Patents

Literature

6144 results about "Manganese oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manganese oxide is any of a variety of manganese oxides and hydroxides. These include Manganese(II) oxide, MnO (aka Ferrite Grade); Manganese(II,III) oxide, Mn 3 O 4; Manganese(III) oxide, Mn 2 O 3; Manganese dioxide, (manganese(IV) oxide), MnO 2; Manganese(VI) oxide, MnO 3; Manganese(VII) oxide, Mn 2 O 7; It may refer more specifically to the following manganese minerals:

Catalyst and method for reducing nitrogen oxides in exhaust streams with hydrocarbons or alcohols

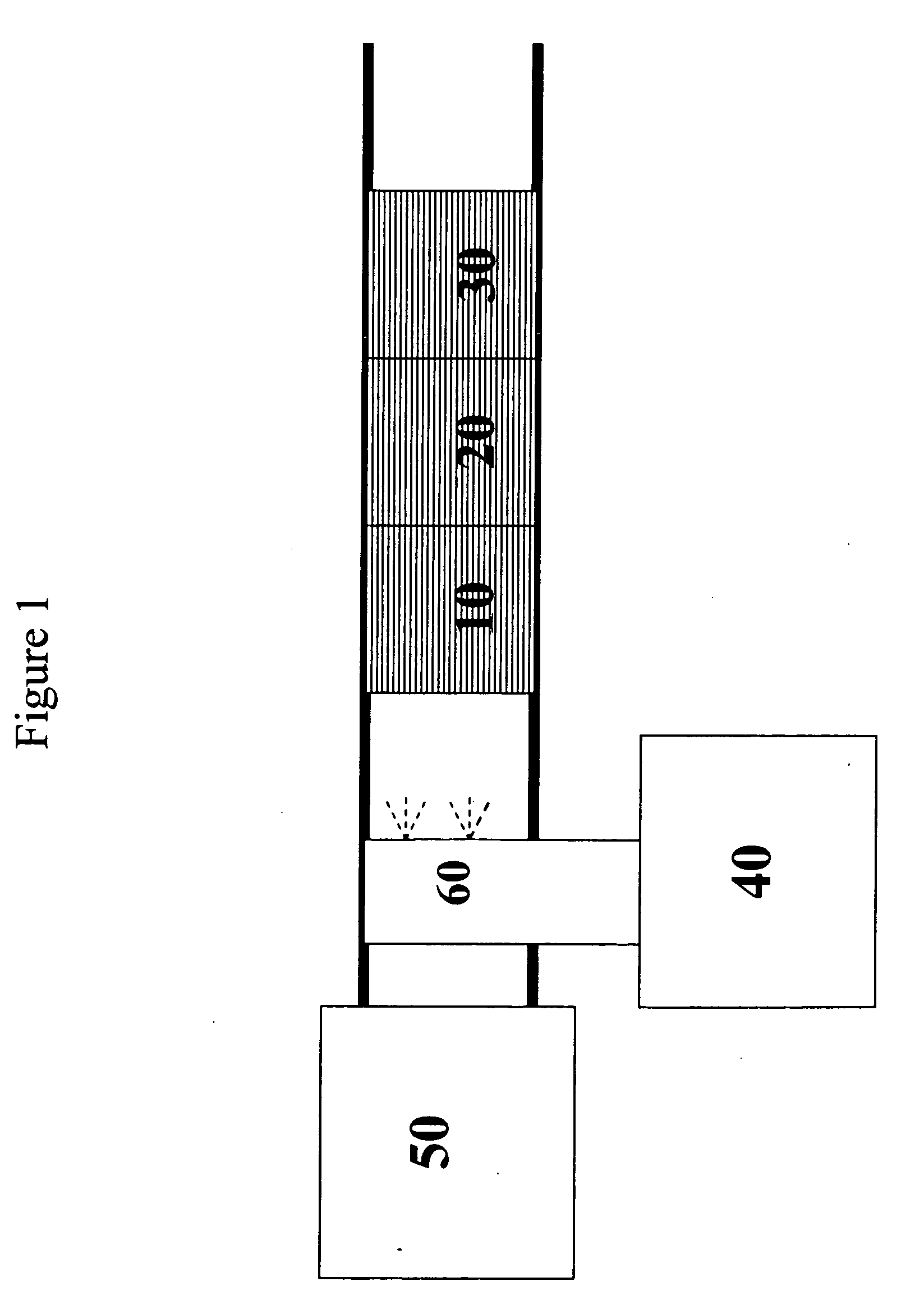

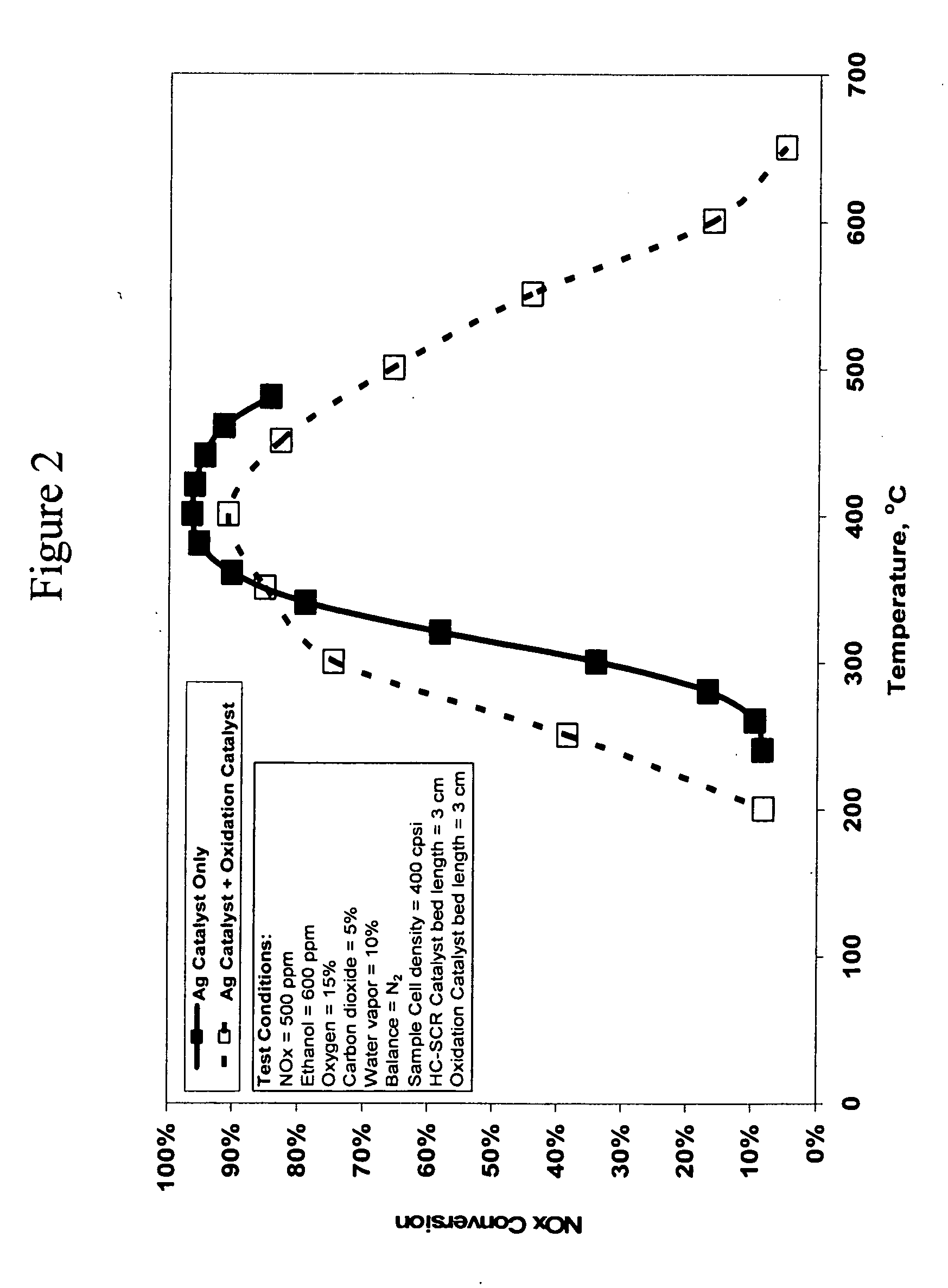

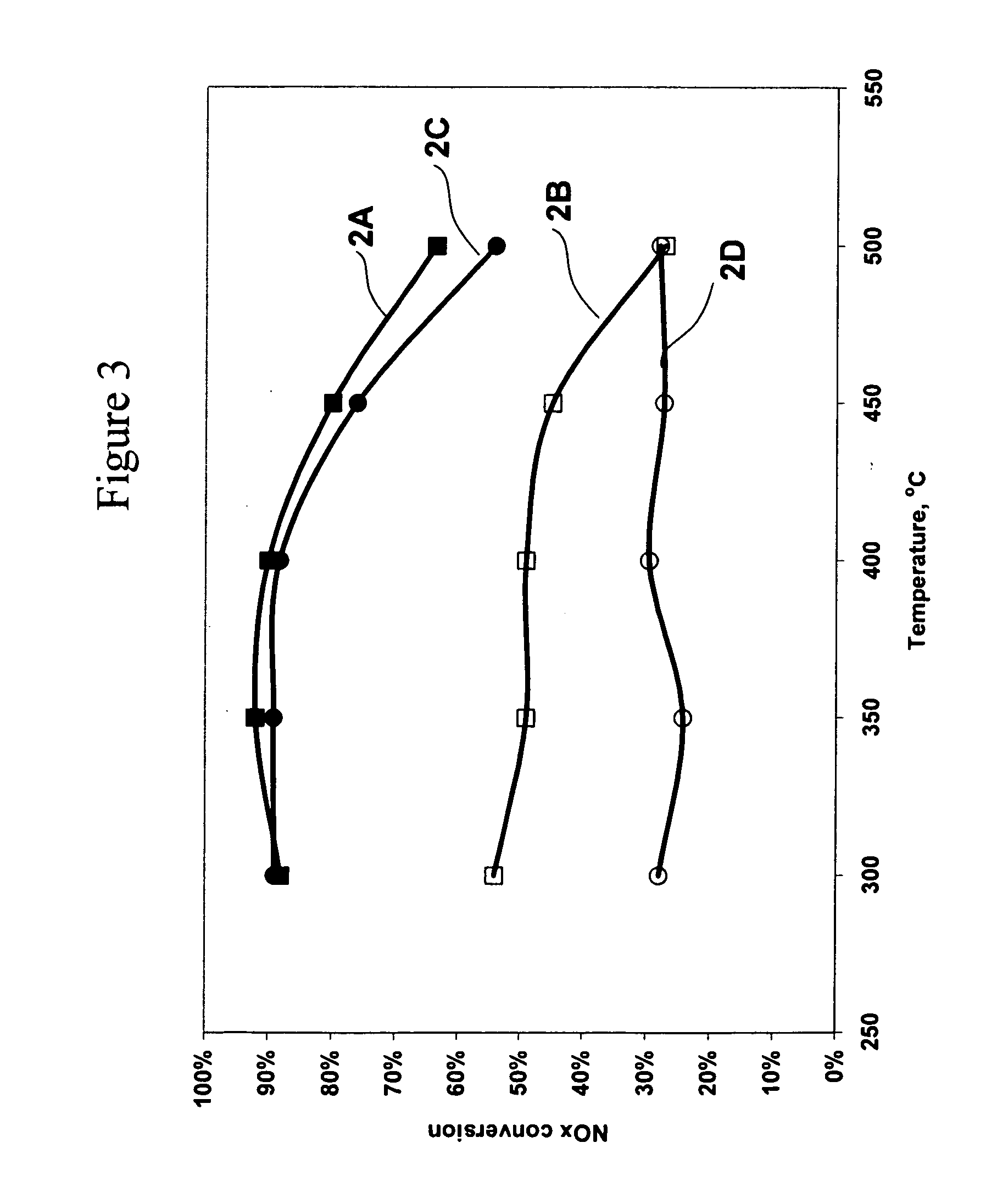

A catalyst system and a method for reducing nitrogen oxides in an exhaust gas by reduction with a hydrocarbon or oxygen-containing organic compound reducing agent are provided. The catalyst system contains a silver catalyst and a modifier catalyst, where the modifier catalyst contains a modifier oxide, where the modifier oxide is selected from the group consisting of iron oxide, cerium oxide, copper oxide, manganese oxide, chromium oxide, a lanthanide oxide, an actinide oxide, molybdenum oxide, tin oxide, indium oxide, rhenium oxide, tantalum oxide, osmium oxide, barium oxide, calcium oxide, strontium oxide, potassium oxide, vanadium oxide, nickel oxide, tungsten oxide, and mixtures thereof. The modifier oxide is supported on an inorganic oxide support or supports, where at least one of the inorganic oxide supports is an acidic support. The catalyst system of the silver catalyst and the modifier catalyst provides higher NOx conversion than either the silver catalyst or the modifier catalyst alone.

Owner:CATALYTIC SOLUTIONS INC

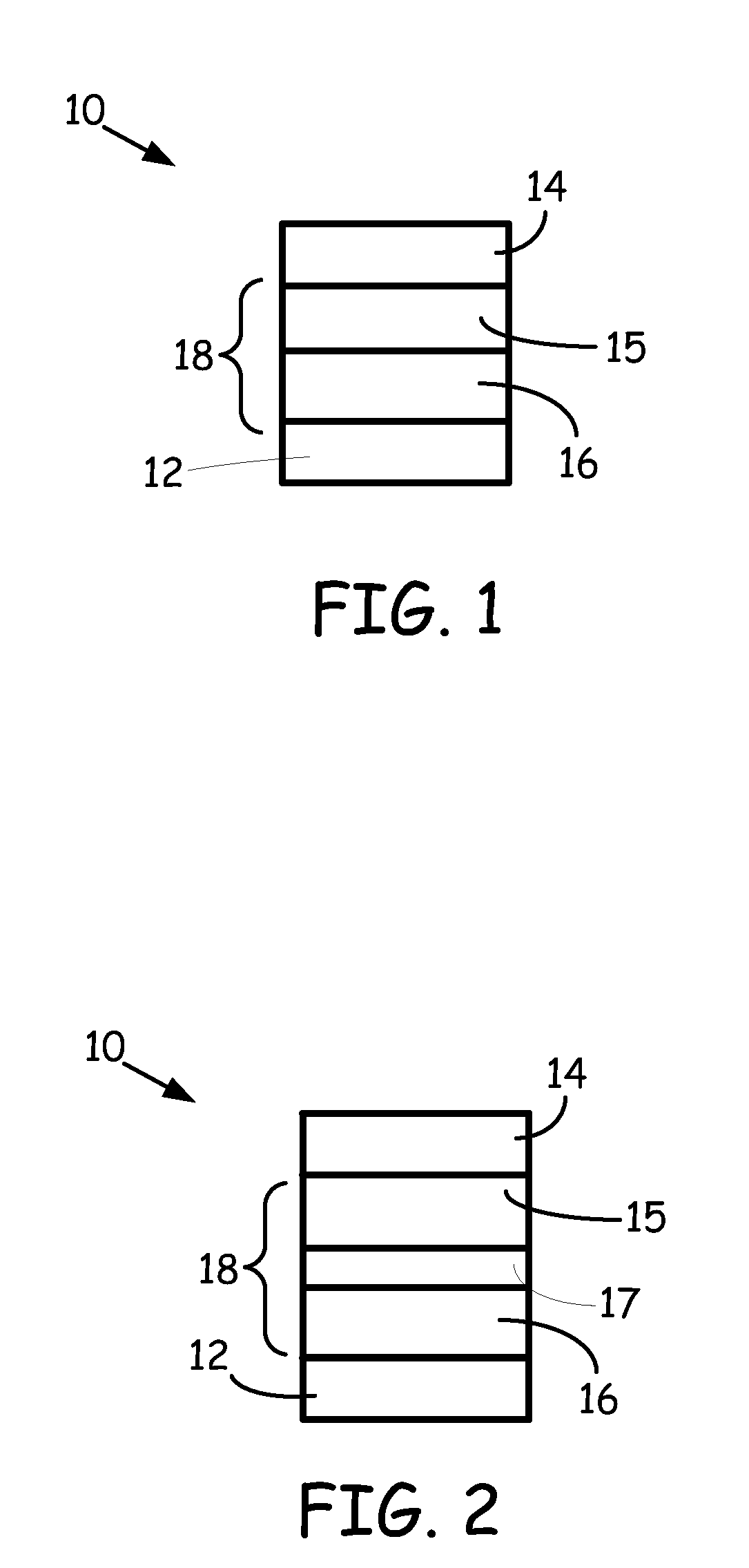

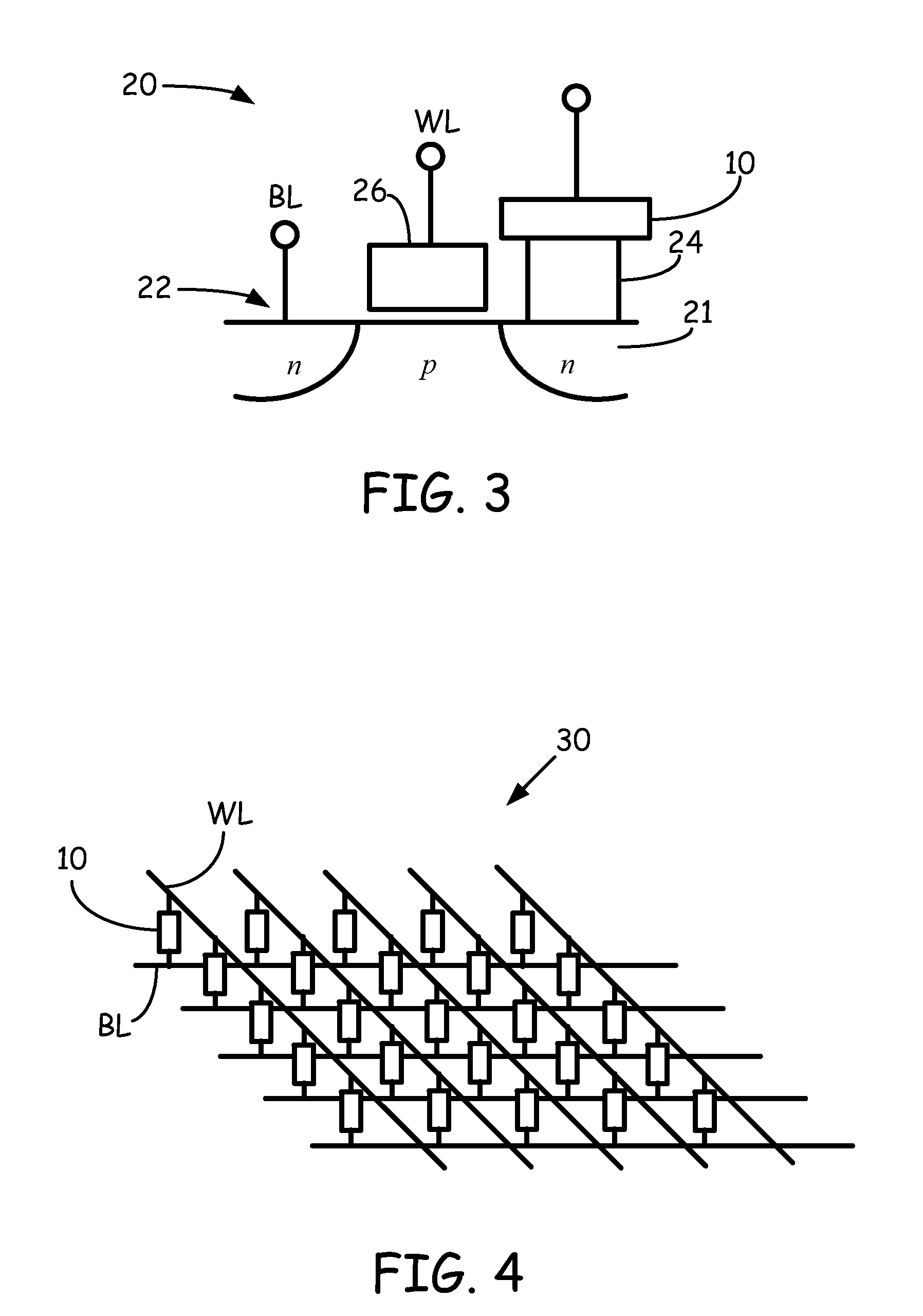

Non-volatile resistive sense memory

ActiveUS20110006275A1Solid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsManganese oxide

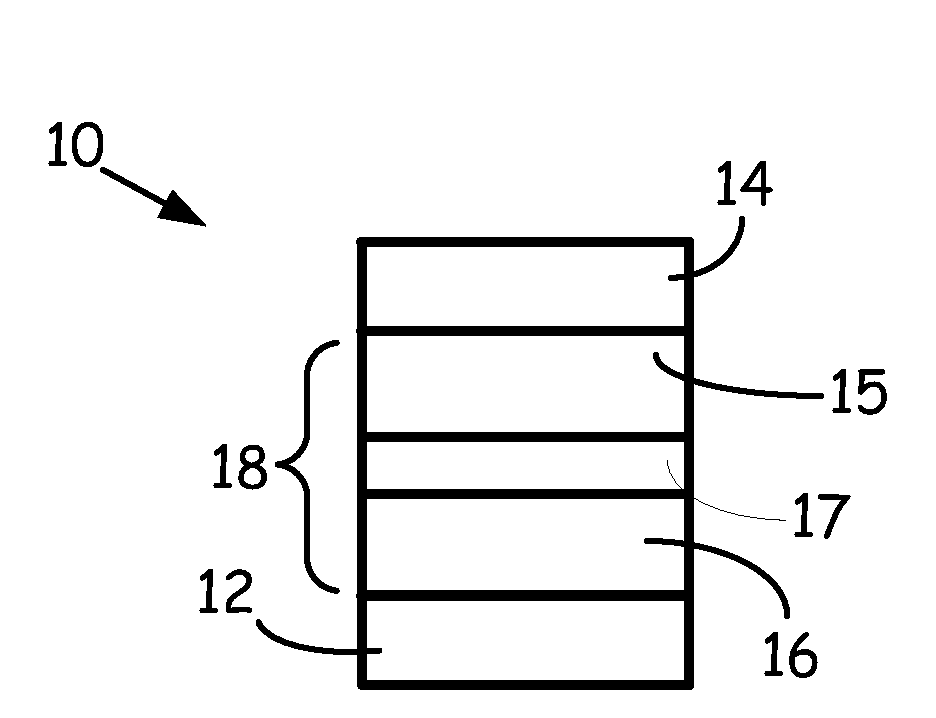

A resistive sense memory cell includes a layer of crystalline praseodymium calcium manganese oxide and a layer of amorphous praseodymium calcium manganese oxide disposed on the layer of crystalline praseodymium calcium manganese oxide forming a resistive sense memory stack. A first and second electrode are separated by the resistive sense memory stack. The resistive sense memory cell can further include an oxygen diffusion barrier layer separating the layer of crystalline praseodymium calcium manganese oxide from the layer of amorphous praseodymium calcium manganese oxide a layer. Methods include depositing an amorphous praseodymium calcium manganese oxide disposed on the layer of crystalline praseodymium calcium manganese oxide forming a resistive sense memory stack.

