Patents

Literature

57631 results about "Conductor Coil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

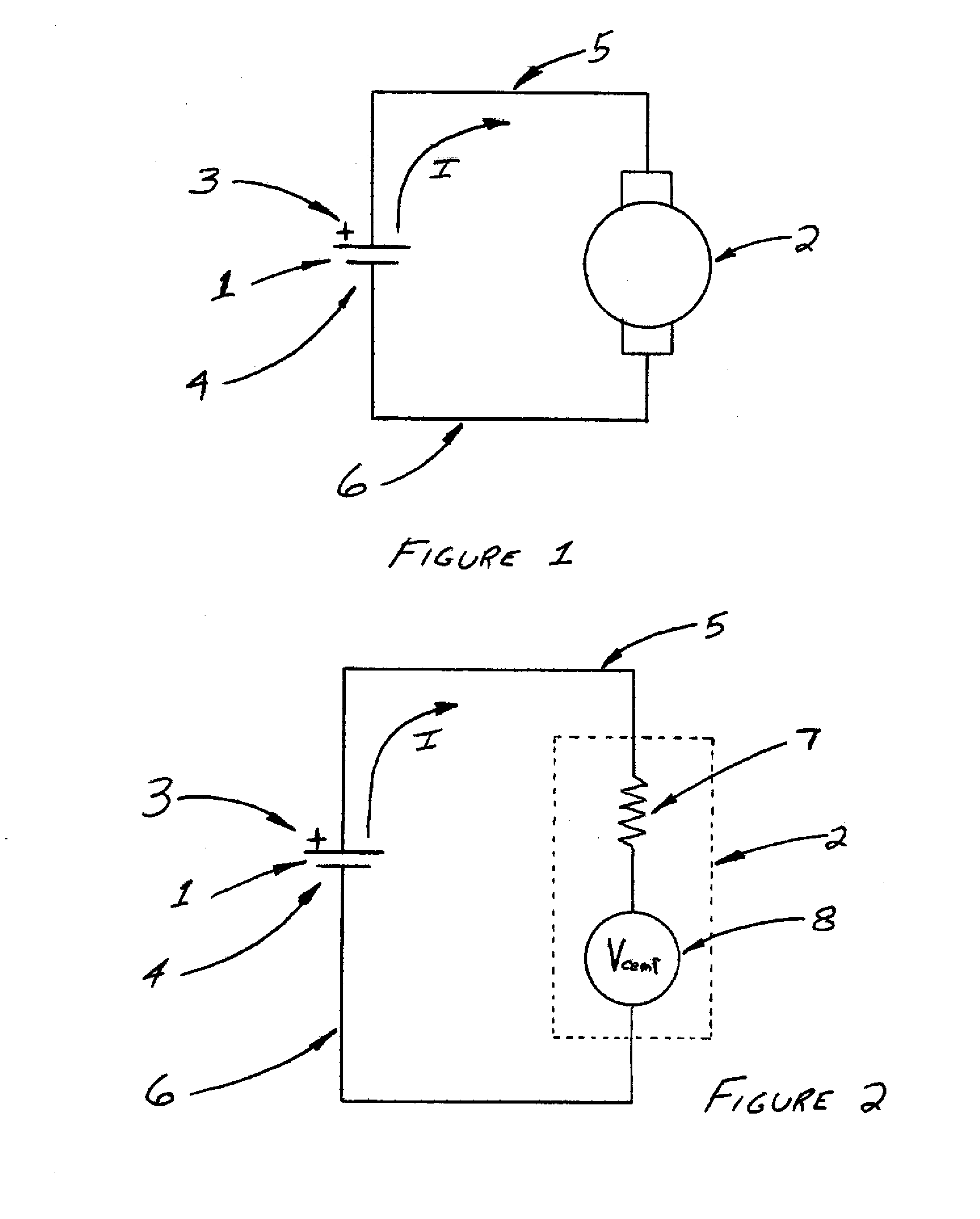

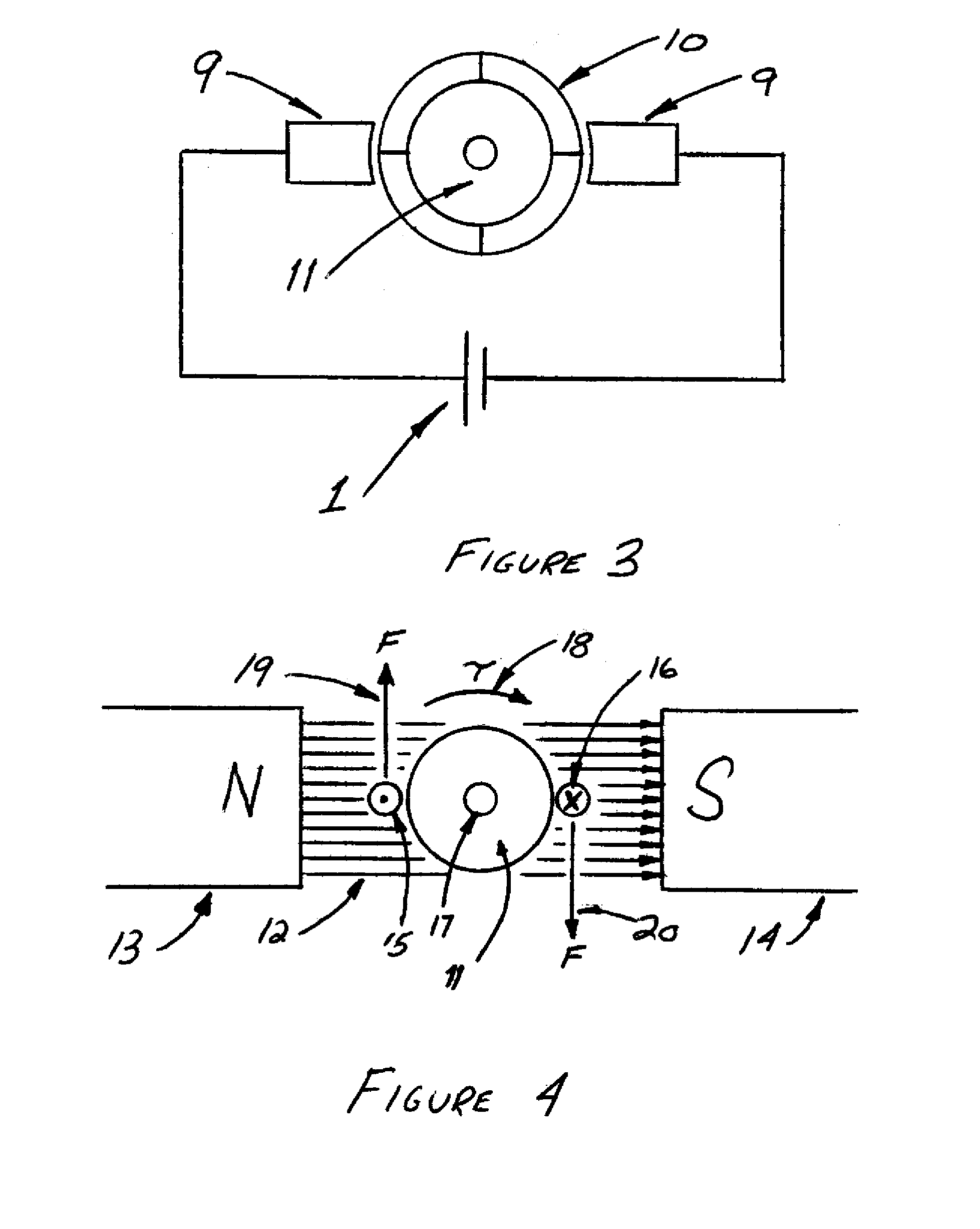

An electromagnetic coil is an electrical conductor such as a wire in the shape of a coil, spiral or helix. Electromagnetic coils are used in electrical engineering, in applications where electric currents interact with magnetic fields, in devices such as electric motors, generators, inductors, electromagnets, transformers, and sensor coils.

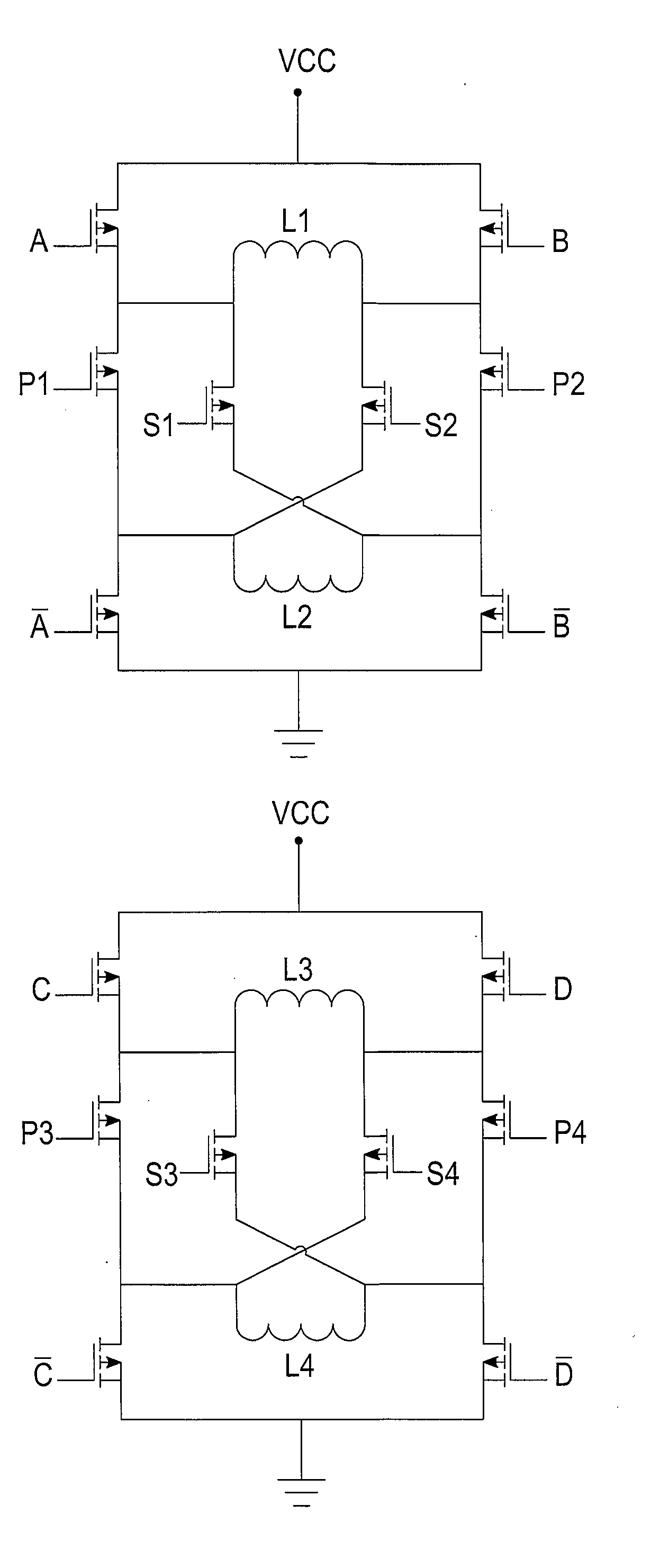

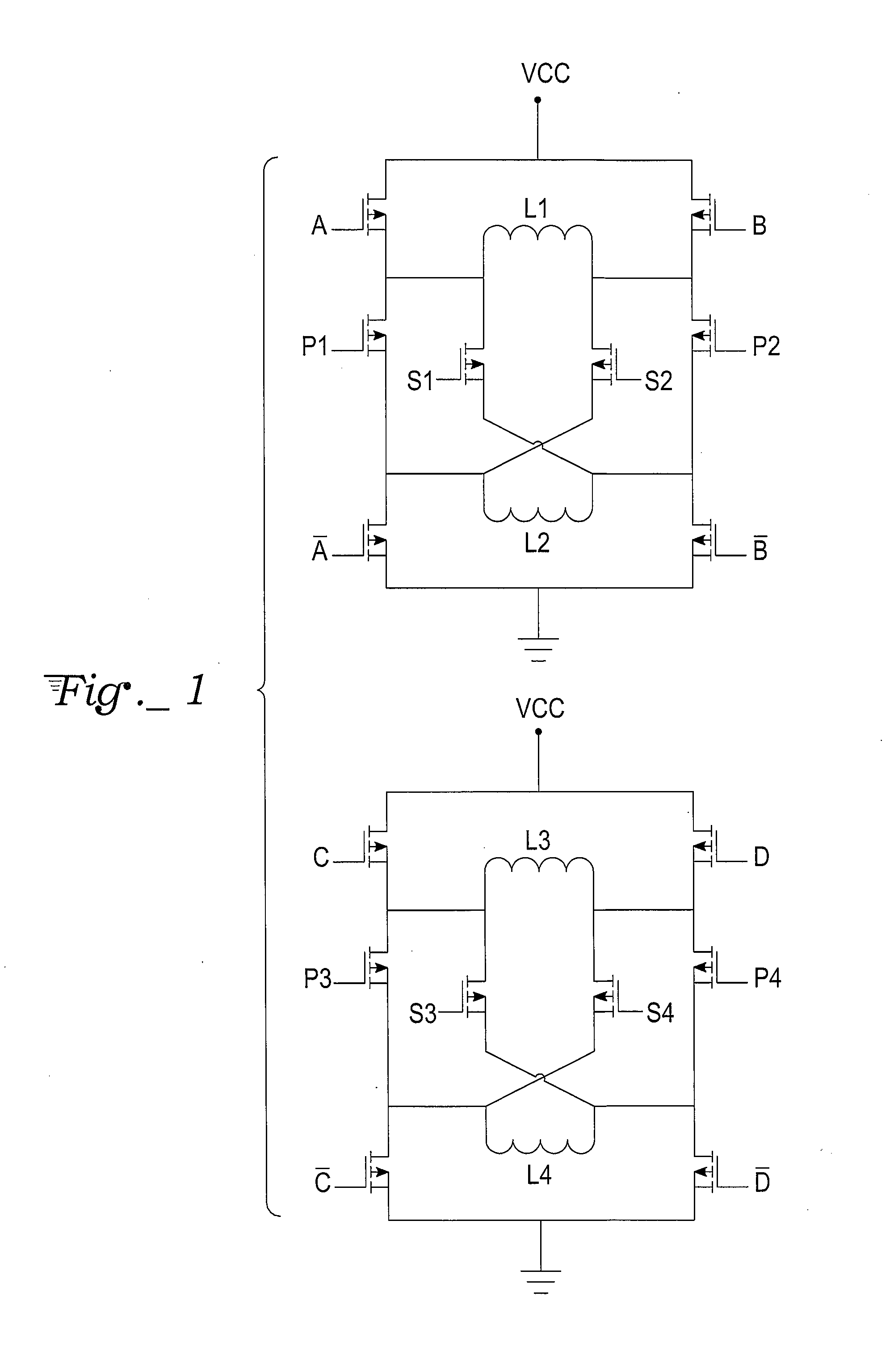

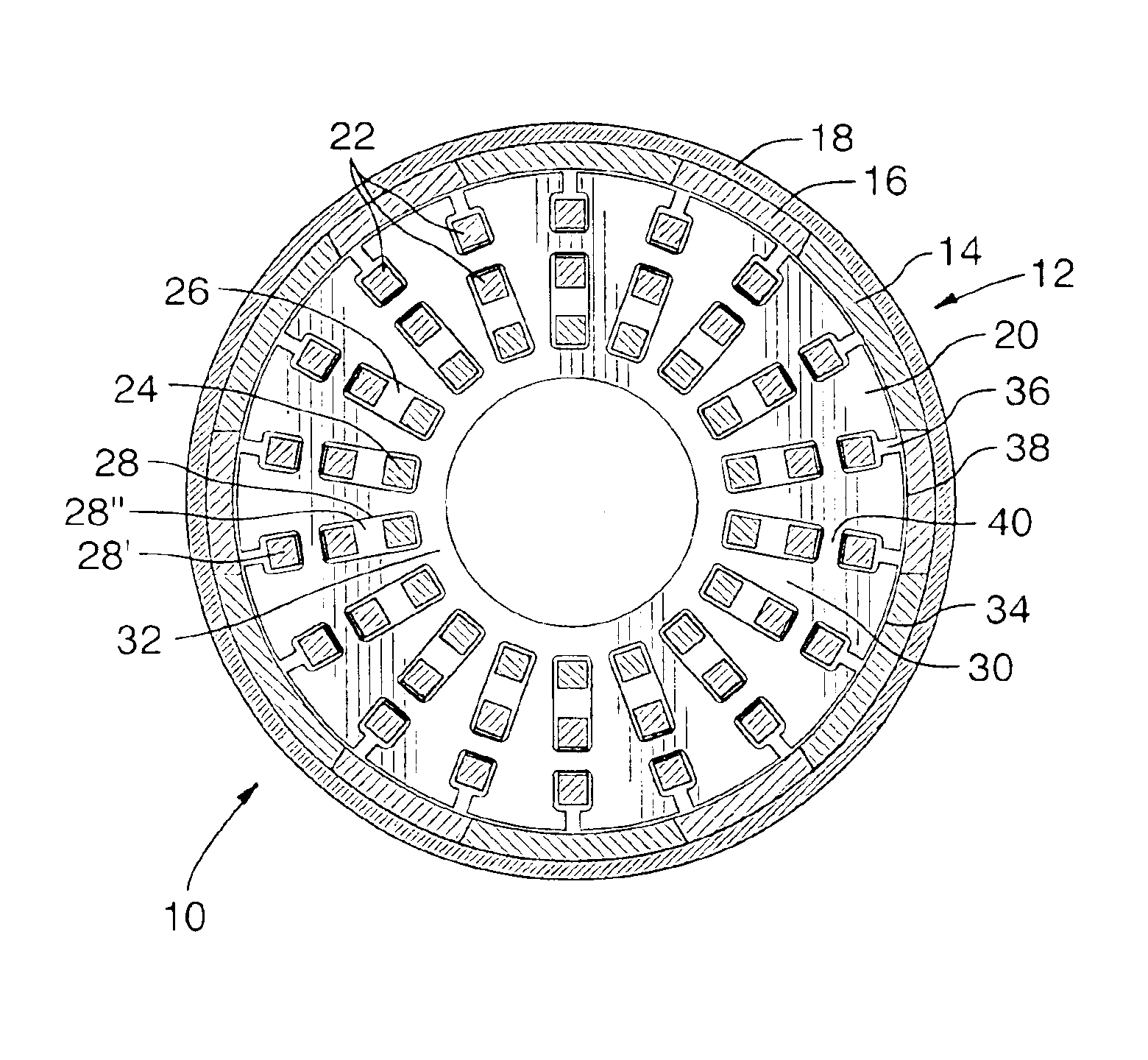

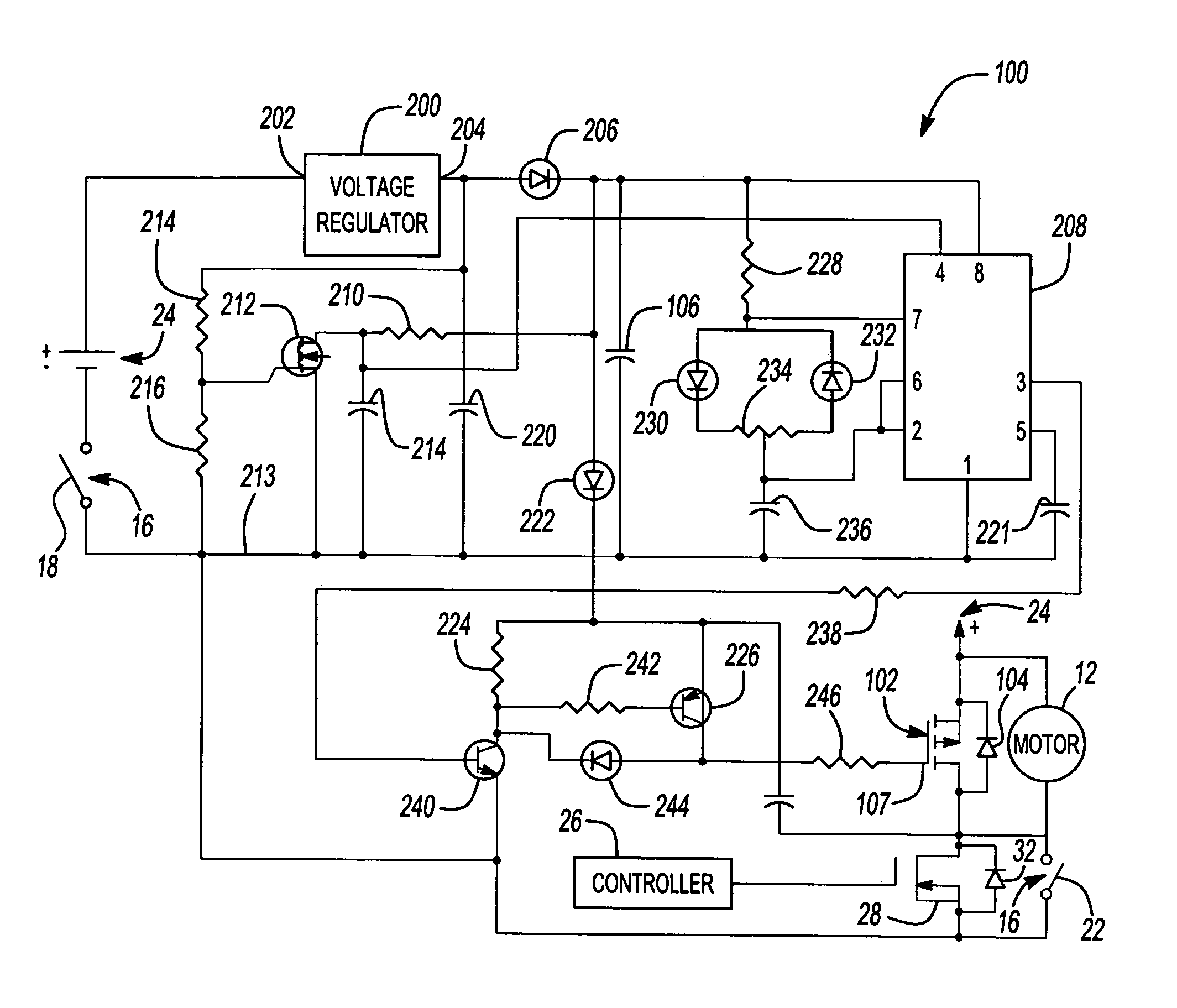

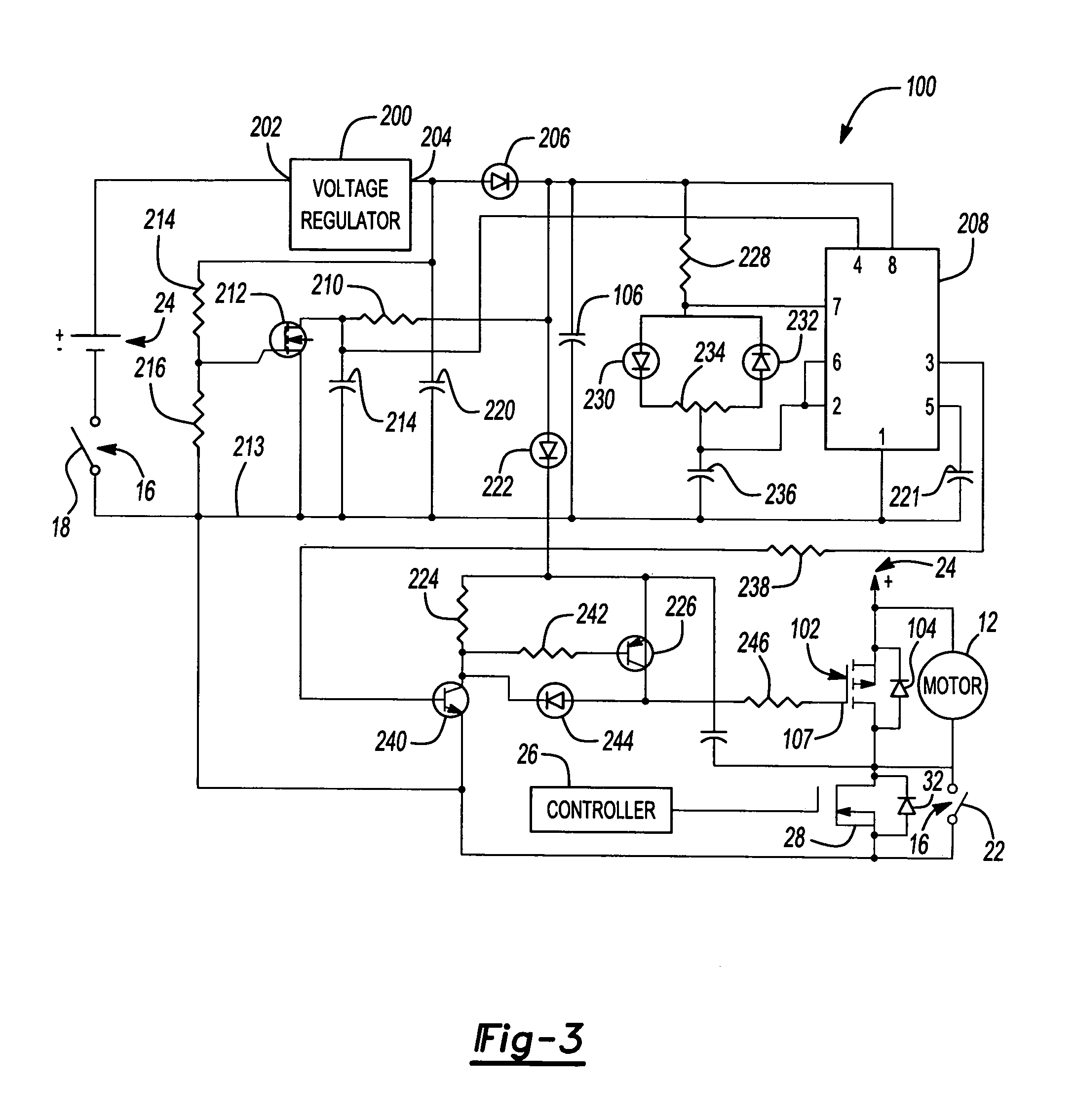

H-bridge drive circuit for step motor control

InactiveUS20110241597A1Improve stand-alone performanceEasy to implementDynamo-electric converter controlMotor speedDriving current

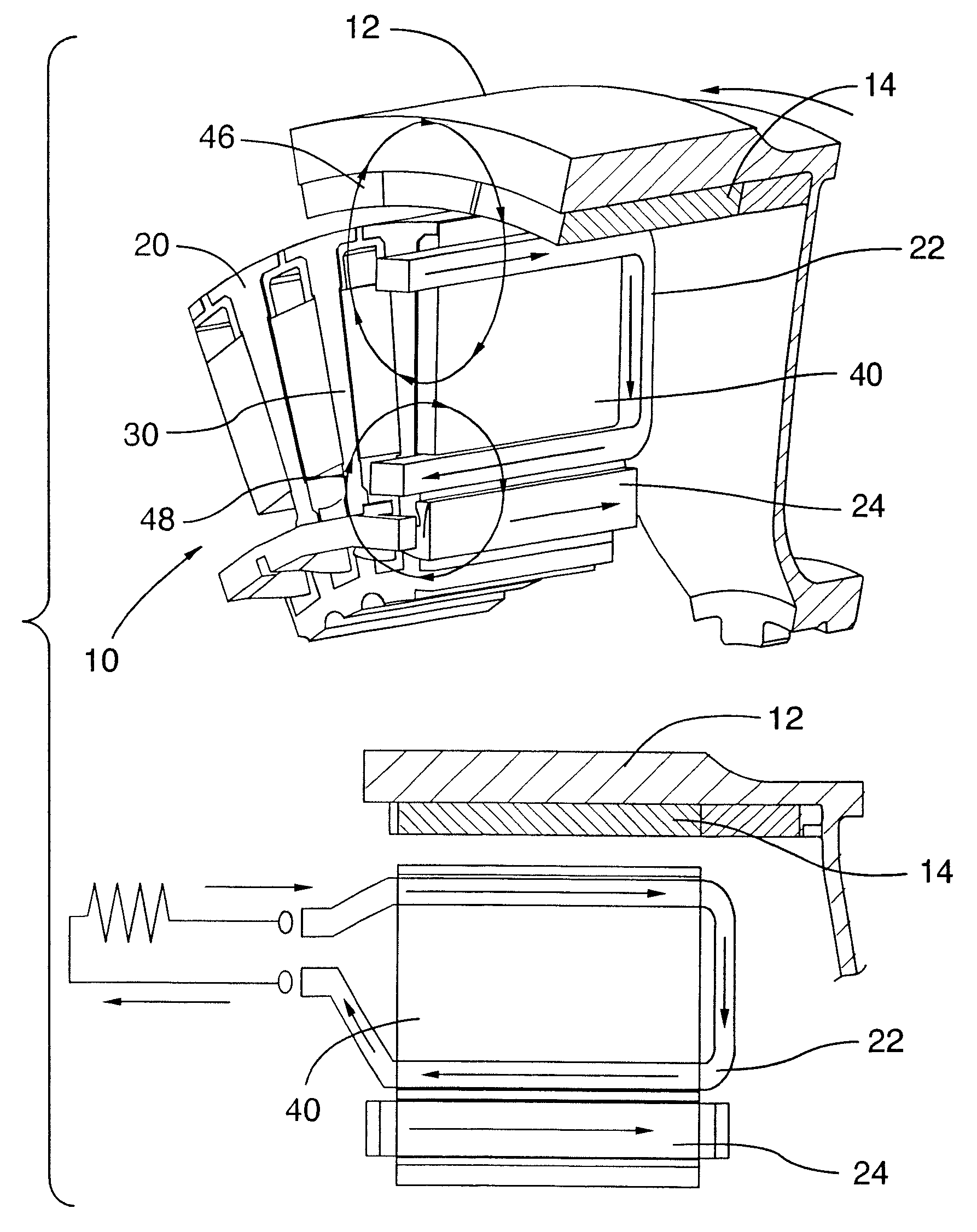

A drive circuit for step motors with bifilar windings is provided in which both parallel and series winding configurations for the stator coils are selectable by a motor controller based on the motor speed. For low speeds a series configuration is selected, while for higher speeds a parallel configuration is selected. Dynamic torque is optimized by the selection for more efficient motor operation with less drive current.

Owner:LIN ENG INC

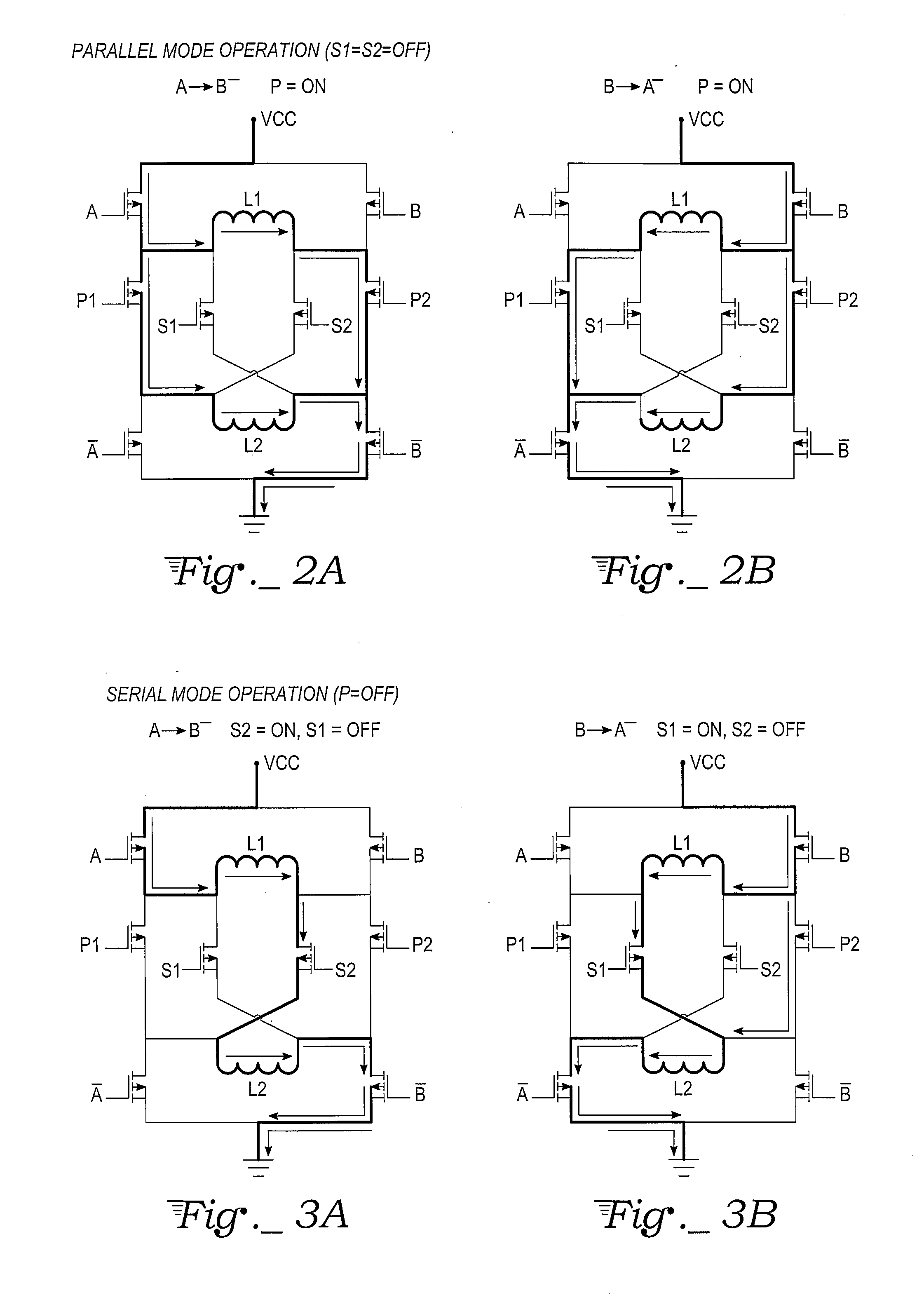

Electric machine having an integrally continuous stator winding and stator slot bridges

The invention includes an electric machine having a rotor, stator and at least one winding in the stator adapted to conduct a current, and a secondary winding, electrically isolated from the first winding and inductively coupled to the first winding, which may be used to control at least one of the output voltage and current of the first winding.

Owner:PRATT & WHITNEY CANADA CORP

Architecture for electric machine

InactiveUS7583063B2Magnetic circuitEmergency protective circuit arrangementsElectricityElectric machine

The invention includes an electric machine having a rotor, stator and at least one winding in the stator adapted to conduct a current, and a secondary winding, electrically isolated from the first winding and inductively coupled to the first winding, which may be used to control at least one of the output voltage and current of the first winding.

Owner:PRATT & WHITNEY CANADA CORP

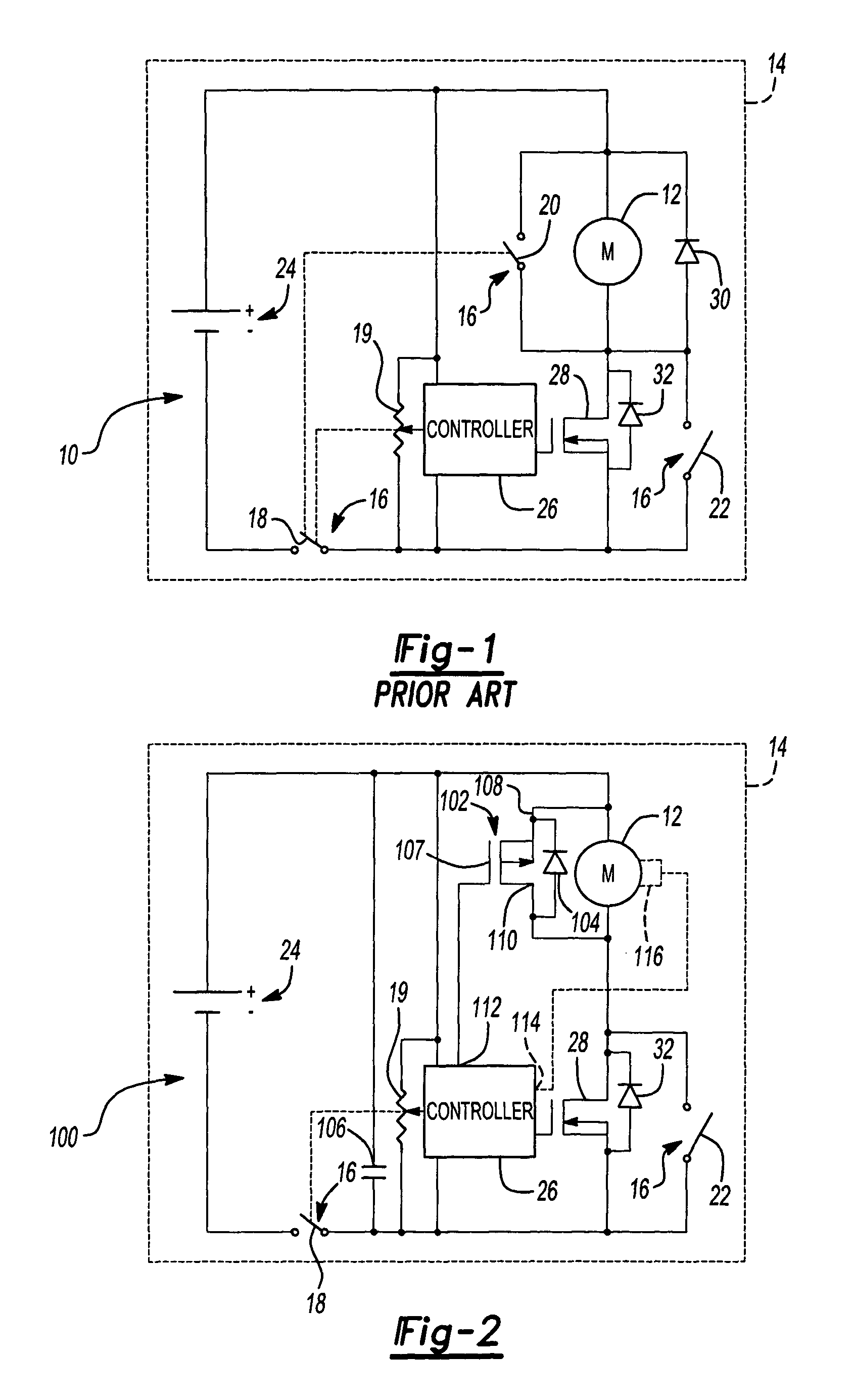

Method and device for braking a motor

InactiveUS7023159B2Eliminate needAC motor controlDC motor speed/torque controlPower switchingConductor Coil

A method and apparatus for braking a motor has a braking power switching device coupled across windings of the motor. To brake the motor, the braking power switching device is cycled on and off.

