Patents

Literature

326 results about "Viscous oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Viscous Oil is heavy or extra heavy crude oil with high viscosity. Oil Viscosity helps to measure a fluid's resistance to flow. If the oil contains higher viscosity (thickness), it does not flow easily under normal conditions.

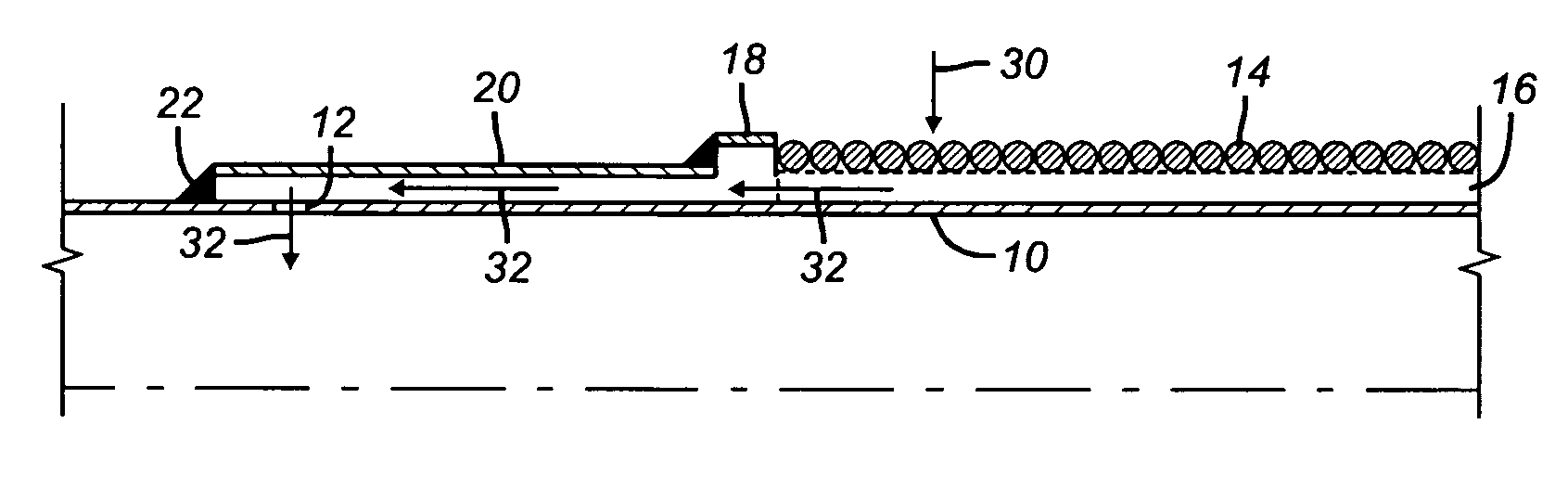

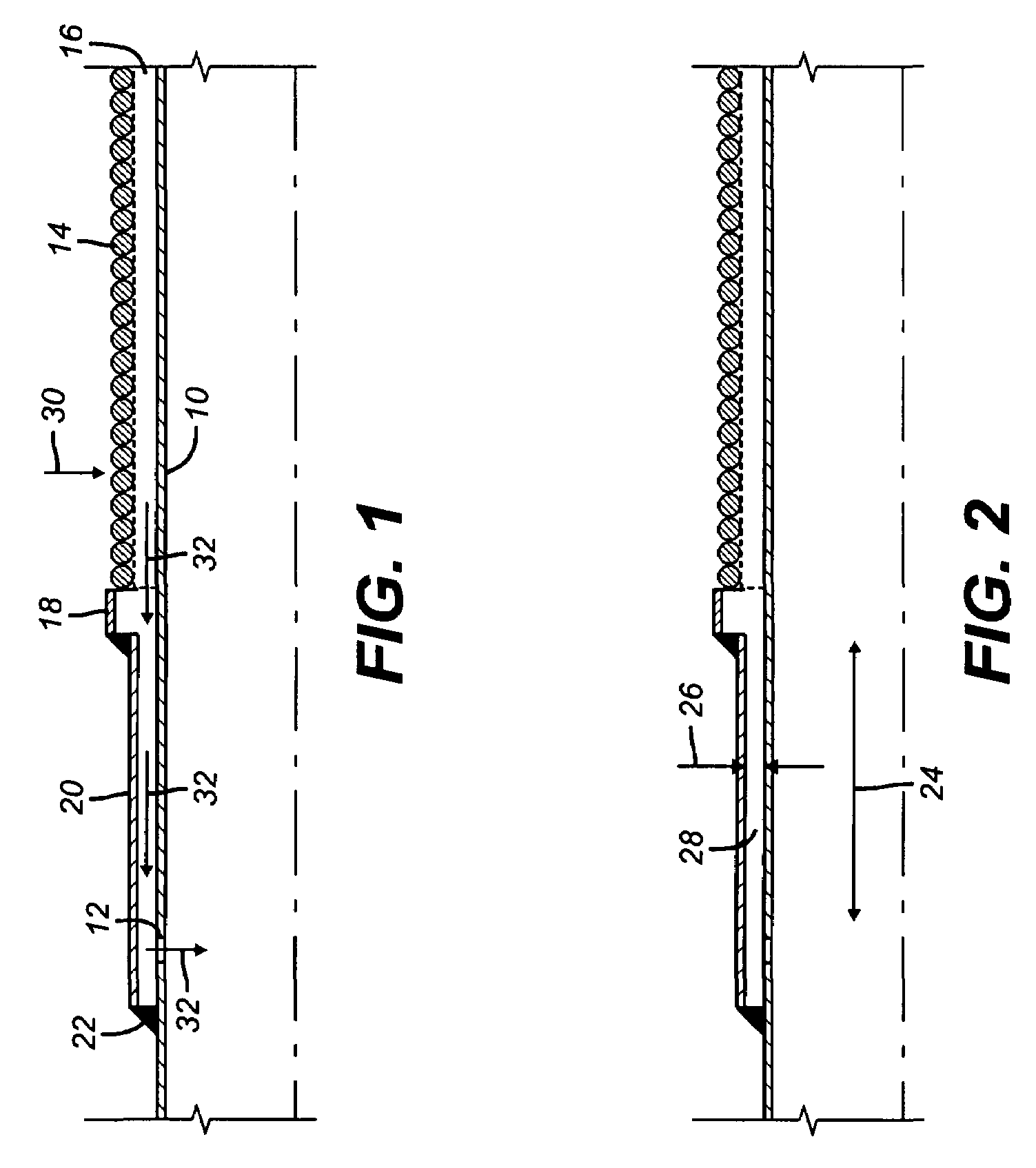

Viscous oil inflow control device for equalizing screen flow

A flow balancing system for long screen sections particularly useful in high viscosity hydrocarbon production features an annular flow path whose height and length can be varied to provide a predetermined resistance to a given flow rate of a material of a given viscosity. In assembling a long length of screen sections, greater resistance configurations are placed closer to the wellhead end of the screen section with the more remote sections having progressively less restriction until the furthest section of the screen string where low or no resistance to flow internally to the screen section is offered.

Owner:BAKER HUGHES INC

A w/o/w active heavy oil plugging agent for oil wells and its preparation method

InactiveCN102277143AEffective blockingSolve water problemsFluid removalDrilling compositionInjection pressureSURFACTANT BLEND

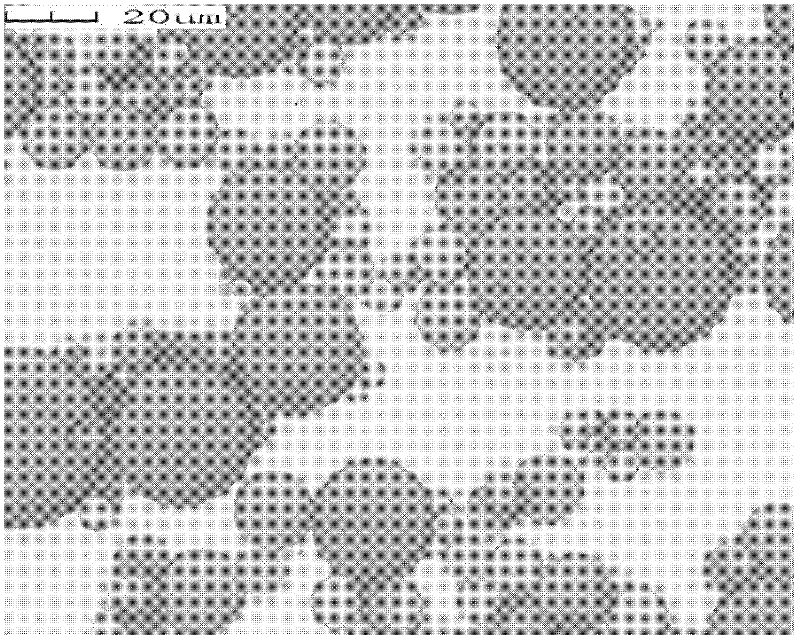

The invention discloses a W / O / W type active viscous oil blocking agent. The blocking agent comprises internal phase water, viscous oil and external phase water. A nonionic surfactant is adopted between the internal phase water and the viscous oil. An ionic surfactant is adopted between the viscous oil and the external phase water. According to the invention, a W / O / W composite structure is adopted, W / O with a relatively large viscosity is coated by the external phase water layer, such that defects in prior arts of high viscosity, high construction pressure and poor selectivity upon an oil-water layer during an active viscous oil blocking agent injection process are overcome. With the blocking agent provided by the invention, the ground fluidity is good, and the injection pressure is low. When the blocking agent enters the stratum, the emulsion is demulsified, and W / O emulsion with a high viscosity is released, such that oil well water exits can be effectively blocked, and defects of existing active viscous oil blocking agents are overcome. The technical scheme provided by the invention is especially suitable for technical features of offshore oilfields.

