Patents

Literature

1534 results about "Silicon particle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

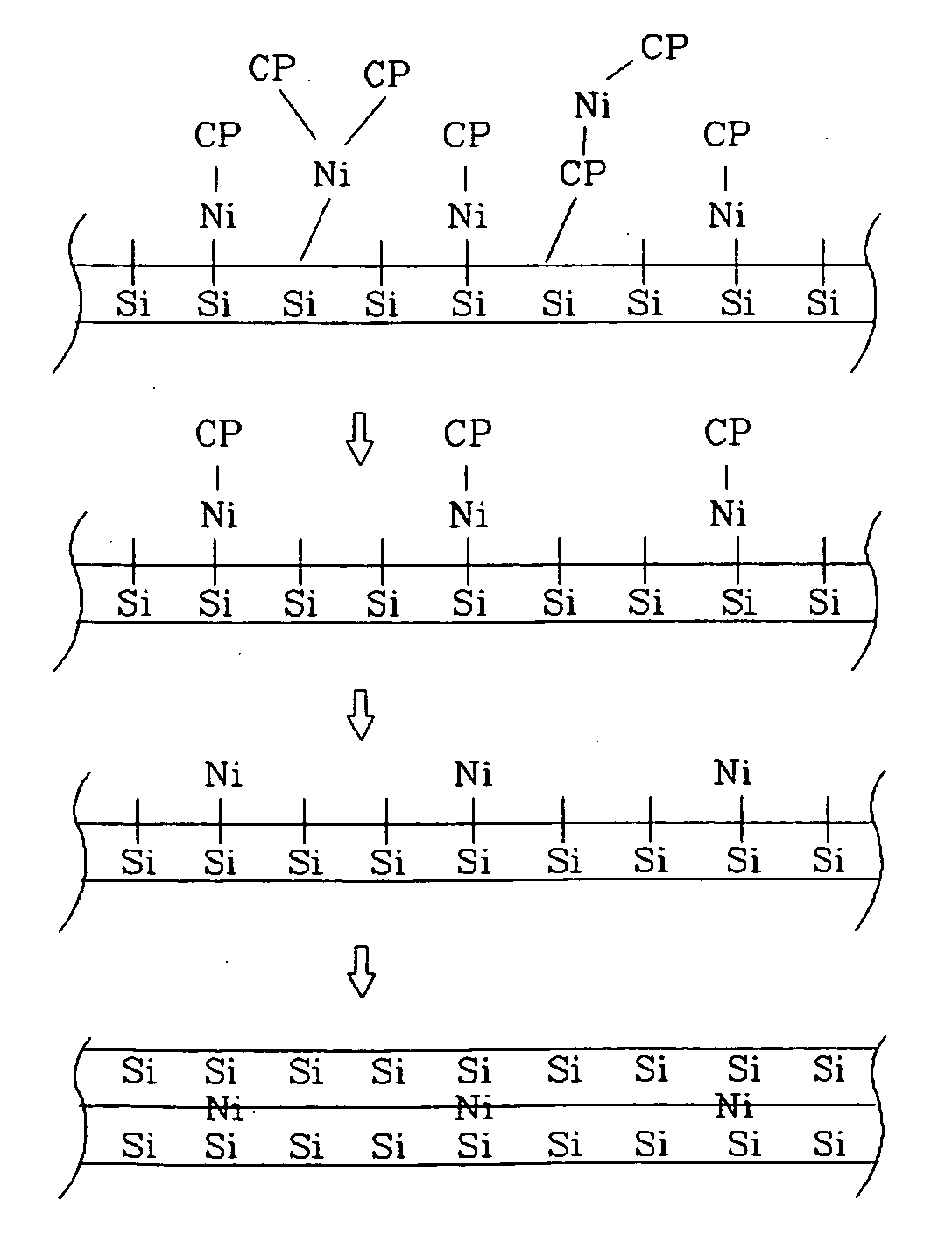

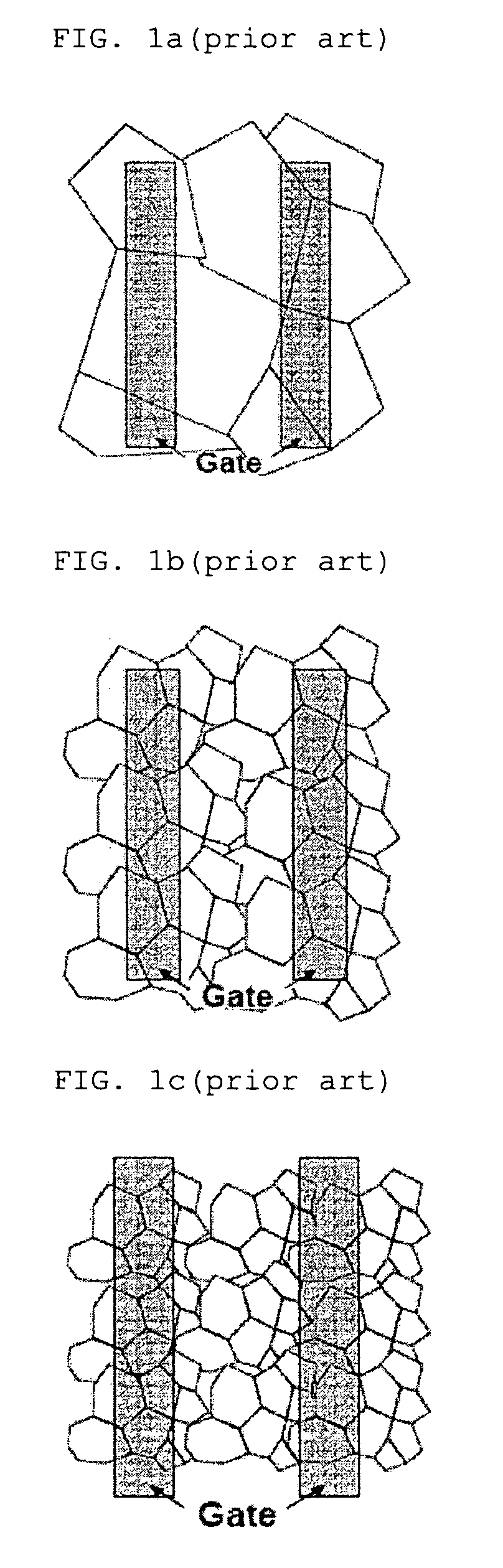

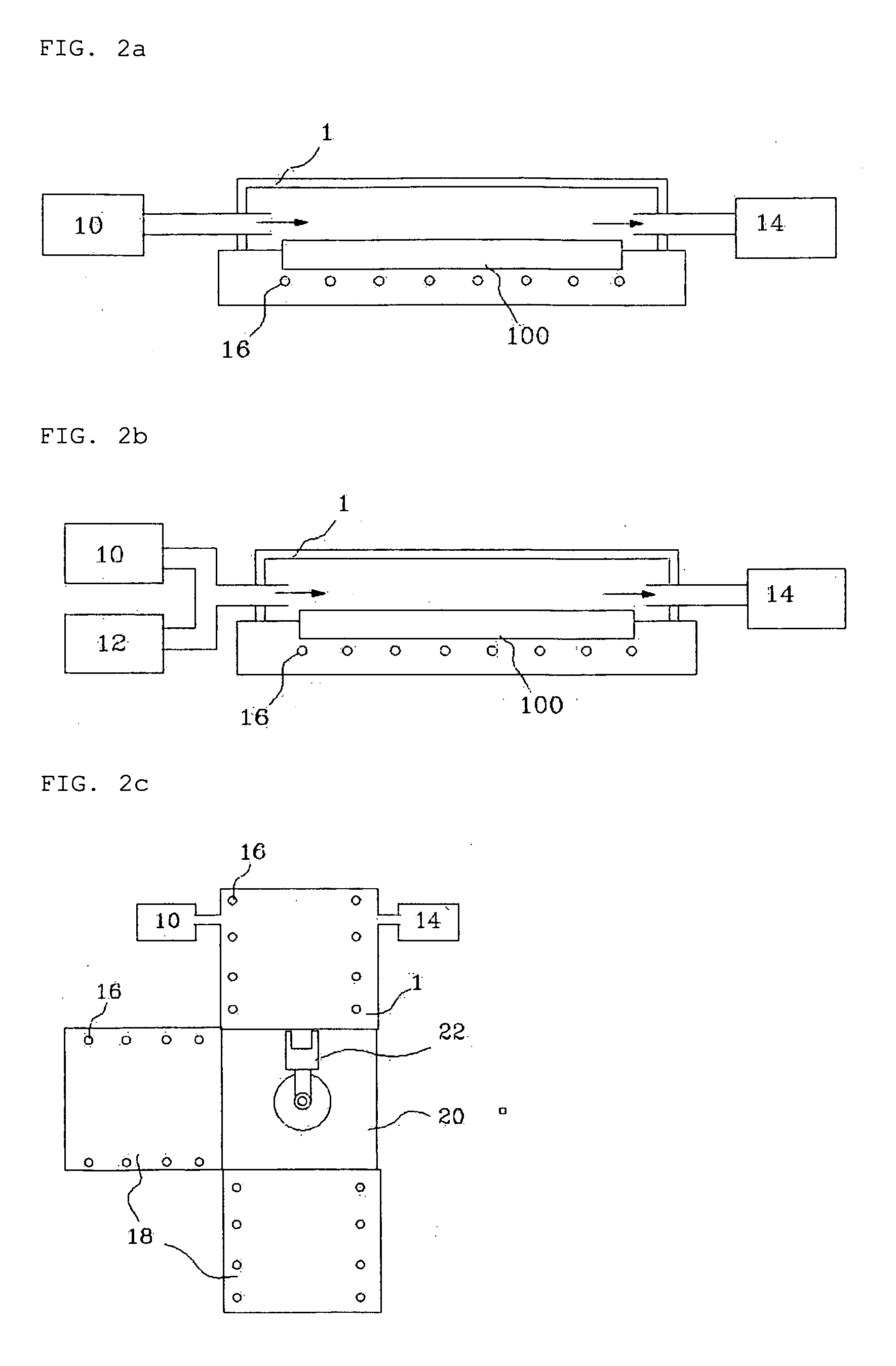

Apparatus and method for forming polycrystalline silicon thin film

ActiveUS20070054499A1Increase the rate of crystallizationDecrease in crystallization temperatureAfter-treatment apparatusSemiconductor/solid-state device manufacturingGas phaseAmorphous silicon

Apparatus and method for forming a polycrystalline silicon thin film by converting an amorphous silicon thin film into the polycrystalline silicon thin film using a metal are provided. The method includes: a metal nucleus adsorbing step of introducing a vapor phase metal compound into a process space where the glass substrate having the amorphous silicon formed thereon is disposed, to adsorb a metal nucleus contained in the metal compound into the amorphous silicon layer; a metal nucleus distribution region-forming step of forming a community region including a plurality of silicon particles every metal nucleus in a plane boundary region occupied by the metal compound by a self-limited mechanism due to the adsorption of the metal nucleus; and an excess gas removing step of purging and removing an excess gas which is not adsorbed in the metal nucleus distribution region-forming step.

Owner:WONIK IPS CO LTD

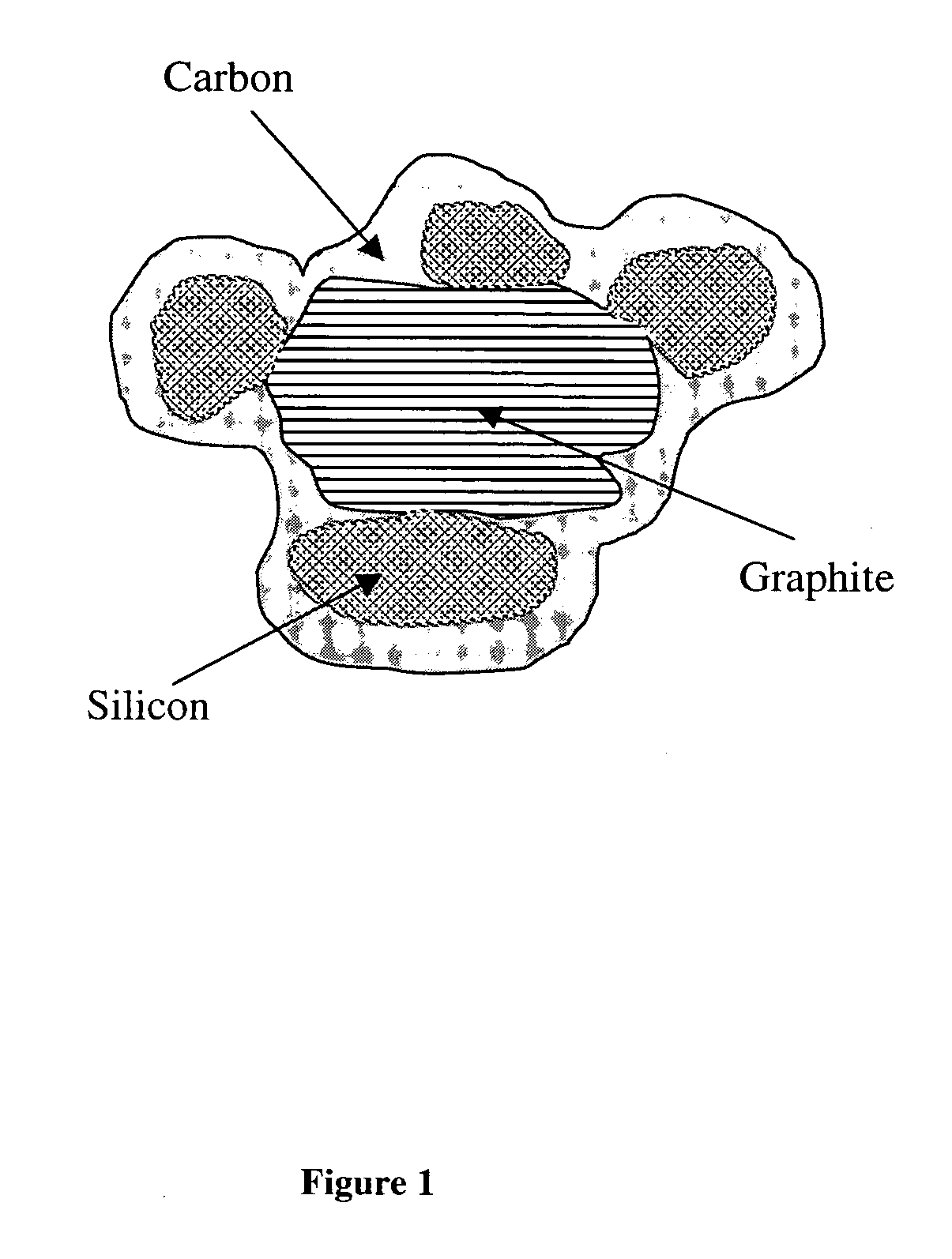

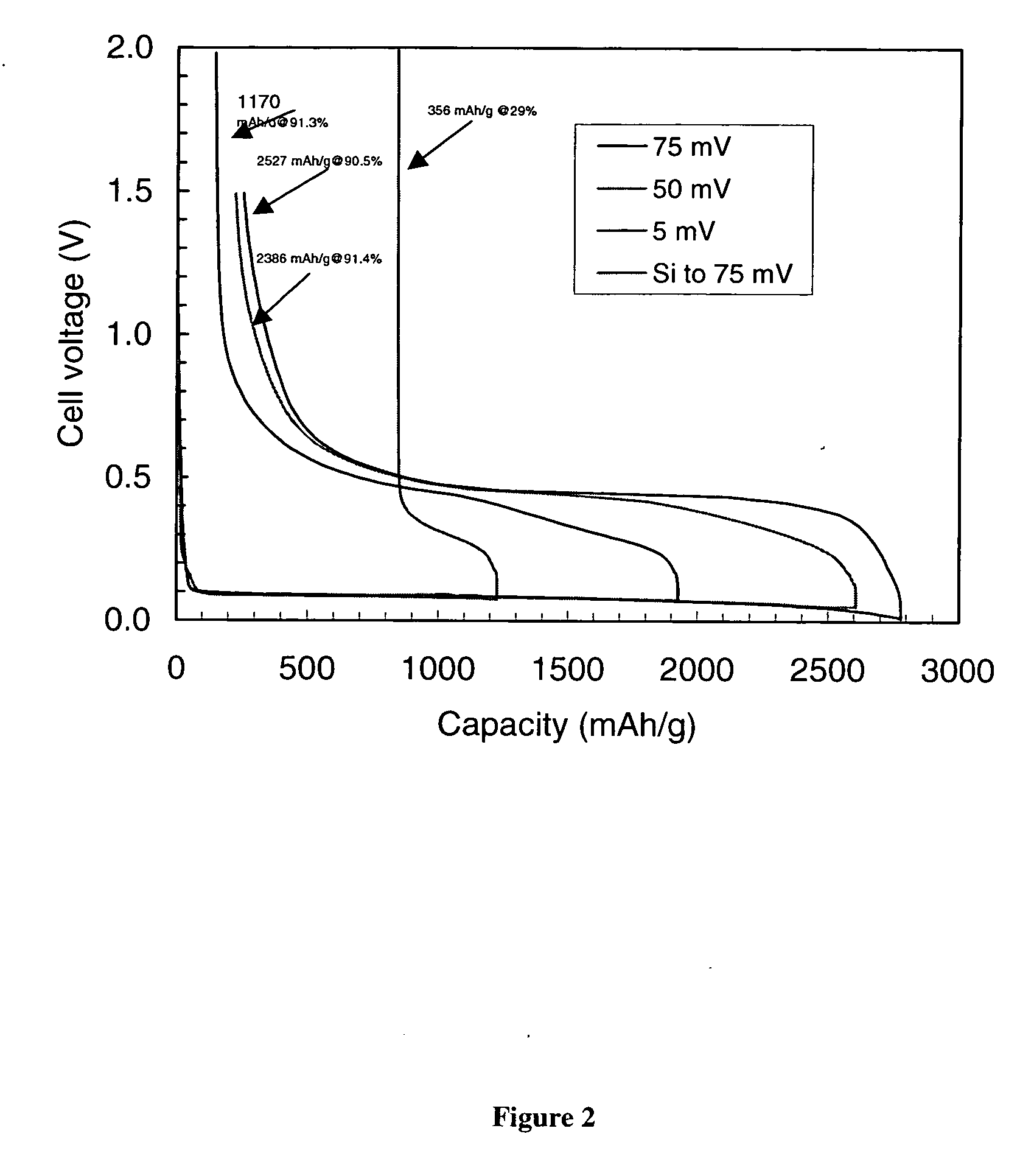

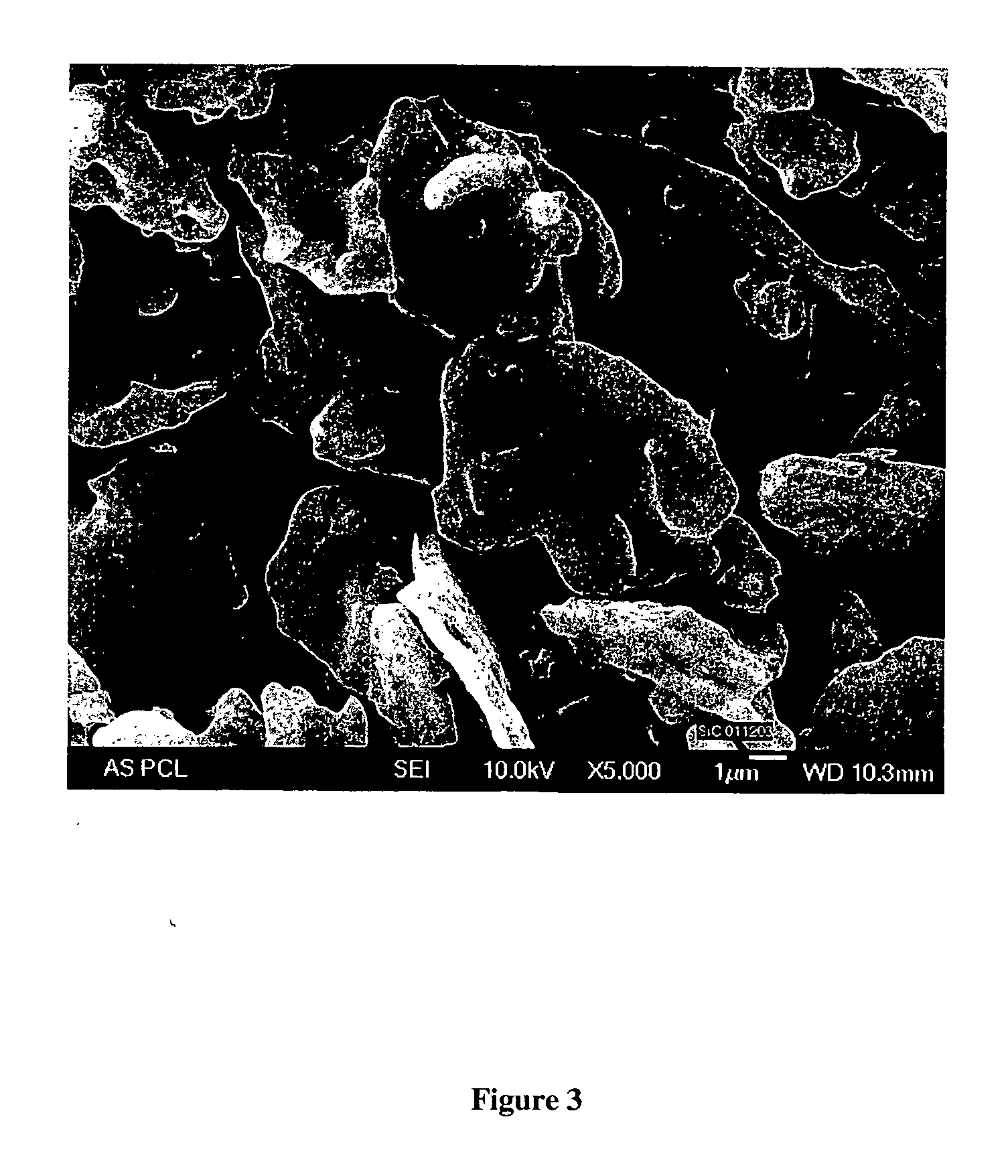

Carbon-coated silicon particle power as the anode material for lithium batteries and the method of making the same

InactiveUS20050136330A1Large capacityImprove efficiencyElectrode thermal treatmentElectrode carriers/collectorsCarbon compositesSilicon particle

A process for the production of coated silicon / carbon particles comprising: providing a carbon residue forming material; providing silicon particles; coating said silicon particles with said carbon residue forming material to form coated silicon particles; providing particles of a carbonaceous material; coating said particles of carbonaceous material with said carbon residue forming material to form coated carbonaceous particles; embedding said coated silicon particles onto said coated carbonaceous particles to form silicon / carbon composite particles; coating said silicon / carbon composite particles with said carbon residue forming material to form coated silicon / carbon composite particles; and stabilizing the coated composite particles by subjecting said coated composite particles to an oxidation reaction. The coated composite particles will have a substantially smooth coating. The particles may be coated with multiple layers of carbon residue forming material /

Owner:PYROTECK INC

Non-aqueous electrolyte secondary battery, negative electrode material, and making method

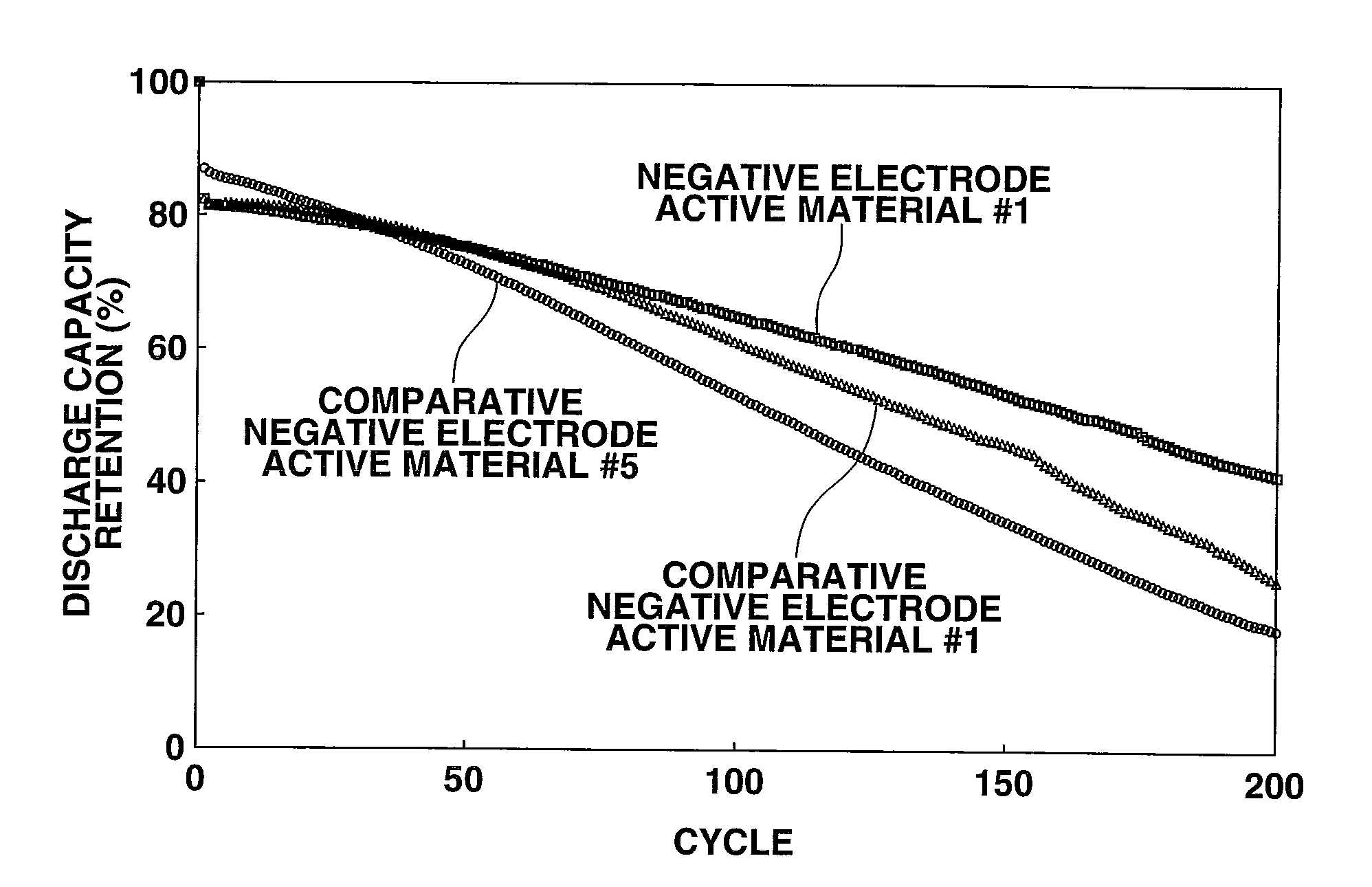

ActiveUS20090239151A1Improve cycle performanceImprove efficiencyNon-aqueous electrolyte accumulatorsActive material electrodesSilicon oxideSilicon particle

A negative electrode material comprising an active material and 1-20 wt % of a polyimide resin binder is suitable for use in non-aqueous electrolyte secondary batteries. The active material comprises silicon oxide particles and 1-50 wt % of silicon particles. The negative electrode exhibits improved cycle performance while maintaining the high battery capacity and low volume expansion of silicon oxide. The non-aqueous electrolyte secondary battery has a high initial efficiency and maintains improved performance and efficiency over repeated charge / discharge cycles by virtue of mitigated volumetric changes during charge / discharge cycles.

