Patents

Literature

88results about How to "Simple preparation route" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of preparing carbon fiber by using coal to directly liquefy residue-based asphalt vinyl material

InactiveCN102733008AEfficient use ofSimple preparation routeFibre chemical featuresCarbon fibersSorbent

The method of the present invention provides a Method of preparing a spinnable mesophase and carbon fiber by using coal to directly liquefy residue-based asphalt vinyl material. According to the invention, the residue-based asphalt vinyl material which is subjected to direct coal liquefaction as a raw material, and the method comprises the following steps: grinding the asphalt vinyl material, and then placing in a high temperature tube type furnace or a high pressure reaction kettle under the inert gas protection, and preparing under the temperature of 200-500 DEG C and the pressure of 0.1-10 MPa to obtain the spinnable mesophase, performing processes of melt spinning, preoxidation and carbonization treatment on the mesophase to prepare the carbon fiber. The invention has the advantages of simple preparation method, conventional equipment, cheap raw material, good product quality and environmental protection, and is a method for high-value utilization of coal resource. The prepared carbon fiber can be used for high performance aerospace materials, adsorbents with high efficiency, separating agents, catalysts and catalyst carriers and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

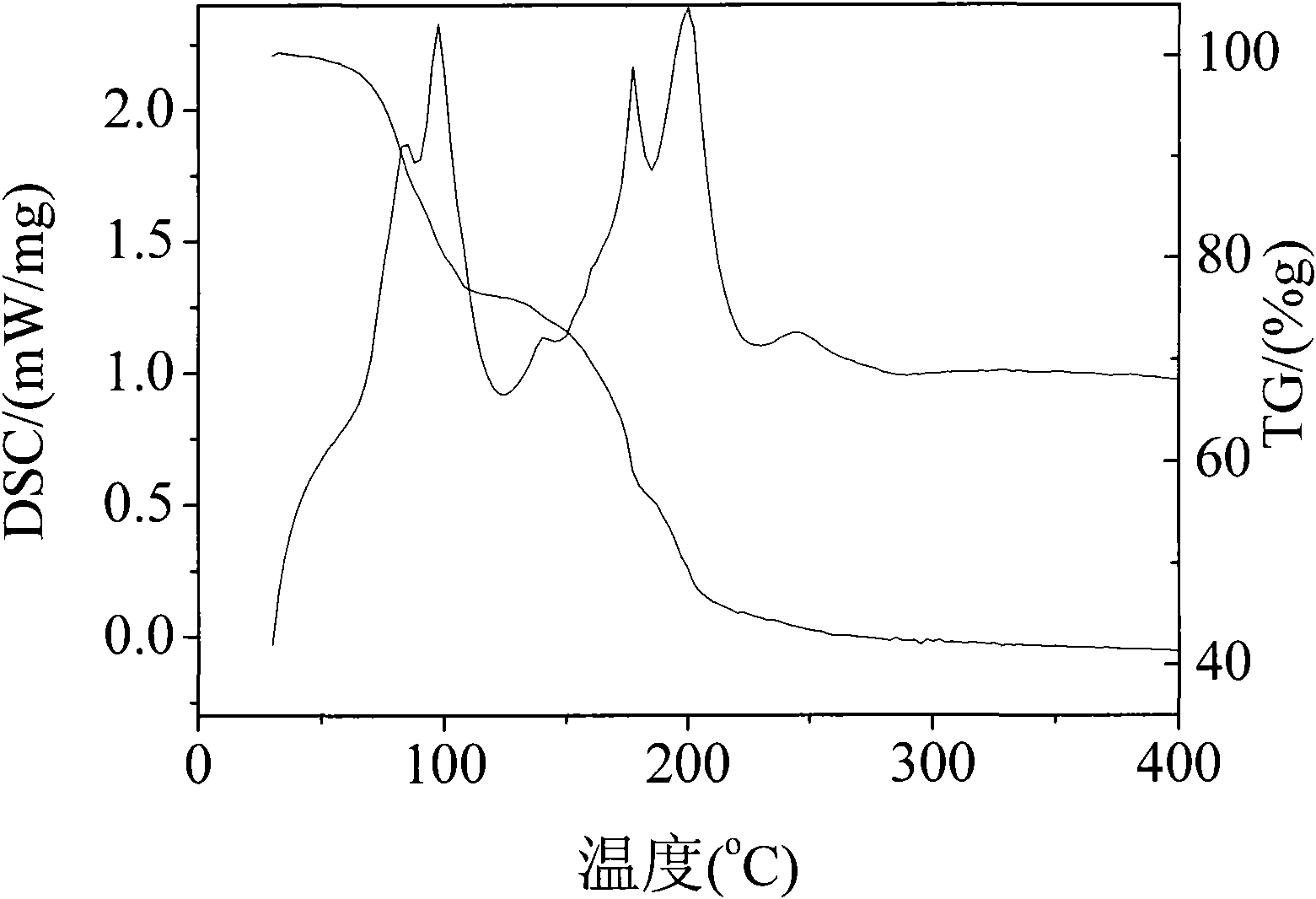

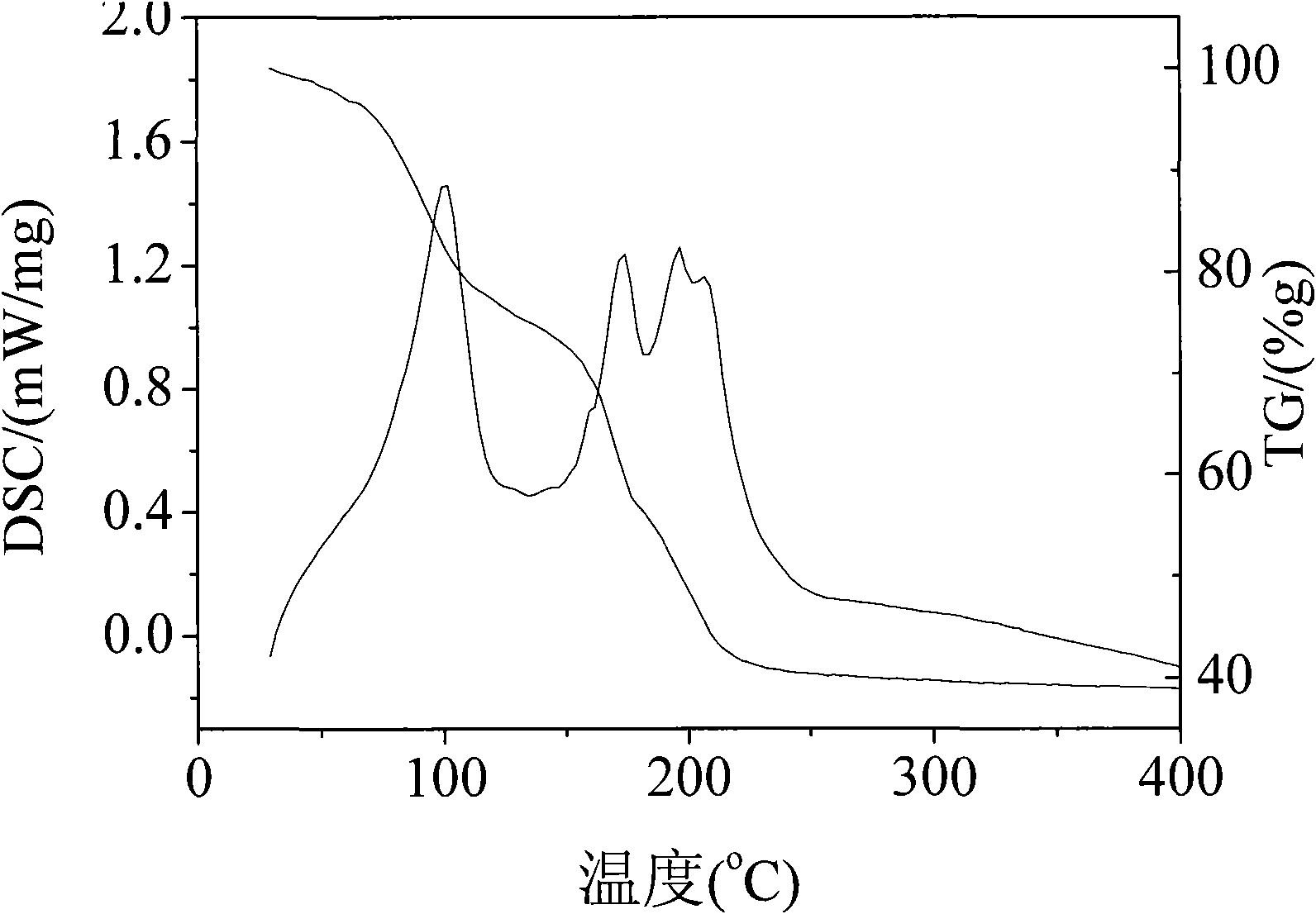

Spherical magnesium halide alcohol polymer as well as preparation method and application thereof

The invention relates to a catalyst component for olefinic polymerization particularly for propylene polymerization or copolymerization, in particular to a novel alcohol polymer containing three components of magnesium halide, alcohol and polyester and an application of the alcohol polymer in the preparation of an olefin polymerization catalyst. When a catalyst prepared by using the alcohol polymer as a carrier is used for the olefinic polymerization, particularly the propylene polymerization, the catalyst shows better polymerization activity, and a polymer has higher isotacticity. The catalyst is used in the field of petrochemical engineering.

Owner:CHINA PETROLEUM & CHEM CORP +1

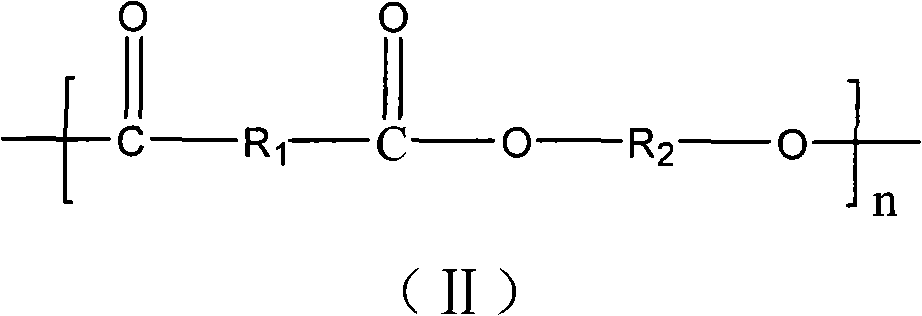

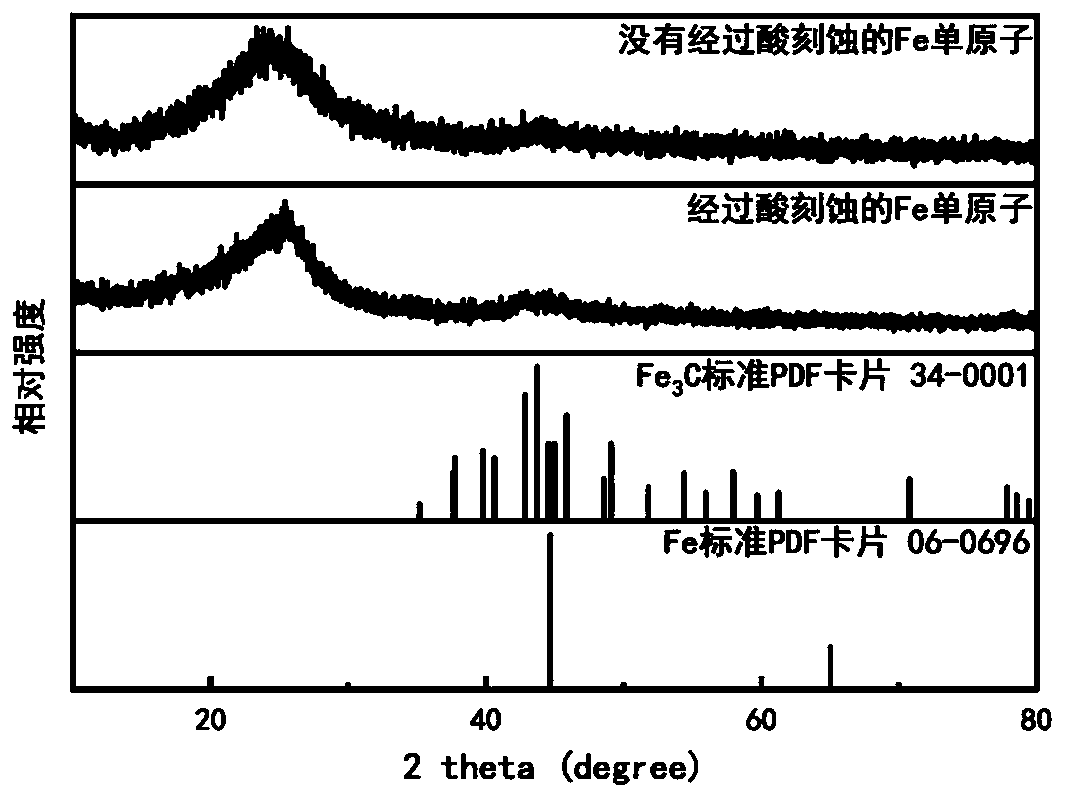

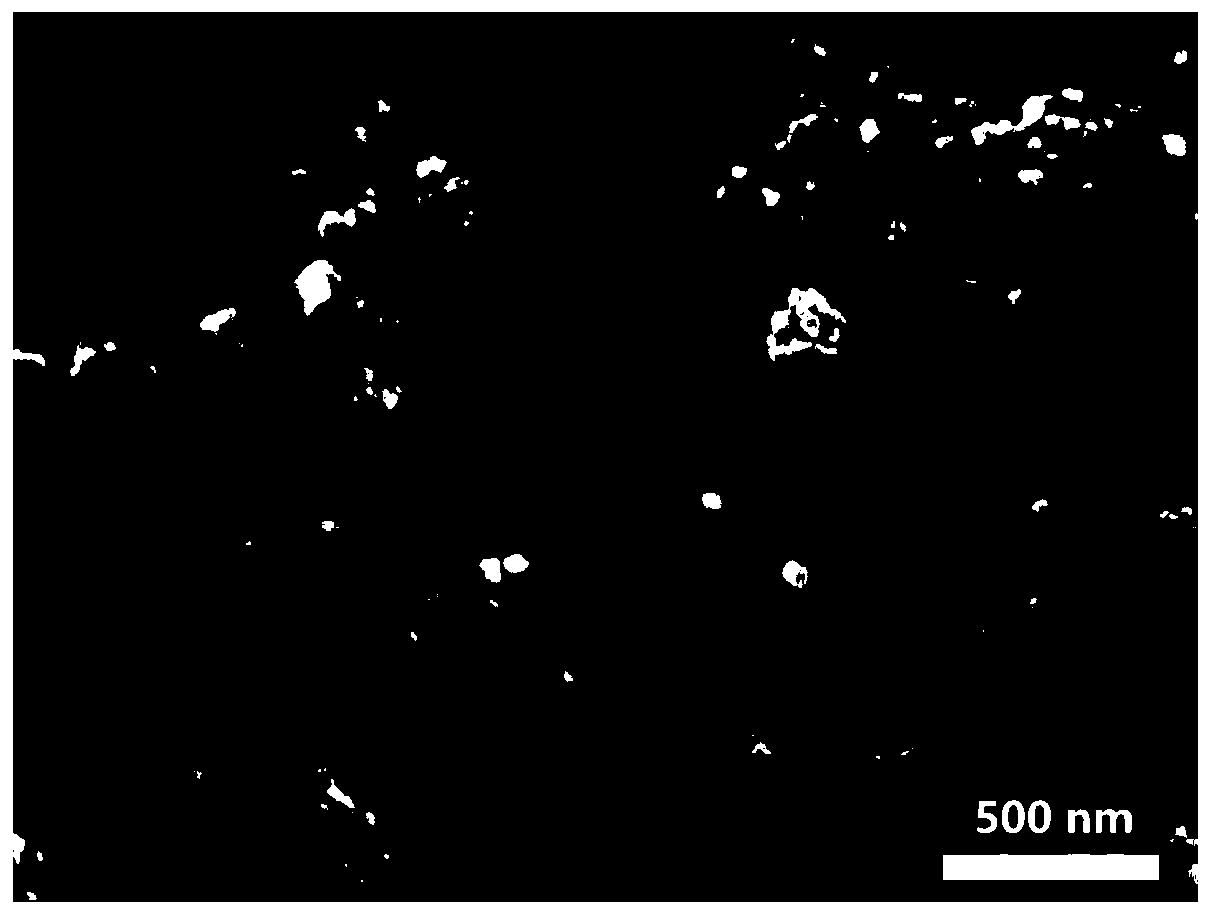

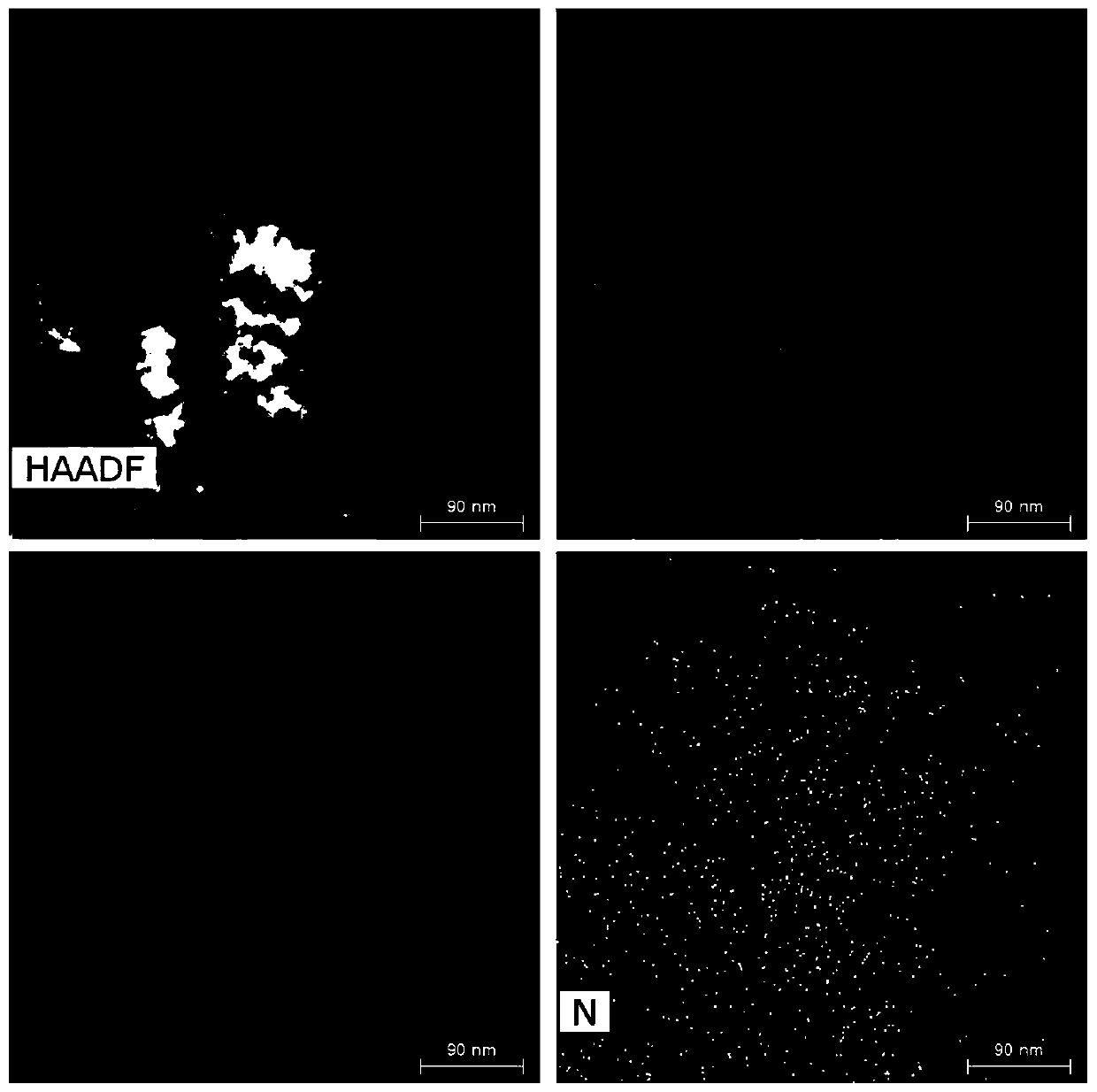

Preparation method and applications for metal monoatomic material

InactiveCN110860289AEasily control the loadImprove performanceMetal/metal-oxides/metal-hydroxide catalystsElectrodesPhysical chemistryMaterials science

The invention provides a preparation method and applications for a metal monoatomic material. The method selects a metallic compound containing a metal-nonmetal coordination structure; destruction toa catalytically active structure can be effectively prevented through a processing mode of performing pyrolysis after the metallic compound, a protective agent and any carbon substrates are simply mixed; and therefore, the metal monoatomic material can be efficiently prepared and shows good performance. The technical route of the method is simple and effective and has universality and good application prospects.