Owner:BLACK & DECKER INC

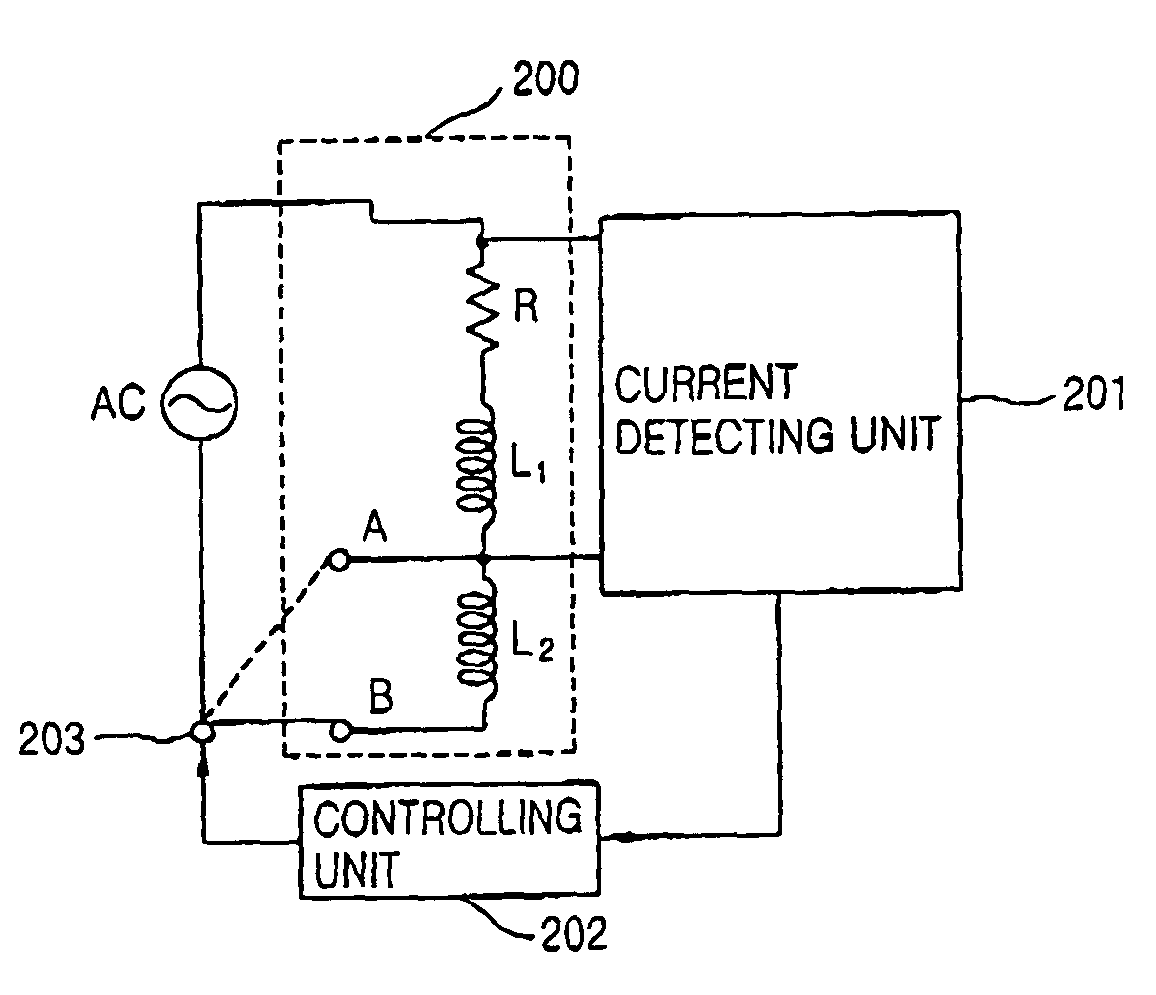

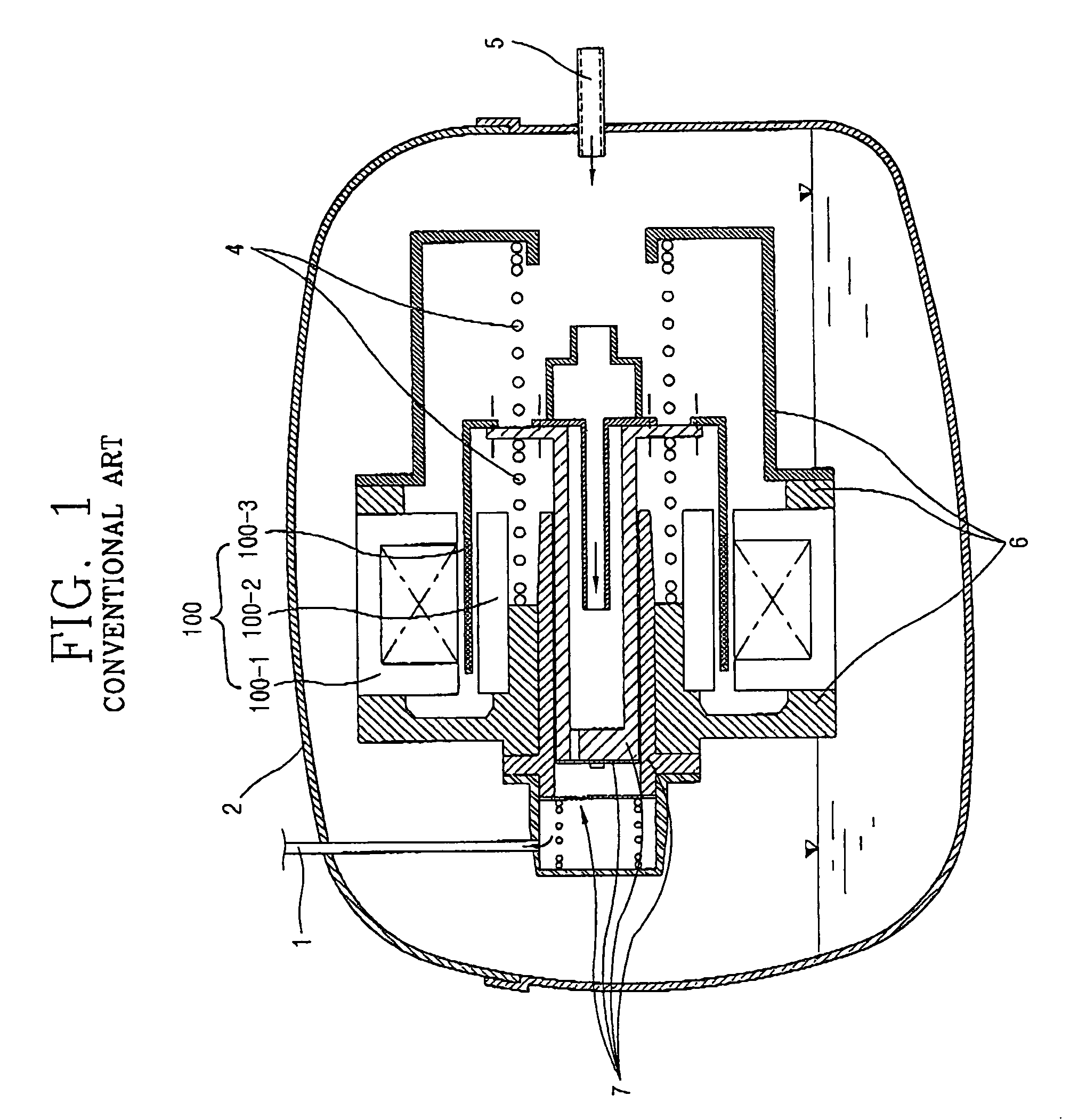

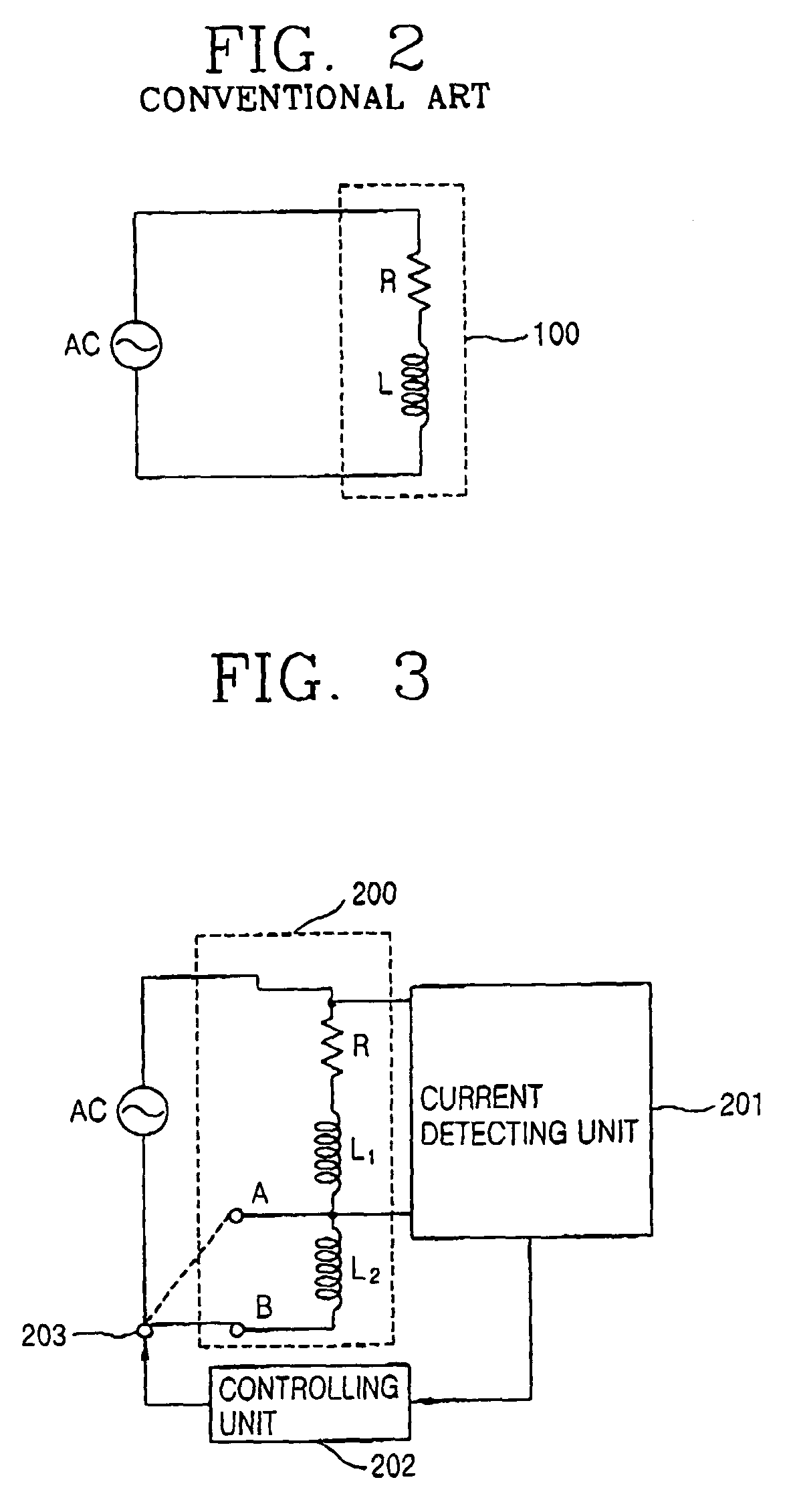

Apparatus and method for controlling driving of linear motor

InactiveUS6998736B2Increase efficiency of linearMotor/generator/converter stoppersDC motor speed/torque controlControl signalLinear compressor

Owner:LG ELECTRONICS INC

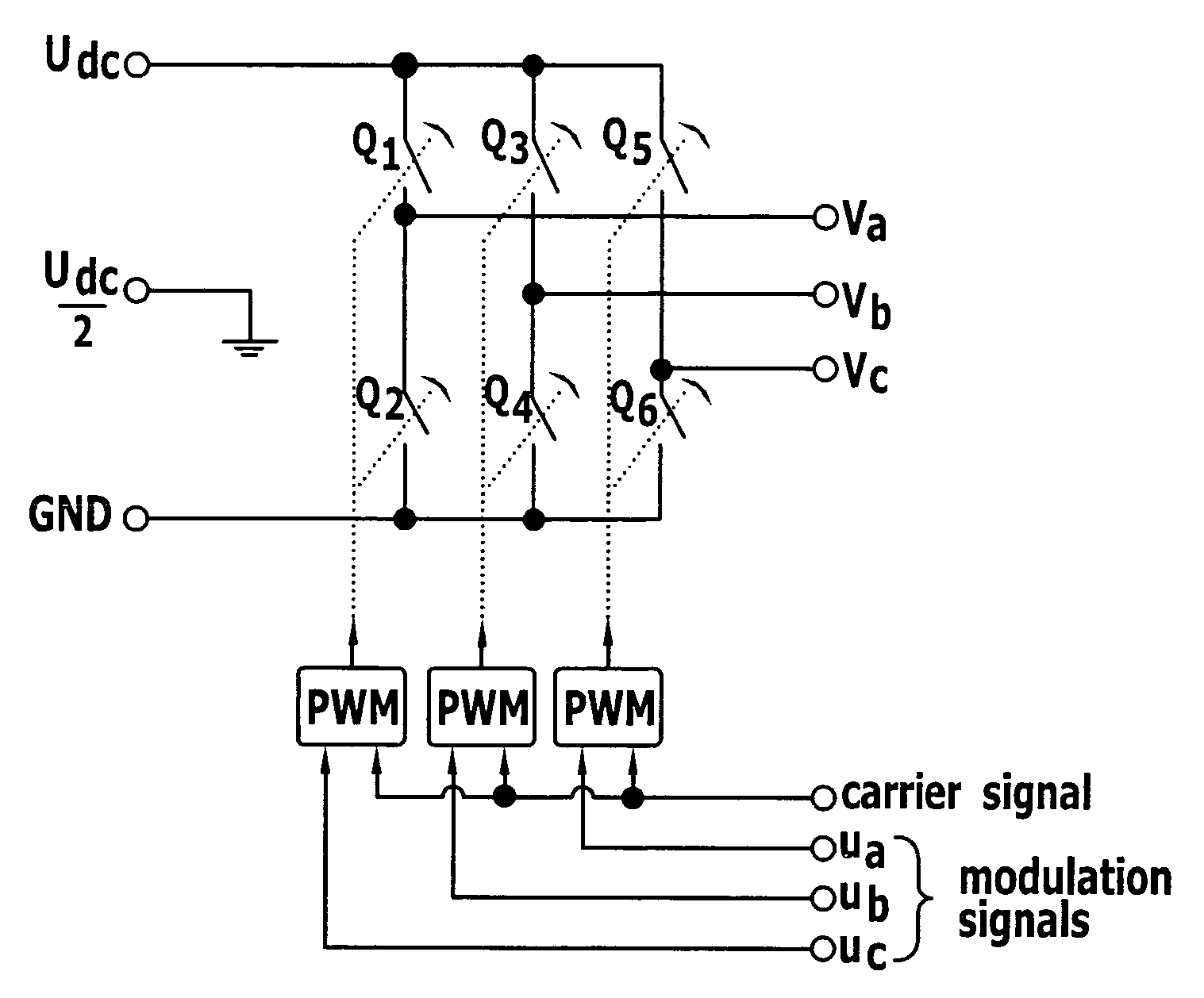

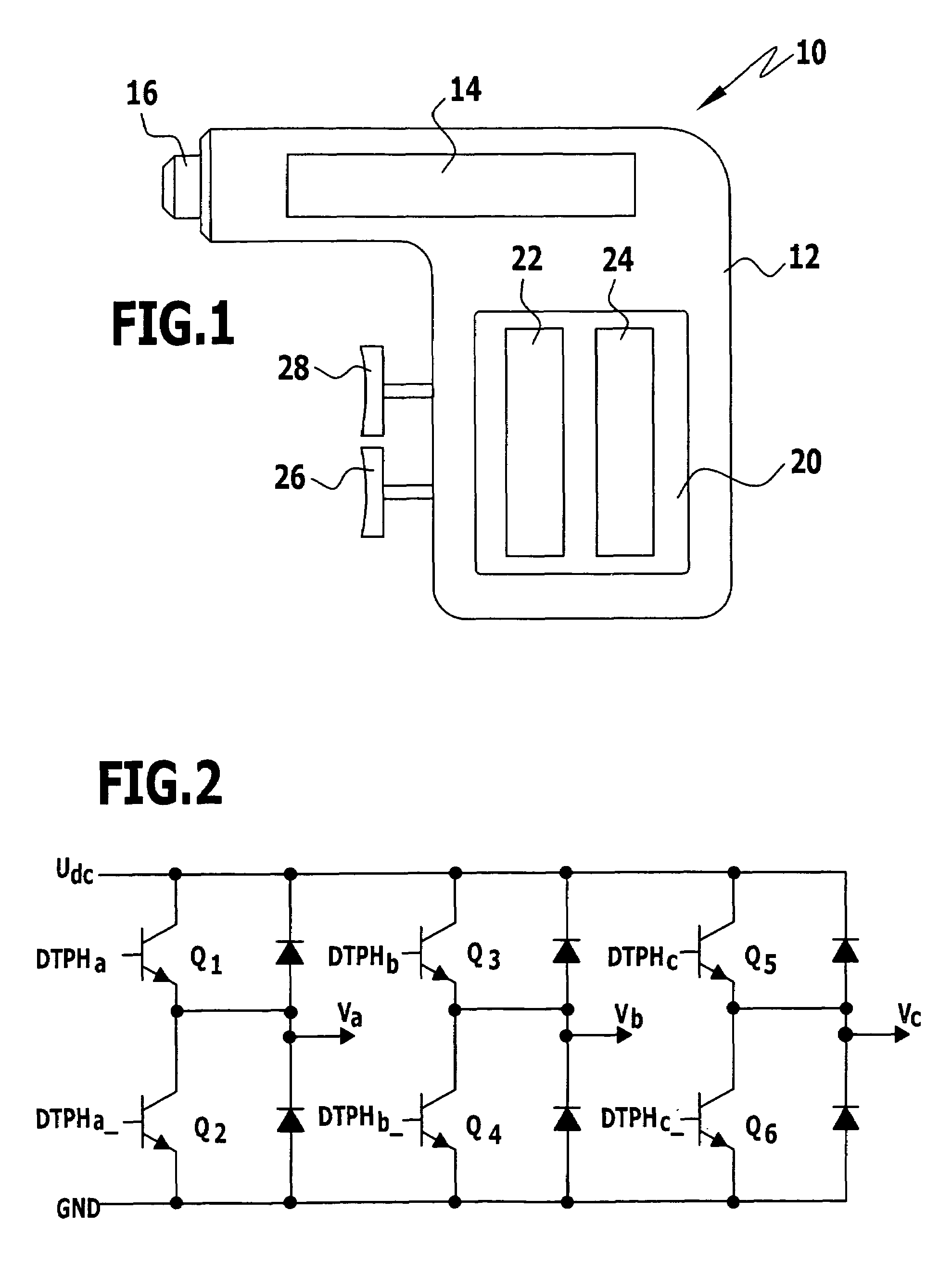

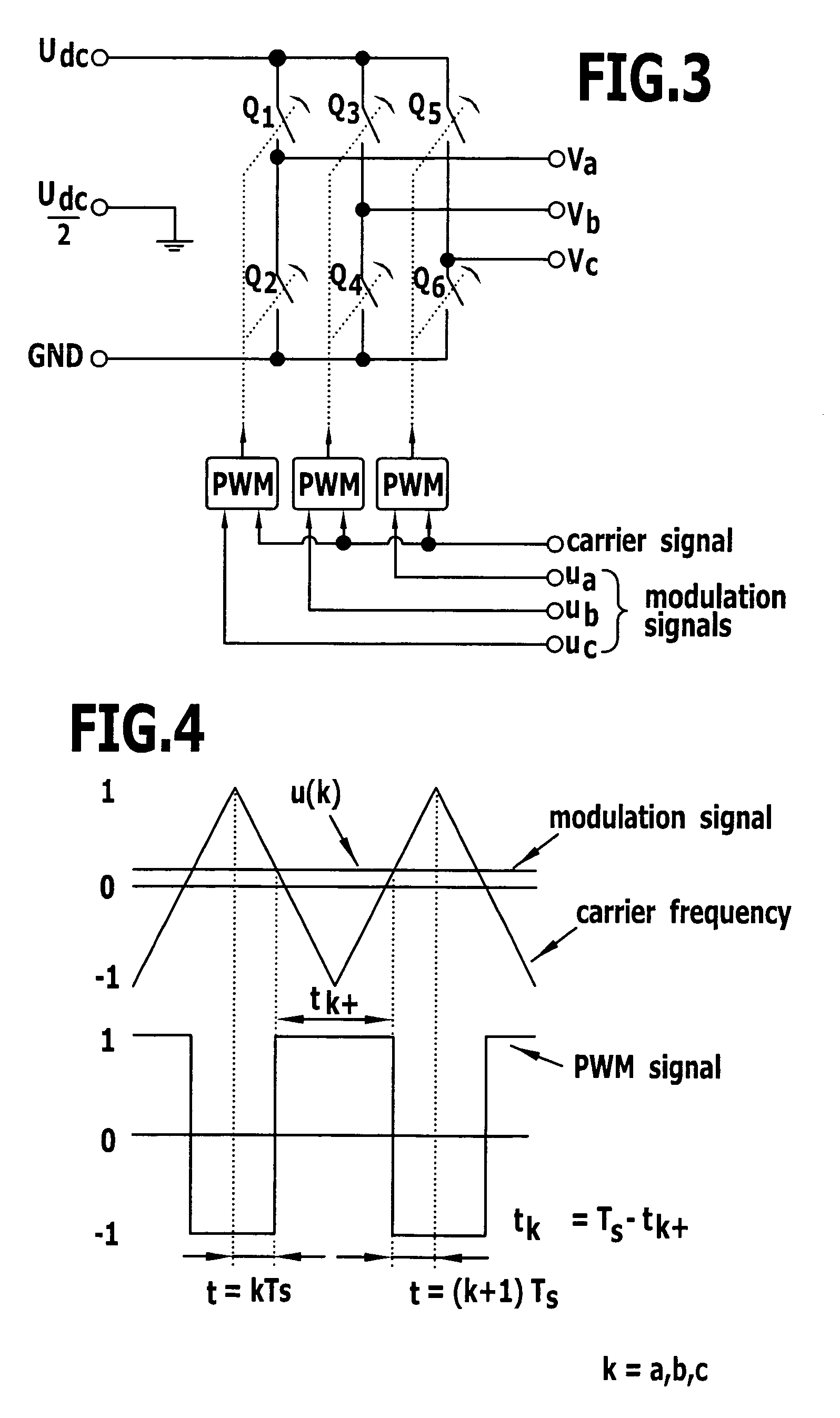

Surgical machine and method for controlling and/or regulating a surgical machine

ActiveUS7362062B2Guaranteed uptimeEasy to startElectronic commutation motor controlDC motor speed/torque controlMotor controllerControl theory

To improve a surgical machine with a sensorless electric motor comprising a rotor and at least two motor windings, and with a motor controller for controlling and / or regulating the electric motor, so that the electric motor is operable with optimum efficiency at low rotational speeds and a starting of the motor in accordance with the purpose, also under load, is enabled, it is proposed that a space vector pulse width modulation (SVPWM) method for controlling and / or regulating the electric motor, in which all motor windings are able to be simultaneously supplied with electric current, be performable with the motor controller. A method for controlling and / or regulating a surgical machine is also proposed.

Owner:AESCULAP AG

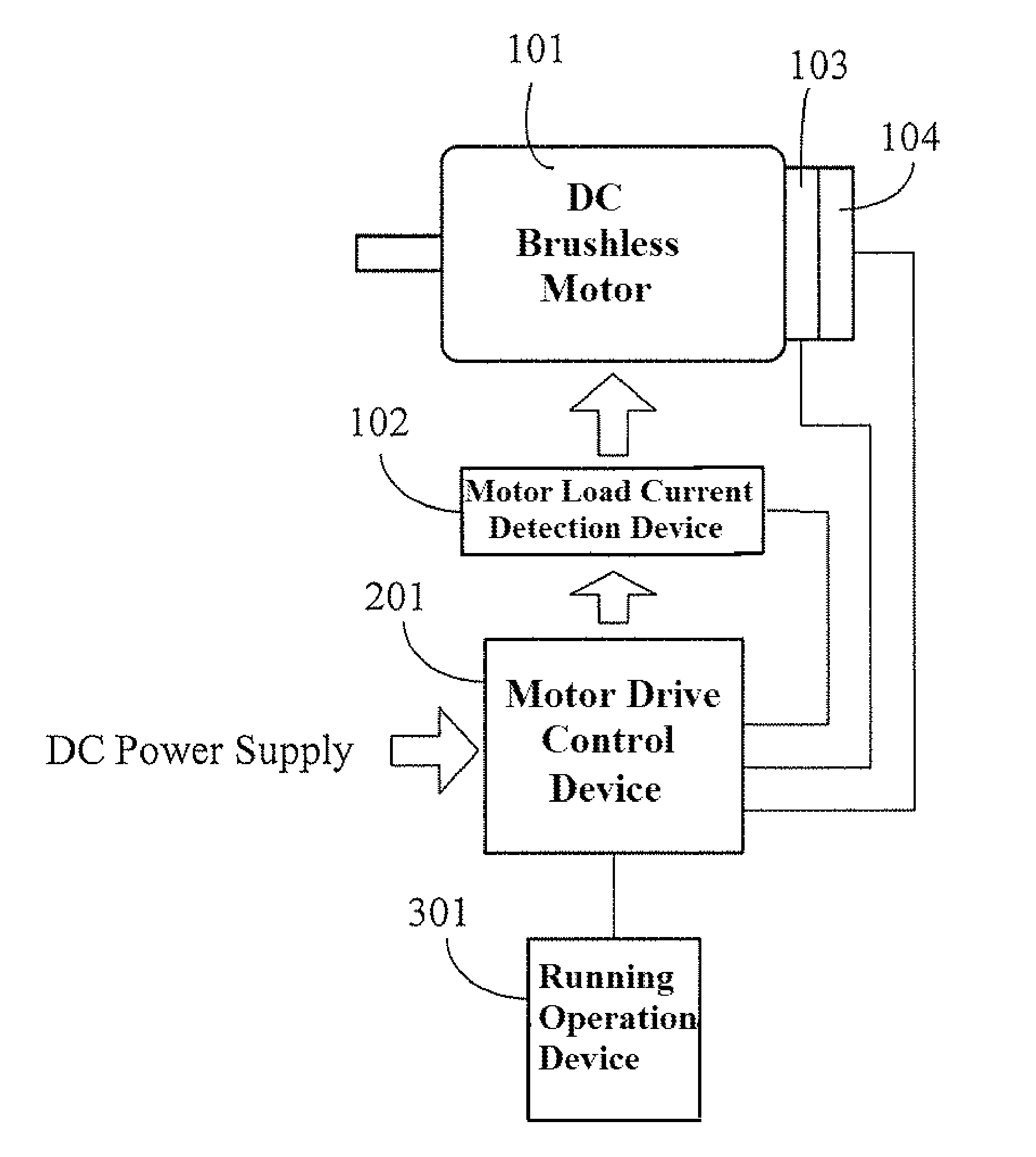

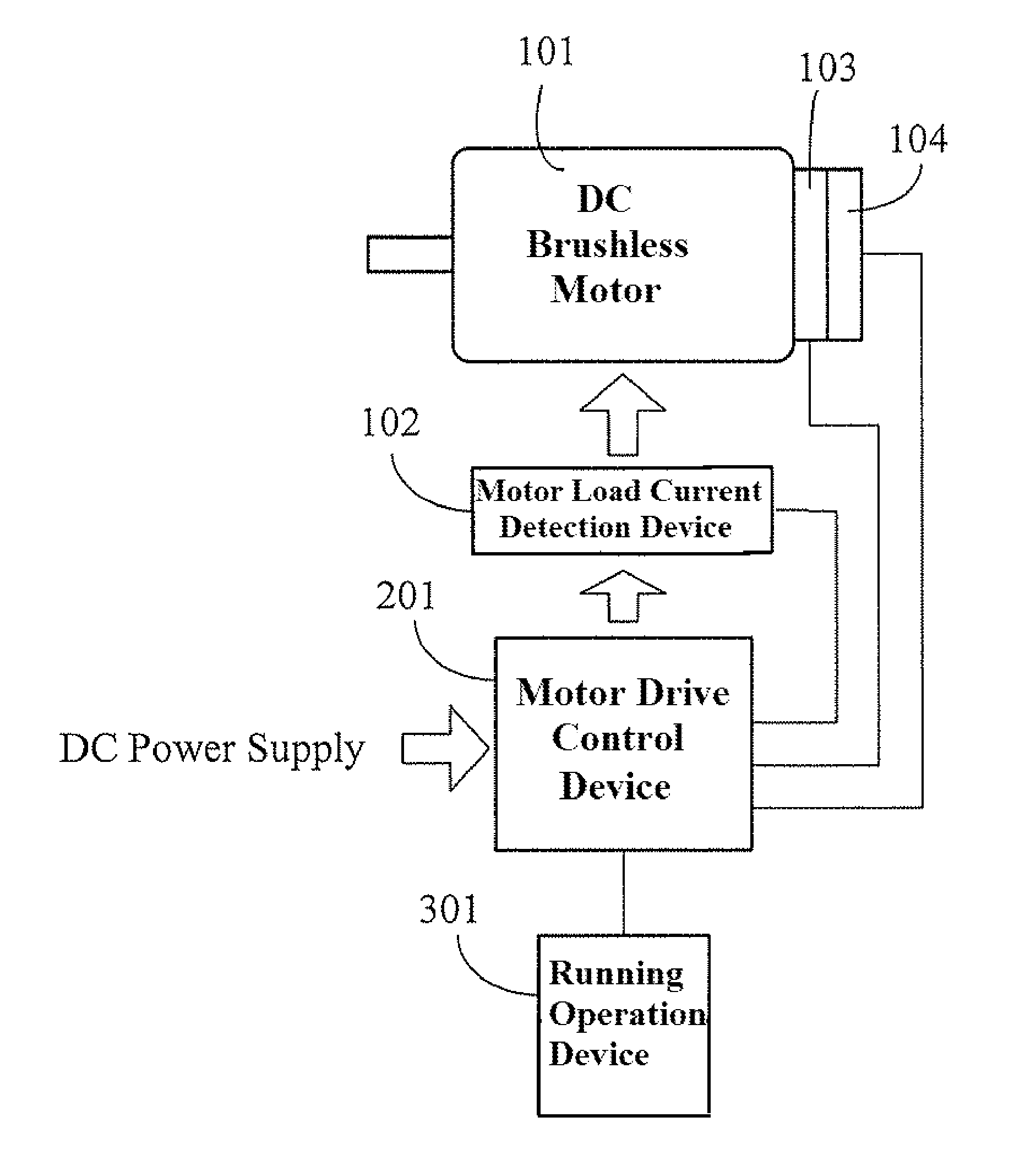

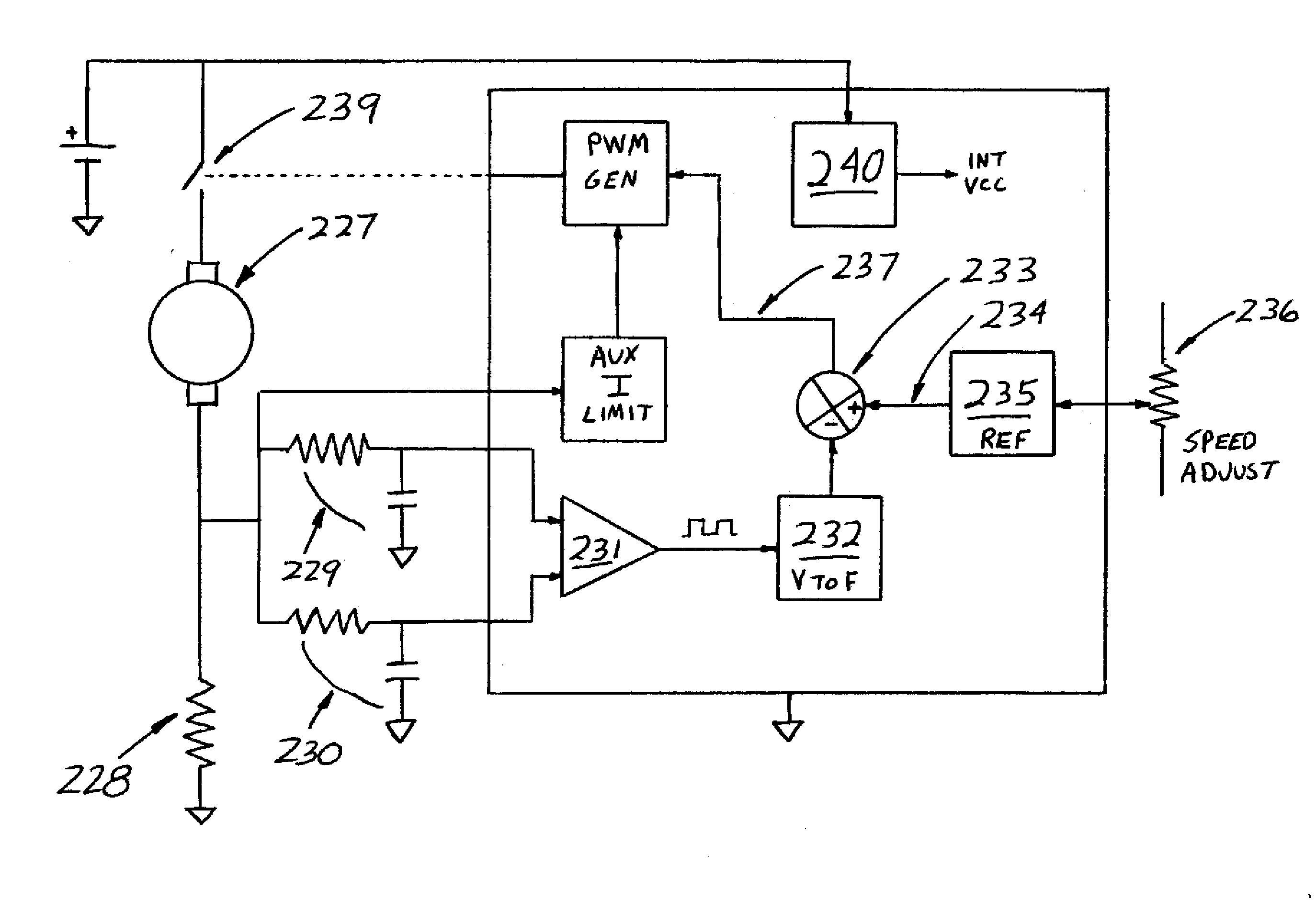

DC brushless motor drive circuit with speed variable-voltage

ActiveUS8288984B2Increase inputOvercome increased inductive impedanceTorque ripple controlMotor/generator/converter stoppersBrushless motorsMotor drive

For the present invention, under various running speeds statuses, the voltage supplied to the DC brushless motor is relatively increased or decreased on the basis of the internal setting of the motor drive control device according to the increased or decreased rotational output speed, so as to prevent the shortcoming of too much variation of the input impedance caused by the inductive reactance of the winding accordingly changed when the speed of the DC brushless motor is changed, specifically, to prevent the shortcoming of unable producing required torque resulting from the increased inductive reactance caused by increasing the rotational speed which makes the current value become too low when input by the original working voltage.

Owner:YANG TAI HER

Method of Sensing Speed of Electric Motors and Generators

InactiveUS20080298784A1Simple and inexpensiveLow costMotor/generator/converter stoppersField or armature current controlMotor speedMotor control

A method and circuit for determining the speed and / or counting the revolutions of brush and commutator motors is described. The method and circuitry detects signals present on the windings of the motor due to commutation that occurs at the brushes and commutator of the motor. This method can be used to simply monitor & indicate the motor speed and revolutions or to form the basis of a motor control.

