Patents

Literature

23956results about "AC motor control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

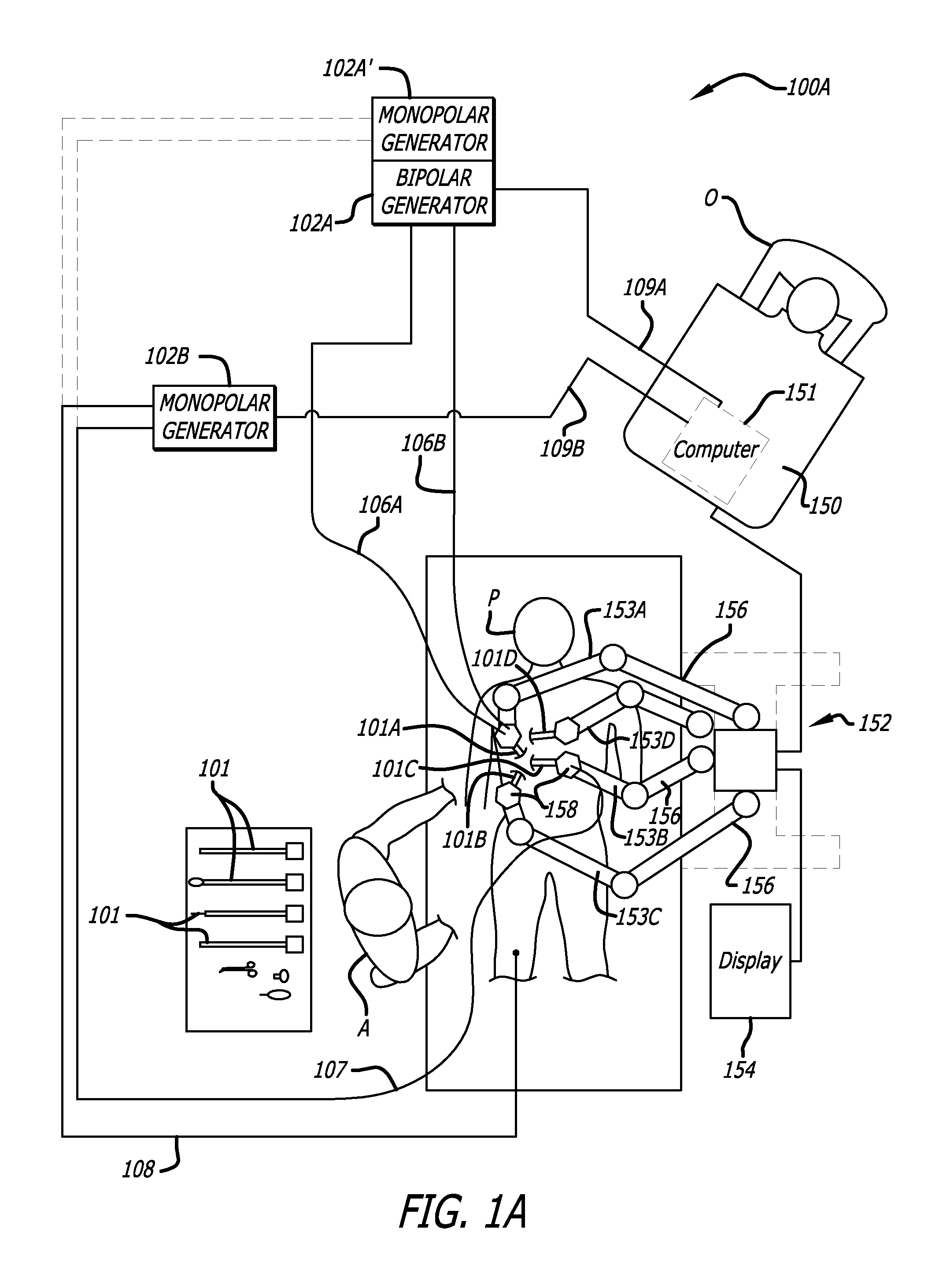

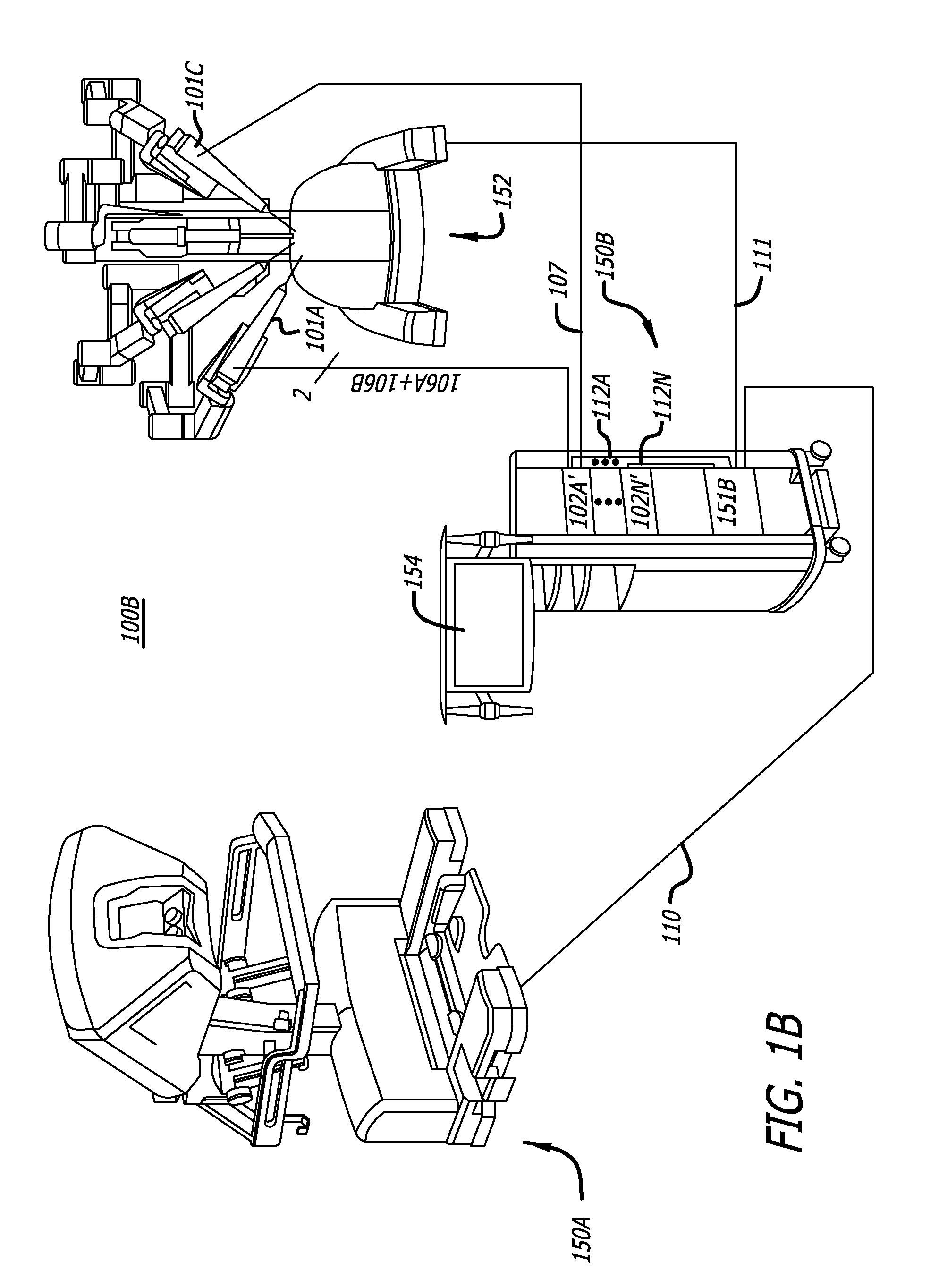

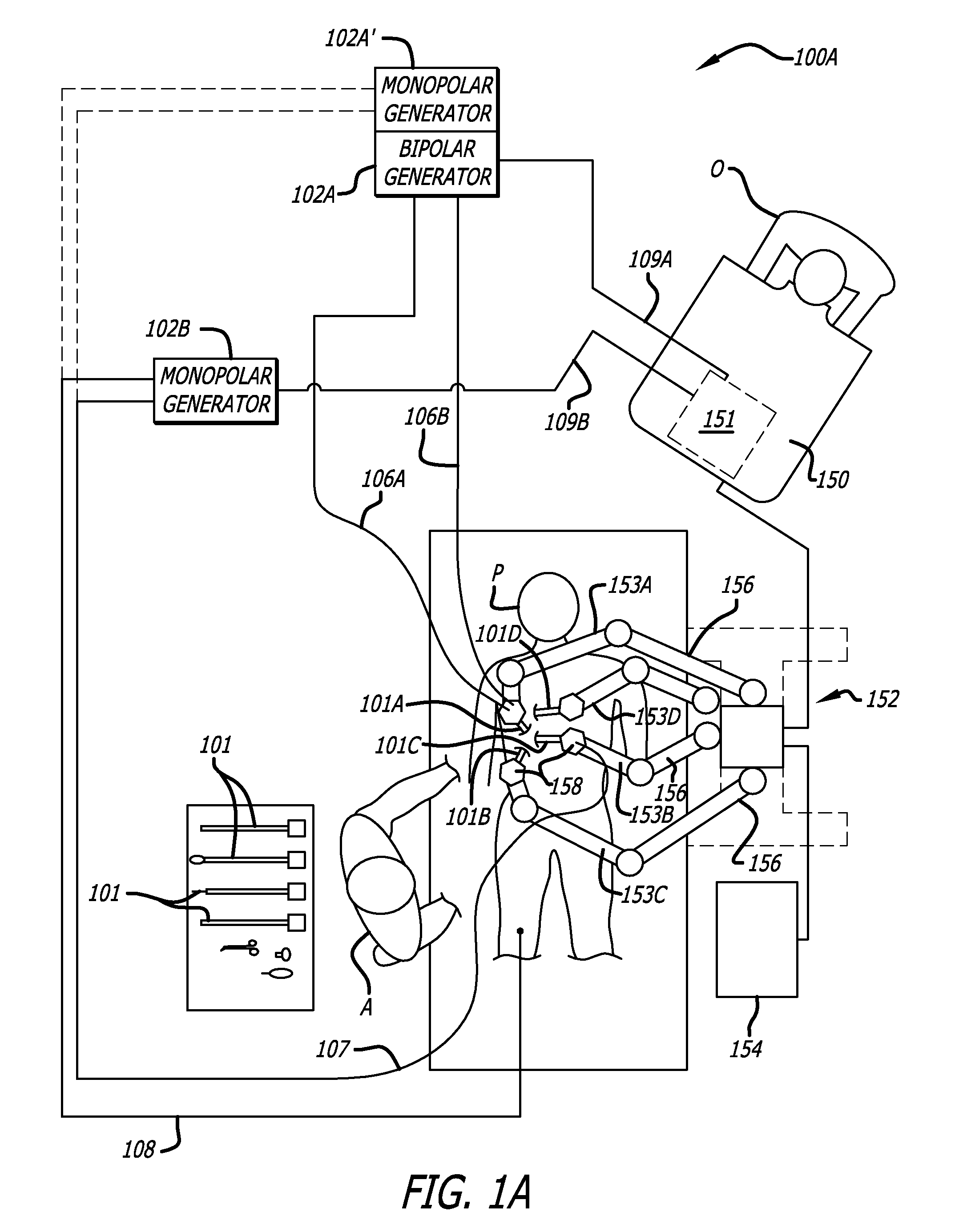

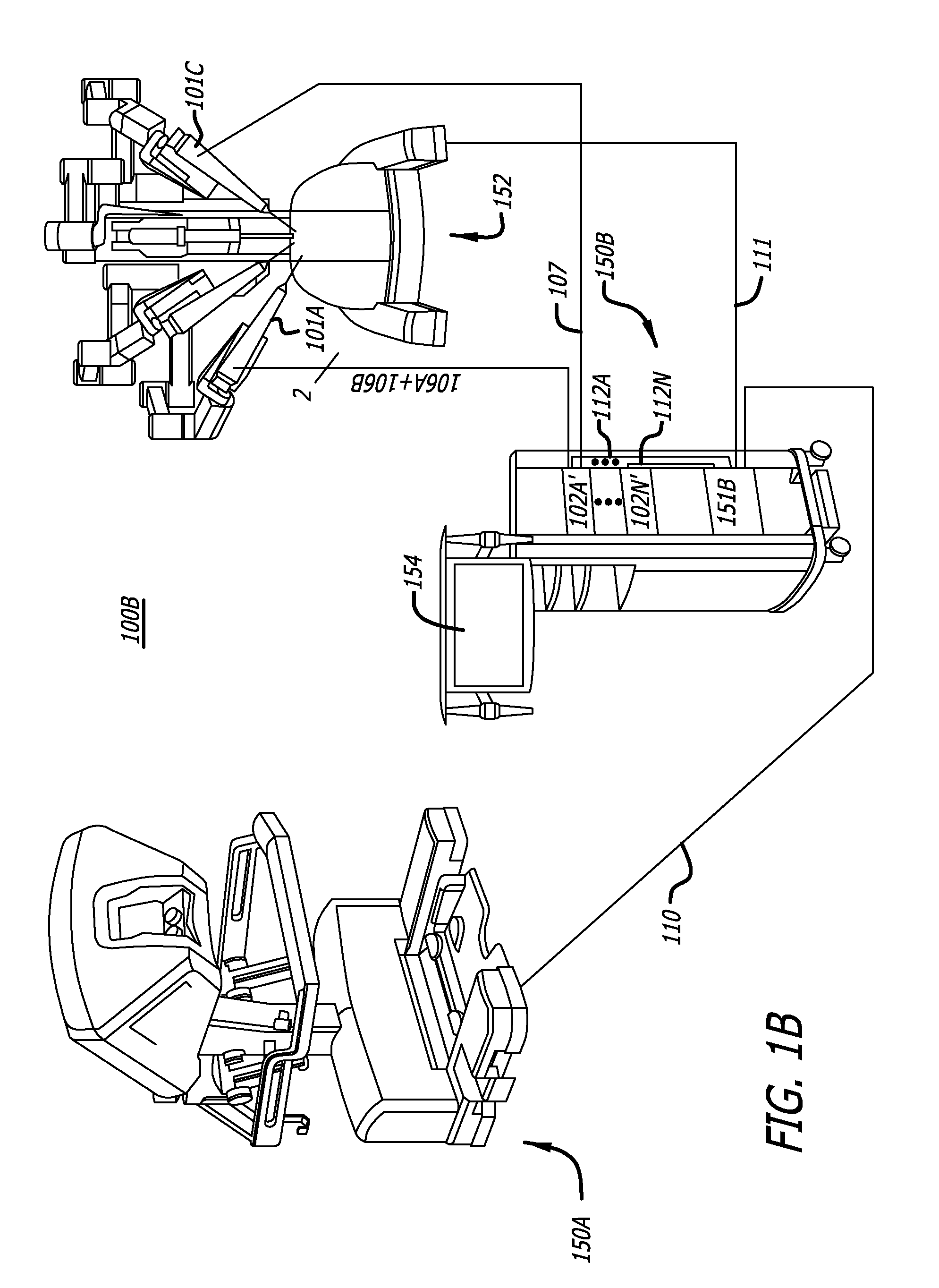

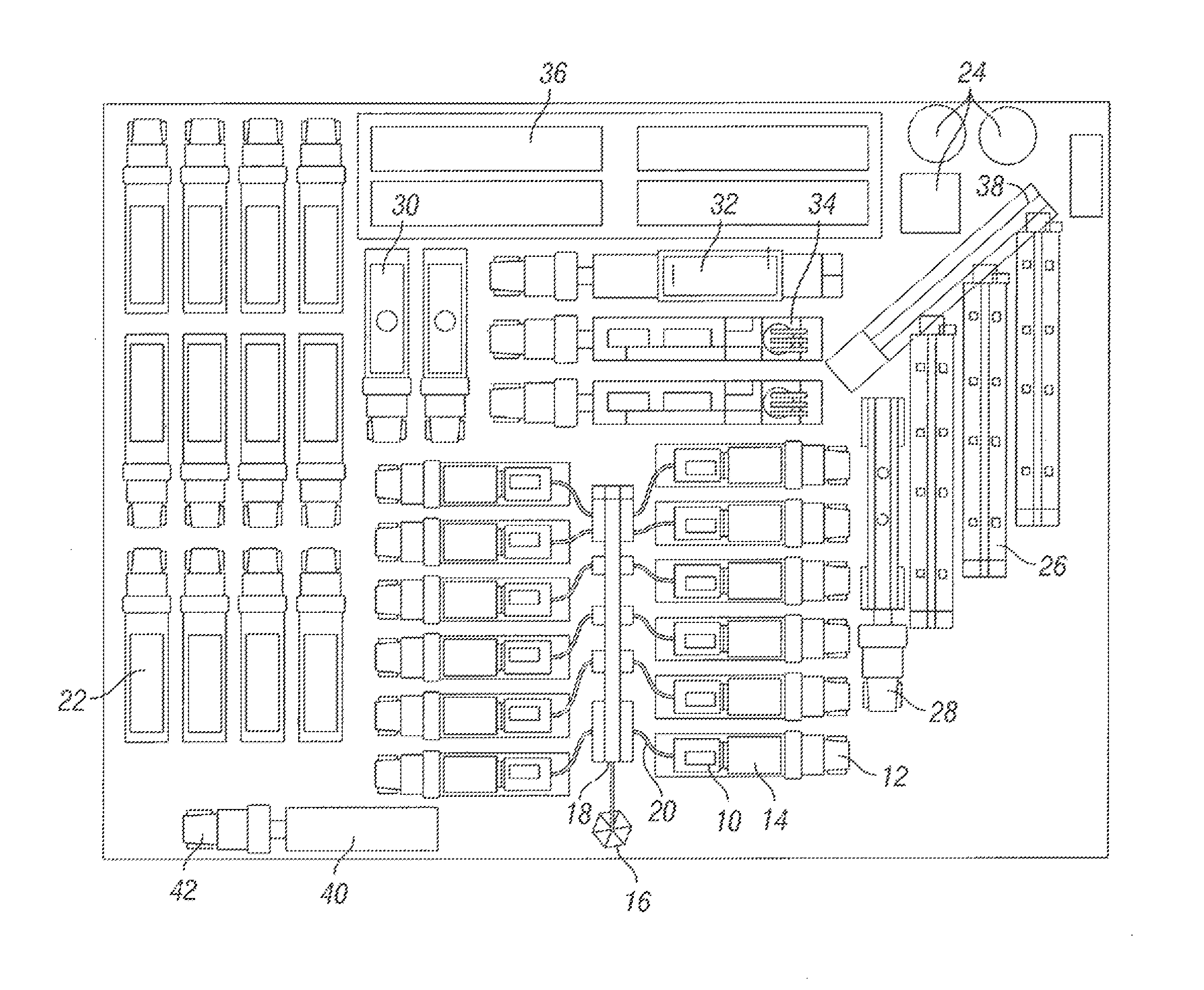

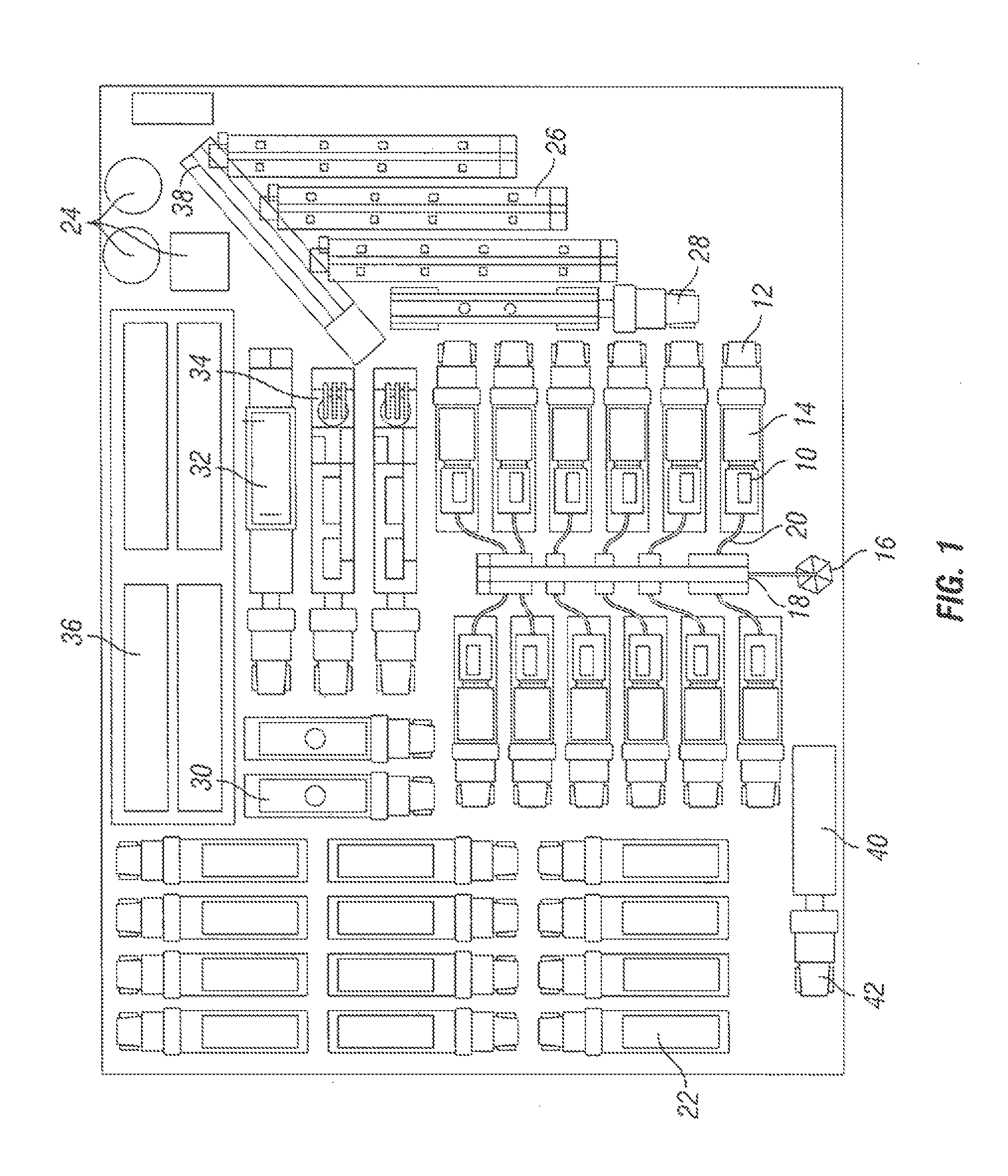

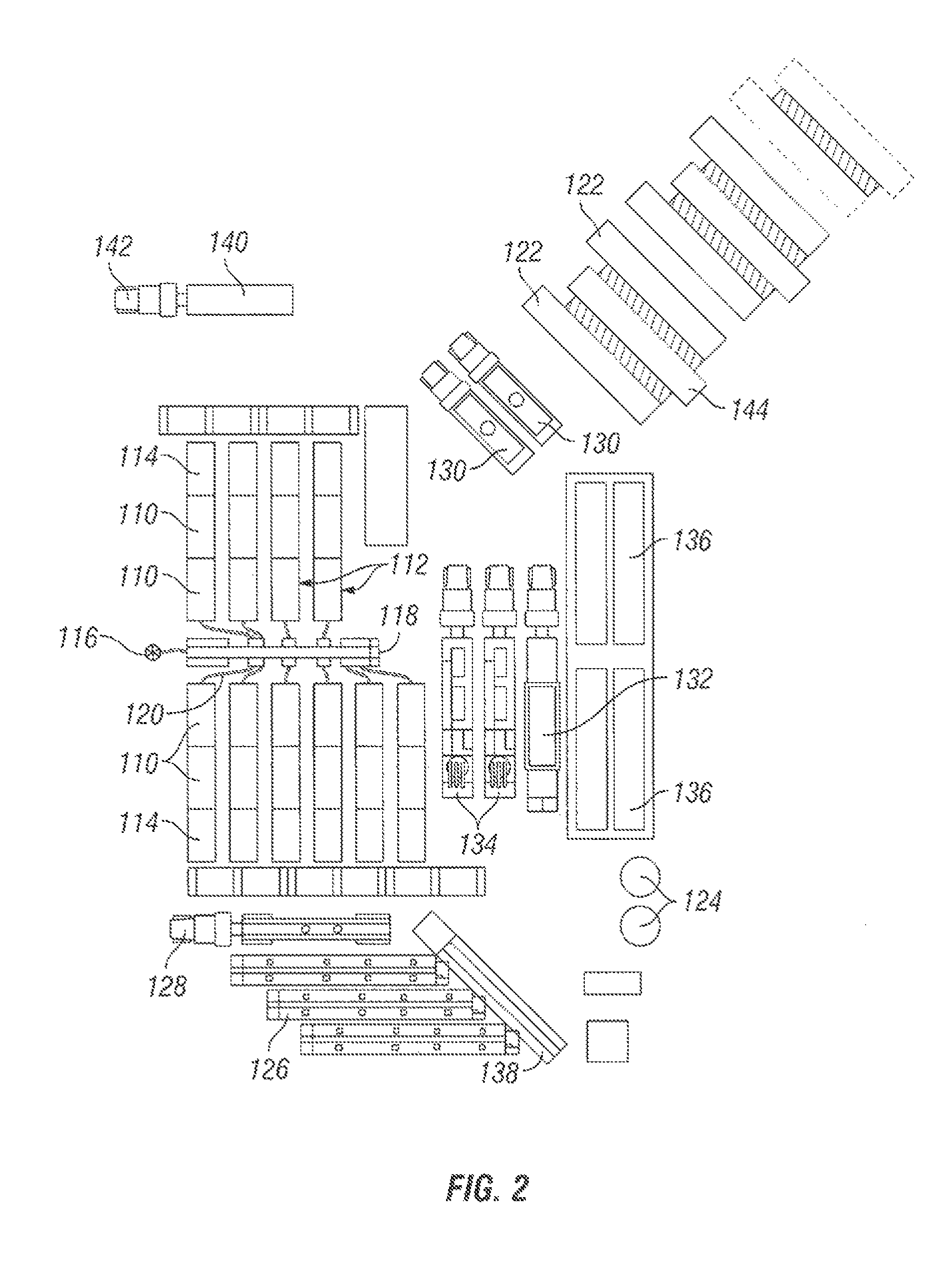

Ergonomic surgeon control console in robotic surgical systems

A control console to remotely control medical equipment is disclosed having a base with an ergonomically adjustable pedal system. The base further has an opening to receive the pedal system. The pedal system includes a moveable pedal tray with a pedal base. The tray includes a first left pedal assembly and a first right pedal assembly, and an upper tier having a second left pedal assembly and a second right pedal assembly respectively in alignment with and elevated above the first left pedal assembly and the first right pedal assembly. Rollers are rotatable coupled to the moveable pedal tray to allow it roll over a floor. A drive assembly is coupled between the moveable pedal tray and the base. The drive assembly applies a force to the to roll the moveable pedal tray over the floor within the opening of the base.