Owner:CHINA NAT OFFSHORE OIL CORP +1

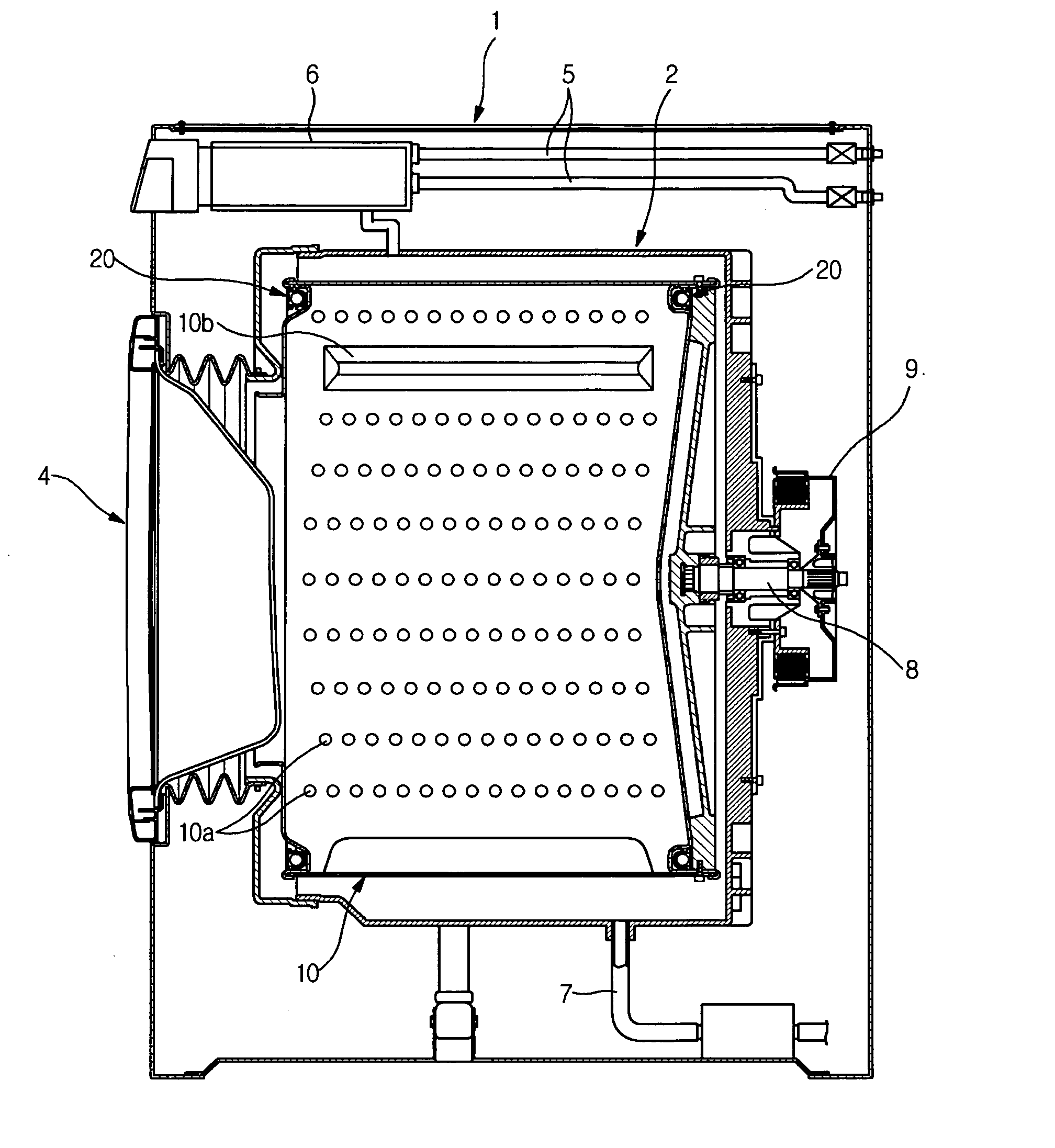

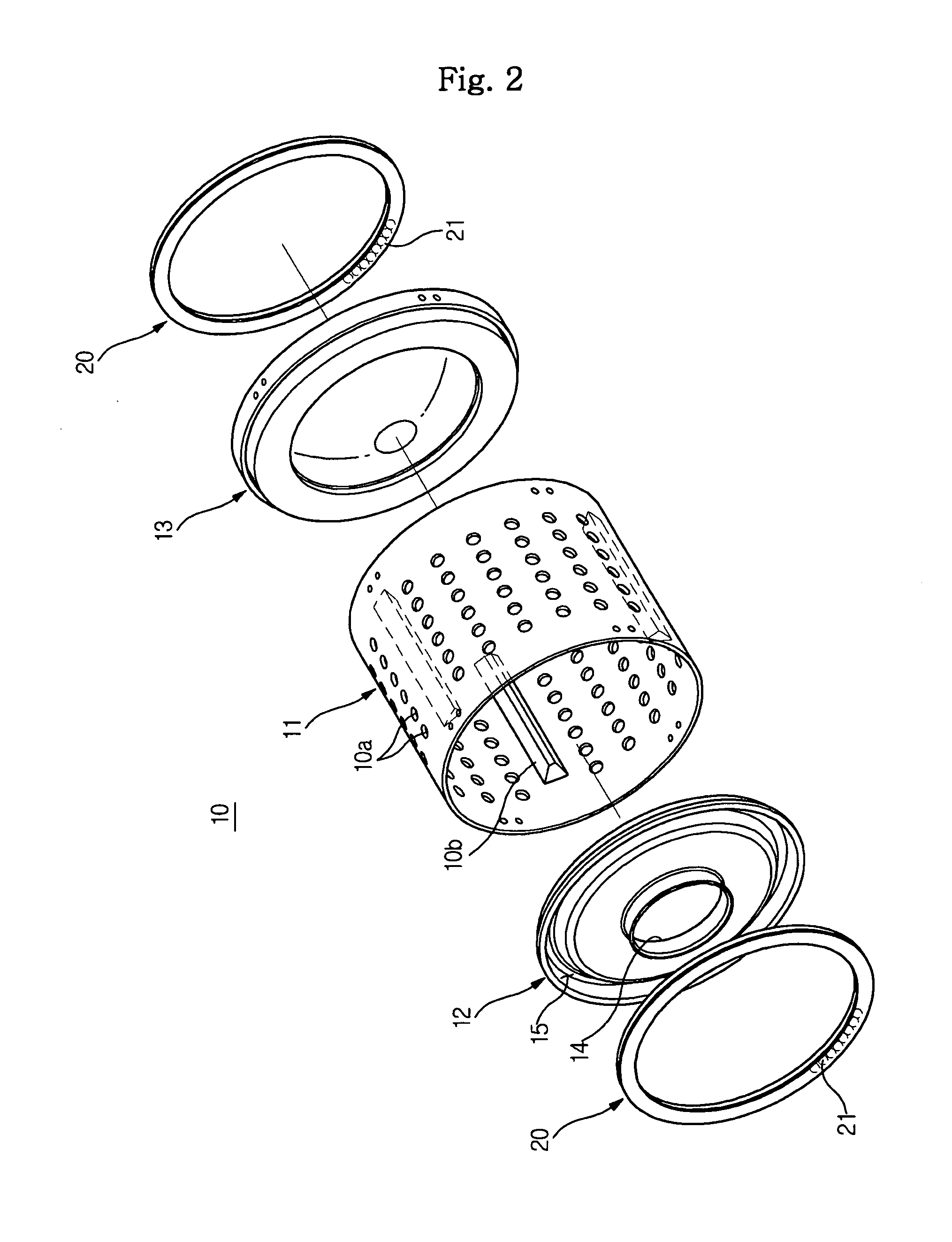

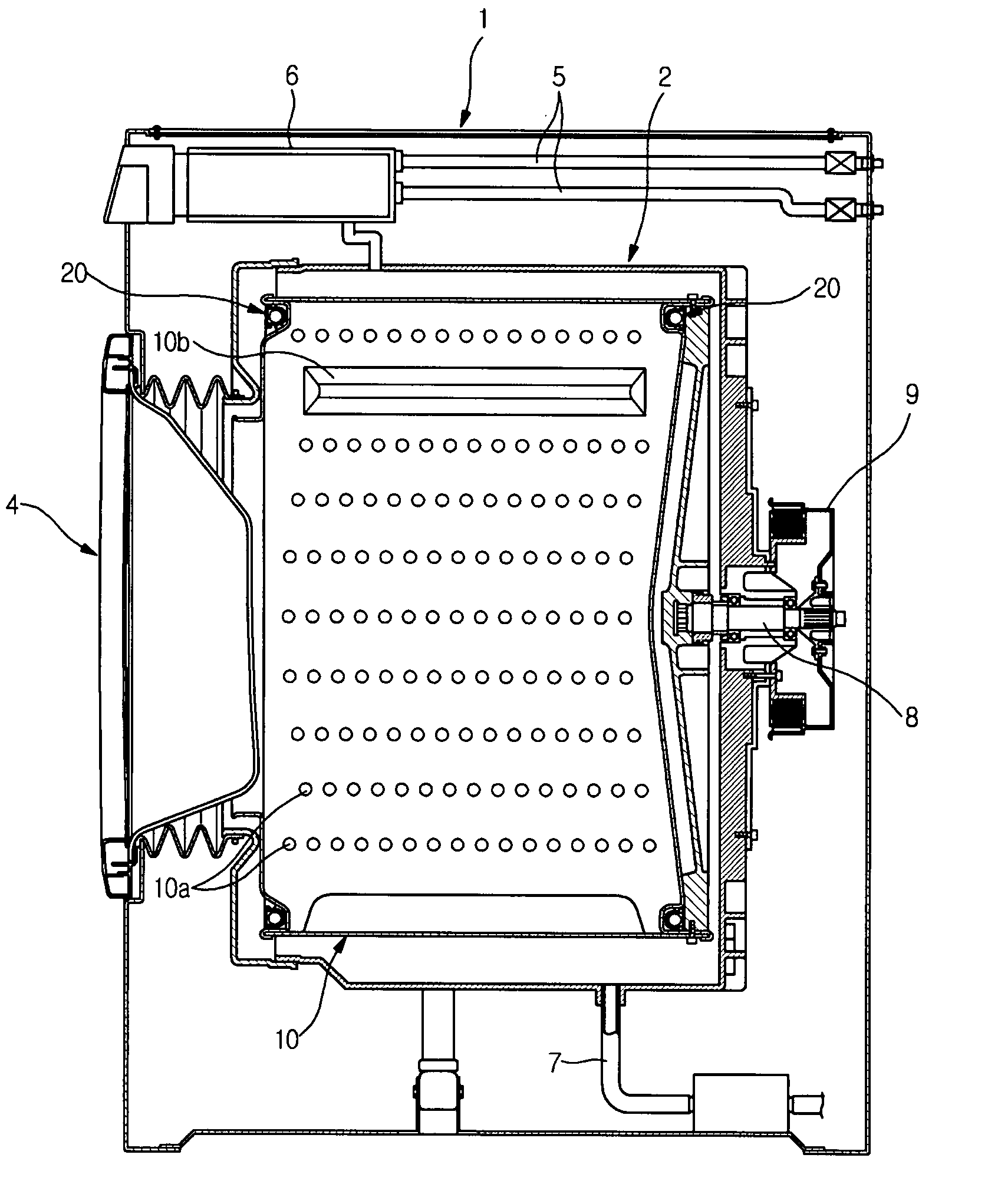

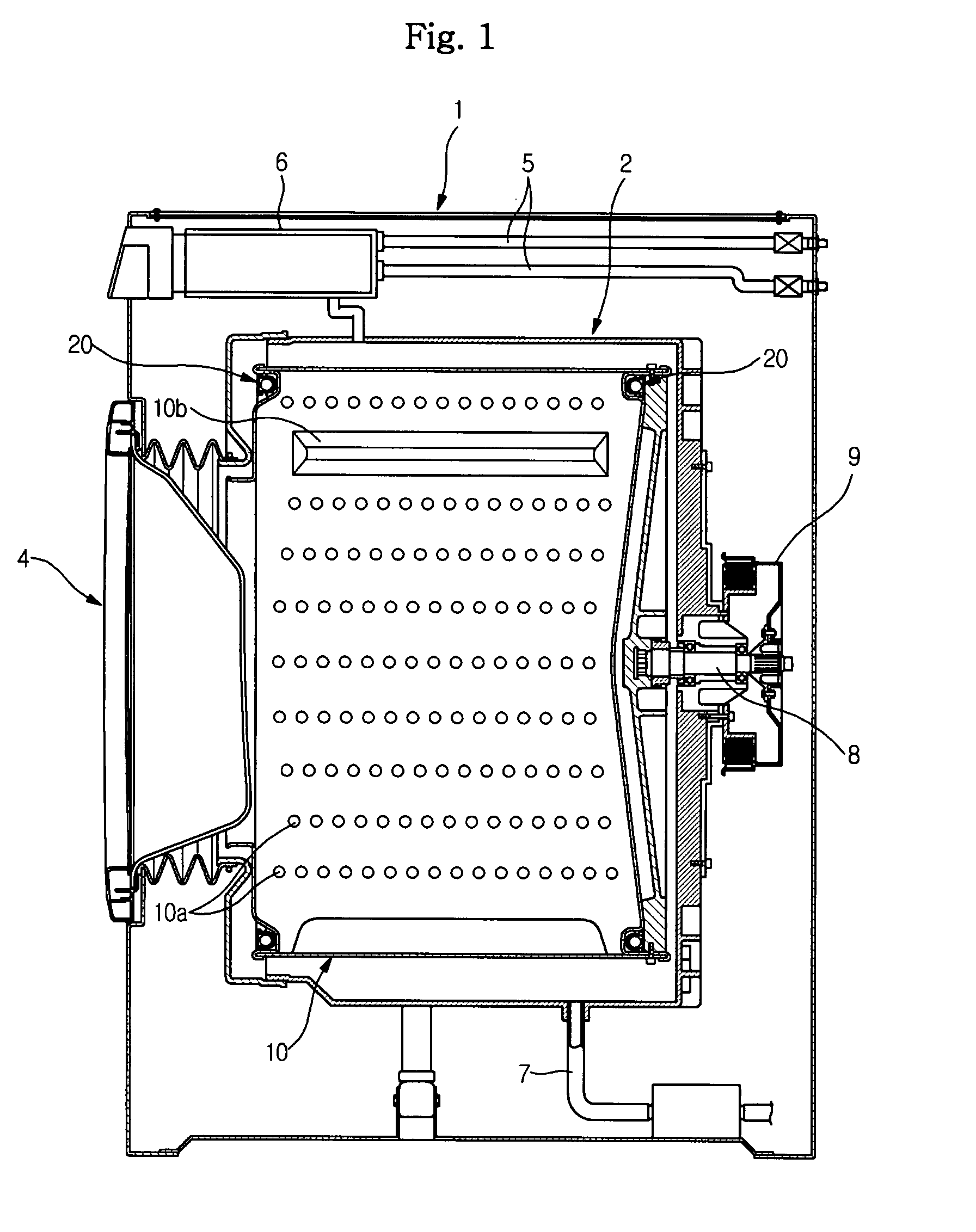

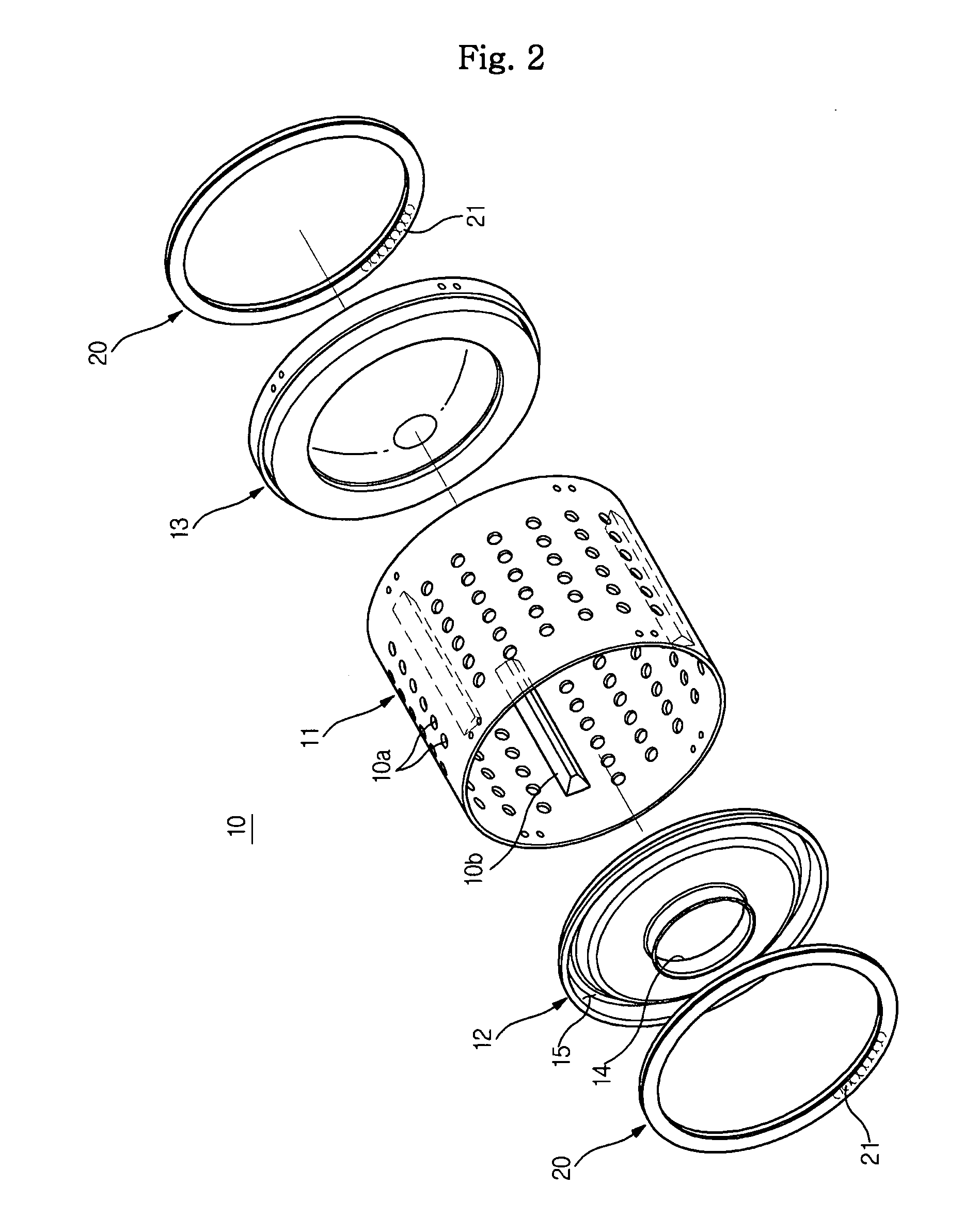

Washing machine having ball balancers

ActiveUS20110203325A1Reducing of vibration and noiseMaintain dynamic balanceRotating vibration suppressionControlling membersMechanical engineeringViscous oil

A washing machine having a ball balancer coupled to the drum to compensate for a dynamic imbalance during rotation of the drum, the ball balancer including a ring-shaped racer having a closed internal space in which a plurality of balls and viscous oil are accommodated, the ring-shaped racer including a first injection molded member and a second injection molded member joined to each other to form the closed internal space, the first injection molded member including a first side wall, a second side wall and a connecting wall between the first side wall and the second side wall, the first injection molded member having an open side opposite to the connecting wall, and the second injection molded member is adapted to cover the open side of the first injection molded member.

Owner:SAMSUNG ELECTRONICS CO LTD

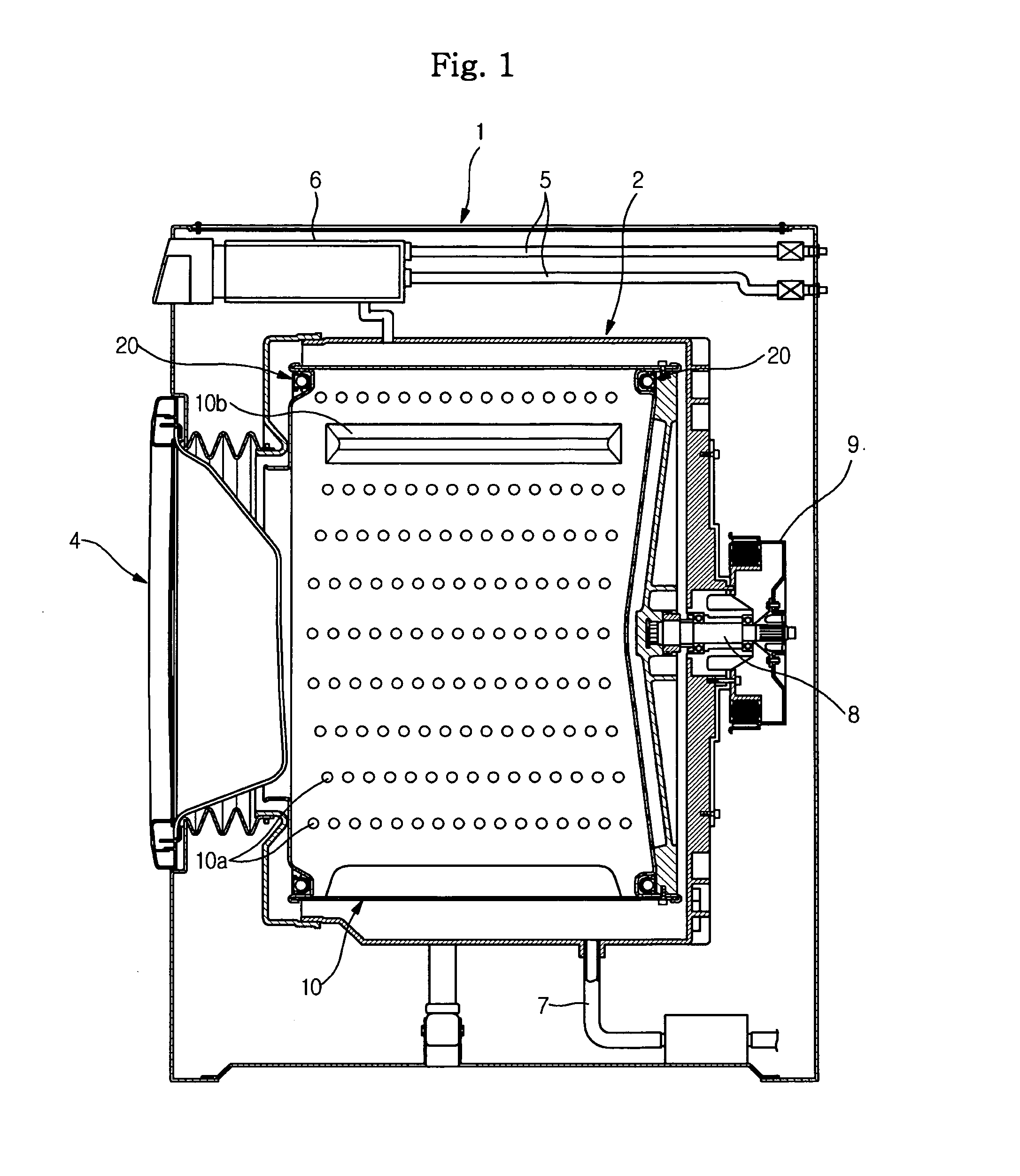

Washing machine having ball balancers

ActiveUS20080110212A1Reduce vibrationReduce noiseControlling membersRotating vibration suppressionProcess engineeringViscous oil

Disclosed is a washing machine having ball balancers, which adjust a relation between a gap, between the inner wall of a racer of each of the ball balancers and balls, and viscous oil, so as to reduce the vibration and noise of the washing machine. Each of the ball balancers of the washing machine includes balls and viscous oil accommodated in a racer, and the viscosity of the viscous oil is varied in proportion to a gap between the racer and the balls. When the viscosity of the viscous oil is 1˜100 cSt, the gap is set to 0.5˜1.0 mm, when the viscosity of the viscous oil is 100˜380 cSt, the gap is set to 1.0˜2.0 mm, and when the viscosity of the viscous oil is 380˜1,000 cSt, the gap is set to 2.0˜3.0 mm. Thereby, the relation between the gap and the viscous oil is optimized, and the ball balancers effectively exhibit a balancing function and thus minimize the vibration and noise of the washing machine.

Owner:SAMSUNG ELECTRONICS CO LTD

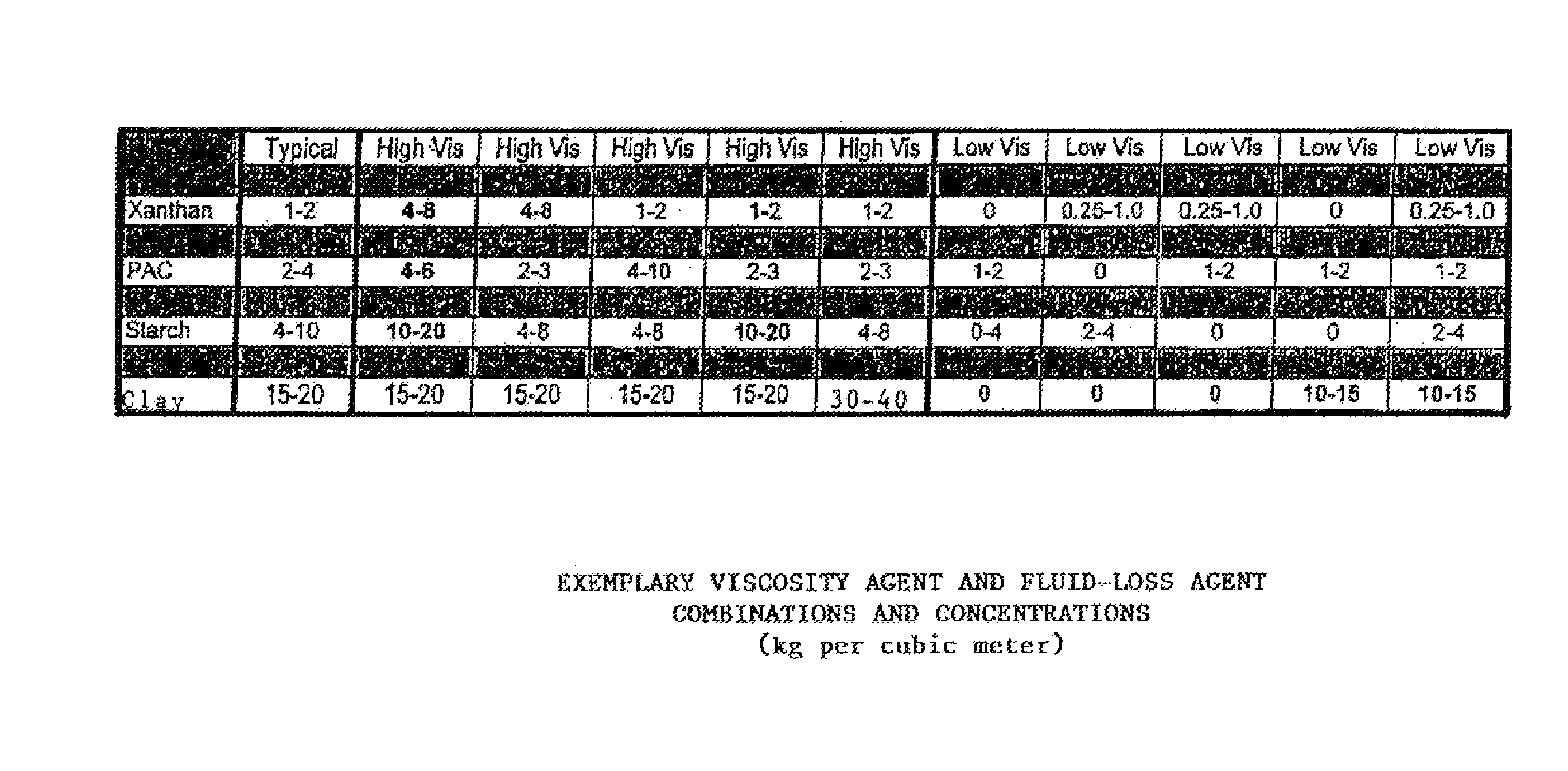

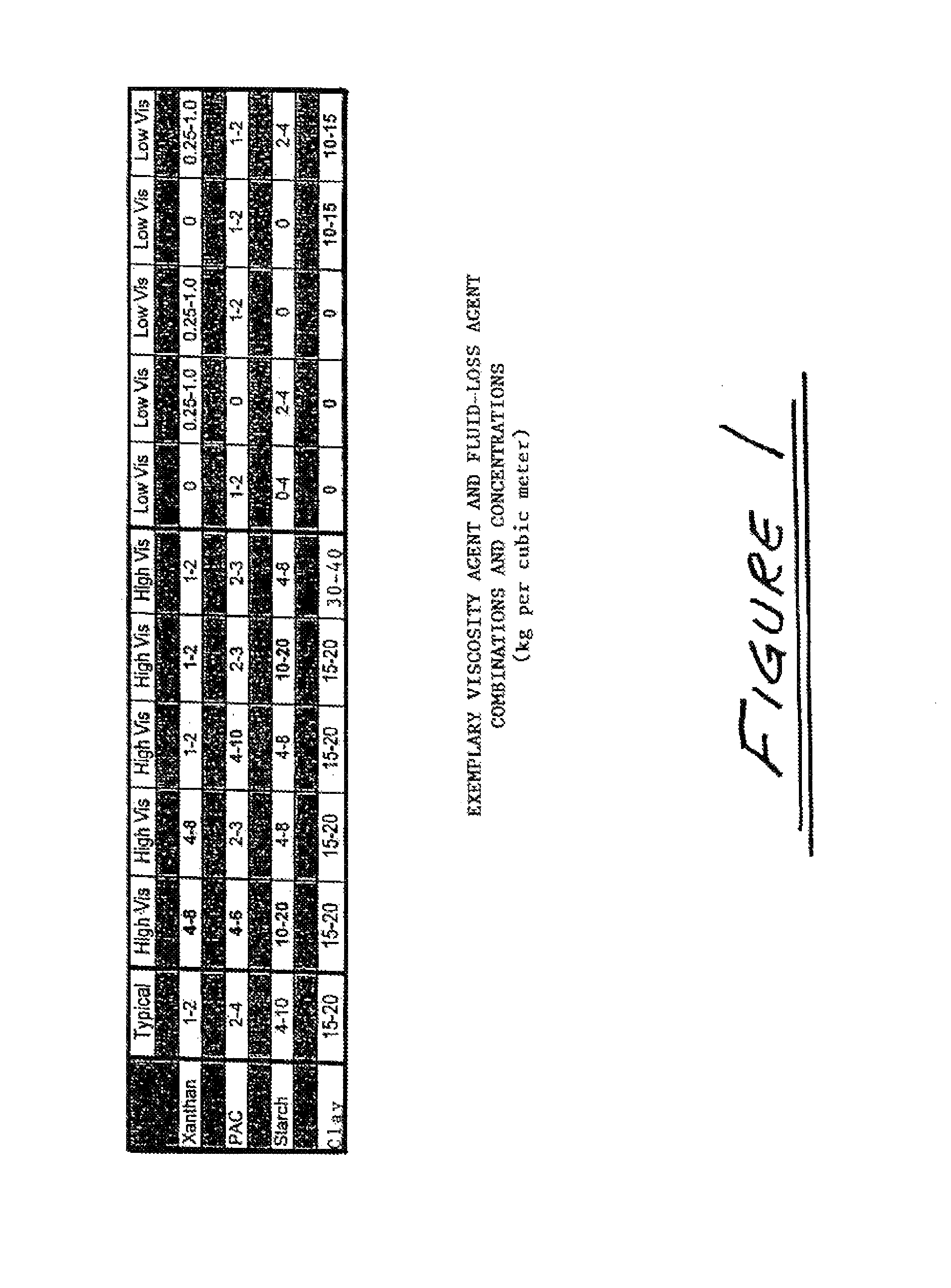

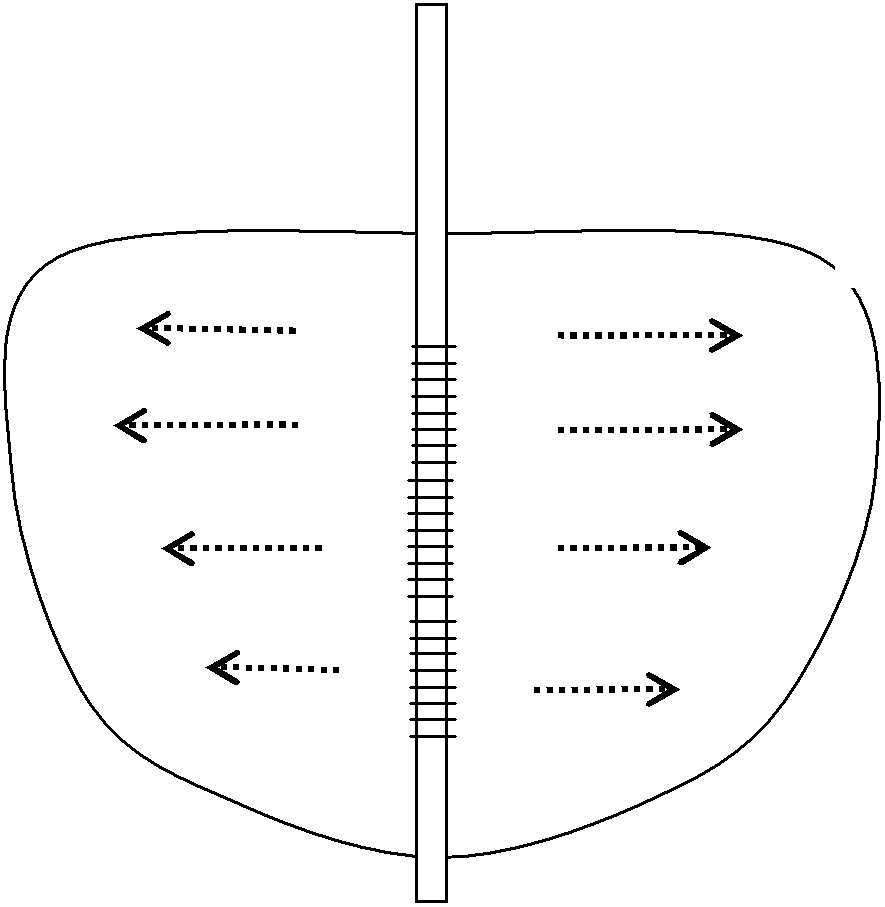

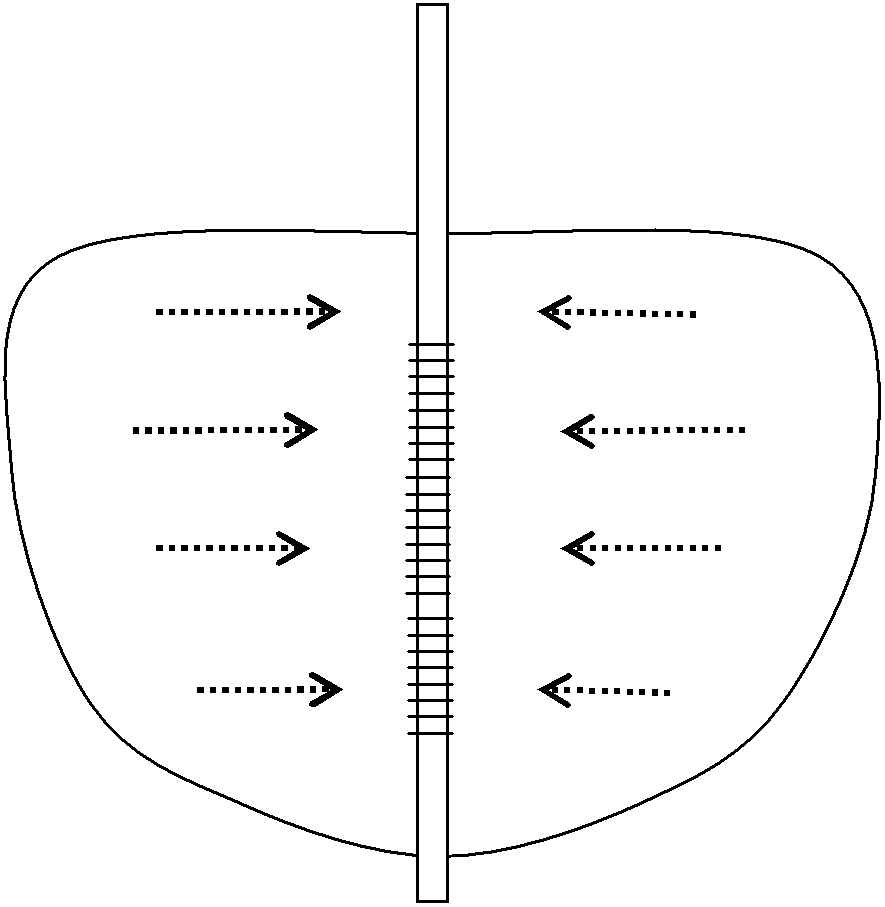

Emulsified polymer drilling fluid and methods of preparation

A water-based polymer drilling fluid, containing effective quantities of surfactants having HLB numbers equal to or greater than approximately 7, emulsifies oil and bitumen contained in oil sand cuttings, resulting in the oil and bitumen being dispersed into the mud as an emulsion. This eliminates or significantly reduces the ability of the oil, bitumen, and cuttings to clog the well or stick to drill string components when drilling a well through oil-bearing sands, particularly sands containing highly viscous oil or bitumen. The emulsification process separates the sand particles from the oil and bitumen, such that the sand particles can be removed when the mud is run through a conventional shale shaker or other suitable apparatus.

