Patents

Literature

603 results about "Mesophase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemistry and chemical physics, a mesophase is a state of matter intermediate between liquid and solid. Gelatin is a common example of a partially ordered structure in a mesophase. Further, biological structures such as the lipid bilayers of cell membranes are examples of mesophases.

Carbon-silicon composite material with spherical nucleocapsid, and its preparing method and use

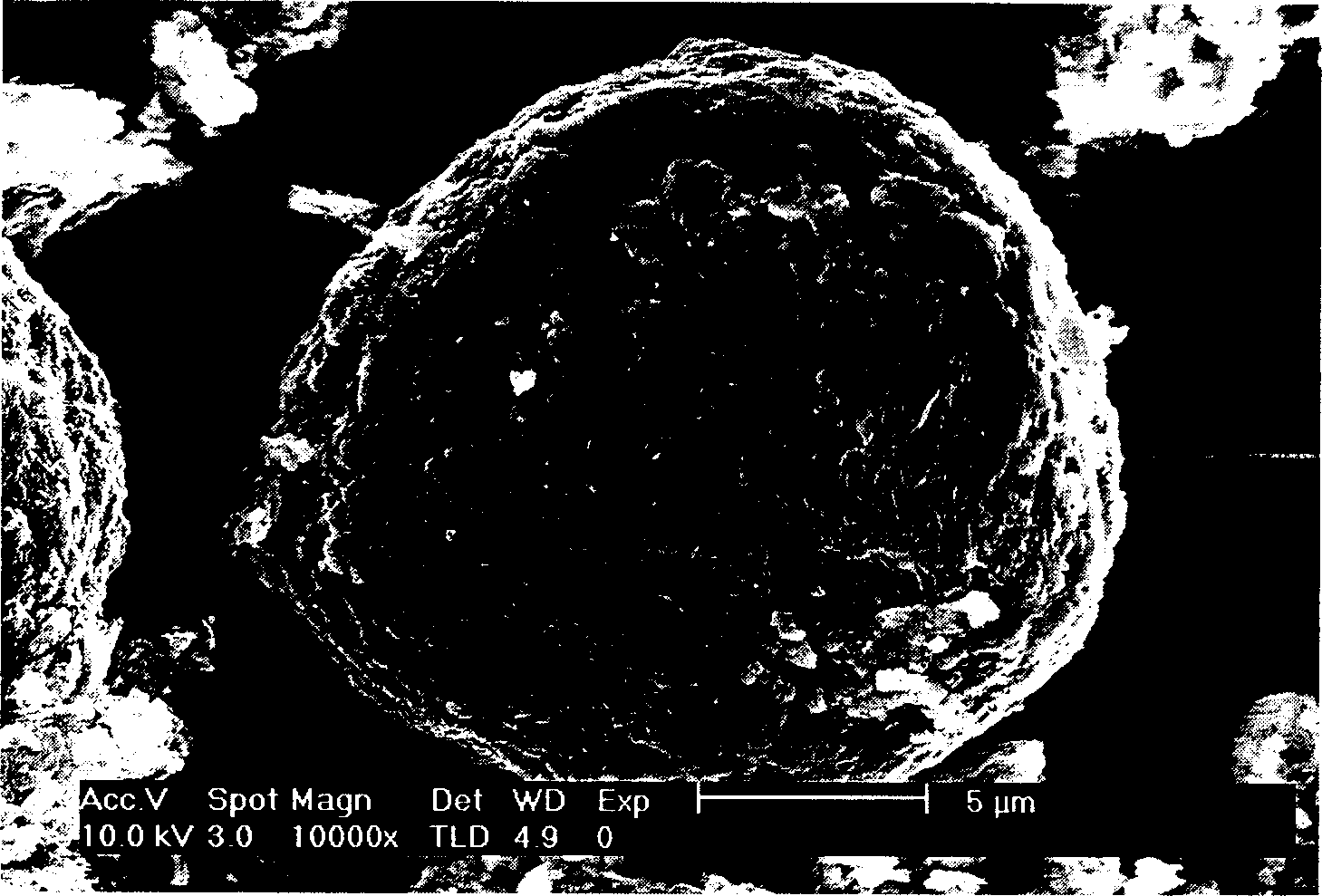

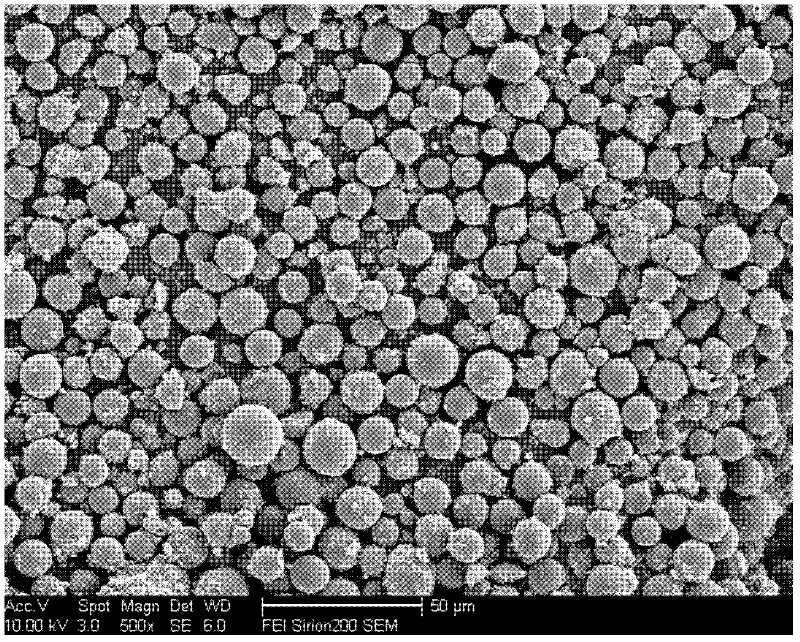

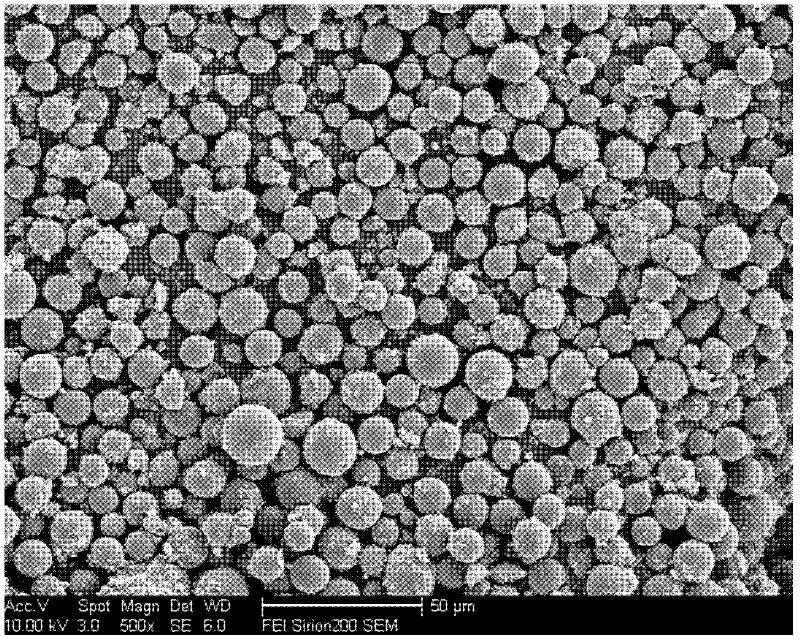

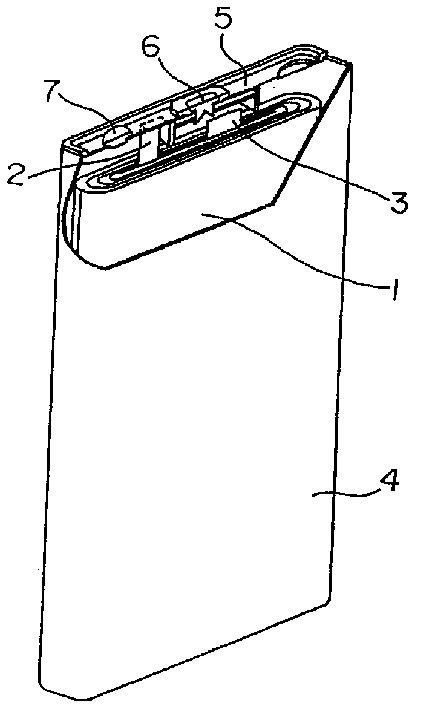

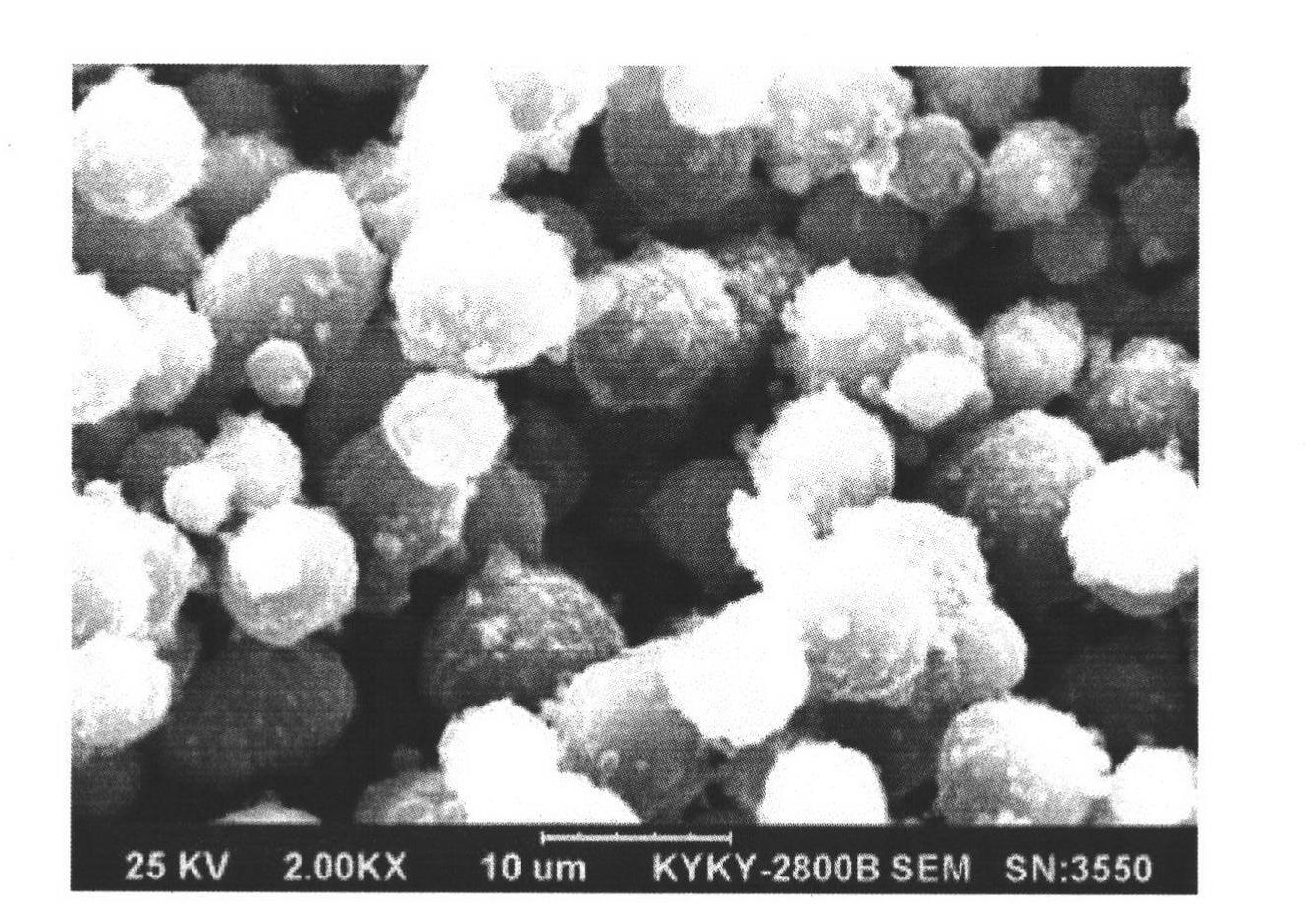

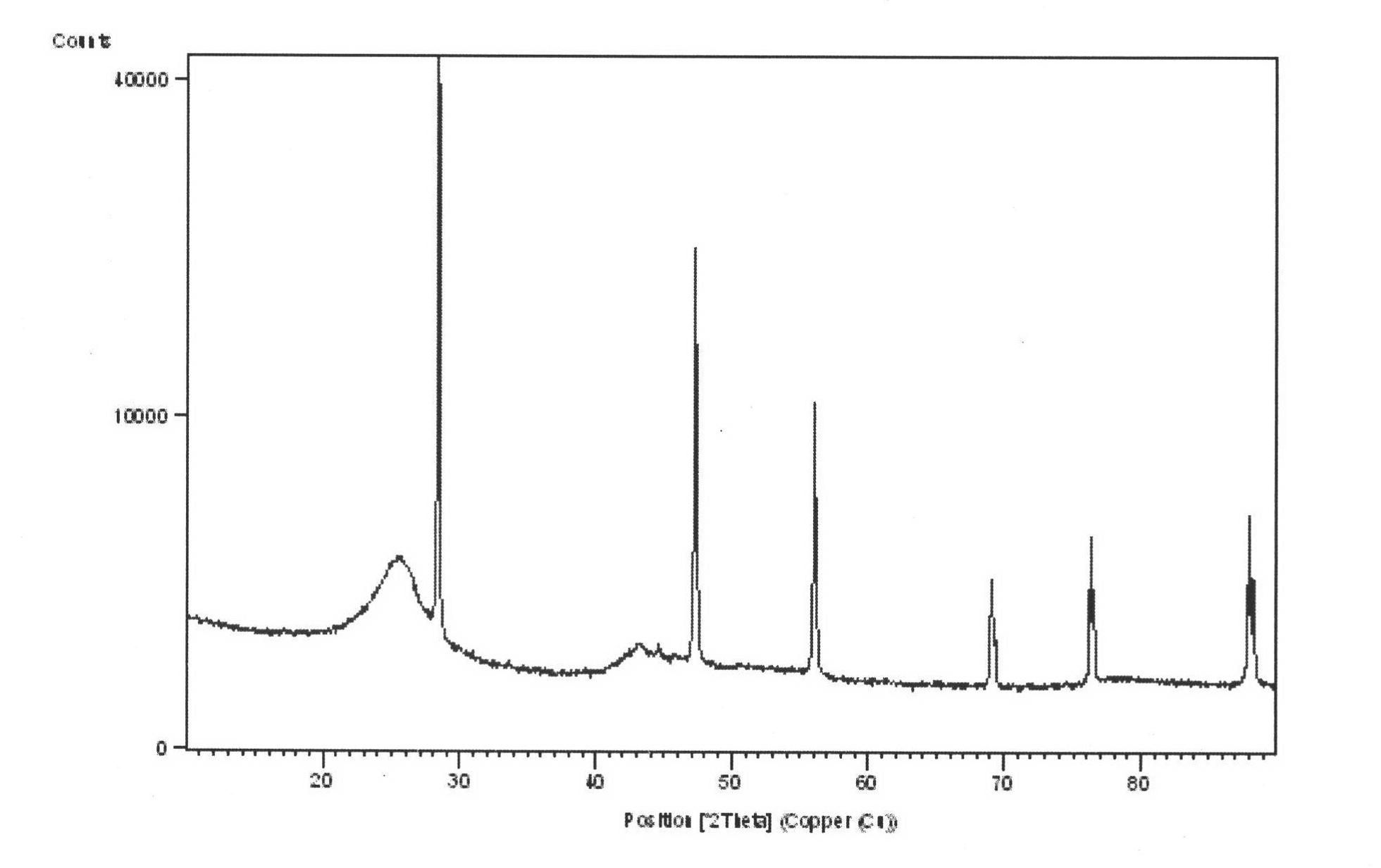

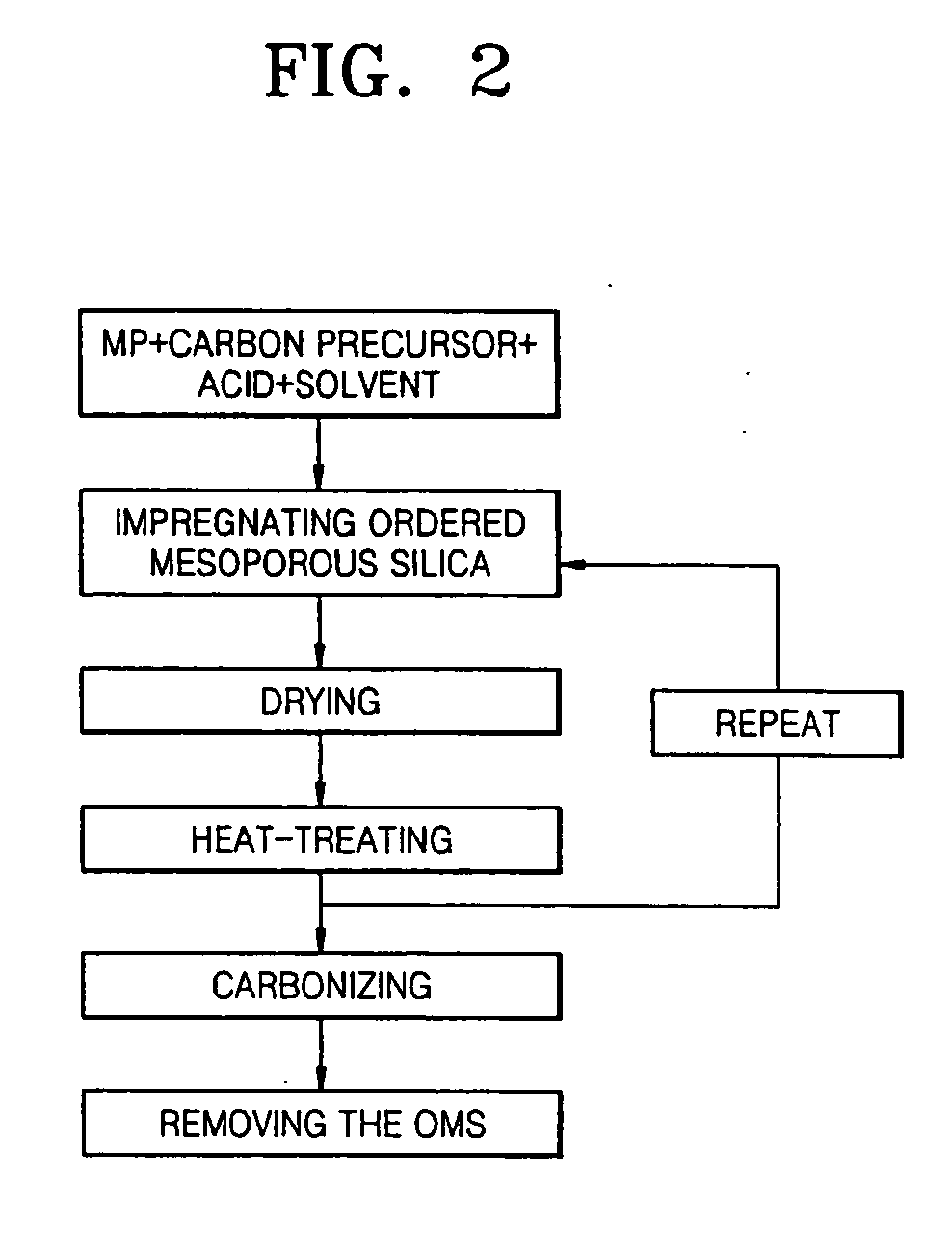

This invention relates to a kind of silicon&carbon composite material with a spherical appearance and core-shell structure in spherical particles with a mean diameter of 1.2~53 micron and a 'core-shell' structure, there are silicon particles 5~50wt% and carbon particles 50~95wt%, the core of which is spherical carbon particles with a mean diameter of 1~45 micron. The carbon particles are the mixture of one, two or three kinds of mesophase carbon graphite balls, hard carbon balls and spherical graphite ball. The thickness of the shell is 0.1~4 microns composed of carbon and silicon grains with the average size of 10 nm~4 micron. The carbon&silicon composite materials are achieved through thermal decomposition and chemical vapor deposition after the spherical carbon particles are coated with silicon and carbon composite ultrafine silica slurry.

