Carbon-silicon composite material with spherical nucleocapsid, and its preparing method and use

A composite material, core-shell structure technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of low reversible capacity, low Coulombic efficiency, and high delithiation potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

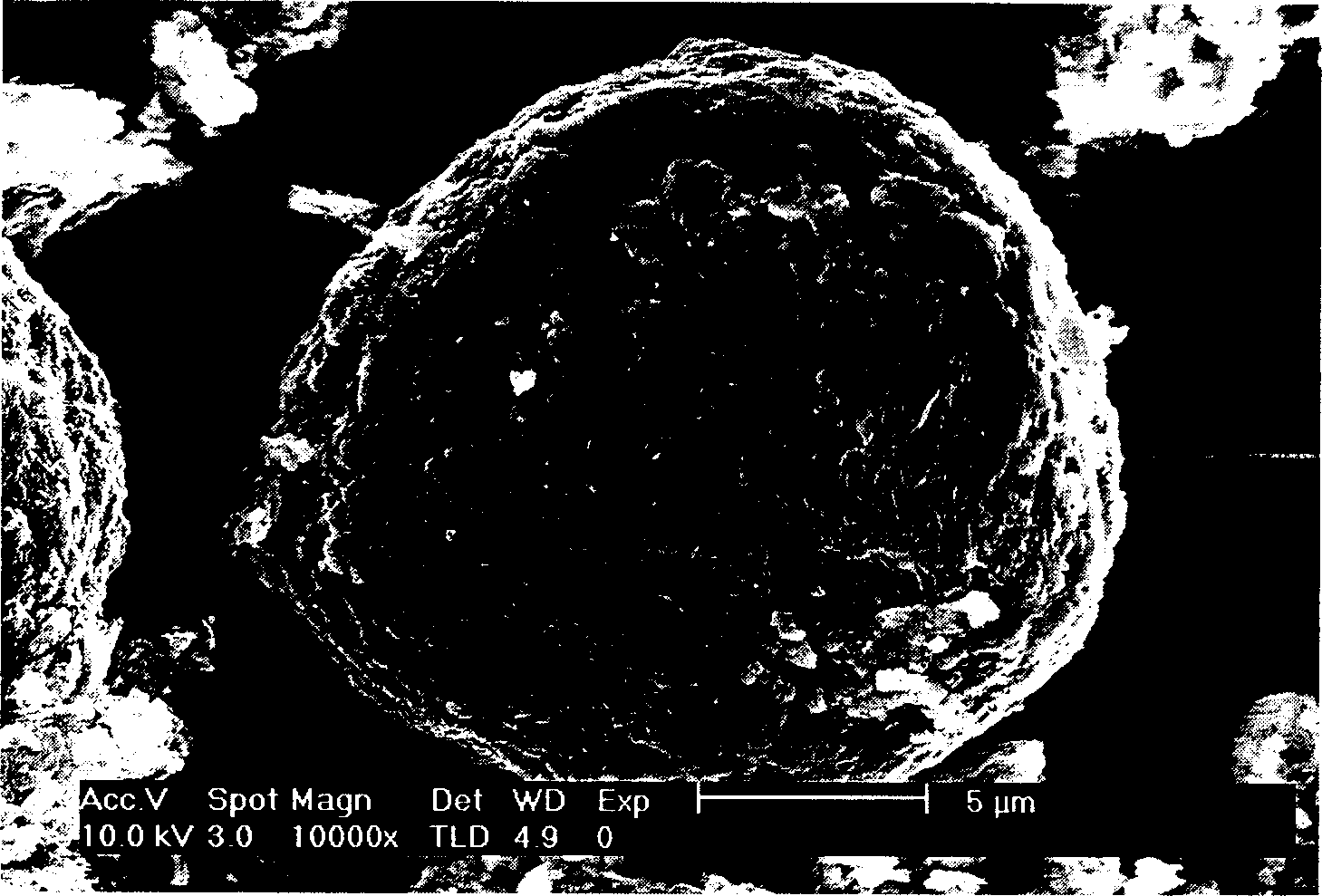

[0041] Embodiment 1, prepare the carbon-silicon composite material I of spherical core-shell structure

