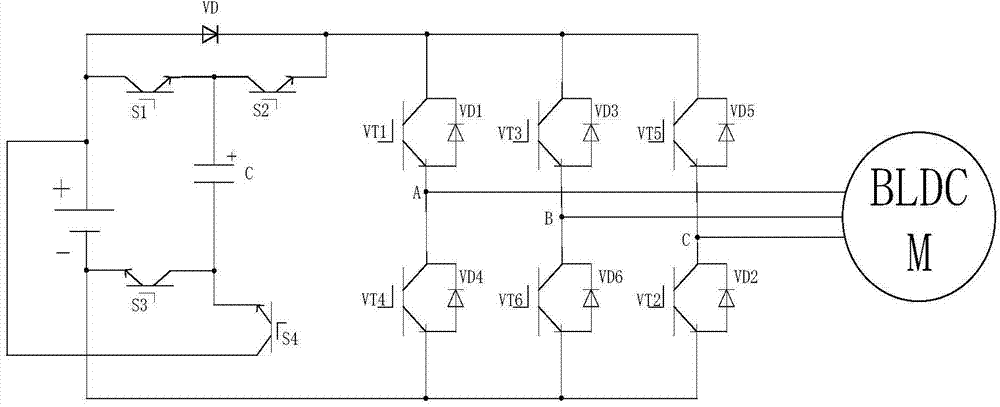

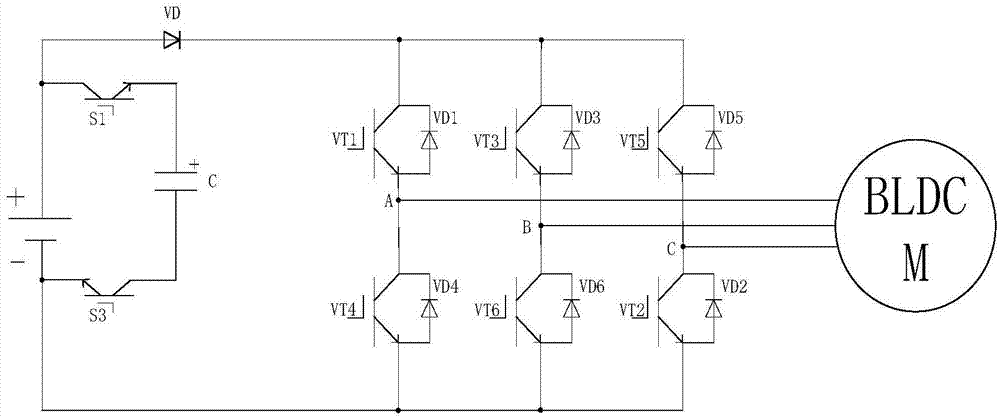

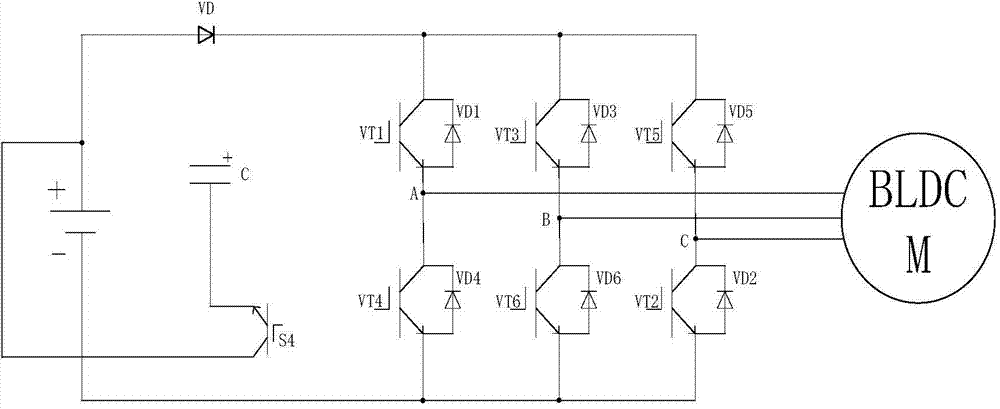

Compensating circuit for restraining torque ripple of brushless DC motor

A technology of brush DC motor and torque ripple, applied in the direction of torque ripple control, etc., can solve the problems of non-commutation current fluctuation, commutation torque ripple, etc., and achieve the effects of low cost, easy engineering implementation, and simple control mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] The invention adopts a brushless DC motor with a rated power of 3.7kW, a rated voltage of 300V, and a rated speed of 1500rmp. The measured inductance is 0.188425mH, and the amplitude of the counter electromotive force is 92.99V. Therefore, the compensation voltage, that is, the voltage across the capacitor is 71.96V.

[0035] image 3 In (a), the driving voltage is a DC voltage of 300V during non-commutation, and the driving voltage is a DC voltage plus a compensation voltage of 371.96V during commutation. Figure 4 with Image 6 It is the three-phase current waveform diagram and the current torque waveform diagram of the embodiment under the control of the method of the present invention. When the motor commutates, it can be seen that the rate of decline of the off-phase current is inconsistent with the rate of rise of the conduction phase current, and the non-commutation current There are fluctuations, which cause commutation torque ripple, the average torque is 26N*...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com