Owner:LIYANG TIANMU PILOT BATTERY MATERIAL TECH CO LTD

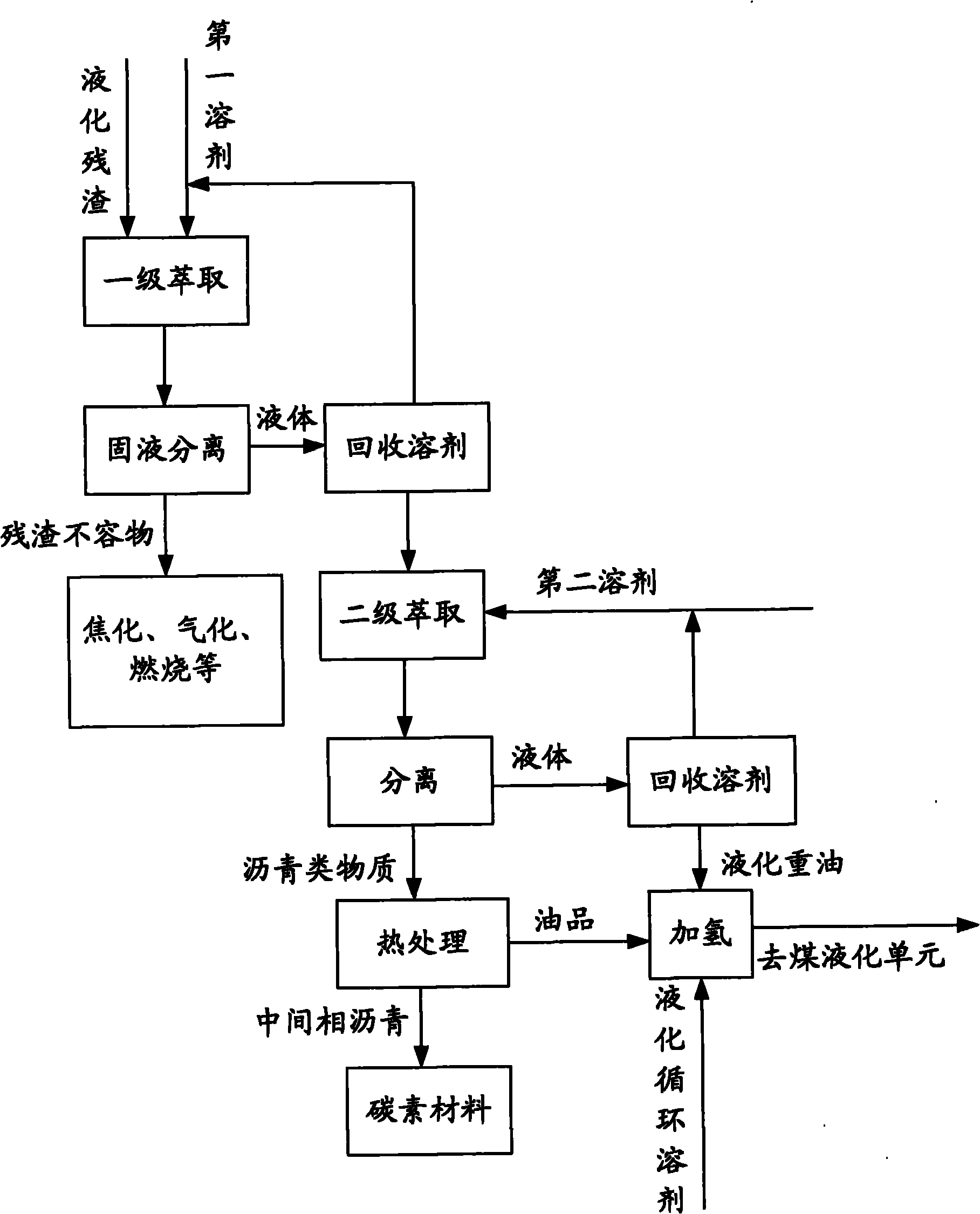

Extraction method of direct coal liquefaction residues and application of extracts

ActiveCN101962560ASimple processOperational securityWorking-up pitch/asphalt/bitumen by selective extractionLiquid hydrocarbon mixture productionSolventAsphalt

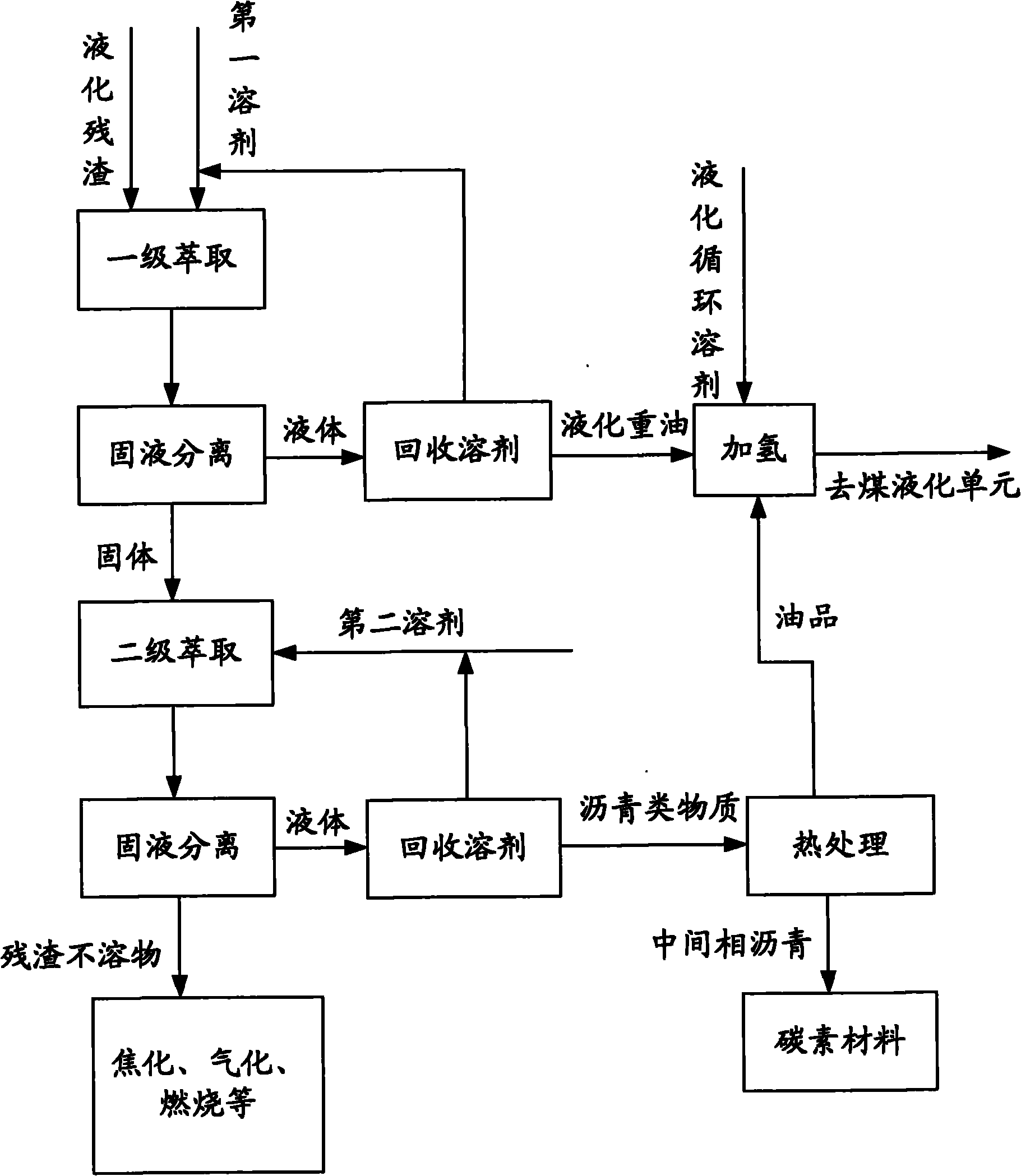

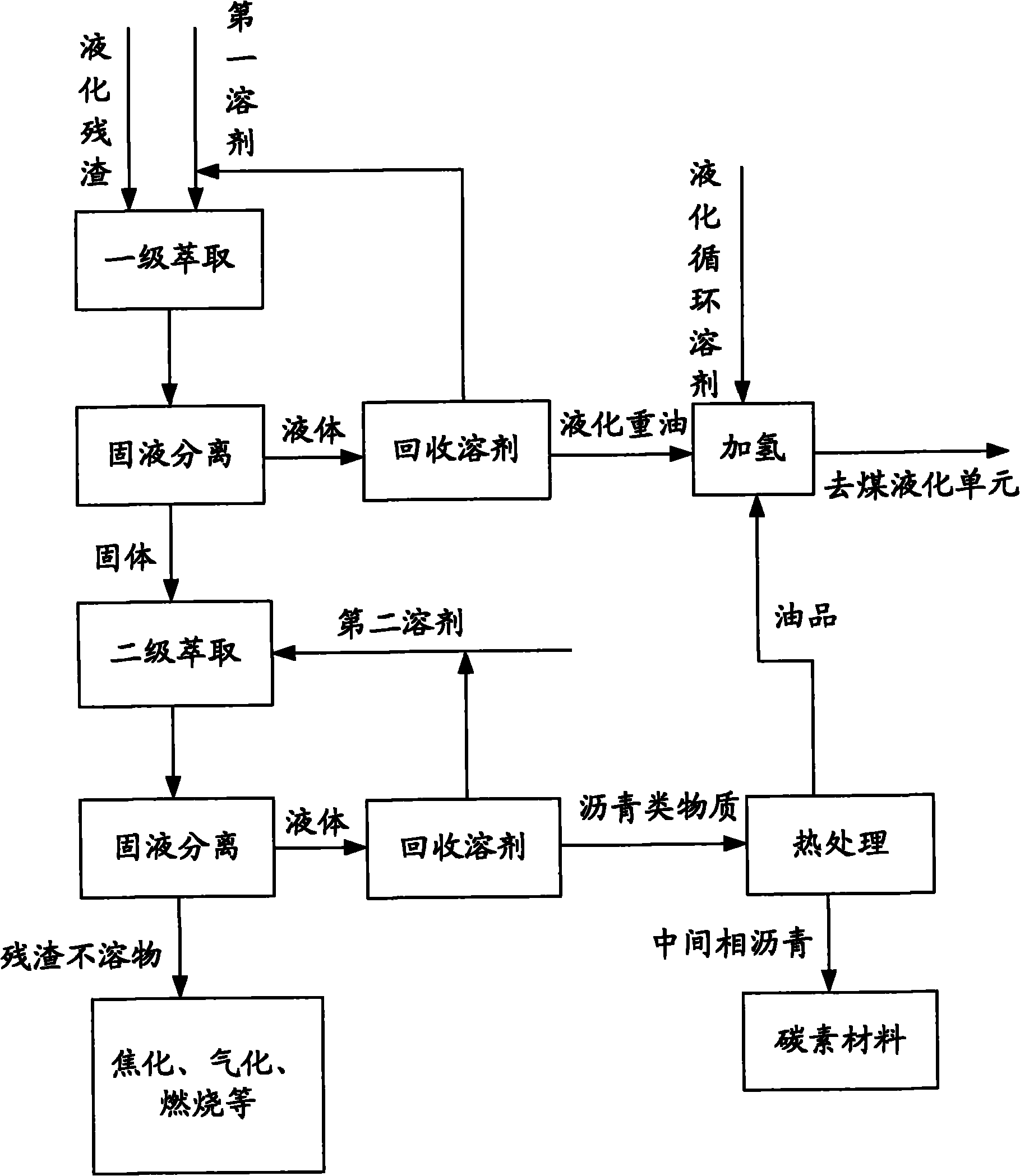

The invention relates to an extraction method of direct coal liquefaction residues and application of extracts. The extraction method comprises the following steps: a) adding coal liquefaction residue powder and a first extraction solvent to a stirred tank to undergo primary extraction; b) carrying out solid-liquid separation on the extracted mixture obtained in the step a), recovering the first extraction solvent from the obtained liquid in a solvent recovery unit and recycling the first extraction solvent, obtaining heavy liquefied oil after recovering the first solvent, carrying out moderate hydrogenation on the heavy liquefied oil and other recycled solvents in a coal liquefaction solvent hydrogenation unit and using the product as the recycled solvent in the coal liquefaction process; c) mixing solid obtained through solid-liquid separation of extracts obtained after primary extraction with a second extraction solvent to undergo secondary extraction; d) carrying out solid-liquid separation on the extracted mixture obtained after secondary extraction, obtaining asphaltic substances after recovering the second solvent from the obtained liquid in the solvent recovery unit and carrying out heat treatment on the asphaltic substances by heating and carbonizing to obtain mesophase asphalt and oils.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

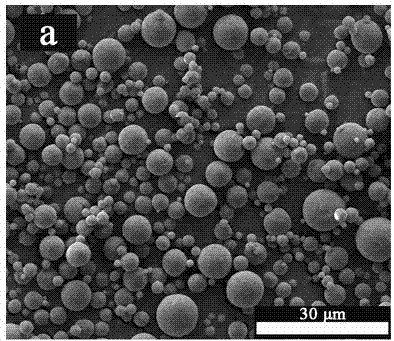

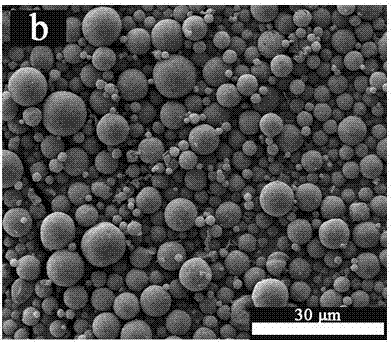

Preparation method of mesophase carbon microspheres from coal liquefaction residues

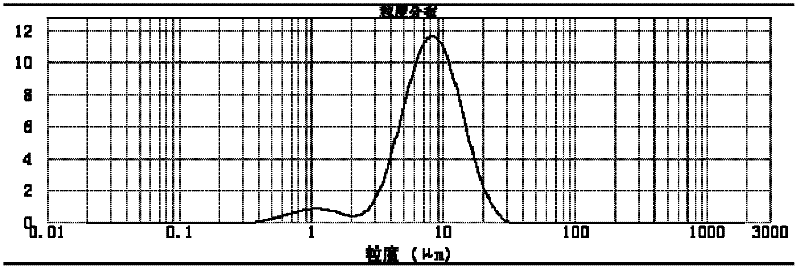

InactiveCN102225755ANarrow particle size distributionSimple processWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by chemical meansMicrosphereQuinoline

The invention discloses a preparation method of mesophase carbon microspheres from coal liquefaction residues serving as raw materials, which comprises the following steps of: firstly carrying out solvent extraction on the coal liquefaction residues, then carrying out a series of processing to obtain refined asphalt with different contents of quinoline insoluble substances, and carrying out thermal polycondensation reaction on the refined asphalt in the presence of a chemical auxiliary agent and a nucleating accelerator at the temperature of 380-450 DEG C, the pressure of 0-5 MPa and the stirring rotation speed of 40-500 r / min for 1-20 hours to obtain the mesophase microspheres. According to the invention, the chemical auxiliary agent and the nucleating accelerator can be added during theheat treatment process to improve the yield and narrow the particle size distribution of the mesophase carbon microbeads, and the mesophase carbon microspheres are prepared from the coal liquefactionresidues serving as the raw materials and have the advantages of low cost, simple preparation process, high yield (up to 35%), narrow particle size distribution, good sphericity, etc.

Owner:ZIBO MINING GRP

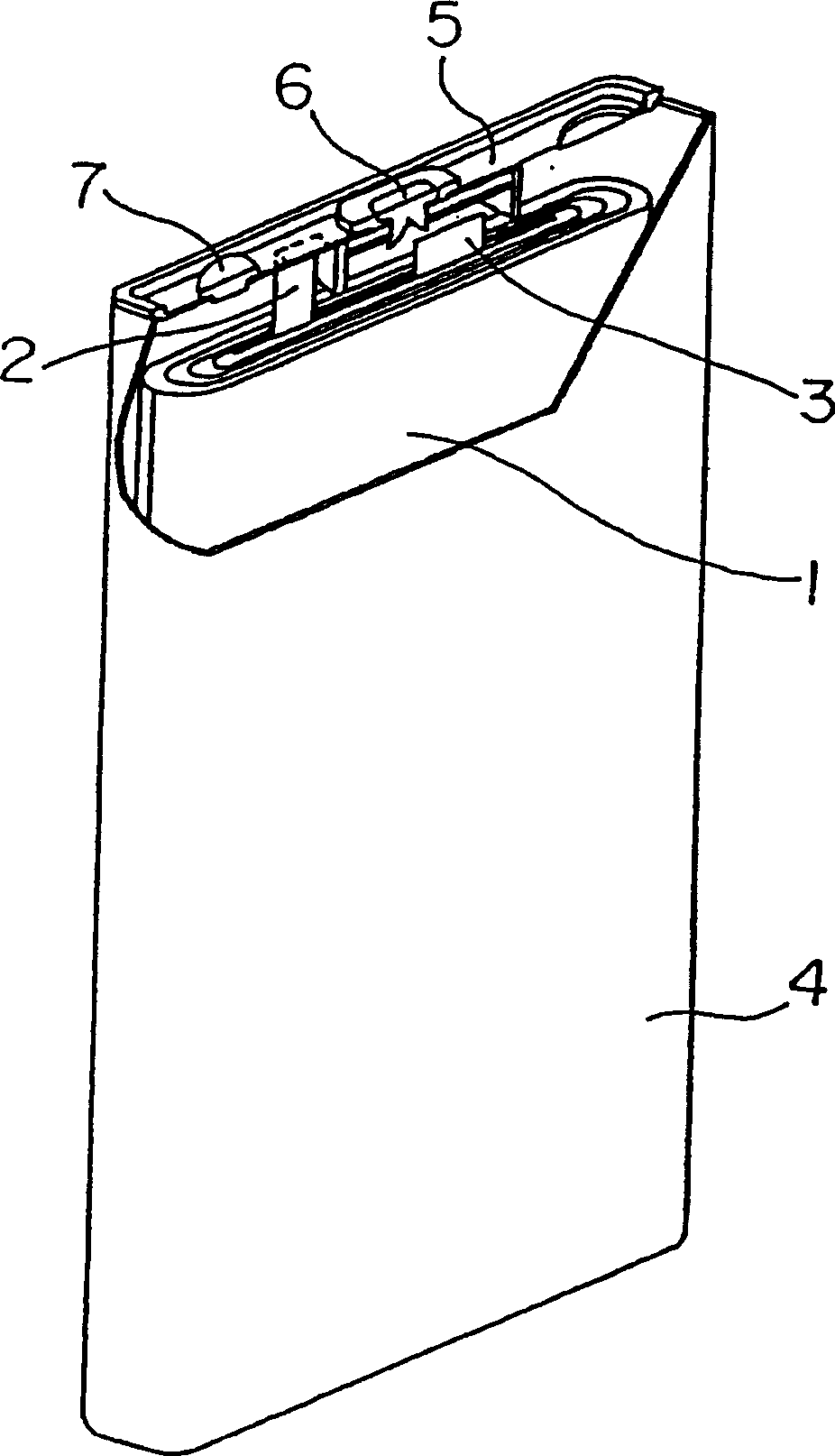

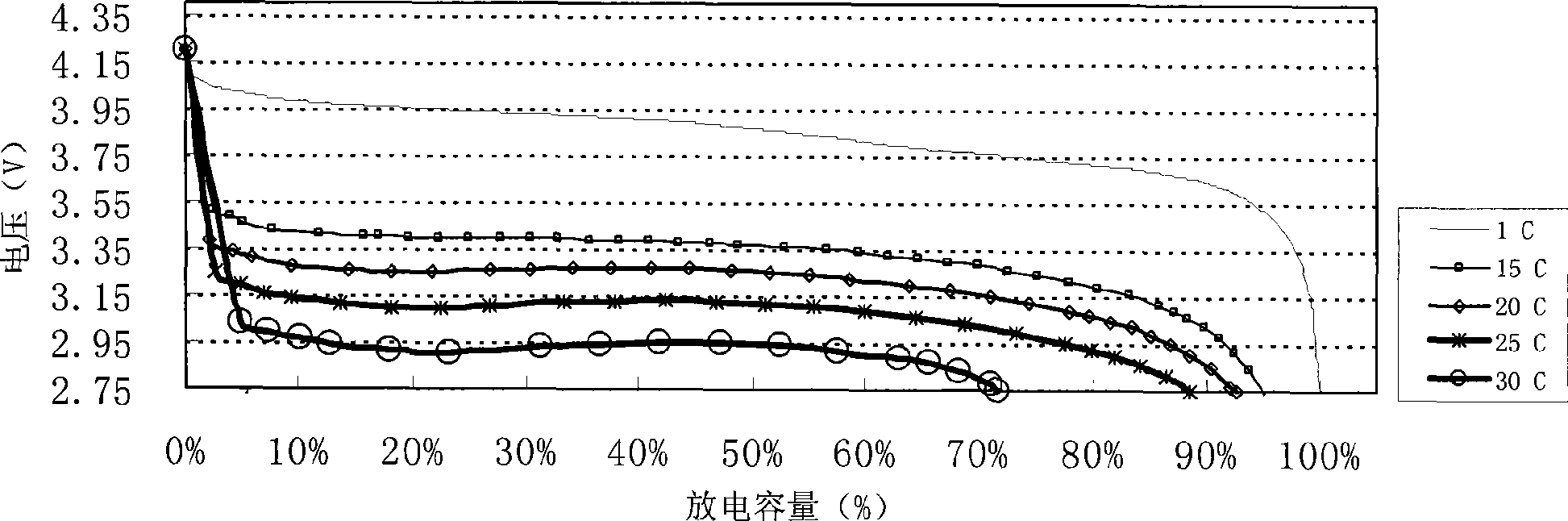

Lithium secondary cell

The present invention provides a lithium rechargeable battery including a negative electrode comprising a copper core material, to which is fixed an active material made by mixing artificial graphite particles A obtained by kneading and granulating a base material of pulverized bulk mesophase pitch with pitch in a softened state and / or thermosetting resin, carbonizing the resulting granules at 700 to 1,500 DEG C. and graphitizing the carbonized granules at 2,500 to 3,000 DEG C. with spherical graphite particles B having a high mean circularity, with a view to inhibiting the deterioration in battery capacity through the repeated charge / discharge cycles, which occurs remarkably in a high energy density lithium rechargeable battery, and providing excellent discharge characteristic and safety.

