Patents

Literature

136 results about "Background current" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sliver type autonomous biosensors

InactiveUS20040180391A1Bioreactor/fermenter combinationsBiological substance pretreatmentsIn vivoElectrochemistry

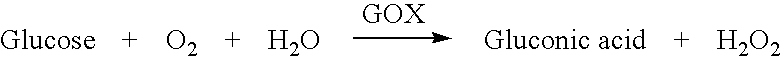

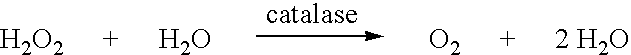

In vivo or in vitro monitoring of chemical and biochemical species (e.g., pH, or glucose levels) in the interstitial fluid of patients or in a sample of a fluid to be analyzed is provided by a probe (10, 70, 210, 270). For in vivo monitoring, the probe is readily inserted by a minimally invasive method. Optical or electrochemical sensing methods are employed to detect a physical or chemical change, such as pH, color, electrical potential, electric current, or the like, which is indicative of the concentration of the species or chemical property to be detected. Visual observation by the patient may be sufficient to monitor certain biochemicals (e.g., glucose) with this approach. A CAP membrane allows high enzyme loadings, and thus enables use of microminiature probes, and / or diagnosis of low levels of the analyte(s), with sufficient signal-to-noise ratio and low background current.

Owner:CASE WESTERN RESERVE UNIV

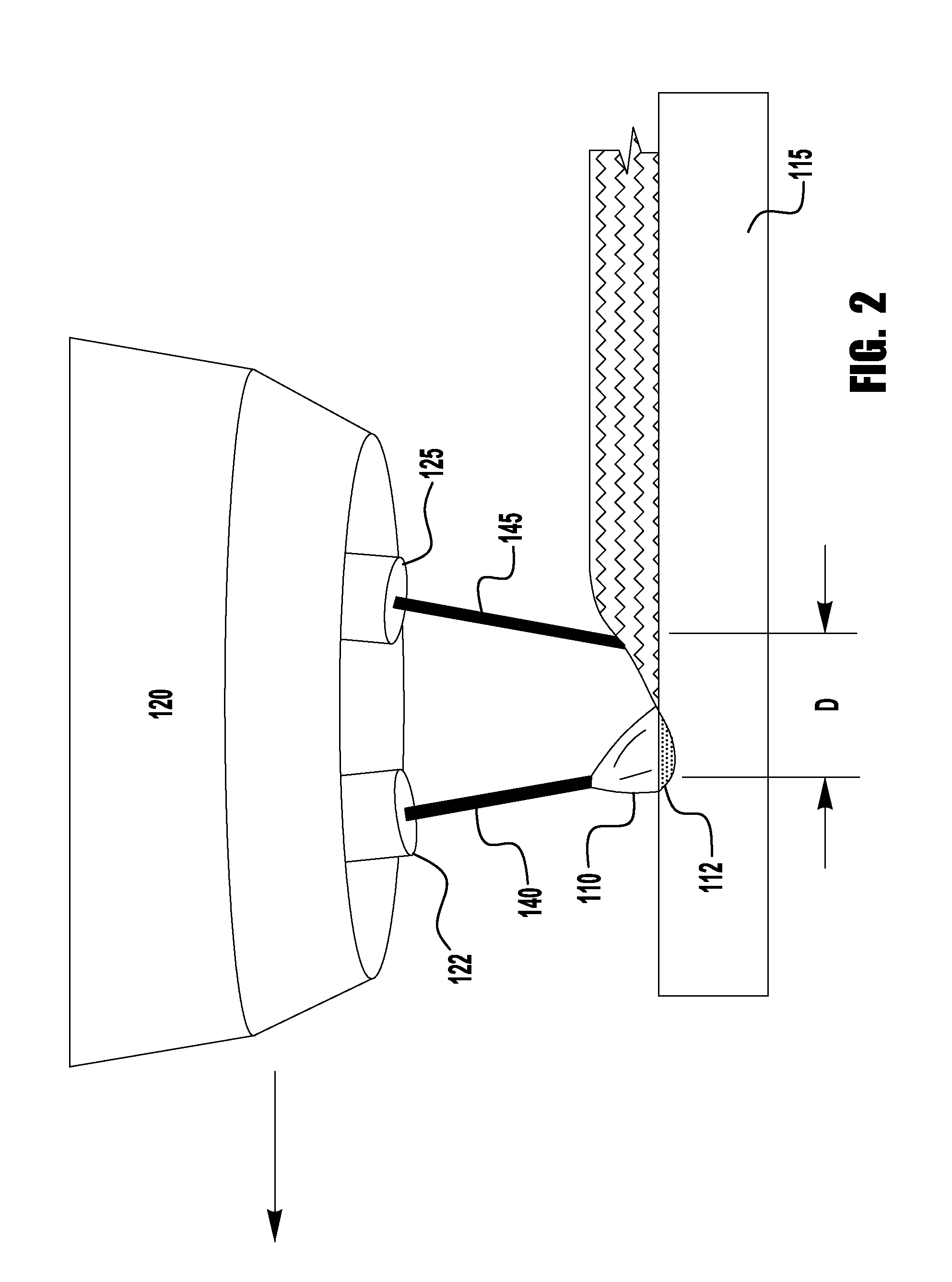

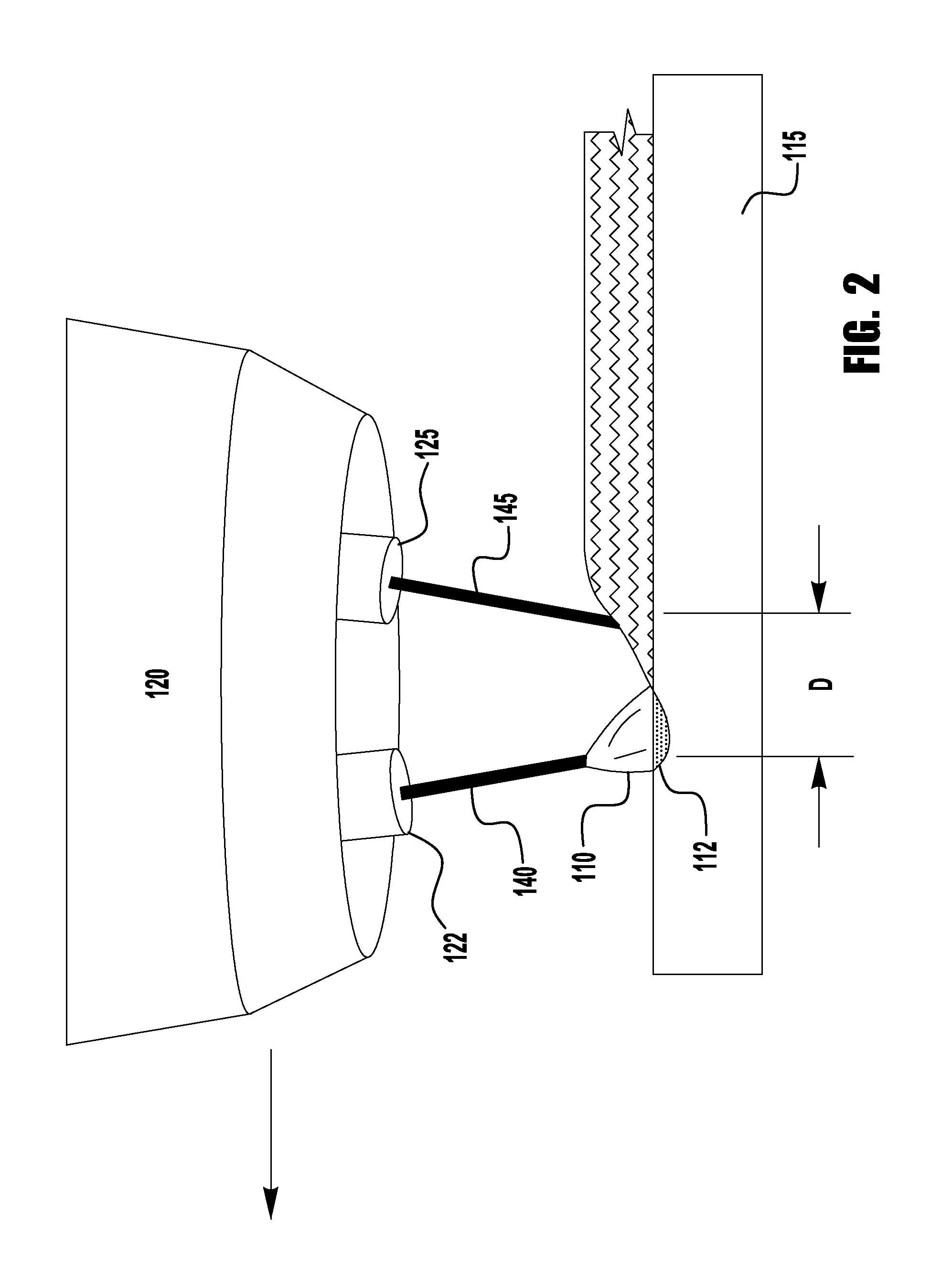

Method and device to build-up, clad, or hard-face with minimal admixture

ActiveUS20080006612A1Improve the level ofBlocking may occurArc welding apparatusWelding/soldering/cutting articlesPeak currentAlloy

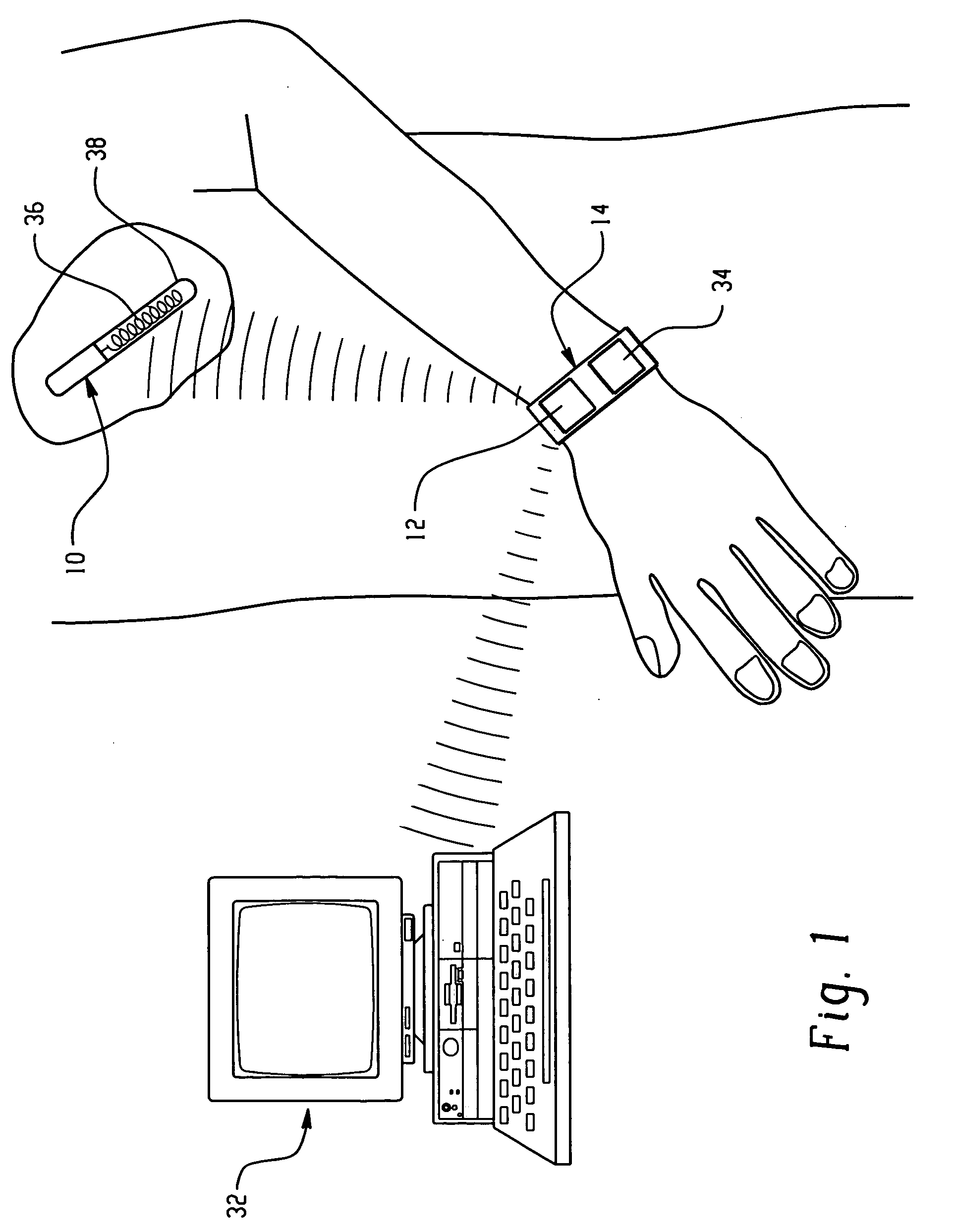

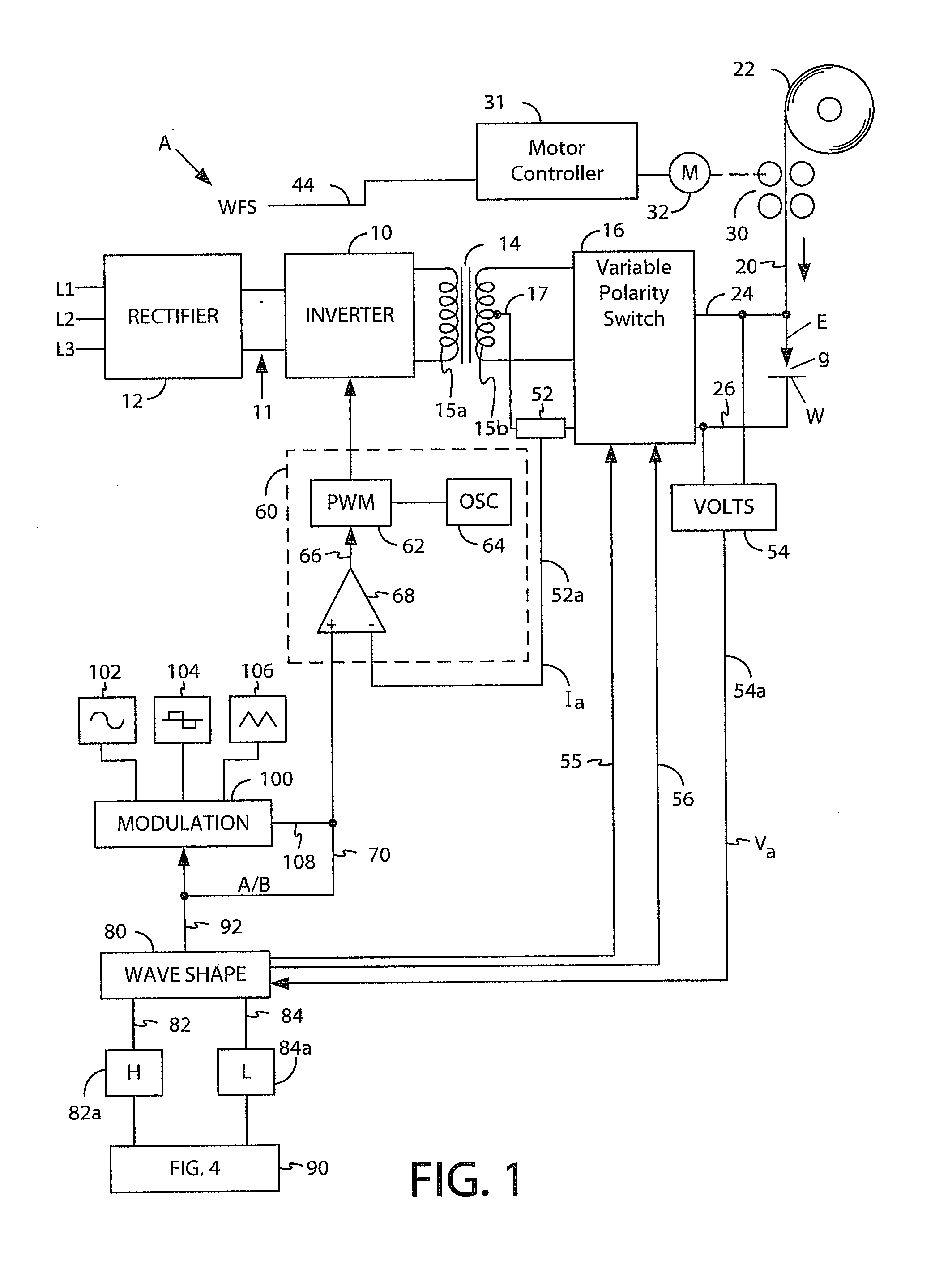

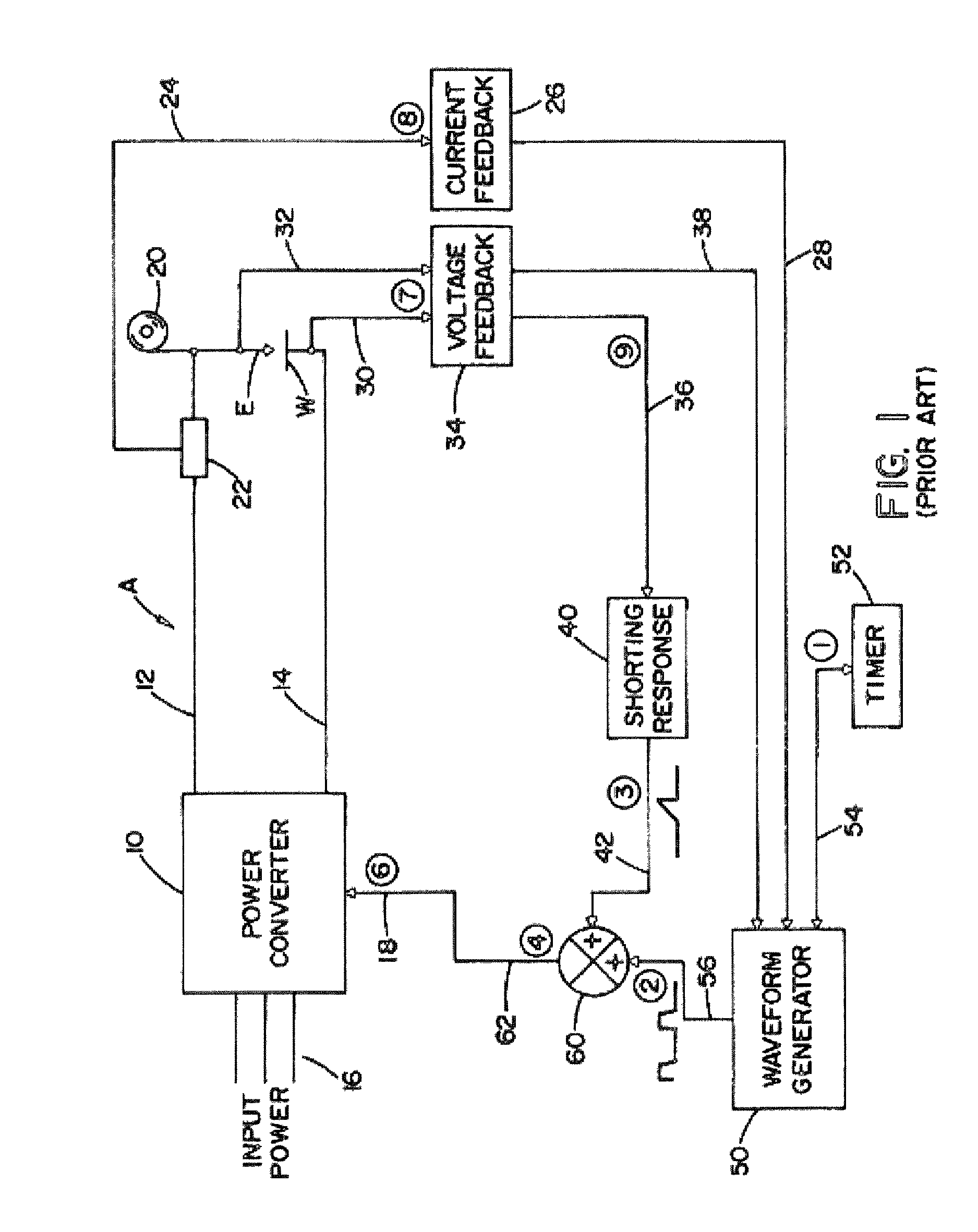

An electric arc device and methods to build up, clad, join, or overlay an alloyed metal onto a parent metal with minimal admixture. The methods employed in the electric arc device provide a high frequency waveform with a high amplitude pulse, a low amplitude background current, and a special shorting routine, to alleviate the problem of generating too much ad-mixture. A fast transition from a peak current level to a background current level along with a shorting response and a plasma boost pulse reduces the droplet size and reduces the heat input required to achieve good welding performance.