Owner:EVERSPIN TECHNOLOGIES

Lithium ion battery positive pole material cobalt nickel oxide manganses lithium and method for making same

ActiveCN101202343AHigh specific capacityExcellent cycle characteristicsElectrode manufacturing processesLithium compoundsLithium oxideAntioxidant

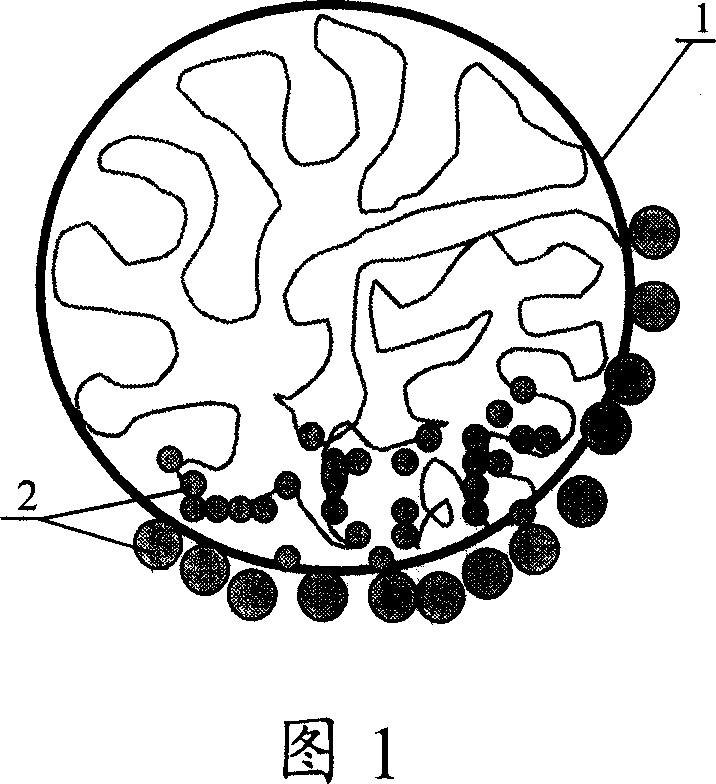

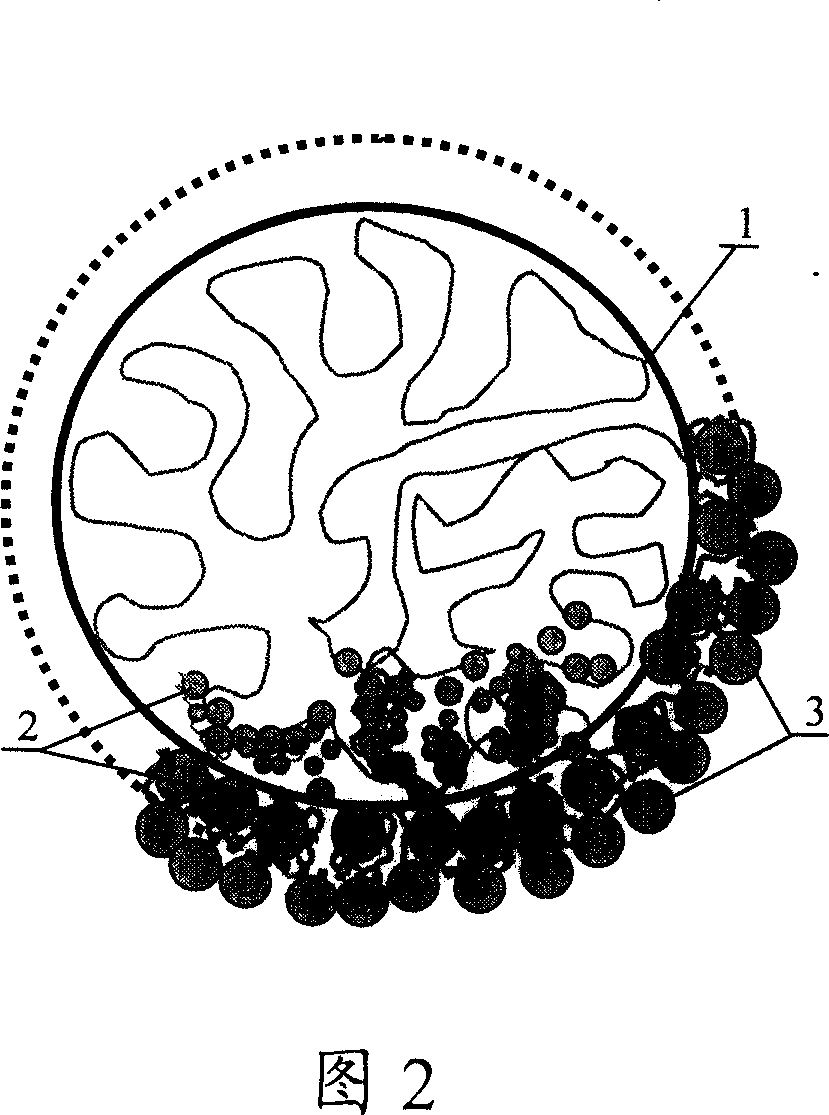

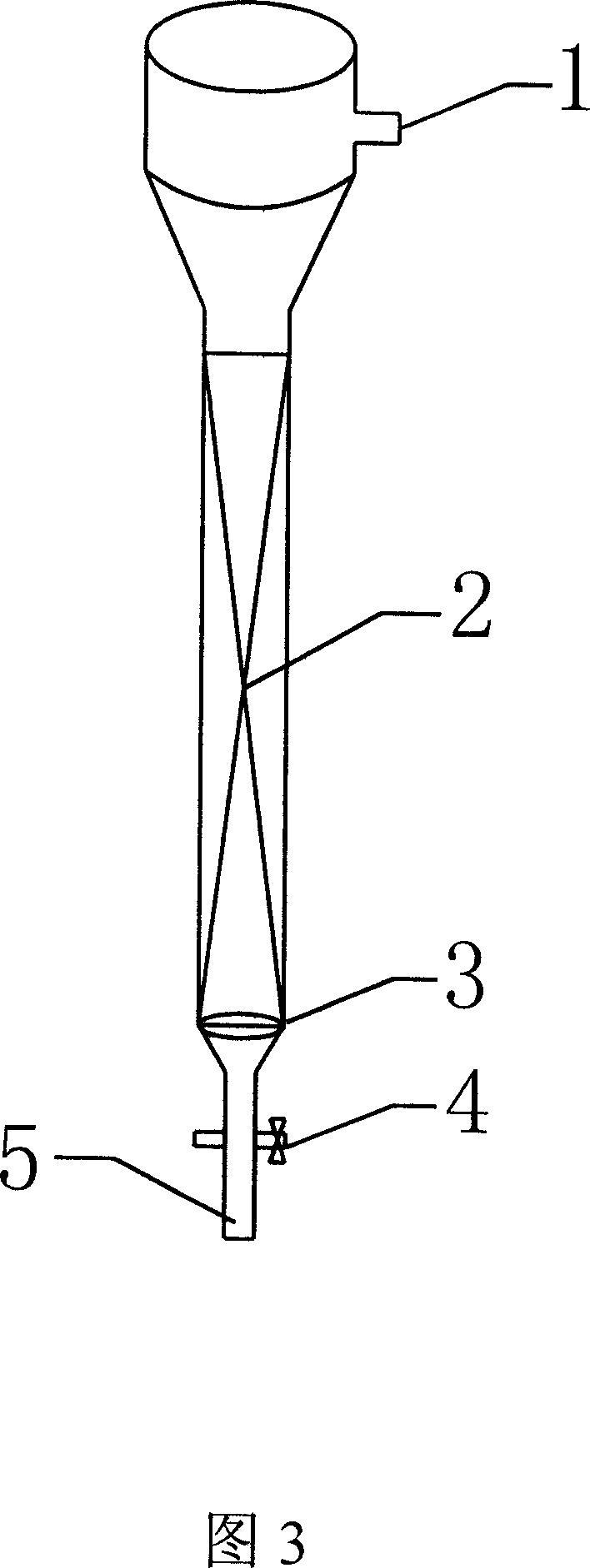

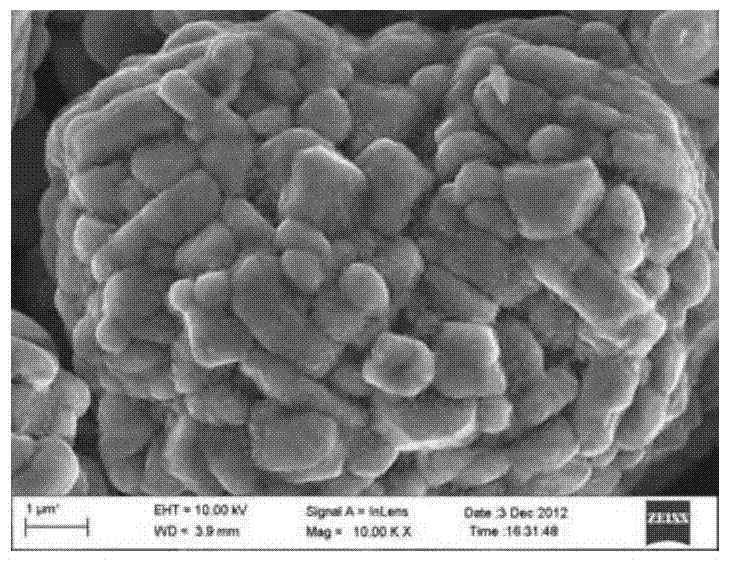

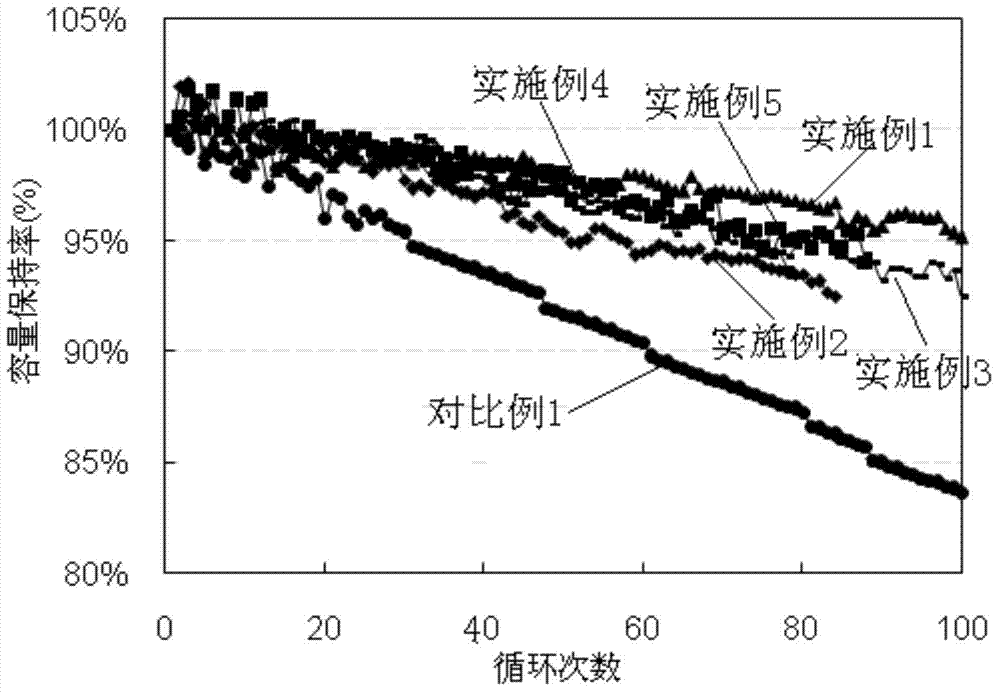

The invention relates to a nickel cobalt manganese lithium oxide material used for an anode of a li-ion battery and a preparation method. The invention belongs to the li-ion battery technical field. The nickel cobalt manganese lithium oxide material used for the anode of the li-ion battery is a li-rich laminated structure with the chemical component of Li1+zM1-x-yNixCoyO2; wherein, z is less than or equal to 0.2 and more than or equal to 0.05, x is less than or equal to 0.8 and more than 0.1, and y is less than or equal to 0.5 and more than 0.1. The preparation method of the invention is that dissoluble salt of the nickel, cobalt and manganese is taken as the raw material; ammonia or ammonium salt is taken as complexing agent; sodium hydroxide is taken as precipitator; water-dissoluble dispersant and water-dissoluble antioxidant or inert gas are added for control and protection; in a cocurrent flow type the solution is added to a reaction vessel for reaction; after alkalescence disposal, aging procedure, solid-liquid separation and washing and drying, the nickel cobalt manganese oxide is uniformly mixed with the lithium raw material; the nickel cobalt manganese lithium oxide powder is obtained by sintering the mixed powder which is divided into three temperature areas. The invention has the advantages of high specific capacity, good circulation performance, ideal crystal texture, short production period, low power loss, and being suitable for industrial production, etc.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST +1

Electrophoretic particles, and processes for the production thereof

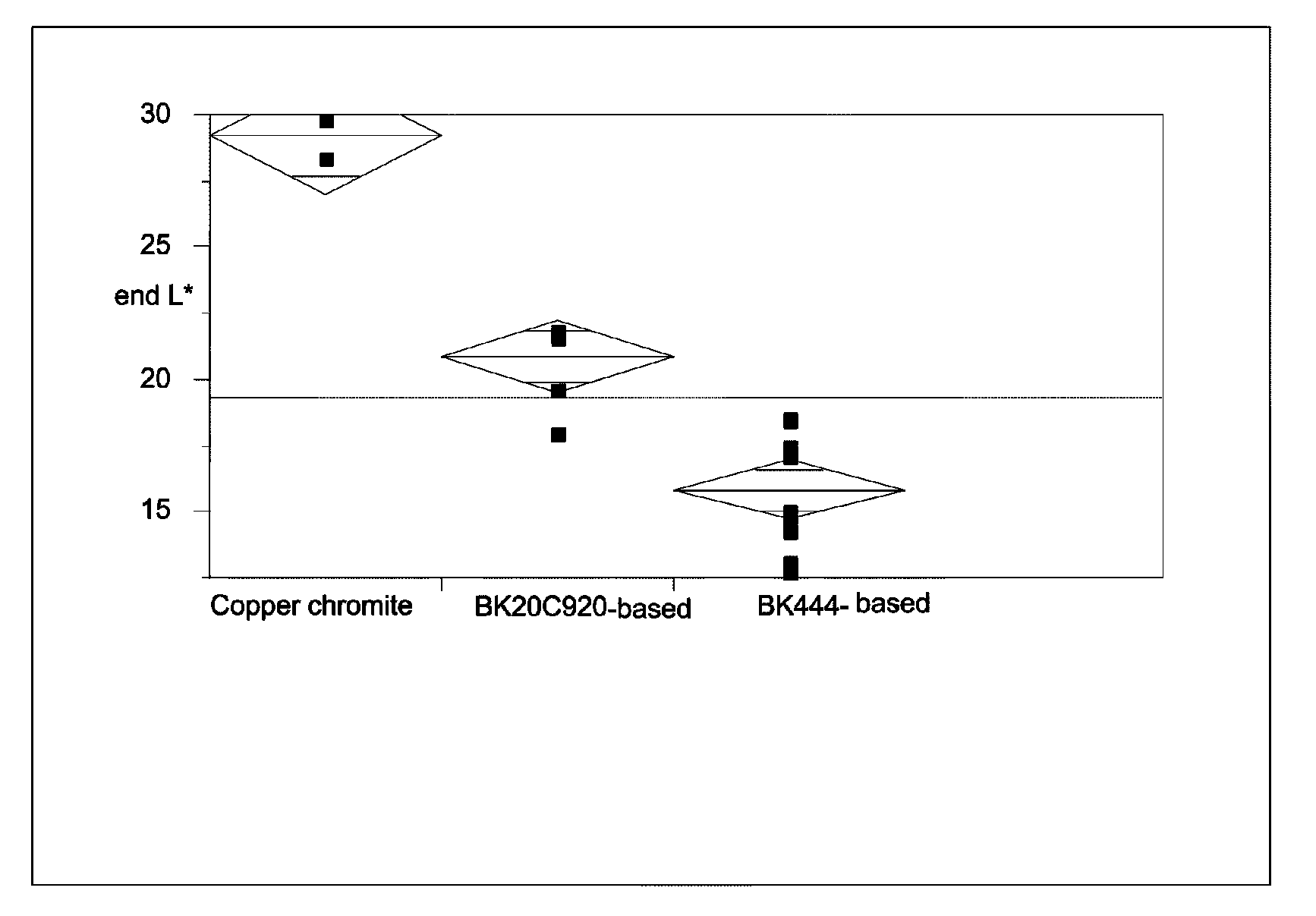

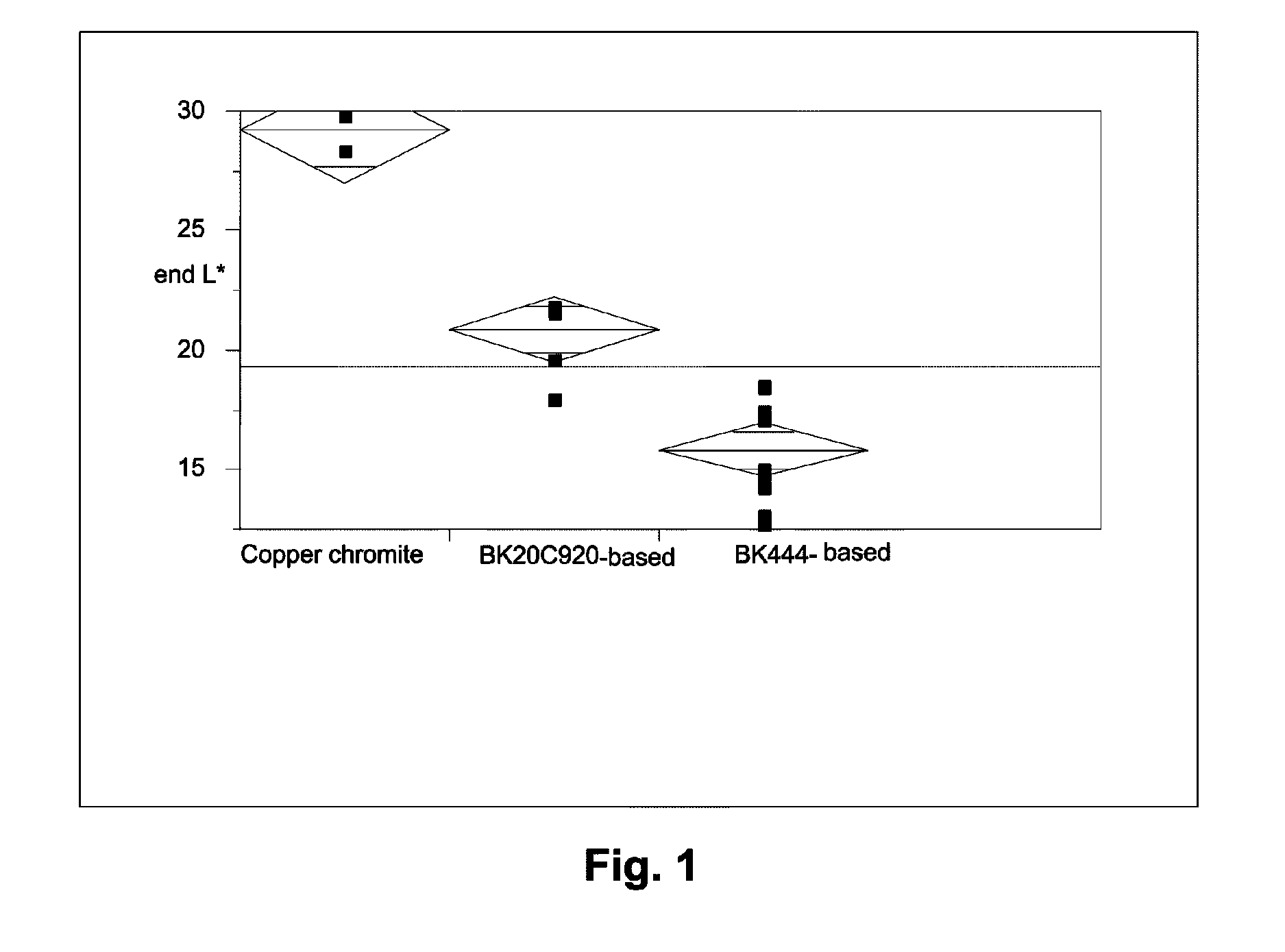

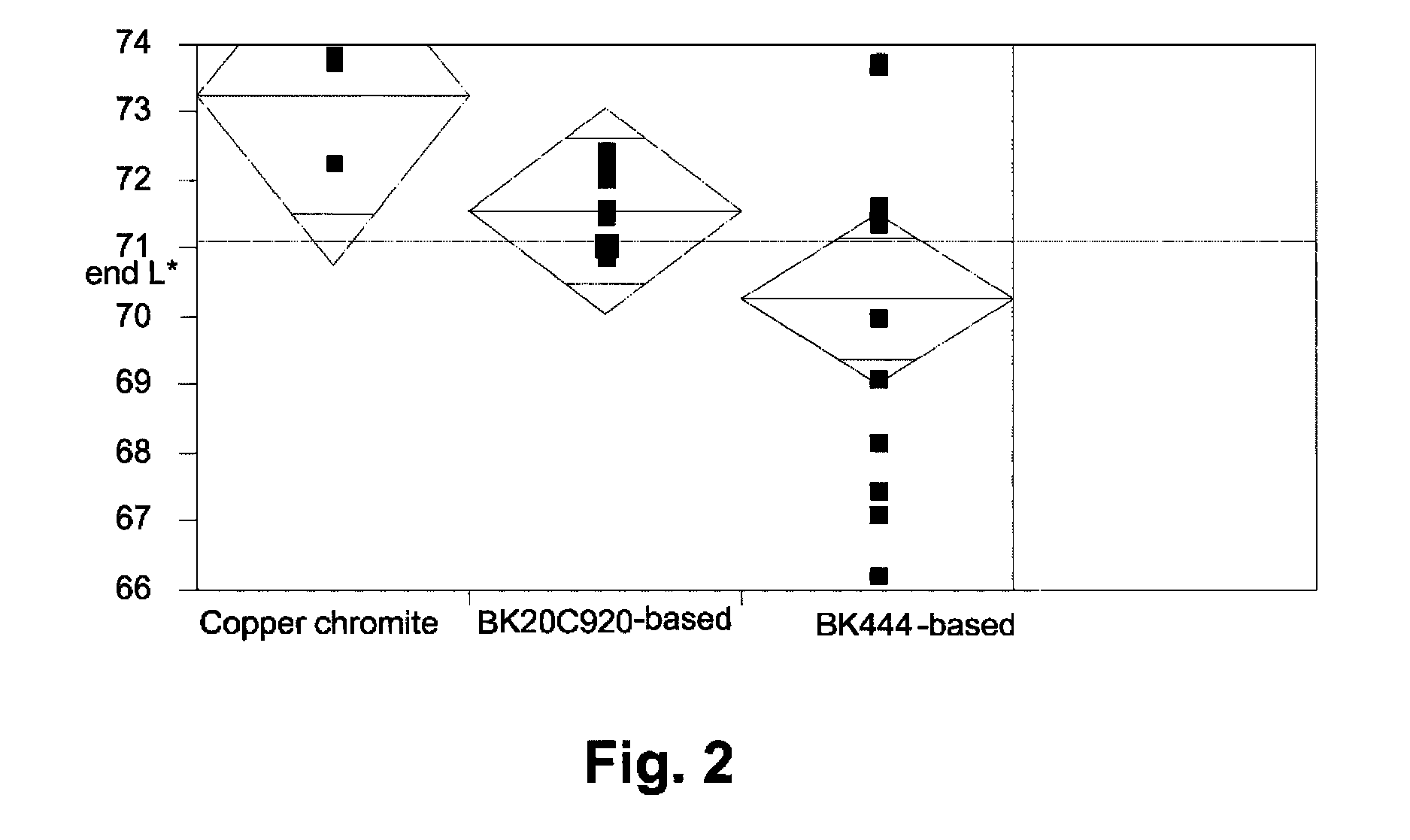

ActiveUS8270064B2Easy to useGood color saturationPigmenting treatmentStatic indicating devicesMagnetiteManganese oxide

An electrophoretic medium comprises at least one electrically charged particle dispersed posed in a fluid. The electrically charged particle comprises an inorganic black pigment having a surface area of at least about 7 m2 / g. Preferred pigments are magnetite and mixed metal oxides containing two or more of iron, chromium, nickel, manganese, copper and cobalt, for example copper iron manganese oxide spinel and copper chromium manganese oxide spinel. The inorganic black pigment may bear a polymer coating.

