Flushing fluid for cementing of horizontal shale gas well

A technology for horizontal wells and shale gas, applied in drilling compositions, chemical instruments and methods, etc., can solve problems such as the deterioration of cement sheath interface bonding performance, and achieve the effect of wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

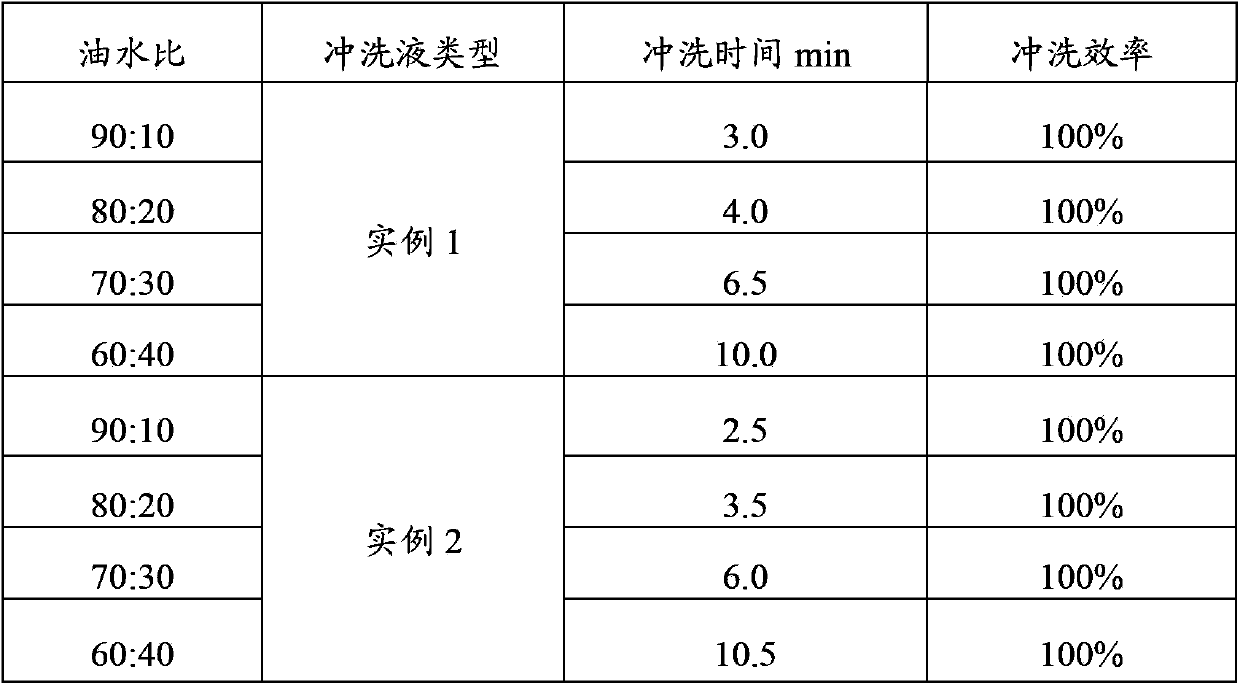

example 1

[0024] Add 1.0g sodium carboxymethylcellulose to 200g domestic water and stir for 60 minutes, then add 10g fatty alcohol polyoxyethylene ether + 10g polyoxyethylene alkyl alcohol amine + 6g alkyl alcohol polyoxyethylene ether sodium phosphate +1g sulfonic acid.

example 2

[0026] Add 10g of sakado into 200g of deionized water and stir for 30 minutes, then add 2g of nonylphenol polyoxyethylene ether + 2g of polyoxyethylene alkyl alcohol amine + 14g of sodium alkyl alcohol polyoxyethylene ether phosphate + 3g of sulfonic acid .

example 3

[0028] Add 2.0g sodium carboxymethylcellulose to 200g deionized water and stir for 60 minutes, then add 4g fatty alcohol polyoxyethylene ether + 6g polyoxyethylene alkyl alcohol amine + 4g fatty acid polyoxyethylene ether potassium sulfate + 8g sulfuric acid acid.