Owner:LINCOLN GLOBAL INC

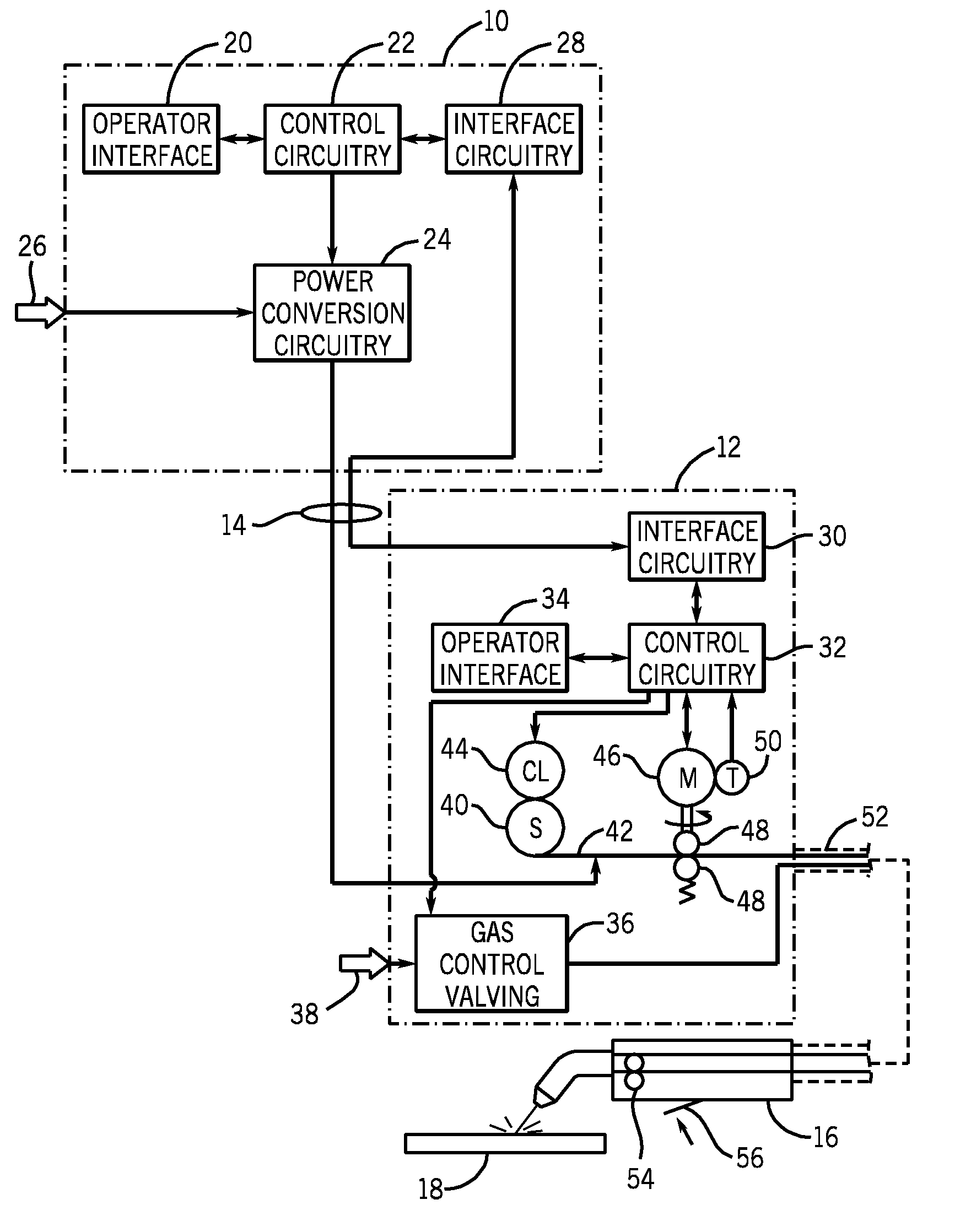

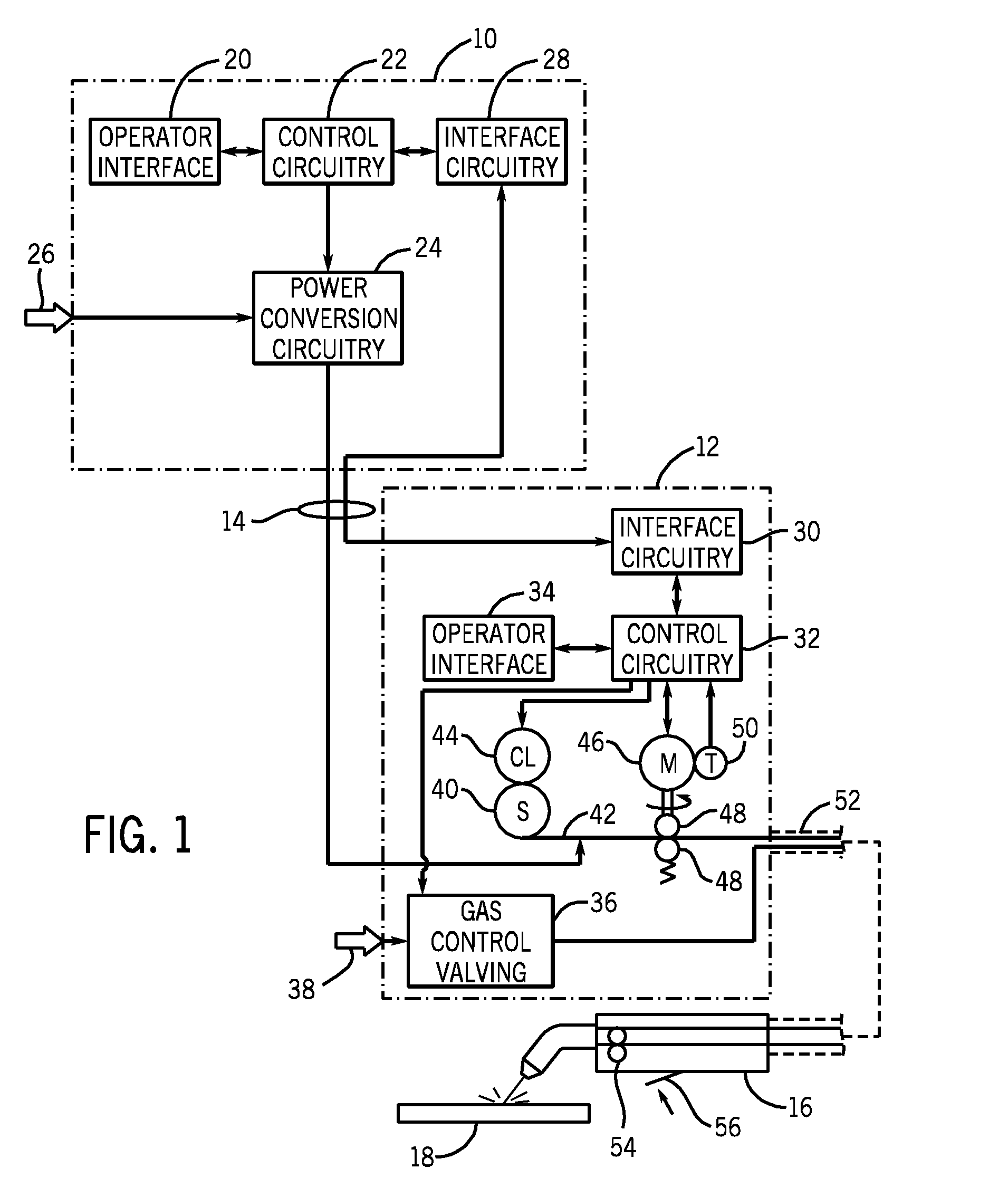

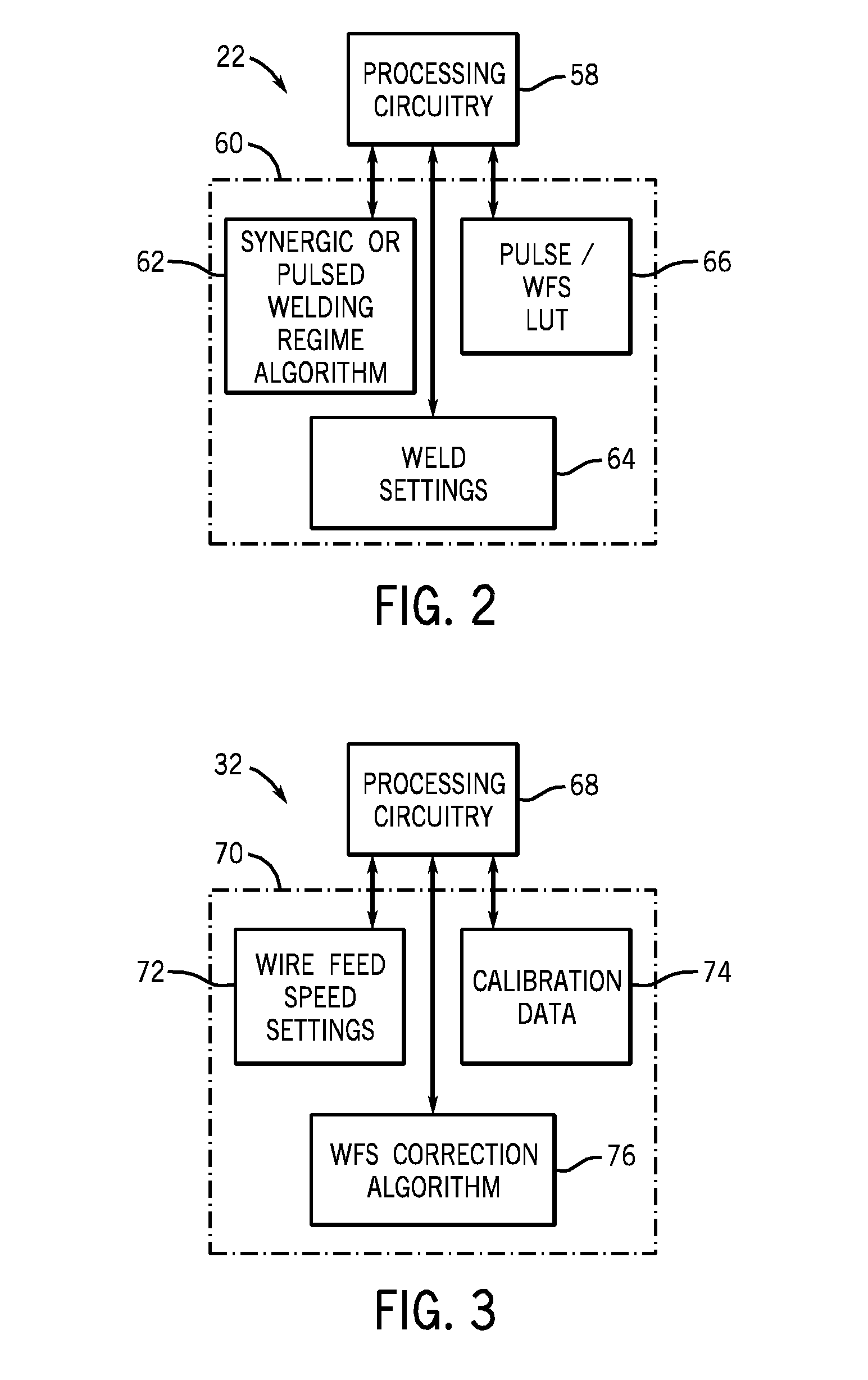

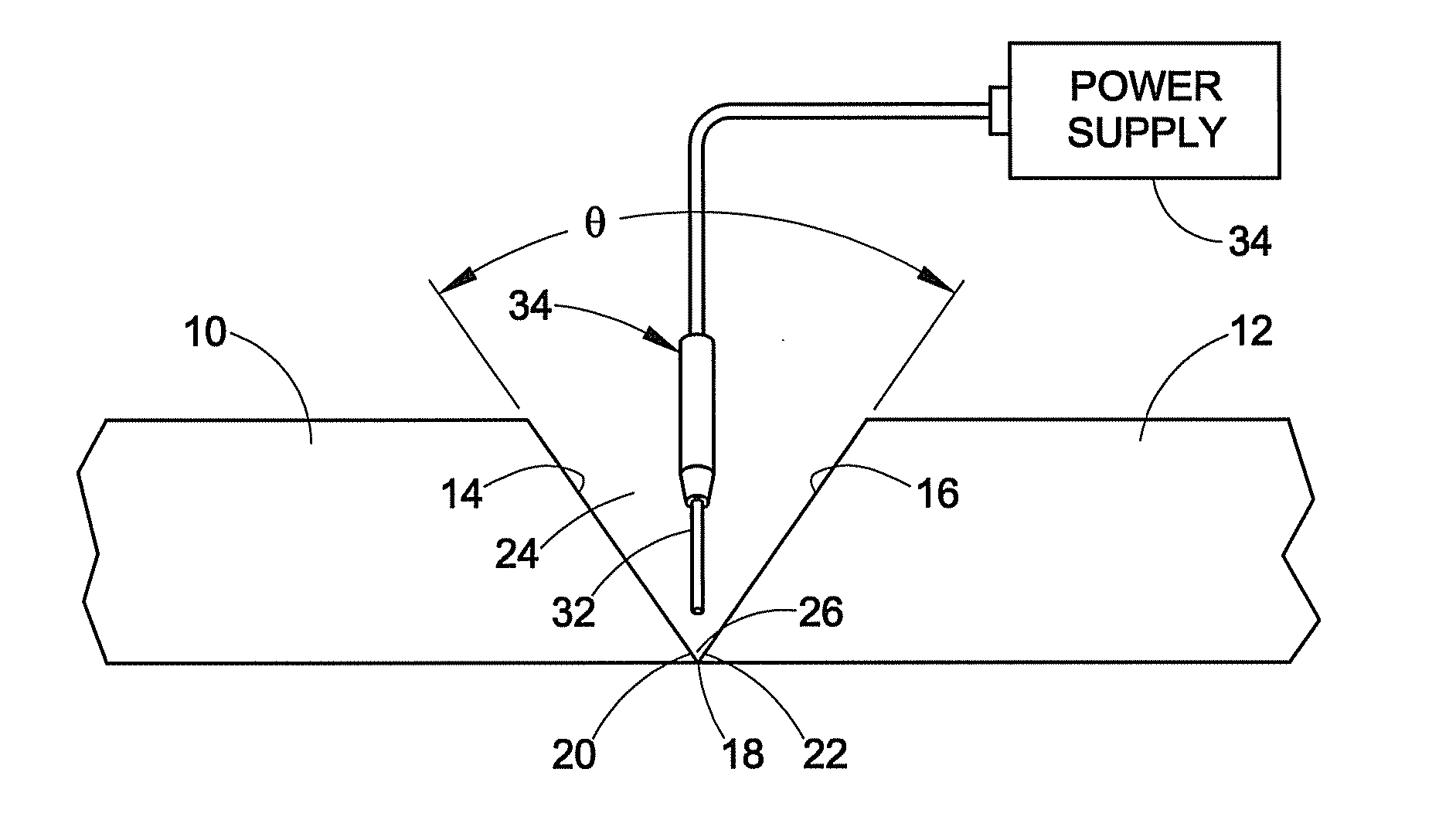

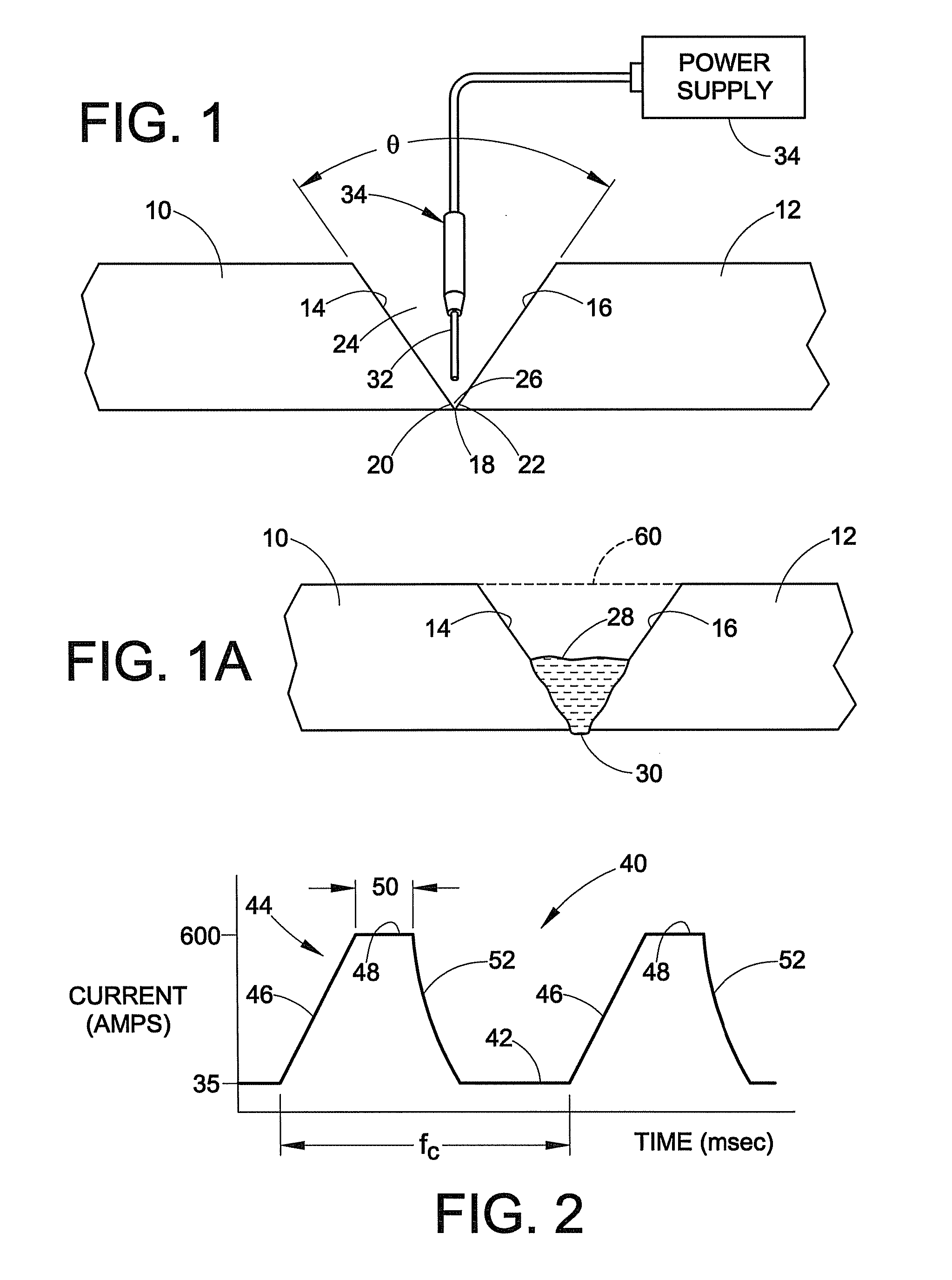

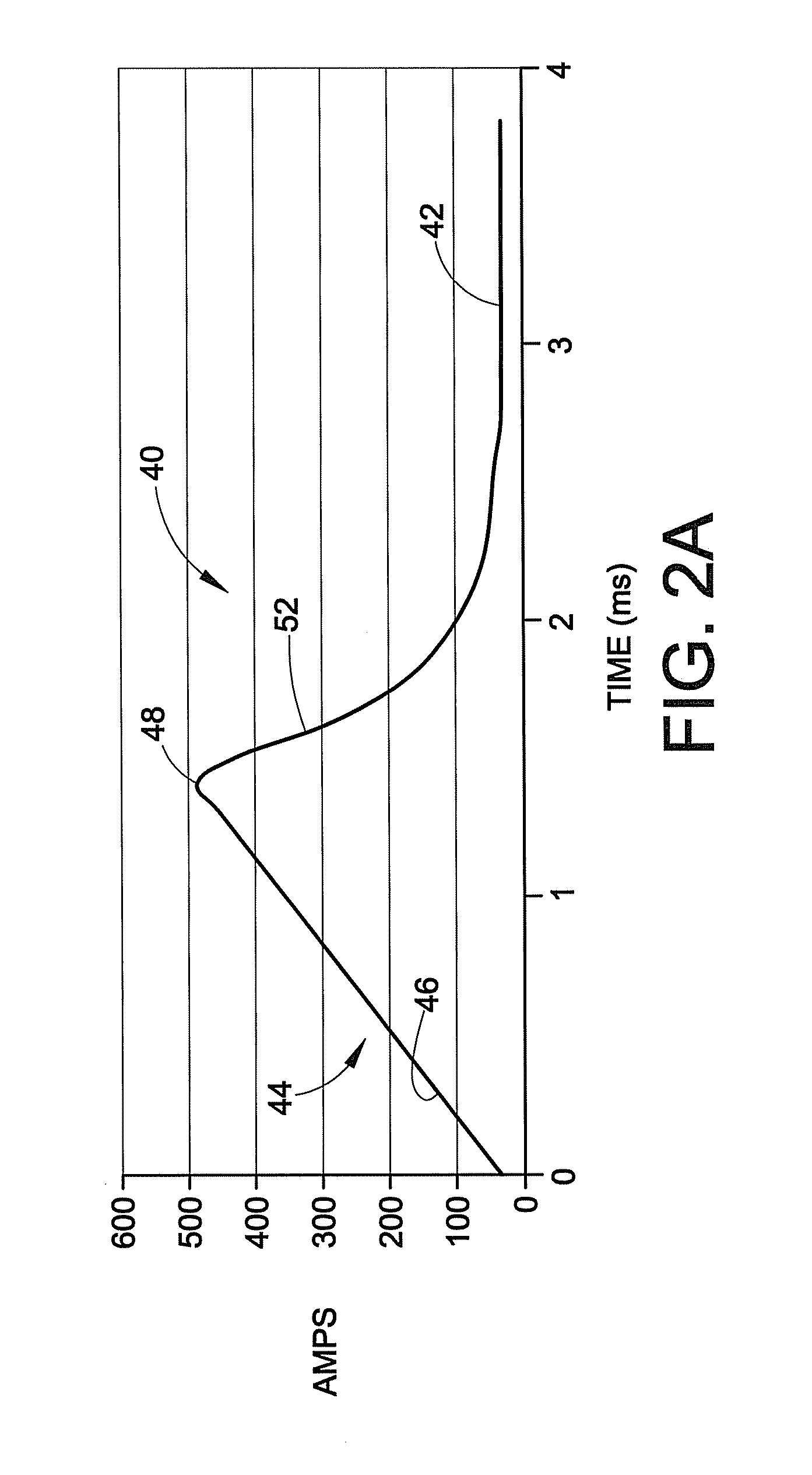

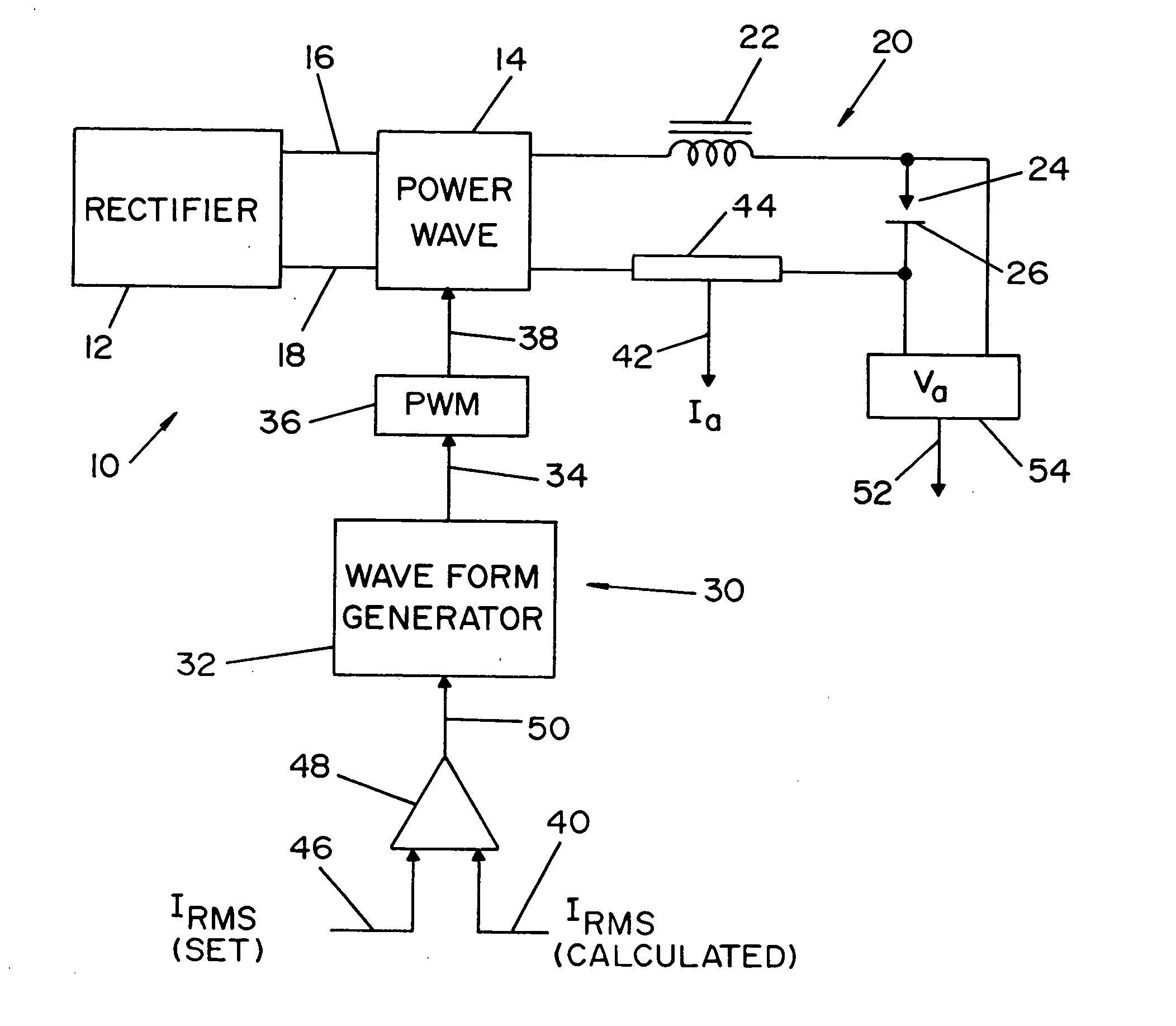

Wire feed speed referenced variable frequency pulse welding system

A pulsed waveform welding operation is implemented by reference to a commanded wire feed speed set by an operator. The wire feed speed is set on a wire feeder, and a signal representative of the commanded wire feed speed is applied to a power supply. The power supply control circuitry references a look-up table in which pulsed waveform parameters are provided based upon wire feed speed. The parameters may include multiple parameters such as pulse frequency, peak current, background current, and current ramp rates. The control circuitry commands power conversion circuitry to generate the commanded waveform as a function of the commanded wire feed speed.

Owner:ILLINOIS TOOL WORKS INC

Method of arc welding root pass

InactiveUS20110108527A1Facilitates welding root jointArc welding apparatusWelding/cutting media/materialsSheet steelPower flow

A method for root pass welding steel plate and pipe is provided that uses pulse arc welding having a current pulse waveform exhibiting a low constant background current and fixed frequency. The welding process may be performed without a backer or backing material.

Owner:LINCOLN GLOBAL INC

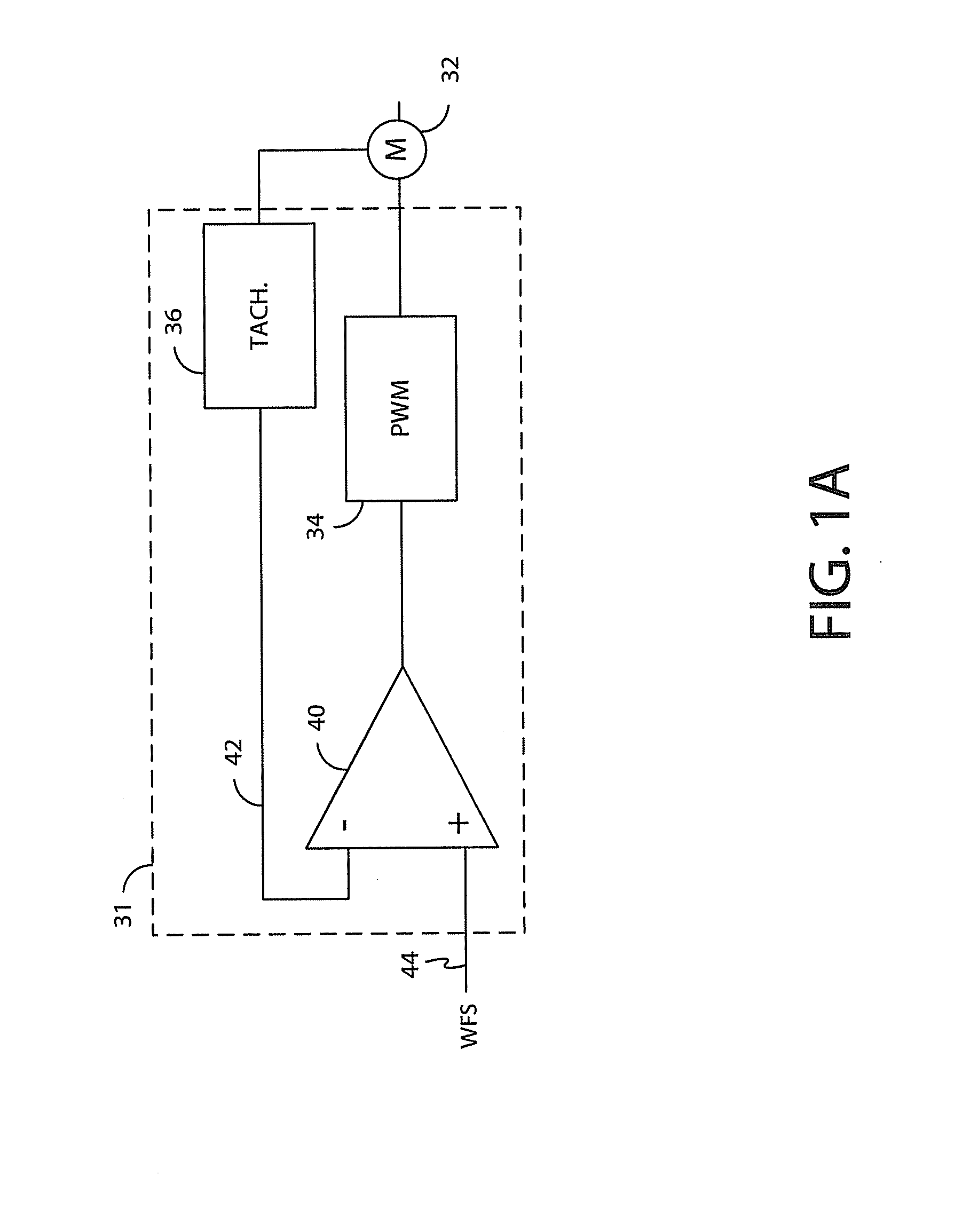

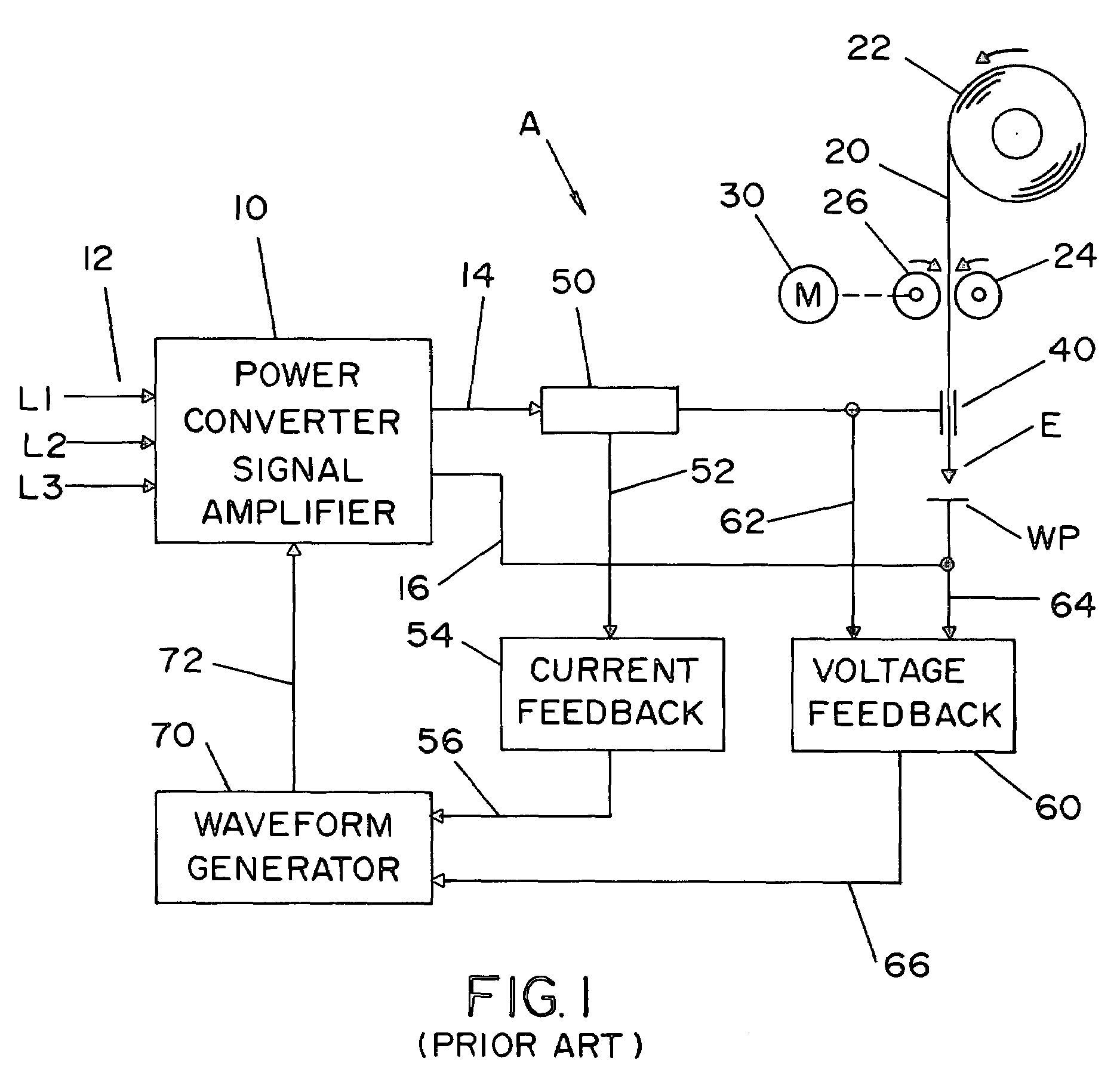

Electric arc welder using high frequency pulses and negative polarity

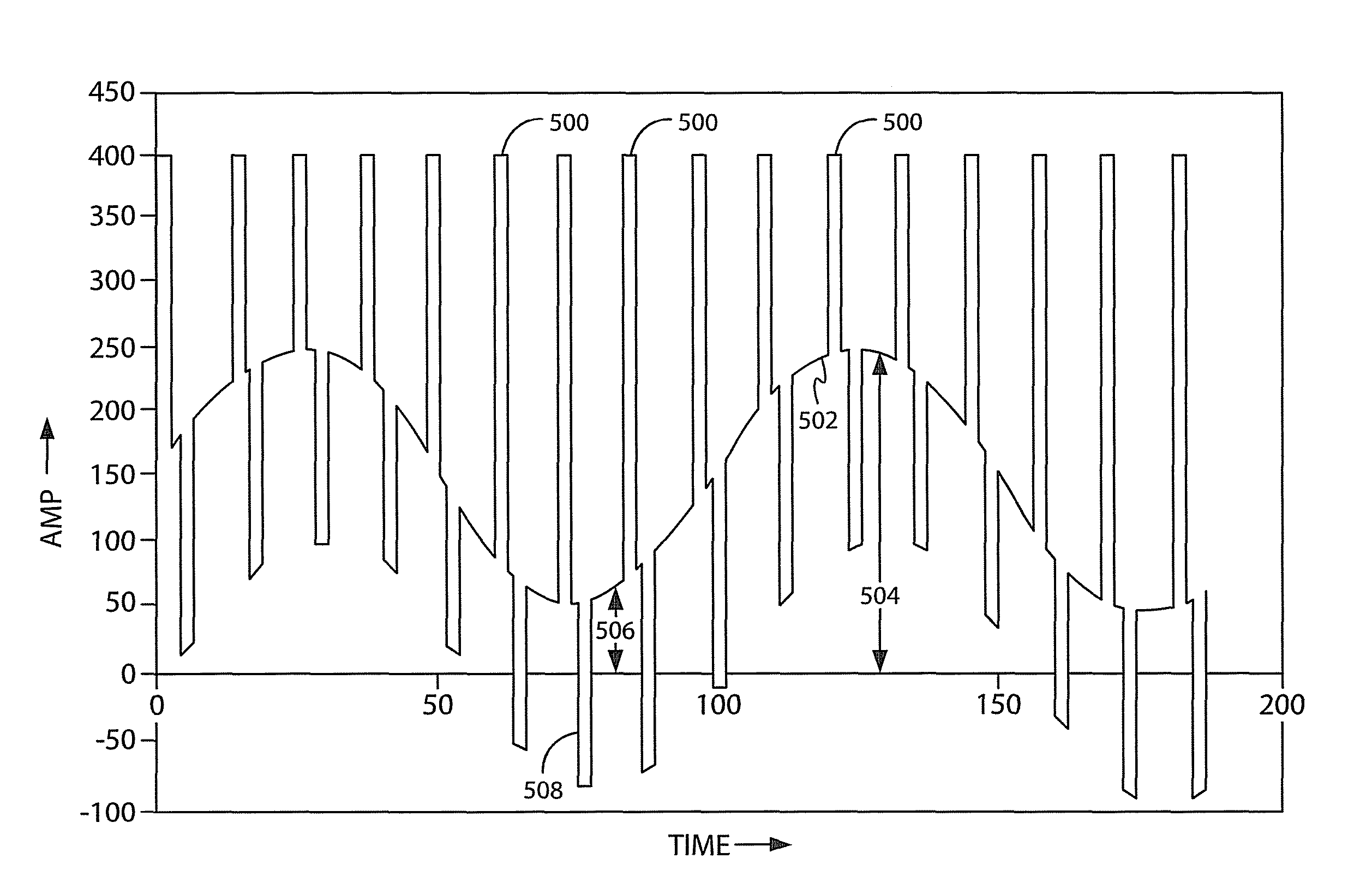

An electric arc welder including a high speed switching power supply with a controller for creating high frequency current pulses with negative polarity components through the gap between a workpiece and a welding wire advancing toward the workpiece, where the pulses and a background current defining a series of weld cycles. A wave shape generator defines the shape of the pulses and the background current including a controlled ramp up and / or ramp down in each of said cycles, and a circuit to change the shapes of the pulses and / or background current in a repeating pattern in each of the weld cycles, including a negative current in at one of said pulses. The shape change in a cycle can be between first and second shapes or by a rhythmic AC modulation.

Owner:LINCOLN GLOBAL INC

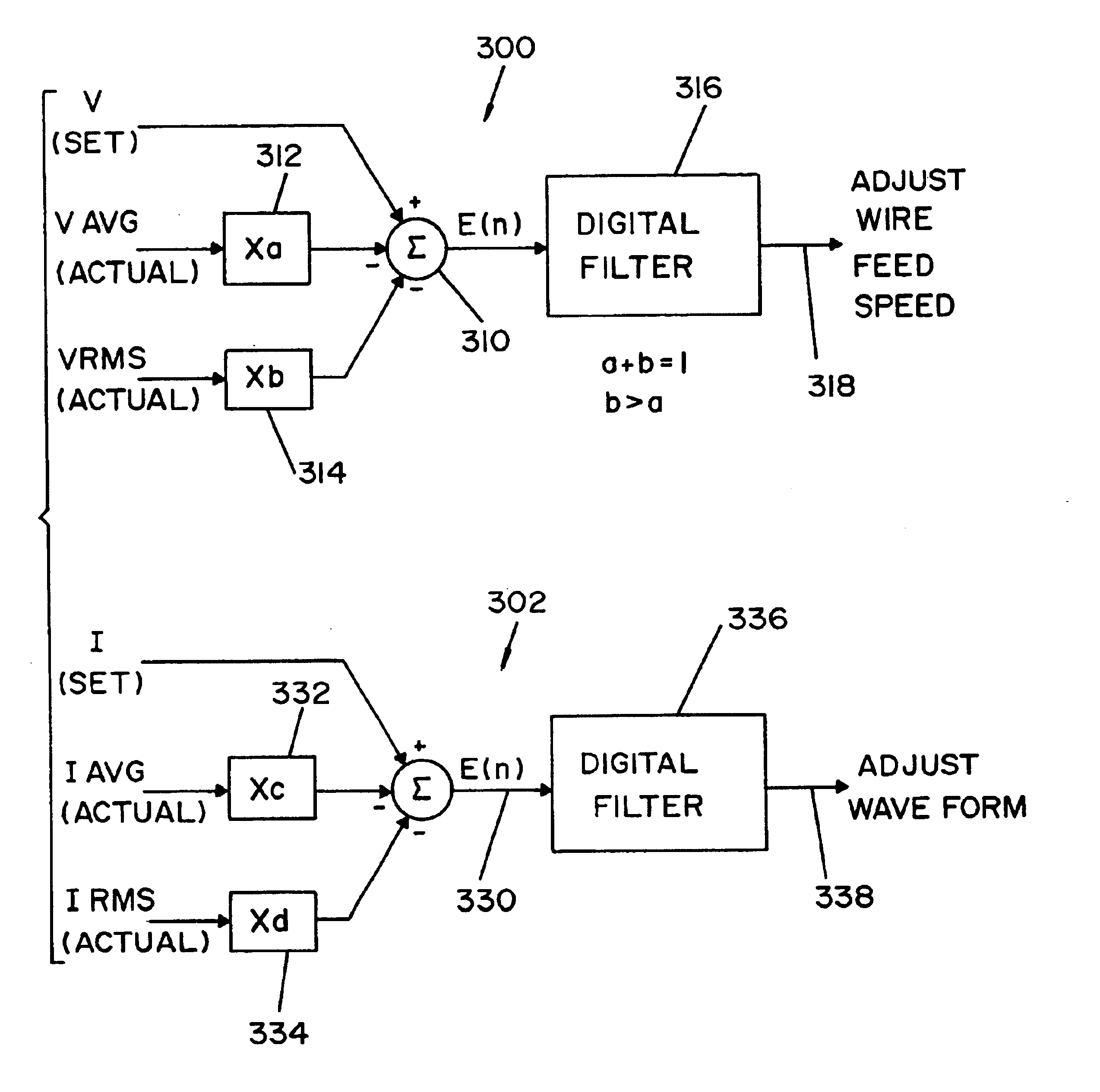

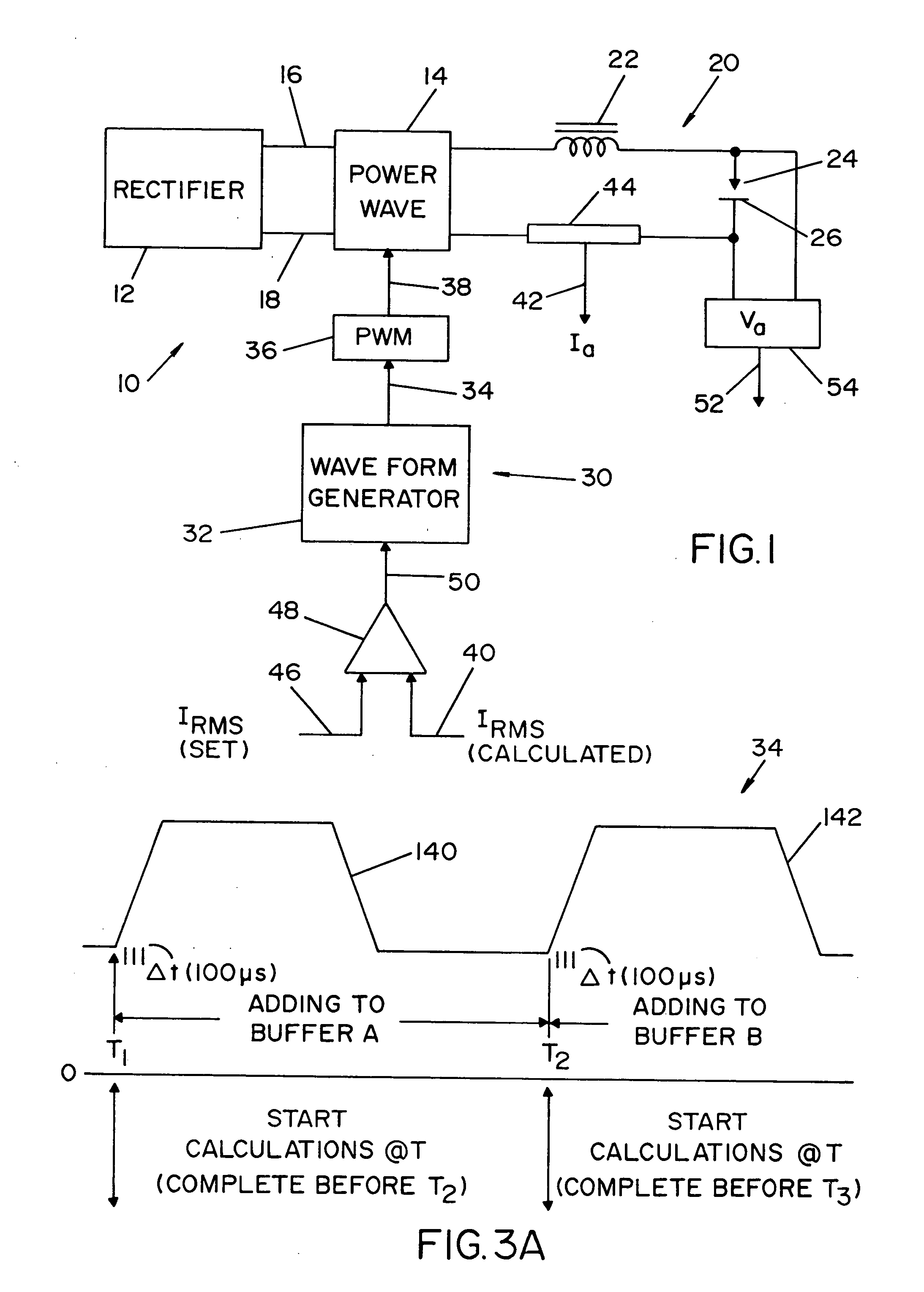

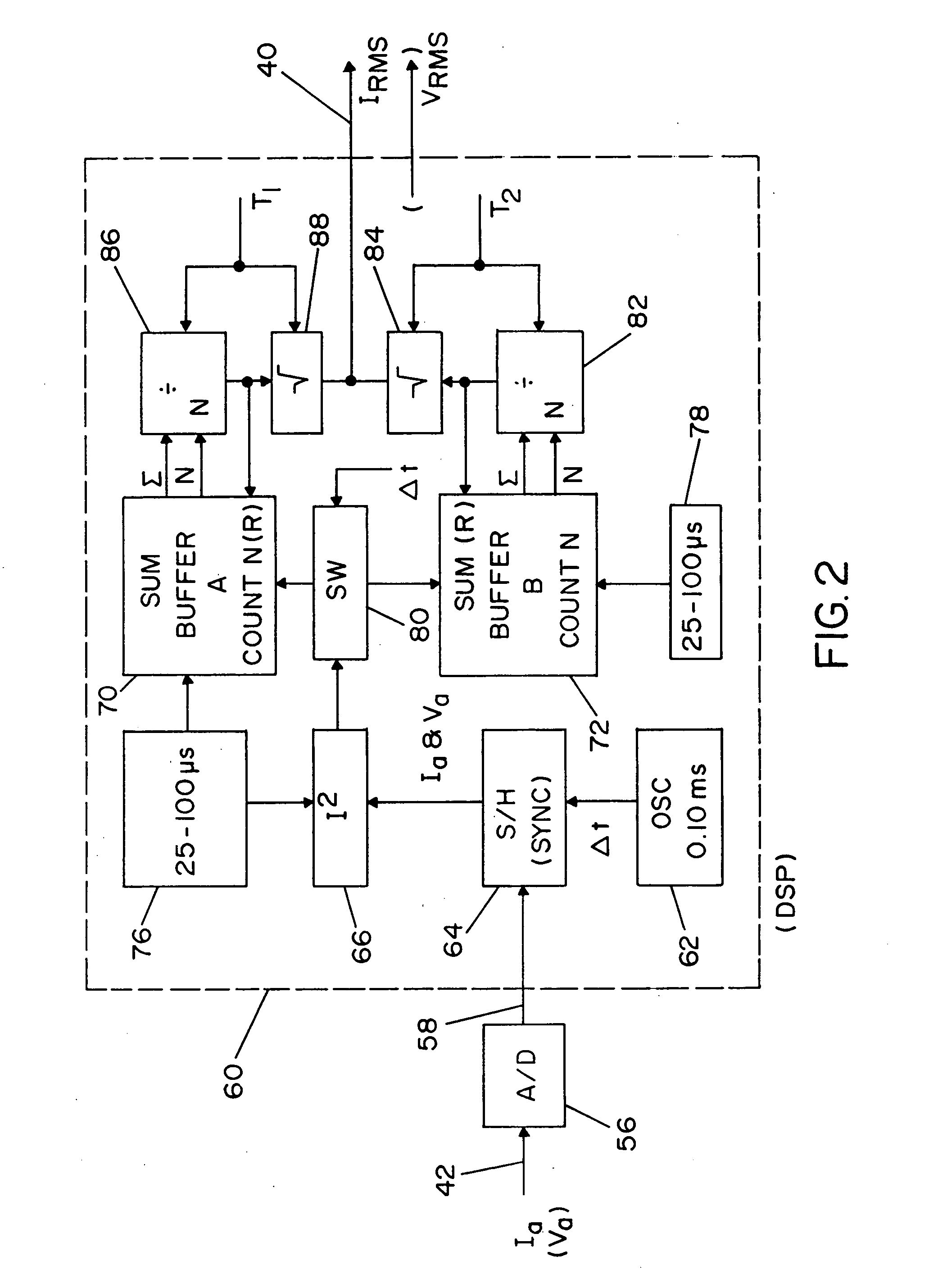

Electric arc welder and method for controlling the welding process of the welder

An electric arc welder for performing a given weld process with a selected A.C. pulse current waveform performed between an electrode and a workpiece, where the current waveform includes a positive segment and a negative segment, with at least one segment including a peak current and background current. The welder comprises: a power source with a controller having a digital processor including a program to calculate the real time power factor of the weld current and weld voltage where the program includes an algorithm to calculate the rms weld voltage, the rms weld current and the average power of said power source; a circuit to multiply the rms current by the rms voltage to produce an rms power level; a circuit to divide the average power by the rms power to create a value representing the actual real time power factor of said power source; and, a circuit to adjust said background current to maintain said power factor at a given level, which is manually adjusted to set the heat of the weld.

