Patents

Literature

40 results about "Expansive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In mathematics, the notion of expansivity formalizes the notion of points moving away from one another under the action of an iterated function. The idea of expansivity is fairly rigid, as the definition of positive expansivity, below, as well as the Schwarz-Ahlfors-Pick theorem demonstrate.

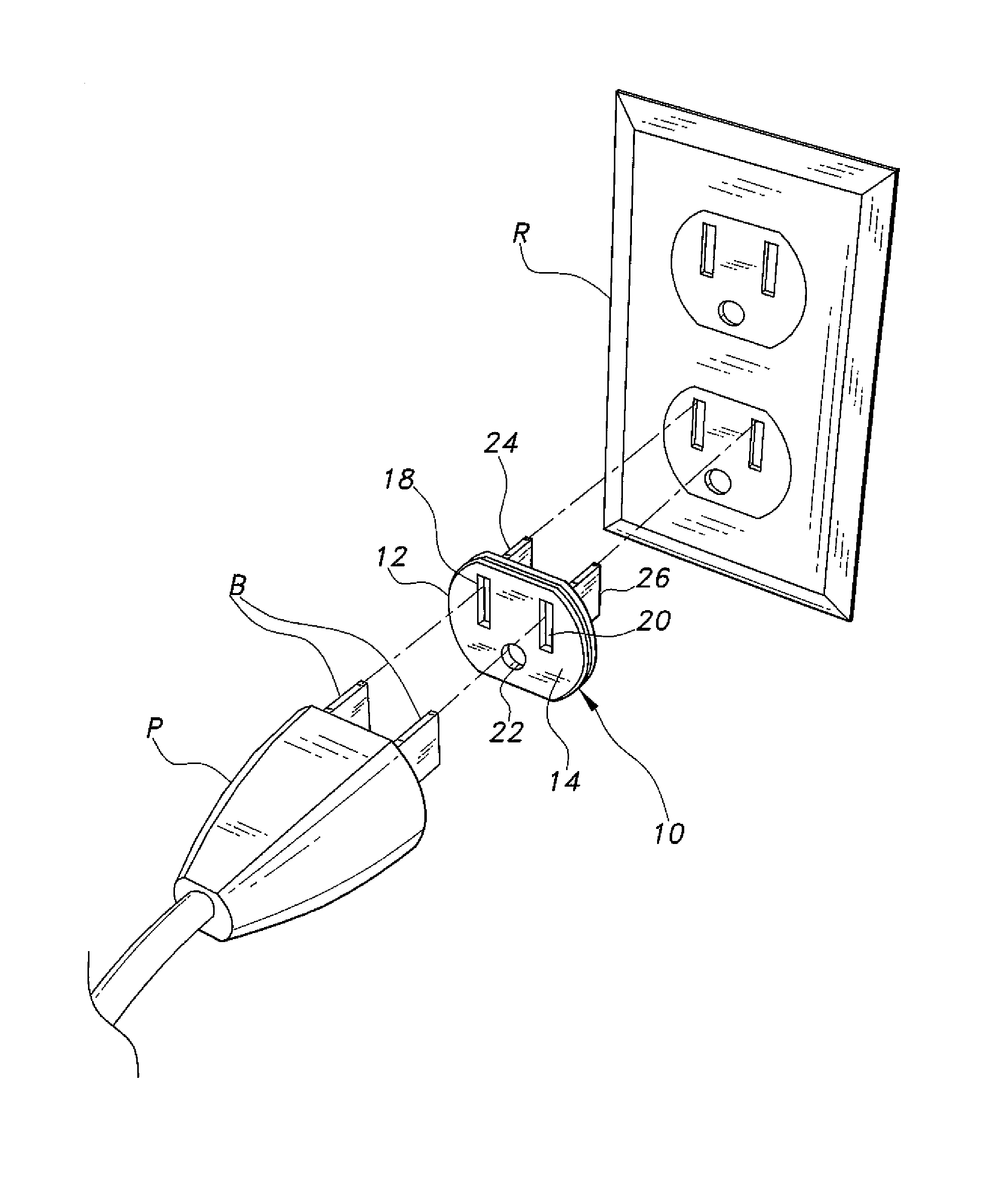

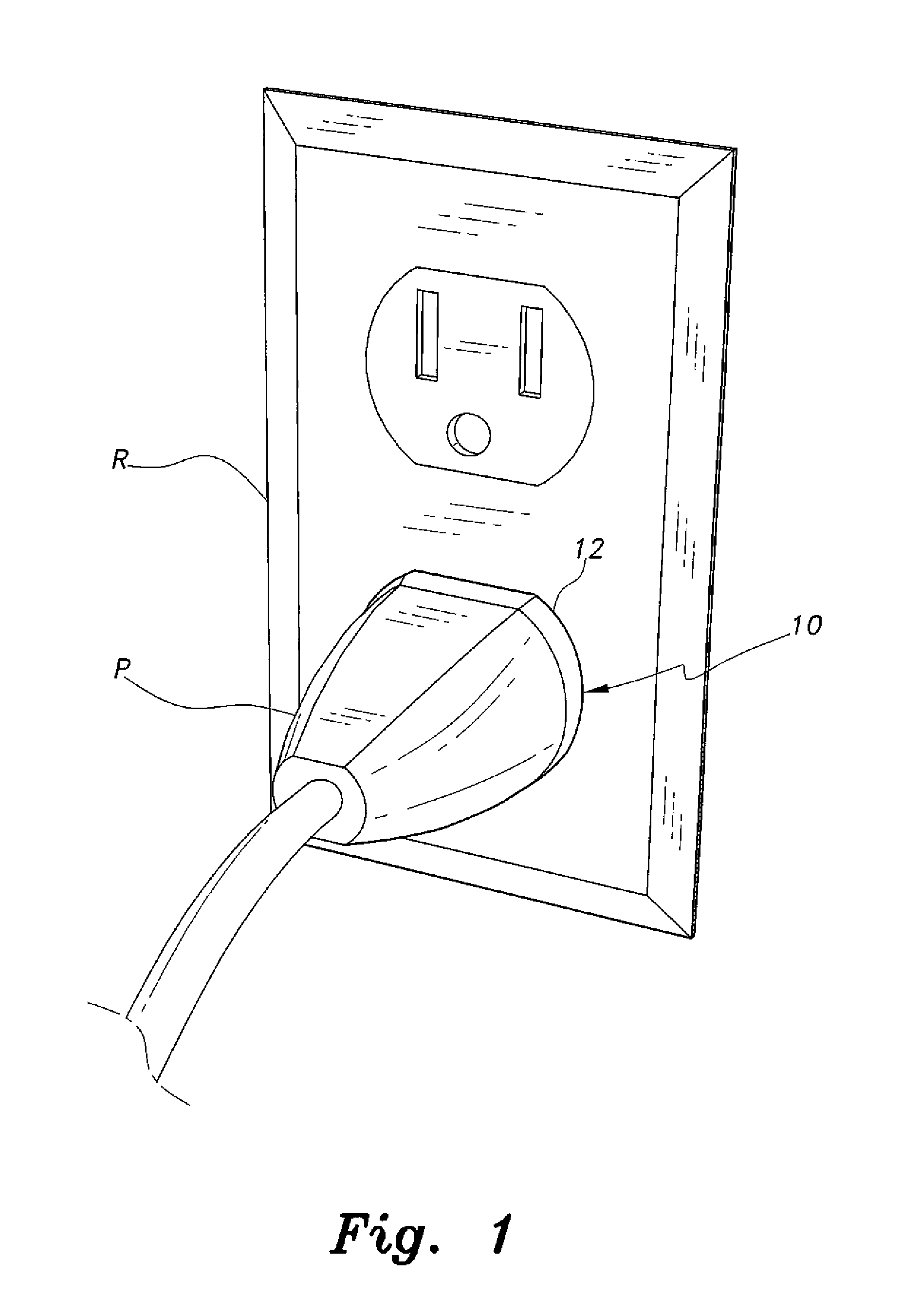

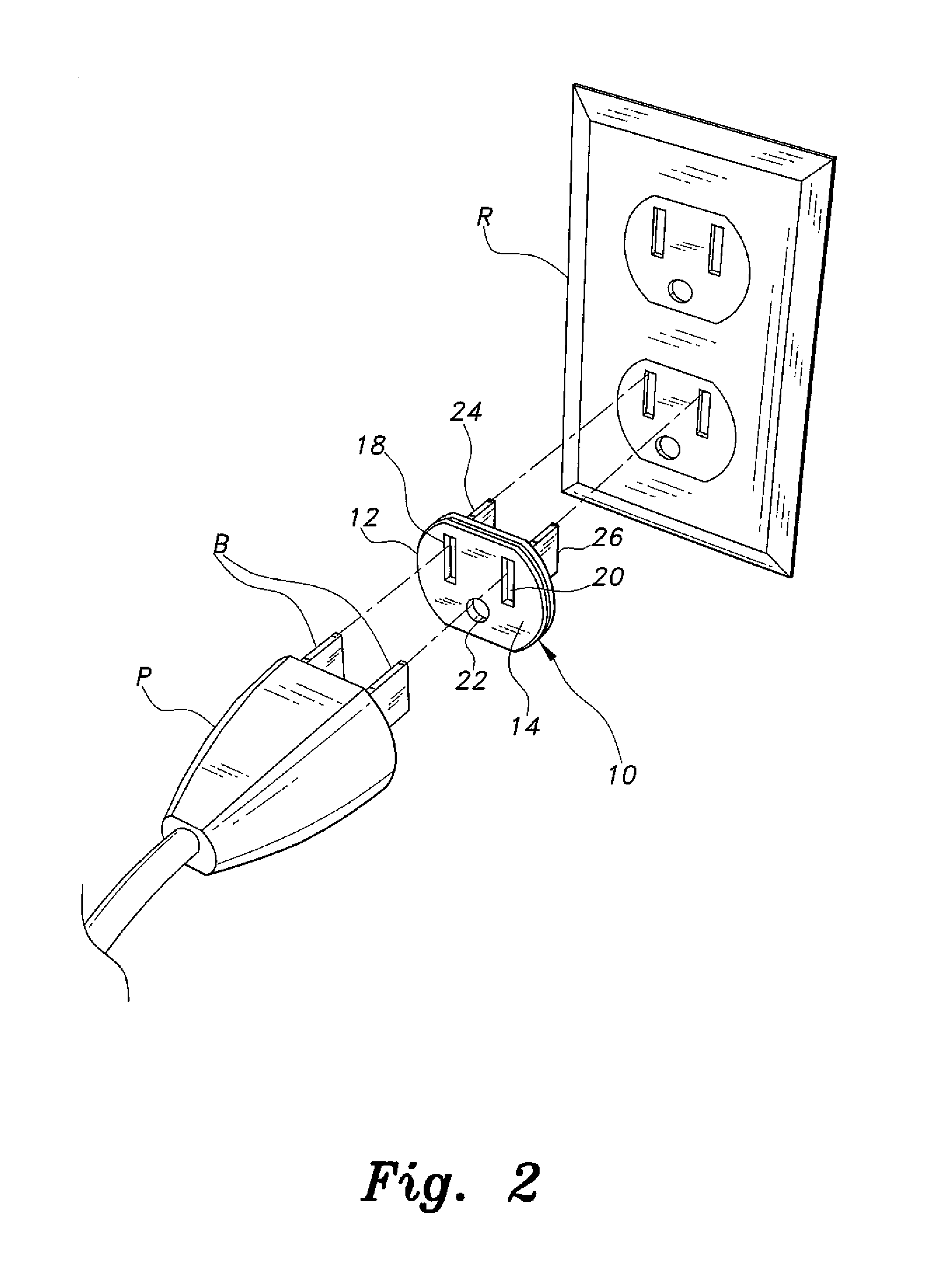

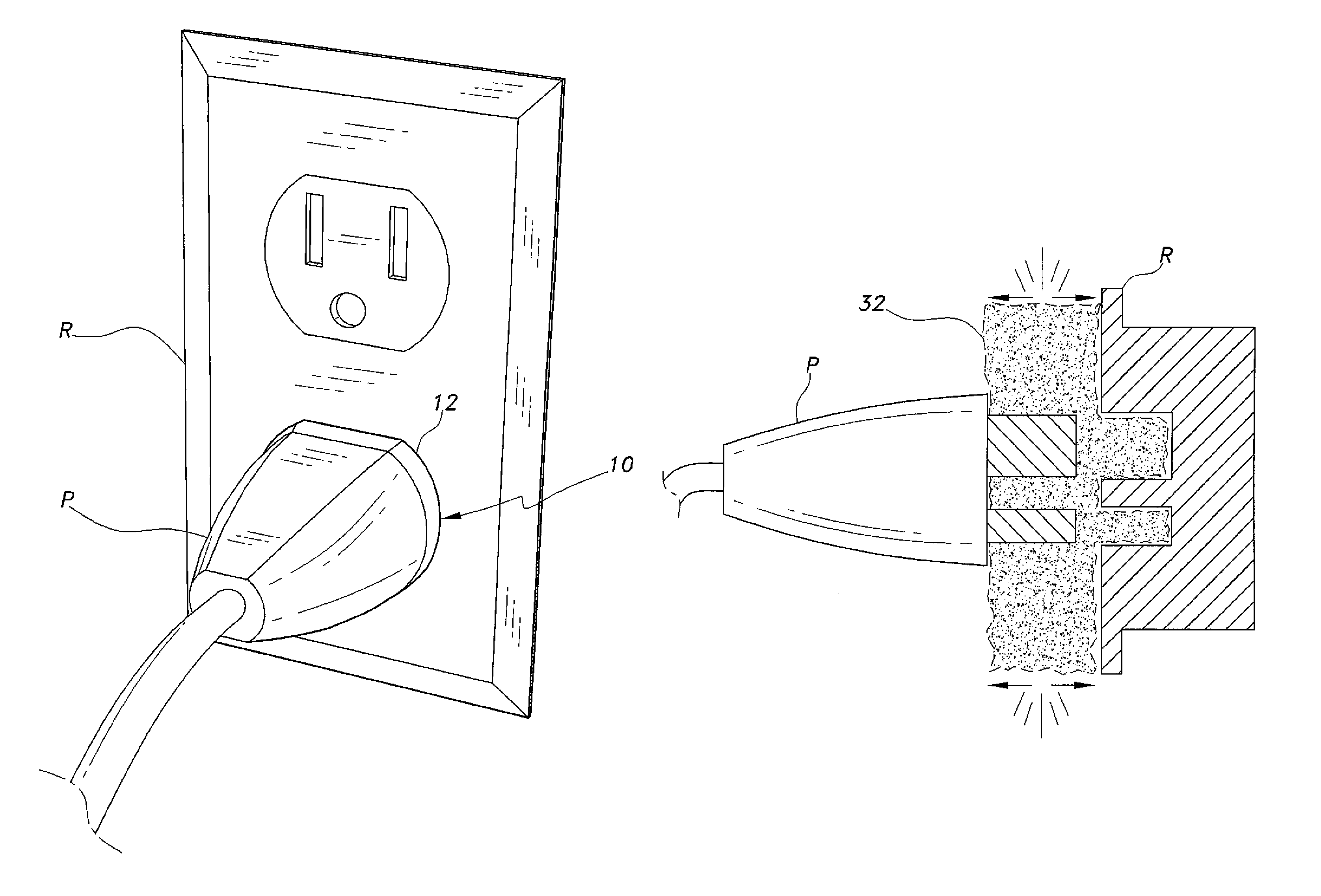

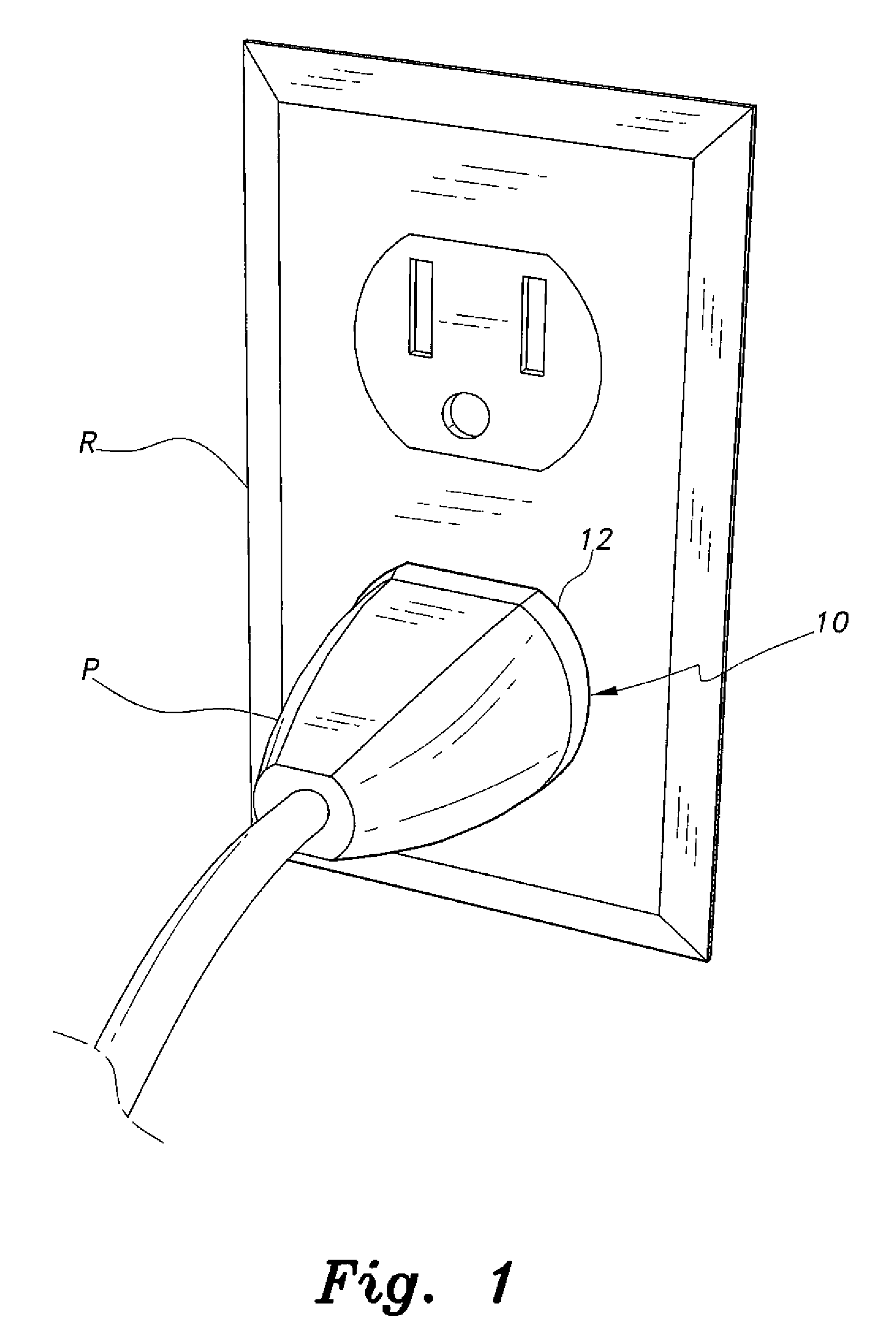

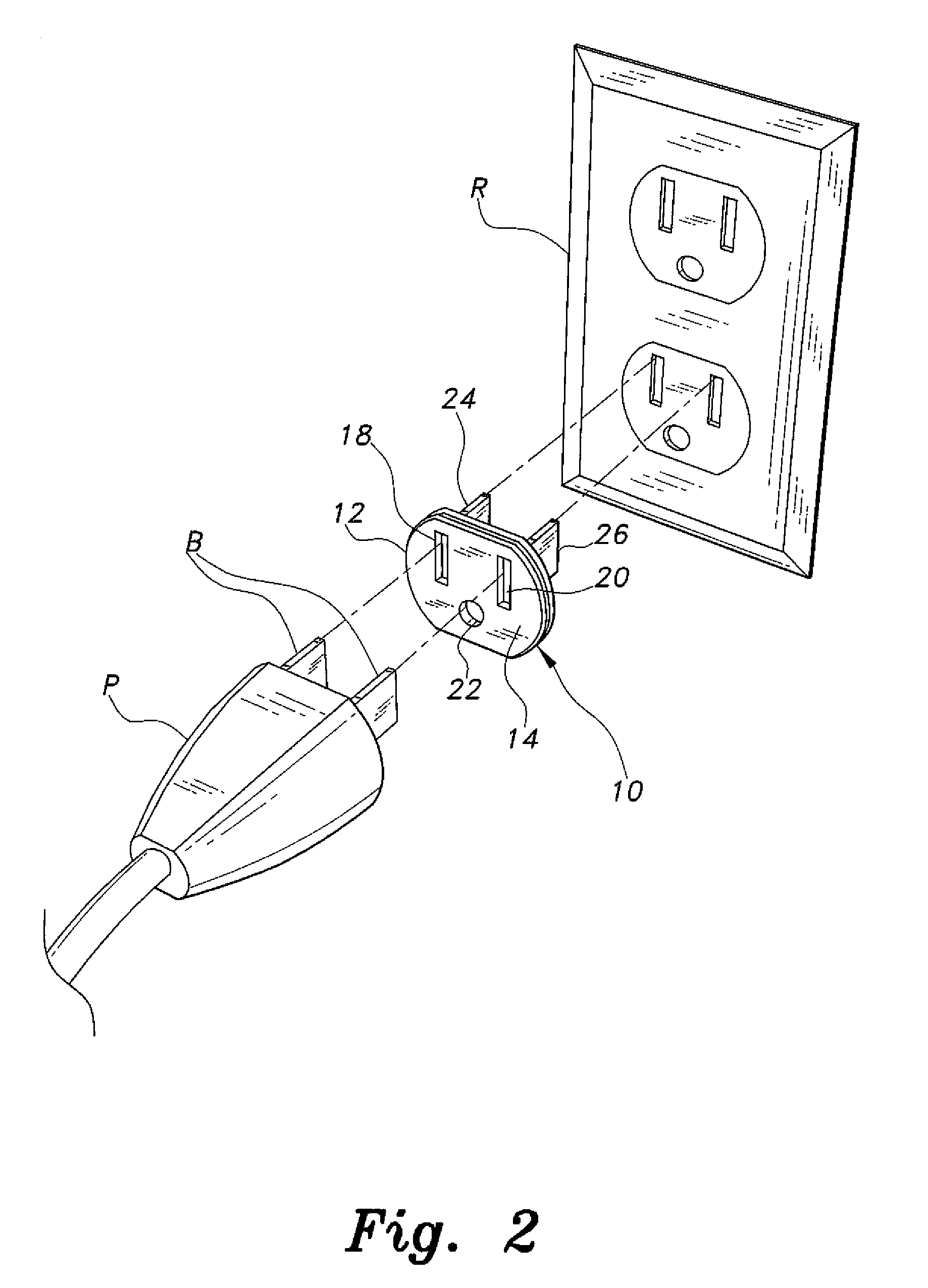

Electrical outlet safety device

ActiveUS20140342590A1Engagement/disengagement of coupling partsTwo-part coupling devicesElectrical resistance and conductanceElectricity

The electrical outlet safety device is placed between an electrical plug and the corresponding electrical outlet or receptacle to which the plug is connected. The safety device includes a thin body portion formed of a material adapted to expand rapidly if exposed to a predetermined temperature. A series of thin, electrically and thermally conductive blades extends from the body, with the blades being captured between the prongs of the plug and the internal contacts of the receptacle when installed therewith. If excessively high electrical resistance and correspondingly high temperature are produced in one or more of the electrical connections between the plug and the outlet, the blades of the safety device transmit the excessive temperature to the body, whereupon the body is transformed to an expansive electrically insulating foam that expels the plug from the receptacle. Springs may be included within the body to provide additional expansive force.