Owner:SECURE ENERGY DRILLING SERVICES

A method of gravity drainage assisted steam flooding to enhance the recovery of deep ultra-heavy oil reservoirs

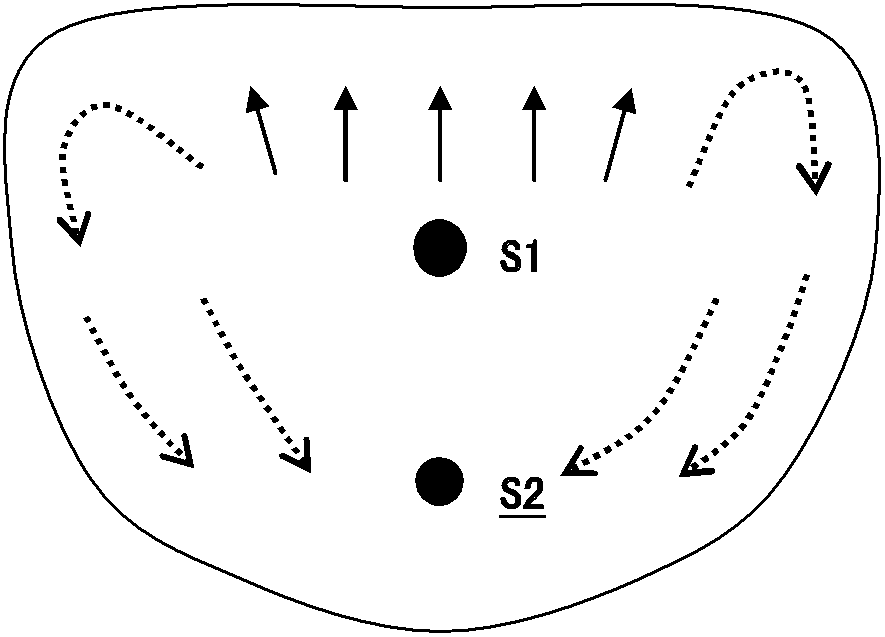

The invention relates to a method for improving the oil deposit recovery ratio of deep massive extremely-viscous oil in an extraction mode of gravity drainage assisted steam flooding. In the method, superposition horizontal wells are arranged among wells by combining results of researches on the fine contrast of small geological strata of massive oil deposit, the distribution rule of interlayer, the distribution rule of remaining oil and the like and a fine research on numerical simulation; an upper superposition horizontal well is used for injecting steam, a peripheral vertical shaft is used for production, and a lower superposition horizontal well is used for discharging liquid (crude oil between condensate water and the horizontal wells); and thus, a production-injection ratio of high-speed steam injection of deep oil deposit is improved, the dryness of steam on the well bottom is improved, the pressure of an oil layer is reduced, a steam cavity is easy to expand, the swept volume is improved, a development effect is improved, and the aim of improving the recovery ratio finally is fulfilled.

Owner:PETROCHINA CO LTD

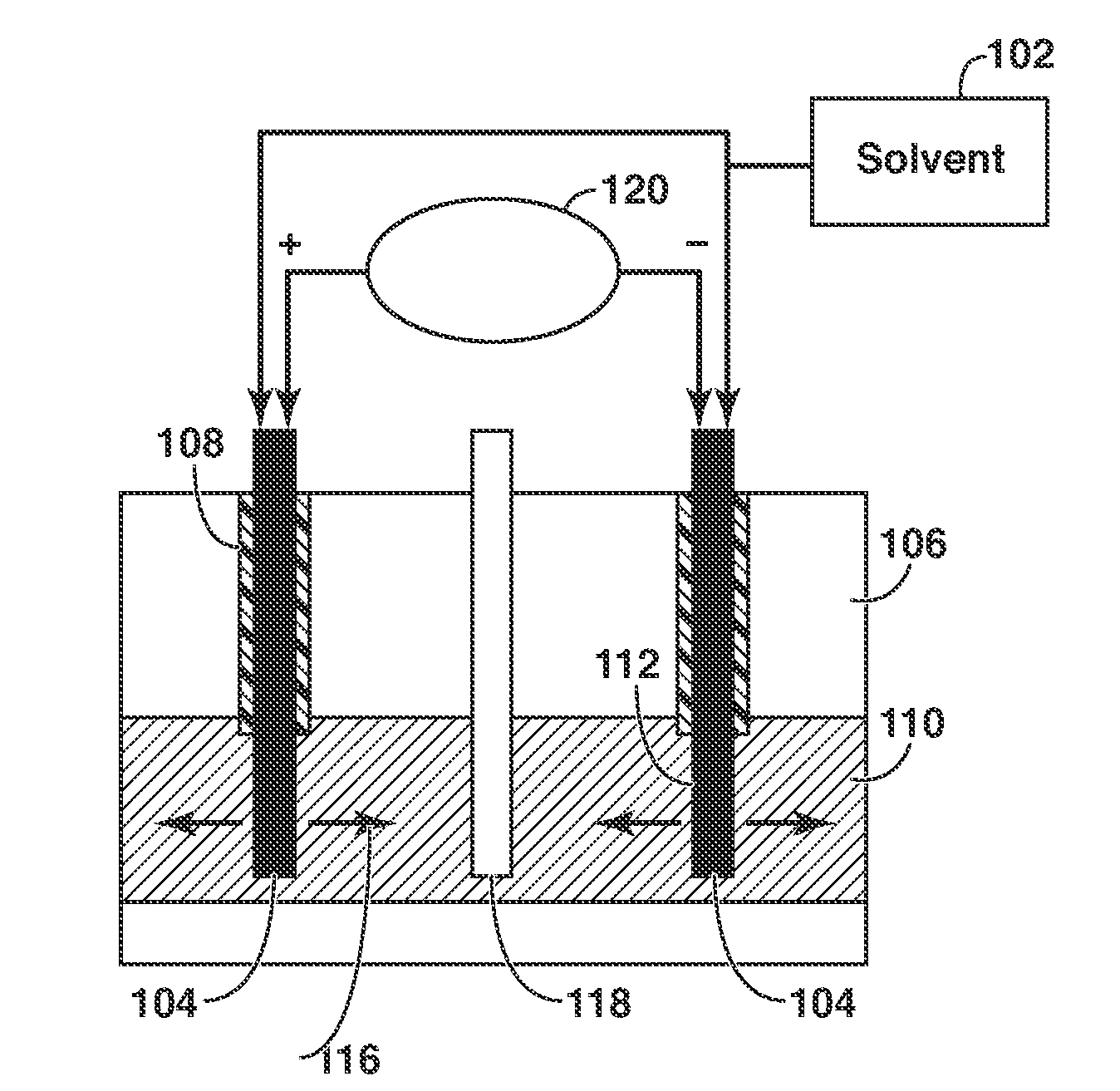

Viscous oil recovery using electric heating and solvent injection

InactiveUS20110303423A1Improve conductivityReduces viscosity of oilFluid removalDrilling compositionElectricityPower flow

To recover in situ viscous oil from an underground reservoir, electricity is conducted through the underground reservoir by at least two electrodes in an amount that would, in the absence of solvent injection, cause water in the reservoir to vaporize adjacent to the electrodes, and injecting solvent into the reservoir to mitigate water vaporization adjacent to the electrodes by vaporizing solvent in this region. Oil and solvent are produced through one or more production wells.

Owner:EXXONMOBIL UPSTREAM RES CO

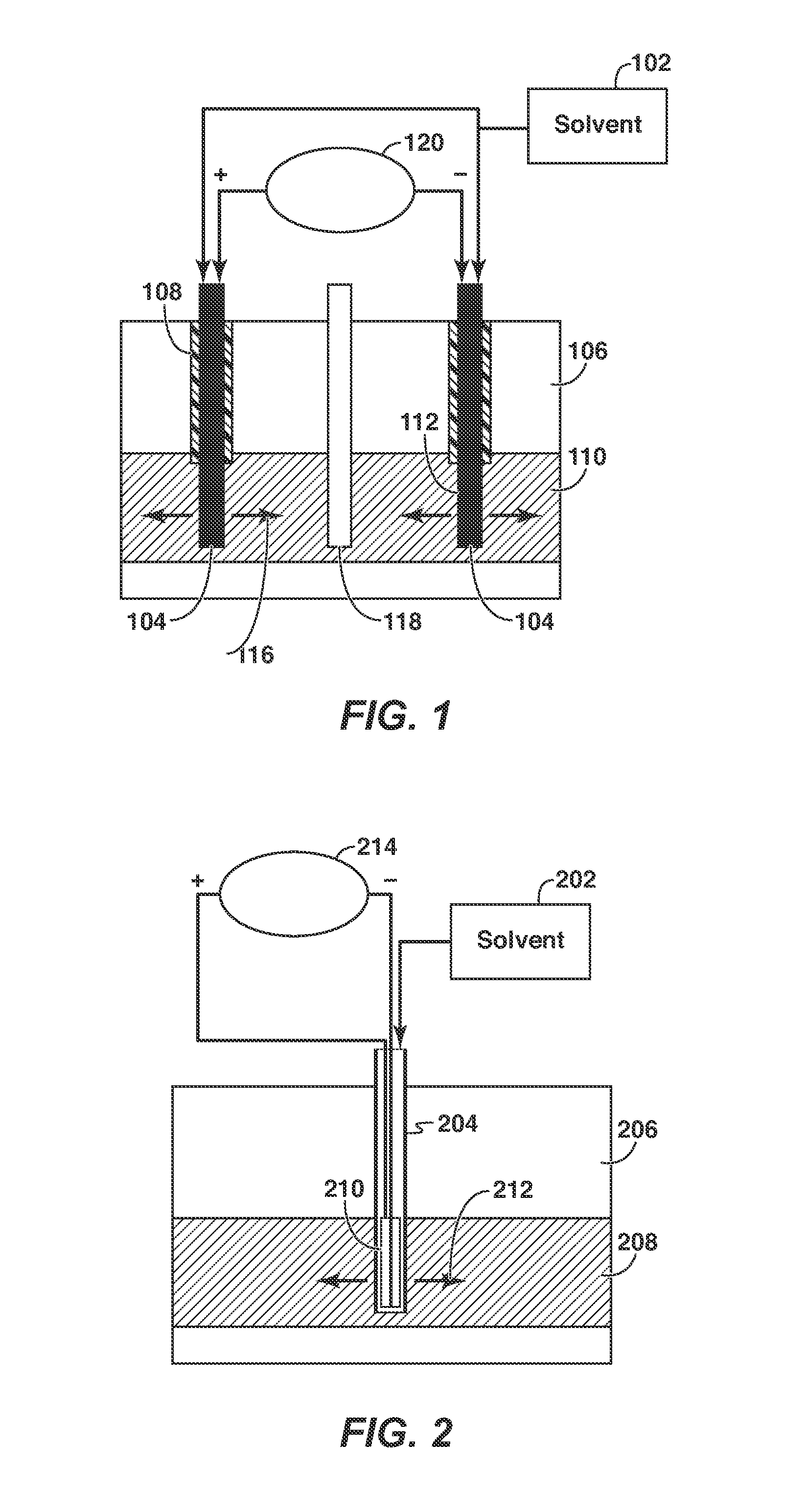

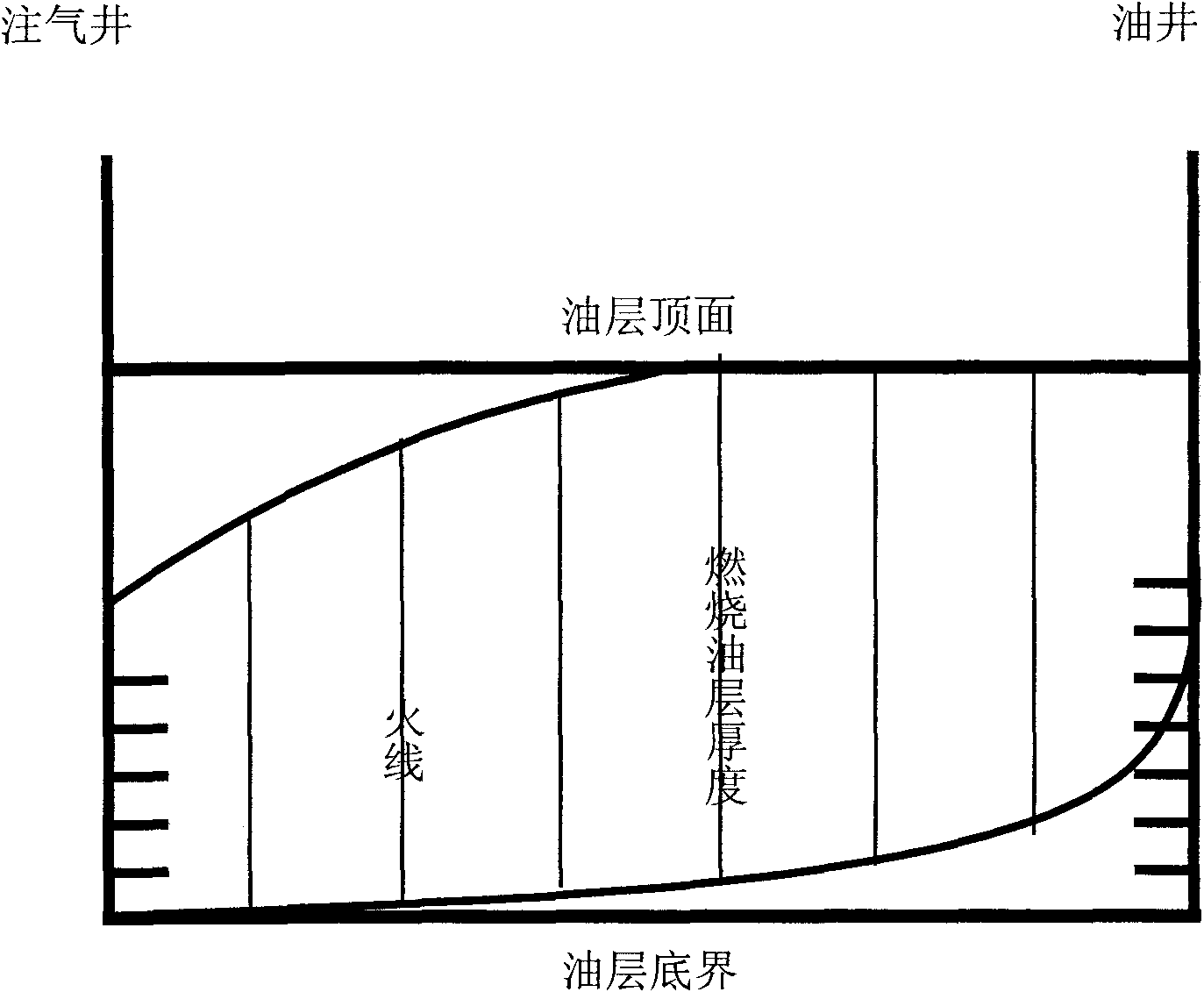

Fire flooding oil extraction method for vertical well gas-injection horizontal well oil extraction

InactiveCN101122225AEnhanced ultimate recoveryThe vertical well steam injection method is simpleFluid removalWell drillingHorizontal wells

The invention relates to a viscous oil exploitation method, in particular to a fire flooding oil exploitation method used for gas injection by a vertical well and oil exploitation by horizontal well. The invention adopts the compound well-layout manner of steam injection by vertical wells and oil exploitation by horizontal wells, which means that six vertical wells are for gas injection and two oil exploitation wells for oil exploitation, or nine vertical wells for gas injection and three oil exploitation wells for oil exploitation. When the wells are drilled, the vertical wells are drilled until they reach the half thickness of an oil layer, and gas is injected above the half thickness of the oil layer. The horizontal wells are under the half thickness of the oil layer. The gas-cap pressure produced by burning of the gas-injected oil layer of the above vertical wells presses the crude oil of the lower part, while the crude oil flows to the horizontal well sections by the self-gravity and then is exploited from the exploitation wells . The invention overcomes the shortcoming that gas channeling can be easily formed horizontally along an oil layer in a high-penetration passage inside the oil layer, and promotes the final recovery rate of the oil layer through fire flooding by fifteen percent.

Owner:尤尼斯油气技术(中国)有限公司

Viscous oil emulsification and viscosity reduction agent

ActiveCN102876310AStrong resistance to mineral saltModerate cost of emulsificationDrilling compositionSalt resistanceAlcohol

The invention relates to a viscous oil emulsification and viscosity reduction agent. The emulsification and viscosity reduction agent comprises an anionic surfactant, a nonionic-anionic Gemini surfactant, a C1-C8 alcohol and water, wherein the weight ratio of the anionic surfactant to the nonionic-anionic Gemini surfactant to the C1-C8 alcohol is 1:0.1-40:0.01-10, and the water amount is 0.2-5000 times the total weight of the anionic surfactant, the nonionic-anionic Gemini surfactant and the C1-C8 alcohol. The emulsification and viscosity reduction agent has the advantages of no alkalis, strong mineral salt resistance, realization of emulsifying ultrahigh-viscosity viscose oil having above 30% of asphaltene, low viscosity of the emulsified oil, moderate emulsification cost and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

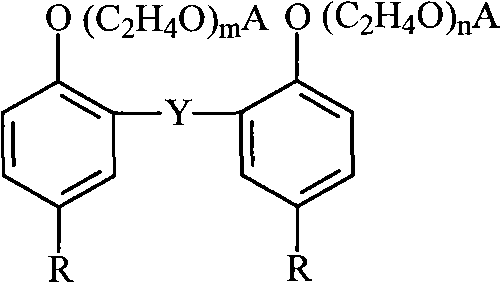

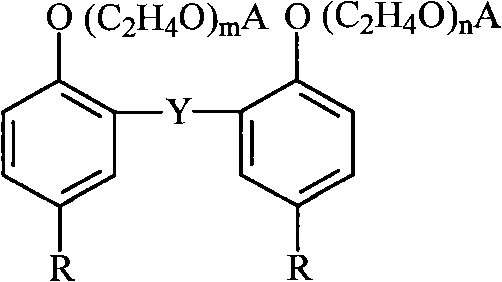

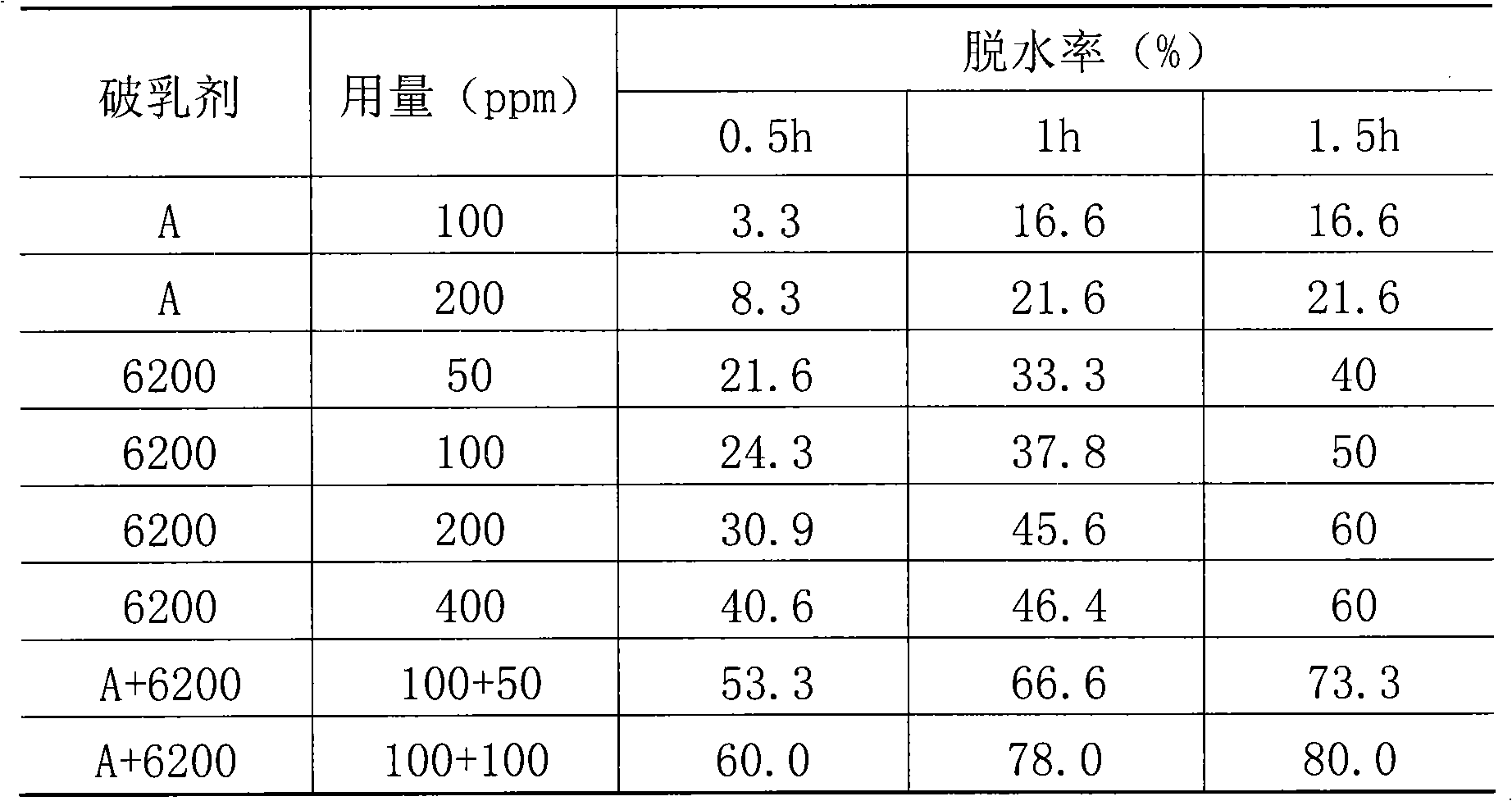

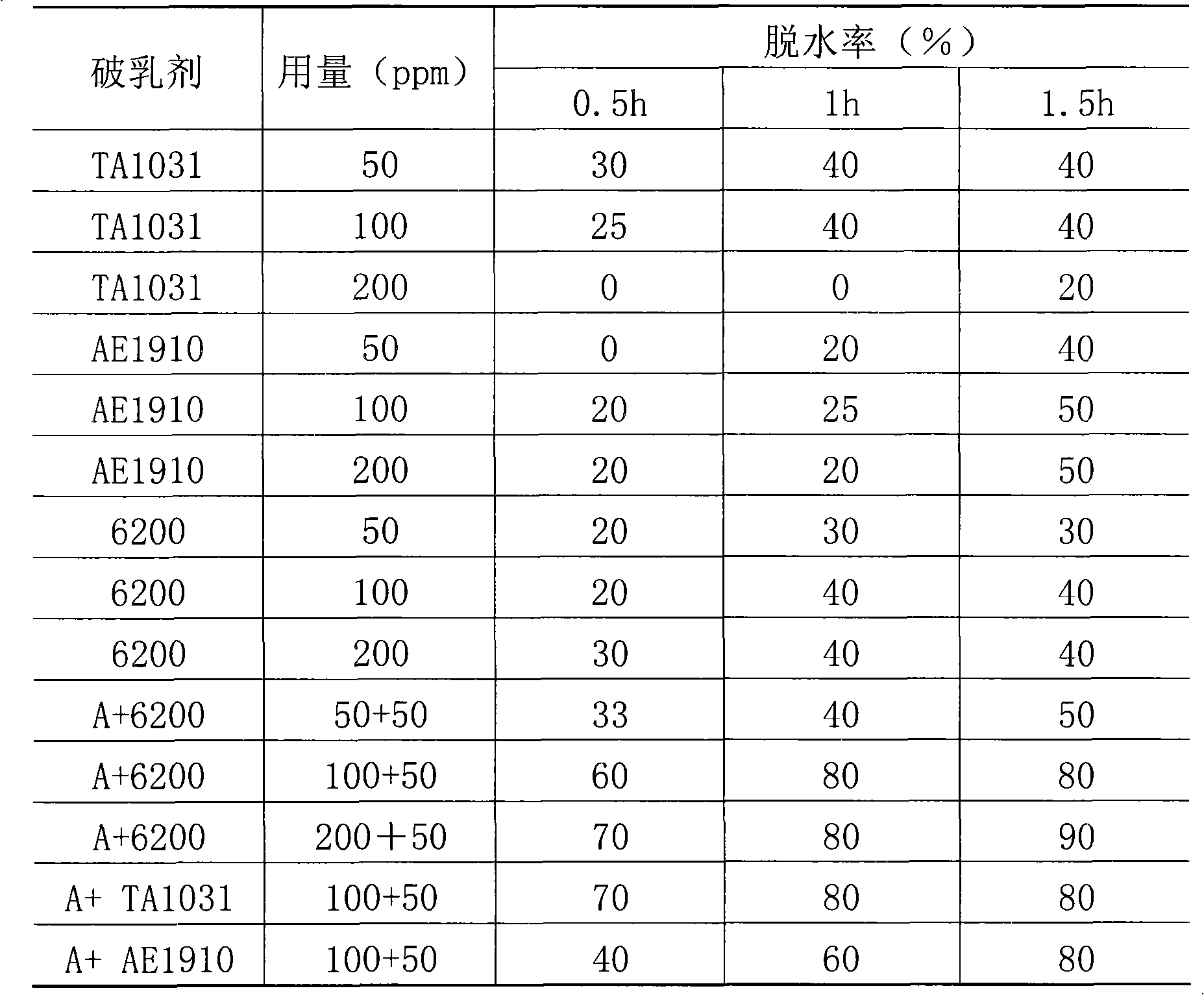

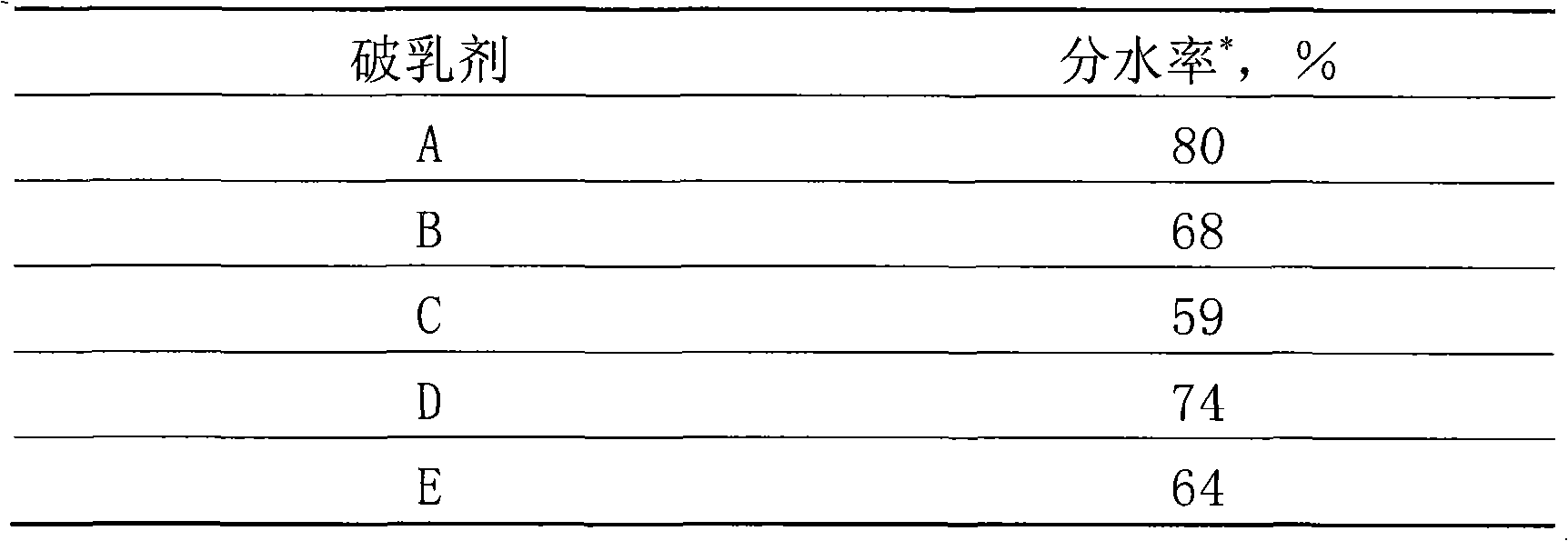

Demulsifying agent and preparation method and use thereof

ActiveCN101352667ADewatering/demulsification with chemical meansTransportation and packagingDemulsifierEster bond