Owner:SHIN ETSU CHEM IND CO LTD

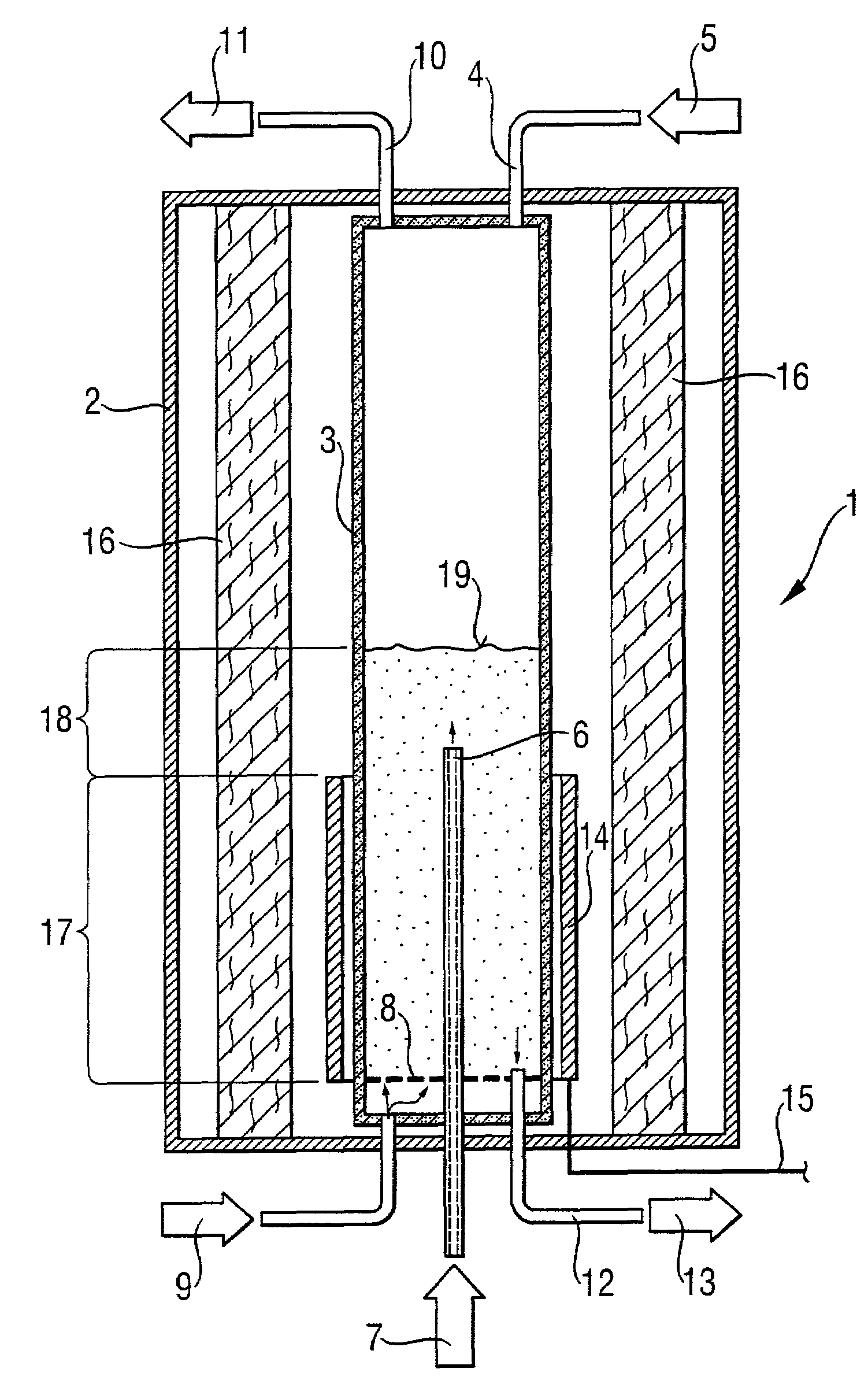

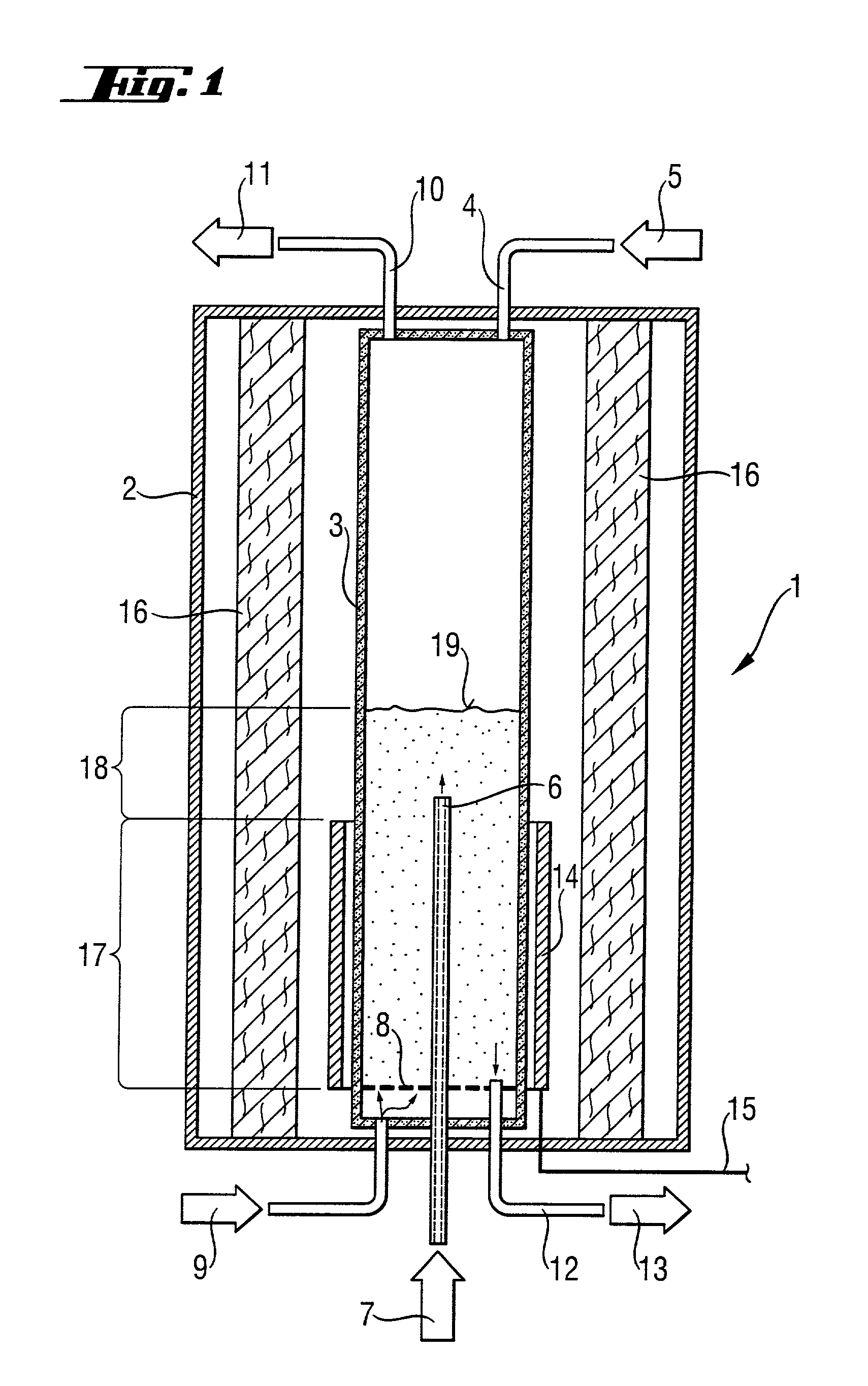

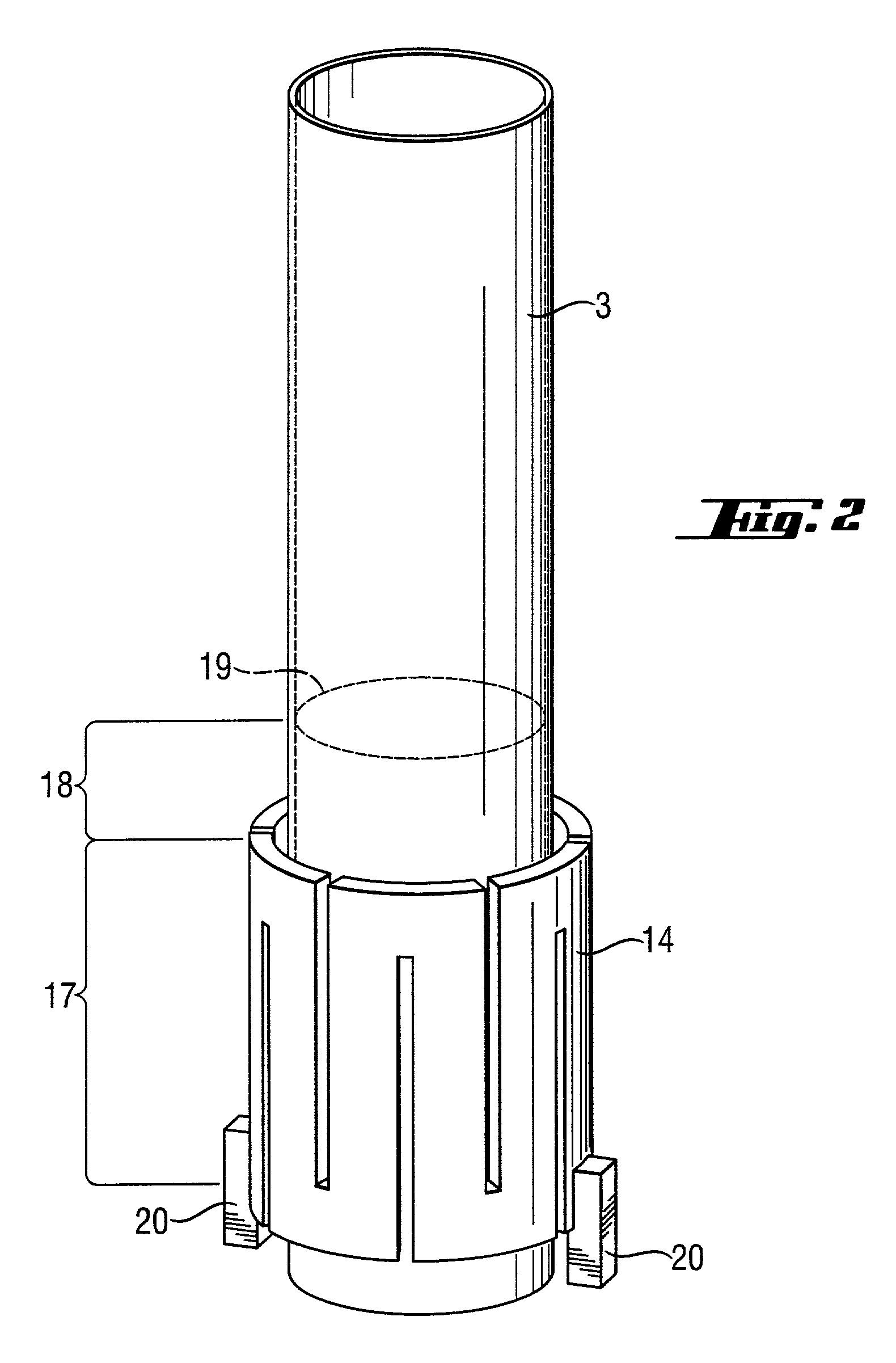

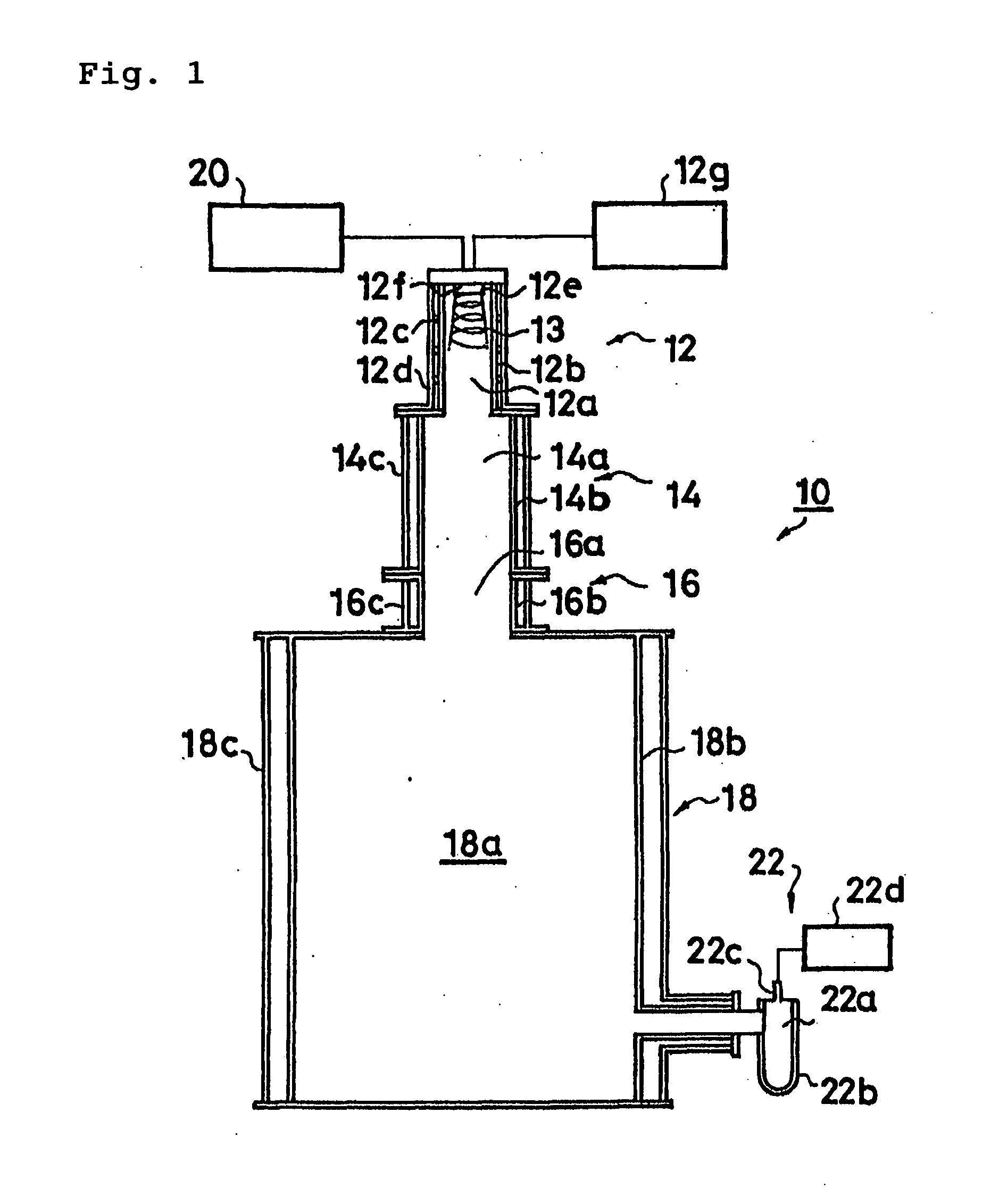

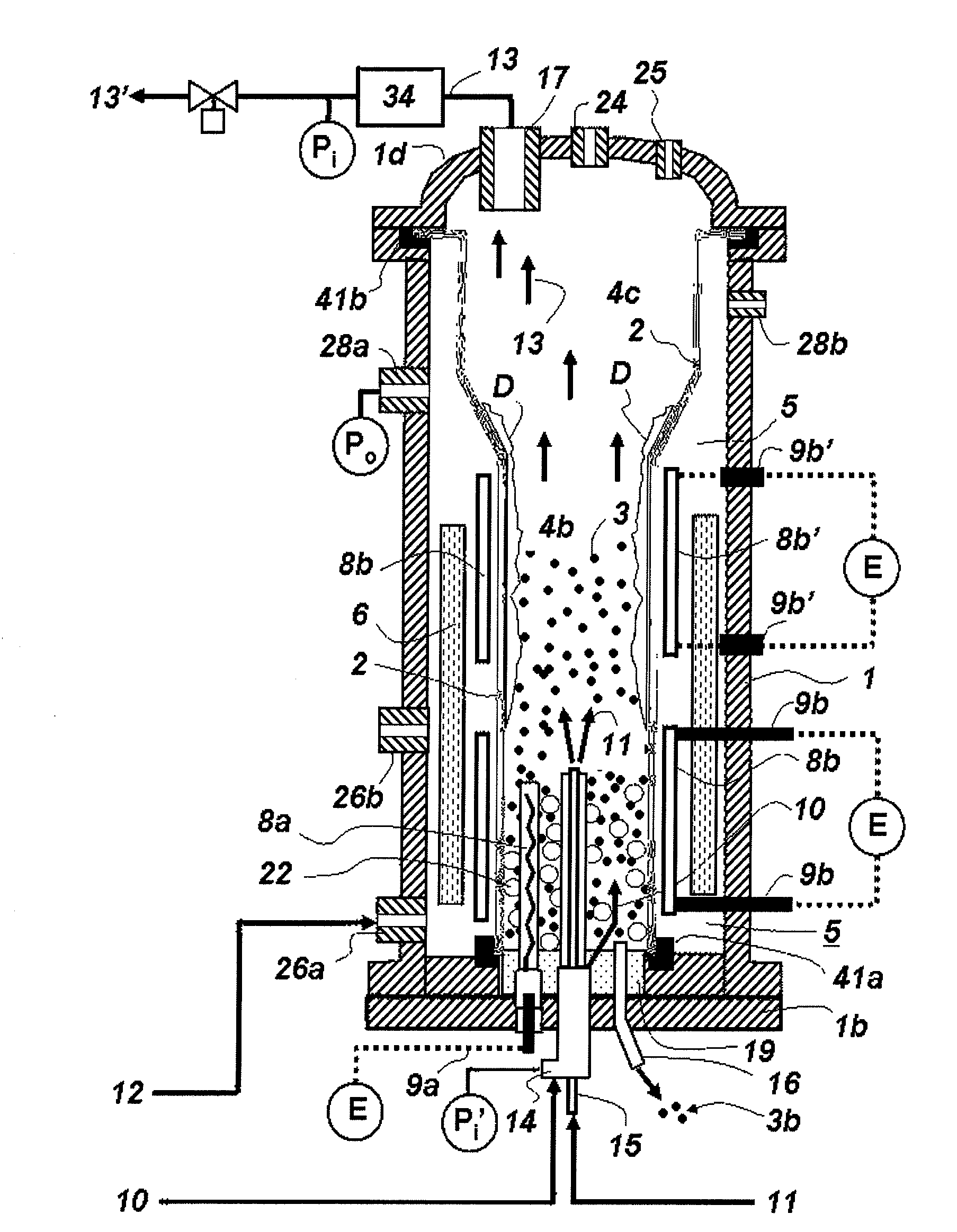

Radiation-heated fluidized-bed reactor

InactiveUS7029632B1Low levelHigh puritySiliconFluidised-bed furnacesFluidized bedReaction temperature

A radiation-heated fluidized-bed reactor and a process for producing high-purity polycrystalline silicon by using this reactor are provided. In this reactor, a heater device (14) is a radiation source for thermal radiation which is arranged outside the inner reactor tube and as a cylinder around the heater zone, without being in direct contact with the inner reactor tube. The inner reactor tube is designed in such a manner that it uses thermal radiation to heat the silicon particles in the heating zone to a temperature which is such that the reaction temperature is established in the reaction zone.

Owner:WACKER CHEM GMBH

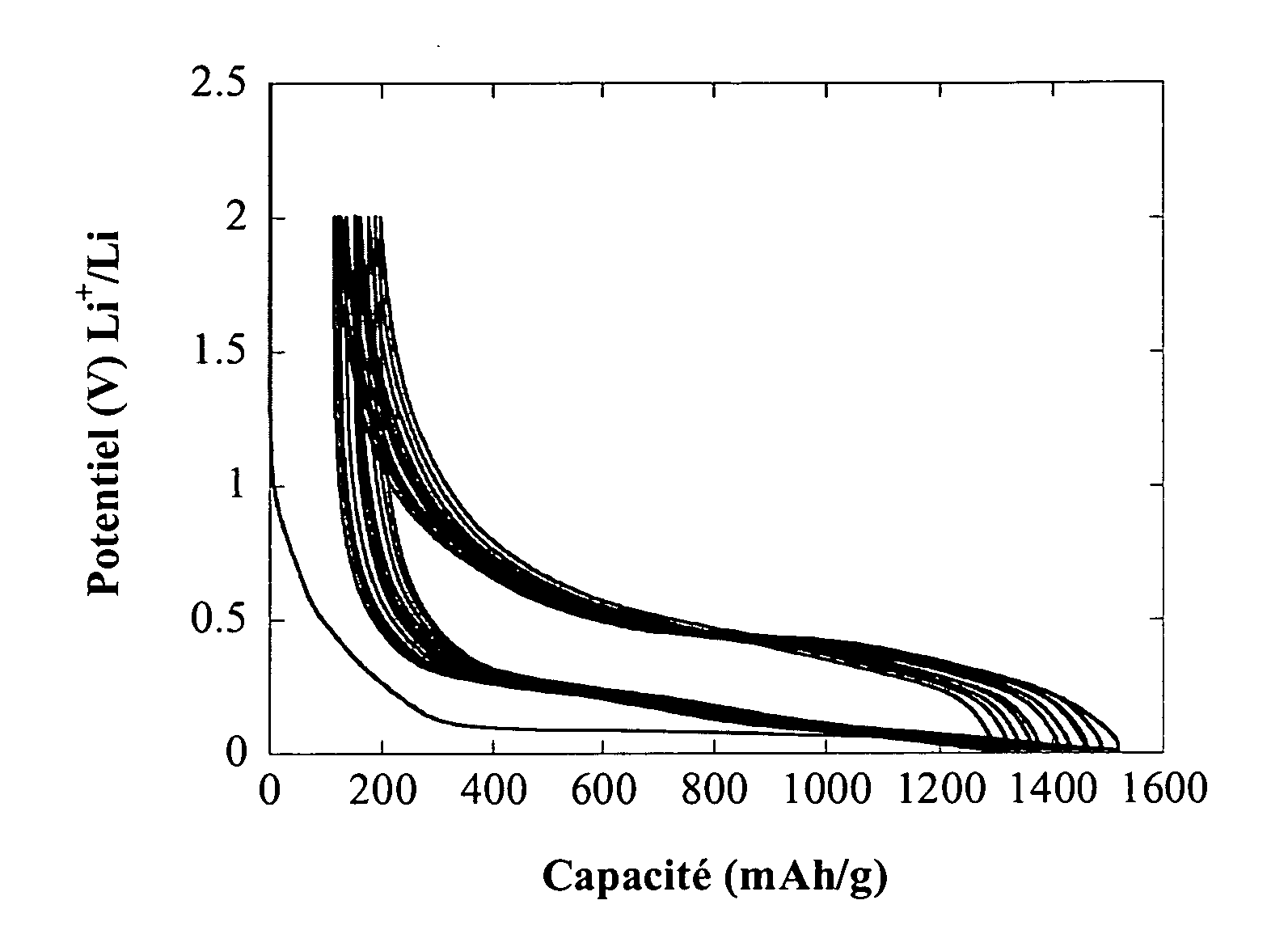

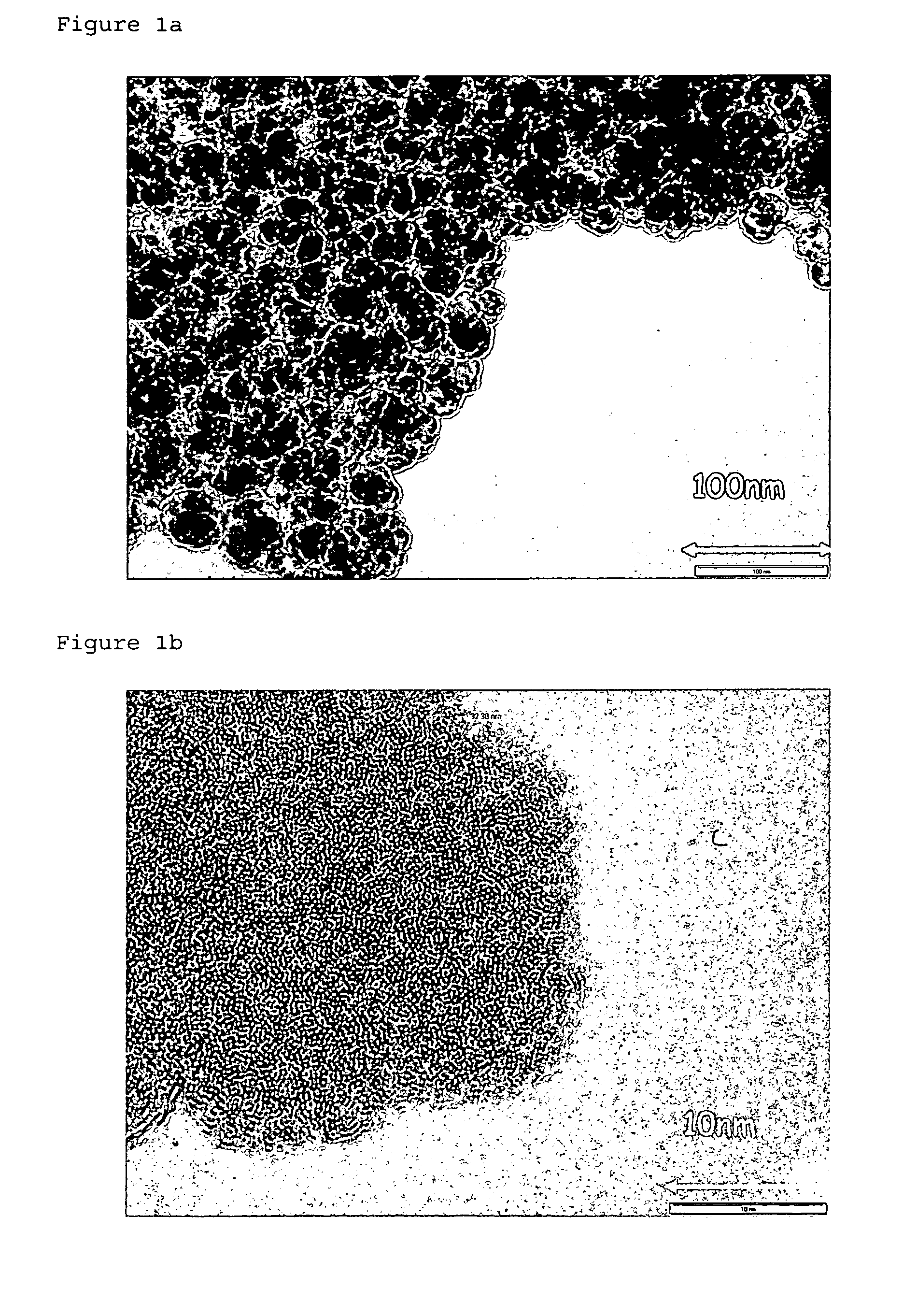

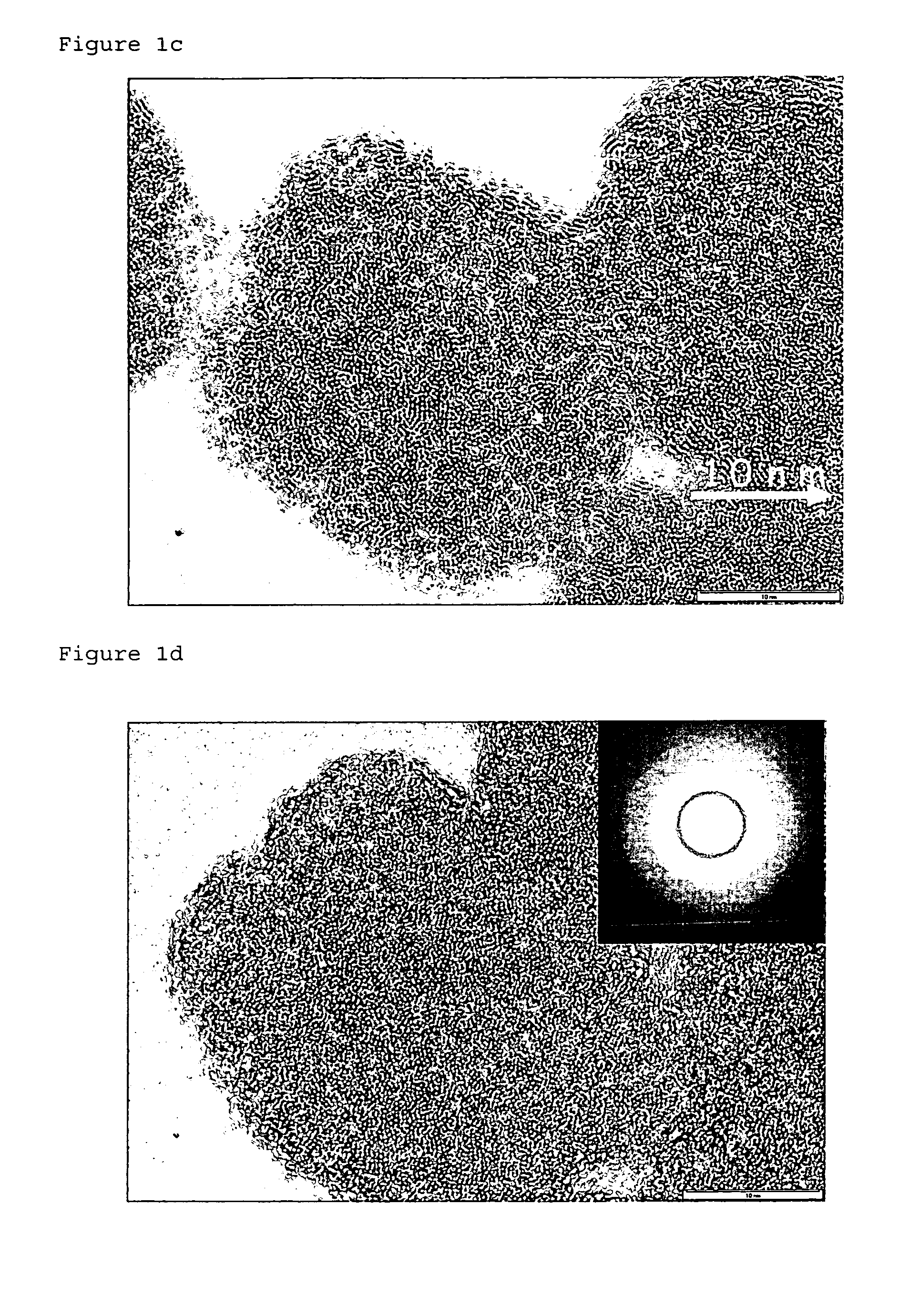

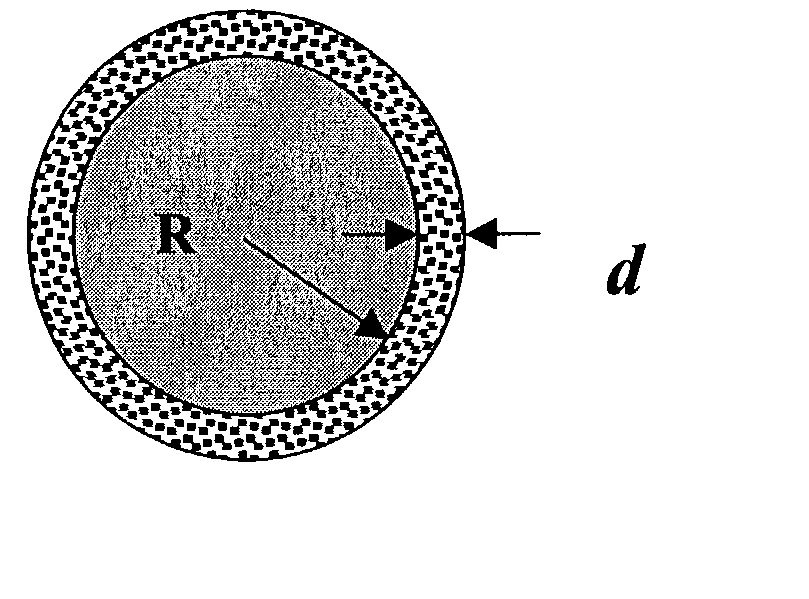

Nanocomposite material for the anode of a lithium cell

ActiveUS20060275668A1Material nanotechnologyLiquid surface applicatorsCarbon compositesChemical vapor deposition

The subject of the invention is an anode material of the silicon-carbon composite type, for a lithium cell, having a high mass capacity and good cycling stability. This material is obtained by a preparation method comprising the steps consisting of: a) providing a silicon powder obtained by the plasma-enhanced chemical vapour deposition (PECVD) technique or by CO2 laser, the size of the silicon particles being less than 100 nm; b) mixing the silicon powder with a carbon-containing polymer, and c) carrying out the pyrolysis of the mixture. The invention also proposes a lithium cell containing at least one anode the material of which contains the nanocomposite material produced by this method.