Owner:KUWAIT UNIV

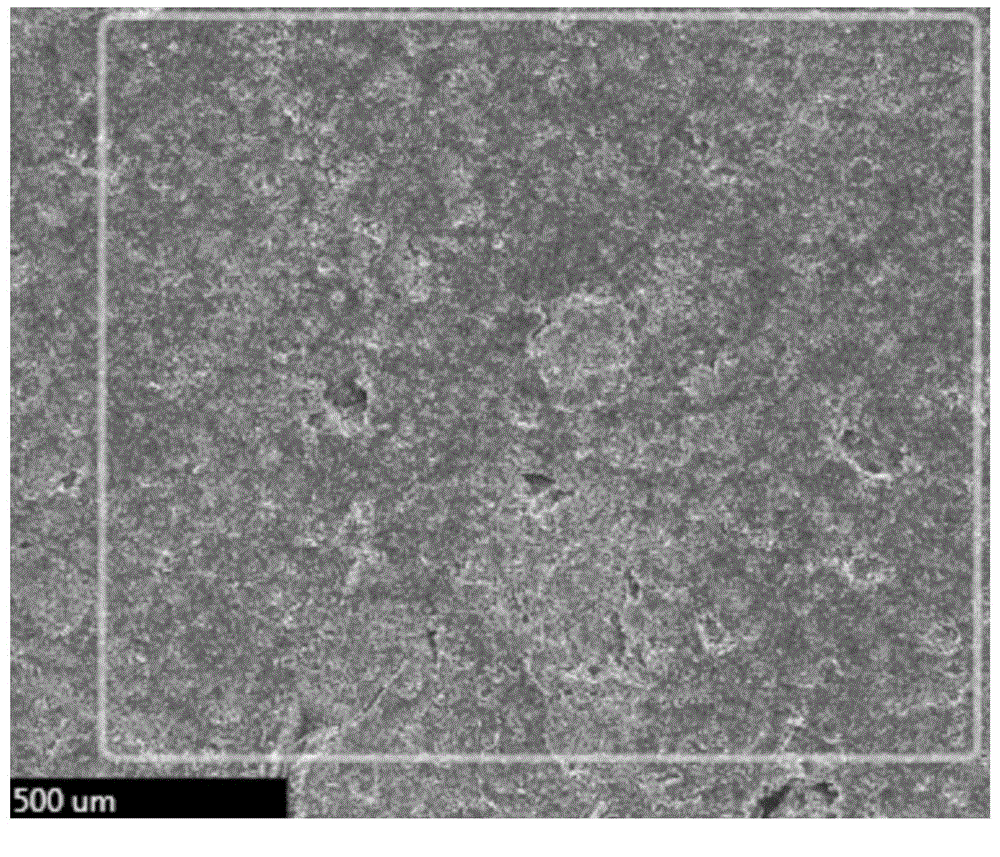

High-magnesium micro-expansive moderate heat Portland cement for water-power engineering and preparation method thereof

ActiveCN103693873ACompensation for temperature drop shrinkageControl of periclase contentHigh magnesiumPortland cement

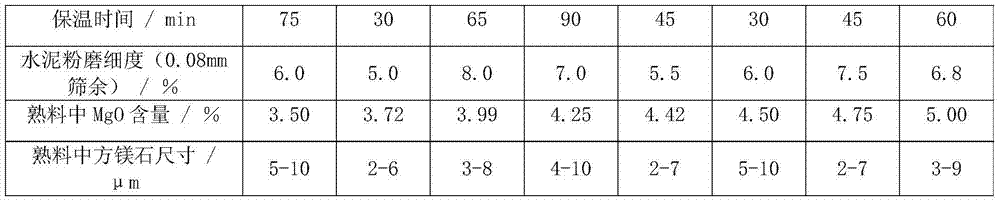

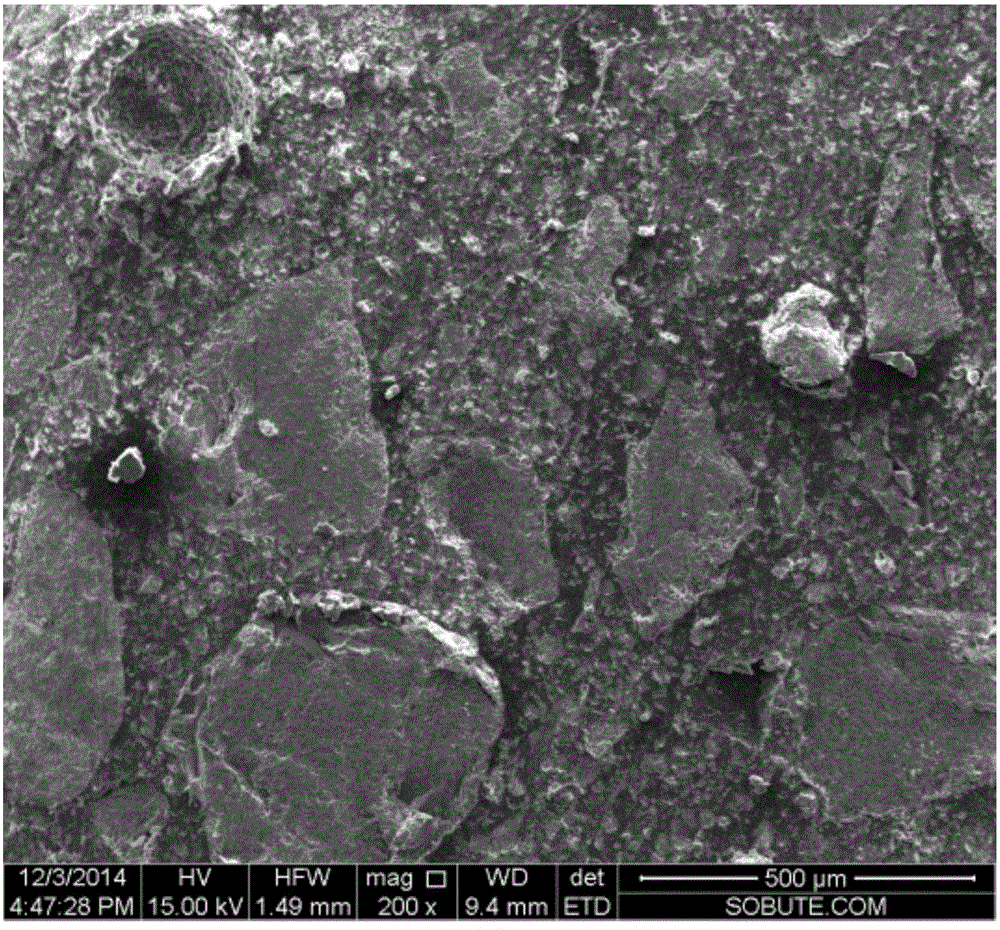

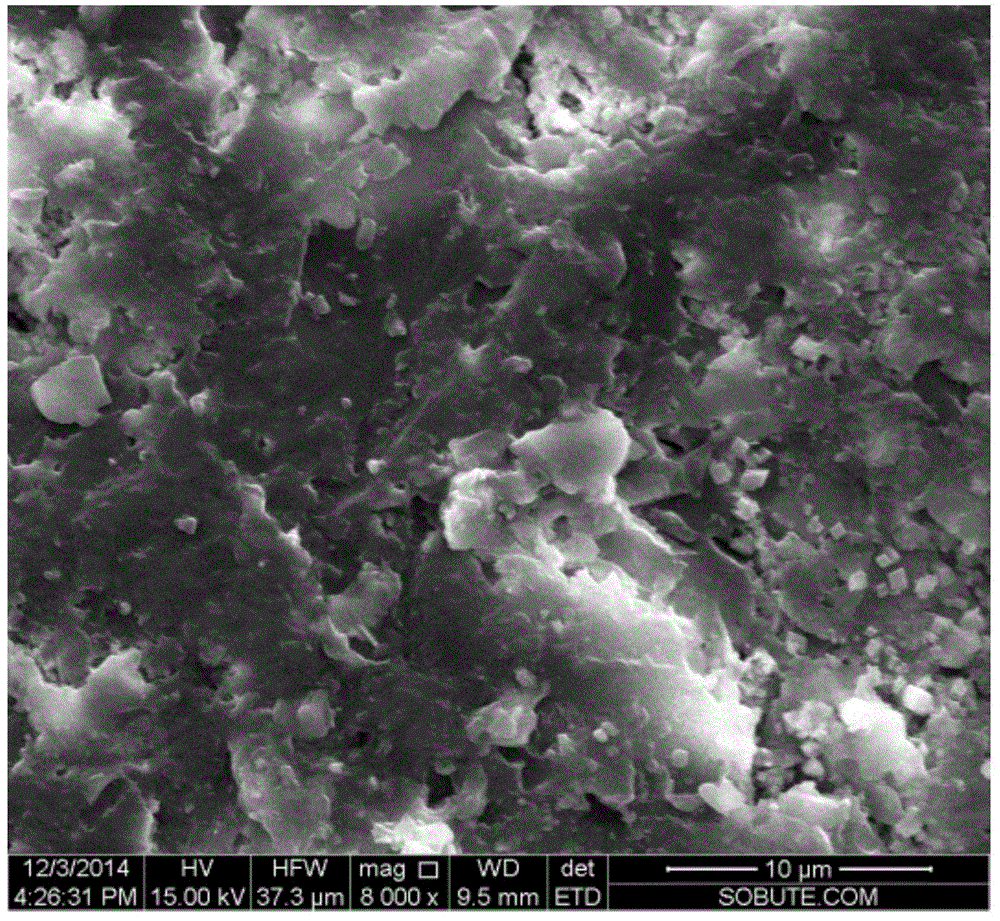

The invention discloses a high-magnesium micro-expansive moderate heat Portland cement for water-power engineering and a preparation method thereof. Through control on the grinding fineness of raw materials, sintering temperature of a cement clinker, insulation time, cooling system and cement grinding fineness, reasonable control of expansion effect time and expansion size of periclase in the cement clinker is realized, so that the content of MgO is 3.5%-5%, and periclase size is 2-10 mum. Experiments show that the high-magnesium micro-expansive moderate heat Portland cement for water-power engineering has late expansion mainly occurred 28 days after hydration of the cement and has expansion enhancement in 28-180 days of 0.011%-0.020%, and the expansion time basically fits the late temperature drop stage of large-volume concrete in the water-power engineering, so as to effectively compensate for the late thermal shrinkage of concrete in the water-power engineering.

