Patents

Literature

5794results about How to "High specific capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Conductive nanocomposite-based electrodes for lithium batteries

ActiveUS20090305135A1High specific capacityHigh reversible capacityMaterial nanotechnologyNon-aqueous electrolyte accumulator electrodesCarbon layerComposite electrode

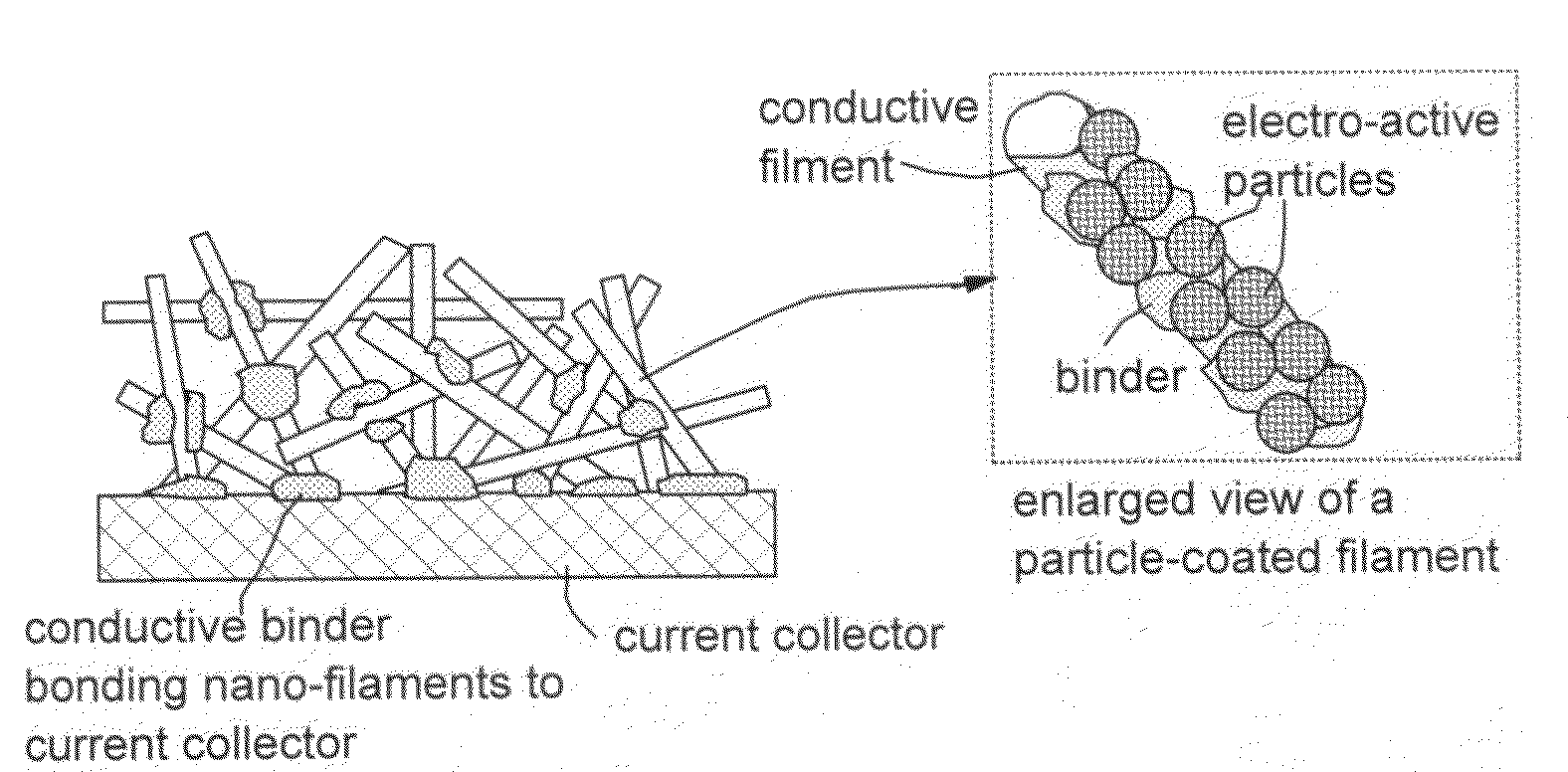

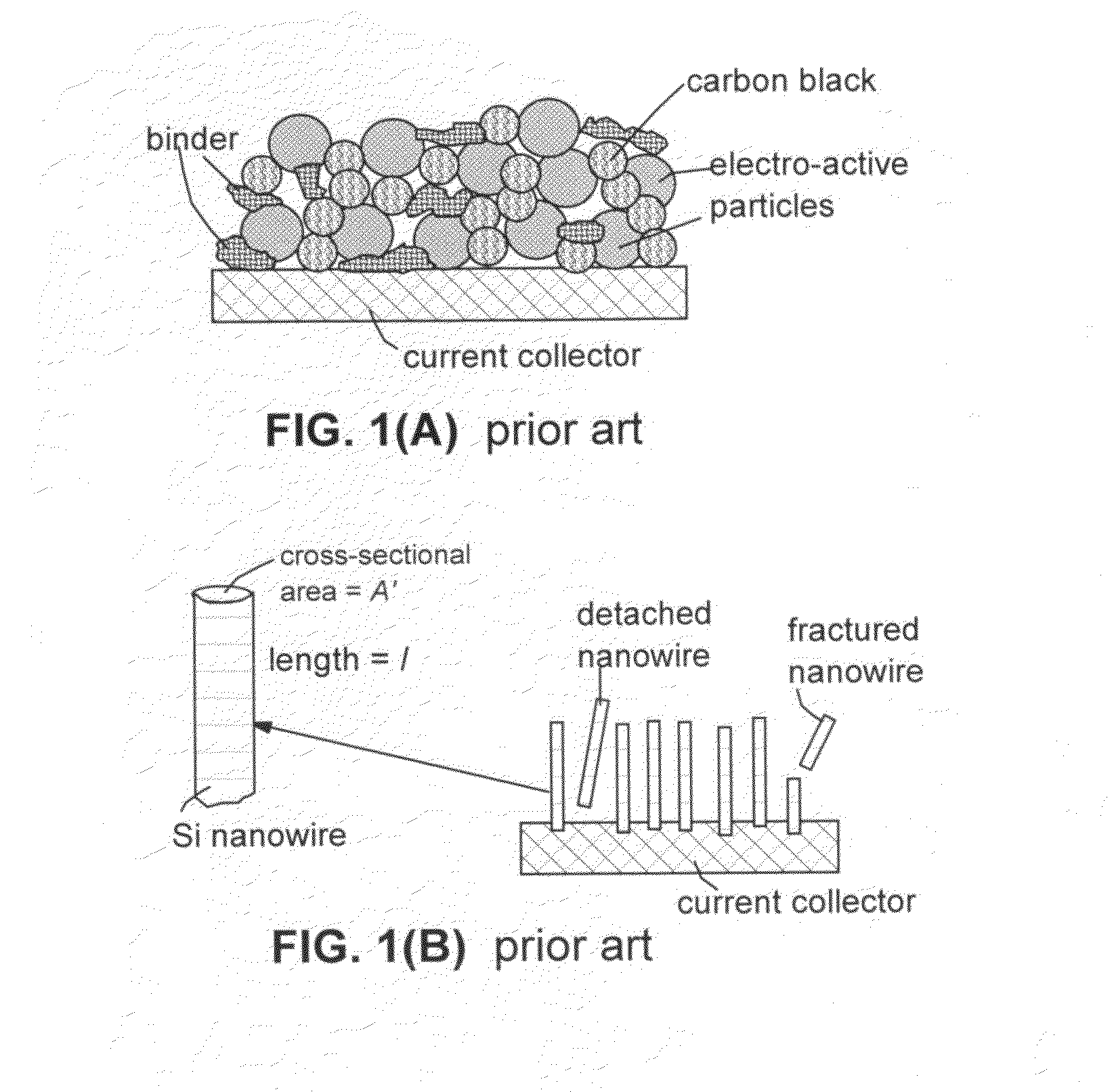

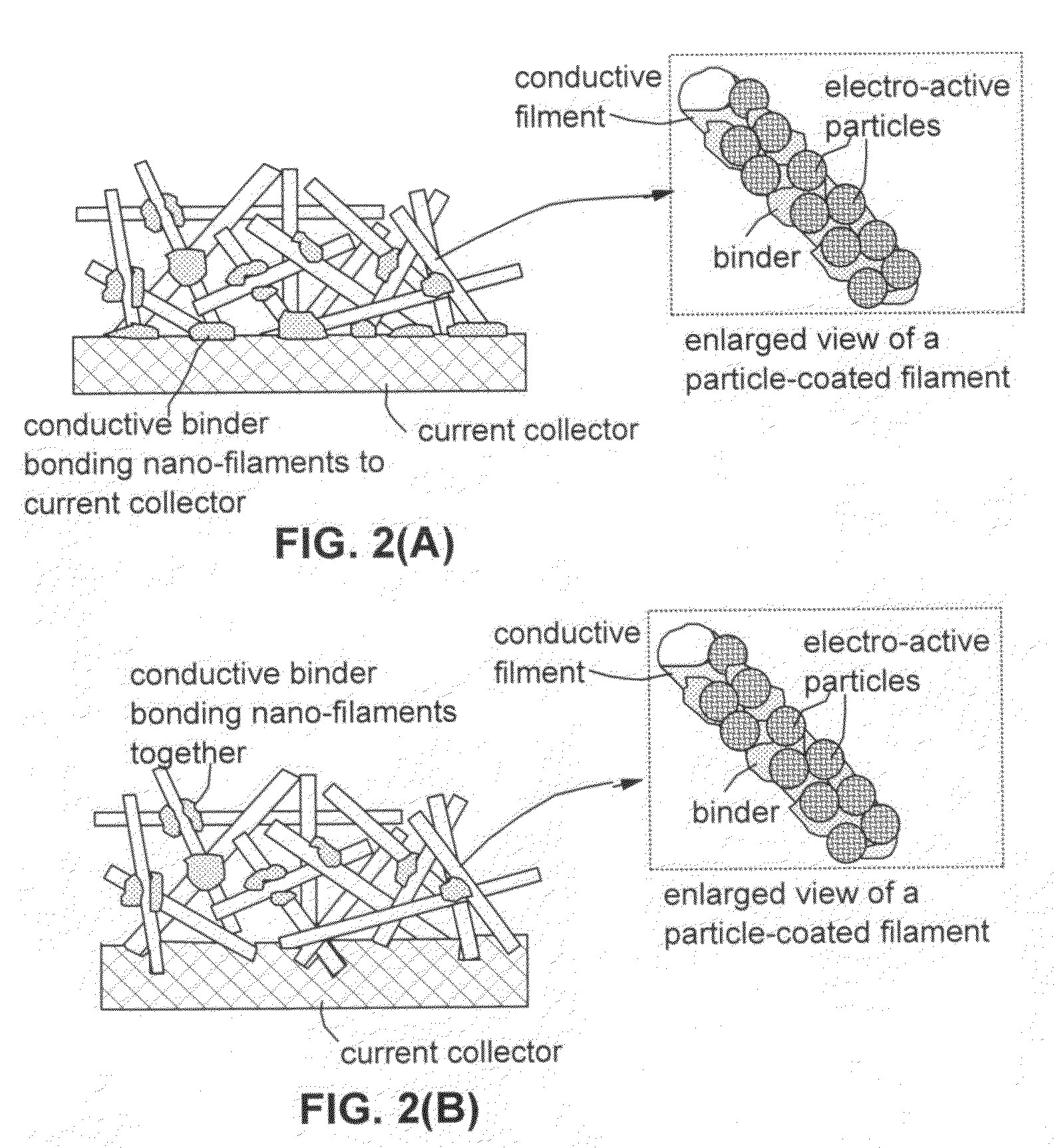

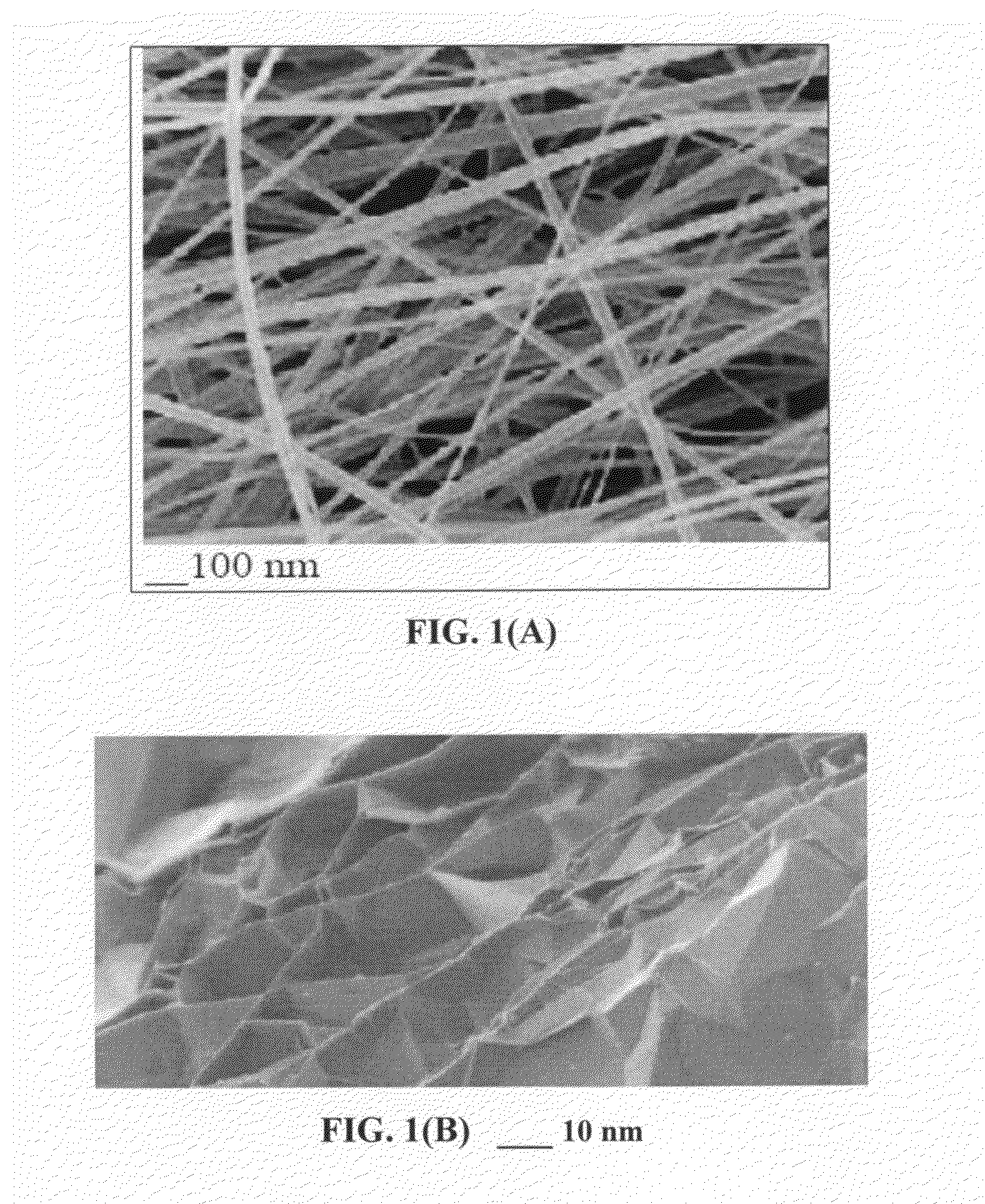

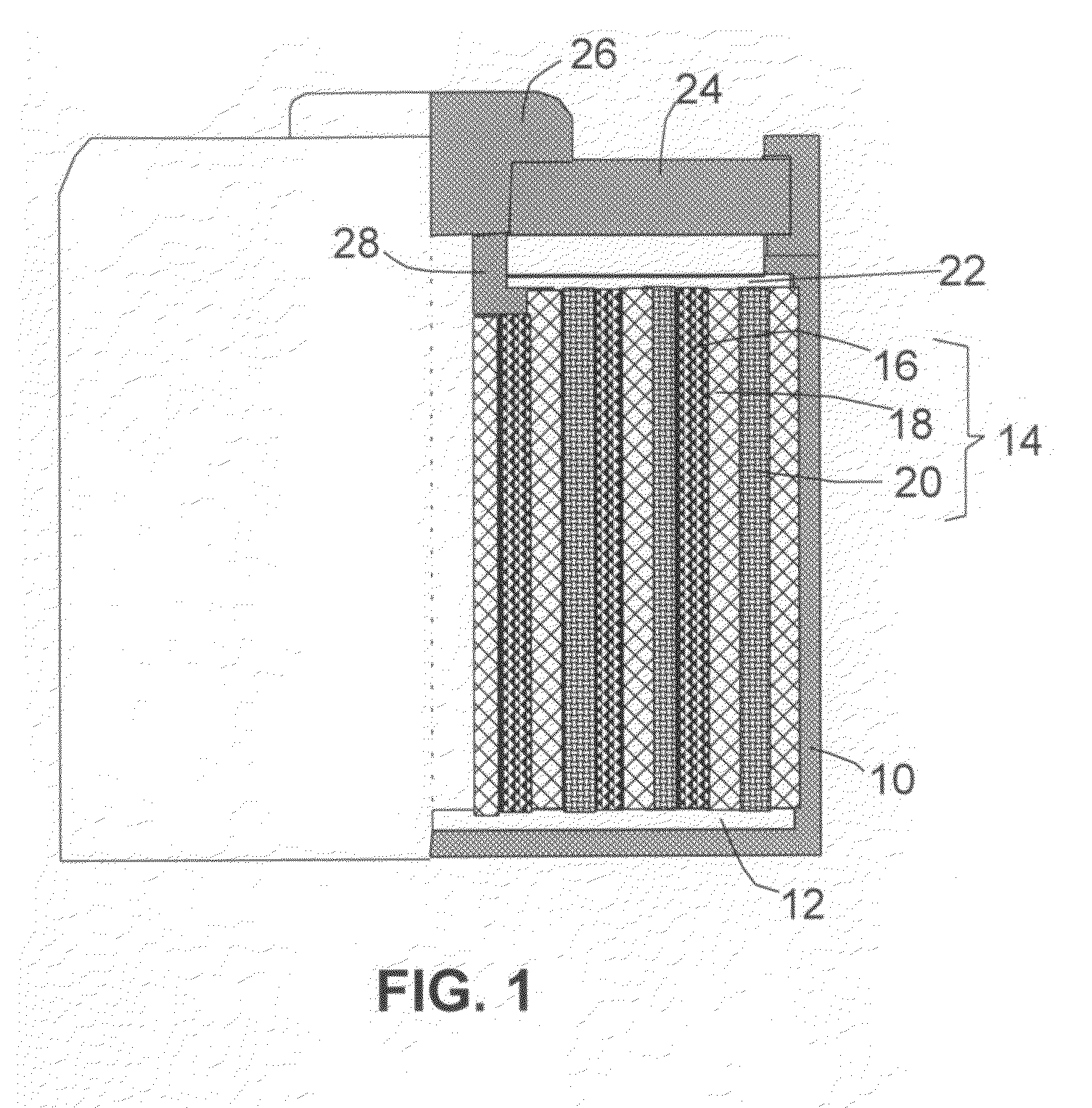

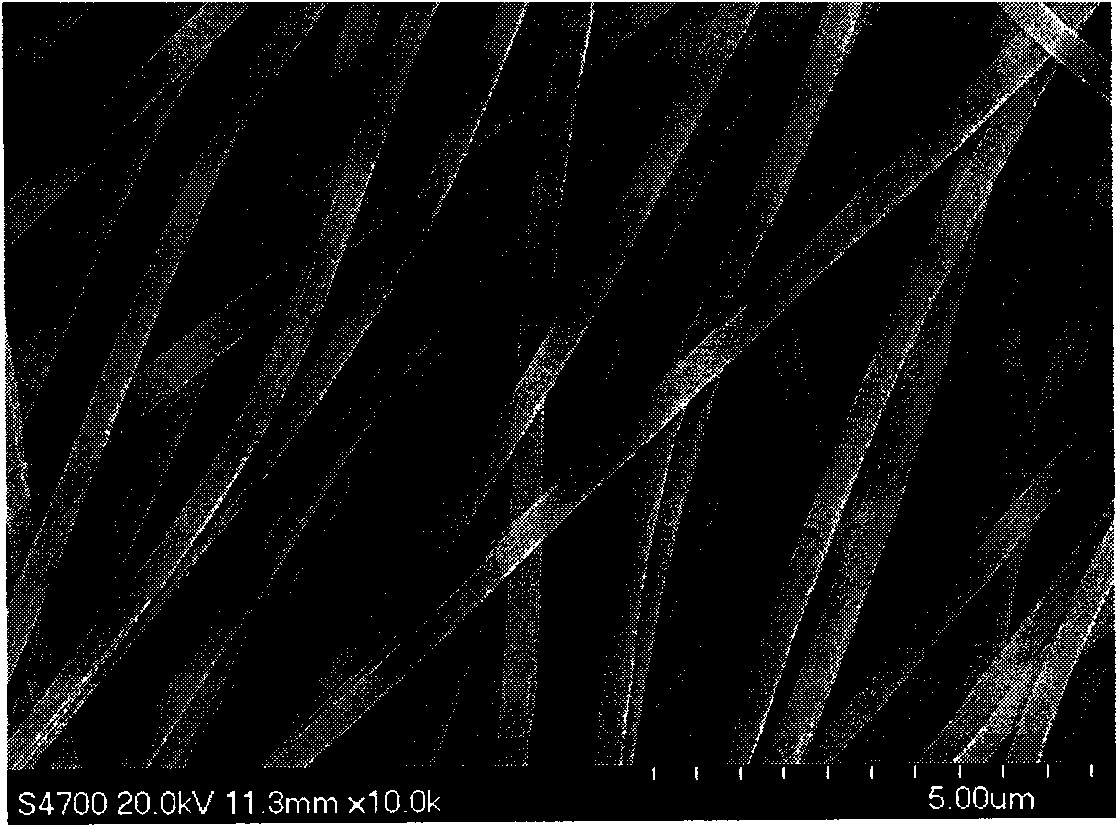

This invention provides a nanocomposite-based lithium battery electrode comprising: (a) A porous aggregate of electrically conductive nano-filaments that are substantially interconnected, intersected, physically contacted, or chemically bonded to form a three-dimensional network of electron-conducting paths, wherein the nano-filaments have a diameter or thickness less than 1 μm (preferably less than 500 nm); and (b) Sub-micron or nanometer-scale electro-active particles that are bonded to a surface of the nano-filaments with a conductive binder material, wherein the particles comprise an electro-active material capable of absorbing and desorbing lithium ions and wherein the electro-active material content is no less than 25% by weight based on the total weight of the particles, the binder material, and the filaments. Preferably, these electro-active particles are coated with a thin carbon layer. This electrode can be an anode or a cathode. The battery featuring such an anode or cathode exhibits an exceptionally high specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

Lithium metal-sulfur and lithium ion-sulfur secondary batteries containing a nano-structured cathode and processes for producing same

ActiveUS20110165466A1High specific capacityImprove the immunityMaterial nanotechnologyElectrochemical processing of electrodesSpecific energyLithium metal

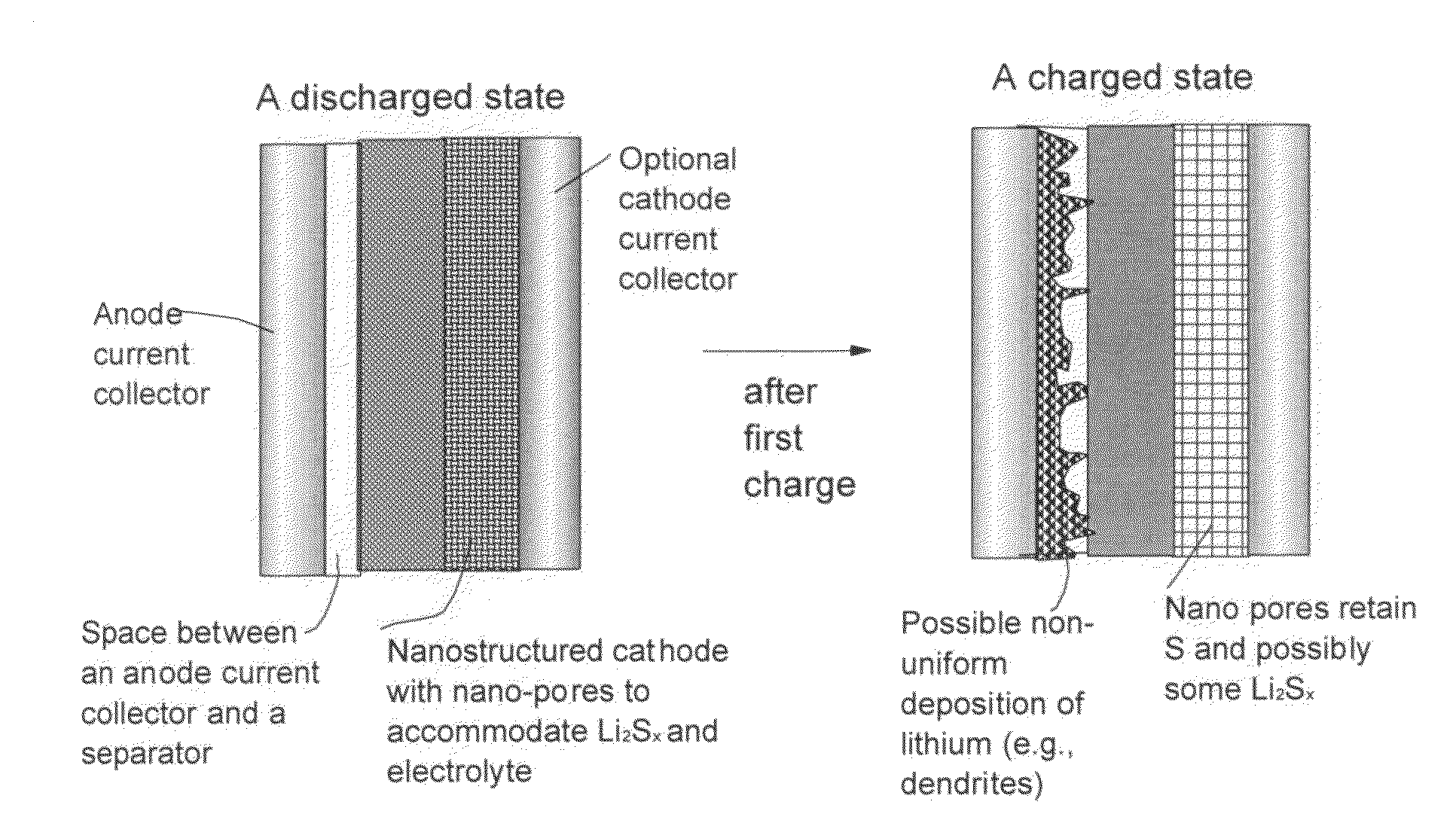

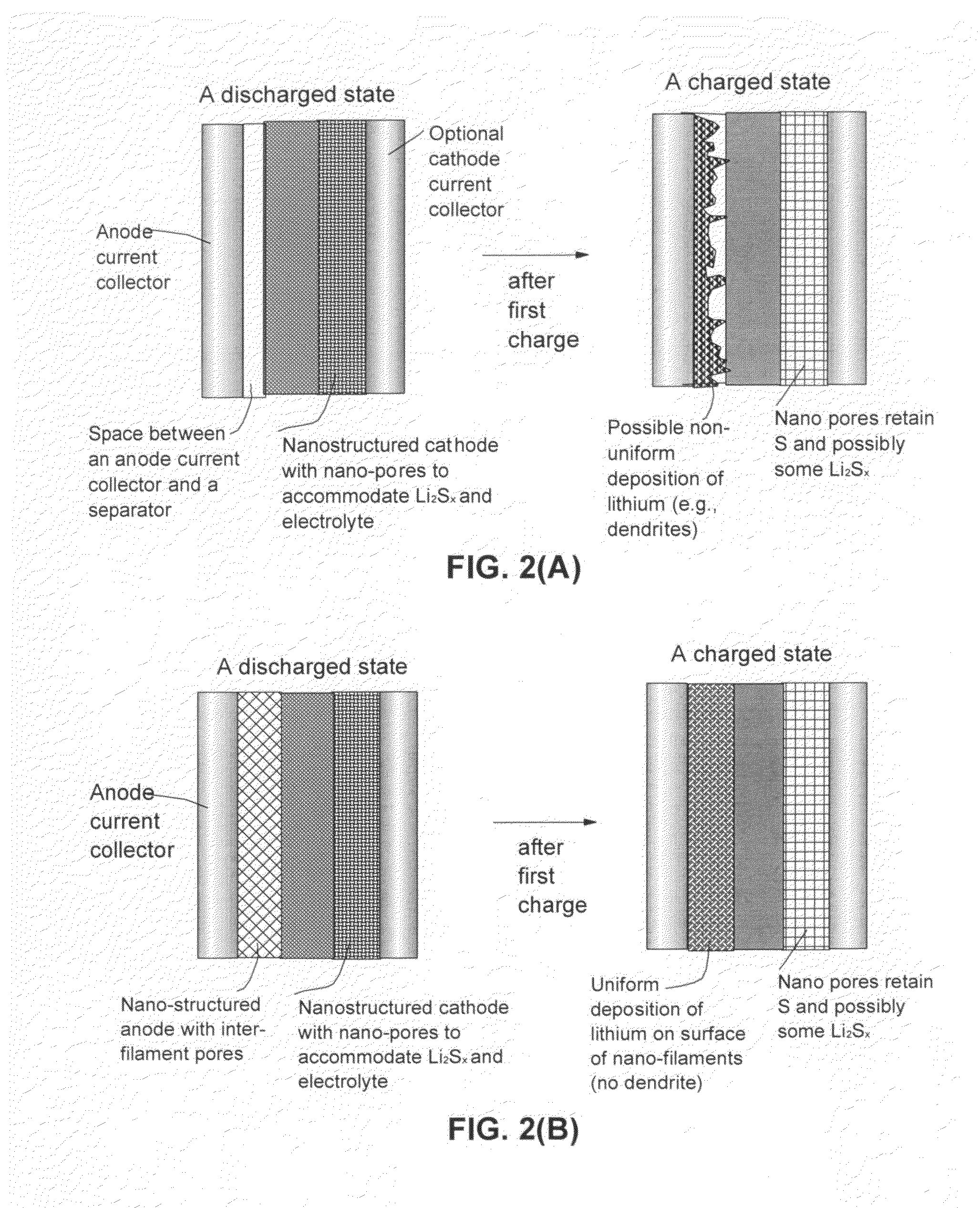

An electrochemical cell comprising an anode, electrolyte or an electrolyte / separator combination, and a nano-structured cathode, wherein the cathode comprises: (a) an integrated nano-structure of electrically conductive nanometer-scaled filaments that are interconnected to form a porous network of electron-conducting paths comprising pores with a size smaller than 100 nm (preferably smaller than 10 nm), wherein the filaments have a transverse dimension less than 500 nm (preferably less than 100 nm); and (b) powder or salt of lithium-containing sulfide (lithium polysulfide) disposed in the pores, or a thin coating of lithium-containing sulfide deposited on a nano-scaled filament surface wherein the lithium-containing sulfide is in contact with, dispersed in, or dissolved in electrolyte liquid and the lithium-containing sulfide-to-filament weight ratio is between 1 / 10 and 10 / 1 which is measured when the cell is in a fully discharged state. The cell exhibits an exceptionally high specific energy and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

