Patents

Literature

4201 results about "Motor power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

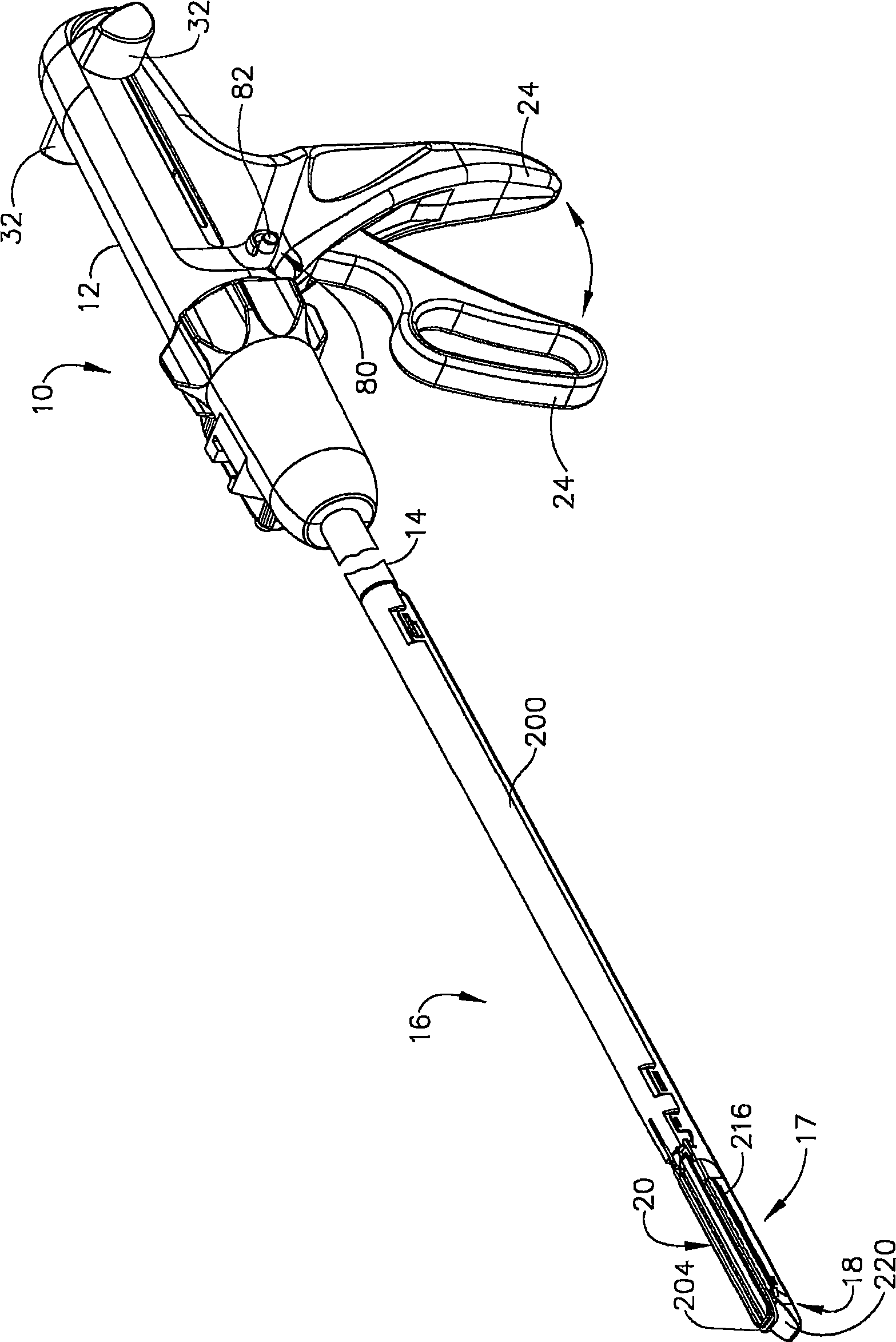

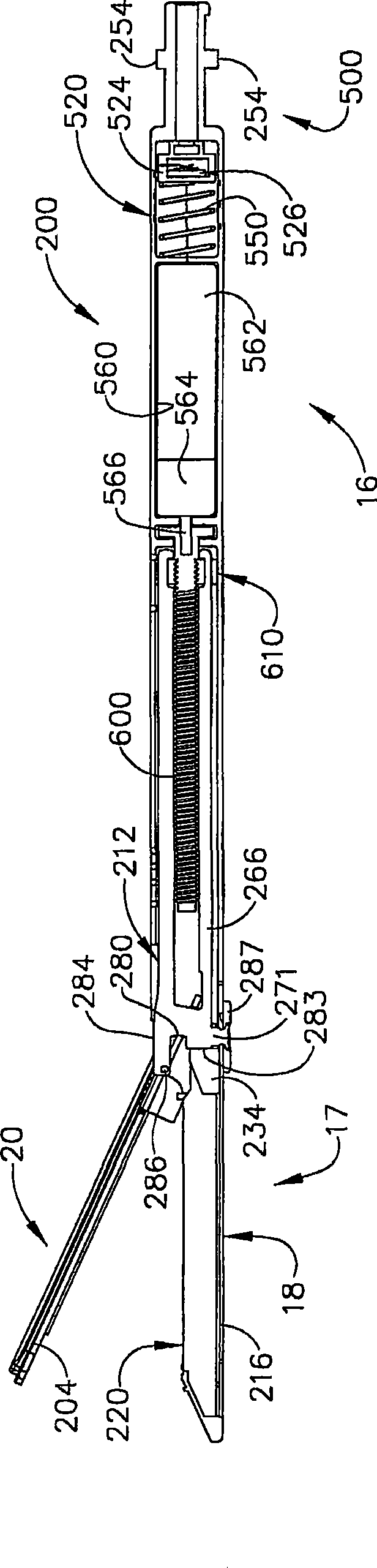

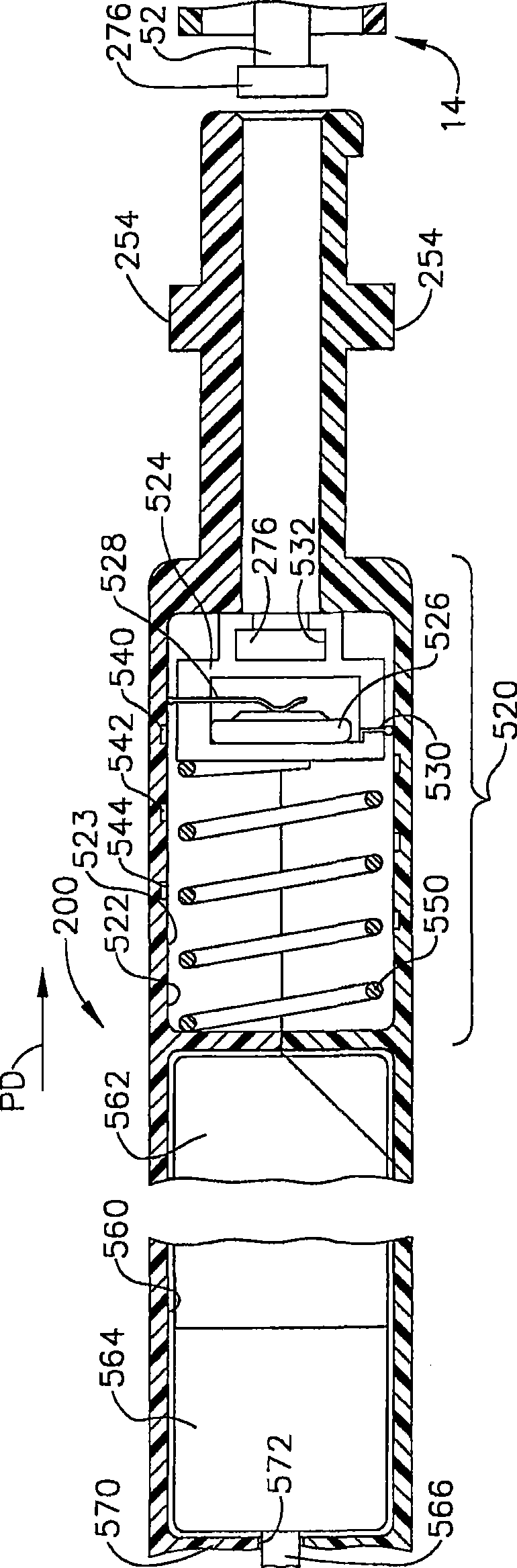

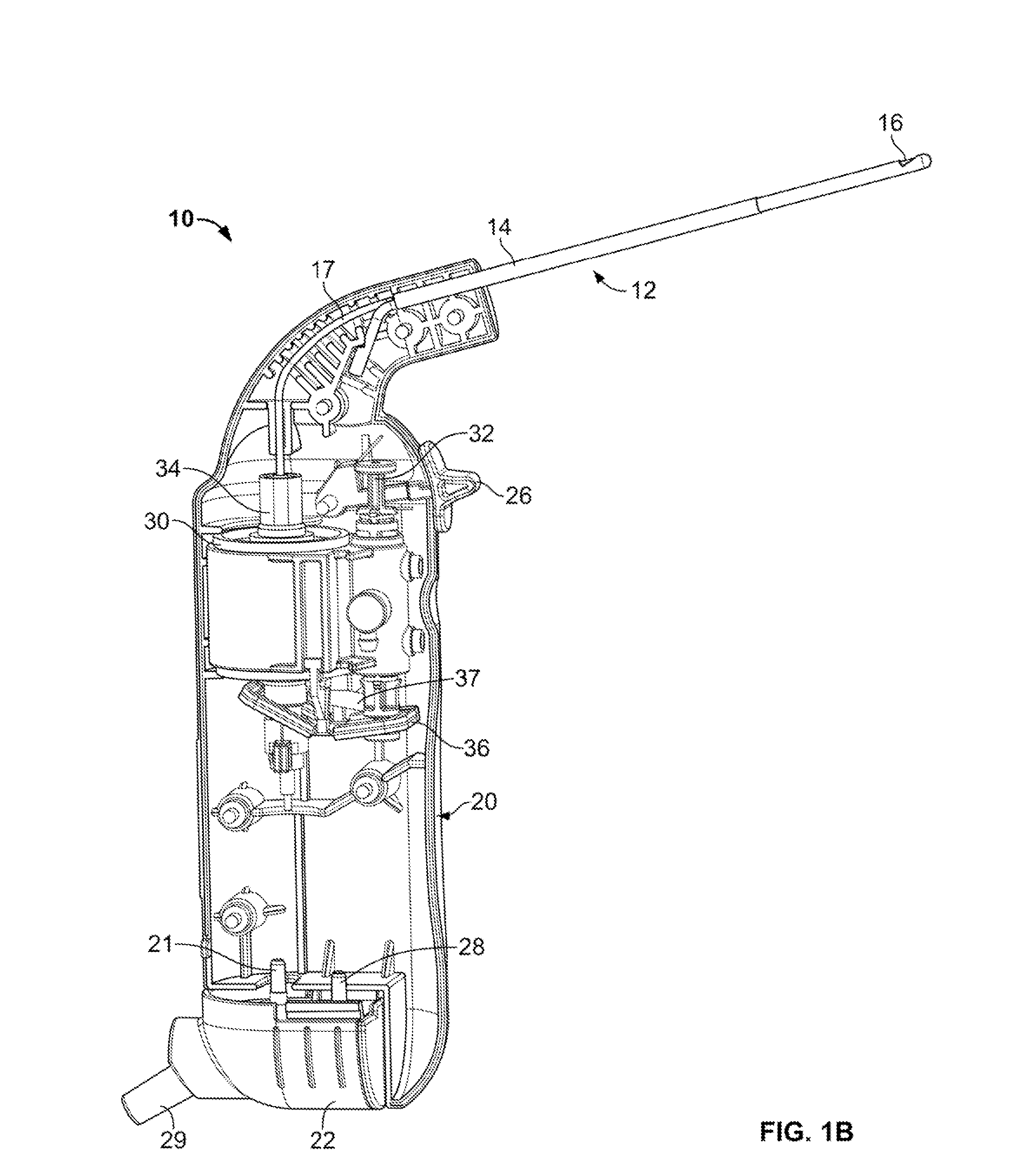

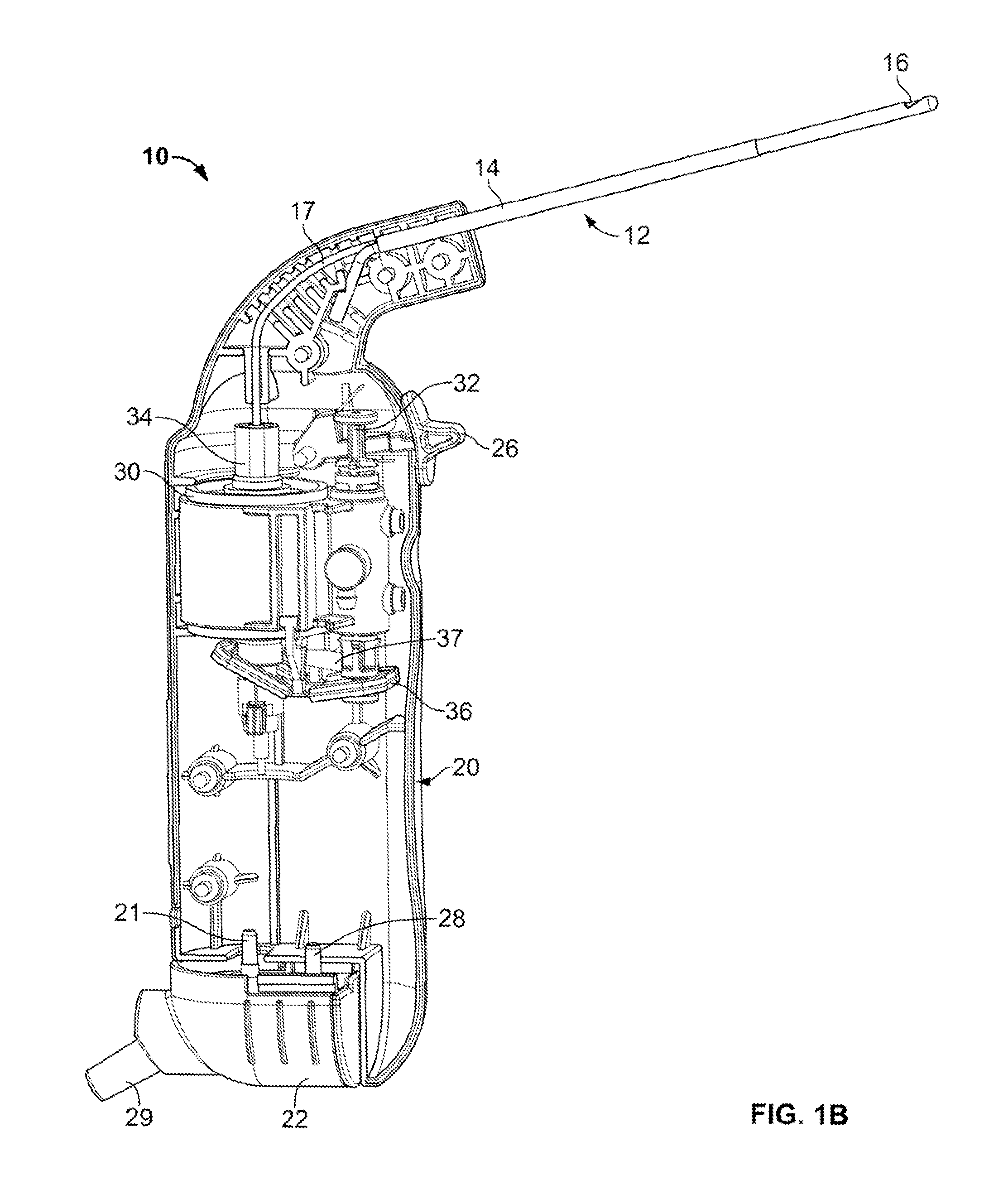

Disposable motor-driven loading unit for use with a surgical cutting and stapling apparatus

A self contained motor-powered disposable loading unit for use with a surgical cutting and stapling apparatus. The disposable loading unit may contain a battery that is retained in a disconnected position when the disposable loading unit is not in use and is moved to a connected position when the disposable loading unit is coupled to the surgical cutting and stapling apparatus to permit the motorto be selectively powered thereby. Indicators may be supported on the disposable loading unit to indicate when the axial drive assembly thereof is in a starting position and an ending position. Another indicator may be provided to indicate when the anvil assembly is in a closed position.

Owner:ETHICON ENDO SURGERY INC

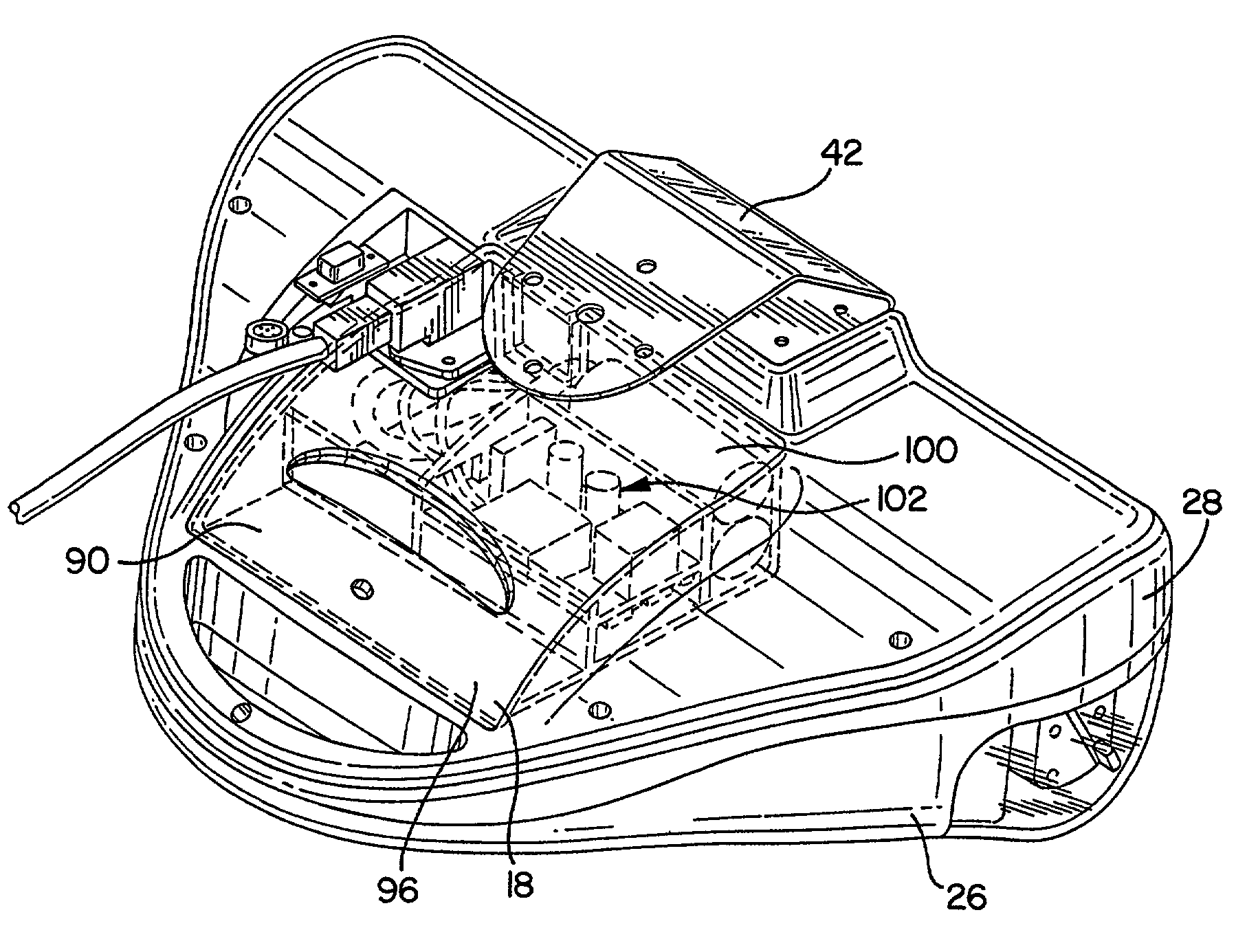

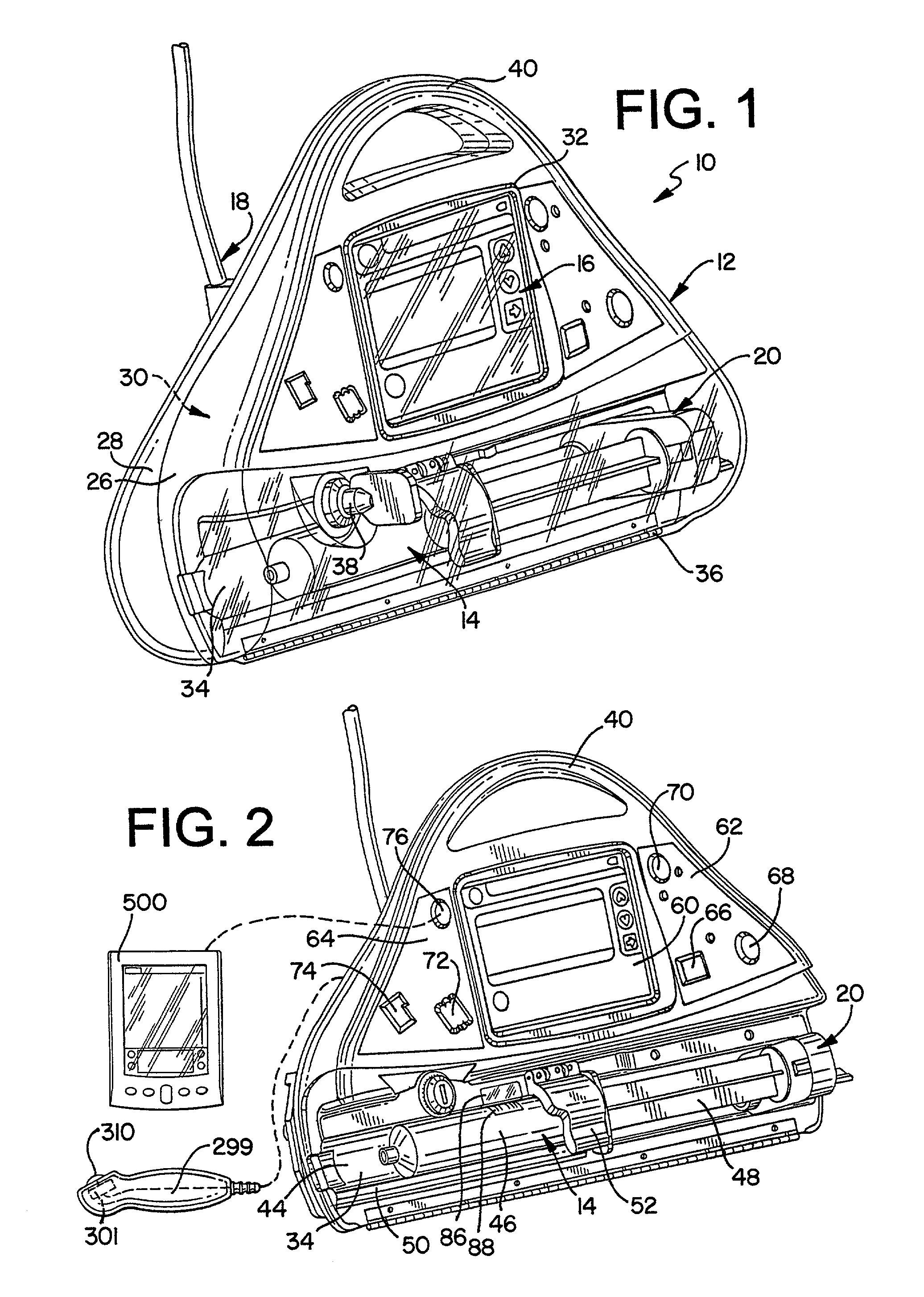

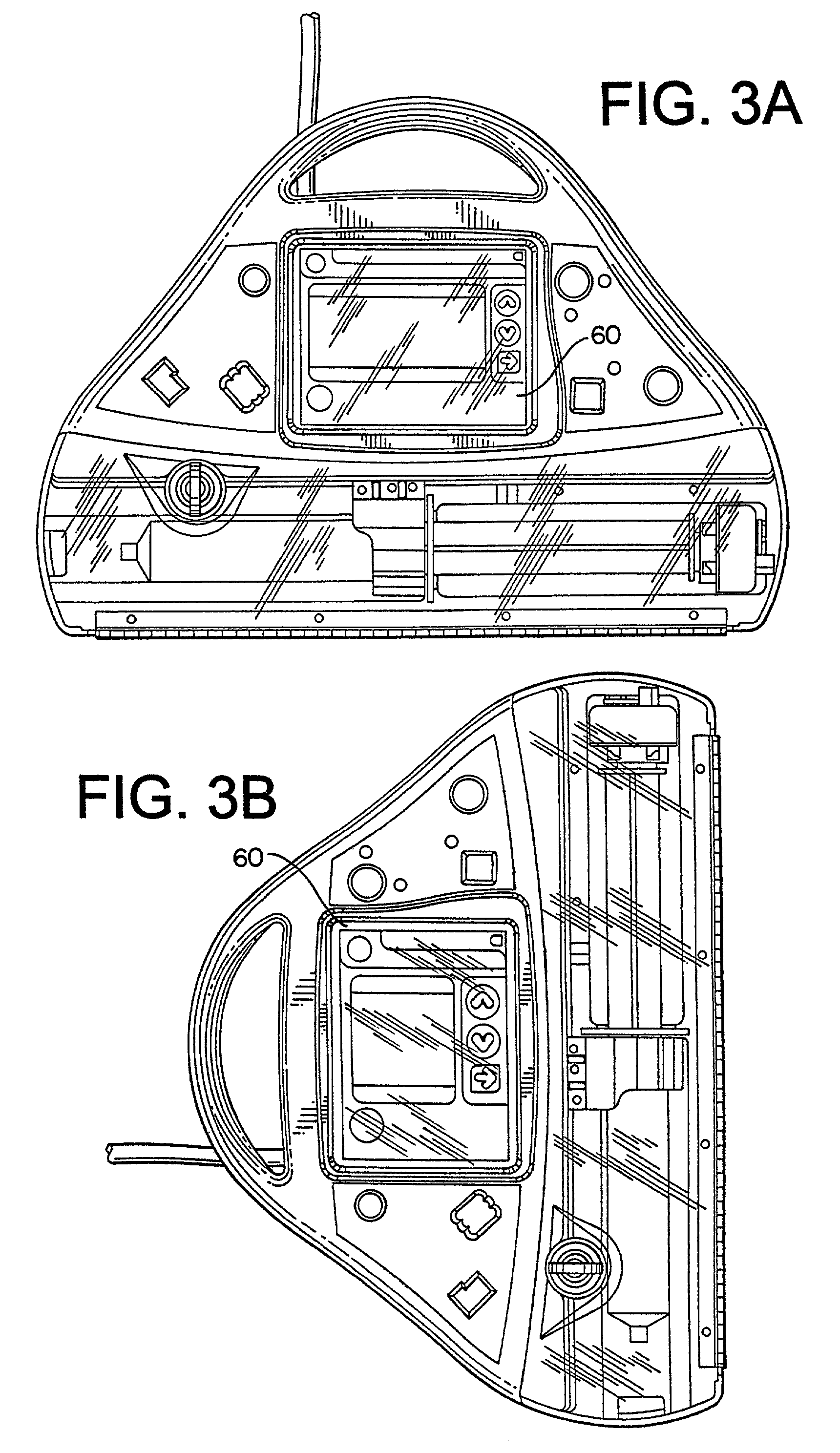

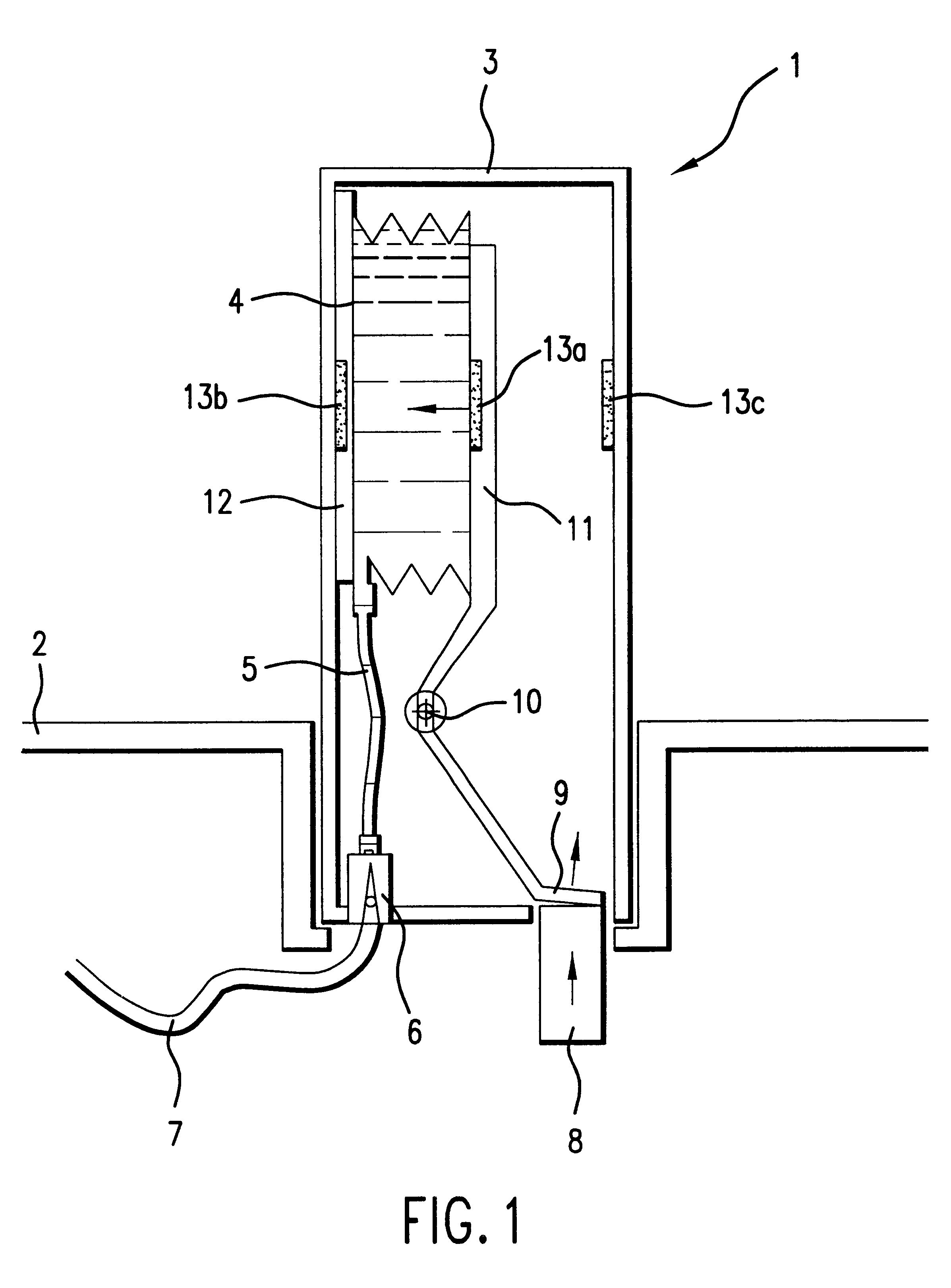

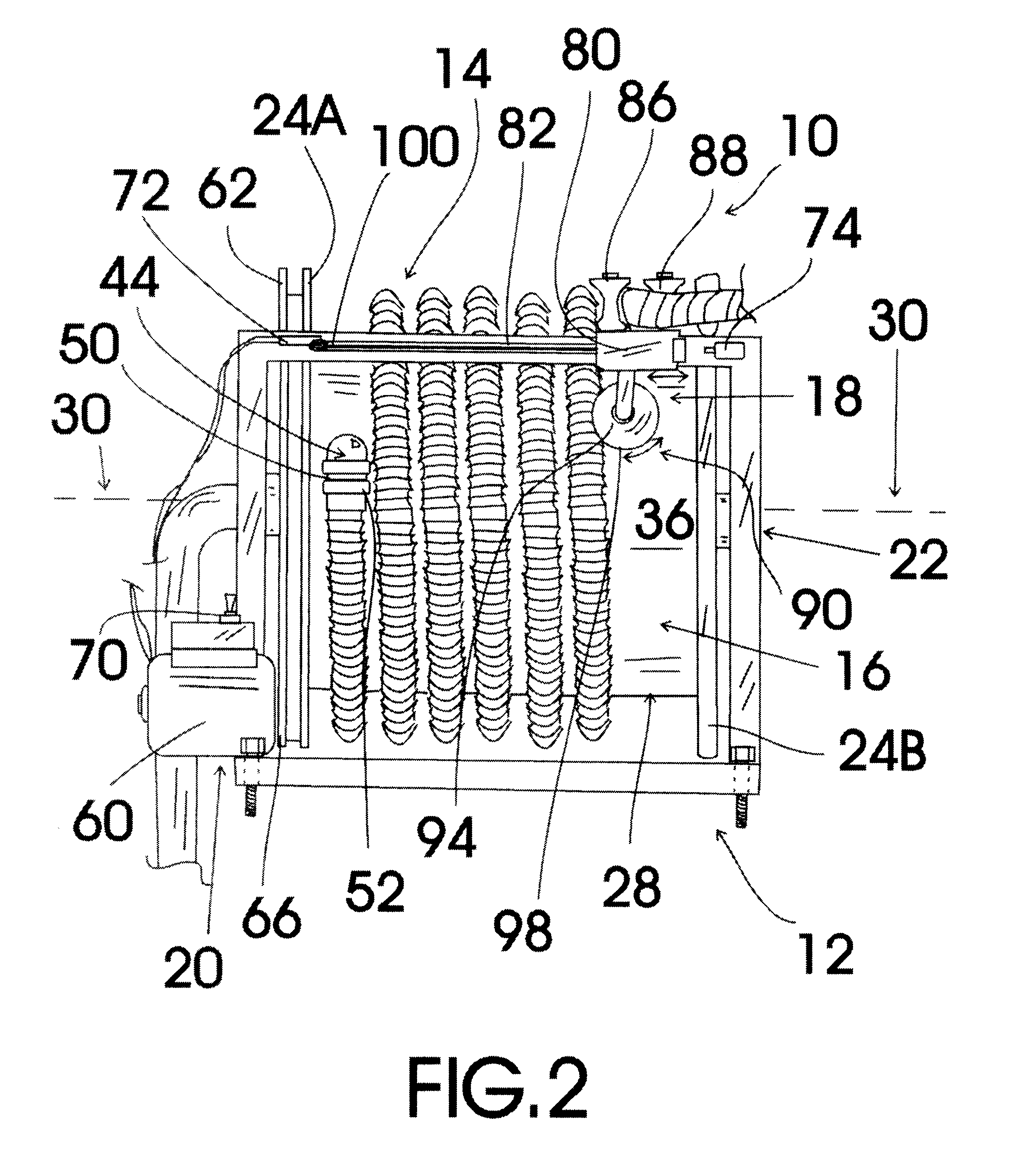

Infusion pump

InactiveUS7018361B2Improve communication performanceGeometric image transformationDrug and medicationsRechargeable cellEngineering

An infusion pump (10) is configured to be powered by either a disposable battery source or a rechargeable battery source. The infusion pump (10) has a housing (12) having a recess (33). A motor is positioned within the housing (12) and is operably connected to an electrical contact (94) disposed in the recess (33). The motor powers the pump (10). The recess (33) receives one of a rechargeable battery unit (90) having an electrical contact (98) that contacts the recess electrical contact (94), and a disposable battery unit (92) having an electrical contact (144) that contacts the recess electrical contact (94).

