Patents

Literature

296 results about "Dc motor control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

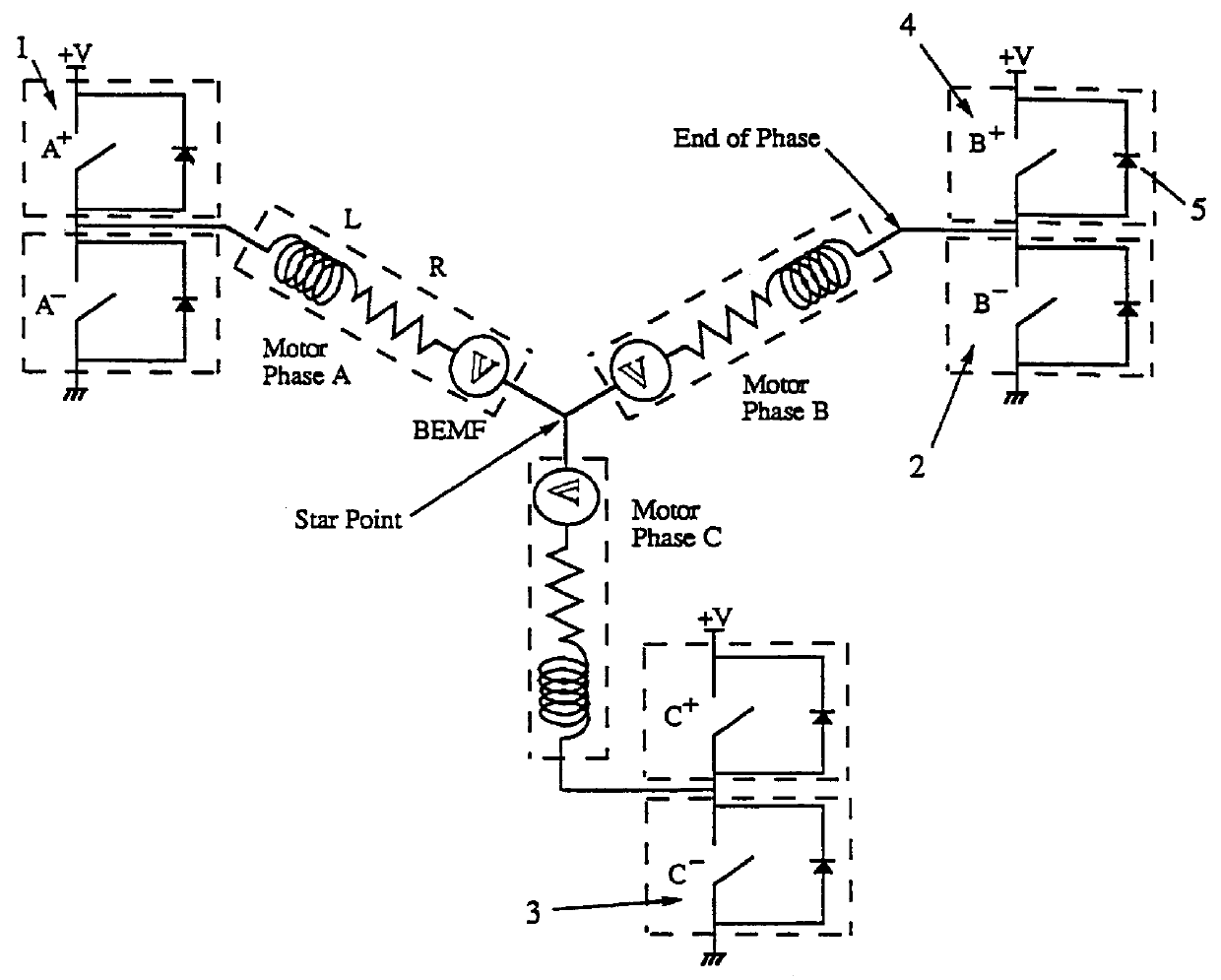

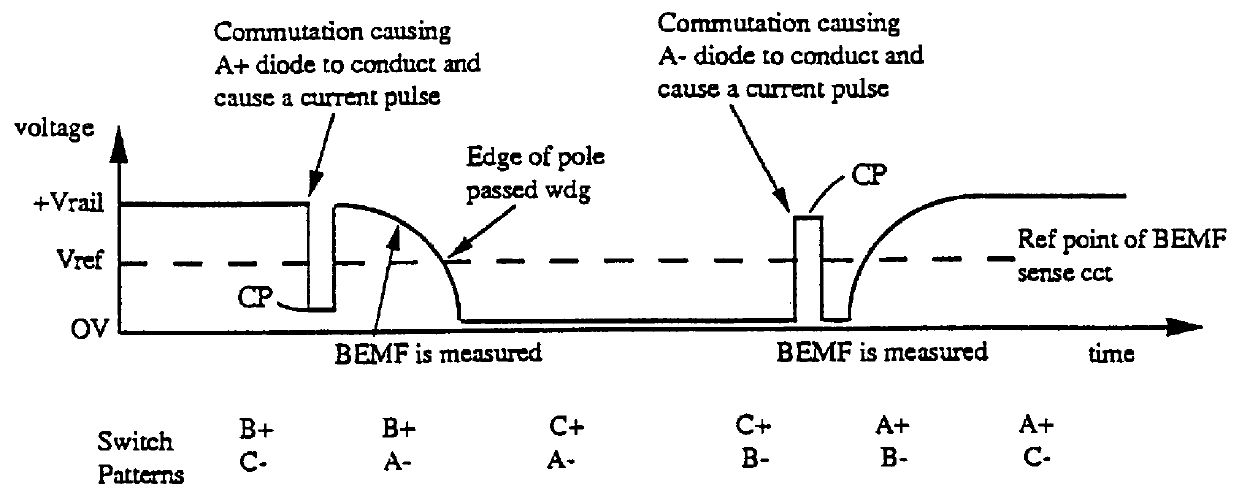

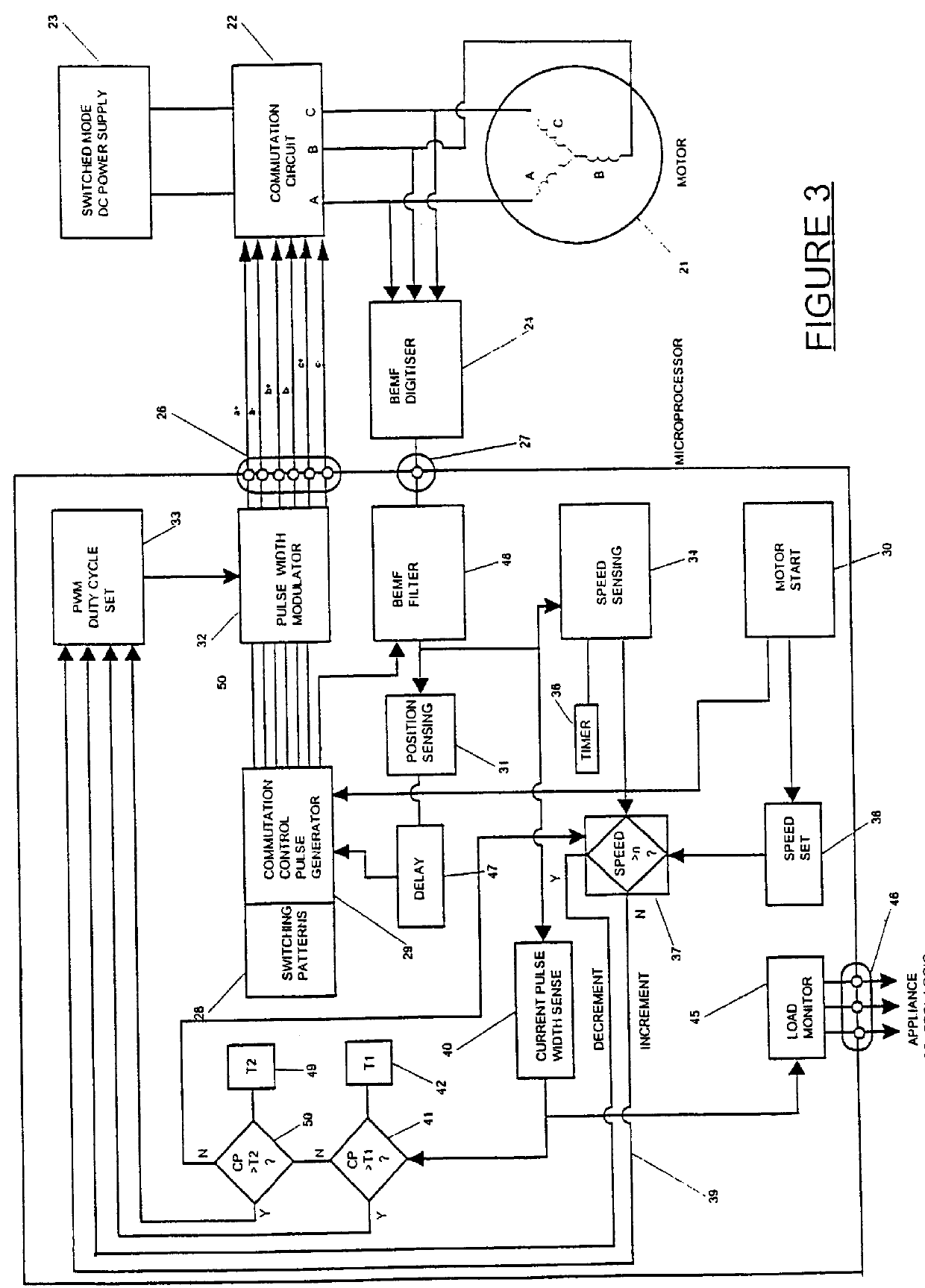

Brushless DC motor control

An electronically commutated brushless DC motor primarily for fractional horsepower applications of the type where at any instant one motor winding is unpowered and used to detect back EMF zero-crossings which information is used to initiate winding commutations. The duration of the pulse produced in this winding due to dissipation of stored energy by free-wheel diodes in parallel with the commutation devices after supply of current has been removed from this winding is used to provide a measure of motor current. This allows for simplified commutation device current limiting circuits and is available for control purposes which are a function of motor torque. There is also disclosed a method for maximizing useful power output by reducing the phase angle between the motor current and the back EMF. This is accomplished by introducing a delay in commutating the motor windings beyond the occurrence of each back EMF zero-crossing, with the delay being a function of the time between commutations.

Owner:FISHER & PAYKEL APPLIANCES LTD

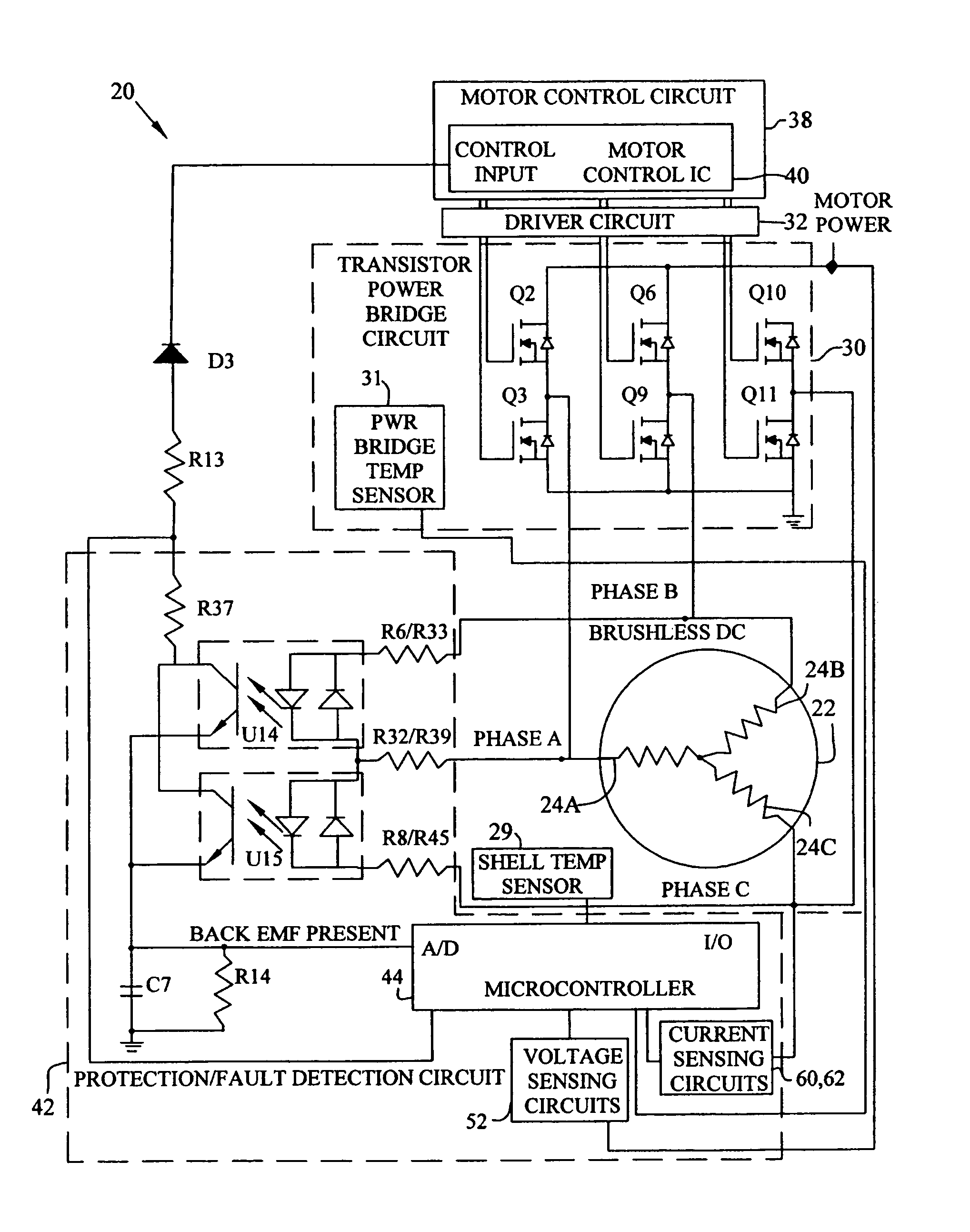

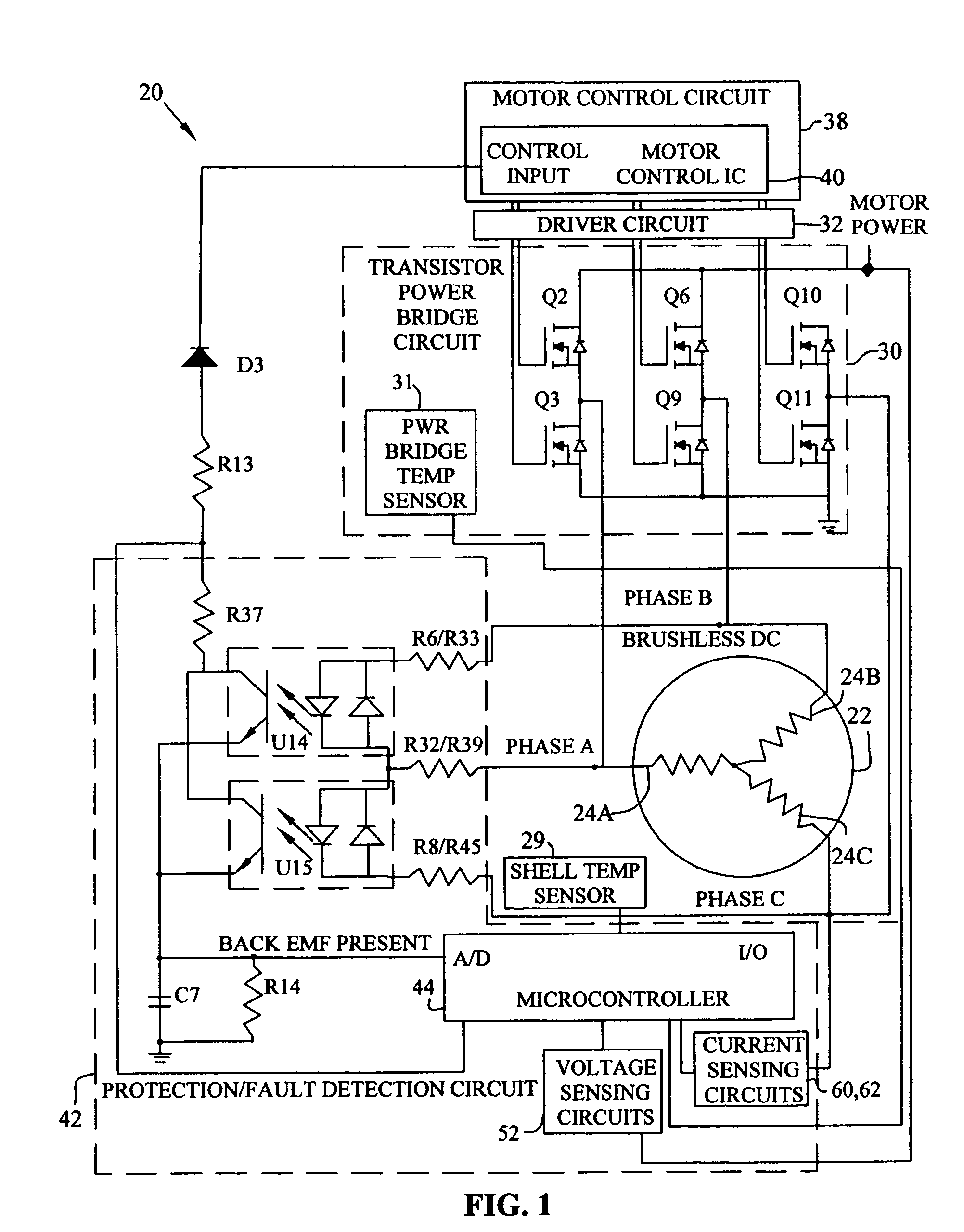

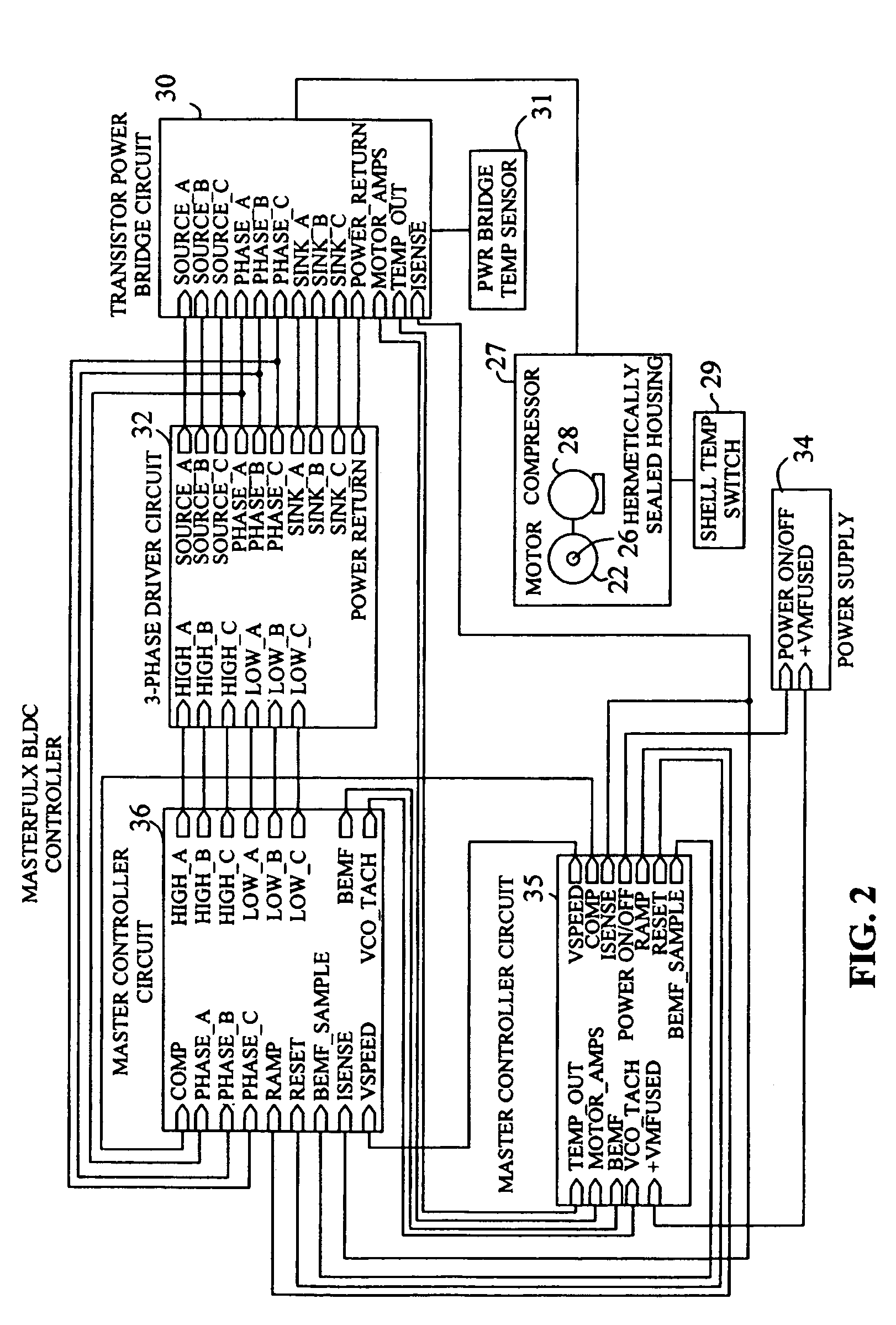

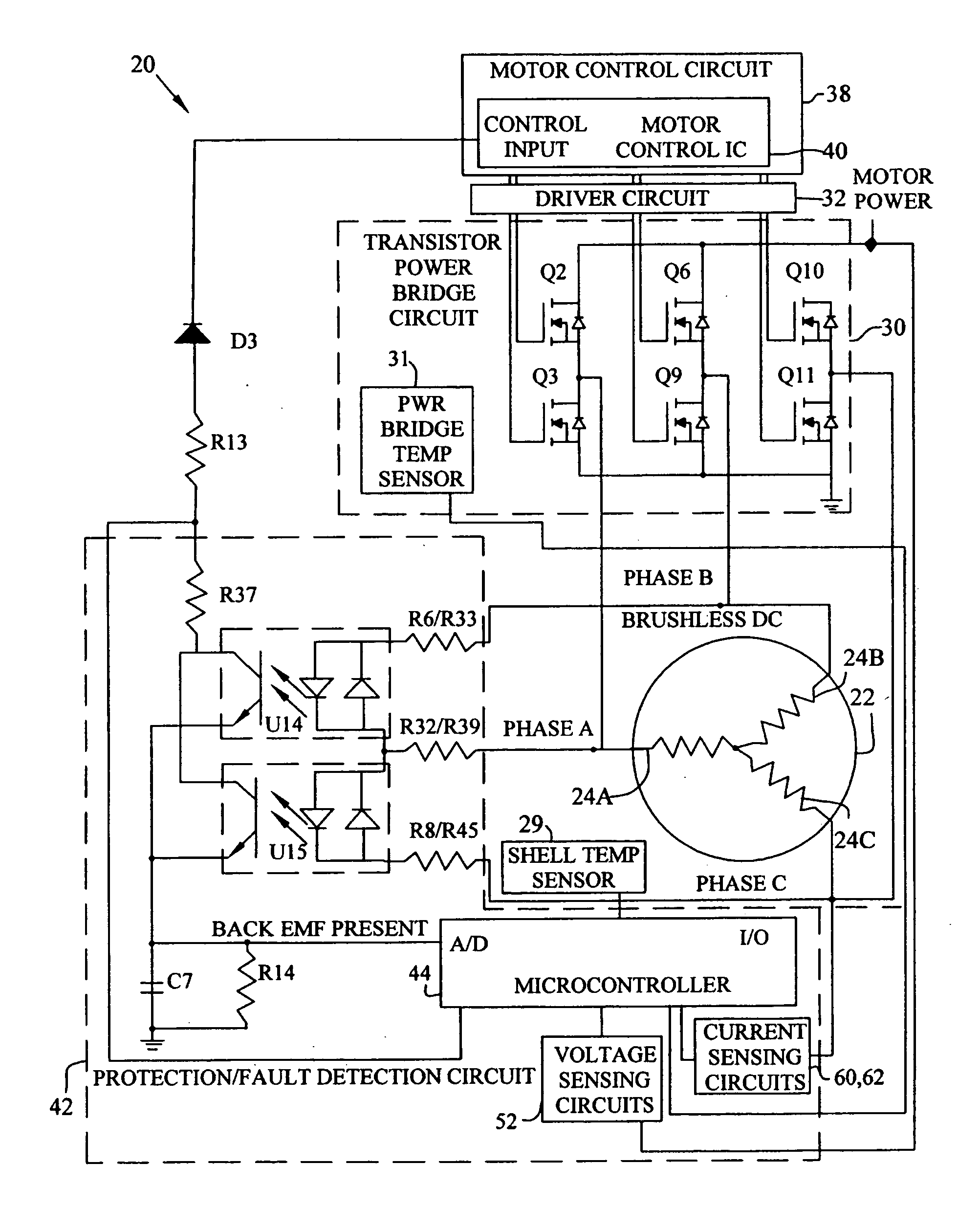

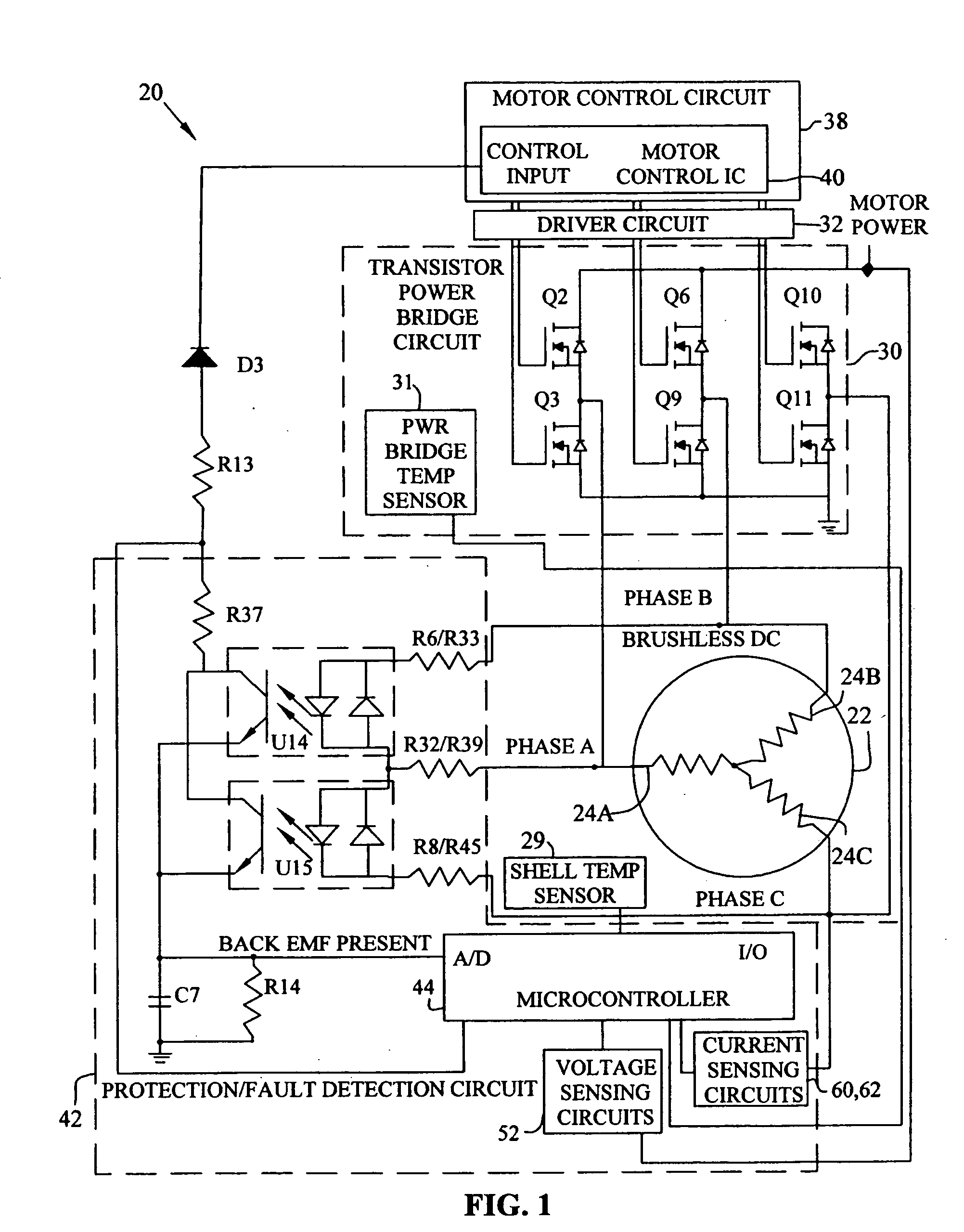

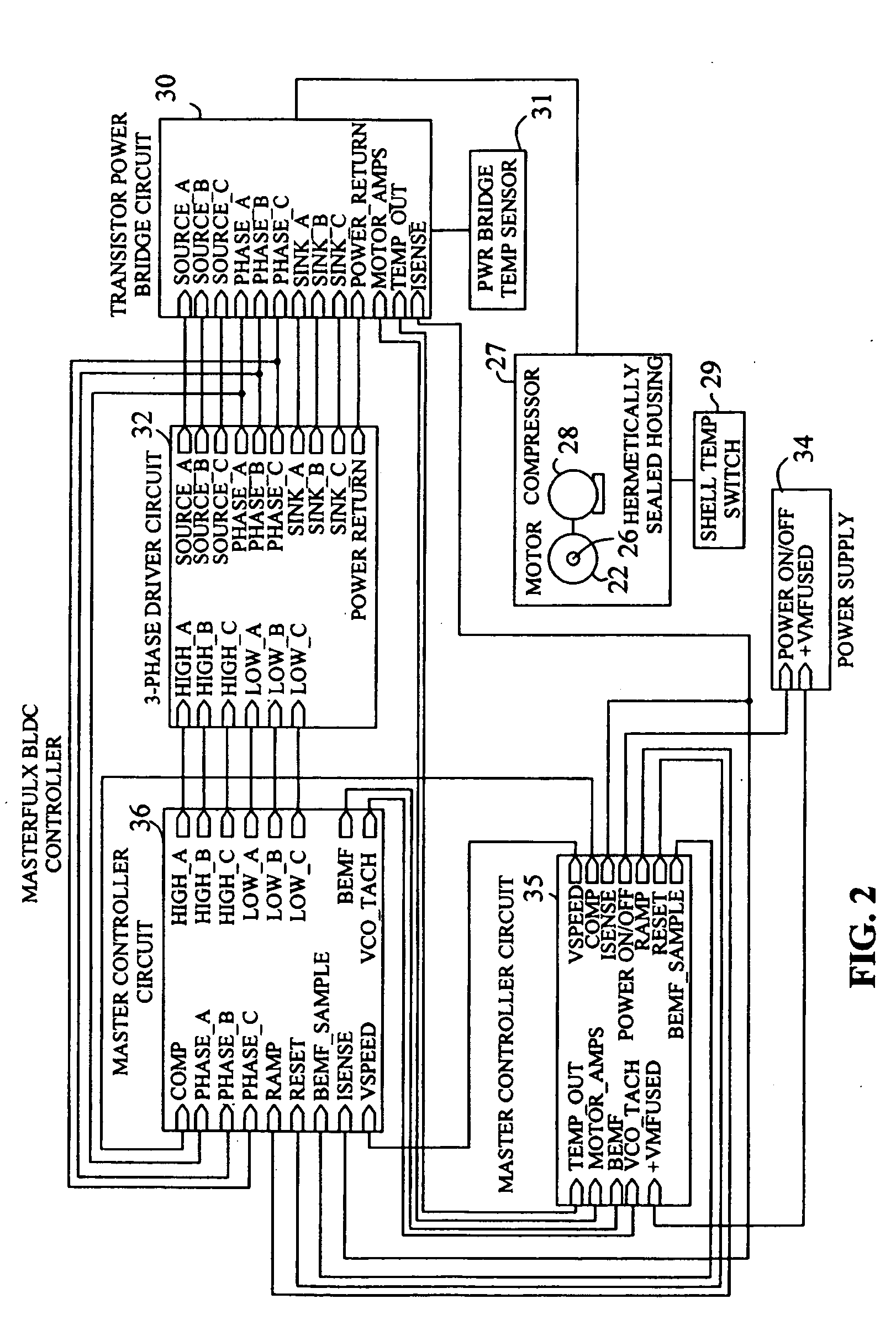

Brushless and sensorless DC motor control system with locked and stopped rotor detection

ActiveUS7042180B2Simple control methodEasily interfaceCommutation monitoringAC motor controlMotor speedDc motor control

A motor control system for a brushless and sensorless DC motor for driving a compressor, pump or other application, includes a protection and fault detection circuit for detecting a locked rotor and a rotor which has stopped because of lost rotor phase lock. The motor control system also includes an off-the-shelf motor control integrated circuit having an input for disabling power outputs to the motor phase coils. The protection and fault detection circuit uses a back EMF sampling circuit coupled to the motor phase coils and momentarily disables power to the motor phase coils, via the motor control integrated circuit input, to determine if the motor rotor is rotating. The system also monitors supply voltage, supply current, temperature, and motor speed limits to detect faults and protect system components.

Owner:REGAL BELOIT AMERICA

Brushless and sensorless DC motor control system with locked and stopped rotor detection

ActiveUS20050029976A1Easy to modifyEasily interfaceCommutation monitoringDC motor speed/torque controlMotor speedDc motor control

A motor control system for a brushless and sensorless DC motor for driving a compressor, pump or other application, includes a protection and fault detection circuit for detecting a locked rotor and a rotor which has stopped because of lost rotor phase lock. The motor control system also includes an off-the-shelf motor control integrated circuit having an input for disabling power outputs to the motor phase coils. The protection and fault detection circuit uses a back EMF sampling circuit coupled to the motor phase coils and momentarily disables power to the motor phase coils, via the motor control integrated circuit input, to determine if the motor rotor is rotating. The system also monitors supply voltage, supply current, temperature, and motor speed limits to detect faults and protect system components.