Owner:INTUITIVE SURGICAL +1

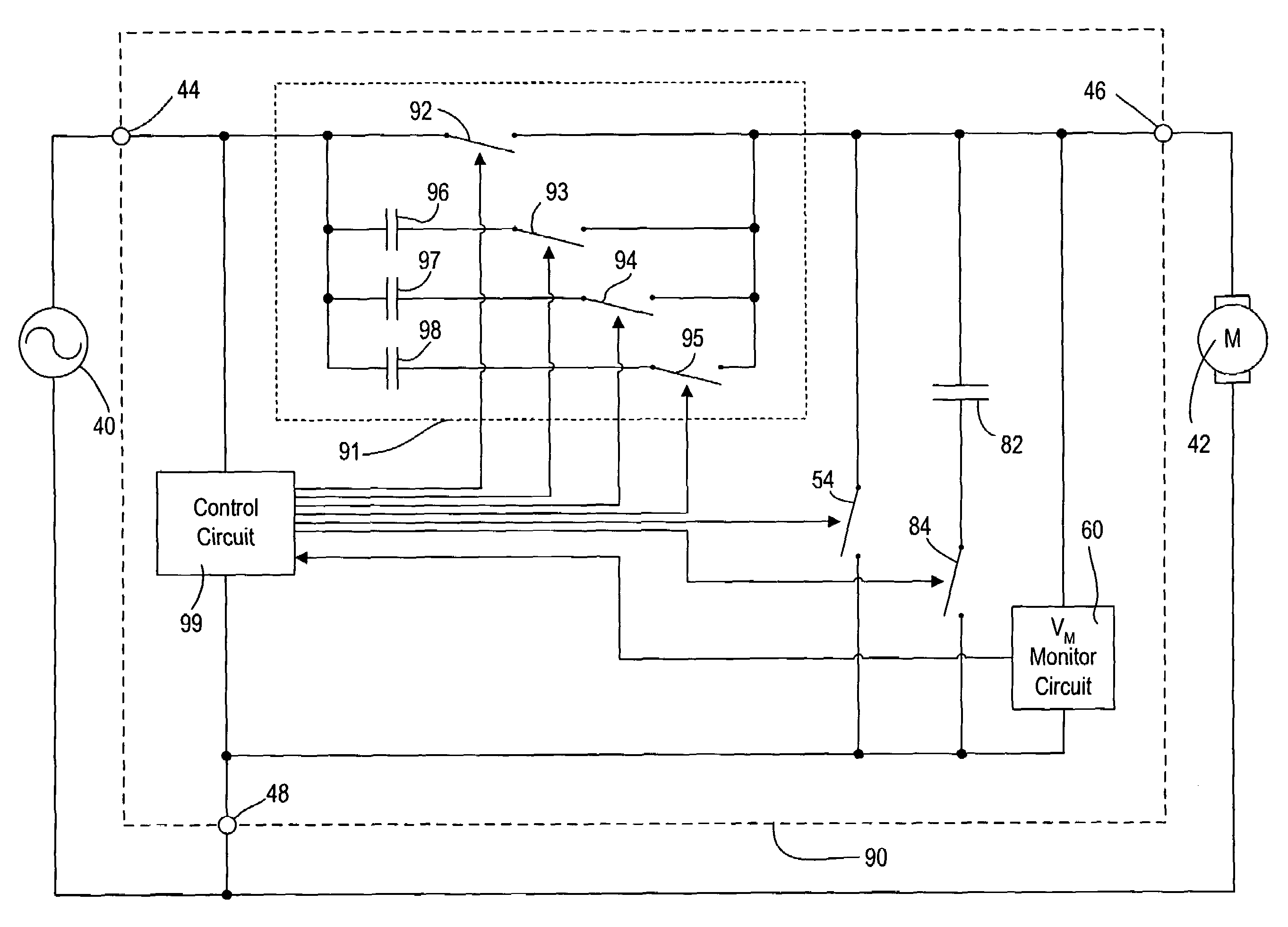

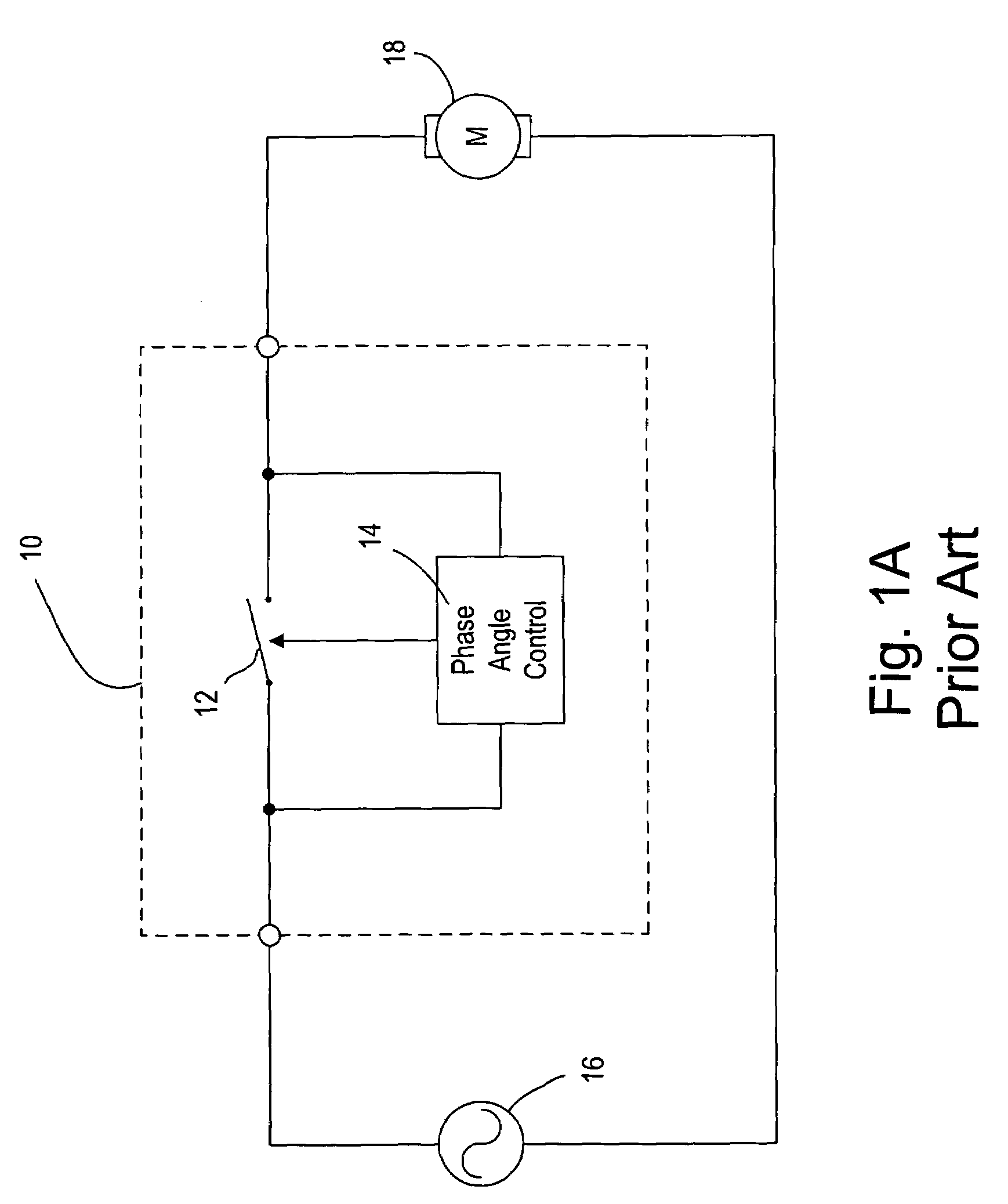

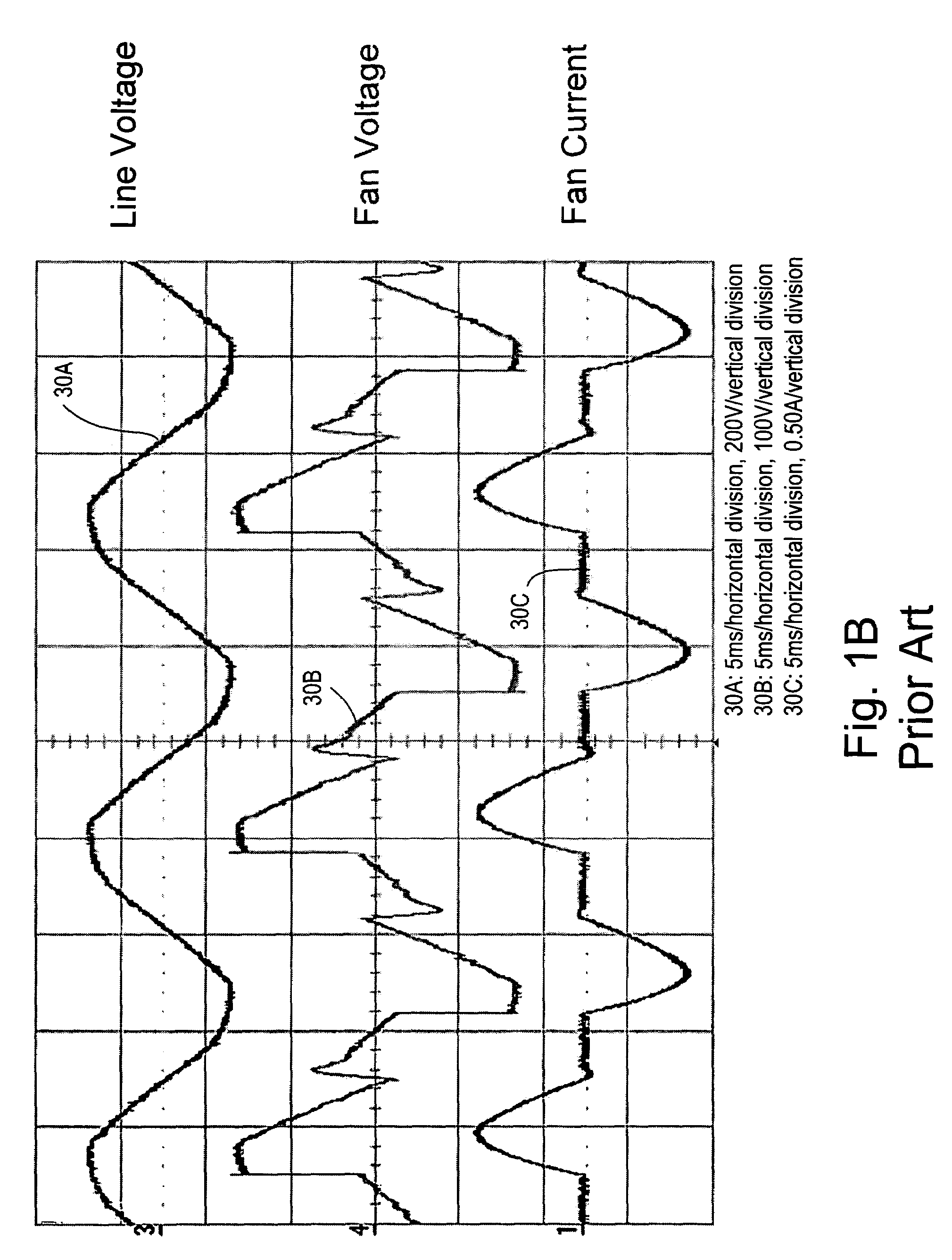

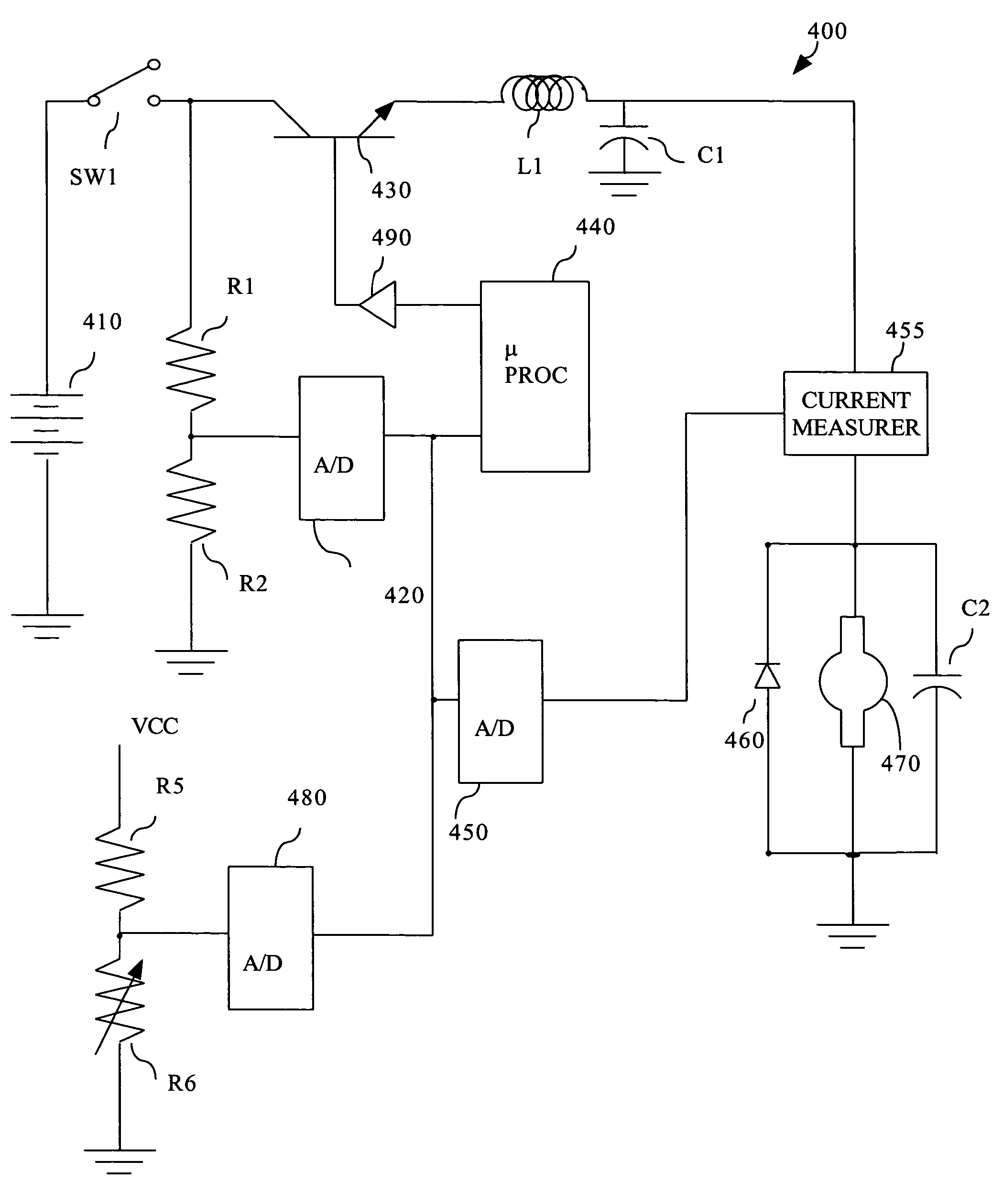

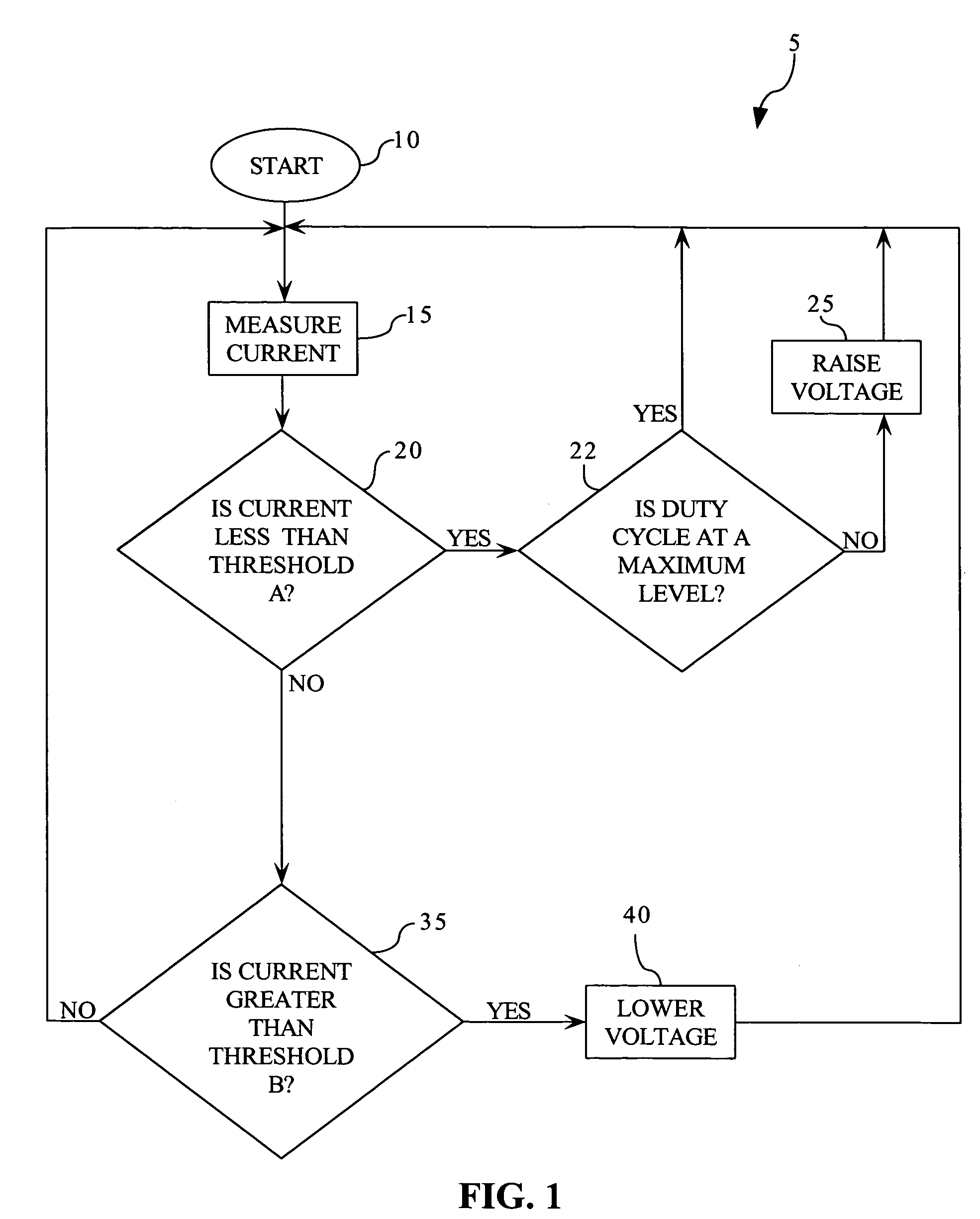

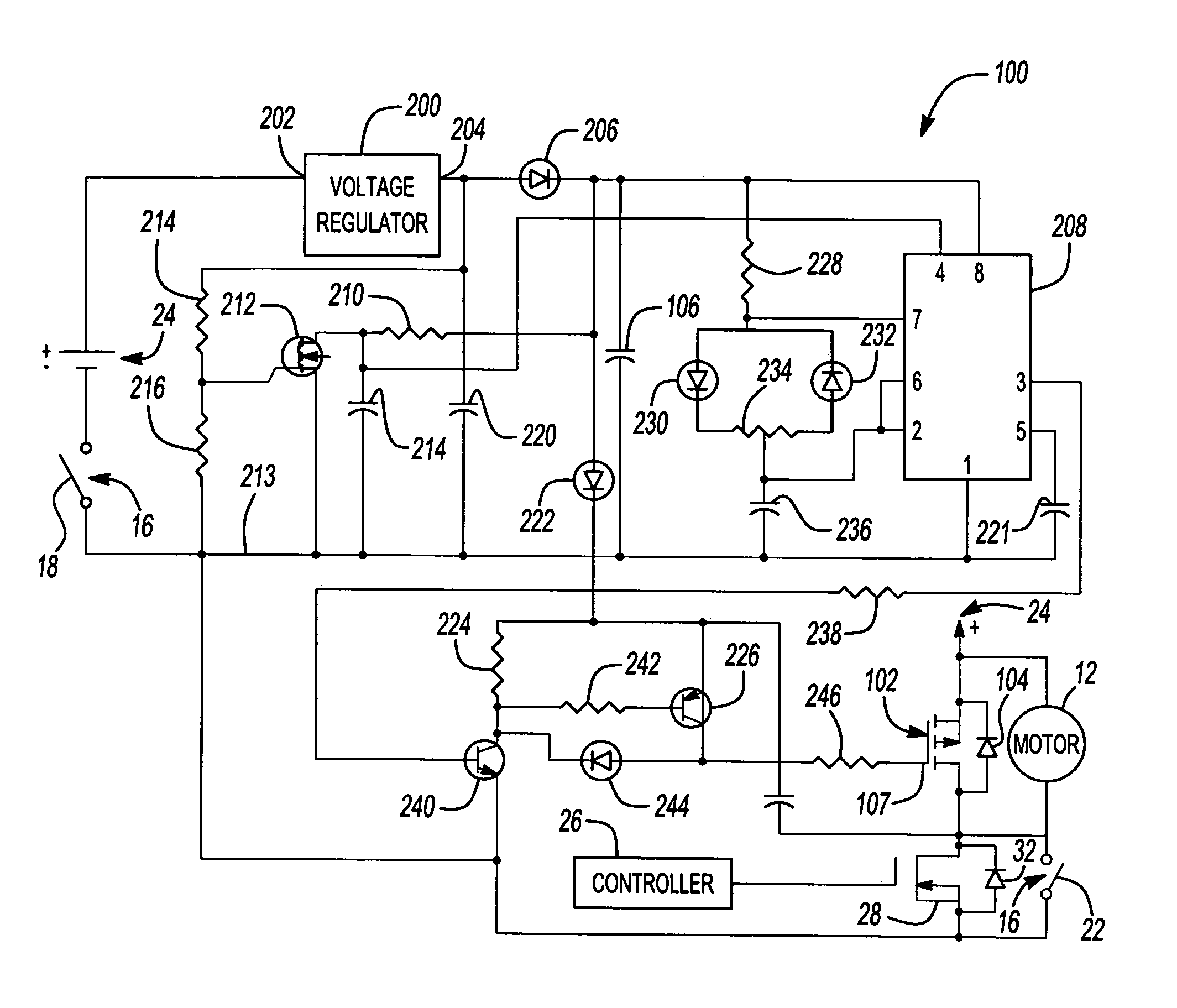

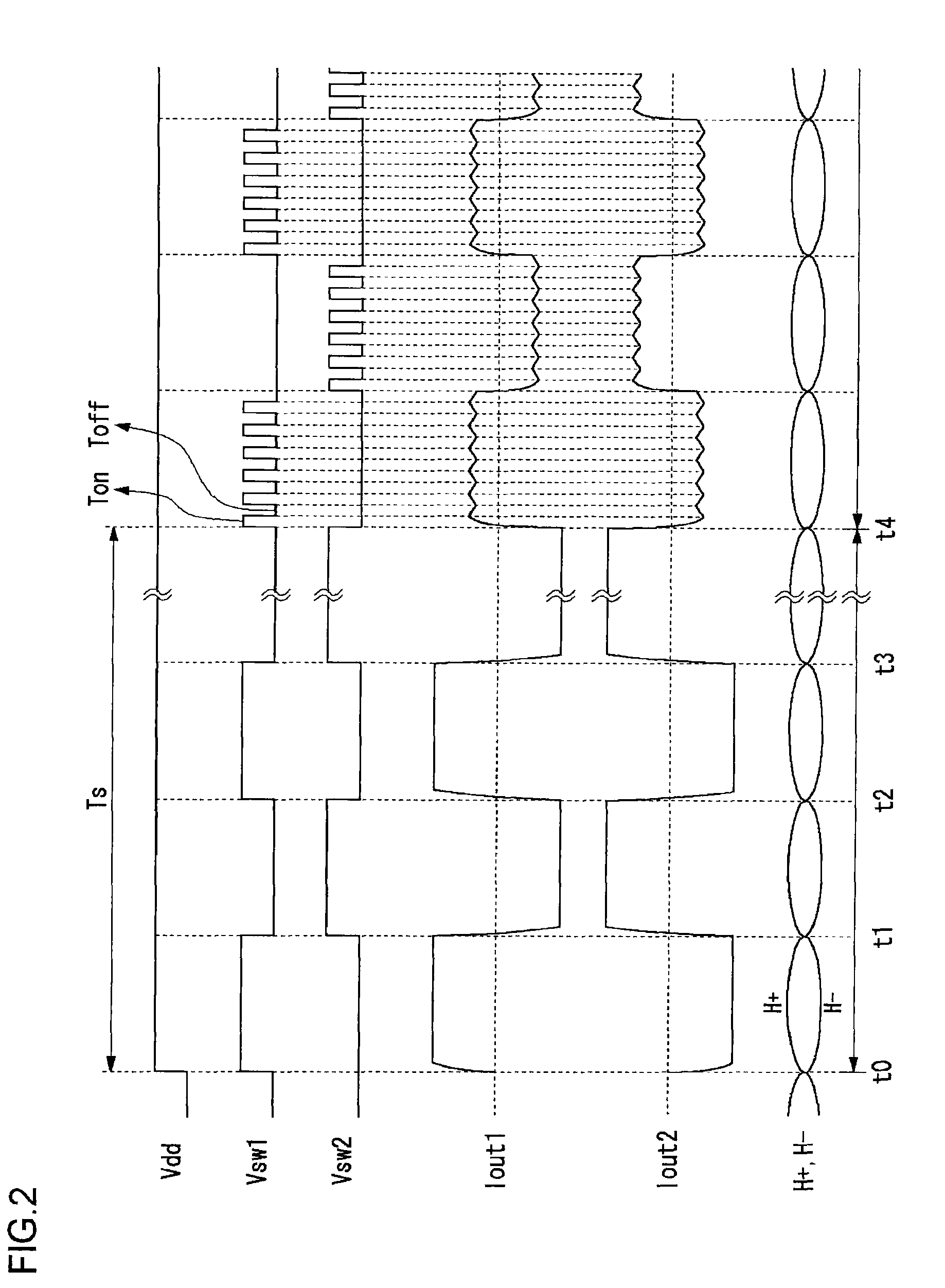

Method and apparatus for quiet variable motor speed control

ActiveUS7330004B2Single-phase induction motor startersMotor/generator/converter stoppersMotor speedEngineering

An apparatus for controlling the speed of an AC motor comprising a switch adapted to be coupled in parallel with power terminals for the AC motor; a capacitor coupled in series with the parallel combination of the switch and the motor; the capacitor adapted to provide an AC supply voltage from an AC source to the parallel circuit comprising the motor and the switch; and a control circuit for controlling the conduction time of the switch in order to vary the speed of the motor. The switch is preferably pulse-width modulated at a frequency twice the line frequency of the AC supply voltage, and the switch is turned on when the voltage across the AC motor is zero volts. The apparatus is operable to provide for continuously variable control of the motor speed while minimizing acoustic noise in the motor.

Owner:LUTRON TECH CO LLC

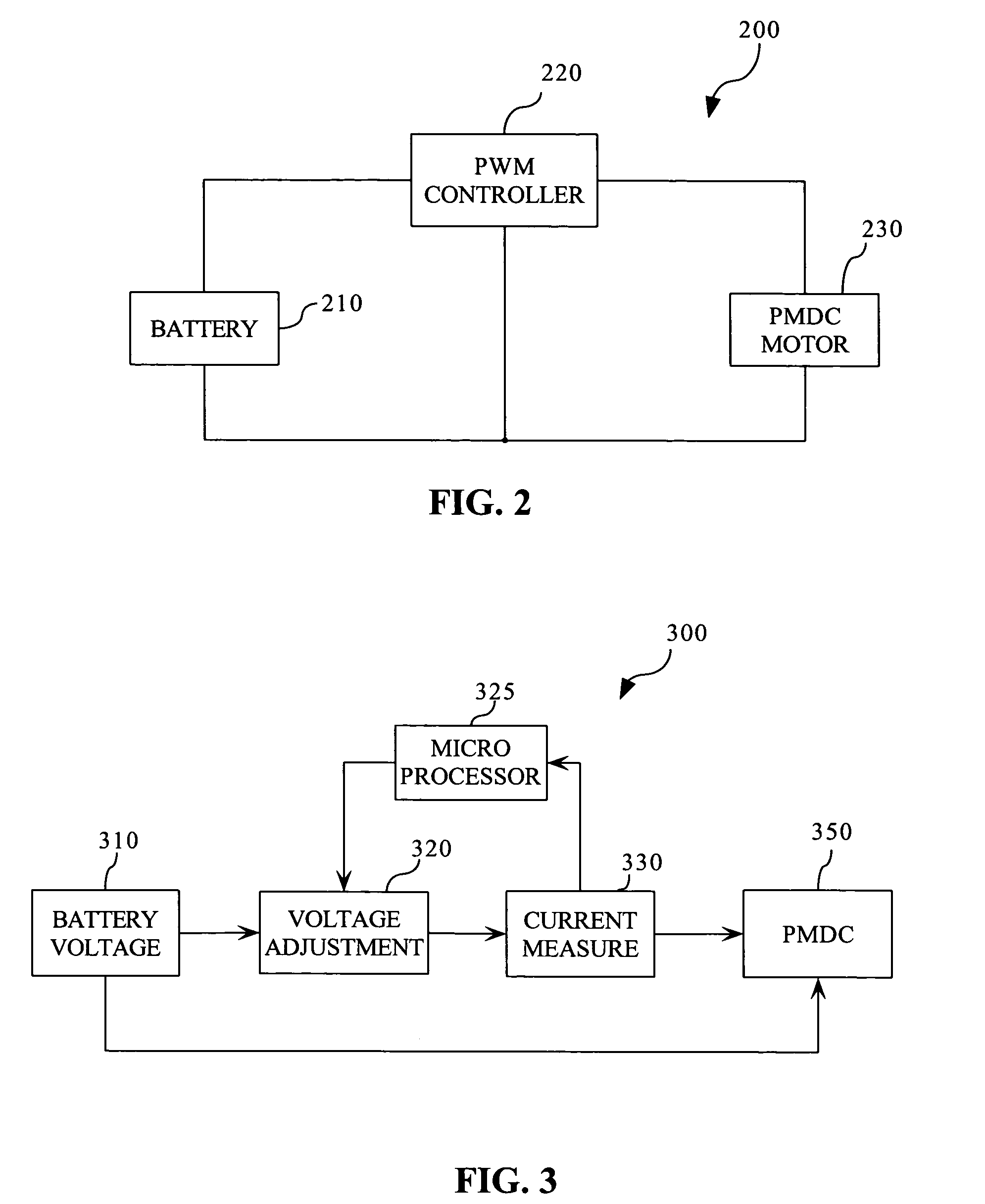

Amperage control for protection of battery over current in power tools

InactiveUS7133601B2Battery protectionHigh currentAC motor controlElectric motor controlLithiumNickel cadmium

Amperage control of a power tool motor is provided by pulse width modulation of current from a power supply. The pulse width modulation may be varied according to the determined motor current and measured power supply voltage. The power supply preferably includes a battery, such a lithium ion or nickel cadmium.

Owner:BLACK & DECKER INC

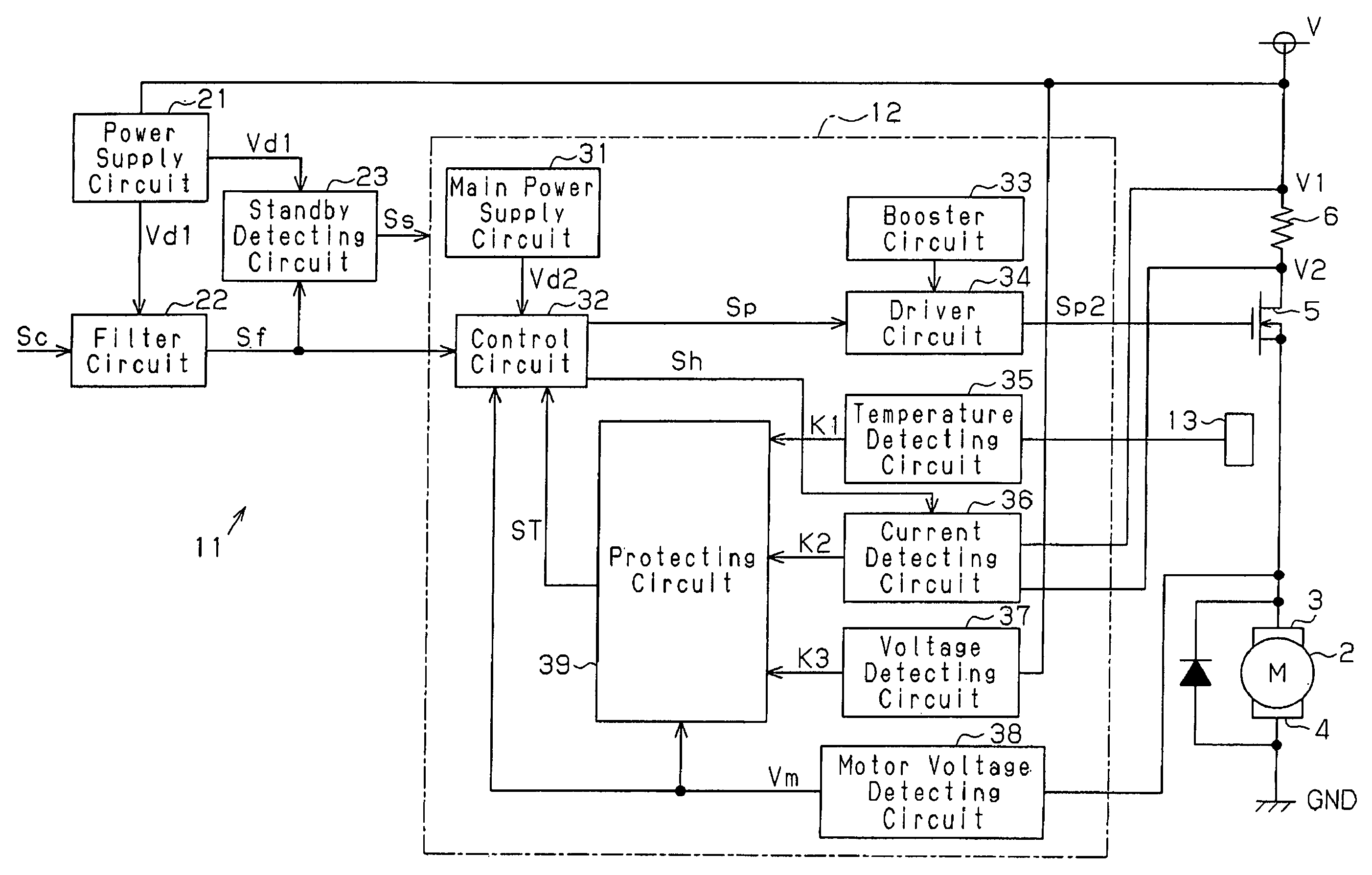

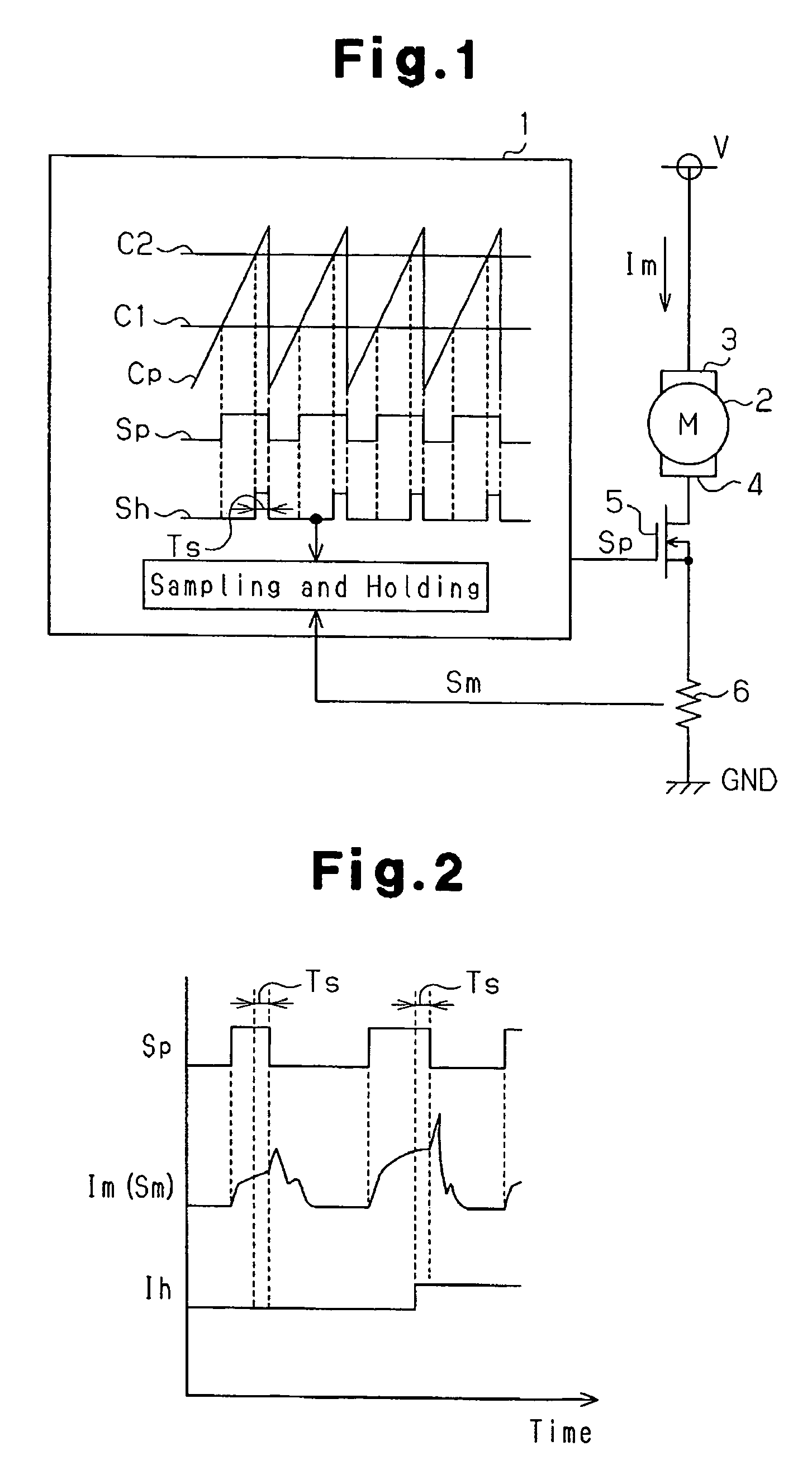

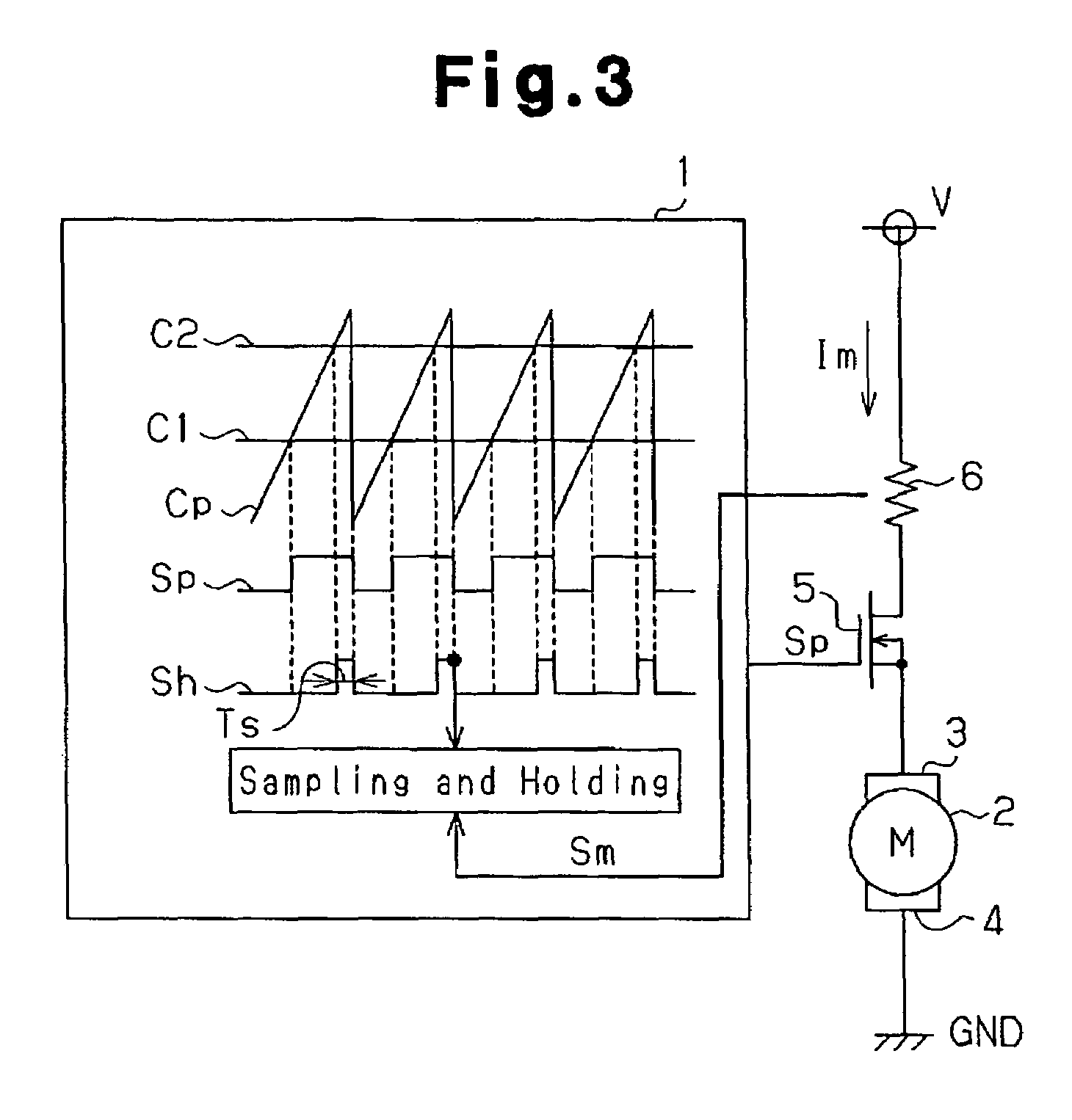

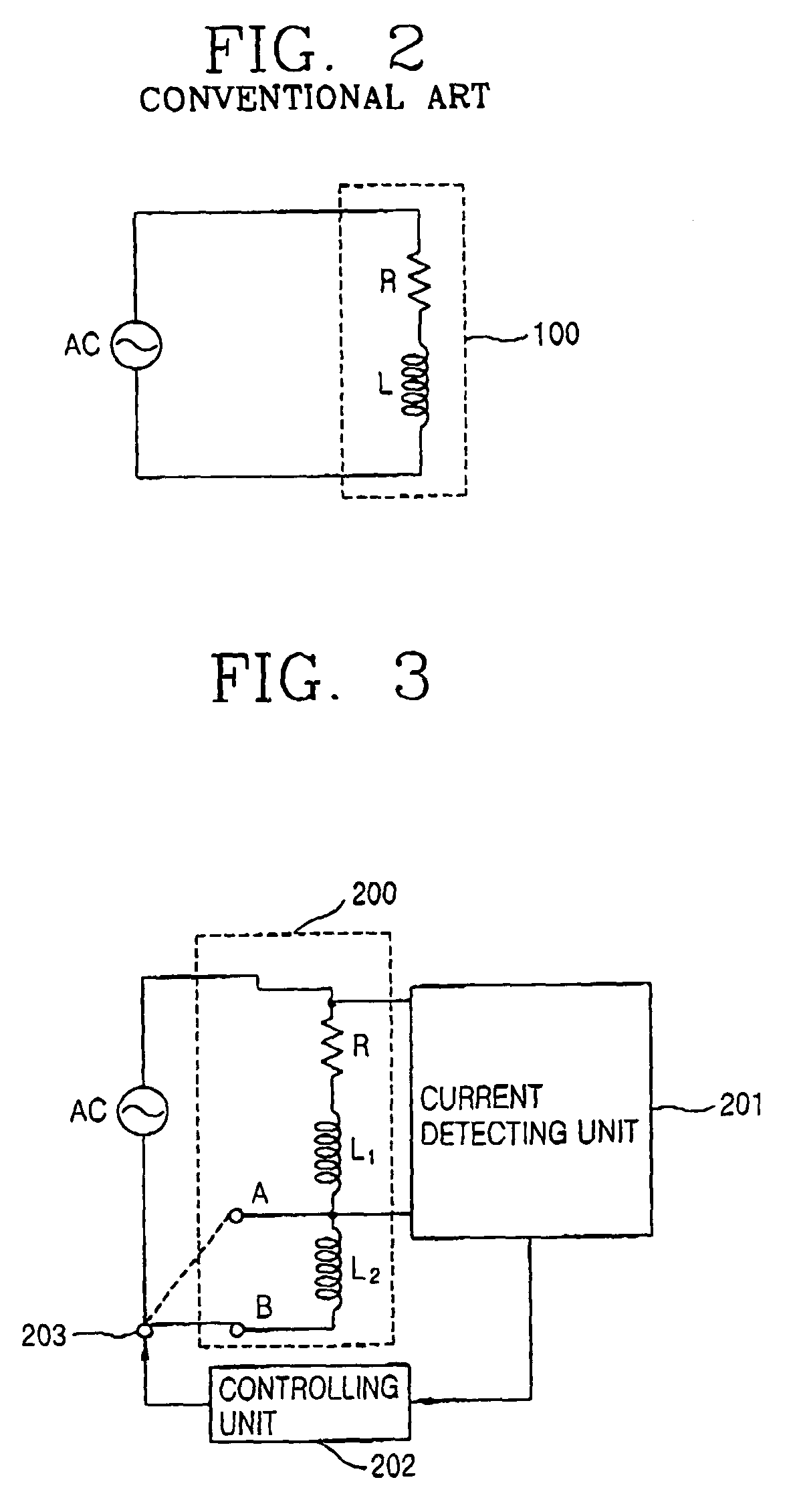

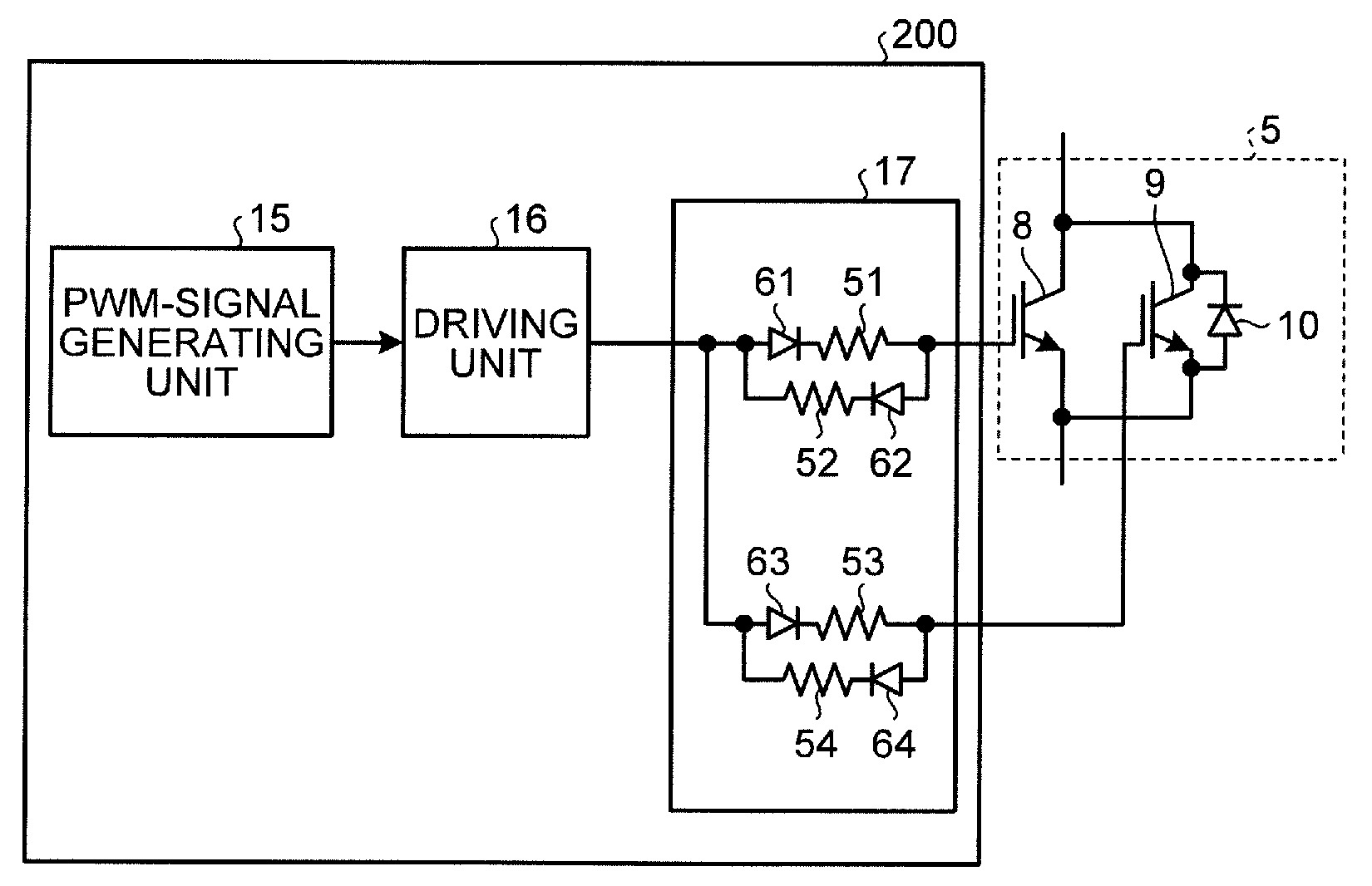

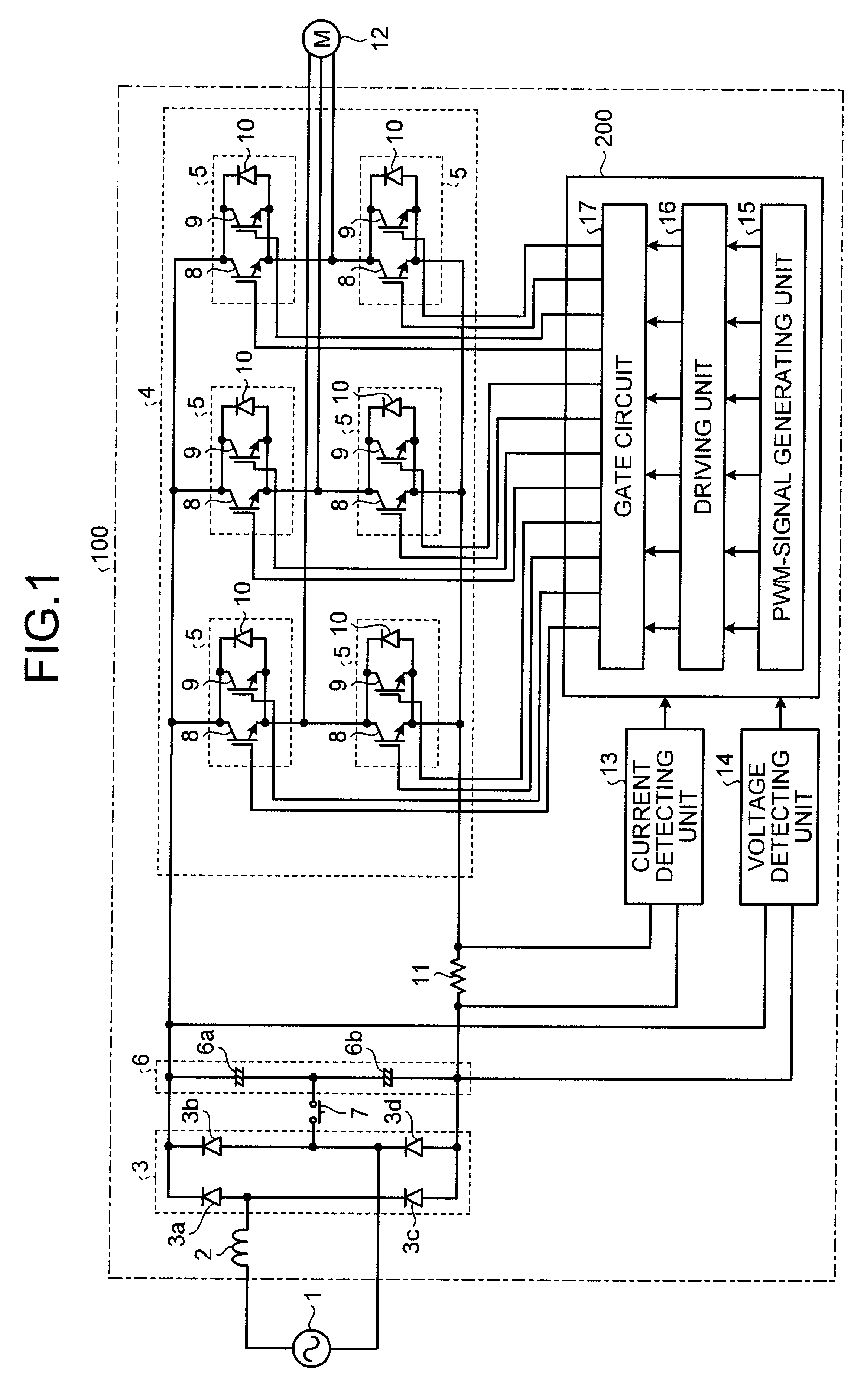

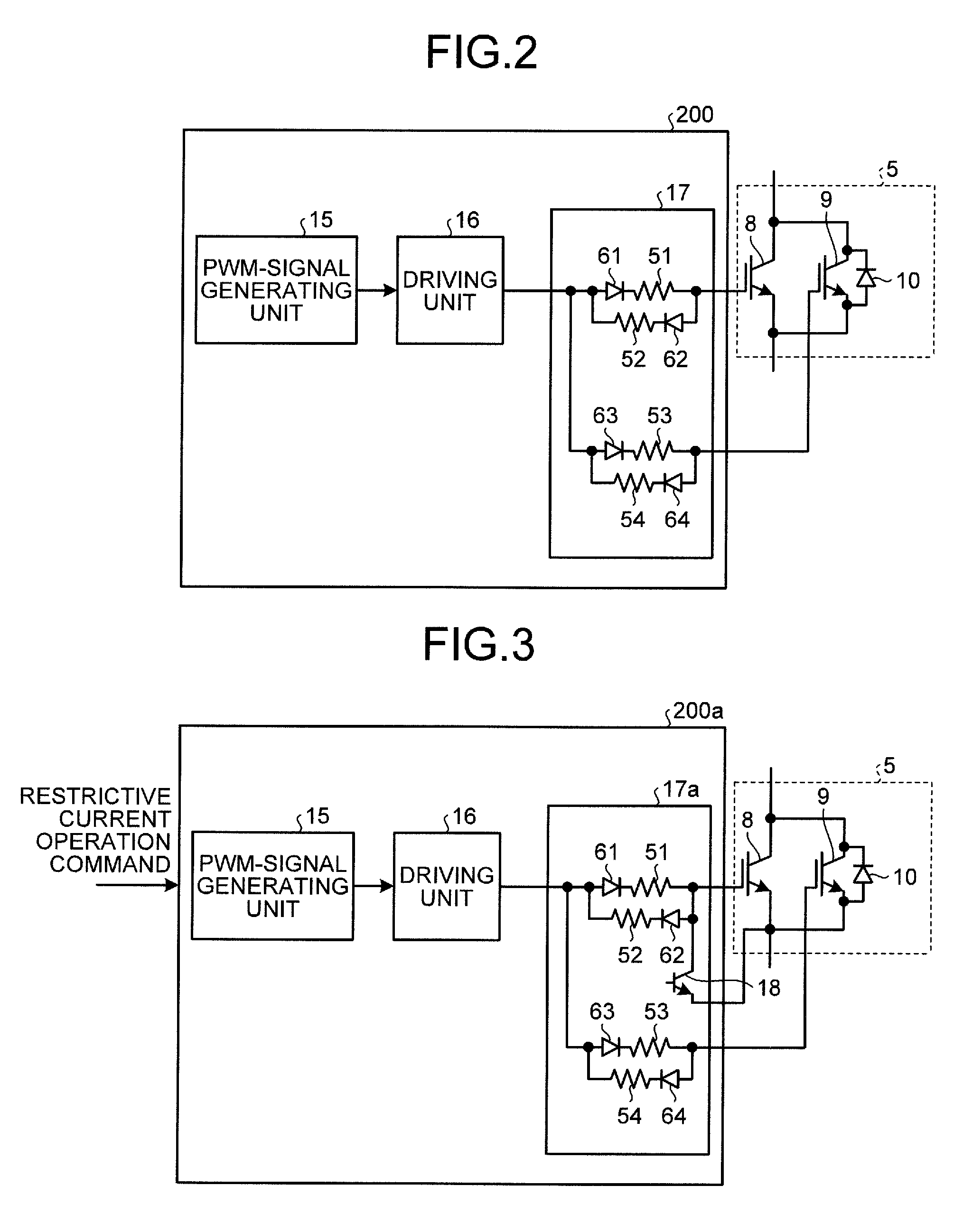

Motor control device and motor control method

InactiveUS7183737B2Improve accuracyCurrent detectionAC motor controlElectric motor controlDriving currentControl signal

A motor control device selectively turns on or off a drive transistor in-accordance with a PWM control signal Sp, such that a drive current Im supplied to a motor is adjusted. The device also samples and holds a motor current Sm for obtaining a motor current value Ih. With reference to the motor current value Ih, the device protects the motor from an overcurrent. Sampling and holding of the motor current Sm is performed for a sampling and holding time Ts. The sampling and holding time Ts corresponds to a time period between a first point in time when the level of the PWM control signal Sp is switched for turning off the drive transistor and a second point in time that precedes the first point in time by a predetermined period. As a result, the motor current value Ih is detected with high accuracy.

