Patents

Literature

5978 results about "Cement mortar" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

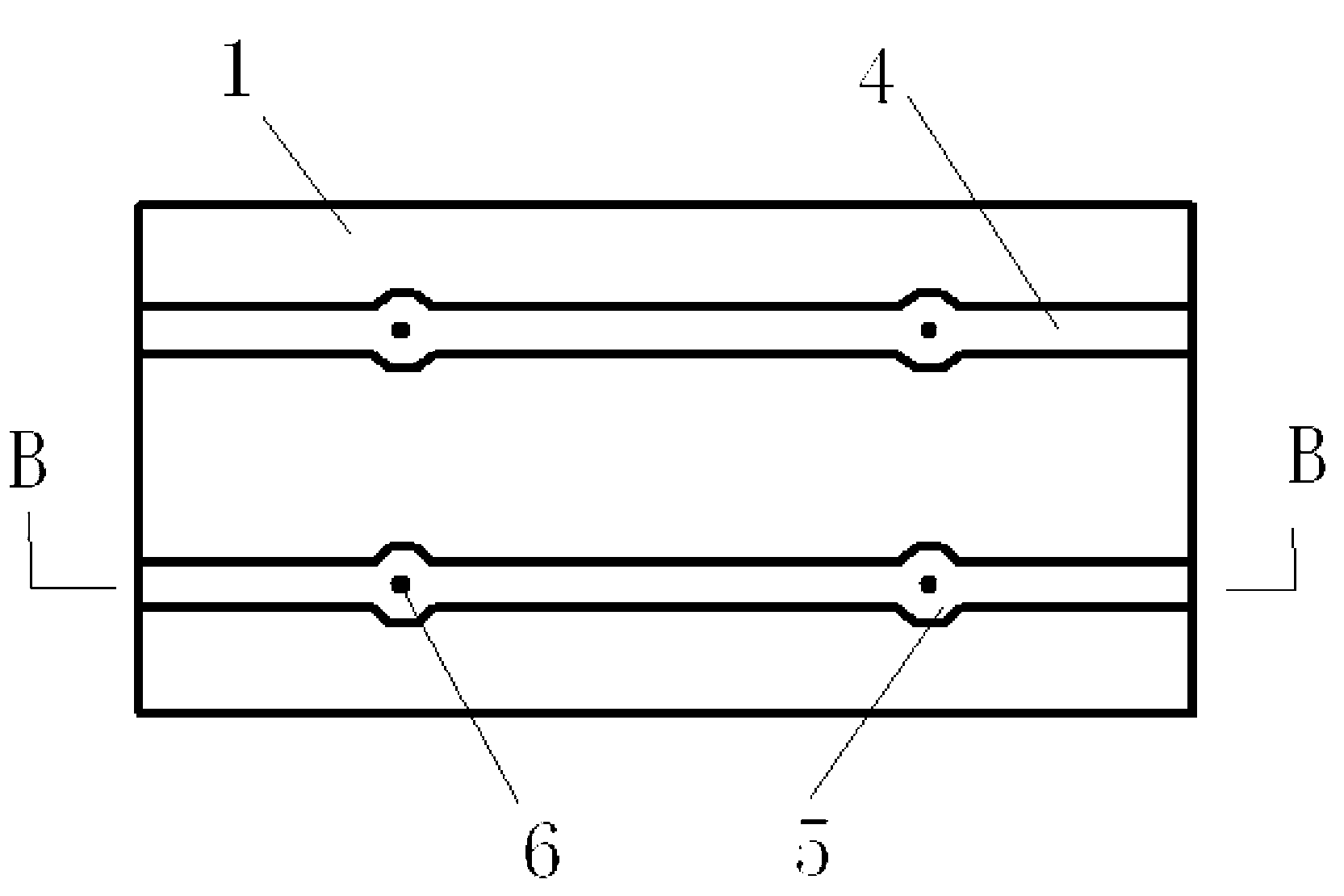

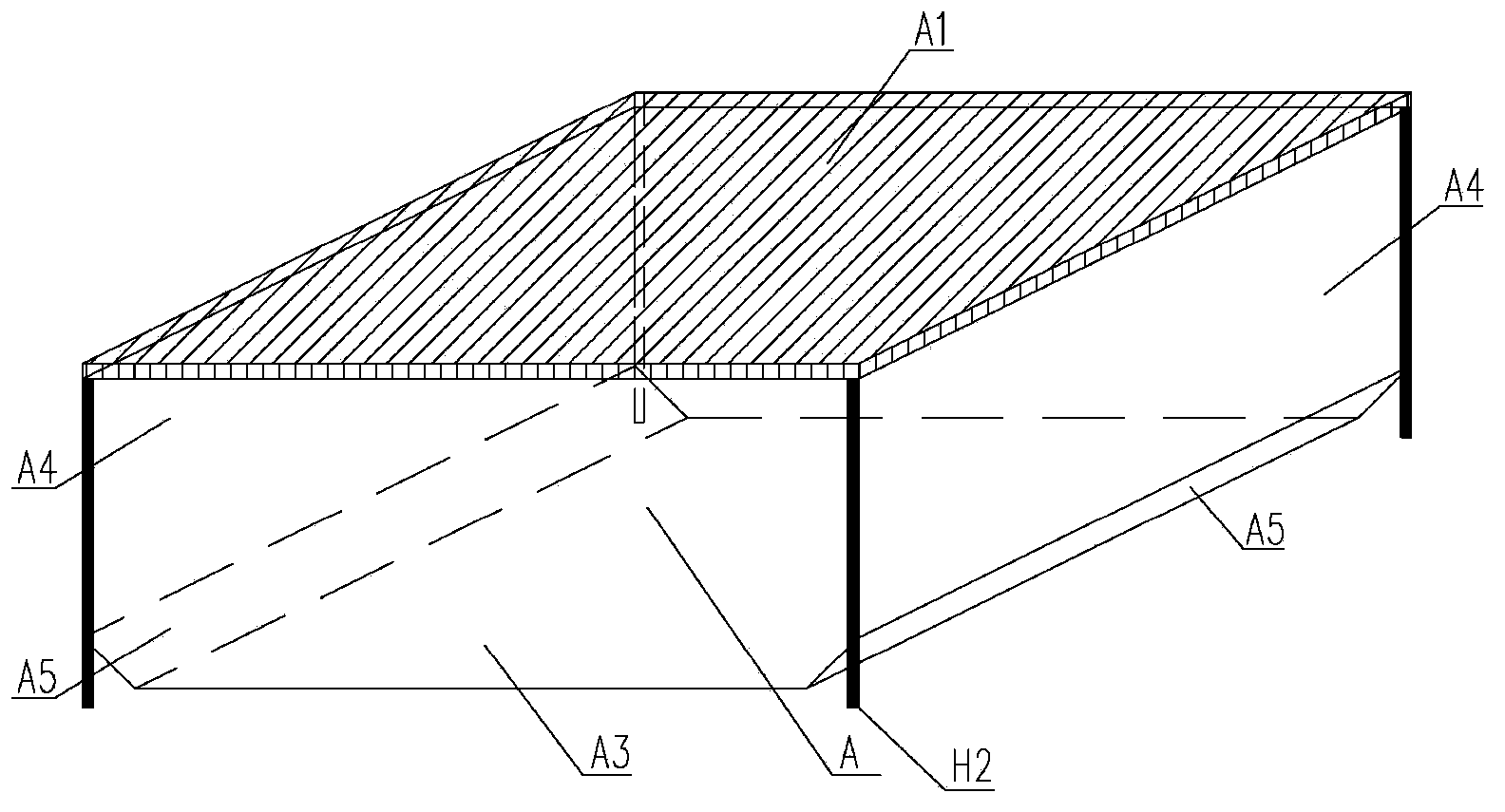

Self-heat-preservation building block and self-heat-preservation wall body consisting of self-heat-preservation building blocks

ActiveCN103243857AMeet heat preservation and energy saving requirementsPlay a role in heat preservationConstruction materialWallsWhole bodySlurry

The invention relates to the field of building materials, and in particular relates to a self-heat-preservation building block and a self-heat-preservation wall body consisting of self-heat-preservation building blocks, which aim to solve the technical problem that conventional building wall body materials cannot have the functions of bearing, heat preservation and fire prevention simultaneously. According to the technical scheme, the self-heat-preservation building block comprises a building block body which is made of foamed cement; transverse through slots are formed in the upper surface of the building block; vertical through holes are formed in the building block; one or several of concrete slurry, cement mortar, plaster and heat preservation plaster is / are filled into the transverse through slots to form core columns; concrete slurry or cement mortar is filled into the vertical through holes to form core columns; and the core columns and the building block body are combined to form a whole body. The self-heat-preservation wall body consists of the self-heat-preservation building blocks. The self-heat-preservation building block and the self-heat-preservation wall body have functions of heat preservation and fire prevention as well as bearing.

Owner:丹东市兄弟建材有限公司

Gelatinization material gypsum-cement and producing method thereof

The invention relates to a gypsum-cement binding material and a production method thereof. The material contains gypsum binding material, active admixture, alkaline excitant, oagulation accelerator, lime, water-reducing agent, early-strength agent and gypsum hemihydrate. The weight proportions of the components are as follows: 40%-80% of gypsum binding material, 10%-45% of active admixture, 4%-15% of alkaline excitant, 0-6% of coagulation accelerator, 0-1% of early-strength agent, 0-1% of water-reducing agent, 0-5% of lime and 0-10% of gypsum hemihydrate. The production method comprises the following steps: weighing raw materials at the given ratio, mixing all raw materials, and packaging. The inventive gypsum-cement material has high strength, good water resistance and good volume stability; and can be used as masonry cement, cement mortar, gypsum plaster, jointing gypsum and heat-insulating mortar.

Owner:长沙归一新材料科技股份有限公司

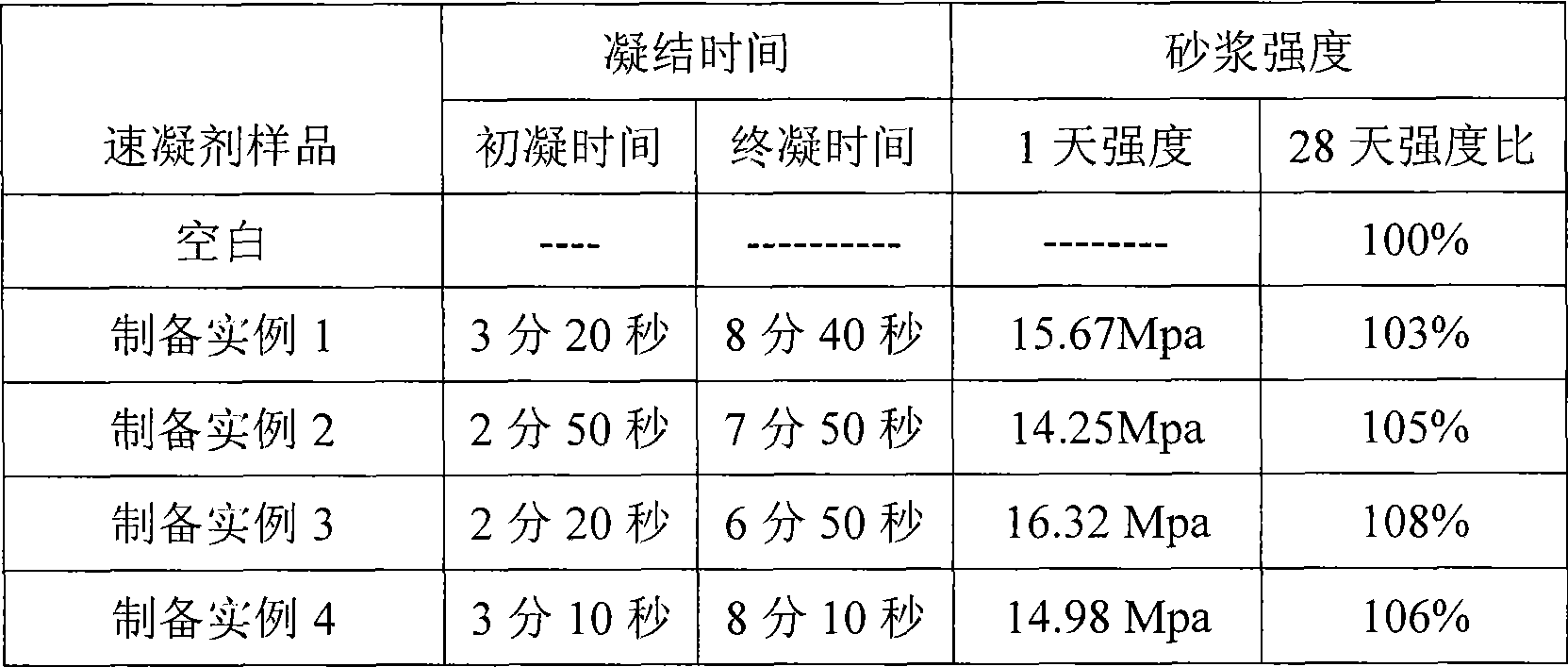

Alkali-free liquid accelerating agent and preparation method thereof

The invention belongs to the technical field of tunnel construction, and relates to an alkali-free liquid accelerating agent for tunnel wet jet concrete and a preparation method thereof. The alkali-free liquid accelerating agent is characterized in that aluminium sulphate is adopted to serve as a main accelerating component; aluminium is added to an aluminium sulphate solution to be polymerized in a form of aluminium fluoride; aluminium ions are introduced to the greatest extent so as to reduce other ion introduction; and the accelerating effect is ensured. The alkali-free liquid acceleratingagent comprises the following components in percentage by mass: 30-55% of aluminium sulphate, 5-15% of aluminium hydroxide, 10-30% of hydrofluoric acid, 0.5-5% of water glass, 0-0.2% of stabilizing agent, and the balance of water. For jetting concrete, the alkali-free liquid accelerating agent disclosed by the invention has the positive effects that: ordinary cement can be initially solidified within 2 min in lower doping quantity and finally solidified within 4 min; the 1d strength of cement plaster can achieve above 15 MPa; the 28d compressive strength ratio is more than 100%; and the alkali-free liquid accelerating agent has good adaptability to different types of cements.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

