Patents

Literature

6499 results about "Arc welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Arc welding is a welding process that is used to join metal to metal by using electricity to create enough heat to melt metal, and the melted metals when cool result in a binding of the metals. It is a type of welding that uses a welding power supply to create an electric arc between a metal stick ("electrode") and the base material to melt the metals at the point of contact. Arc welders can use either direct (DC) or alternating (AC) current, and consumable or non-consumable electrodes.

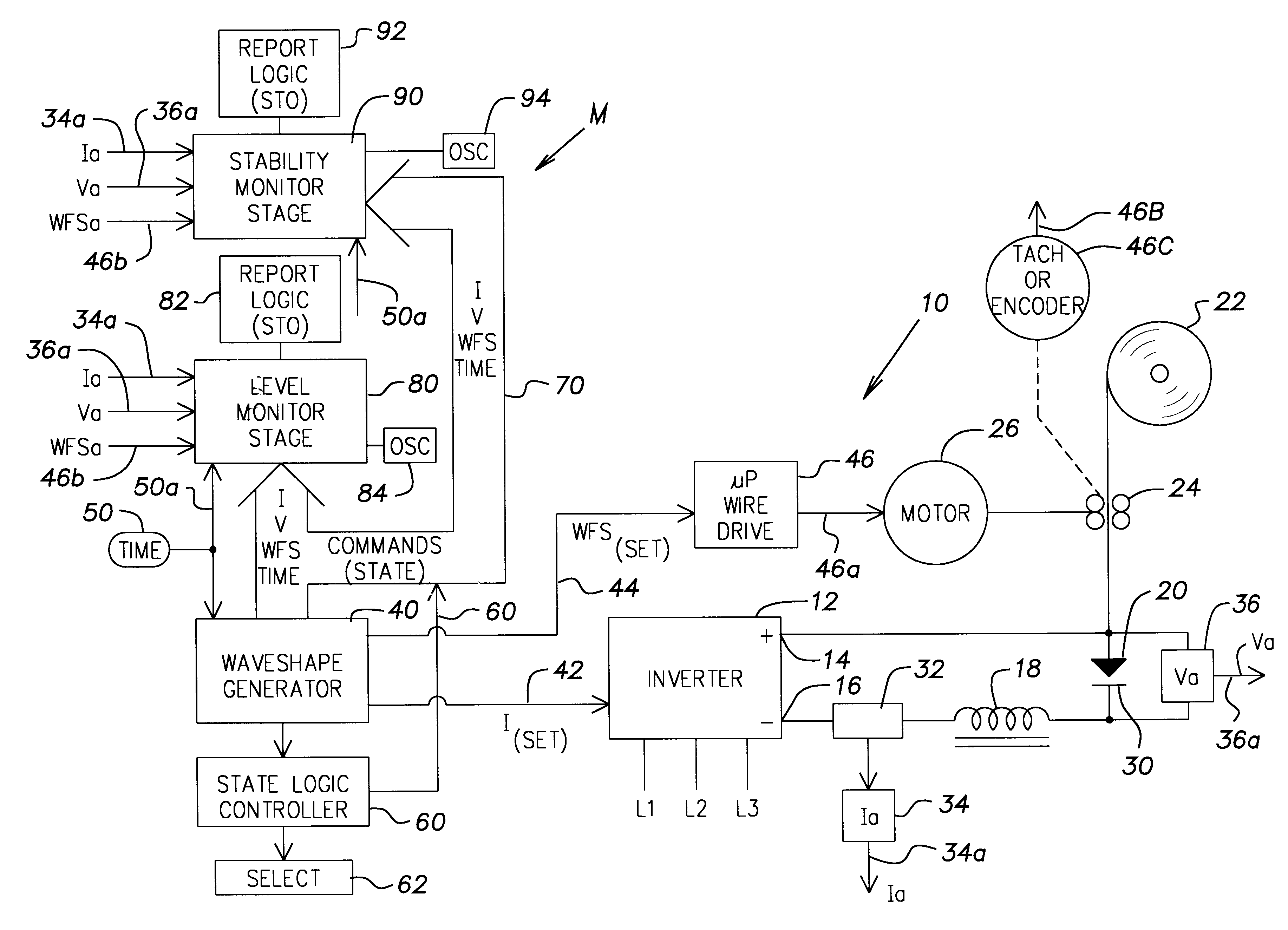

Monitor for electric arc welder

InactiveUS6441342B1Rapid data acquisition rateSufficient memoryArc welding apparatusWave shapeSimulation

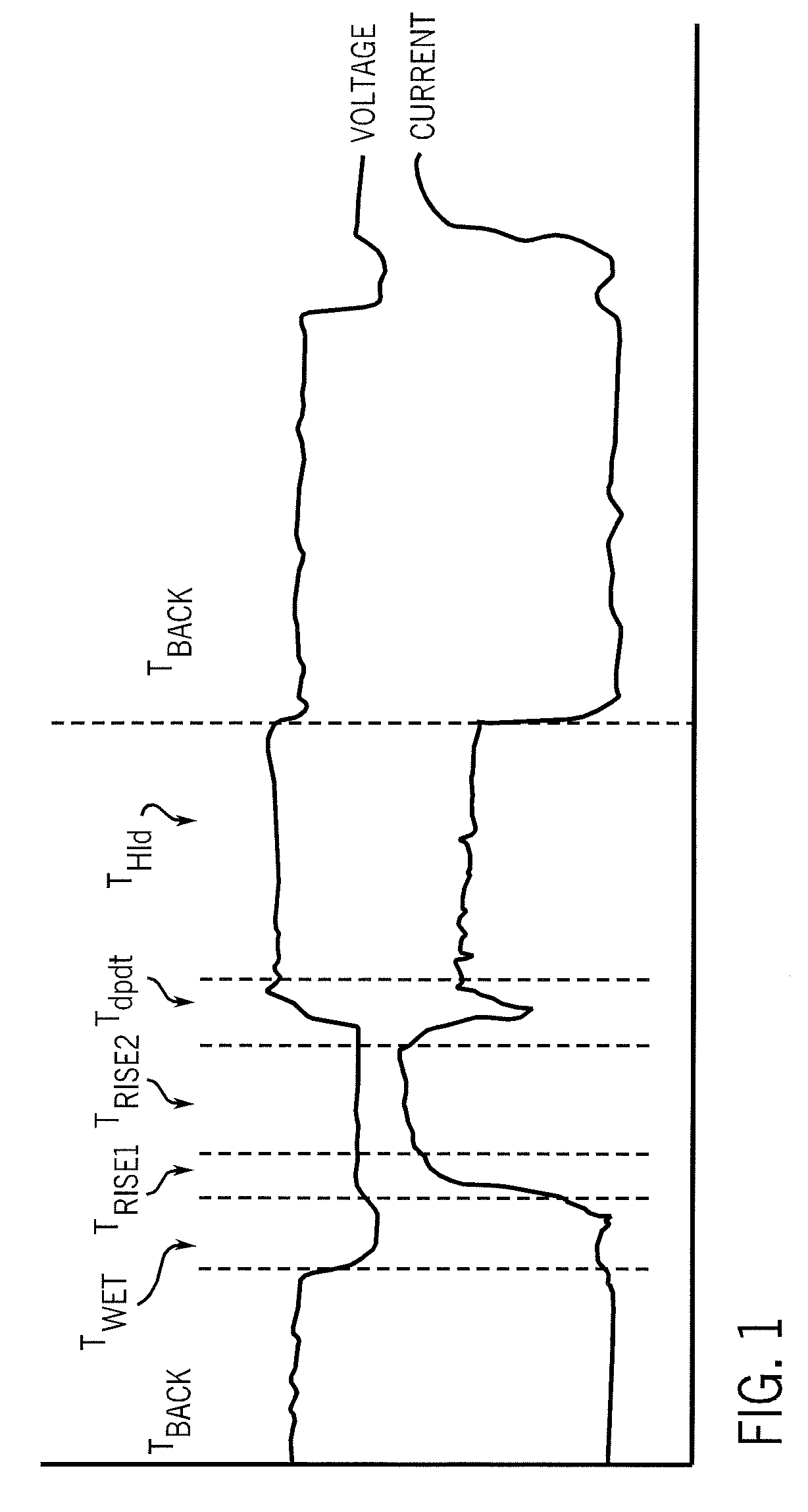

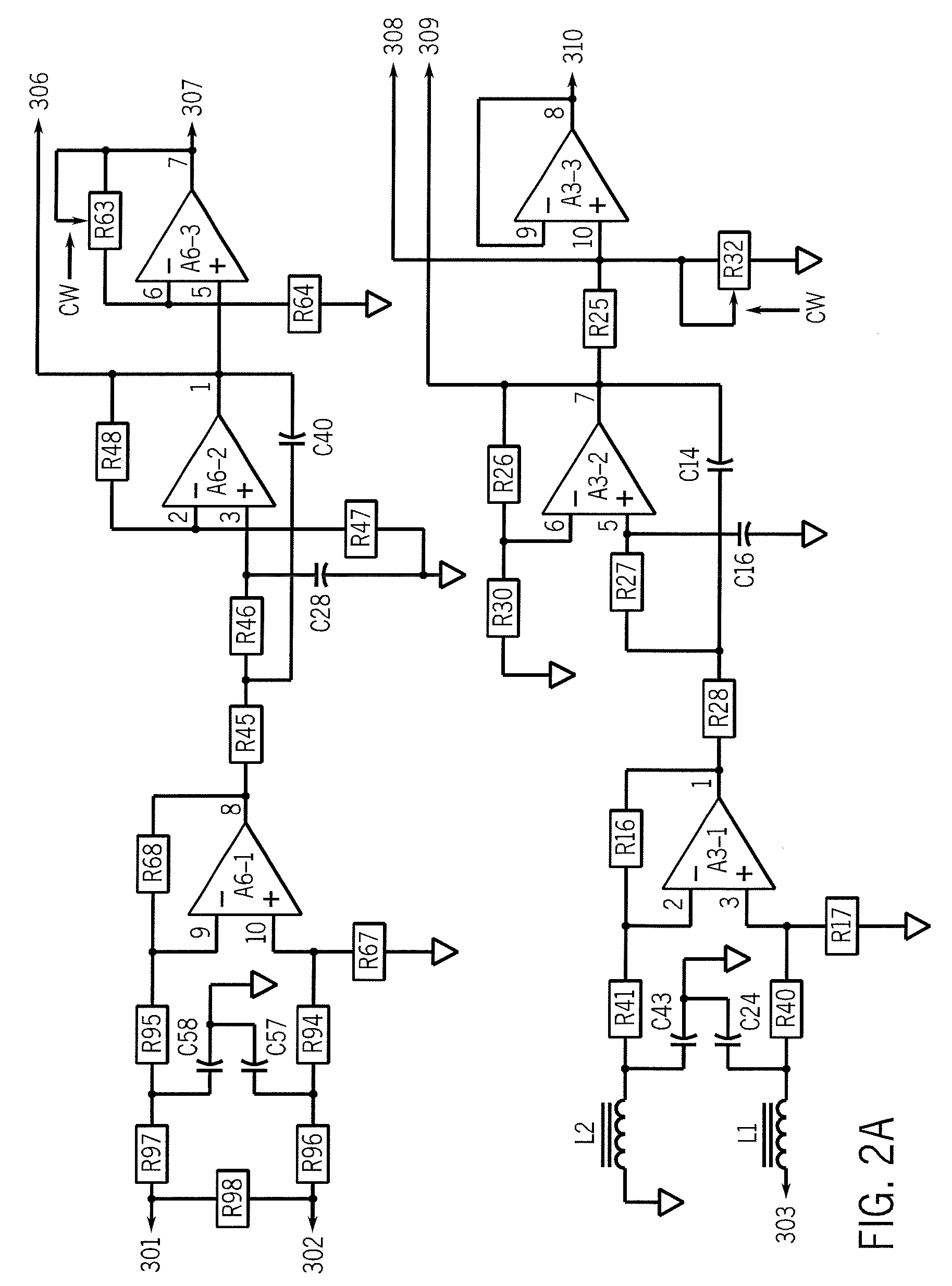

A monitor for an electric arc welder as the welder performs a selected arc welding process by creating actual welding parameters, such as arc current and arc voltage, between an advancing welding wire and a workpiece, where the process involves an arc and is defined by a series of rapidly repeating wave shapes constituting a weld cycle with a cycle time, the wave shapes are each segmented into time states having command signals corresponding to the actual parameters and a time duration. The monitor selects a specific wave shape state, reads one of the actual parameters, compares the actual read parameter with a function of the command signal corresponding to the actual parameter, and uses-the comparison to generate a characteristic of the welding process during the selected state.

Owner:LINCOLN GLOBAL INC

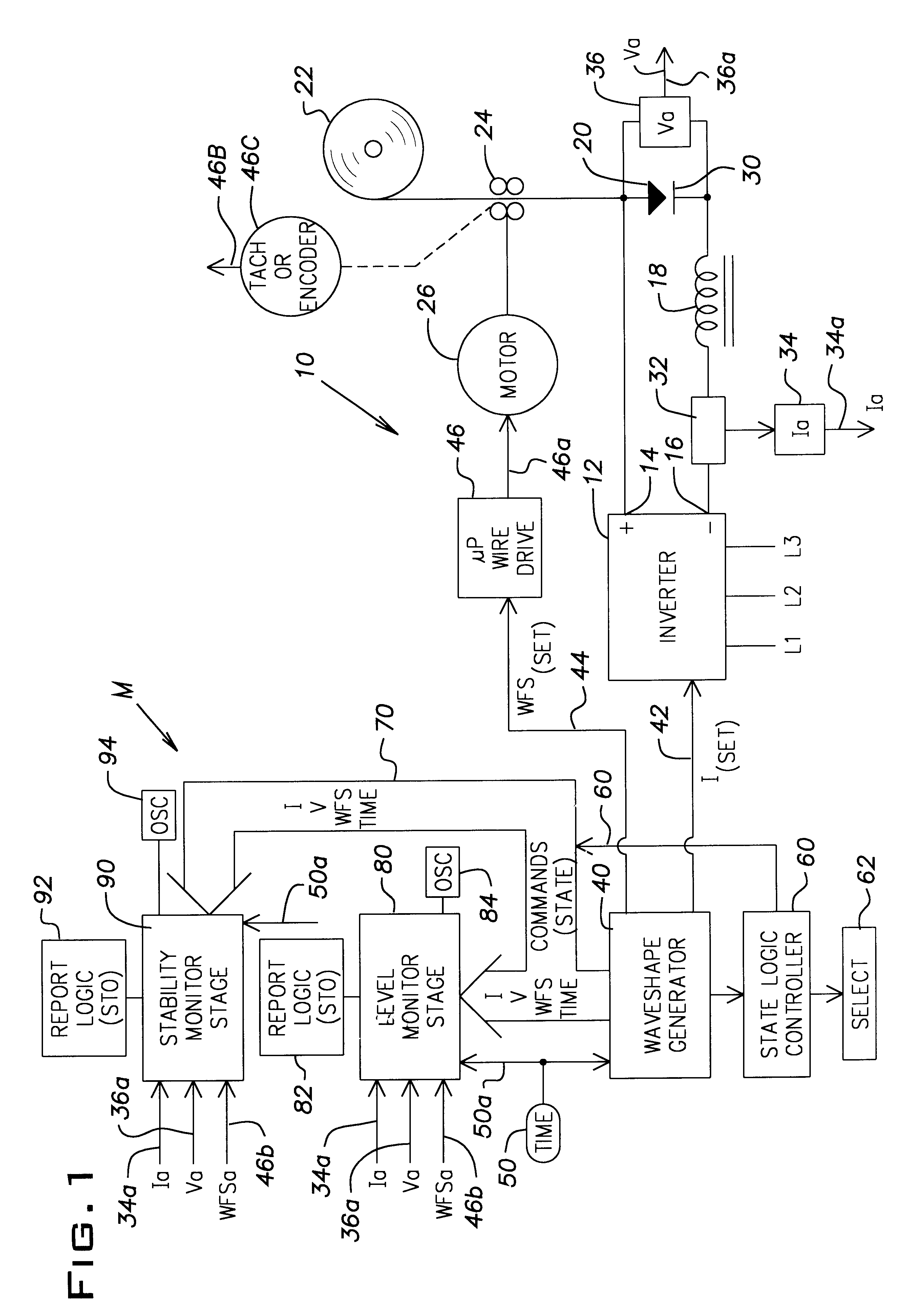

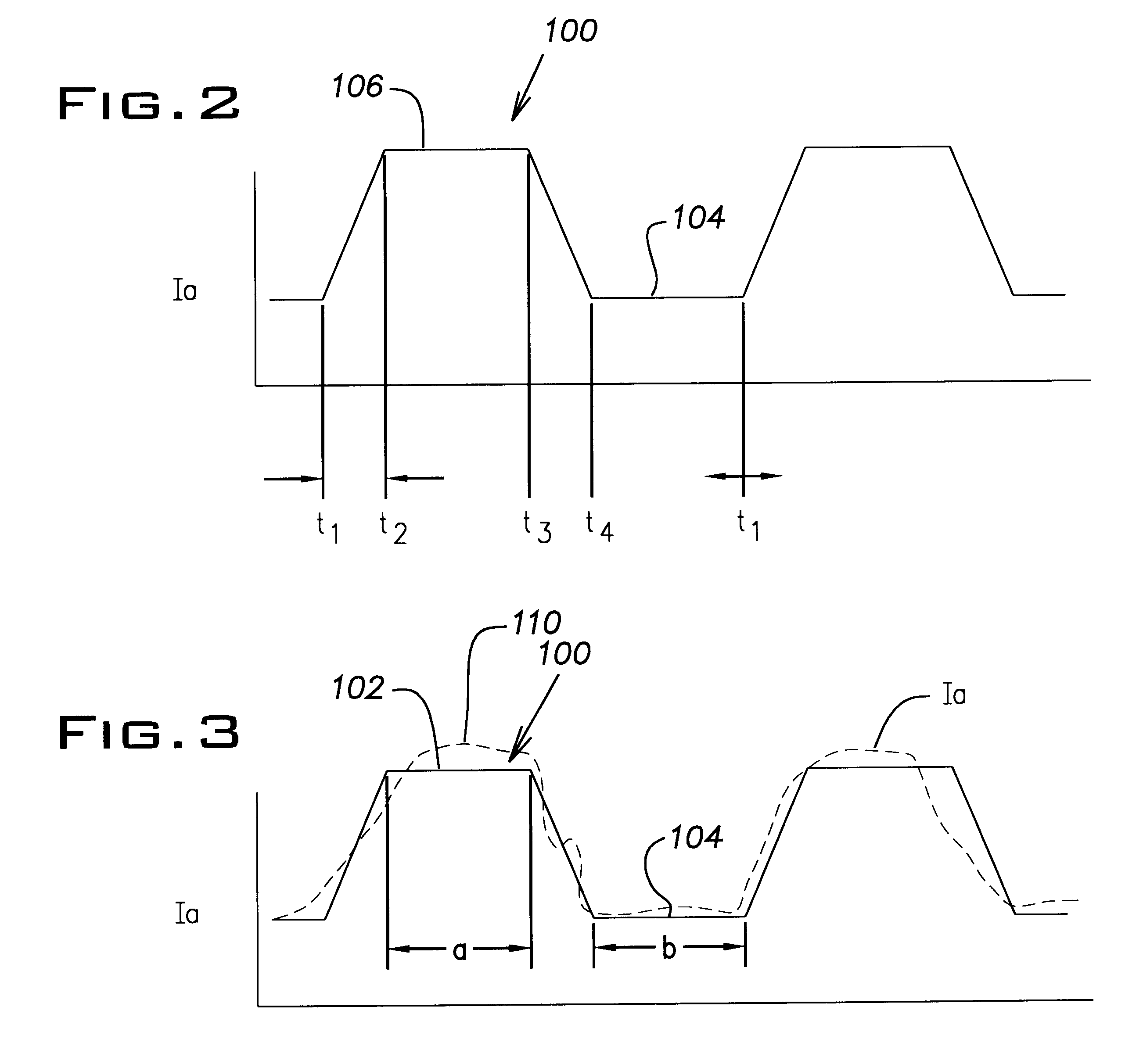

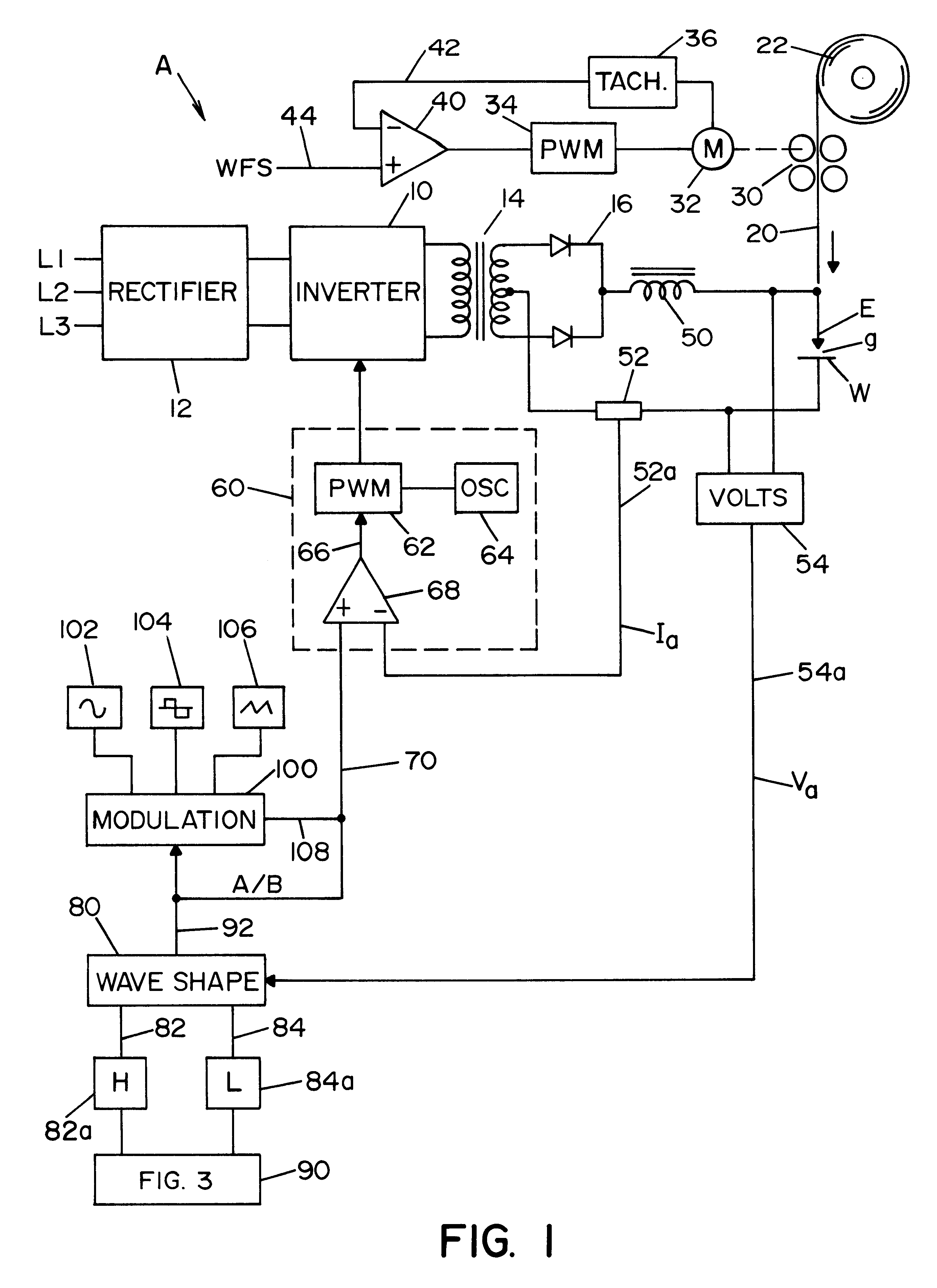

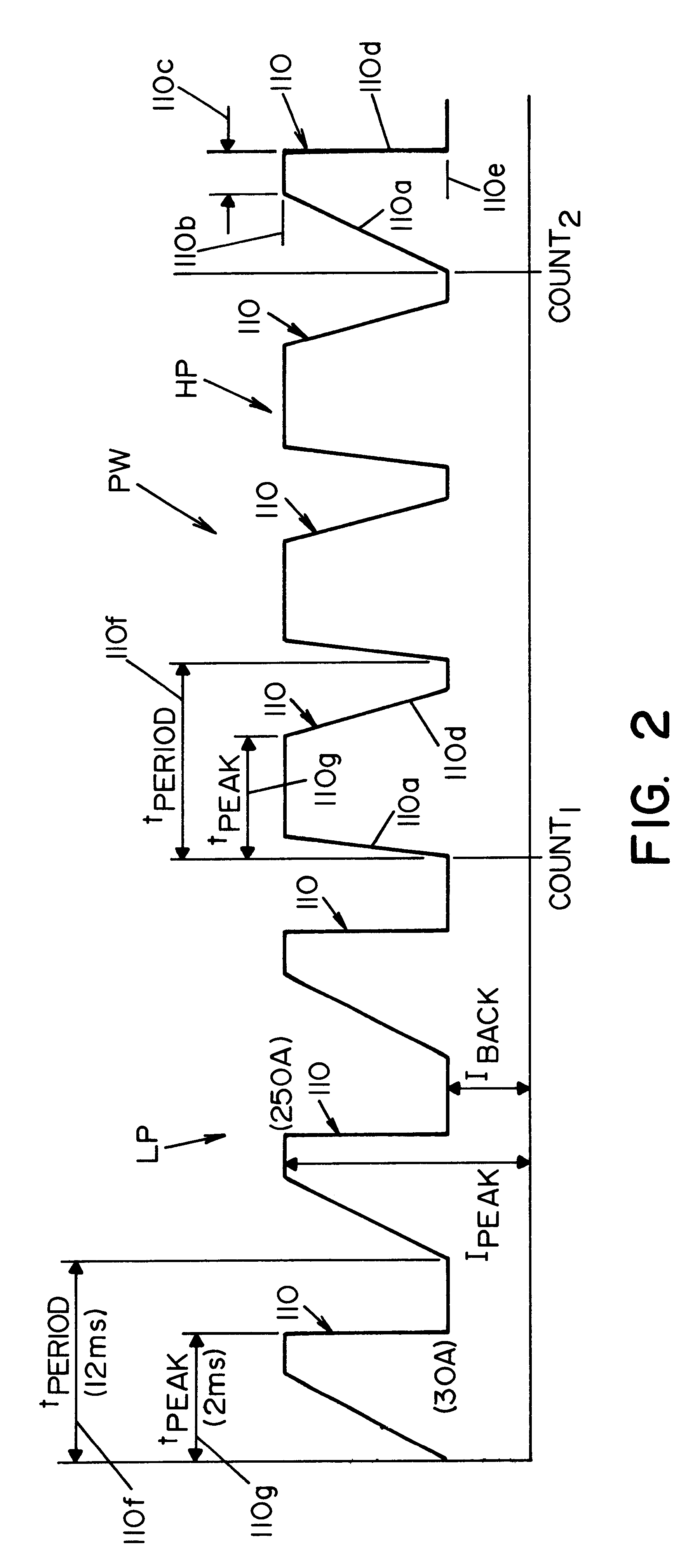

Electric arc welder using high frequency pulses

InactiveUS6515259B1Efficiently transferredMaximized efficiency and heatArc welding apparatusWave shapeElectric arc

An electric arc welder including a high speed switching power supply with a controller for creating high frequency current pulses through the gap between a workpiece and a welding wire advancing toward the workpiece, where the pulses and a background current defining a series of weld cycles. A wave shape generator defines the shape of the pulses and the background current including a controlled ramp up and / or ramp down in each of said cycles and a circuit to change the shapes of the pulses and / or background current in a repeating pattern in each of the weld cycles. The shape change in a cycle can be between first and second shapes or by a rhythmic AC modulation.