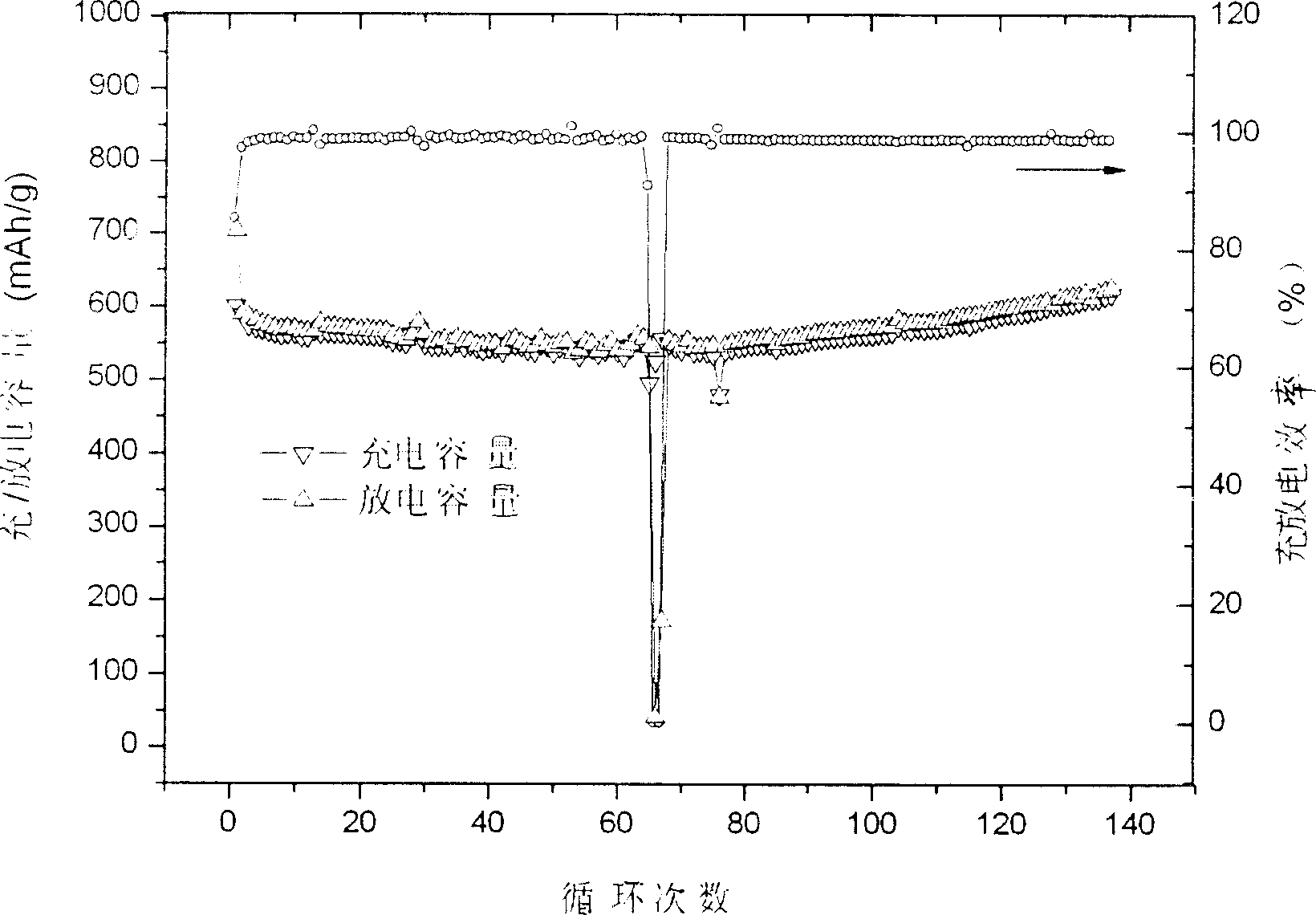

[0042] Firstly, commercial silicon powder (325 mesh, purity>99%) was ground for 8 hours by a planetary mill, and its average particle size was 1 micron. Dissolve 20 g of sucrose in a mixed solvent of 100 ml of ethanol and water (volume ratio 1:4) to form a sucrose solution. Put 10 grams of ball-milled silicon powder and 1 gram of carbon black (average particle size: 30 nm) into the sucrose solution and stir for one hour to form a uniform slurry. Then 30 grams of spherical graphite (with an average particle size of 10 micrometers) was added into the above slurry to continue stirring, and the slurry was dried at 120° C. for 8 hours to completely remove the solvent. The obtained product was heated at 600°C with high-purity N 2 Under the atmosphere, pyrolyze in a tube furnace for 8 hours, take it out after cooling, grind it, and pass through a 400 mesh sieve, then put the abo...

Embodiment 2

[0051] Embodiment 2, prepare the carbon-silicon composite material II of spherical core-shell structure

[0052] Firstly, commercial silicon powder (325 mesh, purity>99%) was ground for 2 hours by a planetary mill, and its average particle size was 4 microns. Dissolve 40 g of water-soluble starch in a mixed solvent of 100 ml of ethanol and water (volume ratio 1:4) to form a starch solution. Put 20 grams of ball-milled silicon powder and 2 grams of acetylene black (average particle size of 40 nm) into the starch solution and stir for one hour to form a uniform slurry. Then 30 grams of mesocarbon pellets (MCMB28, with an average particle size of 32 μm) were added to the above slurry and continued to stir, and the slurry was dried at 120° C. for 8 hours to completely remove the solvent. The obtained product was heated at 700°C with high-purity N 2 Under the atmosphere, pyrolyze in a tube furnace for 5 hours, take it out after cooling, grind it, and pass through a 400 mesh sieve...

Embodiment 3

[0055] Embodiment 3, prepare the carbon-silicon composite material III of spherical core-shell structure

[0056] Firstly, commercial silicon powder (325 mesh, purity>99%) was ground by a planetary mill for 12 hours, and its average particle size was 0.2 microns. Dissolve 20 g of dextrin in a mixed solvent of 100 ml of ethanol and water (volume ratio 1:4) to form a starch solution. Put 2 grams of ball-milled silicon powder into the dextrin solution and stir for one hour to form a uniform slurry. Then 30 grams of hard carbon spheres (HCS, treated at 1000° C., with an average particle size of 10 μm) were added to the slurry and continued to stir, and the slurry was dried at 120° C. for 8 hours to completely remove the solvent. The obtained product was heated at 700°C with high-purity N 2 Under the atmosphere, pyrolyze in a tube furnace for 5 hours, take it out after cooling, grind it, and pass through a 400 mesh sieve, then put the above pyrolysis product into a tube furnace w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com