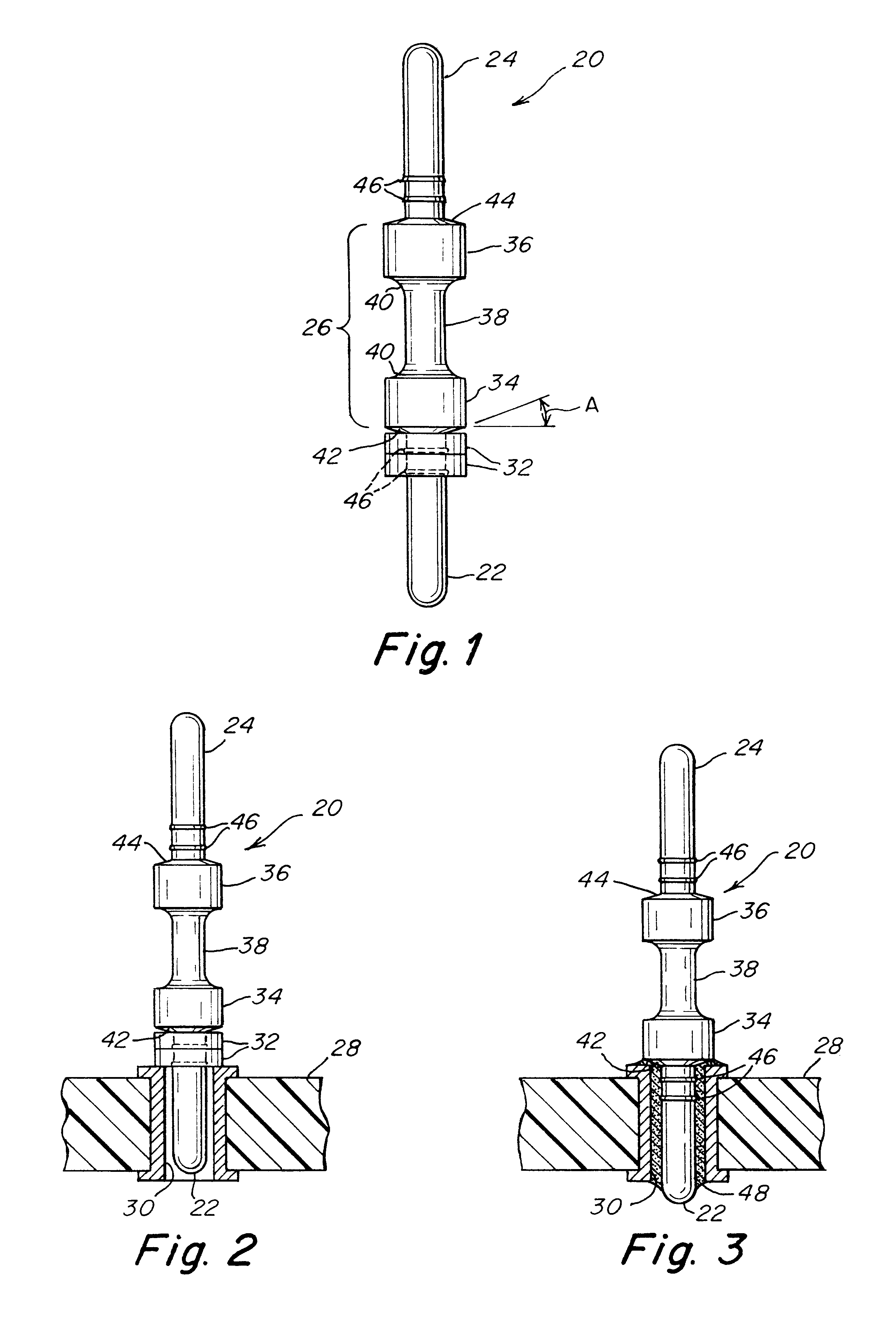

Friction stir welding fastener

ActiveUS9555580B1Joining is strengthenedReduce the amount requiredLaminationLamination apparatusMulti materialEngineering

A heat assisted friction stir welding system and fastener for use therewith allows the joining a variety of dissimilar materials, including joining composites and plastics to metal, in which the fastener becomes part of the bond. The fastener can be constructed from multiple materials, allowing for the joining of dissimilar metals. Heating the materials to be joined reduces the clamping force and torque required by the friction stir weld process. The result is a bond that is stronger with less energy input.

Owner:TEMPER IP

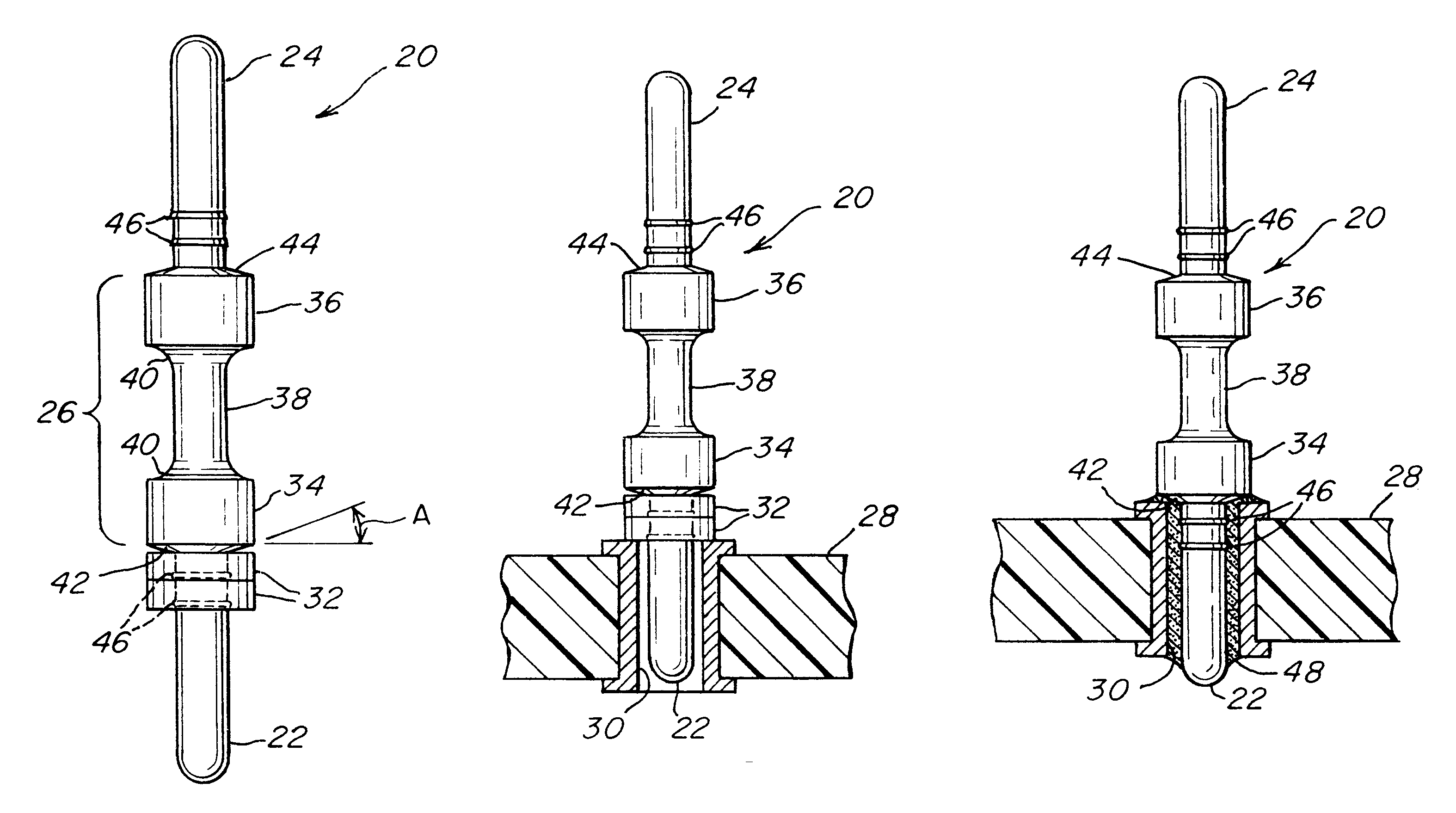

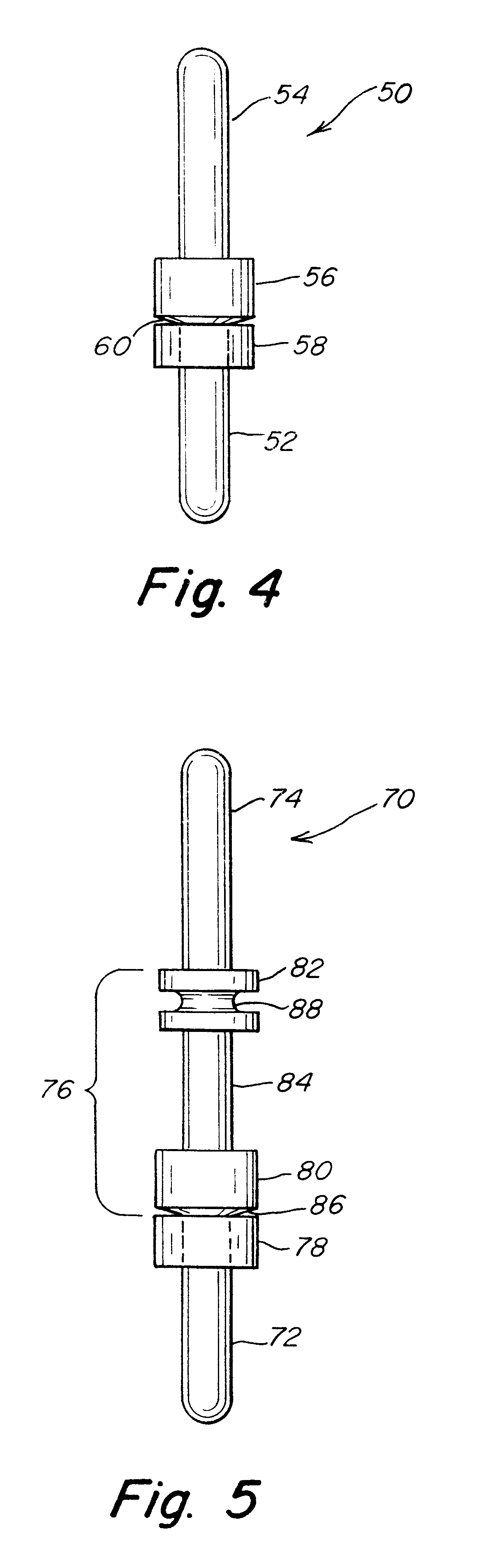

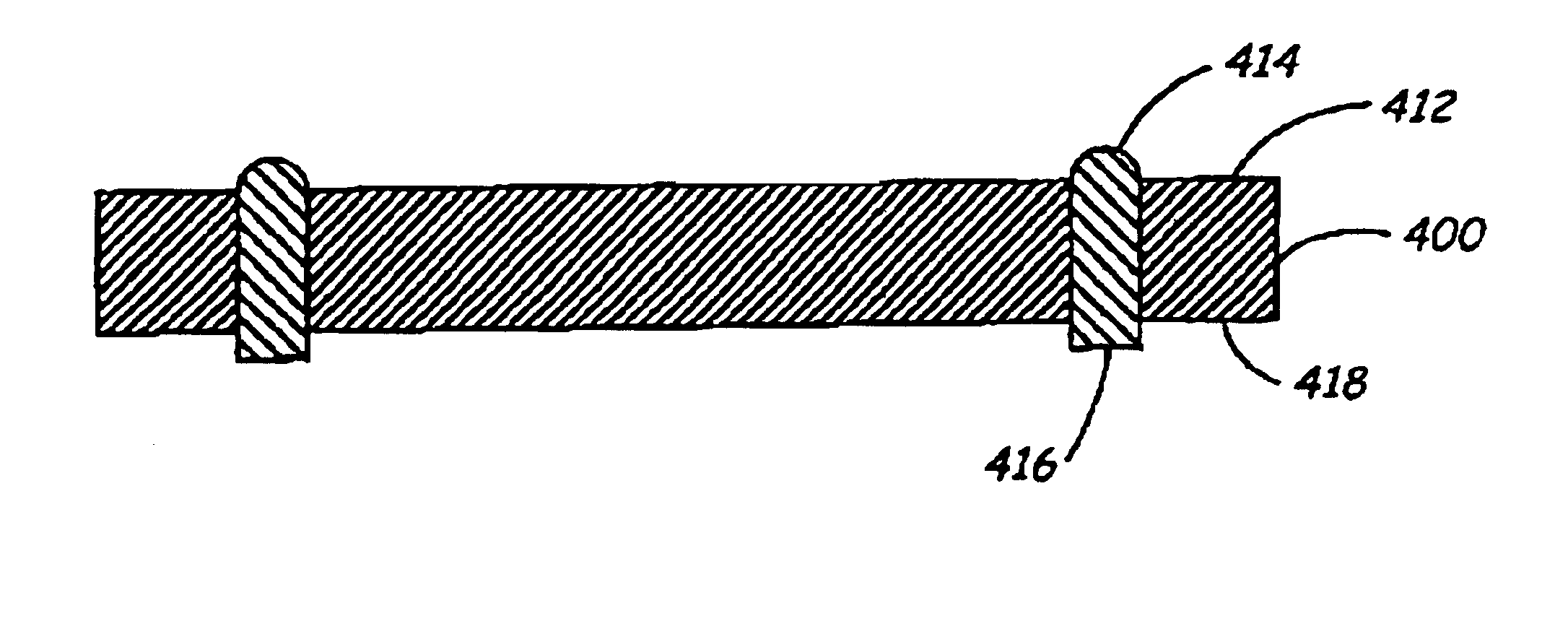

Electrical contact for a printed circuit board

InactiveUS6179631B1Printed circuit assemblingLine/current collector detailsSurface mountingElectrical connection

An electrical contact that is mounted on a printed circuit board to provide an electrical connection to the printed circuit board. The contact has the structural integrity of a through-hole component with the capability of being soldered to the circuit board using a surface mount reflow process. The contact includes a pair of elongated, conductive pins with a base disposed therebetween, and a solder preform supported on one of the conductive pins adjacent the base. The pin supporting the solder preform is insertable into a plated-through hole on the circuit board so that the solder preform can be reflowed into the hole along the pin to form a solder joint between the contact and the hole. The contact may include a retainer to secure the solder preform to the pin and the end of the base adjacent the pin may be beveled to facilitate gas ventilation from the hole during the soldering process. The base may be configured so that it can be grasped with a test instrument or support a wire connection to the contact. The contact may be symmetrical so that the solder preform can be supported on either conductive pin.

Owner:EMC IP HLDG CO LLC

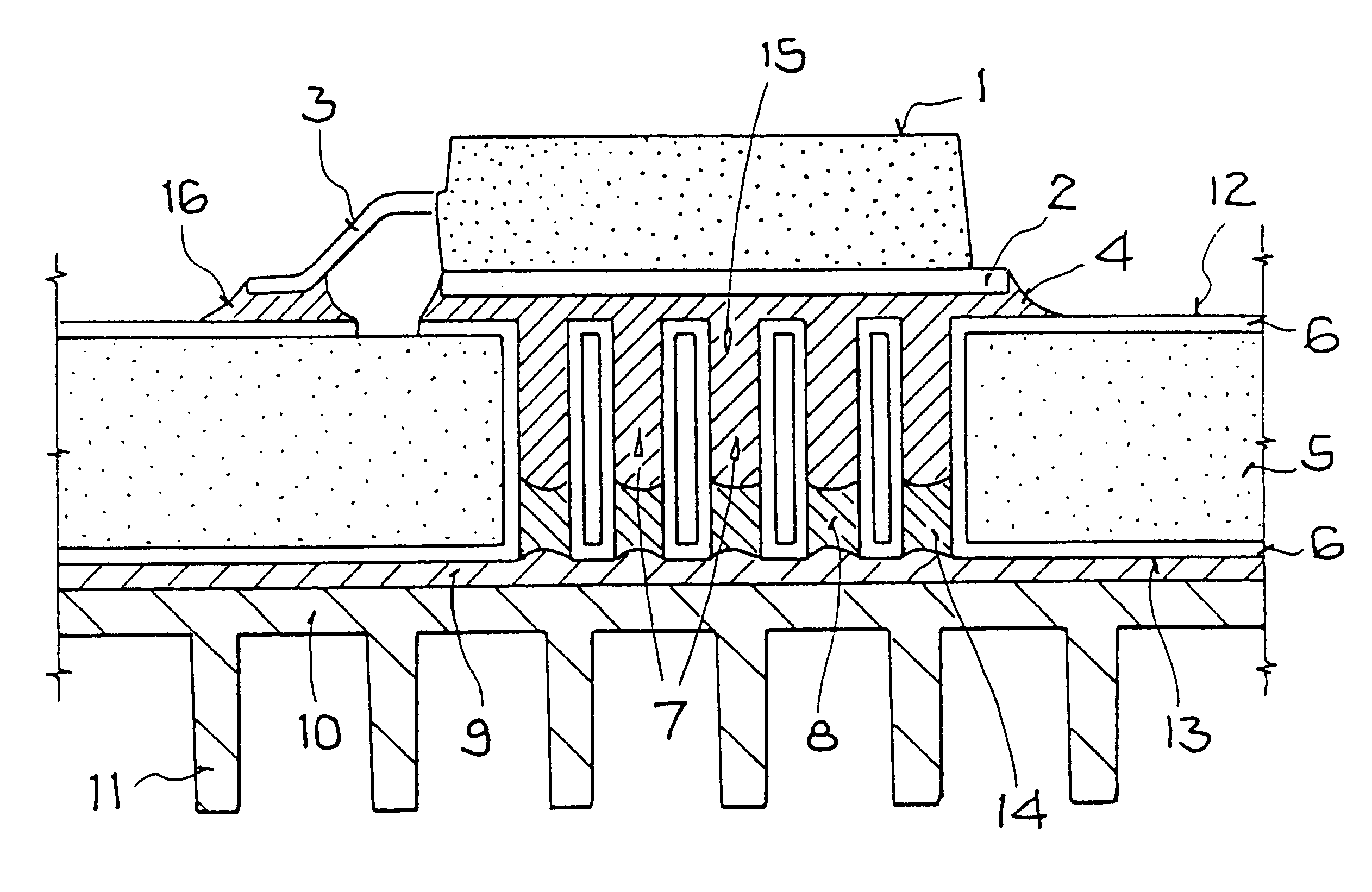

Method of fabricating a circuit arrangement with thermal vias

InactiveUS6190941B1Prevent penetrationThe method is simple and reliablePrinted circuit assemblingFinal product manufactureScreen printingEngineering

An electronic component is mounted on a substrate such as a circuit board by means of a soldering process such as reflow soldering. The circuit board has a thermal via hole therethrough to provide a heat dissipation path from the top surface to the bottom surface of the circuit board, for dissipating heat from the electronic component. To prevent molten solder from penetrating through the via hole during the soldering process, the via hole is sealed prior to the soldering process. The via hole is sealed from the bottom surface of the substrate by carrying out a screen printing process including at least two printing passes to print a sealing material into the open hole of the thermal via.