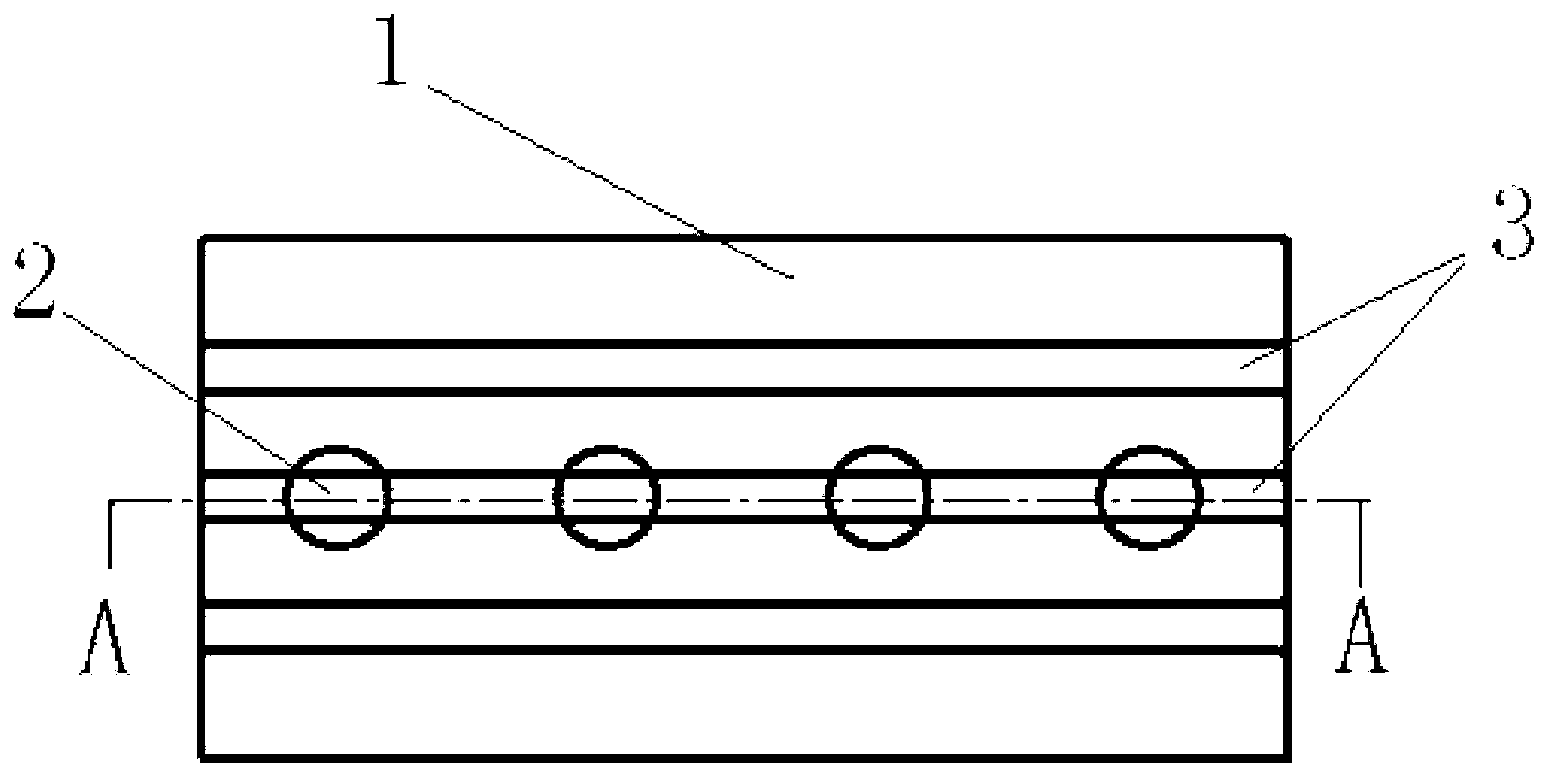

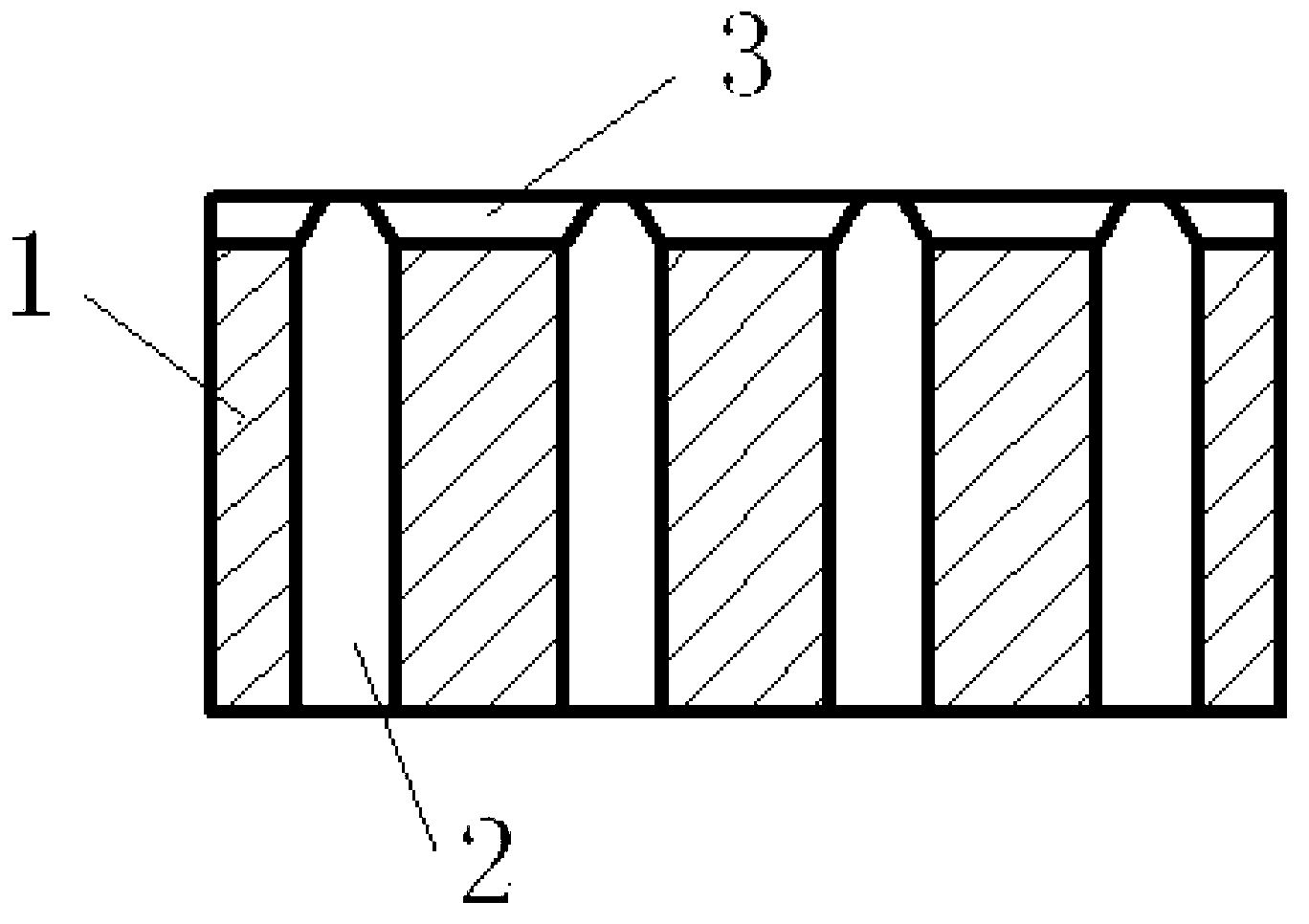

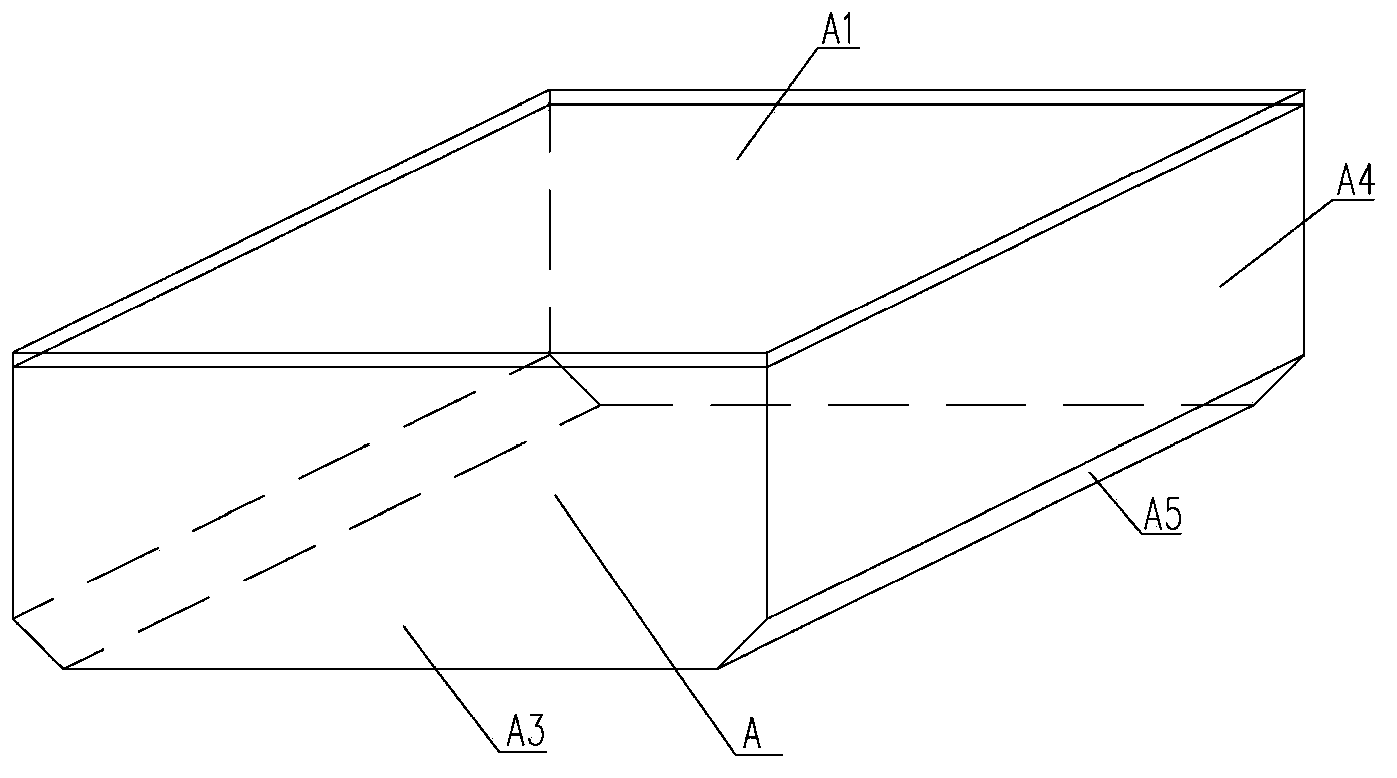

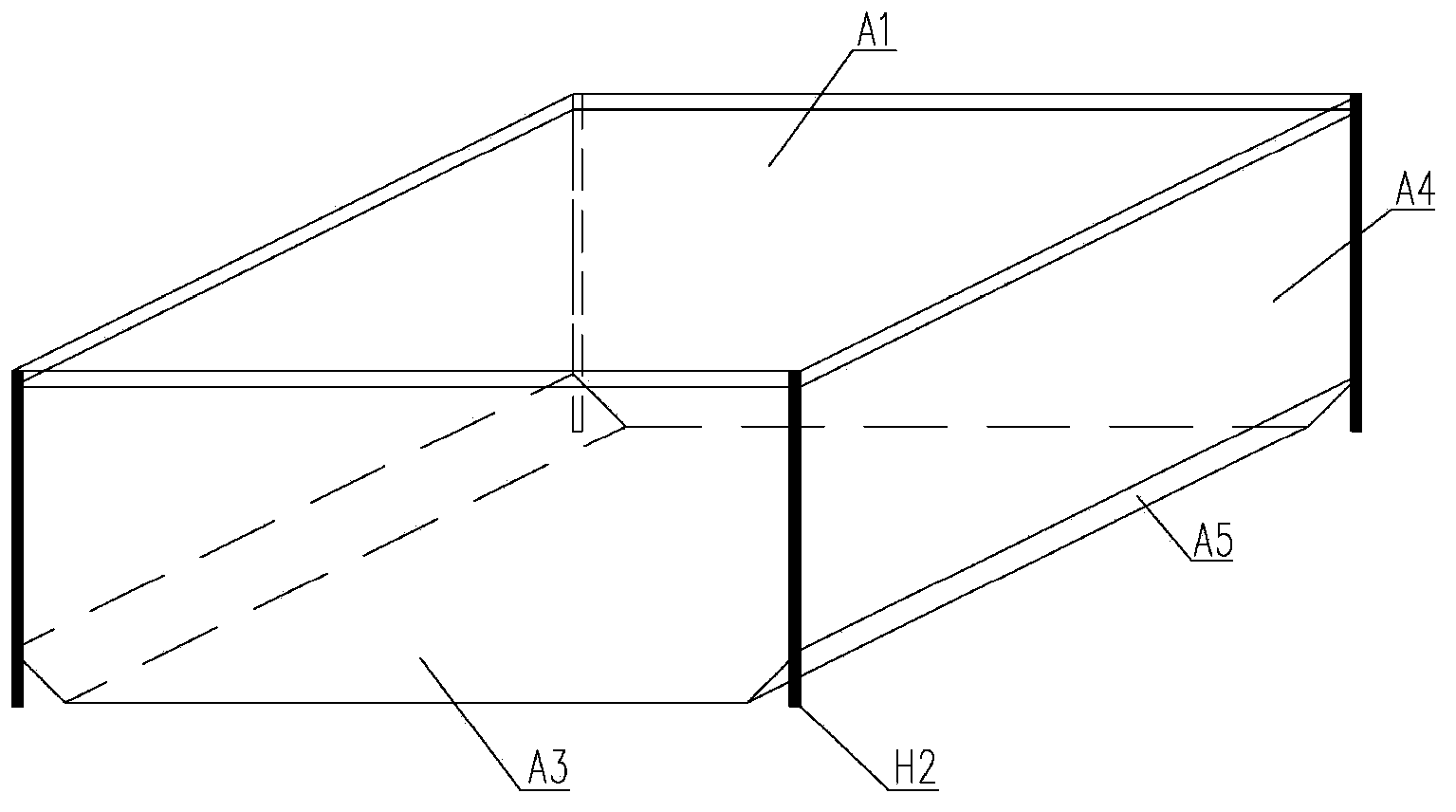

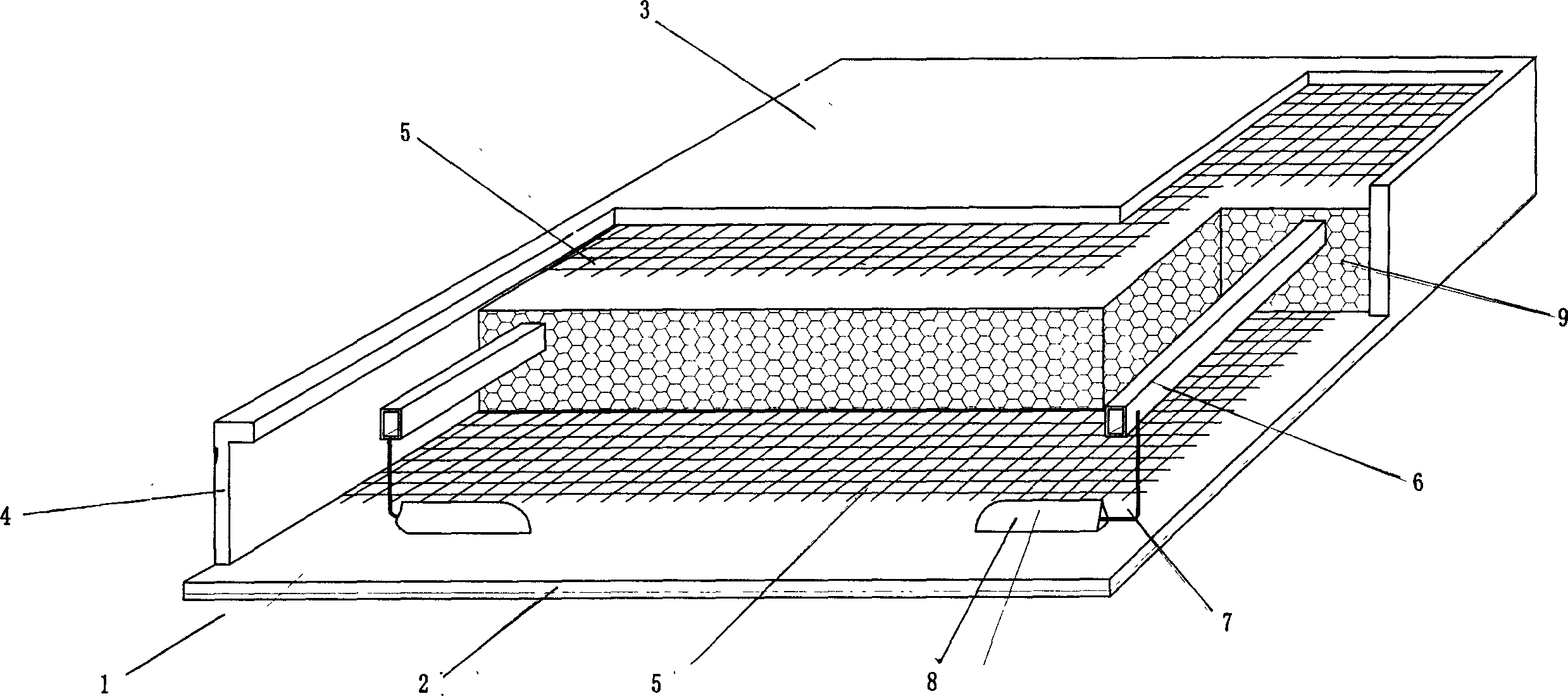

Netlike box-shaped component for forming holes in cast-in-situ hollow floor

The invention provides a netlike box-shaped component for forming holes in a cast-in-situ hollow floor. The netlike box-shaped component is formed by combining a box roof, a box body (side wall) and a box bottom; the box roof is compounded with cement mortar or styrofoam or a board; the box body and the box bottom are manufactured by netlike bodies; each netlike body comprises a netlike board, reinforcing ribs and connecting nets; the netlike board, the reinforcing ribs and the connecting nets form an interacting integral structure; the area of a grid in the netlike board is smaller than 120 mm<2>; the reinforcing ribs are V-shaped; the reinforcing ribs are higher than 3mm; the space between the reinforcing ribs in each netlike body is larger than 30mm; the netlike box-shaped component is formed by combining at least two netlike bodies; at least two structural inclined planes are arranged at corners of the box bottom and the box body of the netlike box-shaped component; the netlike bodies of the netlike box-shaped component are made of steel or plastic. The unsealed netlike box-shaped component replaces a fully-sealed hollow filling body and a solid filling body as a hole forming technology of the conventional cast-in-situ hollow floor, so that technical defects of the existing hollow floor are effectively solved.

Owner:王本淼 +1

Fiber reinforced high-strength mortar used for concrete structure repair

ActiveCN101580369AExcellent structural repair comprehensive performanceIncreasing the thicknessSolid waste managementChemical admixtureCement mortar

The invention relates to a fiber reinforced high-strength mortar used for concrete structure repair, belonging to the technical field of building materials. The mortar is characterized in that the mortar is formed by mixing cement, activated and inert mineral admixtures, expanding agents, micro steel fibers, chemical admixtures, sand and the like based on a certain proportion. At the constructionfields or concrete batching plants, the mortar is added with right amount of water and the mixture is stirred evenly, transported to the construction sites and poured by hand spreading or pumping. Thefiber reinforced high-strength mortar has high strength, good volume stability and durability and large deformability, can be free of vibrating and self-leveling construction, and is convenient, fastand flexible in construction. The structure repair combination property of the fiber reinforced high-strength mortar is greatly superior to that of the current commonly used fine gravel concrete or steel wire mesh-polymer cement mortar system.

Owner:TSINGHUA UNIV

Inorganic heat-insulating dry powder mortar

The invention relates to inorganic heat-insulating dry powder mortar, which comprises the following components in percentage by weight: 30 to 95 percent of inorganic gelled material, 5 to 70 percent of lightweight aggregate and 0 to 10 percent of additive, wherein the inorganic gelled material comprises 75 to 90 weight percent of desulfuration gypsum and 10 to 25 weight percent of cement; the lightweight aggregate is hydrophobic expanded perlite or vitrified micro bubbles or a mixture of the hydrophobic expanded perlite and the vitrified micro bubbles; and the additive comprises a composite retarder, a water retention agent, a thickening agent, a cementing compound and a reinforcing agent. The inorganic heat-insulating dry powder mortar can replace cement mortar and mixed mortar, is applied to non-humid wall surfaces such as the inner side of an outer wall, a separating wall, an inner partition wall, a ceiling and the like, has the characteristics of heat preservation, heat insulation, crack resistance, fire prevention, ageing resistance, environmental protection, biological bite corrosion prevention and the like, and can improve the heat-preserving and heat-insulating performanceof wall bodies.