Owner:REGAL BELOIT AMERICA

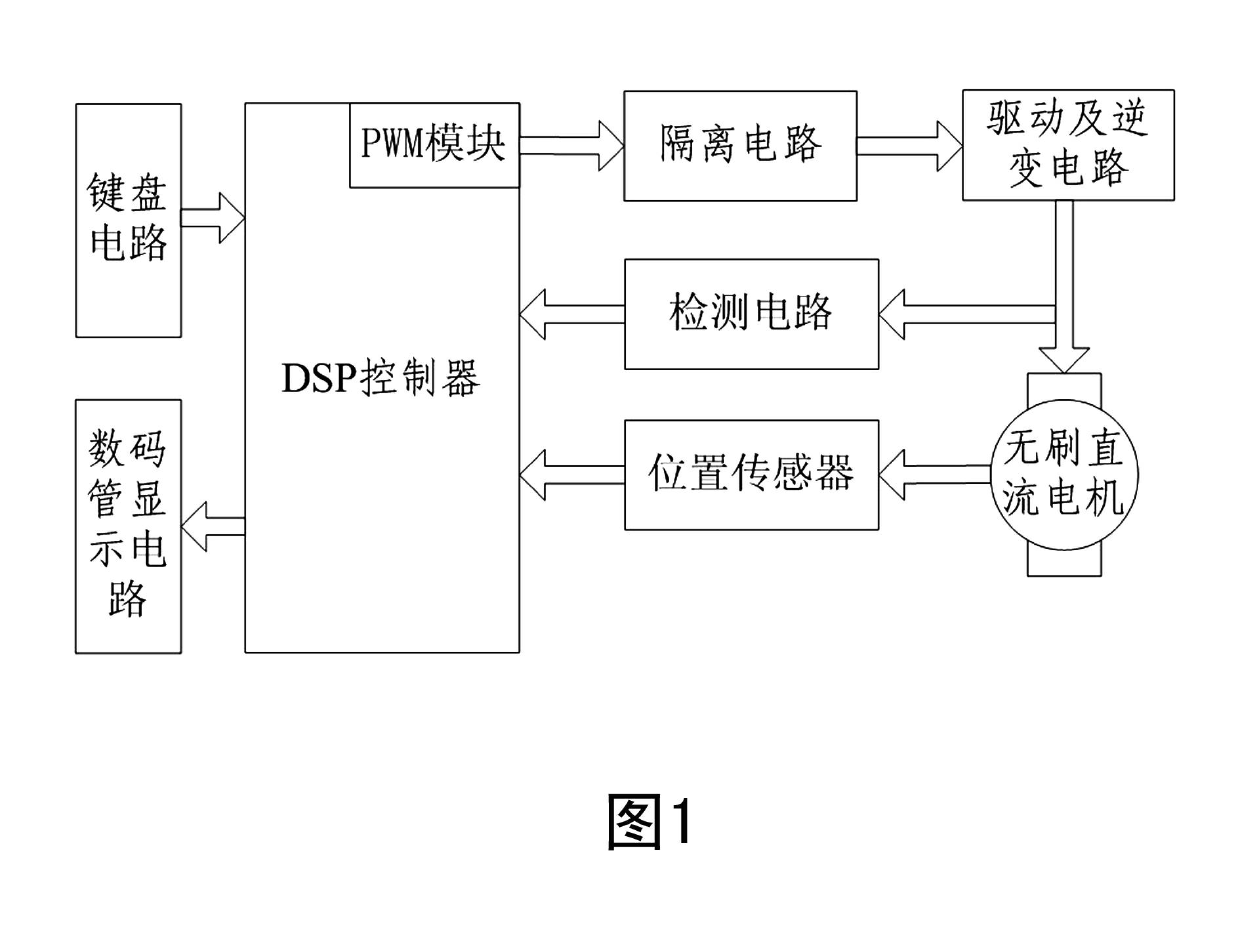

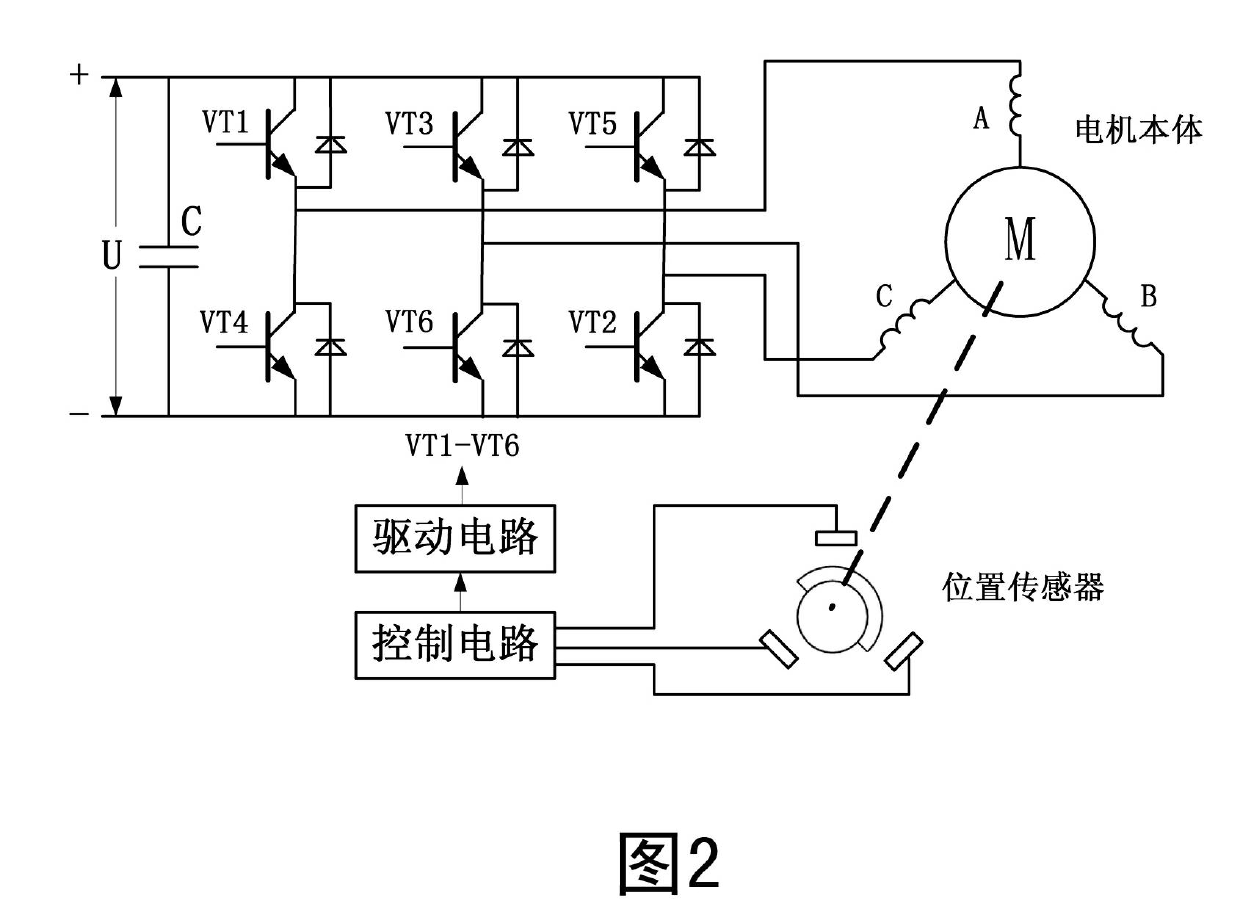

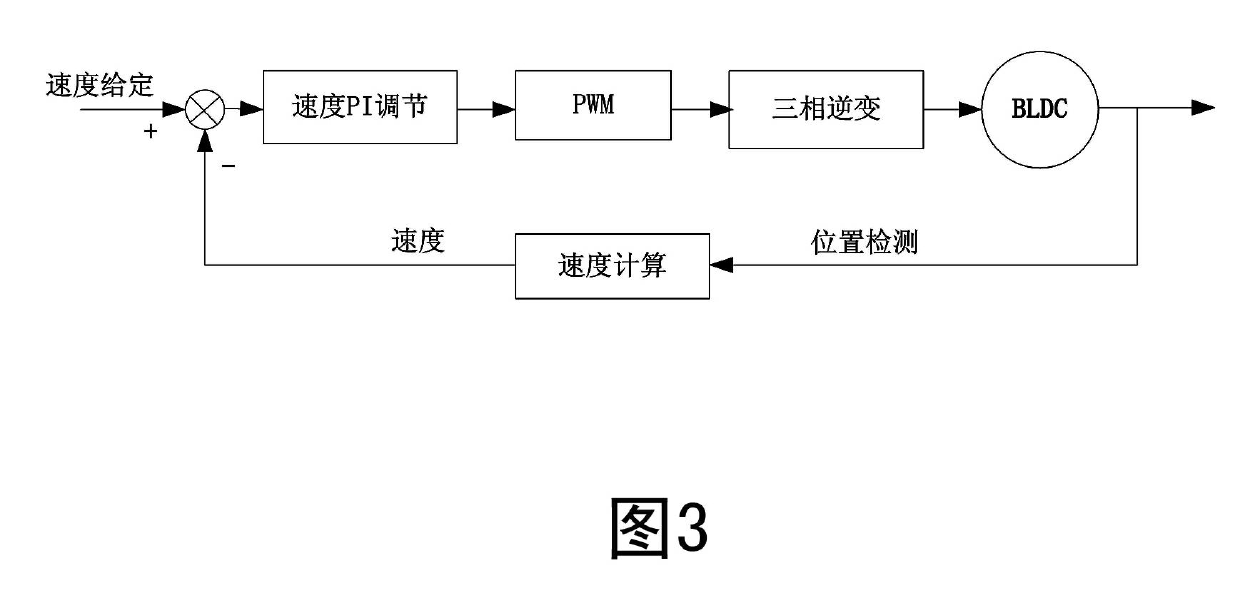

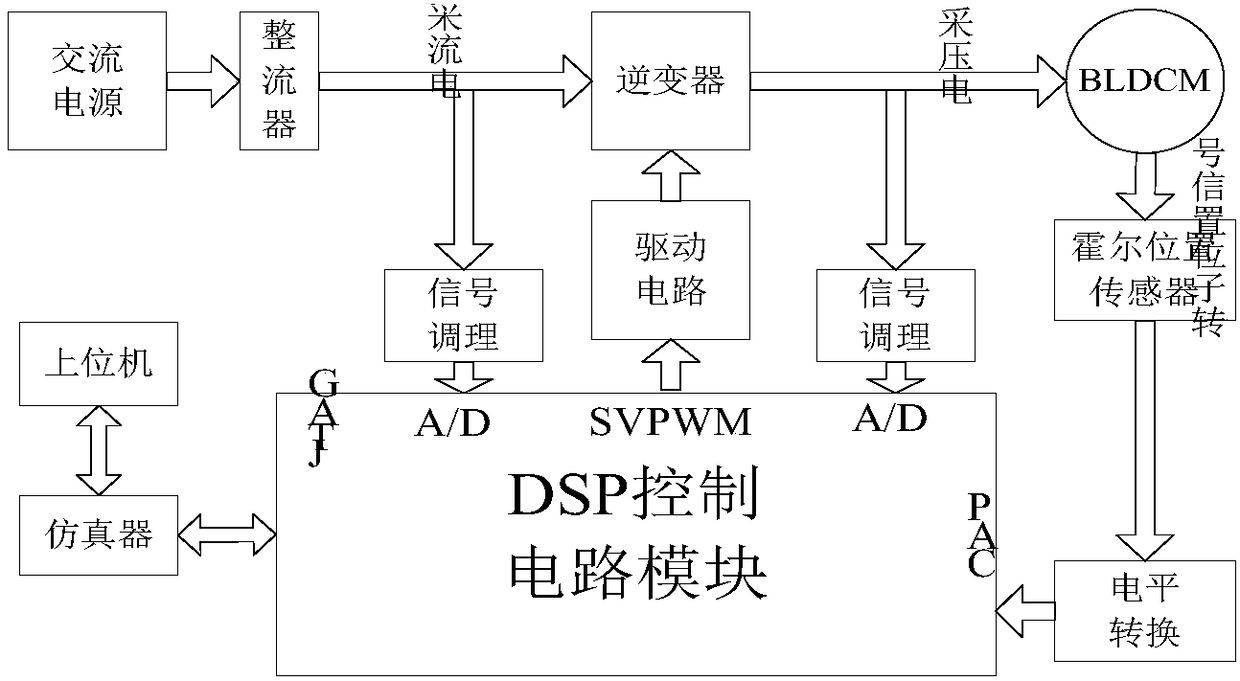

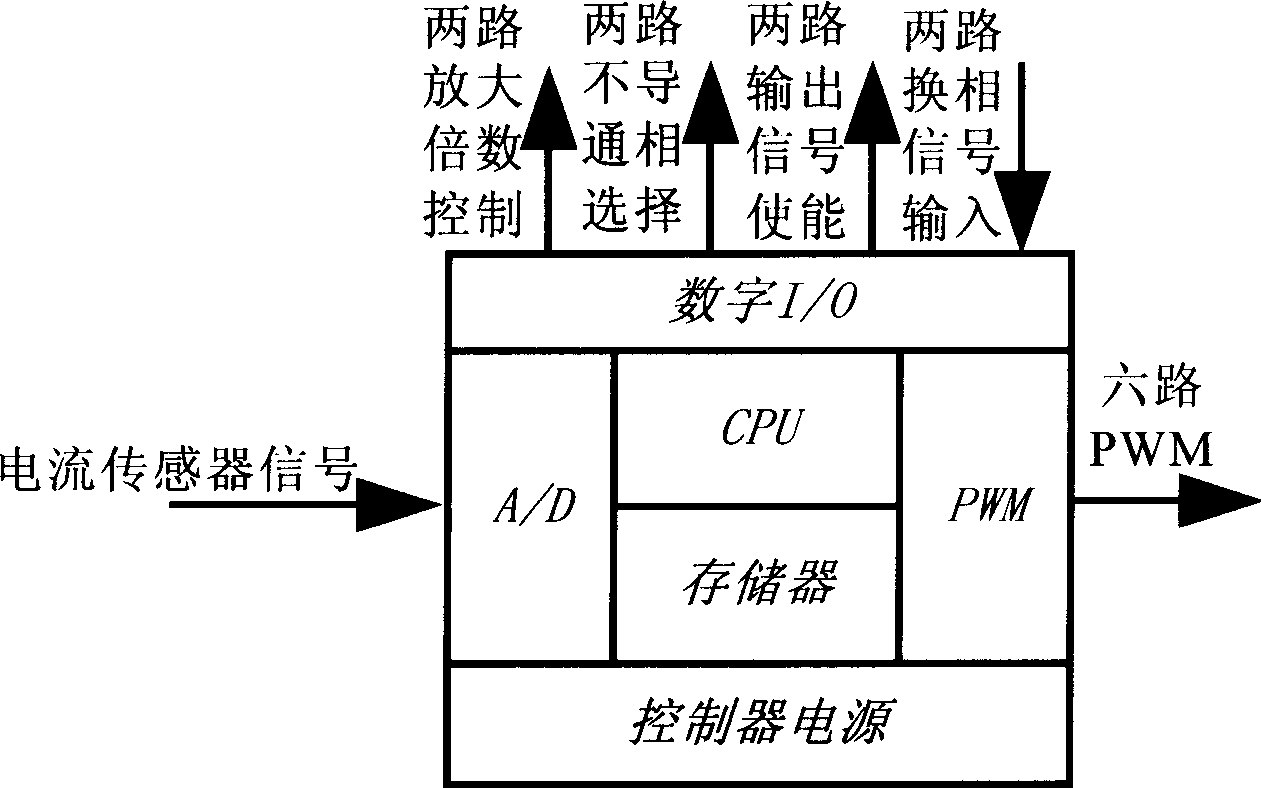

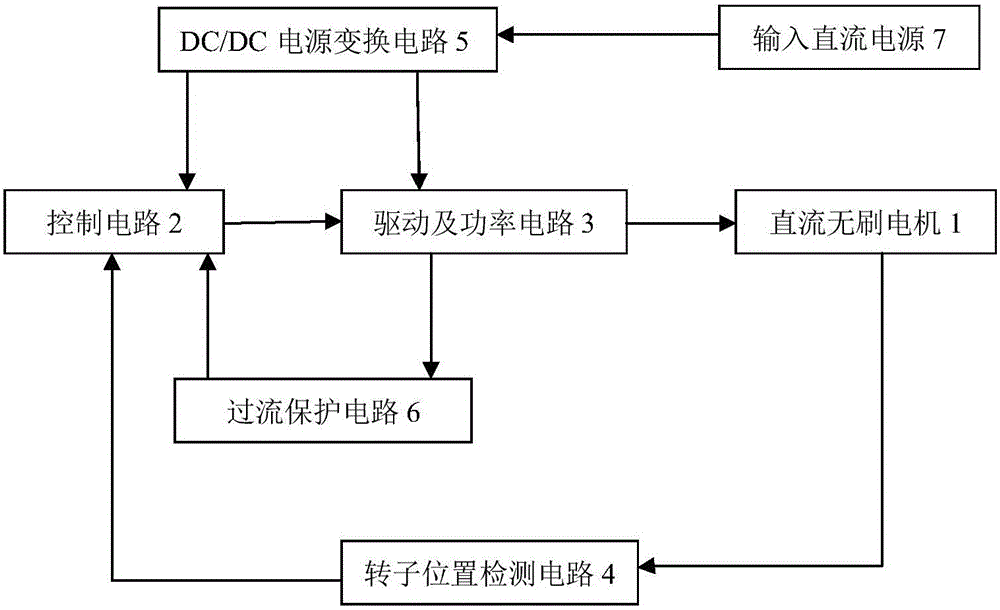

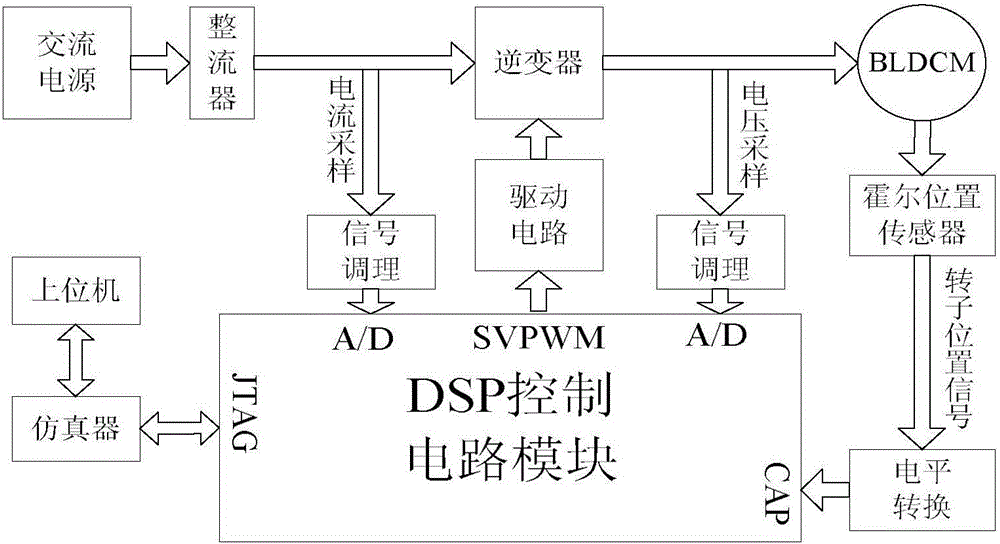

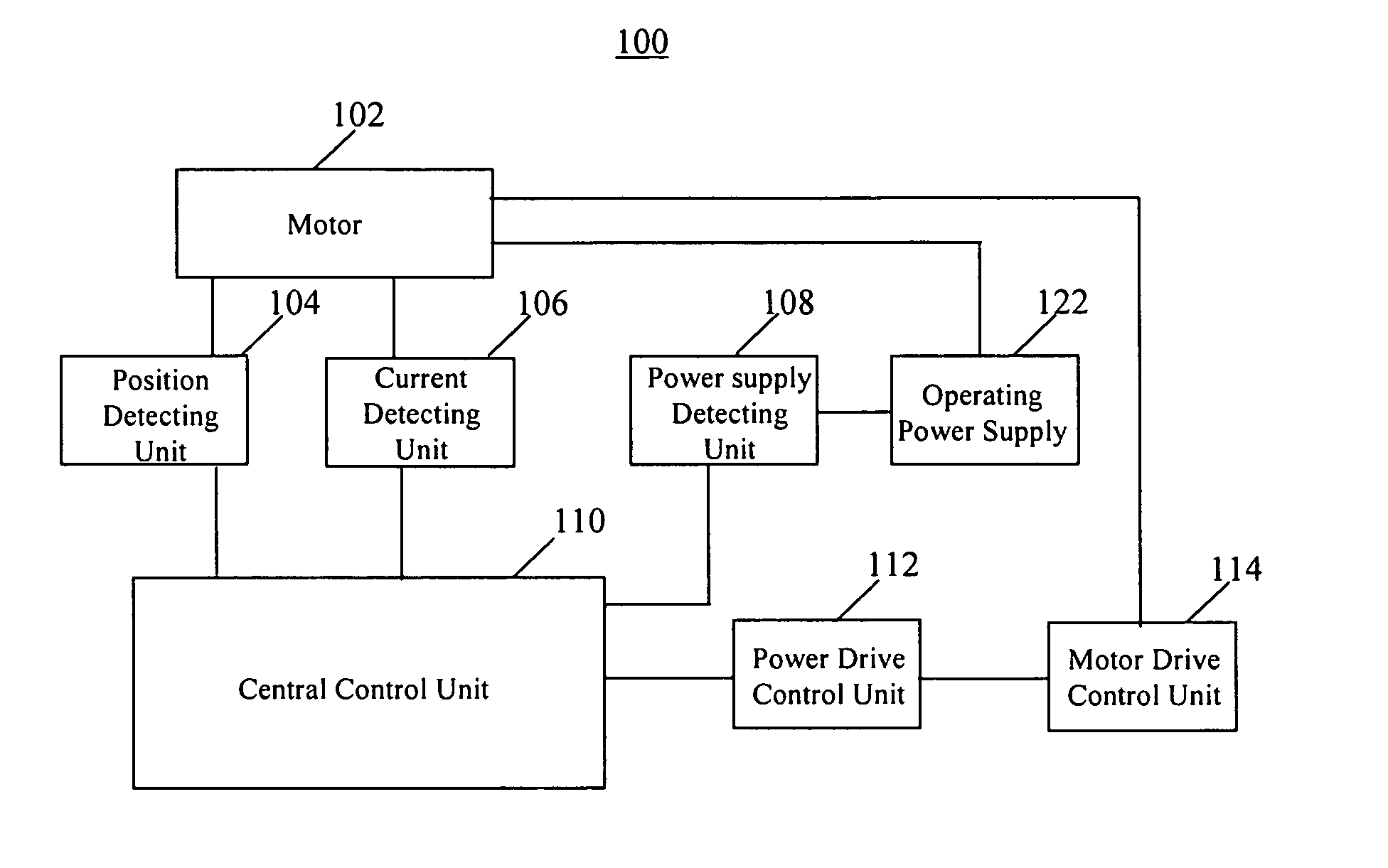

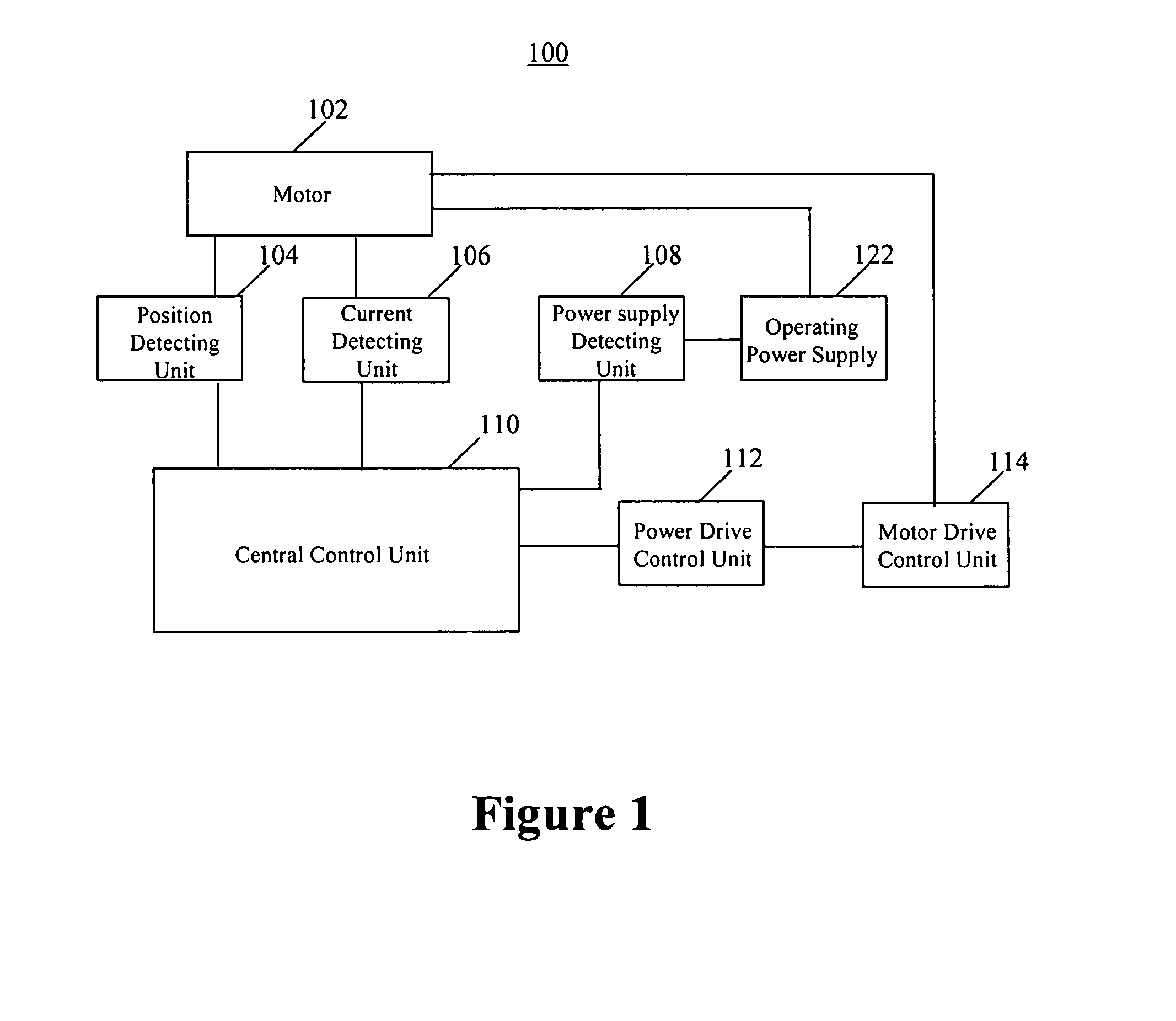

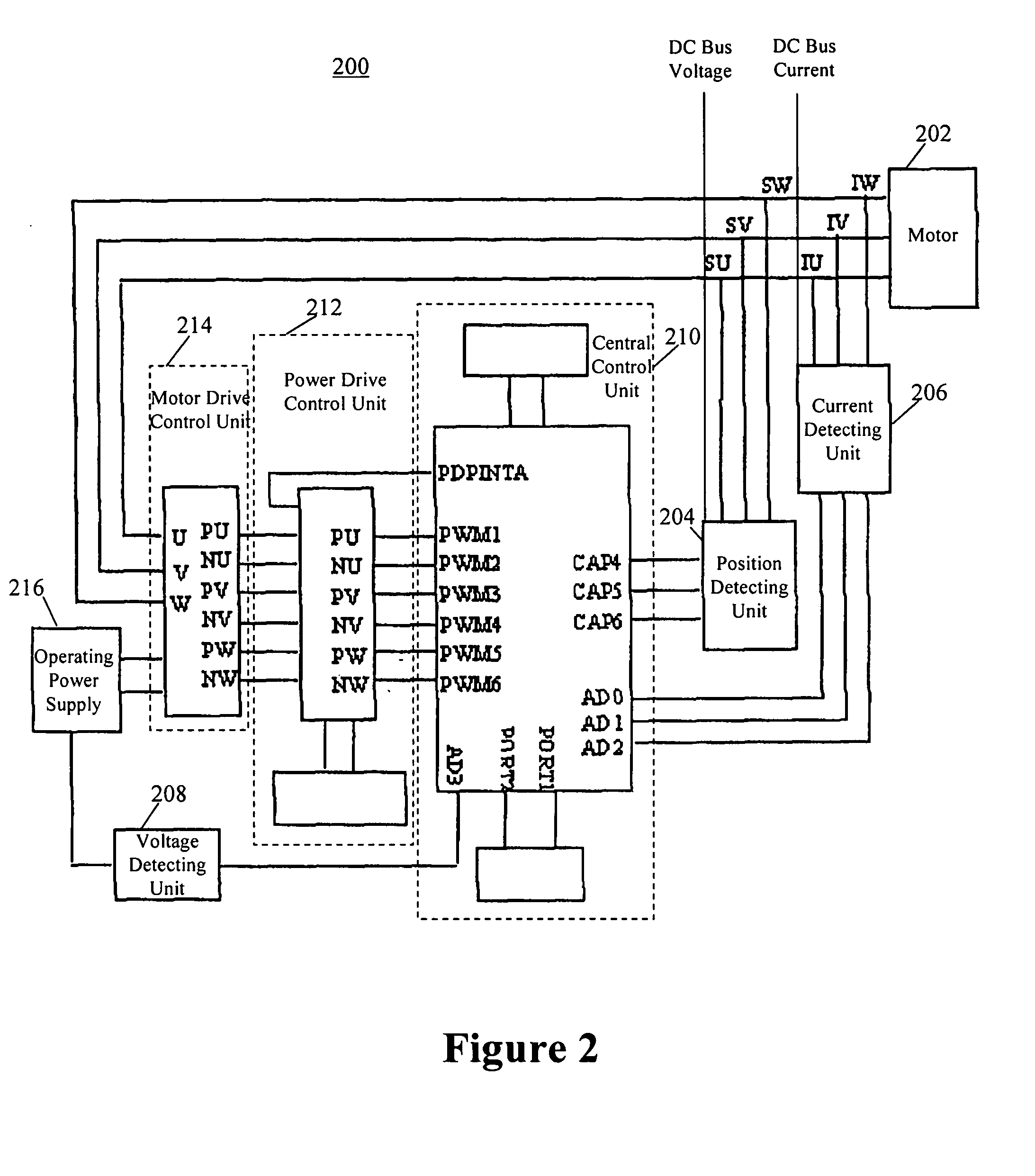

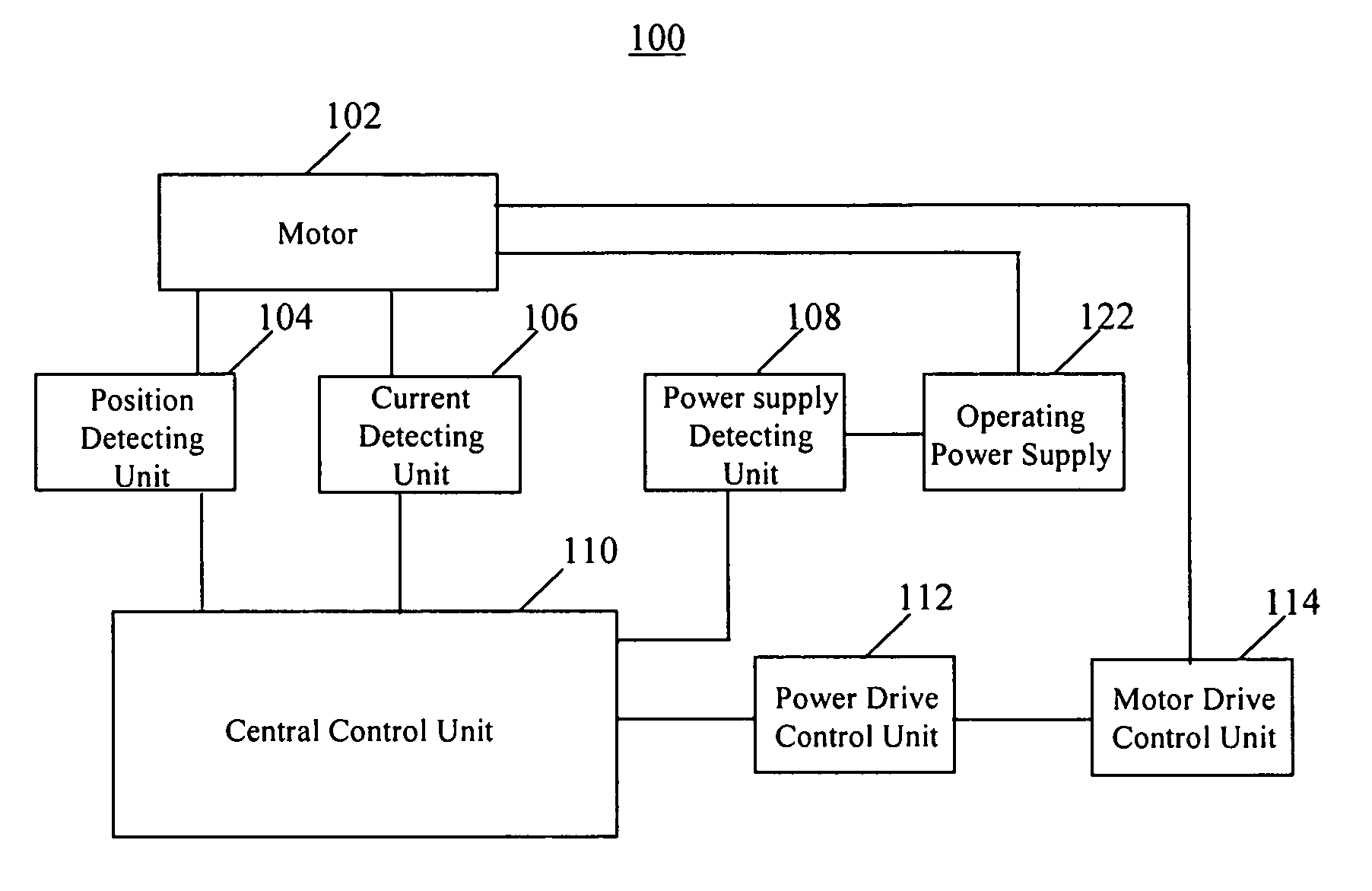

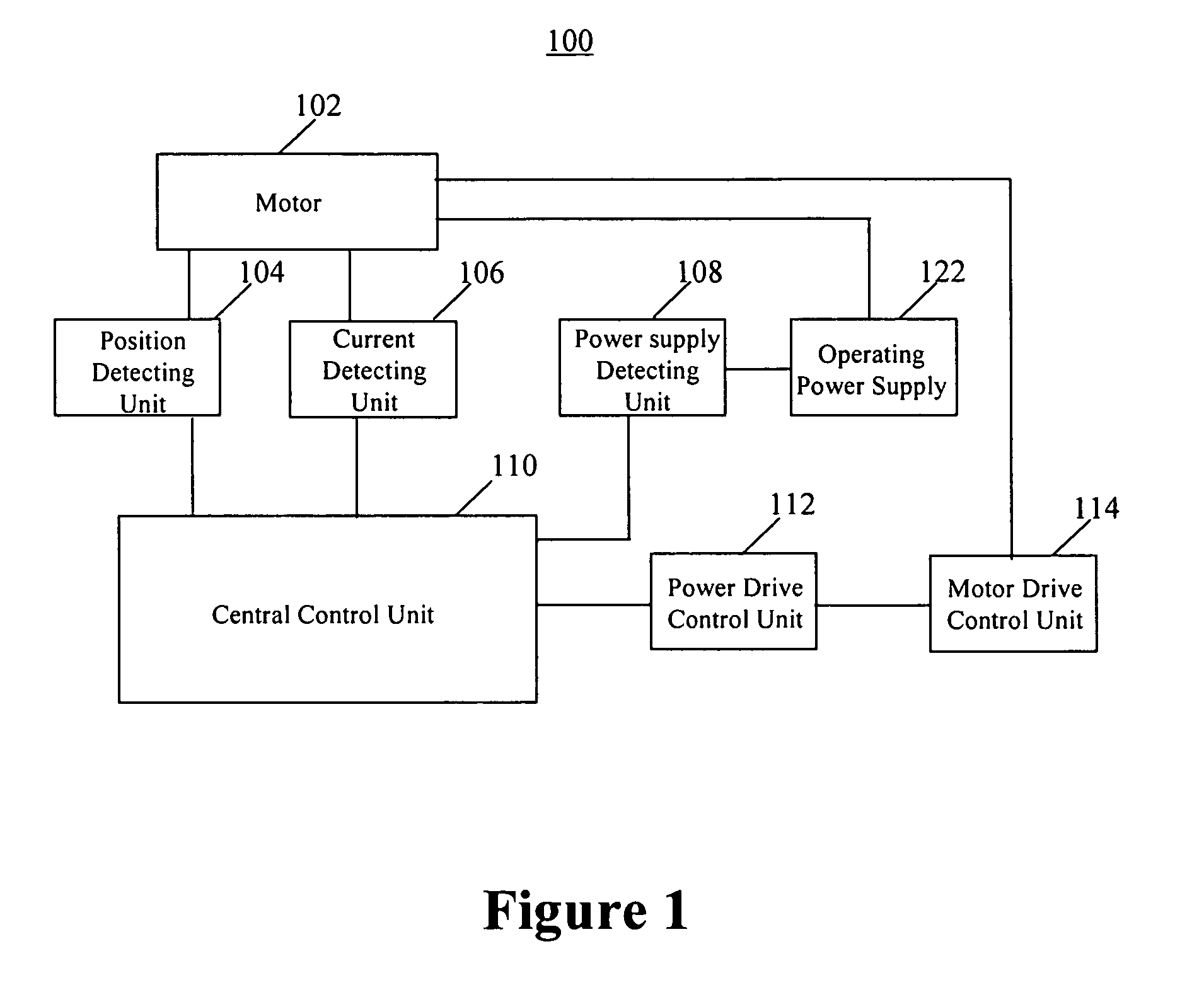

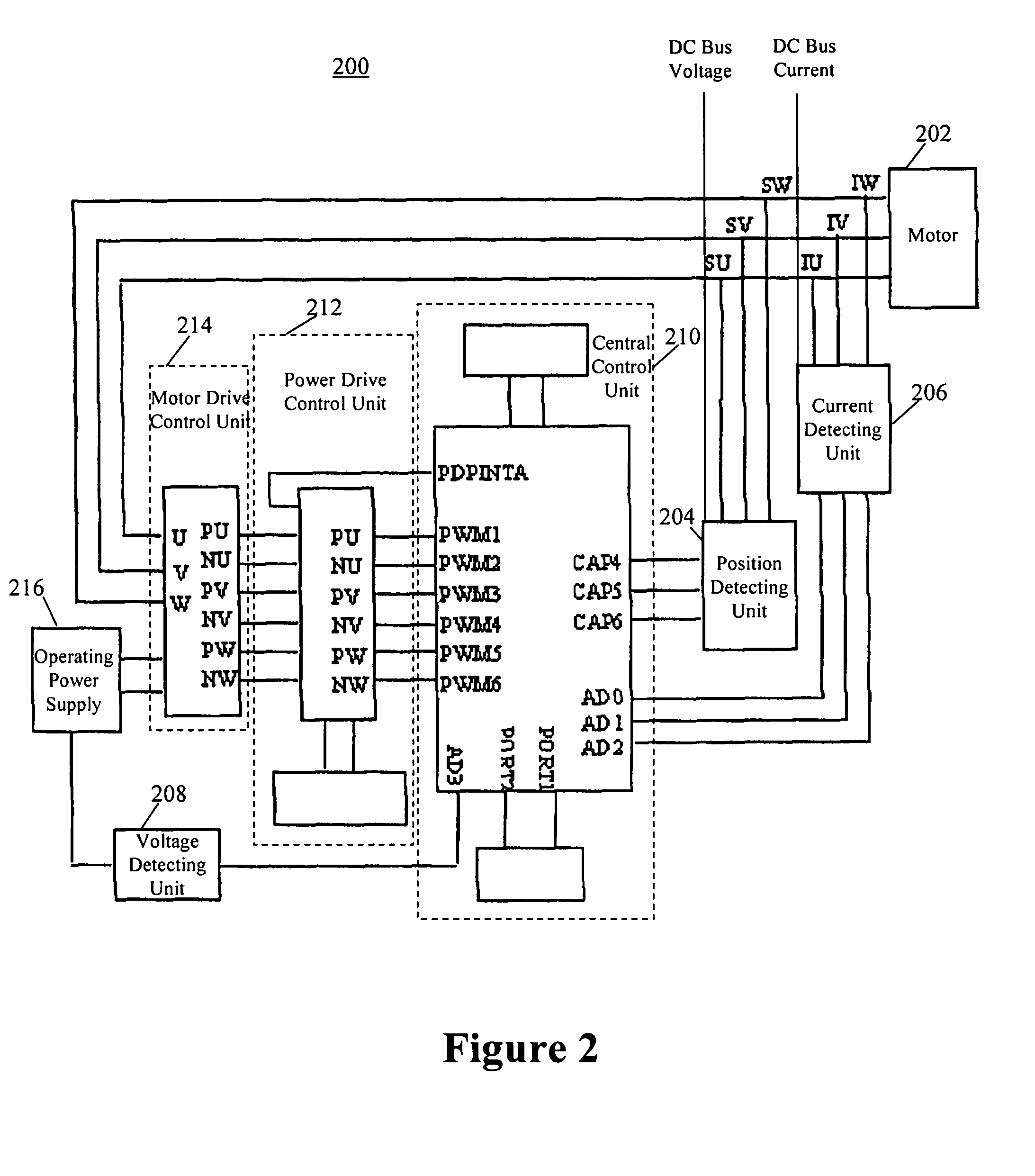

dsp based brushless dc motor control device

InactiveCN102291065AImprove anti-interference abilityStable jobAC motor controlSingle motor speed/torque controlAnti jammingControl signal

The invention discloses a DSP-based brushless DC motor control device, comprising: a position sensor, installed on the stator of the brushless DC motor, used to detect the position information of the rotor of the motor during operation, and send the position information to the DSP control device; DSP controller, used to obtain the real-time speed of the motor according to the adjacent position information sent by the position sensor and the time to obtain the adjacent position information; and compare the real-time speed with the preset target speed, and according to the comparison result Send control signals to the drive and inverter circuit; the drive and inverter circuit is used to control the speed and direction of rotation of the motor according to the control signal of the DSP controller. The DSP-based brushless DC motor control device of the present invention utilizes the high-performance data processing capability and rich peripheral interfaces of the DSP controller to realize a set of DSP-based rotational speed closed-loop control system suitable for the brushless DC motor. The device has good anti-interference performance and the system works stably.