Owner:PANASONIC CORP

Cathode material for lithium-ion power and energy storage battery and preparation method thereof

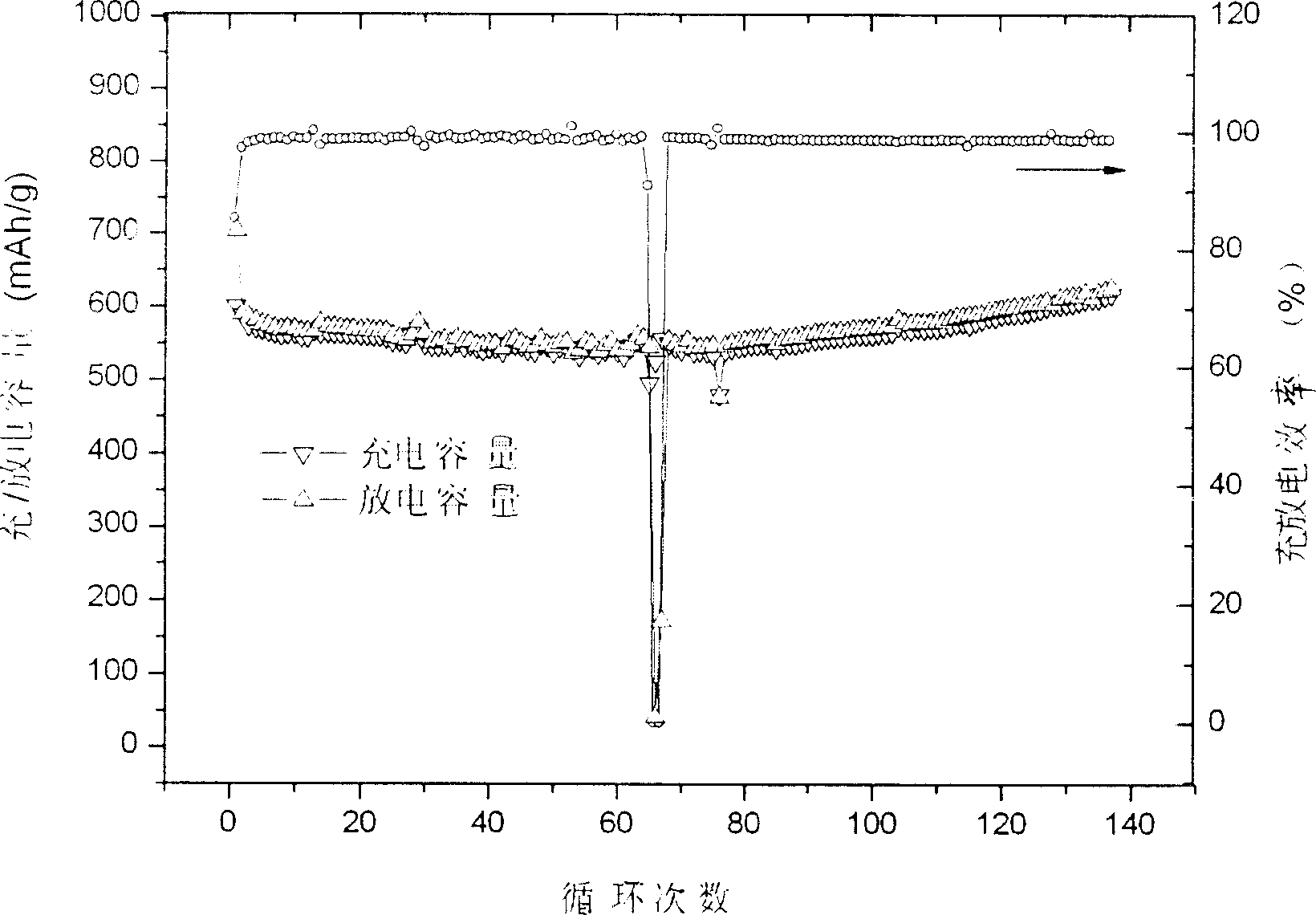

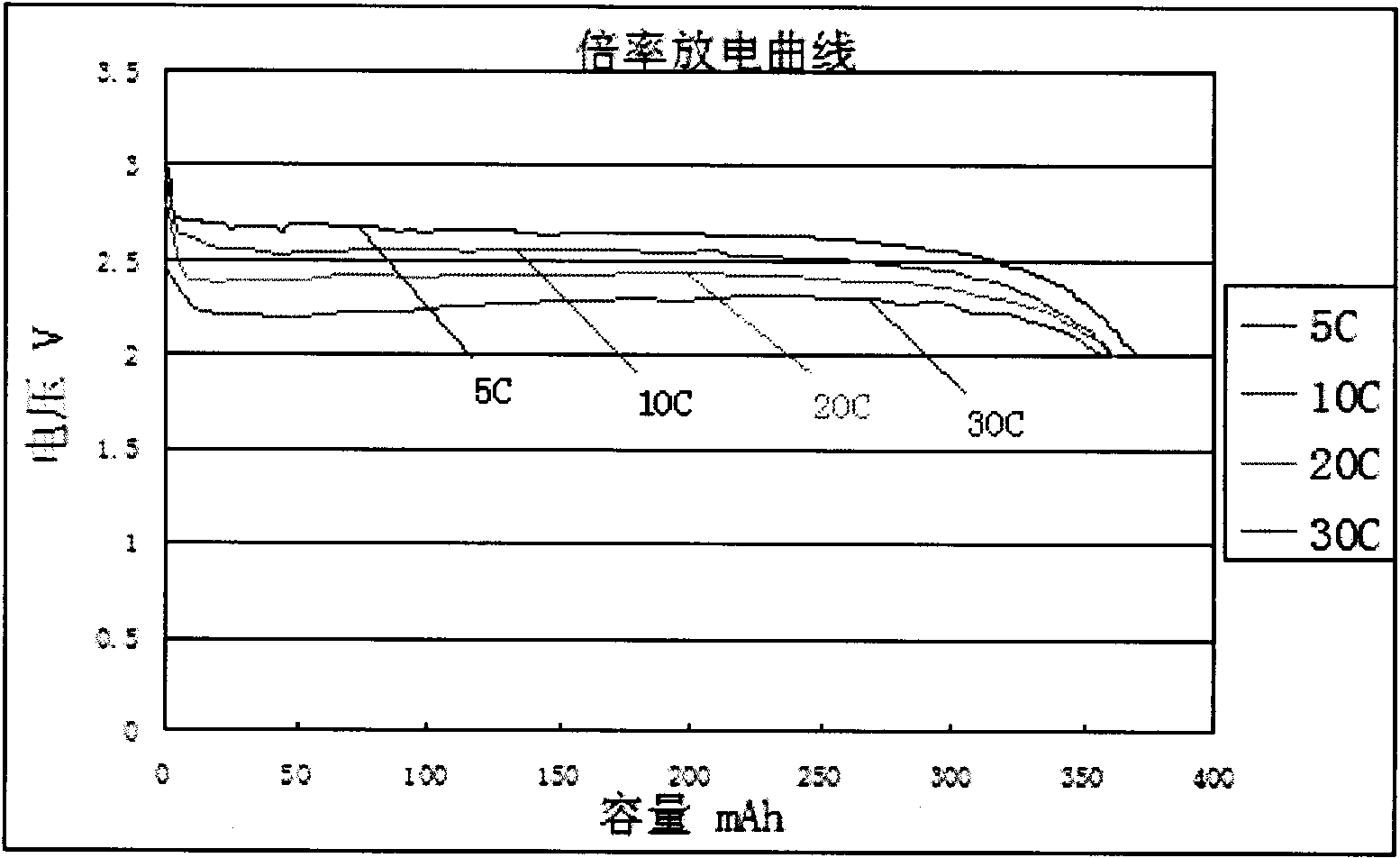

The invention discloses a cathode material for a lithium-ion power and energy storage battery and a preparation method thereof, aiming to solve the problem on how to improve the high-magnification charge-discharge property of the battery and how to enable the battery to have good cycle property. The cathode material is obtained by carbonizing asphalt containing a catalyst at 500-1,300 DEG C. The preparation method comprises the following steps of: raising the temperature and the pressure to have a carbonized thermal polycondensation reaction; washing, extracting and then washing; drying to obtain mesophase microbead precursors; and then carbonizing to obtain the cathode material for the lithium-ion power and energy storage battery. Compared with the prior art, the invention reduces the production cost; because the mesophase soft carbon materials obtained by low-temperature carbonization are adopted, the interior of the cathode material is in a turbostratic structure capable of charging and discharging with high power and high current; and the main raw material of the mesophase soft carbon material is asphalt, so that compared with other hard carbons such as the resin type, the plant, and the like, the cathode material has yield improved by 3-5 times, low cost and higher specific capacity.

Owner:JIXI BTR GRAPHITE IND PARK CO LTD +2

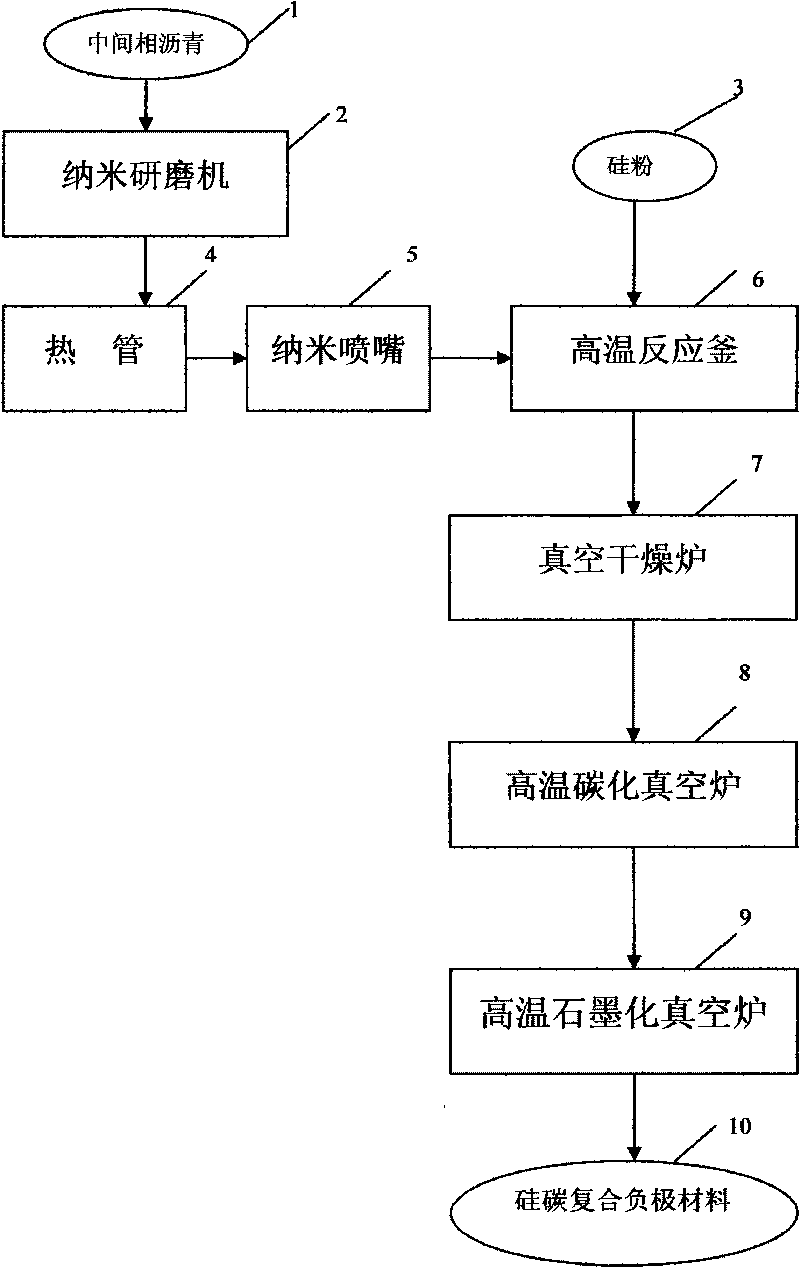

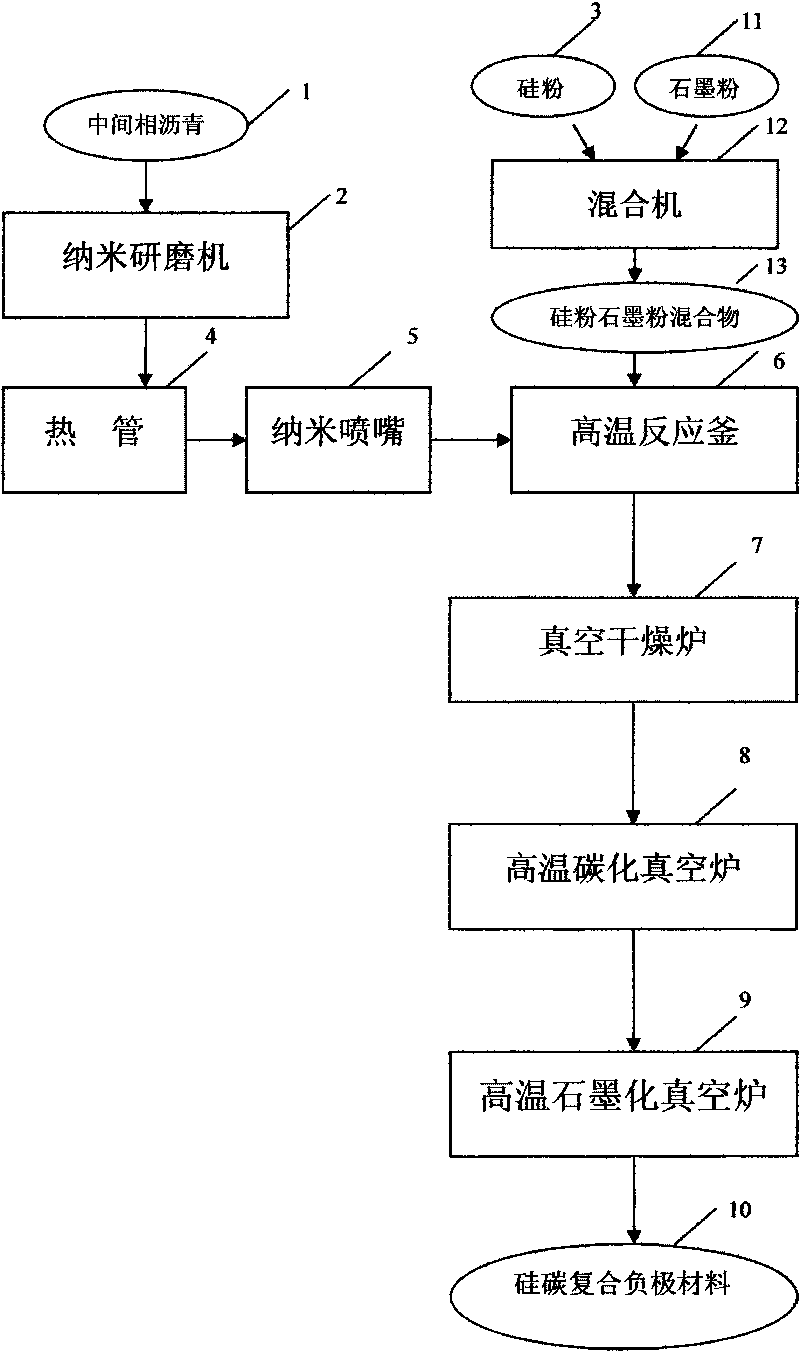

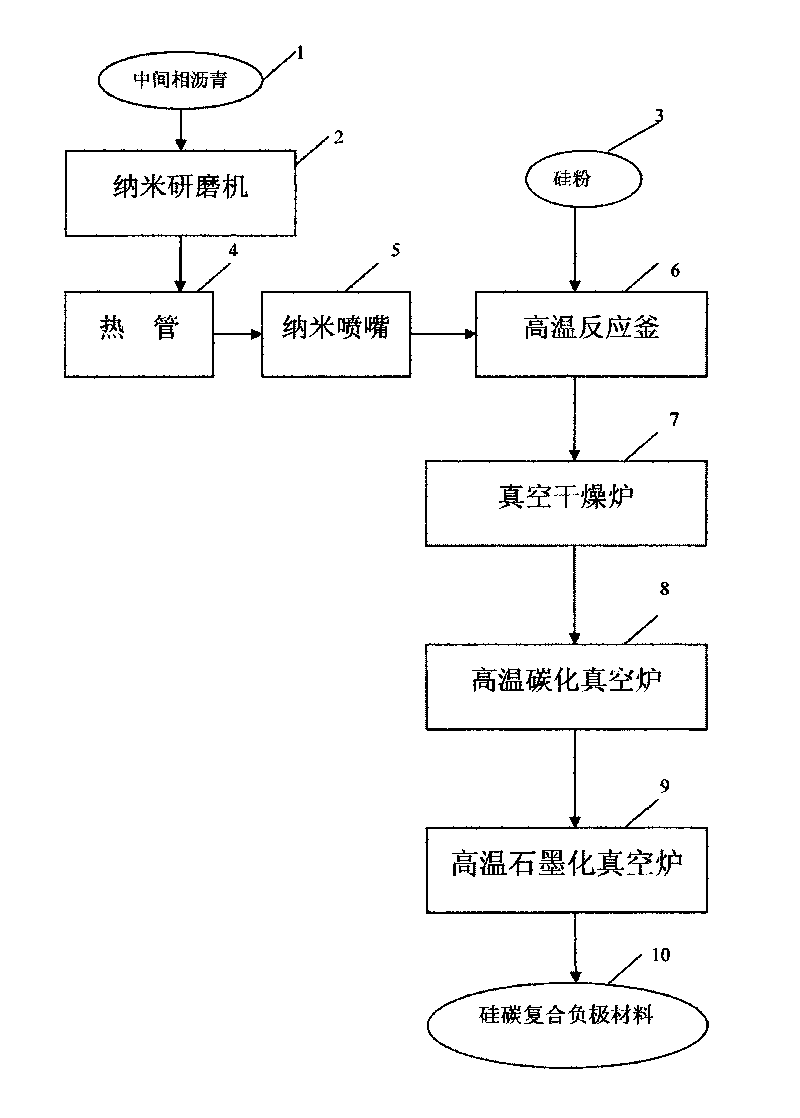

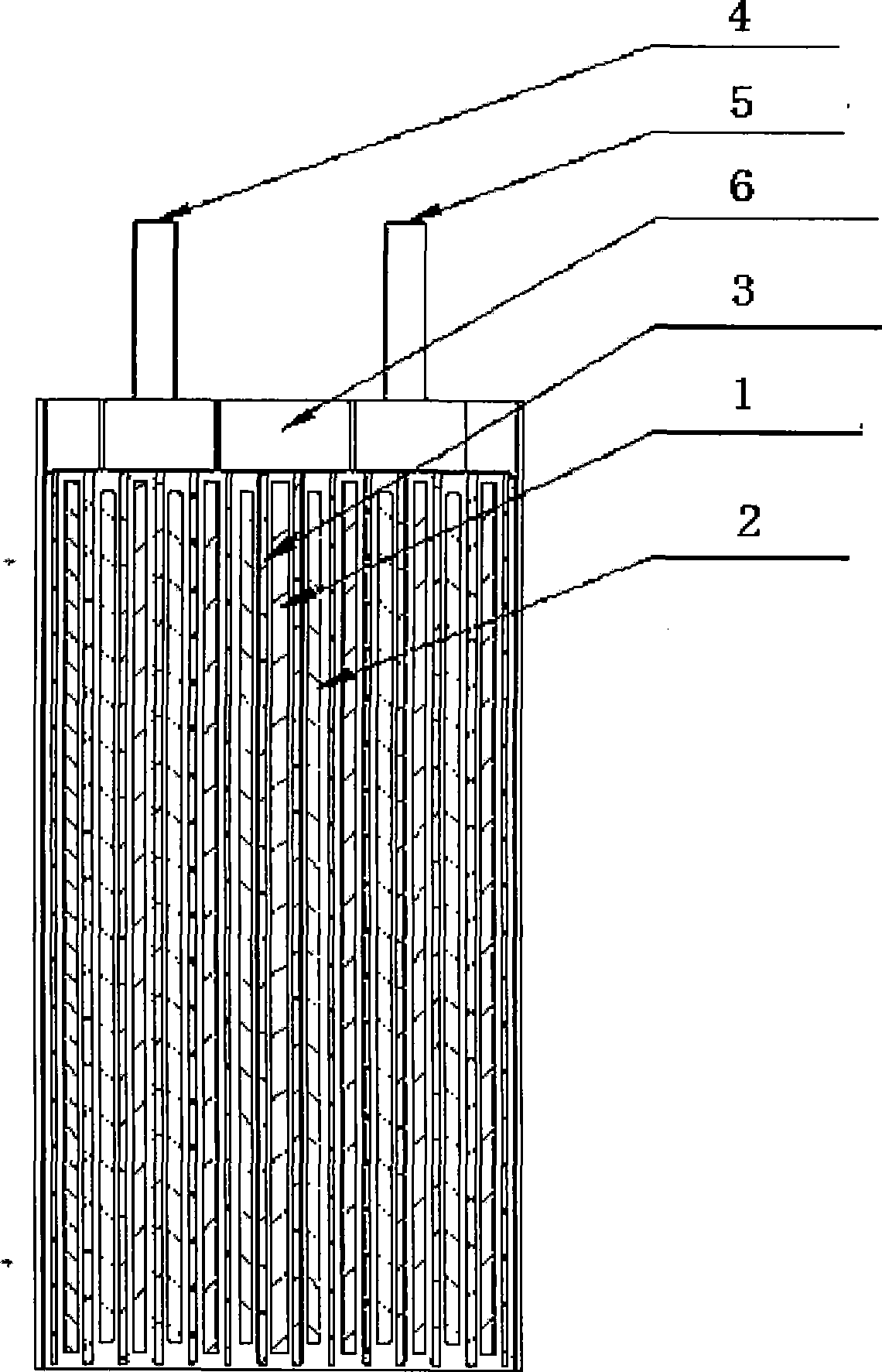

High-energy silicon-carbon composite negative electrode material for lithium ion battery and manufacturing process thereof

InactiveCN101710617AImprove cycle stabilityGive full play to the characteristics of high specific capacityElectrode manufacturing processesCarbon compositesHigh energy

Owner:DALIAN LICHANG NEW MATERIAL CO LTD

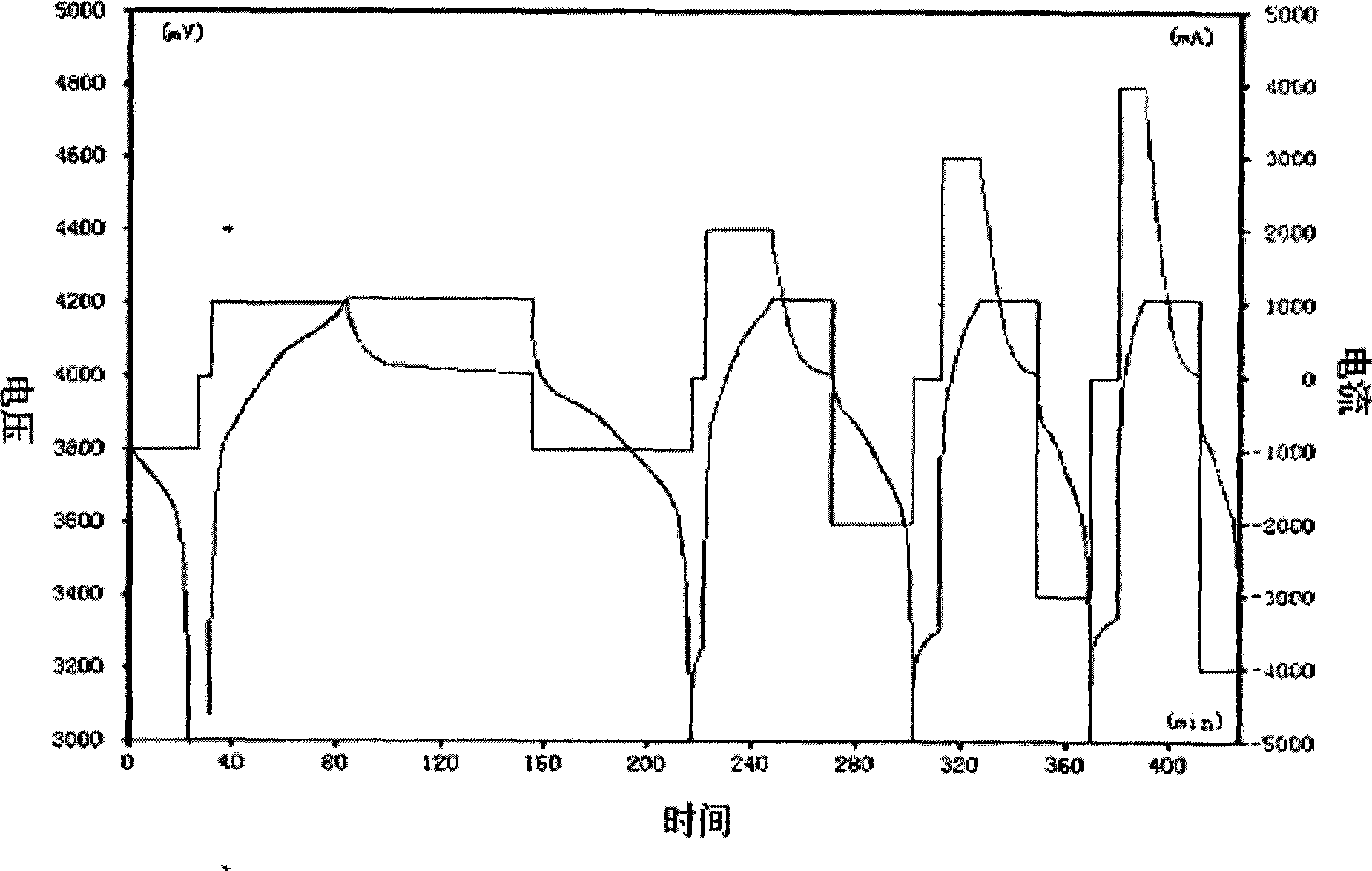

Multi-multiplying power charging-discharging lithium ion battery and method for producing the same

InactiveCN101499530AImprove high rate charge and discharge performanceImprove performanceElectrode manufacturing processesFinal product manufactureHigh rateMicrosphere

The invention provides a high-rate charge-discharge lithium-ion battery and a preparation method thereof. The anode active material of the lithium-ion battery is lithium manganate; the cathode active material is selected from one or more of mesocarbon microbeads, artificial graphite or natural graphite coated by mesophase pitch; a conductive agent is selected from one or more of conductive graphite, conductive carbon black, nano Ag, nano SiO2 or nano Al2O3. The preparation method of the lithium-ion battery comprises the preparation of the anode plate, the parathion of the cathode plate and the assembly of the battery. The lithium-ion battery has the advantages of high-rate charge-discharge performance, long cycle life, high capacity, safe use, environmental protection, low cost and the like. The preparation method has the advantage of simple and easy process operation, and is applicable to the mass production.