Owner:DAIMLER AG

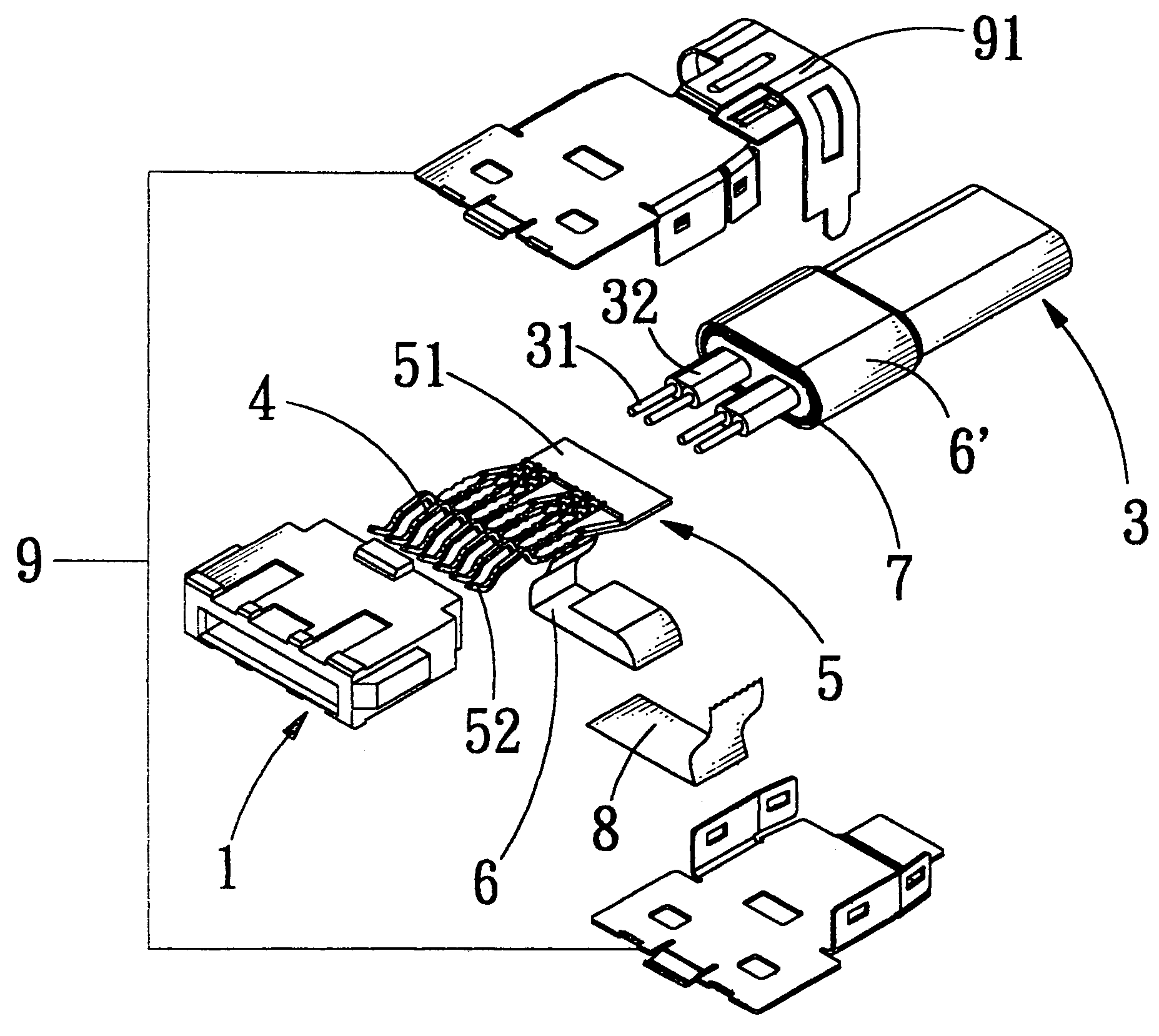

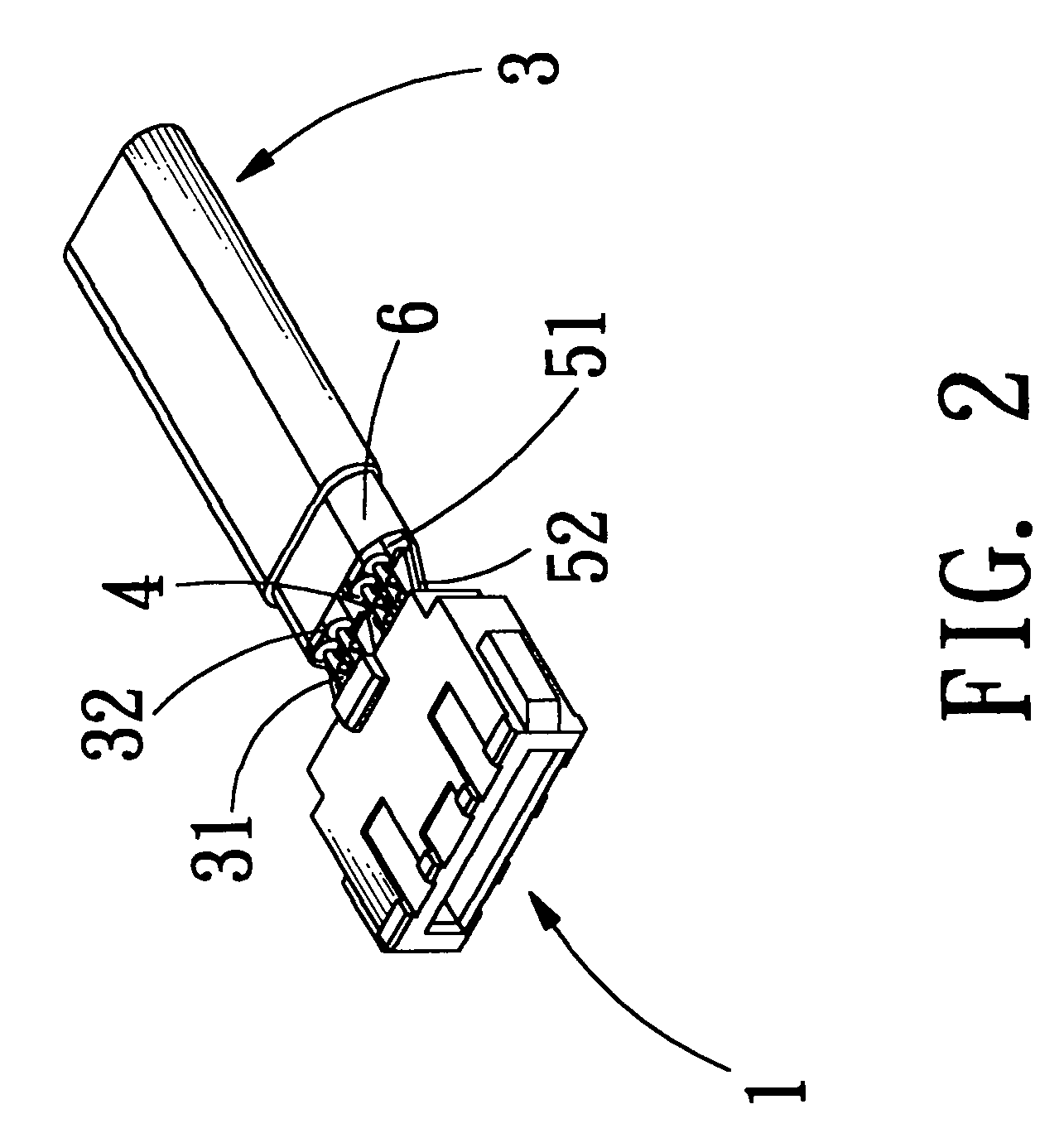

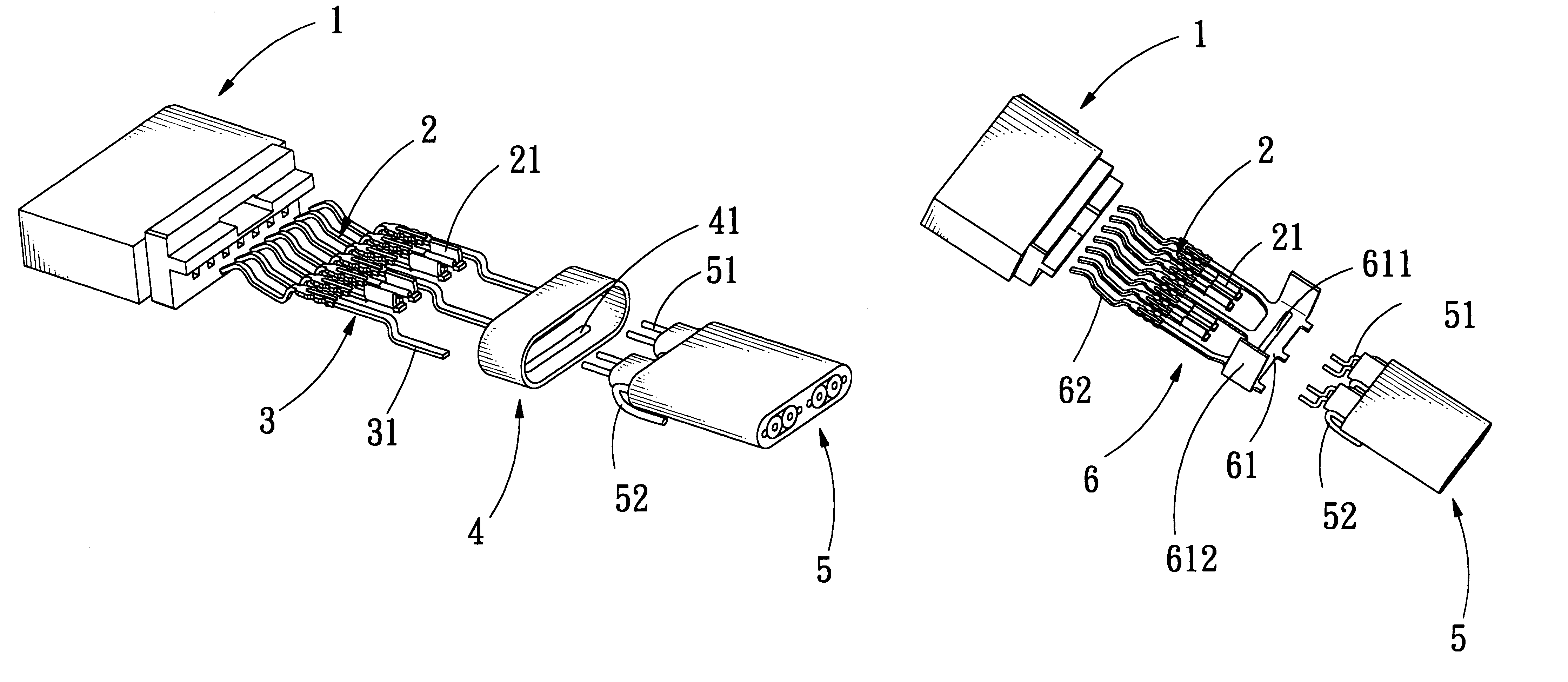

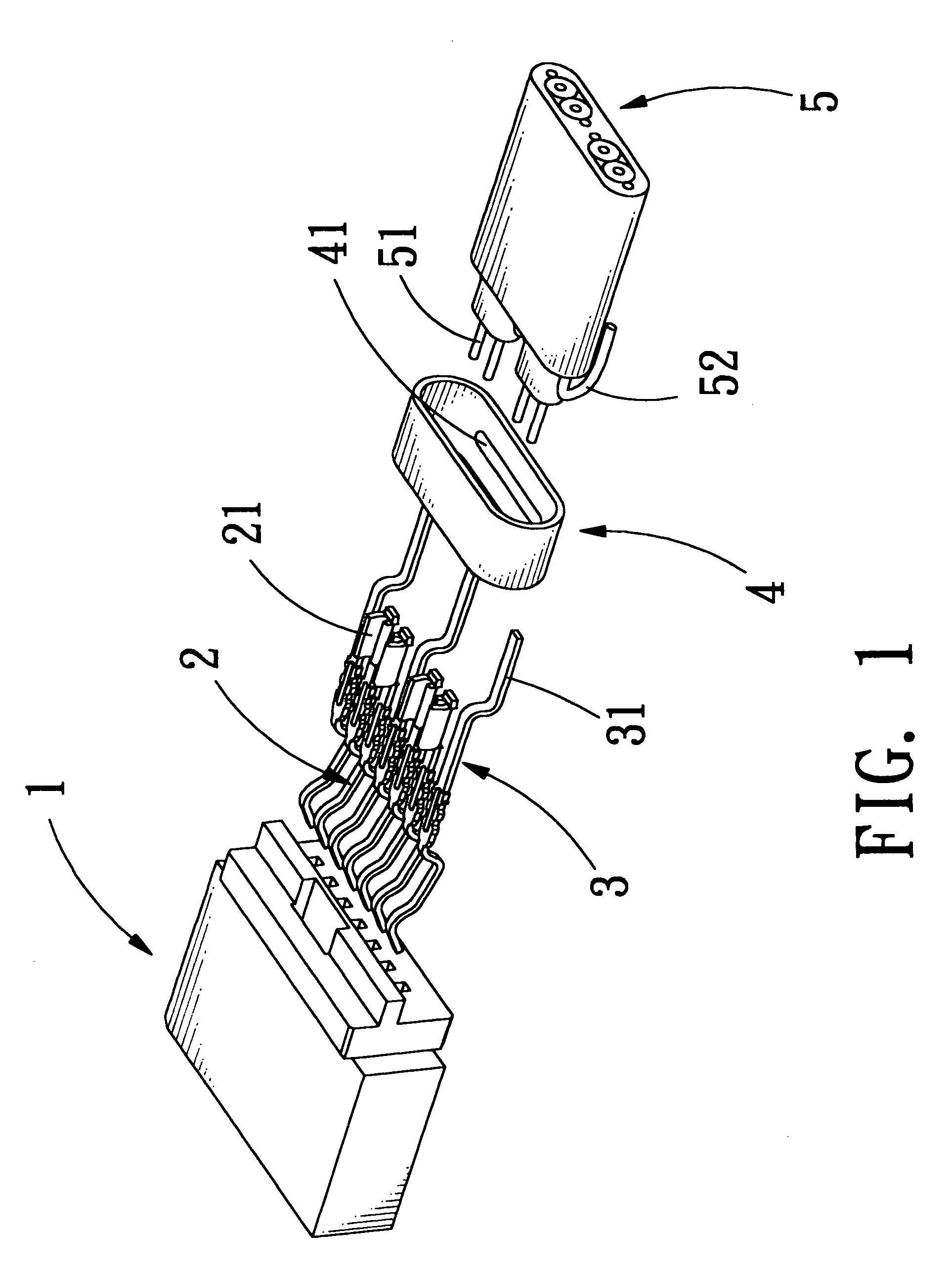

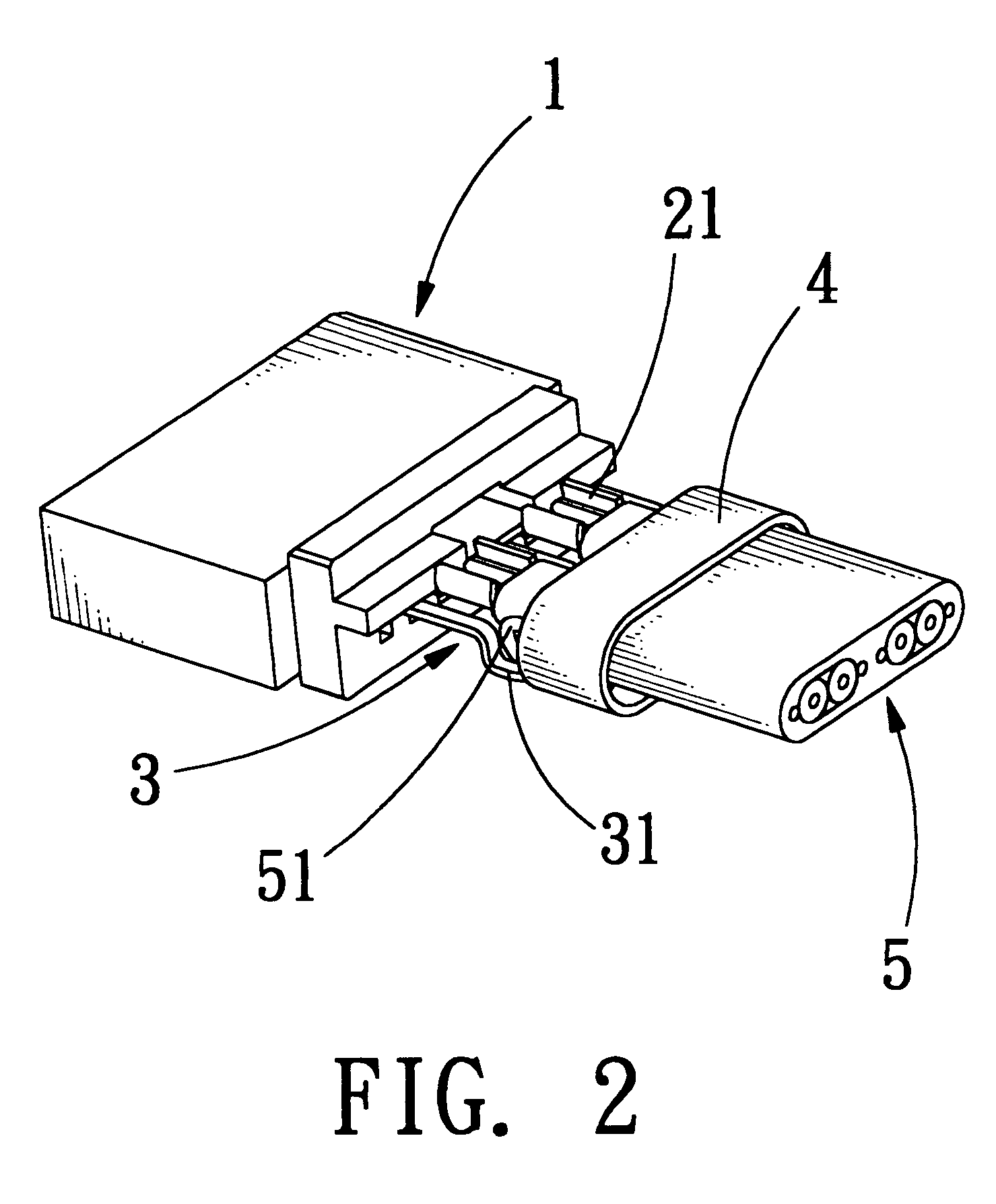

Electrical connector with grounding effect

InactiveUS7214097B1Reduce weldingImprove electrical characteristicsElectrically conductive connectionsTwo-part coupling devicesElectricityBody contact

The present invention relates to an electrical connector with grounding effect, which mainly has grounding part inserted inside the insulating body contacted with the jacket layer enclosed over the signal transmitting units with fixing and contacting effect for generating electrical characteristics, such that the cable assembly of the electrical connector has grounding effect without any grounding line positioned inside cable assembly; wherein, the grounding part has contacting part for providing the jacket layer to contact with, besides it further comprise predetermined grounding terminals extended directly from the grounding part for inserting into the insulating body; such that the cable assembly of the electrical connector of the present invention has grounding effect without any grounding line positioned inside the cable assembly; furthermore, it also can lessen the soldering process and prevent the mistaken probability of the soldering process generated such that the entire assembly process and the relative cost can be reduced.

Owner:ING SHANG LUN

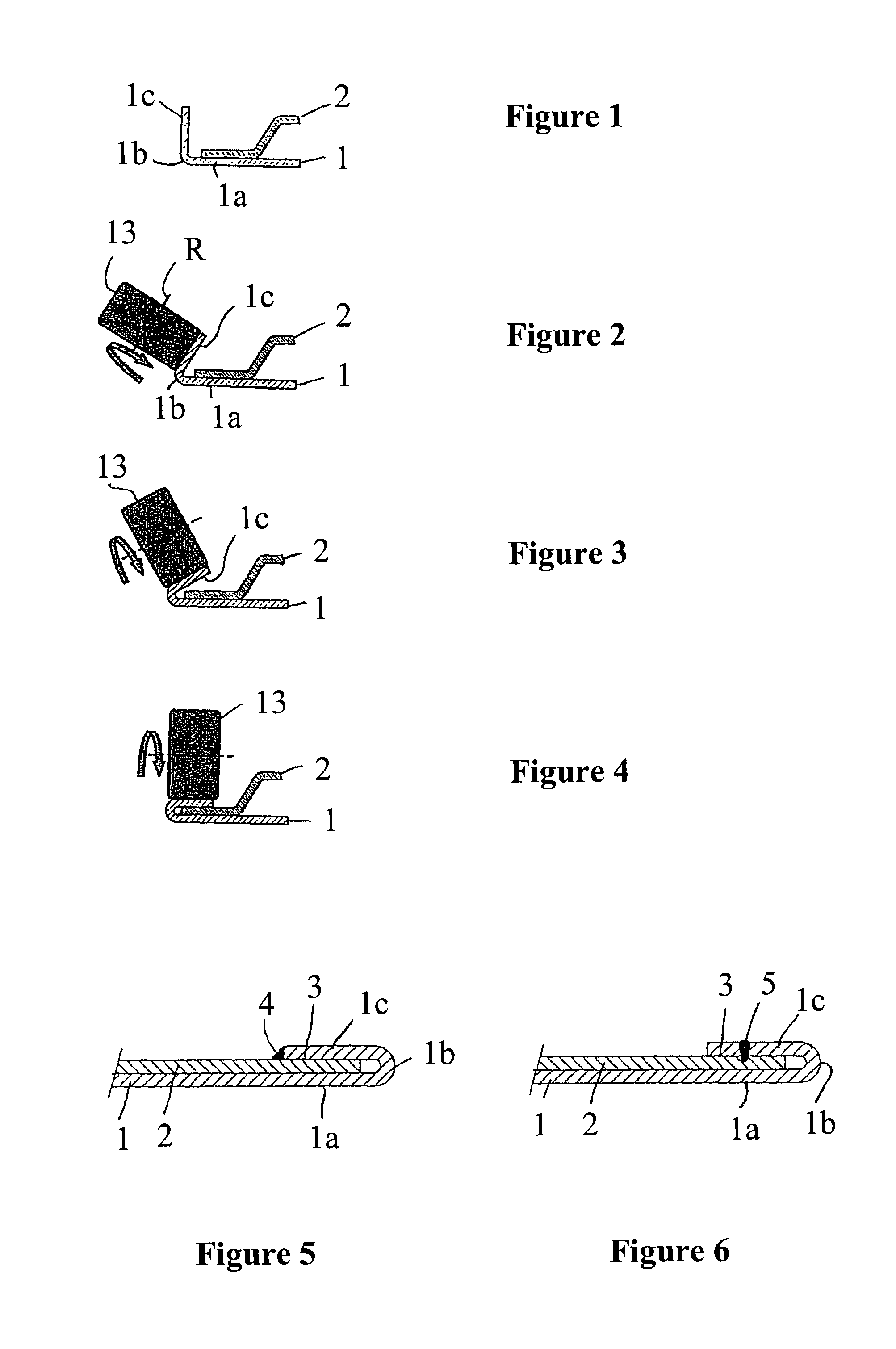

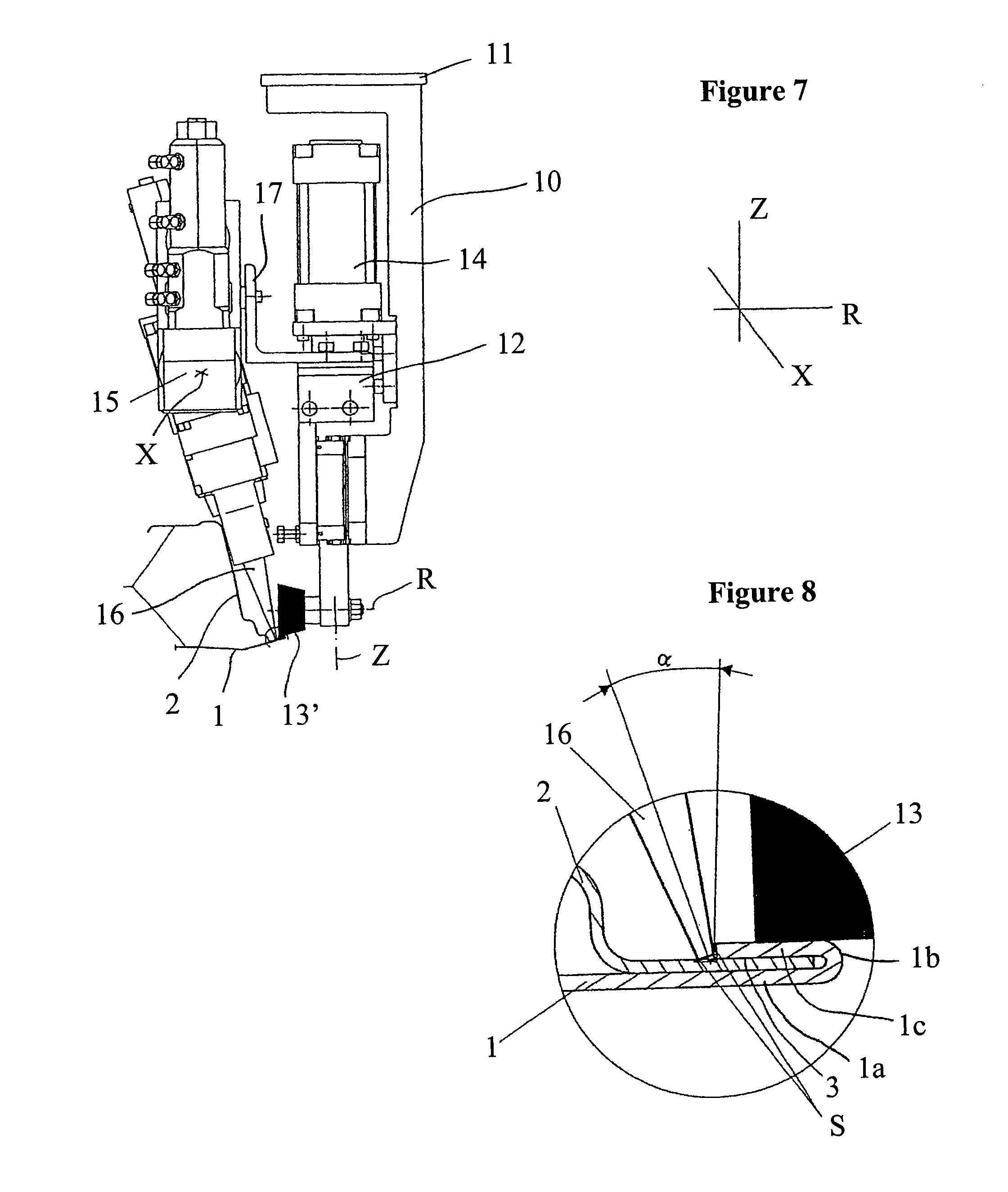

Sheet-metal composite, method for joining sheets and joining device

A metal sheet composite comprising an outer metal sheet having a flange which is folded over around a flanging edge; an inner metal sheet which forms a joint with the flange; and a welding or soldering seam which is produced on or in the joint and fixedly connects the metal sheets to each other. A method for joining metal sheets and a device for flanging and welding or soldering are also disclosed. The device includes: a tool head; a flanging member, arranged on the tool head, for roll-flanging or slide-flanging; and a welding or soldering tool arranged on the tool head, wherein the flanging member and the welding or soldering tool are arranged such that the flanging member forms a pressing means for a welding or soldering process which can be performed using the welding or soldering tool.