Owner:BEIJING INFORMATION SCI & TECH UNIV

Brushless DC motor control

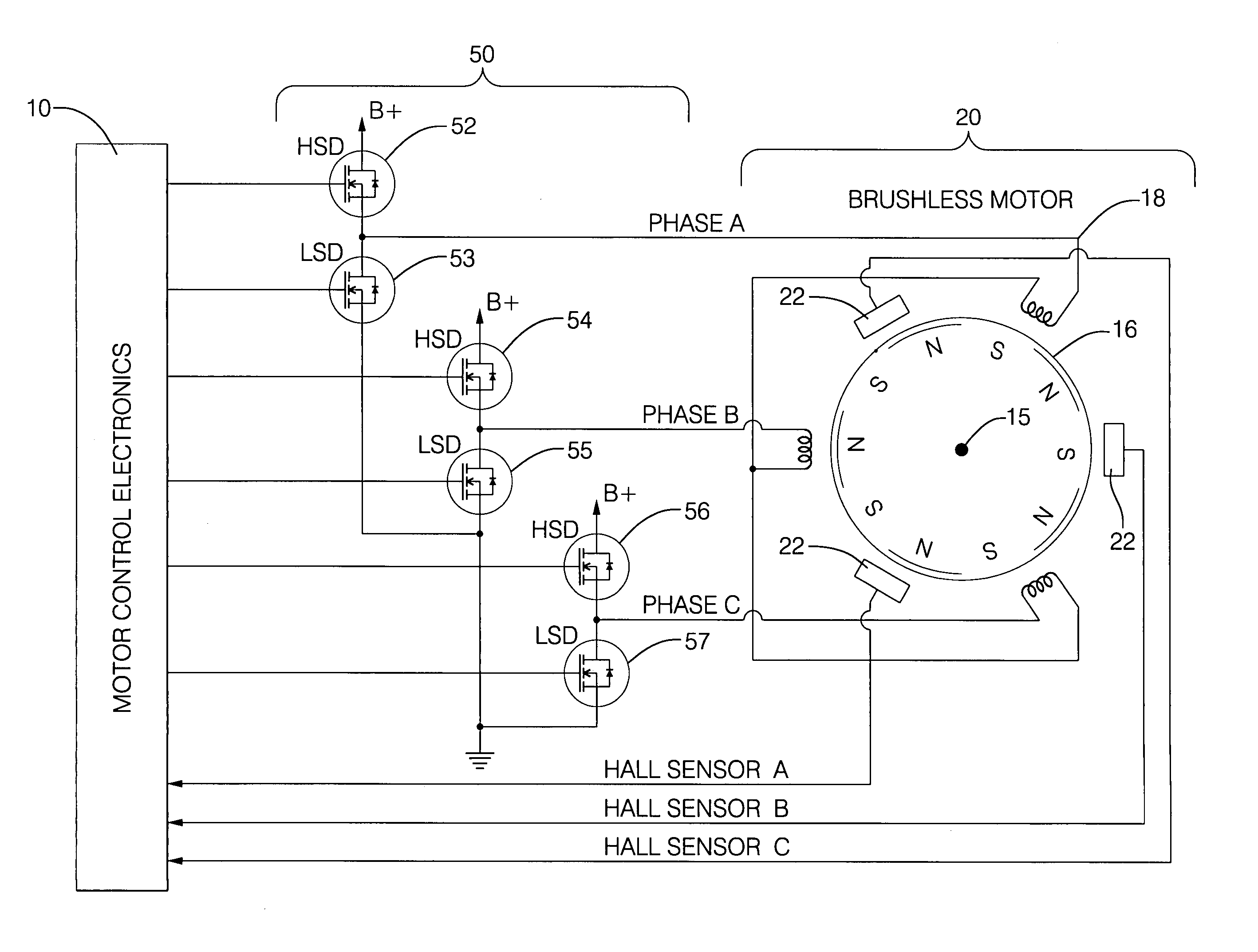

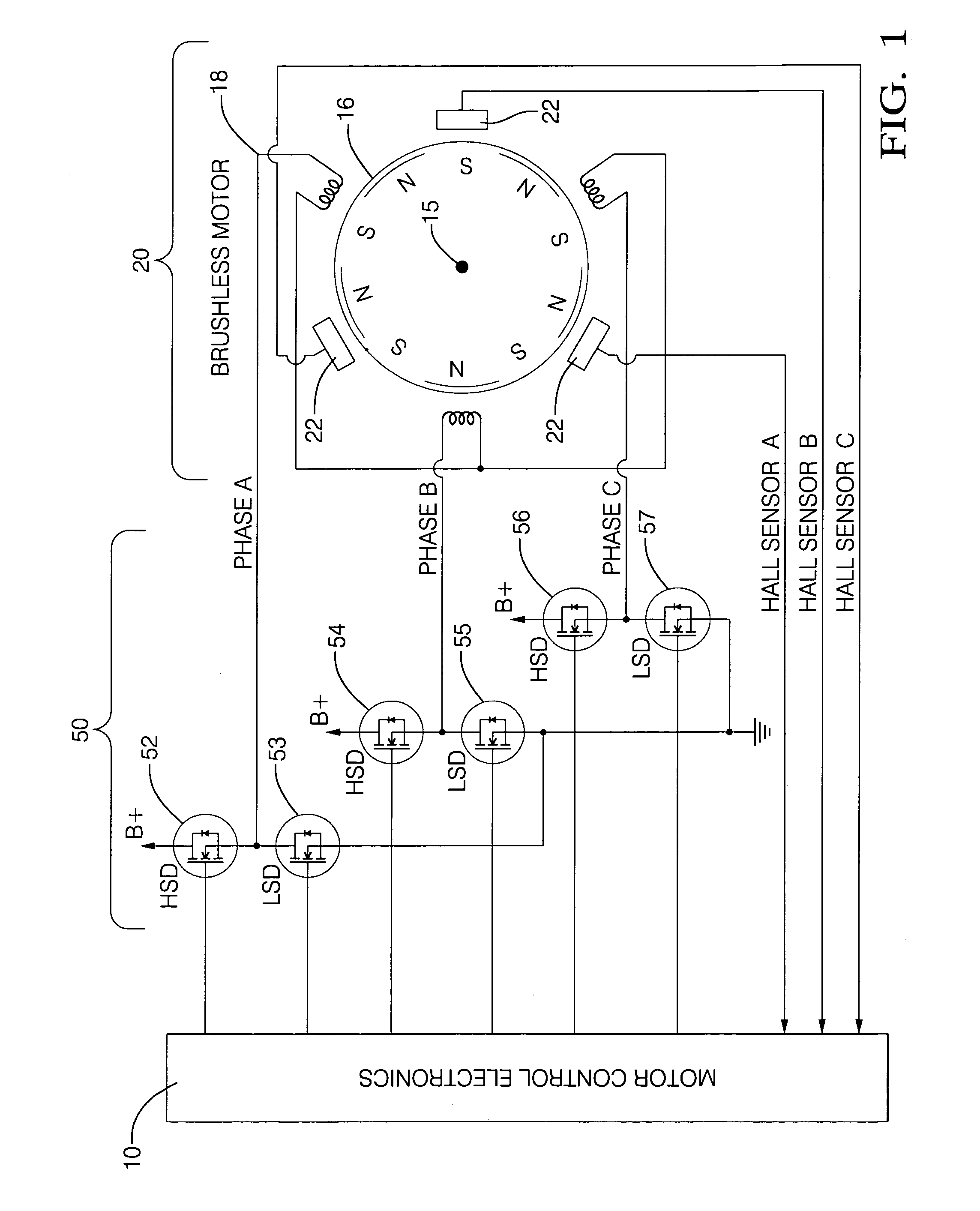

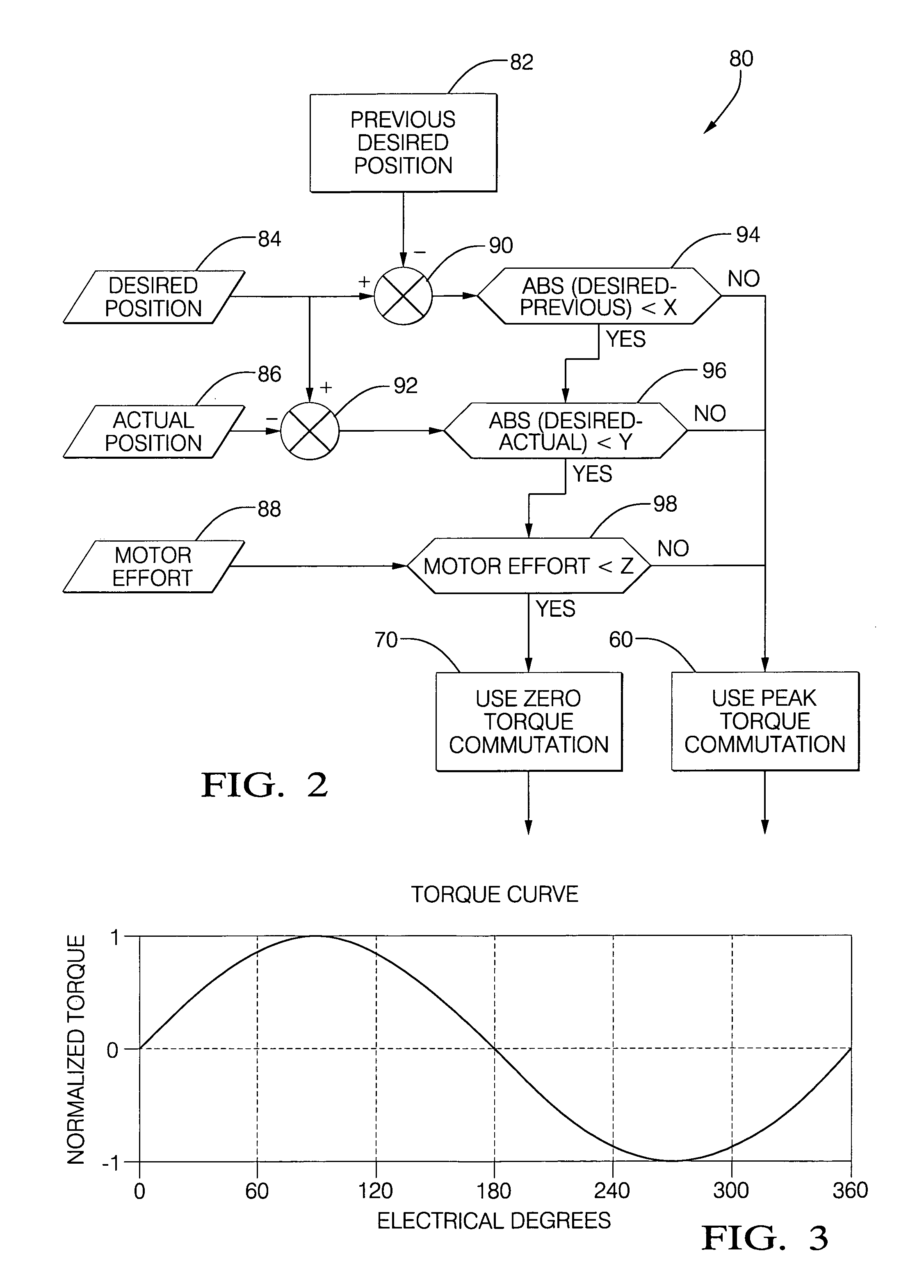

ActiveUS7053583B1Optimizing response timeOptimize energy useMotor/generator/converter stoppersSynchronous motors startersDc motor controlFixed position

A method and control system to control a brushless DC motor to a preferred position is provided. The advantages that accrue to a system employing the method and apparatus to control the brushless DC motor to a preferred position include optimizing response time, energy usage, coil heating, and ability to hold to a fix position. The method to control the brushless DC motor to a position comprises monitoring actual position of the brushless DC motor, monitoring energy used by the brushless DC motor, and determining a commanded position of the brushless DC motor. A zero torque commutation method is employed to control the brushless DC motor to the commanded position only when a time-rate change in the commanded position is less than a first threshold, a difference between the commanded position and actual position is less than a second threshold, and, the monitored energy used is less than a third threshold. A peak torque commutation method is employed to control the brushless DC motor to achieve the commanded position when the time-rate change in the commanded position is greater than the first threshold, the difference between the commanded position and actual position is greater than the second threshold, or the monitored energy used is greater than the third threshold.

Owner:DELPHI TECH IP LTD

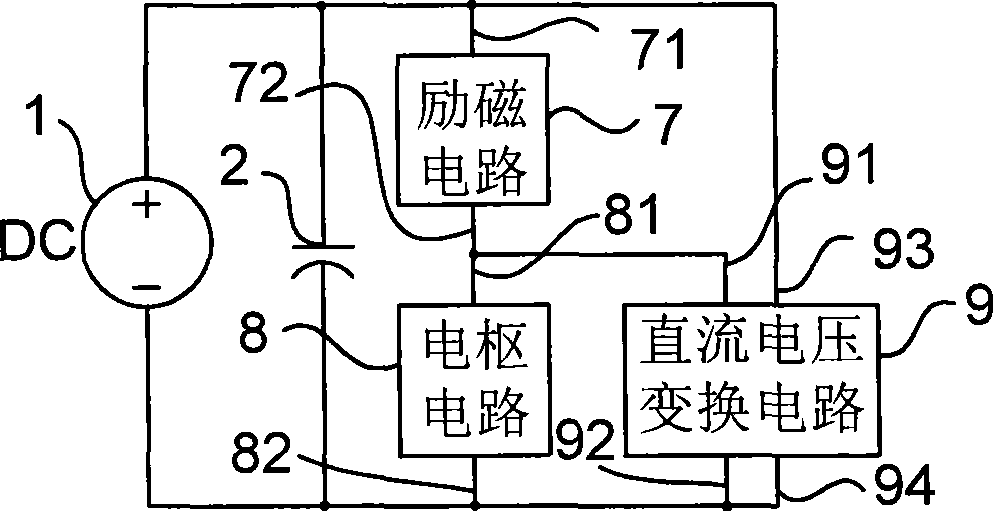

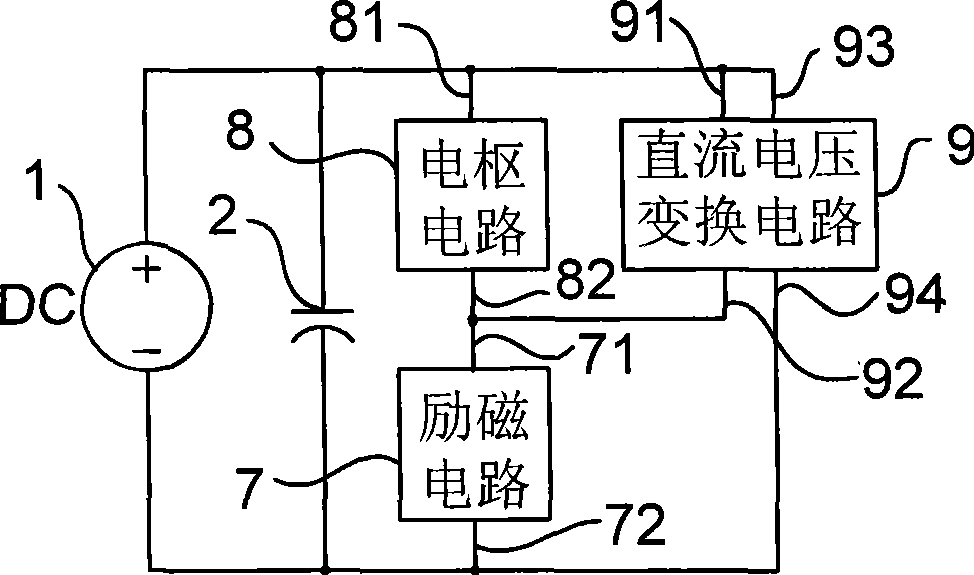

Control circuit, braking method, energy production method and device for DC motor

InactiveCN101425771ASmooth startSmooth brakingField or armature current controlDc motor stoppersElectricityDc motor control

The invention relates to a DC motor control circuit, a braking method, an electricity generating method and a device thereof, in particular to the problems of the starting, the speed regulation, the braking and the reversal rotation of a series excitation DC motor. The control circuit comprises an excitation circuit (7), an armature circuit (8) and a DC voltage transforming circuit (9), and has the characteristics of reusing the braking energy and no mechanical contact point in reversal rotating control. The braking method reuses the braking energy, and the electricity generating method utilizes the rotation of the series excitation DC motor to generate electricity. The device of the invention realizes the stable starting, the stepless speed control, the stepless braking and the running of reversal rotation, the energy in braking is fed back or reused, and the energy in braking can be effectively controlled if the series excitation DC motor rotates when the electricity is cut off. No input electric source exists. If the series excitation DC motor continuously rotates under the action of external force, the device is an electricity generator of the series excitation DC motor and can provide an electric source for the outside.

Owner:杨宇强

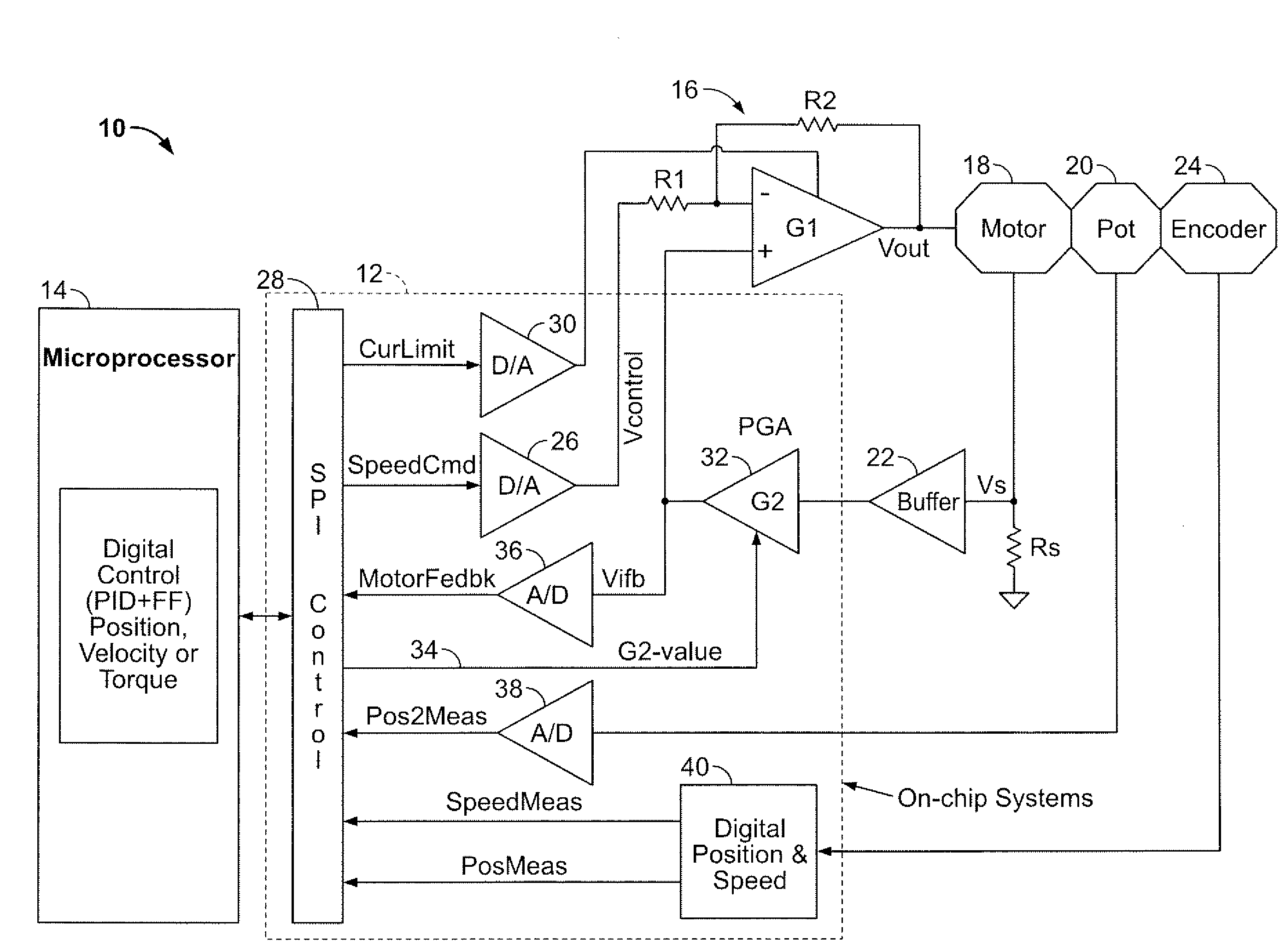

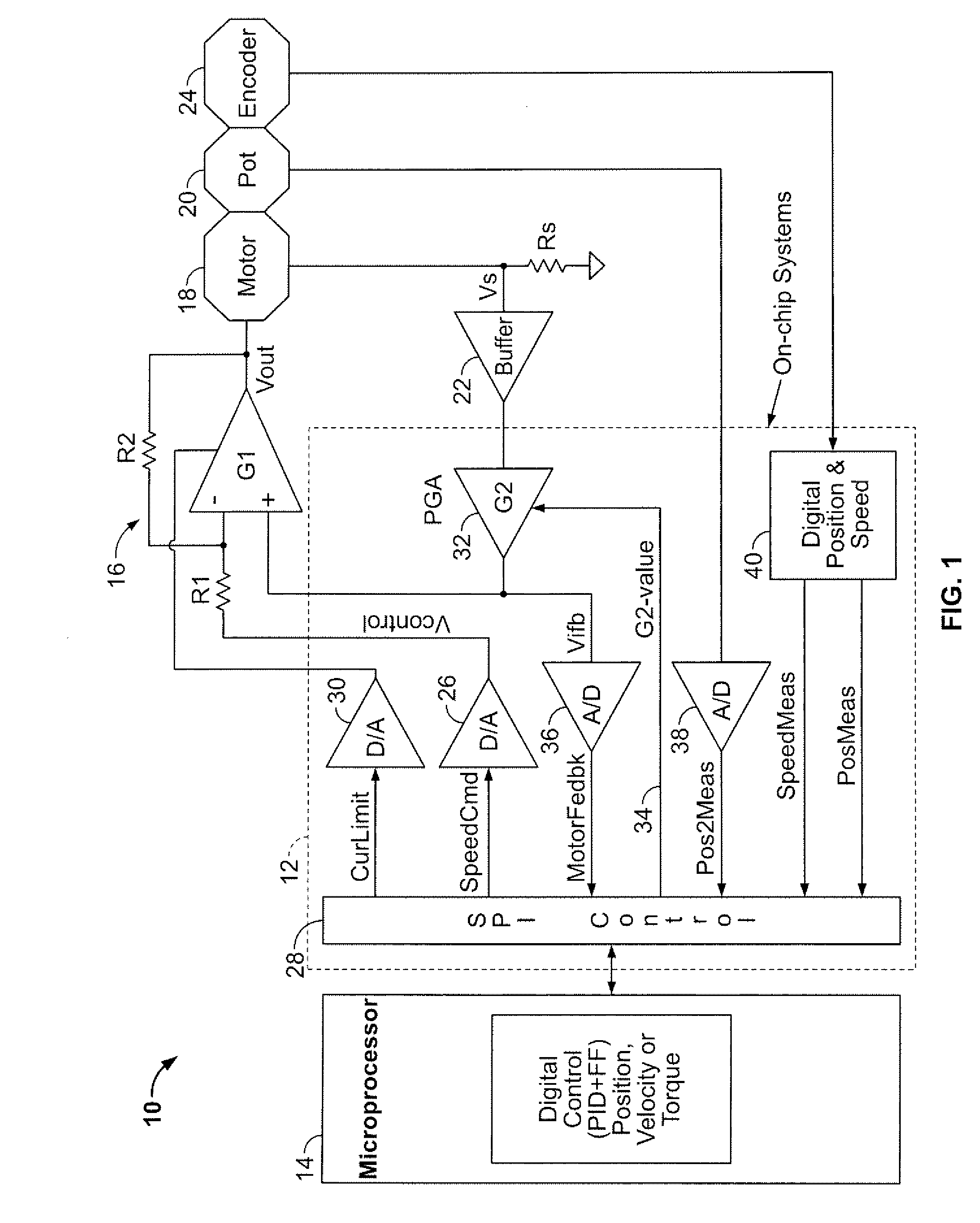

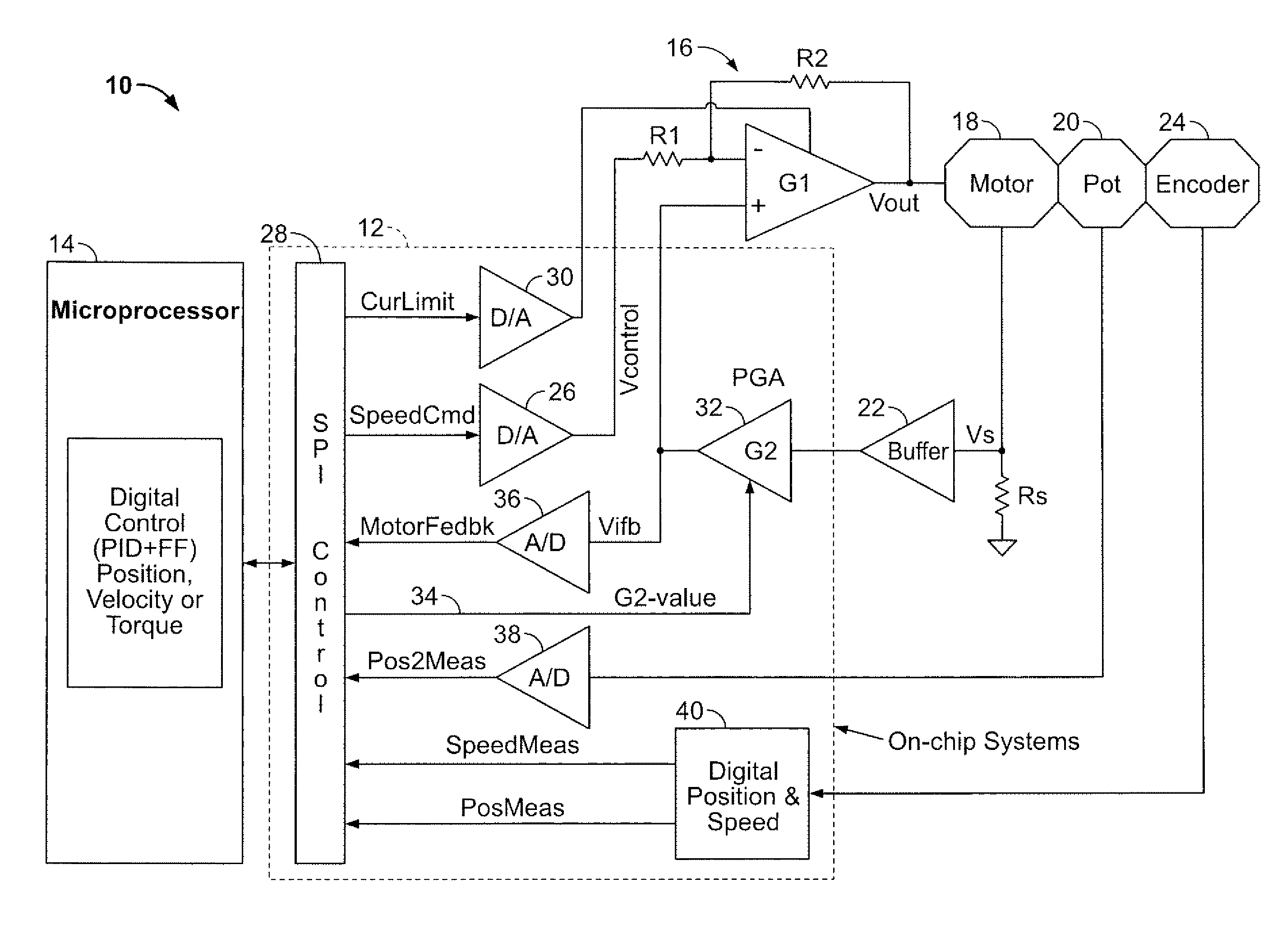

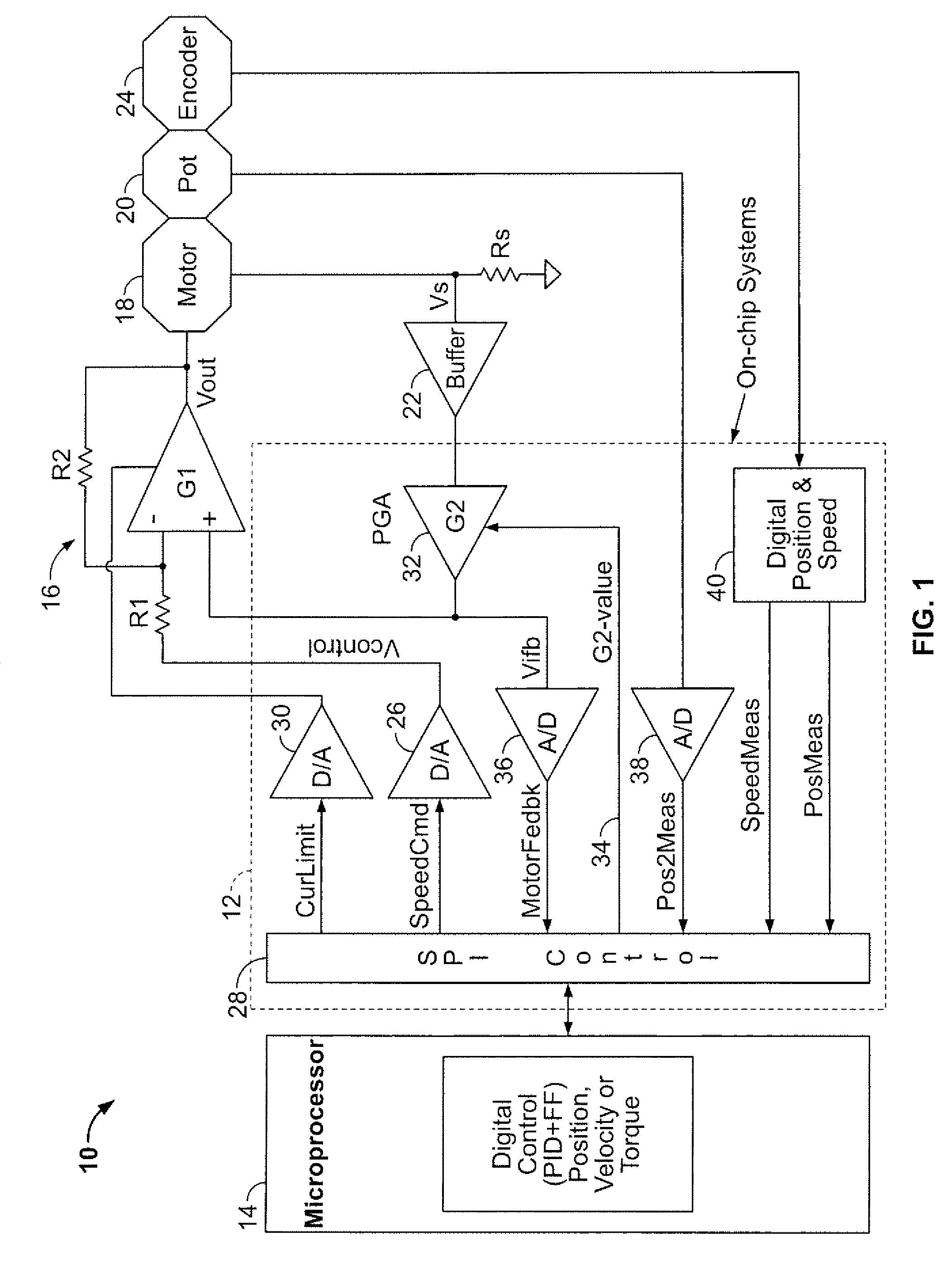

Adaptive and reconfigurable system for DC motor control

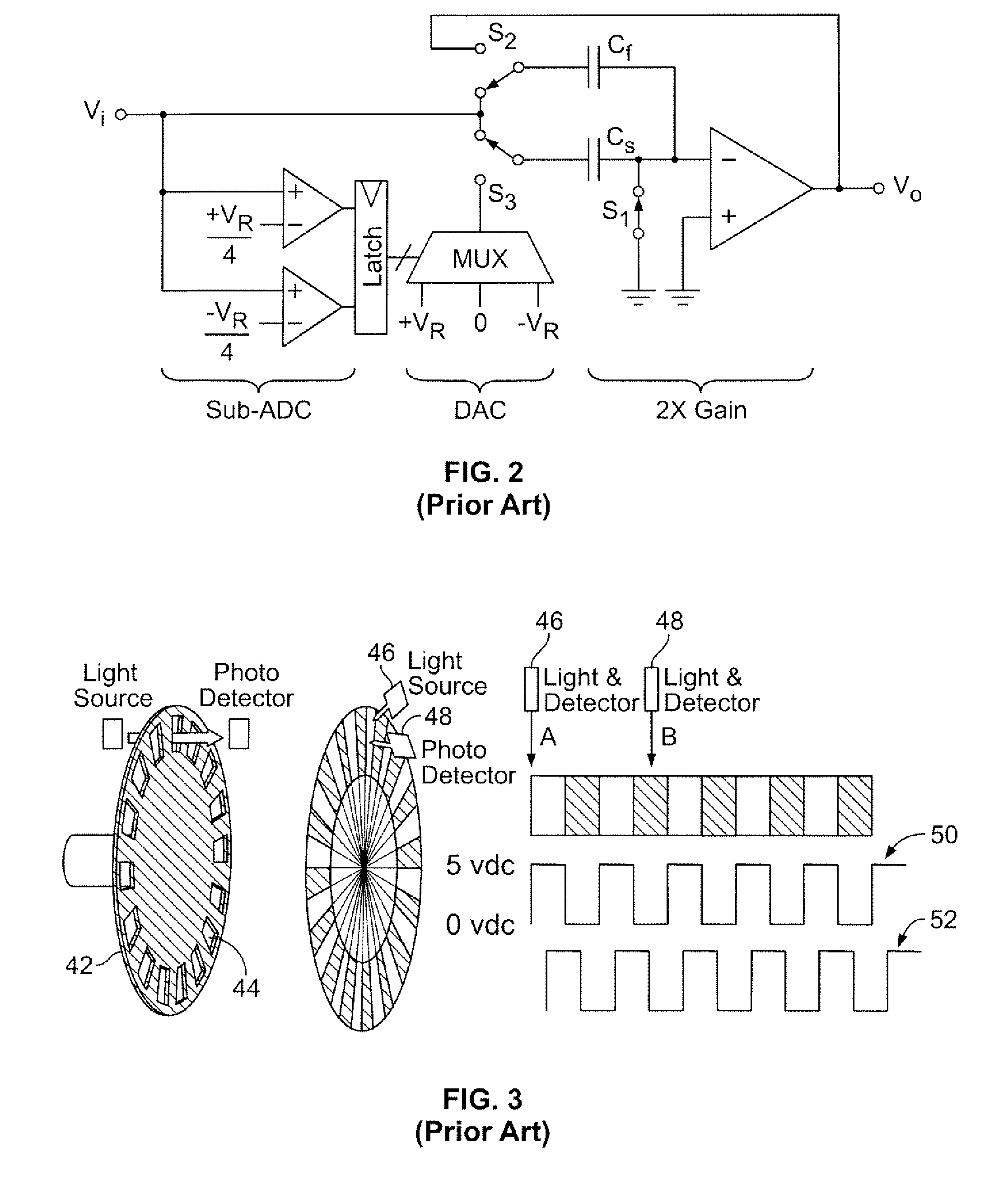

ActiveUS20080247735A1Digital variable displayAcceleration measurement using interia forcesDigital analog converterControl signal