Owner:深圳市崧鼎实业有限公司

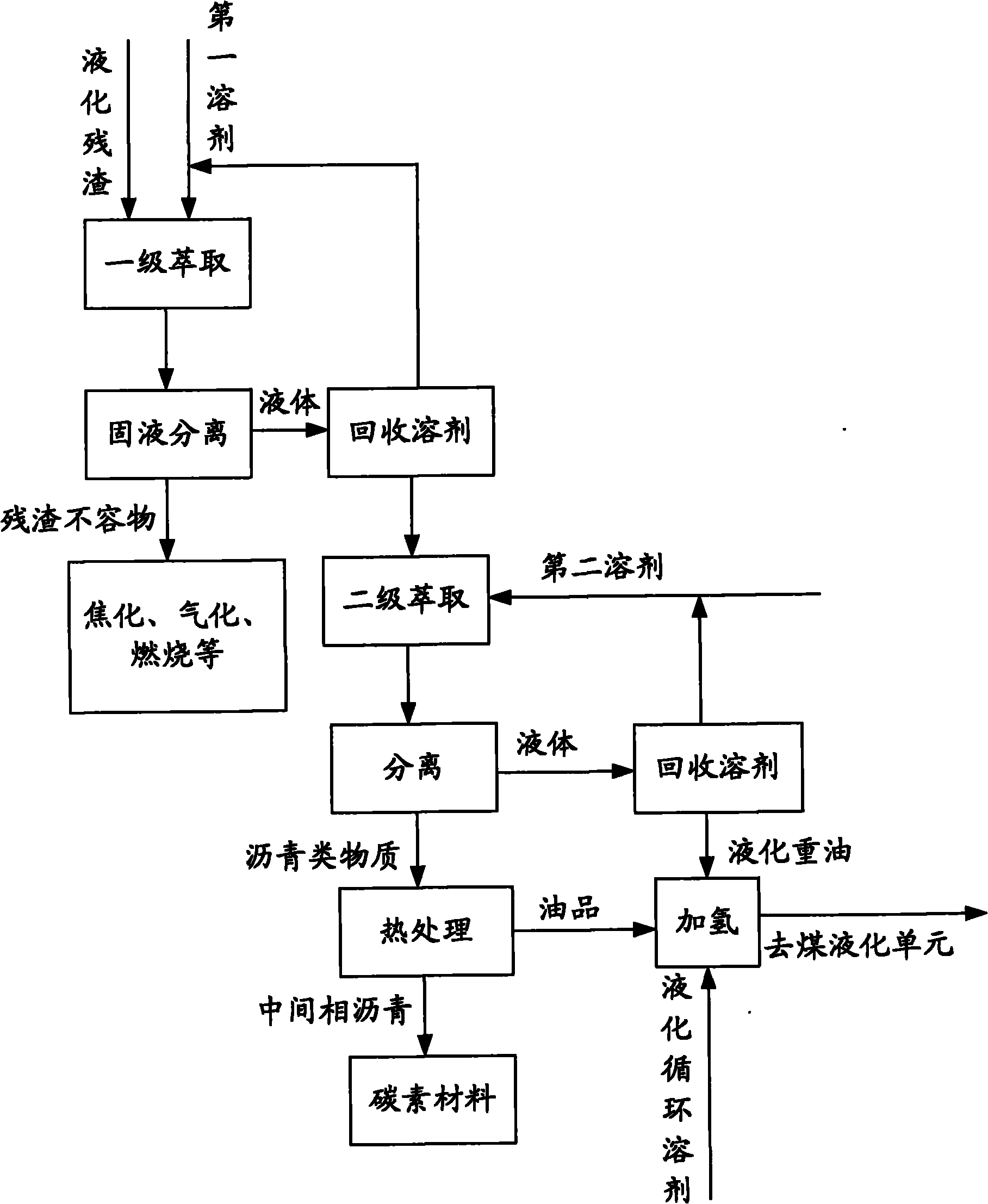

Extraction method of direct coal liquefaction residues and application of extracts

ActiveCN101962561AMake full use ofSimple processWorking-up pitch/asphalt/bitumen by selective extractionLiquid hydrocarbon mixture productionSolventThermal treatment

The invention relates to an extraction method of direct coal liquefaction residues and application of extracts. The extraction method comprises the following steps: a) adding coal liquefaction residue powder and a first extraction solvent to a stirred tank to undergo primary extraction; b) carrying out solid-liquid separation on the extracted mixture obtained in the step a) and recovering the first extraction solvent from the obtained liquid in a solvent recovery unit and recycling the first extraction solvent; c) obtaining extracts after recovering the first solvent and mixing the extracts with a second extraction solvent to undergo secondary extraction; d) carrying out solid-liquid separation on the extracted mixture obtained in the step c), obtaining heavy liquefied oil after recovering the second extraction solvent from the obtained liquid in the solvent recovery unit and then carrying out moderate hydrogenation on the heavy liquefied oil and other recycled solvents in a coal liquefaction solvent hydrogenation unit and using the product as the recycled solvent in the coal liquefaction process; and e) carrying out heat treatment on the asphaltic substances obtained in the step d) by heating and carbonizing to obtain mesophase asphalt and oils.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

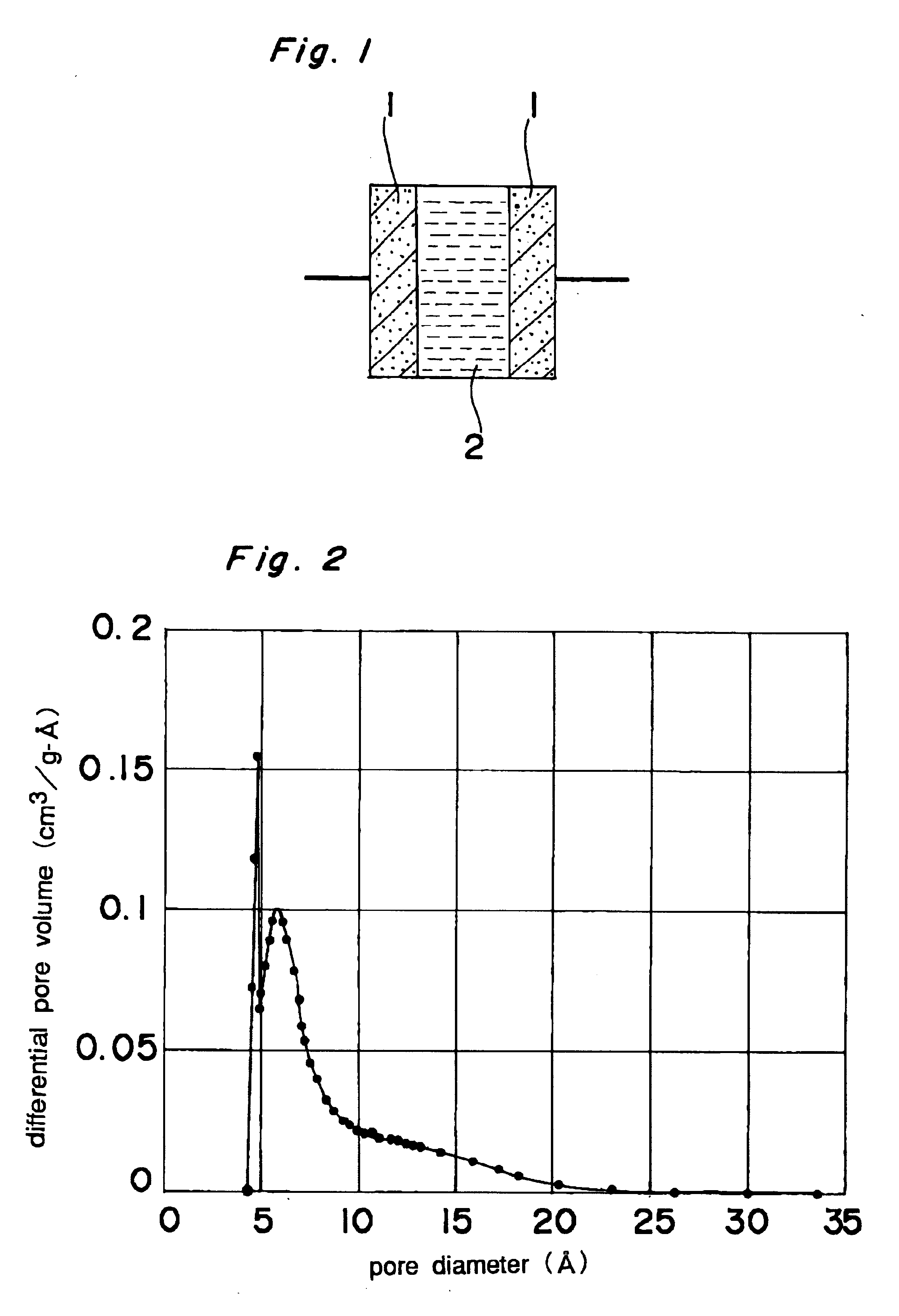

Mesophase pitch-based activated carbon fibers and electric double layer capacitor using the same

InactiveUS6118650ALower internal resistanceImprove conductivityHybrid capacitor electrodesLiquid electrolytic capacitorsActivated carbonFiber

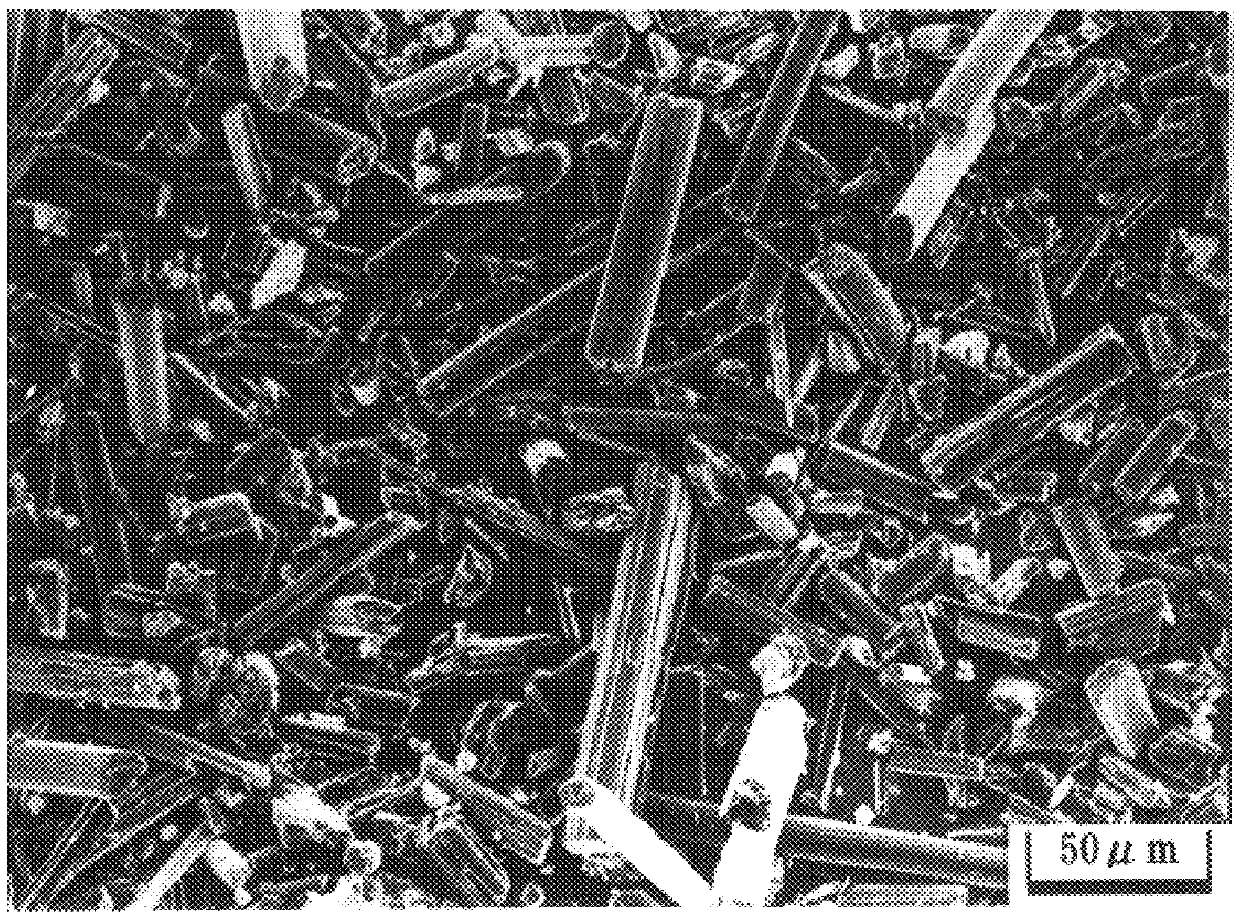

Mesophase pitch-based activated carbon fibers which are obtained by milling infusibilized mesophase pitch fibers, as they are or after carbonizing at a temperature of 350 to 1,000 DEG C., to an average particle diameter of 5 to 50 mu m and then activating in the presence of an alkali metal compound. The activated carbon fibers have a pore distribution suitable for forming a electric double layer and is excellent as the material for an electrode of an electric double layer capacitor. The electric double layer capacitor having the electrode using the activated carbon fiber exhibits high discharge capacity.

Owner:HONDA MOTOR CO LTD

Petroleum pitch-based carbon foam

InactiveUS6833012B2Useful and reliableImprove efficiencyPigmenting treatmentHarvestersLow densityNet shape

Petroleum or coal tar pitch-based cellular or porous products having a density of preferably between about 0.1 g / cm<3 >and about 0.8 g / cm<3 >are produced by the controlled heating of mesophase carbon materials derived from coal tar or petroleum pitch having a softening point in excess of about 300° C. and preferably between about 300 and about 400° C. in a "mold" and under a non-oxidizing atmosphere. The porous product thereby produced, preferably as a net shape or near net shape, can be machined, adhered and otherwise fabricated to produce a wide variety of low cost, low density products.

Owner:TOUCHSTONE RES LAB

Preparation method of soluble mesophase pitch

InactiveCN102942945AImprove solubilityFacilitate subsequent processingWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionFiberCarbon fibers

The invention belongs to the technical field of a preparation method of spinning raw materials of high-performance pitch-based carbon fibers, and particularly relates to a preparation method of soluble mesophase pitch, which mainly solves the problems of the existing mesophase pitch preparation method that the process is complicated, requirements on the equipment are high, the cost is high, the industrialization process is difficult and the like. The invention adopts the technical scheme that the preparation method of the soluble mesophase pitch comprises the following steps of (1) thermally treating raw material pitch or ethylene bottom oil with a low softening point in an inert atmosphere, then distilling the material in a short distance or flashing the material, removing light ends, and collecting heavy fraction, i.e. heavy end pitch; (2) preparing the heavy enbd pitch into mesophase pitch; and (3) cooling the mesophase pitch to 320DEG C to 400DEG C, removing internal light ends, and collecting the heavy fraction, i.e. the mesophase pitch. The preparation method has the advantages of simplicity in process, moderate in reaction condition, low equipment requirement, low cost and adaptability to industrialized production.