Owner:E INK CORPORATION +1

Low-temperature smoke denitration SCR (silicon controlled rectifier) catalyst and preparation method

ActiveCN102114424ARich pore structureLarge specific surface areaDispersed particle separationCatalyst activation/preparationSilicon-controlled rectifierManganese oxide

The invention relates to a low-temperature smoke denitration SCR (silicon controlled rectifier) catalyst, which comprises a carrier, a manganese oxide, and composite oxide of one or more of Ce, Zr, Ti, Co, Fe and Cu, the mass content of manganese is 0.1-66 percent, and the total mass content of the Ce, Zr, Ti, Co, Fe or / and Cu is 0-50 percent; and glass fiber and / or kieselguhr is used as the carrier, wherein the glass fiber of the carrier is calcined for 2-4 hours at temperature of 400-600 DEG C, then placed in a nitric acid, sulfuric acid or hydrochloric acid solution with mass concentration of 5-40 percent for acidizing for 1-8 hours, washed by distilled water to be neutered, dried at temperature of 80-120 DEG C, and crushed to have the fineness of 20-325 meshes. The catalyst uses the glass fiber and the kieselguhr as the carriers, so that the dispersion effect of nanoparticles and specific surface area of the catalyst are increased, the high adsorptive capacity and strong heat resistance and corrosion resistance capacity are achieved, stronger toxic resistance capacity to sulfur dioxide and stream contained in the smoke is realized, the invention can be used for 10-200 DEG C of low temperature smoke denitration, and has strong water resisting and sulphur toxic resisting capacities.

Owner:GUODIAN SCI & TECH RES INST +1

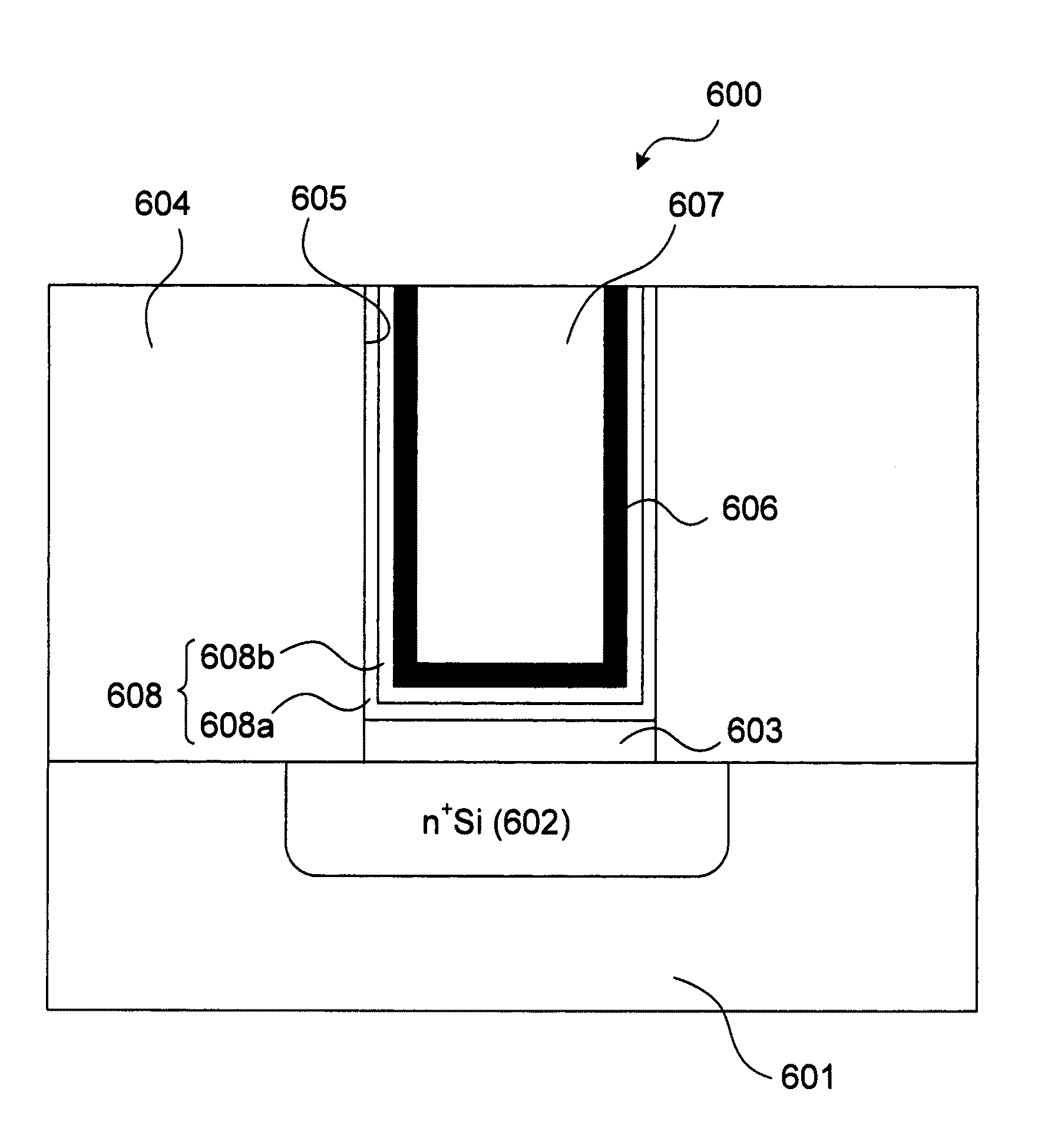

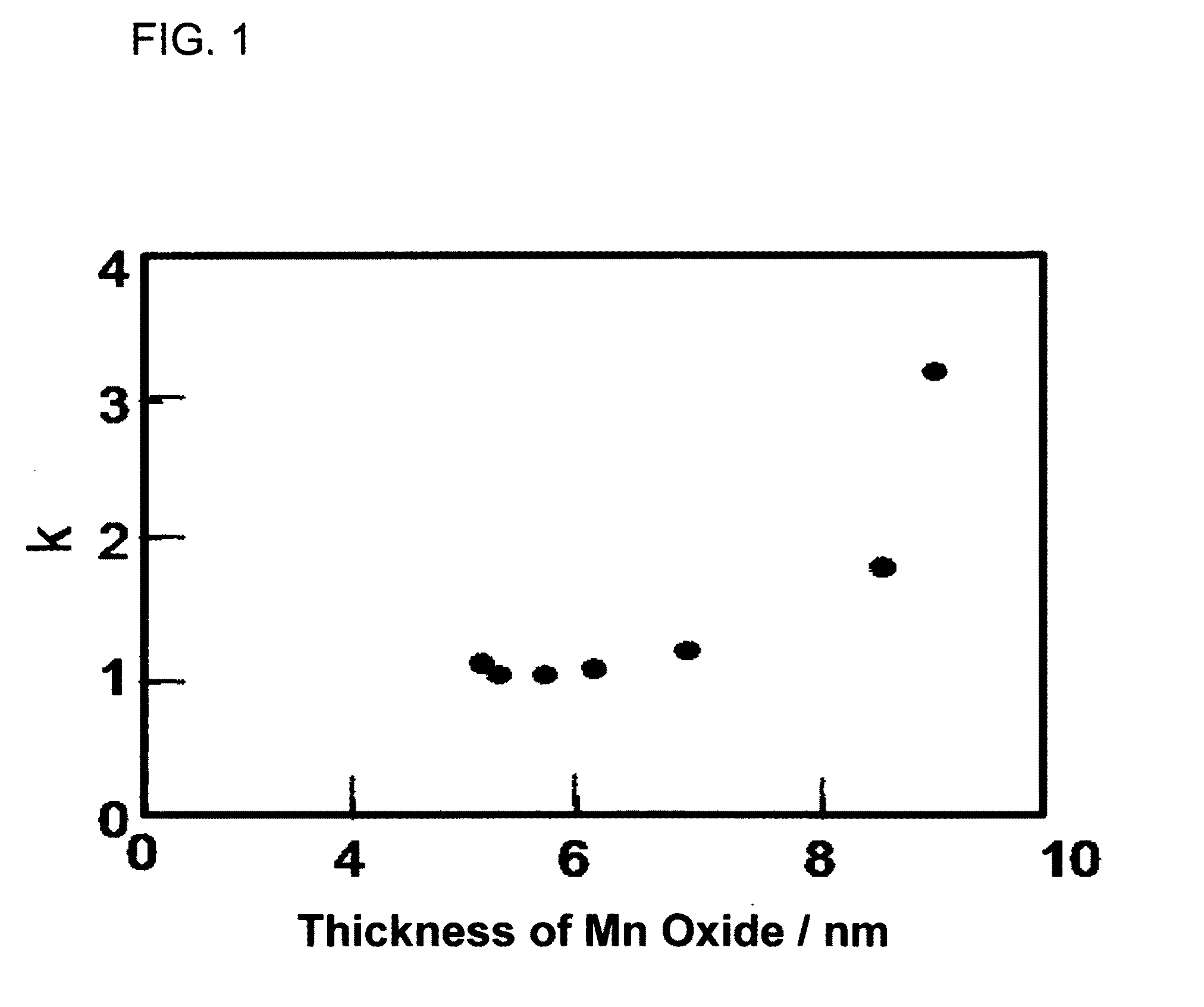

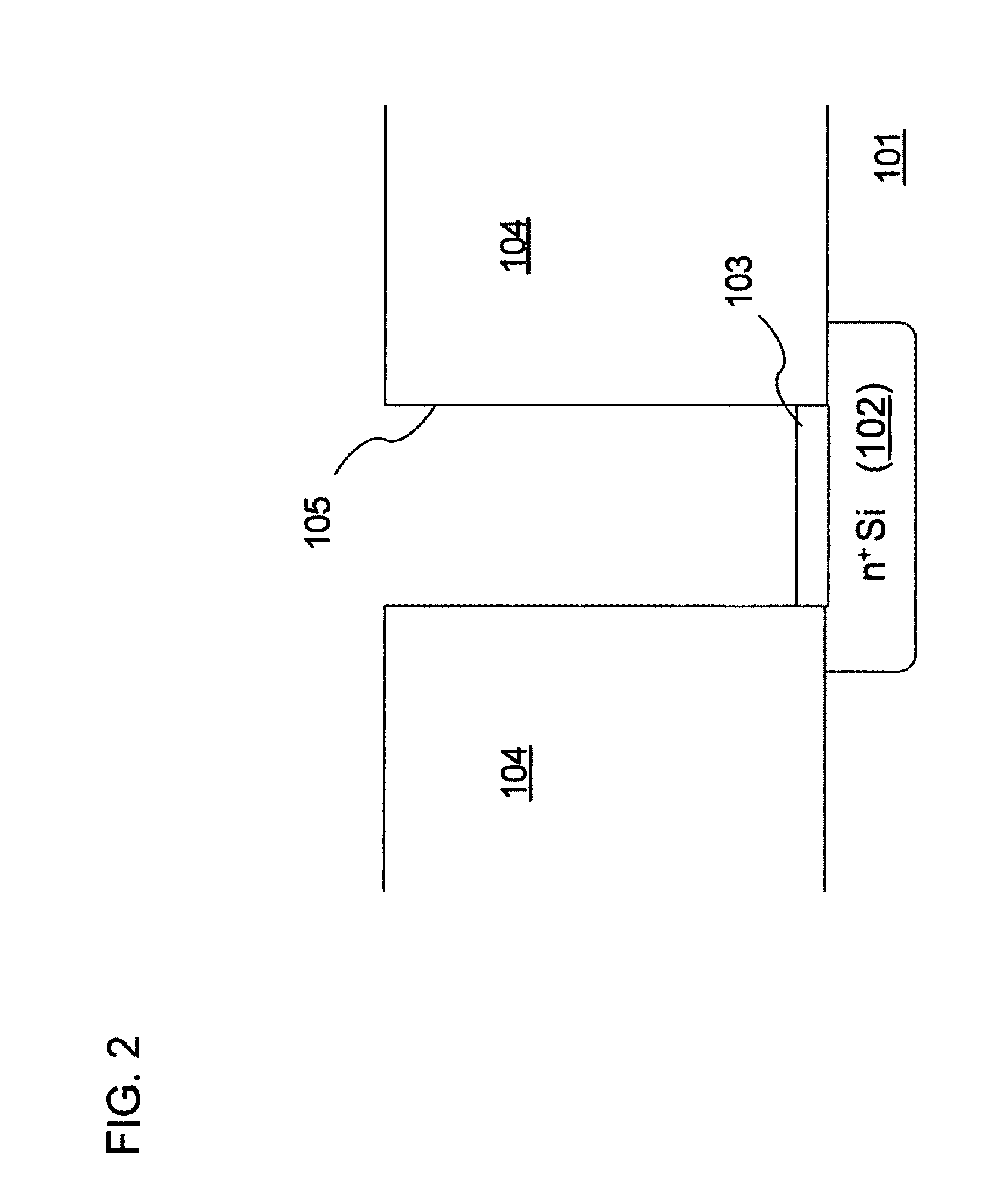

Contact plug structure, semiconductor device, and method for forming contact plug

InactiveUS20110057317A1Suppress DiffuseReduce contact resistanceSemiconductor/solid-state device detailsSolid-state devicesMetal silicideManganese oxide

A contact plug structure formed on a contact hole of an insulating layer of a semiconductor device includes a metal silicide layer formed on a bottom part of the contact hole of the insulating layer, a manganese oxide layer formed on the metal silicide layer in the contact hole, and a buried copper formed on the manganese oxide layer which substantially fills the contact hole.

Owner:ADVANCED INTERCONNECT MATERIAL

Hydrocarbon-Producing Catalyst, Process for Producing the Same, and Process for Producing Hydrocarbons Using the Catalyst

InactiveUS20080064769A1Increase probabilityStably and smoothly promoteHydrocarbon from carbon oxidesOrganic compound preparationRutheniumLiquid hydrocarbons

An object of the present invention is to provide a catalyst which, in the FT process, exhibits a high chain growth probability, and a high catalytic activity, can stably and smoothly promote the reaction, exhibits a high productivity of C5+, and can efficiently produce liquid hydrocarbons, and a process therefor.The invention relates to a hydrocarbon-producing catalyst obtainable by supporting a ruthenium compound on a support composed of a manganese oxide and an aluminum oxide, and which satisfies at least one of characteristics (1) and (2): (1) the catalyst being treated with an aqueous alkaline solution and subsequently subjected to calcination treatment in the air at 150 to 500° C., (2) the aluminum oxide being an aluminum oxide wherein pore volume formed by pores having a pore diameter of 8 nm or more accounts for 50% or more of total pore volume.

Owner:JAPAN OIL GAS & METALS NAT CORP +1

Manganese-based composite oxide catalyst for catalytically decomposing ozone, and preparation method of manganese-based composite oxide catalyst

ActiveCN102600861AAchieve decentralizationAchieve catalytic effectDispersed particle separationPerfluorocarbons/hydrofluorocarbons captureAir treatmentHydrothermal synthesis

The invention relates to a manganese-based composite oxide catalyst for catalytically decomposing ozone, and a preparation method of the catalyst. The catalyst comprises manganese oxide and at least one transition metal oxide. The preparation method is a homogeneous precipitation method or a hydrothermal synthesis method. The manganese-based composite oxide catalyst adopts innocuous and non-poisonous materials, prepares a manganese-based composite oxide catalyst with high catalytic activity, good wet resistance and high catalytic deposition content by the simple and easy method, so that the catalyst is suitable for catalytically decomposing ozone produced in water or air treatment and modern industry and home appliance.

Owner:上海棕晟企业管理合伙企业(有限合伙)

Bifunctional layered photocatalyst/thermocatalyst for improving indoor air quality

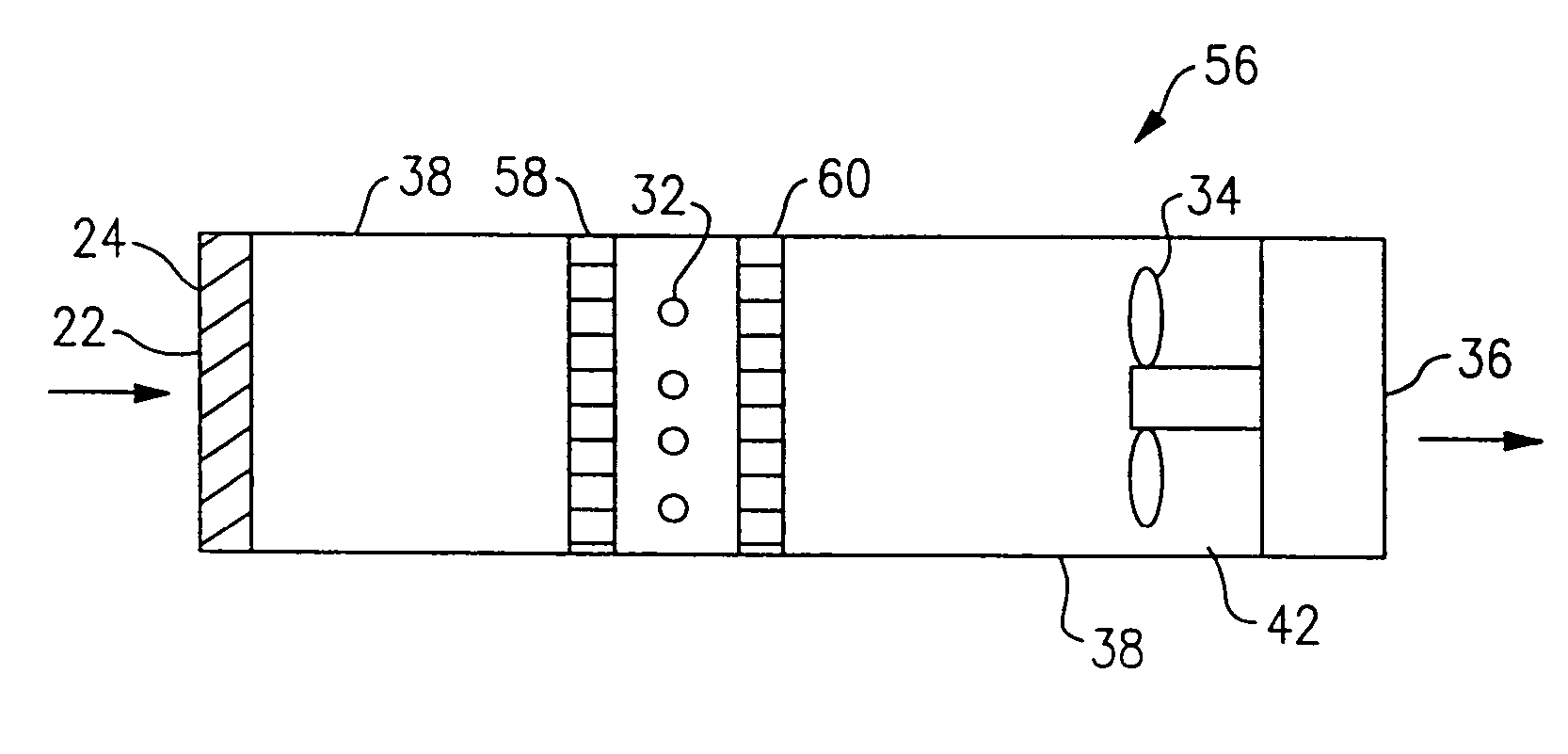

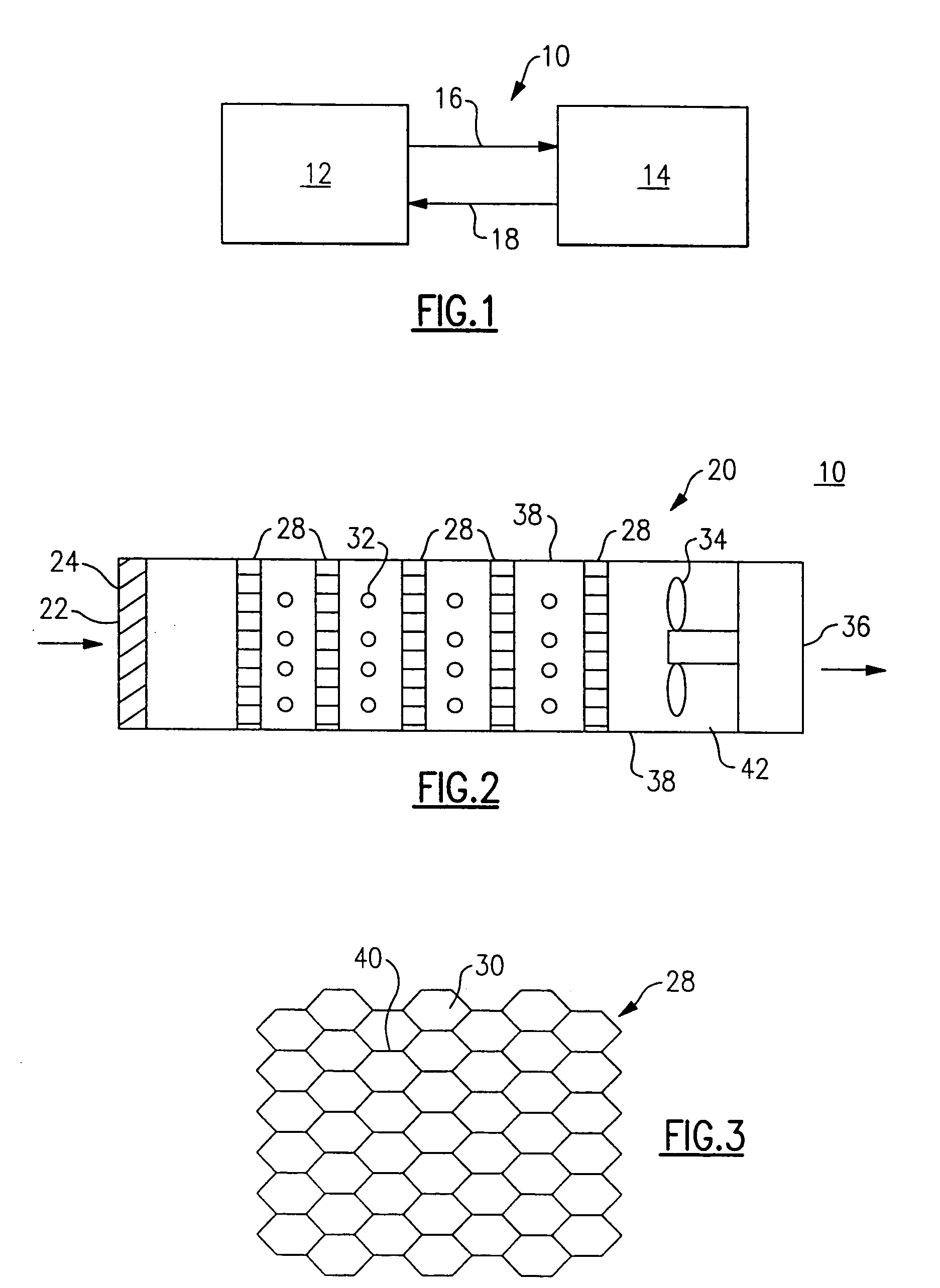

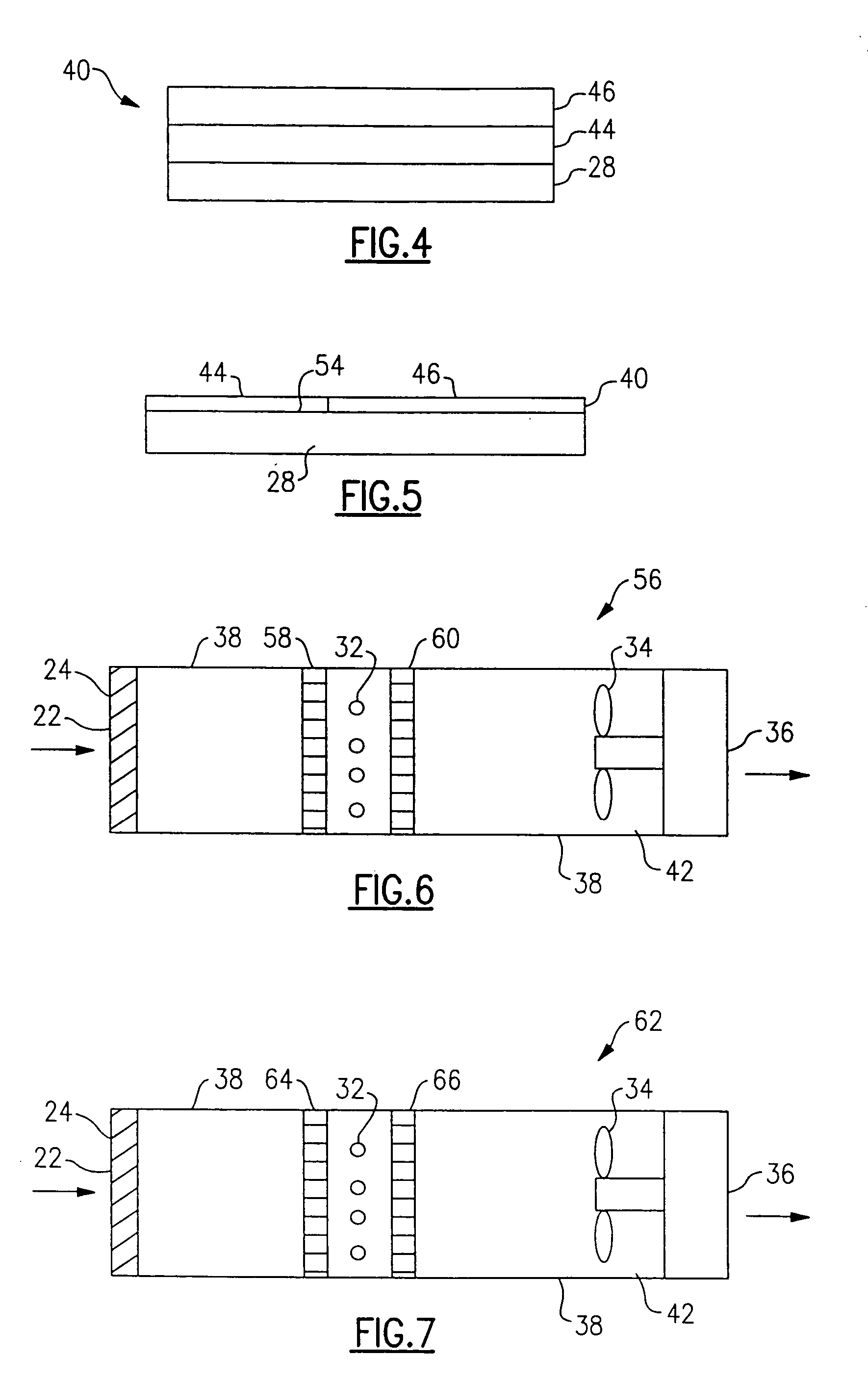

InactiveUS20050129591A1Lower energy barrierMechanical apparatusAir-treating devicesIndoor air qualityBifunctional