Owner:KASTNER MARK ALLEN

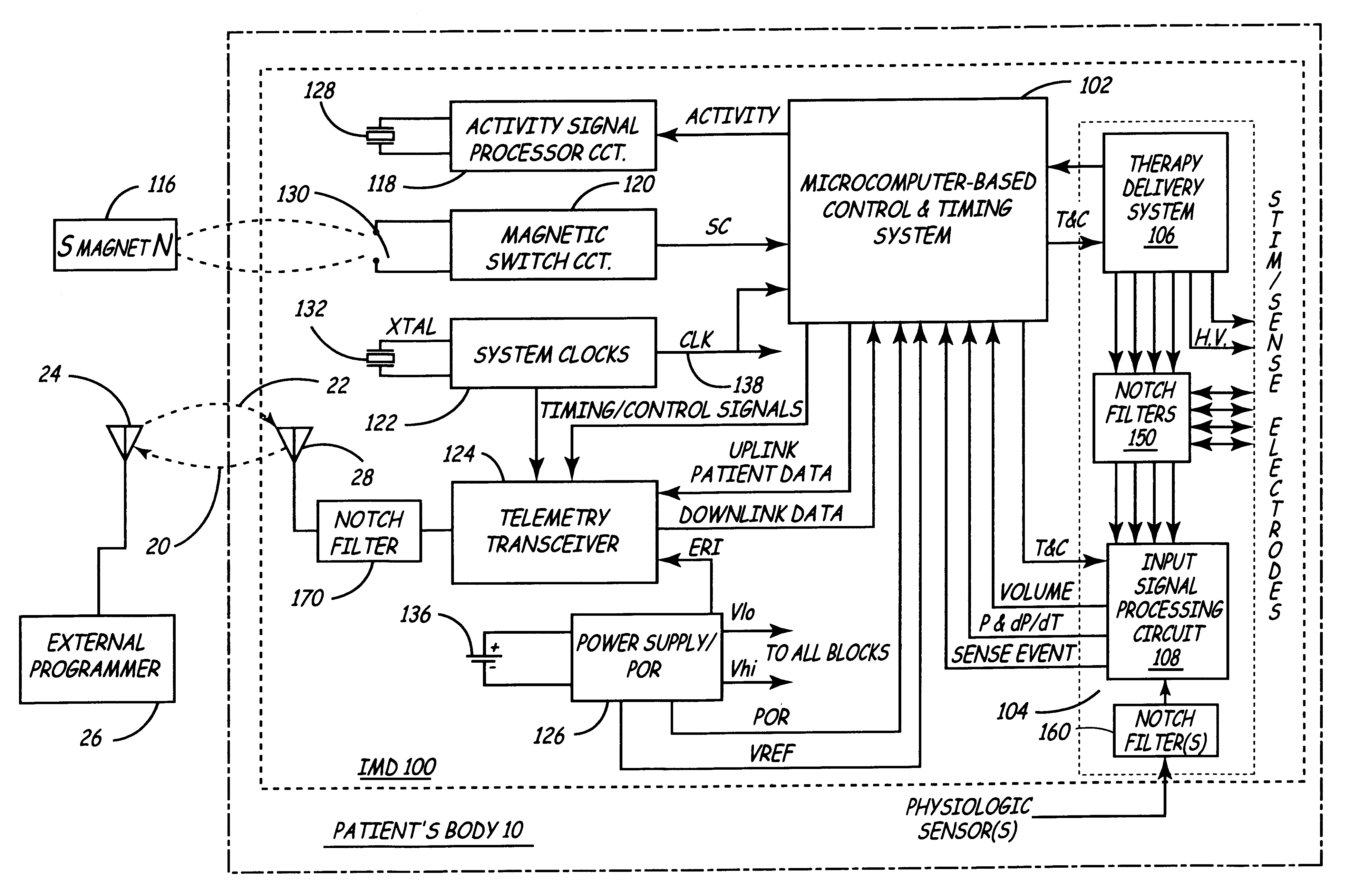

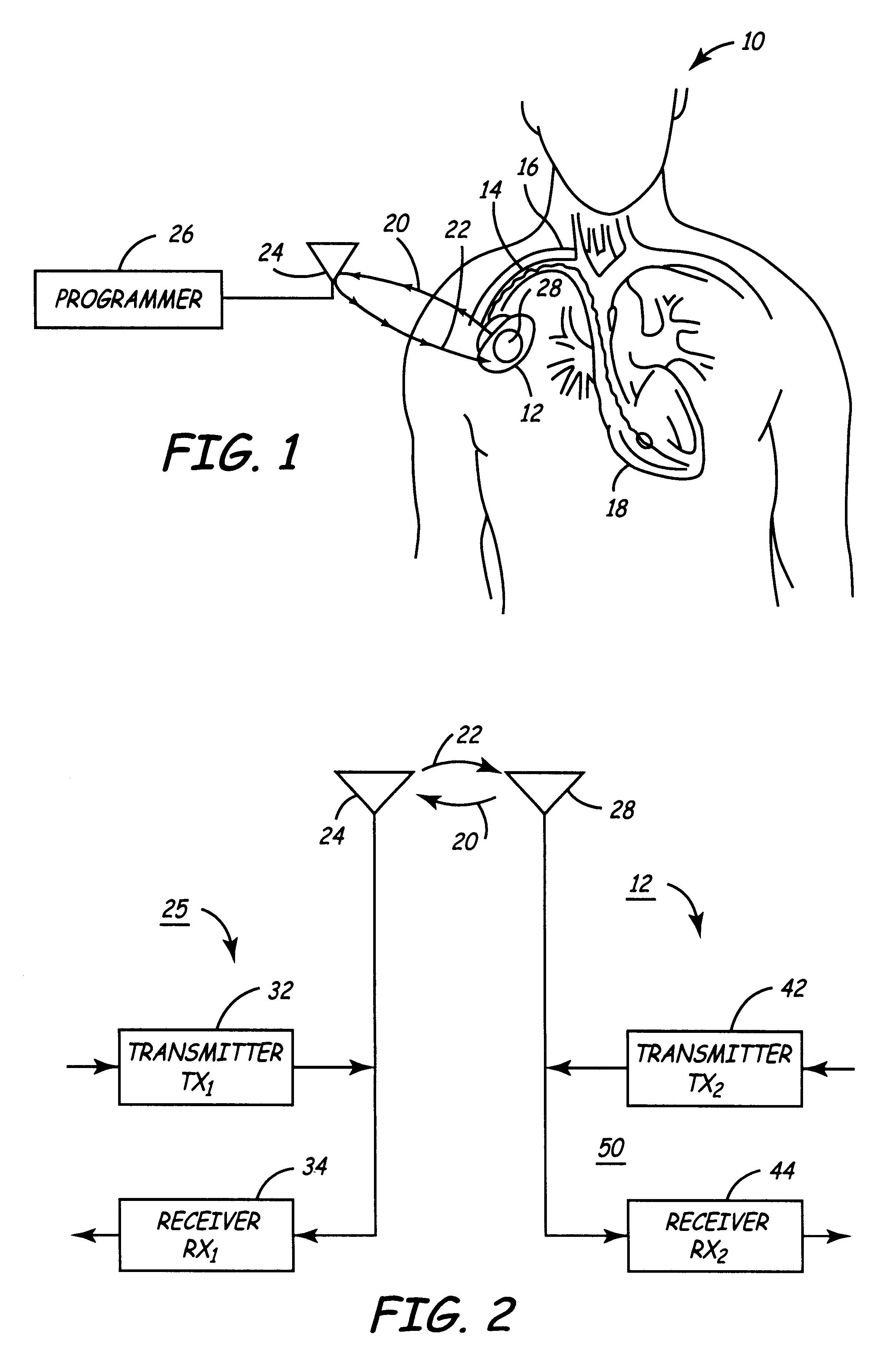

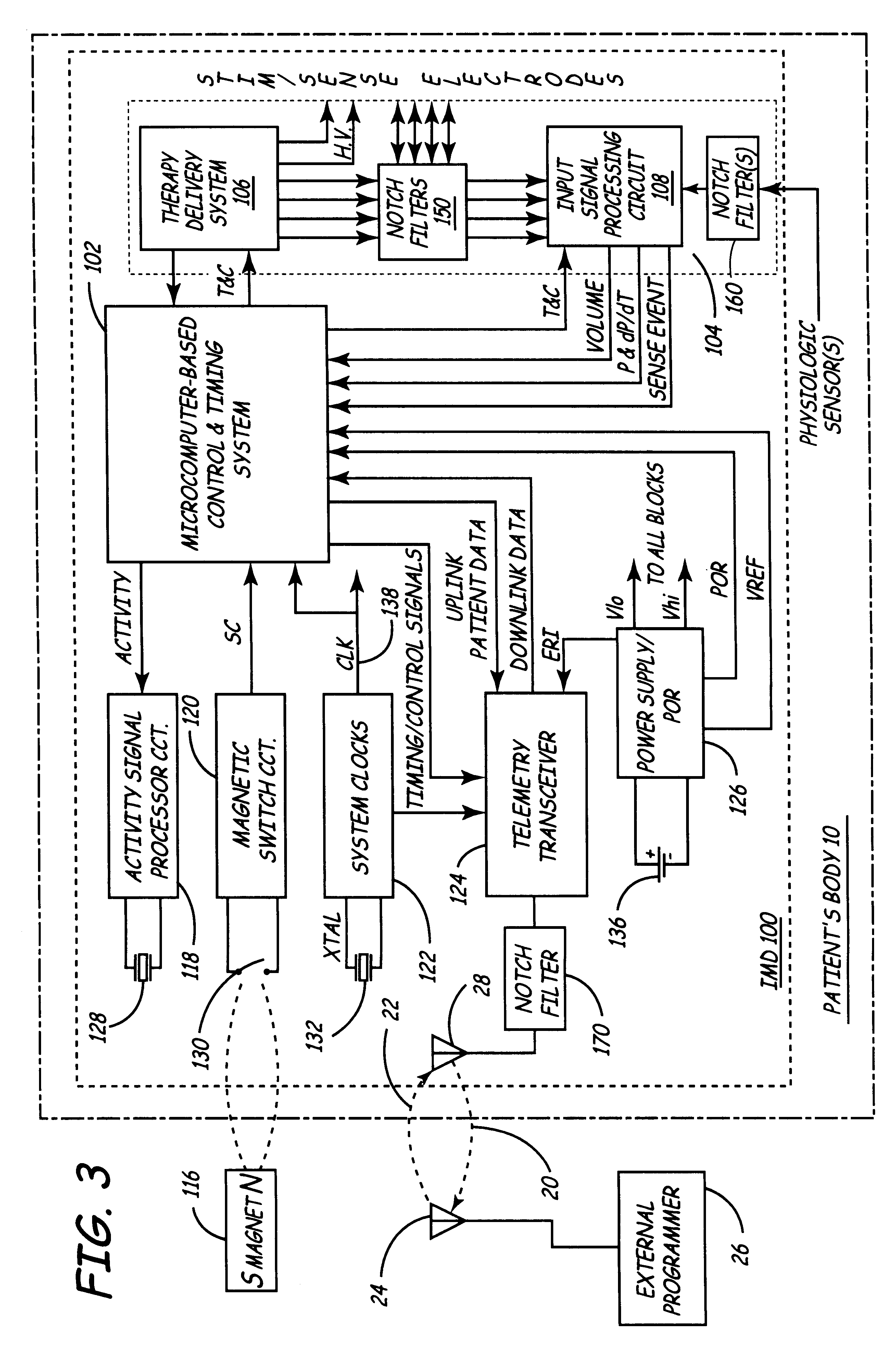

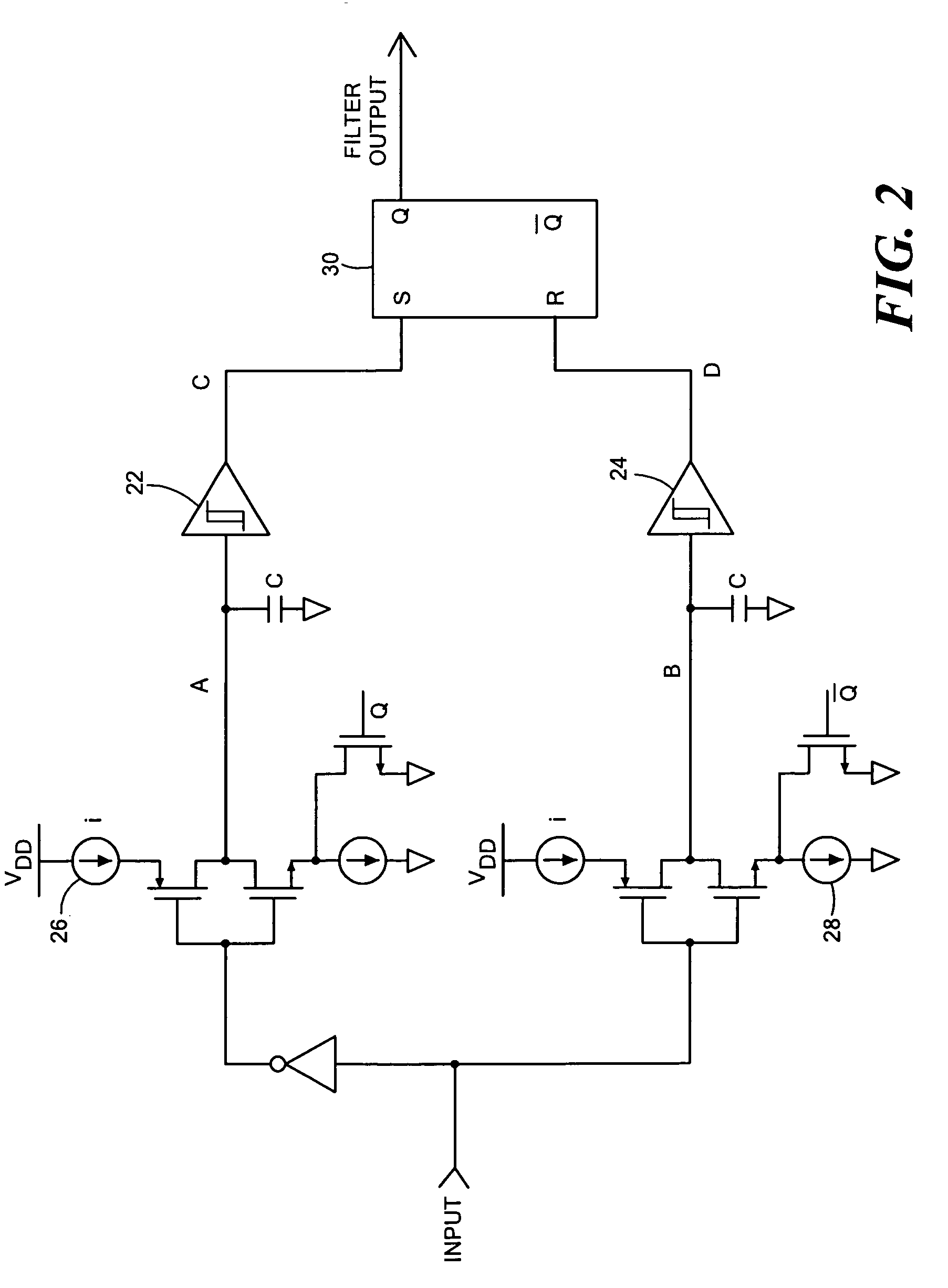

Implantable medical device incorporating integrated circuit notch filters

Implantable medical devices (IMDs) having sense amplifiers for sensing physiologic signals and parameters, RF telemetry capabilities for uplink transmitting patient data and downlink receiving programming and interrogation commands to and from an external programmer or other medical device are disclosed. At least one IC chip and discrete components have a volume and dimensions that are optimally minimized to reduce its volumetric form factor. Miniaturization techniques include forming notch filters of MEMS structures or forming discrete circuit notch filters by one or more of: (1) IC fabricating inductors into one or more IC chips mounted to the RF module substrate; (2) mounting each IC chip into a well of the RF module substrate and using short bonding wires to electrically connect bond pads of the RF module substrate and the IC chip; and (3) surface mounting discrete capacitors over IC chips to reduce space taken up on the RF module substrate. The IC fabricated inductors are preferably fabricated as planar spiral wound conductive traces formed of high conductive metals to reduce trace height and width while maintaining low resistance, thereby reducing parasitic capacitances between adjacent trace side walls and with a ground plane of the IC chip. The spiral winding preferably is square or rectangular, but having truncated turns to eliminate 90° angles that cause point-to-point parasitic capacitances. The planar spiral wound conductive traces are further preferably suspended over the ground plane of the IC chip substrate by micromachining underlying substrate material away to thereby reduce parasitic capacitances.

Owner:MEDTRONIC INC

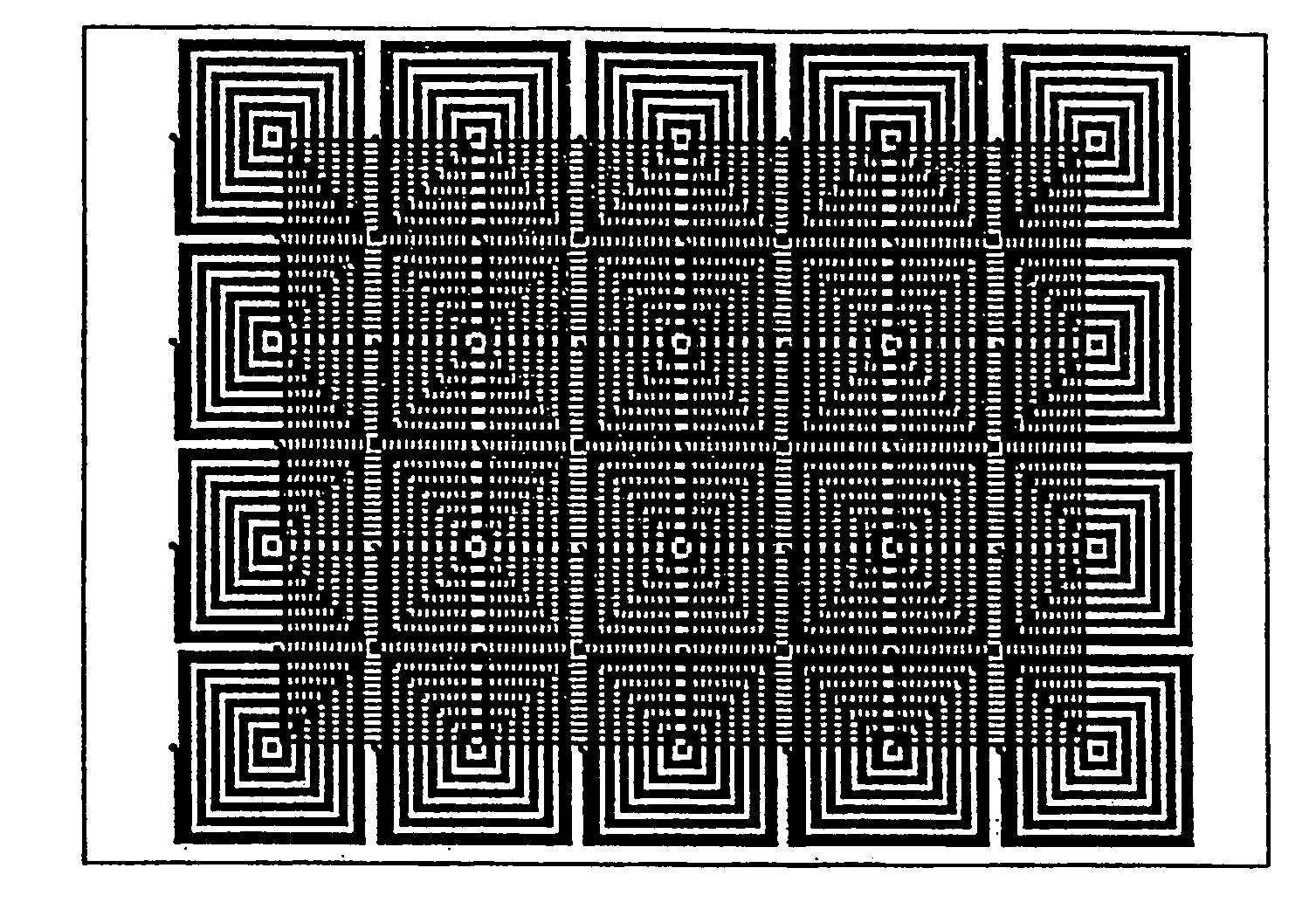

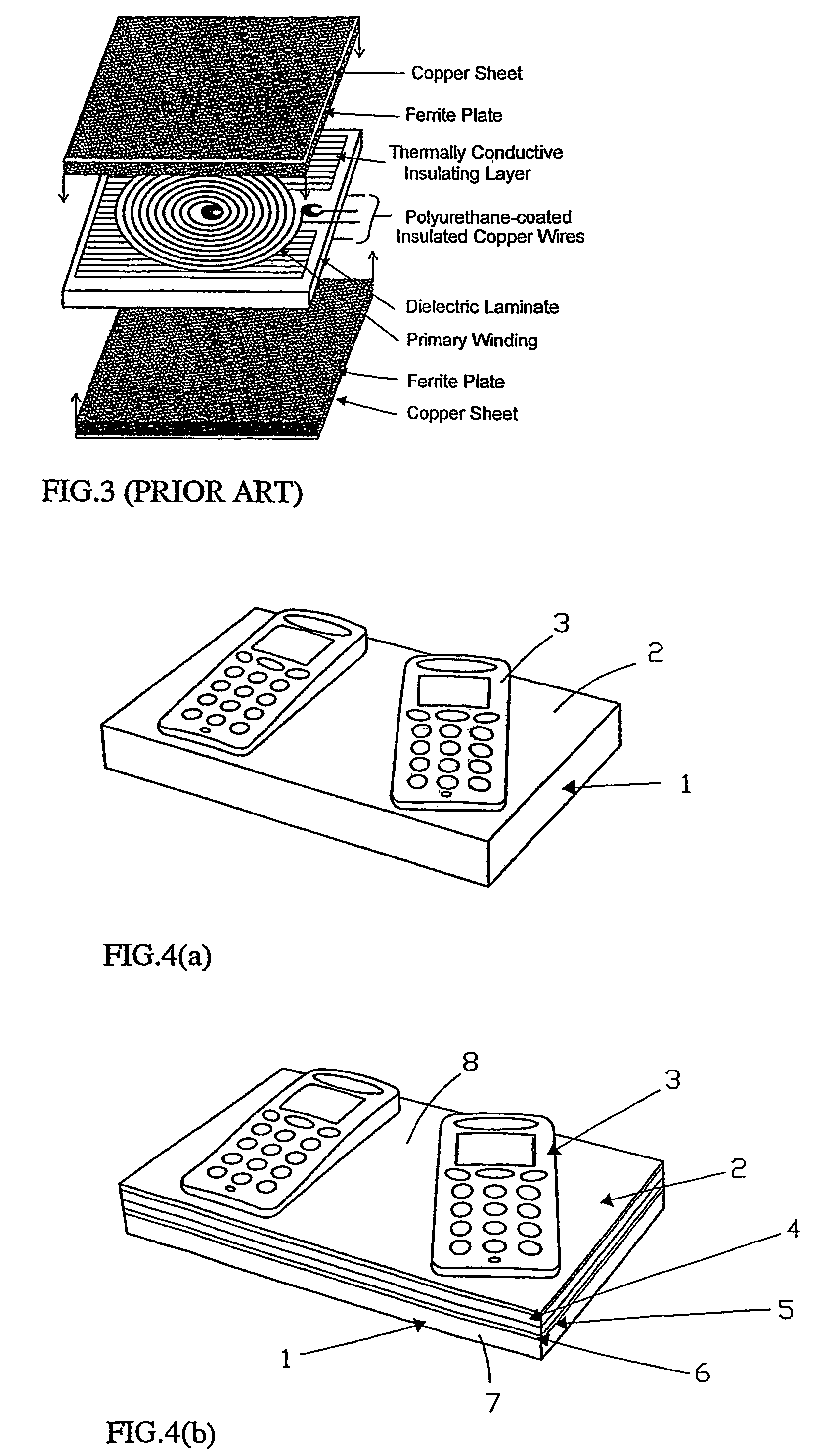

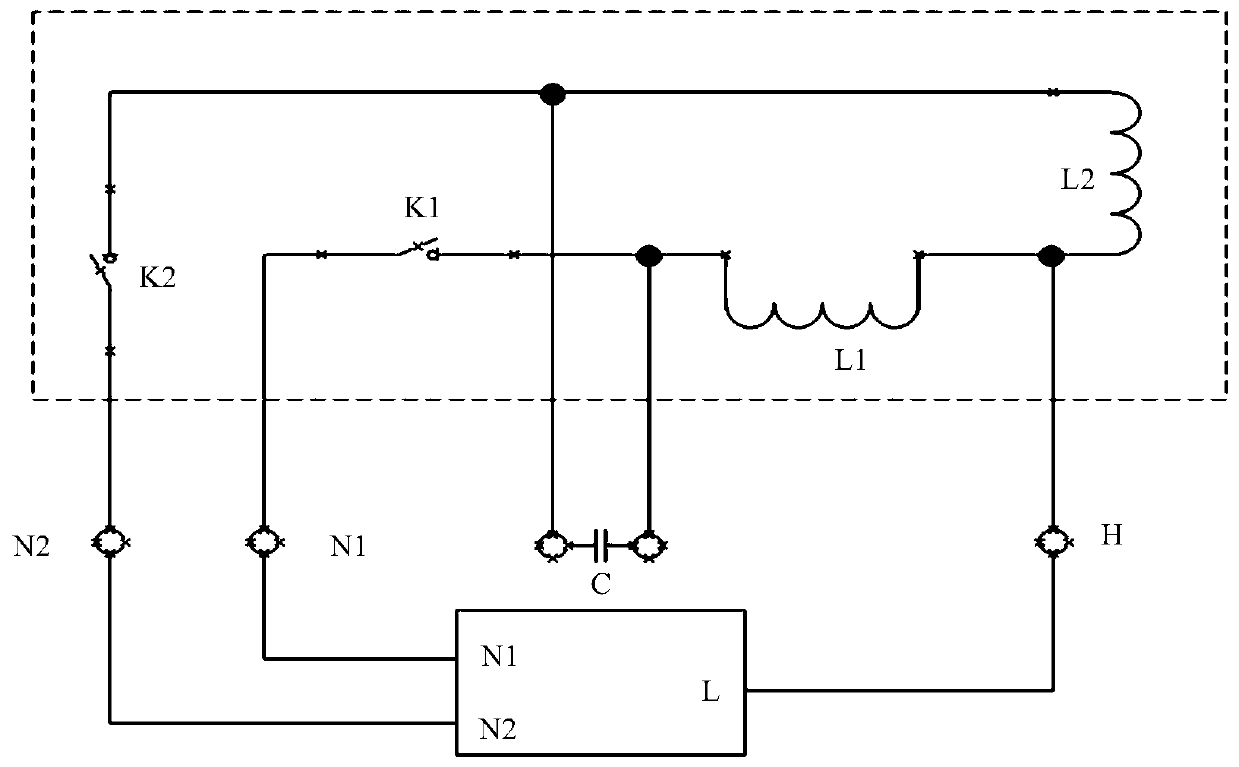

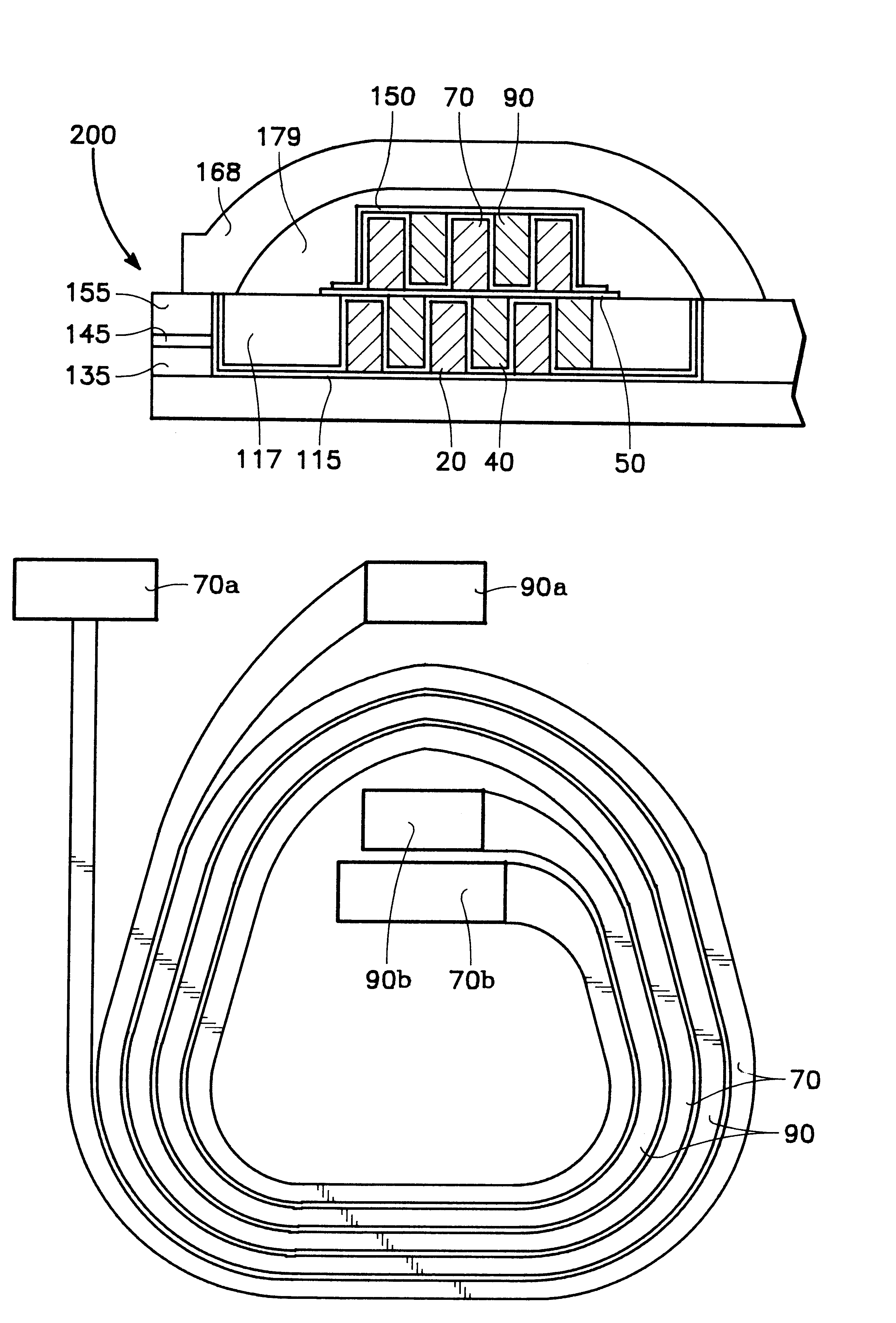

Inductive battery charger system with primary transformer windings formed in a multi-layer structure

InactiveUS7164255B2Promote sportsBatteries circuit arrangementsTransformersSystems designBattery charge

There is provided a planar inductive battery charging system designed to enable electronic devices to be recharged. The system includes a planar charging module having a charging surface on which a device to be recharged is placed. Within the charging module and parallel to the charging surface is at least one and preferably an array of primary windings that couple energy inductively to a secondary winding formed in the device to be recharged. The invention also provides secondary modules that allow the system to be used with conventional electronic devices not formed with secondary windings.

Owner:CITY UNIVERSITY OF HONG KONG

Forward and reverse motor for improving forward and reverse efficiency, and control method thereof

PendingCN109889124ASolve the problem of not being able to achieve high efficiency in both forward and reverse directionsImprove efficiencyAC motor controlPhase differenceControl theory

Owner:GREE ELECTRIC APPLIANCES INC

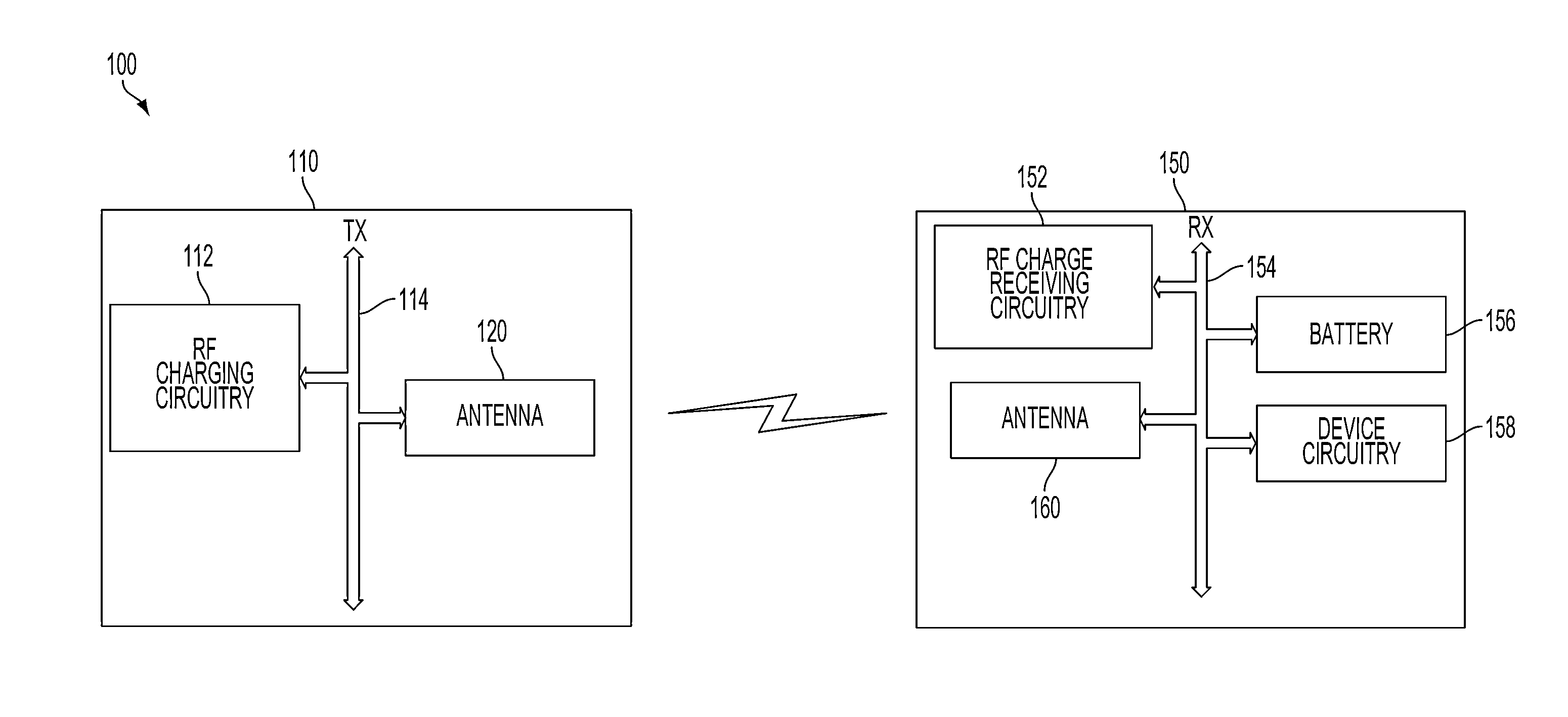

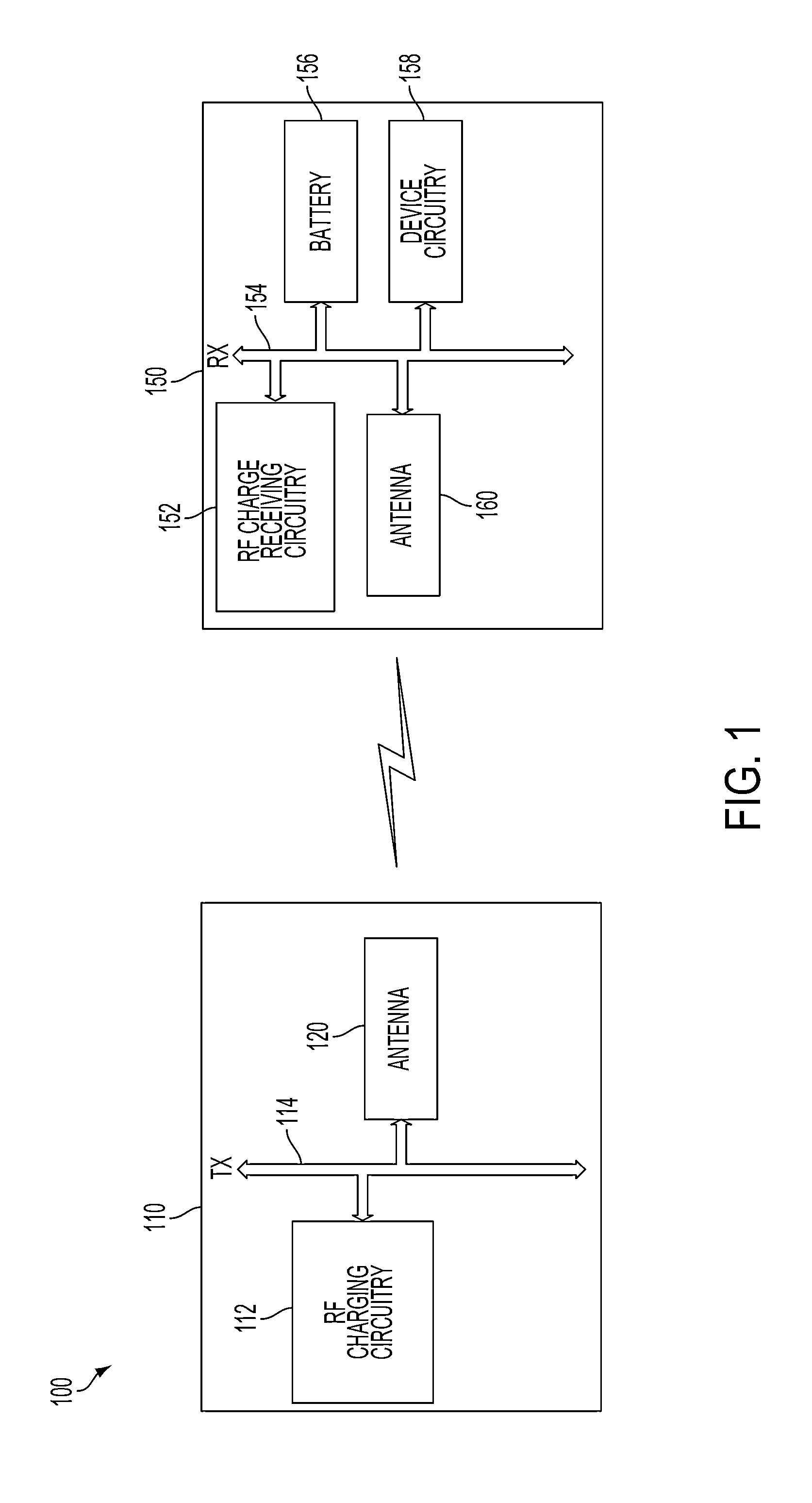

Wireless charging systems and methods

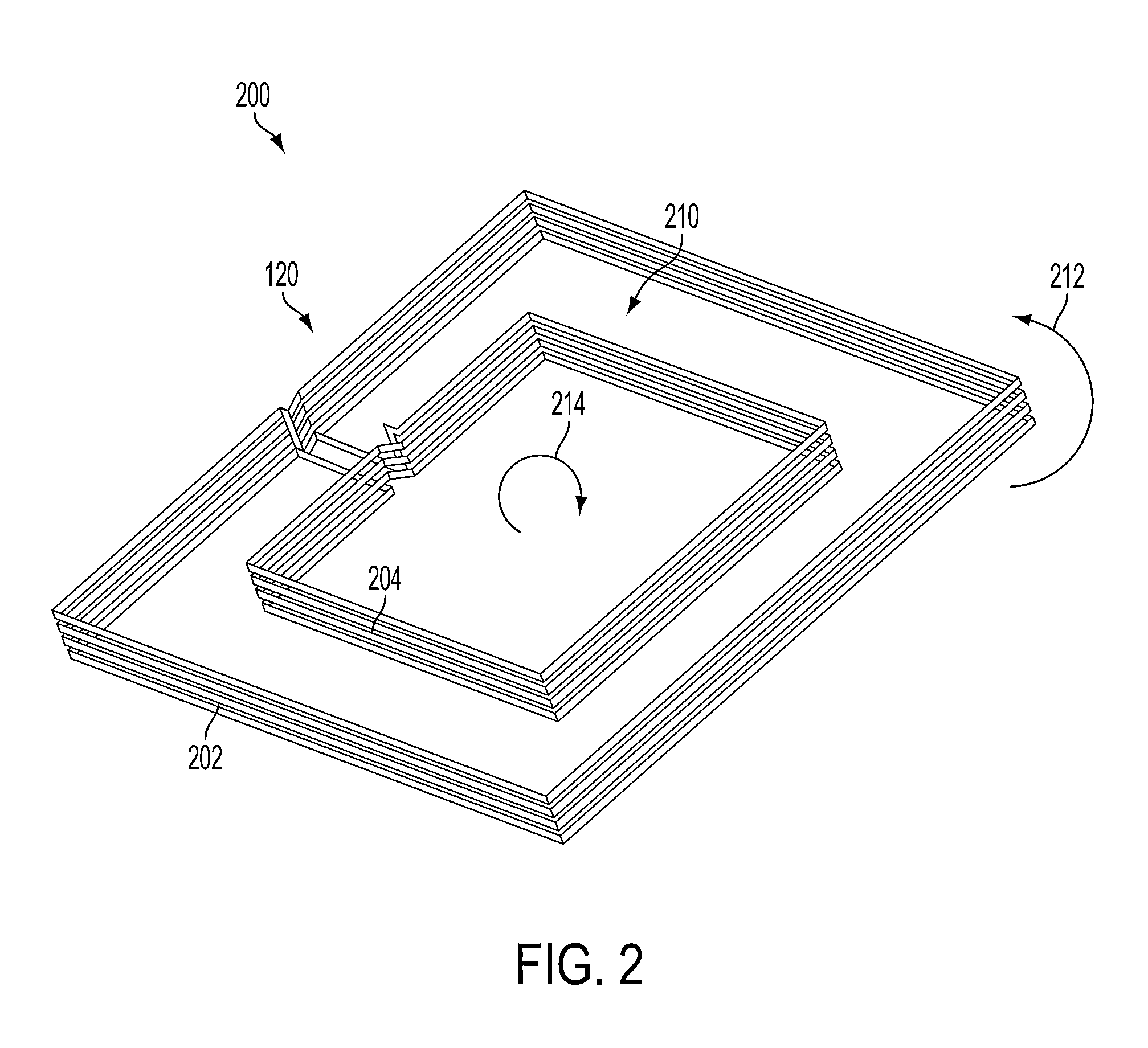

An embodiment of a system for wirelessly charging a wrist-worn device may include a radio frequency (RF) charging energy generating element, and an antenna configured to radiate the RF charging energy, the antenna comprising a first coil and a second coil, the first coil and the second coil each comprising a plurality of windings, the windings of the first coil being wound in a direction opposite the direction of the windings of the second coil. An embodiment of a wrist-worn charge-receiving device may include an antenna coil adapted to receive radio frequency (RF) charging energy, the antenna coil comprising non-uniform windings; and a rechargeable power source coupled to the antenna coil, the antenna coil adapted to provide the RF charging energy to the rechargeable power source.