Owner:LINCOLN GLOBAL INC

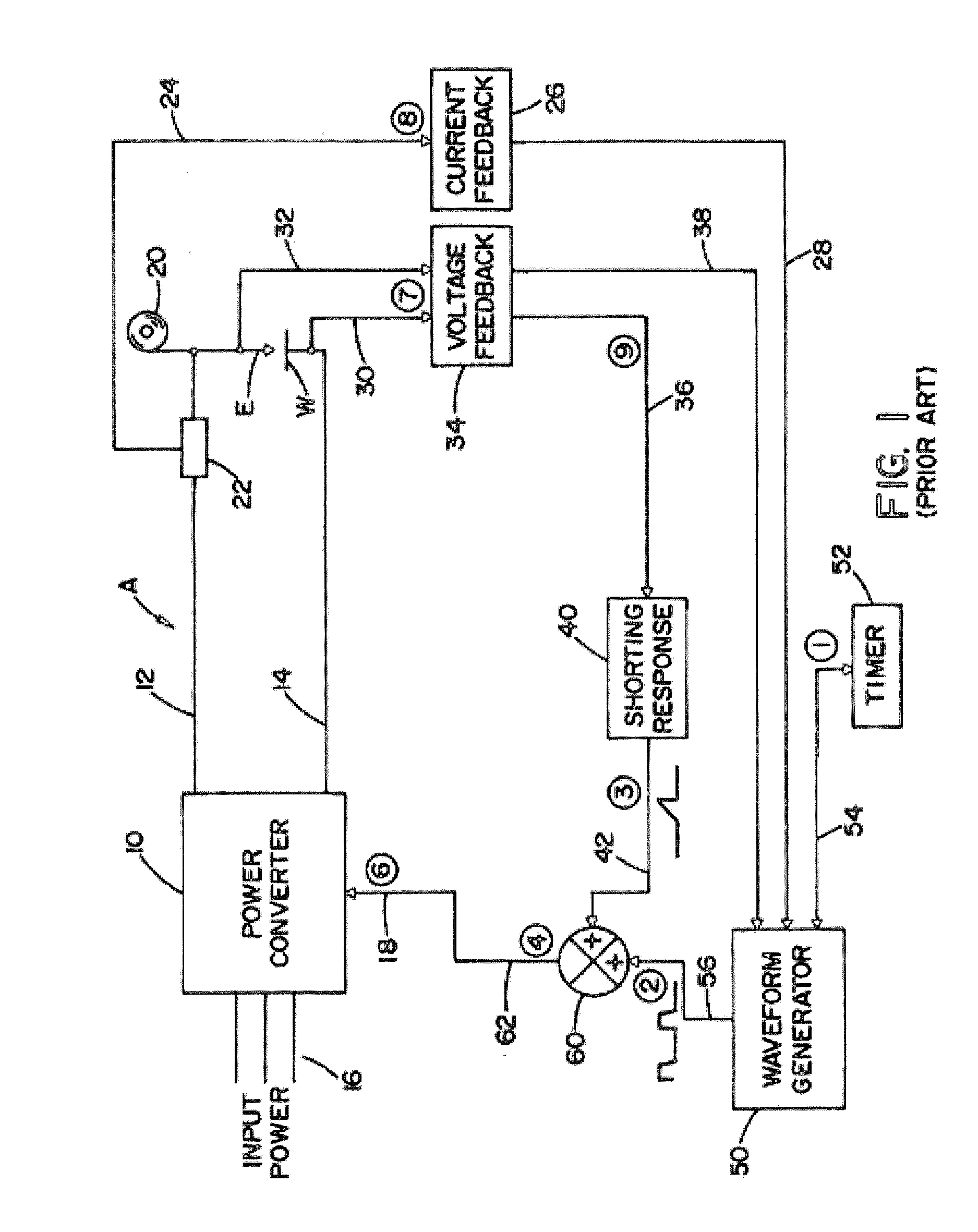

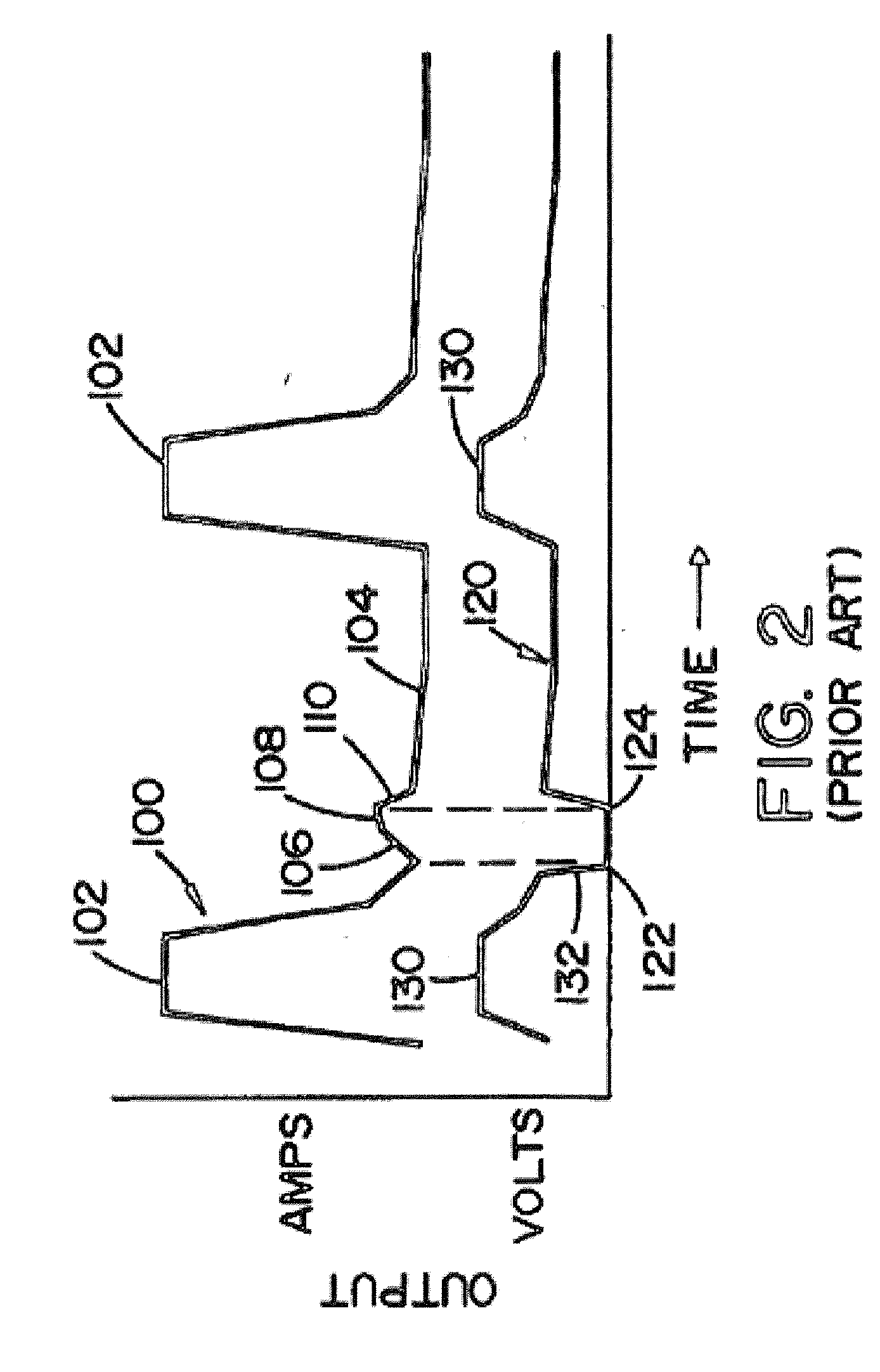

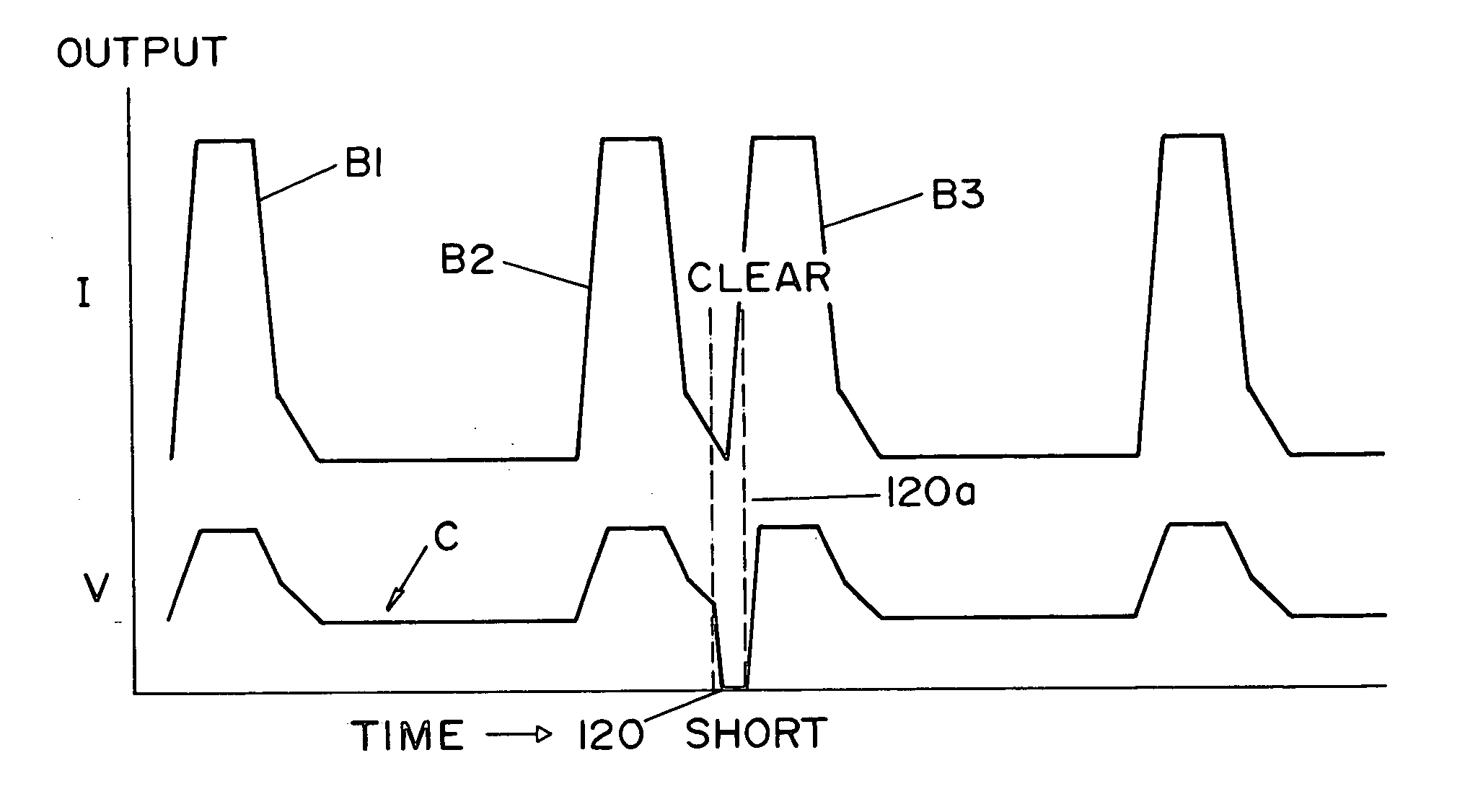

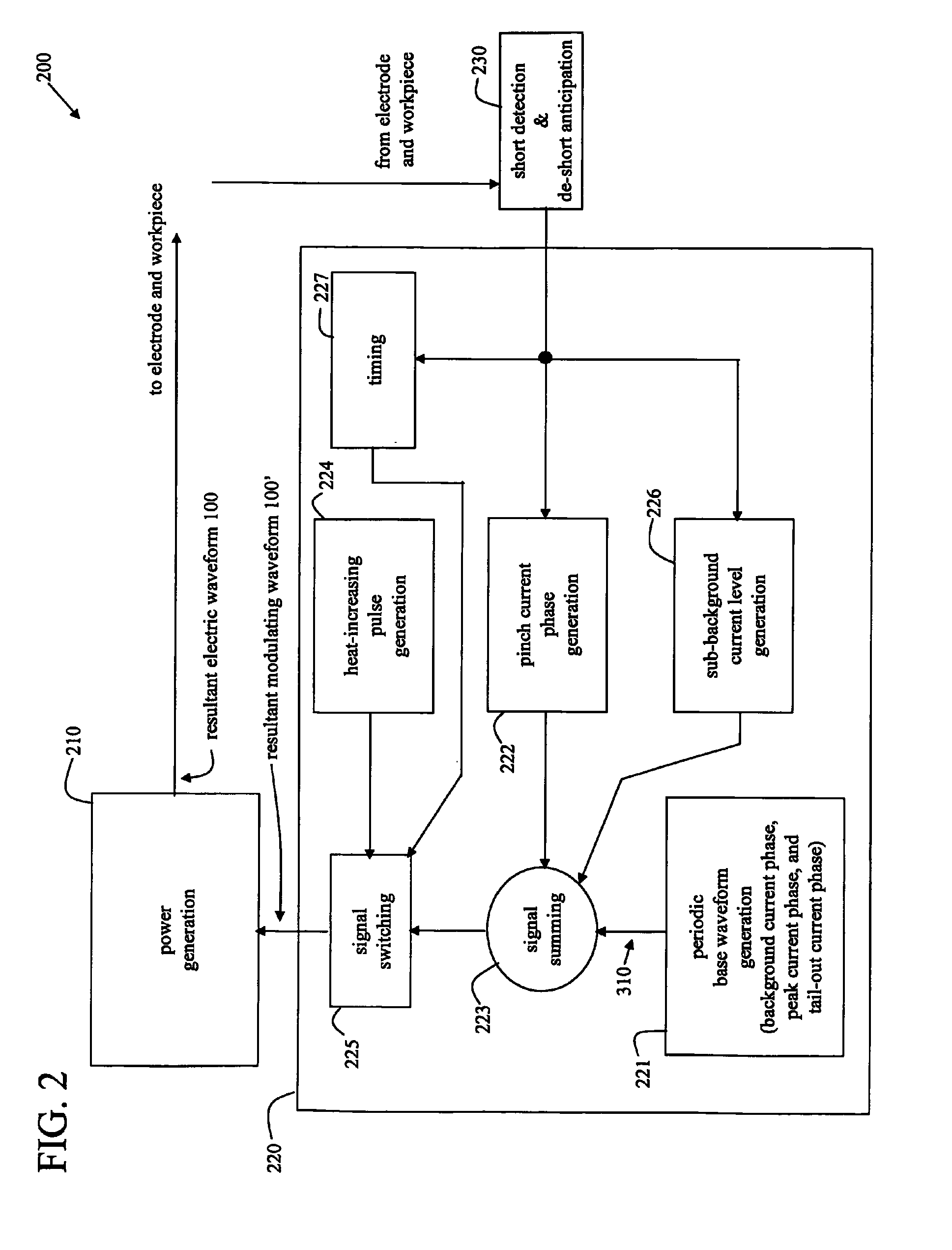

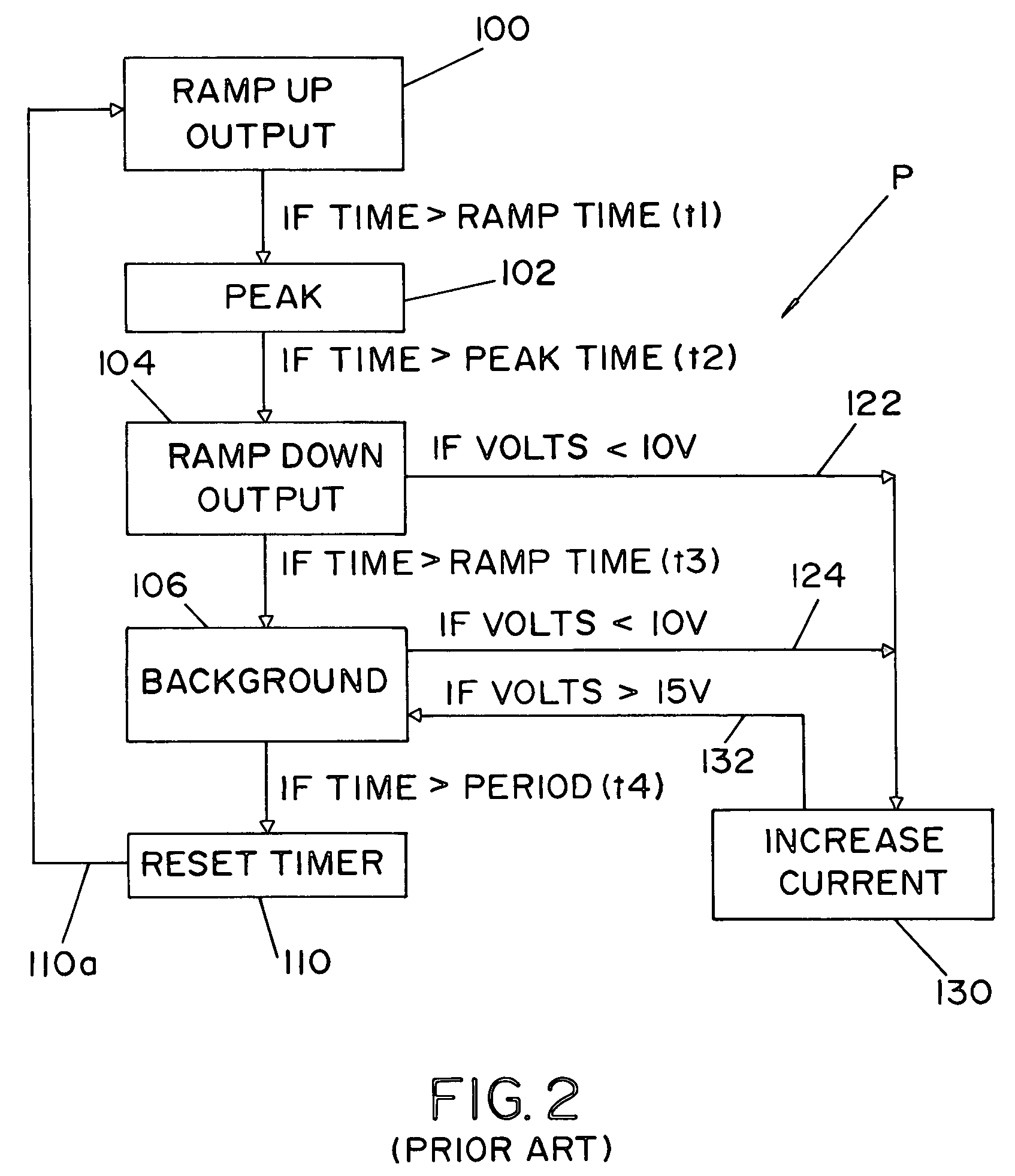

Electric arc pulse welder with short circuit control

ActiveUS20050224481A1Improved short circuit control procedureReduce the amount requiredArc welding apparatusPeak currentPulse waveform

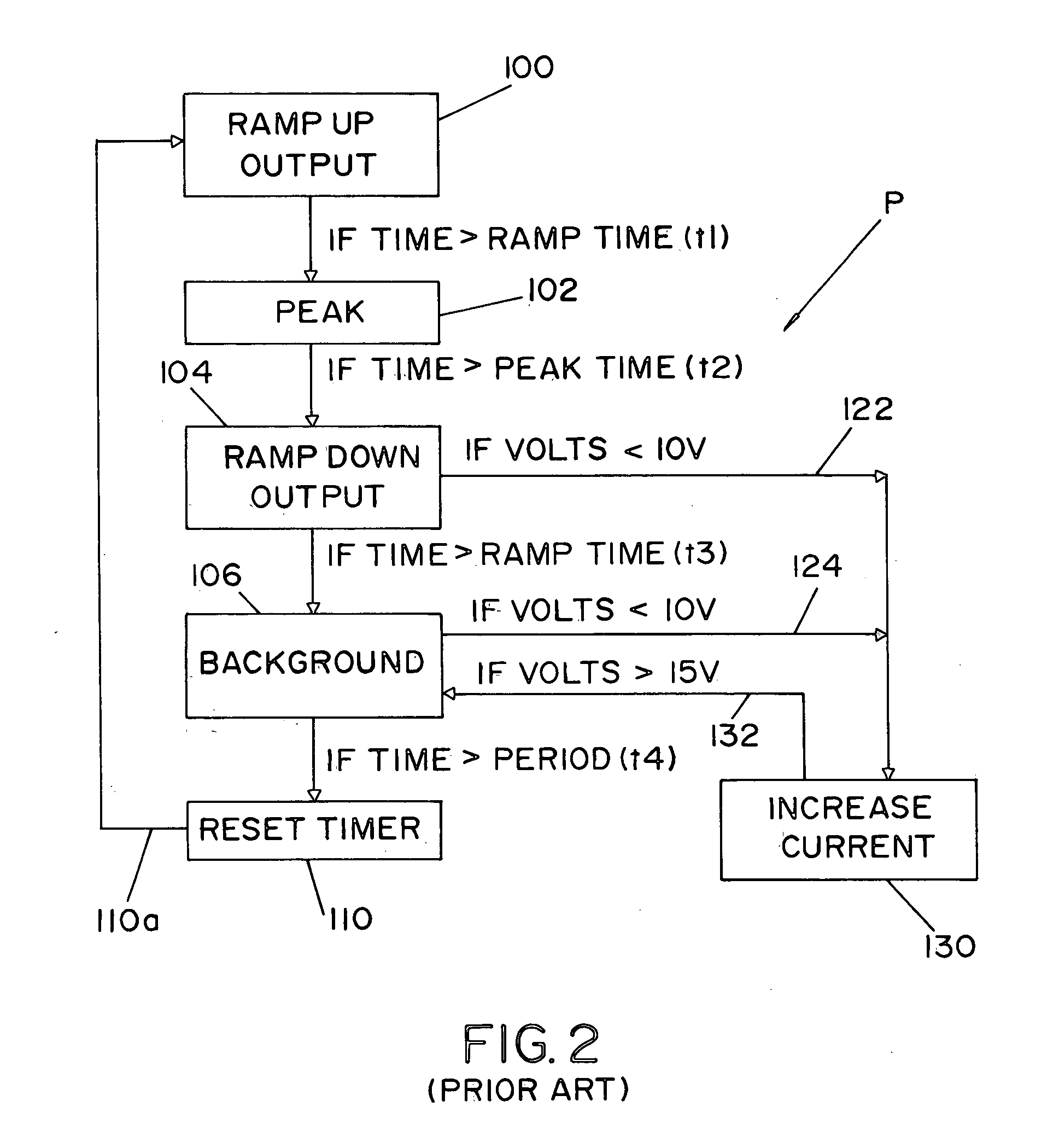

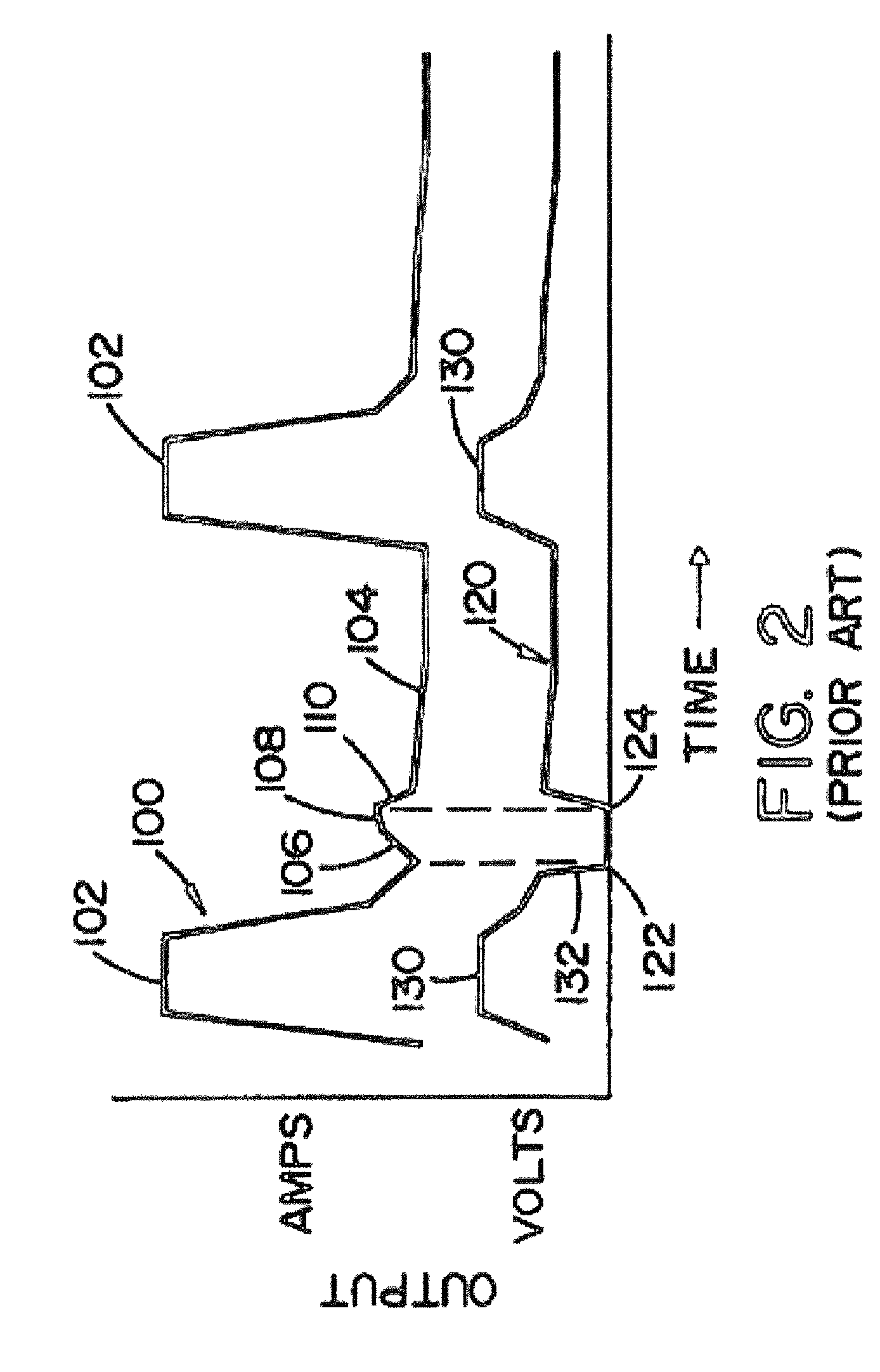

An electric arc welder with a waveform generator controlled to create a welding process involving current flow between an electrode and a workpiece wherein the welding process comprises a succession of pulse waveforms, each having a current ramp up portion, a peak current portion, a current ramp down portion and a background current portion, a voltage sensing circuit to sense a short circuit between the electrode and the workpiece and a reset circuit to reset the waveform generator upon sensing of a short circuit. The preferred electrode is a solid wire which may be in the form of a metal cored wire.

Owner:LINCOLN GLOBAL INC

Pulse arc welding control method

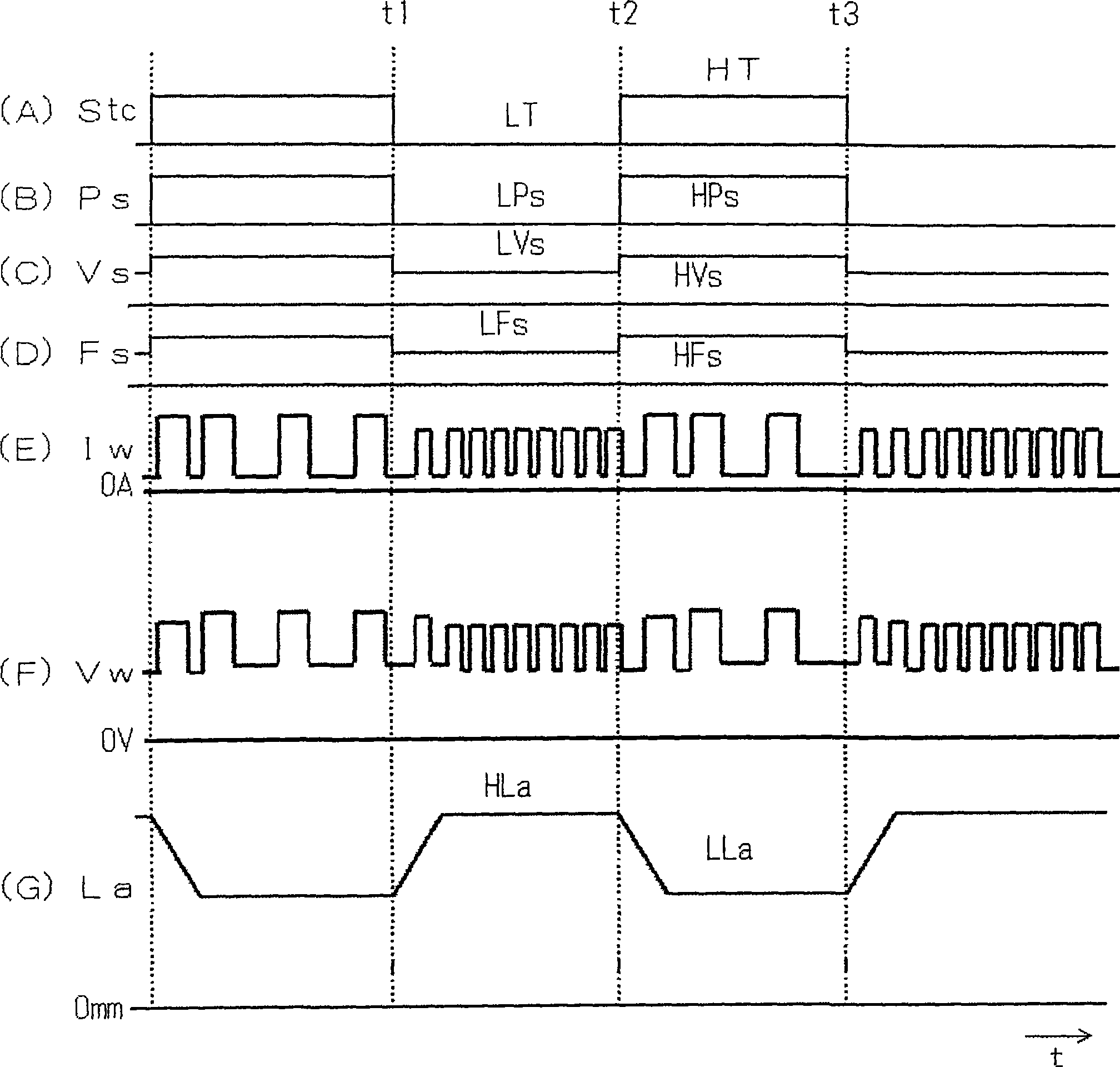

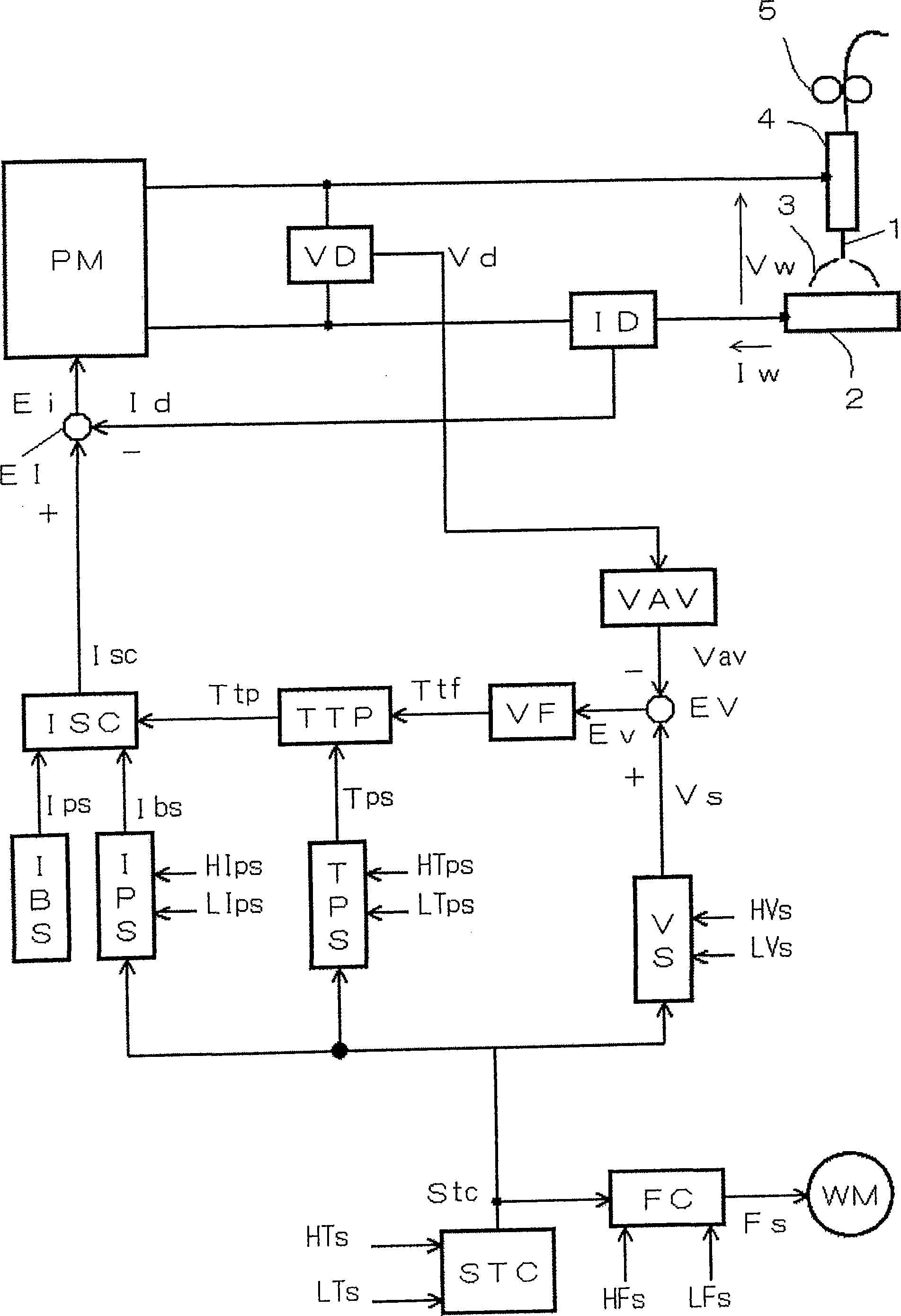

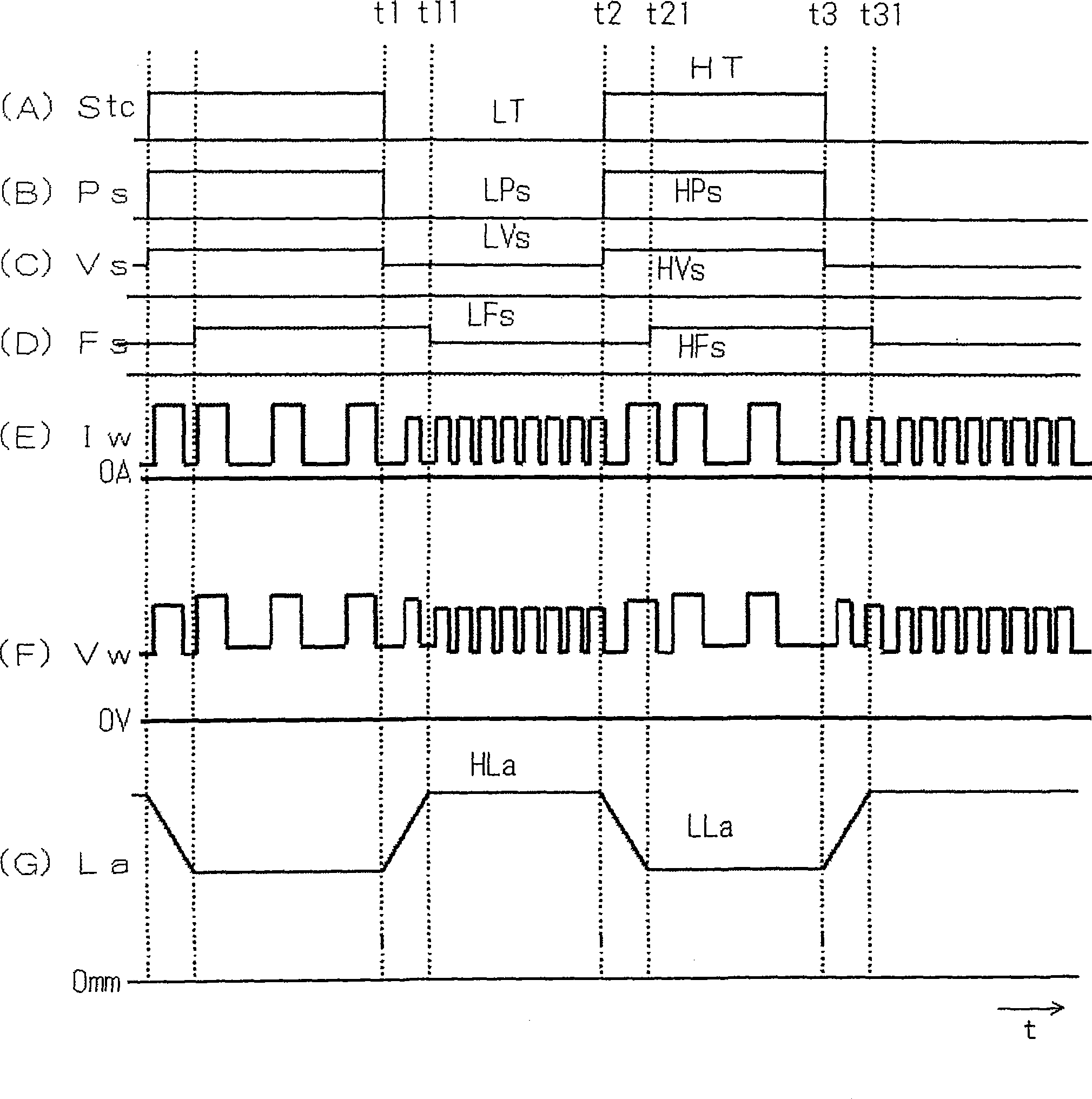

ActiveCN101376191AThe arc force changes greatlyShake violentlyArc welding apparatusPower flowSwitching signal

An impulse arc welding control method comprises: repeating electrifying using the electrifying of peak current of in peak period and the electrifying of background current in background period as impulse period; controlling the arc length in the manner that the welding voltage value (Vw) is approximately equal to the set voltage value (Vs); making the arc length to vary periodically by making the set voltage value (Vs) to vary synchronistically with the switching signal (Stc); making the impulse parameter (Ps) to vary synchronistically with the switching signal (Stc); and changing the sending speed (Fs) from the time the switching signal (Stc) varying starts to the time arc length (La) transition varying approximately converges. Thus, the major varying of arc force make the shake movement of the bath becomes more intensive to improve the air bubble reducing effect. Consequently, the air bubble reducing effect is improved in the impulse arc welding method with arc length varied periodically.