Owner:CHINA BUILDING MATERIALS ACAD

Low-heat micro-expansive cement

ActiveCN102515582AReduce manufacturing costReduce heat of hydrationCement productionExpansiveMaterials science

The invention discloses low-heat micro-expansive cement and relates to the technical field of engineering materials. The low-heat micro-expansive cement is prepared by mixing the following components in parts by weight: 2-30 parts of vanadium-titanium mineral slag, 2-30 parts of phosphorus slag, 20-62 parts of granulated blast furnace slag, 18-45 parts of cement clinker, 7-15 of gypsum or anhydrite and 0.2-5 parts of other additives. The low-heat micro-expansive cement disclosed by the invention is adopted, thus vanadium-titanium slag resources are comprehensively utilized; and under the condition that the resources are deficient, the vanadium-titanium slag, the phosphorus slag and the like are used to replace the formula of the existing low-heat micro-expansive cement, thus production cost is reduced, and the physical property of the produced cement meets the requirement of GB2938 cement standard.

Owner:EMEISHAN QIANGHUA SPECIAL CEMENT

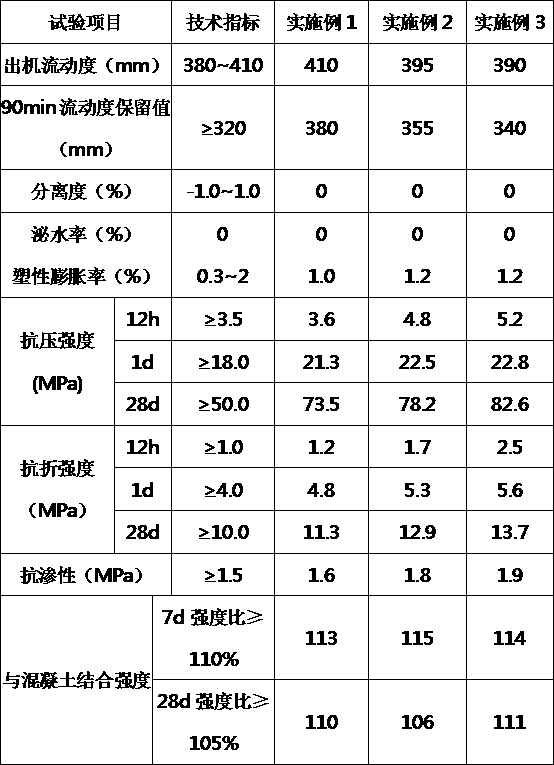

Micro-expansive grouting material for tunnel lining vault mold grouting

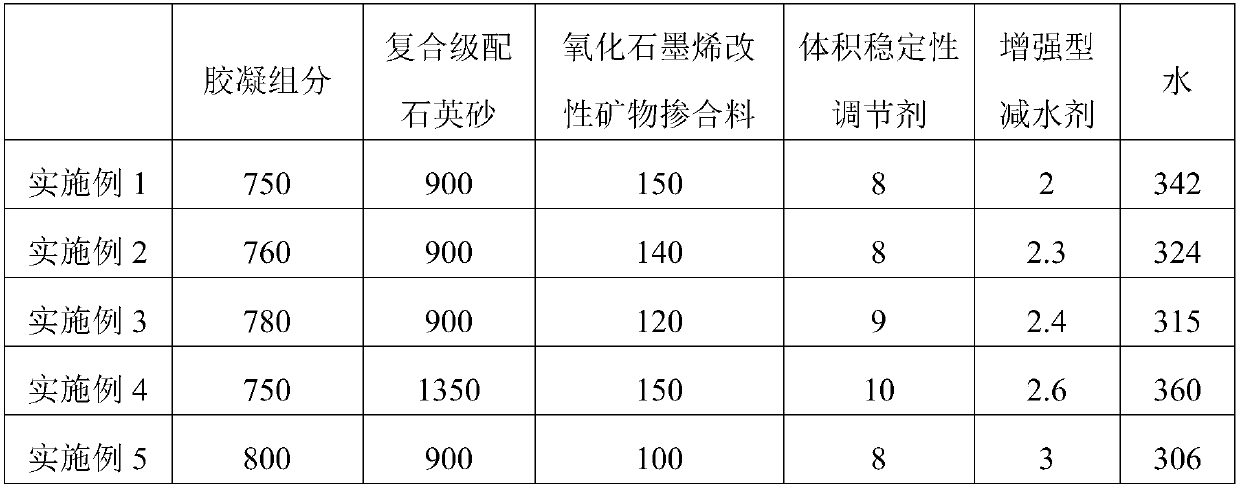

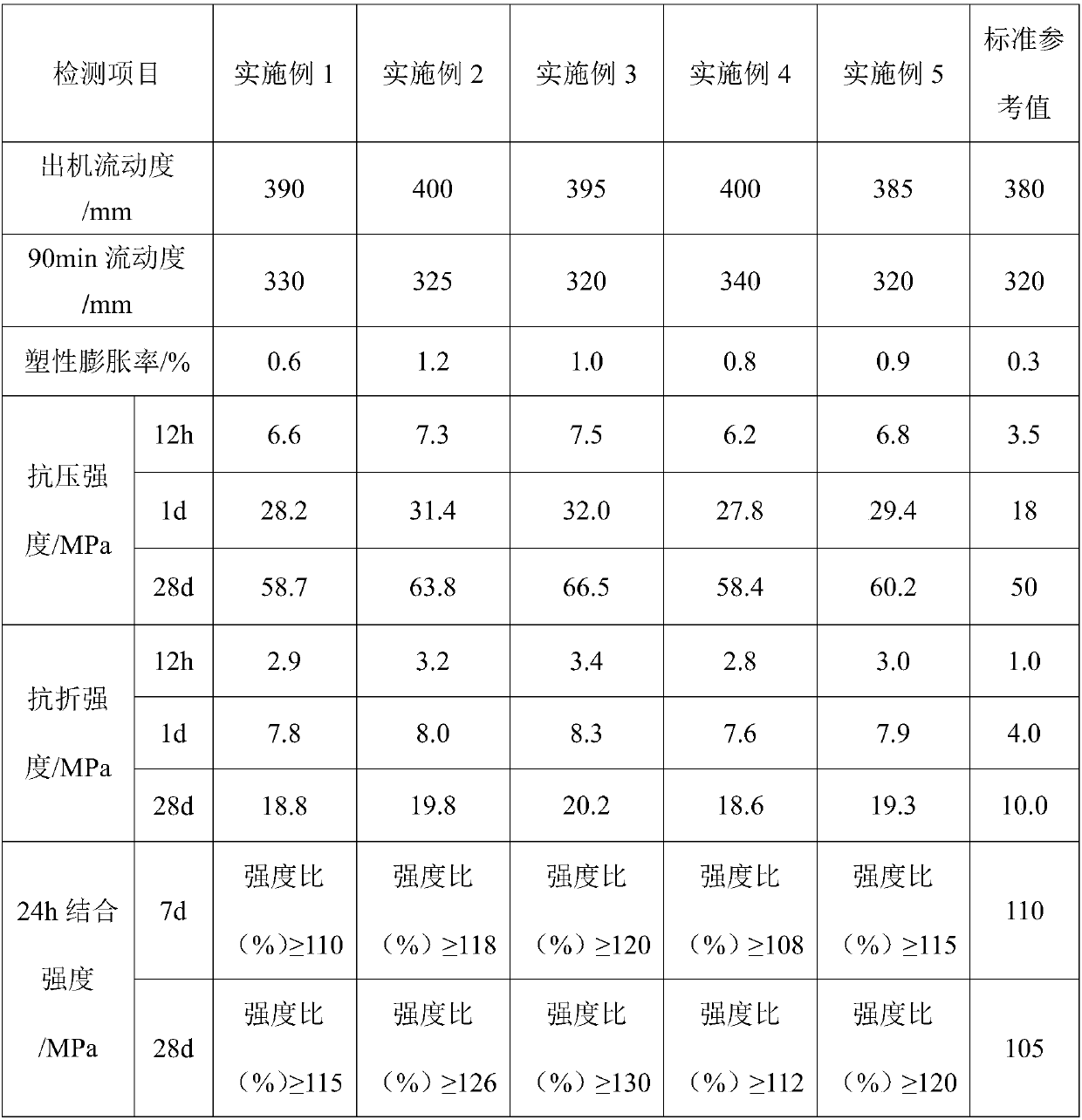

The invention discloses a micro-expansive grouting material for tunnel lining vault mold grouting in order to mainly solve the problems of disengaging, crack and other quality defects of tunnel vaults, caused by easy shrinkage deformation, poor compatibility and poor bonding property of existing like grouting materials. The micro-expansive grouting material is obtained through adding water to 750-800 parts of a gelling component, 900-1350 parts of compounded quartz sands, 100-150 parts of a graphene oxide modified mineral admixture, 8-10 parts of a volume stability regulator and 2-3 parts of areinforced water reducer, and mixing and stirring the above raw materials and the water, wherein a ratio of the water to the total materials is 0.16 to 0.19. The micro-expansive grouting material hasgood fluidity and good pumpability, and has a binding performance with lining concrete, and has significant economic and social benefits in the infrastructure industry.

Owner:WUHAN UNIV OF TECH

Waterproof crack control micro-expansive super-fine sand concrete in high temperature environment

ActiveCN103803905AConsider durabilityTaking physical performance into considerationFiberResource utilization

The invention discloses a waterproof crack micro-expansive super-fine sand concrete in a high temperature environment, which is composed of the following raw materials in parts by weight: 330-350 parts of level-P.O42.5 cement, 560-570 parts of super-fine sand, 480-500 parts of gravels with a particle size of 0-15 mm, 480-500 parts of gravels with a particle size of 15-25 mm, 240-250 parts of gravels with a particle size of 25-40 mm, 55-65 parts of fly ash, 10-12 parts of silicon powder, 160-170 parts of drinking water, 25-30 parts of calcium sulphoaluminate, 0.5-1 part of polystyrene fiber, and 5-6 parts of additives. The concrete disclosed by the invention expands the range of sand for concrete preparation, so that materials are taken more easily, the utilization rate of resources is improved, and the use quality requirements such as durability, physical properties and the like of the concrete can be considered well; and super-fine sand is used as a concrete blending material, so thatan effect of waterproof micro-expansive crack control is achieved, and a desiccation fissure problem is effectively solved.

Owner:ANHUI SHUIAN CONSTR GRP CO LTD

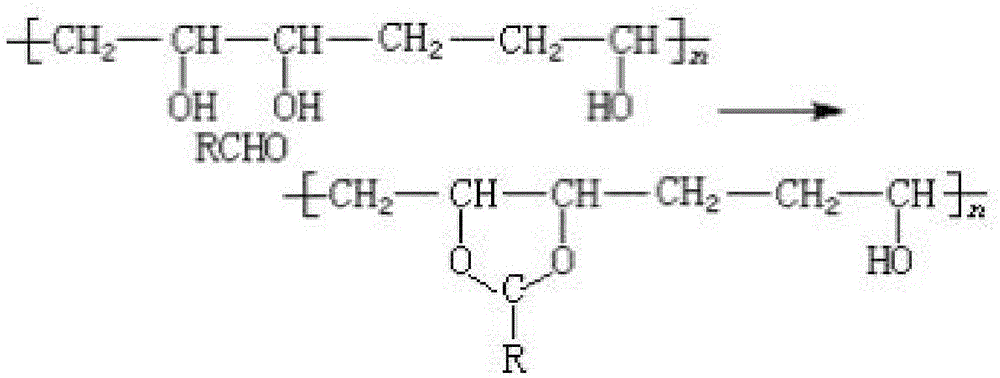

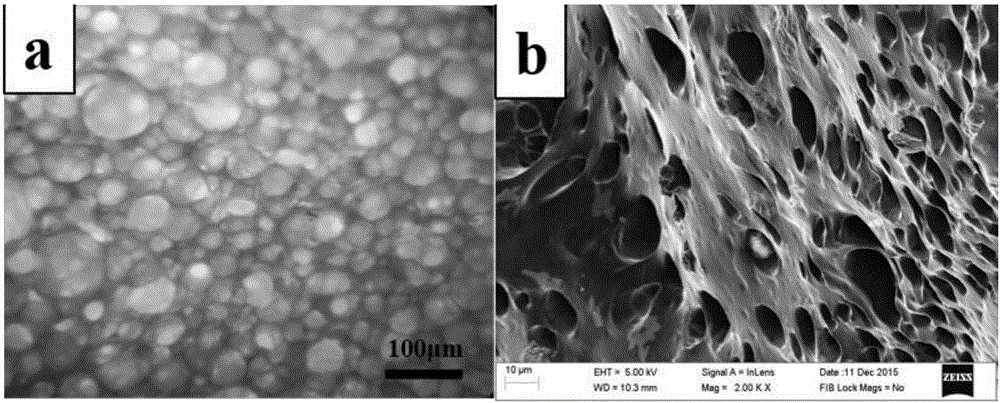

Method for preparing high-elasticity high-absorbency hemostatic and bacteriostatic expansive sponge

The invention discloses a highly elastic and highly liquid-absorbing hemostatic and antibacterial expansion sponge and a preparation method thereof, which belong to the field of medical materials. In the present invention, polyvinyl alcohol is stirred in deionized water to form a solution, and surfactant and sodium alginate are added to the solution, and the sodium alginate is mixed evenly by stirring, then catalyst, cross-linking agent and bacteriostat are added, and high-speed stirring Then pour into the mold for cross-linking reaction. Put the mold into an oven for molding, and then soak the sample in the antibacterial agent solution or sol to make a sodium alginate composite polyvinyl acetalized expansion sponge; or add silver to the polyvinyl alcohol sodium alginate mixed solution Ammonia solution, and then generate silver through silver mirror reaction, and synthesize sodium alginate-nano-silver composite polyvinyl acetalization expansion sponge. The invention is light in weight, small in thermal conductivity, good in biocompatibility, fast in dry state wetting rate, high in strength, high in liquid absorption rate and expansion rate, and can be used as medical hemostasis, antibacterial dressing and orthopedic or nasal surgery filling material.

Owner:北京市中杰瑞康科技发展有限责任公司

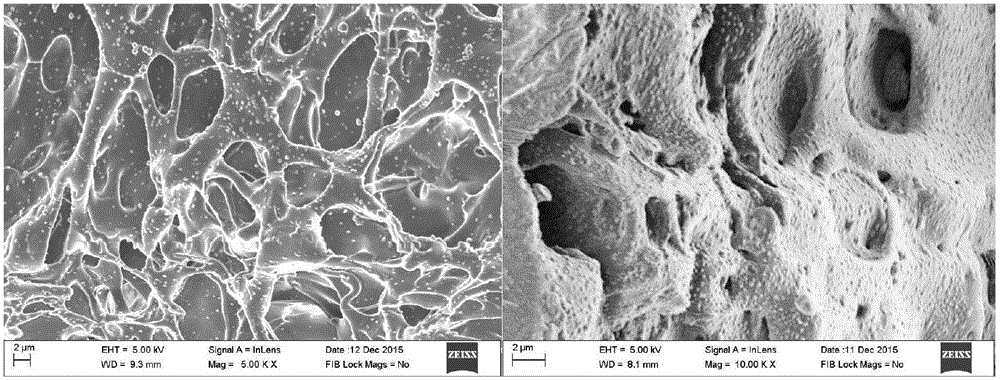

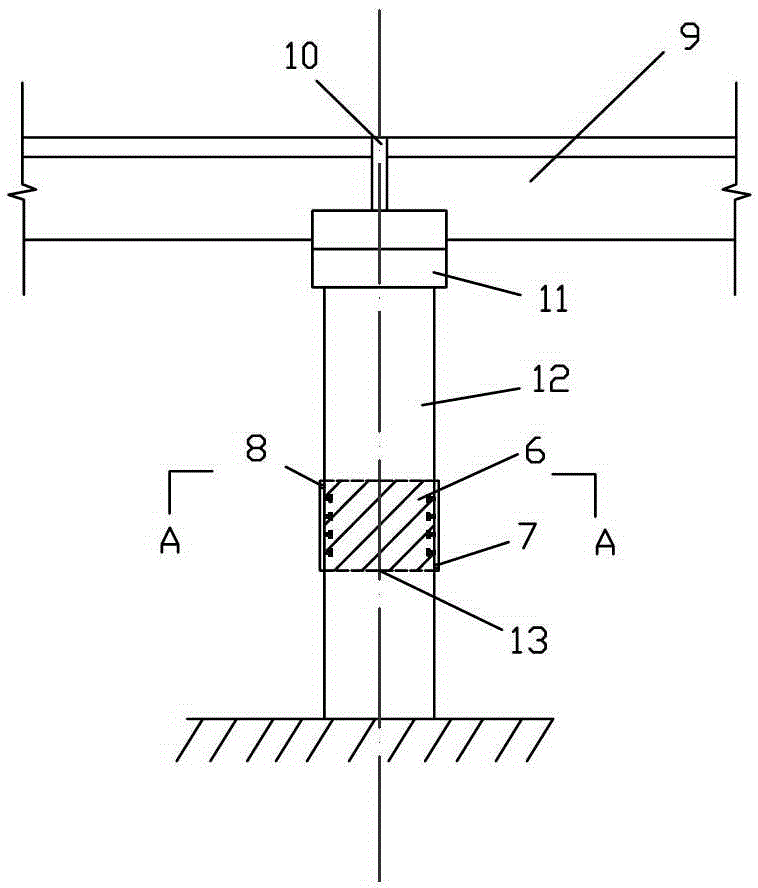

Bridge pier connecting device for bridge lifting process and construction method for bridge pier connecting device

InactiveCN102979042ASave materialSimplify construction stepsBridge structural detailsBridge erection/assemblyReinforced concreteSheet steel

The invention discloses a bridge pier connecting device for a bridge lifting process and a construction method for the bridge pier connecting device, and relates to a connecting technology for bridge piers in bridge reconstruction processes. According to the connecting technology, self-compacting micro-expansive reinforced concrete pier columns and encasing steel plates are involved; the sizes and the numbers of internal vertical reinforcements are the same as those of vertical reinforcements in the conventional pier column structures; sealed stirrups are adopted, and are densely arranged within entire section ranges along connecting sections of the bridge piers; when more than four main vertical reinforcements are arranged on each side in the rectangular pier columns, combined stirrups are arranged; studs are welded on the surfaces of the encasing steel plates to improve the combined mechanical performance of the steel plates and concrete; and the encasing steel plates have a function of restricting core concrete, and can also serve as external dies for the concrete pouring of the connecting sections, and grout holes and weeping holes are reserved in the external dies. According to the connecting technology, requirements on the strength, the rigidity and the stability of the lifted bridge piers which are lifted can be met.