Owner:SAFT GRP SA

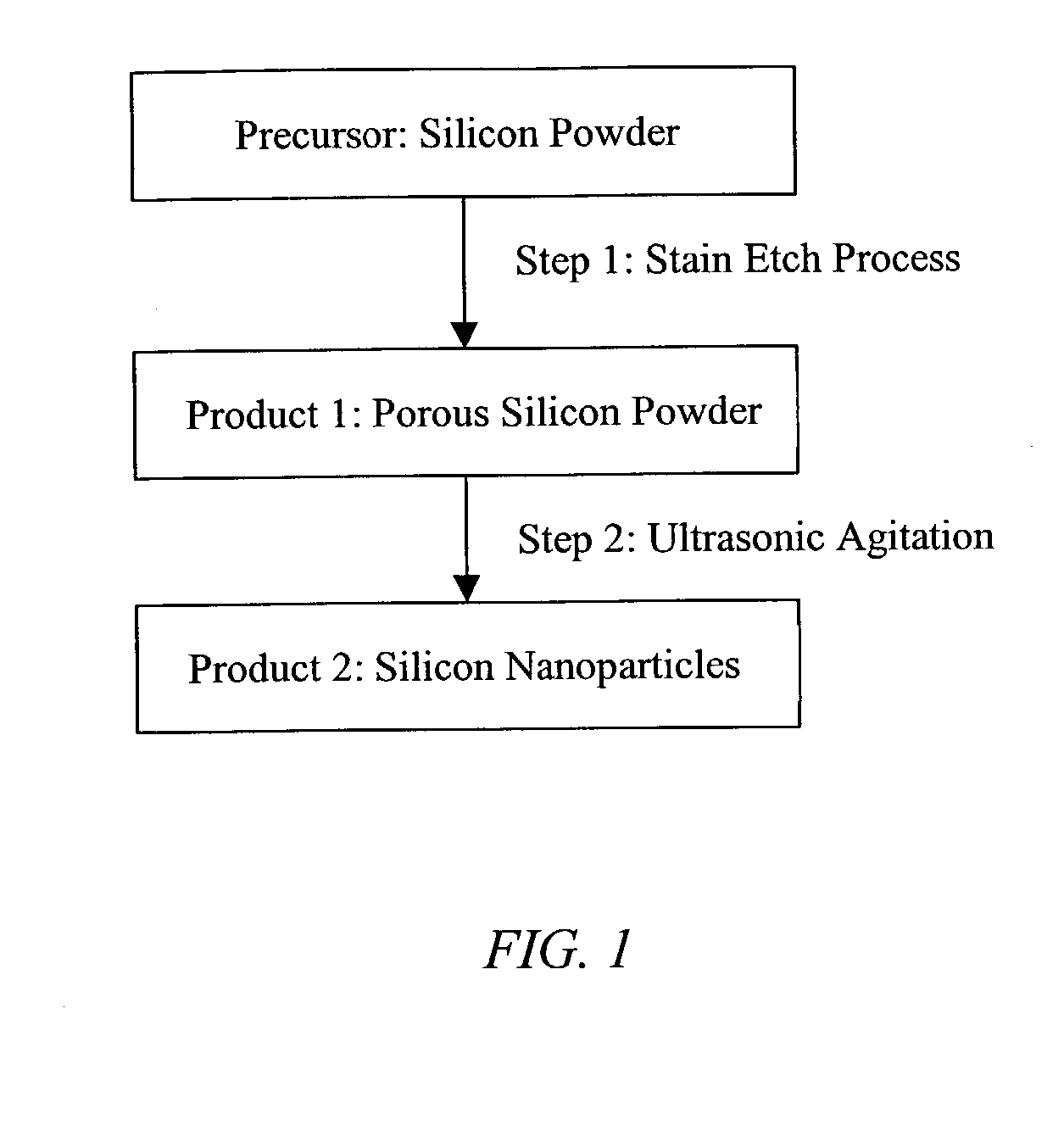

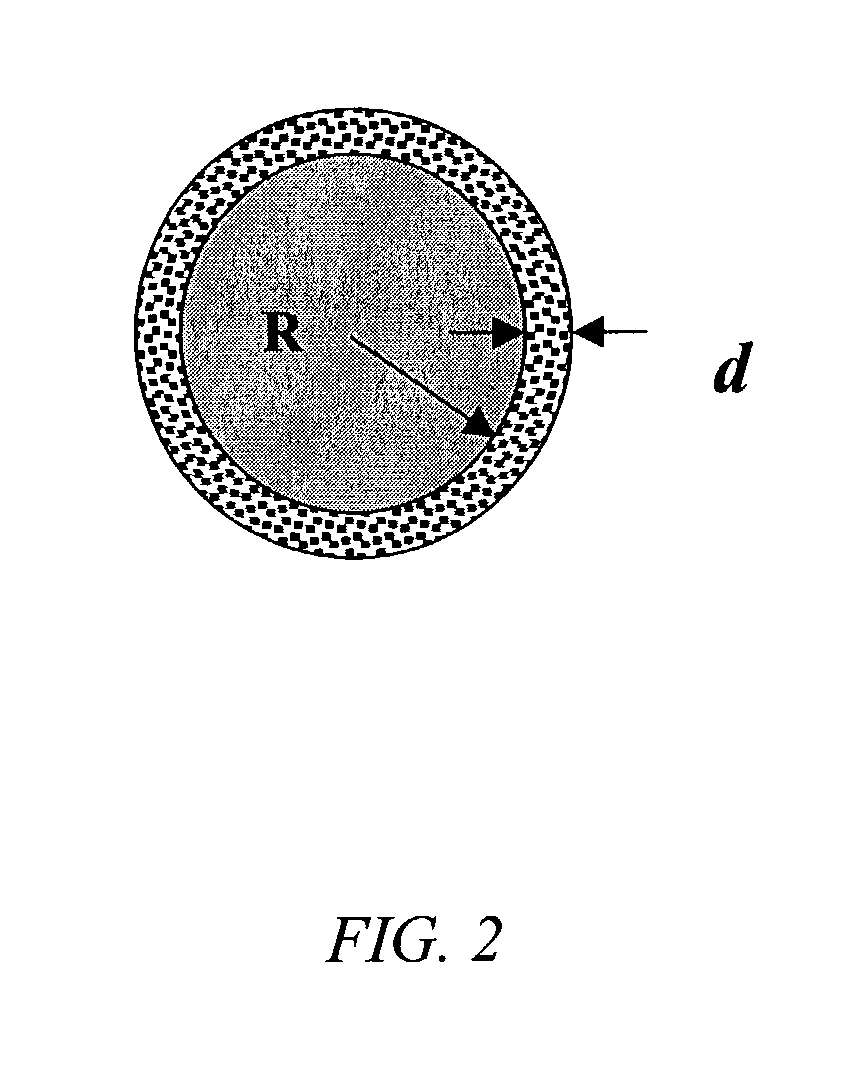

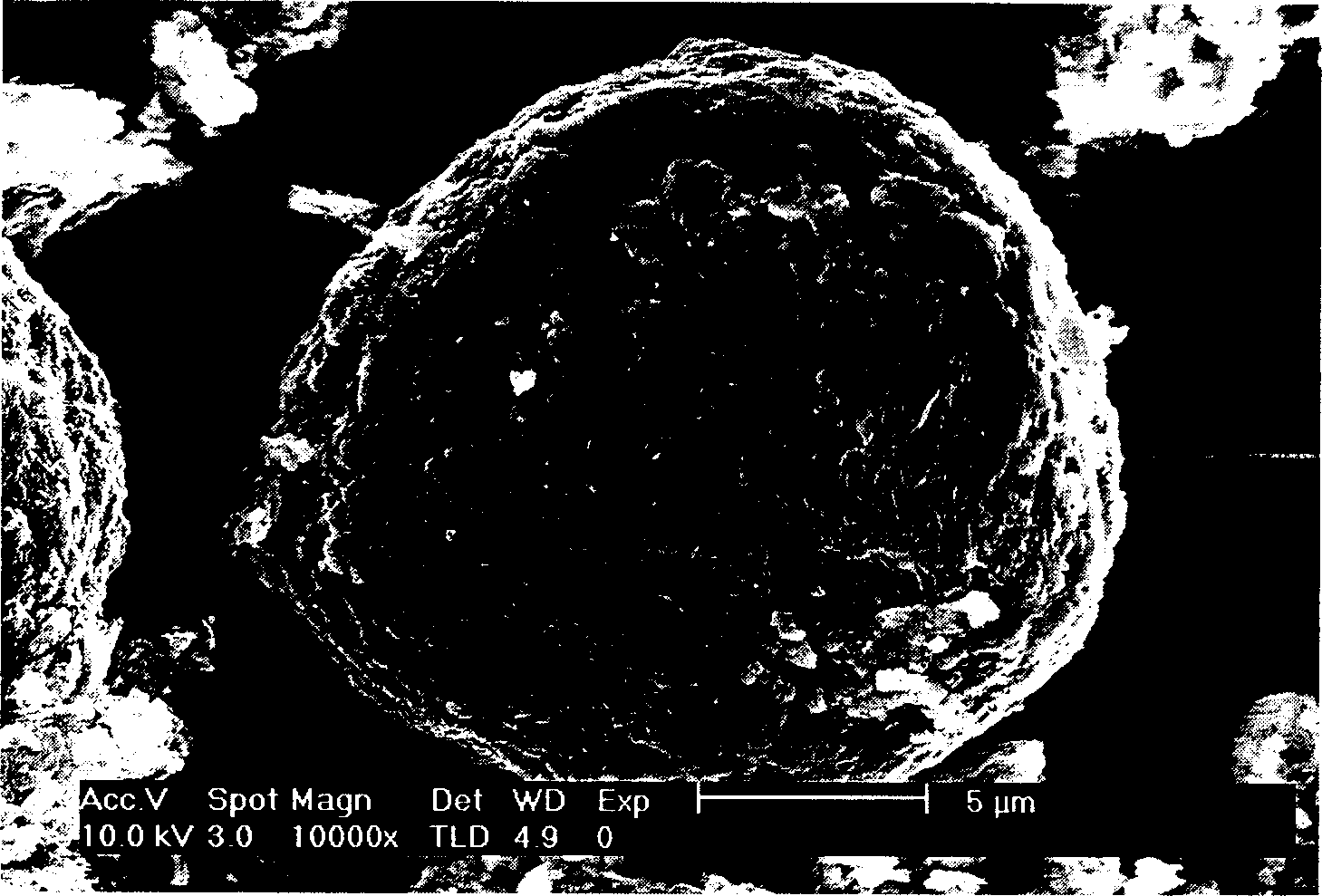

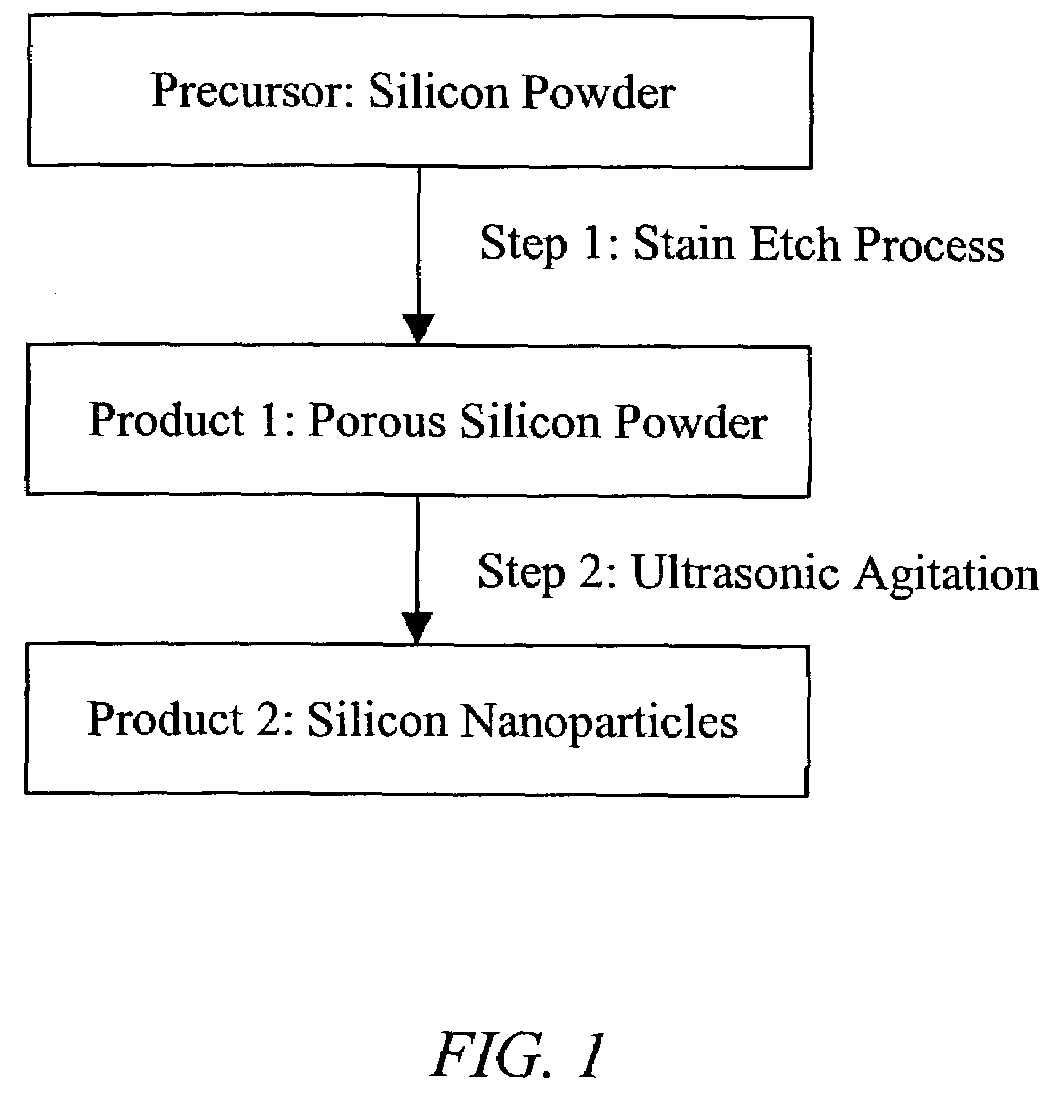

Method of producing silicon nanoparticles from stain-etched silicon powder

The present invention is for a porous silicon powder comprising silicon particles wherein the outermost layers of said particles are porous. The present invention is also directed to a method of making this porous silicon powder using a stain etch method. The present invention is also directed to a method of making silicon nanoparticles from the porous silicon powders using a process of ultrasonic agitation. The present invention also includes methods of processing these silicon nanoparticles for use in a variety of applications.

Owner:SI DIAMOND TECH

Carbon-silicon composite material with spherical nucleocapsid, and its preparing method and use

This invention relates to a kind of silicon&carbon composite material with a spherical appearance and core-shell structure in spherical particles with a mean diameter of 1.2~53 micron and a 'core-shell' structure, there are silicon particles 5~50wt% and carbon particles 50~95wt%, the core of which is spherical carbon particles with a mean diameter of 1~45 micron. The carbon particles are the mixture of one, two or three kinds of mesophase carbon graphite balls, hard carbon balls and spherical graphite ball. The thickness of the shell is 0.1~4 microns composed of carbon and silicon grains with the average size of 10 nm~4 micron. The carbon&silicon composite materials are achieved through thermal decomposition and chemical vapor deposition after the spherical carbon particles are coated with silicon and carbon composite ultrafine silica slurry.

Owner:LIYANG TIANMU PILOT BATTERY MATERIAL TECH CO LTD

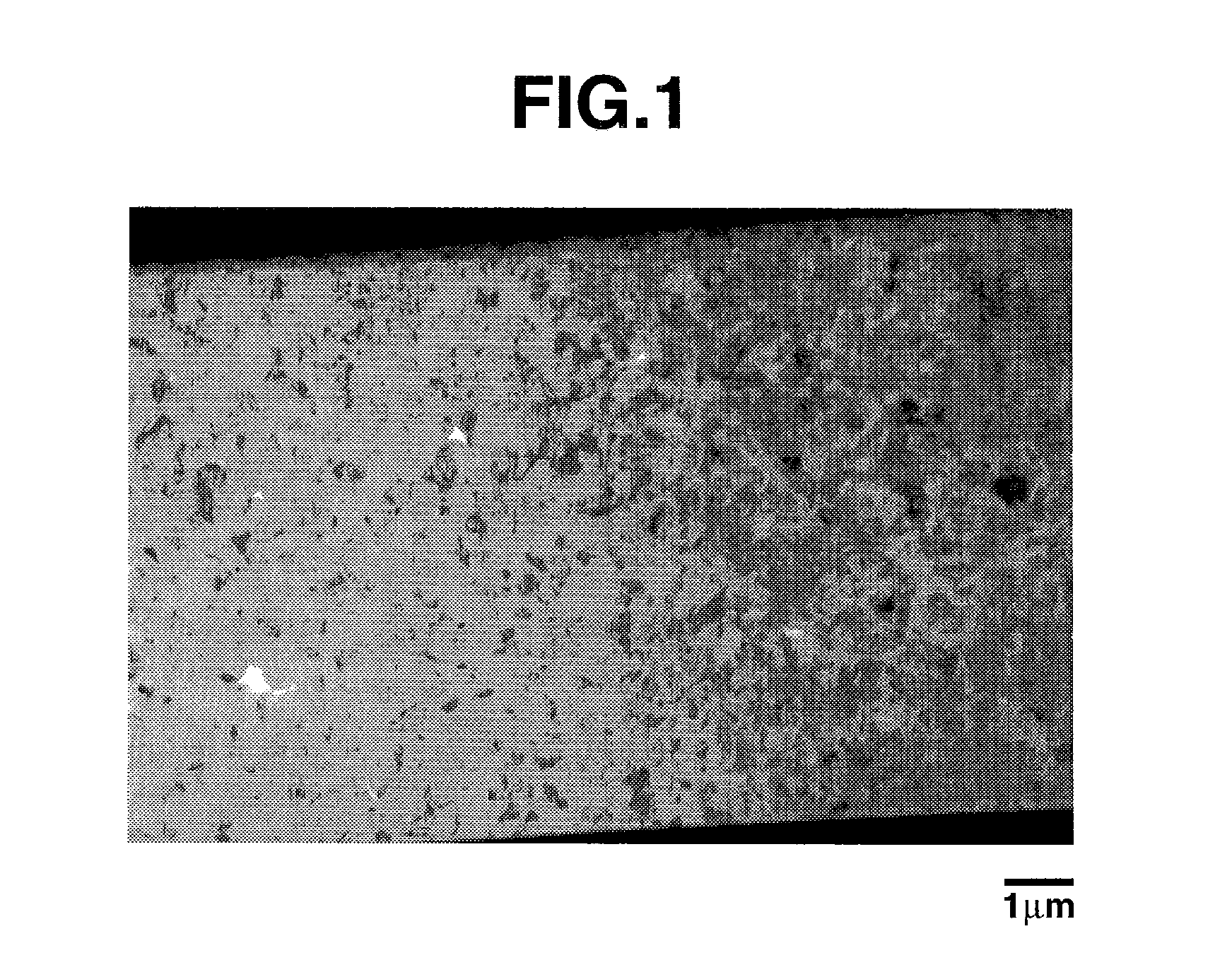

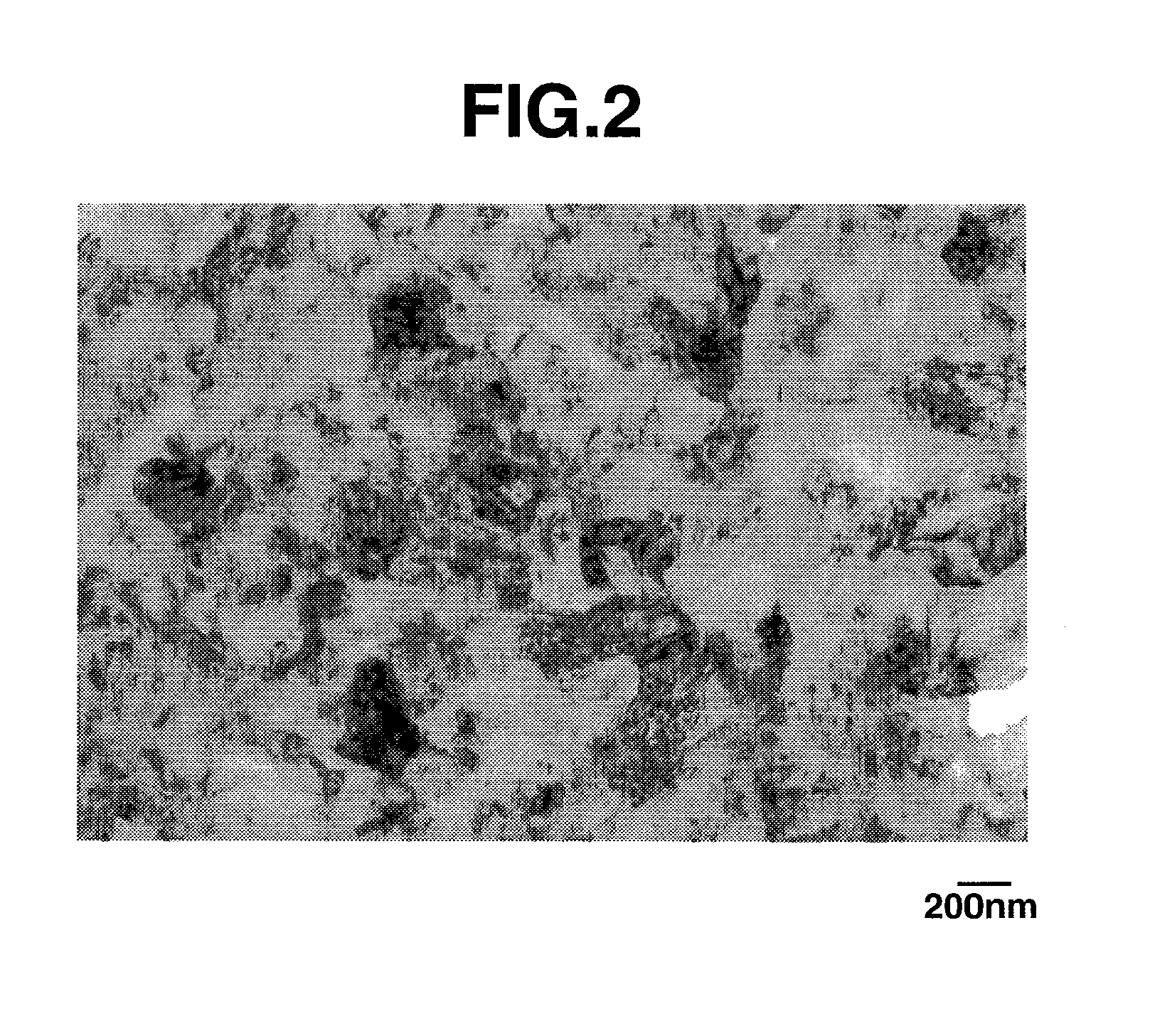

Negative electrode material for secondary battery with non-aqueous electrolyte, method for manufacturing negative electrode material for secondary battery with non-aqueous electrolyte, and lithium ion secondary battery

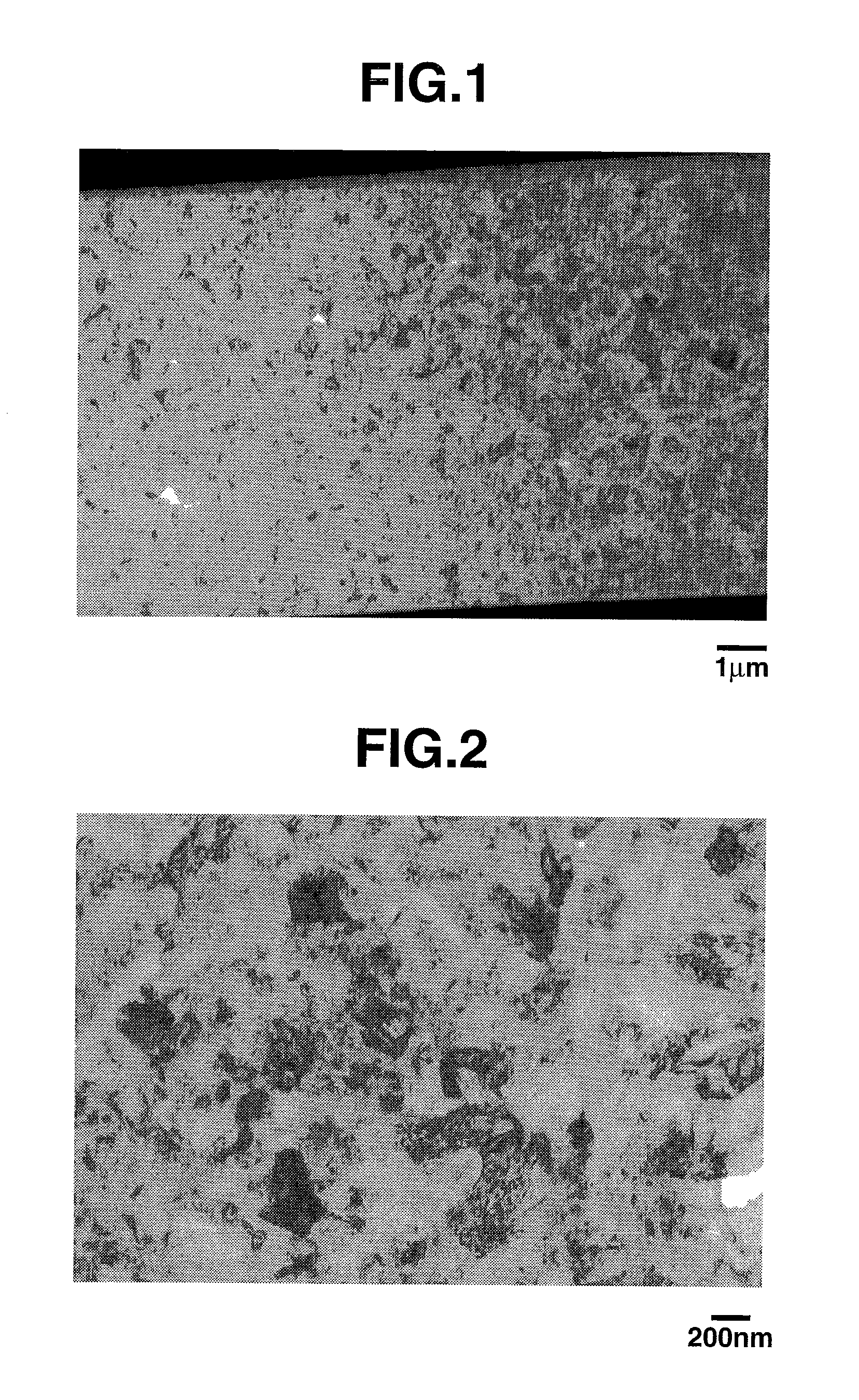

ActiveUS20110244333A1Cycle durability of negativeElectronic conductivity of negativeMaterial nanotechnologyElectrode thermal treatmentOxide compositeAtomic order

The present invention is a method for manufacturing a negative electrode material for a secondary battery with a non-aqueous electrolyte comprising at least: coating a surface of powder with carbon at a coating amount of 1 to 40 mass % with respect to an amount of the powder by heat CVD treatment under an organic gas and / or vapor atmosphere at a temperature between 800° C. and 1300° C., the powder being composed of at least one of silicon oxide represented by a general formula of SiOx (x=0.5 to 1.6) and a silicon-silicon oxide composite having a structure that silicon particles having a size of 50 nm or less are dispersed to silicon oxide in an atomic order and / or a crystallite state, the silicon-silicon oxide composite having a Si / O molar ratio of 1 / 0.5 to 1 / 1.6; blending lithium hydride and / or lithium aluminum hydride with the powder coated with carbon; and thereafter heating the powder coated with carbon at a temperature between 200° C. and 800° C. to be doped with lithium at a doping amount of 0.1 to 20 mass % with respect to an amount of the powder. As a result, there is provided a method for manufacturing a negative electrode material for a secondary battery with a non-aqueous electrolyte that enables a silicon oxide negative electrode material superior in first efficiency and cycle durability to conventional ones to be mass-produced (manufactured) readily and safely even in an industrial scale.

Owner:SHIN ETSU CHEM IND CO LTD

Composition for forming silicon film and method for forming silicon film

InactiveUS20050145163A1Polycrystalline material growthFrom normal temperature solutionsLight treatmentSilicon membrane

There are provided a silicon-film-forming composition containing silicon particles and a dispersion medium and a method for forming a silicon film by forming a coating film of the silicon-film-forming composition on a substrate and subjecting the coating film to instantaneous fusion, a heat treatment or a light treatment. According to the composition and the method, a polysilicon film with a desired thickness which may be used as a silicon film for a solar battery can be formed efficiently and easily.