Owner:QUALCOMM INC

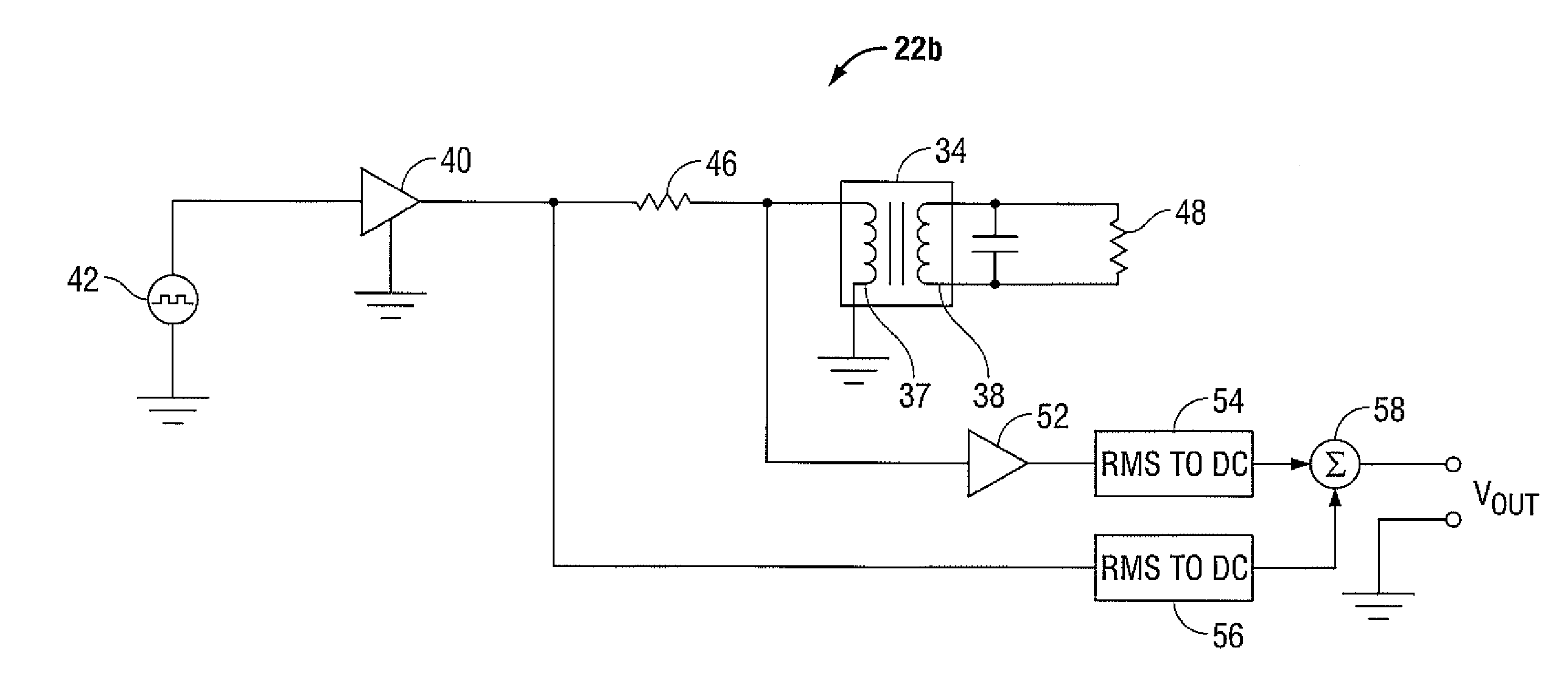

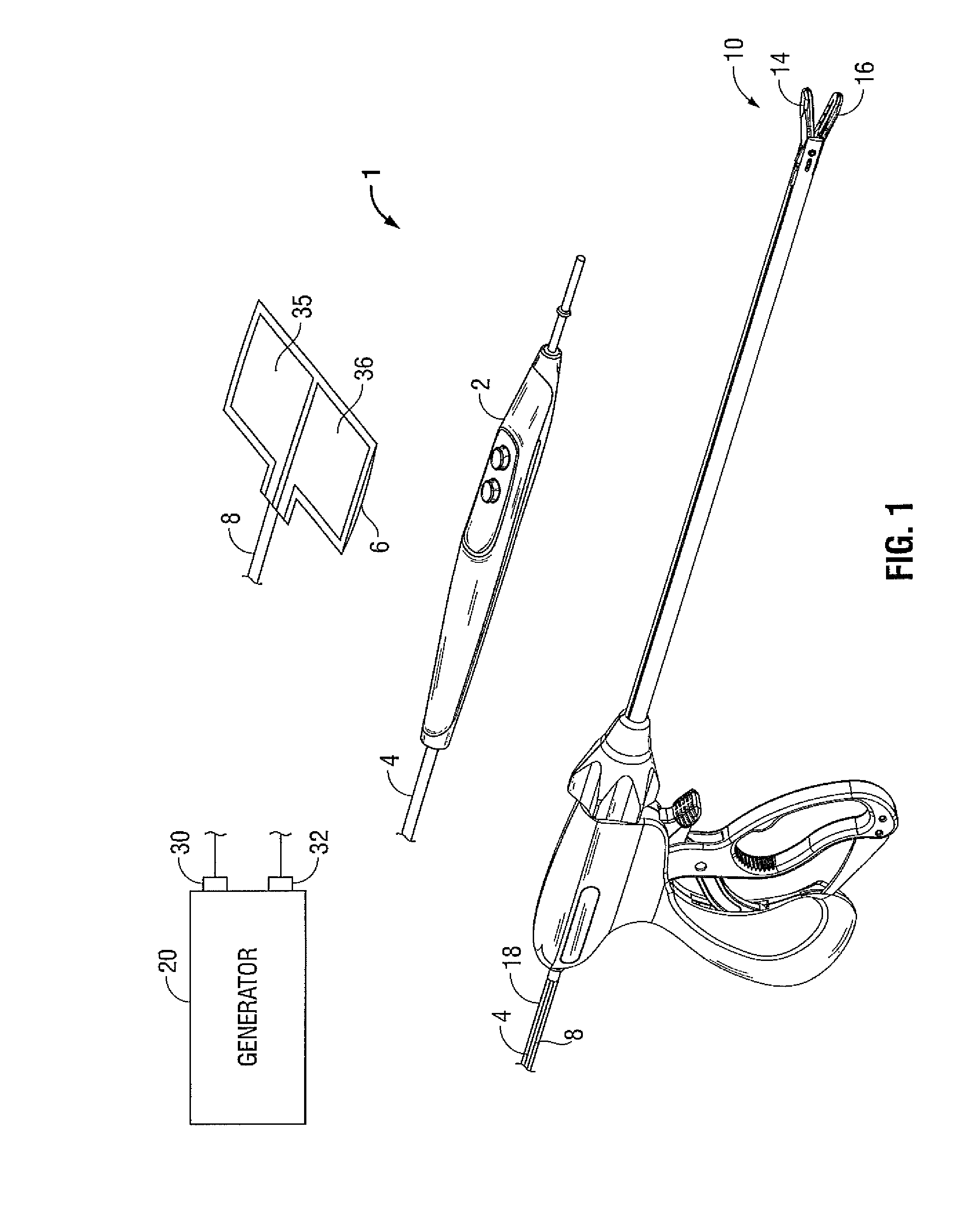

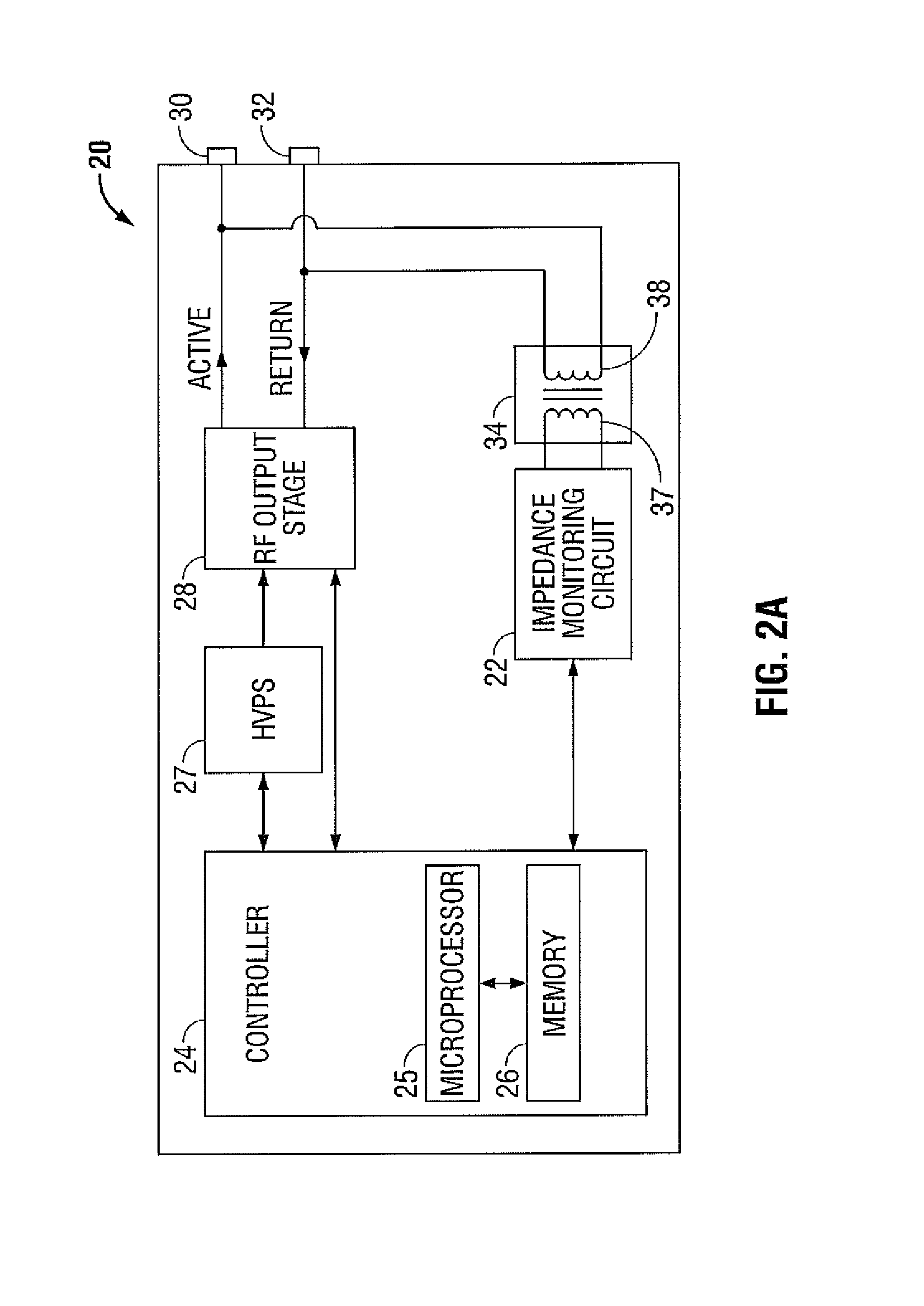

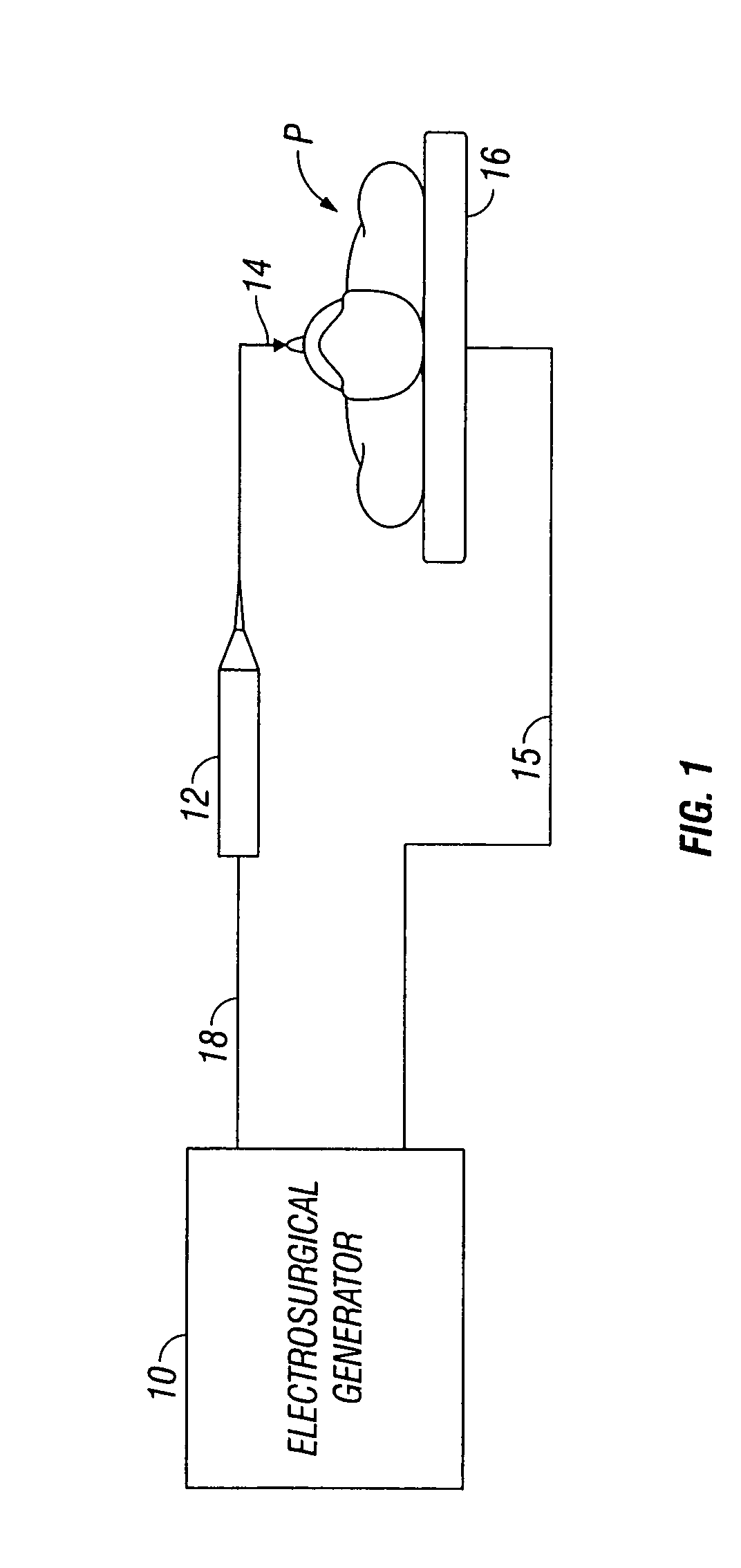

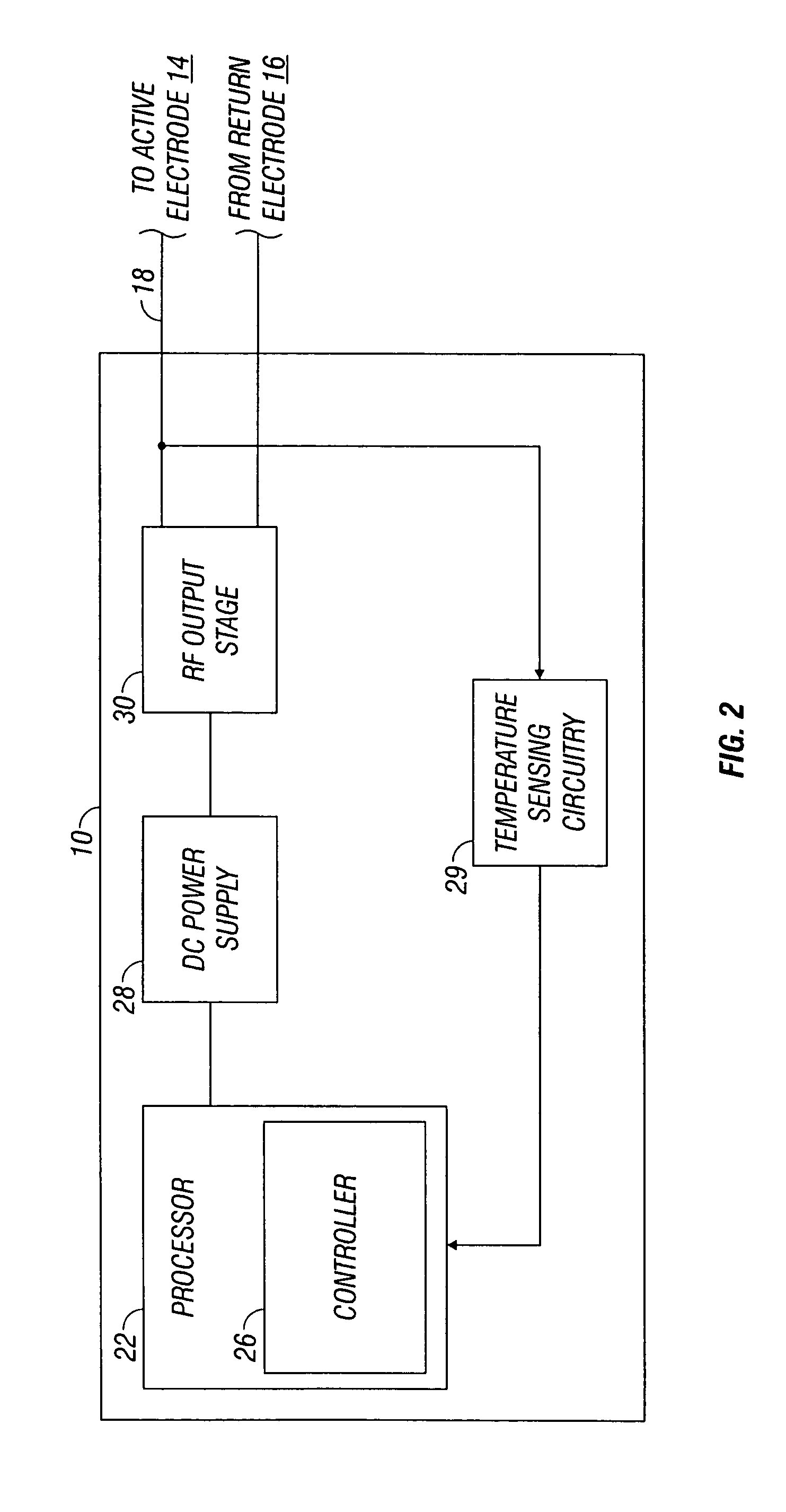

System and method for augmented impedance sensing

InactiveUS7956620B2Resistance/reactance/impedenceSurgical instruments for heatingElectrical resistance and conductanceConductor Coil

An impedance monitoring circuit for an electrosurgical generator is disclosed. The monitoring circuit includes an isolation transformer coupled to at least one of an active terminal and a return terminal of an electrosurgical generator, wherein the isolation transformer includes a primary winding coupled to a reference resistor and a secondary winding coupled to a load. The monitoring circuit also includes a driver configured to transmit a sensor signal to the reference resistor and the load, a primary converter coupled to the reference resistor and the load and configured to detect a primary converted signal as a function of the sensor signal passing through the reference resistor and the load. The monitoring circuit further includes a secondary converter coupled to the driver and configured to detect a secondary converted signal as a function of the sensor signal prior to passing through the reference resistor and the load and a controller configured to determine a fault condition based on the primary and secondary converted signals.

Owner:COVIDIEN LP

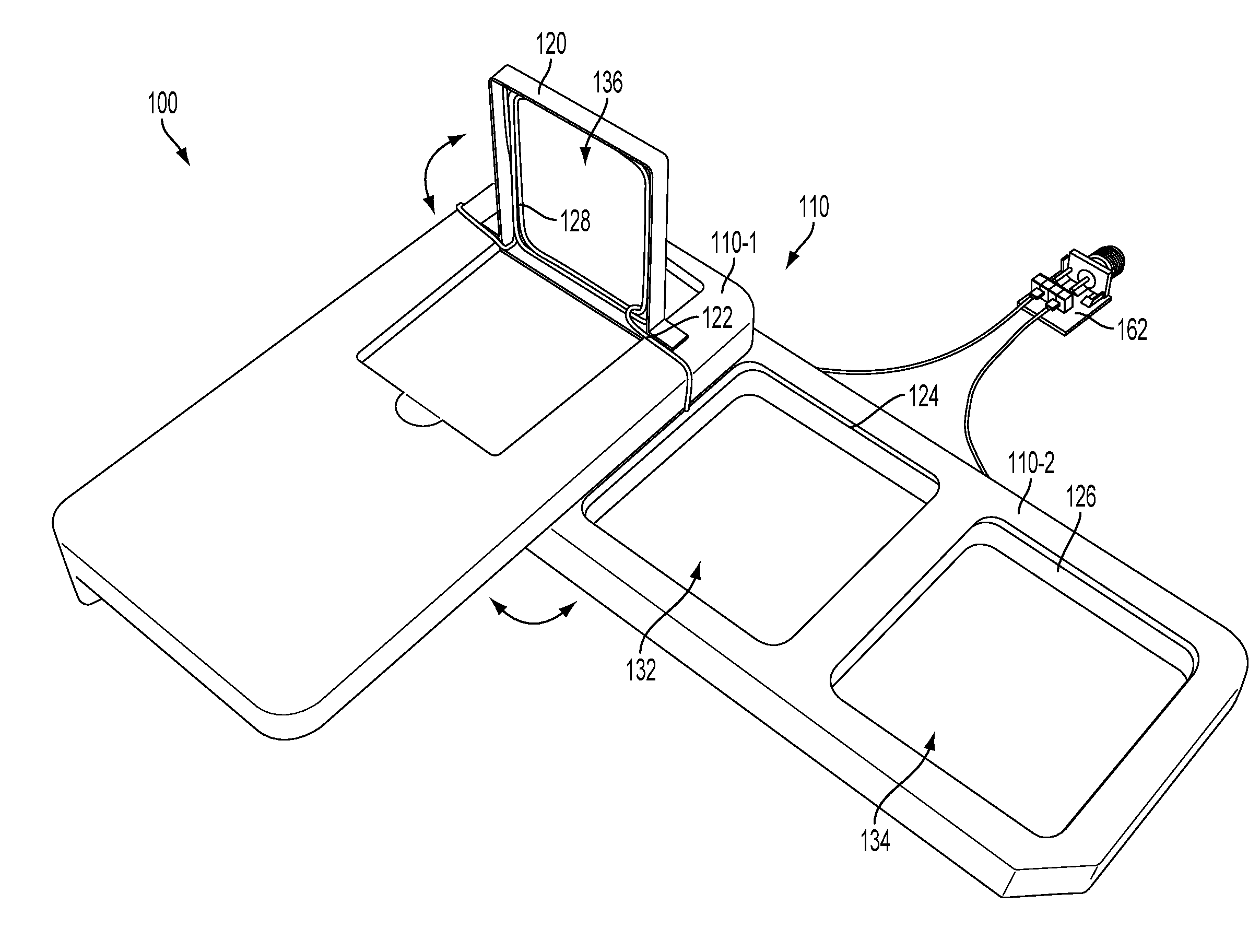

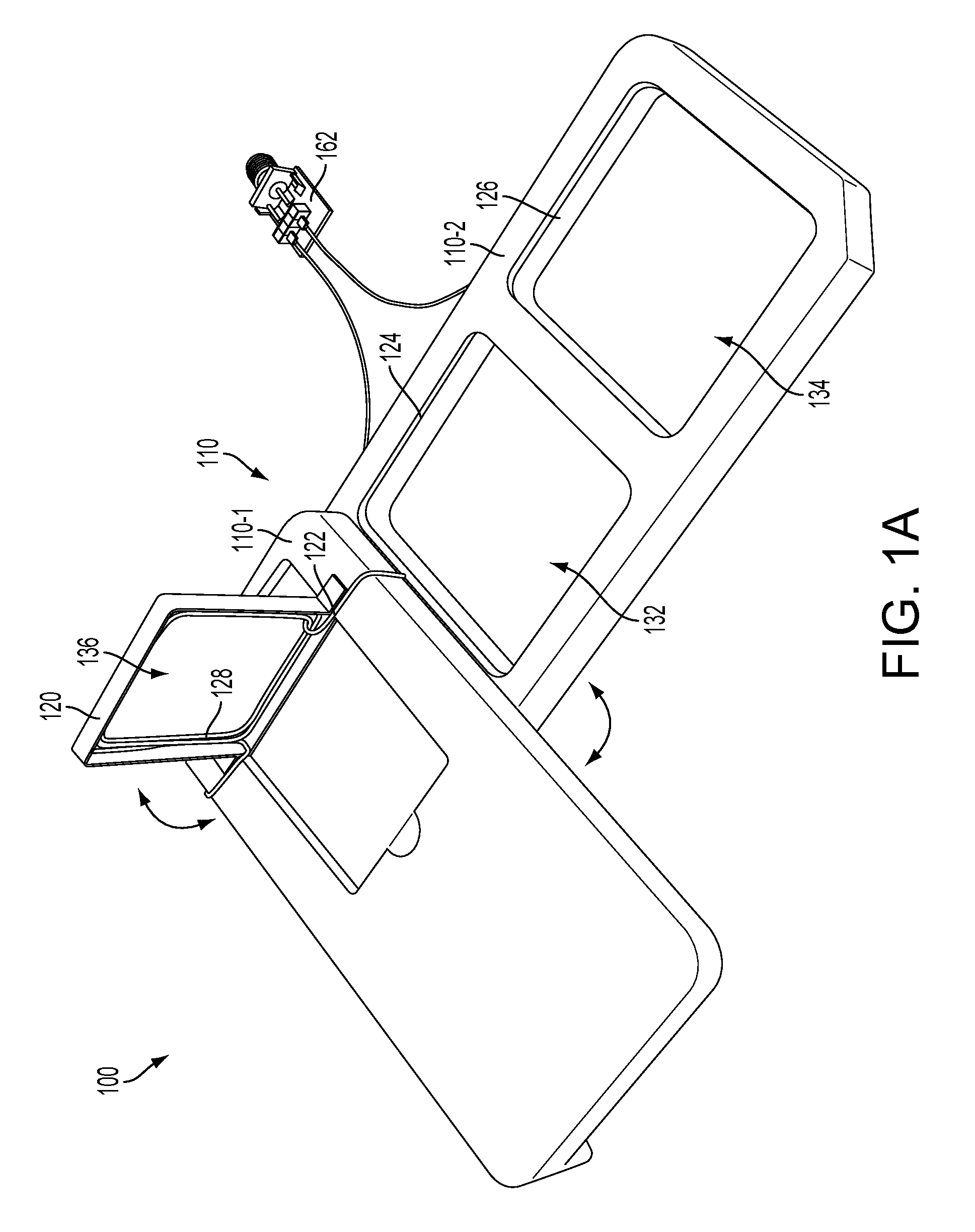

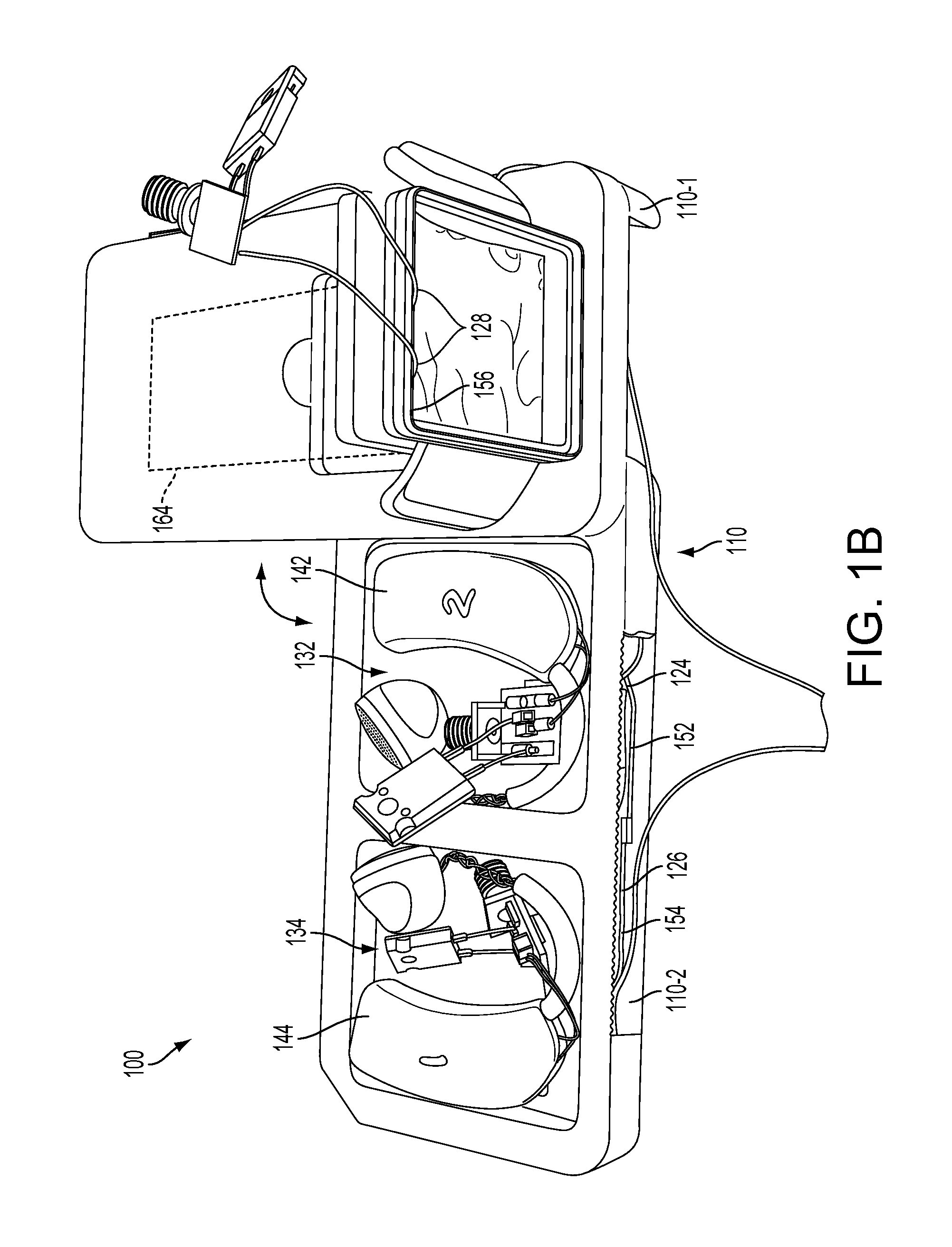

Apparatus for wireless device charging using radio frequency (RF) energy and device to be wirelessly charged

An apparatus for wireless charging using radio frequency (RF) energy includes a first charger portion having first and second charging areas. The first and second charging areas are located in a common plane, each having at least one coil for wirelessly charging a charge-receiving device placed in proximity thereto. The coils include respective windings, which are wound in opposing directions, each coil being connected in series, each coil configured to charge at least one charge-receiving device. A second charger portion has a third charging area having at least one coil including a winding for wirelessly charging a charge-receiving device placed in proximity to the third charging area, the coil in the third charging area being connected in series with the coils in the first and second charging areas, the third charging area located in a plane that is orthogonal to the plane of the first and second charging areas.

Owner:QUALCOMM INC

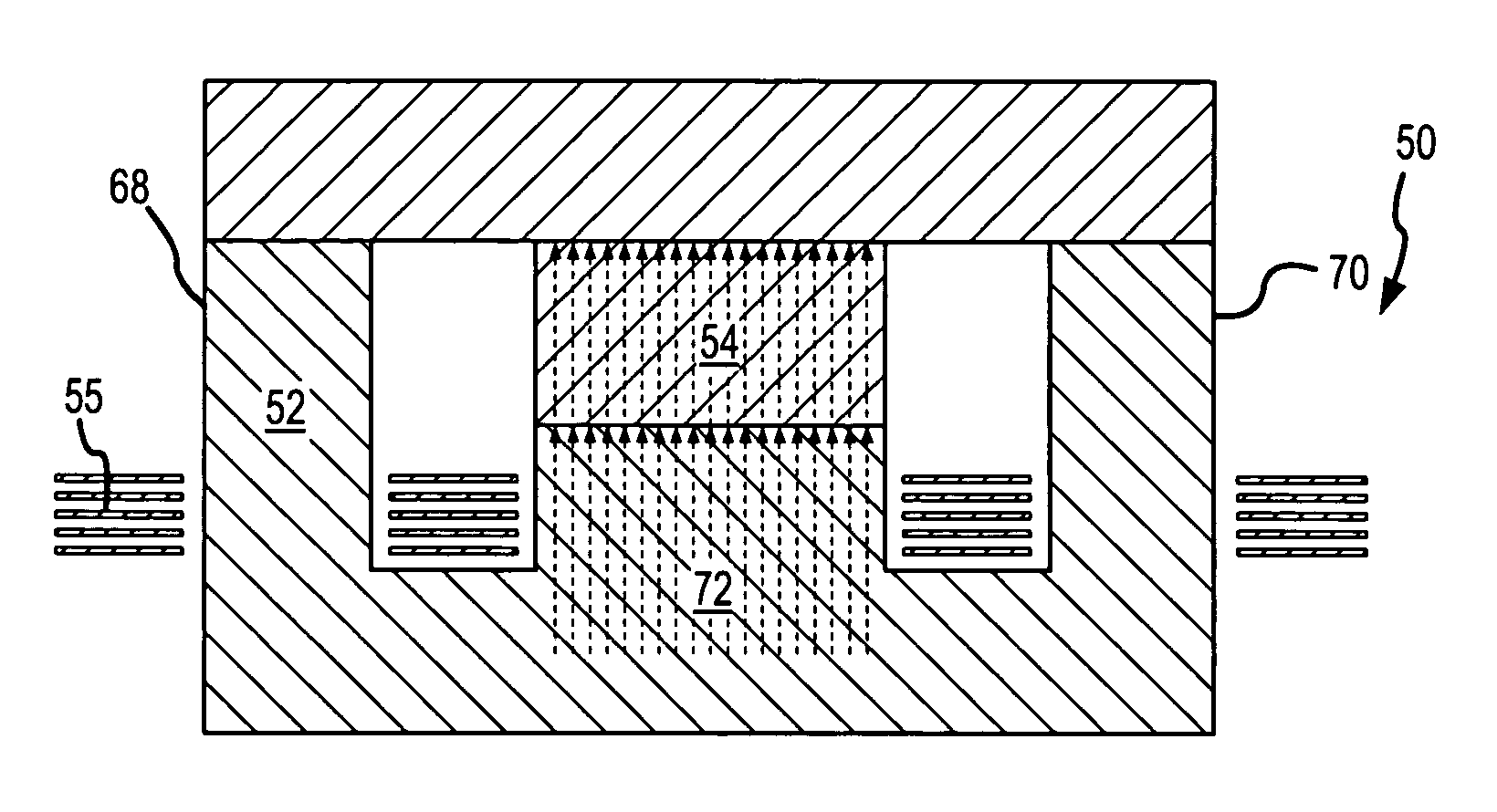

Composite magnetic core for switch-mode power converters

ActiveUS6980077B1Avoid Core SaturationLower average currentTransformers/inductances magnetic coresCores/yokesEddy currentConductor Coil

A composite magnetic core formed of a high permeability material and a lower permeability, high saturation flux density material prevents core saturation without an air gap and reduces eddy current losses and loss of inductance. The composite core is configured such that the low permeability, high saturation material is located where the flux accumulates from the high permeability sections. The presence of magnetic material having a relatively high permeability keeps the flux confined within the core thereby preventing fringing flux from spilling out into the winding arrangement. This composite core configuration balances the requirements of preventing core saturation and minimizing eddy current losses without increasing either the height or width of the core or the number of windings.