Owner:CENT SOUTH UNIV

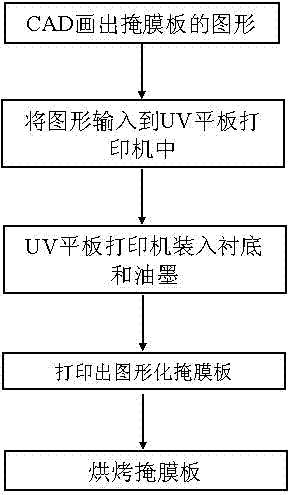

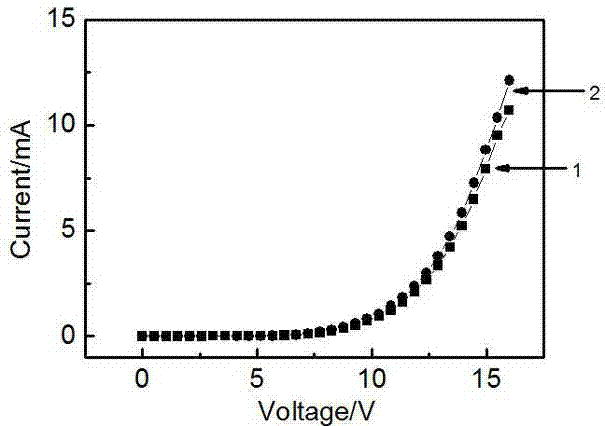

UV-curing ink and method for preparing masking plate by using ink

InactiveCN104710869ASimple preparation routeFast trackInksOriginals for photomechanical treatmentSemiconductor electrodeCooking & baking

The invention belongs to the technical field of semiconductor manufacture, and particularly relates to a UV-curing ink and a method for preparing a masking plate using the ink. The UV-curing ink is composed of a photoactive pre-polymer, a photoinitiator, an active monomer, pigment and additives. The UV-curing ink is put into a UV plate inkjet printer; a graphical masking plate is printed on a substrate through the UV plate inkjet printer; the graphical masking plate is put into an oven for baking to prepare the masking plate; and furthermore, electrodes of organic electronic devices are prepared on the masking plate through photolithography. The masking plate prepared by the method in the invention is tidy in appearance edge and smooth in surface, has no stain, is simple in operation process, requires no special technology and special equipment, is suitable for the normal masking plate for manufacturing semiconductor electrodes, and is easy for popularization and use.

Owner:方圆环球光电技术盐城有限公司 +1

Method for preparing electrolyte of vanadium flow battery

InactiveCN102468508ASimple preparation routeLow costRegenerative fuel cellsAqueous solutionSulfuric acid

The invention, belonging to the field of electrochemical engineering and industry, particularly relates to a method for preparing an electrolyte of a vanadium flow battery, comprising the following steps: using soluble vanadate or its solution as a raw material, reacting deposits obtained by reducing pentavalent vanadium through adding a reducing agent in a neutral or alkaline solution with vanadate or potassium vanadate in a sulfuric acid solution, or precipitating vanadate in an acid solution and then reacting with the reducing agent in the sulfuric acid solution, to prepare an aqueous solution having a sulfuric acid concentration of 1-6 mol / L and a total vanadium concentration of 1-5 mol / L. The electrolyte can be directly used as the electrolyte of positive and negative electrode of the vanadium flow battery. The method has the advantages of few operation steps, simple process, and stable quality, and is especially suitable for the application of vanadium flow batteries.

Owner:NO 63971 TROOPS PLA

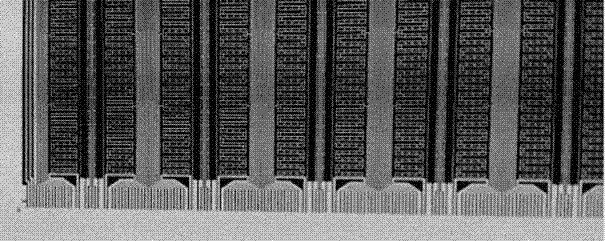

Patterned electrode preparation method

InactiveCN103700784ANeat edgesEasy to operateFinal product manufactureSolid-state devicesEngineeringSemiconductor

The invention belongs to the field of organic electronic devices and particularly relates to a patterned electrode preparation method. The invention adopts the technical scheme as follows: an electrode pattern protection film with oil ink is printed on the substrate of an electrode by a UV flat inkjet printer, the substrate is put into a corrosive liquid to corrode the electrode not protected by the oil ink on the substrate so as to form the patterned electrode on the substrate, the oil ink is removed through ultrasonic washing with the help of deionized water and an alkaline solution, then the patterned electrode is prepared, and the organic electronic device is further prepared on the patterned electrode. The patterned electrode prepared through the method provided by the invention has tidy edges, is not zigzag and simple in operation and does not need special process or equipment, and the patterned electrode preparation method is suitable for manufacturing a metal oxide electrode commonly used for a semiconductor device, and popularization and application are facilitated.

Owner:未名光电盐城有限公司 +1

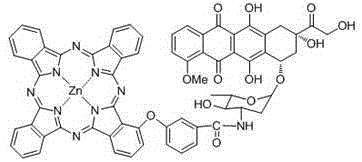

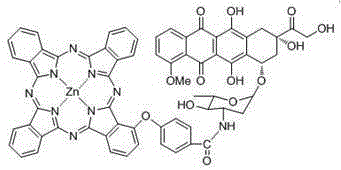

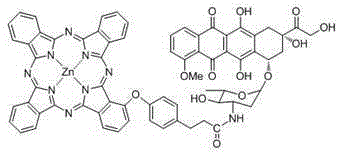

Zinc(II) carboxyl phthalocyanine and adriamycin conjugate and preparation and application thereof

ActiveCN105622682AClear structureImprove stabilityAntibacterial agentsOrganic active ingredientsPhotodynamic therapyPhotosensitizer

The invention discloses a zinc(II) carboxyl phthalocyanine and adriamycin conjugate and preparation and application thereof, and belongs to the field of photosensitizer and drug preparation. A structural formula of the zinc(II) carboxyl phthalocyanine and adriamycin conjugate is (I) or (II) or (III) or (IV) shown in the description. The compound is a novel photosensitive drug and an anti-cancer drug which has the double effects of a photodynamic therapy and chemotherapy. Meanwhile, the product composition is single, the structure is definite, and the preparation technology is simple.

Owner:FUZHOU UNIV

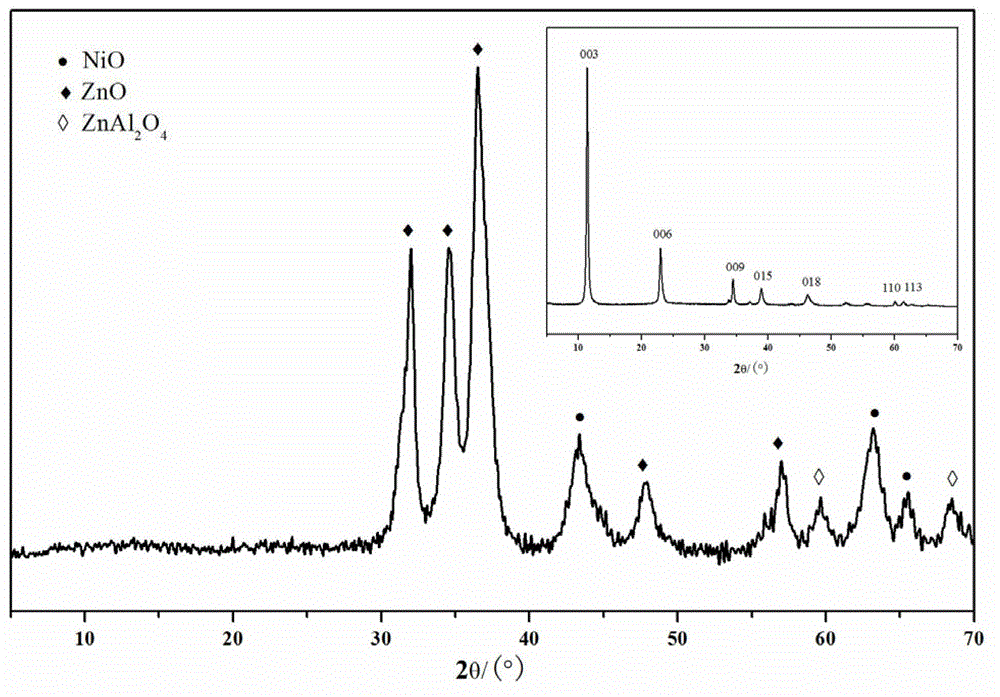

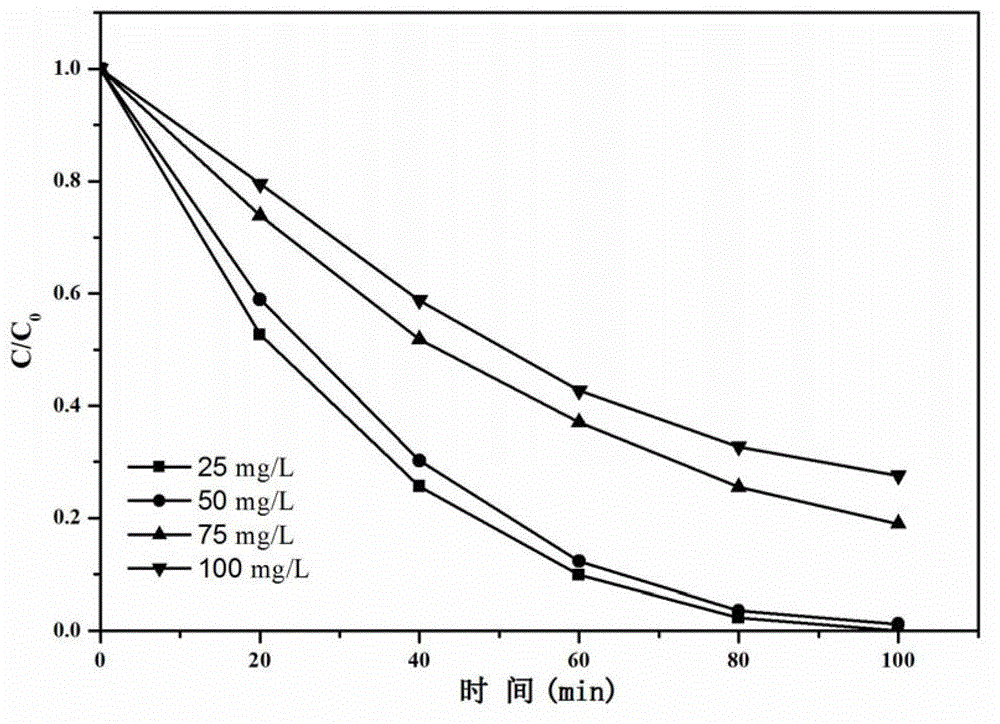

Calcined anionic clay visible-light catalyst and preparation method and purposes thereof

ActiveCN103055872ASimple preparation routeNo strict requirement for airtightnessWater/sewage treatment by irradiationMetal/metal-oxides/metal-hydroxide catalystsDivalent metalWastewater

The invention discloses a calcined anionic clay visible-light catalyst and a preparation method and purposes thereof. The catalyst is prepared by the following steps of preparing mixed solution of metal salts and urea; heating the mixed solution to the temperature of between 100 and 120 DEG, reacting for 36 to 54 h, and obtaining acidic turbid liquid of which the pH value is between 6.0 and 6.5; centrifuging the acidic turbid liquid, taking precipitation out, washing the precipitation by deionized water until the pH value is neutral, and dewatering and drying; and grinding the dried precipitation, calcining the precipitation at the temperature of between 400 and 900 DEG C for 4 to 6 h, and thus obtaining the calcined anionic clay visible light catalyst, wherein the metal salts comprise divalent metal salts and trivalent metal salts. The prepared calcined anionic clay visible light catalyst can catalytically degrade organic wastewater in visible light, ultraviolet light equipment is not required, a feeding ratio is low, the degradation time is short, and the calcined anionic clay visible-light catalyst has low energy consumption and high efficiency and is suitable for the treatment of medium and low-concentration industrial wastewater.

Owner:SOUTH CHINA UNIV OF TECH

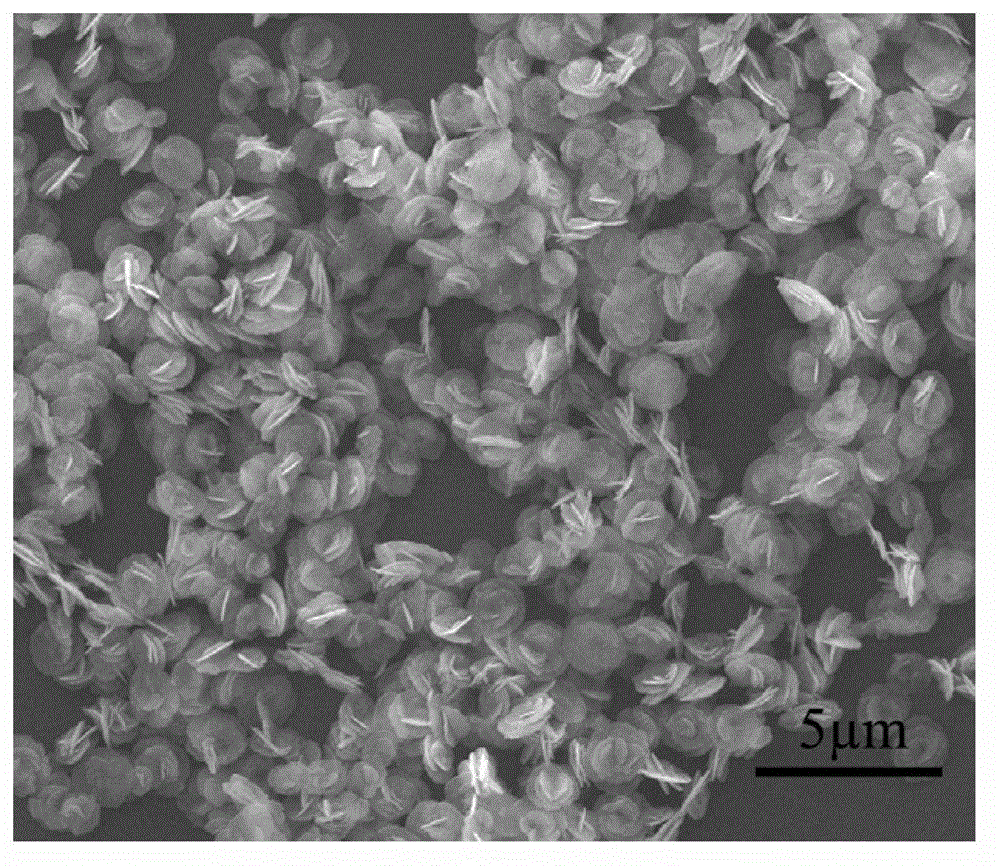

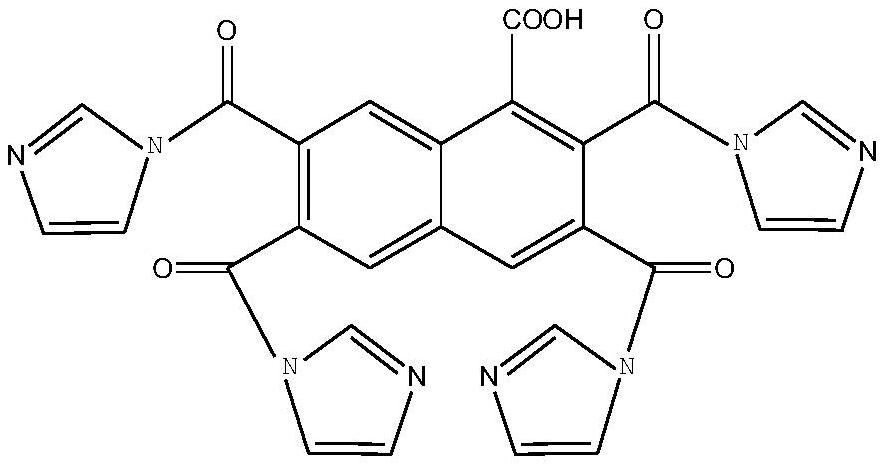

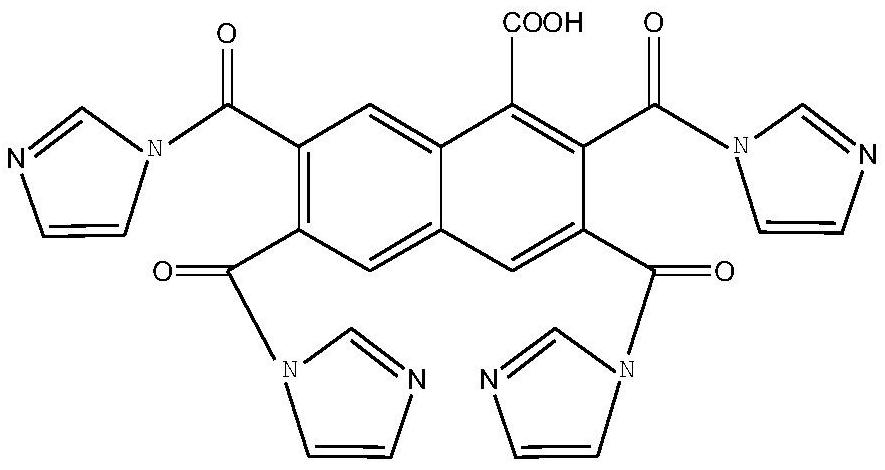

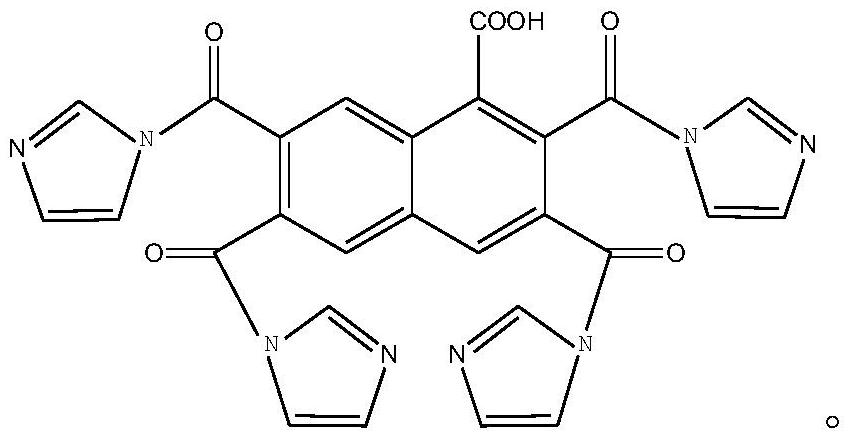

Naphthyl ligand MOF activated carbon composite catalyst and preparation method and application thereof