Owner:JSR CORPORATIOON

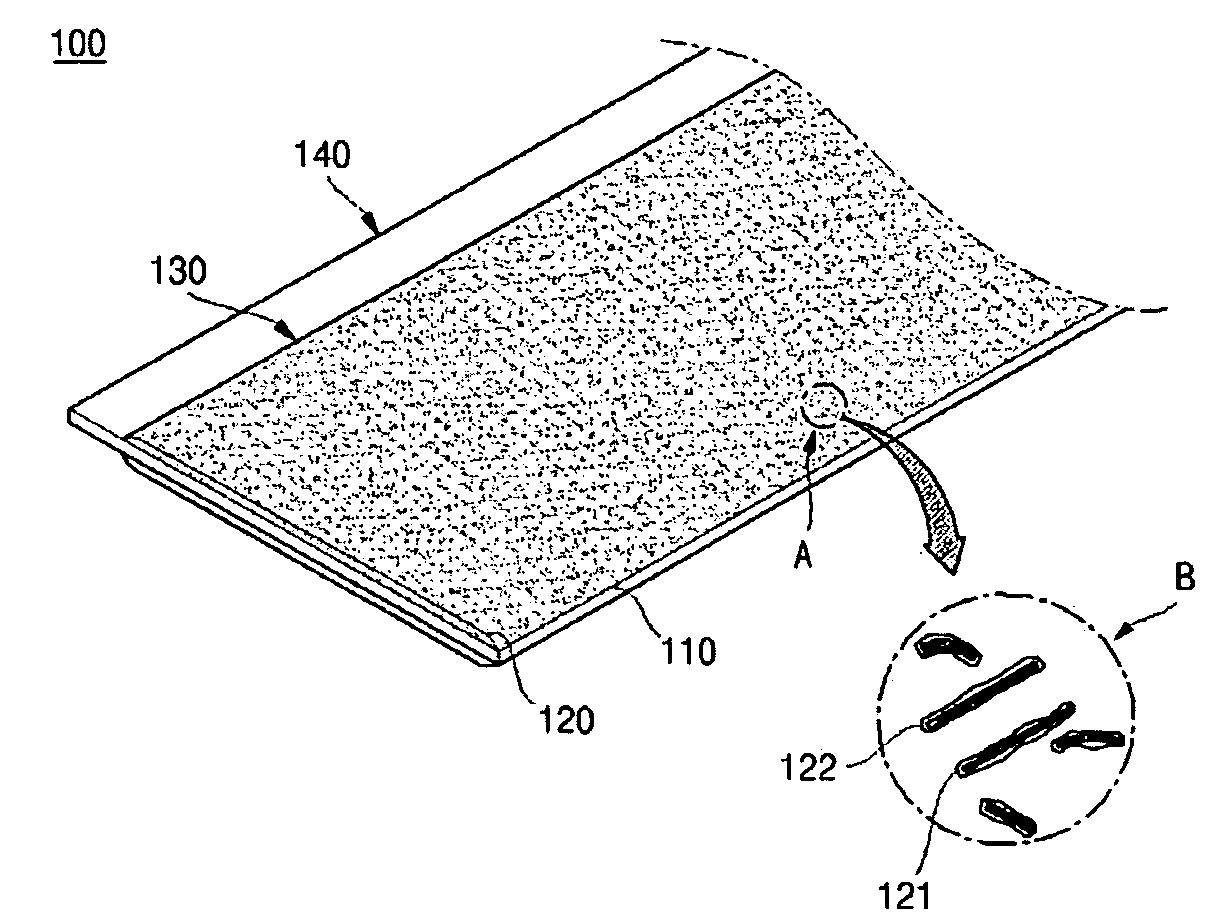

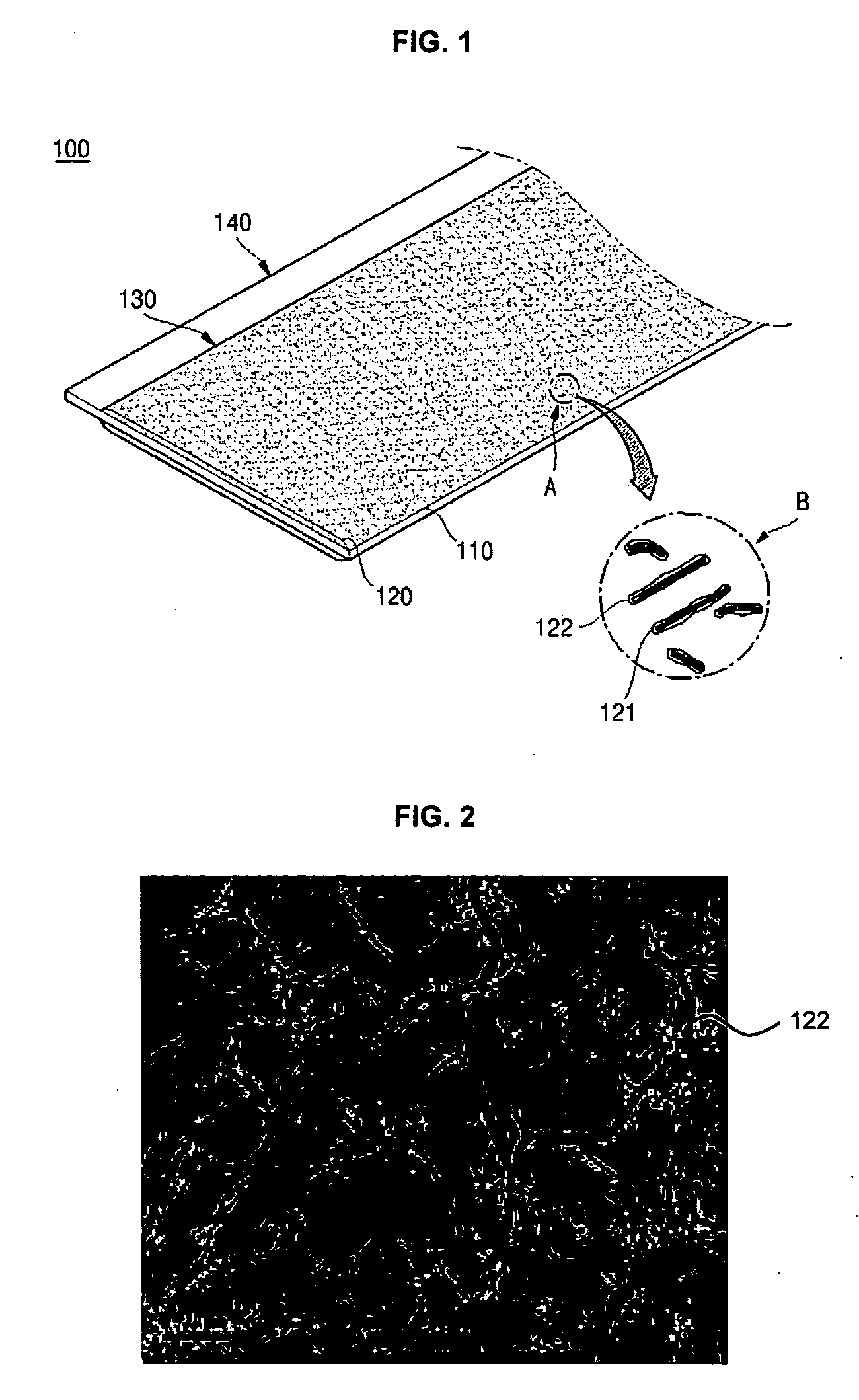

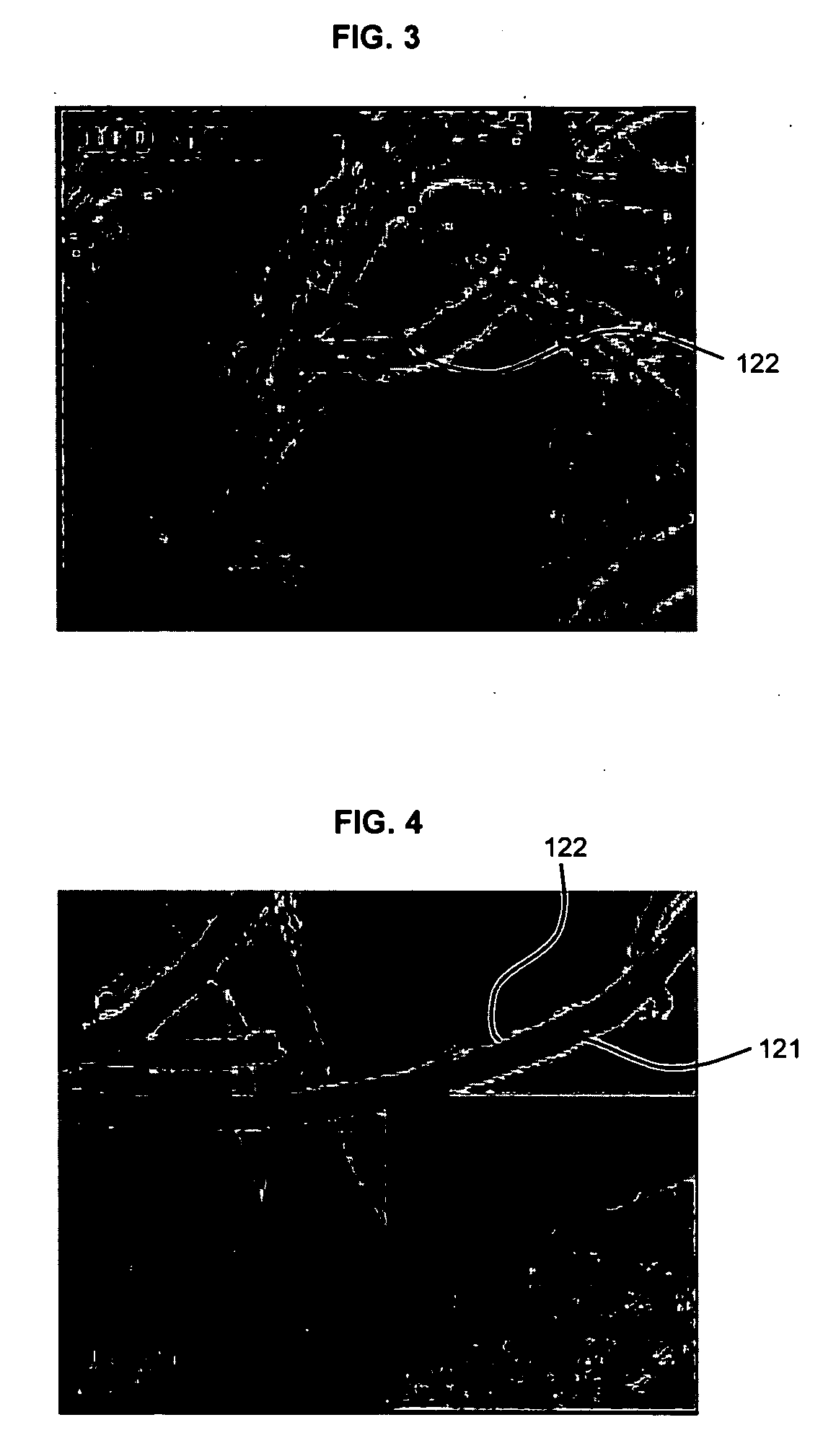

Energy device and method for producing the same

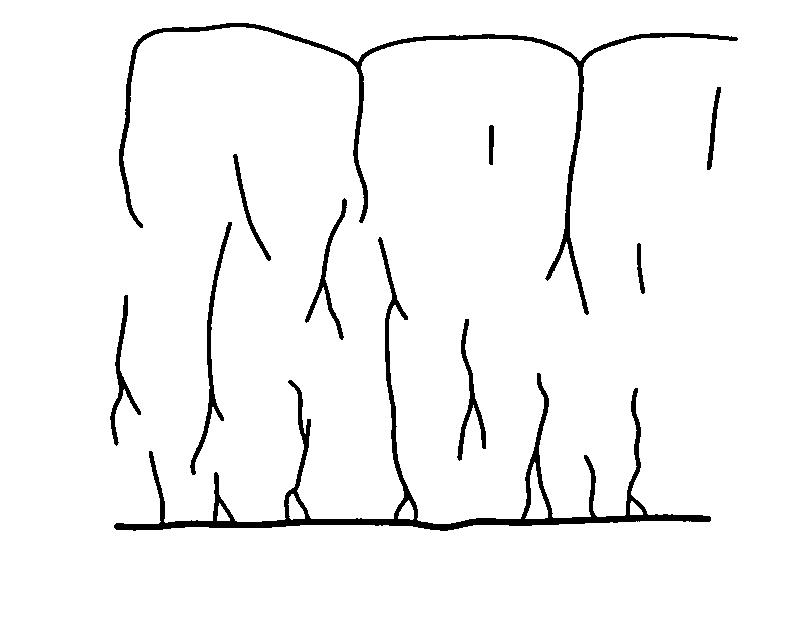

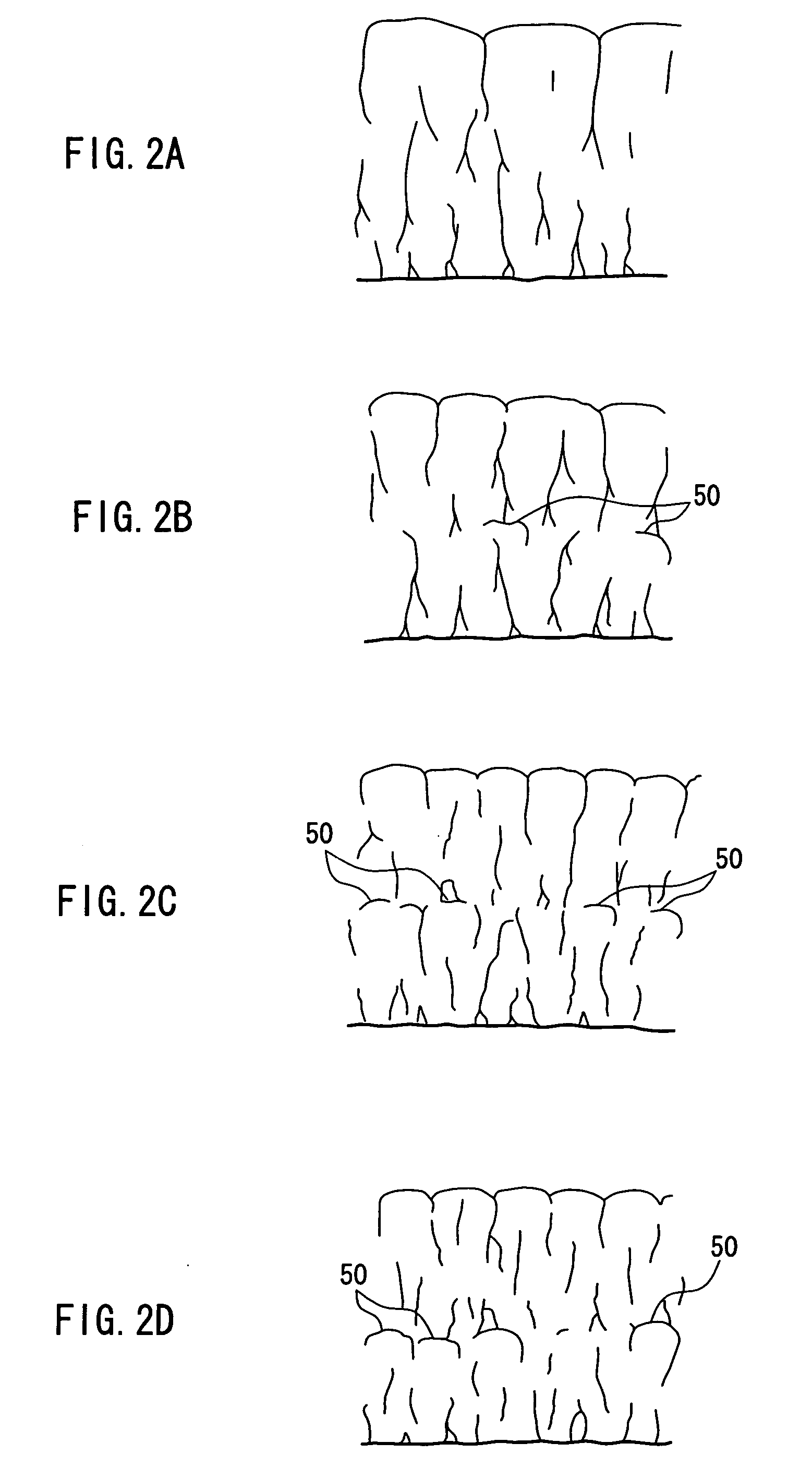

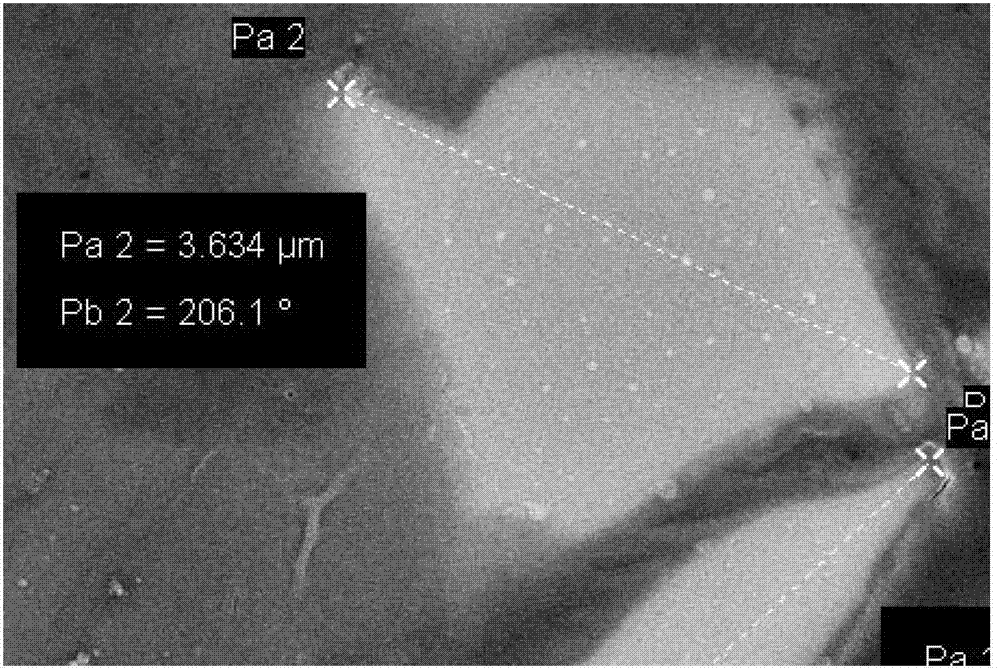

ActiveUS20050118503A1Large capacity and cycle characteristicFinal product manufacturePrimary cellsSilicon thin filmSilicon particle

A negative active material thin film provided on a collector layer directly or via an underlying layer has a multi-layered configuration including at least two silicon thin films containing silicon as a main component. Because of this, even when the thickness of the negative active material thin film is increased, the increase in thickness of one silicon thin film can be prevented by increasing the number of silicon thin films. Thus, the diameter of silicon particles substantially in an inverse truncated cone shape is not enlarged in the silicon thin film. Accordingly, in an energy device having a thin film mainly containing silicon as a negative active material, even when the thickness of the negative active material layer is increased to obtain a larger capacity, cycle characteristics are not degraded.

Owner:PANASONIC CORP

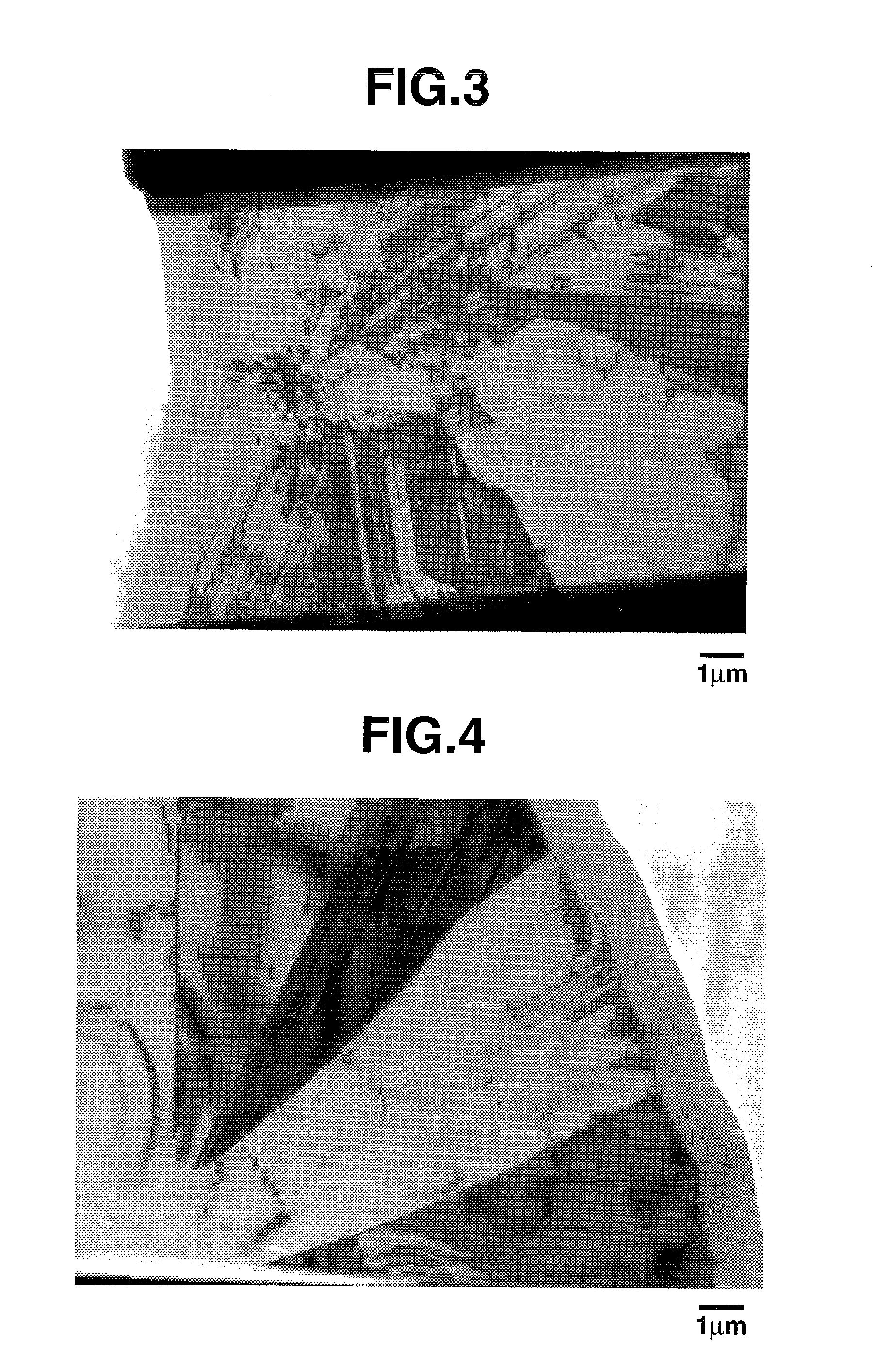

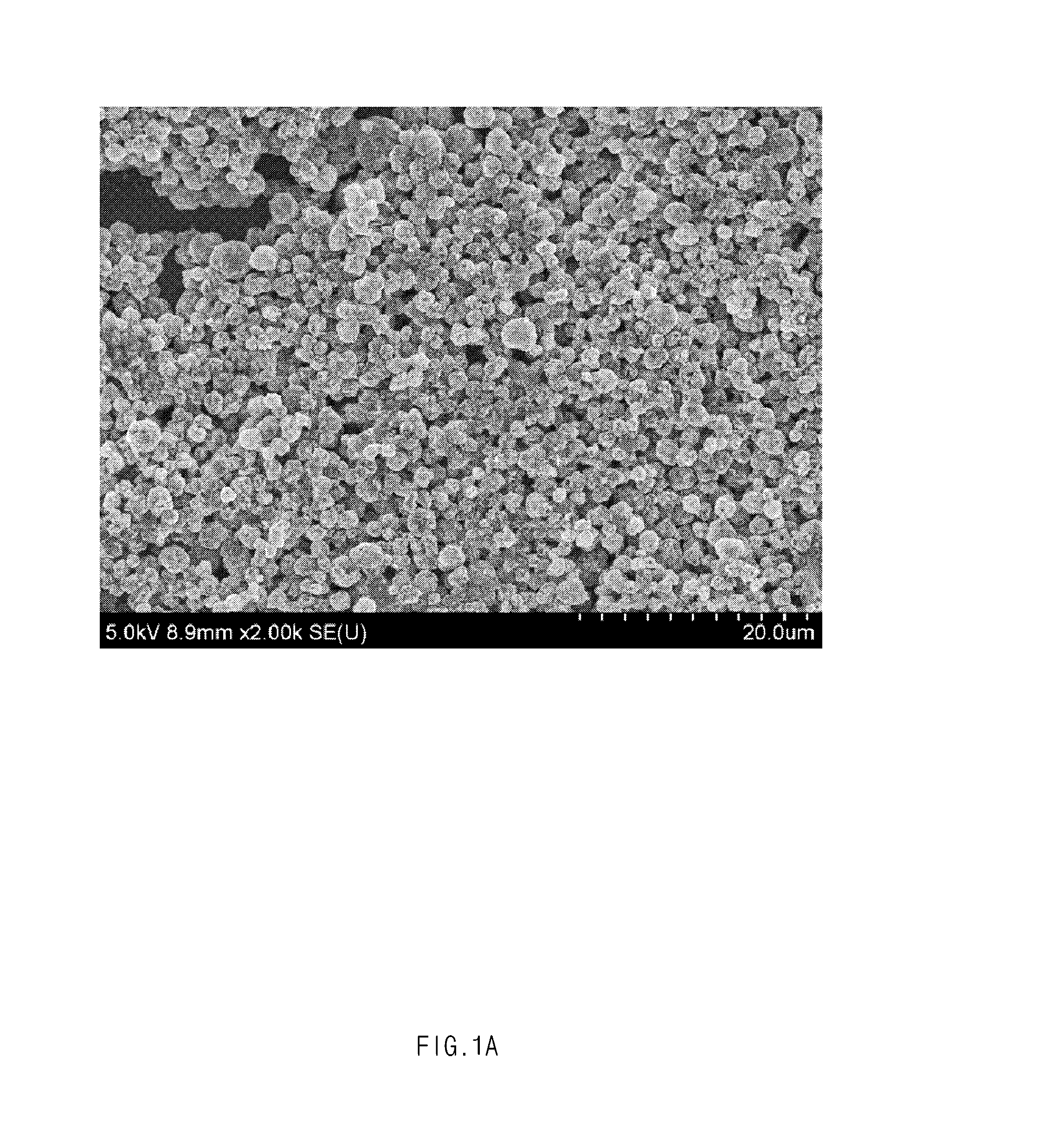

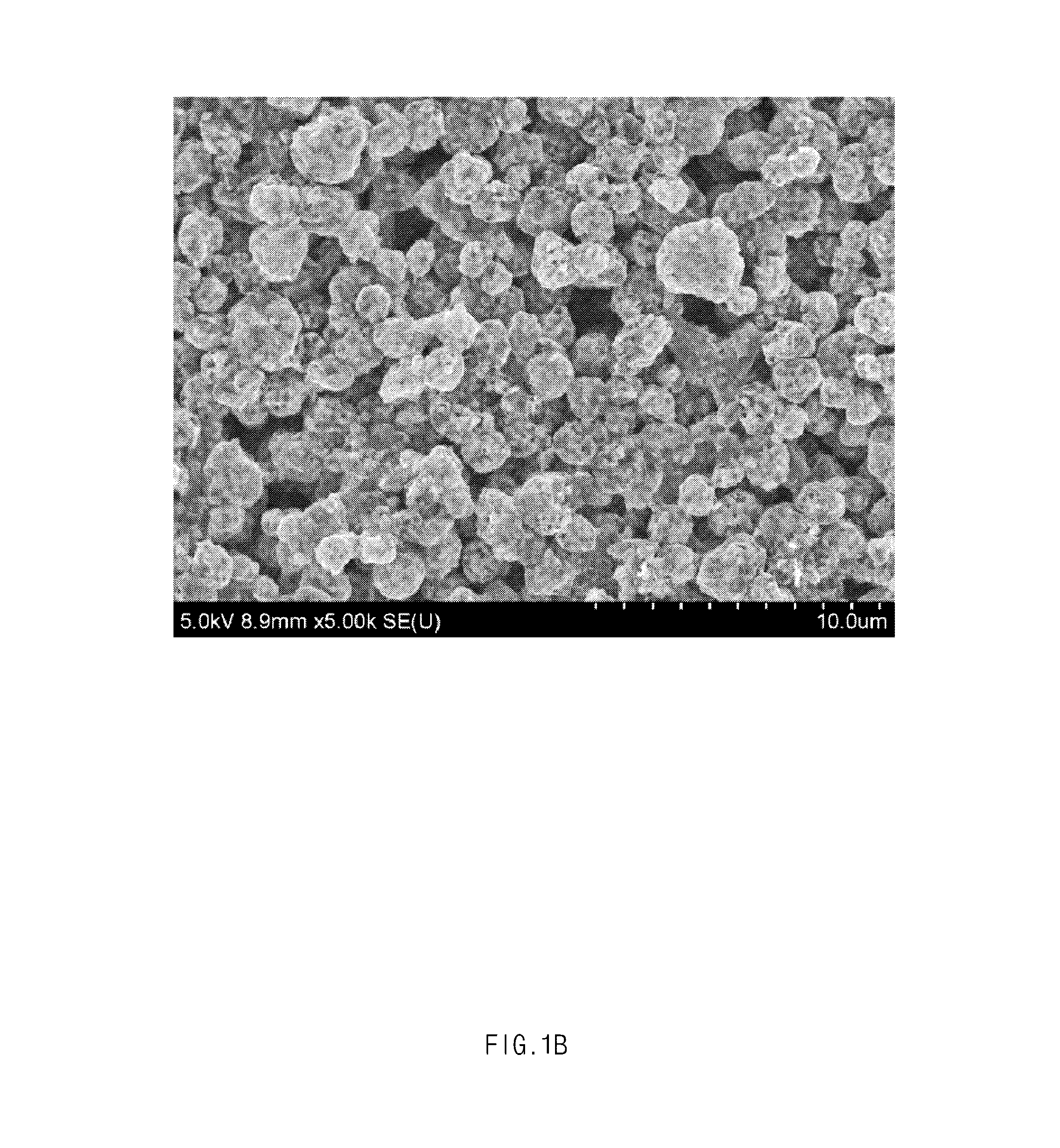

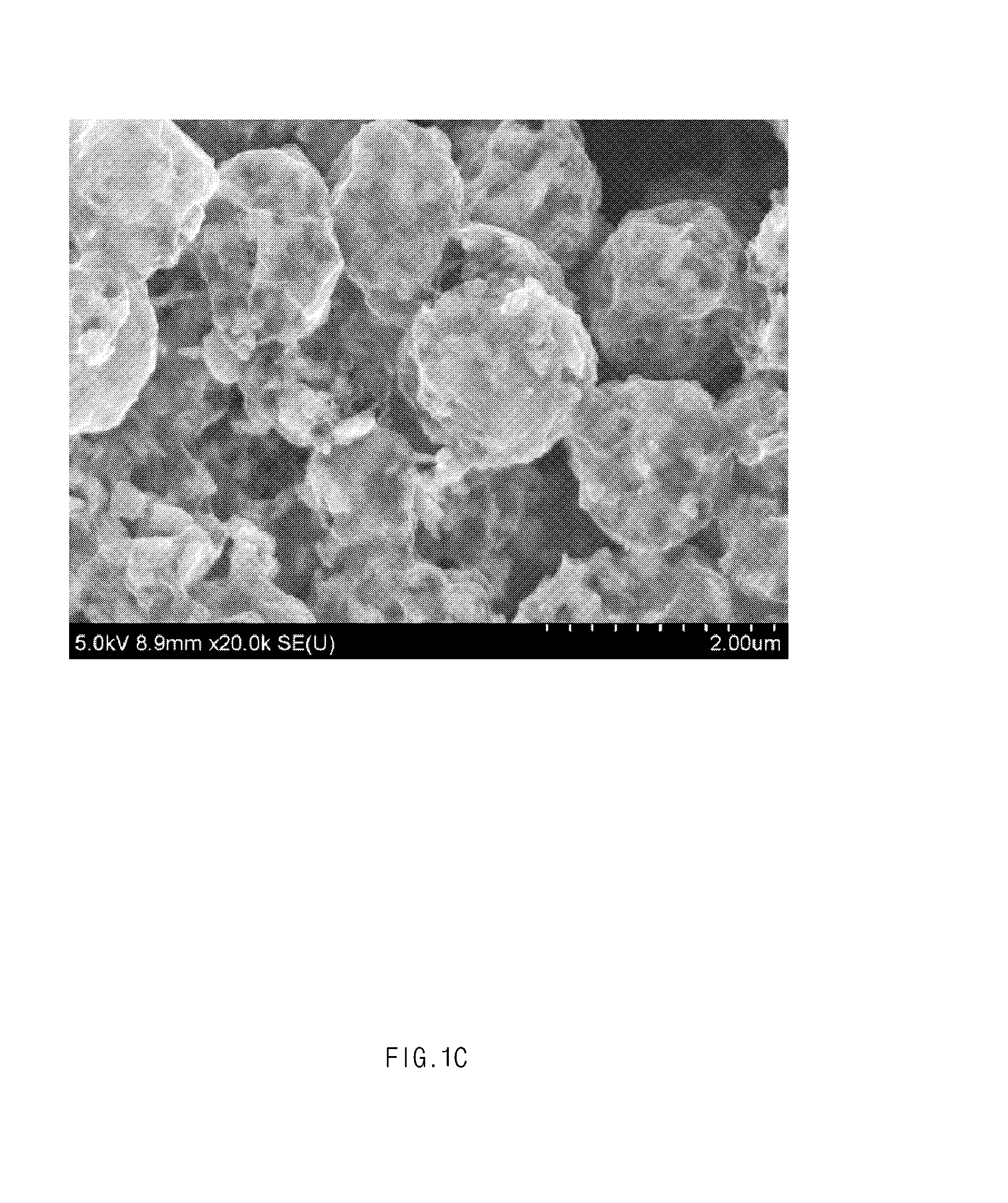

Negative electrode material for rechargeable battery with nonaqueous electrolyte, negative electrode for rechargeable battery with nonaqueous electrolyte, rechargeable battery with nonaqueous electrolyte, and process for producing polycrystalline silicon particles for active material for negative electrode material for rechargeable battery with nonaqueous electrolyte