Nano-structured anode compositions for lithium metal and lithium metal-air secondary batteries

ActiveUS20110104571A1High specific capacityHigh reversible capacityFuel and primary cellsConductive materialLithium metalAlloy

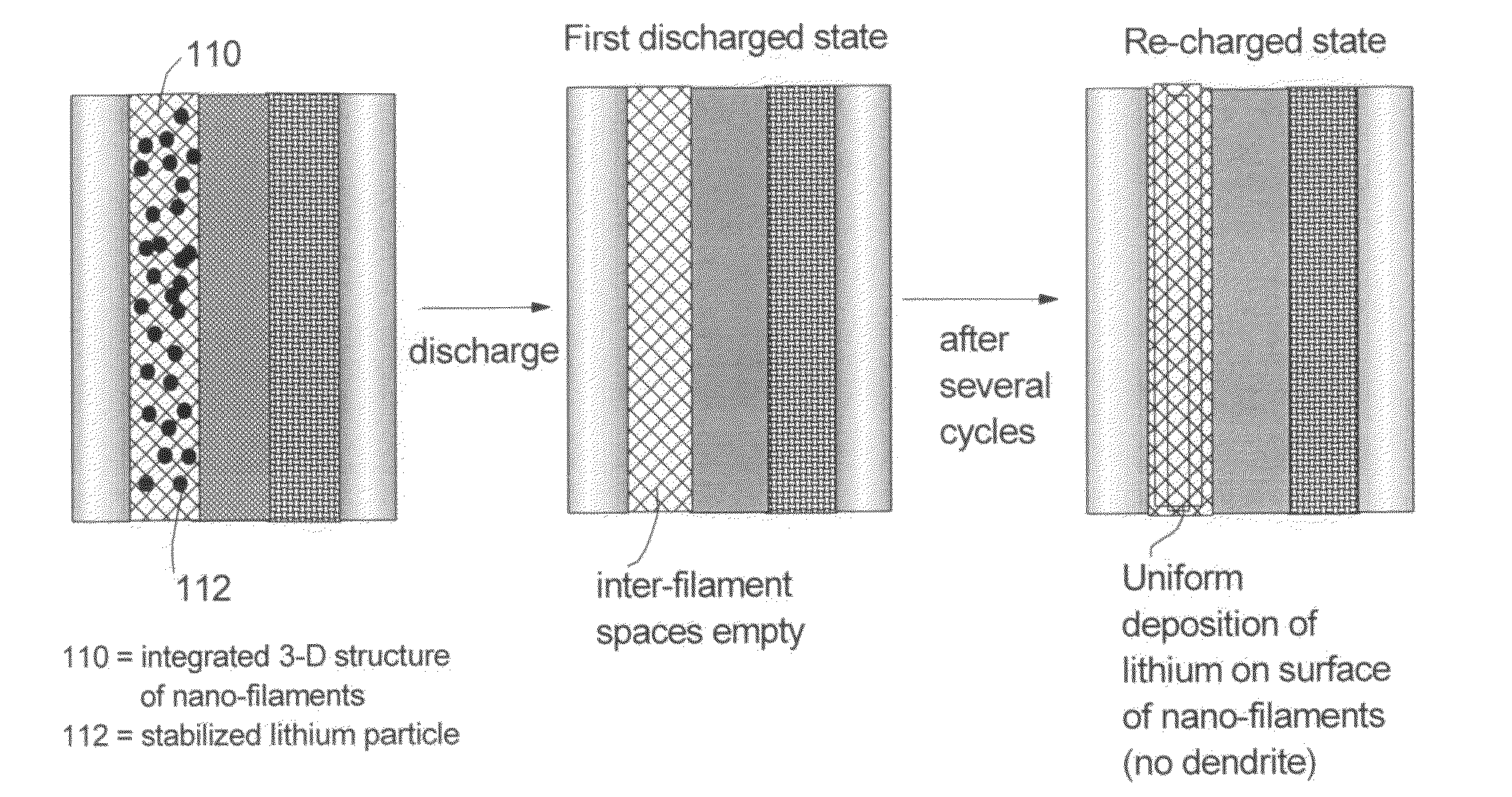

This invention provides a nano-structured anode composition for a lithium metal cell. The composition comprises: (a) an integrated structure of electrically conductive nanometer-scaled filaments that are interconnected to form a porous network of electron-conducting paths comprising interconnected pores, wherein the nano-filaments have a transverse dimension less than 500 nm; and (b) micron- or nanometer-scaled particles of lithium, a lithium alloy, or a lithium-containing compound wherein at least one of the particles is surface-passivated or stabilized and the weight fraction of these particles is between 1% and 99% based on the total weight of these particles and the integrated structure together. Also provided is a lithium metal cell or battery, or lithium-air cell or battery, comprising such an anode. The battery exhibits an exceptionally high specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

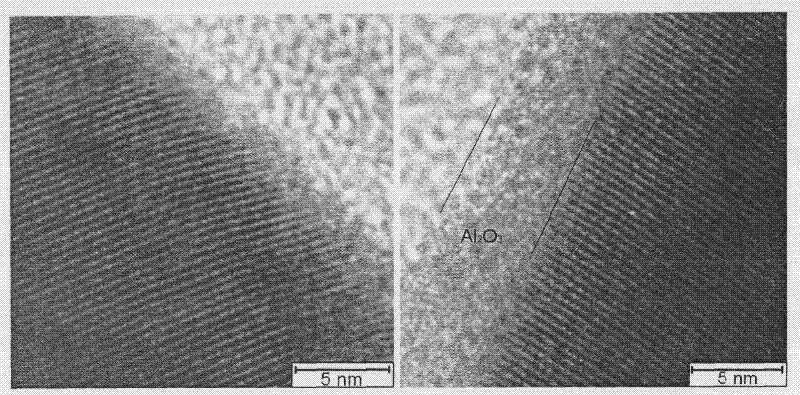

Method for cladding surfaces of active material of anode and/or anode and methods manufacturing anode and battery

InactiveCN102244231AStructurally intactStable structureNon-aqueous electrolyte accumulator electrodesMetallurgyLithium-ion battery

The invention provides a method for cladding surfaces of an active material of an anode and / or the anode and methods for manufacturing the anode and a battery. In the cladding method, an atomic layer deposition technology is adopted to deposit surface modification substances on the surfaces of the active material of the anode and / or the anode of a lithium battery. According to the invention, the cycle performance and the specific capacity of the lithium-ion battery can be improved obviously and electrode materials are more stable.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

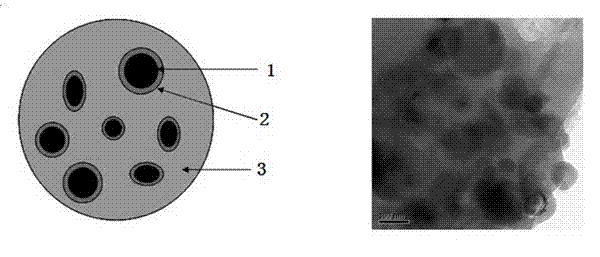

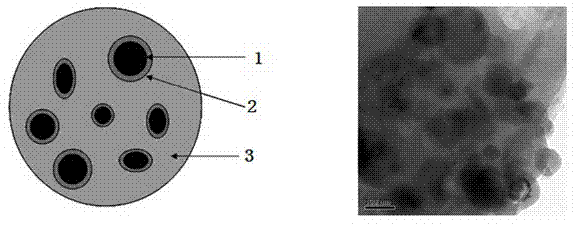

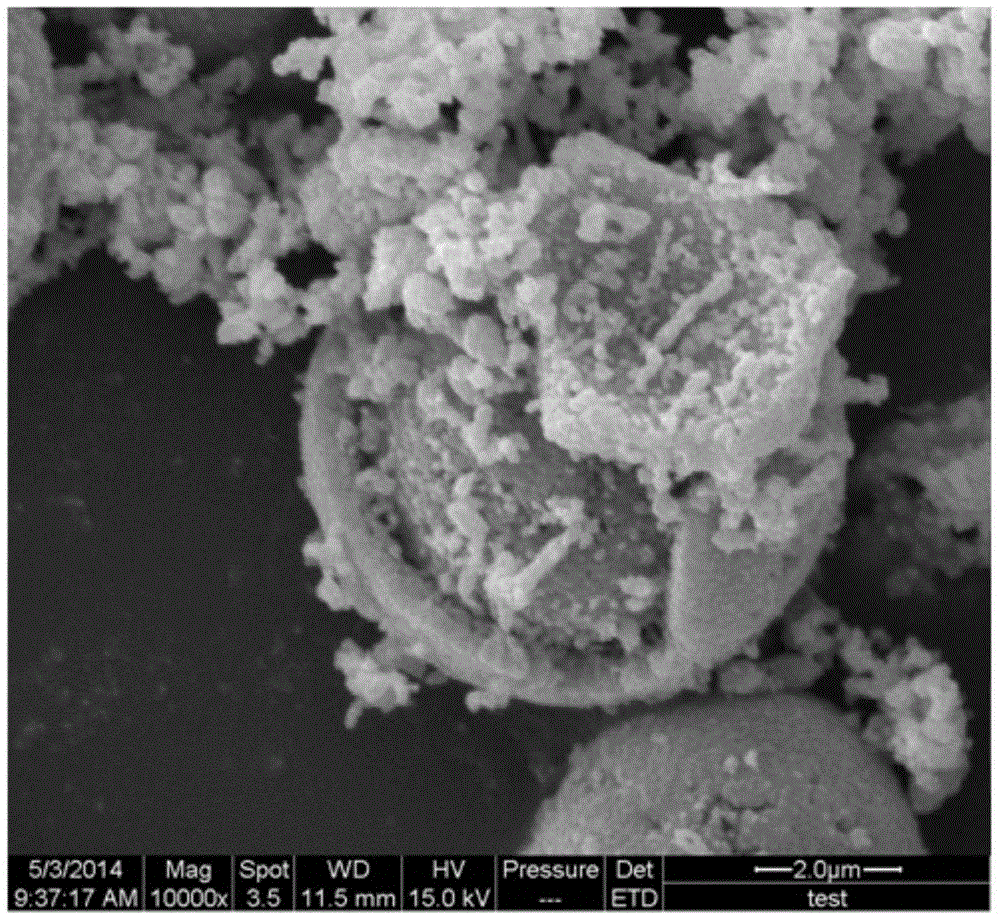

Silicon-carbon composite anode material and preparing method thereof

ActiveCN102509781AHigh specific capacityImprove cycle performanceCell electrodesCarbon compositesPorous carbon

The invention provides a silicon-carbon composite anode material, which comprises a nuclear shell structure and a support substrate, wherein particle size of the silicon-carbon composite anode material is 1-200 micrometers, and porous carbon serving as the support substrate is obtained through decomposition of biomass materials. The invention further provides a preparing method of the silicon-carbon composite anode material, which includes the following steps: 1 reaming the biomass materials in physical activation or chemical activation mode to prepare the porous carbon, or preparing small molecular organics serving as a precursor of the porous carbon in hydrolyzing mode; 2 mixing silica particles and the obtained porous carbon or the precursor of the porous carbon in solution and performing ultrasonic treatment; 3 evaporating the solution mixture to dry so as to obtain solid-state powder; and 4 drying the solid-state powder, and performing thermal treatment, crushing and sieving on the solid-state powder to obtain the silicon-carbon composite anode material. The silicon-carbon composite anode material and the preparing method thereof are simple in process, short in flow path, easy to operate and low in cost, and lithium ion batteries manufactured by the silicon-carbon composite anode material are suitable for various mobile electronic equipment or devices driven by mobile energy.

Owner:SHANGHAI JIAO TONG UNIV

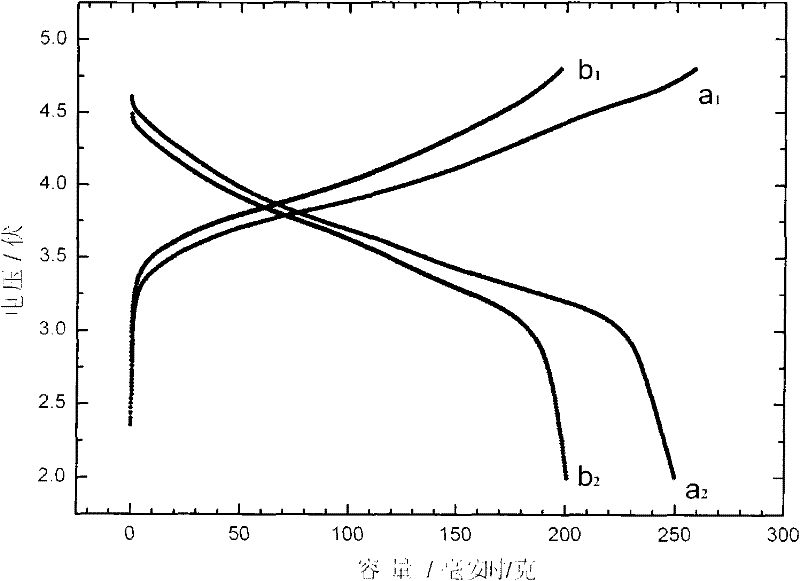

Lithium ion battery positive pole material cobalt nickel oxide manganses lithium and method for making same

ActiveCN101202343AHigh specific capacityExcellent cycle characteristicsElectrode manufacturing processesLithium compoundsLithium oxideAntioxidant

The invention relates to a nickel cobalt manganese lithium oxide material used for an anode of a li-ion battery and a preparation method. The invention belongs to the li-ion battery technical field. The nickel cobalt manganese lithium oxide material used for the anode of the li-ion battery is a li-rich laminated structure with the chemical component of Li1+zM1-x-yNixCoyO2; wherein, z is less than or equal to 0.2 and more than or equal to 0.05, x is less than or equal to 0.8 and more than 0.1, and y is less than or equal to 0.5 and more than 0.1. The preparation method of the invention is that dissoluble salt of the nickel, cobalt and manganese is taken as the raw material; ammonia or ammonium salt is taken as complexing agent; sodium hydroxide is taken as precipitator; water-dissoluble dispersant and water-dissoluble antioxidant or inert gas are added for control and protection; in a cocurrent flow type the solution is added to a reaction vessel for reaction; after alkalescence disposal, aging procedure, solid-liquid separation and washing and drying, the nickel cobalt manganese oxide is uniformly mixed with the lithium raw material; the nickel cobalt manganese lithium oxide powder is obtained by sintering the mixed powder which is divided into three temperature areas. The invention has the advantages of high specific capacity, good circulation performance, ideal crystal texture, short production period, low power loss, and being suitable for industrial production, etc.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST +1

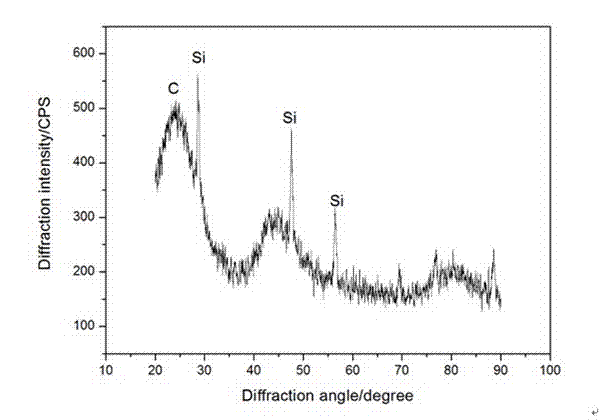

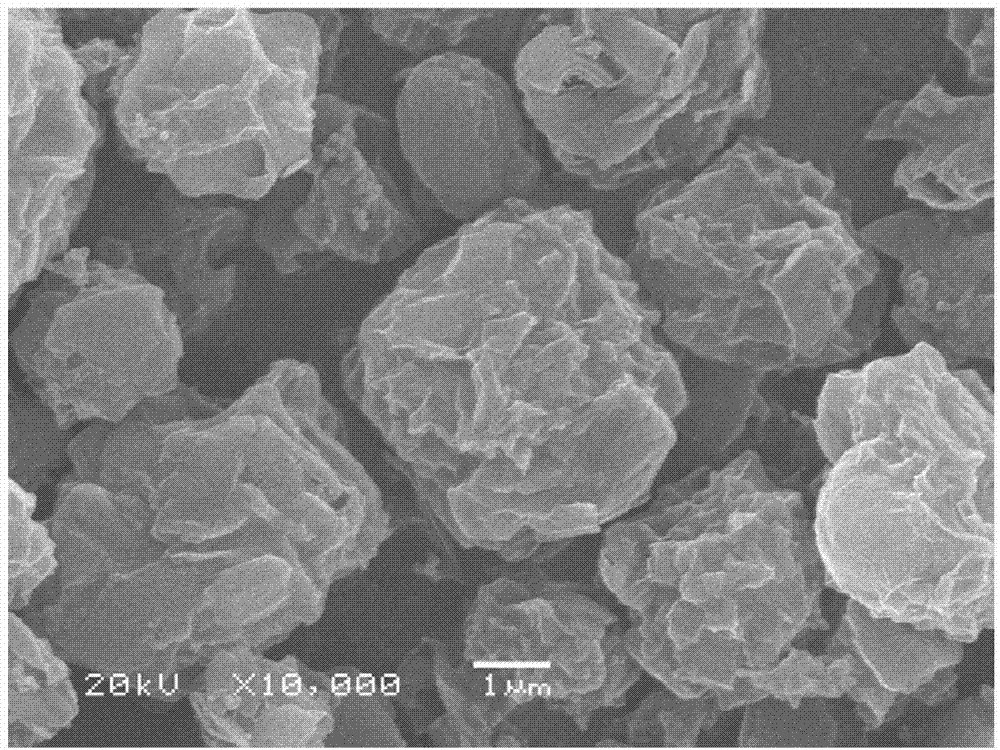

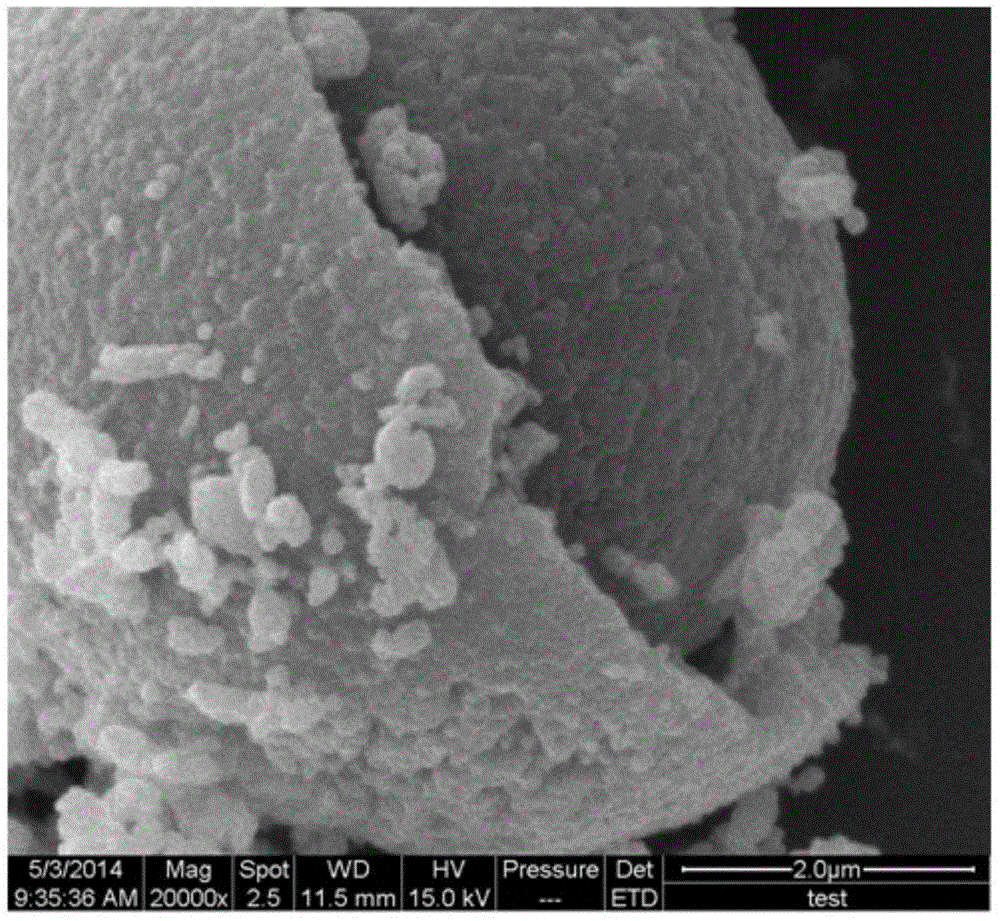

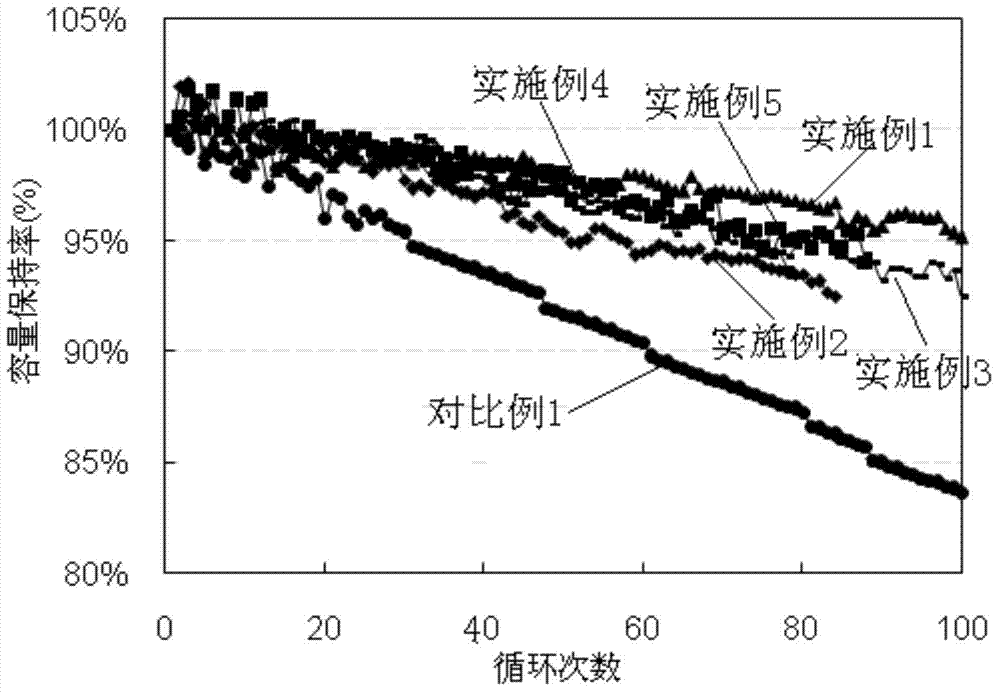

Lithium ion battery silicon-carbon anode material and preparation method thereof

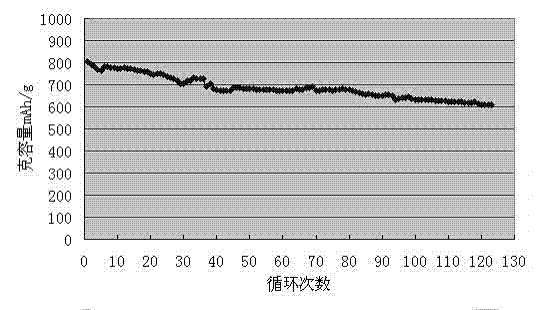

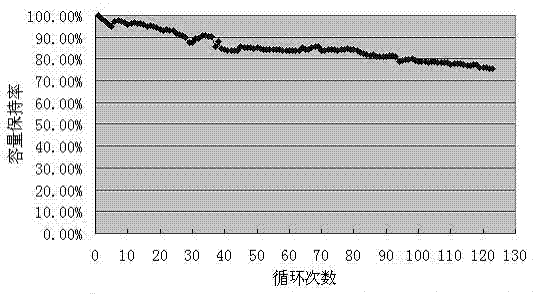

ActiveCN103367727APromote circulationHigh specific capacityCell electrodesSecondary cellsLithium-ion batteryRetention ratio

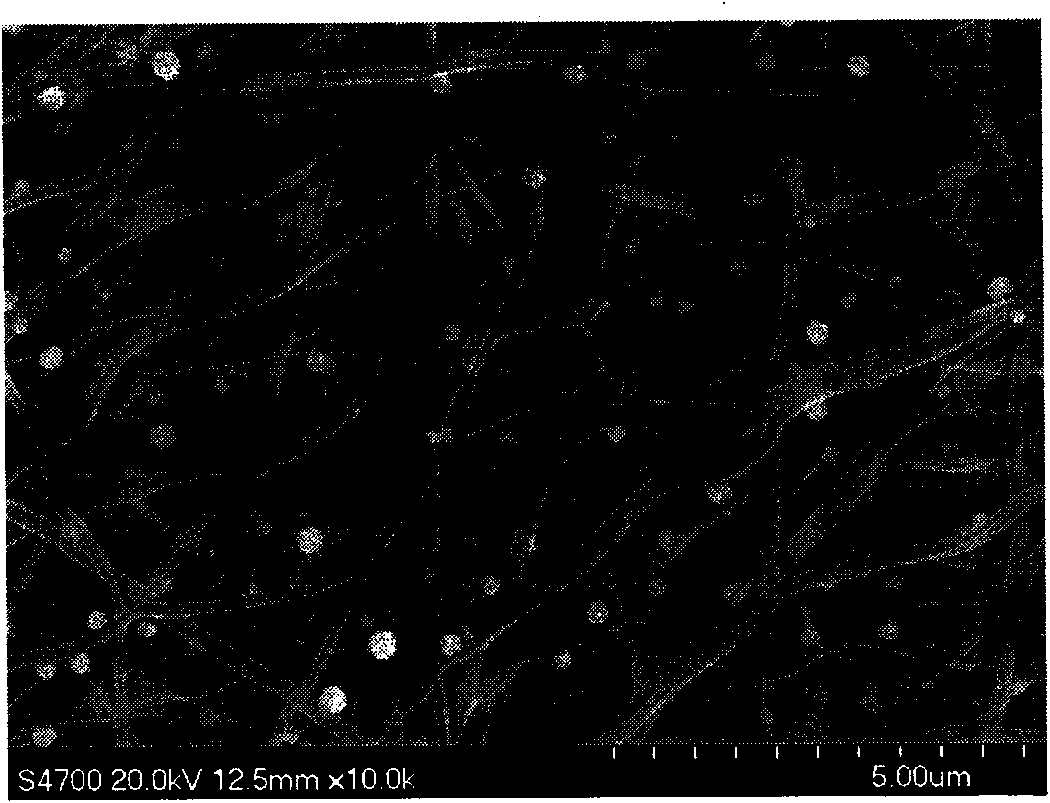

The invention relates to a lithium ion battery silicon-carbon anode material which comprises nanometer silicon, graphite polymer and organic matter pyrolysis carbon, wherein the graphite polymer is formed by granular graphite; the nanometer silicon is embedded and clamped among gaps of the granular graphite or attached on the surface of the granular graphite; nanometer silicon / graphite polymer is covered by the organic matter pyrolysis carbon. A preparation method of the lithium ion battery silicon-carbon anode material comprises the steps of: mixing the nanometer silicon, a dispersing agent, a bonding agent and the granular graphite in an organic solvent, and drying to obtain composite nanometer silicon / graphite polymer; adding the obtained composite nanometer silicon / graphite polymer into the dispersion liquid of a carbon source precursor, mixing and drying; and carrying out heat treatment on material to obtain the lithium ion battery silicon-carbon anode material. The prepared silicon-carbon material has high specific capacity, high first time efficiency and excellent cycle performance, the capacity is larger than 450mAh / g, the first time efficiency is more than 85%, and the capacity retention ratio is more than 97% after circulation is carried out for 60 times.