An integrated circuit for controlling a DC motor is disclosed. The integrated circuit includes at least one digital position and speed circuit (DPS) for providing measurements of speed, position, and direction of the motor, the DPS being in signal communication with the motor for receiving a pair of signals having a quadrature relationship; and at least one programmable gain amplifier (PGA) electrically coupled to the motor, the PGA being configured to receive a feedback signal indicative of current flowing through the motor and to apply a second signal to the motor for adjusting the speed of the motor; and at least two analog-to-digital converters (A / D), one A / D being used to quantize the output of the PGA for an off-chip processor; and another A / D to provide motor reference position from an analog sensor, such as a potentiometer; and at least two digital-to-analog converters (D / A), one D / A used to set the motor voltage; and another D / A used to set the motor current limit. The integrated circuit can be incorporated into a larger motor control loop which further includes a summing amplifier for providing the feedback signal to the motor that is indicative of current flowing through the motor; a buffer amplifier electrically for sensing the output current of the motor, and a processor for providing control signals to the system monolithic module and for receiving the measurements of speed, position, and direction of the motor.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

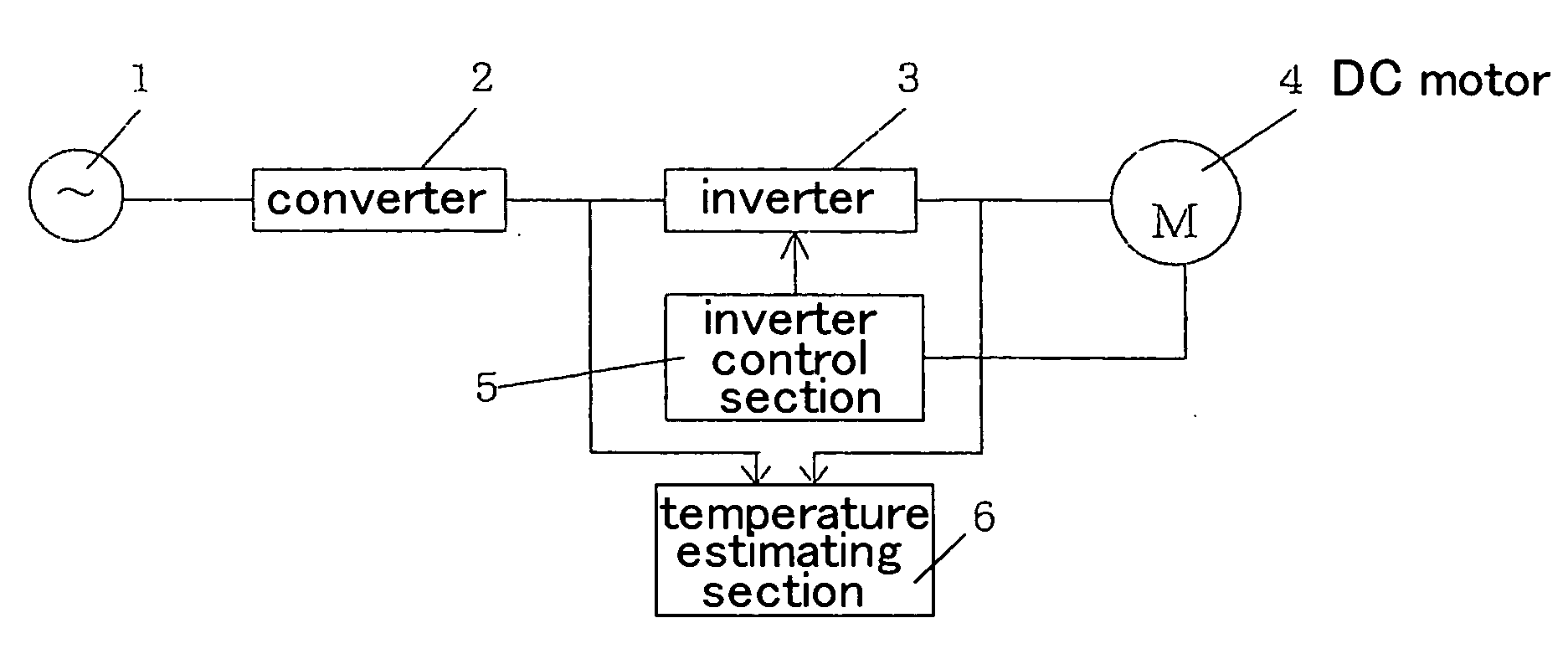

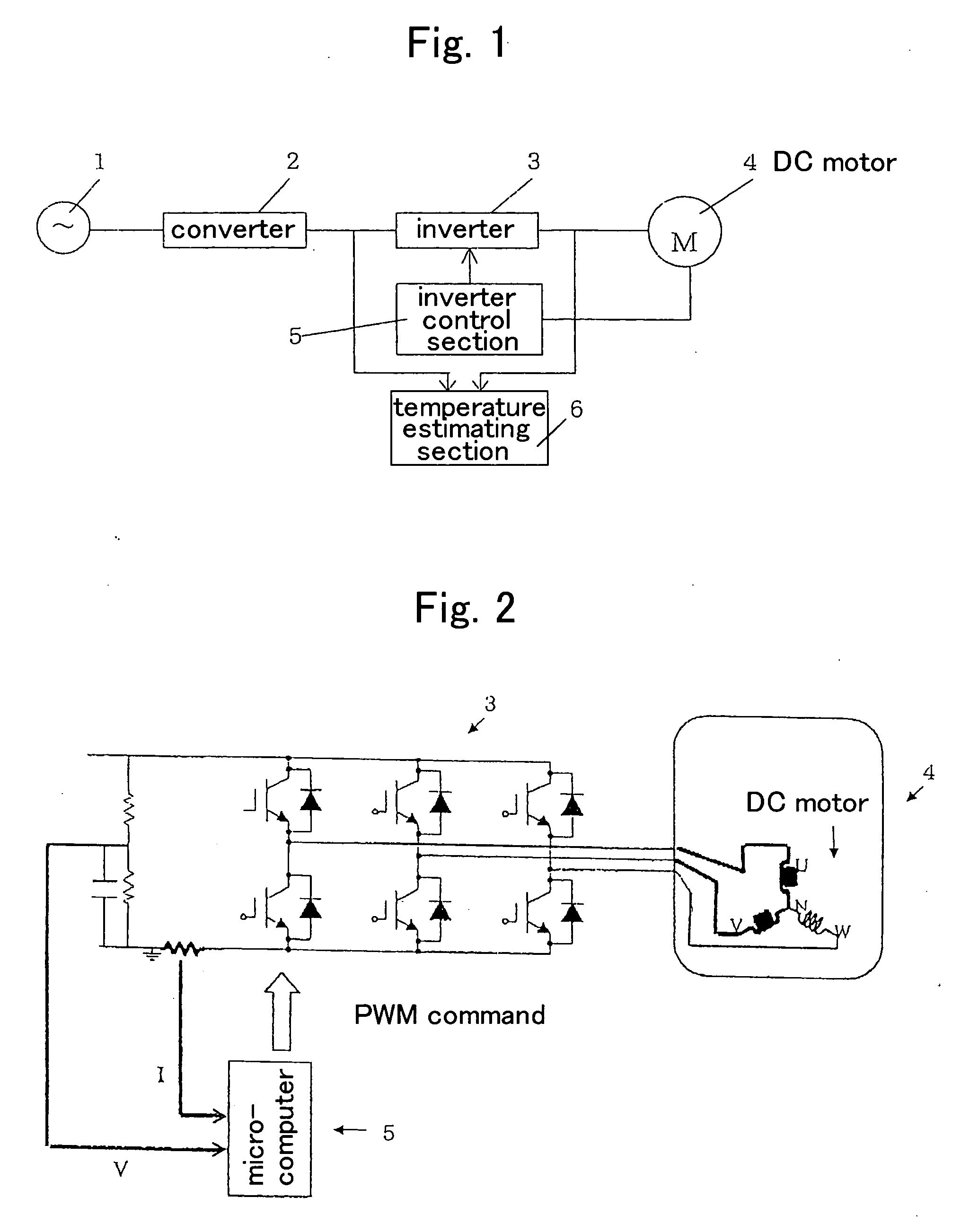

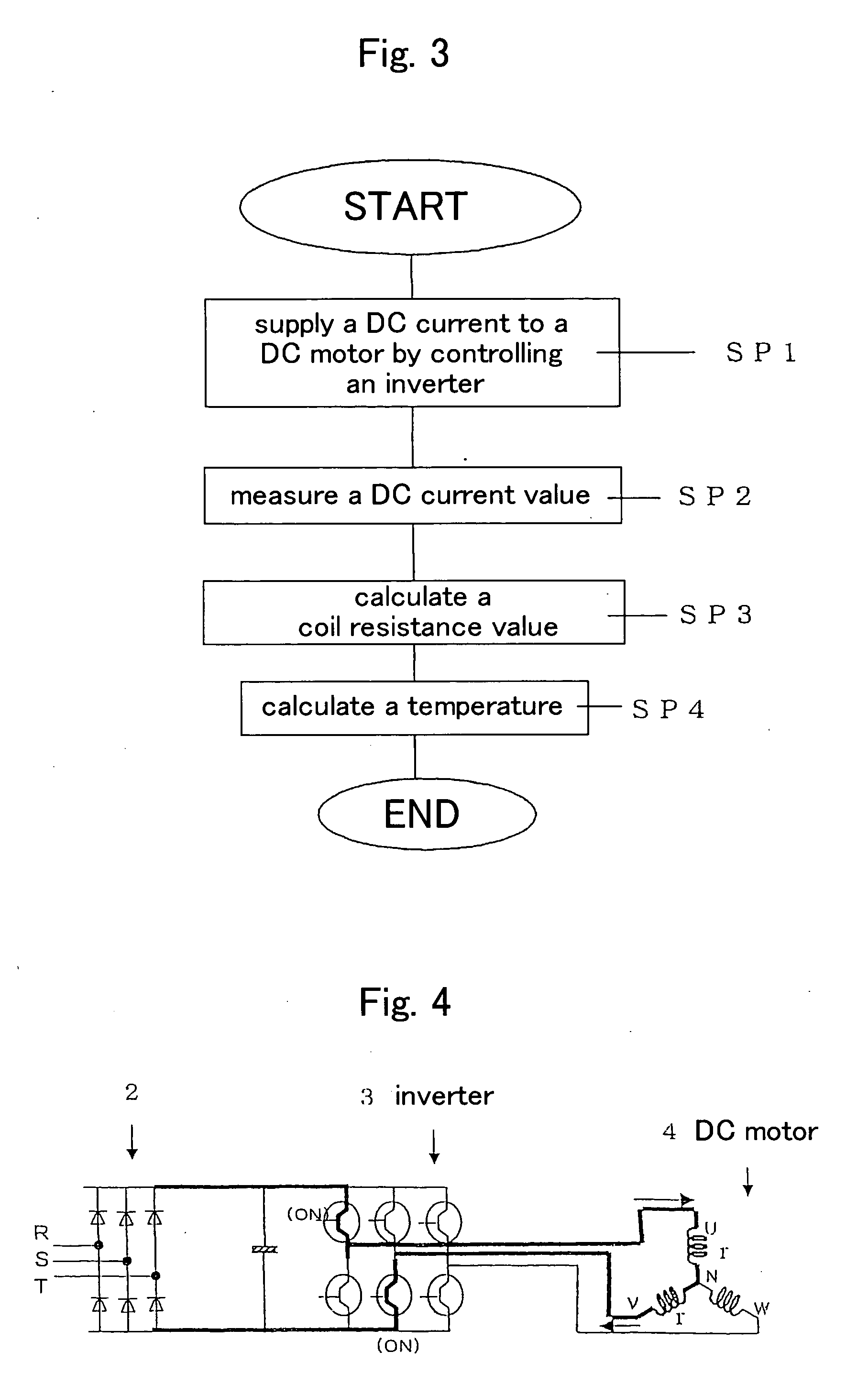

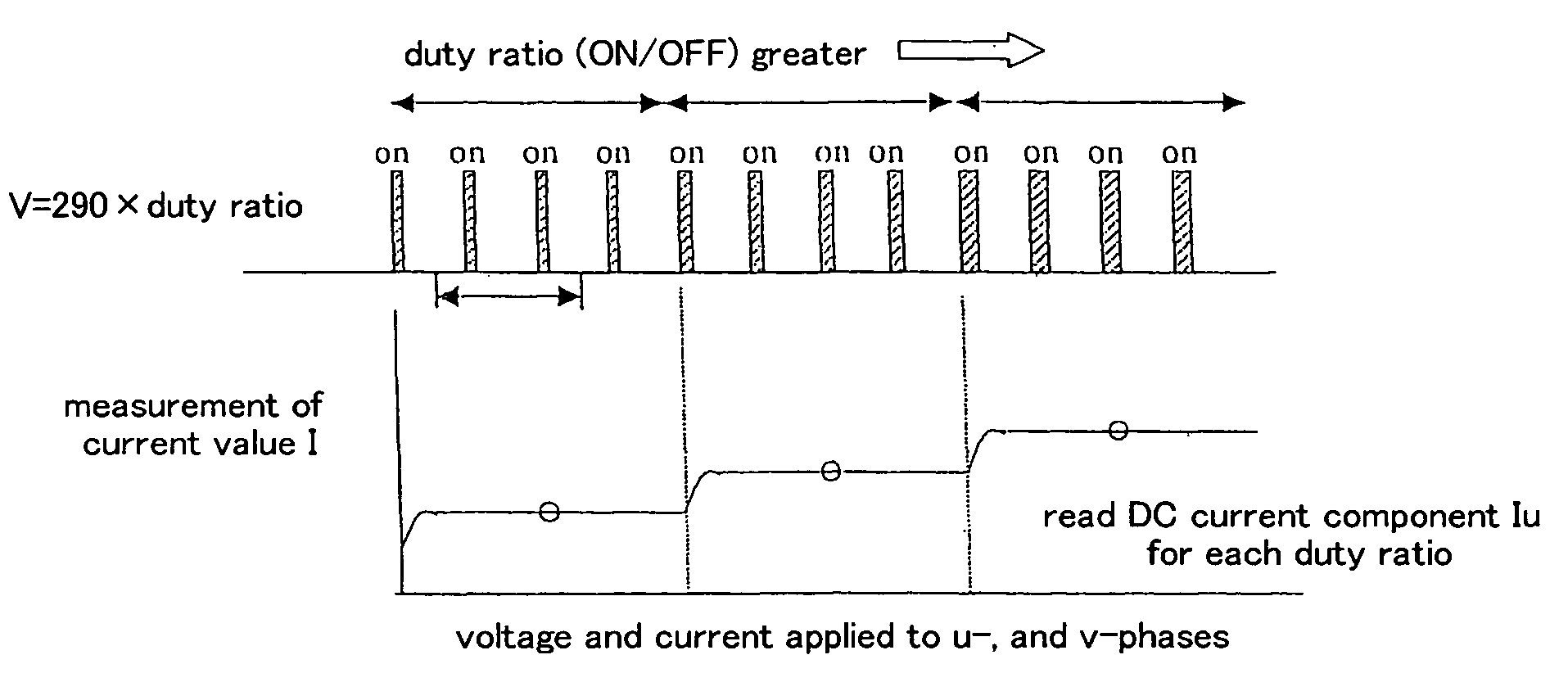

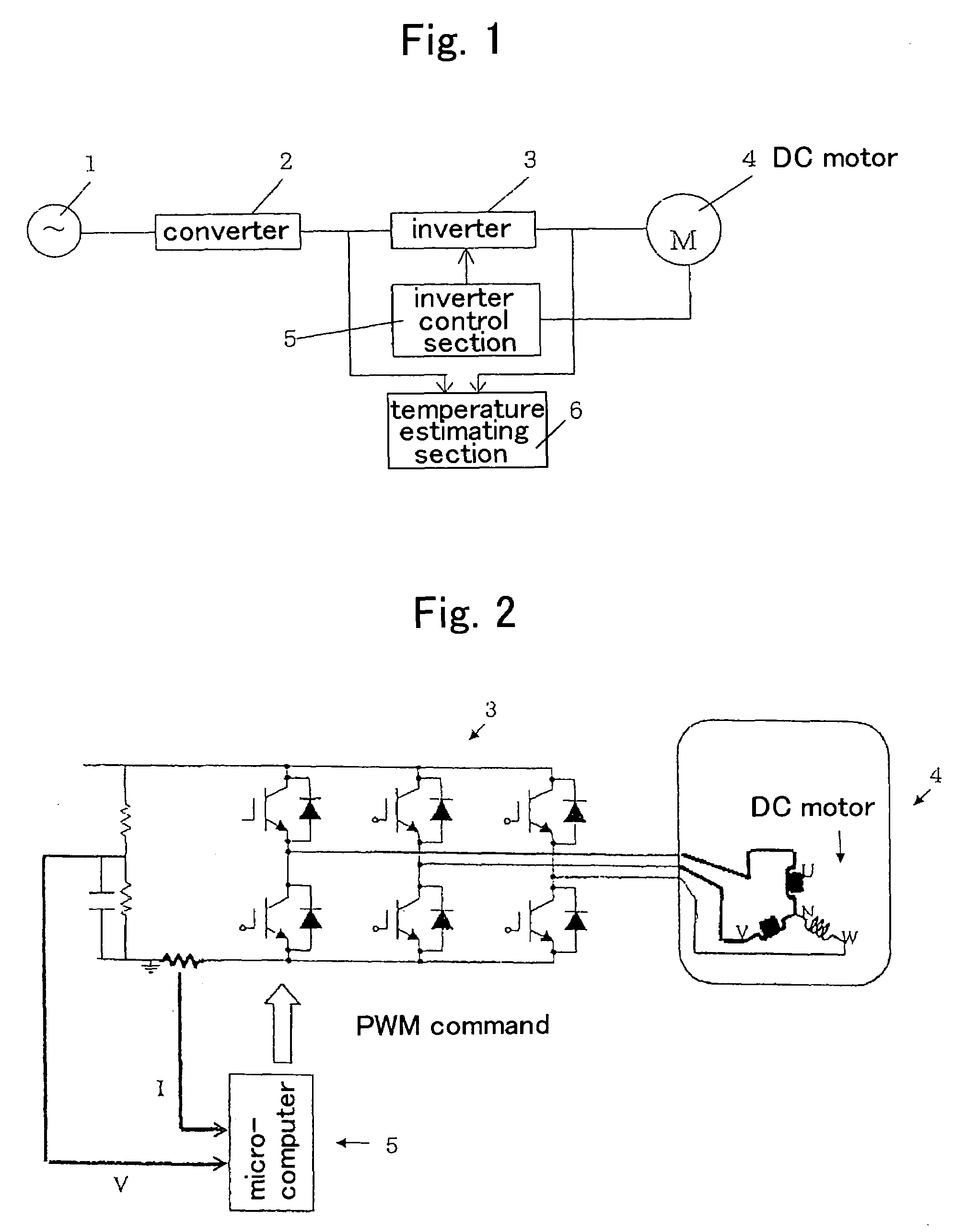

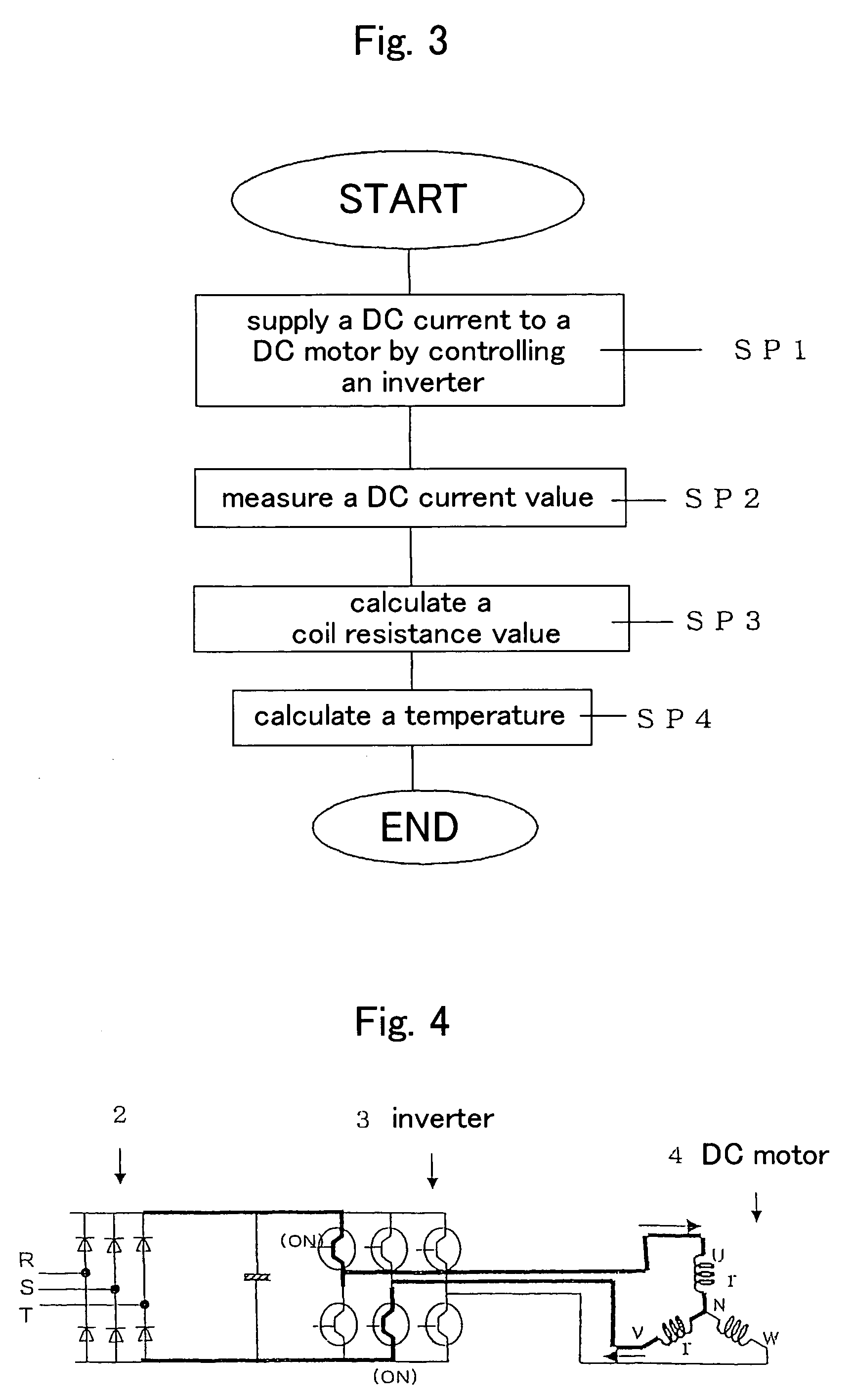

Method for estimating dc motor coil temperature, dc motor control method and their devices

InactiveUS20070070560A1Improve estimation accuracyImprove accuracyCommutation monitoringDC motor speed/torque controlDc motor controlEngineering

Owner:DAIKIN IND LTD

Method for estimating DC motor coil temperature, DC motor control method and their devices

InactiveUS7265954B2Low costConvenient and accurateCommutation monitoringDC motor speed/torque controlDc motor controlVoltage

Owner:DAIKIN IND LTD

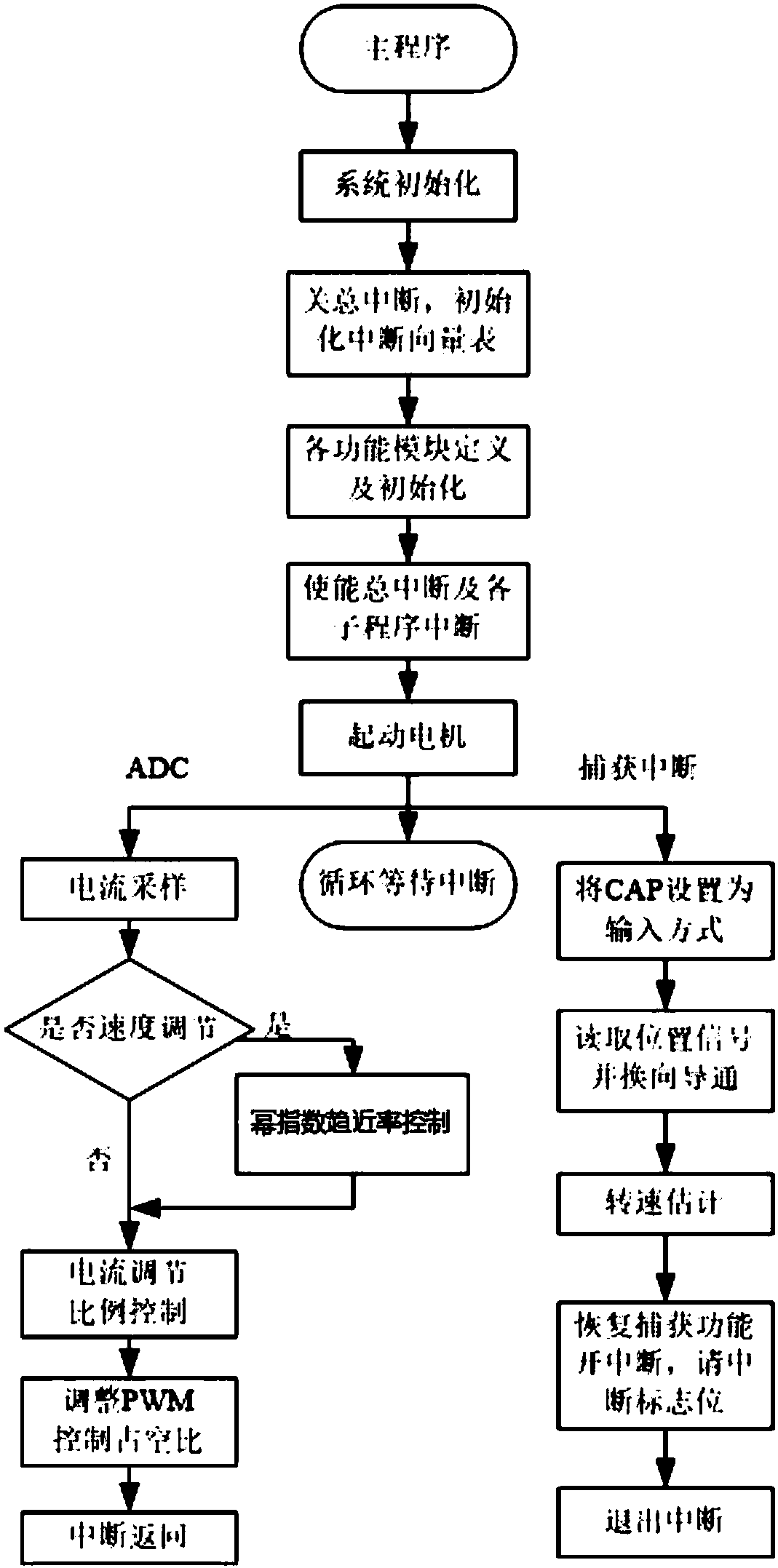

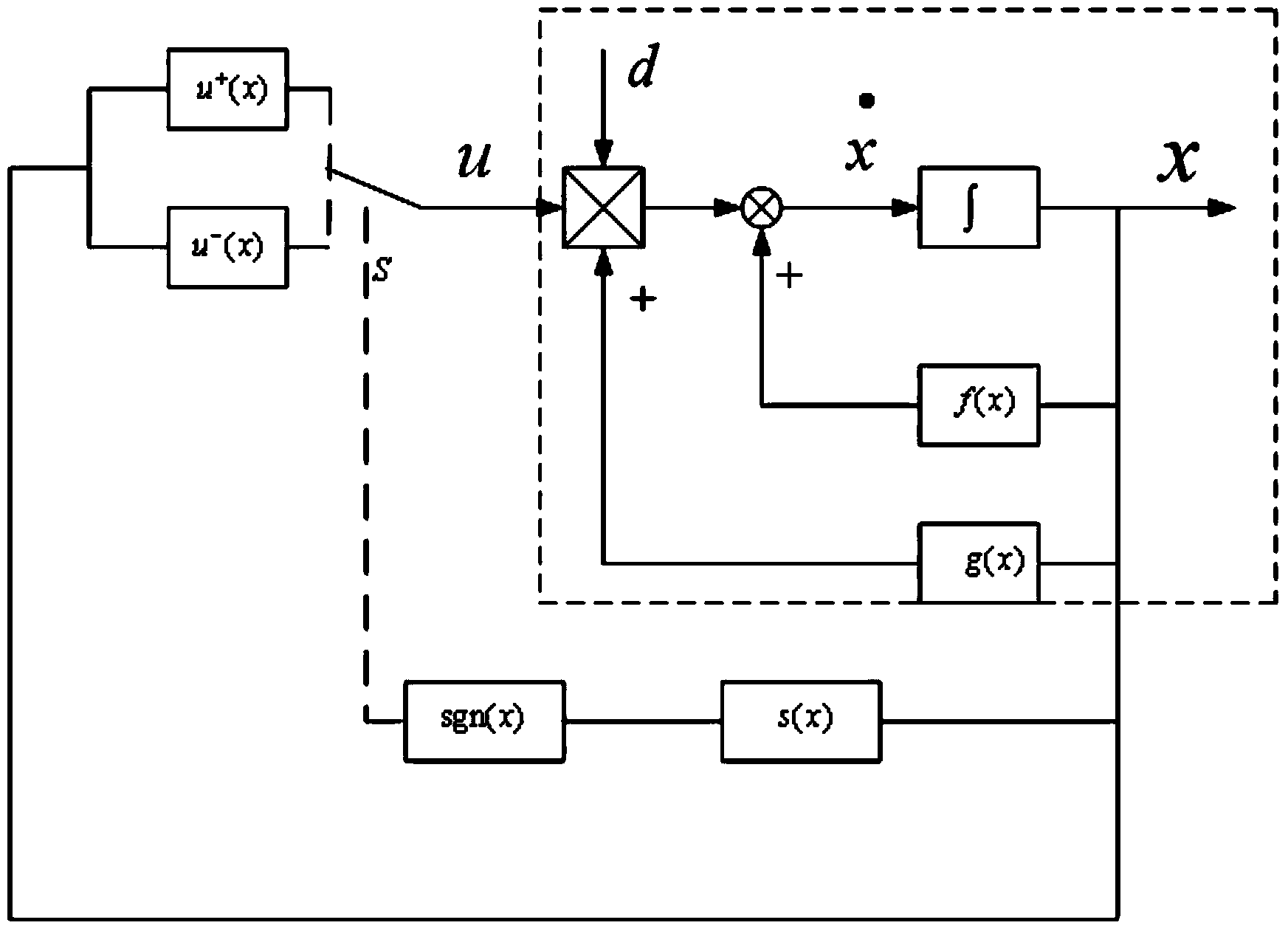

Method for controlling slip mode variable structure of brushless direct current motor based on power exponential reaching law

InactiveCN108233788AImproved speed response performanceImprove control qualitySingle motor speed/torque controlGeneral control strategiesProportional controlMode control

The invention provides a method for controlling a slip mode variable structure of a brushless direct current motor based on a power exponential reaching law. The method comprises the following steps of S1, analyzing a mathematics model of the brushless direct current motor; S2, designing a slip mode controller; combining a power reaching law and an exponential reaching law, so as to obtain the improved reaching law-power exponential reaching law, and calculate the slip mode control rate at the current time; S3, setting a current loop and a speed loop for controlling the brushless direct current motor, wherein the current loop adopts the integral and proportional control type, and the speed loop adopts the slip mode variable structure control type using the power reaching law; S4, repeatedly updating the value of slip mode control rate i, so as to control the brushless direct current motor. The method has the advantages that the control quantity on the brushless direct current motor adopts three adjustable parameters, so that the control and adjusting are more flexible; a control strategy with high control quality, simple type and convenient implementing on the brushless direct current motor is provided.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