Owner:KOPIN CORPORATION

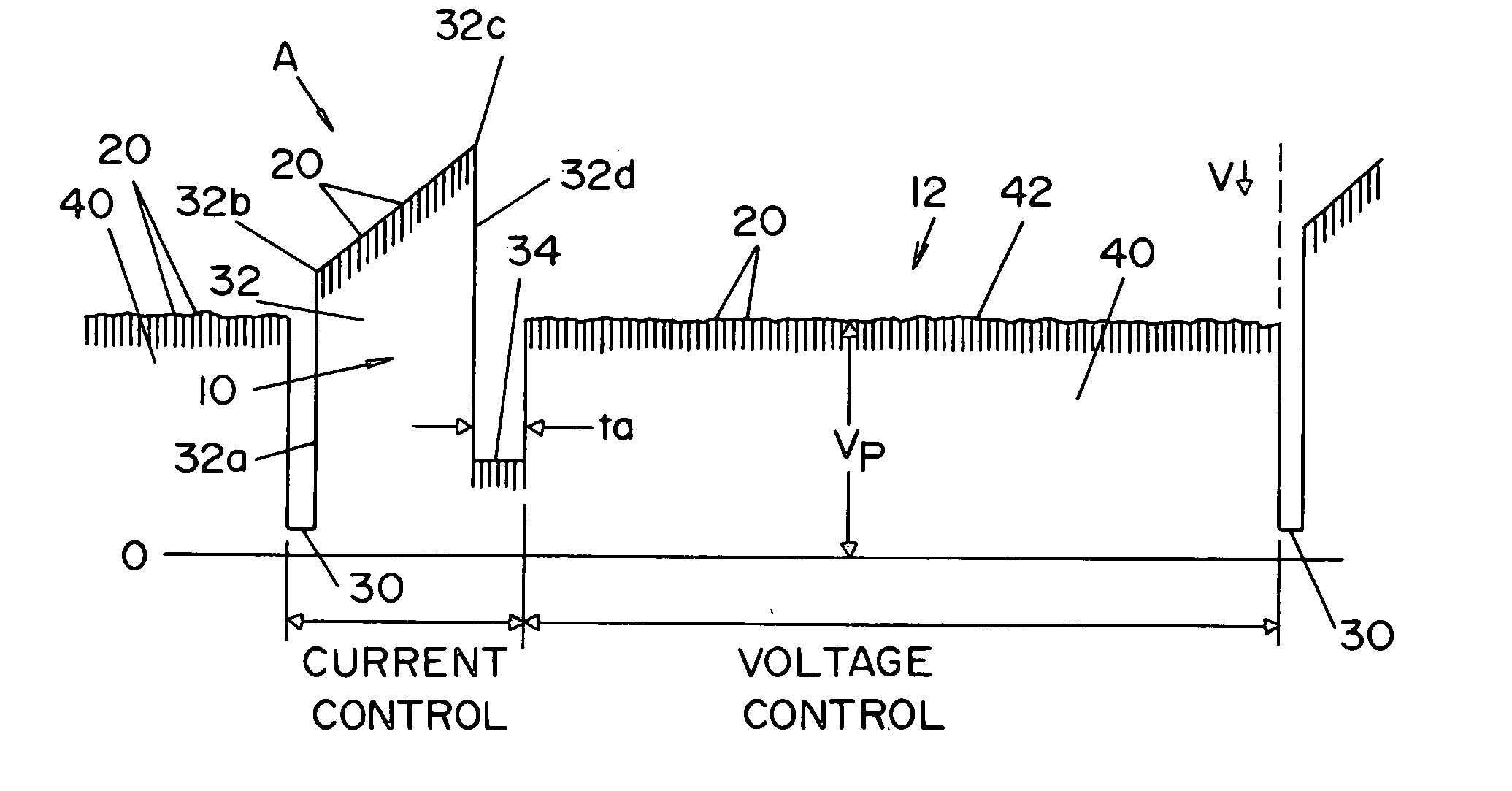

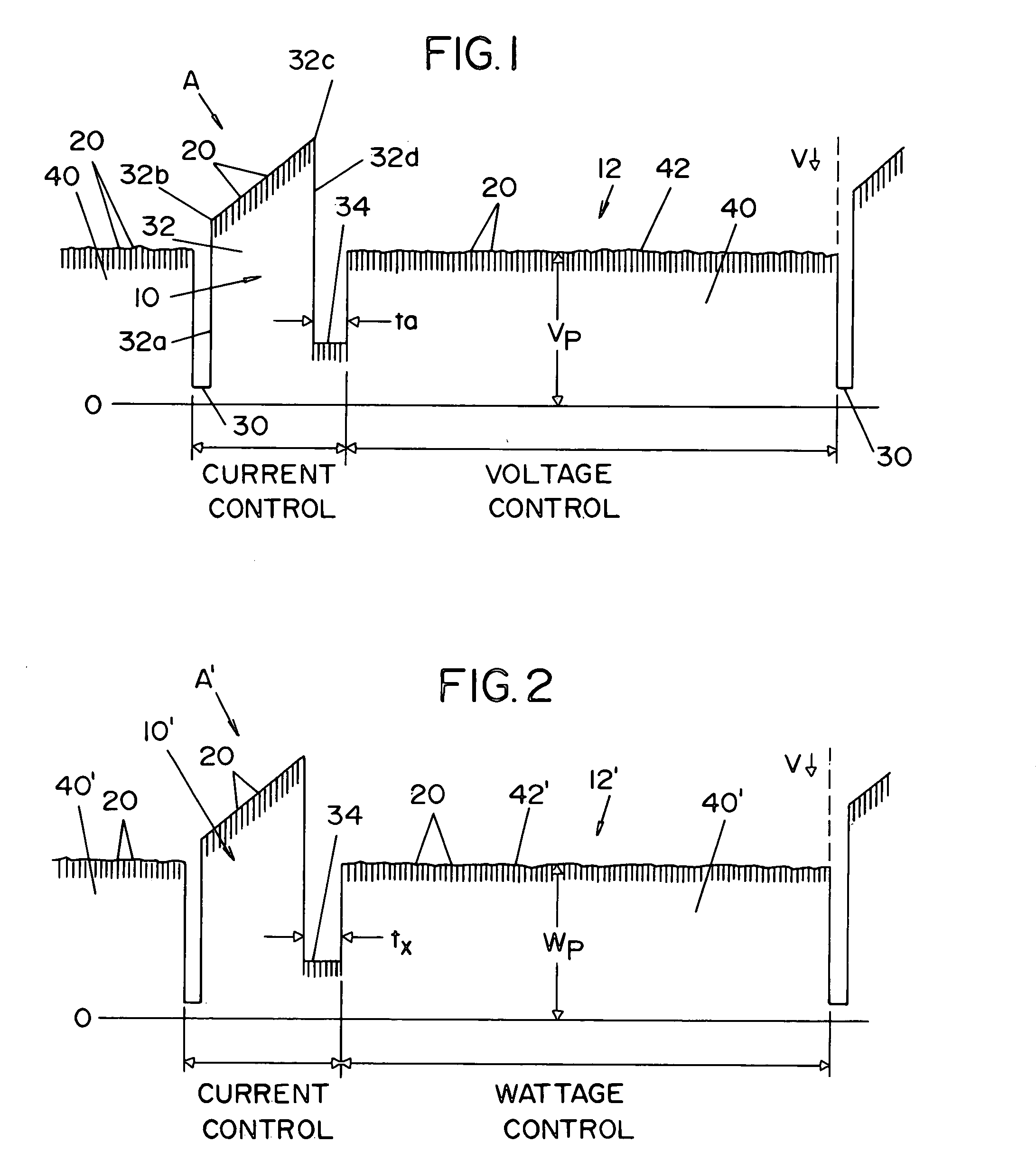

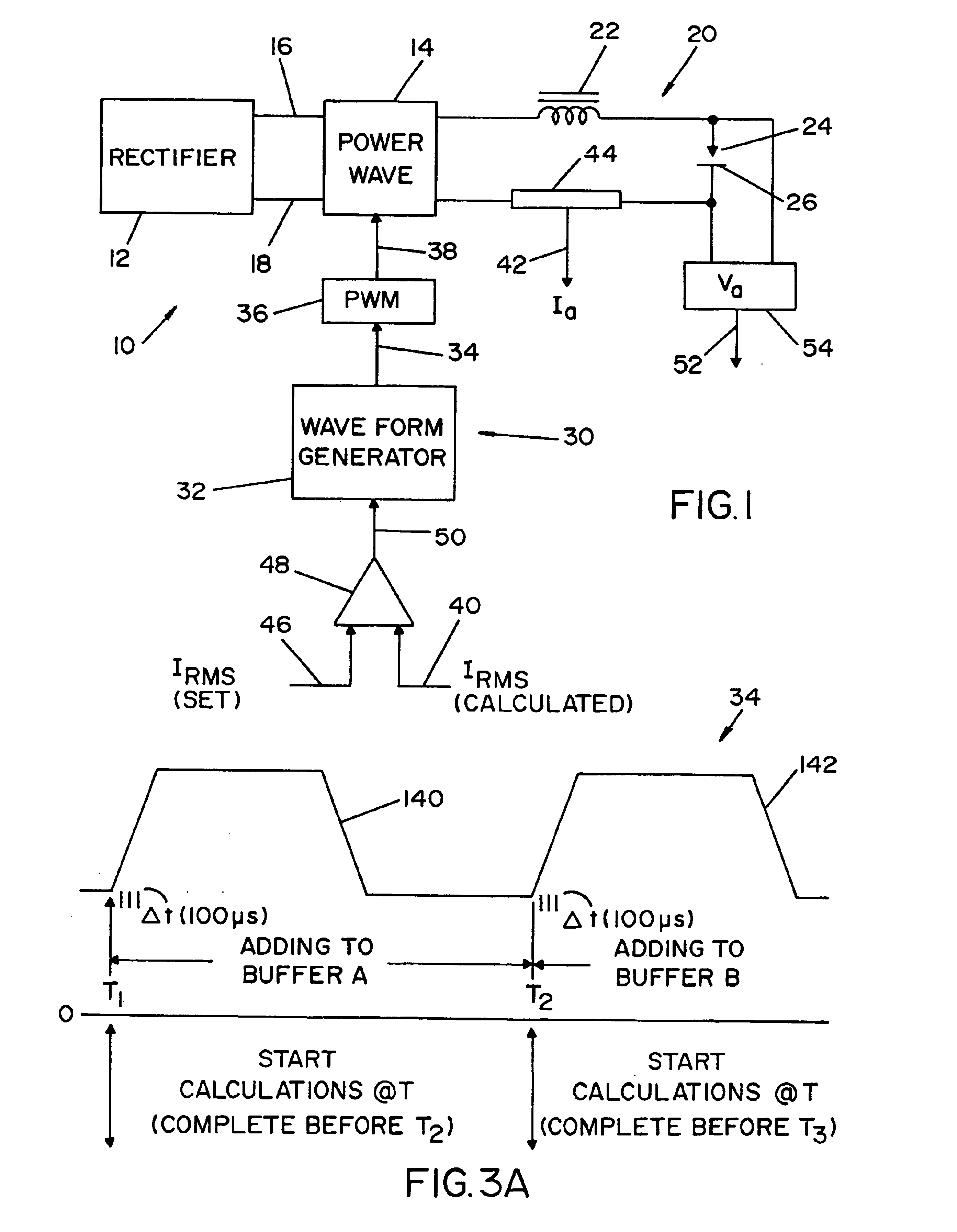

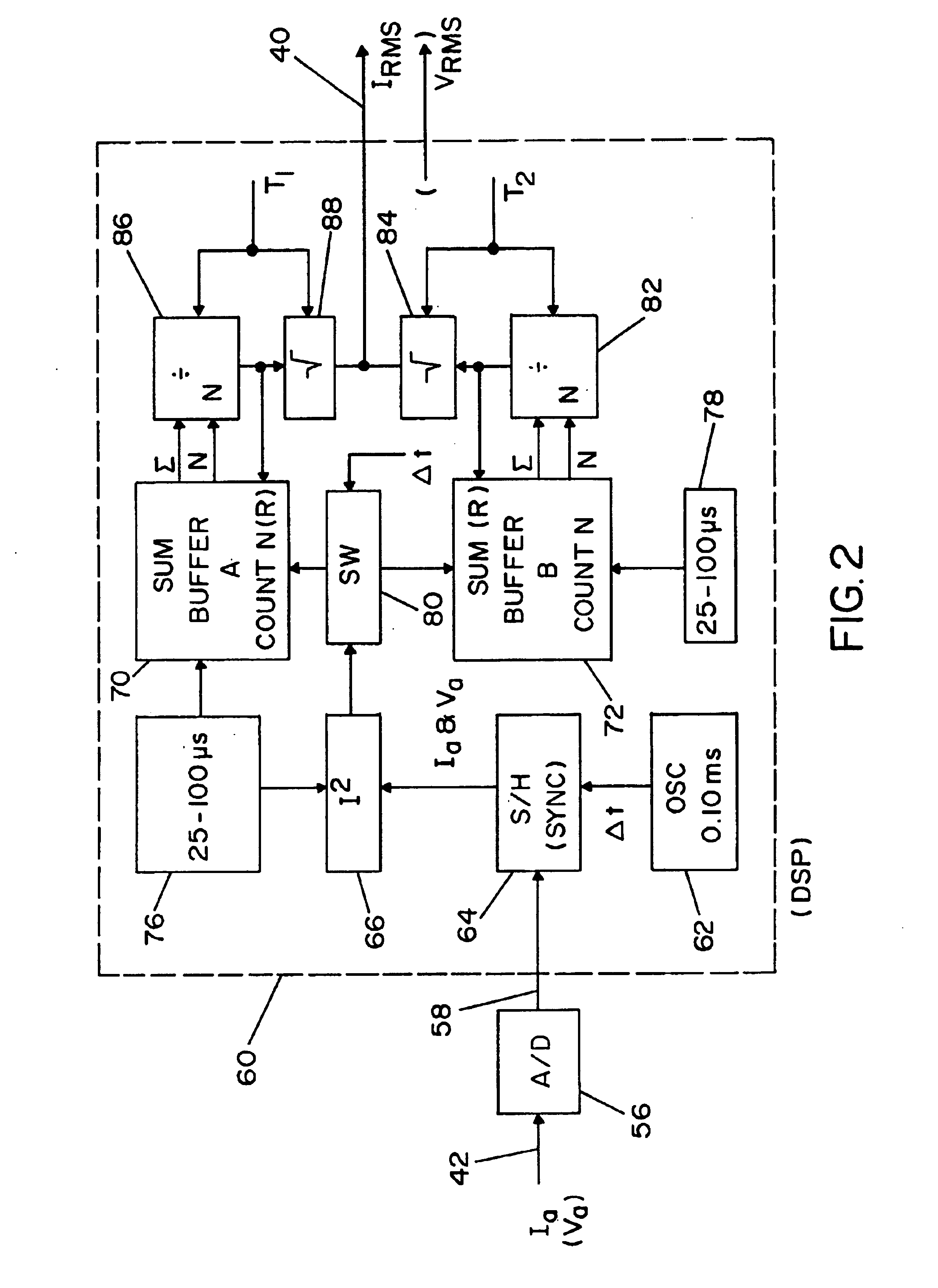

Short circuit arc welder and method of controlling same

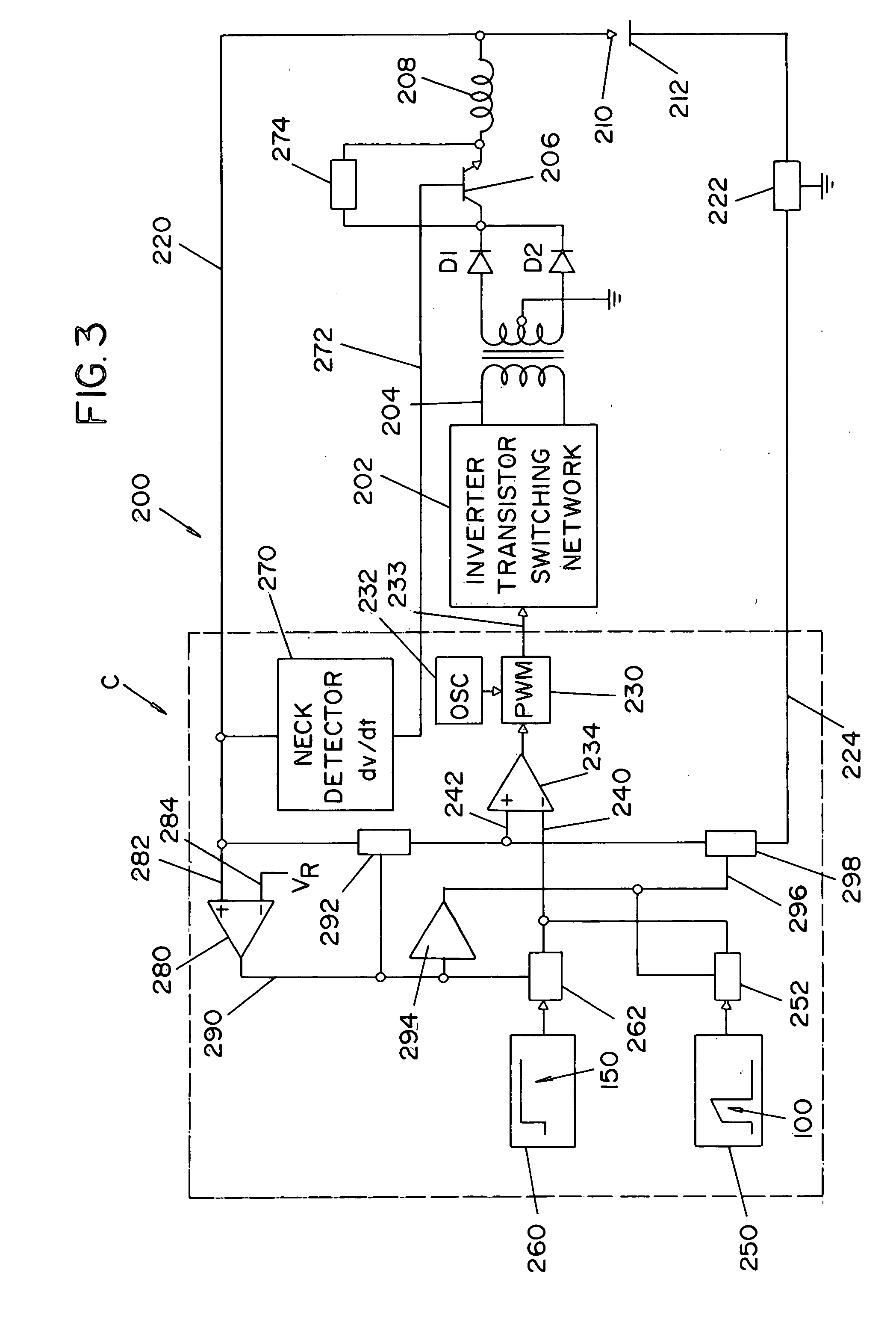

ActiveUS20050184039A1Easy to controlAccurate heating controlArc welding apparatusPipeline systemsPulse waveCurrent pulse

An electric arc welder operated to perform a short circuit welding process between an electrode and a workpiece, where the process comprises a succession of alternate short circuit conditions and arc conditions, with a first current waveform during the short circuit condition and a second voltage waveform during the arc condition. A first waveform generator constructs the first waveform from a series of current pulses controlled by a pulse wave modulator operated at a rate greater than 18 kHz and a second waveform generator constructs the second waveform from a series of current pulses controlled by a pulse wave modulator operated at a rate greater than 18 kHz. The second waveform generator has a circuit to generate the second waveform with a generally constant arc parameter, generally voltage.

Owner:LINCOLN GLOBAL INC

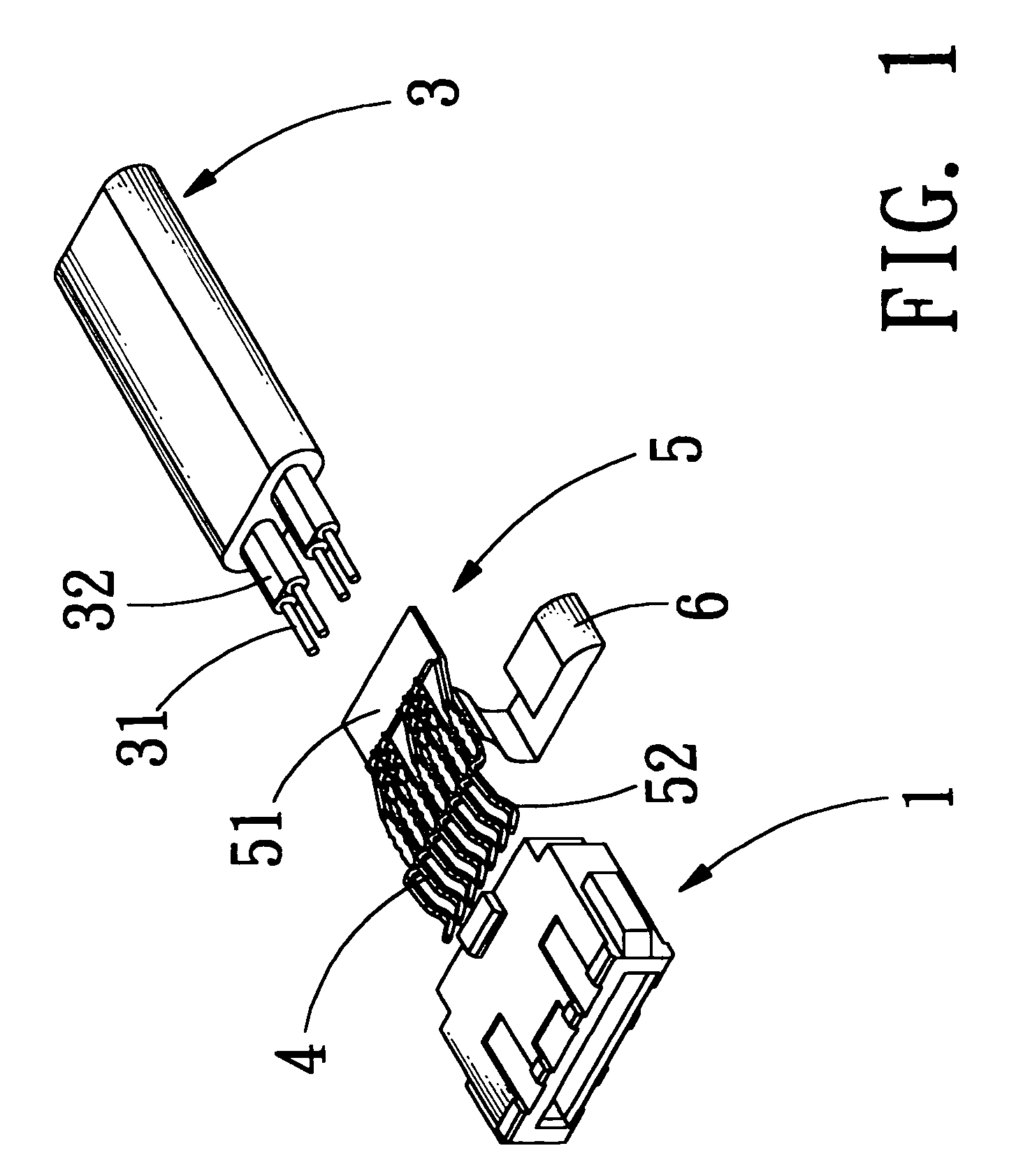

Grounding structure of an electrical connector

InactiveUS7052292B2Best electrical characteristicEasy to connect partsCoupling protective earth/shielding arrangementsConnection contact member materialElectricityEngineering

The present invention relates to a grounding structure of an electrical connector suitable for high frequency transmitting. The high frequency connector mainly has a connecting part being combined with a plurality of grounding lines to improve the electrical characteristics of the high frequency connector when it transmits a signal. Wherein, the connecting part further comprises a wing portion and a protrusion portion; thereby the connecting part can engage the grounding terminals with the grounding line of the cable to form electrical contact. Furthermore, one end of the connecting part is extended directly and comprises predetermined grounding terminals, such that the grounding line can be directly connected to connecting part; such as, the electrical connector can have better electrical characteristics and the grounding line can directly be coupled to the grounding terminals without the soldering process by using aforesaid structure meanwhile, the entire assembly process and the relative cost can be lessened.