Owner:ASMO CO LTD

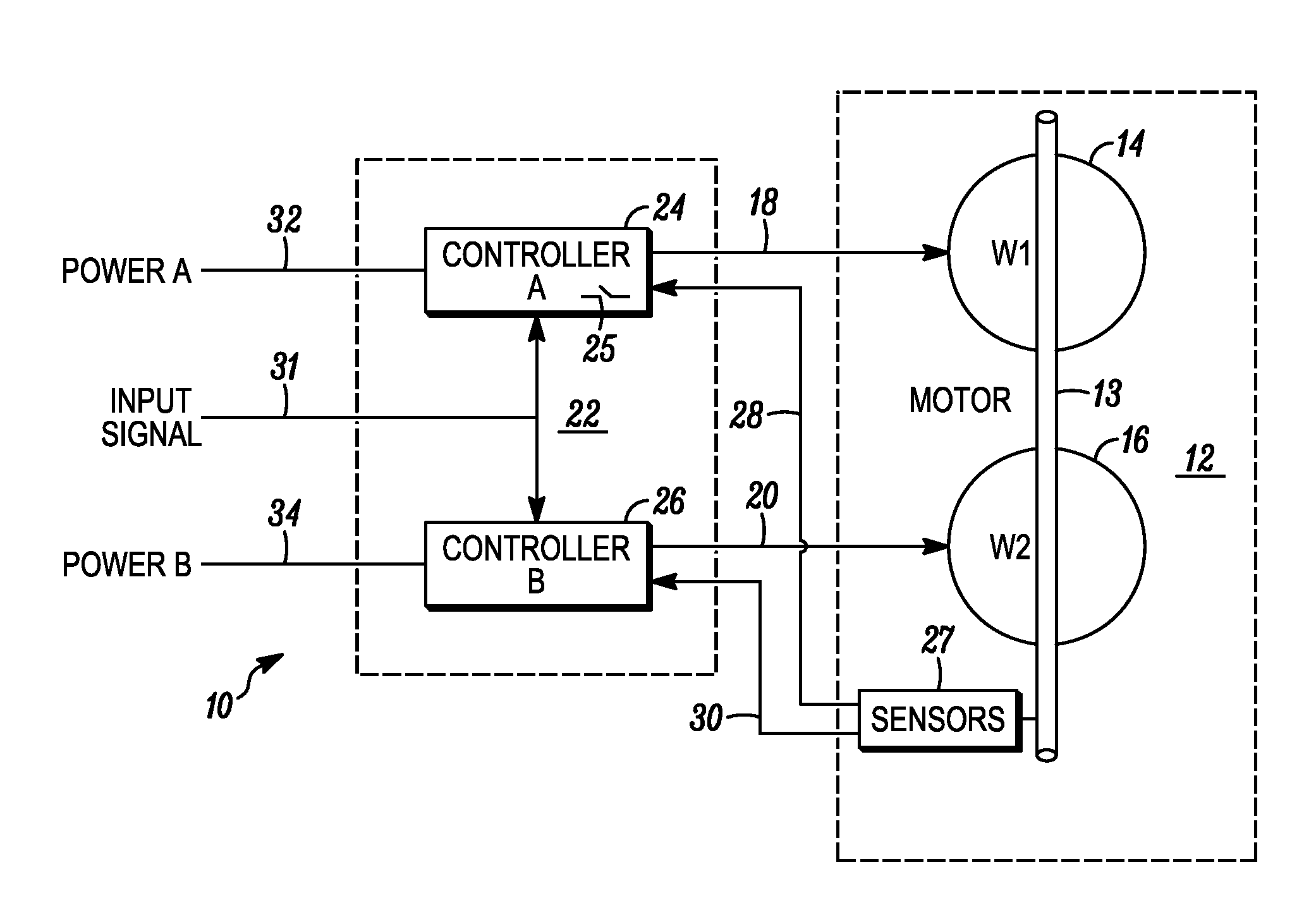

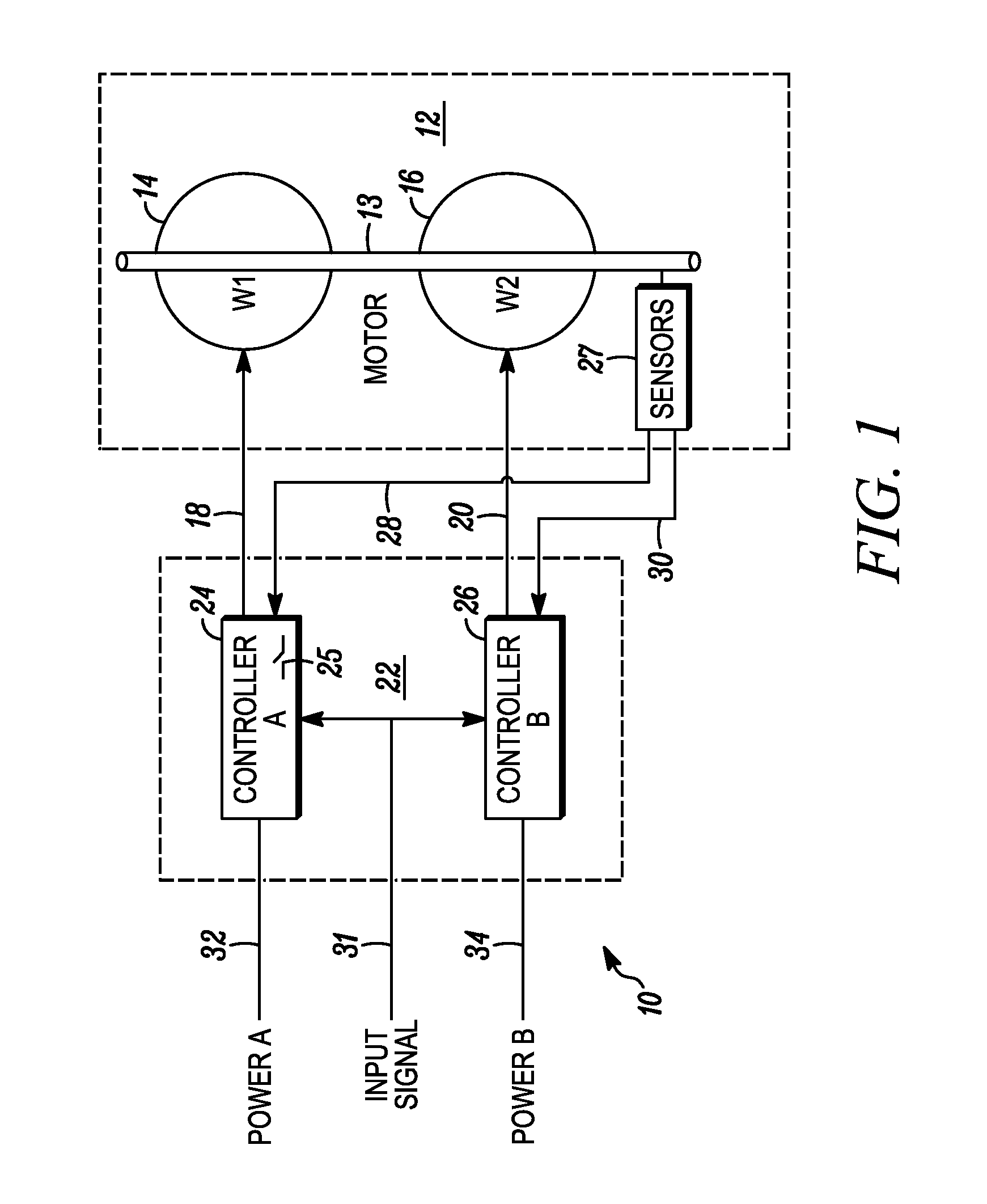

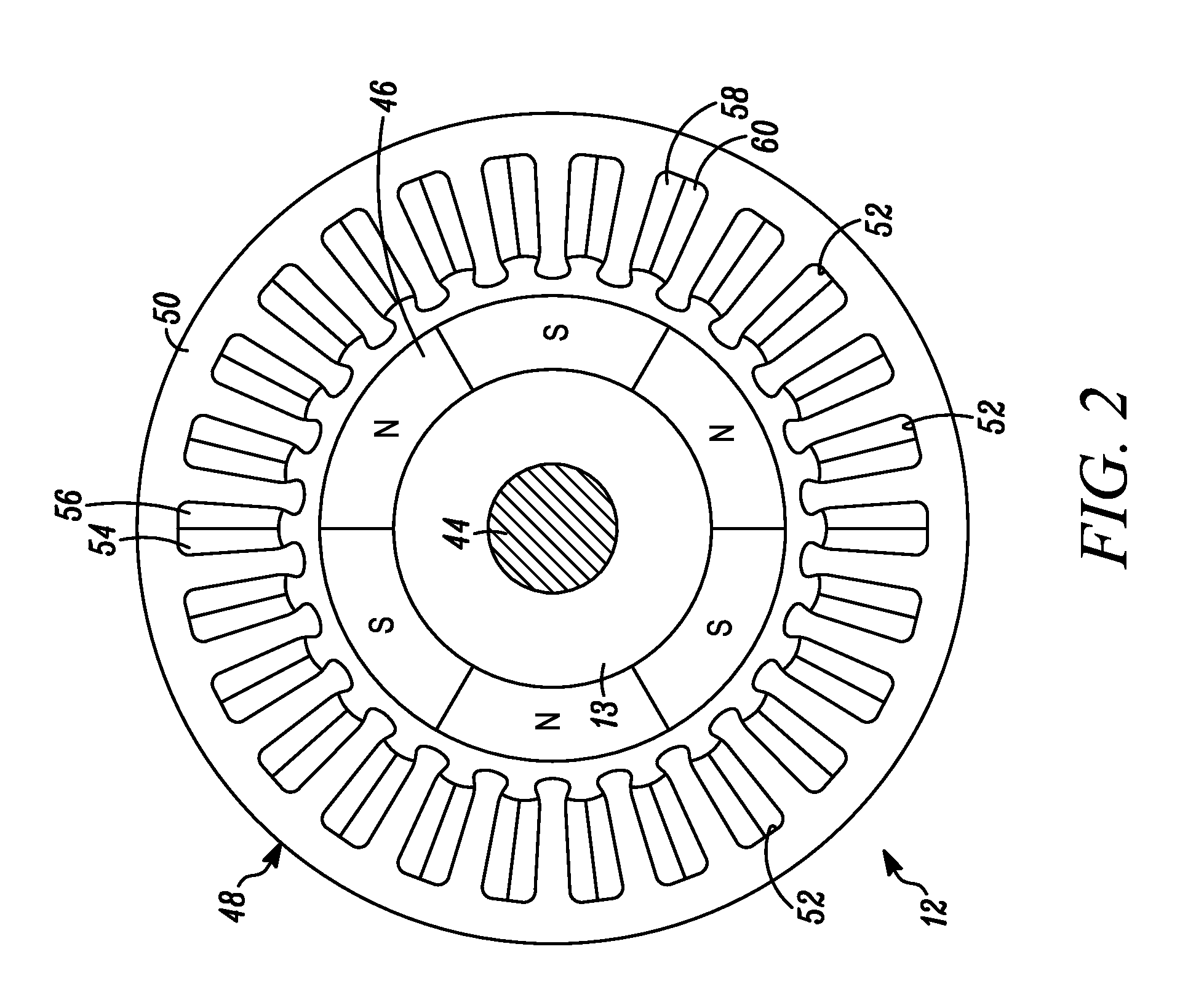

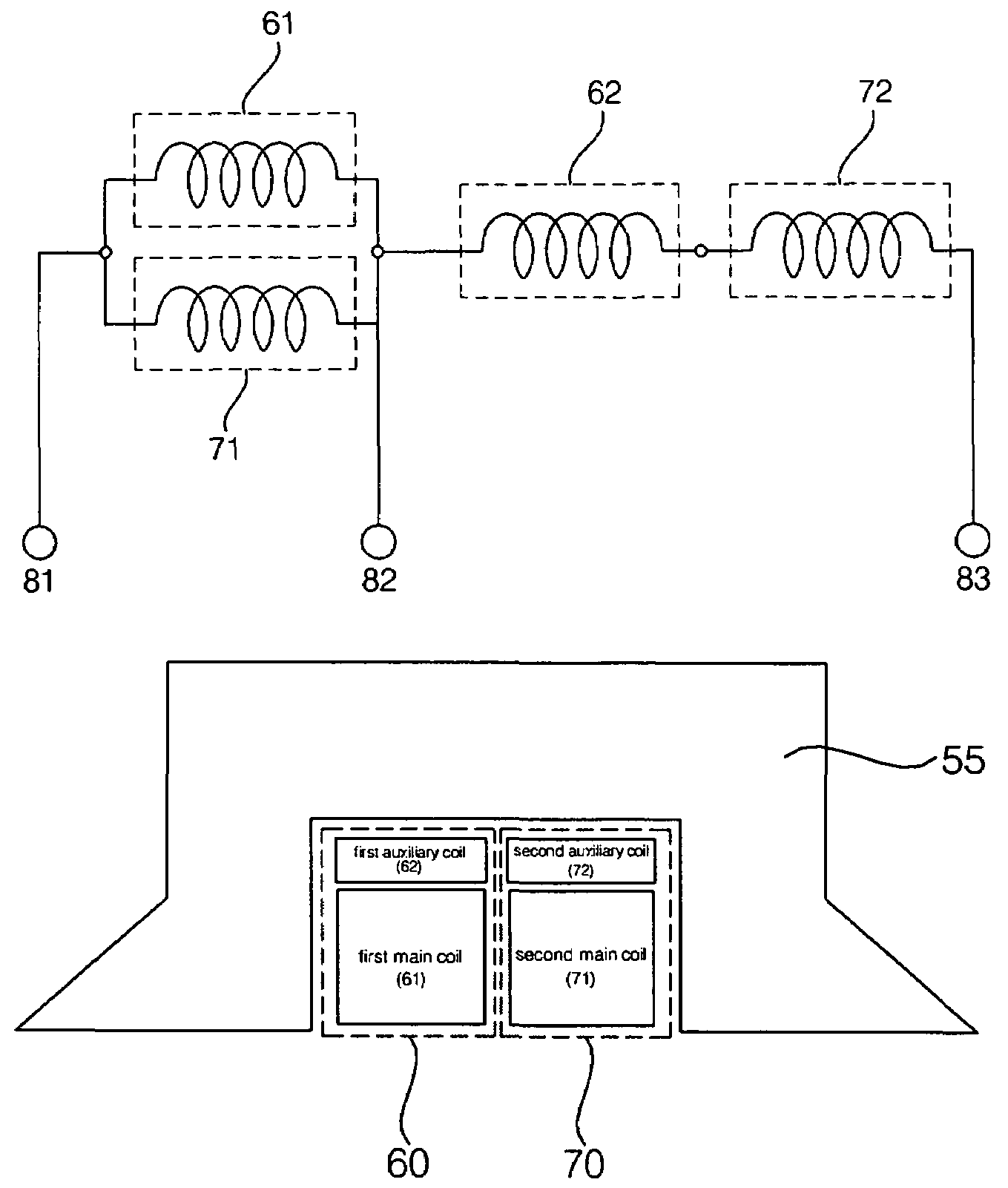

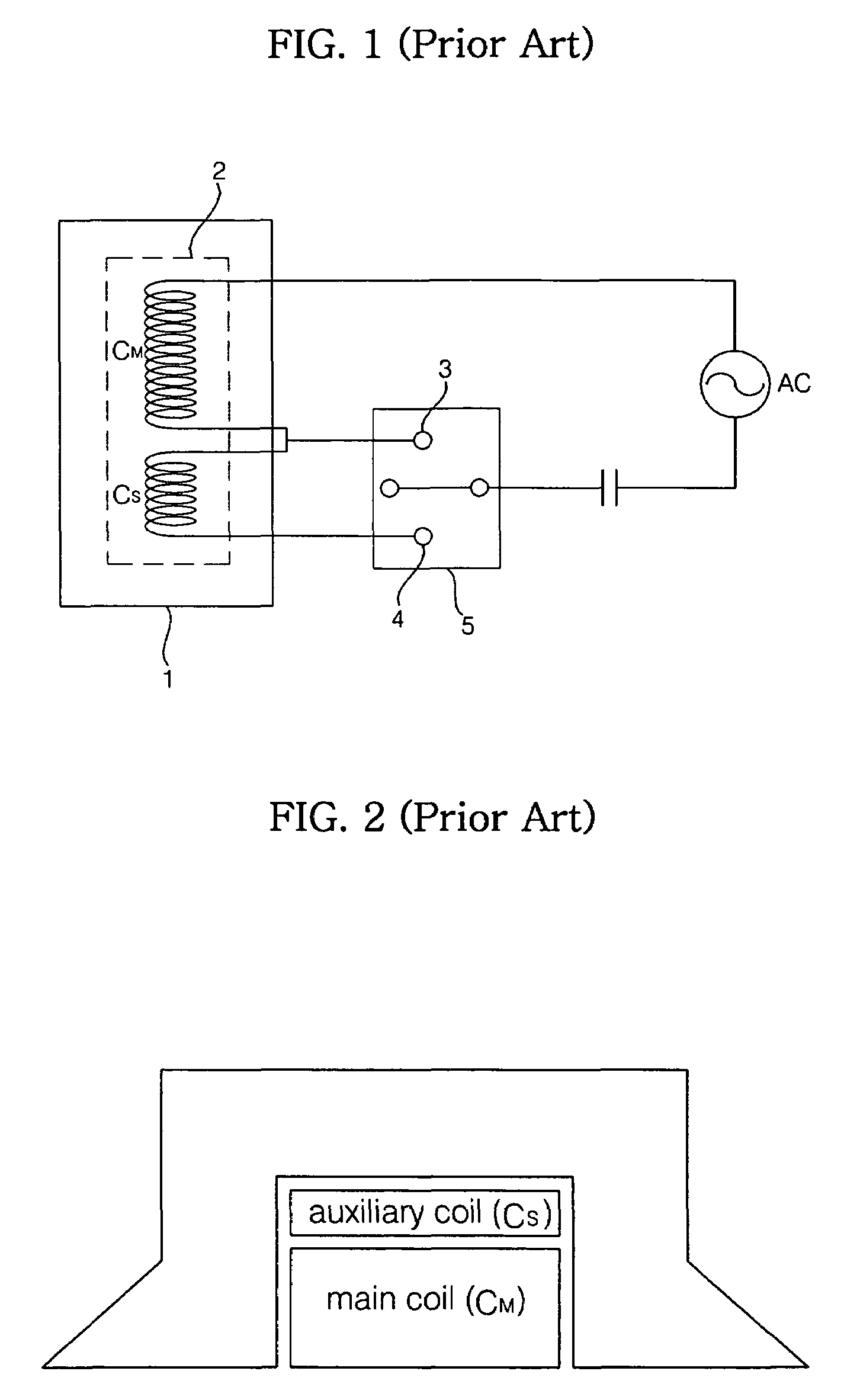

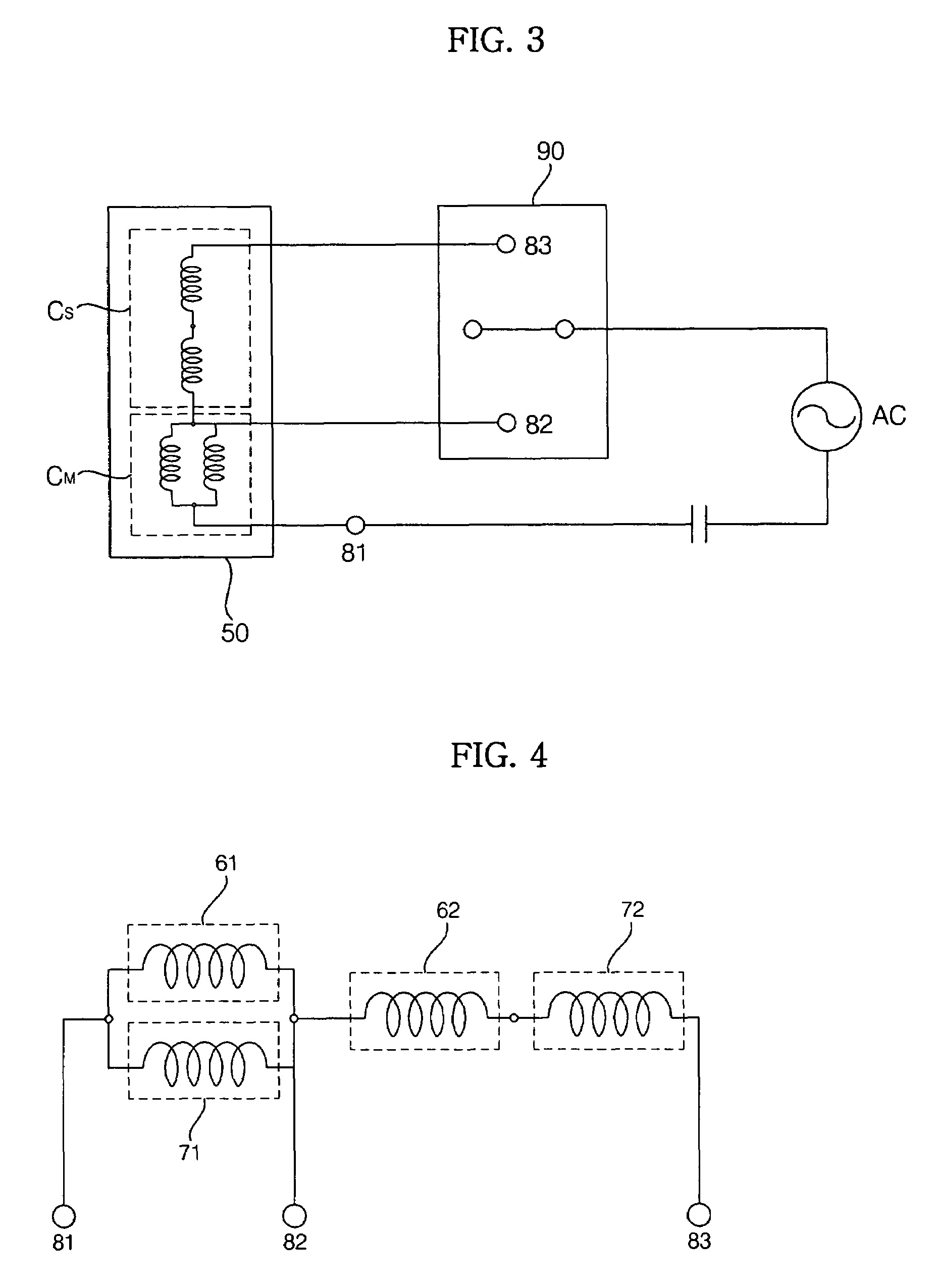

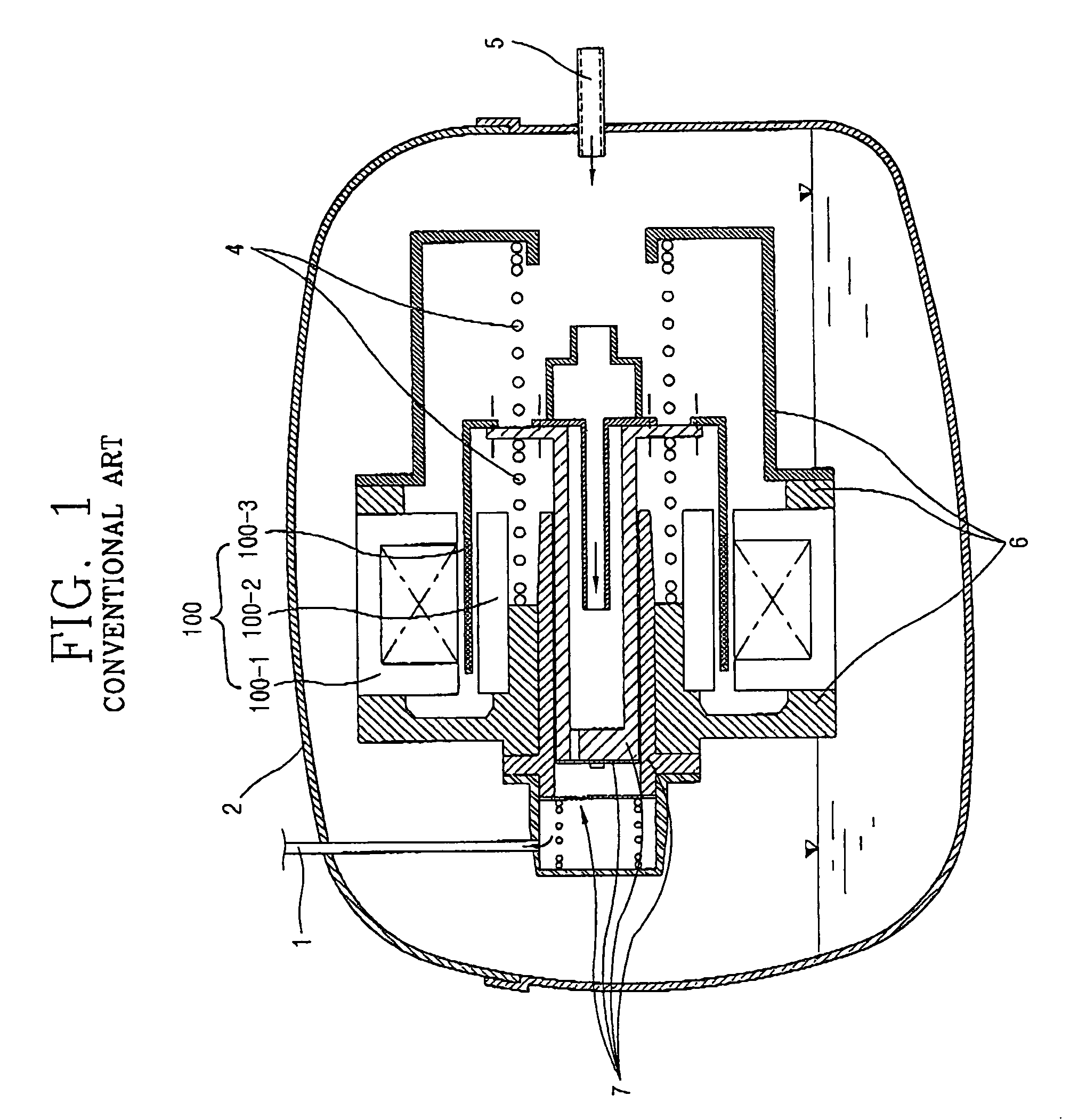

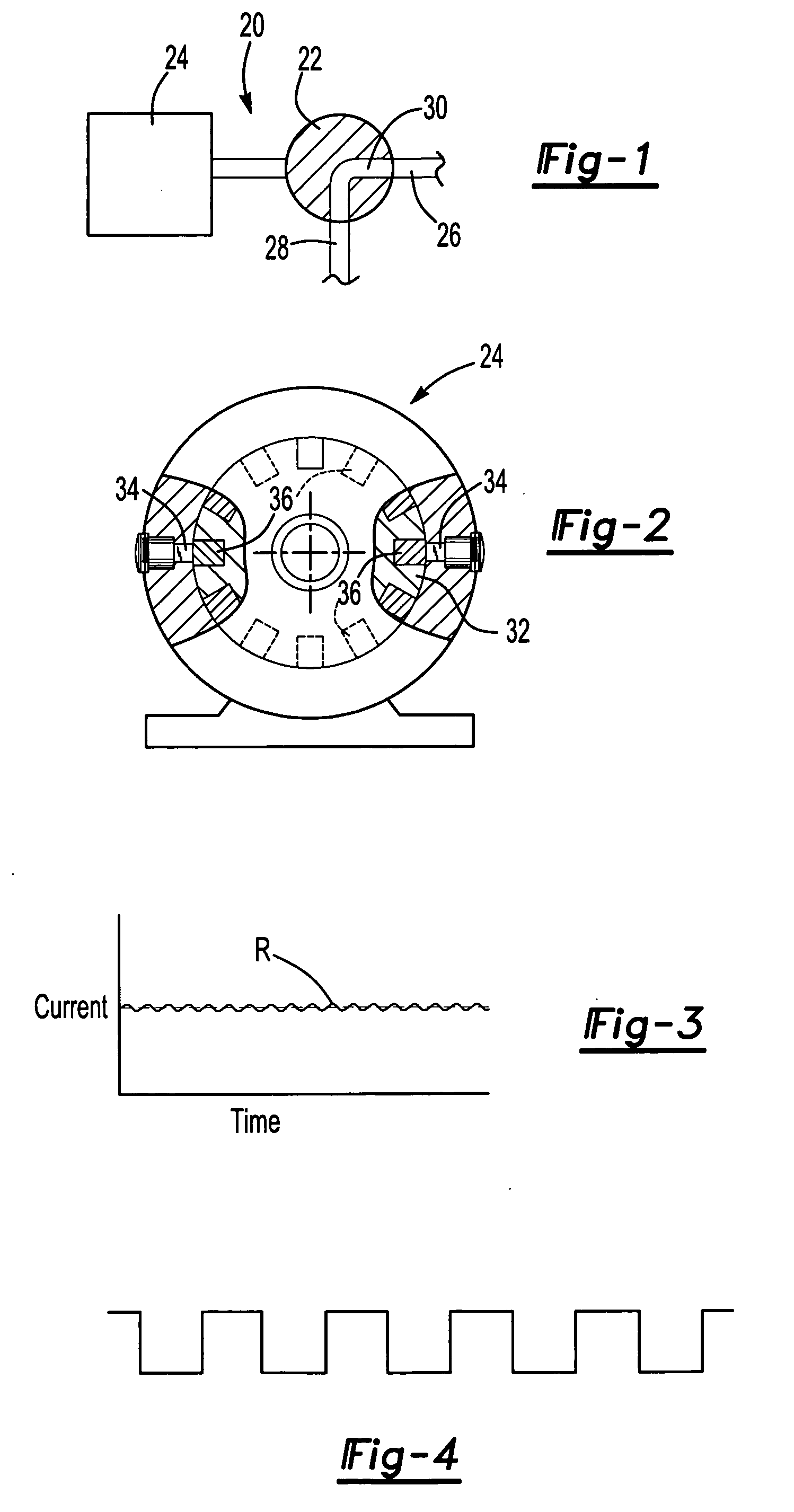

Motor having controllable torque

InactiveUS8125168B2Single-phase induction motor startersCommutation monitoringMotor controlElectric motor

A controllable motor includes a rotor. A first stator winding set is operable, upon being energized, to generate and apply a first torque to the rotor. A second stator winding set independent of the first stator winding set is operable, upon being energized, to generate and apply a second torque to the rotor. A motor control is coupled to the first and second stator winding sets. The motor control is operable to selectively energize one of the first or second stator winding sets to thereby generate and apply one of the first or second torques to the rotor, and simultaneously energize both the first and second stator winding sets to thereby generate and apply a third torque greater than the first or the second torque.