ActiveCN111905828AReduce vacuumLower temperature conditionsOrganic-compounds/hydrides/coordination-complexes catalystsOrganic chemistry methodsActivated carbonPtru catalyst

The invention provides a naphthyl ligand MOF composite activated carbon catalyst and a method for preparing high-purity lactide from Llactic acid by using the naphthyl ligand MOF composite activated carbon catalyst, which are characterized in that a polymerization reaction of Llactic acid is catalyzed by using an MOF organic metal framework activated carbon composite catalyst, metal elements are used as active components, and 2, 3, 6, 7tetraformyl imidazolyl alpha naphthoic acid is used as an MOF catalyst ligand. Activated carbon is used as carrier. Raw material of the catalyst has the advantages of cheap raw materials, high thermal stability, certain acid resistance, is not easily decomposed under low pressure and easily made. The catalyst has good catalytic activity. The application of the catalyst in synthesis of lactide can greatly reduce vacuum degree required by the process, yield of lactide is increased and industrial cost is reduced. The invention has certain potential in industrial application.

Owner:WANHUA CHEM GRP CO LTD

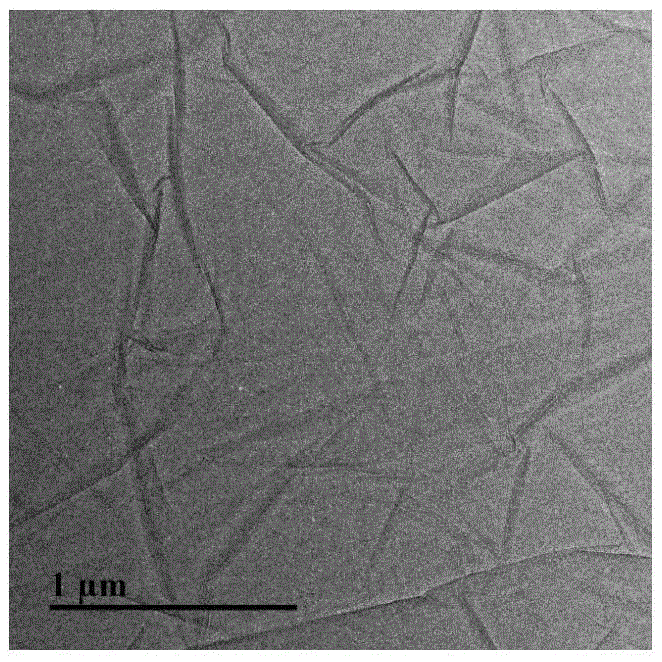

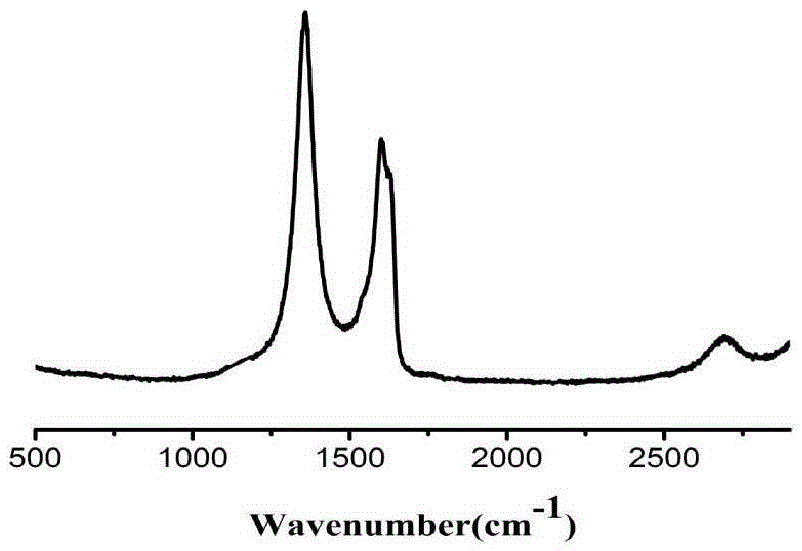

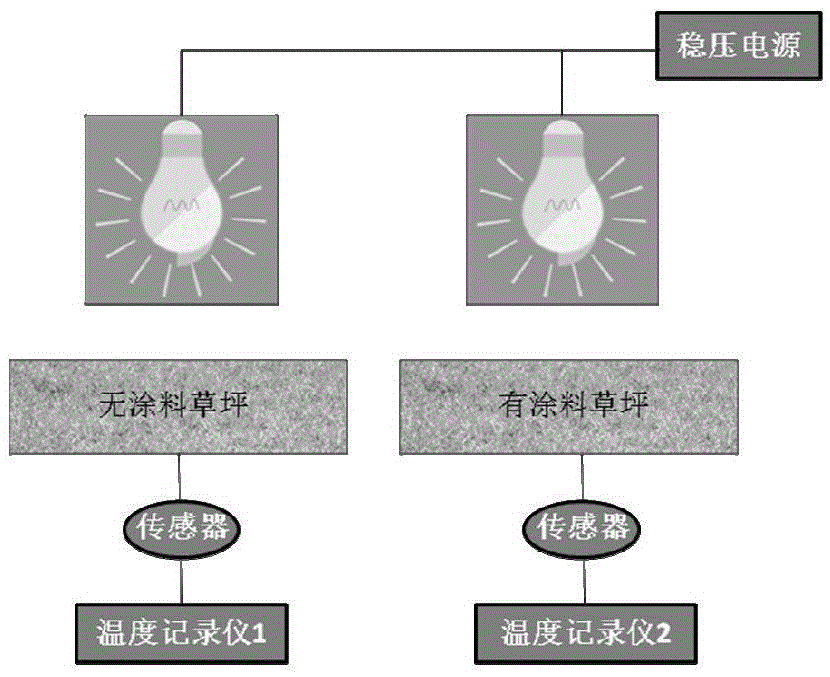

Antibiosis oxidized graphene heat dissipation coating for artificial turf and preparing method thereof

The invention discloses an antibiosis oxidized graphene heat dissipation coating for artificial turf and a preparing method thereof. The coating comprises, by weight, 1-10 parts of light-cured oxidized graphene, 50-80 parts of plant-based light-cured resin, 10-30 parts of antibacterial activated monomer, 1-4 parts of photoinitiator and 1-3 parts of antibiosis assistant. The coating can effectively solve the problem that the heat dissipation of artificial turf is hard, and has the advantages that heat dissipation property and antibacterial property are excellent, cost is low, environment friendliness is realized, and the preparing process is simple.

Owner:WUXI GREEN LAWN CO LTD

Cycloolefin copolymer with polar group and preparation method thereof

The invention relates to C08F, in particular to a cycloolefin copolymer with polar groups and a preparation method of the cycloolefin copolymer. Structural units of the cycloolefin copolymer comprise a vinyl unit A, a non-polar unit B and a polar unit. According to the cycloolefin copolymer provided by the invention, the polar cyclic unit is introduced, so that the compatibility and cohesiveness of the material in the use process can be promoted, and meanwhile, the structure of the non-polar unit and the polar unit can be controlled, so that the cycloolefin copolymer has high light transmission and provides high optical performance under different vinyl chain unit copolymers. By adjusting the use amount of a polar unit and a non-polar unit relative to a vinyl unit, the inventor finds that the polar copolymer is controlled to have a wide-range adjustable glass transition temperature, the formation of an amorphous structure can be promoted, the generation of a crystalline chain segment is avoided, and the improvement of optical characteristics is further promoted; the copolymer application range is expanded.

Owner:广东新华粤石化集团股份公司 +1

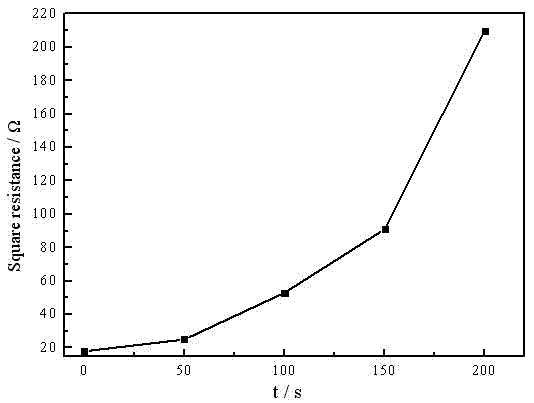

Preparation method of novel all-vanadium redox flow battery ion exchange membrane

The invention discloses a preparation method of a novel all-vanadium redox flow battery ion exchange membrane. The preparation method comprises the steps of dissolving a given amount of PVDF (polyvinylidene fluoride) powder in NMP to form a uniform solution, and forming a membrane in a coating manner; placing the PVDF membrane in a 0.5mol / L KOH ethanol solution, carrying out the alkaline treatment under the protection of N2, taking out the PVDF membrane, and washing the PVDF membrane by utilizing deionized water until the pH value is constant; immersing the washed PVDF membrane in a mixed solution of styrene and tetrahydrofuran to have the grafting reaction to obtain a PVDF-g-PS membrane, swelling the PVDF-g-PS membrane for 2 hours in 1, 2-dichloroethane, then immersing the membrane in thick sulfuric acid of which the mass fraction is 98 percent, sulfonating the membrane to obtain the PVDF-g-PSSA membrane, and washing and drying the membrane. By adopting the preparation method, the conductivity of the ion exchange membrane can be improved, the chemical stability of the ion exchange membrane can be improved, and the vanadium ion permeation resistance can be improved.