Owner:谢日清

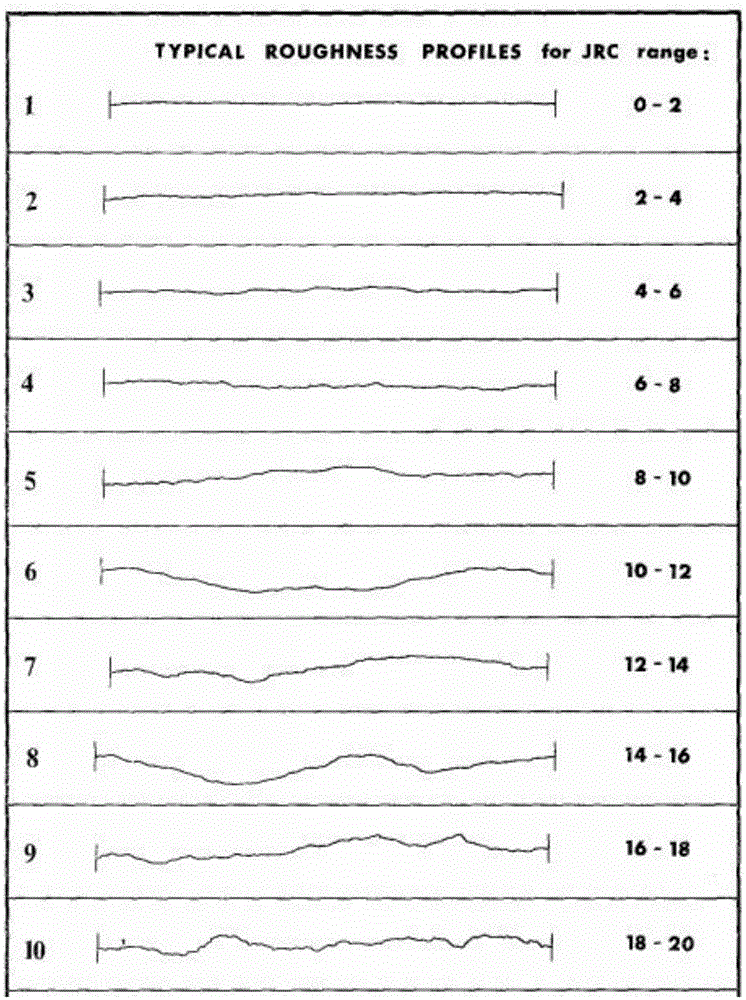

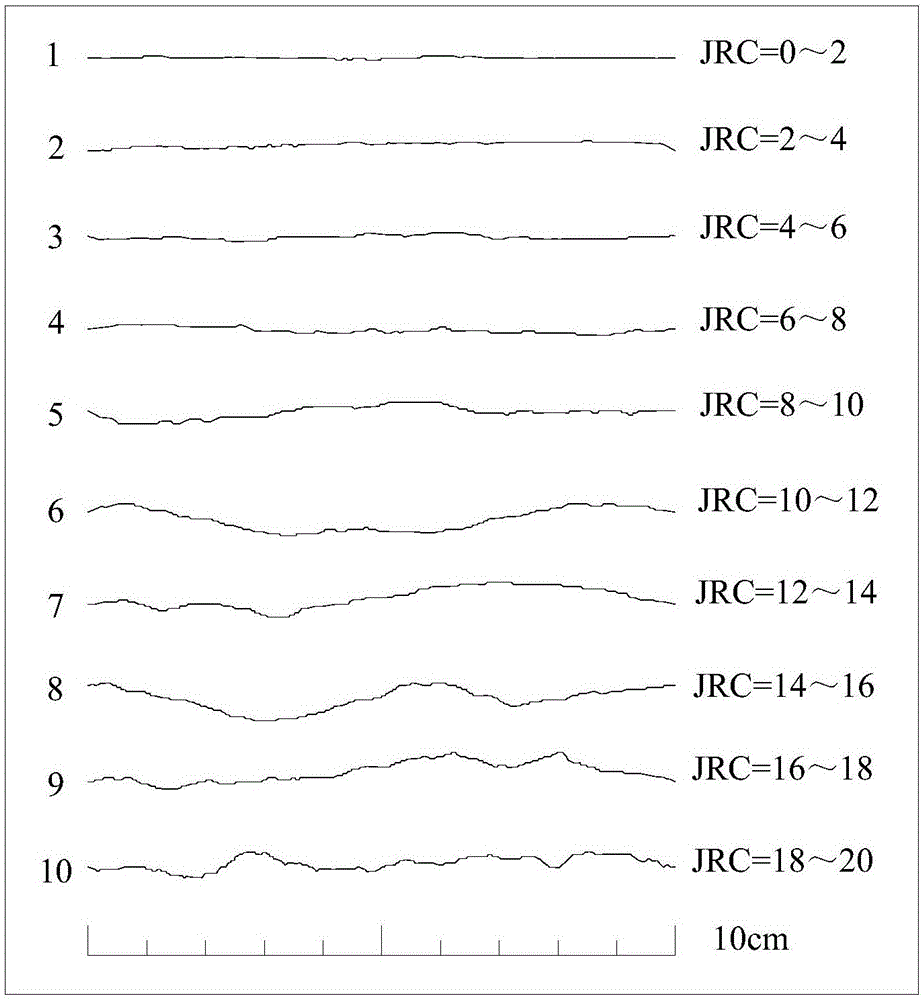

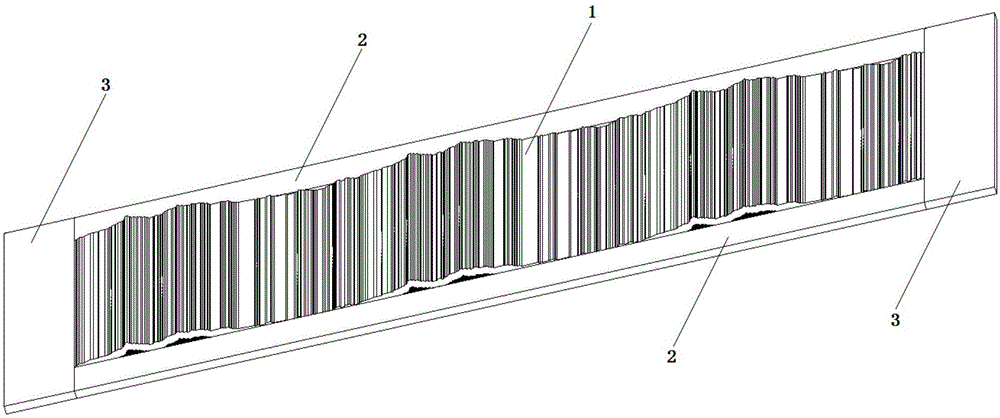

Manufacturing method of simulation fracture for fractured rock mass seepage test

InactiveCN105158039AOvercome limitationsHigh precisionPreparing sample for investigationPermeability/surface area analysisComputer Aided DesignSurface roughness

The invention discloses a manufacturing method of a simulation fracture for a fractured rock mass seepage test. The manufacturing method comprises the steps of drawing a fracture digitized profile curve, constructing a fracture three-dimensional model, making a fracture plate through 3D (three-dimensional) printing, making a fracture test piece casting model and performing casting and maintenance of a fracture test piece, specifically, through digitizing a rock structural surface joint roughness profile curve, drawing the fracture three-dimensional model on the basis of CAD (Computer Aided Design) software, making the fracture plate satisfying JRC value fluctuation by adopting a 3D printing technology, making the fracture test piece casting model by combining the fracture test piece, forming by using cement mortar to cast, and making the fracture test piece by performing maintenance in a cement test piece maintenance box for 28 days. The manufacturing method has the beneficial effects: the manufacturing method of rock rough fracture analogue simulation which is easy in observing, simple in manufacturing, convenient in testing, convenient for adjusting fracture opening, and capable of truly and accurately reflect rock mass fracture structural surface roughness is provided, the working procedures are simple and clear, the manufacturing duration is short, economy and efficiency are realized, the accuracy is high, and the adaptability is good.

Owner:HOHAI UNIV

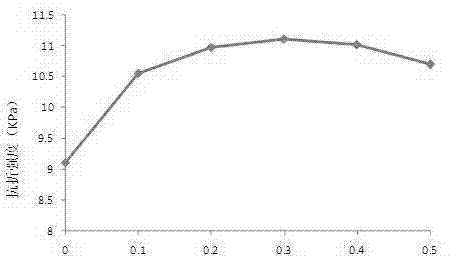

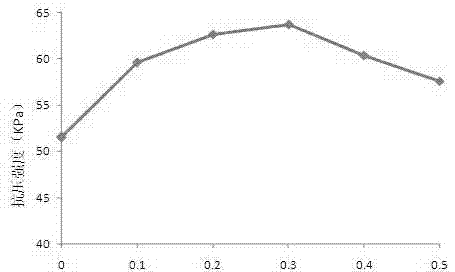

High-strength polypropylene fiber polymer cement mortar and preparation method thereof

The invention discloses a high-strength polypropylene fiber polymer cement mortar and a preparation method thereof. The mortar is composed of the following components in parts by mass: 0.28-0.3 part of silica fume, 0.68-0.7 part of cement and 1.97-2 part of sand. The SiO3 content in the silica fume is higher than 95%; the water-cement ratio is 0.31; the volume content of the polypropylene fiber is 0.9 kg / m<3>; the water reducer:cementing material ratio is 0.9-1%; the defoaming agent:cementing material ratio is 0.5-0.55%; the coupling agent and diluter:cementing material ratio is 0.3%; the polymer modifier:cementing material ratio is 10-11%; and the reducer:cementing material mass ratio is 3-3.5%. By combining the excellent physical and chemical characteristics of the silica fume, when the silica fume is substituted for cement, the consumption of the cement clinker is saved, and the industrial waste is reutilized, thereby greatly enhancing the pressure resistance and bending resistance of the modified cement mortar.

Owner:ZHENGZHOU UNIV

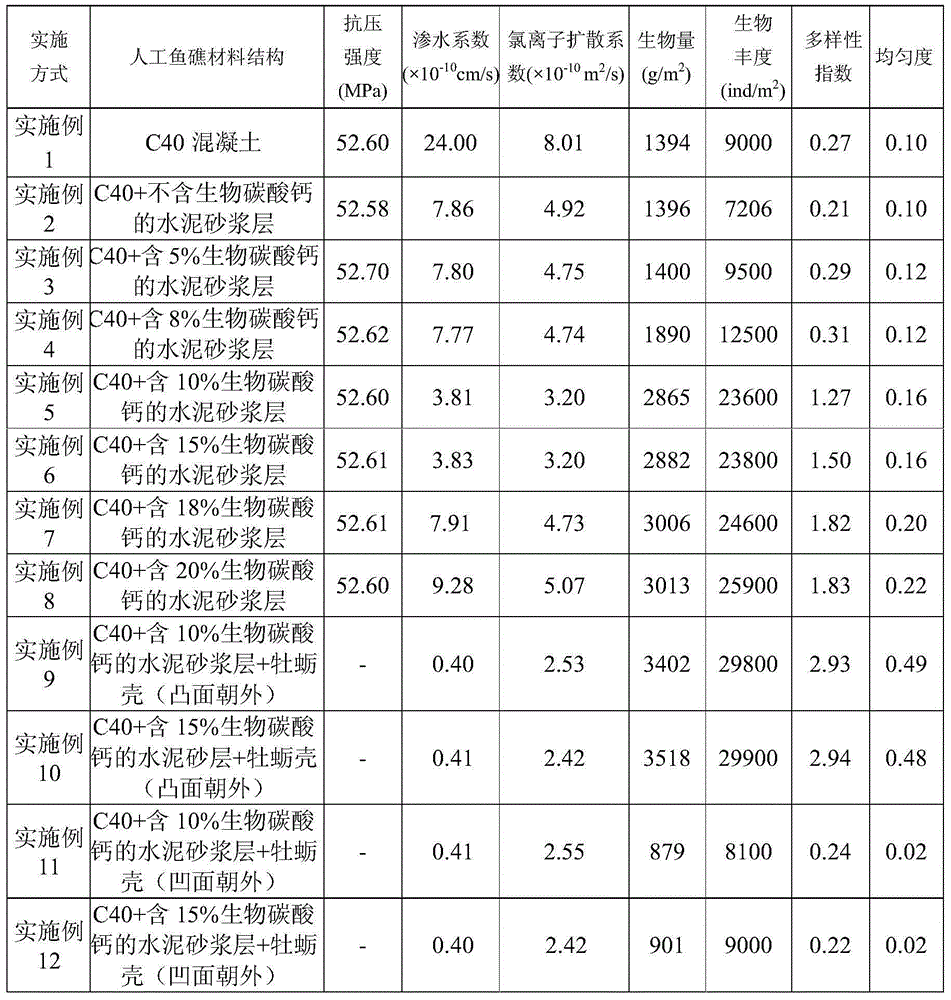

Bionic concrete artificial fish reef and preparation method thereof

InactiveCN104938384AReduce porosityIncreased Durability LifeClimate change adaptationPisciculture and aquariaEggshellOyster shells

The invention discloses a bionic concrete artificial fish reef arranged on the seafloor. According to the fish reef, C40 concrete is used for pouring to form an artificial fish reef base body, the surface of the base body is covered with a protective layer which is composed of cement mortar, biological calcium carbonate and oyster shells, the biological calcium carbonate is made of eggshells, corals, seashells and fishbone and is used as an additive to be added into the cement mortar, the cement mortar mixture is smeared on the surface of the fish reef base body to form cement paste after the biological calcium carbonate and the cement mortar are evenly stirred together, and the oyster shells are inlaid in the cement paste in a convex face outward mode. According to the artificial fish reef, the environment-friendly function, the durable function and the trapping function are integrated, the cement mortar covering layer doped with the biological calcium carbonate and the coating of the oyster shells can attract marine organisms to inhabit, and thus the trapping effect of the artificial fish reef can be better achieved; compared with a traditional concrete fish reef, the artificial fish reef has good waterproof property and chloride ion resistance, surface roughness and alkalinity of the surface of the fish reef are appropriate, bionic performance is achieved, and the fish collecting effect is excellent.

Owner:GUANGDONG UNIV OF TECH +1

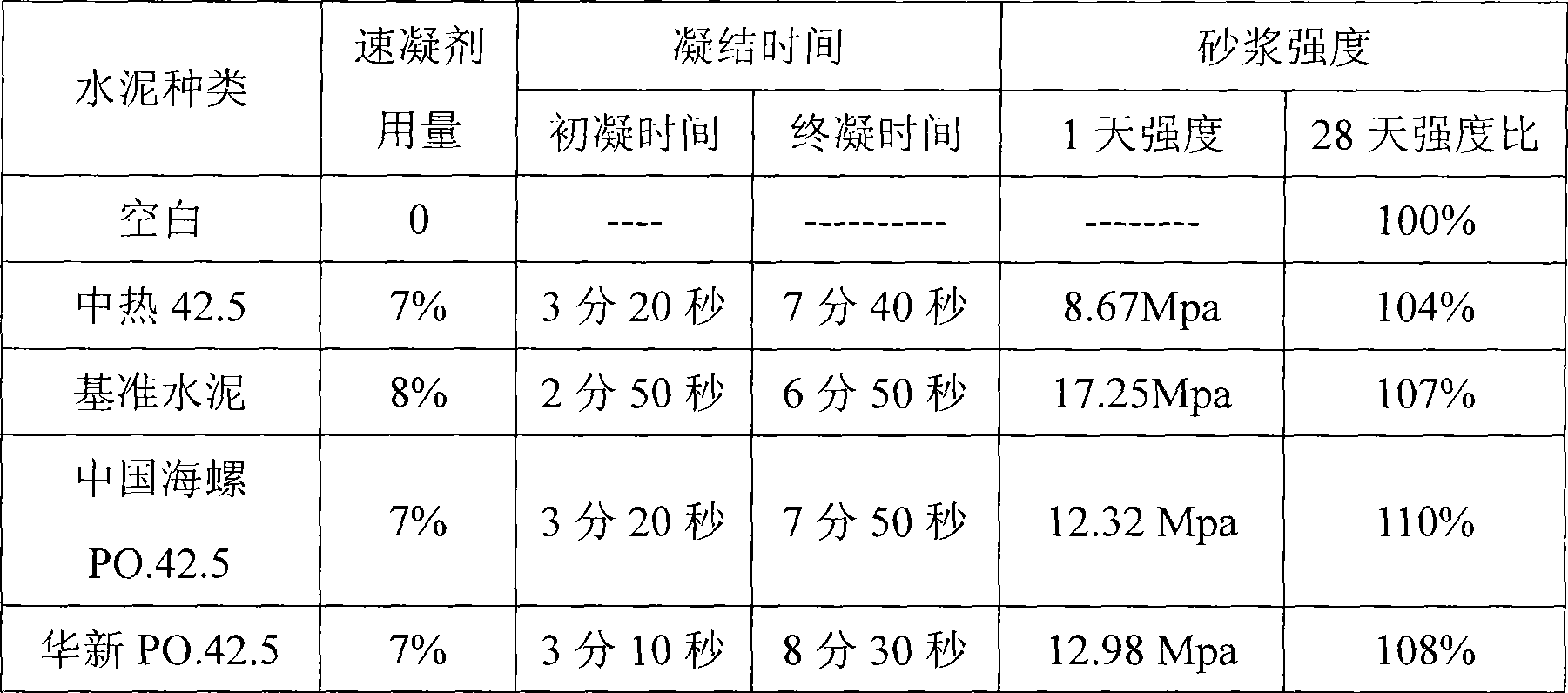

Liquid accelerator for sprayed concrete and preparation thereof

The invention relates to a liquid accelerator for shotcrete and a method for preparing the same. The liquid accelerator is prepared from the following components in percentage by weight: 25 to 70 percent of aluminum sulfate, 0 to 8 percent of metal fluoride, 1 to 10 percent of amine substance, 0.5 to 7 percent of pH regulator, 0.01 to 1 percent of thickening agent, and the balance being water. The method for preparing the liquid accelerator comprises the following steps: firstly, dissolving the fluoride into the water; secondly, adding the amine substance to the mixture and heating the solution to a temperature of between 40 and 80 DEG C; thirdly, adding the aluminum sulfate to the solution to perform heat preservation reaction until the solution becomes a uniform liquid; and fourthly, adding the pH regulator and the thickening agent to the uniform liquid and stirring the mixture evenly to finally obtain a uniform liquid substance which is the liquid accelerator for the shotcrete. The liquid accelerator is free from corrosion, has no penetrating odor, has good storage stability so that the phenomena of deposition, crystallization and the like do not appear after the storage of more than 6 months at a temperature of between 0 and 35 DEG C, and does not influence the effect in practice. Using the liquid accelerator with lower mixing proportion (5 to 8 percent), cement can be initially set within 4 minutes and finally set within 10 minutes, and the strength of cement mortar within one day is more than 10 MPa and the storage rate of the strength within 28 days is more than 100 percent.

Owner:JIANGSU SUBOTE MATERIAL

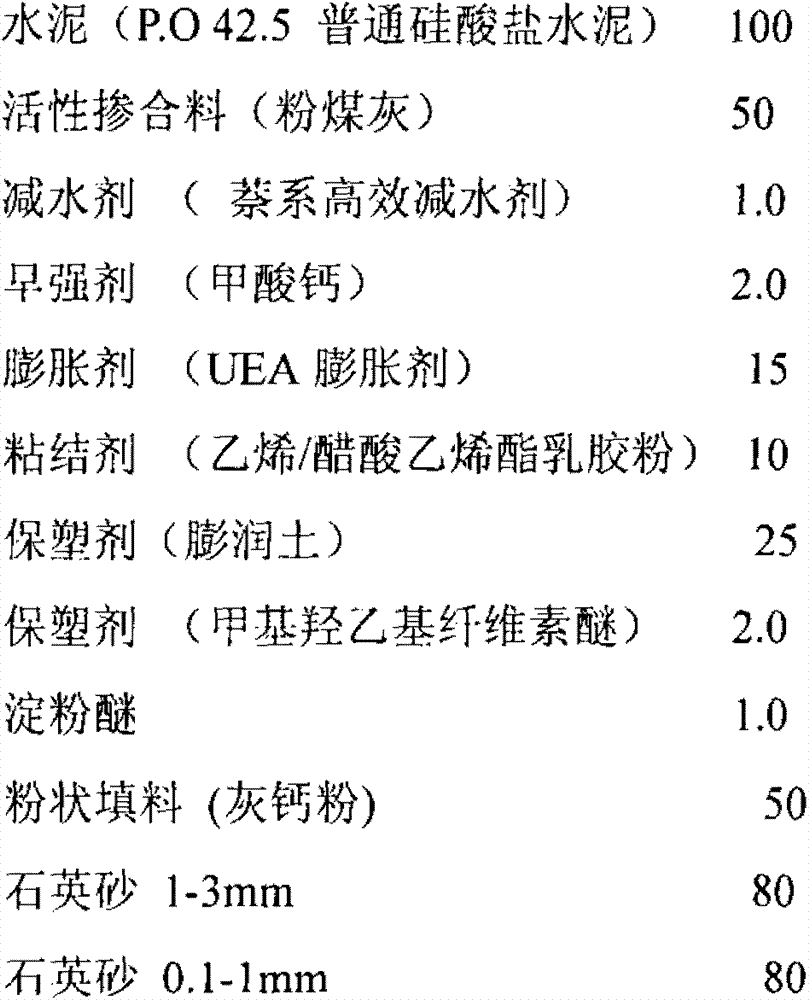

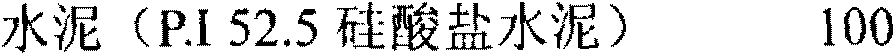

Rebar grouting connecting element sealing materials and preparation method and application thereof

ActiveCN103159441AImprove early strengthImprove construction efficiencySolid waste managementBuilding reinforcementsSlurryRebar

The invention relates to rebar grouting connecting element sealing materials, and a preparation method and application thereof. The materials are prepared by the following raw materials, by weight, 100 parts of cement, 0-80 parts of activity admixtures, 0.01-10 parts of water reducing agents, 0.01-10 parts of early strength agents, 0.01-30 parts of expanding agents, 0-30 parts of adhesion agents, 0.01-50 parts of plastic retaining agents, 0.01-10 parts of starch ether, 0-100 parts of powder stuffing and 10-300 parts of quartz sand. The sealing materials are prepared through stirring and blending and can be used for sealing process before rebar grouting connection. Compared with the prior art, the sealing materials are good in plasticity, adhesive power and drop smoothness resistance, slurry does not contract, and defects that cracking, water seepage, dropping off and the like are easily generated due to the fact that common cement mortar is used for sealing are overcome. The sealing materials have excellent construction performance, and can be applied to quick extrusion and jetting construction of a caulking gun or a power-driven caulking device. After the sealing materials are adopted to carry out a sealing process, rebar connecting grouting construction can be carried out after one day, and construction efficiency can be greatly improved.