Owner:BAXTER INT INC

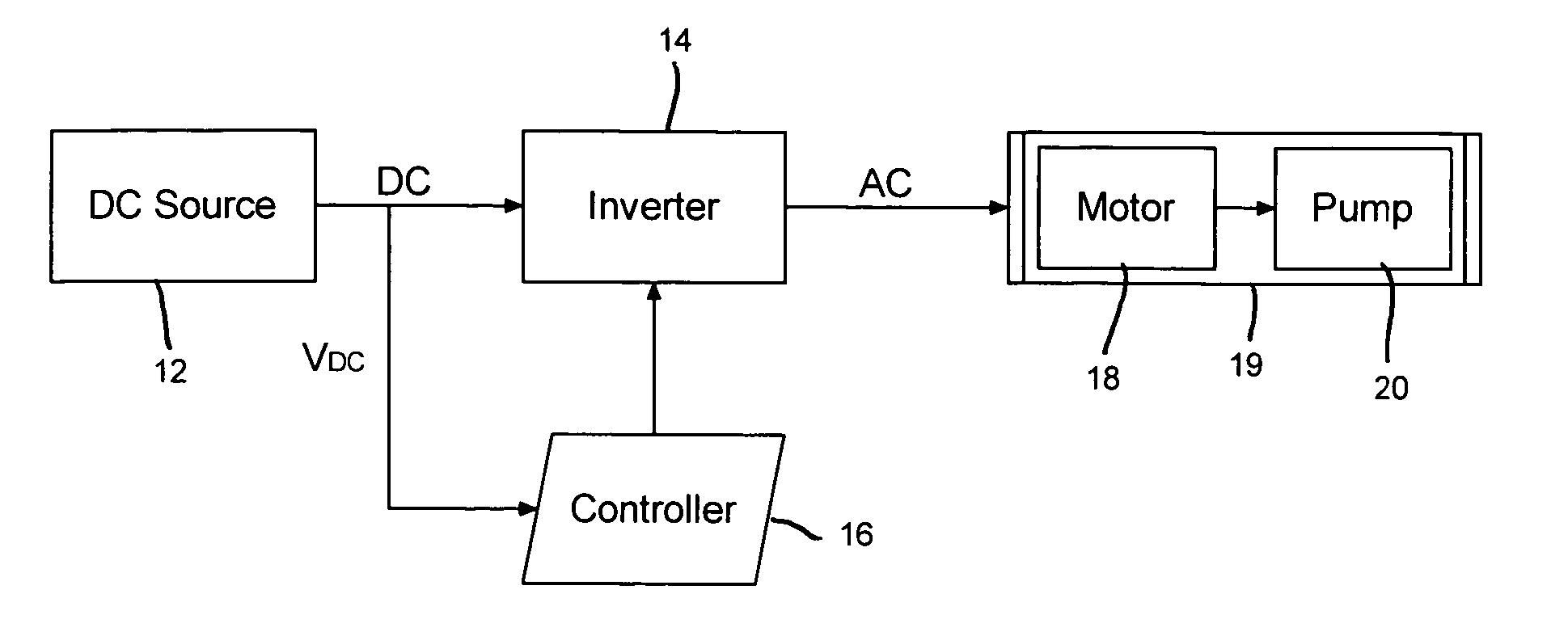

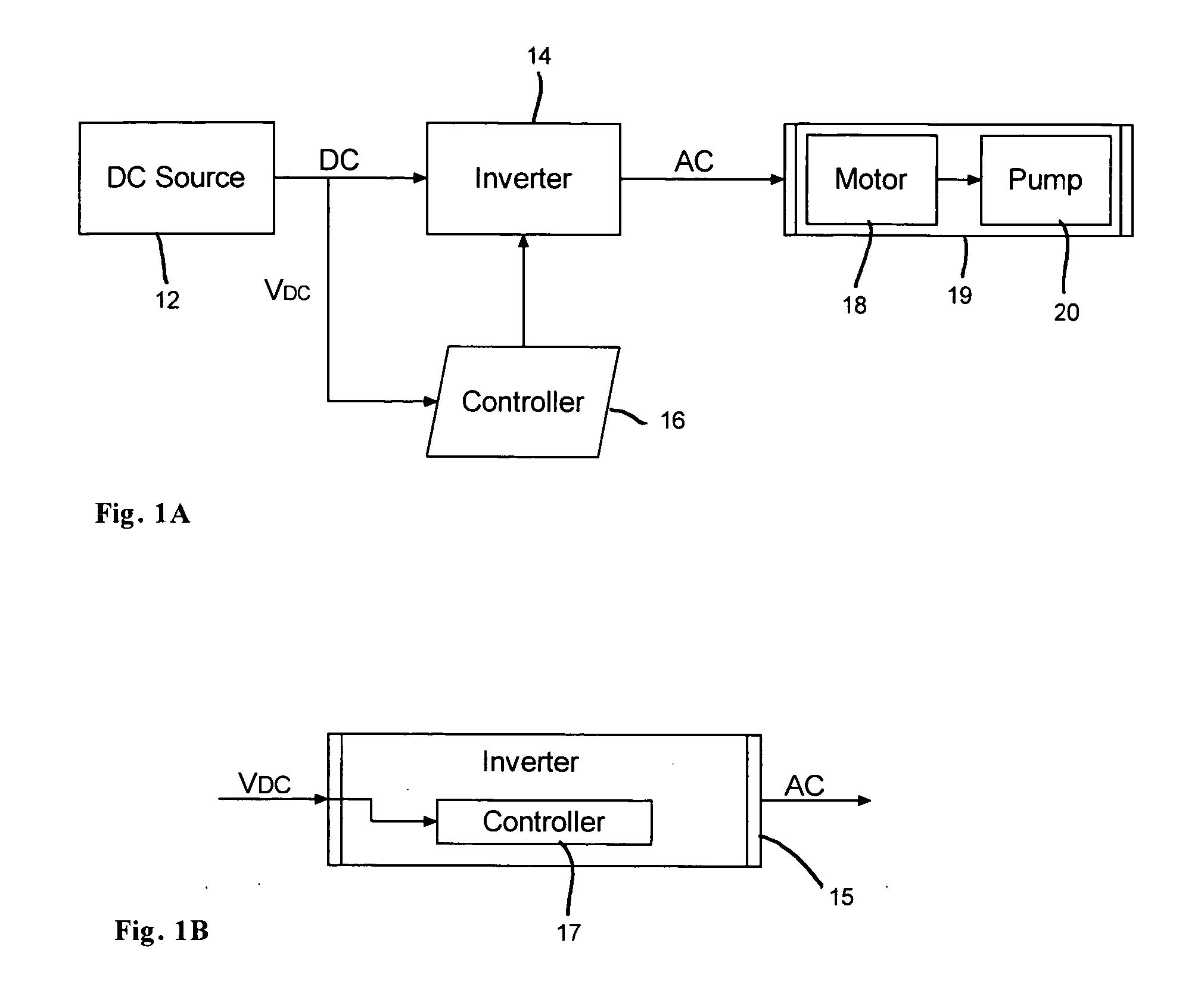

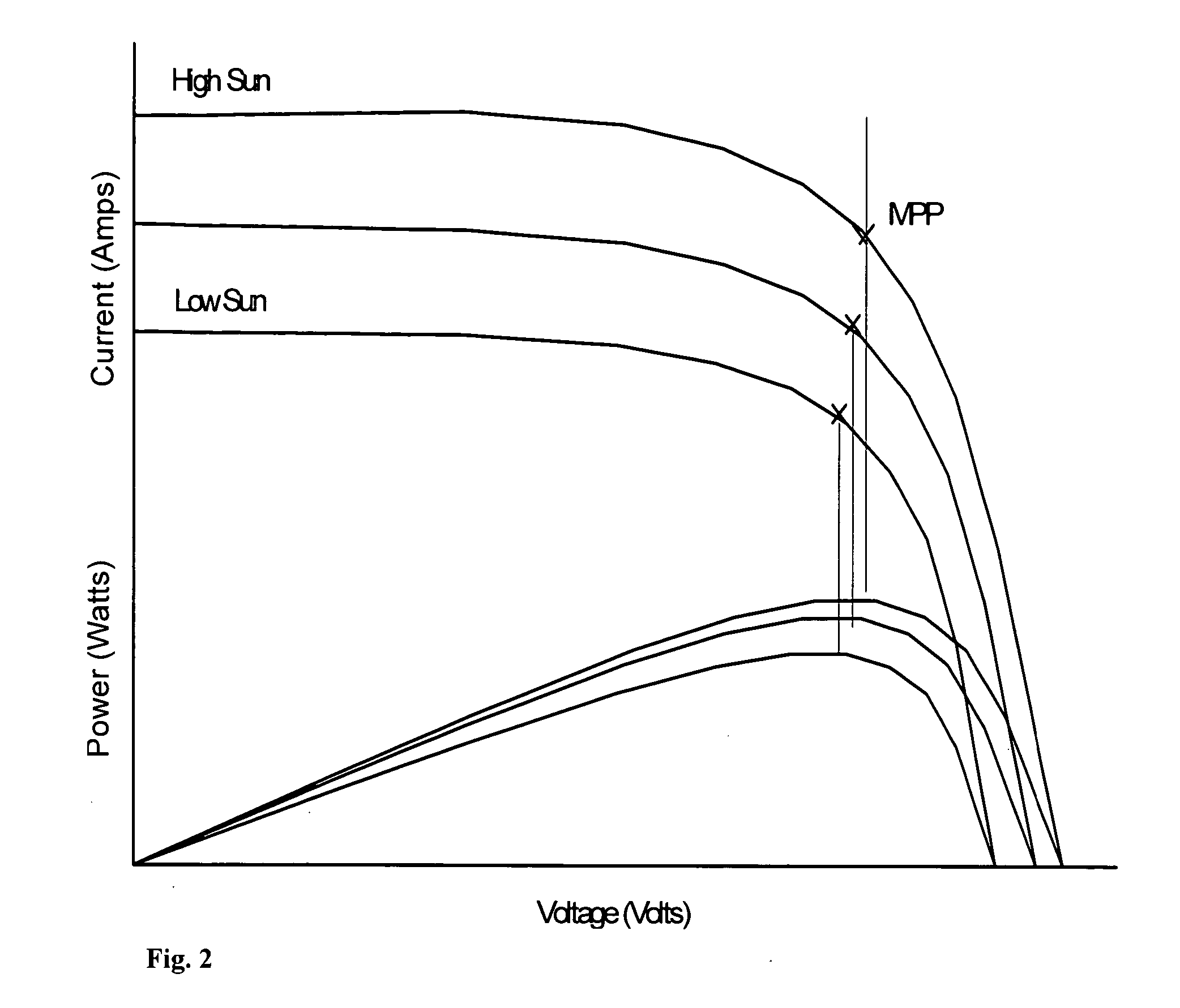

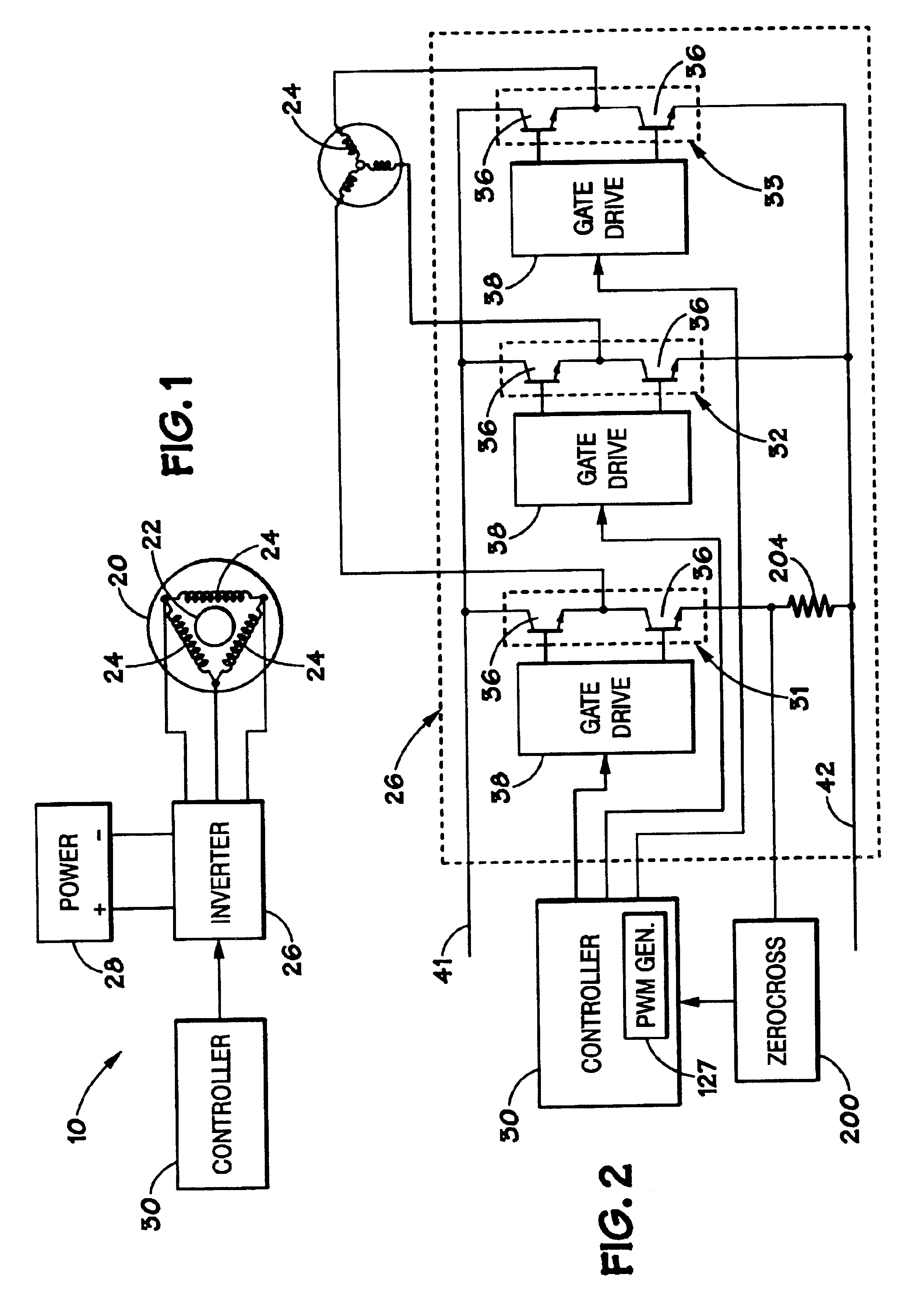

Maximum power point motor control

InactiveUS20060290317A1Batteries circuit arrangementsDC motor speed/torque controlMotor speedMotor drive

A method and apparatus are implemented in software to control motor speed as a function of available power in a DC source—inverter—AC motor system, i.e. to perform maximum power tracking of motor speed. An inverter or motor drive converts DC power from a DC source, such as a solar panel, to AC power, to power the motor. The inverter or motor drive is controlled by software, implemented either by programmable features built directly into the inverter or drive or by a separate programmable device connected to the inverter or drive, to track motor power as a function of source power. The software-controlled inverter or drive sets motor speed as a function of source power by sensing only a single parameter, the DC source voltage. The software-controlled inverter or drive samples the source voltage at preset intervals, and changes the frequency of the AC output of the inverter or drive to match or track the available power so that the motor operates at or near its optimum for any source voltage.

Owner:WORLDWATER & SOLAR TECH

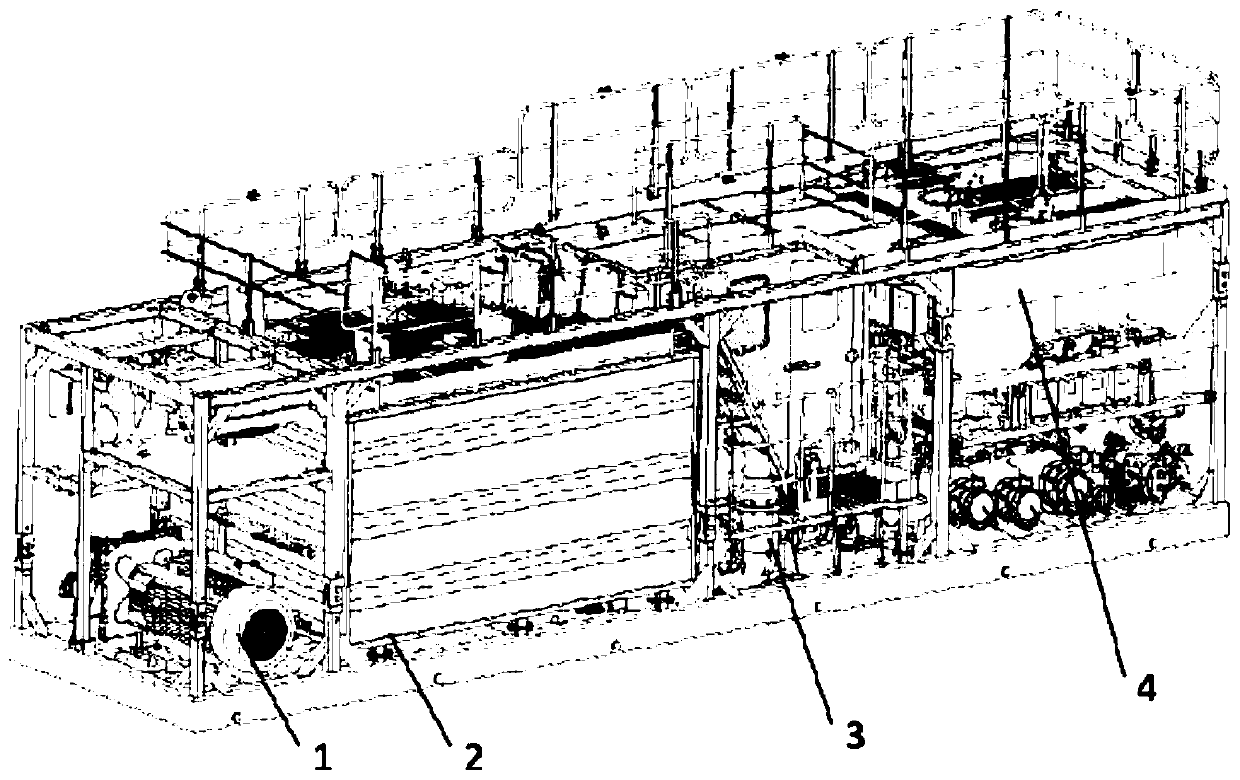

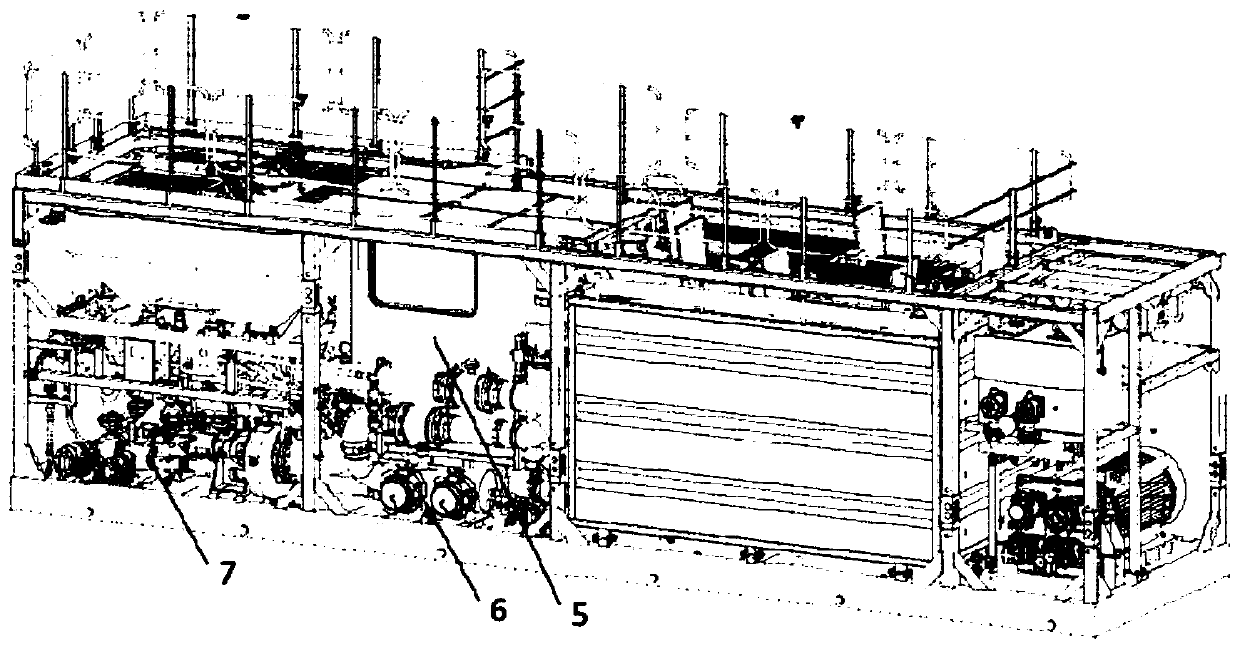

Electric-drive mixing device

PendingCN110252191ALow calorific valueSmall footprintMixing methodsTransportation and packagingElectricityFrequency conversion

The invention discloses an electric-drive mixing device, and relates to the technical field of mixing equipment. The electric-drive mixing device comprises a motor power unit, a mixing tank, a discharge centrifugal pump, a suction centrifugal pump, a powder tank, a control chamber, a drainage manifold, a water-powder mixing manifold, a chemical adding pump and a suction header. The mixing tank is fixedly mounted on one side of the motor power unit, and the control chamber is fixedly mounted on one side of the mixing tank. The electric-drive mixing device has the advantages that a selected motor is a variable-frequency all-in-one machine, that is to say, a frequency converter is integrated with the motor, and there is no independent frequency conversion cabinet, so that the occupied space is remarkably saved, and the device is suitable for vehicle transportation; the variable-frequency all-in-one machine has much lower heat than the motor, a radiator is integrated to a cabinet casing of the motor and the frequency converter, and no plate-fin radiating holes are provided; a large-channel air duct is arranged at a motor and frequency converter casing position of a fan, and accordingly, blockage is avoided.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

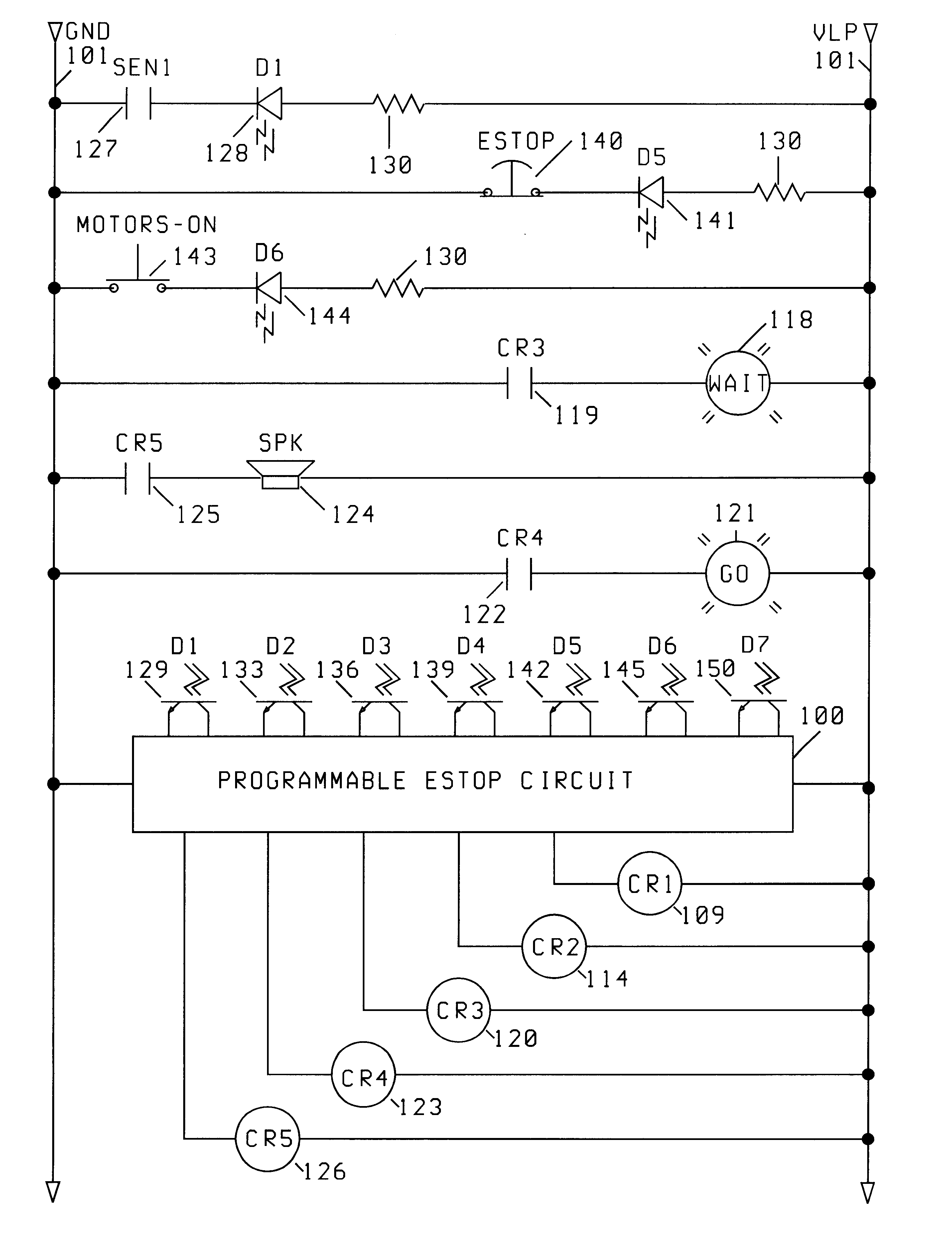

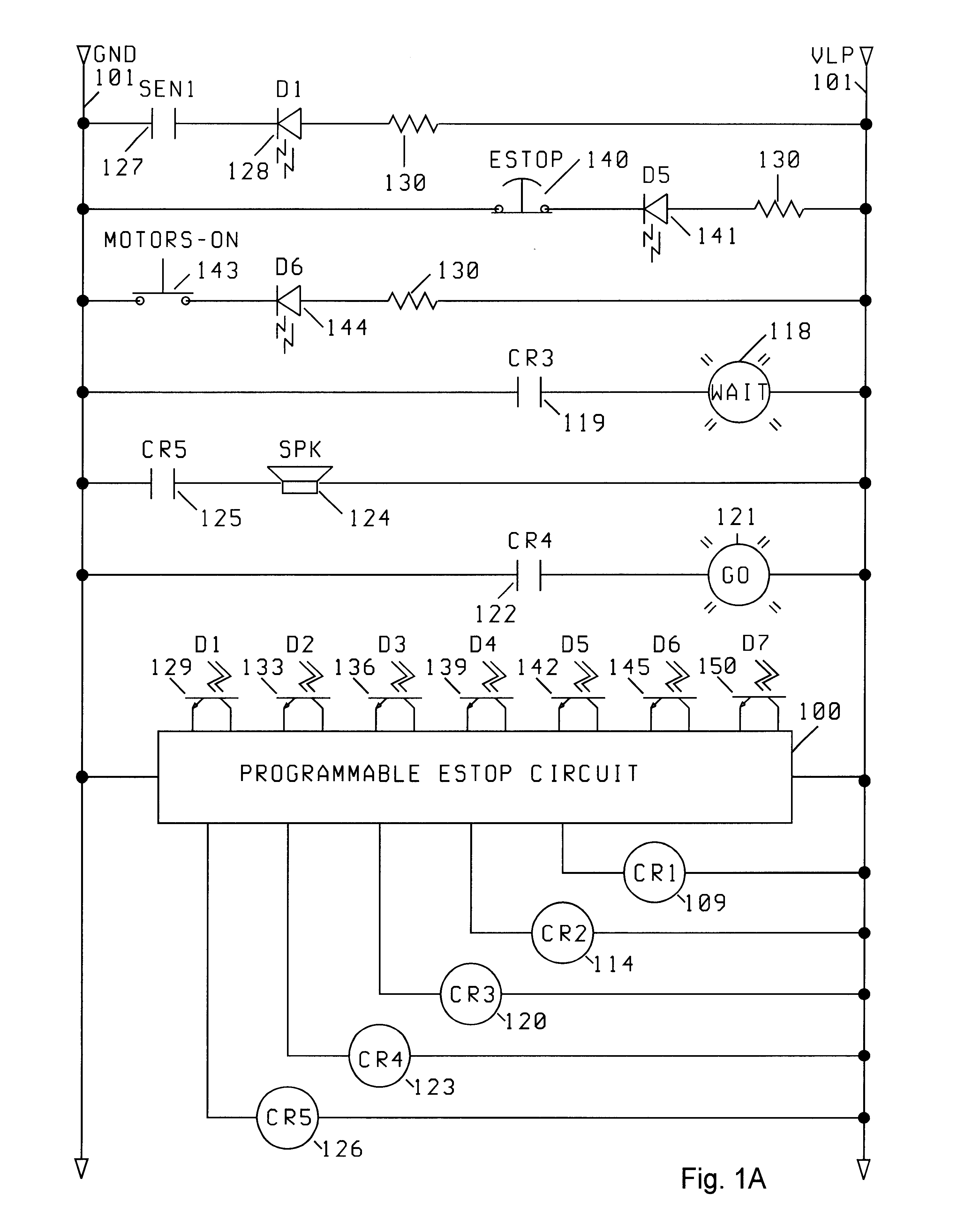

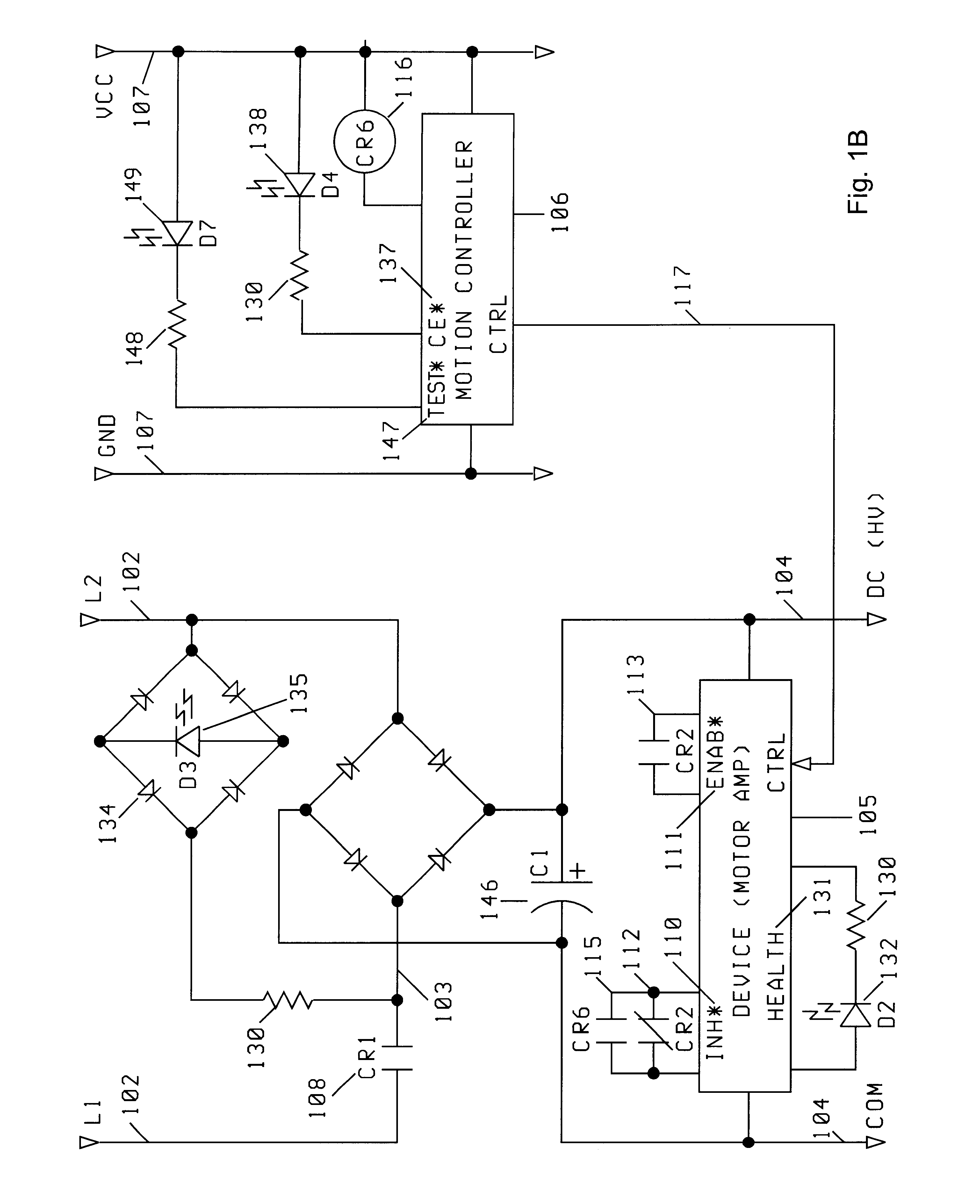

Programmable emergency-stop circuit with testing

InactiveUS6734581B1Safely incorporatedReduce sensitivityBatteries circuit arrangementsEmergency protective circuit arrangementsTest inputKill switch

The invention includes a programmable emergency-stop circuit apparatus and method that provides advanced function not found in other systems. The circuit centralizes the control of high voltage motor power into one place, by providing connections for, in its minimum configuration, several different kill switches, a motors-on button, and an AC motor power relay coil. In the present invention, kill switches, test inputs, emergency-stop and motors-on buttons, computer ready and watchdog signals are all conveniently connected in one location, alongside the AC motor power relay coil driver. Programmable options exist for testing kill inputs online, while the emergency stop is energized.

Owner:EIGENPOINT

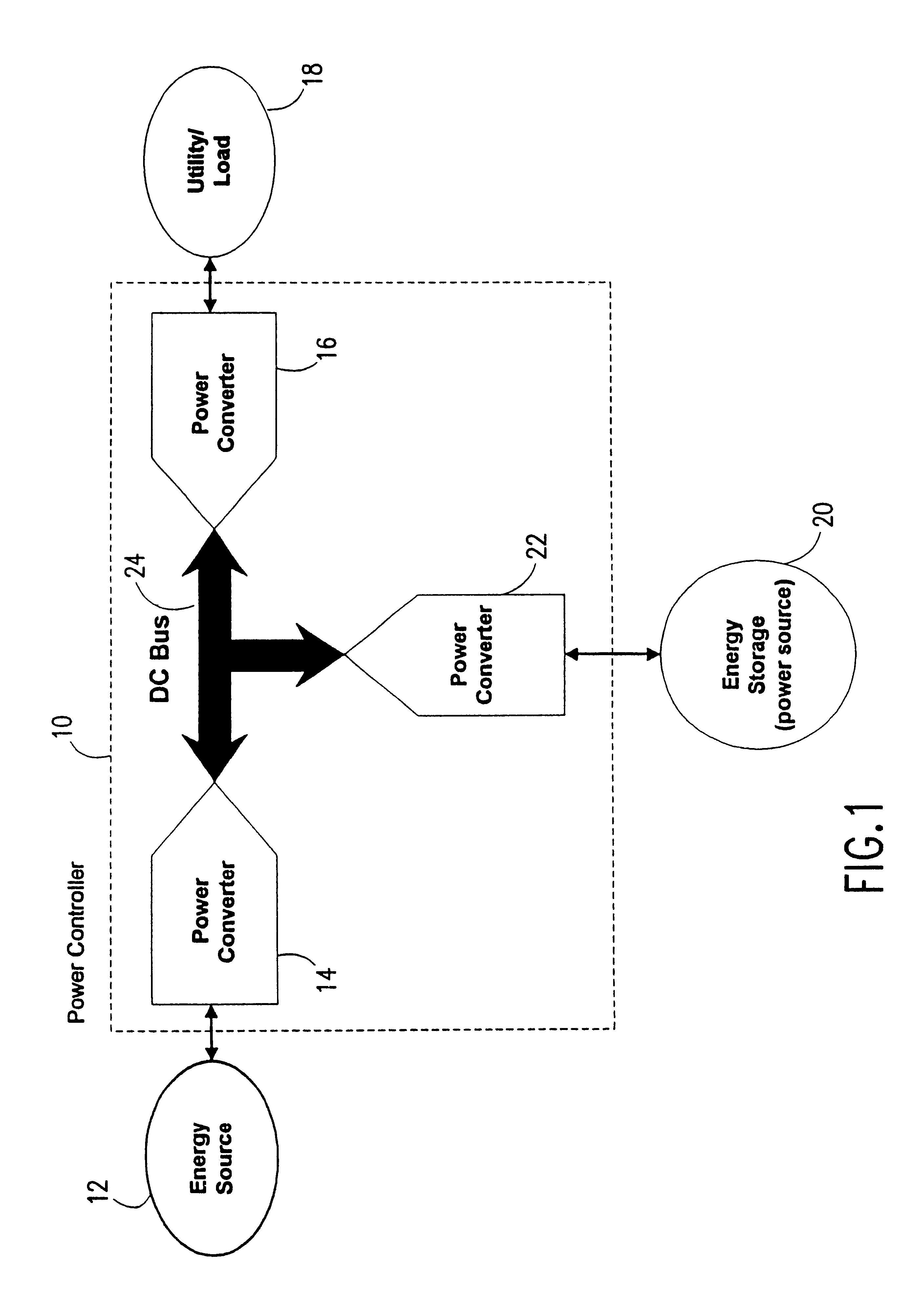

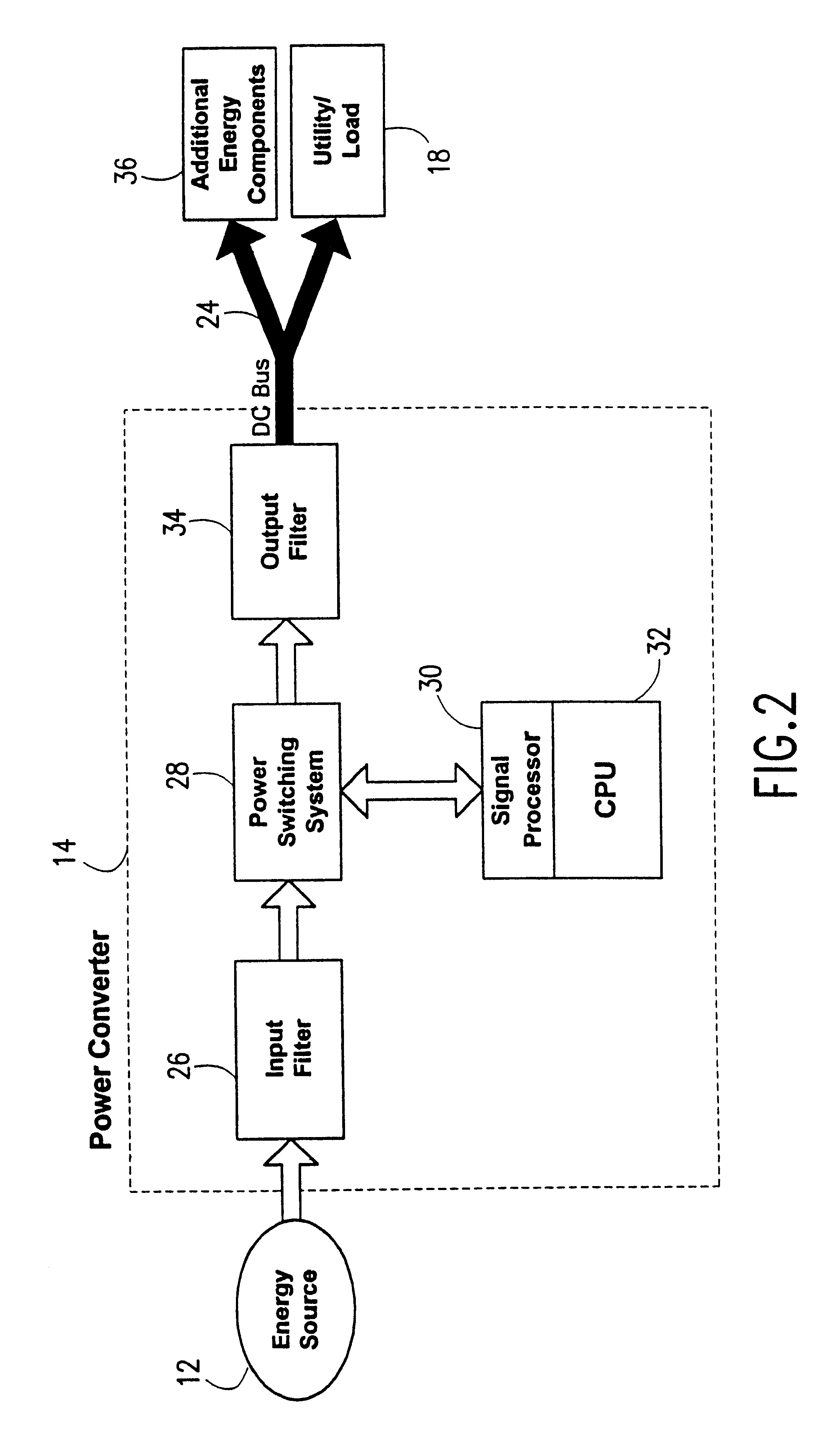

Method and system for control of turbogenerator power and temperature

InactiveUS6870279B2Maximize efficiencyIncrease speedAnalogue computers for vehiclesLoad balancing in dc networkPower controllerTurbine

A power controller controls the turbine of a turbine powered generating system regardless of the load on said system to maximize the efficiency of the turbine and maintains the turbine at a substantially constant temperature during a system load change by using an energy storage device to provide power to the load while the turbine is changing speed to meet the new load demand.