Owner:SHENZHEN SINOCREDO NEW ENERGY TECH

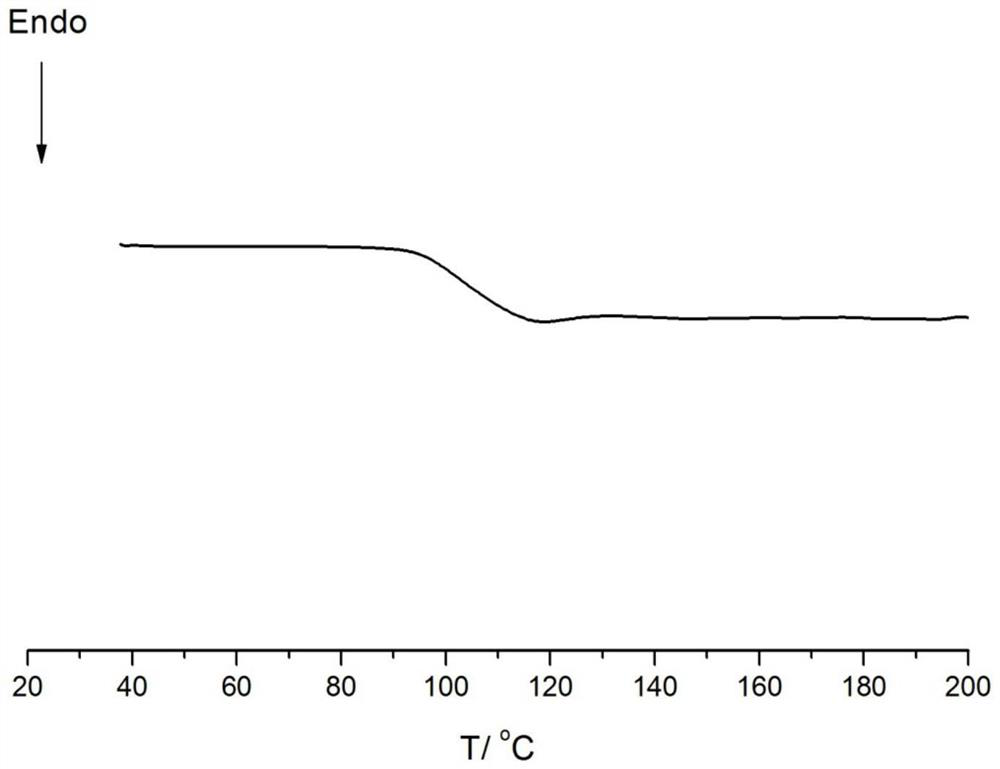

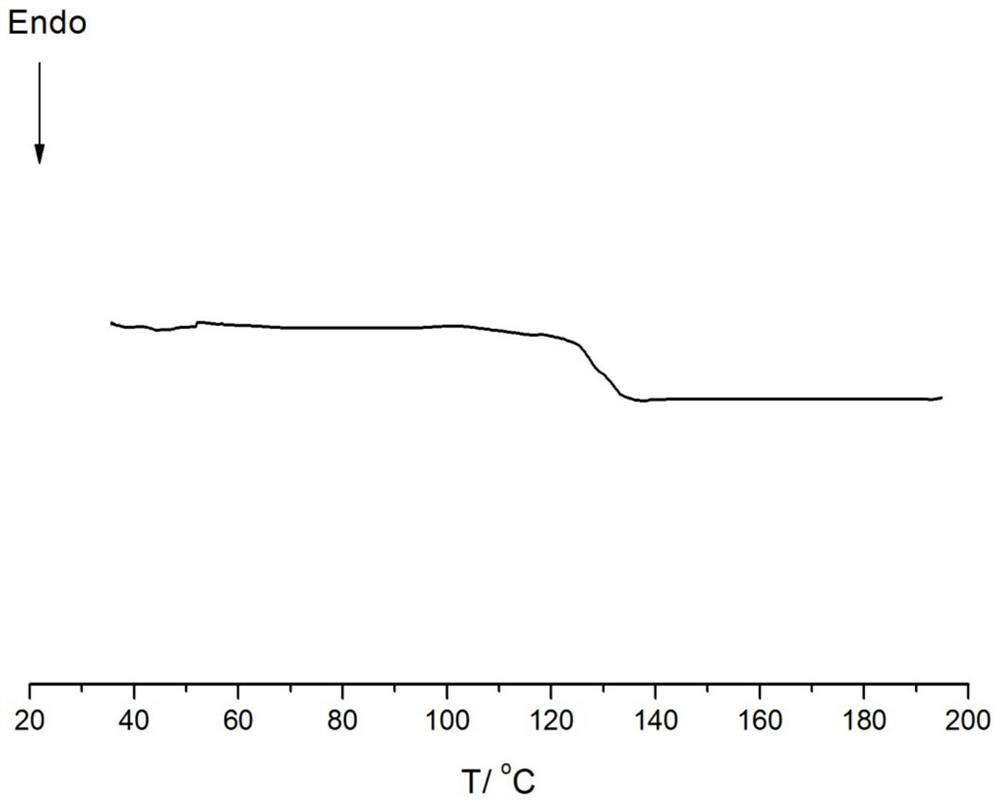

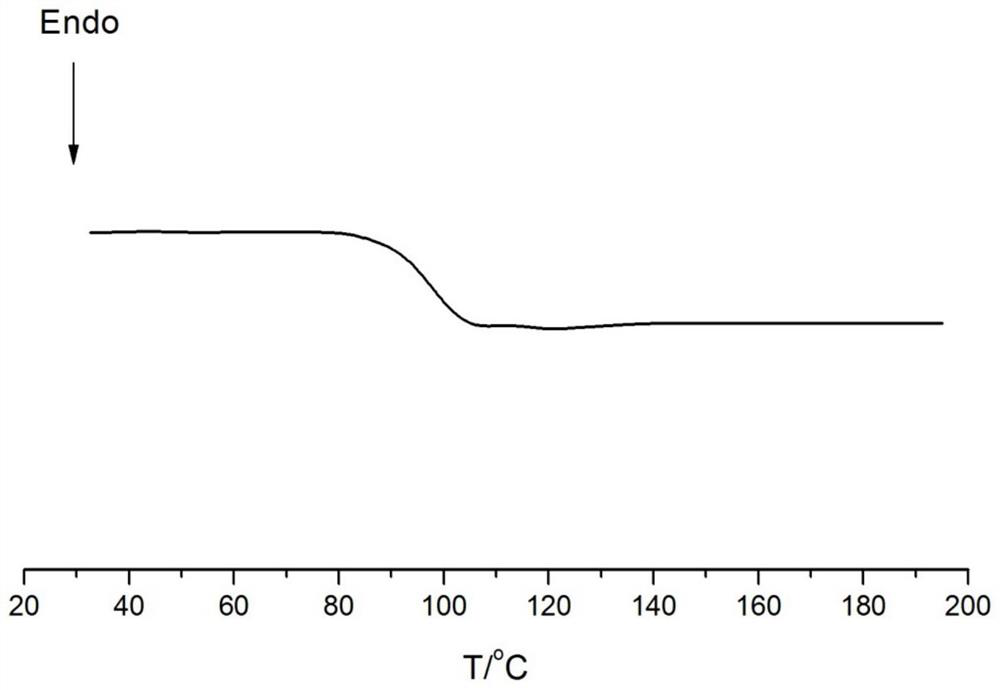

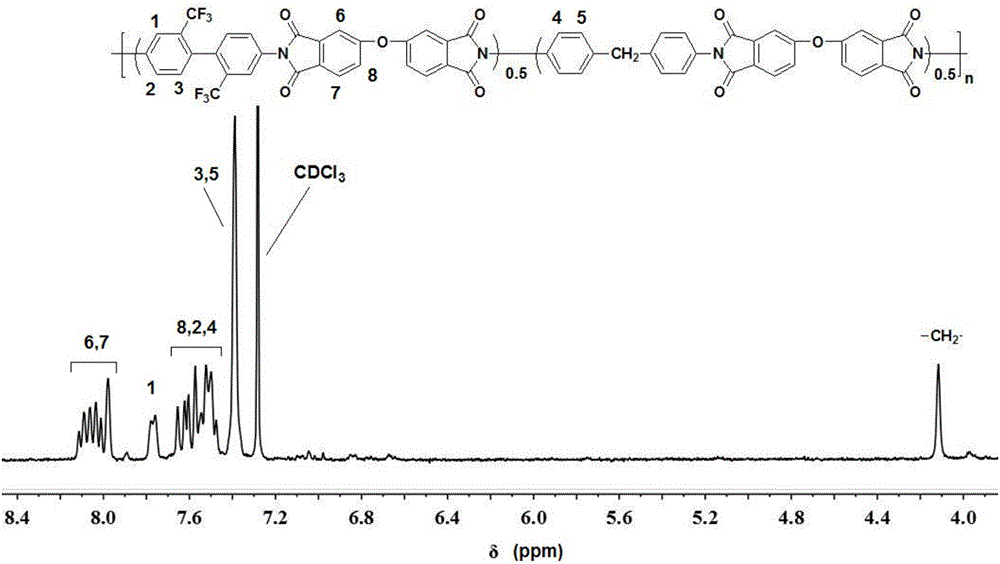

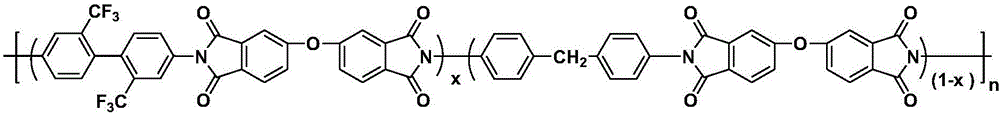

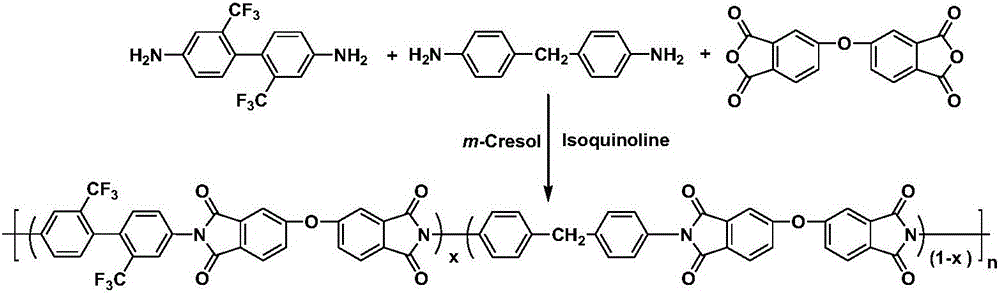

High-transparency copolymerization type fluorine-containing polyimide thin material and preparation method of high-transparency copolymerization type fluorine-containing polyimide thin material

The invention provides a high-transparency copolymerization type fluorine-containing polyimide thin material and a preparation method of the high-transparency copolymerization type fluorine-containing polyimide thin material. The polyimide thin material has good solubility and firm forming property; a prepared polyimide thin film has excellent optical transparency and good thermal performance. The preparation method of the high-transparency copolymerization type fluorine-containing polyimide thin material comprises the following steps: under nitrogen protection, dissolving an aromatic diamine monomer containing a bistrifluoromethyl structure, a non-fluorine-containing monomer and a tetracarboxydiphthalic ether dianhydride monomer into an organic solvent according to a certain metering ratio; adding a certain amount of a catalyst and raising temperature to 170 DEG C to 190 DEG C; carrying water through a nitrogen gas flow; after stirring and reacting for 8h to 12h, finishing reaction; precipitating, filtering and drying to obtain fiber-shaped copolymerization type fluorine-containing polyimide resin; furthermore, coating a film on flat plate glass through a polymer solution of the fiber-shaped copolymerization type fluorine-containing polyimide resin, and drying to obtain the high-transparency polyimide film.

Owner:江苏德瑾绿水环保科技有限公司 +1

Method for preparing homogeneous-phase ion exchange membrane of all-vanadium battery by use of slurry coating method

InactiveCN104779405ASimple preparation routeLow costCell electrodesRegenerative fuel cellsIon-exchange membranesDibenzoyl Peroxide

The invention discloses a method for preparing a homogeneous-phase ion exchange membrane of an all-vanadium battery by use of a slurry coating method. The method comprises the following steps: adding styrene, divinylbenzene, chlorinated polyethylene and benzoyl peroxide to a reaction kettle and stirring evenly to obtain a slurry; secondly, spreading a polyester thin film on a smooth polished aluminum plate and placing long-filament polyvinyl chloride fiber cloth on the polyester thin film, pouring the slurry onto the long-filament polyvinyl chloride fiber cloth, and finally, covering with another polished aluminum plate, putting into a press, pressurizing and heating, cooling, taking out, and stripping to obtain a base film; putting the base film in concentrated sulfuric acid containing silver sulfate for sulfonating, cooling, and then taking out the base film and soaking the base film into the aqueous solution of sulfuric acid; putting the base film in chloromethyl ether for reacting for 8 hours at 40-50 DEG C in an airtight state, thereby obtaining a chloromethyl film; soaking the chloromethyl film in the aqueous solution of trimethylamine for reacting for 8-10 hours at 30-35 DEG C, taking out, and washing by use of purified water to obtain a strong base quaternary ammonium anion-exchange membrane. With the method, large-size homogeneous-phase ion exchange membranes can be prepared, and the chemical stability and the like of the ion exchange membranes can be improved.

Owner:SHENZHEN SINOCREDO NEW ENERGY TECH

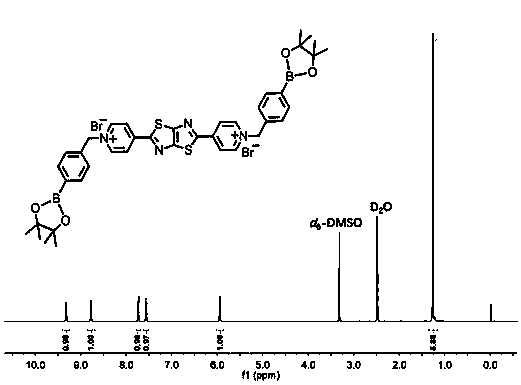

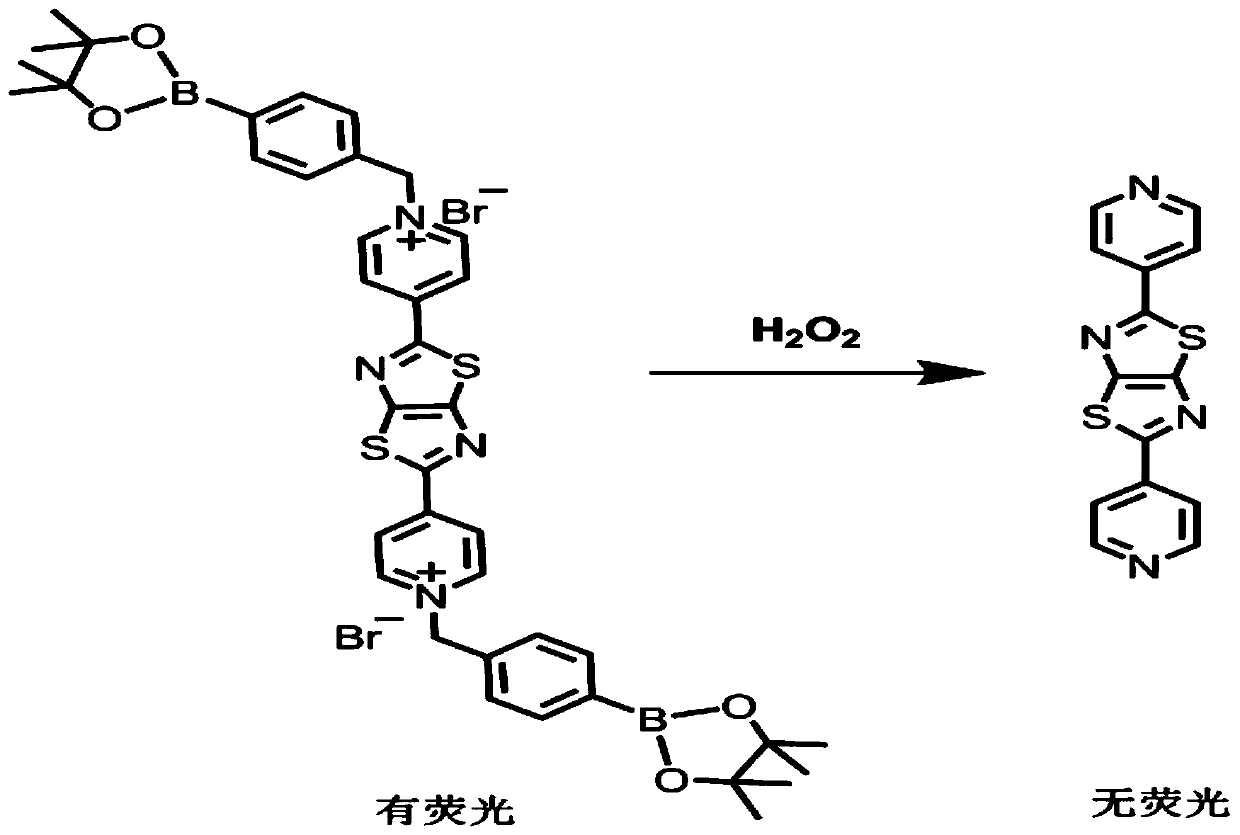

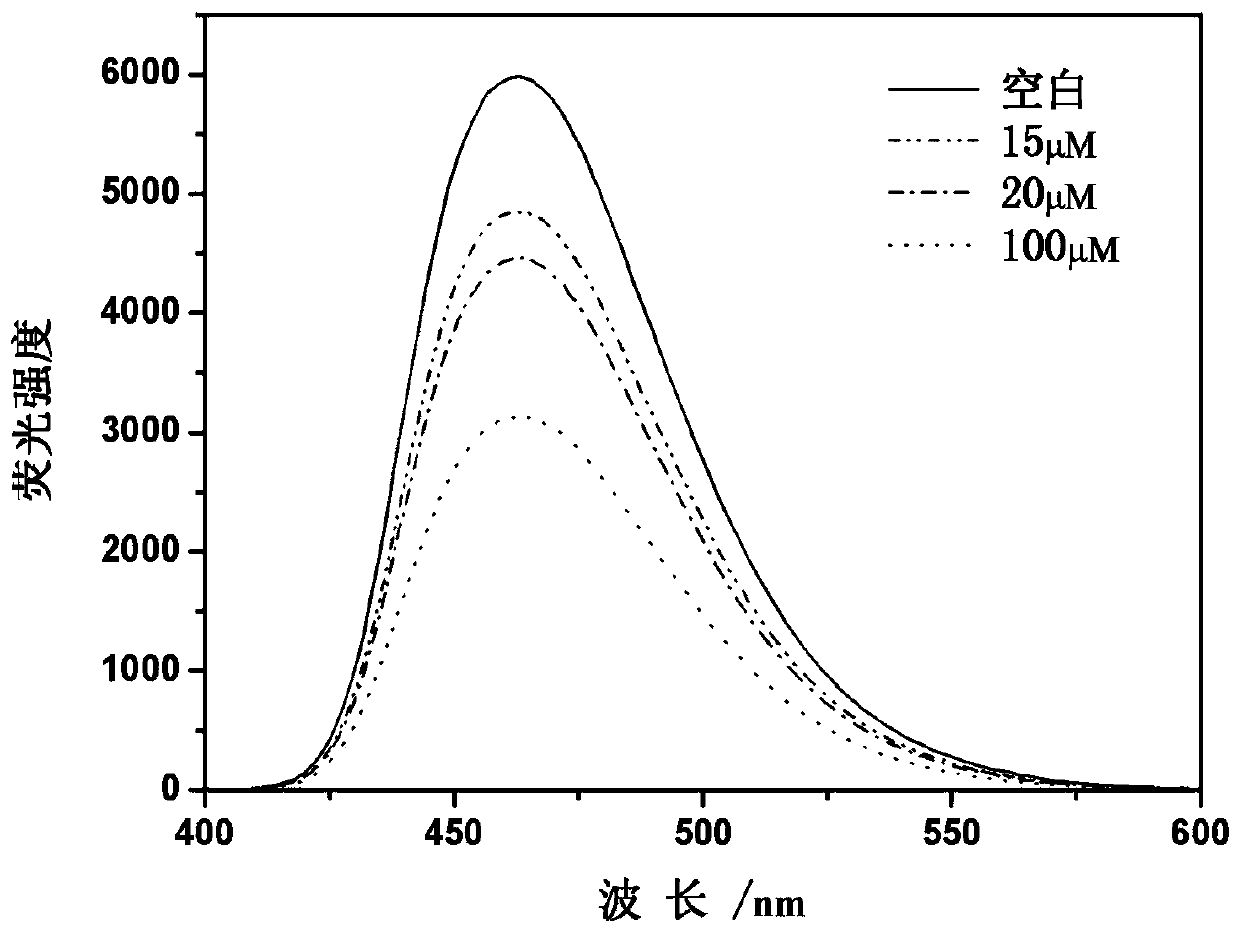

Fluorescent probe having hydrogen peroxide detection function and preparation method and application thereof

ActiveCN109970777ASimple preparation routeLower synthesis costGroup 3/13 element organic compoundsFluorescence/phosphorescenceOrganic solventFluorescence

The invention discloses a fluorescent probe having a hydrogen peroxide (H2O2) detection function and a preparation method and application thereof. The fluorescent probe is a novel fluorescent probe prepared by using 4-pyridine formaldehyde, dithiooxamide and 4-bromomethyl phenylborate pinacol ester as raw materials. Further studies show that the probe can achieve rapid and sensitive detection of H2O2. Compared with existing fluorescence detection technologies, the fluorescent probe obtained by means of the method has the advantages that the selectivity to H2O2 is high, there are no organic solvent residues, the response is sensitive, a synthesis route is simple, and a detection method is simple. The preparation method is applicable to practical production application and has a great application prospect in the technical fields of analytical chemistry, medicine, life science, environmental engineering and the like.

Owner:XIANGTAN UNIV

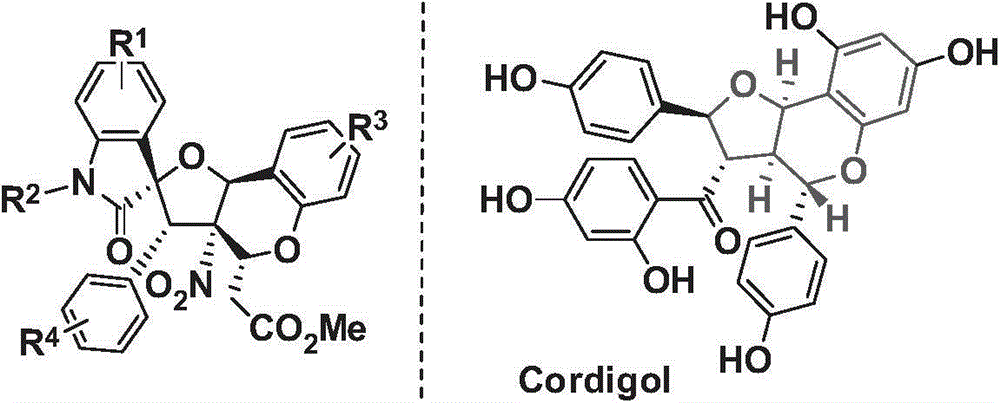

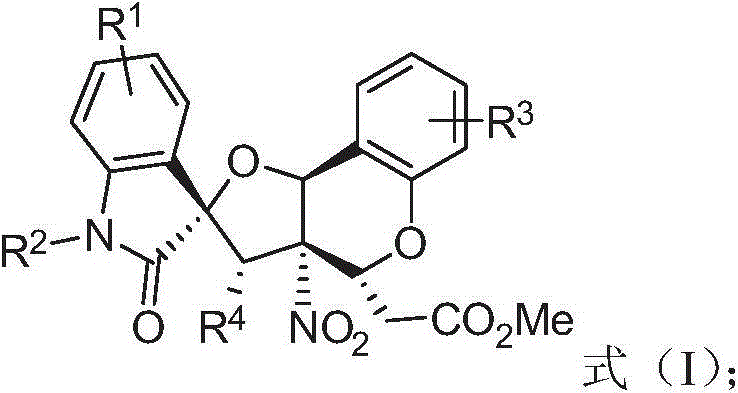

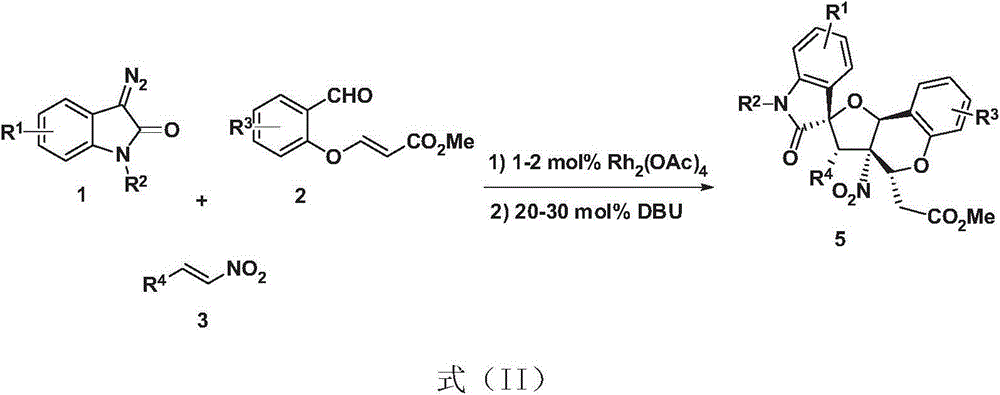

Tetrahydrofuran benzodihydropyran polycyclic compound and application thereof

InactiveCN103554118ALower synthesis costShort preparation routeOrganic chemistryAntineoplastic agentsBenzaldehydeBenzene

The invention discloses a tetrahydrofuran benzodihydropyran polycyclic compound shown as a formula (I). The tetrahydrofuran benzodihydropyran polycyclic compound is prepared by the following steps: performing 3+2 cycloaddition on isatin diazo, ortho-substituted benzaldehyde and nitrophenyl alkene under the catalysis of rhodium acetate to construct a multi-substituted tetrahydrofuran intermediate; adding a base and performing intramolecular Michael addition to further cyclize so as to synthesize the tetrahydrofuran benzodihydropyran polycyclic compound. The compound has excellent inhibitory activity on histone deacetylase.