Owner:TONGJI UNIV

Low-alkaline liquid accelerating agent and preparation method thereof

The invention belongs to the technical field of tunnel construction, and relates to a low-alkaline liquid accelerating agent and a preparation method thereof. For the low-alkaline liquid accelerating agent, aluminium sulfate solution is neutralized with sodium aluminate solution to produce aluminium hydroxide collosol, and then aluminium sulfate and aluminium hydroxide collosol conduct polymerization reaction in an original solution system to produce polymerized aluminium sulfate, so that the accelerating agent solution has higher aluminium ion content and liquid stability; the low-alkaline liquid accelerating agent is prepared by aluminium sulfate, sodium aluminate and stabilizing agent; and the mass percentage of the components are as follows: 40 to 60 percent of aluminium sulfate, 6 to12 percent of sodium aluminate, 0 to 0.2 percent of stabilizing agent, and the balance of water. The invention has the following positive effects to sprayed concrete: initial set of common cement can be realized in five minutes and final set of the common cement can be realized in eight minutes under lower doping amount; the 1d strength of cement mortar can reach more than 12MPa, and the 28d compression strength ratio of the cement mortar is more than 100 percent; and the invention has good adaptability to cement of different varieties.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

Construction method for reconstructing old concrete pavement by paving asphalt-concrete surface layer

InactiveCN101691736ALow costShorten the construction periodRoads maintainenceSurface layerRoad surface

The invention relates to pavement reconstruction, in particular to a construction method for reconstructing an old concrete pavement by paving an asphalt-concrete surface layer, which is characterized by comprising the following: 1) a step of old concrete pavement processing, which comprises breaking and removing damages blocks and pouring again, mudjacking the old concrete pavement, impacting and rolling old concrete pavement, crack pouring and replacing hardened verges; and 2) a step of paving a asphalt-concrete pavement, which comprises spraying a prime coat and viscous oil and spreading the asphalt-concrete pavement. The breaking and removing damages blocks and pouring again comprise: breaking and removing seriously damaged blocks of the old pavement; shoveling loose parts of an old cement stabilized base away, and pouring concrete in a 15-centimeter thickness which is the same as that of the old base for leveling; filling up the pits on the base with cement mortar and tamping the filled cement mortar; and pouring a 24-centimeter C35 concrete pavement board. In the method, the requirements on cost, quality, construction period, environmental protection and the like are met when the old concrete pavement is reconstruction by paving the asphalt-concrete pavement.

Owner:中交二公局第六工程有限公司

Emulsified asphalt

InactiveCN101153118AEasy to control air contentEasy to control fluidityBuilding insulationsLight railCement mortar

The present invention provides emulsified asphalt made of asphalt, surfactant, additive and water. Wherein, the contents of each component are: 38 percent to 58 percent of asphalt, 1 percent to 15 percent of ionic surfactant and 2.5 to 19 percent of non-ionic surfactant of the surfactant, 0.5 to 8 percent of additive; and the left is water; all are calculated according to a weight percentage. The product of the present invention is the emulsified asphalt of good stability and simple production process. In the actual use, the CA mortar can avoid eduction and contraction; thus the CA mortar has appropriate work time and high strength in the early period, which can fully meet the requirements of plate type ballastless track. Therefore, the product of the present invention can be effectively used in emulsified asphalt cement mortar (also known as CA mortar) for plate type ballastless track of high-speed railway or urban light rail.

Owner:张洪武

Rapid repairing materials for ultrathin layer on the surface of road and airfield runway

InactiveCN1654409AGood value for moneyMinimal disruption to daily traffic operationsWater dispersibleCrushed stone

The super thin fast repair material for highway and airport runway consists of early strengthened hydraulic cementing material 30-90 wt%, polymer resin emulsion or water dispersible polymer powder 0.1-40 wt%, fine sand 8-60 wt% and inorganic modifier 0.1-15 wt%. The repair material is suitable for thin layer and super thin layer repairing of concrete and asphalt road surface, may be also used for repairing damaged part when sand, crushed stone and other aggregate are added. It is also suitable for repairing inner and outer walls of building. The finishing super thin cement mortar layer has the breaking strength reaching 2-4 MPa in 2-3 hr and compression strength up to 20-30 MPa. The present invention can raise the antiwear performance, weather resistance and engine oil and hydraulic oil corrosion resistance.

Owner:桂永全

Karst grouting reinforcement water-stop constructing method

The invention discloses a karst grouting reinforcement water-stop constructing method, which is to construct according to sizes of karst caves by adopting a principle of from big to small regarding a certain area, construct by adopting a principle of from outside to inside for the karst caves with the same size, and construct by adopting a principle of from the bottom to the top in a vertical direction. On the basis of the construction principles, the method comprises the following steps of: (1) forming grouting holes by adopting a core drill; (2) forming construction exhaust and drainage pressure relief holes; (3) inserting grouting pipes into the grouting holes, wherein the grouting pipes comprise steel pipes, grouting shock pipes and sleeve valve pipes; (4) cleaning the holes, wherein when the step (3) is completed, the grouting pipes are cleaned with clean water; (5) grouting; and (6) drawing out the grouting pipes after the grouting is completed, and blocking the grouting holes with cement mortar or concrete. By adopting the constructing method, the pertinence to karst caves is strong, the grouting quantity is small, the engineering work amount is small, the cost is low, and the effect of filling and reinforcing is good.

Owner:GUANGZHOU URBAN PLANNING & DESIGN SURVEY RES INST

Light thermal insulation soundproof damping floor mortar

ActiveCN102249614AFully hydrated and hardenedBatch scratch smoothSolid waste managementCelluloseFiber

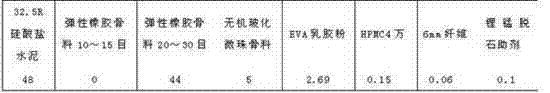

The invention discloses light thermal insulation soundproof damping floor mortar, which is prepared by mixing the following components in percentage by mass: 30 to 40 percent of cement, 0 to 28 percent of coarse elastic rubber aggregate, 5 to 50 percent of fine elastic rubber aggregate, 5 to 15 percent of inorganic vitrified microsphere aggregate, 0.5 to 3 percent of redispersible emulsion powder, 0.05 to 0.15 percent of cellulose ether, 0.02 to 0.06 percent of 6mm fiber and 0.05 to 0.1 percent of hectorite aid. Inorganic silicate is taken as a binding material, so the light thermal insulation soundproof damping floor mortar has good compatibility with cement mortar and a concrete base, is firmly bound, avoids a hollowing phenomenon, is suitable for various base conditions, has a leveling function under the condition of poor evenness, is easy and convenient to construct, and can be scraped after being added with water and uniformly stirred; the whole soundproof layer is a whole, sound bridges are greatly reduced, the compression strength is moderate, the deformation hardly occurs, and the load of a building cannot be increased greatly; and the light thermal insulation soundproof damping floor mortar has low coefficient of heat conductivity, makes floors soundproof, and has the thermal insulation effect.

Owner:上海曹杨建筑粘合剂厂

Composite fiber reinforced foam concrete and preparation method thereof

InactiveCN102199044APrevent shrinkage crackingImprove flexural strengthSolid waste managementCeramicwareFoam concreteFoaming agent

The invention relates to composite fiber reinforced foam concrete and a preparation method thereof. The foam concrete comprises the following components in parts by weight: 0-400 parts of fly ash, 100-900 parts of cement, 500-1000 parts of sands, 300-600 parts of water, 0.4-1 part of organic fiber, 1-3 parts of plant fiber, 0.2-15 parts of early strength agent, 3-20 parts of foaming agent, 0.5-4 parts of water reducing agent and 0.5-2 parts of water retention agent. The preparation method of the foam concrete comprises the following steps of: generating foams by using the foaming agent, adding the foams to fully stirred cement mortar containing composite fibers and the like and keeping stirring so that the foams are dispersed in the mortar uniformly, measuring the volume weight and carrying out casting forming or coating forming and carrying out standard curing for 28 days. In the invention, industrial and agricultural wastes, such as fly ash, plant fiber and the like, are used, shrinkage crack of the foam concrete is inhibited obviously, and the composite fiber reinforced foam concrete has low price; and the foam concrete has simple formula, good workability, long foam stabilizing time, light weight and low coefficient of thermal conductivity and is suitable for exterior wall thermal insulation, roof thermal insulation and non-load-bearing wall manufacturing.

Owner:TONGJI UNIV

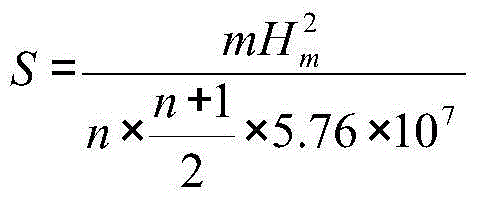

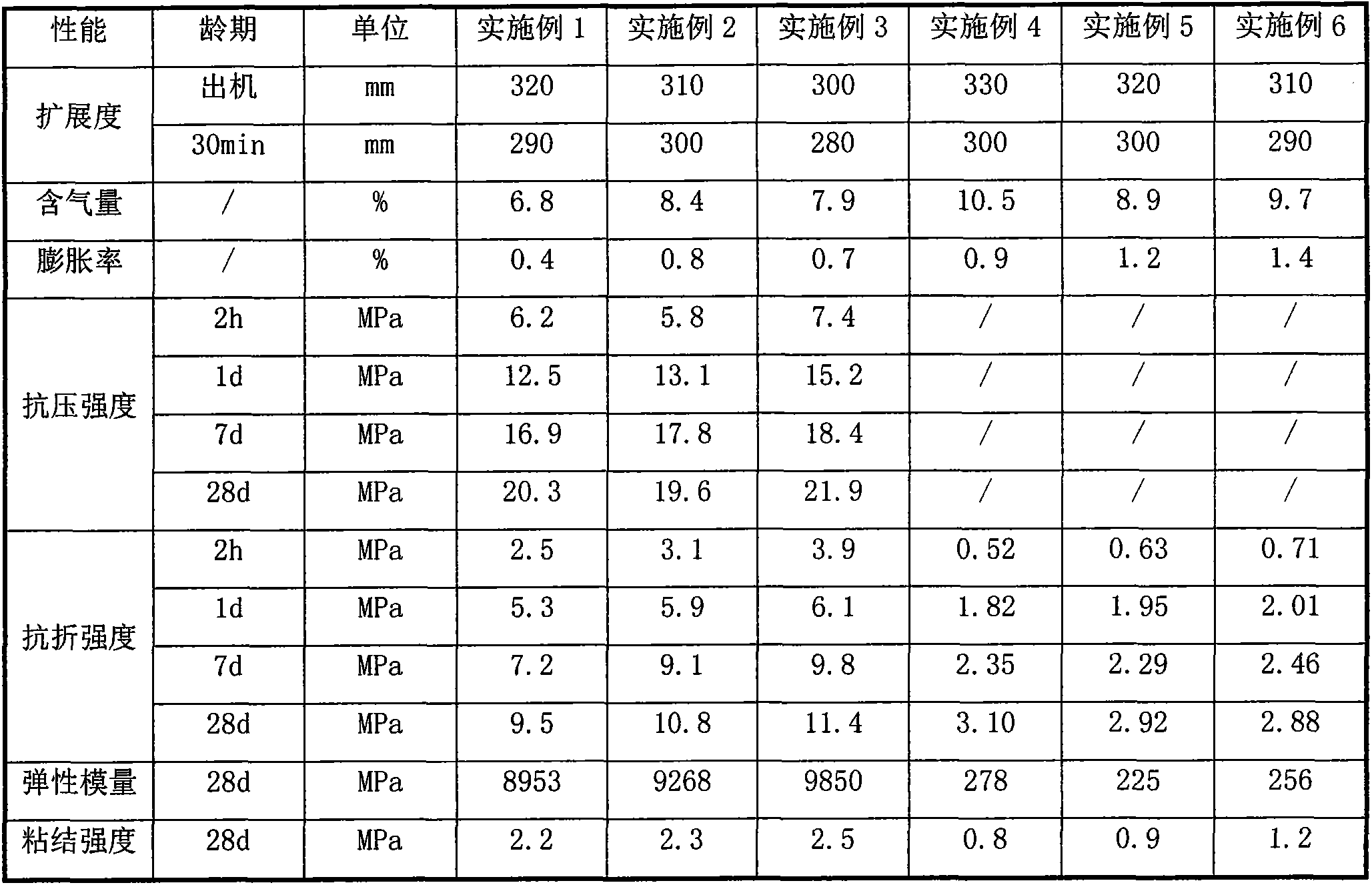

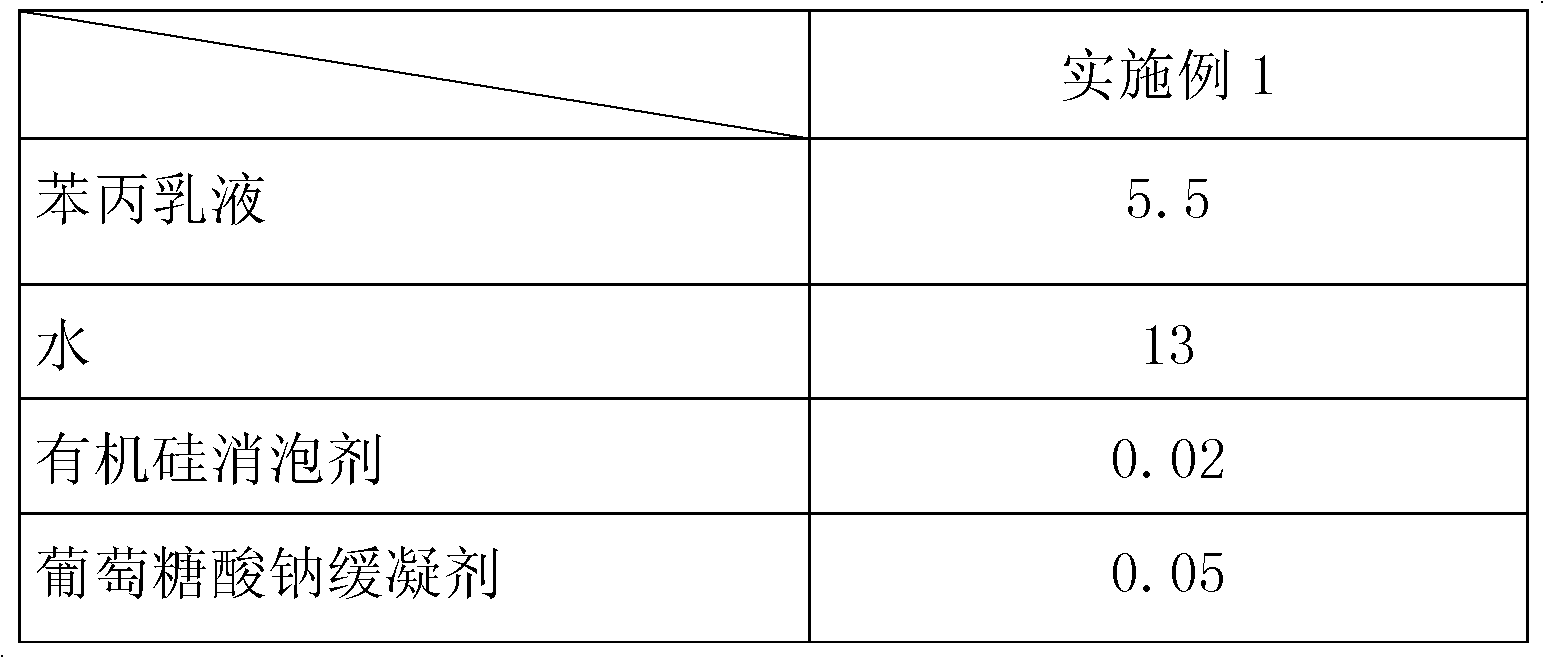

Polymer cement mortar for slab ballastless track of high-speed railway

The invention discloses polymer cement mortar for a slab ballastless track of a high-speed railway. The polymer cement mortar a comprises a dry raw material and a liquid raw material, wherein the dry raw material comprises a binding material component, an elastic adjusting component, an expanding component, an internal curing component, an aggregate component and a coagulation adjusting component; the liquid raw material comprises a polymer emulsion, a water reducing agent, a defoaming agent, an air entraining agent and water; and the weight ratio of the dry raw material to the liquid raw material is 100:(15-25), and the dry raw material and the liquid raw material are uniformly mixed in a proportion to prepare the polymer cement mortar. The polymer cement mortar has the advantages of controllable coagulation time, high adhering strength, adjustable elastic modulus, good elasticity and toughness, high durability and the like, and is capable of replacing cement emulsified asphalt mortar to be applied to a packing material of the slab ballastless track or can be used as a quick repairing material of a filling layer of cement emulsified asphalt mortar.