Owner:CAPSTONE TURBINE

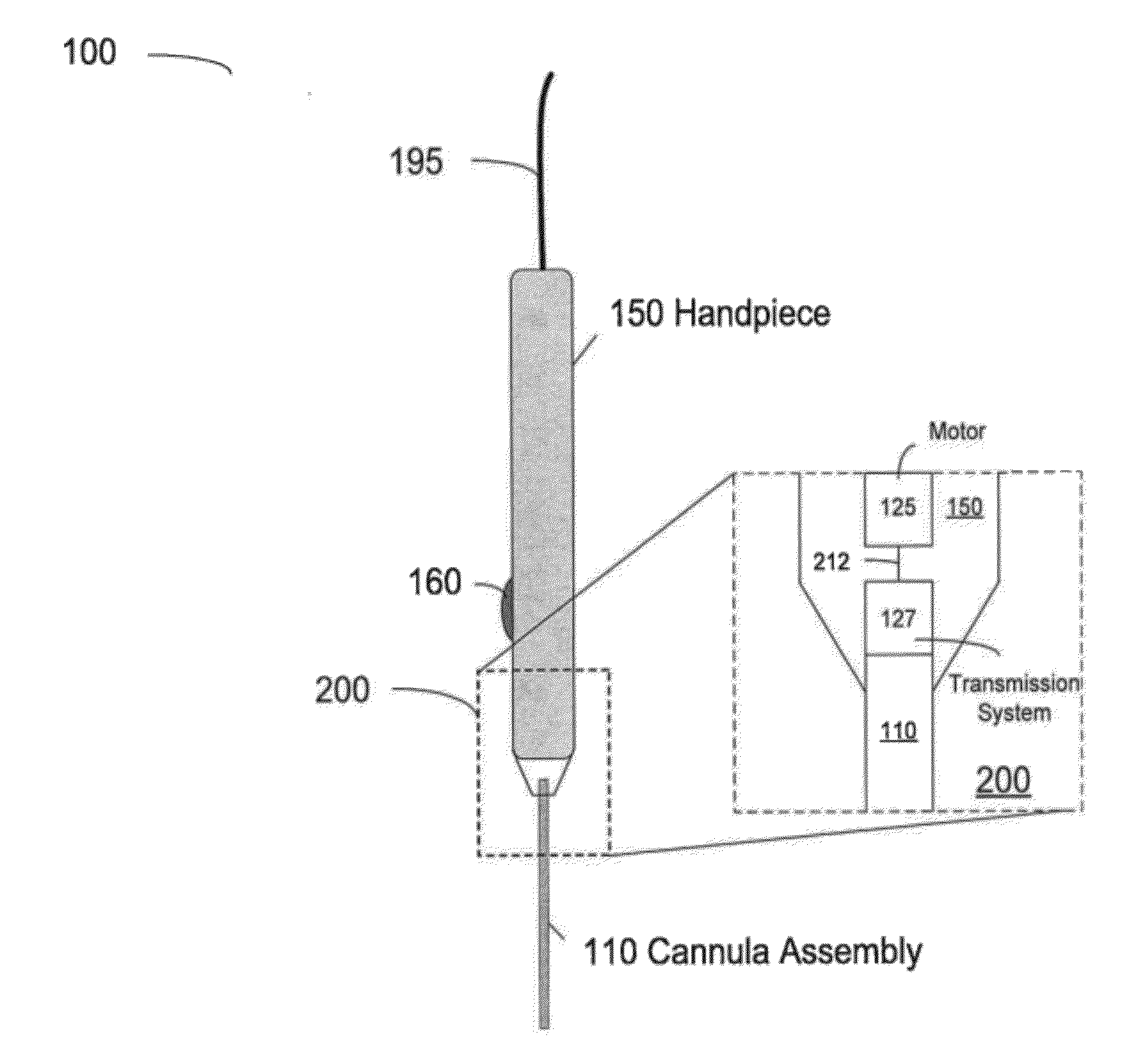

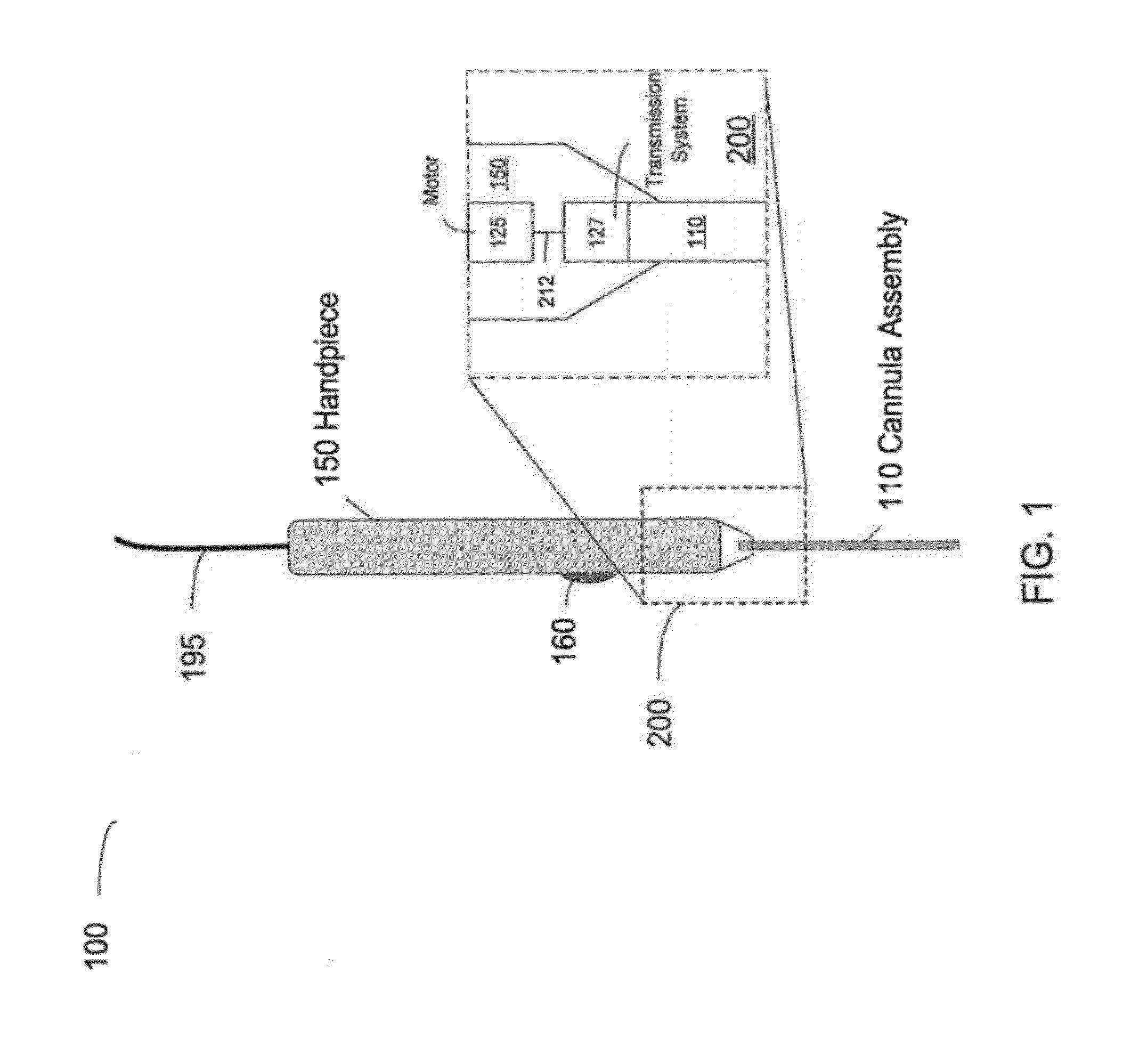

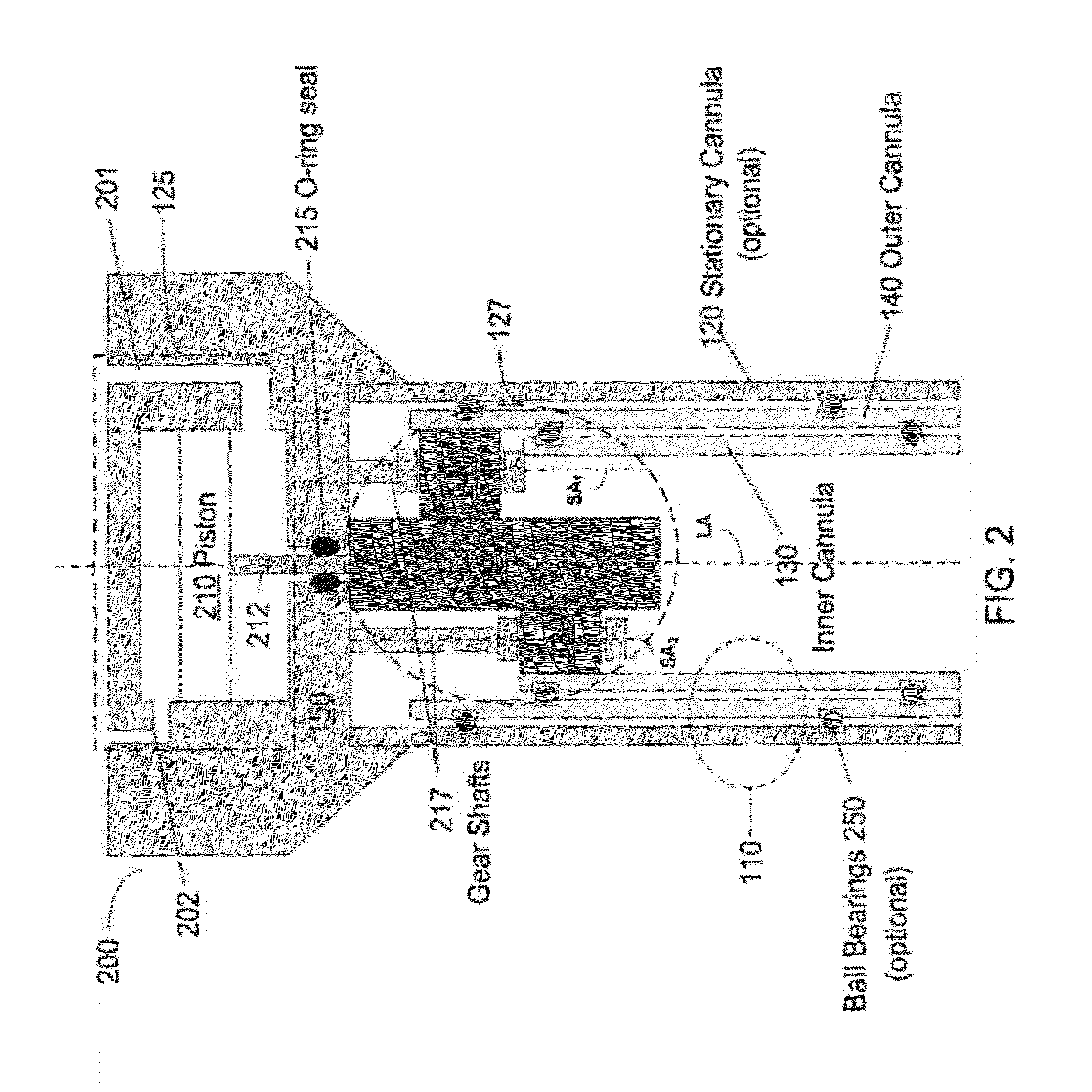

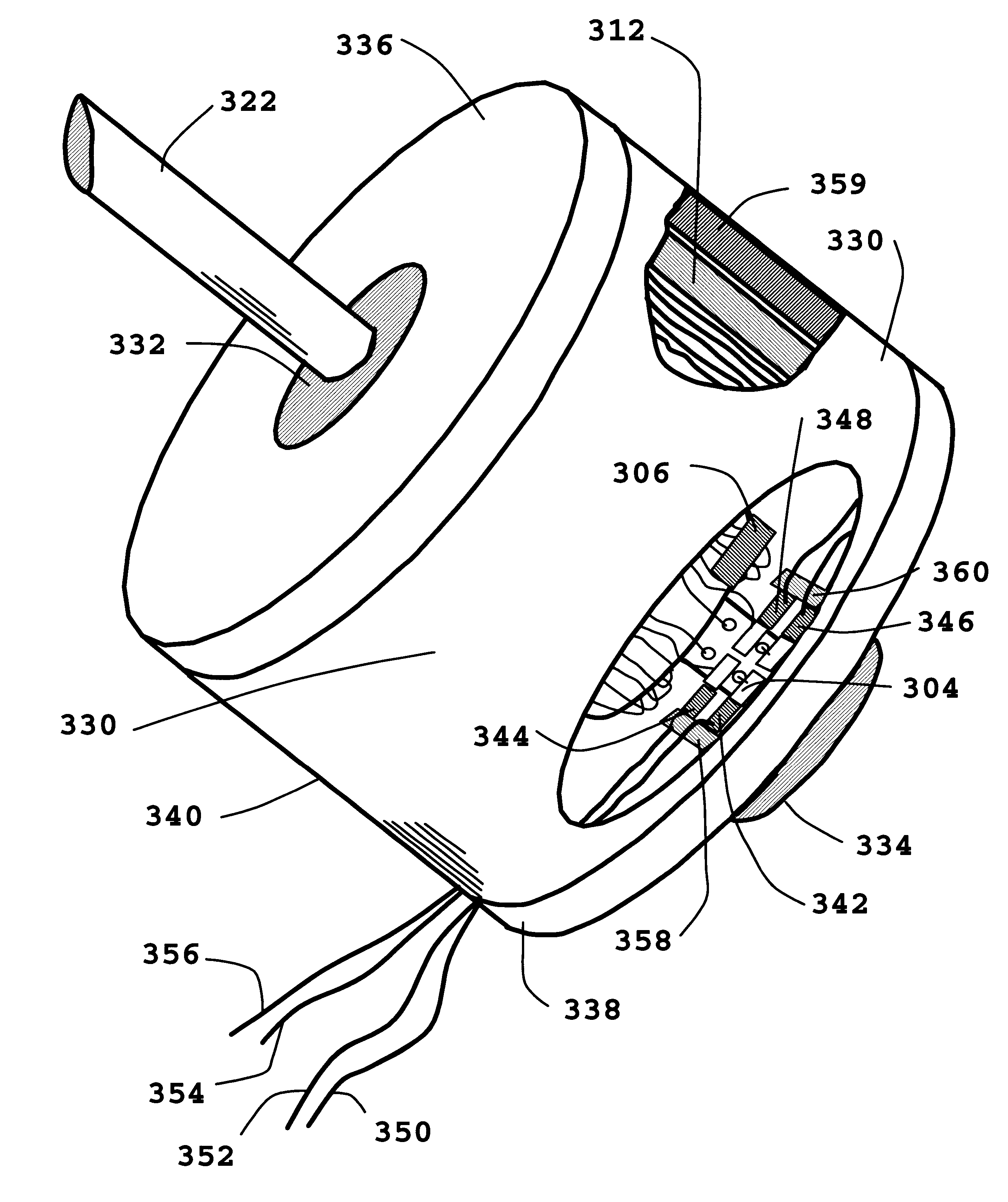

Pneumatically driven ophthalmic scanning endoprobe

An ophthalmic endoprobe including a hand-piece and a cannula assembly having a longitudinal axis is provided. The cannula assembly including an inner tube concentric with an outer tube; wherein the hand-piece may further include a motor powered by a pneumatic energy source, the motor providing motion to a transmission shaft; and a transmission system to couple the shaft motion to the cannula assembly; wherein the transmission system provides a counter-rotating motion to the inner tube and the outer tube about the longitudinal axis of the cannula. A fluid console for use in endoscopic ophthalmic microsurgery including a pneumatics module to obtain a pneumatic force from an external source and provide an adjustable pneumatic force; a scanning module coupled to the pneumatics module; and an endoprobe coupled to the scanning module is also provided.

Owner:ALCON INC

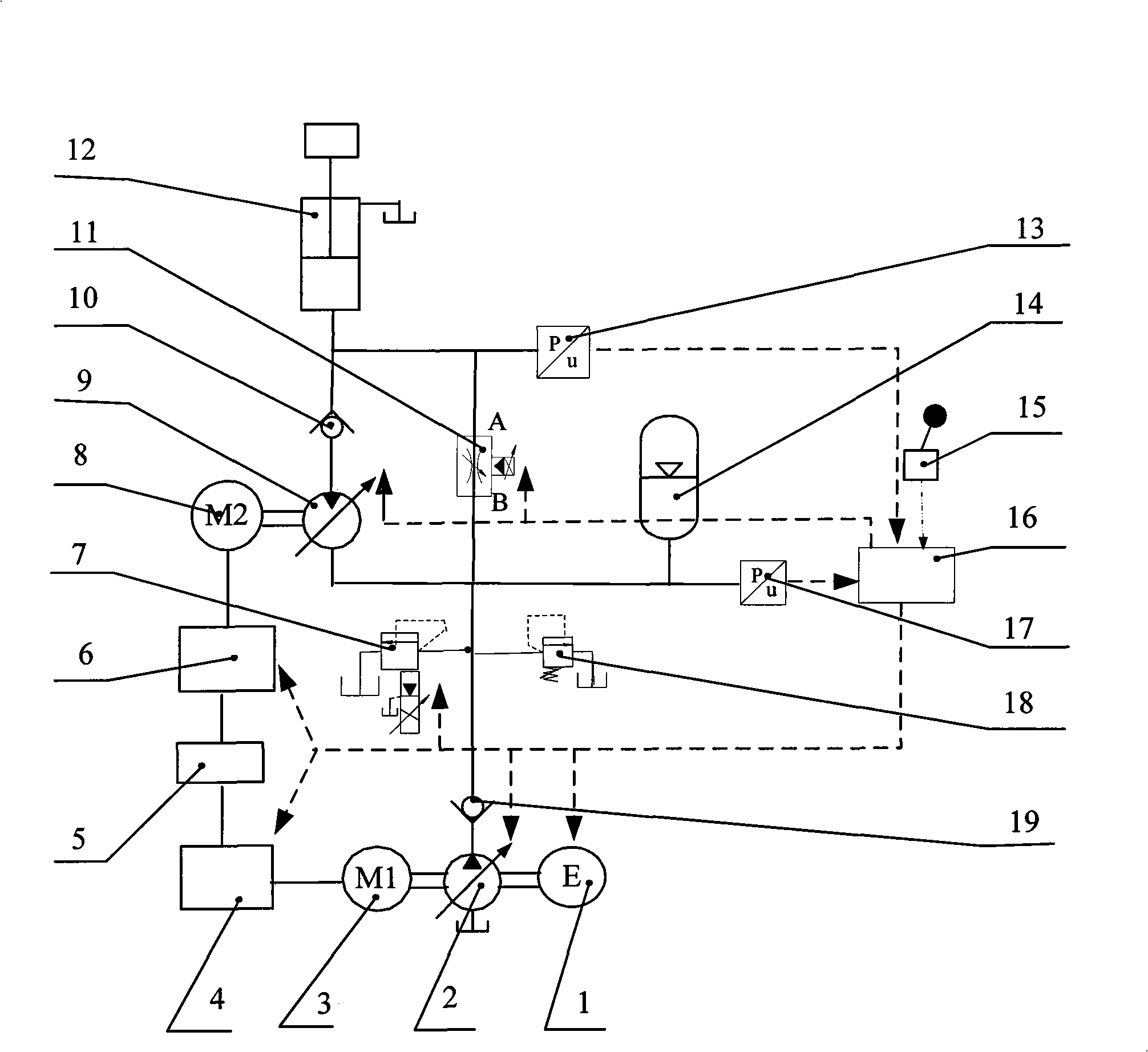

Energy recovery system of hybrid power engineering machinery energy accumulator-hydraulic motor

InactiveCN101408213AHigh specific powerFast absorptionAccumulator installationsGas pressure propulsion mountingHydraulic motorEnergy recovery

The invention discloses a hybrid power engineering mechanical accumulator-hydraulic motor energy recovery system. The system mainly comprises an engine, a variable pump, variable frequency motors, a variable motor, a signal control unit, an accumulator and a hydraulic implementation element, and the like. In the system, the variable motor is coaxially connected with a variable frequency motor M2 and forms a composite energy recovery system with the accumulator so as to recover the gravitational potential energy and braking energy in the lowering process of an implementation mechanism. The variable pump, the engine and a variable frequency motor M1 are coaxially connected; a hybrid power system which consists of the engine and the variable frequency motor M1 drives the hydraulic implementation mechanism to rise and lift heavy objects together with the accumulator. The system overcomes the defects that the variable motor-power generator energy recovery system responds slowly and the specific energy of the accumulator is low, enhances the dynamic response performance of the energy recovery system, improves the working conditions of power generation of an electric generator, and simultaneously can directly recover part of potential energy by the accumulator, thus raising the energy recovery efficiency of the system.

Owner:ZHEJIANG UNIV

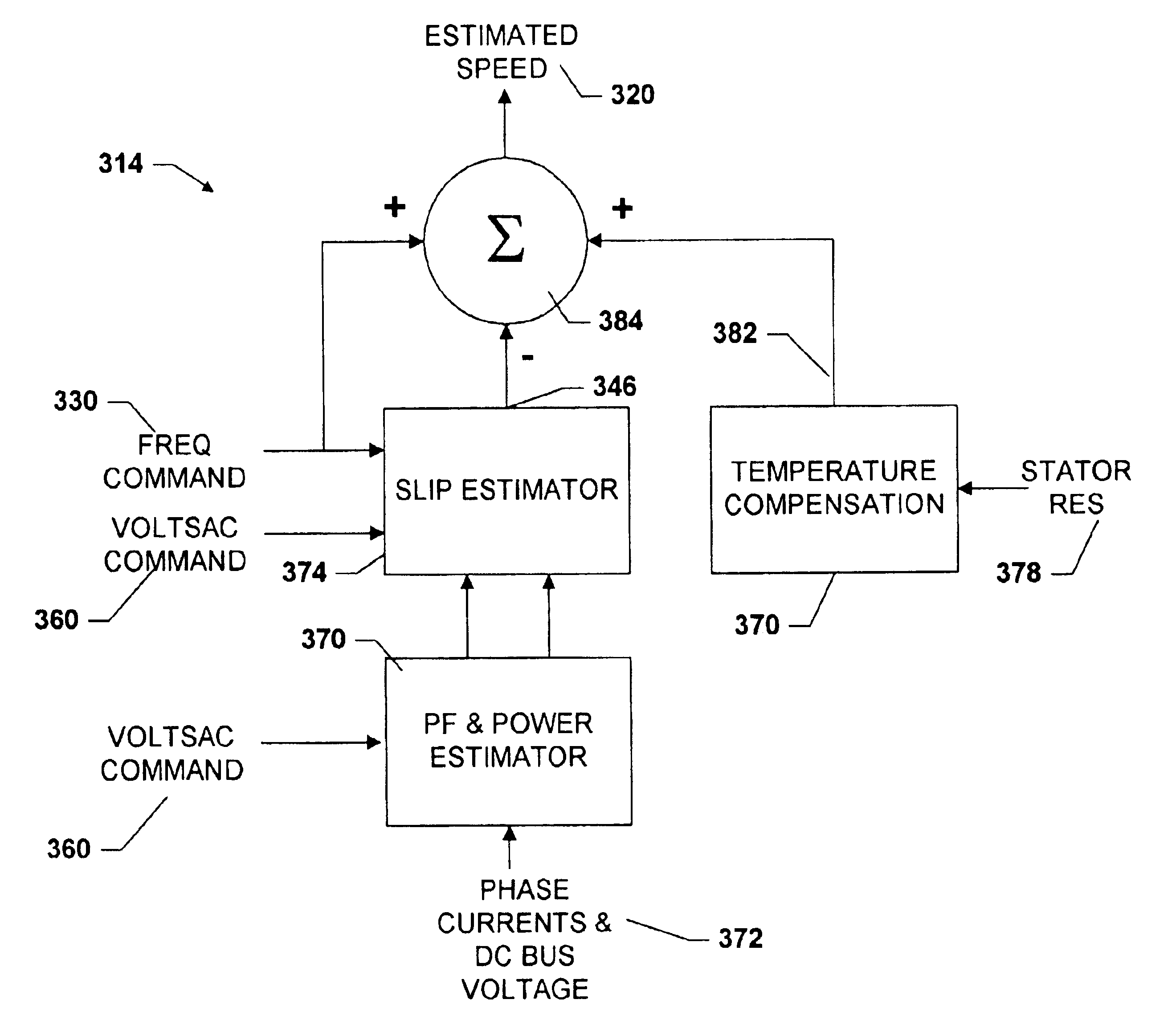

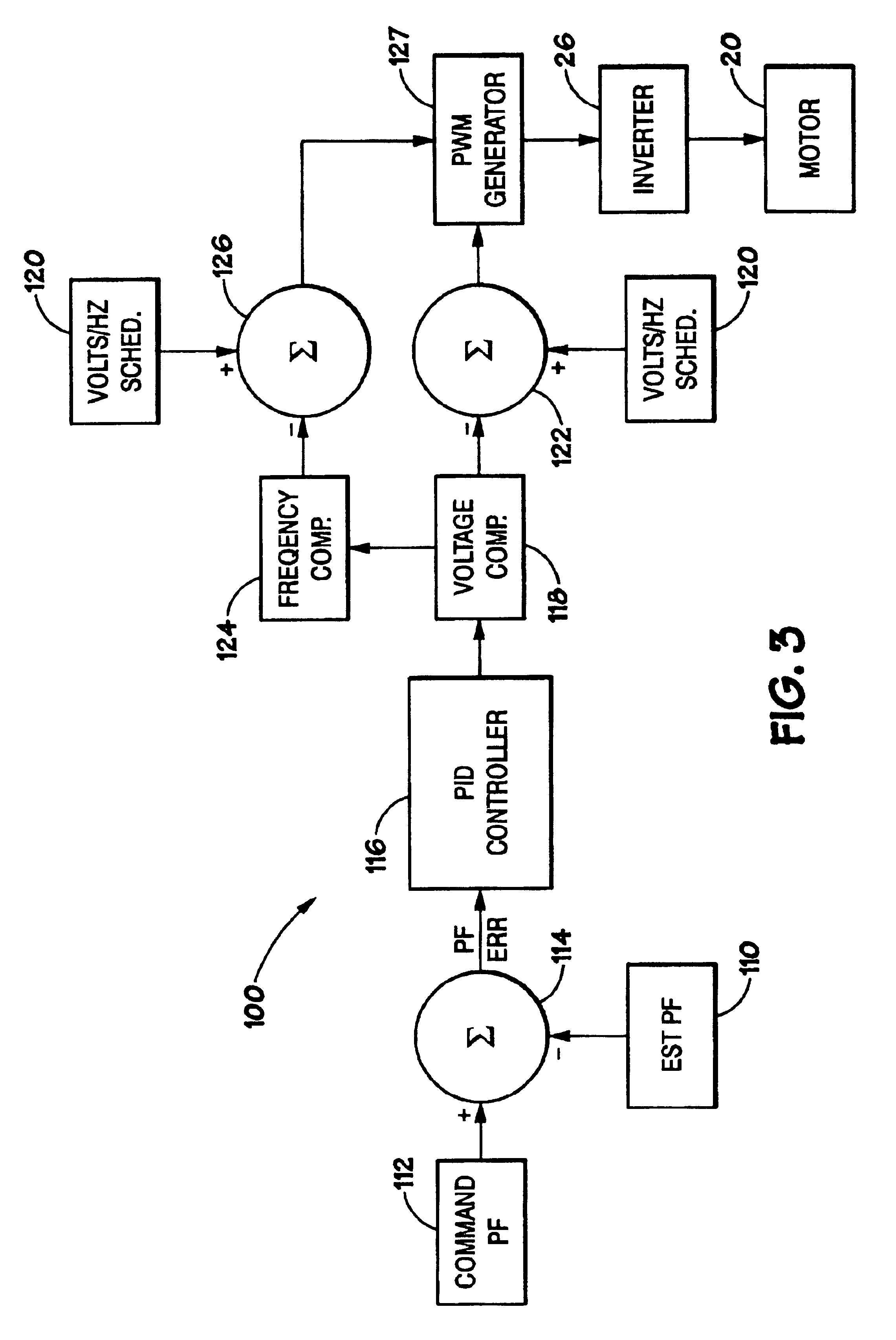

Induction motor control system

InactiveUS6828751B2Single-phase induction motor startersMotor/generator/converter stoppersPower factorInduction motor

Owner:NIDEC MOTOR CORP

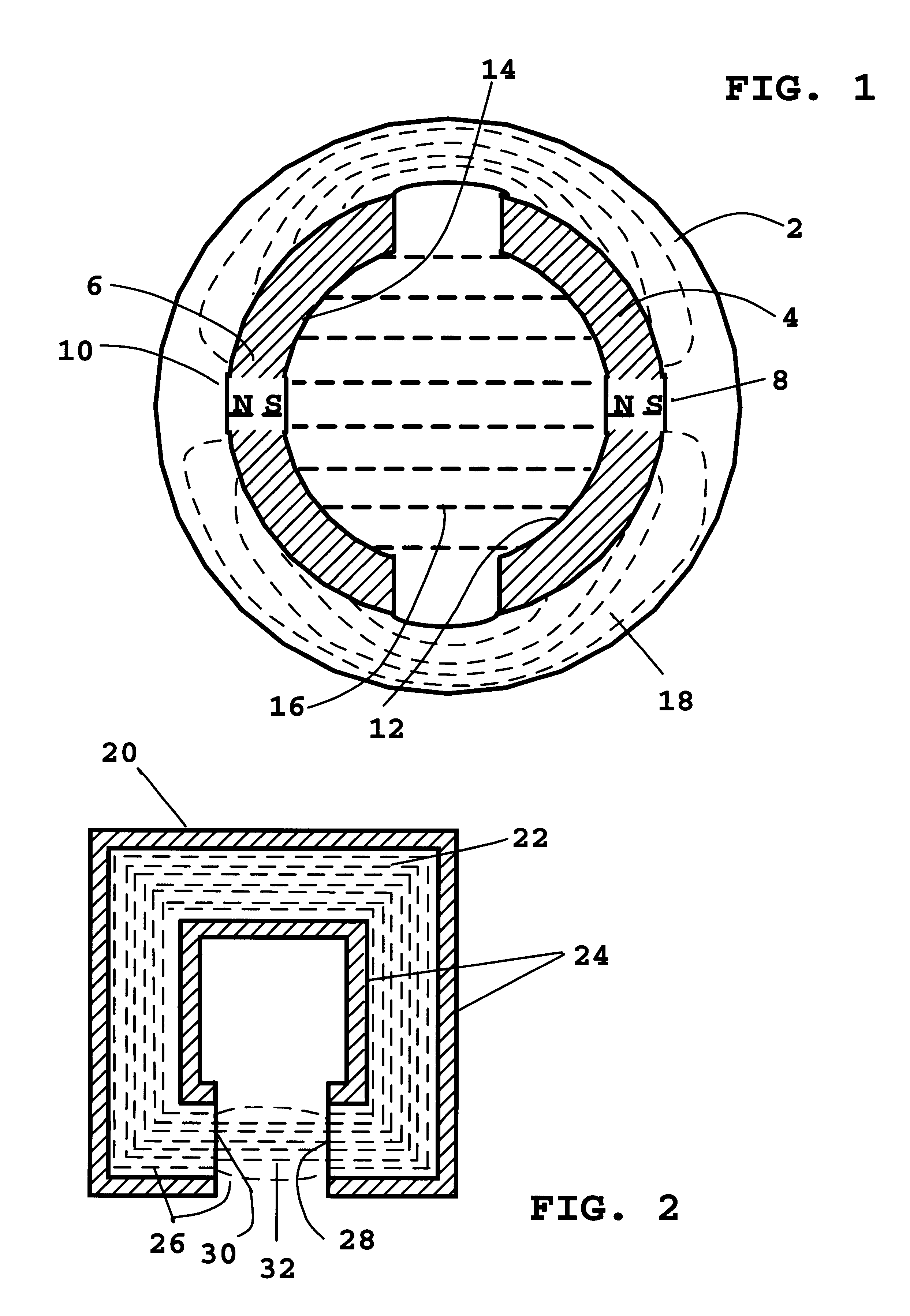

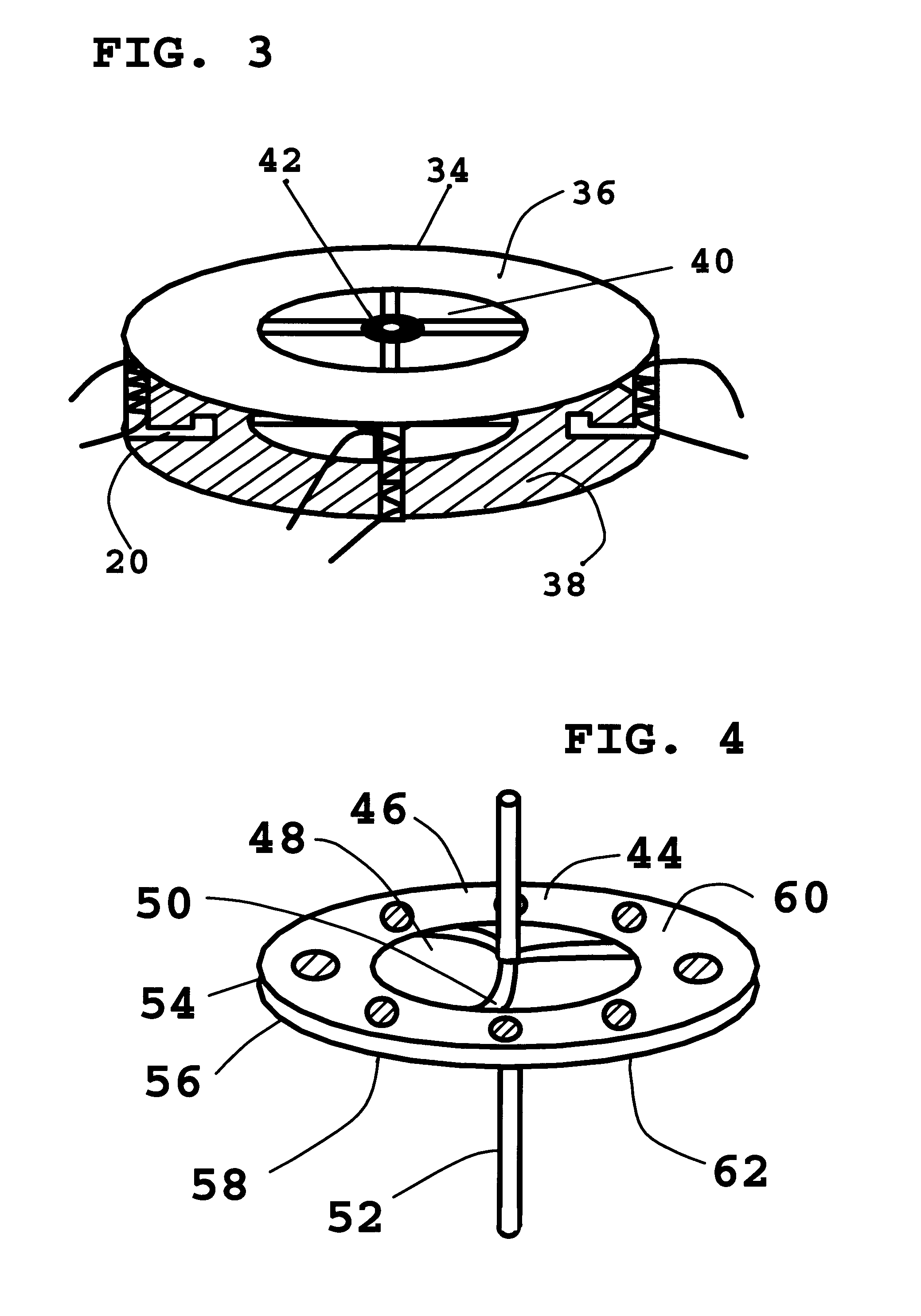

High-power low-RPM DC motor

InactiveUS6194799B1Increase profitIncreasing motor torqueAsynchronous induction motorsPropulsion by batteries/cellsEngineeringConductor Coil

A high power low RPM direct current electric motor is disclosed whereby the high power output is achieved in one of two ways or both. In the first case, the need for cooling is reduced simultaneously along with an increase in the utilization of the magnetic field present in the motor permanent magnets. This is achieved by wrapping the electromagnet core with windings that are capable of demagnetizing the rotor permanent magnets under stall conditions. Interlocking motor circuitry is provided which prevents the full activation of these motor windings until motor RPM values reach a safe level. This increases motor power while decreasing resistive losses in electromagnet windings. In the second case, the rotary portion consists of a large diameter relatively flat rotor containing permanent magnets and having built in vanes for moving air over the electromagnet stator windings providing forced air cooling.