Owner:EAST CHINA NORMAL UNIVERSITY

Preparation method of gamma-valerolactone spice and application method in cigarettes

ActiveCN101633649AProduction operation safetySimple preparation routeOrganic chemistryTobacco treatmentAcetic acidFlavor

The invention discloses a preparation method of gamma-valerolactone spice and an application method in cigarettes. The preparation method comprises the steps: using levulinate as a raw material; reacting for 3 to 5 hours at normal temperature and normal pressure in NaOH solution under the action of KBH4; decompressing for steaming out ethanol; regulating the pH of mother solution by dilute sulphuric acid; then extracting by ethyl acetate; drying by anhydrous sodium sulfate; standing over a night; decompressing; condensing; and obtaining the spice. The obtained spice is added to cigarette tobacco or tobacco groups by the dosage of 0.05% to 0.2% for smoking and commenting by sense organs. The spice increases and regulates cigarette fragrance and increases complete degree, mellow feel, fluency and sweet feel of the cigarette fragrance.

Owner:云南天宏香精有限公司

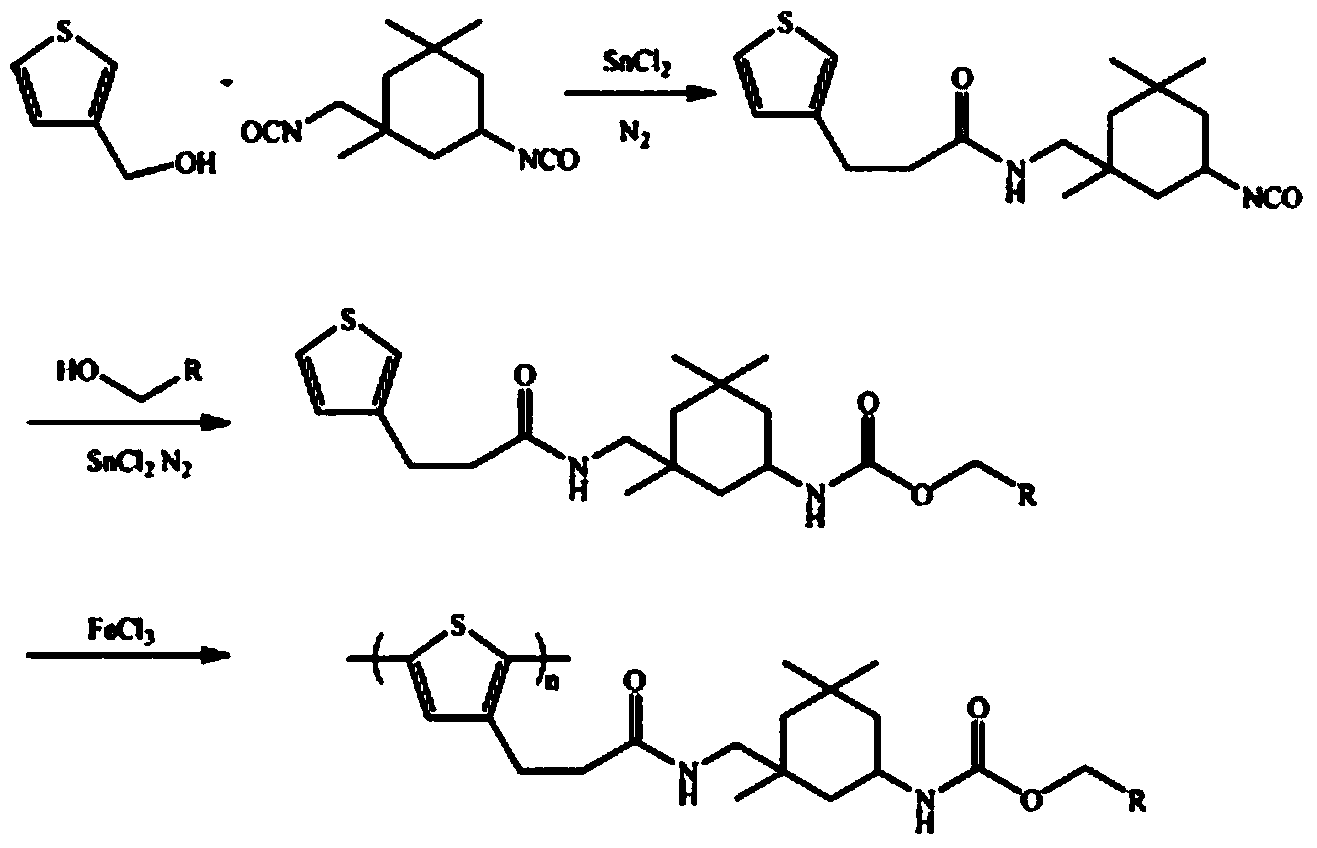

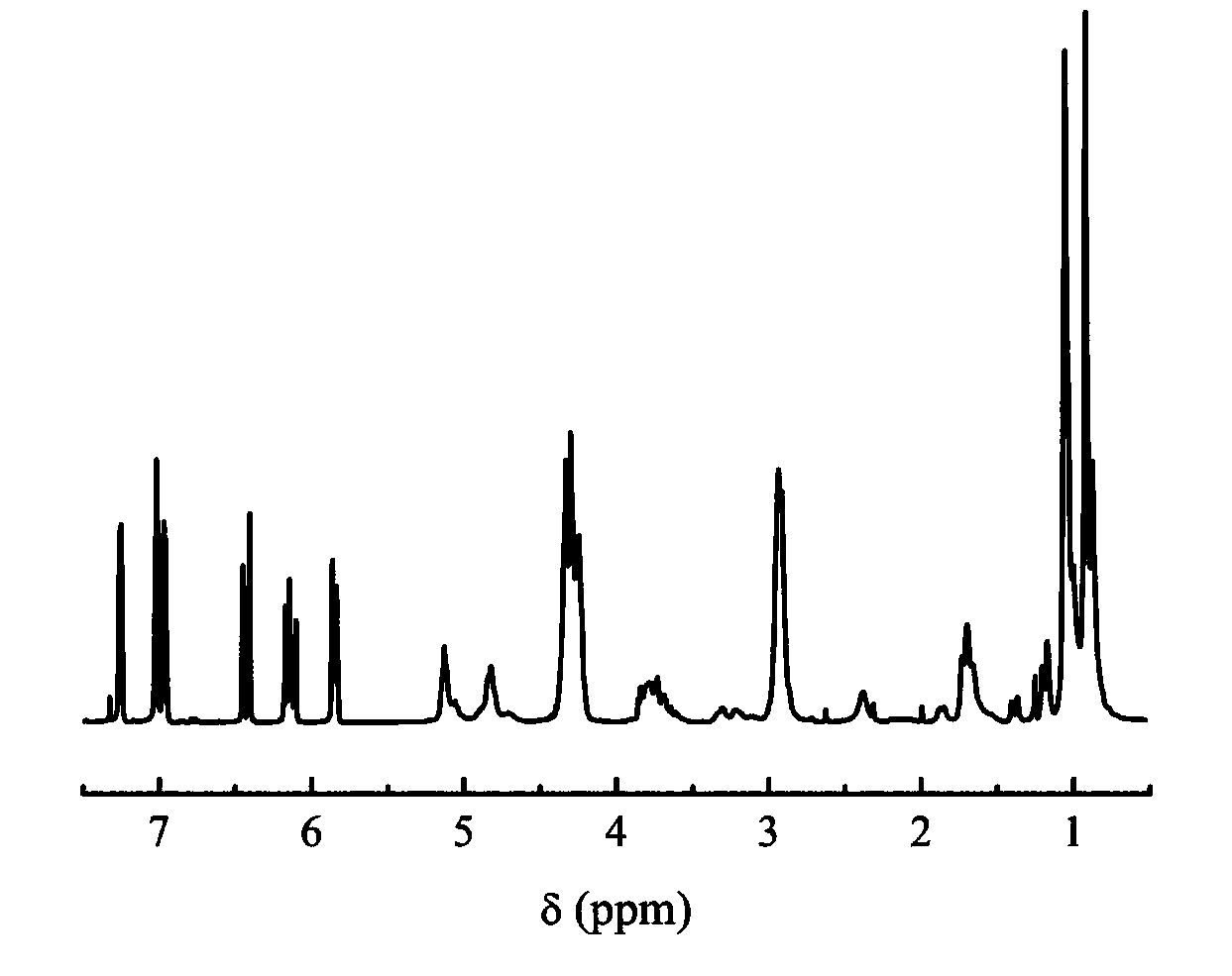

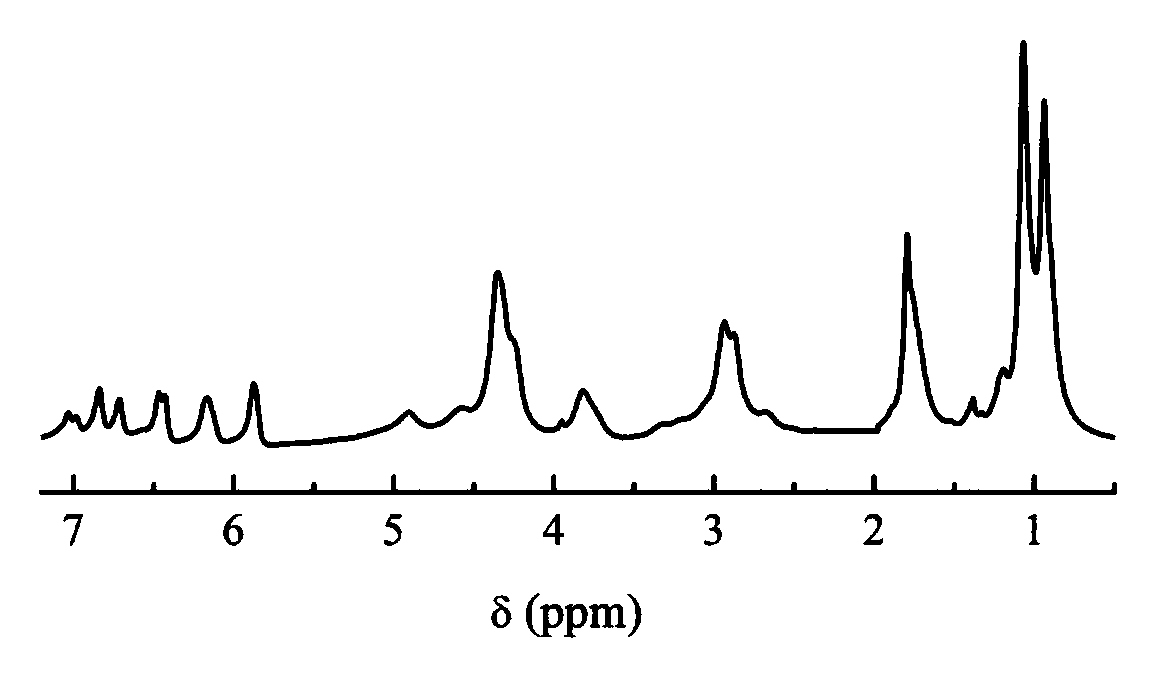

Preparation method of UV (ultraviolet) curing polythiophene derivative conductive polymer material

ActiveCN103588961AWide selectionWell-characterized structureOrganic chemistryPolymer scienceUV curing

The invention relates to a preparation method of a UV (ultraviolet) curing polythiophene derivative conductive polymer material, and belongs to the technical field of a conductive polymer material. According to the preparation method, a thiophene derivative monomer with a UV curing photosensitive group is prepared through a reaction of diisocyanate and a thiophene derivative, and then the thiophene derivative monomer is polymerized, so that a product of the UV curing polythiophene derivative conductive polymer material is obtained. The conductive polymer material fills up the blank of the UV curing conductive polymer material, further, an adopted preparation process is simple and easy to operate, a catalyst and a reaction medium solvent have a wide selection range, the processing condition is mild, and the requirement for reaction equipment is not high; and moreover, a reversible reaction is not caused easily, the yield is higher than 65%, and favorable conditions are provided for industrialization of the material and the preparation method in the future.

Owner:JIANGNAN UNIV

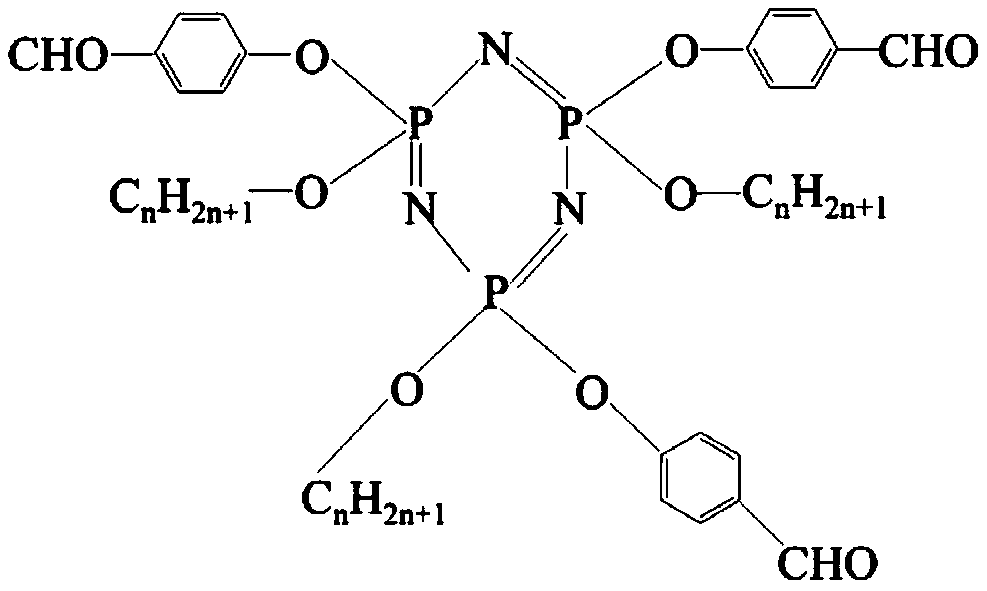

Modified coal gangue powder filled polyolefin flame-retardant composite material and preparation process

The invention discloses a modified coal gangue powder filled polyolefin flame-retardant composite material and a preparation process, and belongs to the technical field of polyolefin flame-retardant composite material preparation. The weight ratio of the modified coal gangue powder to the polyolefin in the composite material is (10-60):100, and the modified coal gangue powder contains a cyclotriphosphazene derivative, which has a novel structure and can be used as a surface modifier and a flame retardant. The coal gangue powder modified by cyclotriphosphazene is easy to disperse uniformly in apolyolefin matrix, wherein the interface bonding force between the coal gangue powder and the polyolefin matrix can be enhanced, so that the mechanical properties of the composite material are remarkably improved, and the composite material has a relatively good flame-retardant property. The novel composite material has the advantages of high coal gangue filling amount, low polyolefin consumption, no need of calcining the coal gangue powder, energy saving and low cost. The composite material has the advantages of excellent comprehensive mechanical properties, obvious flame retardancy, simplepreparation technique, no use of strong acids or alkalis in the preparation process, and no environmental pollution.

Owner:BEIJING UNIV OF TECH

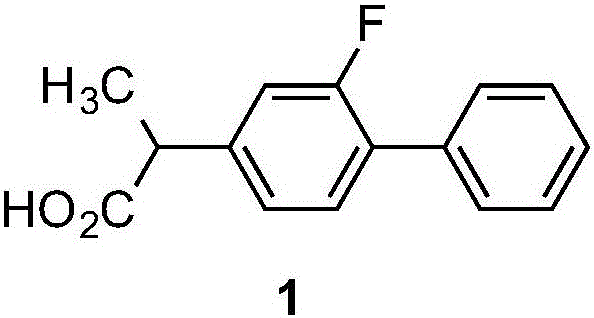

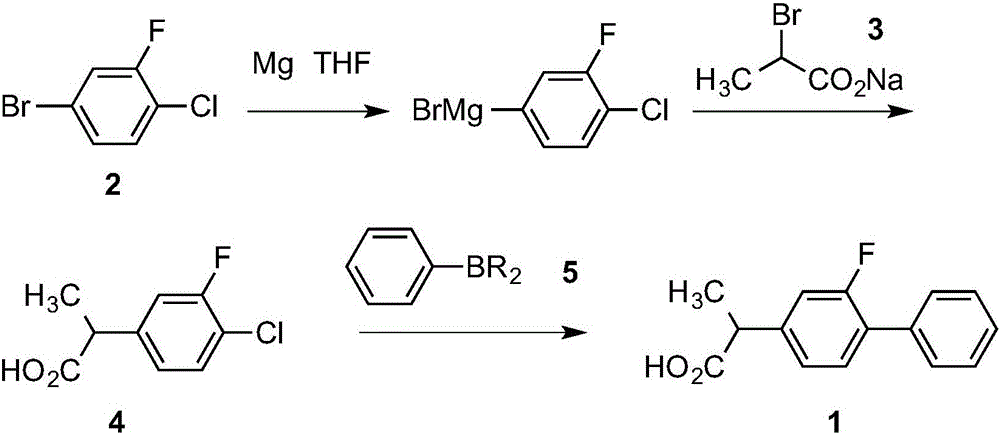

A preparing method of flurbiprofen

ActiveCN106496015AAvoid security issuesAvoid environmental pollutionOrganic compound preparationMagnesium organic compoundsPhenylboronic acidOrganic solvent

A preparing method of flurbiprofen is disclosed and belongs to the technical field of medicine preparation. A Suzuki coupling reaction is adopted. 2-(3-fluoro-4-chloro-phenyl)-propionic acid and a phenylboronic acid reagent are subjected to the palladium catalyzed Suzuki coupling reaction in an organic solvent under existence of an alkali to obtain the flurbiprofen, wherein the mole ratio of the 2-(3-fluoro-4-chloro-phenyl)-propionic acid to the phenylboronic acid reagent is 1:(0.9-1.1). The method is simple. The prepared flurbiprofen is high in yield and high in purity.