Owner:DAIHEN CORP

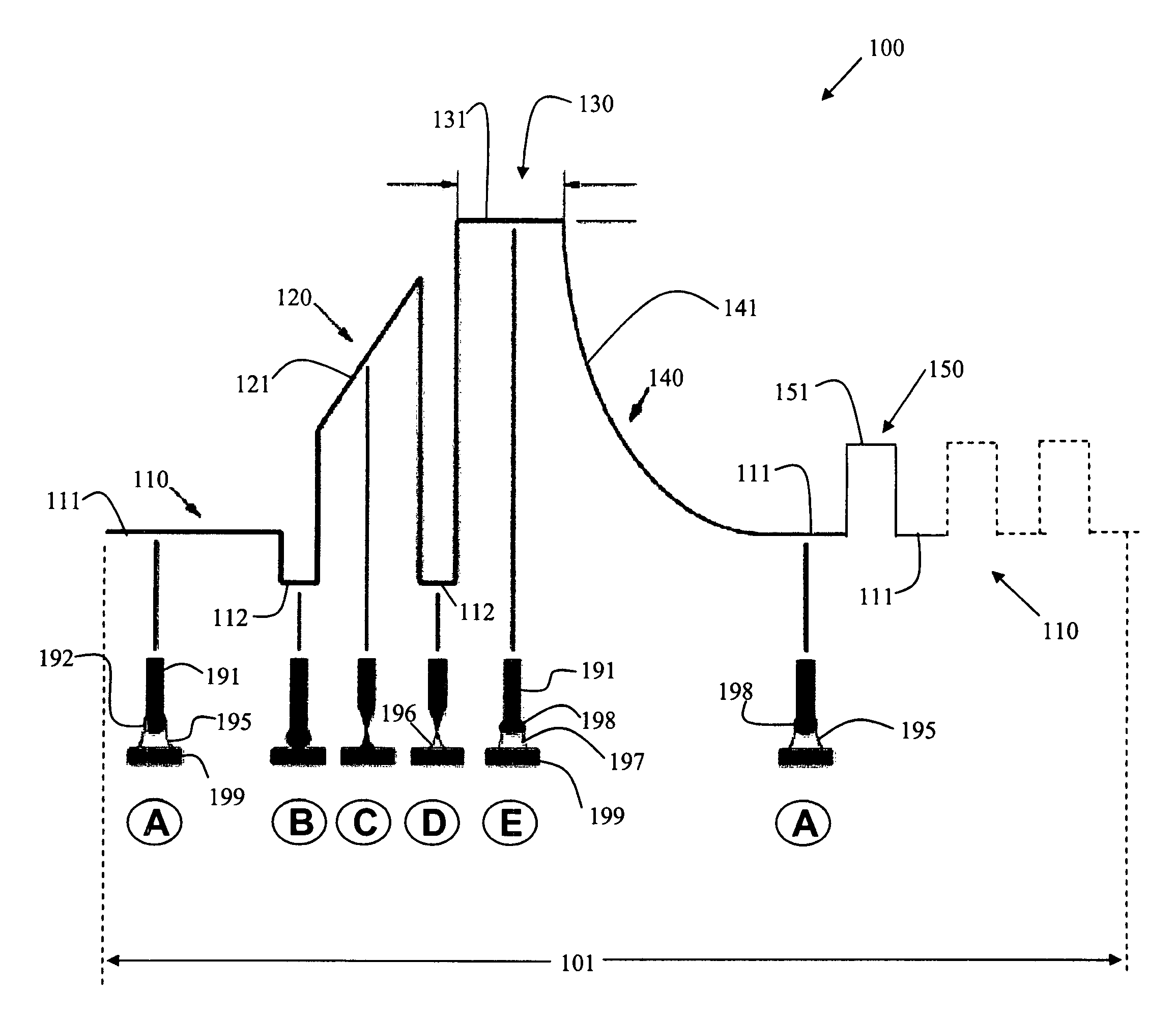

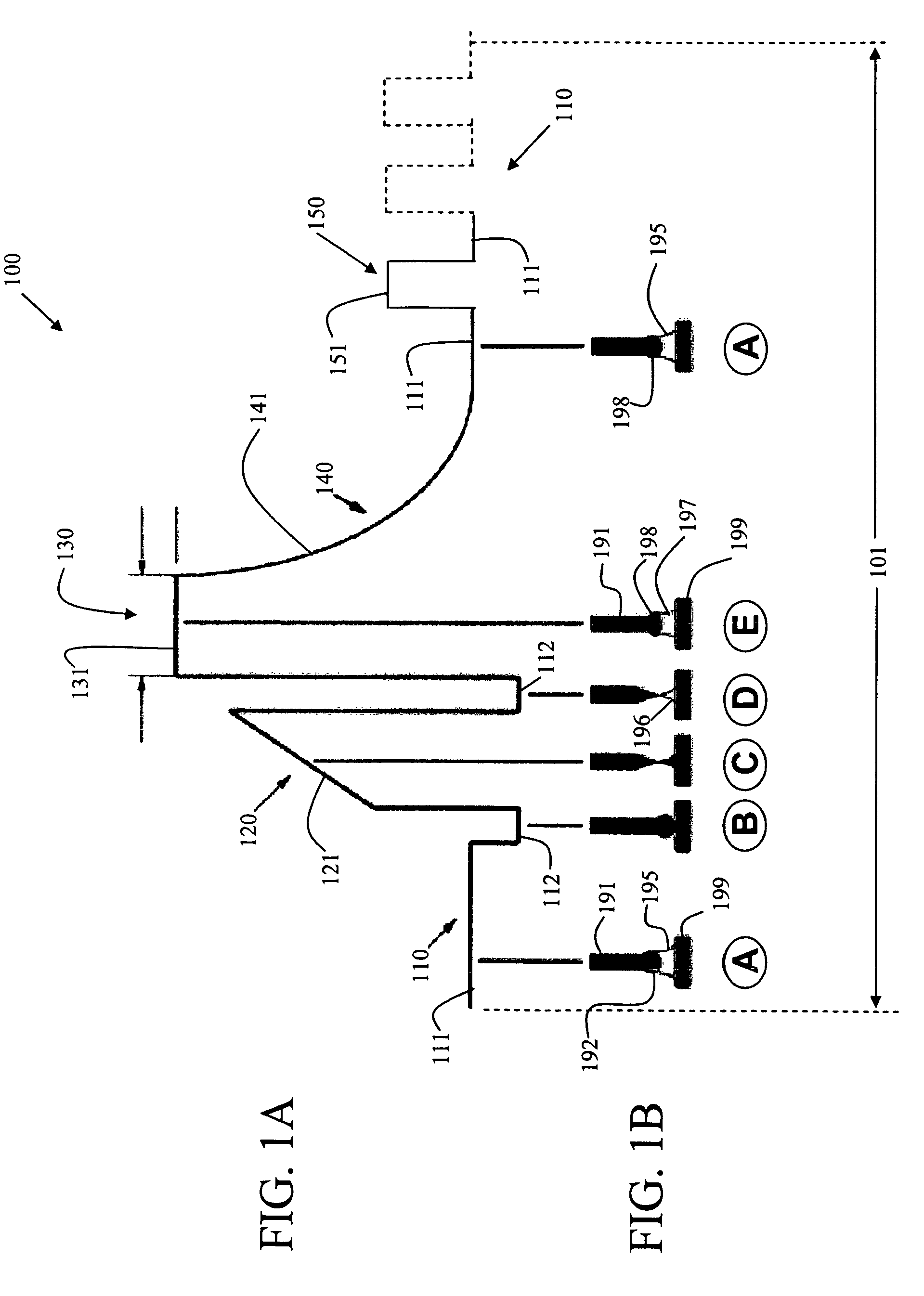

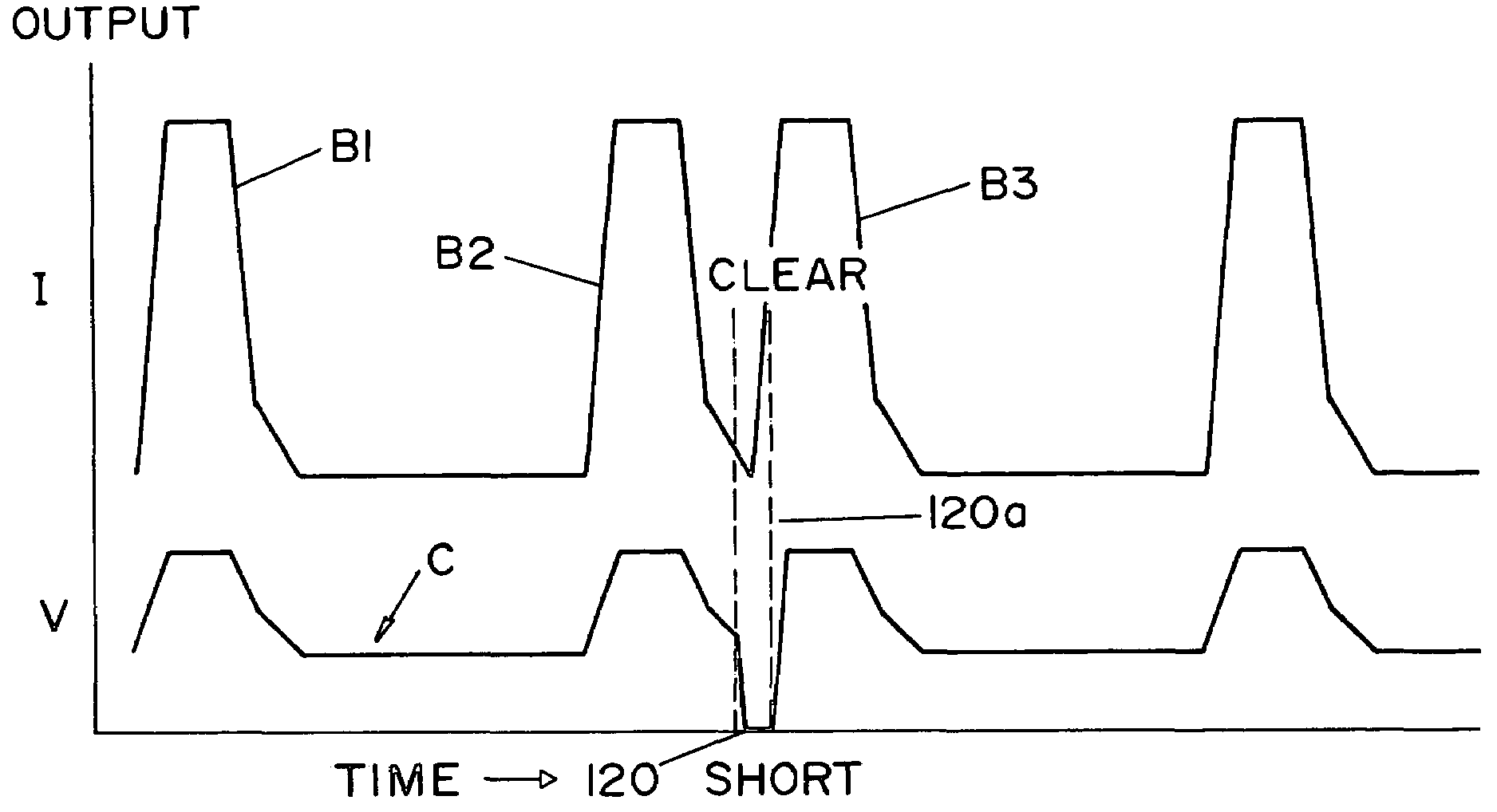

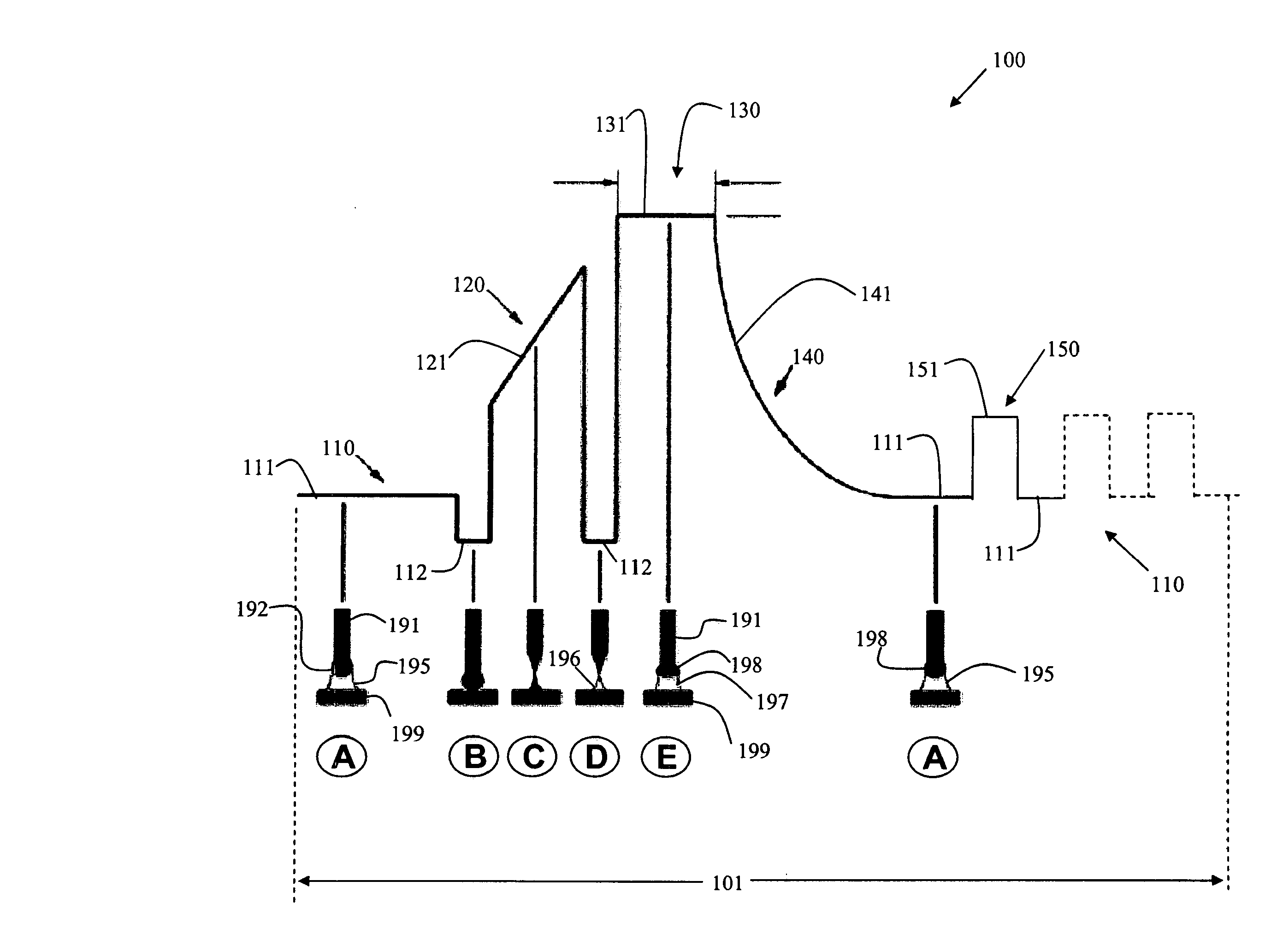

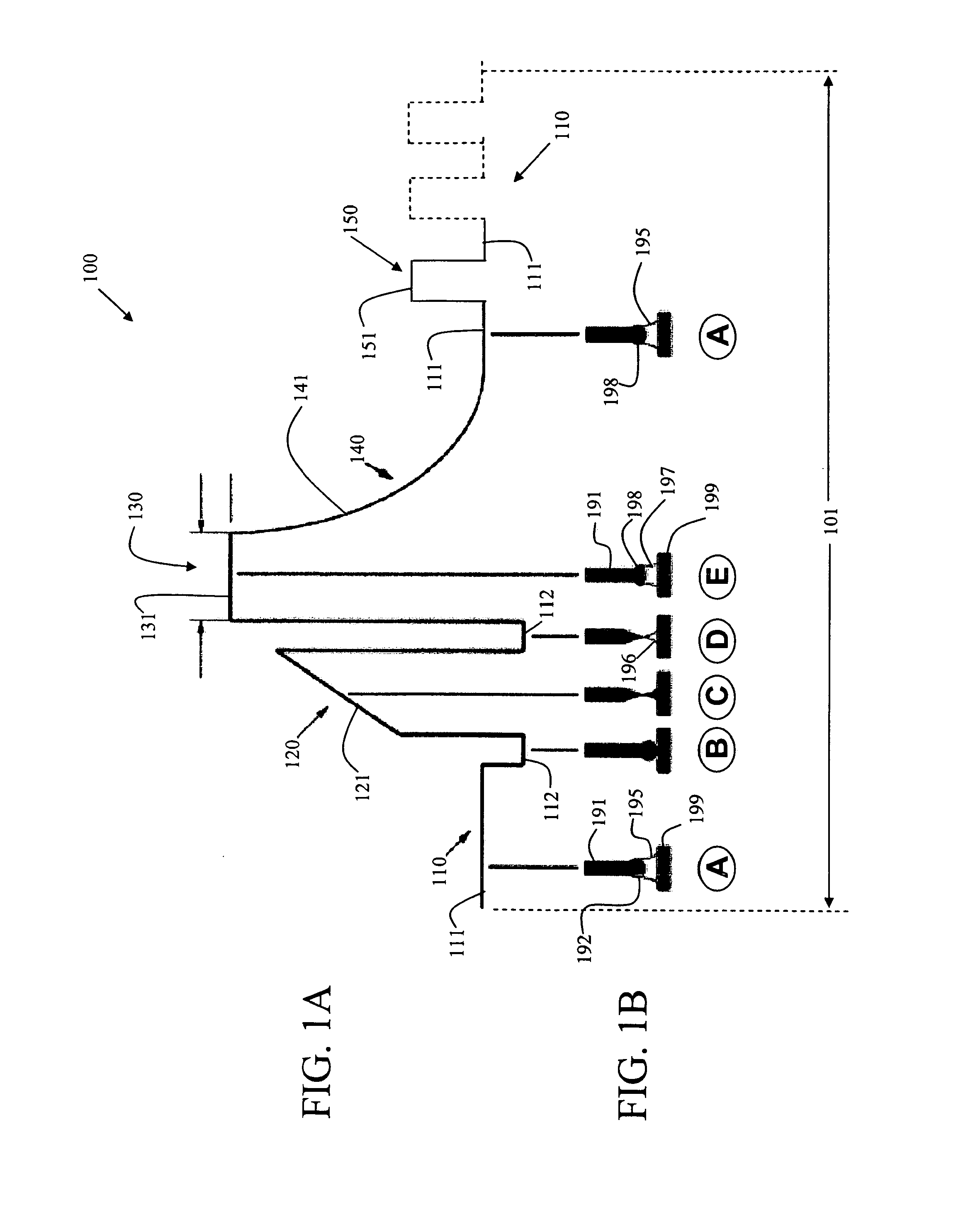

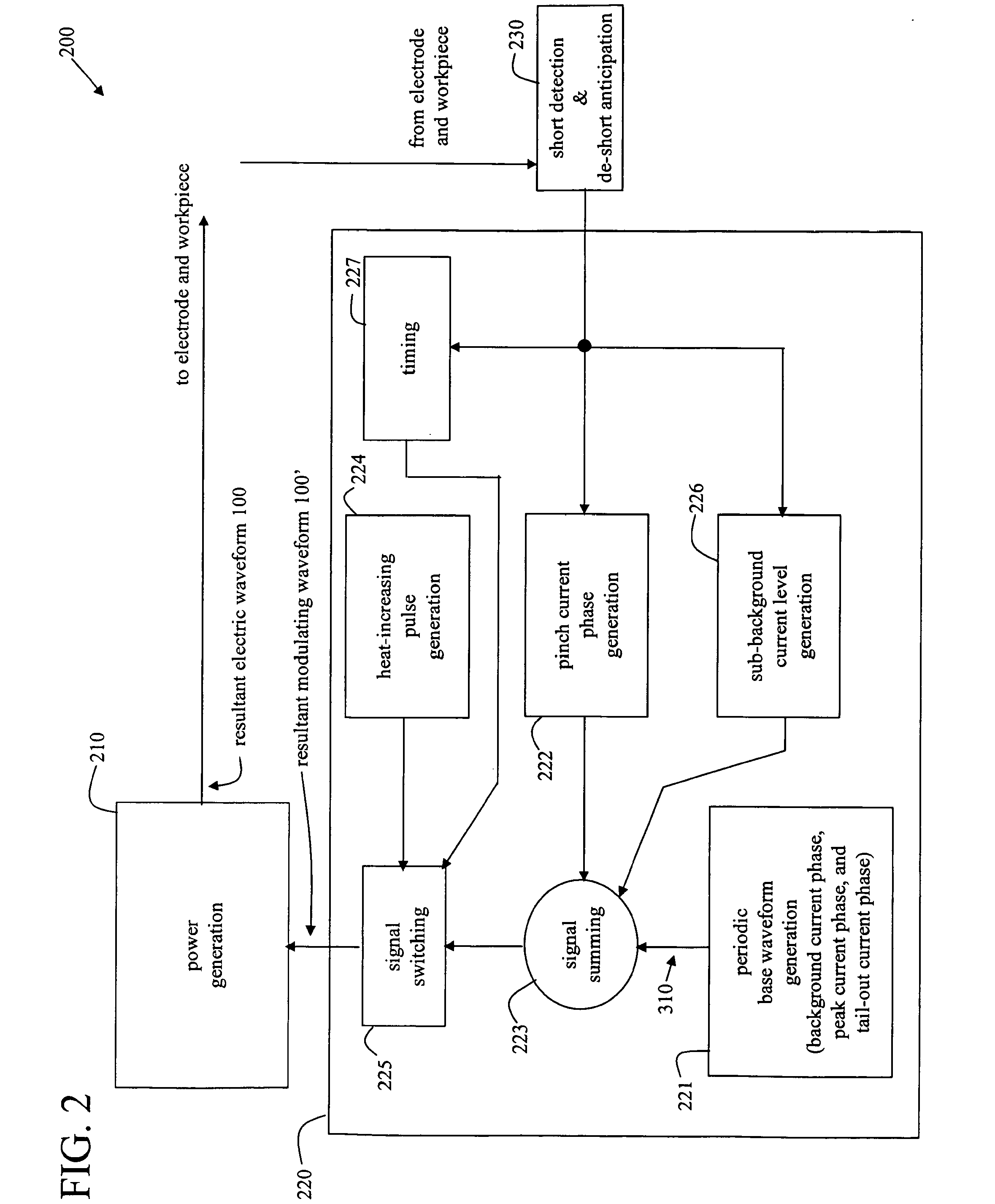

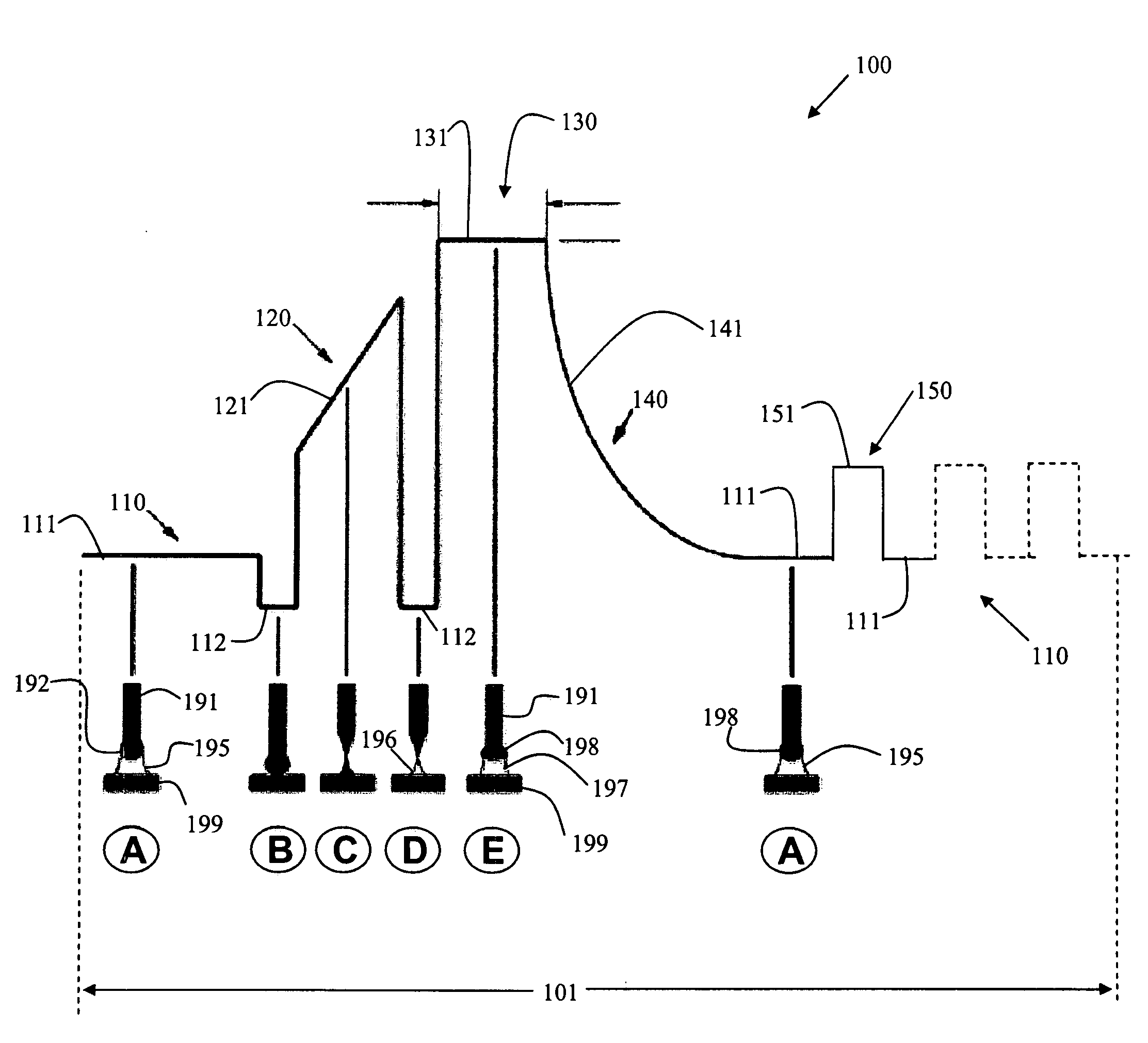

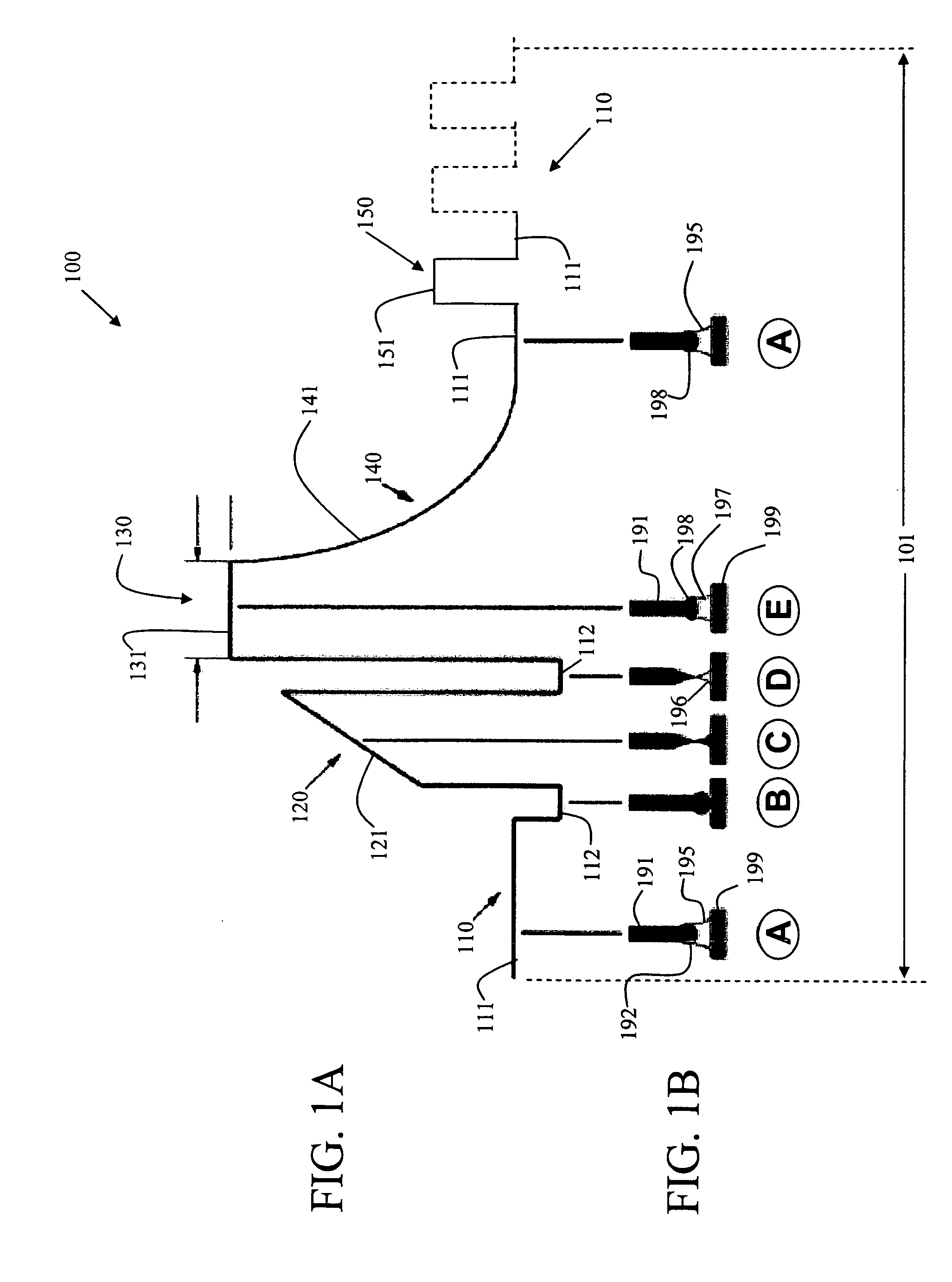

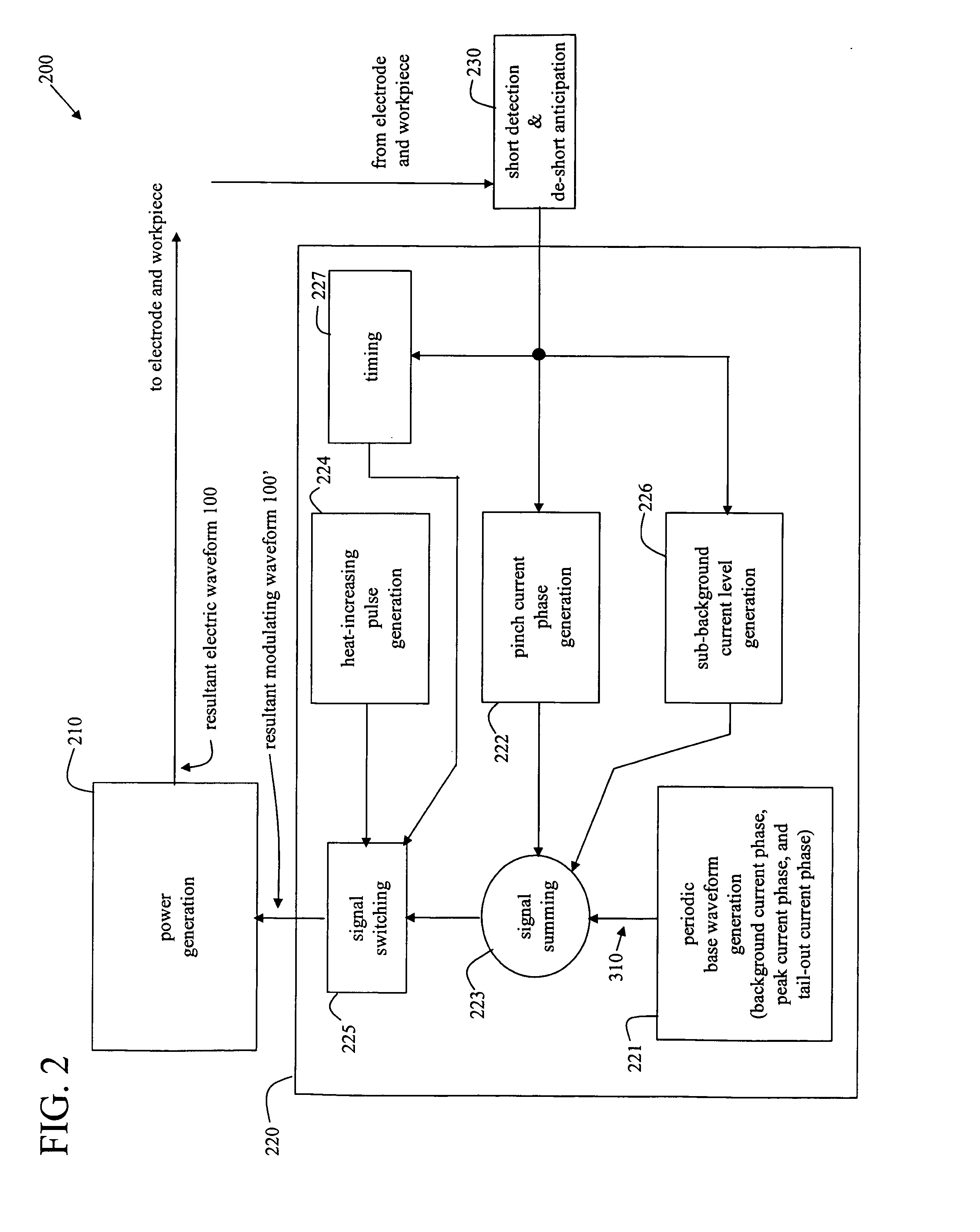

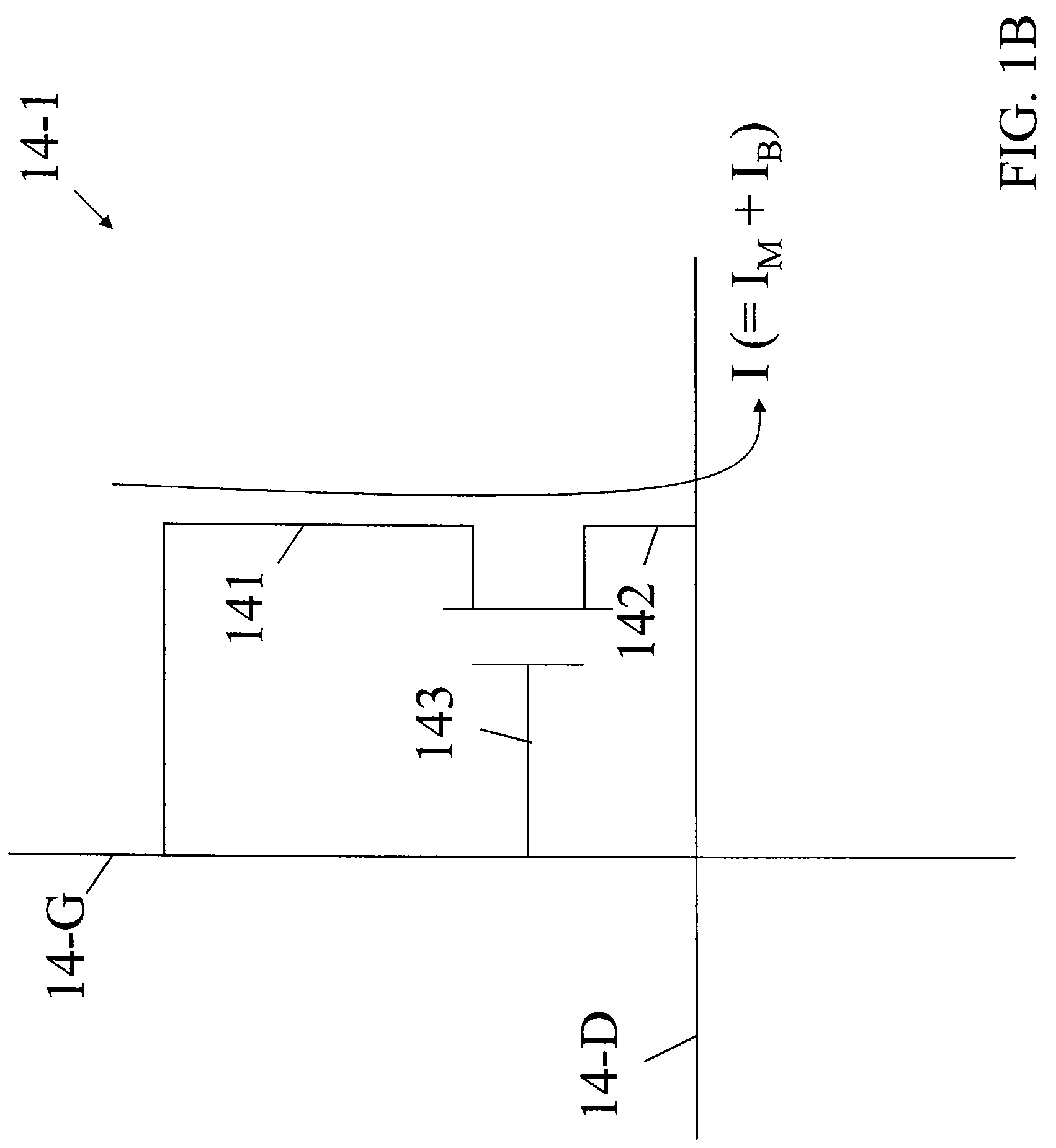

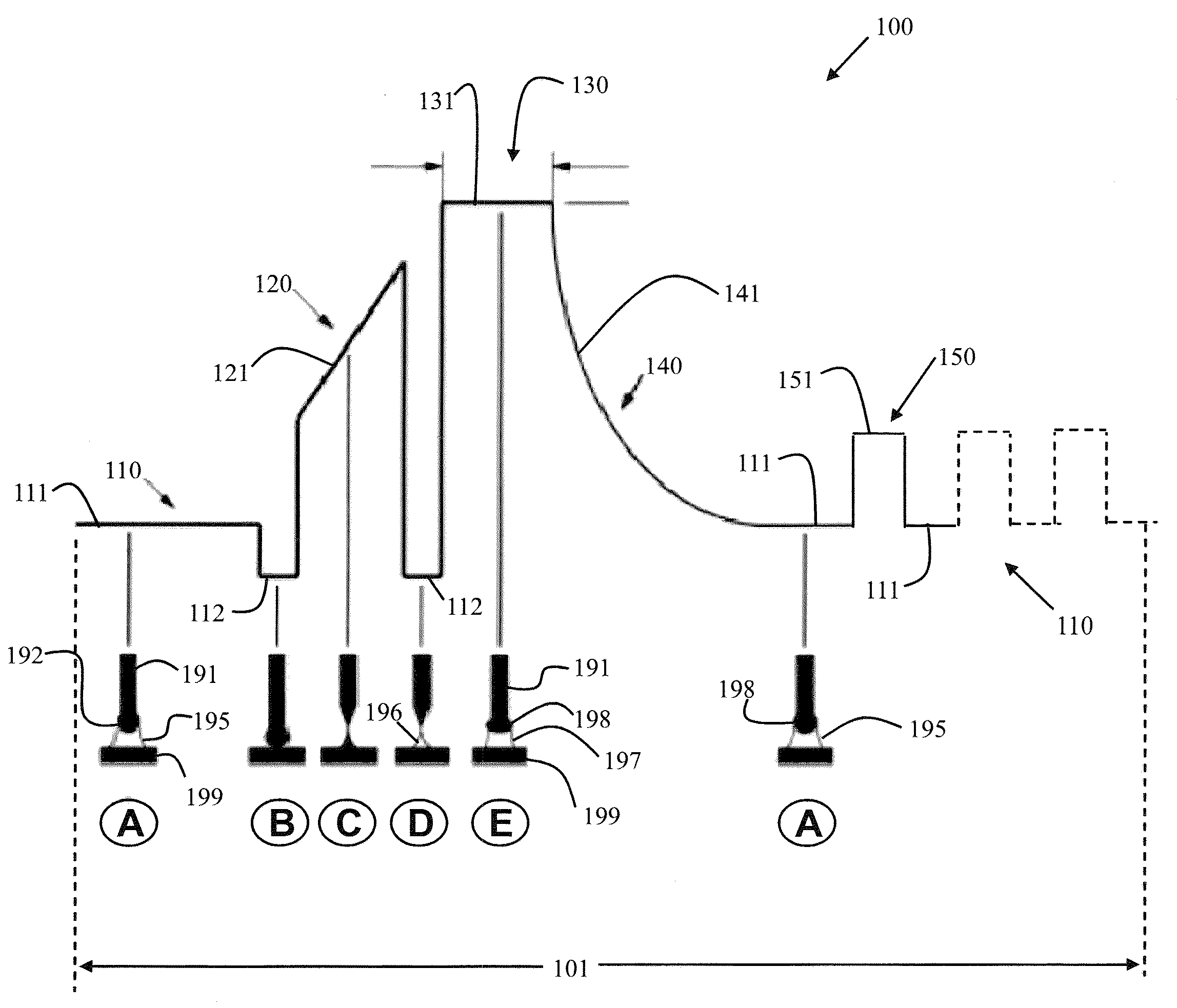

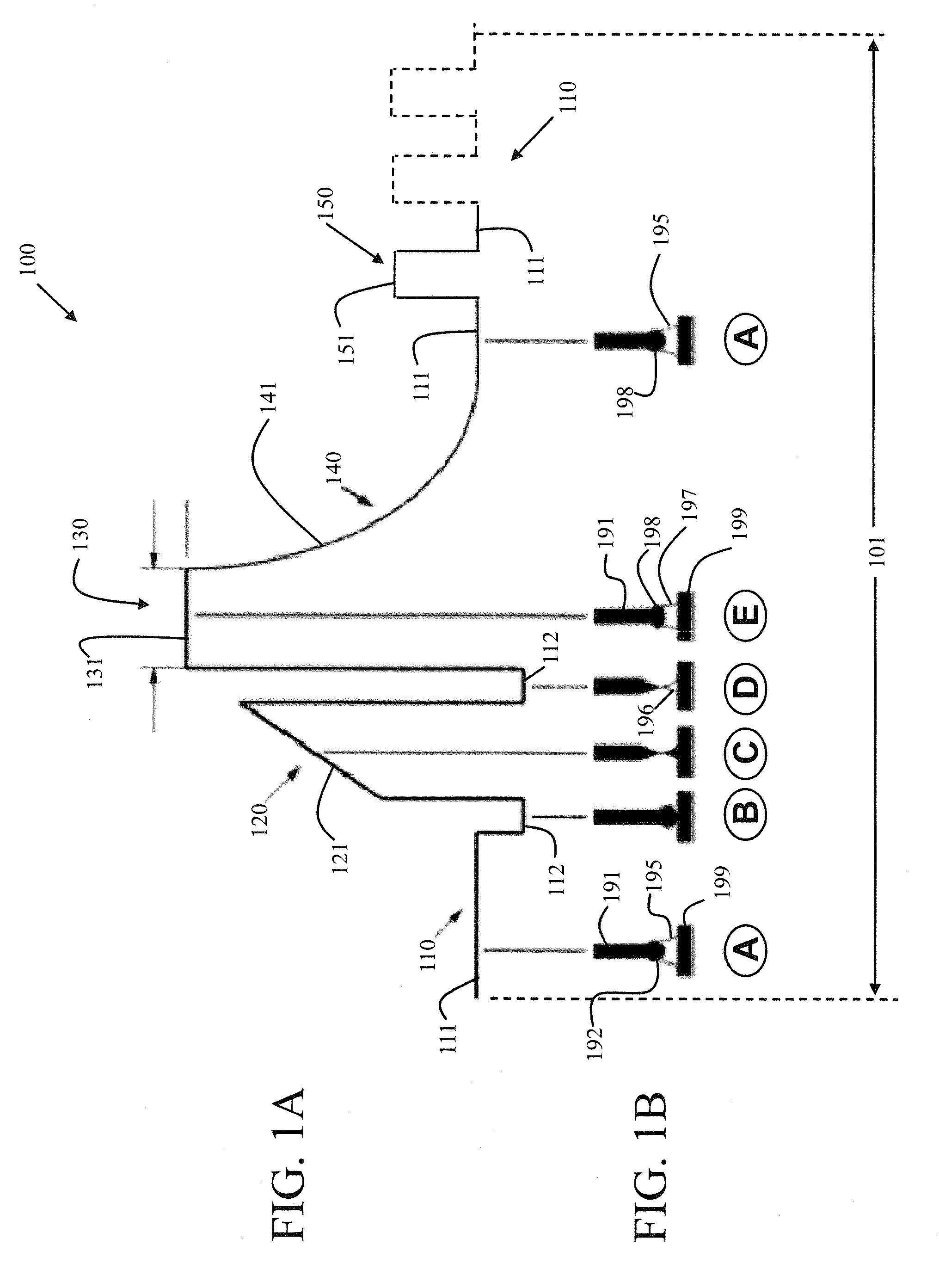

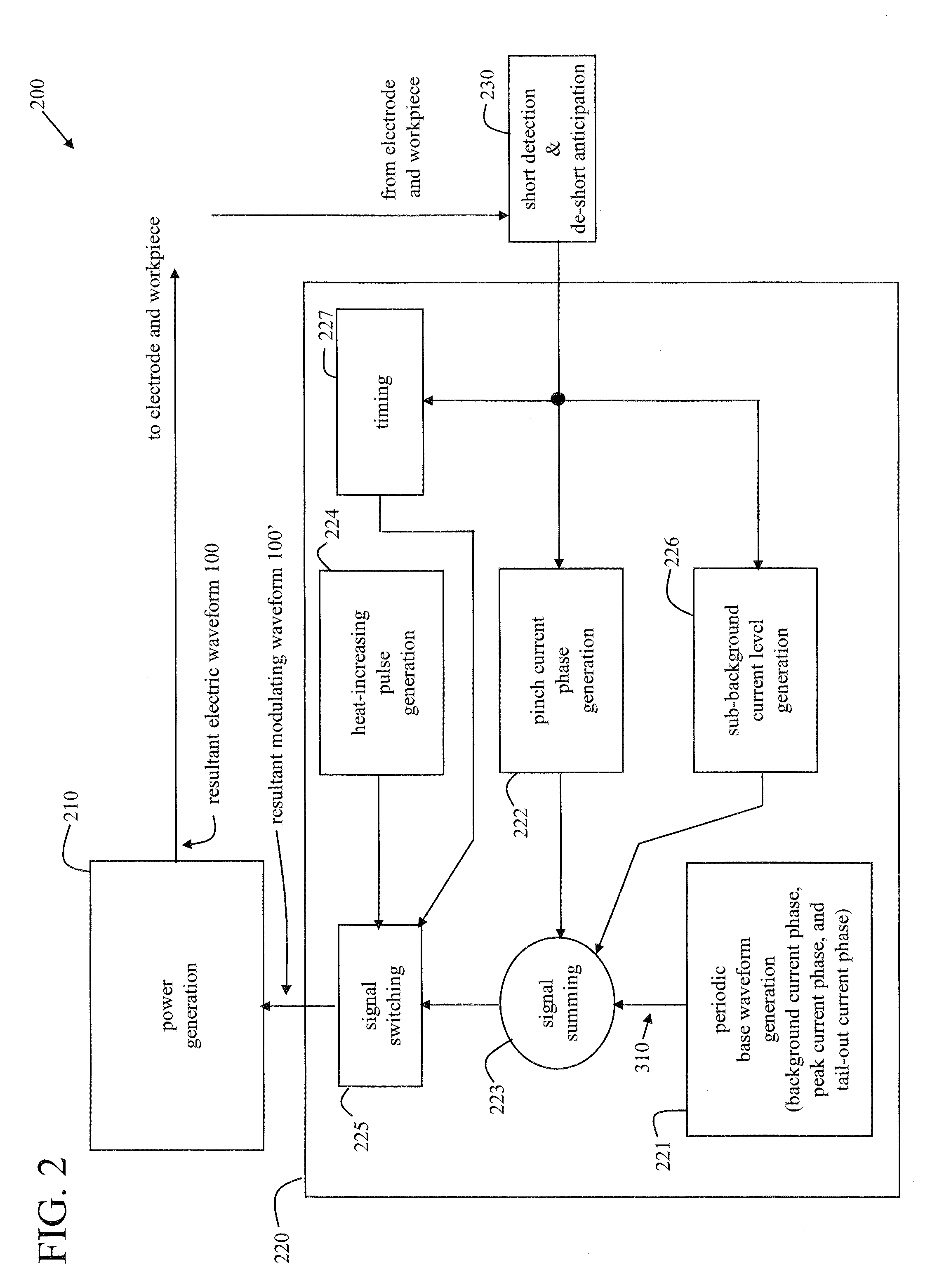

Method and system to increase heat input to a weld during a short-circuit arc welding process

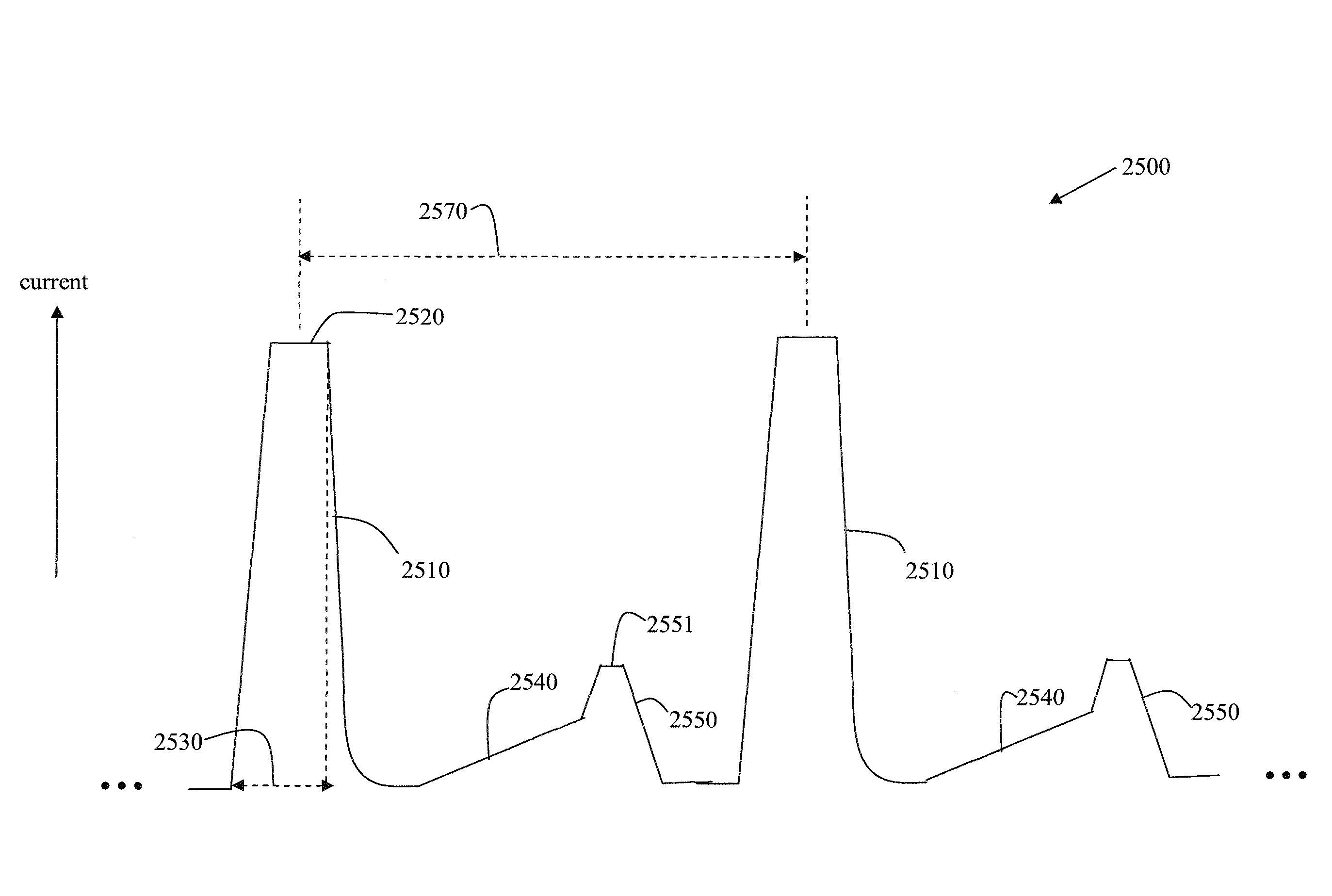

A method and a system to increase heat input to a weld during an arc welding process. A series of electric arc pulses are generated between an advancing welding electrode and a metal workpiece using an electric arc welding system capable of generating an electric welding waveform to produce the electric arc pulses. A cycle of the electric welding waveform includes a pinch current phase providing an increasing pinch current level, a peak current phase providing a peak current level, a tail-out current phase providing a decreasing tail-out current level, and a background current phase providing a background current level. At least one heat-increasing current pulse of the cycle is generated, providing a heat-increasing current level, during the background current phase, where the heat-increasing current level is above the background current level. The cycle of the electric welding waveform with the at least one heat-increasing current pulse may be repeated until the arc welding process is completed.

Owner:LINCOLN GLOBAL INC

Electric arc pulse welder with short circuit control

ActiveUS7173214B2Reduce the amount requiredLow hydrogenArc welding apparatusPeak currentPulse waveform

An electric arc welder with a waveform generator controlled to create a welding process involving current flow between an electrode and a workpiece wherein the welding process comprises a succession of pulse waveforms, each having a current ramp up portion, a peak current portion, a current ramp down portion and a background current portion, a voltage sensing circuit to sense a short circuit between the electrode and the workpiece and a reset circuit to reset the waveform generator upon sensing of a short circuit. The preferred electrode is a solid wire which may be in the form of a metal cored wire.

Owner:LINCOLN GLOBAL INC

Method and system to increase heat input to a weld during a short-circuit arc welding process

InactiveUS20130015170A1Lower Level RequirementsIncrease heat inputArc welding apparatusPower flowElectrical polarity

A method and a system to control heat input to a weld during an arc welding process. A series of electric arc pulses are generated between an advancing welding electrode and a metal workpiece using an electric arc welding system capable of generating an electric welding waveform to produce the electric arc pulses. The welding waveform has droplet transfer pulses and at least one heat input pulse which is generated during a background portion of the waveform. The at least one heat-increasing current pulse is above the background current level and has a polarity opposite of that of the droplet transfer pulse.