Owner:MAGNETIC MOTORS

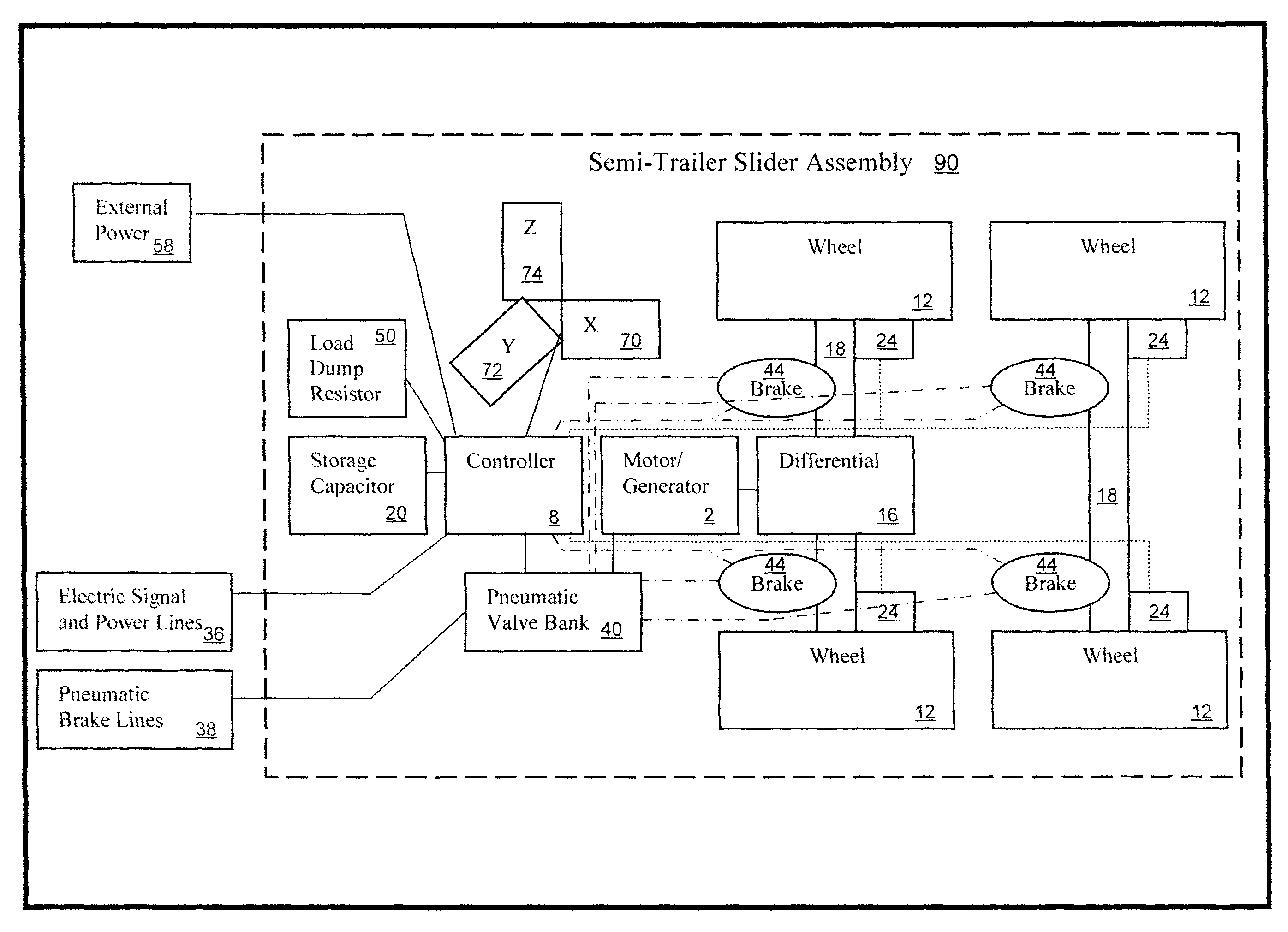

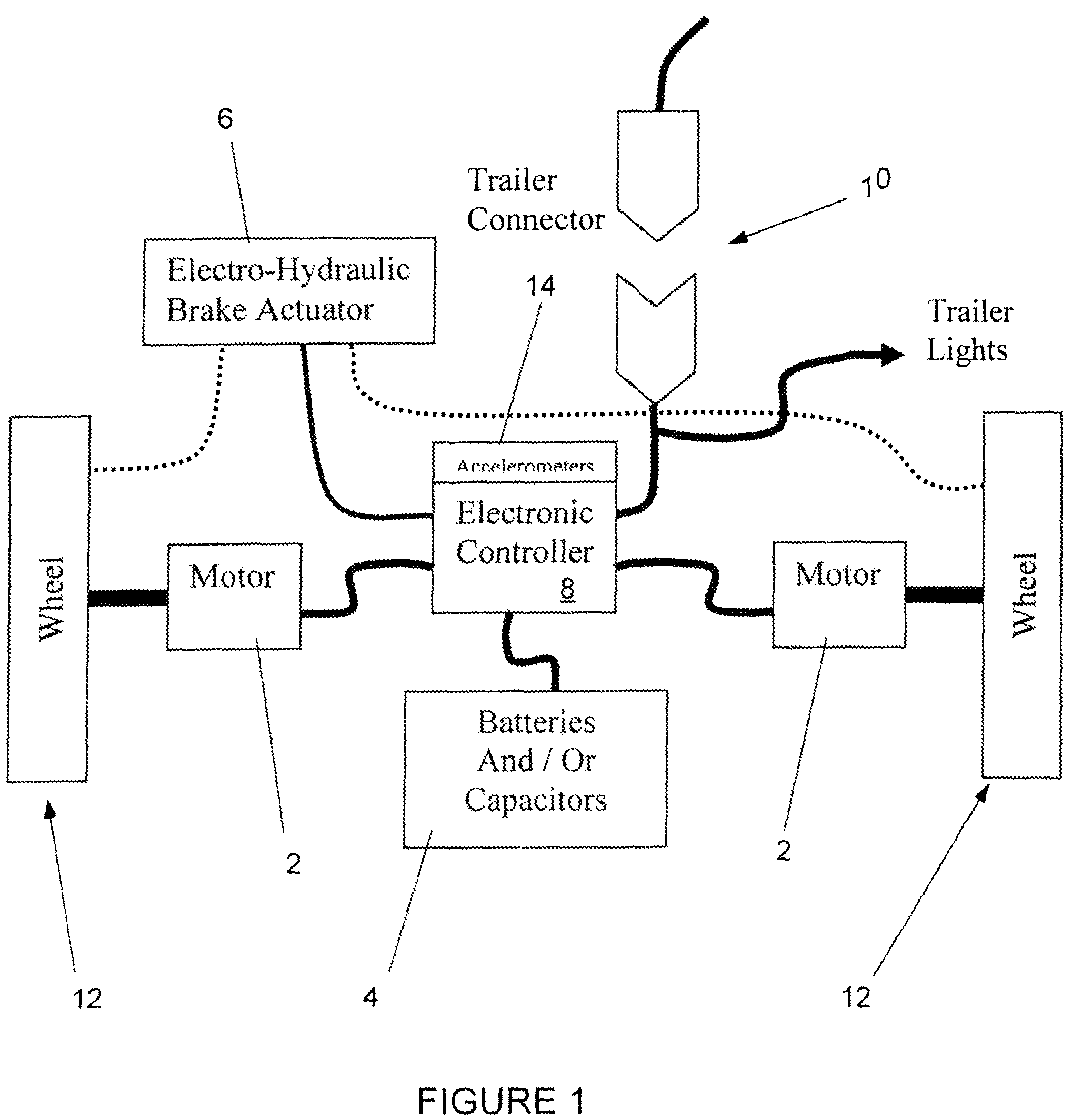

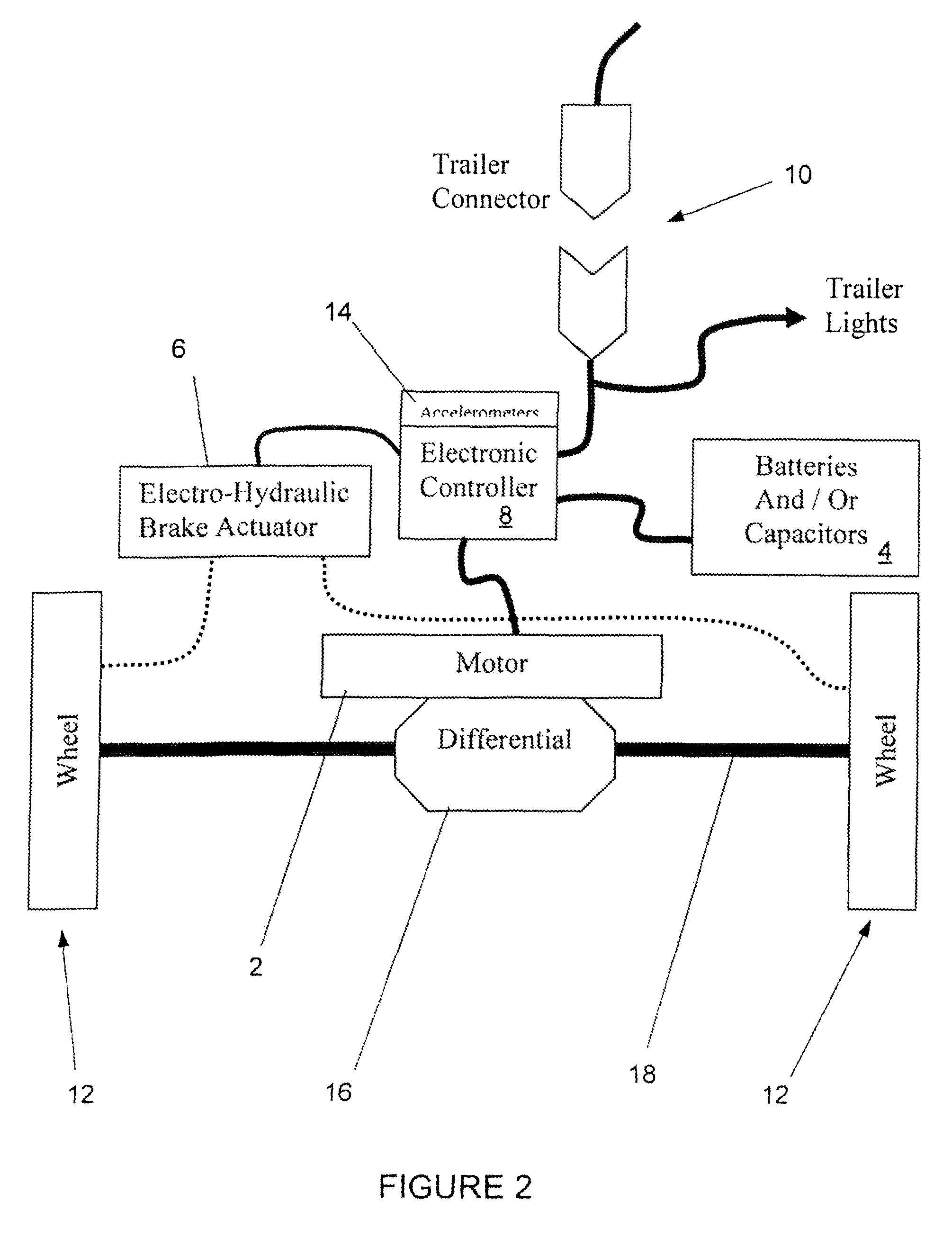

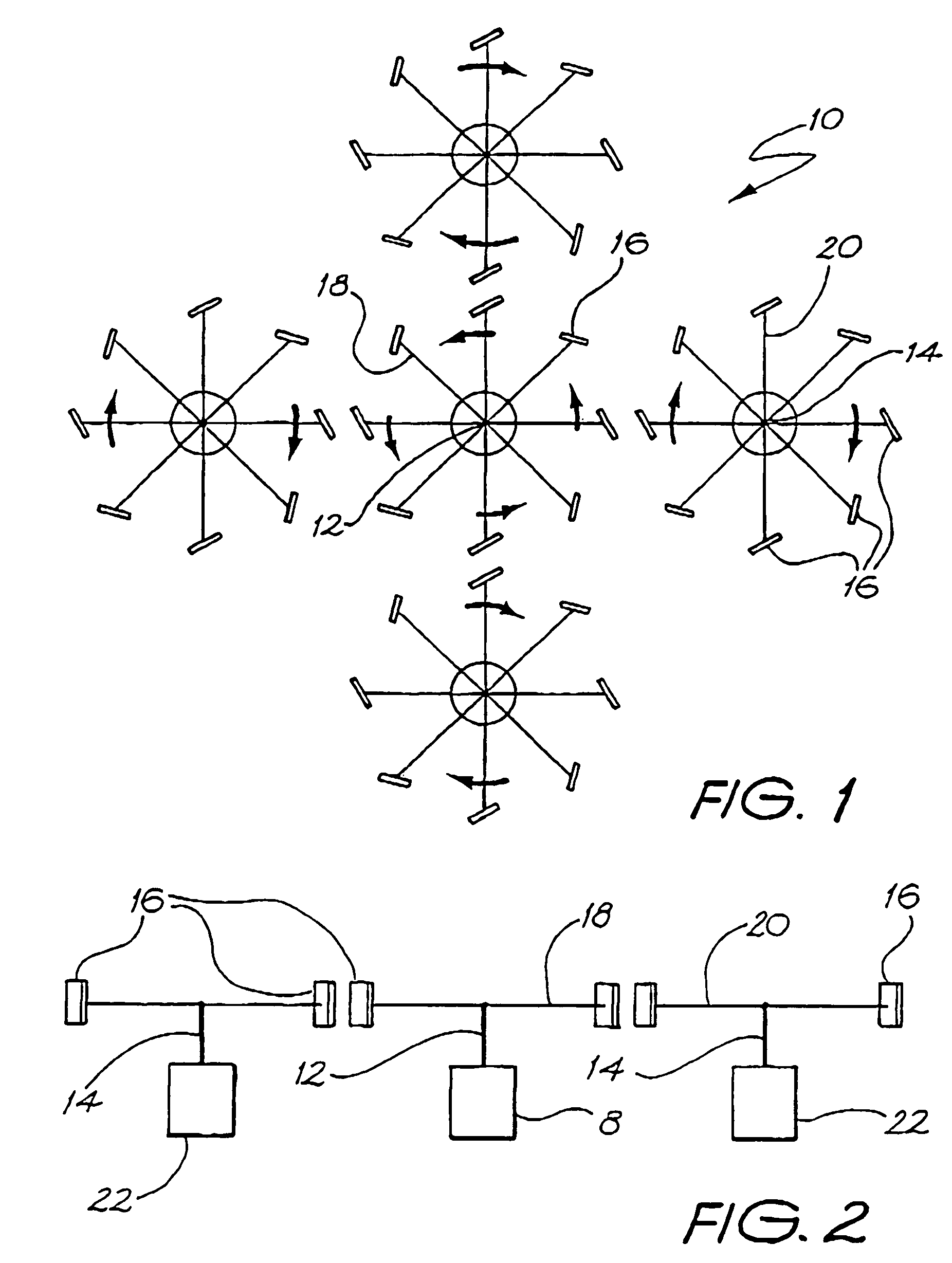

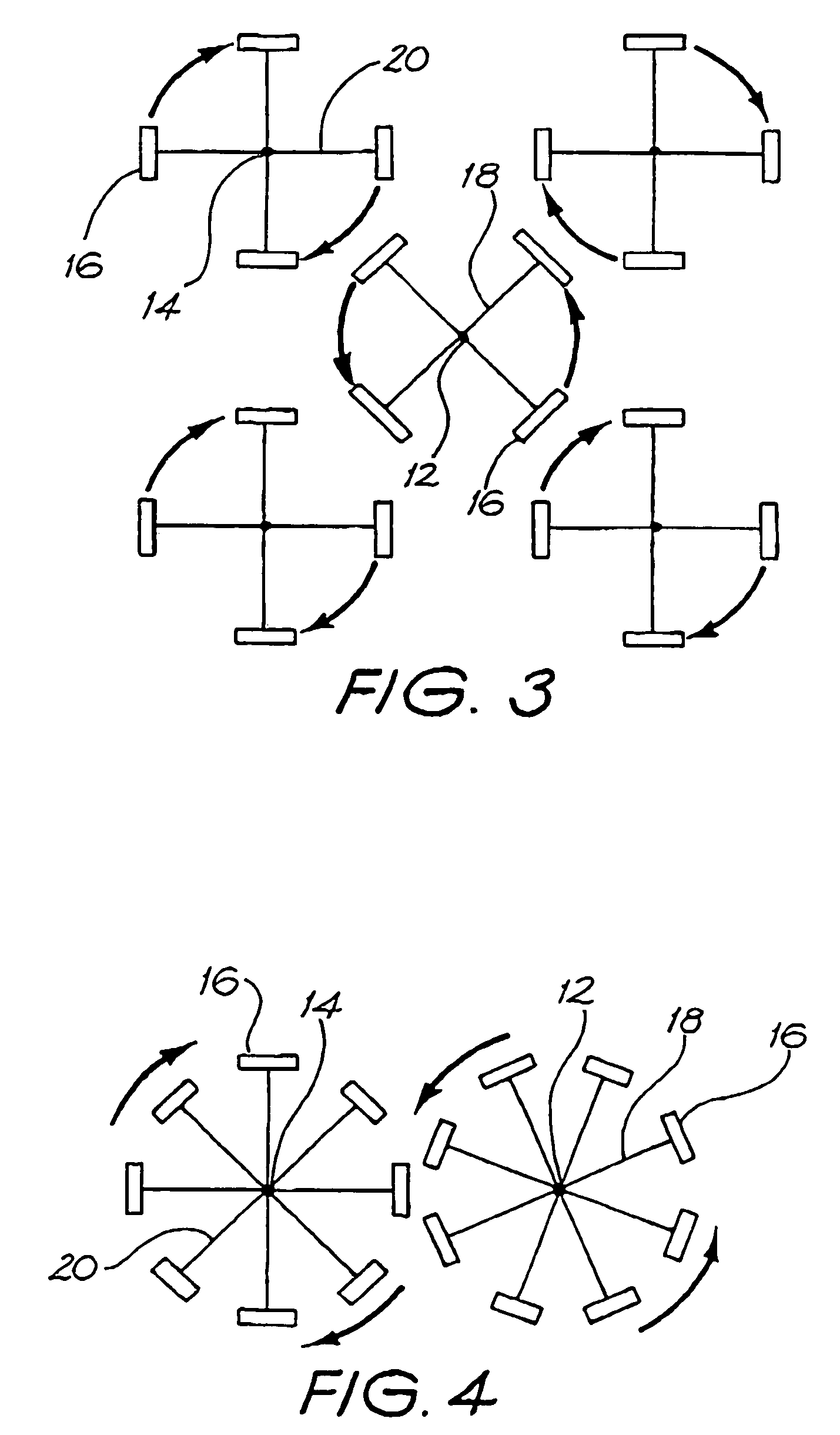

Hybrid trailer system

InactiveUS8215436B2Easily retrofit into new and used trailerReduce maintenanceAuxillary drivesConvertible cyclesCapacitanceCapacitive storage

A system and related method for a regenerative braking system on a towed vehicle, such as a trailer or semi-trailer. The system provides power and braking to the respective trailer wheels, as needed, to help stabilize the trailer. Power is regenerated during braking. While batteries may be used to store the energy, the system also may use capacitive storage units, which charge and discharge large amounts of energy at a fast rate. A multiple-axis sensor system in conjunction with wheel sensors, load sensors, and proportional control of the brakes and motor power to the axles and wheels, is used to achieve superior load stabilization. The invention can be easily retrofit into new or used trailers, and is self-contained with low maintenance.

Owner:DEGRAVE KEN +1

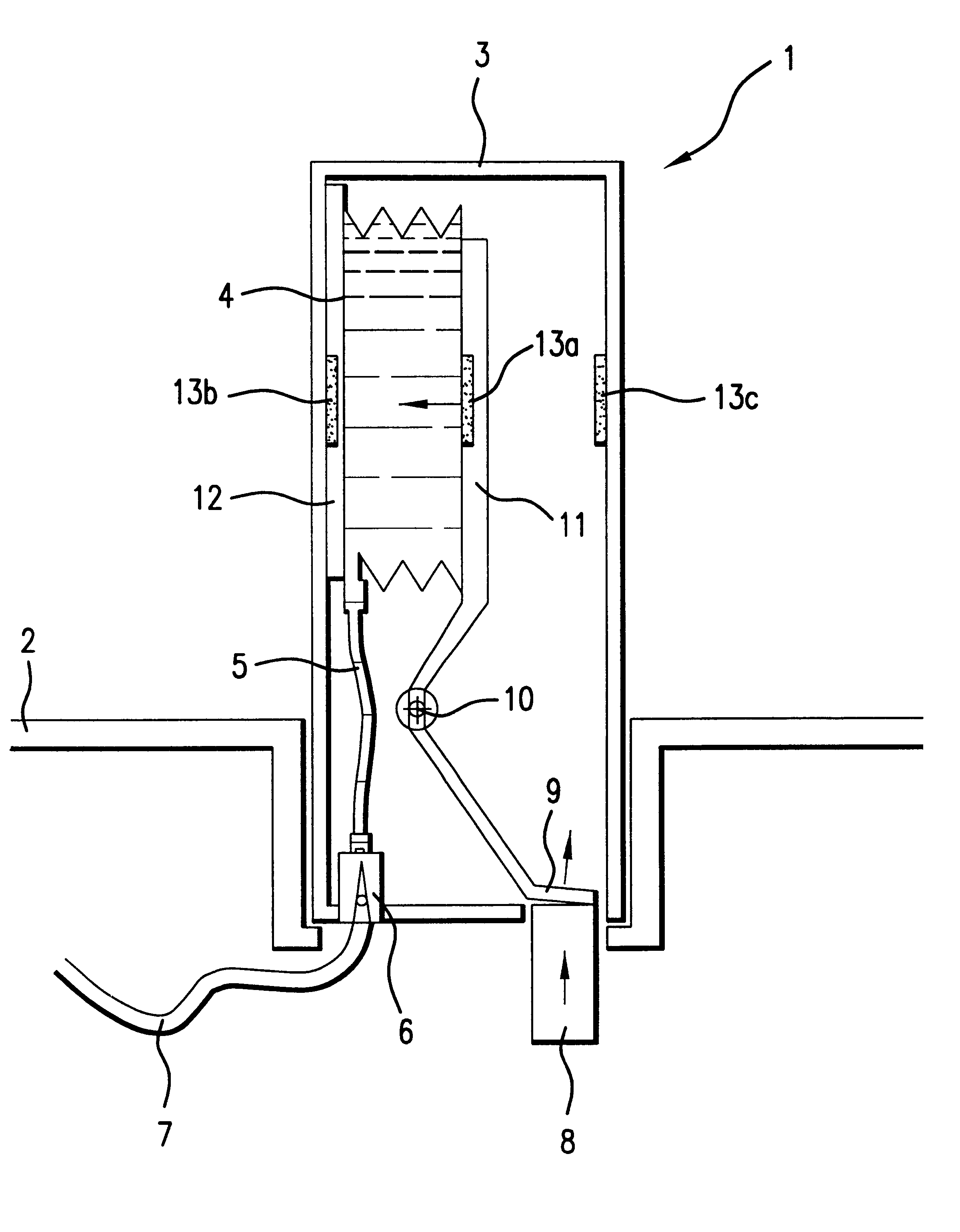

Ink supply tank for an inkjet print head

The present invention pertains to an ink supply tank for an inkjet print head that can be installed in fixed fashion in an inkjet printer, having an ink reservoir that can be connected to an ink supply line leading to an inkjet print head, and having an ink delivery device that has actuating elements accessible from the outside, which can be brought into active engagement with corresponding, motor-powered drive elements of the inkjet printer, in which the ink delivery device feeds ink into the ink supply line at overpressure upon actuation of the actuating elements. In order to reduce the manufacturing effort and ensure a high level of functional reliability with an ink supply tank of such a type, the invention suggests that the ink delivery device have a pressure-generating device that acts on the ink reservoir and is coupled with the actuating elements, and that provides the ink reservoir with overpressure when the actuating elements are driven.

Owner:ARTECH DESIGN PRODN & PLASTIC

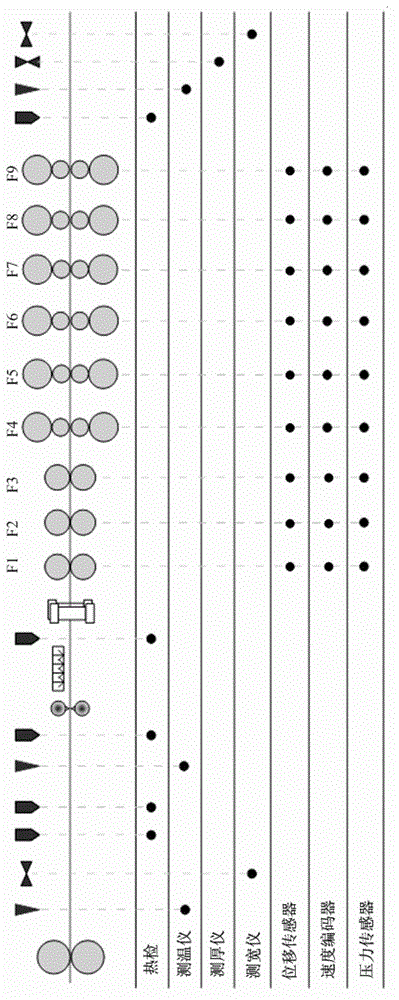

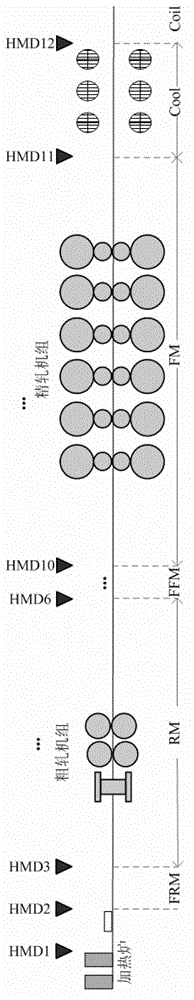

Method for controlling hot continuous rolling finish rolling process

InactiveCN102941232AHigh precisionAccurately predict the service lifeRoll mill control devicesMetal rolling arrangementsAutomatic controlControl system

The invention provides a method for controlling a hot continuous rolling finish rolling process, which belongs to the technical field of automatic steel rolling control. The method is that after the parallel data interface (PDI) data is obtained, according to the technological requirements which are established in a rolling plan, the thickness of a hot continuous rolling finish rolling target outlet and the target temperature of the finish rolling outlet are determined; the practical temperature of a hot continuous rolling finish rolling inlet is obtained; the load distribution of a rack is determined; rolling parameters including the roller linear velocity, inlet temperature, rolling force, roller gap position and motor power parameter of various racks are calculated; the rolling parameters are subjected to limit checking and are judged whether to meet the operation conditions of equipment or not, if yes, the rolling parameters are sent to a control system in a command mode, and the hot continuous rolling finish rolling process is controlled; and if not, calculation is carried out again. Through calculating the rolling force, the prediction precision and the thickness precision are improved, the service cycle of a roller is accurately predicted, based on a roller thermal expansion model, the rolling process has different rolling intervals, and good thickness controlling precision is obtained.