Owner:HOHAI UNIV

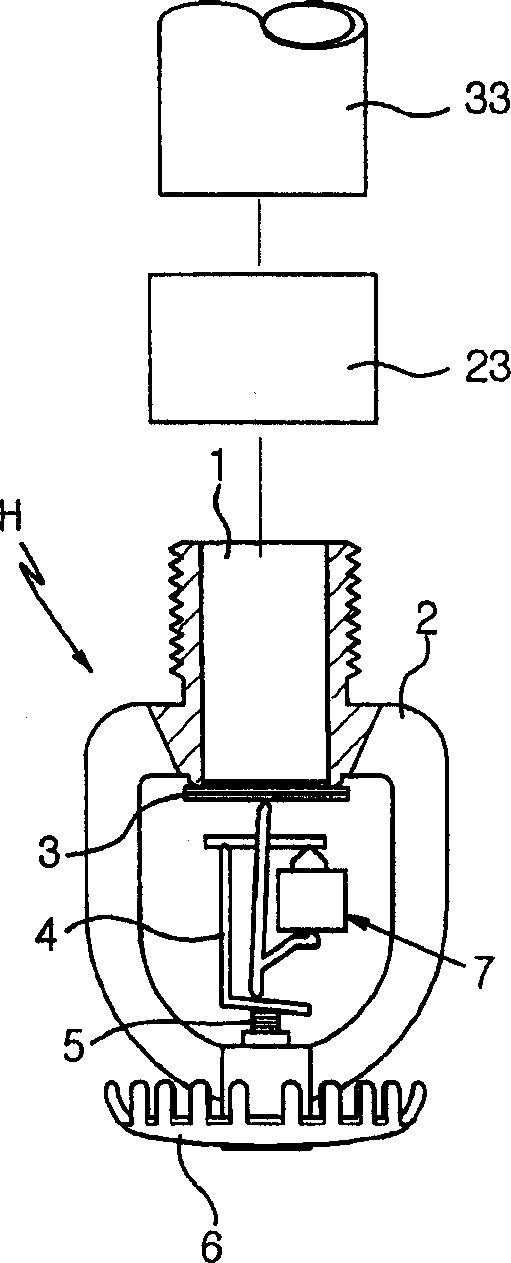

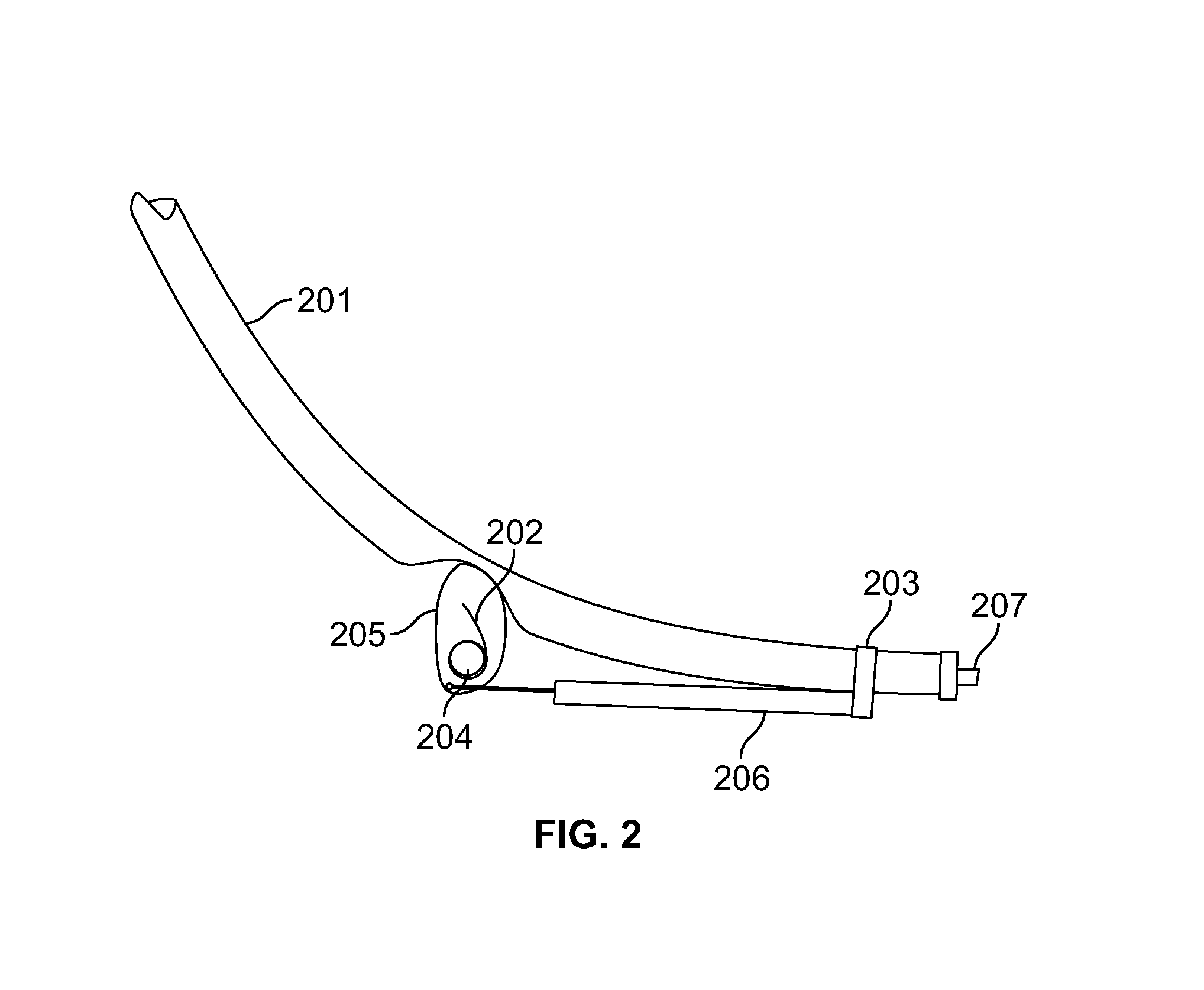

Thermal ampoule for sprinkler

InactiveCN1358114AImprove heat transfer efficiencyIncreased durabilityMovable spraying apparatusFire rescueEngineeringExpansive

An electrical thermal glass ampoule for fire fighting sprinkler is disclosed. The ampoule(200) according to the present invention comprises a closed hollow cylindrical glass casing(100), an electrically heating coil(120) installed inside of said glass casing, a negative electrode(140) provided on outer surface at bottom end of said casing and electrically connected with one end of said coil, a positive electrode(142) provided on outer surface at side wall of said casing and electrically connected with the other end of said coil, and heat expansive gas(G) entrapped inside the casing. The glass ampoule(200) can be precisely manufactured as a single body integrated with a thermal coil(120) inside of the casing, have good install handiness due to no necessity of coil being wound around the ampoule and has long term duration because the coil(120) is installed inside the glass casing(100) and, thus can be prevented from corrosion. Further, the glass ampoule(200) according to the present invention has another advantage of much faster actuating response because the coil(120) is heated inside the glass casing and, thus, can give heat directly to the gas(G).

Owner:吉钟镇

Micro-expansion hydrophobic polyurethane cement mortar composition and preparation method thereof

The invention provides a micro-expansion hydrophobic polyurethane cement mortar composition which comprises the following components in parts by weight: 50-90 parts of a water hardened mortar aggregate system, 1-5 parts of water-dispersed polyol resin, 5-20 parts of water emulsified castor oil polyol resin, 5-25 parts of an isocyanate curing agent, and 5-15 parts of water. The invention further provides a preparation method of the micro-expansive hydrophobic polyurethane cement mortar composition. The micro-expansion hydrophobic polyurethane cement mortar composition is simple in preparation process, and is convenient to construct, and after curing molding, the micro-expansion hydrophobic polyurethane cement mortar composition has high micro-expansion performance and favorable hydrophobicity, and has a self compacting ability, shock resistance, wear resistance and hydrophobic and waterproof properties at the same time.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

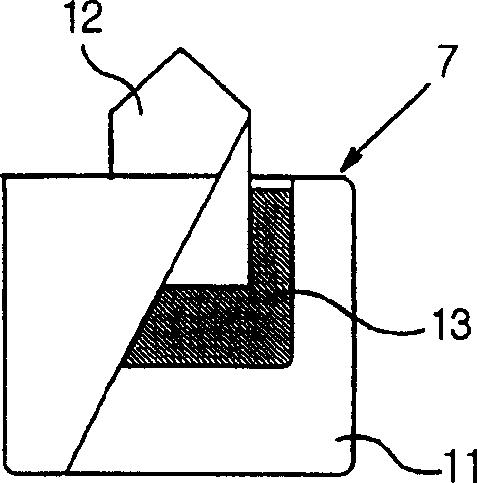

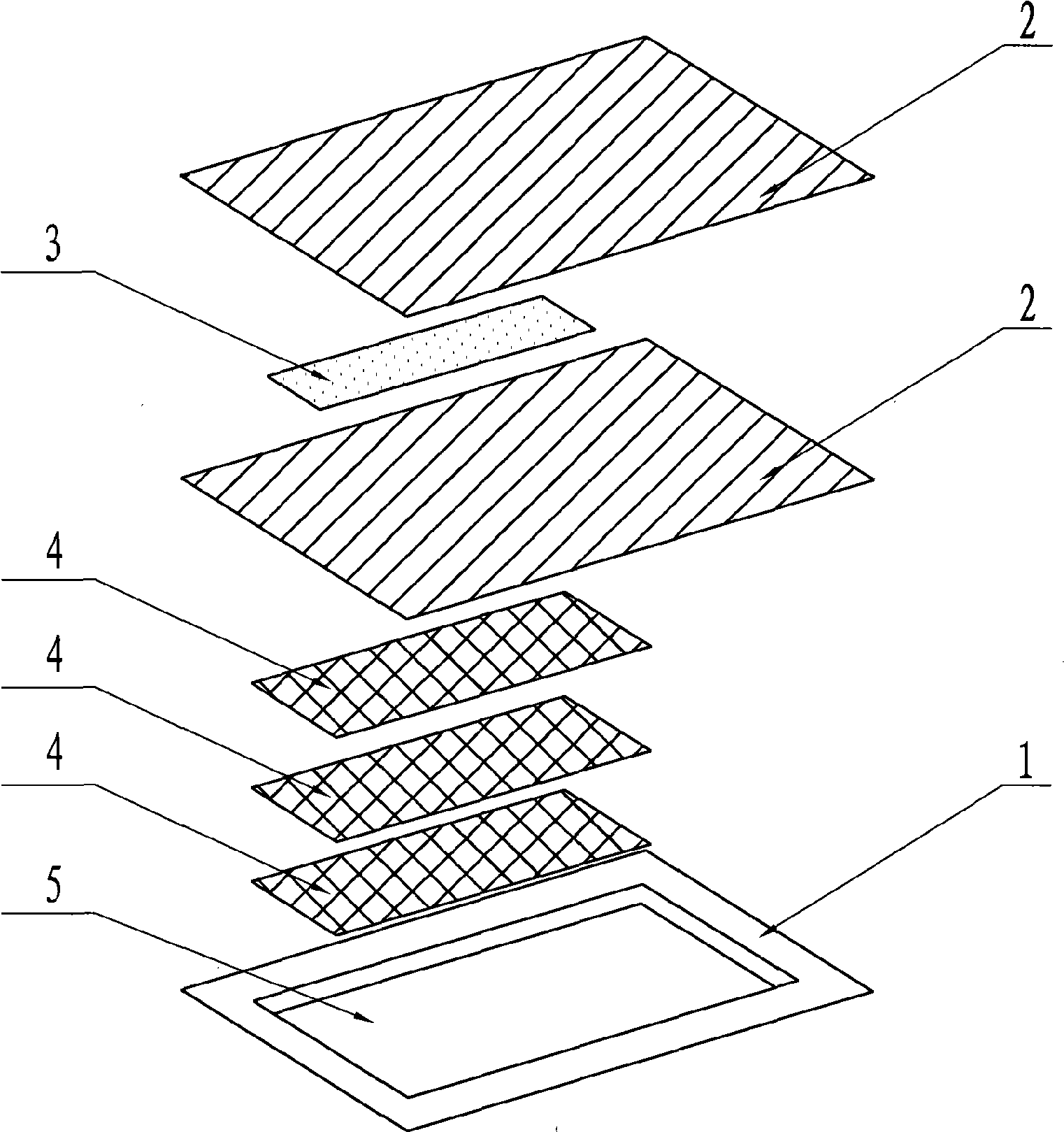

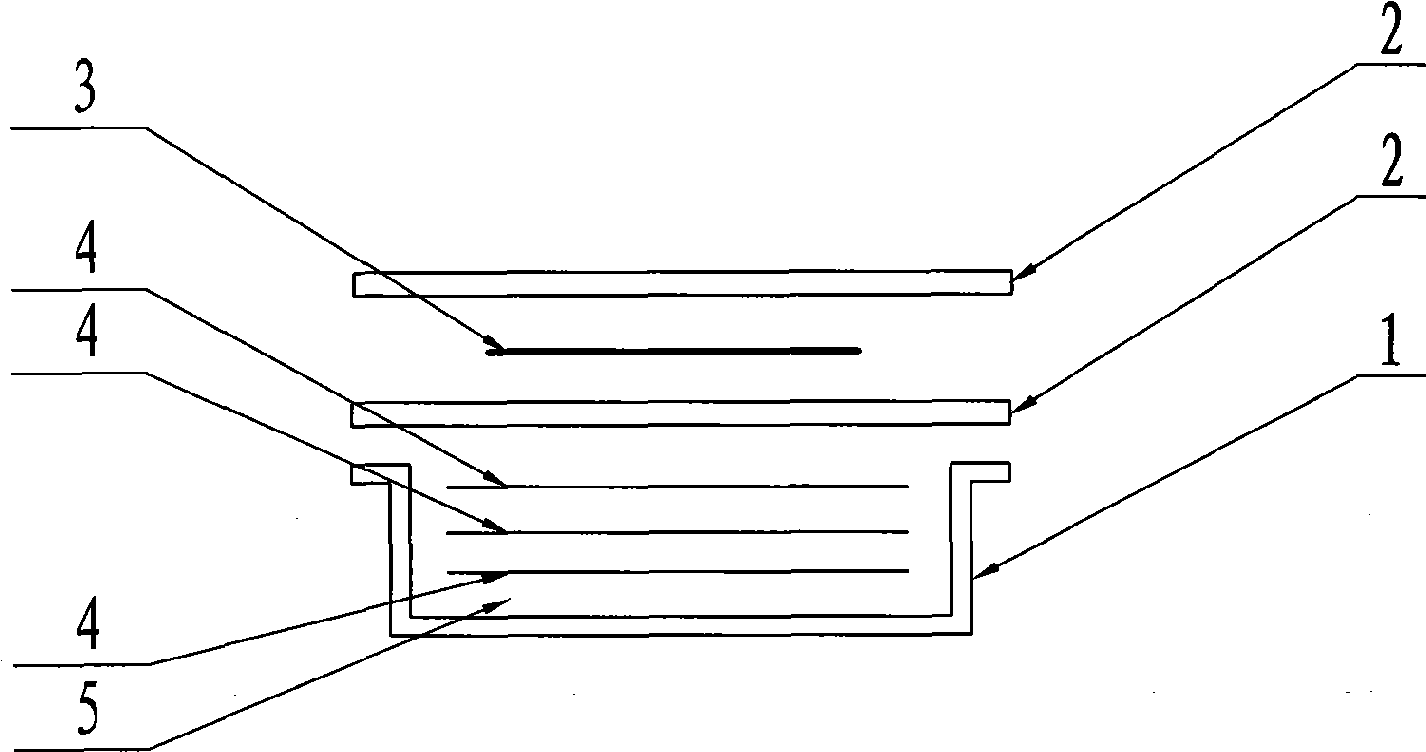

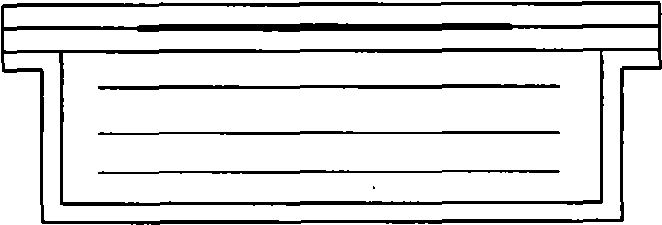

Anti-theft audio magnetic label capable of being throwing into liquid goods

The invention relates to an anti-theft protection alarm device for commercial purpose, in particular to an anti-theft acoustic magnetic label which can be put into a liquid commodity. The label comprises a long narrow box body and a magnetic offset piece, wherein, at least a resonance piece is arranged in a cavity of the box body; the label further comprises a sealing membrane which is in sealed connection with the box body to ensure that the label remains in a sealing state; and the sealing membrane, the magnetic offset piece and the resonance piece are arranged by layers. The invention is characterized in that the acoustic magnetic label is manufactured without any glue, so that the sealed label can be directly put into the liquid commodity for the purpose of theft prevention. Meanwhile, the invention has the characteristics of small size, aesthetic appearance, reliable sealing and the like, and achieves the effects of reducing previous surplus procedures, saving the cost for an expansive under glue, and completely solving the problem that the liquid commodity causes pollution after a plastic sealing membrane which is added onto the outer surface of the original label on the commodity ruptures.