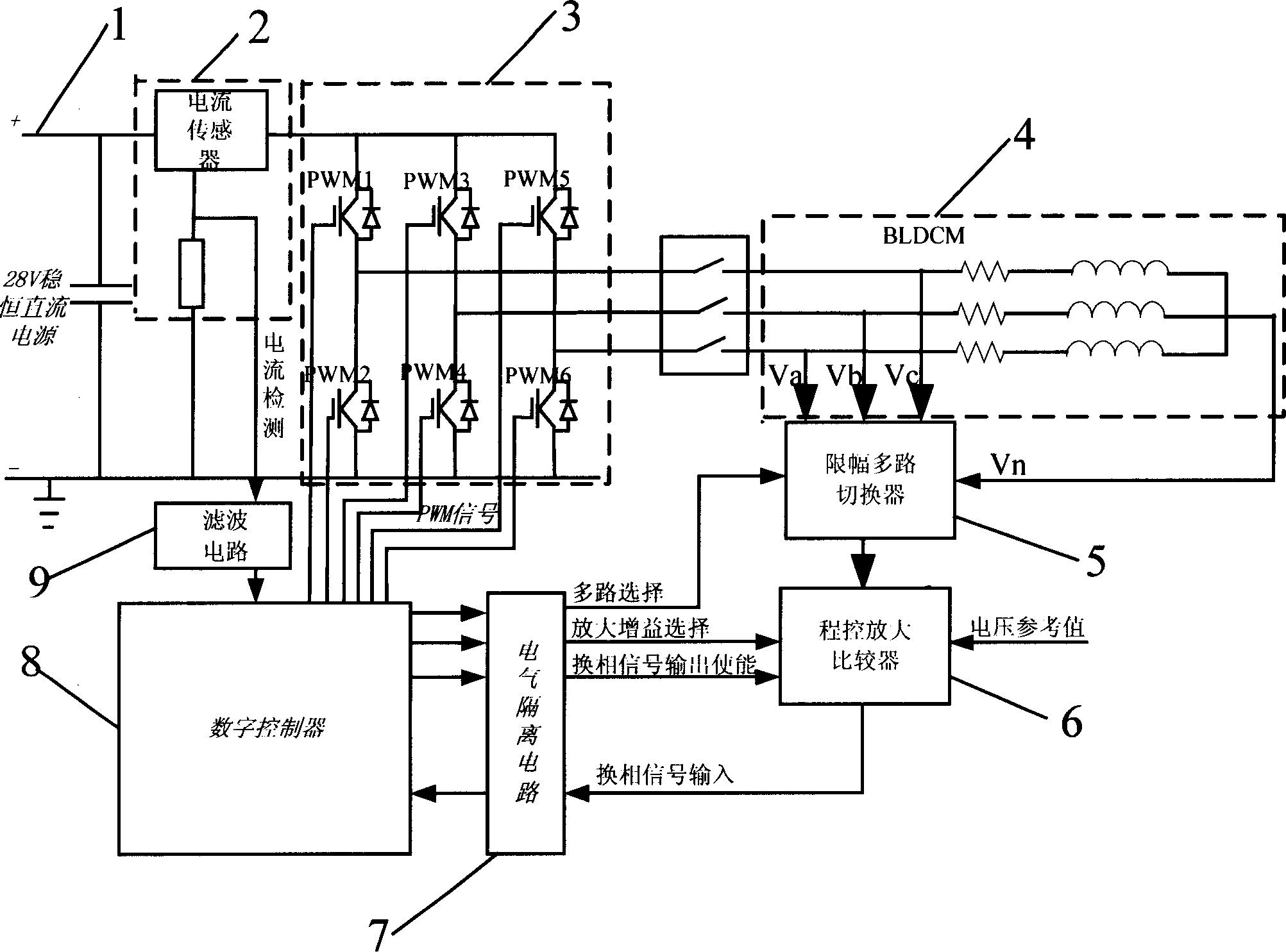

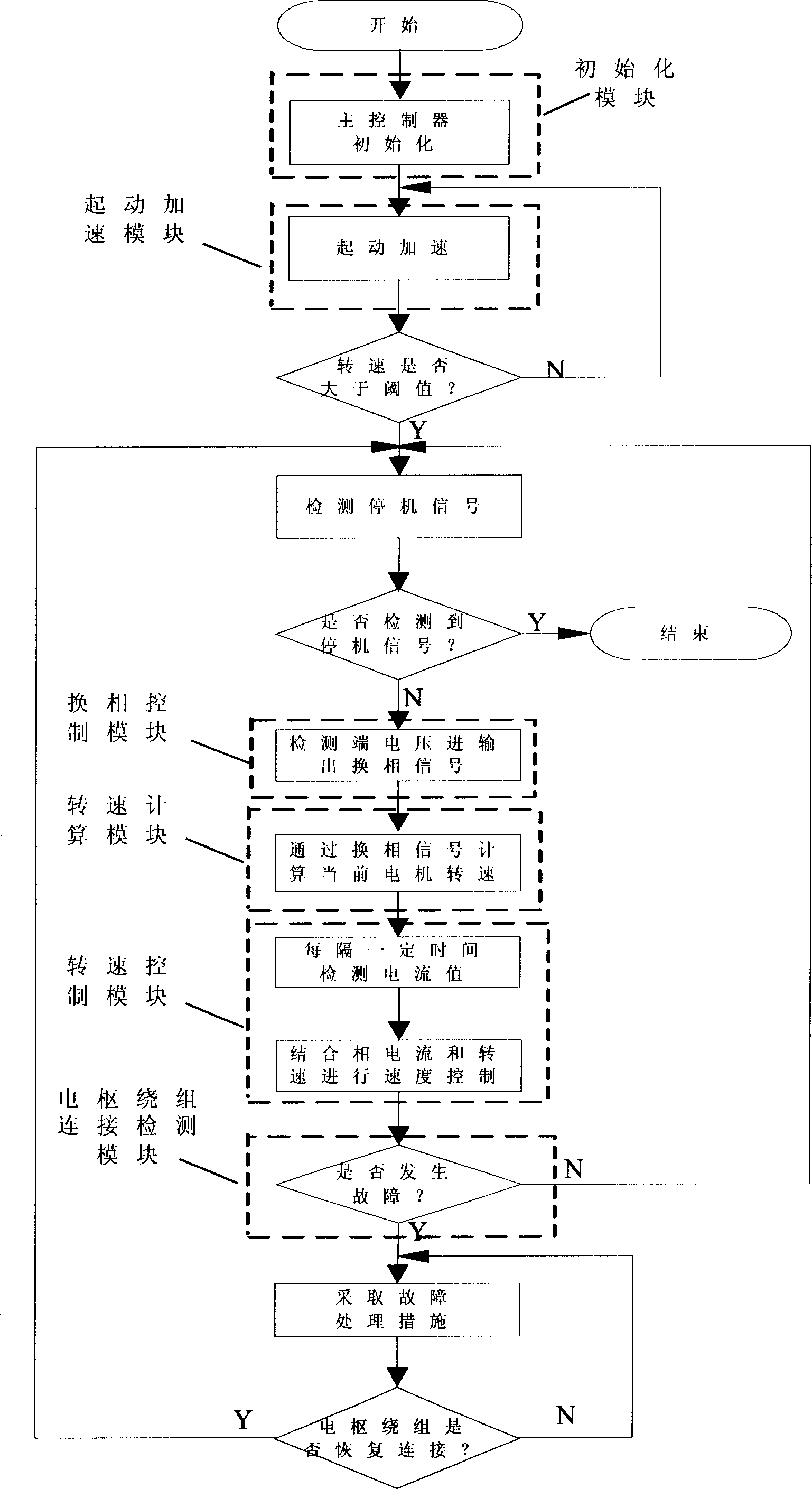

Small armature inductance high-speed permanent-magnet brushless DC motor control system without position sensor

InactiveCN1829070AHigh commutation accuracyEasy to controlSingle motor speed/torque controlElectronic commutatorsCurrent transducerTerminal voltage

Small armature induction high-speed permanent magnetism brushless D.C. motor non - position transducer control system is composed of amplitude limiting multiplepath switching unit, program control amplifier comparator, electric isolation circuit, current transducer, filter circuit, small armature induction permanent magnetism brushless D.C. motor, triphase inversion bridge and digital controller etc part. When PWM has larger duty ratio, comparing no conduction phase terminal voltage with supply voltage reference value, outputting phase conversion signal, when PWM has less duty ratio, comparing no conduction phase terminal voltage with armature winding midpoint voltage, outputting phase conversion signal, when armature winding and inversion bridge is disconnected due to fault, said digital controller still capable of obtaining motor rotor positional information. The present invention effectively solves phase conversion controlled problem, raising driving parts reliability and precision.

Owner:BEIHANG UNIV

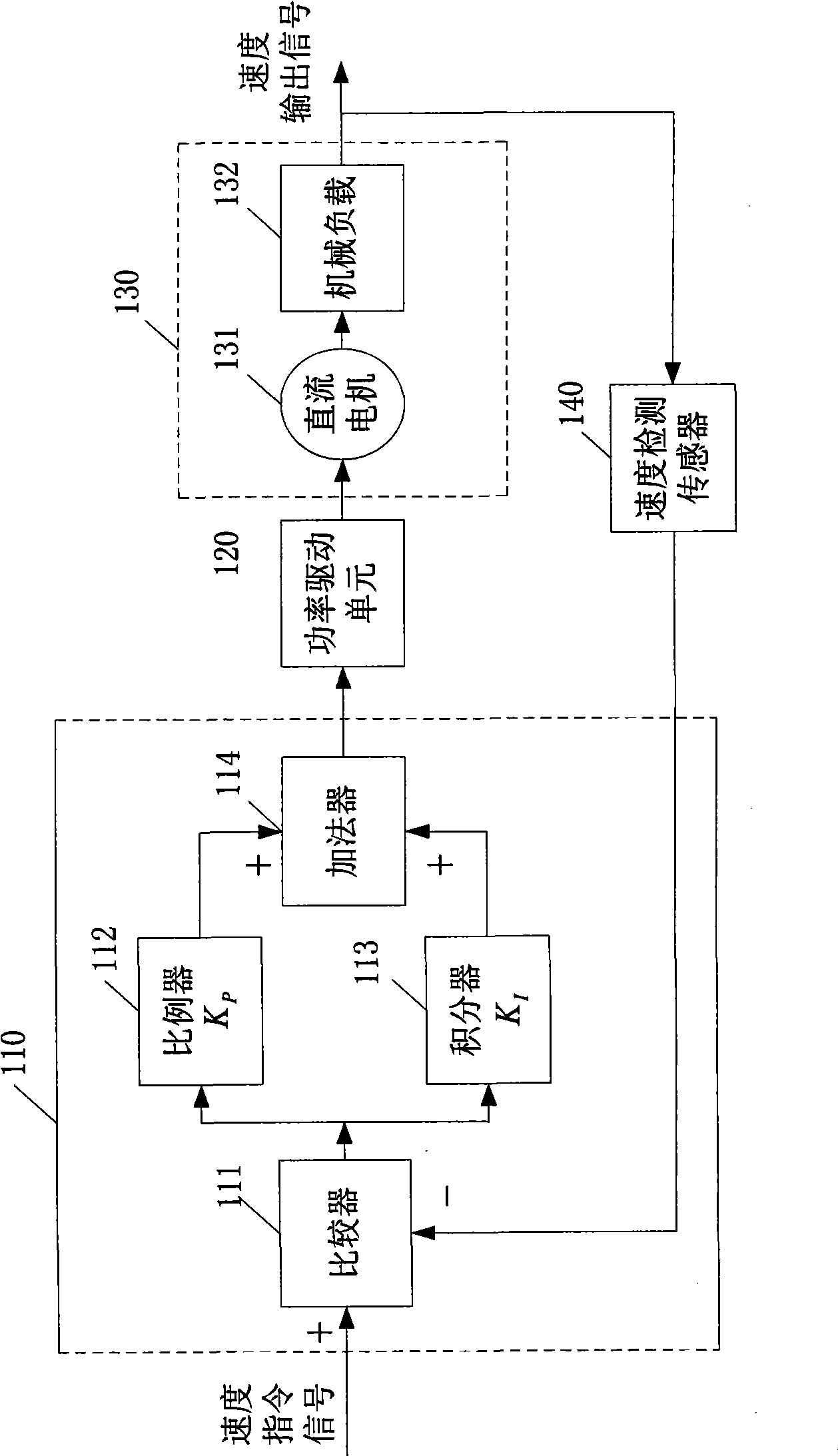

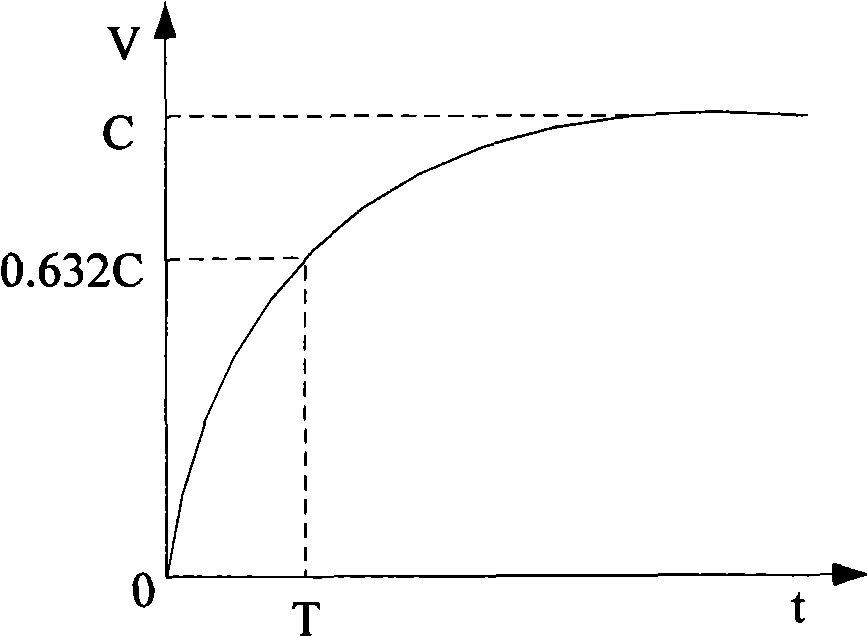

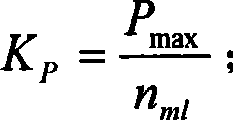

PID control system for DC motor speed and control method thereof

ActiveCN101499755ACurb blindnessShorten the timeSingle motor speed/torque controlField or armature current controlProportional controlDC - Direct current

The invention discloses a system and a method for controlling the speed PID of a direct current (DC) motor, belonging to the field of DC motor control. The structure comprises a controller, a power drive unit, a controlled object and a speed detection sensor, wherein, the controller comprises a comparator, a proportioner, an integrator and an adder; the controlled object comprises a DC motor and a mechanical load; the control method of the control system comprises the steps as follows: an equivalent damping parameter K and an equivalent inertia parameter A of the controlled object are recognized; furthermore, an proportion control parameter KP and an integral control parameter KI of the controller are adjusted. During the debugging process of the control system, the controller parameters can be adjusted effectively, the blindness of adjusting the PID controller parameter is avoided so that the time and energy are saved, and the best speed control effect can be obtained.

Owner:常熟紫金知识产权服务有限公司

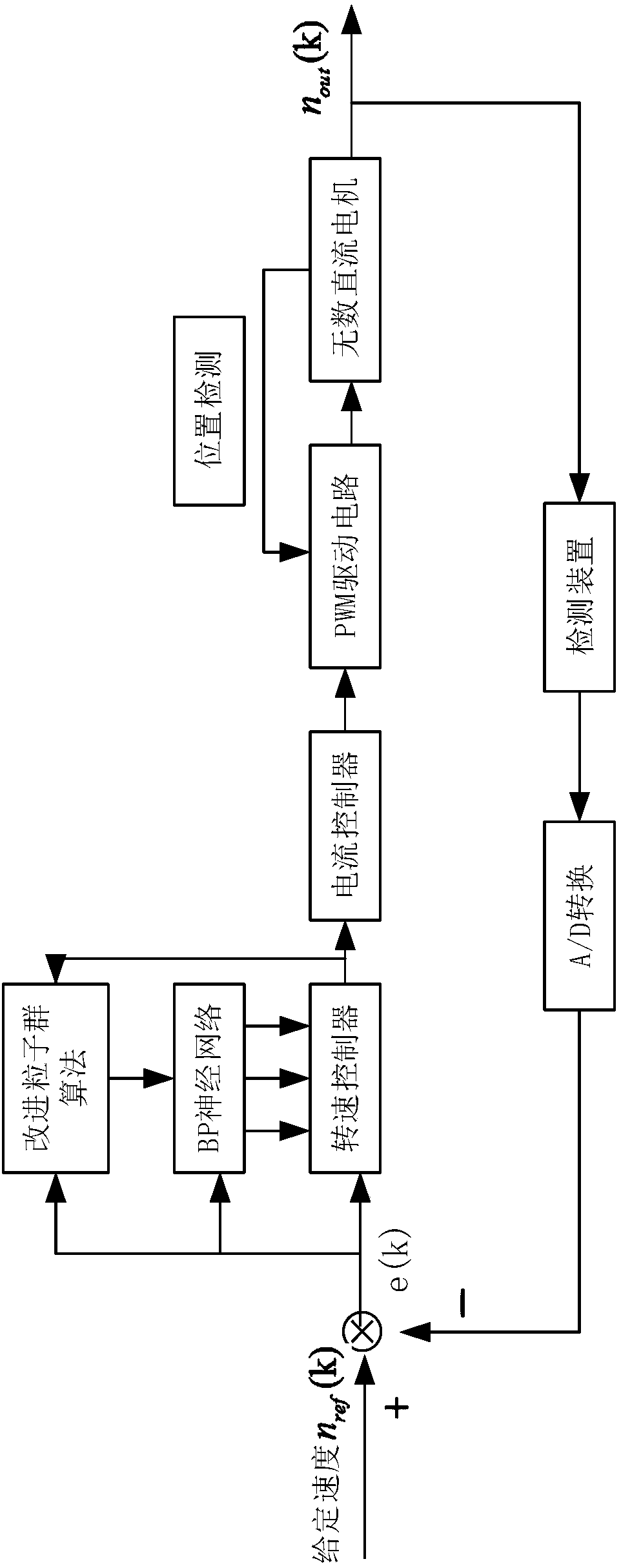

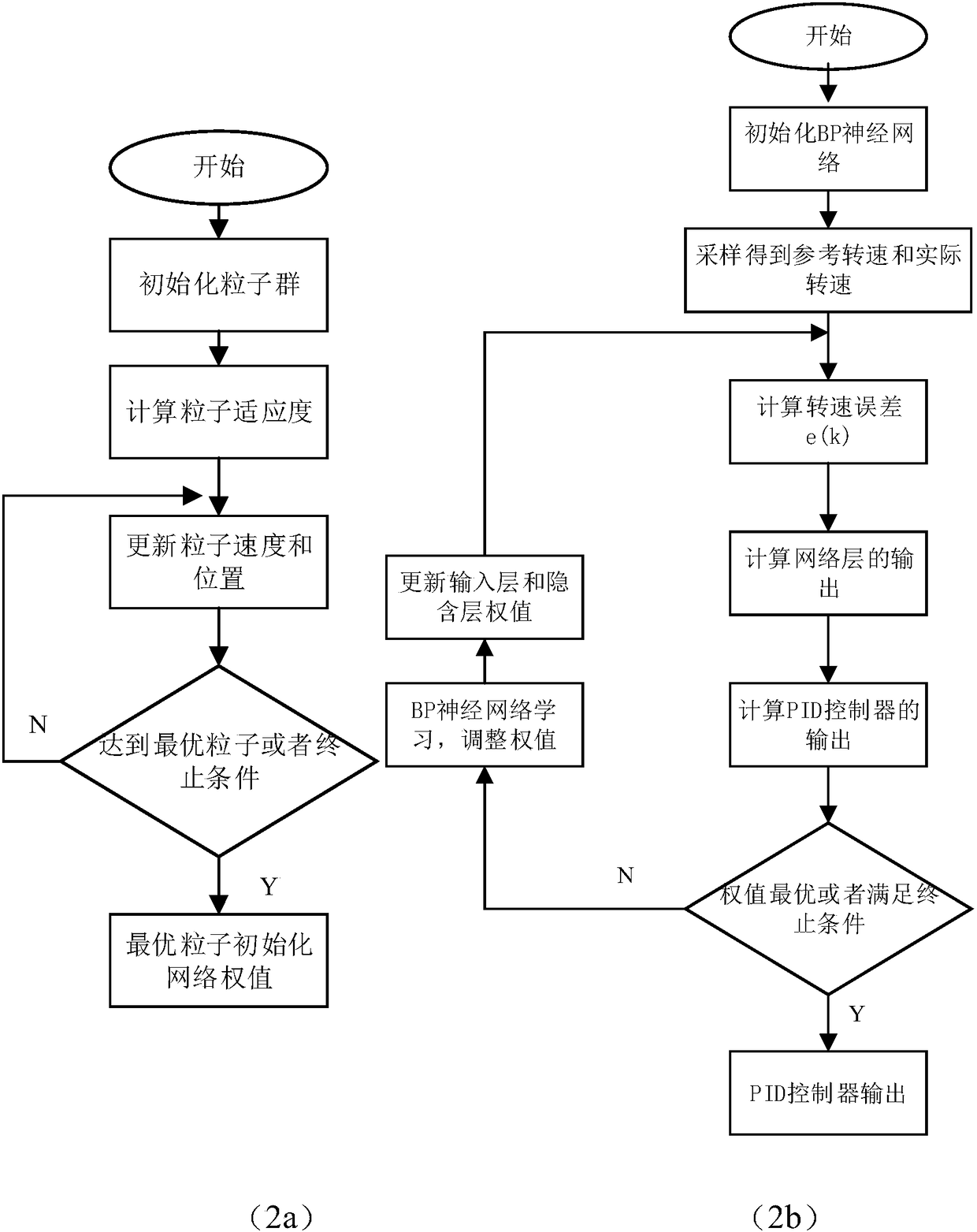

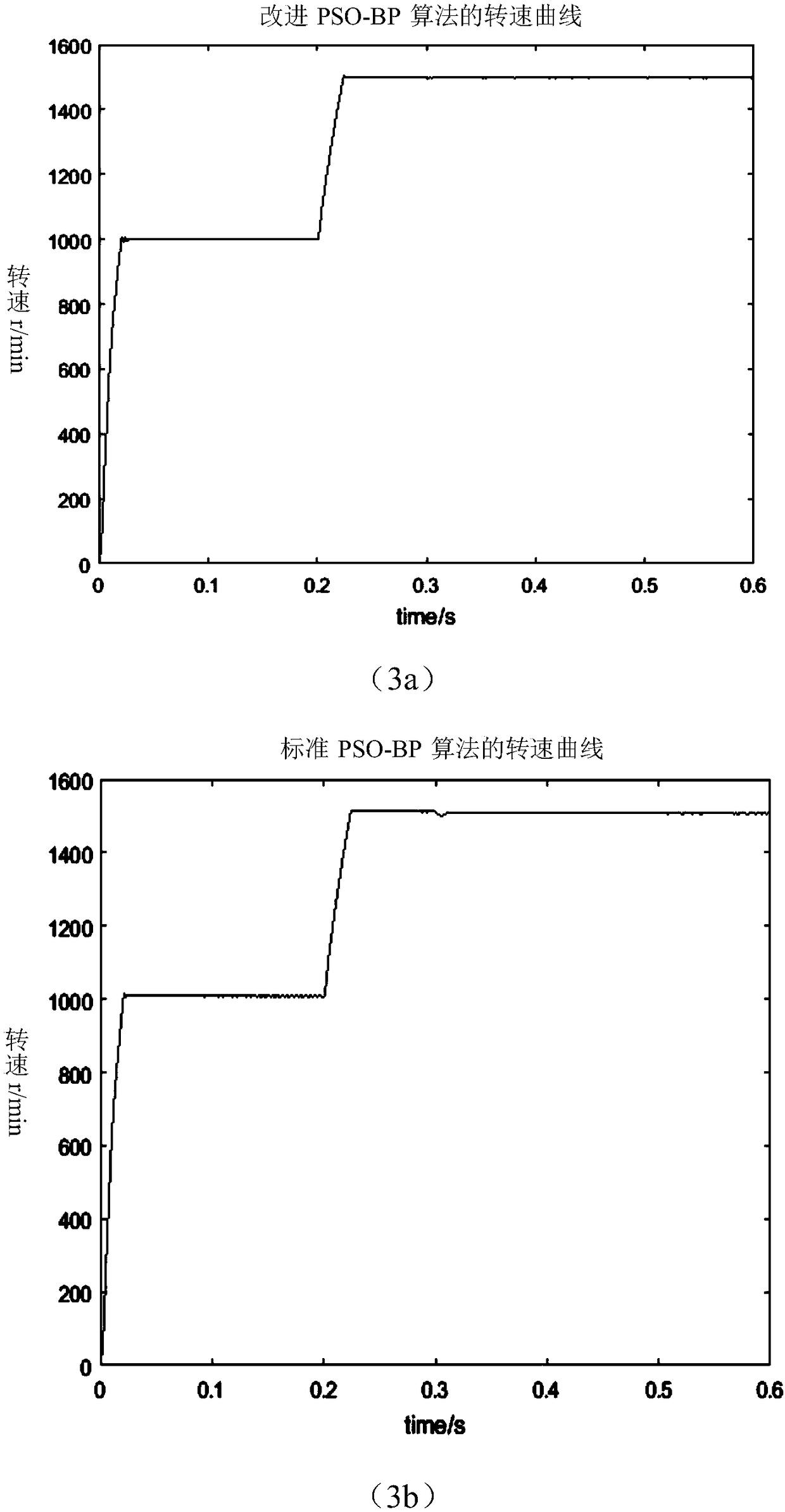

Improved PSO-BP neural network-based brushless DC motor control method

InactiveCN108365784AModern intelligent controlSmall speed errorElectronic commutation motor controlVector control systemsDc motor controlComputer science

The invention discloses an improved PSO-BP neural network-based brushless DC motor control method. The improved PSO-BP neural network-based brushless DC motor control method comprises the steps of firstly, performing off-line training on an initial weight value of a BP neural network by an improved particle swarm optimization (PSO); and secondly, taking optimal network weight value obtained by off-line training as the initial weight value of the BP neutral network, adjusting the network weight value by self learning of the BP neutral network so that on-line adjustment is performed on three control parameters of PID and a brushless DC motor is further controlled. Compared with the prior art, the improved PSO-BP neural network-based brushless DC motor control method has the advantage that arotational speed error in brushless DC motor control is greatly reduced.