Owner:NORTHEASTERN UNIV

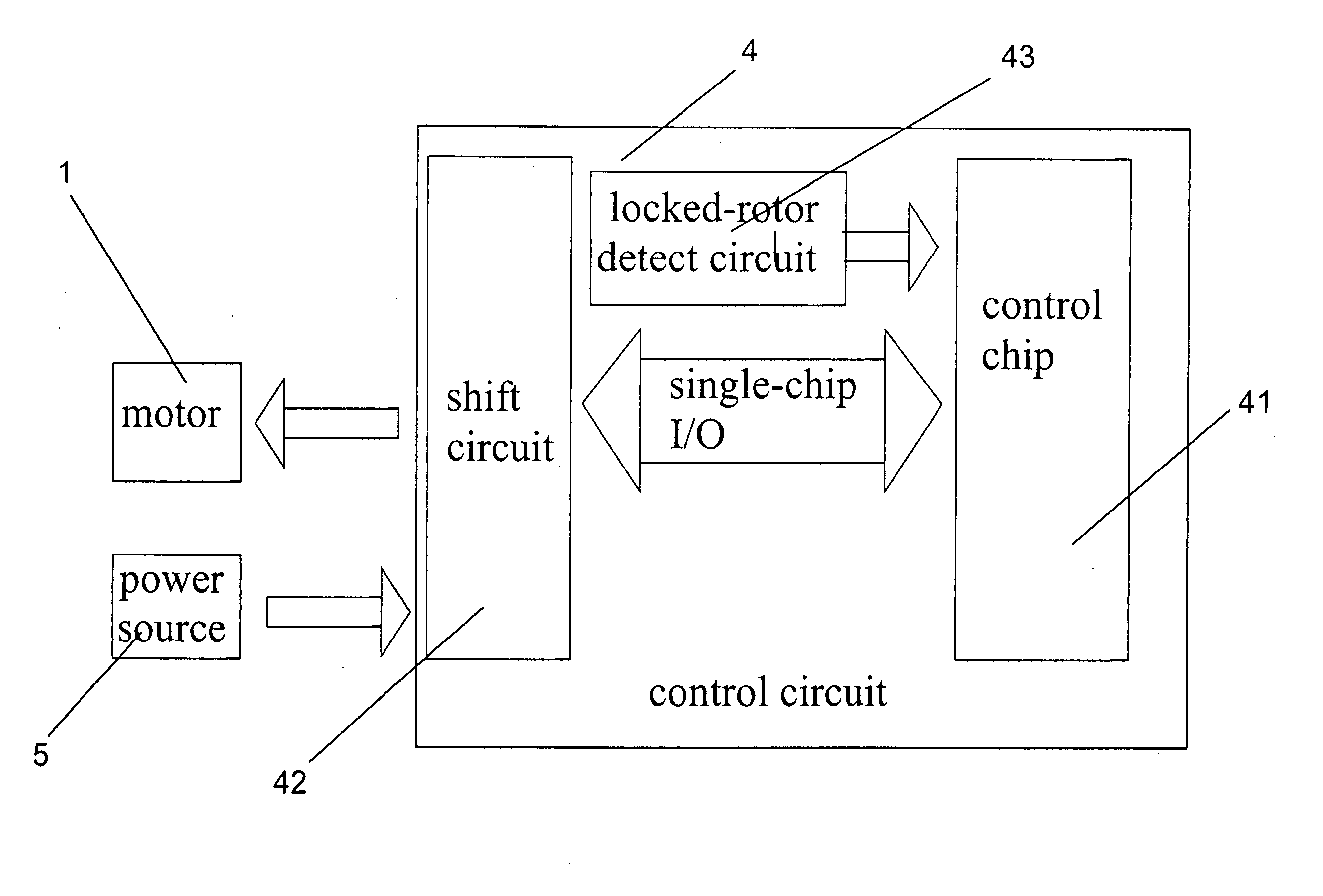

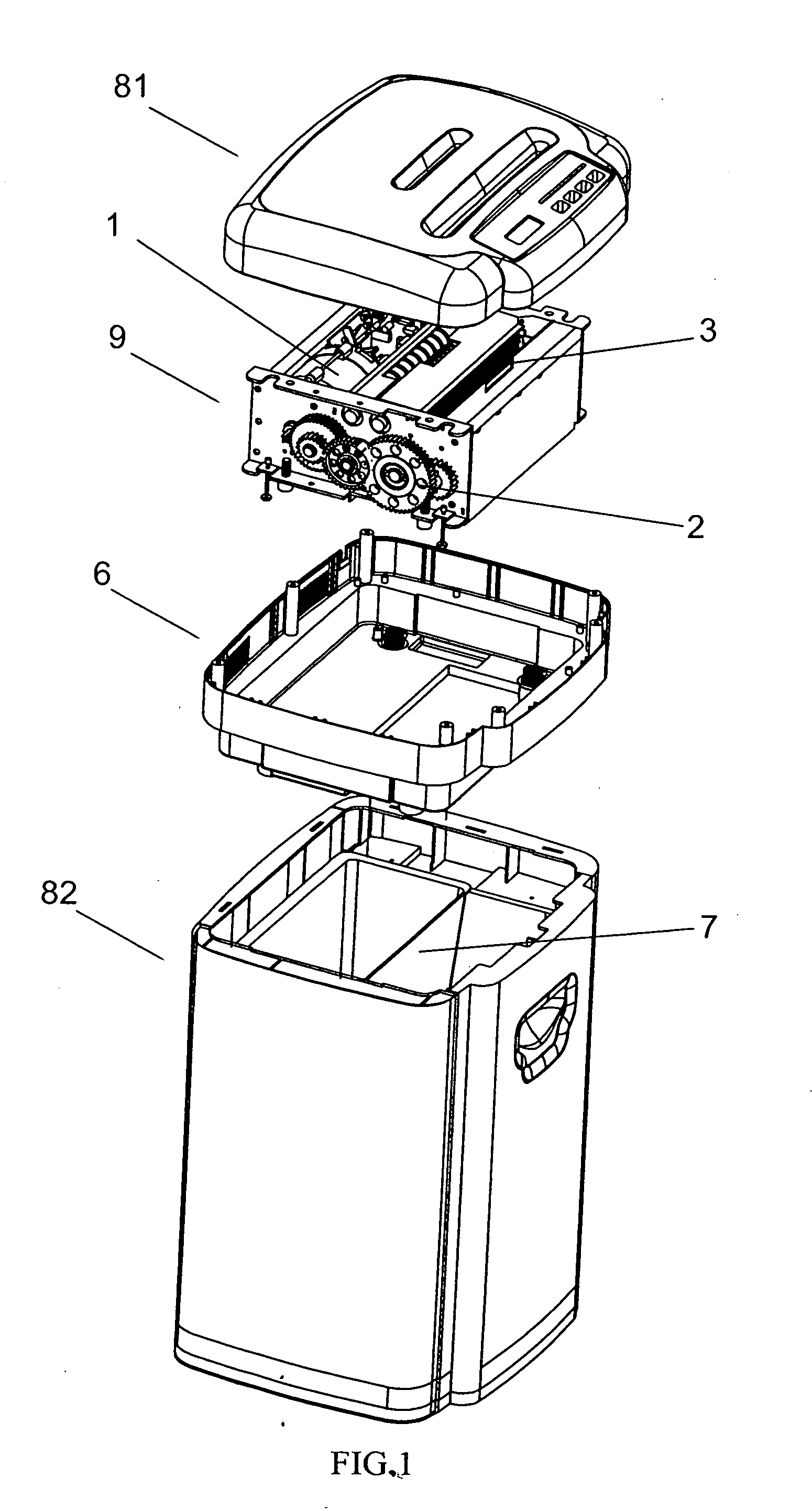

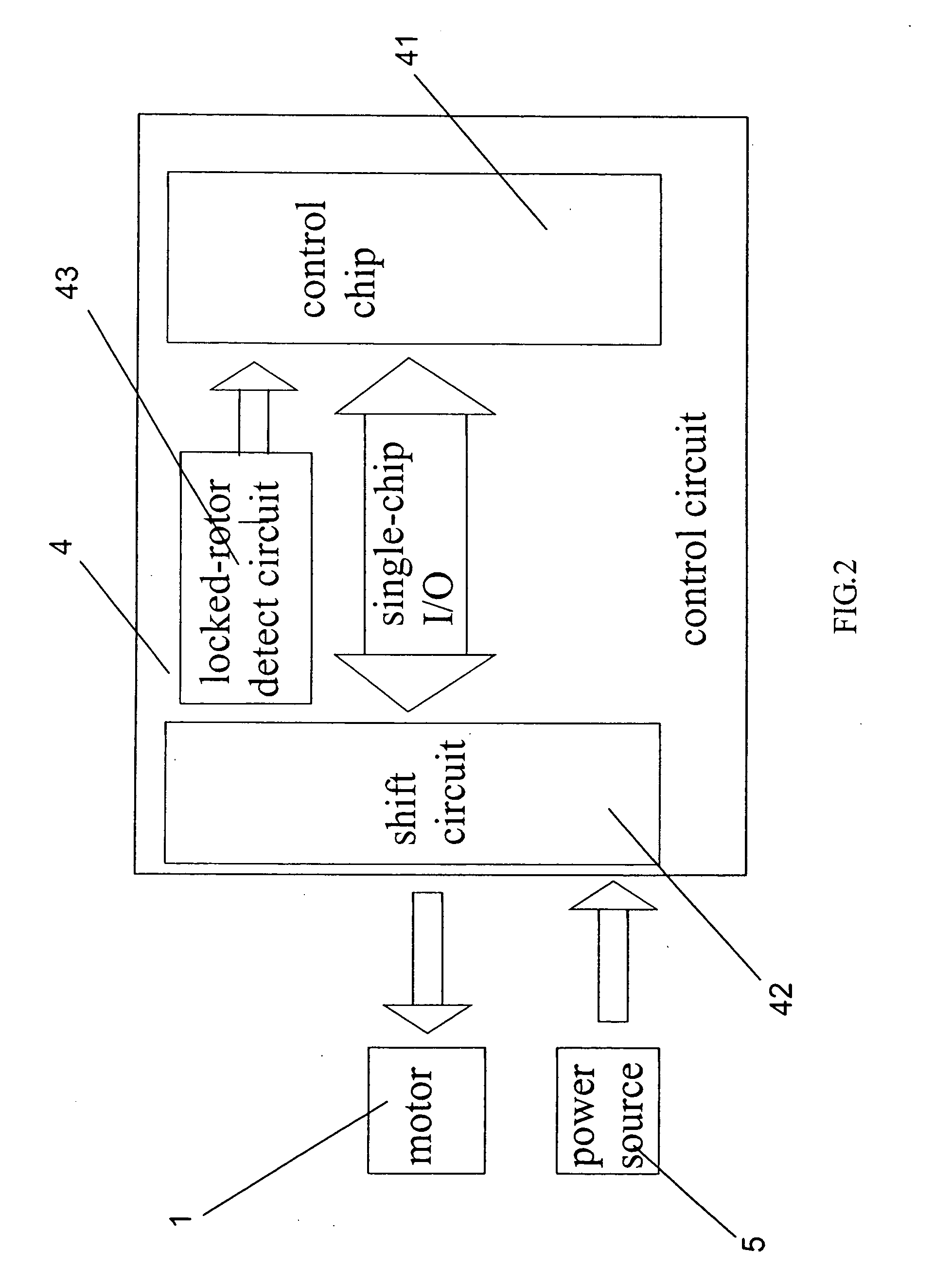

Intelligent shift paper shredding mechanism and method of automatic shift of the same

An intelligent shift paper shredding mechanism and a method of automatic shift of the same in accordance with the present invention includes a control circuit including a control chip electrically connecting with a shift circuit and a locked-stator detect circuit. The shift circuit electrically connects with a motor. The method of adjusting power of the motor includes steps of: a) turning on the highest tap position switch circuit to initiate the motor; b) automatically switching to the lowest tap position switch circuit after a predetermined time delay; c) when the locked-rotor detect circuit detecting the current tap position cannot shred papers, automatically switching to higher tap position switch circuit, repeating this step until to the highest tap position switch circuit, otherwise keeping on the electrical connection to the current tap position switch circuit; d) when the locked-rotor detect circuit detecting a paper jam, automatically turning on a normal-reverse switch circuit and corresponding tap position switch circuit at the same time to exit the jammed papers. The cooperation between the shift circuit and the locked-rotor detect circuit realizes the goal of adjusting power of the motor intelligently according to different quantities of the papers, and thus, makes the paper shredder in which the paper shredding mechanism is used more economic in energy.

Owner:GUANGZHOU COMET

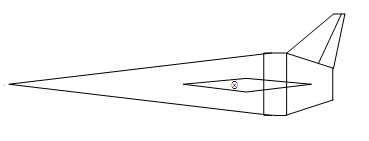

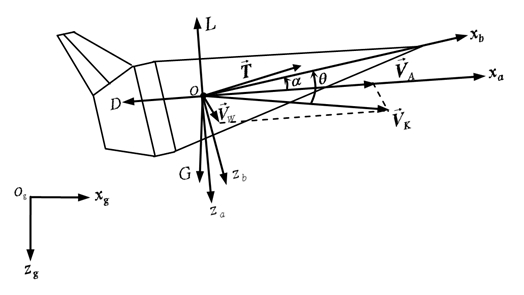

Motion control simulation method for near-space hypersonic aircraft

InactiveCN102073755ASolve the problem of closed-loop controlSimple designCosmonautic condition simulationsSpecial data processing applicationsKineticsFlight vehicle

The invention discloses a control simulation method for a near-space hypersonic aircraft. The method comprises the following steps of: (1) establishing a motion model of the aircraft under the condition of a variable wind field; (2) establishing a motor power model of the near-space hypersonic aircraft; (3) establishing a pneumatic parameter base and an engine parameter base related with the motion model and the power model; (4) designing an attitude steady tracking control law and a centre-of-gravity motion control law on the basis of the motion model according to different task requirements; and (5) calculating atmosphere data and wind field data in the current state in real time, calculating all states of the aircraft according to the atmosphere data and wind field data and the designed control law, and repeating the steps until the simulation is finished. In the method, a whole set of the motion model of the near-space hypersonic aircraft under the condition of the variable wind field is provided on the basis of fully analyzing dynamic and kinematic laws of the near-space hypersonic aircraft and by combining the actual conditions of the motor power model and the atmospheric wind field environment. The invention also discloses an aircraft-based control simulation platform.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

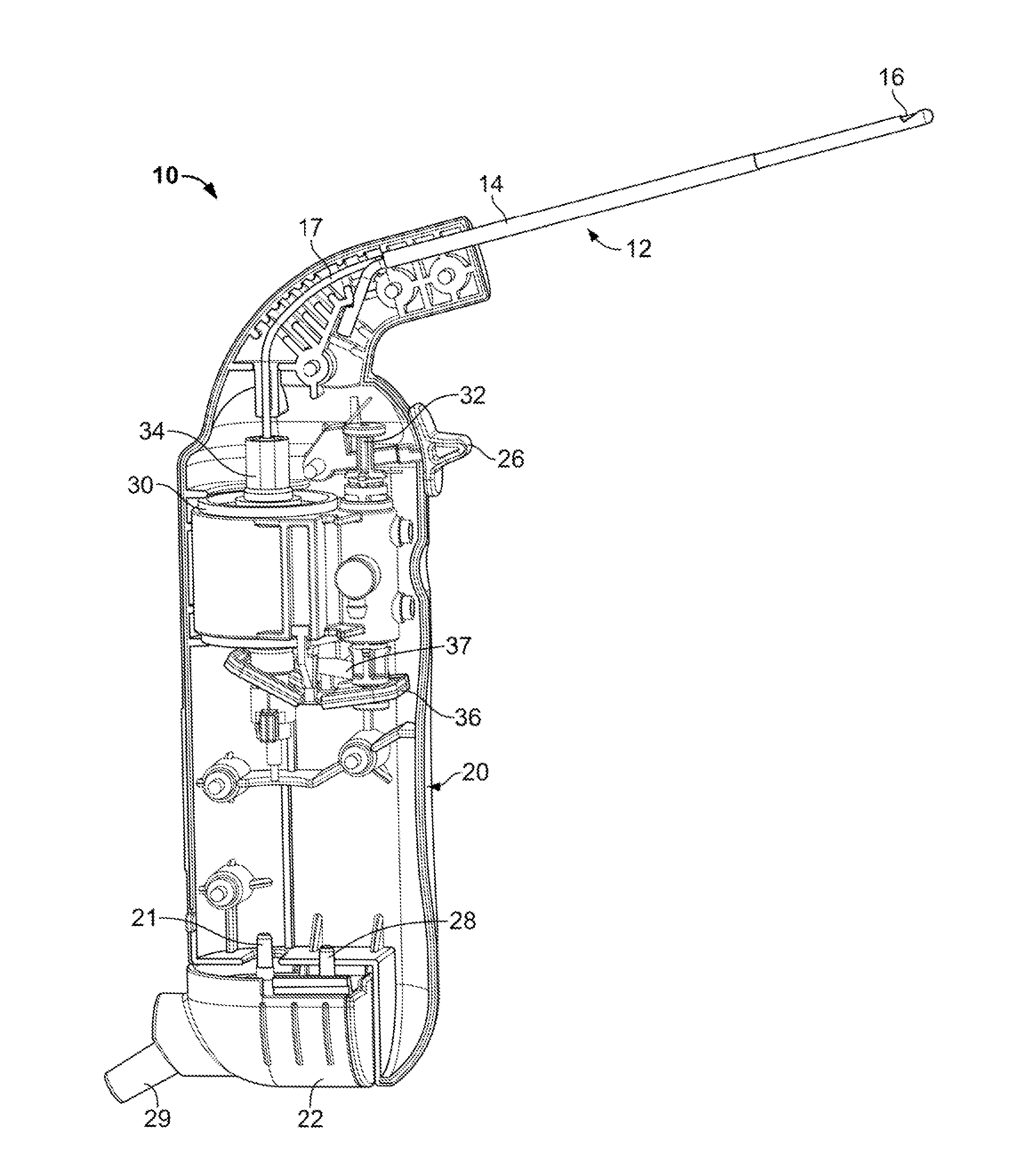

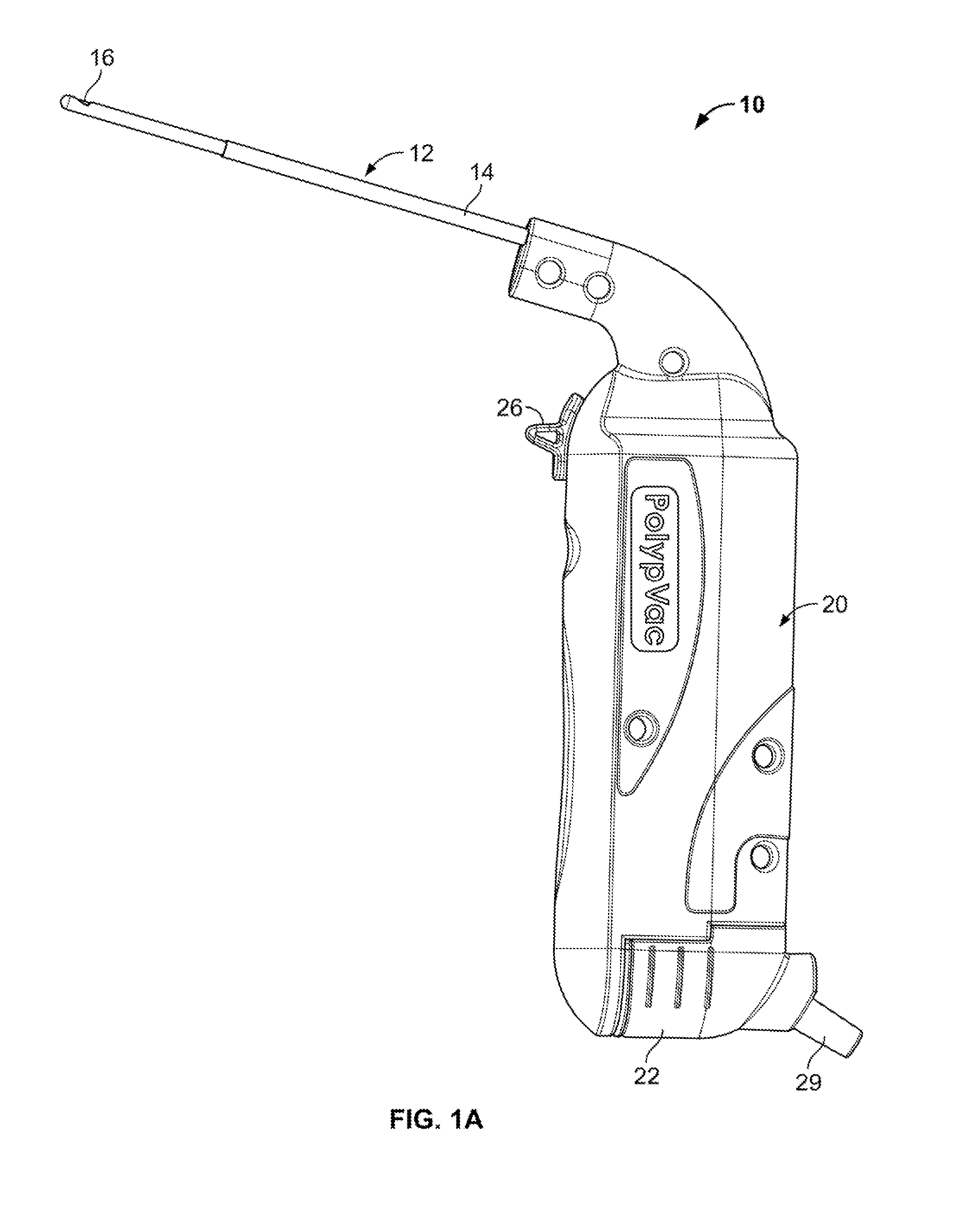

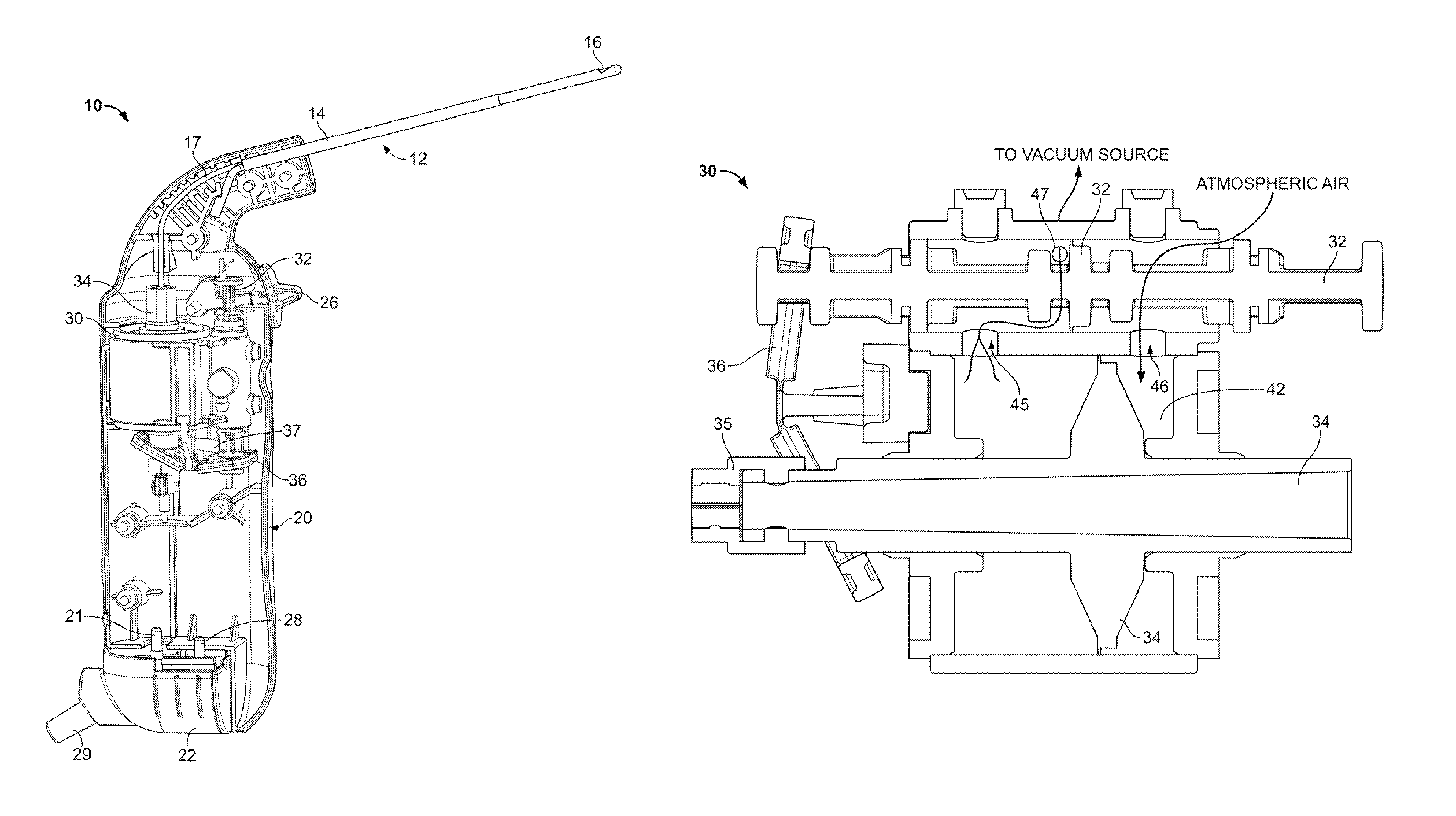

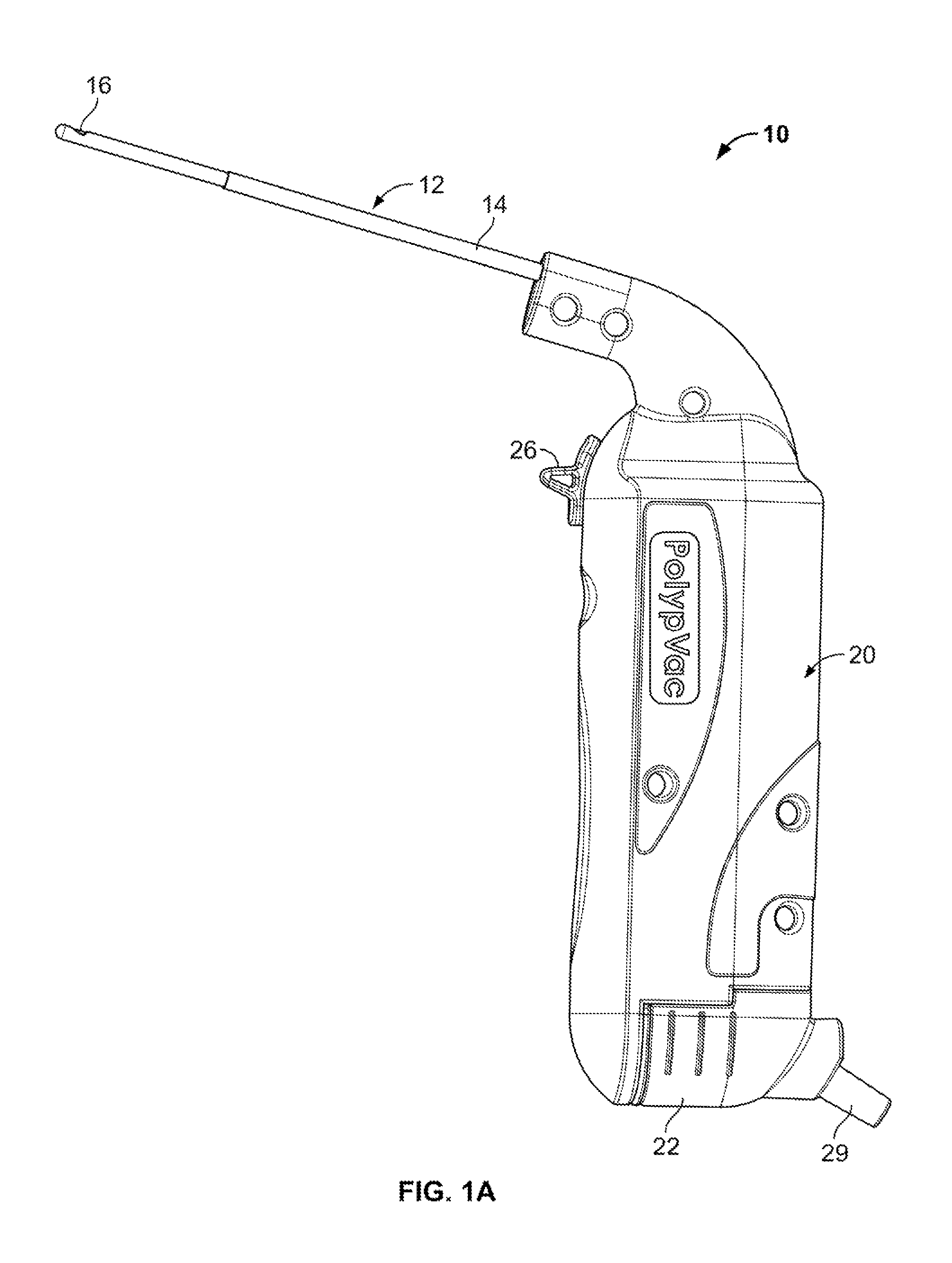

Devices and methods for cutting and evacuating tissue

Various medical devices and methods for cutting and / or evacuating tissue are provided. The devices and methods may utilize a reciprocating mechanism or motor powered by suction from a vacuum source. The medical devices and methods may be used on tissue in various regions of a patient's body and for treating various conditions, e.g., for performing a polypectomy or discectomy.

Owner:MYROMED LLC

High power low RPM D.C. motor

InactiveUS6037692AIncrease motor powerHigh strengthAC motor controlAsynchronous induction motorsEngineeringConductor Coil

A high power low RPM direct current electric motor is disclosed whereby the high power output is achieved in one of two ways or both. In the first case, the need for cooling is reduced simultaneously along with an increase in the utilization of the magnetic field present in the motor permanent magnets. This is achieved by wrapping the electromagnet core with windings that are capable of demagnetizing the rotor permanent magnets under stall conditions. Interlocking motor circuitry is provided which prevents the full activation of these motor windings until motor RPM values reach a safe level. This increases motor power while decreasing resistive losses in electromagnet windings. In the second case, the rotary portion consists of a large diameter relatively flat rotor containing permanent magnets and having built in vanes for moving air over the electromagnet stator windings providing forced air cooling.

Owner:MAGNETIC MOTORS

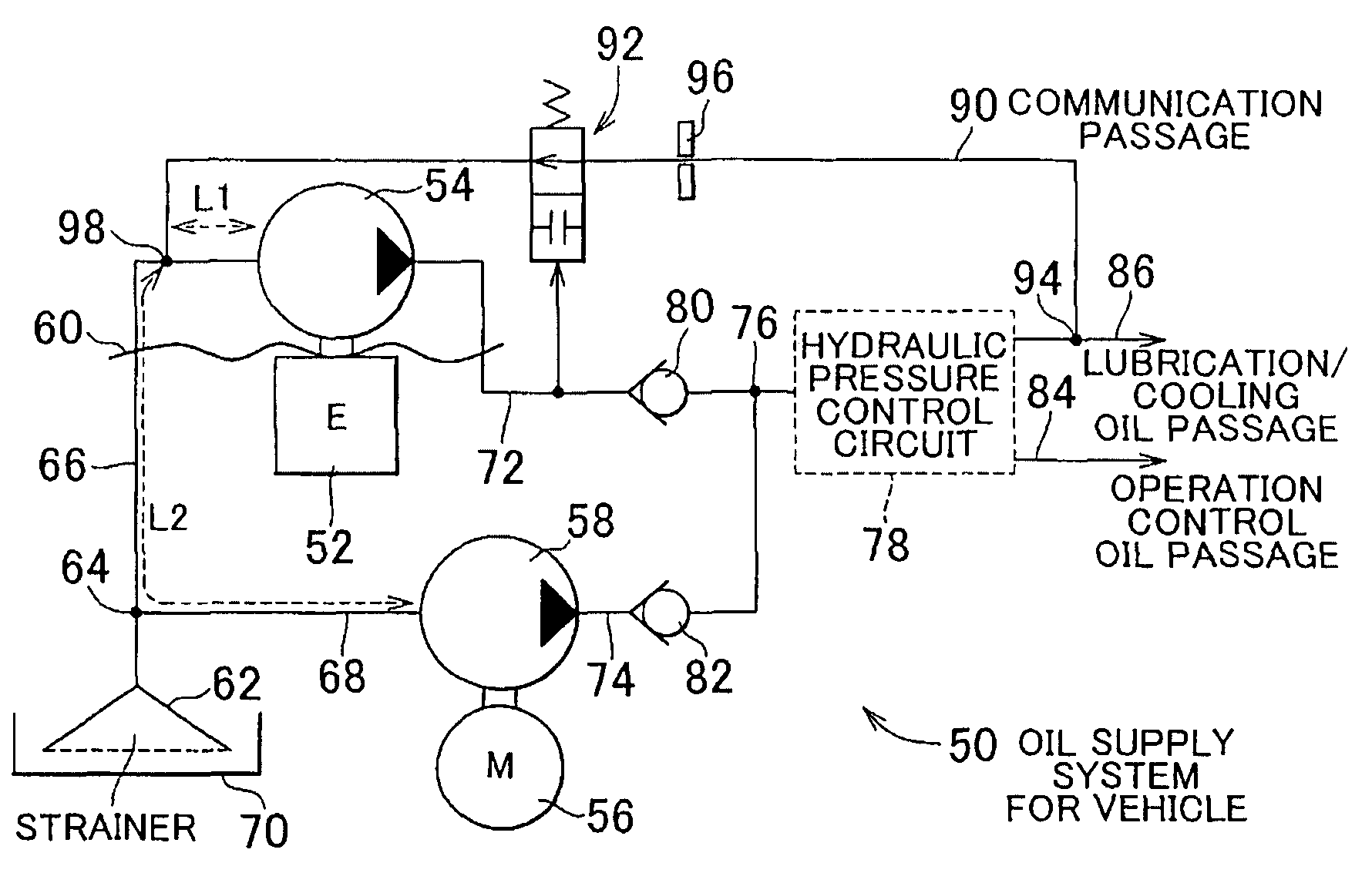

Oil supply system for vehicle

InactiveUS20080308355A1Deterioration of characteristicAvoid airGearboxesGear lubrication/coolingControl circuitLubrication

An oil supply system for a vehicle includes: a mechanical oil pump driven by an engine; an electric oil pump driven by an electric motor; a hydraulic pressure control circuit supplied with oil from the mechanical oil pump and the electric oil pump through an oil discharge passage for the mechanical oil pump and an oil discharge passage for the electric oil pump, which are connected to each other; a lubrication / cooling oil passage that is supplied with the oil from the hydraulic pressure control circuit; and a communication passage that provides communication between the lubrication / cooling oil passage and the mechanical oil pump. With this oil supply system, it is possible to prevent the electric oil pump from causing air-sucking noise, for example, in the motor-power cruise mode, and to improve the rising characteristics of the hydraulic pressure produced by the mechanical oil pump during startup of the engine.