Owner:MAISON CHEM

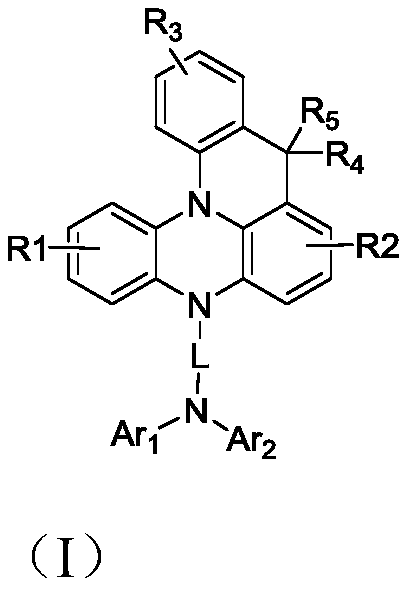

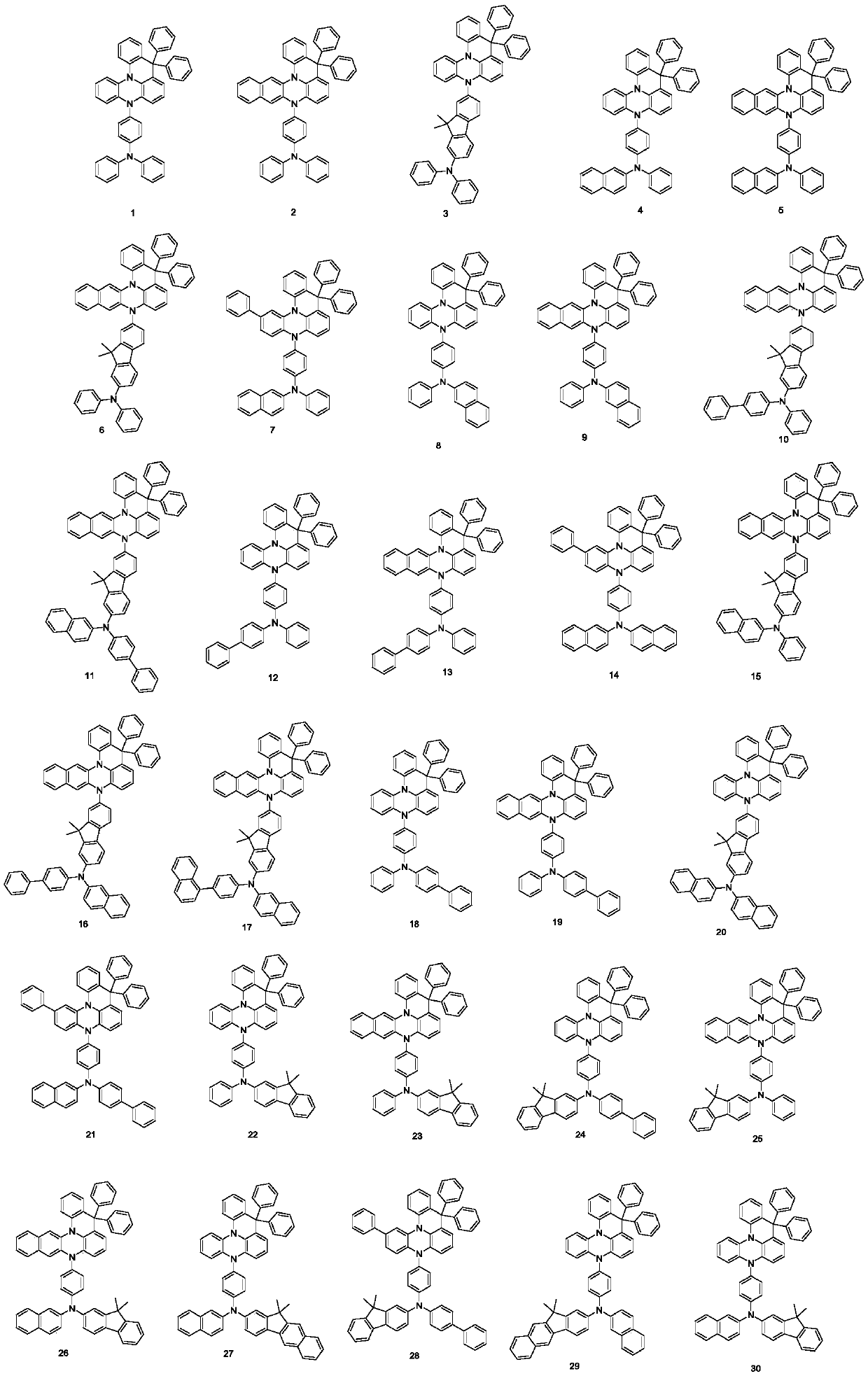

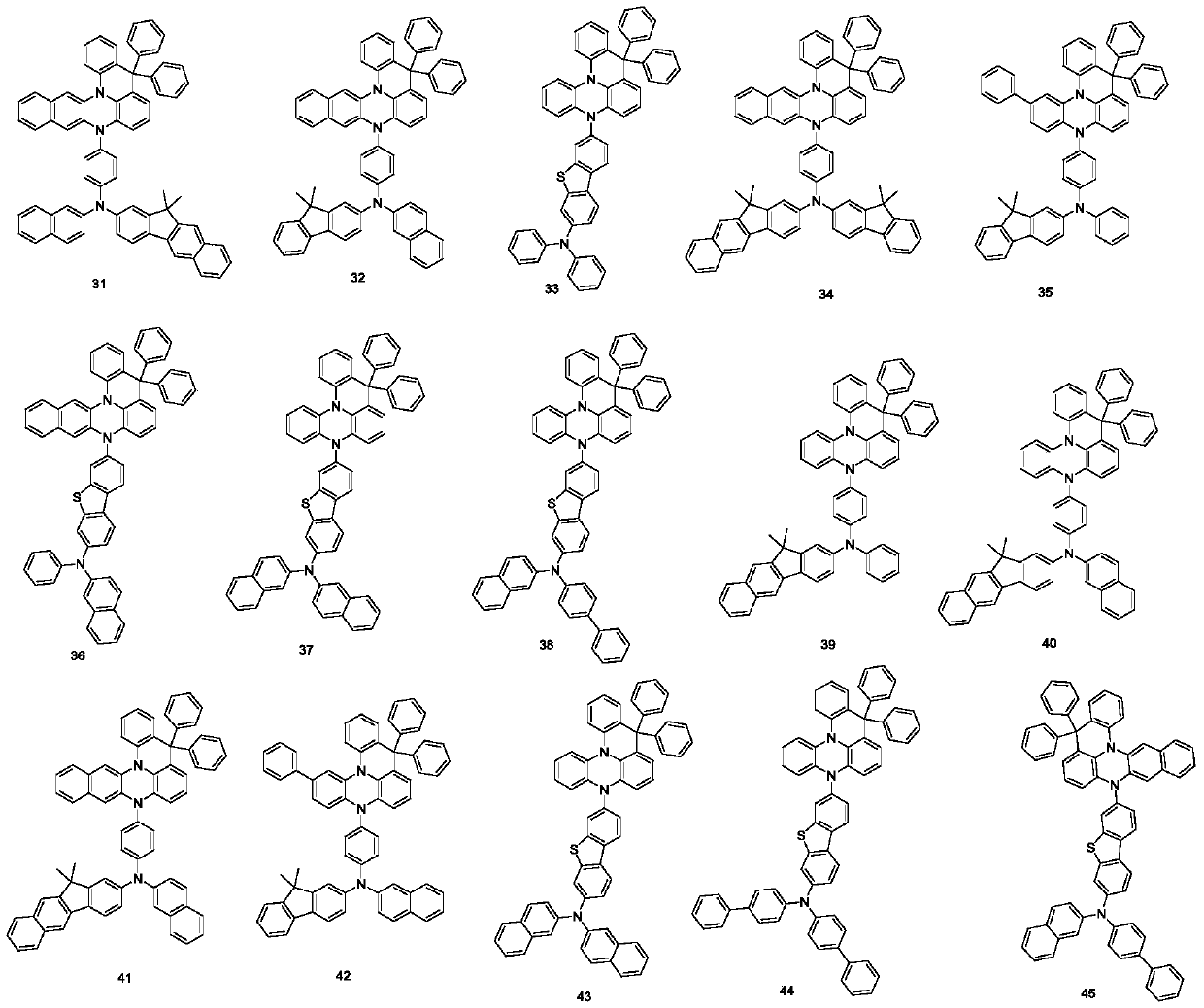

Organic electroluminescent compound and preparation method thereof and organic electroluminescent device

InactiveCN111153902AImprove thermal stabilitySimple preparation routeOrganic chemistrySolid-state devicesOrganic electroluminescenceOrganic chemistry

The invention relates to the technical field of organic luminescent materials, and in particular, relates to an organic light-emitting compound and a preparation method thereof and an organic electroluminescent device. The structural formula of the compound is shown in the specification; the compound has good thermal stability and a simple preparation route, and the organic electroluminescent device containing the compound has excellent luminous efficiency and long service life, is an organic electroluminescent compound with excellent performance, and has simplicity, maturity and repeatabilityin preparation.

Owner:JILIN OPTICAL & ELECTRONICS MATERIALS

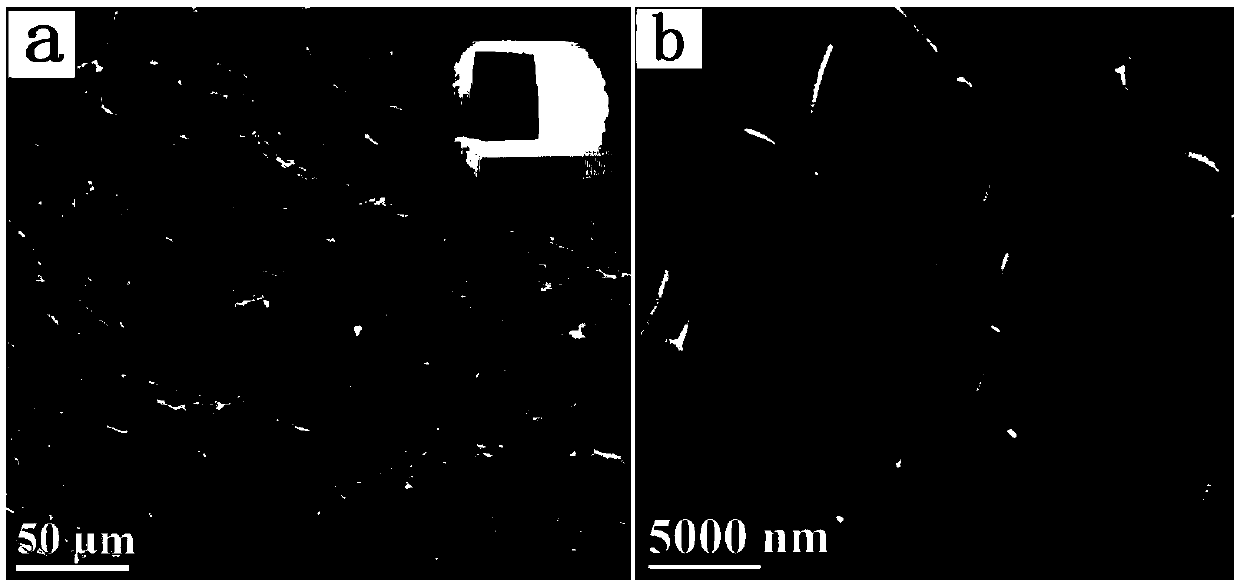

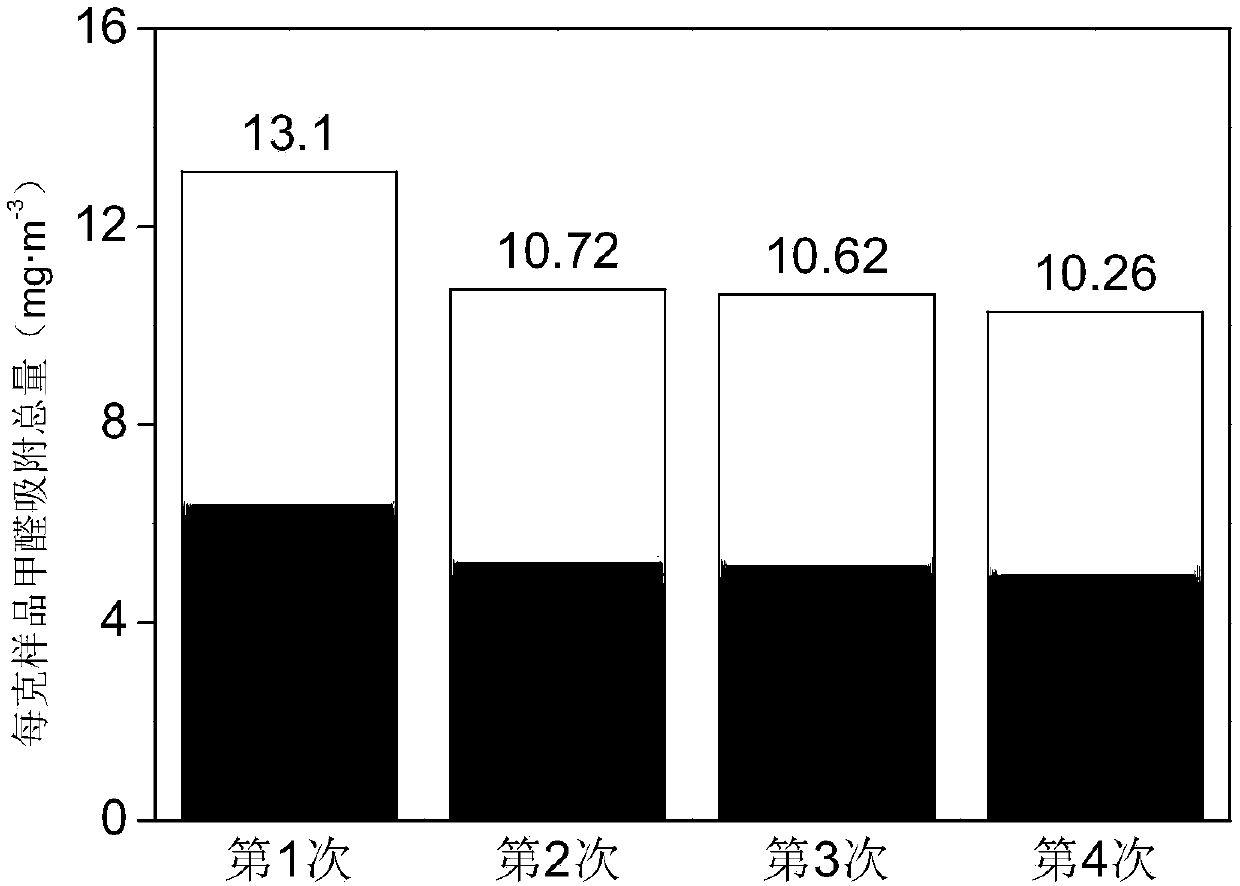

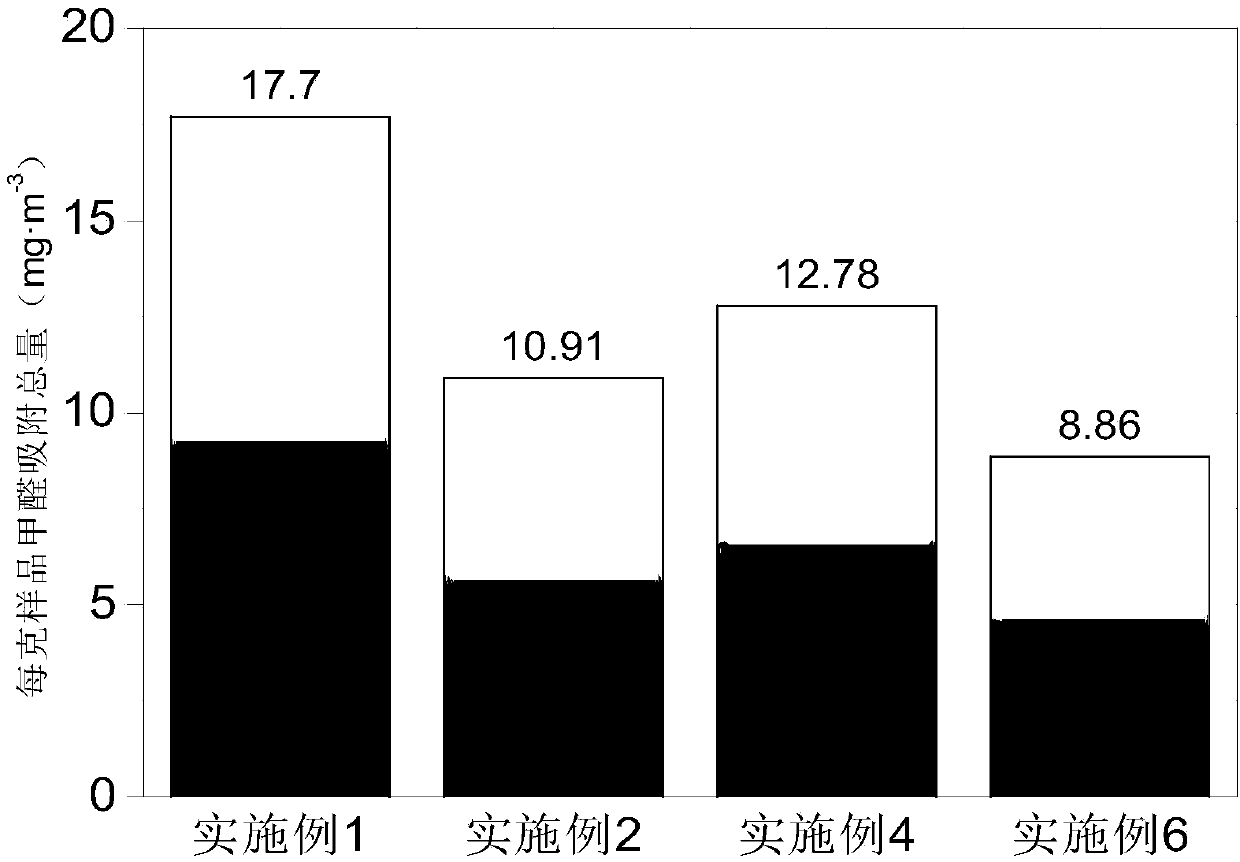

Hierarchical porous carbon block material for formaldehyde purification and preparation method and application thereof

InactiveCN107804845AGood mechanical propertiesSimple preparation routeGas treatmentCarbon compoundsMechanical properties of carbon nanotubesHierarchical porous

Owner:SOUTH CHINA AGRI UNIV

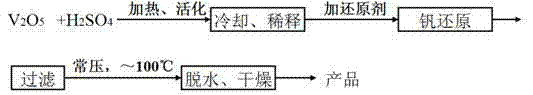

Method for preparing positive electrolyte of all-vanadium redox flow battery through chemical synthesis method

InactiveCN104852073AImprove charge and discharge performanceSimple preparation routeRegenerative fuel cellsChemical synthesisSulfur

The invention discloses a method for preparing positive electrolyte of an all-vanadium redox flow battery through a chemical synthesis method. Through the method, a high-valence oxide which is insoluble in water is reduced to a low-valence vanadium ion which is easily soluble in water through redox reaction. The adopted chemical synthesis method mainly comprises the following steps of (1) preparing with vanadium ores; (2) preparing by reducing V2O5 through sulfur dioxide; (3) preparing by reducing V2O5 through elemental sulfur; and (4) preparing by reaction of oxides of different valences of vanadium. The activated V2O5 is diluted and reduced to pure blue VOSO4 solution, and the pure blue VOSO4 solution is just dehydrated and dried under the temperature condition of 100 DEG C. The electrolyte prepared by the method has good charge and discharge performance, and is an ideal vanadium battery electrode active material.