Owner:ING SHANG LUN

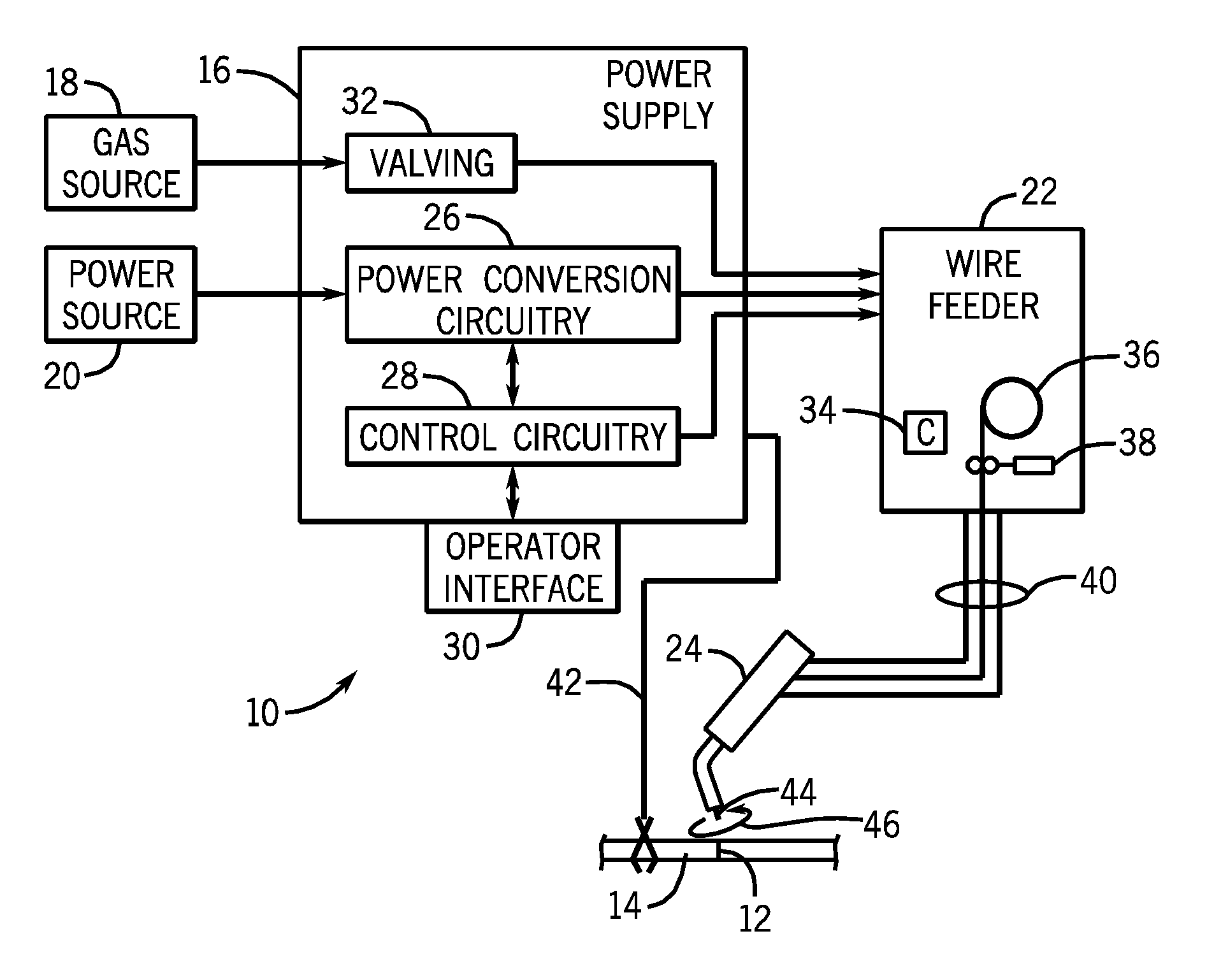

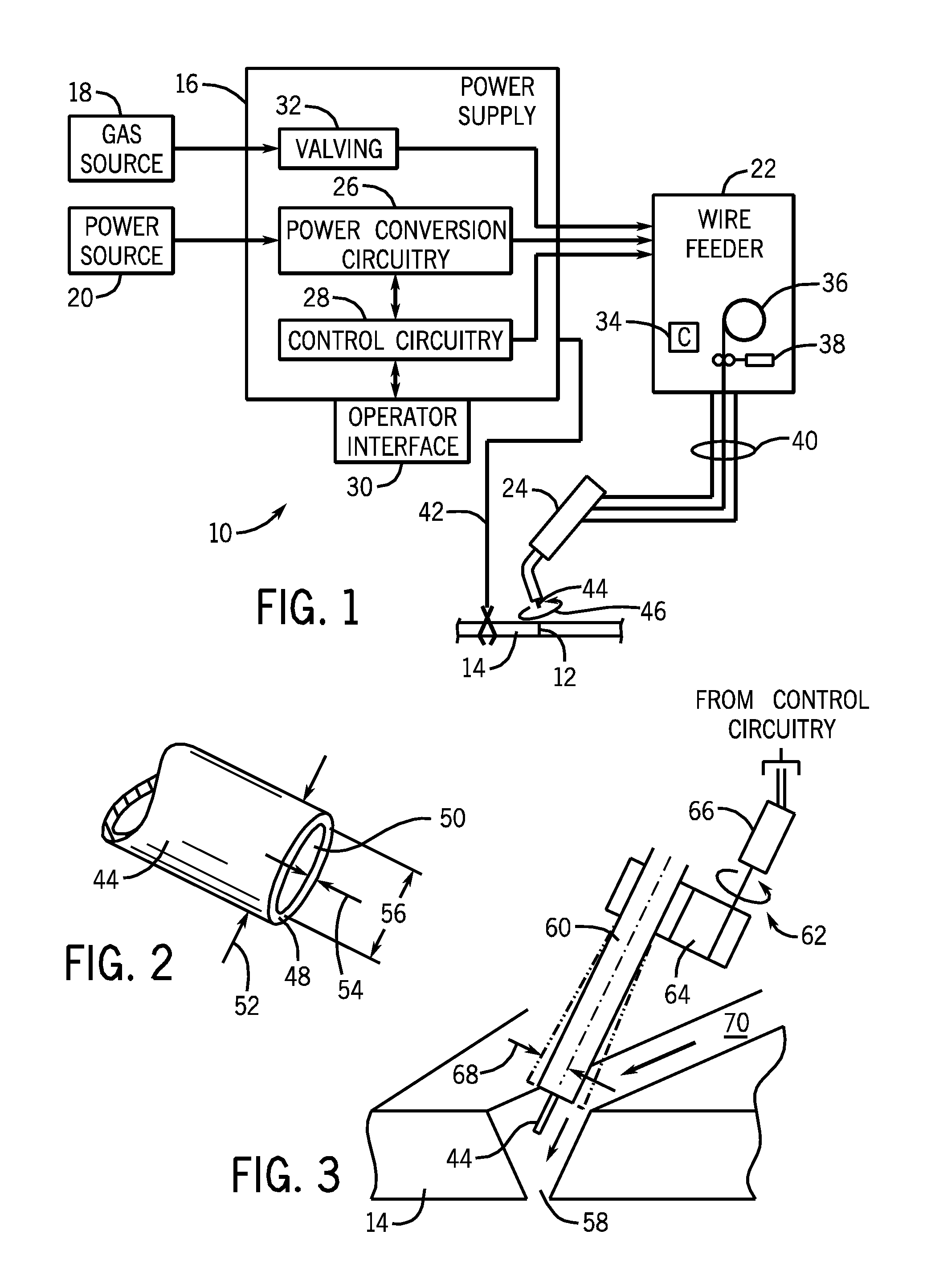

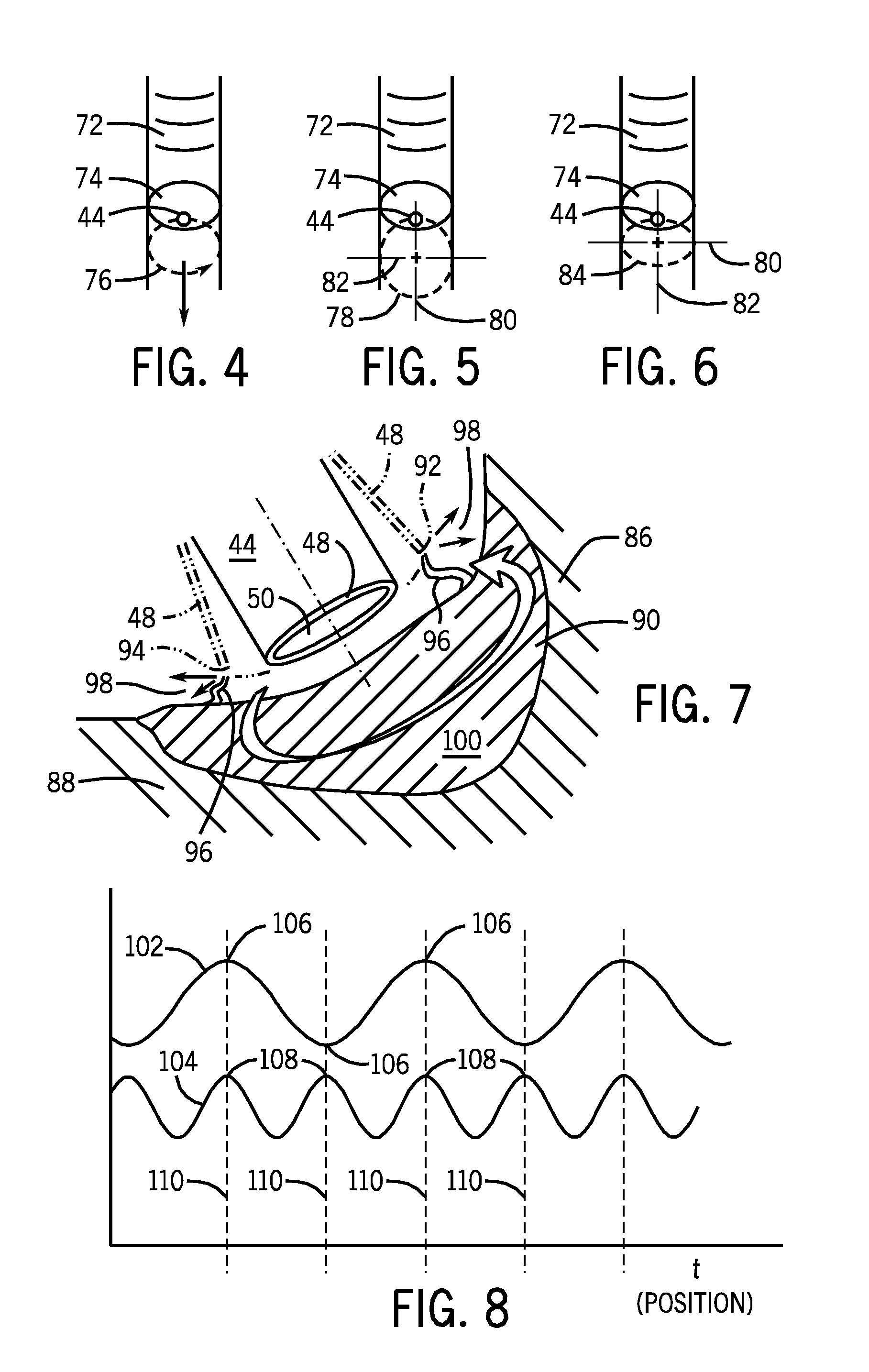

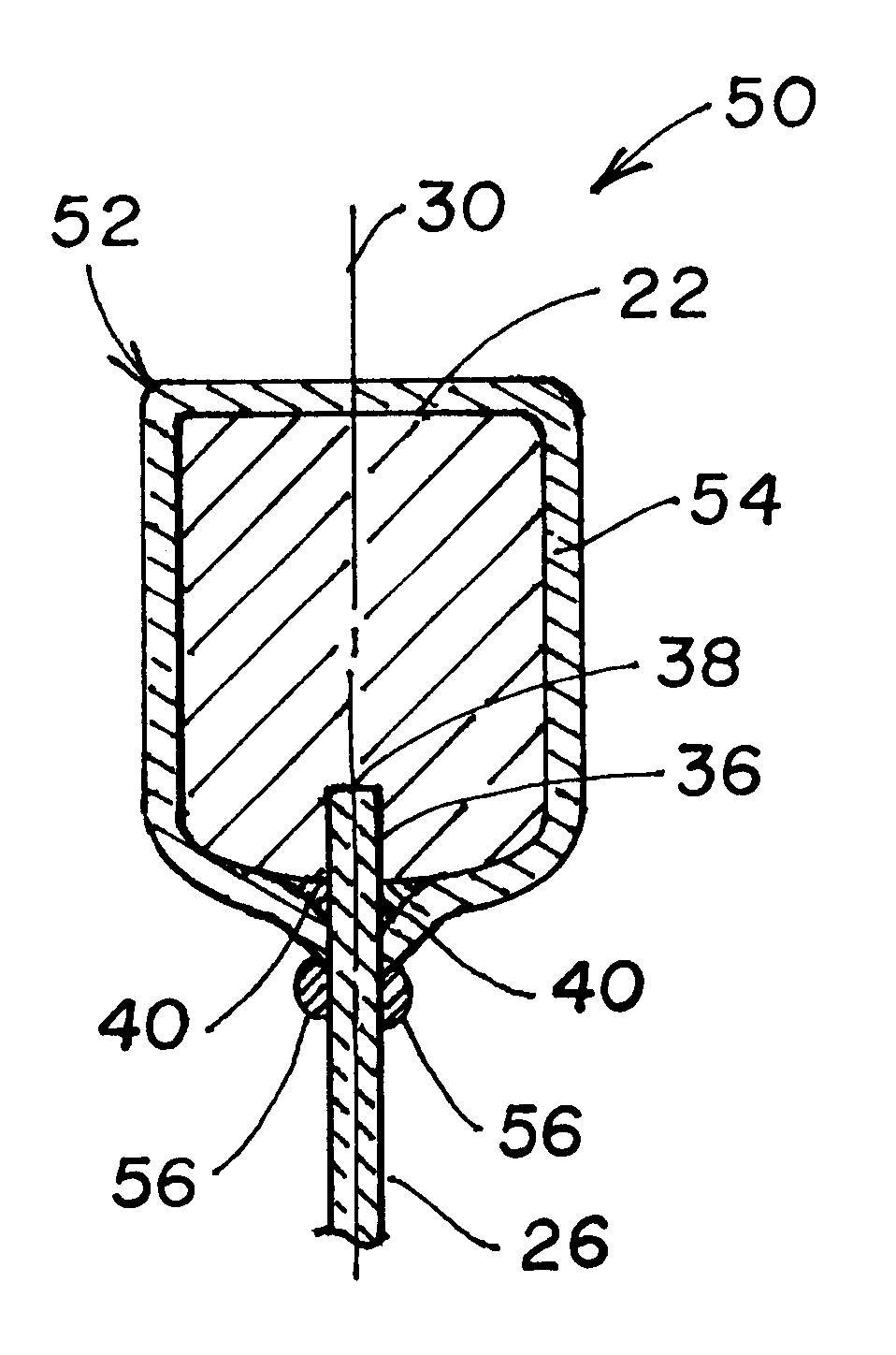

DC electrode negative rotating arc welding method and system

ActiveUS20130153557A1Increase adoptionImprove performanceArc welding apparatusWelding/cutting media/materialsMetallurgyDirect current

A welding operation is performed by moving or rotating an arc in a welding torch, and feeding a metal cored wire through the torch in a direct current, electrode negative welding process. The electrode may include one or more arc stabilizers. The welding process may be pulsed or non-pulsed. Moreover, the process may be used with a number of different base metals intended to be welded, such as thin plate, galvanized metals, painted metals, coated metals, and so forth.

Owner:ILLINOIS TOOL WORKS INC

Steel-clad cathode for electrolytic refining of copper

InactiveUS6569300B1Simplify the assembly processEnsure durabilityCellsMachining electrodesElectrical connectionCopper

An electrolytic cathode consists of a solid copper hanger bar and a stainless-steel mother plate attached to a receiving groove in the underside of the hanger bar. In the preferred embodiment of the invention, the entire length of connection is welded, thereby establishing a large boundary surface for good electrical conductance. The solid hanger bar further includes a cladding of stainless steel wrapped over the copper bar and the upper portion of the mother plate, leaving only the ends of the copper bar exposed for electrical connection with conventional bus-bars. The lower edges of the cover are attached to the mother plate by a steel-to-steel weld that produces a strong and durable connection. The lateral edges of the cover are also connected to the copper bar by a conventional copper weld that completely seals the cover over the copper bar, thereby preventing contamination from the electrolytic solution. The cover is then welded to the mother plate and sealed around the copper bar. The heat produced by the welding process, which causes the steel cladding material to expand during welding, is used to improve the tightness of the fit between the cover and the copper bar as a result of the cover's shrinkage occurring during cooling.

Owner:SAMUEL SON & CO USA INC

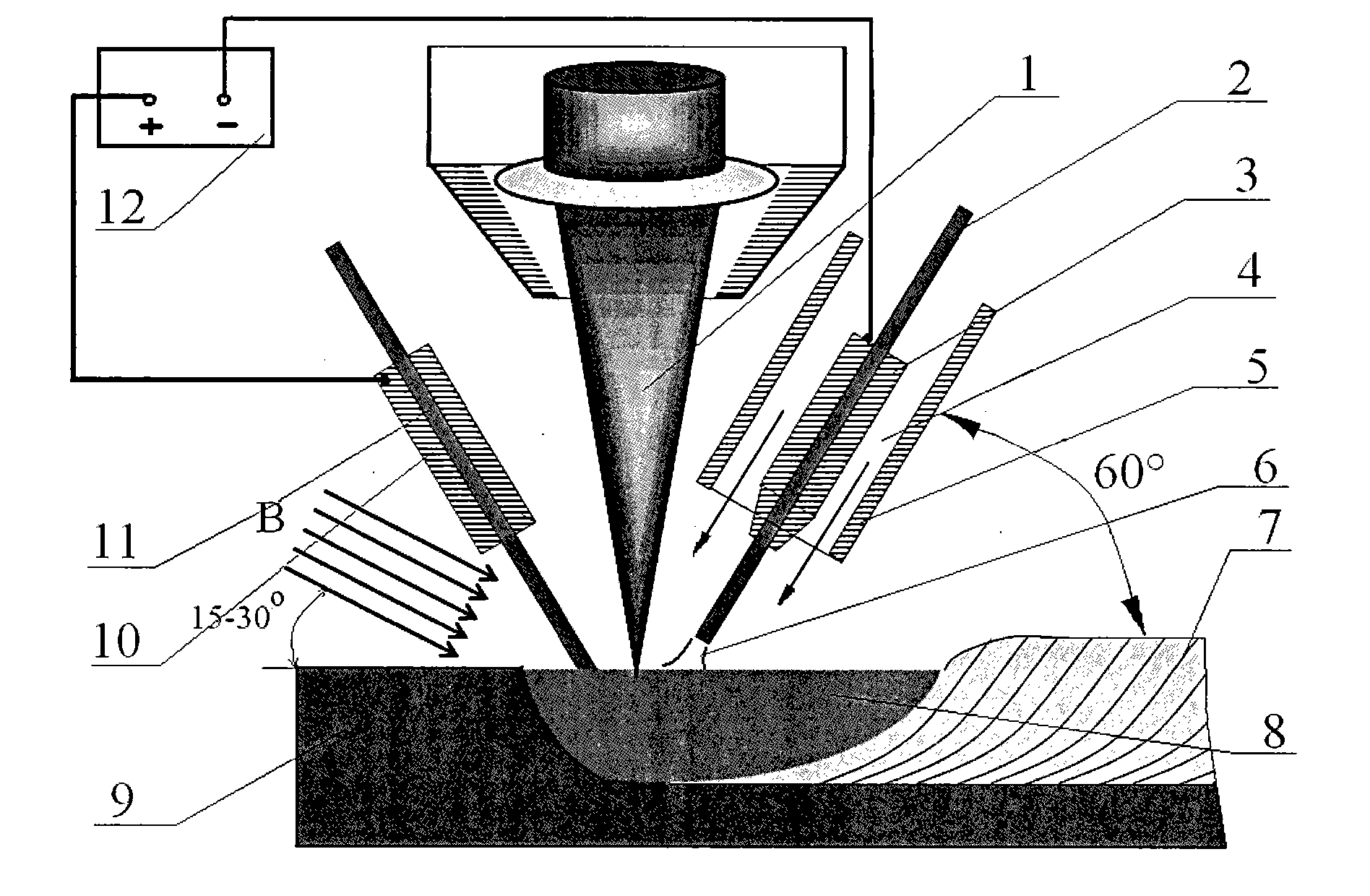

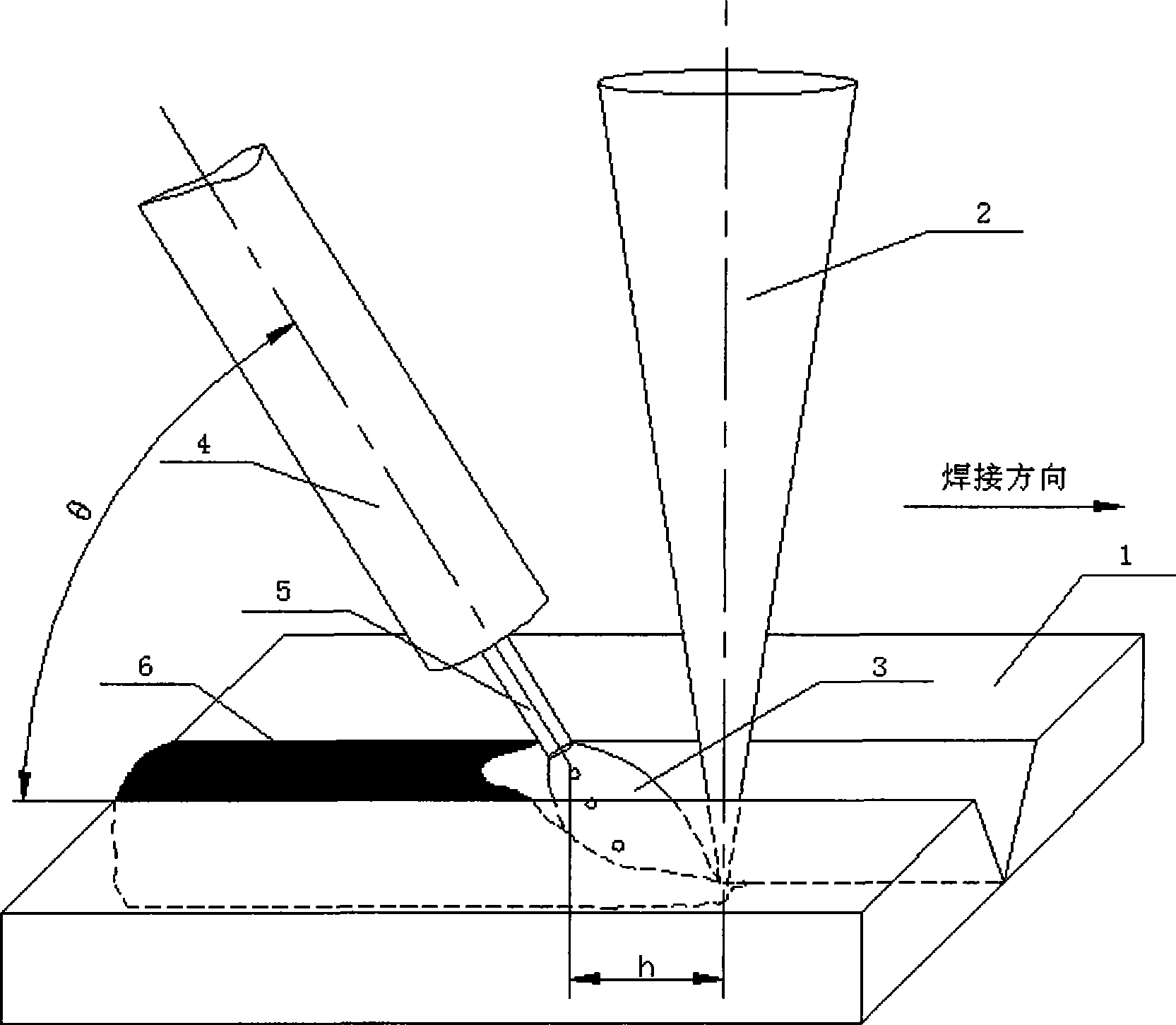

Electromagnetic current coupling field assisted hybrid melting-brazing method for laser-TIG arc and equipment

InactiveCN101862913AImprove connection qualityInhibition formationSoldering apparatusWelding apparatusMetallic materialsWelding defect

The invention discloses an electromagnetic current coupling field assisted hybrid melting-brazing method for a laser-TIG arc and equipment. In addition to the use of the welding zone, an alternating magnetic field is added to control properties of plasma formed through ionization of laser, arc and a raw material metal, thereby improving the laser utilization rate. Under the electric field assisted comprehensive effect, the weld melting depth is increased, and the assistant effect on the melting bath of the liquid-state brazing filler metal for laser-arc melting-brazing is realized through electromagnetic stirring and excitation and enhancement, thereby promoting the orderly flow of the liquid-state brazing filler metal and the rupture, wetting, spreading and proliferation of the liquid-state brazing filler metal on the surface of the high metal material, improving the full mixing of the liquid-state brazing filler metal and the base metal formed by melting the low-melting-point metal material, improving the uniformity of the components of the brazed weld, stabilizing the welding process, reducing welding defects, increasing the welding speed, improving the weld formation, optimizing the structure and performance of the brazed weld, and improving the quality of the brazed joint. Moreover, the equipment has the advantages of simple structure, flexible application, low cost, good effect and easy realization.