Owner:TOYOTA JIDOSHA KK +1

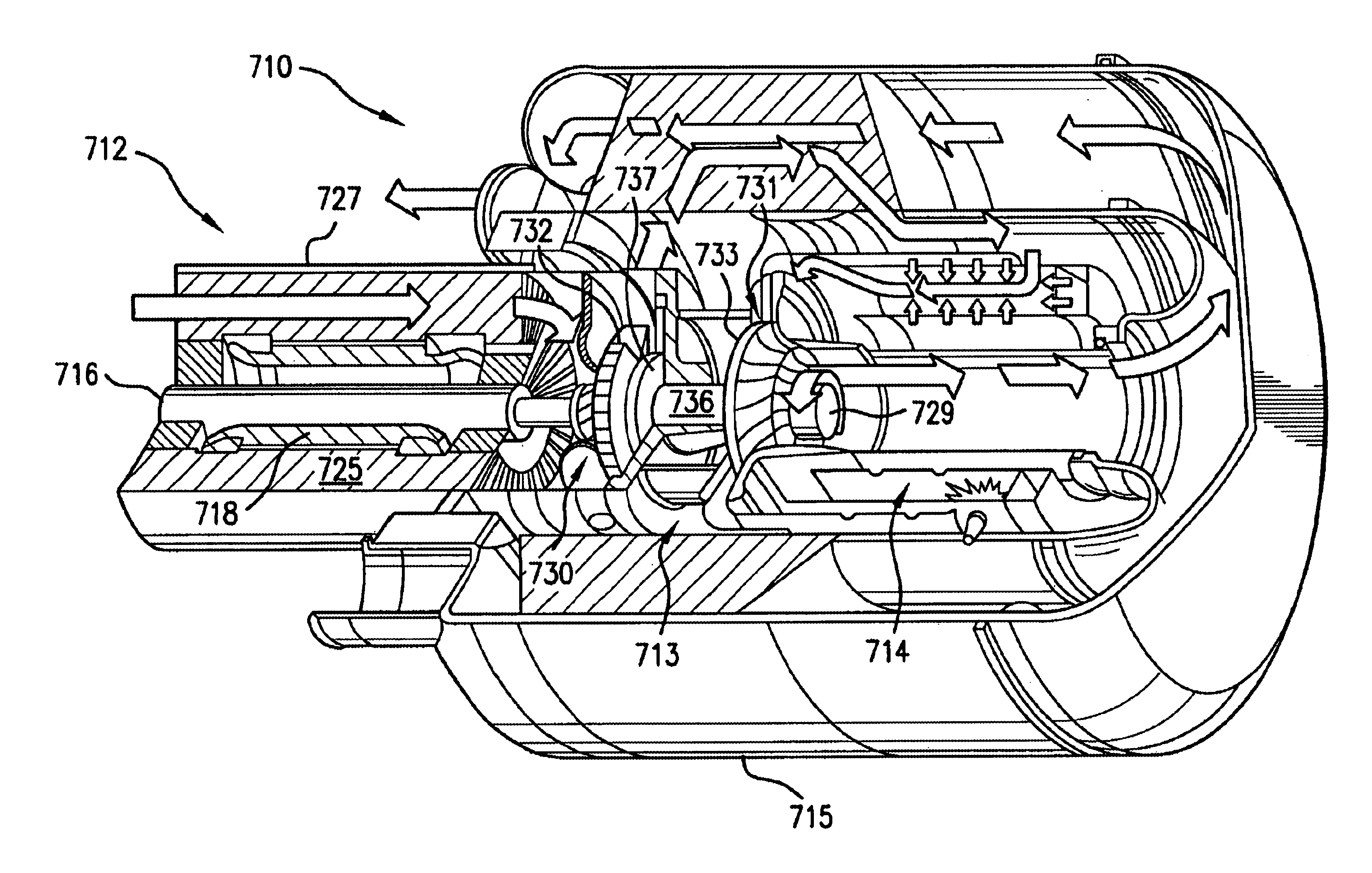

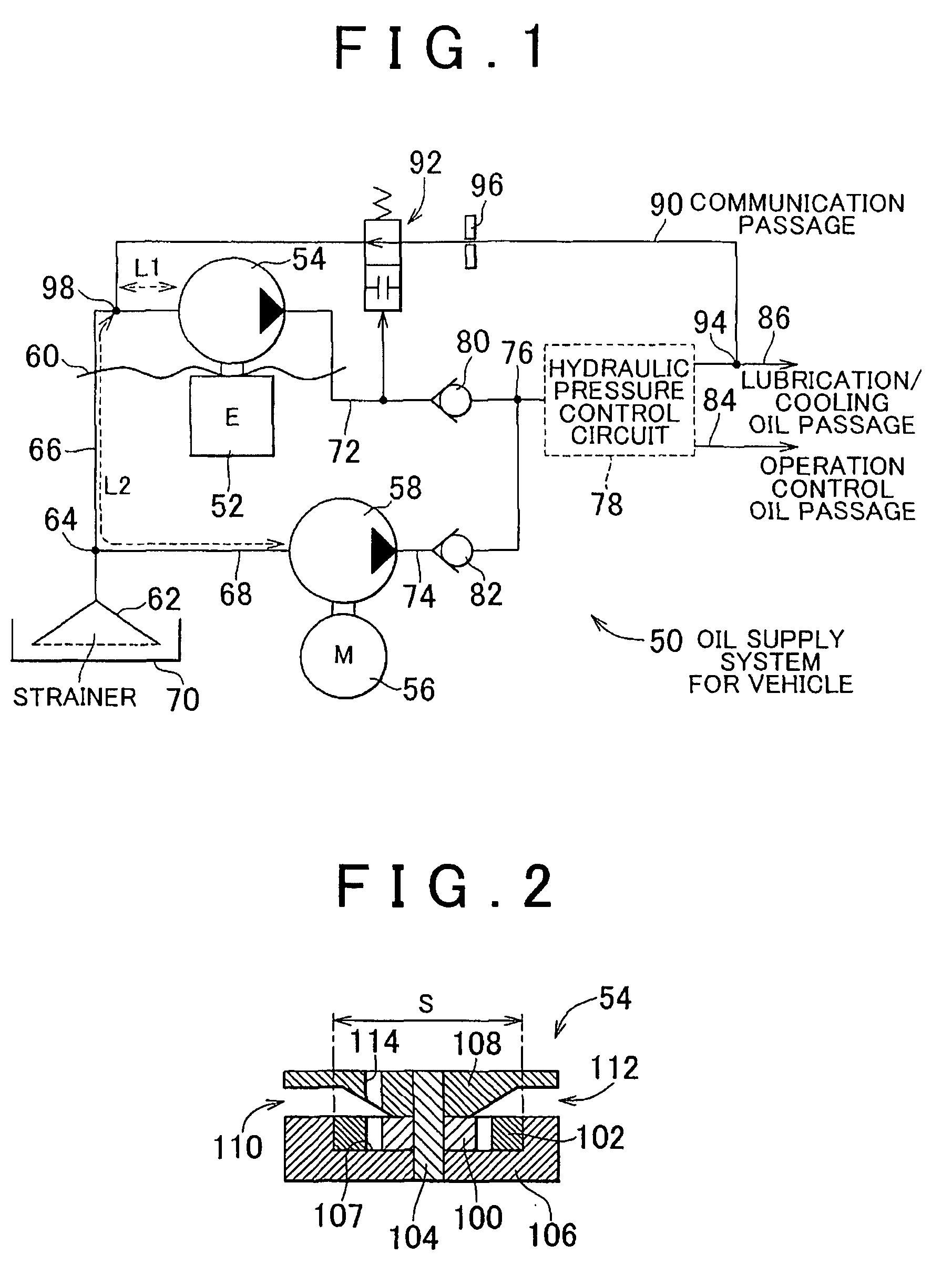

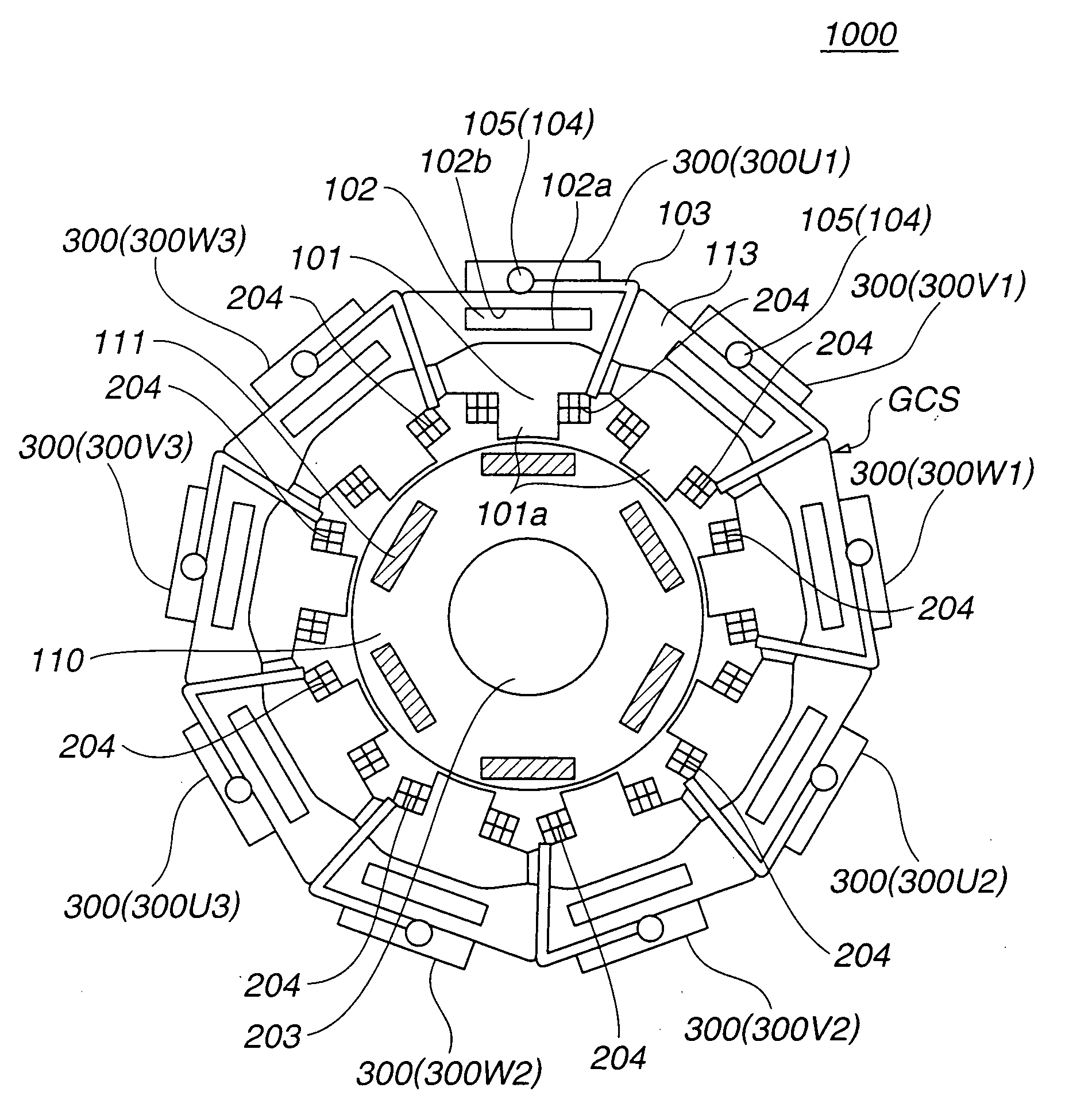

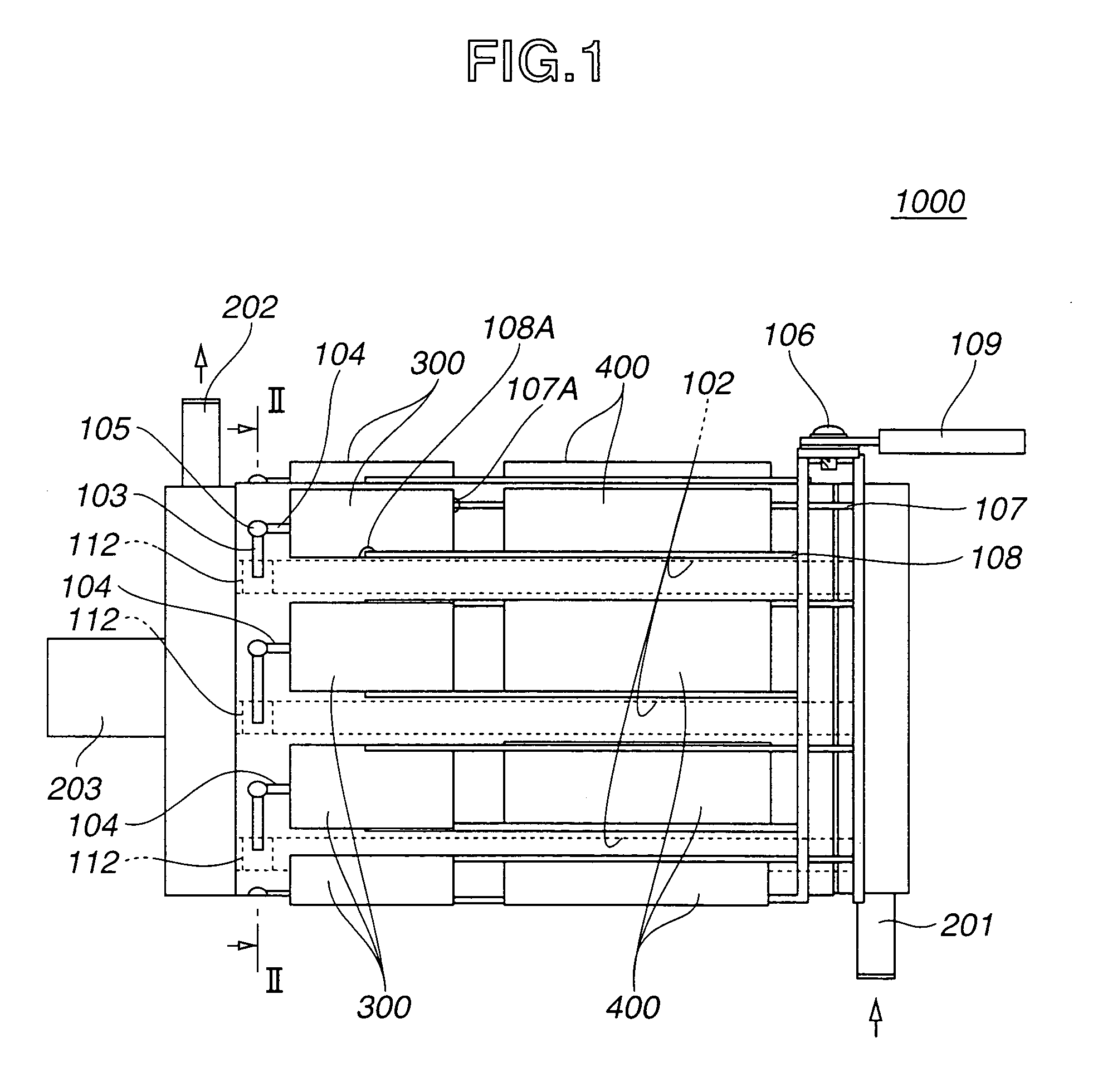

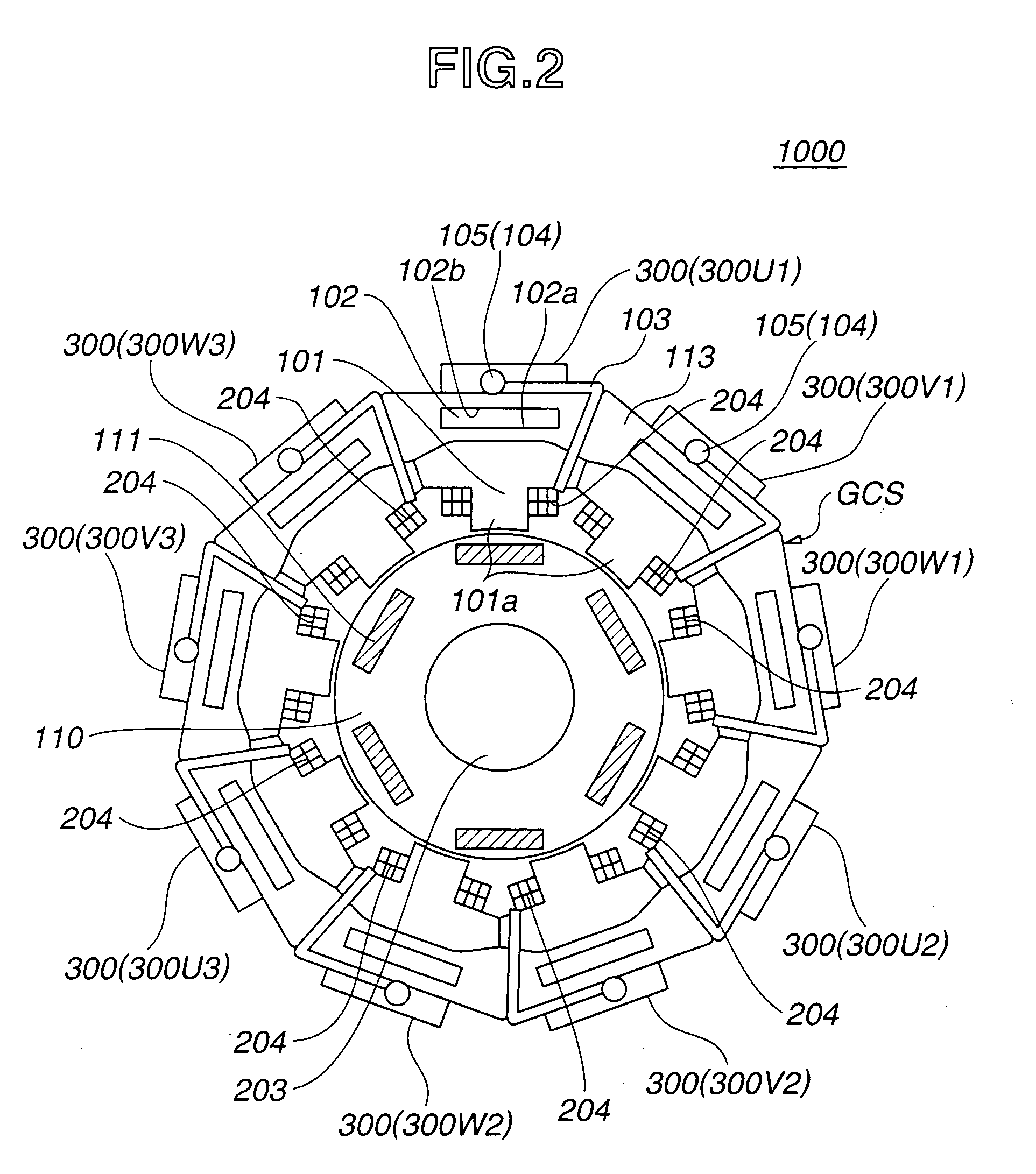

A.C. motor-inverter integrated drive unit

ActiveUS20040090130A1Association with control/drive circuitsCooling/ventillation arrangementStator coilEngineering

An a.c. motor-inverter integrated drive unit comprises an a.c. motor powered by an alternating current. The motor includes a rotor rotatable about a rotation axis, a plurality of stator cores arranged about the rotation axis at evenly spaced intervals to constitute a cylindrical stator structure, a plurality of stator coils disposed on the stator cores respectively and a plurality of cooling passages formed in the stator cores respectively. An inverter is combined with the motor. The inverter converts a direct current to an alternating current and includes a plurality of power drivers which are arranged on the stator cores respectively. Wire members are used for connecting the power drivers and the stator coils respectively.

Owner:NISSAN MOTOR CO LTD

Devices and methods for cutting tissue

InactiveUS8292909B1Prevents unstable flutterPreventing unstable flutterEndoscopic cutting instrumentsAbrasive surgical cuttersDiscectomyMedical device

Various medical devices and methods for cutting and / or evacuating tissue are provided. The devices and methods may utilize a reciprocating mechanism or motor powered by suction from a vacuum source. The medical devices and methods may be used on tissue in various regions of a patient's body and for treating various conditions, e.g., for performing a polypectomy or discectomy.

Owner:MYROMED LLC

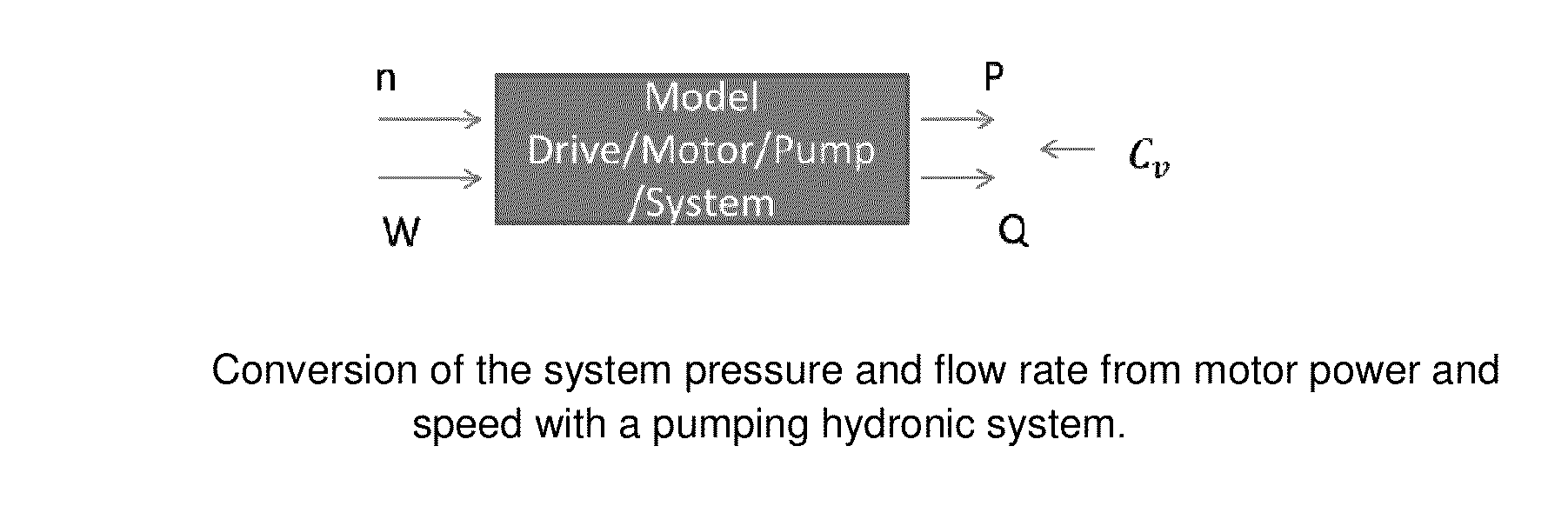

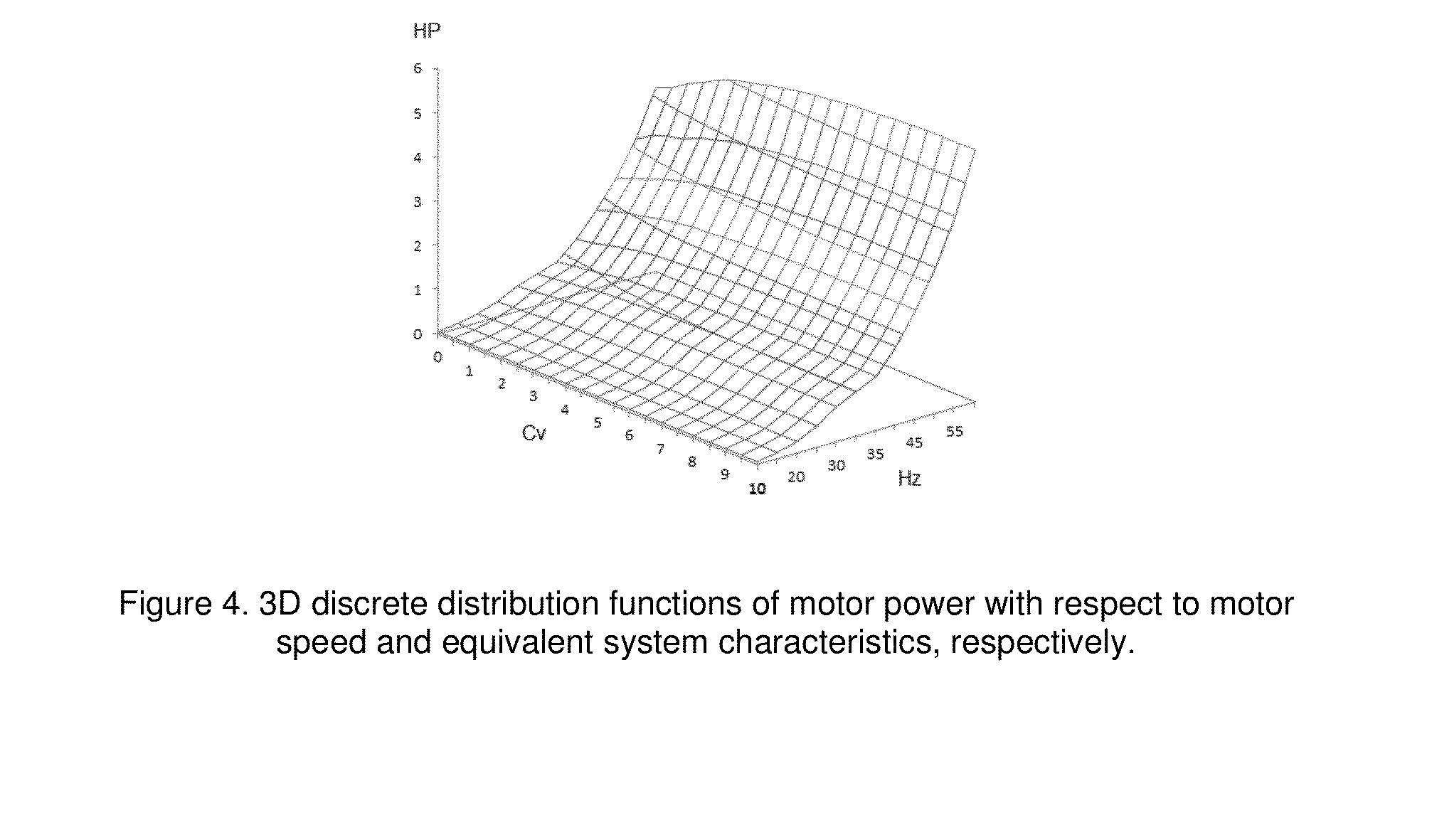

Mixed theoretical and discrete sensorless converter for pump differential pressure and flow monitoring

ActiveUS20140288716A1More accuracyFlow control using electric meansPump controlDifferential pressureComputer module

The present invention provides apparatus featuring a signal processor or processing module that may be configured at least to: process signaling containing information about an equilibrium point of pump differential pressure and system pressure formulated in a hydronic domain by utilizing pump and system characteristic curve equations so as to yield system pressure and flow rate at any particular load and time in a pump hydronic system, including using a multi-dimensional sensorless conversion technique; and determine equivalent hydronic system characteristics associated with the pump differential pressure and flow rate to their corresponding motor power and speed reconstructed and remapped by using a discrete numerical approach, based at least partly on the signaling received. The signal processor or processing module may provide corresponding signaling containing information about the system pumping flow rate and pressure determined.