Owner:BTR NEW MATERIAL GRP CO LTD

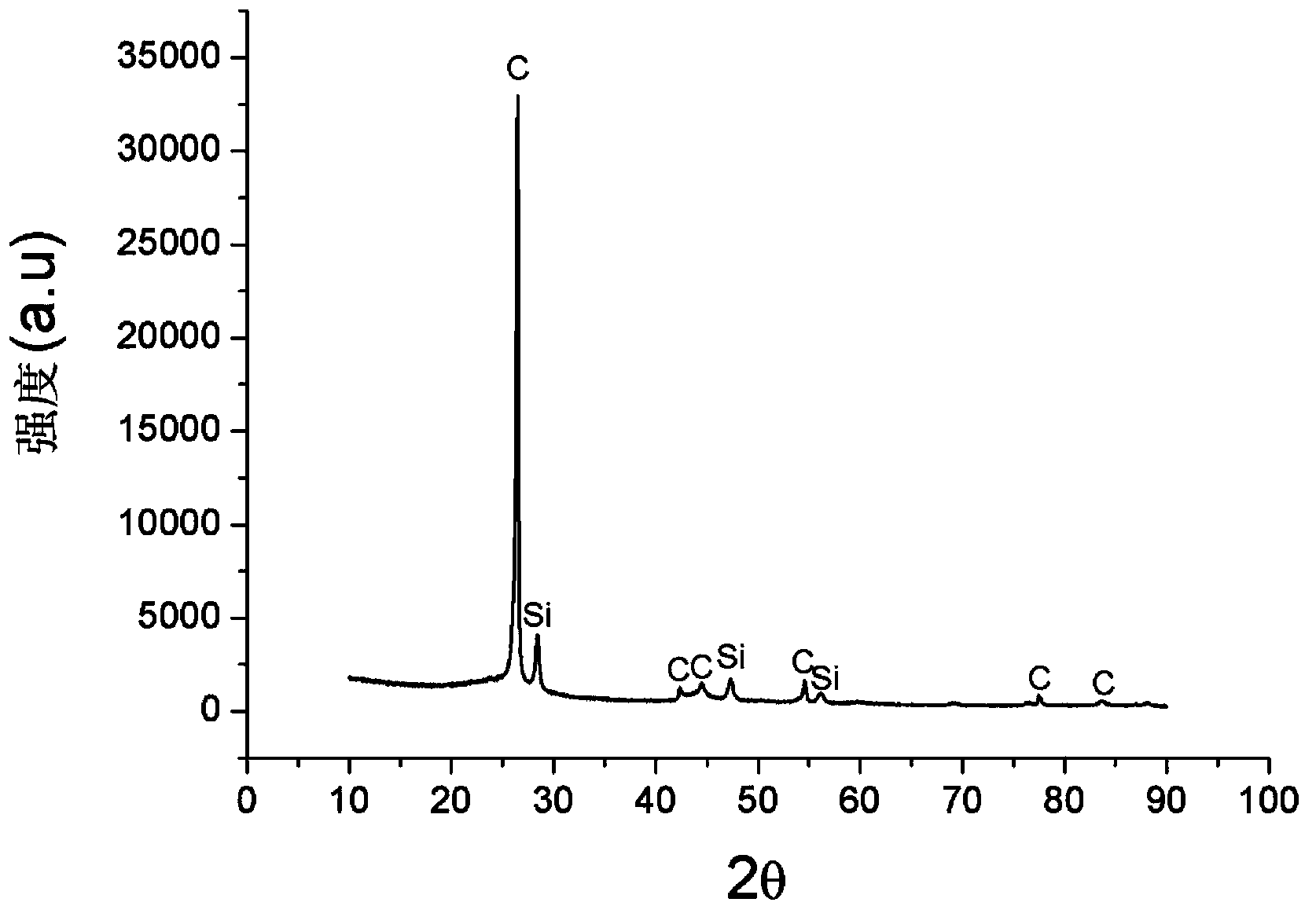

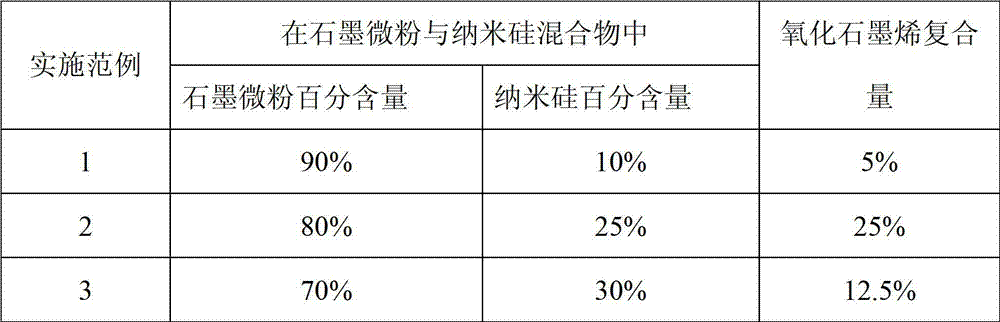

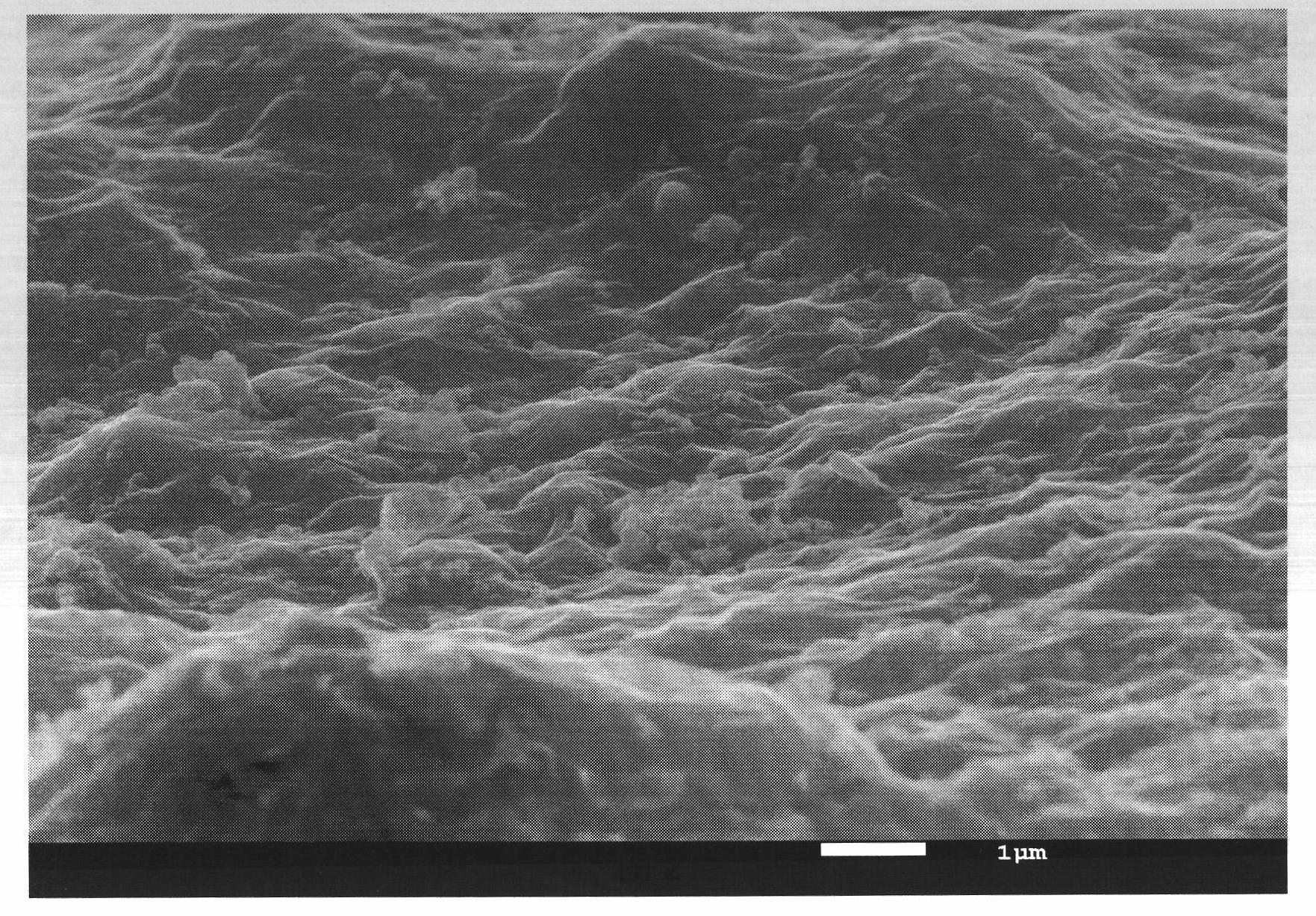

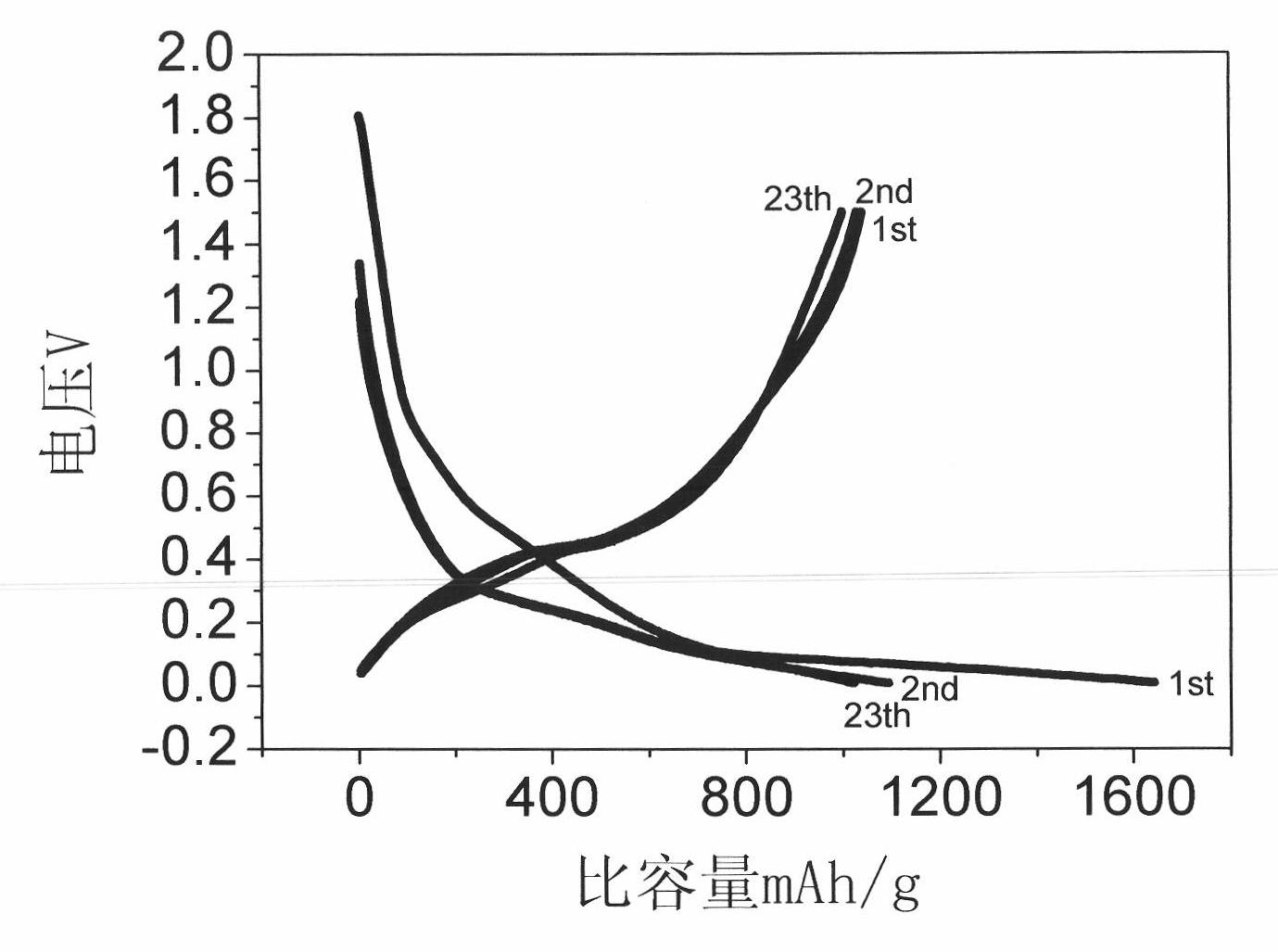

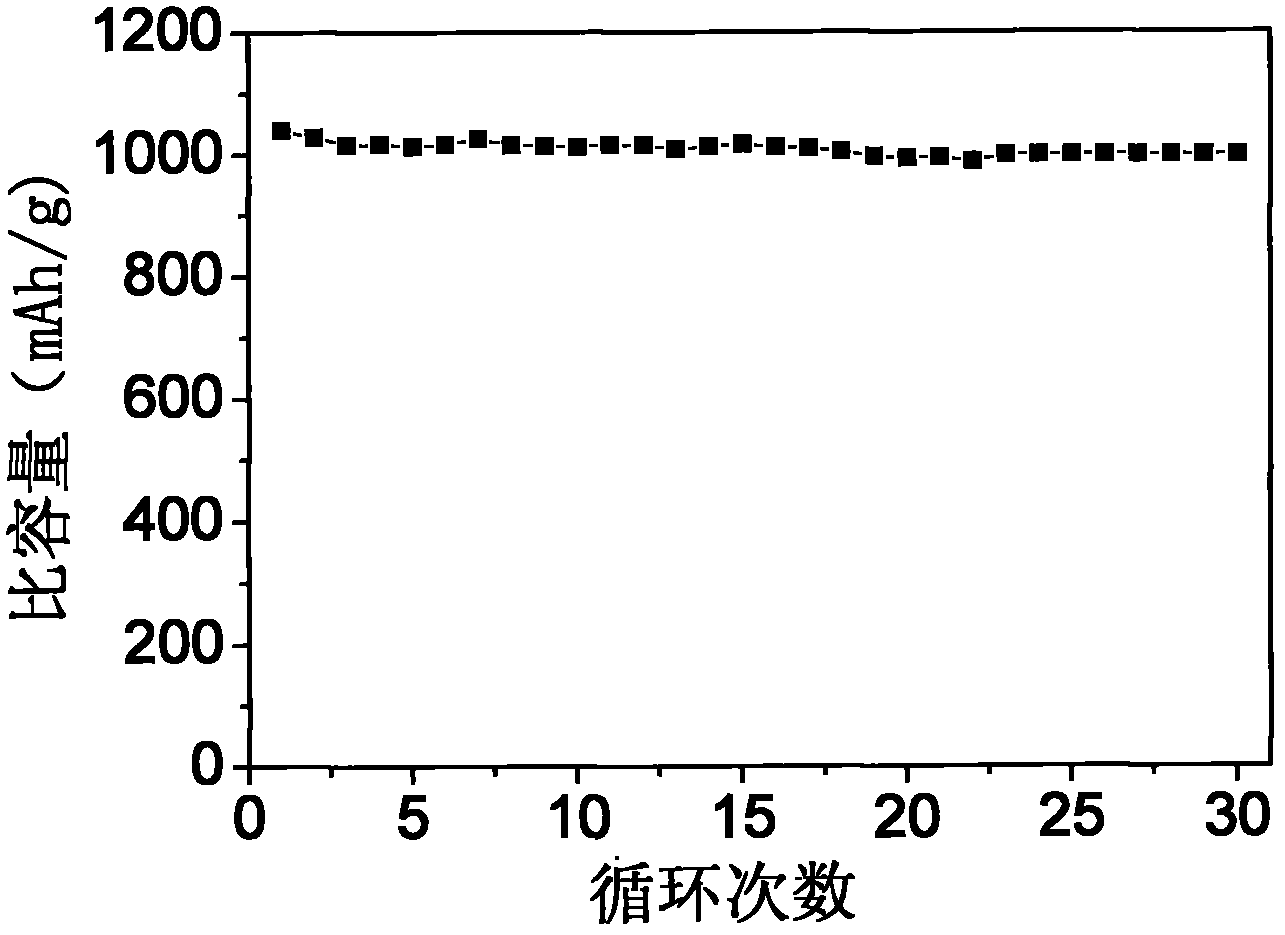

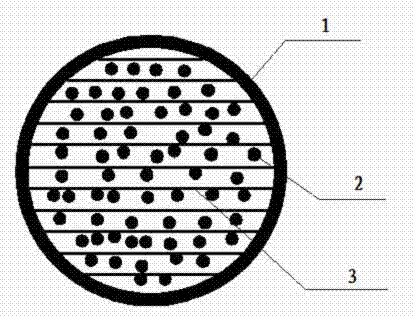

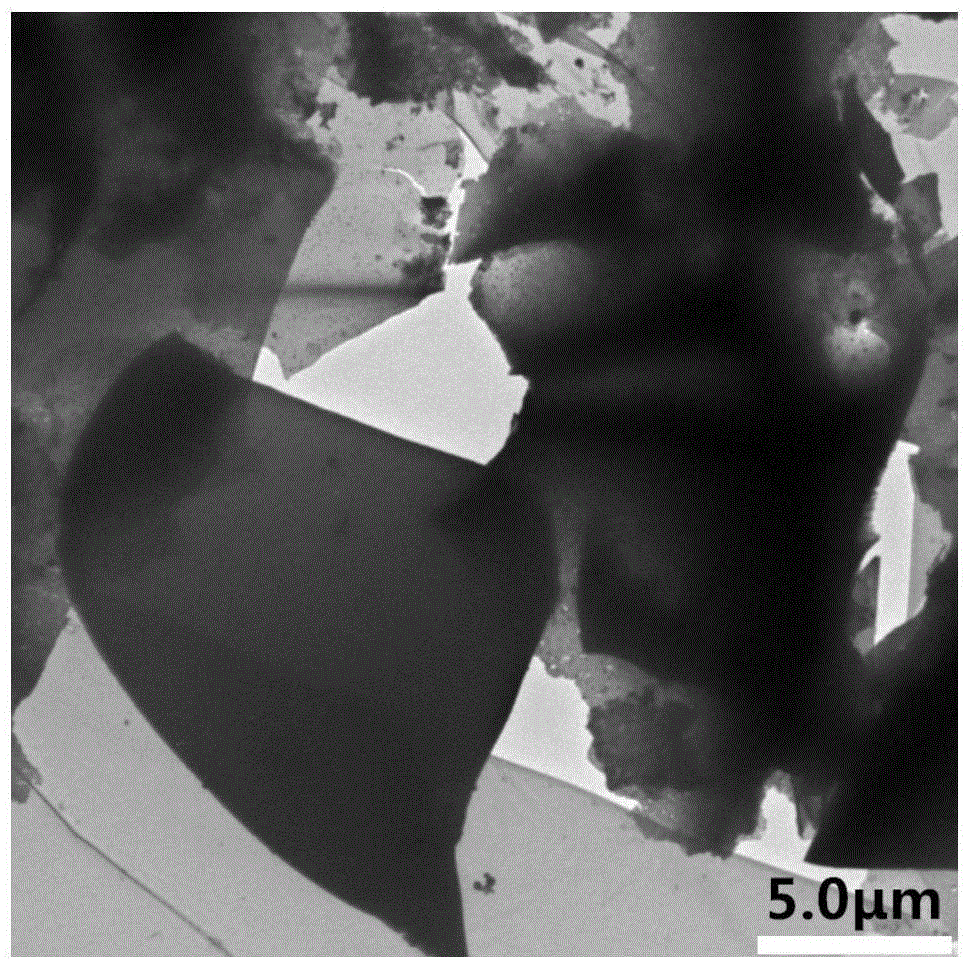

Preparation method of silicon and carbon-coated graphene composite cathode material

ActiveCN103050666ARealize in situ restorationThe preparation process is simple, convenient and practicalMaterial nanotechnologyCell electrodesCarbon coatedStructural stability

The invention discloses a preparation method of a silicon and carbon-coated graphene composite cathode material. The technical problem to be solved is to enhance the electronic conductivity of the silicon-based cathode material, buffer the volume effect produced in the process of deintercalation of the lithium in the silicon-based cathode material and enhance the structure stability in the circulation process of the material at the same time. The material is prepared by using a spray drying-thermally decomposing treatment process in the invention. The preparation method comprises the following steps of: evenly dispersing nano silicon and graphite micro powder in a dispersion solution of oxidized graphene, carrying out thermal treatment under an inert protection atmosphere after spray drying, subsequently cooling along a furnace to obtain the silicon and carbon-coated graphene composite cathode material. The extra binder does not need to add in the process of manufacturing balls in the invention and the outer oxidized graphene is thermally reduced in situ to graphene in the thermal treatment process of the composite precursor, so that the process is simple and easy to operate; and the practical degree is high. The prepared composite material has the advantages of great reversible capacity, designable capacity, good cycling performance and high-current discharging performance, high tap density and the like.

Owner:CENT SOUTH UNIV

Graphene/silicon lithium ion battery cathode material and preparation method thereof

InactiveCN101924211AHigh specific capacityImprove cycle stabilityCell electrodesComposite filmNew energy

The invention discloses a grapheme / silicon composite material for a lithium ion battery cathode material and a preparation method thereof, belonging to the fields of electrochemistry and new energy materials. The method comprises the following steps of: using graphite as a raw material; oxidizing the graphite into oxidized graphite by adopting oxidants of concentrated sulfuric acid and potassium permanganate; then, ultrasonically stripping the oxidized graphite to prepare oxidized graphene; mixing oxidized graphene in different proportions with nano silicon powder; ultrasonically dispersing, filtering or directly drying into a cake / film; and roasting under a reduction atmosphere to prepare self-support graphene / silicon composite film materials in different proportions. Proved by electrochemistry tests, the graphene / silicon composite film material prepared by the method has higher specific capacity and cycle stability, simple preparation method and easy mass production and consequently is an ideal high-energy lithium ion battery cathode material.

Owner:UNIV OF SCI & TECH BEIJING +1

Preparation method of high power capacity lithium ion battery cathode material

ActiveCN102769139AHigh specific capacityImprove cycle stabilityCell electrodesNanotechnologyCyclic stability

A preparation method of a high power capacity lithium ion battery cathode material uses natural spherical graphite to serve as raw materials, uses concentrated sulfuric acid to serve as an inserting layer agent, uses potassium permanganate to serve as an oxidizing agent, conducts expansion treatment at high temperature to obtain micro-expanded graphite, then enables the micro-expanded graphite in different proportions to be mixed with nanometer ganister sand, conducts ultrasonic dispersion, suction filtration and dying to obtain the micro-expanded graphite with the nanometer ganister sand inserted in layers, enables the micro-expanded graphite to be mixed and coated with carbon source carbon source according to certain proportion, and finally conducts carburizing sintering under inert gas shielding to prepare completely coated silicon carbon composite cathode material with sufficient obligated obligate inside. Electrochemistry shows that the silicon carbon composite material prepared by the preparation method has high specific capacity and cycling stability and is the ideal high power capacity lithium ion battery cathode material.