Owner:CHONGQING UNIV

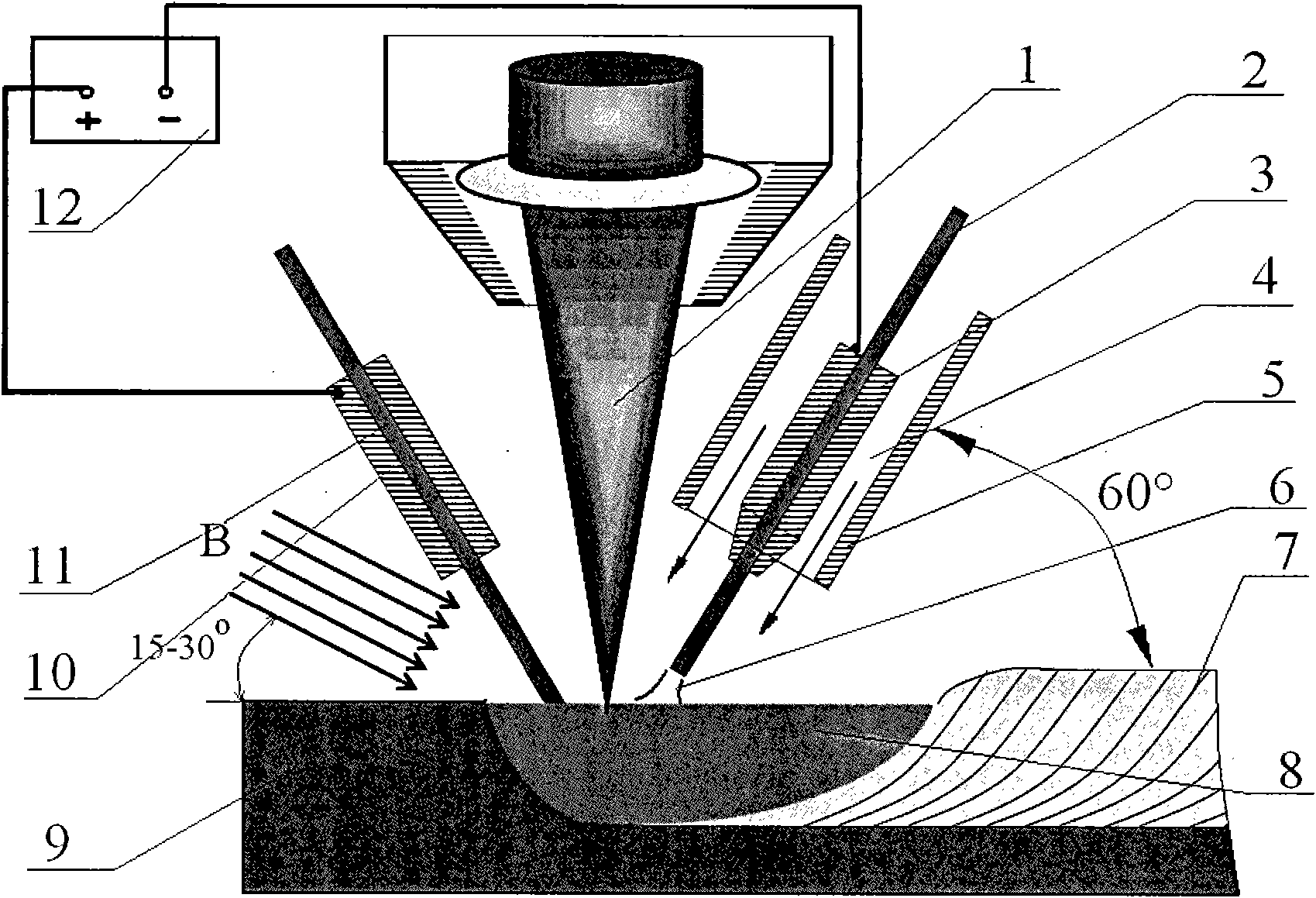

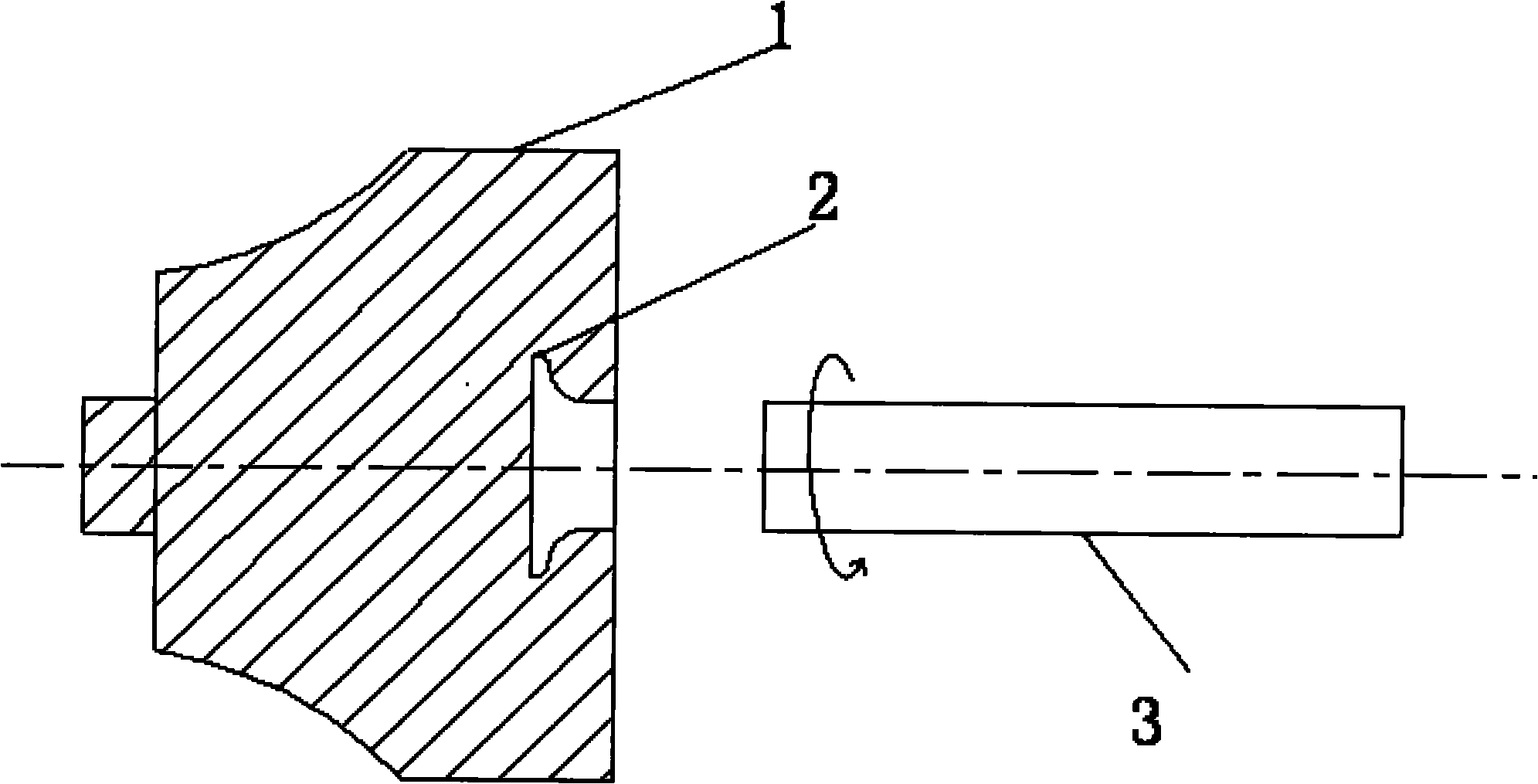

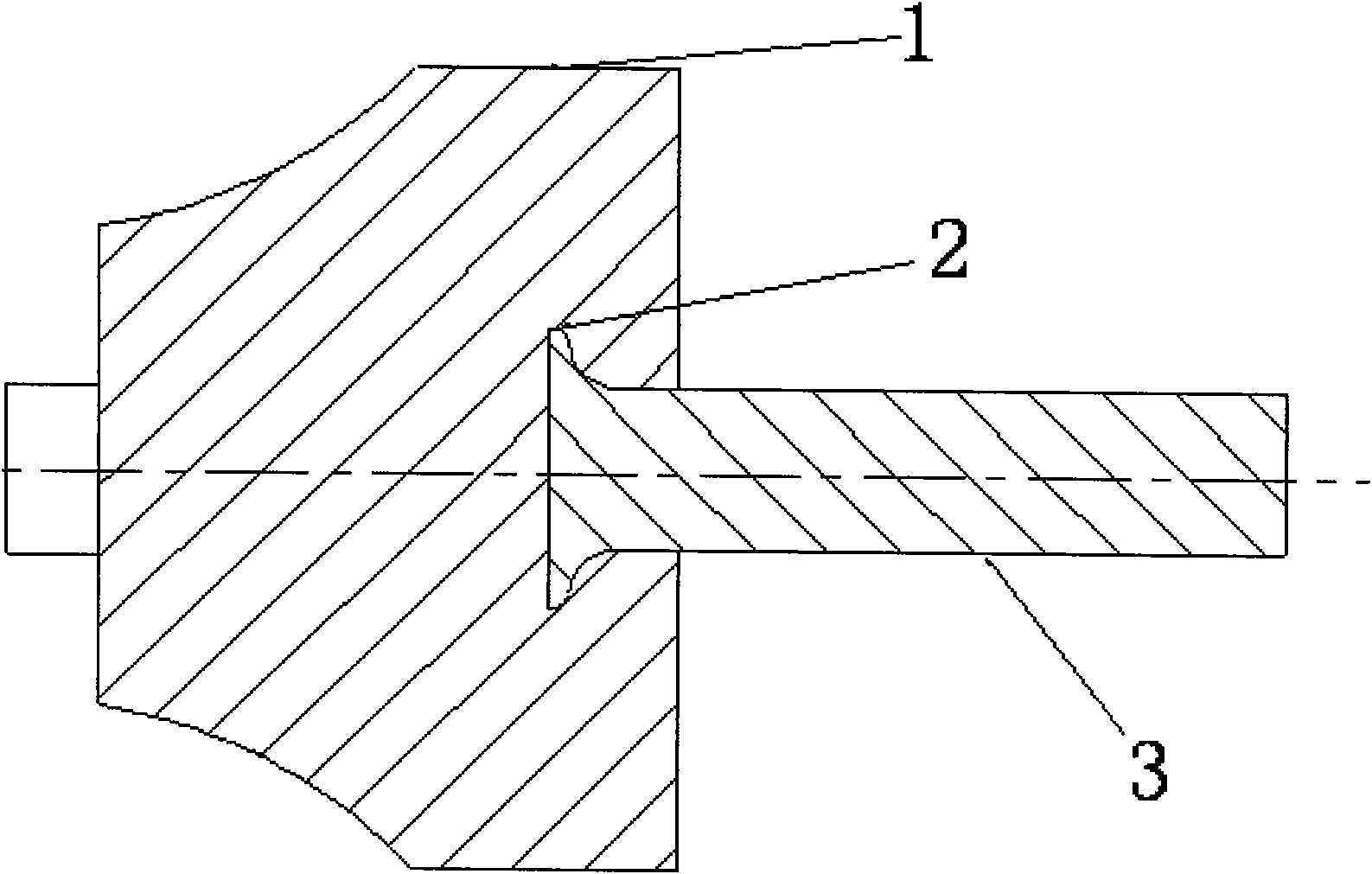

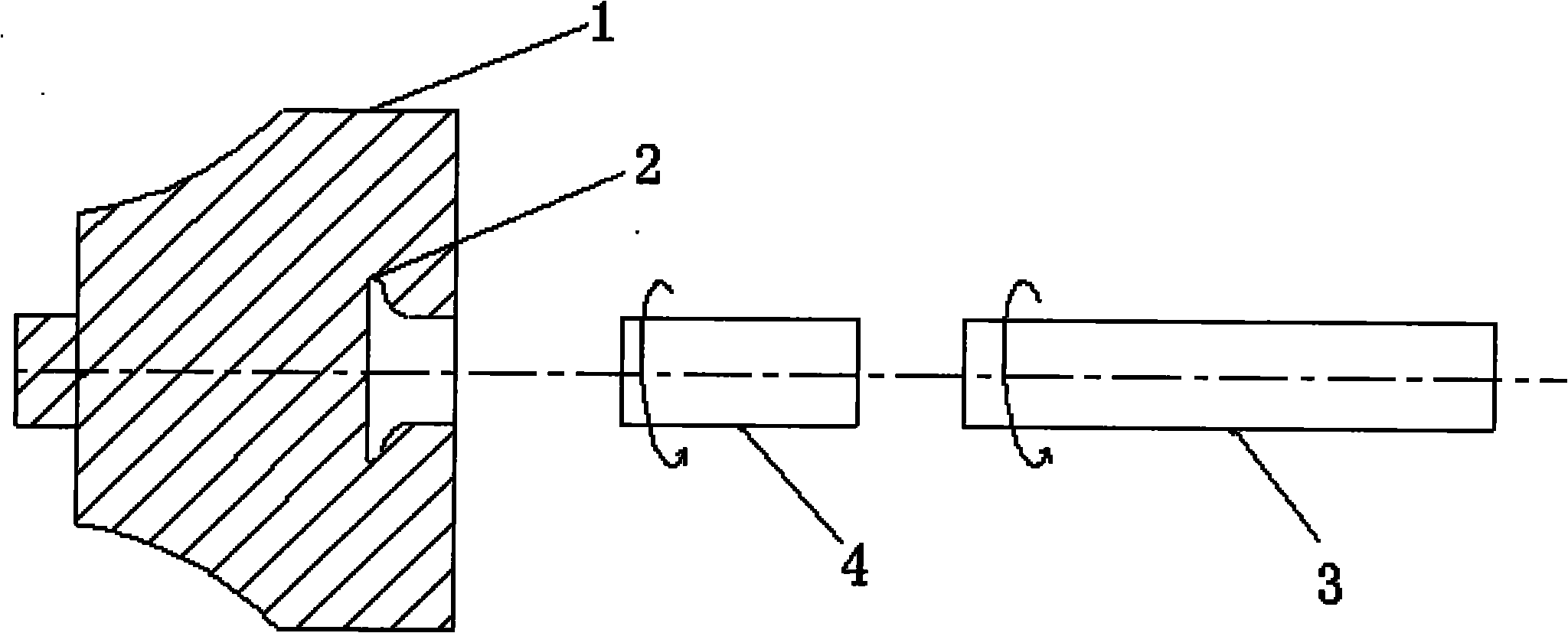

High-strength or ultra-high strong steel laser-electrical arc composite heat source welding method

InactiveCN101367157AImprove performanceLow preheat weldingLaser beam welding apparatusMetalSoldering process

The invention provides a novel high-strength or ultrahigh-strength steel laser-arc composite heat source welding method, which belongs to the technical field of the welding of high-strength or ultrahigh-strength steel. The method aims to solve the technical problem that the higher temperature needs to be adopted for preheating in order to prevent cold cracks during the welding of the high-strength or ultrahigh-strength steel. The welding method mainly comprises the following steps: the laser power is higher than 800 watts, a composite form that laser (2) is ahead and electric arc (3) follows is adopted along the welding direction, the filament spacing h is controlled to between 3 and 7 millimeters, and an included angle theta between an electric arc welding gun (4) and the horizontal plane is between 45 and 60 DEG. When the method is used to weld, a composite heat source welding pool is elongated and the oscillation of the pool is sharpened, so that the solidification rate of pool metal is reduced and grains are refined, thereby reducing the cold crack sensitivity during the welding process of the high-strength or ultrahigh-strength steel. The welding method can reduce the preheating temperature of the welding of the high-strength or ultrahigh-strength steel, and even can realize high-strength non-preheating welding.

Owner:HARBIN WELDING INST LTD

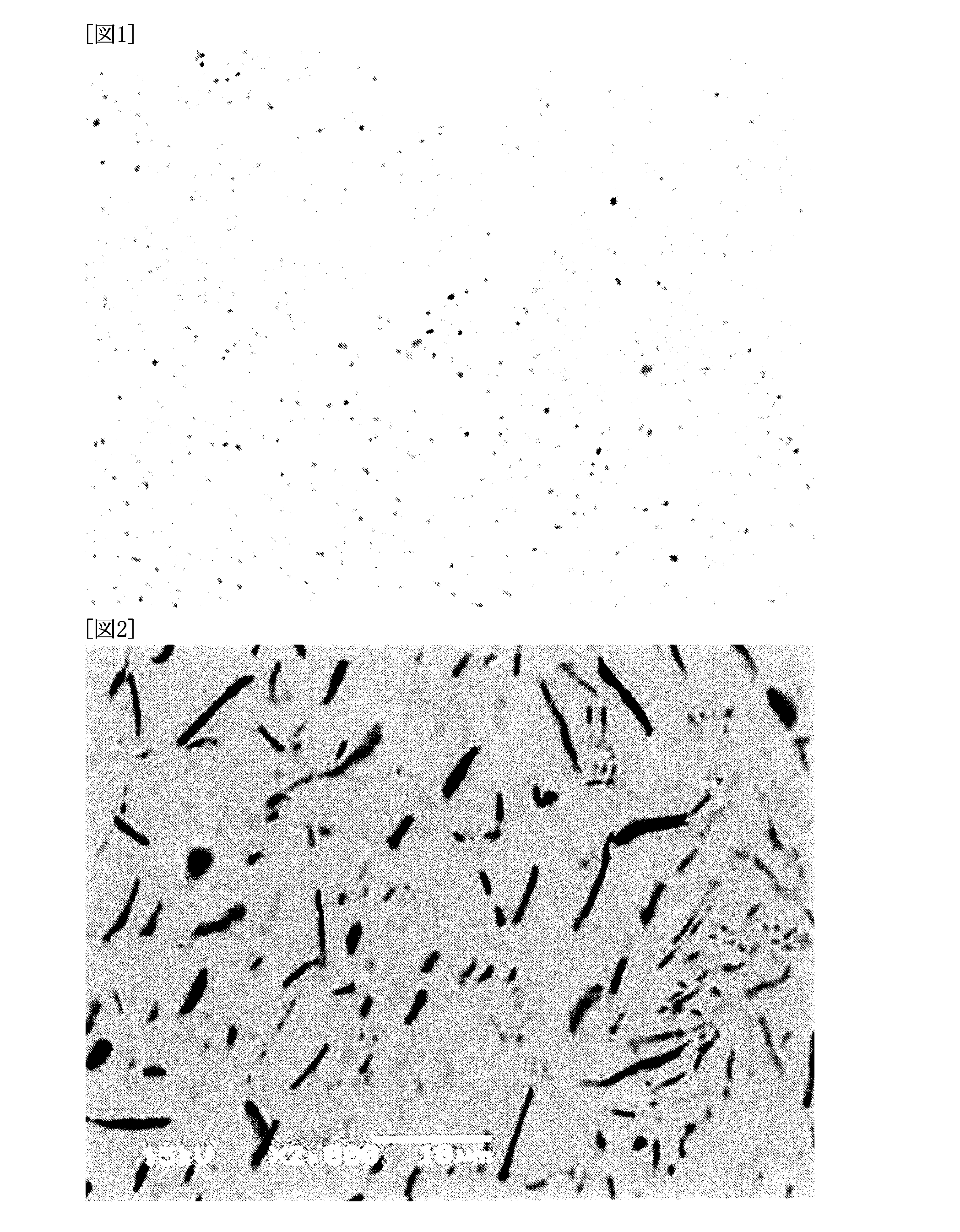

Lead-free solder paste

ActiveUS20090301606A1Reduced strengthImprove heat resistancePrinted circuit aspectsPrinted circuit manufactureAlloySolder paste

In a conventional Sn—Zn based lead-free solder, Zn crystallized to a large size of several tens of micrometers, and it was difficult to suppress the formation of coarse crystallizates and to increase the bonding strength without changing the soldering temperature. There were alloys which improved strength by the addition of a minute amount of a Group 1B metal, but the alloys had an increased melting temperature so that reflow could not be performed with the same temperature profile as for Sn—Pb, so the alloys had advantages and disadvantages.By using a solder paste formed by mixing an ethanol solution containing nanoparticles having a particle diameter of 5-300 nm and containing at least one of Ag, Au, and Cu with a flux and solder powder for an Sn—Zn based lead-free solder paste, the formation of an alloy of Au, Au, or Cu with Zn occurs during soldering, thereby forming fine clusters in the resulting liquid phase of molten solder, and a fine solder structure is obtained following melting.

Owner:SENJU METAL IND CO LTD

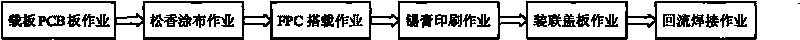

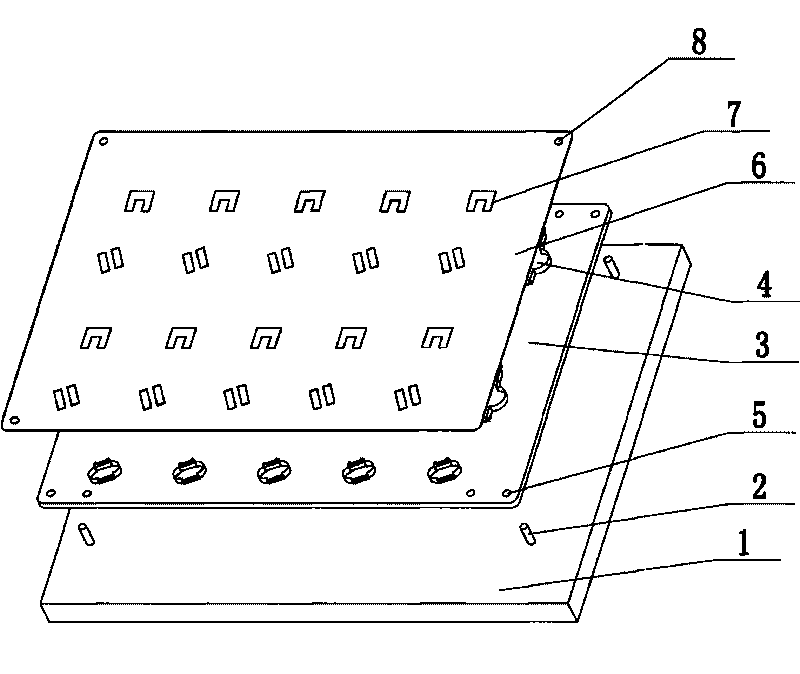

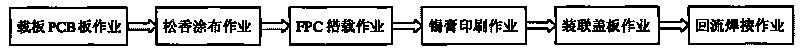

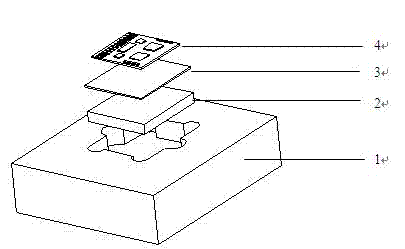

Method for assembly and reflow soldering of PCB and FPC and special positioning fixture thereof

InactiveCN101720172AIncrease productivitySimplify the initial positioning methodPrinted circuit assemblingPrinted element electric connection formationEngineeringProcessing cost

The invention discloses a method for the assembly and the reflow soldering of a PCB and an FPC and a special positioning fixture thereof, which mainly solve the problems of inaccurate positioning, low efficiency of welding efficiency, difficulty for ensuring product quality and the like of manual assembly in the processes of assembling and soldering the PCB and the FPC. The method comprises the following steps: firstly, supporting, positioning and fixing the PCB by using a magnetic carrier board; secondly, carrying the FPC; next, preliminarily positioning the PCB and the FPC with a bonding agent; thirdly, printing a solder paster on a solder pad at the junction of the FPC and the PCB; and finally, pressing a magnetic cover board on the magnetic carrier board, fixing the positions of the FPC and the PCB, and performing the reflow soldering on the FPC and the PCB through a reflow oven. The method for the assembly and the reflow soldering of the PCB and the FPC and the special positioning fixture thereof have the advantages of simple operation, good reliability, great improvement on the production efficiency and the production quality of the FPC and the PCB in the processes of assembling and soldering, and processing cost reduction.

