Super speed inverting square wave composite pulse current pole-changing arc-welding power supply device

A technology of composite pulse and arc welding power source, applied in arc welding equipment, welding equipment, manufacturing tools and other directions, can solve the problem of inability to realize output variable polarity current welding and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in detail below in conjunction with the accompanying drawings.

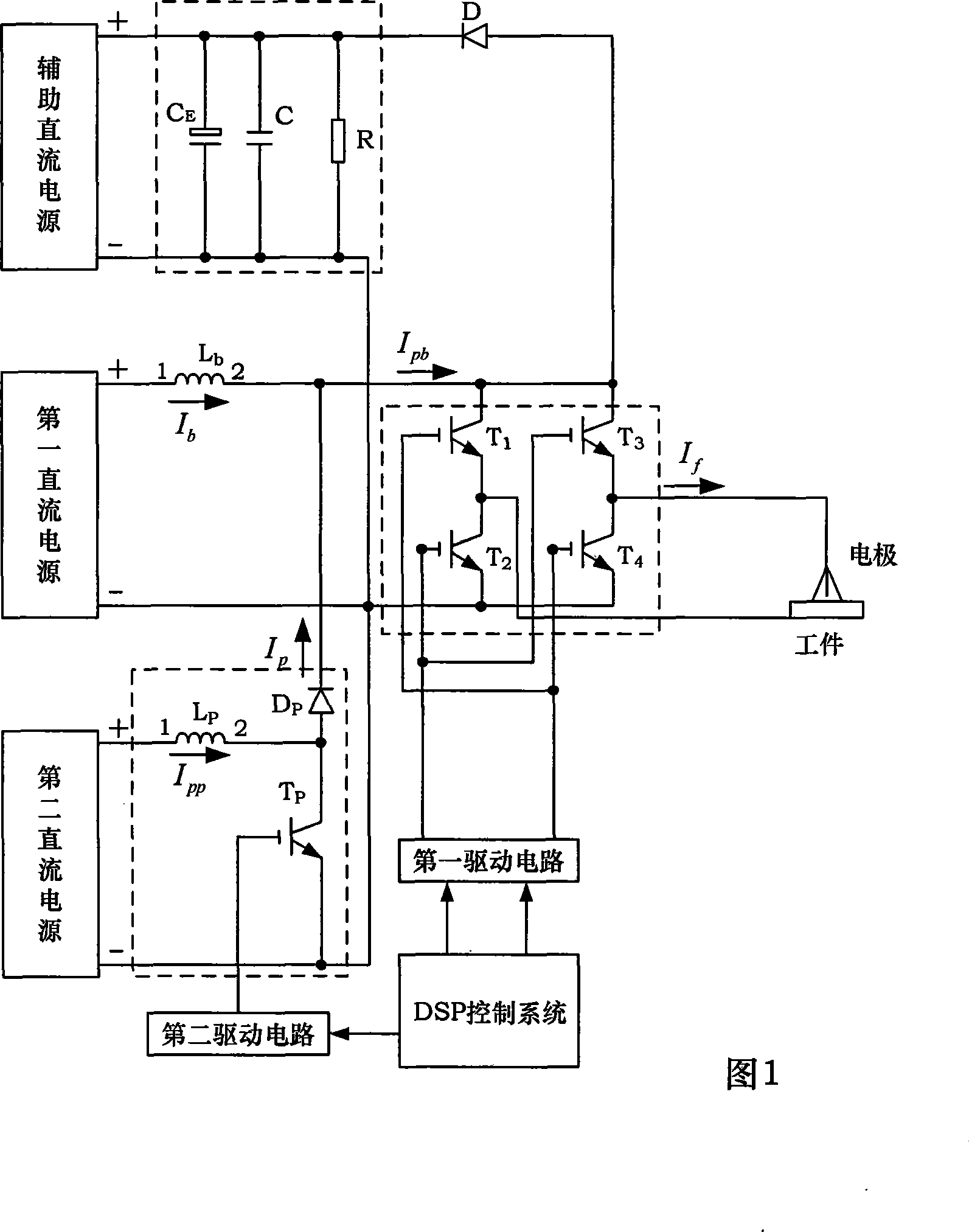