Owner:LINCOLN GLOBAL INC

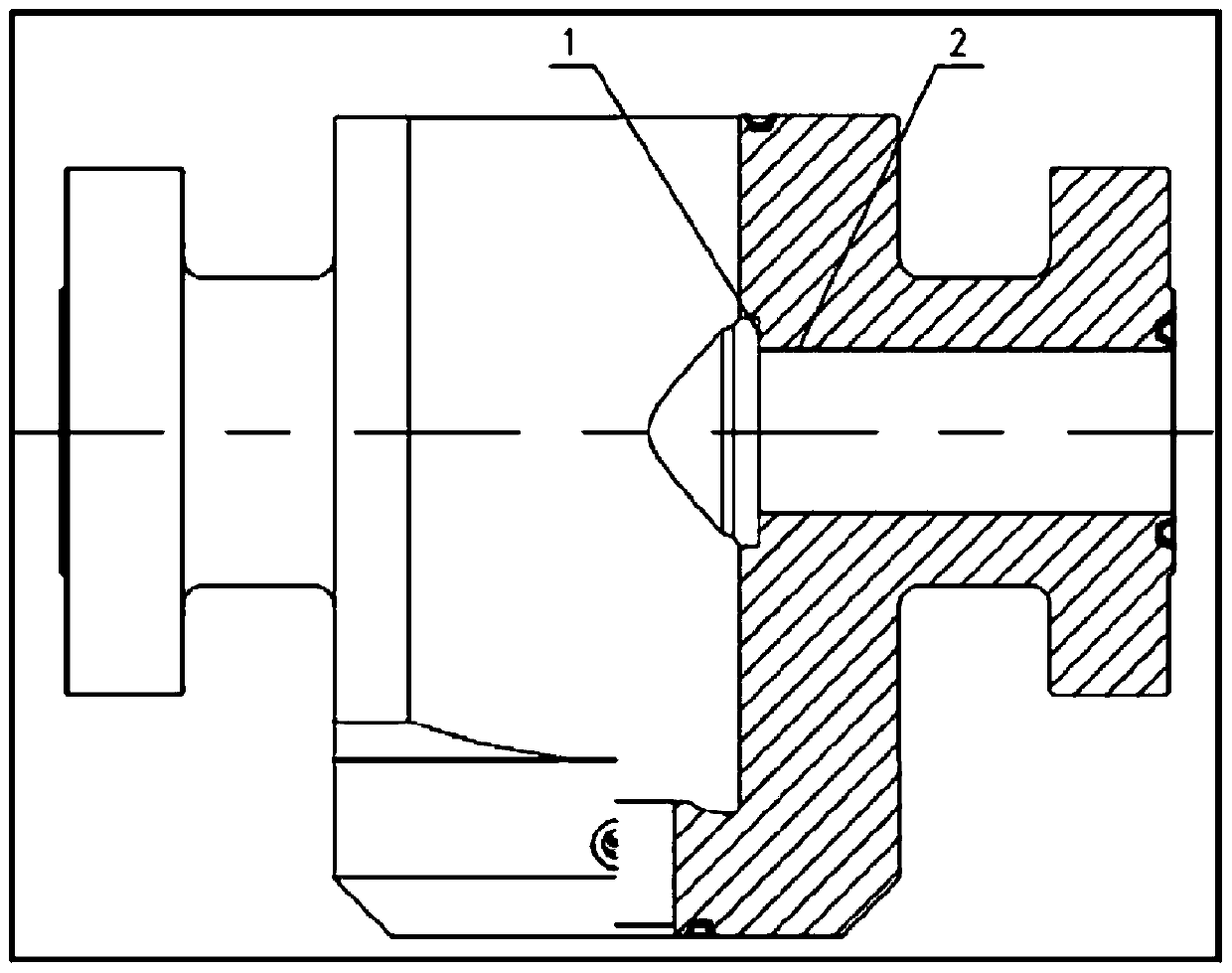

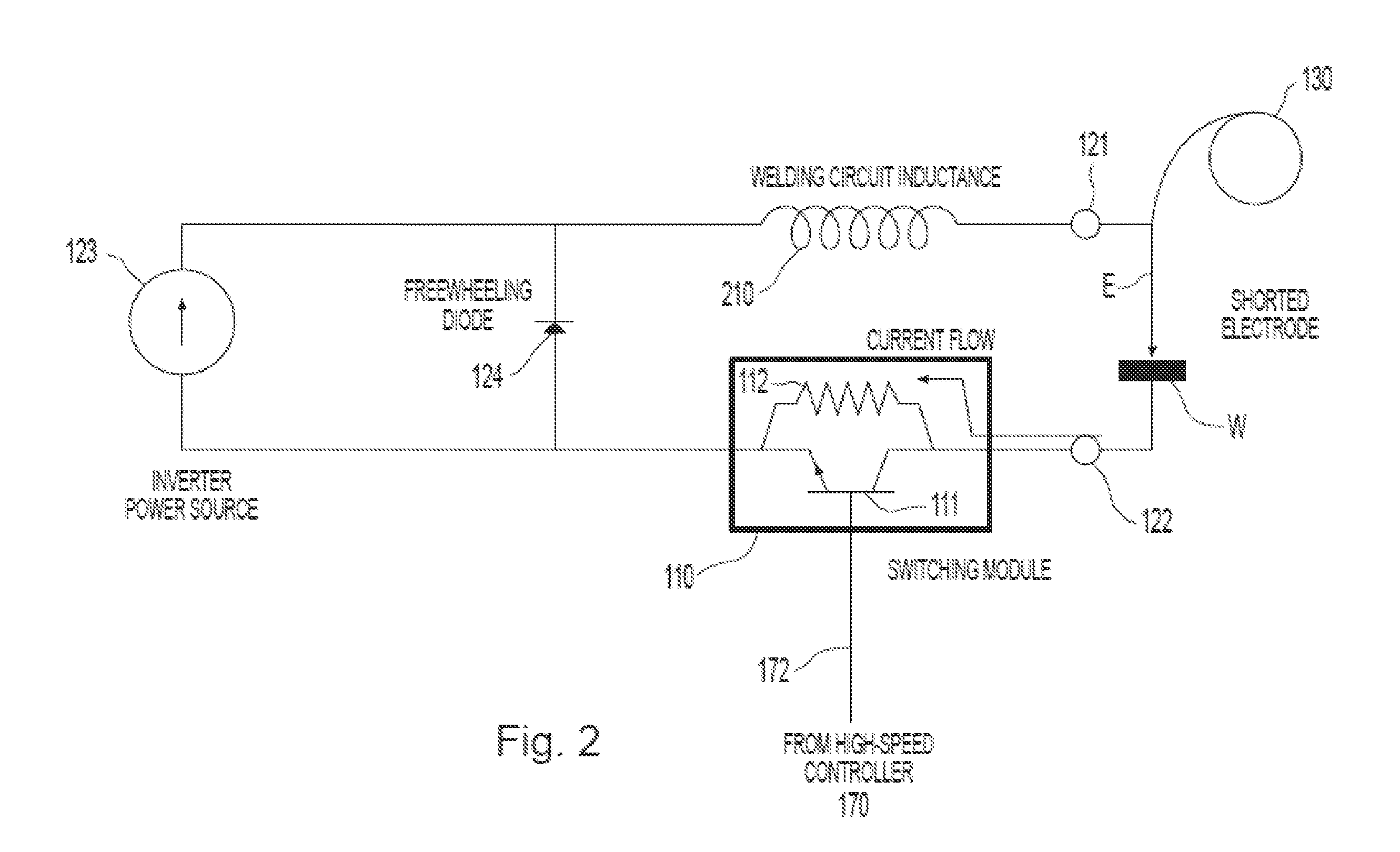

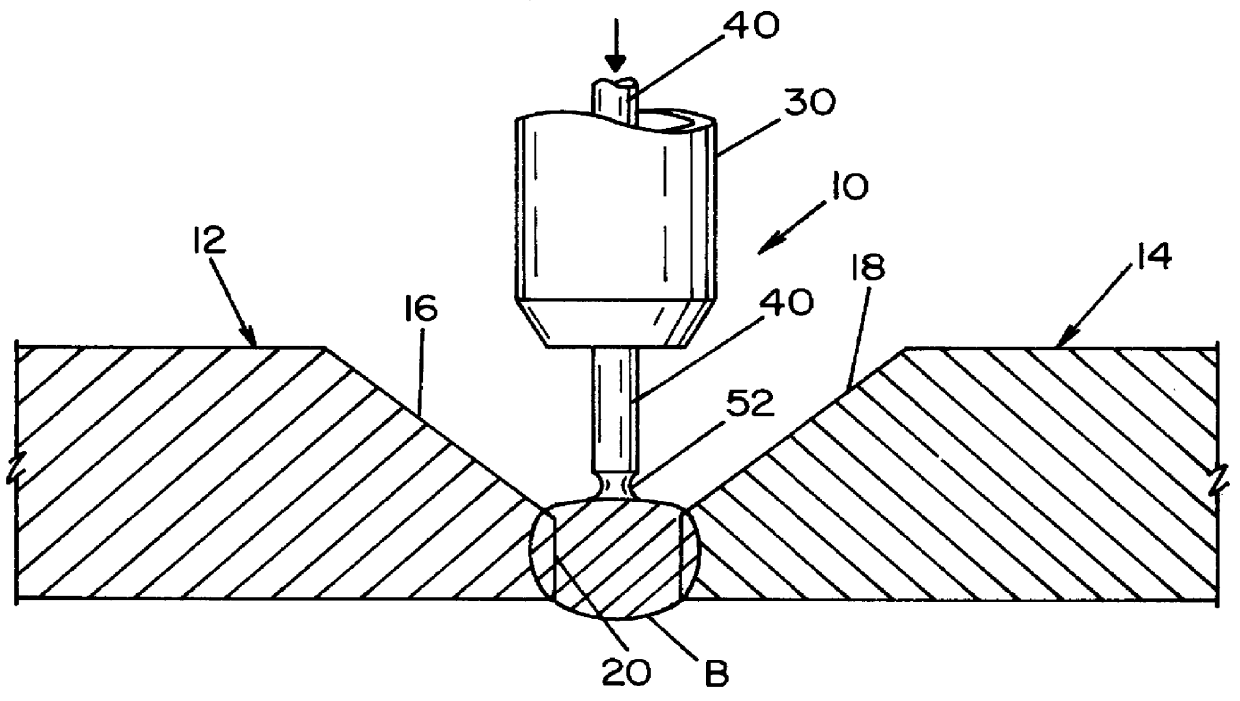

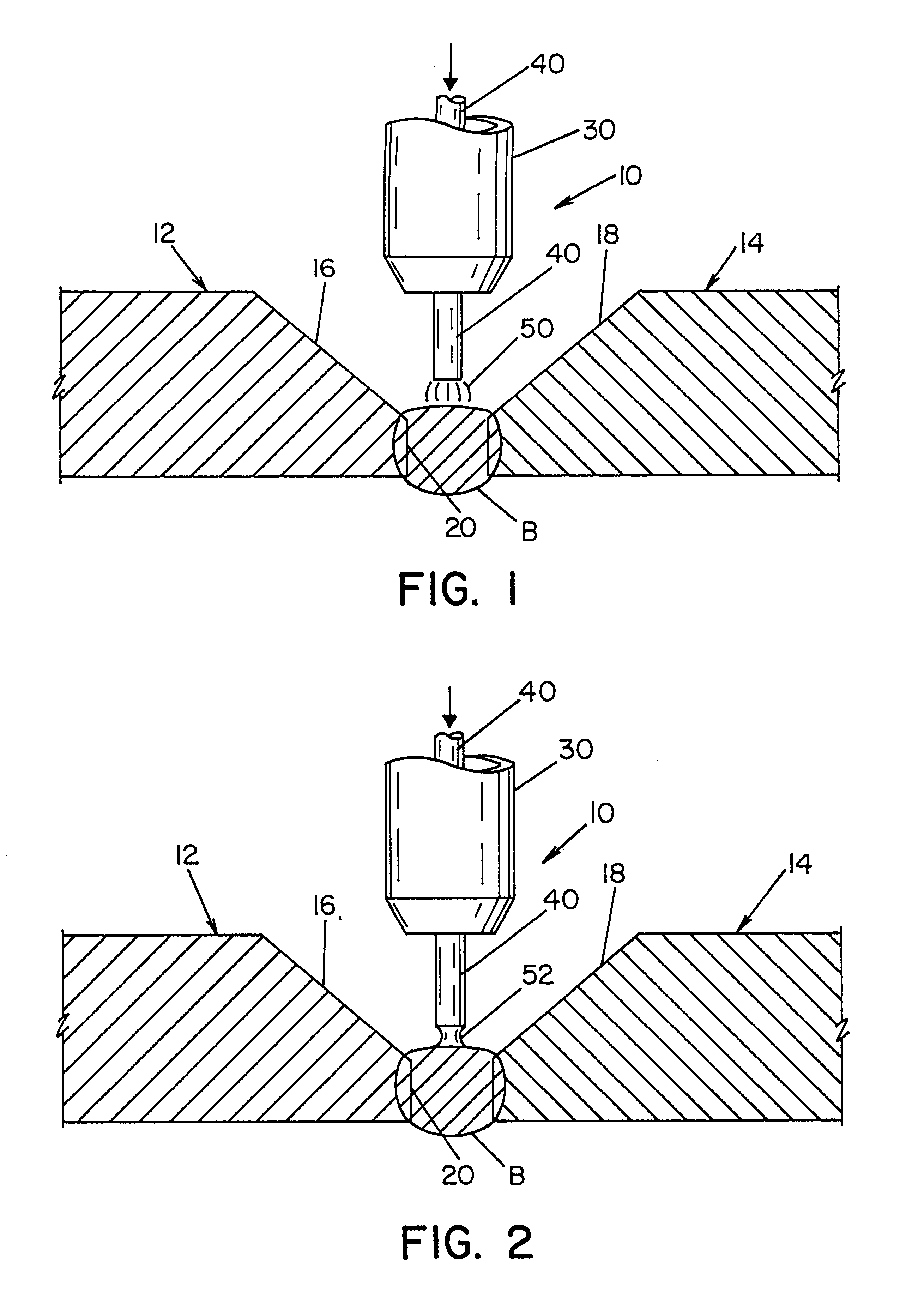

Method and apparatus for electric arc welding

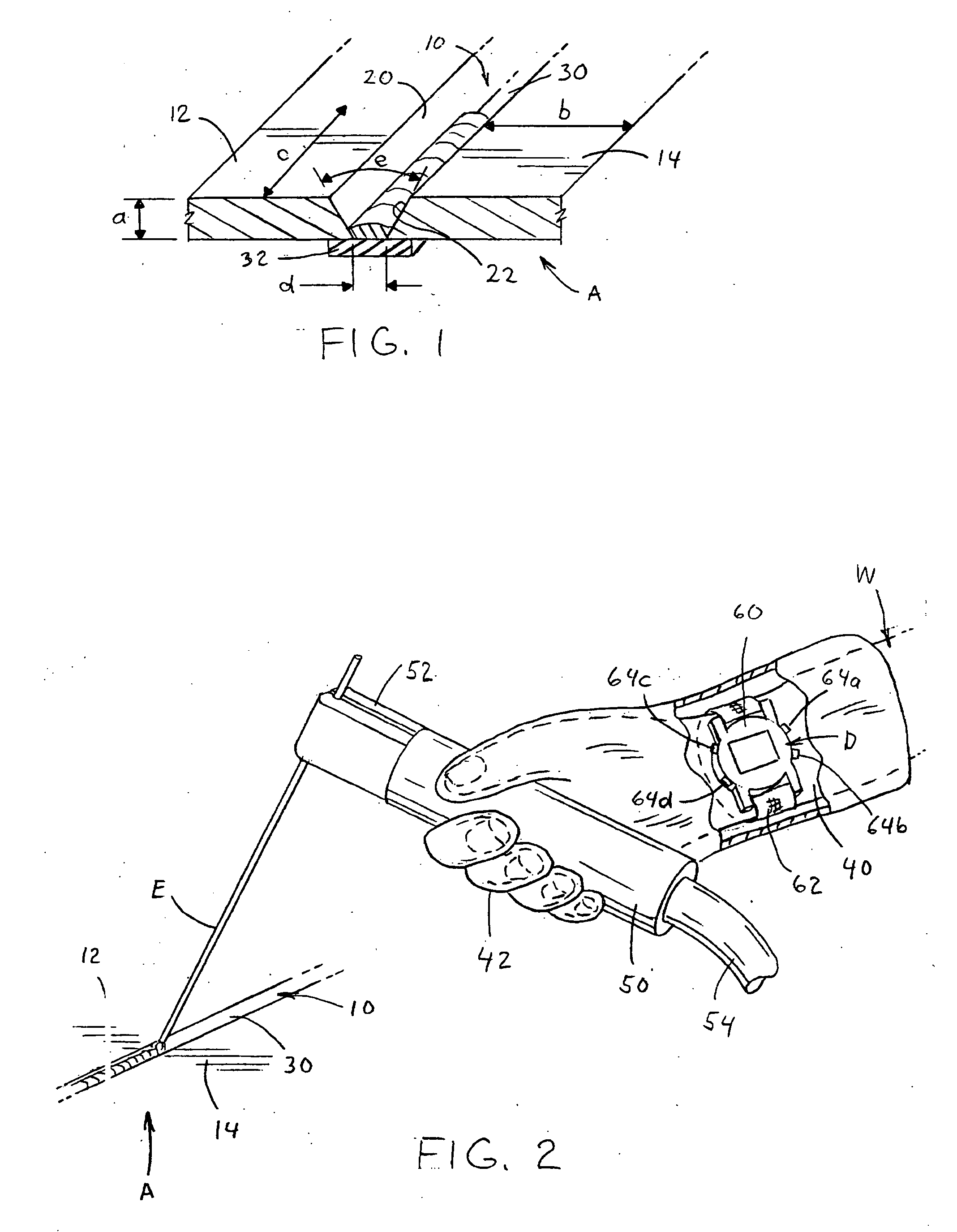

An electric arc welding apparatus for depositing molten metal from an advancing welding wire into a weld puddle in an open root between two juxtapositioned plates where the root extends in a welding path and is formed by converging walls terminating in generally parallel walls spaced to define a gap, which apparatus comprises a contact holder with a wire outlet, a switching power supply directing welding current to the wire as the wire passes from the outlet toward the open root, with the advancing wire defining an electrode stick out between the contact holder and the weld puddle, a circuit for sensing the length of the stick out, and control means for adjusting the welding current as a function of the sensed stick out length.

Owner:LINCOLN GLOBAL INC

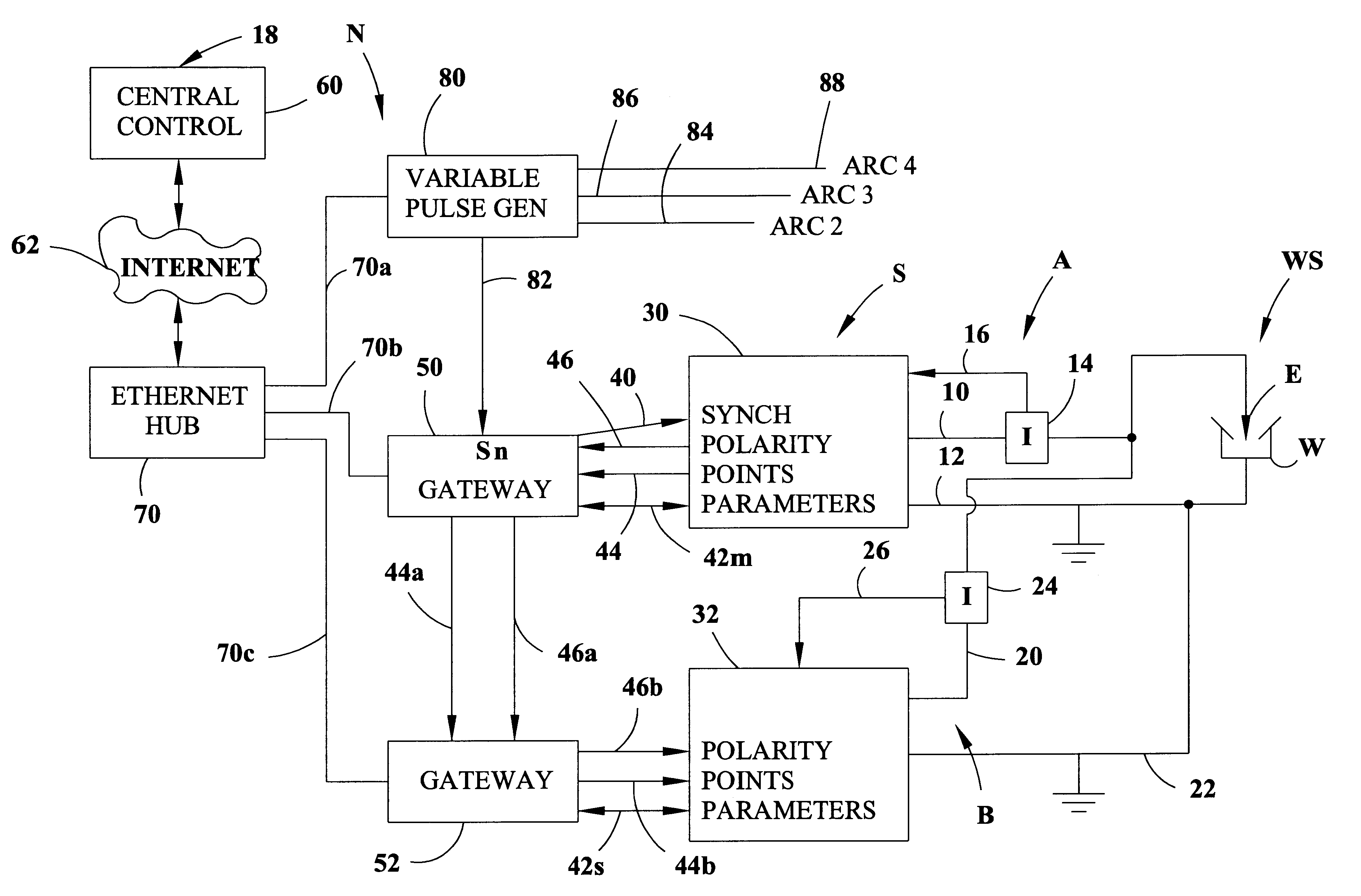

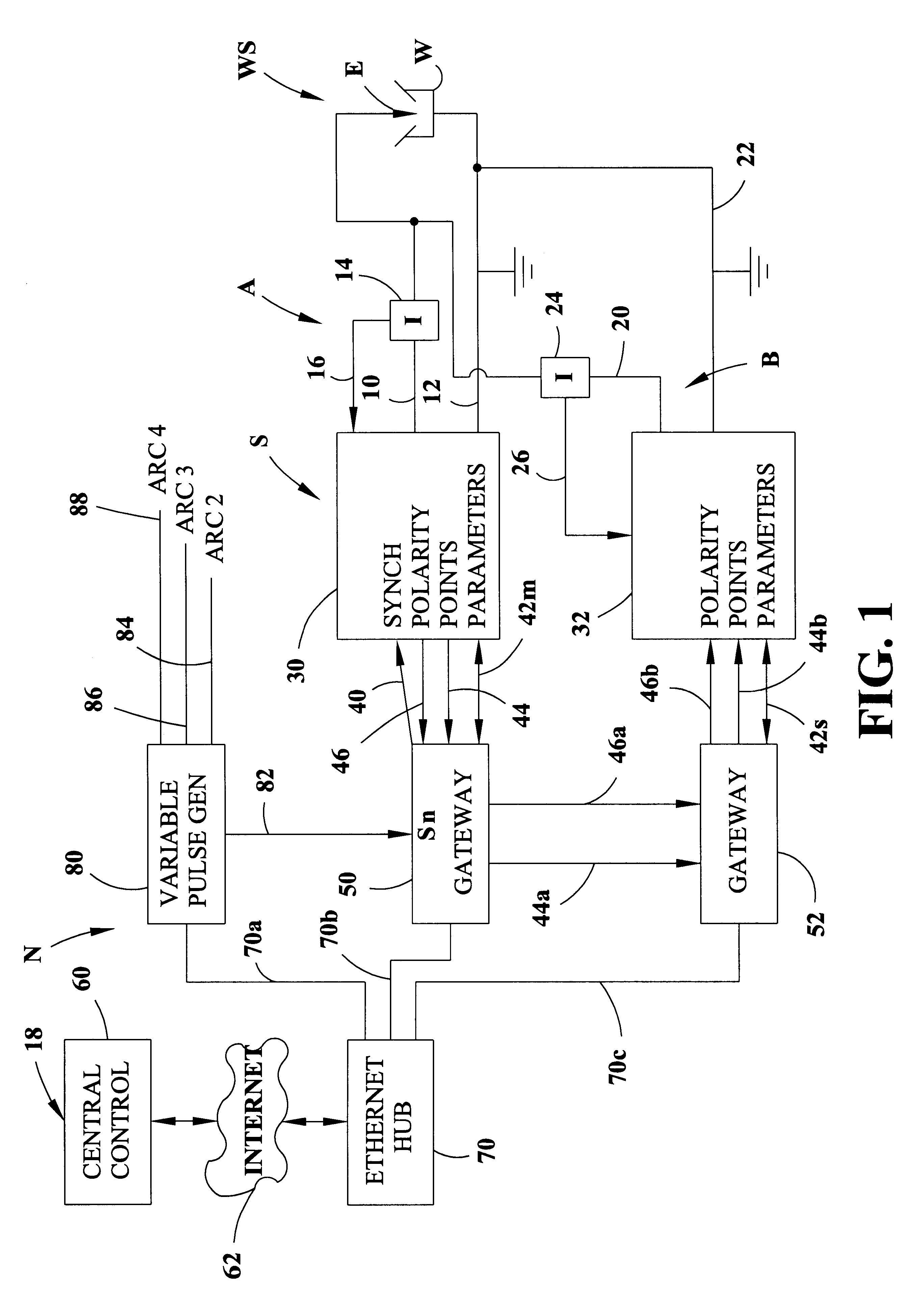

Electric arc welding system

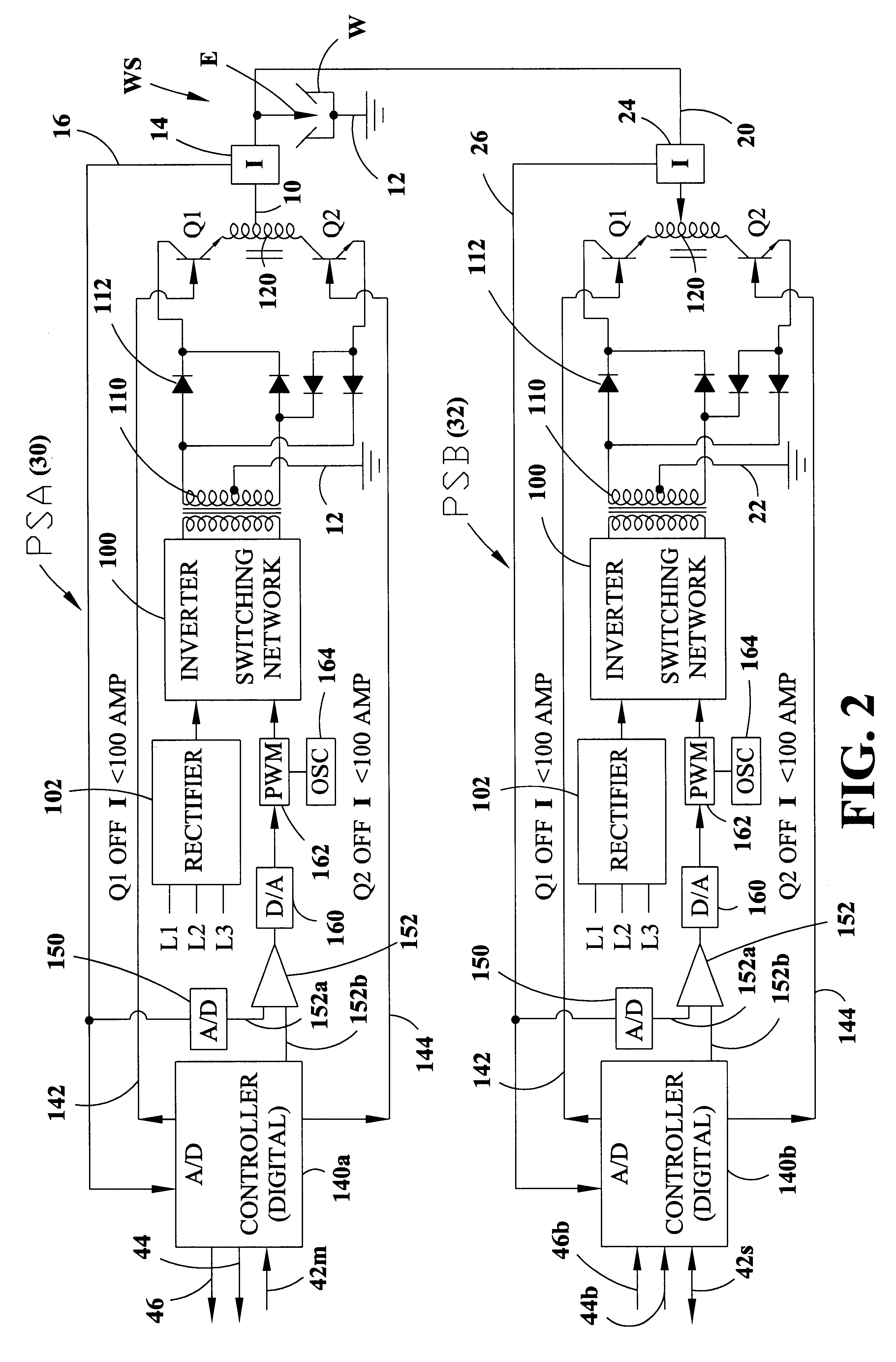

InactiveUS6472634B1Prevent and reduce electrode interferenceLarge capacityElectric discharge heatingArc welding apparatusPower flowDigital interface

An electric arc welding system for creating an AC welding arc between an electrode and a workpiece wherein the system comprises a first controller for a first power supply to cause the first power supply to create an AC current between the electrode and workpiece by generating a switch signal or command with polarity reversing switching points in the first controller, with the first controller operated at first welding parameters in response to first power supply specific parameter signals to the first controller. The system has at least one slave controller for operating a slave power supply to create an AC current between the electrode and workpiece by reversing polarity of the AC current at switching points where the slave controller is operated at second welding parameters in response to second power supply specific parameter signals to the slave controller. An information network connected to the first controller and the slave controller and containing digital first and second power supply specific parameter signals for the first controller and the slave controller and a digital interface connects the first controller with the slave controller to control the switching points of said second power supply by the switch signal or command from the first controller.