Owner:内蒙古斯诺新材料科技有限公司

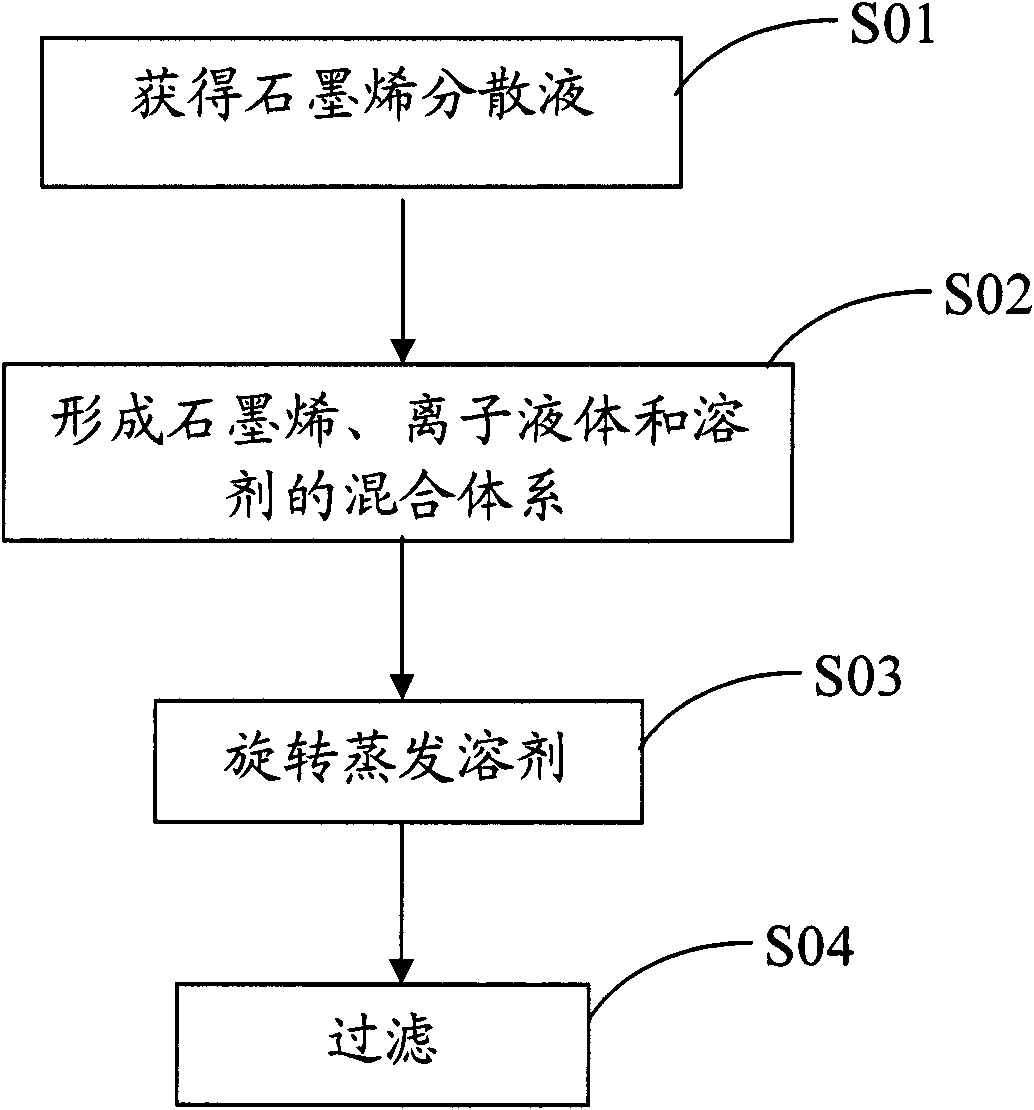

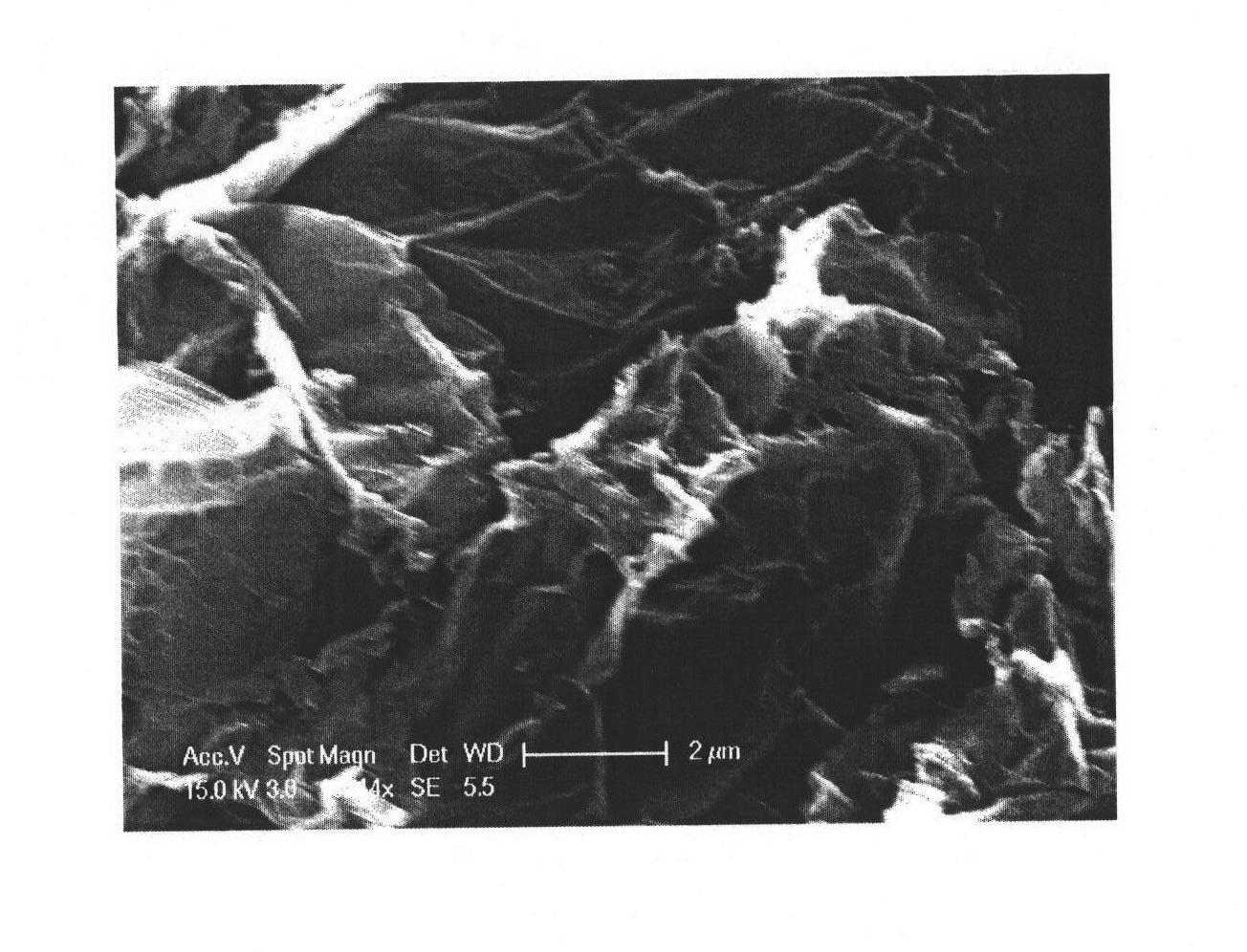

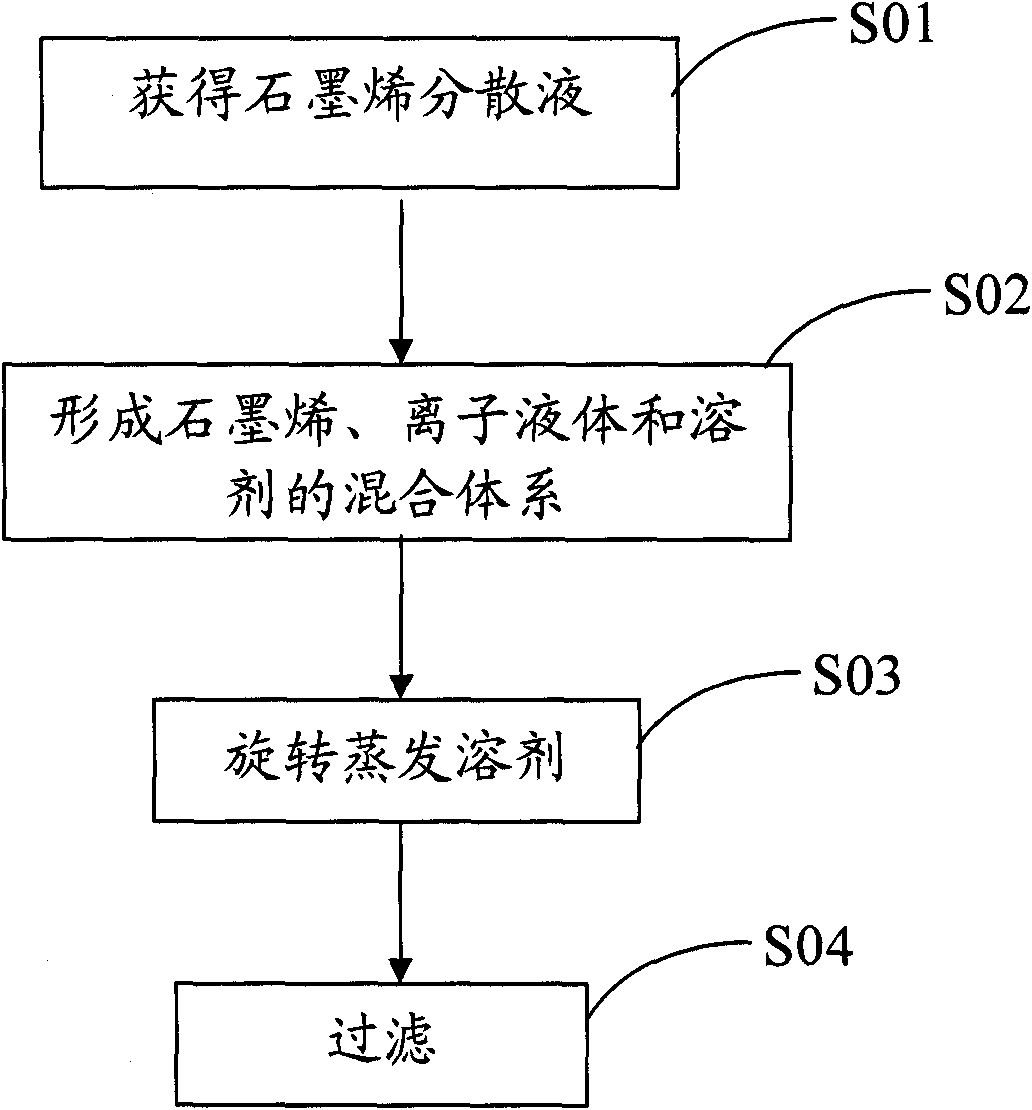

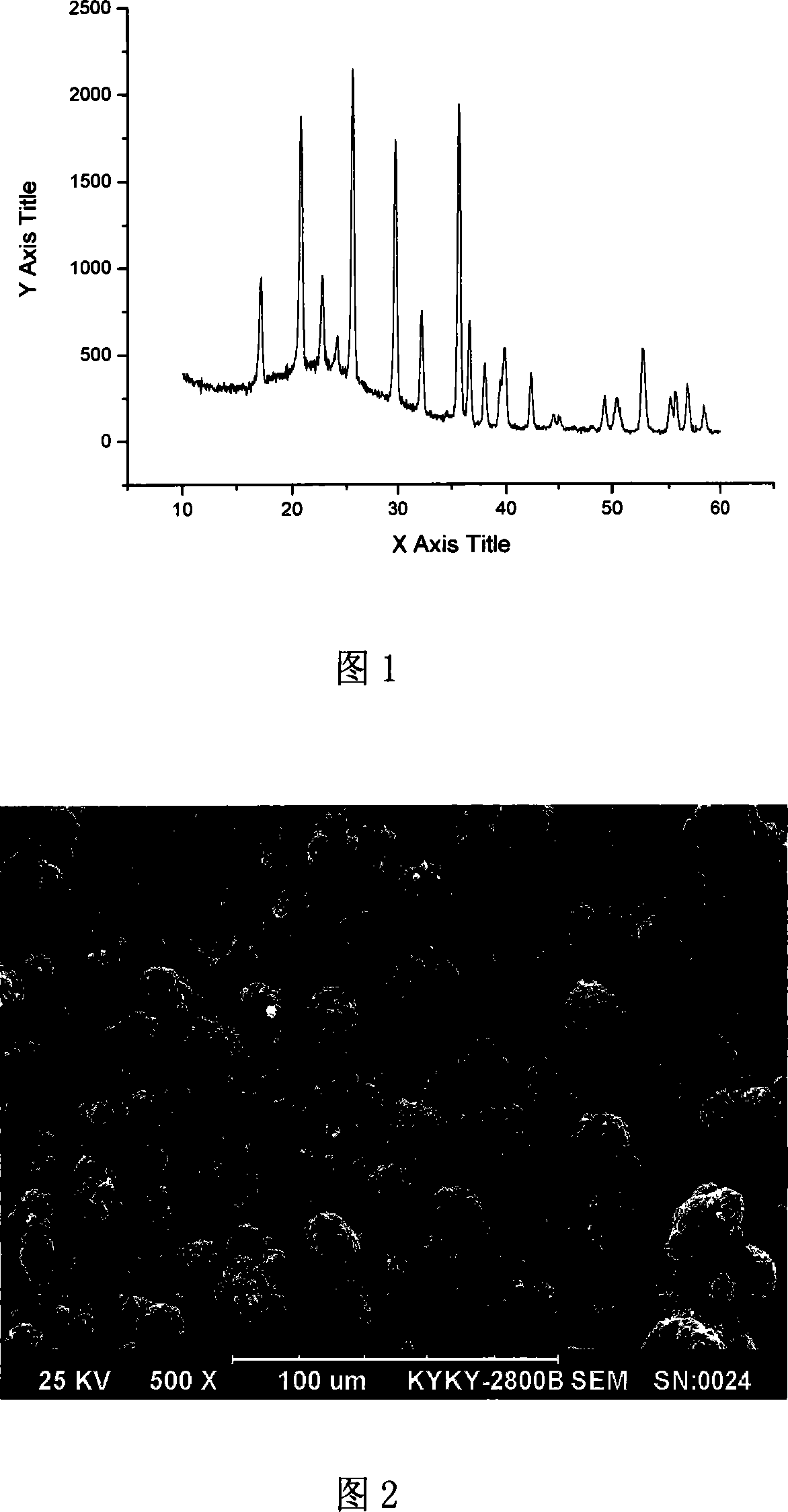

Graphene-ionic liquid composite material and preparation method thereof

InactiveCN102142294AReduce aggregationLarge specific surface areaConductive materialCapacitor electrodesGraphiteCvd graphene

The invention provides a graphene-ionic liquid composite material and a preparation method thereof. The composite material comprises the following compositions in percentage by mass: 0.01-99.99% of graphene and 0.01-99.99% of ionic liquid, wherein the ionic liquid has a polar electron cloud structure, the graphene is in a graphene sheet structure, and the ionic liquid is doped in the graphene sheets through the polar electron cloud structure of the ionic liquid so a to form a graphene-ionic liquid composite structure. Because the polar electron cloud structure of the ionic liquid can damage the interaction force between the graphene sheets and reduce the gathering of the graphene, the obtained composite material has a high specific surface area and a large specific capacity, and can be suitable to be used as the electrode materials of batteries or capacitors, and the like.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

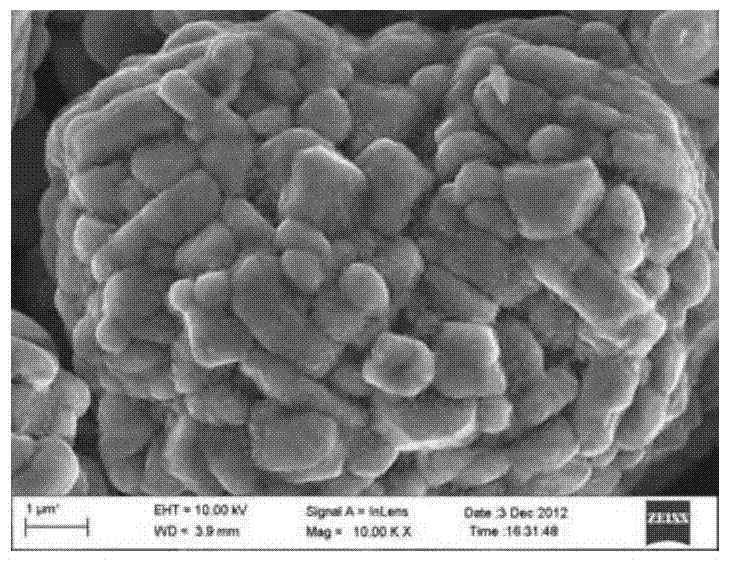

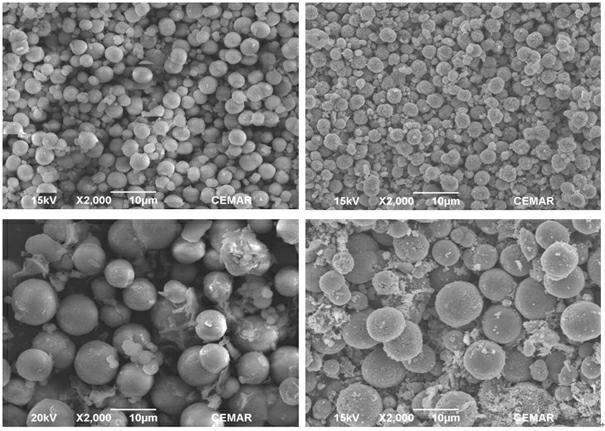

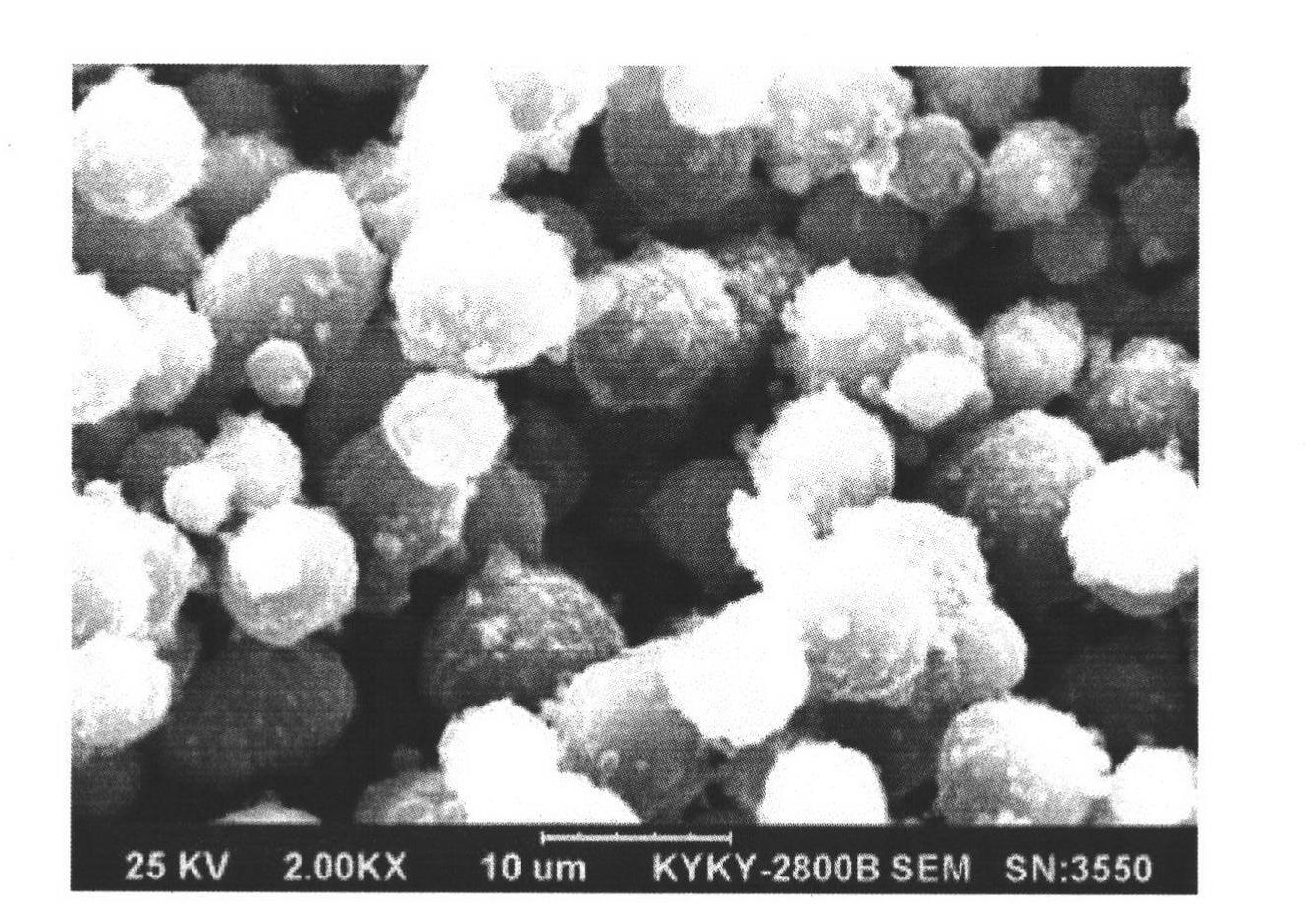

Ferric phosphate lithium material for lithium ion powder cell and preparation method thereof

ActiveCN101081696APromote crystallizationSingle structureElectrode manufacturing processesLithium compoundsCarbon layerLithium iron phosphate

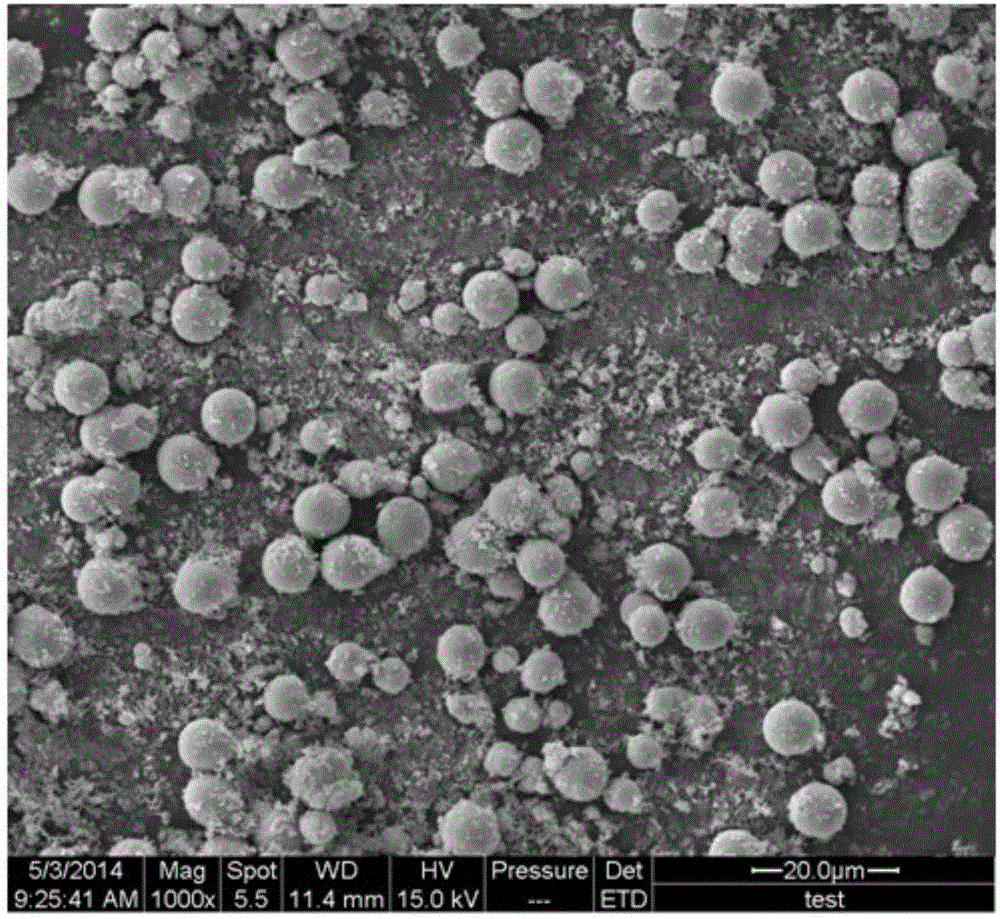

The present invention discloses lithium iron phosphate material for lithium ion power cell and its preparation process, and dissolves the technological problem of raising the discharge power and safety performance. The lithium iron phosphate material is spherical or spheroid composite particle with one base body of lithium iron phosphate and doping and modifying agent and one coating carbon layer. Its preparation process includes wet ball milling the mixture comprising lithium salt, ferric salt, phosphoric acid, doping and modifying agent and dispersant, spraying to pelletize, heating for pre-treatment, maintaining temperature, cooling, pulverizing and shaping. Compared with available technology, the present invention has the features of high crystallization, single structure, average composite particle size of 5-60 microns, specific surface area of 8.0-15.0 sq m / g, bulk density of 1.4-1.7 g / cu cm, high specific capacity, high safety, etc.