Owner:HONEYWELL INT INC

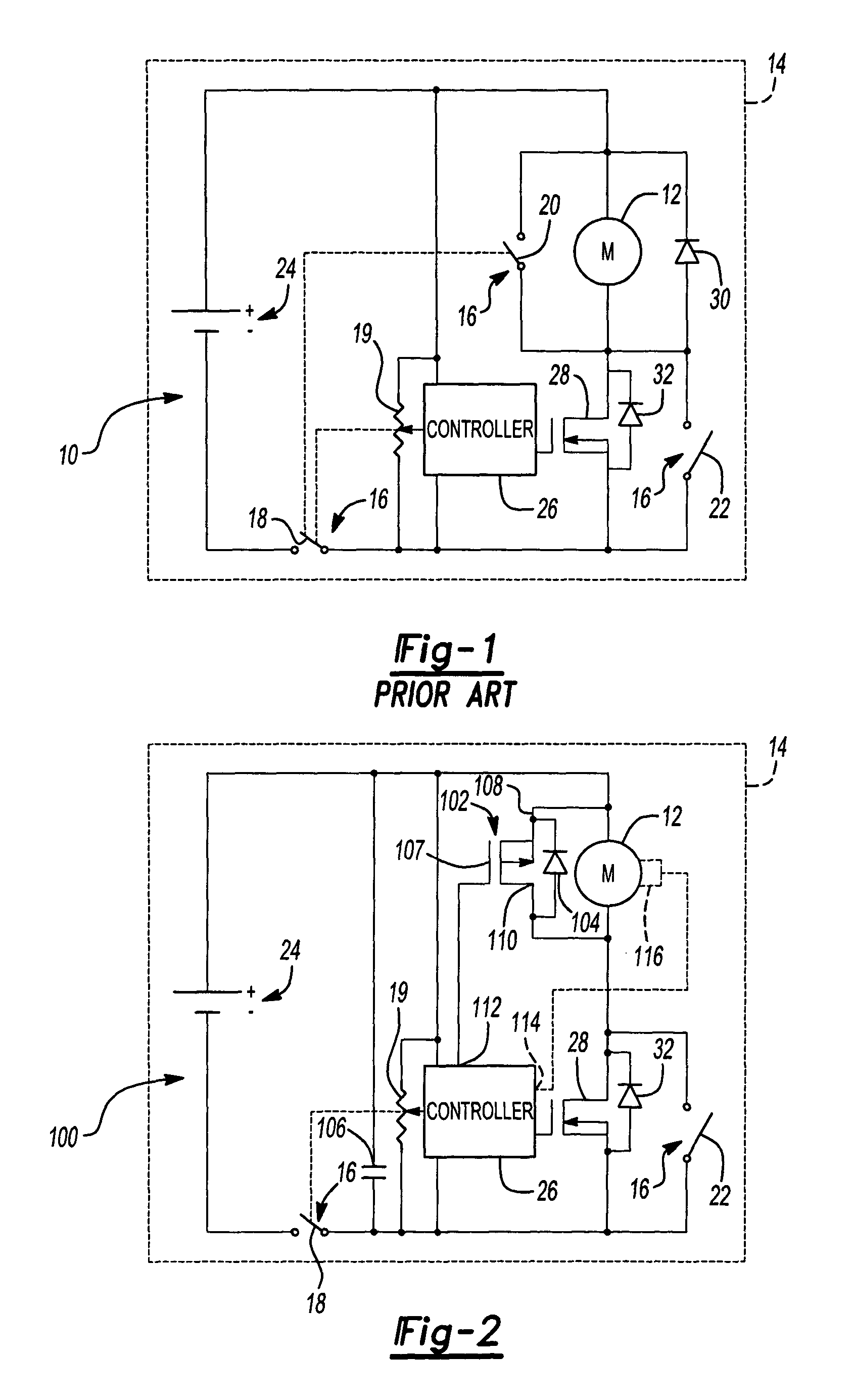

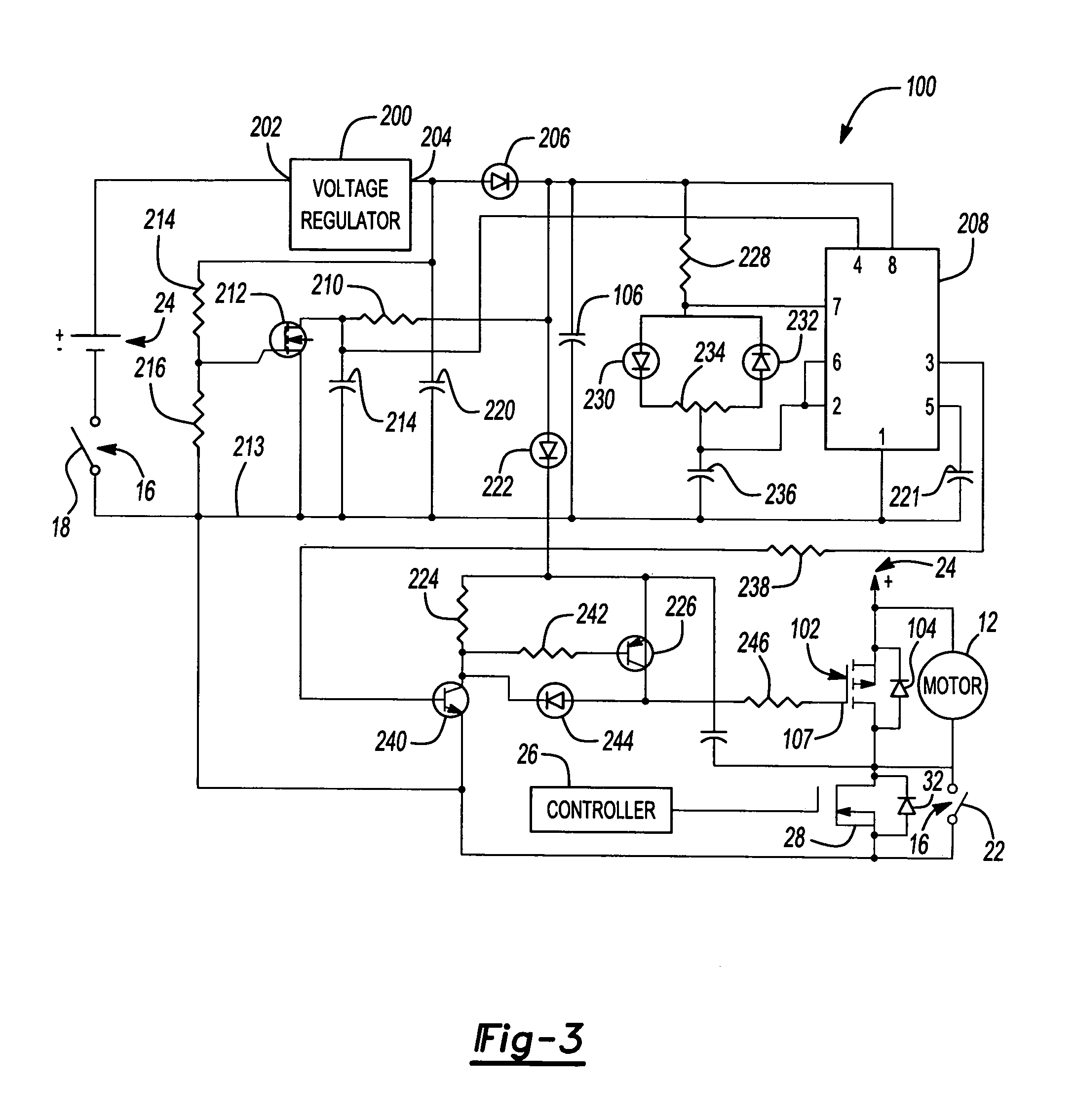

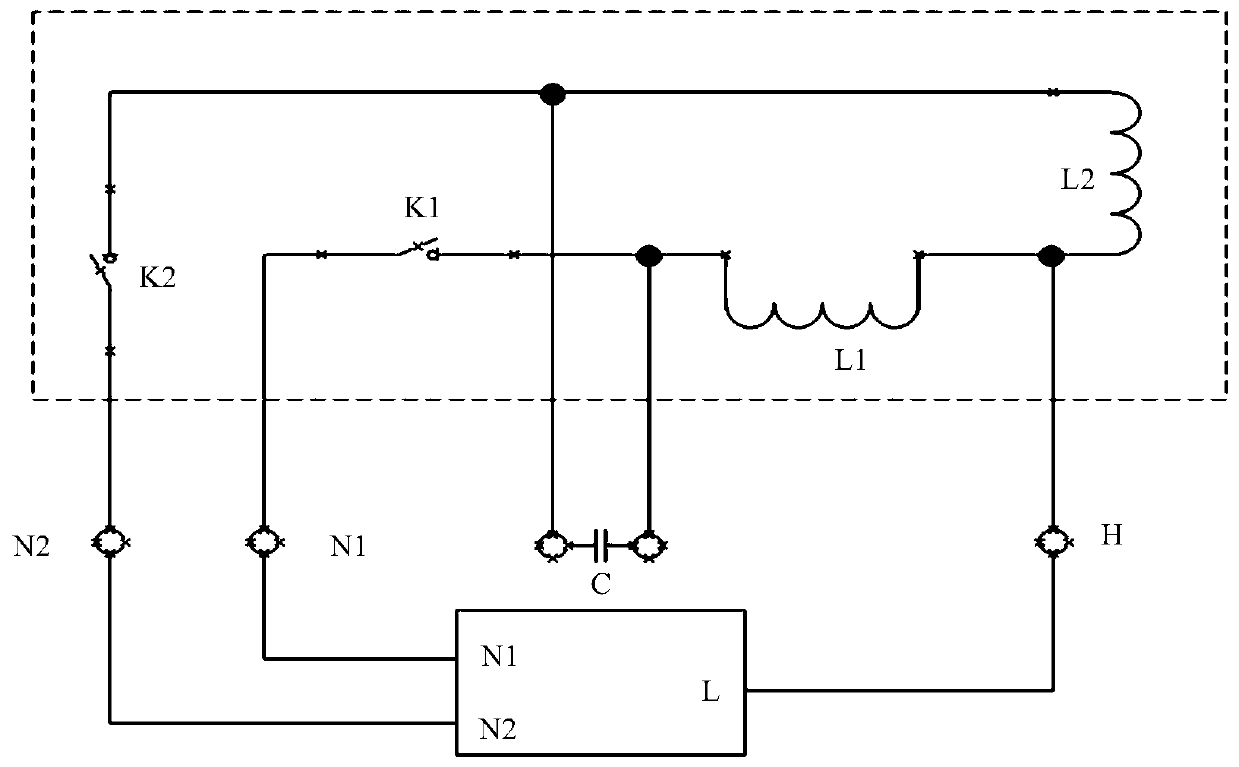

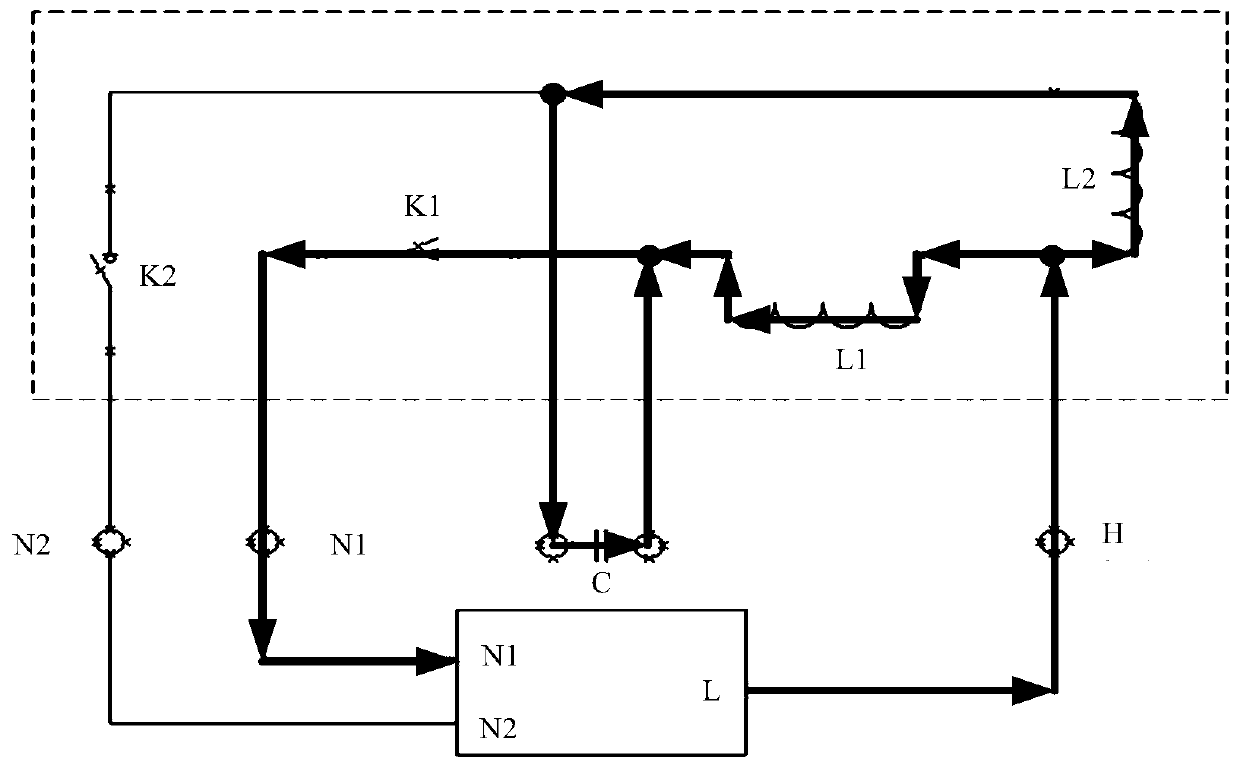

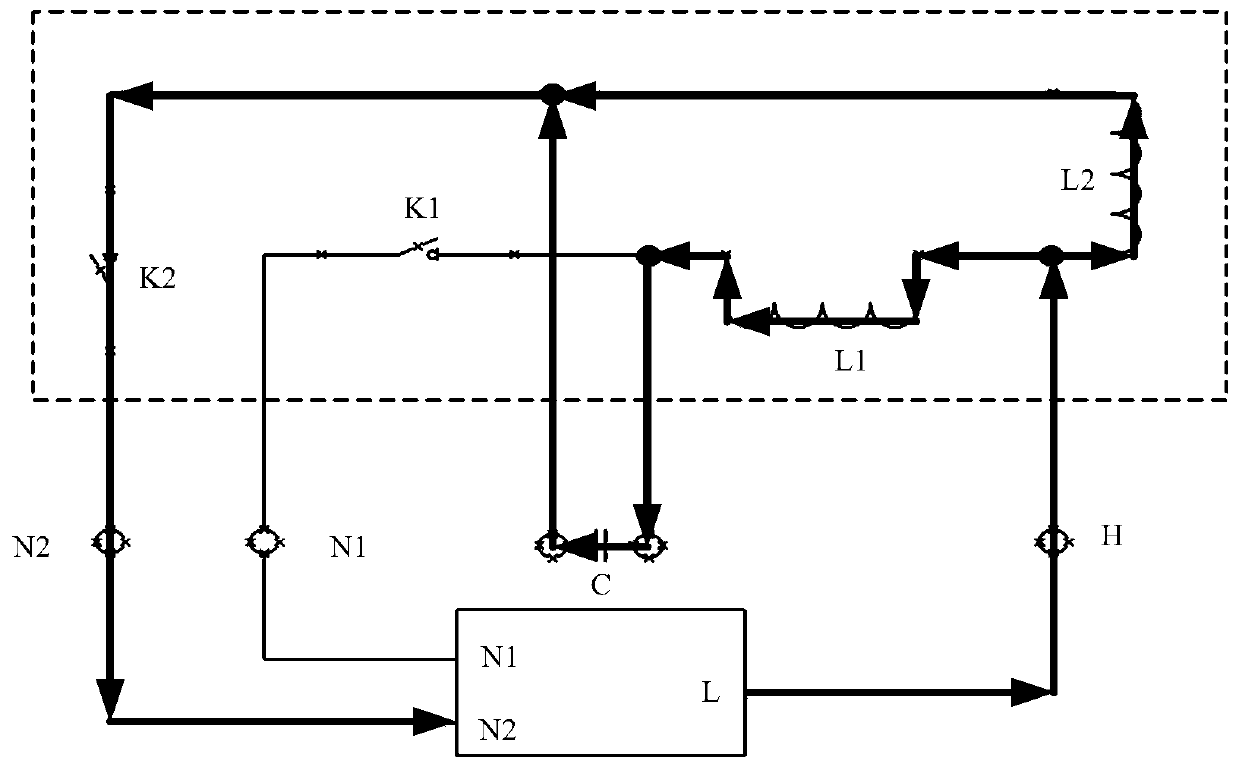

Method and device for braking a motor

InactiveUS7023159B2Eliminate needAC motor controlDC motor speed/torque controlPower switchingConductor Coil

A method and apparatus for braking a motor has a braking power switching device coupled across windings of the motor. To brake the motor, the braking power switching device is cycled on and off.

Owner:BLACK & DECKER INC

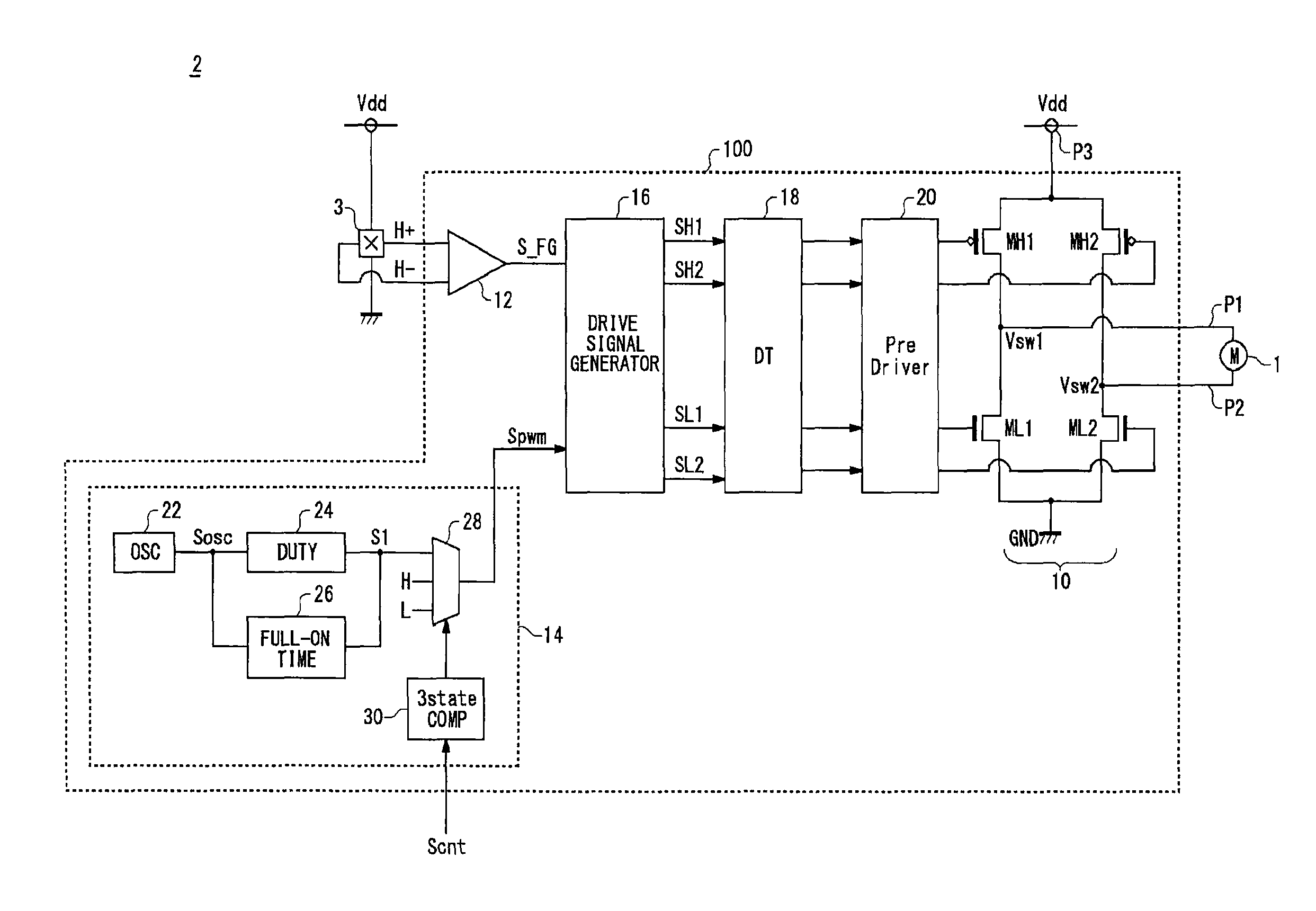

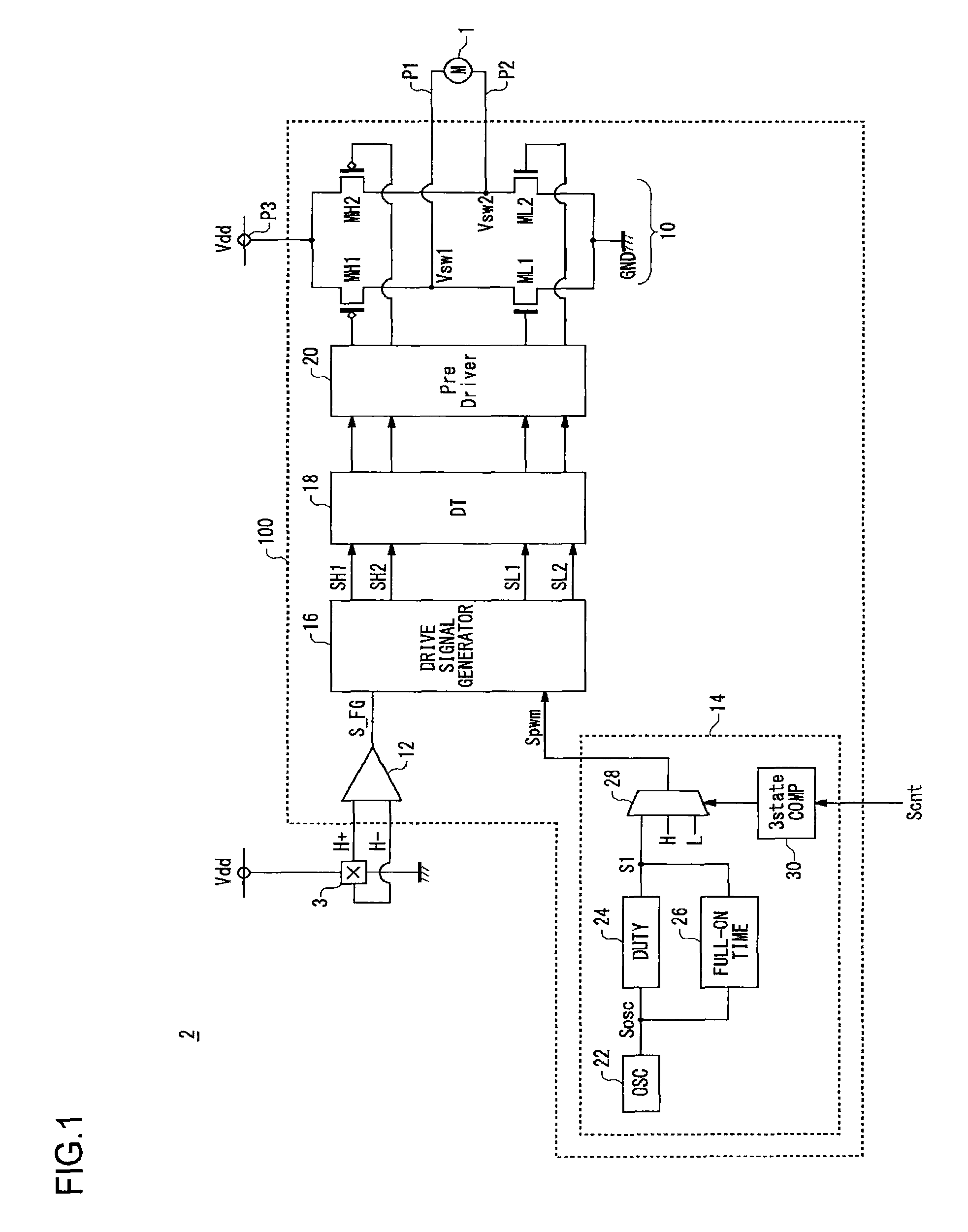

Motor drive circuit with short startup time

An H-bridge circuit is connected to a coil of the vibration motor that is to be driven. A comparator receives Hall signals indicating position information of a rotor of the vibration motor, and converts to an FG signal. A pulse width modulator generates a pulse-modulated pulse signal specifying energization time of the coil of the vibration motor. The pulse width modulator, in a first mode, after commencing start-up of the vibration motor, sets a duty ratio of the pulse signal to 100%, and after that, switches the duty ratio to a predetermined value in accordance with rotational frequency of the motor. In a second mode, the duty ratio of the pulse signal continues to be set to 100%. In a third mode, frequency and the duty ratio of the pulse signal are set based on a control signal of a pulse form inputted from outside. The control signal is used also in switching mode.

Owner:ROHM CO LTD

Linear motor and linear compressor using the same

ActiveUS7489055B2Improve efficiencySmall sizeAC motor controlDC motor speed/torque controlBobbinElectrical conductor

Disclosed herein is a linear motor in which a plurality of coil groups are connected in series or in parallel and driving power is applied to part or all of the coil groups according to load applied to the linear motor, thereby achieving improved motor efficiency with a reduced motor size. The linear motor includes a bobbin, the plurality of coil groups wound on the bobbin, the plurality of coil groups being connected in series or in parallel to allow the driving power to be applied to part or all of the coil groups, and a magnet adapted to be linearly reciprocated by a magnetic field produced by the coil groups depending on load current flowing through the coil groups. As a result of connecting the plurality of coil groups, which are formed of a plurality of coil conductors, in series or in parallel, the capacity of the coil groups is variable depending on the load of the motor, resulting in improved motor efficiency. Also, using the coil conductors having a small cross sectional area enables reduction in the size of the motor.

Owner:LG ELECTRONICS INC

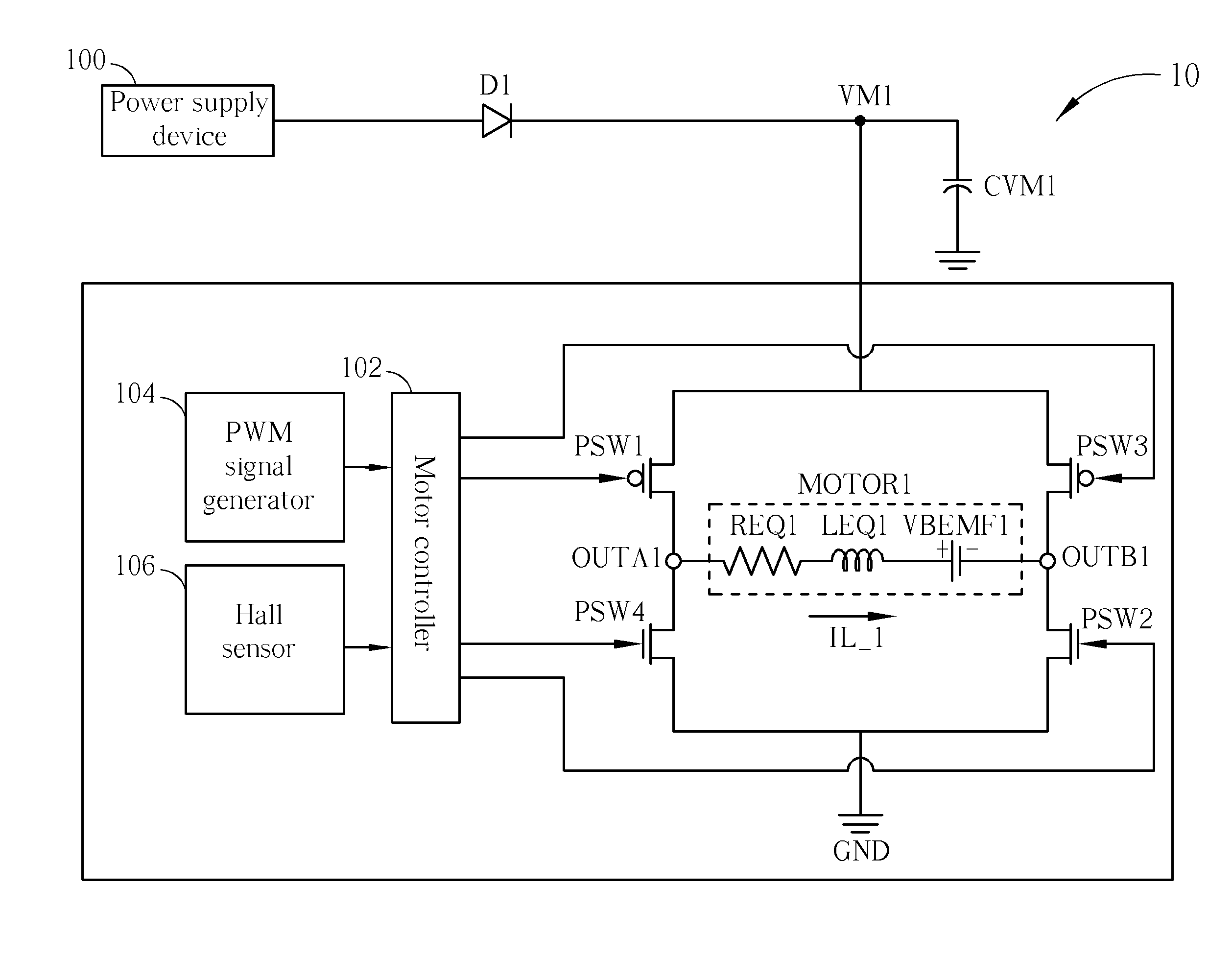

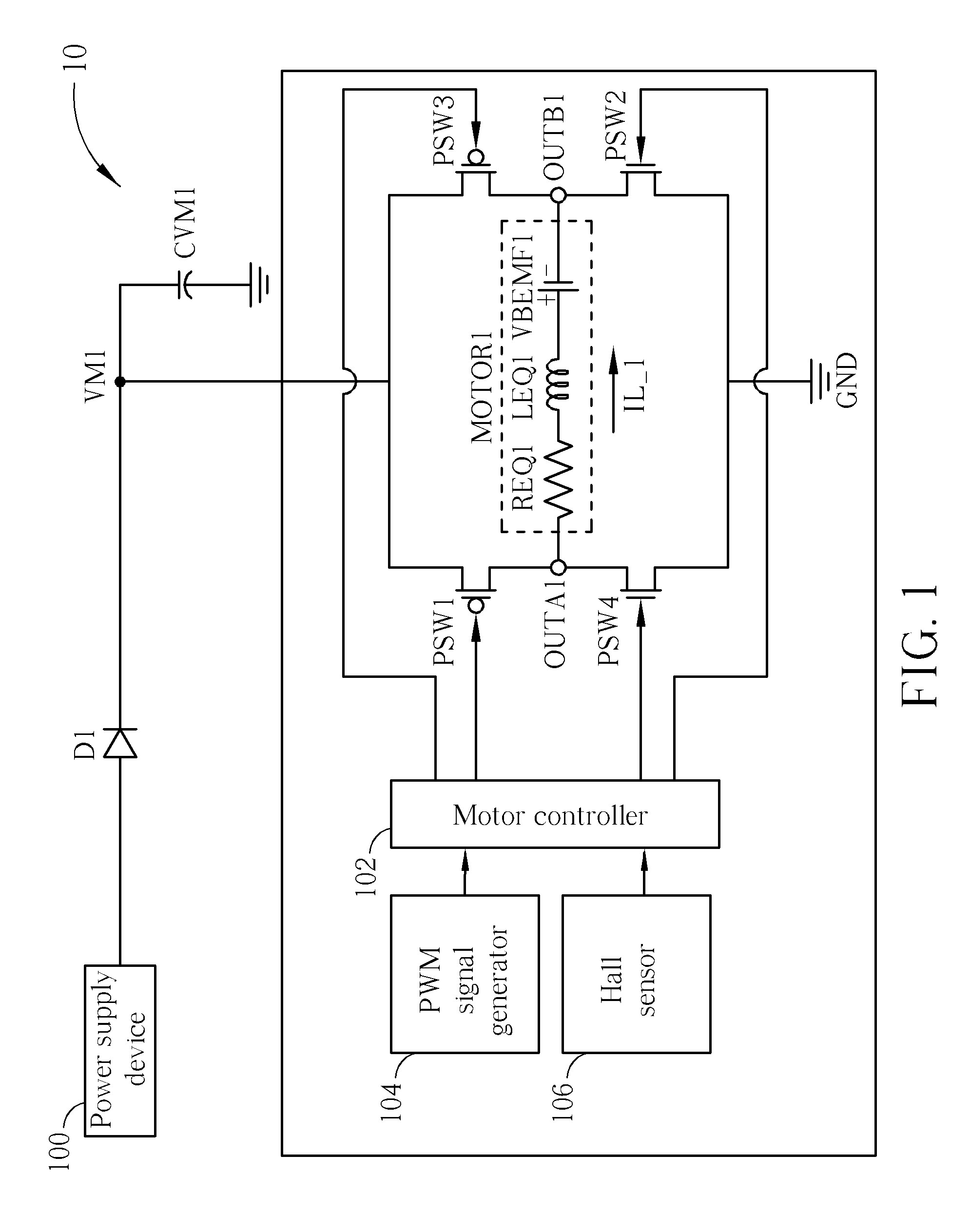

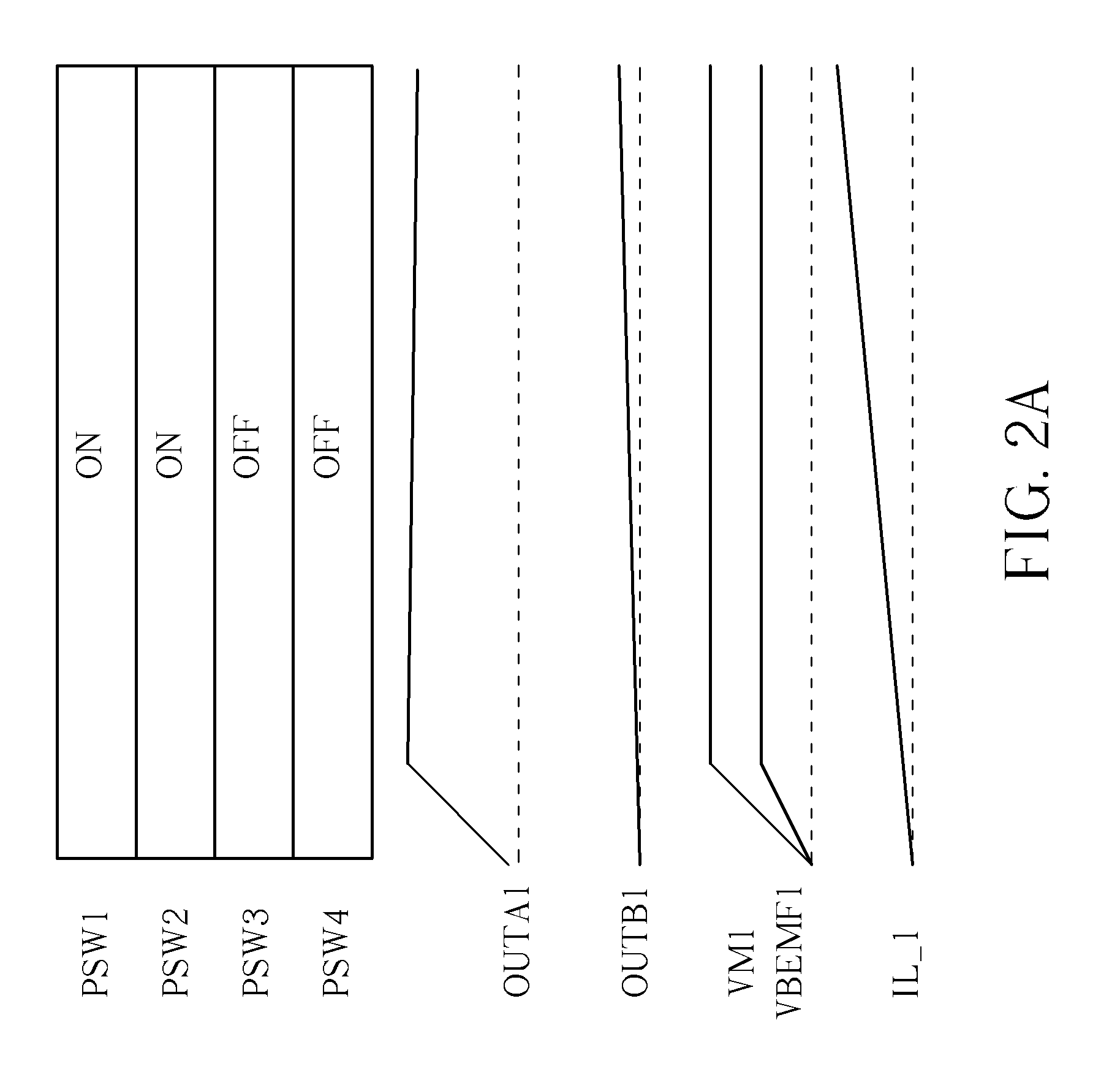

Method of driving DC motor and related circuit for avoiding reverse current

ActiveUS8183807B2Avoid it happening againMotor/generator/converter stoppersAC motor controlDriver circuitPower flow

Owner:ANPEC ELECTRONICS CORPORATION

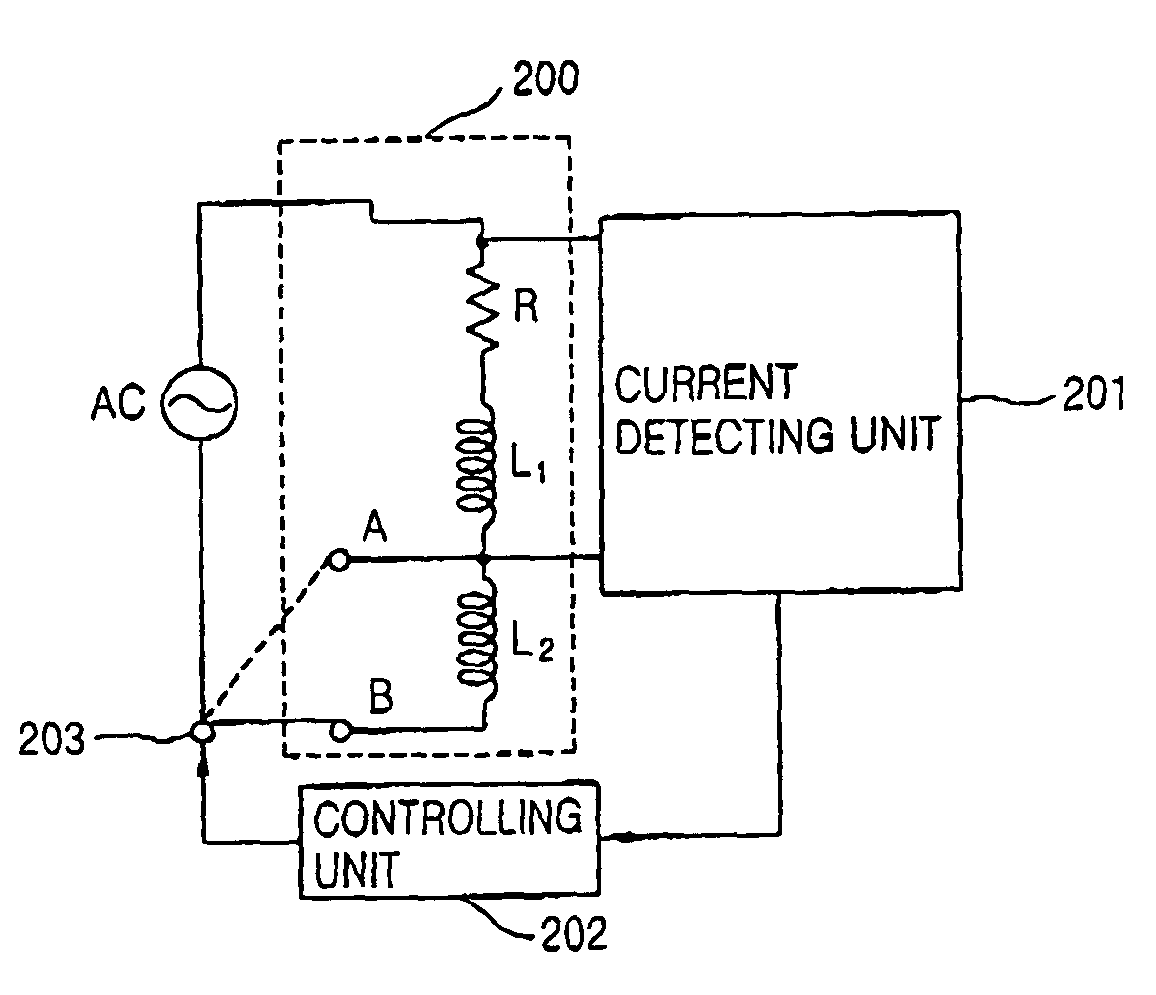

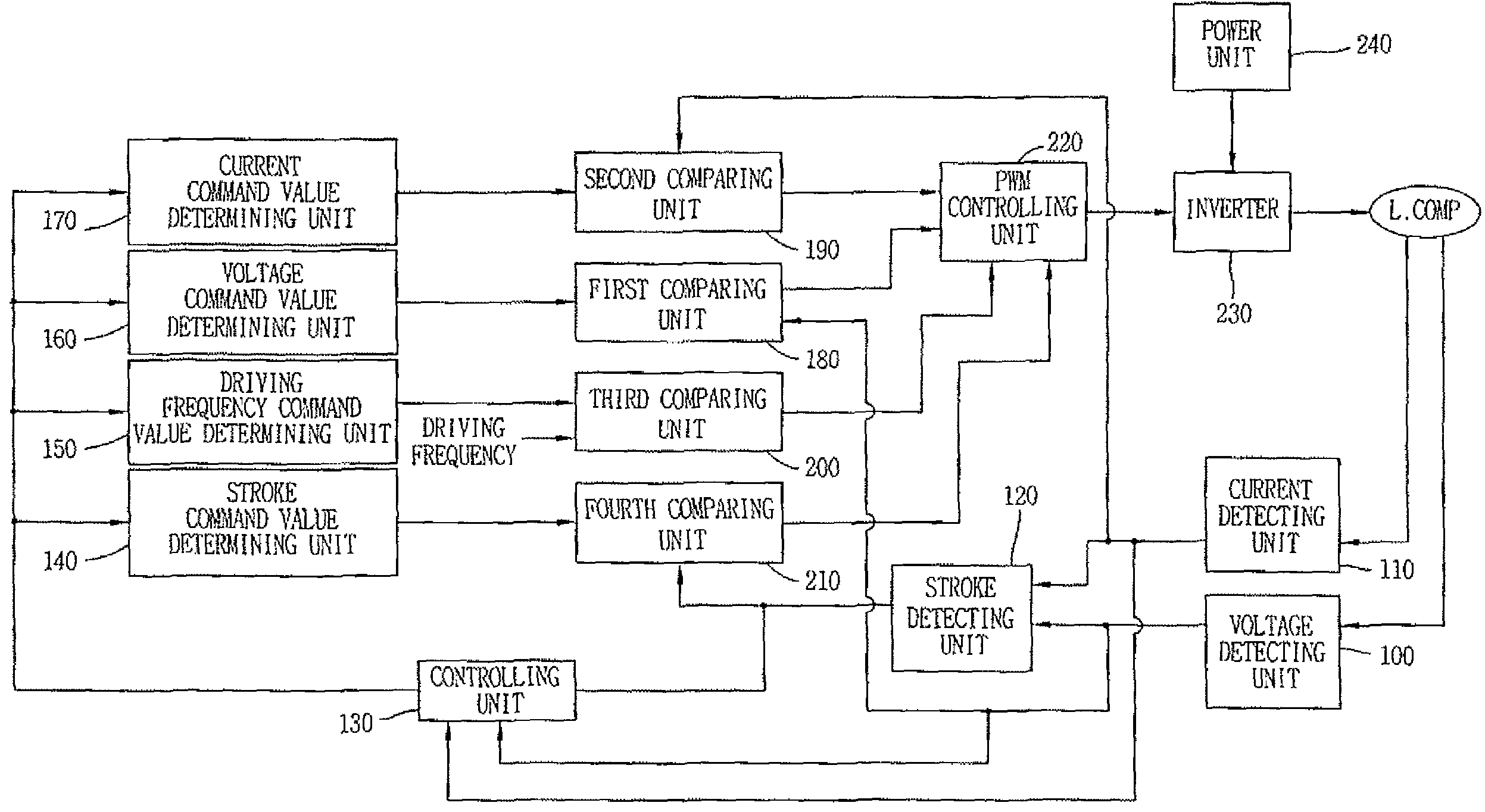

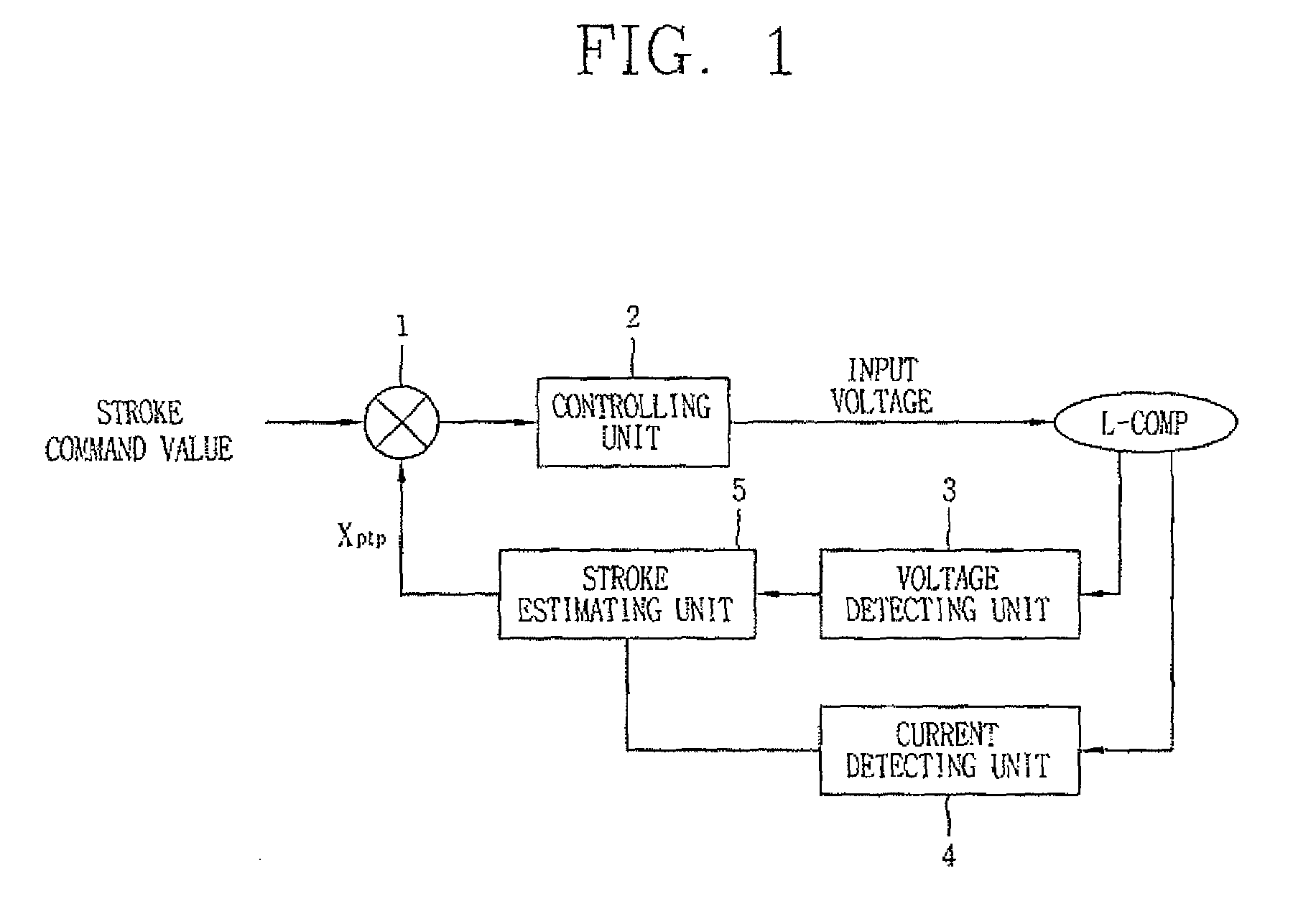

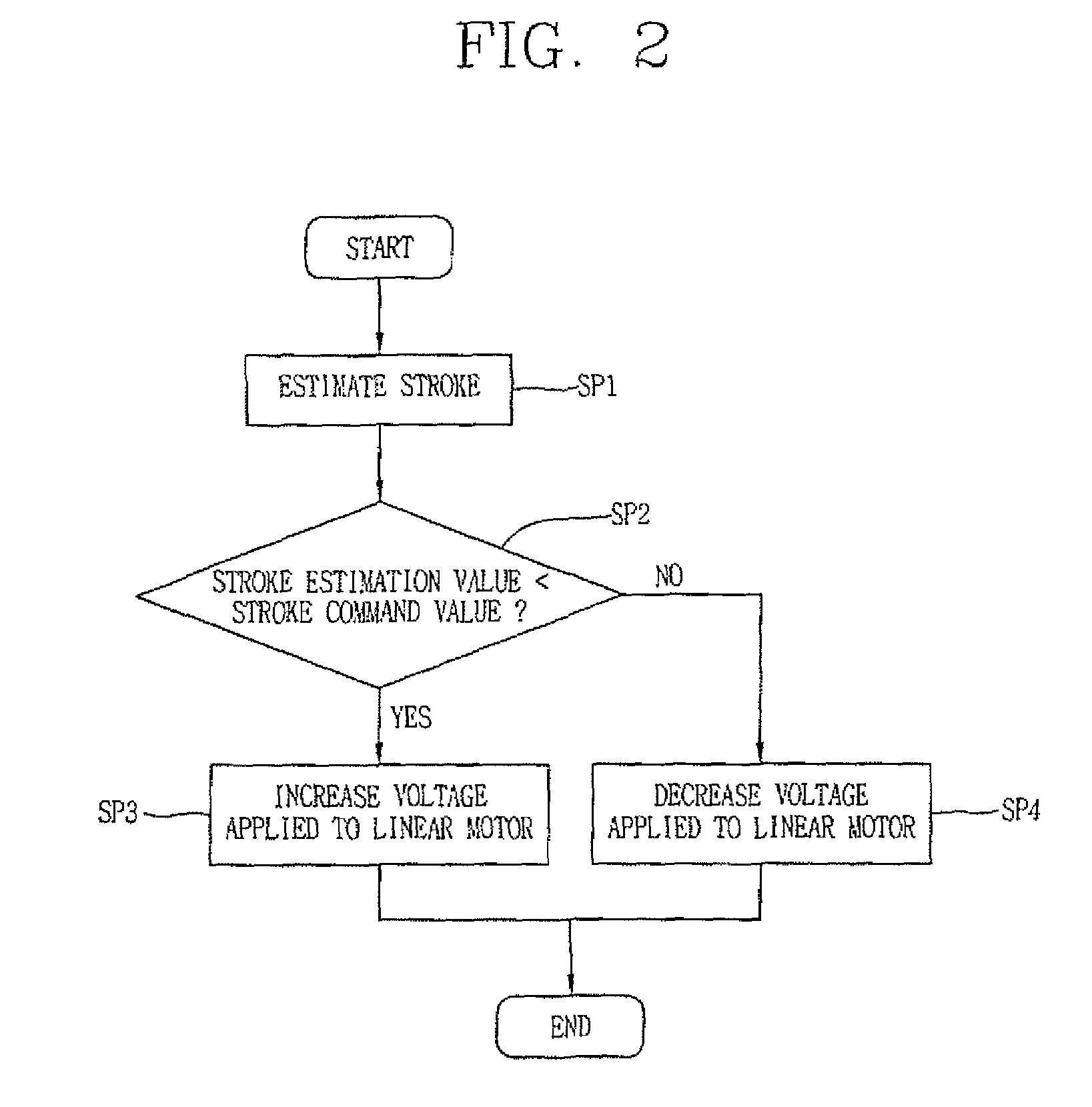

Apparatus and method for controlling driving of linear motor

InactiveUS6998736B2Increase efficiency of linearMotor/generator/converter stoppersDC motor speed/torque controlControl signalLinear compressor

Owner:LG ELECTRONICS INC

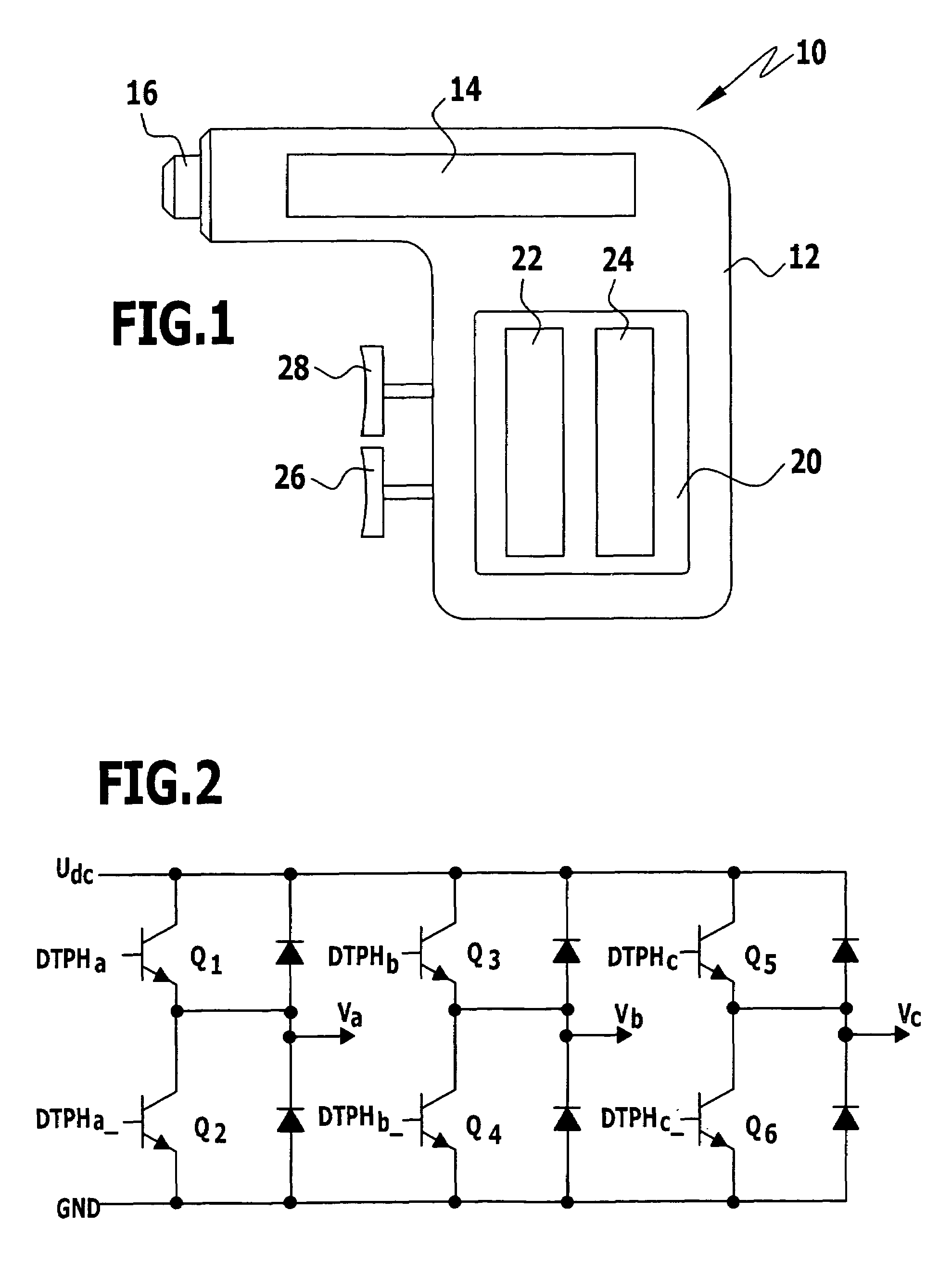

Powered Hand Tool

The invention relates to a hand tool for use with attachments. The hand tools of the invention may be used with attachments with various speed and torque requirements. Preferred hand tools comprise a body with a brushless DC motor and means. which control the energisation of the motor. In use the brushless DC motor of the preferred hand tool is electrically supplied to drive a power output means connected to said motor. Another preferred hand tool comprises a body with a motor contained therein, a void space between an internal surface of the body and at least a part of the motor, a fluid inlet port provided and a fluid outlet port provided in or on the body, and ducting means which provides a channel for fluid supplied via the fluid inlet port to and from the void space and then on to the fluid outlet port.