A photocatalytic / thermocatalytic coating includes an inner layer of metal / titanium dioxide or metal oxide / titanium dioxide that is applied on a honeycomb and an outer layer of titanium dioxide or metal oxide doped titanium dioxide applied on the inner layer. The inner layer of can be gold / titanium dioxide, platinum / titanium dioxide, or manganese oxide / titanium dioxide. The outer layer of titanium dioxide or metal oxide doped titanium dioxide oxides volatile organic compounds to carbon dioxide, water, and other substances. As the outer layer is thin and porous, the contaminants in the air can diffuse through the outer layer and adsorb onto the inner layer. When photons of the ultraviolet light are absorbed by the coating, reactive hydroxyl radicals are formed that oxidize the contaminant to produce water, carbon dioxide, and other substances.

Owner:CARRIER CORP

Method for preparing nickel and cobalt doped lithium manganate by using waste and old lithium ionic cell as raw material

InactiveCN101450815ASimultaneous recyclingShort processManganates/permanganatesManganateManganese oxide

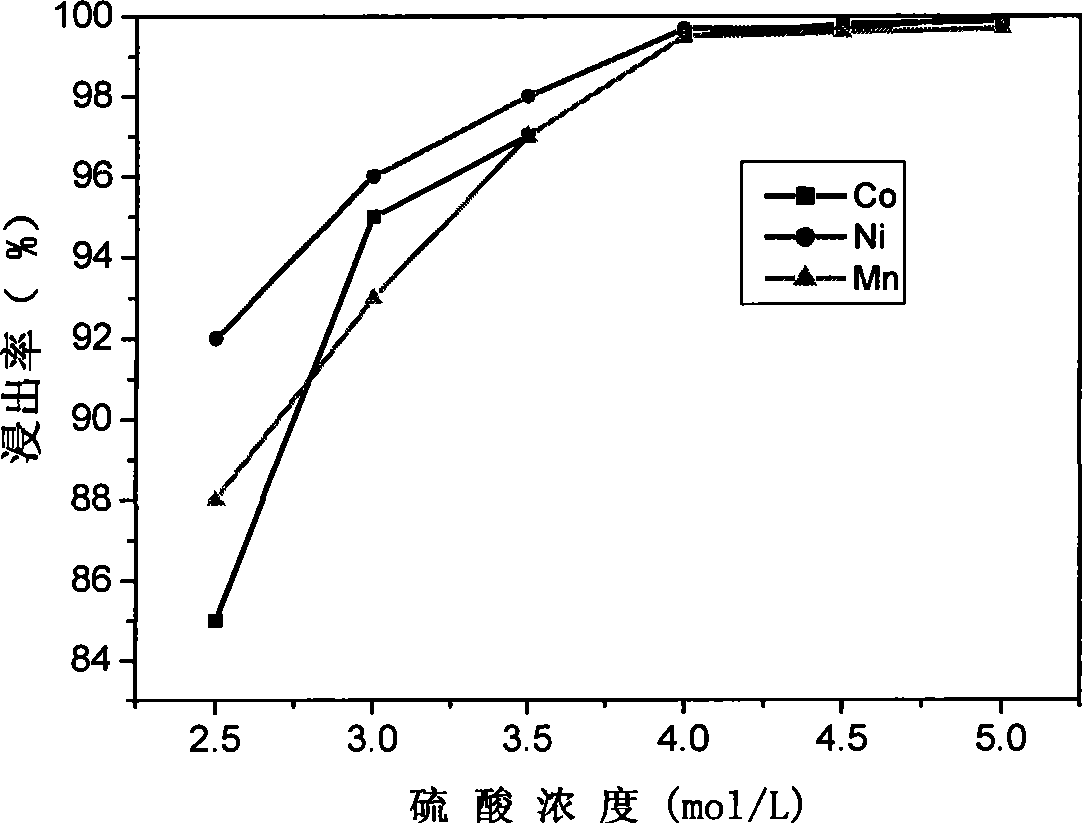

The invention discloses a method for preparing lithium nickel cobalt manganese oxide by taking a waste lithium ion battery as a raw material. The method is mainly characterized in that a waste lithium ion battery taking the lithium nickel cobalt manganese oxide, lithium nickel cobalt oxide and so on as a battery positive material is selected as the raw material and is pretreated through disassembly, separation, crushing, screening and so on, and then processes such as adhesive removal at high temperature and aluminum removal by sodium hydroxide are adopted to obtain an inactivated positive material containing nickel, cobalt and manganese; then a sulfuric acid and hydrogen peroxide system is adopted to leach, and P204 is adopted to remove impurities by extraction to obtain pure nickel, cobalt and manganese solution, and proper manganese sulfate, nickel sulfate or cobalt sulfate is blended to ensure that the mol ratio of nickel, cobalt and manganese elements in the solution is 1: 1: 1; and then ammonium carbonate is adopted to adjust the pH value to form a nickel cobalt manganese carbonate precursor, and then a proper amount of lithium carbonate is blended for high temperature sintering to synthesize a lithium nickel cobalt manganese oxide battery material. The first discharge capacity of the material is 150 mAh / g, the discharge capacity is still kept more than 130mAh / g after the circulation for 30 times, and the material has good electrochemical performance.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

Composite oxide catalyst for cryogenic selective catalystic reductic oxide nitrogen

InactiveCN101028594AEasy to makeEasy to operateCatalyst carriersDispersed particle separationManganese oxideNitrogen gas

A composite oxide catalyst for removing NOx from the tail gas generated by combustion through low-temp selective catalytic reduction reaction in which ammonia gas or urea is used as reducing agent for reducing the NOx into N2 and H2O is prepared from a composite metallic oxide (whose main component is manganese oxide) and a porous inorganic oxide as carrier through citric acid complexing method.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

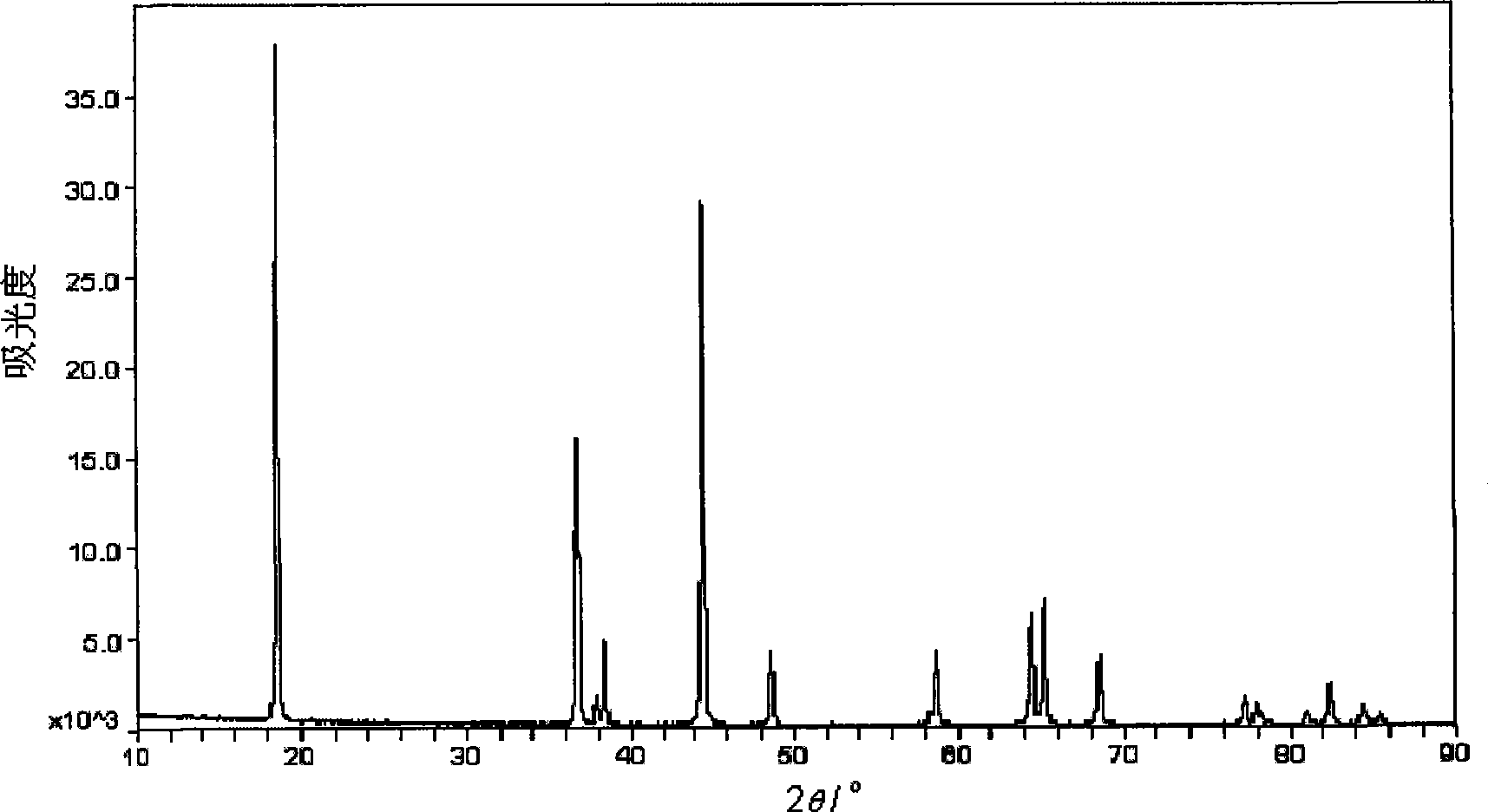

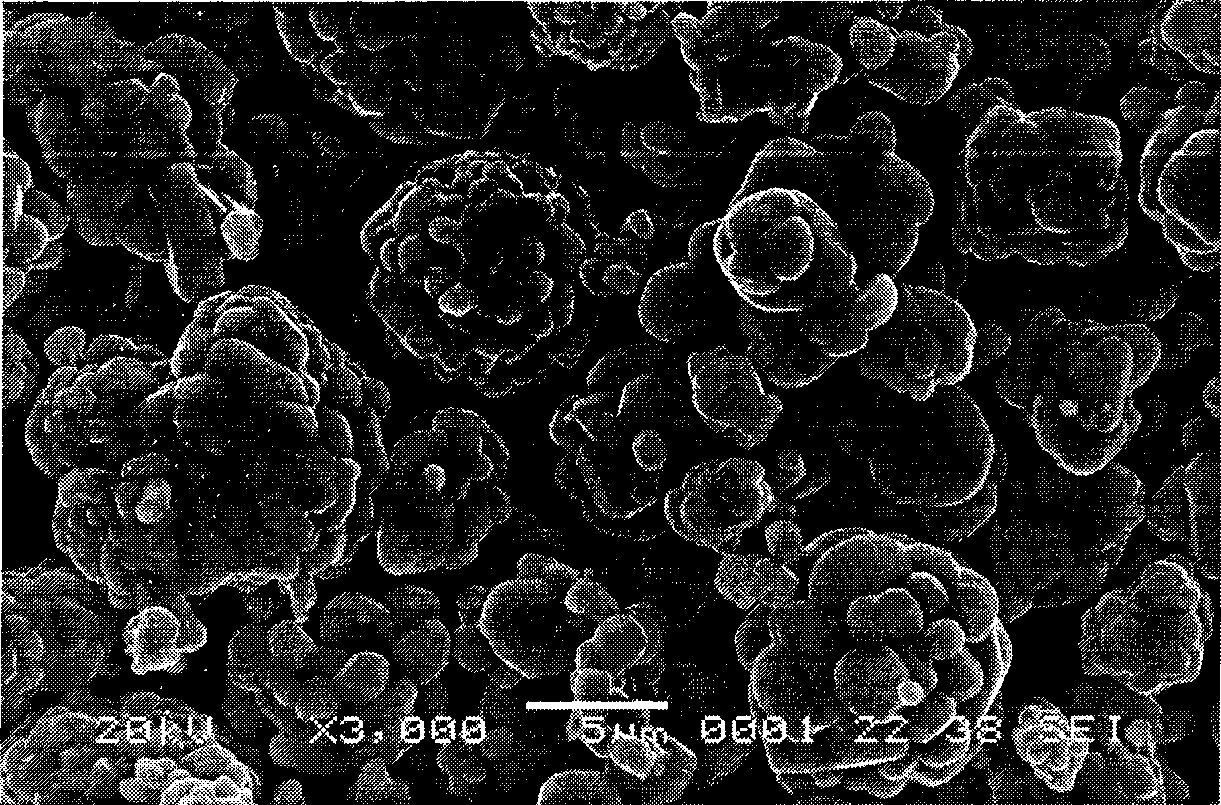

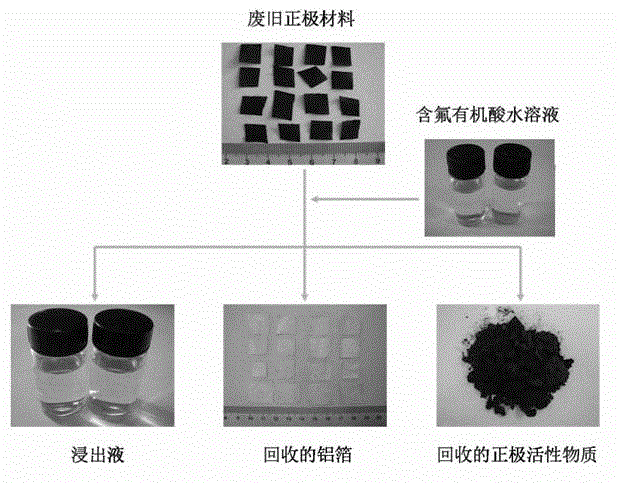

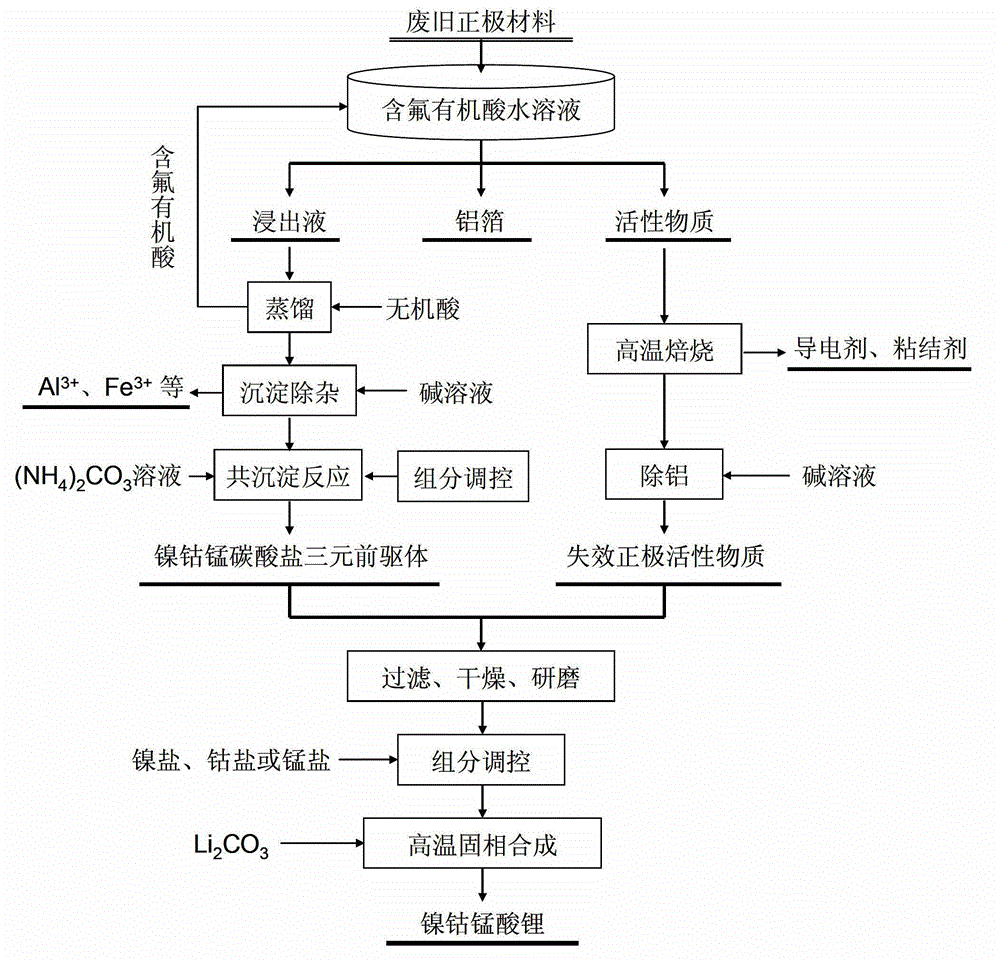

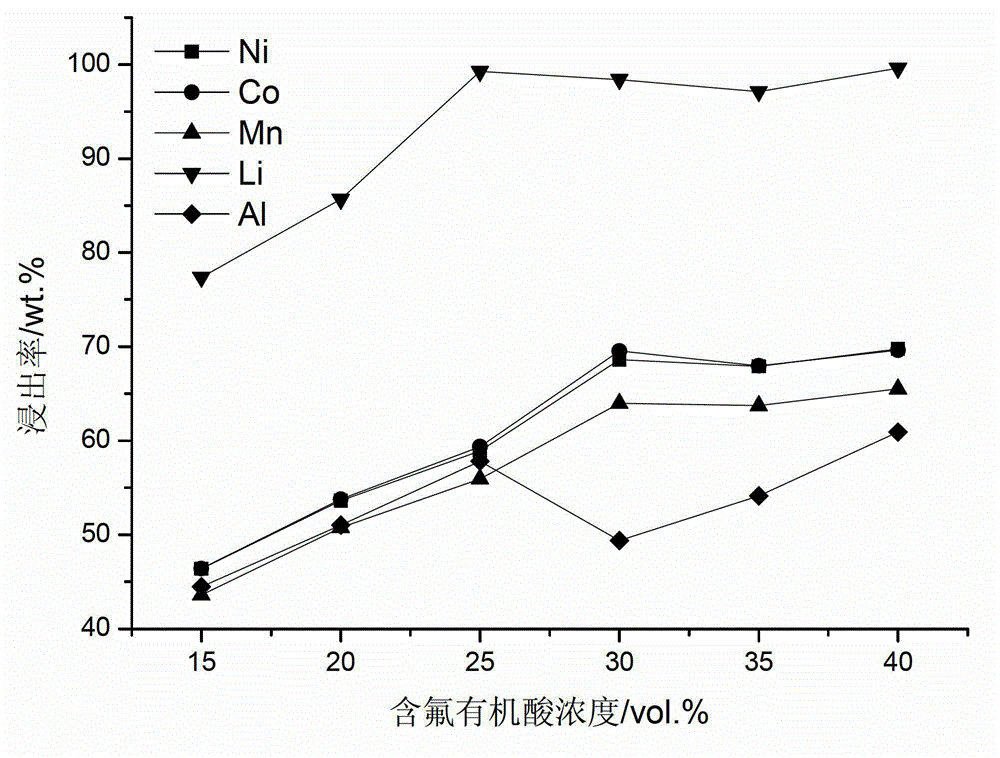

Full-component resource reclamation method for waste positive electrode materials of lithium ion batteries

ActiveCN102751549AAvoid secondary pollutionImprove separation efficiencyWaste accumulators reclaimingBattery recyclingRecovery methodDistillation

The invention provides a full-component resource reclamation method for waste positive electrode materials of lithium ion batteries. The method comprises the following steps: 1) separating active substances and aluminum foils in waste positive electrode materials of lithium ion batteries by using an aqueous solution of fluorine-containing organic acid and carrying out liquid-solid-solid separation so as to obtain leachate, the lithium-containing active substances and the aluminum foils; 2) respectively carrying out high temperature roasting and impurity removal with alkali liquor on the lithium-containing active substances; 3) respectively carrying out recovery of the fluorine-containing organic acid through addition of acid and distillation, deposition of impurity ions through addition of alkali and ammonium carbonate coprecipitation on the leachate so as to prepare nickel-cobalt-manganese carbonate ternary precursor; and 4) carrying out component regulation on a mixture of the treated active substances and the nickel-cobalt-manganese carbonate ternary precursor, adding lithium carbonate in a certain proportion and carrying out high temperature solid phase sintering so as to prepare a lithium nickel cobalt manganese oxide ternary positive electrode material. The method provided in the invention has the following advantages: the application scope of the method is wide; separation efficiency of the lithium-containing active substances and the aluminum foils is high; short-flow direct re-preparation of positive electrode materials in waste lithium ion batteries is realized; and the method is applicable to large-scale resource reclamation of waste lithium ion batteries.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