Owner:SHENZHEN SINOCREDO NEW ENERGY TECH

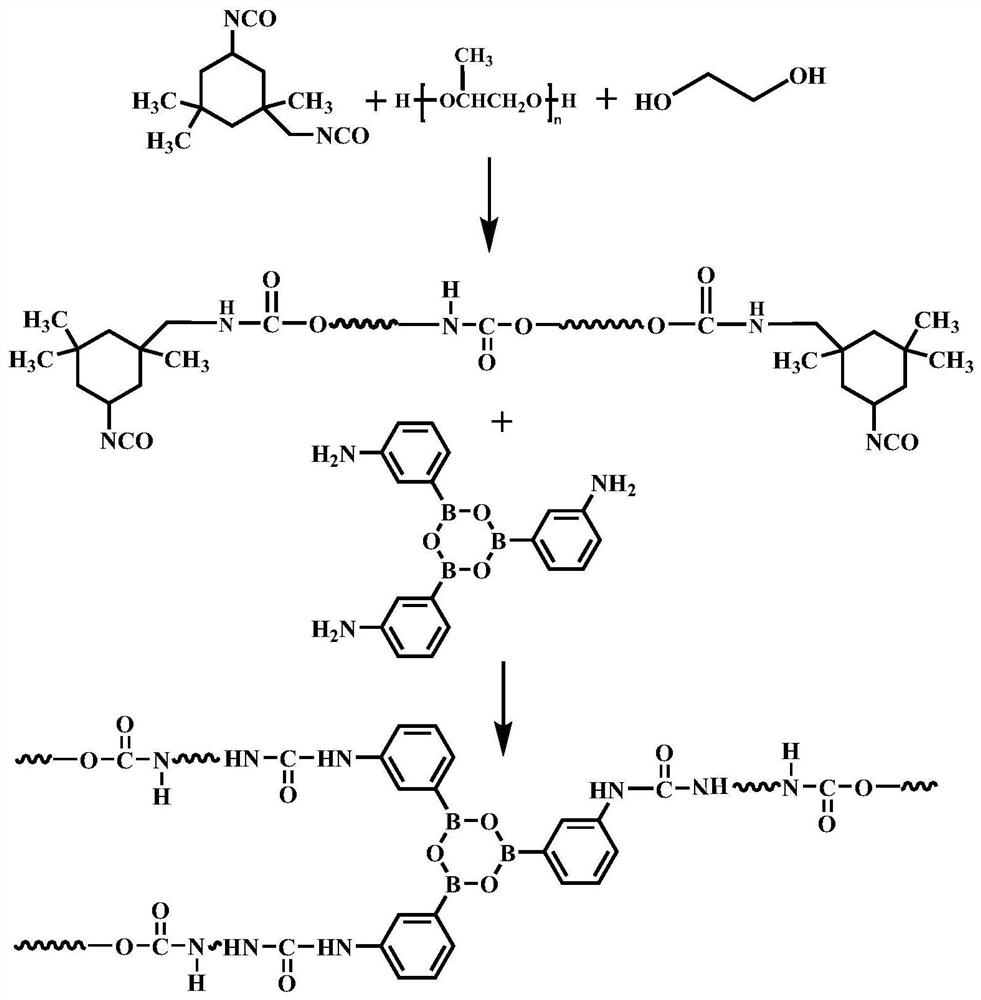

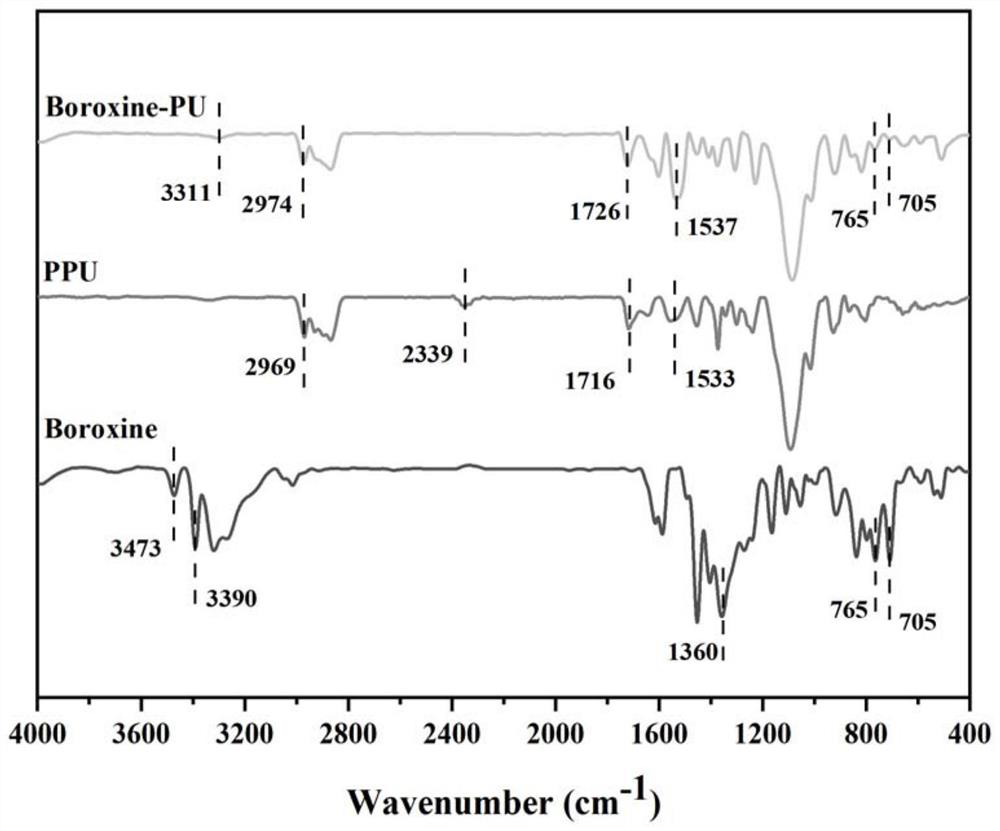

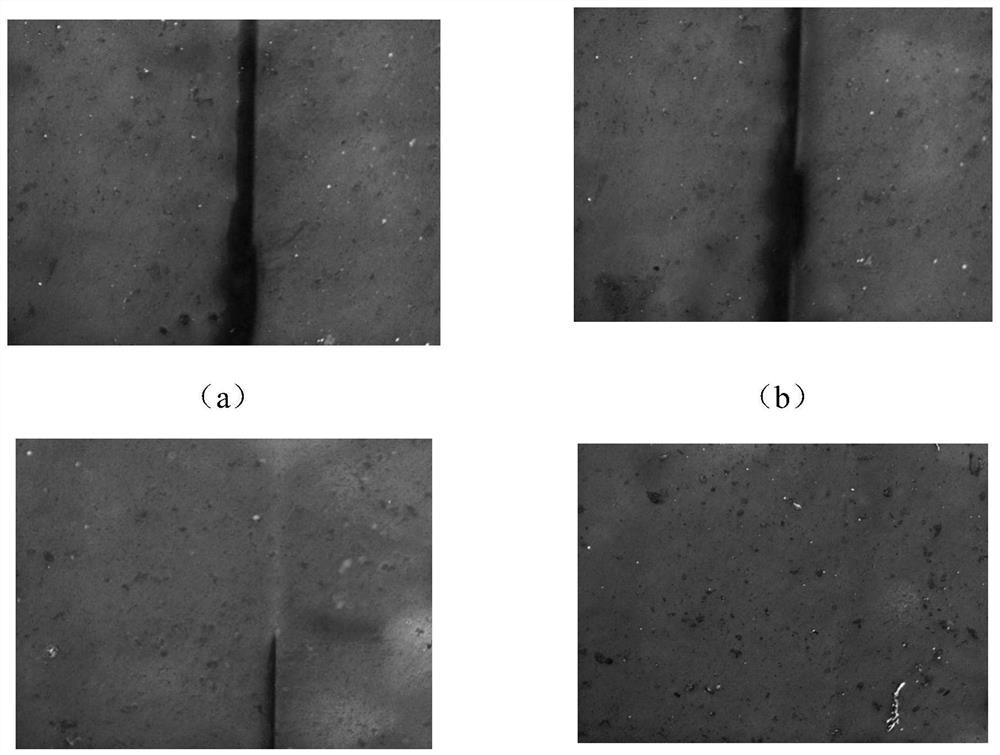

Self-repairing polyurethane based on boroxine and preparation method of self-repairing polyurethane

The invention discloses self-repairing polyurethane based on boroxine and a preparation method of the self-repairing polyurethane, belonging to the technical field of material science. The preparation method comprises the following steps: firstly, preparing an isocyanate-terminated polyurethane prepolymer, and then subjecting the isocyanate-terminated polyurethane prepolymer to reacting with boroxine having different terminal groups under different conditions to prepare the self-repairing polyurethane based on the boroxine. According to the invention, the boroxine with a three-foot structure and dynamic reversible performance is introduced into a polyurethane chain as a cross-linking agent, so the cross-linking density of polyurethane is improved, and the self-repairing polyurethane with more excellent mechanical performance is prepared; and through combination with the advantages of designability of polyurethane and adjustability of soft and hard segments of polyurethane, the preparation route of the method is simple, the complexity of the system in design and processing is reduced, and an effective way is expected to be provided for solving contradiction between high mechanical strength and good repairing performance of a polyurethane material.

Owner:SHAANXI UNIV OF SCI & TECH

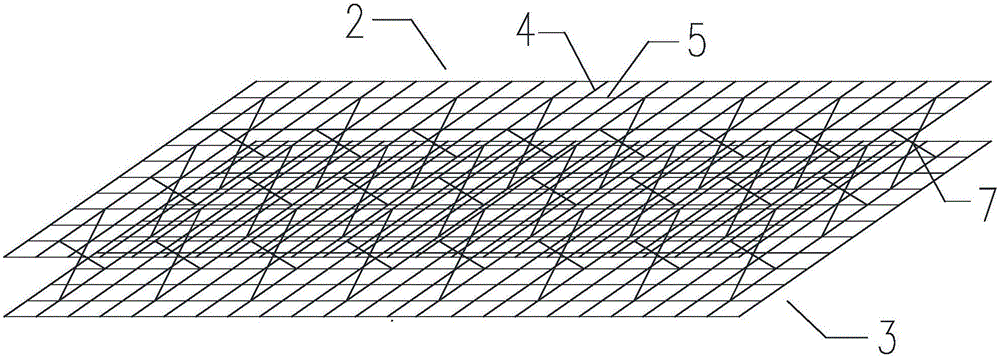

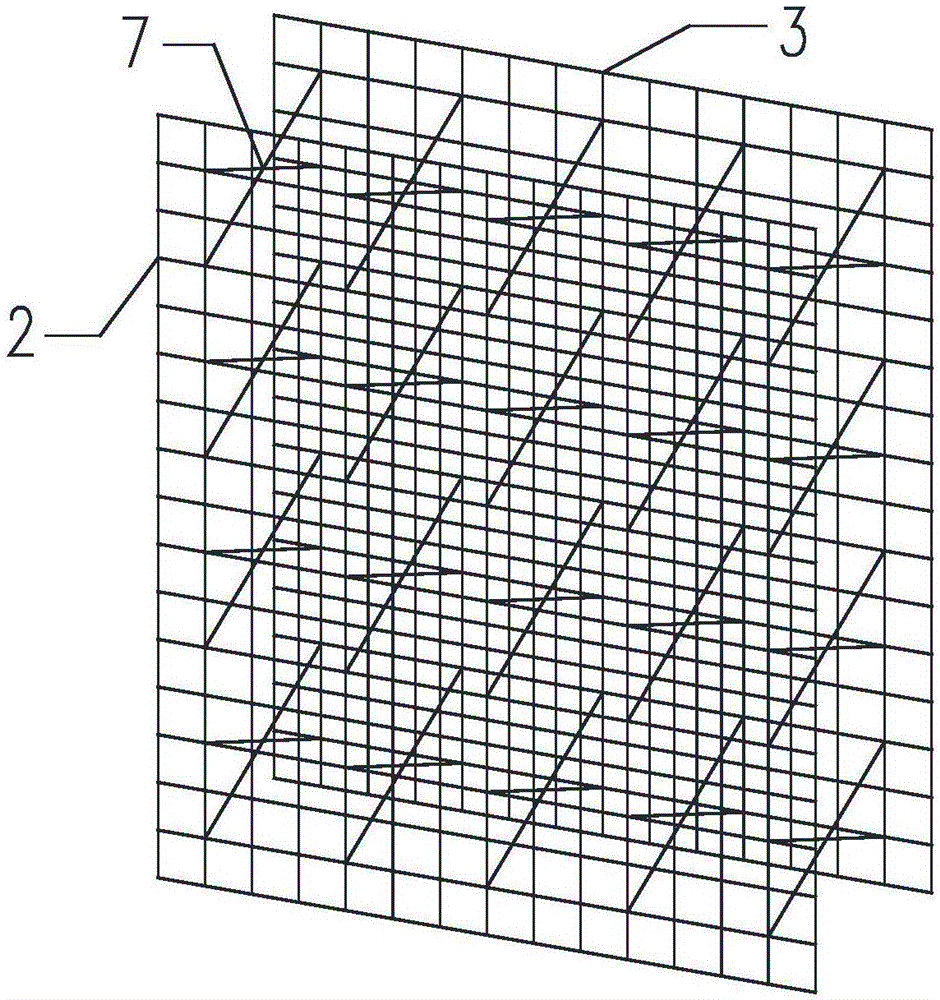

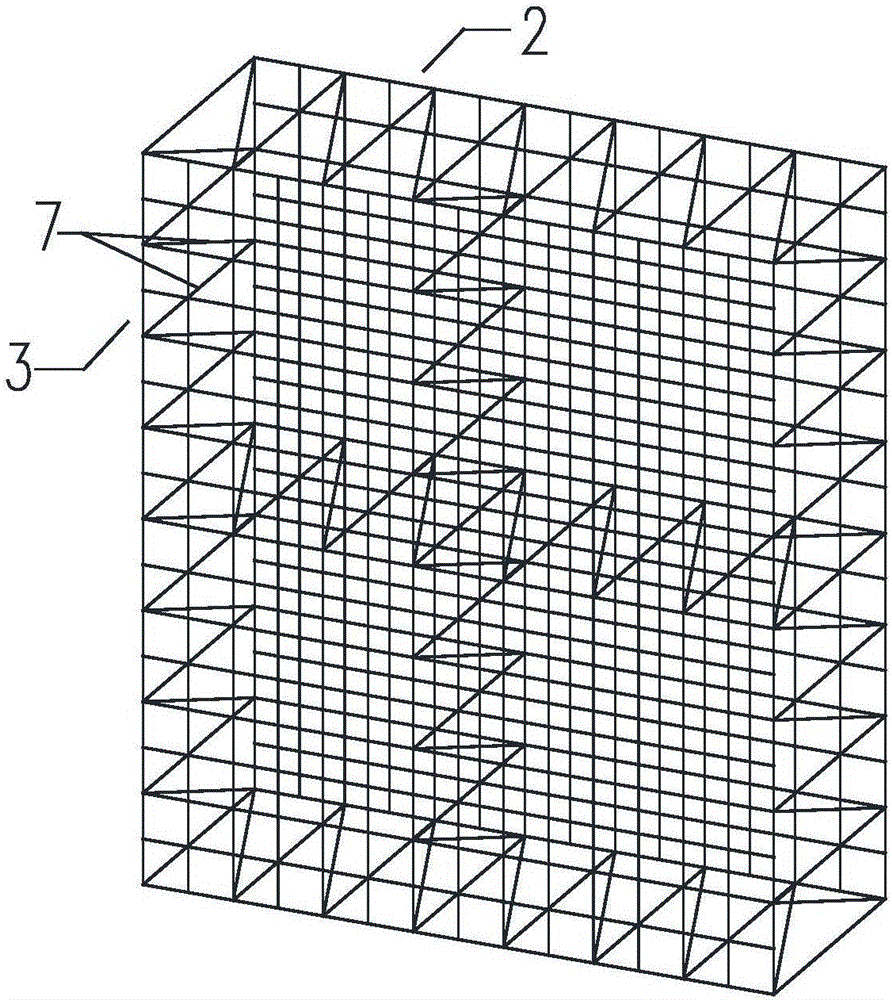

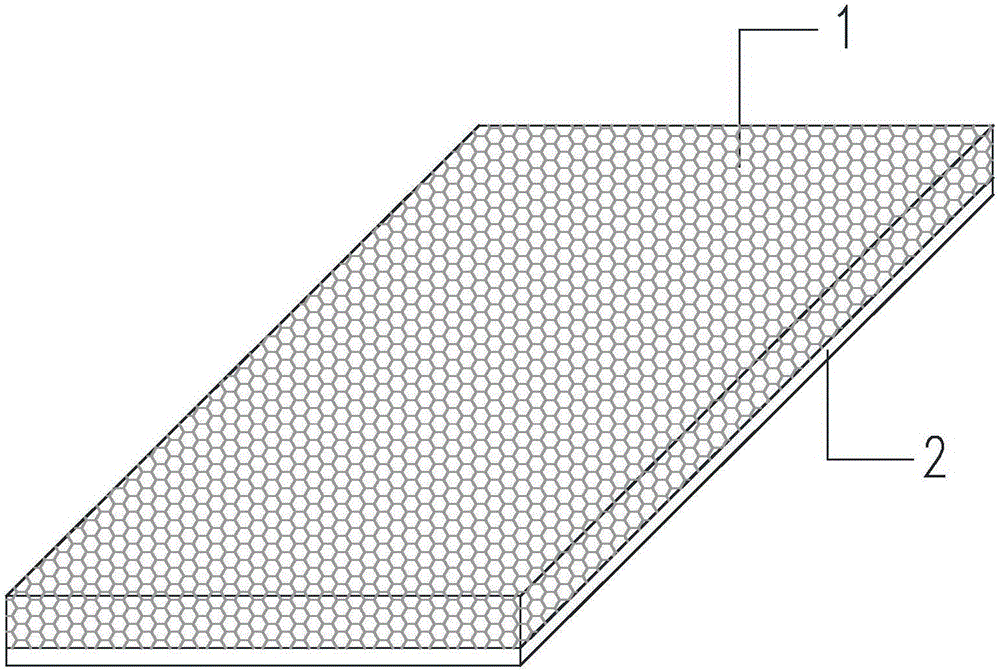

Cement steel mesh frame heat insulation board foamed from magnesian salt gel material

The invention discloses a cement steel mesh frame heat insulation board foamed from a magnesian salt gel material. The heat insulation board comprises a magnesium-based cement foamed board, a first steel wire screen piece and a second steel wire screen piece, the first steel wire screen piece and the second steel wire screen piece are arranged in the magnesium-based cement foamed board and are both of a screen-shaped structure composed of transverse steel wires and longitudinal steel wires, and the transverse steel wires and the longitudinal steel wires are perpendicular to each other. Inclined joint bar sets are arranged between the first steel wire screen piece and the second steel wire screen piece. The prepared cement steel mesh frame heat insulation board foamed from the magnesian salt gel material is simple in preparation line, capable of saving energy, environmentally friendly and capable of using waste, the required raw materials are low in price and easy to obtain, and production cost of the product is low.