Owner:HUIZHOUSRTY INFORMATION ELECTRONICS

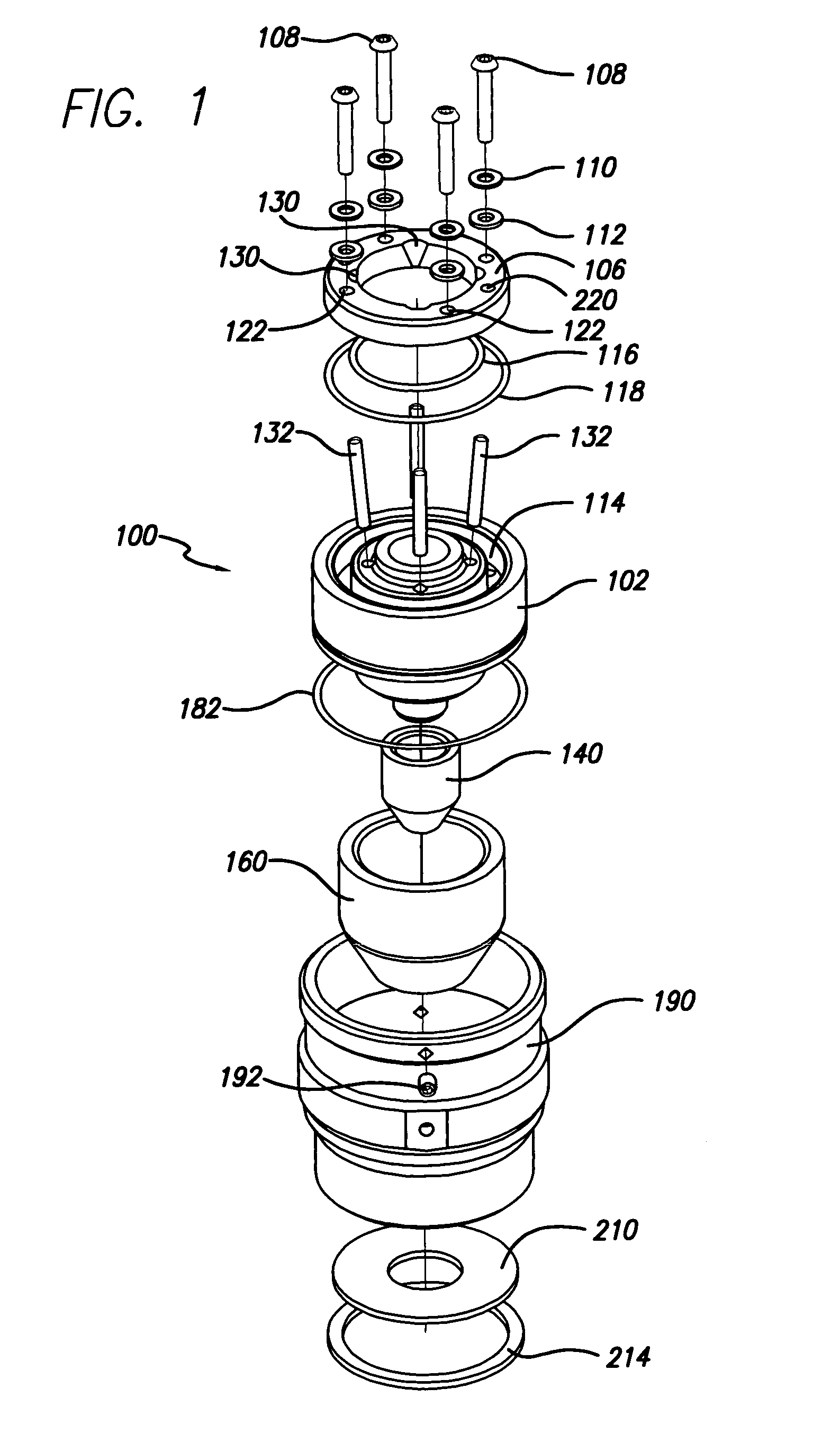

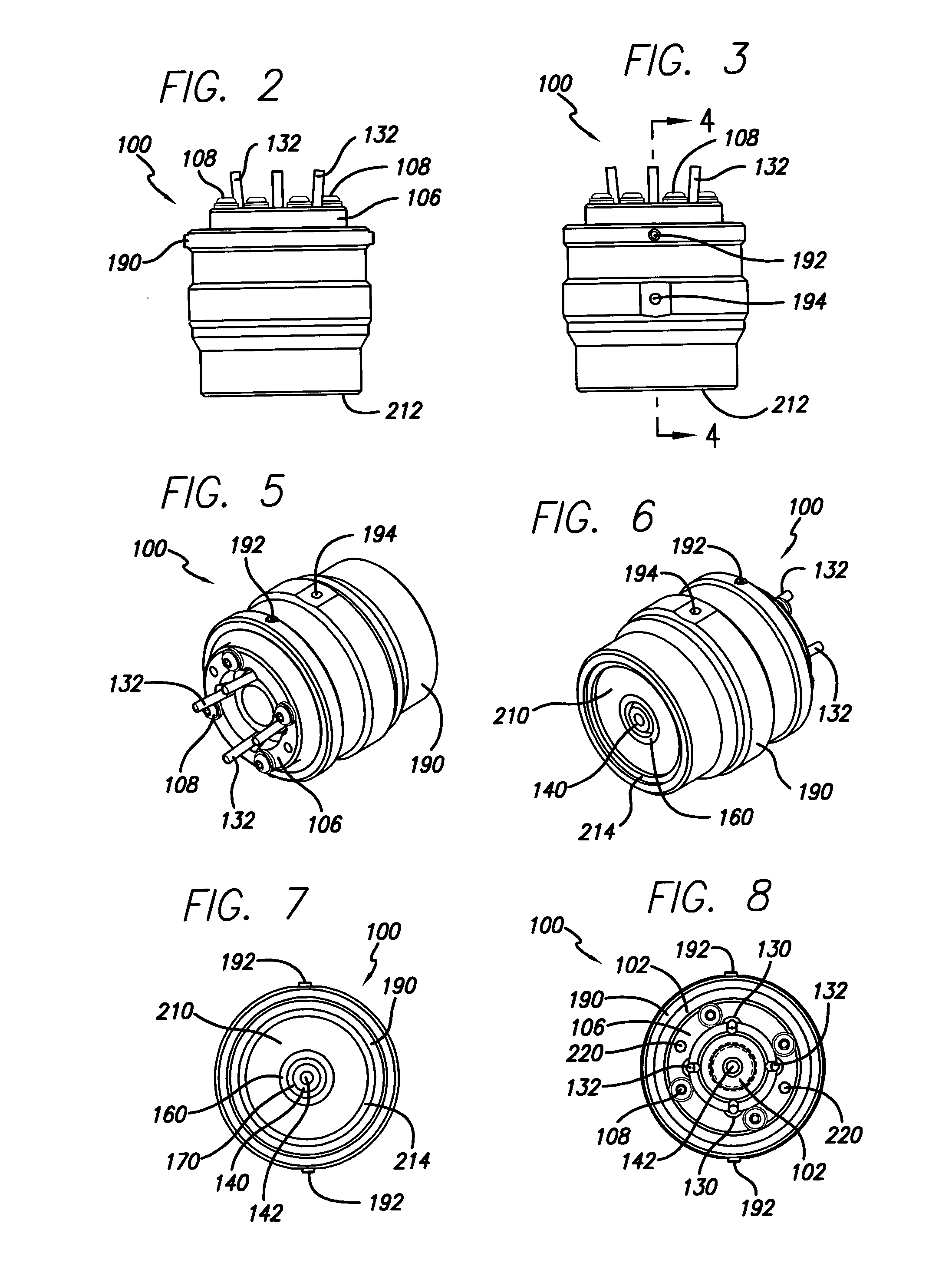

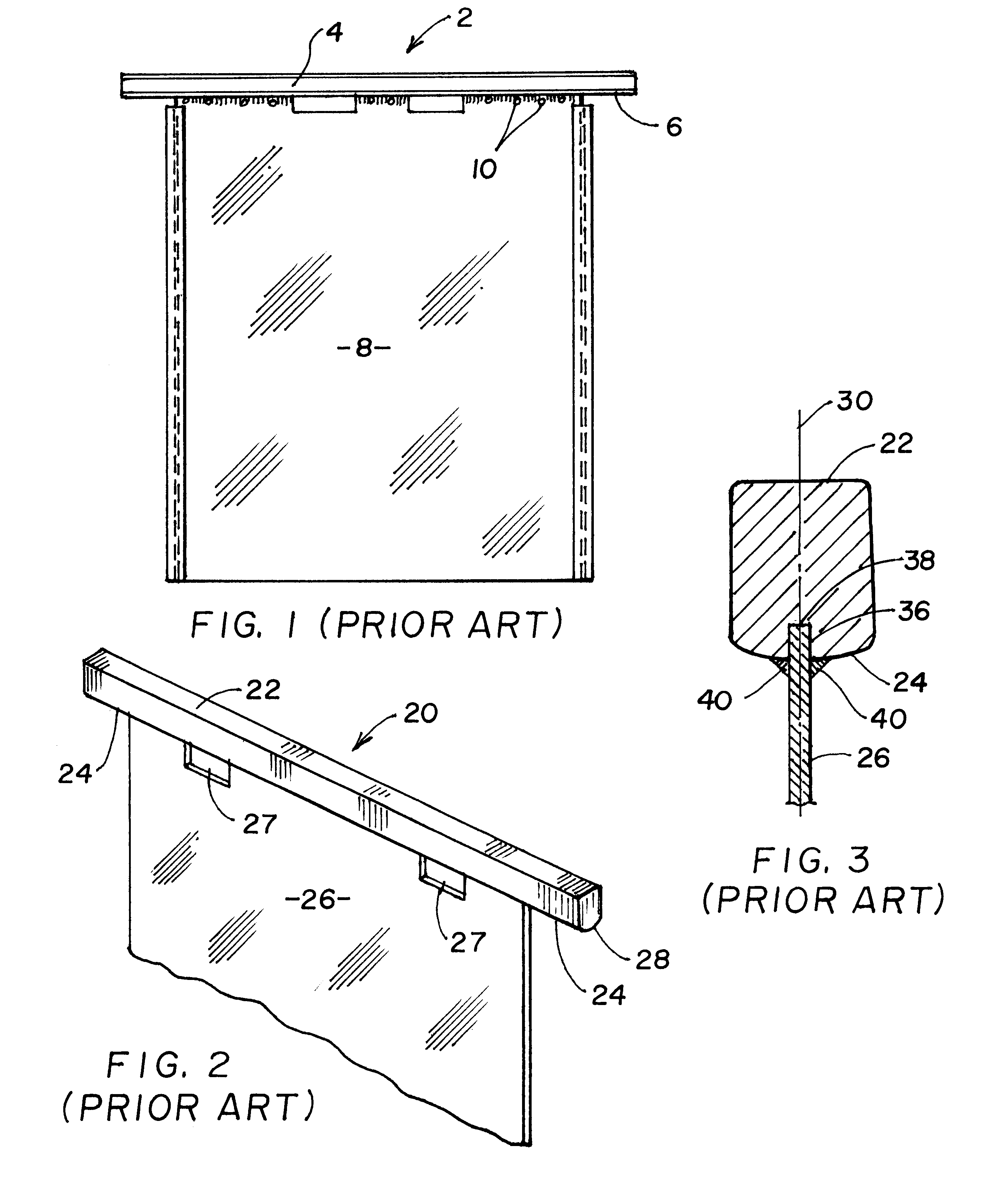

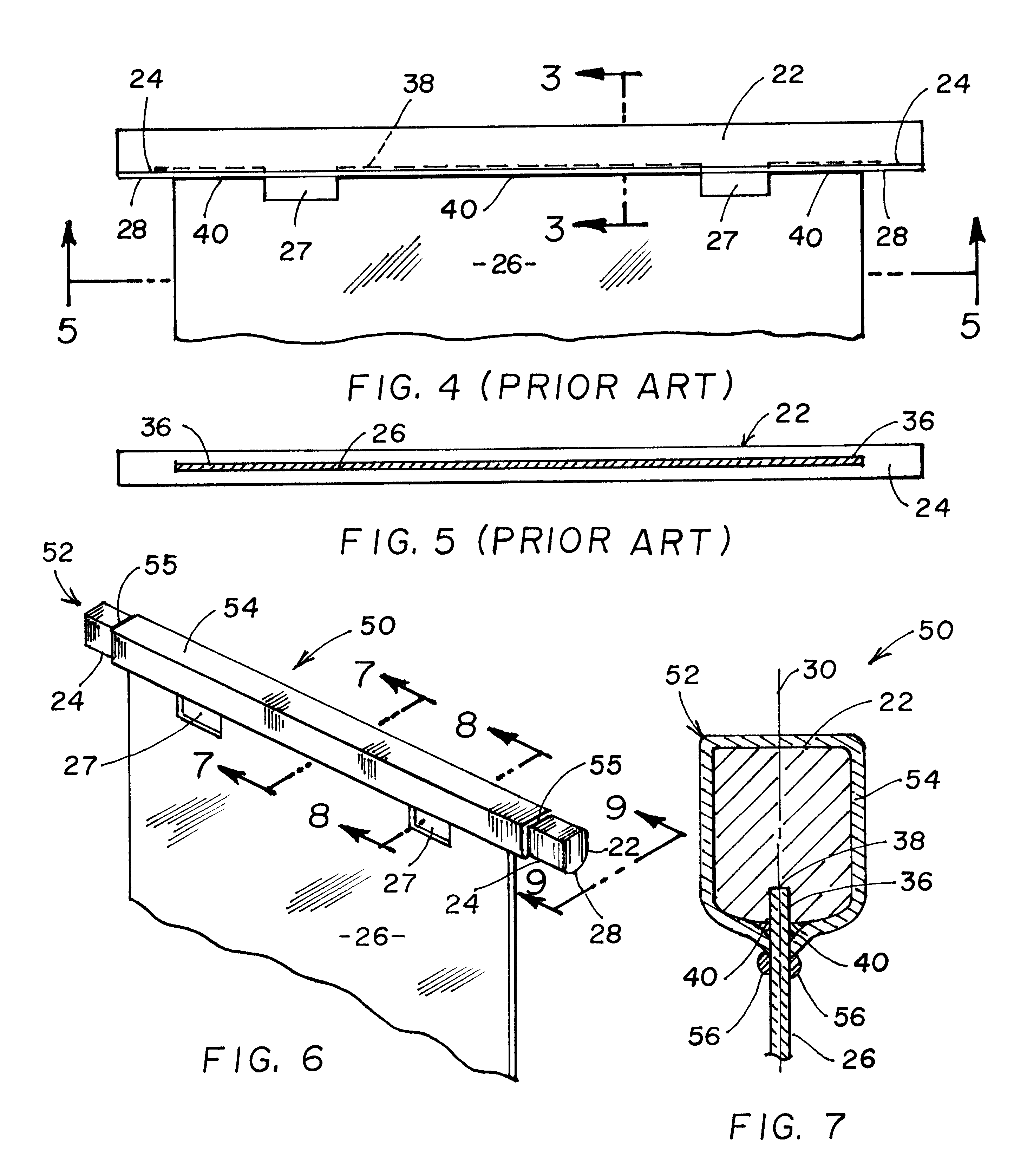

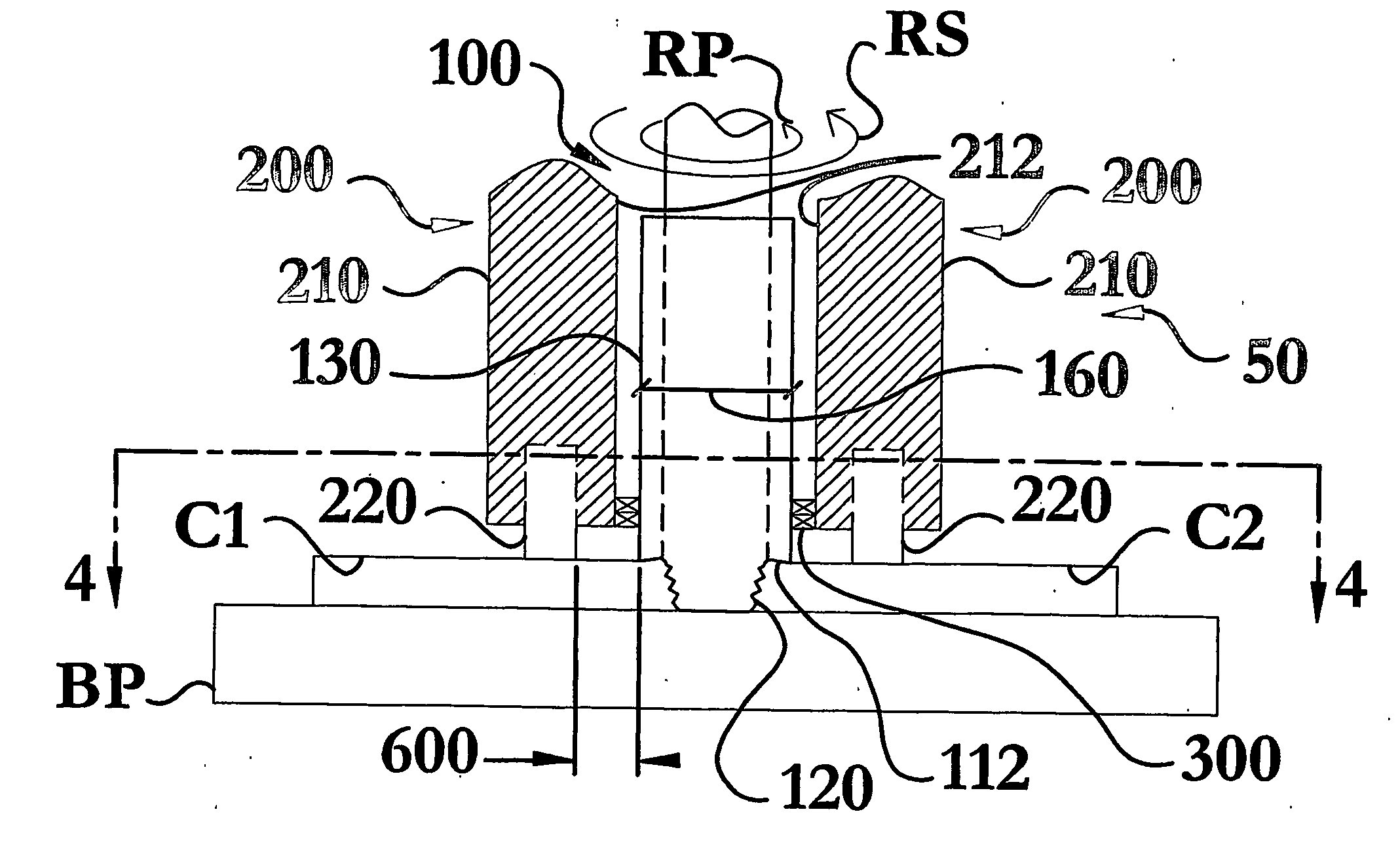

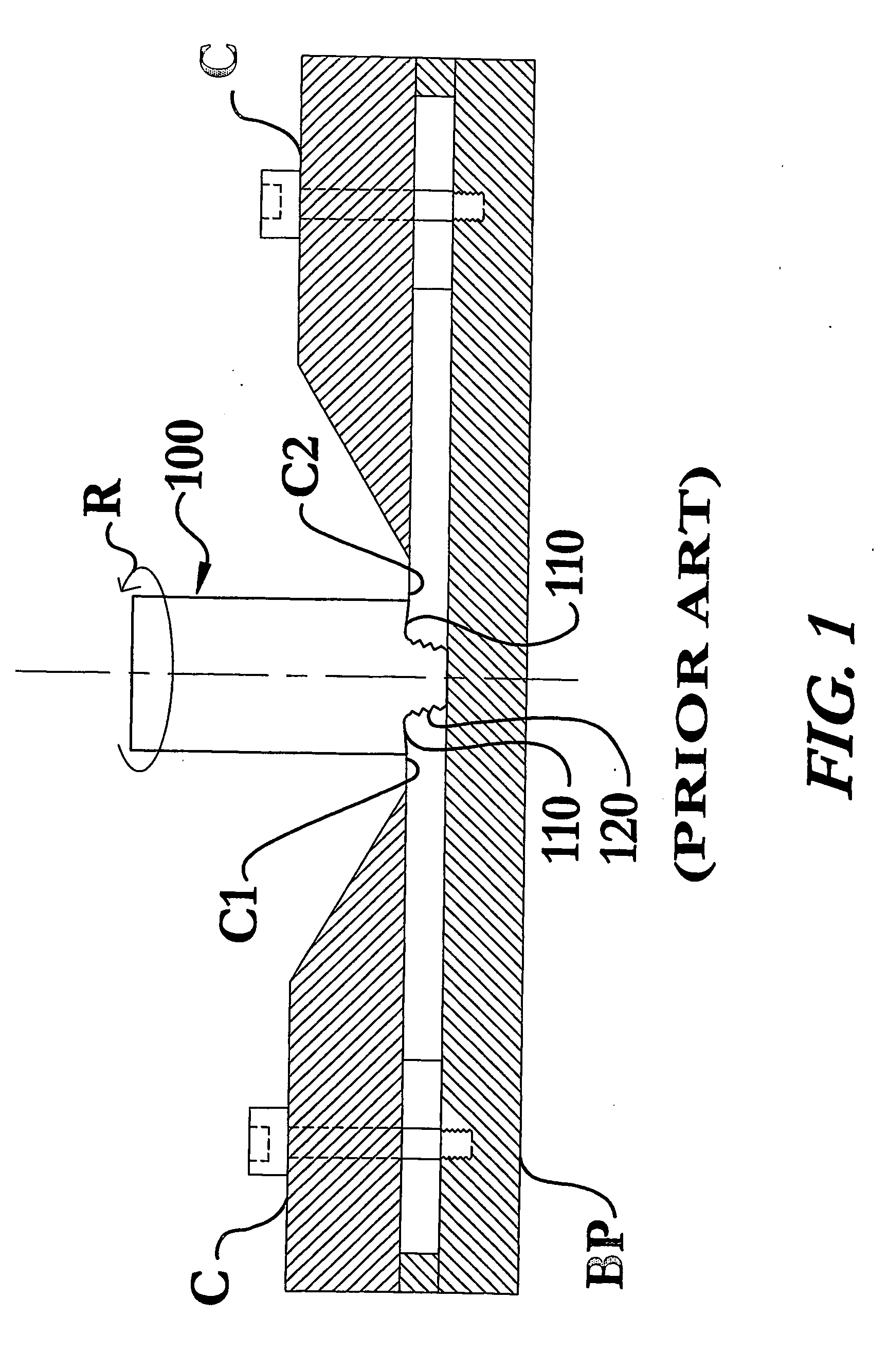

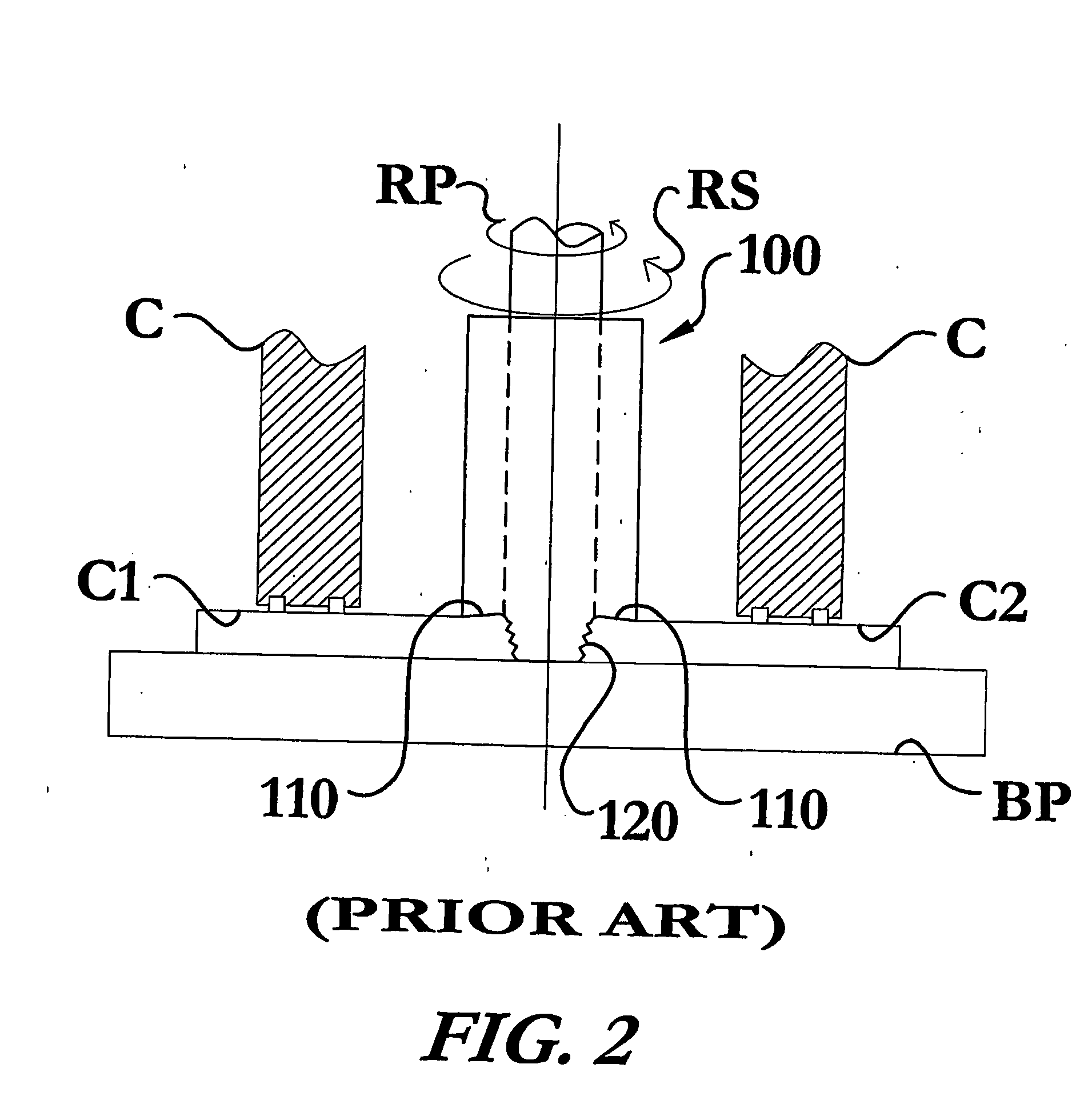

Method and apparatus for locally clamping components that are to be joined by friction stir welding

InactiveUS20060102689A1Welding/cutting auxillary devicesLaminationBall bearingBiomedical engineering

The apparatus (50) includes a friction stir welding tool (100), a local clamping means (200), and an interface (300) that joins the tool (100) and the local clamping means (200). The local clamping means (200) is in close proximity to the at least one sidewall (130) of the tool (100) and has a housing (210) and a plurality of contact devices (220). The local clamping means (200) transfers a clamping force to the first and the second components (C1, C2) and holds them firmly in place during welding. The local clamping means (200) includes a plurality of contact devices (220) that may take the form of casters, rollers (222), and ball bearings (224). The location of the contact devices (220) is significant as external clamping is greatly reduced, and often eliminated, as the contact devices (220) are brought into close proximity to the area of the weld.

Owner:EDISON WELDING INSTITUTE INC

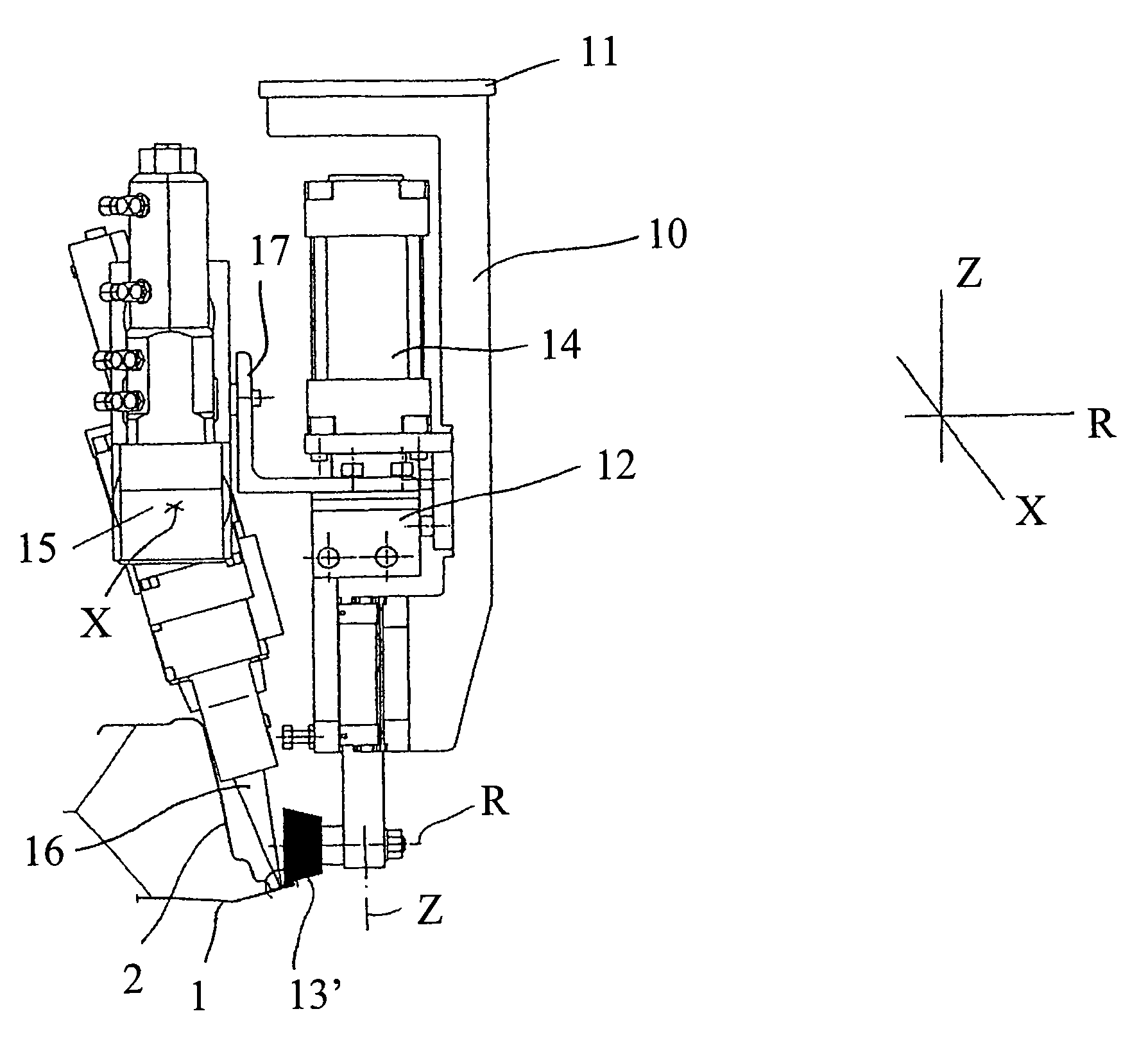

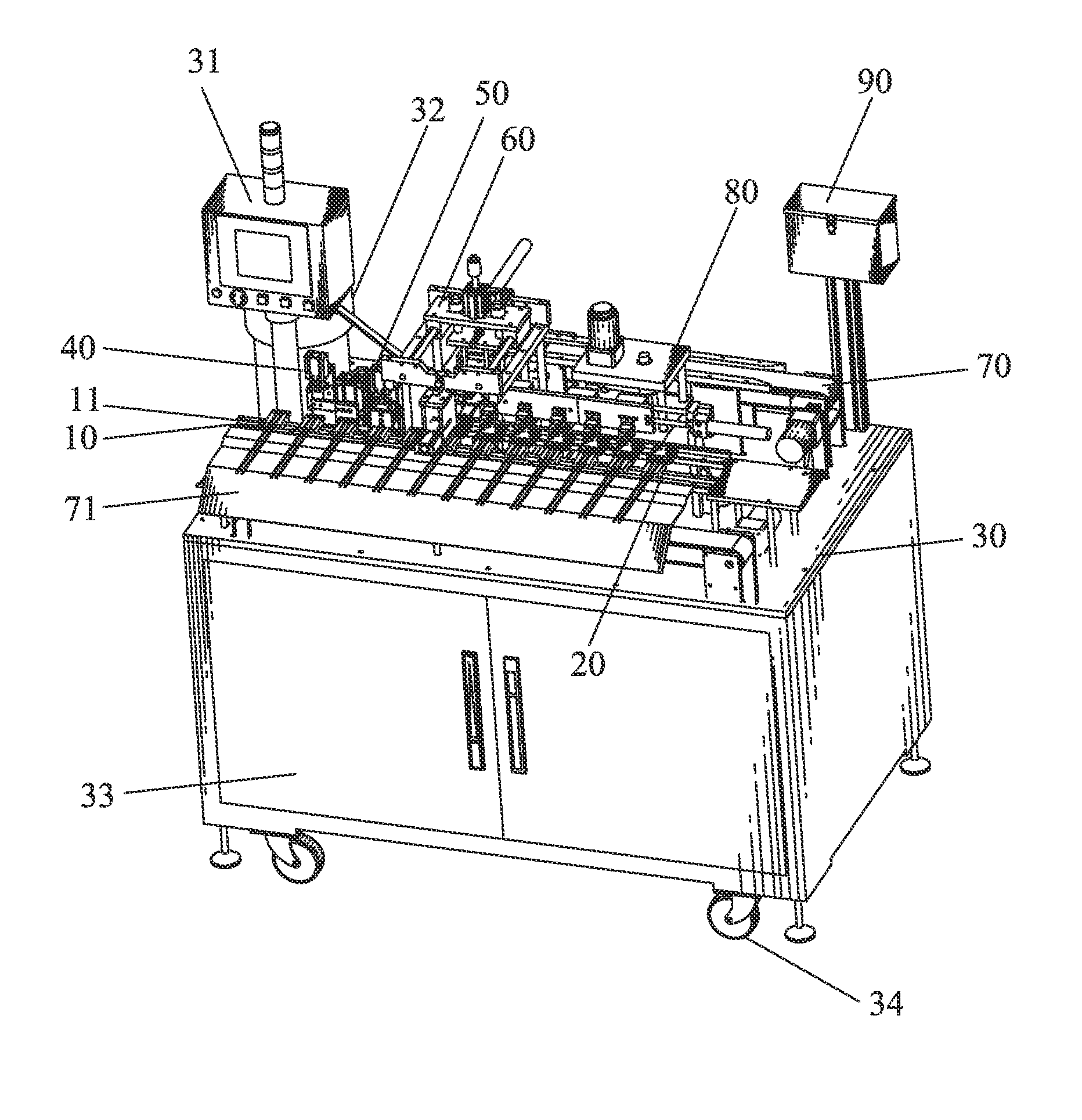

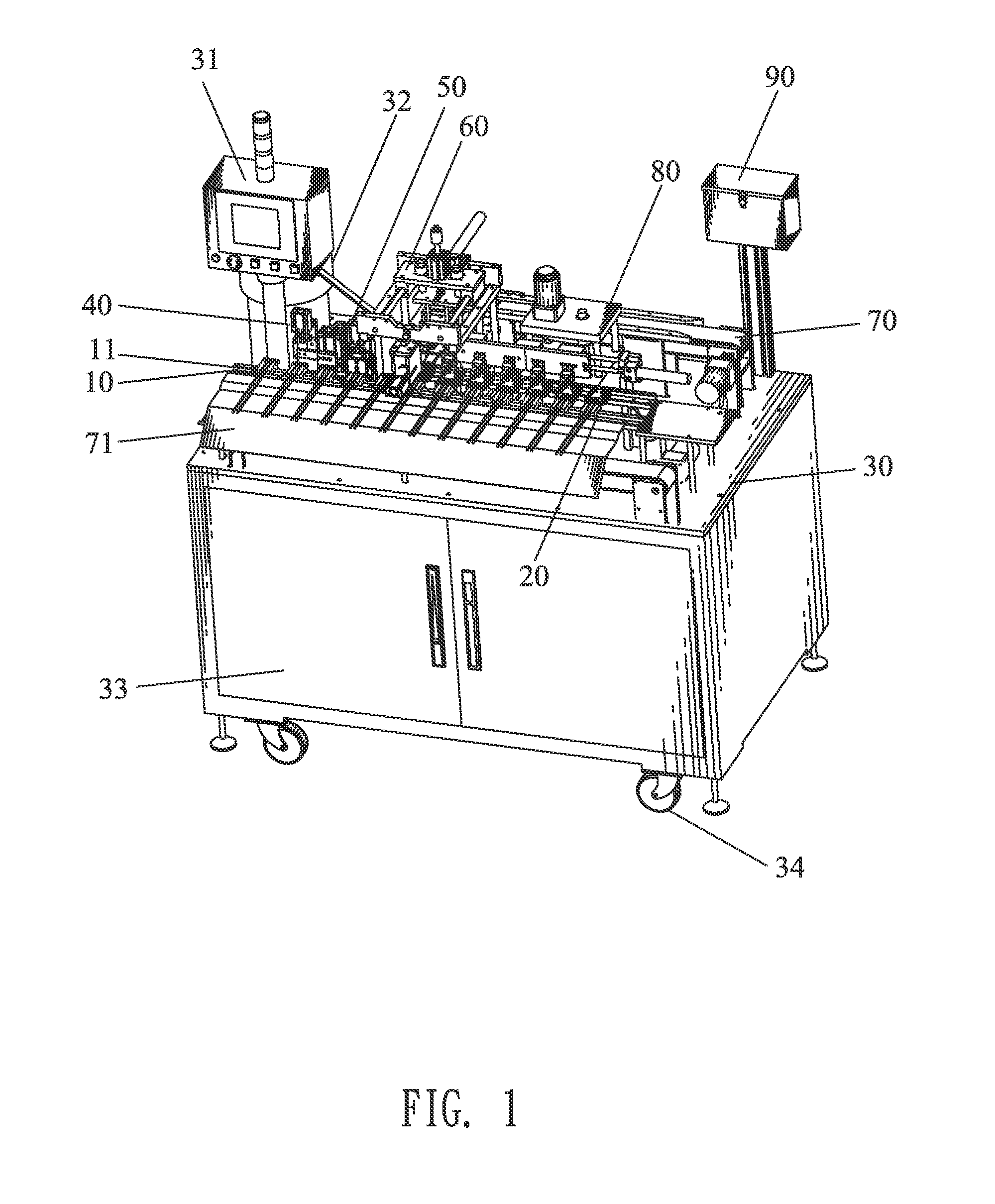

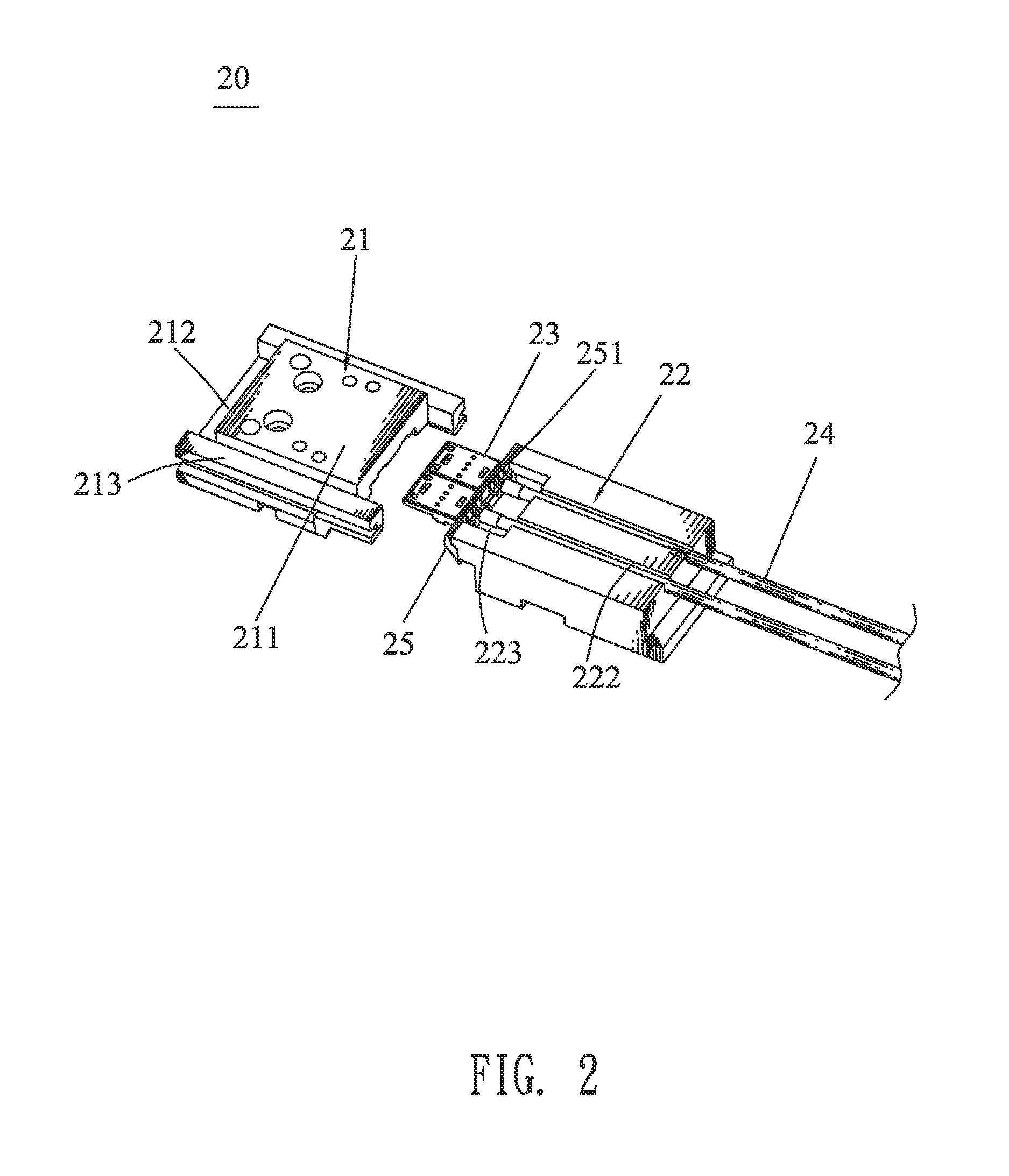

Automatic soldering machine

InactiveUS8517245B1Solve low manufacturing efficiencyQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesMan machineEngineering

An automatic soldering machine adapted for soldering cables with electronic products includes a main frame module, a man-machine control interface, a sliding tray located in front of the man-machine control interface, a loading tool slidably disposed in the sliding tray, a feeding module close to a bottom of the sliding tray, a removing module located between the man-machine control interface and a reforming module, a container, a loading tool combination module located above the sliding tray, a spraying module located in rear of the sliding tray, and a loading tool reflow module mounted on a rear of the main frame module. The man-machine control interface is connected with and controls the loading tool, the feeding module, the removing module, the reforming module, the loading tool combination module, the spraying module and the loading tool reflow module for realizing an automatic soldering process of the electronic products and the cables.

