Maximum power point motor control

a power point motor and maximum power technology, applied in the direction of electric variable regulation, process and machine control, instruments, etc., can solve the problems of damage to the motor, difficult to meet the power requirements of the load, and difficult to efficiently operate the ac pump from a solar array

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

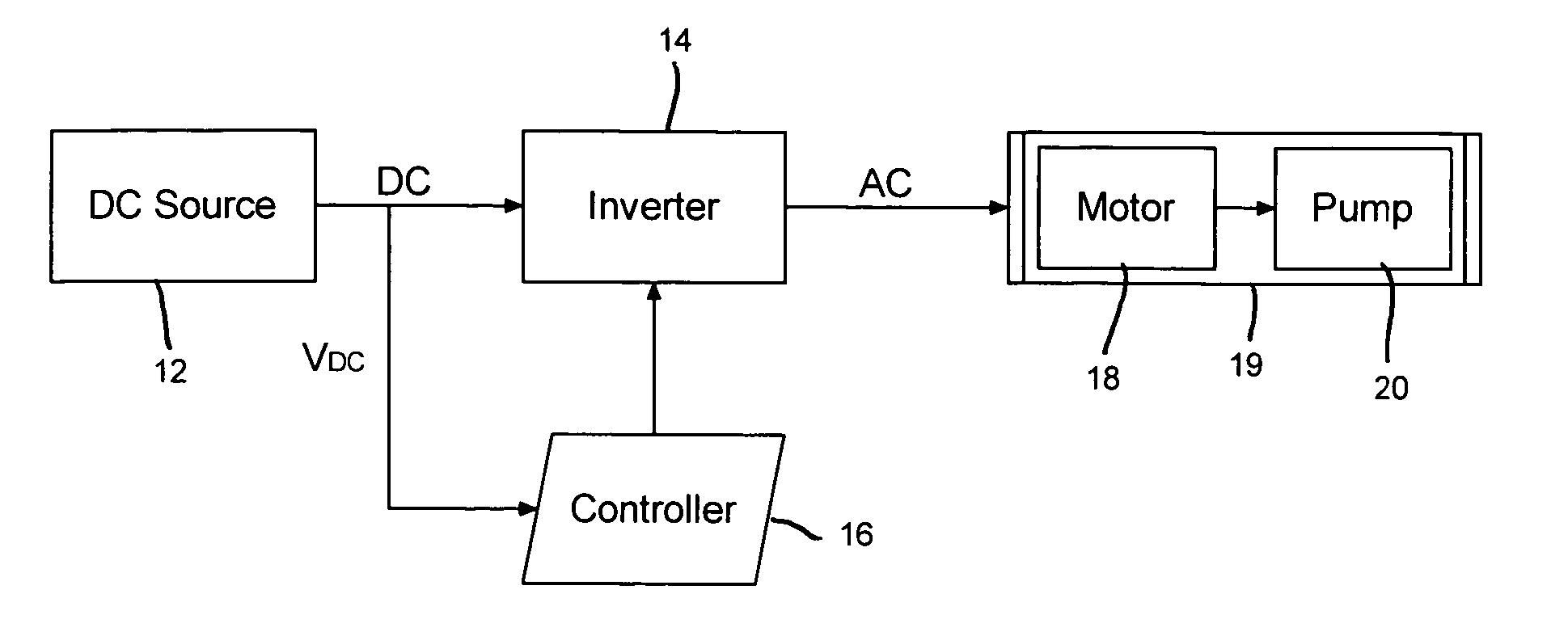

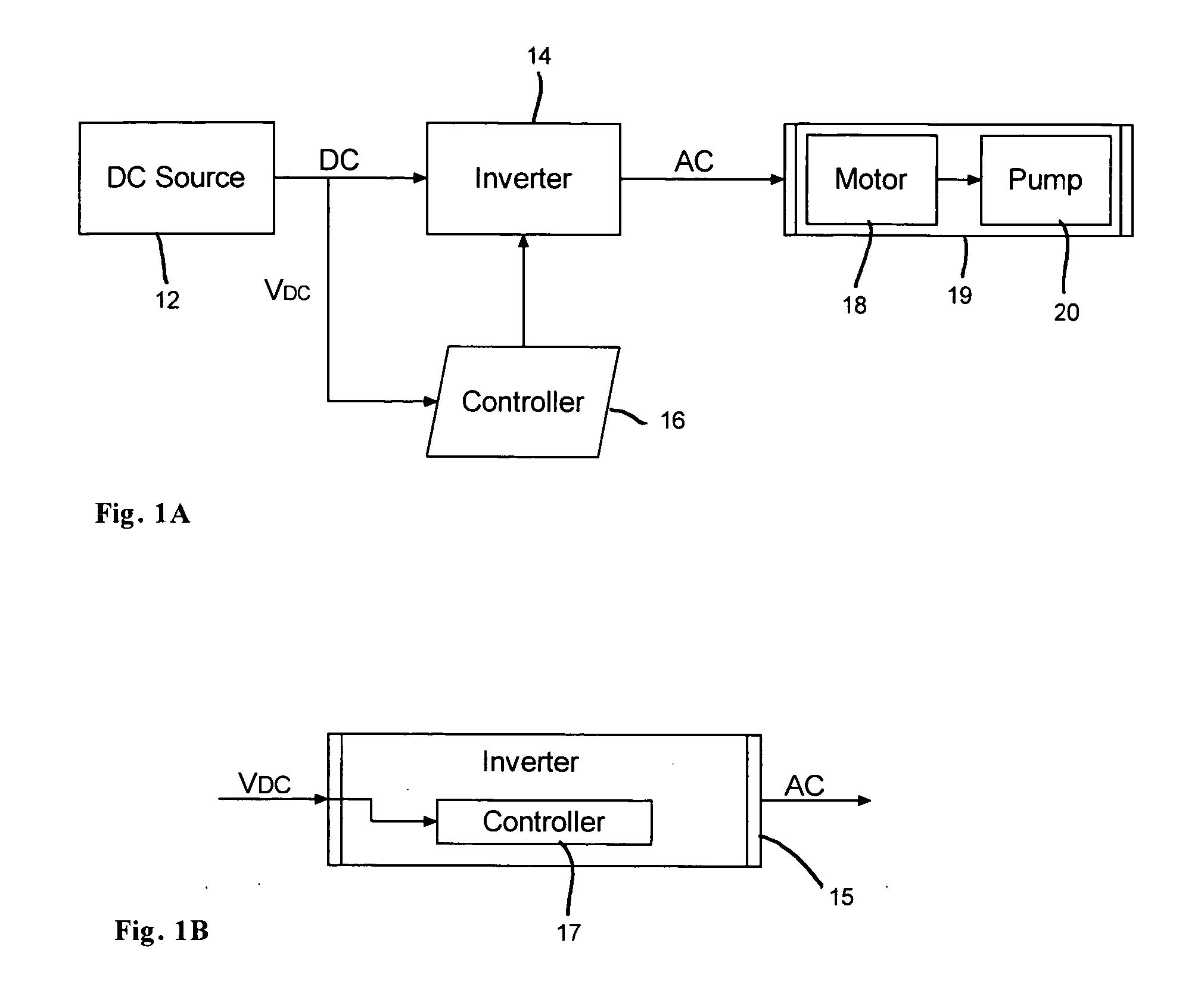

[0025] As shown in FIG. 1A, a DC source—software controlled inverter—AC motor system 10 according to the invention comprises a DC source 12, an inverter 14 connected to the DC source 12, a programmed controller 16 connected to the inverter 14, and an AC motor 18 connected to the inverter 14. DC source 12 is preferably a solar array made up of conventional silicon solar cells or panels, but may be another type of DC source. The DC source will generally be a source whose output voltage and power vary. The AC motor is typically a three phase motor, and may drive a water pump 20 (or other device), which may be combined with motor 18 into a single integral unit 19. The invention may also be applied to other loads that have load characteristics similar to motor 18.

