Micro-expansion hydrophobic polyurethane cement mortar composition and preparation method thereof

A cement mortar and hydrophobic technology, which is applied in the field of building materials, can solve problems such as poor compatibility, and achieve the effects of good hydrophobic performance, convenient construction, and strong environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

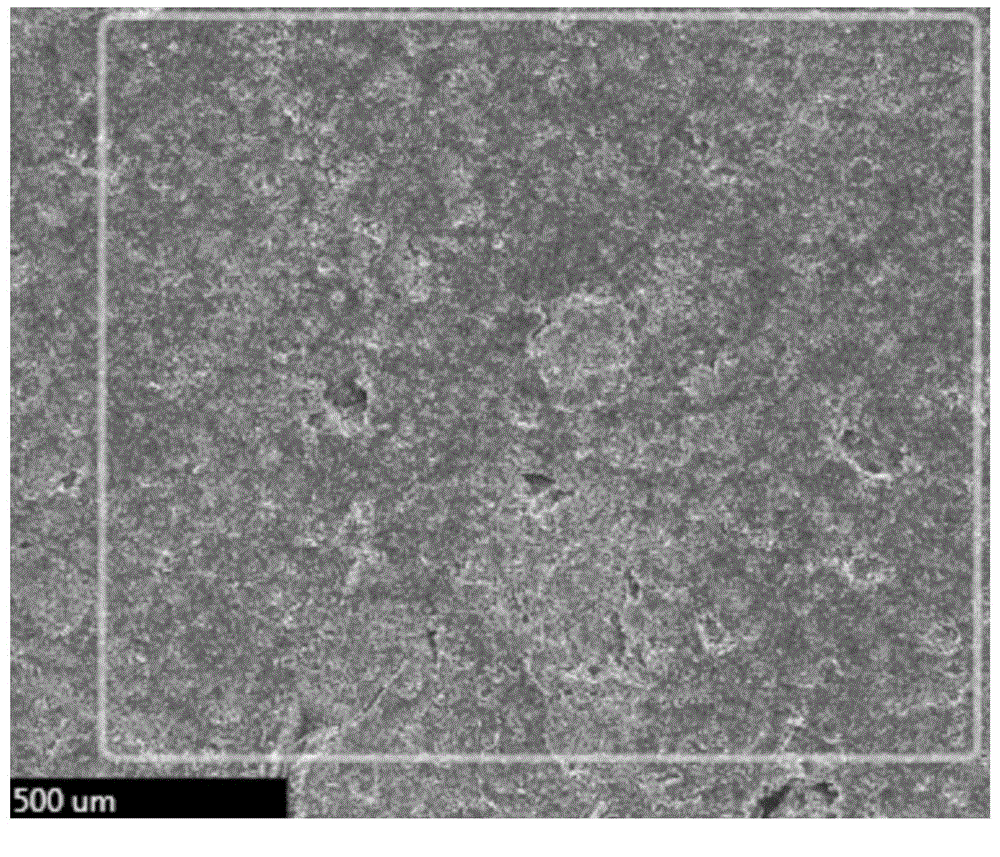

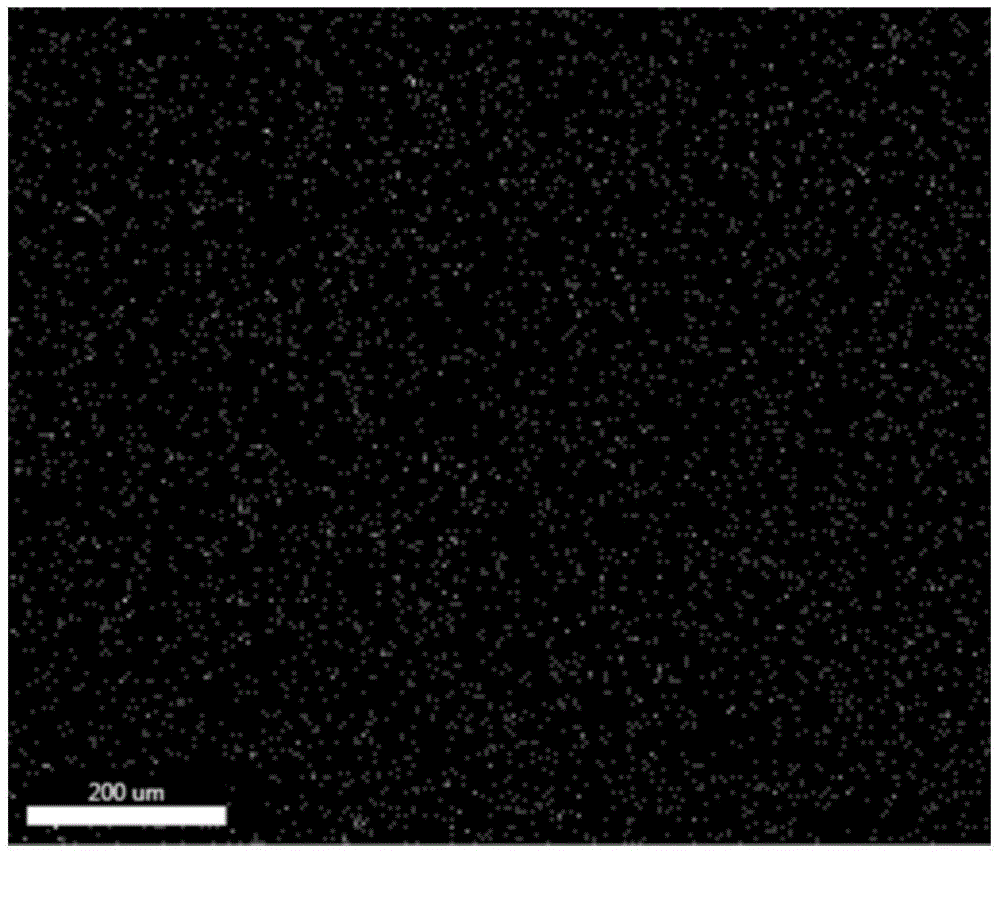

Image

Examples

Embodiment 1

[0033] Add 2 parts of water-dispersible polyol resin (PEG200, commercially available) to 10 parts of water in a high-speed dispersion environment of 1000r / min, and heat up to 35°C for dissolution; water-emulsifiable castor oil polyol resin heated to 35°C (Ito Oil Co., Ltd., H-306) 18 parts were successively added to the dispersion system, and continued to emulsify and disperse at a high speed of 1000r / min for 20 minutes to obtain a composite polyol emulsion system; add 20 parts of isocyanate curing agent (PAPI, Bayer 44V20), Stir for 2 minutes, add 62 parts of water-hardening mortar aggregate system (32.5 white Portland cement: 0.35-0.5mm sand: 0.25-0.5mm sand: 0.1-0.25mm sand = 25:10:50:15) successively, Stir for 5 minutes to obtain polyurethane cement mortar.

Embodiment 2