Owner:MYPAQ HLDG LTD

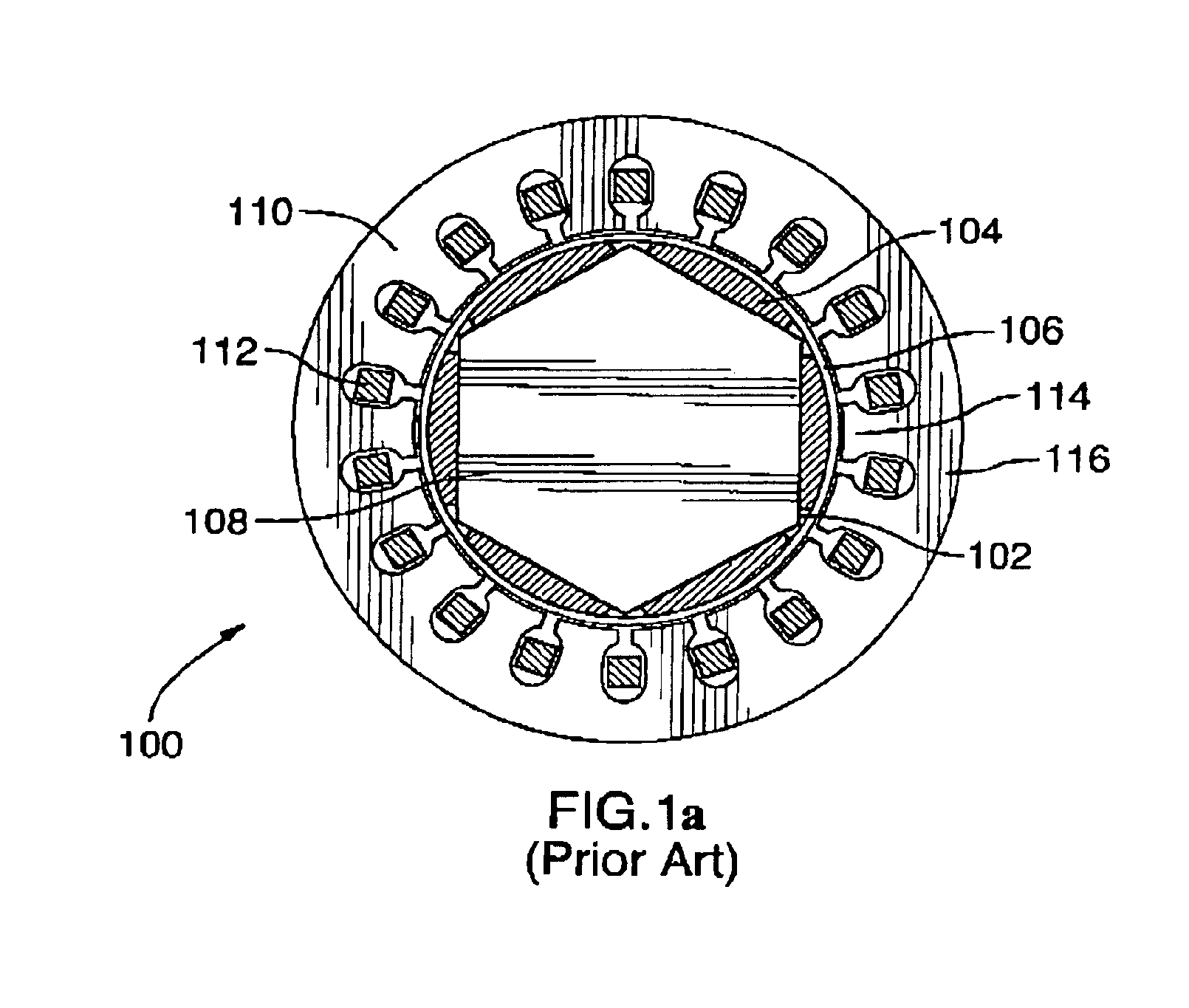

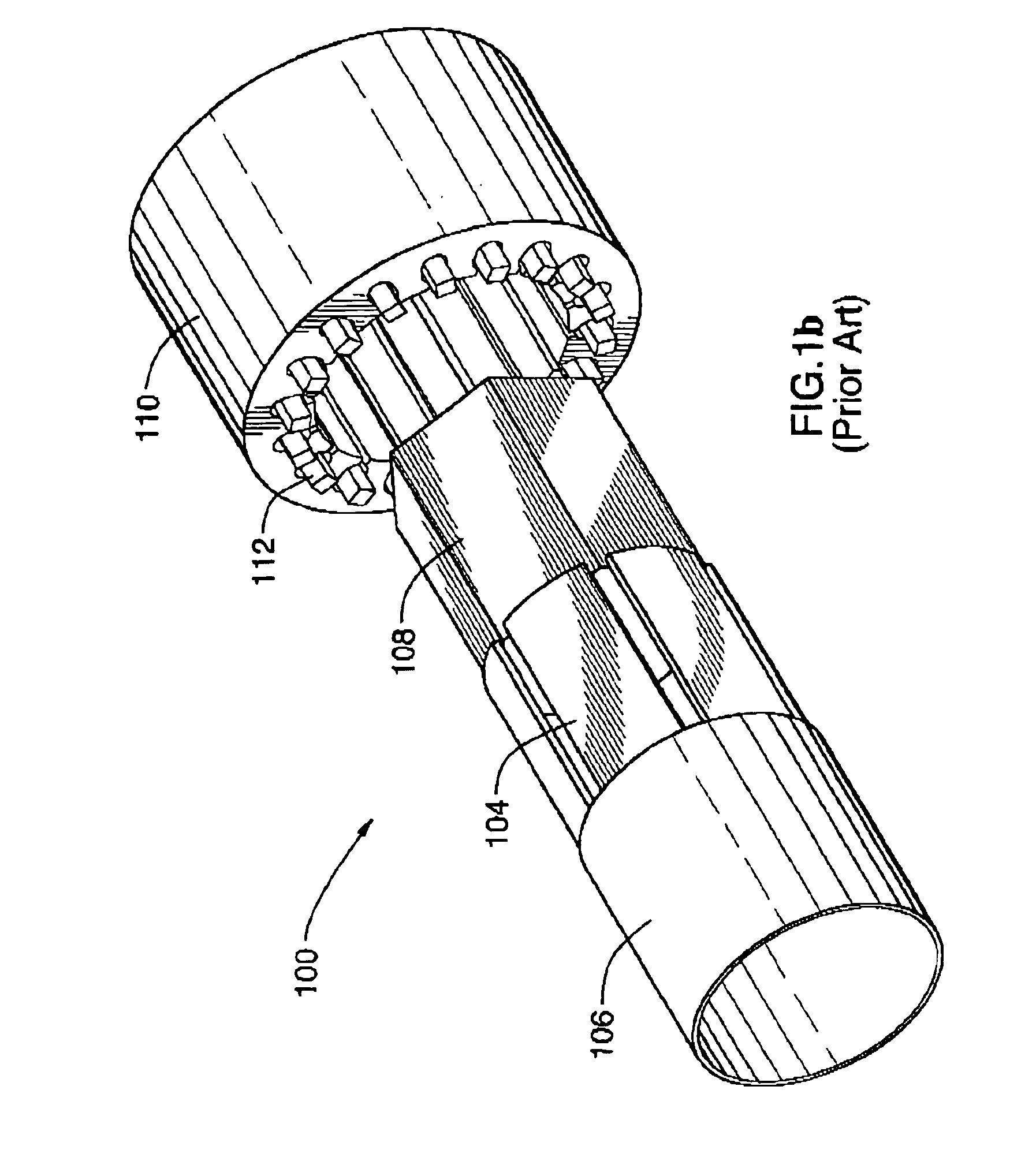

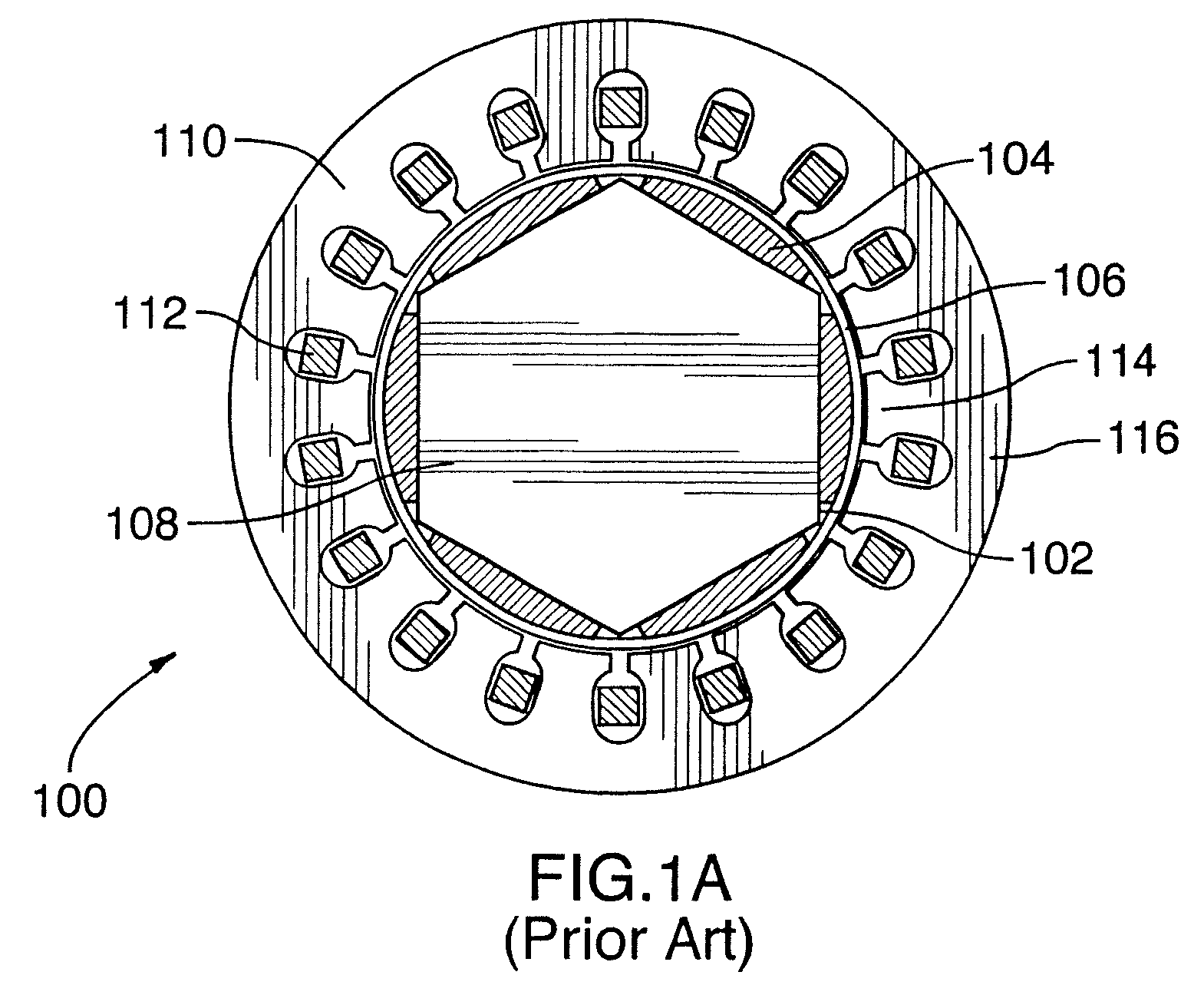

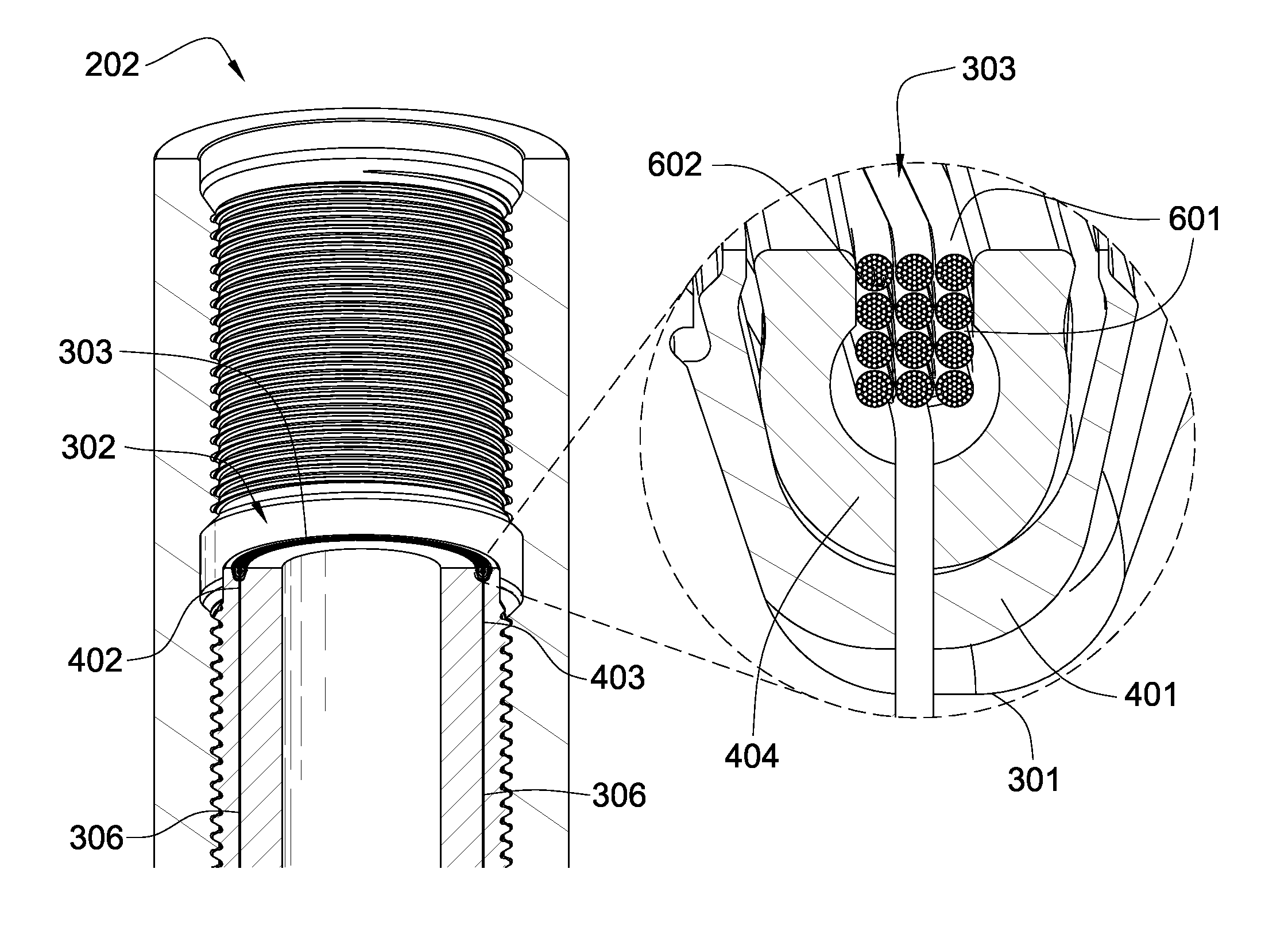

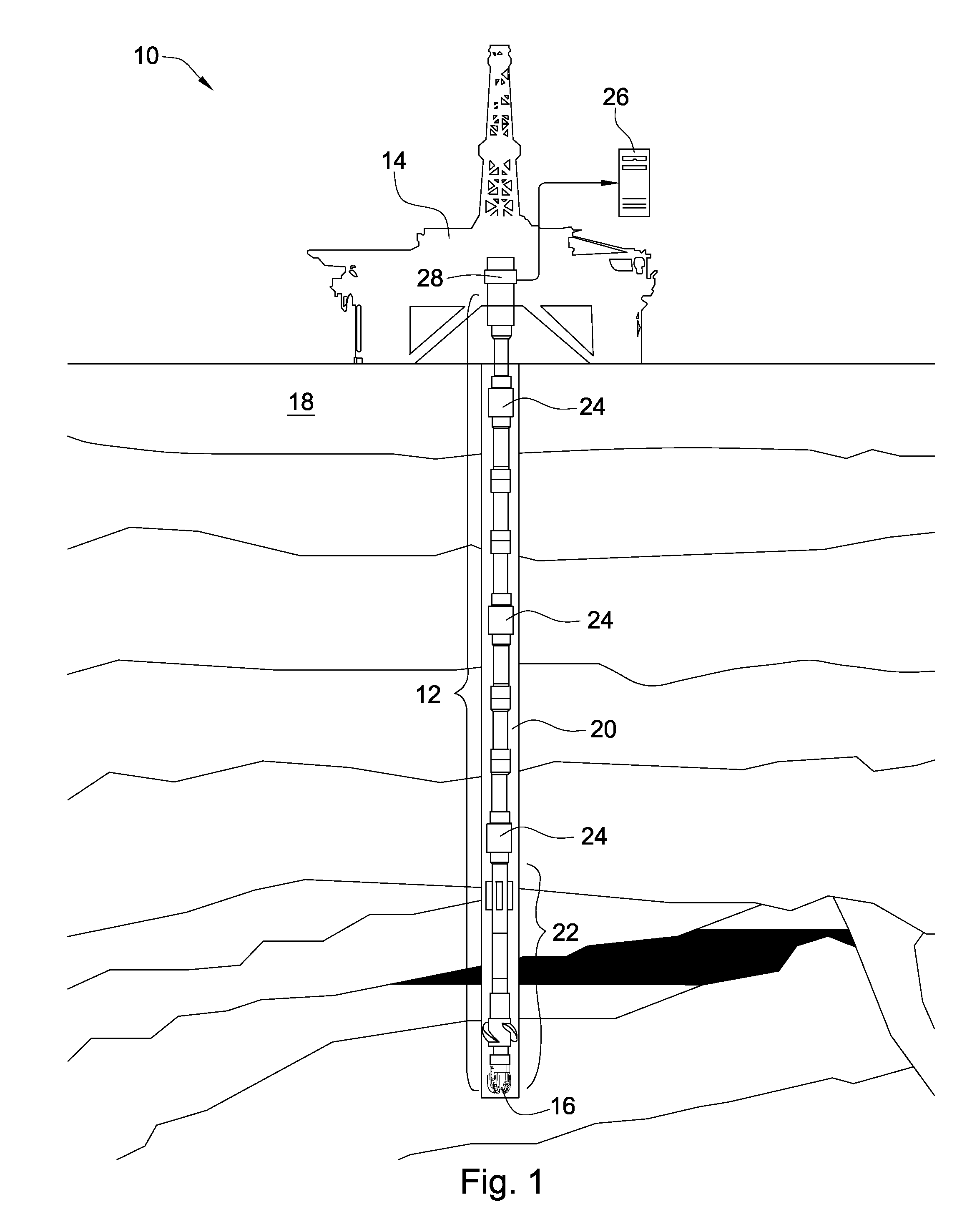

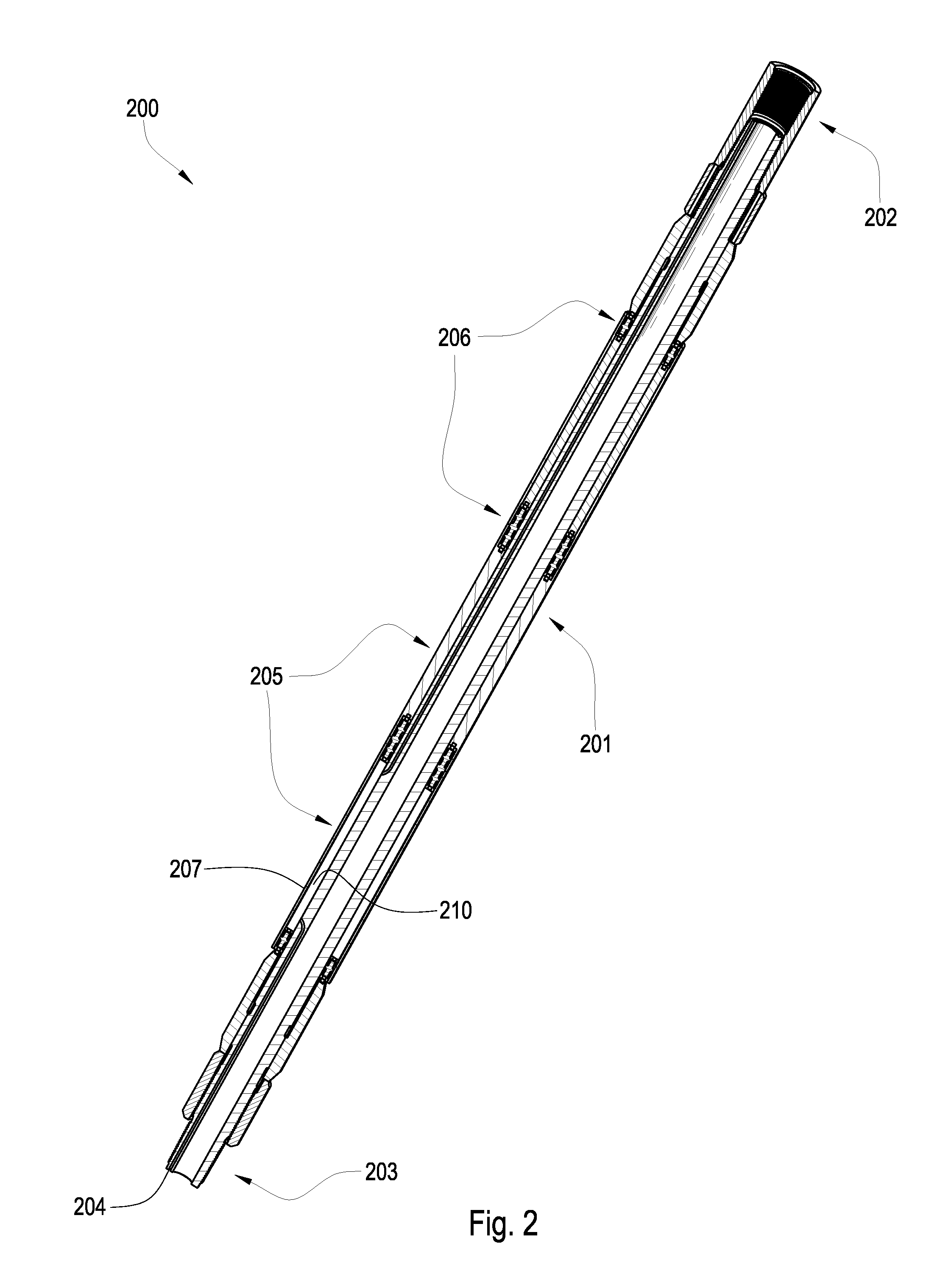

Downhole Coils

In one aspect of the invention, a downhole tool string component comprises a tubular body with at least one end adapted for threaded connection to an adjacent tool string component. The end comprises at least one shoulder adapted to abut an adjacent shoulder of an adjacent end of the adjacent tool string component. An annular magnetic coupler is disposed within an annular recess formed in the at least one shoulder, and the magnetic coupler comprises a coil in electrical communication with an electrical conductor that is in electrical communication with an electronic device secured to the tubular body. The coil comprises a plurality of windings of wire strands that are electrically isolated from one another and which are disposed in an annular trough of magnetic material secured within the annular recess.

Owner:SCHLUMBERGER TECH CORP

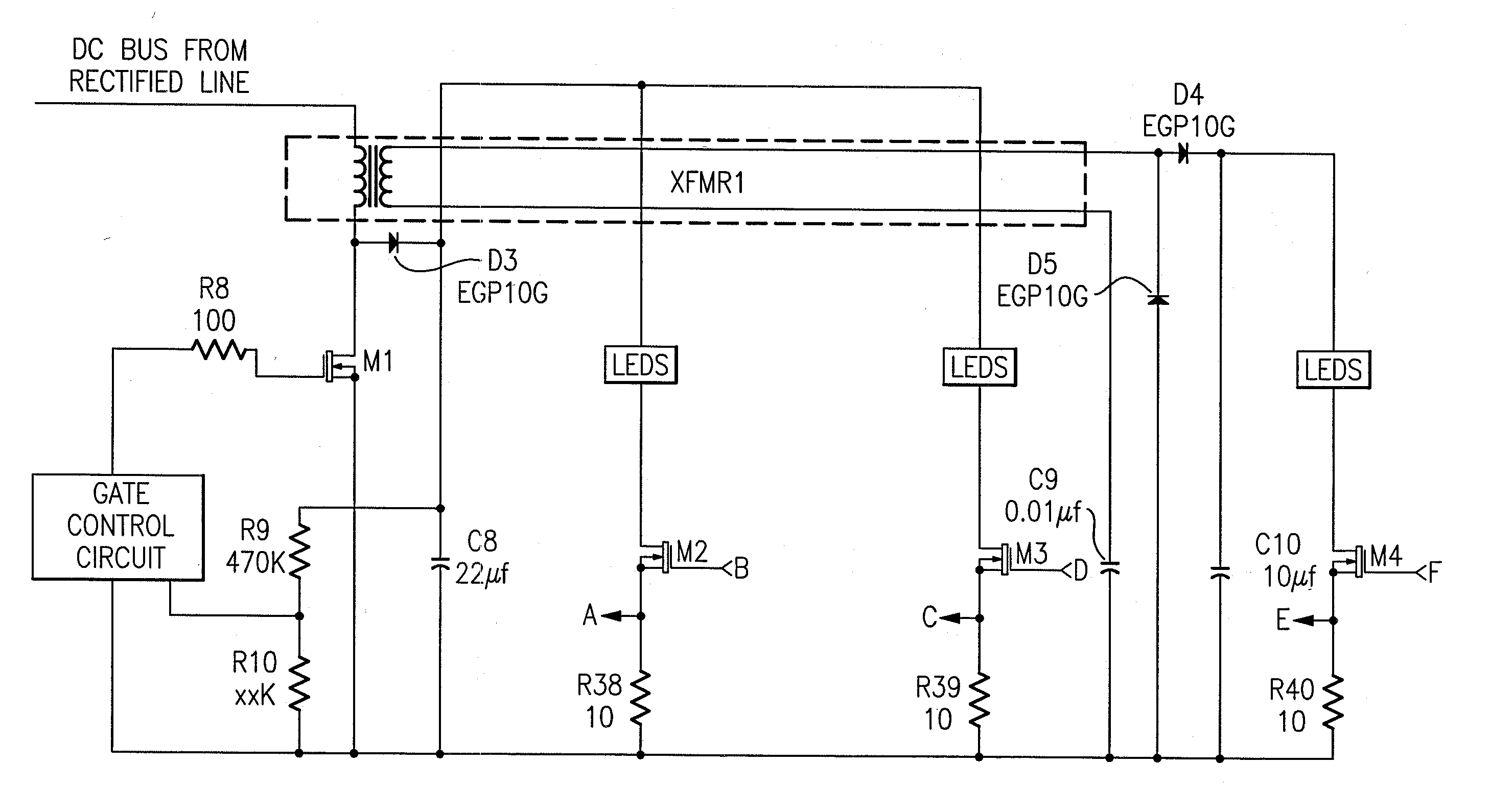

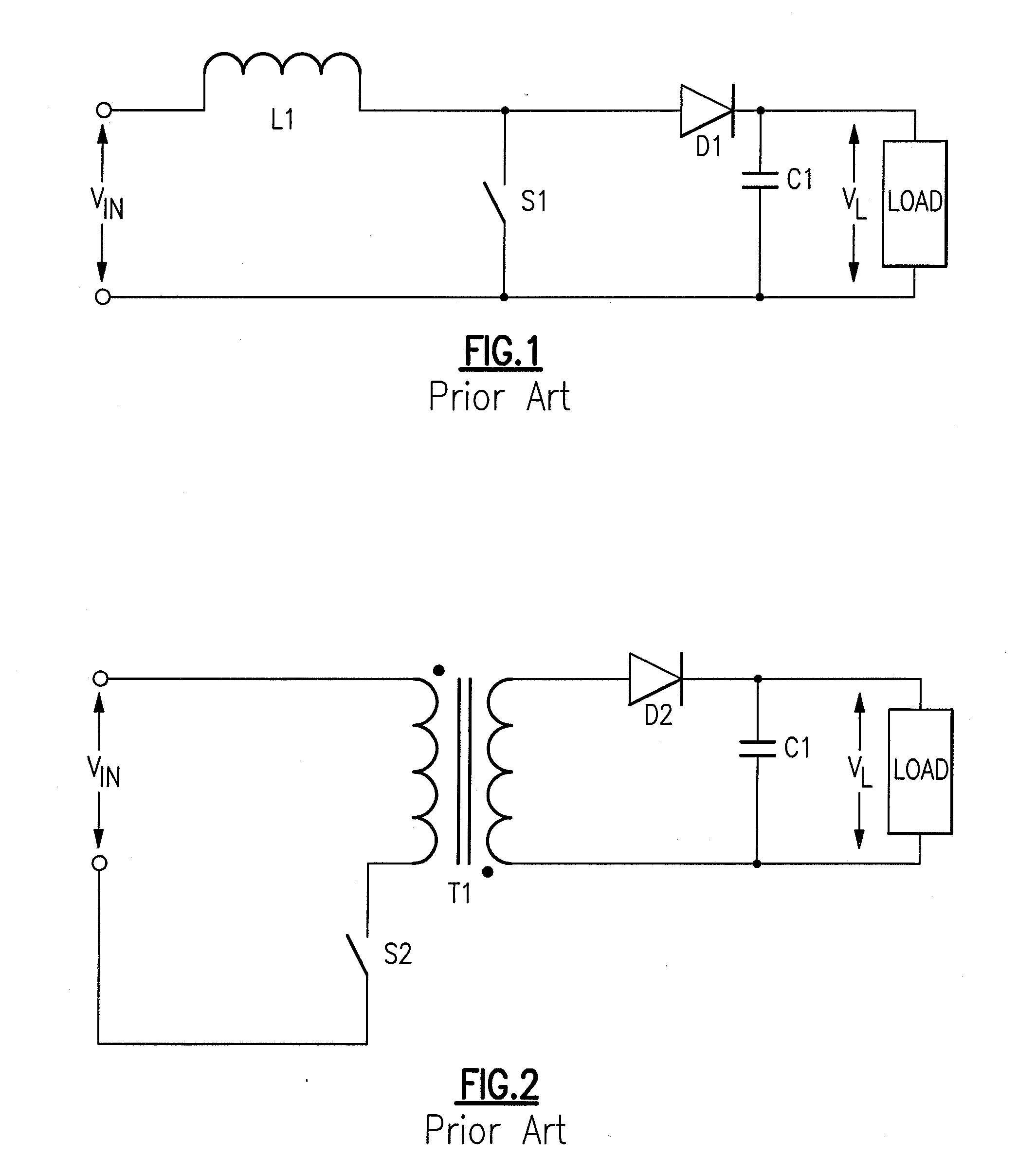

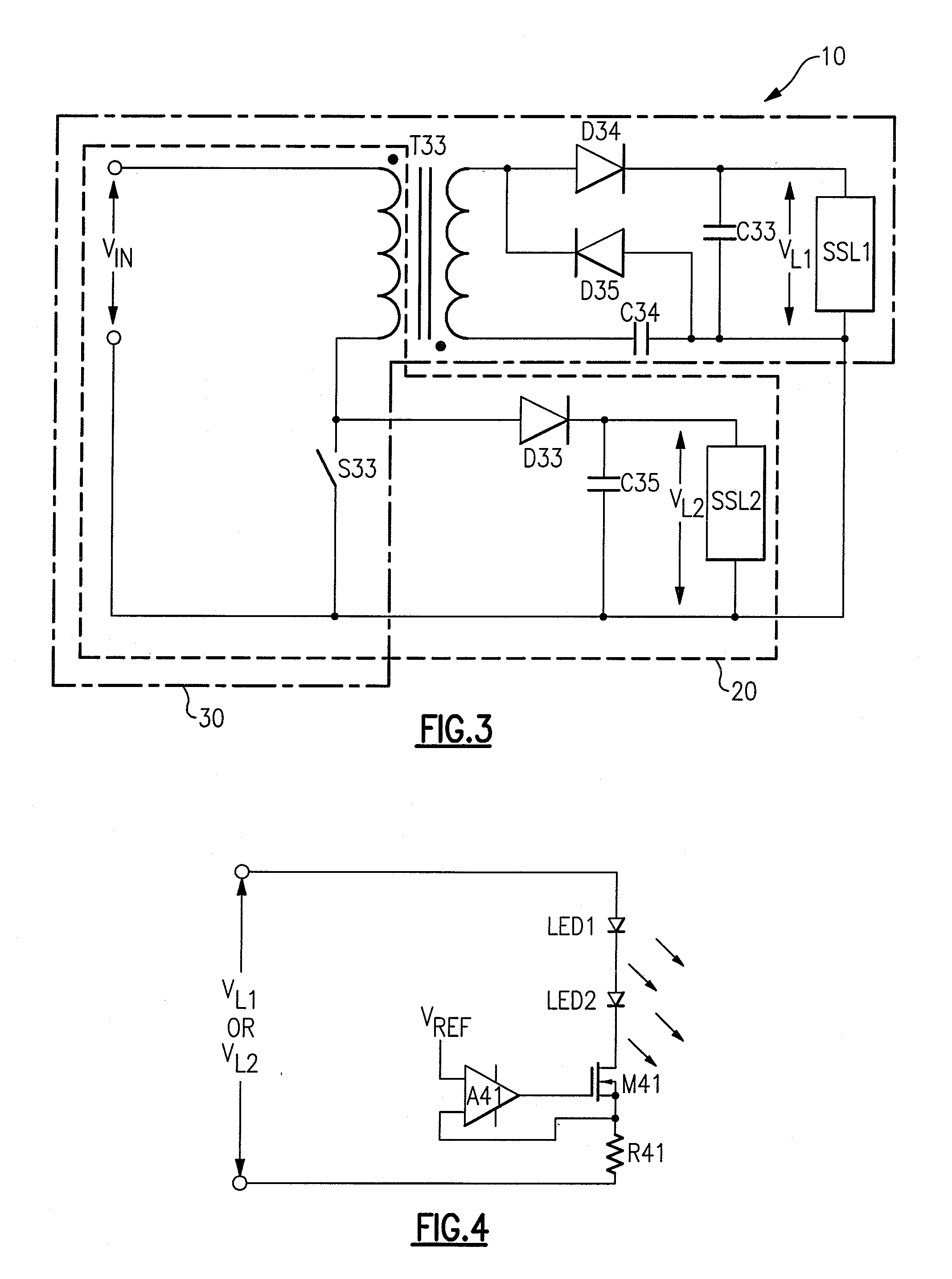

Circuitry for supplying electrical power to loads

ActiveUS20080088248A1Consumes spaceIncrease lossDc network circuit arrangementsDc-dc conversionMOSFETTransformer

A power supply, comprising a boost converter which provides voltage to a first load, and a flyback converter which provides voltage to a second load and which utilizes an inductive element of the boost converter as a primary winding of a transformer of the flyback converter. Also, a power supply comprising a MOSFET which is disposed between solid state elements and a second reference potential and which controls current flowing through the solid state elements. Also, a circuit comprising a transformer, a first circuit portion comprising the primary winding of the transformer and a second circuit portion comprising the secondary winding of the transformer. Also, a power supply comprising means for using a common transformer for providing a boost converter and a flyback converter. Also, a power supply comprising a transformer, means for providing a boost converter utilizing the transformer, and means for providing a flyback converter utilizing the transformer.

Owner:IDEAL IND LIGHTING LLC

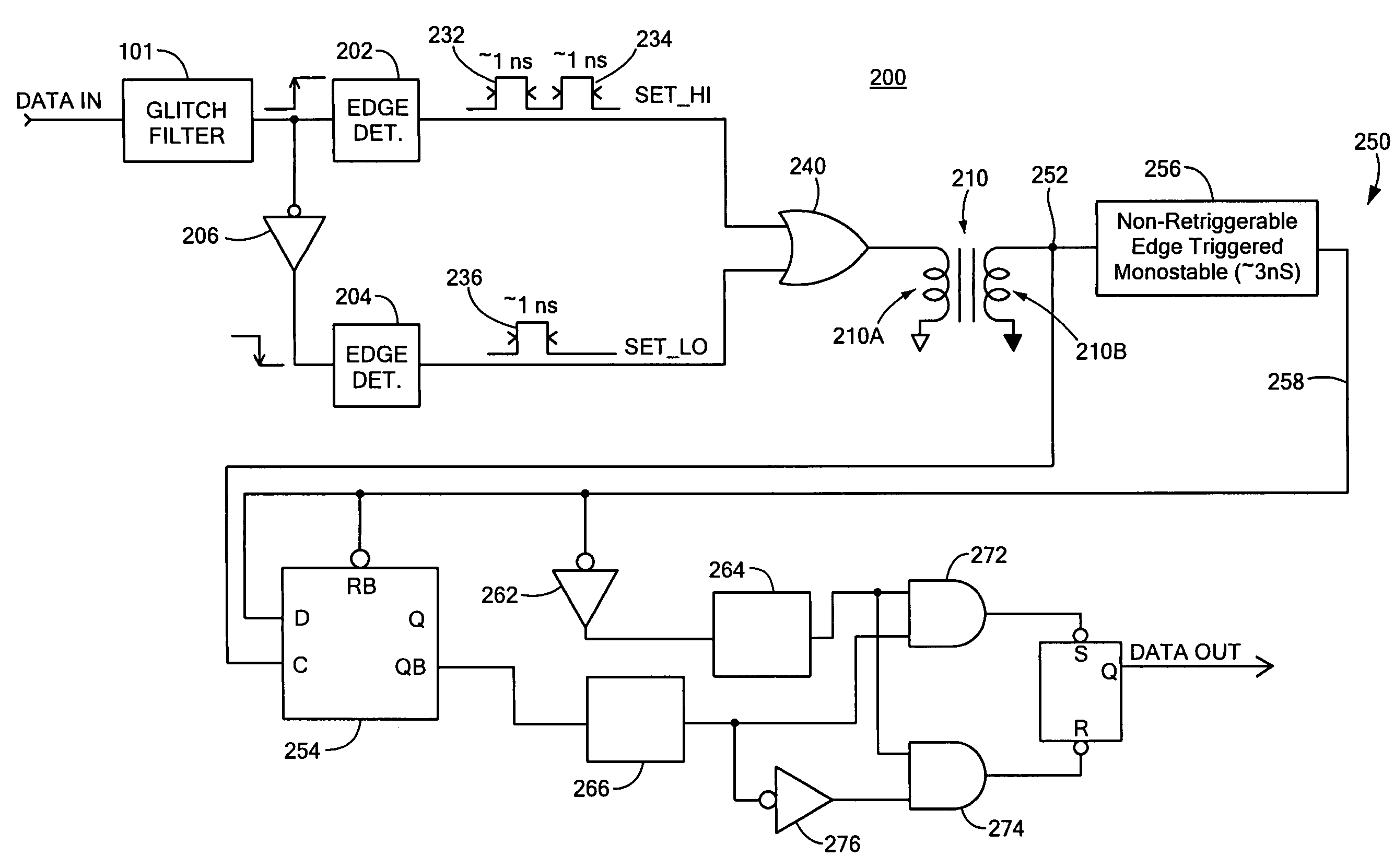

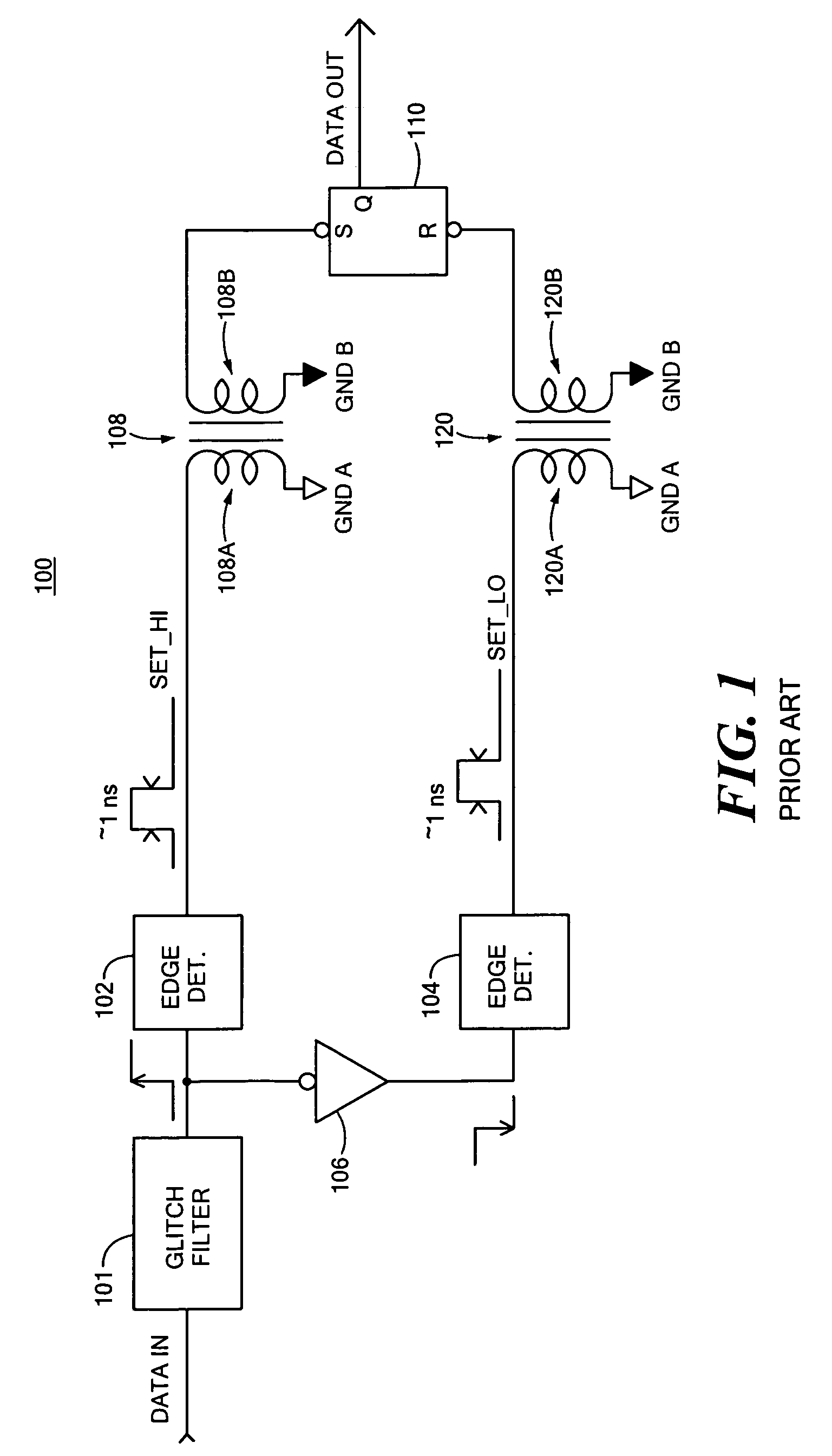

Signal isolators using micro-transformers

ActiveUS7075329B2Reliability increasing modificationsSemiconductor/solid-state device detailsTransformerEngineering

A logic signal isolator comprising a transformer having a primary winding and a secondary winding; a transmitter circuit which drives said primary winding in response to a received logic signal, such that in response to a first type of edge in the logic signal, a signal of a first predetermined type is supplied to the primary winding and in response to a second type of edge in the logic signal, a signal of a second predetermined type is supplied to said primary winding, the primary winding and the transmitter being referenced to a first ground; and the secondary winding being referenced to a second ground which is galvanically isolated from the first ground and said secondary winding supplying to a receiver circuit signals received in correspondence to the signals provided to the primary winding, the receiver reconstructing the received logic signal from the received signals.

Owner:ANALOG DEVICES INC

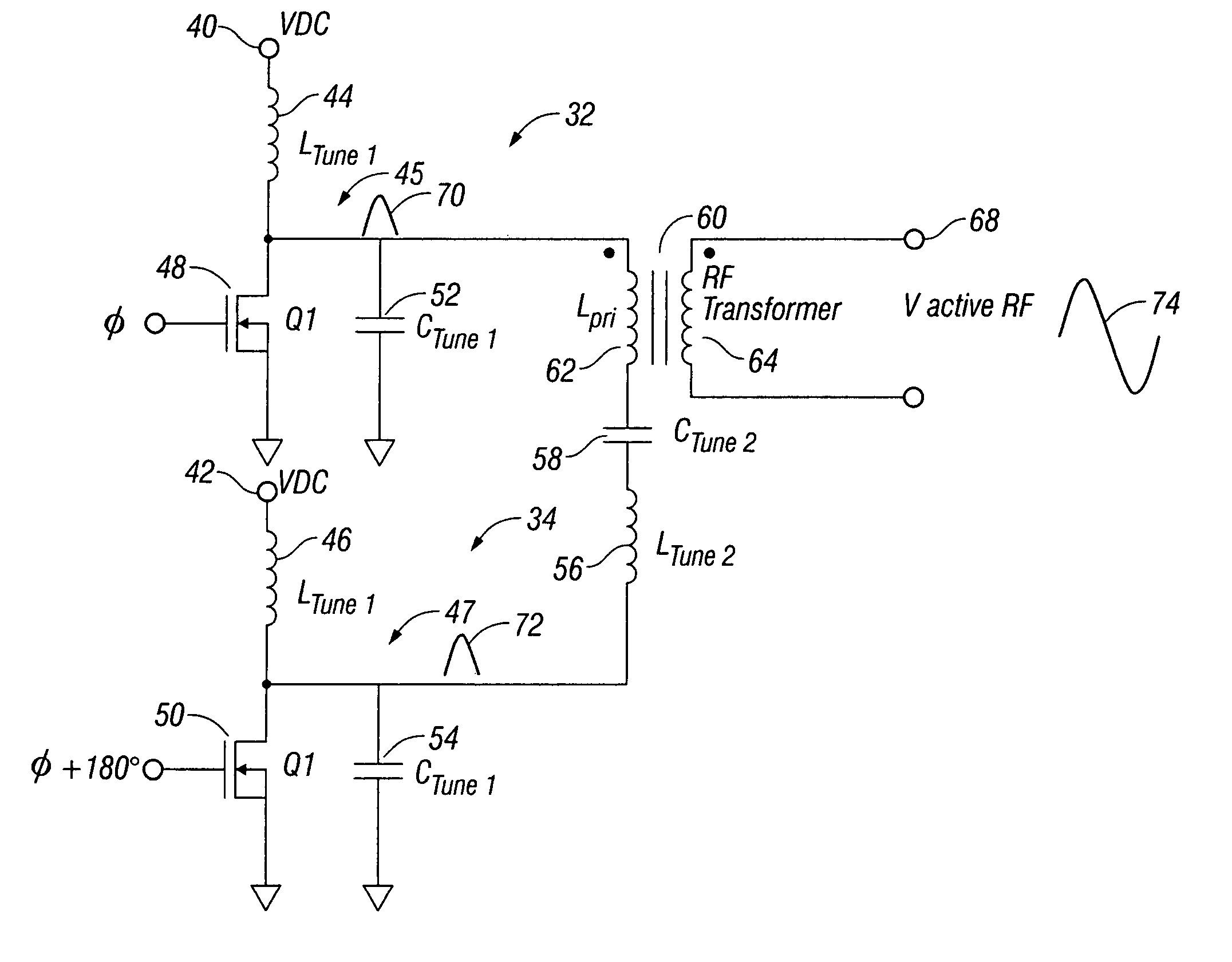

System and method for generating radio frequency energy

An electrosurgical generator is disclosed. The electrosurgical generator includes a power supply for generating a DC voltage. The electrosurgical generator also includes a first parallel inductor-capacitor circuit being driven by a first signal at a first predetermined frequency and a second parallel inductor-capacitor inductor-capacitor circuit driven by a second signal at the first predetermined frequency phase shifted 180°. The electrosurgical generator further includes a series inductor-capacitor resonant circuit operably connected in series with a primary winding of a transformer. The first and second parallel inductor-capacitor circuits are operably connected to the transformer, such that the first inductor-capacitor circuit generates a positive half sine wave and the second inductor-capacitor circuit generates a 180° phase-shifted positive half sine wave to generate a full sine wave in a secondary winding of the transformer.