Owner:BTR (TIANJIN) NANO MATERIAL MFG CO LTD

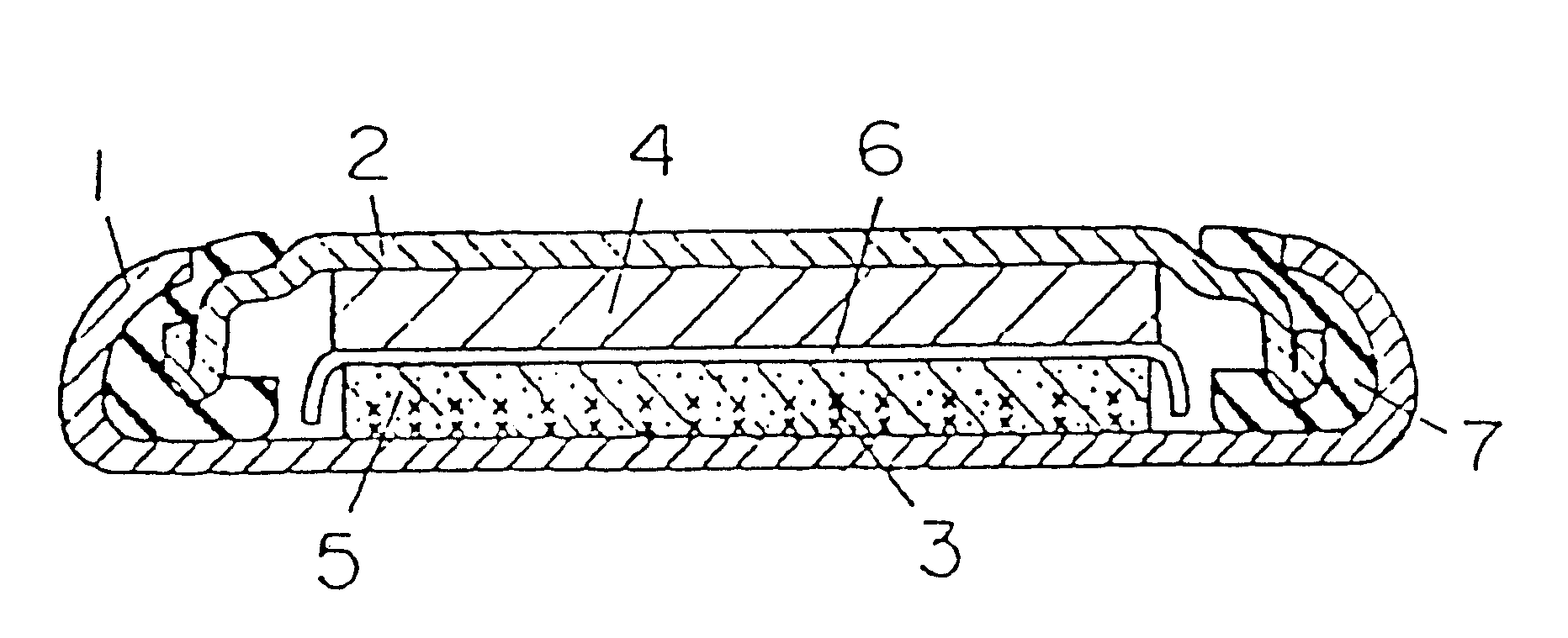

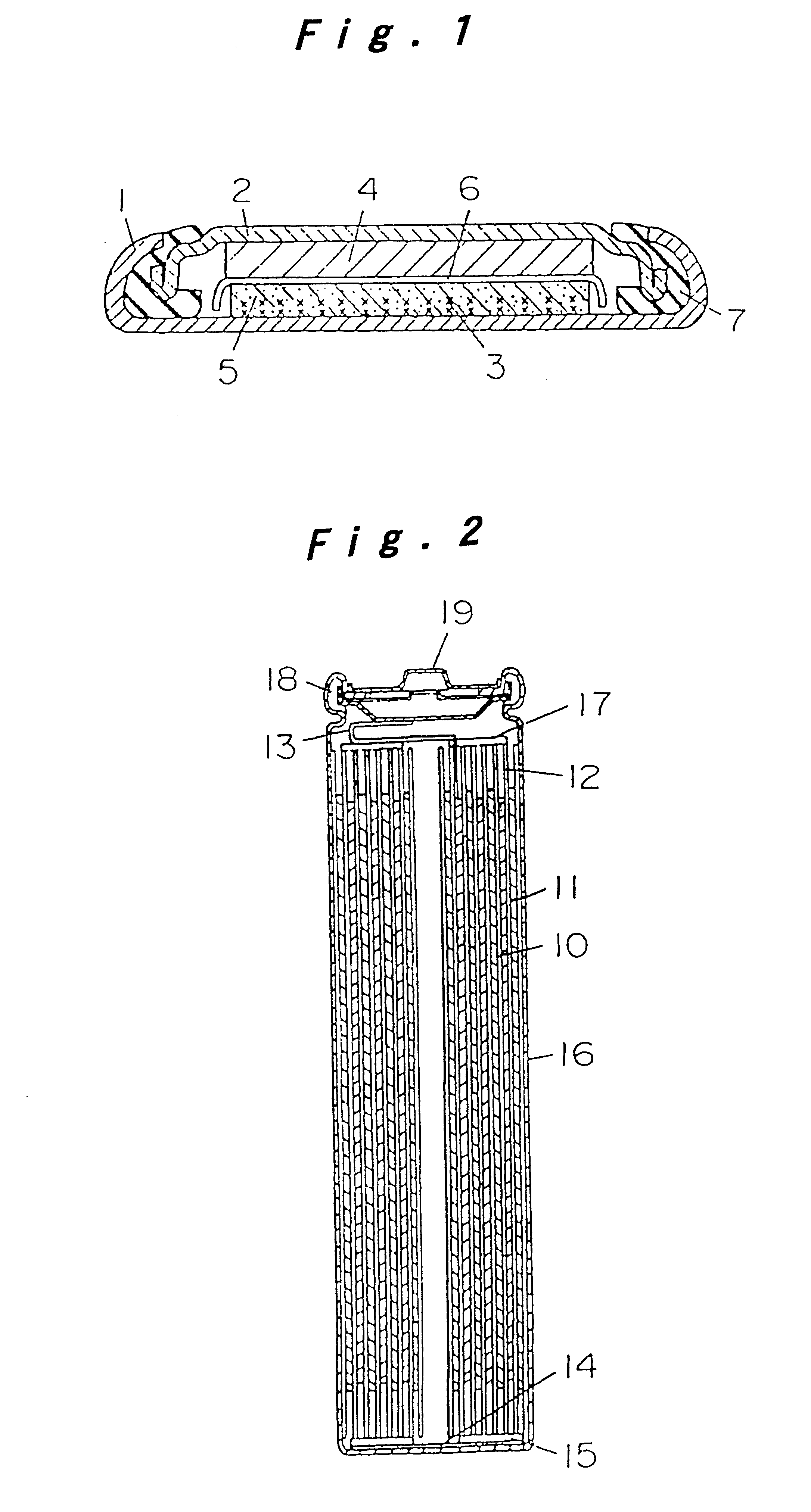

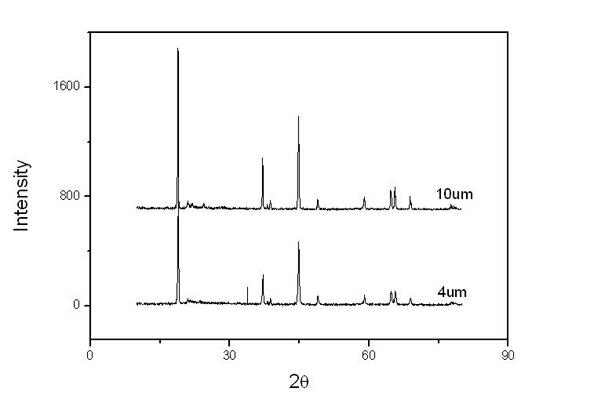

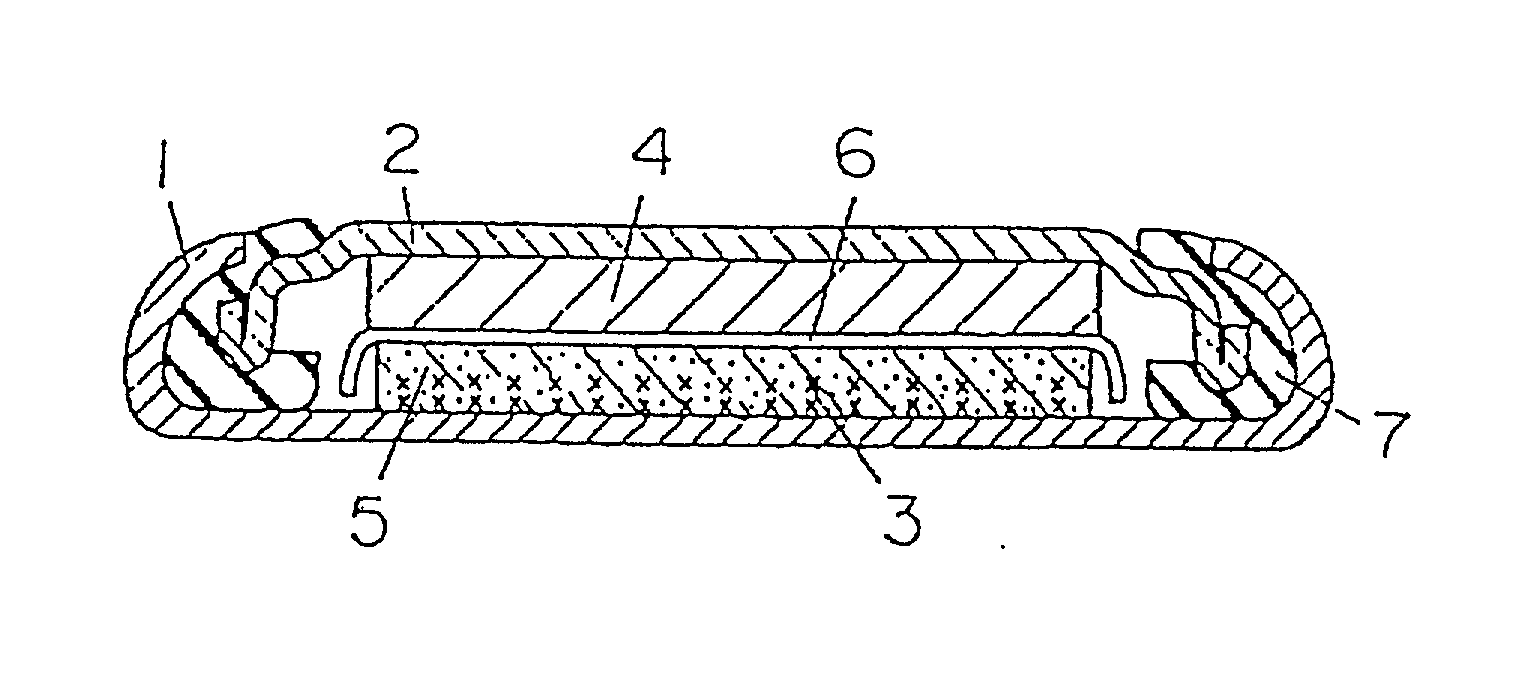

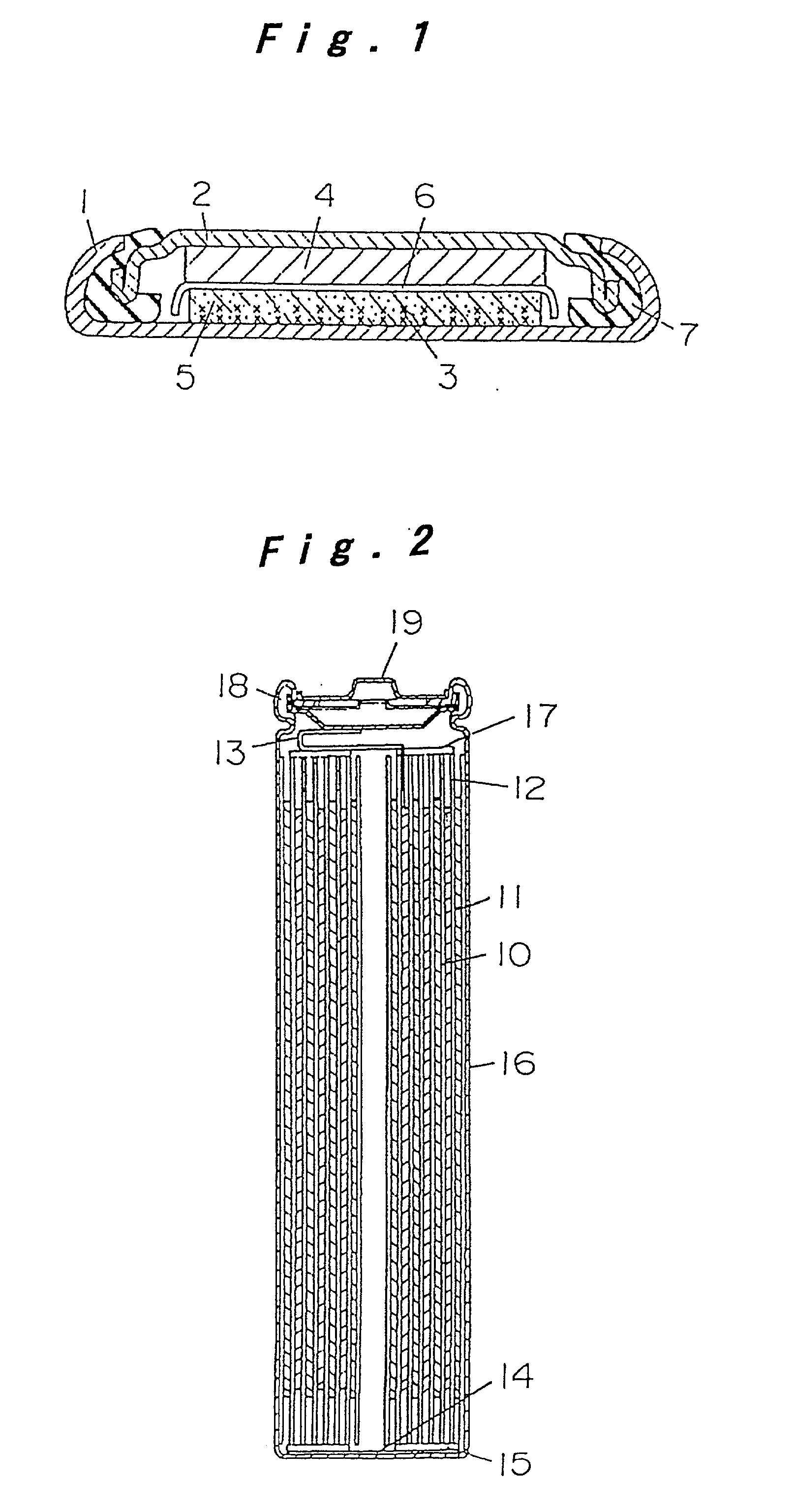

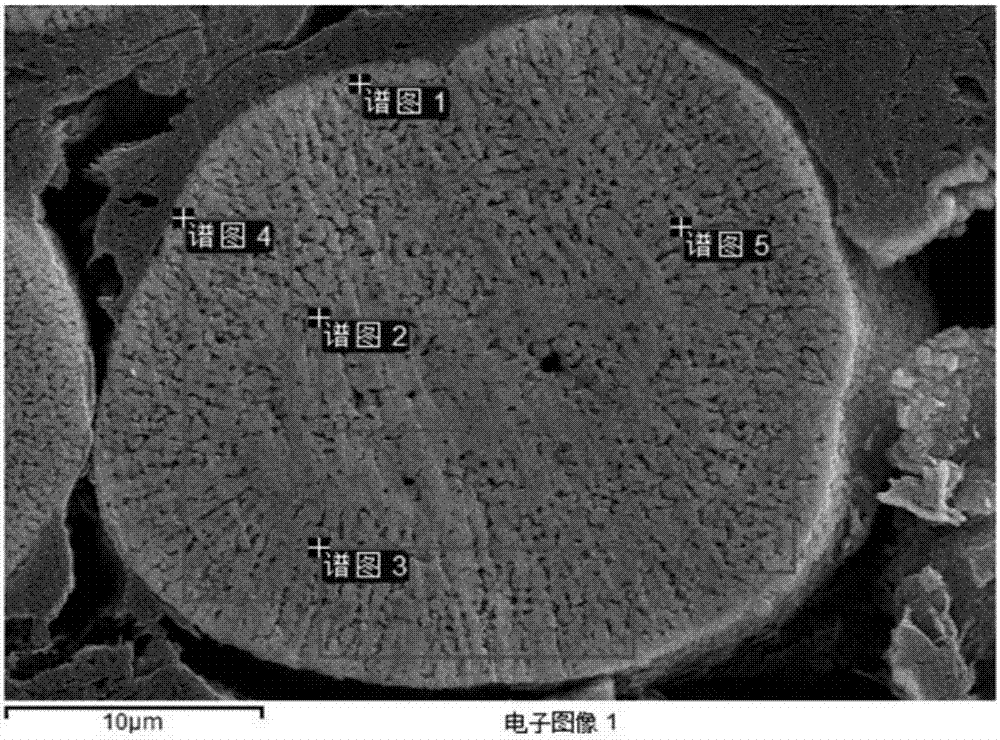

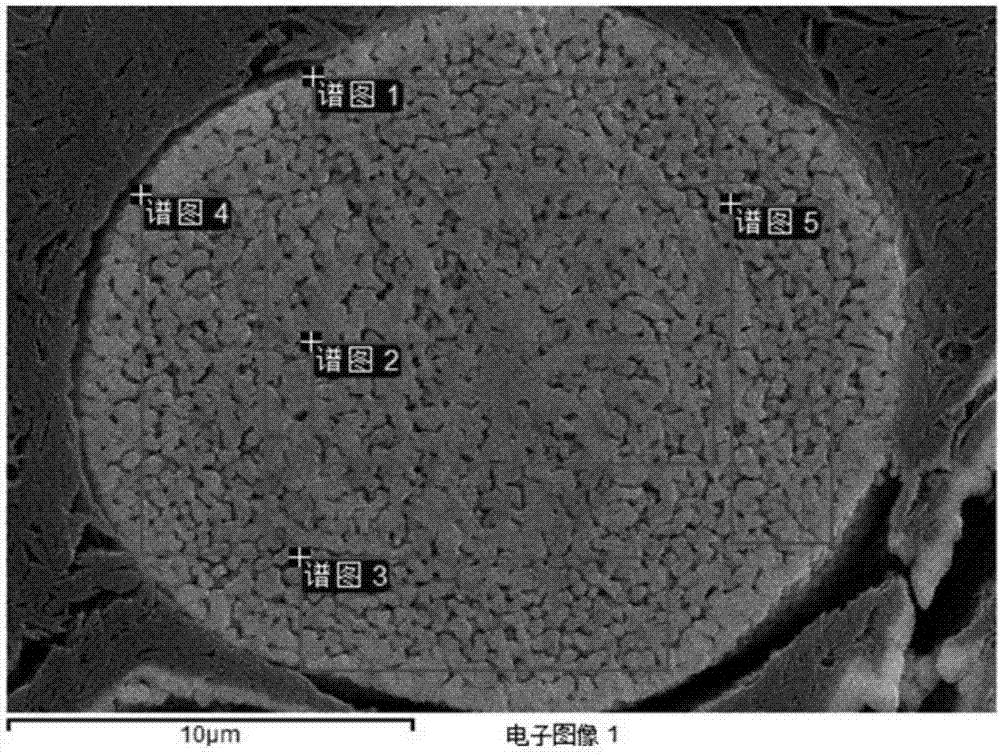

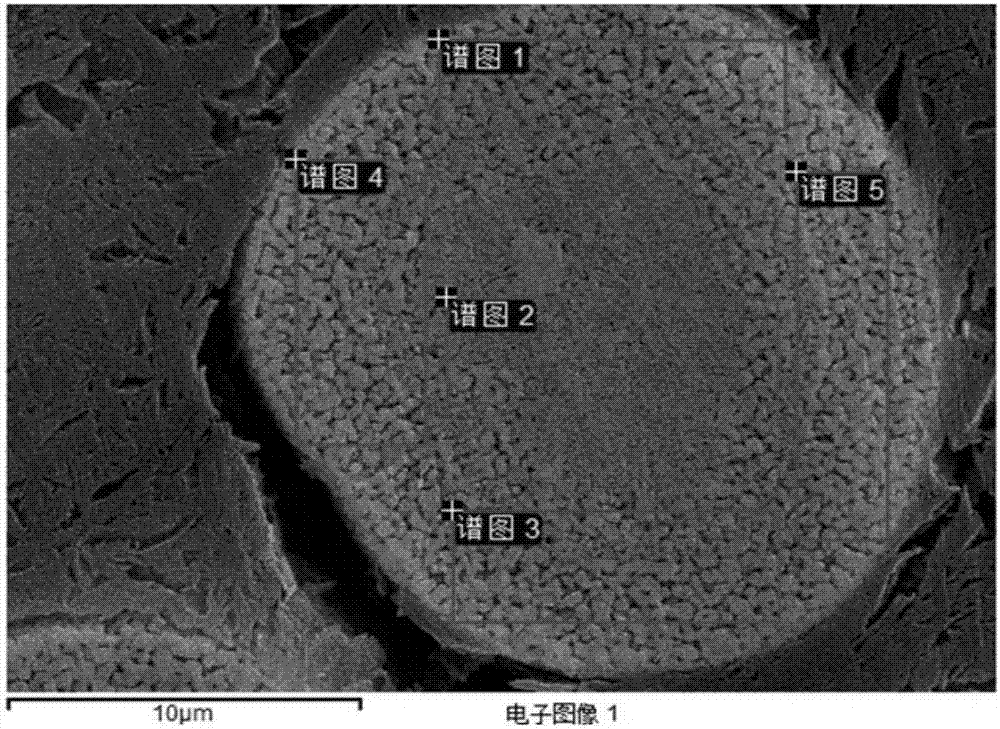

Nonaqueous electrolyte secondary battery comprising carbon particles with a plural-layer structure

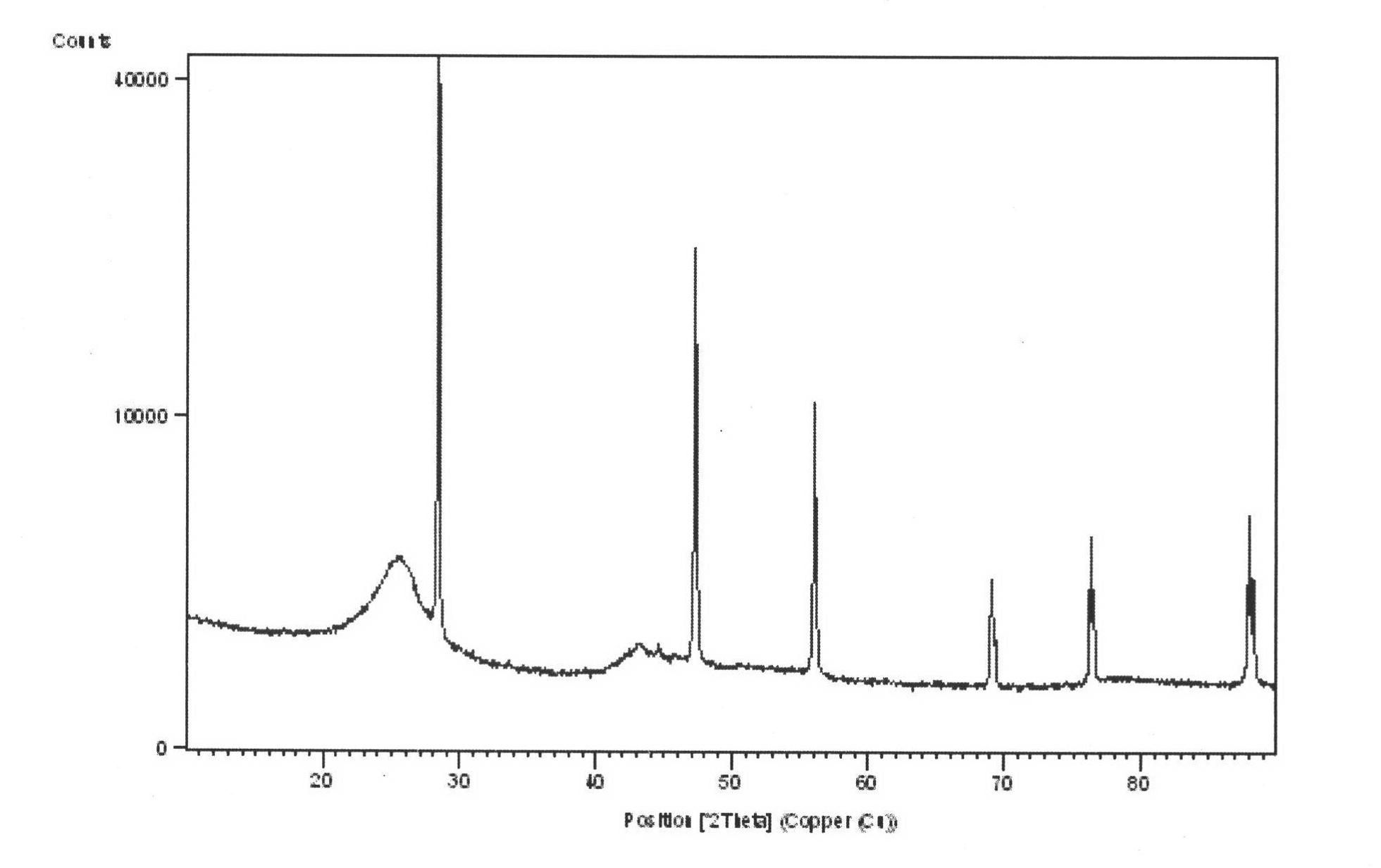

InactiveUS6403259B1High specific capacityImprove propertiesElectrode thermal treatmentActive material electrodesX-rayGraphite

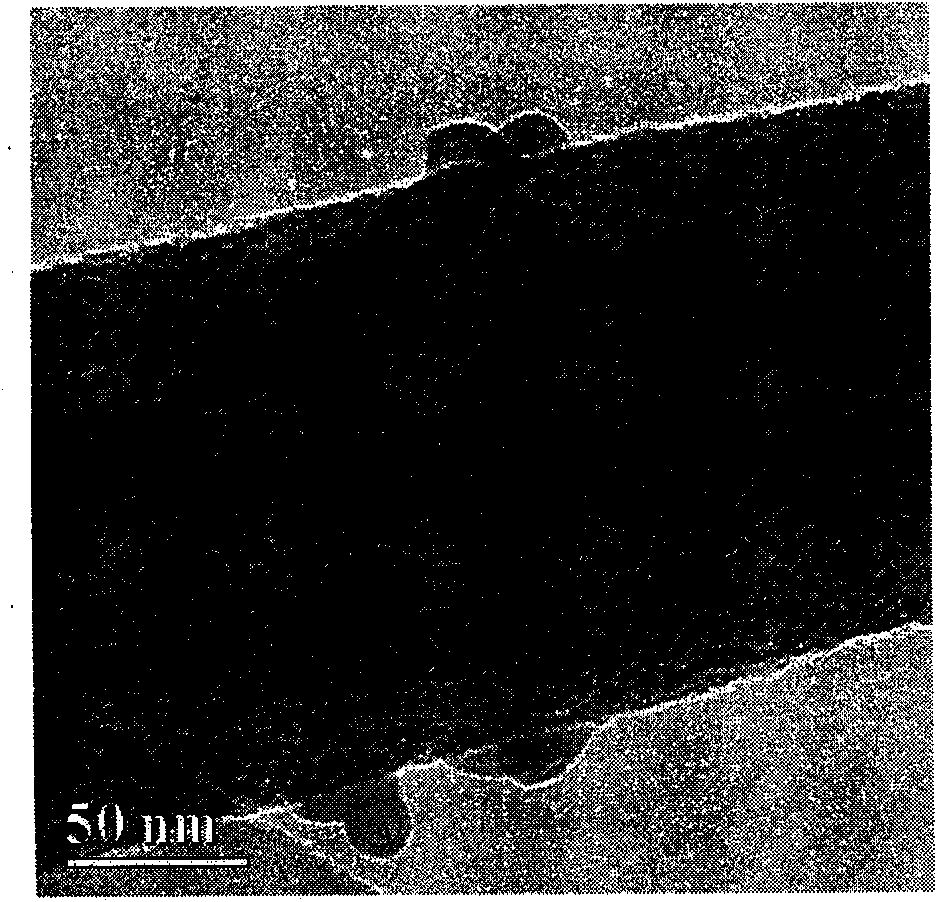

Enhancement of the storage property at a high temperature and discharge characteristics at a low temperature of a nonaqueous electrolyte secondary cell is intended. A negative electrode material which is prepared by covering the surface of a nucleus made of a graphite powder with a carbonaceous matter, the graphite powder having a specified plane interval, spectrum value, mean particle size, specific surface area, tapping density, and (110) / (004) X-ray peak intensity ratio, is used in the nonaqueous electrolyte secondary cell.

Owner:PANASONIC CORP +1

Core-shell composite anode material for lithium ion battery and preparation method thereof

ActiveCN101740752AImprove conductivityHigh specific capacitySecondary cellsIron compoundsLithium iron phosphateElectrical battery

The invention discloses a core-shell composite anode material for a lithium ion battery. The composite anode material has a core-shell structure; the core-shell structure consists of a core-layer active material and a shell-layer active material; the core-layer active material is LiFePO4 or lithium manganate; the shell-layer active material is carbon-containing LiFePO4; the LiFePO4 has an Li1-XMXFePO4 or LiFe1-yMyPO4 structure; the lithium manganate has a LiMnO2 or LiMn2O4 structure; the carbon is selected from one or more of carbon nano tubes, superfine conductive black and an agraphitic carbon material; and the composite anode material comprises 65 to 99 mass percent of core-layer active material and 1 to 35 mass percent of shell-layer active material. The composite anode material of the invention has stable performance and excellent electrochemical properties; and the lithium ion battery manufactured by using the material has relatively high charge-discharge capacity and excellent cycle performance, can perform quick charging and large multiplying-factor discharging, can adapt to an ultra-low temperature working environment and is safe and stable.