Owner:LINCOLN GLOBAL INC

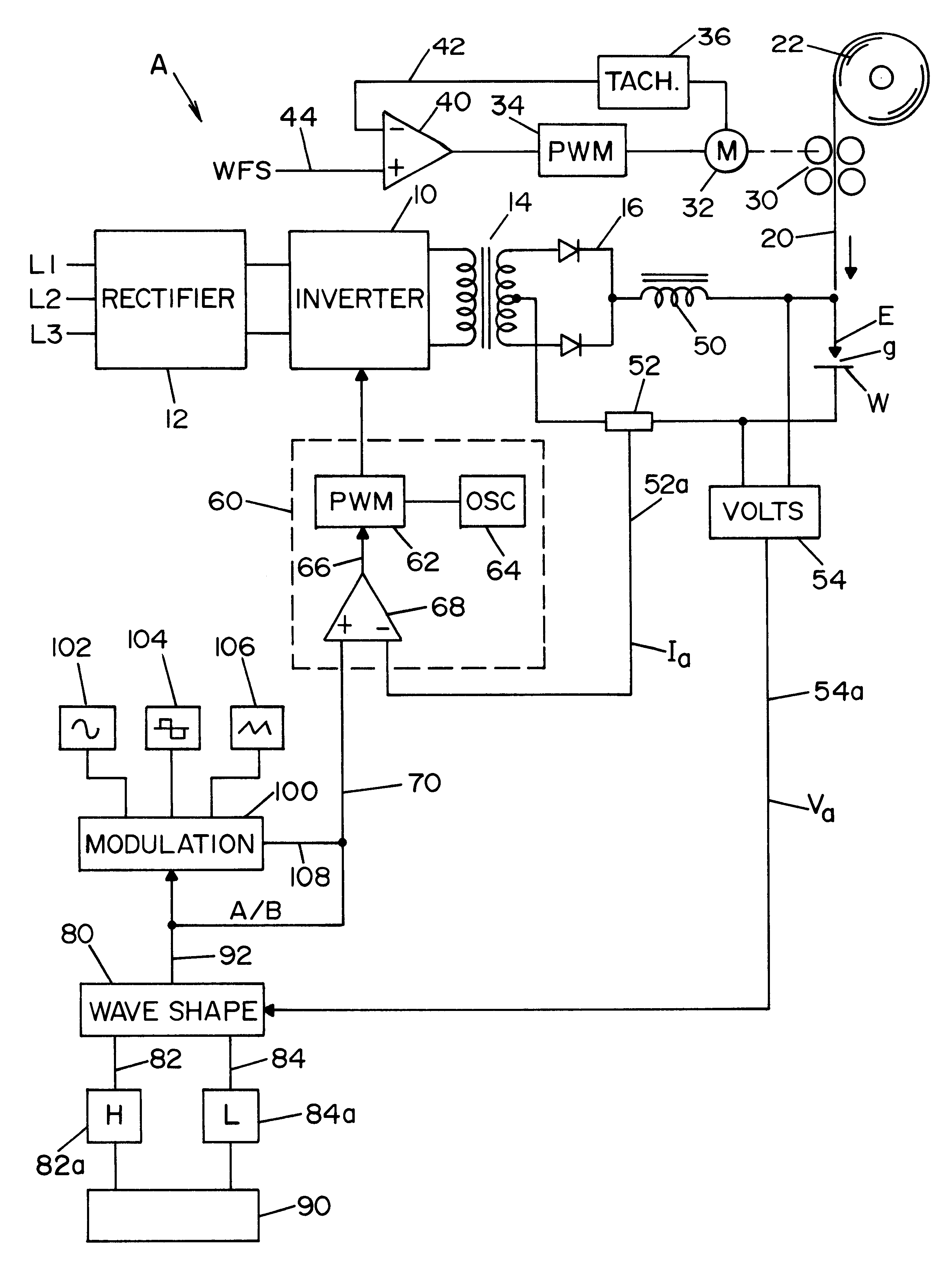

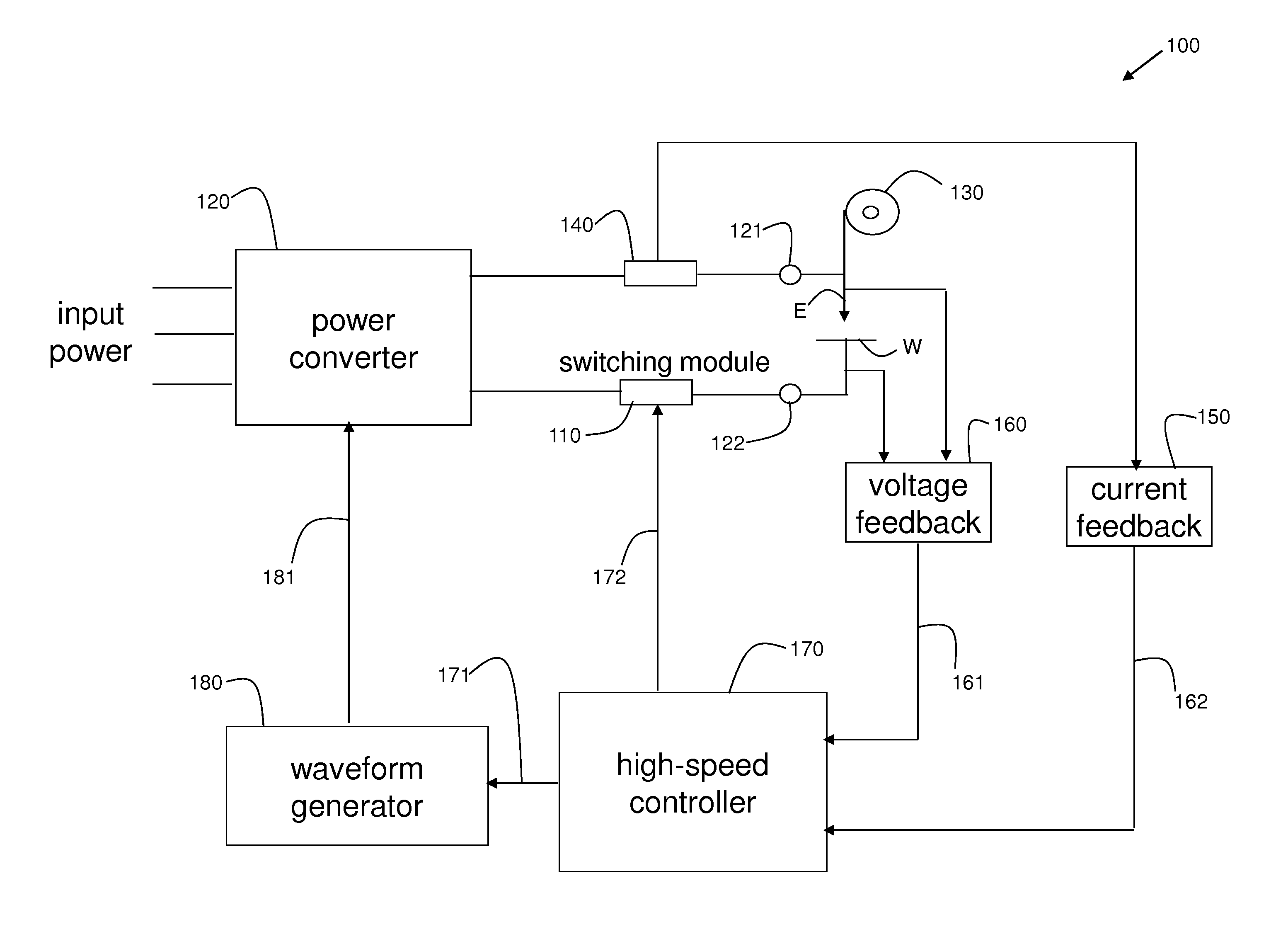

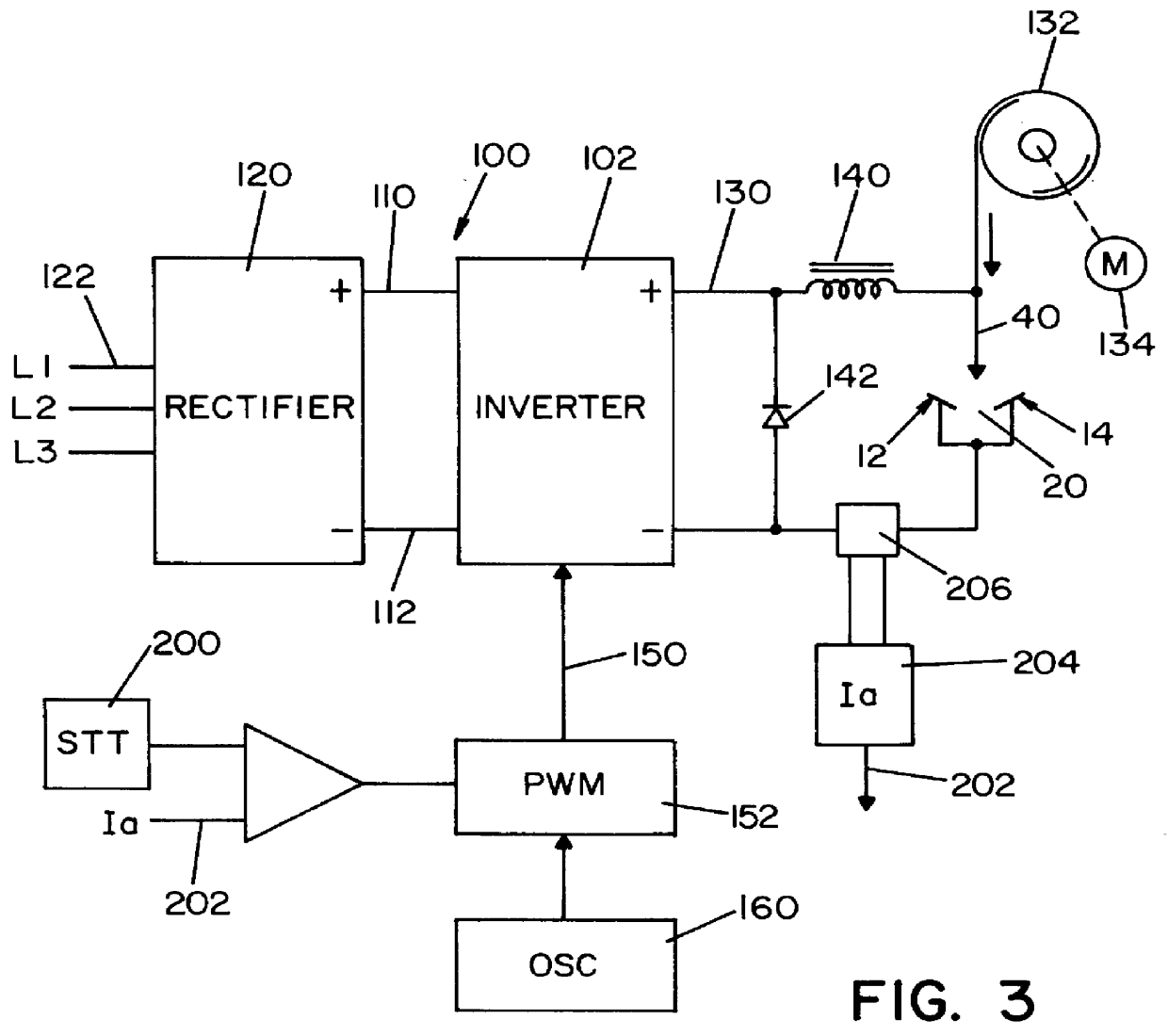

System and method for controlling an electric arc welder

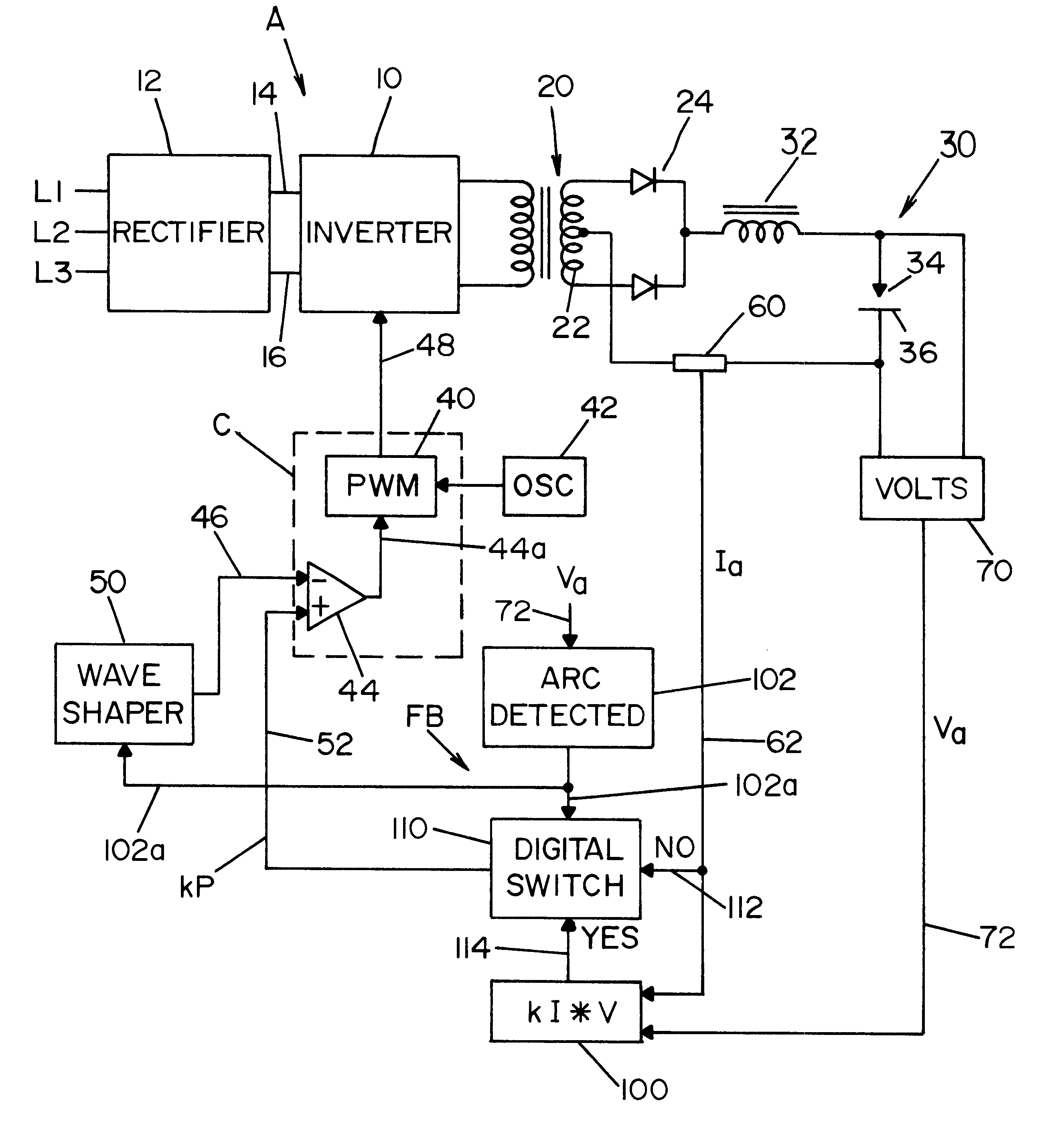

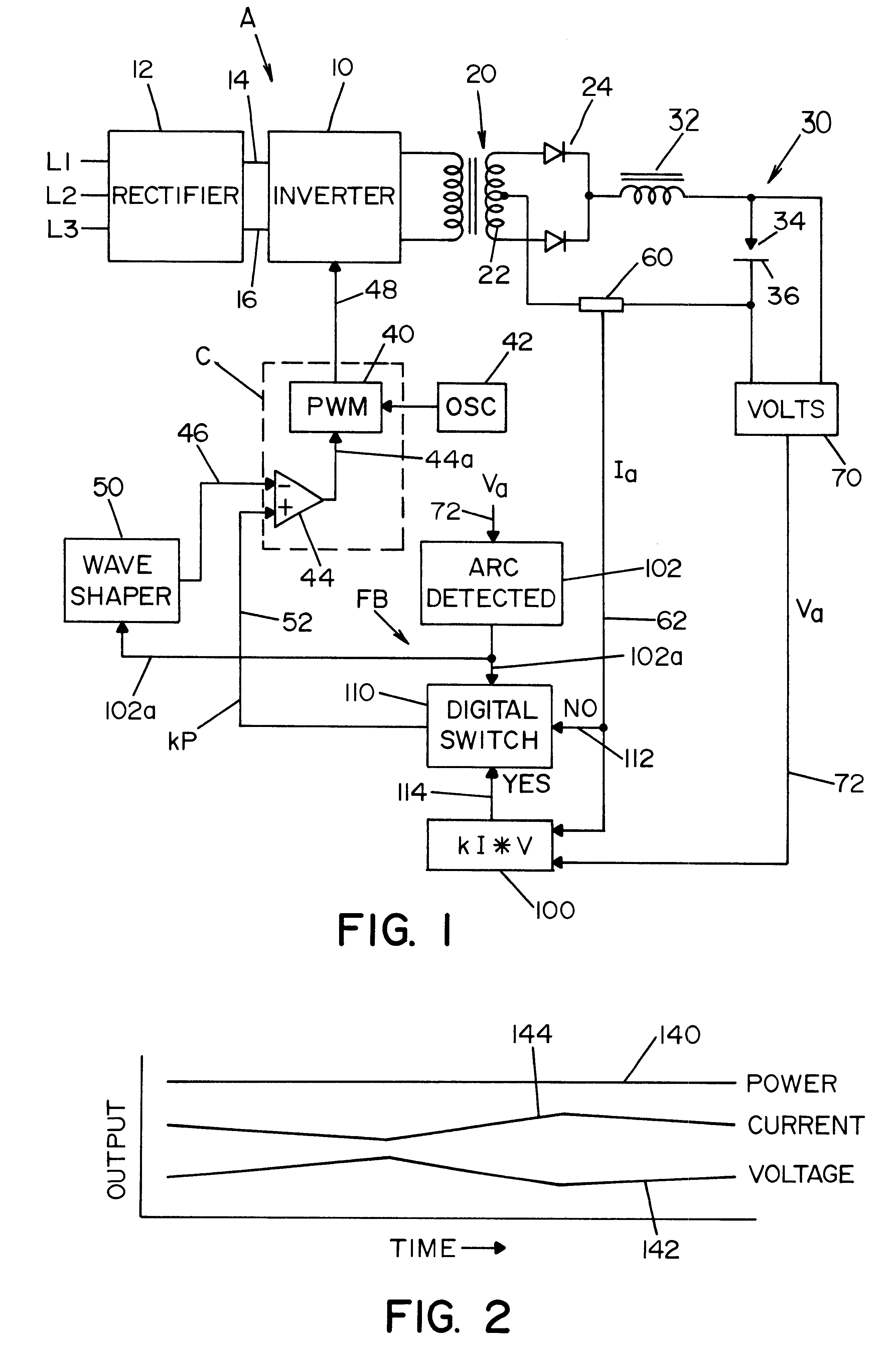

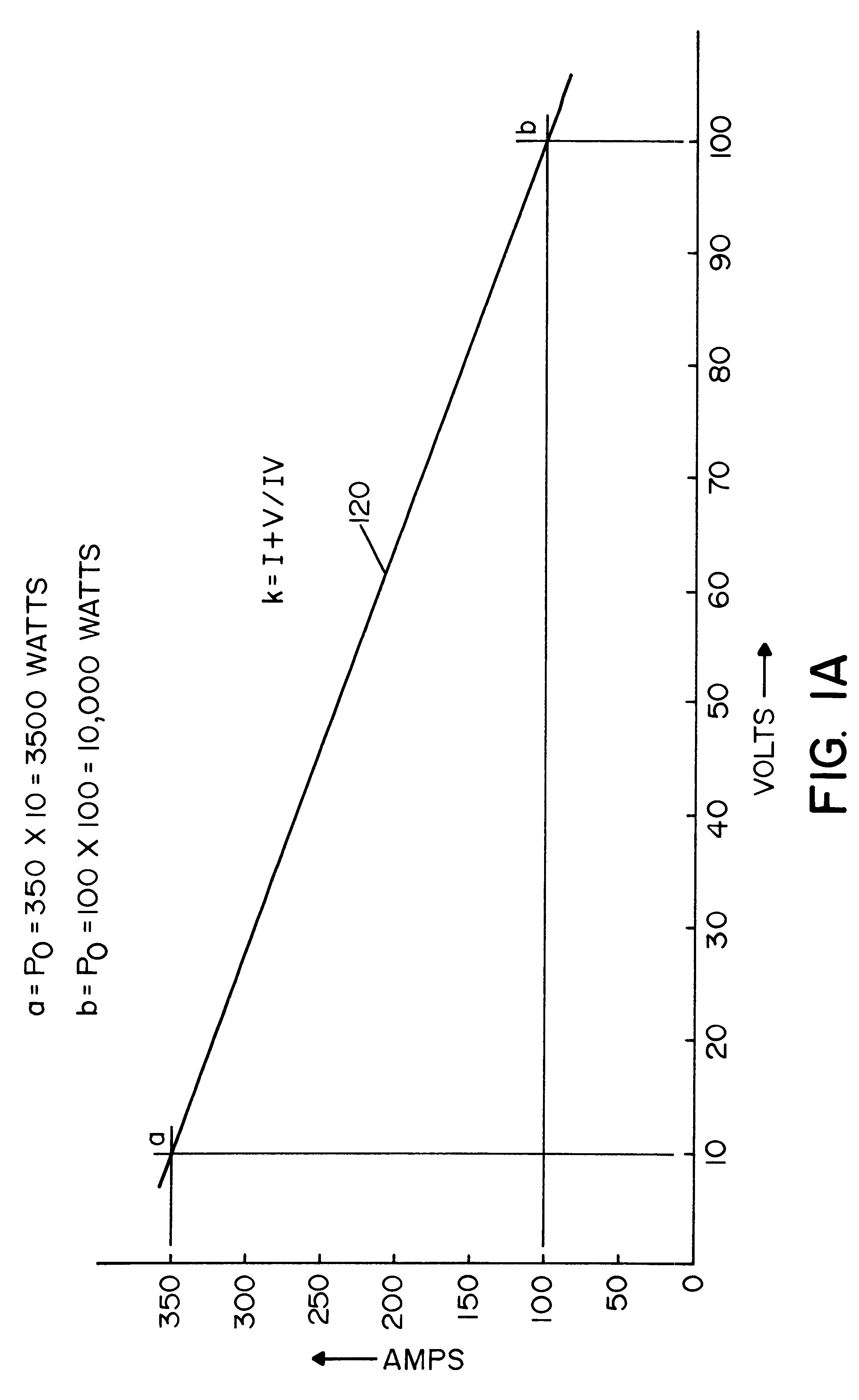

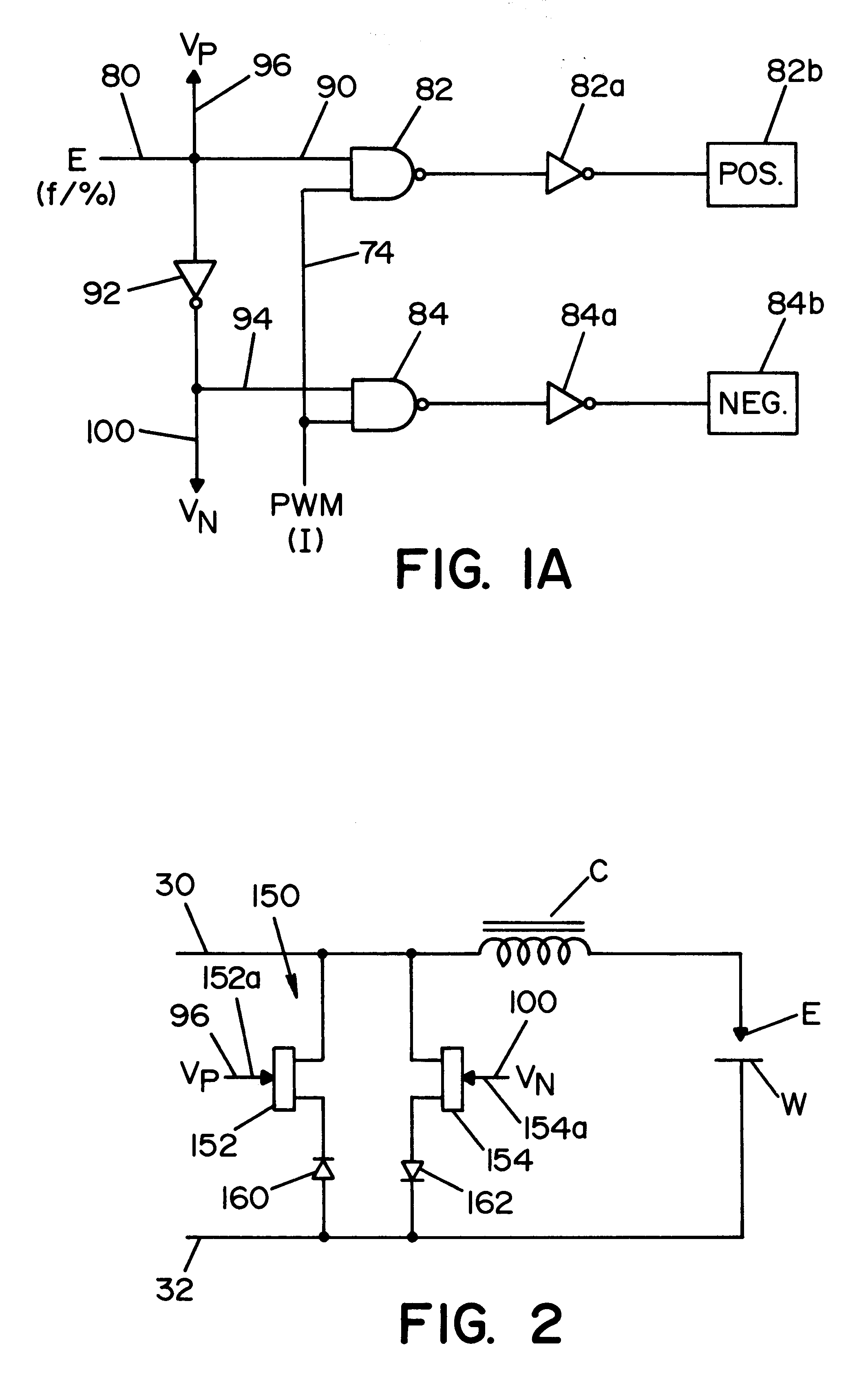

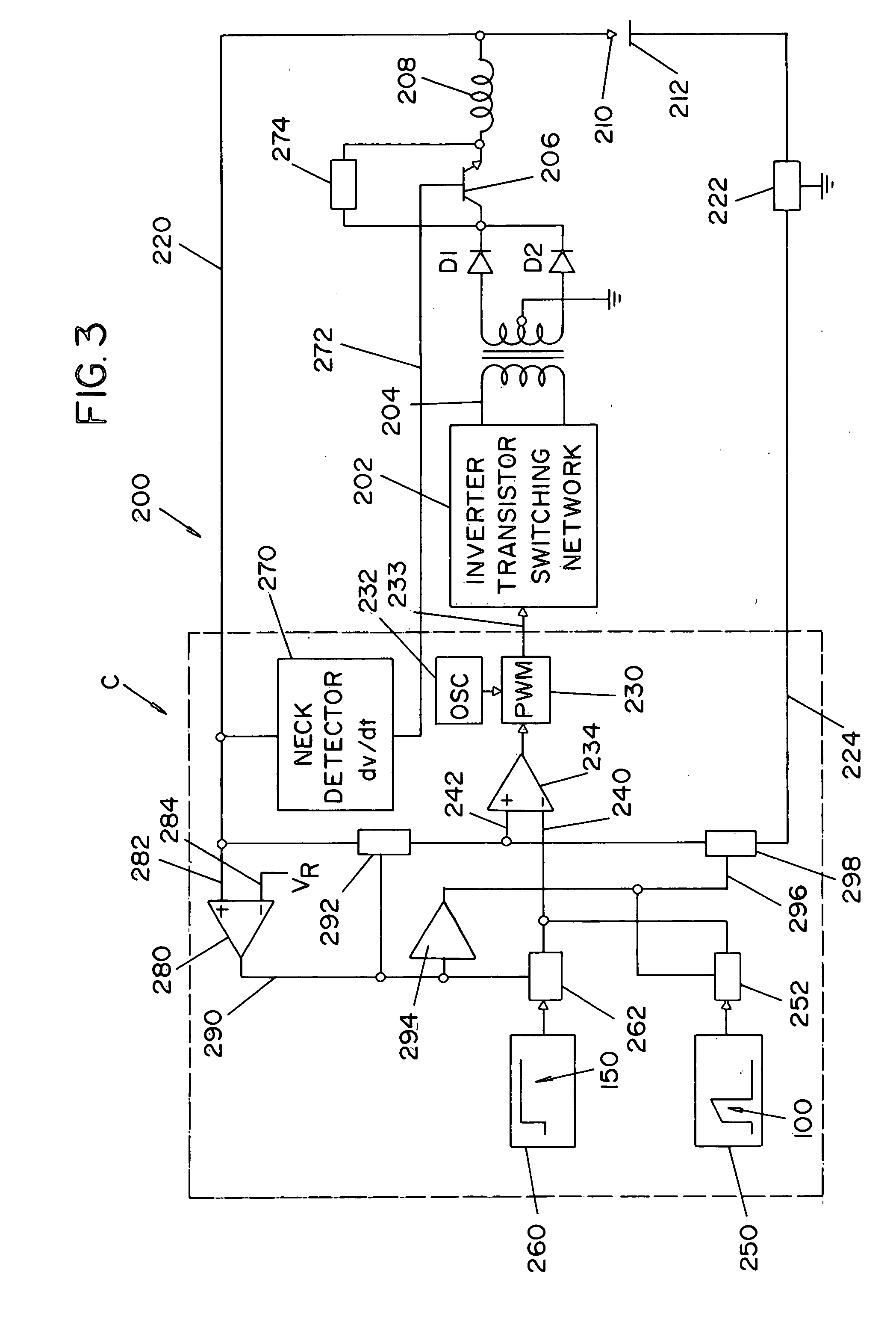

InactiveUS6498321B1Inhibit currentRealize automatic adjustmentArc welding apparatusControl signalControl system

A control system for an electric arc welder performing a welding process between an electrode and a workpiece, which system comprises: a high speed switching type power supply with a controller operated at a switching frequency of at least about 10 kHz with an input current control signal to adjust the output current of the power supply; a first sensor sensing the actual arc voltage; a second sensor sensing the actual arc current; a first circuit for creating a power signal representing the desired real time power level at progressive times during the welding process; a second circuit for creating a function of the sensed actual voltage and the sensed actual current; and a third circuit for adjusting the current control signal in accordance with the difference between the power signal and the function of the actual voltage and current, preferably arc power.

Owner:LINCOLN GLOBAL INC

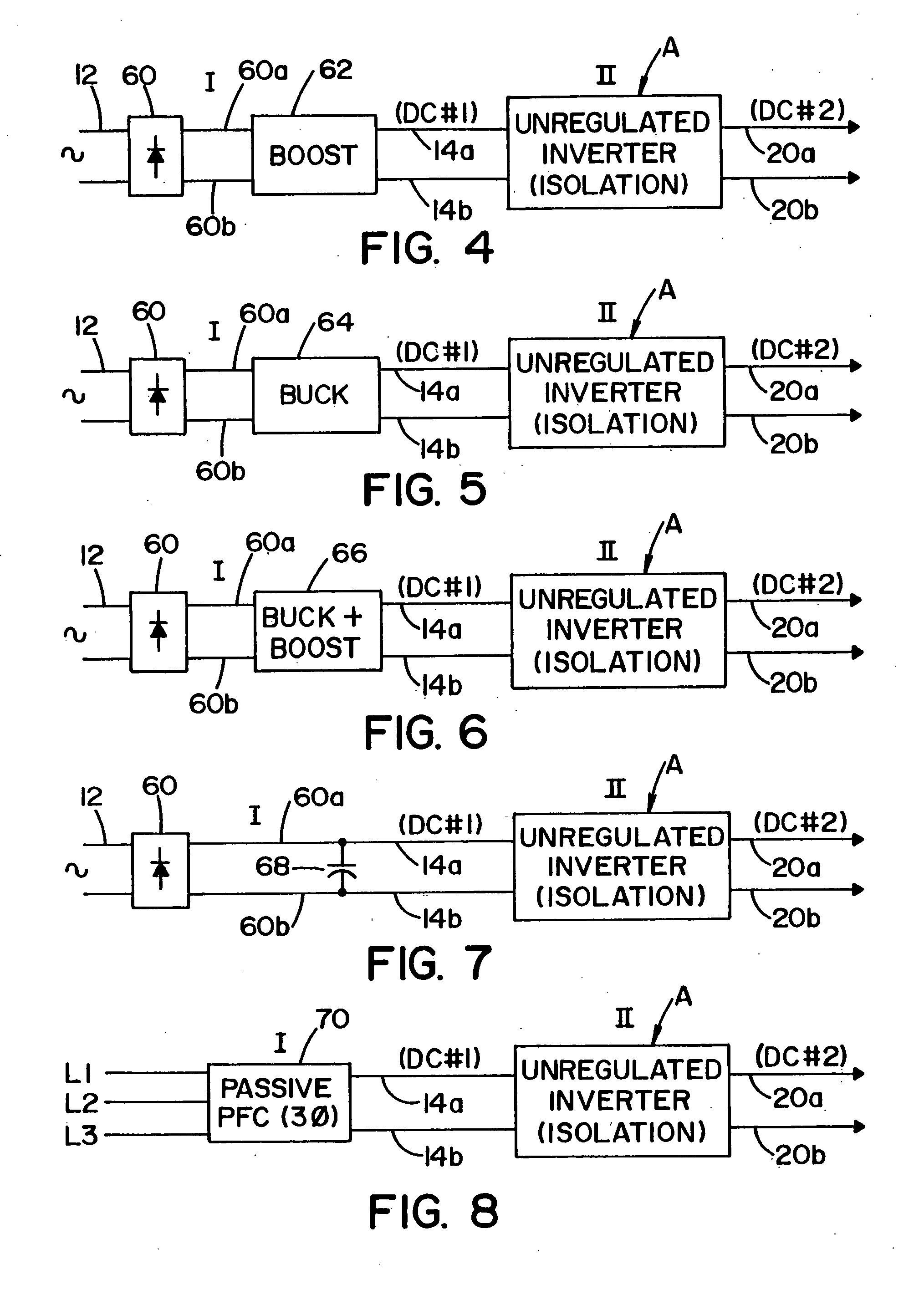

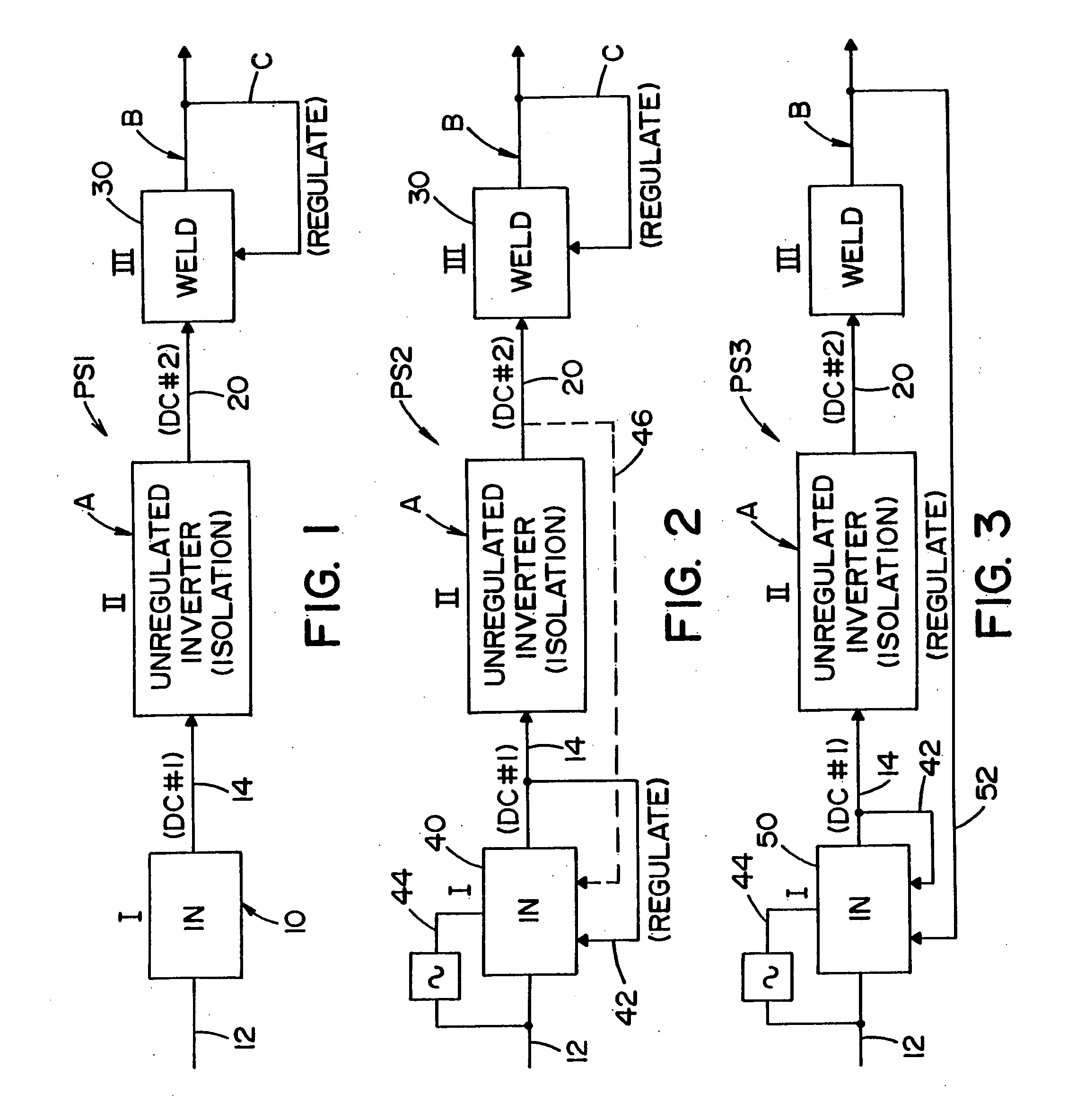

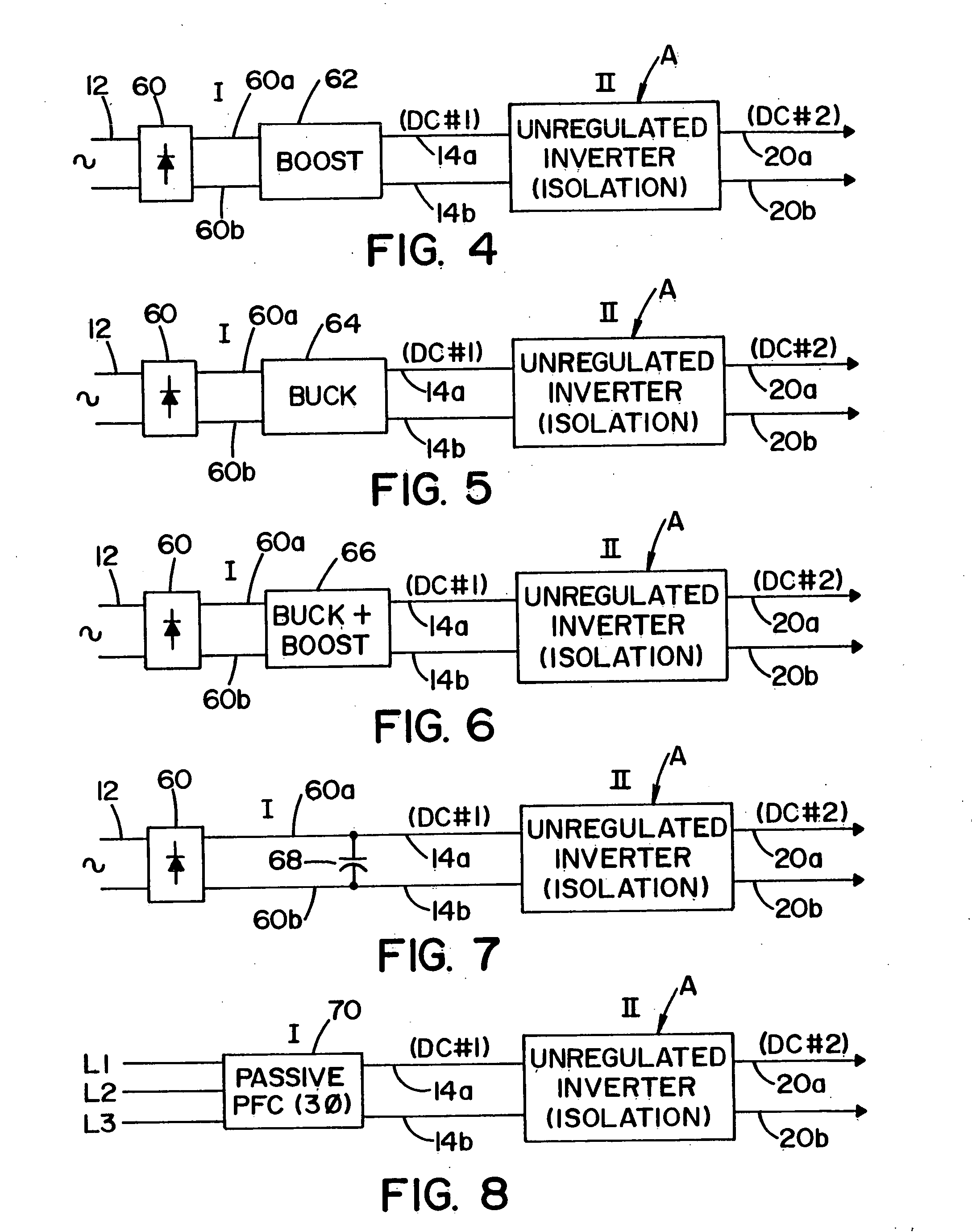

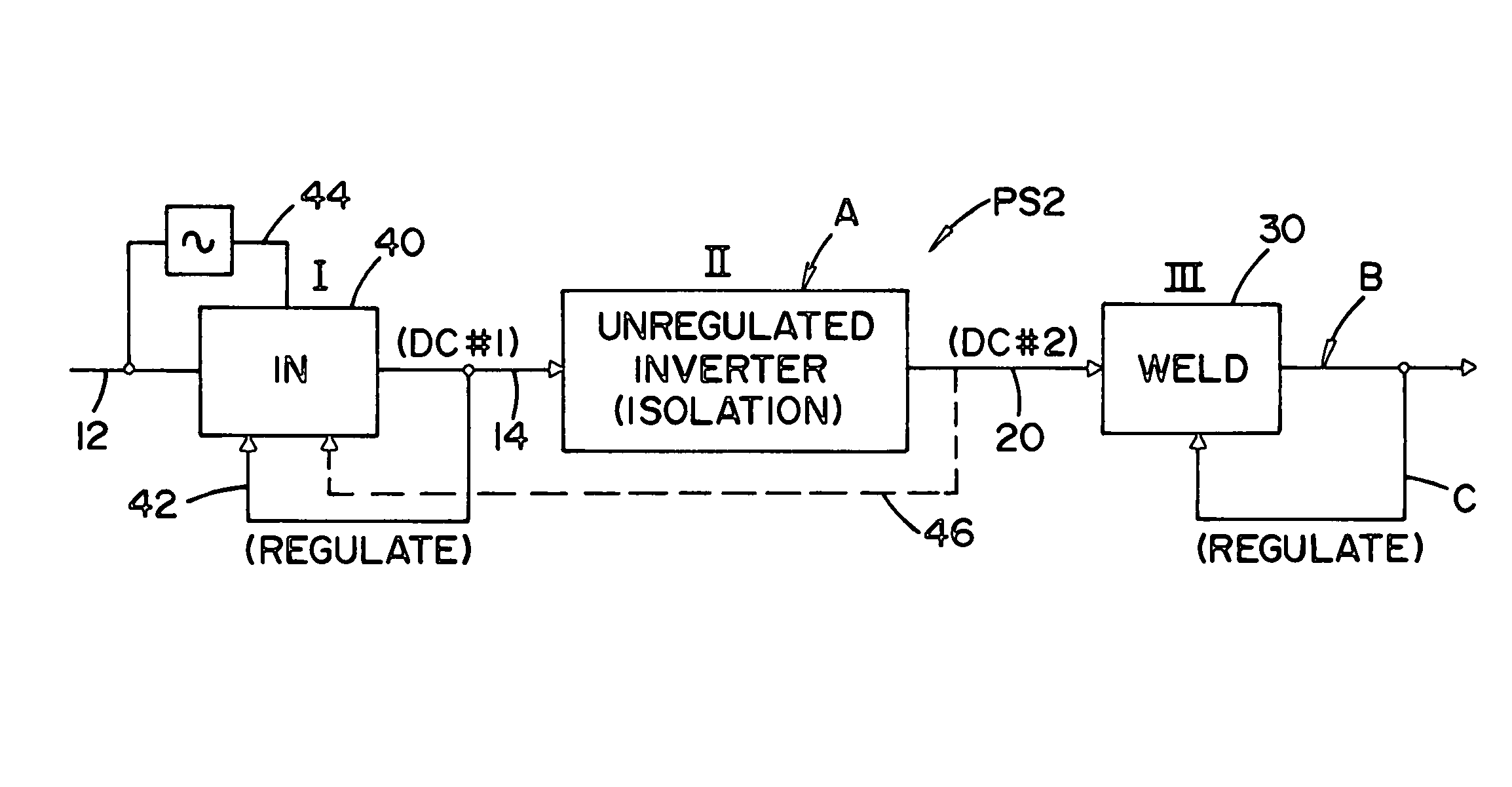

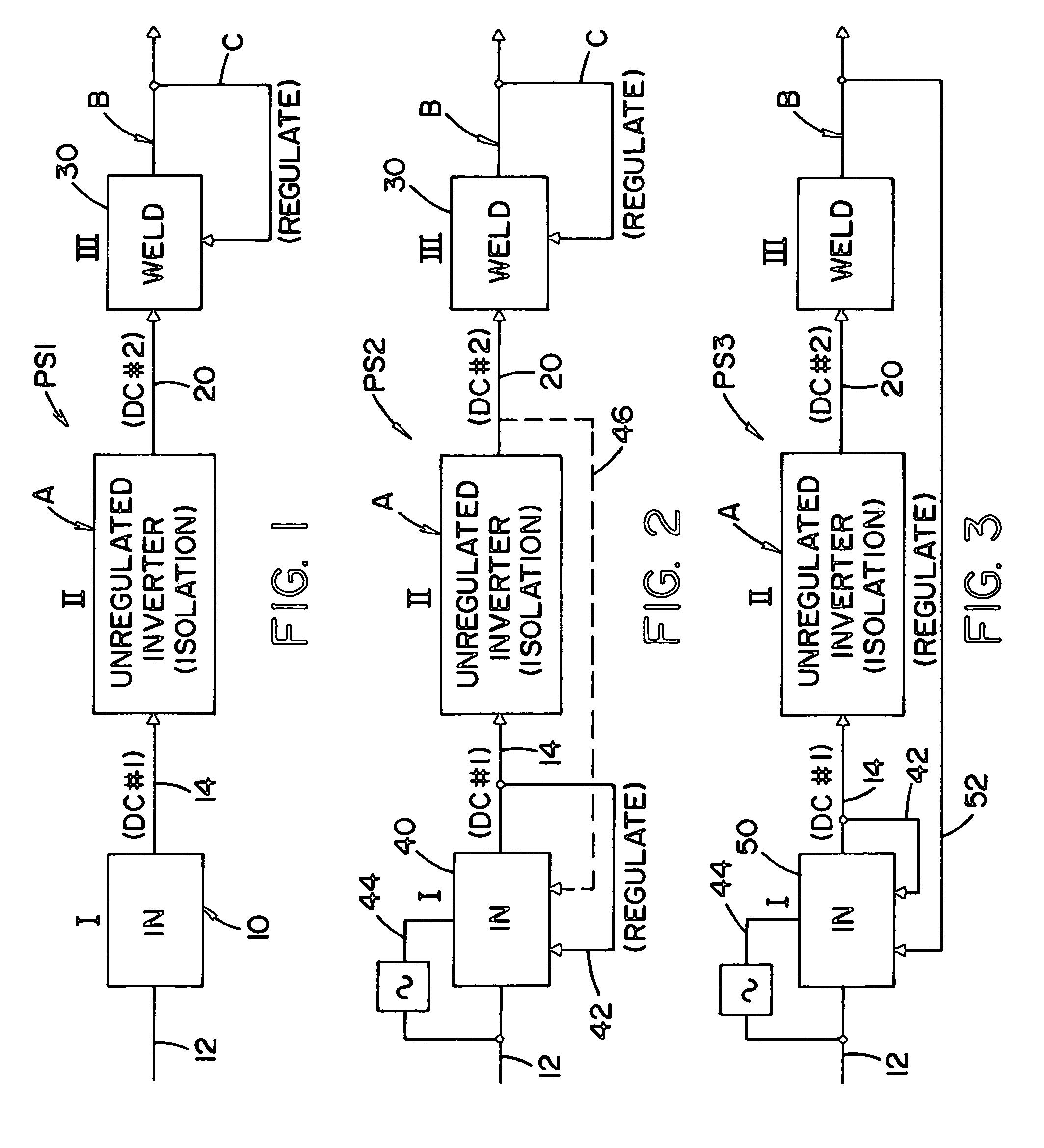

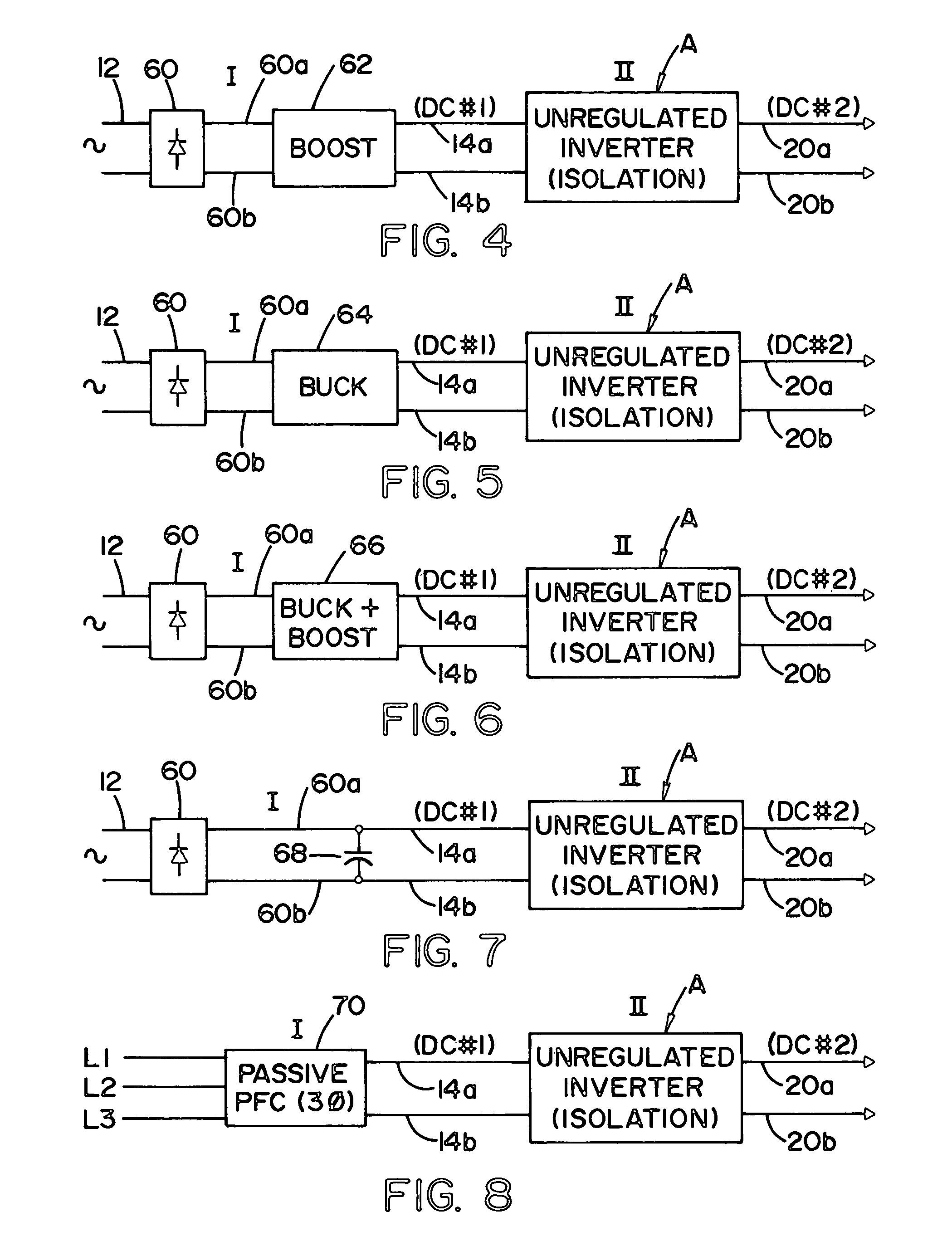

Three stage power source for electric ARC welding

ActiveUS20060213890A1Fast switching speedImprove portabilityEfficient power electronics conversionAc-dc conversionSoft switchingEngineering

A three stage power source for an electric arc welding process comprising an input stage having an AC input and a first DC output signal; a second stage in the form of an unregulated DC to DC converter having an input connected to the first DC output signal, a network of switches switched at a high frequency with a given duty cycle to convert the input into a first internal AC signal, an isolation transformer with a primary winding driven by the first internal high frequency AC signal and a secondary winding for creating a second internal high frequency AC signal and a rectifier to convert the second internal AC signal into a second DC output signal of the second stage, with a magnitude related to the duty cycle of the switches; and, a third stage to convert the second DC output signal to a welding output for welding wherein the input stage has a regulated DC to DC converter with a boost power switch having an active soft switching circuit.