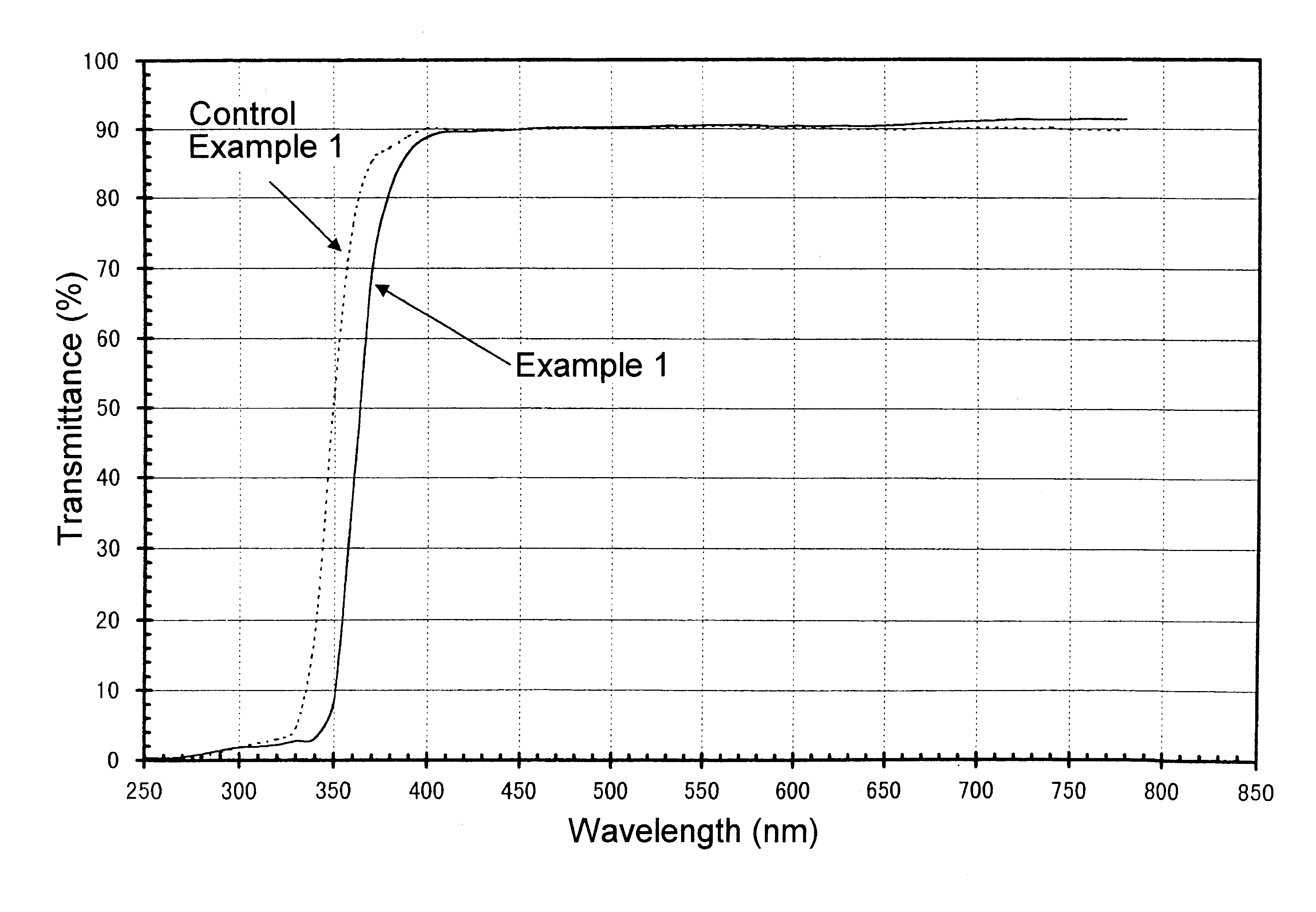

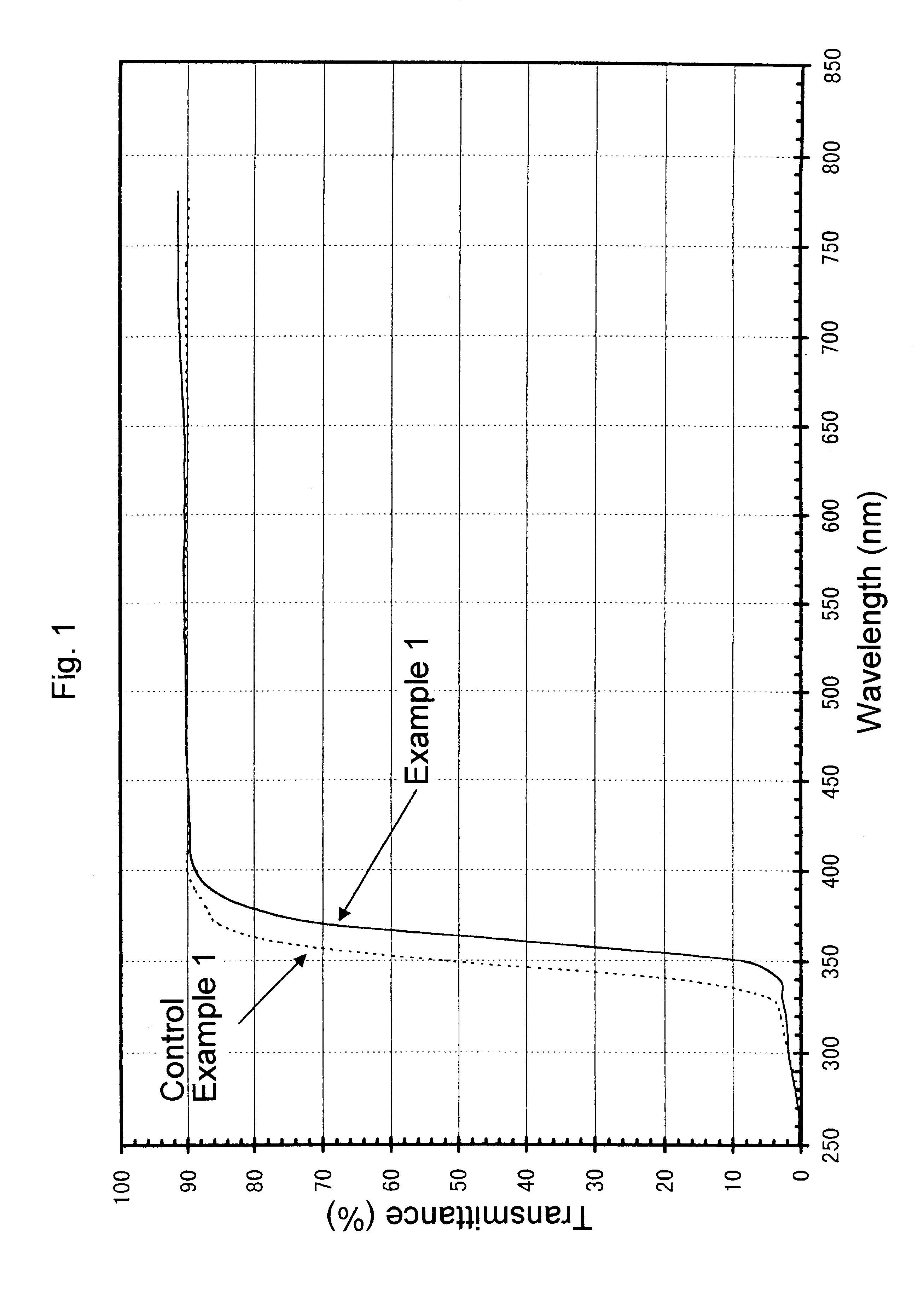

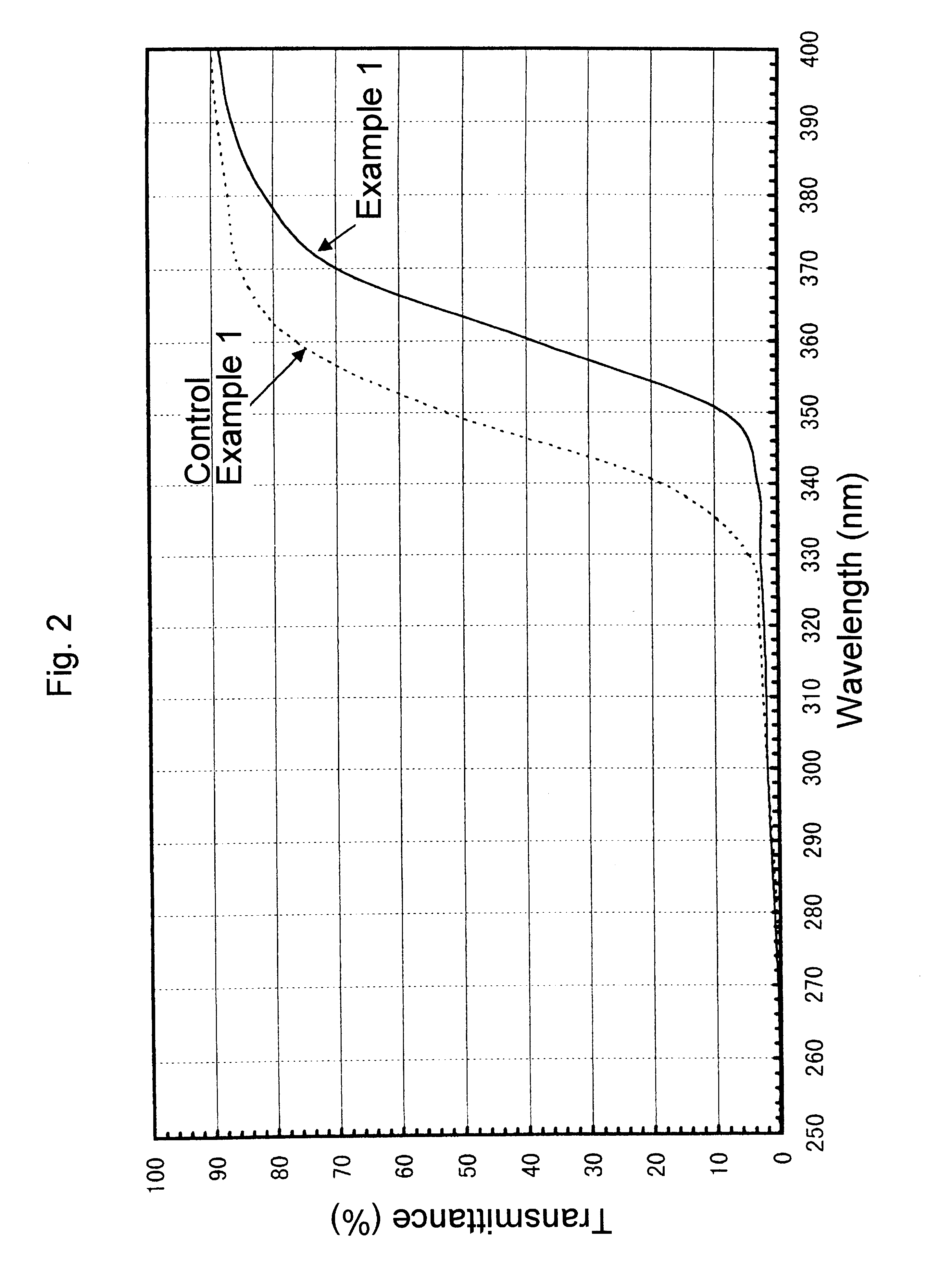

Ultraviolet radiation-absorbing, colorless, transparent soda-lime silica glass

An ultraviolet radiation-absorbing, colorless, transparent soda-lime-silica glass as well as glass bottles formed out of the glass are disclosed which, while maintaining high transmittance to light in the visible region and thereby allowing the contents to be seen clearly, absorbs ultraviolet radiation and thus prevents coloration, discoloration, fading in color or deterioration of the flavor of the contents caused by ultraviolet radiation. The glass is characterized in that its composition includes, in % by weight, SO3 . . . 0.15-0.4%; Cerium oxide . . . 0.2-1% (calculated as CeO2); Fe2O3 . . . 0.01-0.08%; FeO . . . 0-0.008%; Manganese oxide . . . 0.01-0.08% (calculated as MnO); and Cobalt oxide . . . 0-0.0005% (calculated as CoO).

Owner:NIHON YAMAMURA GLASS CO LTD

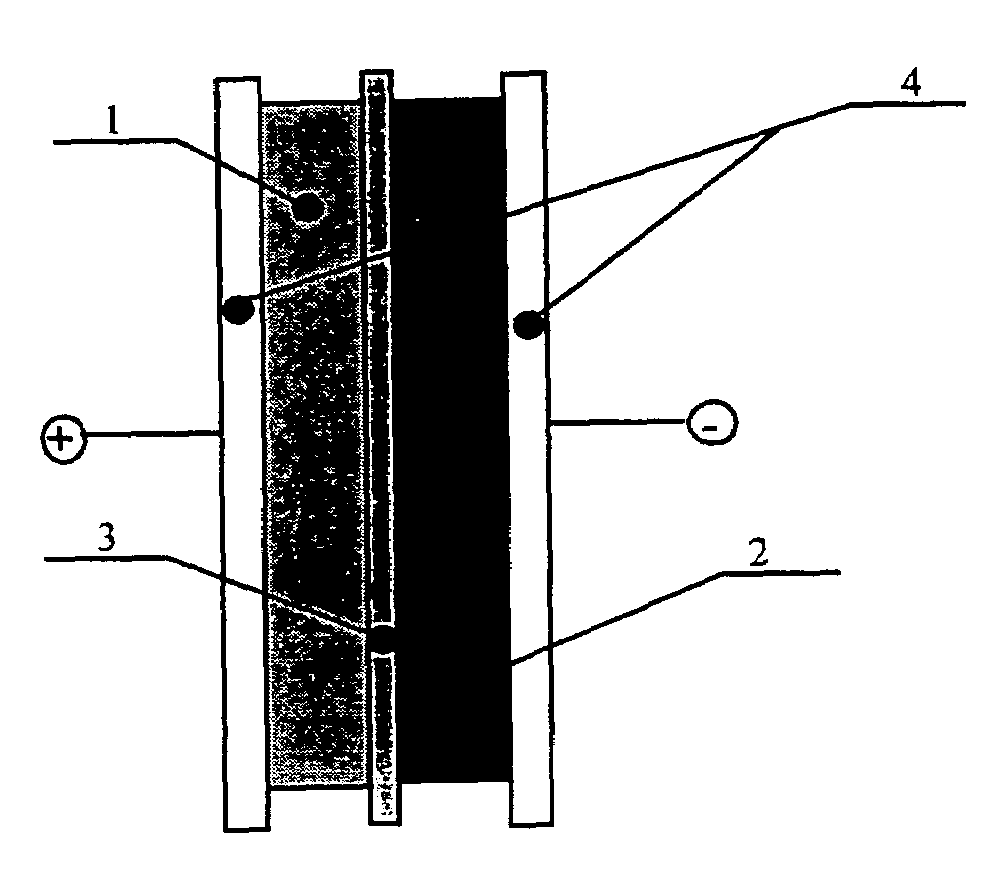

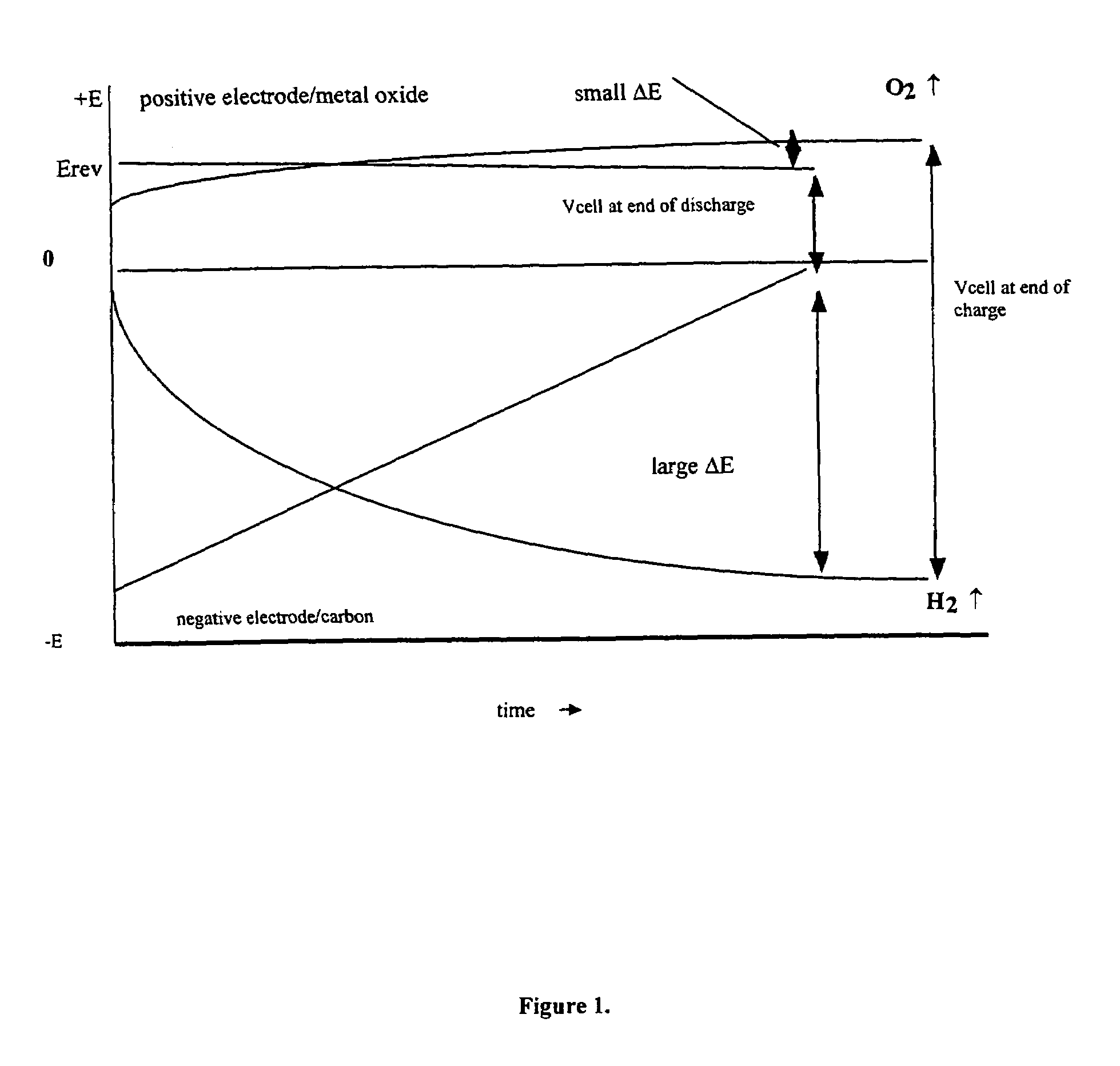

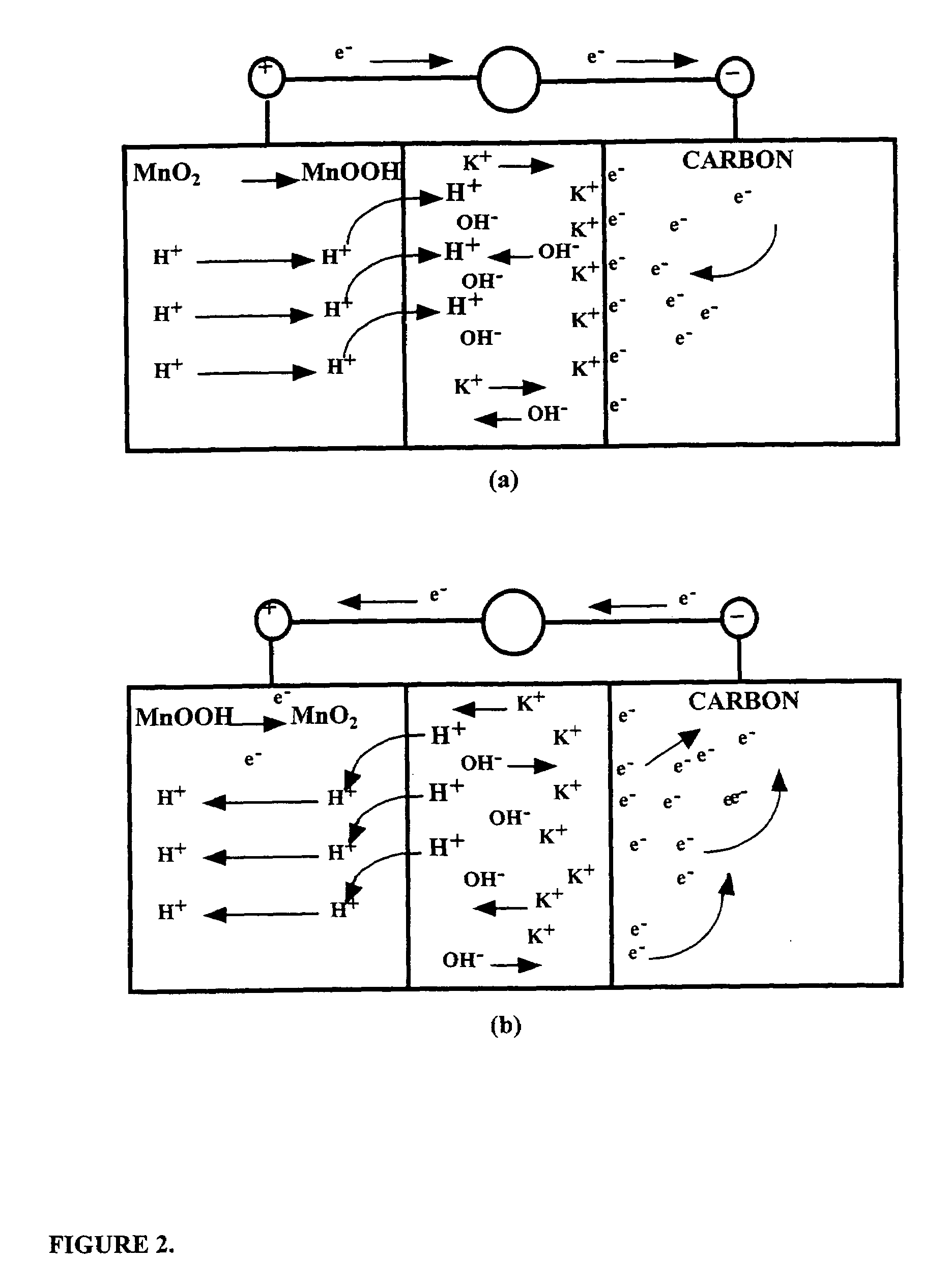

Asymmetric electrochemical supercapacitor and method of manufacture thereof

InactiveUS7199997B1Increase energy densityImprove power densityHybrid capacitor electrodesLiquid electrolytic capacitorsFiberCharge separation

An asymmetric supercapacitor has a positive electrode having a current collector an active material selected from the group consisting of manganese dioxide, silver oxide, iron sulfide and mixtures thereof, a negative electrode having a carbonaceous active material carbon and optional current collector, an electrolyte, and a separator plate. In a preferred embodiment at least one of the electrodes has nanostructured / nanofibrous material and in a more preferred embodiment, both electrodes have nanostructured / nanfibrous material. The electrolyte can be liquid or solid although liquid electrolytes are preferred.The asymmetric supercapacitor has improved energy density by electrically coupling an electrode of high faradaic capacity such as one having manganese oxide (MnO2) with an electrode such as carbon that stores charge through charge separation at the electric double-layer. The asymmetric supercapacitor also improves power density by using high surface area nanostructured / nanofibrous electrode materials.