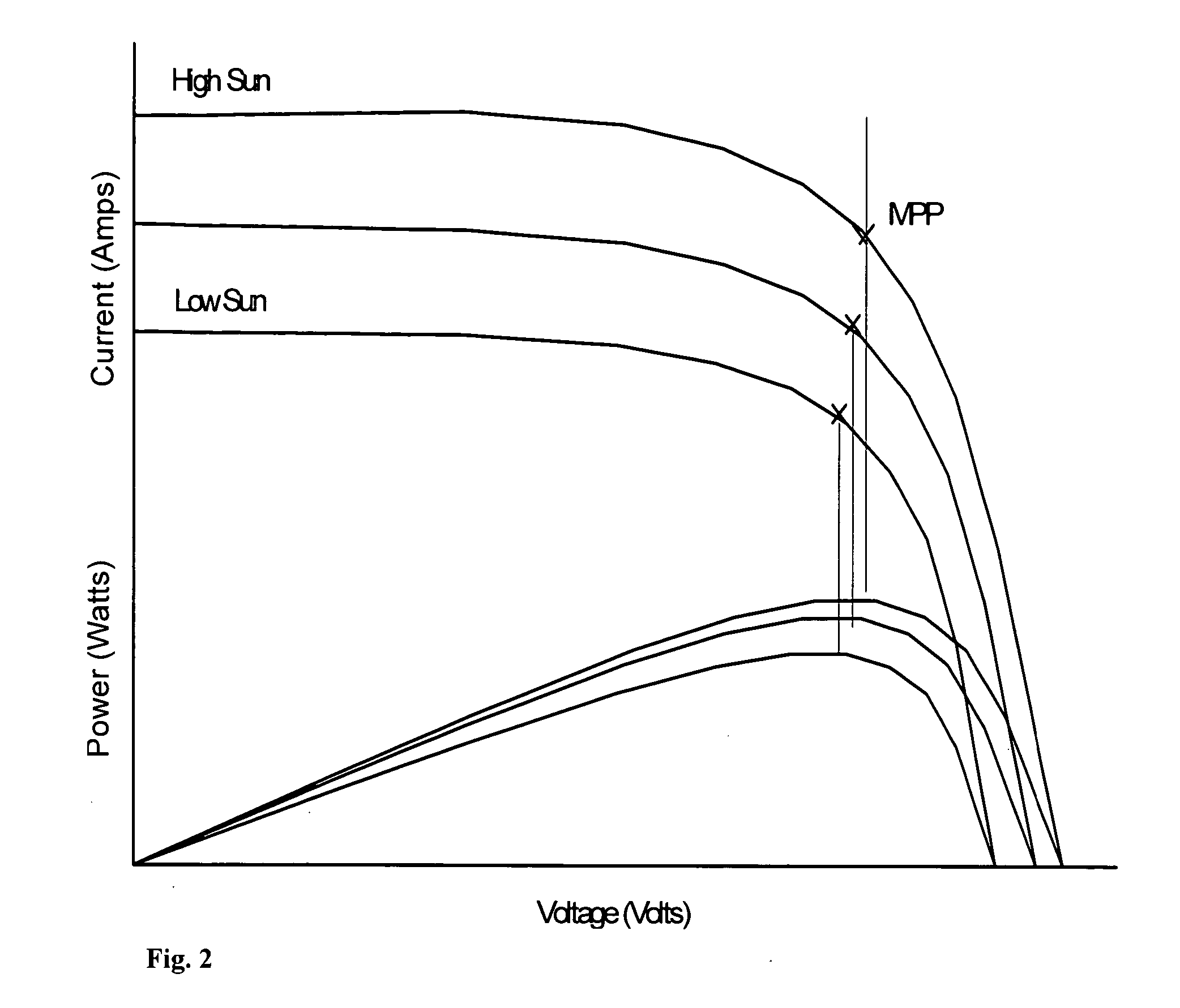

[0026] Inverter 14 is a conventional DC to AC converter, also commonly known as a motor drive or variable speed drive (VFD). Controller 16 is programmed to carry out an algorithm which produces maximum power point tracking by v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com