Owner:IBEX INDS

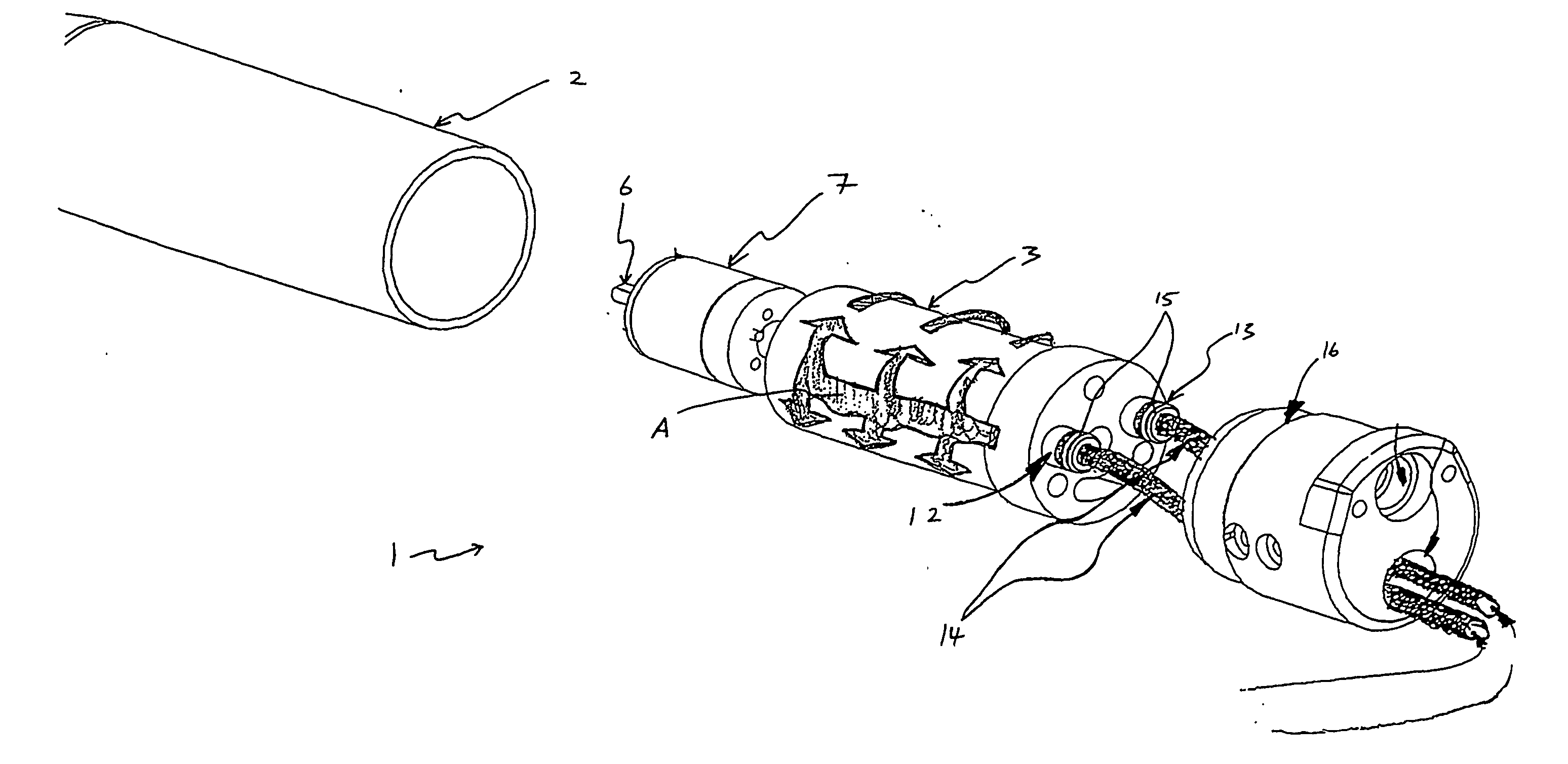

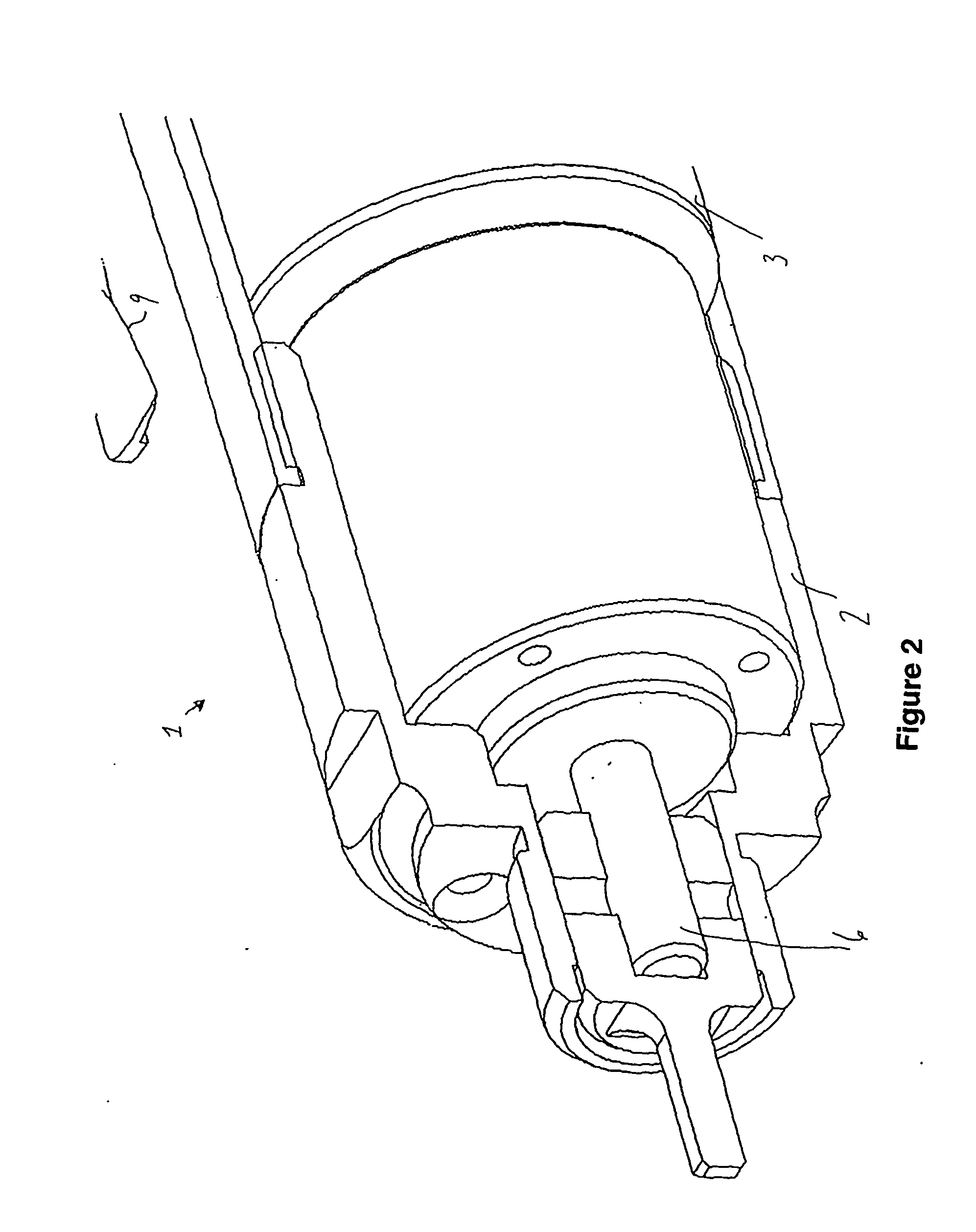

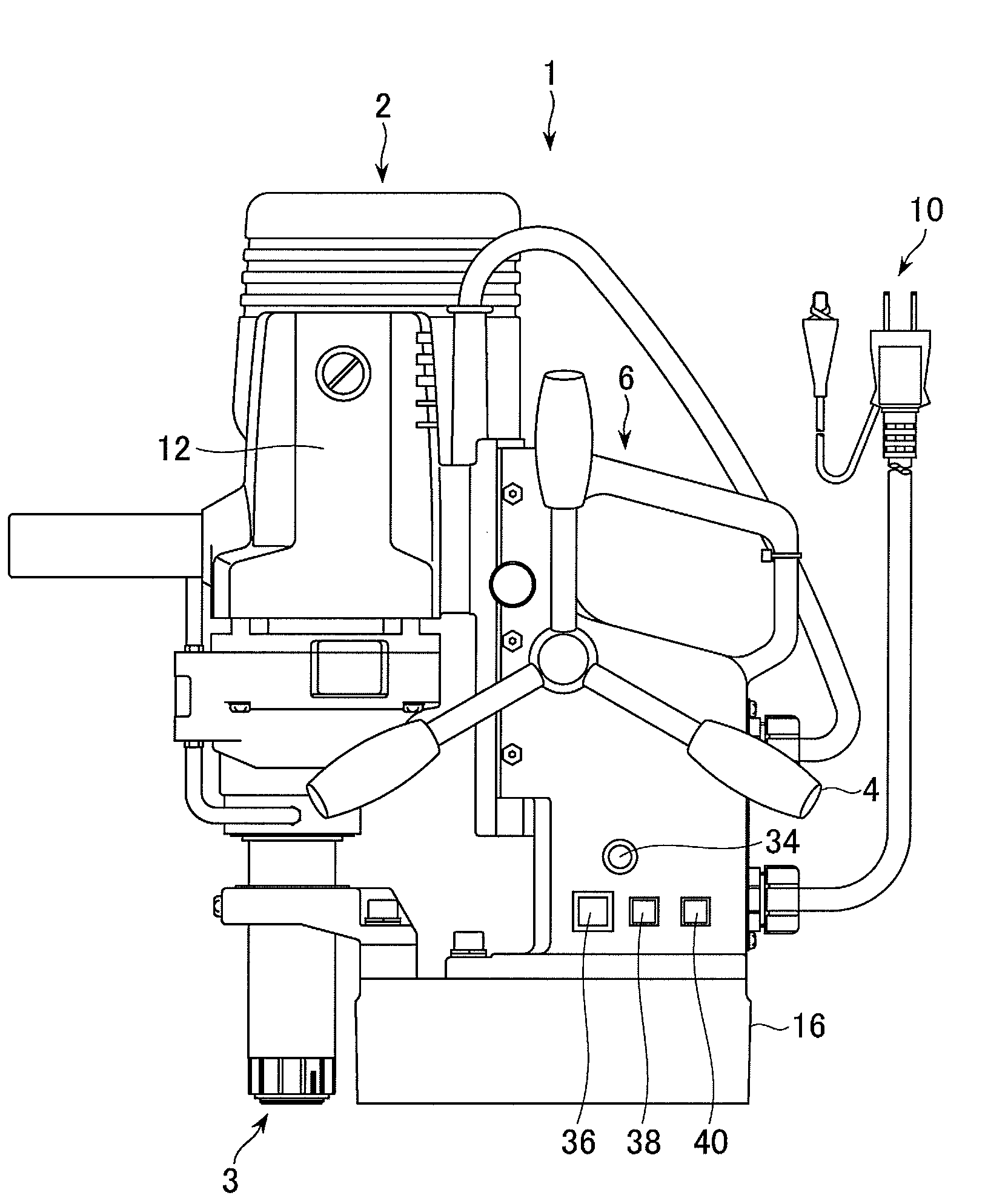

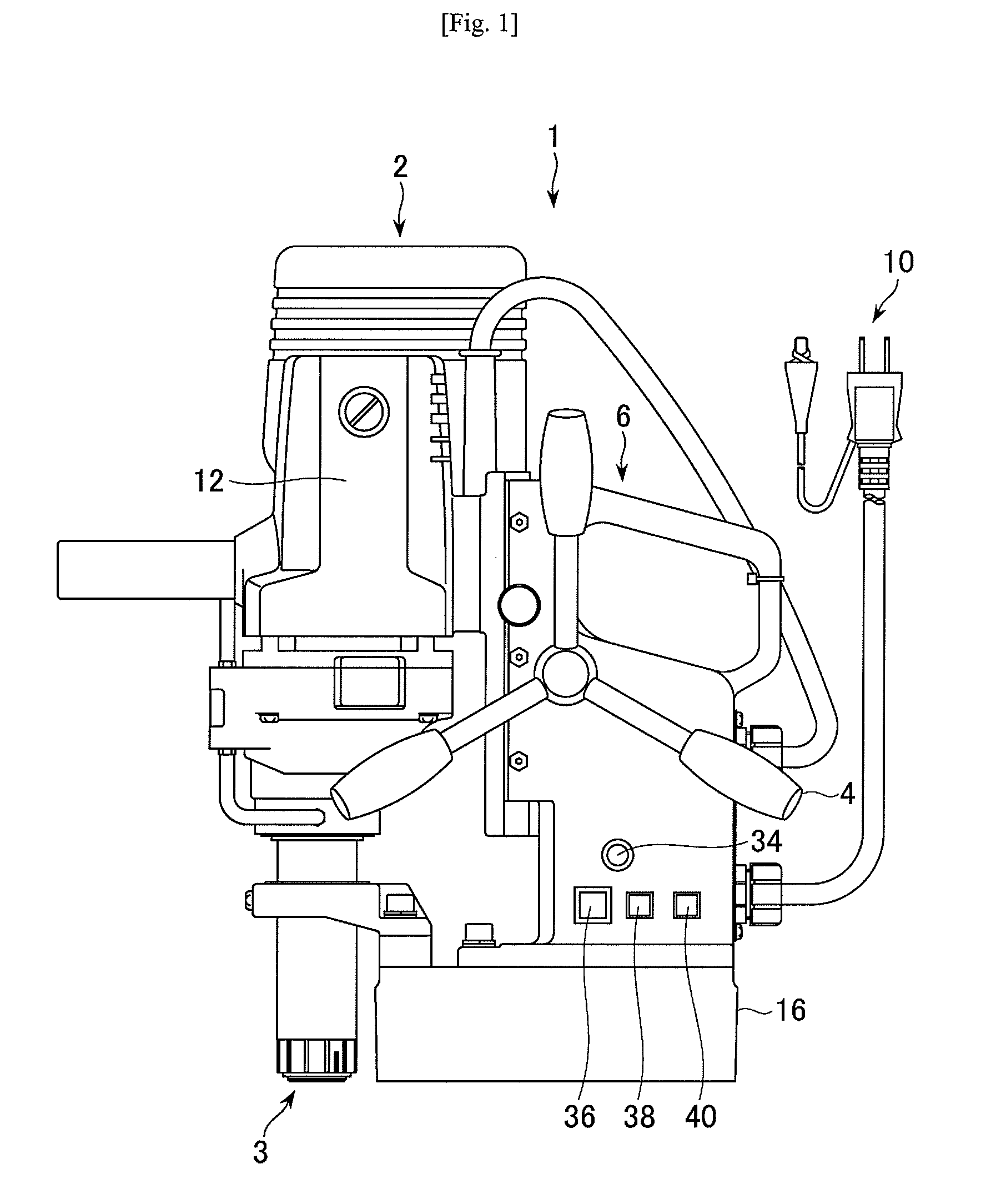

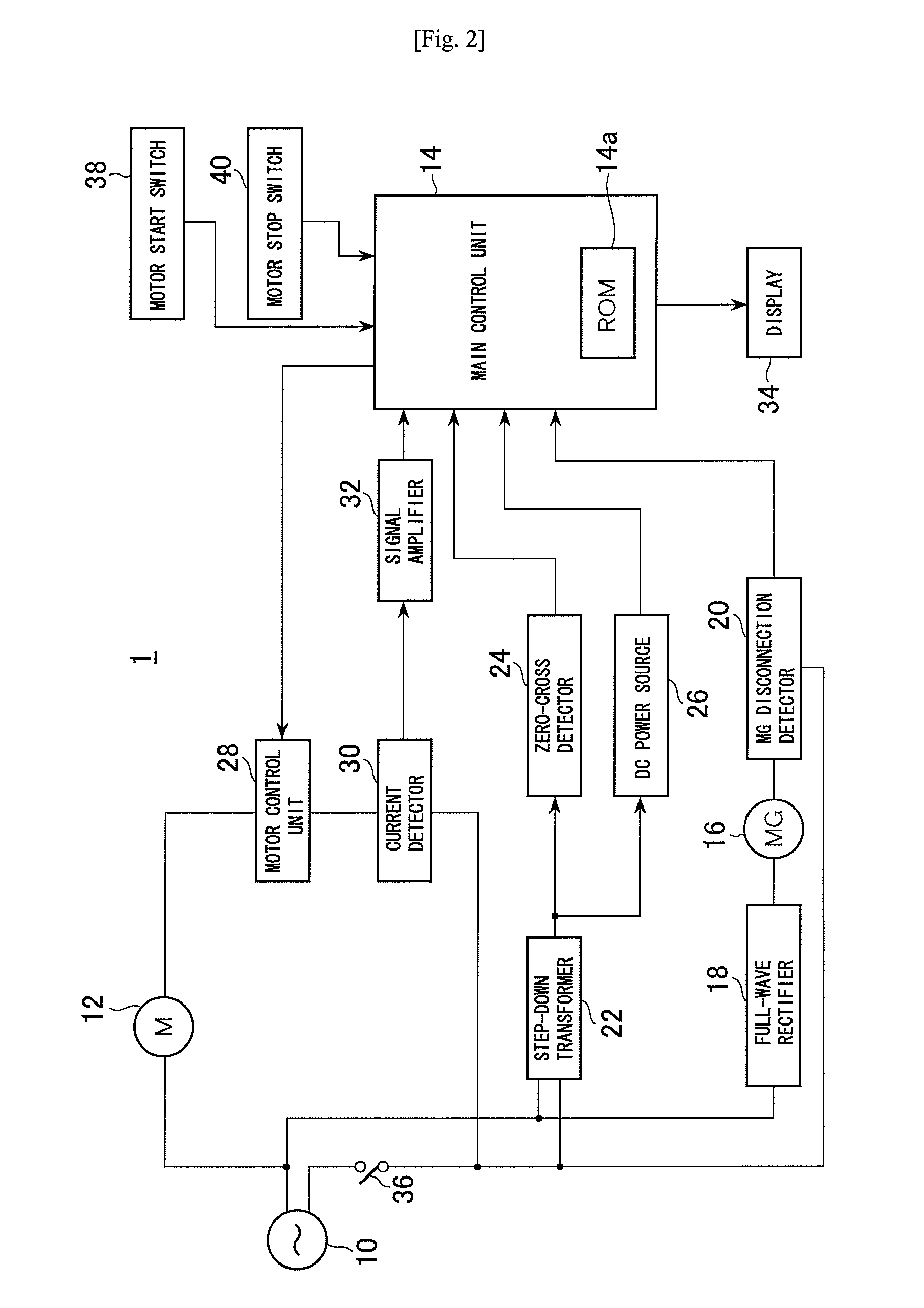

Portable drilling device

ActiveUS7936142B2Easy to operateImprove securityAC motor controlDC motor speed/torque controlFull waveEngineering

A drilling device prevents recurrence of an overload condition after occurrence of the overload condition, thereby improving operability and safety in the drilling device. A motor for rotating a drill is connected to an AC power source through a motor control unit, a current detector, and a power switch. A magnet is also connected to the AC power source through the power switch and a full-wave rectifier. The motor control unit rotationally drives the motor on the basis of a signal sent from a main control unit according to a state in which a motor start switch is on. The main control unit controls the motor control unit to gradually reduce a supply voltage to the motor when the motor becomes overloaded, to gradually increase the voltage to the normal power supply condition when the overload condition is vanished, and to stop power supply to the motor if the overload condition continues for a predetermined period.

Owner:NITTO KOHKI CO LTD

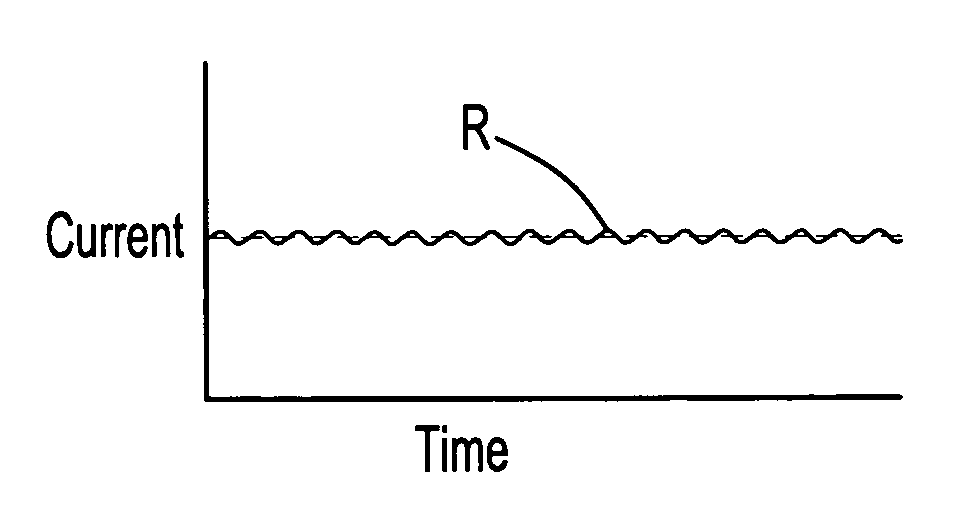

Brushed motor position control based upon back current detection

InactiveUS20060261763A1Exact numberStop preciseElectronic commutation motor controlMotor/generator/converter stoppersReverse currentEngineering

Owner:MASCO CORP

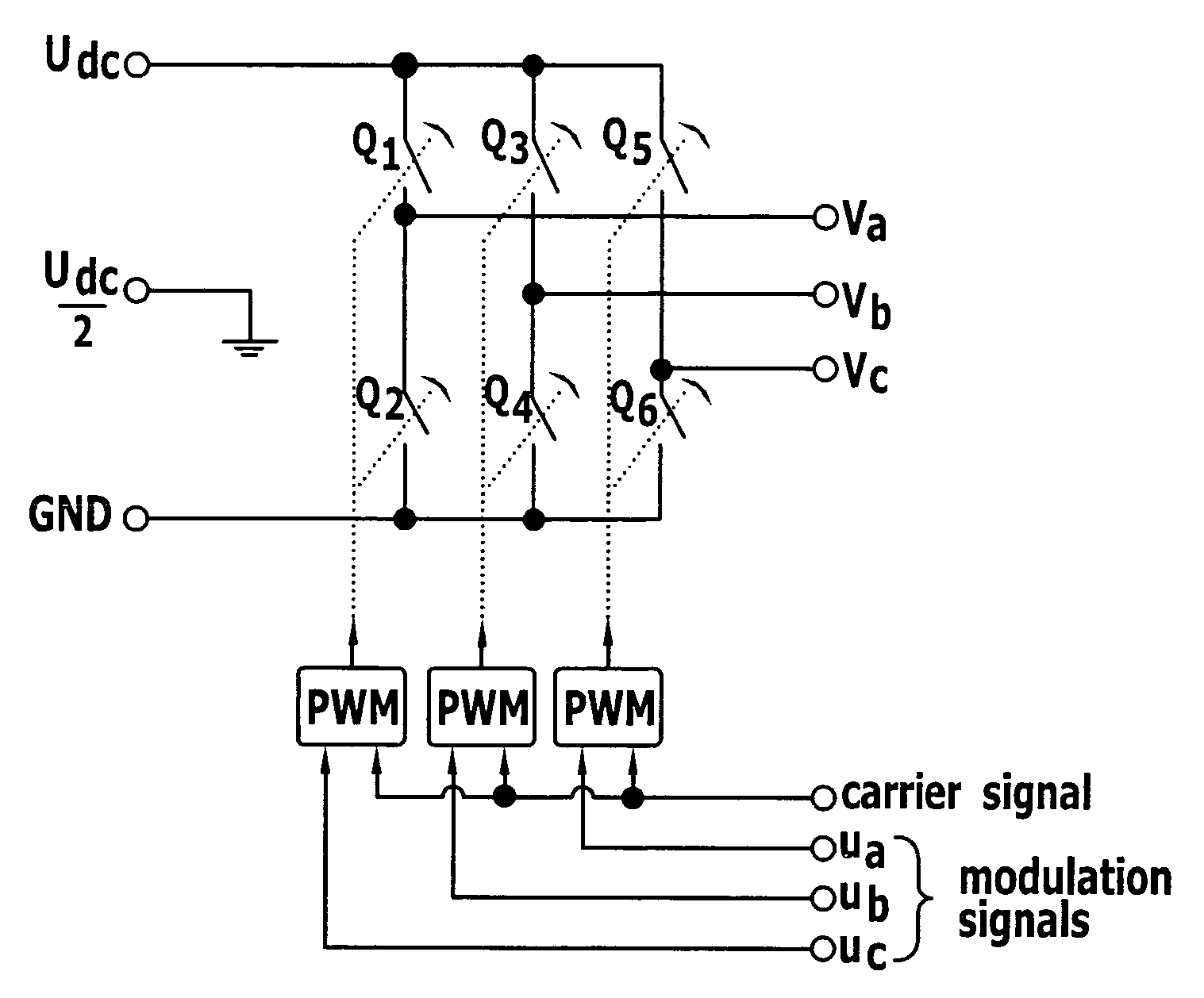

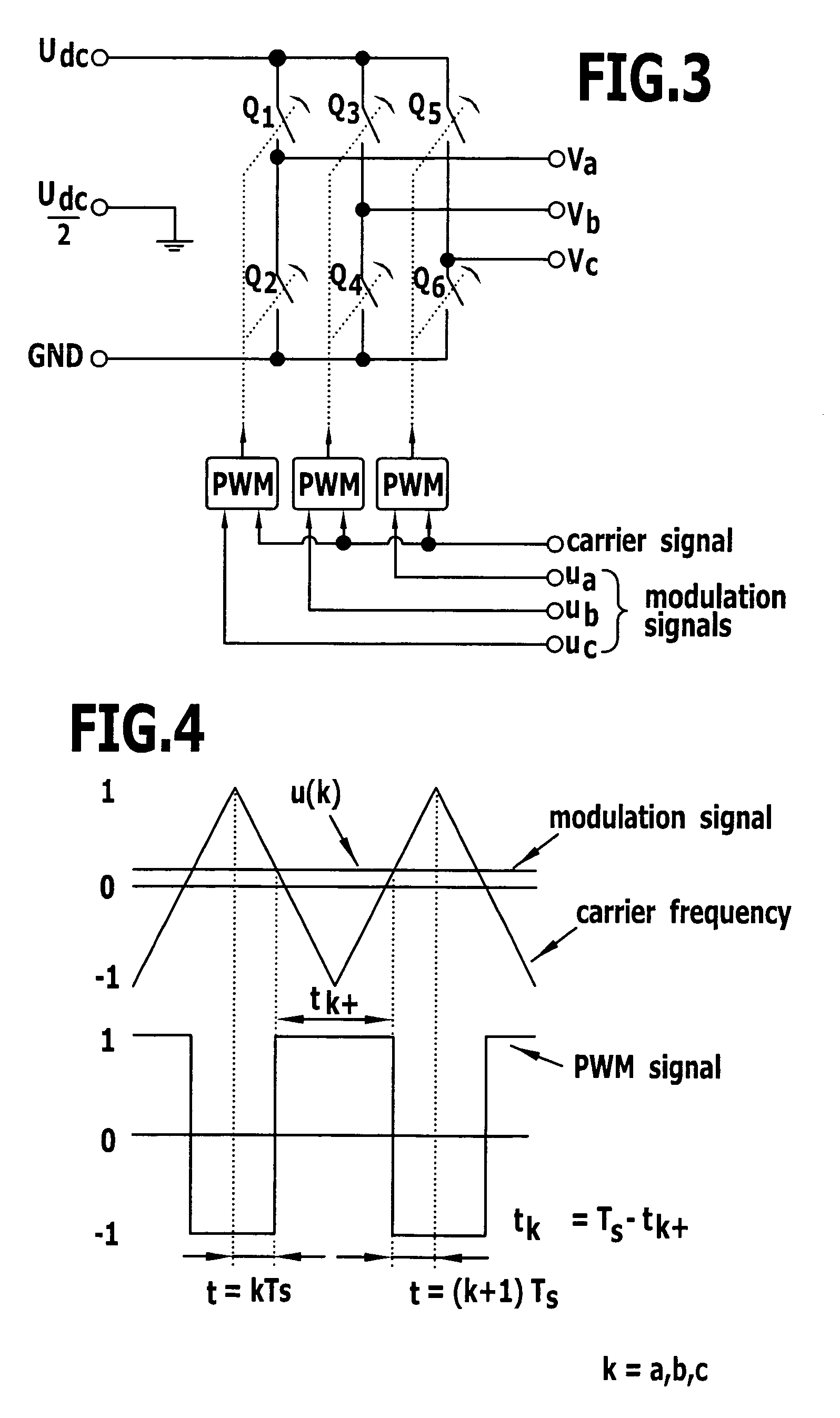

Surgical machine and method for controlling and/or regulating a surgical machine

ActiveUS7362062B2Guaranteed uptimeEasy to startElectronic commutation motor controlDC motor speed/torque controlMotor controllerControl theory

To improve a surgical machine with a sensorless electric motor comprising a rotor and at least two motor windings, and with a motor controller for controlling and / or regulating the electric motor, so that the electric motor is operable with optimum efficiency at low rotational speeds and a starting of the motor in accordance with the purpose, also under load, is enabled, it is proposed that a space vector pulse width modulation (SVPWM) method for controlling and / or regulating the electric motor, in which all motor windings are able to be simultaneously supplied with electric current, be performable with the motor controller. A method for controlling and / or regulating a surgical machine is also proposed.

Owner:AESCULAP AG

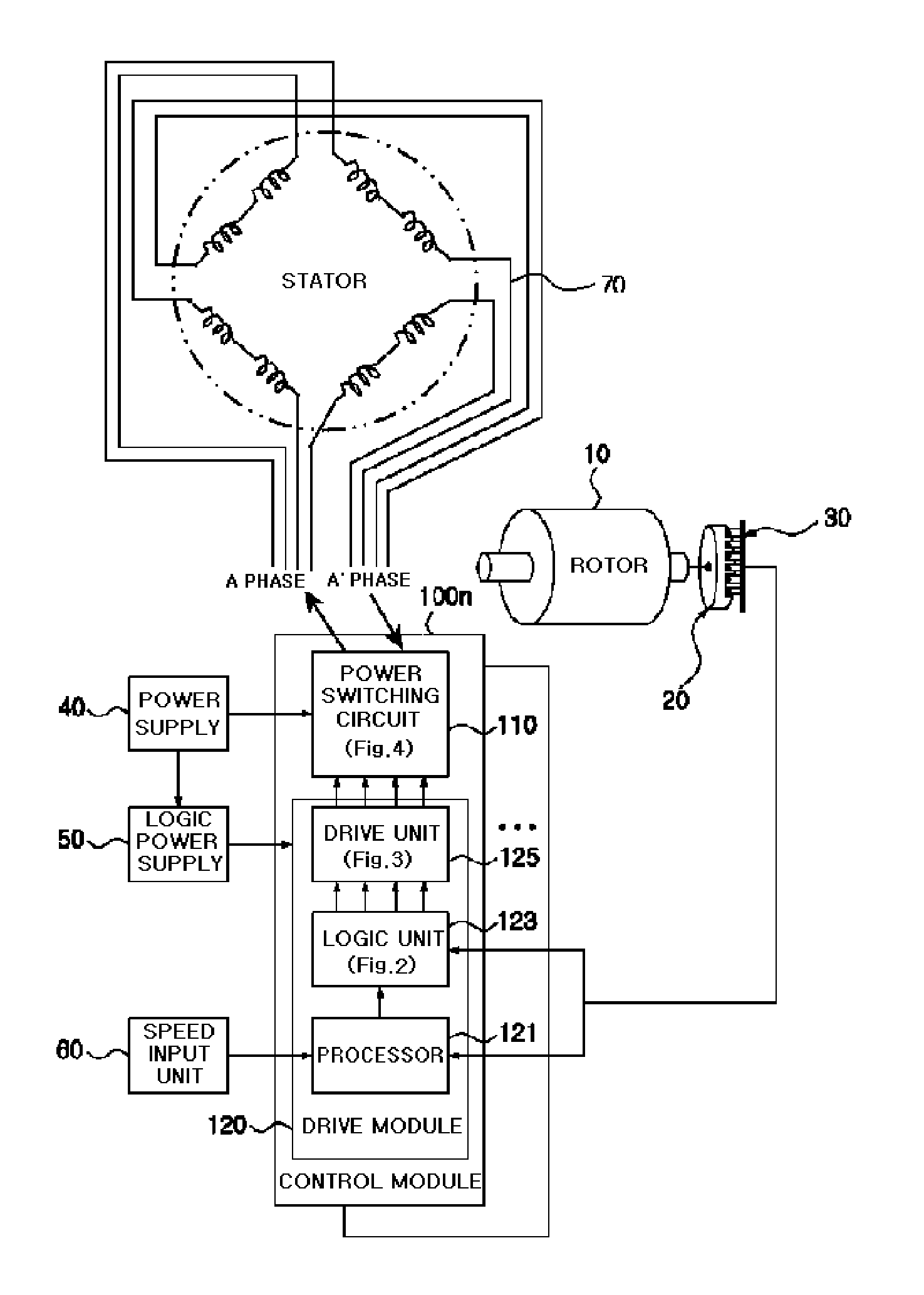

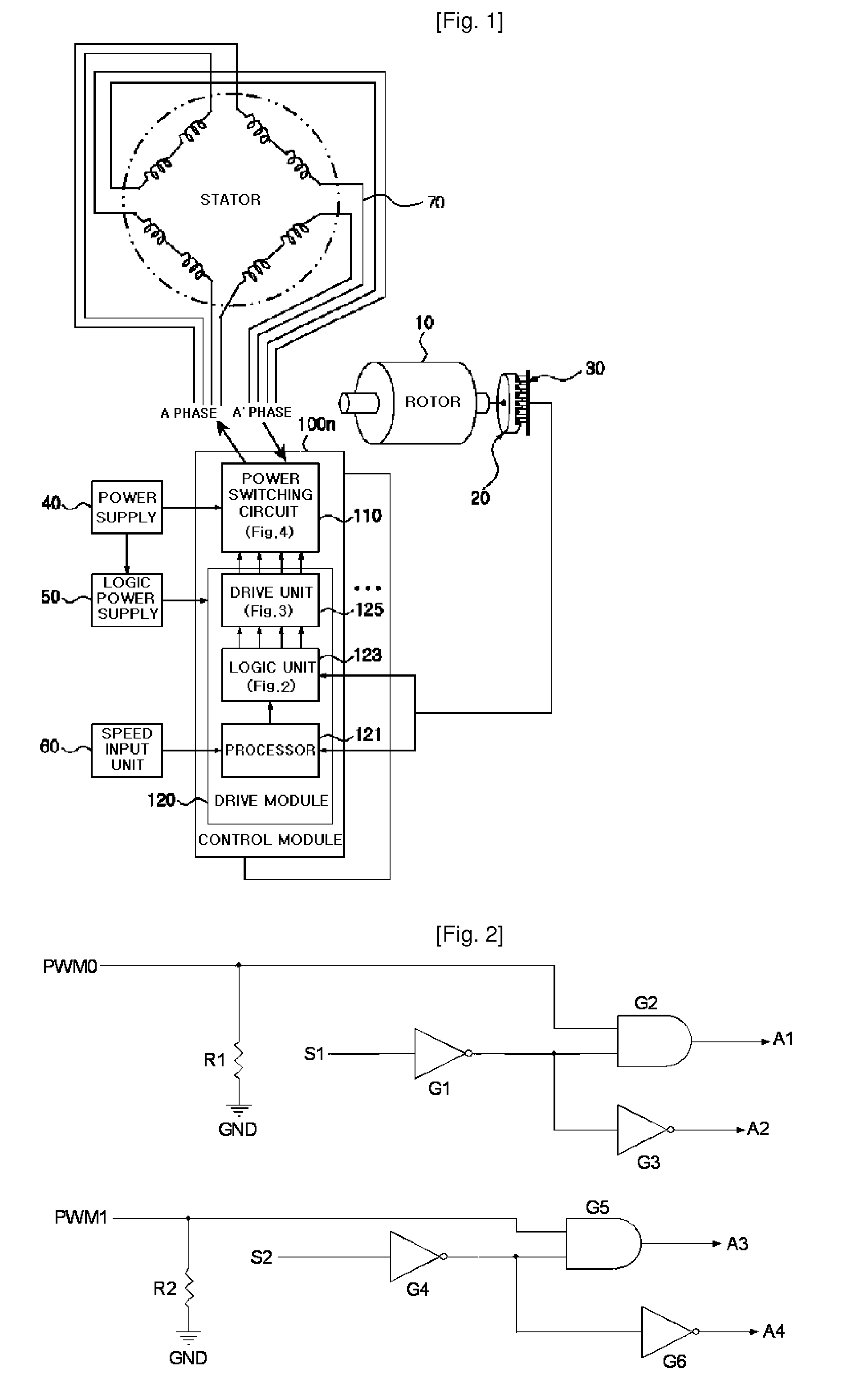

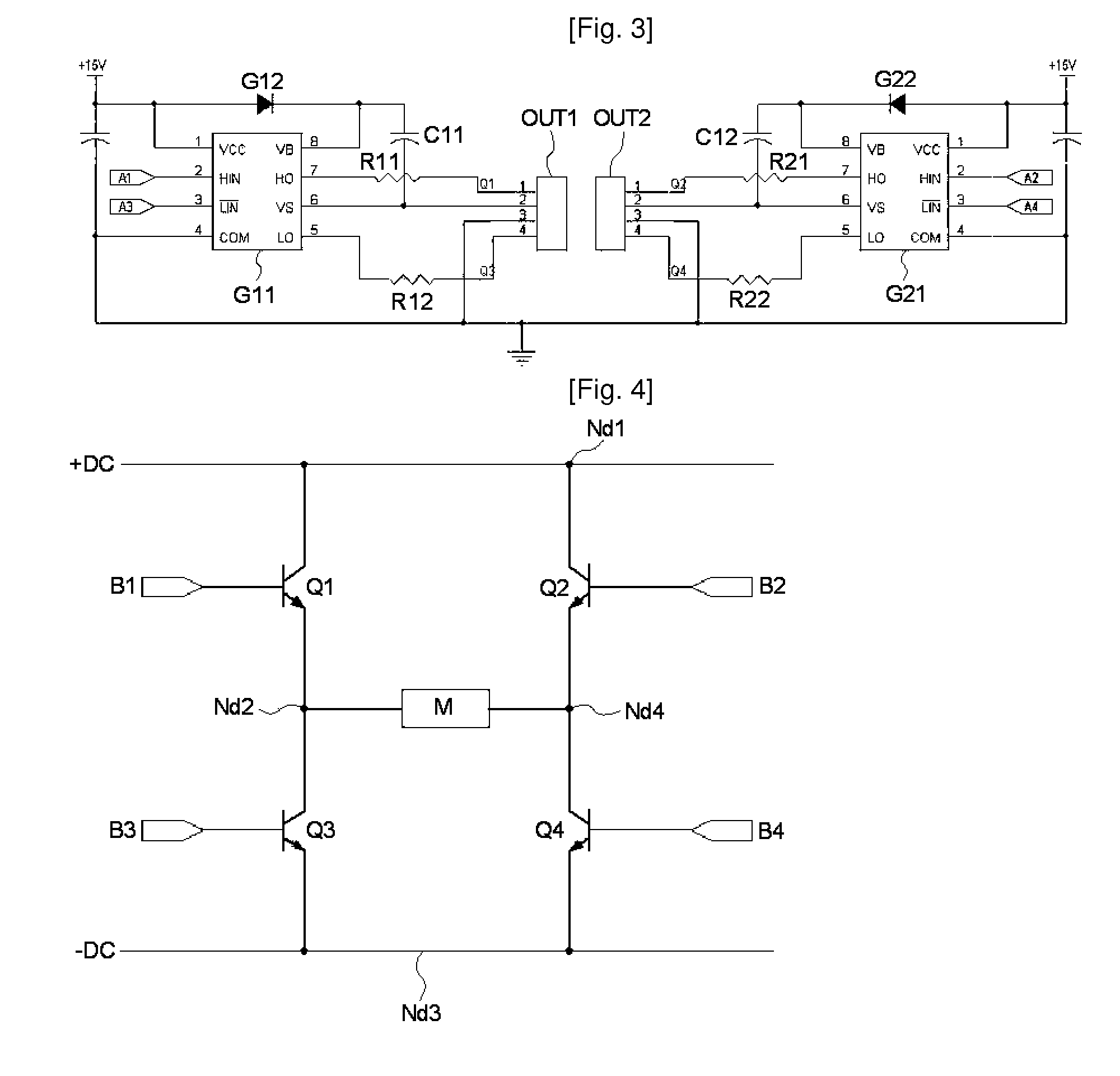

Apparatus and method for controlling hybrid motor

ActiveUS8228020B2Reduce capacityReduce electricity loadSingle-phase induction motor startersWindingsDriver circuitPower switching

An apparatus and method for controlling a hybrid motor, The hybrid motor, uses a permanent magnet instead of a field coil for a rotor, winds a coil round a stator in a multi-phase independent parallel manner, fixes a rectifying type encoder to the rotor and connects a sensor to a driving circuit. The apparatus comprises: an encoder attached to a rotor in cooperation with a pole sensor a speed input unit for generating a speed instruction signal a power switching circuit to generate motor driving signals; a drive module receiving the speed instruction signal and the sensor signal and outputting the speed instruction signal synchronized with the sensor signal as a driving motor signal; a power supply for applying a DC voltage to the power switching circuit; A logic power supply for converting the DC voltage into a logic voltage, and applying logic voltage to the drive module. The motor has n phases, n power switching circuits and n drive modules.