Owner:李霖

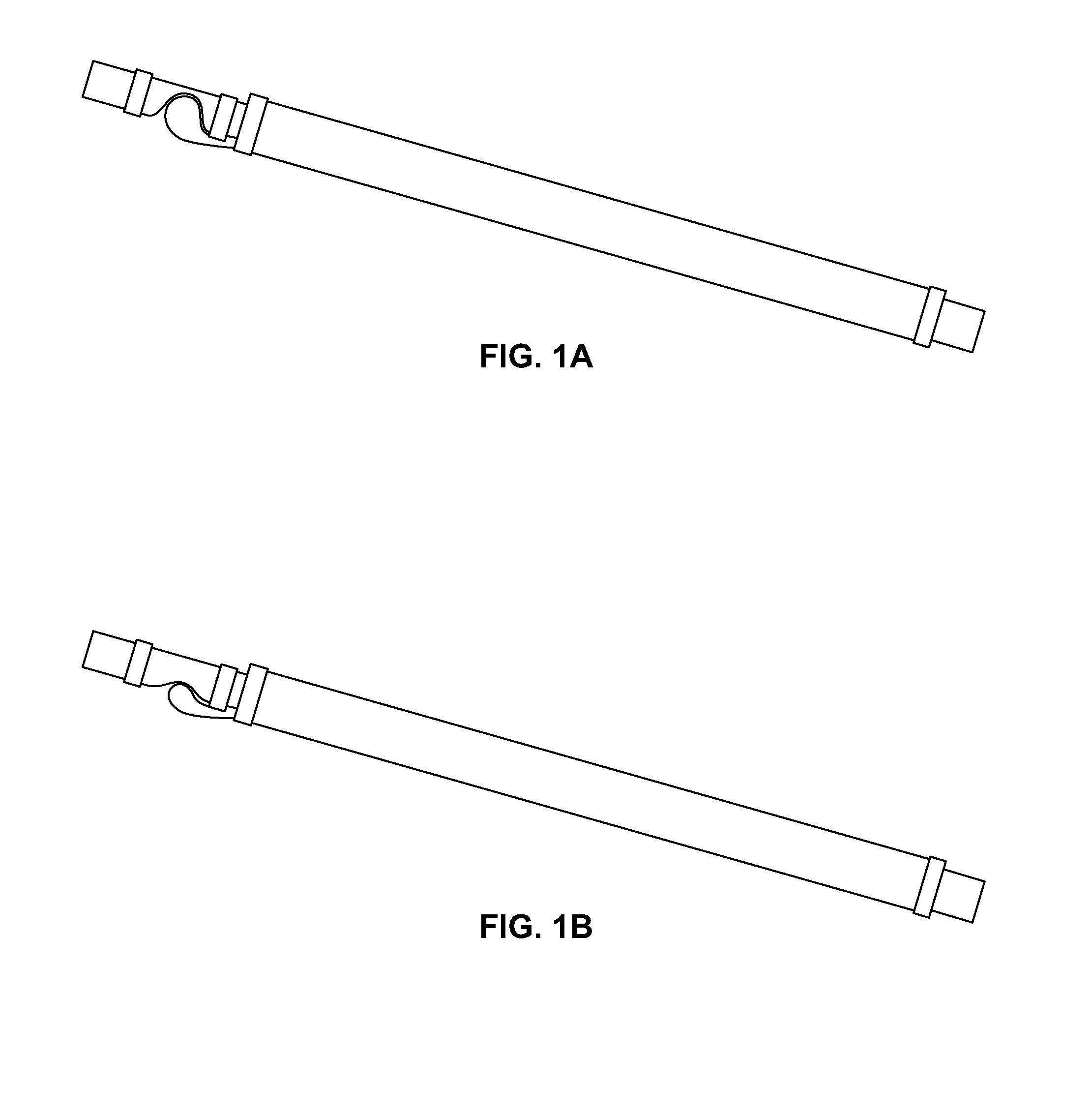

Electrical outlet safety device

ActiveUS8956168B2Engagement/disengagement of coupling partsTwo-part coupling devicesElectrical resistance and conductanceElectricity

The electrical outlet safety device is placed between an electrical plug and the corresponding electrical outlet or receptacle to which the plug is connected. The safety device includes a thin body portion formed of a material adapted to expand rapidly if exposed to a predetermined temperature. A series of thin, electrically and thermally conductive blades extends from the body, with the blades being captured between the prongs of the plug and the internal contacts of the receptacle when installed therewith. If excessively high electrical resistance and correspondingly high temperature are produced in one or more of the electrical connections between the plug and the outlet, the blades of the safety device transmit the excessive temperature to the body, whereupon the body is transformed to an expansive electrically insulating foam that expels the plug from the receptacle. Springs may be included within the body to provide additional expansive force.

Owner:KUWAIT UNIV

High-performance micro-expansive grouting binder

InactiveCN110171951ASmall heat releaseSolve the problem of low early strengthCompressive strengthExpansive

The invention relates to a high-performance micro-expansive grouting binder used for mold grouting after concrete pouring of a tunnel lining, belongs to the technical field of building materials, andis applicable to high-speed railway and highway tunnel construction. The invention aims to provide the micro-expansive grouting binder used in the mold grouting process of a tunnel. The grouting binder overcomes the defects that the strength of traditional cement paste is slowly increased, the binding strength between the traditional cement paste and concrete is low, and layering and weepage are likely to occur, the grouting binder has the advantages that the grouting binder has super-fluid and self-leveling performance, the ratio of water to material is fixed, the grouting binder is micro-expansive in the plasticizing stage, the grouting binder can repair circular construction joints generated in the lining in time and achieve filling of voids in an arch crown, and the grouting binder plays an important role in protection of the quality of the tunnel lining. The micro-expansive grouting binder is simple in composition and convenient to produce, the grouting binder can be used simply by directly adding water on site, the fluidity is 400 mm, the degree of separation is 0.28 d, the compressive strength is actually close to 80 MPa, the micro expansion is 0.5%, the anti-permeability ishigher than 1.5 MPa, the binding strength between the grouting binder and the concrete is 112%, the paste is completely bound with the concrete, and the structural integrity of the lining is high.

Owner:石家庄市易达恒联路桥材料有限公司

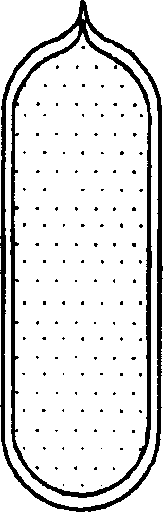

Progesterone vaginal expansive suppository as well as preparation method and detection method thereof

ActiveCN103735492AGuaranteed effective concentrationPrevent outflowOrganic active ingredientsSuppositories deliveryCross-linkCarboxymethyl cellulose

The invention relates to a progesterone vaginal expansive suppository as well as a preparation method and a detection method thereof. The expansive suppository consists of a medicated substrate consisting of progesterone and a substrate as well as an expansion carrier, wherein the medicated substrate further contains cross-linked glucan gel, sodium carboxymethyl cellulose, monolauroyl glycerol, diacetin, glycerol and sodium citrate, and a clathrate compound is formed from the cross-linked glucan gel, sodium carboxymethyl cellulose and progesterone. The progesterone vaginal expansive suppository disclosed by the invention has the beneficial effects of high bioavailability, uniform dispersion of medicine and the like.