Owner:BEIJING TIEKE SPECIAL ENG TECH CO LTD +1

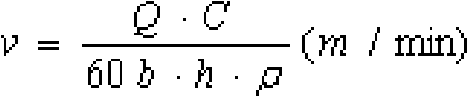

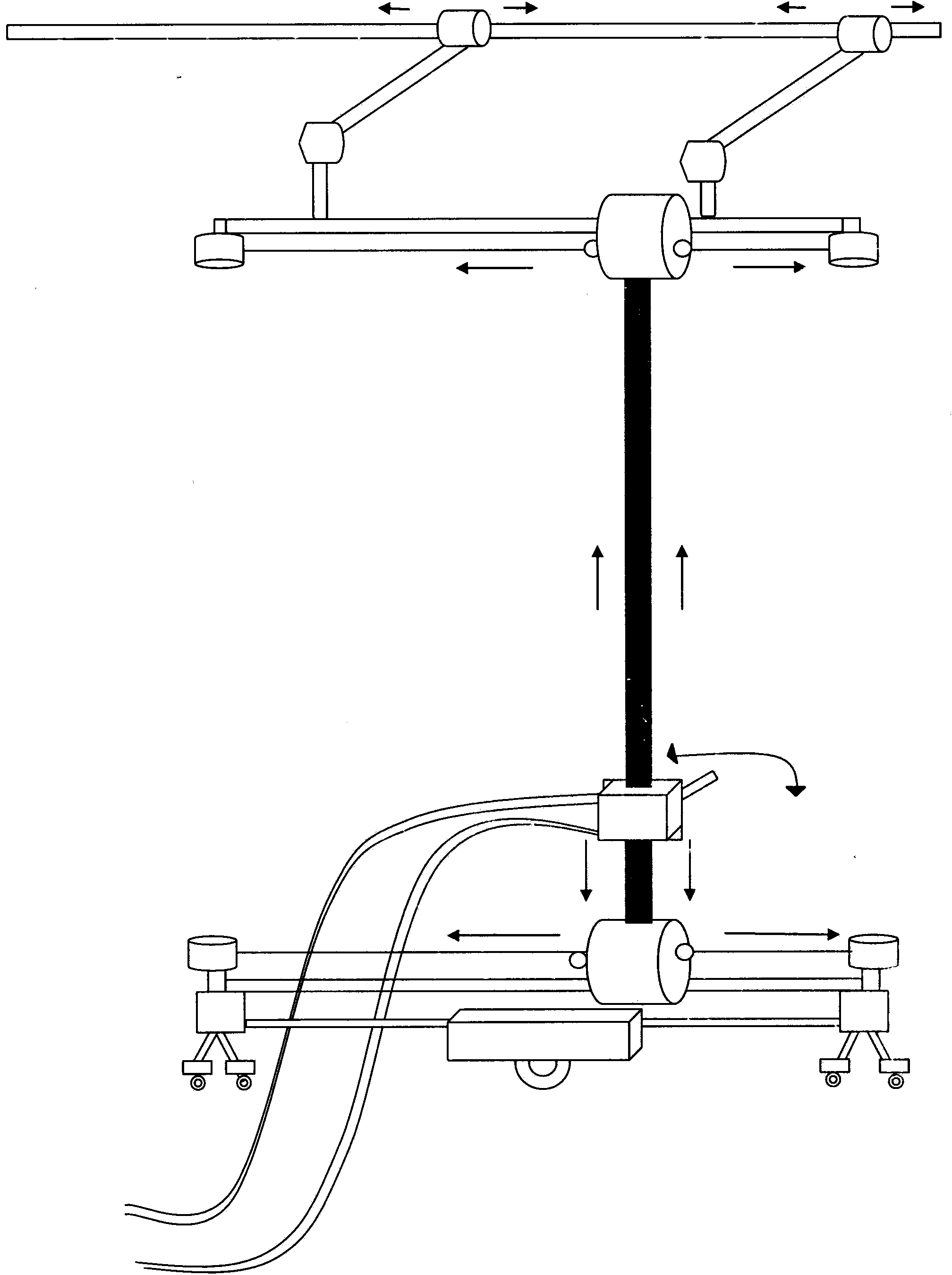

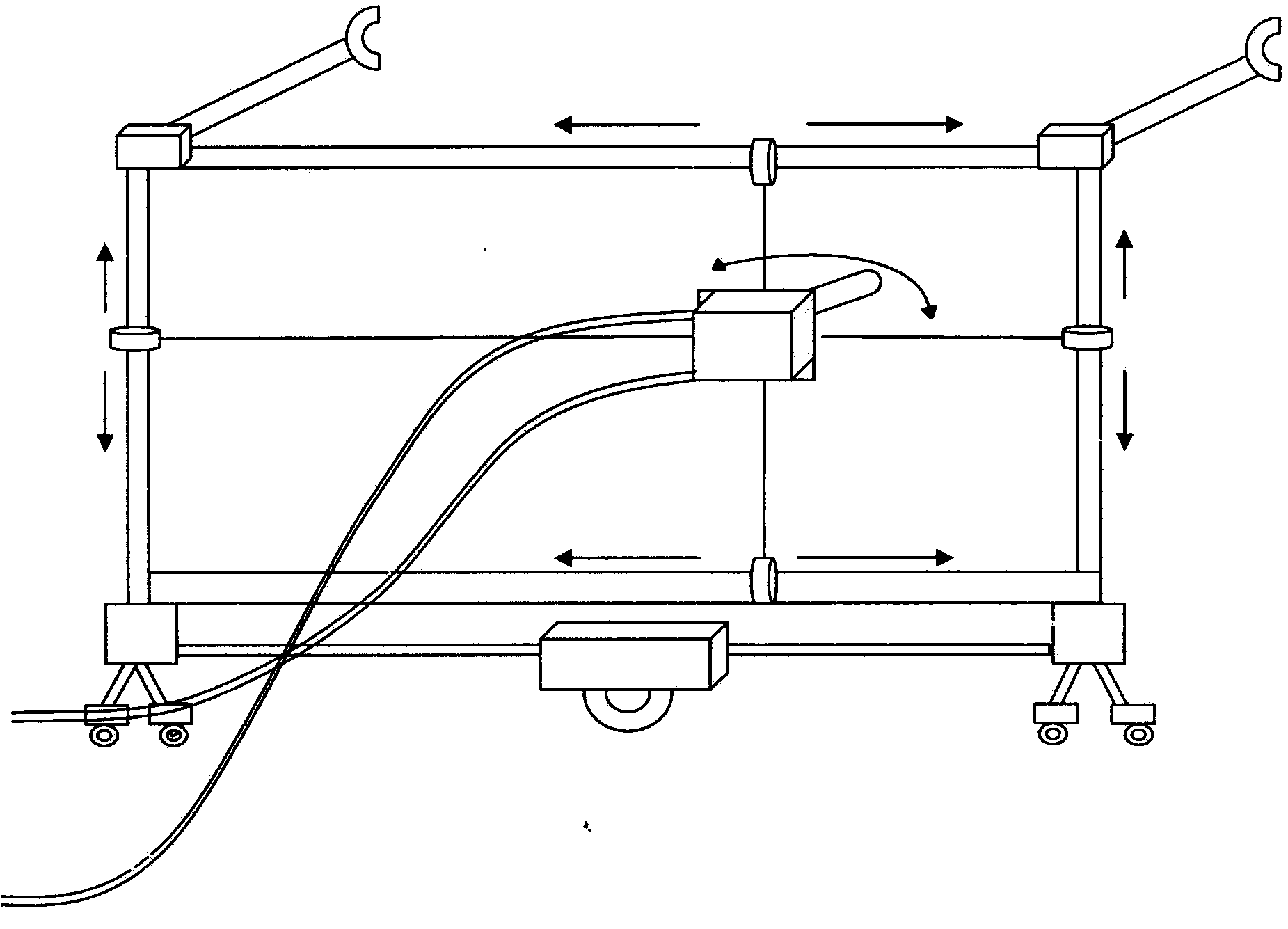

Surface spraying and rendering robot for building

InactiveCN104343230AImprove construction efficiencyApply evenlyBuilding constructionsGraphicsAngular velocity

The invention provides a surface spraying and rendering robot for a building. The robot can be used for automatically spraying and rendering cement mortar, lime mortar, putty mortar and other materials, and can also be used for spraying embossed graphics. The robot is of two structures according to the height of a wall body of the building. The robot is characterized in that a spraying and rendering head is fixed through a transverse and longitudinal moving device and used for accurately moving and spraying and rendering in the transverse and longitudinal directions; the spraying and rendering head is equipped with a camera device; the self-cleaning function is brought, so that the camera shooting picture cannot be influenced by the spraying of mortar, and a worker can remotely monitor the spraying and rendering effect; the spraying thickness is controlled through the swinging angular velocity and moving rate of the spraying head; a spraying and rendering device is equipped with a touch part and a distance sensor which enables uniform coating and rendering, and the efficiency and reliability are higher than manual operation. According to the robot, a plurality of spraying heads or rendering knives can be arranged and switched by program control; different building materials can be loaded; the colorful embossed graphics can be sprayed based on the computer picture; the working scope and route of the robot can be set by the computer program, and the learning can be performed automatically through the teaching program.

Owner:郑西涛

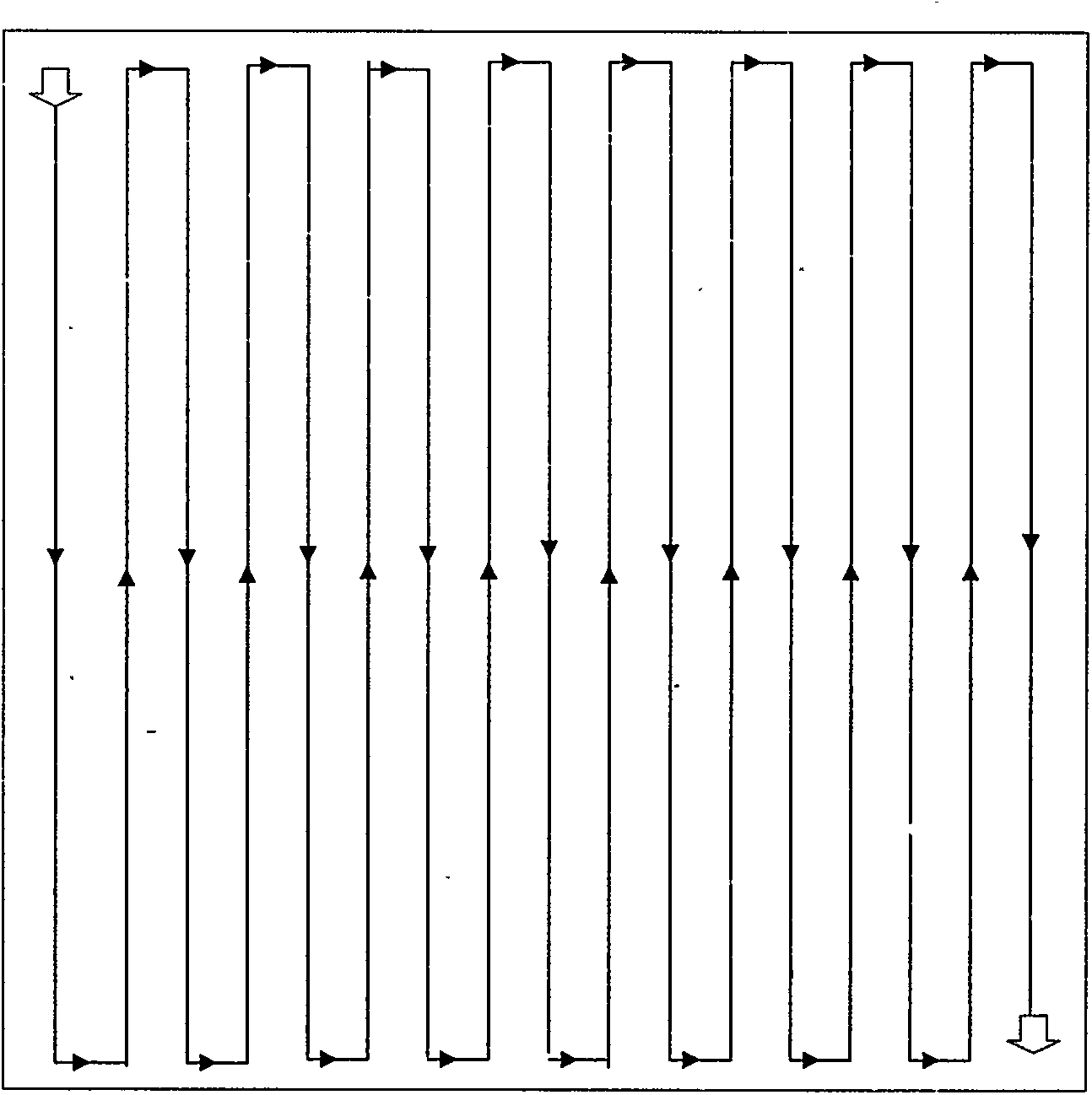

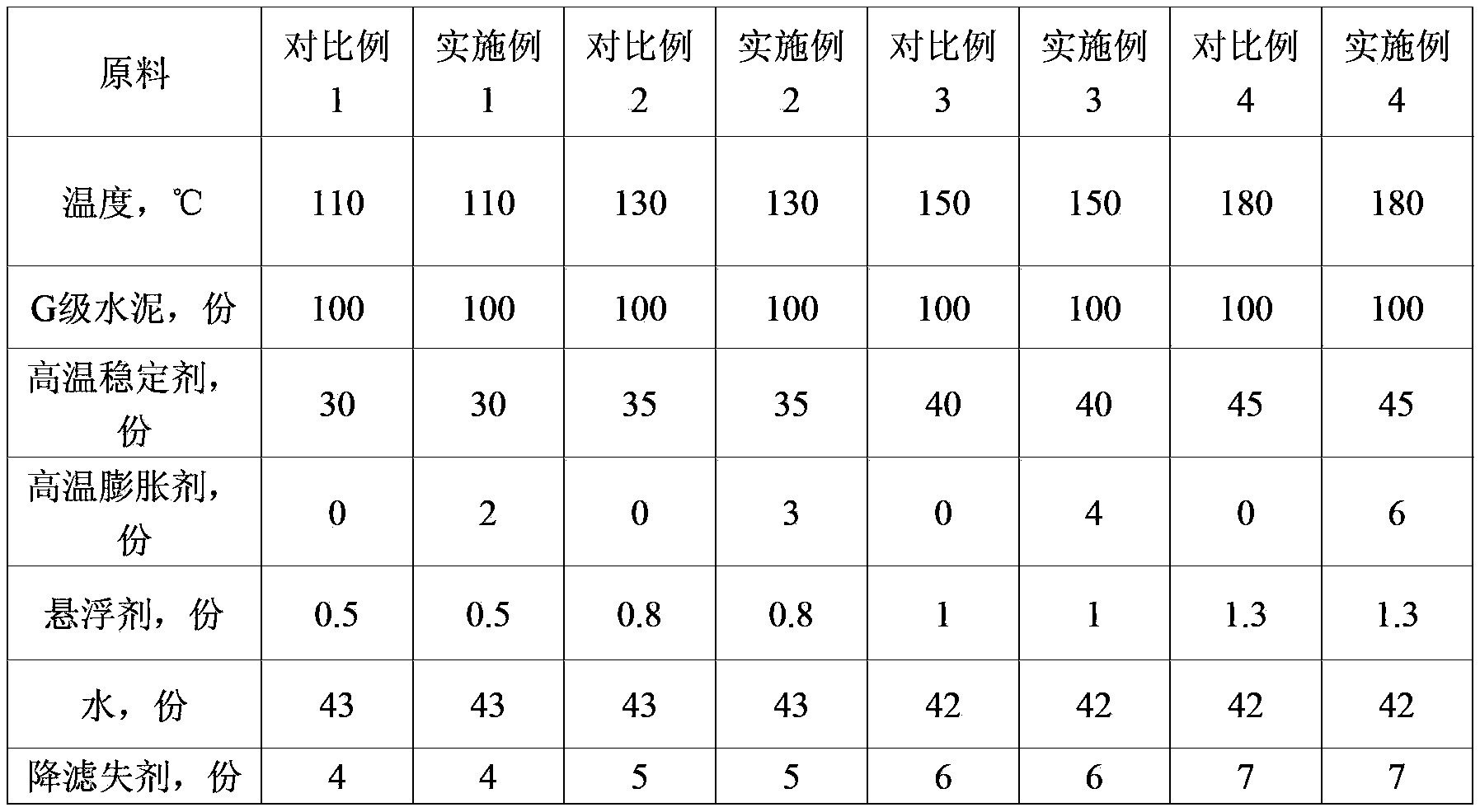

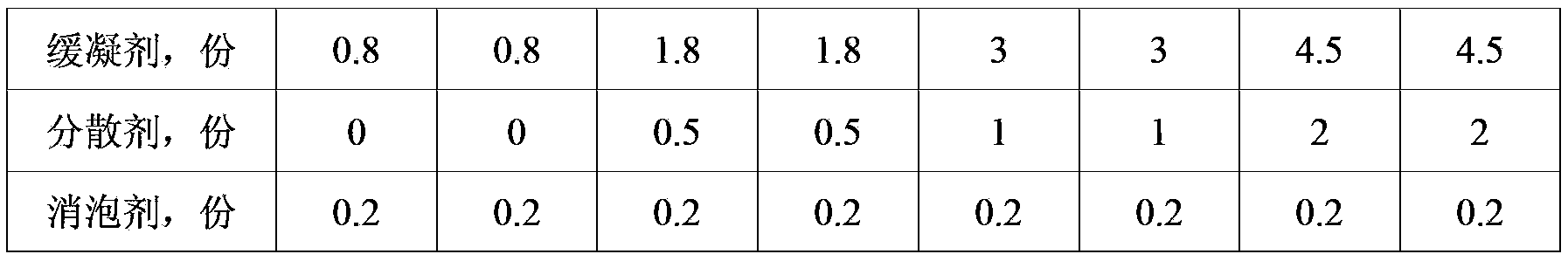

Horizontal well-cementation expandable cement mortar and preparation method thereof

InactiveCN104099071AImprove high temperature resistanceAppropriate expansion rateDrilling compositionSealing/packingReducerSuspending Agents

The invention discloses horizontal well-cementation expandable cement mortar and a preparation method thereof, and belongs to the technical field of oil and gas well cementation cement. The horizontal well-cementation expandable cement mortar comprises 100 parts of cement, 30-45 parts of a high-temperature stabilizing agent, 1-10 parts of a high-temperature expanding agent, 0-3 parts of a suspending agent, 4-10 parts of a filtrate-loss reducer, 0-2 parts of a dispersant, 0-5 parts of a retarder, 40-50 parts of water and 0.2 parts of an antifoaming agent. The cement is oil well G-grade cement satisfying the API standard. The high temperature stabilizing agent comprises one or two of micro-silicon and silica powder having purity greater than 98%. Indoor research and test prove that the horizontal well-cementation expandable cement mortar has excellent integrated performances. The cement stone prepared from the horizontal well-cementation expandable cement mortar has good settlement stability and slight expansion characteristics at a high temperature. The horizontal well-cementation expandable cement mortar satisfies requirements on high-temperature and superhigh-temperature horizontal well or high-inclination solid well cementation and has on-site operation feasibility.