Owner:SICHUAN CHUANGYUE CARBON MATERIAL

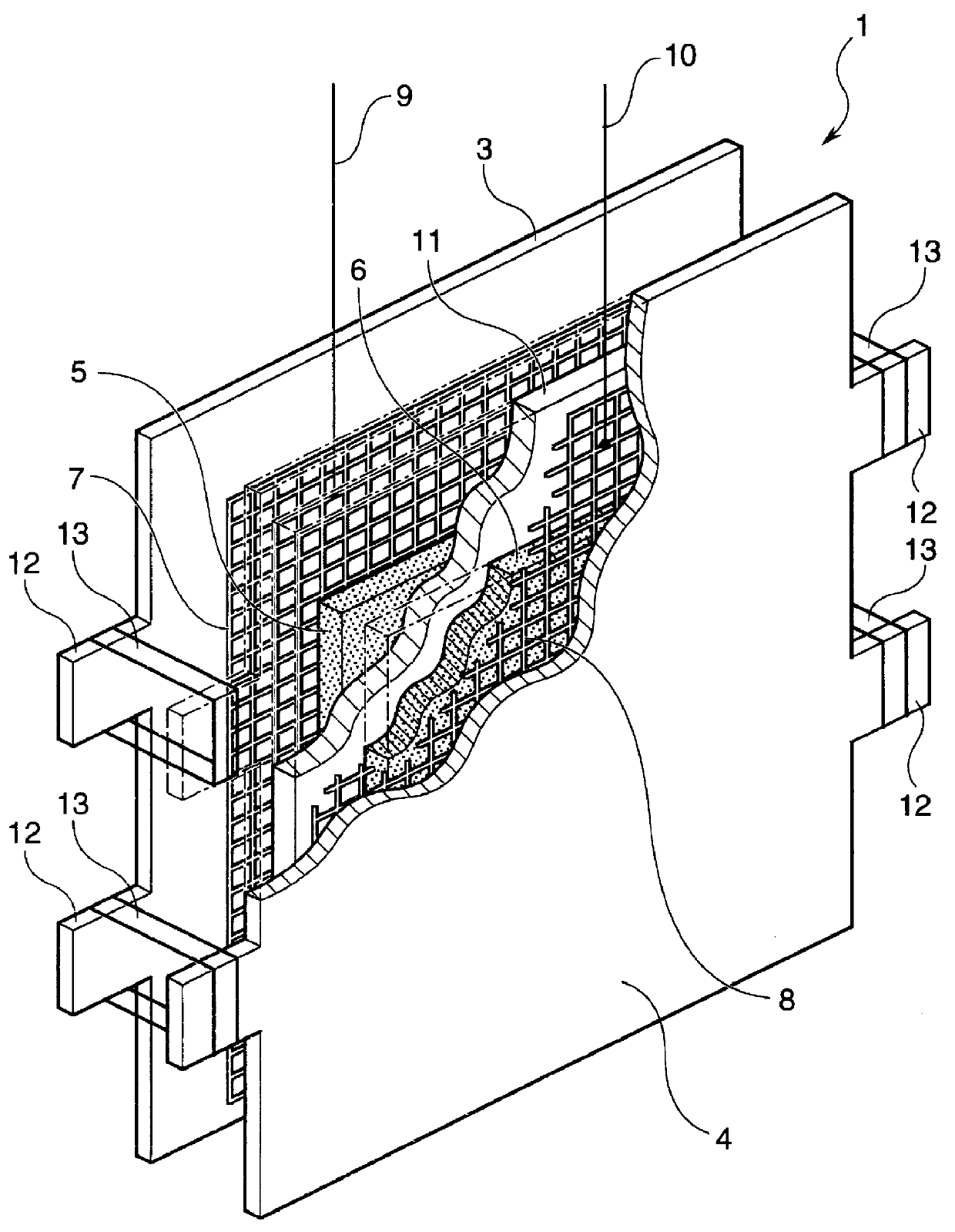

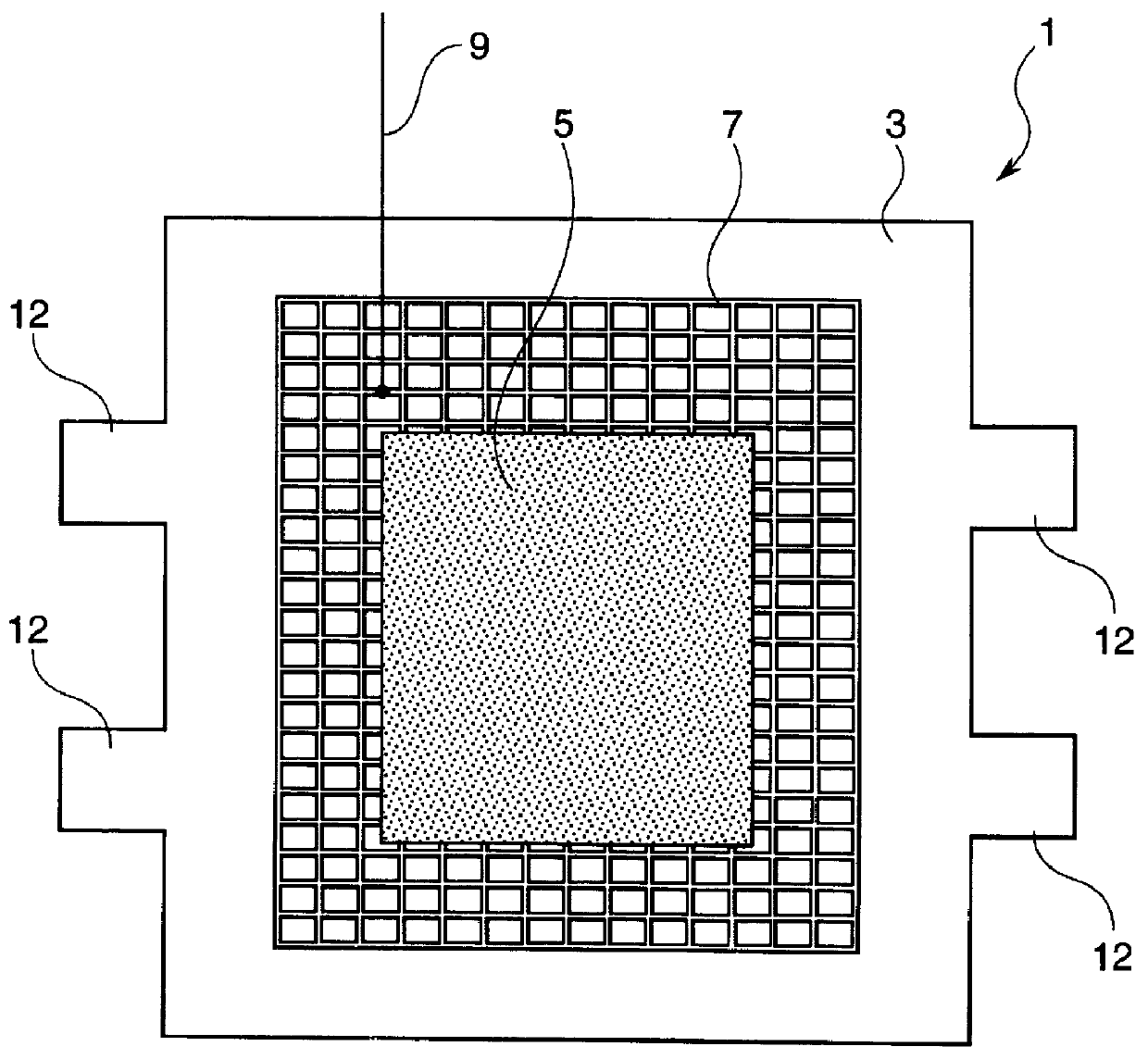

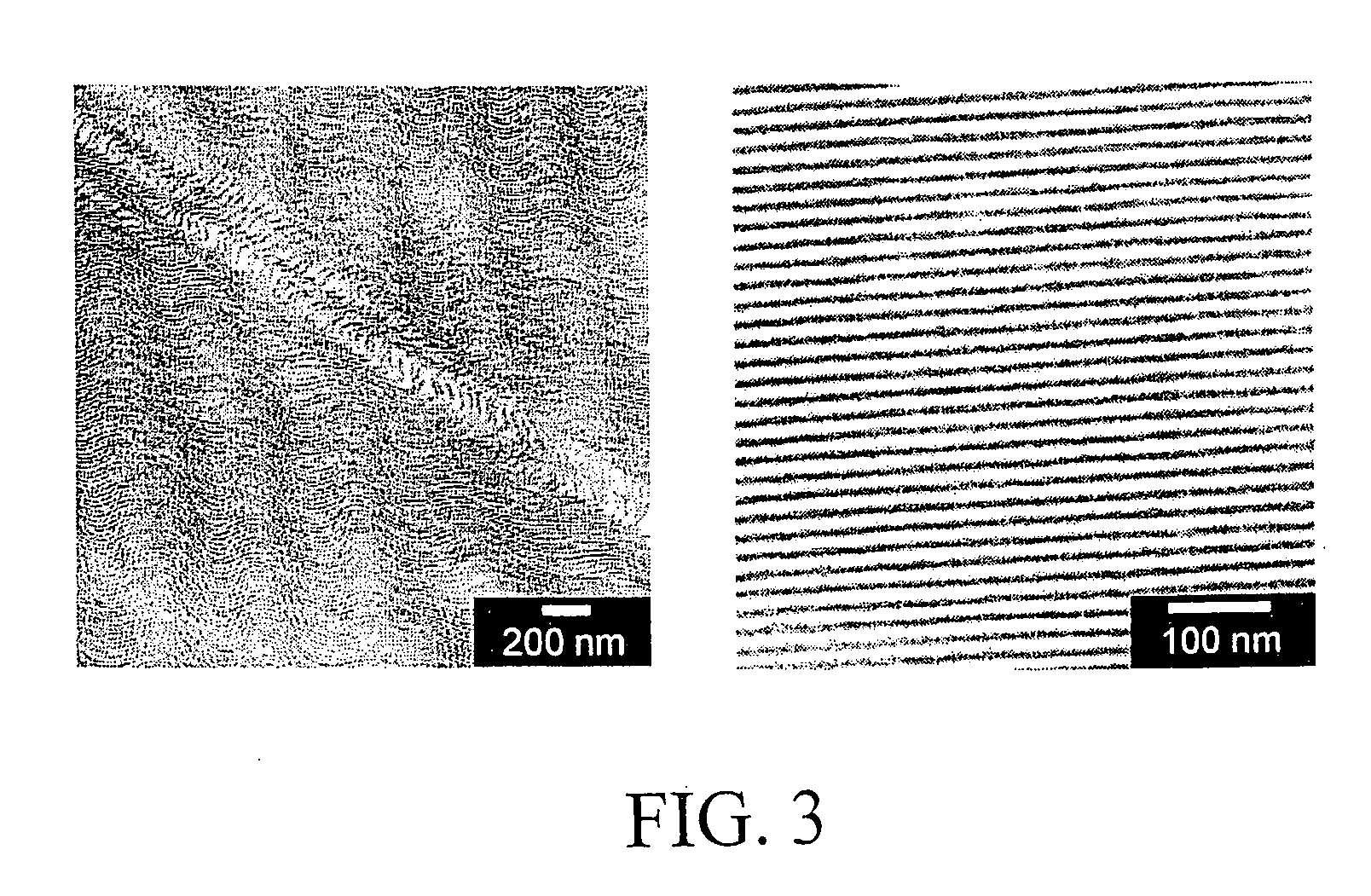

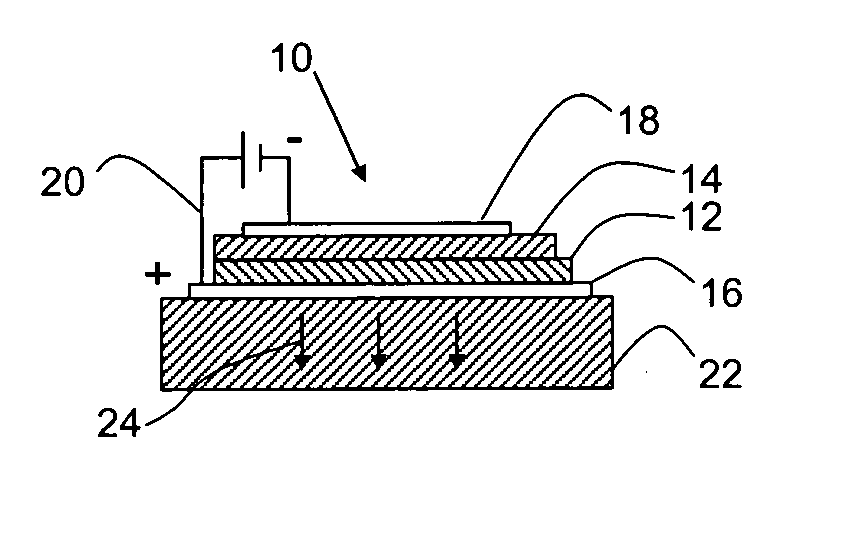

High temperature SiCN and SiC-type nanostructured ceramic material from block copolymer mesophases

InactiveUS20050036931A1Simple and easily controlled pathwayCarbon compoundsNitrogen and non-metal compoundsNon oxide ceramicsPolymer science

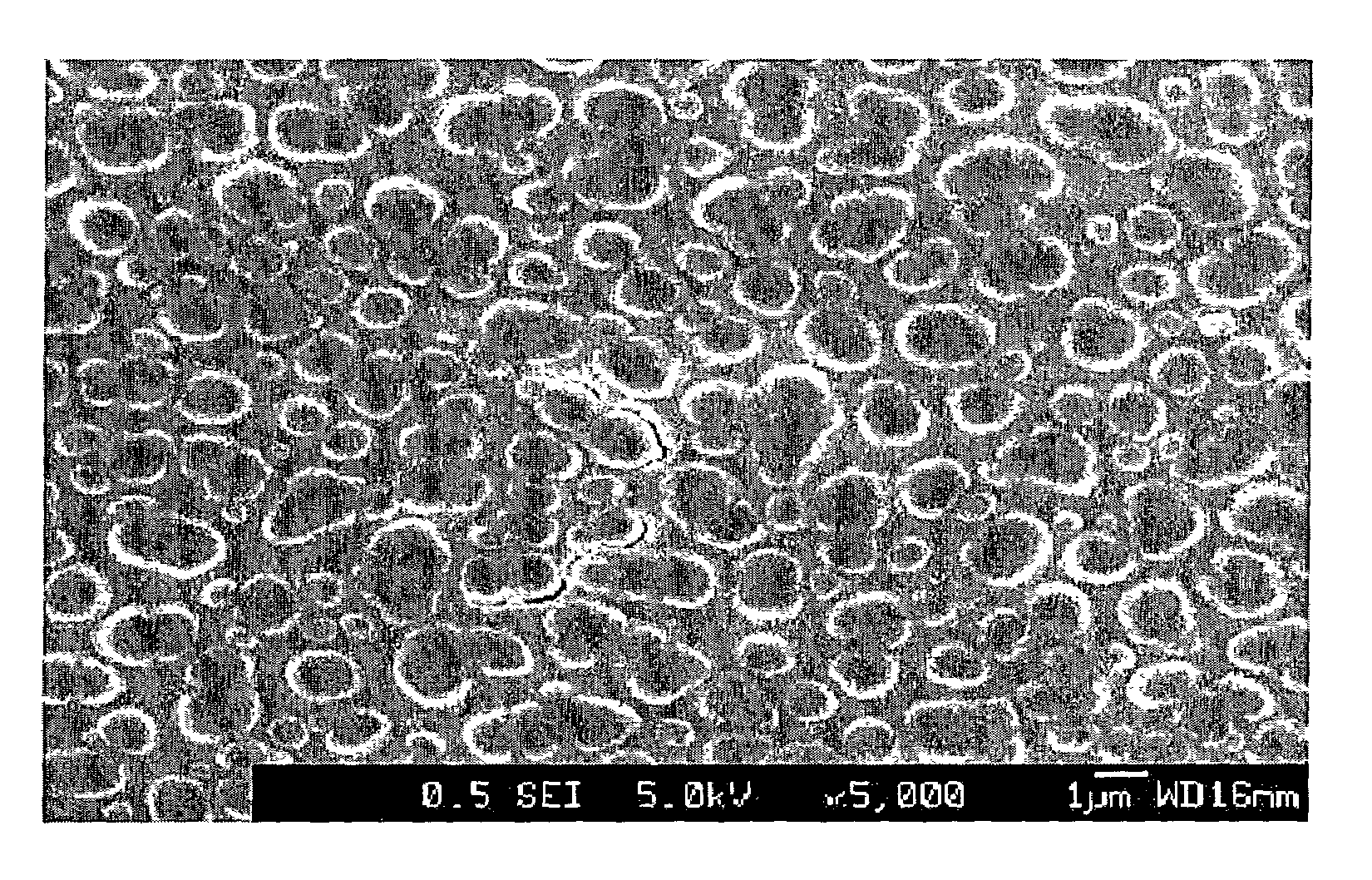

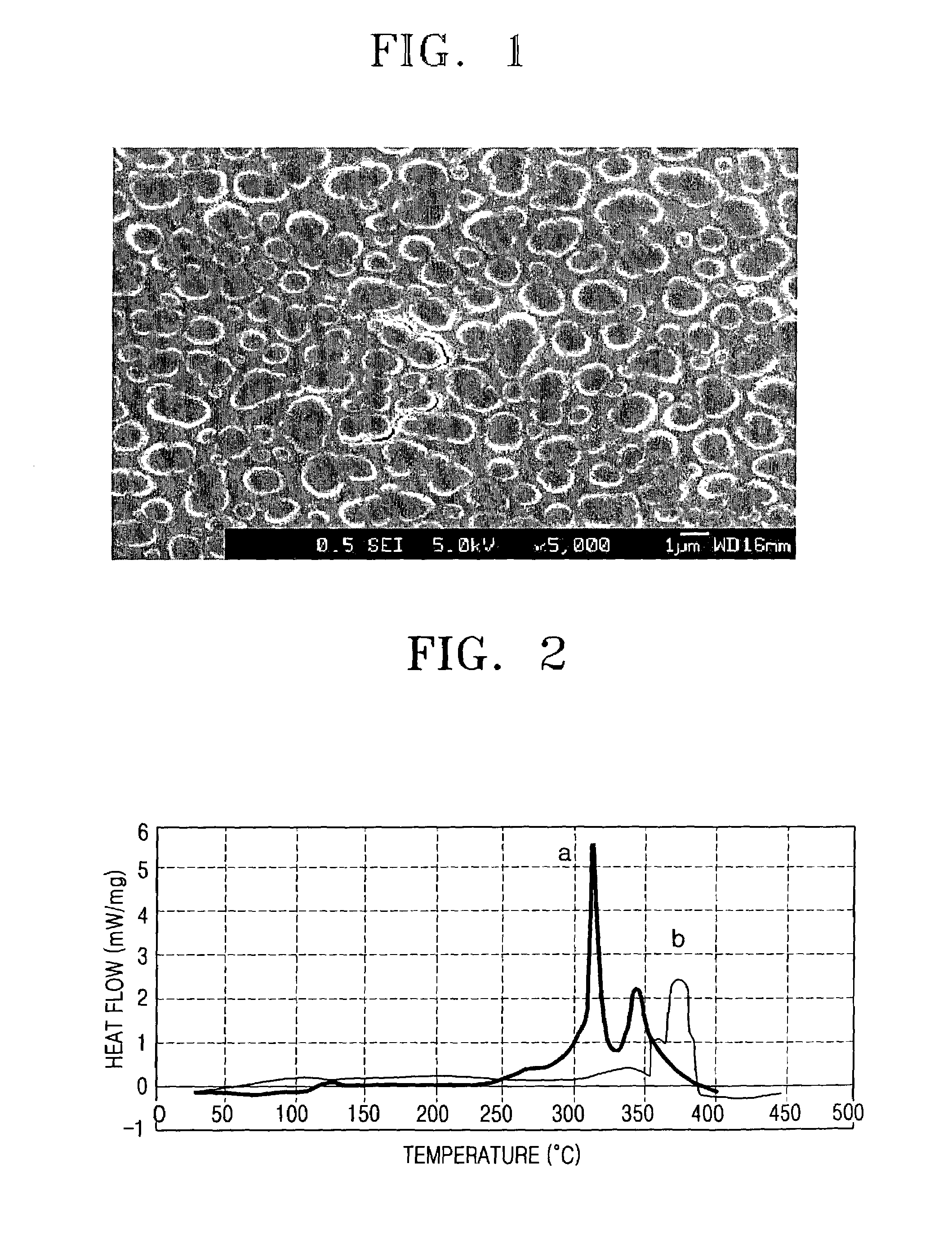

A block copolymer, preferably a block copolymer such as poly(isoprene-block-ethylene oxide), PI-b-PEO, is used as a structure directing agent for a polymer derived ceramic (PDC) precursor, preferably a silazane, most preferably a silazane commercially known as Ceraset. The PDC precursor is preferably polymerized after mixing with the block copolymer to form a nanostructured composite material. Through further heating steps, the nanostructured composite material can be transformed into a nanostructured non-oxide ceramic material, preferably a high temperature SiCN or SiC material.