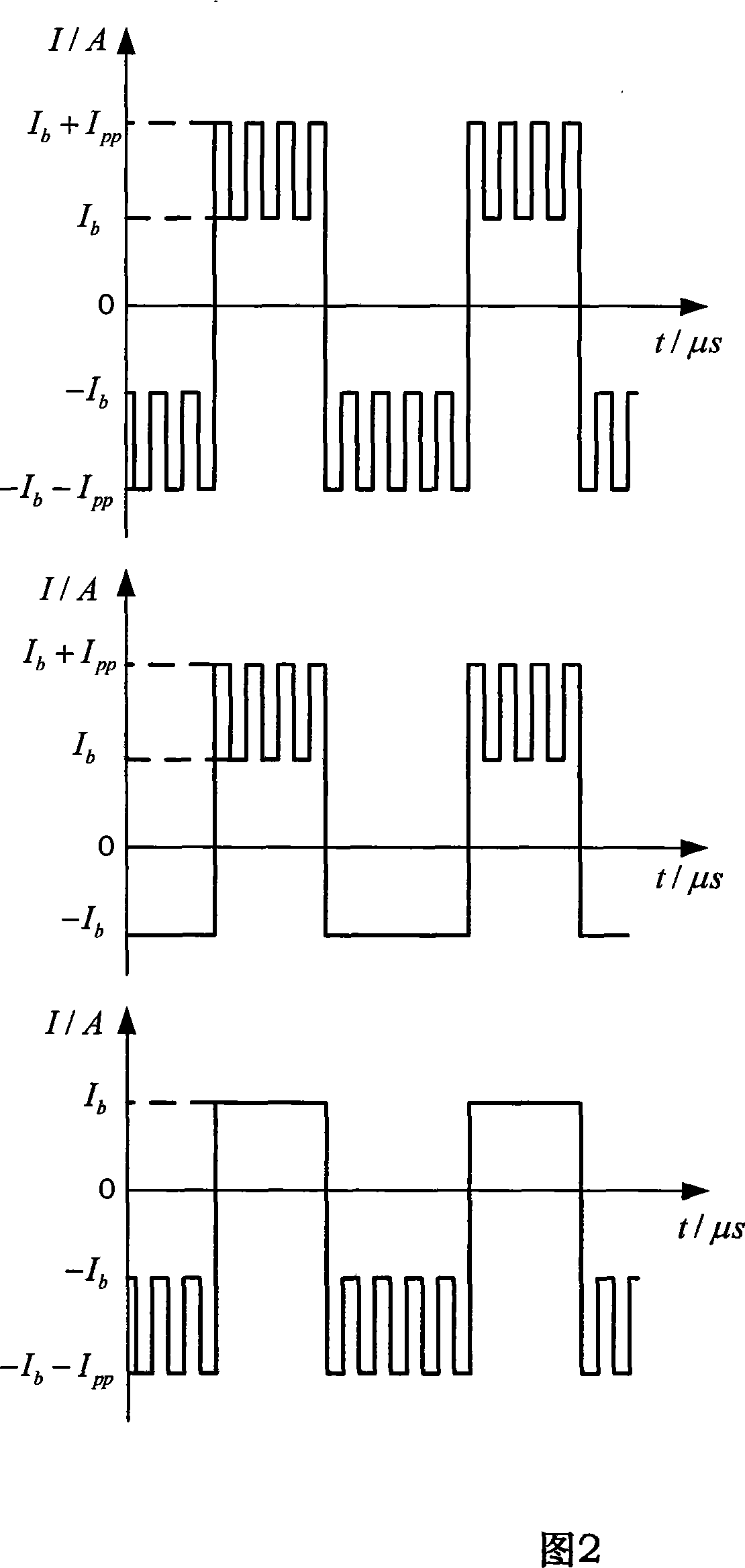

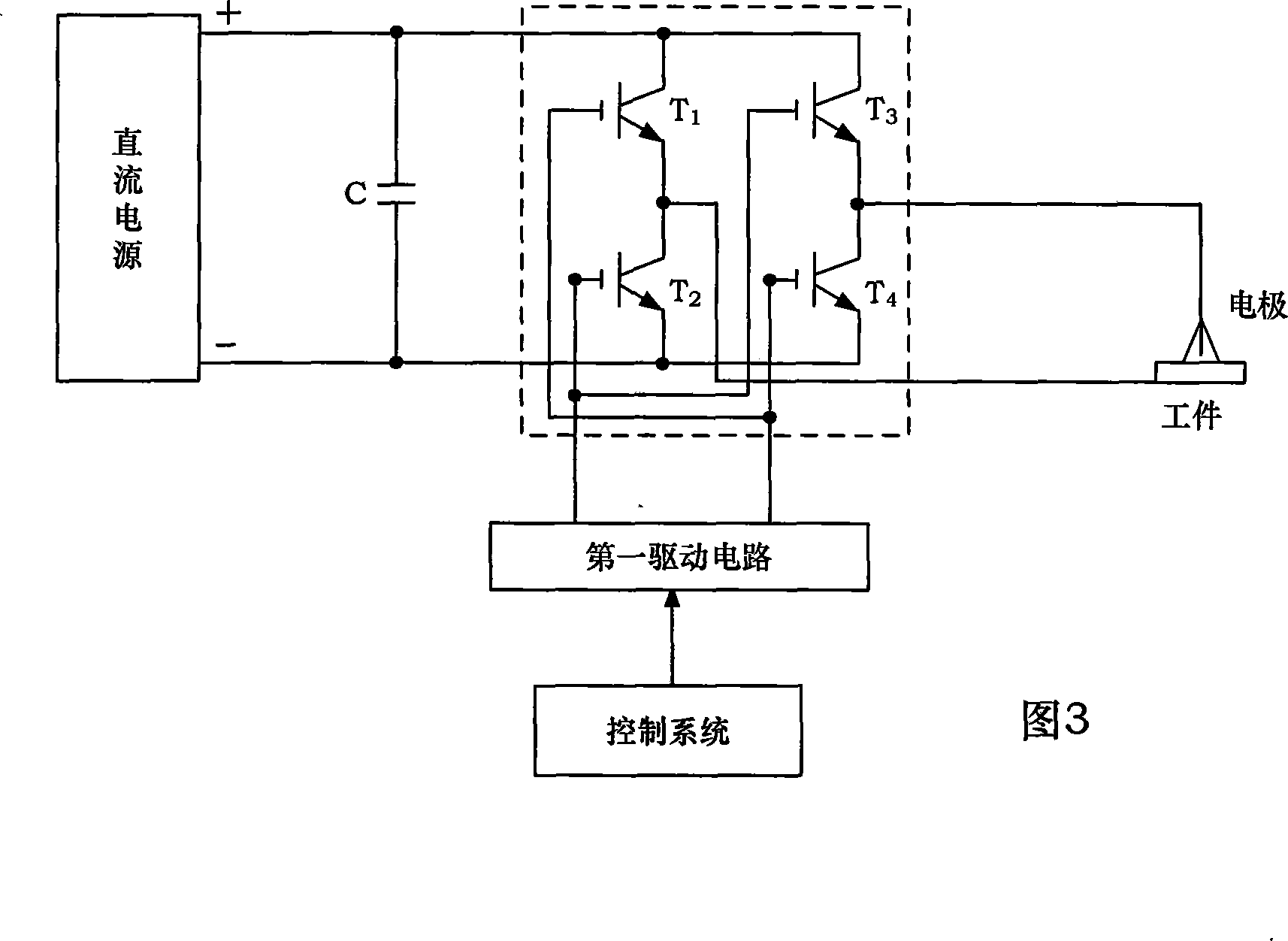

[0011] Please refer to Fig. 1, the present invention is an ultra-fast conversion square wave compound pulse electrorheological polarity arc welding power supply device, the DC power supply includes an auxiliary DC power supply, a first DC power supply and a second DC power supply, the first direct current power supply The current source is used to provide the base value current I b , the second DC power supply is used to provide the peak current I pp , The control system adopts DSP processor chip.

[0012] In the present invention, the positive pole of the first DC power supply and the first freewheeling inductance L b 1-terminal connection, the first freewheeling inductance L b The 2 terminals are connected with the first power switch tube T 1 collector, the third power switch tube T 3 collector connection; the negative pole of the first DC power supply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com