Owner:NAMYANG NEXMO CO LTD

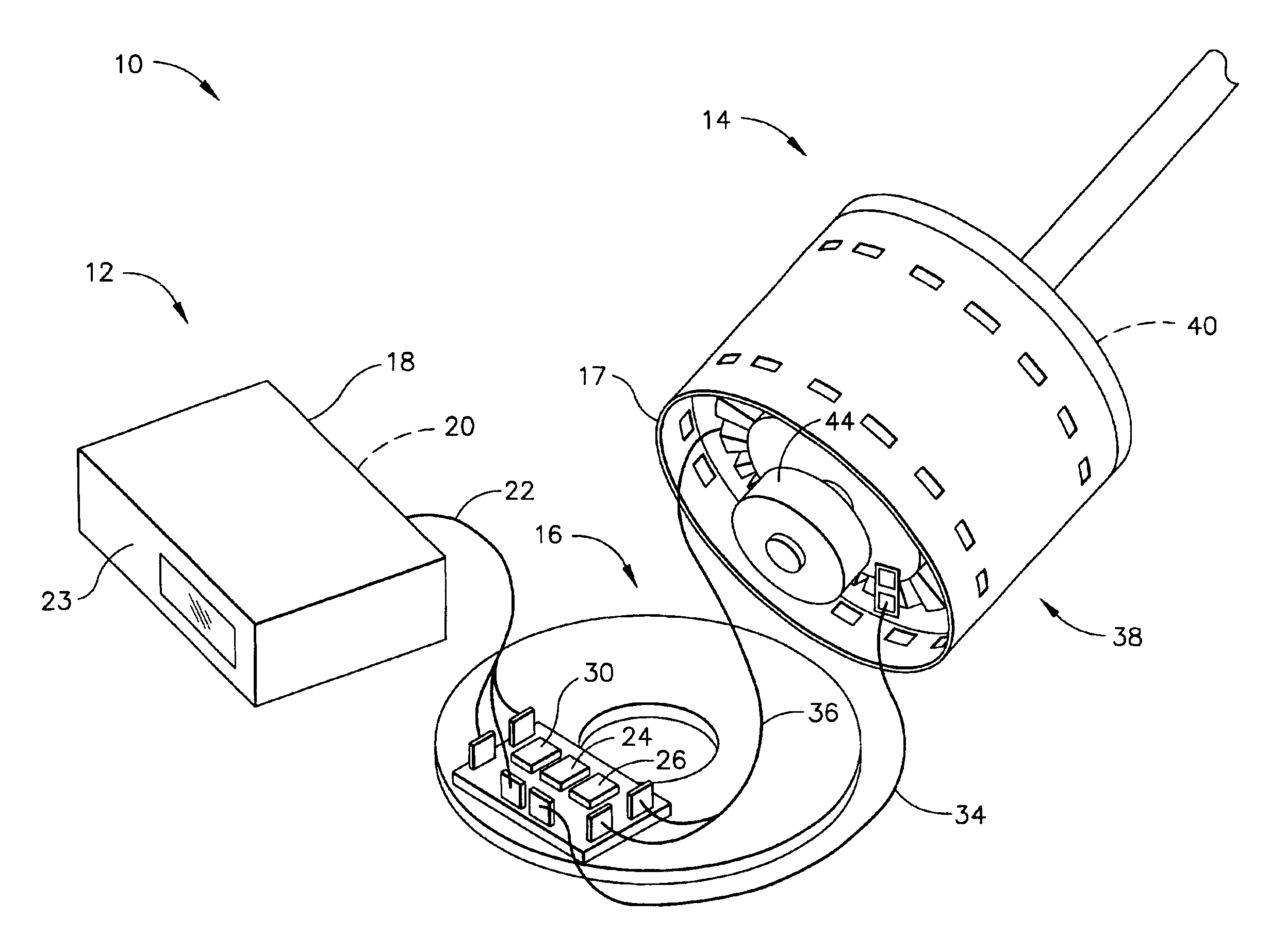

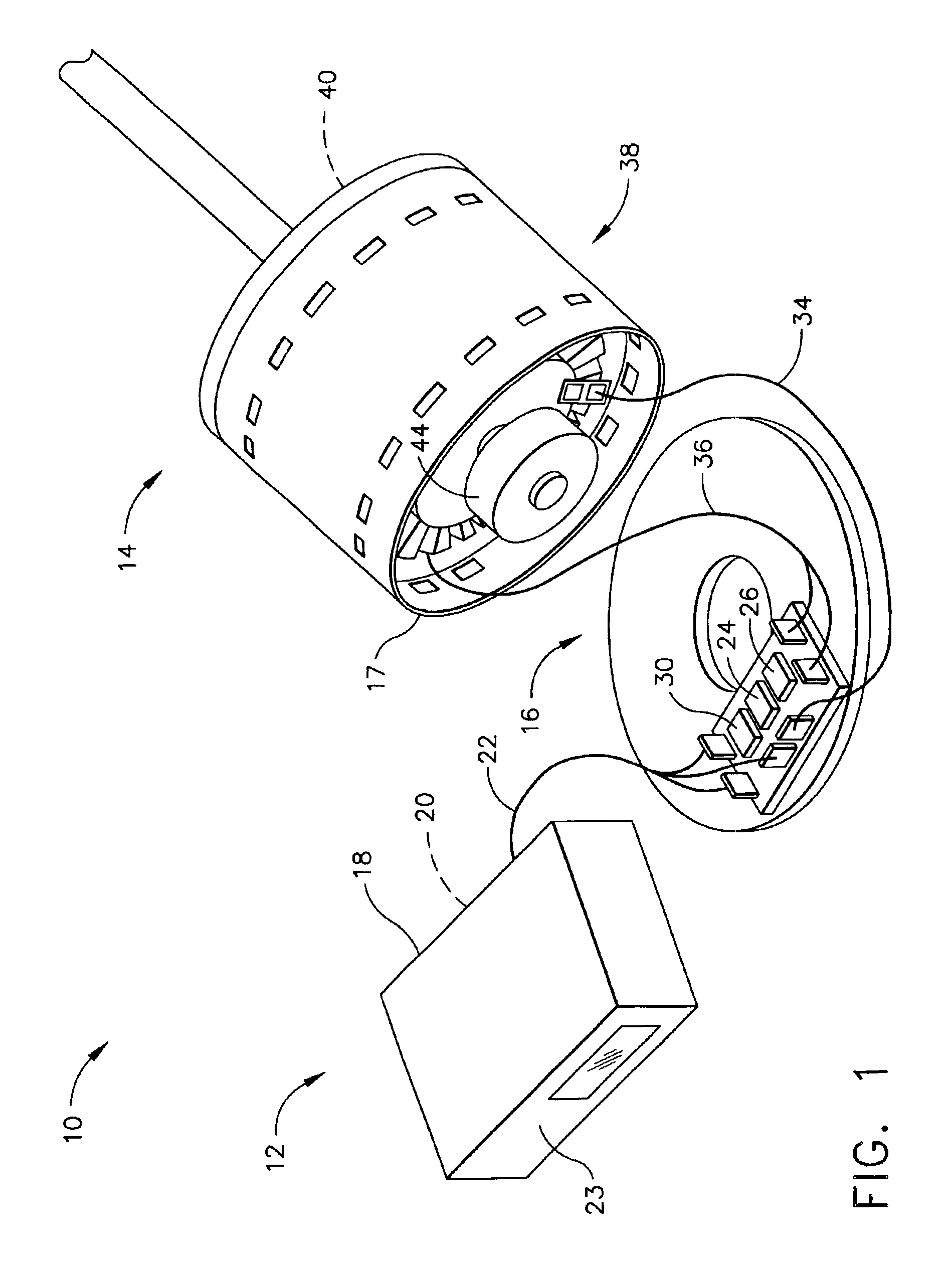

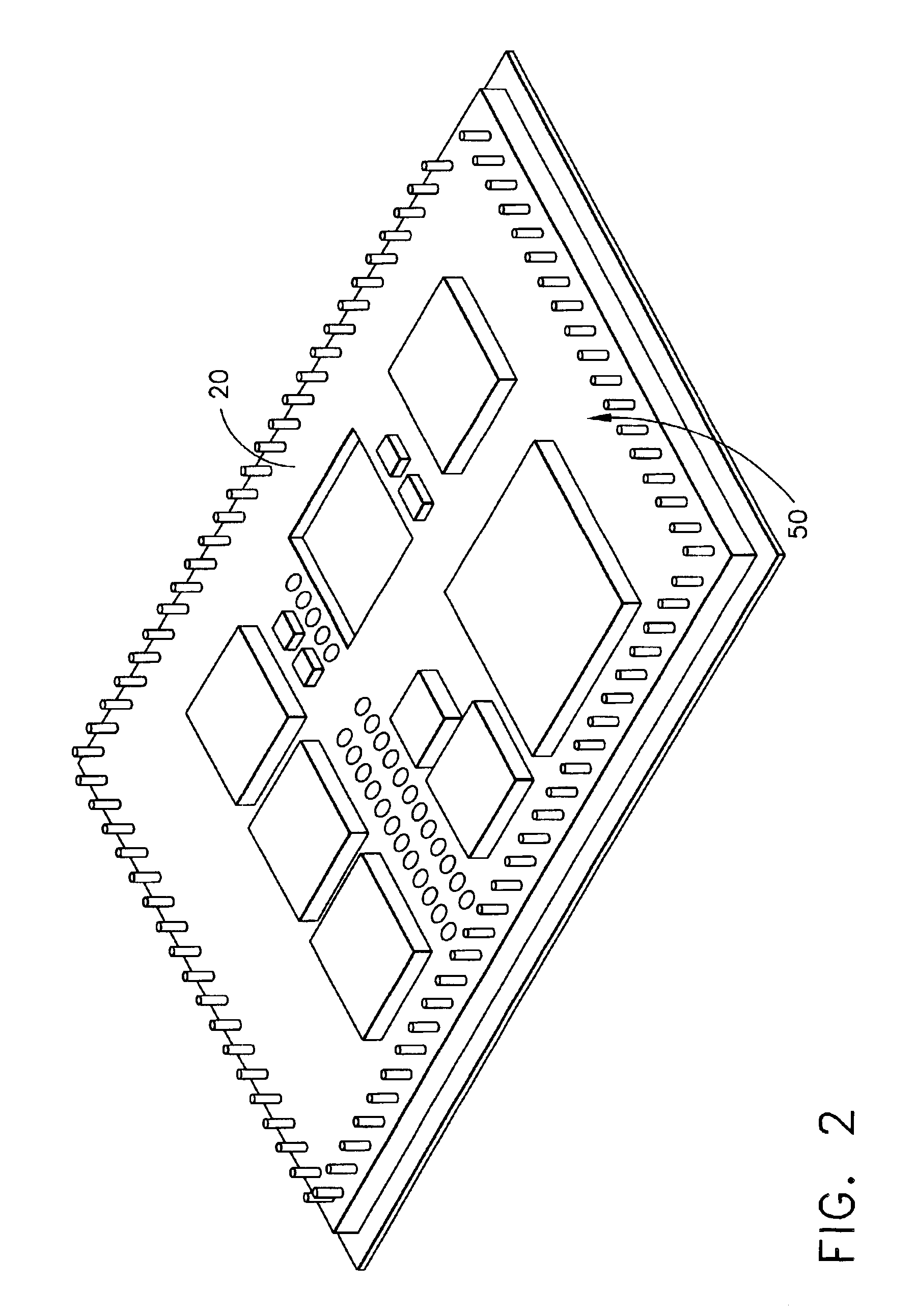

Method and apparatus for controlling electronically commutated motor operating characteristics

InactiveUS6895176B2Operation controlSingle-phase induction motor startersAC motor controlBrushless motorsControl electronics

A permanent magnet DC brushless motor control assembly permits a user to select the permanent magnet DC brushless motor operating characteristics by selecting appropriate control circuits to interface with the motor. The assembly includes a permanent magnet DC brushless motor, a commutator electrically coupled to the motor, and at least one control module electrically coupled to the commutator, to control operating characteristics of the permanent magnet DC brushless motor.

Owner:REGAL BELOIT AMERICA

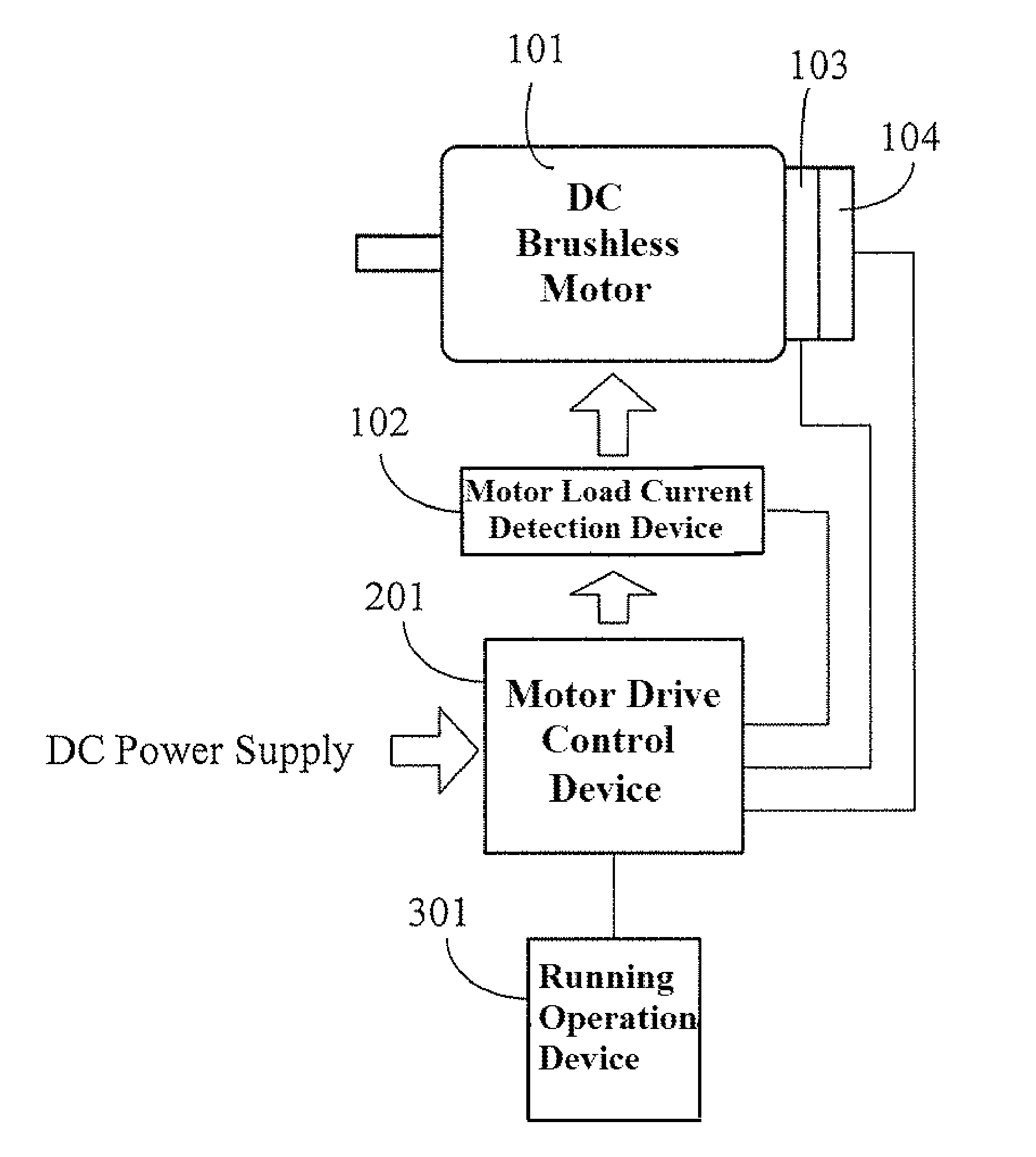

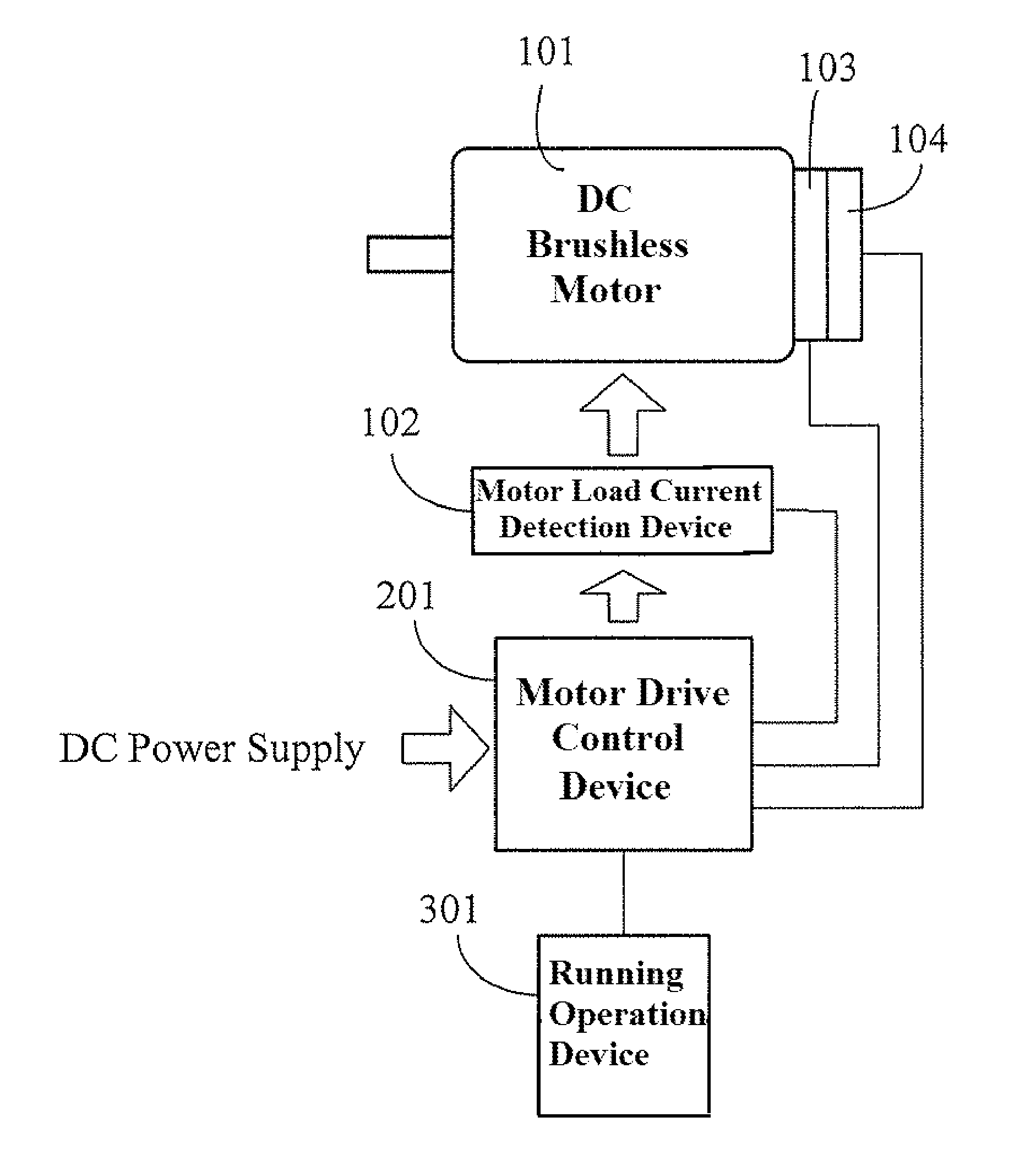

DC brushless motor drive circuit with speed variable-voltage

ActiveUS8288984B2Increase inputOvercome increased inductive impedanceTorque ripple controlMotor/generator/converter stoppersBrushless motorsMotor drive

For the present invention, under various running speeds statuses, the voltage supplied to the DC brushless motor is relatively increased or decreased on the basis of the internal setting of the motor drive control device according to the increased or decreased rotational output speed, so as to prevent the shortcoming of too much variation of the input impedance caused by the inductive reactance of the winding accordingly changed when the speed of the DC brushless motor is changed, specifically, to prevent the shortcoming of unable producing required torque resulting from the increased inductive reactance caused by increasing the rotational speed which makes the current value become too low when input by the original working voltage.

Owner:YANG TAI HER

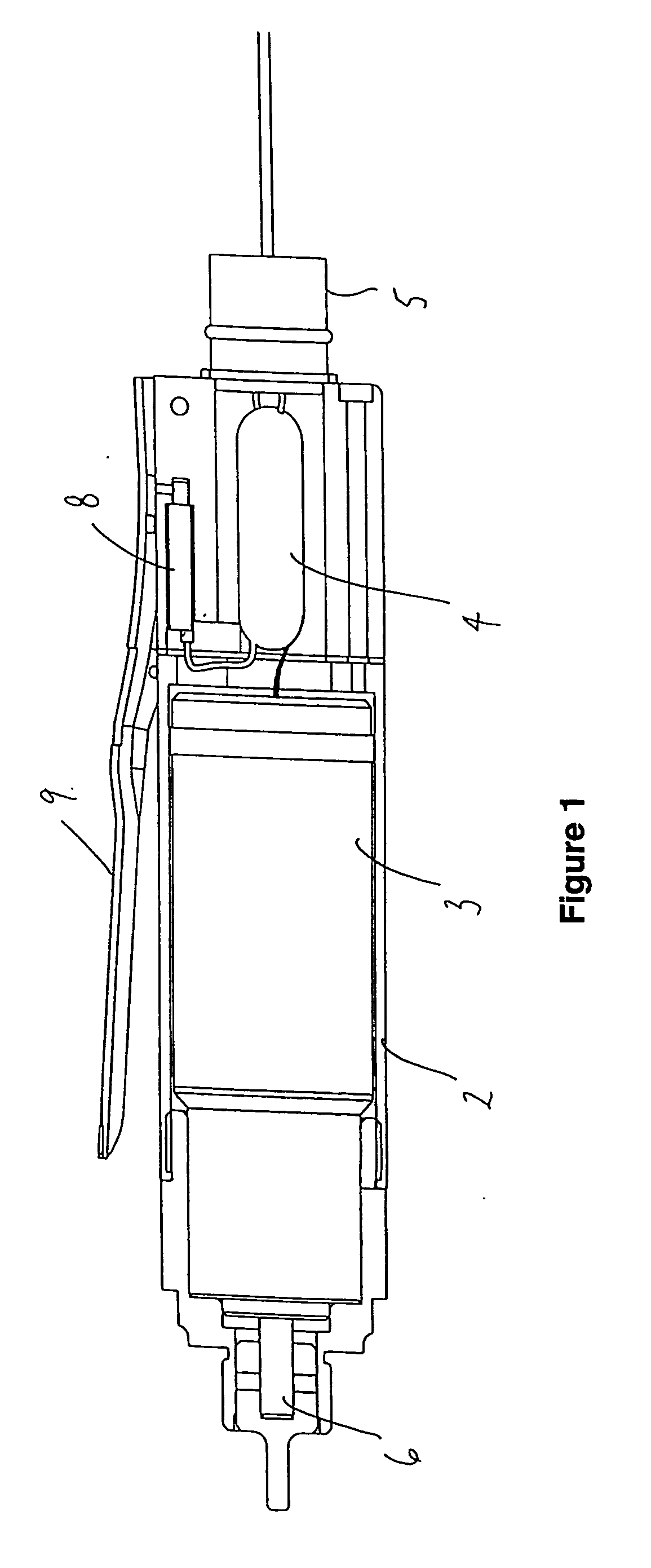

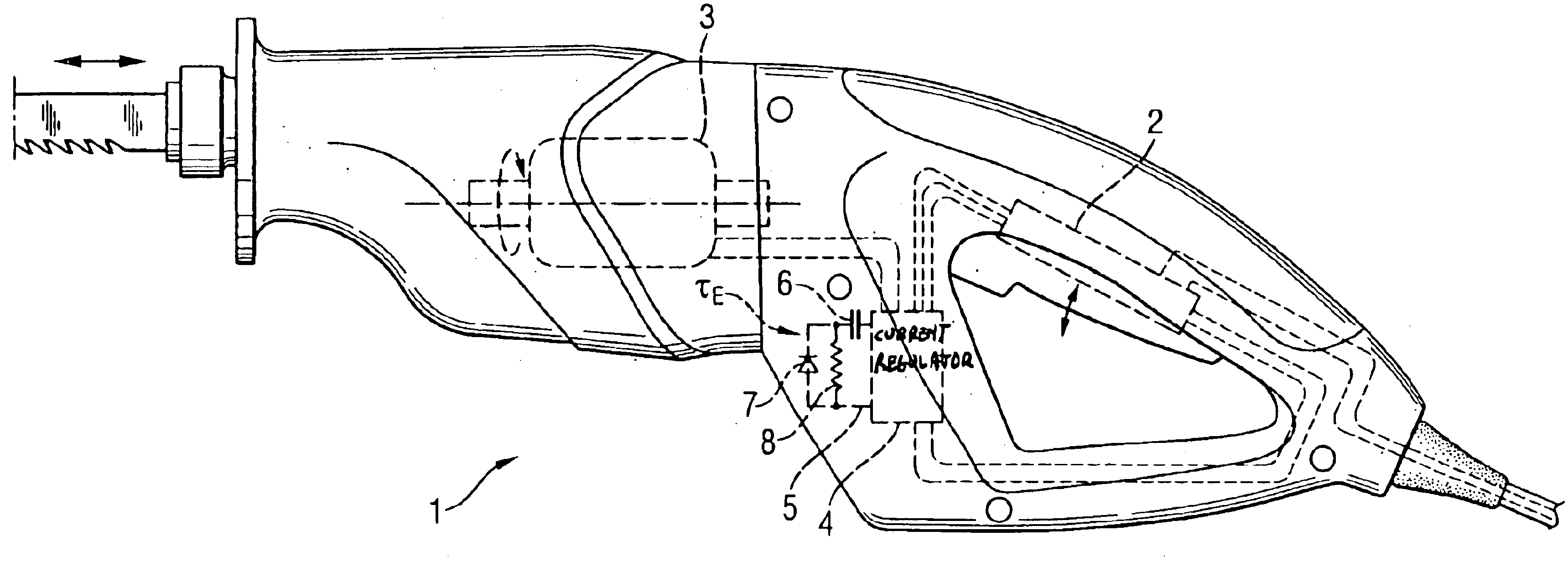

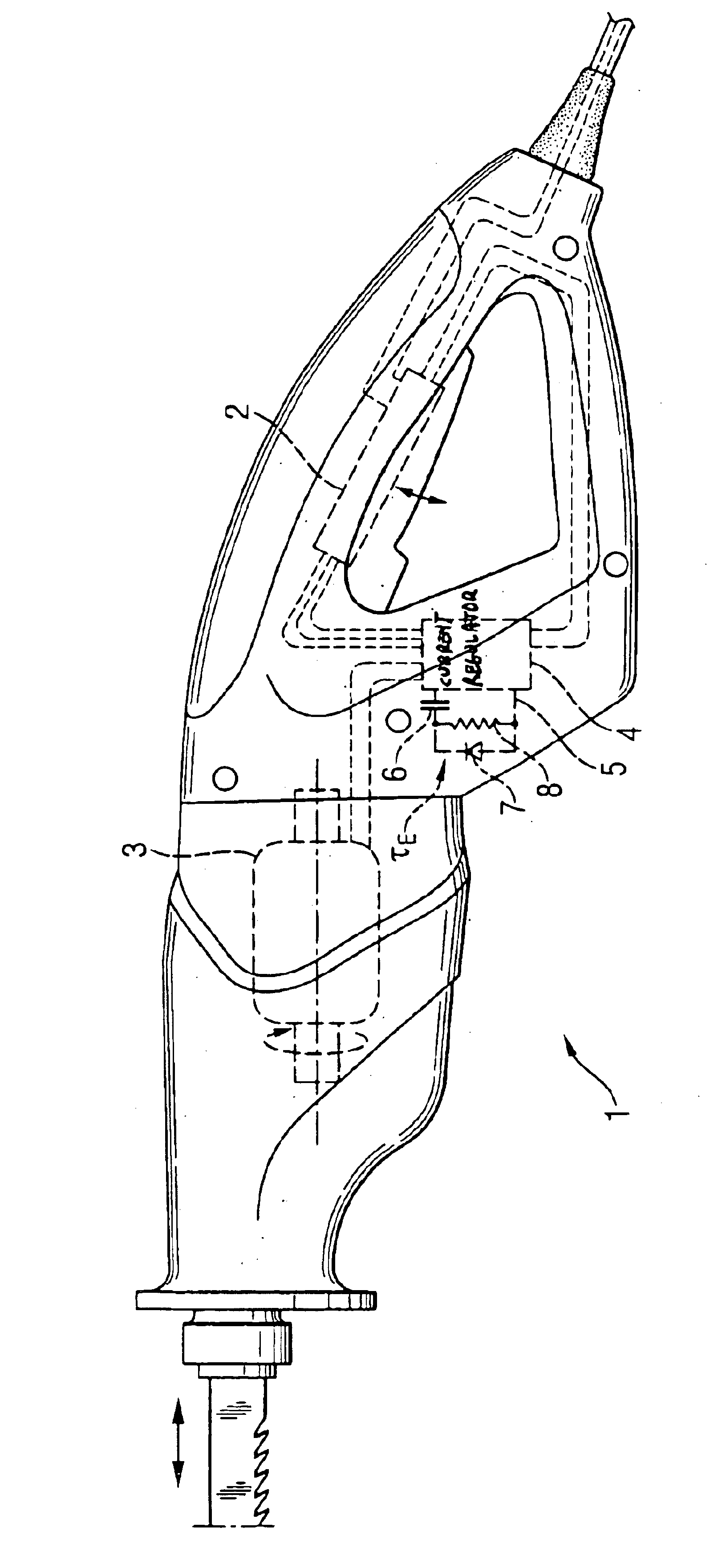

Electrical hand tool machine with soft-start

An electrical hand tool machine (1) having a motor switch (2) configured as a button and a current regulator (4) disposed in the current circuit of an electrical motor (3), having a soft-start input (5), in whose branch current a timing capacitor (6) is arranged. A current-direction-dependent element (7) is arranged between the soft-start input (5) and the capacitor (6).

Owner:HILTI ELLSCHAFAT

Forward and reverse motor for improving forward and reverse efficiency, and control method thereof

PendingCN109889124ASolve the problem of not being able to achieve high efficiency in both forward and reverse directionsImprove efficiencyAC motor controlPhase differenceControl theory

Owner:GREE ELECTRIC APPLIANCES INC

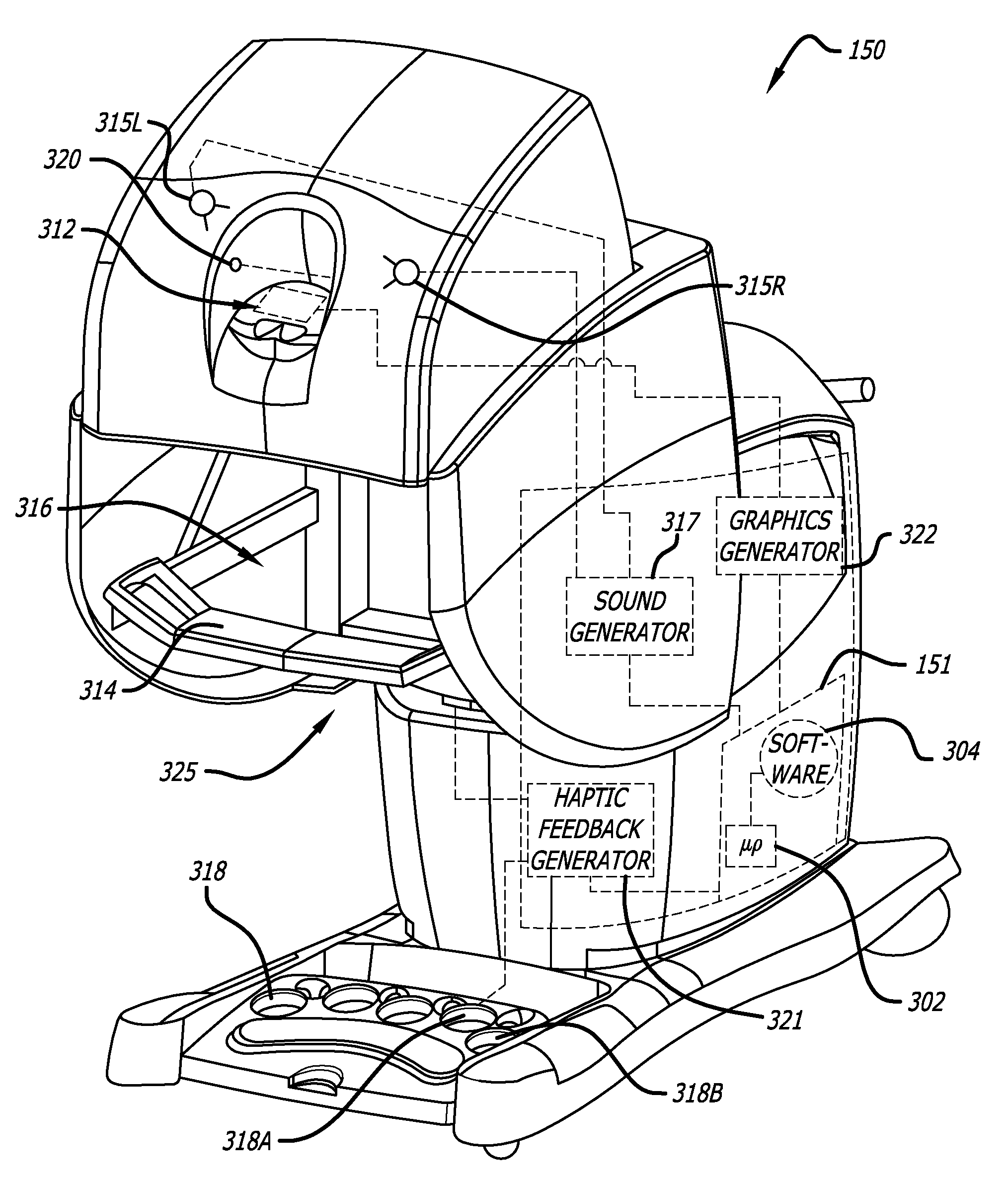

Ergonomic surgeon control console in robotic surgical systems

A control console to remotely control medical equipment is disclosed having a base with an ergonomically adjustable pedal system. The base further has an opening to receive the pedal system. The pedal system includes a moveable pedal tray with a pedal base. The tray includes a first left pedal assembly and a first right pedal assembly, and an upper tier having a second left pedal assembly and a second right pedal assembly respectively in alignment with and elevated above the first left pedal assembly and the first right pedal assembly. Rollers are rotatable coupled to the moveable pedal tray to allow it roll over a floor. A drive assembly is coupled between the moveable pedal tray and the base. The drive assembly applies a force to the to roll the moveable pedal tray over the floor within the opening of the base.