Owner:LINCOLN GLOBAL INC

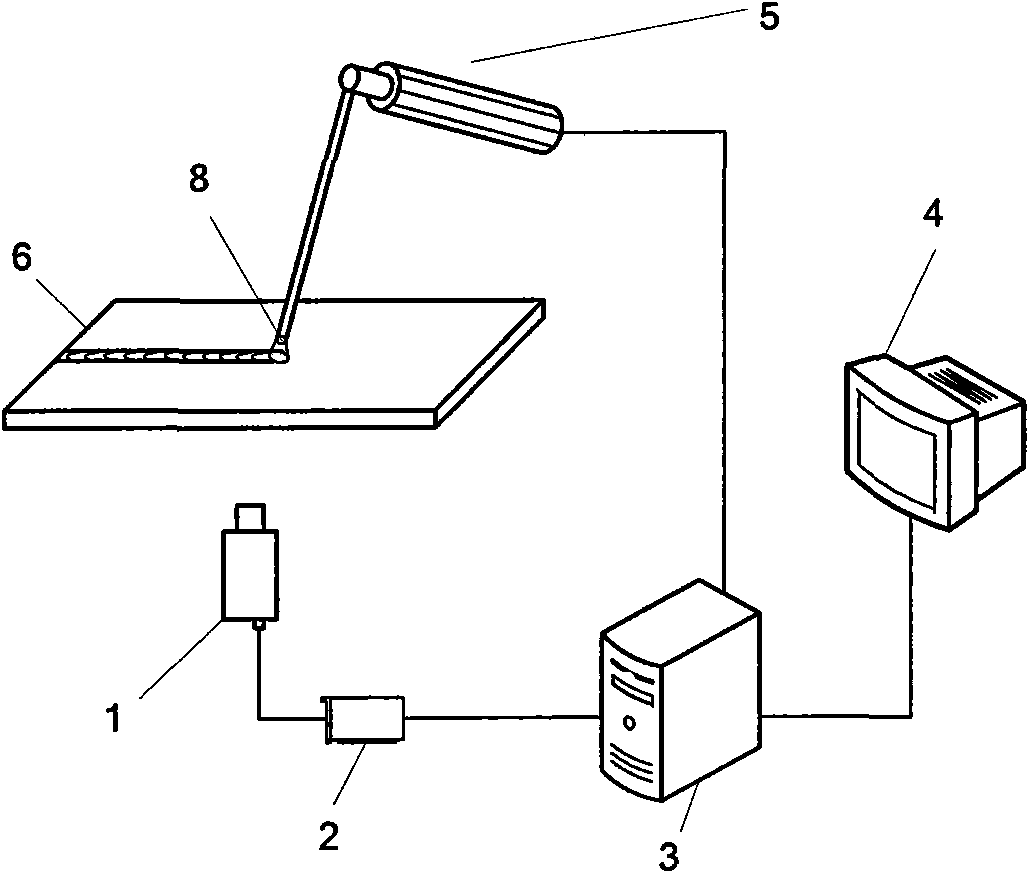

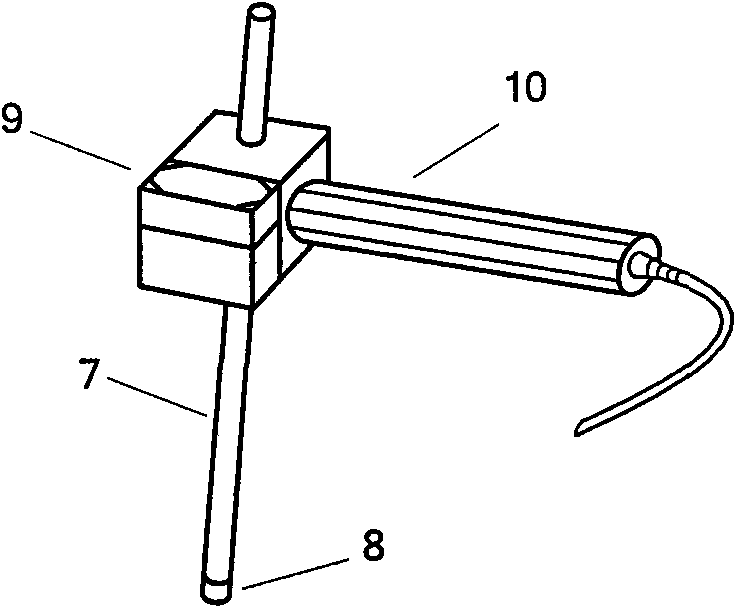

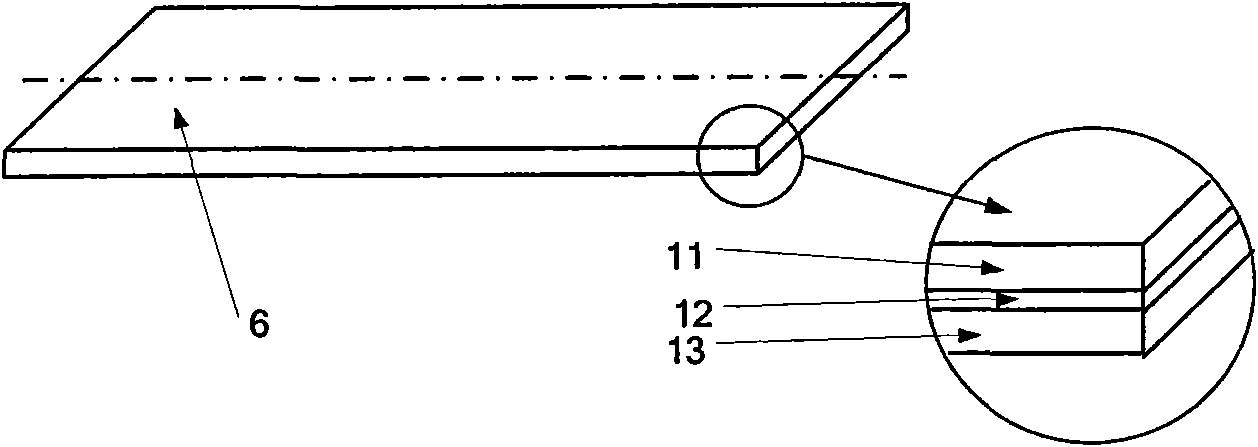

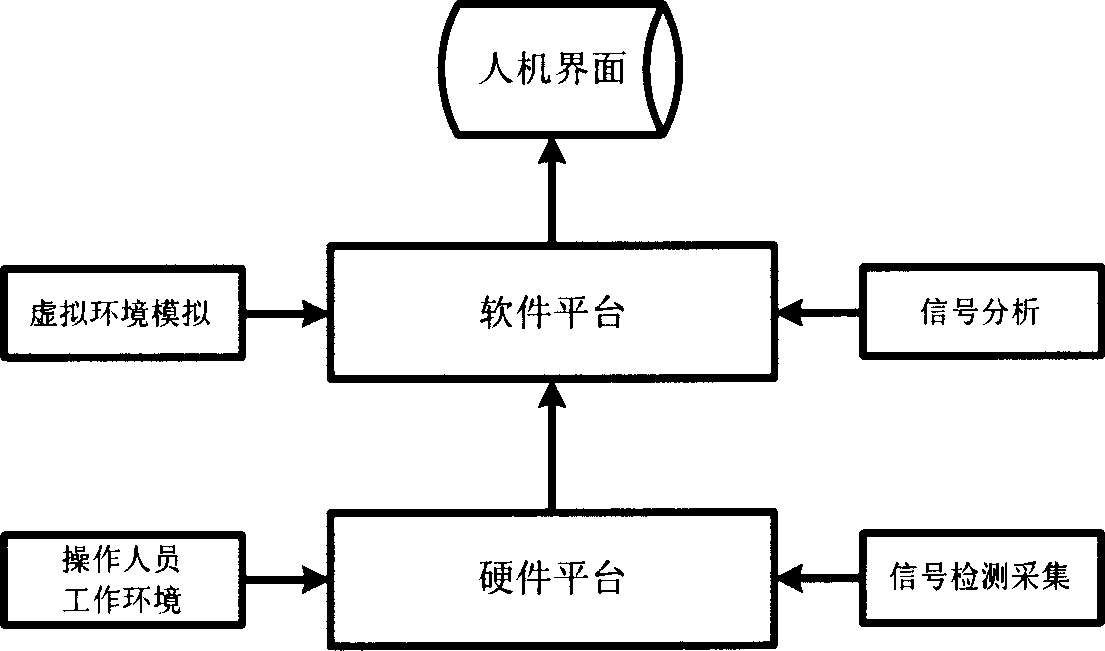

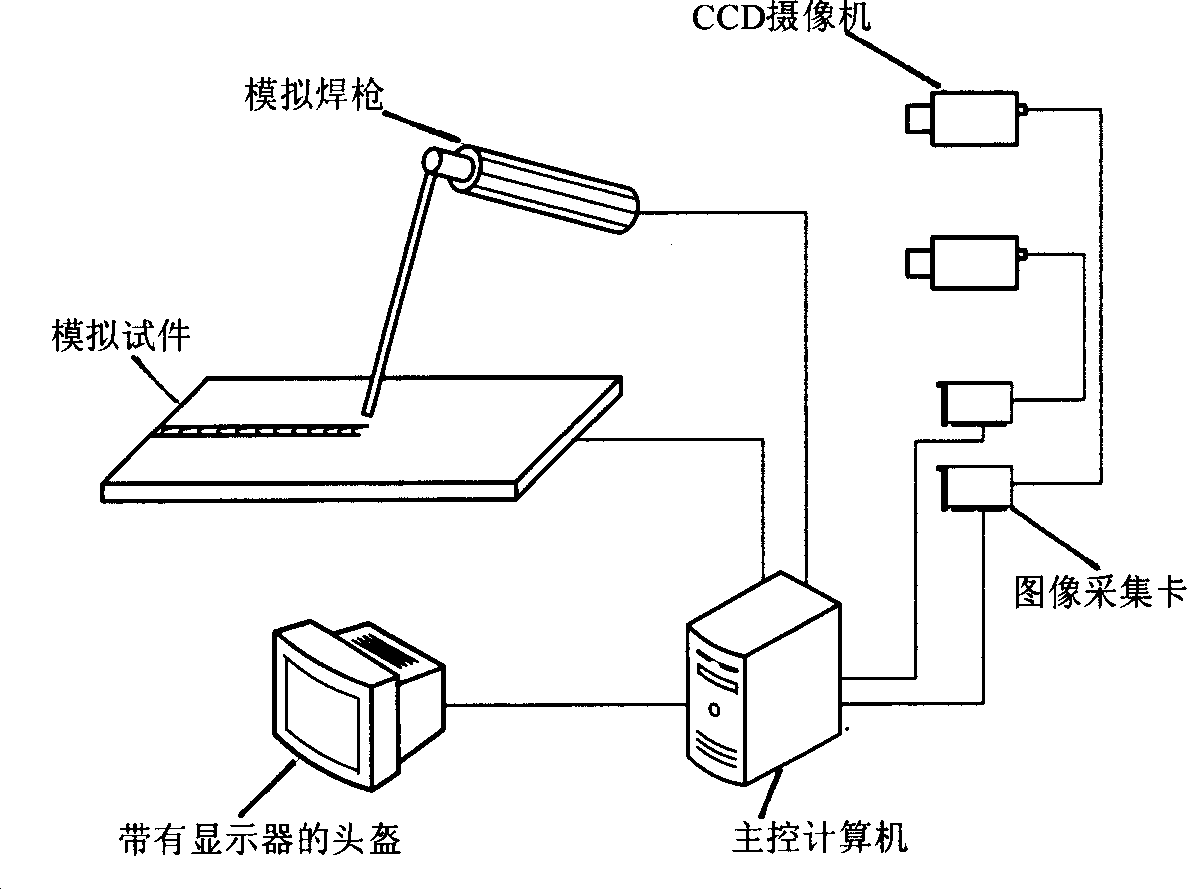

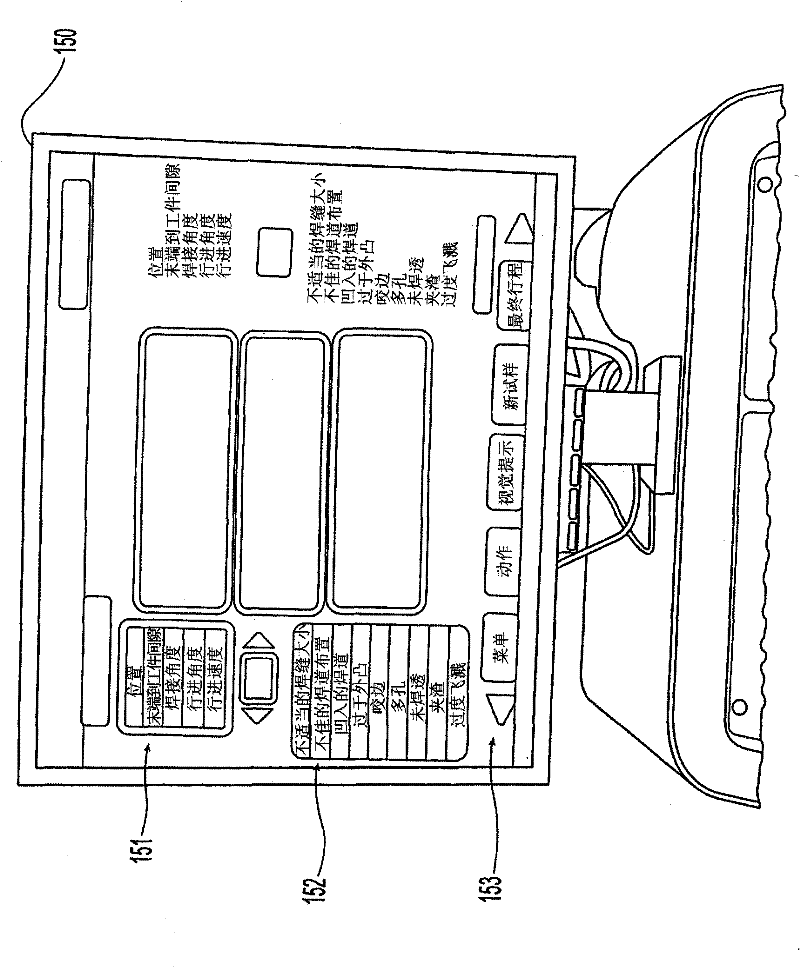

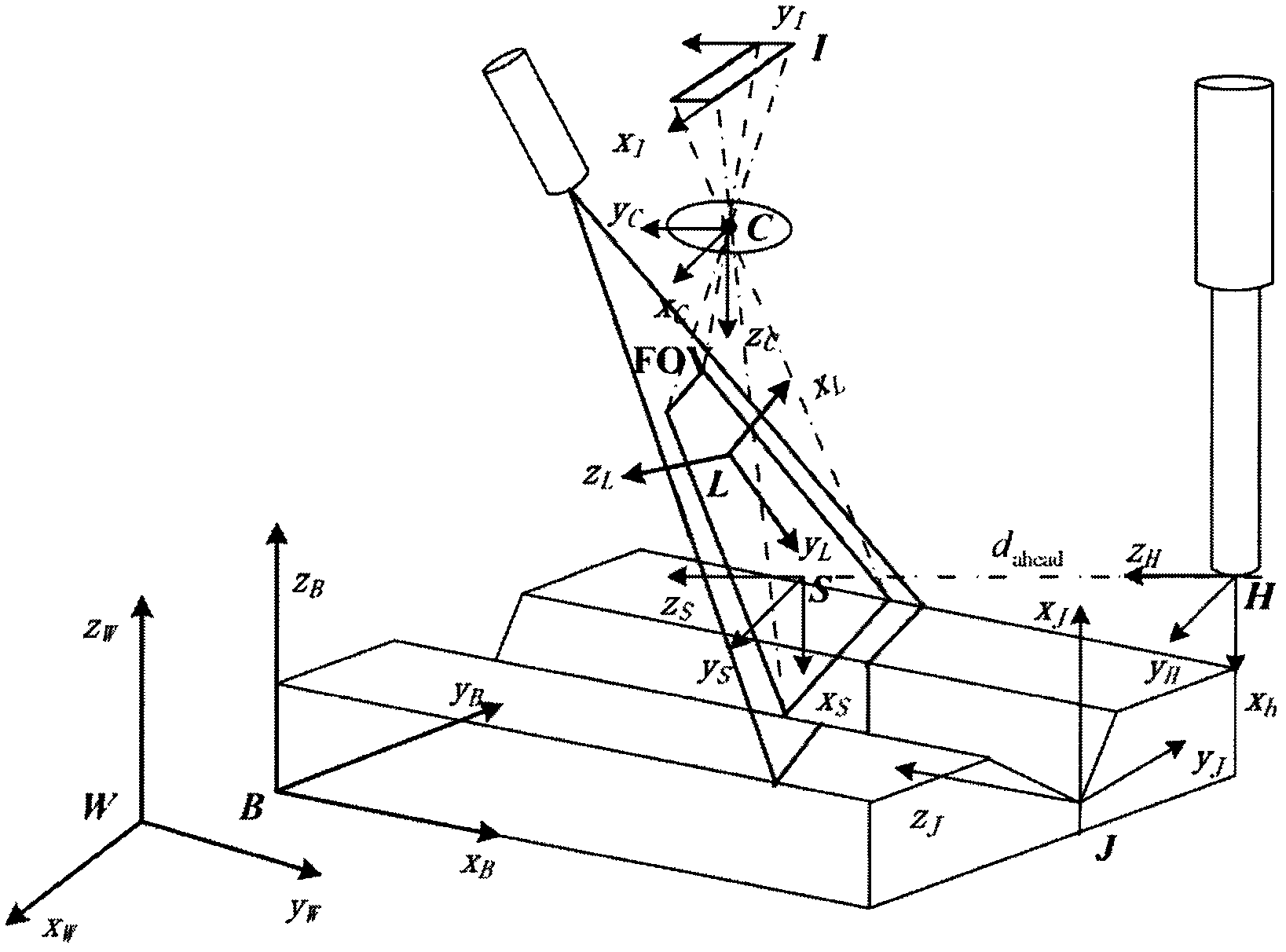

Simulation training device for manual arc welding rod-moving operation, and arc welding rod-moving detection method

InactiveCN101587659ARealize high-precision detectionImprove learning efficiencyUsing optical meansTeaching apparatusShielded metal arc weldingImage detection

The invention provides a simulation training device for manual arc welding rod-moving operation, and an arc welding rod-moving detection method, which is used for the introduction, improvement and enhancement training of welders in welding rod-moving operation. The device comprises a simulated welding torch, a simulated test plate, an image detection module, a dip-angle sensor, a master control computer and an evaluation system. Through the reasonable choice and layout of sensors and efficient data processing, high-precision detection and evaluation of real-time positions of simulated welding rods operated by the welders are realized. The device can record the arc striking, rod moving, ending and a series of operation of welding students during operation, and allows operation tracks to reappear after the operation is completed so as to improve learning efficiency and learning effects.

Owner:XI AN JIAOTONG UNIV

A welding repair method for anti-sulfur wellhead valve body

ActiveCN107520526BMeet the requirements of low temperature impact absorption energy greater than 27JAvoid softeningArc welding apparatusWelding/cutting media/materialsMachined surfaceMixed gas

The invention belongs to the welding industry, and particularly relates to an anti-sulfur well mouth valve body welding repair method, and in particular to a welding repair method of 4130 medium-carbon alloy steel in an anti-sulfur valve body with the hardness being 197 HBW -237 HBW. The anti-sulfur well mouth valve body welding repair method is characterized by comprising the following steps that a product to be repaired is cleaned to determine a damage position; a pit badly eroded needs to be polished; a workpiece is totally preheated to 130 DEG C before welding; filling of the pit is firstly achieved by adopting the argon tungsten-arc welding; then, the machined surface is subject to repair welding; the local or total heat treatment insulation is performed for 3 hours at 640 DEG C; in the welding repair method, preheating is performed to reach 130 DEG C before welding; the local or total heat treatment insulation is performed for 3 hours at 640 DEG C after welding; and the Ar+CO2 mixed gas arc welding is adopted in the method, and the method greatly increases the product utilization rate and improves the comprehensive efficiency.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

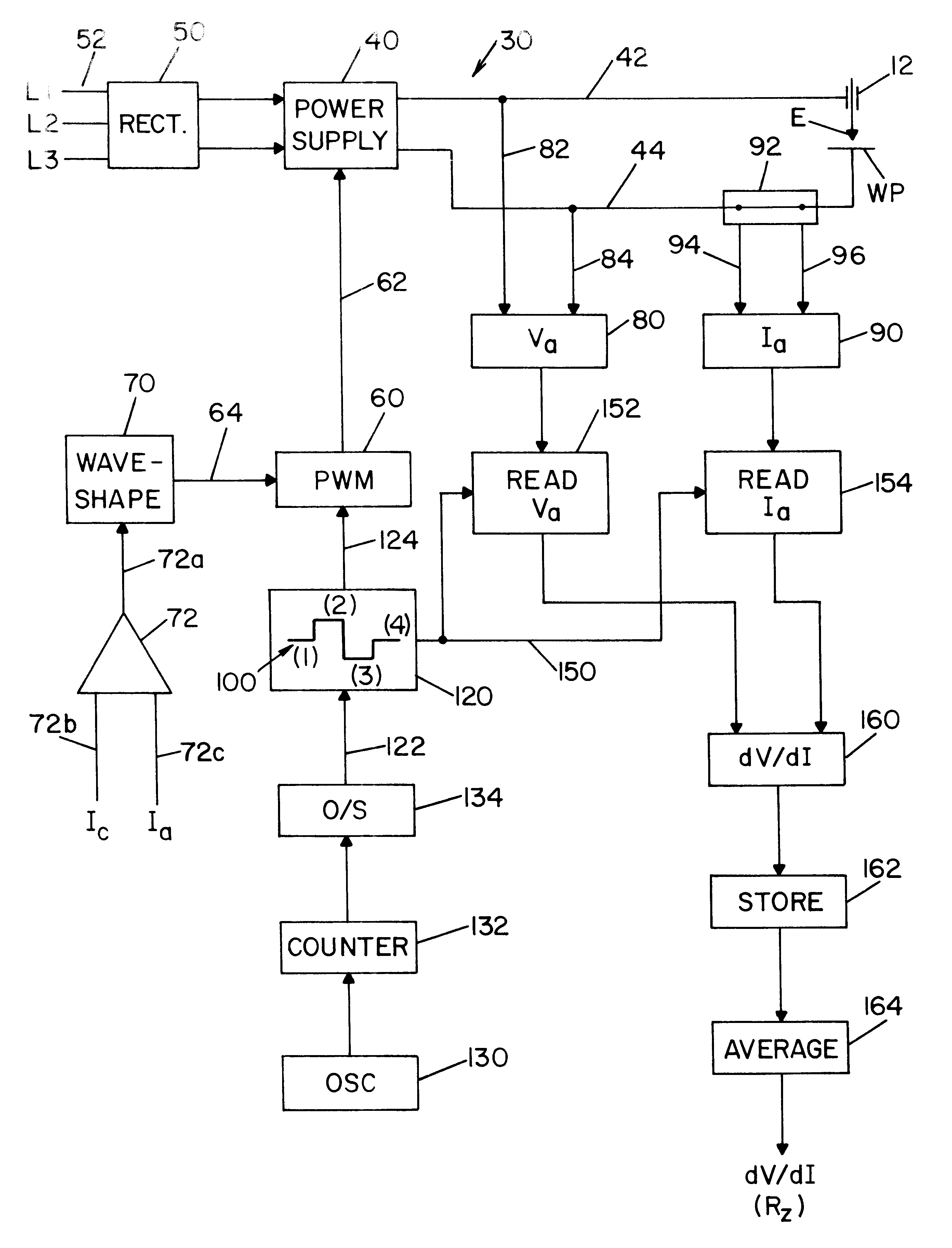

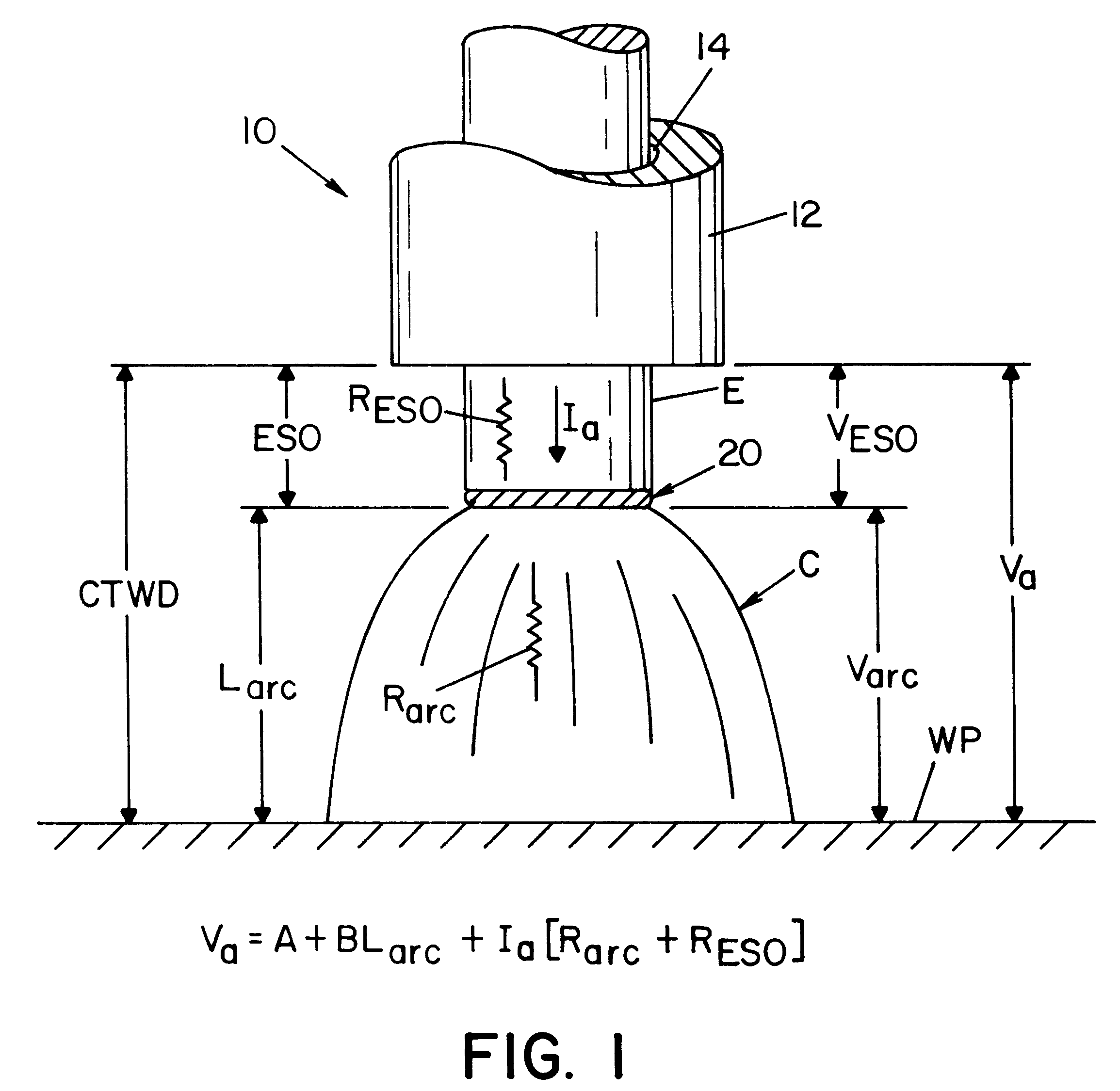

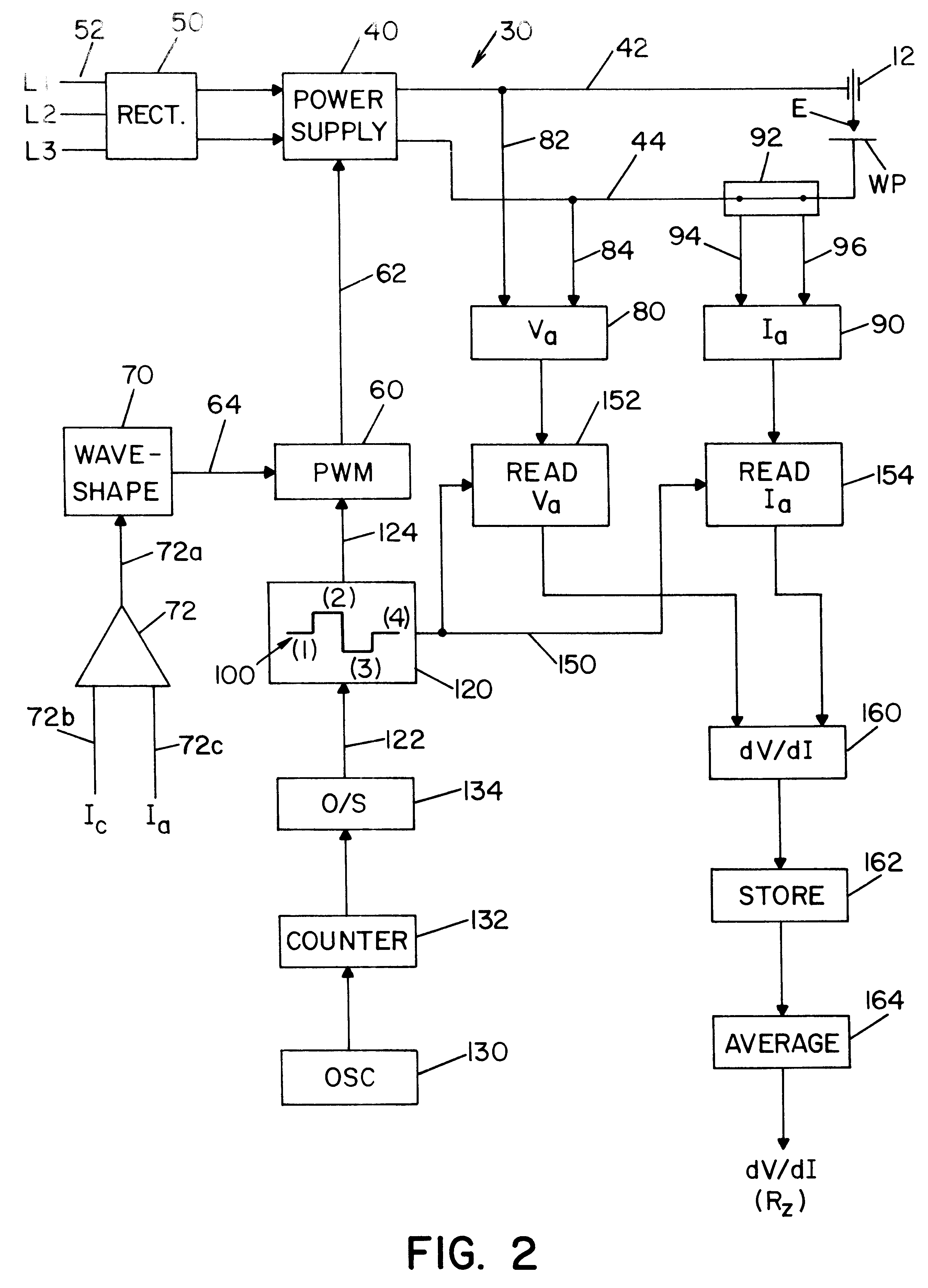

Method of controlling arc welding processes and welder using same

A method of generating a real time control signal for use in an electric arc welding process having welding voltage and welding current, said method comprising: measuring the welding voltage and welding current at a first time, momentarily changing either the welding voltage or welding current by less than about 10%, then measuring the welding voltage and the welding current after the change at a second time, determining the welding voltage difference between the first time and the second time, determining the welding current difference between the first time and the second time, producing a derivative value representing the desired control signal by dividing the welding voltage difference between the first and second times by the welding current difference between the first and second times and generating the control signal by the derivative value.

Owner:LINCOLN GLOBAL INC

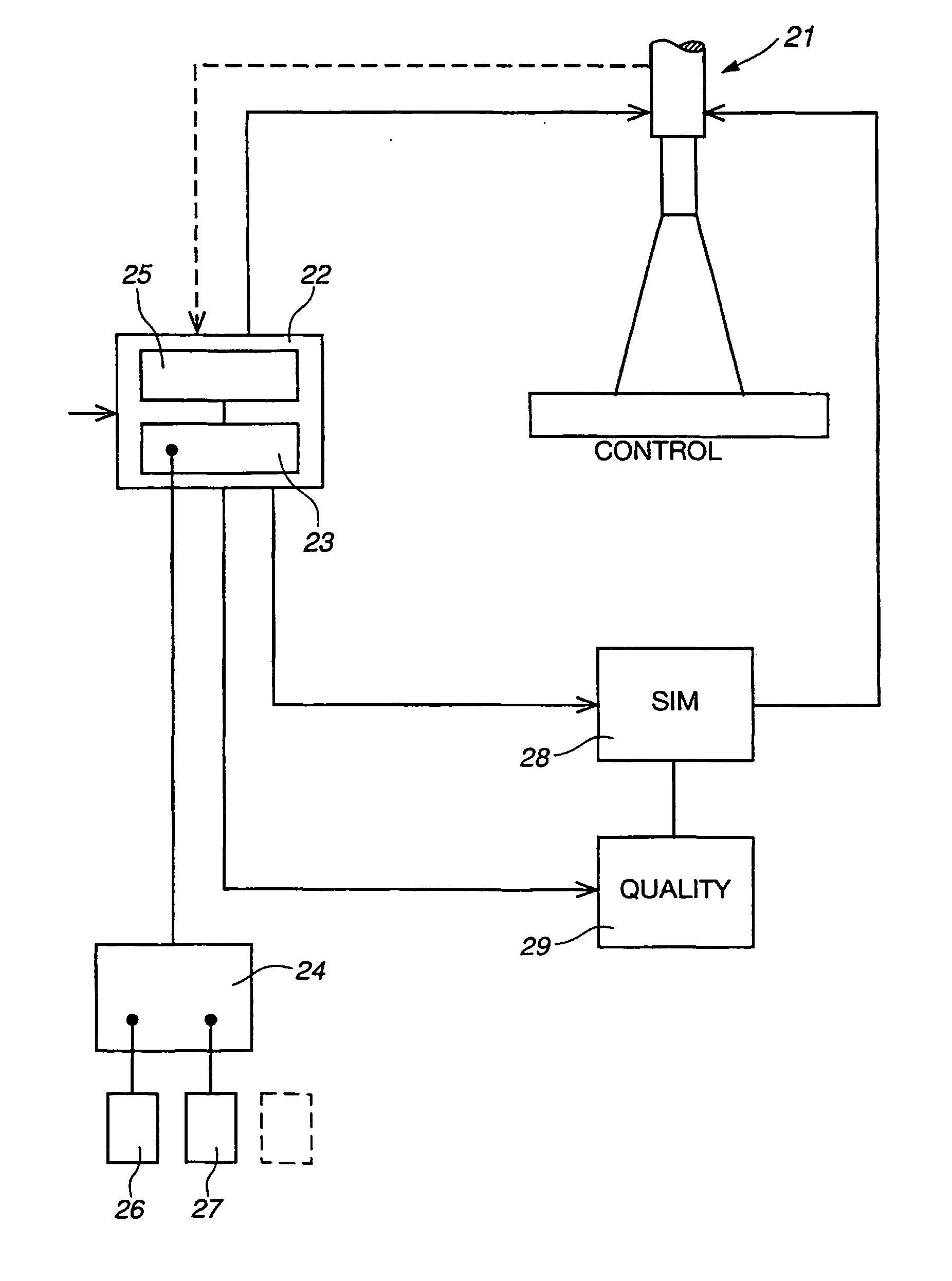

Arc welding method

InactiveUS20050199602A1Quick fixShort calculation timeArc welding apparatusControl engineeringWelding process

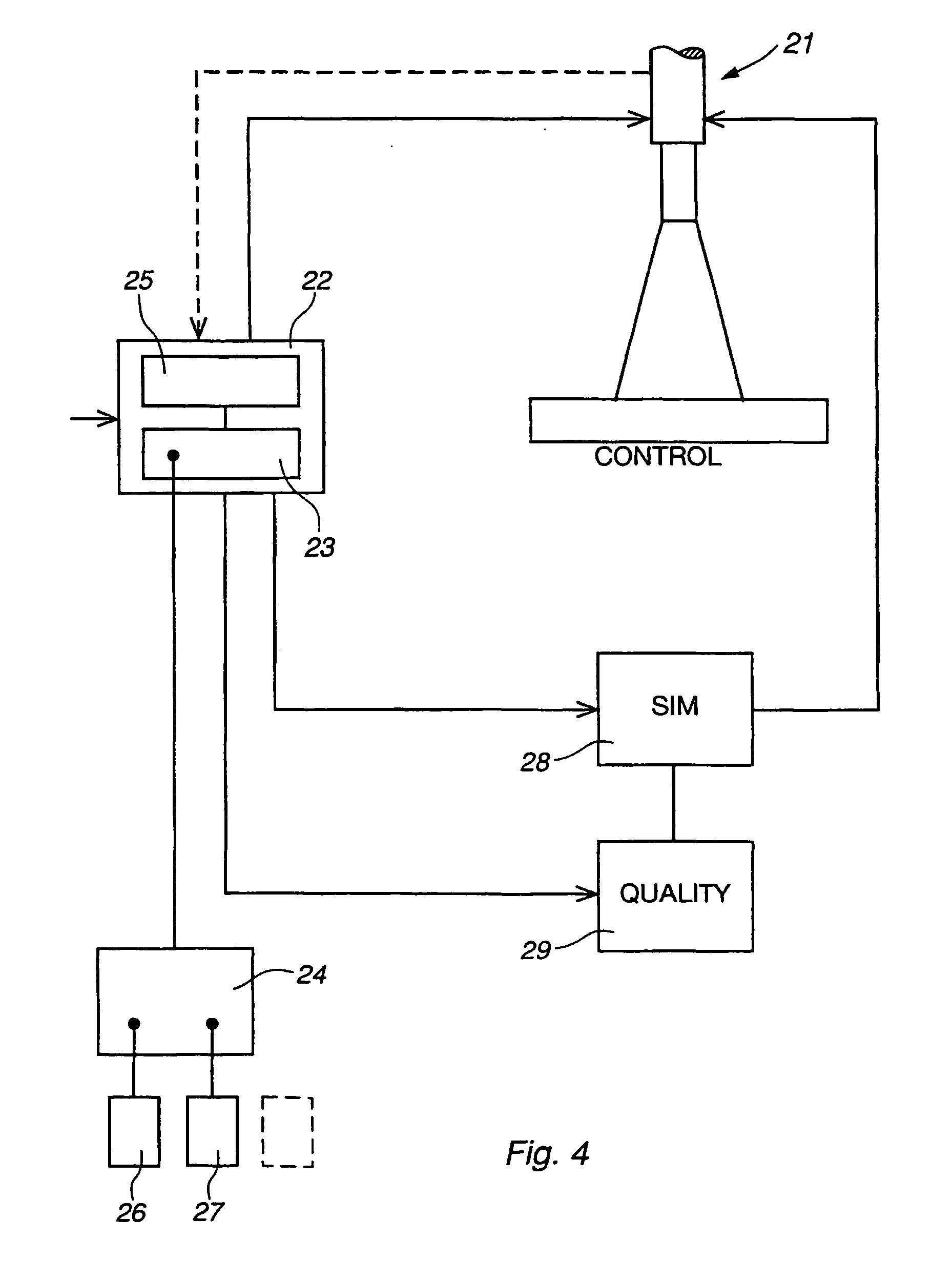

A method for controlling an arc welding equipment (21) used in a welding operation and adjustable by varying at least one welding parameter value, comprising the steps of determining said at least one welding parameter while using a theoretical model (24) of the welding process associated with the welding operation, and controlling the operation of the welding equipment and the welding process associated therewith by using said at least one welding parameter for adjusting the welding equipment and a device comprising an arc welding equipment (21) used in a welding operation and adjustable by varying at least one welding parameter and an arrangement (22) for controlling the operation of the arc welding equipment, said control arrangement including a means (23) adapted to determine the value of said at least one welding parameter while using a theoretical model (24) of the welding process, and a member (25) adapted to control the operation of the welding equipment and the welding process associated therewith by using said at least one welding parameter value for adjusting the welding equipment.