Owner:CORNELL RES FOUNDATION INC

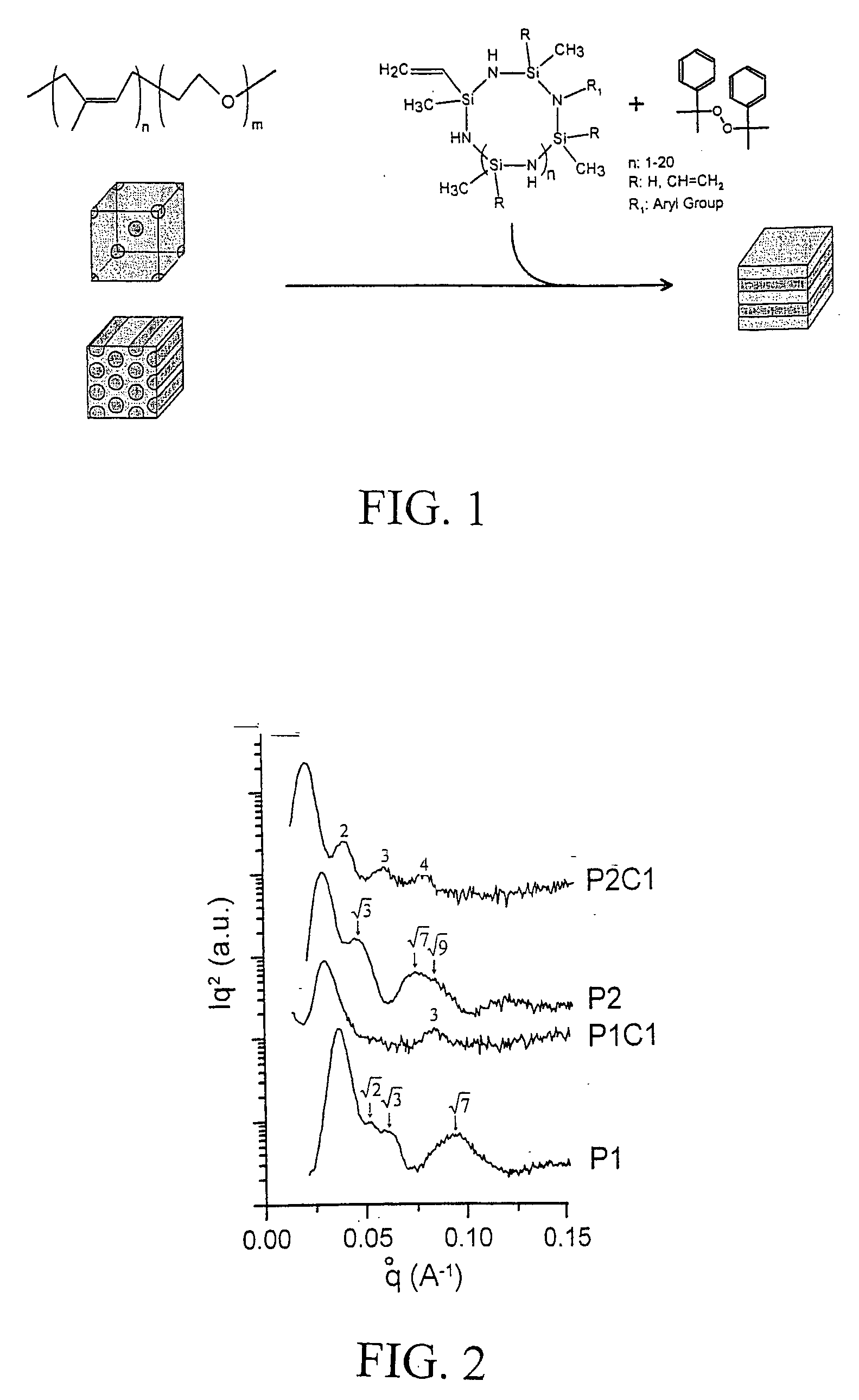

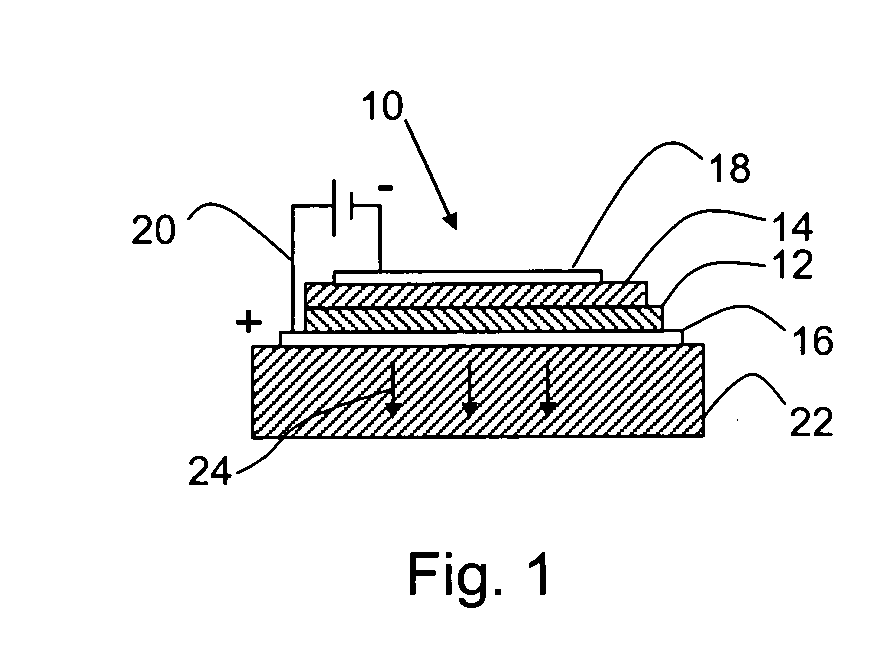

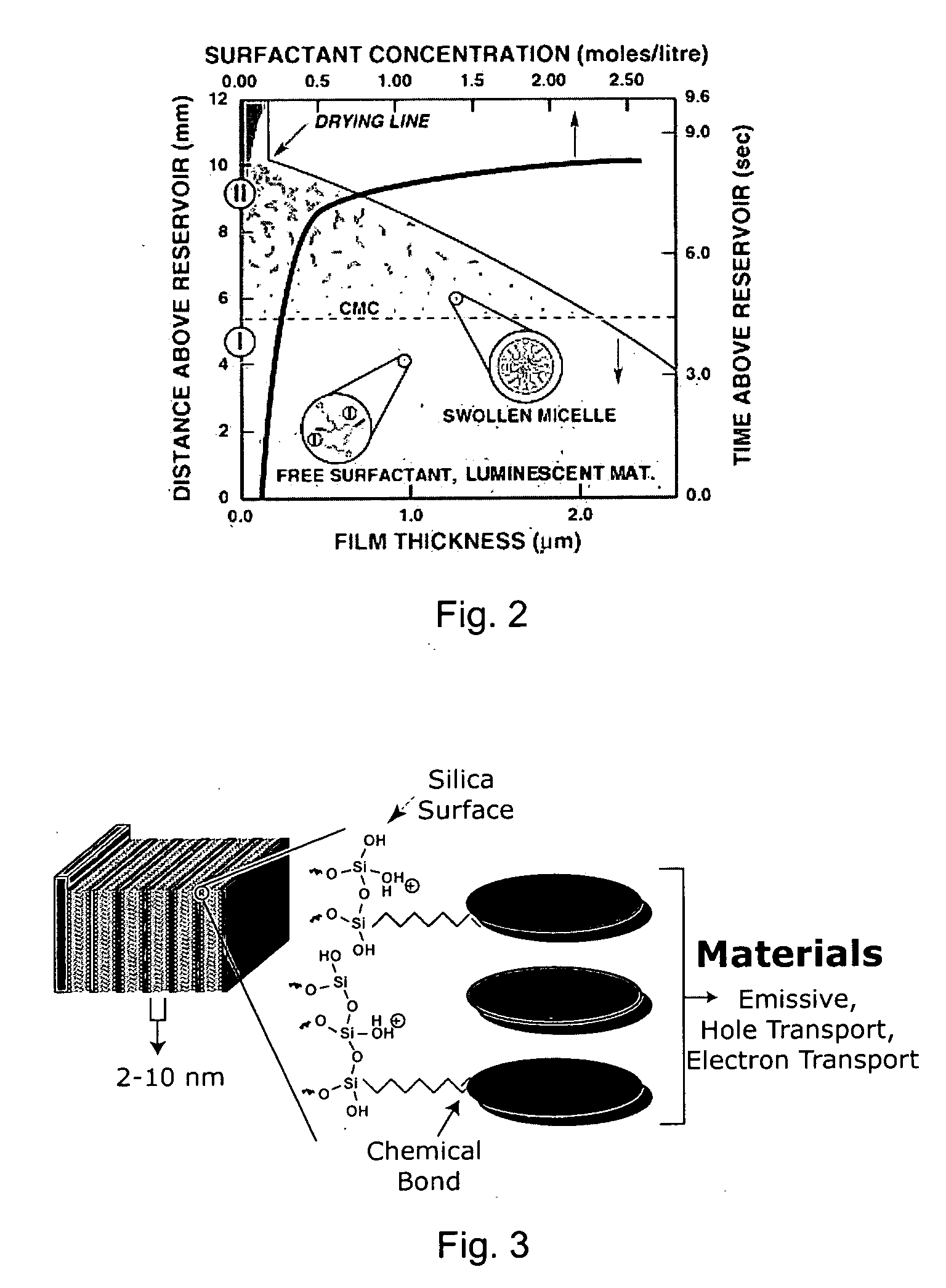

Self-assembly of organic-inorganic nanocomposite thin films for use in hybrid organic light emitting devices (HLED)

InactiveUS20050019602A1Improve light emission efficiencySuperior device lifetimeSolid-state devicesSemiconductor/solid-state device manufacturingLiquid crystallineElectronic transmission

A self-assembly process for preparing luminescent organic-inorganic nanocomposite thin films is disclosed. A homogeneous solution in water and an organic solvent is obtained containing a soluble silicate, a silica coupling agent, a surfactant, and an organic material having a hole transport, electron transport, and / or emissive material moiety. The silica coupling agent is selected to chemically react with the organic material. A film of the homogeneous solution is deposited onto a substrate. Preferentially evaporating the organic solvent enriches the concentration of water and non-volatile solution components to promote micelle formation. Organic materials migrate into the hydrophobic portion of the forming micelles. Continued evaporation promotes self-assembly of the micelles into interfacially organized liquid crystalline mesophases. Reacting the organic material and silica coupling forms a nanostructure self-assembly. Luminescent ordered nanocomposite structures prepared by the process, and organic-inorganic HLED devices fabricated from the luminescent organic-inorganic nanocomposite structures are disclosed.

Owner:CANON KK

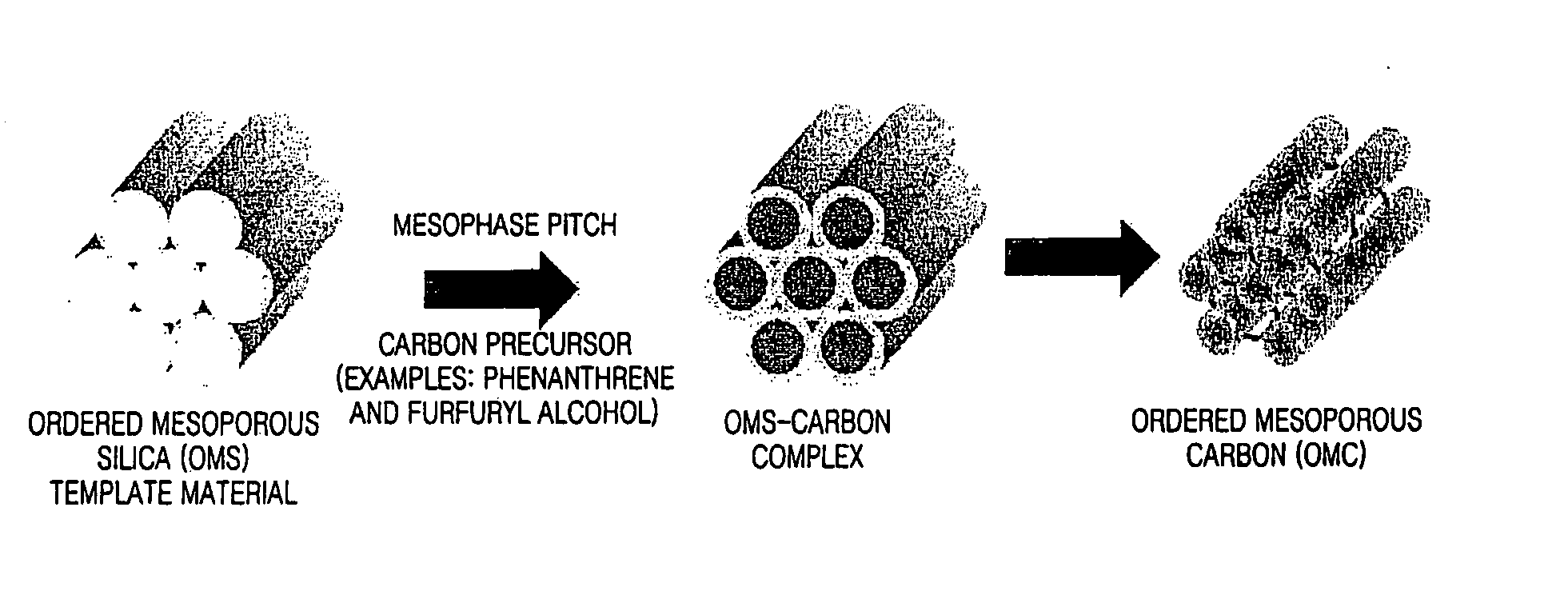

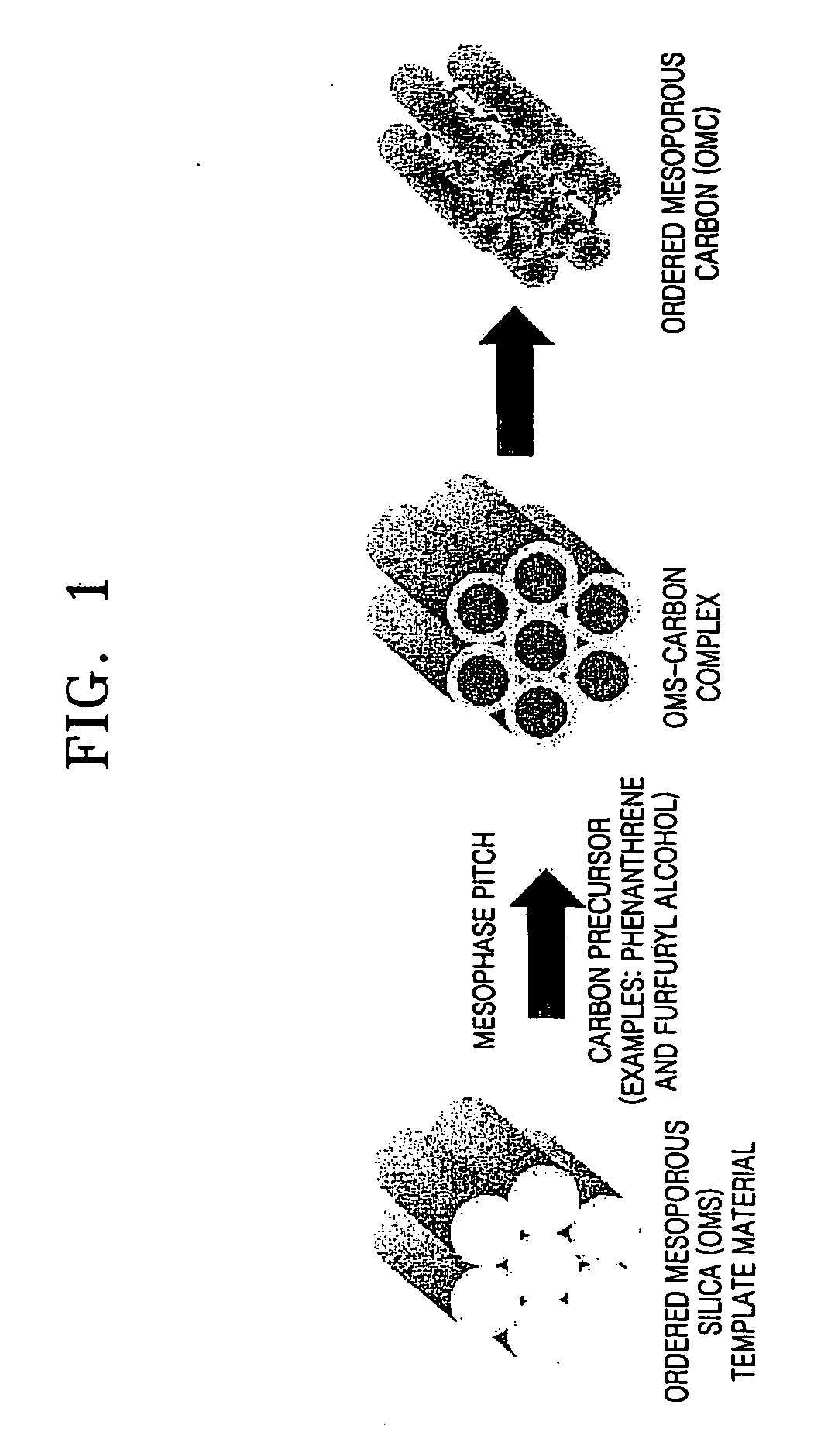

Mesoporous carbon, manufacturing method thereof, and fuel cell using the mesoporous carbon

InactiveUS20070116625A1Improve efficiencyMaterial nanotechnologyMolecular sieve catalystsCarbon compositesFuel cells

A method of preparing a mesoporous carbon includes mixing a mesophase pitch, a carbon precursor, an acid, and a solvent to obtain a carbon precursor mixture; impregnating an ordered mesoporous silica (OMS) with the carbon precursor mixture; heat-treating and carbonizing the impregnated OMS to form an OMS-carbon composite; and removing the OMS from the OMS-carbon composite. The mesoporous carbon uses the mesophase pitch and the carbon precursor to reduce sheet resistance, and thus can efficiently transfer electric energy. Such mesoporous carbon can be used as a conductive material of electrodes for fuel cells. When the mesoporous carbon is used as a support for catalysts of electrodes, a supported catalyst containing the support can be used to manufacture a fuel cell having high efficiency.

Owner:SAMSUNG SDI CO LTD

Carbon foam, graphite foam and production processes of these

A carbon foam obtained by heat-treating a mesophase pitch whose softening point is 300° C. or less according to an elevated flow tester, whose ratio (Daromatic / Daliphatic) of the absorption intensity of an aromatic C-H stretching vibration, measured with FT-IR, to the absorption intensity of an aliphatic C-H stretching vibration, measured with FT-IR, is 4.0 or less and whose optically anisotropic content is at least 80%, a graphite foam obtained by heat-treating the carbon foam recited above at a temperature of 2,000° C. or higher and production processes of these.

Owner:MITSUBISHI GAS CHEM CO INC

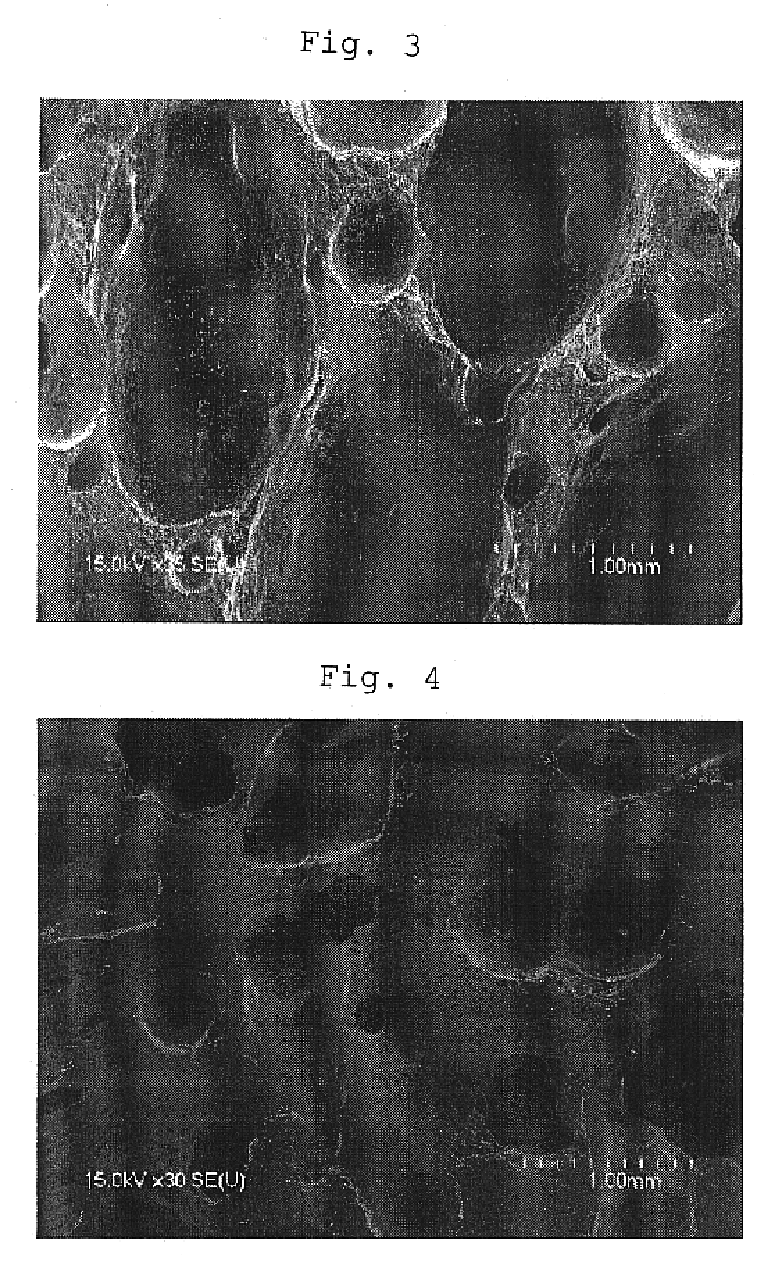

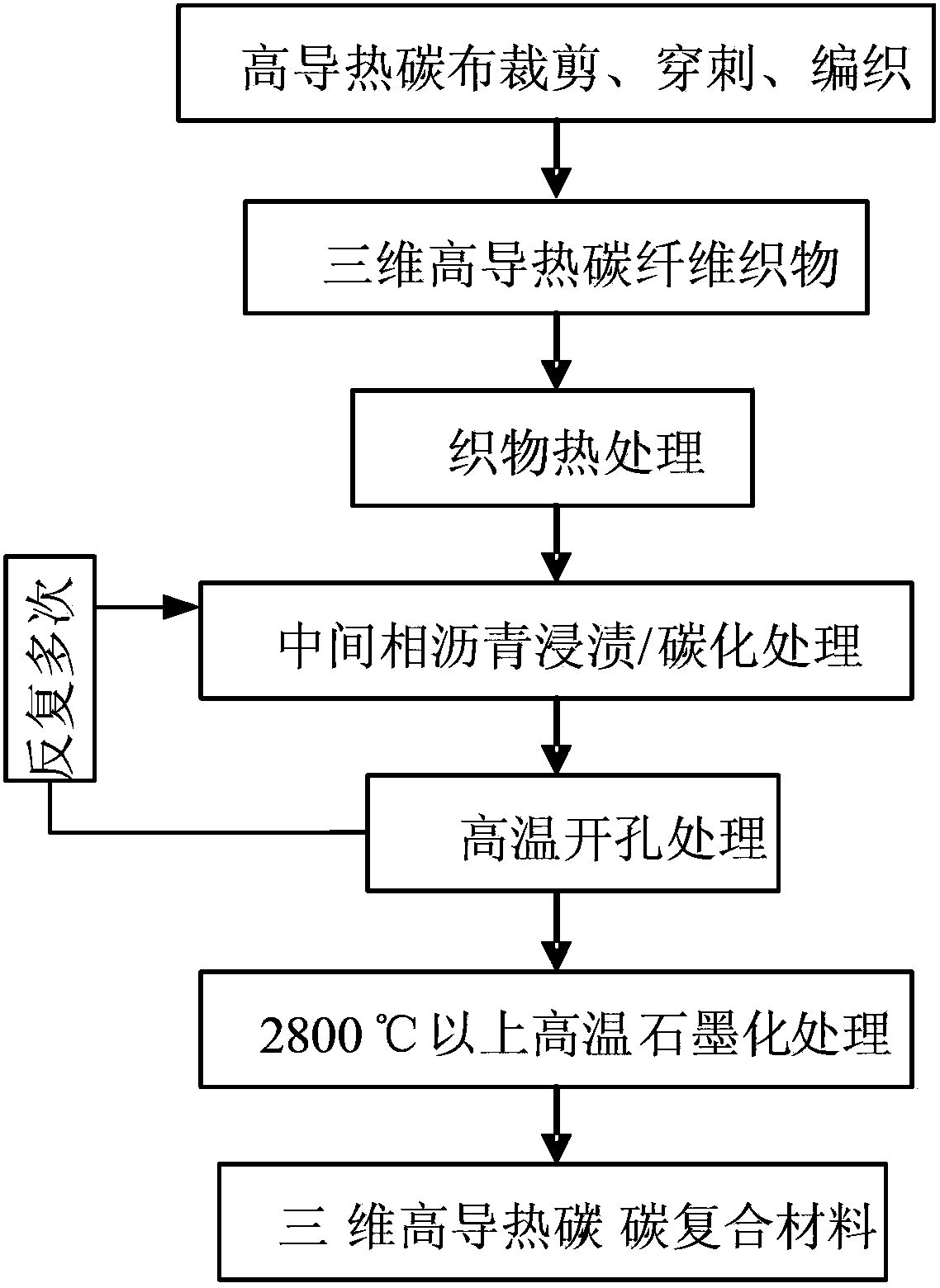

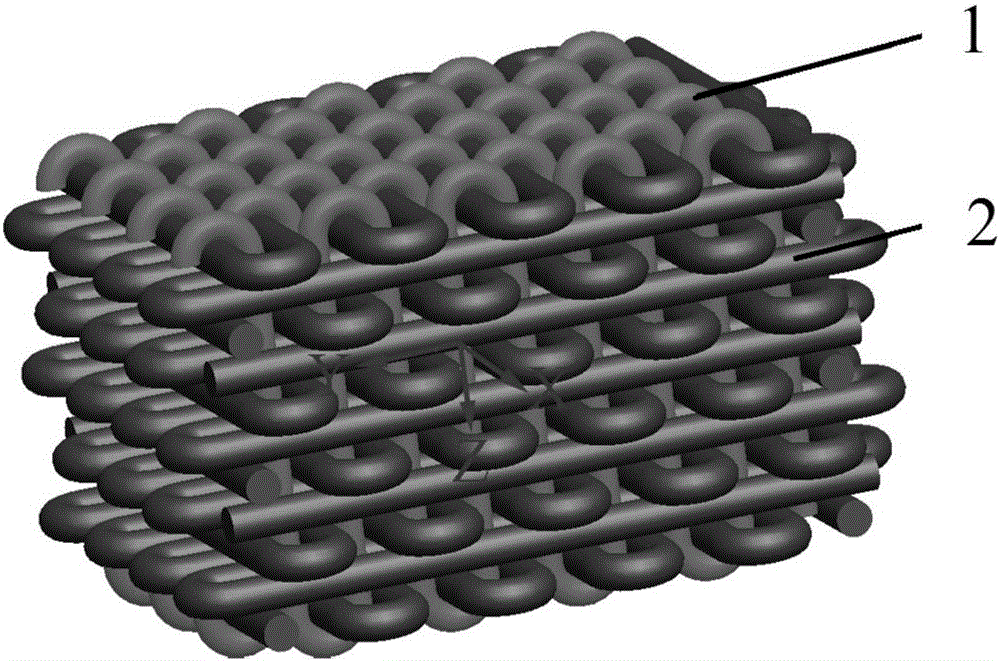

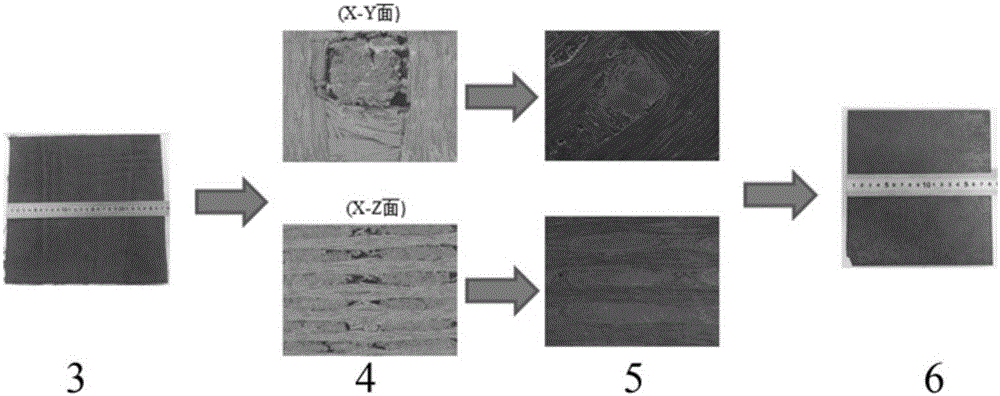

Three-dimensional mesophase pitch-based carbon/carbon composite material with high heat conductivity and preparation technology thereof