Owner:PETROCHINA CO LTD

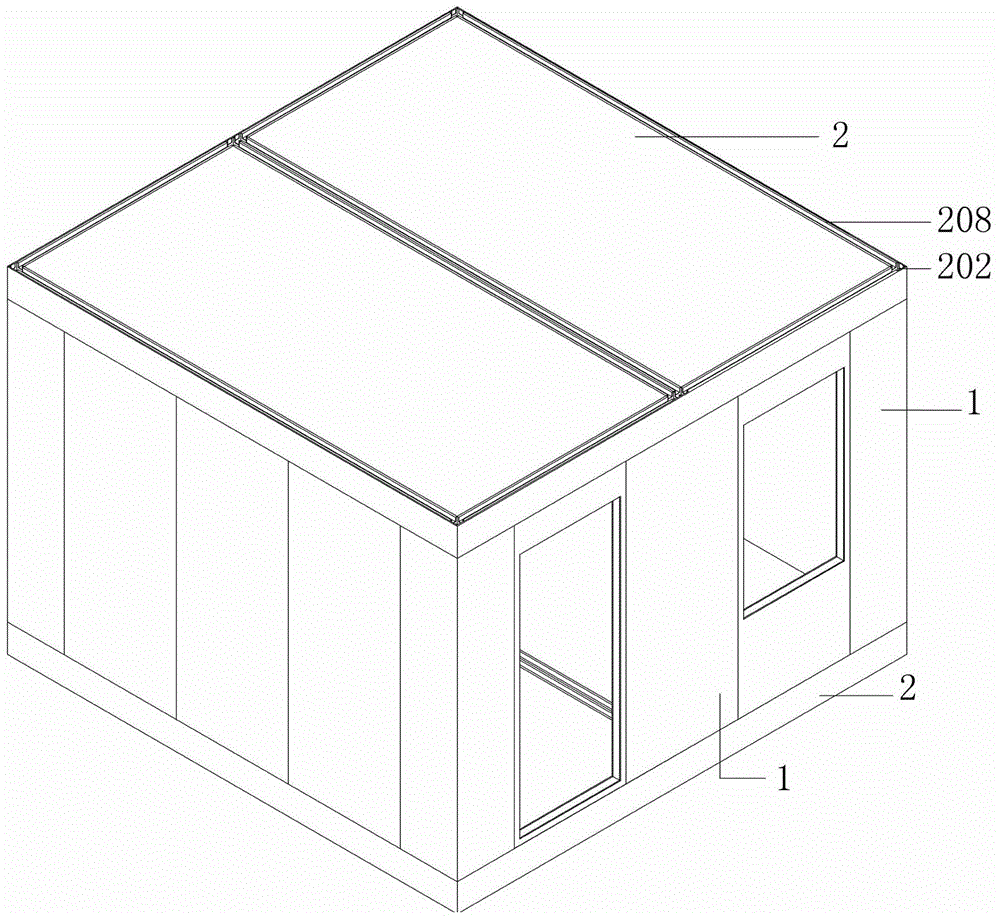

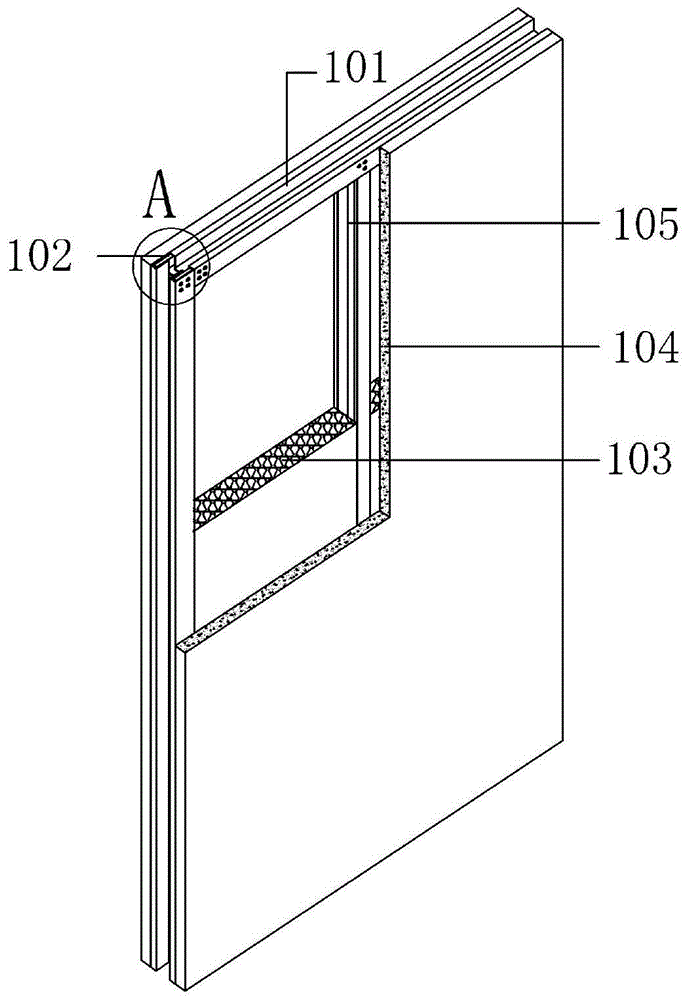

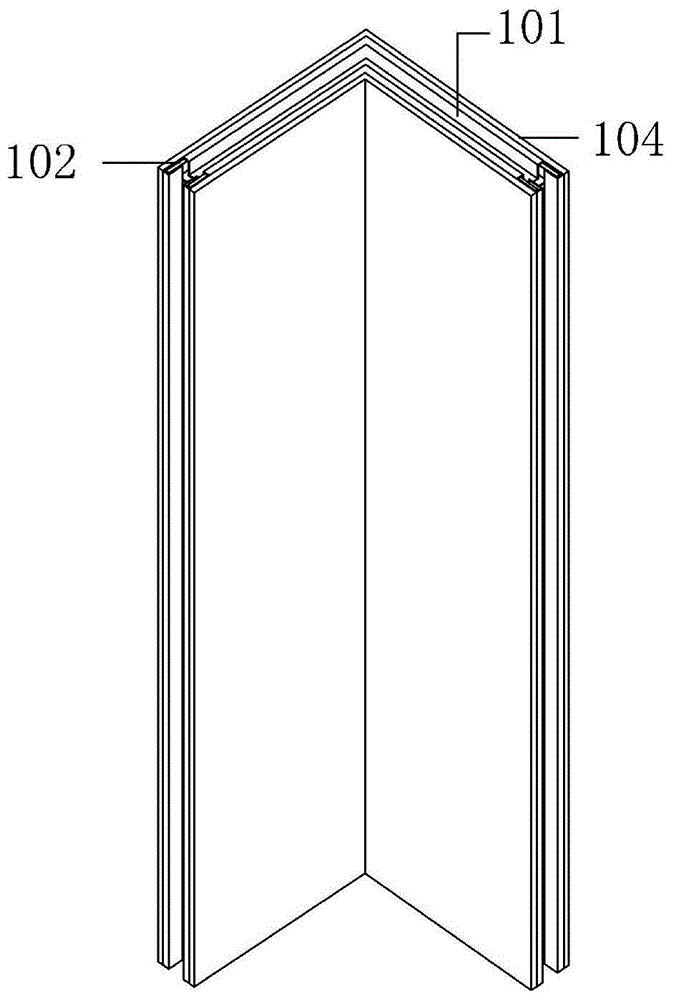

DGC modular fabricated building system and building method thereof

Provided are a DGC modular fabricated building system and a building method thereof. Wallboards are composite boards prefabricated in a factory. Light steel profiles and light steel keels are connected through self-tapping screws. The corners of the light steel profiles with grooves in frames are connected through self-tapping screws and light steel keel connecting pieces. The interiors of the wallboards are filled with heat preservation materials. Pouring layers of modified cement mortar or light aggregate concrete materials are arranged on the outermost sides of the wallboards. Floors are composite boards prefabricated in the factory, and each composite board is a foundation bottom plate or a floorboard or a roof panel of the DGC modular fabricated building system. The wallboards are connected through board connecting pieces, the wallboards and the floors are connected through board connecting pieces, and the floors are connected through board connecting pieces. The DGC modular fabricated building system is simple in structure, convenient to mount and low in cost, the construction period can be saved, and therefore the defects that an existing fabricated building is single in structure, complex in mounting process and high in manpower cost are overcome.

Owner:江苏保力装配式住宅工业有限公司

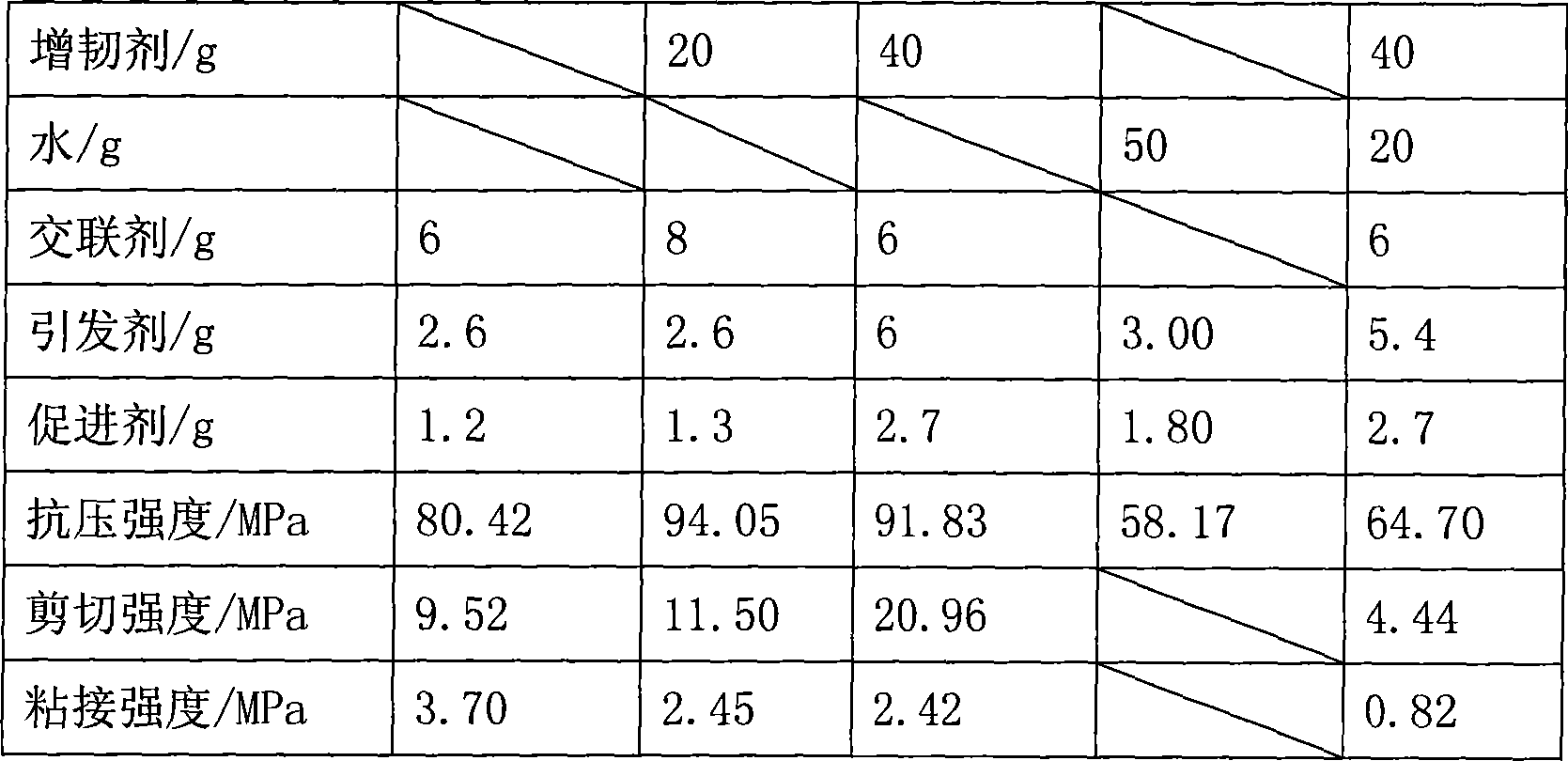

High-strength water-based itaconic acid epoxide resin grouting material and preparation method thereof

The invention discloses a high-strength grouting material of aqueous itaconic acid epoxy ester resin and making method, which comprises the following parts: 30-80% neutralized aqueous itaconic acid epoxy ester resin, 10-70% diluent, 0-100% water, 1-10% crosslinking agent, 0-0.1% storing stabilizer, 0-0.5% deoxidizer, 1-4% initiator, 0.5-4% accelerant and 0-2% boosting accelerant. The invention reduces the water content of grouting material to add the content of polymerisable component and increase the mechanic strength of the material, which is fit for kinds of engineering reinforcing and water shutoff course to make high-strength aqueous epoxy cement slurry through blending with cement slurry.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

Insulation block and method of using thermal insulation mortar to prepare insulation block

InactiveCN101781918AImprove mechanical propertiesIncreased durabilityConstruction materialShear modulusThermal insulation

The invention relates to an insulation block and a method of using thermal insulation mortar to prepare the insulation block. The insulation block comprises a hollow block, wherein an insulation block is filled in the hollow part of the hollow block. The preparation method of the insulation block comprises the following steps: firstly, preparing thermal insulation mortar with good flowing property; secondly, filling the thermal insulation mortar in the hollow part of the hollow block; and finally, connecting the hardened thermal insulation mortar with the hollow block to obtain the insulation block. The thermal insulation mortar is one kind of cement mortar, wherein the aggregate is selected from light particles with low coefficient of thermal conductivity. By using the method of the invention, the insulation block with 5-40MPa of compression strength, 0.20-0.70MPa of bending tensile strength, 0.20-0.70MPa of shear strength, 1*10<3>-3*10<3>MPa of elastic modulus, 500-1000MPa of shear modulus, 0-0.04% of coefficient of linear expansion and 0.20-0.40W / (m2.K) of heat transfer coefficient can be prepared and the insulation block can be used in various thermal insulation works of buildings.