[0035] Add 3 parts of water-dispersed bifunctional polyol resin (PEG2000, commercially available), 2 parts of tetrafunctional polyol resin (N403, Jiangsu Zhongshan Chemical Industry) into 13 parts of water in a high-speed dispersion environment of 3000r / min, and heat up to 55 ℃; add 8 parts of water-emulsifiable castor oil polyol resin heated to 55℃ (Ito Oil Co., Ltd., HF-1300) into the dispersion system successively, and continue emulsifying and dispersing at 2000r / min for 40min at a high speed to obtain a composite Polyol emulsion system; add 15 parts of isocyanate curing agent (PAPI, Bayer 44V20), stir for 3 minutes, mix 70 parts of water-hardening mortar aggregate system (32.5 white Portland cement: 0.35~0.5mm sand: 0.25~~0.5mm sand : 0.1 ~ 0.25mm sand = 35:5:55:5) added successively, stirred for 10 minutes, and the obtained polyurethane cement mortar.

Embodiment 3

[0037]Add 4 parts of water-dispersed polyol resin (EO / PO=4:6, bifunctionality, molecular weight 2000, Nanjing Bote New Material Co., Ltd.) to 7 parts of water in a high-speed dispersion environment of 5000r / min, and heat up to 70 ℃; add 12 parts of water-emulsifiable castor oil polyol resin heated to 70℃ (Ito Oil Co., Ltd., HM-306) into the dispersion system successively, and continue to emulsify and disperse at 5000r / min for 50min at a high speed to obtain a composite Polyol emulsion system; add 13 parts of isocyanate curing agent (PAPI, Wanhua PM200), stir for 5 minutes, mix 78 parts of water-hardening mortar aggregate system (32.5 white Portland cement: 0.35~0.5mm sand: 0.25~~0.5mm Sand: 0.1 ~ 0.25mm sand = 35:5:55:5) add in succession, stir for 8 minutes, and obtain polyurethane cement mortar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com