Owner:TIANJIN UNIV

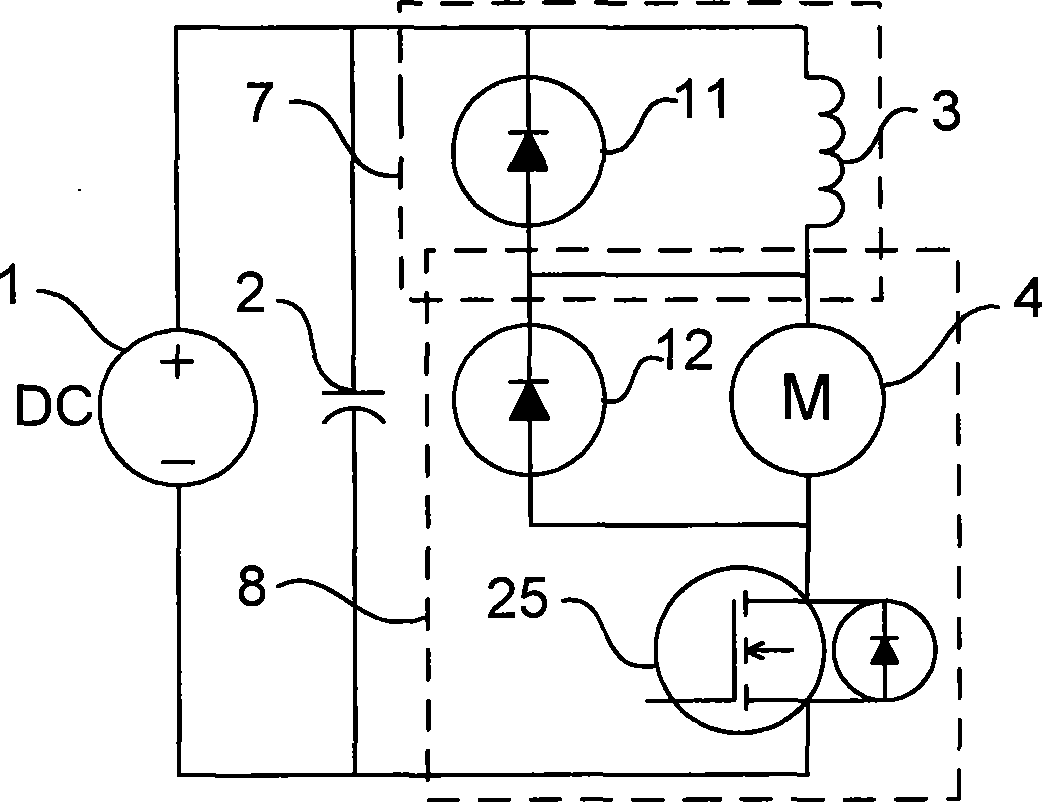

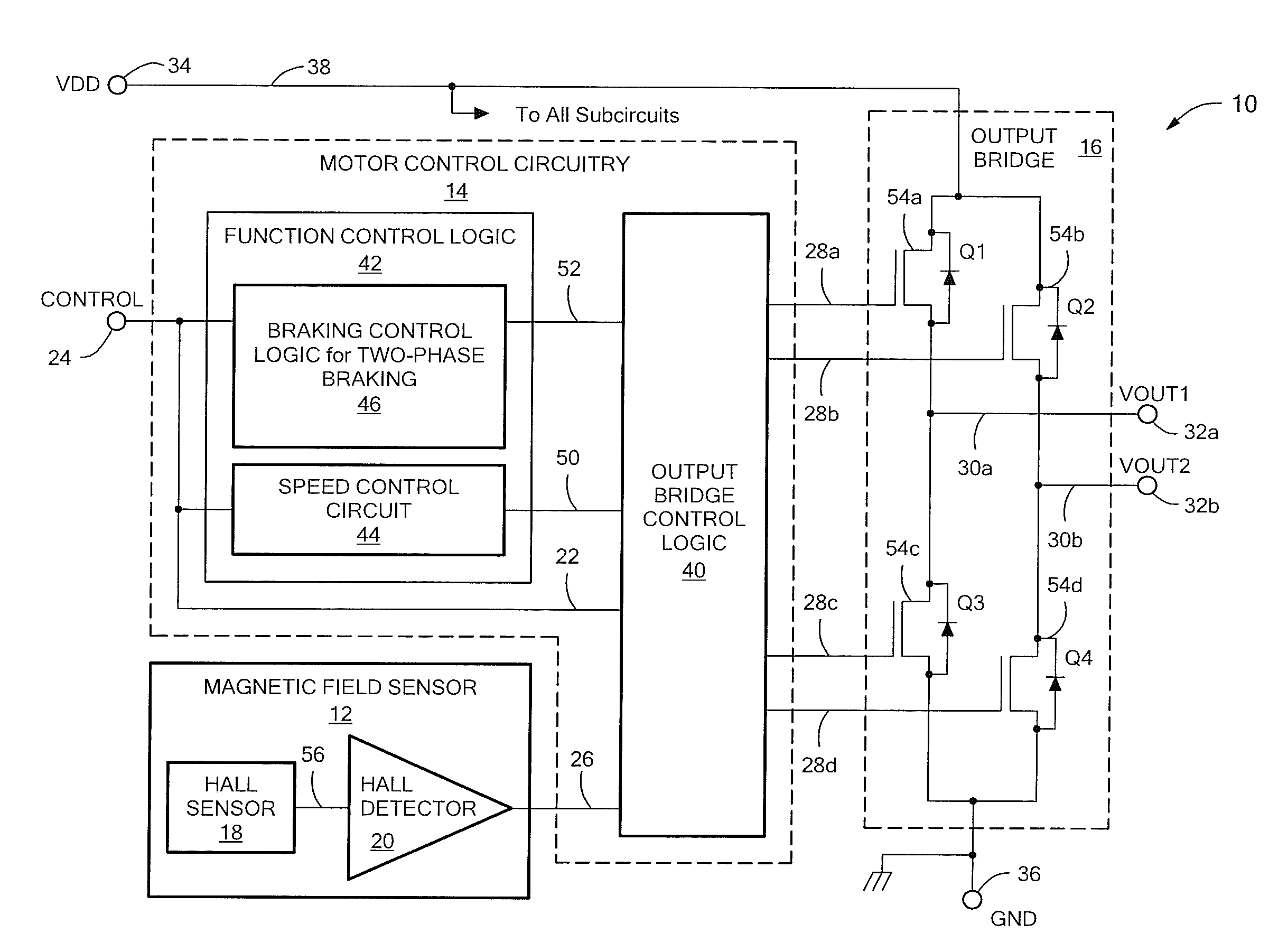

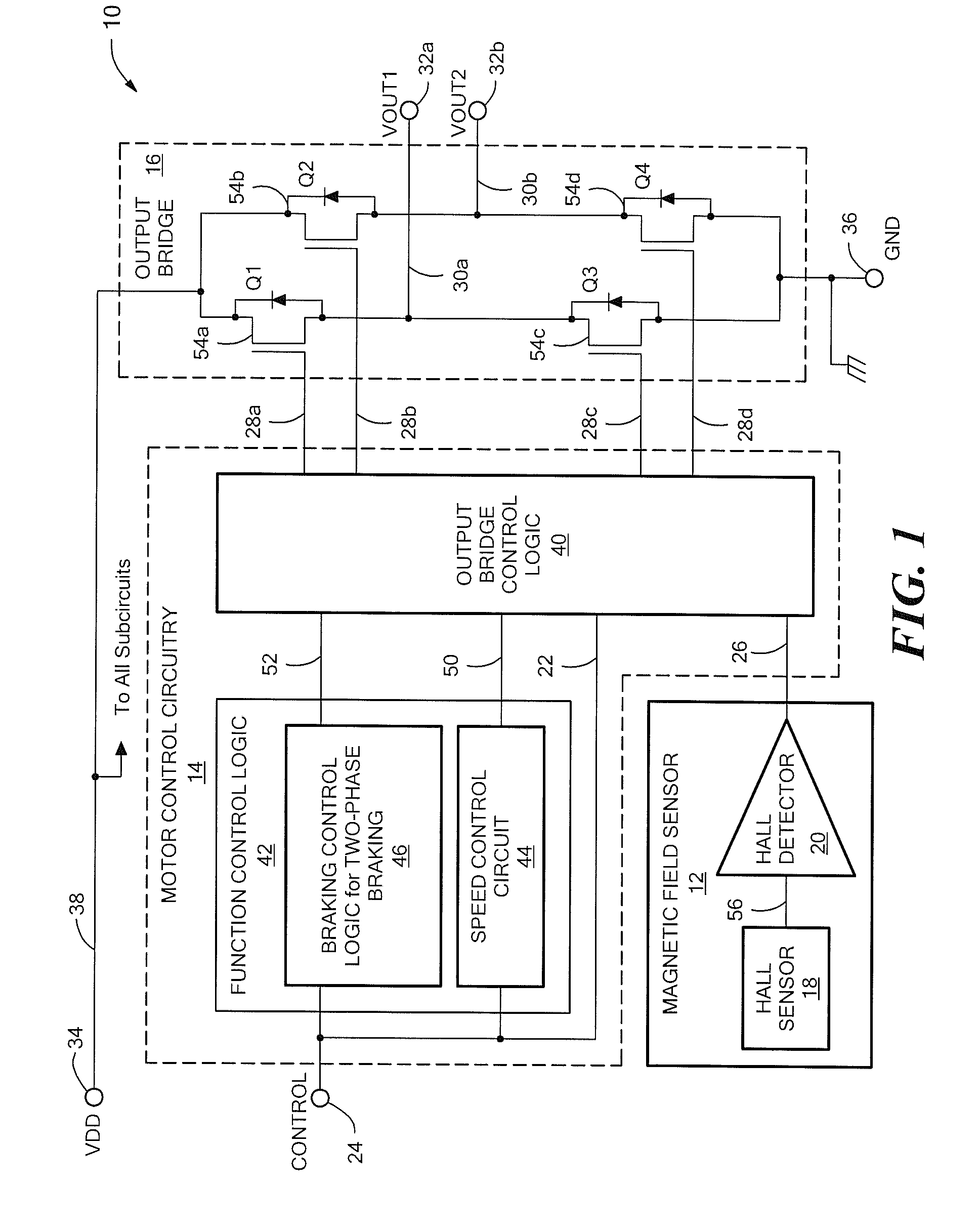

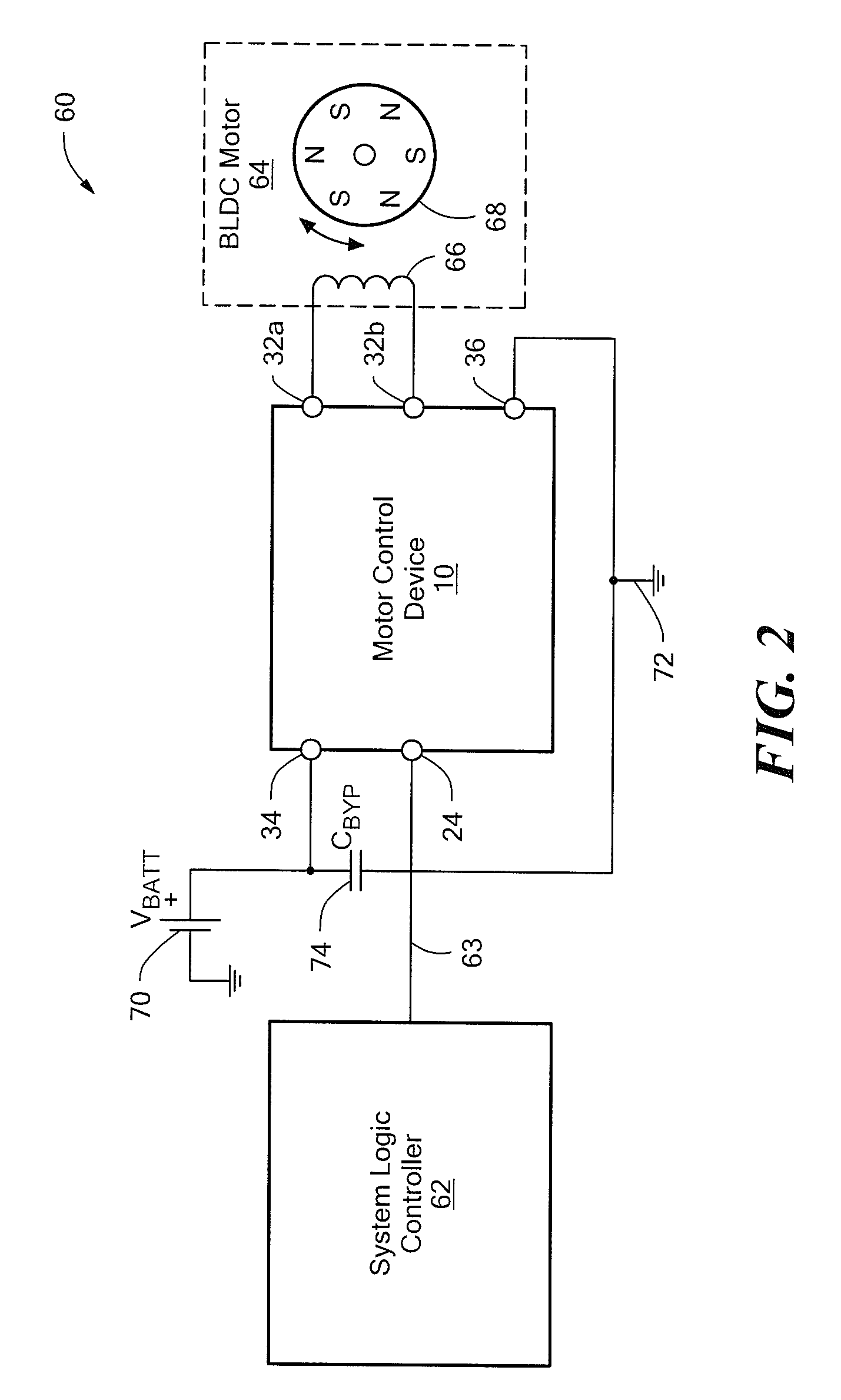

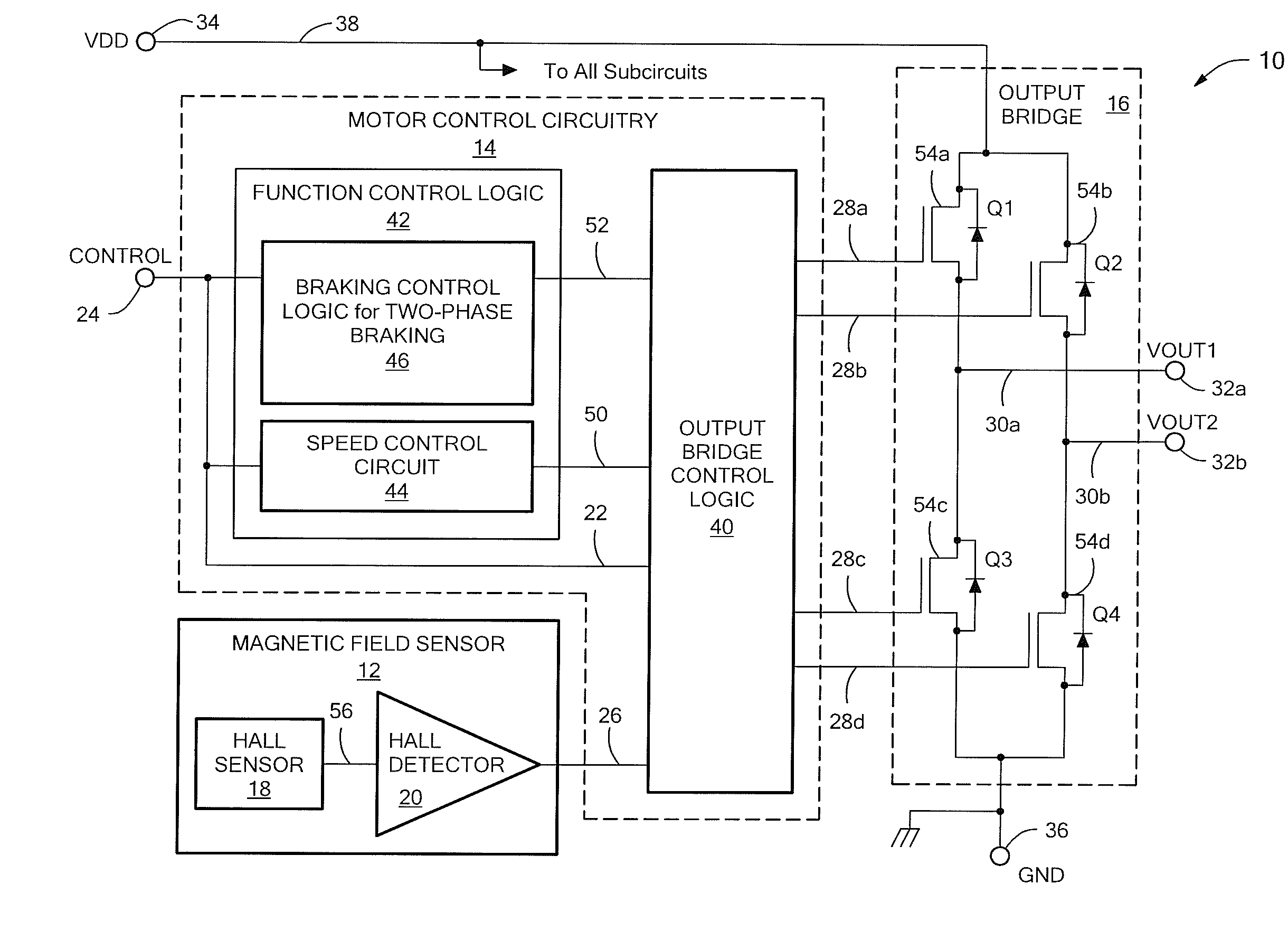

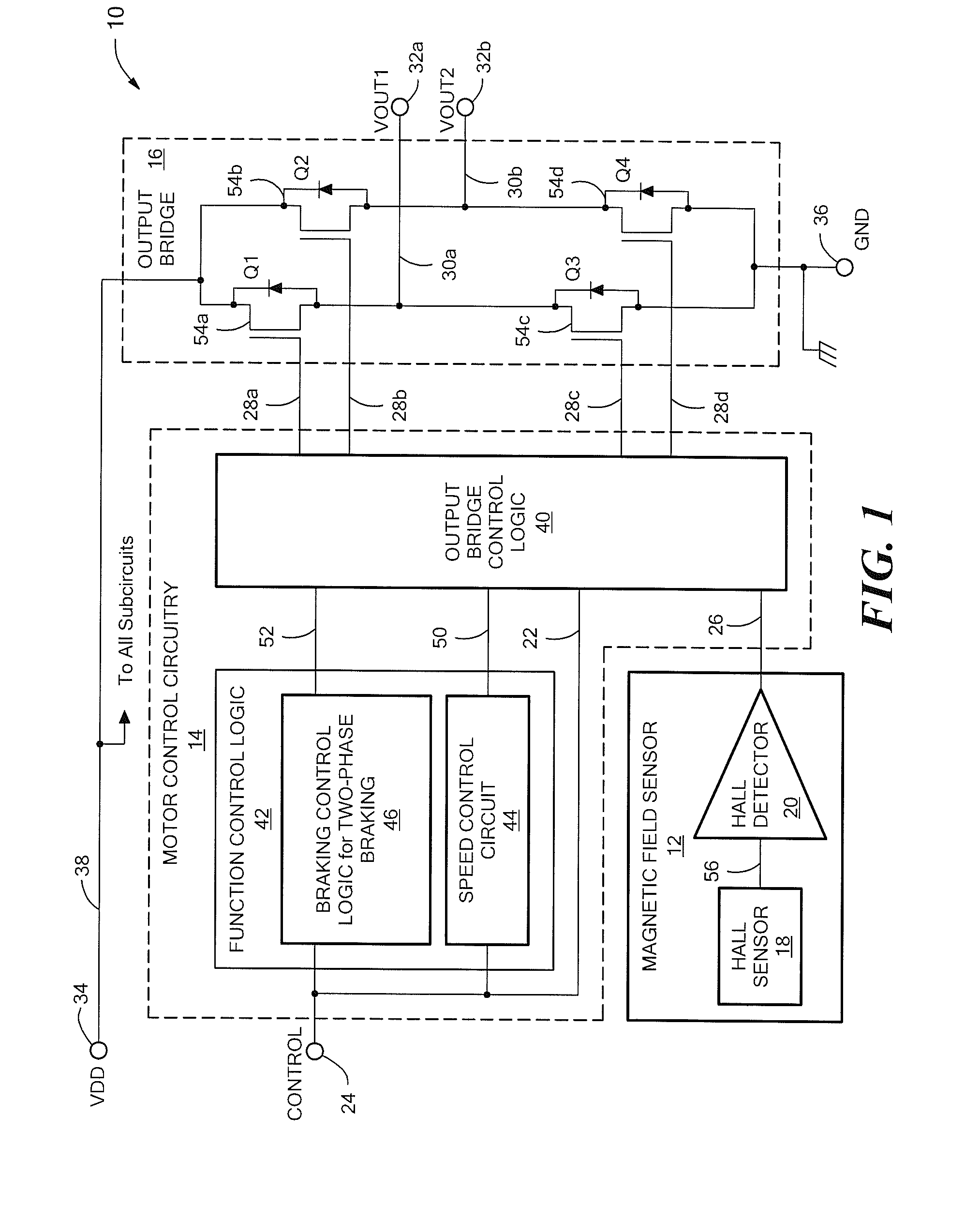

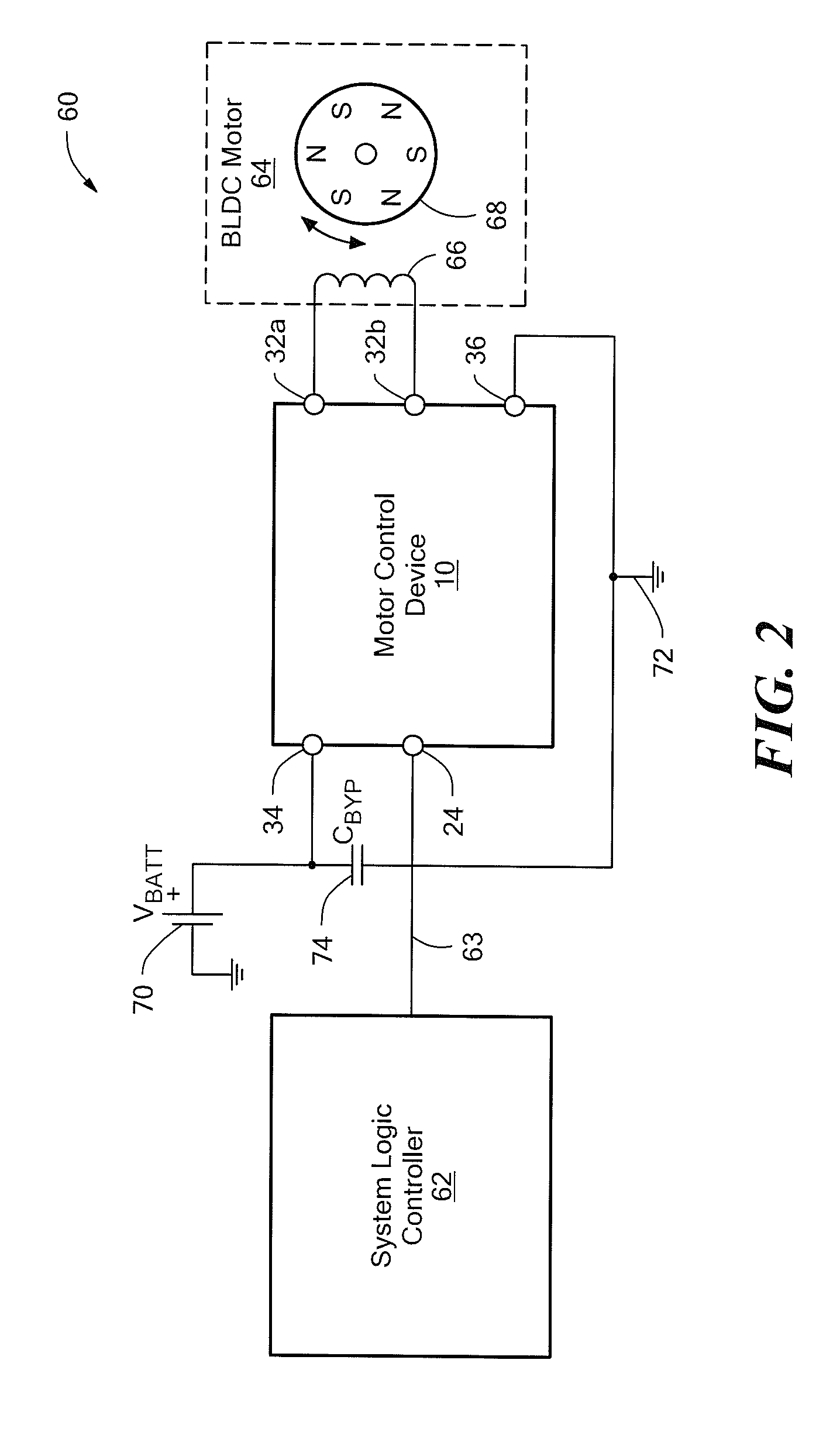

Braking function for brushless DC motor control

A motor control circuit that features a smart, two-phase braking operation is presented. The motor control circuit includes a motor drive circuit to apply a brake current to a coil of an external motor for active braking of the motor. The motor control circuit further includes a braking control circuit, coupled to the motor drive circuit and responsive to an externally generated control signal, to control the active braking by the motor drive circuit so that the active braking occurs in two phases. The two phases include a first phase that includes a first portion of the active braking and a second phase that includes back electromotive force (BEMF) voltage sensing and a second portion of the active braking.

Owner:ALLEGRO MICROSYSTEMS INC

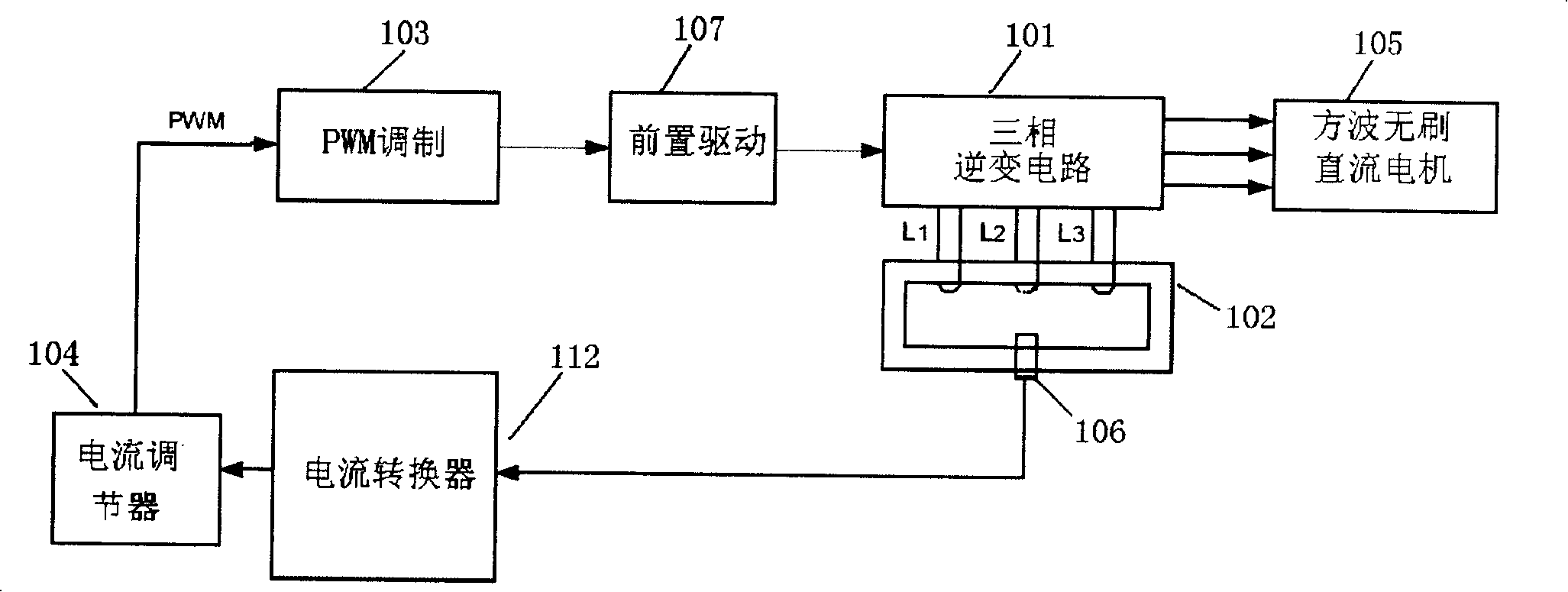

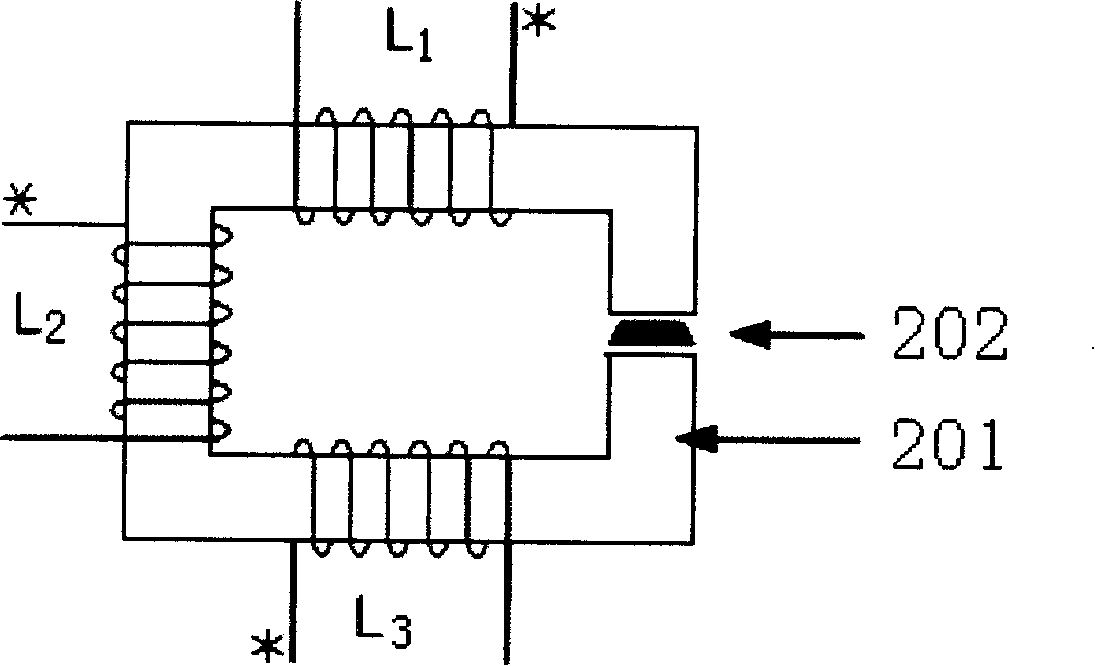

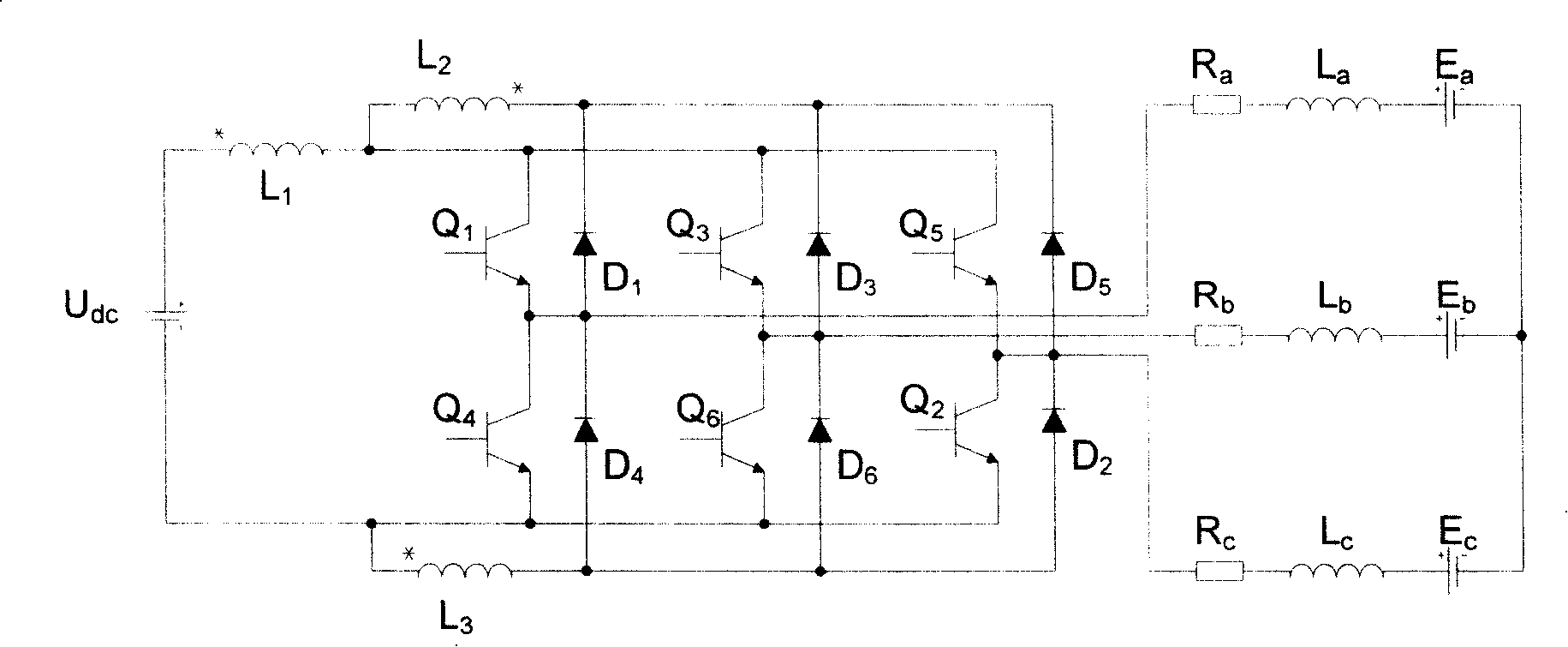

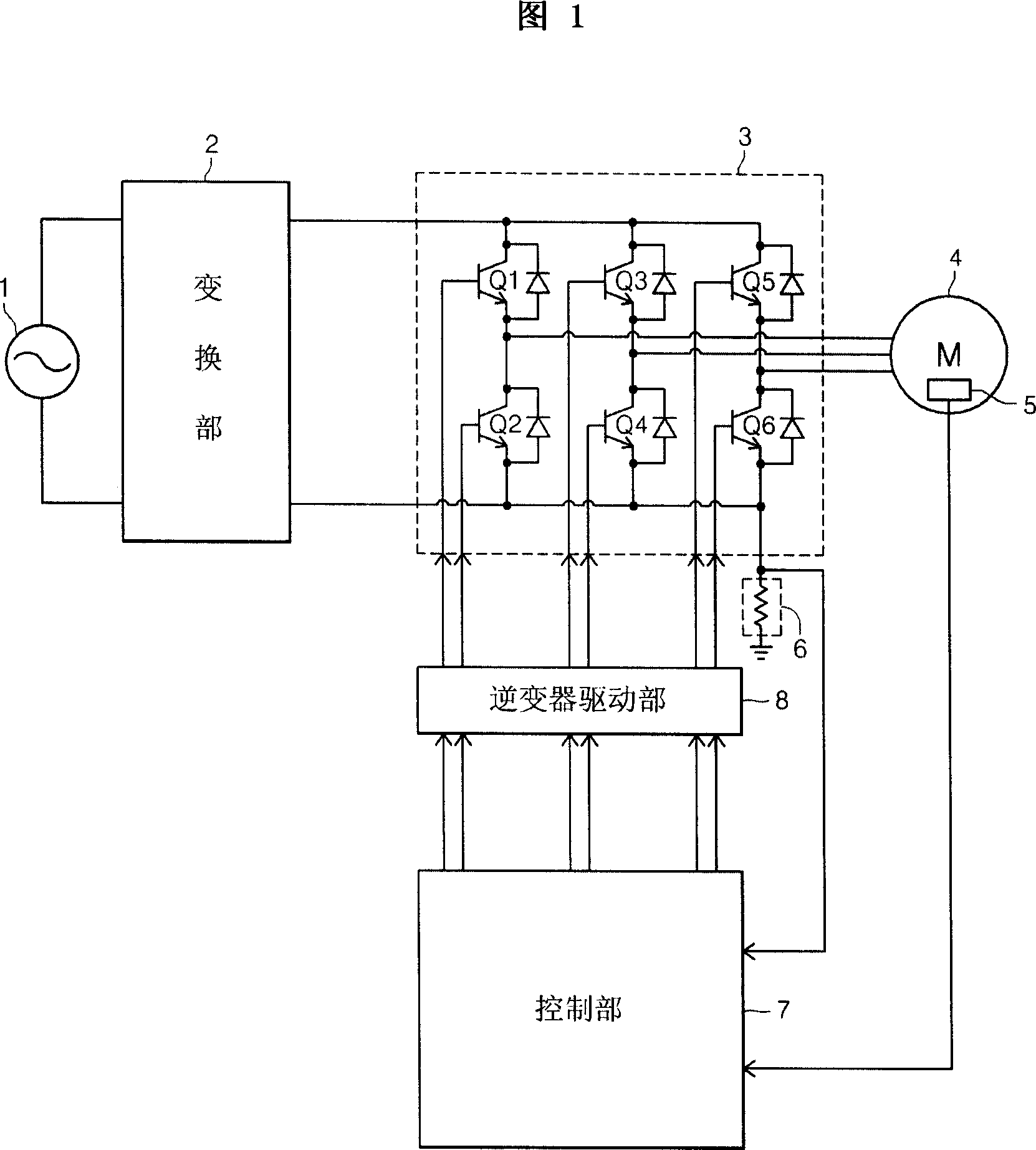

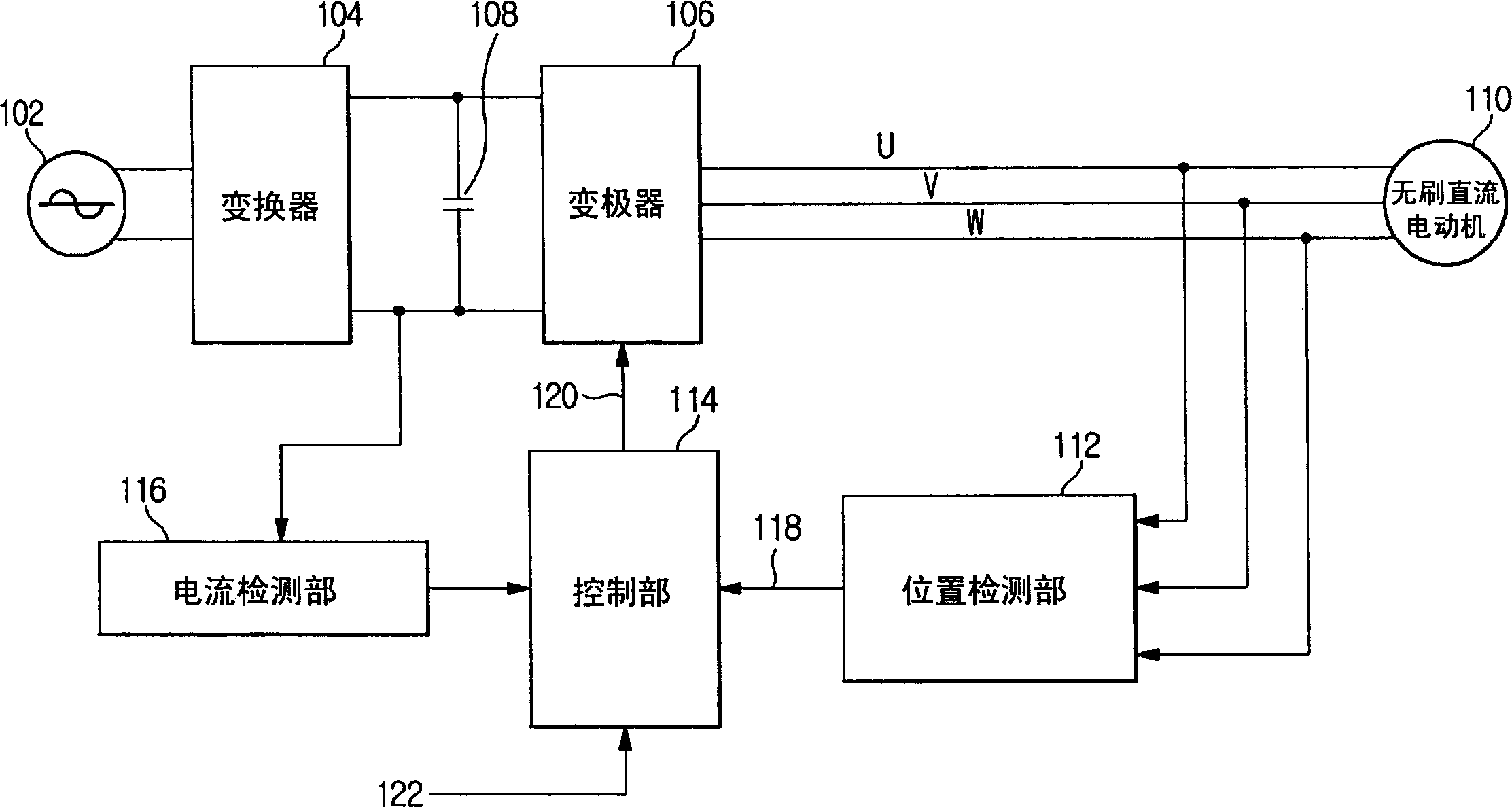

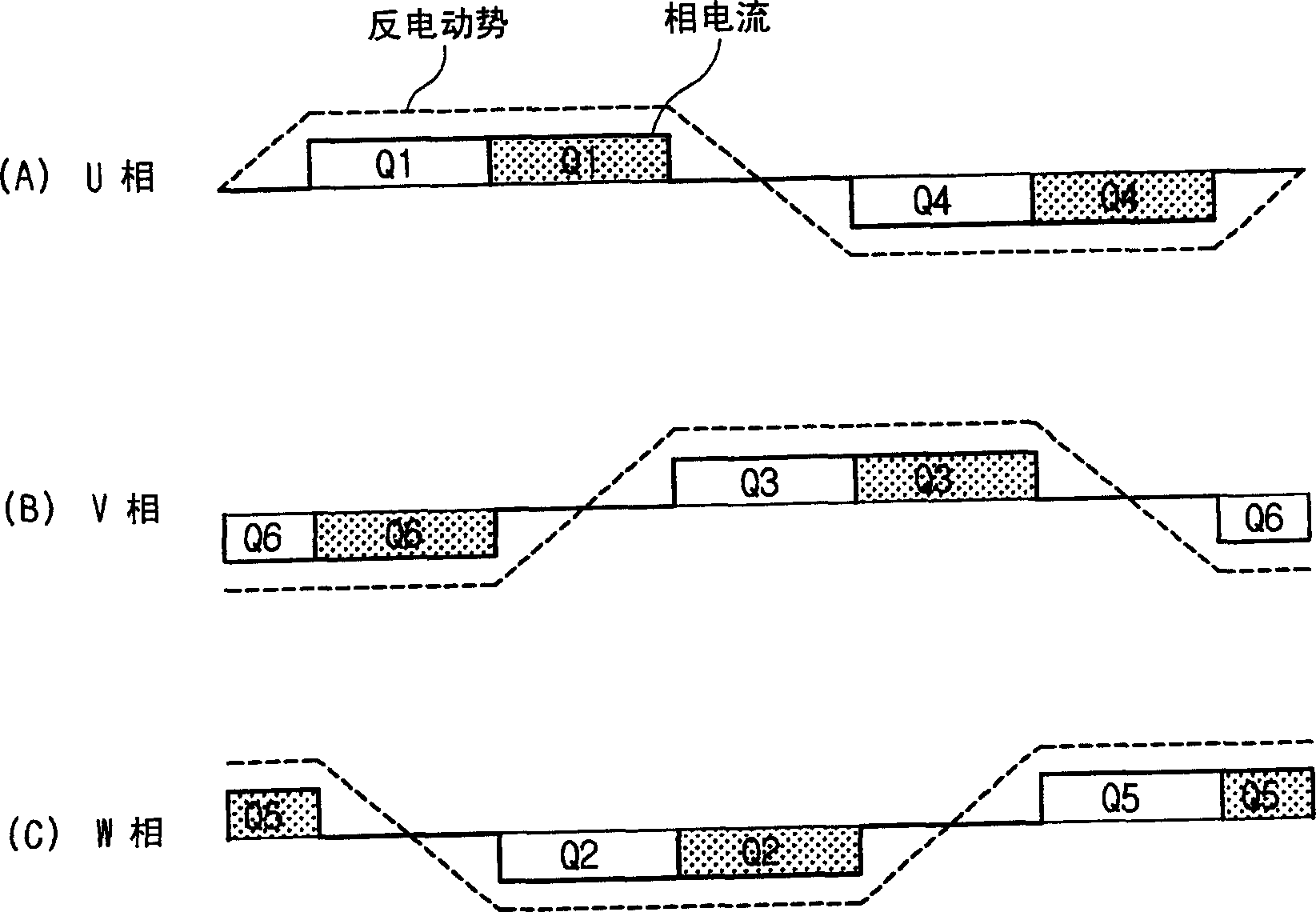

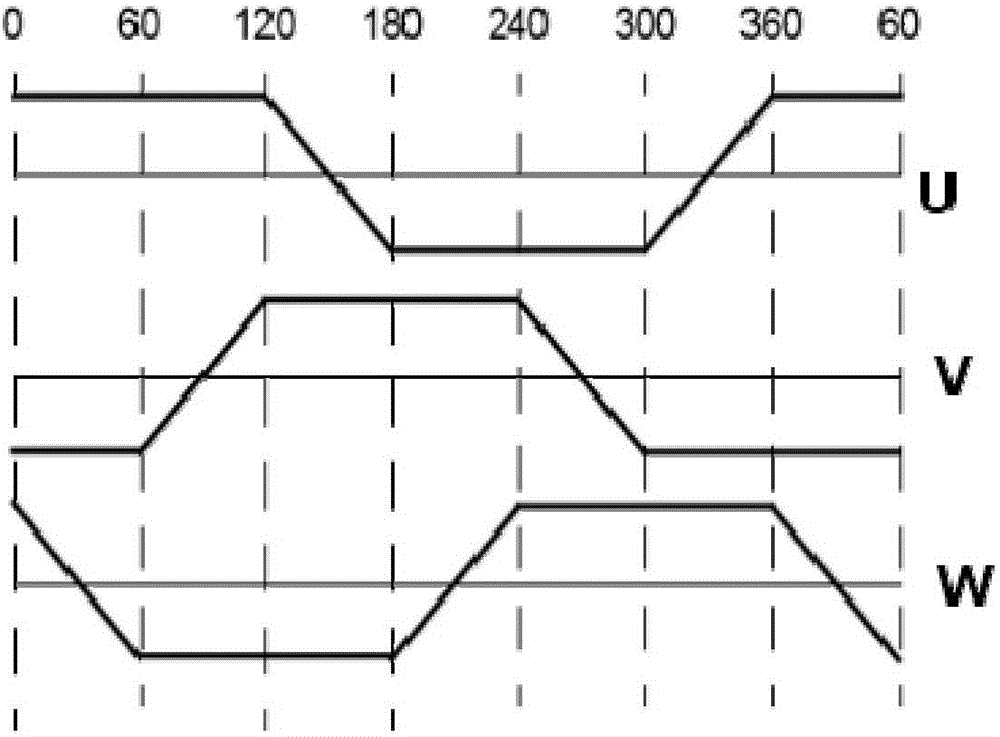

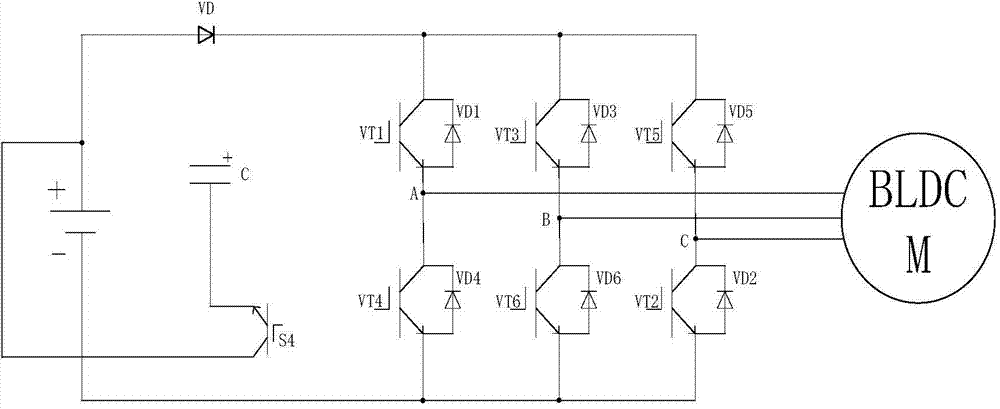

Control system and control method of brushless DC motor

ActiveCN101227163ASolve the problem of current closed-loop controlIncrease dynamicsSingle motor speed/torque controlAc-dc conversionPhase currentsLoop control

The invention relates to the controlling technique of a three-phase direct current motor, which aims at solving the problem that the existing technique can not realize good electric current closed-loop control of a three-phase square-wave brushless direct current motor. The invention provides a novel proposal for realizing electric current closed-loop control of the square-wave brushless permanent magnet direct current motor, particularly comprises a brushless direct current motor controlling system, a controlling method and a corresponding inversing module. The cathodes of freewheeling diodes D1, D3, D5 are independent from each input end of self switch pipe and mutually connected in parallel to a sample-taking coil L2, and / or the anodes of freewheeling diodes D4, D6, D2 are independent from each output end of self switch pipe and mutually connected in parallel to a sample-taking coil L3. The invention can adopt a single resultant current sensing device to completely continuously take sample of three-phase electric current when the motor is conducted and freewheeled, and continuous closed-loop control can be carried out to three-phase electric current by a single electric current closed-loop regulating device, and therefore, dynamic and static index of the motor are greatly increased.