Owner:U S NANOCORP +1

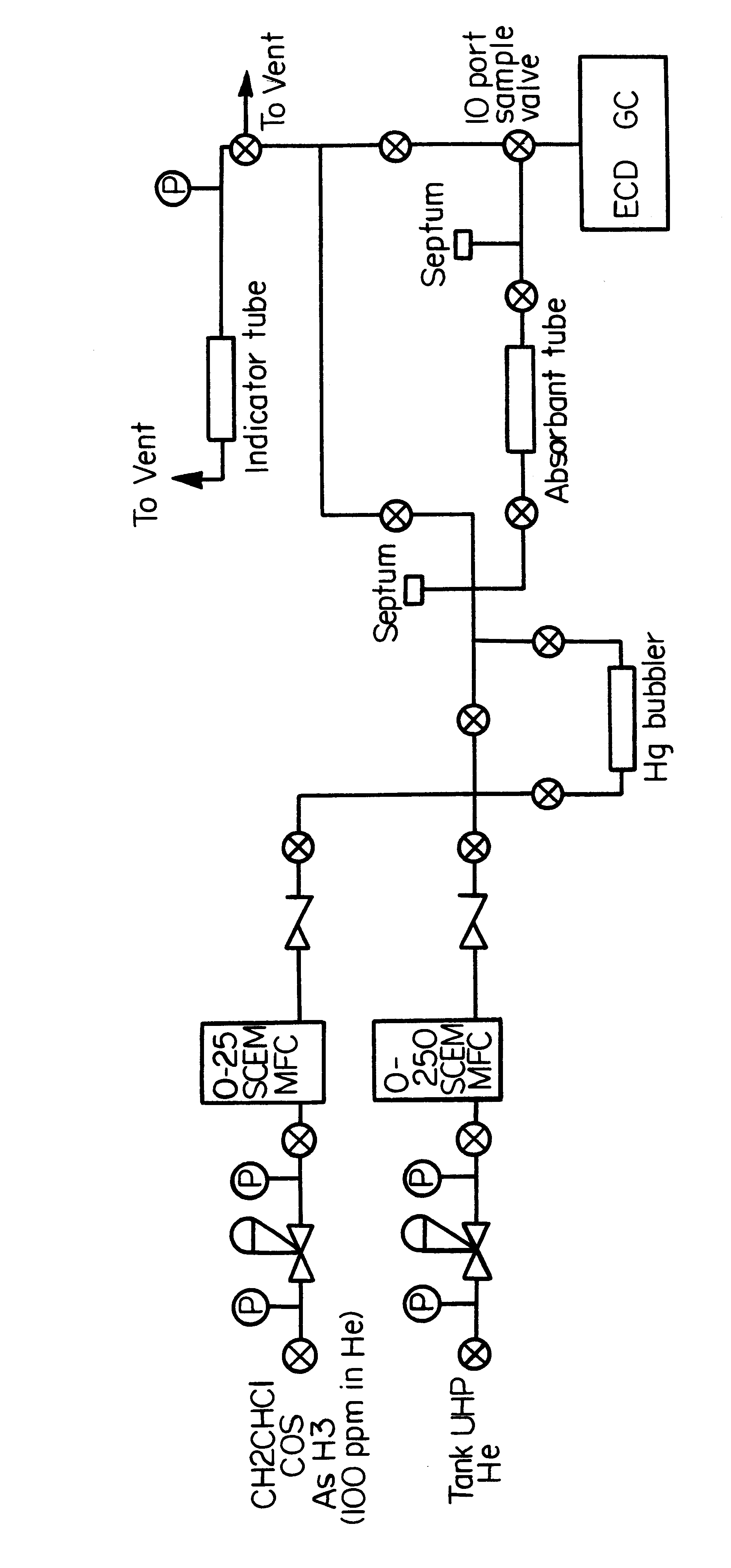

Adsorbent for the removal of trace quantities from a hydrocarbon stream and process for its use

An adsorbent product for the adsorption of trace elements of sulfur, arsenic, mercury, compounds which contain these elements or metal hydrides from a hydrocarbon gas stream, preferably an olefinic or paraffinic stream, wherein the adsorbent product is iron oxide and manganese oxide placed on a support material, preferably aluminum oxide. Also disclosed is a process for the use of this adsorbent product for the removal of trace elements of arsenic, mercury and sulfur or compounds containing those elements or metal hydrides from a hydrocarbon gas stream, preferably an olefinic or paraffinic gas stream.

Owner:UNITED CATALYSTS INC

Manganese oxide based materials as ion intercalation hosts in lithium batteries

InactiveUS20050135993A1Enhances electrochemical property and performance of materialImprove stabilityActive material electrodesManganese oxides/hydroxidesRechargeable cellPERMANGANATE ION

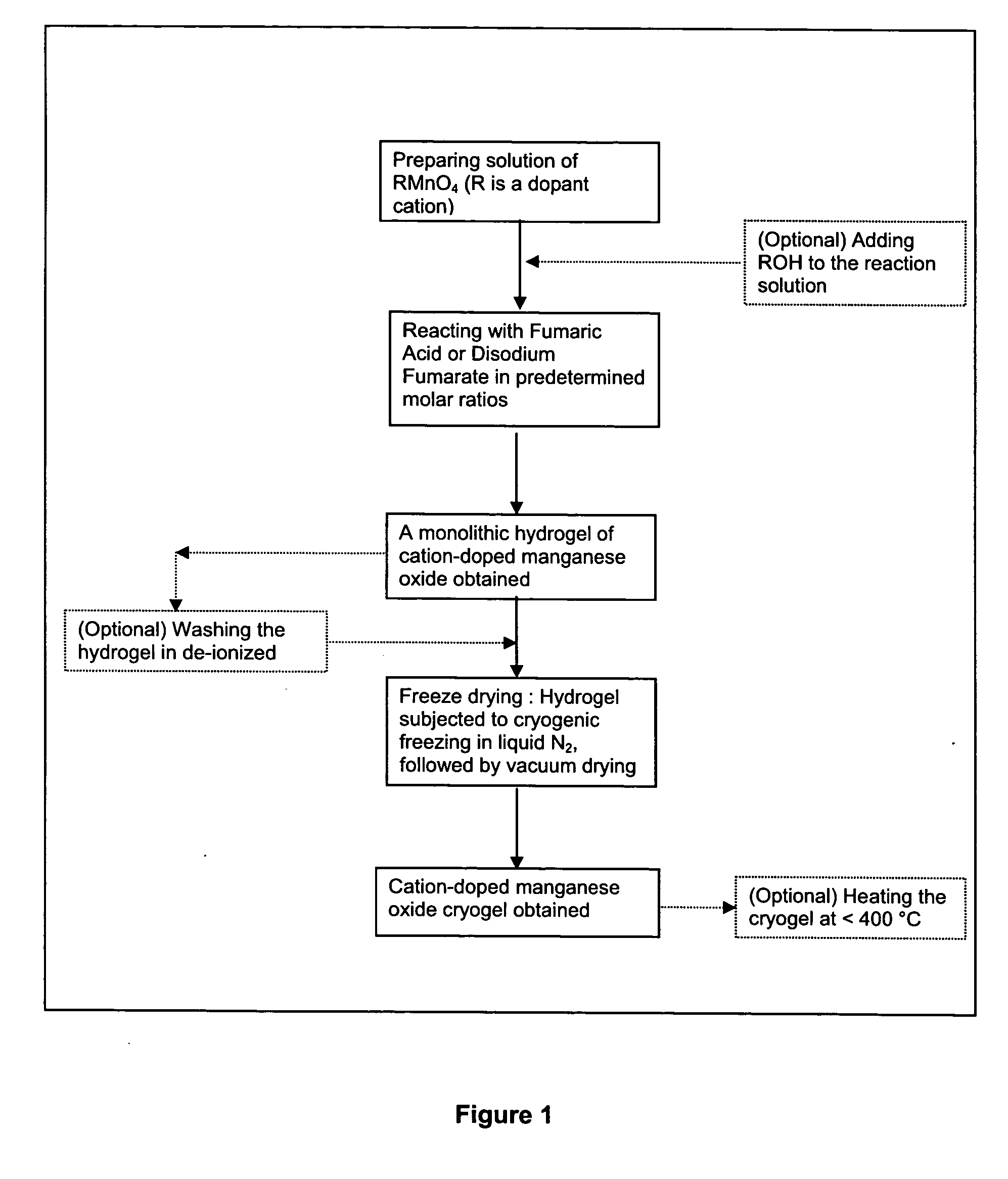

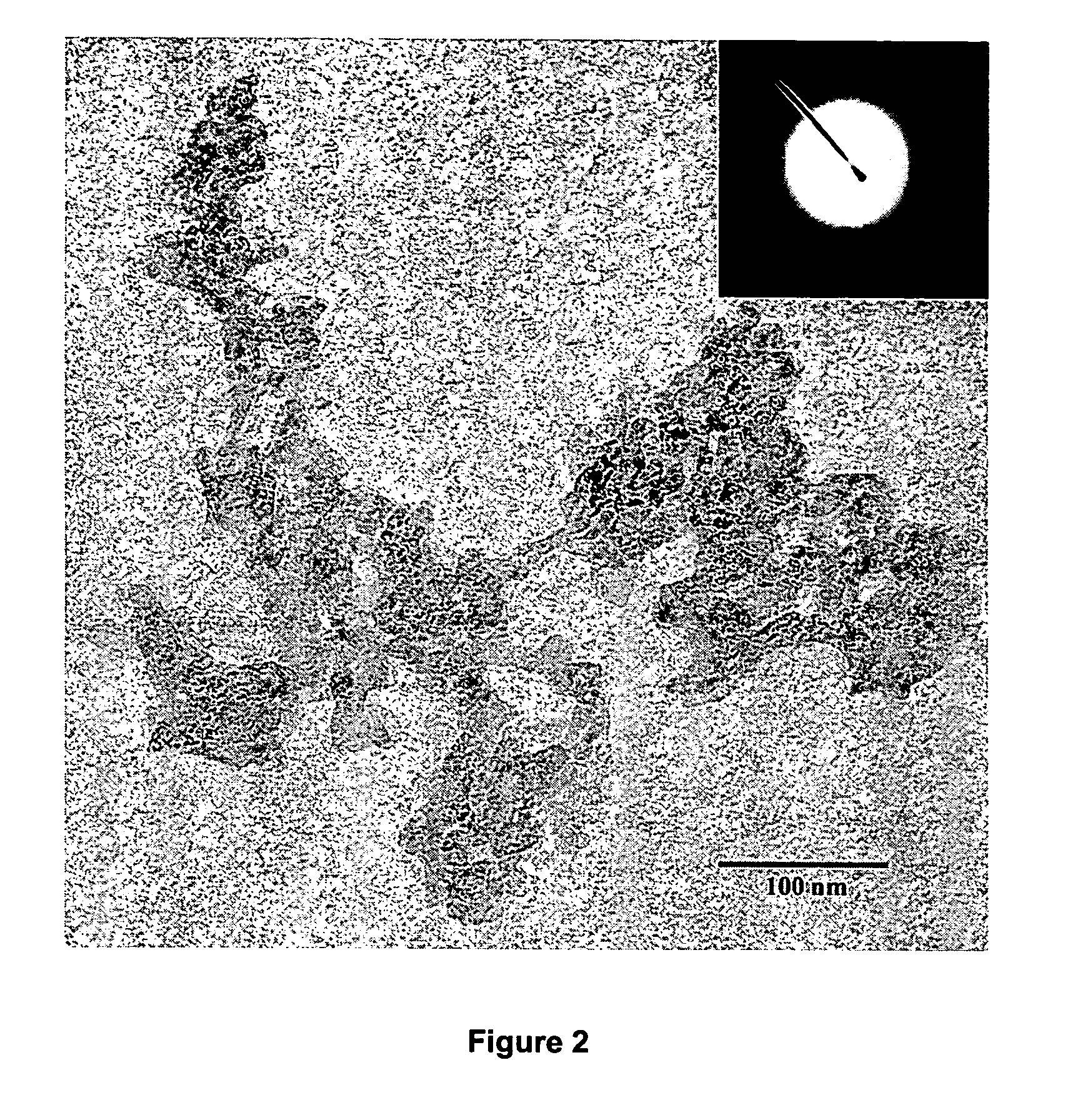

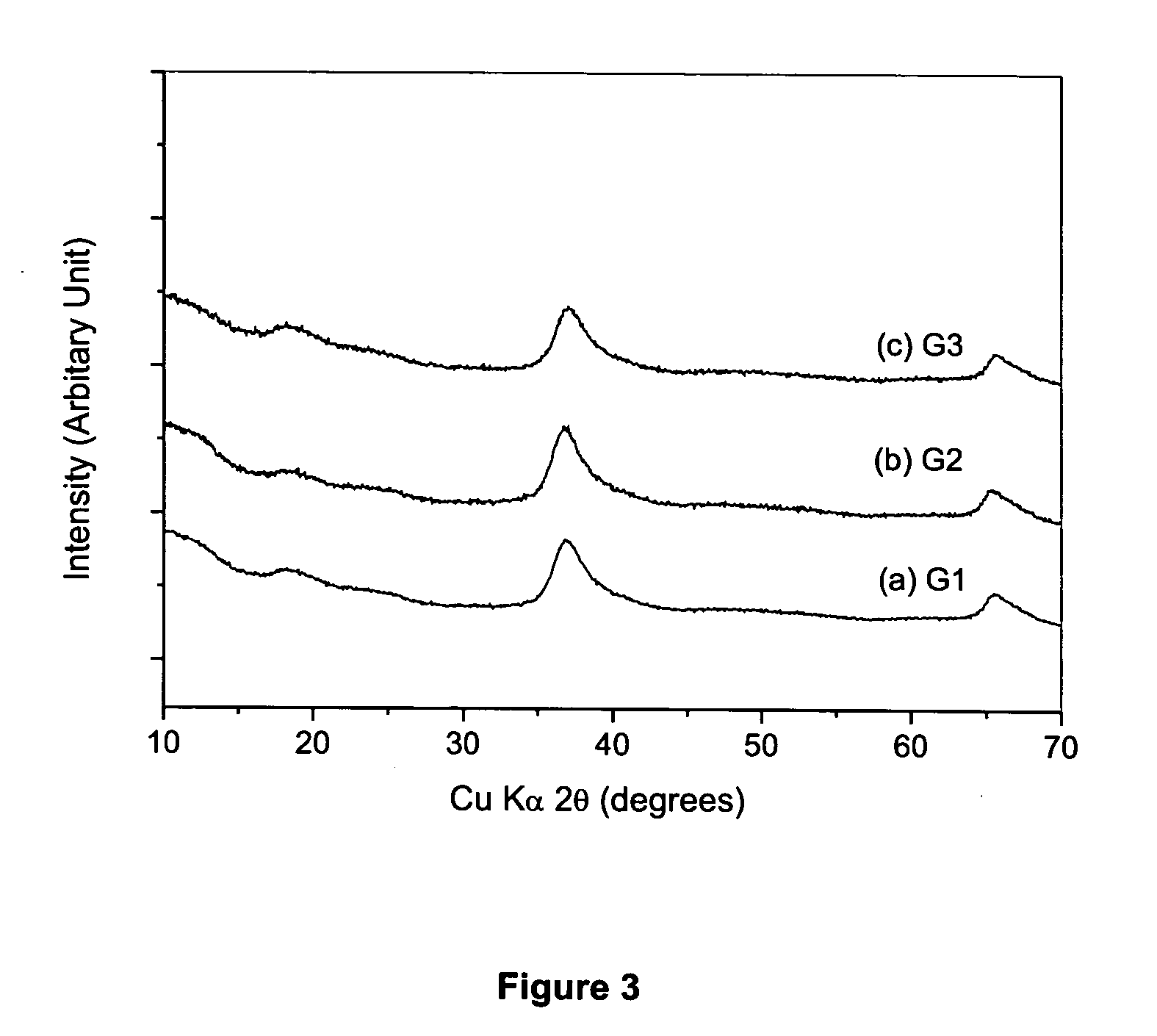

The present invention is directed to a process for making an amorphous nanostructured cation-doped manganese oxide material useful as an ion intercalation host for rechargeable batteries, including the steps of preparing a solution containing cation permanganate combined optionally with a cation donor compound, mixing the solution with a reducing agent to yield a hydrogel comprising a manganese oxide compound, cryogenically freezing the hydrogel, drying the frozen gel to yield a cryogel amorphous nanostructured cation-doped manganese oxide, and heat treating the dried cryogel.

Owner:RUTGERS THE STATE UNIV

Electrodes comprising mixed active particles

ActiveUS7041239B2Improve cycle performanceHigh capacity retentionConductive materialOxide conductorsChemical compositionManganese oxide

Electrode active materials comprising two or more groups of particles having differing chemical compositions, wherein each group of particles comprises a material selected from:(a) materials of the formula A1aM1b(XY4)cZd; and(b) materials of the formula A2eM2fOg; andwherein(i) A1, A2, and A3 are Li, Na, or K;(ii) M1 and M3 comprise a transition metal;(iv) XY4 a phosphate or similar moiety; and(v) Z is OH, or halogen.In a preferred embodiment, A2eM3fOg is A3hMniO4 having an inner and an outer region, wherein the inner region comprises a cubic spinel manganese oxide, and the outer region comprises a manganese oxide enriched in Mn+4 relative to the inner region. In a preferred embodiment, the compositions also comprise a basic compound.