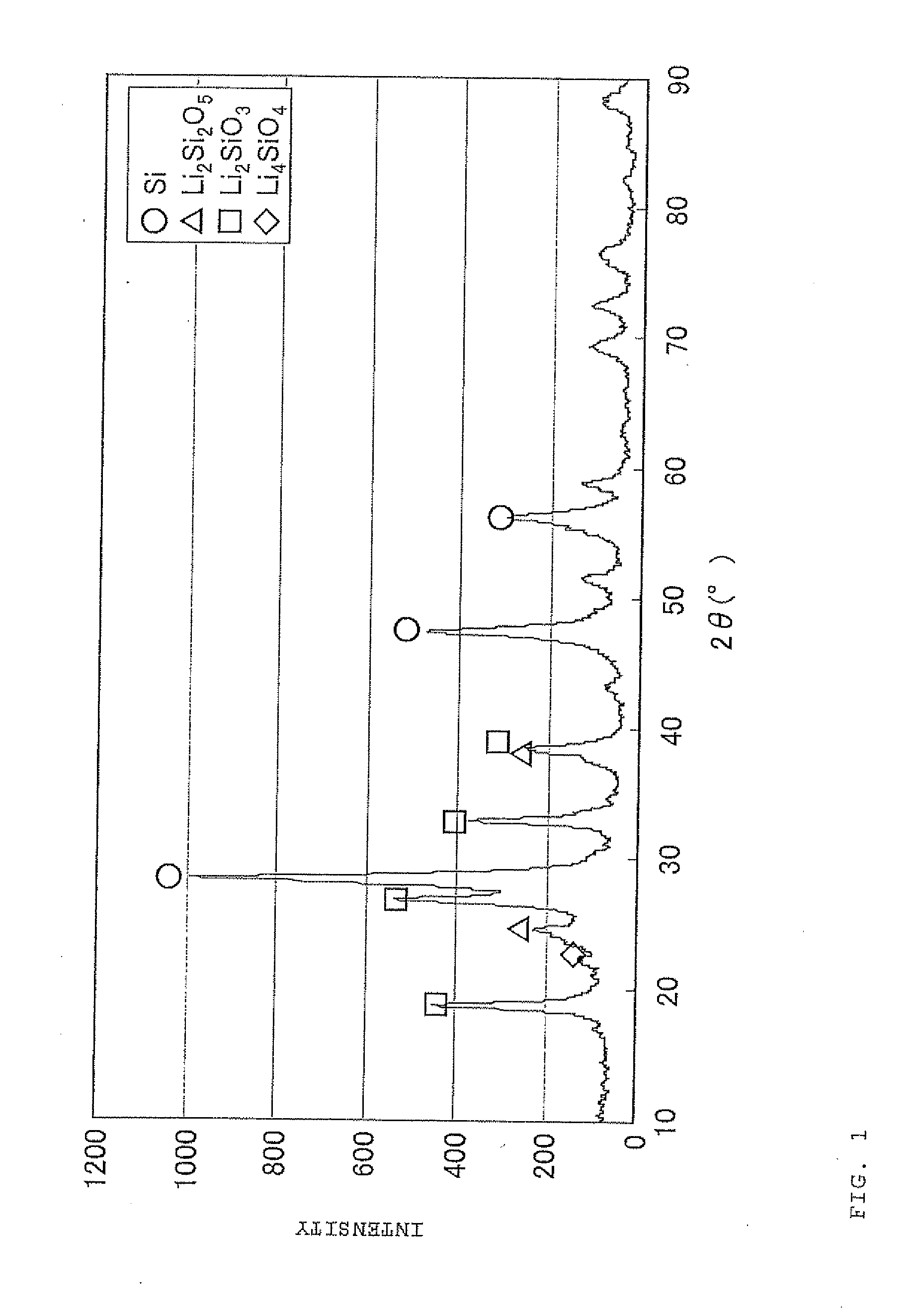

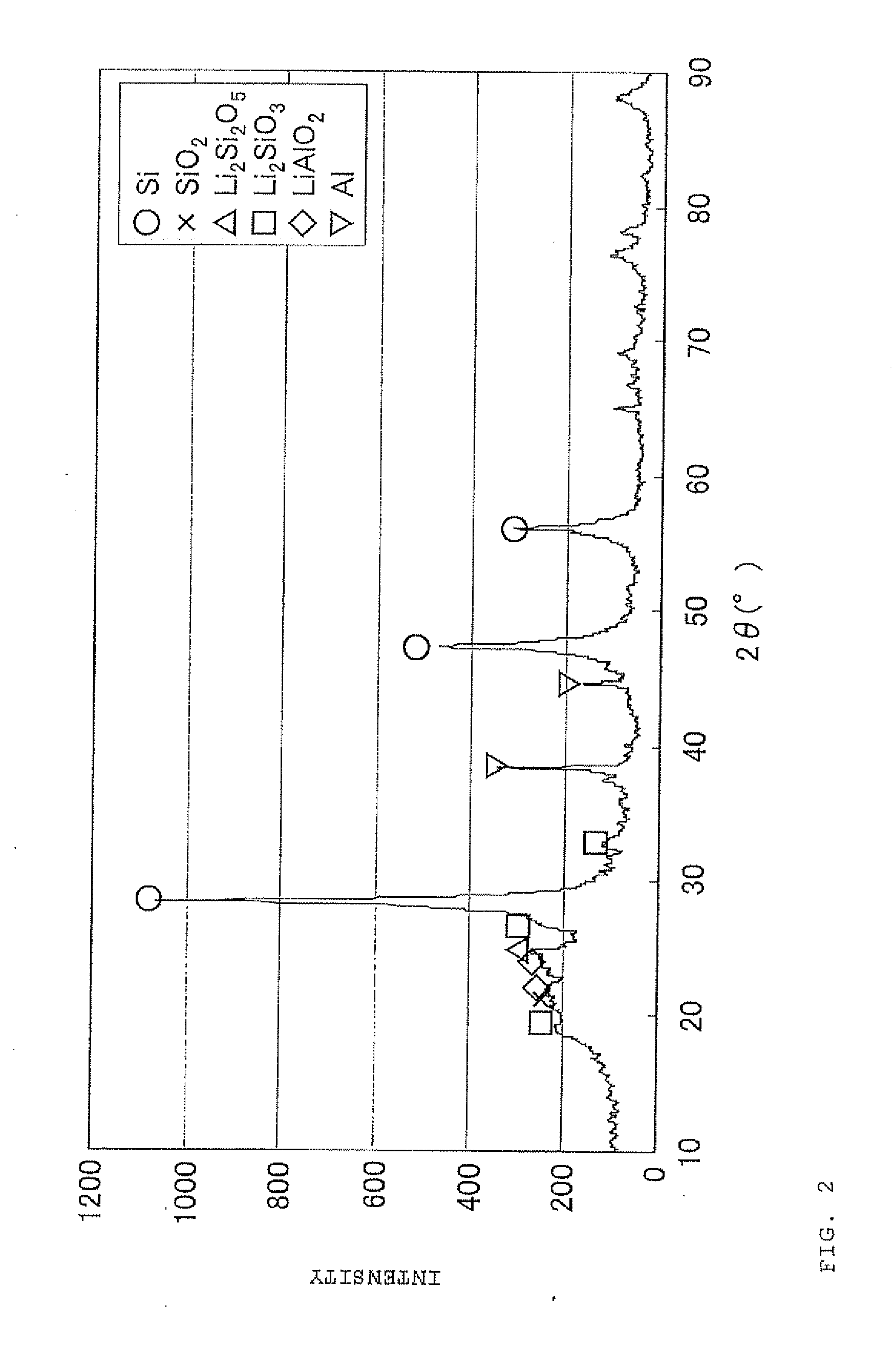

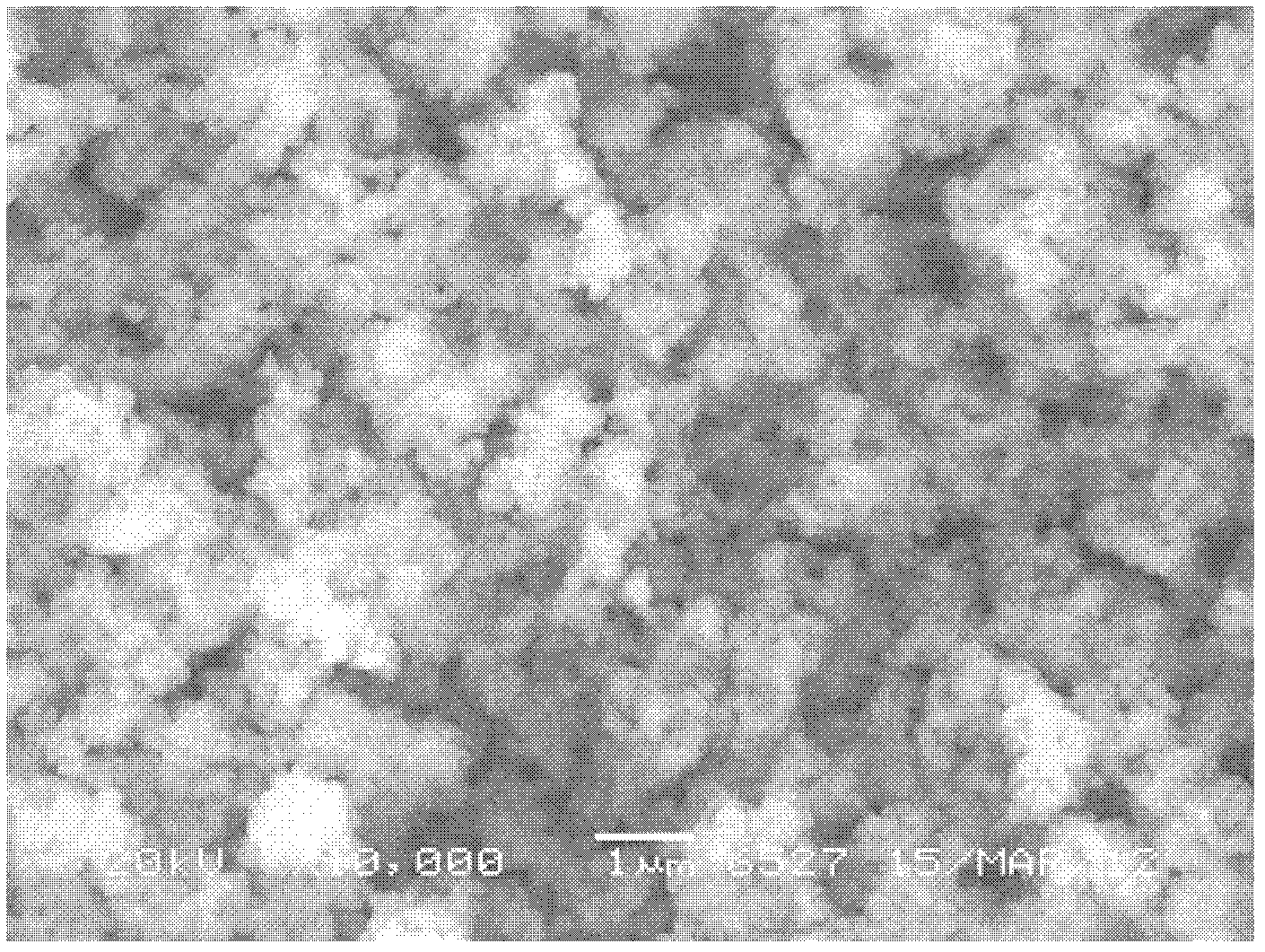

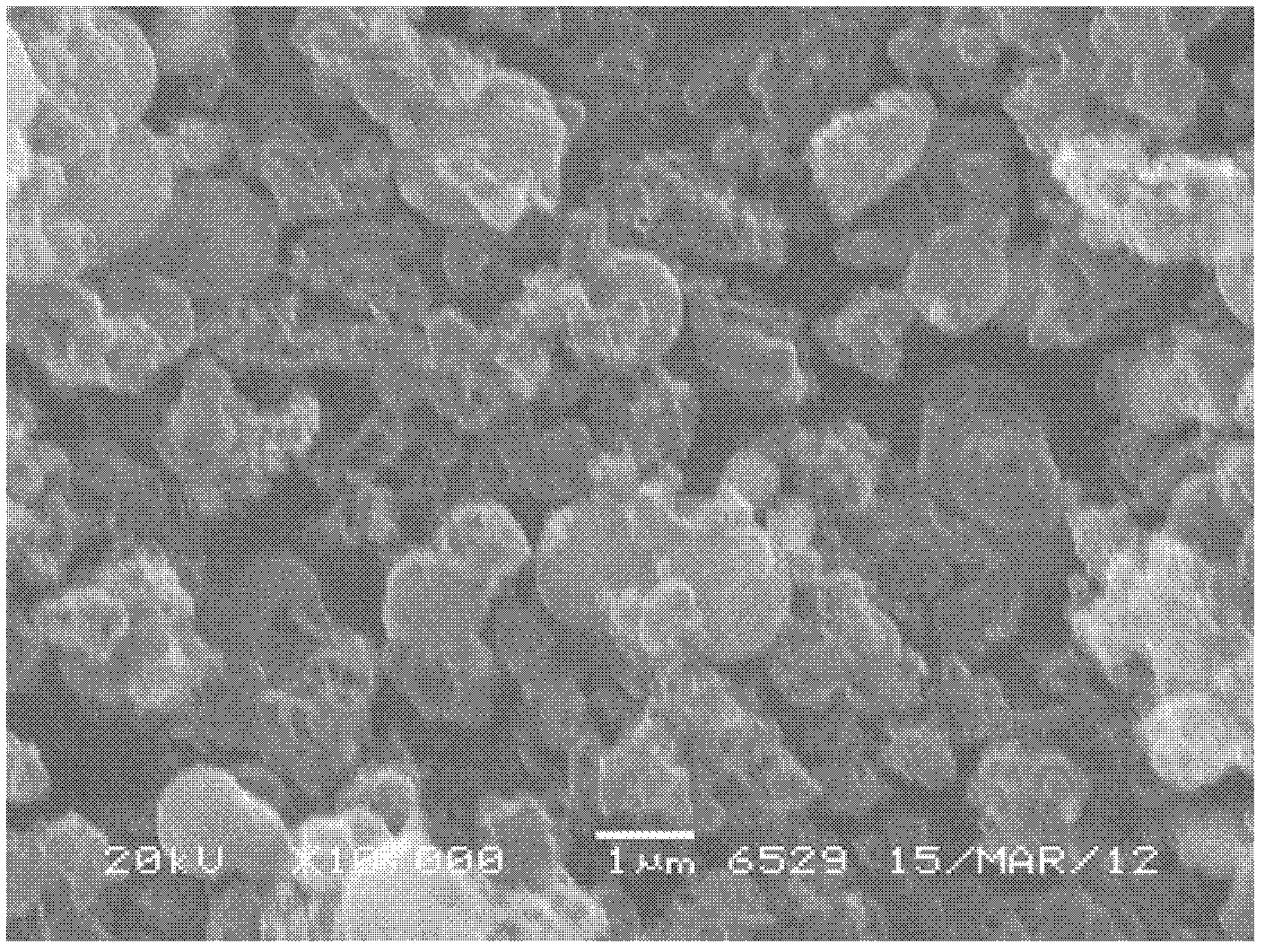

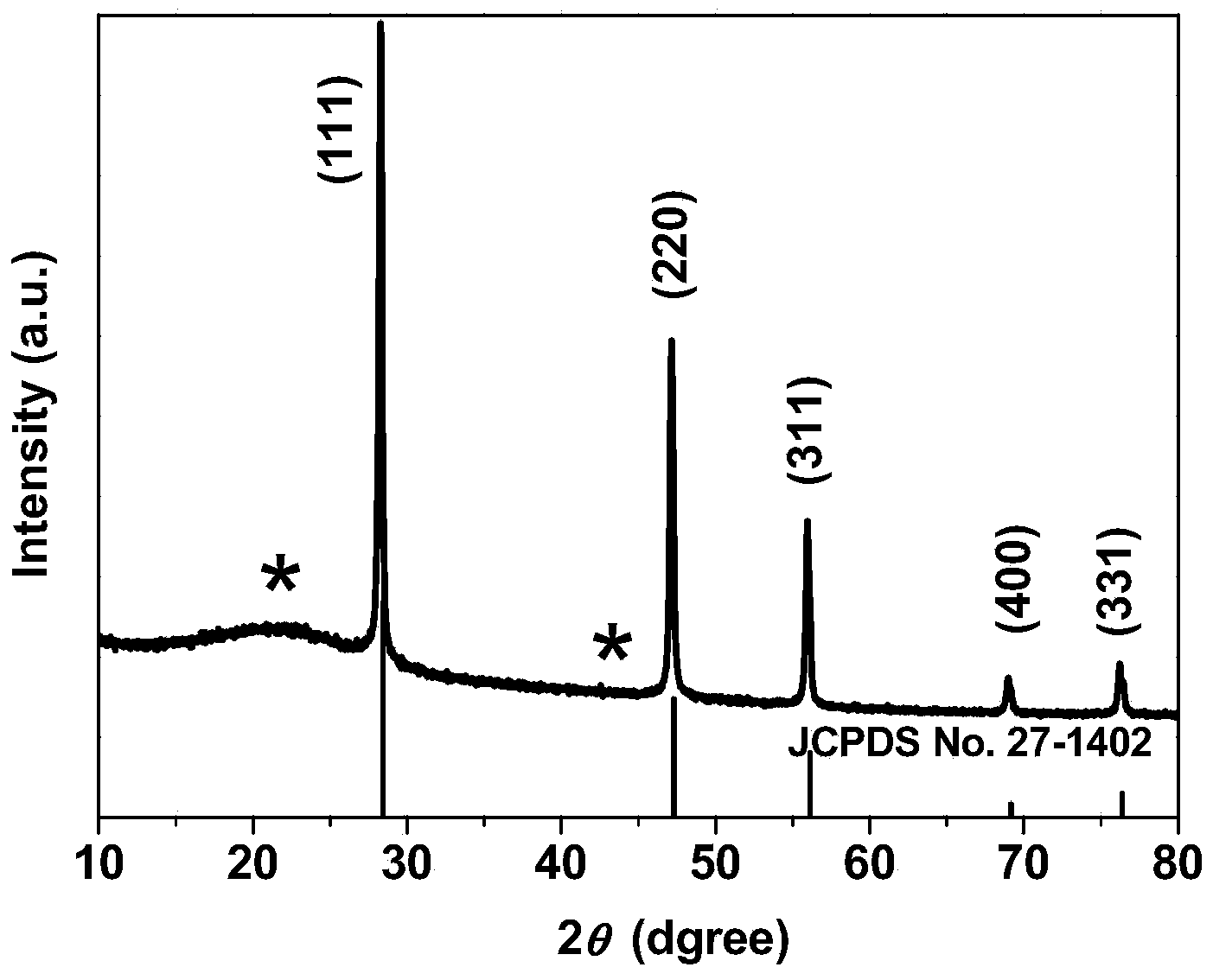

ActiveUS20100266902A1Increase capacityImprove efficiencyMaterial nanotechnologySiliconX-rayFull width at half maximum

This invention provides a negative electrode material for a rechargeable battery with a nonaqueous electrolyte, characterized in that the negative electrode material contains polycrystalline silicon particles as an active material, the particle diameter of crystallites of the polycrystalline silicon is not less than 20 nm and not more than 100 nm in terms of a crystallite size determined by the Scherrer method from the full width at half maximum of a diffraction line attributable to Si (111) around 2θ=28.4° in an x-ray diffraction pattern analysis, and the true specific gravity of the silicon particles is 2.300 to 2.320.

Owner:PANASONIC ENERGY CO LTD +1

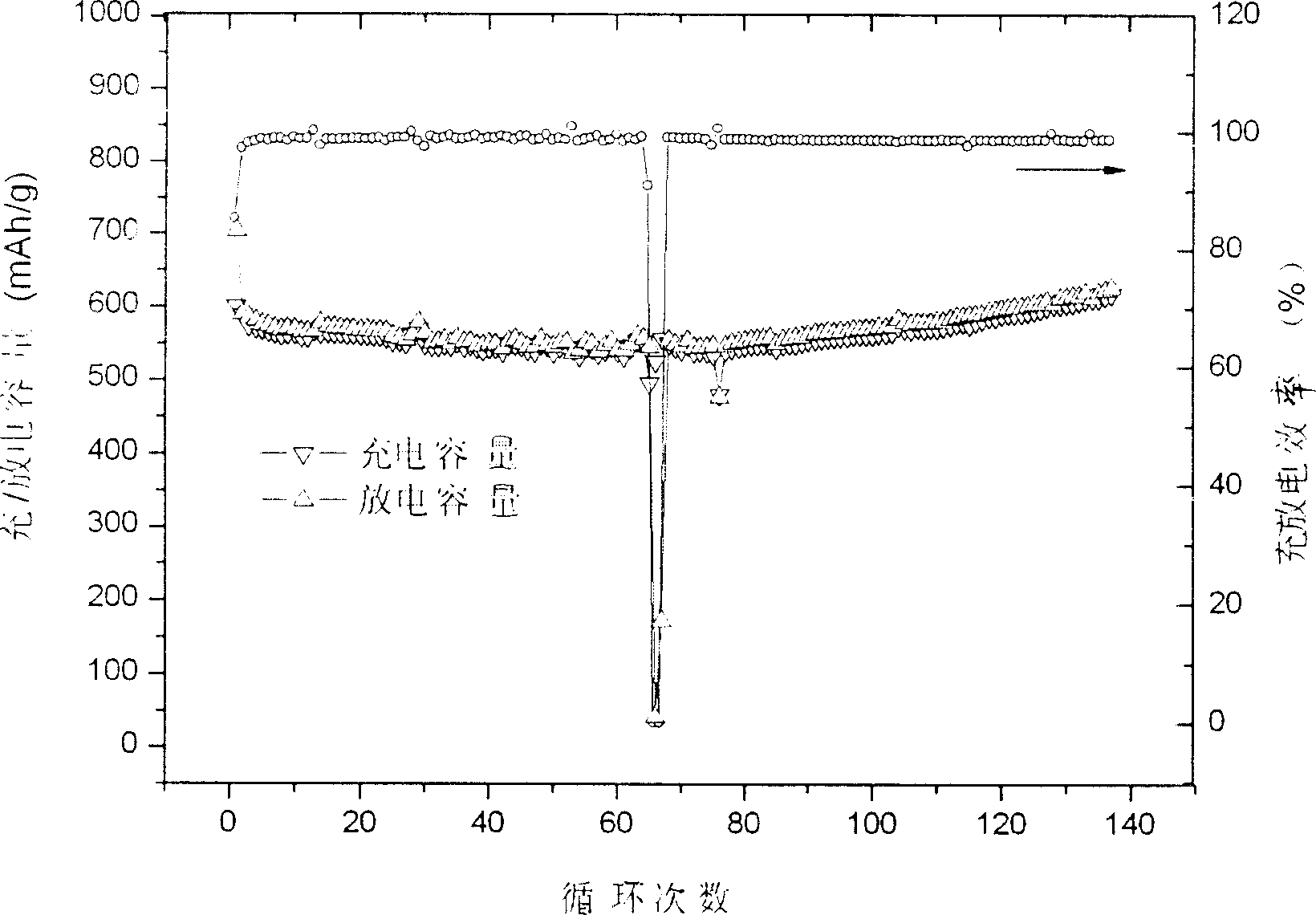

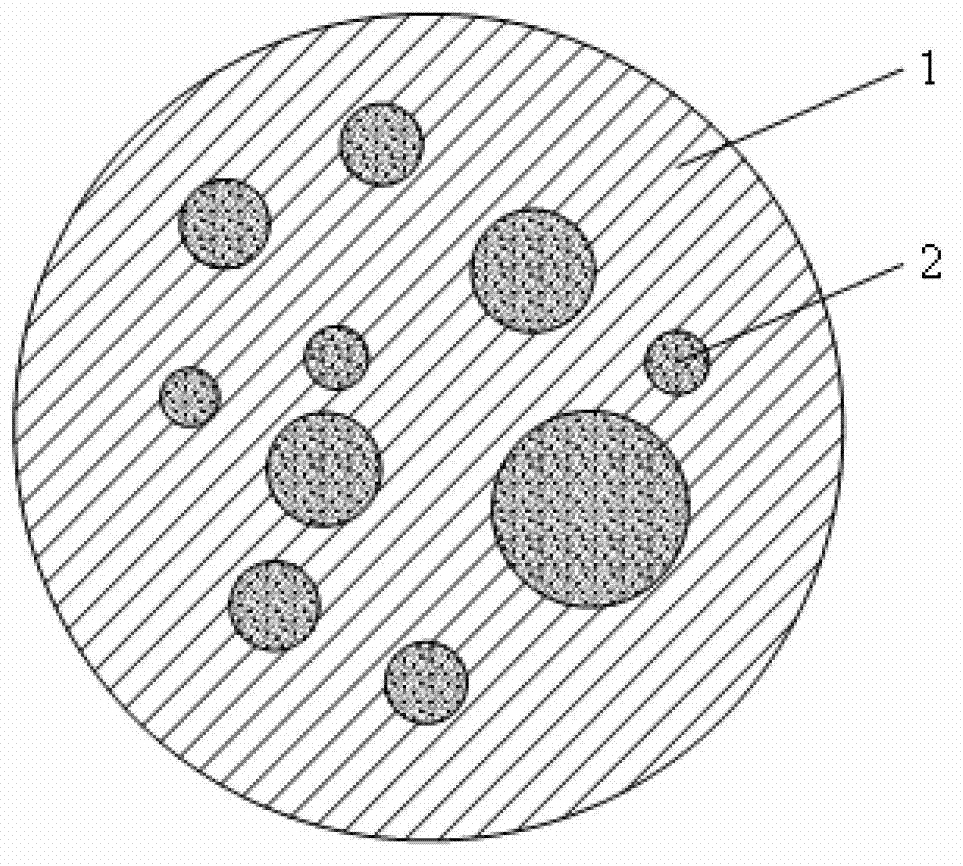

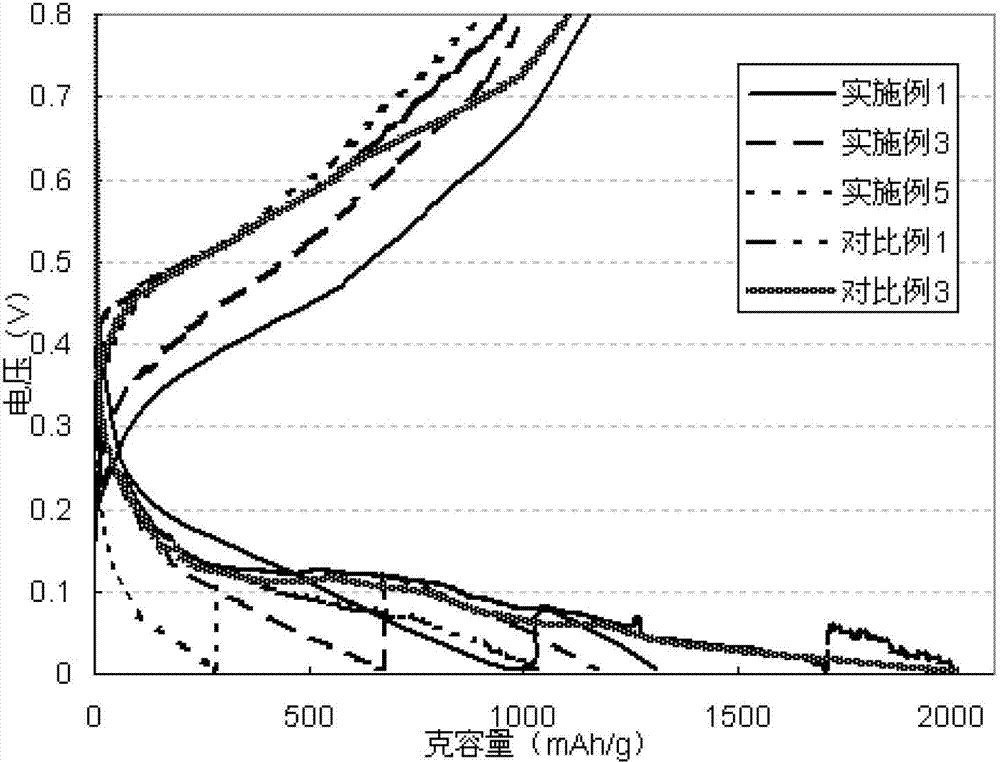

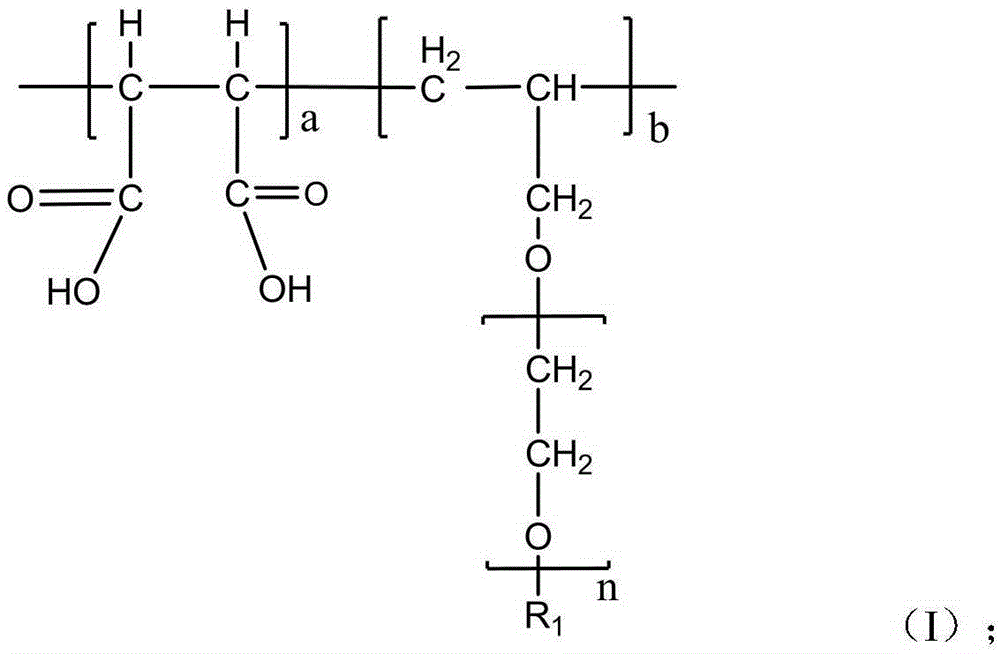

Silicon-based composite material and preparation method and applications thereof

ActiveCN103400971AGuaranteed lattice structureKeep aliveCell electrodesHigh temperature storageAlcohol

The invention provides a silicon-based composite material, which is prepared from silicon particles, silicate and optional carbon, wherein the mixture of the silicate and the optional carbon forms a massive body, and the silicon particles are dispersed in the massive body. A preparation method comprises the following steps of: dispersing the silicon particles into absolute ethyl alcohol and / or deionized water to form suspension liquid; dispersing the silicate and the optional carbon into the absolute ethyl alcohol and / or the deionized water to form suspension liquid; ultrasonically oscillating the two kinds of suspension liquid respectively, and then stirring; dropwise adding the suspension liquid of the silicon particles into the suspension liquid of the silicate and the optional carbon to form mixed liquid, heating and stirring the mixed liquid until evaporating the mixed liquid into paste; then, putting the paste in an oven to be dried to obtain masses, and grinding and sieving to obtain undersize particles; and conducting heat treatment in an inert atmosphere, and grinding and sieving to obtain the silicon-based composite material. According to the silicon-based composite material, a lattice structure of the silicon particles can be ensured, therefore the activity of the silicon particles is ensured, and the energy density, the first-time coulomb efficiency and the high-temperature storage performance of lithium ion batteries are increased.