Owner:CHENG UEI PRECISION IND CO LTD

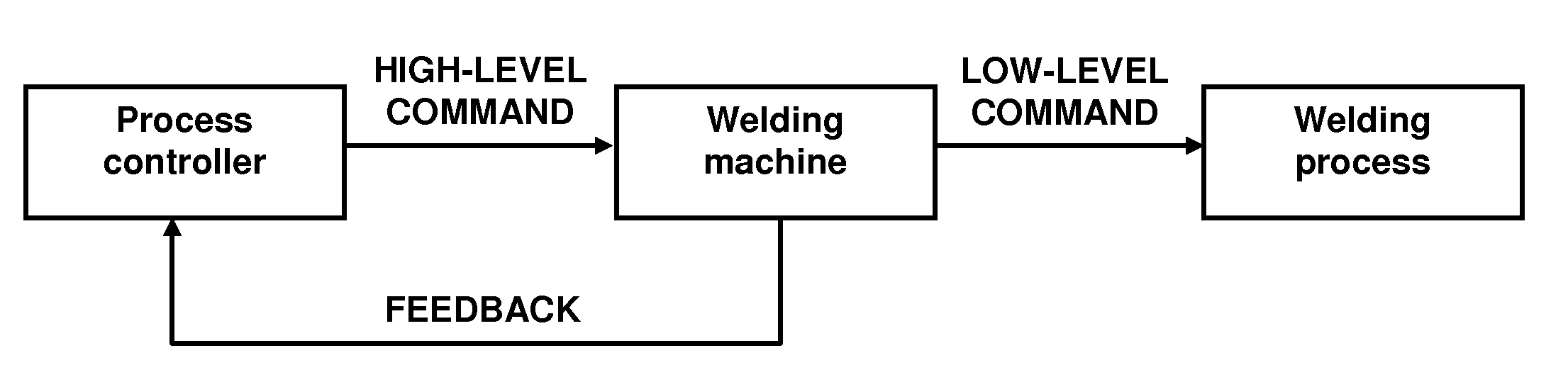

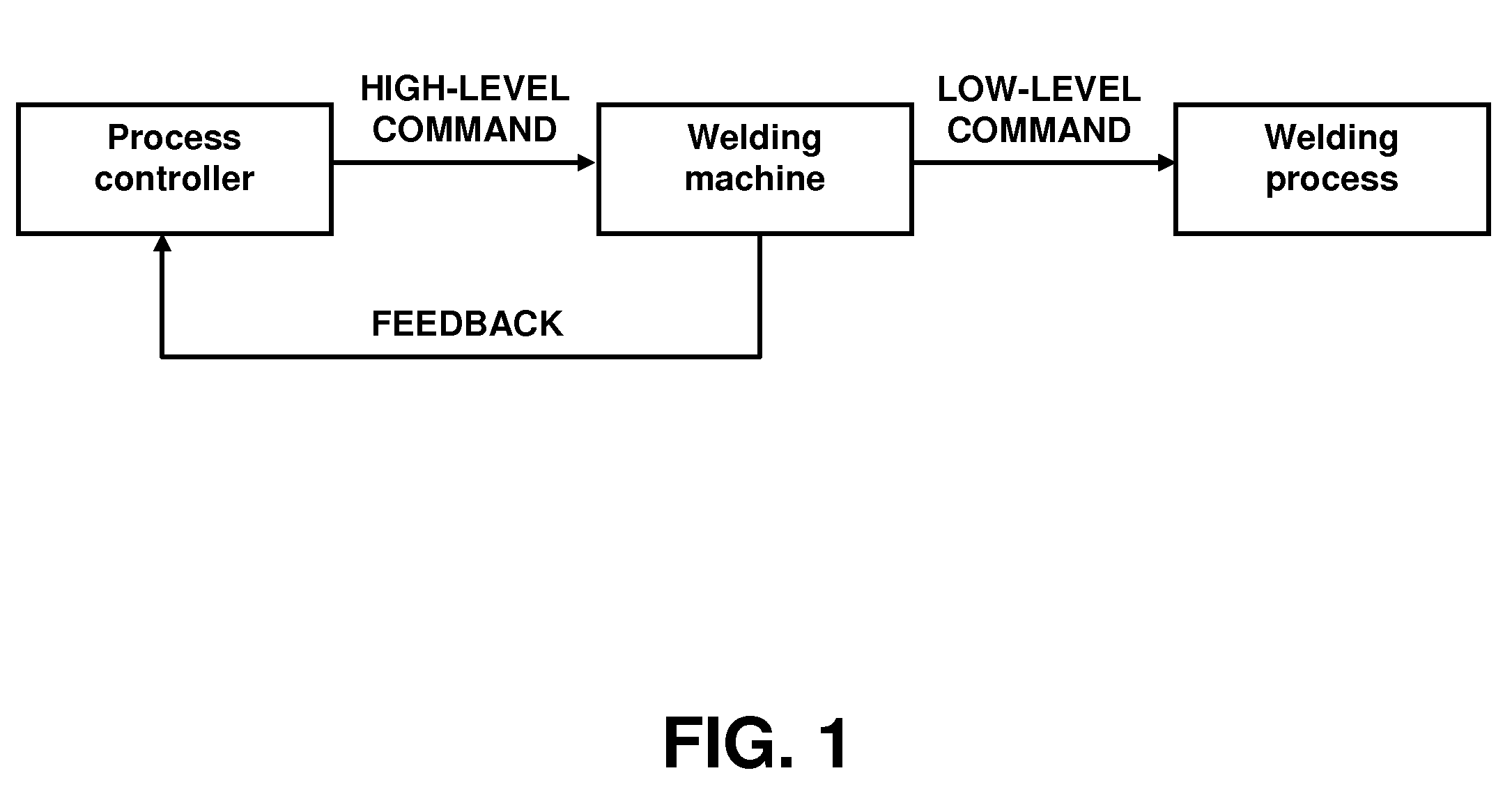

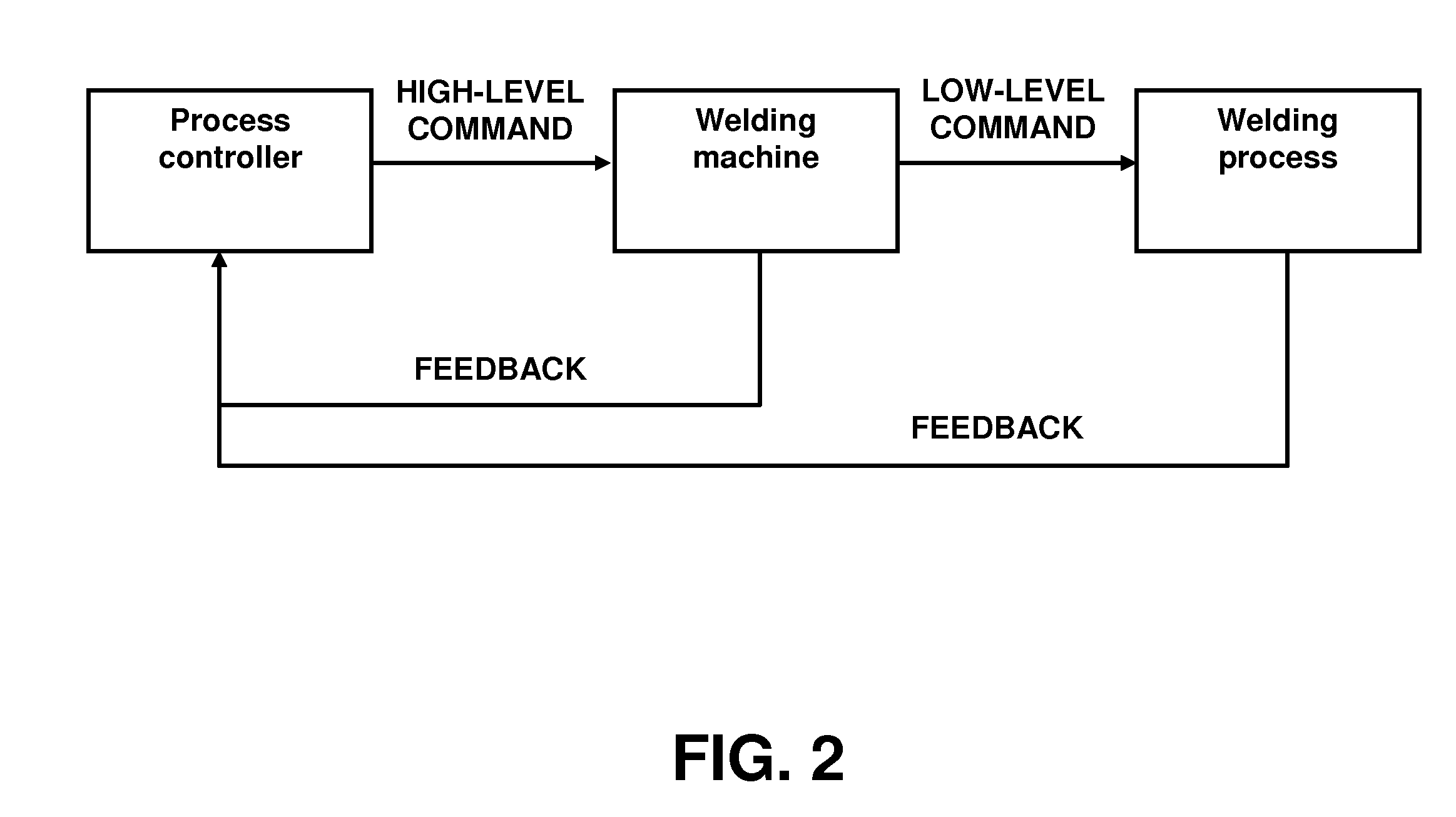

Controlled weld pool volume control of welding processes

ActiveUS20100288734A1Easy to controlAccurate volumeTemperatue controlElectron beam welding apparatusReal-time dataEngineering

A new method of process control for fusion welding maintains a controlled weld pool size or volume, for example in some applications a substantially constant weld pool size or volume. The invention comprises a method of linking machine and process variables to the weld pool size or volume in real time, thereby enabling constant weld pool volume control. The invention further comprises a method of using thermal inverse models to rapidly process real-time data and enable models-based control of welding processes so as to implement constant weld pool volume control.

Owner:SIGMA LAB OF ARIZONA

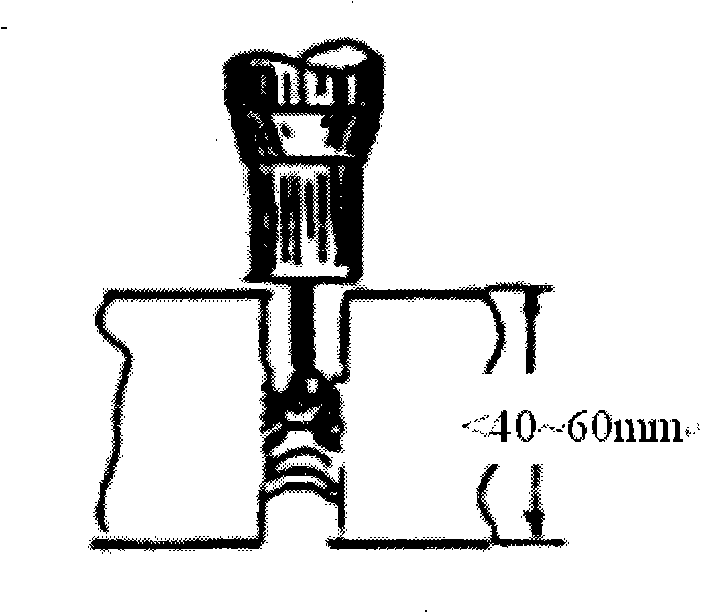

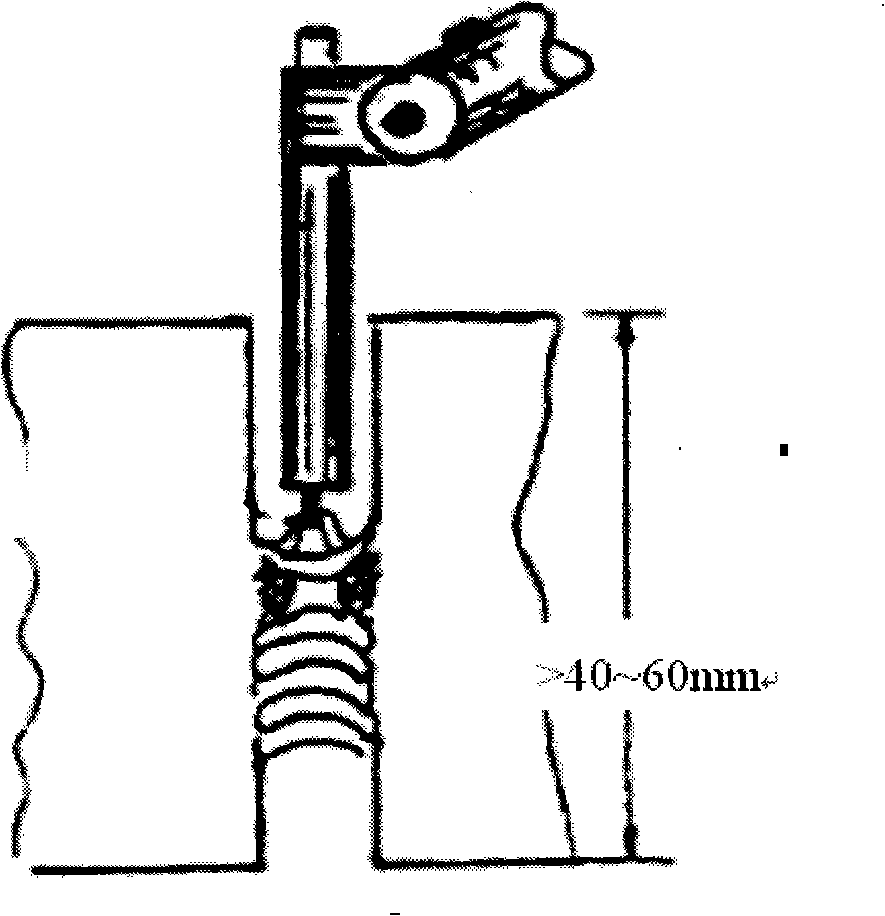

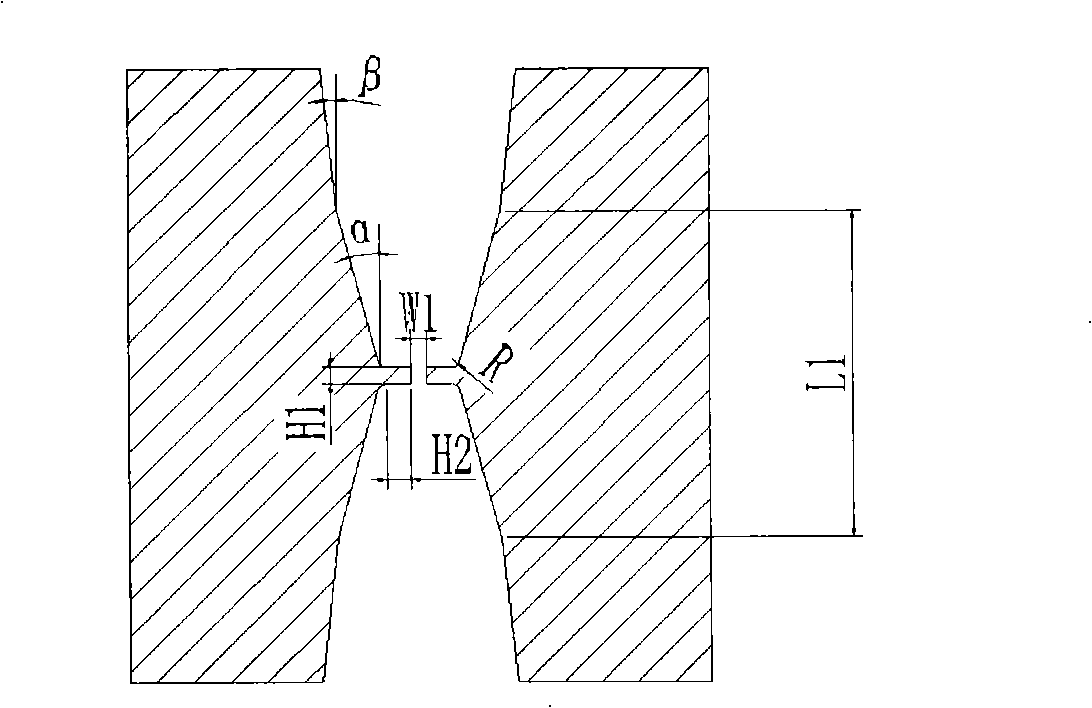

TIG automatic welding technique for titanium alloy thick plate narrow interstice

InactiveCN101293303AEnables narrow gap weldingWeld firmlyElectrode supporting devicesWorkpiece edge portionsEngineeringTitanium alloy

The invention discloses a narrow clearance TIC automatic welding technique for a thick plate of titanium alloy. The welding technique comprises six items of a welding torch form, a welding line spreading form, a bevel for welding form, selecting the parameters of the welding process, selecting the protection atmosphere of the welding process and eliminating a welding stress adopted by welding process. The welding technique of the invention realizes the narrow clearance welding for the large thick plate of the titanium alloy, has stable welding process, can obtain the welding lines which have no defects, qualified properties and 10mm to 16mm of widths of the welding lines on a cover surface layer, thus solving the key technical problems of the narrow clearance TIC automatic welding for the large thick plate of the titanium alloy, realizing the narrow clearance TIC automatic welding for the thick plate of the titanium alloy and having the advantages of high manufacture efficiency, low manufacture cost, small residual stress and residual deformation of joints, relatively thin and small welding line tissues and good mechanical property of the joints.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

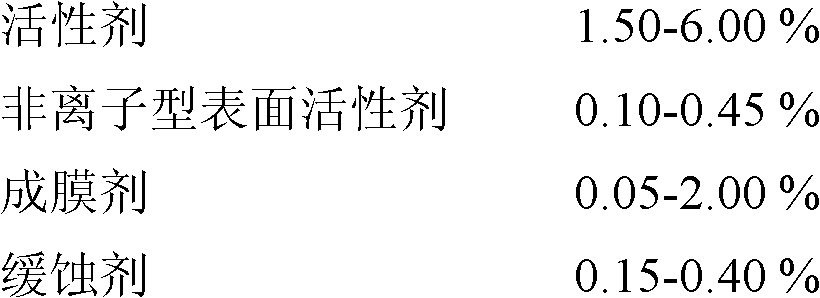

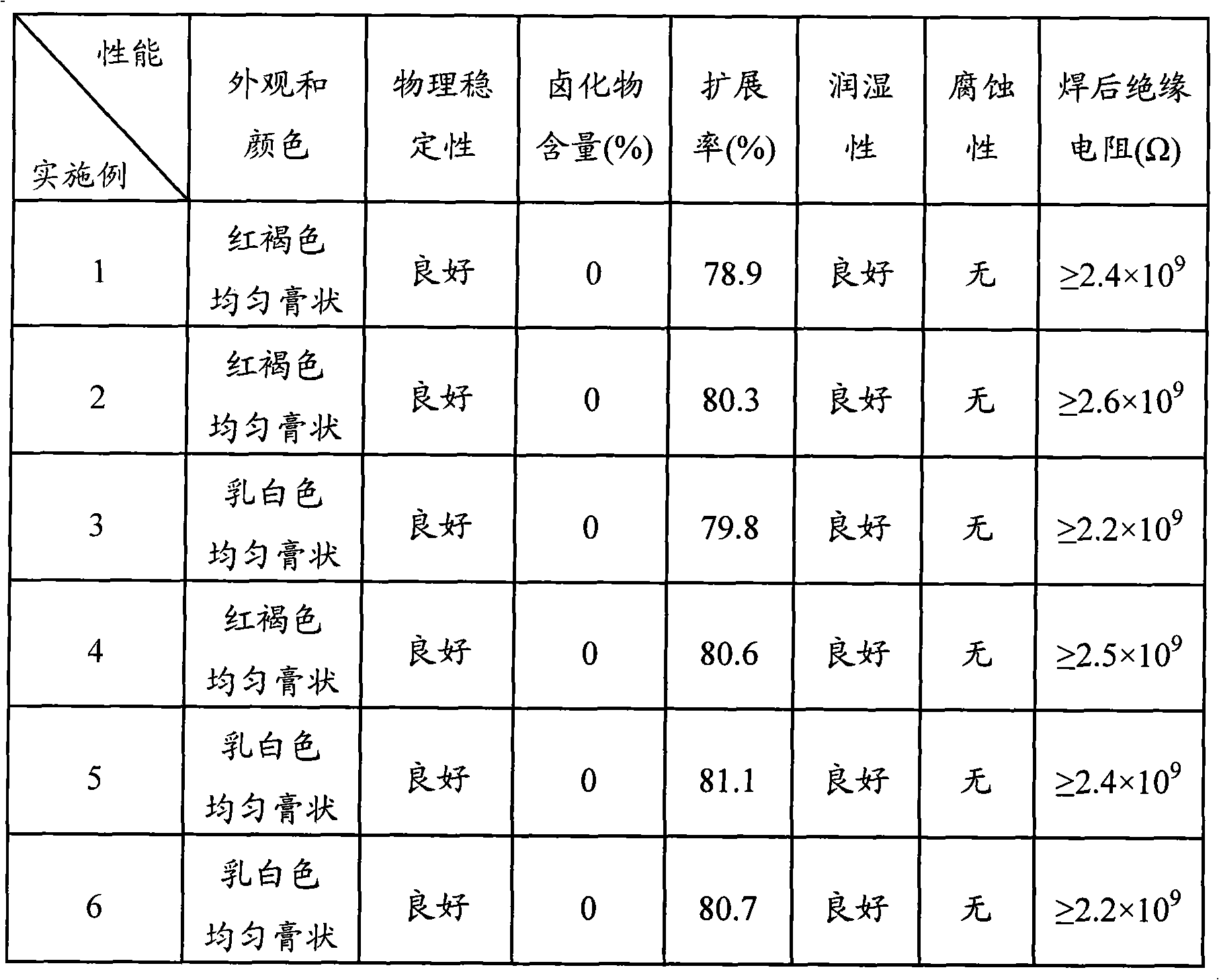

Halogen-free high-impedance water-based washing-free scaling powder as well as preparation method and application thereof

ActiveCN102350599AActive enoughReduce dosageWelding/cutting media/materialsSoldering mediaWater basedElectrical resistance and conductance

The invention discloses a halogen-free high-impedance water-based washing-free scaling powder as well as a preparation method and application thereof. The scaling powder disclosed by the invention comprises the following components in percentage by weight: 1.50-6.00% of activating agent, 0.10-0.45% of nonionic surfactant, 0.05-2.00% of film forming agent, 0.15-0.40% of corrosion inhibitor, 4.00-25.00% of cosolvent and the balance of deionized water. The scaling powder disclosed by the invention does not contain halogen and uses the deionized water as the main component of a scaling powder solvent, thus the scaling powder is safe and environment-friendly. In the invention, the coordination mode and dosage of each component of the scaling powder are accurately computed; the scaling powder has the advantages of good stability and excellent soldering performance; and the obtained soldered dots are full, thereby effectively reducing the occurrence of defects such as continuous soldering or missing soldering and the like. The composition materials of the scaling powder disclosed by the invention can be periodically volatilized in the soldering process; the residuals after the soldering are less; the electric insulating property is excellent; the surface insulating resistance after the soldering is larger than 1.0*108; and the washing is not needed.