Owner:LITHIUM WERKS TECH BV +1

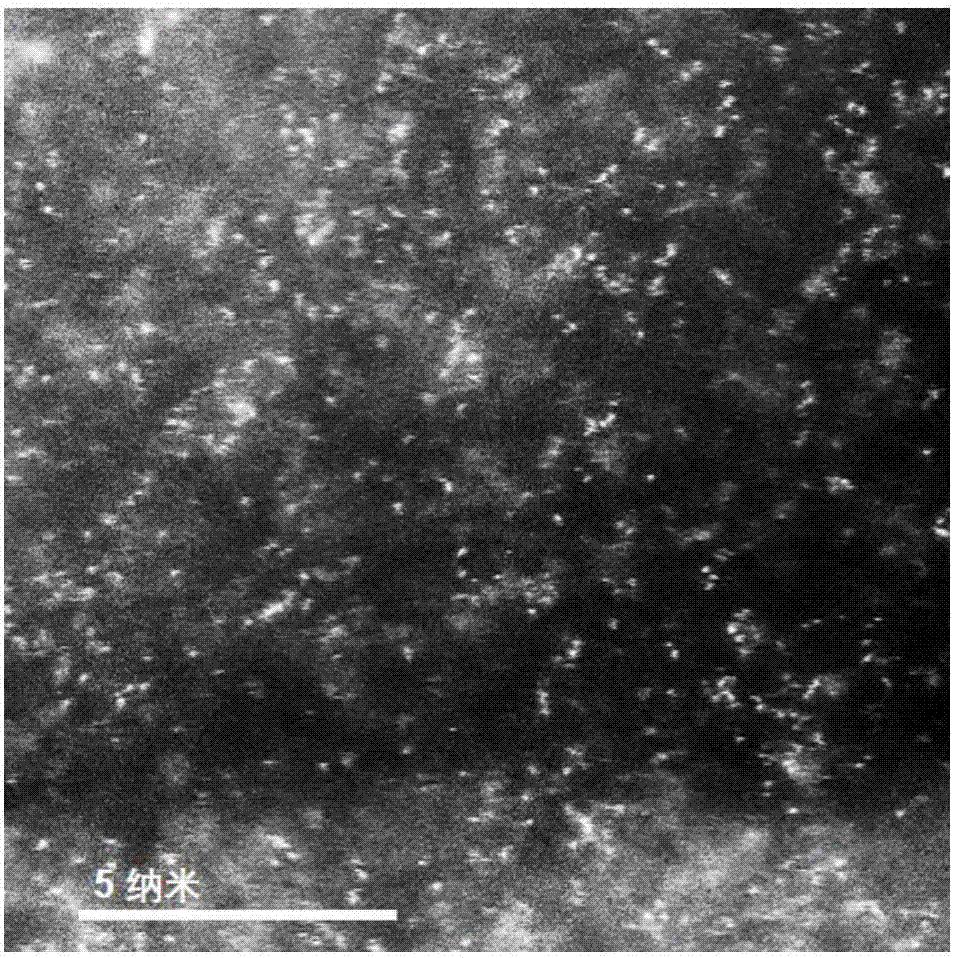

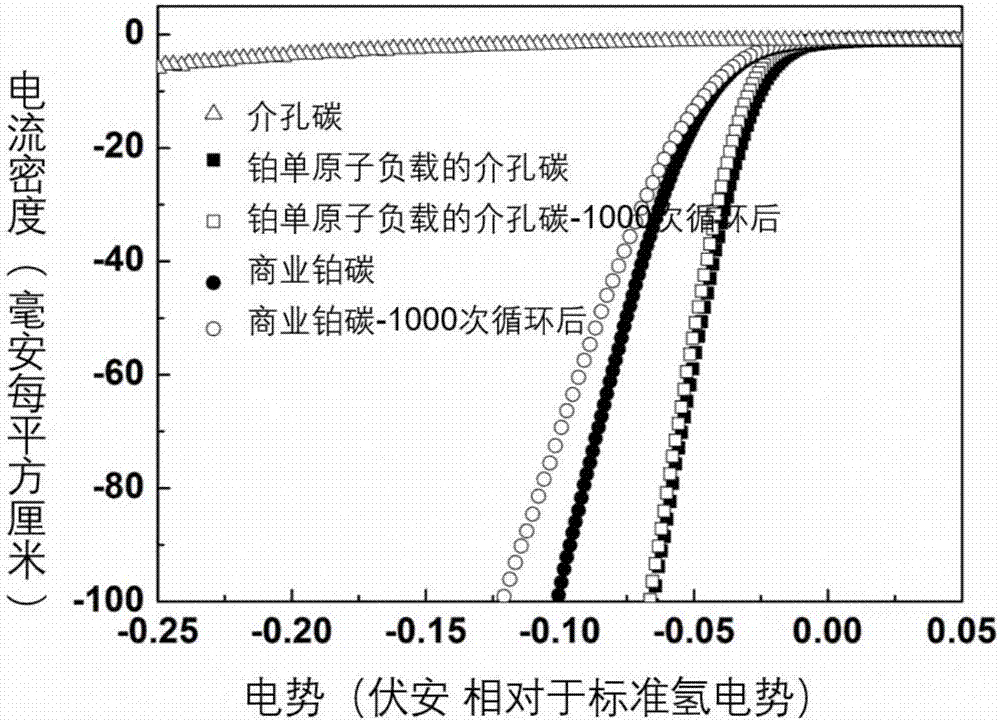

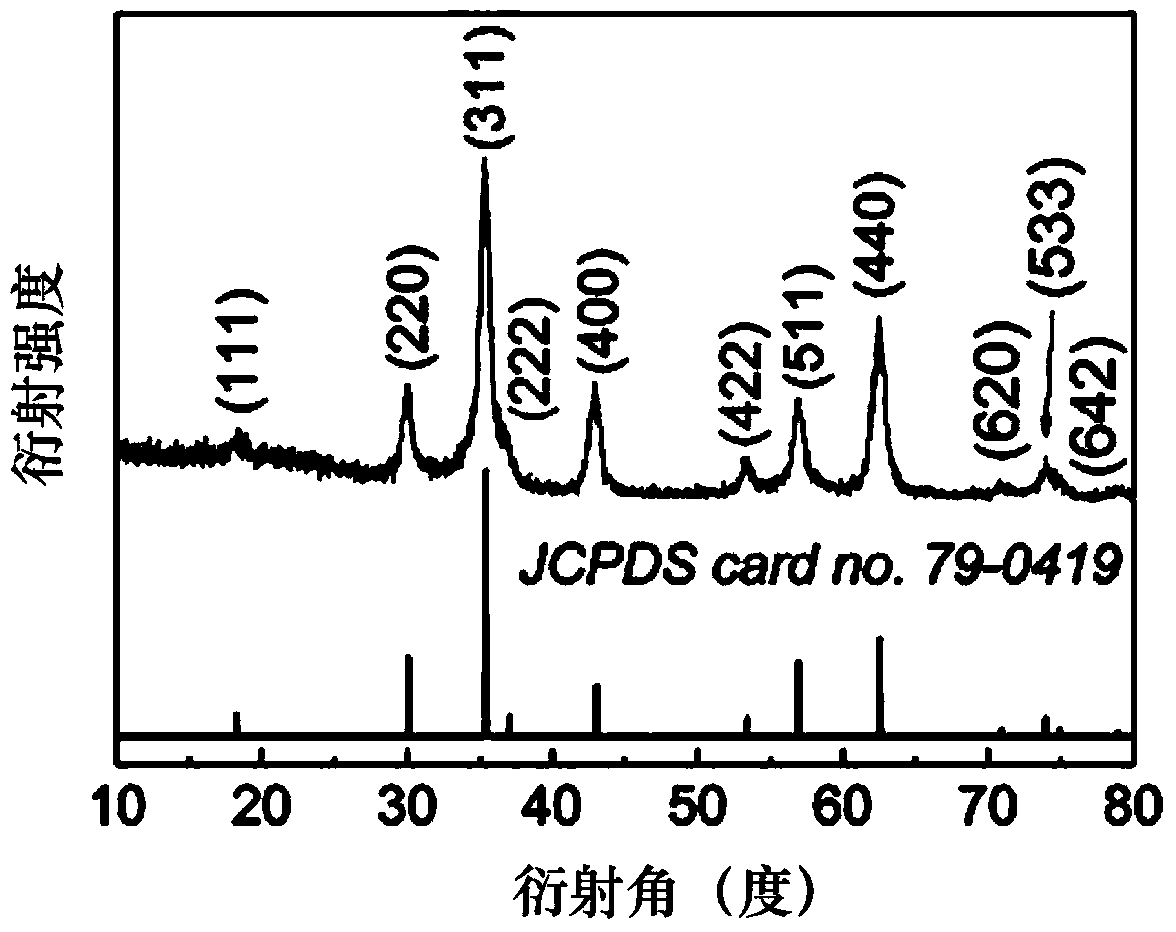

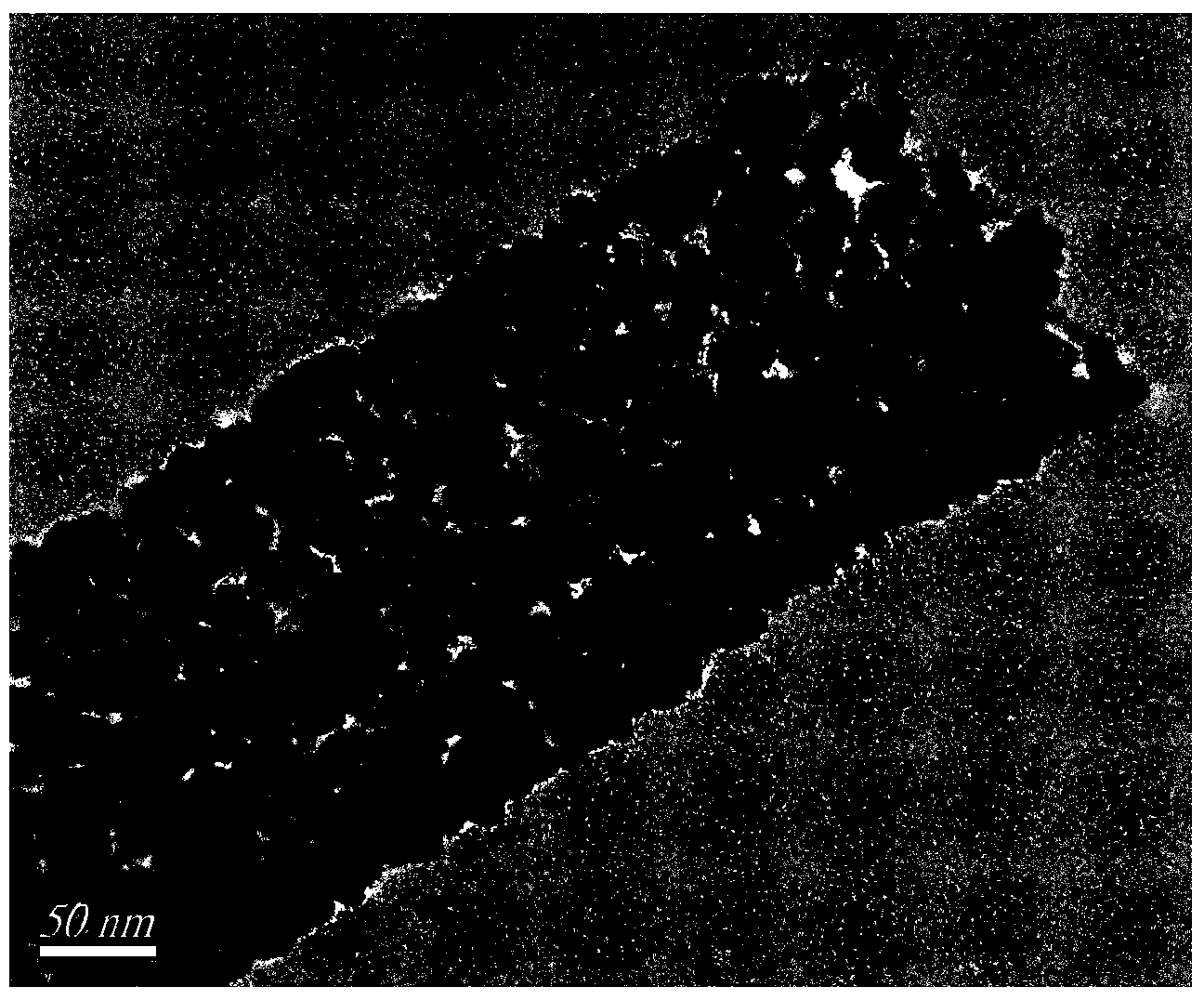

Preparation method of metal mono-atoms

ActiveCN106914237AImprove performanceLow costMolecular sieve catalystsMetal/metal-oxides/metal-hydroxide catalystsCarbon filmFiltration

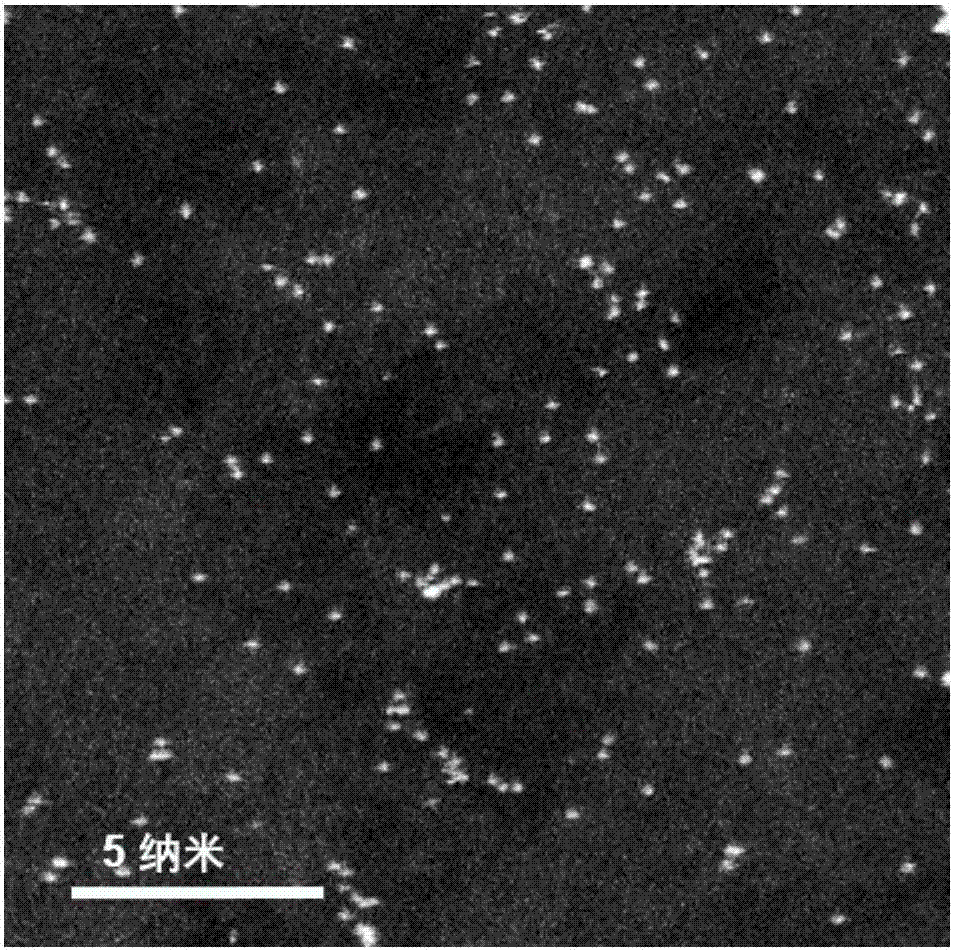

The invention relates to a preparation method of metal mono-atoms and belongs to the technical field of materials science and engineering. The metal mono-atoms prepared through the method may include: Pt, Ag, Au, Pd, Rh, Ir, Ru, Co, Ni and Cu, and metal mono-atoms supported on TiO2, zinc oxide, cerium oxide, aluminum oxide, silicon oxide, ferric oxide, manganese oxide, C3N4, mesoporous carbon, ultrathin carbon films, graphene, carbon nano tubes or molecular sieve materials, etc. The method includes the steps of: preparing a precursor solution in a certain concentration, and freezing the solution; and under an ice phase, processing ice cubes by means of external field or reaction between reactants in the ice cubes, and when the ice cubes are molten, a mono-atom solution is finally produced; mixing the mono-atom solution with different materials, performing ultrasonic treatment, filtration, cleaning and drying to finally obtain the mono-atoms supported on various materials. The preparation method is quick, has high product density, allows mass production, is high in efficiency and has wide application range, and compared with a co-precipitation method and an impregnation method, the method has significant advantages.

Owner:TSINGHUA UNIV

Thermal protective coating for ceramic surfaces

ActiveUS6921431B2Extended shelf lifeConvenience to workFireproof paintsOther chemical processesColloidal silicaSodium Bentonite

A coating admixture, method of coating and substrates coated thereby, wherein the coating contains colloidal silica, colloidal alumina, or combinations thereof; a filler such as silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides, copper chromium oxides, cerium oxides, terbium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide is also added.

Owner:WESSEX

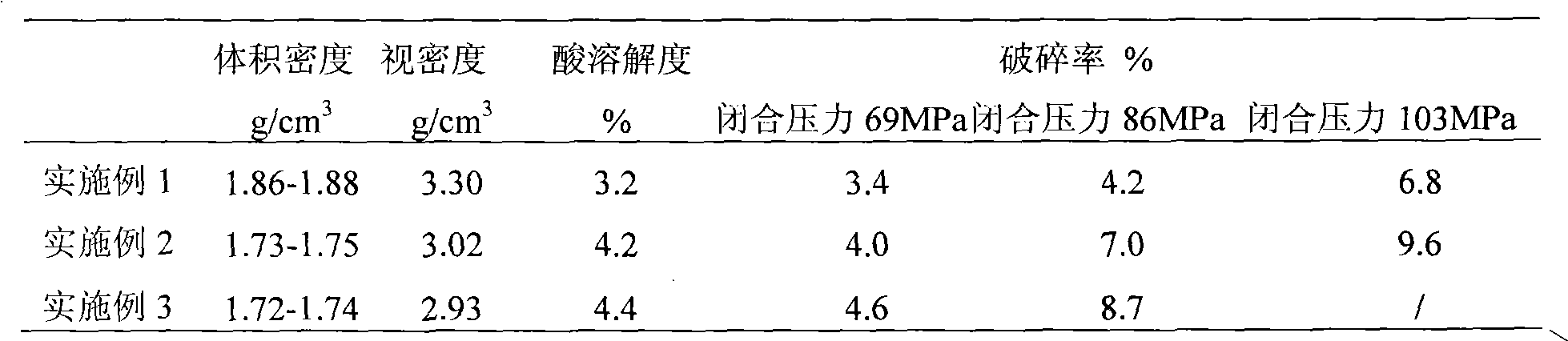

High-strength compress supporting agent for coarse oil and preparation method thereof

ActiveCN101575503AGood effectHas high strengthFluid removalDrilling compositionChemical compositionRed mud

The invention relates to a high-strength compress supporting agent for coarse oil and a preparation method thereof. The high-strength compress supporting agent for the coarse oil is prepared from the following raw materials by mass portion: 60 to 85 portions of ceramic roller waste, 1 to 20 portions of red mud, 0 to 20 portions of fly ash, 0 to 5 portions of manganese oxide or barium carbonate, 0 to 3 portions of dolomite and 5 to 10 portions of ceramic clay. The ceramic roller waste refers to corner waste or / and damaged and broken ceramic roller waste in the processing process of ceramic roller manufactures, and Al2O3 content of chemical compositions of the ceramic roller waste is not less than 68 percent. The high-strength compress supporting agent for the coarse oil prepared from the ceramic roller waste with high alumina content has the characteristics of high strength and acid resistance, and is used for oil fracturing in medium-deep wells; and the preparation method is simple and feasible, and is suitable for batch production.

Owner:JINGANG NEW MATERIALS

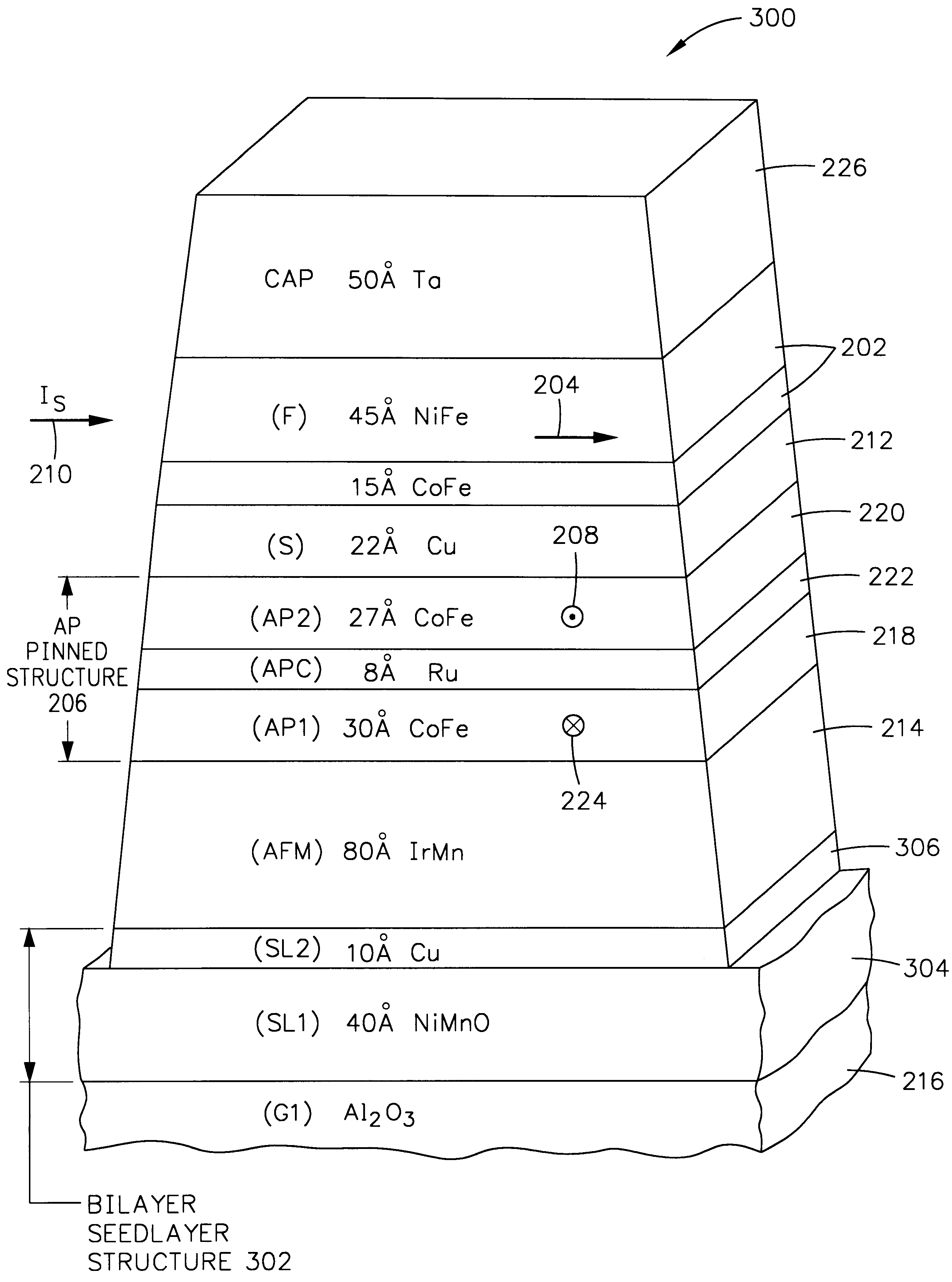

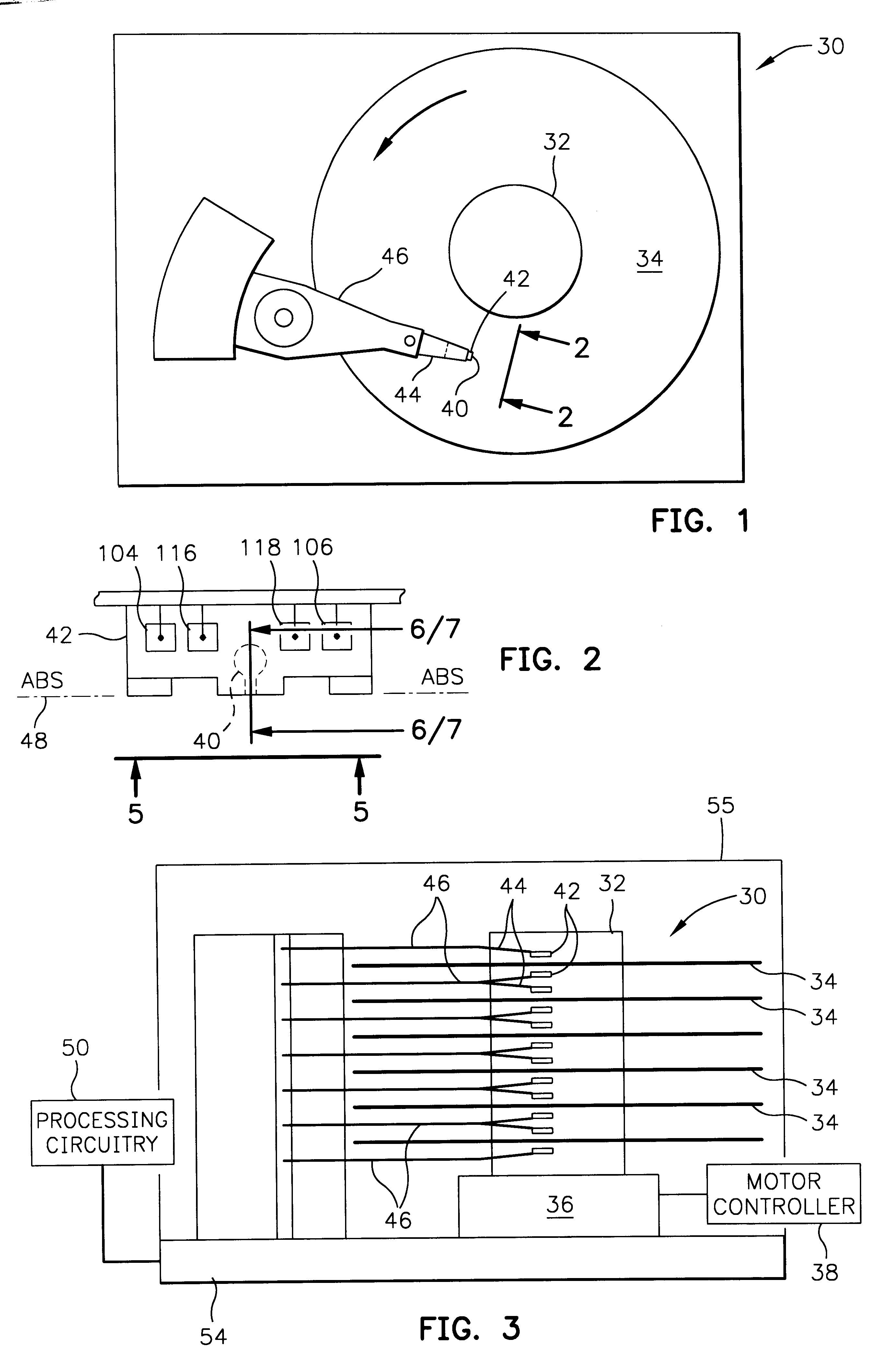

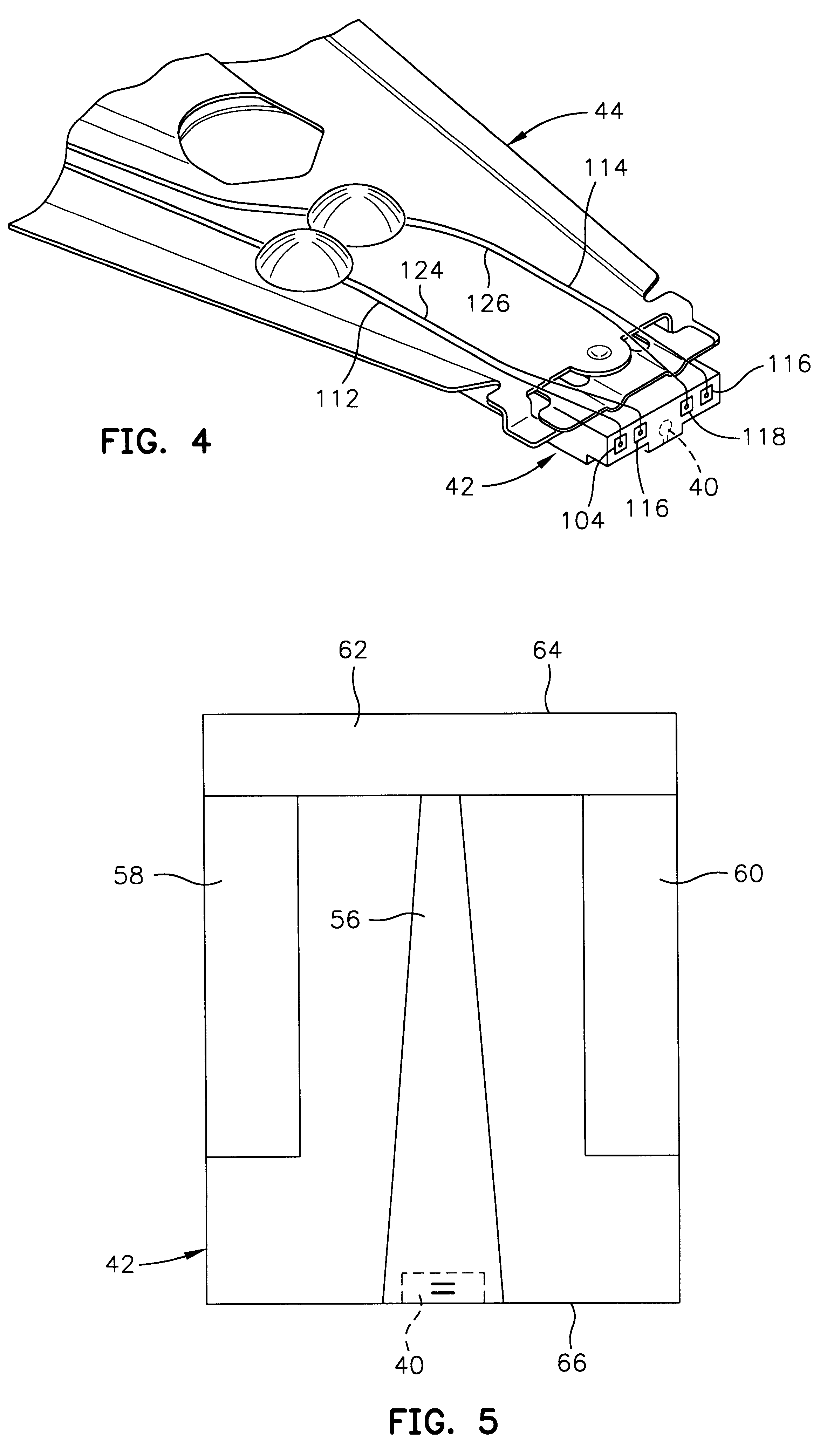

Seed layer structure for spin valve sensor

InactiveUS6208492B1Increase the gapImprove thermal stabilityNanomagnetismNanoinformaticsManganese oxideNickel

A bilayer seed layer structure is employed between a first read gap layer and a spin valve sensor for increasing the magnetoresistive coefficient (dr / R). In a bottom spin valve sensor the bilayer seed layer structure is located between the first read gap layer and a pinning layer and in a top spin valve sensor the bilayer seed layer structure is located between the first read gap layer and the free layer. The pinning layer is preferably iridium manganese (IrMn). The bilayer seed layer structure includes a first seed layer which is a metallic oxide and a second seed layer that is a nonmagnetic metal. A preferred embodiment is a first seed layer of nickel manganese oxide (NiMnO) and a second seed layer of copper (Cu).