The invention relates to a three-dimensional mesophase pitch-based carbon / carbon composite material with high heat conductivity and a preparation technology thereof. The preparation technology comprises the following steps: firstly, by taking a mesophase pitch-based carbon fiber cloth with high heat conductivity as a reinforced body in the XY direction and a high-modulus carbon fiber as a reinforced fiber in the Z direction, preparing three-dimensional carbon fiber fabric with high heat conductivity by adopting a carbon cloth puncturing technology; secondly, by taking mesophase pitch as a precursor of matrix carbon, performing densifying treatment on the three-dimensional carbon fiber fabric with high heat conductivity by adopting a dipping / carbonizing technology; finally, performing graphitization treatment at a high temperature of 2800 DEG C above on the obtained materials, so as to obtain the three-dimensional mesophase pitch-based carbon / carbon composite material with high heat conductivity. Through the adoption of the technology method, the heat conductivity, modulus and dimensional stability of the carbon / carbon composite material are greatly improved, and the highest heat conductivity reaching 3600 w / mK of the material in the XY direction is increased by more than 5 times as compared with the common three-dimensional carbon / carbon composite material.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Method for preparing spherical active carbon employing water soluble bitumen

InactiveCN103693641ALow priceWide variety of sourcesCarbon compoundsSpray GranulationActivated carbon

The invention discloses a method for preparing spherical active carbon employing water soluble bitumen. The method comprises the following processes: washing commercial sulfonated asphalt to obtain a complete water-soluble material; preparing a bituminous solution from the obtained water-soluble material or water-soluble mesophase pitch and deionized water; carrying out spray granulation on the bituminous solution, so as to obtain a bituminous ball; carbonizing and activating the bituminous ball, so as to obtain the spherical active carbon. The method has the advantages that the commercial sulfonated asphalt and the water-soluble mesophase pitch are adopted, so that the spherical active carbon is low in price and wide in source, no organic solvent is added in the balling process, the bituminous ball is controllable in particle size distribution, the prepared spherical active carbon is large in specific surface area, and industrial production is easy to achieve.

Owner:TIANJIN UNIV

SnAgAu solder bumps, method of manufacturing the same, and method of bonding light emitting device using the same

ActiveUS20050072835A1Improve thermal stabilityHigh melting pointLaser detailsSemiconductor/solid-state device detailsEngineering physicsLight emitting device

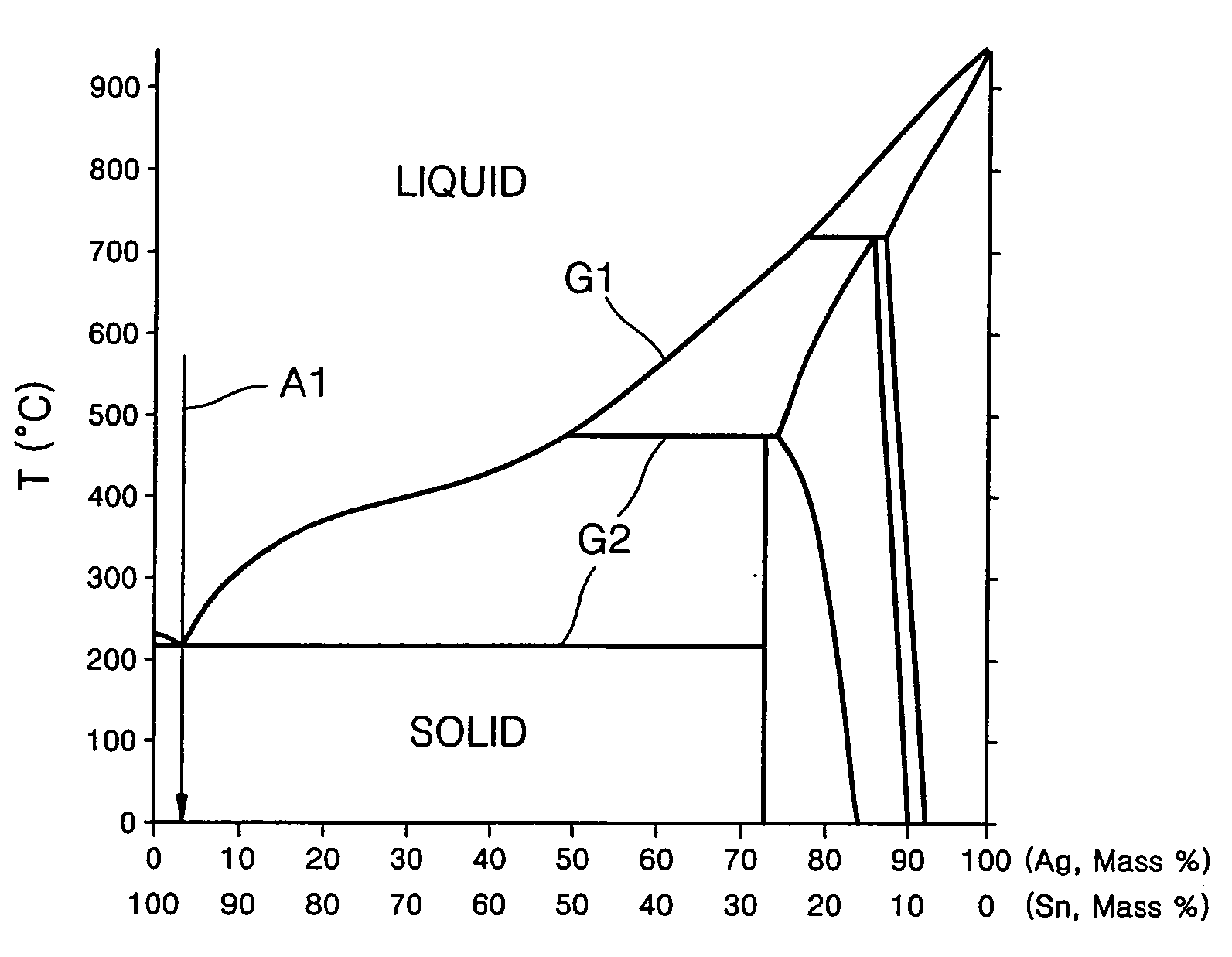

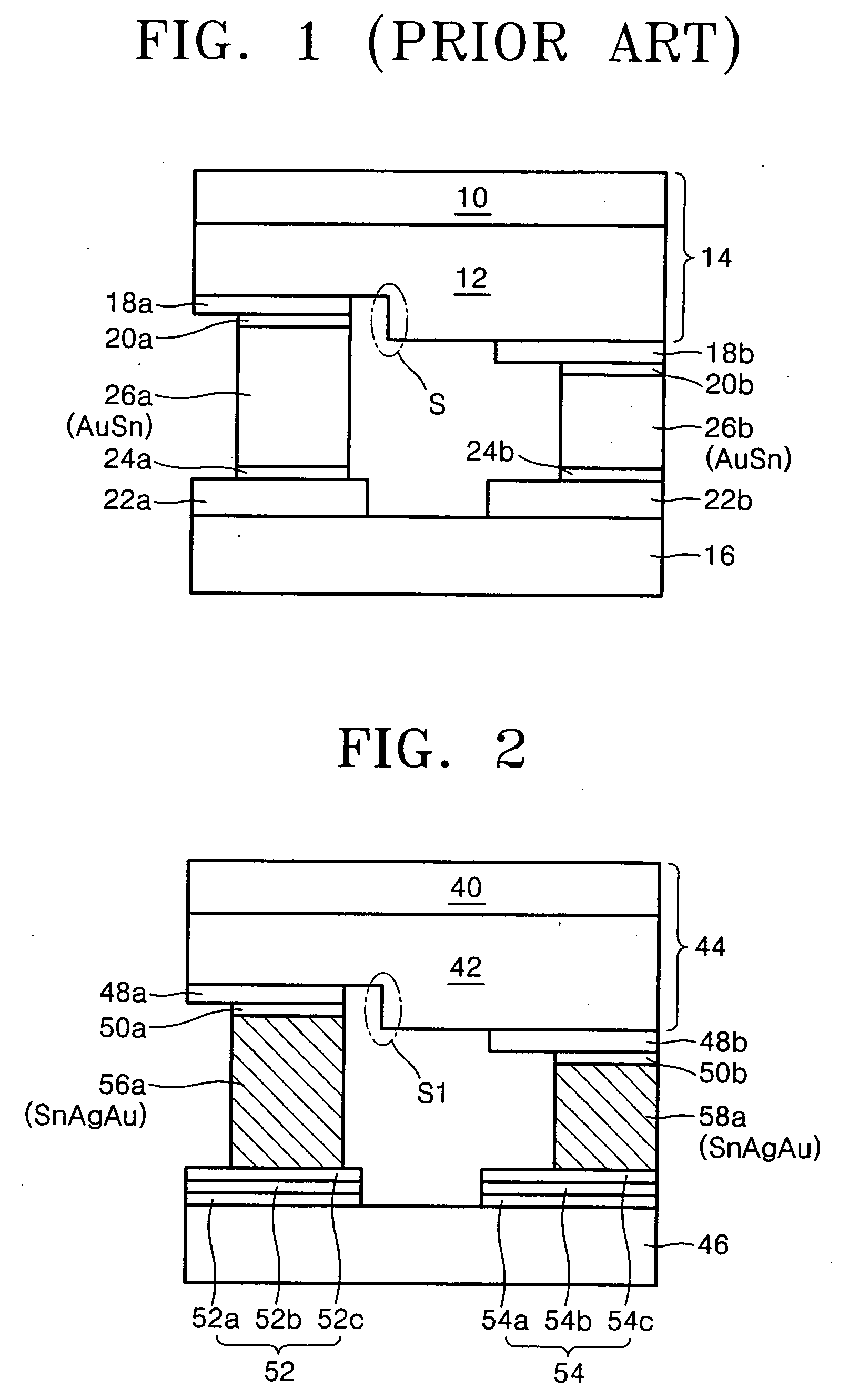

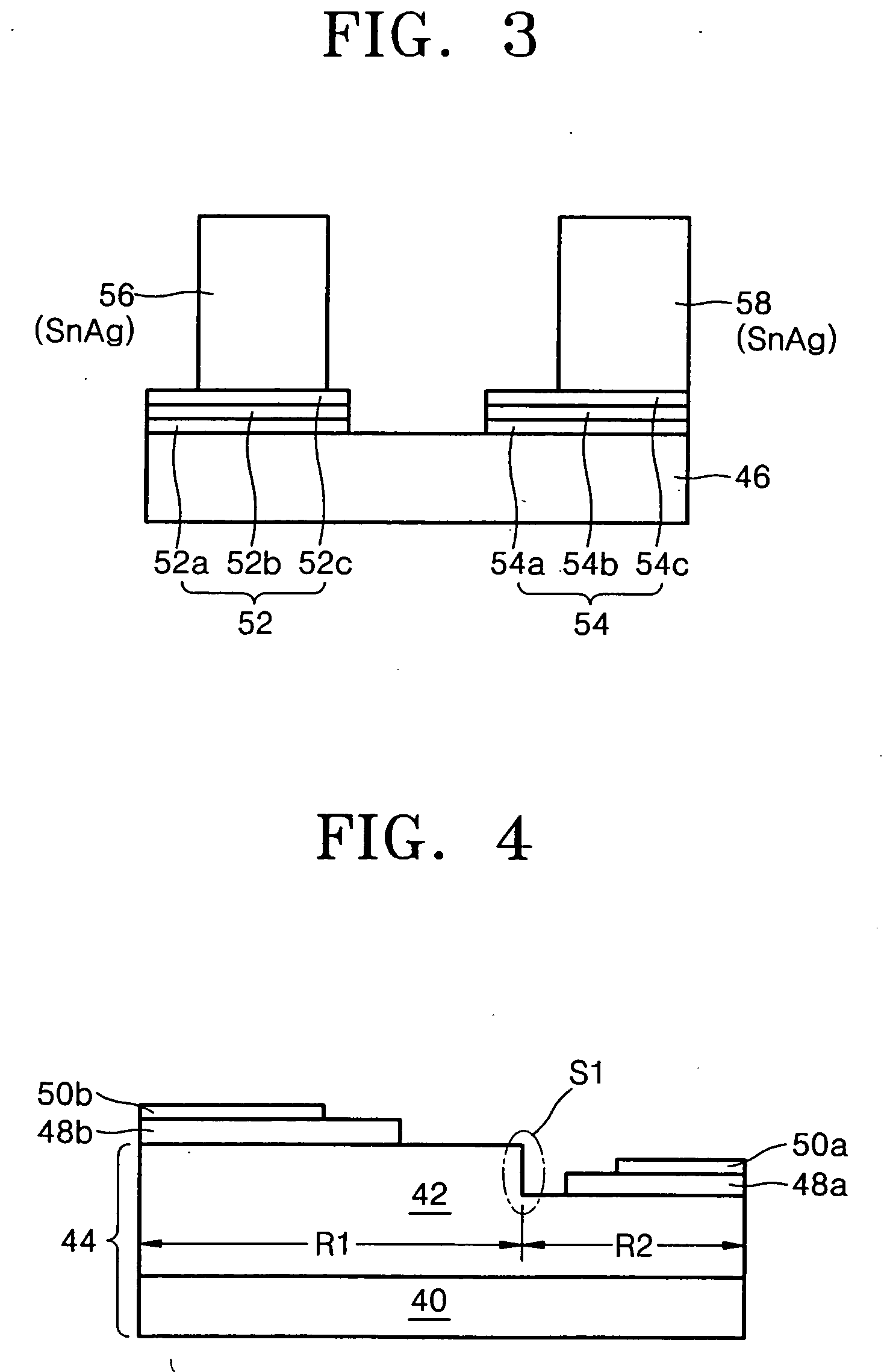

Provided are a solder bump, a method of manufacturing the same, and a method of bonding a light emitting device using the method of manufacturing the solder bump. In particular, the solder bump is formed of a compound including a first element through a third element, in which the first and third elements together form a compound having a plurality of intermediate phases and solidus lines.

Owner:SAMSUNG ELECTRONICS CO LTD

Mesophase-pitch-based carbon fiber and preparation method thereof

The invention discloses a mesophase-pitch-based carbon fiber and a preparation method thereof. The preparation method comprises the steps of conducting mesophase pitch polymerization, modification and visbreaking, conducting centrifugal spinning, conducting hot jetting drafting, conducting oxidation, carbonization and graphitization, and obtaining the mesophase-pitch-based carbon fiber. The diameter of the mesophase-pitch-based carbon fiber ranges from 120 nm to 2000 nm, the draw ratio is 500-20000: 1, the tensile strength is 1.5-4.0 GPa, the tensile modulus is 300-600 GPa, the electrical resistivity is less than 0.2 * 10 <-4> omega.cm, the thermal conductivity is 500-800 W / m.k, and the mesophase-pitch-based carbon fiber is low in fabrication cost and can be applied to fields such as static electricity resistance, heat dissipation, electromagnetic shielding and heat shielding.

Owner:ANHUI HONGCHANG NEW MATERIAL CO LTD

Mesophase pitch and preparation method thereof

ActiveCN104004536AHigh carbon contentModerate carbon-hydrogen ratioWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionOrganic solventSolvent

The invention provides a method for preparing mesophase pitch from direct coal liquefaction residues. The method mainly comprises the following steps: 1, extracting the direct coal liquefaction residues by using an organic solvent I to obtain extracted pitch; 2, dissolving the extracted pitch by using a polar organic solvent II, and carrying out solvent recovery on the soluble part to obtain refined pitch; 3, carrying out thermal polycondensation on the obtained refined pitch at a high temperature to obtain a thermal polycondensation product; and 4, carrying out reduced pressure flash evaporation on the thermal polycondensation product to obtain the mesophase pitch. The invention also provides the mesophase pitch. The spinnable indexes of the mesophase pitch are characterized in that the softening point, the aromatic carbon rate and the quinoline insoluble substance content of the mesophase pitch are 250-280DEG C, not lower than 0.9 and 35-45% respectively.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Electrode, lithium battery having the electrode, and method of manufacturing the same

ActiveUS7005211B2Improve thermal stabilityExcellent cycle characteristicsNon-aqueous electrolyte accumulatorsFinal product manufactureEngineeringFluorinated polymer

Owner:SAMSUNG SDI CO LTD

Method of preparing carbon fiber by using coal to directly liquefy residue-based asphalt vinyl material

InactiveCN102733008AEfficient use ofSimple preparation routeFibre chemical featuresCarbon fibersSorbent

The method of the present invention provides a Method of preparing a spinnable mesophase and carbon fiber by using coal to directly liquefy residue-based asphalt vinyl material. According to the invention, the residue-based asphalt vinyl material which is subjected to direct coal liquefaction as a raw material, and the method comprises the following steps: grinding the asphalt vinyl material, and then placing in a high temperature tube type furnace or a high pressure reaction kettle under the inert gas protection, and preparing under the temperature of 200-500 DEG C and the pressure of 0.1-10 MPa to obtain the spinnable mesophase, performing processes of melt spinning, preoxidation and carbonization treatment on the mesophase to prepare the carbon fiber. The invention has the advantages of simple preparation method, conventional equipment, cheap raw material, good product quality and environmental protection, and is a method for high-value utilization of coal resource. The prepared carbon fiber can be used for high performance aerospace materials, adsorbents with high efficiency, separating agents, catalysts and catalyst carriers and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for producing activated carbon for electrode of electric double-layer capacitor

InactiveUS7214646B1Solve the small densityFacilitated DiffusionHybrid capacitor electrolytesHybrid capacitor electrodesActivated carbonAtmospheric air

To produce activated carbon for an electrode of an electric double-layer capacitor, the following steps are carried out sequentially: a step of subjecting a massive mesophase pitch to a pulverizing treatment to provide a pulverized powder; a step of subjecting the pulverized powder to an infusibilizing treatment under conditions of a temperature in a range of 300° C. (inclusive) to 450° C. (inclusive) in the atmospheric air current, a step of subjecting the pulverized powder to a carbonizing treatment under conditions of a temperature in a range of 600° C. (inclusive) to 900° C. (inclusive) in an inert gas current to provide a carbonized powder, a step of subjecting the carbonized powder to an alkali activating treatment under conditions of a temperature in a range of 500° C. (inclusive) to 1,000° C. (inclusive) in an inert gas atmosphere, followed by the post treatments, thereby producing alkali-activated carbon, and a step of subjecting the alkali-activated carbon to a pulverizing treatment. If an electrode is produced using the activated carbon, the electrode density can be increased.

Owner:HONDA MOTOR CO LTD +1

Solid activated carbon, process for manufacturing the same and electric double layer capacitor using the same

Disclosed is a solid activated carbon and a process for manufacturing the solid activated carbon which is particularly suitable for electrode materials used in an electric double layer capacitor and various batteries. The use of the solid activated carbon makes it possible to prepare an activated carbon substrate having high mechanical strength and practical capacitance while the content of activated carbon is high. The solid activated carbon comprises an activated carbon powder and / or an activated carbon fiber, a carburized substance of a PVA or a resin derived from PVA, and a PVA or a resin derived from PVA. The process for manufacturing the solid activated carbon comprises, molding a molding material consisting of an activated carbon powder and / or an activated carbon fiber, a PVA or a resin derived from PVA or a mixture of a PVA or a resin derived from PVA and a mesophase using a known molding method, aging the molded compact in air and heat-treating the aged compact in a non-oxidizing atmosphere.