Owner:哈尔滨田美药业股份有限公司

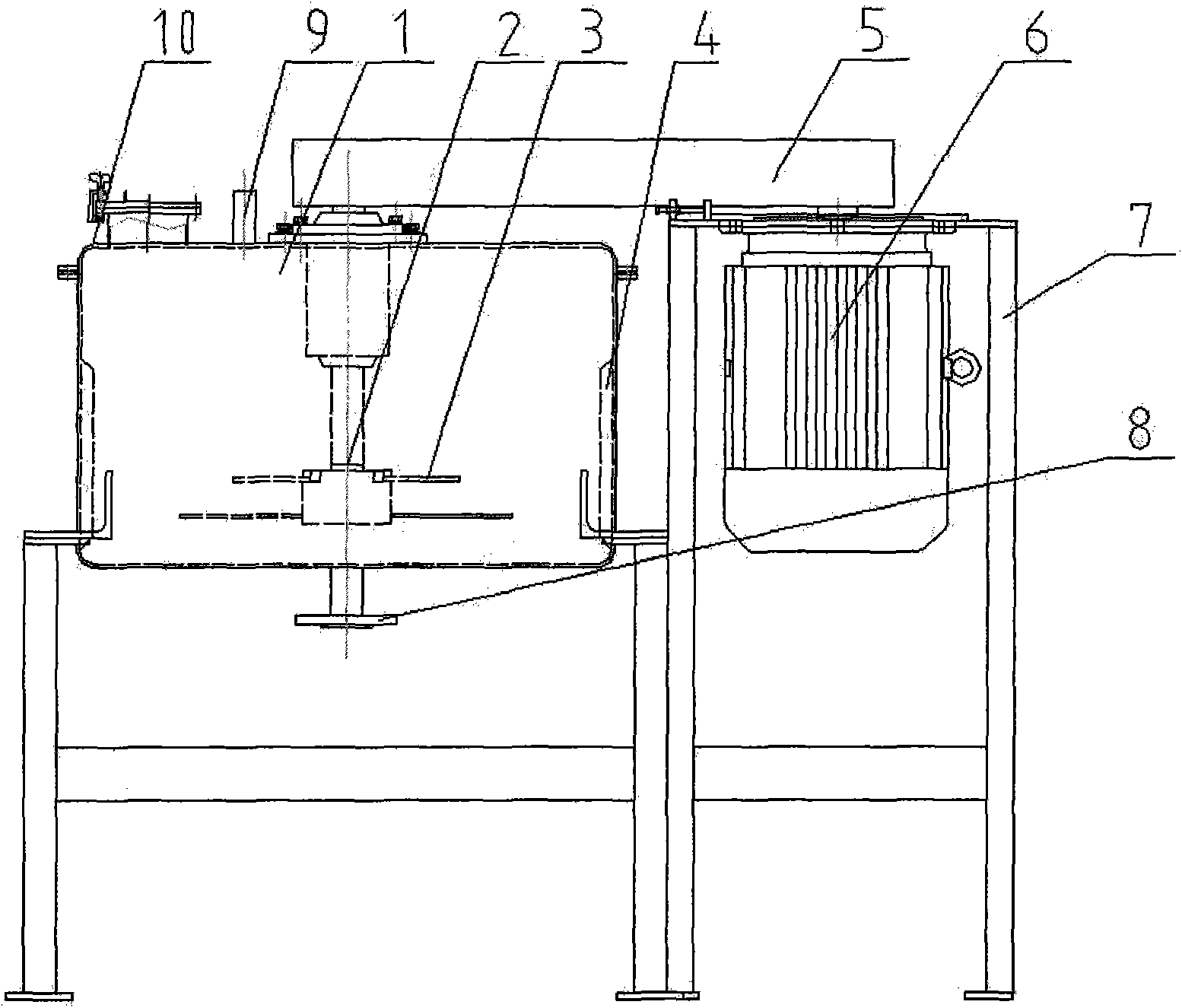

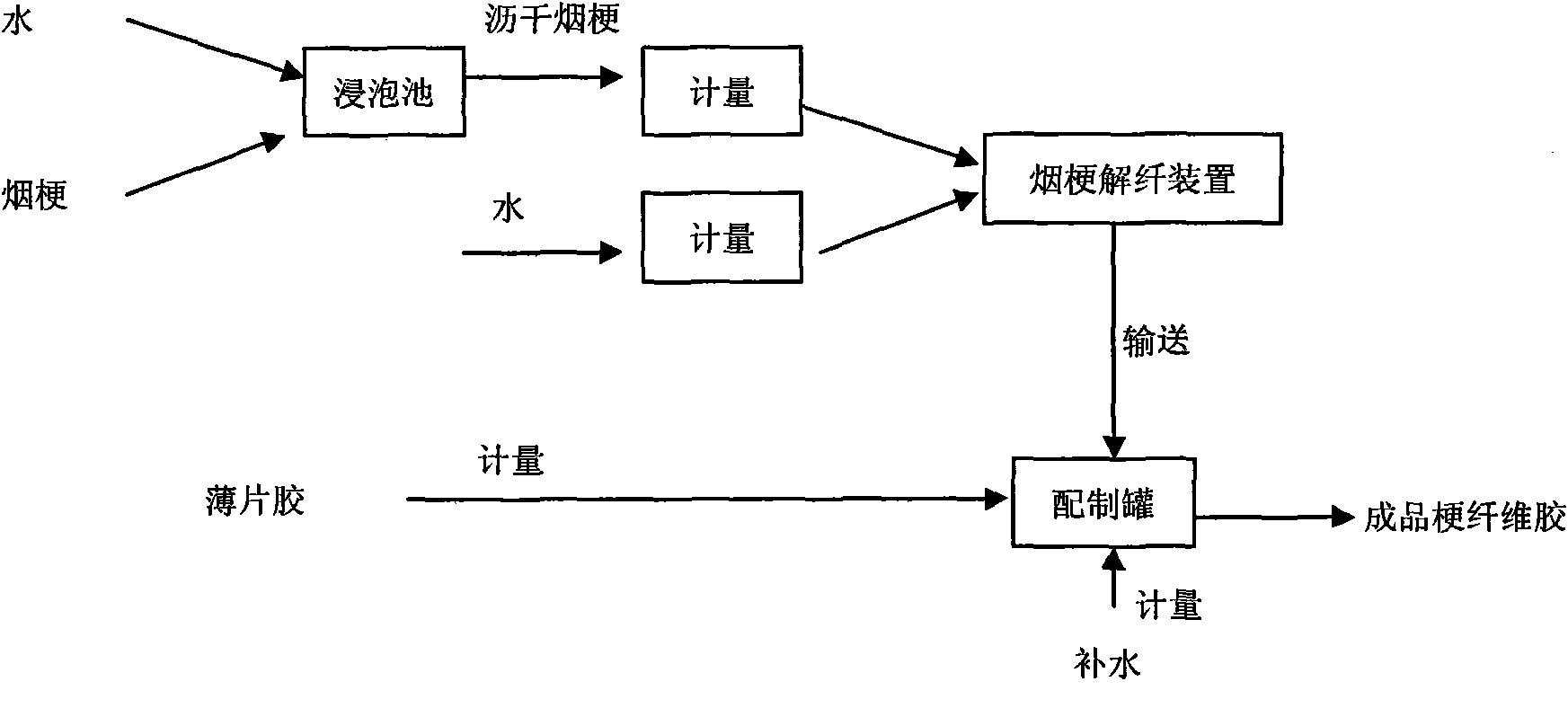

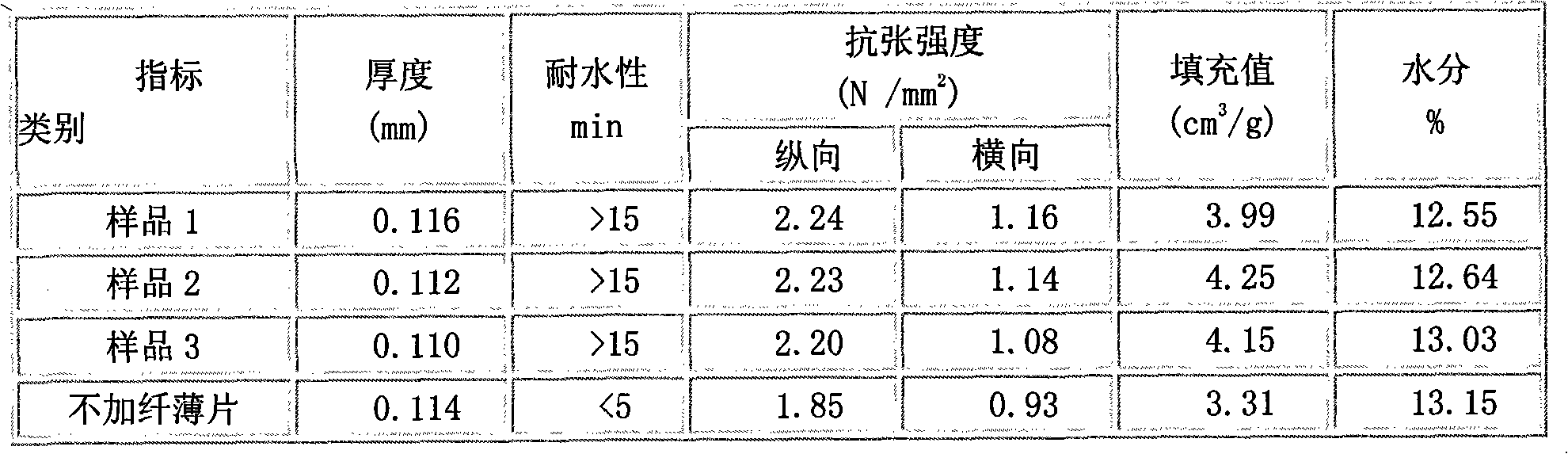

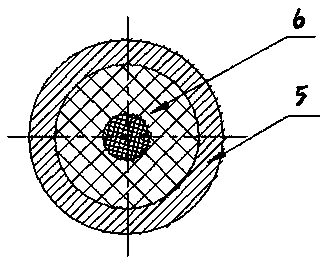

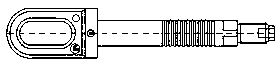

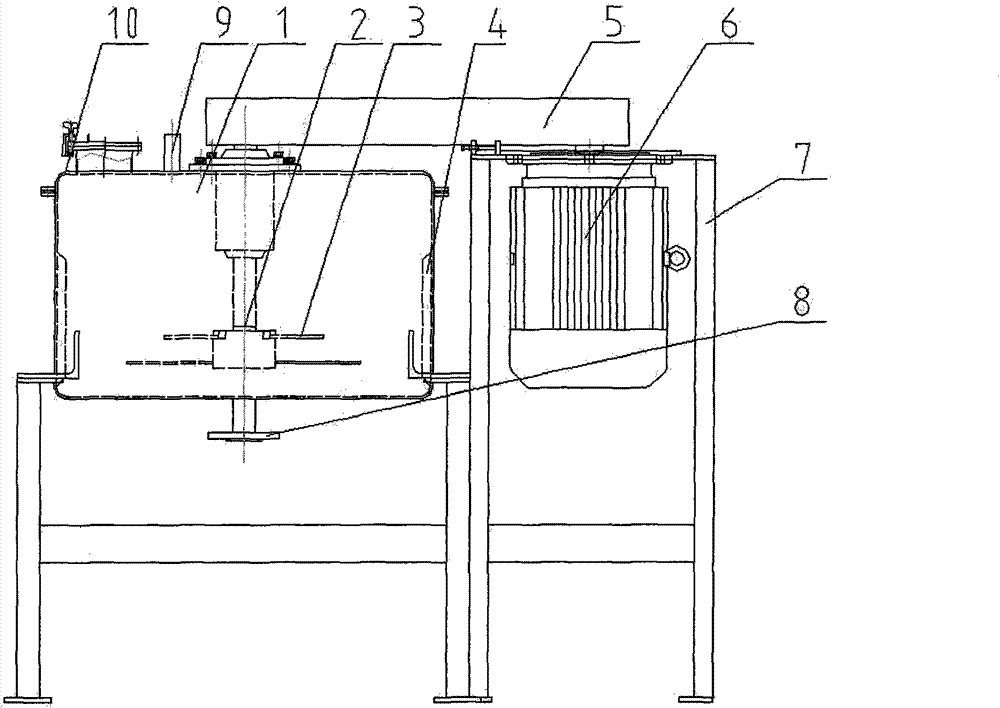

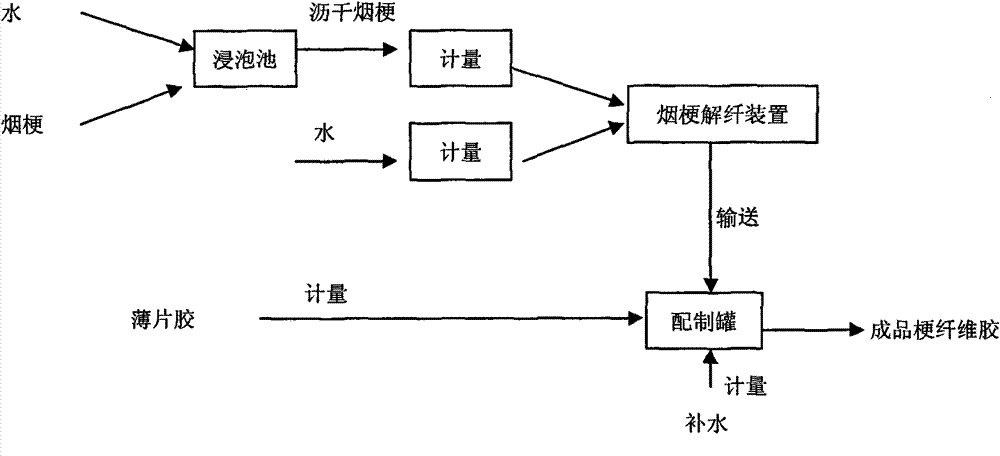

Defibering and fiber-adding process and equipment of tobacco stems of rolling process reconstituted tobacco

InactiveCN101664226AUniform thickness and lengthAvoid destructionTobacco preparationFiberNatural state

The invention discloses a defibering and fiber-adding process of tobacco stems of rolling process reconstituted tobacco, which comprises the following steps: (a) adding the tobacco stems without impurities into a soaking pool, adding appropriate amount of water to soak for 24-36h, spooning and dewatering to a natural state without separating out water; (b) putting the dewatered tobacco stems and water according to the weight proportion of 1:2-3 into a tank body of special tobacco stem defibering equipment for defibering for 10-30min, obtaining suspended fiber liquid with uniform size; and (c)mixing the fiber liquid obtained in the step b with slice glue according to the mass proportion of 1:1-1.5 into tobacco stem fiber-added glue stuff. The invention also discloses tobacco stem defibering equipment, a plurality of fixed cutters are uniformly arranged on the inner wall of the tank body along the circumference, a movable cutter assembly is arranged in the tank body and is connected with a stand in a cantilever way, the movable cutter assembly is provided with two sets of movable cutters, and a driver is linked with the movable cutter assembly through a drive assembly. The inventionreplaces expansive needlebush-bleaching chemical pulp, not only enables tobacco slices not to contain wood gases, but also greatly lowers the production cost.

Owner:中国船舶工业总公司七一五研究所宜昌分部

Self-compacting micro-expansive C55 concrete

The invention belongs to the technical field of resource utilization of solid waste, and aims at providing the self-compacting micro-expansive C55 concrete. To achieve the technical purpose, according to the technical scheme, the self-compacting micro-expansive C55 concrete is prepared from, by weight, 150-174 parts of finely-ground desulfuration residues, 350-406 parts of cement, 750-800 parts of river sand, 850-900 parts of crushed stone, 150-174 parts of water, 7.5-8.7 parts of activator and 7.0-8.1 parts of water reducing agent; the finely-ground desulfuration residues and the cement are binding materials, the total weight ratio of the activator to the cementing materials is 1.5%, the total weight ratio of the water reducing agent to the cementing materials is 1.4%, and the finely-ground desulfuration residues are prepared by grinding coal gangue desulfuration residues with a ball grinding mill and then sifting the coal gangue desulphurization residues with a 80-micrometer square hole sieve; the specific surface area of the finely-ground desulfuration residues is no less than 390 m<2> / kg; the C55 concrete has the advantages of being high in strength, self-compacting and micro-expansive, and can be widely applied to the field of construction.

Owner:山西晋硅朗科技有限公司

Water expansive polyurethane formed product and producing method thereof

A water-swellable polyurethane molded product obtained by heating and curing a kneaded product consisting of a polyurethane resin (A) and a vulcanizing agent (B), wherein (A) is a compound (a) represented by the following general formula (1) ), polyoxyalkylene polyol (b1) containing at least 20% by mass of ethylene oxide units, polyoxyalkylene polyol (b2) composed of one or more alkylene oxide units having 3 to 4 carbon atoms, organic polyisocyanates (c) and a polyurethane resin with at least one ethylenically unsaturated bond on the side chain obtained by adding the low-molecular active hydrogen-containing compound (d) as required; and the saturated volume water expansion ratio is 1.2 to 8 times. The present invention also relates to a method for its manufacture. (HO)mR(OX)r-m(1) In the formula, R is an r-valent polyol residue, X is a group having one or more ethylenically unsaturated bonds, r is an integer of 3 or more, and m is 2 or more and r-m is an integer of 1 or more.

Owner:SANYO CHEM IND LTD

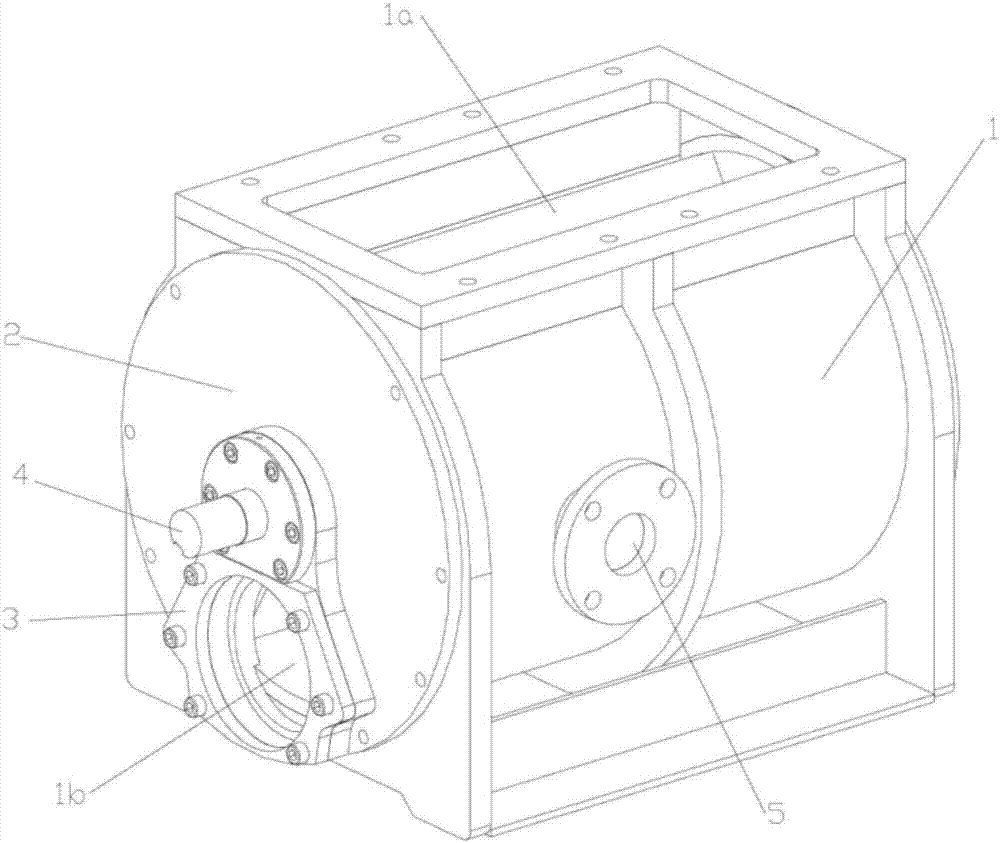

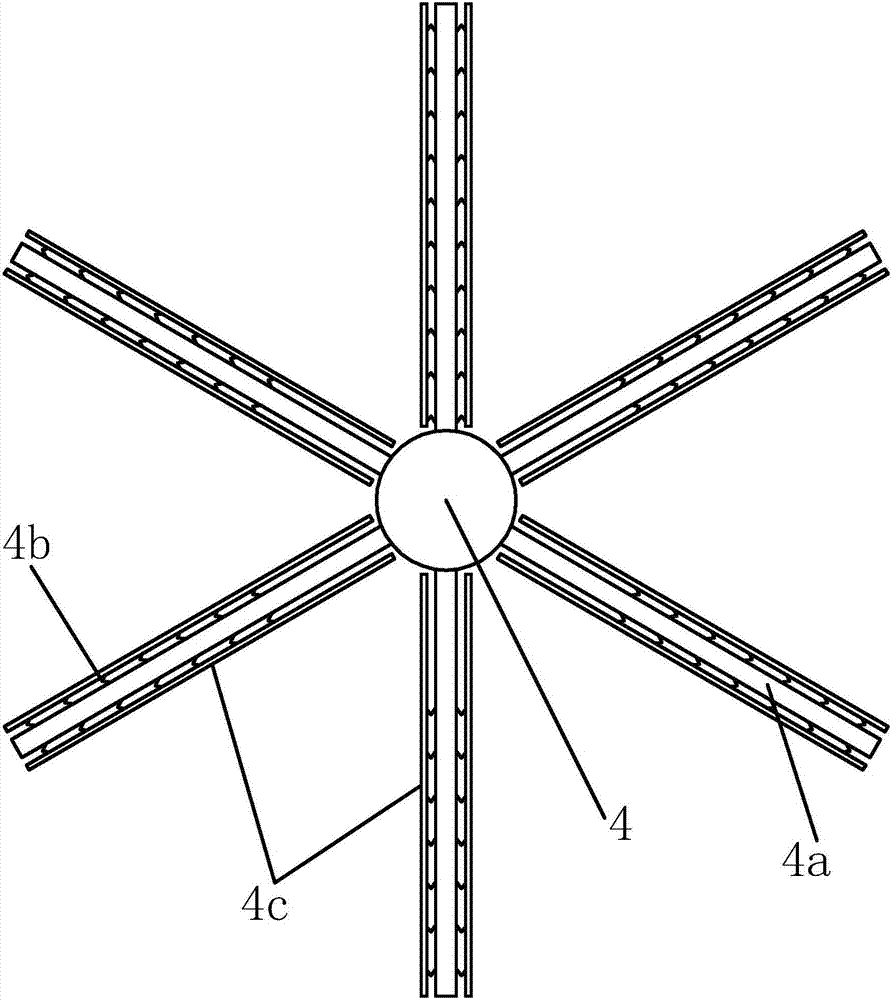

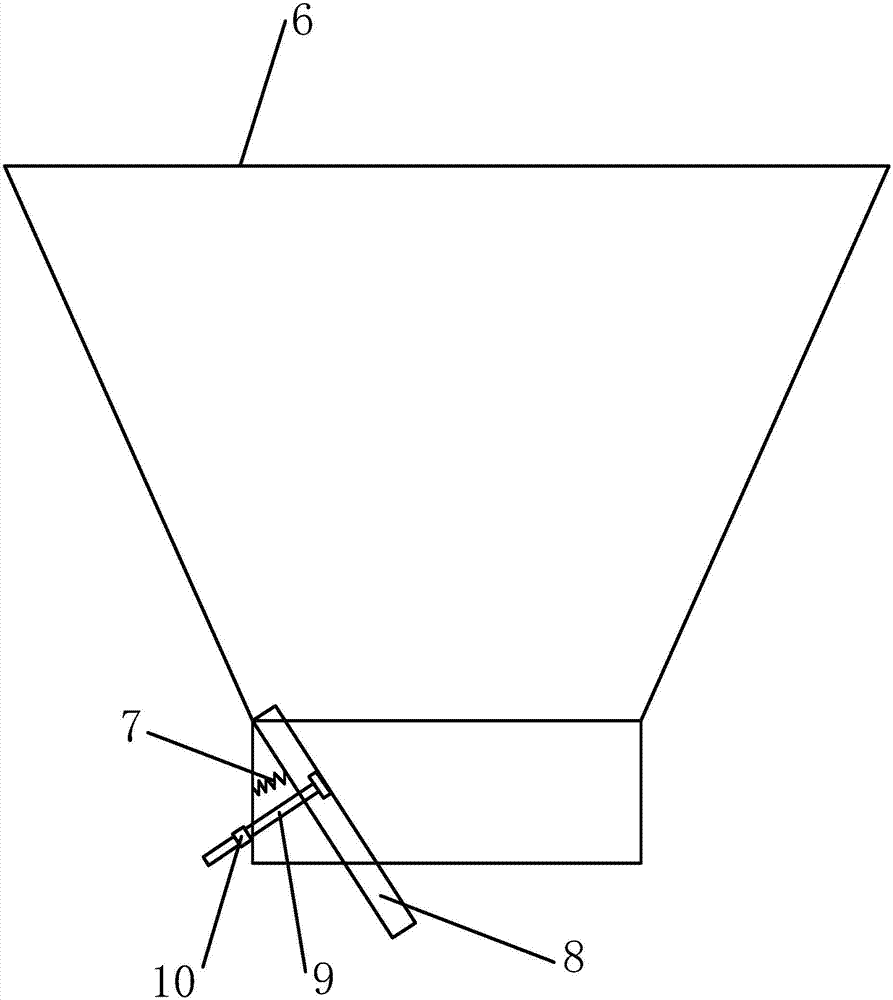

Improved rotary ice feeding system and operating method thereof

InactiveCN107161622AAvoid cloggingEliminate accumulationLarge containersRotary conveyorsBlade plateEngineering

The invention provides an improved rotary ice delivery system and its operation method. The improved rotary ice delivery system includes an ice hopper, a rotary ice delivery device, a blower and an ice delivery pipeline. A material guide plate is arranged at the outlet of the ice hopper, and the top of the material guide plate is hinged on the inner wall of the ice hopper. , a support spring is set between the material guide plate and the inner wall of the ice hopper, and a bolt adjustment assembly is also set between the material guide plate and the inner wall of the ice hopper, and the rotating blade shaft rotates along the axis in the casing, and the rotating blade shaft is radial A number of vanes are evenly distributed, and a trapezoidal cavity is formed between each adjacent two vanes. The trapezoidal cavity between each adjacent two vanes is turned to the upper side to connect with the discharge port. The trapezoidal cavity in the middle turns to the bottom to connect with the ice delivery ports at both ends, and forms a circumferential airtight ice delivery channel. The vibrating plates are set on the two side walls of the vane plate, and a spring layer is set between the vane plate and the vibrating plate. The spring layer It consists of several evenly distributed soft springs.