Owner:COVIDIEN AG

Zero Voltage Switching Half-Bridge Converters

ActiveUS20160056640A1Improve efficiencyBatteries circuit arrangementsElectromagnetic wave systemTransformerEngineering

A power converter comprises a primary switch network coupled to a power source, wherein the primary switch network comprises a plurality of power switches, a controller configured to generate gate drive signals for the plurality of power switches, a secondary rectifier coupled to an output, a first transformer having a first winding coupled to the primary switch network, a second winding coupled to the secondary rectifier and a third winding coupled to the controller and a second transformer having a fourth winding coupled to the primary switch network, a fifth winding coupled to the secondary rectifier and a sixth winding coupled to the controller, wherein a voltage signal from the third winding and / or the sixth winding is processed to provide a feedback of a voltage at the output.

Owner:NUVOLTA TECH

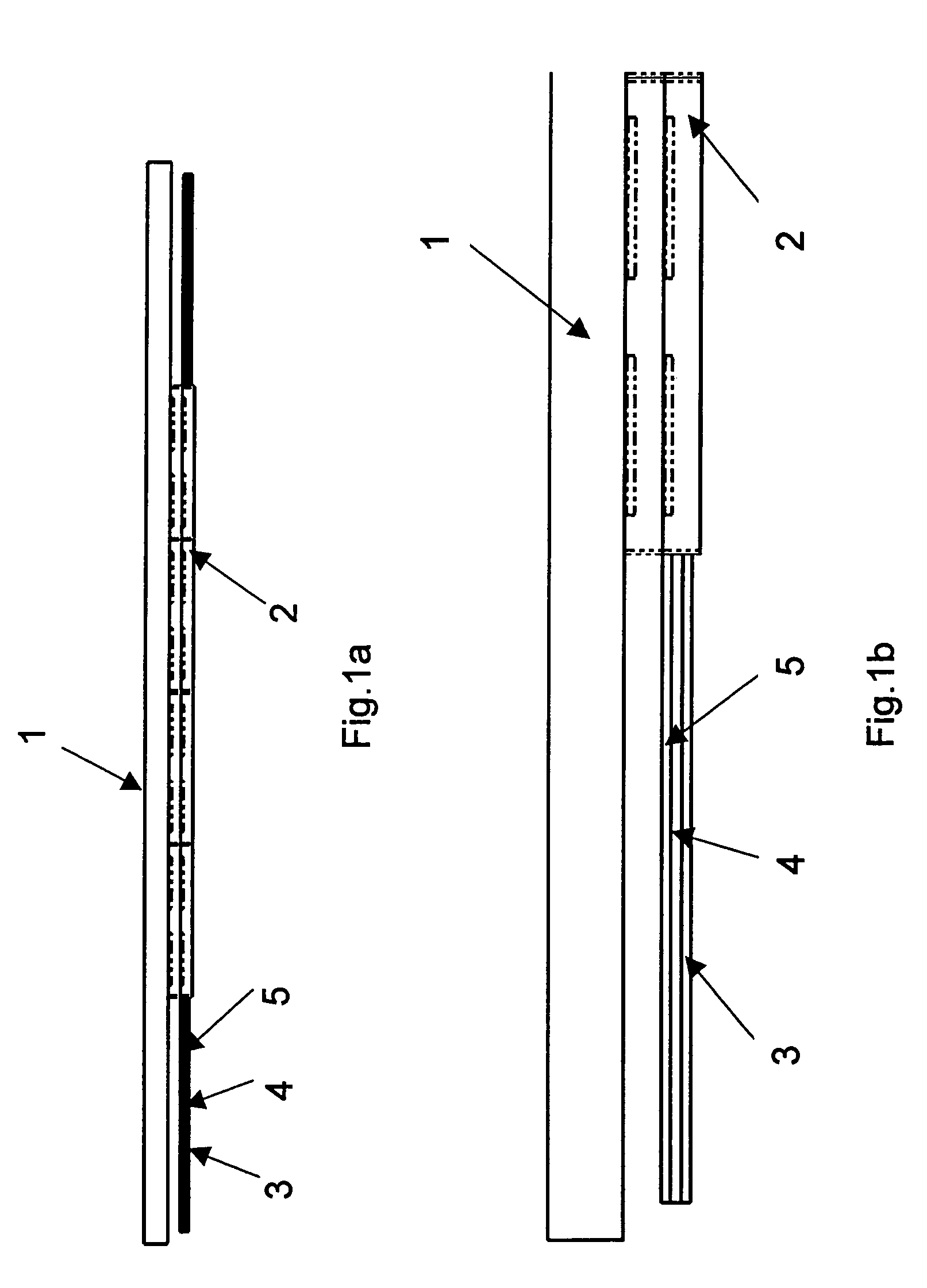

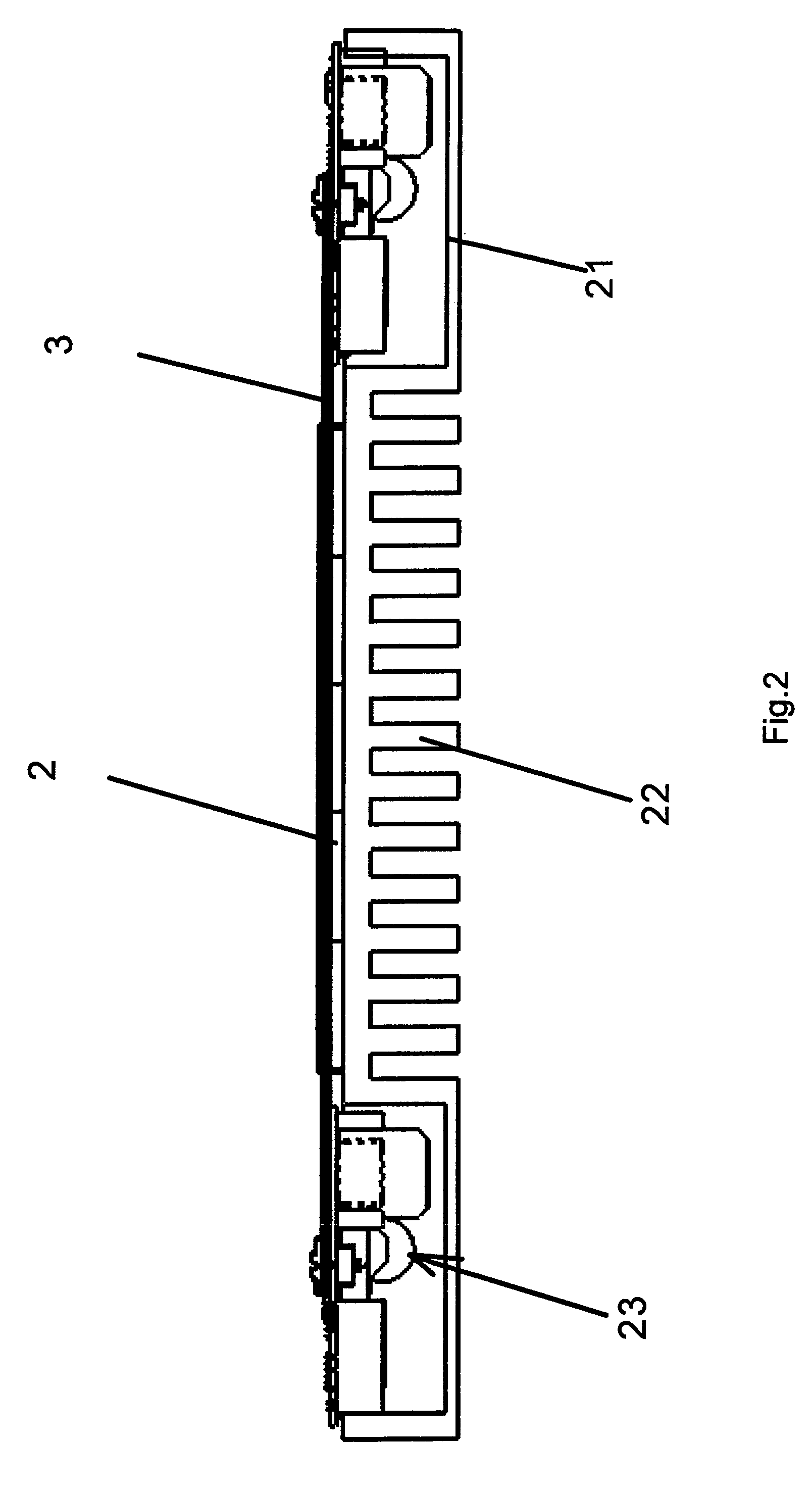

Transmitter head and system for contactless energy transmission

ActiveUS7492247B2Small unit volumeInexpensive and uncomplicated mannerTransformersMagnetic-bias transformersEngineeringConductor Coil

A transmitter head for a system for contactless energy transmission includes a support connected to at least one ferrite core. The ferrite core is embodied at least partially in the E-form and a flat winding is arranged around one leg of the E.

Owner:SEW-EURODRIVE GMBH & CO KG

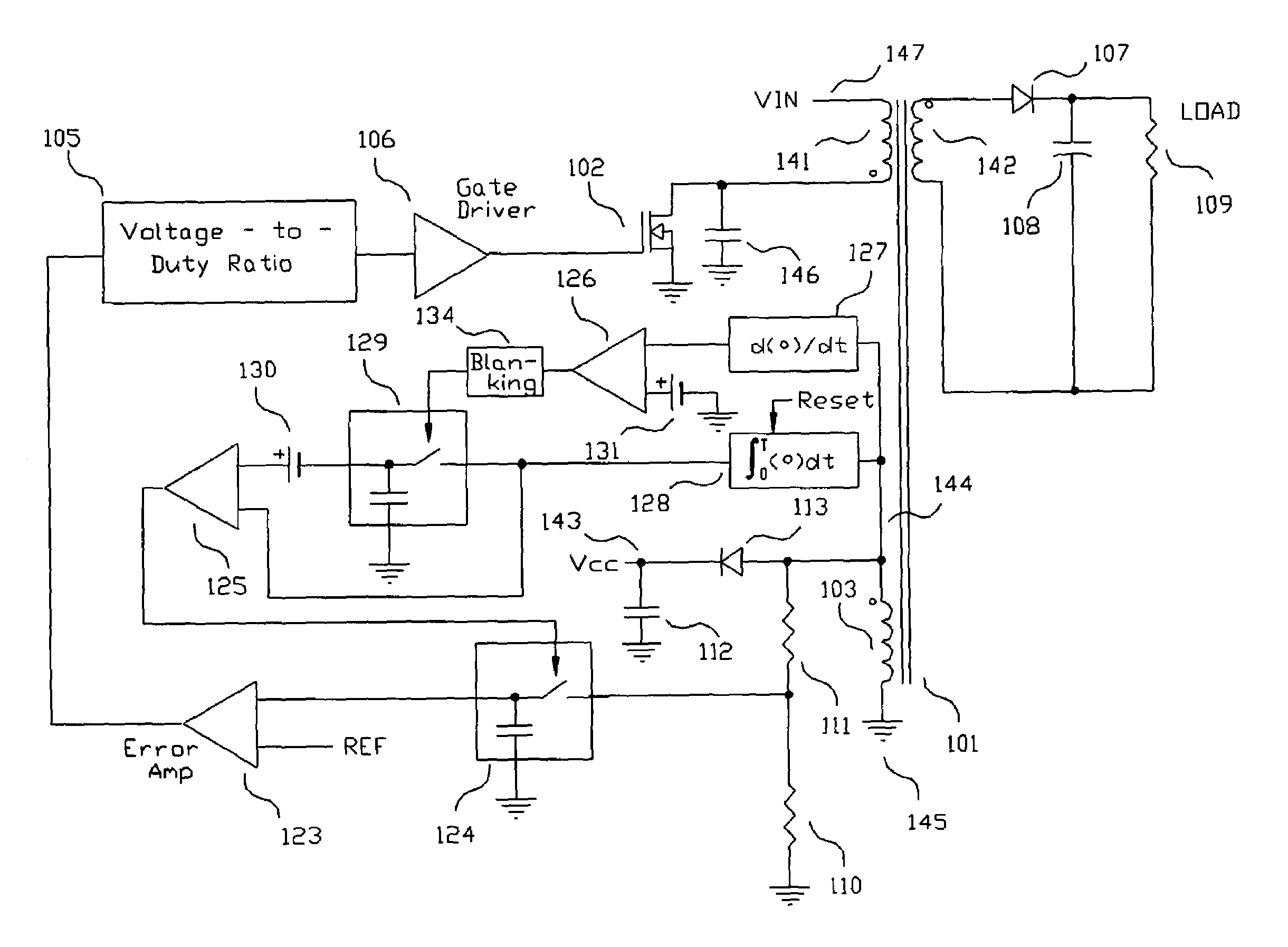

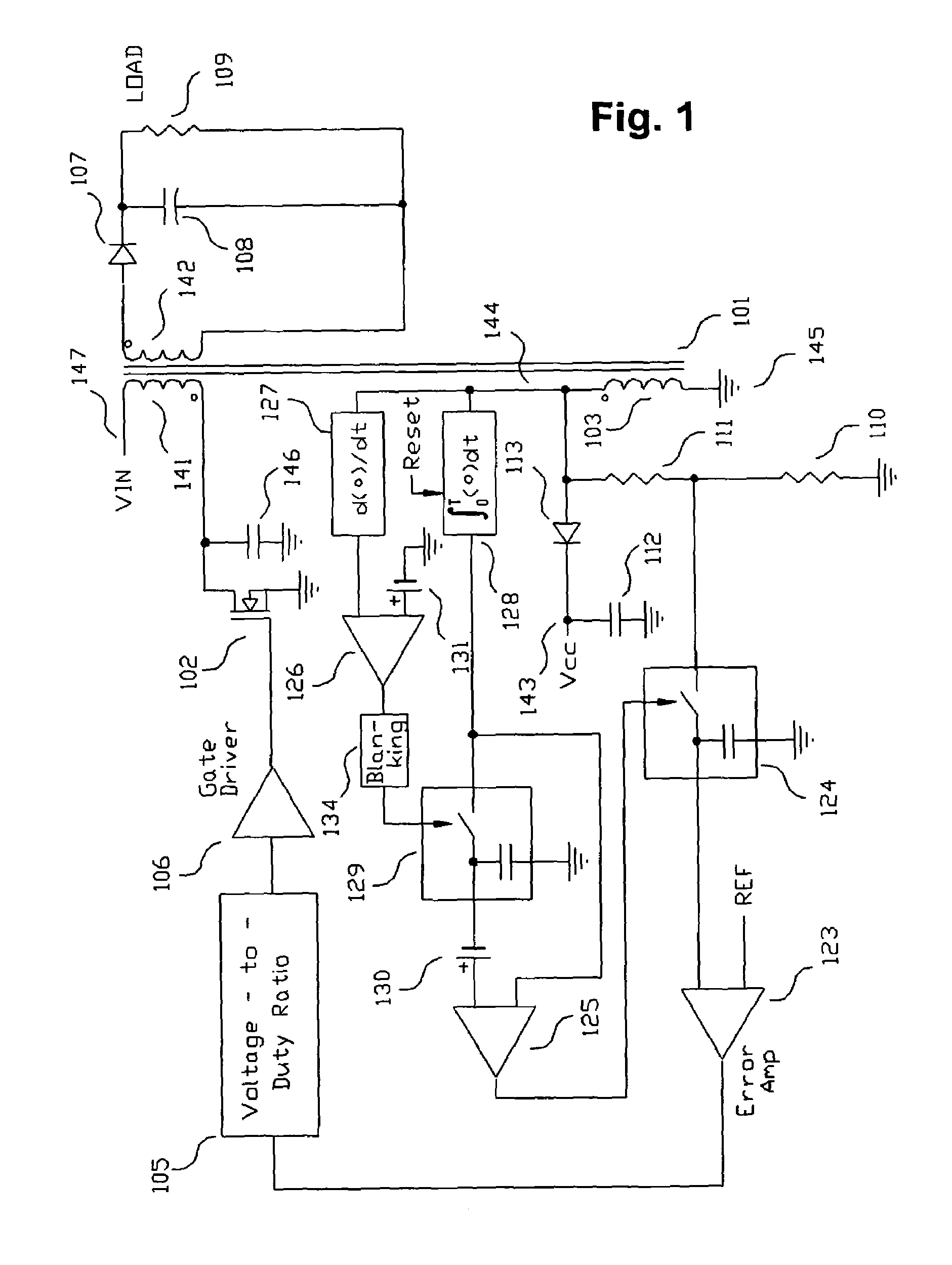

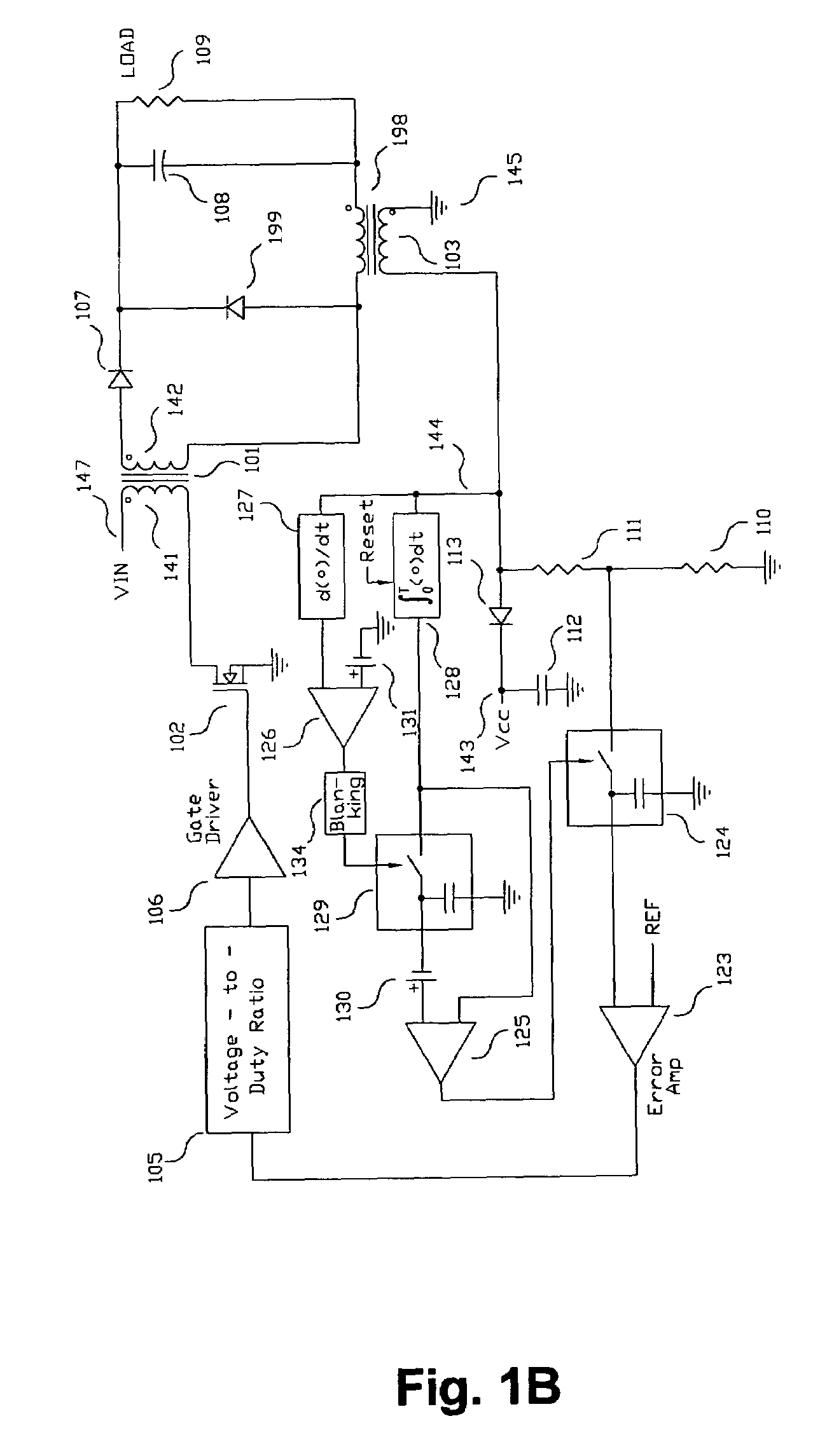

Switching power converter and method of controlling output voltage thereof using predictive sensing of magnetic flux

A switching power converter and method of controlling an output voltage thereof using predictive sensing of magnetic flux provides a low-cost switching power converter via primary-side control using a primary-side winding. An integrator generates a voltage that represents flux within a magnetic element by integrating a primary-side winding voltage. A detection circuit detects the end of a half-cycle of post-conduction resonance that occurs in the power magnetic element subsequent to zero energy level in the power magnetic element. The integrator voltage is stored at the end of the half-cycle and is used to determine a sampling point prior to or equal to the start of post-conduction resonance in a subsequent switching cycle of the power converter. The primary-side winding voltage is then sampled at the sampling point, providing an indication of the output voltage of the power converter by which the output voltage of the converter can be controlled.

Owner:MICROCHIP TECH INC

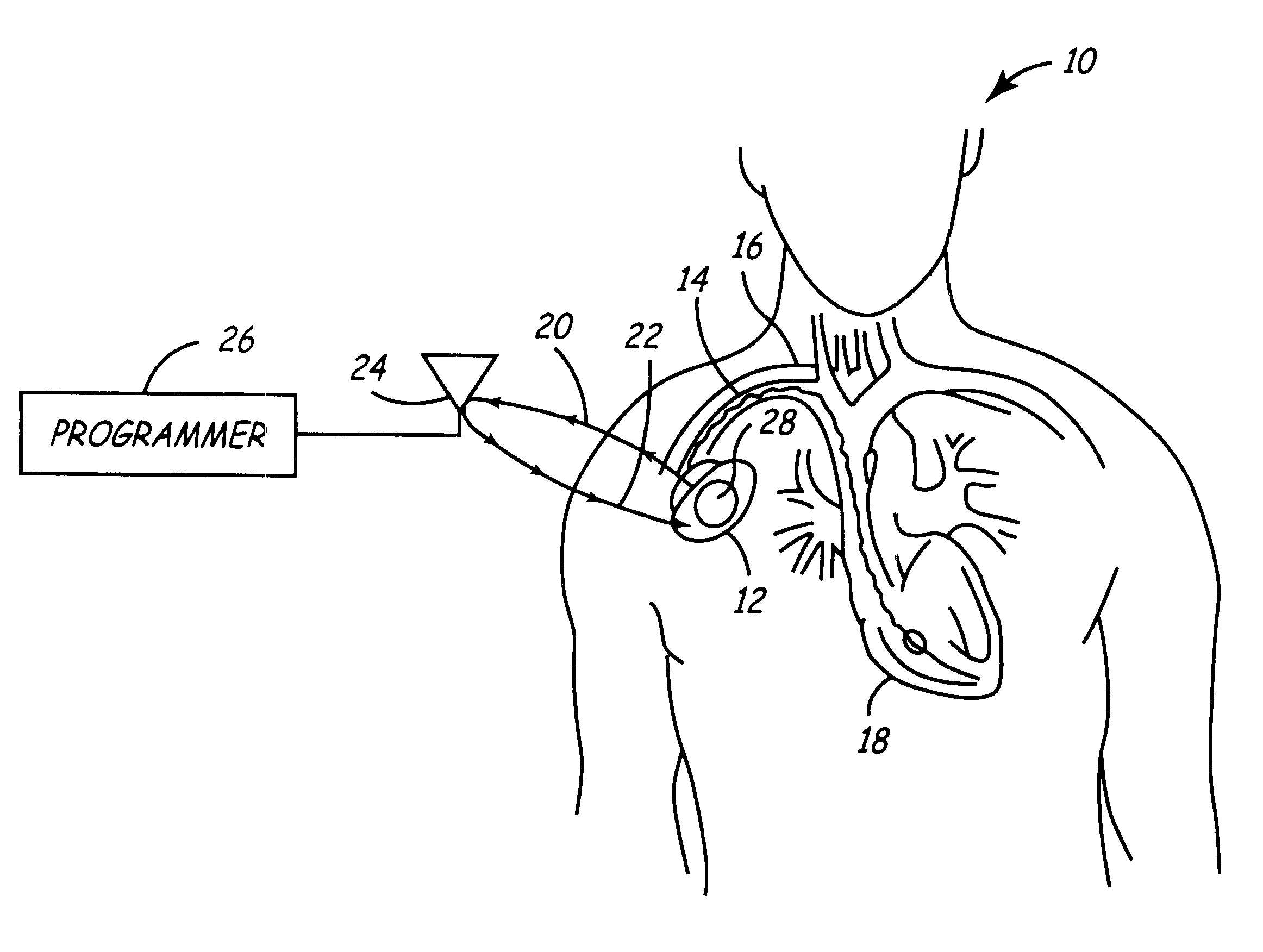

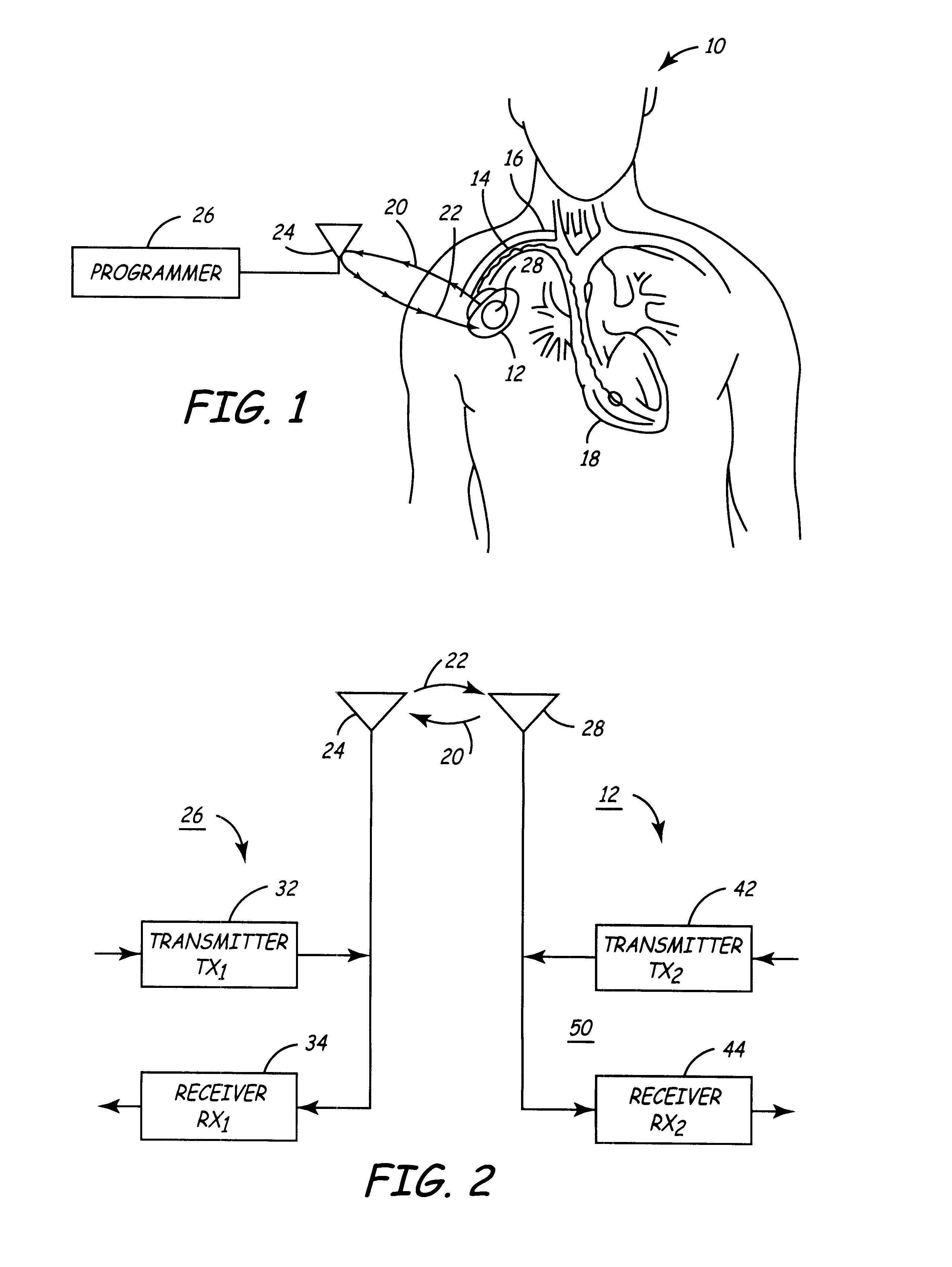

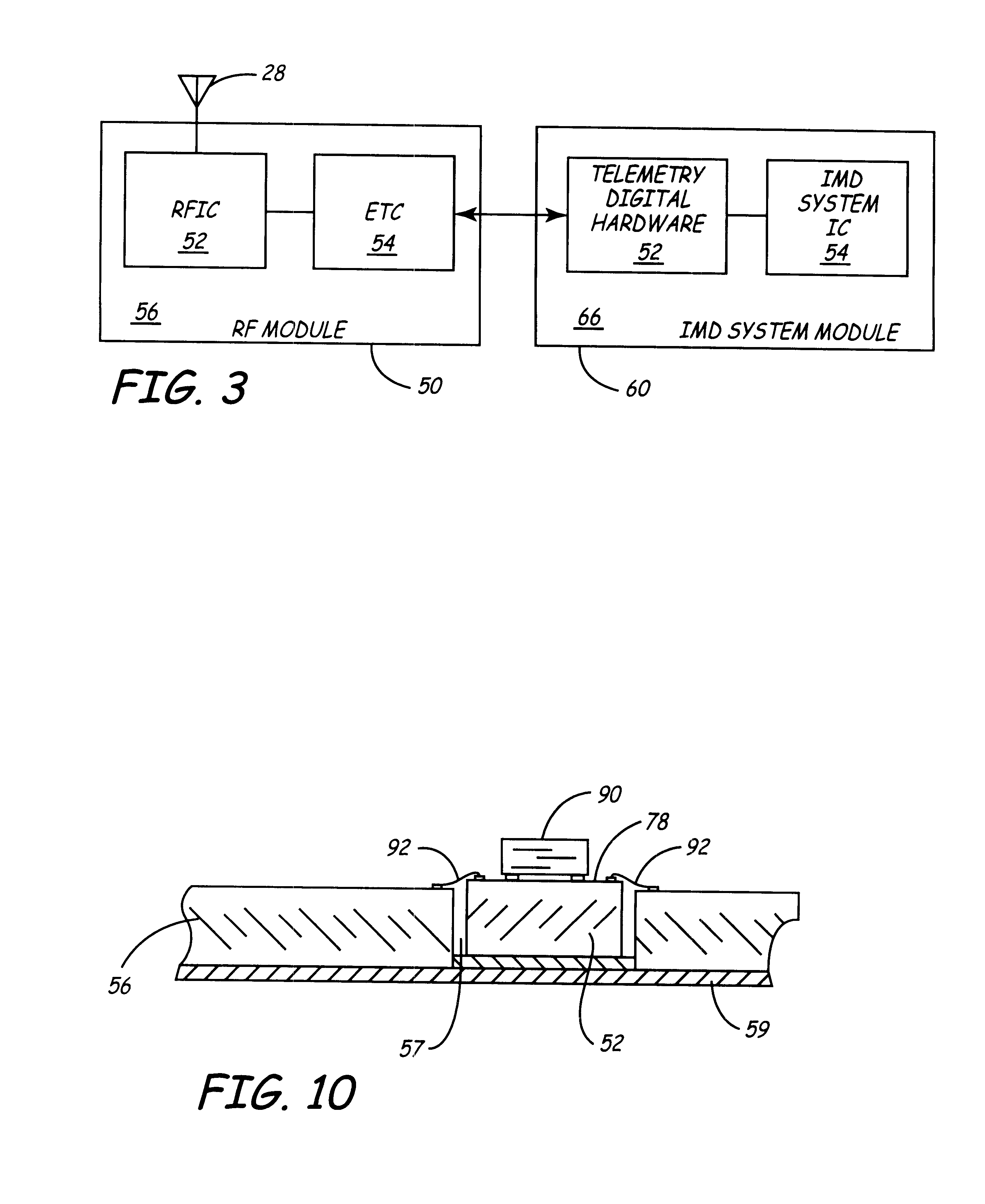

Implantable medical device incorporating miniaturized circuit module

Implantable medical devices (IMDS) having RF telemetry capabilities for uplink transmitting patient data and downlink receiving programming commands to and from an external programmer having an improved RF module configured to occupy small spaces within the IMD housing to further effect the miniaturization thereof. An RF module formed of an RF module substrate and at least one IC chip and discrete components has a volume and dimensions that are optimally minimized to reduce its volumetric form factor. Miniaturization techniques include: (1) integrating inductors into one or more IC chips mounted to the RF module substrate; (2) mounting each IC chip into a well of the RF module substrate and using short bonding wires to electrically connect bond pads of the RF module substrate and the IC chip; and (3) surface mounting discrete capacitors over IC chips to reduce space taken up on the RF module substrate. The integrated inductors are preferably fabricated as planar spiral wound conductive traces formed of high conductive metals to reduce trace height and width while maintaining low resistance, thereby reducing parasitic capacitances between adjacent trace side walls and with a ground plane of the IC chip. The spiral winding preferably is square or rectangular, but having truncated turns to eliminate 90° angles that cause point-to-point parasitic capacitances. The planar spiral wound conductive traces are further preferably suspended over the ground plane of the RF module substrate by micromachining underlying substrate material away to thereby reduce parasitic capacitances.