Owner:FLUID HANDLING

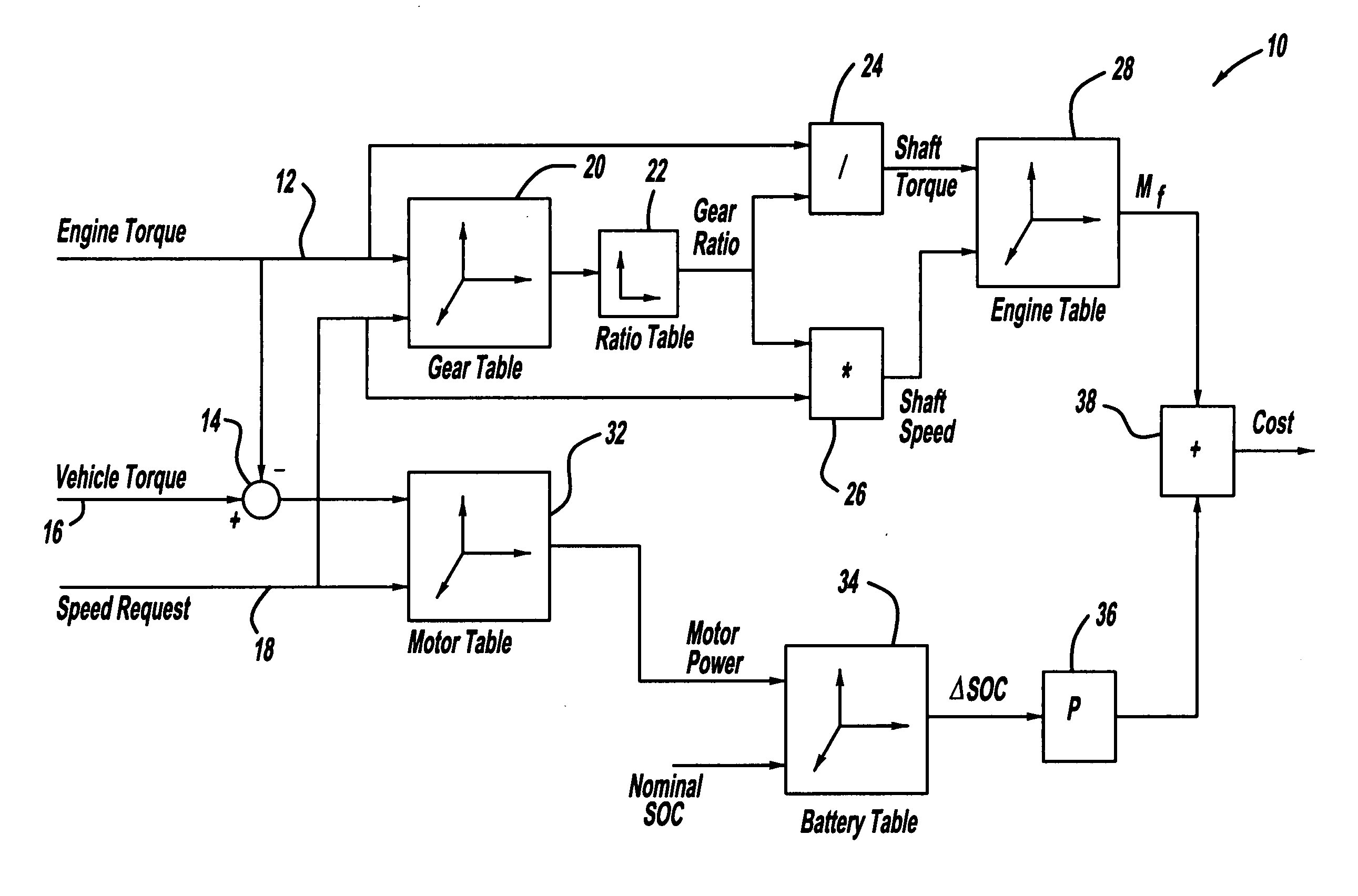

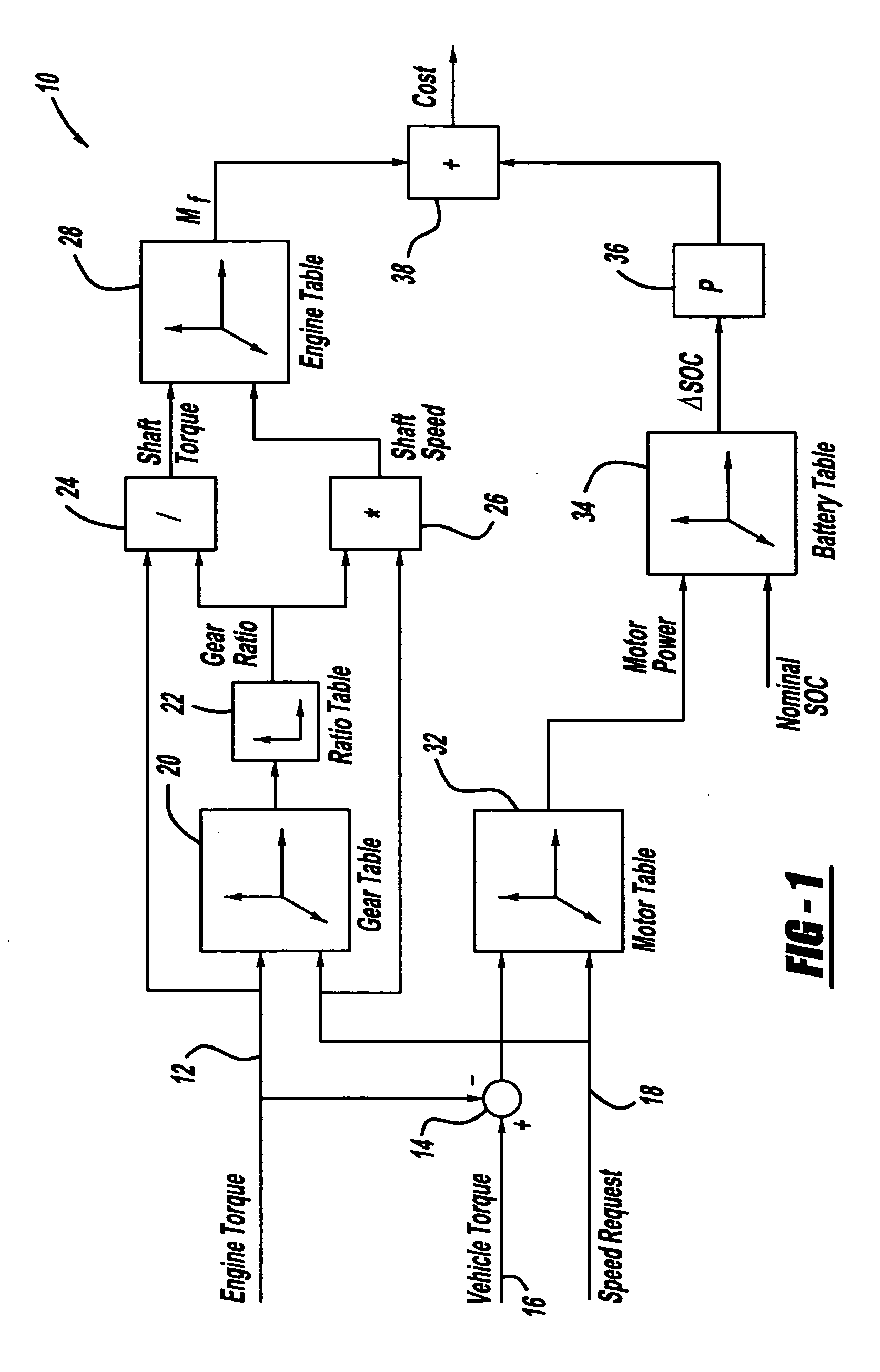

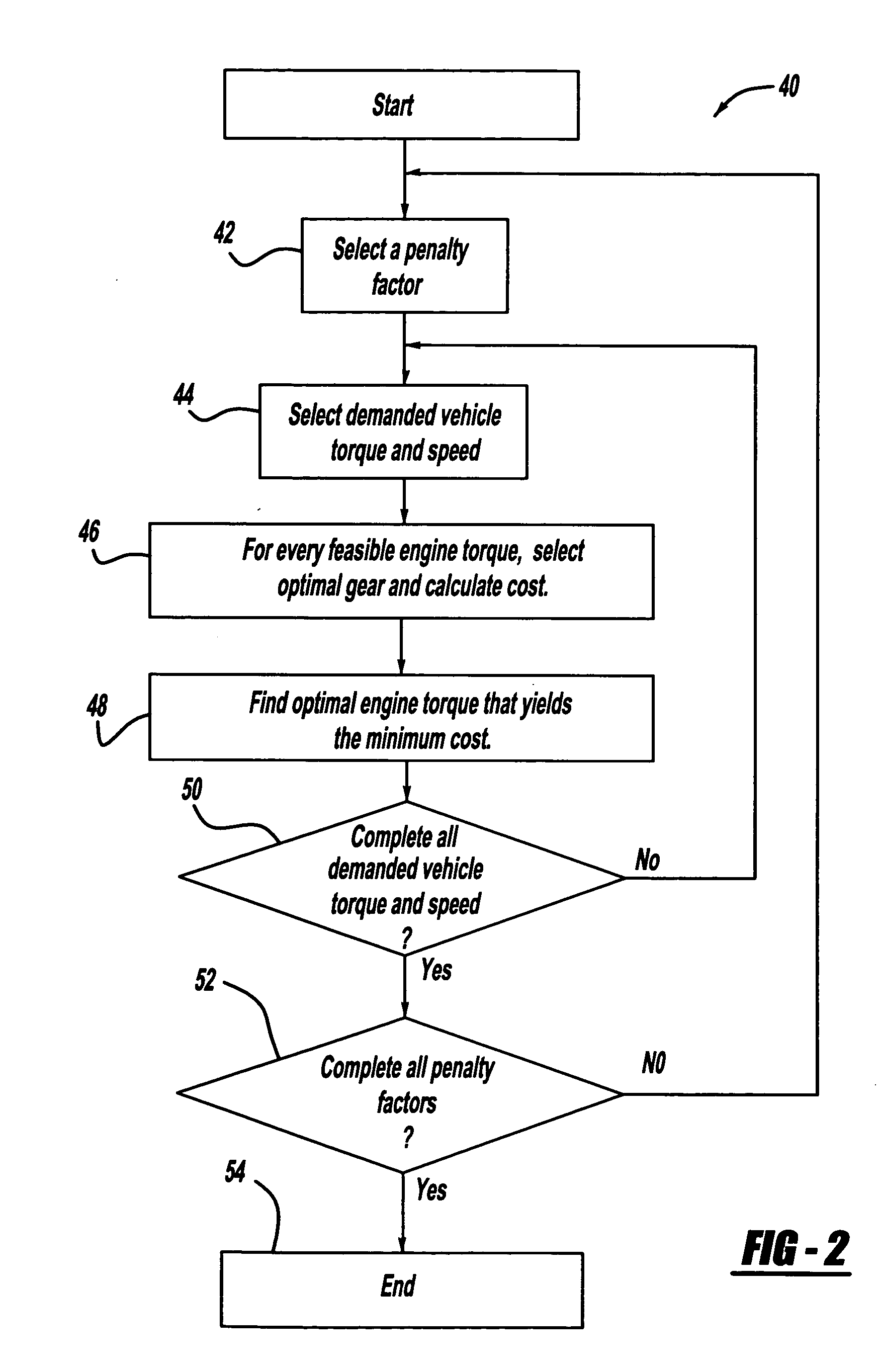

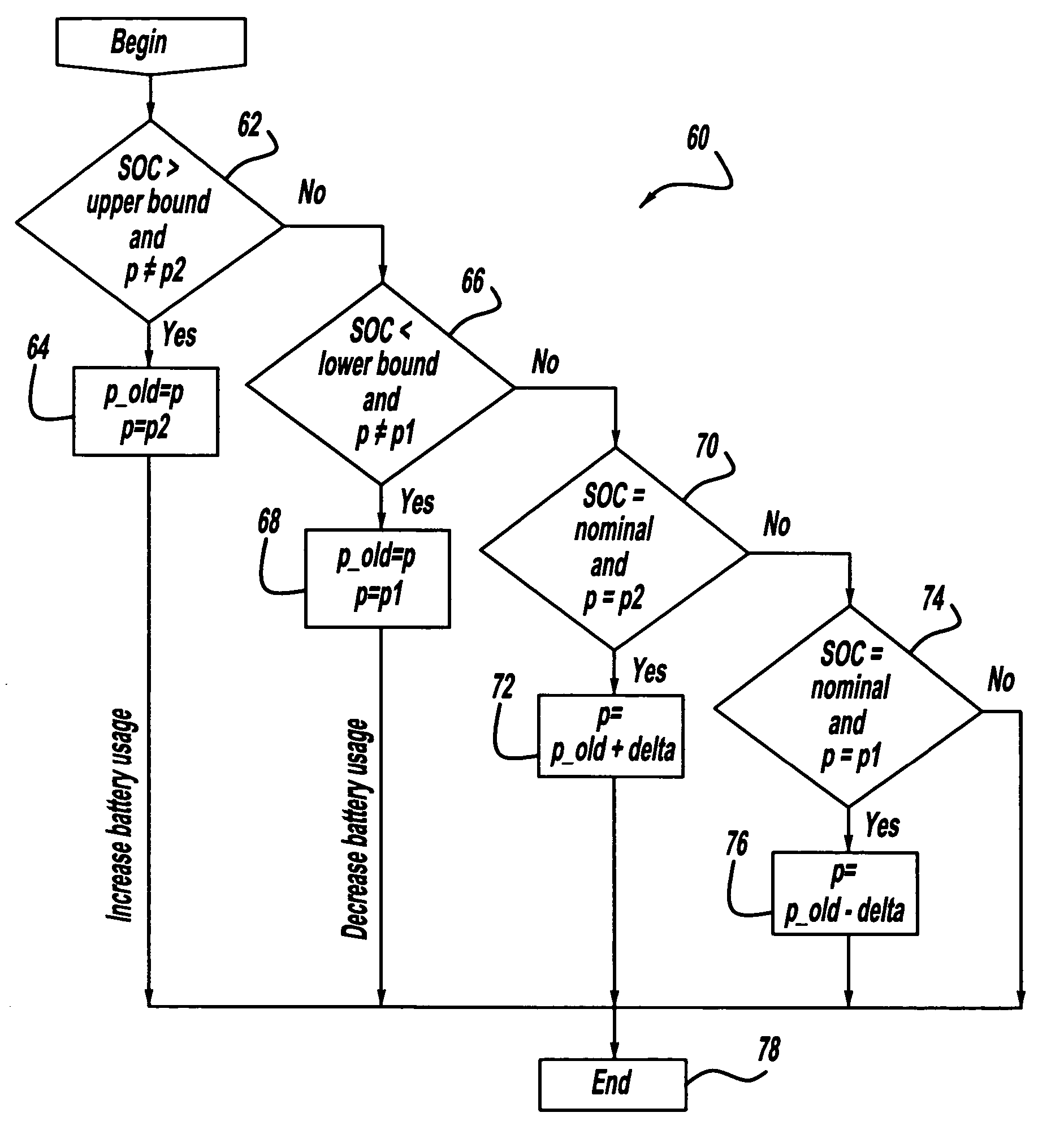

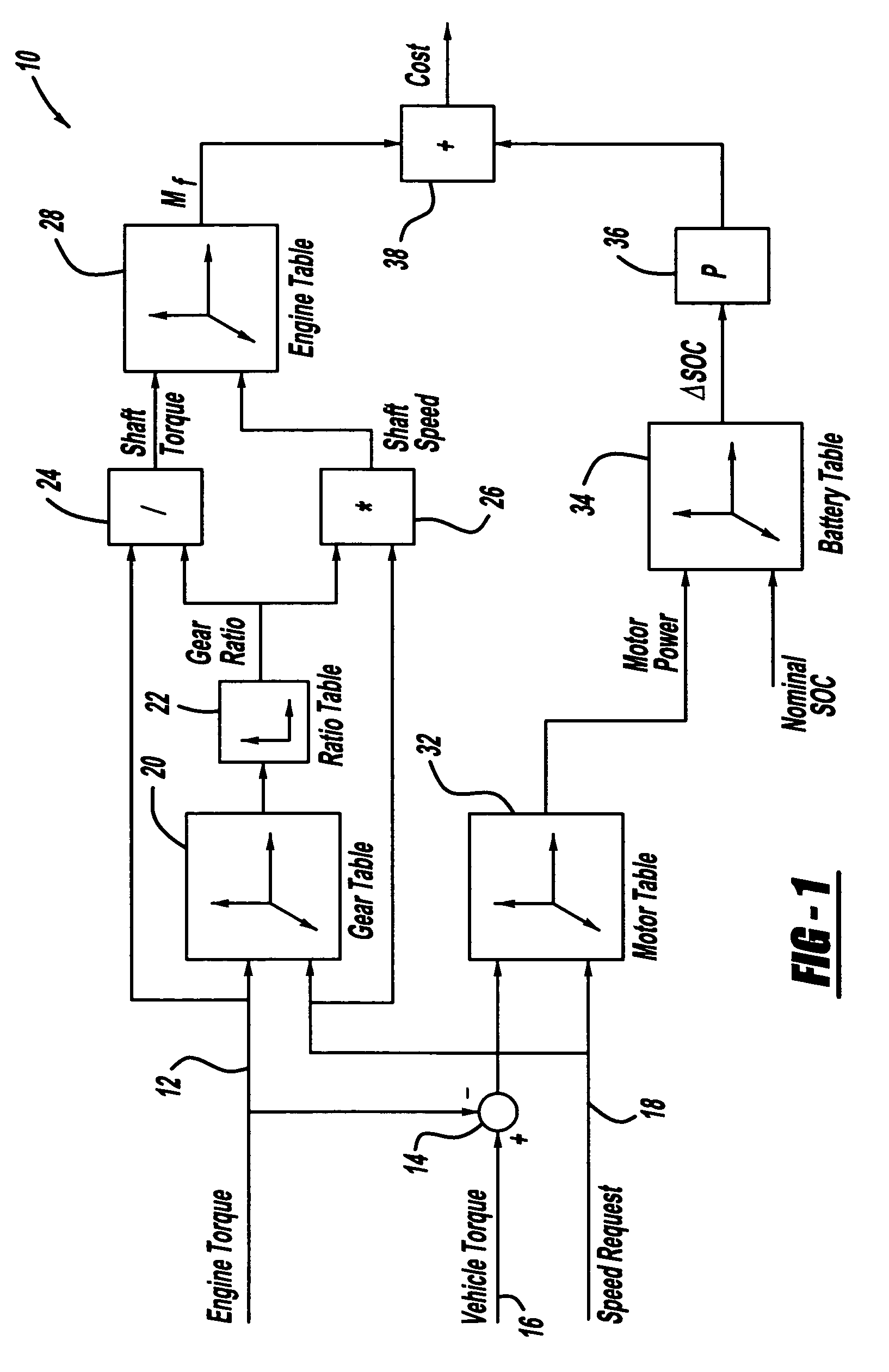

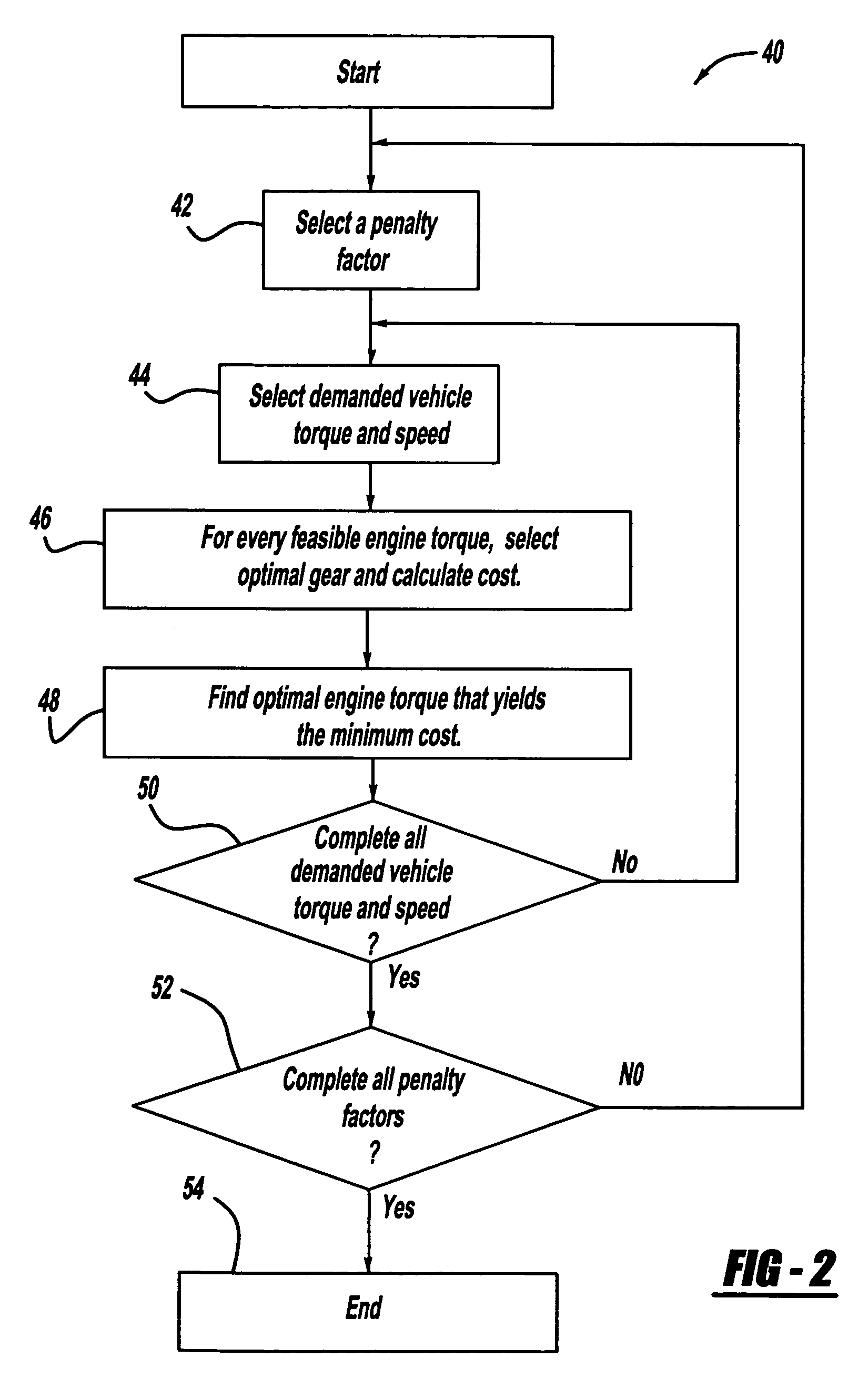

Torque management algorithm for hybrid electric vehicles

InactiveUS20050246076A1Reduce usageHybrid vehiclesAuxillary drivesBattery state of chargeManagement algorithm

A system and method for determining a commanded engine and motor torque to minimize fuel consumption and manage battery state of charge in a hybrid electric vehicle. The method includes determining a penalty factor value that dictates the usage of the battery. A cost value is determined for every feasible engine torque for a selected or demanded vehicle torque and speed request. Each cost value is determined by a fuel consumption value, a change in the battery state of charge and the penalty factor value. The change in the battery state of charge is determined from the motor power and a nominal battery state of charge. For a specific penalty factor, a look-up table for optimal engine torque is generated for different requested vehicle torques at various vehicle speeds. A separate look-up table is provided for each penalty factor.

Owner:GM GLOBAL TECH OPERATIONS LLC

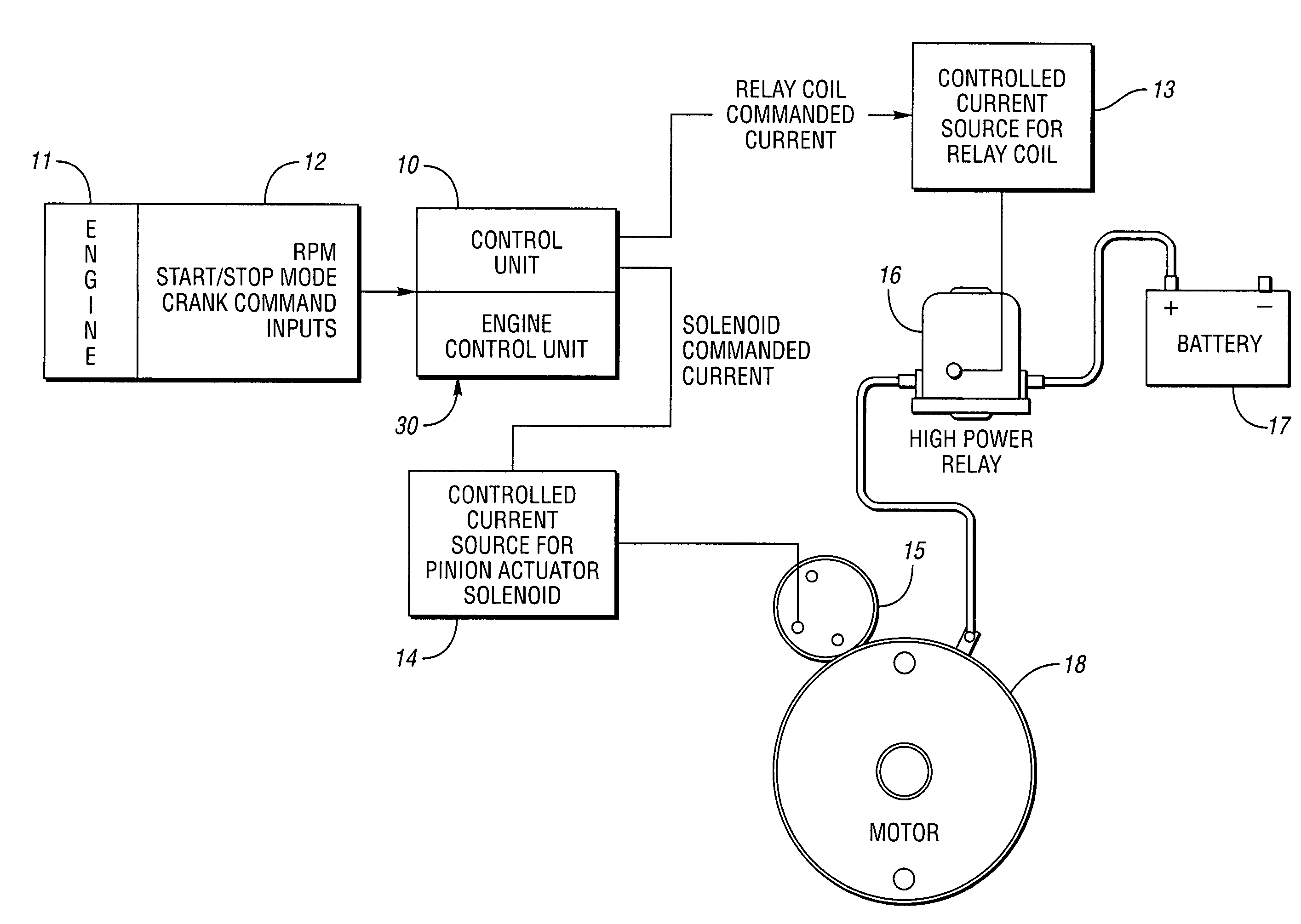

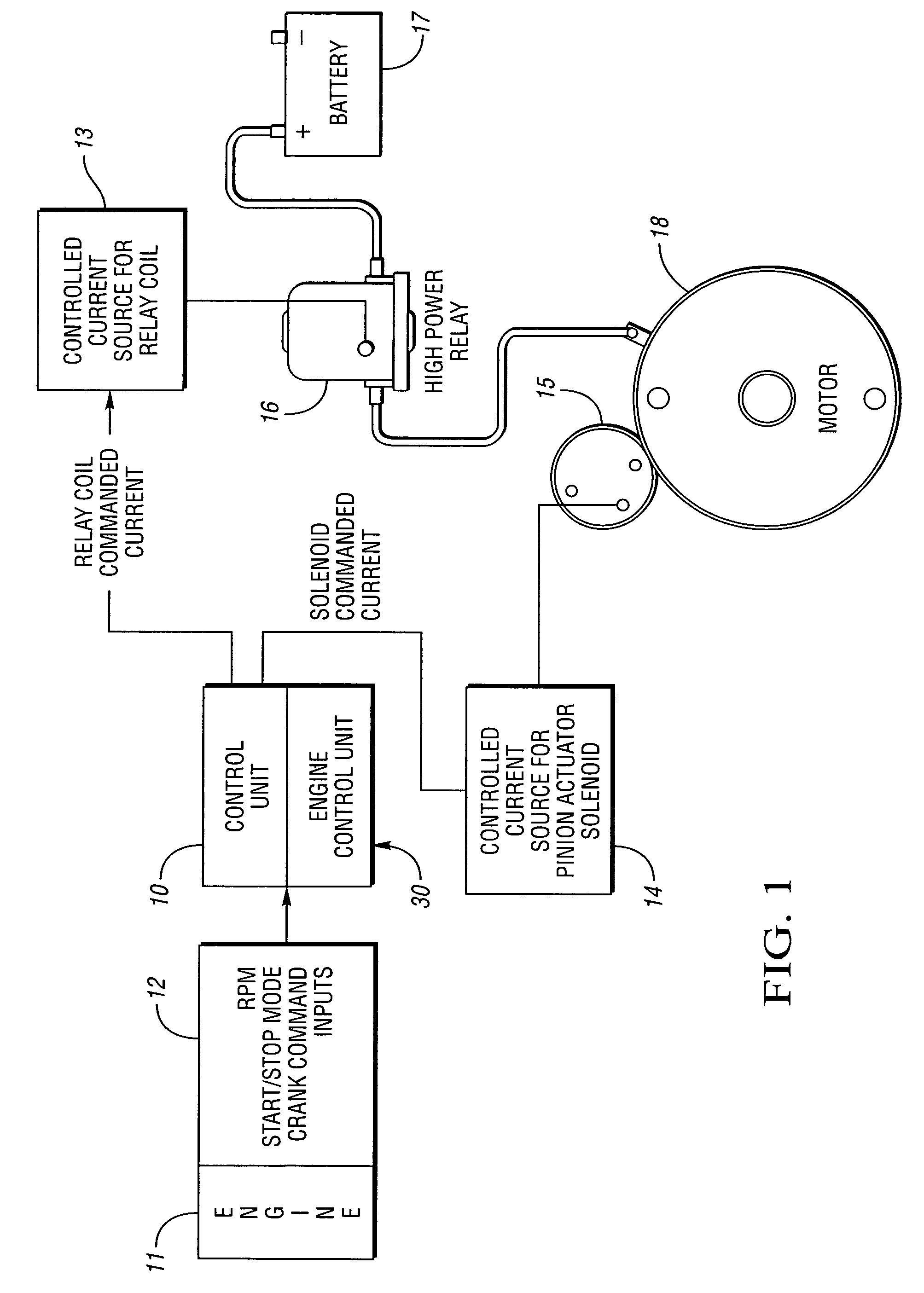

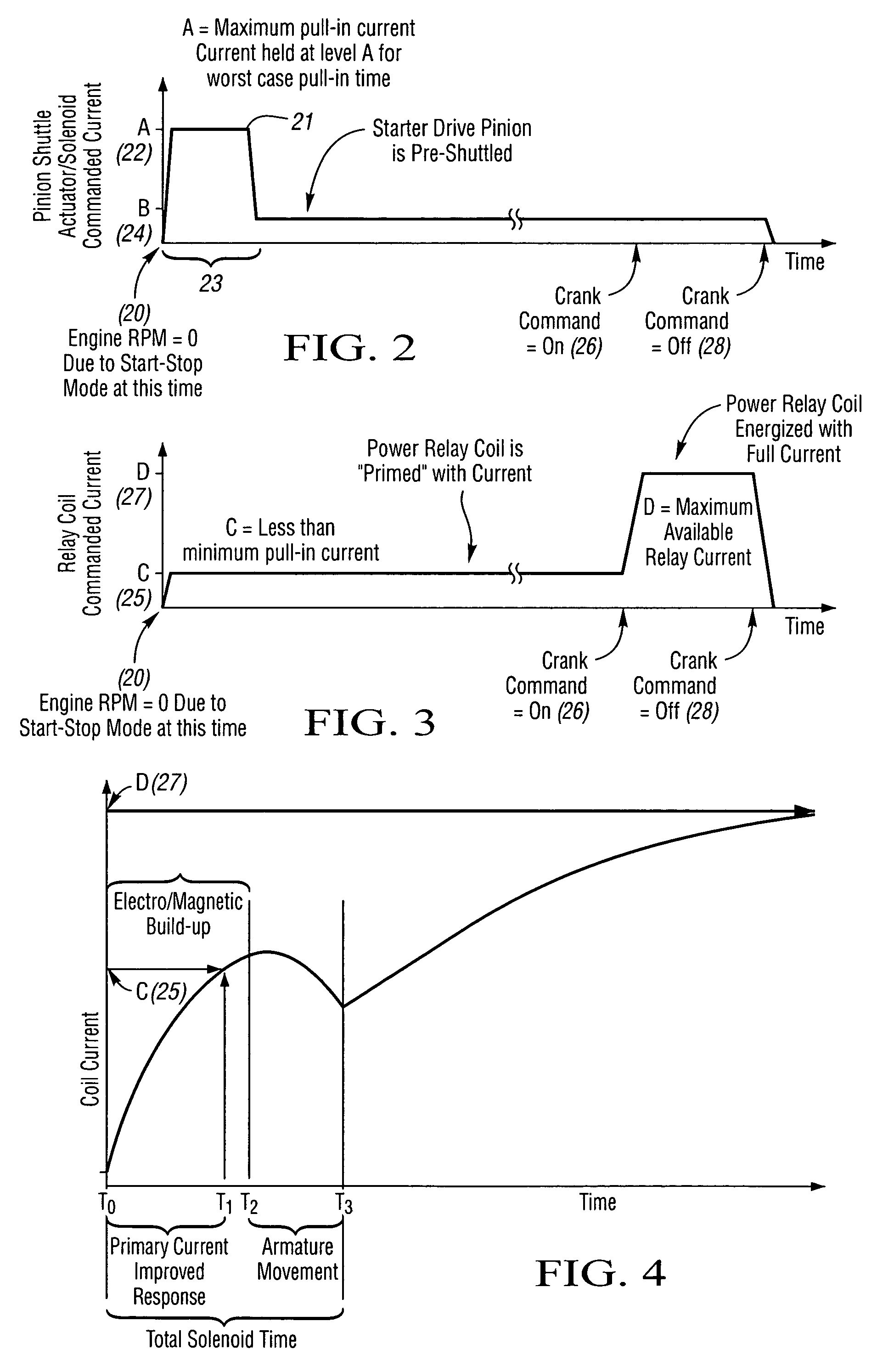

Engine restart apparatus and method

ActiveUS7218010B2Reduce lag timeTotal current dropPower operated startersElectrical controlPower flowStart stop

The present invention relates to a start-stop “mild hybrid” vehicle with a starting system which utilizes traditional engine and transmission architecture. The present invention separates the pinion actuator solenoid from the starter motor power switching circuit. A power relay is provided to switch the starter motor. The pinion gear in the present invention is pre-shuttled to, and held in mesh with, the flywheel ring gear during engine stop conditions. A “prime current” is then applied to the power relay just below that which is required to energize the power relay. Upon request for an engine start, the current will increase to energize the relay and allow the starter motor to spin. A significant amount of time lag is thusly removed from the starting system permitting an expedient restart and launch. The pinion actuator solenoid in this invention may also have two coils which may be selectively energized.

Owner:GM GLOBAL TECH OPERATIONS LLC

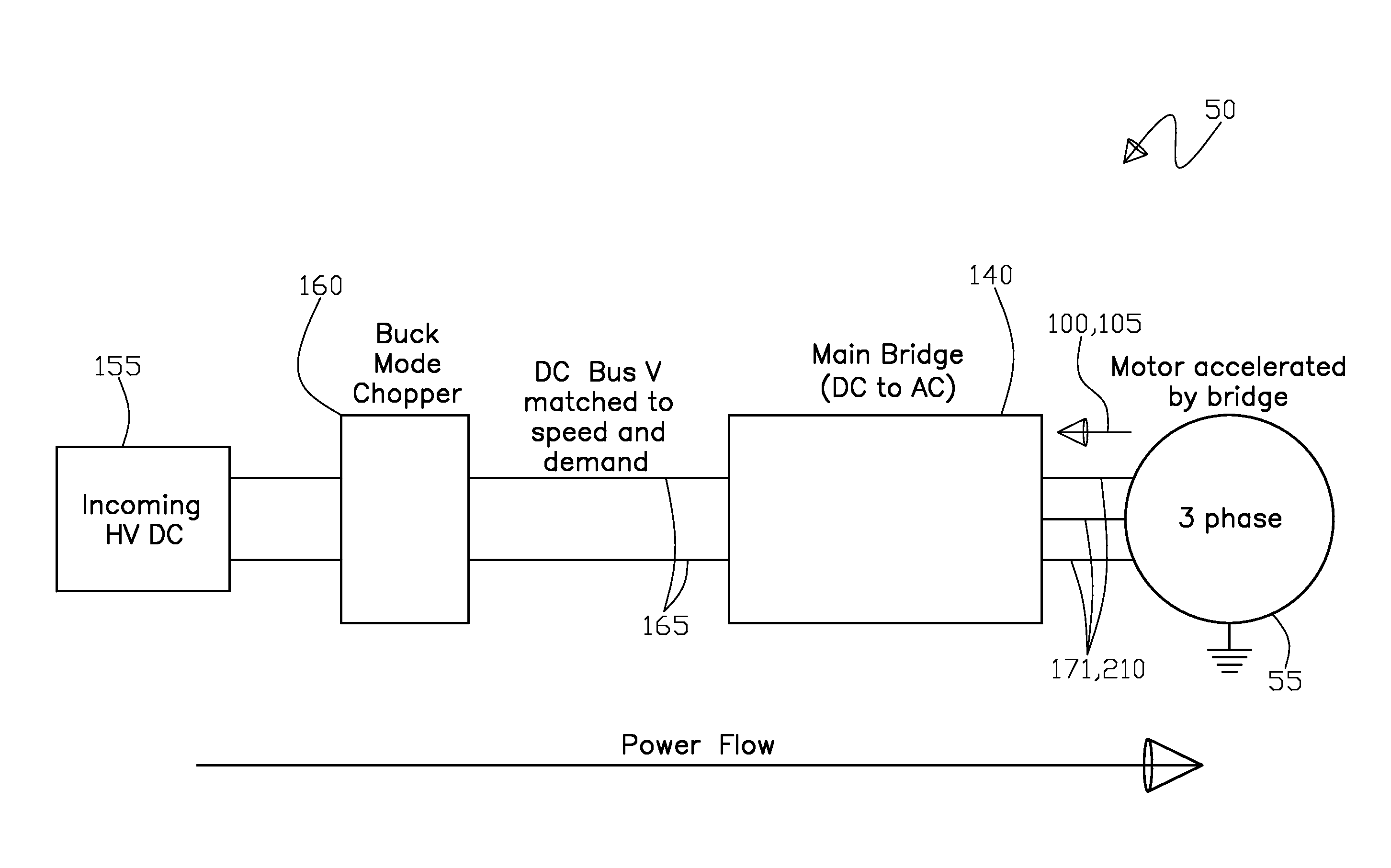

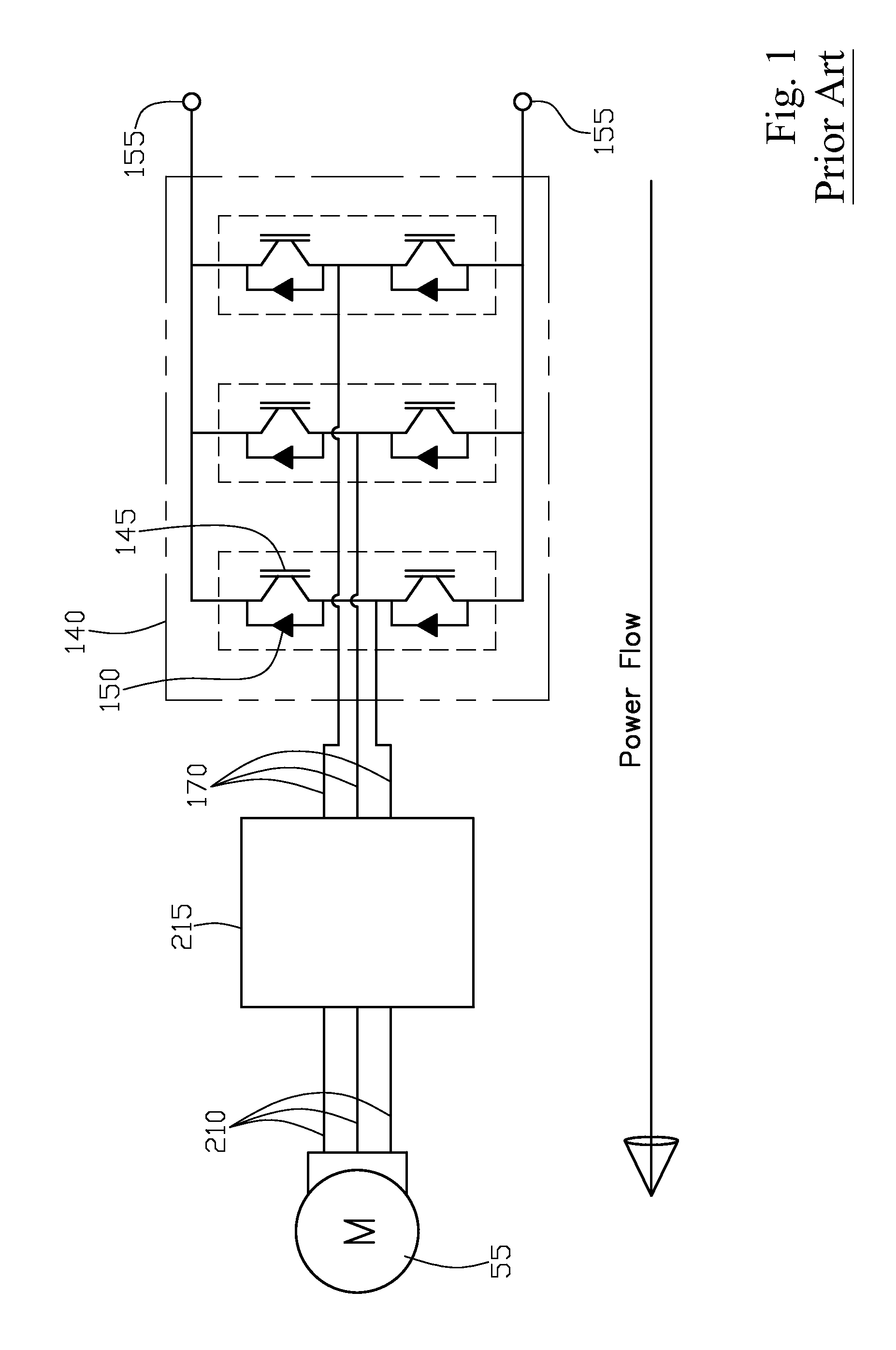

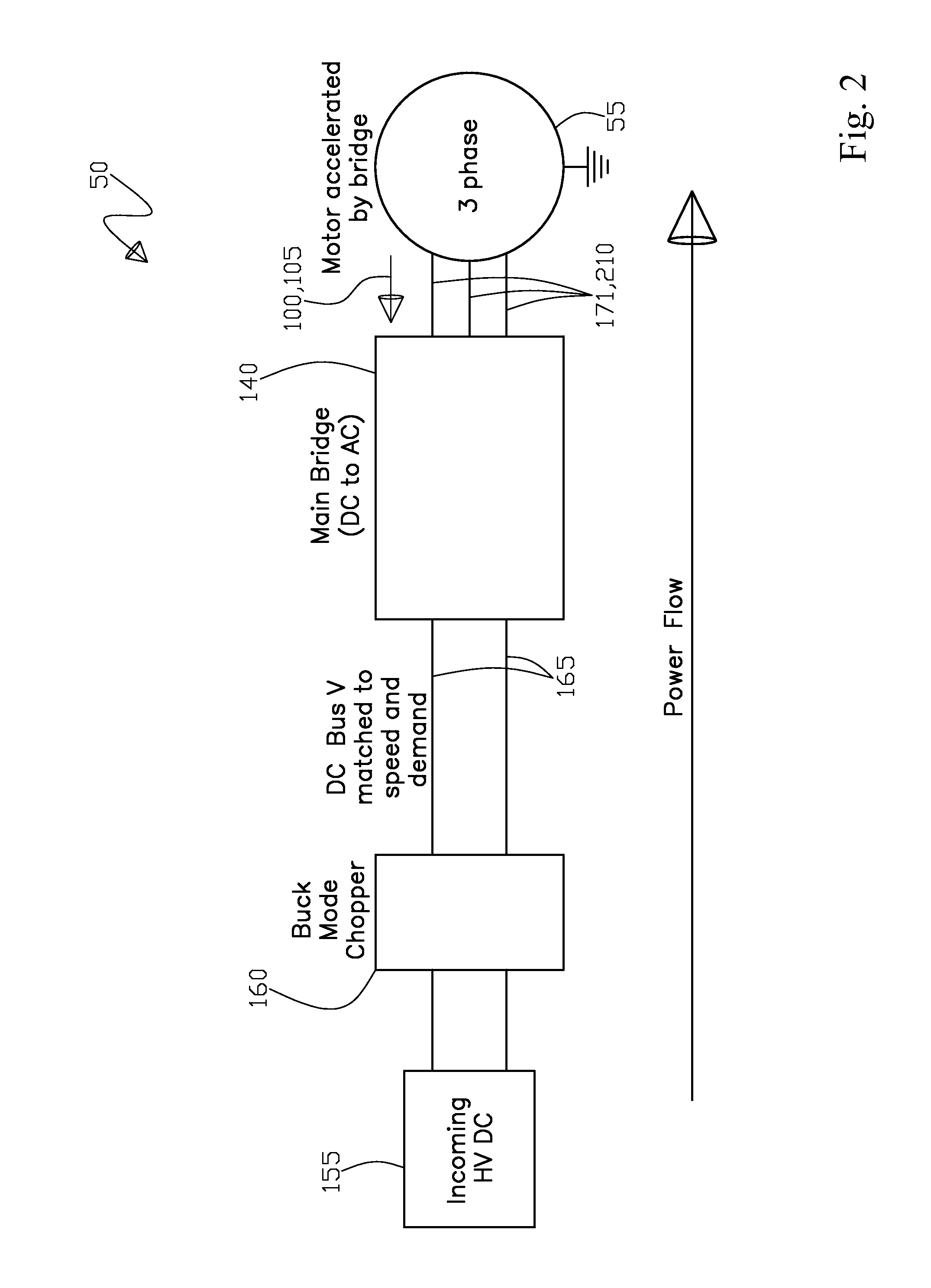

Electrical Control System

ActiveUS20130307450A1Reduce switching frequencyImprove motor efficiencyTorque ripple controlAC motor controlSwitching frequencyAlternating current

An electrical control system having a direct current to direct current regulator receiving a direct current supply input, wherein the regulator outputs a controlled voltage direct current inverter power feed. Included is an inverter in electrical communication with the regulator and receives the controlled voltage direct current inverter power feed, the inverter outputs an alternating current motor power feed to a permanent magnet brushless direct current motor that outputs a shaft rotational speed and a back electromotive force. Also, a control is provided for regulating the controlled voltage direct current inverter power feed based upon criteria utilizing the back electromotive force or an auxiliary motor stator wire loop signal in conjunction with an optional voltage look-up table to substantially make the controlled voltage result in a reduction of a pulse width modulation switching frequency to further smooth and reduce harmonic of the alternating current waveform to increase motor efficiency.

Owner:BARBER NICHOLS

Torque management algorithm for hybrid electric vehicles

A system and method for determining a commanded engine and motor torque to minimize fuel consumption and manage battery state of charge in a hybrid electric vehicle. The method includes determining a penalty factor value that dictates the usage of the battery. A cost value is determined for every feasible engine torque for a selected or demanded vehicle torque and speed request. Each cost value is determined by a fuel consumption value, a change in the battery state of charge and the penalty factor value. The change in the battery state of charge is determined from the motor power and a nominal battery state of charge. For a specific penalty factor, a look-up table for optimal engine torque is generated for different requested vehicle torques at various vehicle speeds. A separate look-up table is provided for each penalty factor.

Owner:GM GLOBAL TECH OPERATIONS LLC

Drive apparatus

InactiveUS7024963B2Minimal heat lossIncrease its rotational inertiaMagnetic circuitGearingElectricityDrive shaft

An apparatus for inducing drive is shown that includes a primary drive shaft and four secondary drive shafts. The primary shaft and secondary shafts are fitted with magnets that are oriented such that when the primary shaft is rotated the secondary shafts are caused to rotate due to attractive or repulsive forces. The primary shaft is connected to and rotated by a rotational energy source such as a motor powered by electricity or a battery, although any source of energy to cause rotation of the primary shaft may be used. Each secondary shaft is fitted with two annular magnetic discs that are oriented to vertically support the weight of the shaft (and any attachments / fittings thereto) above the alternating or generating device. The discs can be arranged to provide either an attractive or repulsive magnetic force between them.

Owner:THE GABRIELLE BAKEY FAMILY TRUST

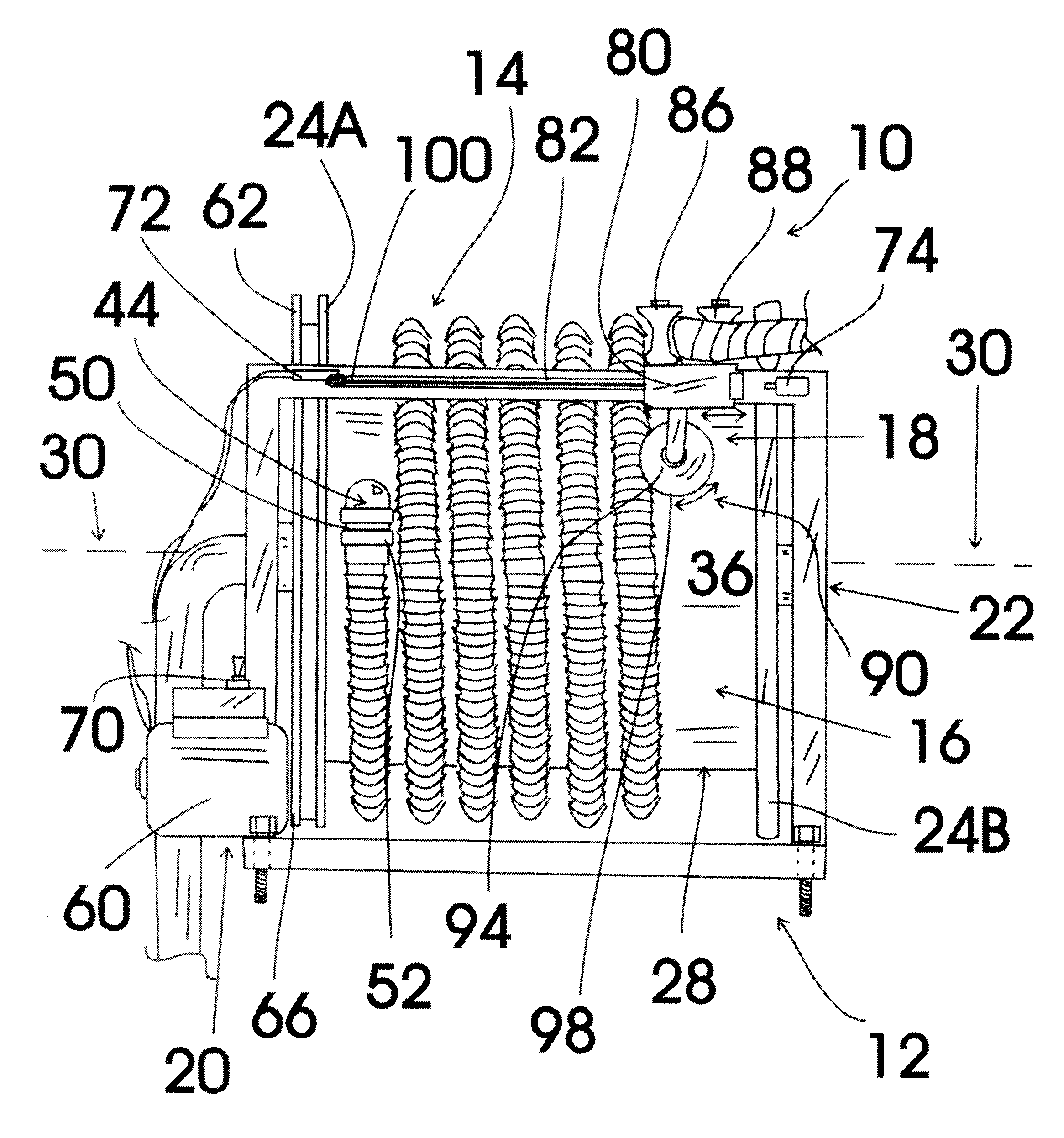

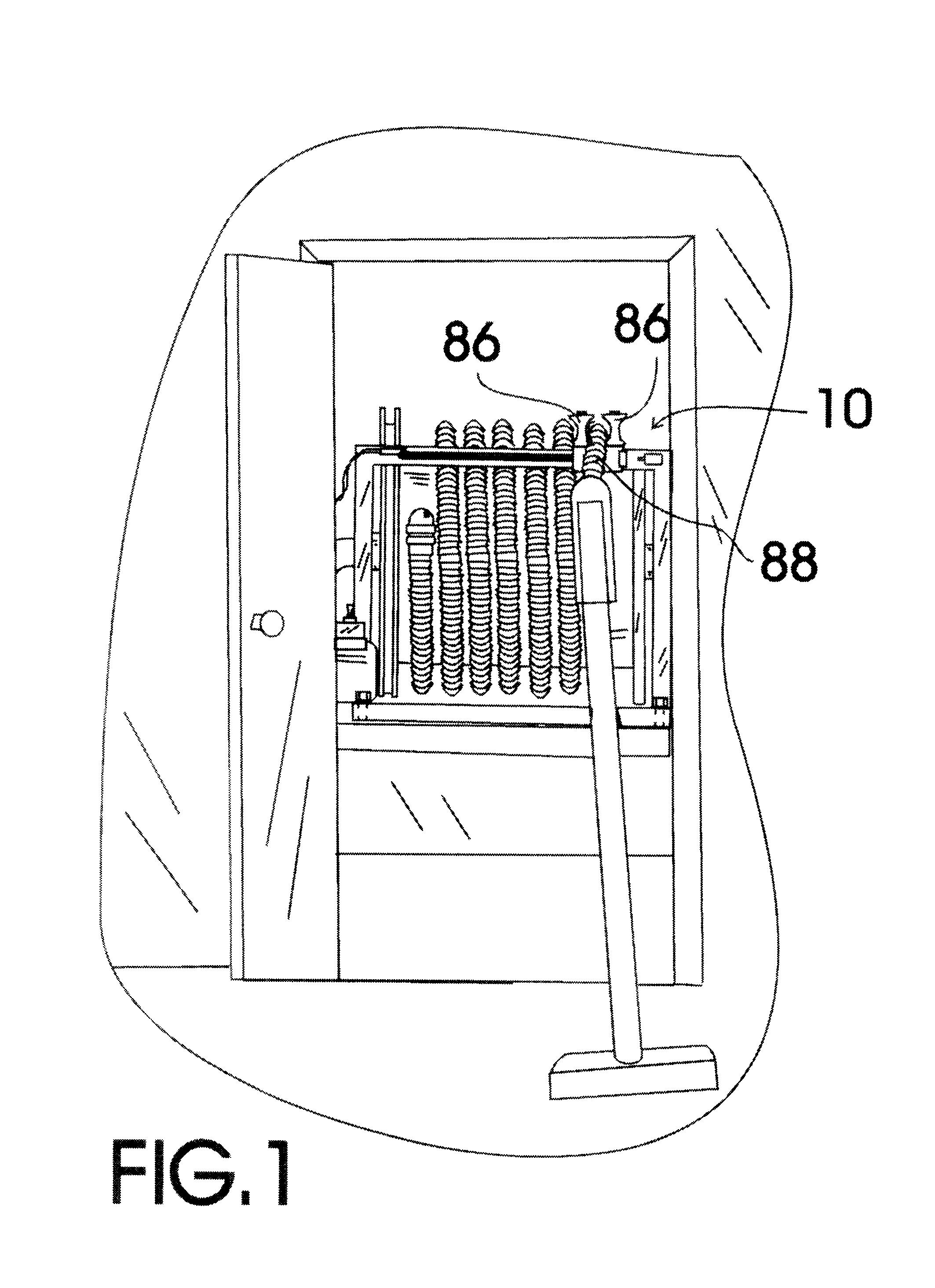

Vacuum hose assembly for a permanently installed building vacuum cleaner system

A vacuum hose assembly for built-in or permanently installed vacuum cleaner systems that includes a motor powered reel assembly for allowing a user to extend and / or retract the flexible vacuum hose as needed and preventing the vacuum hose from becoming entangled while stored between uses. The vacuum hose assembly includes a reel support bracket assembly, a flexible vacuum hose, a motor driven vacuum hose drum reel assembly, a vacuum hose alignment assembly and a drum reel drive motor assembly.