The invention relates to a demulsifier, a preparation method thereof and the application thereof. The basic component of the demulsifier is a polymer, the molecular chain of the polymer is composed of segmers formed from copolymerization of styrene and unsaturated acid and polyether segmers; the two types of segmers are connected by ester bonds. Final products are obtained firstly through reaction of the unsaturated acid with polyether, in which unsaturated groups are induced and then through copolymerization of the polyether, the unsaturated acid and the styrene. The demulsifier of the invention is particularly applicable to the demulsification and dehydration of high-asphaltene viscous oil and is characterized by small dosage, quick dehydration and good demulsification effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

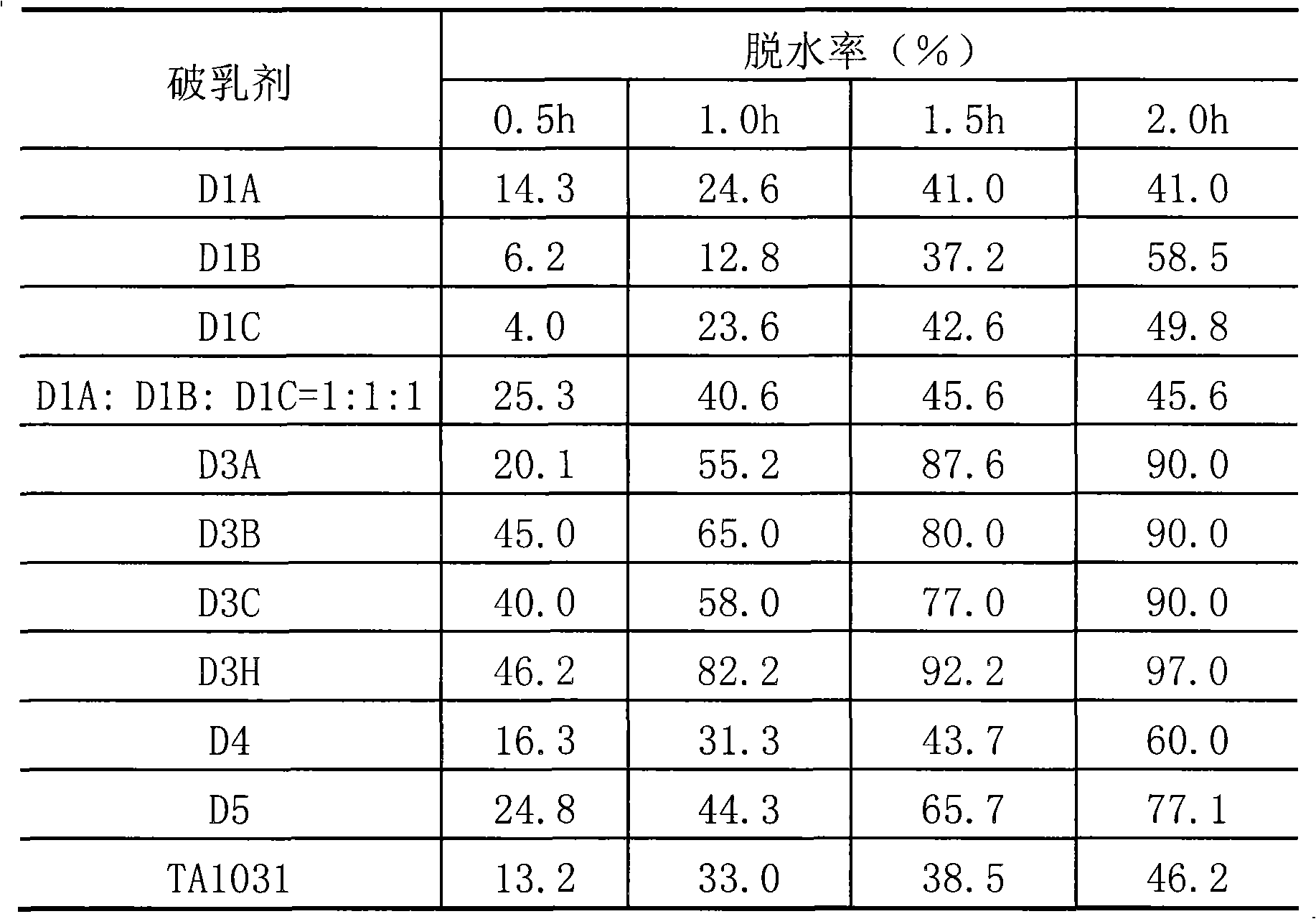

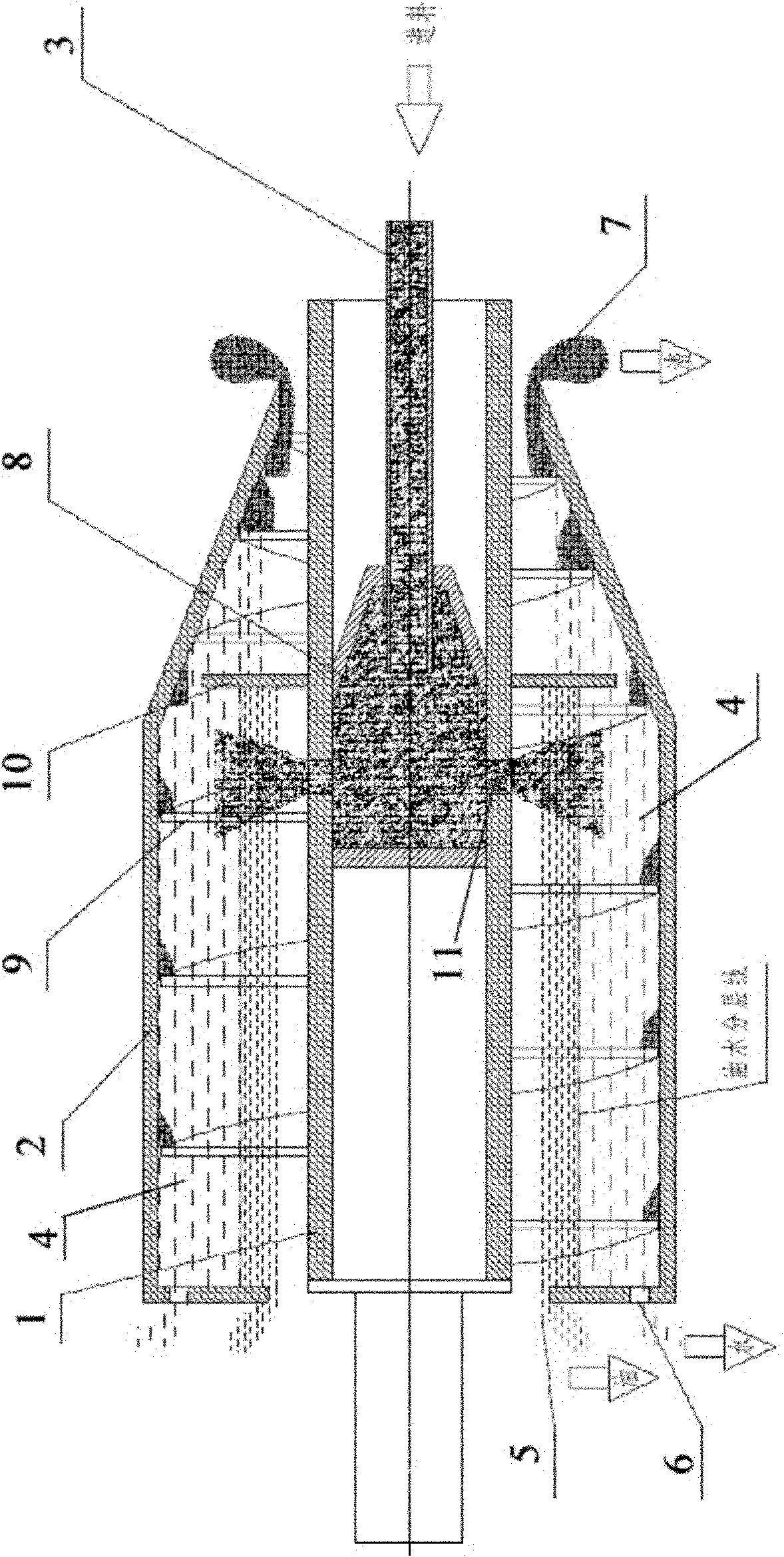

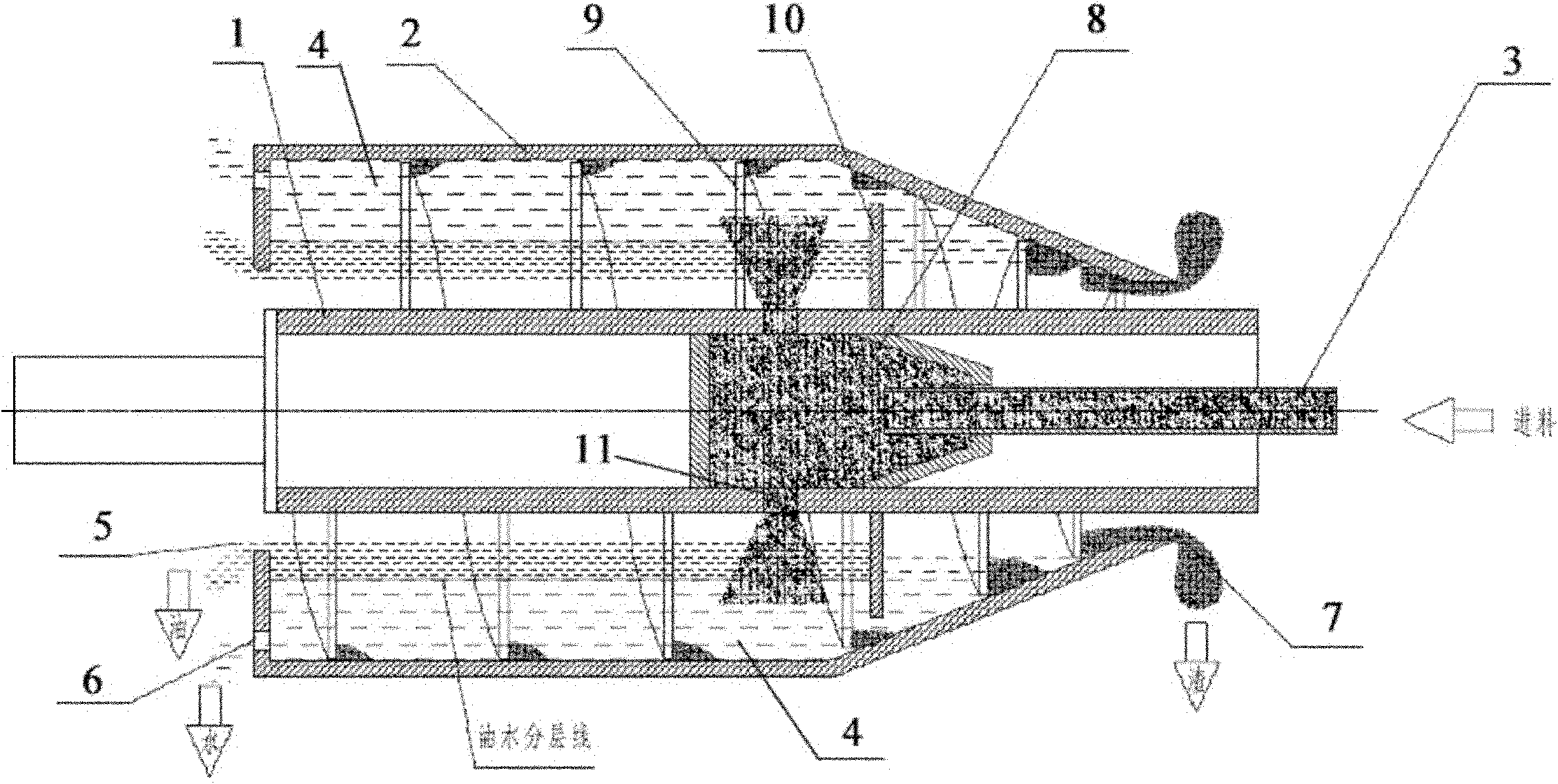

Method for treating ageing oil of viscous oil

ActiveCN102041038AExact decomposition surfaceDecomposition is achieved accuratelyDewatering/demulsification with chemical meansRotary centrifugesPhenolPetroleum engineering

The invention relates to a method for treating ageing oil of viscous oil, which provides a demulsifier for ageing oil of viscous oil, comprising the following raw materials in weight percent: 0.5-1% phenol, 1.5-2% styrene, 0.5-1% ethyleneamine, 0.5-1% formaldehyde, 0.5-1% catalyst, 40-50% ethylene oxide and 40-50% epoxypropane. The invention further provides a three-phase decanter centrifuger, comprising a differential mechanism, a spiral propeller, a rotary drum, a housing, an engine base, a motor and a feed pipe. The invention further provides a method for treating ageing oil of viscous oil, comprising the following steps of: using the demulsifier to perform demulsification treatment to the ageing oil of the viscous oil, then inputting the ageing oil of the viscous oil after the demulsification treatment in the three-phase decanter centrifuger to centrifuging and separating so as to respectively obtain fatlute, sewage and the oil. The ageing oil, especially the ageing oil of the viscous oil, is treated by adopting the demulsifier to combine with the centrifuging method; the demulsification and dehydration problem of the ageing oil of viscous oil in the oil field is solved, and the requirement of the field production can be satisfied.

Owner:PETROCHINA CO LTD +1

Compound demulsifying agent and method of use thereof

ActiveCN101352666AReduce dosageGood desalination effectTransportation and packagingMixingDemulsifierStyrene-maleic anhydride copolymer

The invention relates to a compound demulsifier and a use method thereof. The compound demulsifier comprises alkyl ester of styrene-maleic anhydride copolymer and ethylene oxide-propylene oxide block polymer, the mass ratio of which is 0.1 to 10: 1. The compound demulsifier of the invention, through compound use of the alkyl ester of styrene-maleic anhydride copolymer and the ethylene oxide-propylene oxide block polymer, can achieve better demulsification effect and is particularly applicable to the demulsification and dehydration of high-asphaltene viscous oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