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

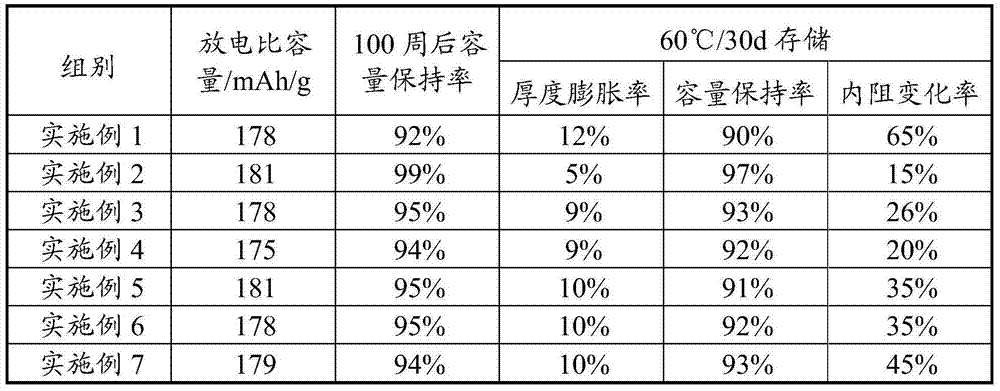

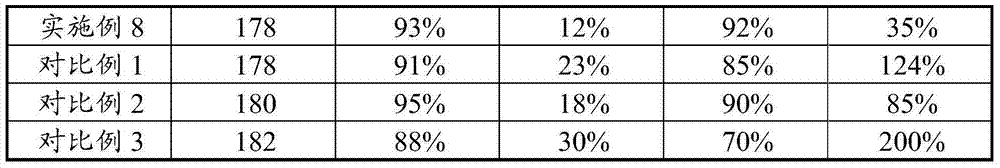

Lithium ion battery and multi-element positive material thereof as well as preparation method of multi-element positive material

ActiveCN103500827AAffect capacity playInfluence factorSecondary cellsNon-aqueous electrolyte accumulator electrodesTi dopingManganese oxide

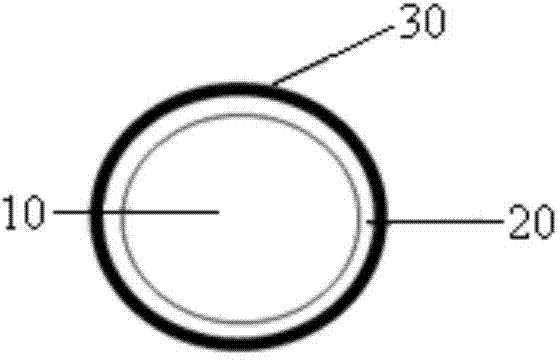

The invention discloses a lithium ion battery and a multi-element positive material thereof as well as a preparation method for the multi-element positive material. The chemical general formula of the multi-element positive material is LixNiaCobMncNyO2, wherein N is one of Ti, Mg and Al; x is more than or equal to 1.0 and less than or equal to 1.15; a is more than 0 and less than 1; b is more than 0 and less than 1; c is more than 0 and less than 1; y is more than or equal to 0.003 and less than or equal to 0.07; the sum of a, b, c and y is equal to 1. The multi-element positive material with a layered structure comprises a kernel pure phase layer containing lithium cobalt nickel manganese oxide, a surface doped layer containing a doped element Ti, an oxide surface cladding layer containing a cladding element Al and a shallow surface doped transitional layer which is positioned between the surface doped layer and the surface cladding layer and contains a doped element Mg. The preparation method of the multi-element positive material comprises the steps of synthesizing a multi-element precursor of which a body phase contains nickel, cobalt and manganese, then performing Ti doping and lithium treatment on the surface of a precursor liquid phase, and finally, doping Mg on the surface by a pyrogenic process and performing Al2O3 cladding treatment to obtain the composite modified multi-element lithium ion positive material.

Owner:NINGDE AMPEREX TECH

Preparation of iron-managanese compounded oxide/diatomite adsorbant, its using and regenerating method

ActiveCN101024160AImprove adsorption capacityGood arsenic removal effectOther chemical processesWater/sewage treatment by sorptionSorbentManganese oxide

The invention supplies a new type adsorbent--mixed oxide of iron and manganese / diatomite preparation, use and regeneration method, belongs to the treatment of technology. The method used the soluble ferrous permanganate and salt as raw materials, respectively prepared the solutions, after adequate lye into permanganate solution, mixed two salt solutions, by adding diatomite particles, full oscillation, standing aging, neutralize, washing and drying to get the manganese oxide / silicon algae absorbent. The adsorbent is larger than the surface area and good adsorption properties can be used to remove arsenic in water pollutants (especially tervalence arsenic), and the adsorption surface activity of the saturated absorption of pollutants can be directly passed to load manganese oxide compound to regeneration.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

High temperature glass fiber insulation

Owner:GLASS

Lithium nickel cobalt manganese positive electrode material and preparation method thereof

InactiveCN103490060AReasonable structureGood ability to withstand high voltageCell electrodesSecondary cellsRare-earth elementLithium

The invention discloses a lithium nickel cobalt manganese positive electrode material. The lithium nickel cobalt manganese positive electrode material comprises a lithium nickel cobalt manganese oxide contained core pure phase layer having a thickness of 5-8mum, a surface coat containing oxides, phosphates or fluorides of coating elements comprising Li, Al, Mg, Ti and Zr and having a thickness of 50-100nm, and a superficial doped transition layer positioned between the core pure phase layer and the surface coat, containing doping elements comprising Al, Mg, Ti and Zr or one of rare earth elements and having a thickness of 1-2mum. The lithium nickel cobalt manganese positive electrode material can inhibit the material dissolving in a cycle process without reducing a specific capacity, and has the characteristics of high capability excellent cycle and rate performances, and excellent thermal stability.

Owner:NINGDE AMPEREX TECH

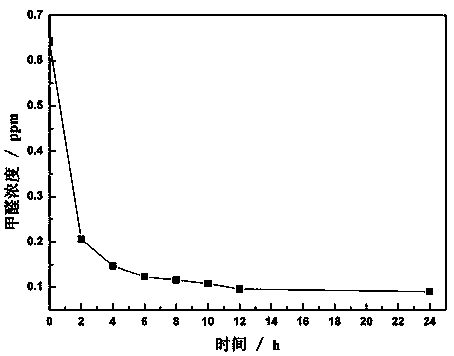

Preparation of room temperature formaldehyde catalyst

Belonging to the technical field of adsorption catalysis and air pollution control, the invention relates to preparation of a room temperature formaldehyde catalyst. The invention is characterized in that: zeolite, sepiolite, a porous activated carbon material, cordierite or a self-made carrier is adopted as the catalyst carrier, one or more non-noble metal oxides, like magnesium oxide, aluminum oxide, silicon oxide, manganese oxide, iron oxide, cobalt oxide, nickel oxide, copper oxide, zinc oxide, zirconium oxide, lanthanum oxide or cerium oxide are taken as active components, and an impregnation technique is employed to prepare the catalyst, which can be powdery, strip, blocky, spherical or honeycomb. The loading amount of the non-noble metal oxides is 2-15wt%, and the content of the catalyst carrier is 85-98%. Under normal temperature and ambient humidity conditions, the catalyst has the capacity of catalytic oxidation of formaldehyde into non-toxic and harmless CO2 and H2O up to over 95%, no intermediate product is generated, and the catalyst has the characteristics of high catalytic oxidation activity, strong moisture resistant ability, stable operation, long service life and the like, thus being suitable for formaldehyde purification treatment in offices, office buildings, living rooms, shopping malls, hospitals, hotels and other places.

Owner:江苏瑞丰科技实业有限公司

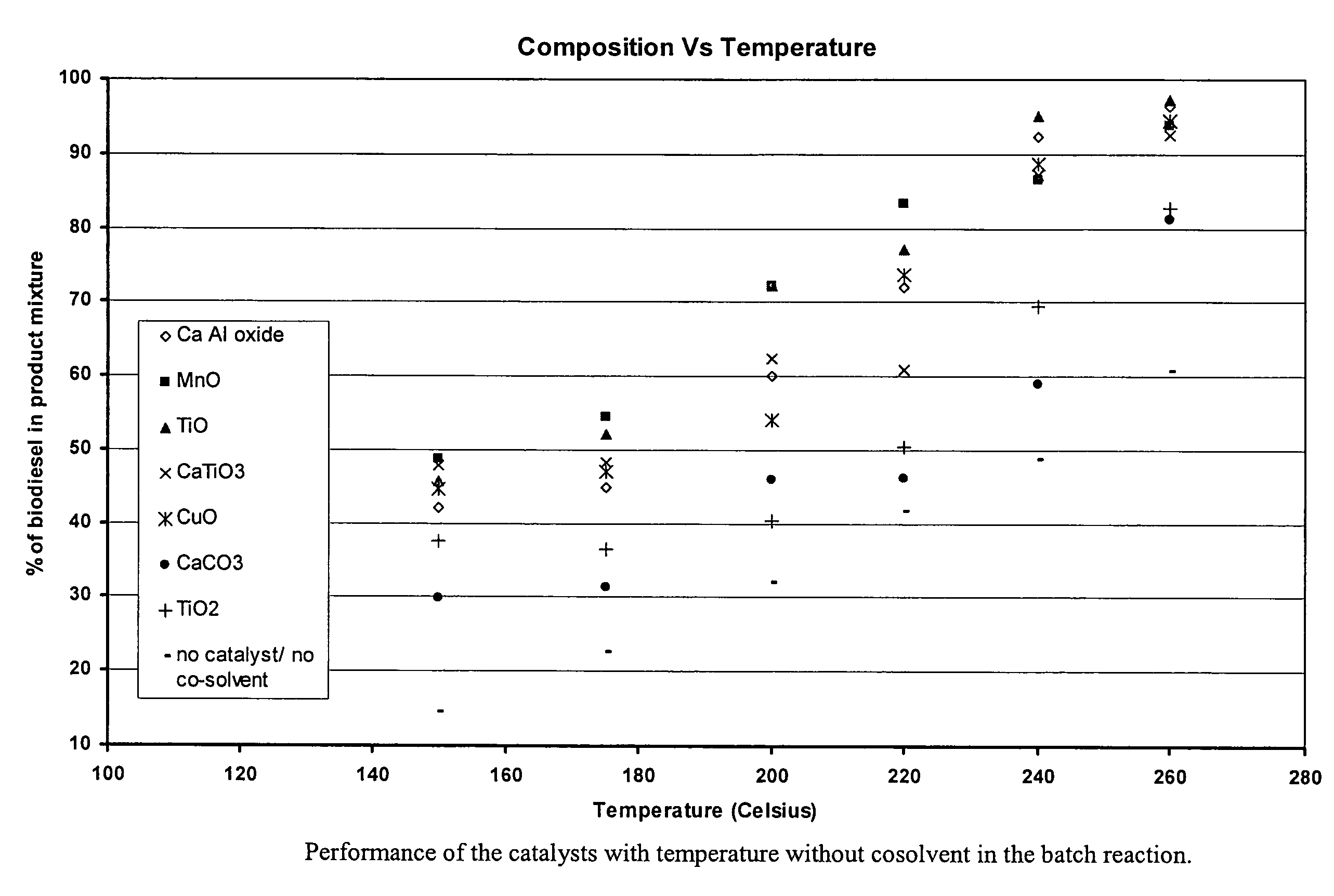

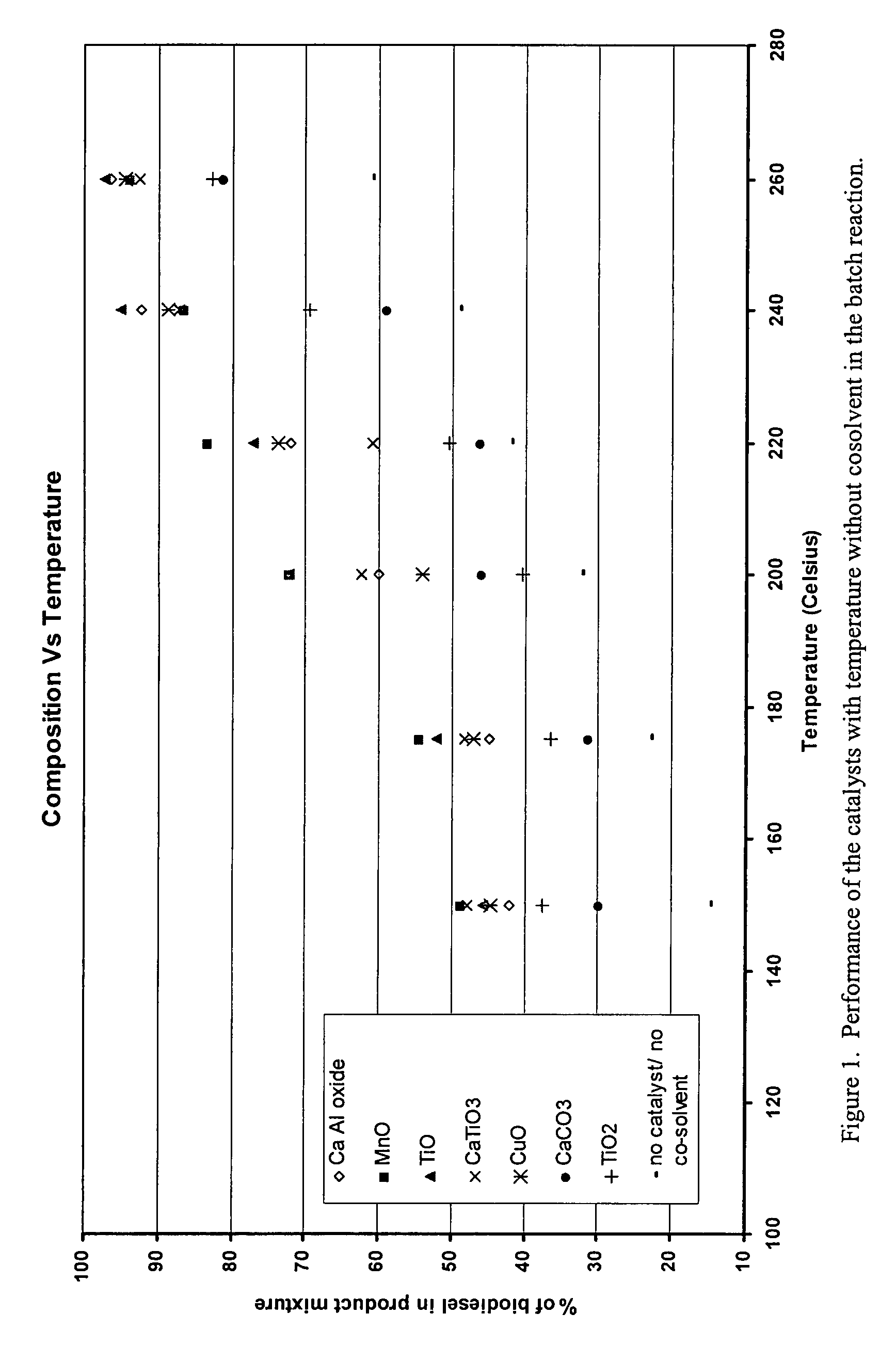

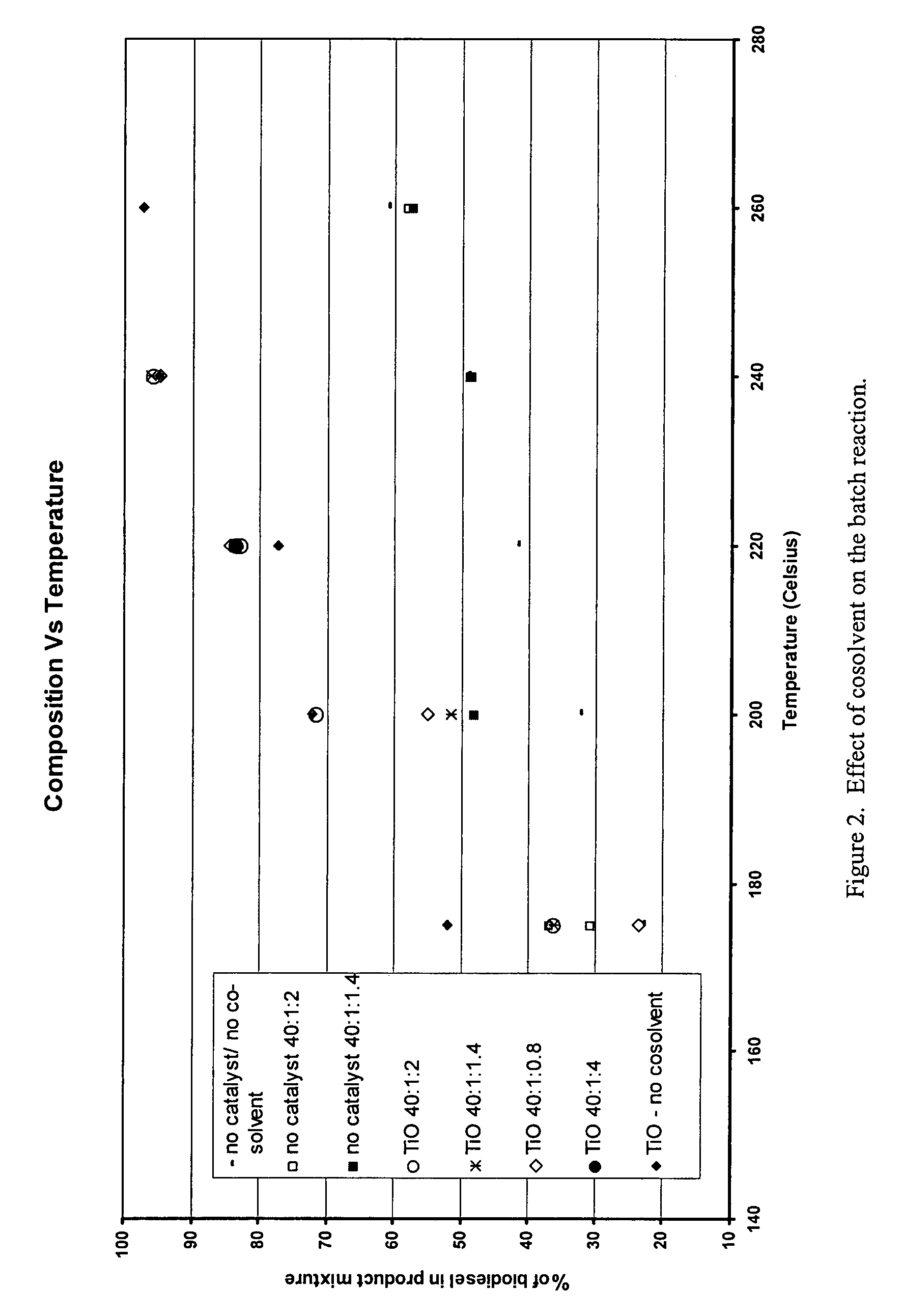

Green biodiesel

InactiveUS7563915B2Reduce wasteSignificant energyFatty oils/acids recovery from wasteFatty acid esterificationCalcium silicateBiodiesel

Methods for improved manufacture of green biodiesel focus on the selection and use of one or more solid metallic oxide base catalyst(s) selected from the group consisting of calcium oxide (CaO), calcium aluminum oxide (CaO—Al2O3), calcium titanate (CaTiO3), barium titanate (BaTiO3), magnesium aluminum oxide (MgO—Al2O3), zinc oxide (ZnO), copper (II) oxide (CuO), nickel oxide (NiO), manganese oxide (MnO), titanium oxide (TiO), vanadium oxide (VO), cobalt oxide (CoO), iron oxide (FeO), chromite (FeCr2O4), hydrotalcite (Mg6Al2(CO3)(OH)16.4(H2O), magnetite (Fe3O4), magnesium silicate and calcium silicate.

Owner:PENN STATE RES FOUND

Thermal protective coating for ceramic surfaces

ActiveUS20050051057A1Extend working lifeReduce surface temperatureFireproof paintsOther chemical processesColloidal silicaSodium Bentonite

A coating admixture, method of coating and substrates coated thereby, wherein the coating contains colloidal silica, colloidal alumina, or combinations thereof; a filler such as silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides, copper chromium oxides, cerium oxides, terbium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide is also added.

Owner:WESSEX

Thermal protective coating

ActiveUS7105047B2Extended shelf lifeReduce weightAlkali metal silicate coatingsPretreated surfacesCalcium silicateSodium Bentonite

A coating, method of coating and substrates coated thereby, wherein the coating contains an inorganic adhesive such as an alkali / alkaline earth metal silicate such as sodium silicate, potassium silicate, calcium silicate, and magnesium silicate; a filler such as a metal oxide for example silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides and copper chromium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide may be added.

Owner:WESSEX

Preparation method of nano porous metal oxide/carbon lithium ion battery cathode material

ActiveCN104045116AImprove cycle performanceImprove conductivityMaterial nanotechnologyCell electrodesHigh energyManganese oxide

The invention provides a preparation method of a nano porous metal oxide / carbon lithium ion battery cathode material. The preparation method comprises the following steps: firstly, weighting ferric salt or manganese salt and carboxylate organic ligands, and putting into a high-pressure reaction kettle; and after a polar solvent is added and dissolved, carrying out a hydrothermal reaction for 10-72h at 100-180 DEG C to generate a transition metal coordination polymer precursor; and after the transition metal coordination polymer precursor is washed and dried, decomposing the precursor for 0.5-6h at a temperature of 300-600 DEG C in an inert atmosphere in a tube furnace, thus obtaining a nano porous metal oxide / carbon lithium ion battery cathode material containing iron oxides or manganese oxides. According to the preparation method, since the transition metal coordination polymer precursor which is structurally designable and controllable is used as a template-type precursor, a nano porous metal oxide / carbon lithium ion battery cathode material is obtained by using an in-situ thermal decomposition method. The method is simple in process, and the obtained products have the advantages of high electrical conductivity, high specific capacity, good cycle stability, excellent high-ratio discharge performance and high energy density.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com