Owner:SOUTH CHINA UNIV OF TECH +1

Vacuum eutectic welding method

InactiveCN102528194AOvercoming the problem of oxidized drossReduce storage requirementsSoldering apparatusSemiconductor/solid-state device manufacturingNitrogen gasContact resistance

The invention belongs to a micro-electronic encapsulation technology and specifically relates to a vacuum eutectic welding method. The method comprises the following steps: reducing gas formic acid vapor or hydrogen is introduced during a vacuum eutectic welding process, so as to reduce an oxidized welding material on a surface layer of a preformed welding material sheet and reduce the oxidized dreg of a welded surface; during a heating process, nitrogen is introduced and the heating rate is increased, so as to shorten the eutectic time and avoid the efficacy loss caused by chip over-welding or high-temperature accelerated ageing; and vacuumizing is carried out during an eutectic process, so as to reduce and even avoid voidage of the welded surface, increase the penetration rate of the chip and reduce the contact resistance and thermal resistance. According to the invention, the problem of the oxidized dreg on the welded surface caused by the oxidation of the surface layer of the welding material sheet in the prior art is overcome; the demand on storage conditions of the welding material sheet is reduced; the eutectic time is shortened; the efficacy loss caused by chip over-welding or high-temperature accelerated ageing is avoided; the void ratio is reduced; and the vacuum eutectic welding method has the characteristics of high reliability, high yield and low cost.

Owner:WUXI HUACE ELECTRONICS SYST

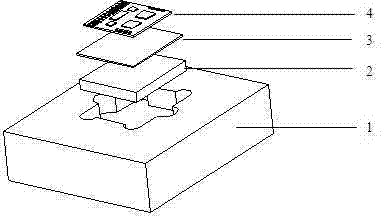

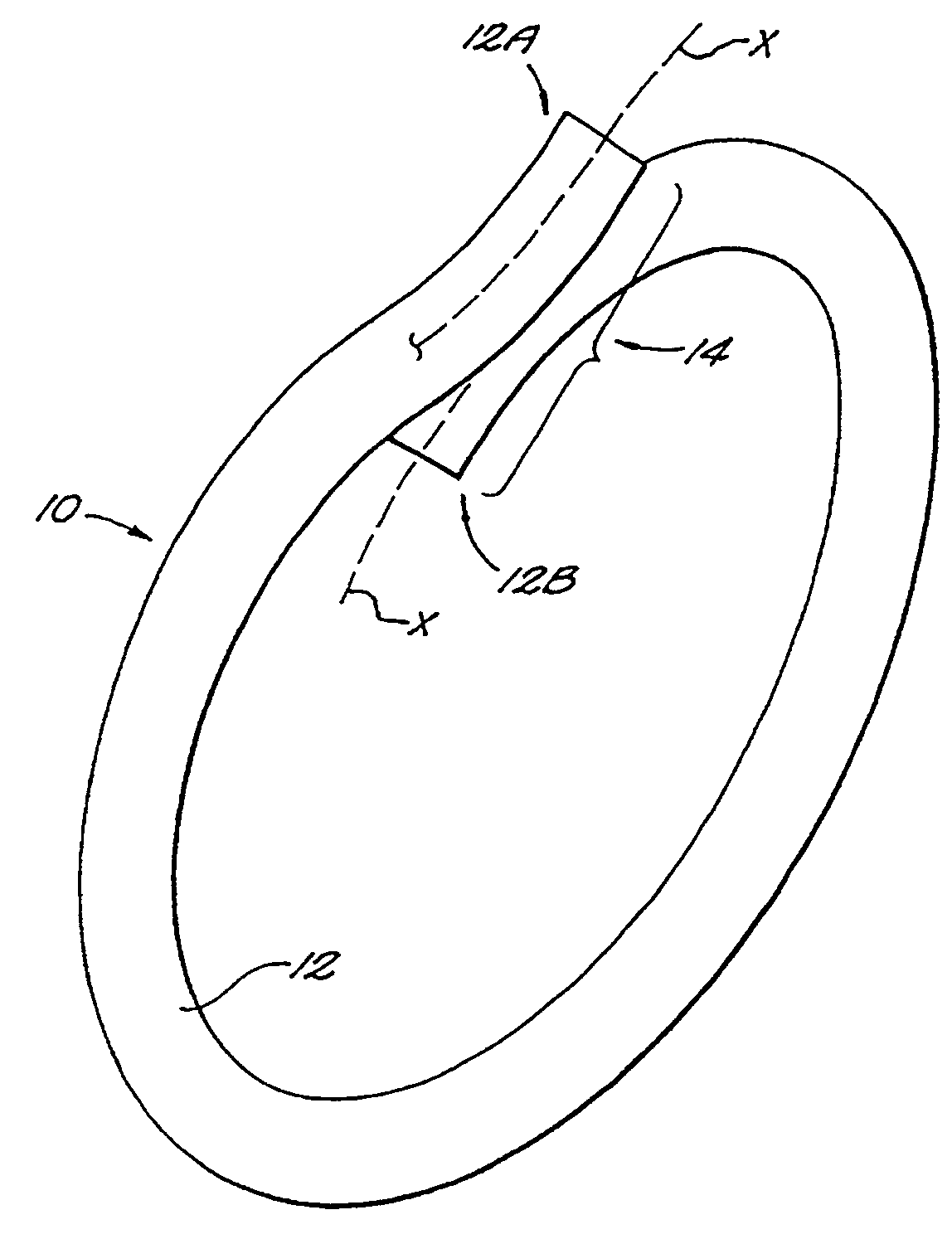

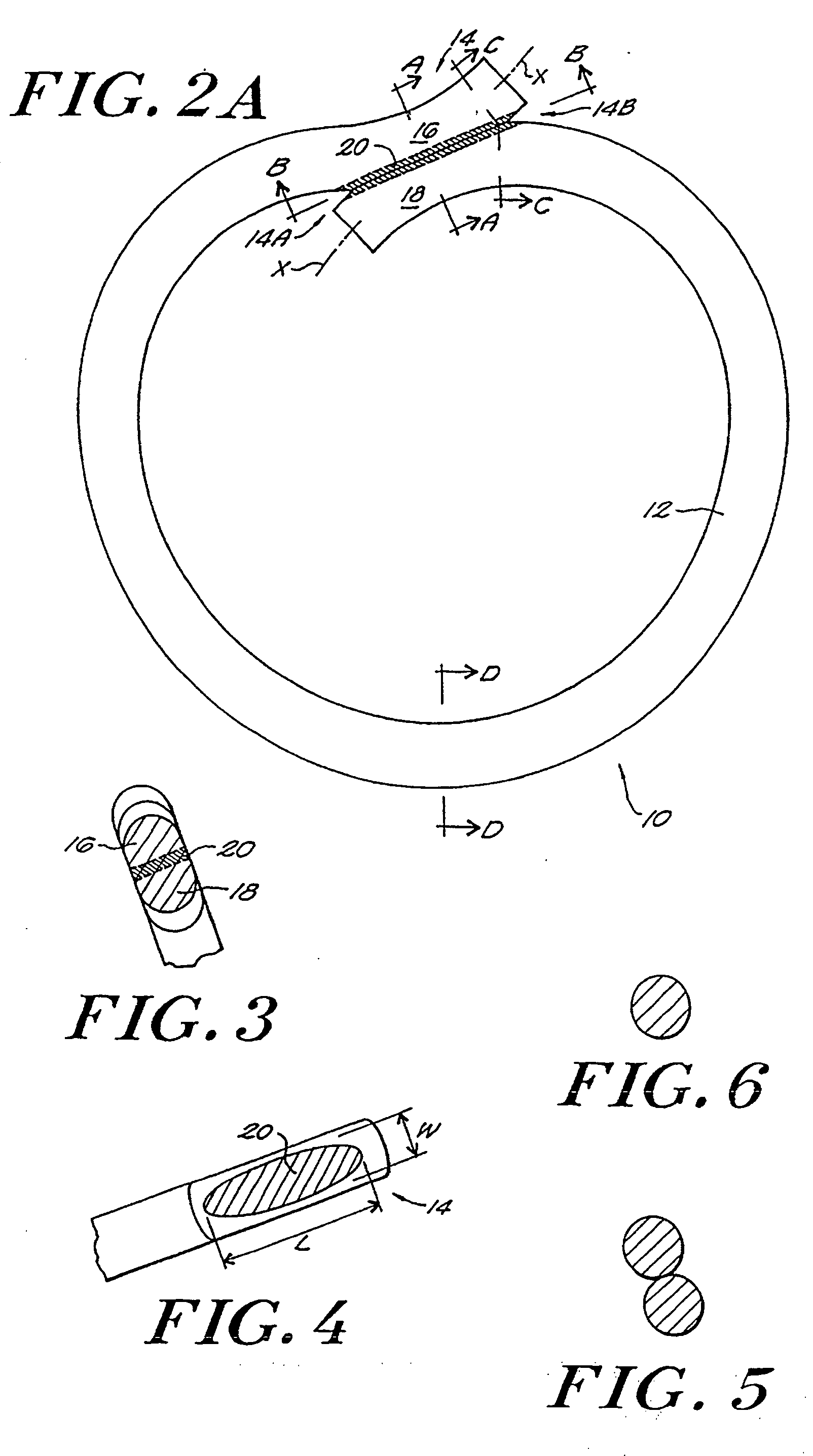

Fused loop of filamentous material and apparatus for making same

InactiveUS20050165448A1Maximize joint strengthSuture equipmentsSurgical needlesUltimate tensile strengthBiomedical engineering

A fused loop of an elongated material, such as a surgical suture, and apparatus for making the loop. Portions of one or more segments to be joined together are fused in a welding process to form a welded joint. The shear area of the fused portion of the joint determines the strength of the joint and is thus preferably relatively large. Various configurations for the welding apparatus facilitate the creation of relatively large fused portions of the joint by maximizing contact between at least one of the welding members of the apparatus and at least one of the segments to be joined.

Owner:TORNIER INC

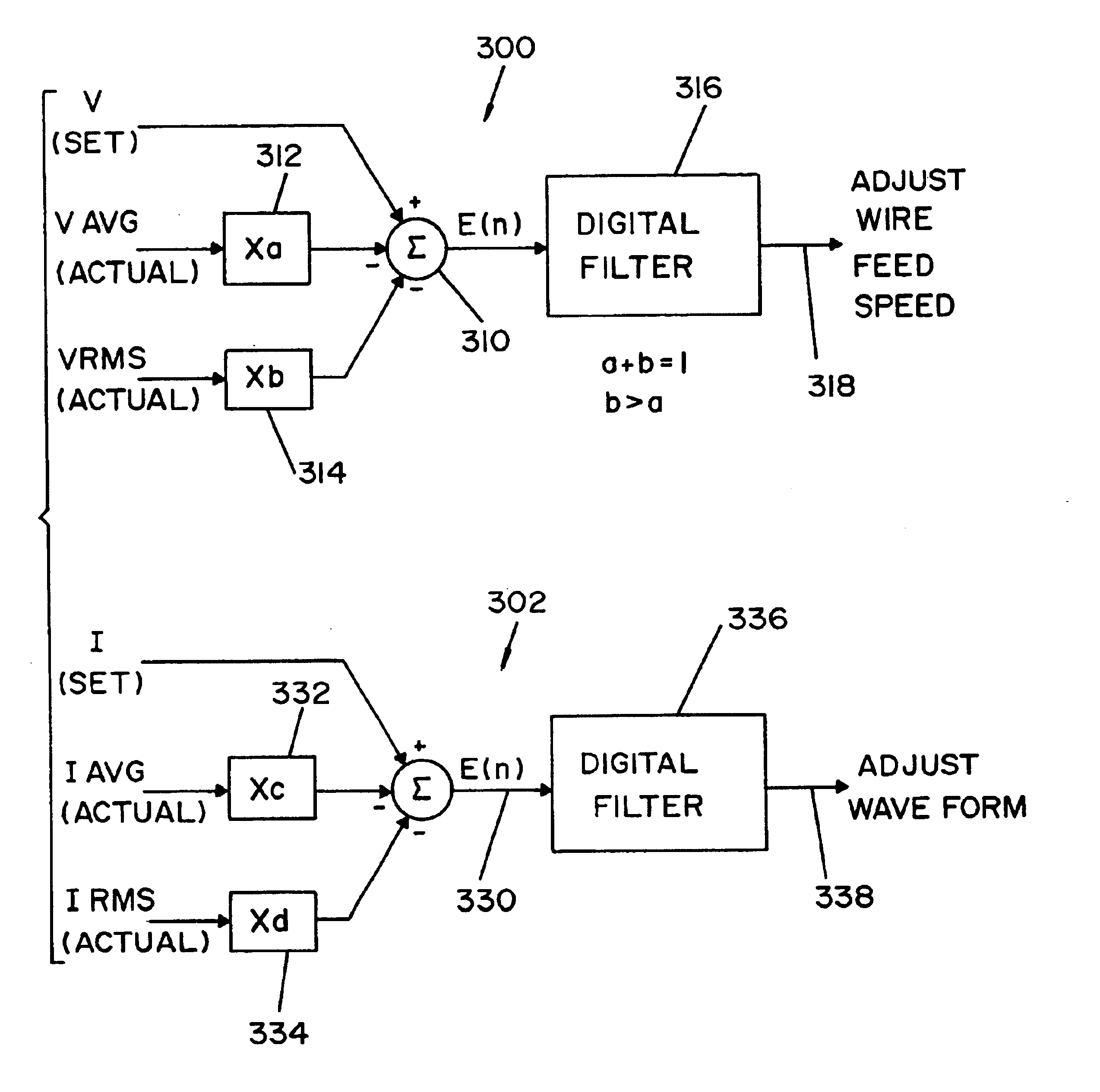

Electric arc welder and method for controlling the welding process of the welder

An electric arc welder for performing a given weld process with a selected A.C. pulse current waveform performed between an electrode and a workpiece, where the current waveform includes a positive segment and a negative segment, with at least one segment including a peak current and background current. The welder comprises: a power source with a controller having a digital processor including a program to calculate the real time power factor of the weld current and weld voltage where the program includes an algorithm to calculate the rms weld voltage, the rms weld current and the average power of said power source; a circuit to multiply the rms current by the rms voltage to produce an rms power level; a circuit to divide the average power by the rms power to create a value representing the actual real time power factor of said power source; and, a circuit to adjust said background current to maintain said power factor at a given level, which is manually adjusted to set the heat of the weld.

Owner:LINCOLN GLOBAL INC

Soldering process

ActiveCN1986133AFast heat conductionSufficient mechanical bond strengthWelding/cutting media/materialsSoldering mediaCopperUltimate tensile strength

The brazing process includes the following steps: preparing the copper back board, pre-heating the copper back board and soldering tin, pre-heating the aluminum target and soldering tin, combining copper back board and the aluminum target, and maintaining pressure and circular cooling water. Thus brazed hetero metal assembly has excellent heat transferring performance and sufficient mechanical binding strength, and the brazing process is simple, practical and reliable.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

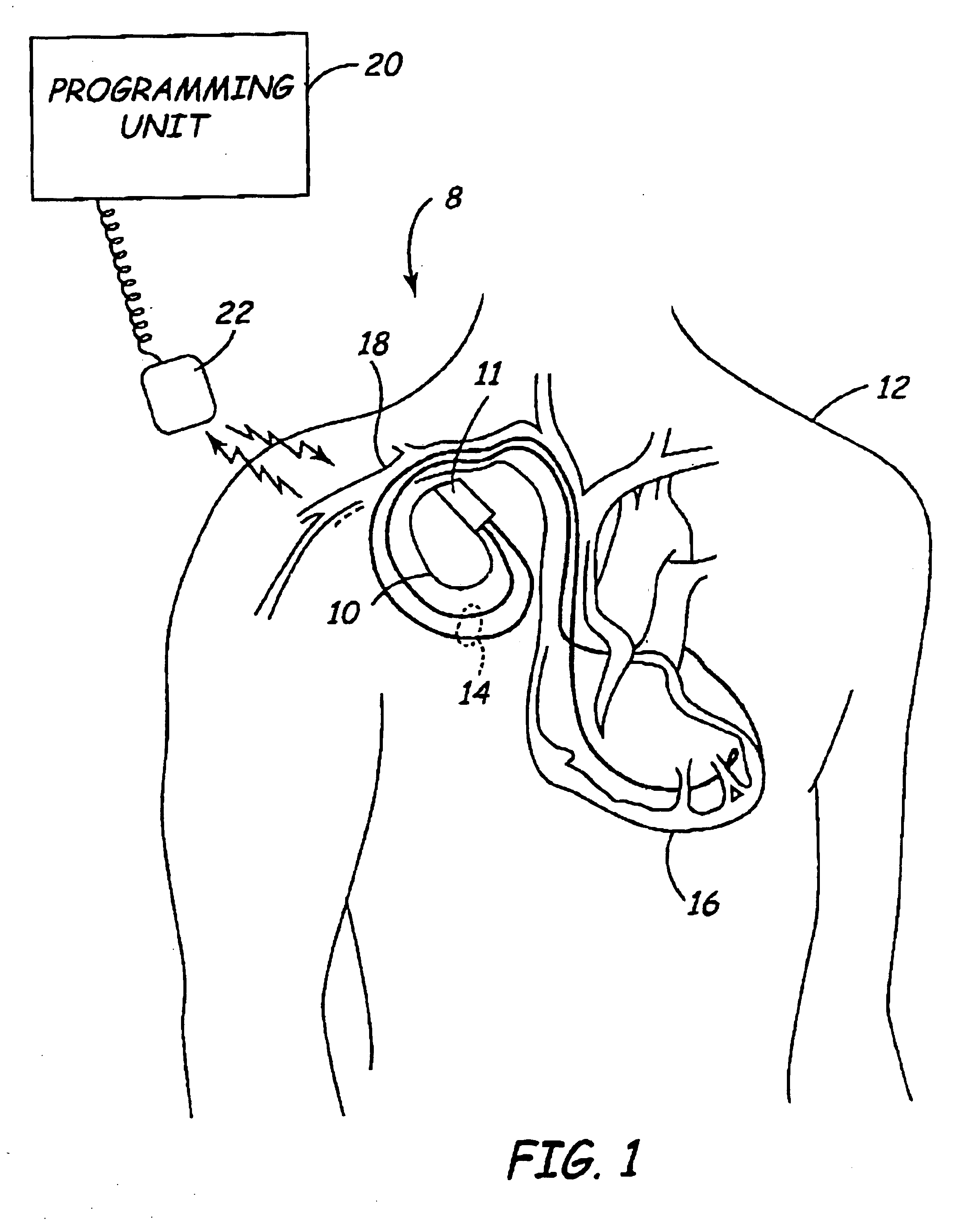

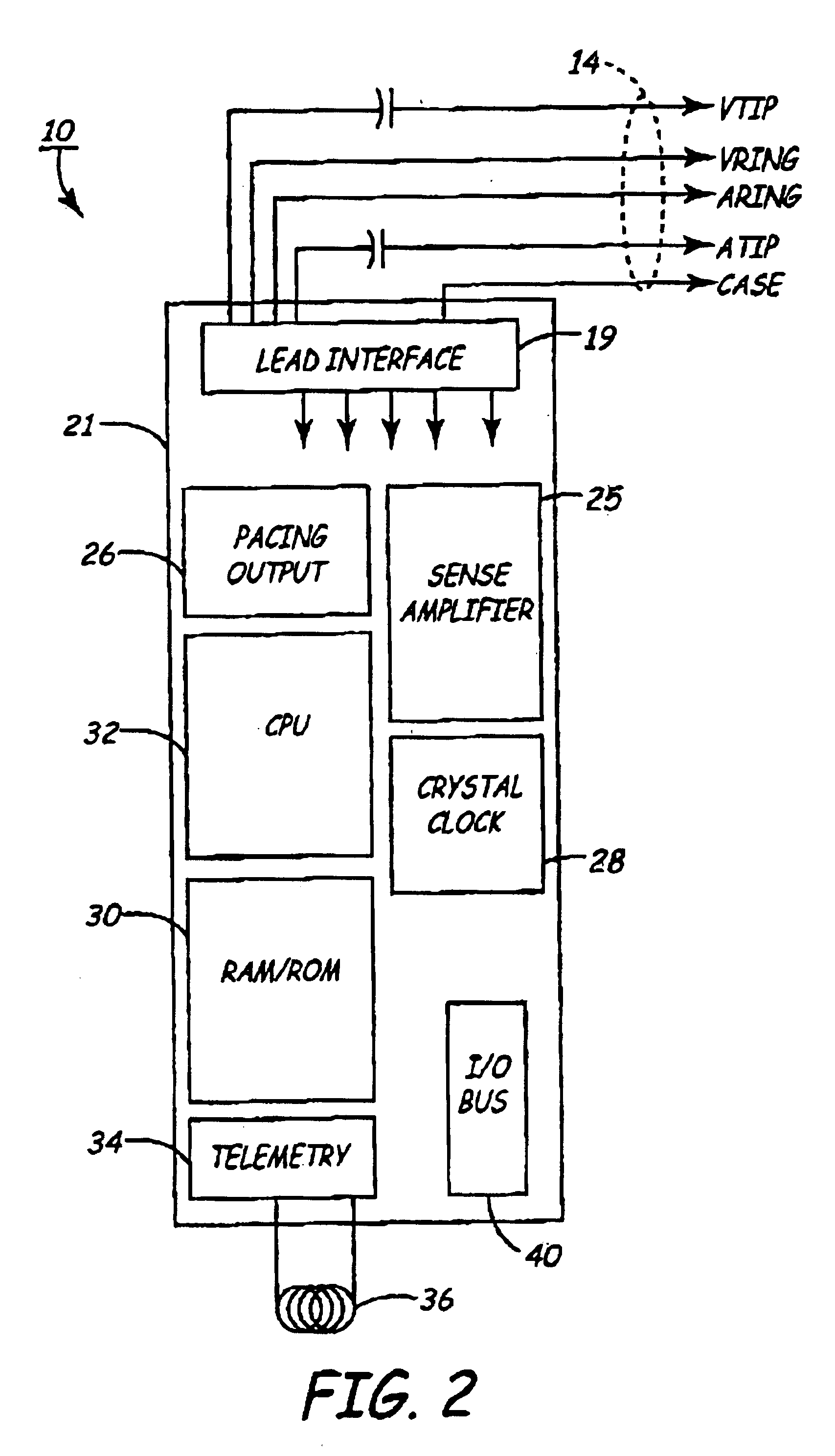

Method for stacking semiconductor die within an implanted medical device

InactiveUS6780770B2Semiconductor/solid-state device detailsSolid-state devicesContact padImplanted device

A method for forming a stackable wafer for use in an implantable device is provided. The method comprises forming an opening extending substantially through the wafer. Thereafter, conductive material is deposited within the opening to substantially fill the opening. A bump is then formed on an upper surface of the wafer adjacent the conductive material, and a contact pad is formed on a lower surface of the wafer adjacent the conductive material. A second wafer formed using substantially the same process may then be stacked on top of the first wafer with the bump of the first wafer being in contact with the contact pad of the second wafer. A soldering process may then be used to couple the adjacent pad and wafer for physically mounting the wafers and providing electrical connectivity therebetween.

Owner:MEDTRONIC INC

Packaging substrates for integrated circuits and soldering methods

InactiveUS20050189636A1Easy maintenanceHigh melting temperaturePrinted circuit assemblingSemiconductor/solid-state device detailsContact padInterposer

A packaging substrate (310) includes a semiconductor interposer (120) and at least one other intermediate substrate (110), e.g. a BT substrate. The semiconductor interposer has first contact pads (136C) attachable to dies (124) above the interposer, and second contact pads (340) attachable to circuitry below the interposer. Through vias (330) are made in the semiconductor substrate (140) of the interposer (120). Conductive paths going through the through vias connect the first contact pads (136C) to the second contact pads (340). The dies (124) are attached to the interposer after the attachment of the interposer to the BT substrate. In sequential soldering operations, the solder hierarchy is maintained by dissolving some material (e.g. copper) in the solder during soldering to raise the solder's melting temperature. For example, all of the solders may initially have the same melting temperature, but each solder's melting temperature is increased during soldering to prevent the solder from melting in the subsequent soldering operations.

Owner:INVENSAS CORP

Friction welding method of titanium-aluminum alloy turbine and 42CrMo quenched and tempered steel shaft

InactiveCN101844271AHigh tensile strength at room temperatureAchieve associativityNon-electric welding apparatusFriction weldingDual effect

The invention discloses a friction welding method of a titanium-aluminum alloy turbine and a 42CrMo quenched and tempered steel shaft, which aims to solve the technical problem that when the titanium-aluminum alloy turbine rotor and the quenched and tempered steel shaft are connected by the current method, the tensile strength of a joint is low. The invention has the technical scheme that an embedded groove in a shape of a solid of revolution is processed at one side of the titanium-aluminum alloy turbine; in the welding process, the welding end surface of the turbine shaft has friction with the welding surface of the embedded groove of the titanium-aluminum alloy turbine; and by controlling the friction shortening amount, the casting fins formed at the turbine shaft side are fully filled into the embedded groove. Thus dual effects of metallurgical bonding and mechanical connection of the welding surface are achieved, and the tensile strength of the joint of connecting pieces at room temperature is increased from 390MPa in the background art to 480-537MPa.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

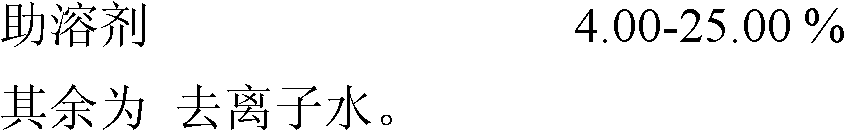

Novel environment-friendly soldering flux for low-silver SnAgCu unleaded soldering paste

InactiveCN101564805AGood moisturizing effectLong storage lifeWelding/cutting media/materialsSoldering mediaBoiling pointSolvent

The invention relates to a novel environment-friendly soldering flux for low-silver SnAgCu unleaded soldering paste, belonging to the field of unleaded solder soldering flux. The invention aims at providing a soldering flux suitable for the low-silver SnAgCu unleaded soldering paste. The soldering flux comprises the following components: 5.0-13.0% of activator, 32.0-41.0% of solvent, 0.8-5.0% of corrosion inhibitors, 1.0-6.0% of thixotropic agent, 2.0 -9.0% of paste forming agent, 0.3-2.5% of stabilizer, 0.5-5.0% of surfactant and 35.0-48.0% of modified rosin. The activator is the compound of a plurality of organic acids, has wide boiling point distribution space, can achieve good activation effect in the whole soldering process, can be mostly volatilized, sublimated or decomposed at the brazing temperature and ensures no corrosion after the soldering. The soldering flux has the advantages of no halogen content, good soldering aiding property, few and hard-film-shaped residuals after the soldering, high insulation resistance, and the like.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com