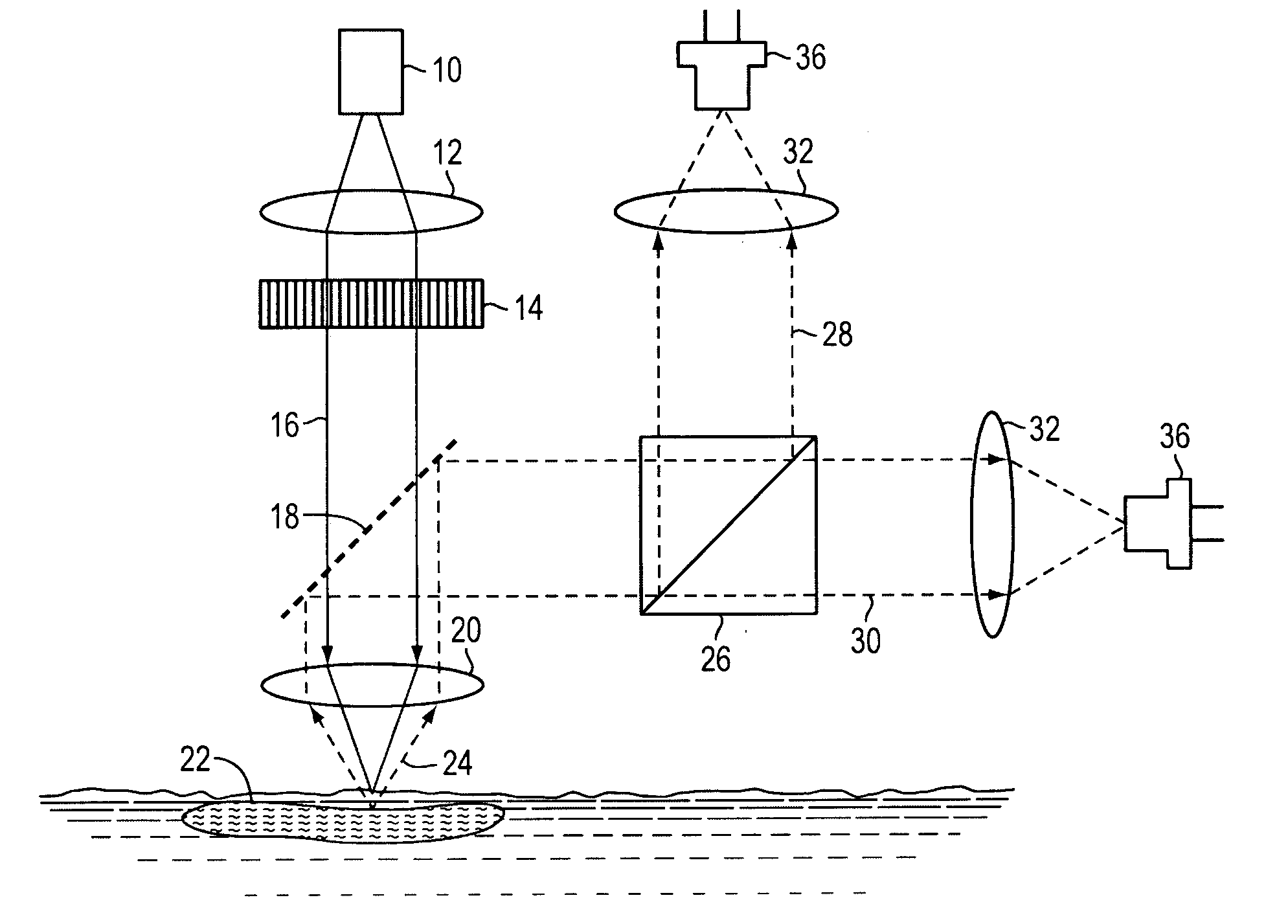

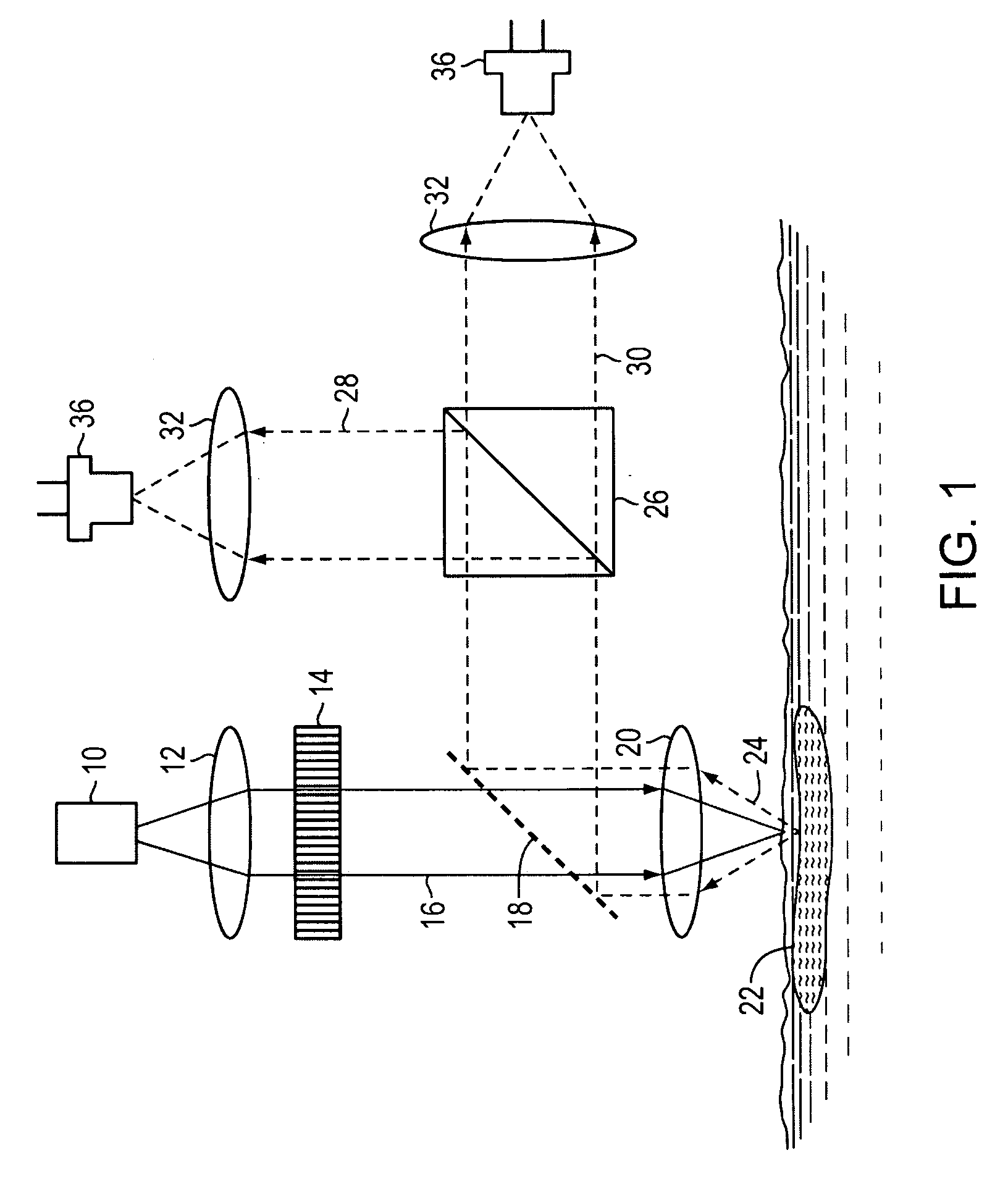

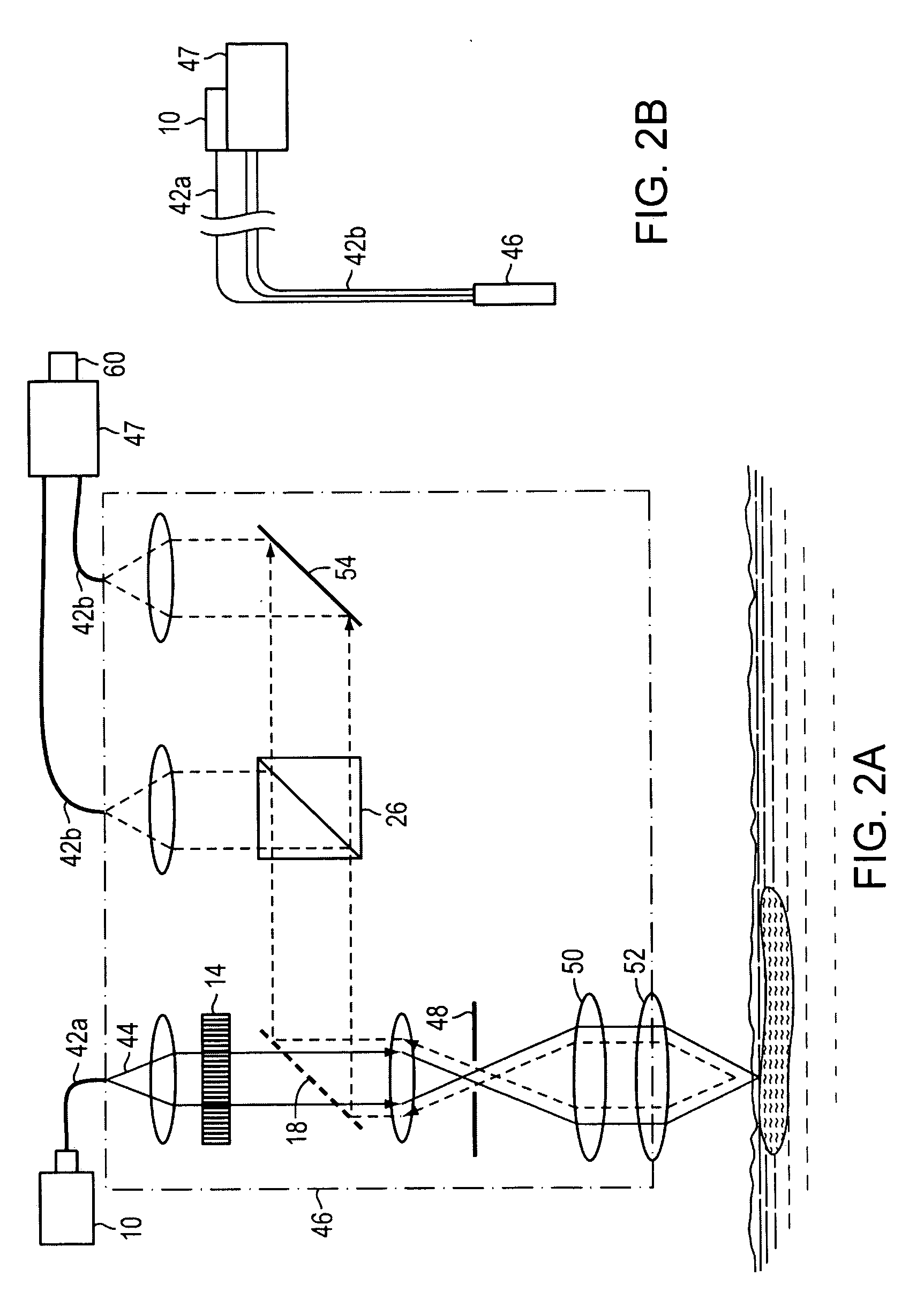

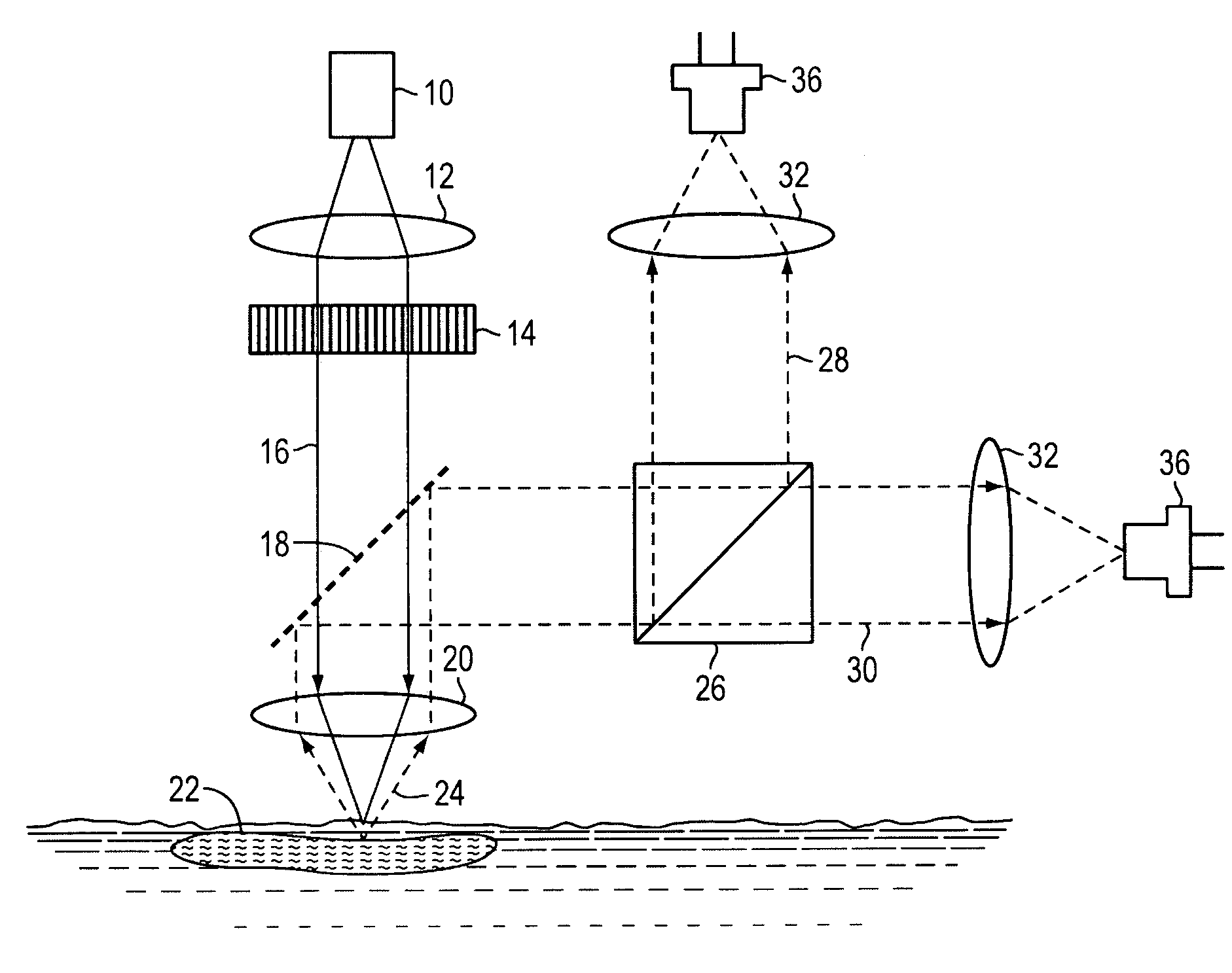

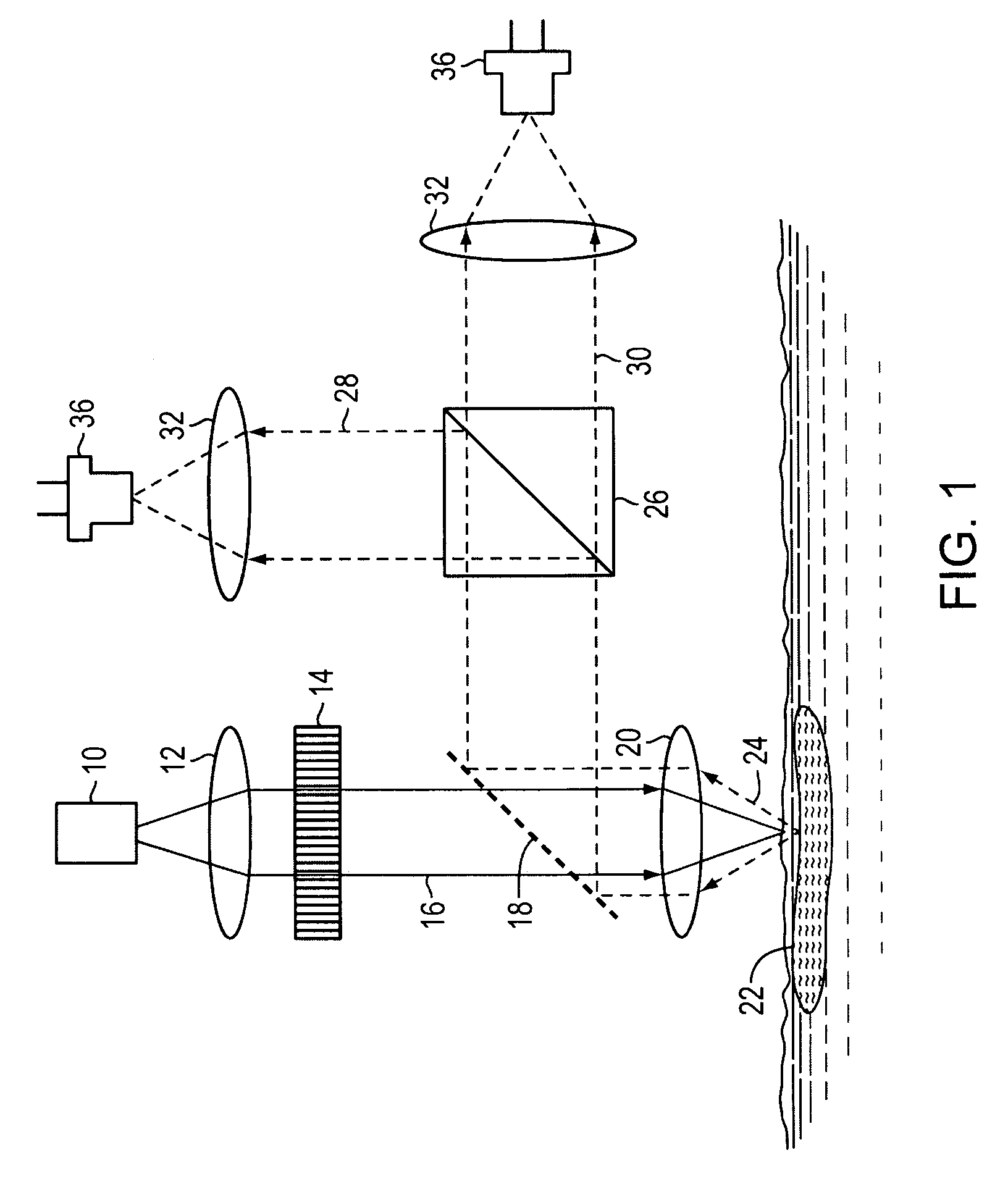

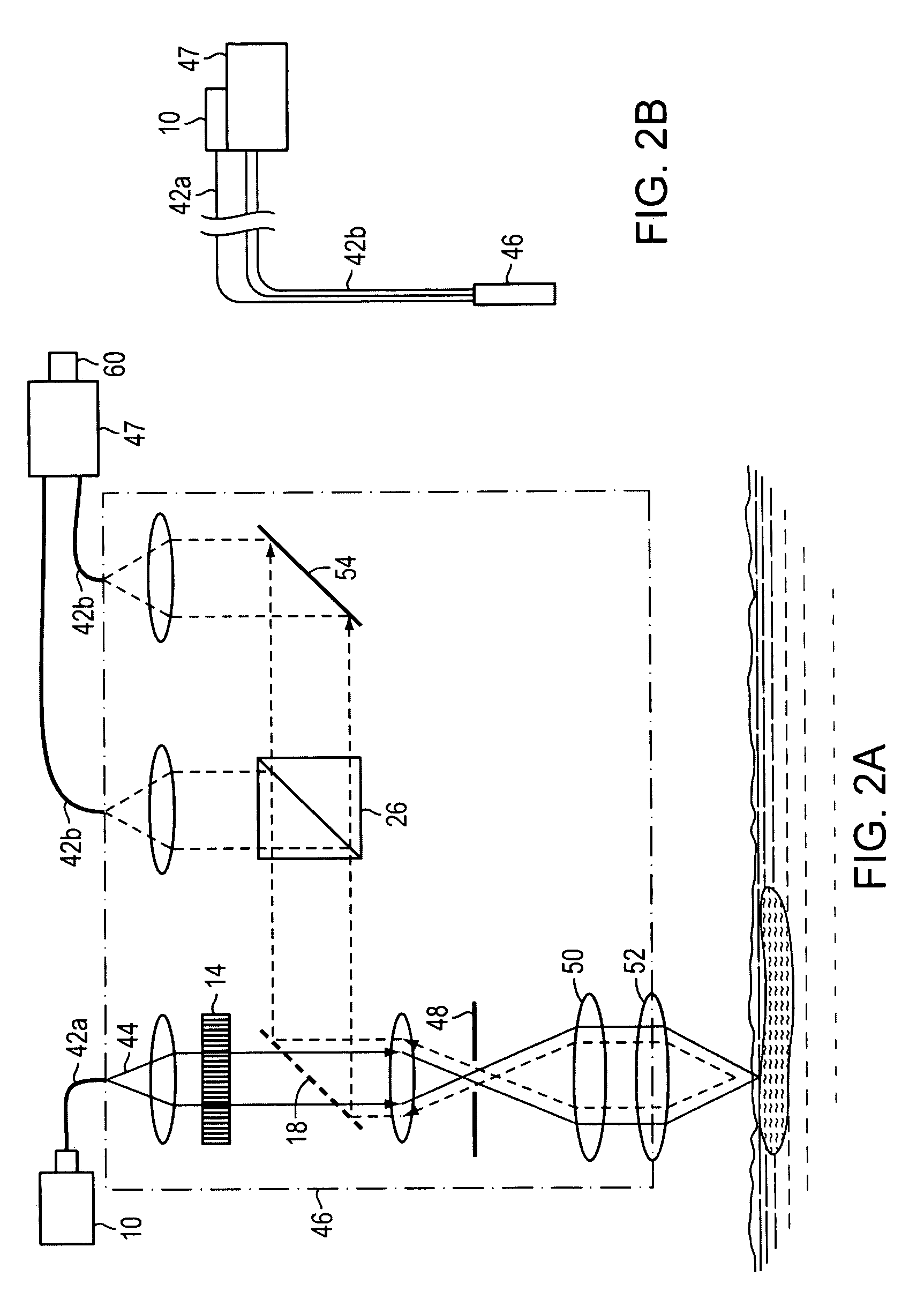

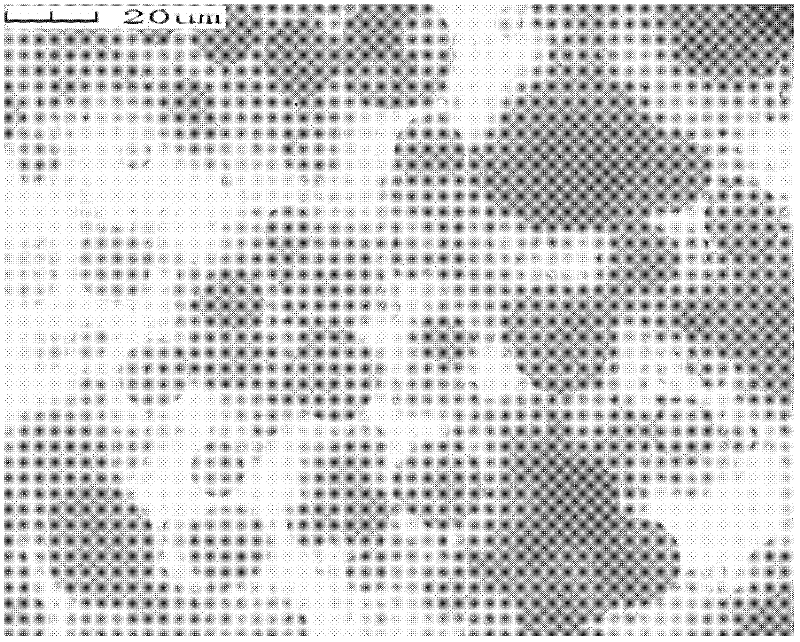

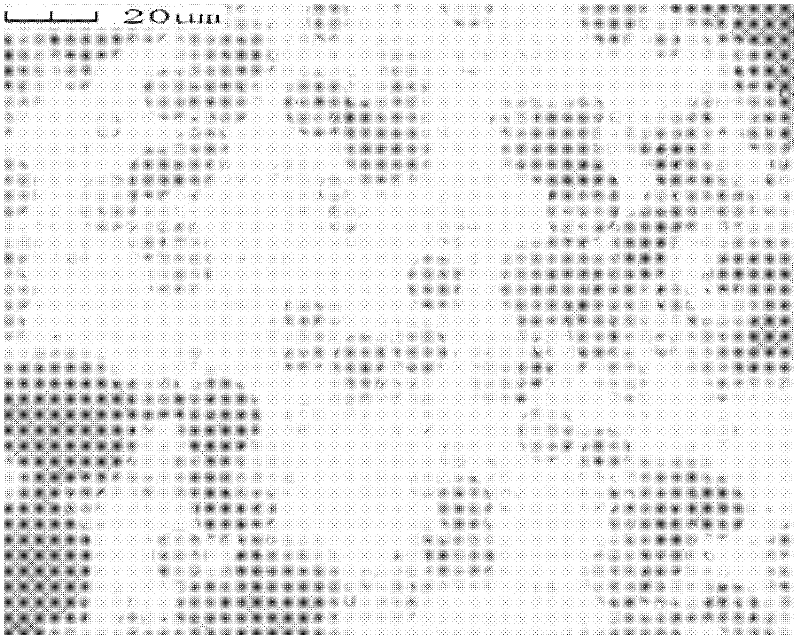

Detection of heavy oil using fluorescence polarization

ActiveUS20090189074A1Avoid interferenceRaman/scattering spectroscopyPolarisation spectroscopyOcean bottomFluorescence

Viscous oil residues are located based on fluorescence polarization. Methods and apparatus in accordance with the invention may be integrated with autonomous and remotely operated undersea vehicles to map the location of oil spills.

Owner:EIC LAB

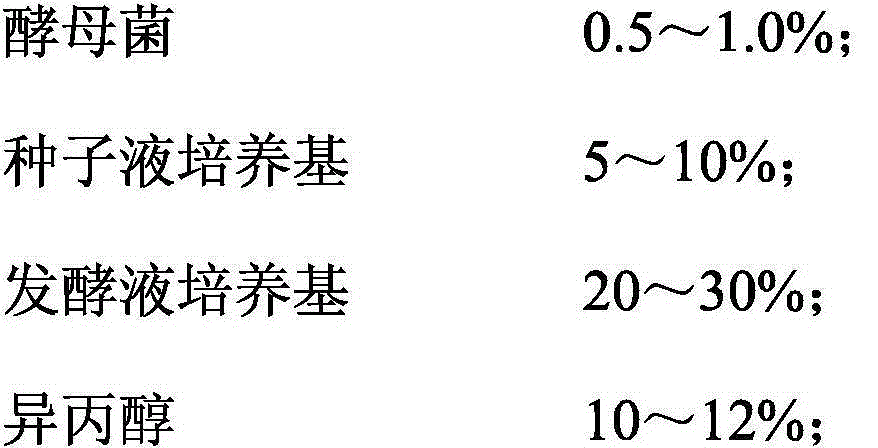

Temperature-resistant salt-tolerant viscous-oil biological viscosity reducer and preparation method thereof

ActiveCN105154050AAvoid scaling and corrosionThe implementation method is simpleDrilling compositionLiquid mediumTemperature resistance

The invention discloses a temperature-resistant salt-tolerant viscous-oil biological viscosity reducer and a preparation method thereof, and belongs to the technical field of petroleum exploitation. The temperature-resistant salt-tolerant viscous-oil biological viscosity reducer is composed of microzyme, a seed liquid medium, a fermentation liquor medium and water. The microzyme is torulopsis candida. The preparation method of the viscosity reducer comprises (1) preparation of a microzyme seed liquid; (2) early-stage preparation of the fermentation liquor medium; (3) fermentation production of microzyme; (4) collection of a fermentation product; and (5) preparation of the viscous-oil biological viscosity reducer. The viscous-oil biological viscosity reducer is green and free of pollution by employing agricultural and sideline products as raw materials. The provided viscous-oil biological viscosity reducer possesses the temperature resistance up to 150 DEG C, the salt tolerance up to 2*10<5> mg / L, and the viscous-oil viscosity reduction rate up to 99% or more. The enforcement method of the viscous-oil biological viscosity reducer is simple. The viscous-oil biological viscosity reducer is substantial in effect, is capable of saving energy, reducing consumption and preventing pipelines from fouling and being corroded, and the subsequent crude-oil demulsification dewatering processing is easy. Therefore, the viscous-oil biological viscosity reducer is widely applicable to shaft elevation of a viscous oil well and ground pipeline conveying technology.