Owner:SHENZHEN DYNANONIC

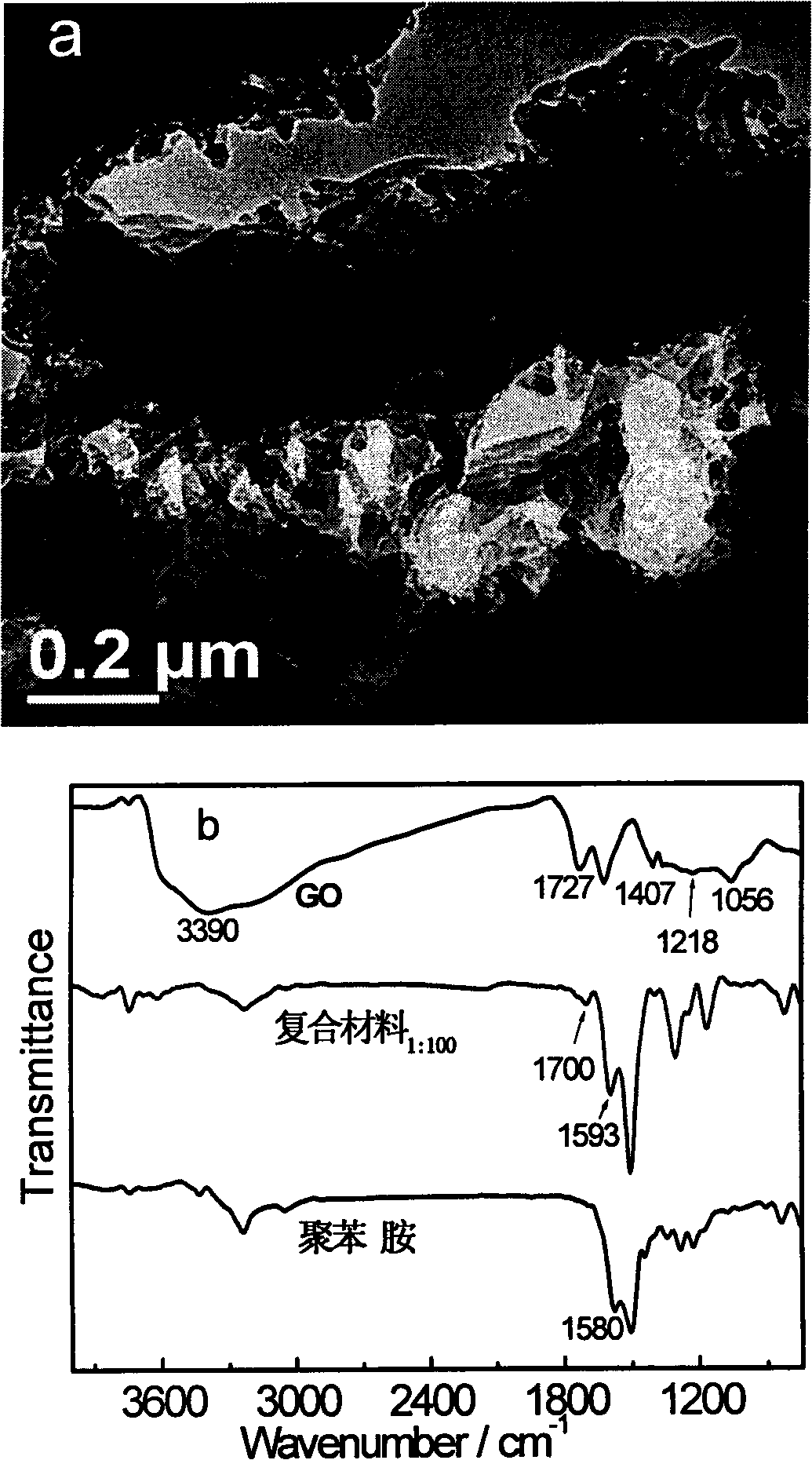

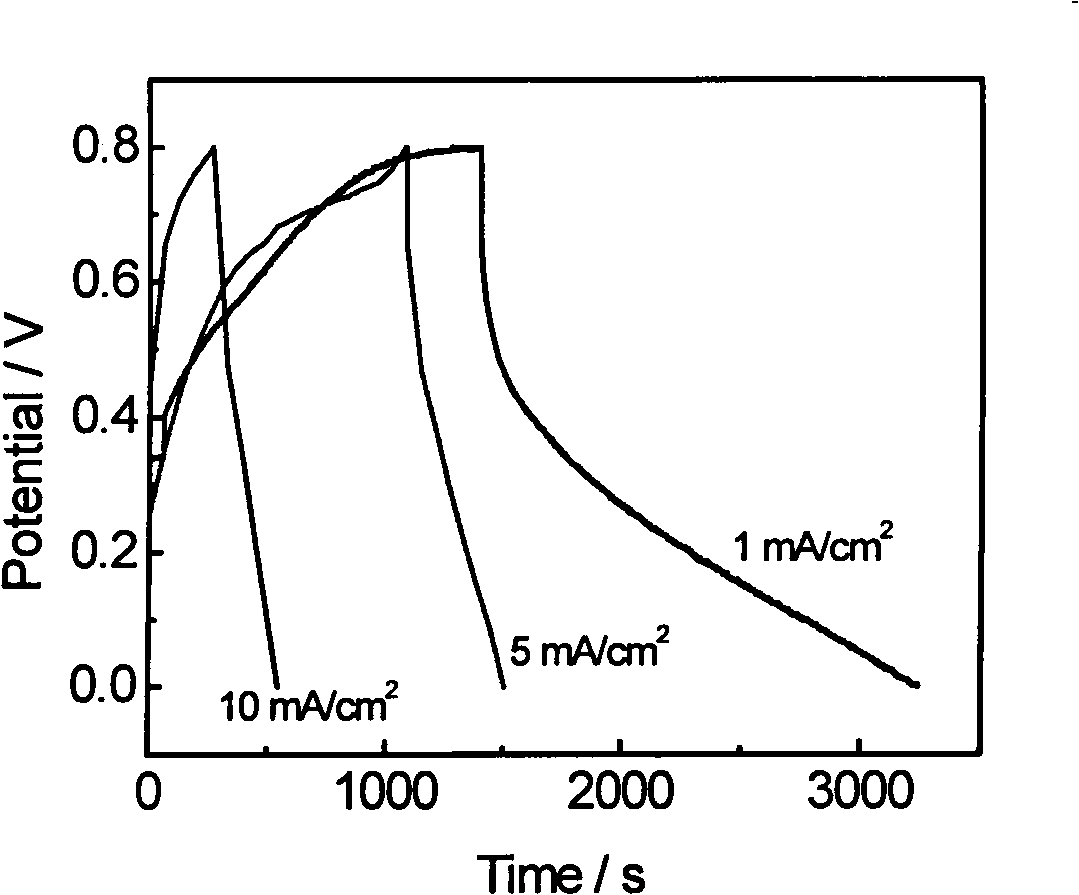

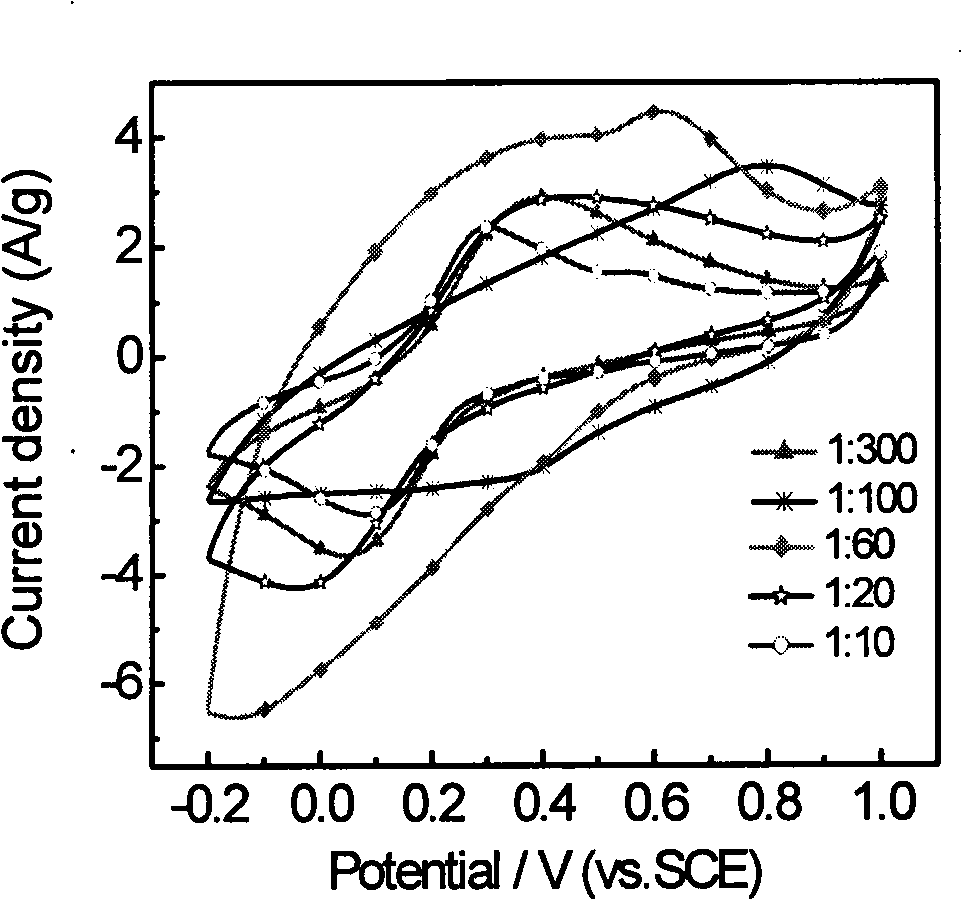

Oxidized grapheme/polyaniline super capacitor composite electrode material and preparation method and application thereof

ActiveCN101527202AImprove double layer capacitanceExcellent supercapacitor performanceElectrolytic capacitorsHybrid capacitor electrodesPolyaniline compositeAniline

The invention discloses an oxidized grapheme / polyaniline super capacitor composite electrode material and the preparation method and the application thereof. The preparation method comprise the following steps: firstly, adding oxidized graphite to water for ultrasonic dispersion so as to form an oxidized grapheme solution with uniformly dispersed single pieces; at room temperature, dropping aniline to the obtained oxidized grapheme solution for continuous ultrasonic dispersion to from a mixed solution; at a low temperature condition, adding hydrogen peroxide, ferric trichloride and a hydrochloric acid solution dropwise to the mixed solution, and stirring the solution for polymerization; and after the reaction is finished, centrifugating, washing and roasting the obtained mixed solution in vacuum to obtain the oxidized grapheme / polyaniline super capacitor composite electrode material which is used as the electrode material of an electricity storage system of a super capacitor and a battery. The oxidized grapheme / polyaniline super capacitor composite electrode material with good electrochemistry performance is obtained by the method, and the specific capacity of the oxidized grapheme and the polyaniline is greatly improved. In addition, the addition of the oxidized grapheme improves the charge and discharge service life of the polyaniline.

Owner:NANJING UNIV OF SCI & TECH

Stannum and carbon composite nano-fiber film negative-electrode material and preparation method thereof

ActiveCN101626075AExcellent discharge performance and charge-discharge cycle stabilitySimple configuration processElectrode manufacturing processesSolventCarbon composites

The invention relates to stannum / carbon nano-fiber composite film material used in the negative electrode of a lithium ion battery and a preparation method thereof and also provides an assembly method of the stannum / carbon nano-fiber composite film material generated according to the preparation method and used as the electrode of the lithium ion battery. The preparation method comprises the following steps: preparing an uniform spinning solution by mixing a stannum precursor compound, a solvent, a precursor polymer of carbon nano-fibers and an organic solvent together; obtaining a polymer nano-fiber film by electro spinning according to a suitable electrostatic spinning technology; and obtaining a stannum / carbon nano-fiber composite film used in the negative electrode of the lithium ion battery through final treatment technologies, such as preoxidation, carbonization, and the like, thereby effectively collaborating the electrochemical performance of stannum / carbon nano-fibers and improving the specific capacity, the first charge-discharge efficiency and the cycle performance of the lithium ion battery.

Owner:BEIJING UNIV OF CHEM TECH

Spinel nickel manganese acid lithium and layered lithium-rich manganese-based composite cathode material with core-shell structure and preparation method thereof

ActiveCN104157831APromote circulationRaise the ratioCell electrodesSecondary cellsComposite cathodeMaterial synthesis

The invention relates to a spinel nickel manganese acid lithium and layered lithium-rich manganese-based composite cathode material with a core-shell structure and a preparation method thereof, which belongs to the technical field of material synthesis. The prepared lithium ion composite cathode material takes a layered lithium-rich manganese-based Li[Lia(NixCoyMnz)]O2 as a core material, takes spinel nickel manganese acid lithium LiNi0.5Mn1.5O4 as a shell material; a coprecipitation method is employed to obtain a core-shell precursor, the core-shell precursor and the lithium source are uniformly mixed and calcined to obtain the spinel nickel manganese acid lithium and layered lithium-rich manganese-based composite cathode material with the core-shell structure. According to the invention, the layered lithium-rich manganese-based is taken as the core material, and the spinel nickel manganese acid lithium is taken as the shell material; under the prerequisite that material gram capacity is kept, material structural stability is increased, material cycle, multiplying power and safety performances are improved, function composite and complementation of the core material and the shell layer material can be realized, and the problem that high capacity and high security can not be achieved simultaneously is solved. The composite cathode material has the advantages of simple process and obviously increased performance.

Owner:南京时拓能源科技有限公司

Lithium nickel cobalt manganese positive electrode material and preparation method thereof

InactiveCN103490060AReasonable structureGood ability to withstand high voltageCell electrodesSecondary cellsRare-earth elementLithium

The invention discloses a lithium nickel cobalt manganese positive electrode material. The lithium nickel cobalt manganese positive electrode material comprises a lithium nickel cobalt manganese oxide contained core pure phase layer having a thickness of 5-8mum, a surface coat containing oxides, phosphates or fluorides of coating elements comprising Li, Al, Mg, Ti and Zr and having a thickness of 50-100nm, and a superficial doped transition layer positioned between the core pure phase layer and the surface coat, containing doping elements comprising Al, Mg, Ti and Zr or one of rare earth elements and having a thickness of 1-2mum. The lithium nickel cobalt manganese positive electrode material can inhibit the material dissolving in a cycle process without reducing a specific capacity, and has the characteristics of high capability excellent cycle and rate performances, and excellent thermal stability.

Owner:NINGDE AMPEREX TECH

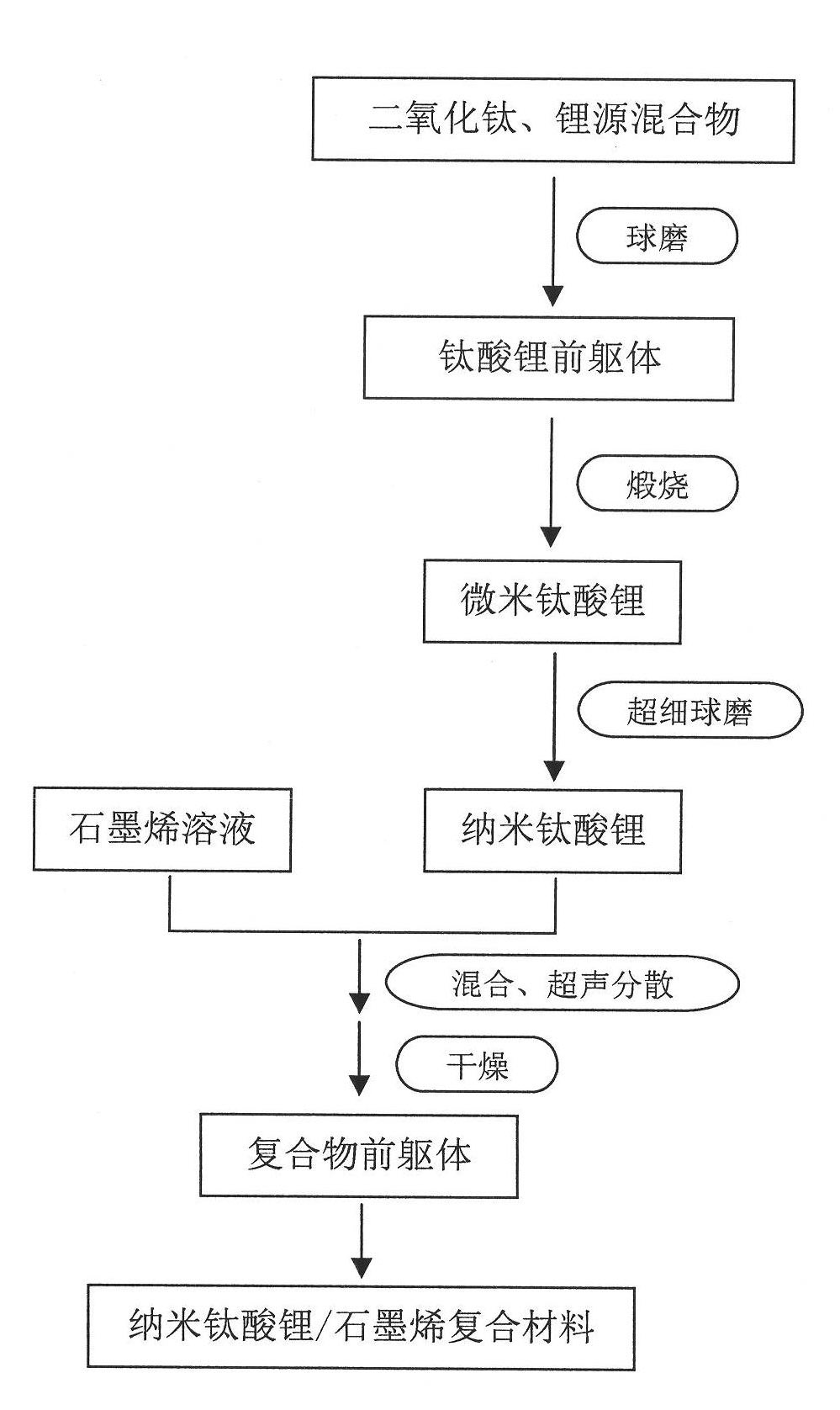

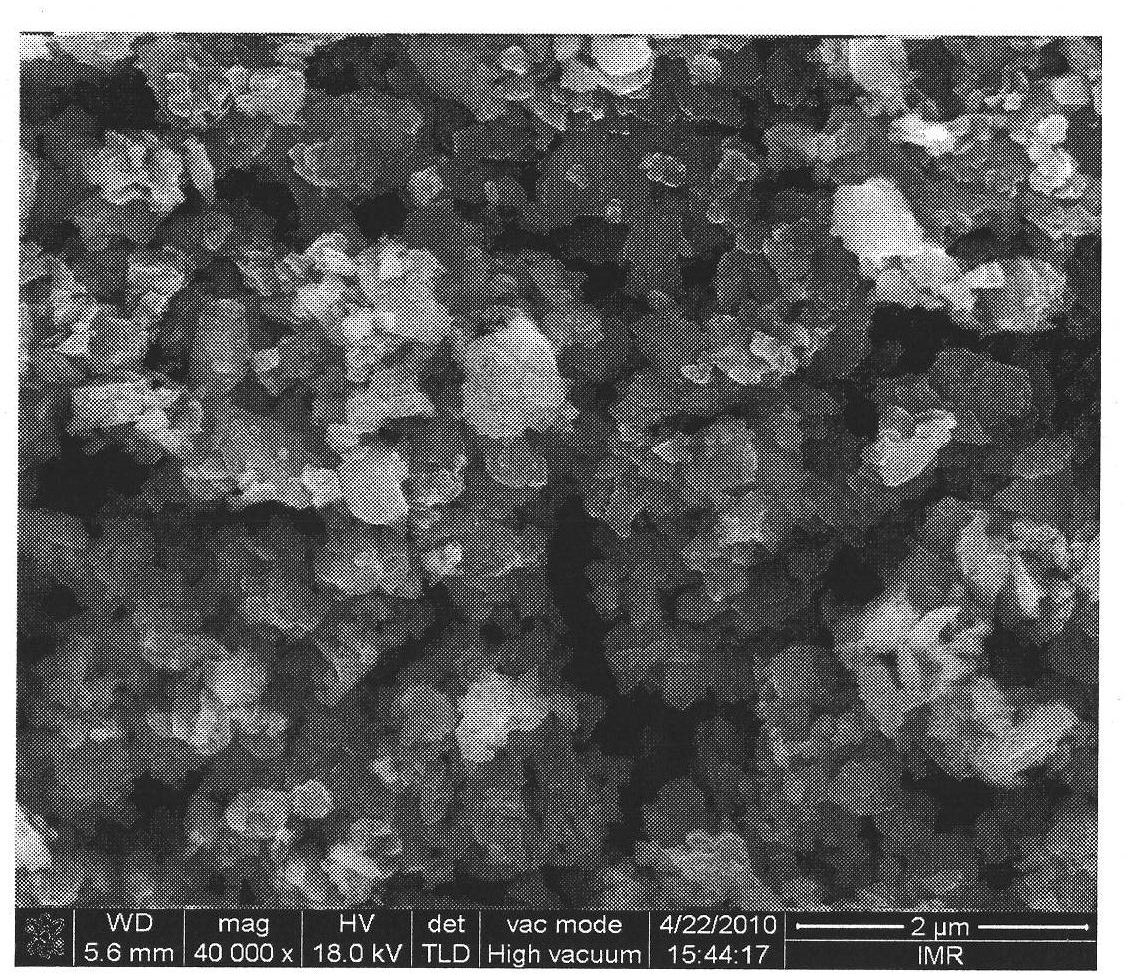

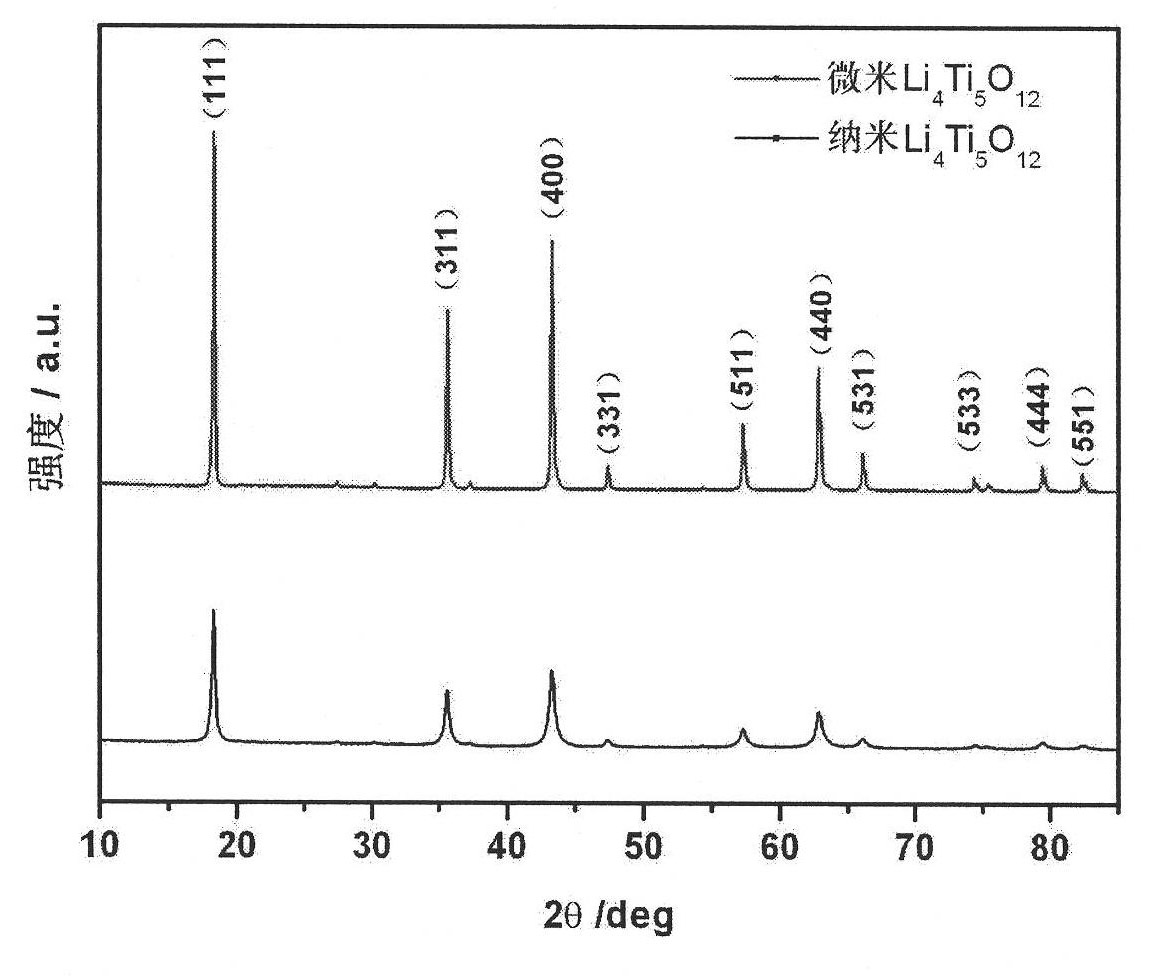

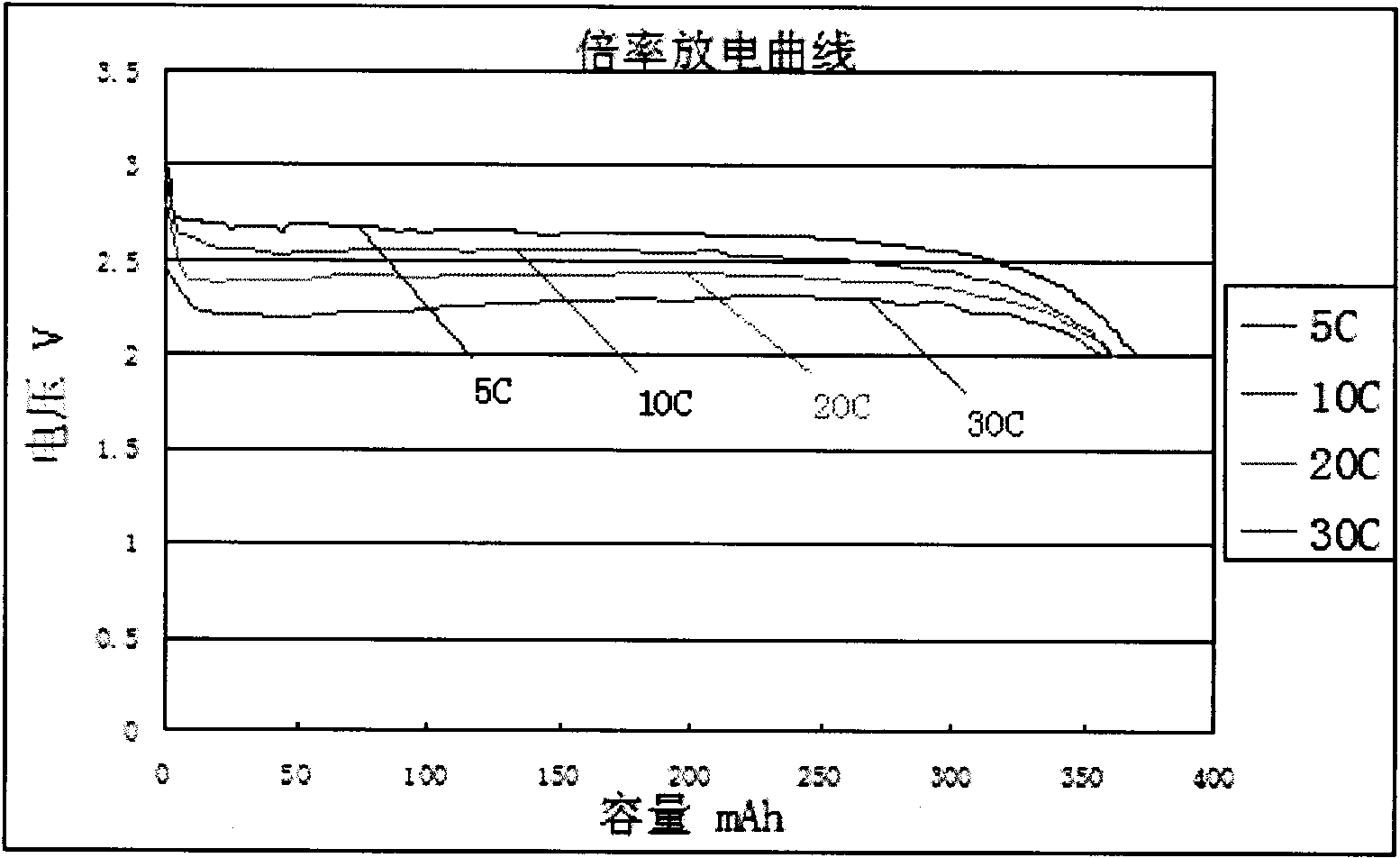

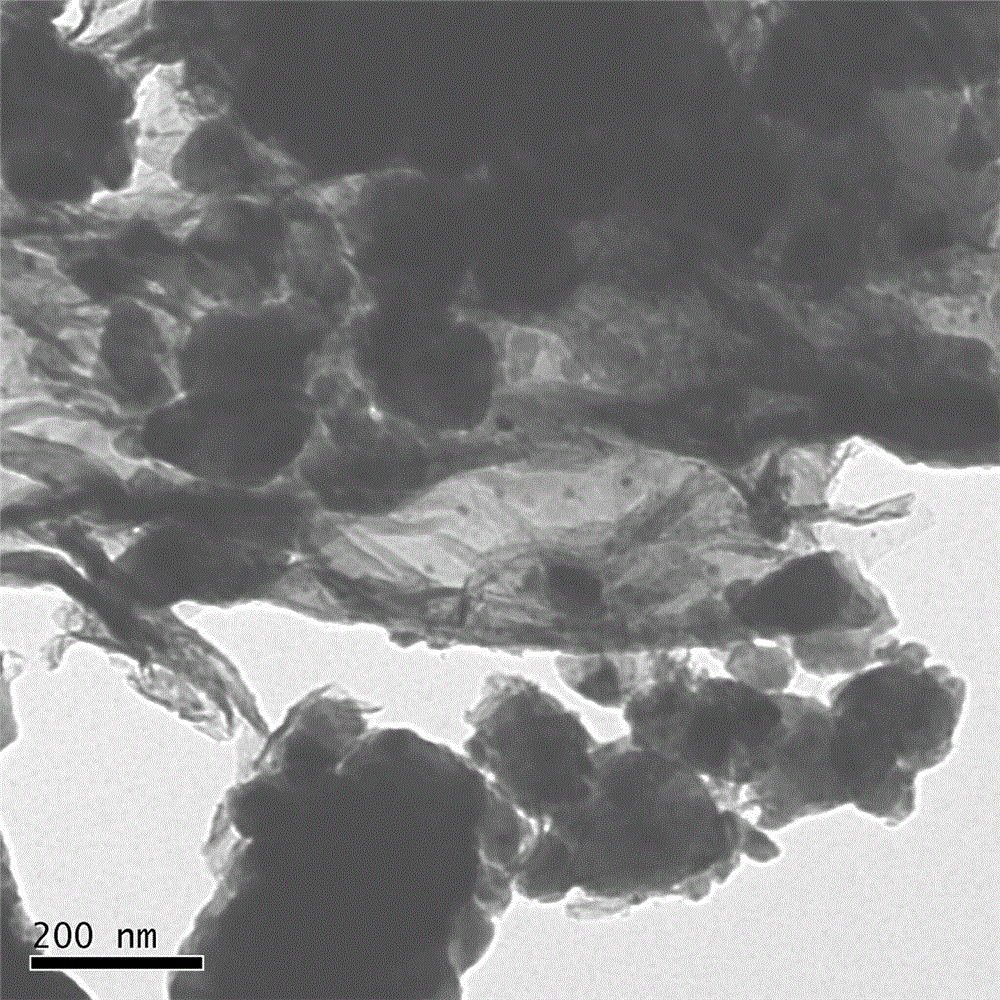

Nanometer lithium titanate/graphene composite negative electrode material and preparation process thereof