Owner:MEDTRONIC INC

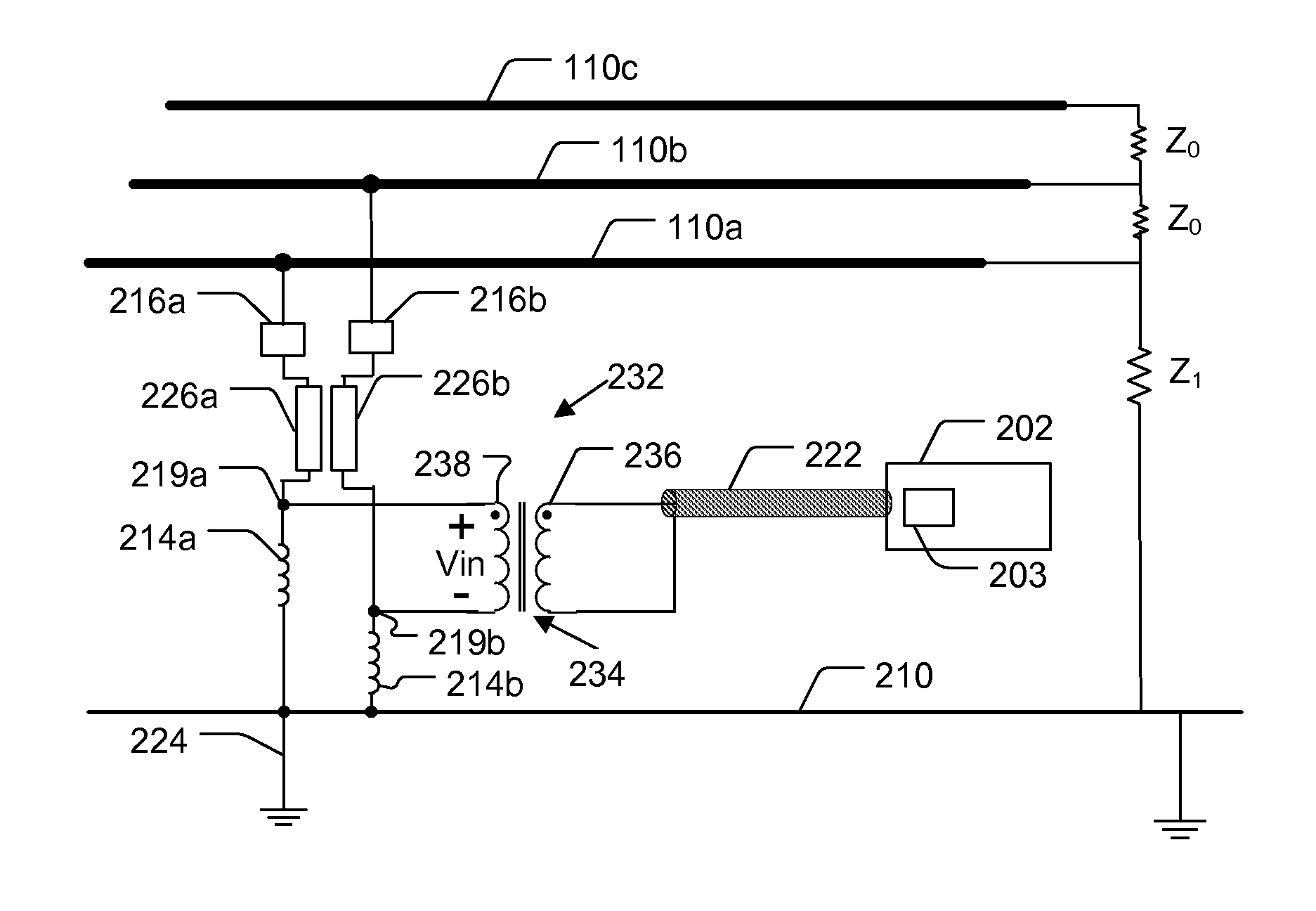

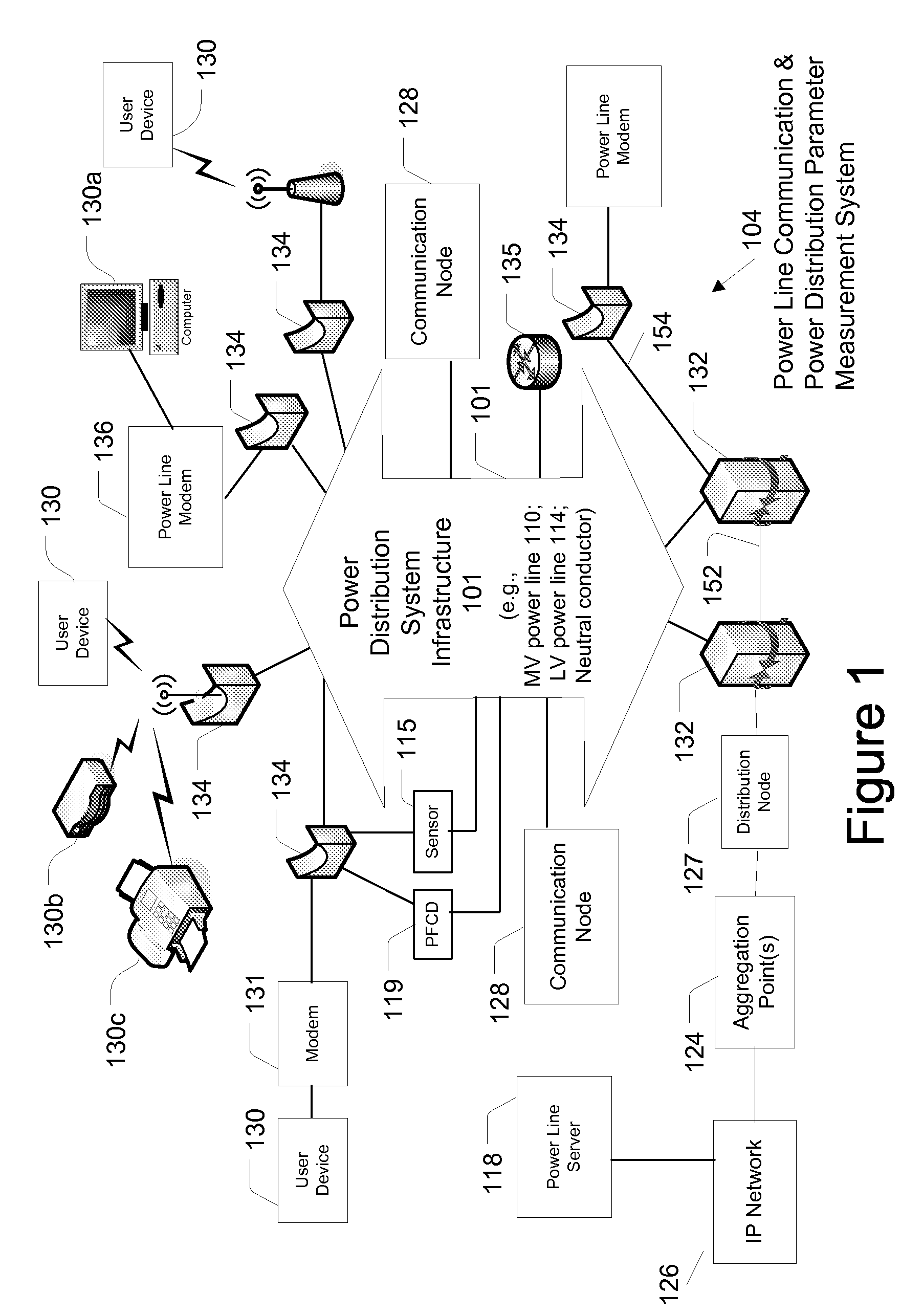

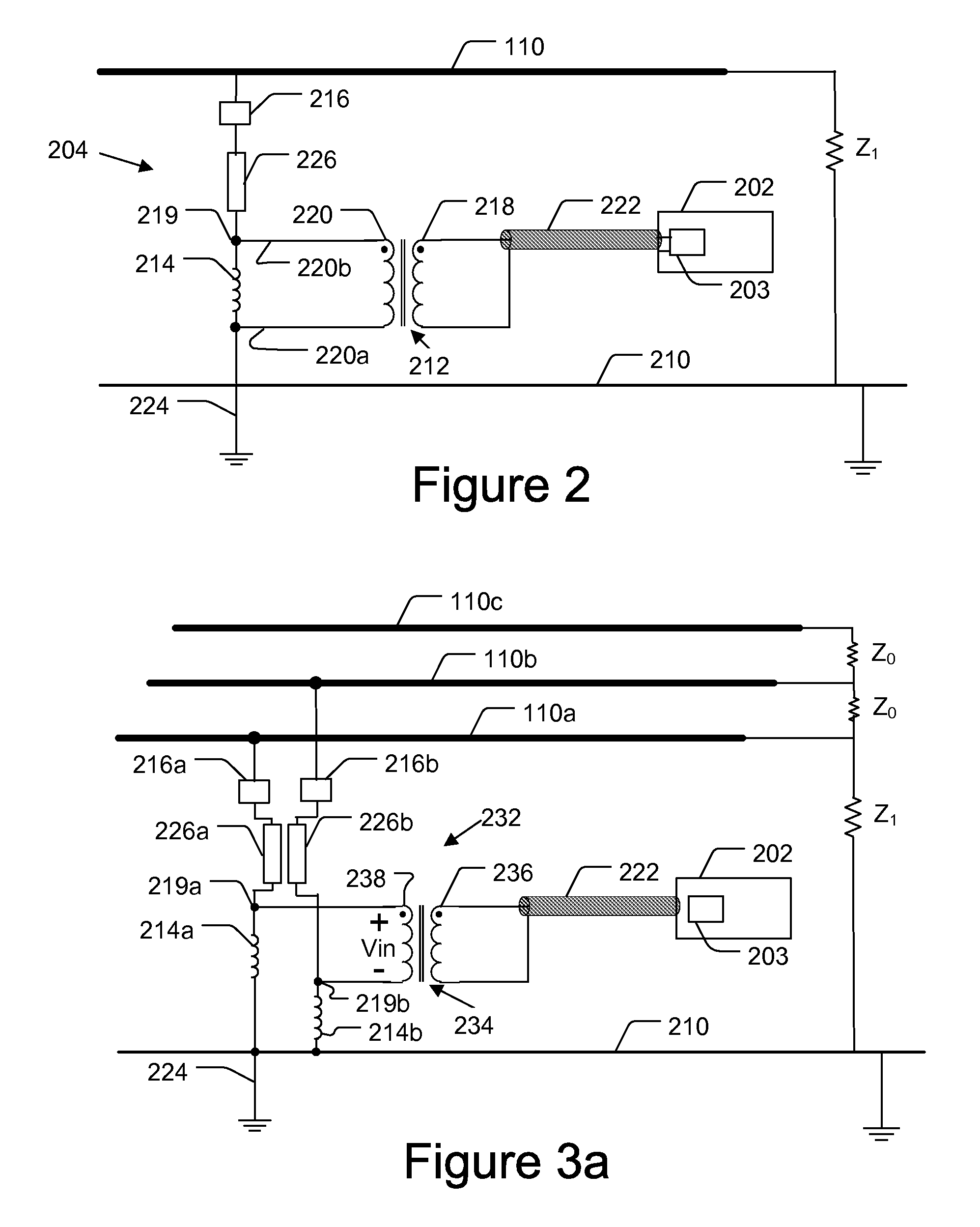

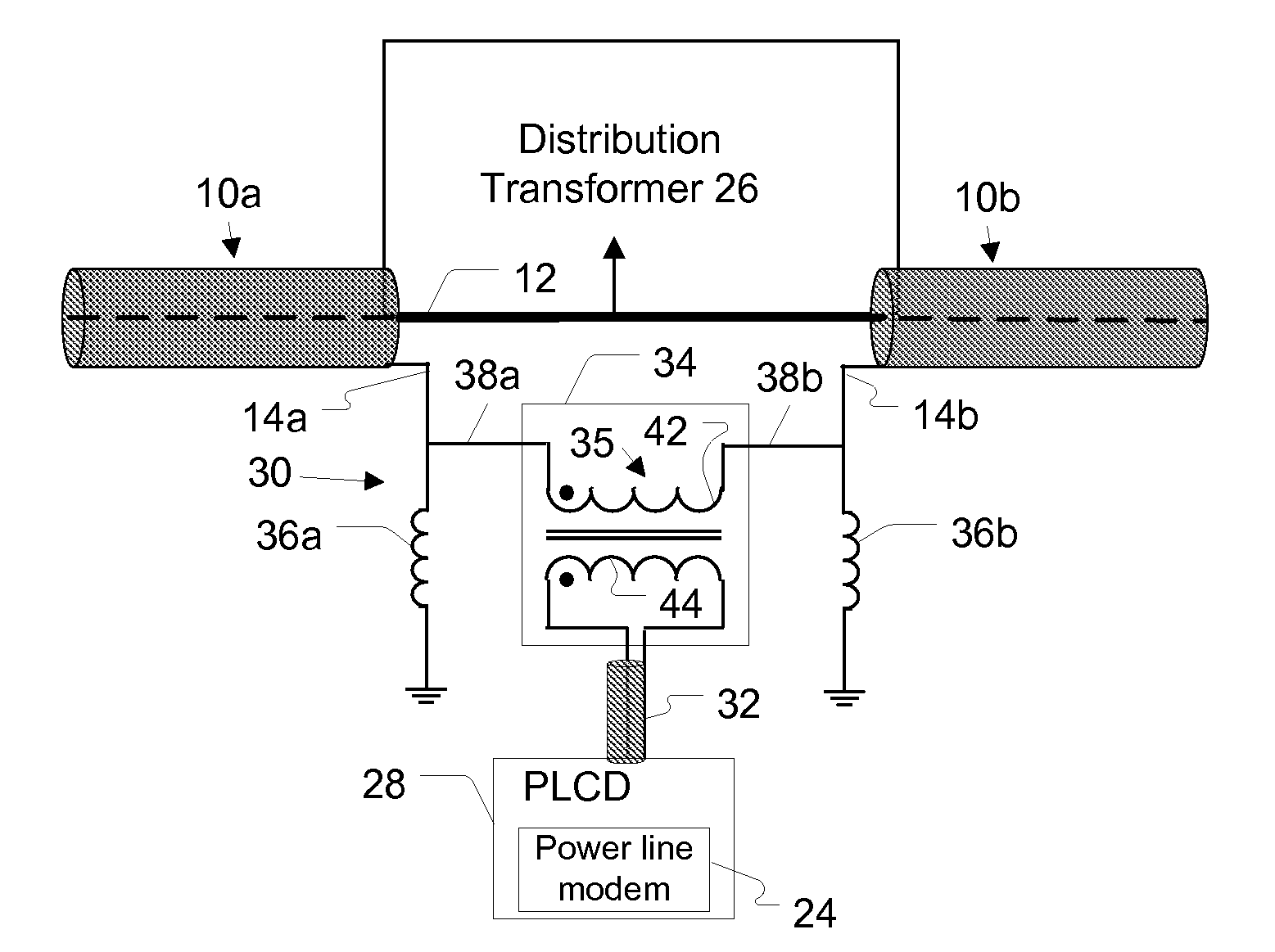

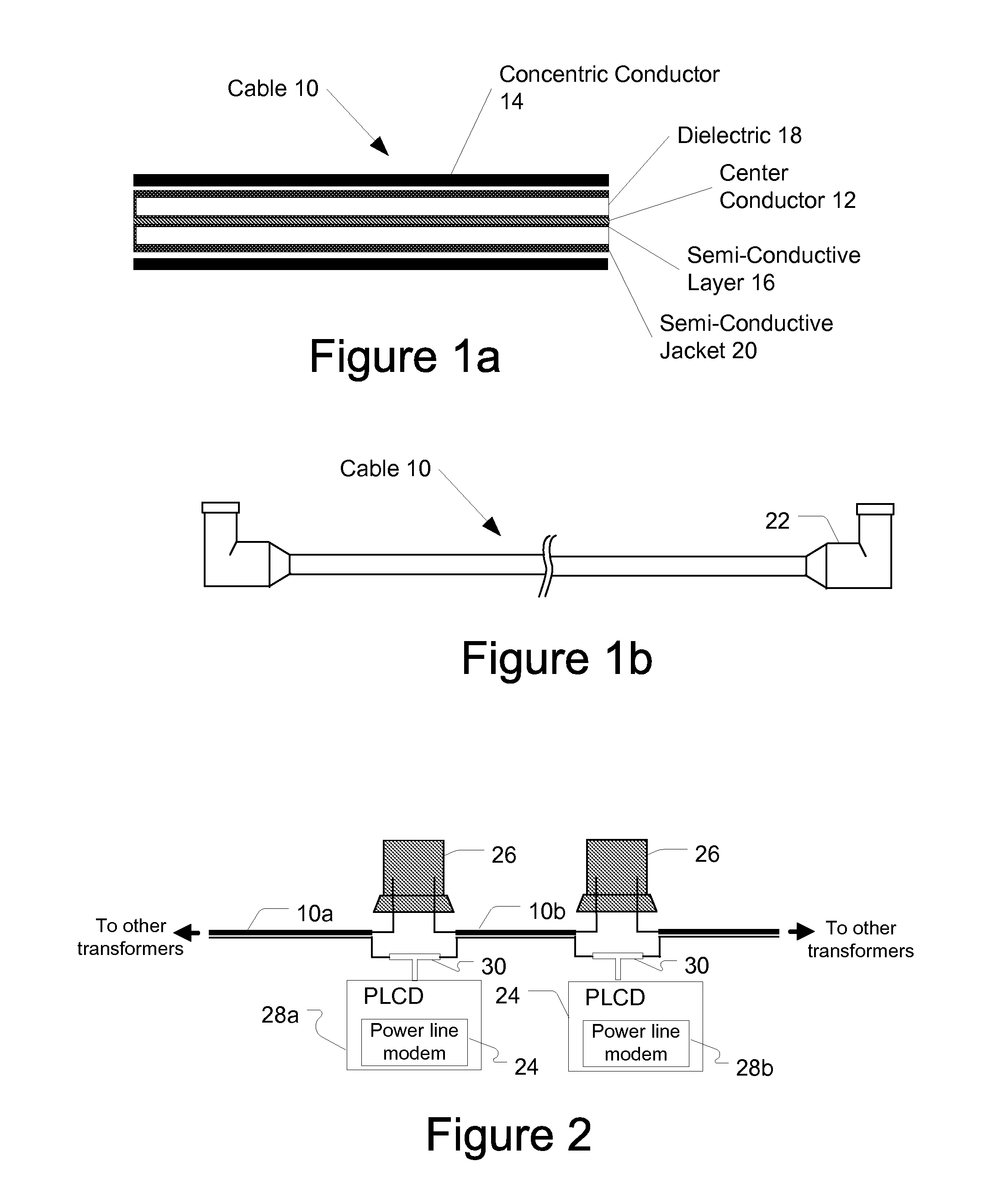

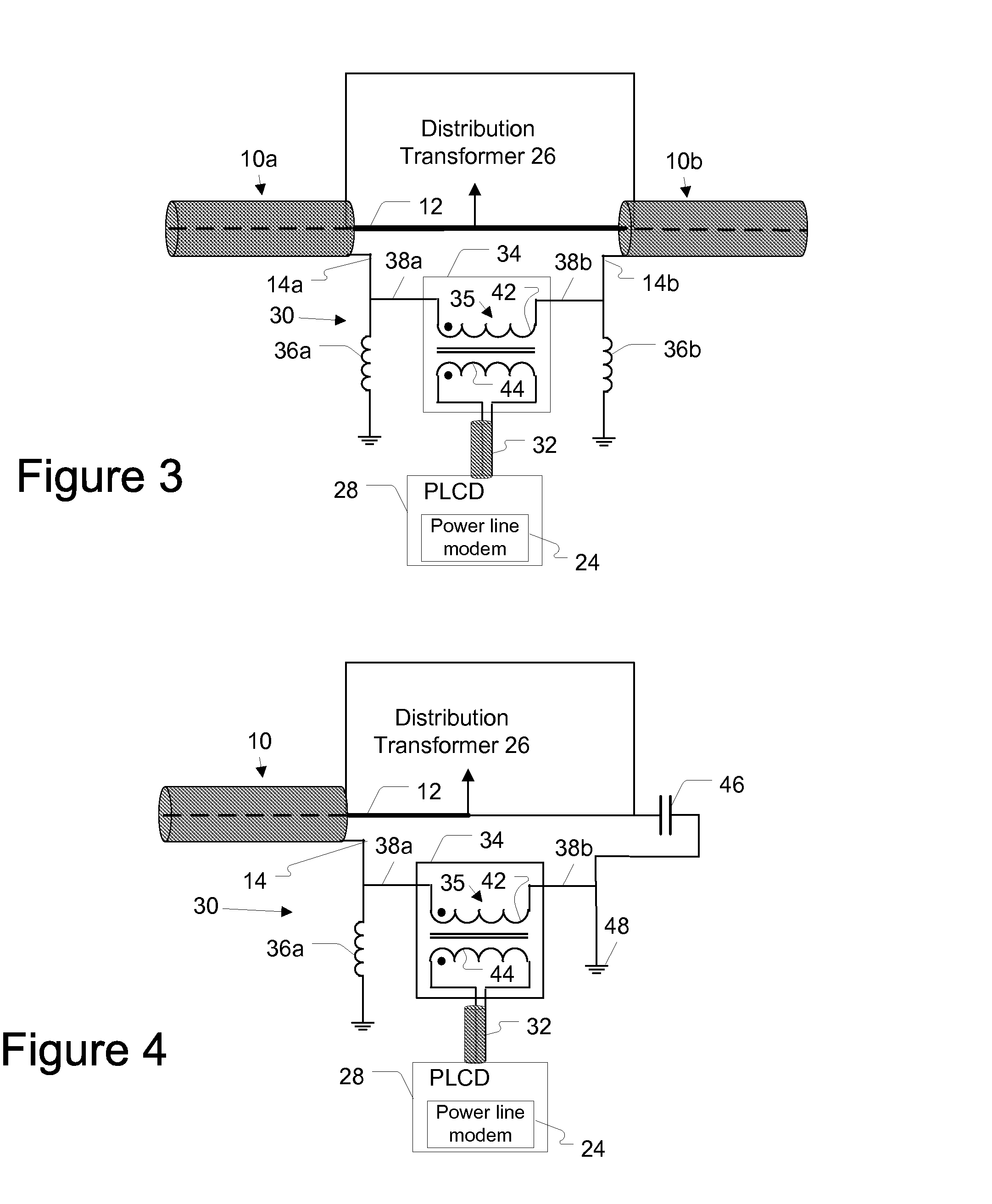

Power line coupling device and method

ActiveUS7795994B2Multiple-port networksElectric signal transmission systemsDistribution power systemConductor Coil

A power line coupler for communicating data signals over a power distribution system having a first and second overhead energized medium voltage power line conductors is provided. In one embodiment, the coupler includes a first lightening arrestor having a first end and a second end, wherein the first end of the first arrestor is connected to the first power line conductor. The coupler further includes a first high frequency impedance having a first end connected to the second end of the first lightening arrestor and the first impedance having a second end connected to a neutral conductor of the power line distribution system. The coupler may further include a second lightening arrestor having a first end and a second end, wherein the first end of the second arrestor is connected to the second power line conductor. The coupler further including a second high frequency impedance having a first end connected to the second end of the second lightening arrestor and a second end connected to the neutral conductor. The first high frequency impedance and the second high frequency impedance may each comprise an air core coil that forms an inductor. The coupler may further include a balun having a first winding and a second winding, wherein the first winding is coupled to a communication device, and wherein the second winding has a first end connected to the first end of the first high frequency impedance and a second end connected to the first end of the second high frequency impedance.

Owner:CHEMTRON RES

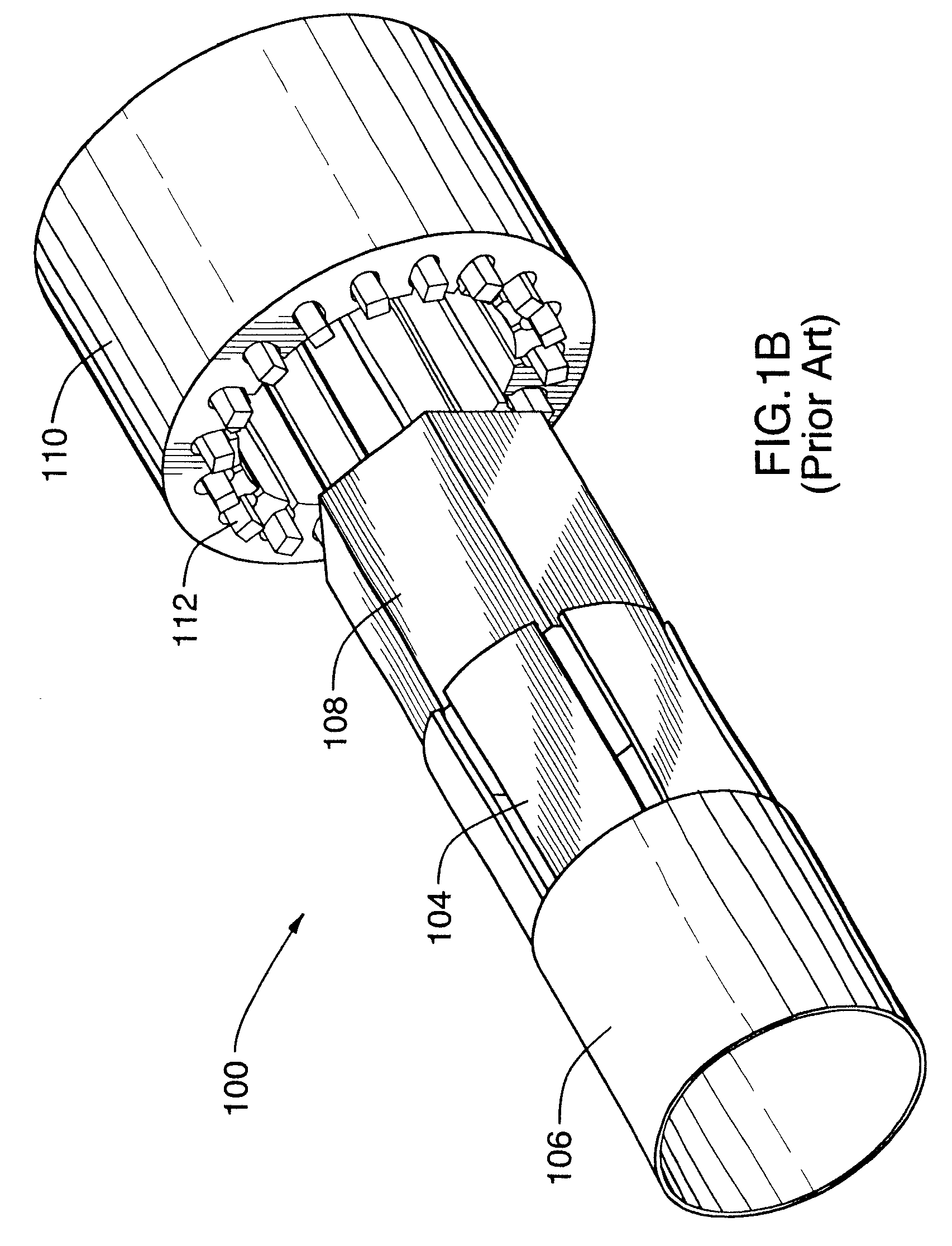

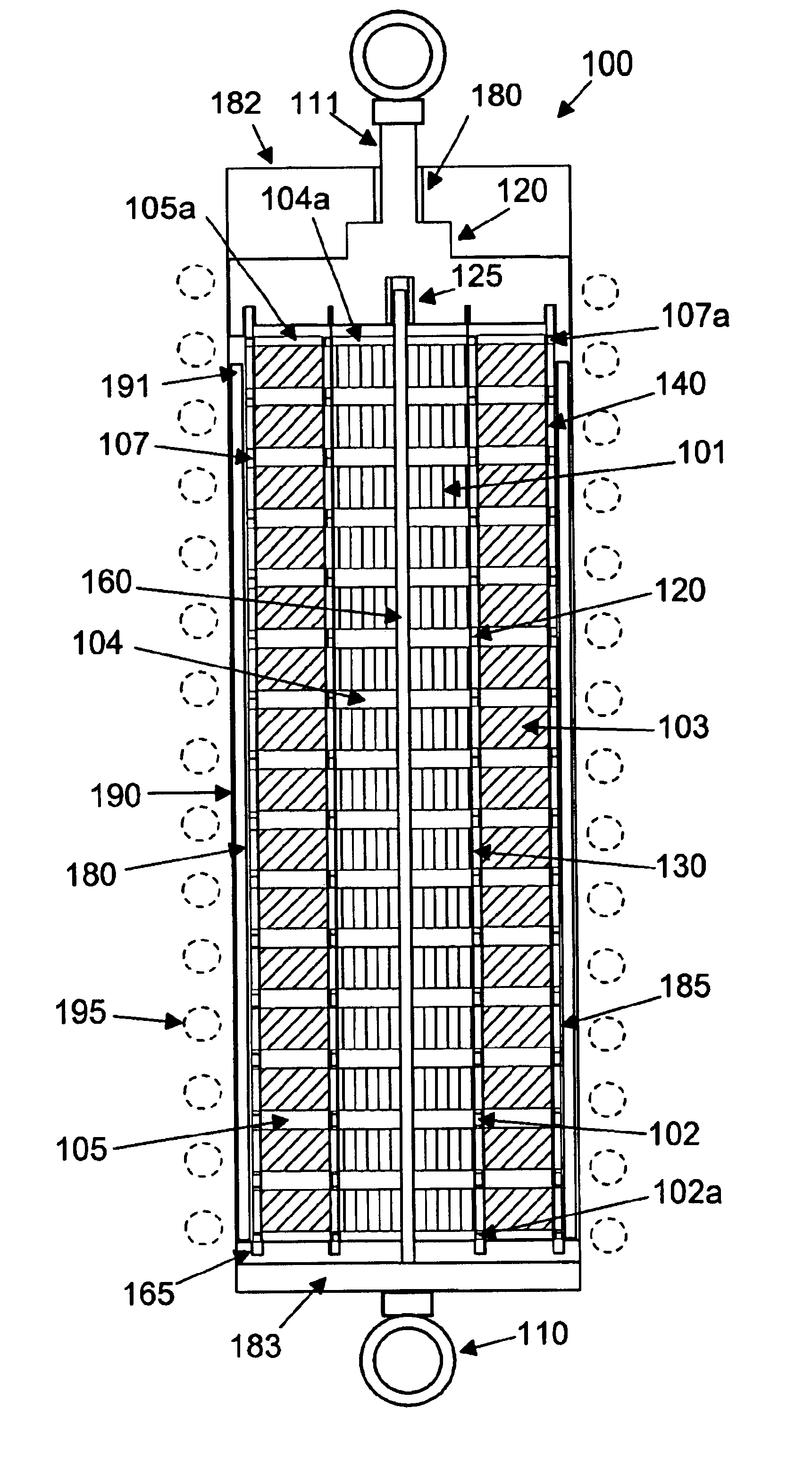

Electromagnetic linear generator and shock absorber

InactiveUS6952060B2Maximizing magnetic flux densityMaximize power generationNon-rotating vibration suppressionMechanical energy handlingElectromagnetic generatorFuel efficiency

An electromagnetic linear generator and regenerative electromagnetic shock absorber is disclosed which converts variable frequency, repetitive intermittent linear displacement motion to useful electrical power. The innovative device provides for superposition of radial components of the magnetic flux density from a plurality of adjacent magnets to produce a maximum average radial magnetic flux density within a coil winding array. Due to the vector superposition of the magnetic fields and magnetic flux from a plurality of magnets, a nearly four-fold increase in magnetic flux density is achieved over conventional electromagnetic generator designs with a potential sixteen-fold increase in power generating capacity. As a regenerative shock absorber, the disclosed device is capable of converting parasitic displacement motion and vibrations encountered under normal urban driving conditions to a useful electrical energy for powering vehicles and accessories or charging batteries in electric and fossil fuel powered vehicles. The disclosed device is capable of high power generation capacity and energy conversion efficiency with minimal weight penalty for improved fuel efficiency.

Owner:TRUSTEES OF TUFTS COLLEGE TUFTS UNIV

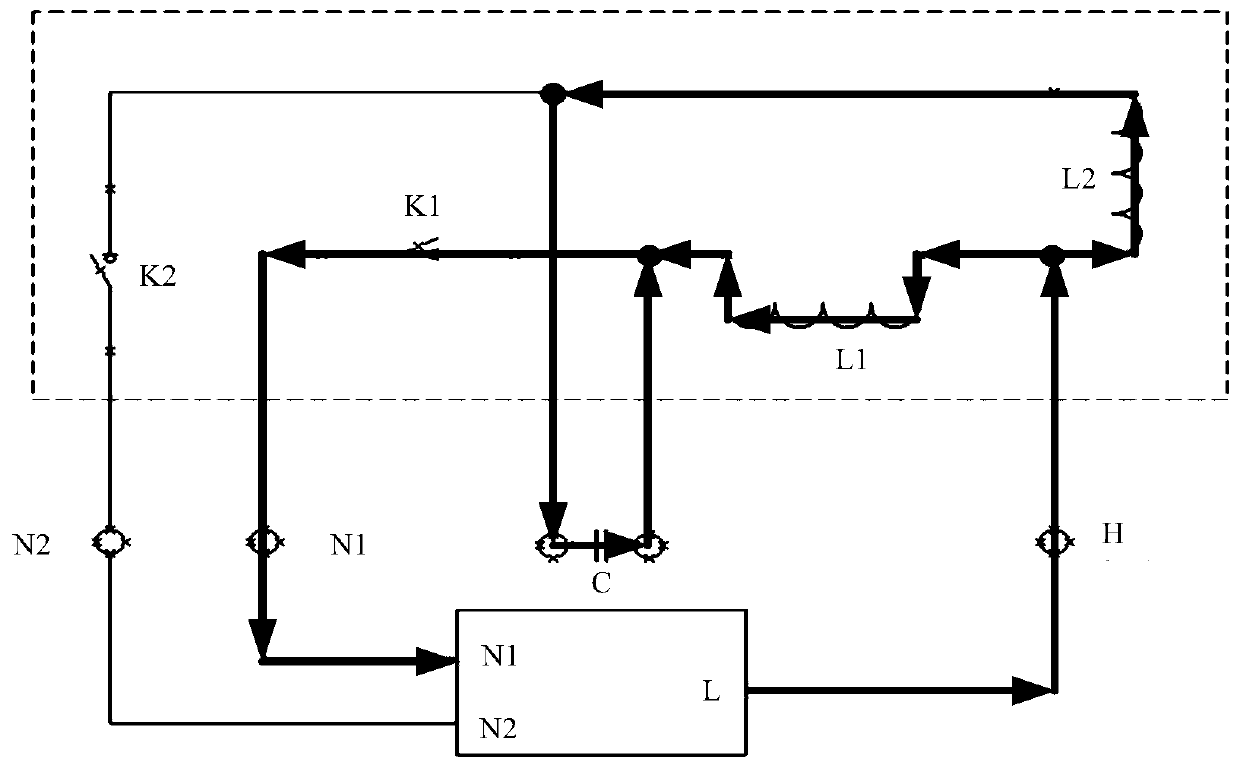

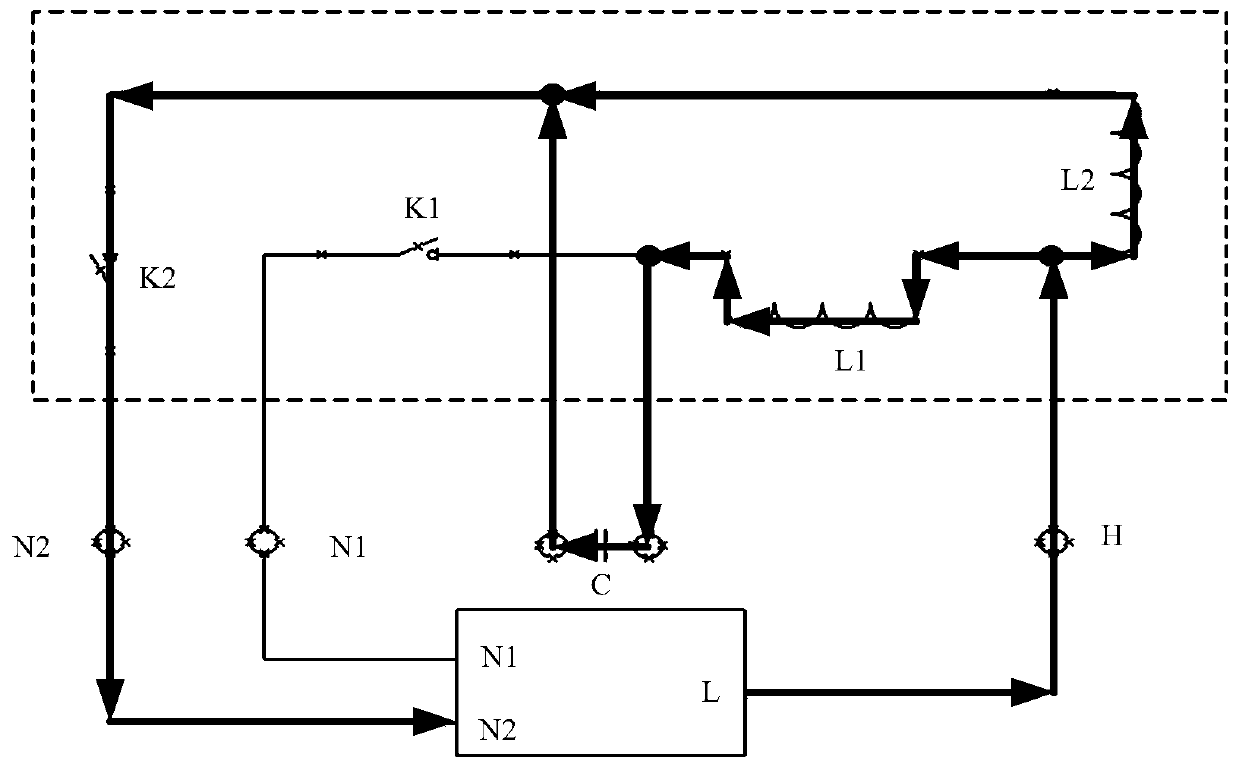

Control of inductive power transfer pickups

InactiveUS6483202B1Reliable fail-safe control featureDecrease in saturation capacityRail devicesElectromagnetic wave systemDc currentEngineering

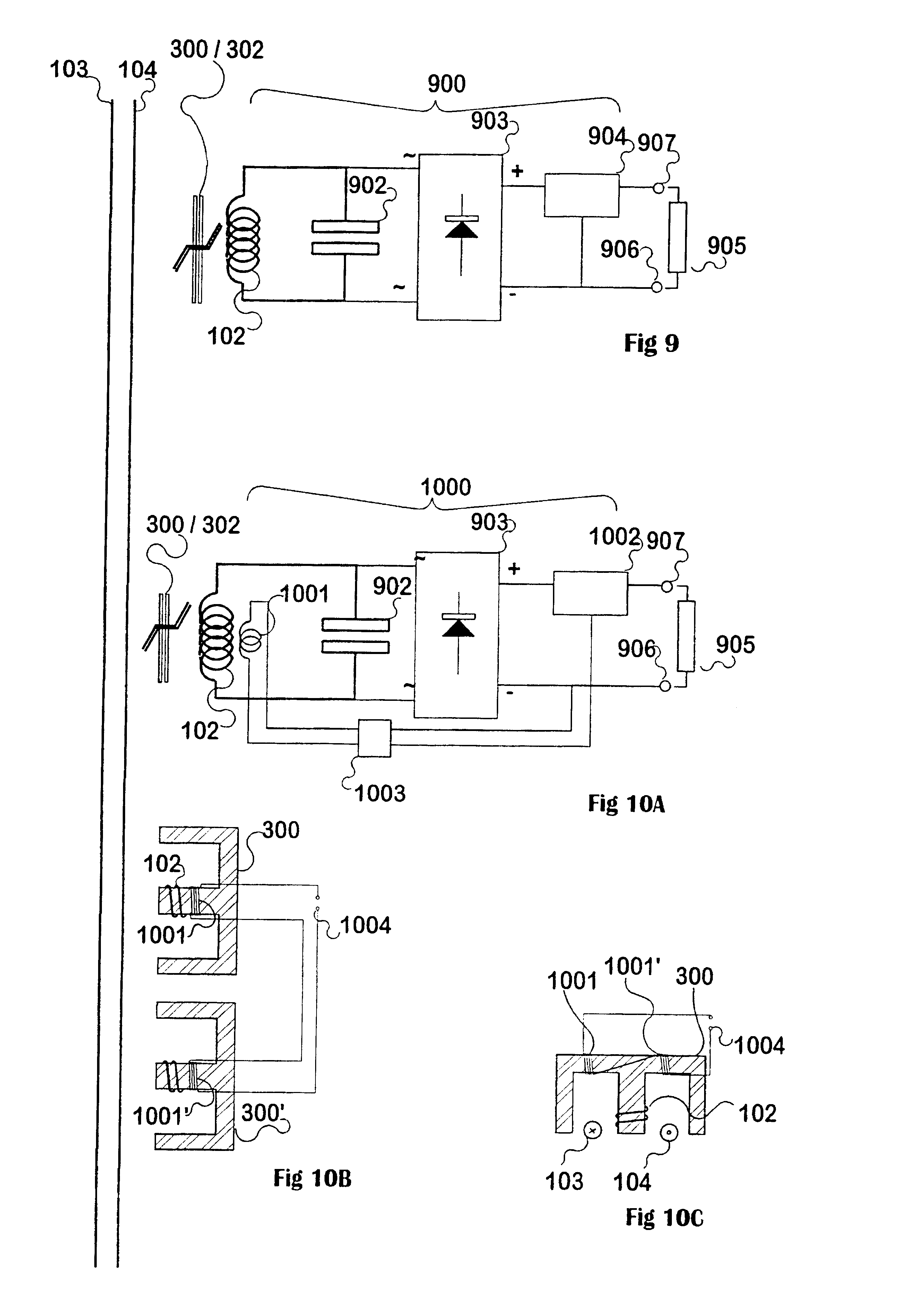

Secondary resonant pickup coils (102) used in loosely coupled inductive power transfer systems, with resonating capacitors (902) have high Q and could support large circulating currents which may destroy components. A current limit or "safety valve" uses an inductor designed to enter saturation at predetermined resonating currents somewhat above normal working levels. Saturation is immediate and passive. The constant-current characteristic of a loosely coupled, controlled pickup means that if the saturable section is shared by coupling flux and by leakage flux, then on saturation the current source is terminated in the saturated inductor, and little detuning from resonance occurs. Alternatively an external saturable inductor (1101, 1102) may be introduced within the resonant circuit (102 and 902), to detune the circuit away from the system frequency. Alternatively DC current may be passed through a winding to increase saturation of a saturable part of a core. As a result, a fail-safe pickup offering a voltage-limited constant-current output is provided.