Owner:NINGDE AMPEREX TECH

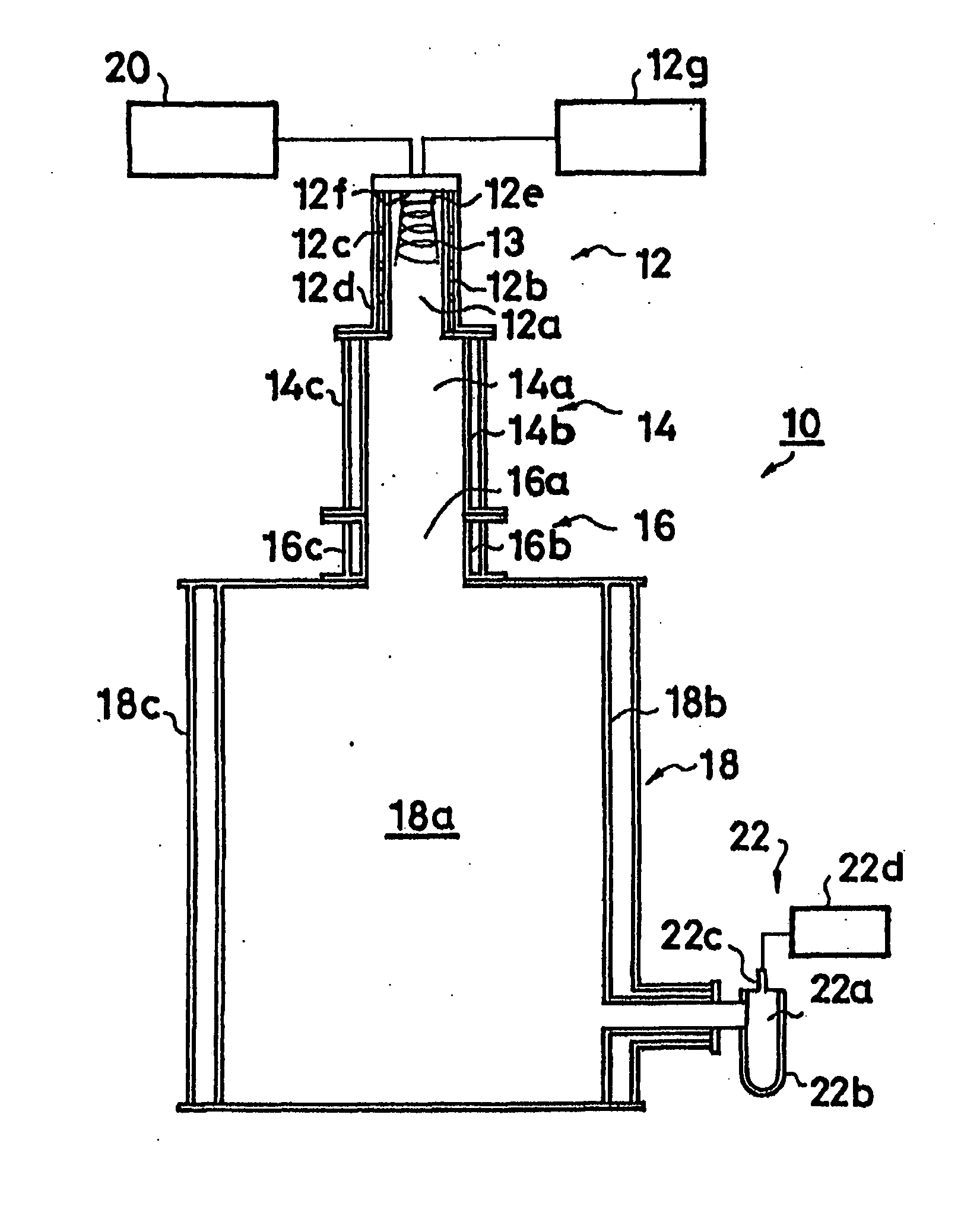

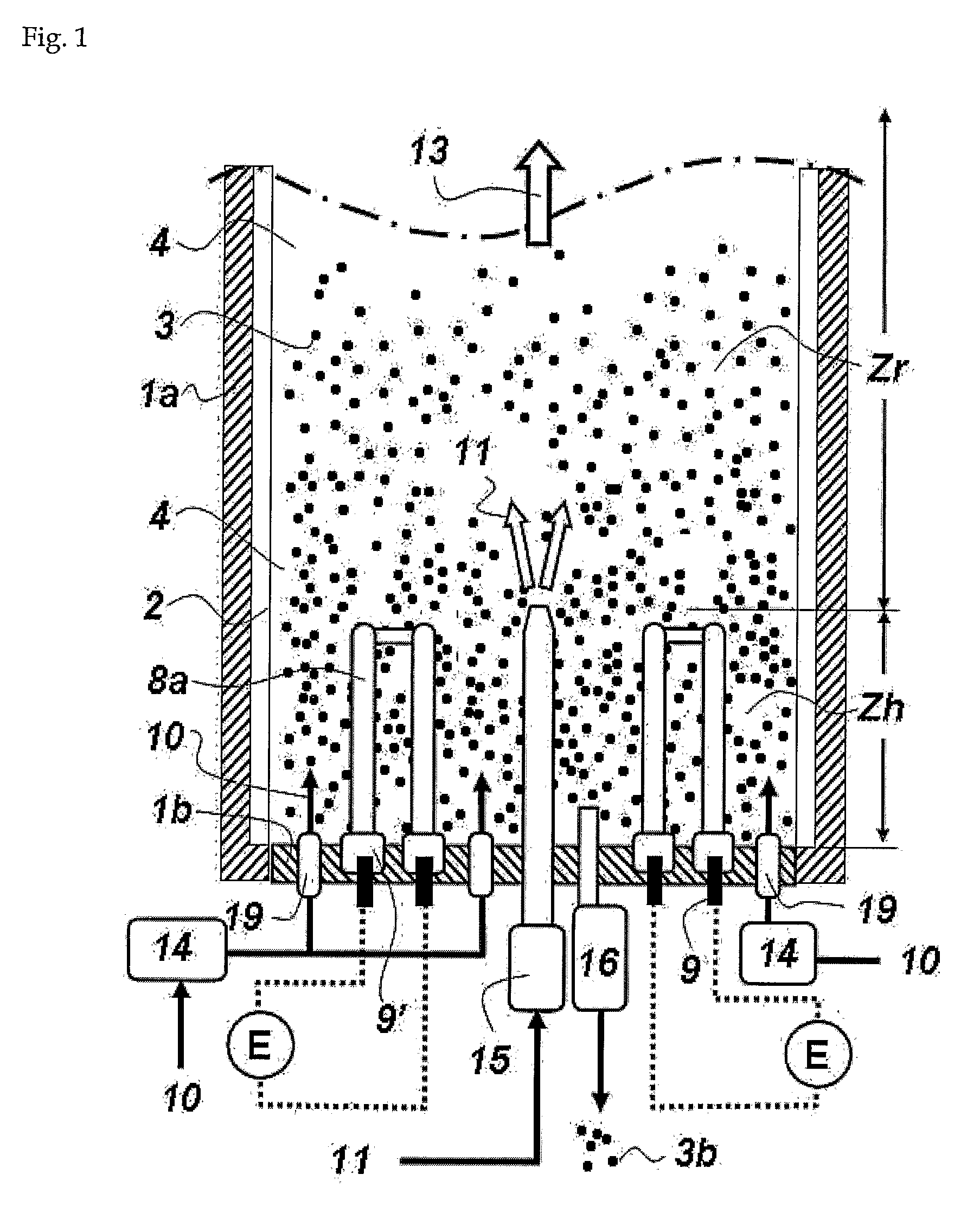

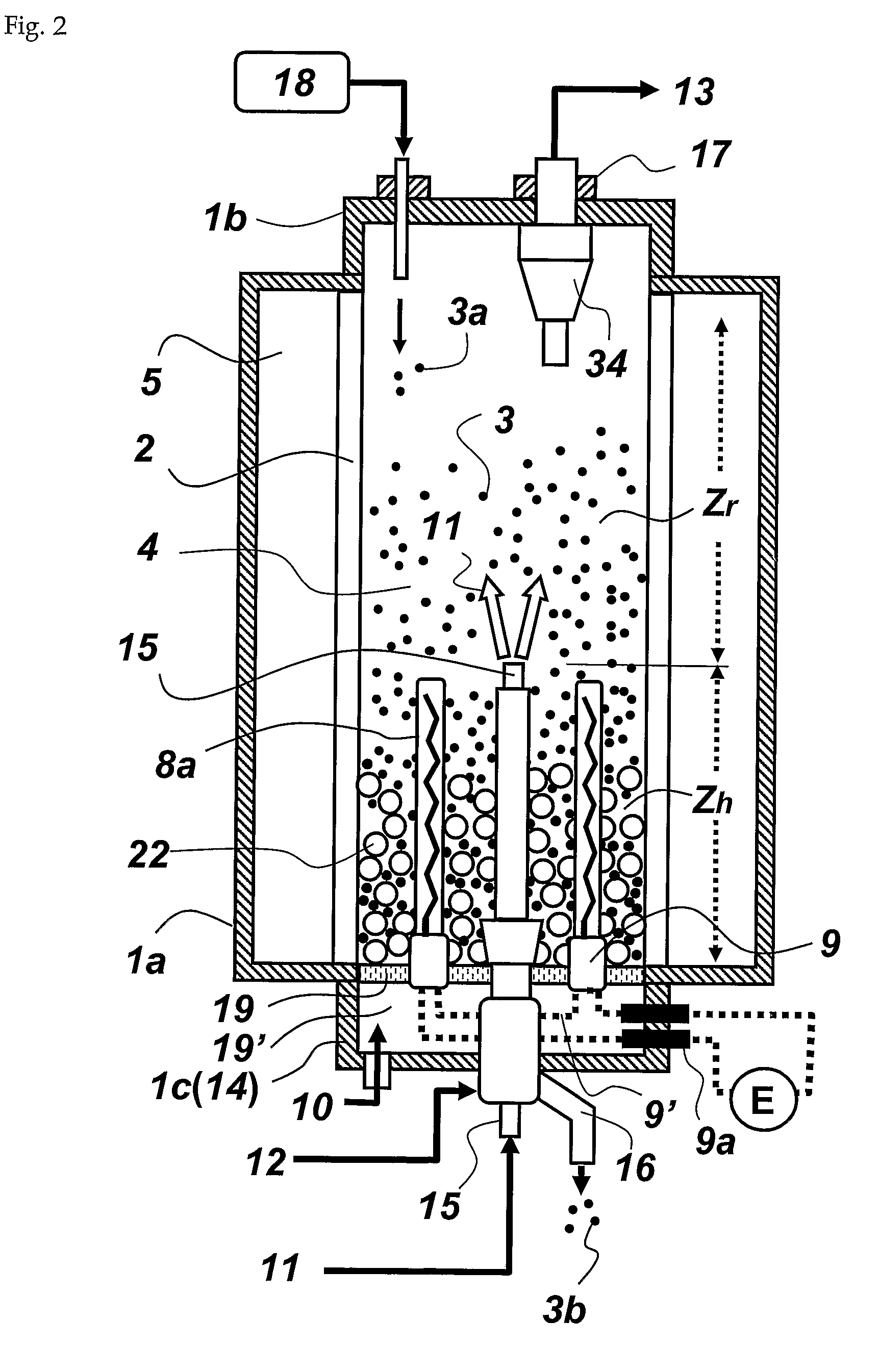

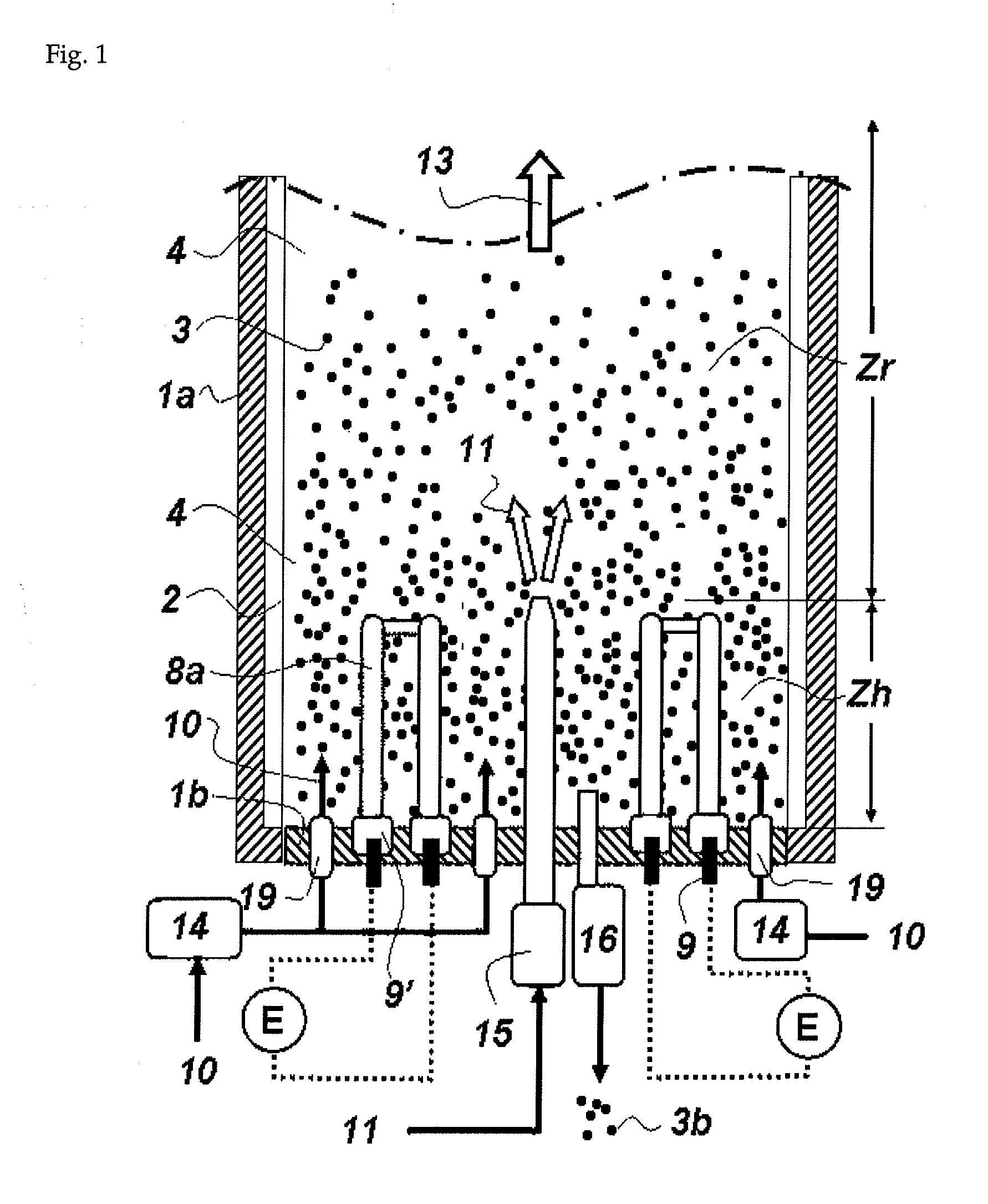

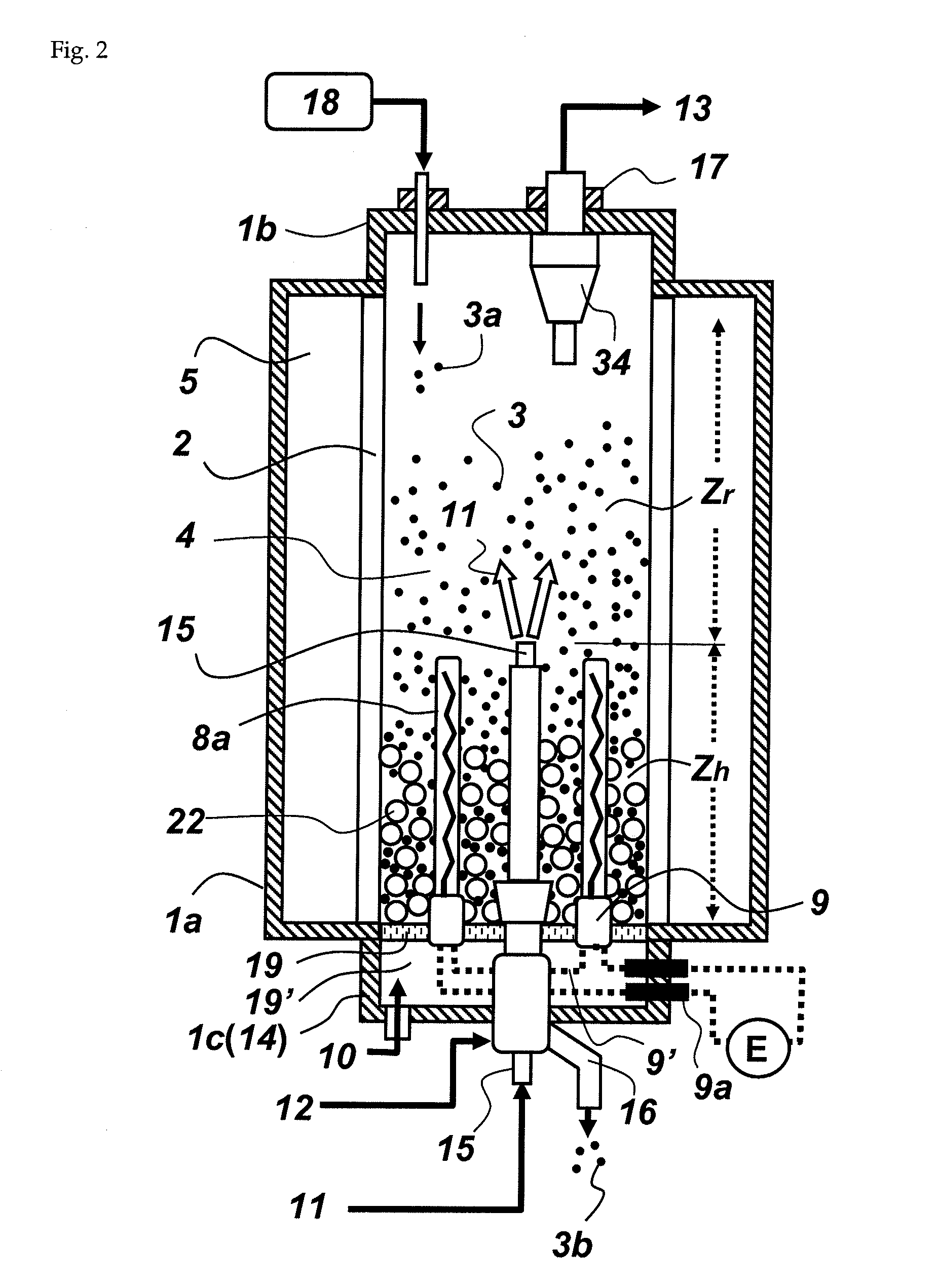

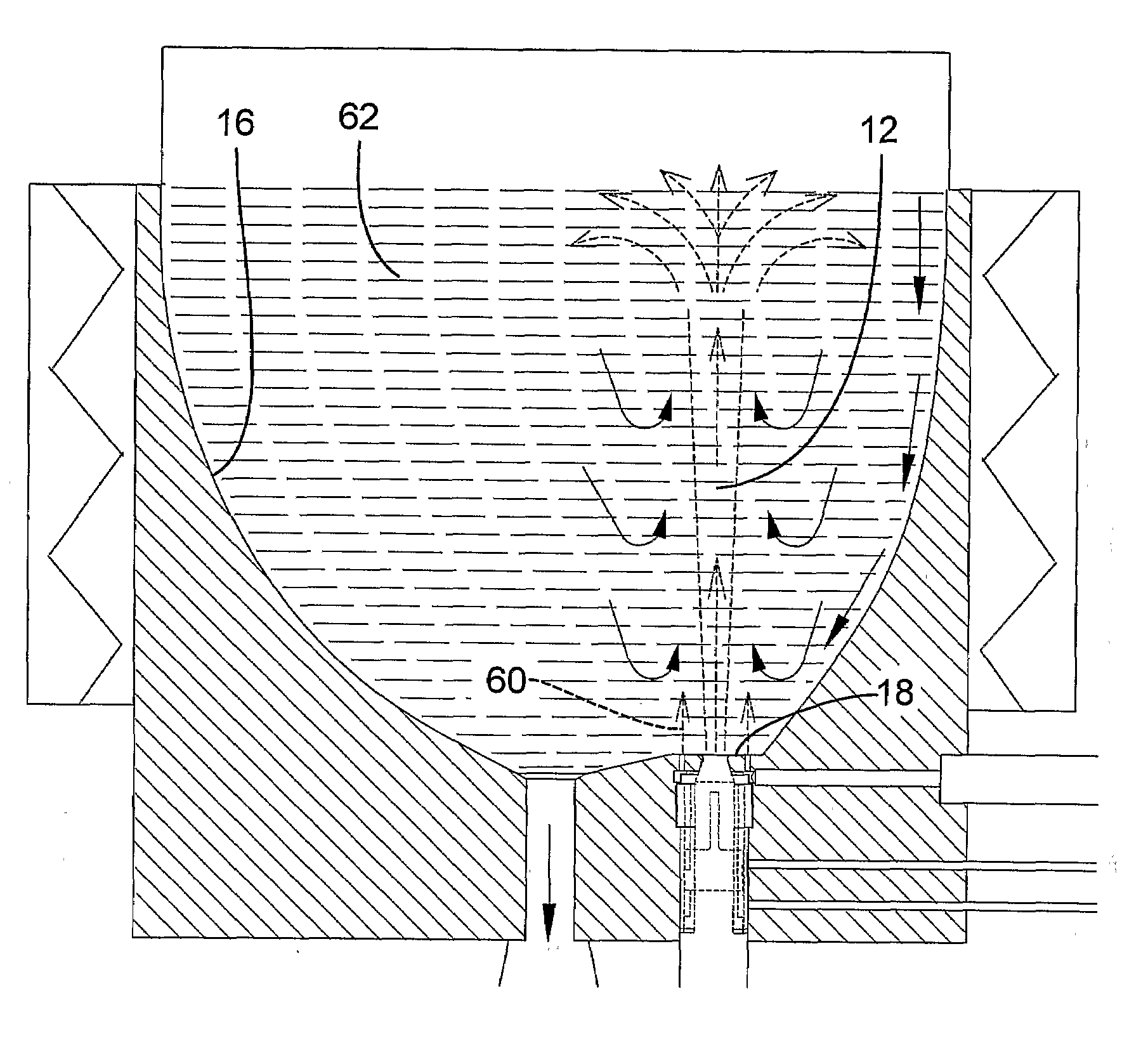

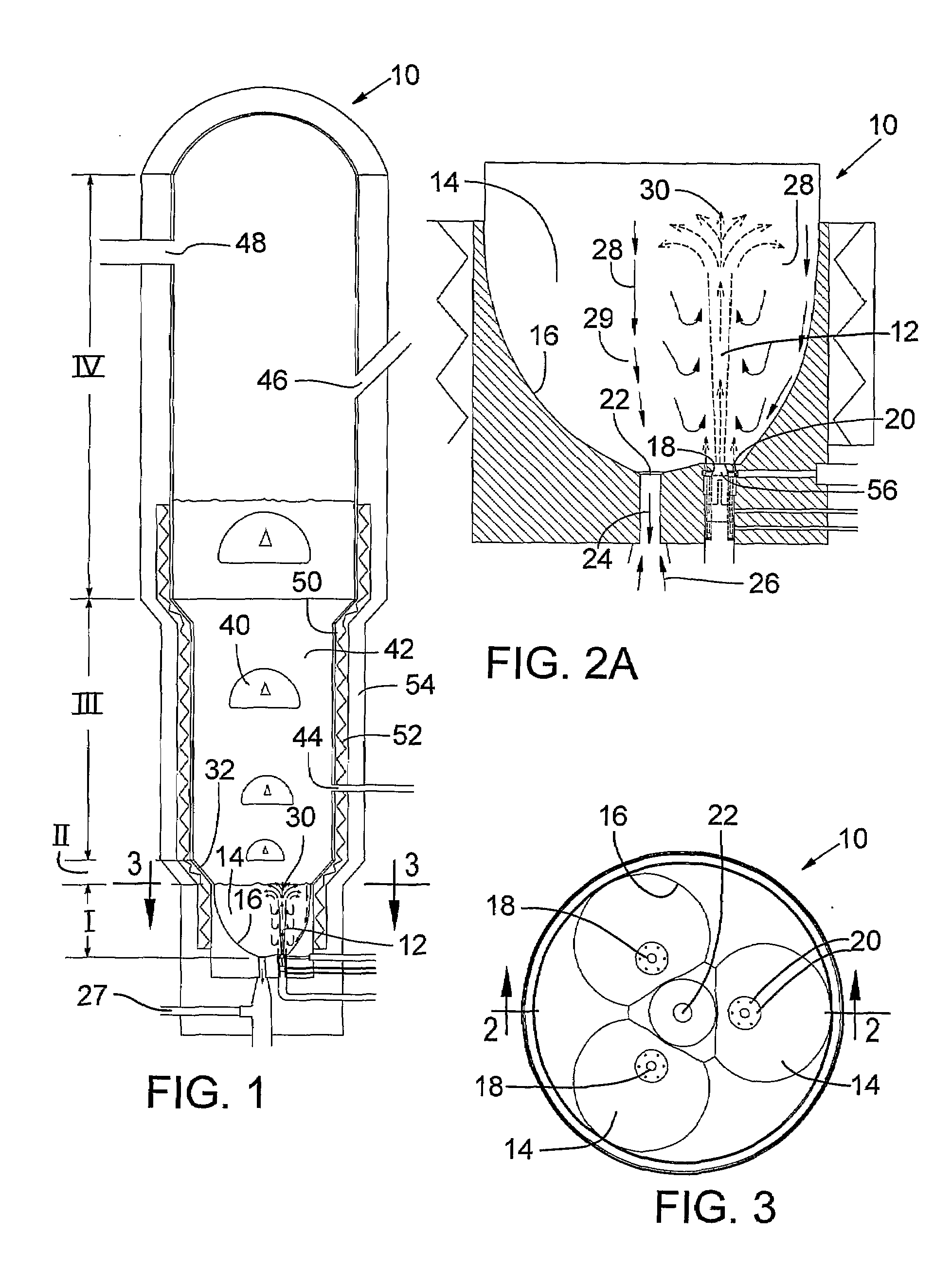

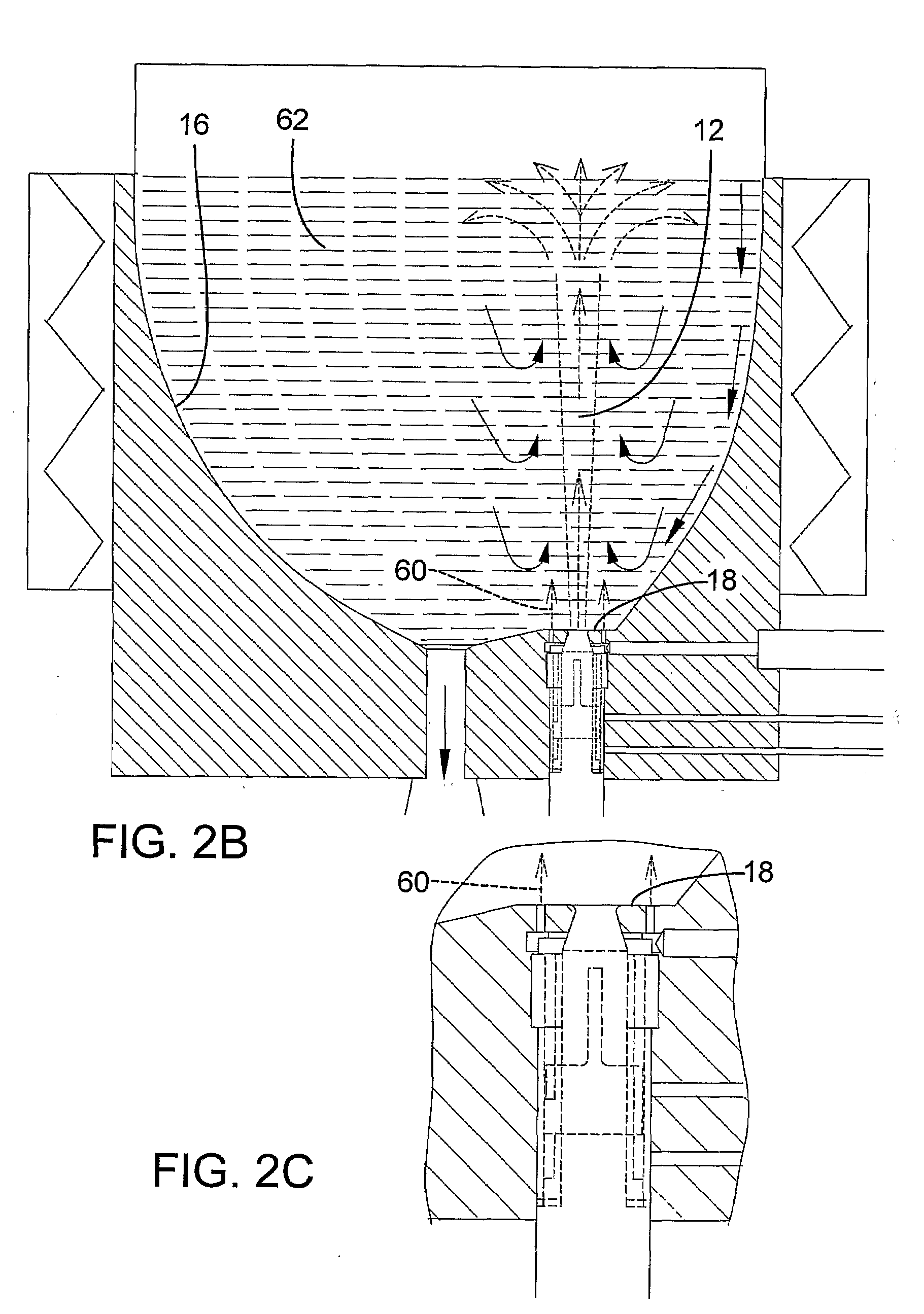

Method and Apparatus for Preparation of Granular Polysilicon

InactiveUS20090047204A1Reduce stepsPolycrystalline material growthSiliconProduction rateElectrical resistance and conductance

A process for preparing granular polysilicon using a fluidized bed reactor is disclosed. The upper and lower spaces of the bed are defined as a reaction zone and a heating zone, respectively, with the height of the reaction gas outlet being selected as the reference height. The invention maximizes the reactor productivity by sufficiently providing the heat required and stably maintaining the reaction temperature in the reaction zone, without impairing the mechanical stability of the fluidized bed reactor. This is achieved through electrical resistance heating in the heating zone where an internal heater is installed in a space in between the reaction gas supplying means and the inner wall of the reactor tube, thereby heating the fluidizing gas and the silicon particles in the heating zone. The heat generated in the heating zone is transferred to the reaction zone by supplying the fluidizing gas at such a rate that the silicon particles can be intermixed between the reaction zone and the heating zone in a continuous, fluidized state.

Owner:KOREA RES INST OF CHEM TECH

Graphene-coated porous silicon-carbon composite and method of manufacturing the same

ActiveUS20170047584A1Good electrical propertiesGood electrical conductivityElectrode thermal treatmentNegative electrodesSilicon particleCarbon composites

Provided are a porous silicon-carbon composite, which includes a core including a plurality of active particles, a conductive material formed on at least a portion of surfaces of the active particles, first pores, and second pores, and a first shell layer which is coated on the core and includes graphene, wherein the active particles include a plurality of silicon particles, silicon oxide particles, or a combination thereof, the first pores are present in the core and are formed by agglomeration of the plurality of active particles, and the second pores are irregularly dispersed and present in the core, has an average particle diameter smaller than an average particle diameter of the active particles, and are spherical, a method of manufacturing the same, and a negative electrode and a lithium secondary battery including the porous silicon-carbon composite.

Owner:LG ENERGY SOLUTION LTD

Porous carbon silicon composite material and preparation method thereof

ActiveCN103840140AImprove stabilitySecondary cellsNon-aqueous electrolyte accumulator electrodesPorous carbonSilicon particle

The invention provides a porous carbon silicon composite material able to be used in lithium battery cathodes. The porous carbon silicon composite material comprises porous carbon and silicon particles attached to the pore walls of the porous carbon. In terms of the total weight, the porous carbon silicon composite material comprises 20-70wt% of silicon and 80-30wt% of porous carbon, and the porous carbon silicon composite material has a BET (Brunauer-Emmett-Teller) specific surface area of 50-250m<2> / g and a pore volume of 0.2-0.6cc / g. The porous carbon silicon composite material has relatively large mass specific capacity and good circulation.

Owner:TSINGHUA UNIV +1

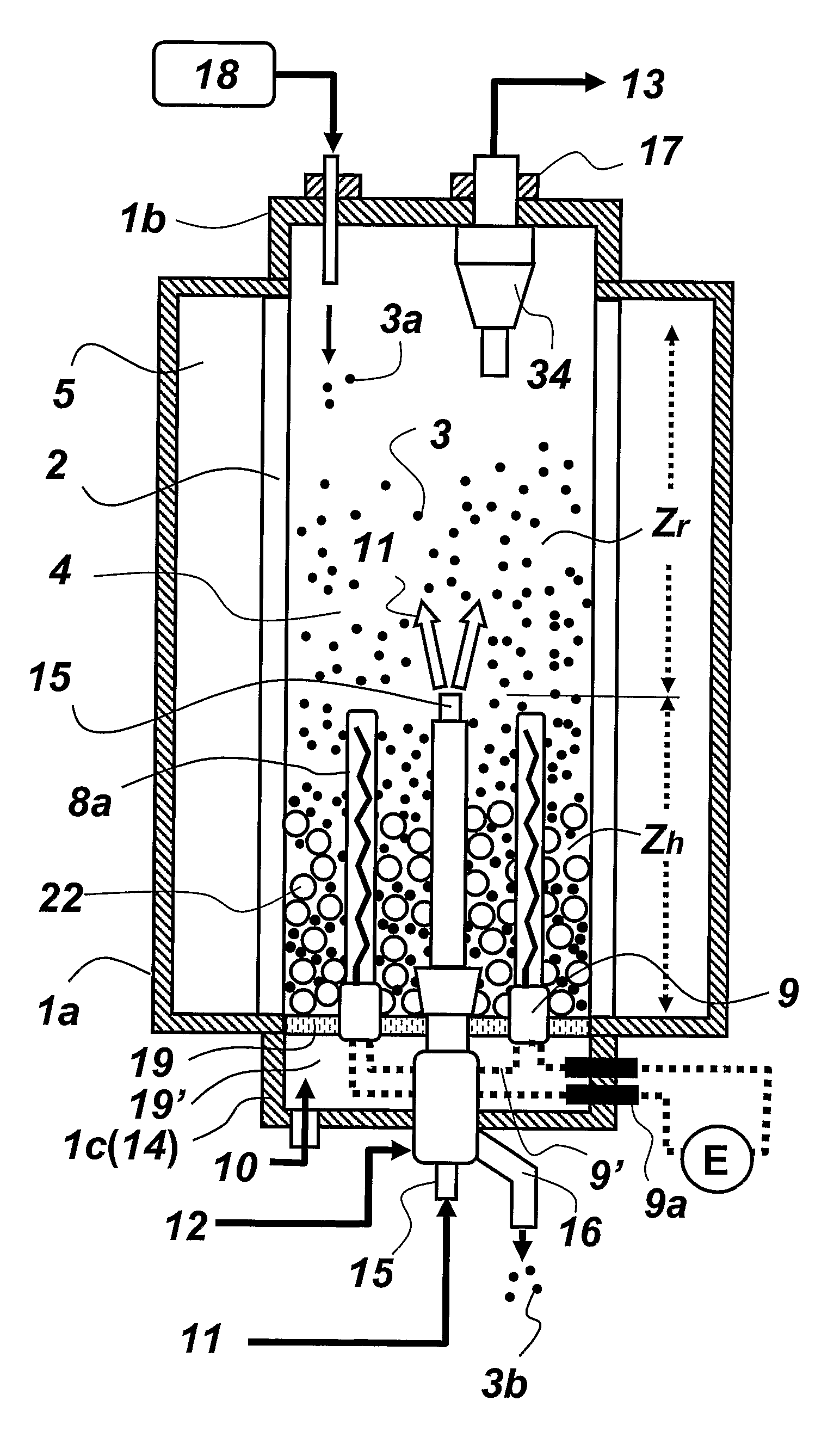

Method and apparatus for preparation of granular polysilicon

InactiveUS20100068116A1Reduce stepsPolycrystalline material growthSiliconProduction rateElectrical resistance and conductance

A process for preparing granular polysilicon using a fluidized bed reactor is disclosed. The upper and lower spaces of the bed are defined as a reaction zone and a heating zone, respectively, with the height of the reaction gas outlet being selected as the reference height. The invention maximizes the reactor productivity by sufficiently providing the heat required and stably maintaining the reaction temperature in the reaction zone, without impairing the mechanical stability of the fluidized bed reactor. This is achieved through electrical resistance heating in the heating zone where an internal heater is installed in a space in between the reaction gas supplying means and the inner wall of the reactor tube, thereby heating the fluidizing gas and the silicon particles in the heating zone. The heat generated in the heating zone is transferred to the reaction zone by supplying the fluidizing gas at such a rate that the silicon particles can be intermixed between the reaction zone and the heating zone in a continuous, fluidized state.