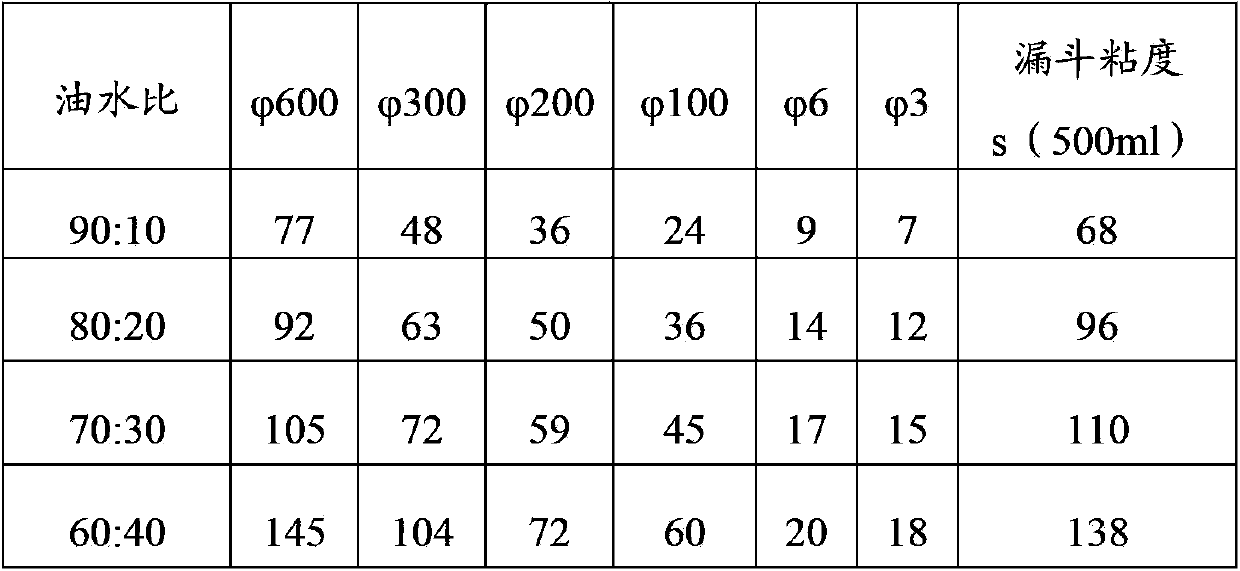

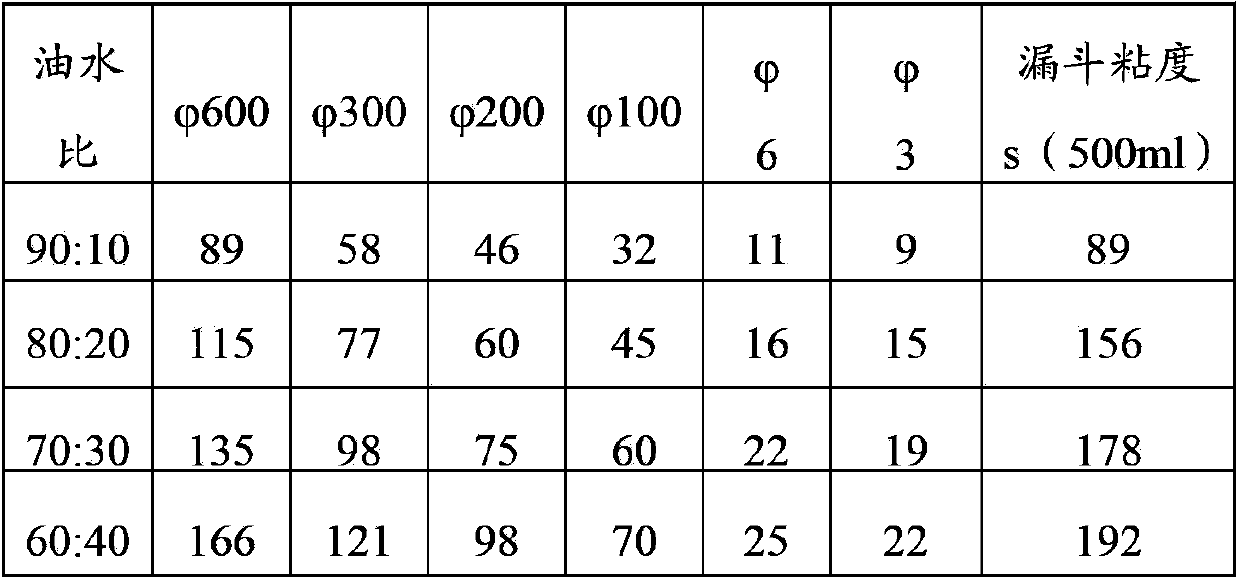

[0029] The basic formula of white oil-based drilling fluid is: base oil + 2.8% primary emulsifier + 0.7% secondary emulsifier + 2% organic soil + 1% viscosifier + 25% CaCl2 solution + 2.5% CaO + 2% fluid loss reducer +3~5% plugging agent + water.

[0030] The basic formula of diesel-based drilling fluid is: base oil + 3.5% organic soil + 2.5% primary emulsifier + 0.9 secondary emulsifier + 1% viscosifier + 20% CaCl 2 Solution + 2% CaO + 3% fluid loss additive + 0.2% flow regulator + 2% plugging agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com