Owner:AUCKLAND UNISERVICES LTD

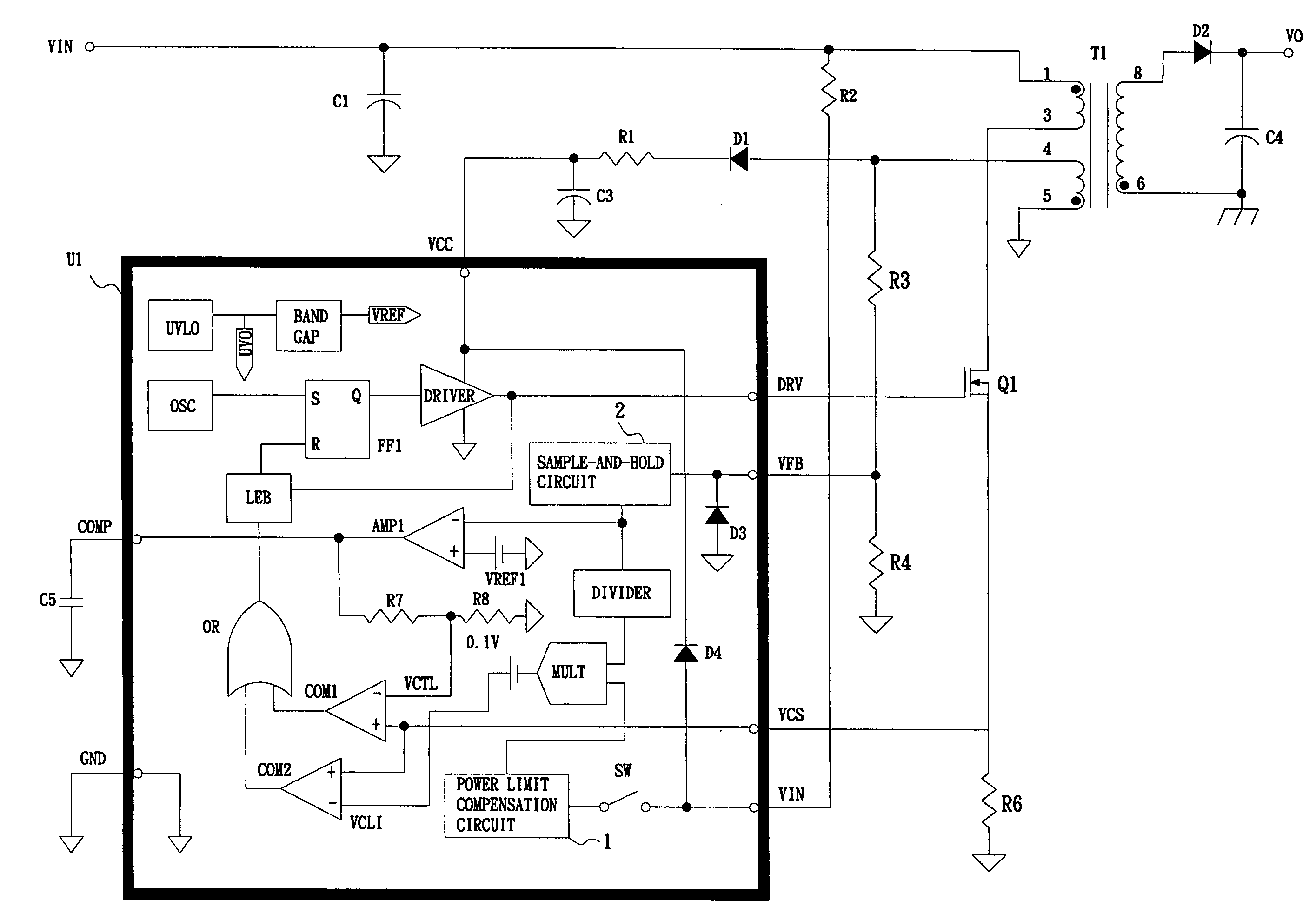

Primary-side feedback switching power supply

The present invention discloses a primary-side feedback switching power supply that uses a sample-and-hold circuit to obtain a corner voltage of a harmonic wave voltage while the primary-side auxiliary winding is operating at a discontinuous mode as a feedback control, and provides both voltage regulation and current limit functions. A stable voltage output is provided within the nominal input voltage and nominal output load, such that when the output reaches a current limit, the output voltage drops but the output current is controlled to remain unchanged, so as to provide an over-current protection.

Owner:NIKO SIMICONDUCTOR CO LTD

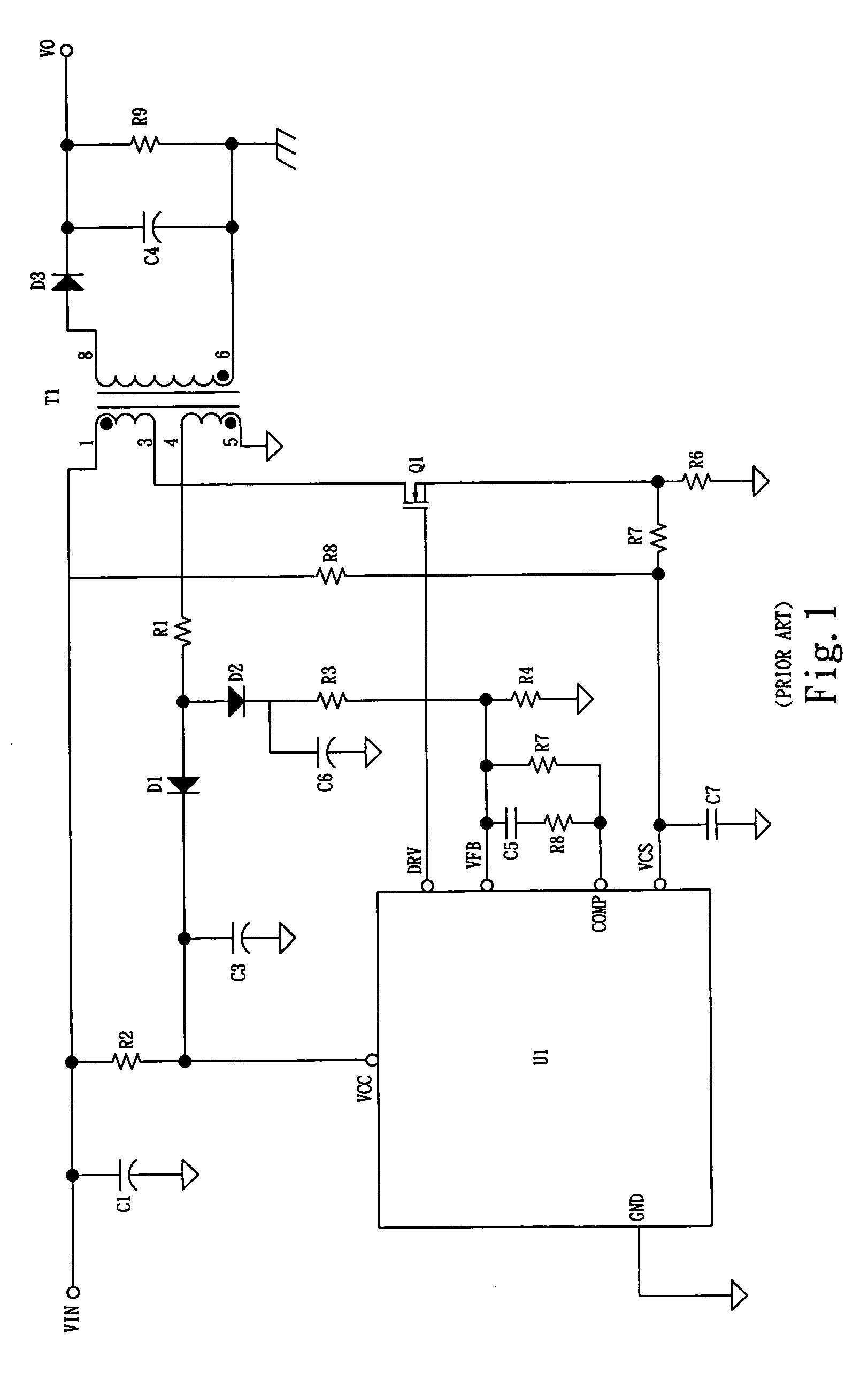

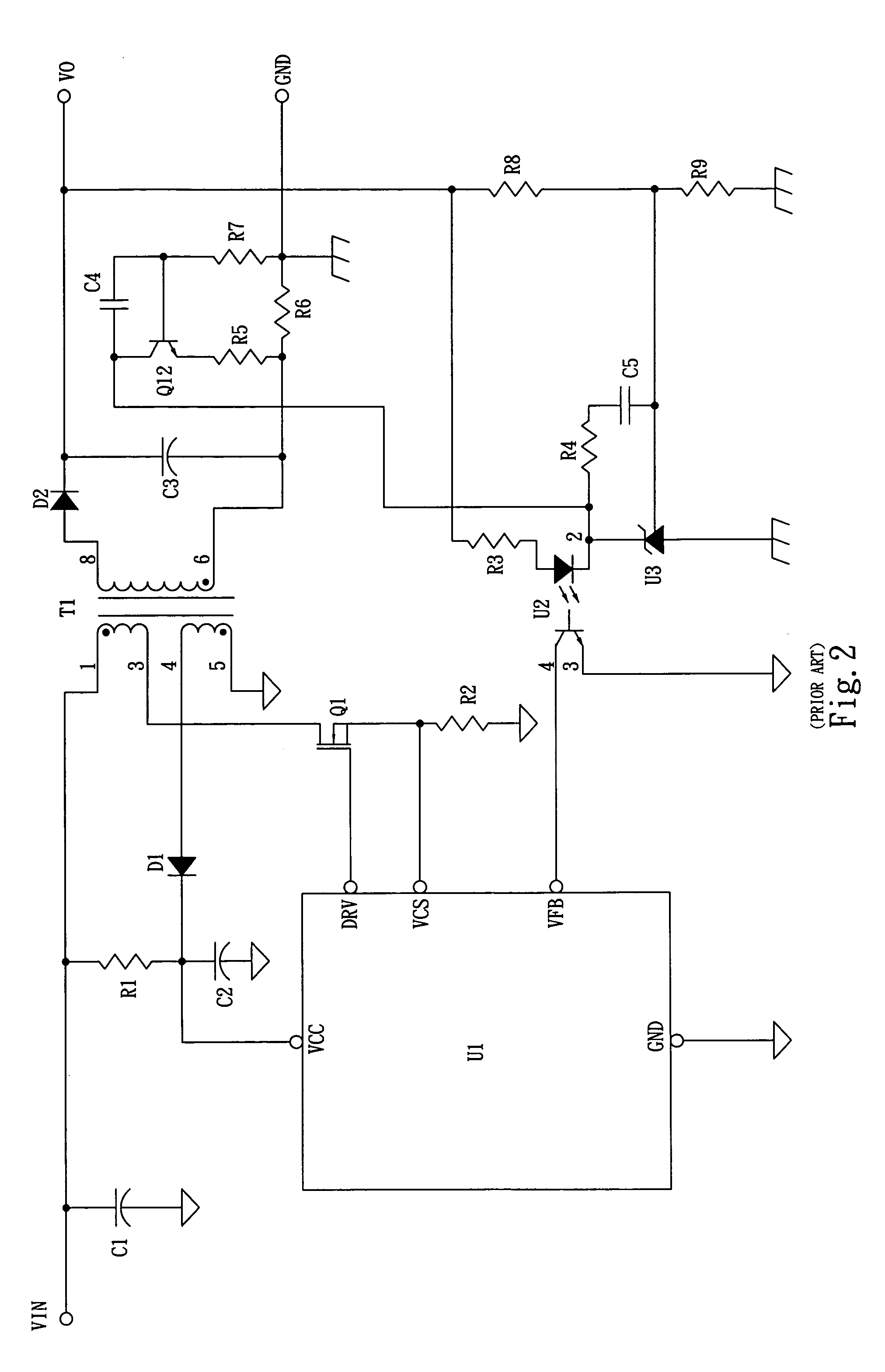

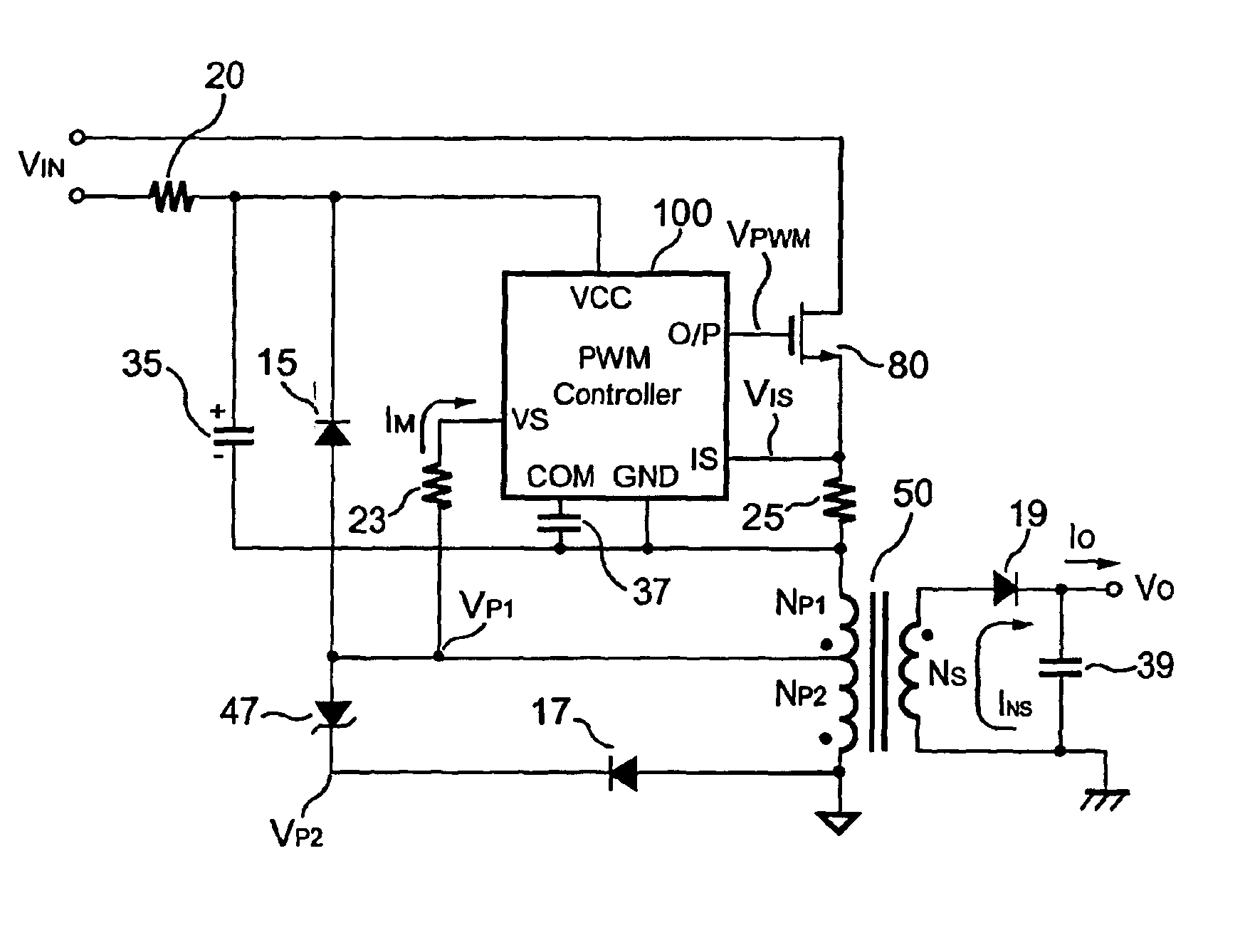

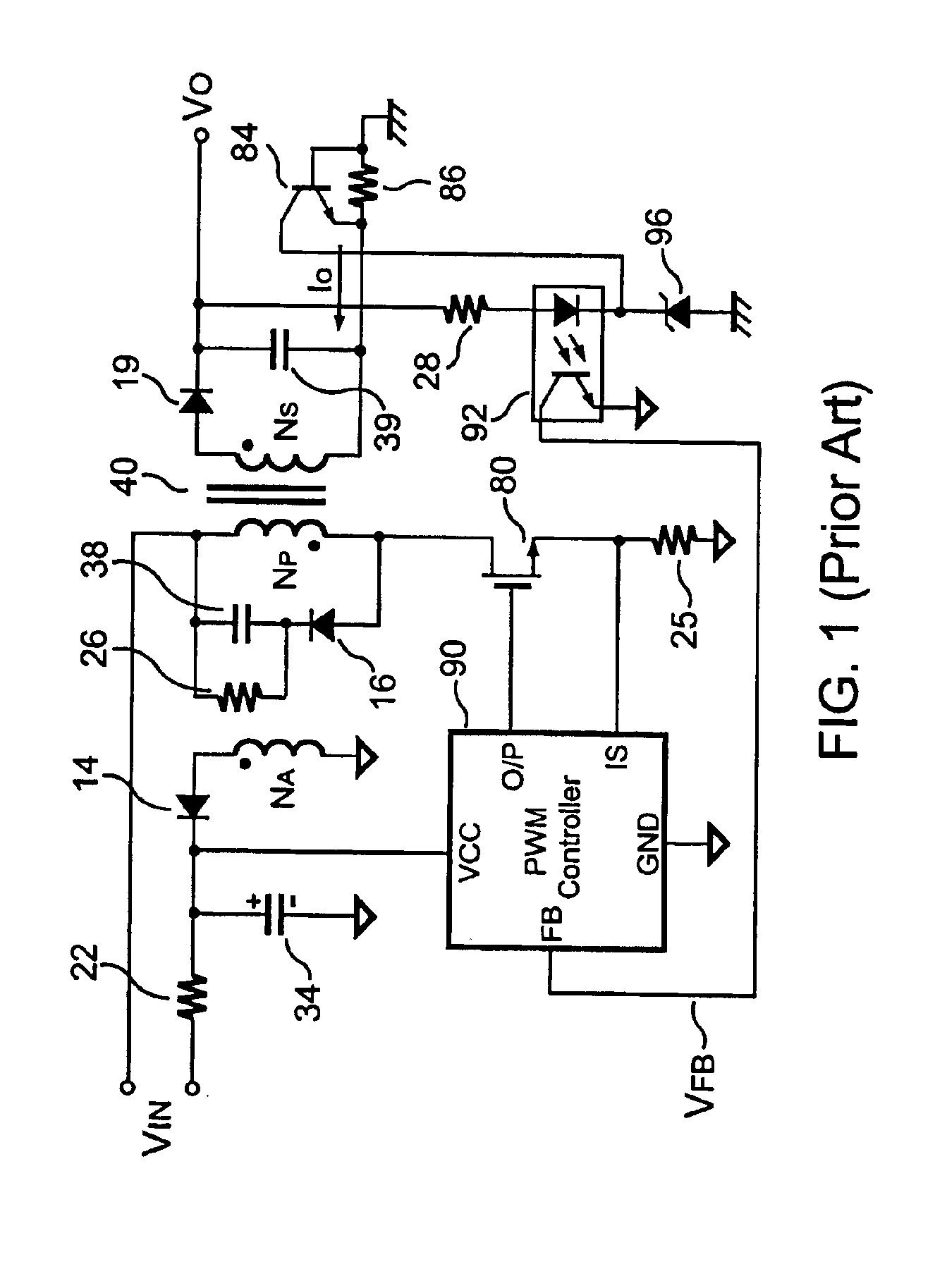

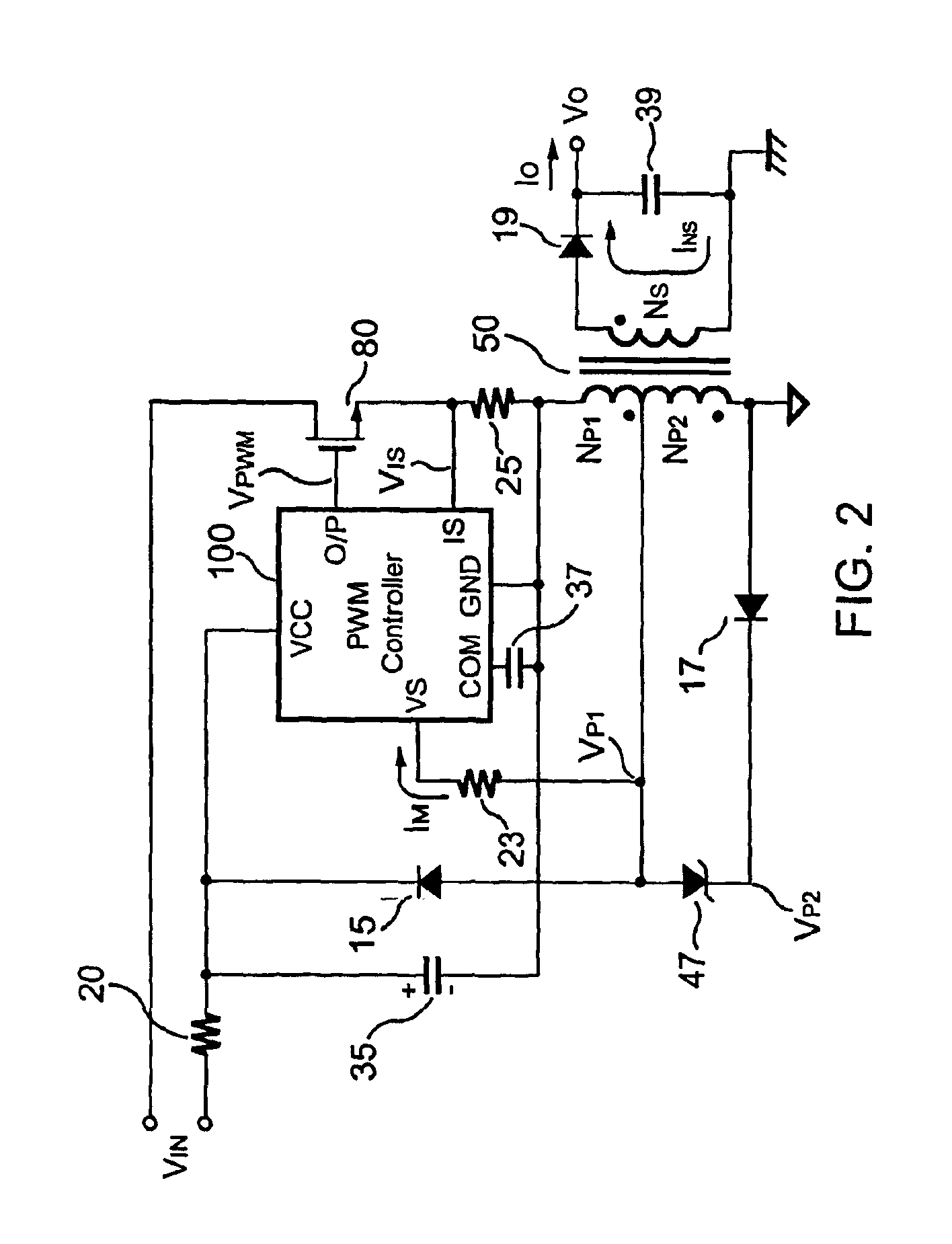

Primary-side controlled flyback power converter

InactiveUS6853563B1Low costSmall sizeEfficient power electronics conversionAc-dc conversionTransformerSwitching frequency

The present invention provides a primary-side flyback power converter that supplies a constant voltage output and a constant current output. To generate a well-regulated output voltage under varying load conditions, a PWM controller is included in the power converter in order to generate a PWM signal controlling a switching transistor in response to a flyback voltage sampled from a first primary winding of the power supply transformer. Several improvements are included in this present invention to overcome the disadvantages of prior-art flyback power converters. Firstly, the flyback energy of the first primary winding is used as a DC power source for the PWM controller in order to reduce power consumption. A double sample amplifier samples the flyback voltage just before the transformer current drops to zero. Moreover, an offset current is pulled from a detection input of the double sample amplifier in order to generate a more accurate DC output voltage. The offset current is generated in response to the temperature in order to compensate for temperature-induced voltage fluctuations across the output rectifier. Ultimately, in order to maintain a constant output current, the PWM controller modulates the switching frequency in response to the output voltage.

Owner:FAIRCHILD TAIWAN

Power Line Communications Coupling Device and Method

InactiveUS20090085726A1Systems using filtering and bypassingElectric signal transmission systemsTransformerInductor

A method and device for providing communications via one or more underground power lines is provided. Underground power lines may comprise a plurality of segments disposed in series with each other and carrying a power having a voltage greater than one thousand volts on an internal conductor, and wherein each segment is coaxial in structure and includes a neutral conductor. In one embodiment, the device may comprise a first inductor having a first end connected to a first node and a second end connected to ground, a second inductor having a first end connected a second node and a second end connected to ground, and a transformer having a first winding having a first end and a second end. The first node may be connected to a neutral conductor of a first segment of the power line and to the first end of the first winding of said transformer. The second node may be connected to a neutral conductor of a second segment of the power line and to the second end of the first winding of said transformer. The transformer comprises a second winding configured to be communicatively coupled to a communication device.

Owner:CURRENT TECH

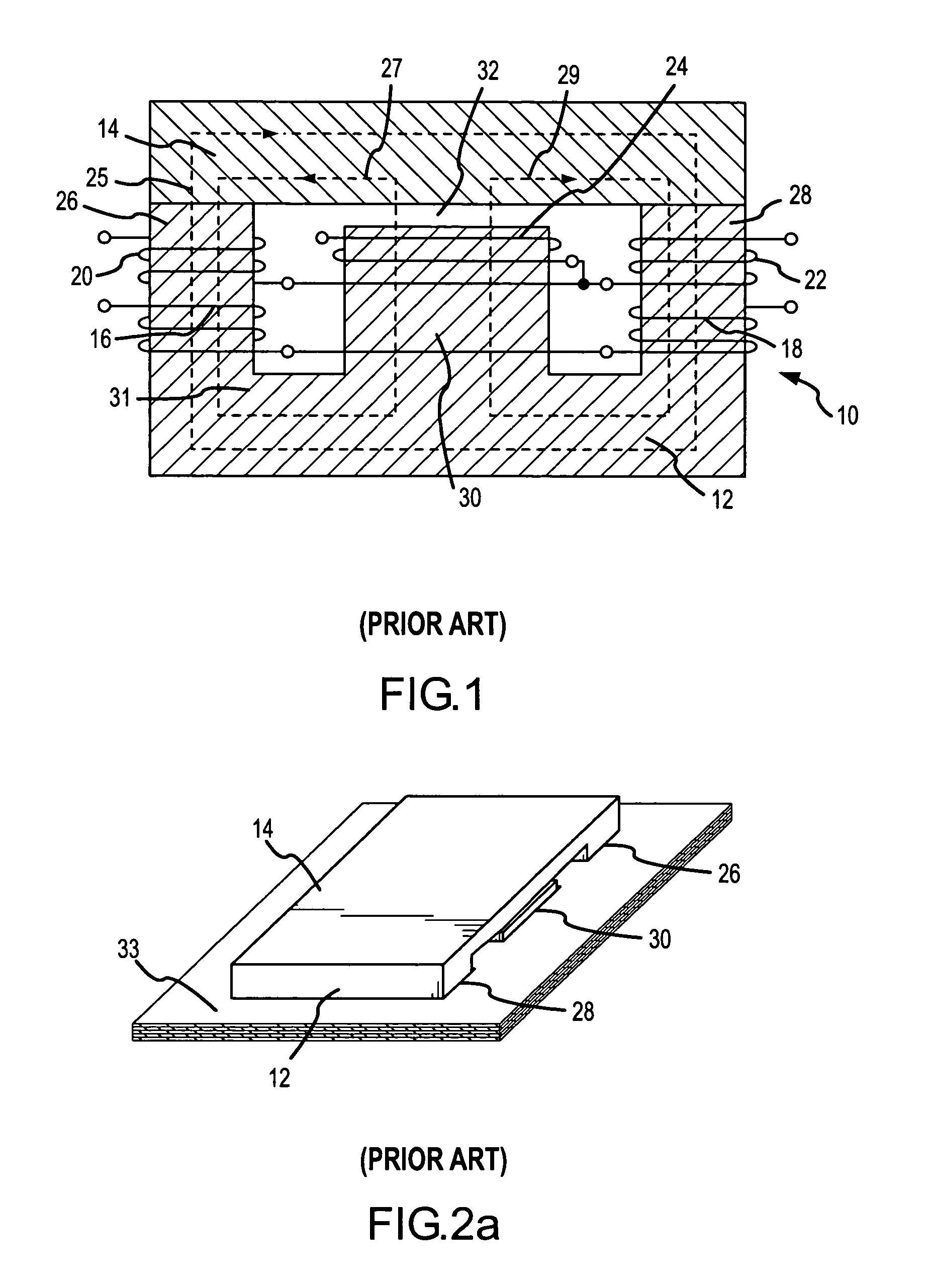

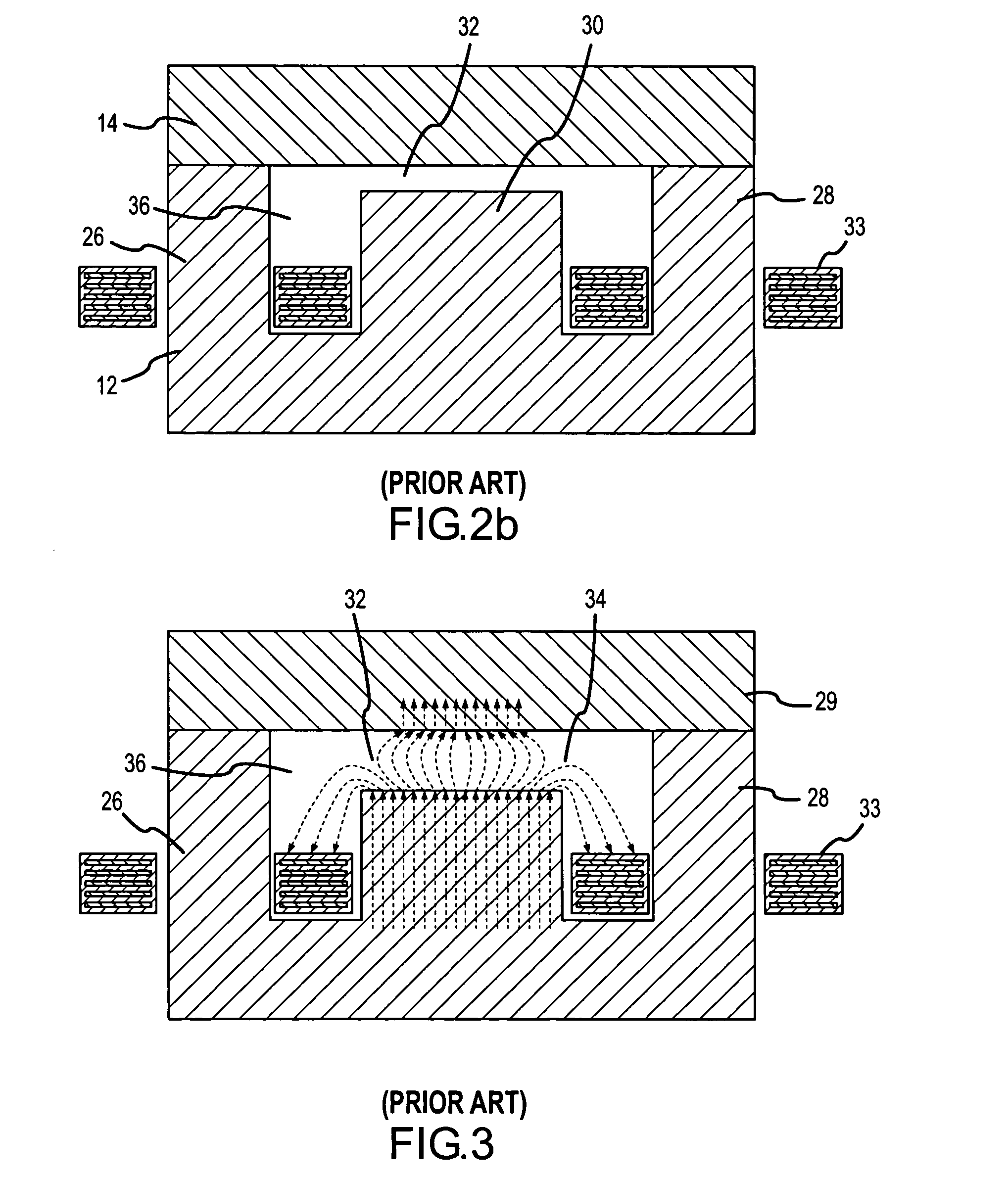

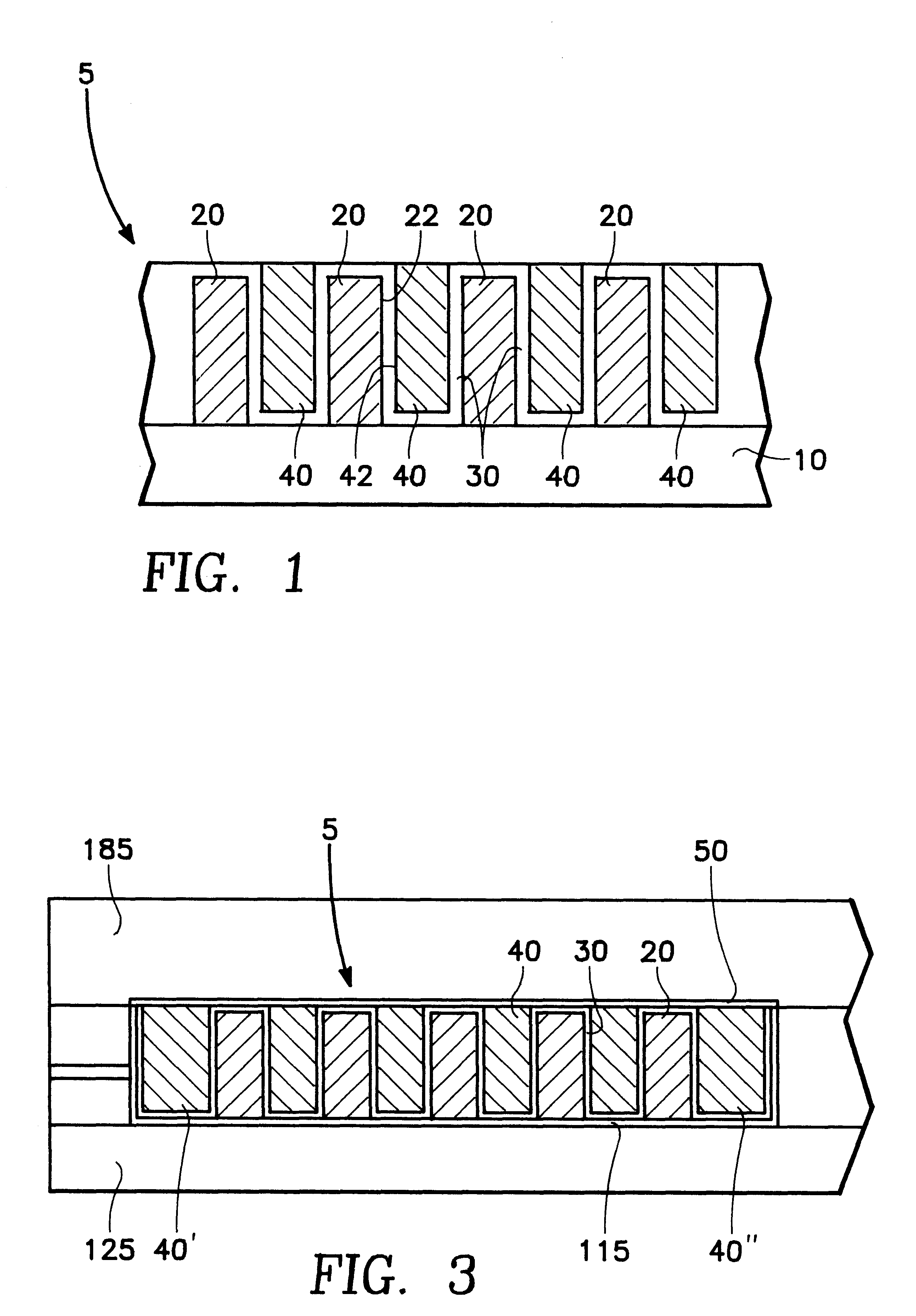

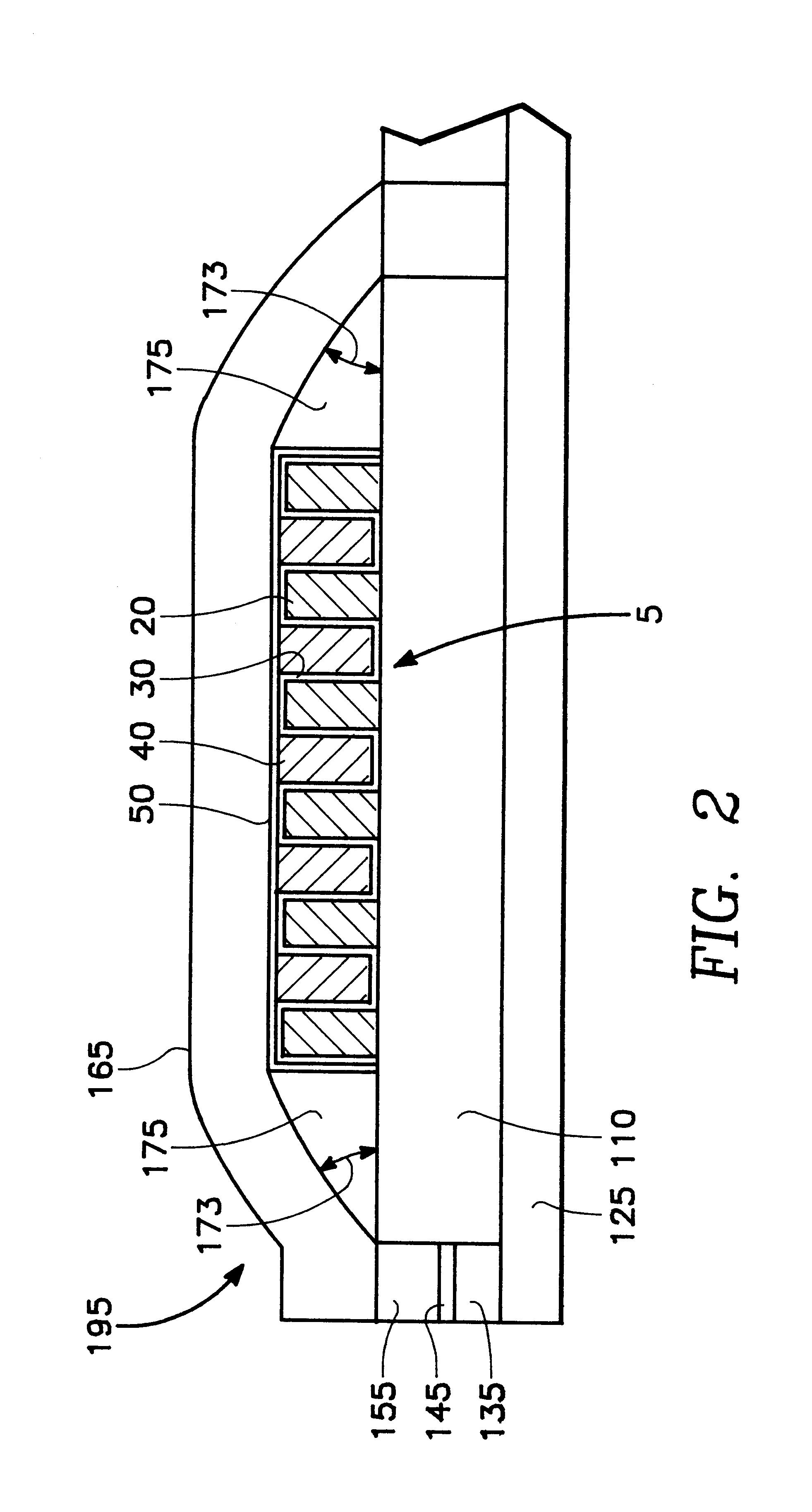

Thin film write head with interlaced coil winding and method of fabrication

InactiveUS6466401B1Increase working frequencySeparationConstruction of head windingsHeads using thin filmsResistConductive materials

The preferred embodiment of the present invention provides a write head having an interlaced conductor coil winding and method of fabrication. The interlaced winding of the present invention may have alternating turns of a first and a second coil. In the preferred embodiment, the side walls of successive coil turns are separated by an ultra thin inorganic insulation which defines the distance between successive turns of the first and second coil. In one method of fabrication, a conductive seed layer is deposited on a generally planar insulative surface, a resist mask is formed on the seed layer, and a conductive material deposited on the exposed seed layer to form the turns of the first coil. The masked portions of the seed layer are removed, after resist mask removal, to electrically isolate the turns of the first coil. The inorganic insulation may be formed in a layer conformal with the first coil. The second coil is formed between the turns of the first coil. A seed layer and mask may be used to facilitate second coil deposition. Etching, or planarization, may be used to electrically isolate the turns of the second coil. A capping layer may be formed over any exposed conductor material to insulate the winding from an upper pole structure or other overlying structure. Embodiments of the present invention may have multiple layers of conductor winding having some conventional, or all interlaced coil structure.

Owner:WESTERN DIGITAL TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com