Owner:LINCOLN GLOBAL INC

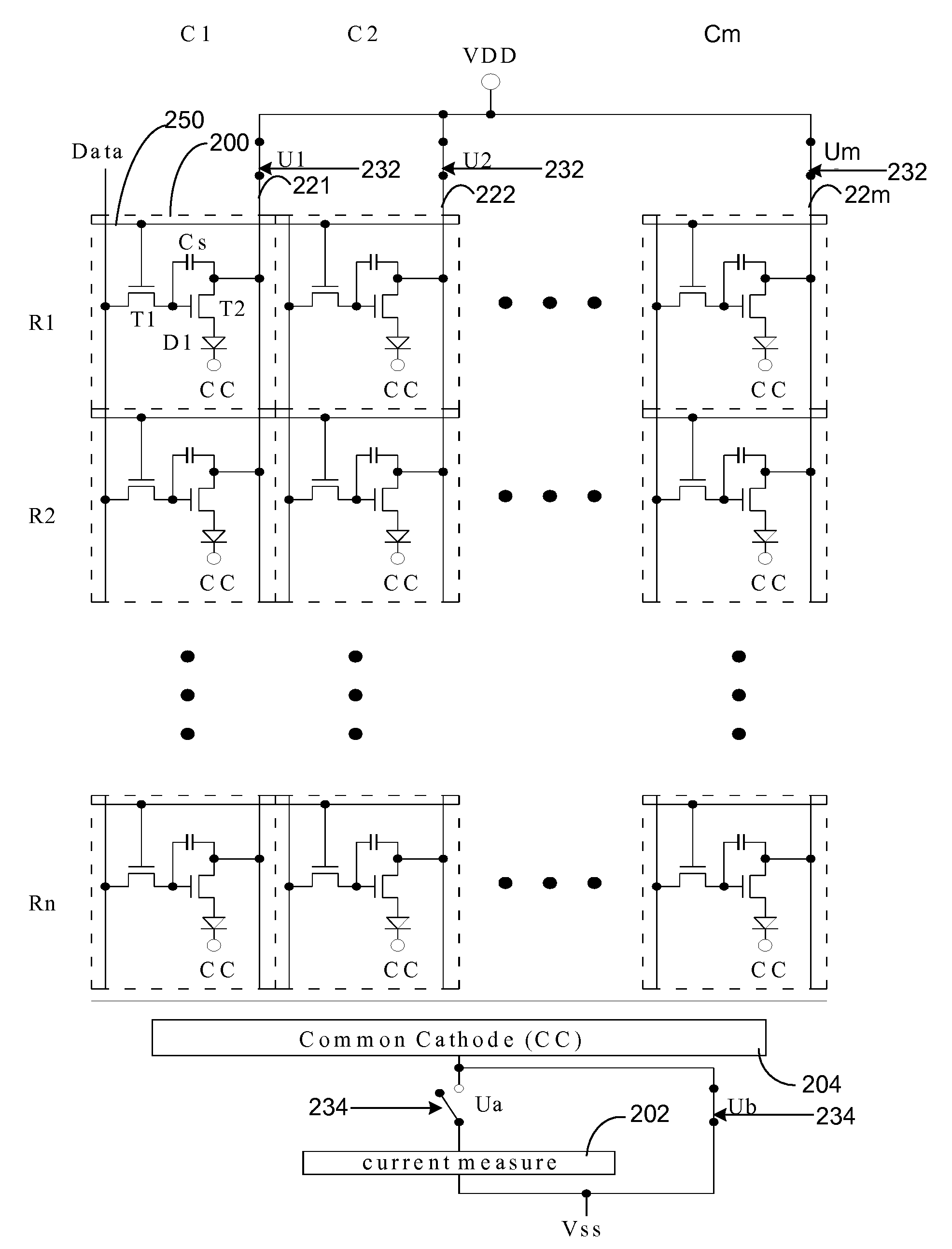

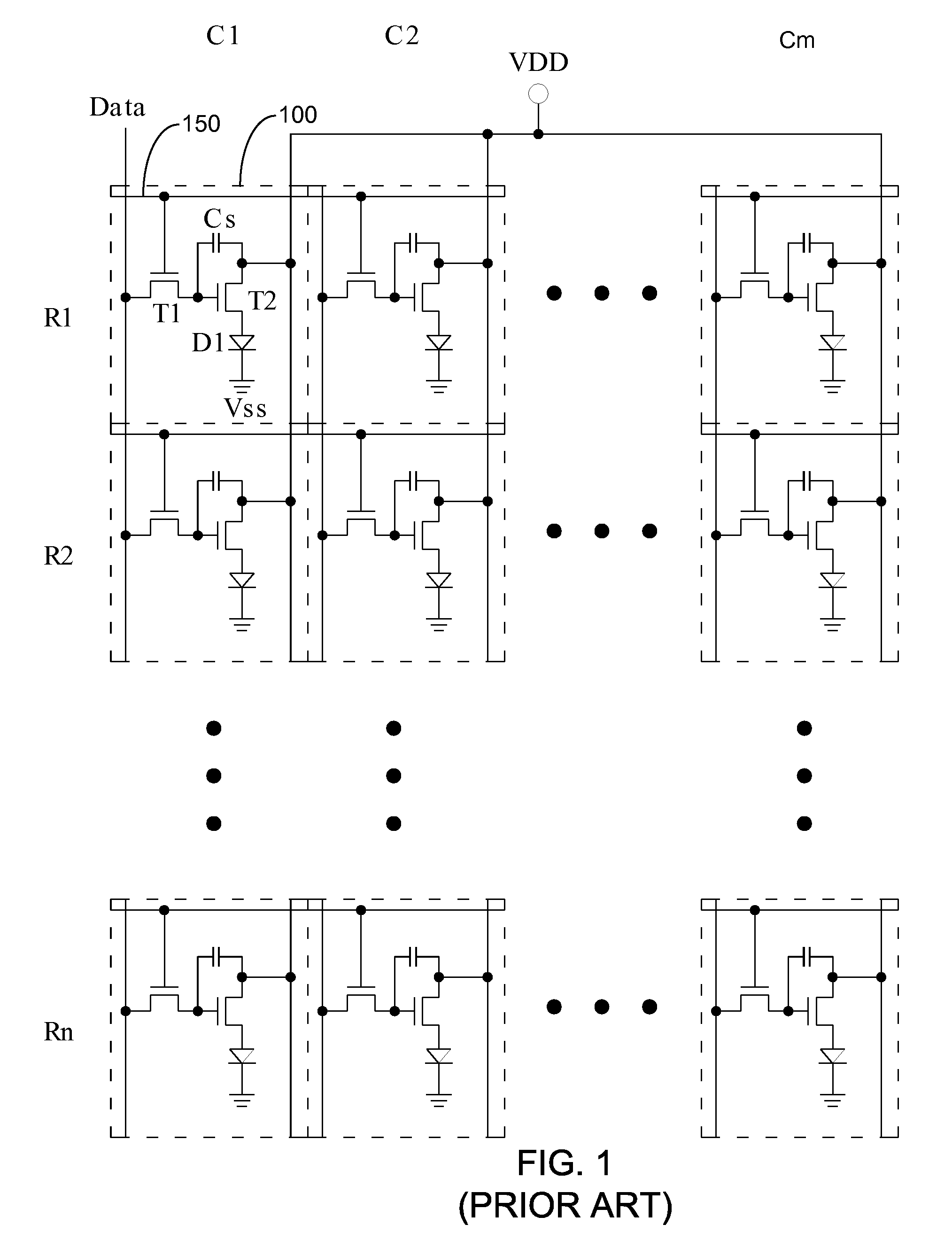

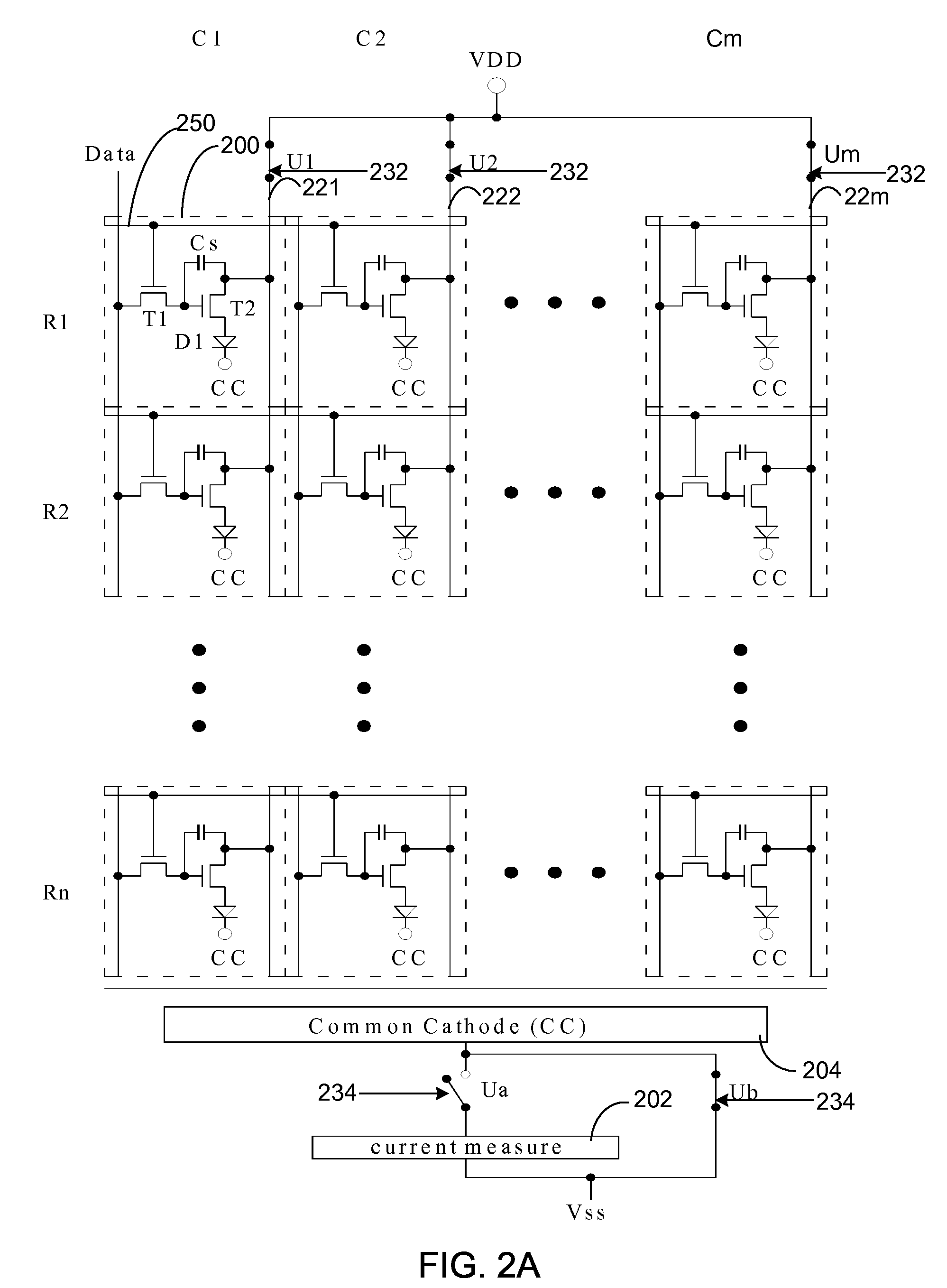

Sub-pixel current measurement for OLED display

InactiveUS20080266214A1Easy and accurate measurementHigh currentStatic indicating devicesActive matrixDisplay device

An active matrix drive system drives an emissive display device such as an organic light-emitting diode display and is configured to measure sub-pixel current in the emissive display device. One or more power column power lines of the emissive display device are turned off while sub-pixel current is measured. As a result, the sub-pixel current is relative large compared to the background current of the emissive display device, which facilitates accurate measurement of the sub-pixel current.

Owner:LEADIS TECH

Method and device to build-up, clad, or hard-face with minimal admixture

ActiveUS8203099B2Improve the level ofBlocking may occurElectric discharge heatingArc welding apparatusPeak currentAlloy

An electric arc device and methods to build up, clad, join, or overlay an alloyed metal onto a parent metal with minimal admixture. The methods employed in the electric arc device provide a high frequency waveform with a high amplitude pulse, a low amplitude background current, and a special shorting routine, to alleviate the problem of generating too much ad-mixture. A fast transition from a peak current level to a background current level along with a shorting response and a plasma boost pulse reduces the droplet size and reduces the heat input required to achieve good welding performance.

Owner:LINCOLN GLOBAL INC

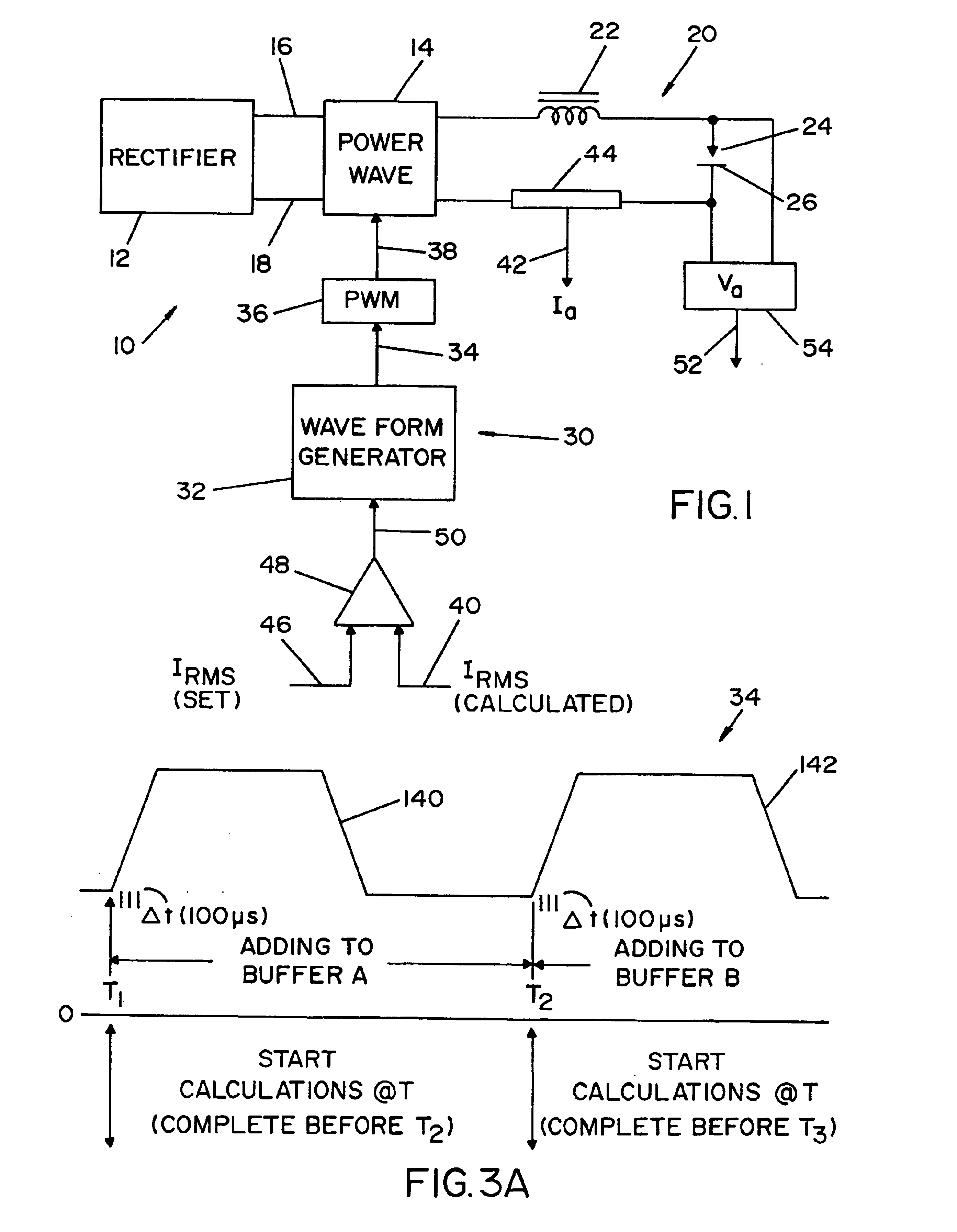

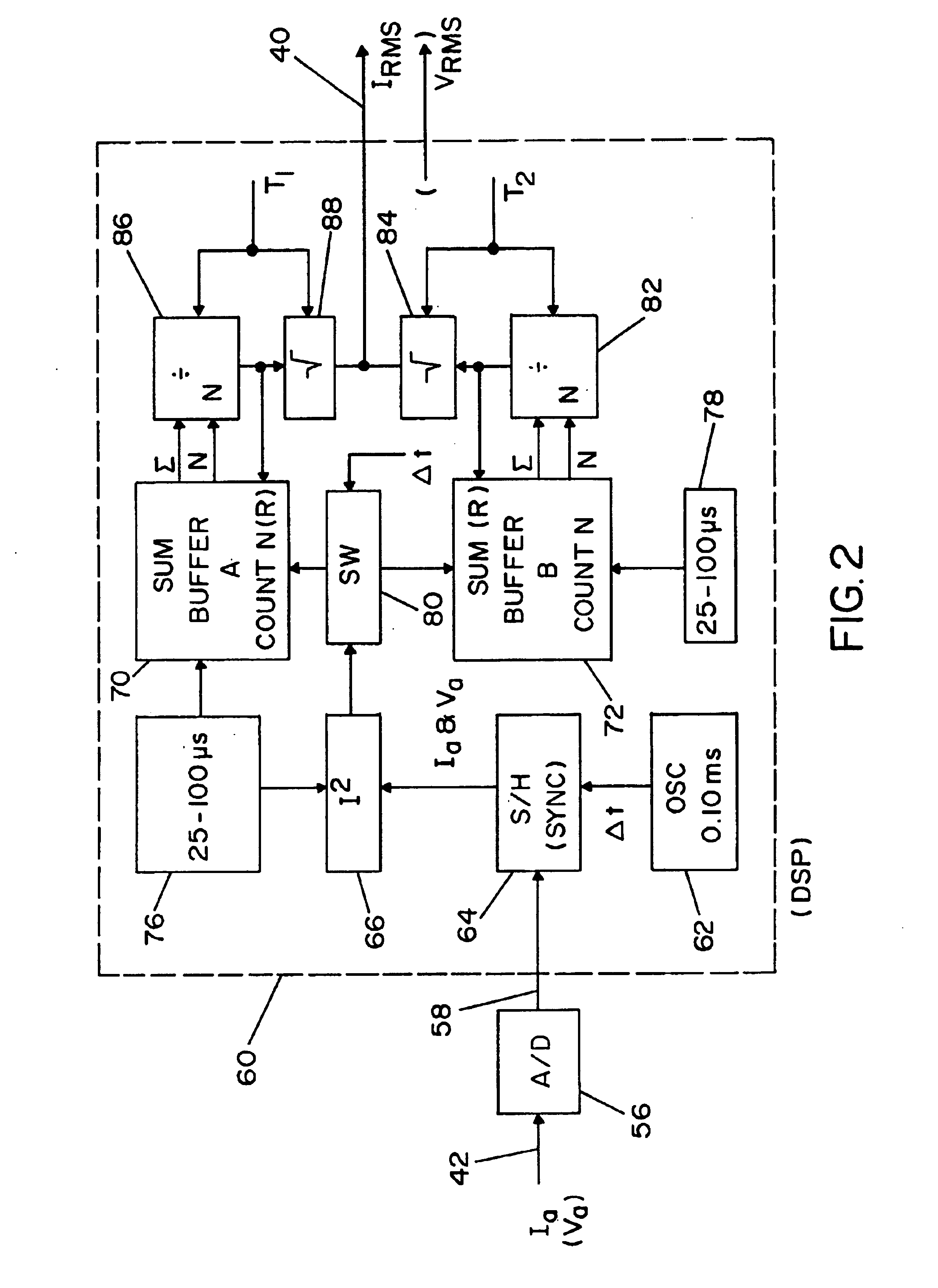

Electric arc welder and method for controlling the welding process of the welder

ActiveUS20050016974A1Accurately reflectEasy to controlArc welding apparatusMetal working apparatusPower factorPeak current

An electric arc welder for performing a given weld process with a selected A.C. pulse current waveform performed between an electrode and a workpiece, where the current waveform includes a positive segment and a negative segment, with at least one segment including a peak current and background current. The welder comprises: a power source with a controller having a digital processor including a program to calculate the real time power factor of the weld current and weld voltage where the program includes an algorithm to calculate the rms weld voltage, the rms weld current and the average power of said power source; a circuit to multiply the rms current by the rms voltage to produce an rms power level; a circuit to divide the average power by the rms power to create a value representing the actual real time power factor of said power source; and, a circuit to adjust said background current to maintain said power factor at a given level, which is manually adjusted to set the heat of the weld.