Owner:SHENZHEN ACAD OF AEROSPACE TECH

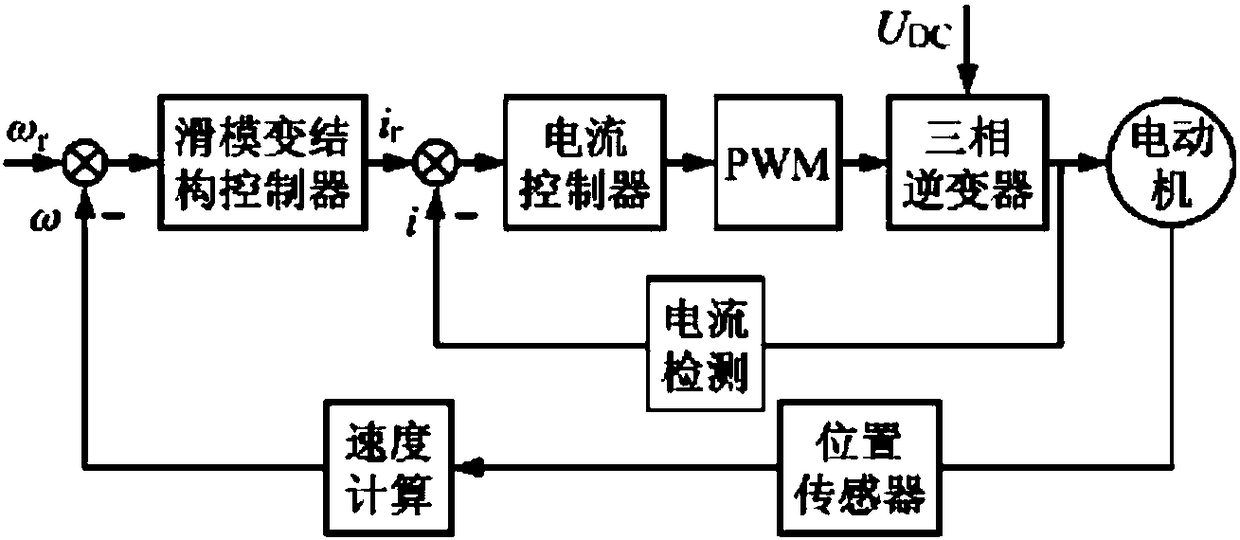

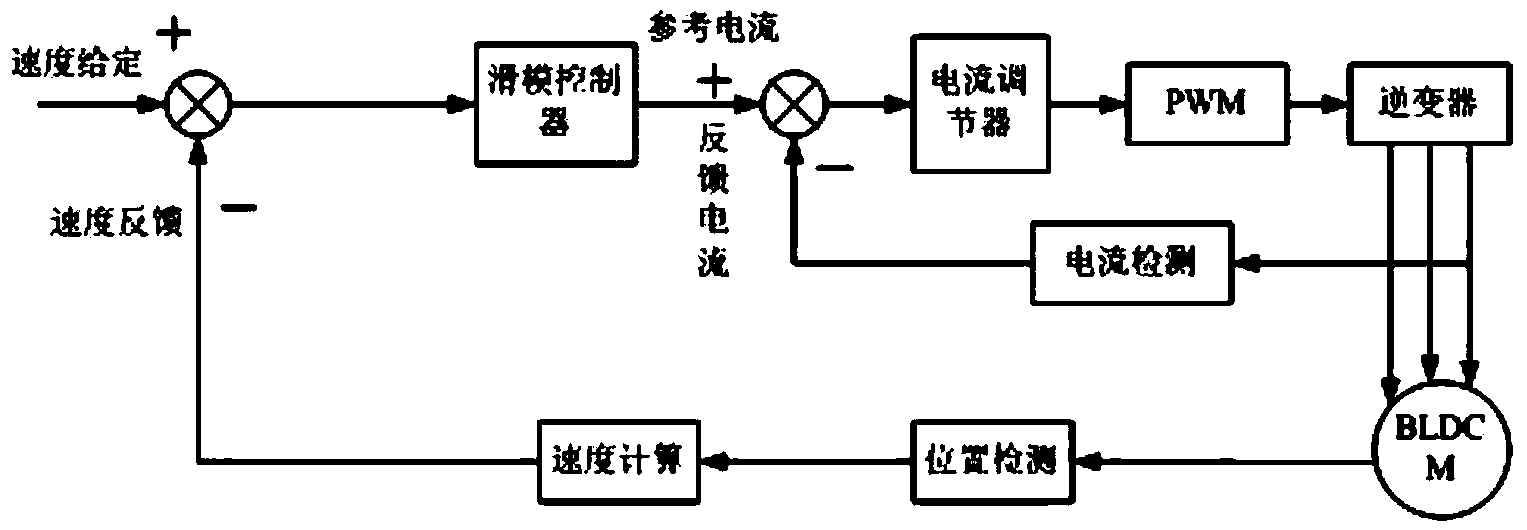

Brushless DC-motor sliding-mode control system used for metro shielding barriers

InactiveCN103780168AReduce buffetingQuick responseSingle motor speed/torque controlElectronic commutatorsLocation detectionInner loop

The invention discloses a brushless DC-motor sliding-mode control system used for metro shielding barriers. The system includes the following parts: a sliding mode variable structure controller, a current regulator, a PWM driving circuit, an inverter, a BLDCM and a position detection device and the like. The whole system adopts a double-closed-loop control system. An inner loop adopts a traditional PI controller and an outer loop adopts the sliding mode variable structure controller. Current brushless DC-motor control systems of metro shielding barriers all adopt traditional PIDs and overly depend on model parameters of controlled objects so that robustness is poor and response speed is not fast enough. The brushless DC-motor sliding-mode control system used for the metro shielding barriers is simple in adopted control algorithm, high in response speed, insensitive to parameter change or disturbance and does not need system online identification.

Owner:江苏新绿能科技有限公司

Braking function for brushless DC motor control

A motor control circuit that features a smart, two-phase braking operation is presented. The motor control circuit includes a motor drive circuit to apply a brake current to a coil of an external motor for active braking of the motor. The motor control circuit further includes a braking control circuit, coupled to the motor drive circuit and responsive to an externally generated control signal, to control the active braking by the motor drive circuit so that the active braking occurs in two phases. The two phases include a first phase that includes a first portion of the active braking and a second phase that includes back electromotive force (BEMF) voltage sensing and a second portion of the active braking.

Owner:ALLEGRO MICROSYSTEMS INC

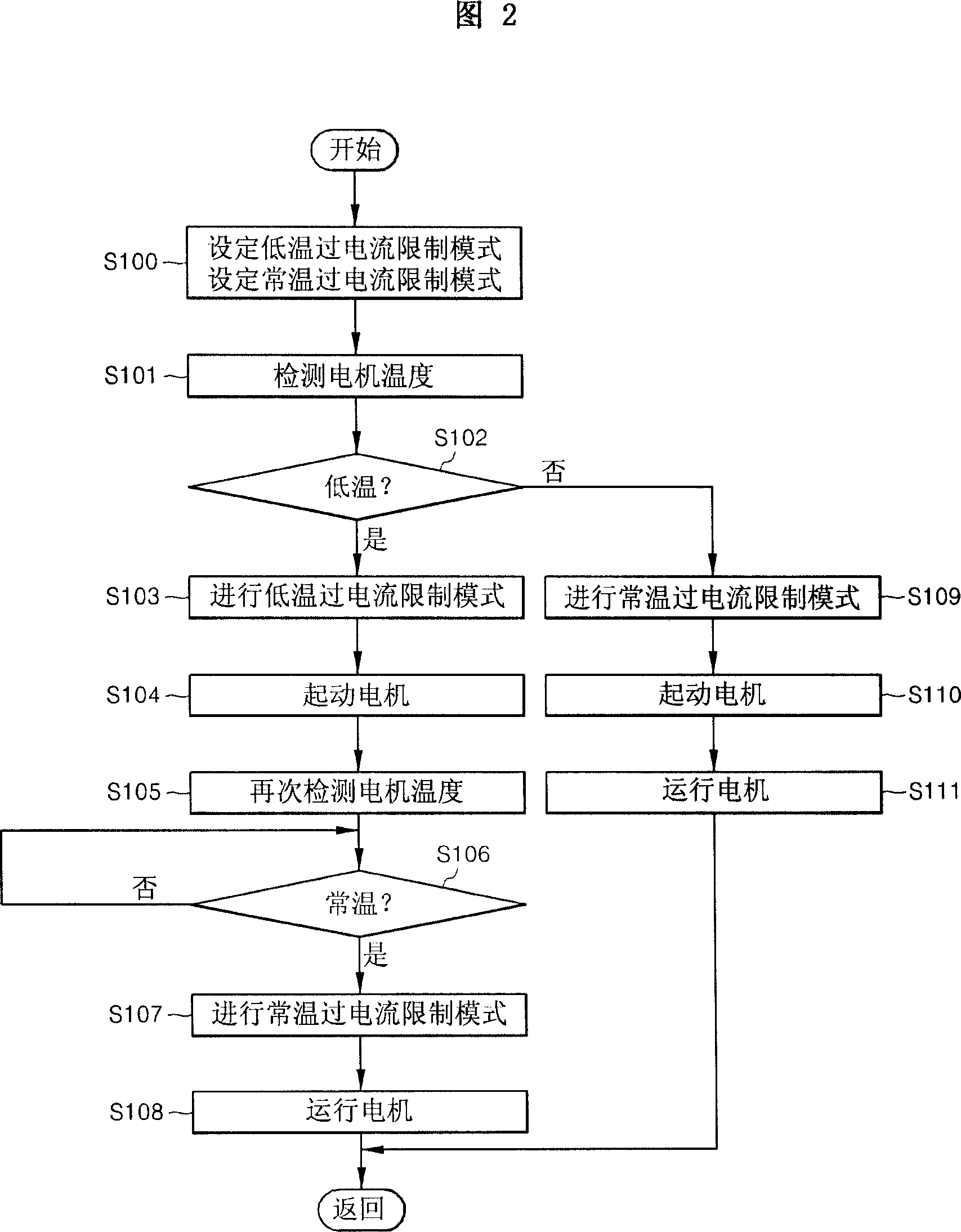

Brushless DC motor control device and control method therefor

InactiveCN1996743AOvercurrent upper limit increasedElectronic commutation motor controlAC motor controlDc motor controlLimit value

The present relates to a control device for brushless DC motor and control method thereof, especially relates to altering overcurrent upper limit value into corresponding value by monitoring operation conditions of brushless DC motor at low or normal temperature and according to each operation conditions, thus when the operation condition of the motor is at low temperature, overcurrent upper limit value is correspondingly reduced to protect demagnetization of the permanent magnet, when the operation condition switches into normal temperature, maximum power of the motor can be ensured by correspondingly improving the overcurrent upper limit value.

Owner:SAMSUNG ELECTRONICS CO LTD

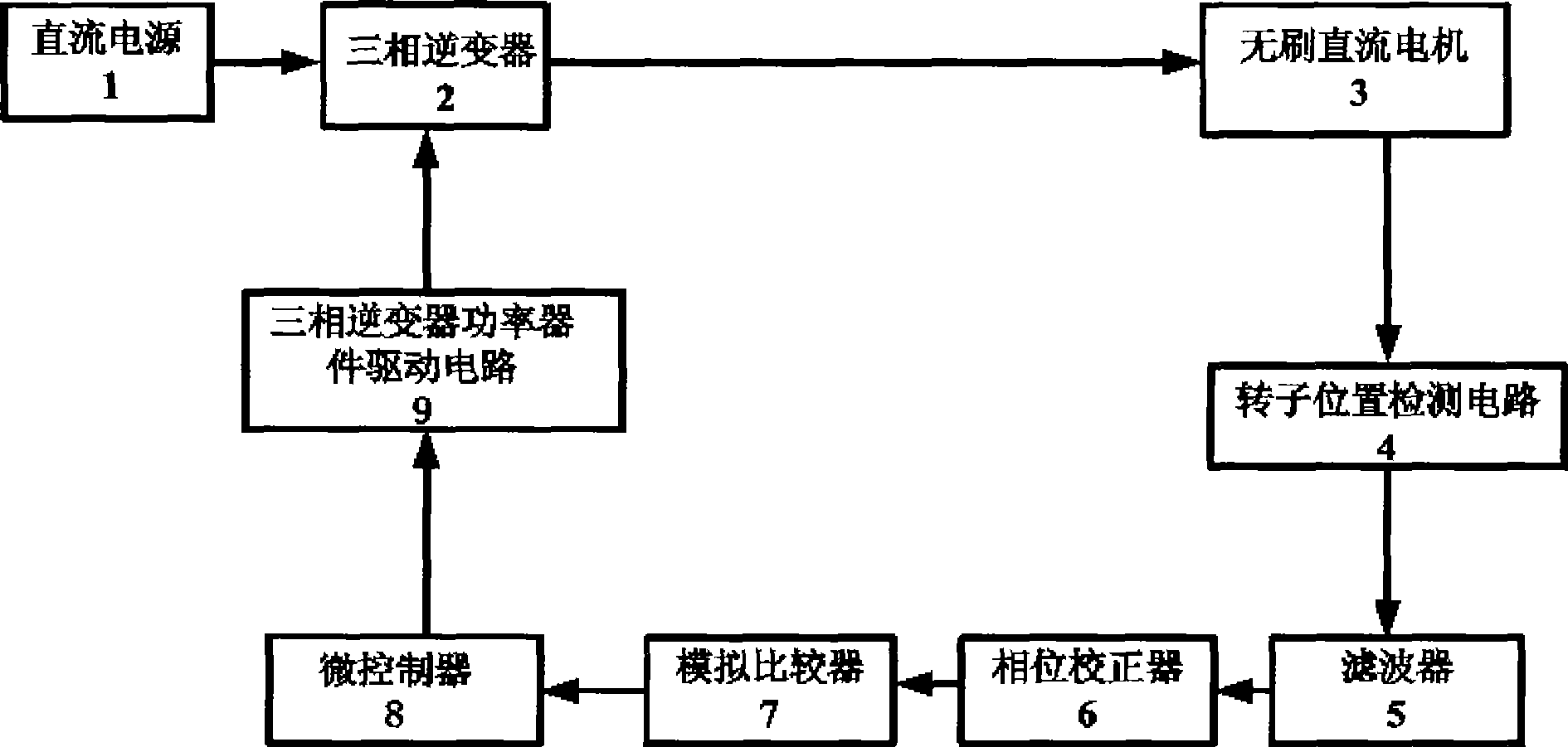

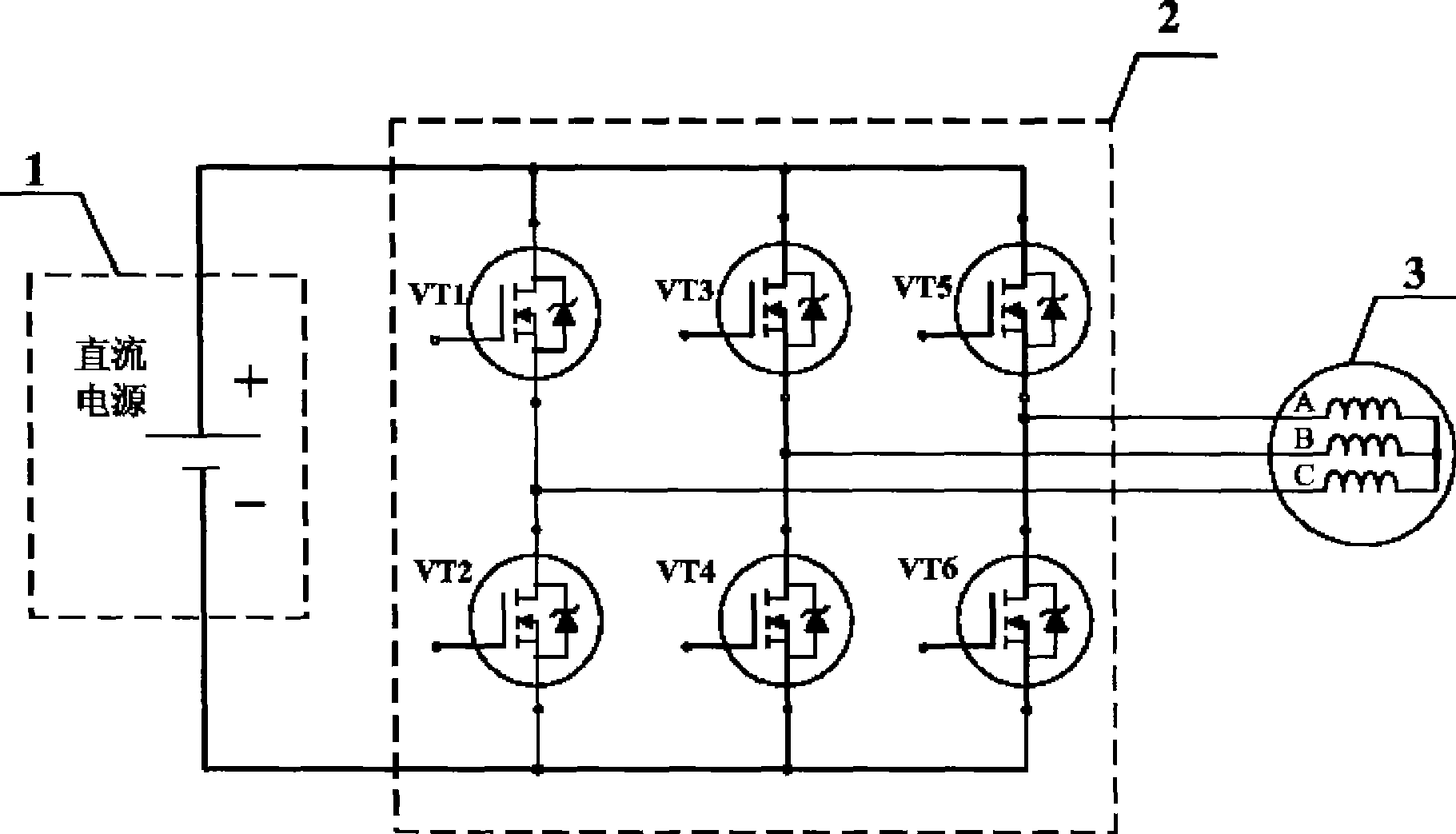

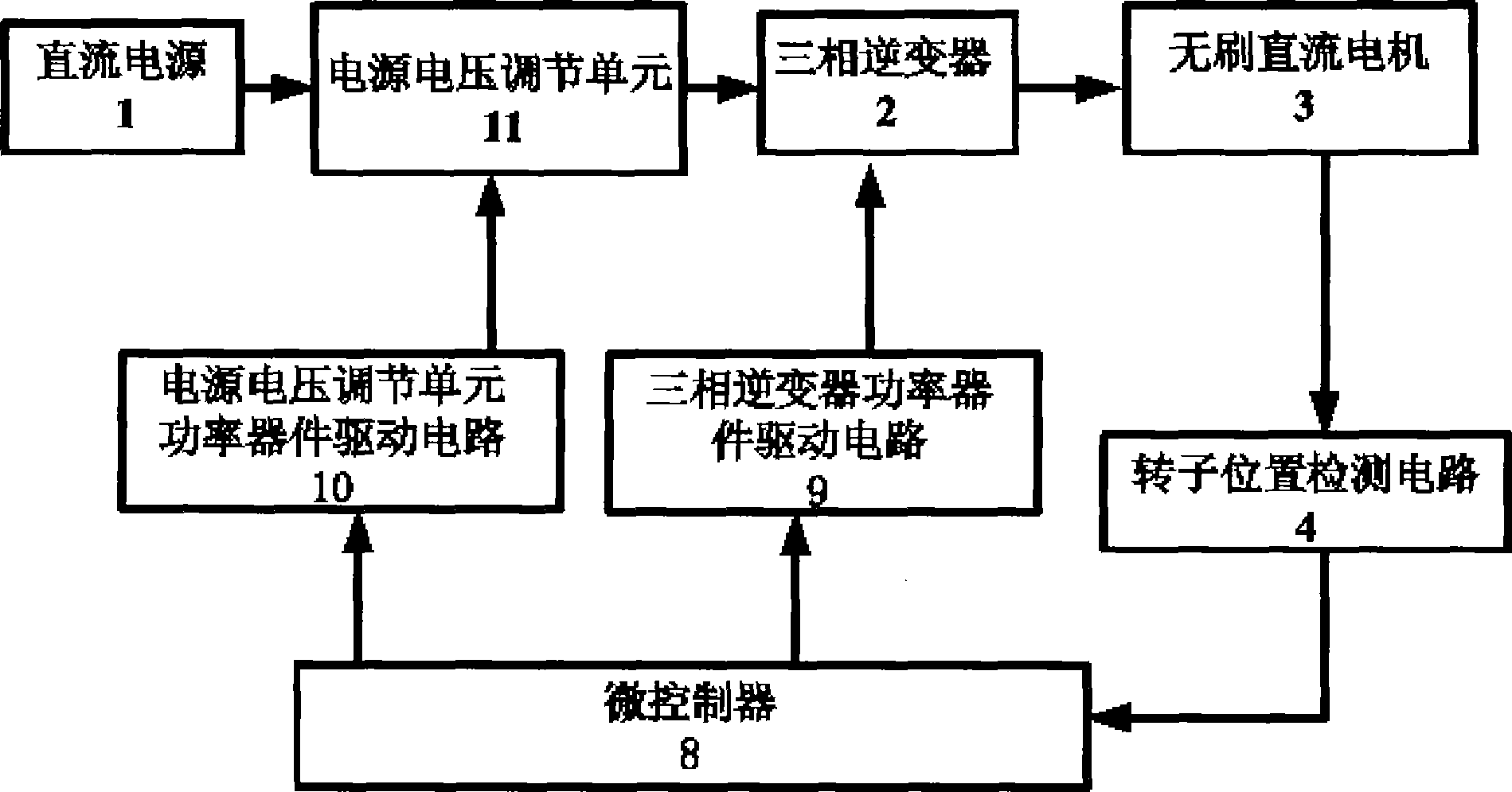

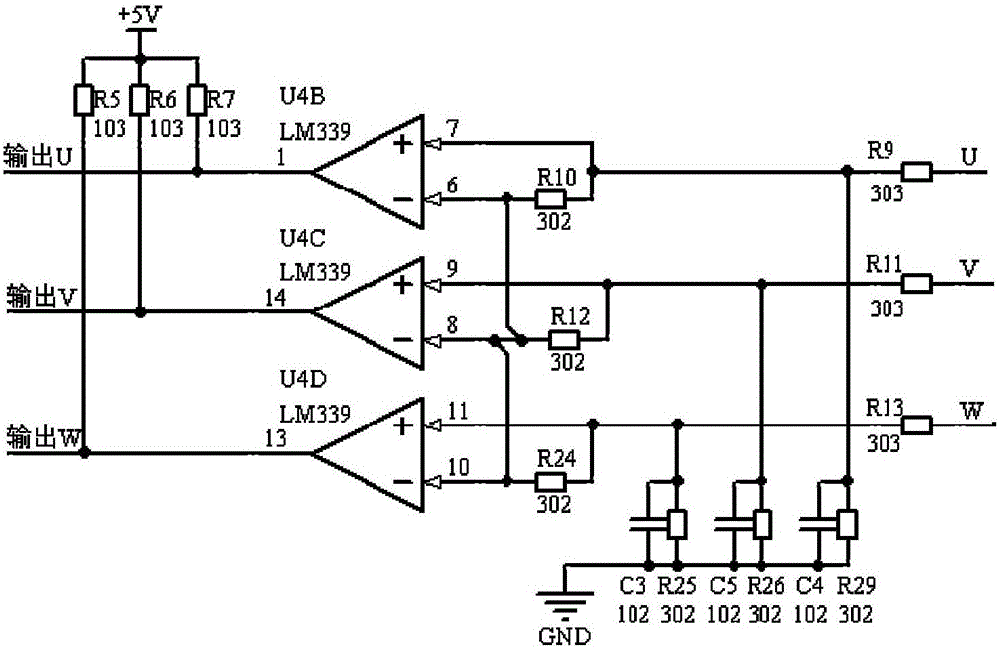

Position-sensorless control device for wide speed regulating range brushless DC motor without filter

InactiveCN101364781AExpand the scope ofImprove performanceSingle motor speed/torque controlElectronic commutatorsDc motor controlPosition sensor

The invention relates to a filter-free brushless DC motor control device with wide speed regulation range and no position sensors. The filter-free brushless DC motor control device comprises a DC power supply, a three-phase inverter, a brushless DC motor, a rotor position detection circuit, a microcontroller and a three-phase inverter power device drive circuit, wherein the DC power supply is connected with the brushless DC motor through a power voltage regulating unit and the three-phase inverter; the output signal of a rotor position detection circuit connected with the brushless DC motor is directly connected with the A / D conversion input pin of the microcontroller; ant the PWM output signal of the microcontroller is connected with the power voltage adjusting unit through a power voltage adjusting unit power device drive circuit. The control device can control the rotation speed of the brushless DC motor by PWM chopping control of a power switch VT7. Six commutation control signals outputted by the microcontroller are connected with the three-phase inverter through the three-phase inverter power device drive circuit to achieve commutation control of the brushless DC motor. The filter-free brushless DC motor control device has the advantages of improved reverse potential detection accuracy of the brushless DC motor, simplified system and lowered cost.

Owner:SHANGHAI UNIV

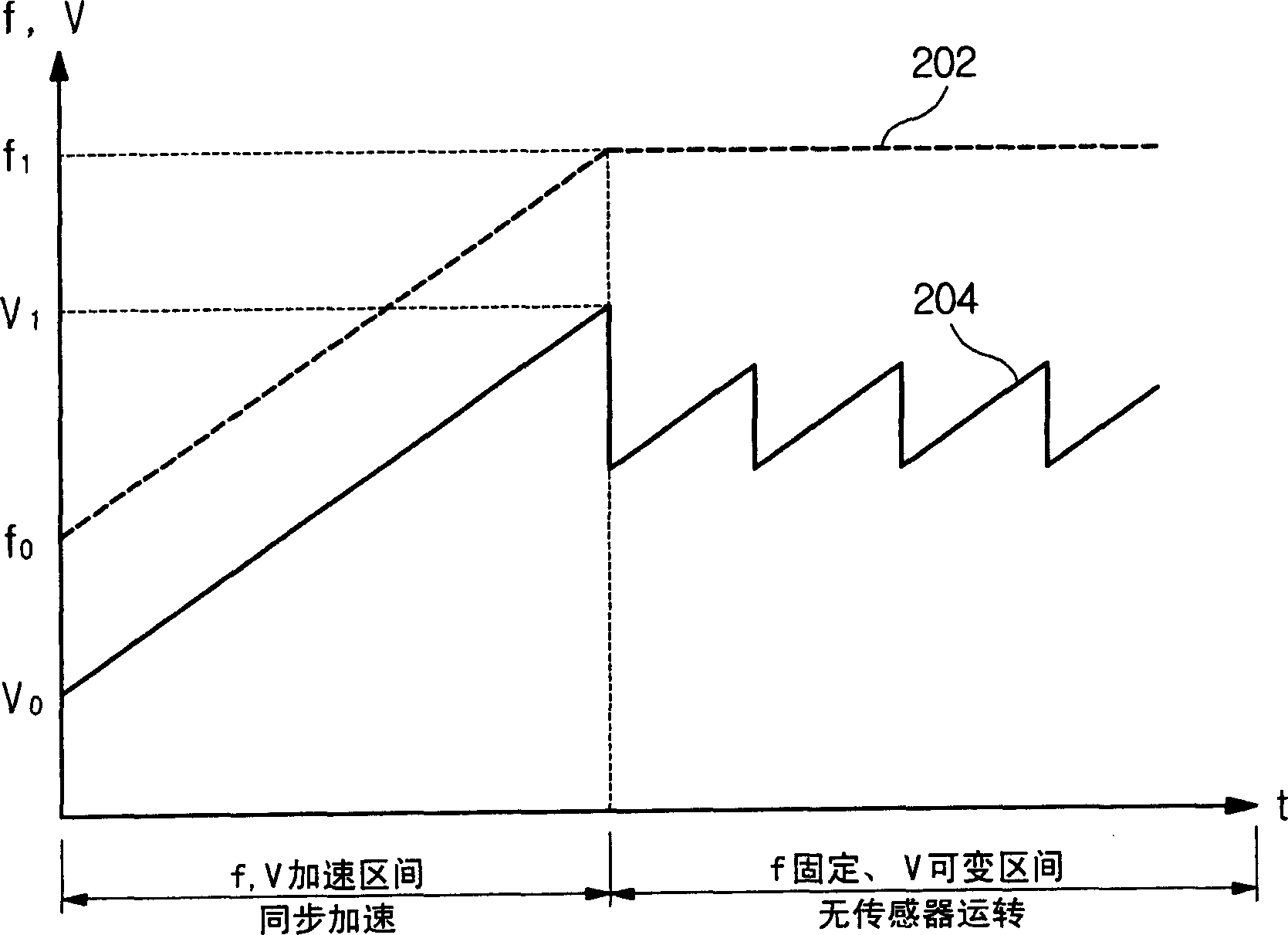

A brushless DC motor controlling method

InactiveCN1716754AReduce torque fluctuationReduce noiseSingle motor speed/torque controlElectronic commutatorsPhase currentsDc motor control

The present invention provides a control method of a brushless direct current motor, which prevents from providing the brushless direct current motor with over large current at a brushless direct current motor initial actuating stage, so as to switch to a no-sensor operation mode stably. The phase steering of a phase current is processed at a regulated phase steering moment during the synchronous acceleration of the brushless direct current motor; a phase current application moment that the volume of the phase current supplied to the brushless direct current motor is more than a preset value is detected, and the moment that voltage is supplied to a stator winding corresponding to a rotating position of a rotor is controlled according to the time from the phase steering moment to the phase current application moment.

Owner:SAMSUNG ELECTRONICS CO LTD

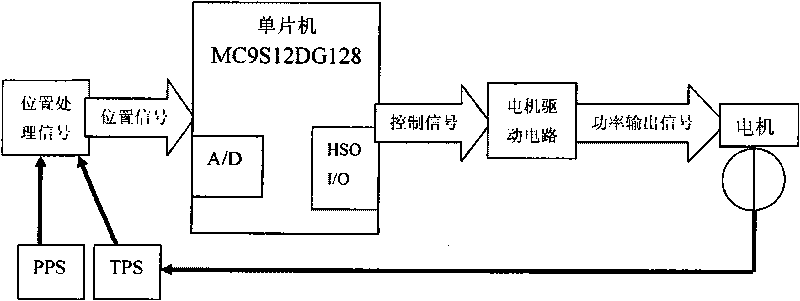

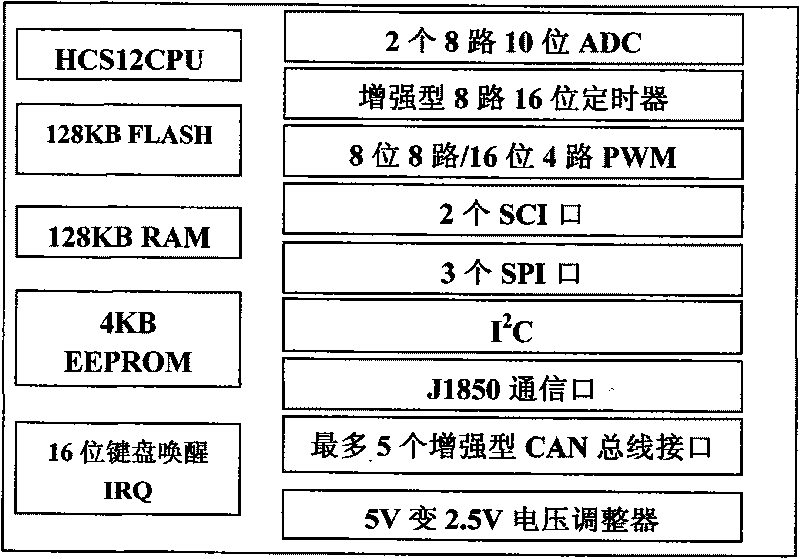

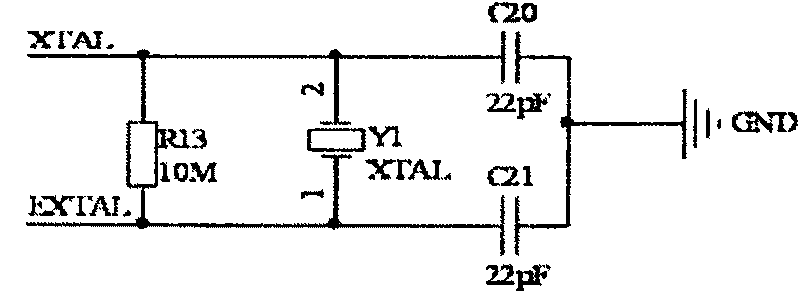

Electronic throttle control simulation experiment system

InactiveCN101739862AContinuous currentGood low speed characteristicsProgramme controlComputer controlMicrocontrollerControl signal

The invention relates to an electronic throttle control simulation experiment system. The overseas research of the electronic throttle control system (ETCS) has over twenty-year history, the products prepared by manufacturers are beginning to be put on the market largely and the current generation of the electronic throttle products has been launched. The system of the invention comprises a control circuit, wherein the control circuit comprises a signal acquiring and processing circuit, a MCU, a power drive circuit, a DC motor control driver, an accelerator pedal position sensor (PPS) and an electronic throttle position sensor (TPS); the accelerator pedal position sensor and the electronic throttle position sensor are used to separately input the accelerator pedal control signal and feed back the throttle position signal, the A / D converter of the MCU converts an input analog signal to a digital signal, after the control algorithm calculates control quantity, the control signal is output from a high-speed outlet (HSO) and an I / O port, the DC motor driver outputs the power drive signal to control the rotation of the DC motor, thus realizing the control of the opening of the throttle. The invention is used in the electronic throttle.