Owner:CHINA PETROLEUM & CHEM CORP +1

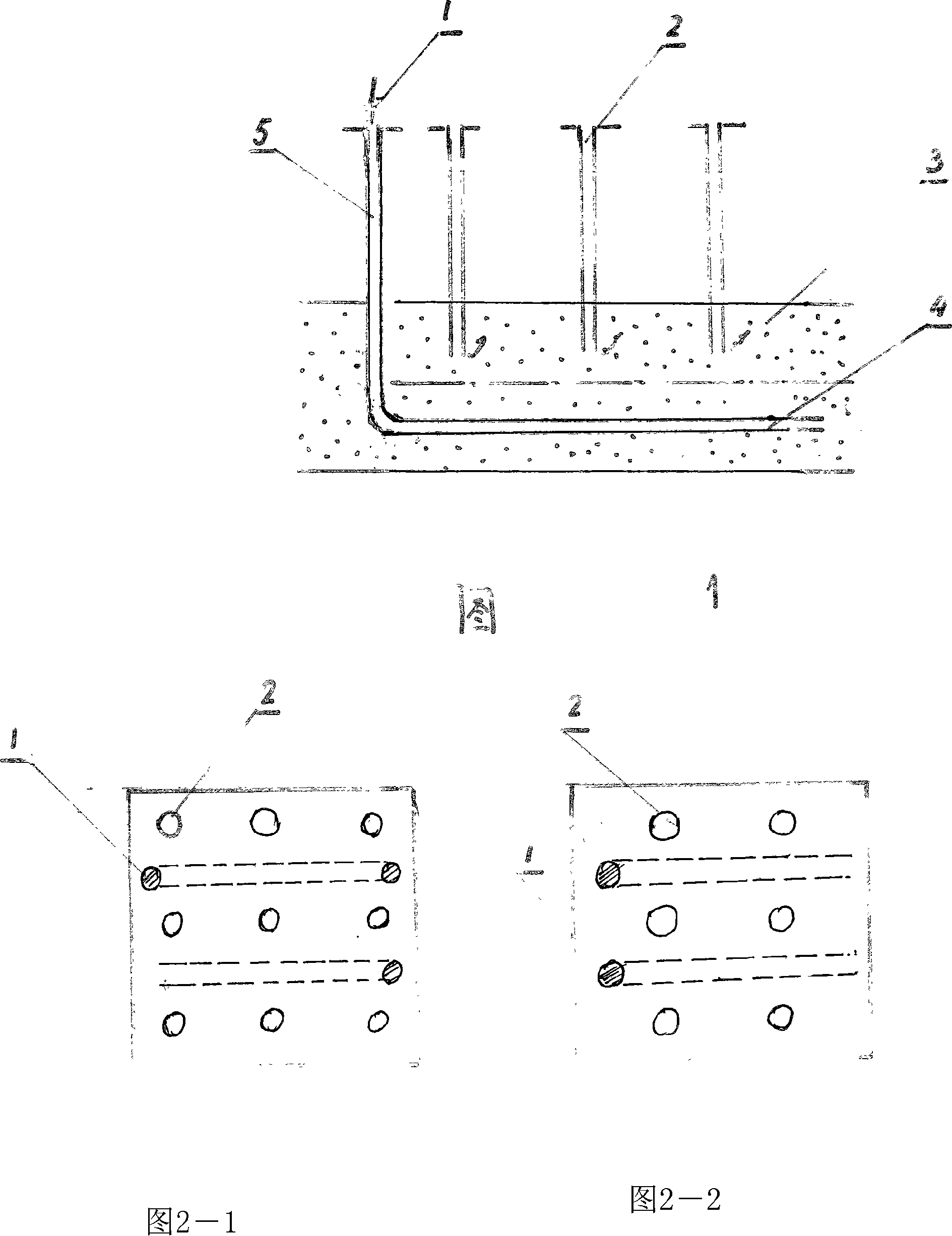

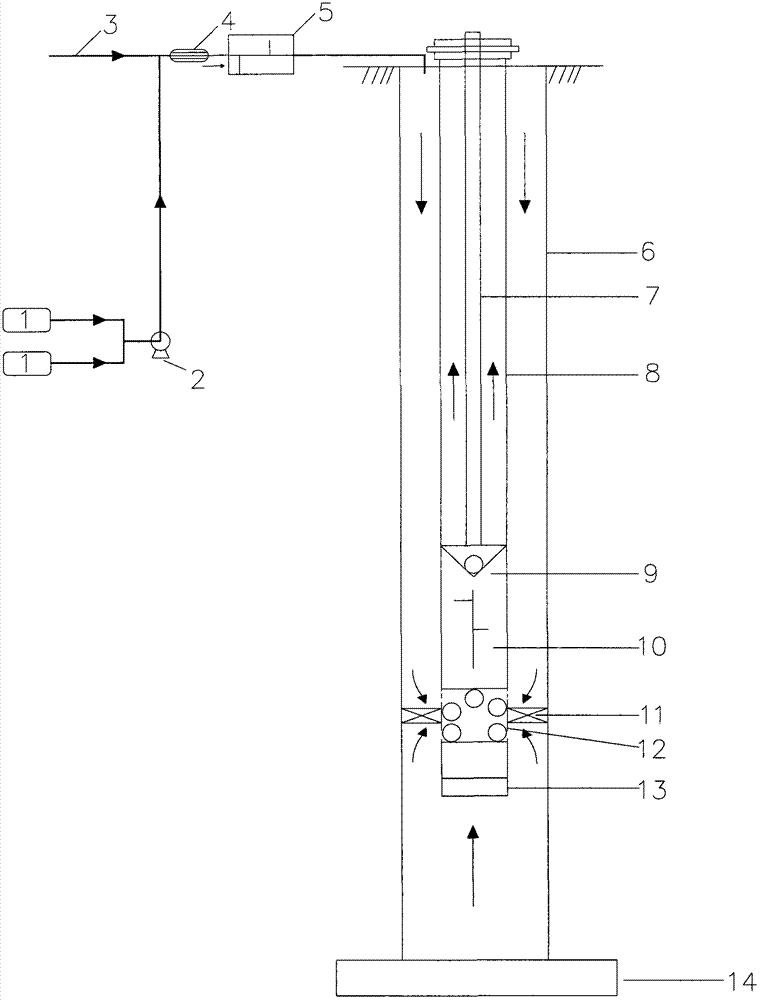

Method and device for reducing viscosity of shaft applicable to extremely-viscous oil recovery

ActiveCN103032056AReduce mining costsSolve the problem of emulsification and viscosity reduction miningFluid removalLine tubingOil well

The invention relates to a method and device for reducing viscosity of a shaft applicable to extremely-viscous oil recovery. The method comprises the steps that mixed liquid of thin oil and viscosity reduction agent is injected to the bottom of an oil well, and the extraction operation of the oil is carried out after the mixed liquid is mixed with the viscous oil. The device comprises an intersected thin oil pipeline (3) and a viscosity reduction agent pipeline which is connected with a medicine storage tank (1) and a measuring pump (2), and the intersected pipelines are sequentially connected with an annular space of a ground mixing device (5) and an oil well bushing (6). Through the simple technique modification, the viscosity reduction agent is used for substituting partial thin oil, so that a good effect can be realized in the recovery process of the extremely-viscous oil, the thin oil can be saved by more than 70 percent, and the recovery cost of the extremely-viscous oil can be greatly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Viscous oil emulsion phase-inversion profile control water blockoff

InactiveCN1395024ARealize the function of profile control and water shutoffHigh viscositySealing/packingCarboxylic saltNon ionic

The present invention provides a viscous crude emulsion phase-converting profile control water-plugging method and its phase-converting agent. In the viscous crude system 0.4-1.0% of oil in water emulsion and 3%-10% of phase-converting agent are added, then injected into formation to implement said ivnented method. The oil in water emulsion is a mixturwe of non-ionic surfactants of OP series. Tween series, Span series and sodium carboxylate, etc. and inorganic salts of sodium carbonate, etc. and the phase-converting agent is a mixture of oil-soluble surfactants of OP series or Span series or non-ionic surfactants or organic acid ester, etc. and rosin or asphalt powder or coal powder or bentonite, etc. Said invention developes a effective phase-converting agent, and can implement profile control water-plugging function.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

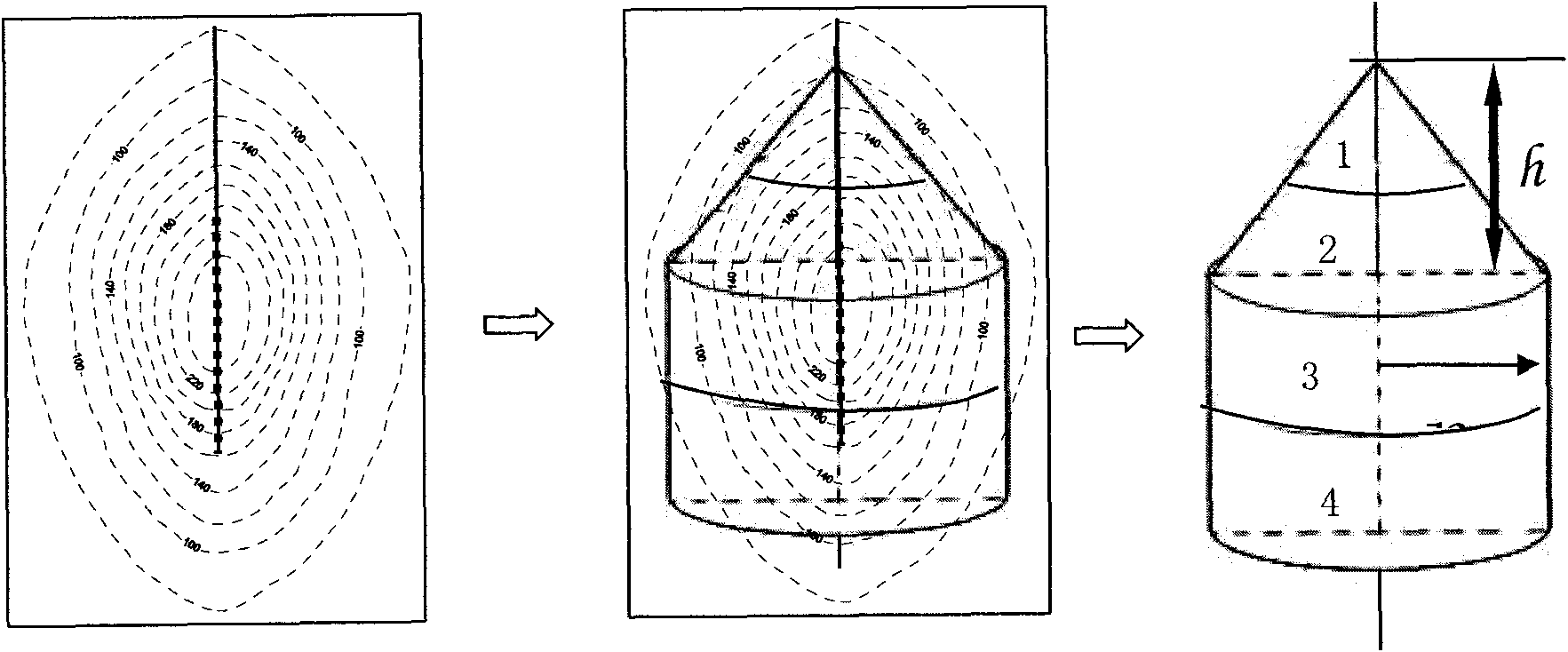

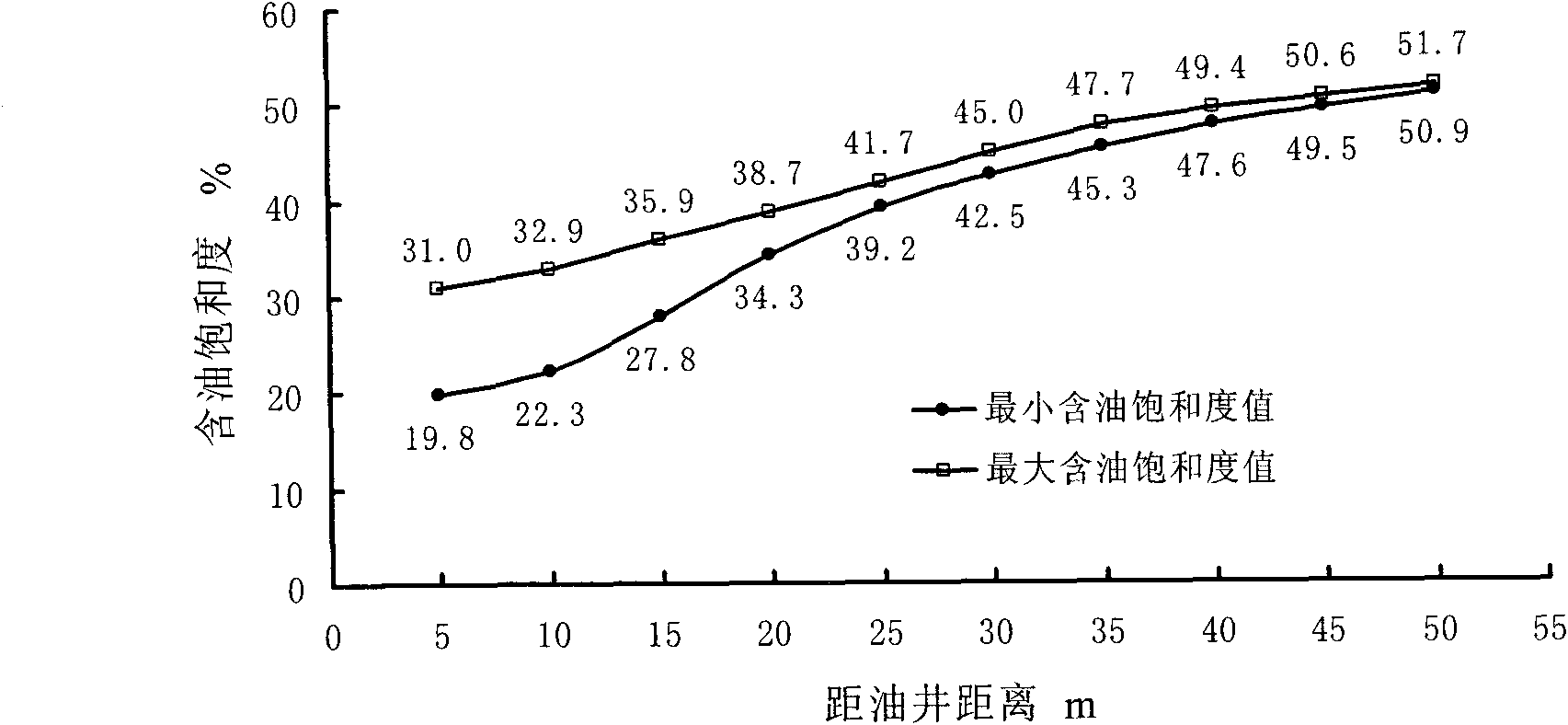

Method for improving recovery rate of thick massive viscous oil reservoir by controlling burning gas injection speed

The invention relates to a method for improving recovery rate of a thick massive viscous oil reservoir by controlling burning gas injection speed, which mainly comprises the following steps of: determining the thickness and residual oil saturation of an oil layer at the burning front edge by stages according to the condition and rule of fire-flooding live wire wave by combining fine research results of double analogs in a massive oil reservoir chamber; then determining planar residual oil saturation and residual oil at different positions apart from a gas injection well, and predicting the burned section area of the burning front edge, the non-homogeneity of the reservoir and the optimal configuration relationship between the residual oil and the gas injection speed; and finally, dynamically adjusting the single-well gas injection speed by stages, and selecting a variable and lower burning gas injection speed to maintain stable and normal burning on the premise of ensuring combustion. The method can fulfill the purposes of improving the burning wave and volume of the massive oil reservoir, the development effect of the burning oil layer and the final recovery rate.

Owner:PETROCHINA CO LTD

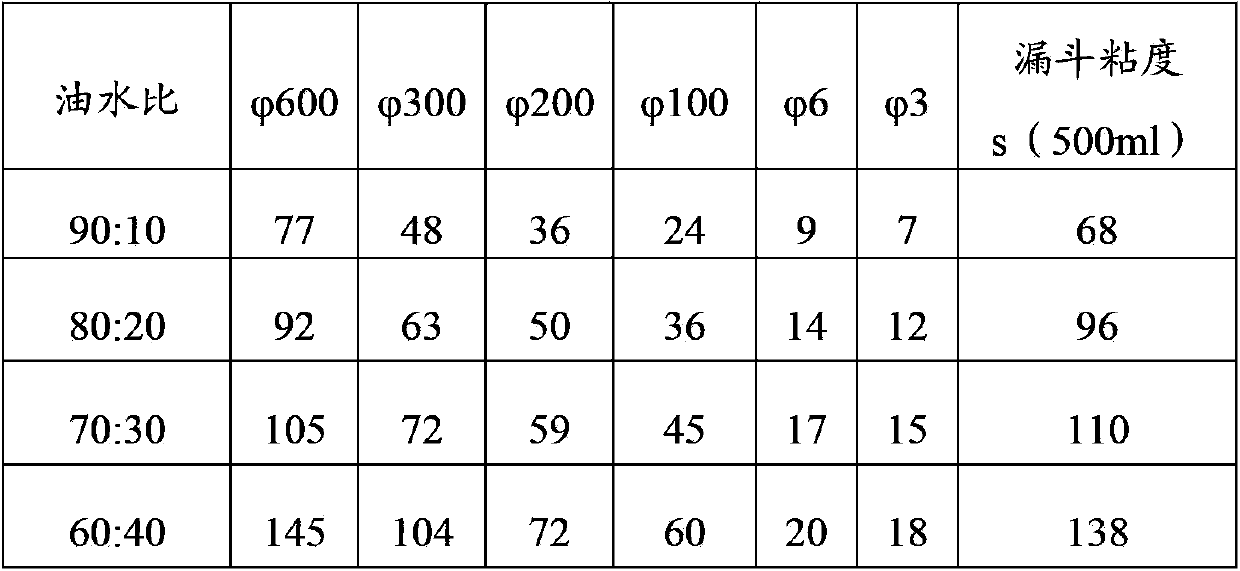

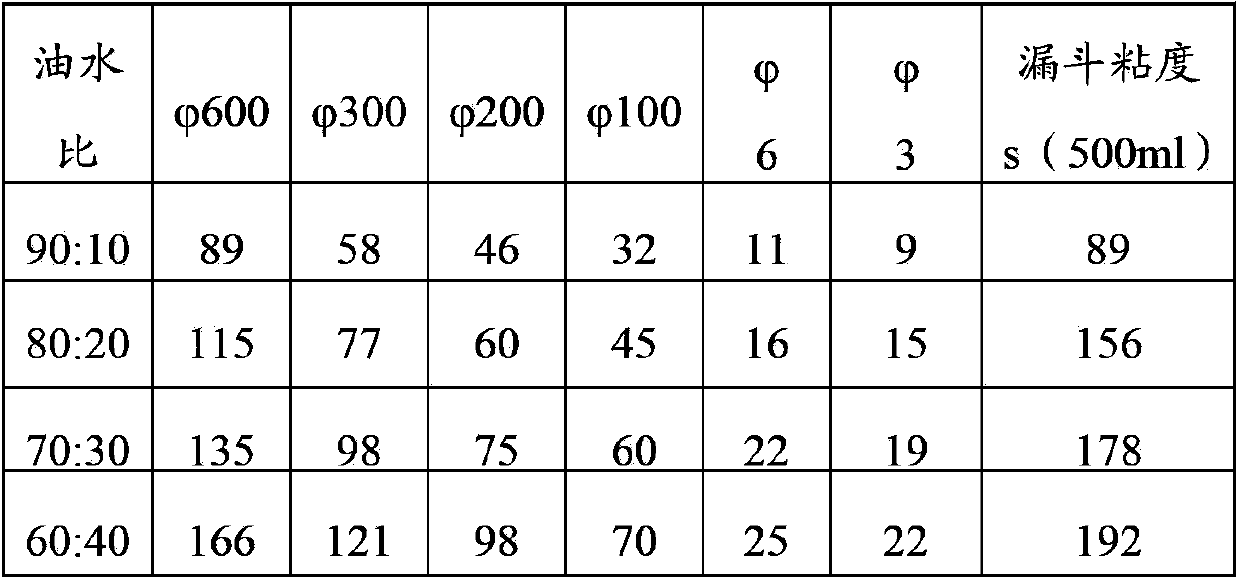

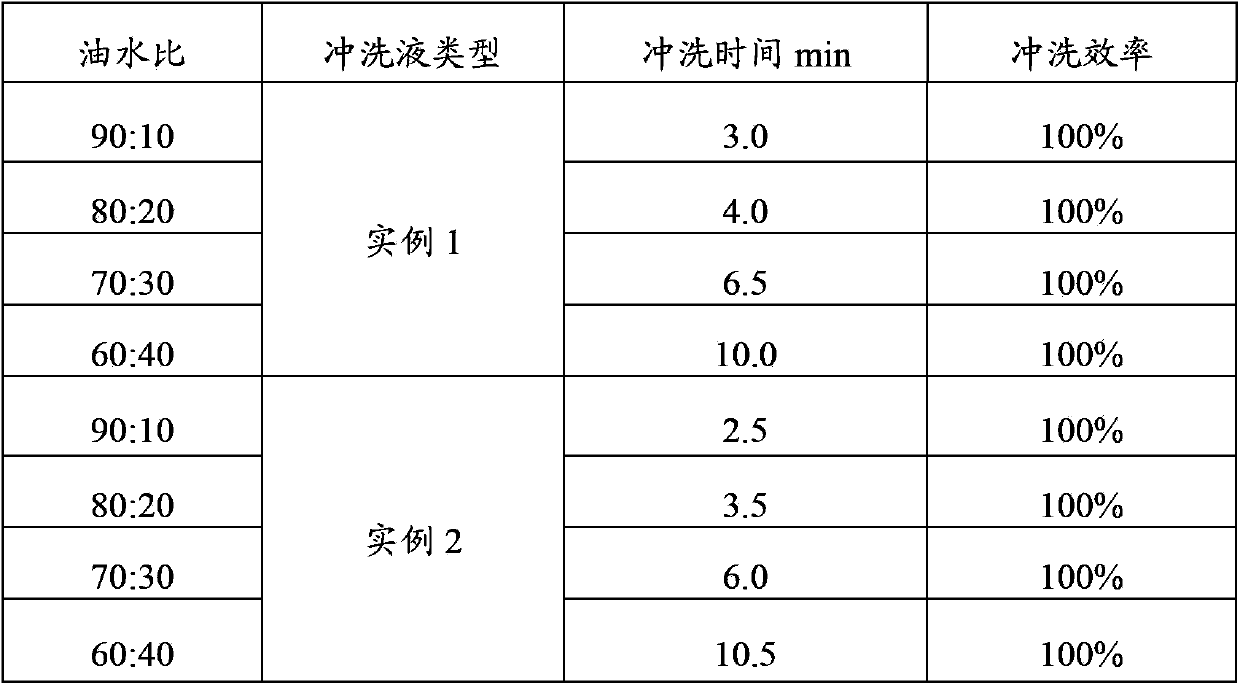

Flushing fluid for cementing of horizontal shale gas well

ActiveCN103965845AWide adaptabilityEasy to cleanDrilling compositionWell cementingHydraulic machinery

The invention provides a high-efficiency flushing fluid applicable to cementing of a horizontal shale gas well. The flushing fluid has certain shearing force and viscosity, exerts a dragging effect on oil slurry and an oil film under the action of hydraulic machinery and achieves the purposes of effective cleaning of the oil film and replacement of a viscous oil-based drilling fluid. The flushing fluid is mainly composed of a nonionic surfactant, an anionic surfactant, organic acid and a viscosity and shearing force improving agent, and comprises, by weight, 2 to 10 parts of the nonionic surfactant, 2 to 7 parts of the anionic surfactant, 2 to 4 parts of organic acid, 0.5 to 5.0 parts of the viscosity and shearing force improving agent and 72 to 100 parts of clear water. The flushing fluid provided by the invention has a high efficiency flushing effect on drilling fluids with high viscosity and shearing force and with a wide range of the oil-water ratio, e.g., from 60 / 40 (v / v) to 90 / 10(v / v).