Owner:TONGJI UNIV

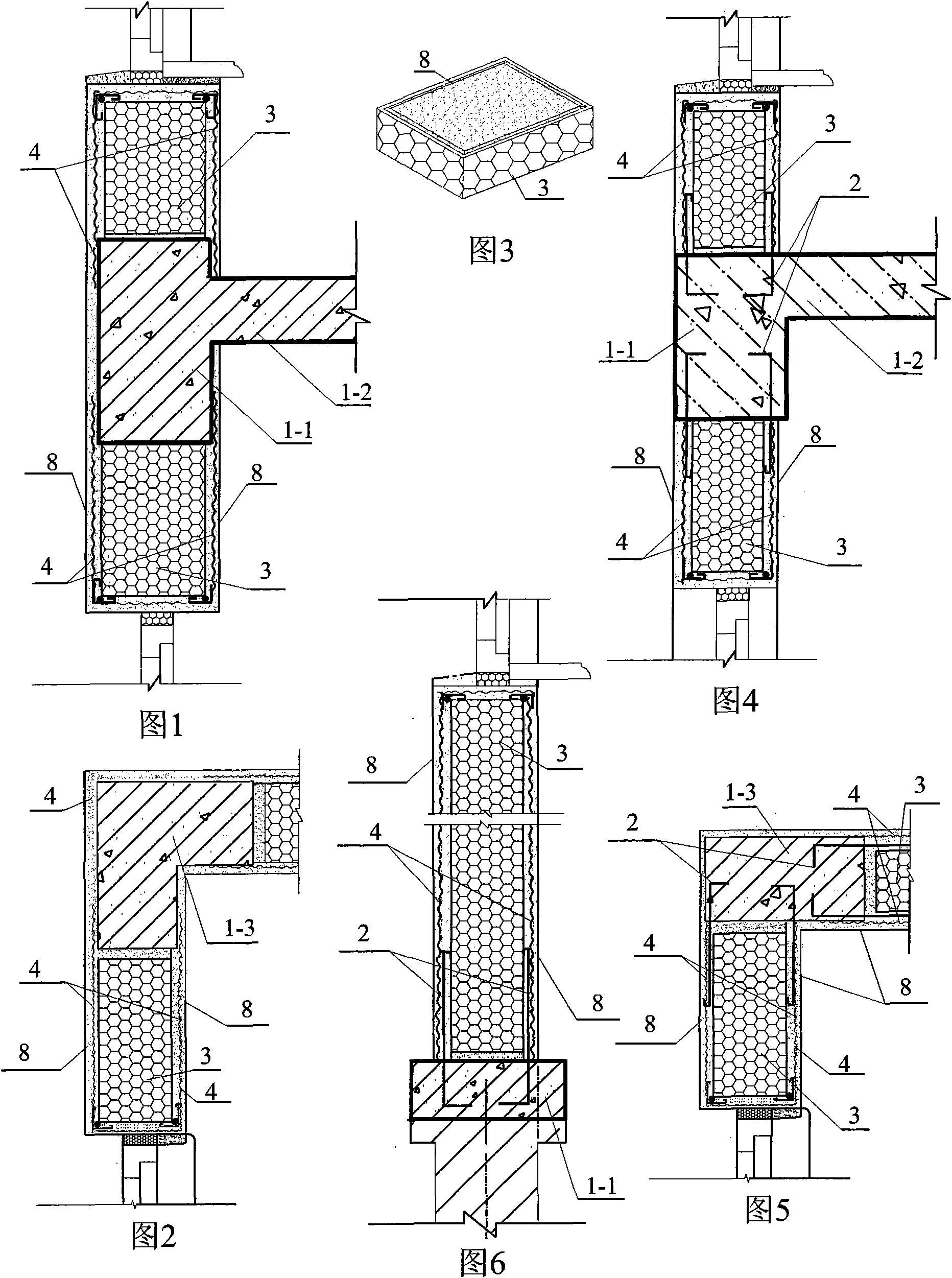

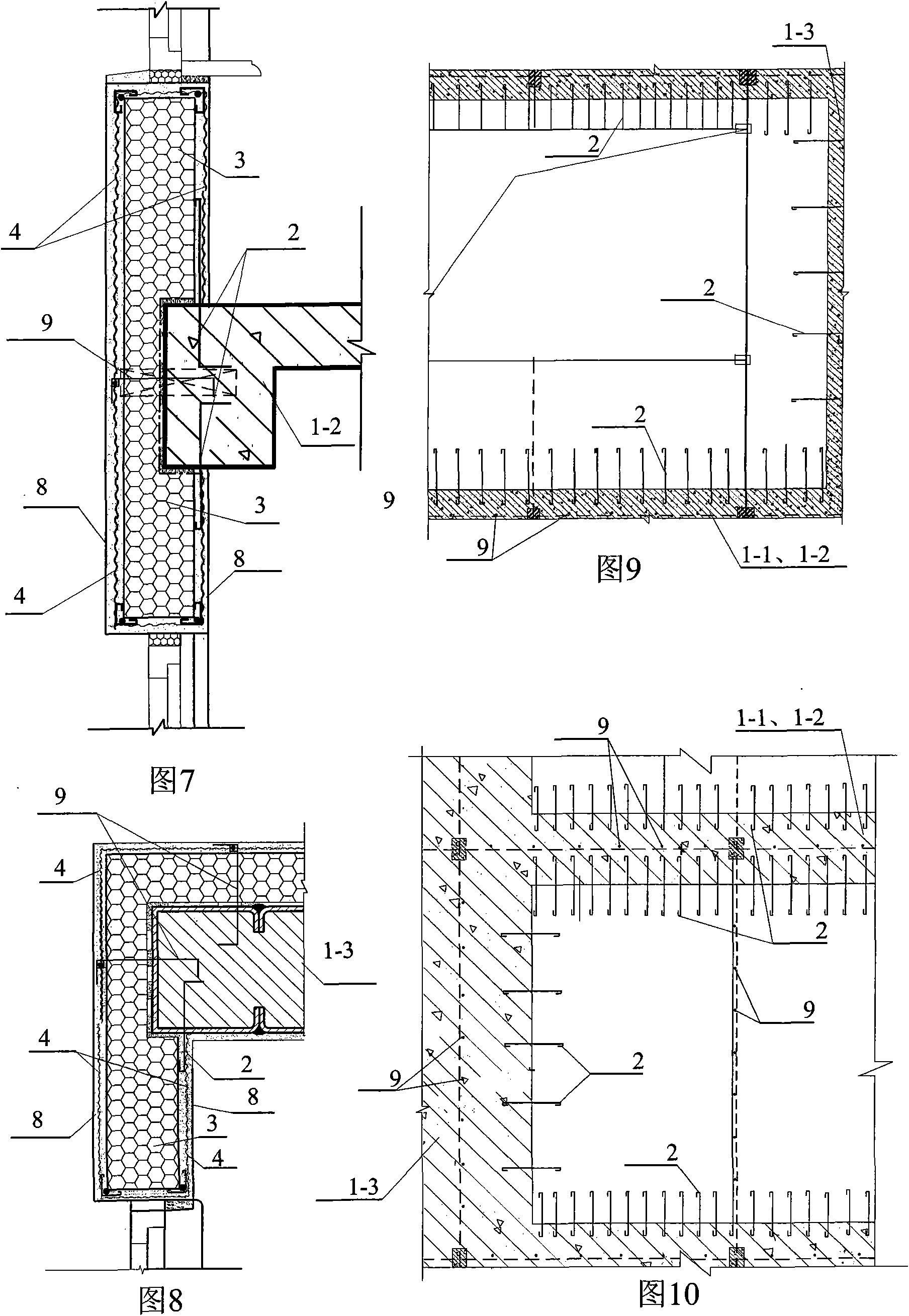

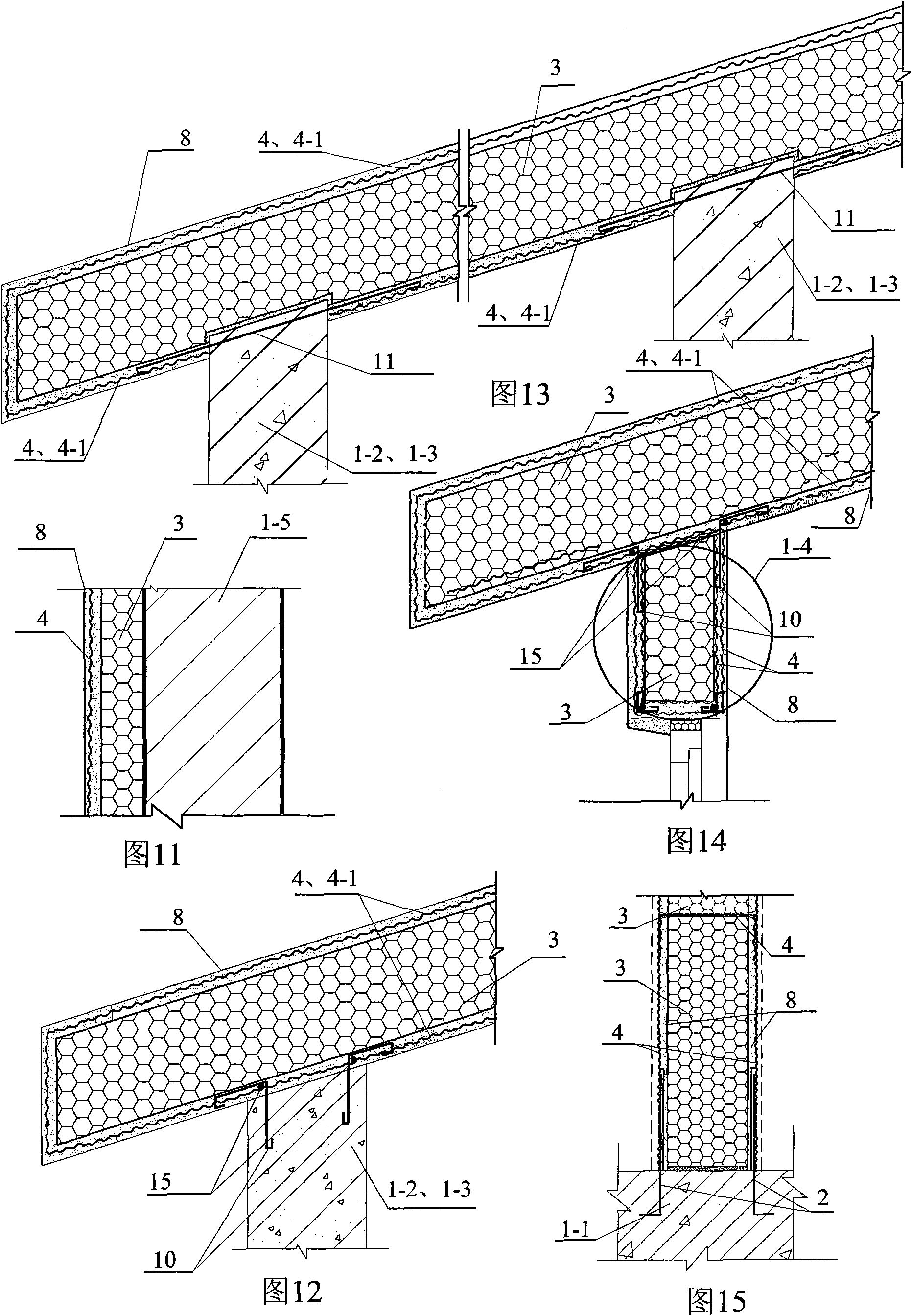

Composite component of alkaline-resisting mesh cloth plastering

InactiveCN101570981AReduce weightGood wind and shock resistanceRoof covering using slabs/sheetsStrutsMoisture barrierProtection layer

The invention relates to a composite component of alkaline-resisting mesh cloth plastering, relating to a building composite component and aiming at the problems of high construction cost, inconvenient construction and the like of the current energy-saving wall body. The structure one is as follows: a sandwich layer 3 is struck to the interior of a beam column frame of a load-carrying member 1; the interior and the exterior the sandwich layer 3 have cement mortar protective courses 8; an alkaline-resisting mesh cloth 4 is embedded in the interior of the protective courses 8 and is connected with the load-carrying member 1 in a sticking way. The structure two is as follows: the sandwich layer 3 is struck to a basic unit wall 1-5; the exterior of the sandwich layer 3 has the cement mortar protective courses 8; the alkaline-resisting mesh cloth 4 is embedded in the interior of the protective courses 8. The structure three is as follows: the sandwich layer 3 is positioned between the upper and lower cement mortar protective courses 8; the lower cement mortar protective course 8 is positioned on a building major structure 1; the upper protective course 8 covers the sandwich layer 3; the alkaline-resisting mesh cloth 4 is embedded in the interior of the protective courses 8. The method of construction is as follows: an interface agent is painted on the sandwich layer or cement mortar to stick the alkaline-resisting mesh cloth 4; when the interface agent is damp, the cement mortar ash is carried out; the glass is used as a waterproof and dampproof moisture barrier; a caking agent is struck to the surface of a structural cement to serve as the waterproof and dampproof moisture barrier. The method has the advantages of low construction cost, convenient construction, etc.

Owner:吴淑环

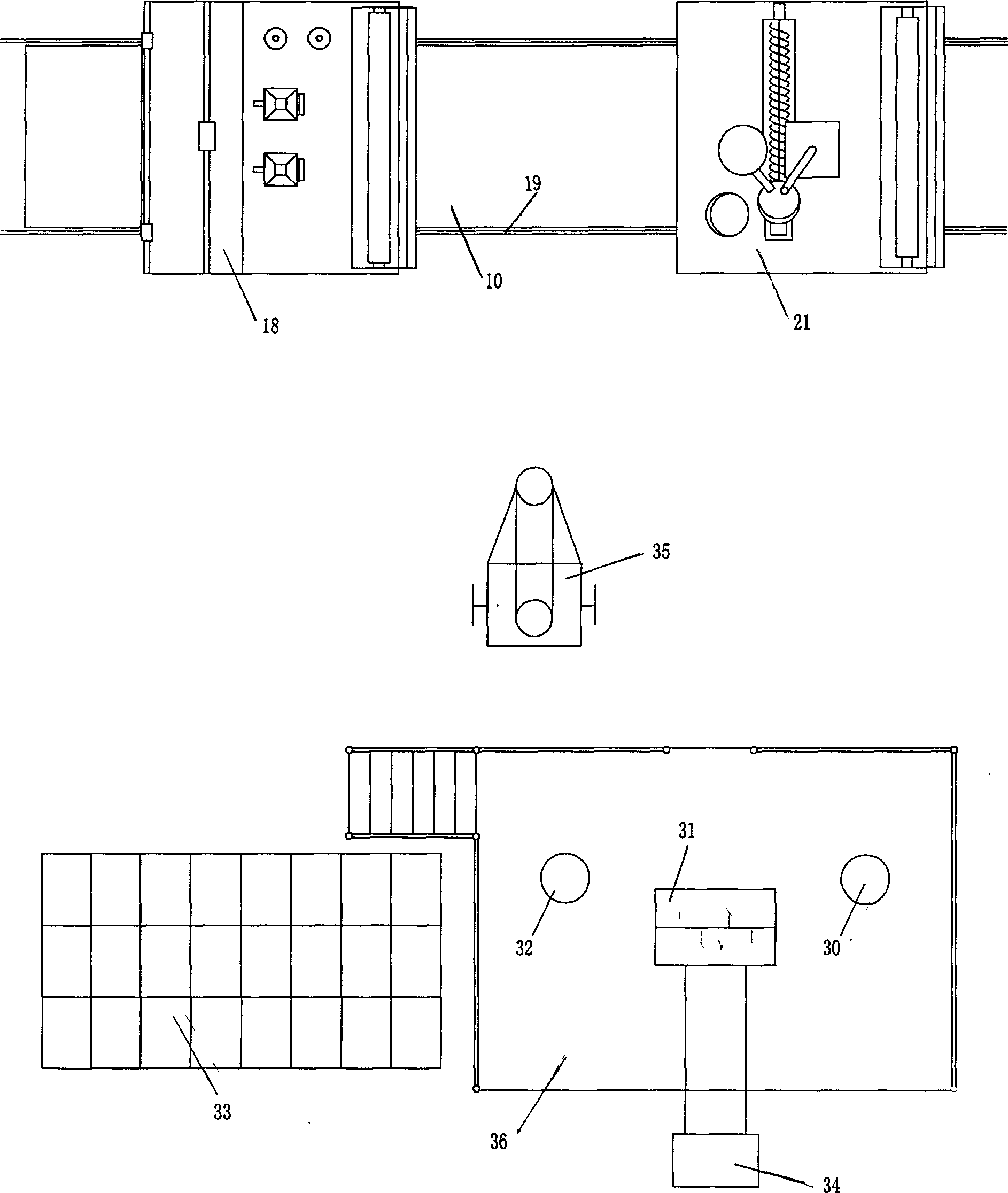

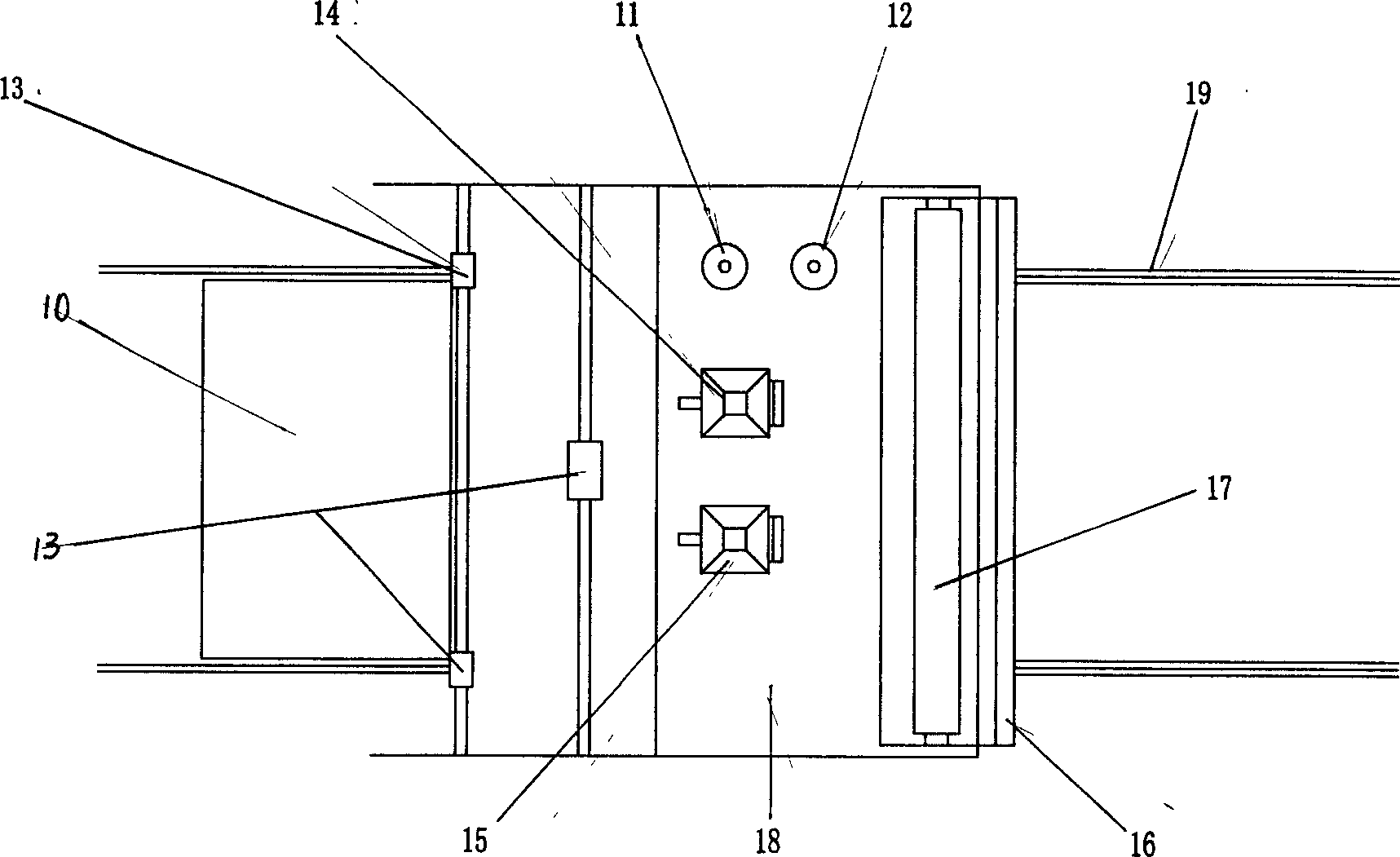

Apparatus and method for producing foaming concrete construction wall plate coated by glass fiber reinforced cement

InactiveCN1557618ASatisfy production capacityHighly flexible and interchangeableCeramic shaping apparatusFoam concreteGlass fiber

The present invention is the production apparatus and process of foamed building wall board coated with glass fiber reinforced cement. The production process includes painting demolding adhesive, jetting pre-mixed glass fiber reinforced cement mortar to form the reinforcing facing layer; laying steel wire net or glass fiber net; setting supporting steel skeleton and fixing it to the net; depositing foamed cement; leveling and curing; laying the second layer of steel wire net or glass fiber net; painting fiber gypsum layer, leveling and press polishing; curing and demolding; finishing the facing layer; and deep curing to form the building wall board. The production apparatus includes combined stirring station comprising decorating material stirrer, pre-mixed material stirrer, slurry stirrer and mold platform; combined facing layer operating vehicle with material distributing manipulator; and combined foaming operation vehicle.