Owner:ABB (SCHWEIZ) AG

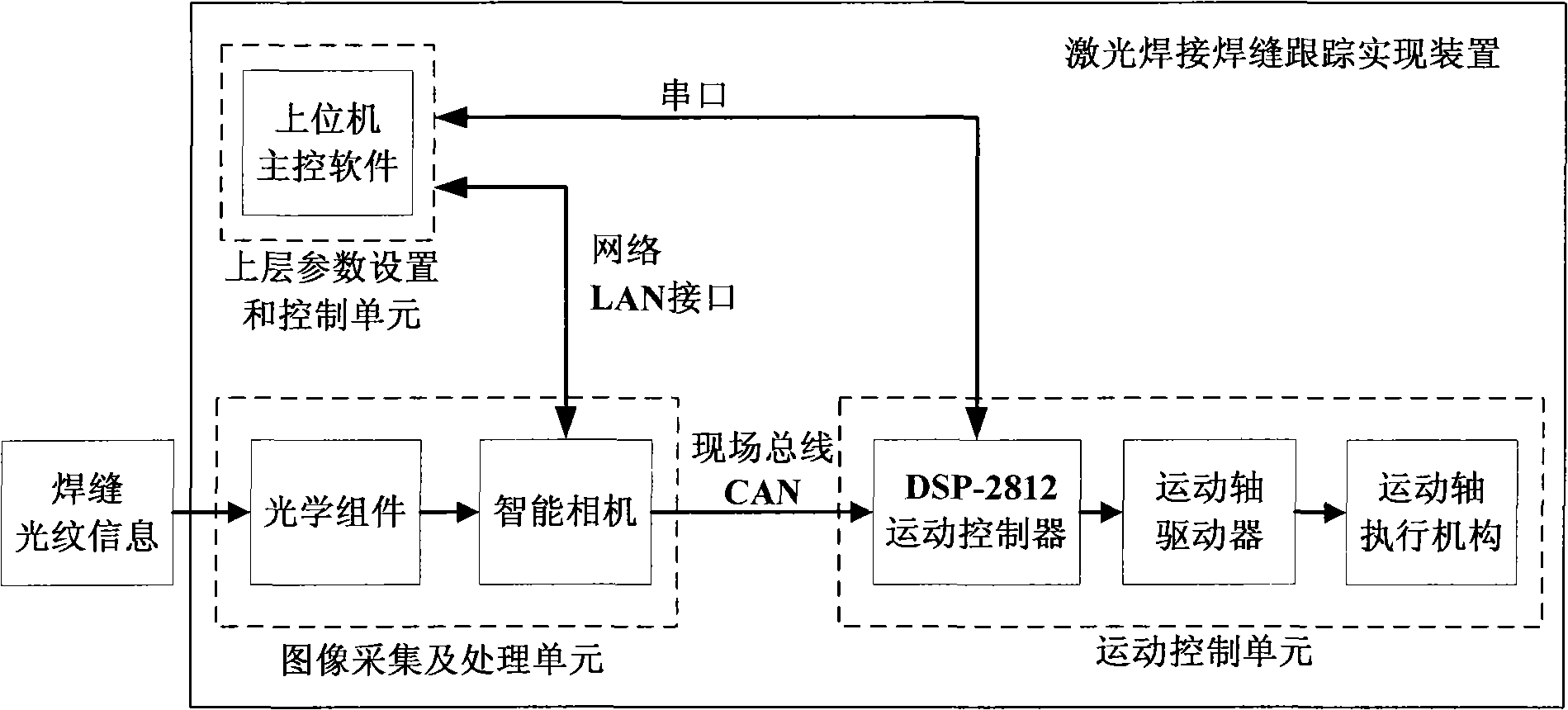

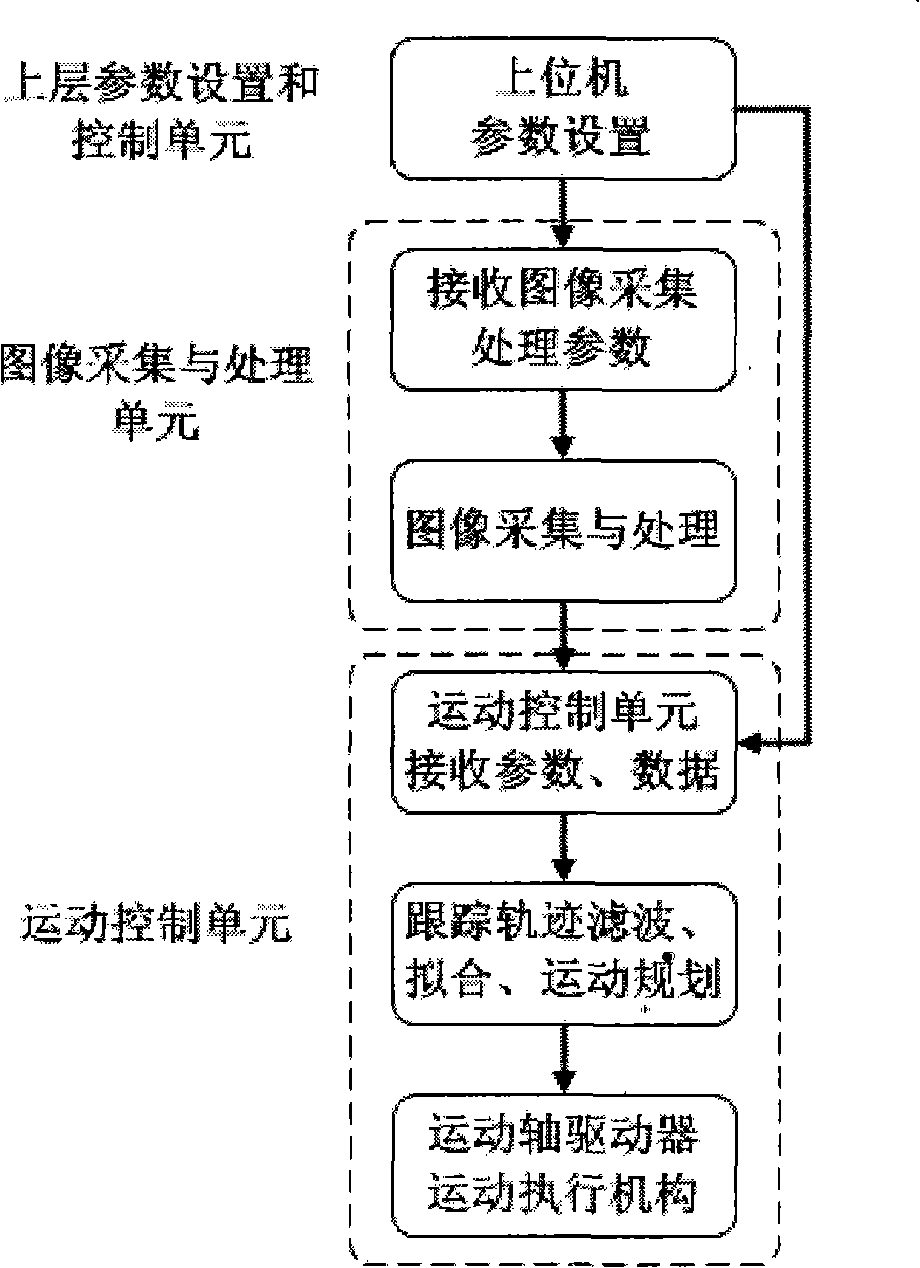

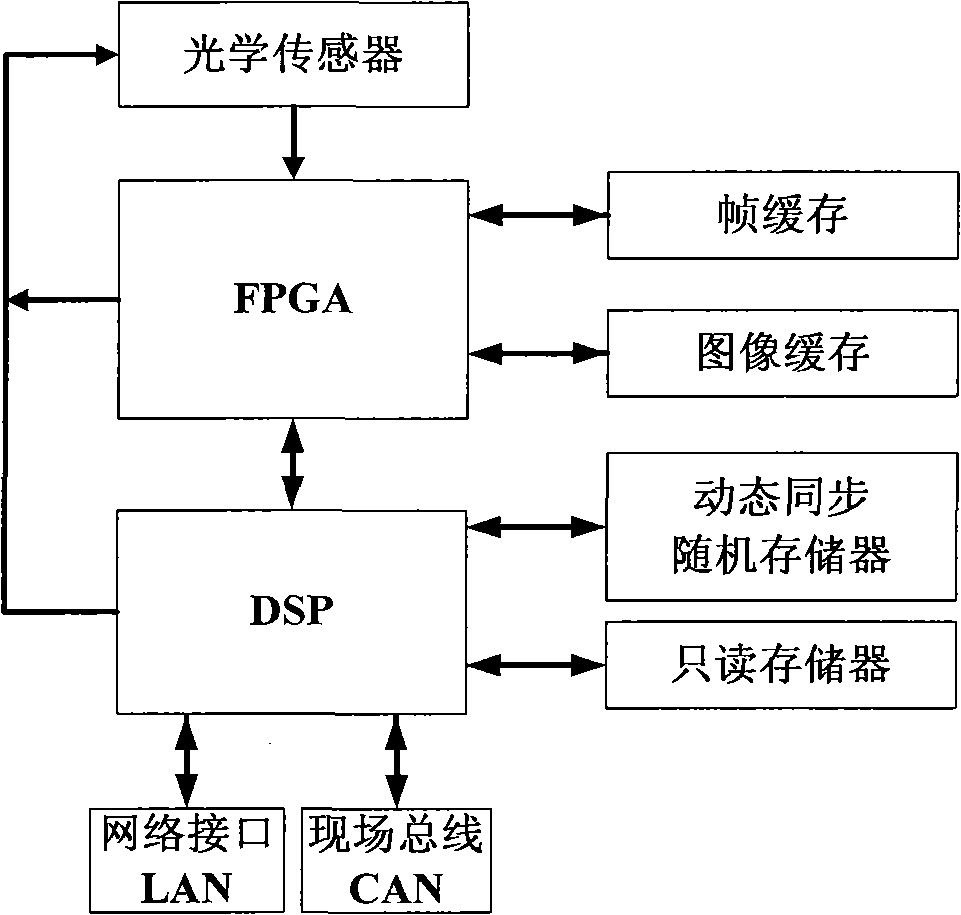

Device for realizing laser welding and seam tracking and control method thereof

InactiveCN101961819AHigh precisionImprove versatilityLaser beam welding apparatusEngineeringMotion controller

The invention relates to a device for realizing laser welding and seam tracking and a control method thereof. The device of the invention comprises an image collecting and processing unit for collecting and processing the image data of laser welding and seam characteristics and outputting the seam position information, a motion control unit for receiving the seam position information and transmitting a motion control command to a motion shaft actuating mechanism, and an upper parameter setting and control unit for setting the parameters and being respectively connected with the image collecting and processing unit and the motion control unit in a communication mode. The method of the invention comprises the following steps: setting the parameters by utilizing the upper parameter setting and control unit; collecting and processing seam images to obtain the seam image data; caching and calibrating the seam image data, and determining the offset of a welding gun; carrying out filtering, fitting and track planning on tracking tracks by utilizing a motion controller in the motion control unit; and transmitting the result to a motion shaft driver. The invention can be suitable for various seam types and techniques and has the advantages of good generality, strong flexibility, high independence, high precision, accurate positioning, strong adaptability, and the like.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

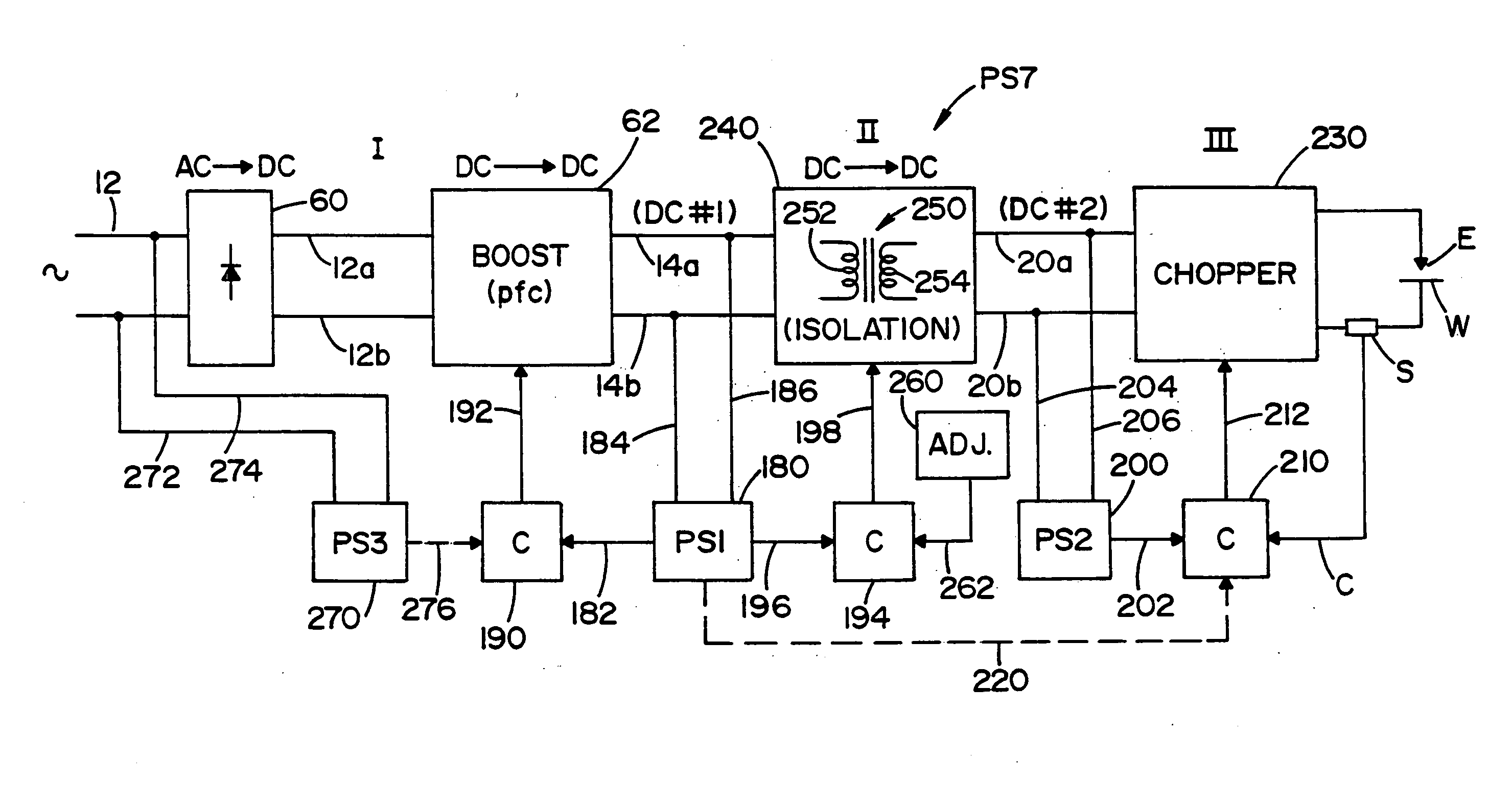

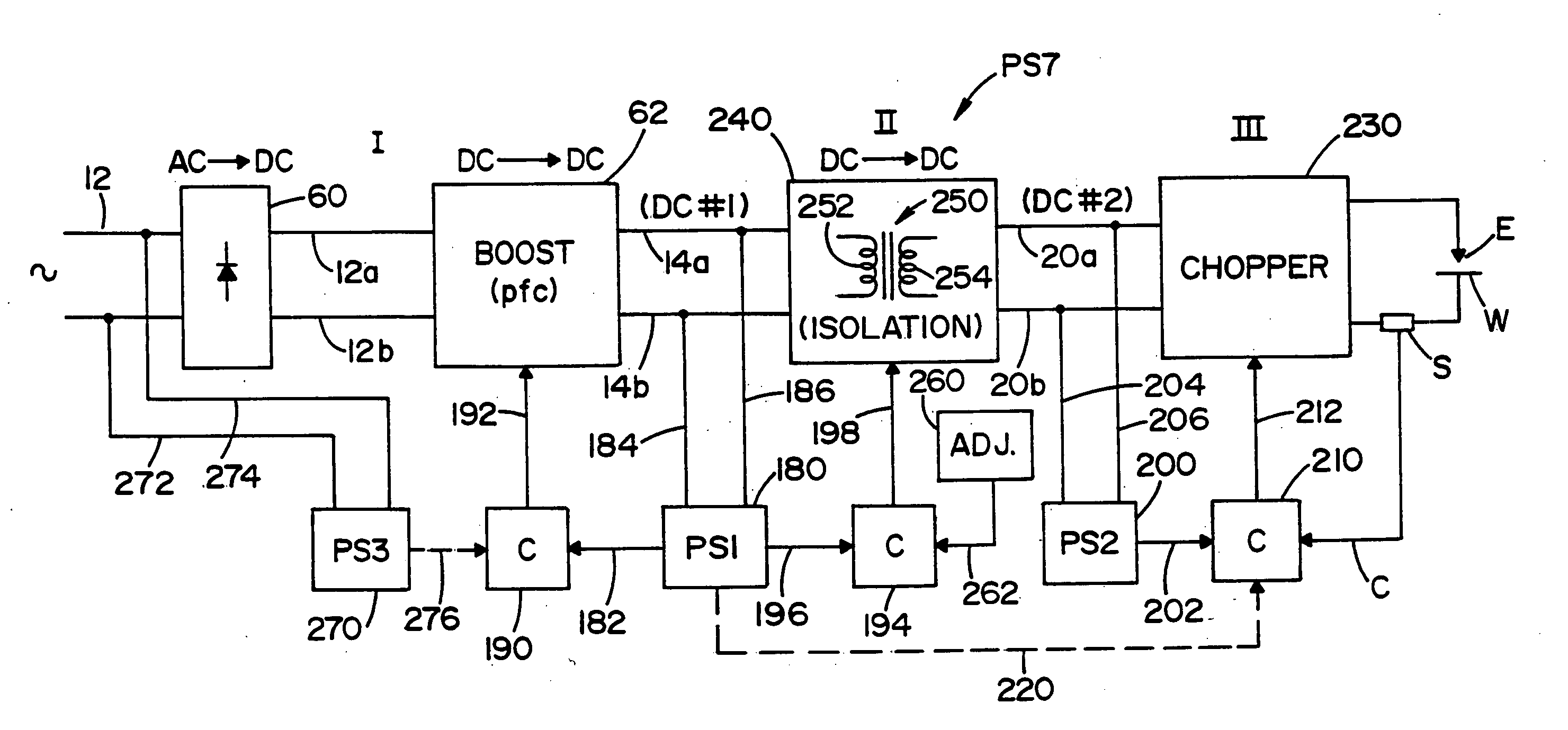

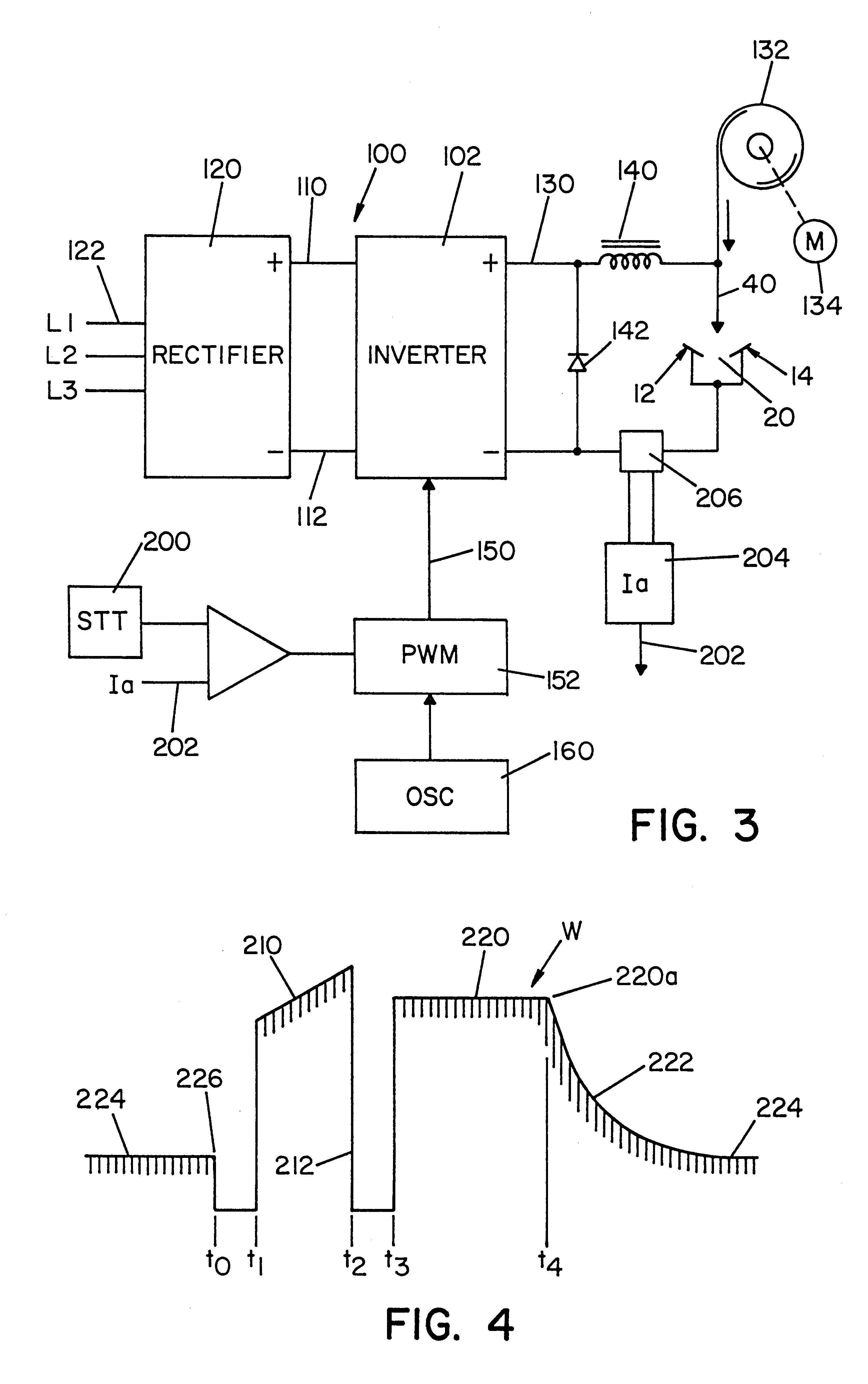

Modular power source for electric ARC welding and output chopper

ActiveUS20060175313A1Ac-dc conversion without reversalArc welding apparatusEngineeringConductor Coil

A three stage power source for an electric arc welding process comprising an input stage having an AC input and a first DC output signal; a second stage in the form of an unregulated DC to DC converter having an input connected to the first DC output signal, a network of switches switched at a high frequency with a given duty cycle to convert the input into a first internal AC signal, an isolation transformer with a primary winding driven by the first internal high frequency AC signal and a secondary winding for creating a second internal high frequency AC signal and a rectifier to convert the second internal AC signal into a second DC output signal of the second stage; with a magnitude related to the duty cycle of the switches and, a third stage to convert the second DC output signal to a welding output for welding wherein the input stage and the second stage are assembled into a first module and the third stage is assembled into a second module connectable to the first module.

Owner:LINCOLN GLOBAL INC

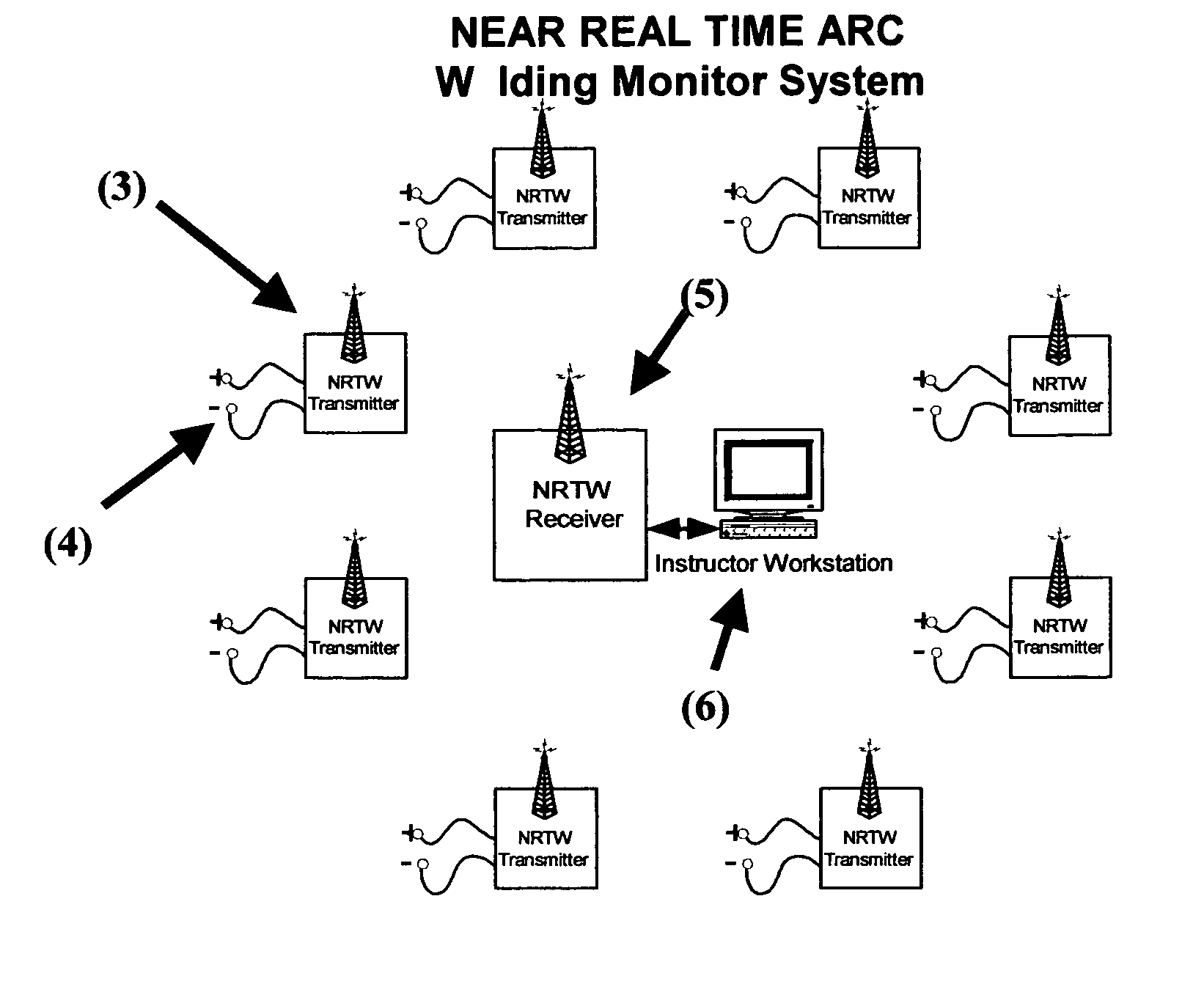

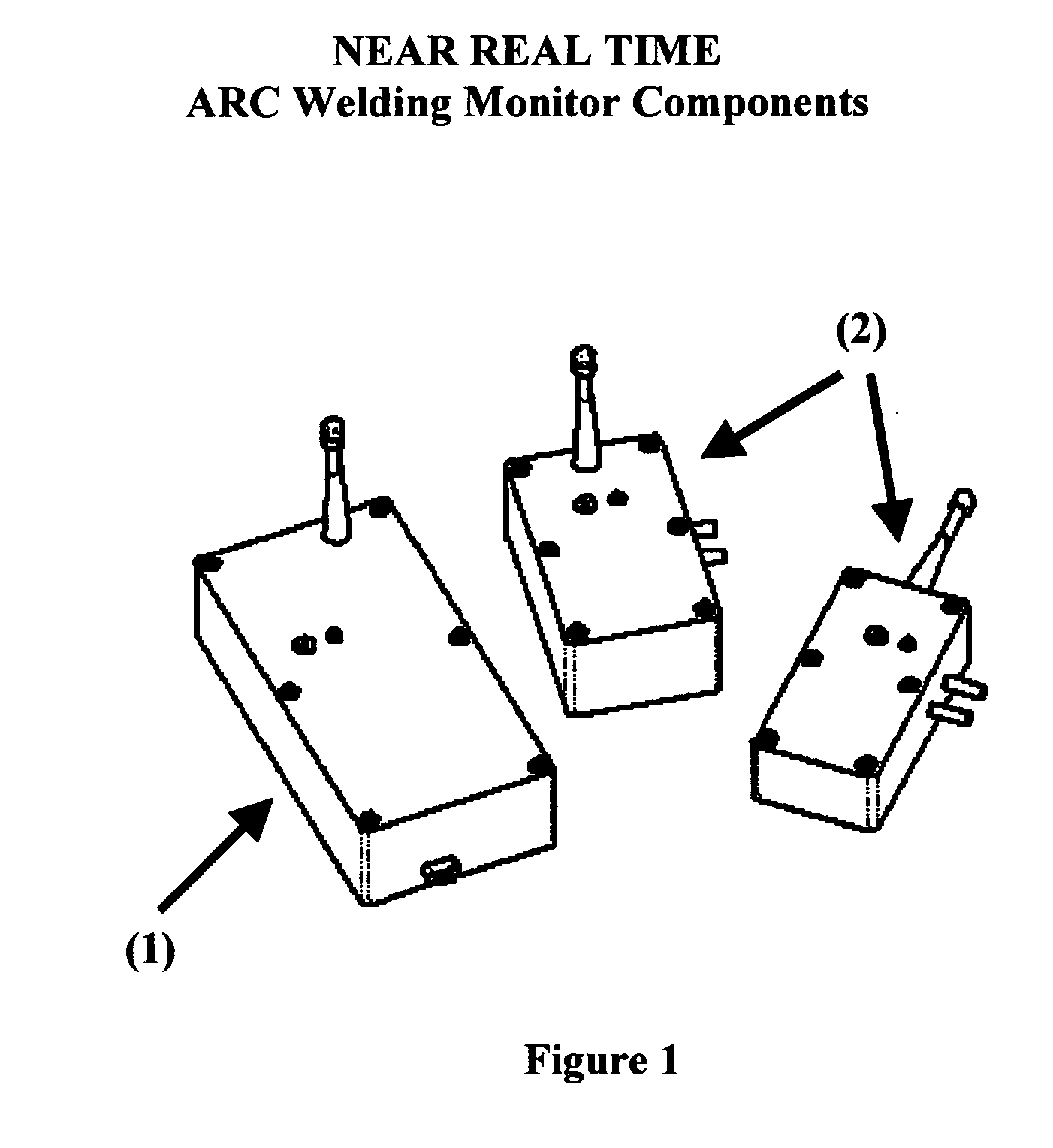

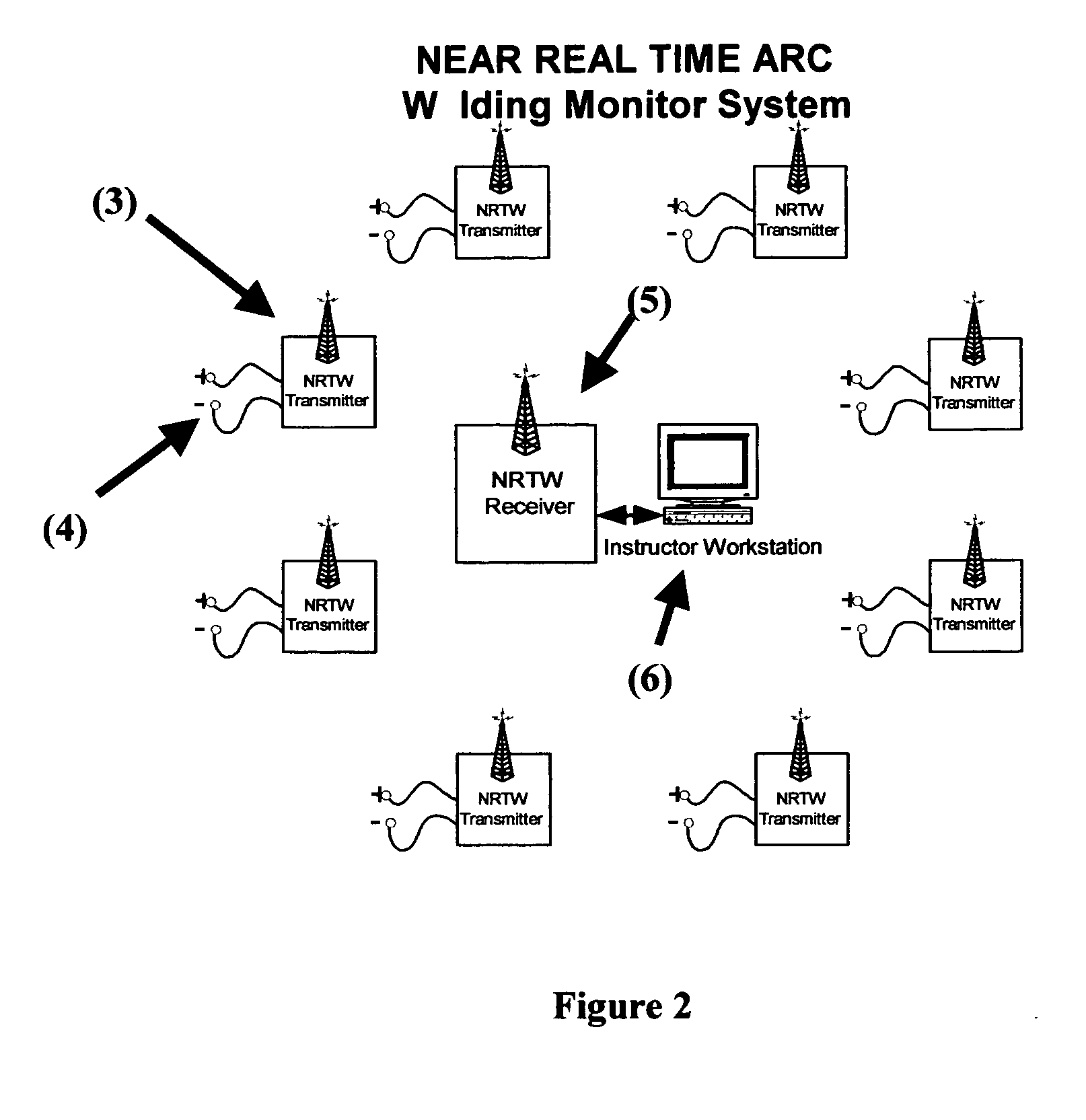

Near real time arc welding monitor

InactiveUS20050127052A1Improve learning experienceProduced economicallyWelding accessoriesGraphicsStatistical analysis

An arc welding monitor designed to aid in the instruction of electric arc welding, provide data that can be used for inspection and quality assurance of individual welds, and provide an archive record of the arc welding process for future reference and analysis. A sensor is used to unobtrusively measure the welding arc parameters. The measurements are transmitted in real-time from the welding station to an instructor / supervisor workstation via a radio frequency data link. The received data is graphically displayed in near-real-time on the instructor / supervisor workstation computer screen. The data can be analyzed by standard statistical analysis tools to qualitatively grade the weld, be stored on computer disk storage media for later retrieval and analysis, or printed in a graphic display. Interpretation of the graphical display and statistical analysis is used to critique and instruct welder operator technique or to indicate process flaws that warrant further inspection of suspected welds.