Owner:CHINA PETROLEUM & CHEM CORP +1

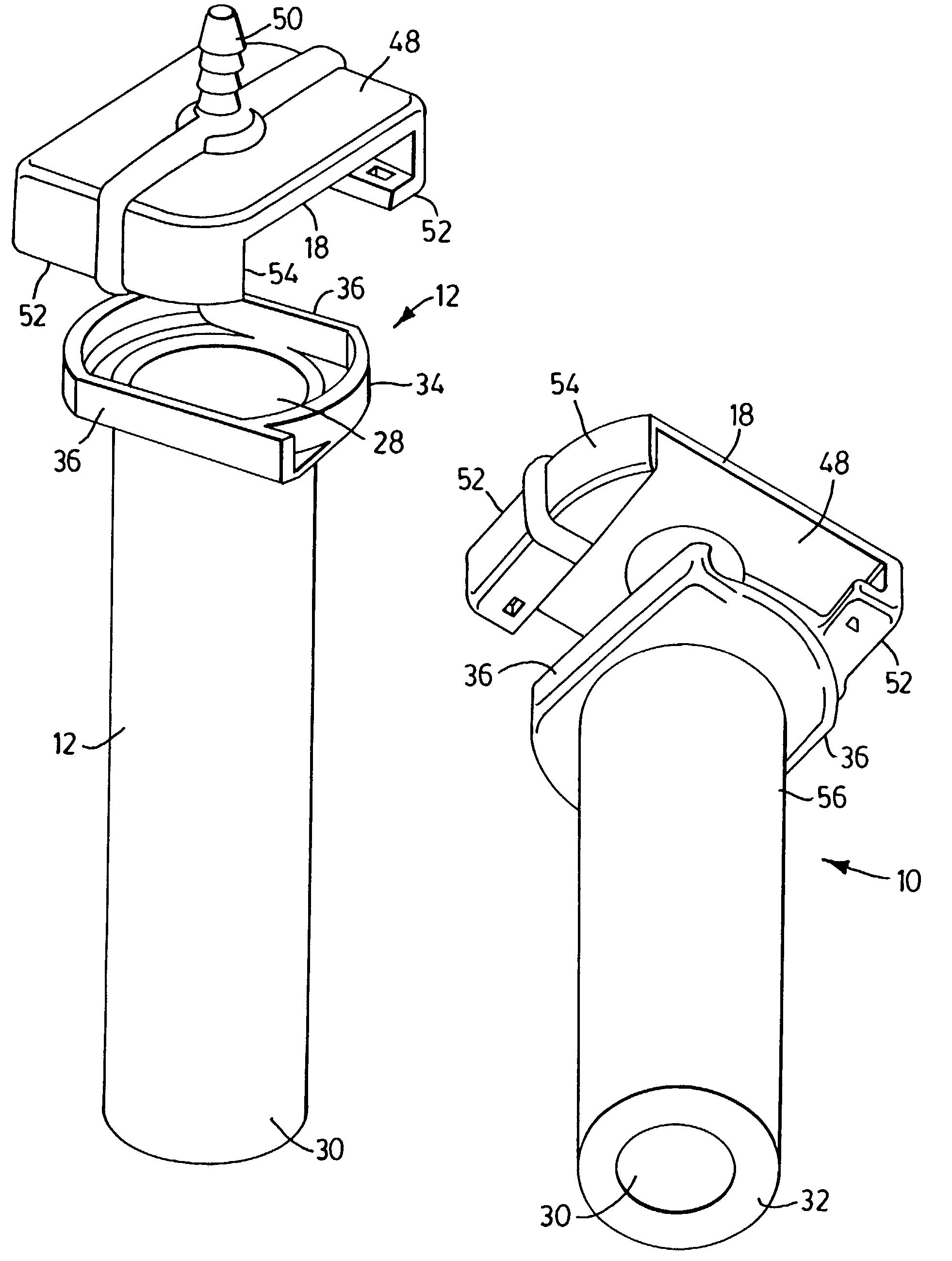

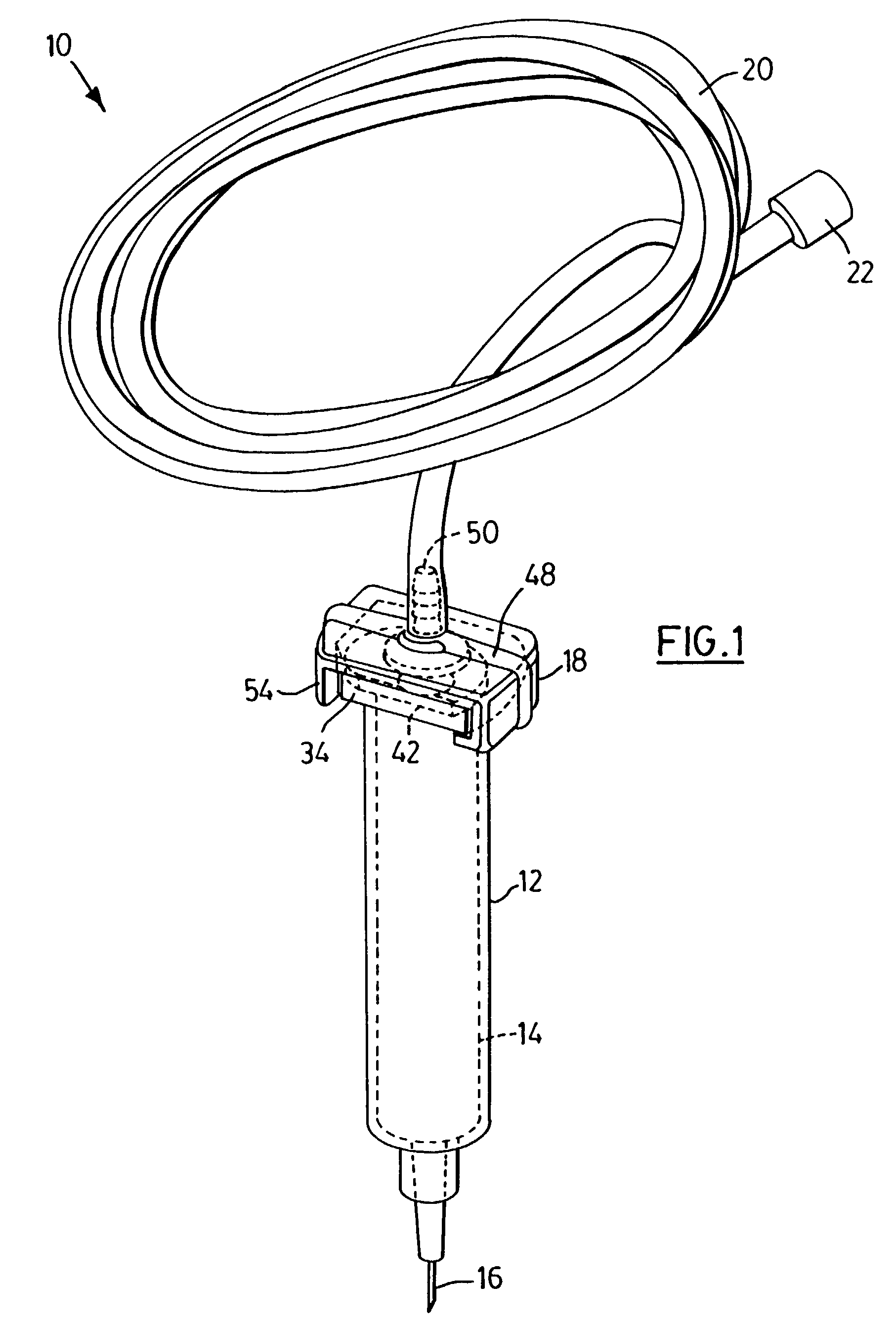

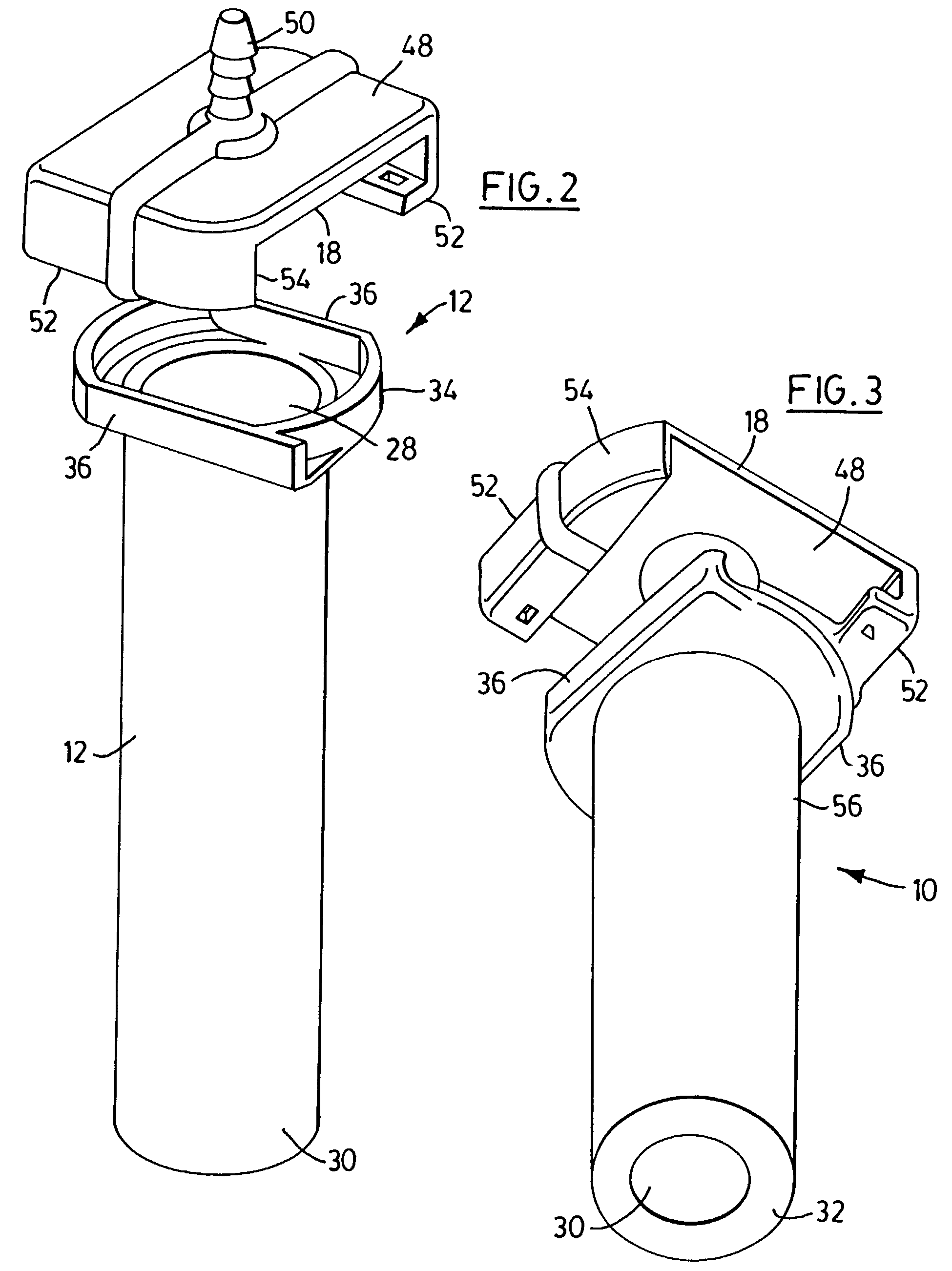

Viscous fluid injection system

InactiveUS6997904B2Large openingSmall retentionAutomatic syringesMedical devicesEngineeringSyringe needle

The present invention provides a fluid injection apparatus for injecting viscous fluids directly from a syringe in which it is commercially delivered. The fluid injection apparatus includes a cylindrical syringe sleeve into which the syringe is inserted from one end with a small hole at the other end of the sleeve through which the syringe needle or cannula protrudes. The apparatus includes a locking head assembly for retaining the syringe in the cylindrical syringe sleeve which includes a top plate and a locking flange which engages with the flange for locking the head assembly to the cylinder. The plunger in the syringe is discarded and when the locking head assembly is placed on the cylindrical syringe sleeve an internal flange with a gasket located on it is inserted into the top of the syringe chamber forming a seal. The head assembly includes a tube coupling for connecting a pressurizing gas such as air to the cylinder through the interior of the internal flange for pressurizing the syringe for expelling the viscous oil through the needle or cannula.

Owner:LABTICIAN OPHTHALMICS

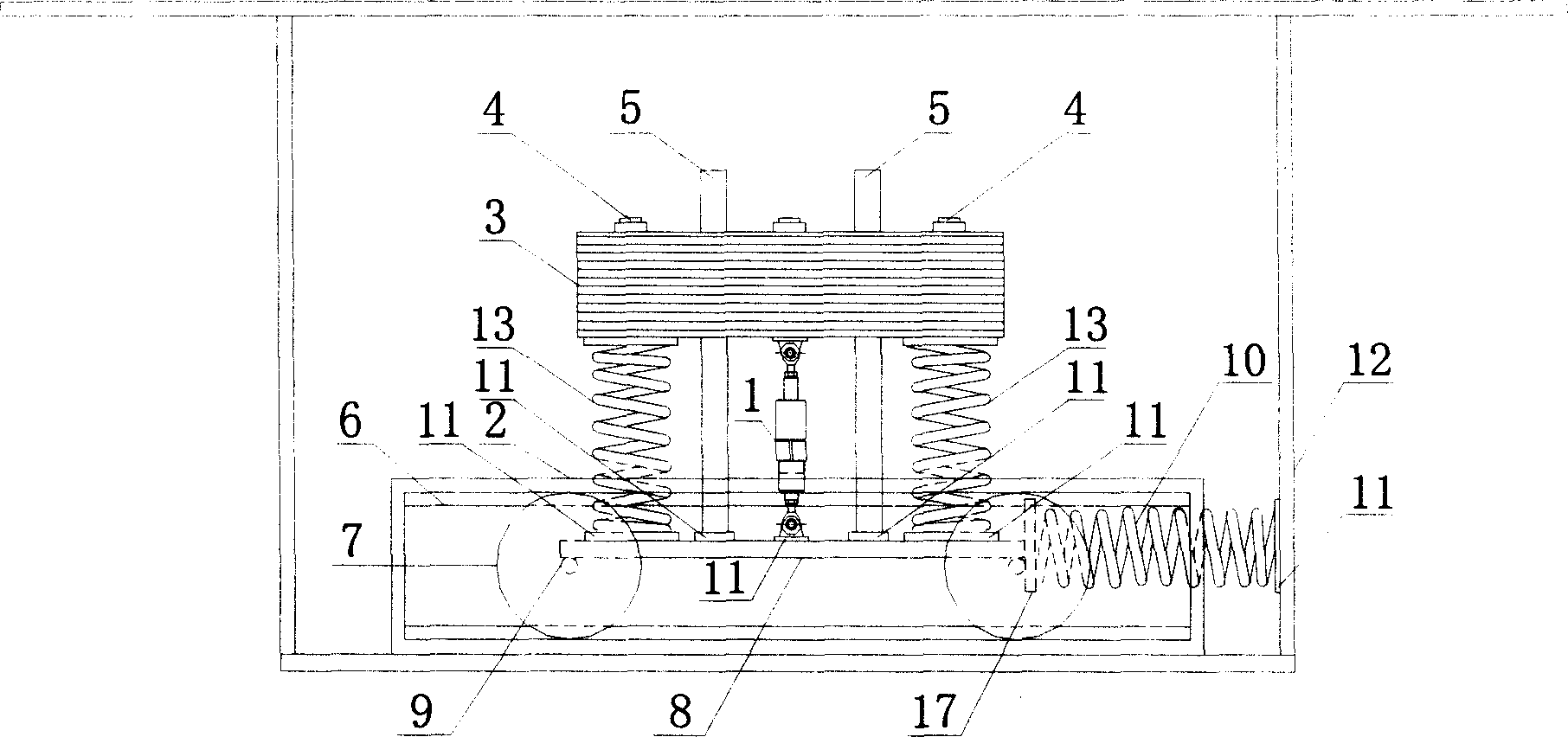

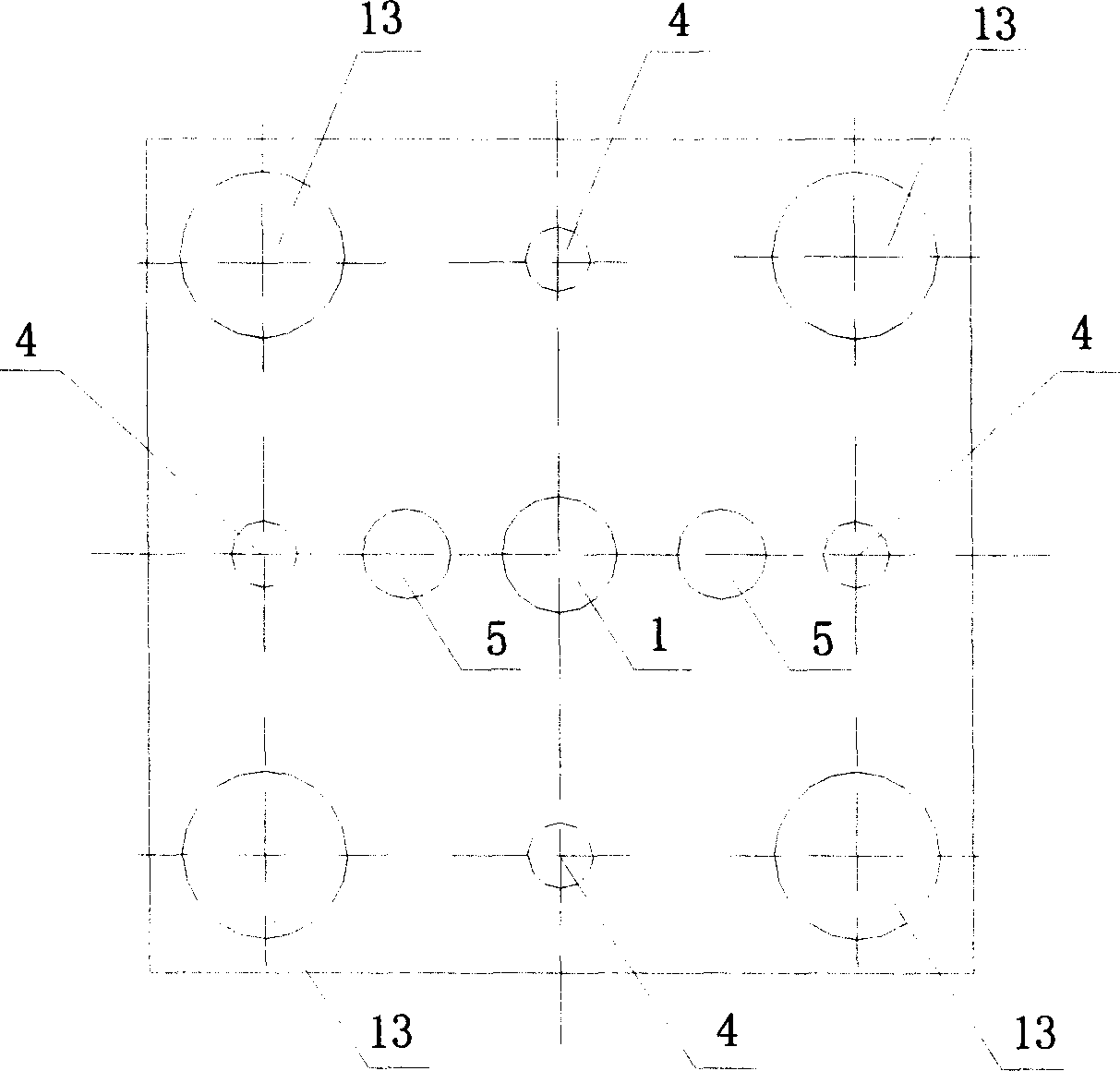

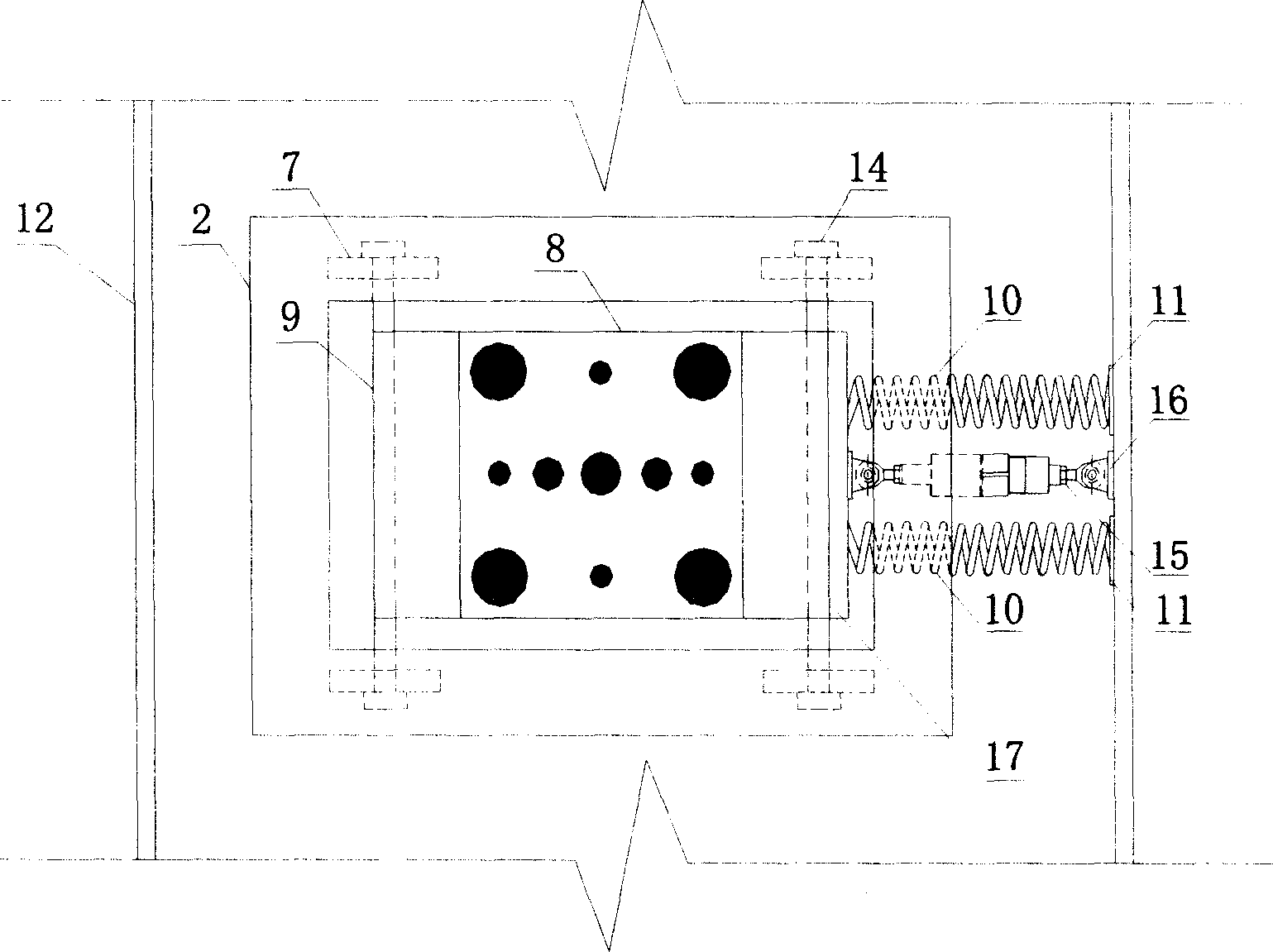

Bidirection adjustable tuning quality escillating damper

InactiveCN1718929AReduce resonanceEnsure safetyBridge structural detailsShock proofingResonanceSnubber

The present invention relates to a shock absorption control equipment for large-span pedestrian overhead bridge, harbour landing stage and related structure, it can be used for reducing the resonance reaction of bridge structure under the action of pedestrian load and transverse wind load. It is characterized by that the bottom portion of mass-tuning shock damper is equipped with a transverse moving mechanism formed from box-type beam-slab, guidway and wheels, and also equipped with transverse spring and transverse viscous oil damper.

Owner:DALIAN UNIV OF TECH

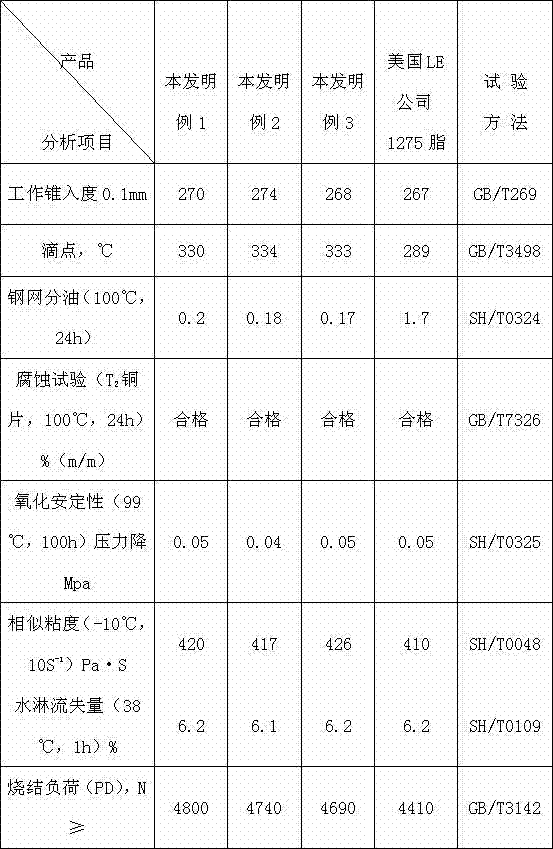

1206 lubricating grease

InactiveCN103897781AEnhanced pumpabilityGood reversibilityLubricant compositionBenzoic acidPhosphoric acid

The invention relates to a 1206 lubricating grease, comprising the following components by weight percent: 2-4% of aluminum isopropoxide, 4-6% of aminated bentonite, 3-5% of stearic acid, 1-3% of benzoic acid, 37-41% of viscous oil in refined naphthenic base, 29-43% of viscous oil in refined paraffin base, 1-3% of zinc dialkyl dithiophosphate, 1.6-2.9% of triazole fatty acid ammonium salt, 0.1-0.5% of a triazole derivative, 0.8-1.8% of tricresyl phosphate, 1.2-5% of polyisobutene and 0.7-1% of ethyl carbamate. Compared with the prior art, the 1206 lubricating grease is high in dropping point, large in sintering load data and relatively good in compression and wear resistance, and the more outstanding feature is as follows: the steel mesh is excellent in oil dividing, the embodiment 3 is 1 / 10 of the 1275 grease of LE company of America, and the embodiment 1 is not greater than 1 / 8; obviously, the pollution in the operation is smaller, the resource can be saved more, and the operation period of the equipment can be prolonged.