Owner:KOREA RES INST OF CHEM TECH

Silicon-carbon composite cathode material with three-dimensional preformed hole structure and preparation method thereof

ActiveCN102623680ALow tap densityReduce volume specific capacityCell electrodesCarbon compositesCarbonization

The invention discloses a silicon-carbon composite cathode material with a three-dimensional preformed hole structure and a preparation method thereof. According to the composite cathode material, a carbon material having high electric conductivity and a stable structure is used as a matrix for dispersedly containing high-volume silicon particles, and proper three-dimensional expansion spaces are reserved around one or several silicon particles. The preparation method comprises the following steps of: carrying out surface modification on the silicon particles; coating the silicon particles by silicon dioxide; coating the silicon dioxide / silicon composite particles by carbon source precursors; carrying out high-temperature carbonization treatment; and removing a silicon dioxide template, and the like. When the composite material prepared by the preparation method is used for a lithium ion battery, the reversible specific capacity is high, and the cycle performance is excellent. The silicon-carbon composite cathode material has the advantages of simple preparation process and wide raw material resource and is suitable for industrial production.

Owner:湖南宸宇富基新能源科技有限公司

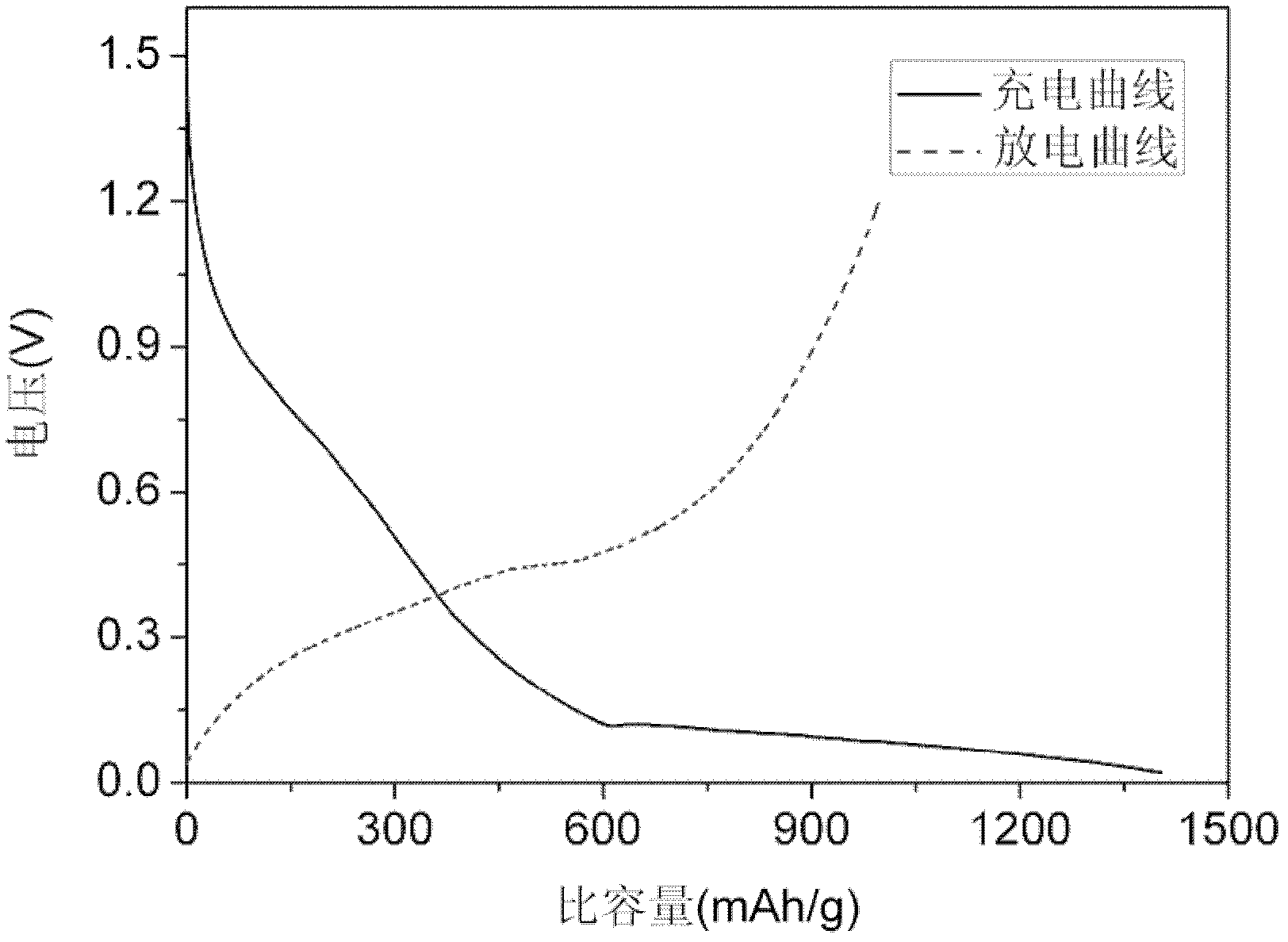

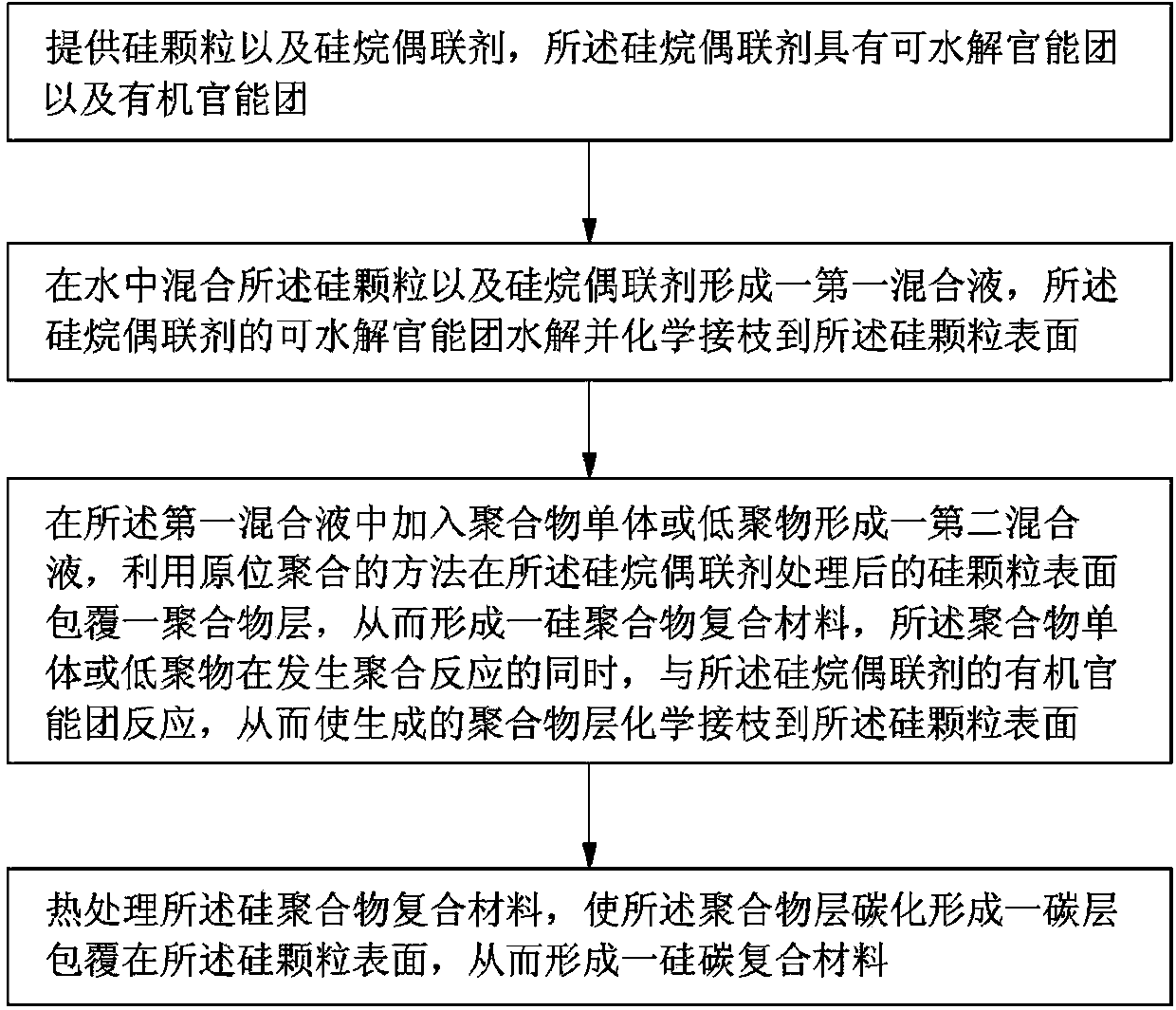

Preparation method for negative electrode active material of lithium ion battery

ActiveCN103474666AImprove conductivityImprove structural stabilityElectrode thermal treatmentSecondary cellsCarbon compositesCarbon layer

The invention relates to a preparation method for a negative electrode active material of a lithium ion battery. The preparation method comprises the following steps: providing a silicon particle and a silane coupling agent which has a hydrolyzable functional group and an organic functional group; mixing the silicon particle with the silane coupling agent in water to form a first mixed liquor, wherein the hydrolyzable functional group of the silane coupling agent is hydrolyzed and chemically grafted onto the surface of the silicon particle; adding a polymer monomer or oligomer into the first mixed liquor to form a second mixed liquor, coating a polymer layer on the surface of the silicon particle by using in situ polymerization so as to form a silicon / polymer composite and allowing the polymer monomer or oligomer to react with the organic functional group of the silane coupling agent during polymerization so as to allow the generated polymer layer to be chemically grafted onto the surface of the silicon particle; and subjecting the silicon / polymer composite to heat treatment to carbonize the polymer layer so as to form a carbon layer coated on the surface of the silicon particle, thereby forming a silicon carbon composite.

Owner:JIANGSU HUADONG INST OF LI ION BATTERY +1

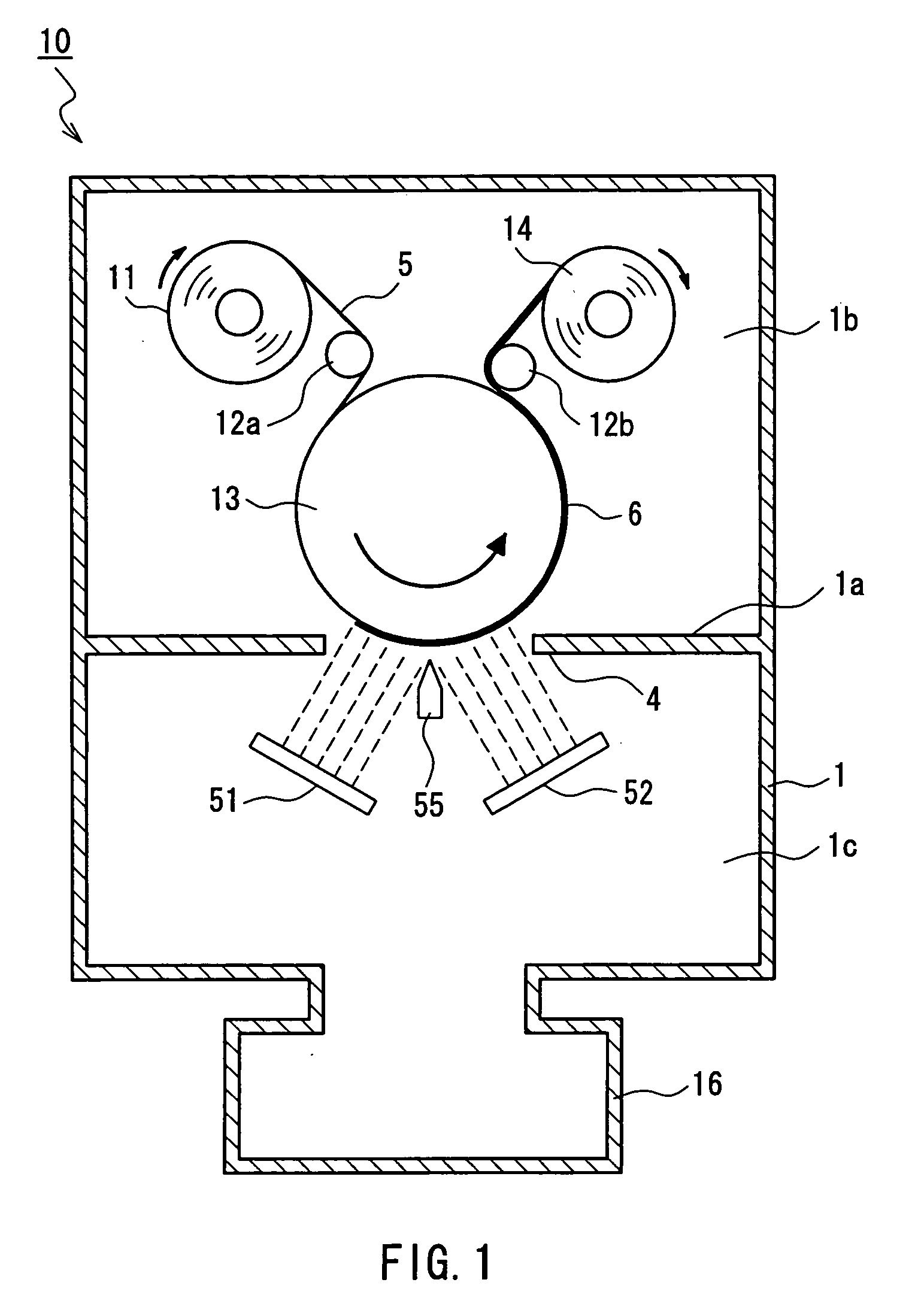

Silicon Spout-Fluidized Bed

InactiveUS20080220166A1Improve usabilityImprove productivitySiliconChemical/physical/physico-chemical nozzle-type rreactorsFluidized bedEngineering

Polysilicon is formed by pyrolytic decomposition of a silicon-bearing gas and deposition of silicon onto fluidized silicon particles. Multiple submerged spout fluidized bed reactors and reactors having secondary orifices are disclosed.

Owner:REC SILICON

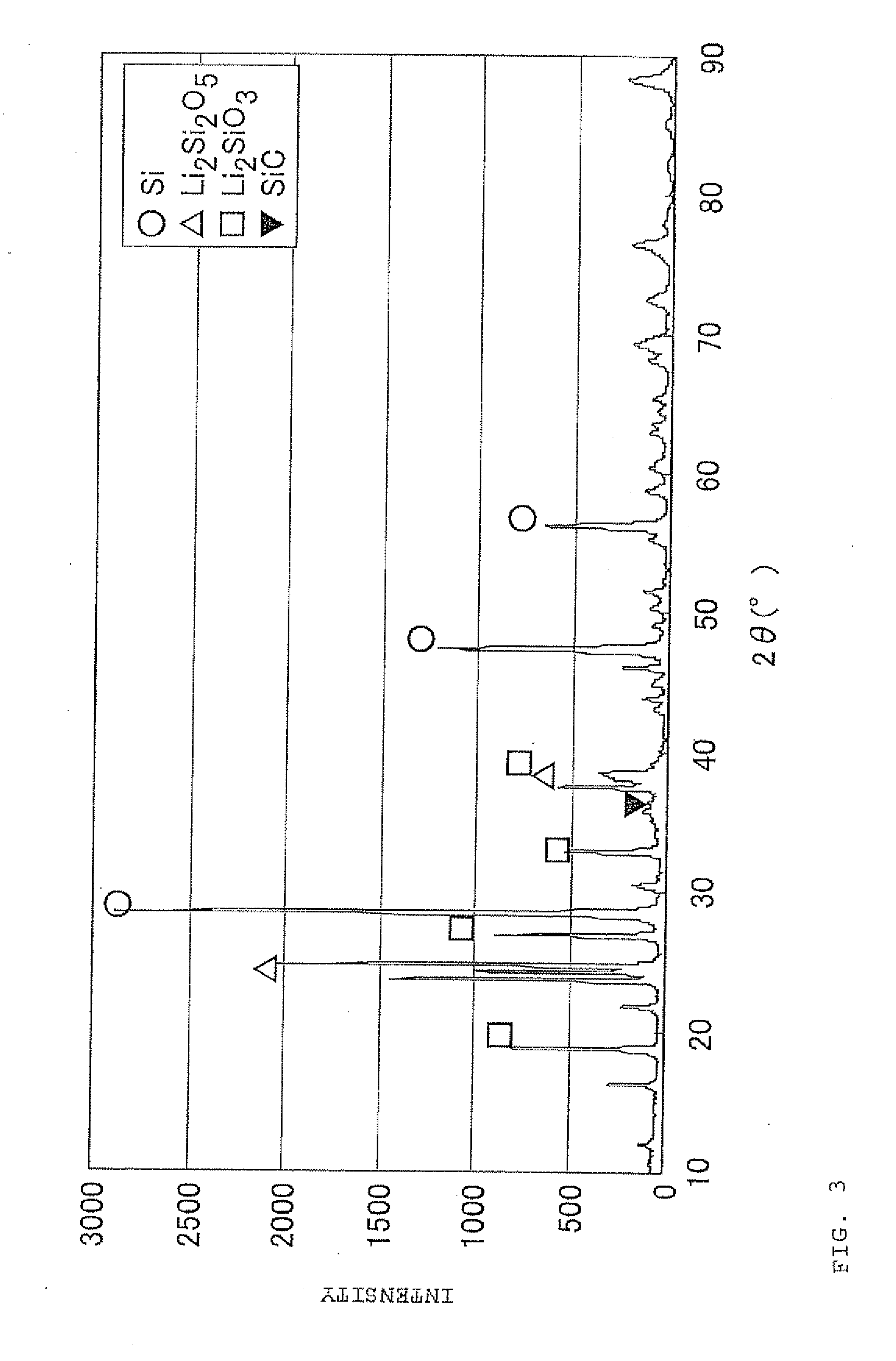

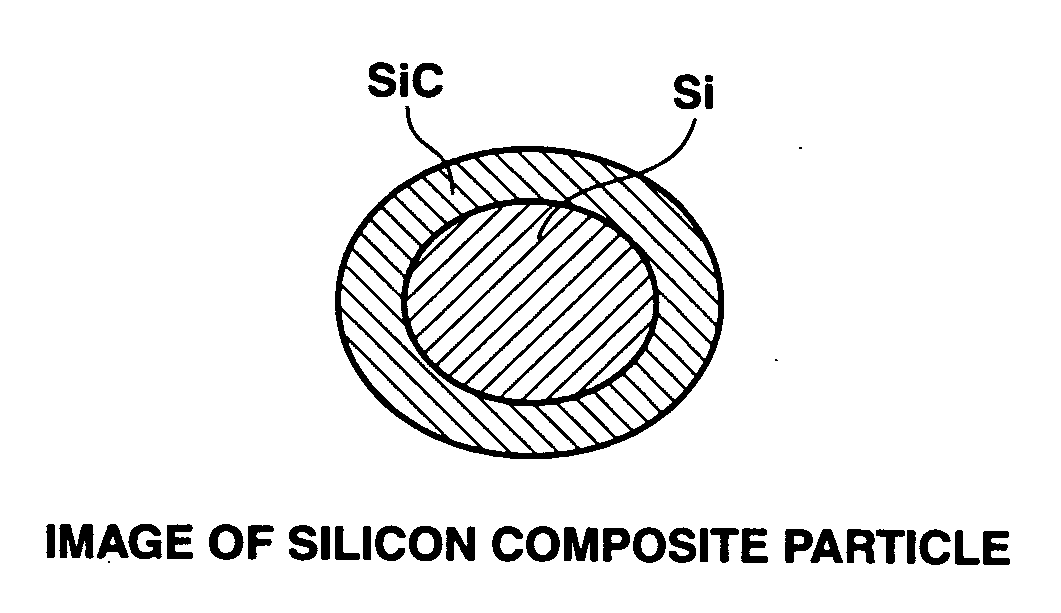

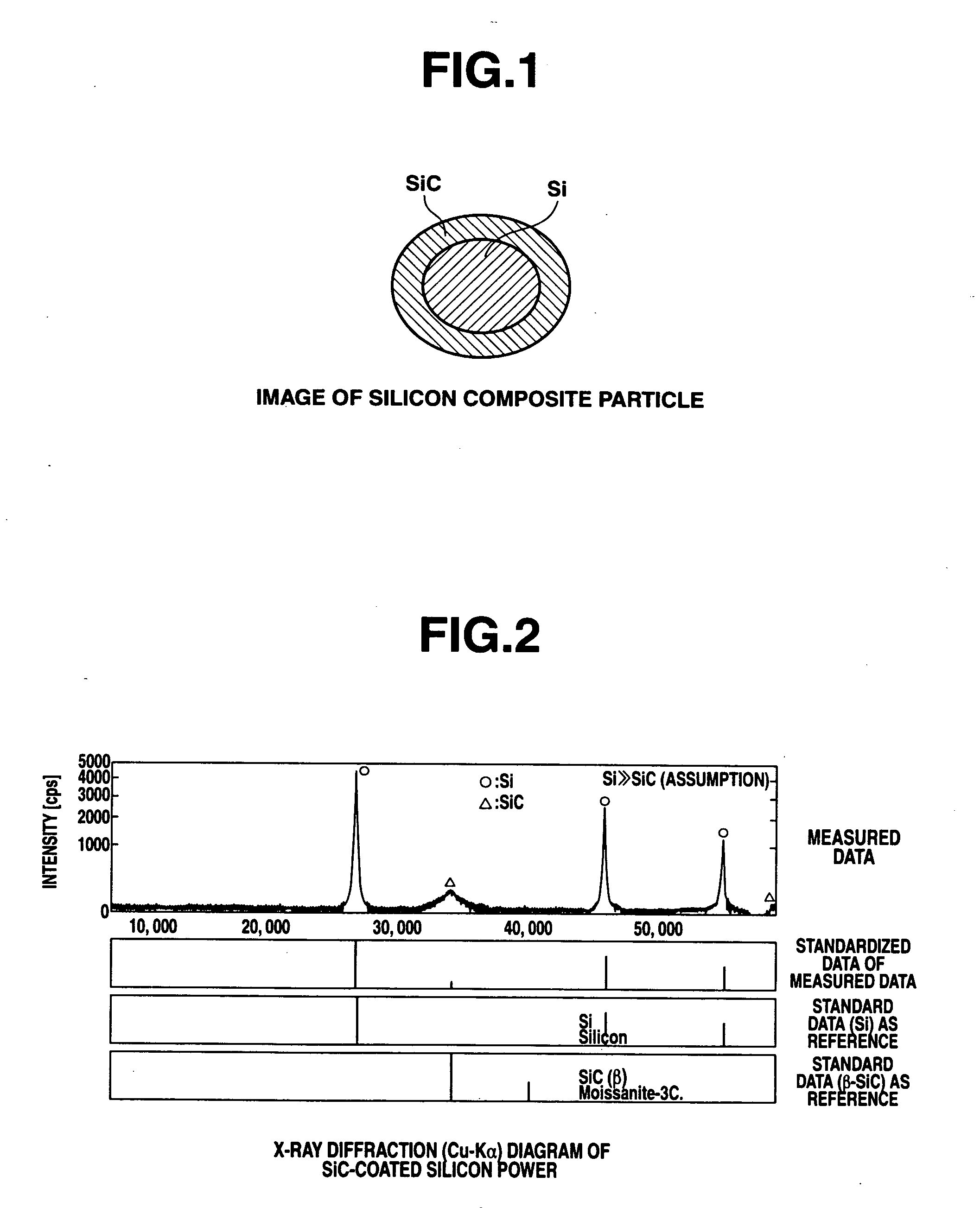

Silicon composite, making method, and non-aqueous electrolyte secondary cell negative electrode material

InactiveUS20060003227A1Improve initial efficiencyImprove cycle performanceFinal product manufactureSecondary cells charging/dischargingCarbon layerDecomposition

A silicon composite comprises silicon particles whose surface is at least partially coated with a silicon carbide layer. It is prepared by subjecting a silicon powder to thermal CVD with an organic hydrocarbon gas and / or vapor at 900-1,400° C., and heating the powder for removing an excess free carbon layer from the surface through oxidative decomposition.

Owner:SHIN ETSU CHEM IND CO LTD

Anode active material and method of manufacturing the same and lithium secondary battery using the same

InactiveUS20090117468A1Improve featuresMaterial nanotechnologyElectrode manufacturing processesInterior spaceLithium

An anode active material that can prominently improve lifetime characteristics of a lithium secondary battery includes carbon nanotubes and silicon particles located in an internal space of the carbon nanotubes. The anode active material is manufactured by removing end caps of the carbon nanotubes to provide carbon nanotubes having lengths in the range of 0.1 to 10 μm, and filling an interior space of the carbon nanotubes with silicon particles. In addition, a lithium secondary battery comprises an anode including an anode collector and the anode active material, a cathode including a cathode collector and cathode active material, and a separator interposed between the anode and the cathode. The anode active material includes carbon nanotubes and silicon particles located in internal spaces of the carbon nanotube.

Owner:SAMSUNG SDI CO LTD

Silicon-containing composite material and its preparation method and application

ActiveCN101210119ASimple processReduce energy consumptionPigment treatment with macromolecular organic compoundsState of artLithium

The invention provides a siliceous composite material, comprising silicon particles and a clad wrapped on the surface of silicon particles, wherein, the clad is conducting polymer. The siliceous composite material provided by the invention takes the conducting polymer as the clad; the polymer does not need to be transformed further into 'hard carbon', and the siliceous composite material is guaranteed to have excellent conductivity; meanwhile, the aggregation between silicon particles can be avoided. When the composite material is taken as negative active material of a lithium iron battery, the lithium iron battery is ensured to have high reversible capacity and good cycle performance. Therefore, the invention can be taken as the negative active material of the lithium iron battery. As the polymer does not need to be transformed further into the 'hard carbon' and the siliceous composite material has good conductivity in the preparation of the siliceous composite material provided by the invention, the manufacturing technique is simplified and the problem of huge energy consumption caused by the high temperature carbonization process in the prior art is solved.

Owner:BYD CO LTD

Silicon-carbon composite negative pole material preparation method and lithium ion battery

ActiveCN106257716AEvenly dispersedAvoid direct contactNegative electrodesSecondary cellsCarbon compositesElectric capacity

The invention relates to a silicon-carbon composite negative pole material preparation method and a lithium ion battery. The preparation method comprises putting nanometer silicon and graphite micro-powder into a ball mill, carrying out ball milling uniform dispersion in an organic solvent environment, carrying out vacuum drying, putting the dried mixture and asphalt into a cone-type mixer, carrying out coarse mixing, putting the mixed powder subjected to coarse mixing into a mechanical fusion machine, carrying out mechanical fusion, carrying out heat treatment in an inert gas protective atmosphere and carrying out cooling to obtain the silicon-carbon composite negative pole material. The preparation method carries out asphalt softening coating on nanometer silicon so that silicon particle and electrolyte direct contact is avoided, a capacity reduction rate is delayed, a lithium ion diffusion path is shortened, an electrode material electron conduction loss is avoided, and first charge-discharge efficiency, a charge-discharge electric capacity and cycle performances are improved. Before coating, nanometer silicon is dispersed through graphite micro-powder so that it is avoided that in asphalt coating, nanometer silicon aggregation causes local capacity excess and nanometer silicon is uniformly dispersed.