Owner:SPENCER MARK SCOTT

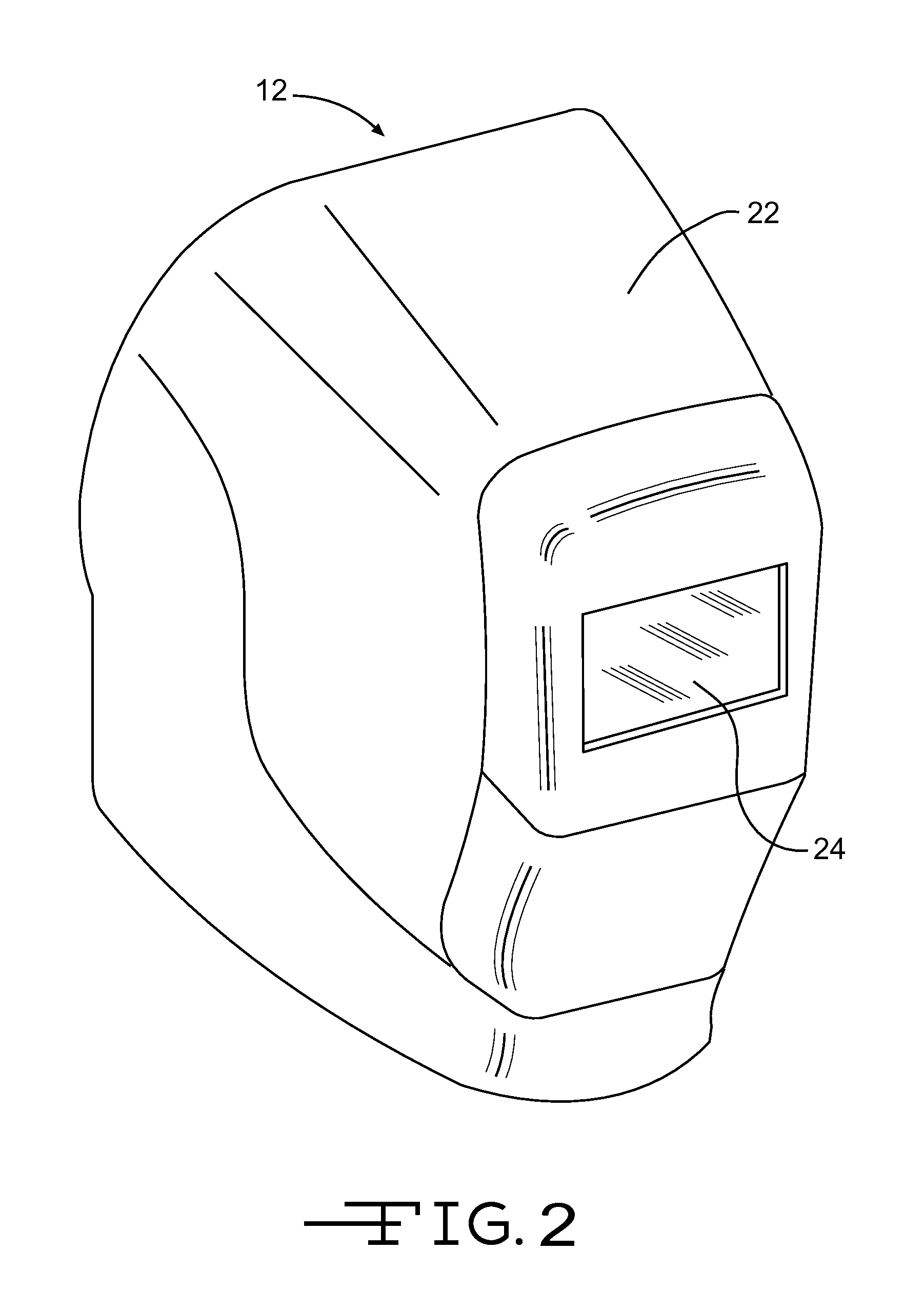

Welding arc apparel with UV activated images

A welding accessory and a system for detecting UV radiation exposure during welding operations are disclosed. The welding accessory may have a surface exposed to UV radiation generated by electric arc welding, a first image visible without exposure to the UV radiation, and a second image formed from UV activated dye that is visible only after exposure to UV radiation generated by the electric welding arc. A system may include a UV exposure indicator with a first state and at least a second state, and include UV activated dye adapted to provide a reversible or persistent visual indication upon exposure to UV radiation. The visual indication may include any combination of symbols, logos, images, text, or other decorative or informational designs as desired.

Owner:LINCOLN GLOBAL INC

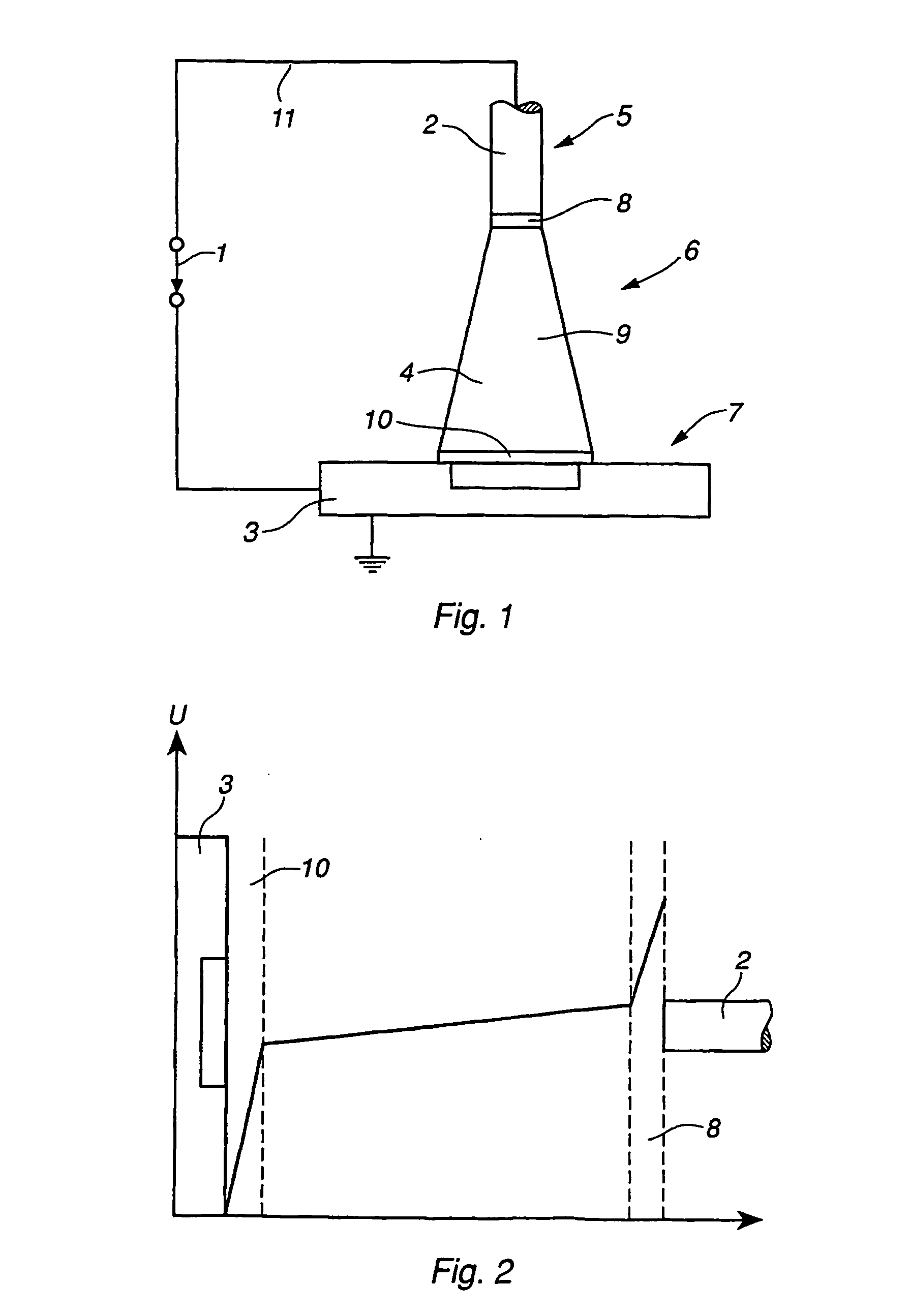

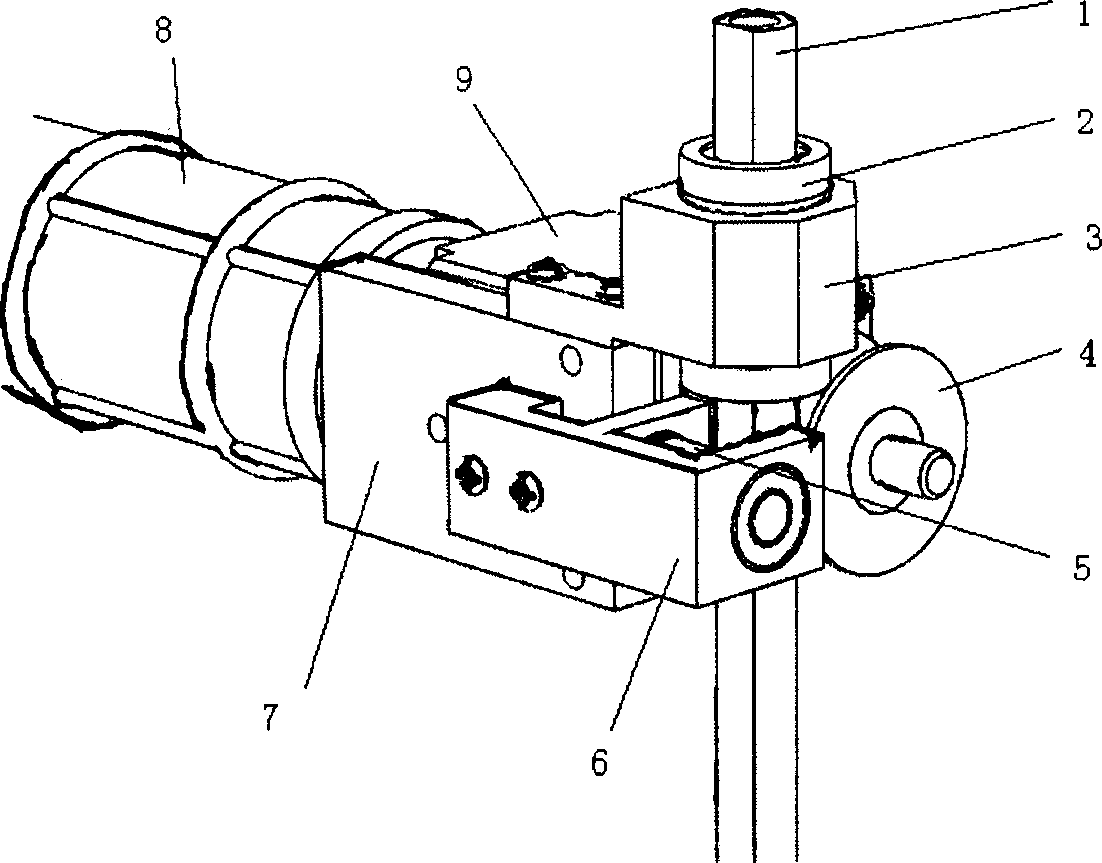

Simulative training device for manual arc welding operation

InactiveCN1866317AChange the melting rateMaster the welding feelEducational modelsTeaching apparatusShielded metal arc weldingElectric machine

The related training simulator for welding operation comprises: a simulating welding gun with a handle (8) connected to a step motor (9); a controller; and a simulated test piece. Wherein, arranging an active rolling wheel (4) on motor output shaft, a rolling base (6) with a driven rolling wheel on the motor base (7), and a welding rod (1) between (4) and (5). This invention can accelerate training with less consumption.

Owner:XI AN JIAOTONG UNIV

Welding arc apparel with UV or themochromic activated images

A welding accessory and a system for detecting thermal and / or UV radiation exposure during welding operations are disclosed. The welding accessory may have a surface exposed to thermal and / or UV radiation generated by electric arc welding, a first image visible without exposure to the thermal and / or UV radiation, and a second image formed from either a UV activated dye that is visible only after exposure to UV radiation generated by the electric welding arc or a thermochromic dye that is visible only after exposure to a predetermined level of thermal radiation generated by the welding arc. A system may include either a thermal or UV exposure indicator with a first state and at least a second state, and include either a thermochromic or UV activated dye adapted to provide a reversible or persistent visual indication upon exposure to radiation. The visual indication may include any combination of symbols, logos, images, text, or other decorative or informational designs as desired.

Owner:LINCOLN GLOBAL INC

High-performance refractory weather-resisting building steel and its production method

InactiveCN1354273AImprove fire resistanceHigh yield strengthManufacturing cost reductionHeat-affected zone

The present invention relates to a high-performance fire-resistant weather-resisting building steel and its production method. Said invention steel contains C, Si, Mn, P, S, Mo, Ti, Al, N, O, Cr, Ni, Cu, Ca, B and one or more than one kind of Nb, V and RE and the rest is Fe. After having been undergone the processes of smelting, rolling and heat treatment, said building steel possesses high strenght, high toughness and excellent fire-resisting and weather-resisting properties. The building steel can be used for providing various steel structural members whose thickness is 4-100 mm in the fields of building, civil engineering and marine structure. Under the large linear energy (50-100 kJ / cm) welding condition of gas-arc welding, electroslag welding and high-frequency resistance welding, its heat affected zone (HAZ) still possesses excellent toughness so as to greatly raise welding efficiency of engineering structure and reduce its manufacture cost.

Owner:武钢集团有限公司

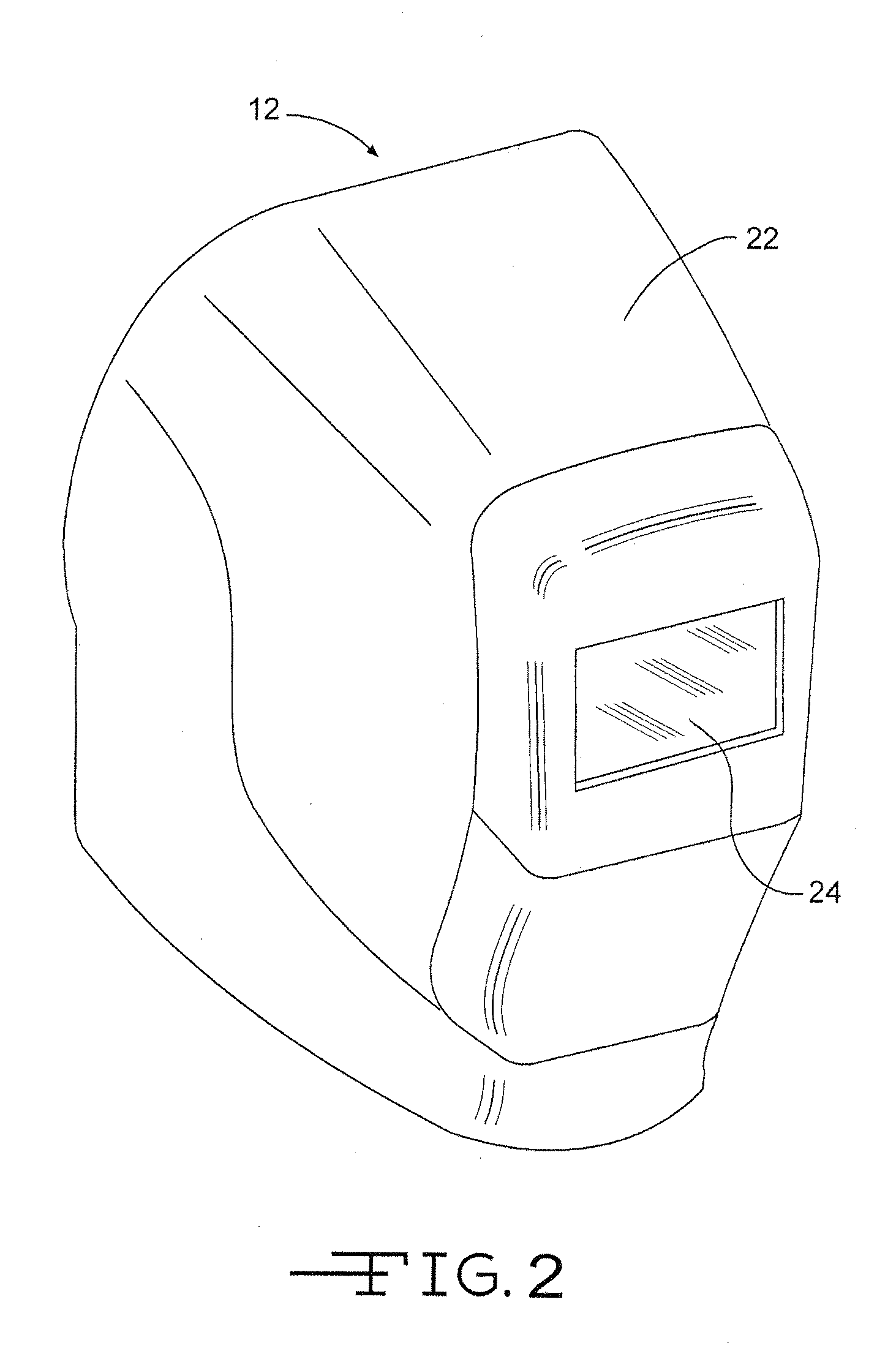

Method of pacing travel speed

InactiveUS20070114215A1Arc welding apparatusWelding/cutting media/materialsEngineeringElectrical current

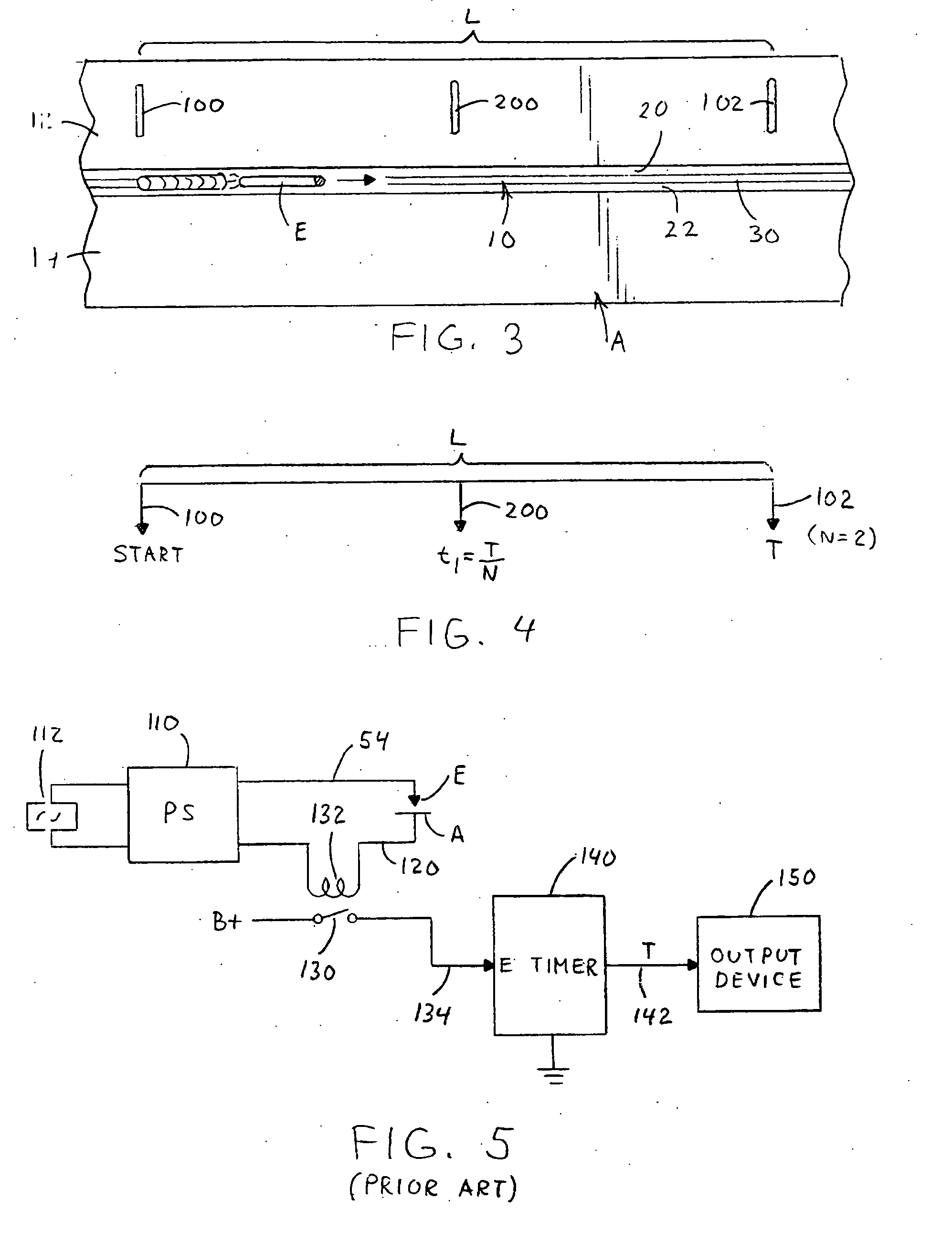

A method of pacing a desired travel speed of a manual arc welding process performed by a welder for depositing weld metal on a workpiece and along a test groove with a given test length defined by a visible start location and a visual end location using a specified amount of energy distributed generally uniformly in the groove between the locations. The method comprises providing a power source with output leads and an arc current and an arc voltage; setting the output welding power of the power source; providing a consumable welding wire; connecting the output leads across the welding wire and the workpiece; determining the time T for the wire to traverse the test length to consume the specific amount of energy; marking the groove with a visible indicia spaced from the start location a given distance; associating a programmable haptic device with an exposed body part of the welder where the device has a tactile alarm activated after a programmed time t from start of the haptic device, which time t is coordinated with the given distance to give the desired travel speed; starting the haptic device when the operator commences welding at the start location and employs a manual rate of travel; and, changing the manual rate of travel according to the relationship of the wire to the indicia when the tactile alarm is activated.