Owner:LINCOLN GLOBAL INC

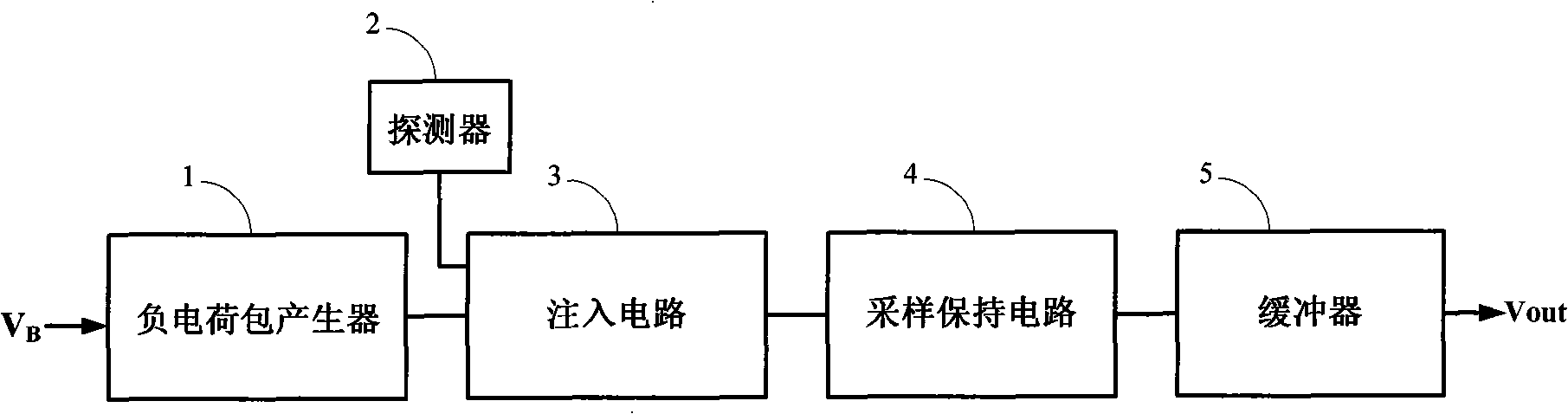

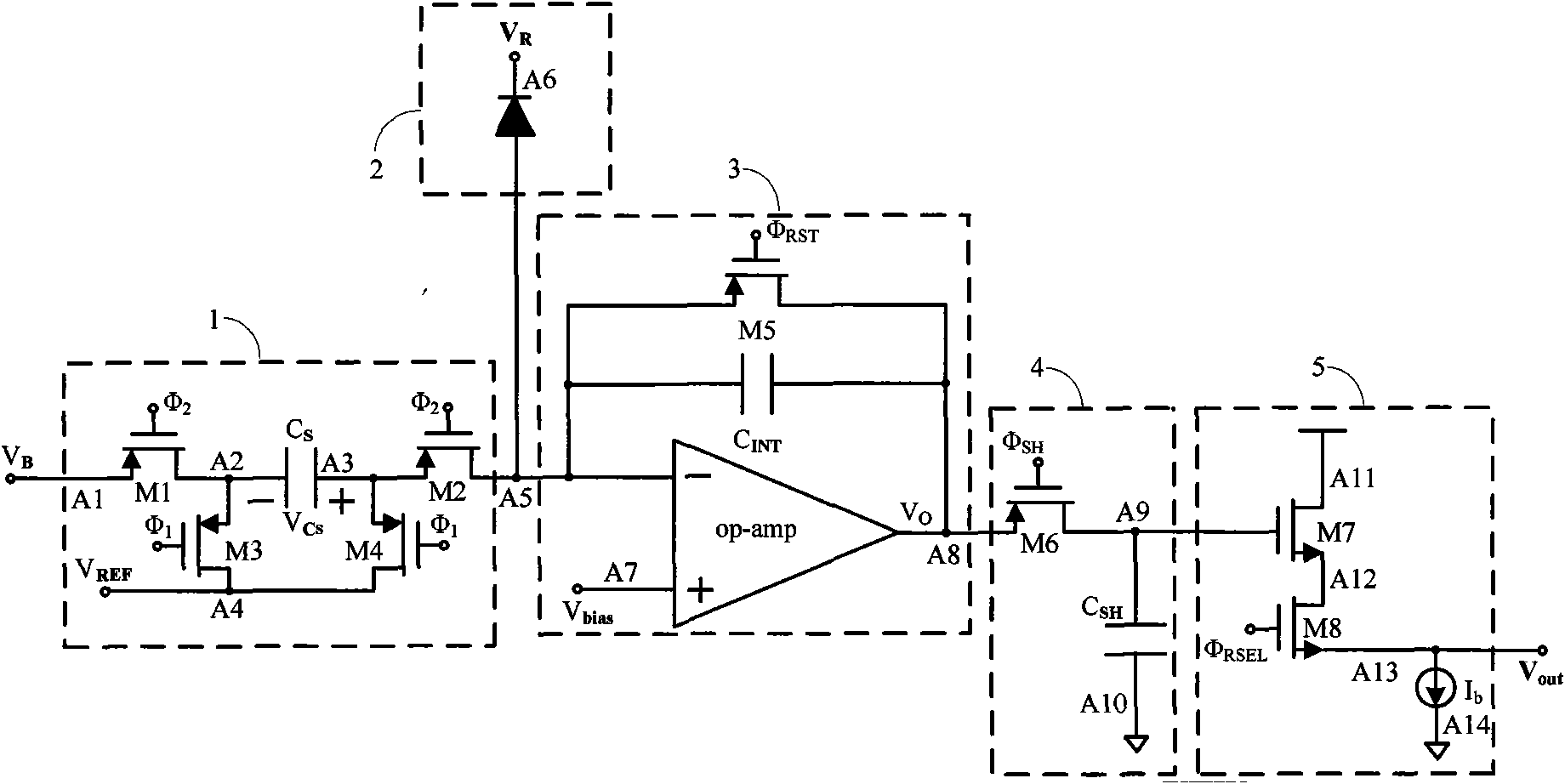

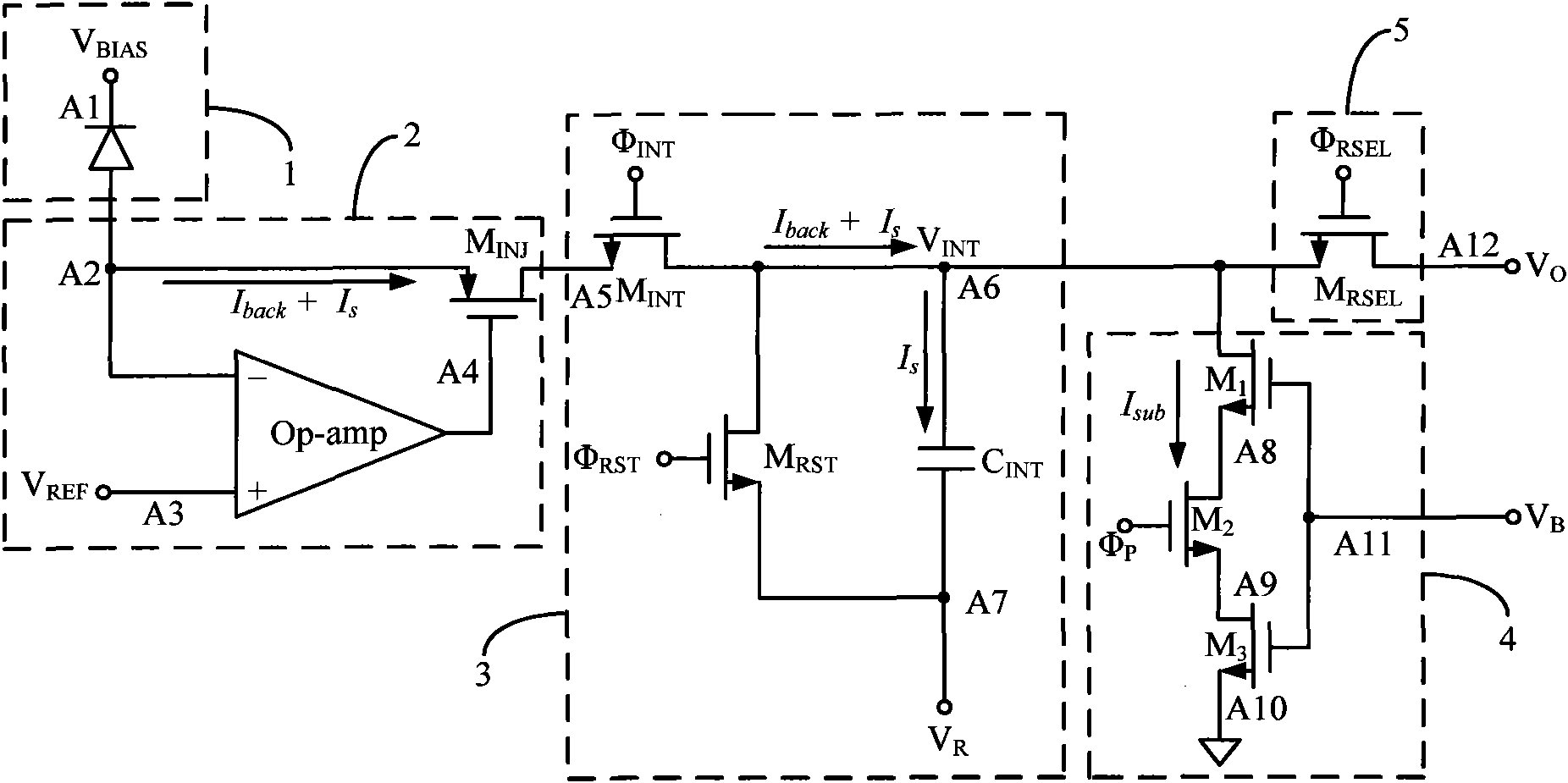

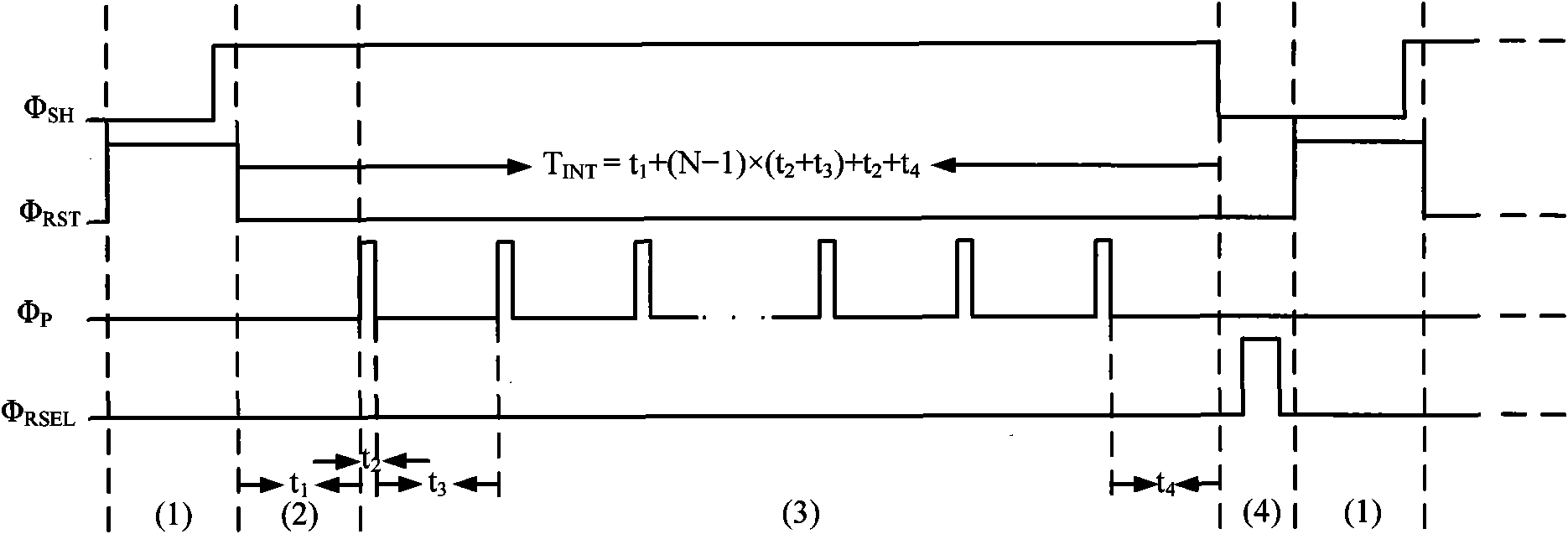

Background suppression method for infrared reading circuit and circuit thereof

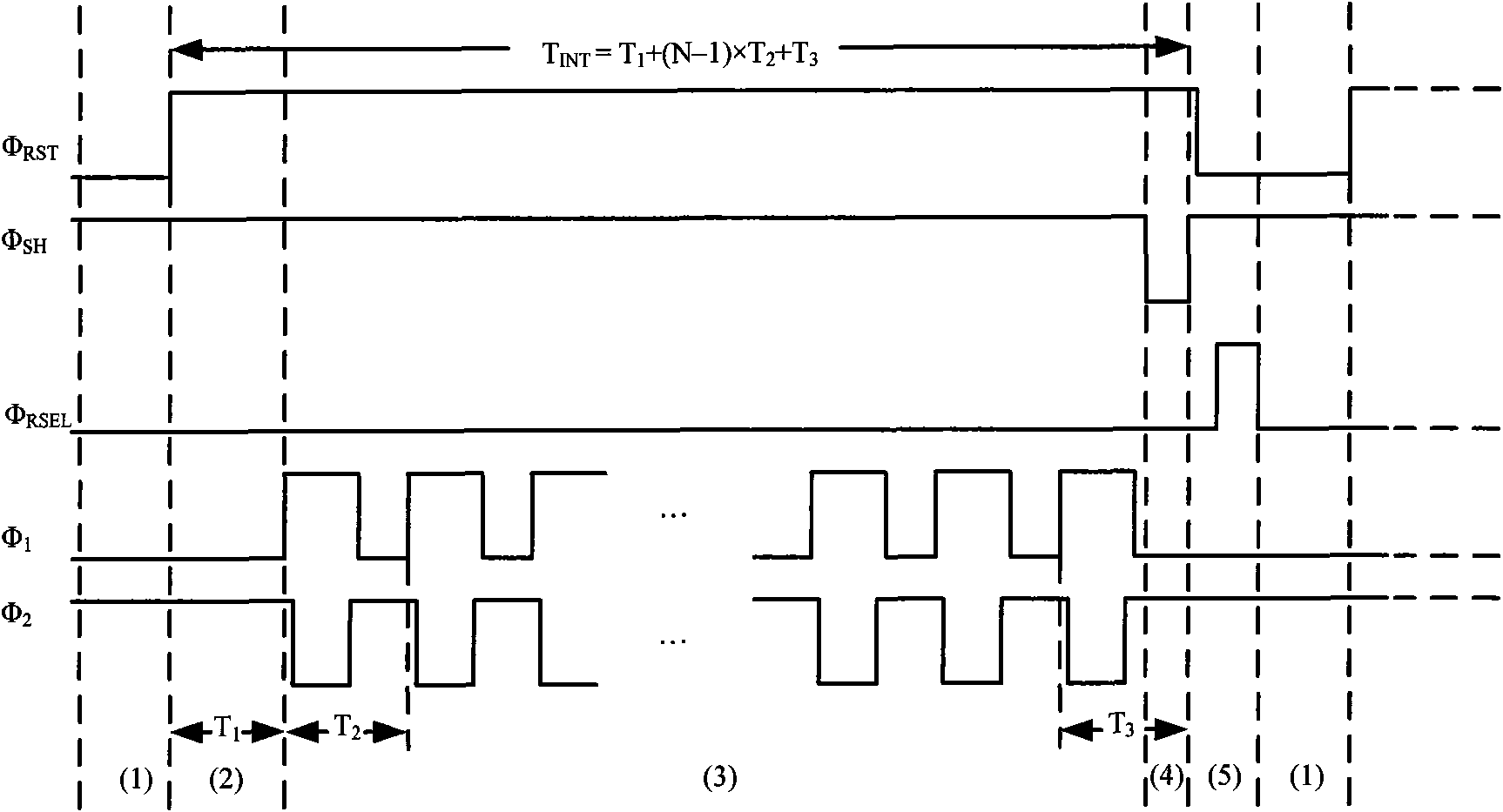

InactiveCN101582978AImproved ability to detect weak signalsExtend integration timeTelevision system detailsRadiation pyrometryCapacitancePacket generator

The invention discloses a background suppression method for an infrared reading circuit and a circuit thereof. The circuit is provided with a negative charge packet generator, a detector, an injection circuit, a sampling hold circuit and a buffer, wherein an output end of the negative charge packet generator is connected with one input end of the injection circuit; and an output end of the detector is connected with the other input end of the injection circuit, an output end of the injection circuit is connected with an input end of the sampling hold circuit, an output end of the sampling hold circuit is connected with an input end of the buffer, and an output end of the buffer is connected with a subsequent signal processing circuit. The method and the circuit adopt the negative charge packet generator to provide a plurality of negative charge packets by stage to reduce charges of background current accumulated on an integrating capacitor, do not need a background current memory of the prior art to generate background reduction current to realize background suppression, have extremely low background suppression non-uniformity, and do not introduce extra noise and power consumption.

Owner:海安江理工技术转移中心有限公司 +1

Welding method of high-nickel alloy and stainless steel dissimilar metal

InactiveCN101508053AMeet performance requirementsImprove welding efficiencyArc welding apparatusWelding/cutting media/materialsImpulse frequencyAustenite

The invention discloses a dissimilar intermetallic welding method for high nickel alloy and stainless steel, which adopts pulsed tungsten argon arc welding, and welding technological parameters comprise that: the background current is between 20 and 50A, the impulse current is between 28 and 60A, the impulse duration is between 5 and 10s, the impulse frequency is between 35 and 75Hz, the welding voltage is between 8 and 12V, the welding speed is between 1.0 and 2.6mm / s, the inert gas flow rate is between 5 and 12L / min, the distance between a nozzle of a welding torch and a workpiece is between 5 and 10mm, and the included angle between a tungsten electrode of the welding torch and a weldment is between 70 and 85DEG. The method adopted has the advantages of high welding efficiency, low cost and convenient and flexible operation, can obtain welding joints without defects of cracks, pores and the like, and can meet the use requirement of a heterogenous composite structure of high nickel casting alloy and austenitic stainless steel.

Owner:SHANDONG UNIV

Method and System to Increase Heat Input To a Weld During a Short-Circuit Arc Welding Process

A method and a system to increase heat input to a weld during an arc welding process. A series of electric arc pulses are generated between an advancing welding electrode and a metal workpiece using an electric arc welding system capable of generating an electric welding waveform to produce the electric arc pulses. A cycle of the electric welding waveform includes a pinch current phase providing an increasing pinch current level, a peak current phase providing a peak current level, a tail-out current phase providing a decreasing tail-out current level, and a background current phase providing a background current level. At least one heat-increasing current pulse of the cycle is generated, providing a heat-increasing current level, during the background current phase, where the heat-increasing current level is above the background current level. The cycle of the electric welding waveform with the at least one heat-increasing current pulse may be repeated until the arc welding process is completed.

Owner:LINCOLN GLOBAL INC

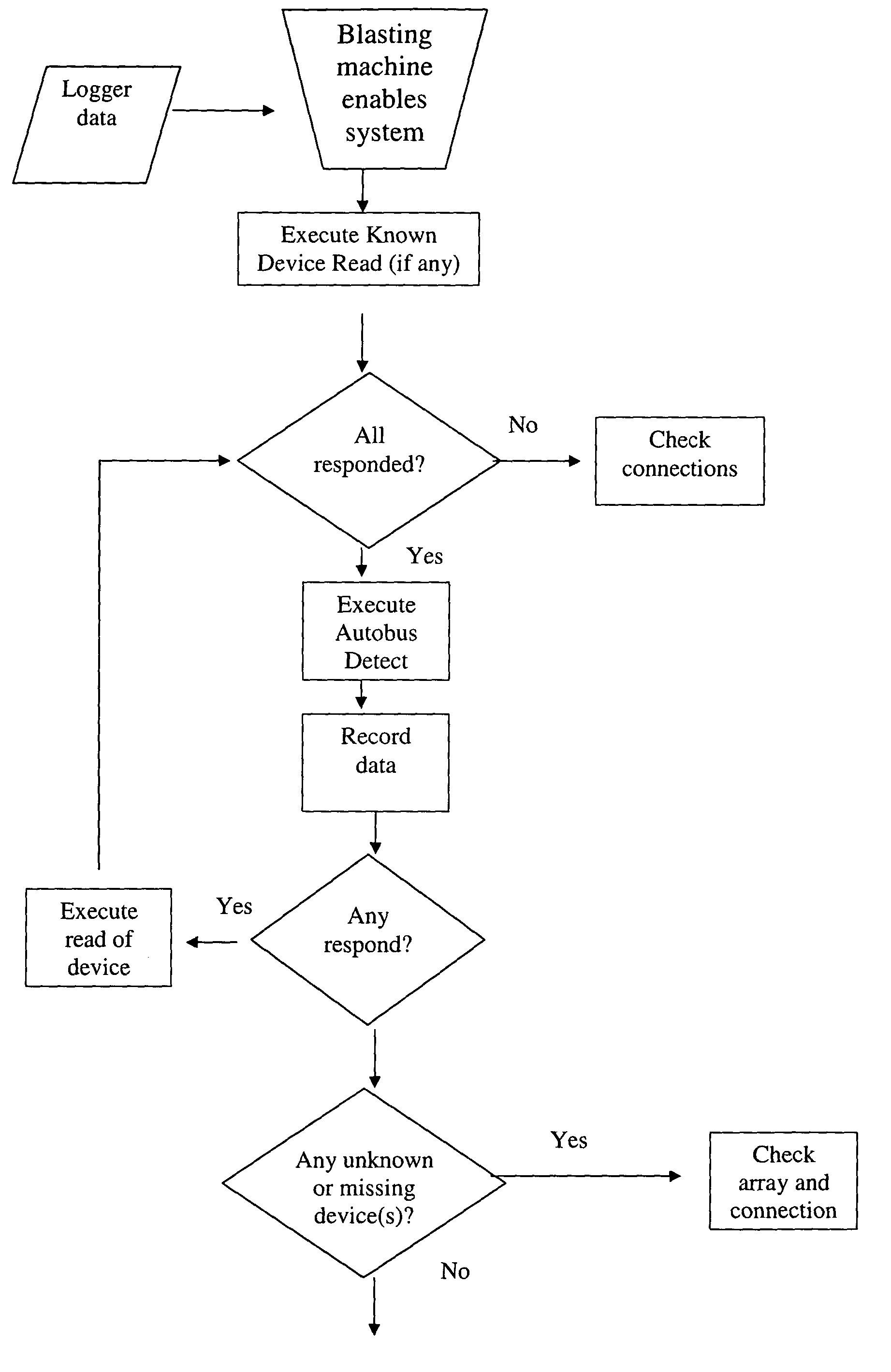

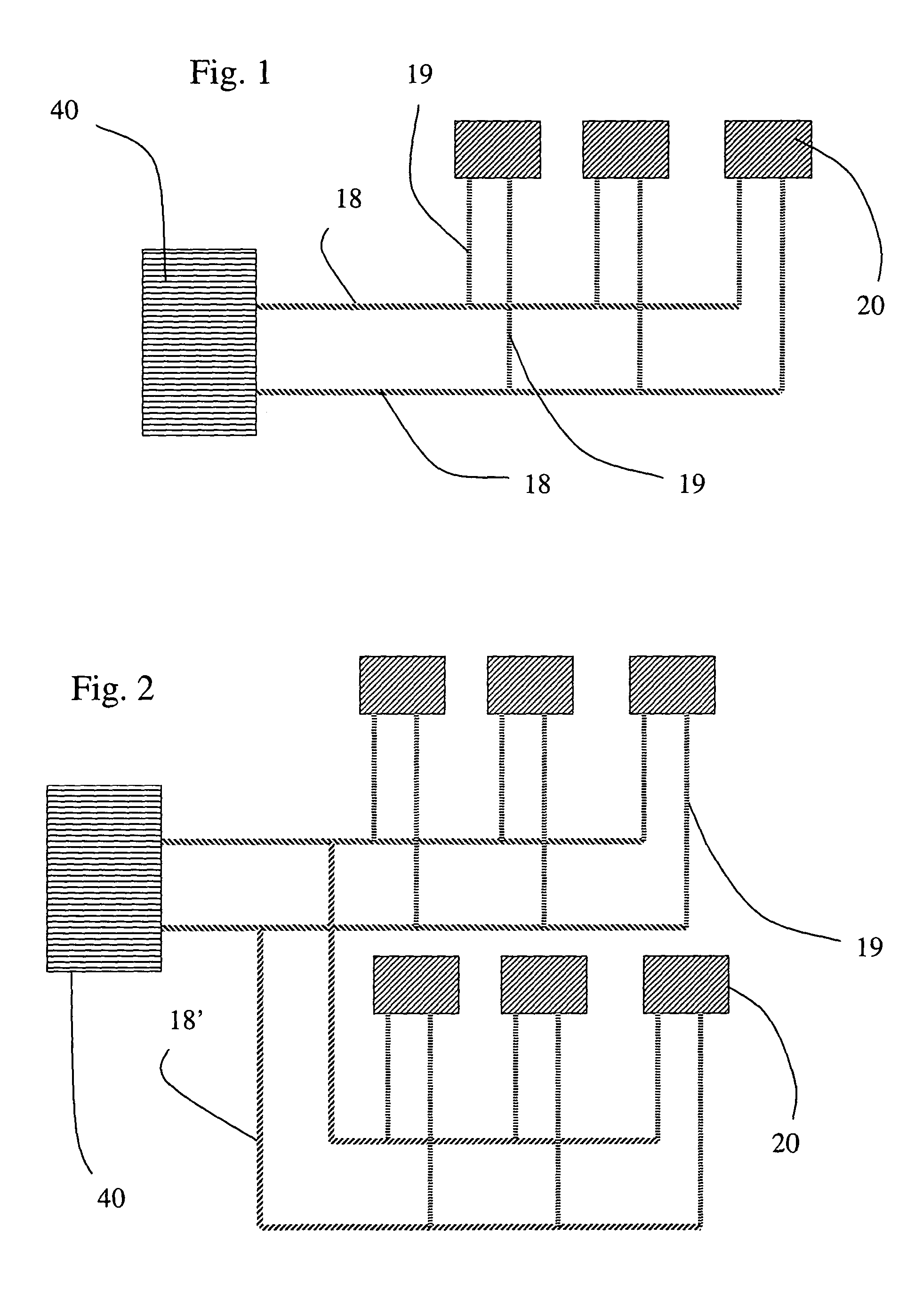

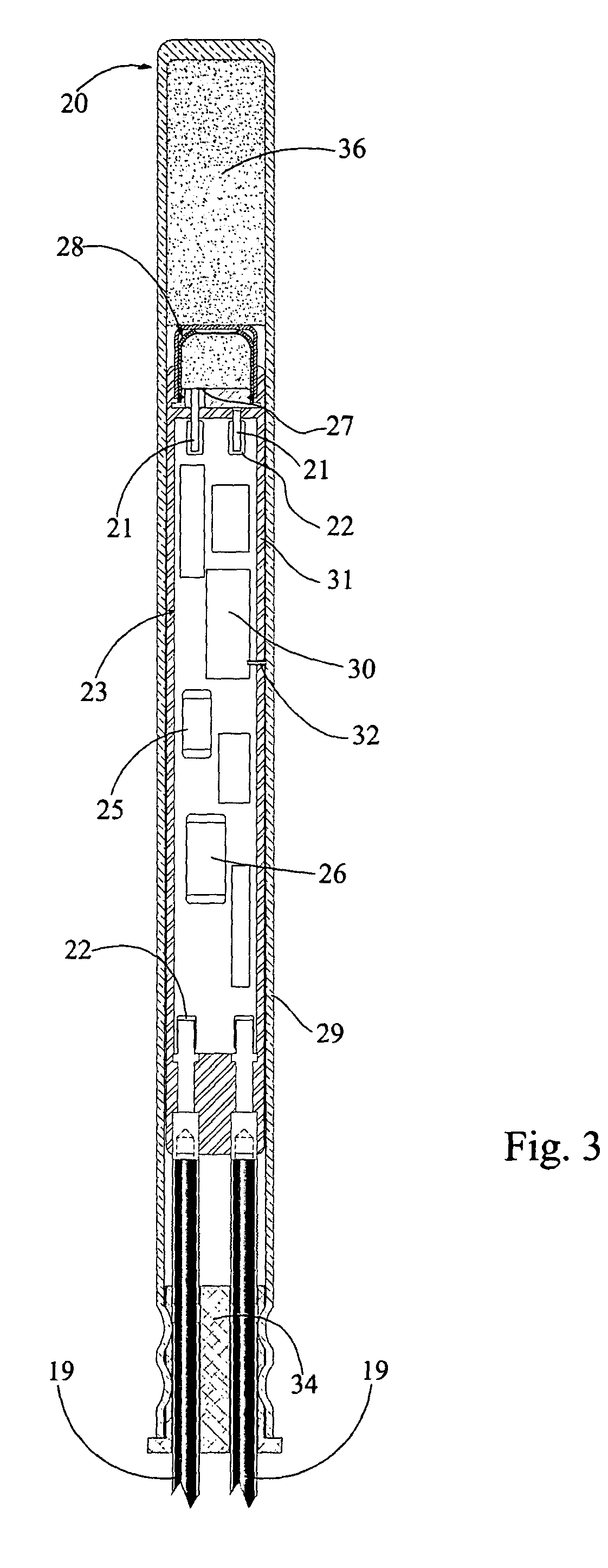

Current modulation-based communication from slave device

InactiveUS6966262B2Incandescent ignitionDc level restoring means or bias distort correctionDetonatorSignal-to-noise ratio (imaging)

Current modulation-based talkback in a system in which the background noise in the level of current draw is minimized such that the talkback is effected with a desirably high signal-to-noise ratio, such as by the master device holding the system voltage low such that the slave devices will not be performing tasks that would cause the current draw on the system to have an undesirable level of background noise, or, in an electronic blasting system, by preventing all other detonators from performing tasks that would create an undesirable background current draw when a particular detonator is talking back.

Owner:AUSTIN STAR DETONATOR

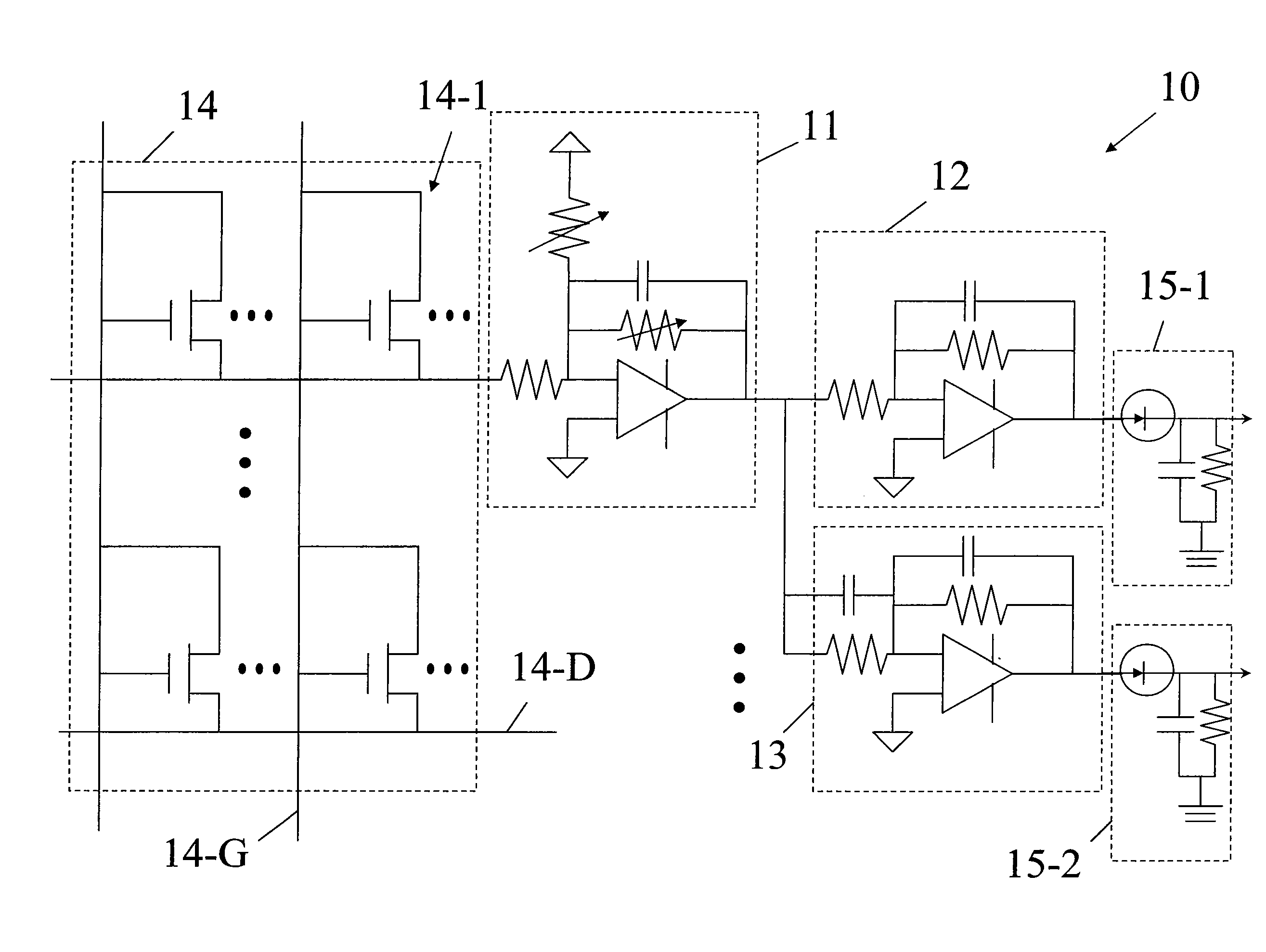

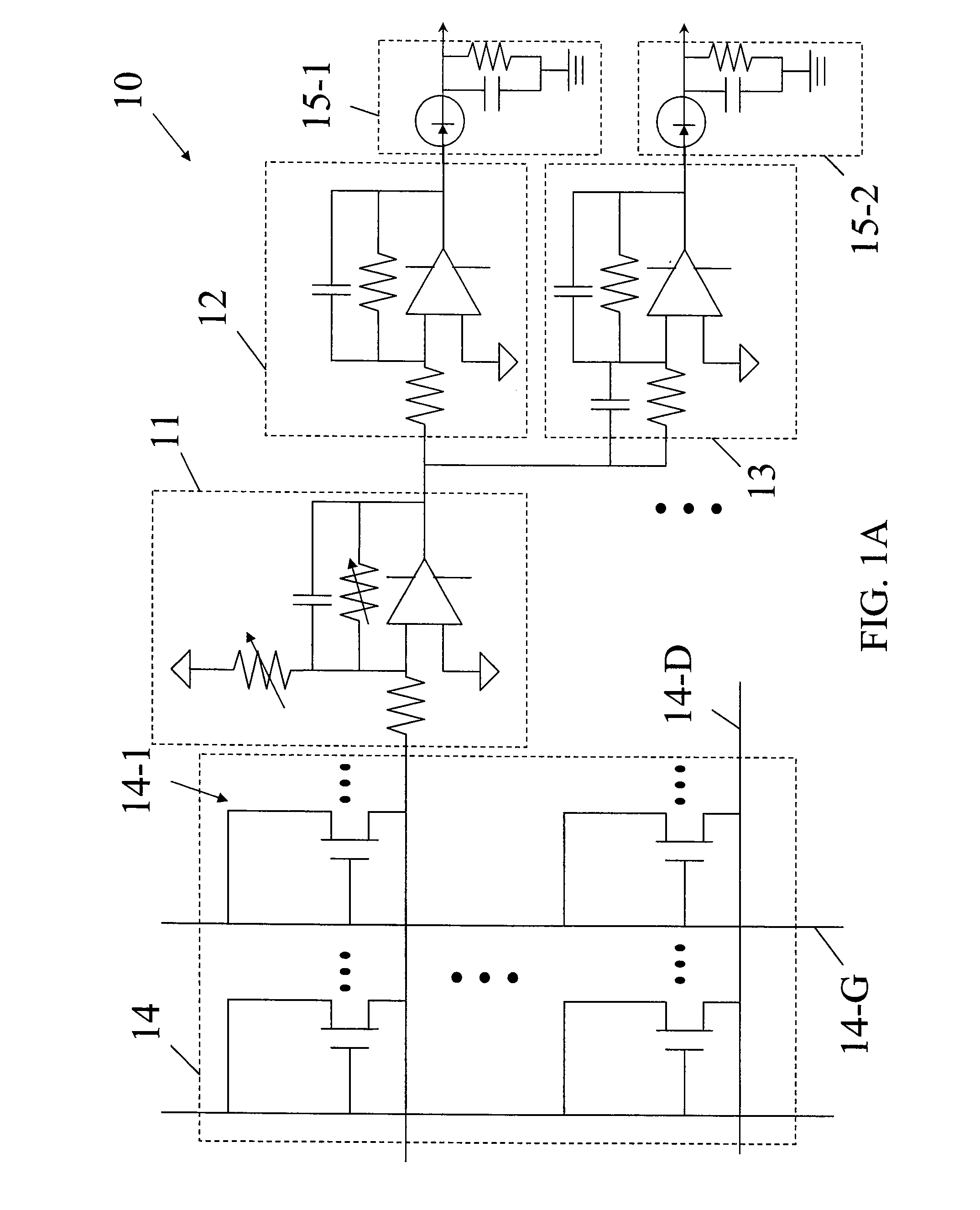

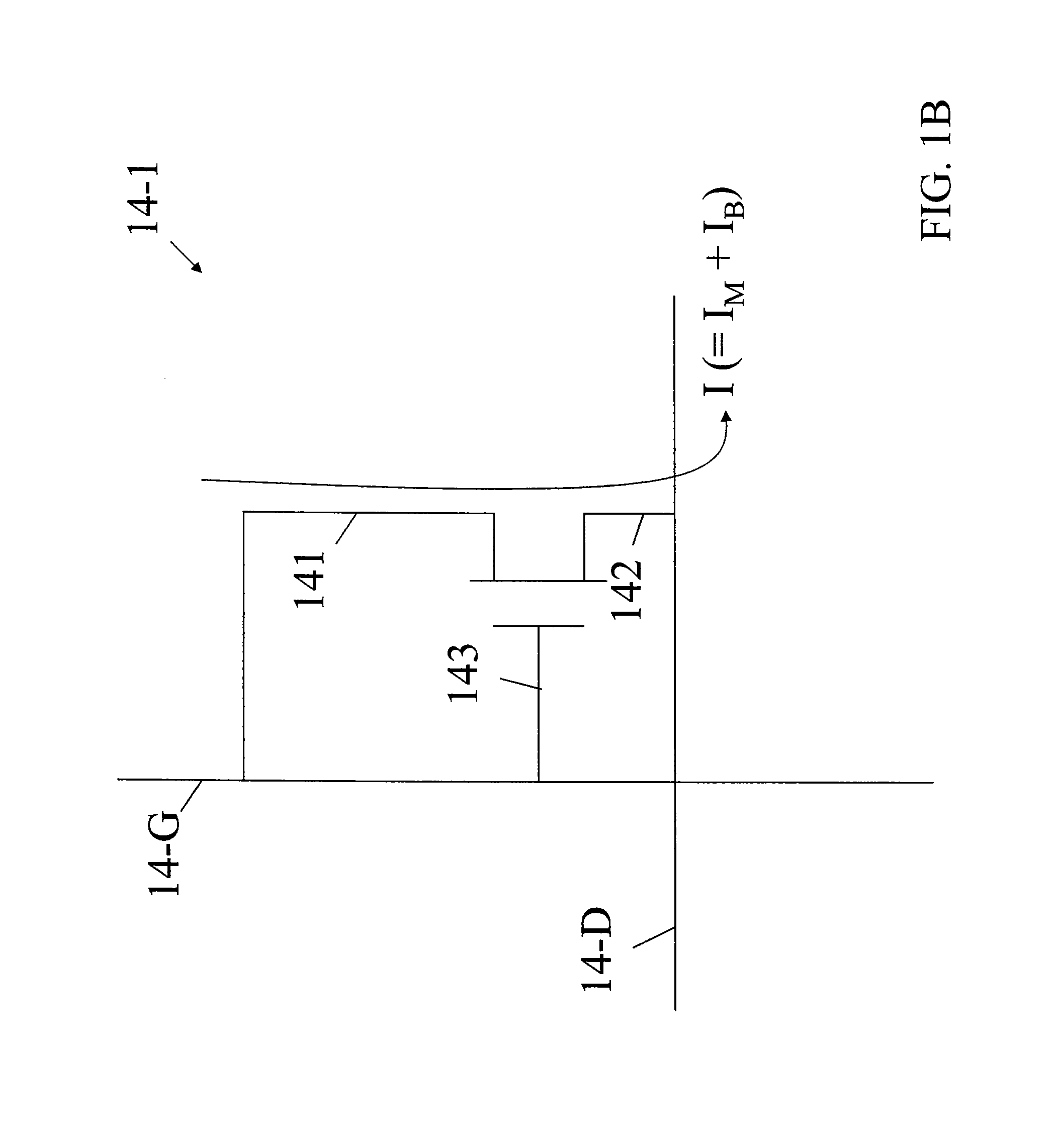

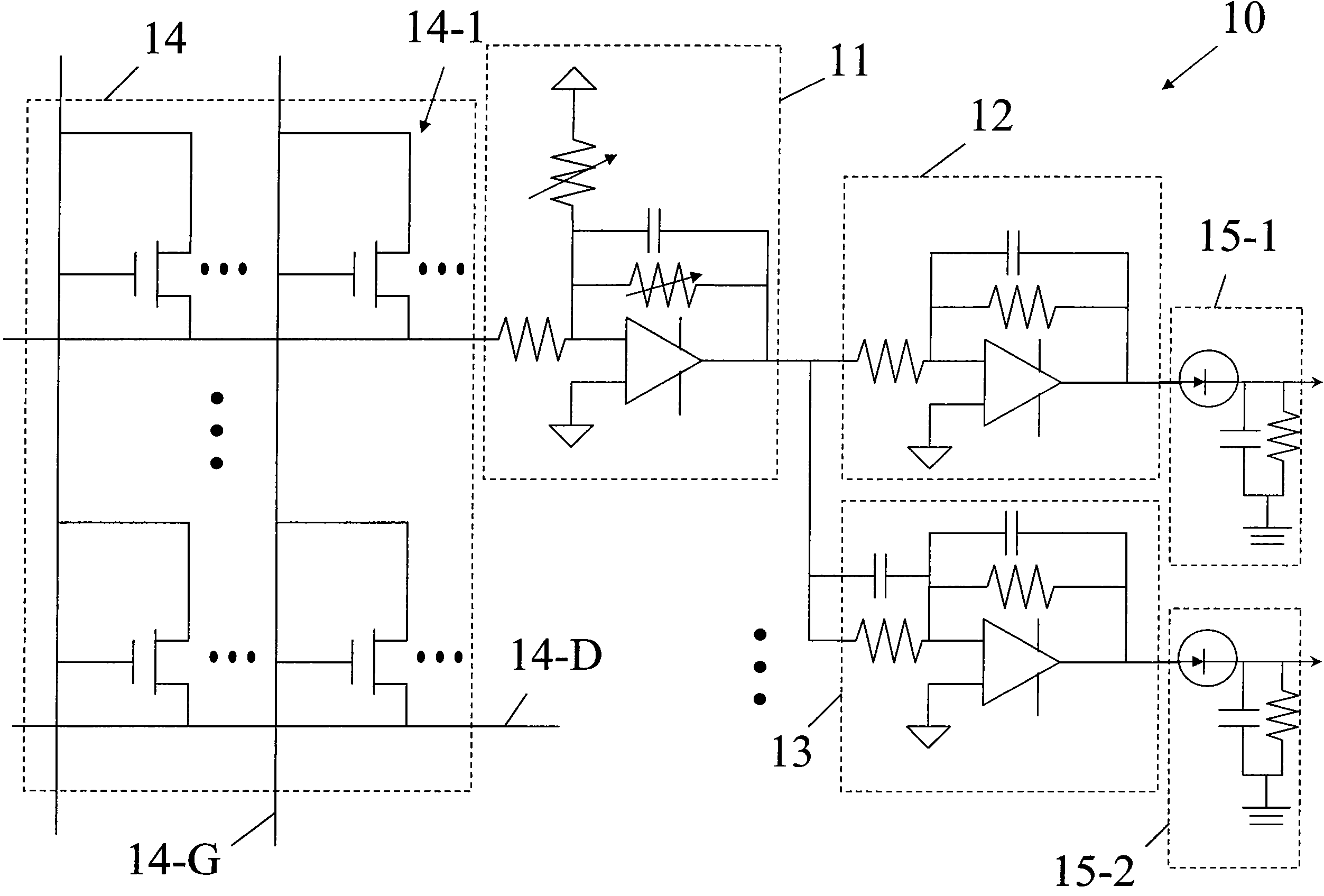

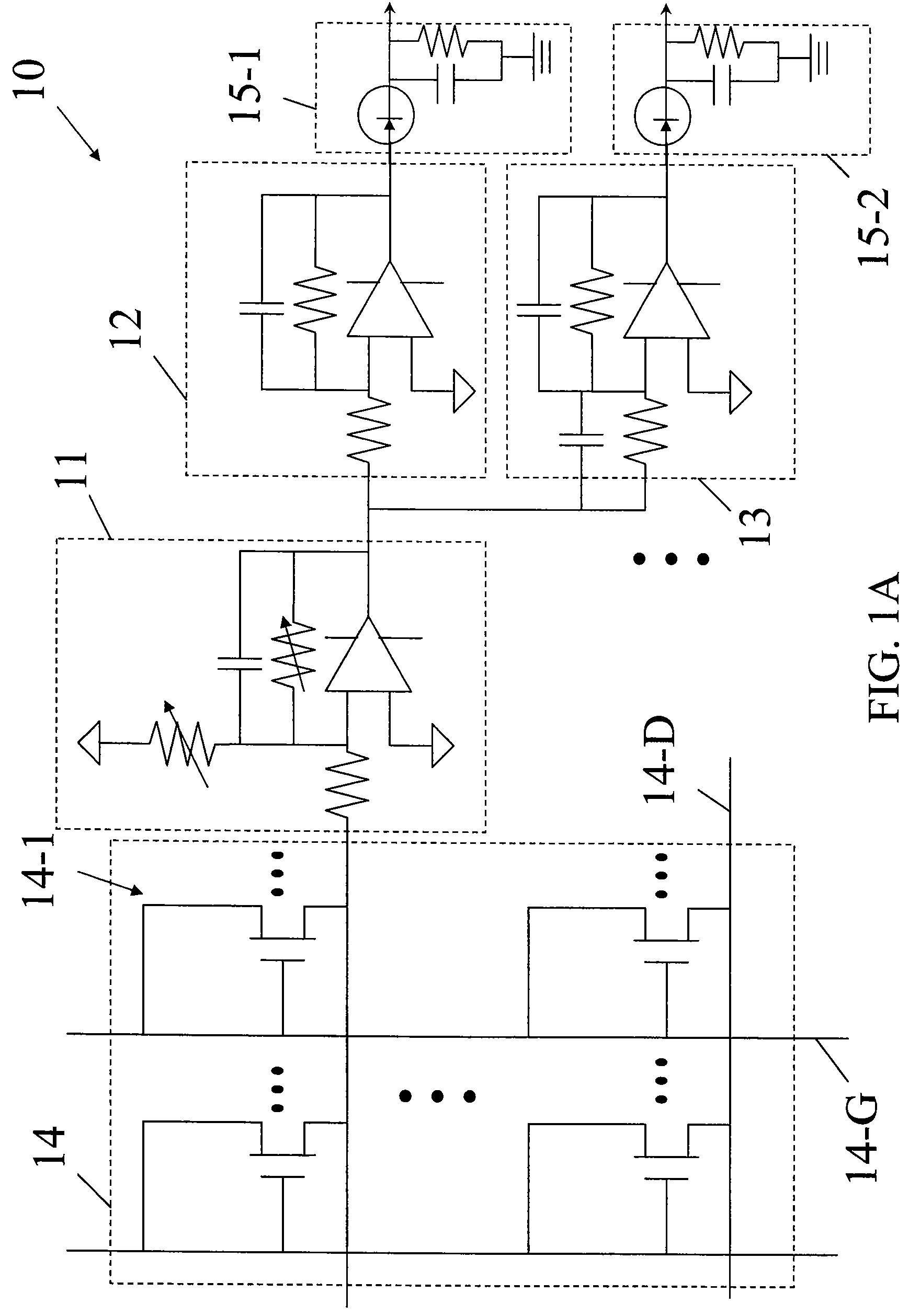

Photo detector array

A photo detector device includes a photosensitive transistor capable of detecting an optical signal including an image component and a background component and converting the optical signal into a current including an image current corresponding to the image component and a background current corresponding to the background component, a first amplifier module electrically connected to the photosensitive transistor capable of canceling the background current and amplifying the image current, and a second amplifier module electrically connected to the first amplifier module capable of detecting a direct-current (dc) portion of the image current.