Owner:浙江超恒动力科技有限公司

Silicon carbon composite negative electrode material for lithium ion battery as well as preparation method and applications of material

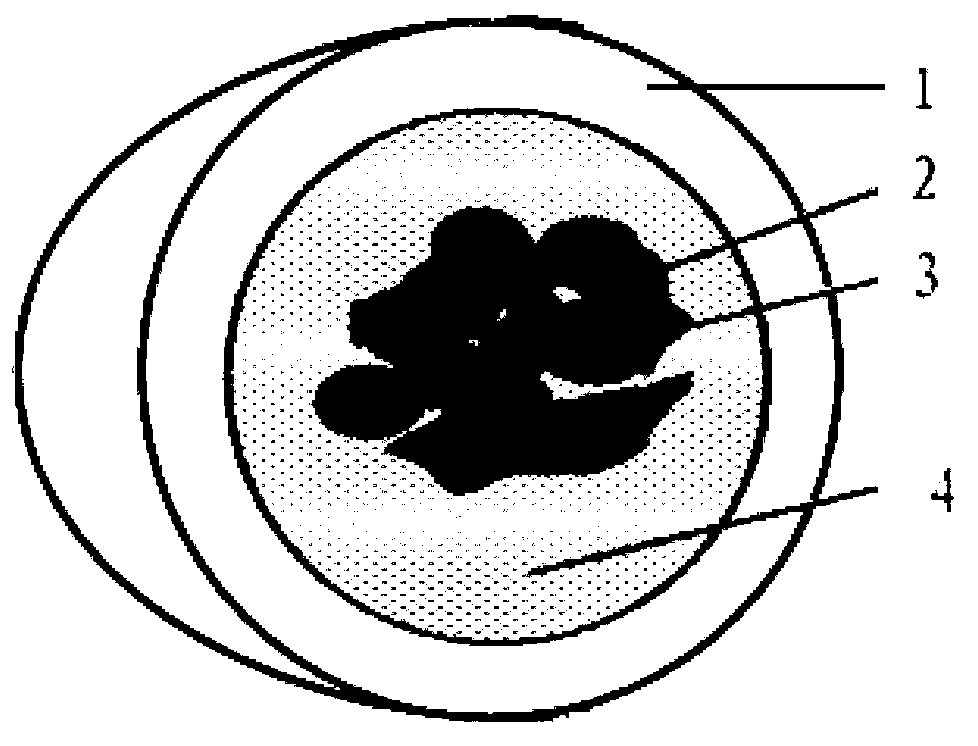

ActiveCN102903896AImprove securityImprove cycle performanceCell electrodesCarbon compositesElectrical battery

The invention is applicable to the field of novel materials, and provides a silicon carbon composite negative electrode material for a lithium ion battery, as well as a preparation method and applications of the material. The negative electrode material is of a nuclear-shell-type composite structure, and consists of nano silicon in the core, amorphous carbon at the middle layer and a one-dimensional nano carbon material at the outermost layer, wherein the amorphous carbon at the middle layer forms an elastic loose surface structure, and thus the circulating performance and multiplying performance of silicon are improved; a network structure built by the one-dimensional nano carbon material at the outermost layer not only plays a role in buffering mechanical stress, but also provides a rapid electric conducting channel for active silicon particles, and improves the circulating performance and multiplying performance of silicon further; and meanwhile, a three-dimensional electric-conducting heat-conducting network formed by the one-dimensional nano carbon material can conduct heat generated by a battery during the discharging process to the space around, and the safety performance of the battery is improved. The preparation method of the silicon carbon composite negative electrode material for the lithium ion battery is simple and feasible in process, environment-friendly and energy-saving, low in cost, and easy for industrialization.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

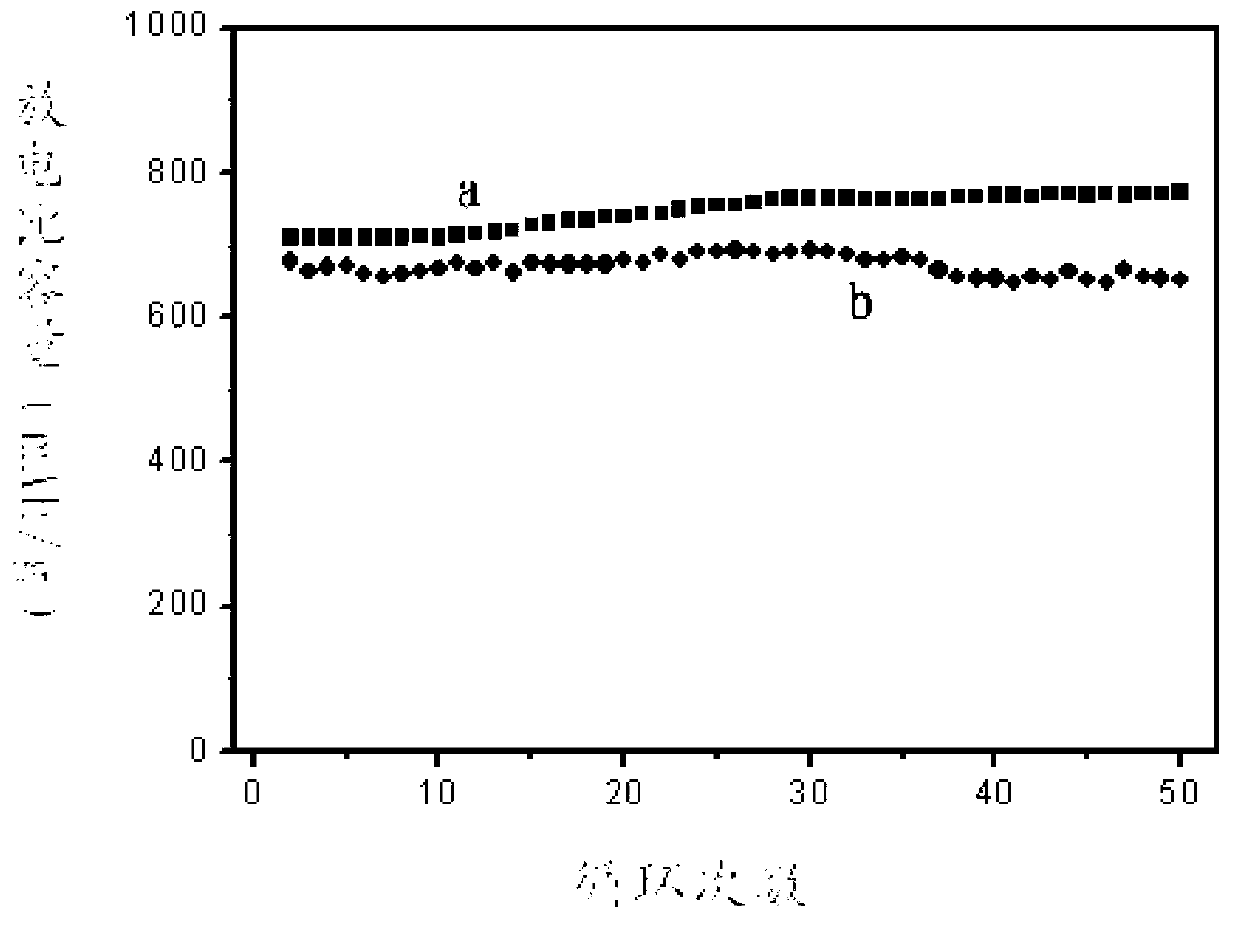

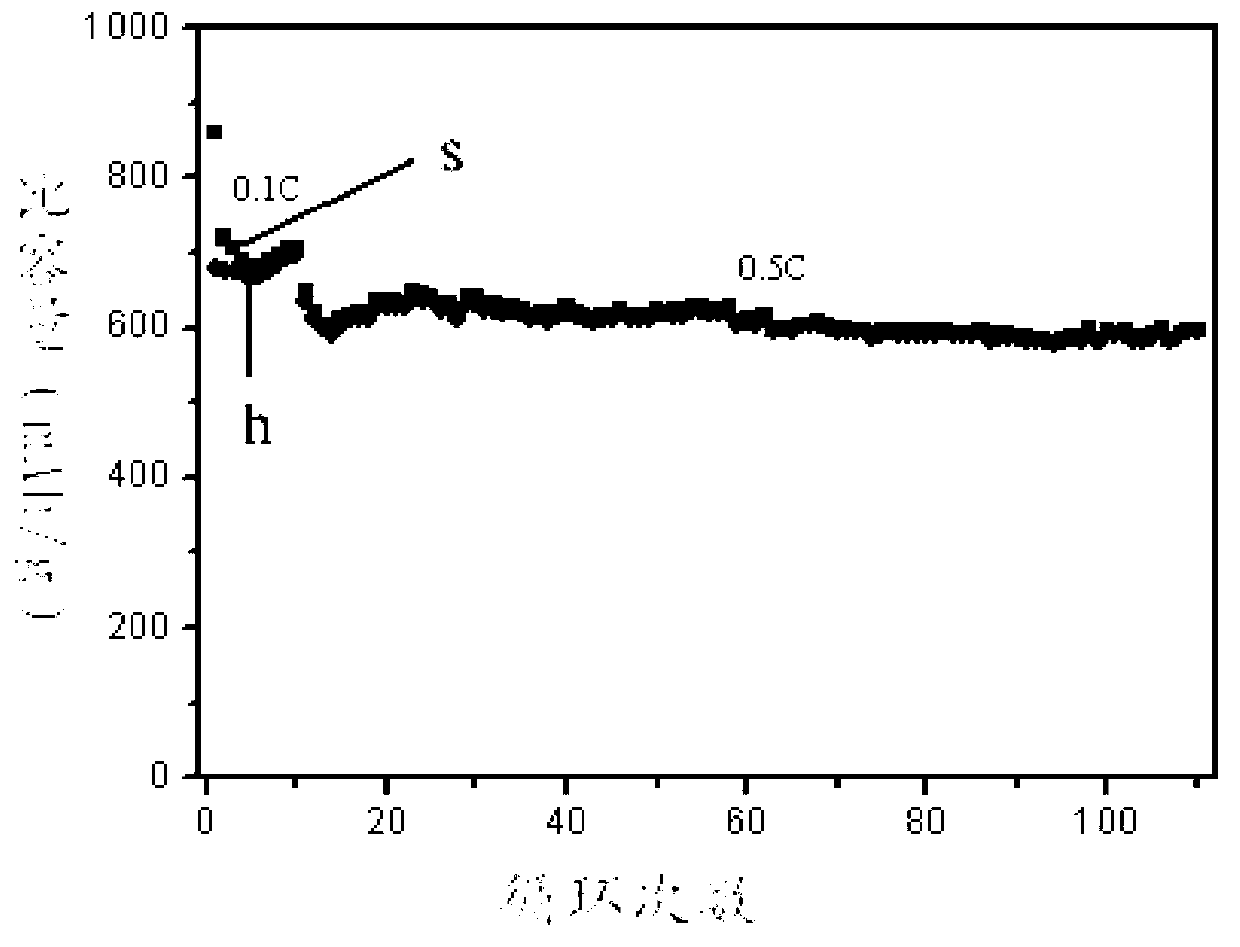

Silicon cathode material coated with graphene and preparation method thereof

InactiveCN104916826AWide variety of sourcesLow priceCell electrodesSecondary cellsOperabilitySilicon particle

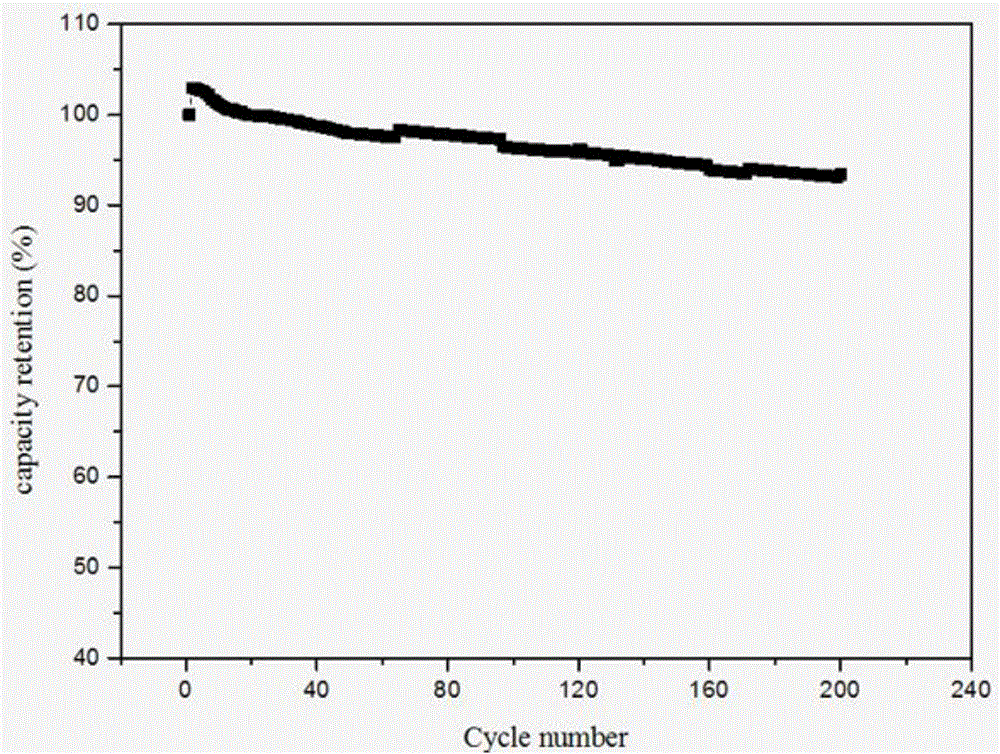

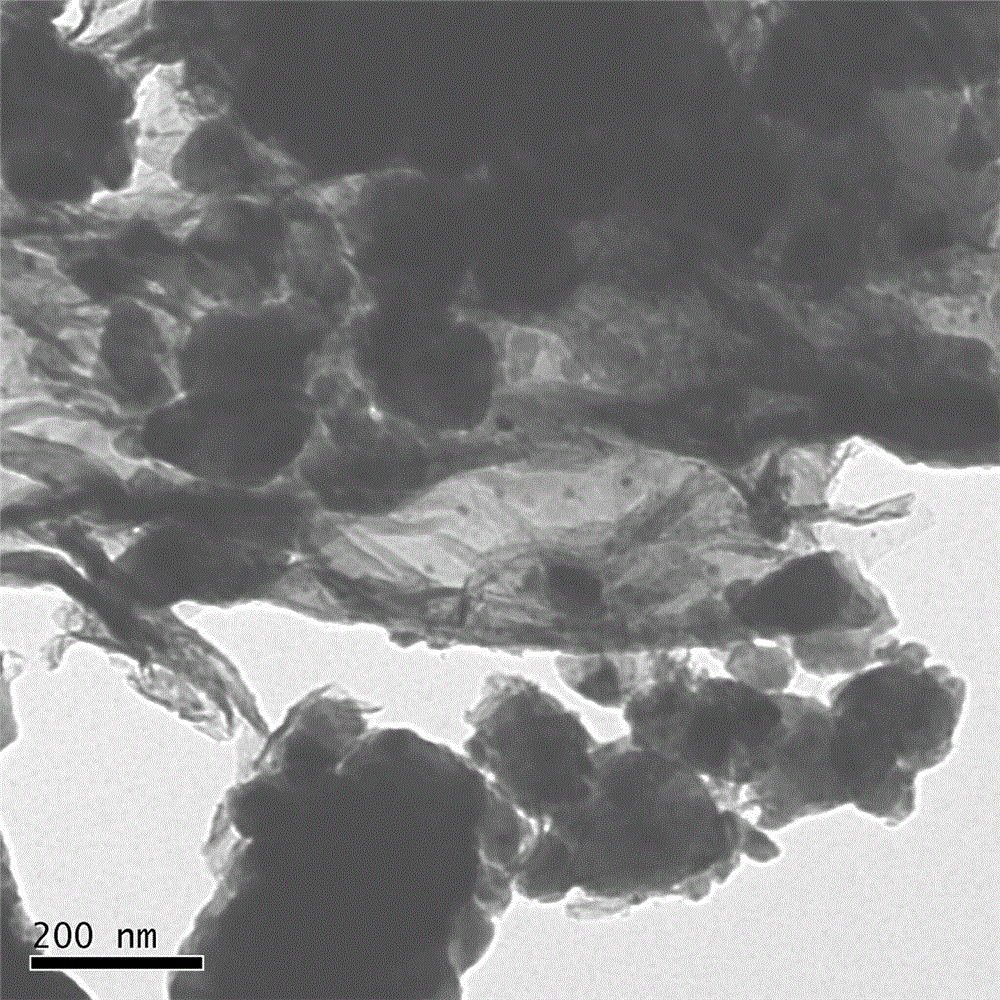

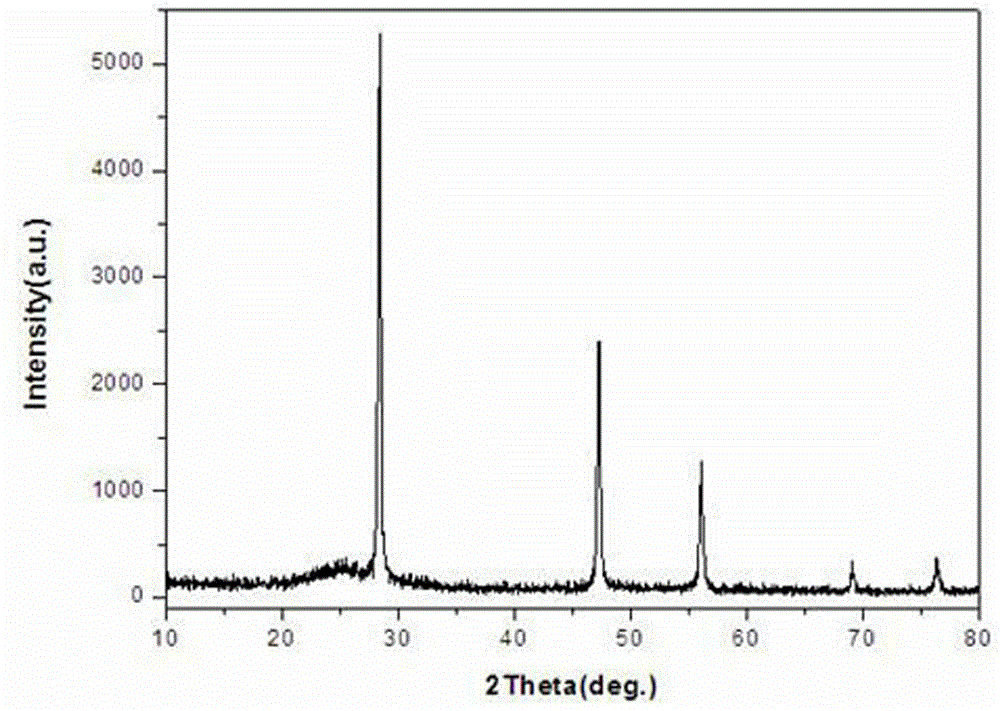

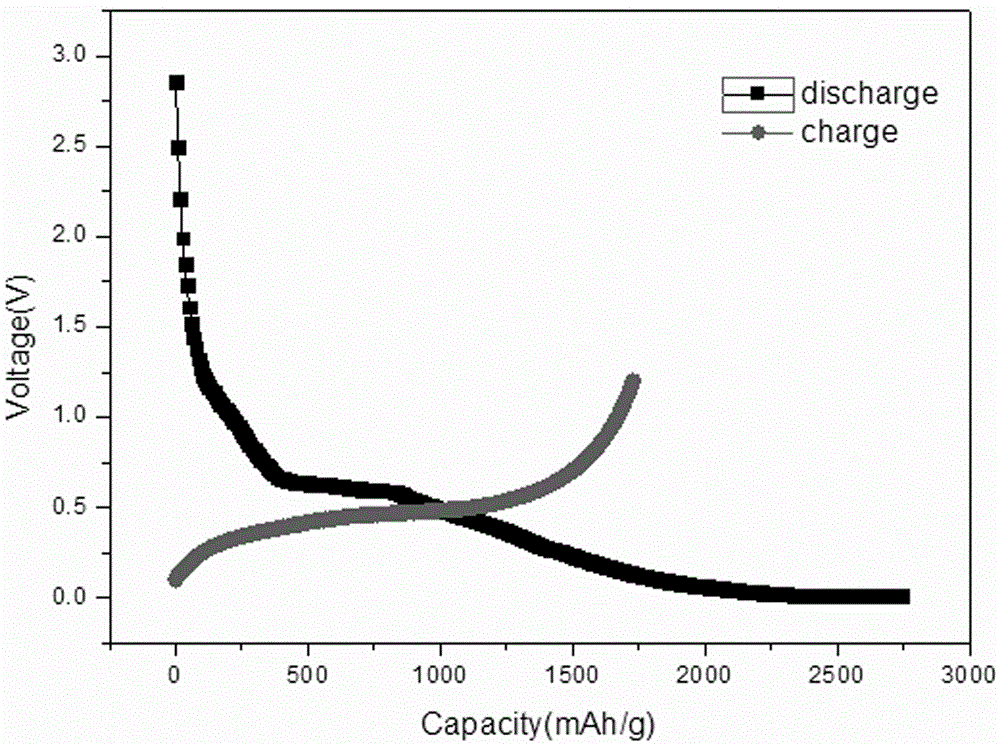

The invention relates to the technical field of lithium-ion cathode material, in particular to silicon cathode material coated with graphene and a preparation method of the silicon cathode material coated with the grapheme. The preparation method comprises the following steps: A, preparing oxidized graphene suspension liquid; B, preparing nanometer silicon particle suspension liquid; and C, preparing silicon cathode material coated with grapheme. The preparation method adopts the electrostatic self-assembly synthetic technology and is wide in source of raw material, low in price, simple in synthetic method, easy for control of process conditions, strong in operability and good in repeatability. The silicon cathode material coated with grapheme is high in specific capacity and good in cycle performance and rate capability, wherein the specific discharge capacity for the first time under the electric current density of 0.01-1.2V, 200mA / g can reach 2746mAh / g, and the specific discharge capacity after 100 times of cycles can maintain 803.8mAh / g.

Owner:MCNAIR TECH +1

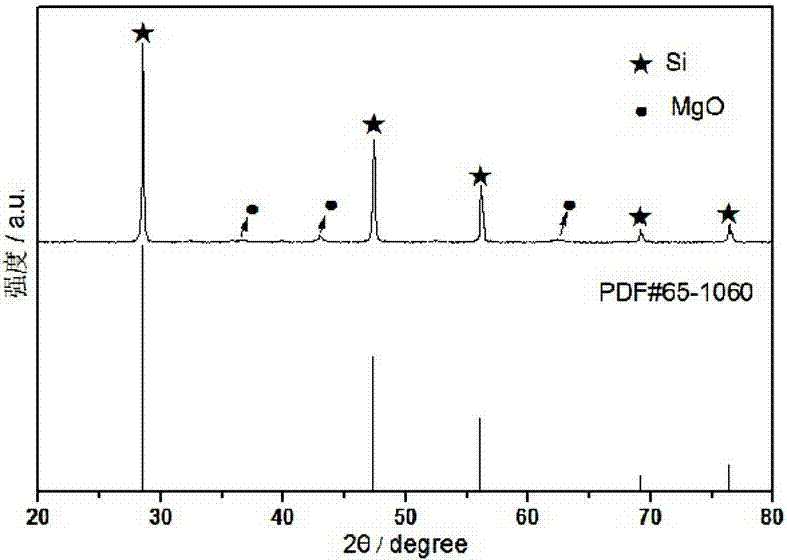

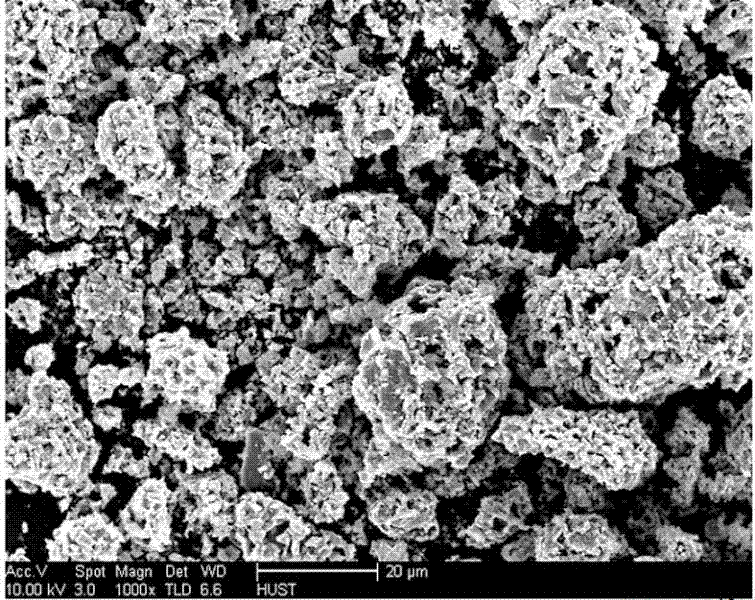

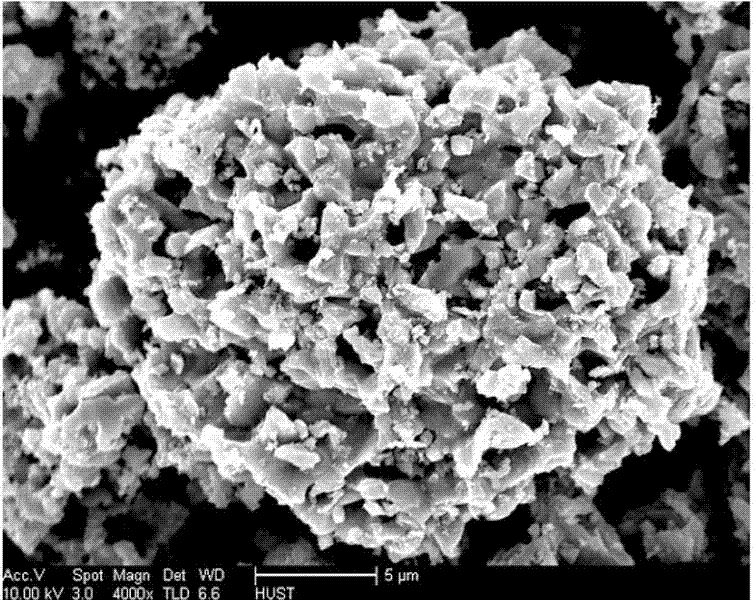

Fluorine-free preparation method for three-dimensional porous silica powder anode material of lithium ion battery

ActiveCN102237519AAvoid pollutionHigh specific capacityCell electrodesSodium-ion batterySilicon particle

The invention discloses a fluorine-free preparation method for a three-dimensional porous silica powder anode material of a lithium ion battery. In the method, combination reaction is performed on ordinary micron-sized silicon and magnesium particles to generate magnesium silicide, and the magnesium silicide is pyrolyzed at high temperature to form magnesium vapor and silica powder with a three-dimensional porous structure. By the fluorine-free preparation method for the three-dimensional porous silica powder anode material of the lithium ion battery, a preparation process is free from fluorine so as to avoid environmental pollutions; the material has the porous structure so as to realize the self-absorption of volume effects of the silicon particles; the specific capacity and recycling stability of the material are improved to a certain extent; and a synthesis process is simple and easy to operate, and the preparation cost of the material is low.

Owner:CHINA THREE GORGES UNIV +1

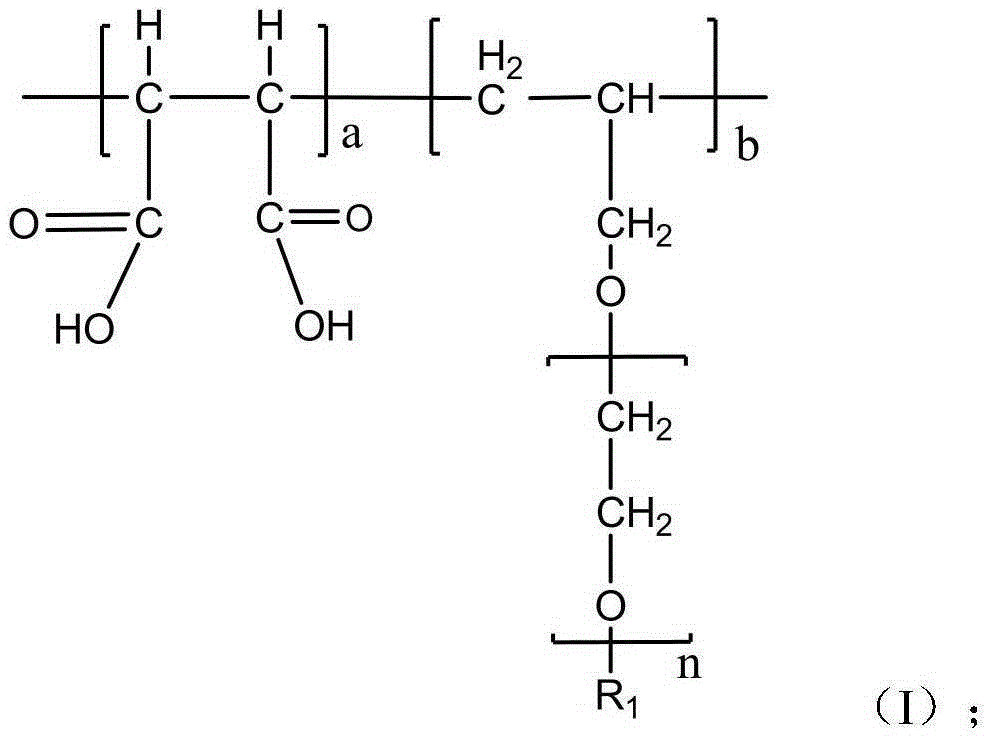

Nano suspension liquid concrete early strength agent and preparation method thereof

The invention provides a nano suspension liquid concrete early strength agent and a preparation method thereof. The nano suspension liquid concrete early strength agent is prepared from transition metal element doped nano calcium metasilicate suspension liquid, the suspension liquid is mainly composed of nanometer silicon particles, the chemical structure of the nanometer silicon particles is aCaO.bAl2O3.cZnO.SiO2.6H2O, 1<=a<=2, 0.50<=b<=1, and 0.25<=c<=0.50. The nanometer silicon particles are prepared from soluble calcium salt, soluble silicate, soluble aluminum salt, soluble zinc salt and a high polymer dispersing agent. On the one hand, the early strength agent contains no chlorine salt and has no corroding function on steel bars in concrete; on the other hand, an extremely stable suspension liquid system is achieved, adding is facilitated, and the early strength agent can be evenly dispersed easily in the concrete preparation process. The early strength of concrete can be remarkably improved, the early strength effect on concrete adopting highly-doped mineral admixtures is especially obvious, the early strength agent is especially suitable for production of precast concrete components, and a steam maintenance process can be effectively reduced and even omitted.

Owner:JIANGSU SOBUTE NEW MATERIALS

Carbon-silicon composite negative electrode material of lithium ion battery and preparation method thereof

InactiveCN103618071ACoated evenlyImprove the first charge and discharge efficiencyCell electrodesSecondary cellsCarbon compositesPorous carbon

The invention discloses a carbon-silicon composite negative electrode material of a lithium ion battery and a preparation method of the carbon-silicon composite negative electrode material. The negative electrode material is prepared by coating the surface of a single silicon particle with a uniform carbon-cladding layer, an impurity-element-doped carbon-cladding layer or a porous carbon-cladding layer. By adopting a hydrothermal method and subsequent calcining method, environmental friendliness can be achieved, the procedure is simple and easiness in operation can be realized; the silicon and a resilient carbon carrier form a composite material, the electrochemical performance of the silicon material can be improved through the complementary advantages under the synergistic effect of carbon and silicon components, and the primary charging-discharging efficiency and the cycling stability can be improved. The prepared silicon-carbon composite negative electrode material of the lithium ion battery has the advantages of high specific capacity, good cycling stability, safety, no pollution and the like, and an effective way is provided for the research of a high-capacity lithium ion battery.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Lithium ion battery cathode material and preparation method thereof as well as lithium ion battery

ActiveCN103346293AImprove conductivityBuffers large volume changesCell electrodesSecondary cellsNanoparticleNetwork structure

The invention provides a lithium ion battery cathode material and a preparation method of the lithium ion battery cathode material as well as a lithium ion battery. The lithium ion battery cathode material comprises an inner core, a middle layer outside the inner core and an outer shell wrapping the middle layer, the inner core is Si-C particles, the middle layer is a foam layer, the outer shell is an amorphous carbon layer and the Si-C particles are formed by Si particles and C materials. Compared with the prior art, a middle carbon foam layer existing between the Si-C particle inner core and the amorphous carbon outer shell can form an conductive network structure, thus improving conductivity of a material and buffering enormous volume change of Si particles in the charge-discharge processes; and the amorphous carbon outer shell layer can maintain the core-shell structure of the cathode material, and the cladding layer of the core-shell structure can buffer the volume change, improve cycling stability of electrodes, reduce contact between active substances and an electrolyte, improve first coulombic efficiency of an electrode, prevent nanoparticle aggregation and enhance electrode conductivity.

Owner:宁波富理电池材料科技有限公司

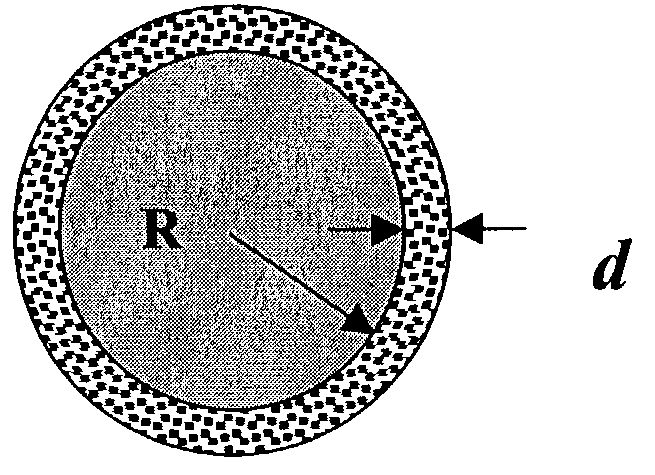

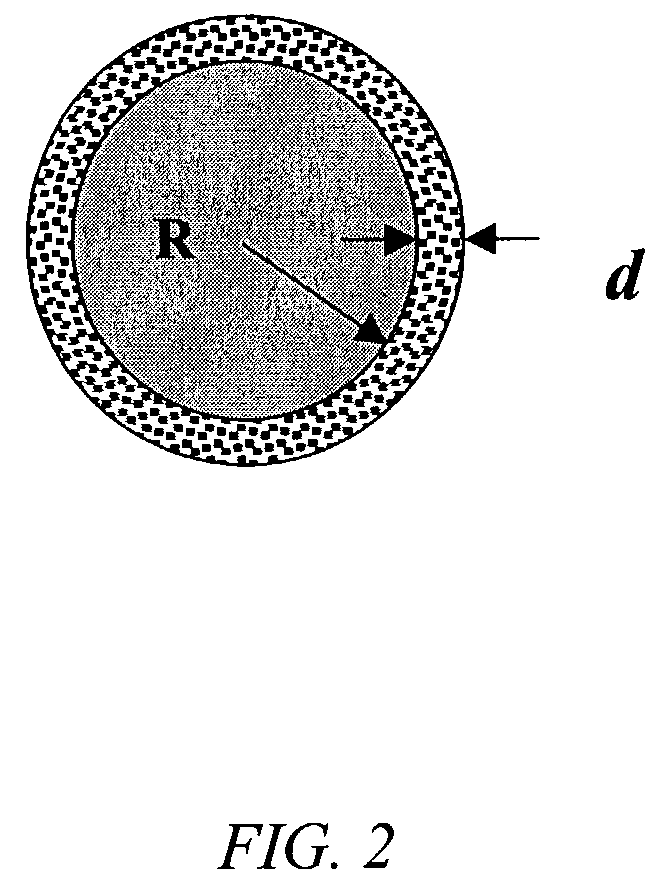

Stain-etched silicon powder

The present invention is for a porous silicon powder comprising silicon particles wherein the outermost layers of said particles are porous. The present invention is also directed to a method of making this porous silicon powder using a stain etch method. The present invention is also directed to a method of making silicon nanoparticles from the porous silicon powders using a process of ultrasonic agitation. The present invention also includes methods of processing these silicon nanoparticles for use in a variety of applications.

Owner:SI DIAMOND TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com