Owner:LINCOLN GLOBAL INC

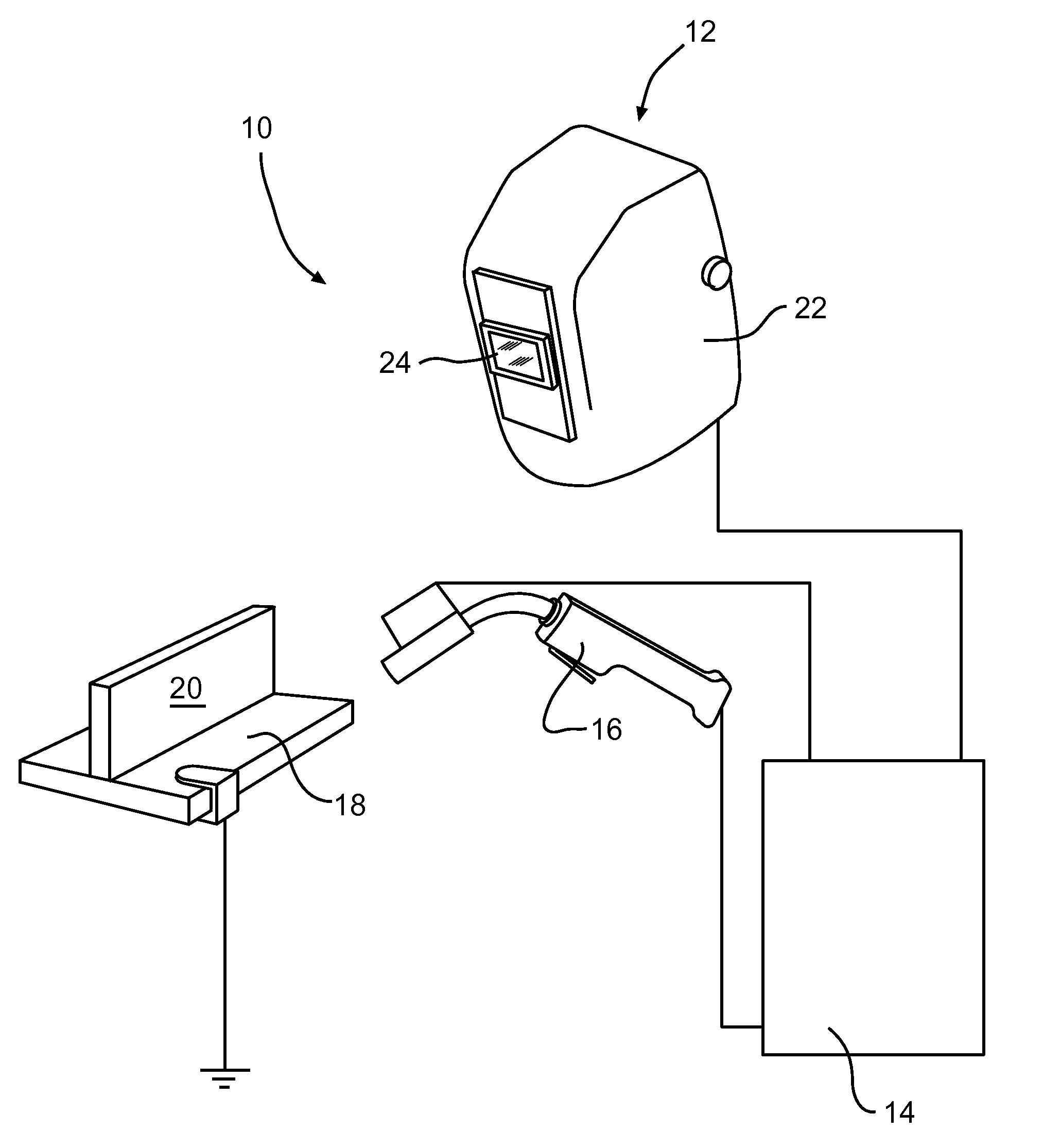

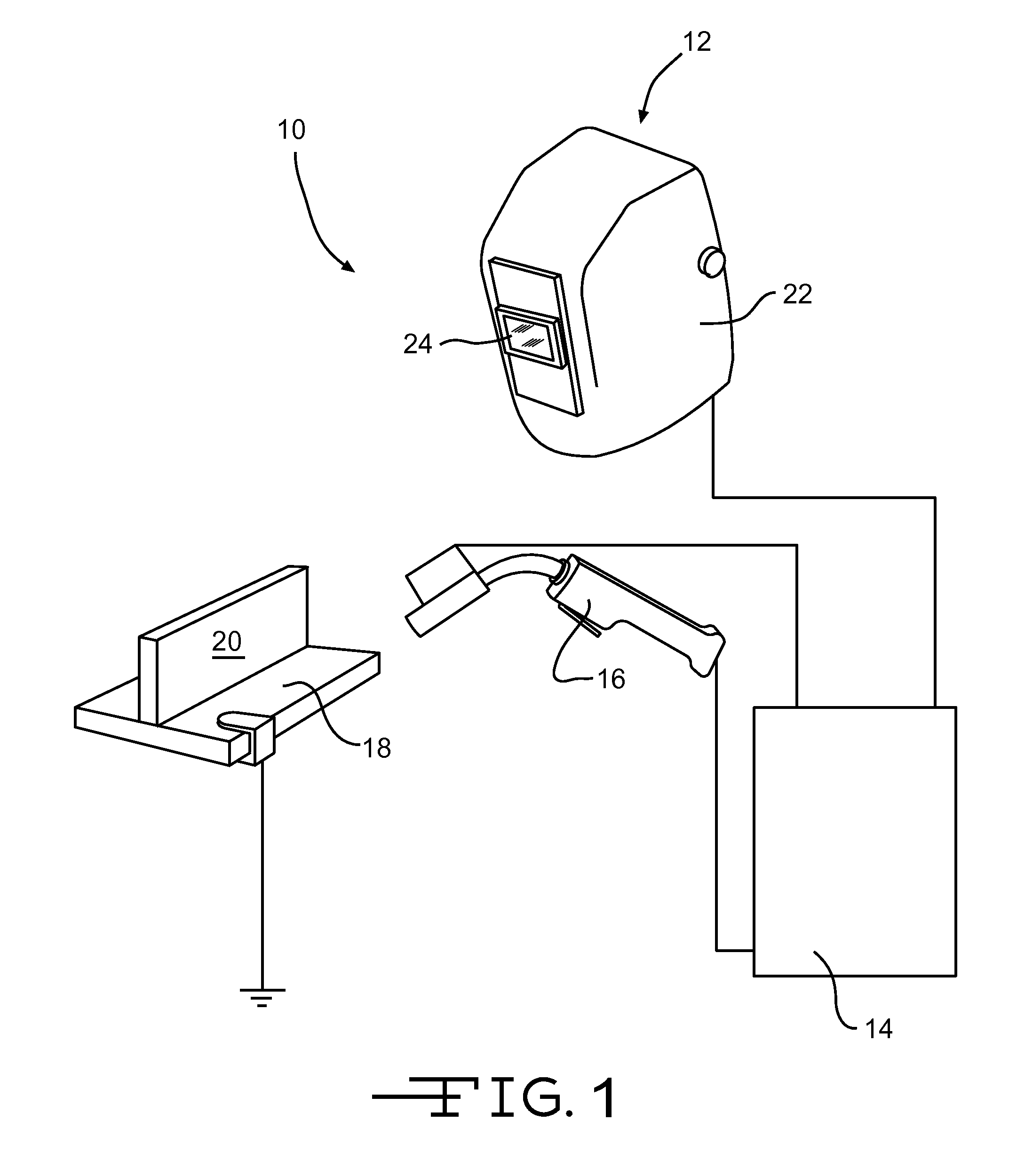

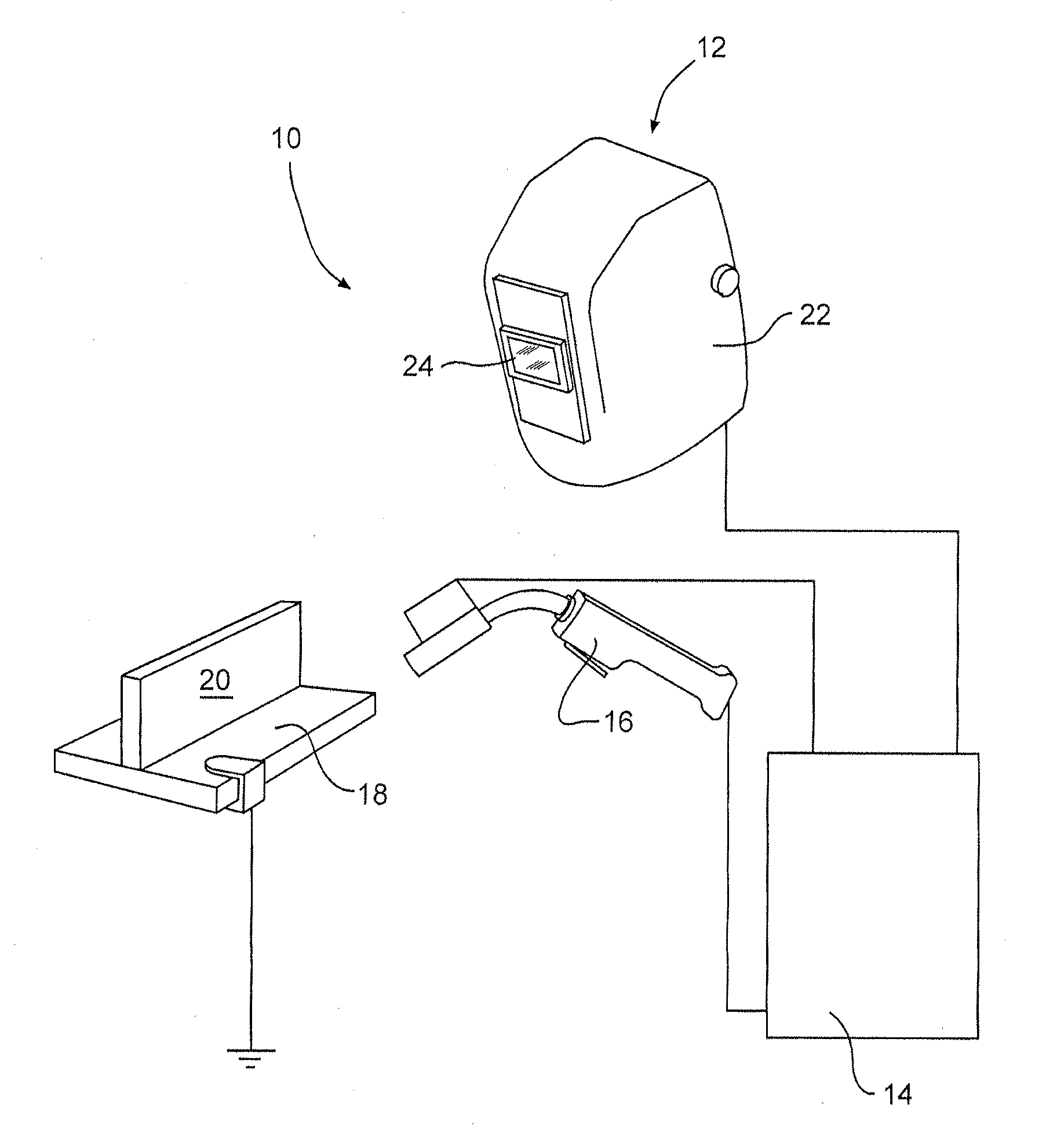

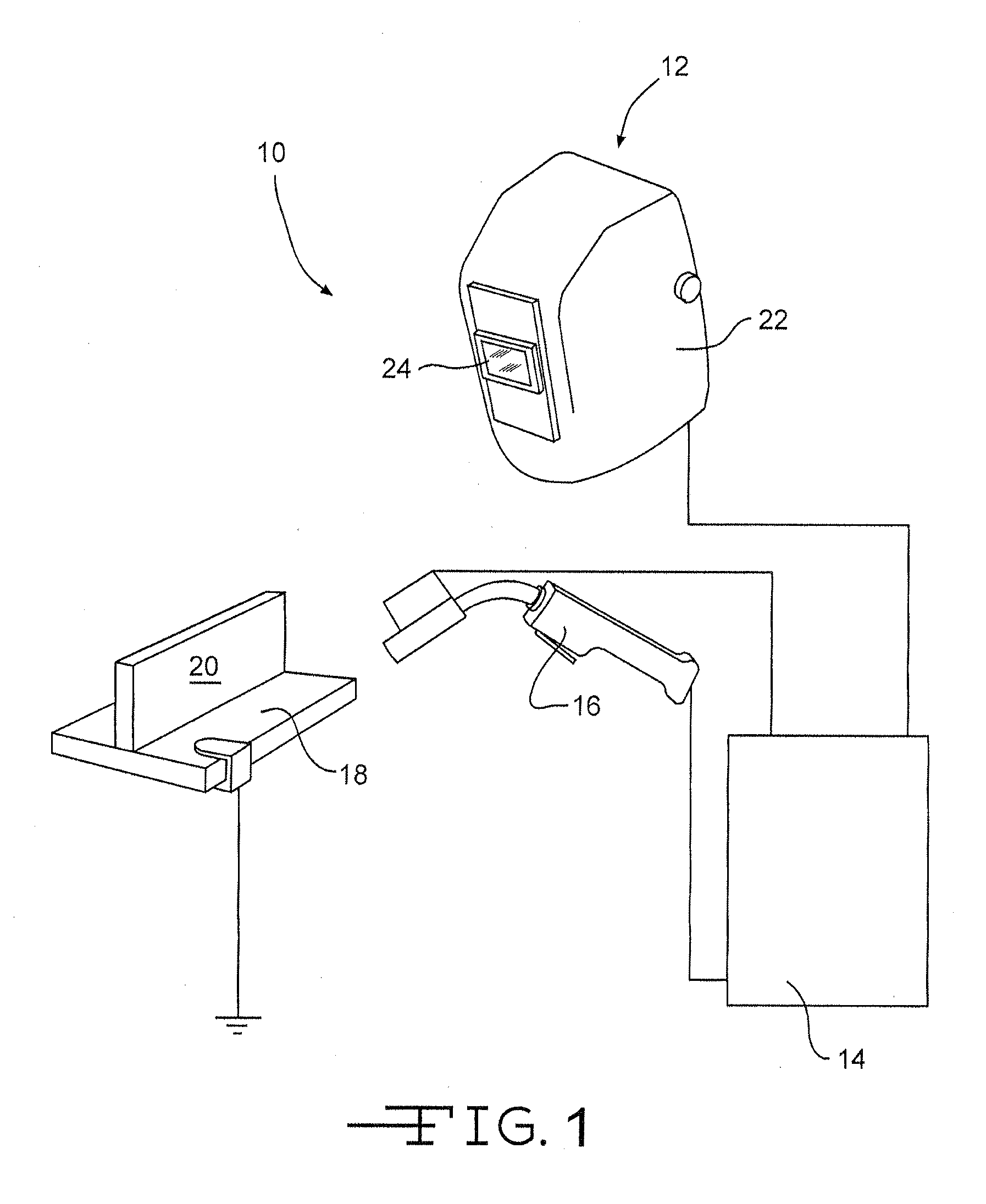

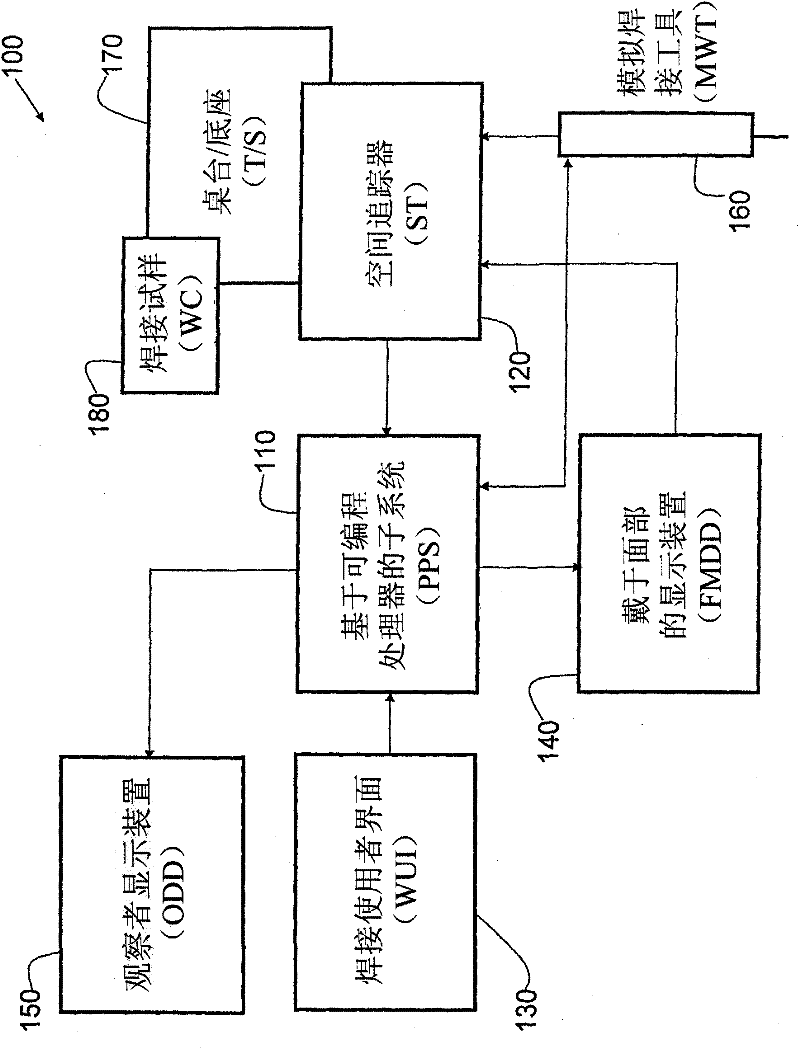

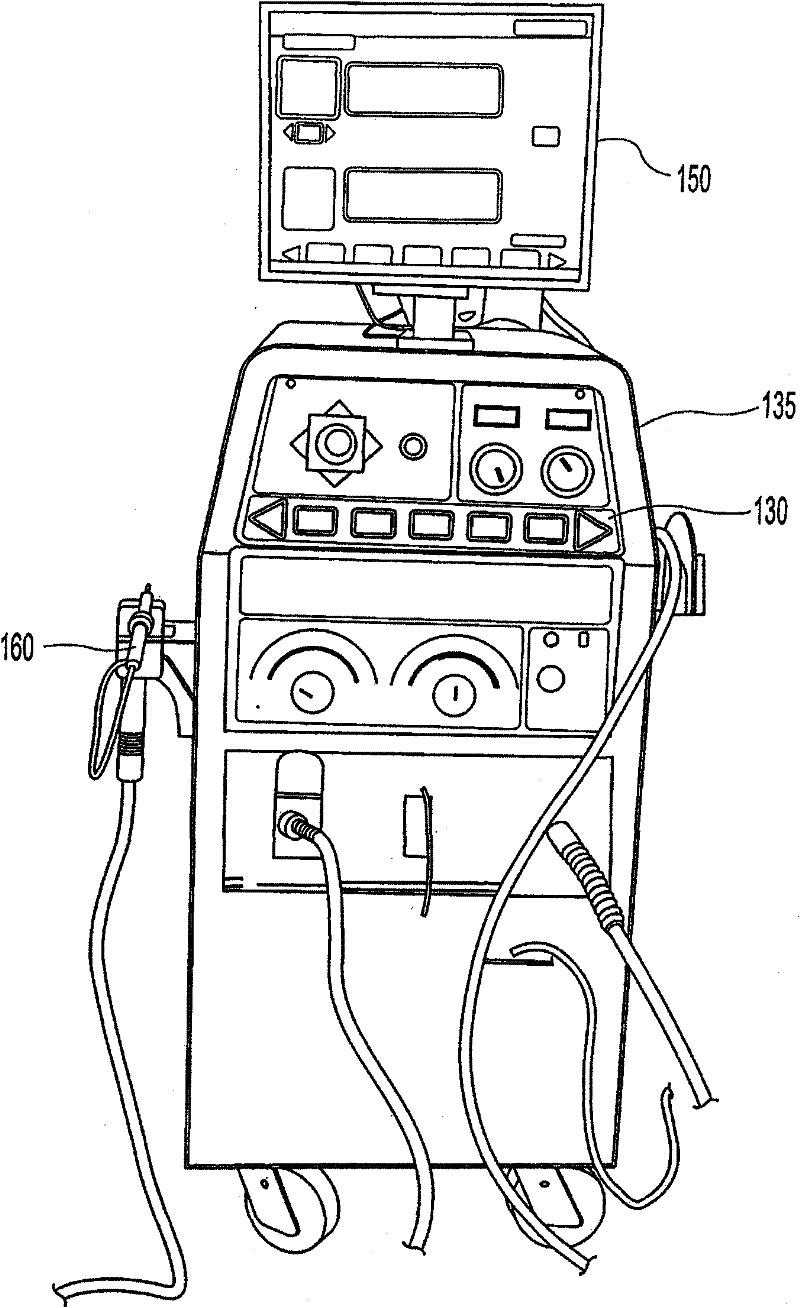

System and method providing arc welding training in a real-time simulated virtual reality environment using real-time weld puddle feedback

A real-time virtual reality welding system including a programmable processor- based subsystem, a spatial tracker operatively connected to the programmable processor- based subsystem, at least one mock welding tool capable of being spatially tracked by the spatial tracker, and at least one display device operatively connected to the programmable processor-based subsystem. The system is capable of simulating, in virtual reality space, a weld puddle having real-time molten metal fluidity and heat dissipation characteristics. The system is further capable of displaying the simulated weld puddle on the display device in real-time.

Owner:LINCOLN GLOBAL INC

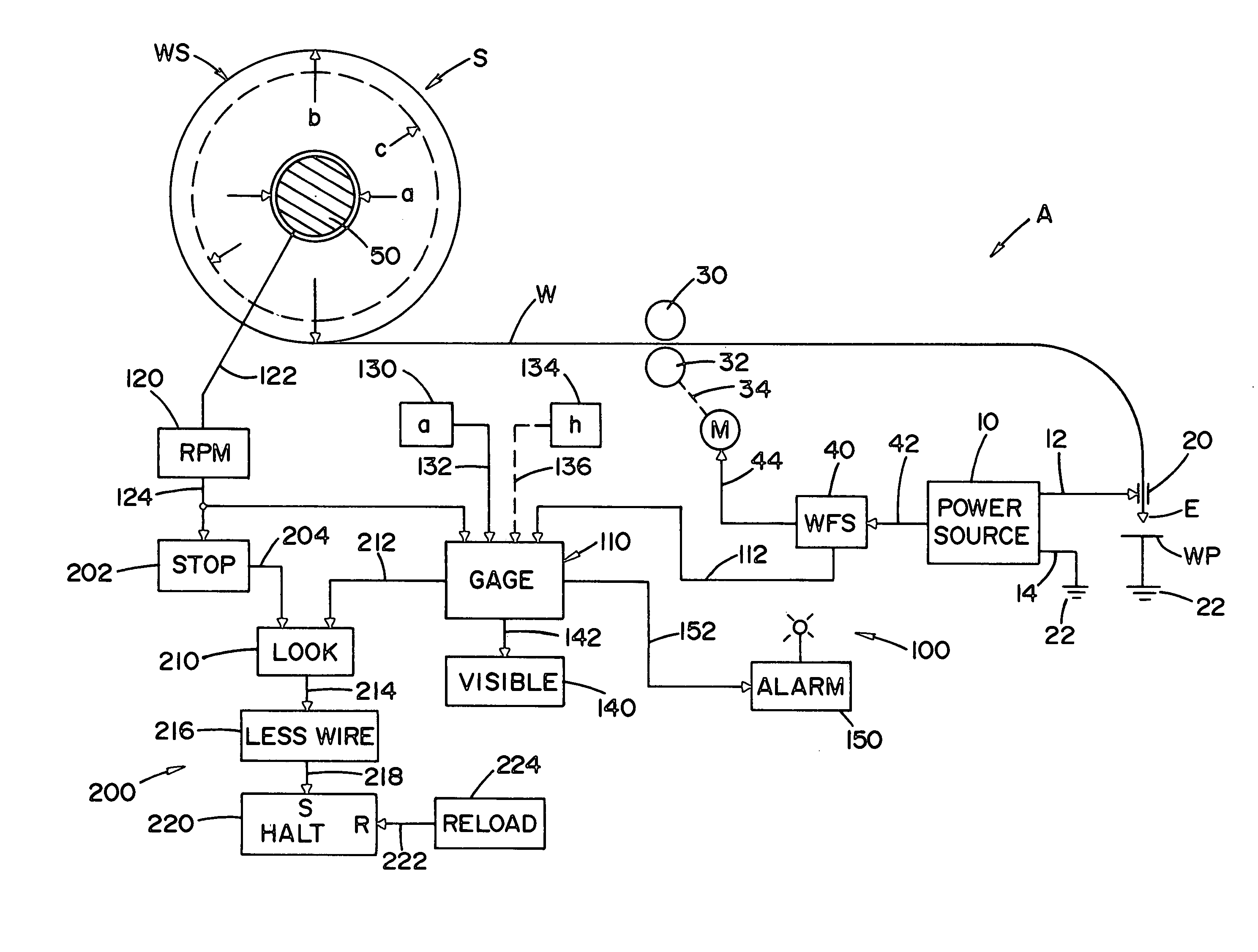

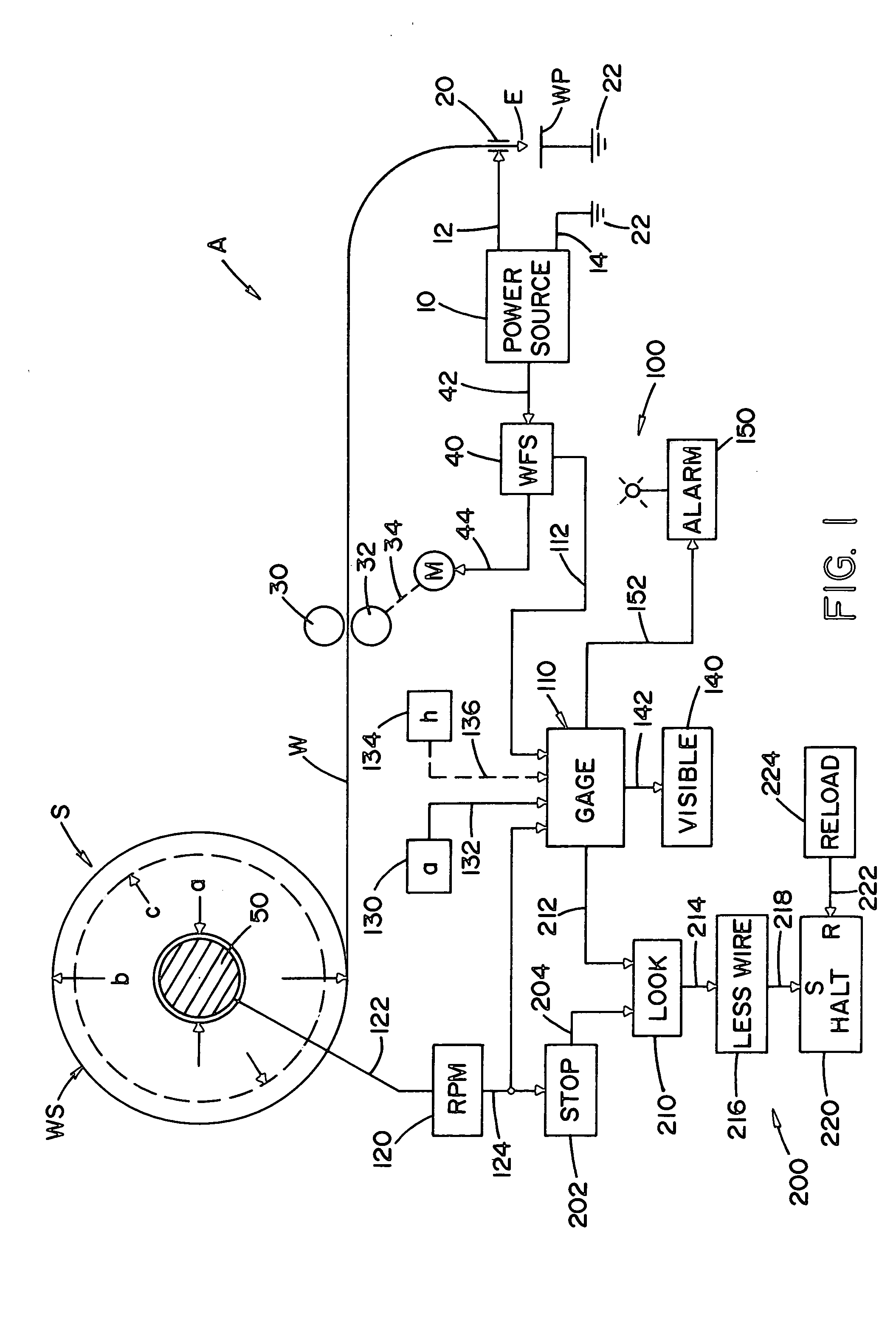

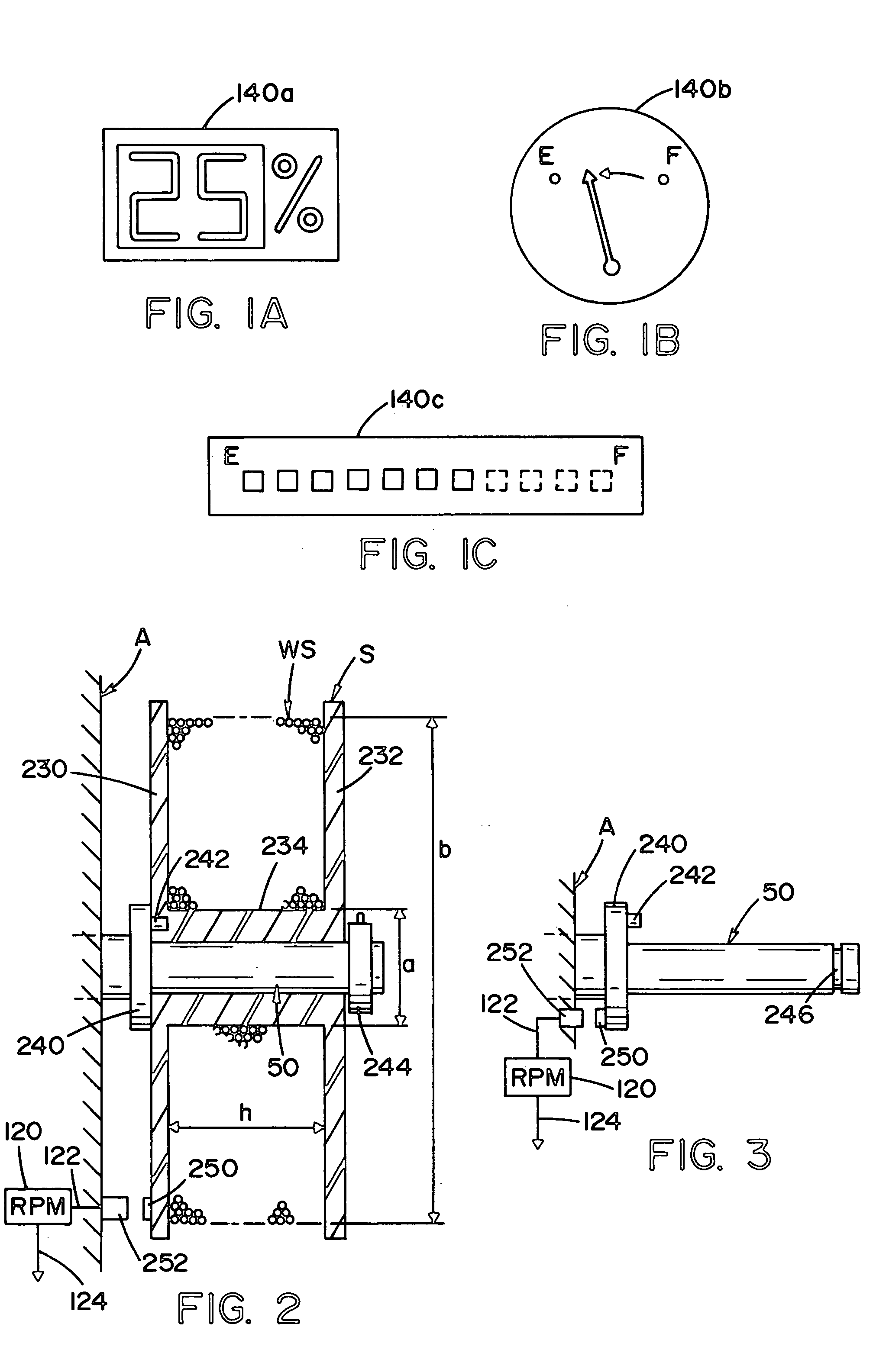

Monitoring device for welding wire supply

A monitoring device for sensing of the actual amount of welding wire on a spool with a minimum wire supply diameter for use in a wire feeder of an electric arc welder, said monitoring device comprising: an RPM device to create a spool speed signal indicative of the rotational speed of the spool as the spool provides wire at the known wire feed speed and a converting device for converting according to a set relationship the spool speed signal into a wire supply signal varying between a high level when the spool speed signal is low at a presumed maximum supply of wire on the spool and a low level when the spool speed signal is high at the minimum supply of wire on said spool determined by the minimum wire supply diameter.

Owner:LINCOLN GLOBAL INC

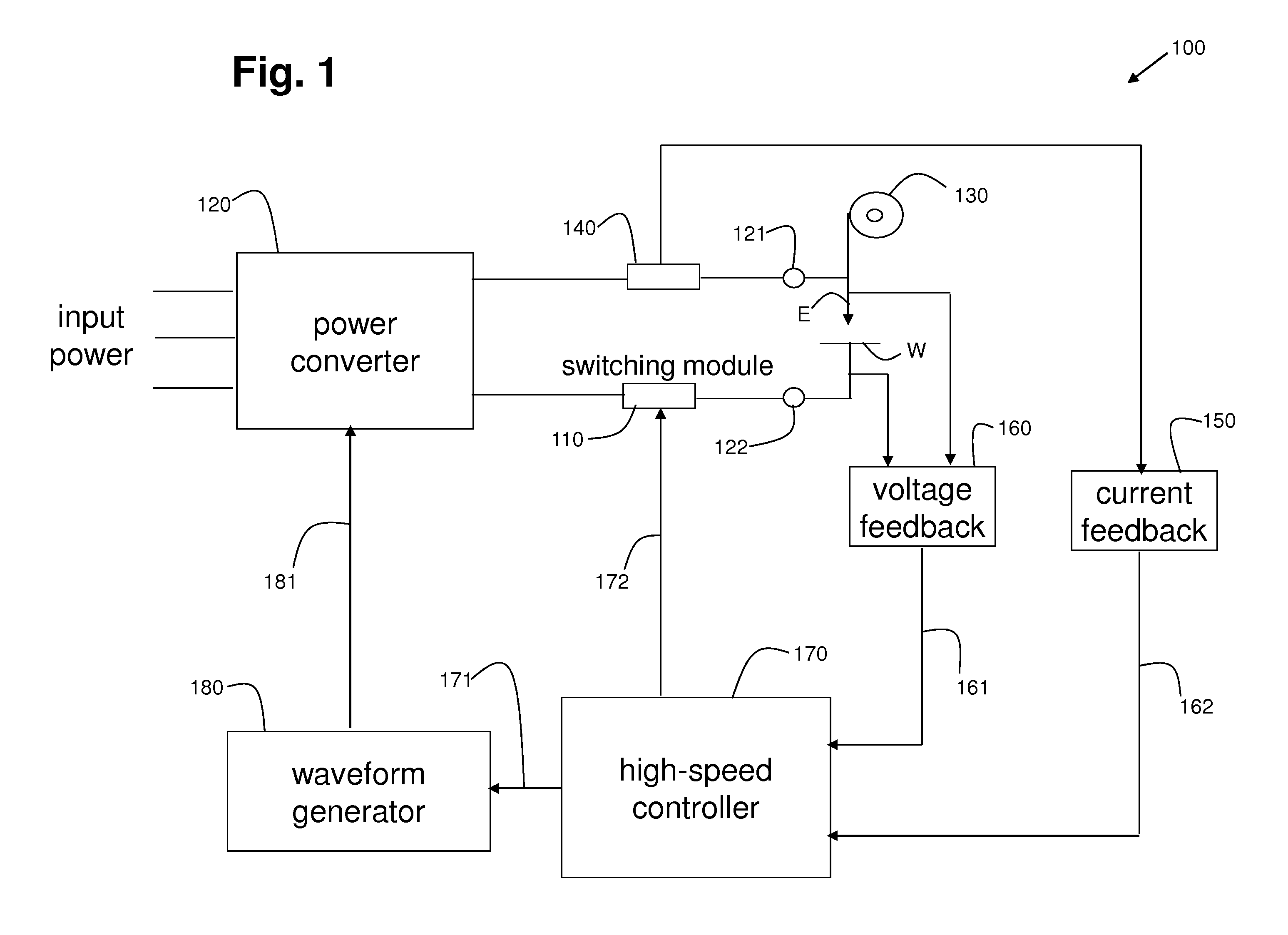

Method to control an arc welding system to reduce spatter

ActiveUS20120097655A1Reduce splashLess spatterArc welding apparatusElectricityElectrical resistance and conductance

An electric arc welder and a method for performing a pulse welding process producing reduced spatter. The welder produces a current between an advancing electrode and a workpiece. The welder includes a short-detecting capability for detecting a short condition upon occurrence of a short circuit between the advancing electrode and the workpiece. The welder may also include a switching module in the welding circuit path of the welder having an electrical switch and a resistive path. Times of occurrence of short intervals can be tracked and a blanking signal can be generated based on the tracked short intervals to anticipate a next short interval in a next pulse period of the pulsed welding process. The blanking signal can be used to reduce a welding current in the welding circuit path by introducing additional resistance into the welding circuit path via the switching module, for example.

Owner:LINCOLN GLOBAL INC

Method of pipe welding

InactiveUS6093906AGood lookingIncrease driving speedArc welding apparatusWelding/cutting media/materialsSulfurManganese

A method of welding the ends of two pipes at the open root between the spaced ends by an STT electric arc welder, which comprises: selecting a welding wire having 0.06-0.15% by weight carbon, 0.90-1.40% by weight manganese, and 0.45-0.75% by weight silicon, as well as phosphorous, copper, stainless steel alloys and sulfur; maintaining the sulfur at a given percentage level of the selected wire in the specific range of 0.015 to 0.035% by weight; and maintaining said phosphorous at a given percentage level of said selected wire in the specific range of less than about 0.015%.

Owner:LINCOLN GLOBAL INC

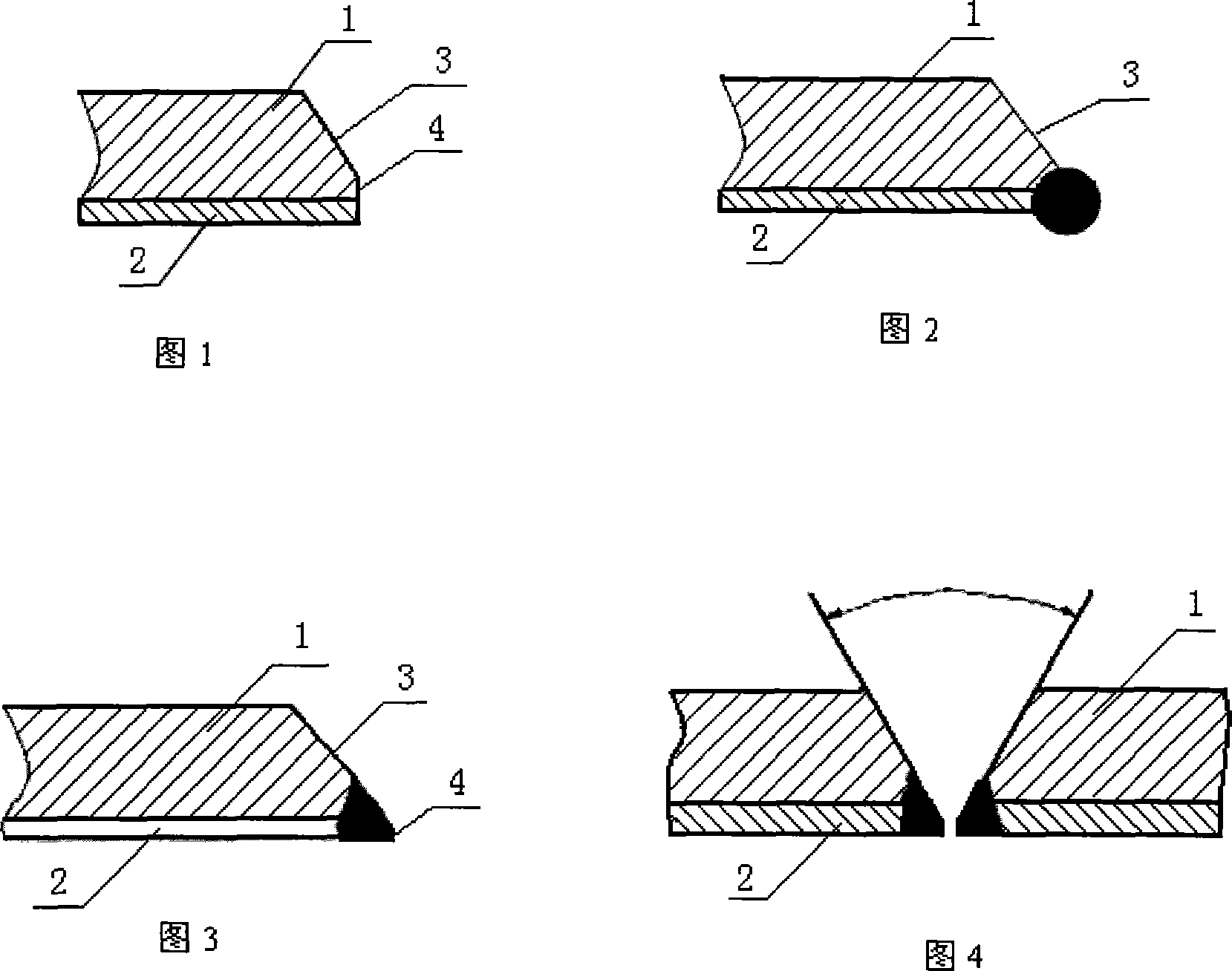

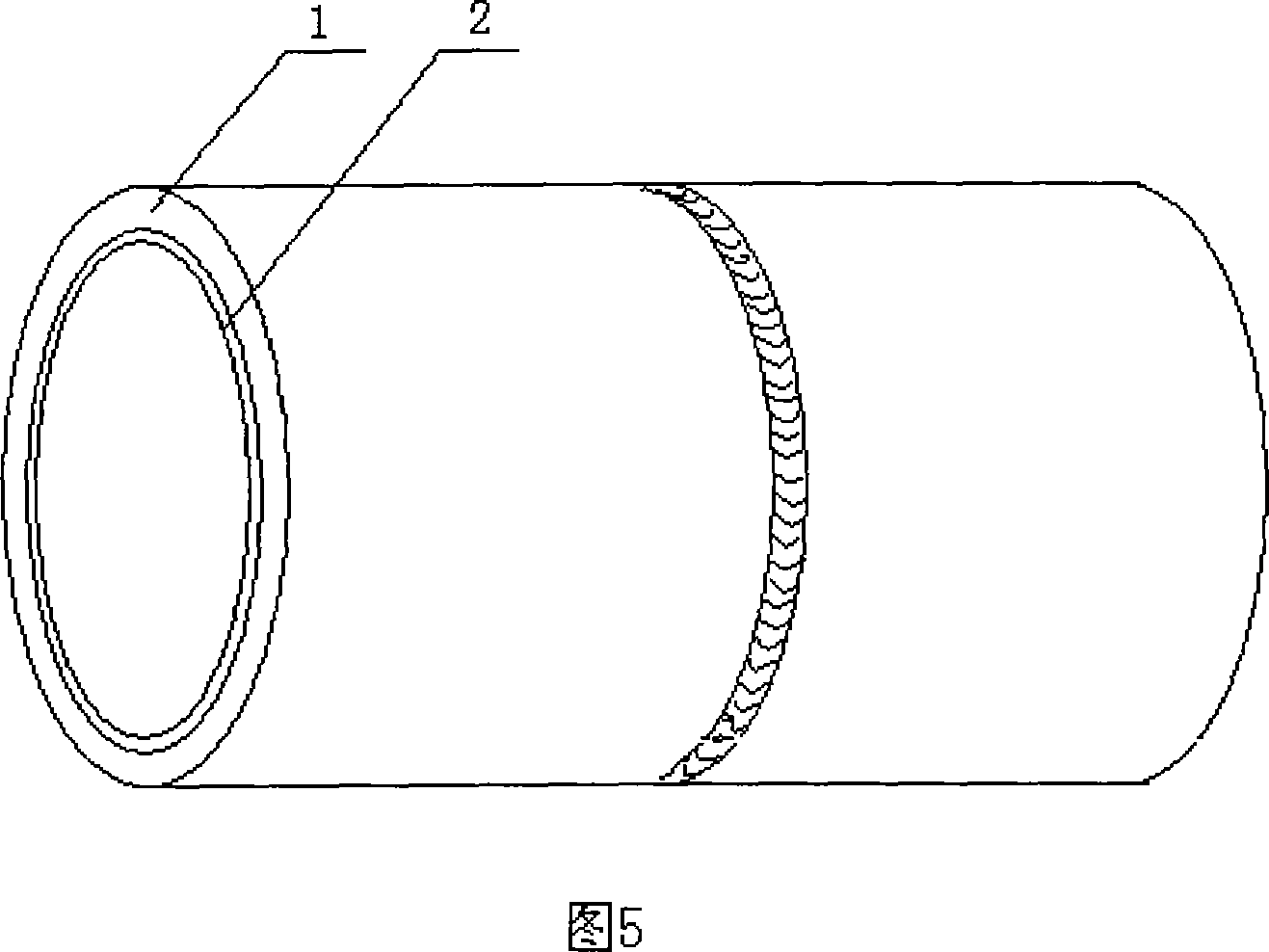

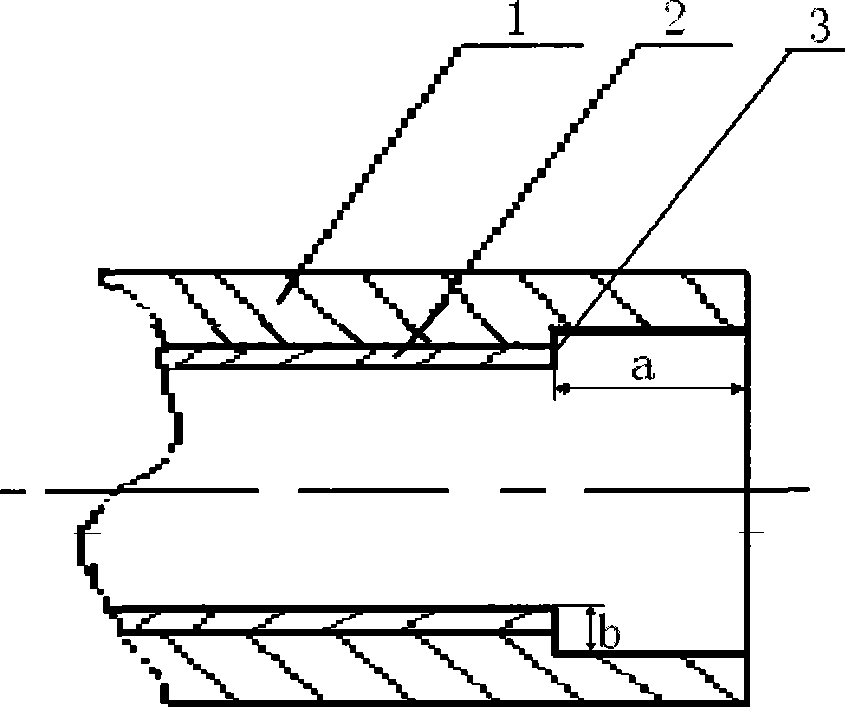

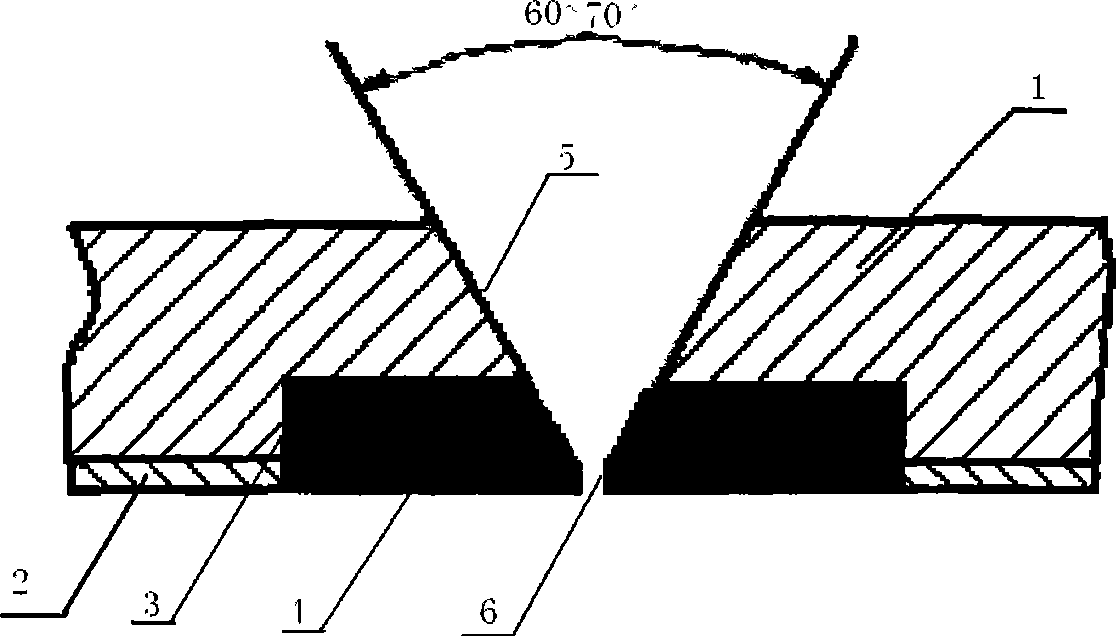

Thin-wall stainless steel double-layer and carbon steel base layer composite tube girth weld welding method

ActiveCN101100013AEliminate gapsIncrease the effective thicknessArc welding apparatusWelding/cutting media/materialsWeld seamMaterials science

The process of ring welding composite pipe comprising one thin stainless steel layer and one carbon steel base layer includes the following steps: 1. chamfering and eliminating oil stain; 2. bead welding and trimming chamfer; 3. pairing bimetal composite pipe chamfers; 4. argon shielded tungsten arc welding in the bottom; 5. welding the second layer to weld the base layers of two composite pipes; and 6. filling welding and finishing welding. During the welding process, stainless steel electrode and 309 or 309Mo welding material are adopted for reaching high strength and high toughness of the weld seam, and the chamfers have increased effective thickness of stainless steel layer for high welding quality and high corrosion resistance.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

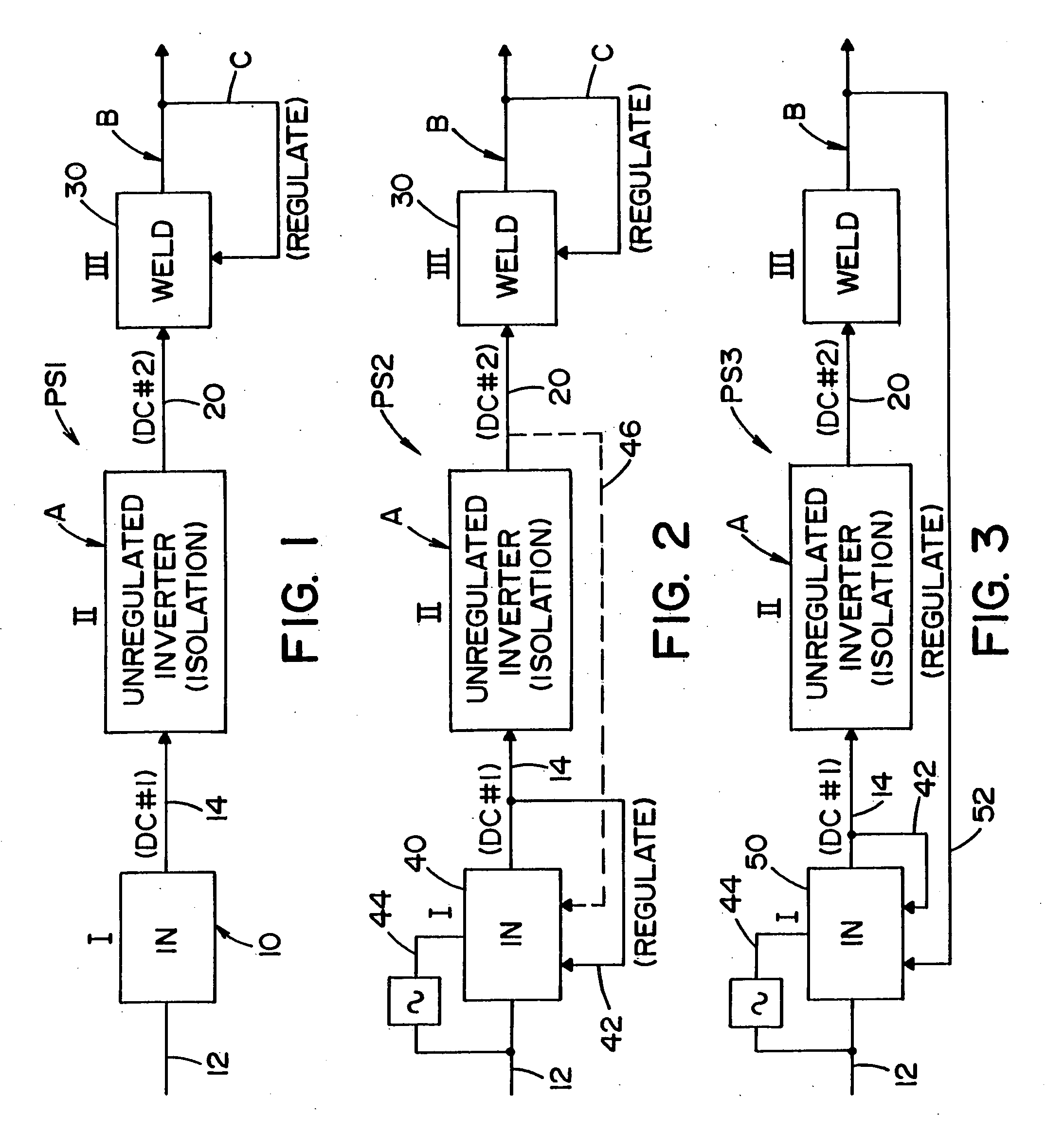

Power source for electric arc welding

A power source for an electric arc welding process, wherein the power source comprises an input stage having an AC input and a first DC output signal; a second stage in the form of an unregulated DC to DC converter having an input connected to the first DC output signal and an output in the form of a second DC output signal electrically isolated from the first DC output signal and with a magnitude of a given ratio to the first DC output signal; and, a third stage to convert the second DC output signal to a welding output for the welding process.