InactiveCN102376937AImprove electrochemical performanceAvoid defectsNon-aqueous electrolyte accumulator electrodesGrain treatmentsSodium-ion batteryCvd graphene

The invention relates to the field of negative electrode materials of lithium ion batteries, and specifically to a nanometer lithium titanate / graphene composite negative electrode material and a preparation process thereof. According to the invention, micron-sized lithium titanate prepared by the solid phase method is subjected to ultrafine ball milling to obtain nanometer powder, and the nanometer lithium titanate powder and graphene are uniformly compounded and subjected to heat treatment so as to obtain a high performance lithium ion battery negative electrode material; the invention is characterized in that uniform distribution of graphene in the nanometer lithium titanate powder is realized through in situ compounding; the weight of graphene in the composite negative electrode material accounts for 0.5 to 20%, and the weight of lithium titanate accounts for 80 to 99.5%. The lithium ion battery negative electrode material has good electrochemical performance, 1C capacity greater than 165 mAh / g, 30C capacity greater than 120 mAh / g and 50C capacity greater than 90 mAh / g. Nanometer lithium titanate in the lithium ion battery negative electrode material prepared in the invention has high phase purity; the preparation process of the material is simple and is easy for industrial production.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

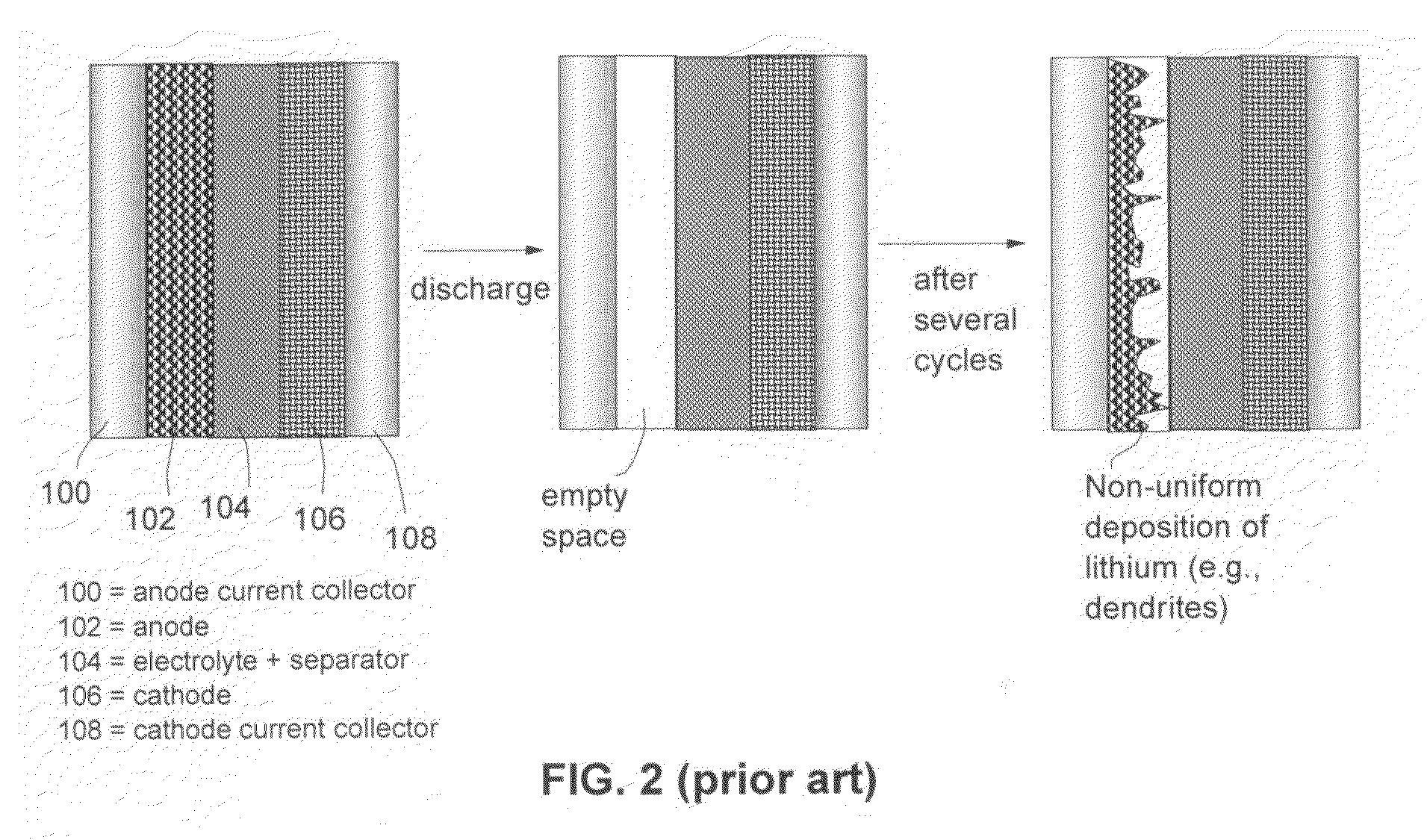

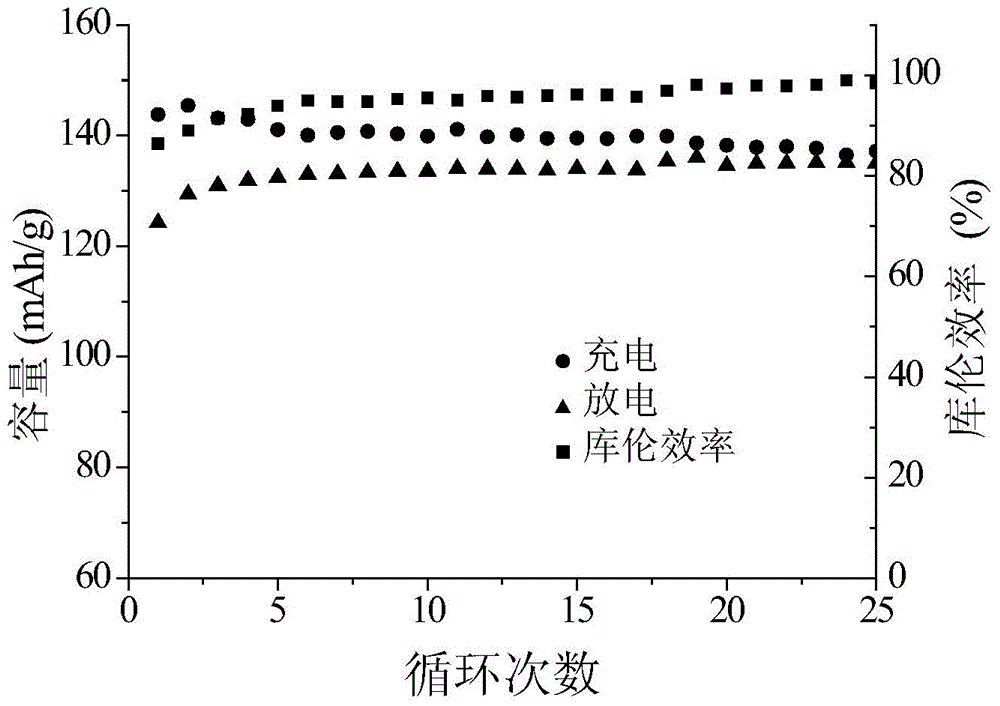

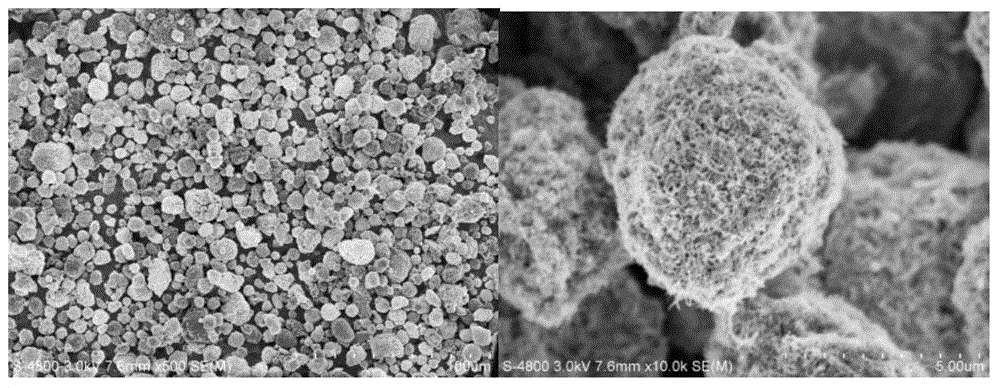

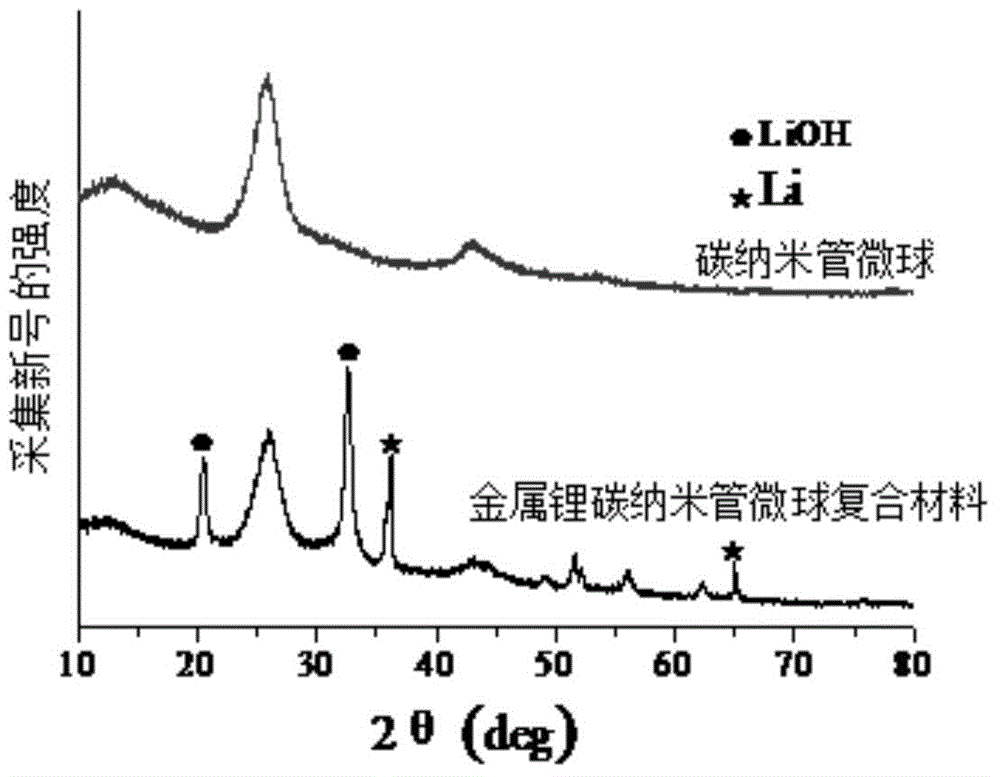

Metal lithium-framework carbon composite material and preparation method thereof, negative electrode and secondary battery

ActiveCN105374991AHigh specific capacityGood cycle performanceSecondary cellsNon-aqueous electrolyte accumulator electrodesMetallic lithiumComposite material

The present application discloses a metal lithium-framework carbon composite material preparation method, which comprises: uniformly mixing metal lithium having a molten state and a porous carbon material carrier, and cooling to obtain the metal lithium-framework carbon composite material. The invention further discloses a metal lithium-framework carbon composite material, a secondary battery negative electrode, a secondary battery and a metal-framework carbon composite material. According to the present invention, with the prepared metal lithium-framework carbon composite material, the dendritic crystal formation can be inhibited, the whole property of the battery can be improved, and the high specific capacity and the good cycle performance are provided.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

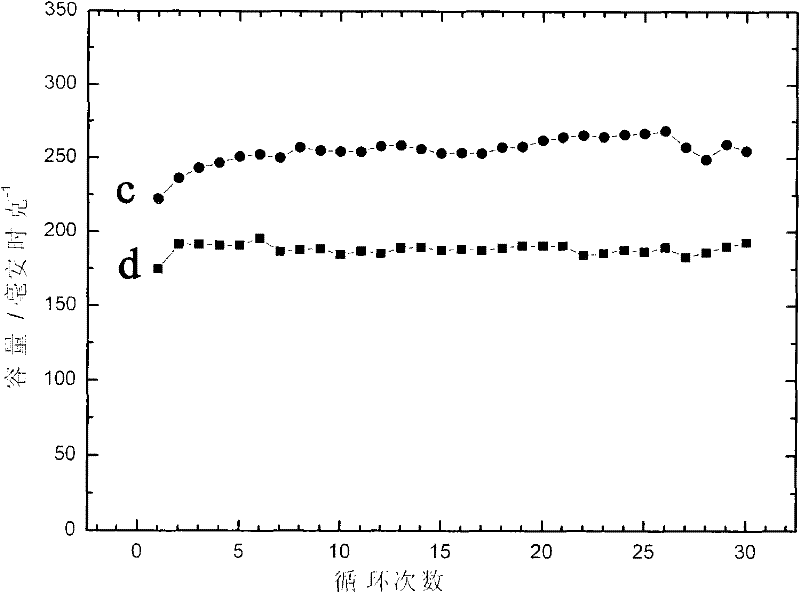

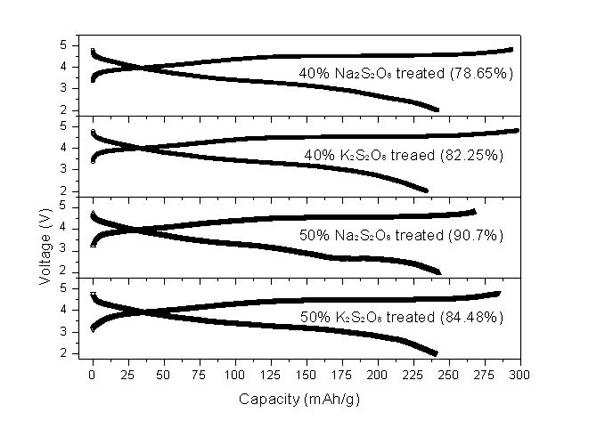

Synthesis and surface modification method of lithium excessive laminar oxide anode material

The invention relates to a synthesis and surface modification method of a lithium rich anode material Li1+xM1-xO2 (M is one or more of Ni, Co and Mn, and X is more than or equal to 0 and less than or equal to 1 / 3) for a lithium ion battery. The method comprises the following steps of: synthesizing a precursor by using a carbonate precipitation method, mixing the precursor and a lithium salt, and calcining for 2 to 20 hours at the temperature of between 800 and 1,100 EG C to obtain a lithium rich material, wherein the prepared lithium rich material has controllable particle size and higher reversible capacity; and dissolving persulfate or sulfate in an amount which is 5 to 80 mass percent of the lithium rich material into deionized water, adding the lithium rich material, stirring for 2 to 100 hours at the temperature of between 25 and 80 DEG C, heating the materials to the temperature of between 100 and 500 DEG C in a muffle furnace, calcining the materials for 2 to 20 hours, fully filtering the obtained materials, and washing off impurities to obtain the surface modified anode material Li1+x-yM1-xO2. The synthesized lithium rich material has controllable particle size; the first charge / discharge efficiency of the lithium rich material and the discharge specific capacity and the cyclical stability under high magnification can be improved; and the method is simple, low in cost, convenient for operation and suitable for industrialized production.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

Nonaqueous electrolyte secondary cell

InactiveUS20020061445A1High specific capacityImprove propertiesElectrode thermal treatmentLayered productsX-rayGraphite

Enhancement of the storage property at a high temperature and discharge characteristics at a low temperature of a nonaqueous electrolyte secondary cell is intended. A negative electrode material which is prepared by covering the surface of a nucleus made of a graphite powder with a carbonaceous matter, the graphite powder having a specified plane interval, spectrum value, mean particle size, specific surface area, tapping density, and (110) / (004) X-ray peak intensity ratio, is used in the nonaqueous electrolyte secondary cell.

Owner:MITSUBISHI CHEM CORP

Modified positive electrode material of lithium ion battery and preparation method of modified positive electrode material

InactiveCN102738451AImprove performanceImproved performance characteristicsCell electrodesDischarge efficiencyElectrical conductor

The invention discloses a modified positive electrode material of a lithium ion battery and a preparation method of the modified positive electrode material. The modified positive electrode material is characterized in that the modified positive electrode material is made of a lithium fast ion conductor and a positive electrode material of lithium ion battery at a molar ratio of n:1, wherein n is larger than 0 and not larger than 0.15. The invention also discloses the preparation method of the modified positive electrode material of the lithium ion battery. The modified positive electrode material provided by the invention is improved in conductivity property performance and surface properties, thereby enhancing the specific volume of the lithium ion battery, and improving the charging-discharging efficiency, rate capacity, cycling performance and temperature adaptability of the lithium ion battery.

Owner:HENAN NORMAL UNIV

Positive plate of lithium ion battery, lithium ion battery and preparation method of lithium ion battery

ActiveCN105552344ANo need to change the preparation processImprove conductivityElectrode carriers/collectorsSecondary cellsPositive currentElectrochemistry

The invention provides a positive plate of a lithium ion battery. The positive plate comprises a positive current collector and a positive active substance layer, wherein the positive active substance layer is coated on the positive current collector and contains a positive active substance, a conductive agent, a binding agent and a lithium-rich compound, and the lithium-rich compound decomposes to generate lithium ions and release one or more of a gas, conductive carbon and a substance having electrochemical lithium storage activity during formation charging of the lithium ion battery. The generated lithium ions are transferred to a negative electrode from a positive electrode and take participation in reaction with the negative electrode (react with a decomposed product of an electrolyte to form an SEI film at the negative electrode) to supplement to lithium required for forming the SEI film, thus, the lithium ion consumption of the positive active substance can be reduced, and the energy density and the cycle performance of the lithium ion battery are improved. The invention also provides a preparation method for the positive plate of the lithium ion battery, the lithium ion battery applying the positive plate of the lithium ion battery and a preparation method of the lithium ion battery.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

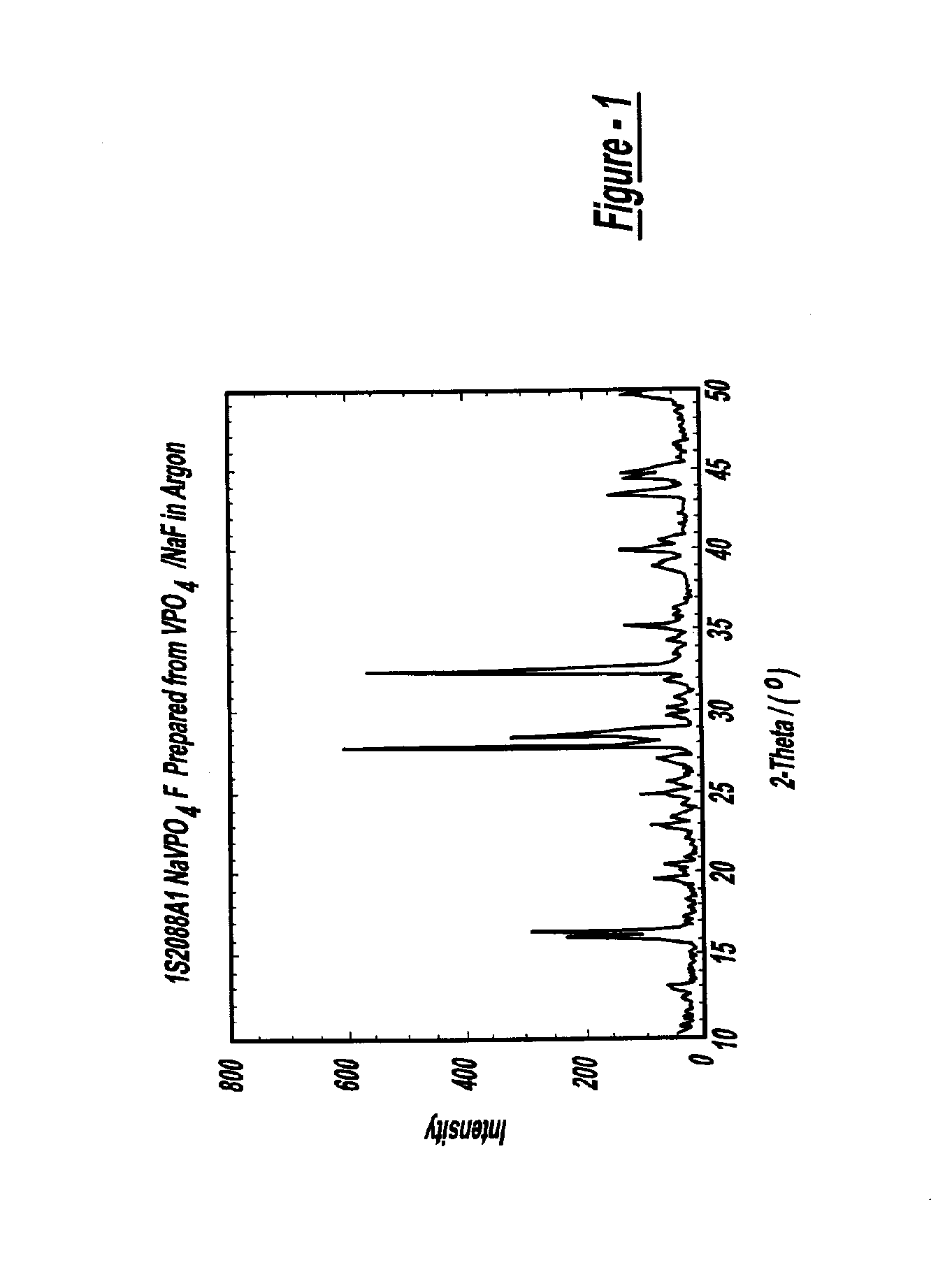

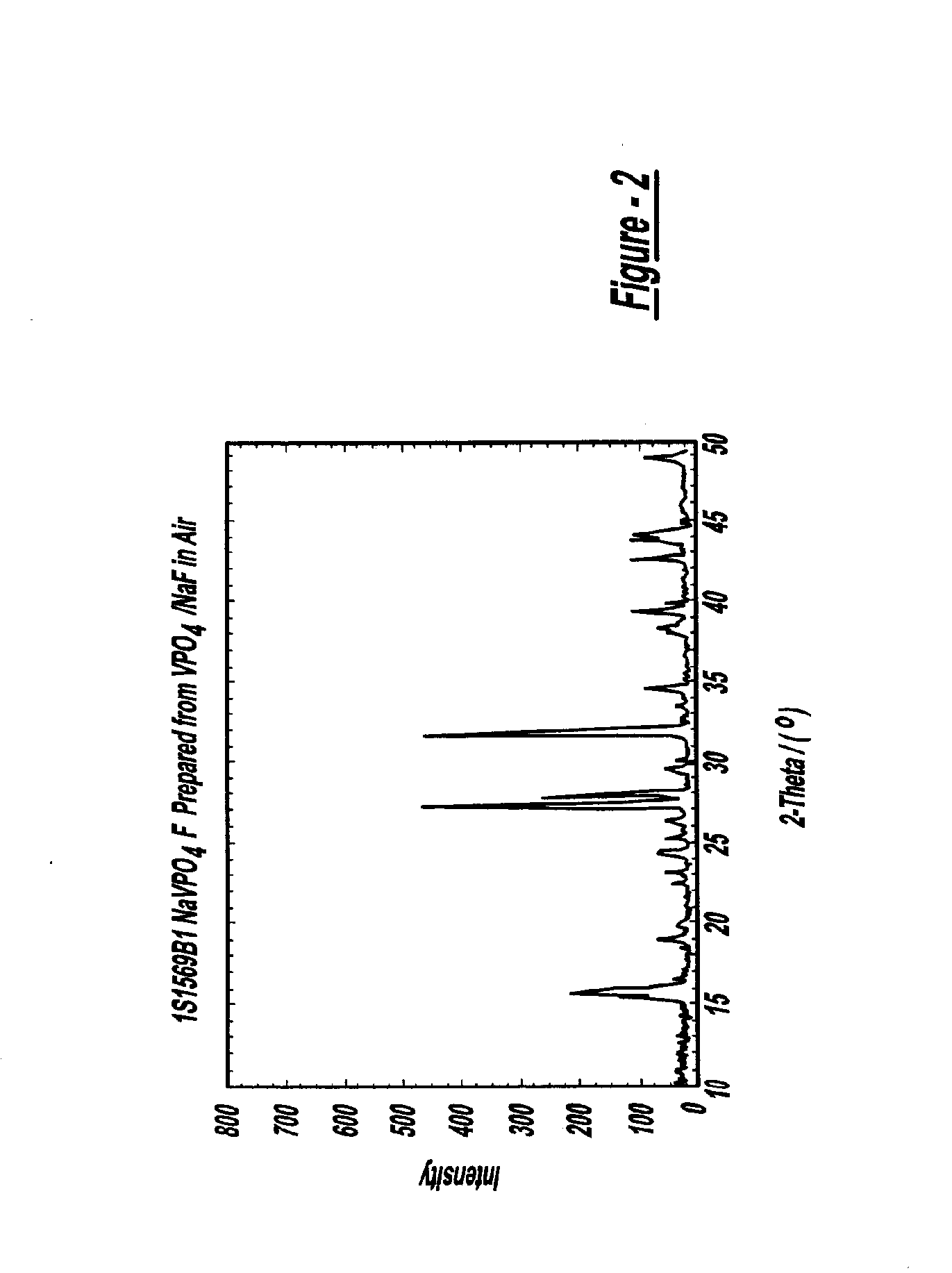

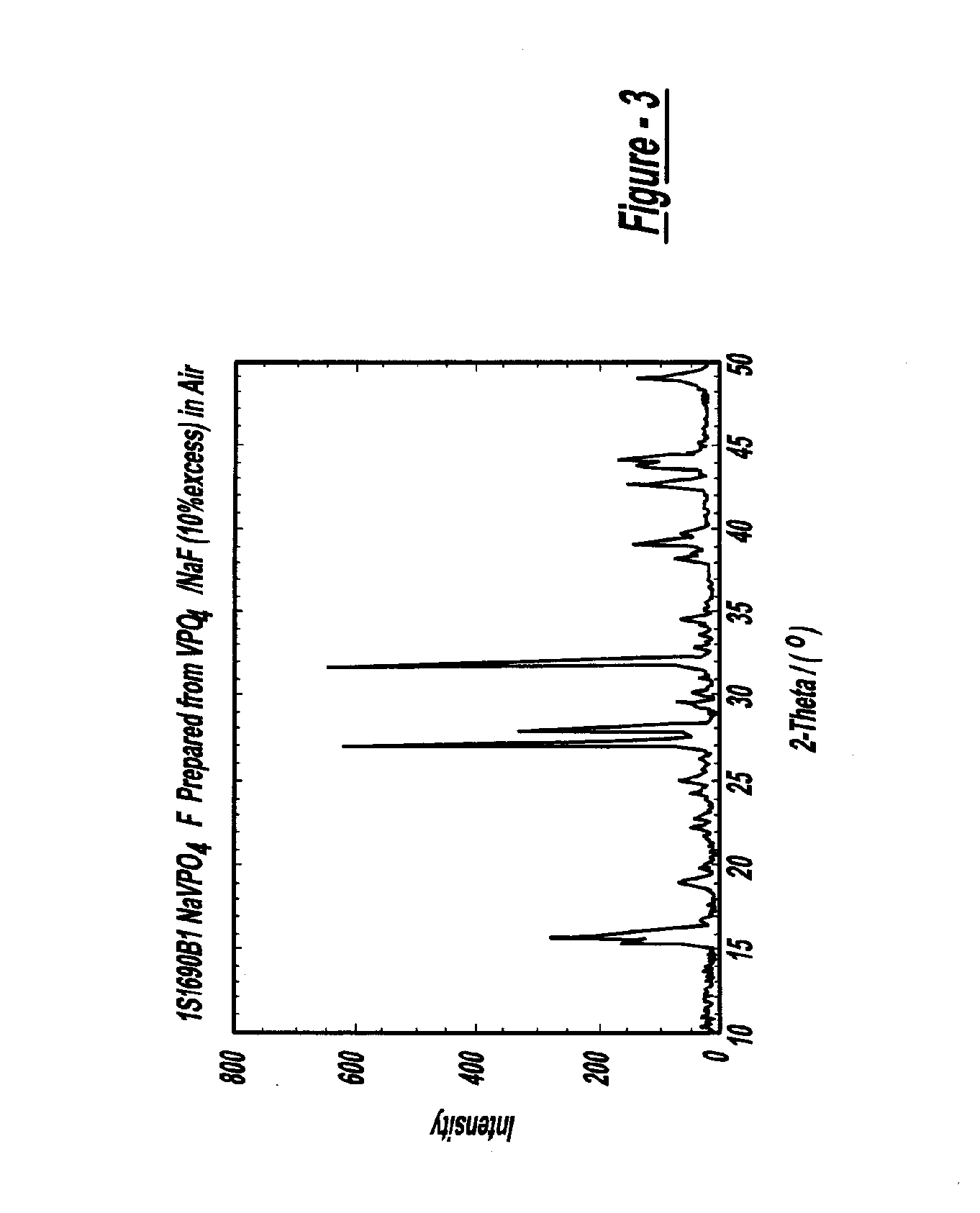

Sodium ion batteries

InactiveUS20050238961A1High operation potentialHigh specific capacityOrganic electrolyte cellsSecondary cellsPhosphateSodium-ion battery

Sodium ion batteries are based on sodium based active materials selected among compounds of the general formula AaMb(XY4)cZd, wherein A comprises sodium, M comprises one or more metals, comprising at least one metal which is capable of undergoing oxidation to a higher valence state, Z is OH or halogen, and XY4 represents phosphate or a similar group. The anode of the battery includes a carbon material that is capable of inserting sodium ions. The carbon anode cycles reversibly at a specific capacity greater than 100 mAh / g.