Owner:HAINING WENSHUO TECH CONSULTING CO LTD

Micro-expansive super early strength modifier for cement and using method thereof

InactiveCN102249585ALow costHigh temperature and corrosion resistanceBreaking strengthPortland cement

The invention relates to a micro-expansive super early strength modifier for cement and a using method thereof. The modifier comprises the following raw materials in part by mass: 30 to 40 parts of CaO, 10 to 20 parts of CaSO4, 45 to 65 parts of C4A3 and 25 to 35 parts of Al2O3. The micro-expansive super early strength modifier is combined with the ordinary portland cement, so that the cement has the advantages that: 'the breaking strength of 12 hours is more than 4.5 MPa; the compression strength of 12 hours is more than 20MPa; the breaking strength of 24 hours is more than 7.5 MPa; the compression strength of 24 hours is more than 30 MPa; the breaking strength of 7 days is more than 12 MPa; the compression strength of 7 days is more than 70 MPa; and the coefficient of linear expansion is more than 0.05 percent'. Compared with the common organic anchoring reinforcement material, the micro-expansive super early strength modifier has the advantage that: the cost of the material is reduced greatly, namely is reduced by over 50 percent on the premise of meeting the requirement of strength.

Owner:福建省交通科学技术研究所

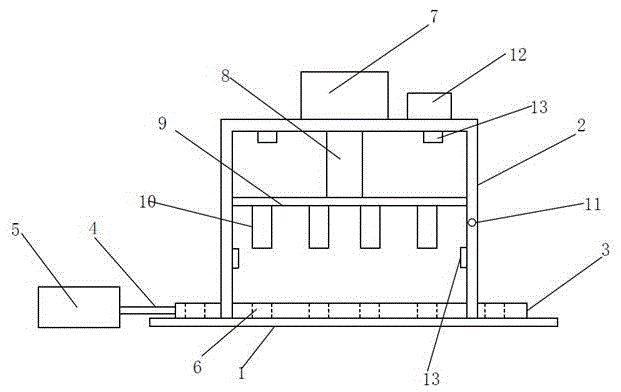

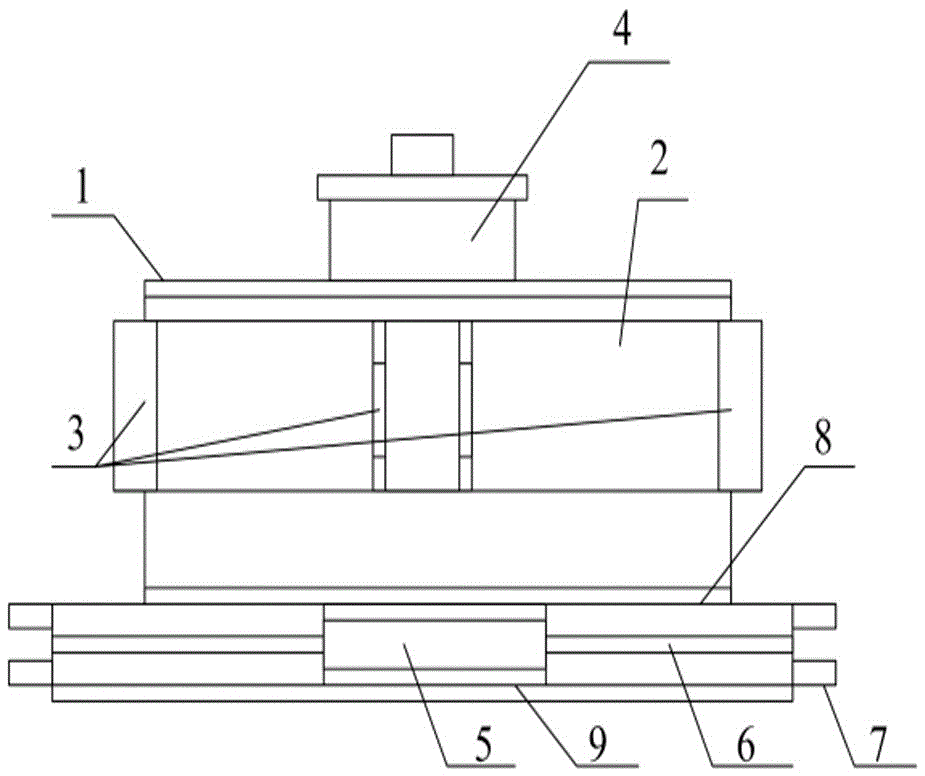

Aluminum foil expansive sticking device for upper shells of gas generators

InactiveCN105537857AReasonable structureEasy to useVehicle componentsMetal working apparatusGas cylinderEngineering

The invention discloses an aluminum foil expansive sticking device for upper shells of gas generators. The device comprises a base, wherein a frame-shaped main support is arranged above the base, a sliding feeding block is movably arranged on the upper surface of the base, one end of the sliding feeding block is connected with the output end of a gas cylinder through a connecting rod, and the gas cylinder is connected with a gas pump; the sliding feeding block is pulled back and forth through the action of the gas cylinder; a hydraulic oil cylinder is arranged above the main support, and an output cylinder rod of the hydraulic oil cylinder is vertically downward and fixedly connected with a press rod. The aluminum foil expansive sticking device is reasonable in structure, convenient to use and high in overall efficiency, can perform aluminum foil expansive sticking on the upper shells of multiple gas generators simultaneously, is provided with a safety mechanism and avoids the injury condition.

Owner:岑立强

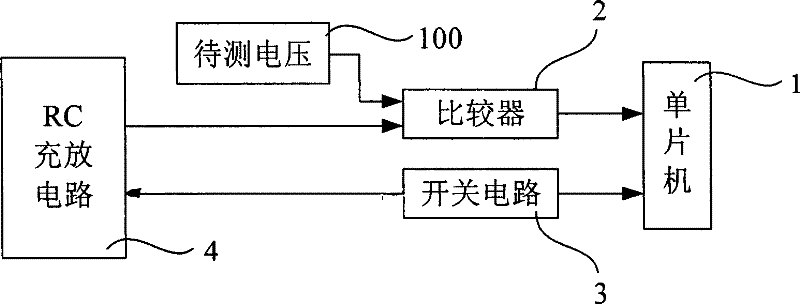

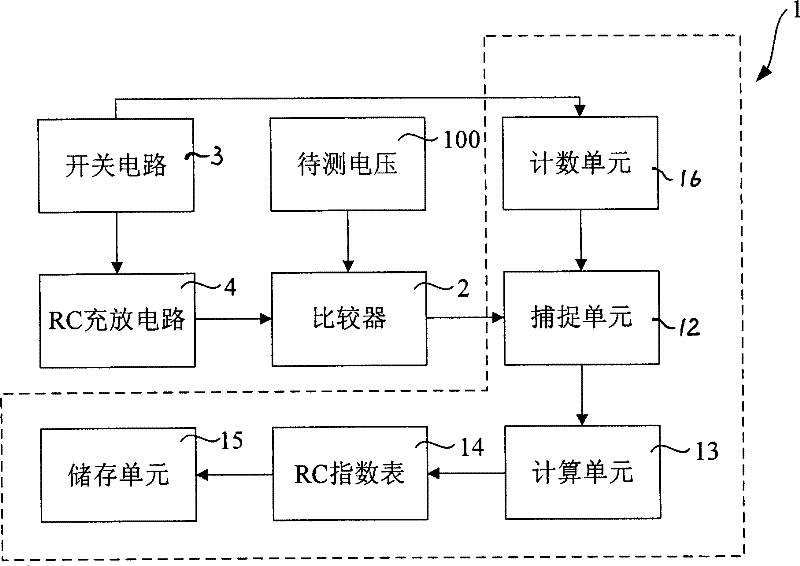

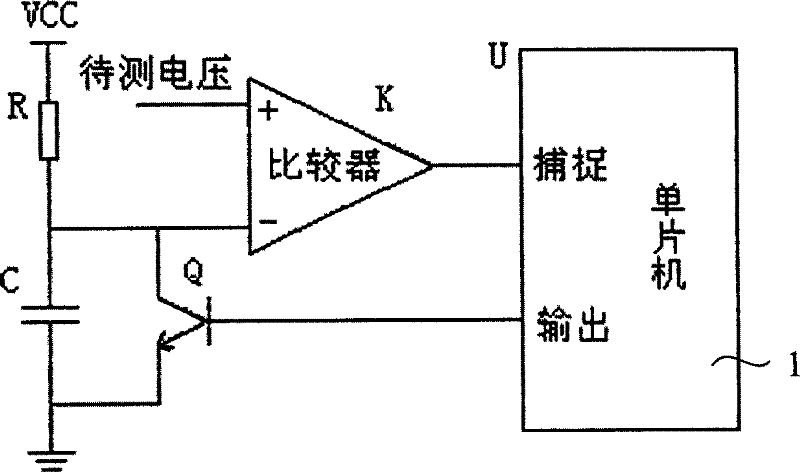

Singlechip signal sampling apparatus without module converter and sampling method thereof

InactiveCN101063693BLow priceHigh precisionMeasurement using digital techniquesMicrocontrollerEngineering

Owner:无锡联源新能源技术有限公司

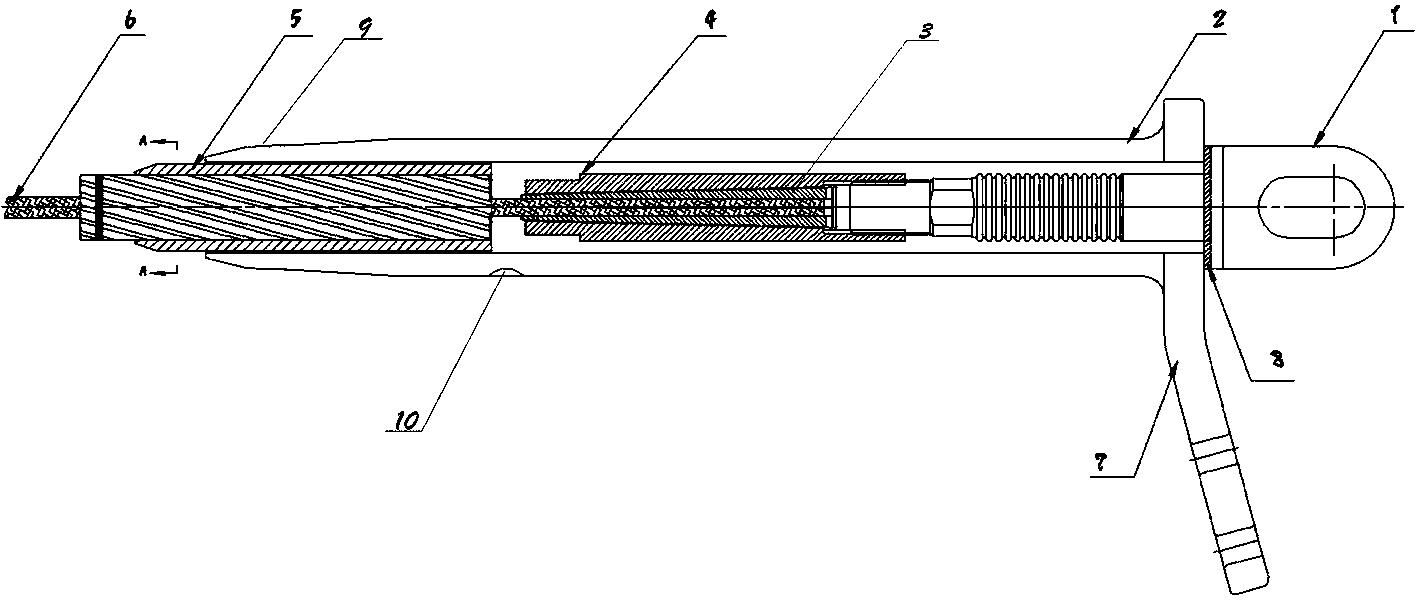

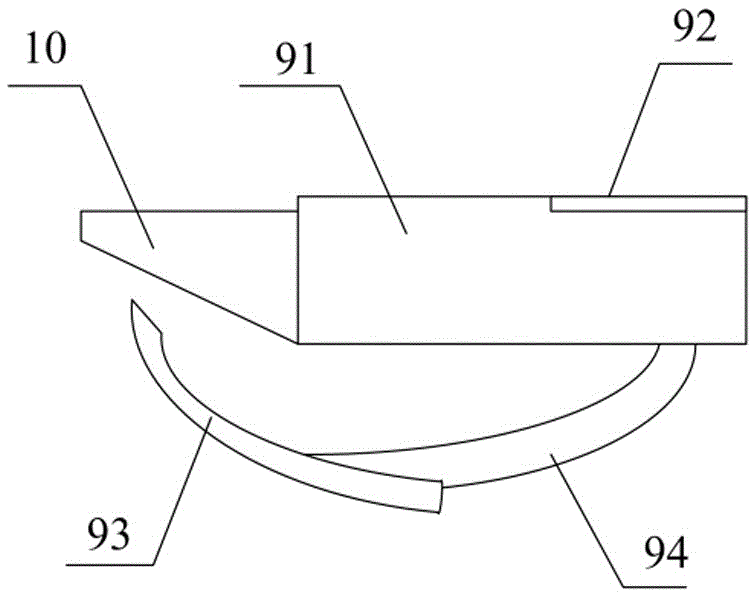

Expansive force terminal strain clamp of composite core aluminum-stranded conductor

InactiveCN103354339AIncrease frictionImprove gripAdjusting/maintaining mechanical tensionEngineeringExpansive

The invention relates to an expansive force terminal strain clamp of a composite core aluminum-stranded conductor. The strain clamp is composed of a spinning type steel anchor, a strain casing tube, a tension clamp core, a strain clamp sleeve, an inner liner tube, a lead core, a drainage board, a silica gel pad, a compressing point, and an exploding pressing point. The tension clamp core is sleeved in the strain clamp sleeve and is arranged at the middle section of the strain casing tube. The front end of the spinning type steel anchor is contacted with the strain clamp sleeve and is fixed with the strain casing tube by a threaded connecting way; and the silica gel pad is arranged at the joint position for sealing. The front end of the strain clamp sleeve is arranged at the exploding pressing point; the inner liner tube is arranged in the front end of the strain casing tube and is compressed and fixed by the compressing point. The advantages of the strain clamp are as follows: the streamline design of the drainage board enables a discharging phenomenon to be alleviated and thus the energy consumption is reduced; a peripheral line is arranged at the outer surface of the inner liner tube and thus the friction force between the inner liner tube and the strain casing tube is increased, thereby improving the stability; and because of arrangement of the compressing point, the tension clamp core can generate a stable radial pressure and generate great gripping power. Moreover, the provided strain clamp has the characteristics of simple structure, convenient installation, and obvious effect.

Owner:蔡威

Defibering and fiber-adding process and equipment of tobacco stems of rolling process reconstituted tobacco

InactiveCN101664226BUniform thickness and lengthAvoid destructionTobacco preparationFiberNatural state

Owner:中国船舶工业总公司七一五研究所宜昌分部

A kind of micro-expansion coral sand concrete and its preparation method

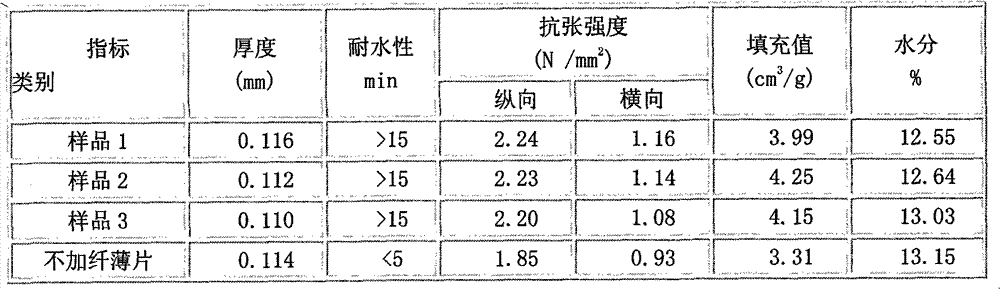

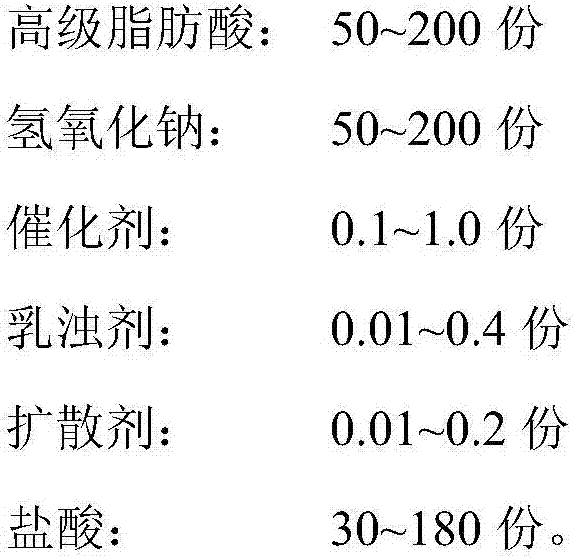

The invention discloses a micro-expansive coral sand concrete and a preparation method thereof. The micro-expansive coral sand concrete is composed of the following components in parts by weight: 300-450 parts of cement, 15-45 parts of admixture, 600-725 parts of coral sand, 975-1150 parts of macadam, 165-205 parts of seawater, 3-7 parts of water reducing agent and 1.5-2.5 parts of liquid expanding agent. The main component of the liquid expanding agent is an emulsion generated by saponifying higher fatty acids. The novel concrete admixture liquid expanding agent is utilized to obviously enhance and improve the dry shrinkage and volume stability of the concrete. The double expansion effects sufficiently enhance the compactness of the concrete, and effectively repair and improve the porosity of the concrete, thereby ensuring the volume stability of the coral sand concrete.