Owner:KYOCERA CORP

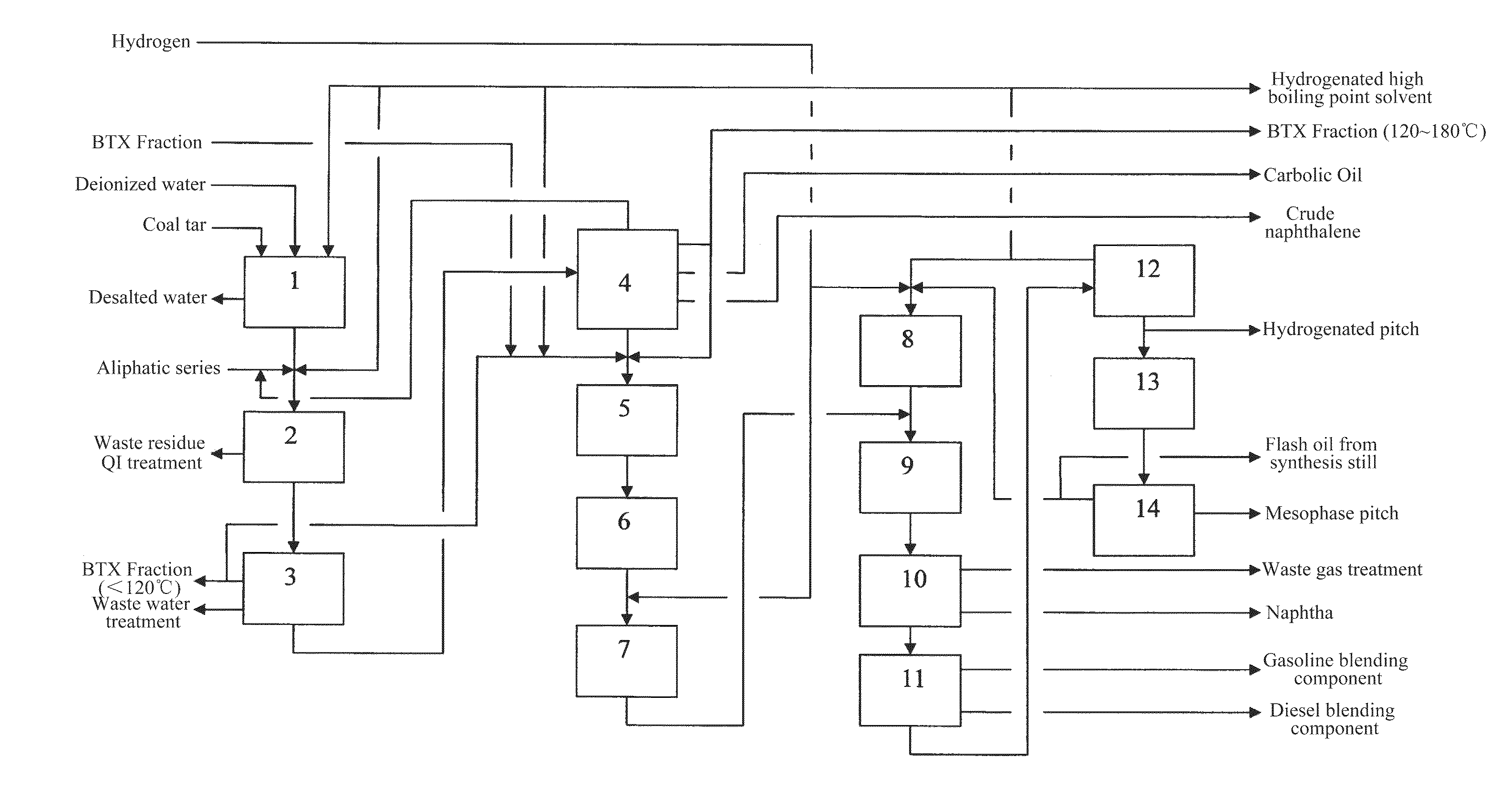

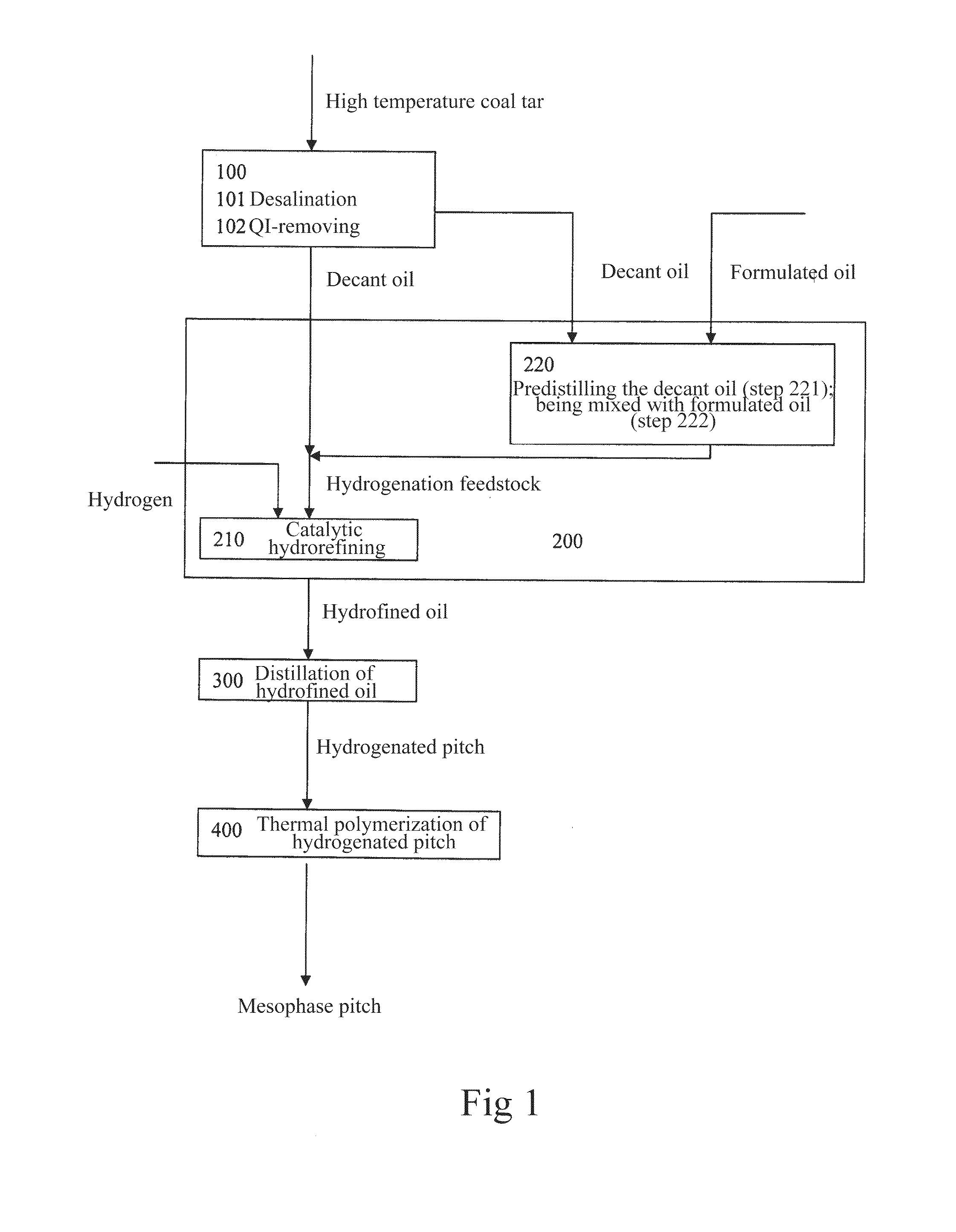

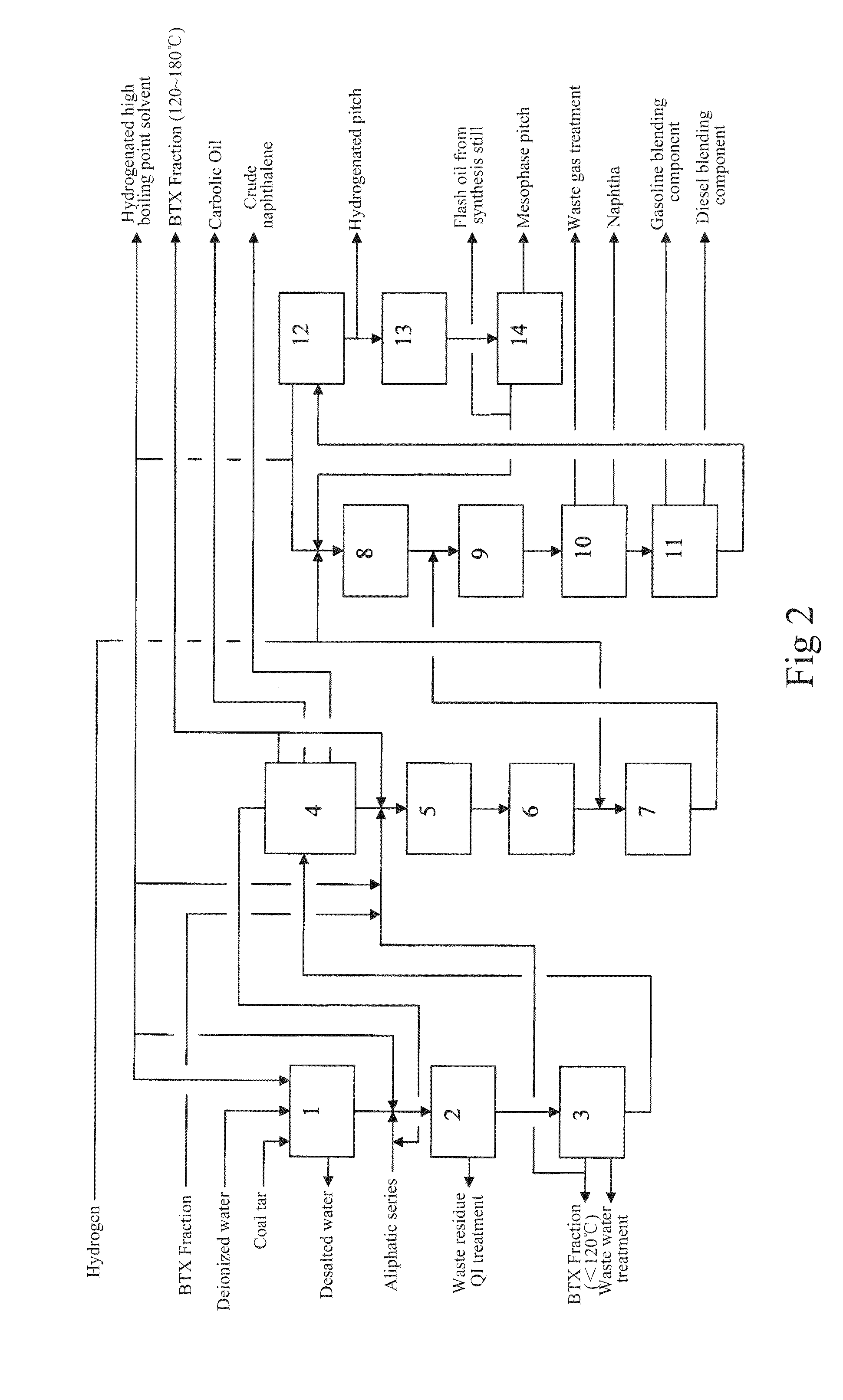

Process for Producing Mesophase Pitch by Hydrogenation of High-temperature Coal Tar

ActiveUS20150076031A1Increase H/C ratioHigh content of mesophase pitchWorking-up pitch/asphalt/bitumen by distillationLiquid hydrocarbon mixtures productionBoiling pointCoal tar

A process for producing mesophase pitch from high-temperature coal tar comprises: removing salts and quinoline insoluble fraction from a high-temperature coal tar to obtain a decant oil; using the decant oil as a hydrogenation feedstock, or pre-distilling the decant oil to obtain a residue with a boiling point higher than 230 and formulating the residue into a hydrogenation feedstock; catalytic hydrorefining the hydrogenation feedstock to obtain a hydrofined oil; distilling the hydrofined oil to obtain hydrogenated pitch; and subjecting the hydrogenated pitch to the thermal polymerization to obtain the mesophase pitch. The process has features such as an easily controllable degree of hydrogenation, complete removal of impurities, good raw material flowability, not tending to form the carbon deposition and the coking during the process, and not tending to jam the reactor. The product has a high content of mesophase pitch, a low softening point and a low impurity content.

Owner:ECO CARBON MATERIALS HLDG (SHENZHEN) CO LTD +1

Method for preparing mesophase pitch through catalytic cracking oil slurry hydroisomerization and thermal condensation

ActiveCN105238430ALimit excessive aggregationDelay or prevent the formationWorking-up pitch/asphalt/bitumen by chemical meansWide areaSlurry

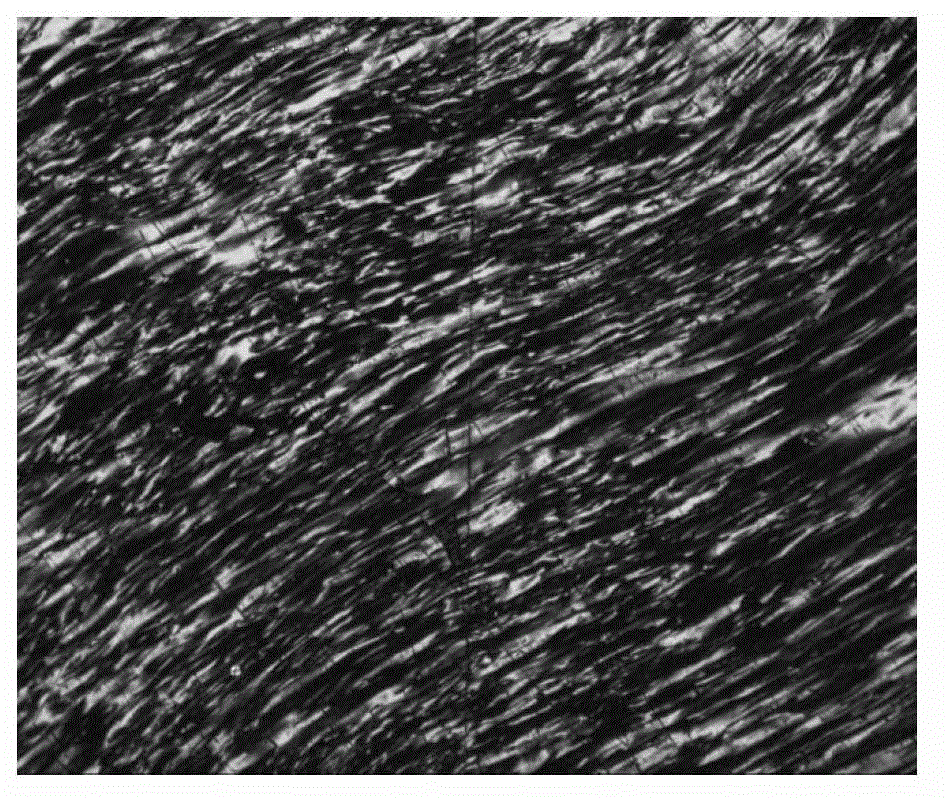

The invention provides a method for preparing mesophase pitch through catalytic cracking oil slurry hydroisomerization and thermal condensation. The method comprises the steps that FCC oil slurry of naphthenic crude oil or intermediate base crude oil and distillate oil which is obtained at the temperature higher than 400 DEG C through vacuum distillation serve as the raw materials, on the condition that a hydroisomerization catalyst exists, the temperature ranges from 250 DEG C to 320 DEG C, the pressure is 5 MPa, reaction is conducted for 4-8 h, and the modified raw materials are obtained. Continuous reaction is conducted on the modified raw materials for 2-10 h at the temperature ranging from 330 DEG C to 460 DEG C and at the pressure of 12 MPa, and the mesophase pitch with the high quality is obtained. According to the method for preparing the mesophase pitch through catalytic cracking oil slurry hydroisomerization and thermal condensation, the preparation technology is simple, the production cost is low, the prepared mesophase content is high and greater than 97 percent, the softening point is low, the temperature ranges from 230 DEG C to 250 DGE C, the large-wide-area linear flow optical anisotropic structure is achieved, and the spinnability is good.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Process for the production of needle coke

ActiveUS20050284793A1Yield minimizationPromote formationThermal non-catalytic crackingTreatment with plural serial cracking stages onlyGraphite electrodeBoiling point

A process is disclosed for producing needle coke from heavy atmospheric distillation residues having sulfur no more than 0.7 wt %, which process involves the steps of heating the feedstock to a temperature in the range of 460 to 540° C. for thermal cracking in a soaking column under pressure in the range of 1 to 10 kg / cm2 to separate the easily cokable material, separating the cracked products in a quench column and a distillation column and then subjecting the hydrocarbon fraction from the bottom of the quench column and a heavy gas oil fraction having 10% true boiling point more than 370° C. and 90% true boiling point not less than 480° C. from the distillation column and / or any other suitable heavier hydrocarbon streams in a definite ratio depending on certain characteristic parameters to thermal cracking in a second soaking column at a temperature of 440 to 520° C., pressure in the range of 2 to 20 kg / cm2 in presence of added quantity of steam for formation of a mesophase carbonaceous structure which on steam stripping and cooling forms a solid crystalline coke suitable for manufacturing of graphite electrode of large diameter having co-efficient of thermal expansion lower than 1.1×10−6 / ° C. measured on graphite artifact in the temperature range of 25 to 525° C.

Owner:INDIAN OIL CORPORATION

Method for preparing binder-free graphite product

The invention provides a method for preparing a binder-free graphite product, which is characterized in that the graphite product is composed of crude petroleum coke and coal pitch mesophase pellet powder, and is characterized by comprising the following steps: drying, dewatering and smashing the crude petroleum coke; grinding the smashed crude petroleum coke to obtain crude petroleum coke powder by using a ball mill and an airflow pulverizer in sequence; heating the coal pitch mesophase pellet powder to carry out pre-oxidation treatment; cooling to room temperature; fully mixing by a blender; charging under vibration and preforming; placing blended power into a hydraulic cylinder, and obtaining isostatic pressing graphite green bodies through the steps of boosting pressure, maintaining pressure, reducing pressure and demoulding in an isostatic pressing forming process; placing the isostatic pressing graphite green bodies into an iron crucible; taking river sand and metallurgical coke powder as fillers in the roasting process, wherein the fillers are used for preventing the products from oxidization and deformation and fixing green body shapes; putting the iron crucible filled with the isostatic pressing graphite green bodies into a roasting furnace for roasting treatment to obtain isostatic pressing graphite roasting products after roasting; carrying out graphitization treatment on the isostatic pressing graphite roasting products by using a graphitized furnace to obtain the binder-free graphite products.

Owner:JILIN CARBON

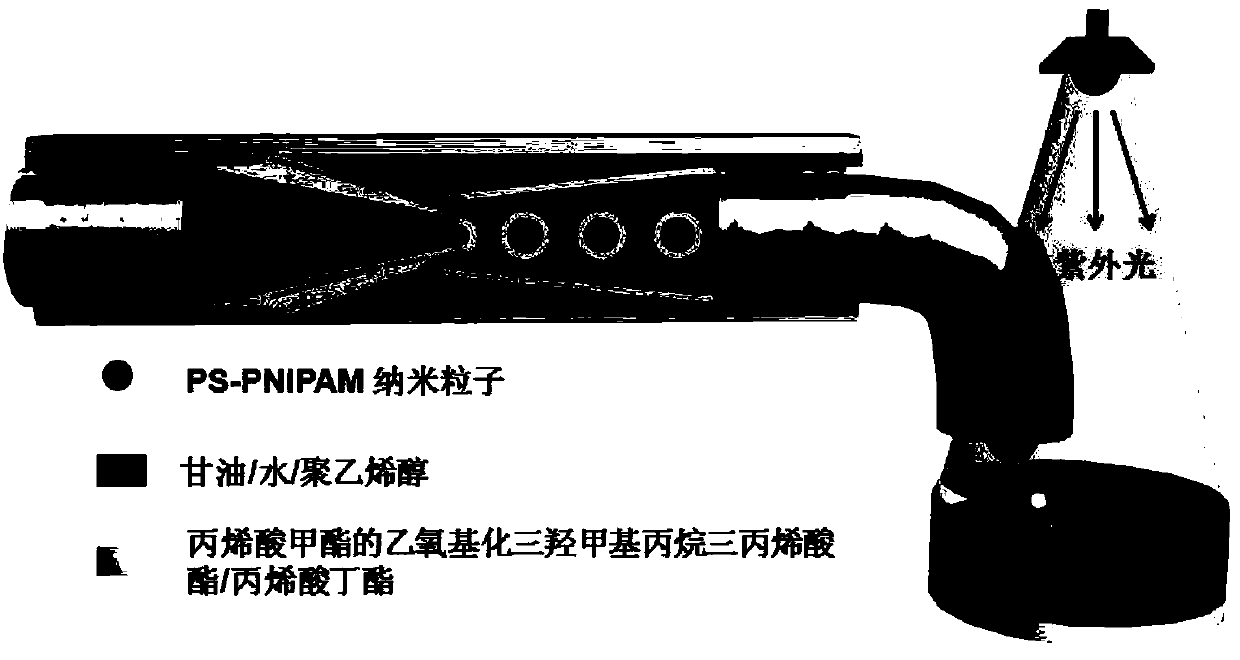

Photonic crystal microsphere as well as preparation method and application thereof

ActiveCN104193906AGood optical performanceThin thickness and high light transmissionFluorescence/phosphorescencePhotoinitiatorDodecylsulfonic acid

The invention discloses a photonic crystal microsphere as well as a preparation method and an application thereof. The photonic crystal microsphere comprises a photonic crystal inner core and a polymer outer shell, wherein the inner core is a suspension of polystyrene-poly(N-isopropyl acrylamide)polymer nanoparticles, the average particle diameter of the nanoparticles is between 110nm and 190nm; and the outer shell is hydrophobic photoinitiator resin of which the thickness is between 30mu m and 50 mu m. The preparation method comprises the following steps: (1) evenly mixing styrene, N-isopropyl acrylamide and sodium dodecyl sulfate with an initiator and carrying out emulsion polymerization reaction to obtain the suspension; (2) forming monodispersed emulsion droplets with core-shell structures under the action of the shearing force of an aqueous solution of a continuous phase by virtue of a microfluidic control technique, wherein the suspension is adopted as an internal phase, the resin monomer and an initiator system are adopted as intermediate phases; and (3) polymerizing and curing the resin monomer by virtue of UV irradiation. The photonic crystal microsphere is applied in bio-molecule detection and coding and has the advantages of good stability, bright color and high recognition.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method of carbon/carbon composite material with high heat conduction

ActiveCN105967715AImprove thermal conductivityOvercoming Poor Weavable PerformanceCarbon compositesCarbonization

The invention discloses a preparation method of a carbon / carbon composite material with high heat conduction. The method comprises the following steps: a mesophase asphalt based carbon fiber which is treated by low temperature carbonization at 350-500 DEG C is prepared into an X-Y directional orthogonal paving layer whose thickness is 5-50mm by a winding method; a piece of PAN based carbon fiber carbon cloth is used for clamping the upper and lower surfaces of the asphalt based carbon fiber paving layer, bundles of the PAN based carbon fiber are used for carrying out puncture at a Z direction of the layer, and a three dimensional orthogonal fiber prefabricated body is obtained. High temperature carbonization and graphitization heat treatment are carried out, and a prefabricated body of the carbon / carbon composite material with high heat conduction is prepared. The carbon fiber prefabricated body is primarily densified to 1.30-1.60g / cm<3>, and the PAN based carbon fiber carbon cloth layers on the surface are removed; liquid phase infiltration pyrolysis is carried out, the material is densified to 1.70-2.10g / cm<3>, and finally the heat conductivity coefficient of the carbon / carbon composite material at X or Y direction is 200-350W / (m.K), and bending strength is 100-250MPa.

Owner:湖南东映碳材料科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com