Owner:LINCOLN GLOBAL INC

Method and apparatus for welding

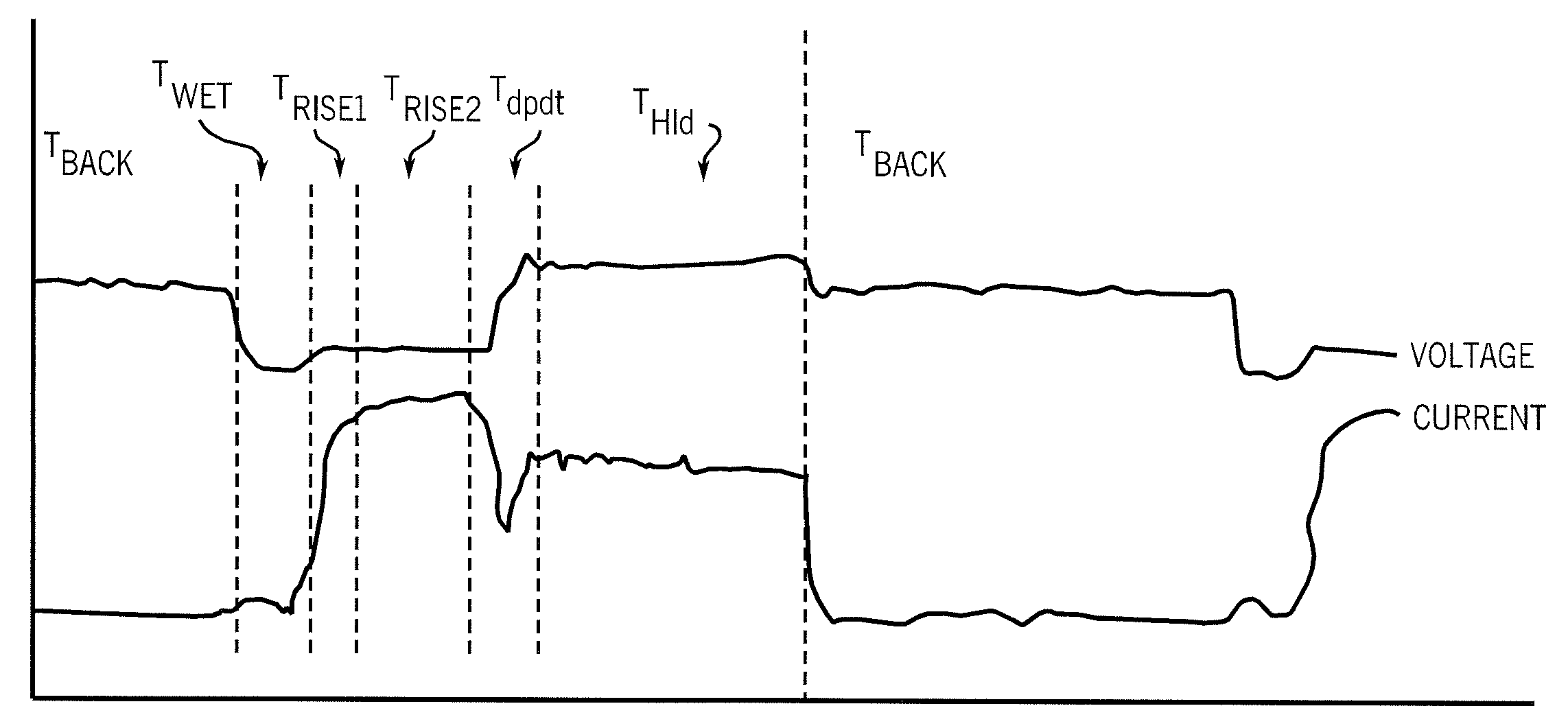

A short circuit arc welding system is disposed. The control scheme uses a current command signal to drive the output current. The command signal is comprised of a long-term current command that sets the long-term current command level and a real-time or short-by-short current command. Arc voltage feedback is used to determine if the desired arc length is present and to adjust the long-term command. The short-by-short current command is derived from real-time arc current feedback and is used to control the burn-off rate by an instantaneous, or short-by-short, adjustment of the current command. A function of the time derivative of arc power, less the time derivative of arc current, is used to detect, in real time, when the short is about to clear. A stop algorithm is employed that monitors the arc on a short-by-short basis. When the process is ending a very low current level is provided to avoid forming a ball. However, if a short is created, (indicated by a drop in arc voltage) after the low current level, a burst of energy is provided to clear of burn off the short. After the short is cleared, very low current is again provided to avoid forming a large ball. This is repeated until the wire stops and the process ends.

Owner:ILLINOIS TOOL WORKS INC

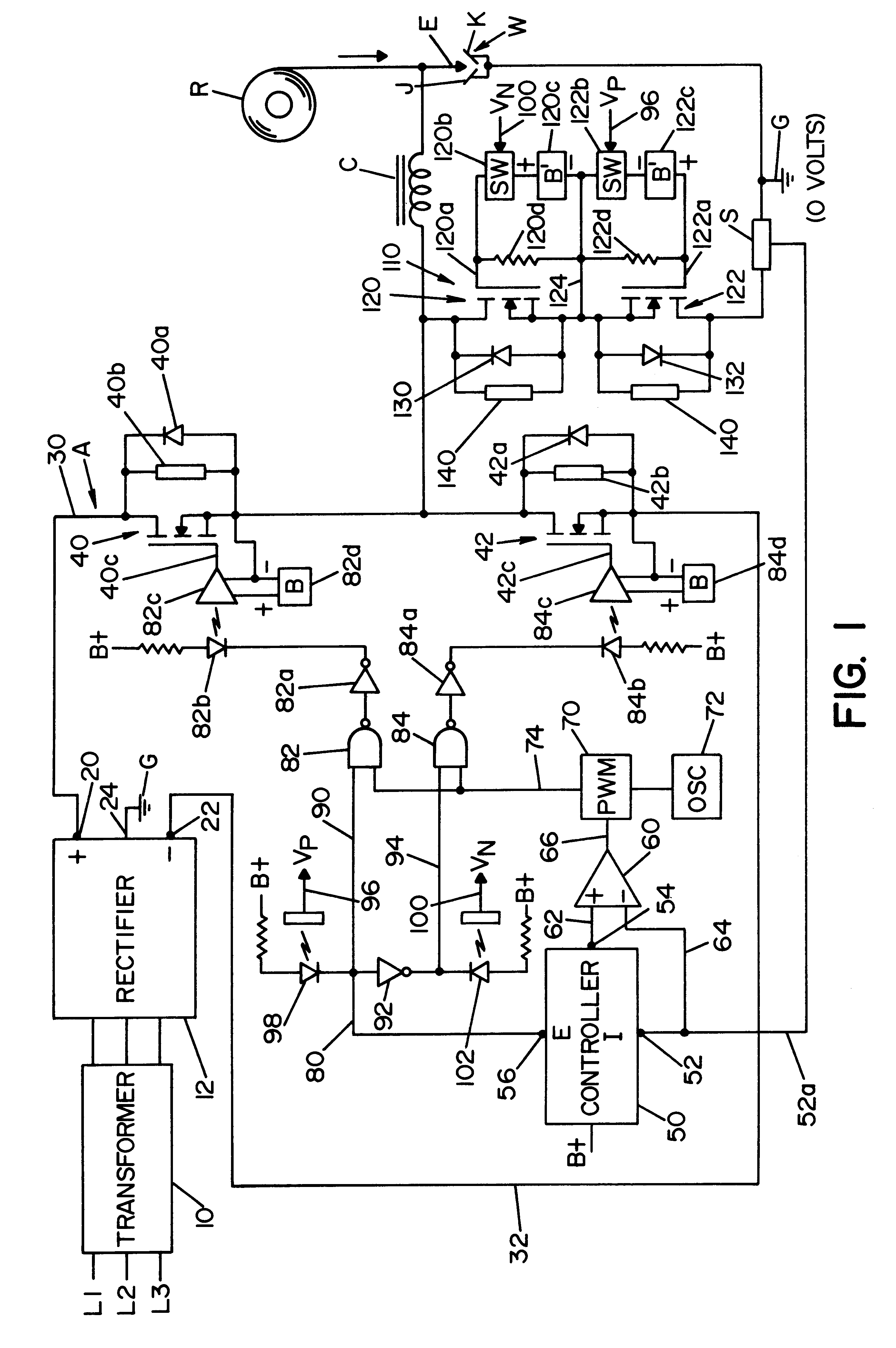

Power supply for electric arc welding

InactiveUS6365874B1Inexpensive power supplySubstantial engineeringArc welding apparatusAc-ac conversionTransformerLogic network

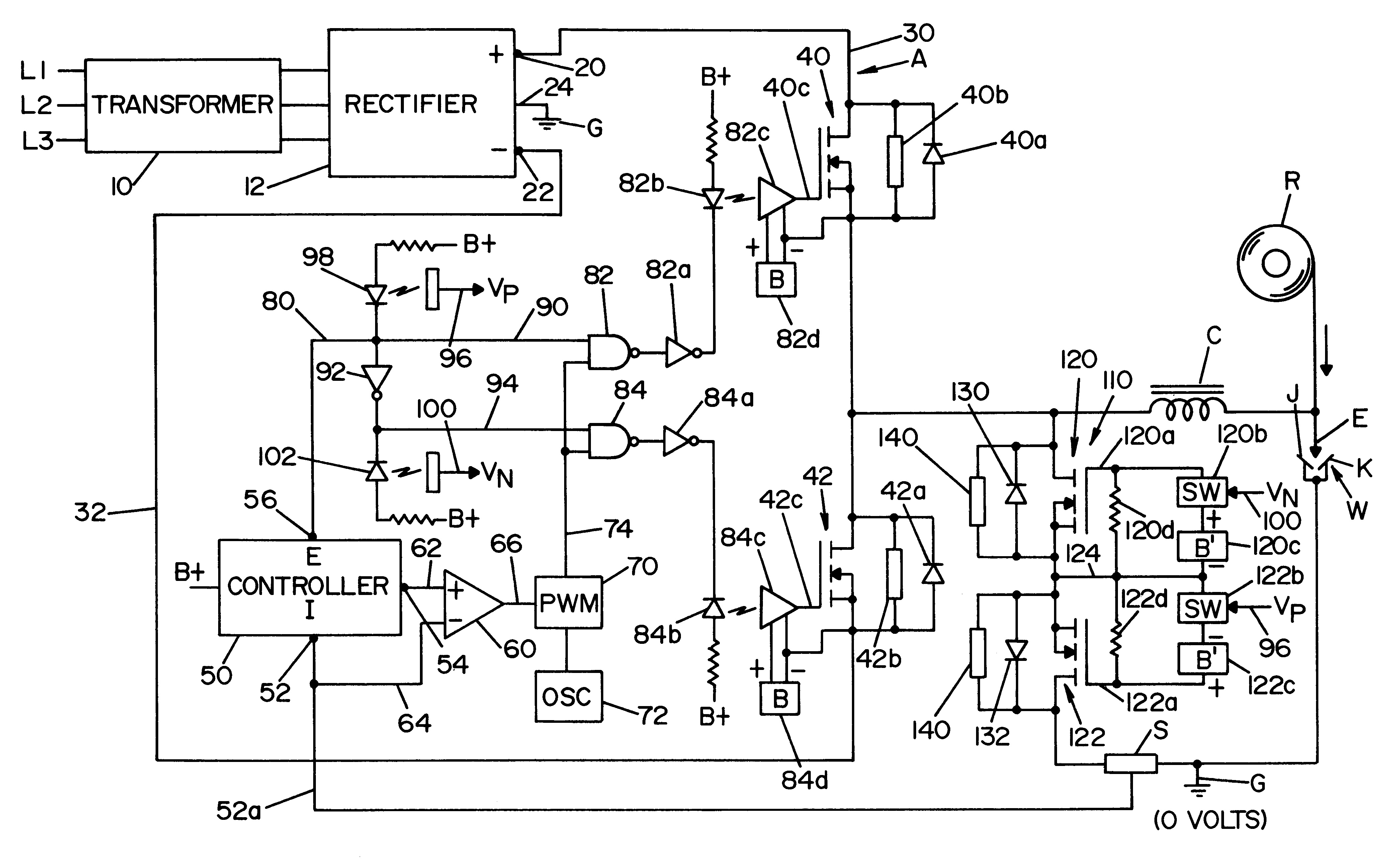

A power supply connectable to a source of AC line voltage for AC electric arc welding by an AC arc current across a welding gap between an electrode and a workpiece, the power supply comprises a high capacity transformer that converts said line voltage to an AC output voltage, and a rectifier that converts the AC output voltage to a DC voltage between a positive terminal and a common terminal at generally zero volts and a negative terminal and the common terminal. The power supply has a first switch that connects the positive terminal to the common terminal across the gap when a gate signal is applied to the first switch, a second switch for connecting the negative terminal to the common terminal across the gap when a gate signal is applied to the second switch and a pulse width modulator operated for generating pulses at a frequency of at least about 18 kHz. A logic network has a first circuit for directing the pulses to the first switch for a first time, a second circuit for directing the pulses to the second switch for a second time and a controller to alternately operate first and second circuits to create AC arc welding current.

Owner:LINCOLN GLOBAL INC

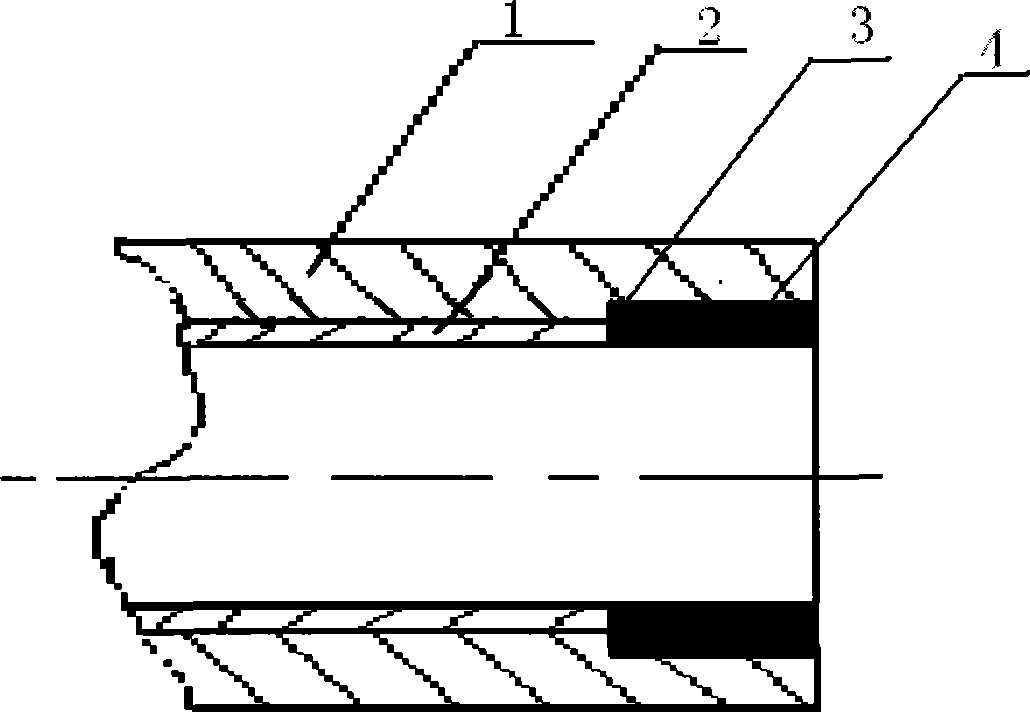

Method for welding thin layer iron nickel base alloy carbon steel composite tube

ActiveCN101462193AIncrease the effective thicknessHigh strengthArc welding apparatusWelding/cutting media/materialsAlloyWeld seam

The invention relates to a method for welding a carbon steel composite pipe of a thin iron-nickel-based alloy. The method comprises: processing a step on the end part of the composite pipe; adopting the surfacing of argon arc welding on the surface of the step and trimming the surfacing layer; processing a groove; adopting tungsten electrode argon arc welding to carry out three-point positioning of spot welding evenly around a welding seam, and adopting the tungsten electrode argon arc welding to carry out back welding on the root; and adopting manual electric arc welding to carry out filling welding and overlay welding on the upper part of a second layer of back welding. The chemical compositions of a welding material by weight percentage: 0.02 to 0.1 percent of C, 0.2 to 1.0 percent of Si, 1.0 to 2.2 percent of Mn, 20.0 to 31.5 percent of Cr, 40.0 to 60.0 percent of Ni, 8.0 to 14.5 percent of Mo, 0.5 to 2.5 percent of Cu, 0 to 5.0 percent of Co, 0.3 to 4.2 percent of Nb, and the balance being Fe. The welding seam has the characteristics of no sensitivity to offset, favorable corrosion resistance, high strength and favorable plastic toughness.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Short circuit arc welder and method of controlling same

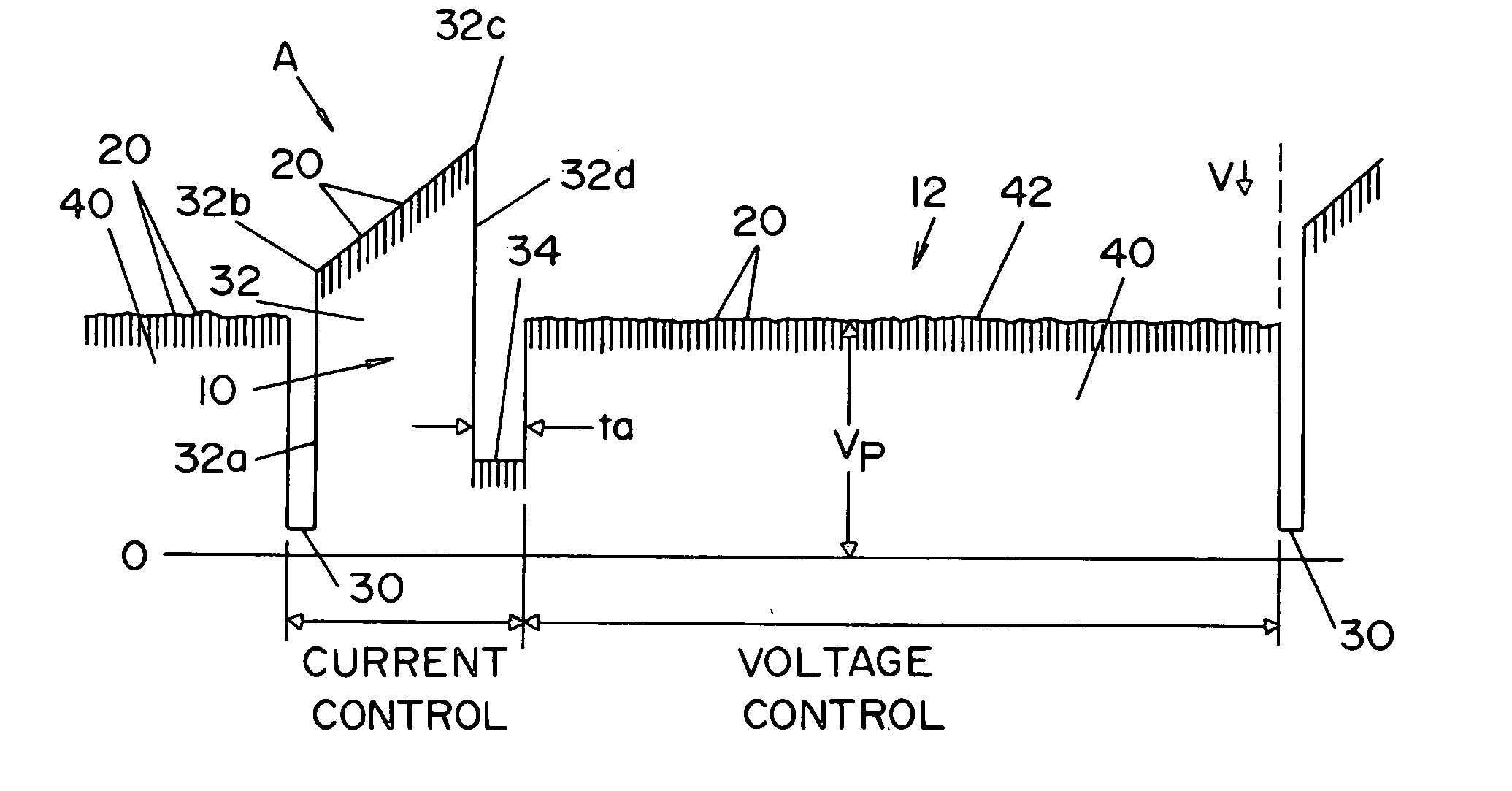

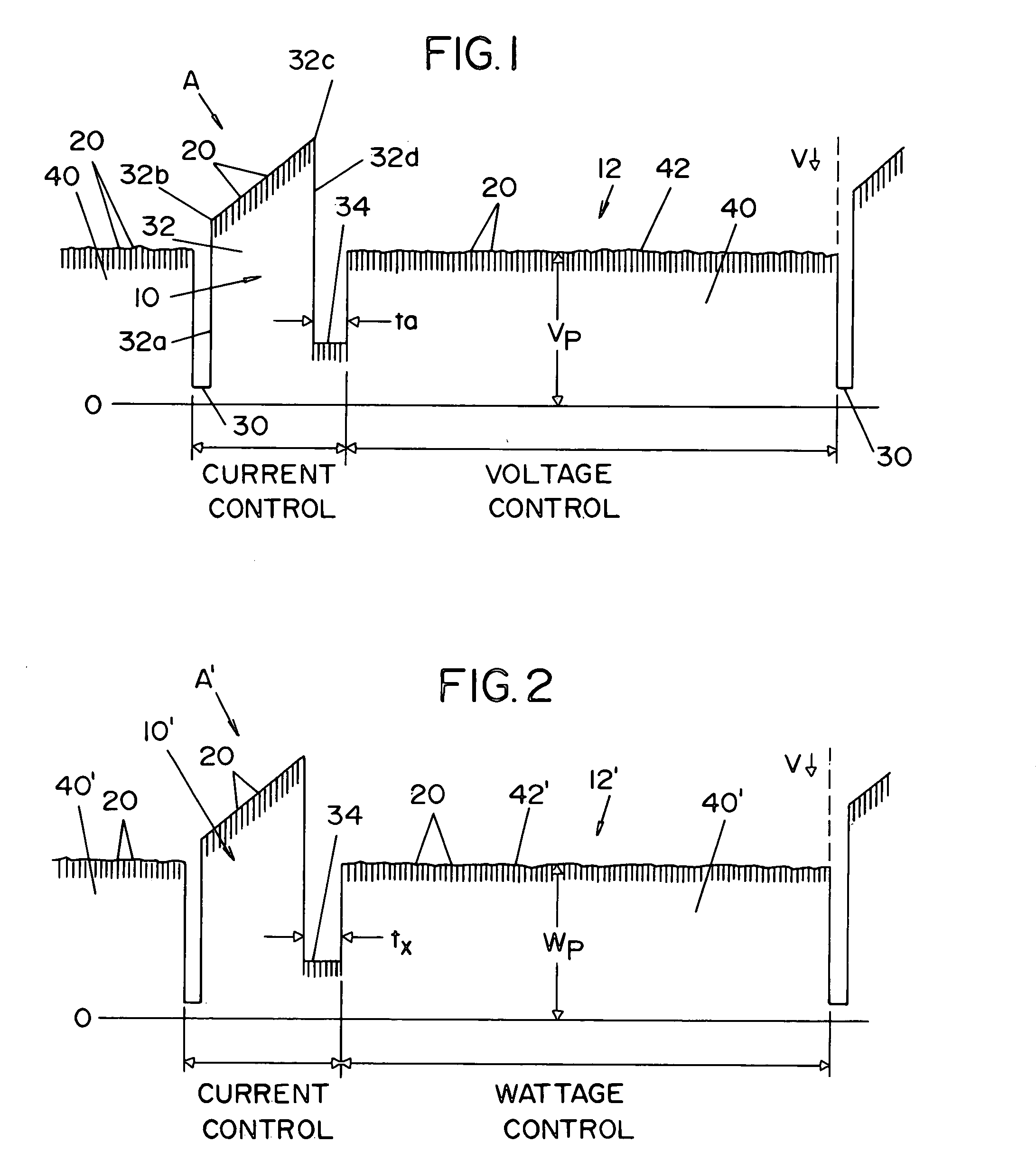

ActiveUS20050184039A1Easy to controlAccurate heating controlArc welding apparatusPipeline systemsPulse waveCurrent pulse

An electric arc welder operated to perform a short circuit welding process between an electrode and a workpiece, where the process comprises a succession of alternate short circuit conditions and arc conditions, with a first current waveform during the short circuit condition and a second voltage waveform during the arc condition. A first waveform generator constructs the first waveform from a series of current pulses controlled by a pulse wave modulator operated at a rate greater than 18 kHz and a second waveform generator constructs the second waveform from a series of current pulses controlled by a pulse wave modulator operated at a rate greater than 18 kHz. The second waveform generator has a circuit to generate the second waveform with a generally constant arc parameter, generally voltage.

Owner:LINCOLN GLOBAL INC

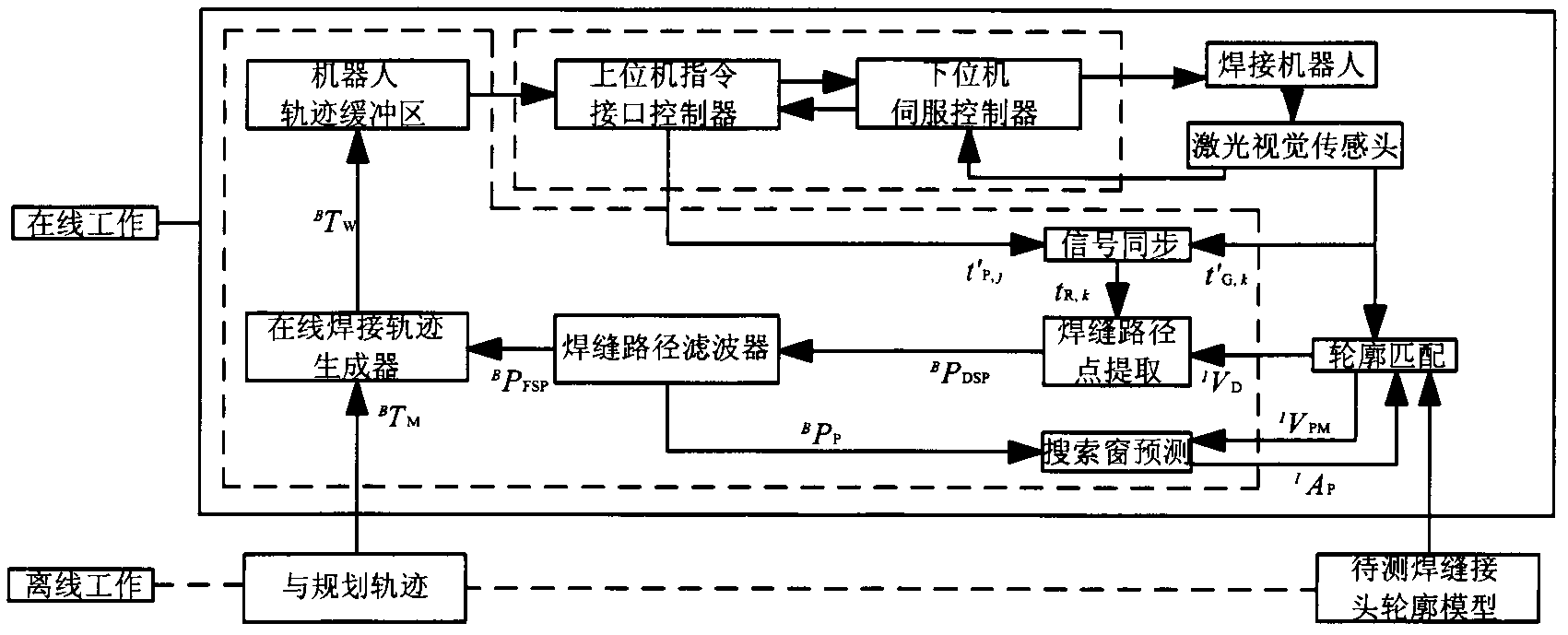

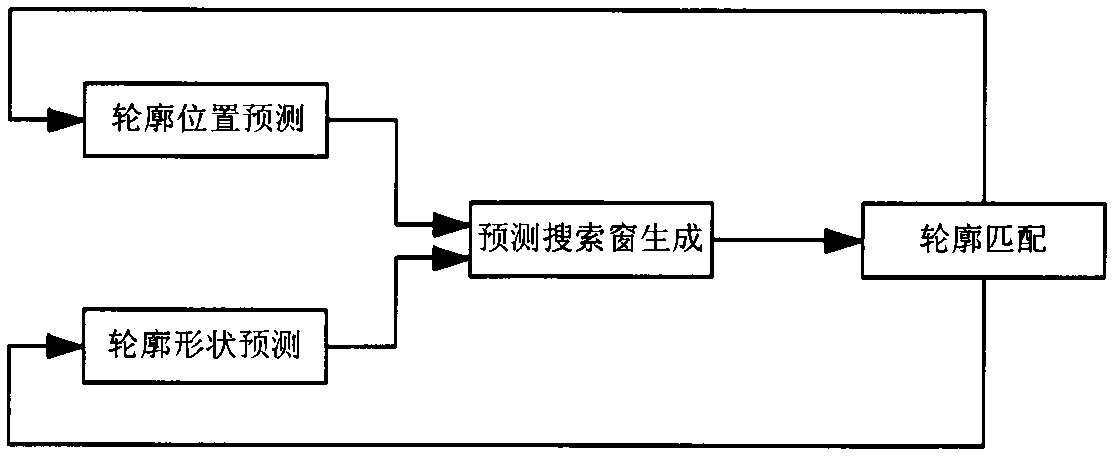

Arc welding robot laser vision seam tracking control method based on offline planning

InactiveCN102430841AAchieving Adaptive WeldingGuaranteed reliabilityArc welding apparatusSimulationVisual perception

The invention relates to an arc welding robot laser vision seam tracking control method based on offline planning. An online robot seam tracking task is completed by combining information such as a prior model of a target to be measured given by seam tracking offline planning, a planned seam tracking movement trace and the like and comprehensively using a sensor detection and predication mechanism, a transmission delay compensation mechanism, an online seam path filtering mechanism and an online 6-dimensional welding trace synthesis mechanism. The sensor planning technology is introduced into offline programming, so that the onsite teaching problem can be solved, and a template of a total solution to entire seam tracking can be provided from the macroscopic aspect on the principle that excellent sensor detection, welding gun welding and robot operating state are ensured by taking the sensor planning technology as a common manner of systematic problem solving. The sensor only needs to effectively correct a part of links of the template on line in real time to finally automatically and symmetrically solve the robot seam tracking problem.

Owner:昆山华恒机器人有限公司

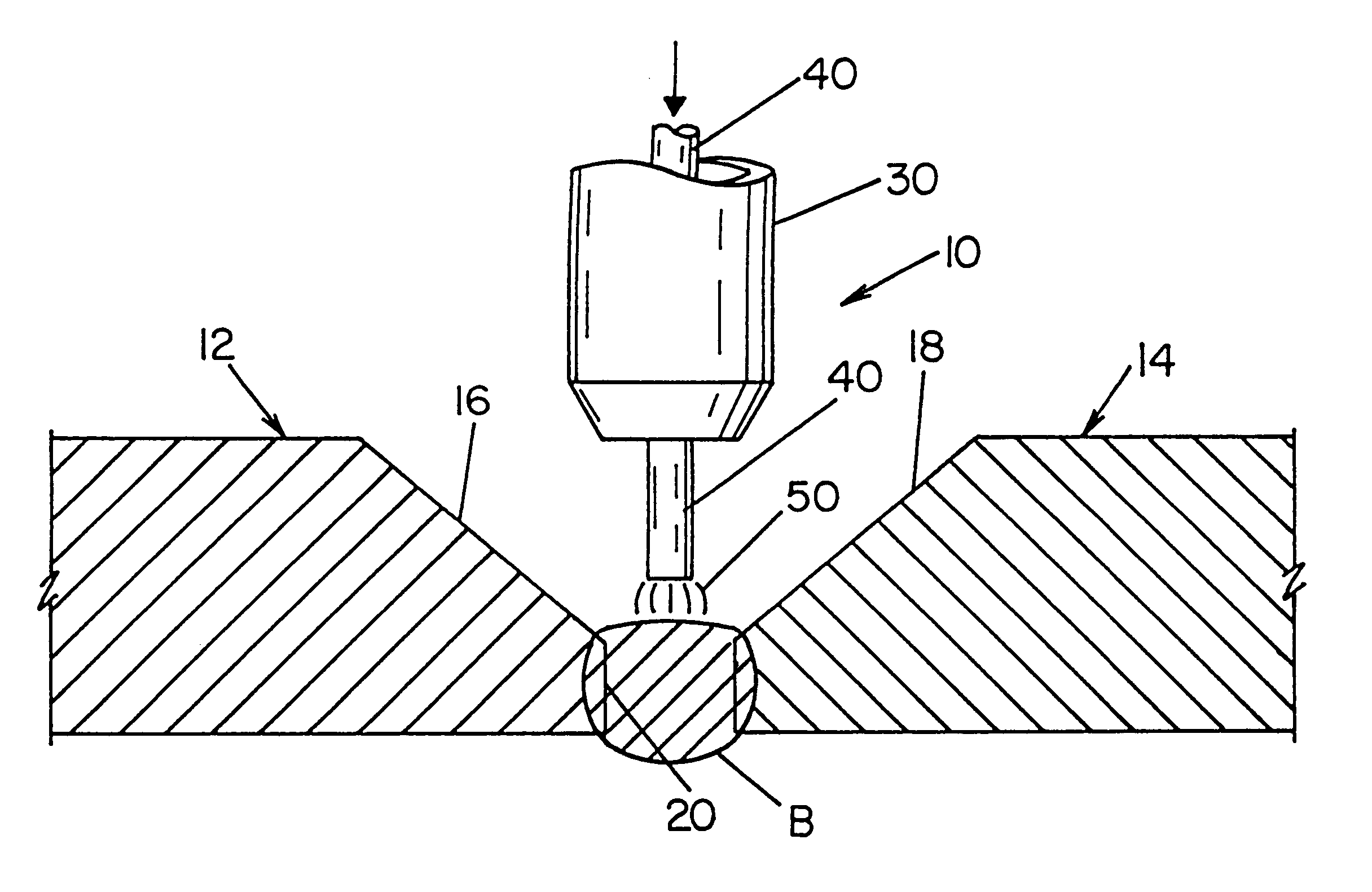

Method of pipe welding

InactiveUS6204478B1Good lookingIncrease driving speedMeasurement of fluid loss/gain rateArc welding apparatusSulfurManganese

A method of welding the ends of two pipes at the open root between the spaced ends by an STT electric arc welder, which comprises: selecting a welding wire having 0.06-0.15% by weight carbon, 0.90-1.40% by weight manganese, and 0.45-0.75% by weight silicon, as well as phosphorous, copper, stainless steel alloys and sulfur; maintaining the sulfur at a given percentage level of the selected wire in the specific range of 0.015 to 0.035% by weight; and maintaining said phosphorous at a given percentage level of said selected wire in the specific range of less than about 0.015%.

Owner:LINCOLN GLOBAL INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com