Owner:SETRUM ARTHUR

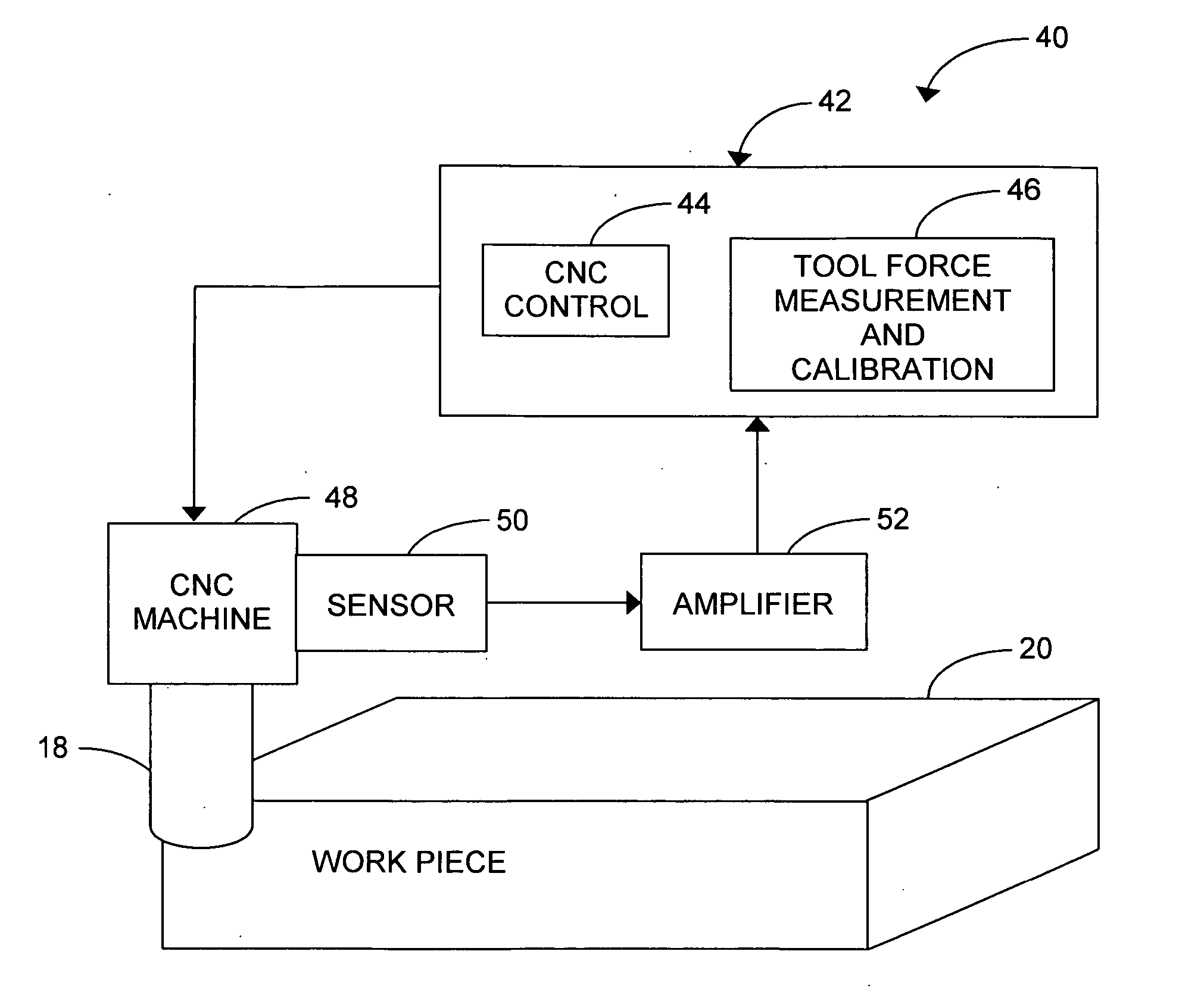

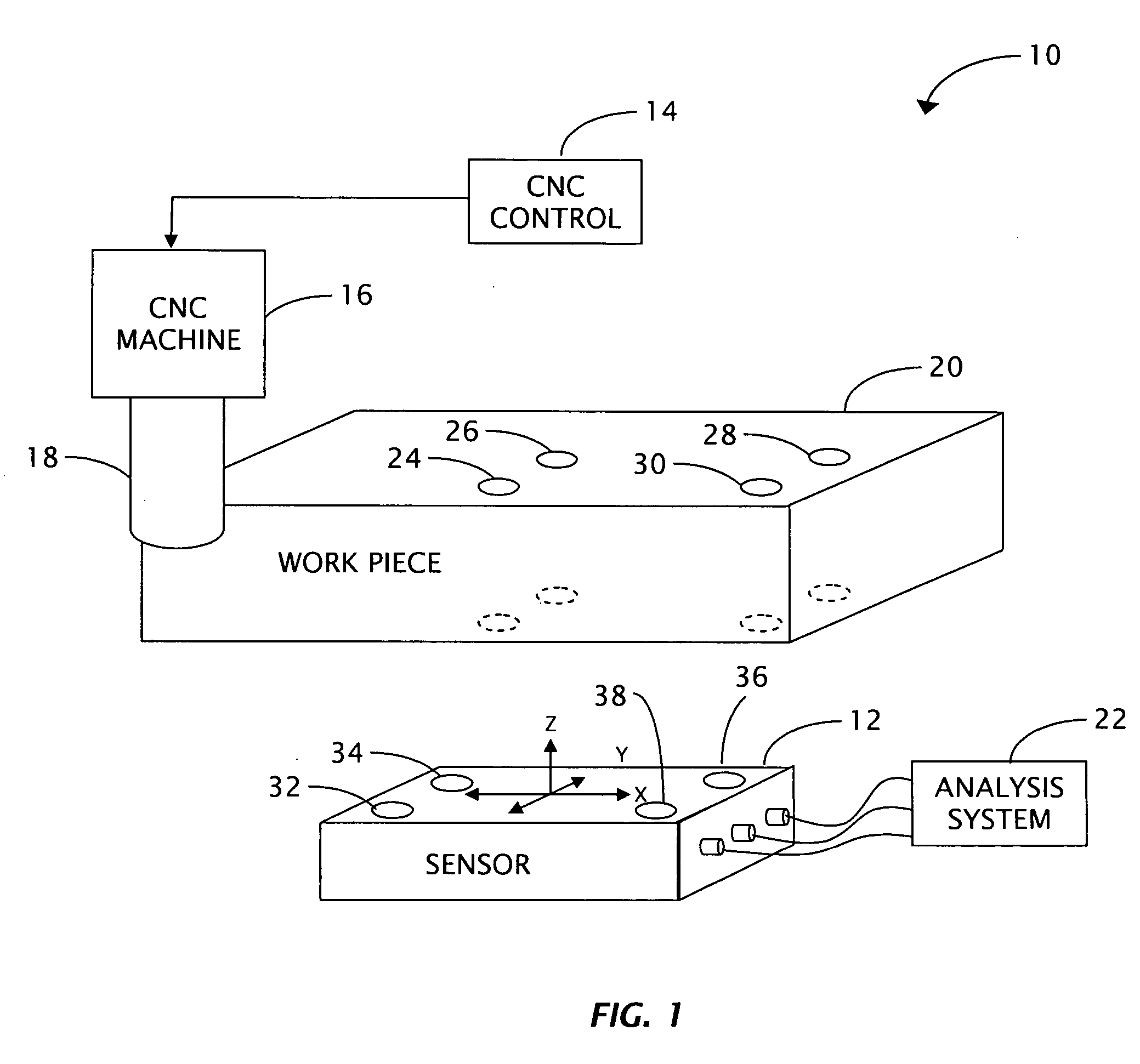

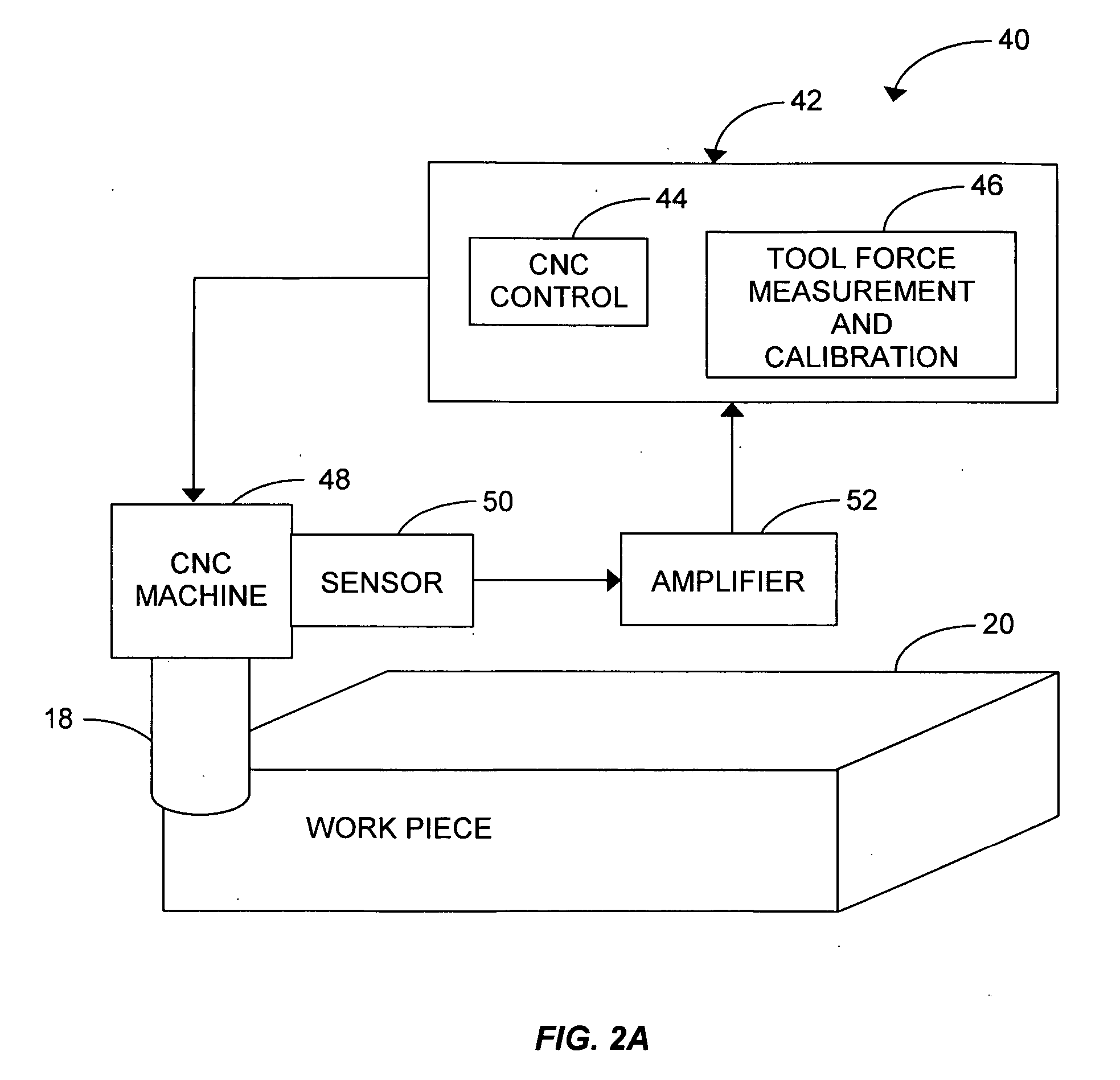

Sensor-based measurement of tool forces and machining process model parameters

InactiveUS20070016325A1Inexpensive but accurate monitoringAddressing Diversity InsufficiencyProgramme controlForce measurementSacrificial partElectric machinery

A system and method are provided for real-time measurement of tool forces. A relationship between a sensor characteristic and tool forces is determined by first directly measuring tool forces for a standard tool, work piece, and part program in a central facility. A force profile indicative of the tool forces and the standard tool, work piece, and part program are provided to a user at a user facility. The sensor characteristic for a CNC machine at the user facility is then measured for the standard tool, work piece, and part program. Based on the force profile determined at the central facility, the relationship between the sensor characteristic and tool forces is determined. Thereafter, the sensor characteristic of the CNC machine is measured for a work piece, part program and desired tool and converted to tool forces using the relationship between the sensor characteristic and tool forces. The resulting tool forces may be combined with a process model to obtain process model parameters or cutting energies for the work piece and the desired tool. In cases where the sensor is not conveniently attached to the work piece or when the part program is not sufficiently robust in cutting conditions to accurately determine the process model parameters, the work piece and part program are replaced by a sacrificial work piece and sacrificial part program. The sacrificial work piece and sacrificial part program are selected to both accommodate the sensors and to provide sufficient robustness in cutting conditions to accurately determine the process model parameters for the sacrificial work piece. The process model parameters for the desired work piece are obtained from the process model parameters by, first, obtaining the averaged tangential tool forces for the desired work piece and for the sacrificial work piece by measuring the spindle motor power and applying the relationship between spindle motor power and tangential tool forces for each work piece, second, obtaining a ratio of the averaged tangential tool forces for the desired work piece and the sacrificial work piece and, third, applying this ratio to the process model parameters for the sacrificial work piece to obtain predicted values for the tool forces and the process model parameters for the desired tool and desired work piece.

Owner:UNIVERSITY OF NEW HAMPSHIRE

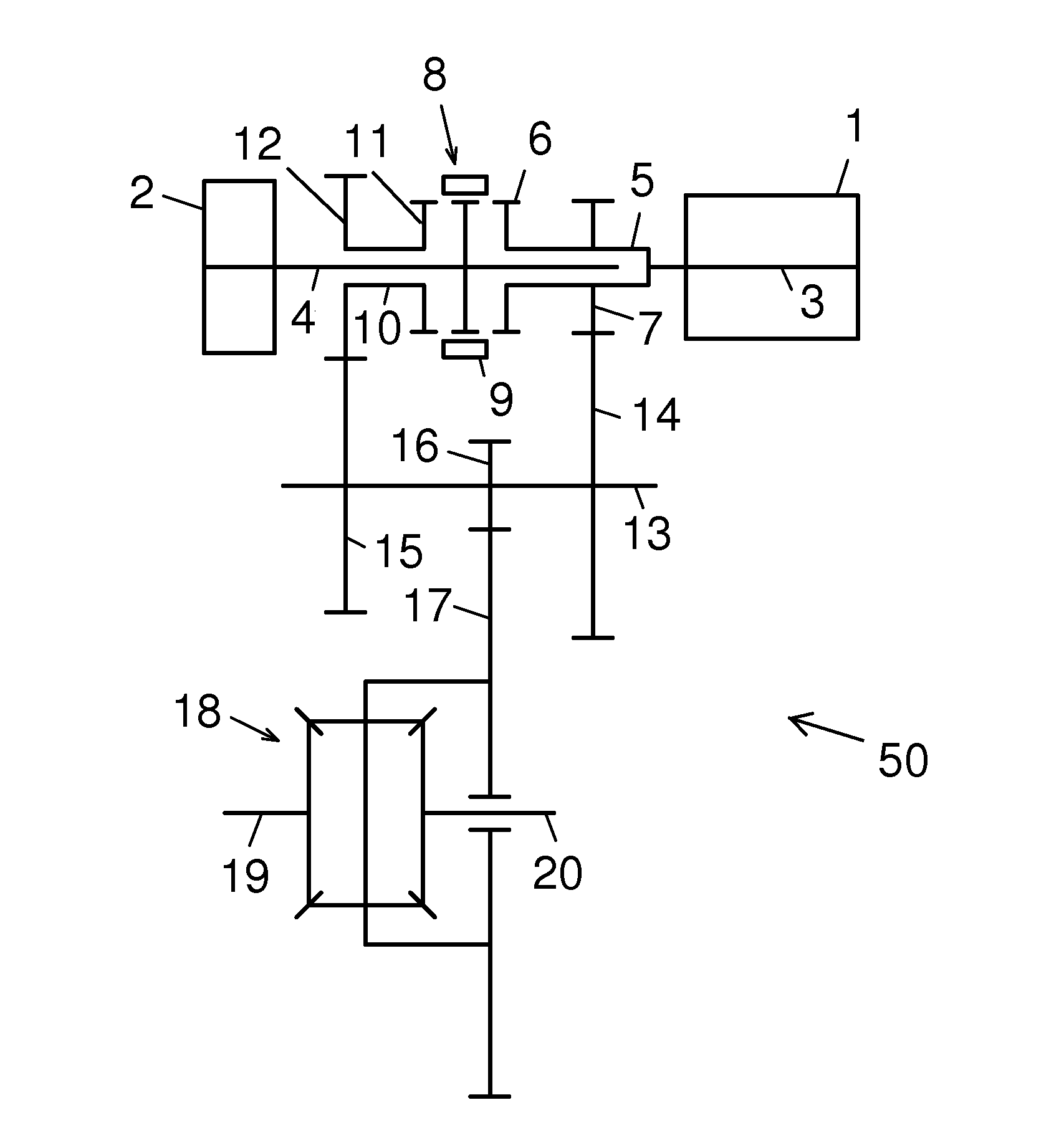

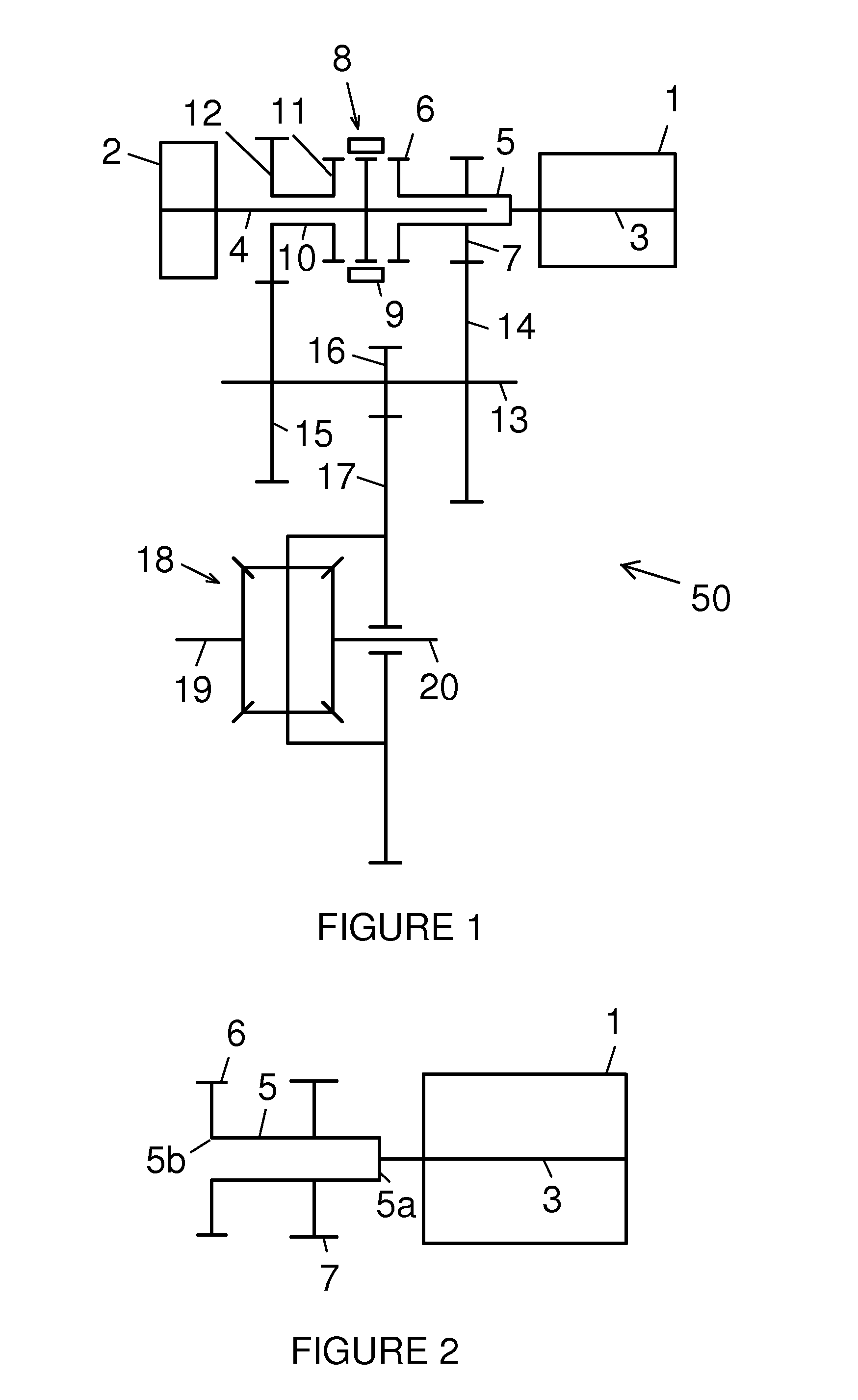

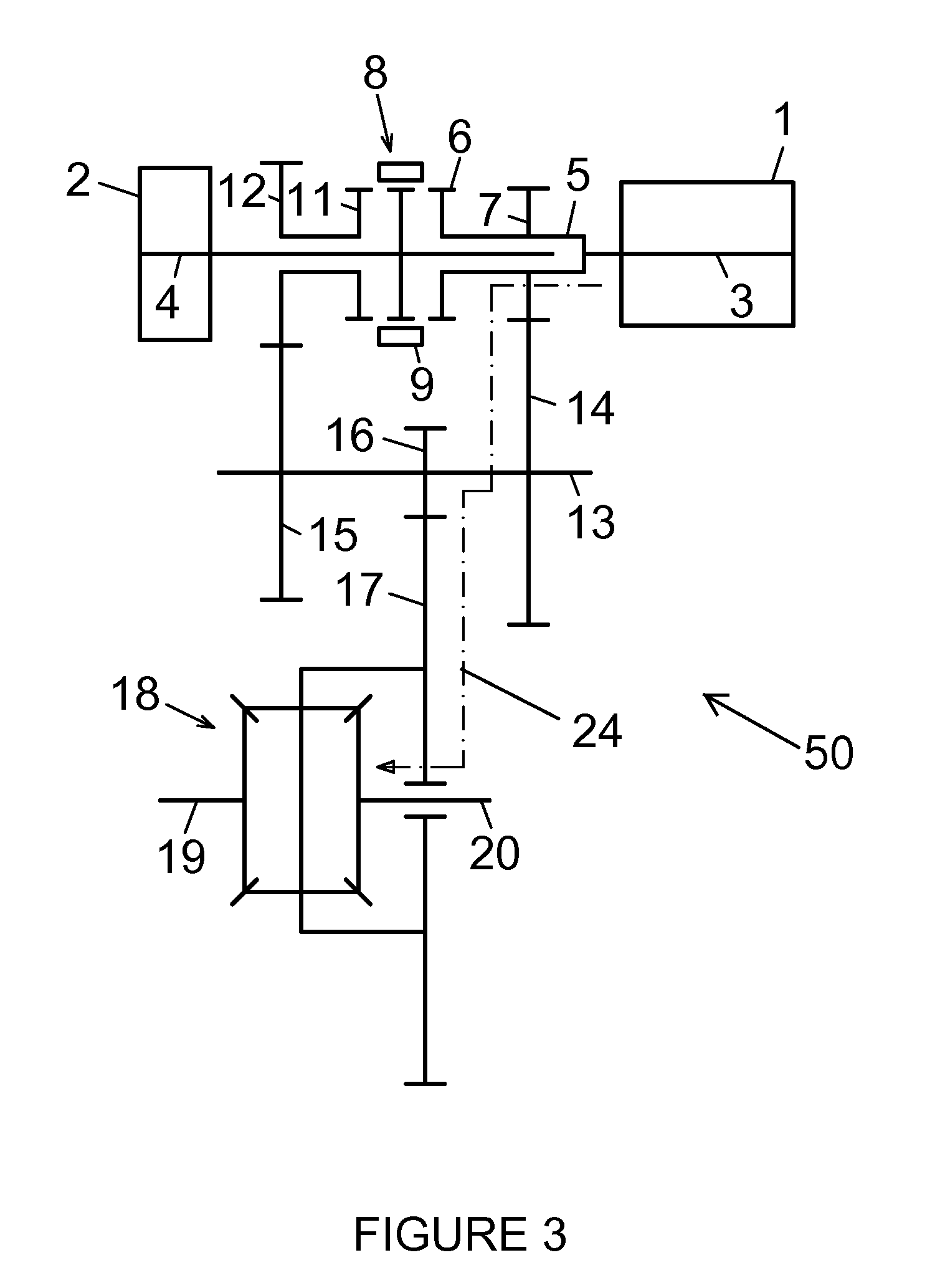

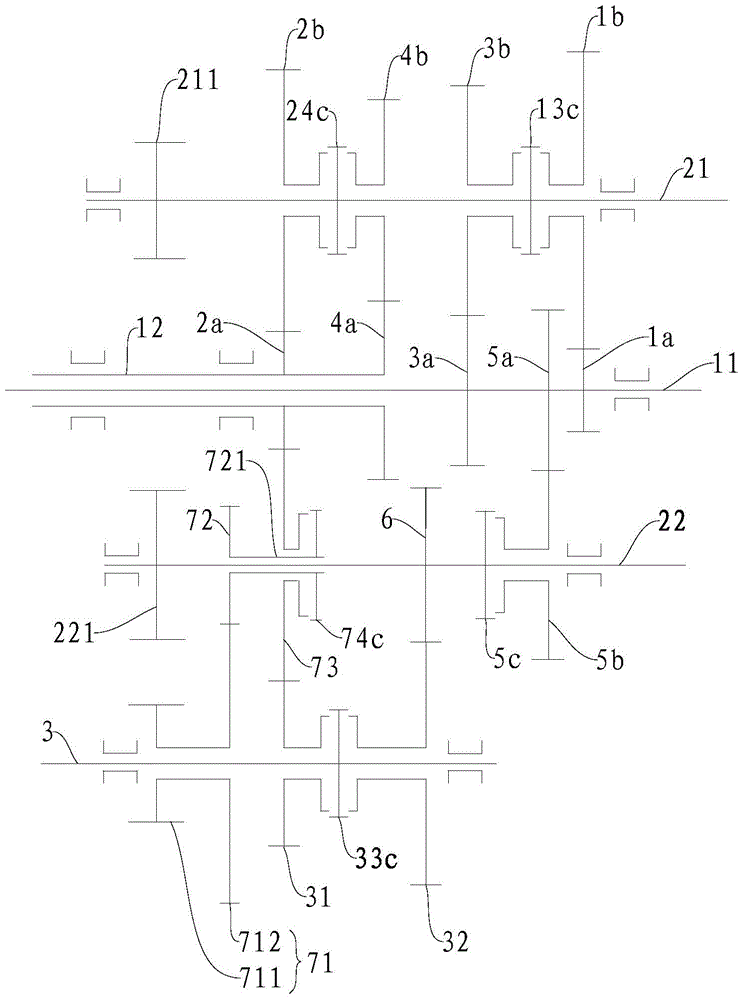

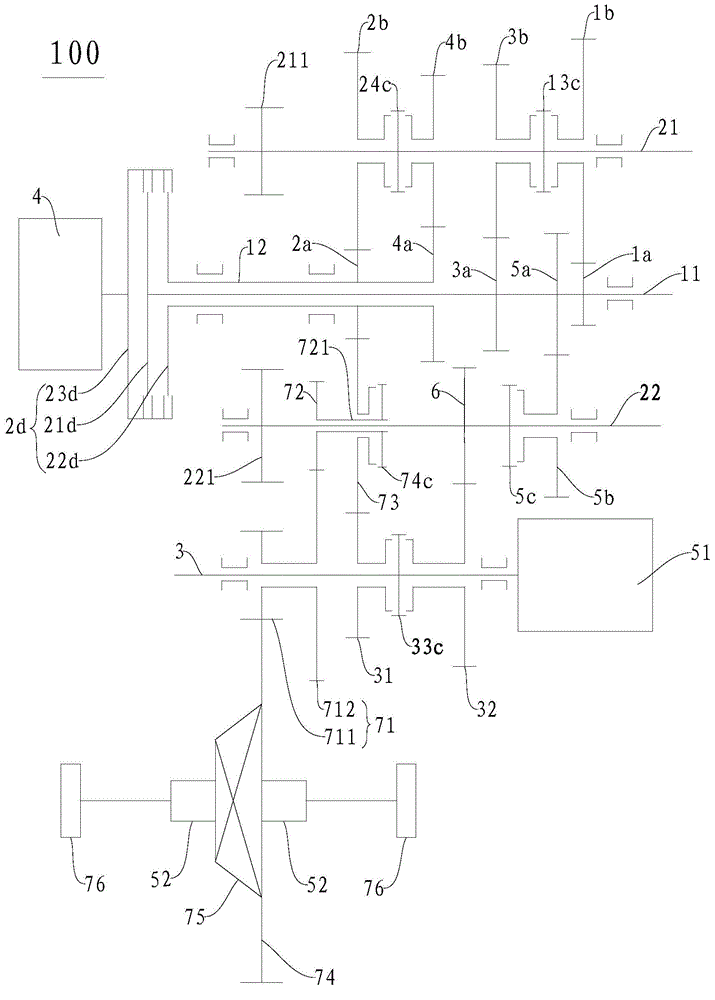

Dual-motor power system and dual-motor hybrid power system for vehicle

ActiveUS20160137045A1Low costSmall sizeHybrid vehiclesElectric propulsion mountingDrive shaftEngineering

A dual-motor power system or a dual-motor hybrid power system for a vehicle comprises a first motor, a second motor, an intermediate shaft, a first gear set disposed between a first driving shaft, and an intermediate shaft. The first driving shaft couples with the intermediate shaft via the first gear set, a second gear set disposed between the second driving shaft and the intermediate shaft, and a single synchronizer disposed around the second driving shaft. The synchronizer can be switched between a neutral position, a first-speed-ratio position, and a second-speed-ratio position. In the neutral position, the second driving shaft is decoupled from the first and second gear sets. In the first-speed-ratio position, the synchronizer couples the second driving shaft with the intermediate shaft via the first gear set. In the second-speed-ratio position, the synchronizer couples the second driving shaft with the intermediate shaft via the second gear set.

Owner:SAIC MOTOR

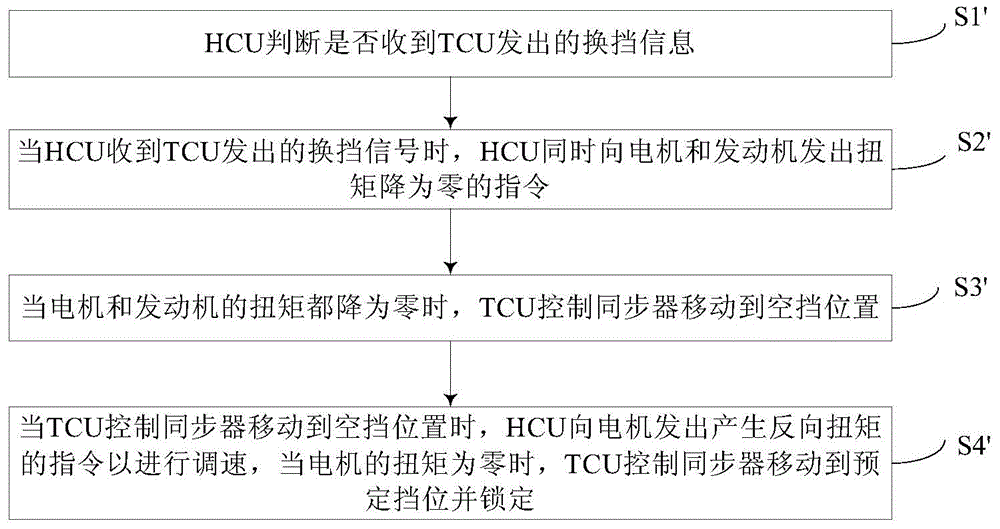

Gear-shifting control method for electric automobile and motor speed adjusting method based on gear-shifting

ActiveCN104608769ADecrease the speed adjustment timeImprove riding performanceHybrid vehiclesSpeed controllerMotor speedElectric machine

The invention discloses a gear-shifting control method for an electric automobile. The gear-shifting control method comprises the following steps: S11, wherein when a request gear released by a motor controller is consistent with a target gear released by a drive control unit, an electrical generator is controlled to conduct a first torque unloading; S12, wherein when the unloading is completed, the drive control unit controls a motor power shaft synchronizer to disconnect, and when the electrical generator is at neutral position, the motor controller calculates the target shift revolving speed of the electric generator and controls the electrical generator to conduct the torque loading, and when the revolving speed reaches a preset motor speed range, the motor controller controls the electric generator to conduct a second torque unloading; S13, wherein when the unloading is completed, the drive control unit controls the motor power shaft synchronizer to initiate combination; S14, wherein the motor controller judges the current gear of the electric generator released by the drive control unit is the request gear and confirms successes of the electrical generator gear-shifting. By means of the gear-shifting control method for the electric automobile, evenness and comfort of the finished automobile can be improved. The invention further discloses a motor speed adjusting method of an electrical automobile.

Owner:BYD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com