Owner:SHANGHAI XUANYAN ELECTRONICS TECH INC

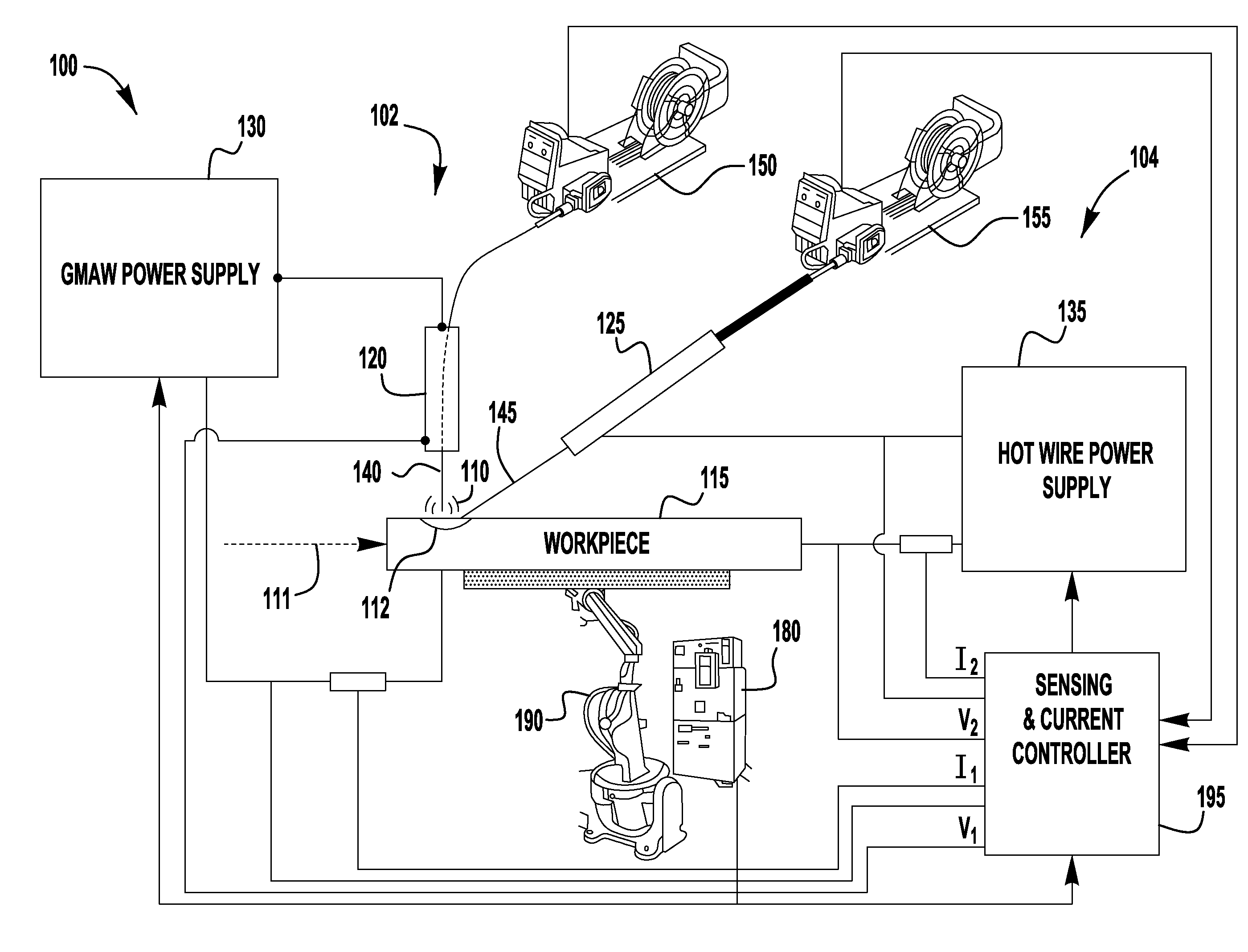

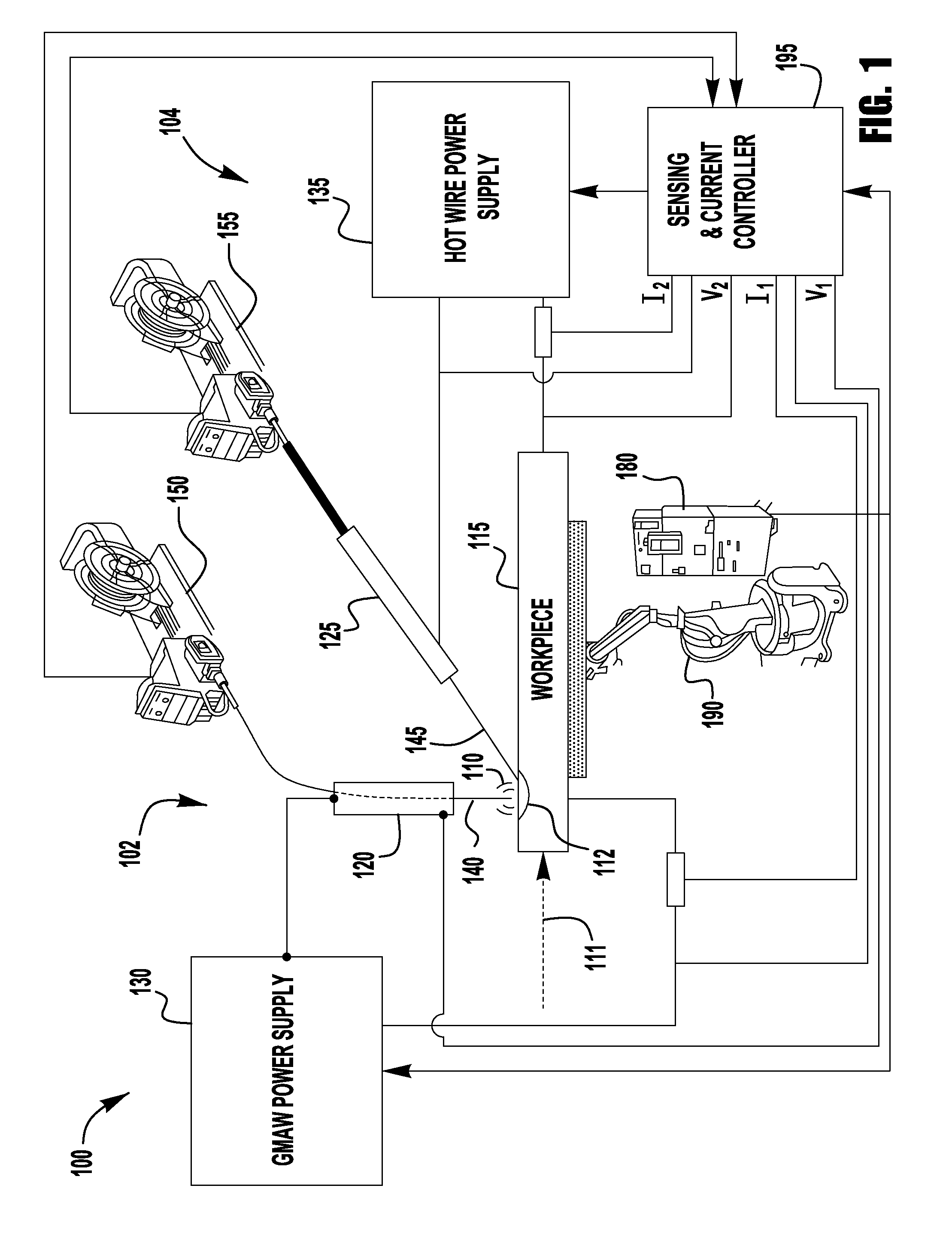

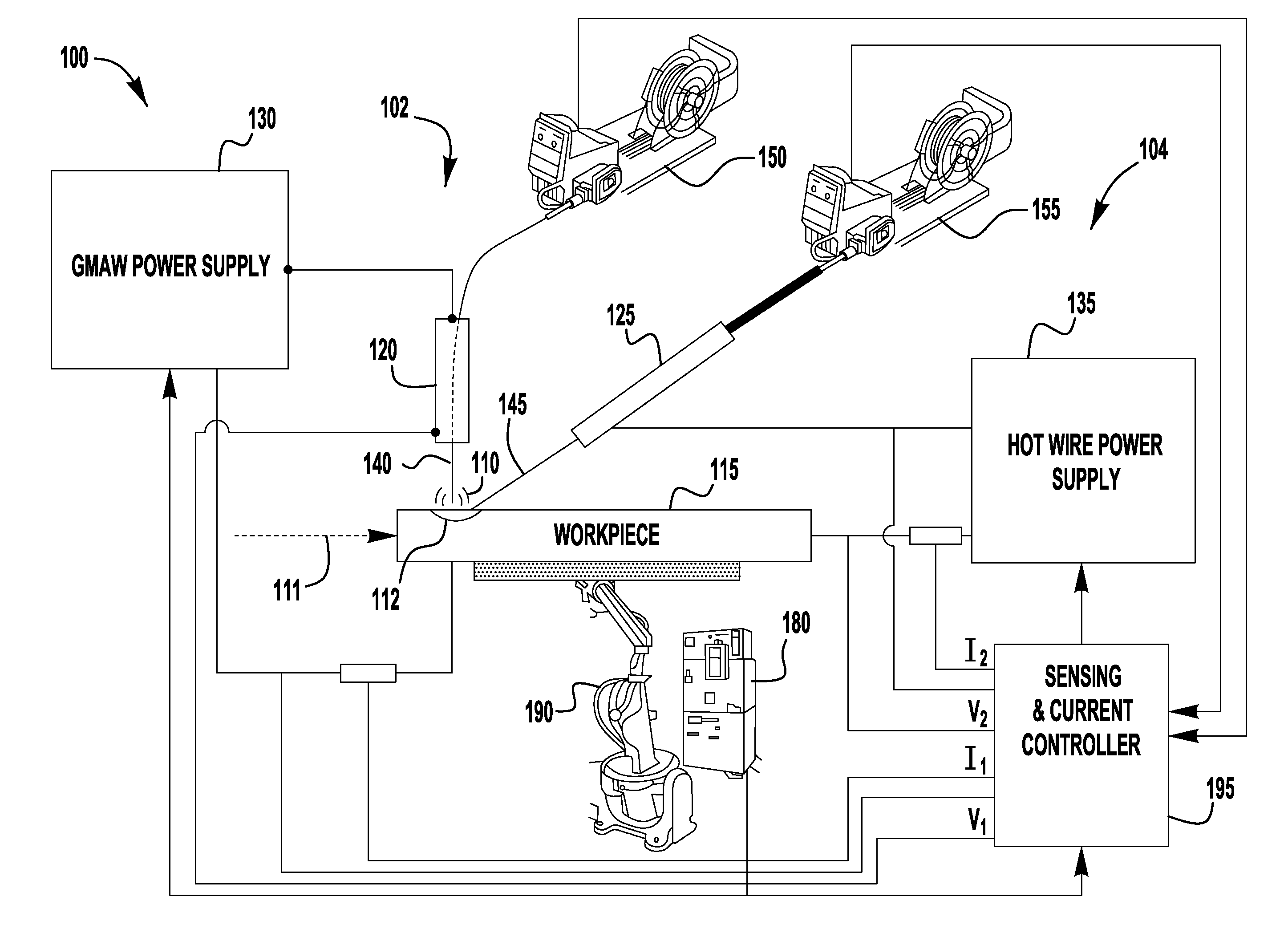

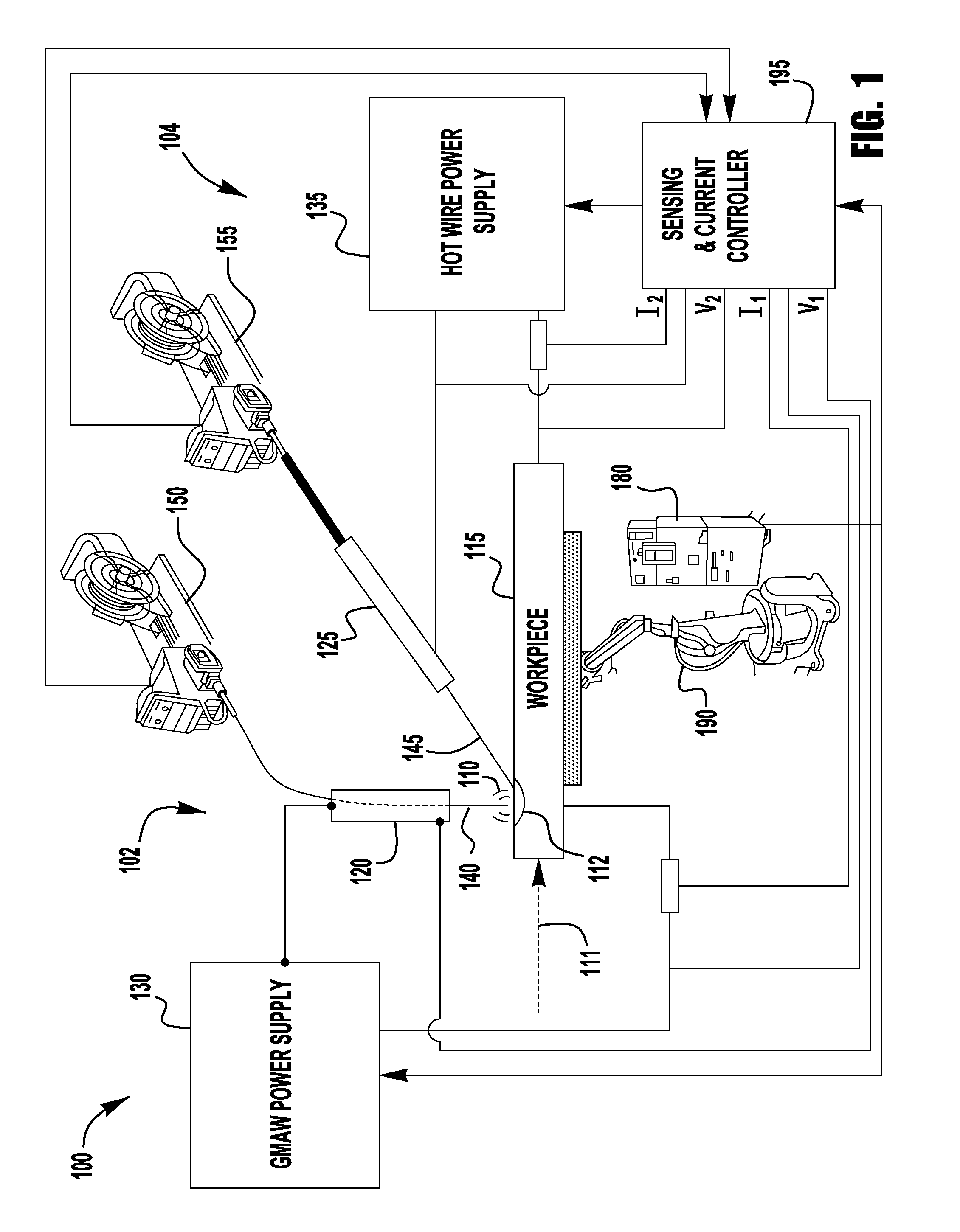

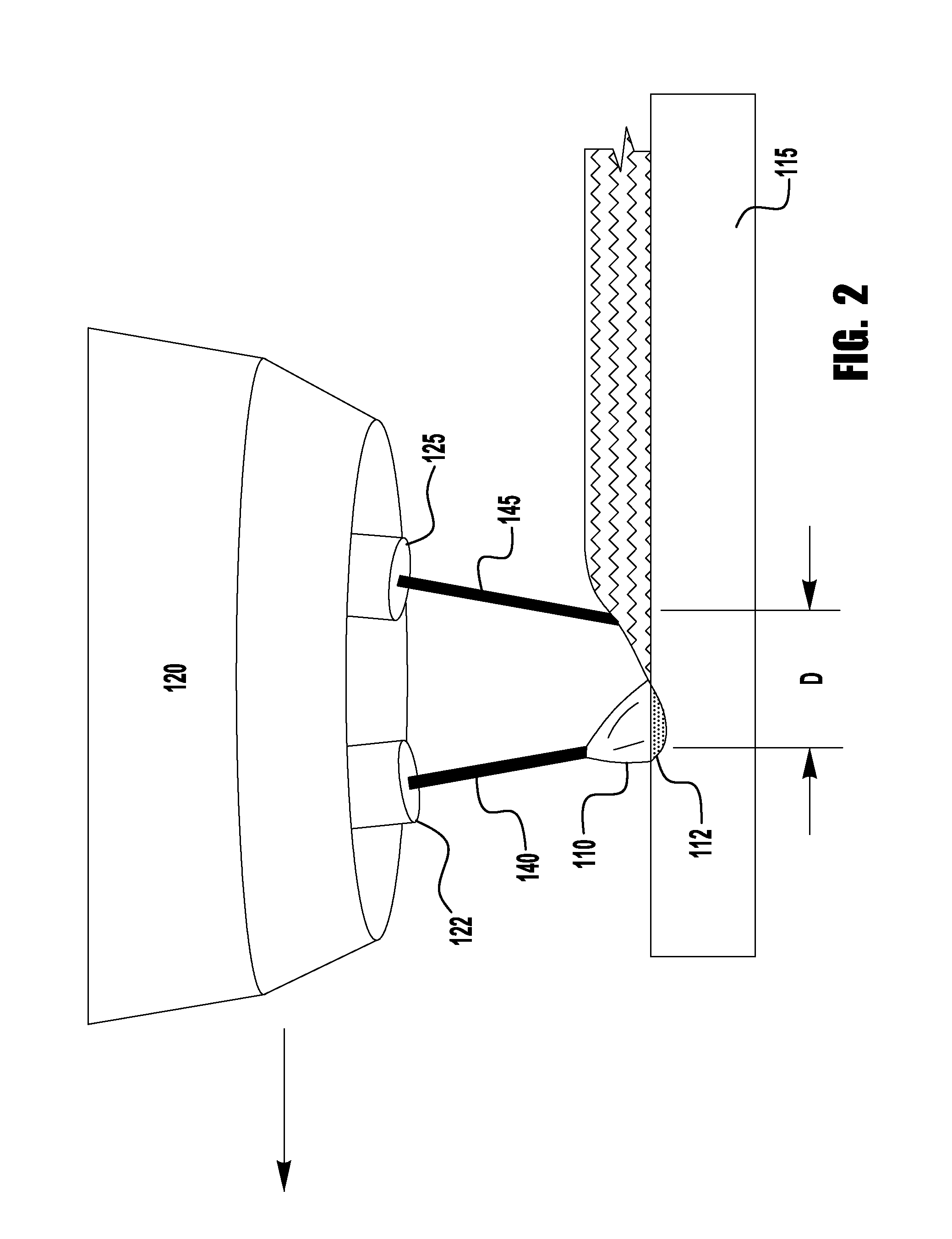

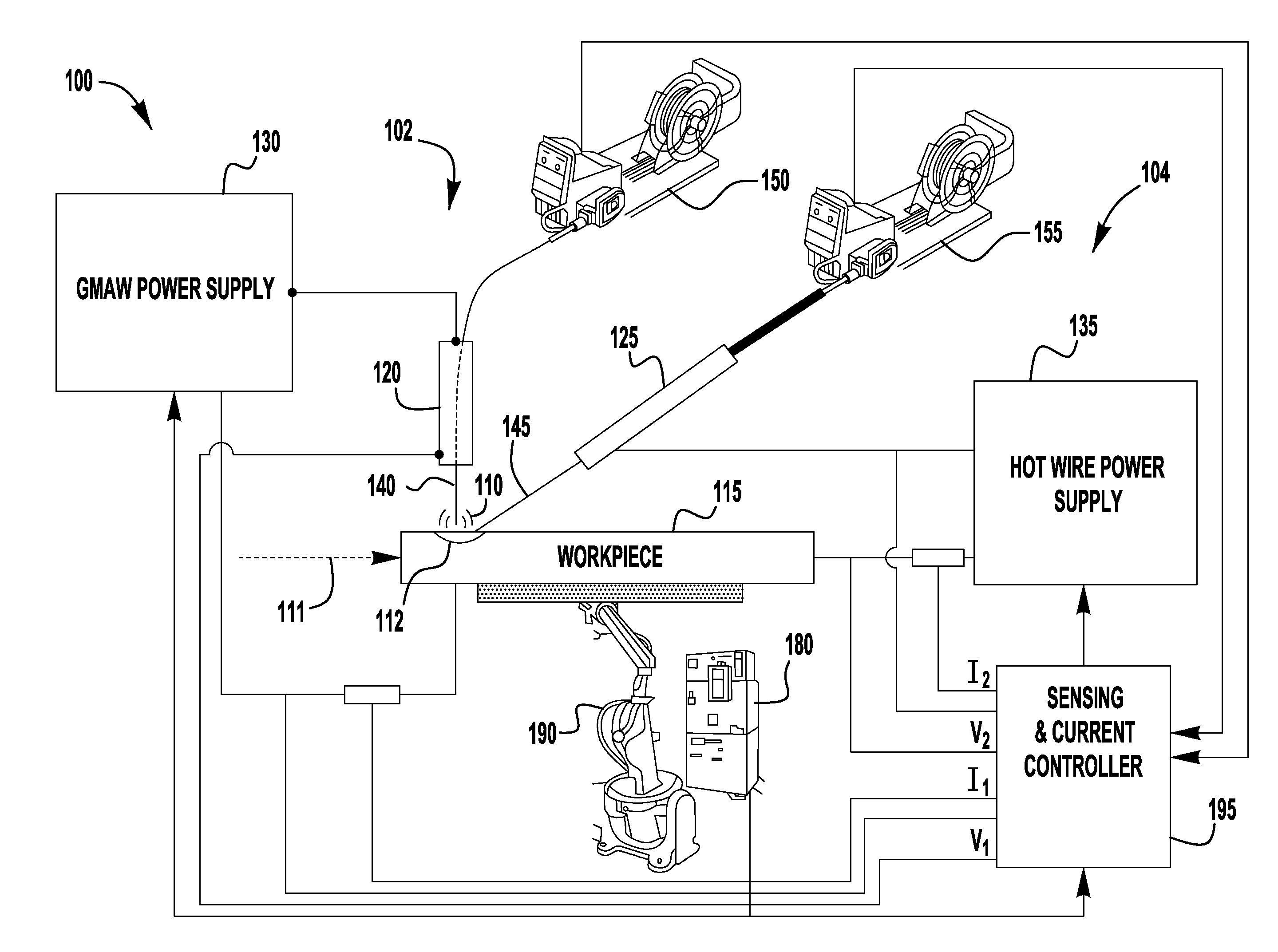

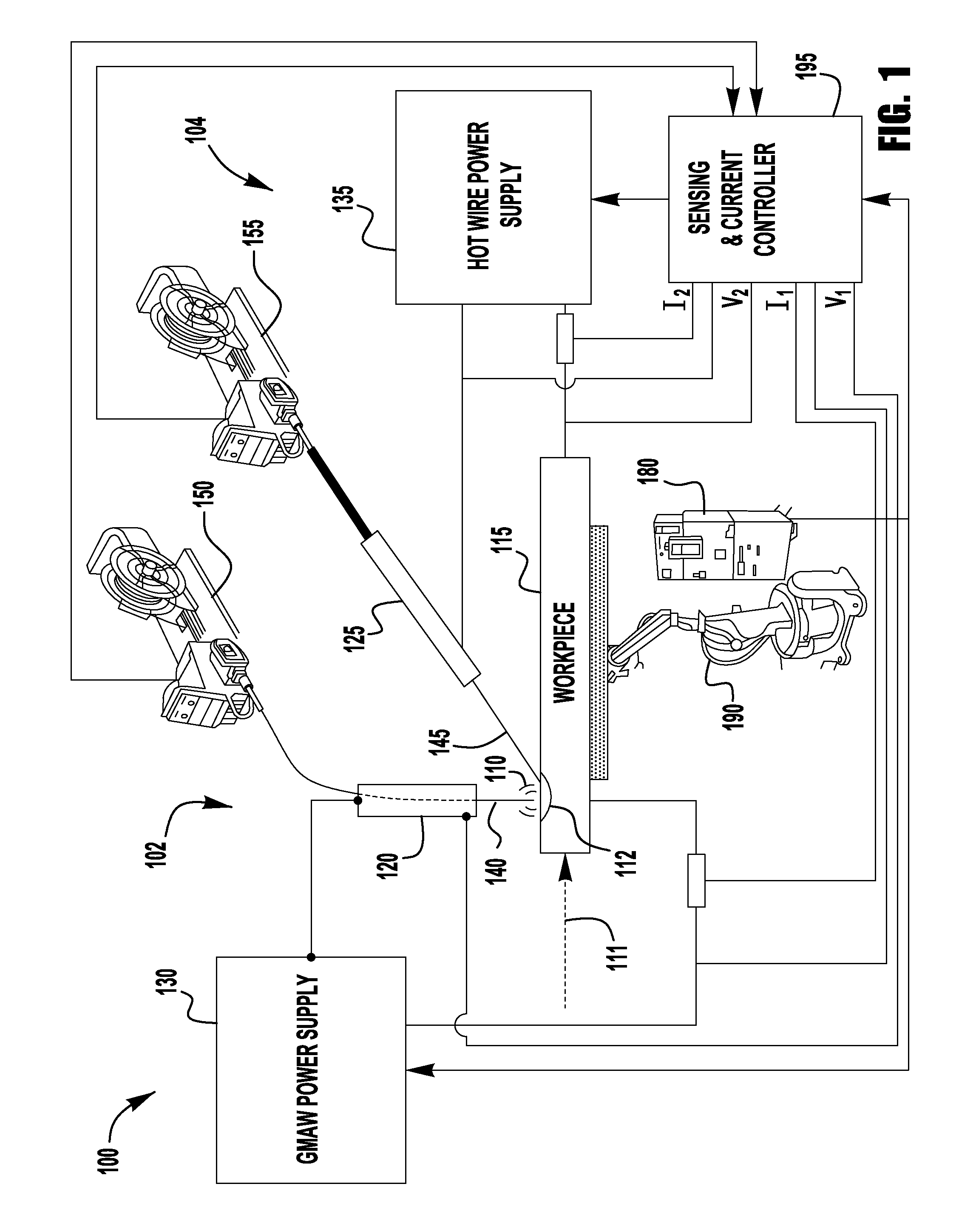

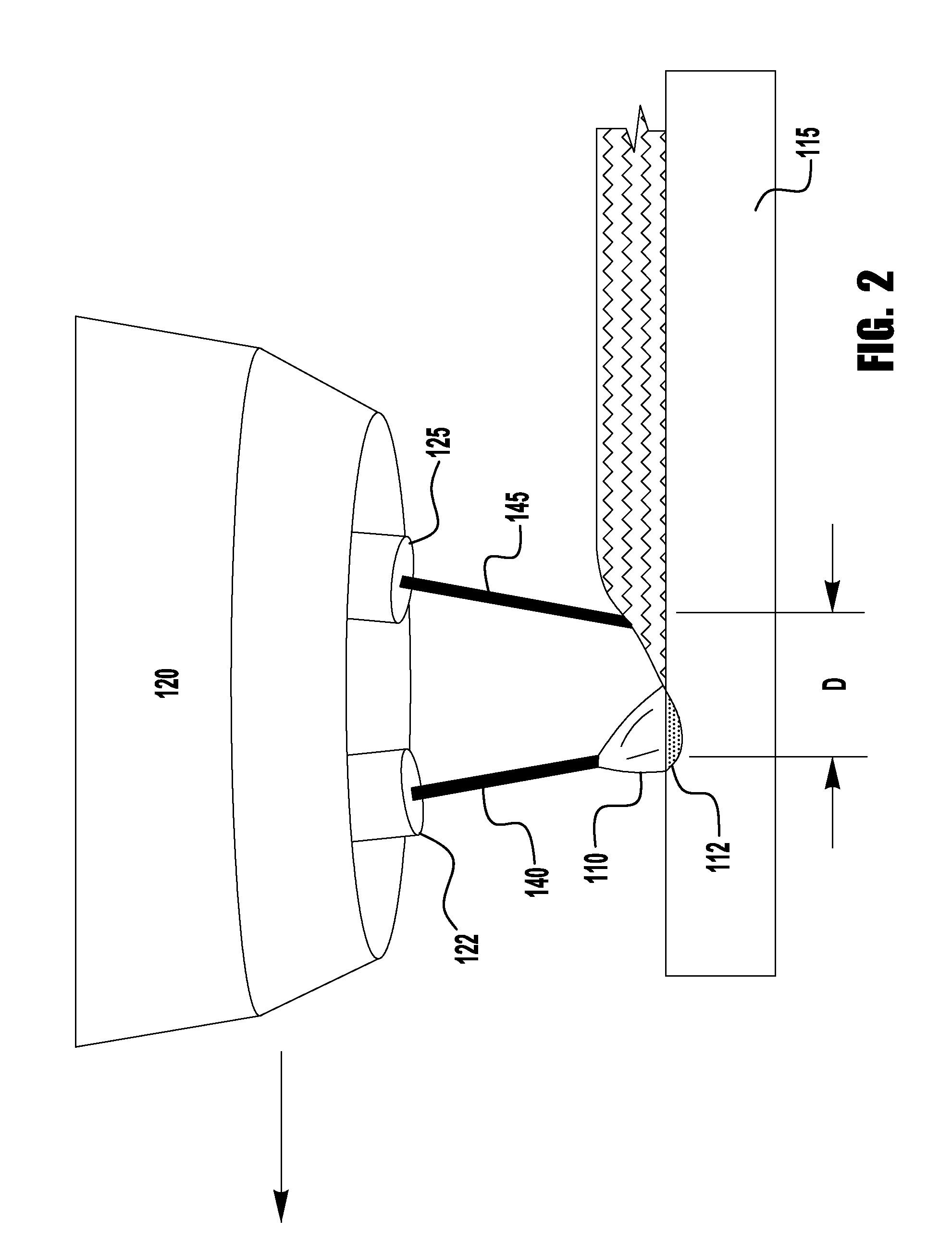

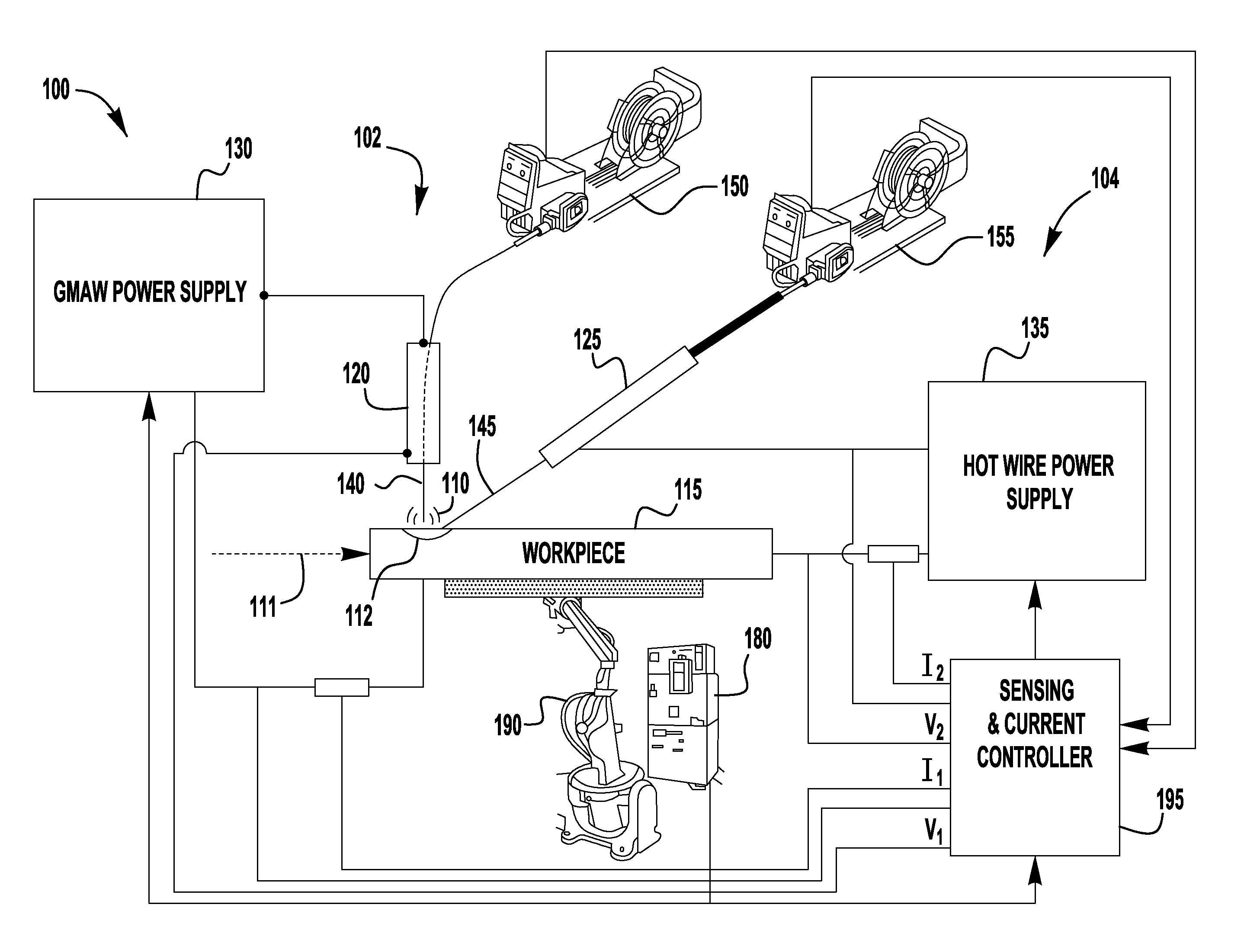

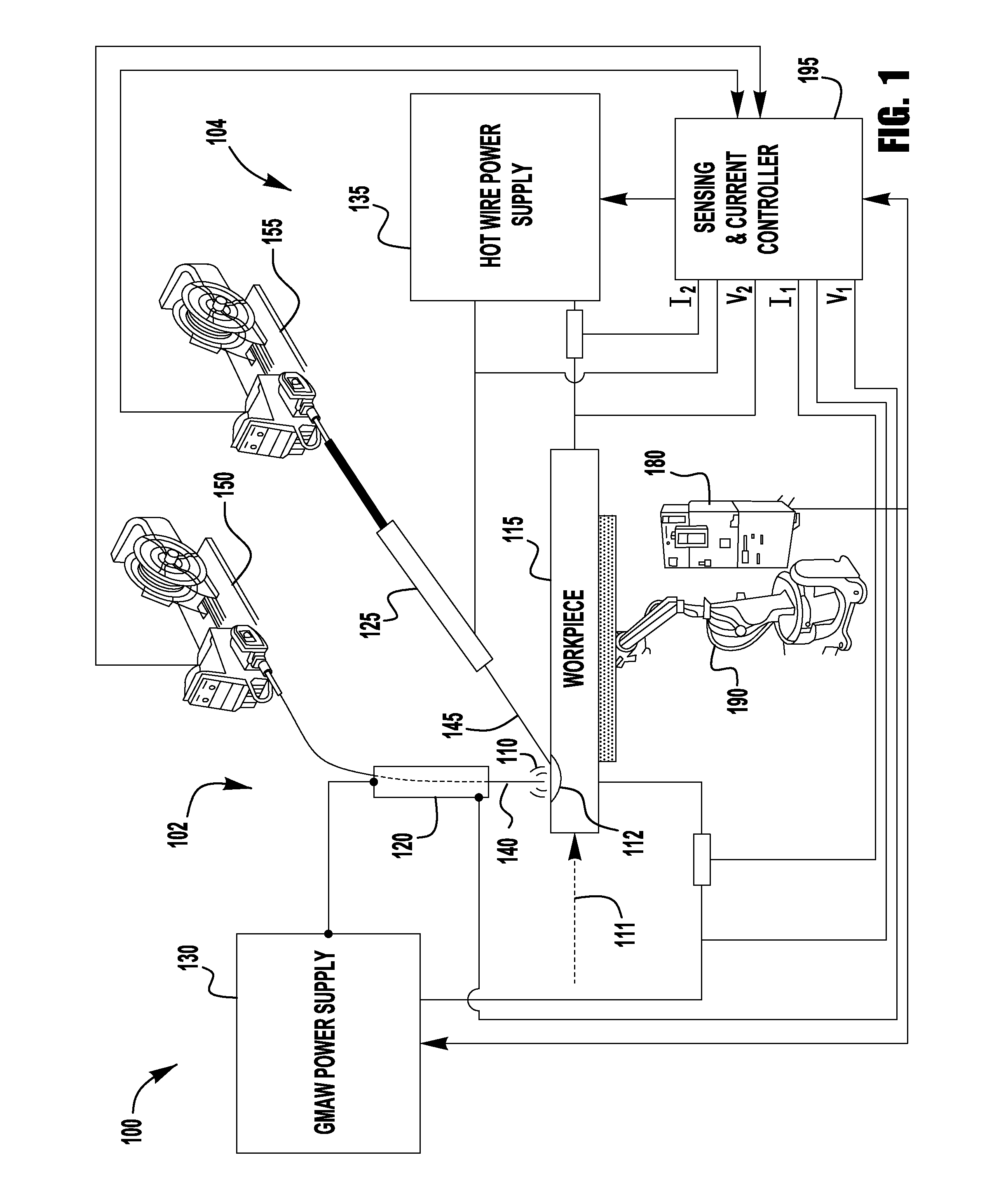

Tandem hot-wire systems

A system and method is provided. The system includes a first power supply that outputs a welding current that includes welding pulse currents and a background welding current. The system also includes a second power supply that outputs a heating current that includes first heating pulse currents at a first polarity and second heating pulse currents at an opposite polarity. The system also includes a controller that synchronizes at least one of the first heating pulse currents and the second heating pulse currents with at least one of the welding pulse currents and the background current to influence a position of an arc relative to a molten puddle based on magnetic fields created by the welding current and the heating current.