Owner:VALENCE TECH INC

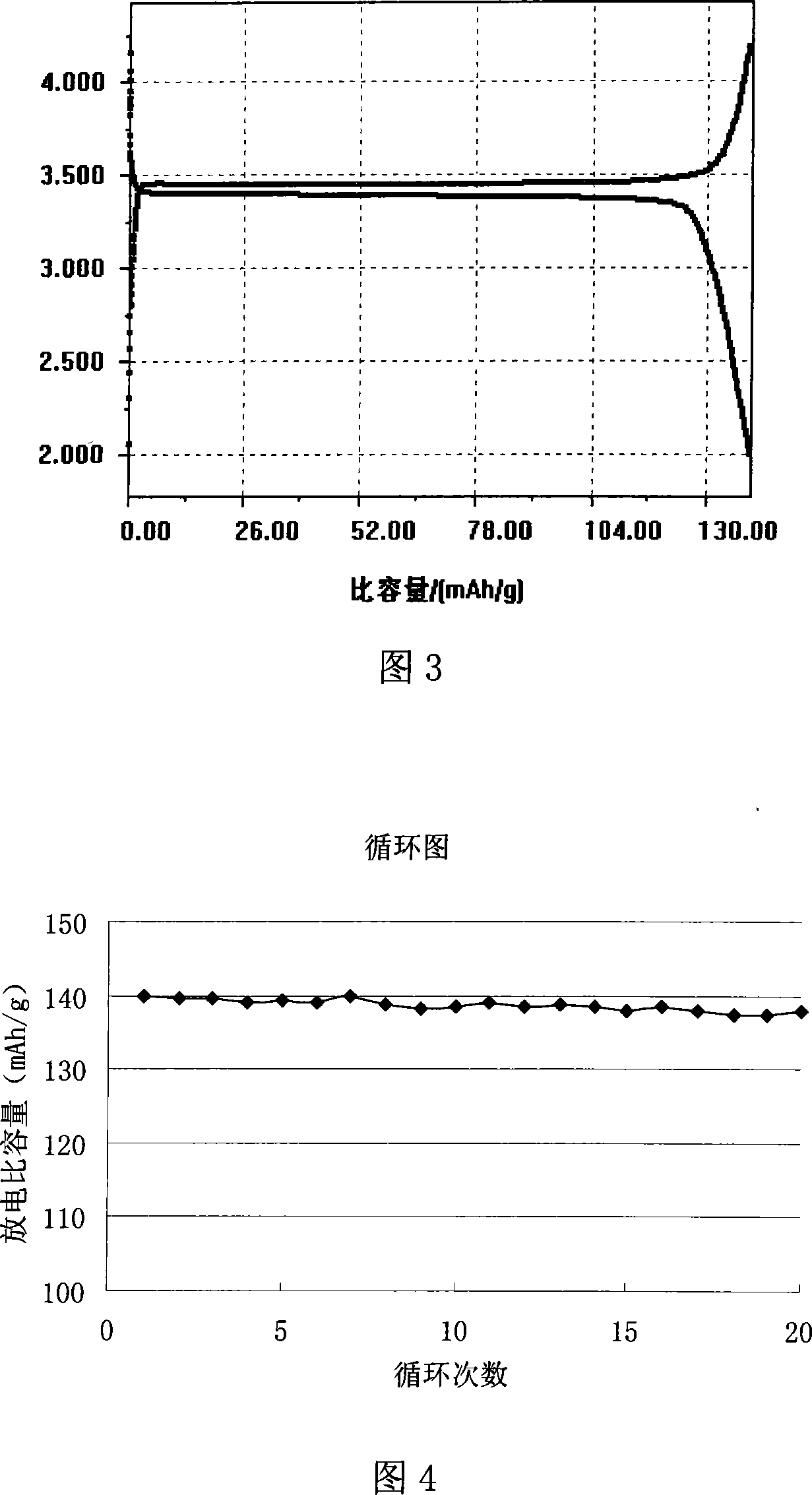

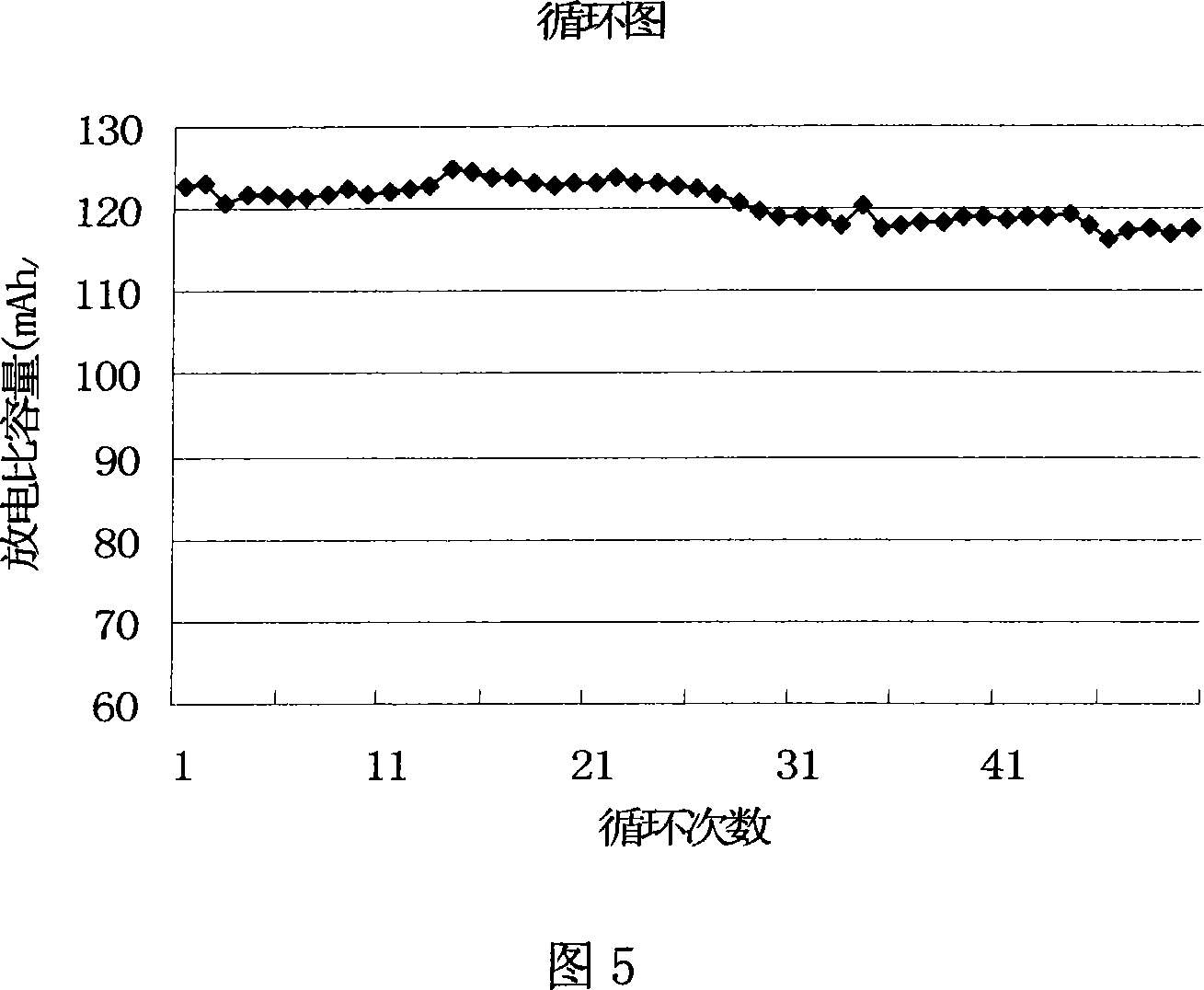

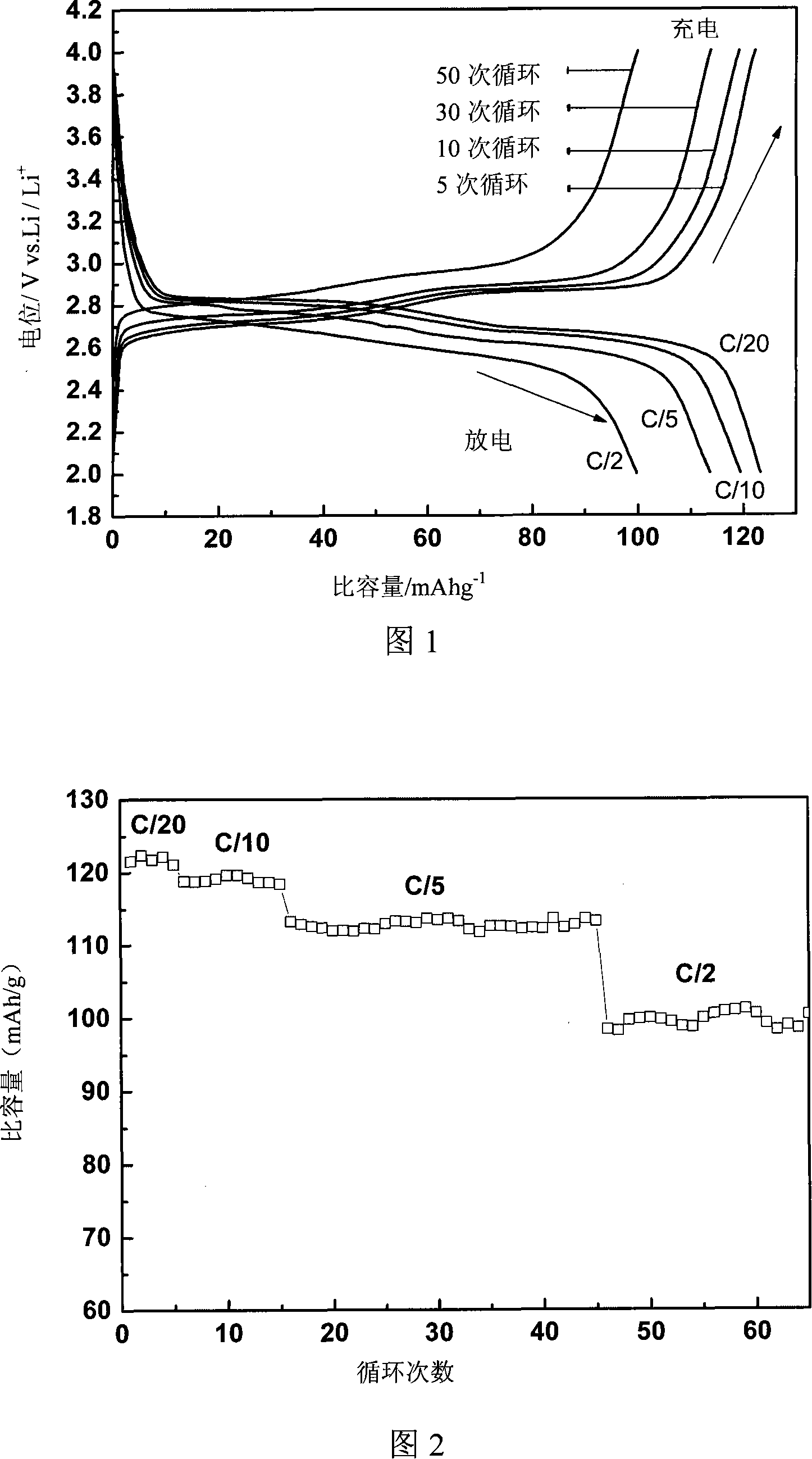

Anode material made of doped lithium-iron phosphate active material and carbon and method for producing the same

ActiveCN101212049ALow priceImprove securityElectrode manufacturing processesPhosphorus compoundsLithium iron phosphateSolid reaction

The invention relates to an anode material composed by doping phosphate iron and lithium active substance and carbon and used for the secondary lithium battery and a manufacturing method thereof. The invention is characterized in that the general expression of the active substance is Li<3+Y>Fe<2-X>Mex(PO4)3(Me = Ti, Sc, Ge, Al, Zr, Mn, Hf, Nb, Ta, Mo, W, Ru, Ag, Sn, and Pb, etc.); the characteristic in preparation is that the raw material is synthesized into the crystal state of Li<3+Y>Fe<2-X>Mex(PO4)3 through a solid reaction, an hydrothermal method and a sol-gel method in a proper proportion. Then the prepared powder and the carbon is grinded and mixed through a planetary ball mill to obtain the anode material Li<3+Y>Fe<2-X>Mex(PO4)3 / C The specific capacity of the anode material can be up to 122mAhg<-1> (charging and discharging at the rate of C / 20) and 100mAhg<-1> (charging and discharging at the rate of C / 2); furthermore, the material has a good circulation performance and retentivity of specific capacity, thus providing a favorable anode material for the practicality of the secondary lithium ion battery.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Preparation method of Co3O4 with large grain size and uniformly doped with aluminum

ActiveCN108011101AEvenly distributedUniform particle size distributionCell electrodesCobalt oxides/hydroxidesCobalt(II,III) oxideMicrometer

The invention relates to a preparation method of Co3O4 with large grain size and uniformly doped with aluminum. The invention provides the preparation method of the Co3O4 which is uniformly doped withaluminum and is large in grain size and uniform in particle distribution, and the obtained Co3O4 with the large grain size and uniformly doped with aluminum can completely conform to the requirementof preparation of 4.45V high-voltage lithium cobalt oxide. According to the method, the large-grain size and aluminum-doped cobalt carbonate is synthesized by a wet method, and the problems of difficulty in enlargement of cobalt hydroxide (or hydroxyl cobalt) system grain size and non-uniform particle distribution are solved; with the regard to the problem of uniform aluminum doping of a cobalt carbonate system, a parameter is set from principle, an aluminum compound is prevented from being independently separated out and gathered, the doped Al element can be uniformly distributed in the Co3O4, the grain size reaches 15 micrometers or above, and the particle distribution is uniform; and the lithium cobalt oxide prepared from the aluminum-doped Co3O4 has high specific capacity and excellentcycle property under 4.45V.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드

Cathode material for lithium-ion power and energy storage battery and preparation method thereof

The invention discloses a cathode material for a lithium-ion power and energy storage battery and a preparation method thereof, aiming to solve the problem on how to improve the high-magnification charge-discharge property of the battery and how to enable the battery to have good cycle property. The cathode material is obtained by carbonizing asphalt containing a catalyst at 500-1,300 DEG C. The preparation method comprises the following steps of: raising the temperature and the pressure to have a carbonized thermal polycondensation reaction; washing, extracting and then washing; drying to obtain mesophase microbead precursors; and then carbonizing to obtain the cathode material for the lithium-ion power and energy storage battery. Compared with the prior art, the invention reduces the production cost; because the mesophase soft carbon materials obtained by low-temperature carbonization are adopted, the interior of the cathode material is in a turbostratic structure capable of charging and discharging with high power and high current; and the main raw material of the mesophase soft carbon material is asphalt, so that compared with other hard carbons such as the resin type, the plant, and the like, the cathode material has yield improved by 3-5 times, low cost and higher specific capacity.

Owner:JIXI BTR GRAPHITE IND PARK CO LTD +2

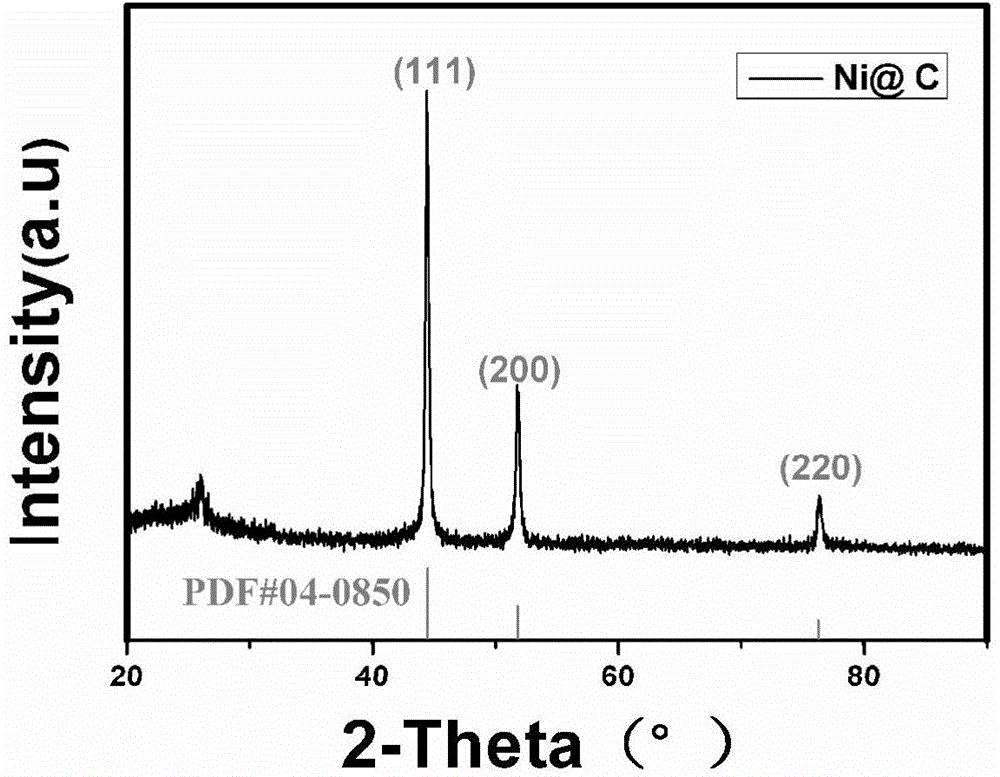

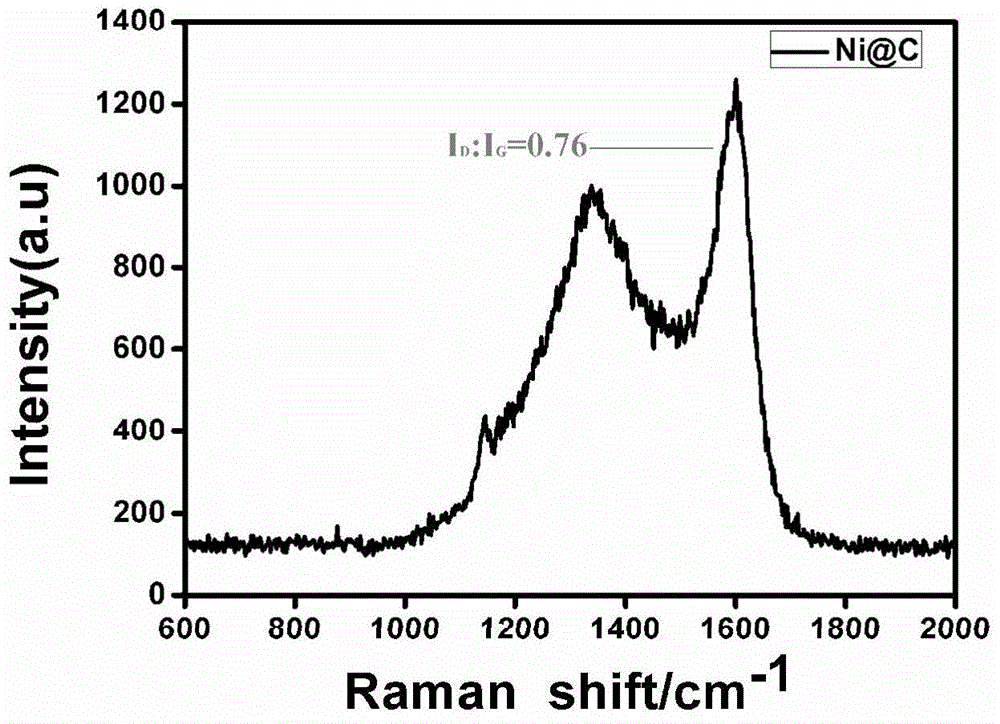

Lithium ion battery cathode material embedded nano metal loaded carbon nanosheet as well as preparation method and application thereof

InactiveCN104538595AUniform sizeRegular shapeMaterial nanotechnologyCell electrodesChemistryCarbon source

The invention discloses a lithium ion battery cathode material embedded nano metal loaded carbon nanosheet as well as a preparation method and an application thereof. By taking sugar (chitosan, cane sugar, fructose and glucose) as a carbon source, nitrate of transitional metals (Fe, Co and Ni) as a metal source and a catalyst and inert salts (sodium sulfate, sodium chloride, potassium chloride and cesium chloride) as a template and a dispersant, a two-dimensional carbon nanosheet which uniformly loads embedded nickel (or iron or cobalt) nanoparticles is prepared by a pyrolytic method in one step. The two-dimensional carbon nanosheet which uniformly loads embedded nickel (or iron or cobalt) nanoparticles prepared by the method is high in degree of graphitization, relatively high in specific surface area and high in conductivity, uniform in distribution and easy to separate, and the surface of the nanosheet is in a porous structure. The nanosheet as the lithium ion battery cathode material has relatively good circulating and rate performances.

Owner:NANJING NORMAL UNIVERSITY

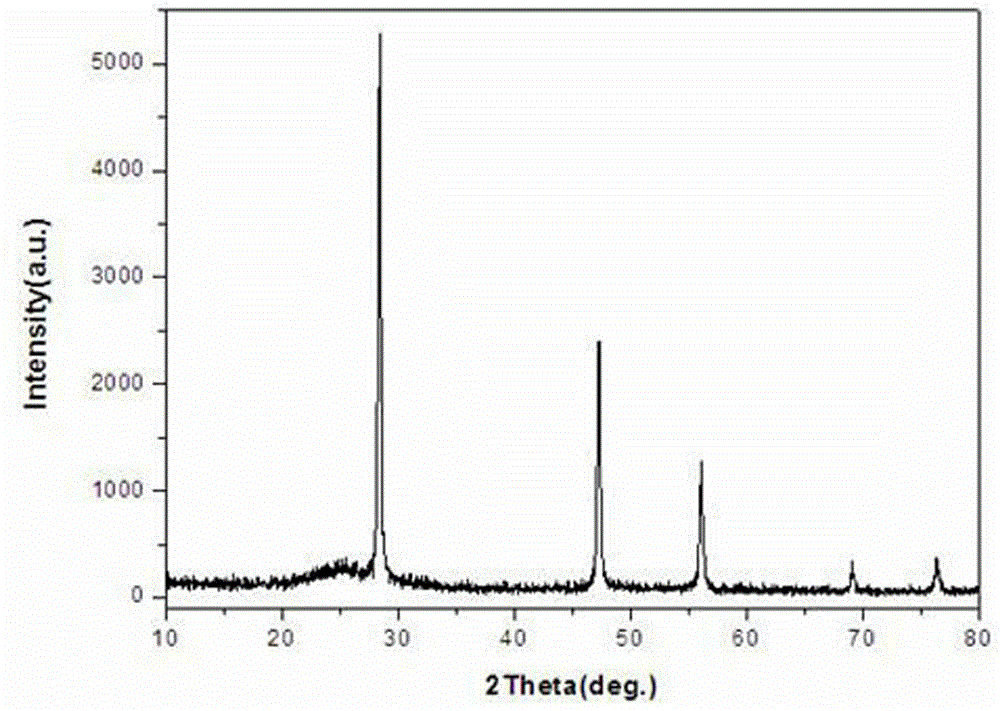

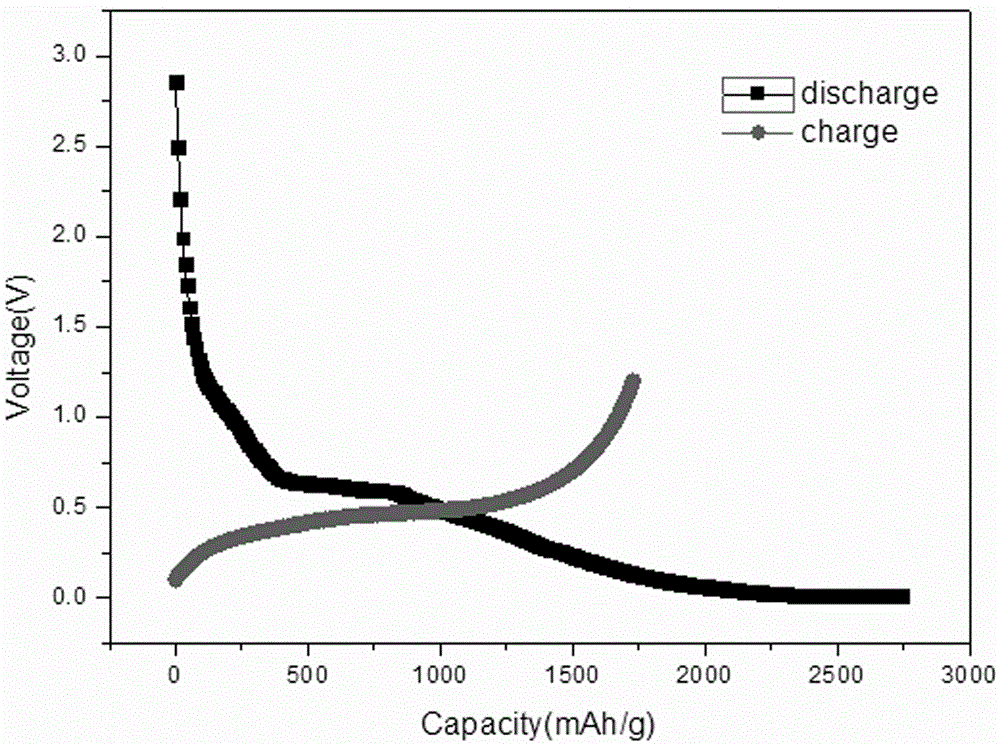

Silicon cathode material coated with graphene and preparation method thereof

InactiveCN104916826AWide variety of sourcesLow priceCell electrodesSecondary cellsOperabilitySilicon particle

The invention relates to the technical field of lithium-ion cathode material, in particular to silicon cathode material coated with graphene and a preparation method of the silicon cathode material coated with the grapheme. The preparation method comprises the following steps: A, preparing oxidized graphene suspension liquid; B, preparing nanometer silicon particle suspension liquid; and C, preparing silicon cathode material coated with grapheme. The preparation method adopts the electrostatic self-assembly synthetic technology and is wide in source of raw material, low in price, simple in synthetic method, easy for control of process conditions, strong in operability and good in repeatability. The silicon cathode material coated with grapheme is high in specific capacity and good in cycle performance and rate capability, wherein the specific discharge capacity for the first time under the electric current density of 0.01-1.2V, 200mA / g can reach 2746mAh / g, and the specific discharge capacity after 100 times of cycles can maintain 803.8mAh / g.

Owner:MCNAIR TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com