Owner:HEILONGJIANG INST OF TECH

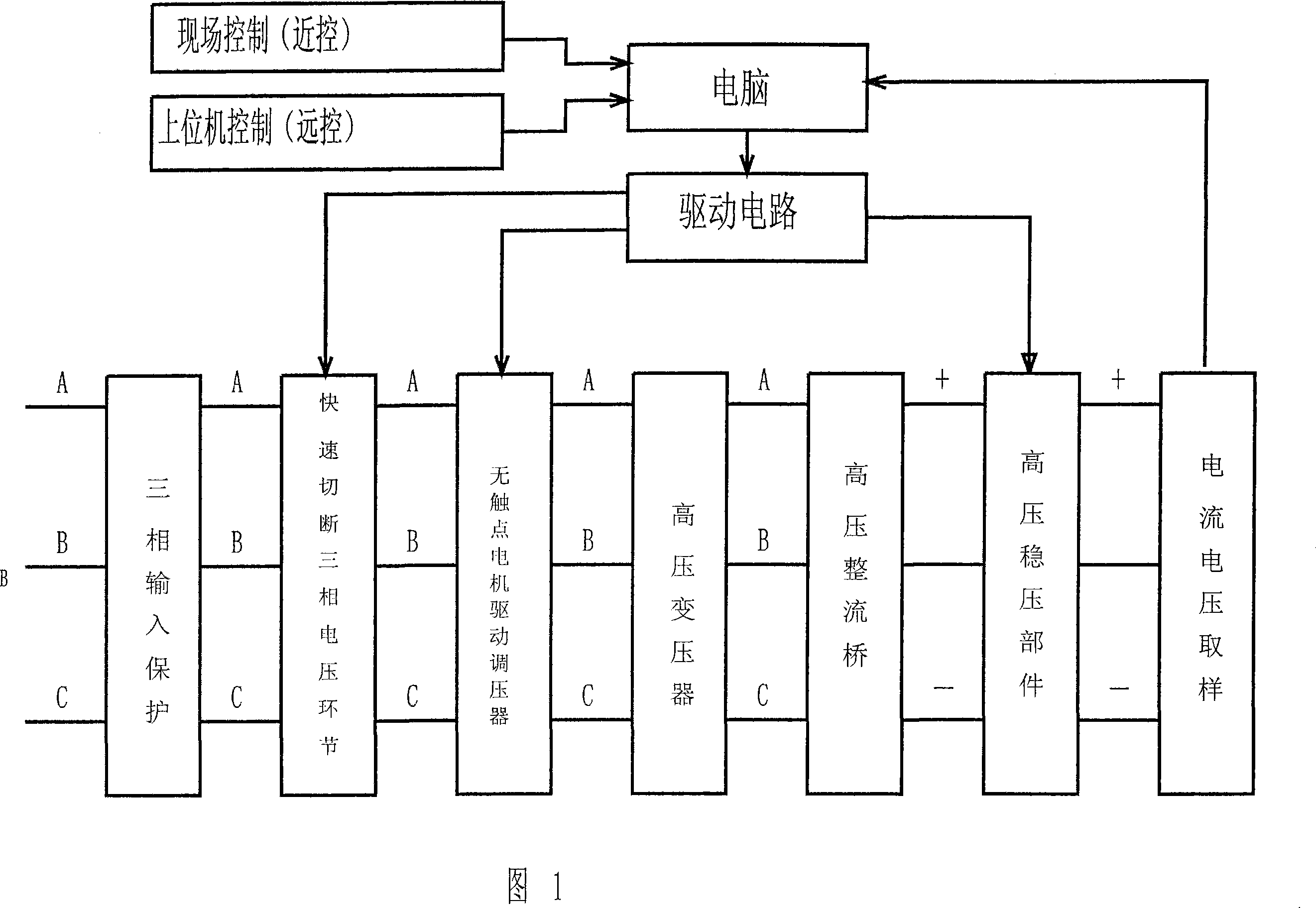

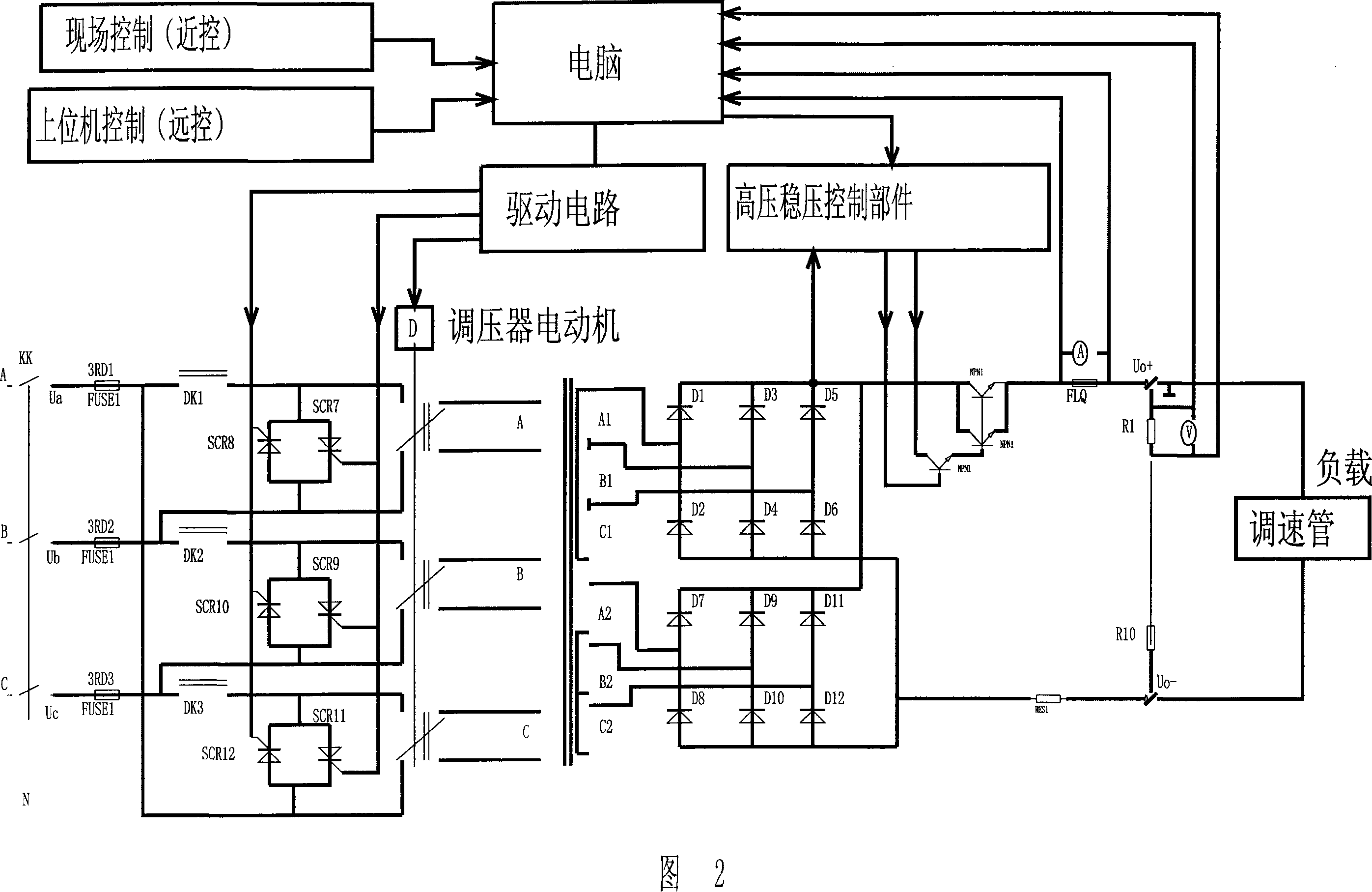

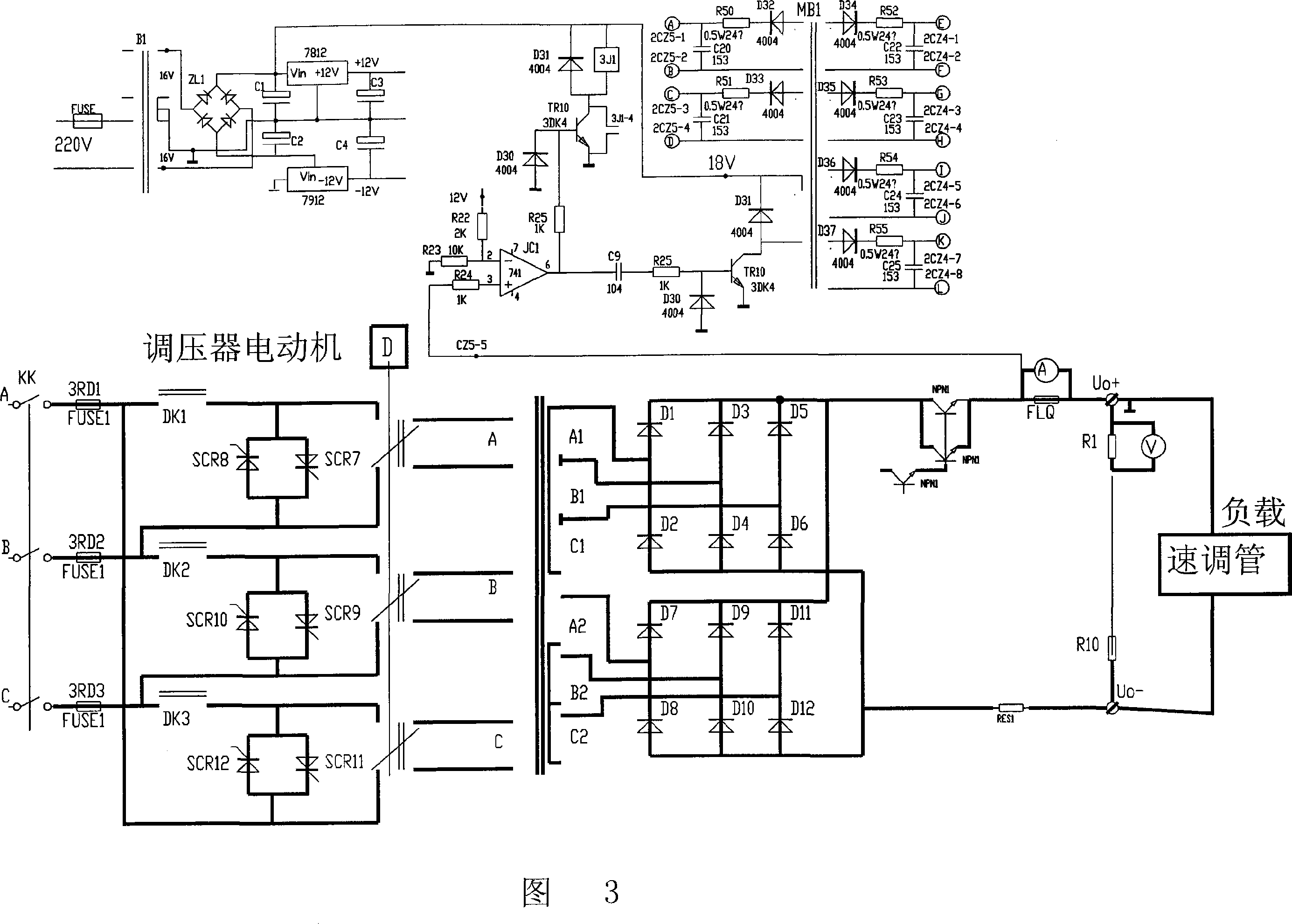

Special DC constant voltage and current power supply for high-voltage speed controller

InactiveCN101075789ASuppress output rippleSmall ripple factorThyristorAc-dc conversion without reversalCapacitanceFull wave

In the invention, for effectively suppressing the output ripple, a non carbon brush electromagnetic voltage regulator controlled by a DC motor is used as a controller; a triangle winding and a star winding are used at the secondary of the high voltage transformer to replace the 6 pulses full wave rectification technology normally using one winding and to compose 2 pulses rectification technology. By the invention, after rectification, the P-P value of the ripple factor is reduced from 13.4% to 3.4%; and after adding an electronic voltage stabilizing unit composed of transistors, the ripple factor can be reduced from 3.4% to 0.1%.

Owner:国充充电科技江苏股份有限公司

Brushless DC motor phase conversion control method and brushless DC motor control system

ActiveCN105763109AFree up spaceUnleash computing powerElectronic commutatorsPhase conversionDc motor control

The invention relates to a brushless DC motor phase conversion control method and a brushless DC motor control system. The method comprises the following steps: S1, when the motor starts to enter a constant speed state, phase conversion time counting increase and zero-crossing time counting increase are carried out starting from any phase conversion point; S2, during the counting process, whether the back electromotive force of a non-conduction phase of the motor achieves a zero-crossing point is detected, and if yes, zero-crossing time counting increase is stopped, and zero-crossing time counting decrease is carried out; and S3, whether the calculation value for the zero-crossing time counting is smaller than the calculation value for phase conversion time counting is judged, and if yes, a next phase conversion point arrives. According to the technical scheme of the invention, the phase conversion point is determined through two-way counting, the data processing amount and the calculation difficulty for phase conversion control are reduced, the space and the calculation ability of an MCU are released, and ultra high rotation speed driving can be realized on the rotation speed of the brushless DC motor.

Owner:SHENZHEN TOPBAND CO LTD

Adaptive and reconfigurable system for DC motor control

ActiveUS7835630B2Digital variable displayAcceleration measurement using interia forcesControl signalEngineering

An integrated circuit for controlling a DC motor is disclosed. The integrated circuit includes at least one digital position and speed circuit (DPS) for providing measurements of speed, position, and direction of the motor, the DPS being in signal communication with the motor for receiving a pair of signals having a quadrature relationship; and at least one programmable gain amplifier (PGA) electrically coupled to the motor, the PGA being configured to receive a feedback signal indicative of current flowing through the motor and to apply a second signal to the motor for adjusting the speed of the motor; and at least two analog-to-digital converters (A / D), one A / D being used to quantize the output of the PGA for an off-chip processor; and another A / D to provide motor reference position from an analog sensor, such as a potentiometer; and at least two digital-to-analog converters (D / A), one D / A used to set the motor voltage; and another D / A used to set the motor current limit. The integrated circuit can be incorporated into a larger motor control loop which further includes a summing amplifier for providing the feedback signal to the motor that is indicative of current flowing through the motor; a buffer amplifier electrically for sensing the output current of the motor, and a processor for providing control signals to the system monolithic module and for receiving the measurements of speed, position, and direction of the motor.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

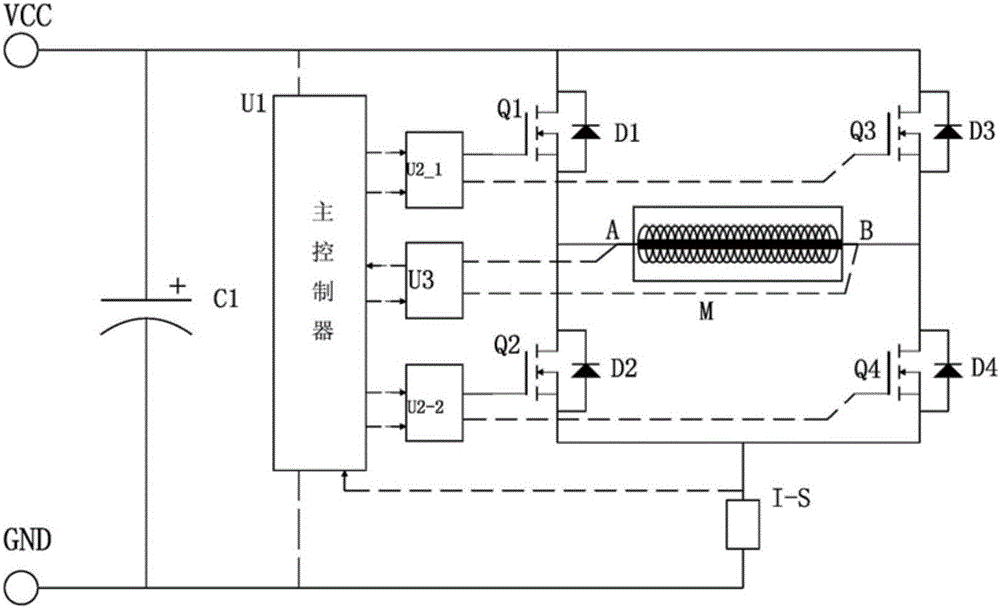

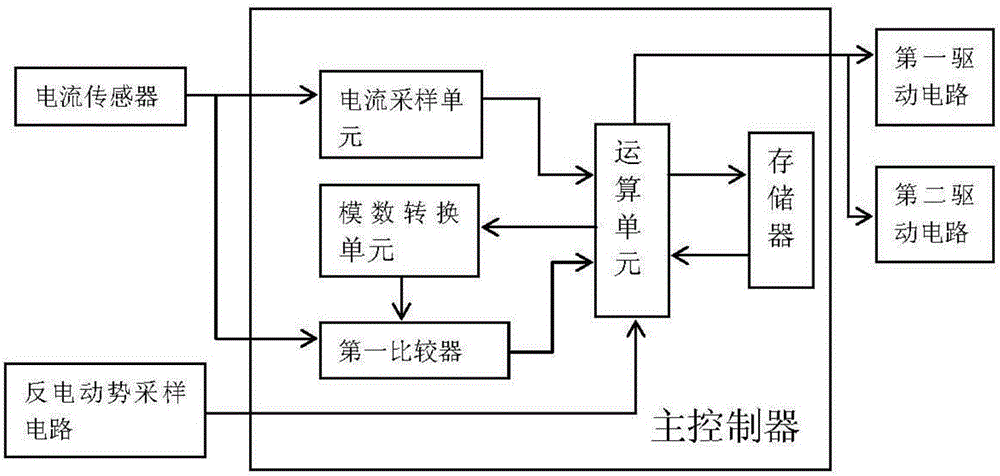

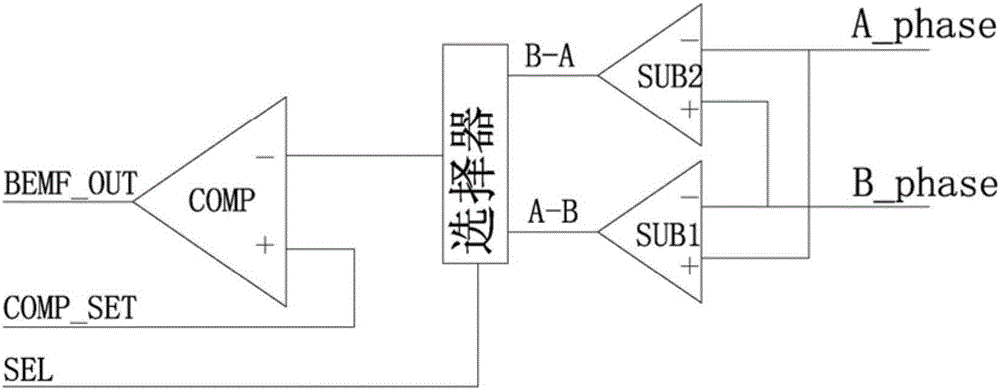

Single-phase sensorless brushless DC motor control system

InactiveCN106026805AAccurate detectionEasy to controlSingle phase motor controlBrushless motorsCurrent transducer

The invention relates to the technical field of motor control, and particularly relates to a single-phase sensorless brushless DC motor control system, which comprises an H-bridge control circuit respectively connected with two phases of wires of the motor. The output end of the H-bridge control circuit is connected with a current sensor; the current sensor is connected with a main controller; the main controller is provided with a first driving circuit and a second driving circuit for driving the H-bridge control circuit respectively; both the two phases of wires of the motor are connected with a counter electromotive force sampling circuit; the counter electromotive force sampling circuit is used for acquiring counter electromotive force comparison signals on the single-phase brushless motor and transmitting the counter electromotive force comparison signals to the main controller; and the main controller controls opening and closing state of the first driving circuit and the second driving circuit. The single-phase sensorless brushless DC motor control system can be well applied to a single-phase brushless motor, the rotor position of the single-phase brushless motor can be accurately detected and controlled, and a good basis is built for promotion and use of the single-phase brushless motor.

Owner:SHENZHEN GAOKERUN ELECTRONICS CO LTD

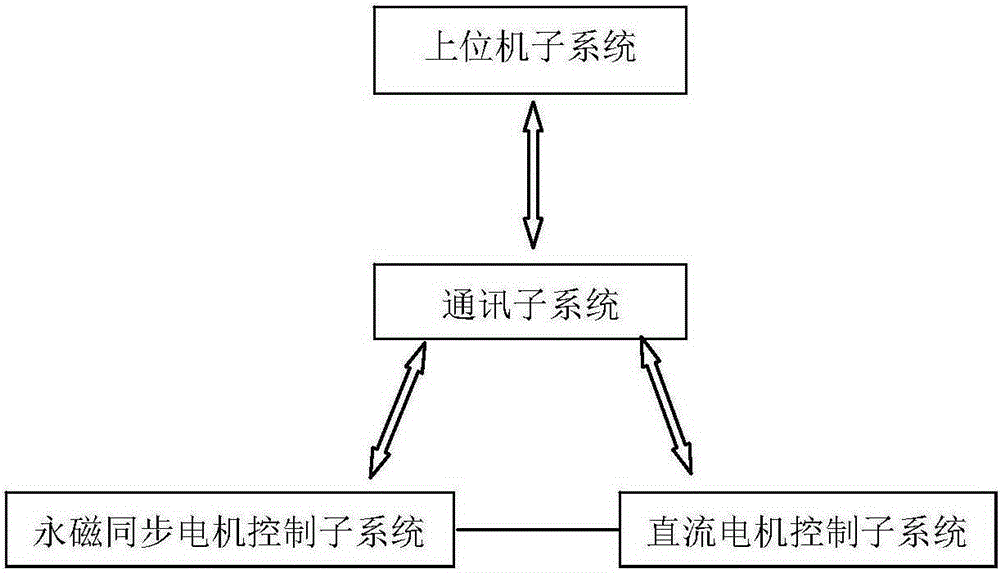

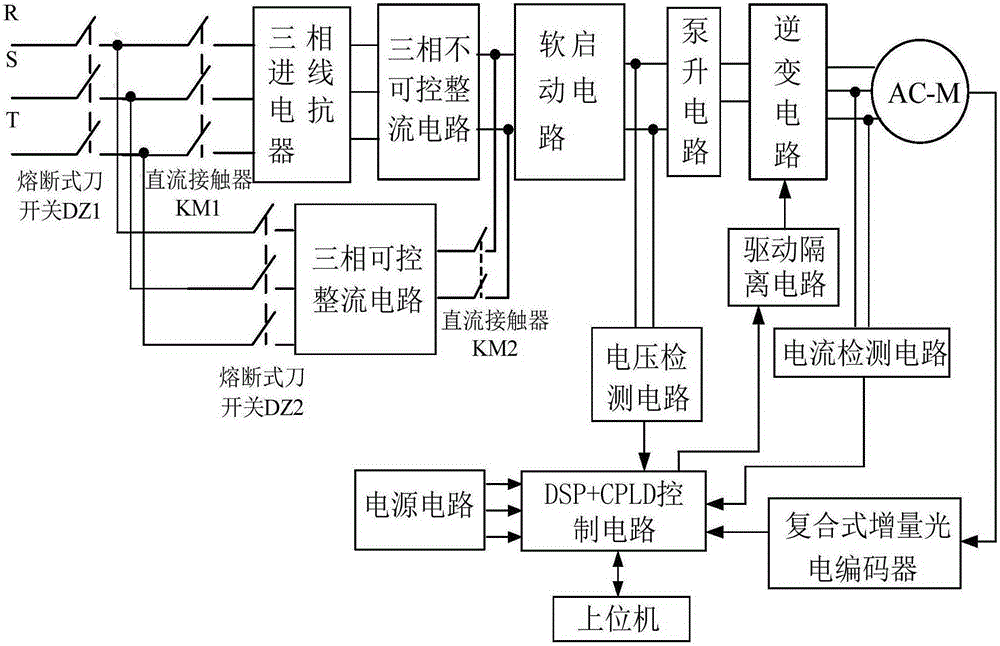

AC motor control performance automatic testing system and testing method

InactiveCN105203956ALoad changeSave energyChemical industryDynamo-electric machine testingDC - Direct currentAC motor

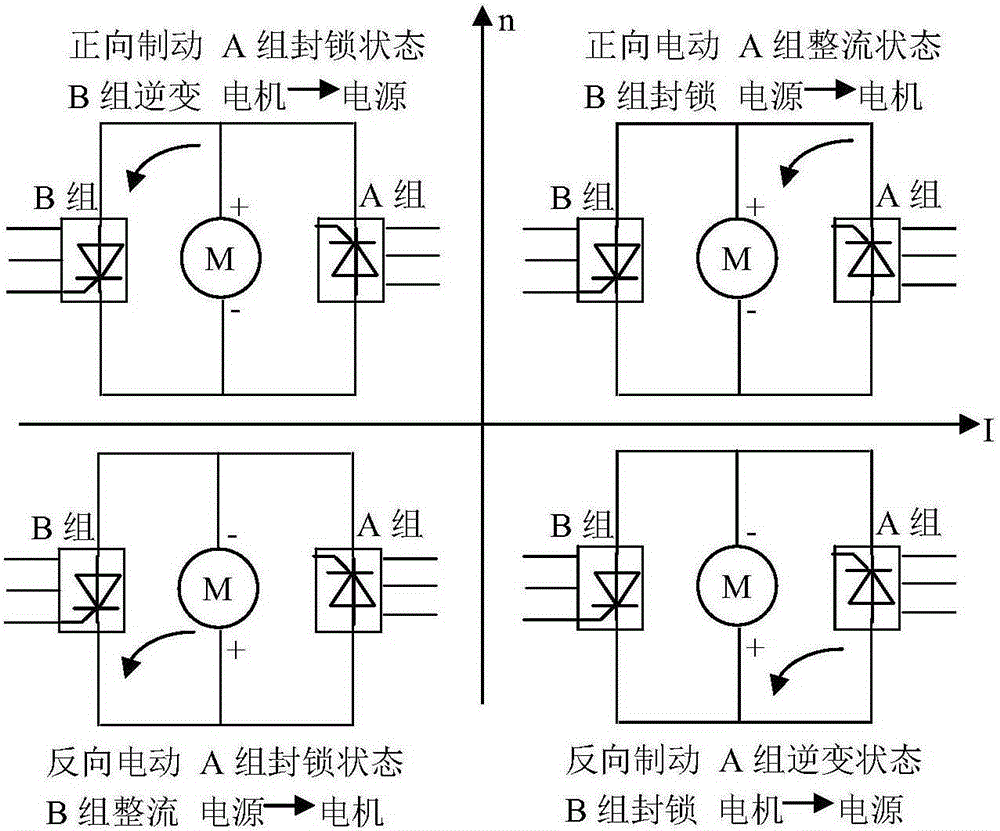

The invention provides an AC motor control performance automatic testing system which includes an AC motor and a DC motor in shaft connection, wherein an AC motor control system includes a power circuit, a control circuit, a detection circuit and a driving circuit; the power circuit includes an uncontrollable rectifying circuit and a controllable rectifying circuit alternatively selected through a switch; an AC power supply is connected with the inverter of the AC motor through the power circuit; the detection circuit detects and transmits current, voltage and the rotating speed of the AC motor to the control circuit; the control circuit sends a control order, and the driving circuit controls the inverter, so as to drive the AC motor; a DC motor control system adopts a logic circulating-current-free reversible DC speed regulating system; the AC motor control performance automatic testing system further includes an upper computer system and a communication system. When the AC motor is used as the load of the DC motor, electric energy is used as energy to feed back a power grid through the controllable rectifying circuit; when the DC motor is used for loading and unloading of the AC motor, electric energy is fed back to the power grid through a direct current speed controller, so that energy is saved.

Owner:WISDRI ENG & RES INC LTD

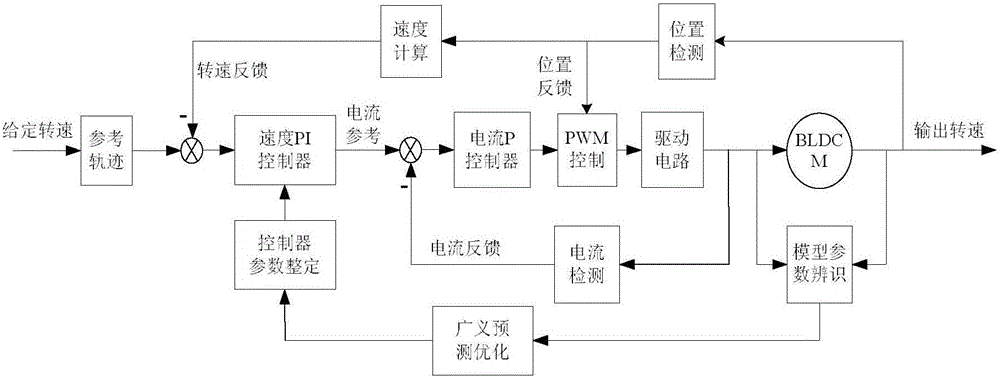

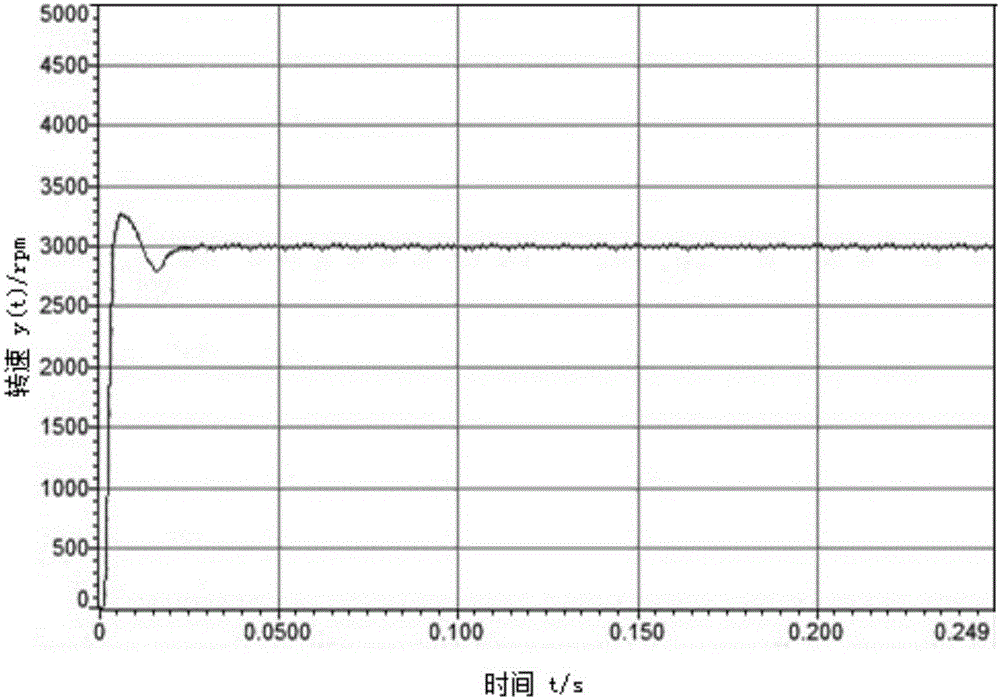

Brushless direct current motor control method

InactiveCN105024610ASimple structureConvenient quality controlElectronic commutation motor controlVector control systemsPower inverterDc motor control

The invention discloses a brushless direct current motor control method, belonging to the technical field of control of a brushless direct current motor. The control method comprises the following steps of: optimizing the parameters of a proportional integral (PI) controller by using generalized predictive control guidance; introducing the parameters into a brushless direct current motor control system to replace a speed ring PI controller and obtain a new generalized predictive PI control method of the speed ring; and converting a controlled quantity obtained through calculation by the generalized predictive PI control method into a space vector pulse width modulation (SVPWM) signal, and inputting the SVPWM signal after amplification into an inversion driving circuit so as to change output voltage of an inverter and further control the rotational speed of an electric motor. By the brushless direct current motor control method, the tracking control on the rotational speed of a brushless direct current electric motor is achieved. The control method has the advantages of no overshot, short adjustment time, low steady-state error, fast response speed, high control quality and form simplicity, and is convenient to implement.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Brushless Dc Motor Control Method and Brushless Dc Motor Controller

InactiveUS20080231217A1Reduce complexityReduce in quantityMotor/generator/converter stoppersSynchronous motors startersControl signalLow-pass filter

The present invention discloses a control technology for brushless DC motor, in which firstly it is to build or import a motor running parameters' database, then detect the signals always running and the signals closely relevant to the rotor's rotating state such as the voltage and the current, and process these signals and figure out the signals about the rotor's position. Wherein these detected signals should be filtered before being used, and the best filter is the low-pass filter to cut out the high frequency components, and the cut-off frequency of the low-pass filter are determined by the motor running voltage U and PWM signal width when the motor is running at no load, finally determine if the motor is working properly by means of the motor running parameters stored in the database in advance, that is to determine if the detected value is identical with the one predicted from the database. Depending on the results from the detecting and comparison above, the control signal is generated to adjust the motor running state. With the technical method in this invention, the position sensor is not needed. This reduces the motor's external wiring amounts and the wiring complexity. Also the motor's seal is improved. Meanwhile, it is possible to measure the rotor's position accurately in any state according to this invention technology. Thus the motor running state can be controlled properly.

Owner:SANDEN HUAYU AUTOMOTIVE AIR CONDITIONING CO LTD +1

Brushless DC motor control method and brushless DC motor controller

InactiveUS7583039B2Reduce complexityReduce in quantityMotor/generator/converter stoppersSynchronous motors startersControl signalLow-pass filter

The present invention discloses a control technology for brushless DC motor, in which firstly it is to build or import a motor running parameters' database, then detect the signals always running and the signals closely relevant to the rotor's rotating state such as the voltage and the current, and process these signals and figure out the signals about the rotor's position. Wherein these detected signals should be filtered before being used, and the best filter is the low-pass filter to cut out the high frequency components, and the cut-off frequency of the low-pass filter are determined by the motor running voltage U and PWM signal width when the motor is running at no load, finally determine if the motor is working properly by means of the motor running parameters stored in the database in advance, that is to determine if the detected value is identical with the one predicted from the database. Depending on the results from the detecting and comparison above, the control signal is generated to adjust the motor running state. With the technical method in this invention, the position sensor is not needed. This reduces the motor's external wiring amounts and the wiring complexity. Also the motor's seal is improved. Meanwhile, it is possible to measure the rotor's position accurately in any state according to this invention technology. Thus the motor running state can be controlled properly.

Owner:SANDEN HUAYU AUTOMOTIVE AIR CONDITIONING CO LTD +1

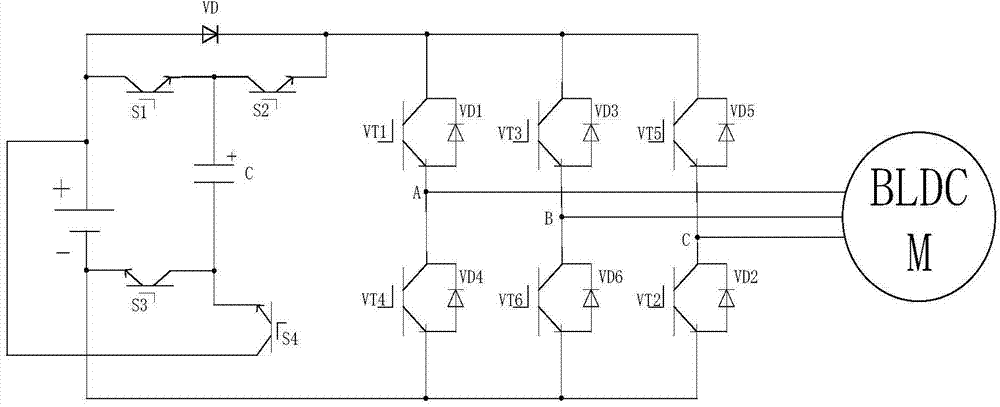

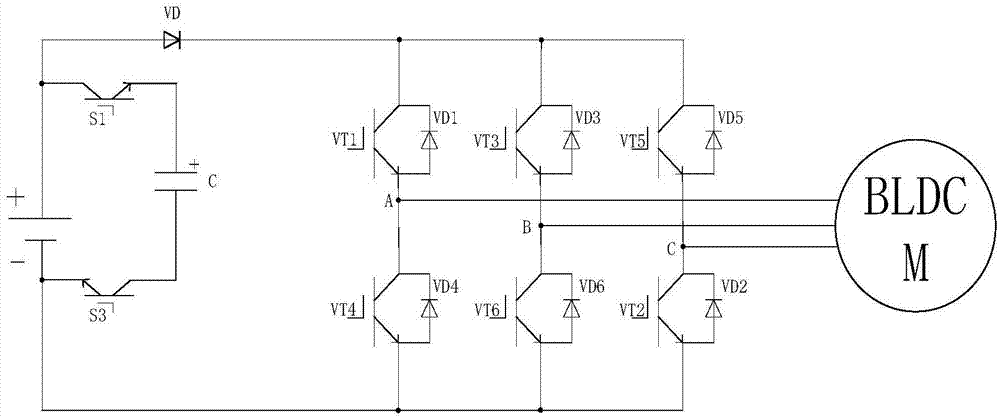

Compensating circuit for restraining torque ripple of brushless DC motor

ActiveCN104852642ASuppress commutation torque rippleSimple controlTorque ripple controlCapacitanceControl manner

The invention belongs to the field of brushless DC motor control, and particularly relates to a compensating circuit for restraining torque ripple of a brushless DC motor. The compensating circuit comprises a DC voltage source U, a diode VD, a capacitor C, a switching transistor S1, a switching transistor S2, a switching transistor S4, a three-phase inverter bridge and a brushless DC motor, and is characterized in that a charging circuit is formed in a mode that a positive electrode of the DC voltage source U is connected to a collector electrode of the switching transistor S1, a negative electrode of the DC voltage source is connected to an emitting electrode of the switching transistor S3, a positive electrode of the capacitor is connected to an emitting electrode of the switching transistor S1, and a negative electrode of the capacitor is connected to a collector electrode of the switching transistor S3; and a voltage compensating circuit is formed by connecting a collector electrode of the switching transistor S4 to the positive electrode of the DC voltage source U. The voltage compensating circuit formed by four electric power switching transistors, one electric power diode and one capacitor can effectively restrain the commutation torque ripple, and is simple in control mode, low in cost and easy for engineering implementation.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com