Air compressor with variable speed motor

a variable-speed motor and air compressor technology, applied in the direction of motor parameters, piston pumps, pump control, etc., can solve the problems of confusing the existence of both the tank pressure and line pressure gauges for a new user, confusing the variable knob and fixed rate spring, and difficulty in adjusting to a desired output pressur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In the following description, various embodiments of the present invention will be described. For purposes of explanation, specific configurations and details are set forth in order to provide a thorough understanding of the embodiments. However, it will also be apparent to one skilled in the art that the present invention may be practiced without the specific details. Furthermore, well-known features may be omitted or simplified in order not to obscure the embodiment being described.

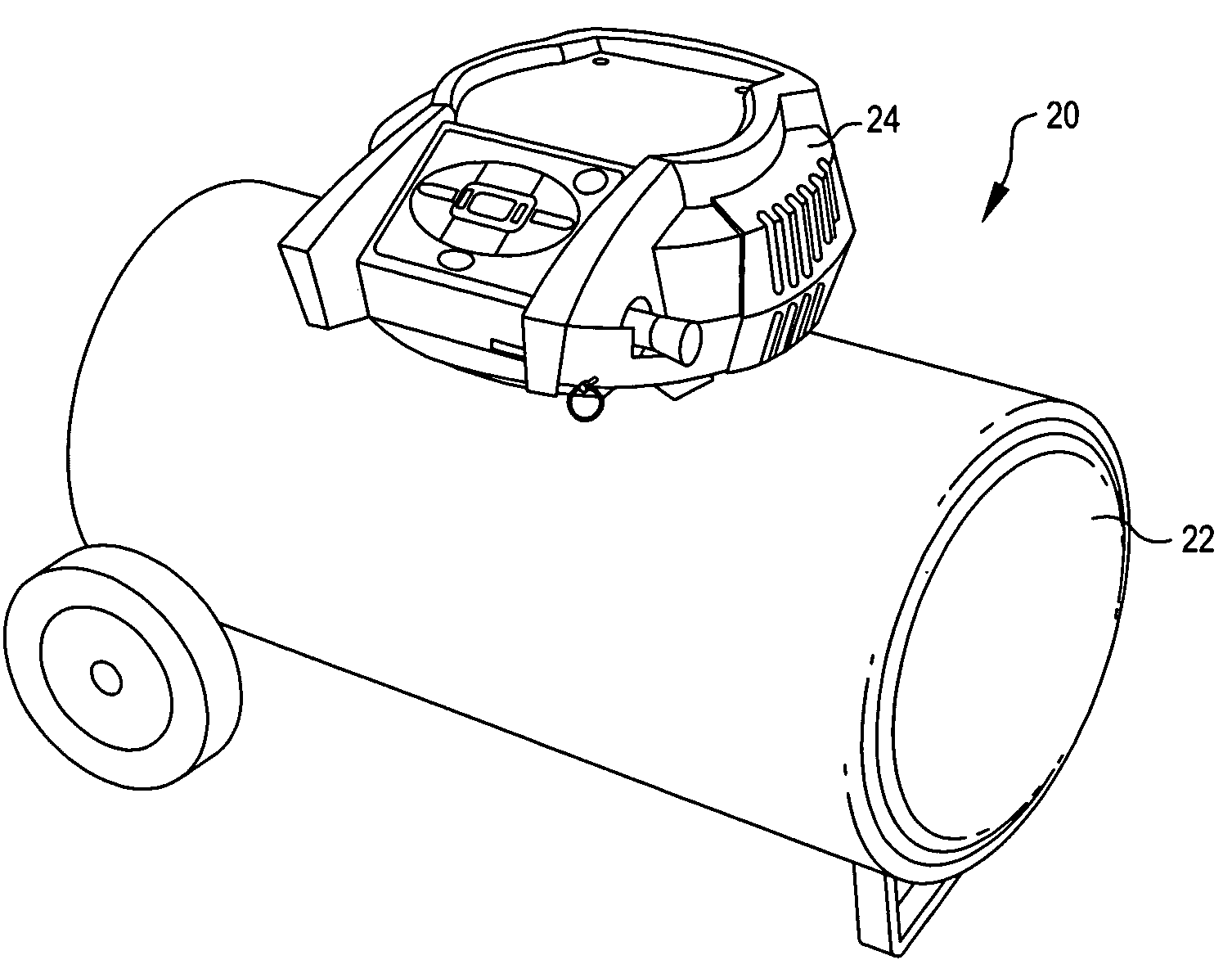

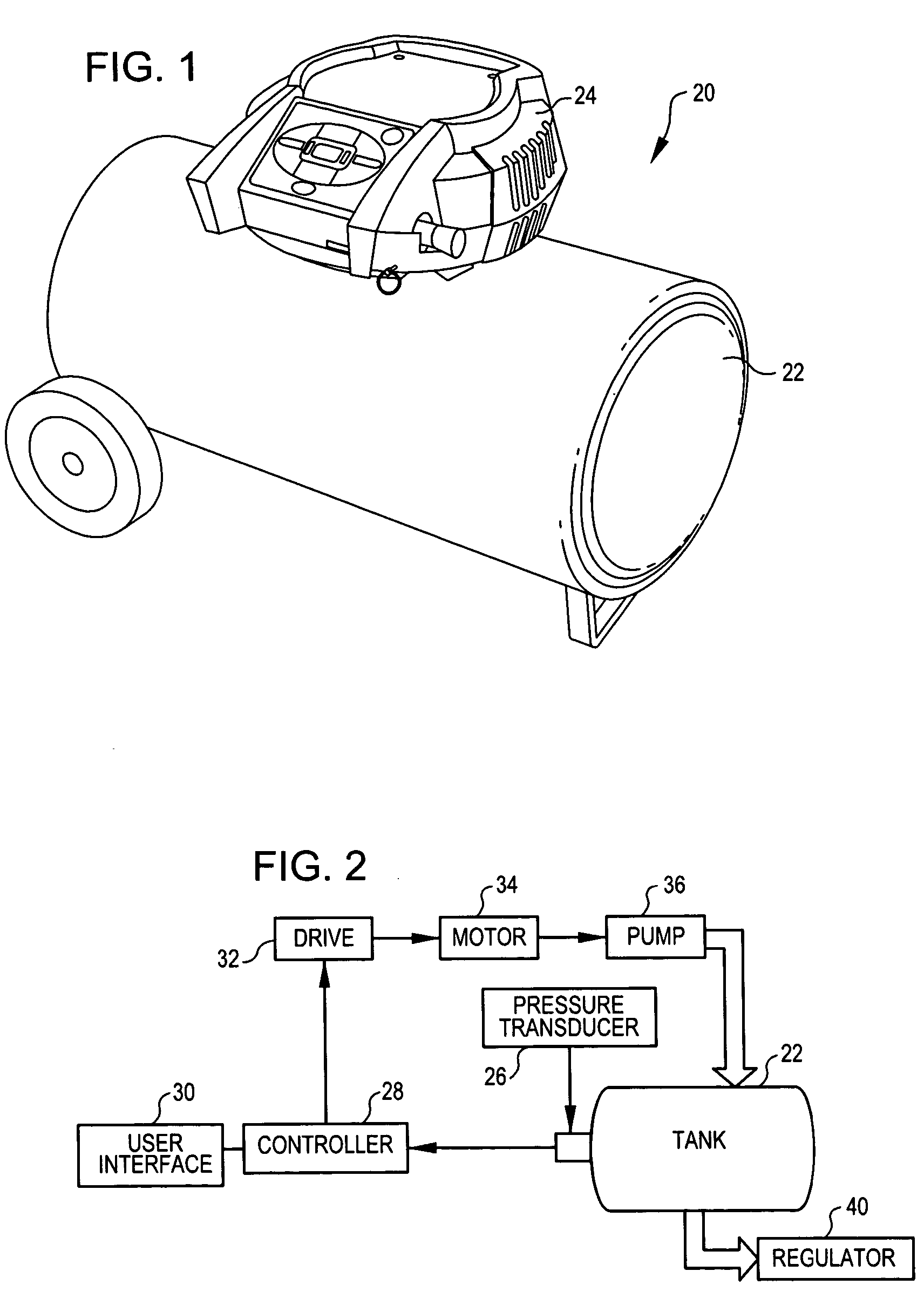

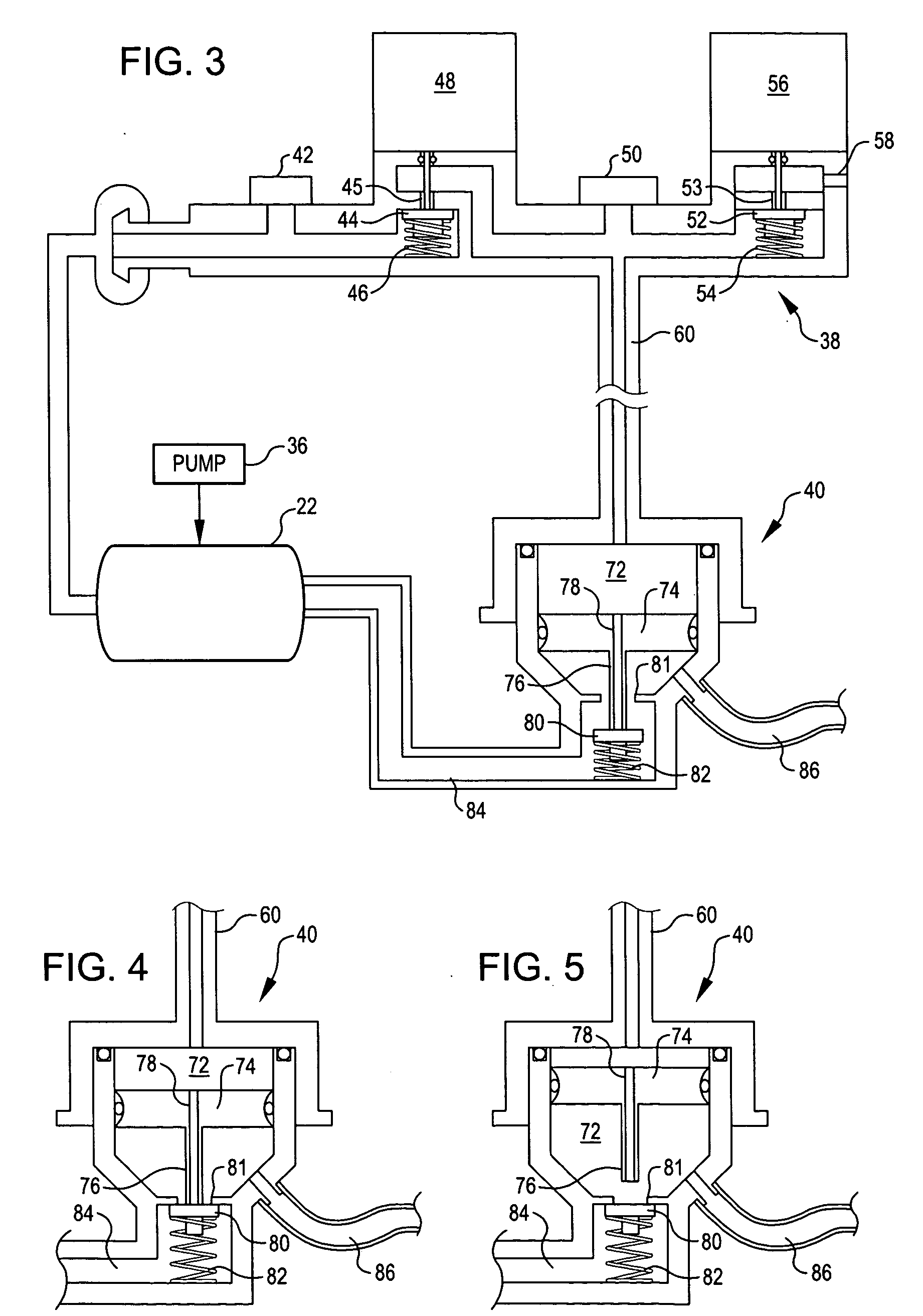

[0042] Referring now to the drawings, in which like reference numerals represent like parts throughout the several views, FIG. 1 shows an air compressor 20 incorporating aspects of the present invention. The air compressor 20 includes a tank 22 with a shroud 24 mounted thereon. Internal components are mounted in the shroud 24, one embodiment of which is shown diagrammatically in FIG. 2.

[0043] The tank 22 for the air compressor 20 is, for example, a 20-gallon cylindrical compressor tank. The tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com