Owner:GUANGZHOU ROSTON PETROCHEM CO LTD

Oxidative thinner for heavy oil exploitation via steam injection and preparation thereof

ActiveCN101440275AHigh viscosity reduction rateLow viscosityDrilling compositionHydrolysateAcid substances

The invention relates to an oxidization viscosity reducer for viscous oil recovery by steam injection and a preparation method thereof. The oxidization viscosity reducer comprises components by weight percentage: 0.5 to 10 percent of component A, 0.5 to 10 percent of component B, 0.1 to 8 percent of component C, 0.1 to 5 percent of component D, and the balance being water, wherein the component Ais peroxide, the component B is transition metal salt of an organic acid, the component C is inorganic salt with the acidity shown in a hydrolysate, and the component D is an alkaline substance. The oxidization viscosity reducer can oxidize gelatine and asphaltine in viscous oil, reduce the viscosity of crude oil by changing a structure of the viscous oil through chain termination, oxidize to generate an acid substance at the same time, ensure that the viscous oil becomes a substance with the effect of a surfactant by adding the alkaline substance, and also play a role in viscosity reduction.The experiments show that the viscosity reduction rate can reach 99.9 percent when the viscosity reducer reacts with the crude oil for 24 hours at the temperature of 100 DEG C. The viscosity reducer has higher viscosity reduction rate, is applicable to the viscosity reduction of oil well stratums with high steam injection temperature, and also has good effect under relatively lower temperature conditions.

Owner:中国石化集团河南石油勘探局有限公司

Oil well water shutoff agent and oil well water shutoff method

ActiveCN102876305AStrong resistance to high salinity waterHigh temperature resistanceDrilling compositionSealing/packingFatty alcoholSURFACTANT BLEND

The invention relates to an oil well water shutoff agent and an oil well water shutoff method. The oil well water shutoff agent comprises an anionic surfactant, a nonionic-anionic surfactant, C1-C8 fatty alcohol, viscous oil and water. The oil well water shutoff agent has the characteristics of strong high-mineralization water resistance, strong temperature tolerance, strong stability, low cost, no pollution to stratums, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

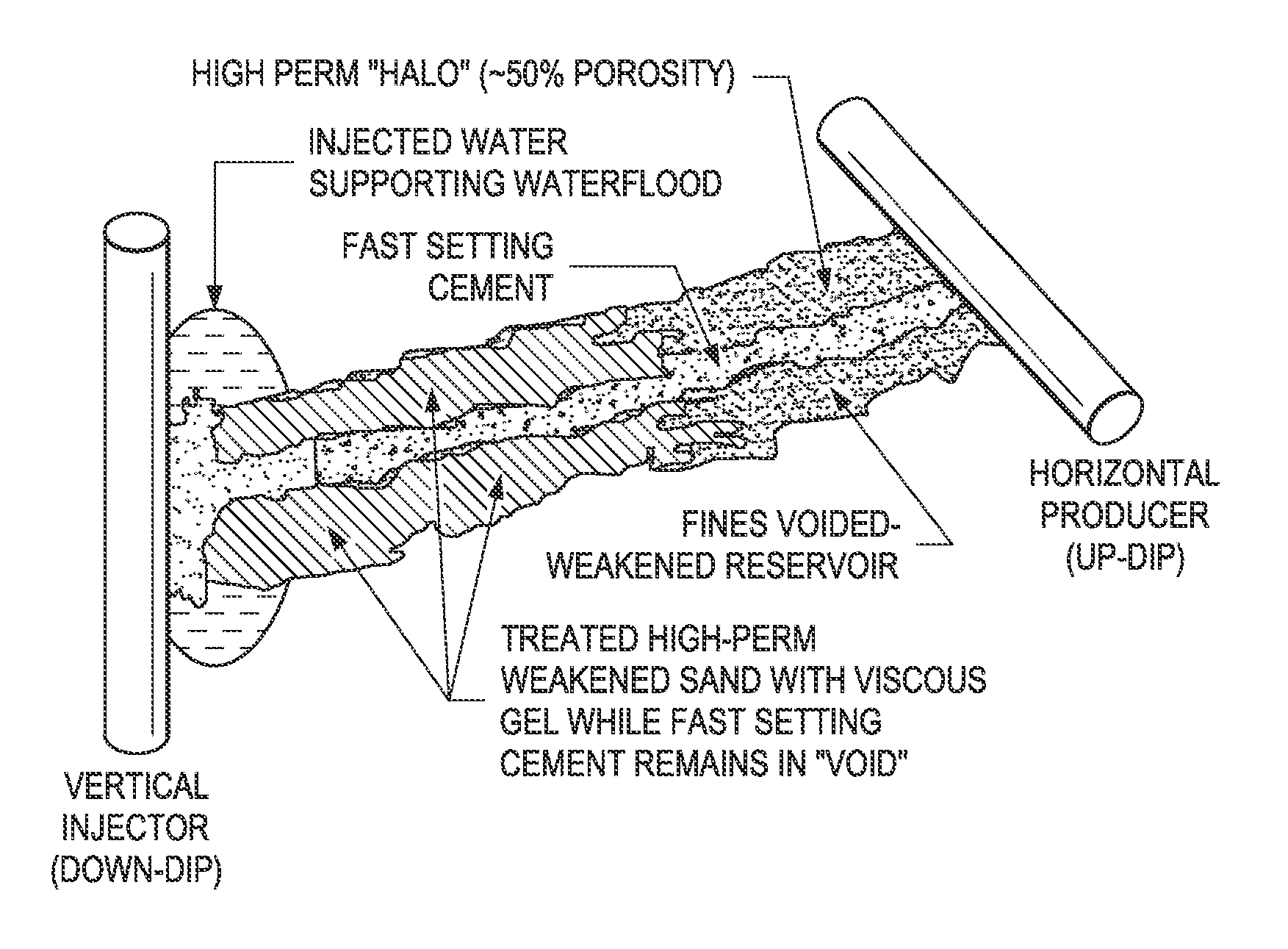

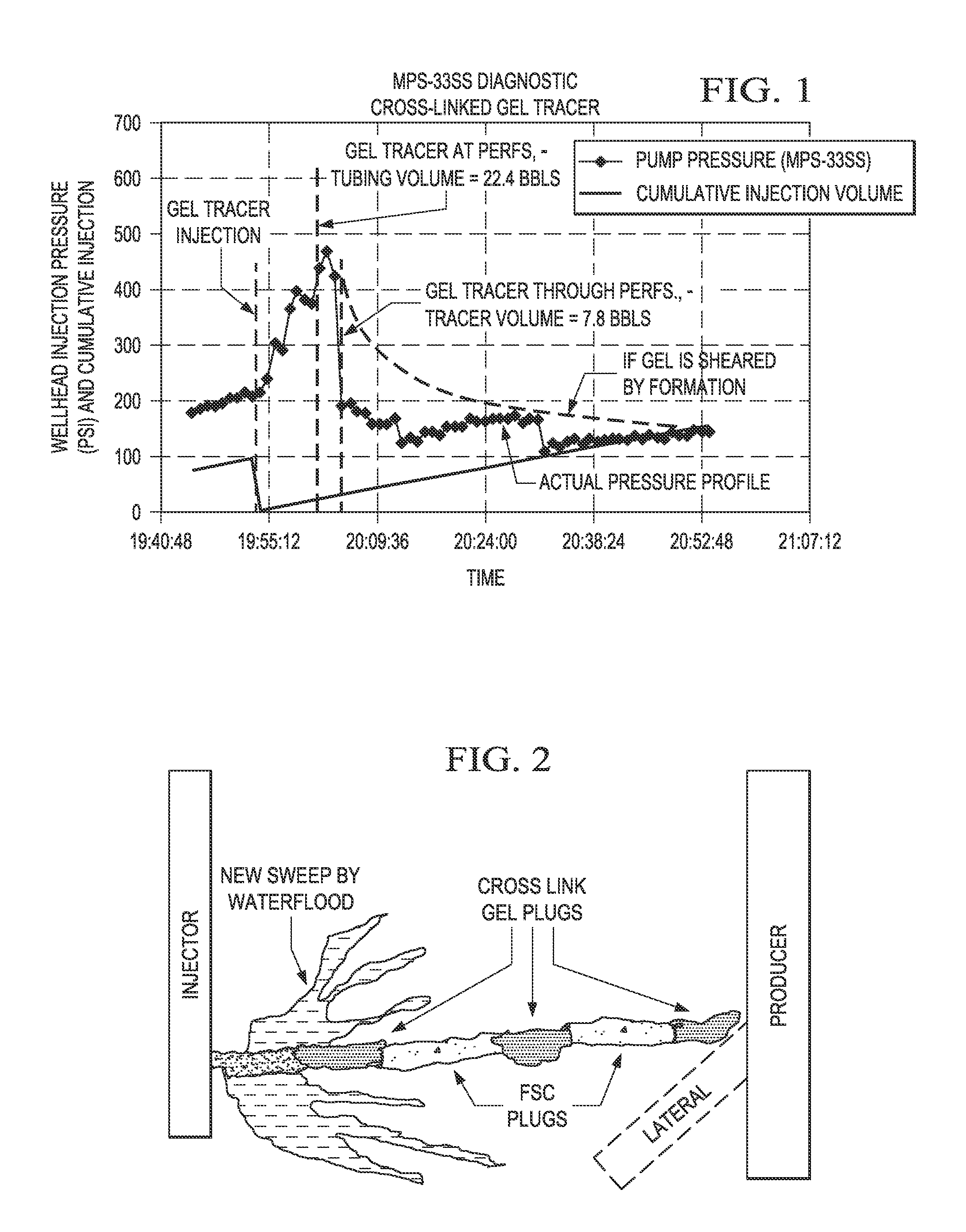

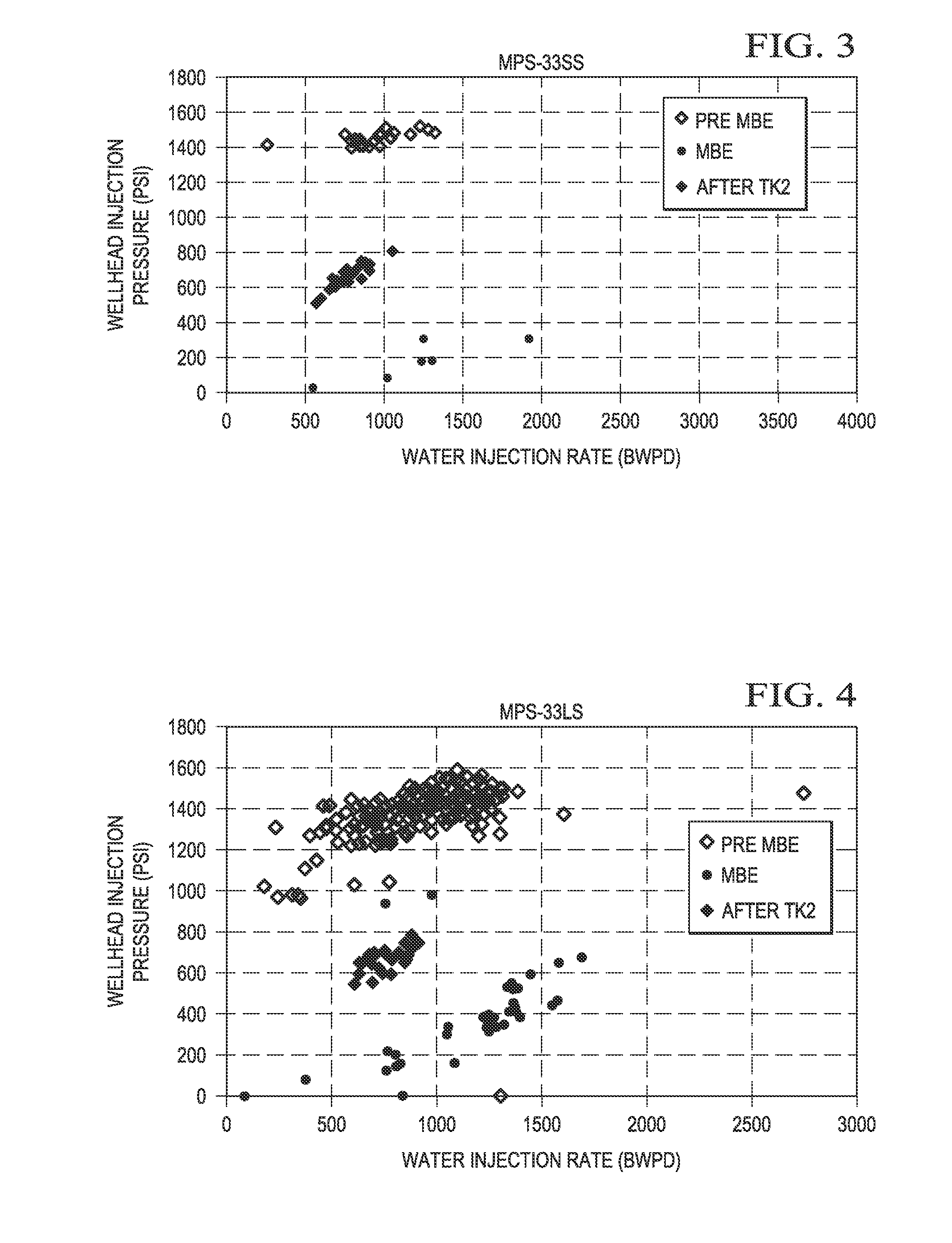

Method to Control Driving Fluid Breakthrough During Production of Hydrocarbons from a Subterranean Reservoir

InactiveUS20110024115A1Reduce flow communicationReduce communicationFluid removalDrilling compositionSlurryEngineering

The invention is directed to a method for controlling driving fluid breakthrough caused by zones of pressure communication, i.e., a matrix bypass event (“MBE”) or a wormhole, having a void space and possibly areas of enhanced permeability (a halo region) associated with the void space, within a subterranean formation arising from use of a driving fluid in reservoirs where heavy / viscous oil is being produced. In particular, the method is directed to remediation of pressure communication between injection and production wells used to produce heavy / viscous oil by way of a waterflood operation combined with a cold production method. Direct or rapid communication of water between the injector and producer wells makes the waterflood recovery process virtually ineffective and limits the production of oil from the reservoir. The invention comprises in embodiments a method wherein a slurry of a cementitious material is injected into the zone, which upon setting, provides a cement plug in the void space that reduces the pressure communication and flow of driving fluid within the zone. Another step is used to inject a gel precursor within the zone, which upon setting, produces a gel plug that also reduces pressure communication and driving fluid flow through the halo region of the zone.

Owner:BP CORP NORTH AMERICA INC

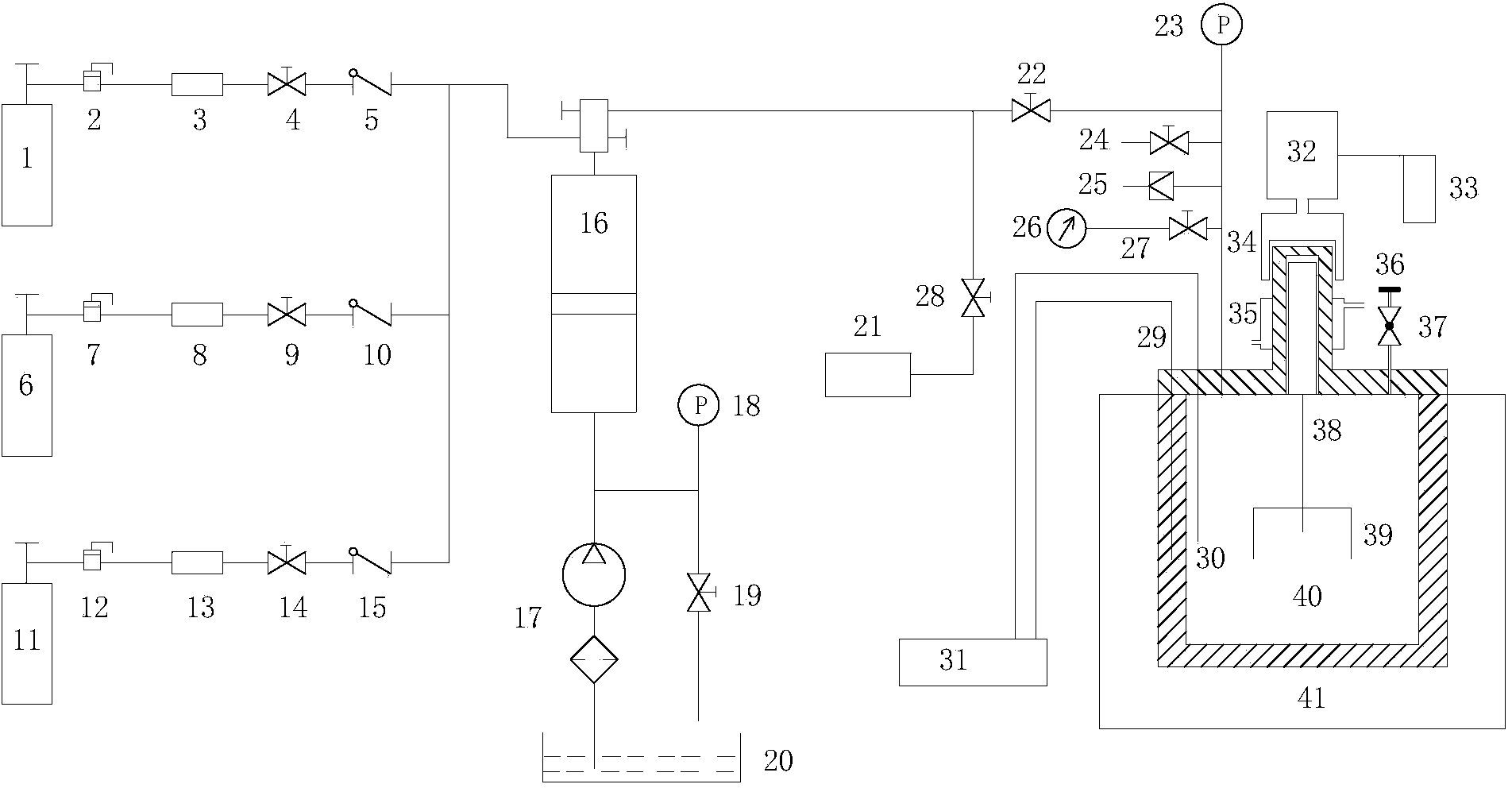

Apparatus for measuring corrosion rate of down-hole string by flue gas, and its application

The invention relates to an apparatus for measuring the corrosion rate of a down-hole string by flue gas. The apparatus comprises a gas source portion, a gas mixing portion and a corrosion environment simulation reaction kettle; the gas source portion comprises an oxygen source, a nitrogen source and a carbon dioxide gas; the gas mixing portion comprises a mixing pressurized container; and the corrosion environment simulation reaction kettle comprises a kettle body, experimental rotating parts axially arranged in the kettle body, and a motor driving the experimental rotating parts, and the experimental rotating parts comprise a rotor and a film hanger. The apparatus can simulate the real corrosion conditions of the down-hole string in flue gas assisted viscous oil recovery, and can meet the test of the corrosivity of the flue gas under different conditions.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Composite catalysis emulsification viscosity reducer used for viscous oil recovery adopting steam injection and preparation method thereof

The invention relates to a composite catalysis emulsification viscosity reducer used for the viscous oil recovery adopting steam injection and a preparation method thereof. The viscosity reducer combines the viscous oil catalytic viscosity reduction technology and the emulsification viscosity reduction technology, is suitable for the underground viscous oil or super viscous oil recovery adopting steam injection and is complexed by using nickel acetylacetonate as catalyst and sodium dodecyl benzene sulfonate as emulsifier. The viscosity reducer comprises the following components by weight percent: 0.1-0.5% of nickel acetylacetonate, 0.1-0.3% of sodium dodecyl benzene sulfonate and the balance water. The viscosity reducer is a composite viscosity reducer and has good viscosity reduction effect; and through complexing, the application range of the viscosity reducer becomes wider and the viscosity reducer has better effect under lower temperature. Tests prove that after the composite viscosity reducer reacts with viscous oil at 200 DEG C for 18h, the viscosity of viscous oil can be reduced from 218284mPa.s to 3095mPa.s and the viscosity reduction rate is up to more than 98.5%.

Owner:SHANGHAI UNIV

Temperature-resistant jelly

The invention provides a temperature-resistant jelly comprising the following components in percentage by mass: 0.3-0.5% of an acrylamide / acryloyloxyethyl trimethyl ammonium chloride copolymer, 0.1-0.5% of sodium tripolyphosphate or / and amino methenesodium phosphate, 0.05-0.15% of phenol, 0.05-0.1% of paraformaldehyde, 0.2-0.4% of thiourea, 0.05-0.2% of sodium malonate or / and D-sodium erythorbate and the balance of water, wherein the total mass percentages of each component are 100%, the relative molecular mass of the acrylamide / acryloyloxyethyl trimethyl ammonium chloride copolymer is 200*10<4> to 500*10<4>, and the mass content of an acryloyloxyethyl trimethyl ammonium chloride monomer is 10-30%. According to the jelly provided by the invention, the gelling time of the jelly can be adjusted in a range of 15-54 hours, the jelly is excellent in temperature-resistant performance, and a water loss shrinkage phenomenon cannot be caused after the jelly is aged for 180 days at 160 DEG C; and the jelly can be used as a plugging agent applied to near borehole zones and oil well deep parts, and can also be used for sealing steam channeling in a thermal exploitation process of viscous oil.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Detection of heavy oil using fluorescence polarization

ActiveUS7728291B2Avoid interferenceRaman/scattering spectroscopyElectrical apparatusOcean bottomFluorescence

Owner:EIC LAB

Fluorine-containing amphiphilic polymer viscosity reducer for crude oil and preparation method thereof

ActiveCN102558435AGood emulsificationReduce dosageDrilling compositionStructural formulaPolymer chemistry

The invention discloses a fluorine-containing amphiphilic polymer viscosity reducer for crude oil and a preparation method thereof. The method comprises the steps as follows: (1) a water-soluble monomer and a perfluoroalkyl acrylate monomer are dissolved in water to obtain a water-phase solution, wherein the water-soluble monomer comprises at least one of acrylamide, acrylic acid, acrylonitrile, acrylic ester and allyl alcohol; the structural formula of the perfluoroalkyl acrylate monomer is CH2=CHCOO(CH2)m(CF2CF2)nF, wherein, m is a natural number from 1 to 3 and n is a natural number from 3to 6; (2) cyclohexane, an emulsifier and an initiator are added into the water-phase solution and stirred to obtain water in oil type emulsion liquid; and (3) after a pH (potential of hydrogen) valueof the water in oil type emulsion liquid is adjusted until representing alkalinity, inverse emulsion polymerization is conducted and then the fluorine-containing amphiphilic polymer viscosity reducerfor the crude oil is obtained. The fluorine-containing amphiphilic polymer viscosity reducer for the crude oil, which is provided by the invention, achieves a good emulsion effect on viscous oil, andthe viscosity reduction rate of the viscous oil is larger than or equal to 90 percent.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Viscosity reducing composition and method for reducing viscosity of viscous oil

ActiveCN104164225ALower dynamic viscosityTo achieve the purpose of reducing viscosityFluid removalDrilling compositionPhenolViscous oil

The invention discloses a viscosity reducing composition, which comprises (a) phenolic compounds and (b) thin oil; wherein the phenolic compounds can be alkyl phenol and / or alkyl naphthol, the alkyl chain comprises 6 to 16 carbon atoms, and the weight ratio of the phenolic compound to the thin oil is 1:1-300. The invention further provides a method for reducing the viscosity of viscous oil, and comprises a step of contacting the provided viscosity reducing composition with viscous oil. The provided method can effectively reduce the dynamic viscosity of viscous oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com