Owner:INTUITIVE SURGICAL +1

Inverter device and air conditioner including the same

Owner:MITSUBISHI ELECTRIC CORP

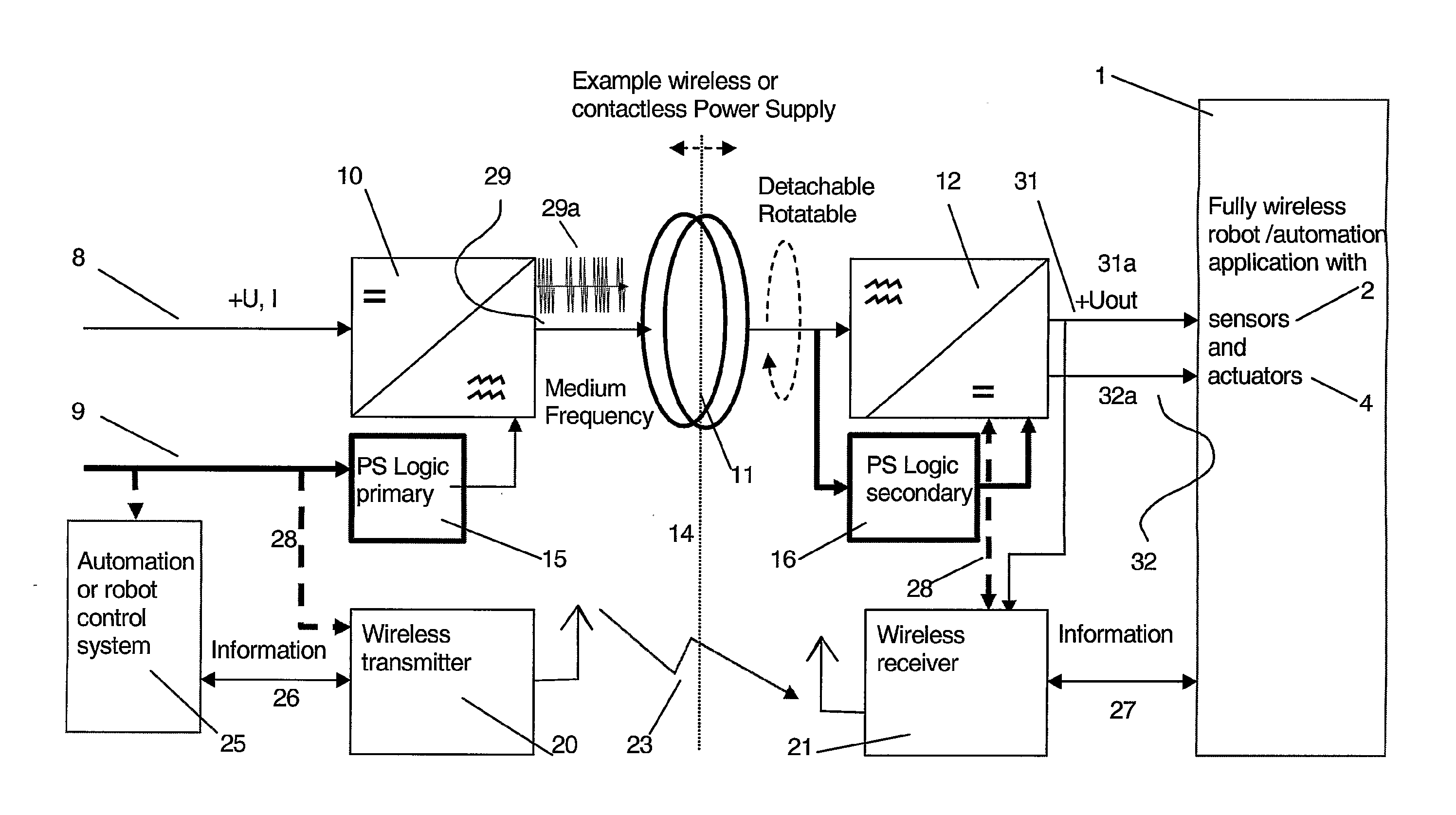

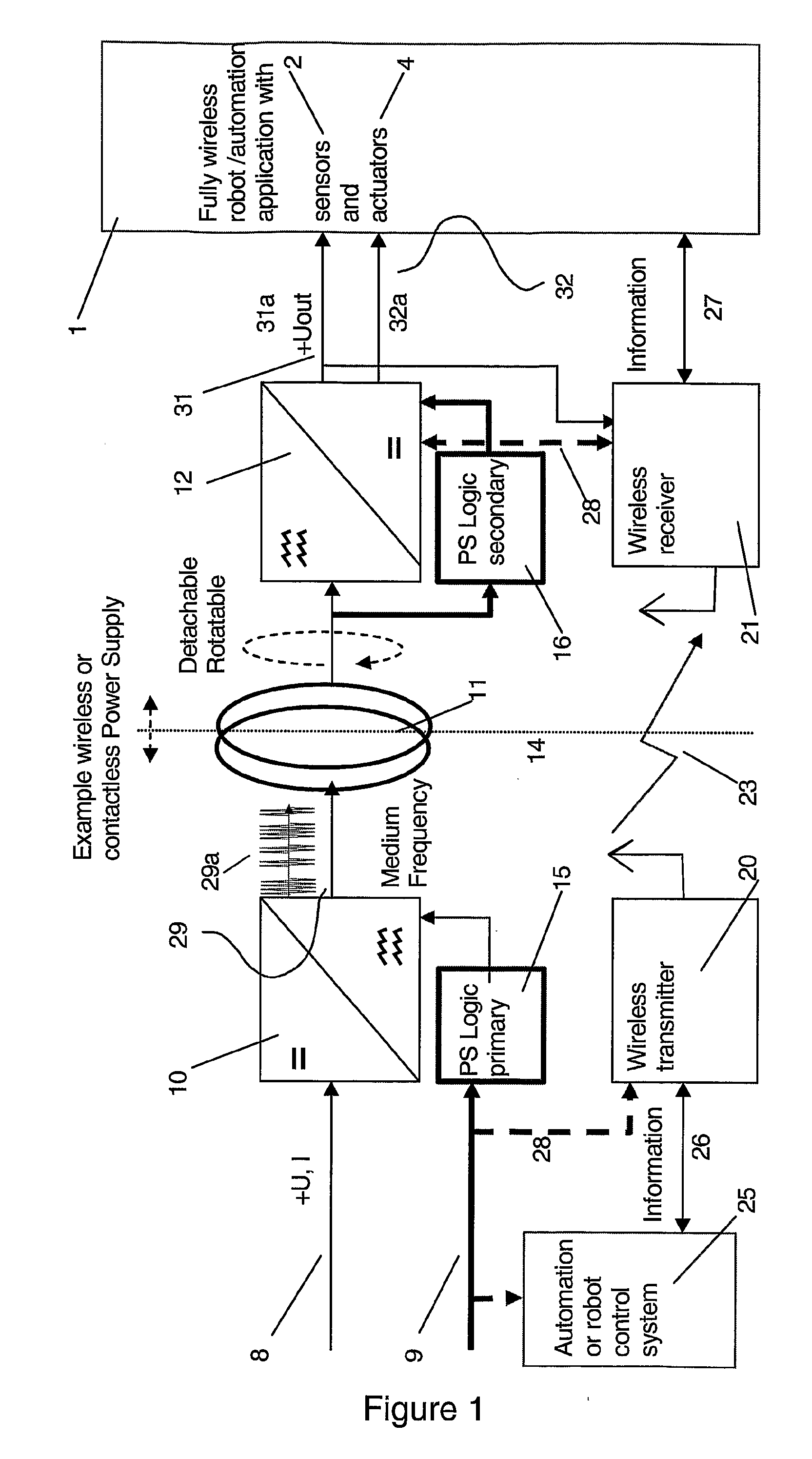

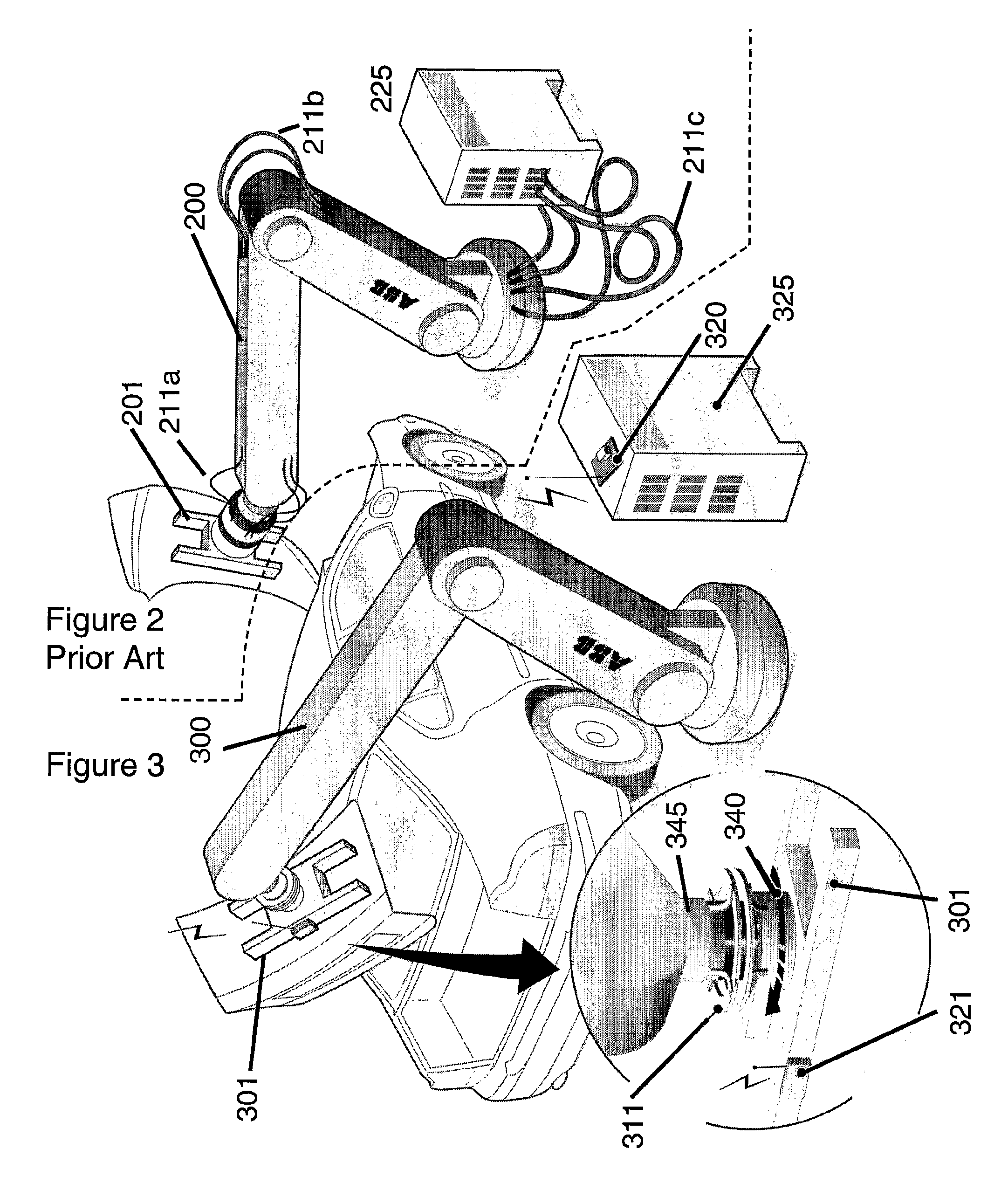

Tool for an Industrial Robot

InactiveUS20070276538A1Speeding up changeReduce downtimeSingle-phase induction motor startersProgramme-controlled manipulatorWireless controlIndustrial robotics

A robot or manipulator including a wireless power supply and a wireless communication device. One or more actuators on the robot tool may be wirelessly powered and wirelessly controlled. The robot tool may have one or more wireless communication members for transmission of data from sensors on the tool. The power supply includes a primary power supply member and secondary power supply member. Tool changes may be carried out automatically by the robot. In other aspects of the invention a method, a control system and a computer program for carrying out the method are described.

Owner:ABB RES LTD

Driving controlling apparatus for linear compressor and method thereof

Owner:LG ELECTRONICS INC

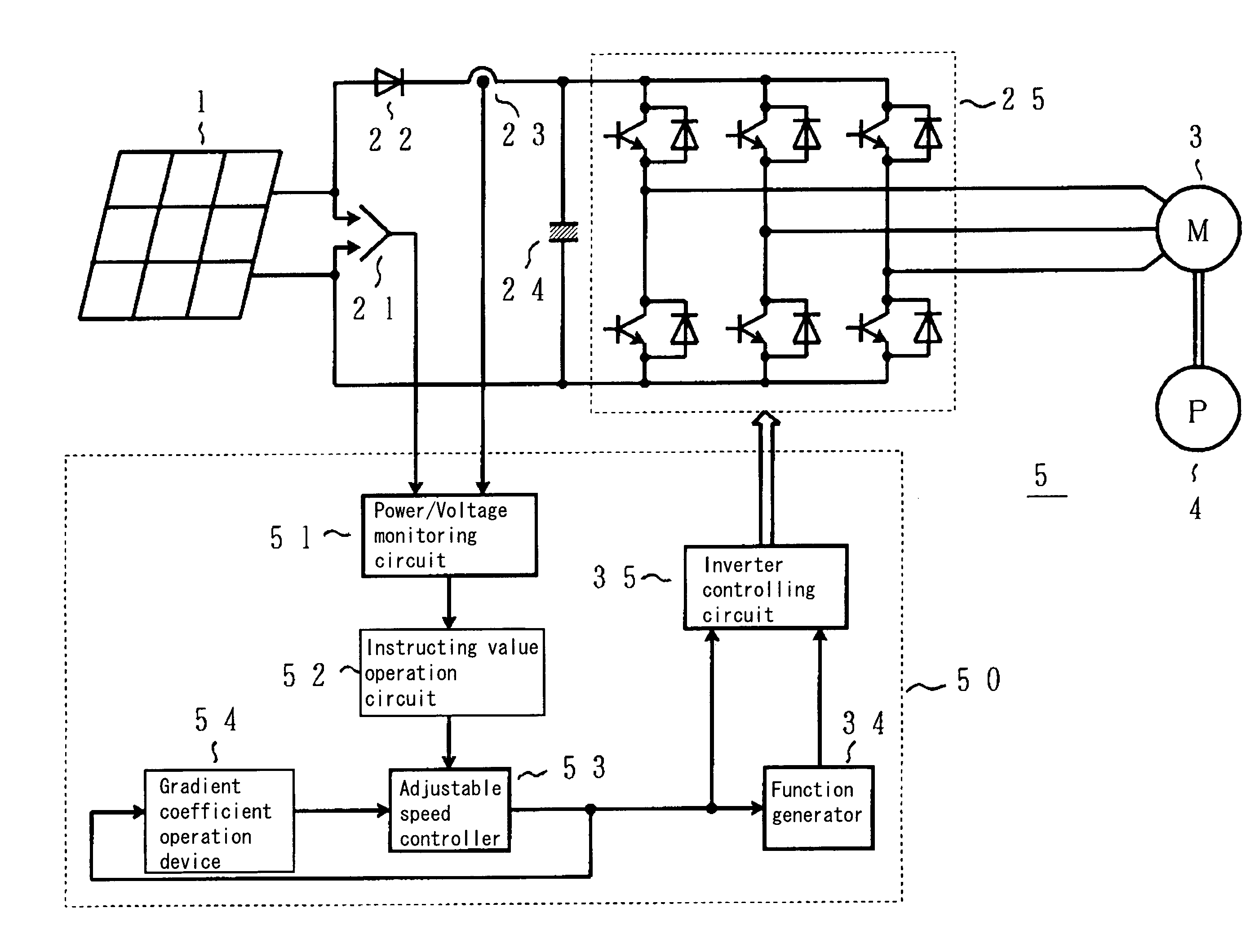

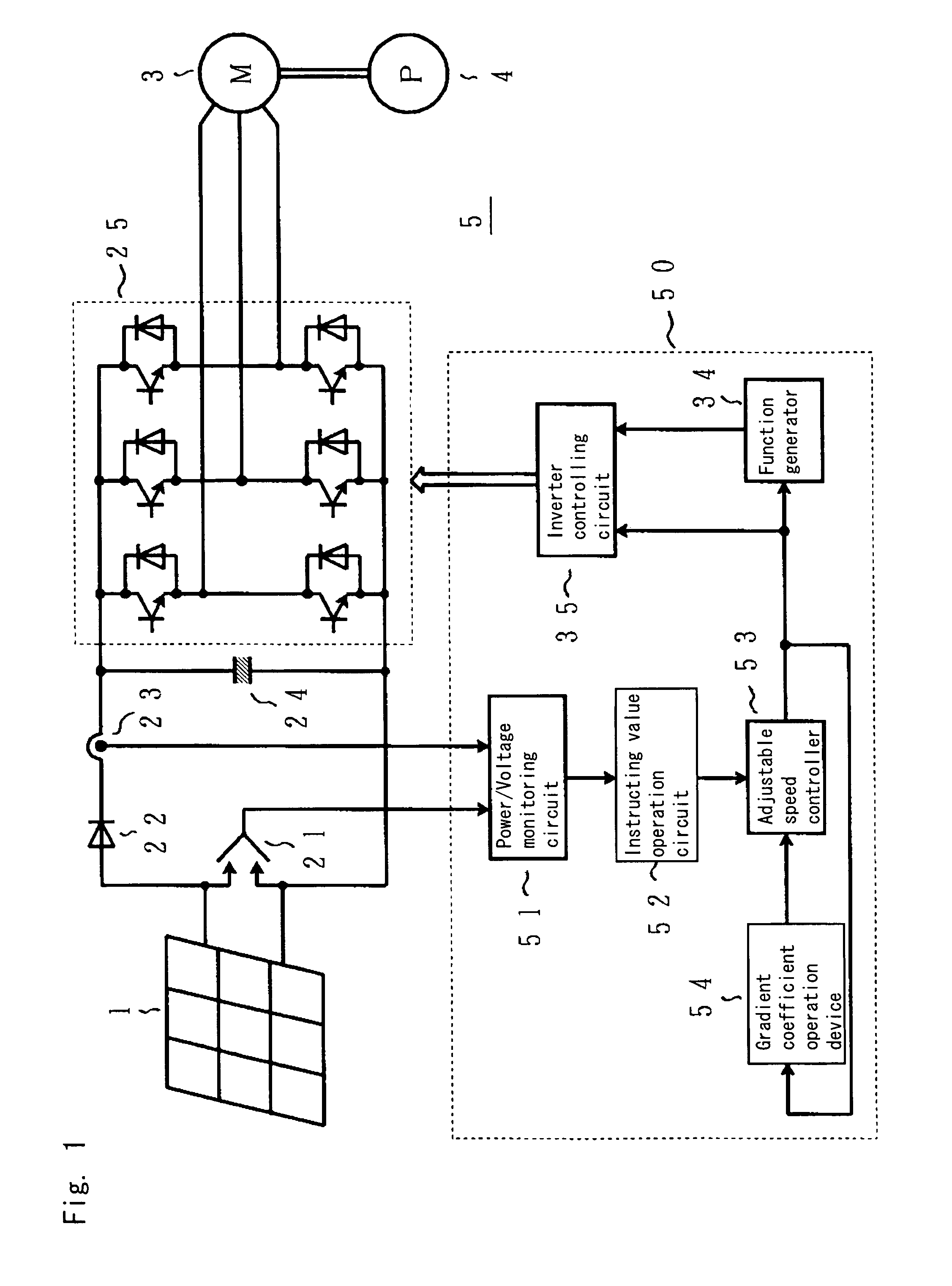

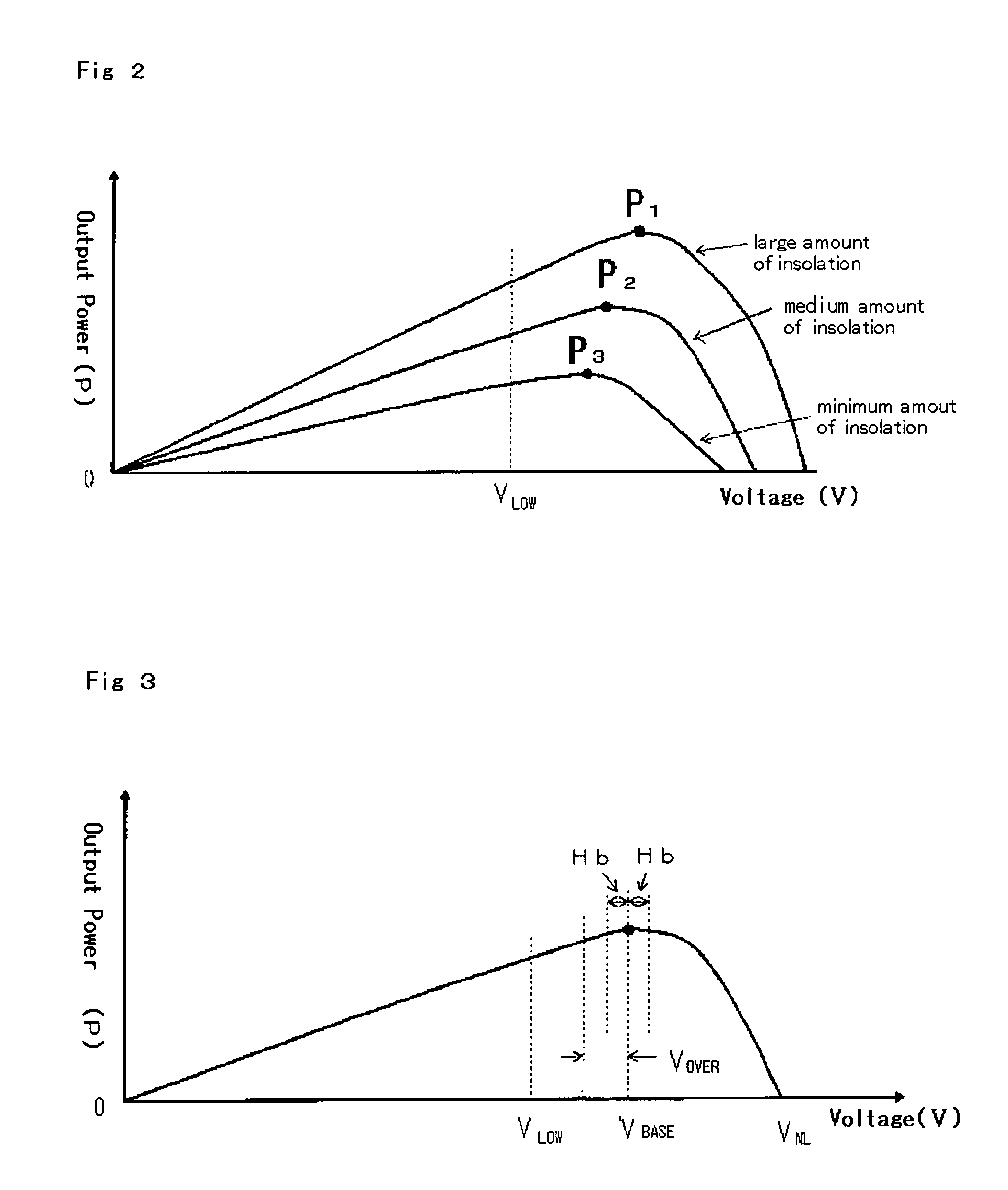

Method and device for controlling photovoltaic inverter, and feed water device

InactiveUS7126294B2Improve stabilityEasy transferBatteries circuit arrangementsAC motor controlElectrical batterySolar battery

Owner:FUJI ELECTRIC CO LTD +1

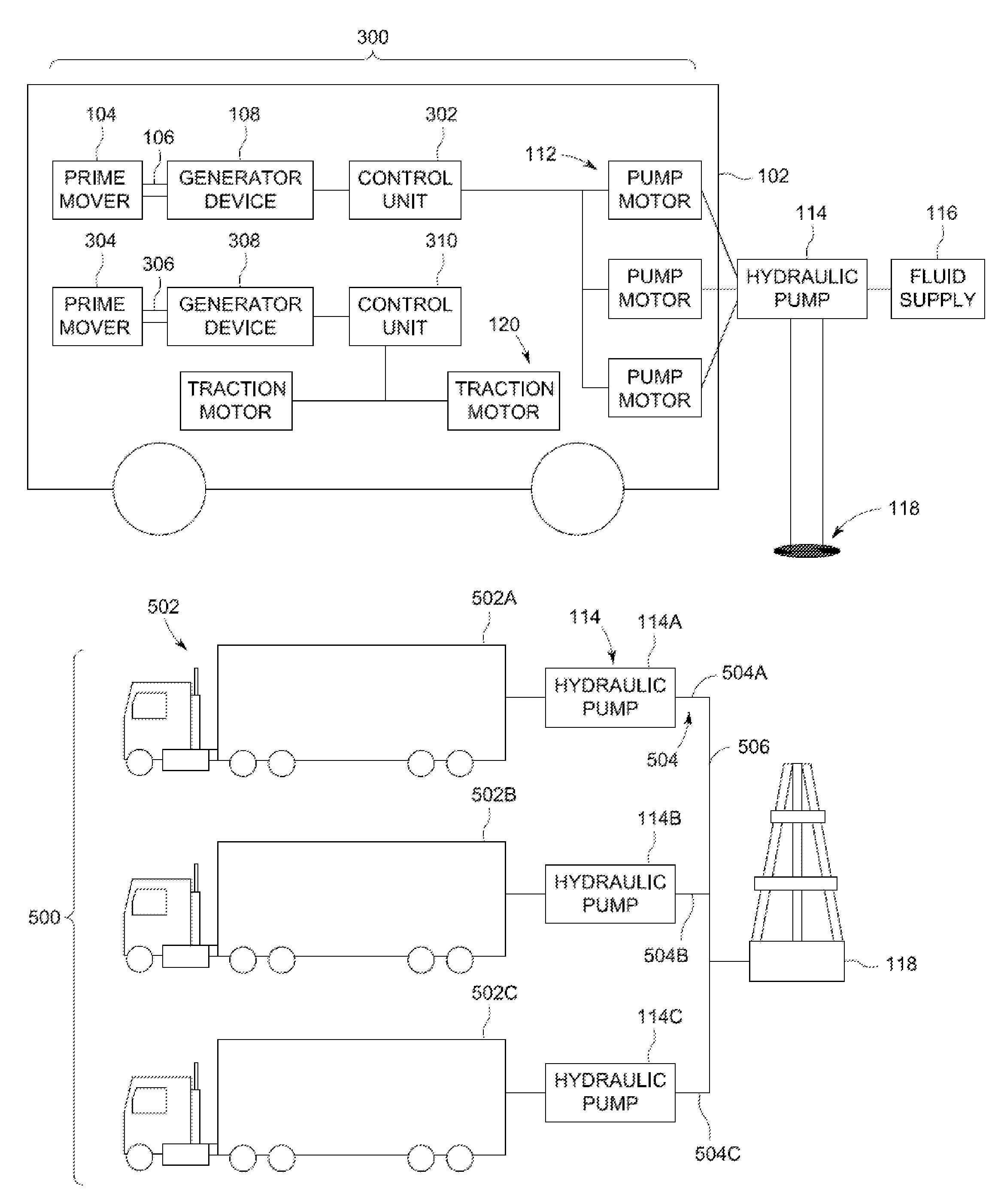

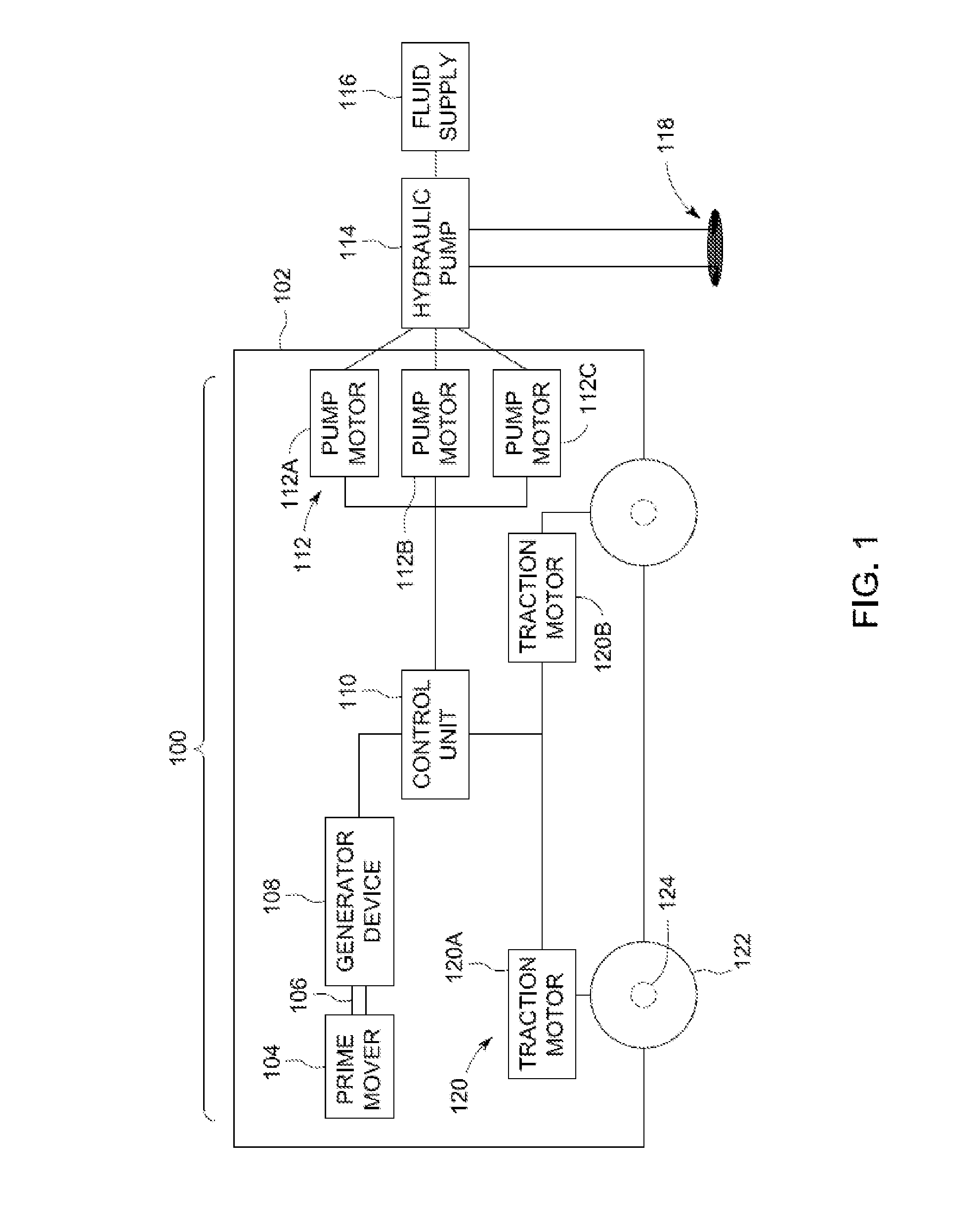

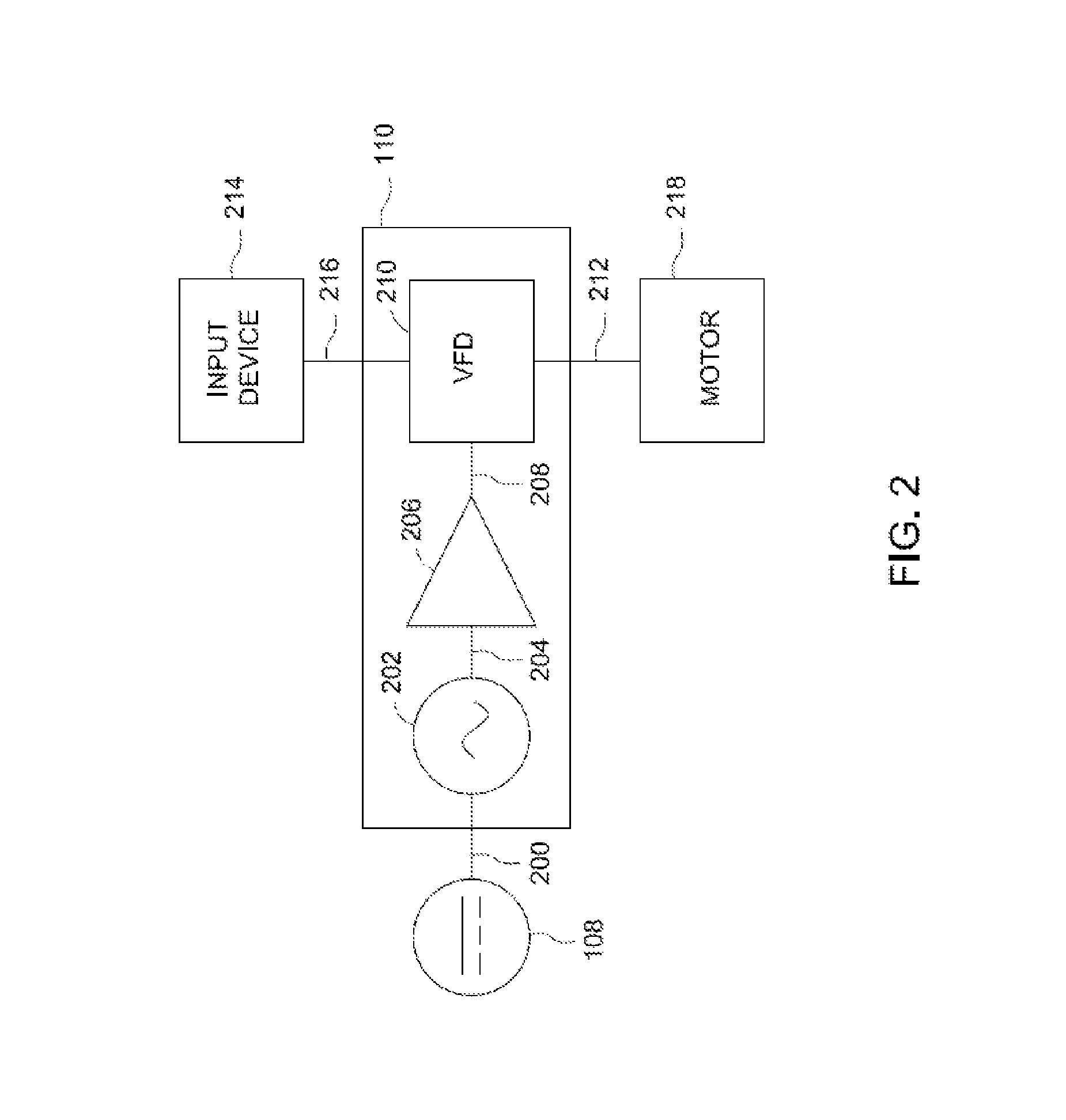

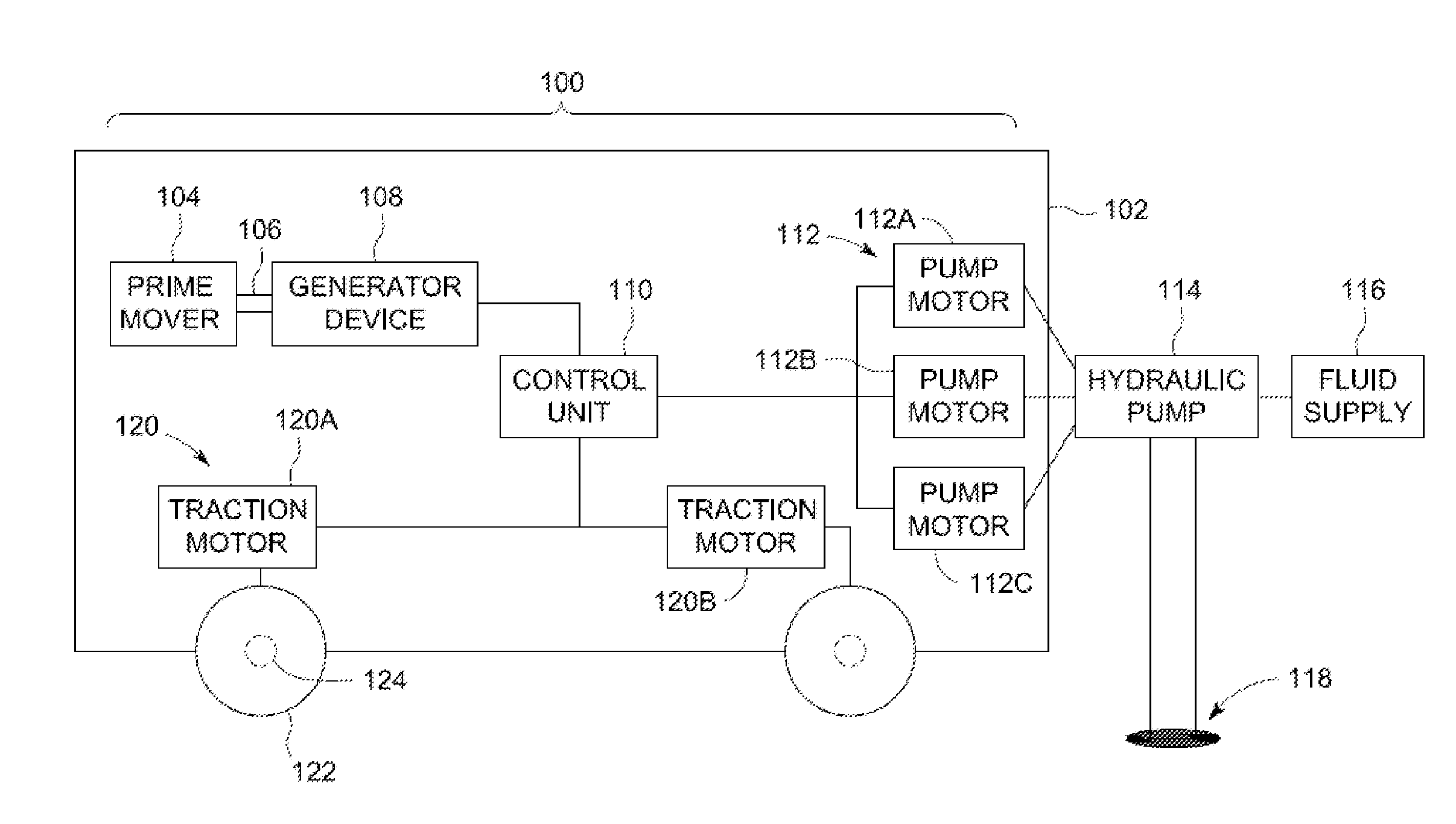

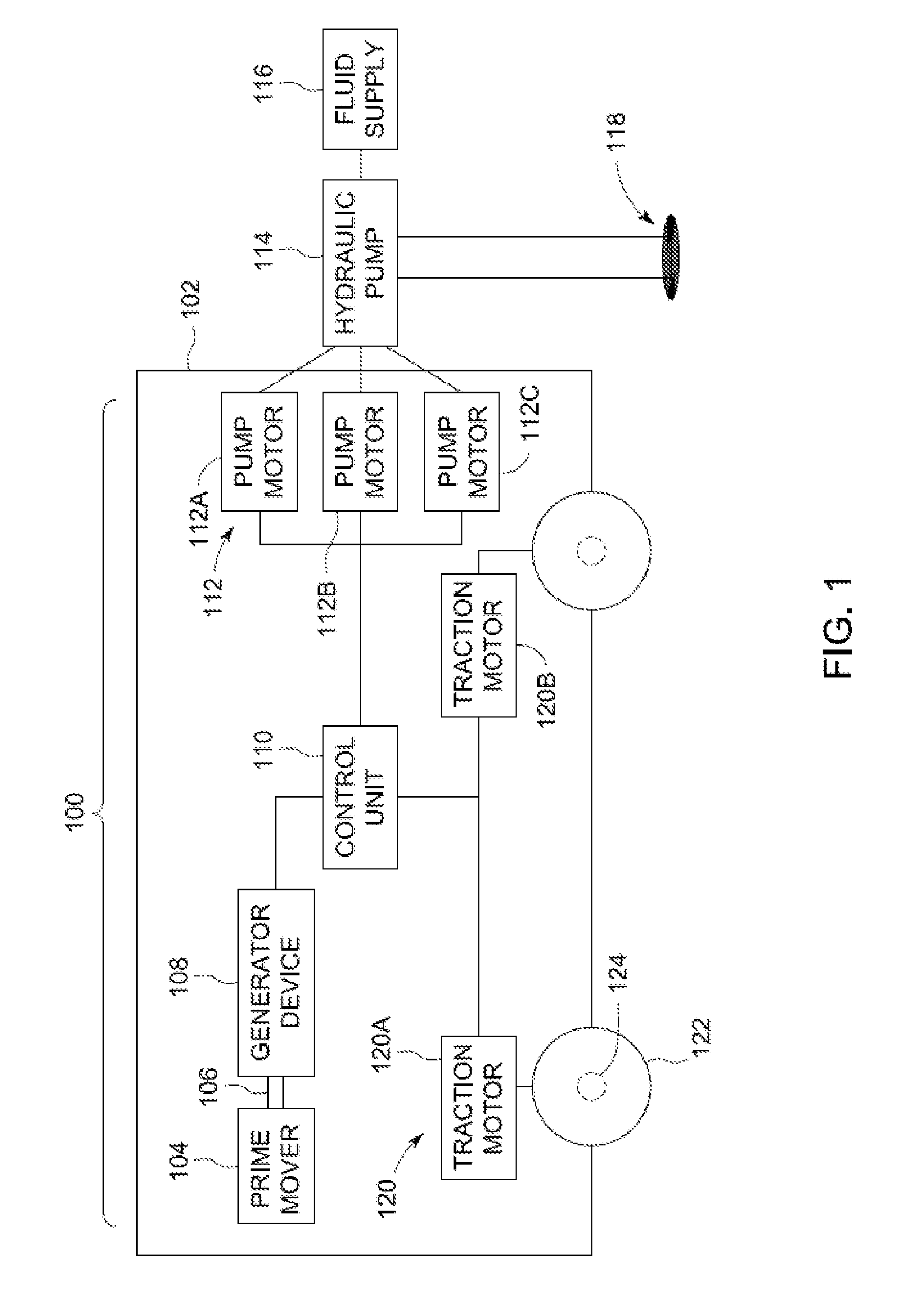

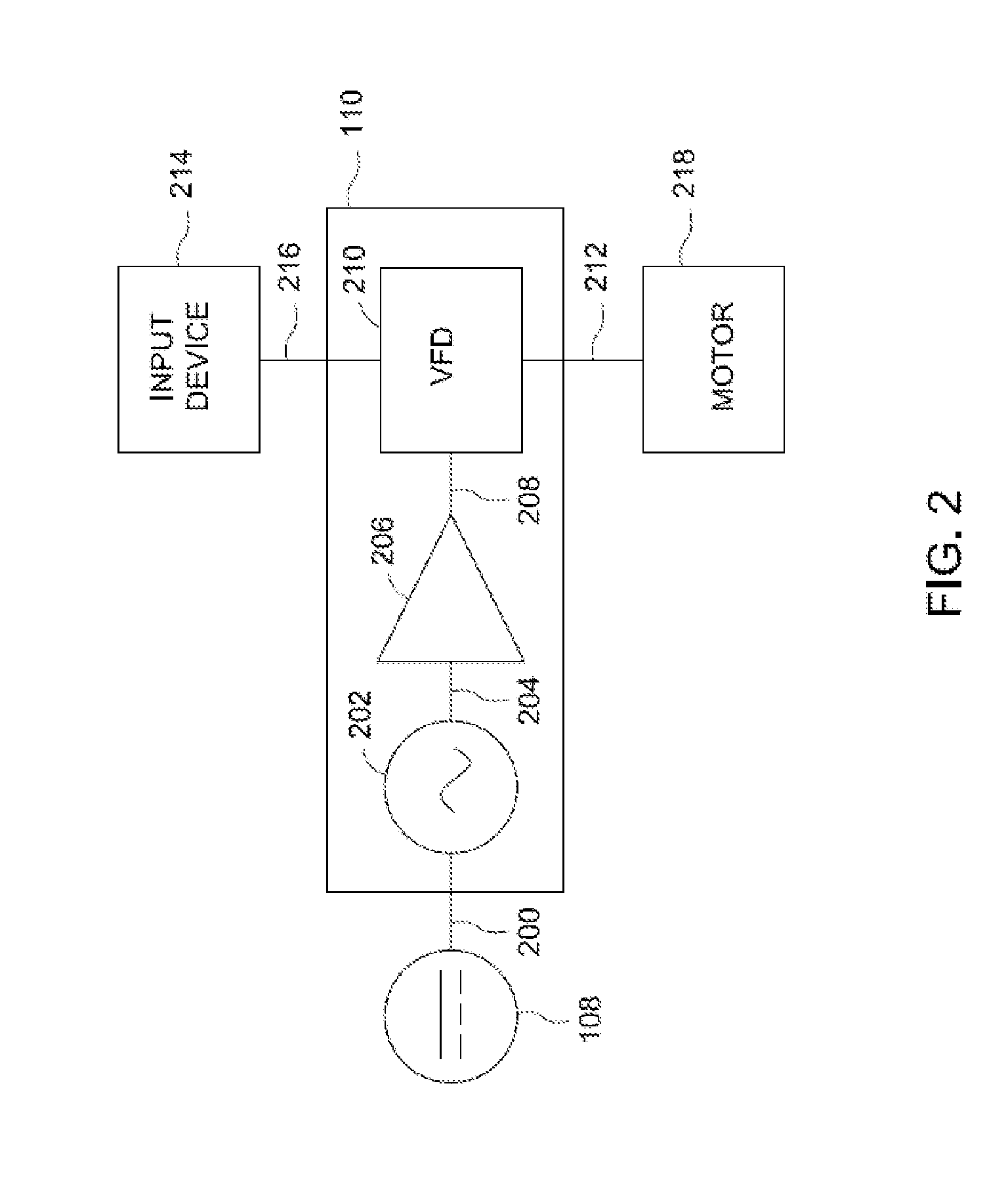

System and method for powering a hydraulic pump

A hydraulic pump powering system includes a mobile vehicle, a first electric current generator device, and one or more electric pump motors. The mobile vehicle has first and second prime movers. The first electric current generator device is disposed onboard the mobile vehicle and is configured to be mechanically coupled with the first prime mover to convert movement created by the first prime mover into first electric current. The one or more electric pump motors are configured to receive the first electric current to power a hydraulic pump. The second prime mover is configured to generate movement that is converted into a propulsive force that propels the mobile vehicle. The one or more electric pump motors are configured to receive the first electric current in order to power the hydraulic pump to pump a fluid into a pumping location located off-board the mobile vehicle.