Owner:NANJING BEILIDA NEW MATERIAL SYST ENG

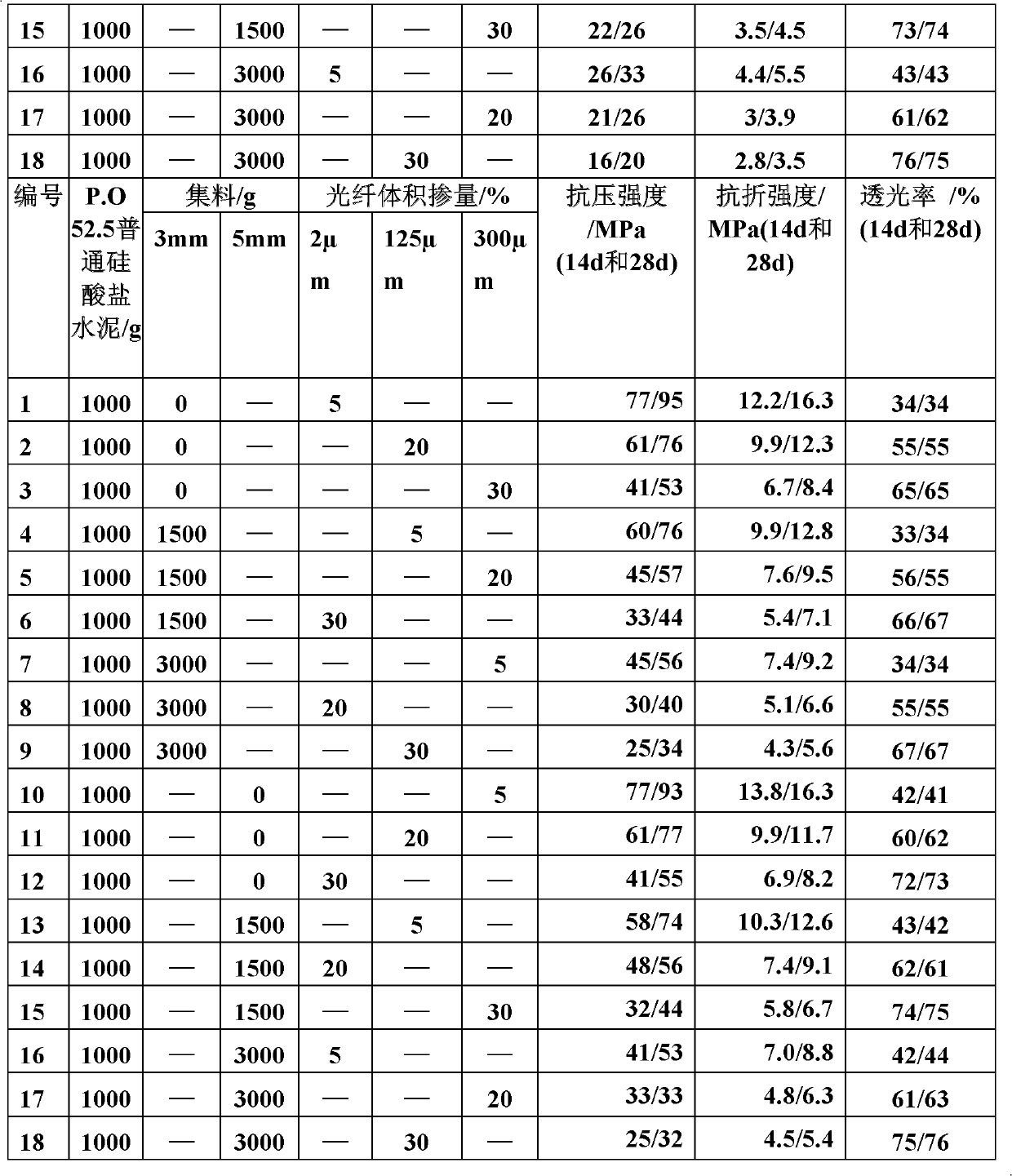

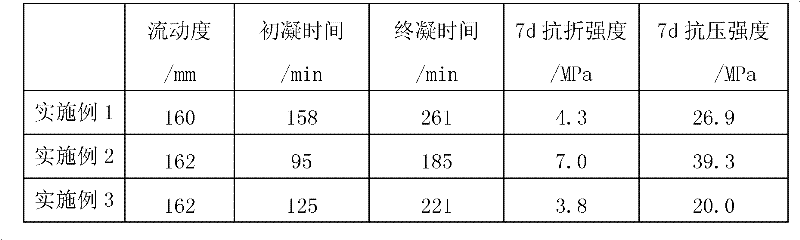

Method for preparing cement-based light transparent material by applying optical fiber parallel arrangement process

The invention discloses a method for preparing a cement-based light transparent material by applying an optical fiber parallel arrangement process, belonging to the field of novel building materials. The cement-based material comprises cement mortar, cement concrete and the like which are dense and light-proof. In the method, vitric multimode fibre is firstly selected, a coating is coated on the surface of the multimode fibre, and a coupling agent is selected for preprocessing the surface of the multimode fibre. The diameter of the multimode fibre is 2-300mum, a large quantity of multimode fibre beams are embedded in the cement-based material in a parallel arrangement mode, the direction of the multimode fibre beams is consistent with the light transmittance direction, and the multimode fibre beams are used as conductors for transmitting light for realizing special effects of transparency image transmission and the like of the cement concrete, and the volume fraction of the multimode fibre in a building block is 5-30 percent. The cement-based light transparent has better light transparency performance and a variable decoration effect, is one revolution of the cognition and the concept of the cement concrete, and has a wide application prospect in the fields of building illumination energy saving and building decoration.

Owner:BEIJING UNIV OF TECH

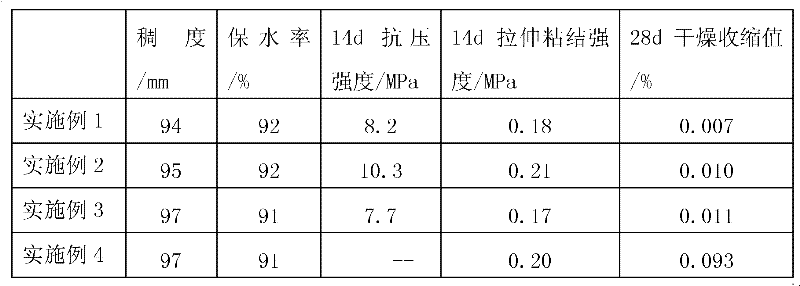

Composite cementitious material of desulfurated waste residue and mortar prepared from same

The invention relates to the field of building material, and particularly discloses a composite cementitious material of desulfurated waste residue, wherein the composition of the composite cementitious material of desulfurated waste residue comprises ingredients in the following ratios by weight: 25-40% of desulfurated waste residue, 60-75% of industrial chemical gypsum, 0-20% of inorganic mineral additive and 0-2% of chemical additive. The desulfurated waste residue is at least one of dry-process desulfurated ash, wet-process desulfurated gypsum and semidry-process desulfurated ash; the inorganic mineral additive is at least one of cement, fly ash, mineral powder and steel slag; and the chemical additive is at least one of K2SO4, Al2(SO4)3 and alums. The performances such as compressive strength and tensile bond strength of the mortar prepared from the cementitious material are basically the same as the performances of cement mortar, and the mortar can achieve related standards and requirements. In the composite cementitious material of desulfurated waste residue disclosed by the invention, solid waste is efficiently utilized for preparing composite cementitious material high in performances and low in cost by burning-free treatment process and efficient excitation pre-treatment technology, so that pollution can be reduced and energy can be saved.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

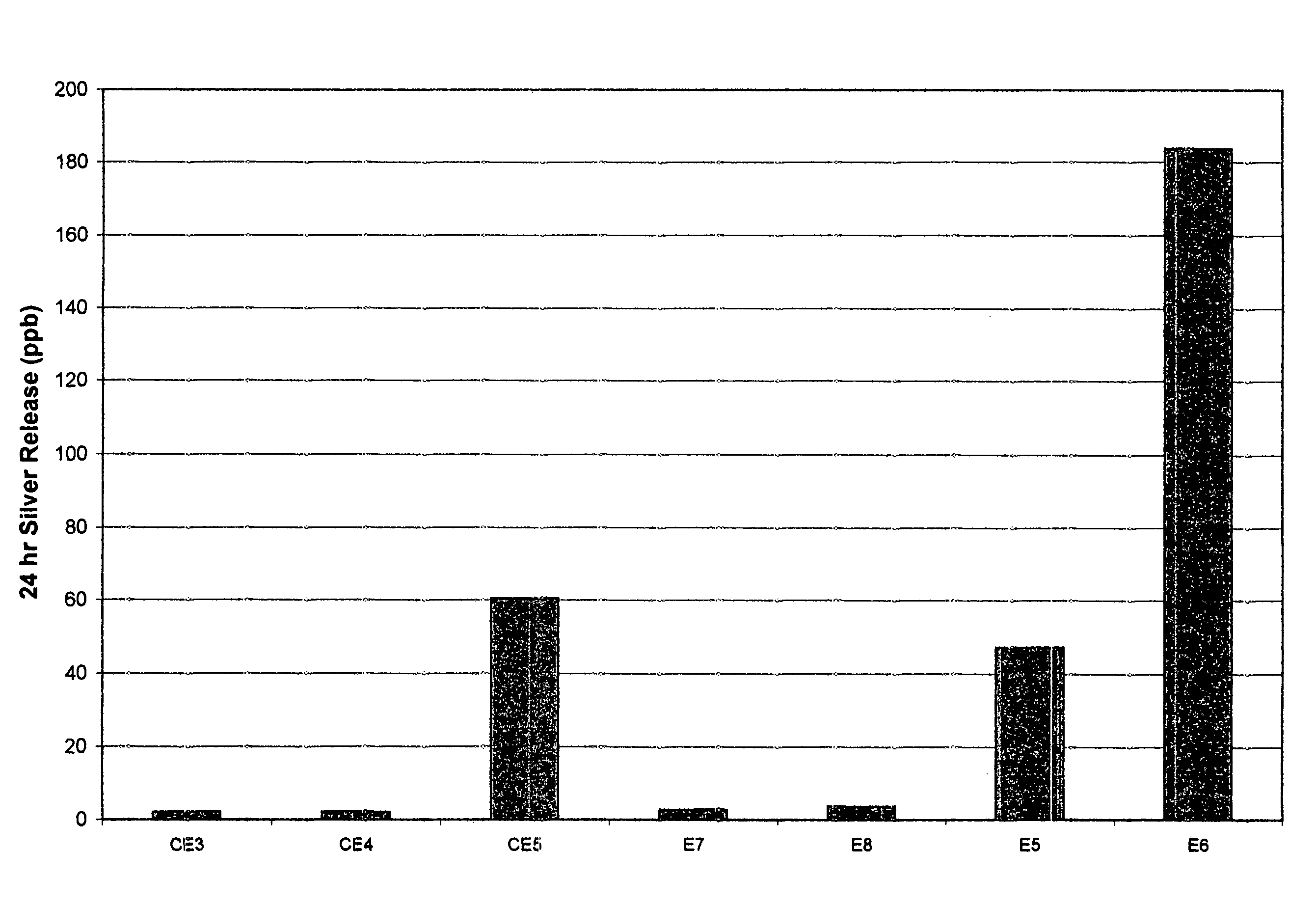

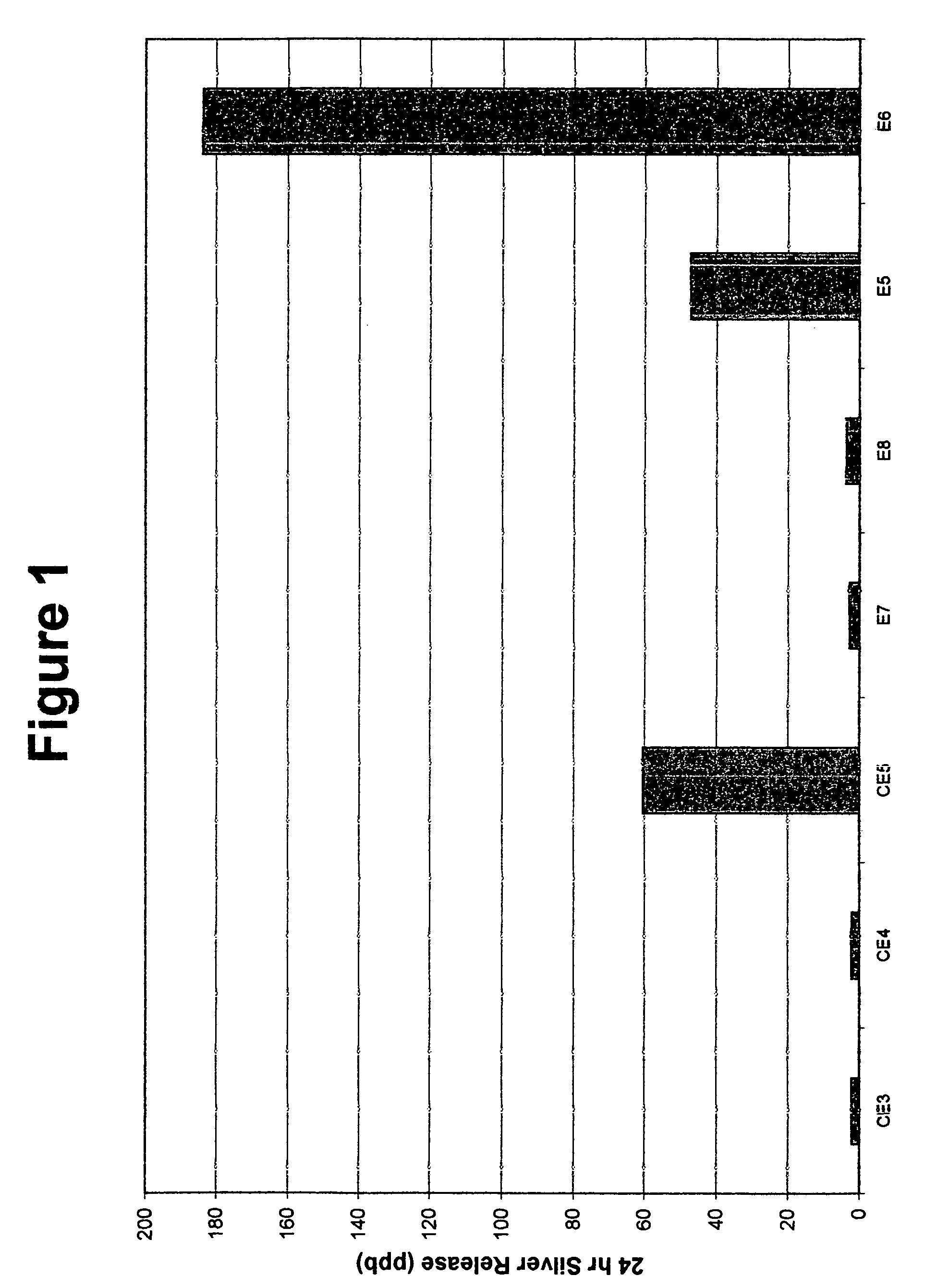

Antimicrobial cements and cementitious compositions

Efficient antimicrobial additives are provided comprising a wettable, cake-forming inorganic material having dispersed therein an inorganic or organometallic antimicrobial agent capable of releasing antimicrobial metal ions. These antimicrobial additives are especially effective for use in cements, mortars and cementitious compositions.

Owner:SCIESSENT LLC

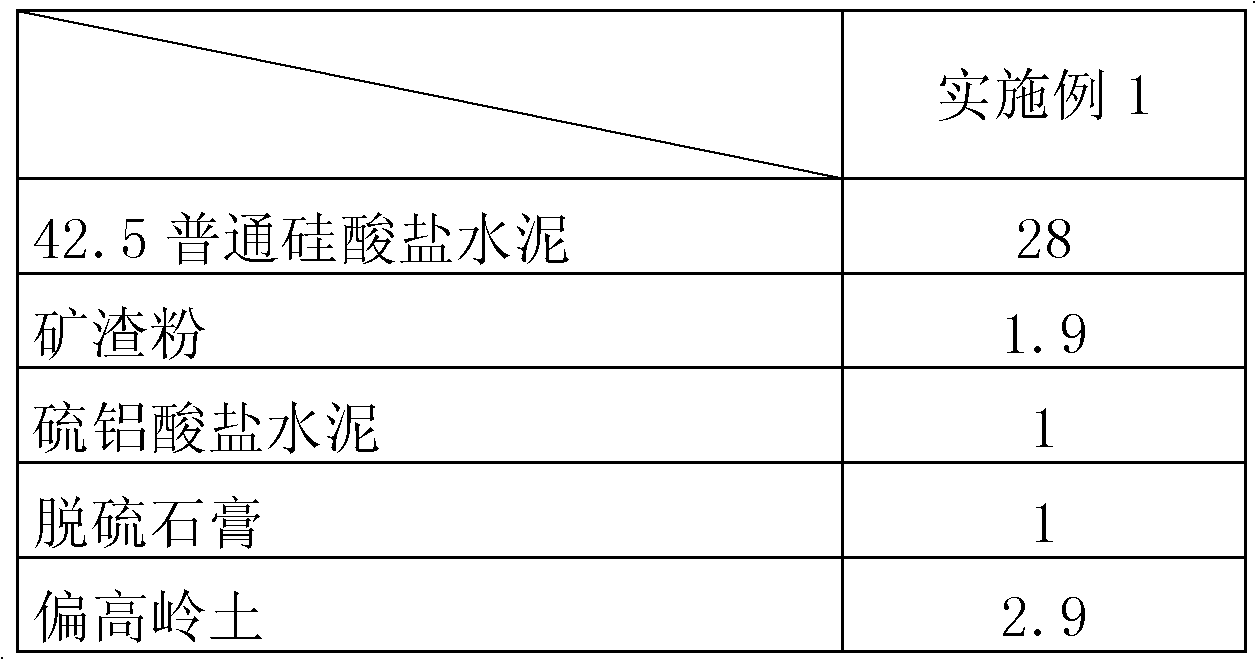

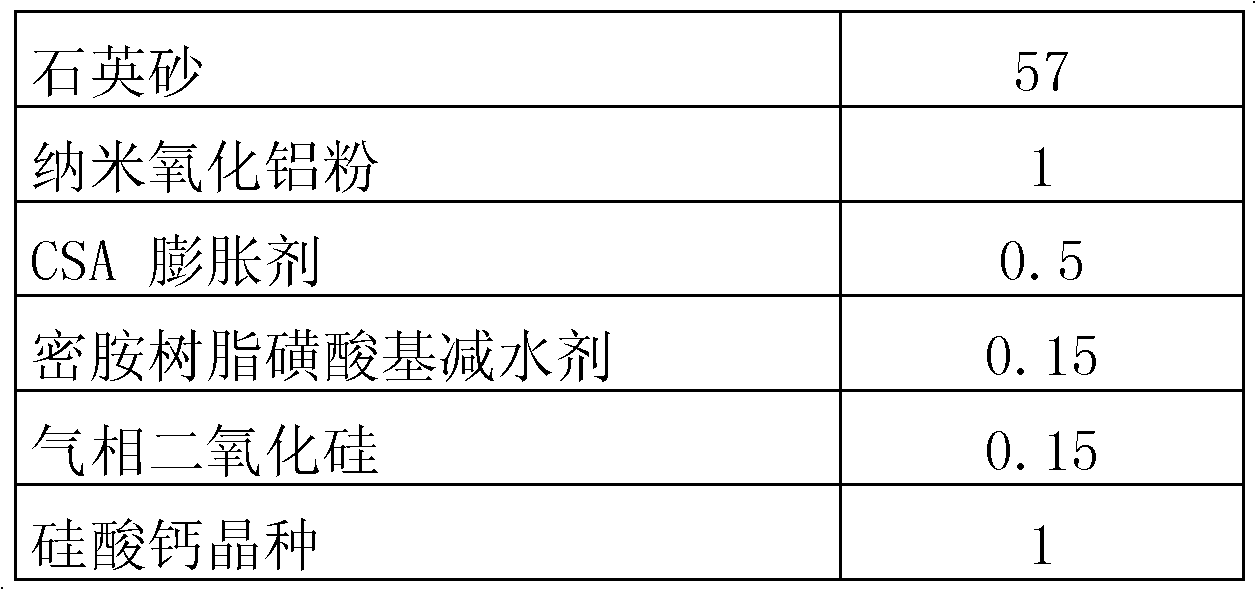

Wear-resistant cement mortar, wear-resistant floor and preparation method thereof

InactiveCN102910885AHas high strengthNon-shrinkableIn situ pavingsFlooringCalcium silicateWear resistant

The invention discloses wear-resistant cement mortar, a wear-resistant floor and a preparation method thereof, wherein the wear-resistant cement mortar is composed by mixing the following components according to a normal method, by weight, 22-40 parts of ordinary portland cement, 1.9-7.5 parts of slag powder, 1-5 parts of special cement, 1-5 parts of metakaolin, 1-5 parts of gypsum, 40-60 parts of quartz sand, 1-3 parts of calcium silicate seed crystal; 1-7 parts of nano alumina powder and 0.1-0.3 part of a water reducing agent, wherein the special cement is sulphoaluminate cement or aluminate cement. The wear-resistant cement mortar has the advantages of excellent hardness and strength. The wear-resistant floor prepared by the wear-resistant cement mortar has no micro-cracks on the surface after being grinded; good smoothness and various fresh brilliant colors can be obtained; color ordonnance can be realized on the surface with extremely high compactness; and aesthetic patterns with paint effects can be obtained.

Owner:MINGLUN BUILDING MATERIALS IND SUZHOU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com