Owner:WUHAN UNIV OF TECH

Progesterone vaginal expansion suppository and its preparation method and detection method

ActiveCN103735492BGood water solubilityImprove bioavailabilityOrganic active ingredientsSuppositories deliveryCross-linkCarboxymethyl cellulose

The invention relates to a progesterone vaginal expansion suppository and its preparation method and detection method. The expansion suppository comprises a drug-containing matrix and an expansion carrier formed by progesterone and a matrix; the drug-containing matrix also includes cross-linked dextran gel, carboxylated Sodium methylcellulose, monolauroyl glycerin, glycerol diacetate, glycerin and sodium citrate; cross-linked sephadex and sodium carboxymethylcellulose form inclusion complexes with progesterone; this The inventive progesterone vaginal expansion suppository has beneficial effects such as high bioavailability and uniform drug dispersion.

Owner:哈尔滨田美药业股份有限公司

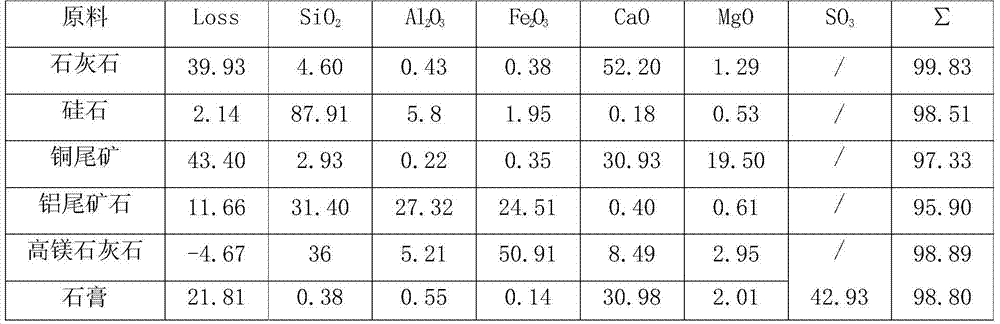

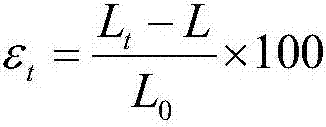

Method for producing low-alkali micro-expansive moderate heat Portland cement from waste aluminum ore

The invention discloses a method for producing low-alkali micro-expansive moderate heat Portland cement from waste aluminum ore. The method comprises the following steps: weighing the following components in parts by weight: 78-83 parts of clinker, 4-6 parts of fly ash waste, 2-3 parts of agar, 6-8 parts of waste aluminum ore powder, and 5-8 parts of desulfurized gypsum, wherein the clinker is produced from the following raw materials in percentage by weight: 85-88% of limestone, 6.5-9% of sandstone, 4.5-7% of aluminum oxide red mud, and 0.05-1% of copper slag; controlling the temperature of the raw materials to a range of at 850-880 DEG C in a decomposing furnace; preparing the clinker by calcining in a rotary kiln revolving at a speed of 3.75-3.85 r / min under the condition of system airdischarging from -7200 Pa to -7500 Pa; and mixing the prepared clinker with the clinker composed of the limestone, the waste aluminum ore powder and the desulfurized gypsum in a weight ratio; and forming the mixed clinker into the micro-expansive moderate heat Portland cement disclosed in the present invention by means of a cement grinding mill. The method for producing low-alkali micro-expansivemoderate heat Portland cement from waste aluminum ore has the advantages that the process is simple, and the product is stable in properties with indexes such as linear expansion rate, hydration heatand the like meeting the anticipated demand, and can be widely used in construction of large-size, high-strength buildings, highway tunnels, culverts and the like.

Owner:安徽珍珠水泥集团股份有限公司

A kind of micro-expansion self-healing polyurethane waterproof mortar and preparation method thereof

The invention provides a micro-expansive self-repaired polyurethane waterproof mortar which comprises the following components in parts by weight: 60-90 parts of a water hardened mortar aggregate system containing organic silicon active matters, 5-25 parts of a compound polyol emulsion system and 5-25 parts of an isocyanate curing agent, wherein the water hardened mortar aggregate system comprises the organic silicon active matters and cement mortar in a mass ratio of 1-7 to 93-99; the compound polyol emulsion system comprises polyol resin, castor oil polyol resin, an emulsifier and water in a mass ratio of 4-30 to 8-50 to 0.05-0.3 to 10-40. The invention further provides a preparation method of the micro-expansive self-repaired polyurethane waterproof mortar. The waterproof mortar is simple in preparation process and convenient to construct and the cured and formed mortar is good in micro-expansive performance and excellent in self-repairing performance. Moreover, the mortar further has self compacting capability, shock resistance, wear resistance, and hydrophobic property and waterproof performance.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

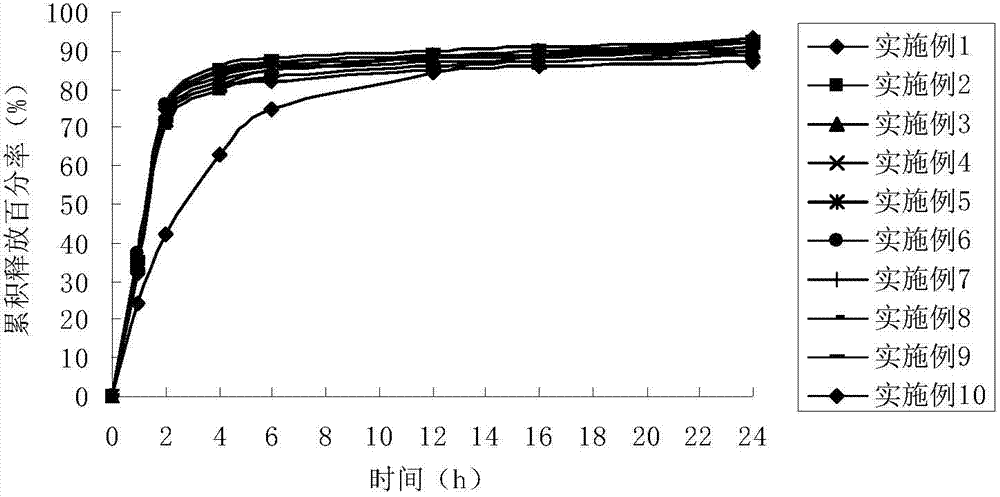

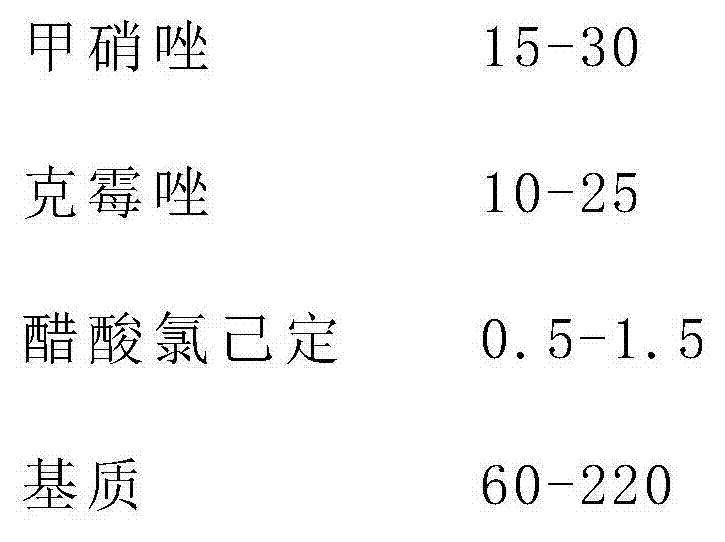

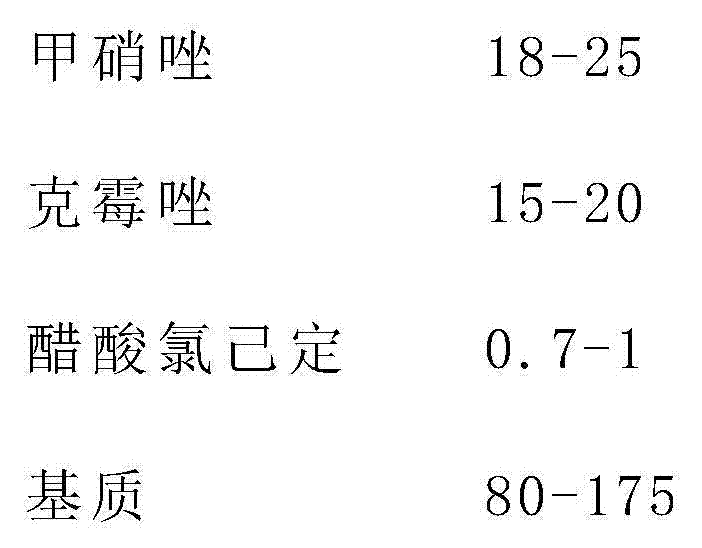

Shuangzotai vaginal expansion suppository controlled-release preparation and its preparation method

ActiveCN103735547BImprove stabilityStable drug releaseOrganic active ingredientsAntisepticsChlorhexidine AcetateIrritation

The invention relates to a metronidazole-clotrimazole-chlorhexidine acetate vaginal expansive suppository controlled-release preparation and a preparation method thereof. The metronidazole-clotrimazole-chlorhexidine acetate vaginal expansive suppository controlled-release preparation comprises a suppository core and a controlled-release coating at the outer layer of the suppository core, wherein the controlled-release coating consists of a special coating material and a plasticizer, so that the expansive suppository controlled-release preparation has a zero-order stable release effect; moreover, by using the controlled-release coating, the expansive suppository controlled-release preparation can be stabilized, and the irritation of the controlled-release preparation on the vagina can be lowered; furthermore, by adopting seven types of unique leading technologies, the metronidazole-clotrimazole-chlorhexidine acetate vaginal expansive suppository controlled-release preparation has the beneficial effects of preventing a liquid medicament from flowing outwards, preventing secondary infection, and the like.

Owner:哈尔滨田美药业股份有限公司

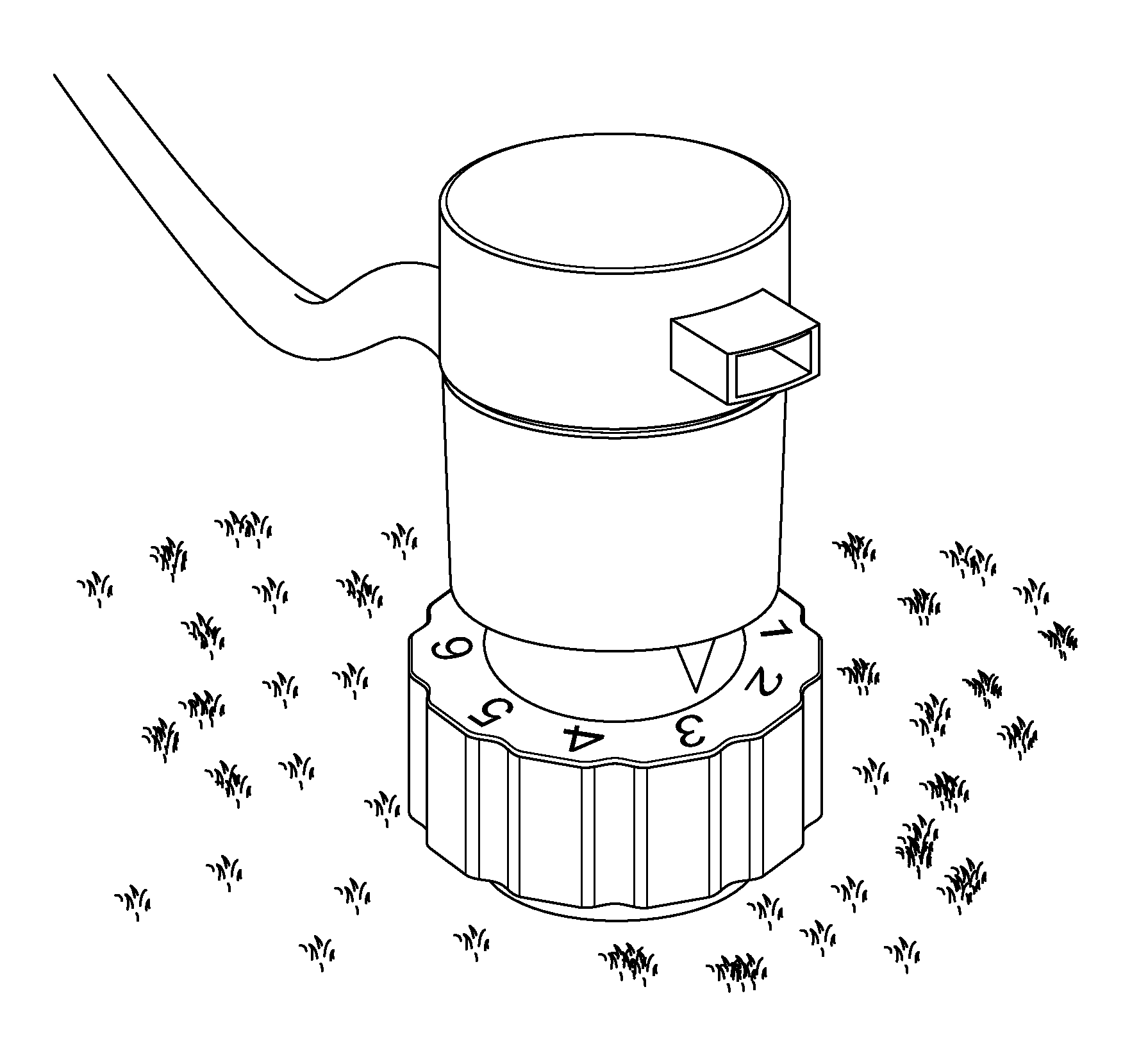

Self-Regulating Irrigation Controller

InactiveUS20140263733A1Restrict water flowAppropriately calibrateWatering devicesSpraying apparatusEngineeringControl valves

Owner:SHIELDS RODNEY M

Expansive well drilling pile grouting equipment with wide adaptability

ActiveCN106401482AStable supportStrong radial expansion forceDrill bitsDrilling machines and methodsHydraulic cylinderWell drilling

The invention provides expansive well drilling pile grouting equipment with wide adaptability. The equipment comprises an expansion table, a machine body, a friction plate, a driving mechanism, a hydraulic cylinder, a piston rod, a drilling bit, an inner cylinder and an expansion arm; the expansion table is arranged at the upper part of the machine body; the friction plate is mounted on the outer side of the machine body; the driving mechanism is connected to the top of the machine body; the outer side of the hydraulic cylinder is connected with the piston rod; and the drill bit is mounted on the outer side of the expansion arm. The expansive well drilling pile grouting equipment with wide adaptability can improve the adaptability through settings of the expansion arm, the hydraulic cylinder and the friction plate, is suitable for operation on rocks with higher hardness, guarantees smooth subsequent pile grouting, is safe and reliable, is stable in operation, and is convenient for market popularization and application.

Owner:山东烟台鑫泰黄金矿业有限责任公司

Low-heat micro-expansive cement

ActiveCN102515582BReduce manufacturing costReduce heat of hydrationCement productionExpansiveMaterials science

The invention discloses low-heat micro-expansive cement and relates to the technical field of engineering materials. The low-heat micro-expansive cement is prepared by mixing the following components in parts by weight: 2-30 parts of vanadium-titanium mineral slag, 2-30 parts of phosphorus slag, 20-62 parts of granulated blast furnace slag, 18-45 parts of cement clinker, 7-15 of gypsum or anhydrite and 0.2-5 parts of other additives. The low-heat micro-expansive cement disclosed by the invention is adopted, thus vanadium-titanium slag resources are comprehensively utilized; and under the condition that the resources are deficient, the vanadium-titanium slag, the phosphorus slag and the like are used to replace the formula of the existing low-heat micro-expansive cement, thus production cost is reduced, and the physical property of the produced cement meets the requirement of GB2938 cement standard.

Owner:EMEISHAN QIANGHUA SPECIAL CEMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com