Owner:GE GLOBAL SOURCING LLC

System for pumping hydraulic fracturing fluid using electric pumps

A system for hydraulically fracturing an underground formation in an oil or gas well to extract oil or gas from the formation, the oil or gas well having a wellbore that permits passage of fluid from the wellbore into the formation. The system includes a plurality of electric pumps fluidly connected to the well, and configured to pump fluid into the wellbore at high pressure so that the fluid passes from the wellbore into the and fractures the formation. The system can also include a plurality of natural gas powered generators electrically connected to the plurality of electric pumps to provide electrical power to the pumps.

Owner:US WELL SERVICS LLC

System and method for powering a hydraulic pump

A hydraulic pump powering system includes a mobile vehicle, a first electric current generator device, and one or more electric pump motors. The mobile vehicle has first and second prime movers. The first electric current generator device is disposed onboard the mobile vehicle and is configured to be mechanically coupled with the first prime mover to convert movement created by the first prime mover into first electric current. The one or more electric pump motors are configured to receive the first electric current to power a hydraulic pump. The second prime mover is configured to generate movement that is converted into a propulsive force that propels the mobile vehicle. The one or more electric pump motors are configured to receive the first electric current in order to power the hydraulic pump to pump a fluid into a pumping location located off-board the mobile vehicle.

Owner:GE GLOBAL SOURCING LLC

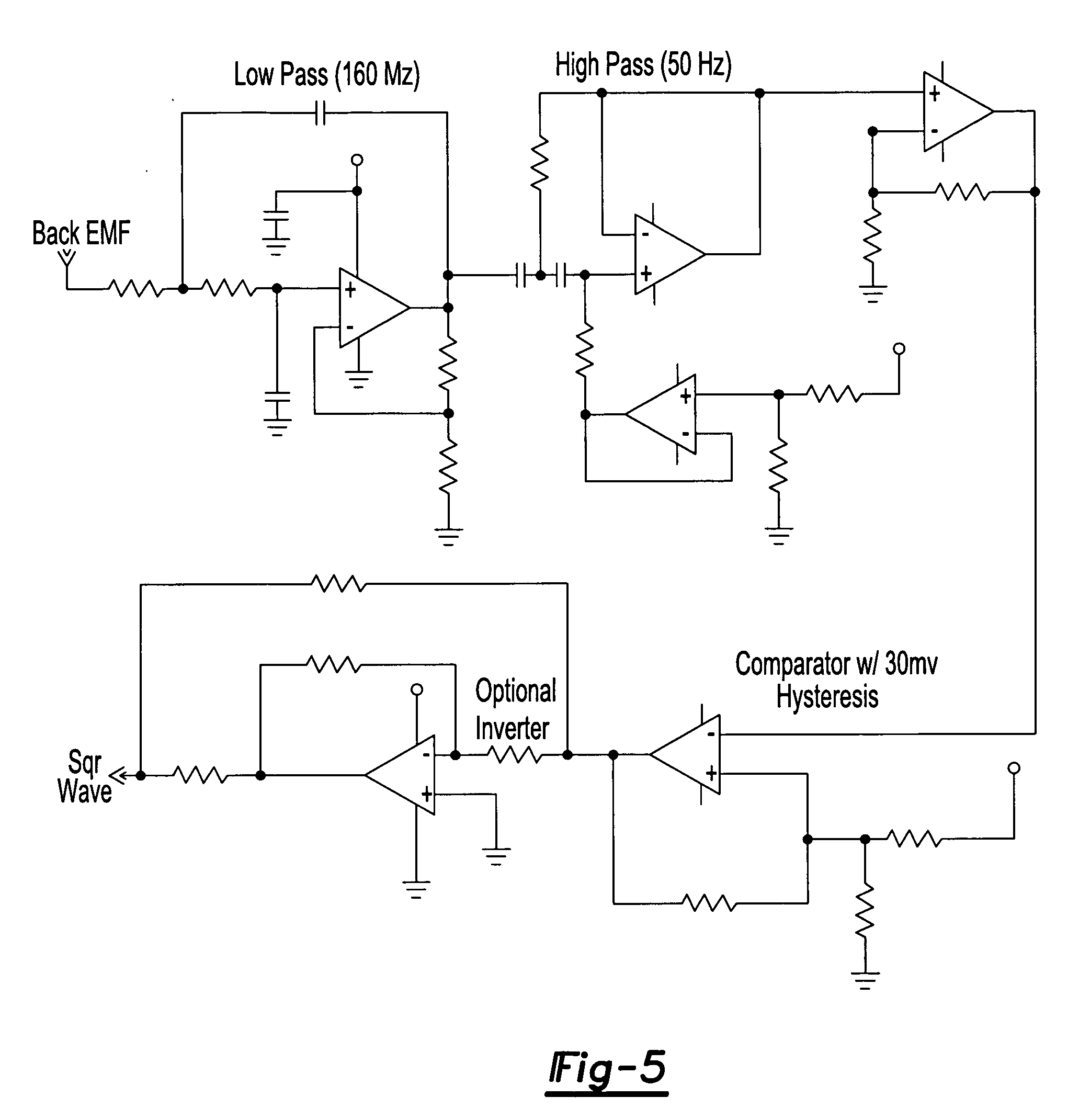

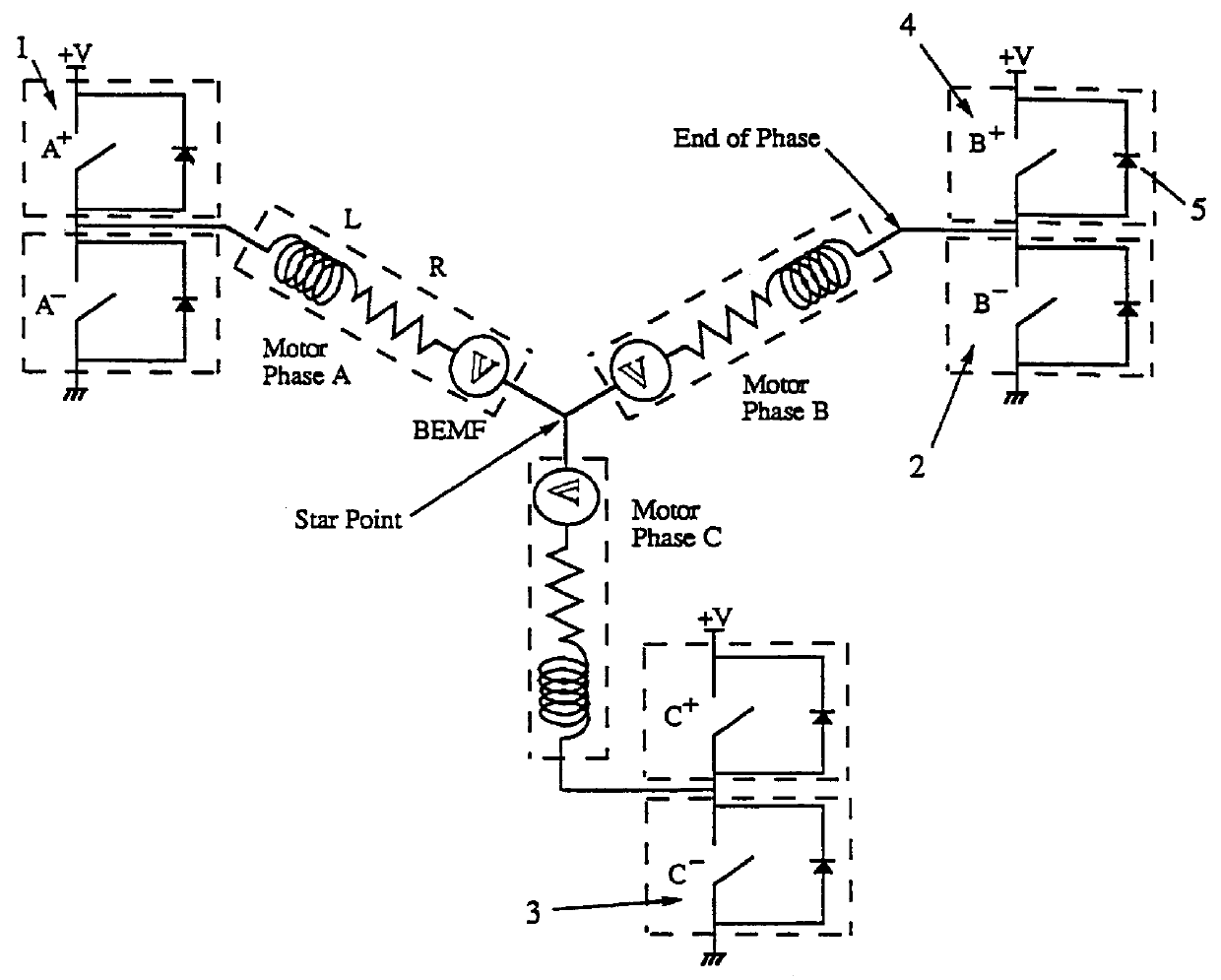

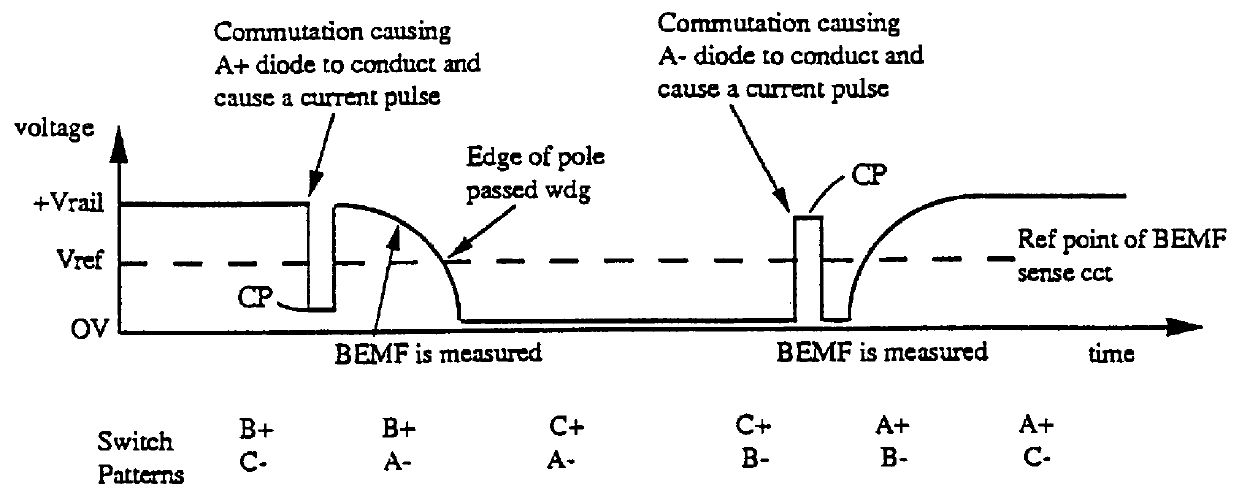

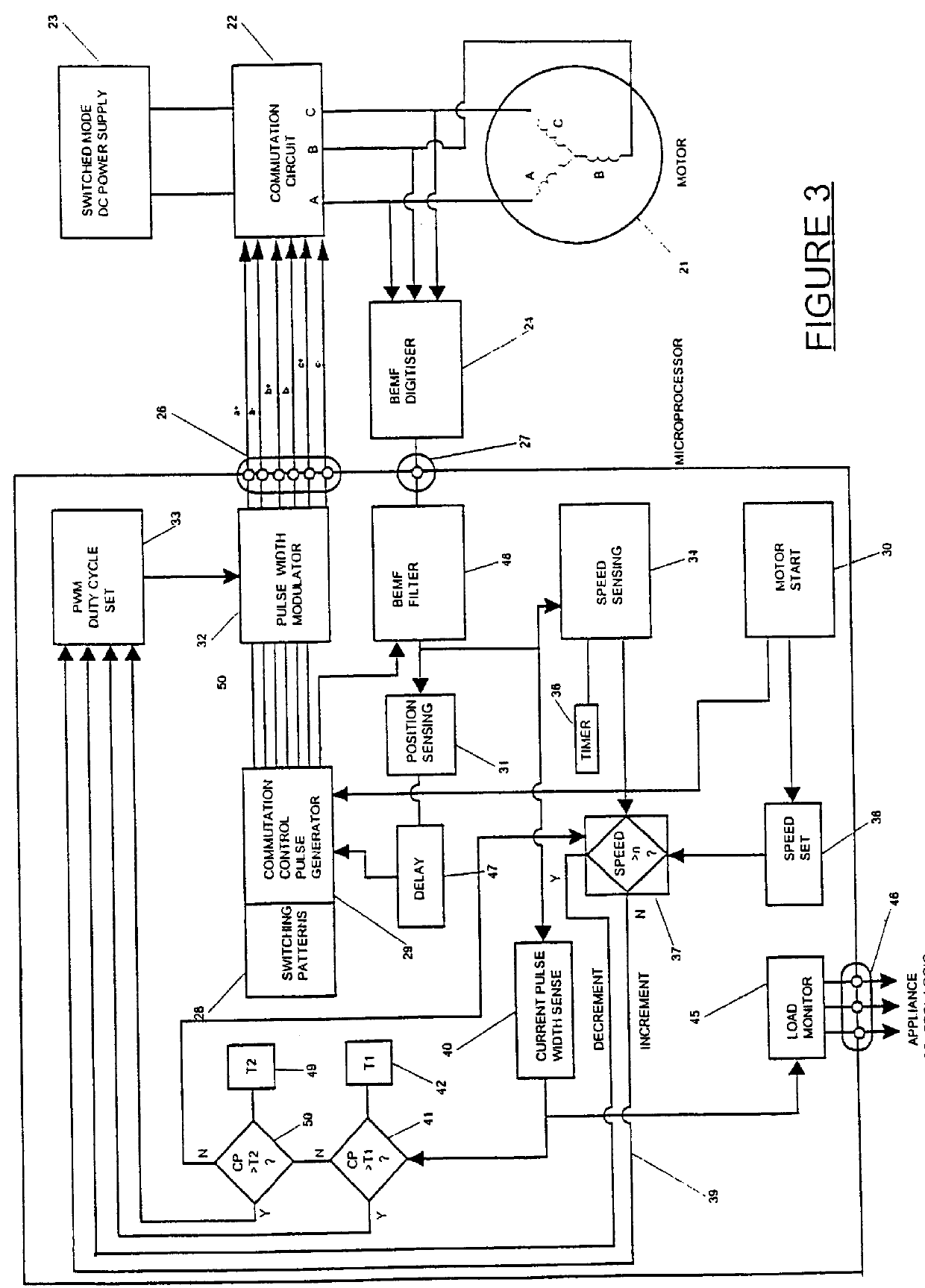

Brushless DC motor control

An electronically commutated brushless DC motor primarily for fractional horsepower applications of the type where at any instant one motor winding is unpowered and used to detect back EMF zero-crossings which information is used to initiate winding commutations. The duration of the pulse produced in this winding due to dissipation of stored energy by free-wheel diodes in parallel with the commutation devices after supply of current has been removed from this winding is used to provide a measure of motor current. This allows for simplified commutation device current limiting circuits and is available for control purposes which are a function of motor torque. There is also disclosed a method for maximizing useful power output by reducing the phase angle between the motor current and the back EMF. This is accomplished by introducing a delay in commutating the motor windings beyond the occurrence of each back EMF zero-crossing, with the delay being a function of the time between commutations.

Owner:FISHER & PAYKEL APPLIANCES LTD

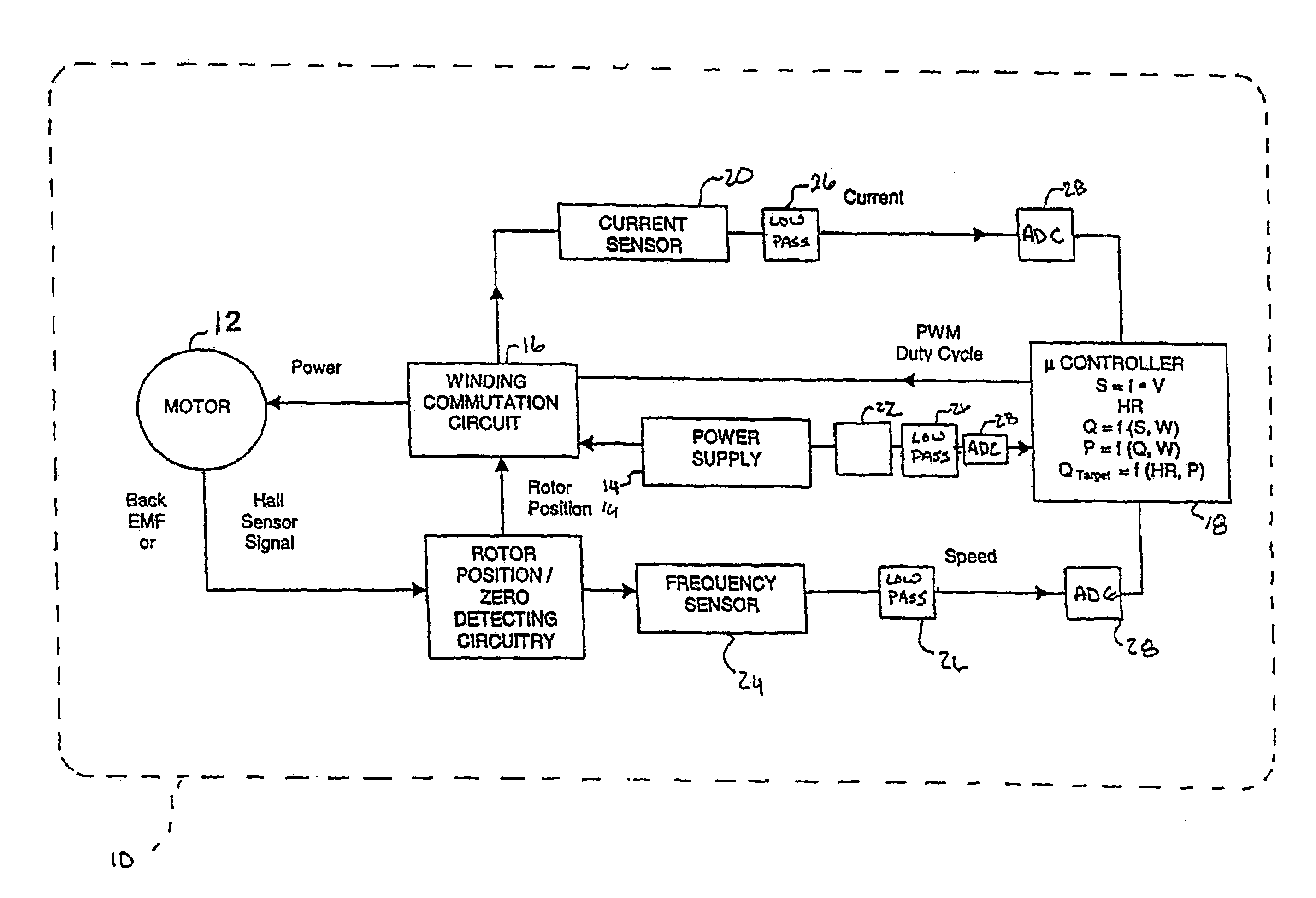

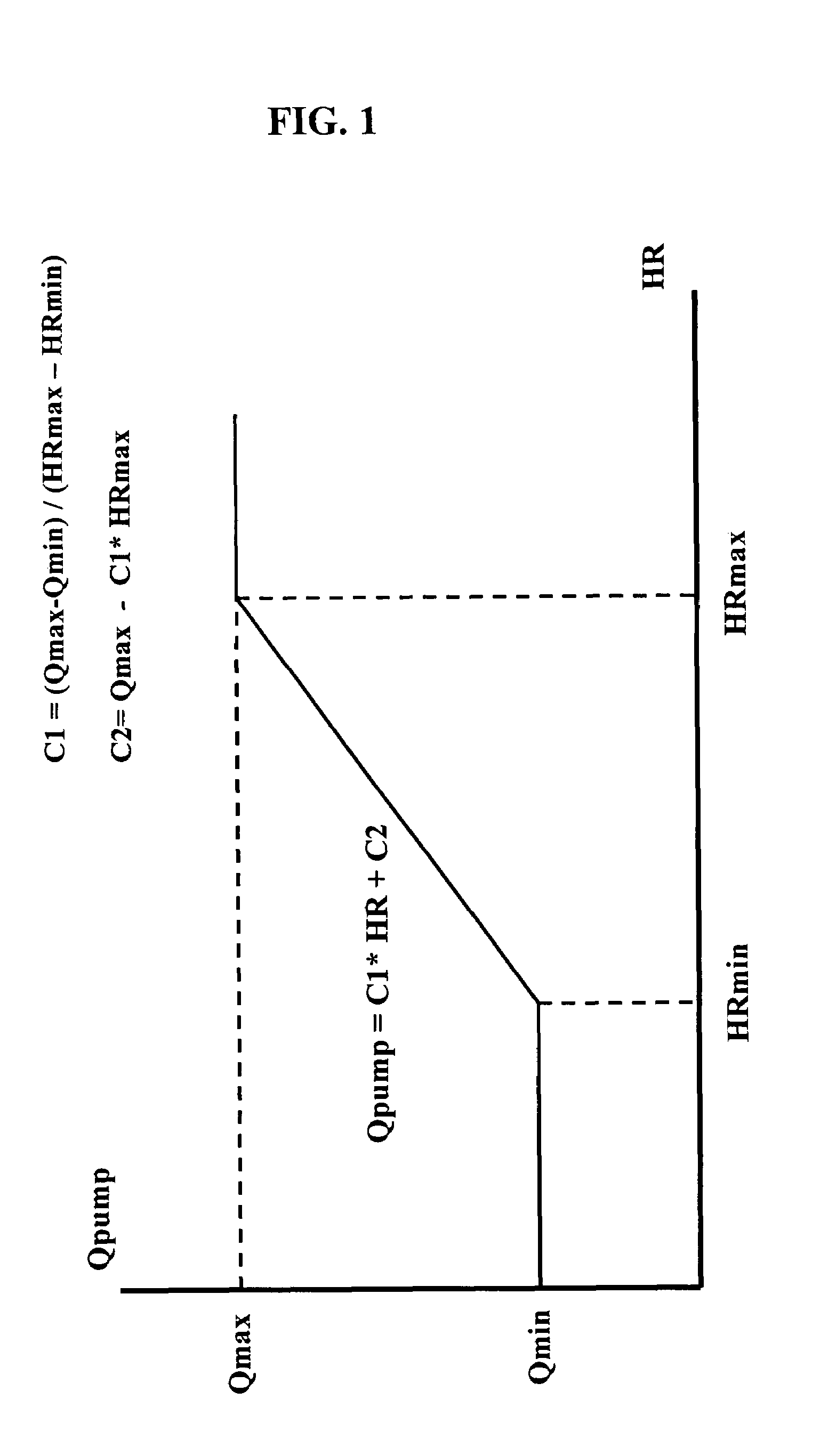

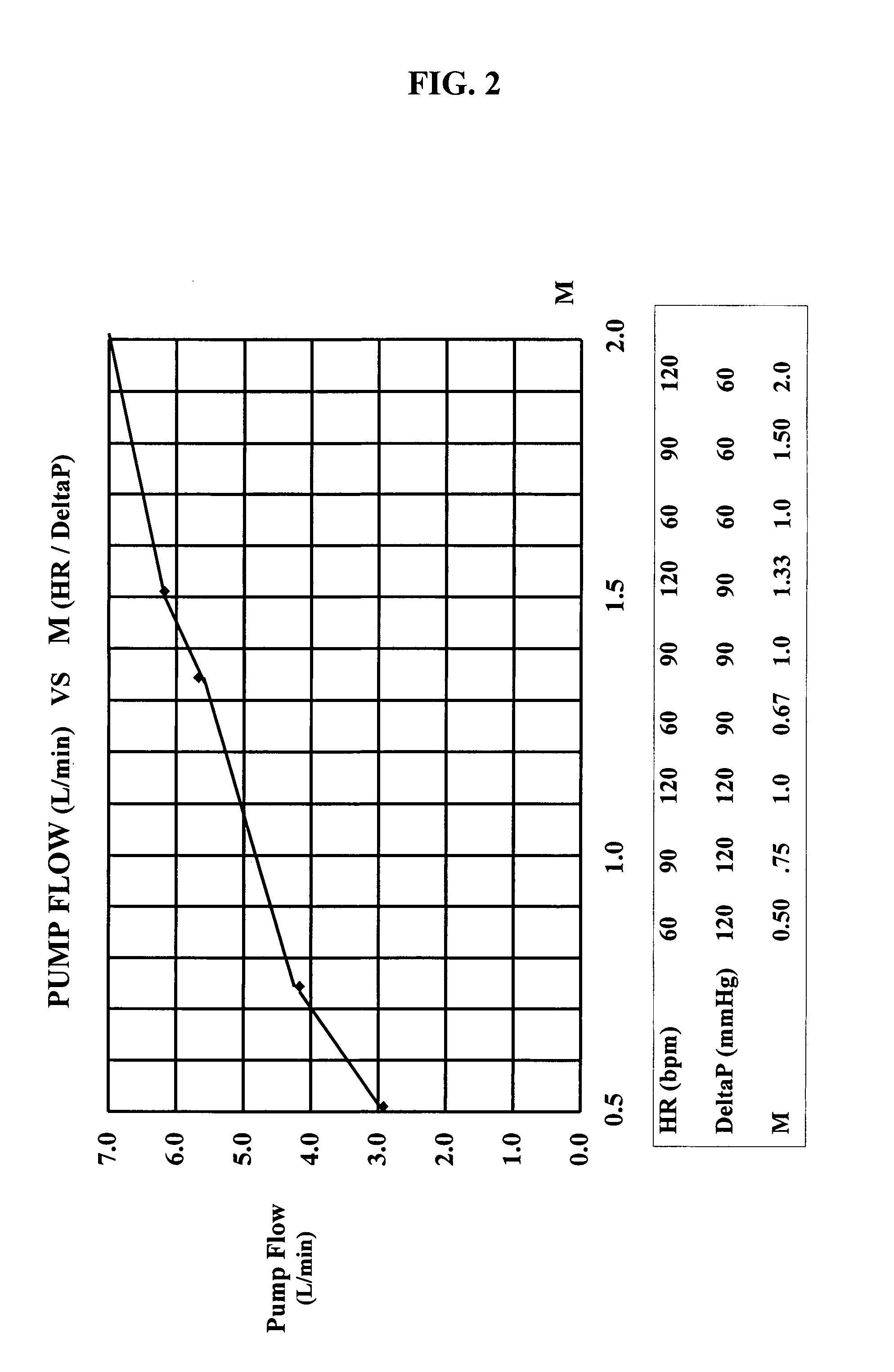

Chronic performance control system for rotodynamic blood pumps

InactiveUS7645225B2Simple control circuitIncrease control flexibilityDC motor speed/torque controlAC motor controlMicrocontrollerMotor speed

In a left ventricular assist device (LVAD) a rotodynamic blood pump (10) is powered by a brushless DC motor (12). A power supply (14) supplies power to the motor (12). Three feedback channels, one for each of voltage, current, and motor speed lead to a microcontroller or microprocessor (18). The three feedback waveforms are analyzed, and from these waveforms, motor input power, patient heart rate, current pump flow rate, and systemic pressure are determined. The microprocessor (18) then calculates a desired flow rate proportional to the patient heart rate. The microprocessor communicates a new power output to a commutation circuit (16), which regulates power to the motor (12). The pump (10) also includes safety checks that are prioritized over desired pump flow. These include prevention of ventricular suction, low pulsatility, minimum and maximum pump speed, minimum speed-relative pump flow, minimum absolute pump flow, minimum and maximum motor input power.

Owner:MEDVEDEV ALEXANDER +2

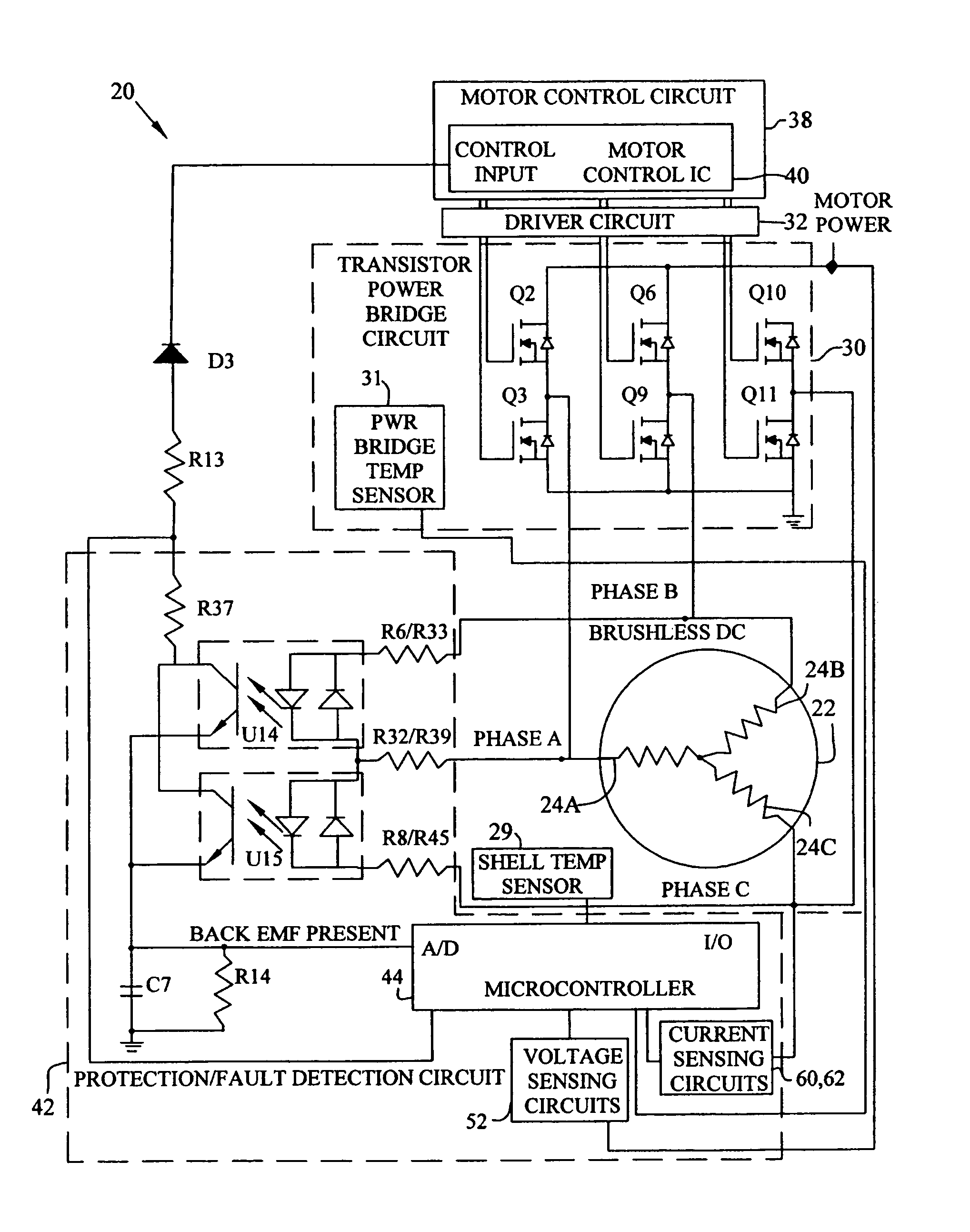

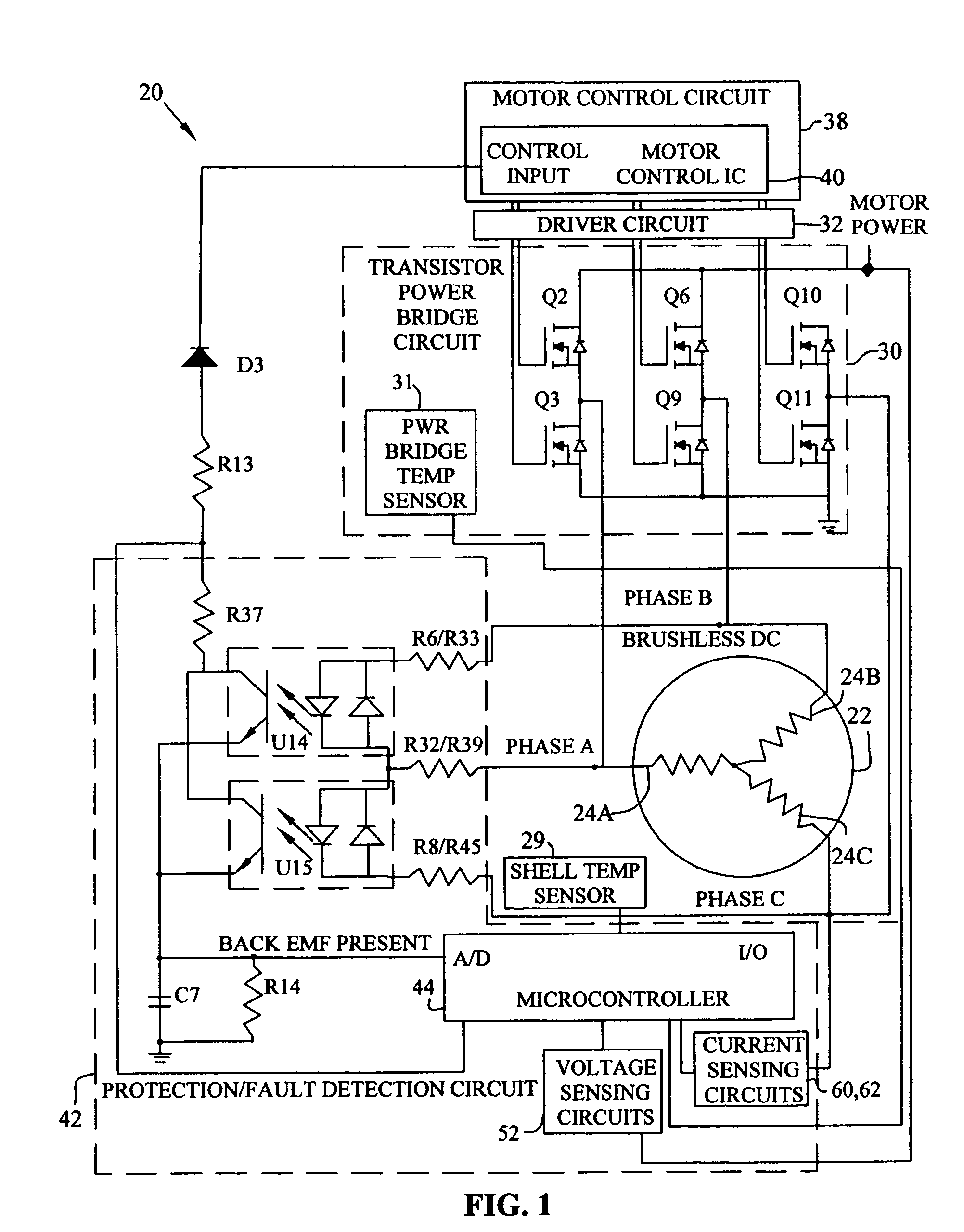

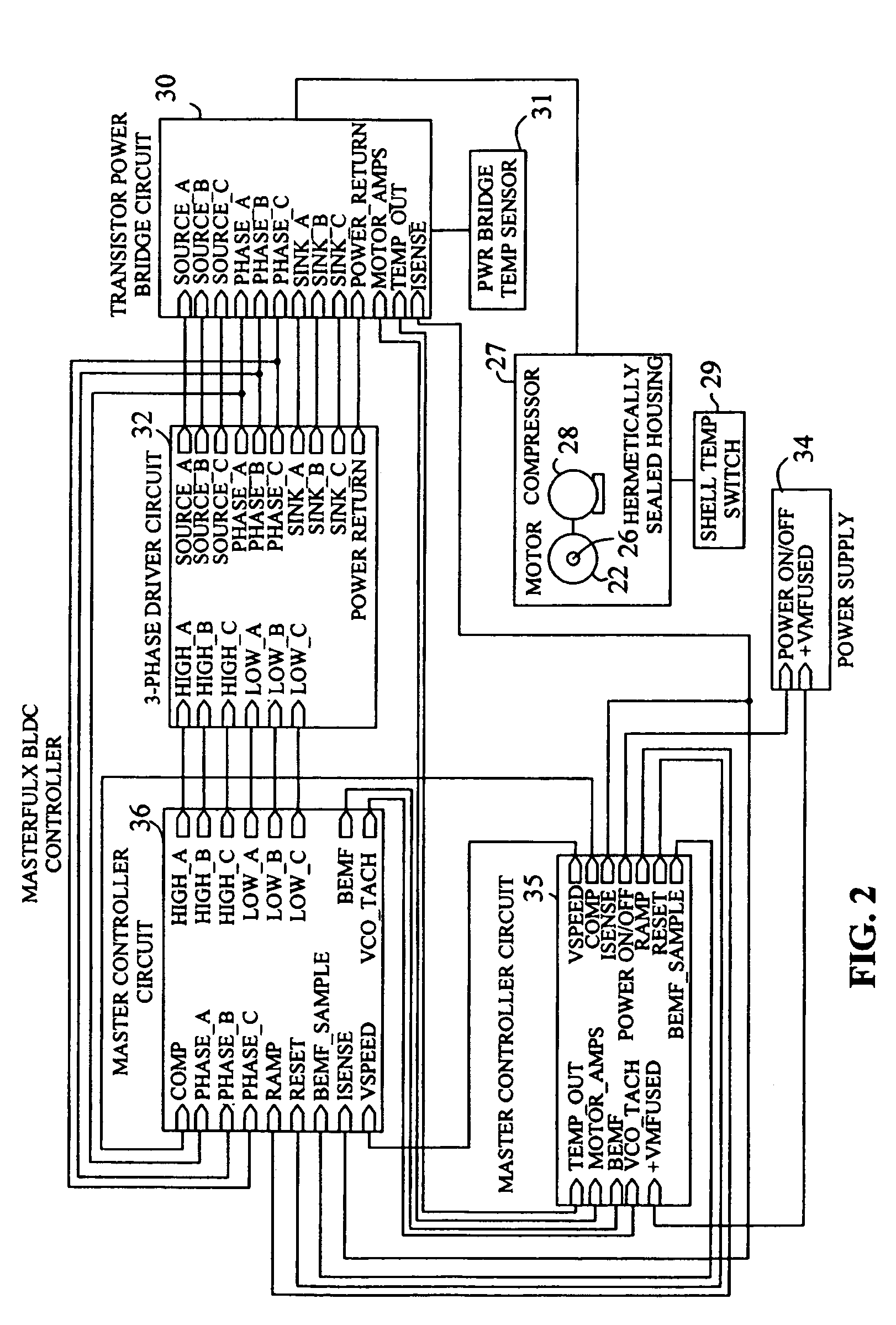

Brushless and sensorless DC motor control system with locked and stopped rotor detection

ActiveUS7042180B2Simple control methodEasily interfaceCommutation monitoringAC motor controlMotor speedDc motor control

A motor control system for a brushless and sensorless DC motor for driving a compressor, pump or other application, includes a protection and fault detection circuit for detecting a locked rotor and a rotor which has stopped because of lost rotor phase lock. The motor control system also includes an off-the-shelf motor control integrated circuit having an input for disabling power outputs to the motor phase coils. The protection and fault detection circuit uses a back EMF sampling circuit coupled to the motor phase coils and momentarily disables power to the motor phase coils, via the motor control integrated circuit input, to determine if the motor rotor is rotating. The system also monitors supply voltage, supply current, temperature, and motor speed limits to detect faults and protect system components.

Owner:REGAL BELOIT AMERICA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com