Owner:LINCOLN GLOBAL INC

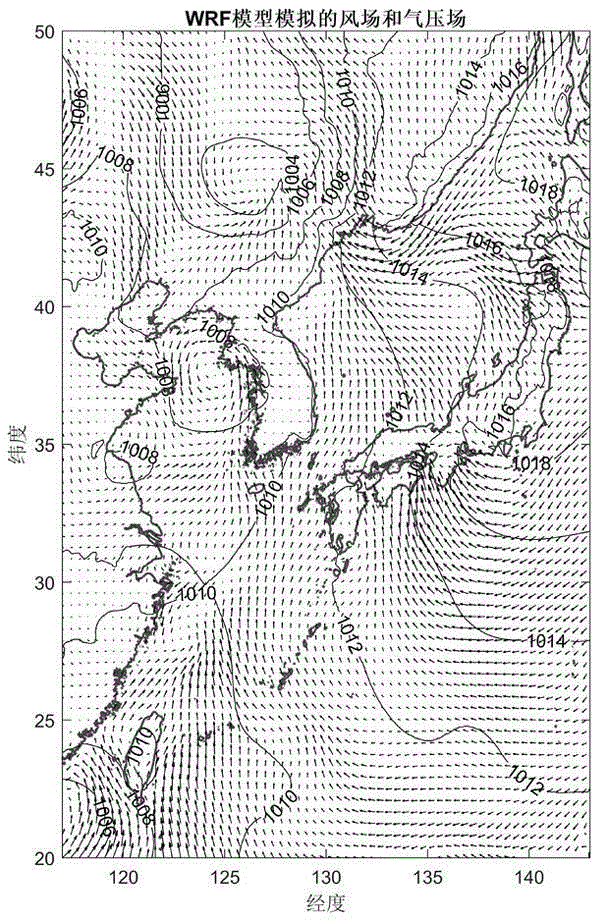

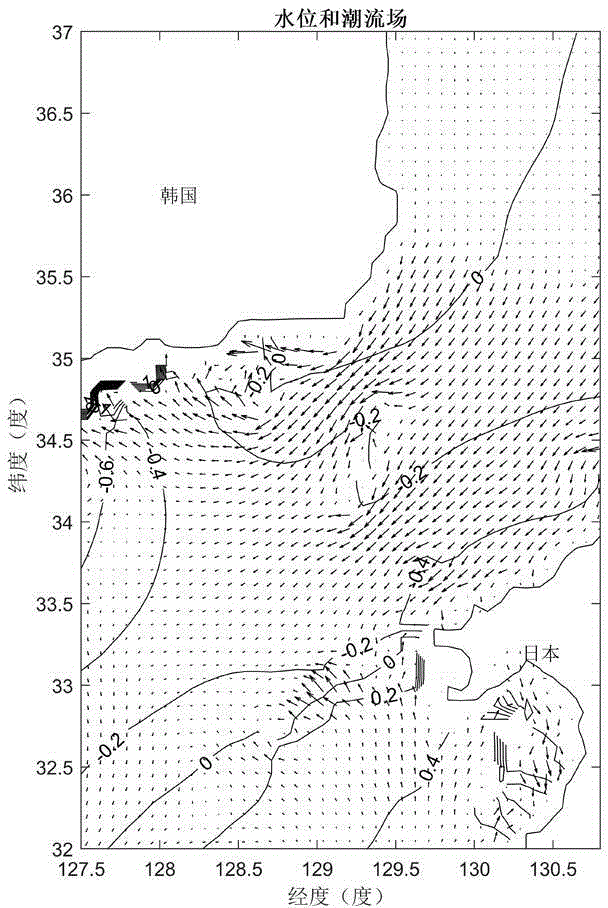

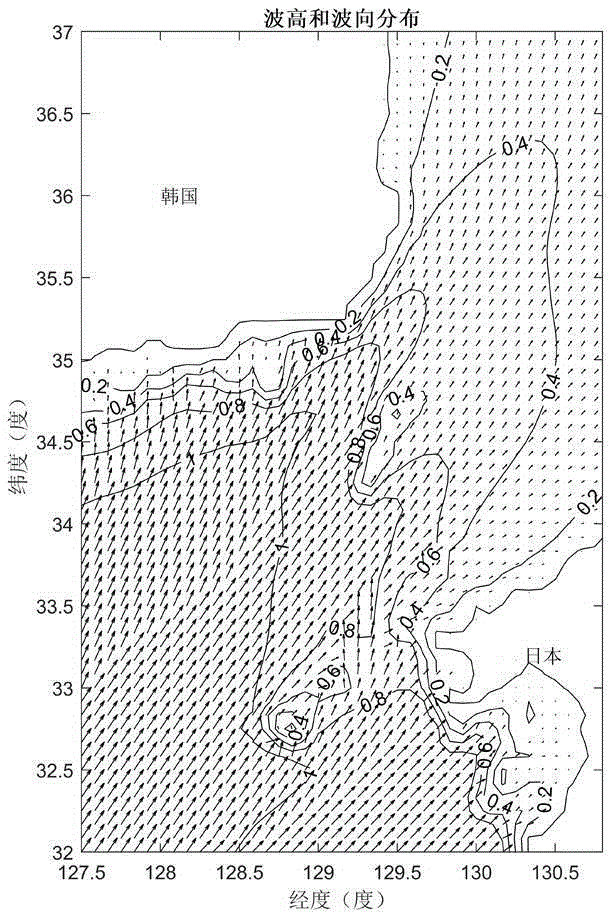

Rip current forecasting method

ActiveCN105389468AReal-time numerical calculationReal-time forecastSpecial data processing applicationsWave fieldNumerical models

The present invention discloses a rip current forecasting method. The method comprises the following steps of: (1) based on a mesoscale marine weather operational forecasting system, acquiring wind fields and pressure fields of a target sea area and surrounding sea areas of the target sea area; (2) establishing a Delft3D hydrodynamic numerical model, and simulating to obtain tidal current fields of the target sea area and the surrounding sea areas of the target sea area; (3) establishing an SWAN wave spectral model, and simulating to obtain wave fields of the target sea area and the surrounding sea areas of the target sea area; (4) extracting boundary conditions from the wave fields, using the tidal current fields as background current fields, establishing an SWASH wave analysis model, and simulating to obtain a time sequence of a water particle velocity of the target sea area; and (5) accounting intensity of a rip current. In order to consider the dynamic characteristics of coupling of multiple physical mechanisms and coexistence of multiple spatial and temporal scales of the rip current, the method comprehensively utilizes various models to respectively stimulate different physical processes, considers the interactions between various models by using data exchange and coupling, and achieves real-time forecasting of the rip current of a bathing beach so as to provide references for beach rescue.

Owner:OCEAN UNIV OF CHINA

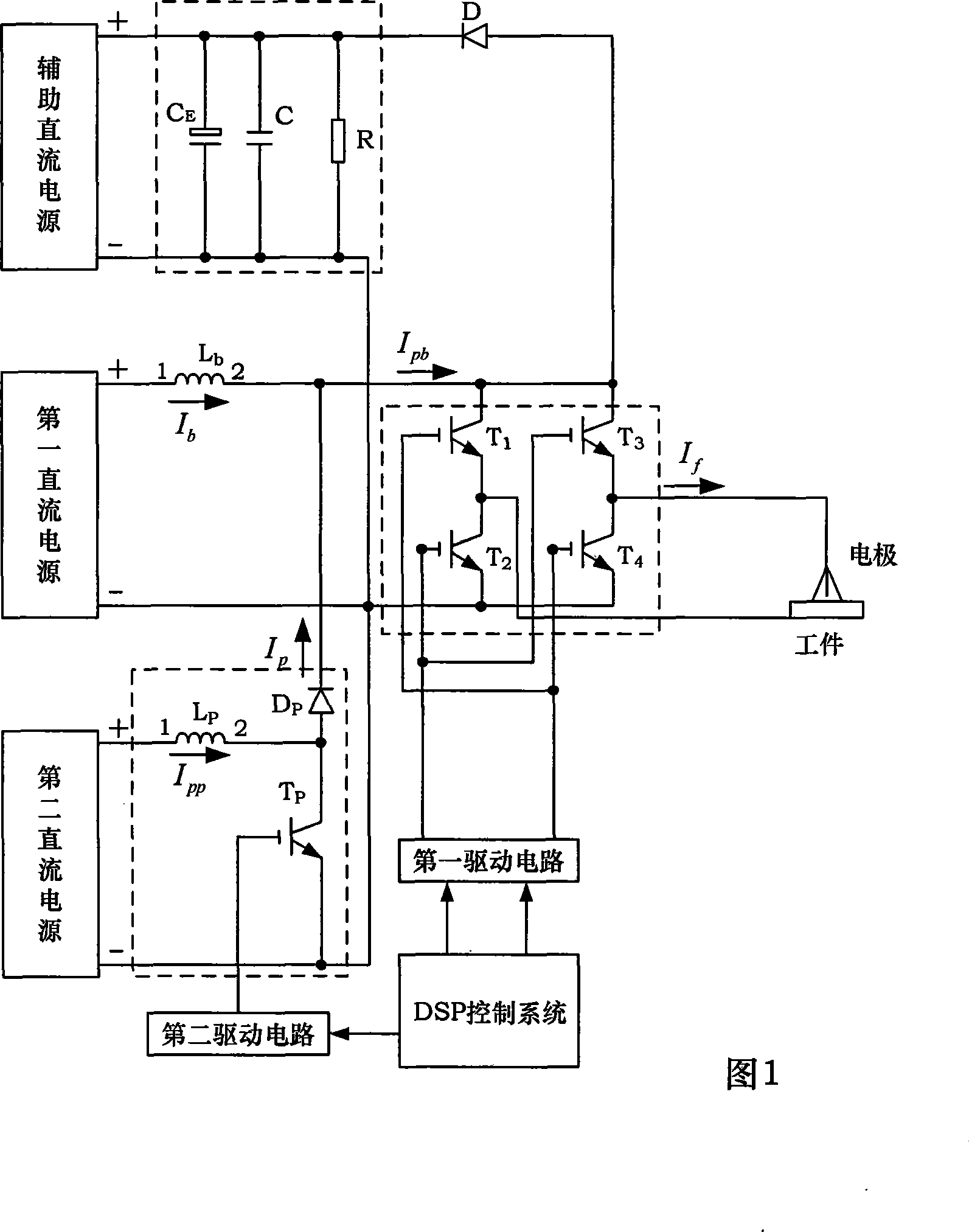

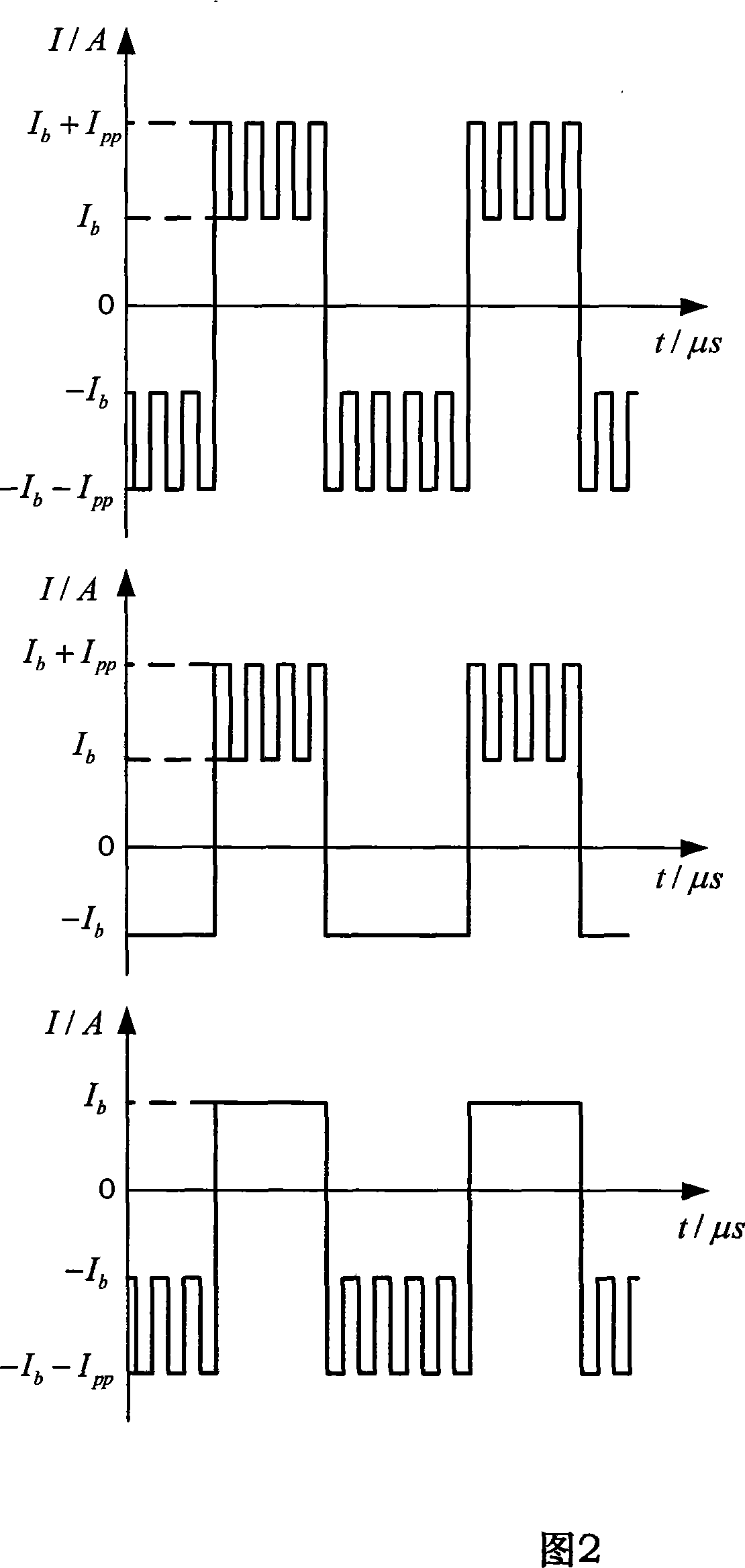

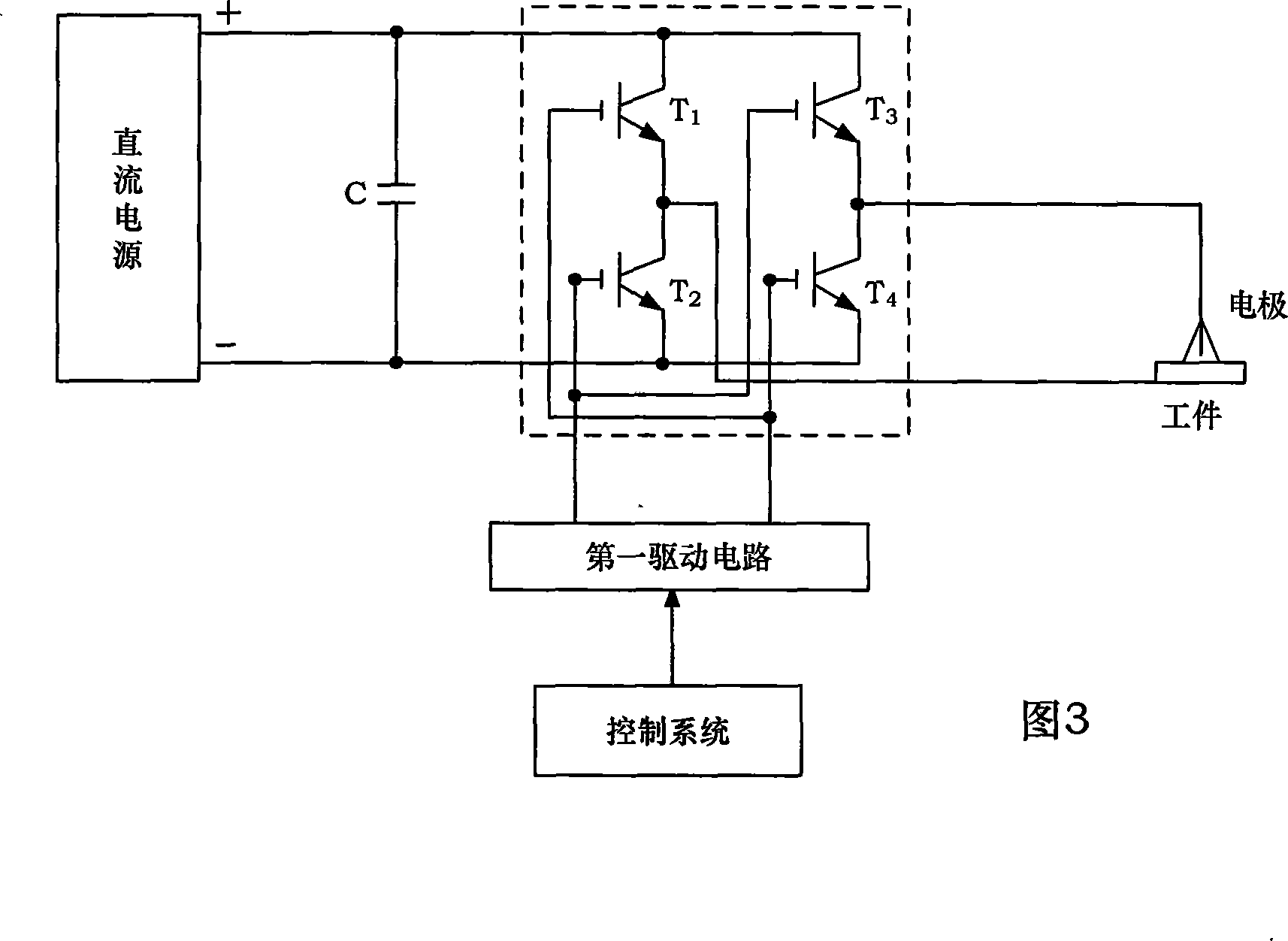

Super speed inverting square wave composite pulse current pole-changing arc-welding power supply device

InactiveCN101125390AUltra-fast current rise rateUltra-fast current fall rateArc welding apparatusCapacitanceFull bridge

The present invention discloses a super rapid exchanging method compound pulse current polarity changing arc welding power supply device used for electric arc welding, which comprises a DC power supply, a full bridge transfer circuit, a control system, a drive circuit, a parallel absorbing protecting circuit and a pulse current output circuit. The parallel absorbing protecting circuit is consists of an electrolytic condenser CE, a high frequency capacitance C and a power resistor R. The pulse current output circuit consists of a second follow current inductance LP, a fifth power switch tube TP and a second power diode DP. The DC power supply comprises an assistant DC power supply, a first DC power supply and a second DC power supply. The first DC power supply is used for providing a background current, and the second DC power supply is used for supplying a peak current Tpp, and the control system adopts a DSP processor chip. The current ascension rate of the power supply equipment output polarity changing square wave current of the present invention is not less than 50A / Mus, and the rate of descent is not less than 50A / Mus, and the current ascension rate of the compound pulse is not less than 50A / Mus, and the current ascension rate is 10 to 15 A / Mus, and the frequency of the compound pulse is 1kHz to 30 kHz, and the duty ratio is 10 percent to 90 percent.

Owner:BEIHANG UNIV

Tandem hot-wire systems

A system and method is provided. The system includes a first power supply that outputs a welding current that includes welding pulse currents and a background welding current. The system also includes a second power supply that outputs a heating current that includes first heating pulse currents at a first polarity and second heating pulse currents at an opposite polarity. The system also includes a controller that synchronizes at least one of the first heating pulse currents and the second heating pulse currents with at least one of the welding pulse currents and the background current to influence a position of an arc relative to a molten puddle based on magnetic fields created by the welding current and the heating current.

Owner:LINCOLN GLOBAL INC

Low-voltage rapid micro-arc oxidation technique

The invention relates to a low-voltage rapid micro-arc oxidation technique for micro-arc oxidation of valve metals such as aluminum, magnesium, titanium, zirconium and niobium by the aid of a constant-current pulse oxidation power supply and silicate system oxidation liquid. The peak current and the background current of the constant-current pulse oxidation power supply are continuously adjustable within the range of 10A-500A, the frequency of the constant-current pulse oxidation power supply is continuously adjustable within the range of 50Hz-100Hz, the duty ratio of the constant-current pulse oxidation power supply is continuously adjustable within the range of 10%-20%, and the voltage of the constant-current pulse oxidation power supply varies from 0V to 200V. The silicate system oxidation liquid comprises deionized water, sodium silicate, a regulator, a low-voltage arcing agent and a reinforcing agent. Compared with a common micro-arc oxidation technique, the low-voltage rapid micro-arc oxidation technique has the advantages that oxidation voltage is reduced to be below 200V, time for preparing ceramic films with the same thickness is shortened to be one third to one eighth of the original, micro-arc oxidation energy consumption is basically unchanged, the thickness of a loose layer of each ceramic film is obviously reduced, and the hardness is averagely improved by about HV300 and reaches more than HV1000.

Owner:SOUTHWEST PETROLEUM UNIV

Photodetector array with background current compensation means

A photo detector device includes a photosensitive transistor capable of detecting an optical signal including an image component and a background component and converting the optical signal into a current including an image current corresponding to the image component and a background current corresponding to the background component, a first amplifier module electrically connected to the photosensitive transistor capable of canceling the background current and amplifying the image current, and a second amplifier module electrically connected to the first amplifier module capable of detecting a direct-current (dc) portion of the image current.

Owner:SHANGHAI XUANYAN ELECTRONICS TECH INC

Method to improve the characteristics of a root pass pipe weld

A method and a system for forming a root pass weld for a root pipe joint. A substantially periodic electric welding waveform is generated and a series of electric arc pulses are generated between an advancing welding electrode and a root pipe joint in response to the electric welding waveform. The electric welding waveform includes a base cycle having a background current phase providing a background current level, a peak current phase providing a peak current level, a tail-out current phase providing a decreasing tail-out current level, and at least one heat-increasing current pulse during the background current phase providing a heat-increasing current level being above the background current level.

Owner:LINCOLN GLOBAL INC +1

Tandem hot-wire systems

A system and method is provided. The system includes a first power supply that outputs a welding current that includes welding pulse currents and a background welding current. The system also includes a second power supply that outputs a heating current that includes first heating pulse currents at a first polarity and second heating pulse currents at an opposite polarity. The system also includes a controller that synchronizes at least one of the first heating pulse currents and the second heating pulse currents with at least one of the welding pulse currents and the background current to influence a position of an arc relative to a molten puddle based on magnetic fields created by the welding current and the heating current.

Owner:LINCOLN GLOBAL INC

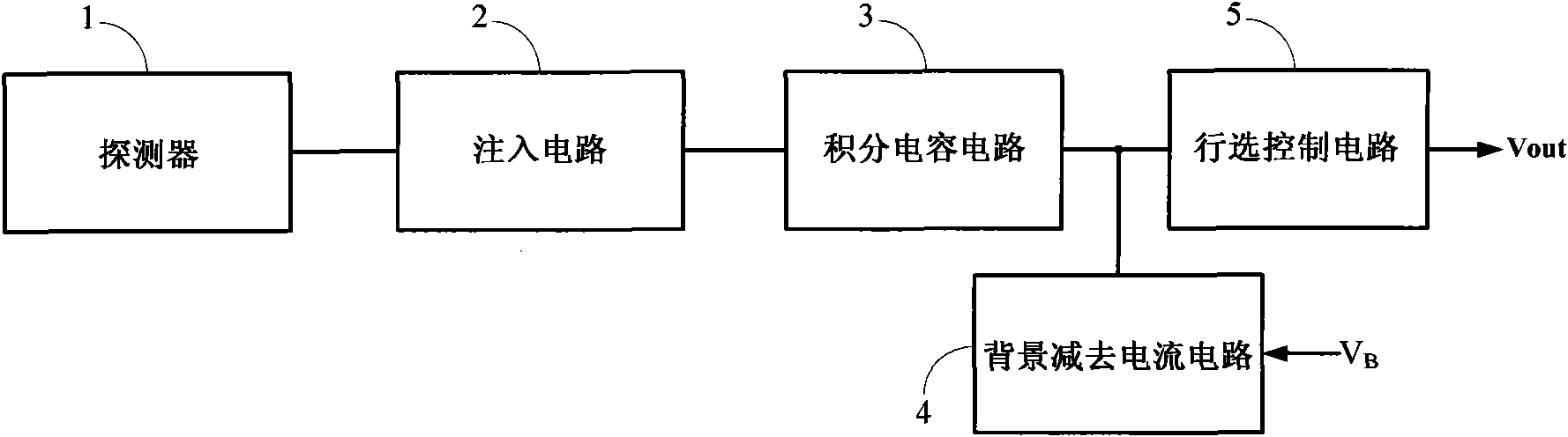

Staged background suppression method of ultrared focal plane readout circuit

InactiveCN101639381AImproved ability to detect weak signalsExtend integration timeTelevision system detailsRadiation pyrometryCapacitanceSignal processing circuits

The invention relates to a staged background suppression method of an ultrared focal plane readout circuit. The staged background suppression method is characterized in that unit circuits in the ultrared focal plane readout circuit comprise an injection circuit, an integral capacitor circuit, a background current reduction circuit and a row-selection control circuit, wherein the output end of a detector is connected with the input end of the injection circuit; the output end of the injection circuit is connected with the input end of the integral capacitor circuit; the output end of the integral capacitor circuit, the output end of the background current reduction circuit and the input end of the row-selection control circuit are mutually connected; the input end of the background currentreduction circuit is connected with an input voltage VB; and the output end of the row-selection control circuit is connected with a subsequent signal-processing circuit. The background current reduction circuit is utilized to be switched on by stages in an integral process so that a charge packet is reduced form the integral capacitor circuit every time when the background current reduction circuit is switched on, and charges collected on an integral capacitor by a background current are eliminated for a plurality of times to realize background suppression.

Owner:江苏久日数控机床有限公司 +2

Tandem hot-wire systems

A system and method is provided. The system includes a first power supply that outputs a welding current that includes welding pulse currents and a background welding current. The system also includes a second power supply that outputs a heating current that includes first heating pulse currents at a first polarity and second heating pulse currents at an opposite polarity. The system also includes a controller that synchronizes at least one of the first heating pulse currents and the second heating pulse currents with at least one of the welding pulse currents and the background current to influence a position of an arc relative to a molten puddle based on magnetic fields created by the welding current and the heating current.

Owner:LINCOLN GLOBAL INC

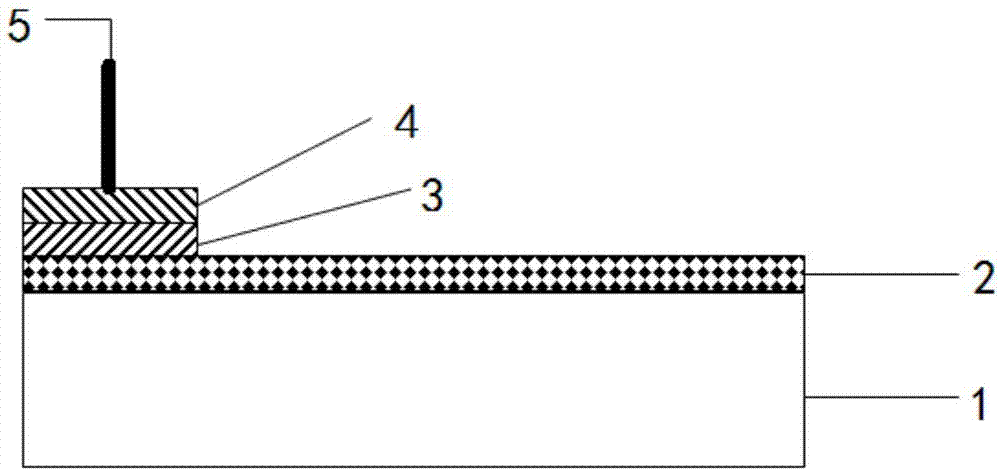

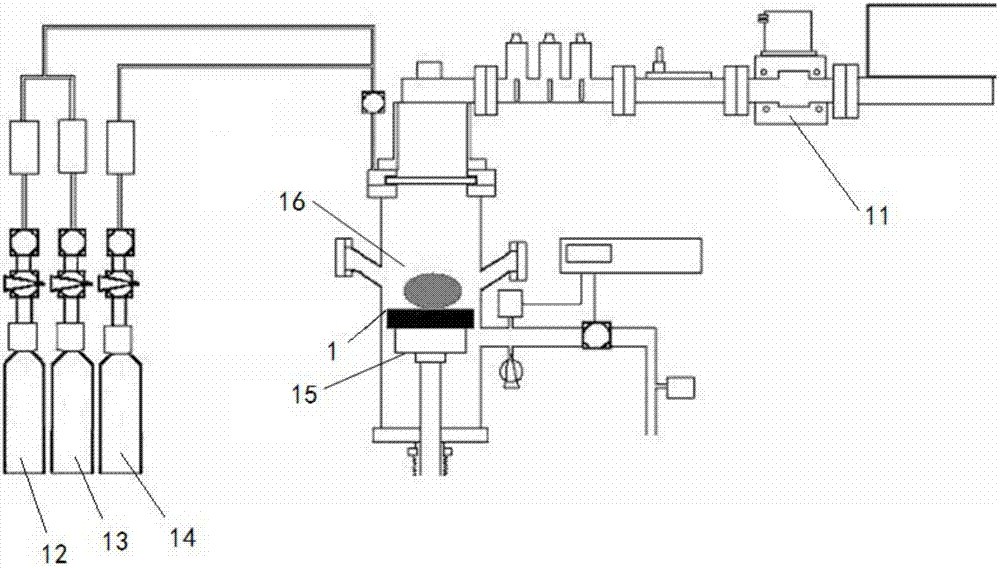

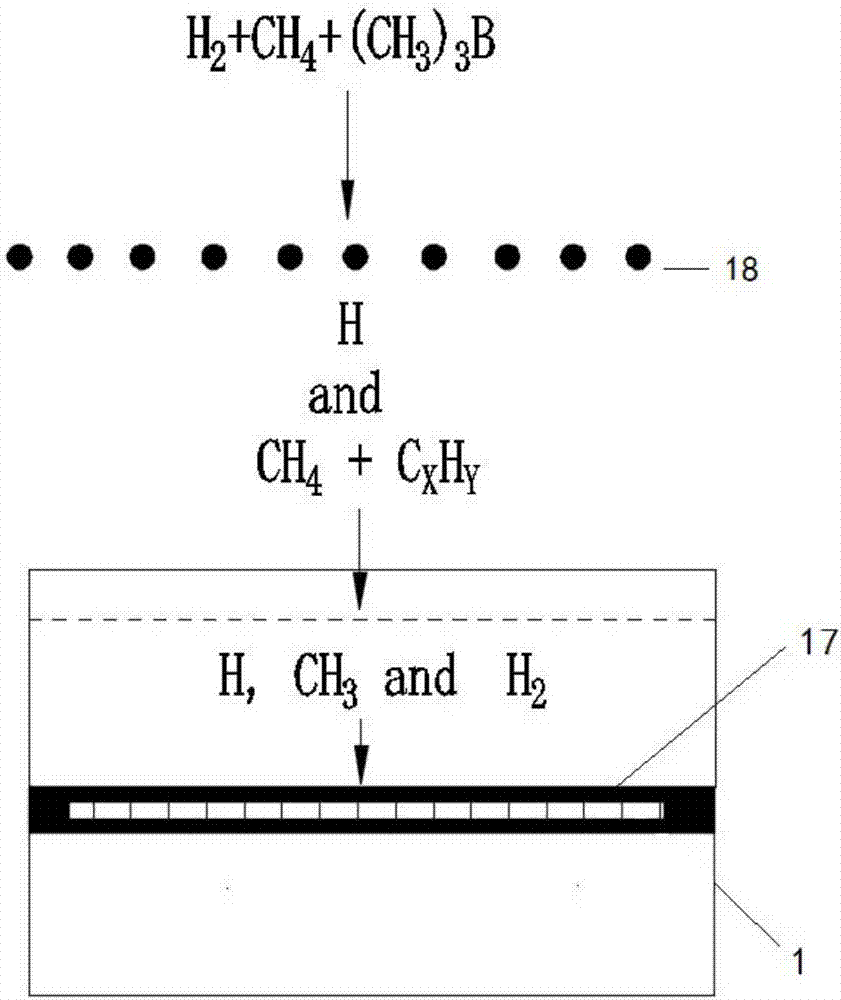

Diamond-based electrode material of seawater salinity sensor

ActiveCN107142462ALow background currentImprove signal-to-noise ratioVacuum evaporation coatingSputtering coatingComposite filmBiocompatibility Testing

The invention discloses a diamond-based electrode material of a seawater salinity sensor. A diamond thin film material and a diamond composite thin film material are used as the electrode material of the seawater salinity sensor. The diamond thin film material comprises a boron-doped polycrystalline diamond thin film material body and a boron-doped nano diamond thin film material body. The diamond composite thin film material comprises a diamond and graphite composite thin film material body, a diamond and carbide composite thin film material body, boron-doped diamond and amorphous carbon composite thin film material body and a diamond thin film material body with the surface being decorated or modified through metal, or organic matters or inorganic molecules. The electrode material has the advantages of wide electrochemical window, low background current, high corrosion resistance, strong biological adhesion prevention capacity, high mechanical strength, high stability of chemical performance, more functional ways, good reprocessability, high biocompatibility and the like. The measurement precision and reliability of the seawater salinity sensor are further improved, and the service life of the seawater salinity sensor is prolonged.

Owner:青岛浦泽海洋科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com