Owner:内蒙古绿汇住房产业化技术有限公司 +1

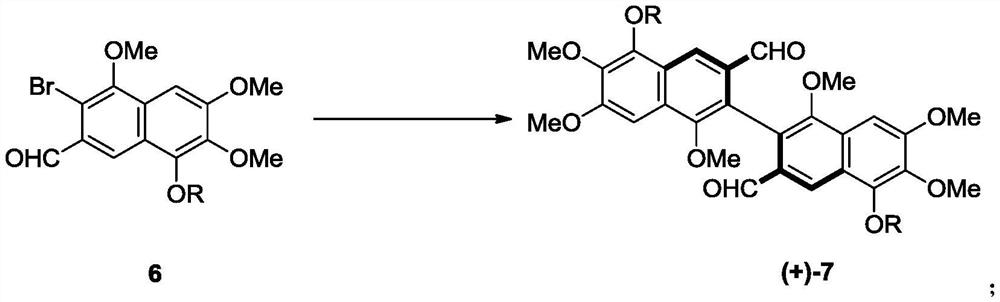

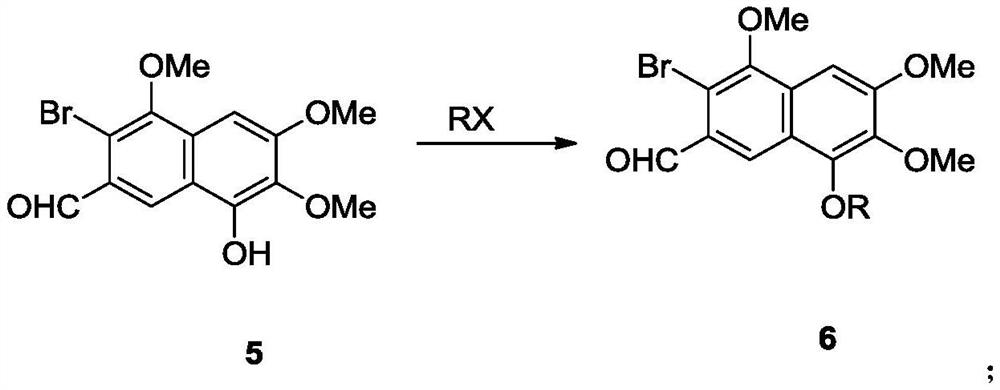

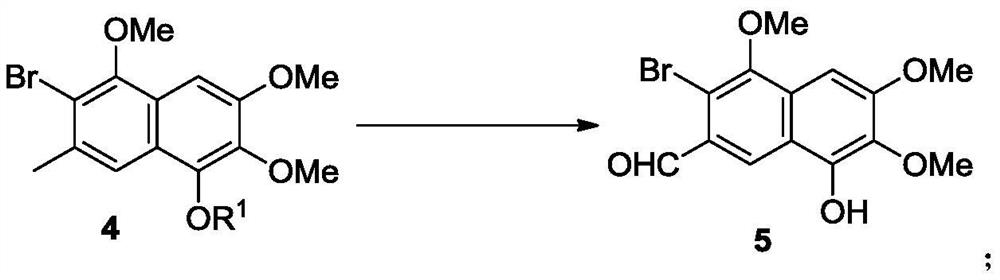

Preparation method and intermediate of gossypol and derivative thereof

ActiveCN111848374ASimple preparation routeStarting materials are cheap and readily availableOrganic compound preparationOrganic chemistry methodsPalladium catalystCombinatorial chemistry

The invention discloses a preparation method and an intermediate of gossypol and derivatives thereof. The preparation method comprises the following steps: in a solvent, under the action of alkali, apalladium catalyst and a chiral ligand, carrying out a coupling reaction shown in the specification on a compound 6 and a double-boron reagent to obtain a compound (+)-7, wherein the structure of thechiral ligand is shown as a formula L1. The preparation method is simple, easy to operate and suitable for industrial production.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

Preparation method of gamma-valerolactone spice and application method in cigarettes

ActiveCN101633649BProduction operation safetySimple preparation routeOrganic chemistryTobacco treatmentFlavorAcetic acid

The invention discloses a preparation method of gamma-valerolactone spice and an application method in cigarettes. The preparation method comprises the steps: using levulinate as a raw material; reacting for 3 to 5 hours at normal temperature and normal pressure in NaOH solution under the action of KBH4; decompressing for steaming out ethanol; regulating the pH of mother solution by dilute sulphuric acid; then extracting by ethyl acetate; drying by anhydrous sodium sulfate; standing over a night; decompressing; condensing; and obtaining the spice. The obtained spice is added to cigarette tobacco or tobacco groups by the dosage of 0.005% to 0.02% for smoking and commenting by sense organs. The spice increases and regulates cigarette fragrance and increases complete degree, mellow feel, fluency and sweet feel of the cigarette fragrance.

Owner:云南天宏香精有限公司

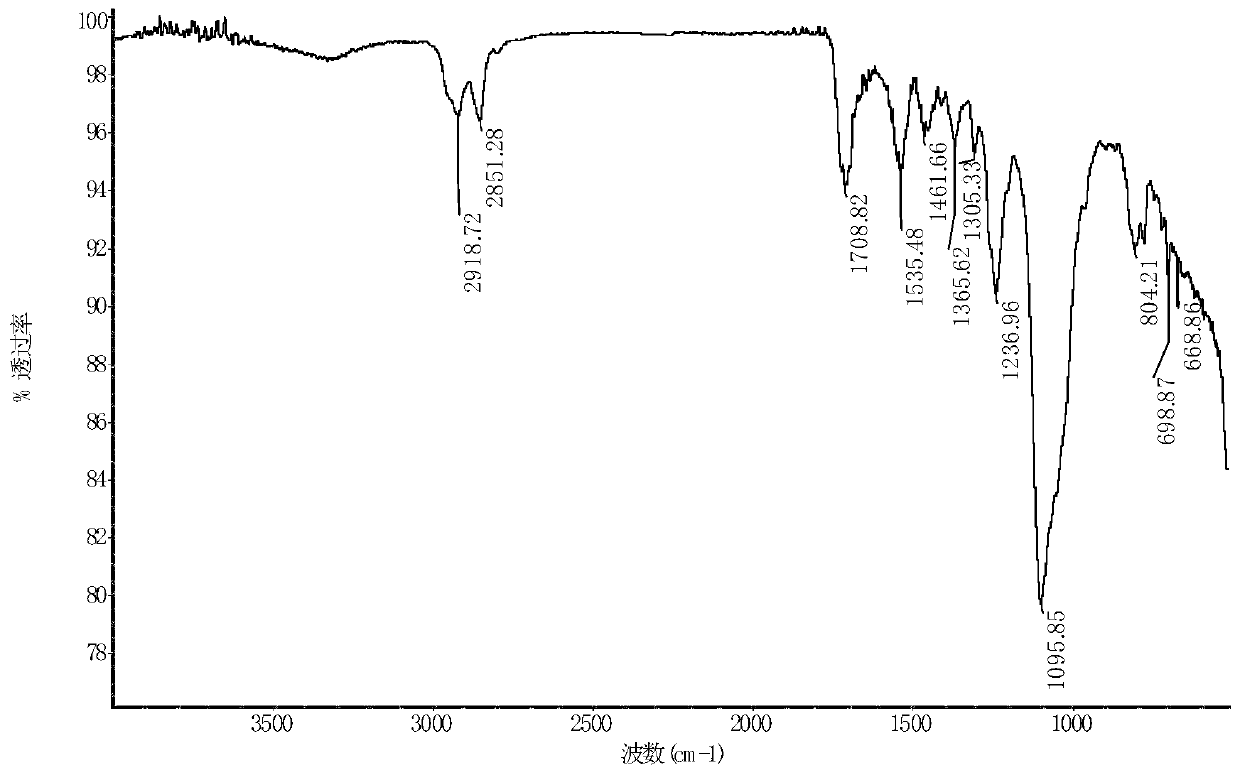

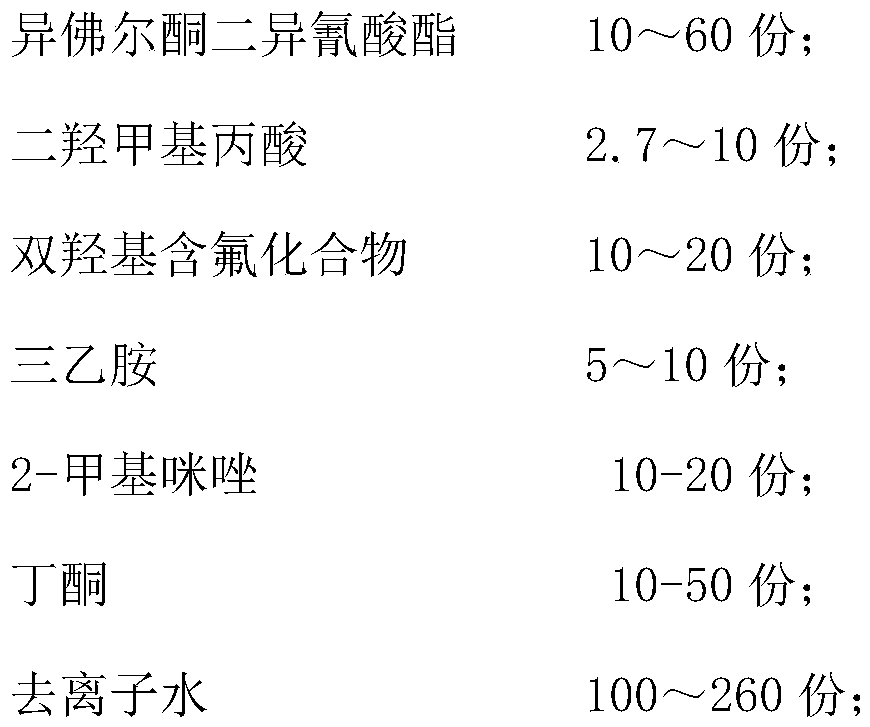

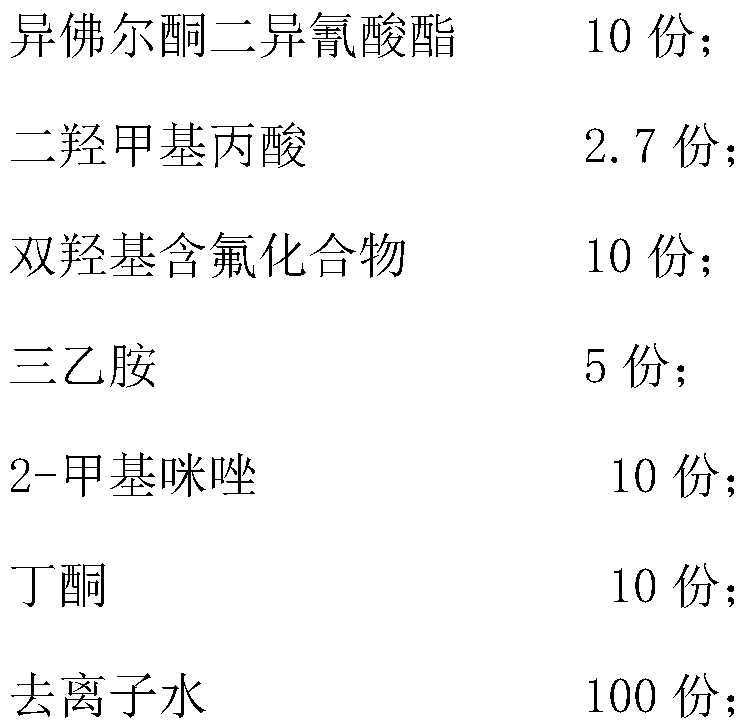

Curing agent for water-based resin and preparation method thereof

InactiveCN109942786AIncrease contact angleImprove hydrophobicityPolyurea/polyurethane coatingsWater basedMechanical equipment

The invention provides a curing agent for water-based resin and a preparation method thereof. The curing agent is characterized by being prepared from the following raw materials in parts by weight: 10-60 parts of isophorone diisocyanate, 2.7-10 parts of dimethylolpropionic acid, 10-20 parts of dihydroxy fluorinated compound, 5-10 parts of triethylamine, 10-20 parts of 2-methylimidazole, 10-50 parts of butanone and 100-260 parts of deionized water, wherein the dihydroxy fluorinated compound is prepared from hexafluoroisopropanol, isophorone diisocyanate, trimethylolpropane, solvent and catalyst in a weight ratio of (100-200):(100-200):(60-100):(10-100):(0.01-0.02); the solvent is one or mixture of more than two of acetone and ethyl acetate, and the catalyst is dibutyltin dilaurate. The curing agent can be used for preparing films with excellent lyophobic effect, and can be widely applied to protection of airplanes, ships, construction, traffic and various mechanical equipment.

Owner:SHANGHAI INST OF TECH

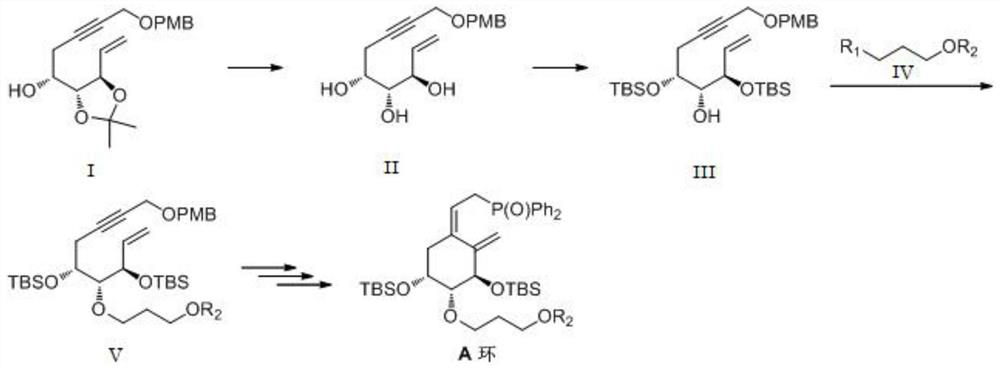

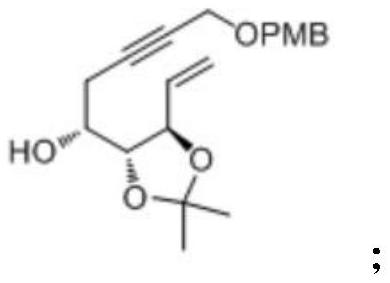

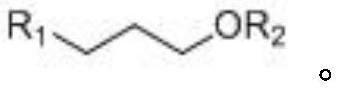

Preparation method of eldecalcitol A ring intermediate

ActiveCN112094290AEasy to prepareEasy to purifyGroup 4/14 element organic compoundsBulk chemical productionOrganic solventCombinatorial chemistry

The invention discloses a preparation method of an eldecalcitol A ring intermediate, and belongs to the technical field of organic chemistry, and the preparation method comprises the following steps:(1) dissolving a compound I in an organic solvent, and removing a propylidene protecting group under an acidic condition to obtain a compound II; (2) dissolving the compound II in an organic solvent,adding imidazole as an acid-binding agent, and adding tert-butyl dimethyl chlorosilane to react with the compound II to obtain a compound III; and (3) dissolving the compound III in an organic solvent, and carrying out etherification reaction on the compound III and a compound IV under the action of alkali to obtain a compound V; the preparation method is simple and convenient, the preparation route is greatly simplified, the raw materials are cheap and easy to obtain, the reaction conditions are mild, and the product is easy to purify.

Owner:甘肃皓天医药科技有限责任公司

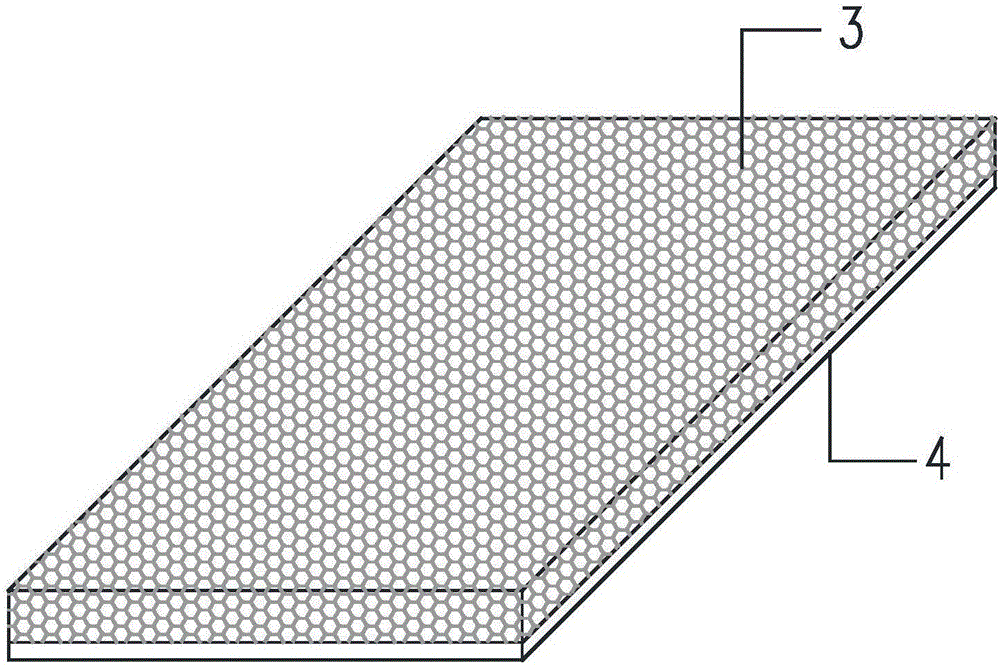

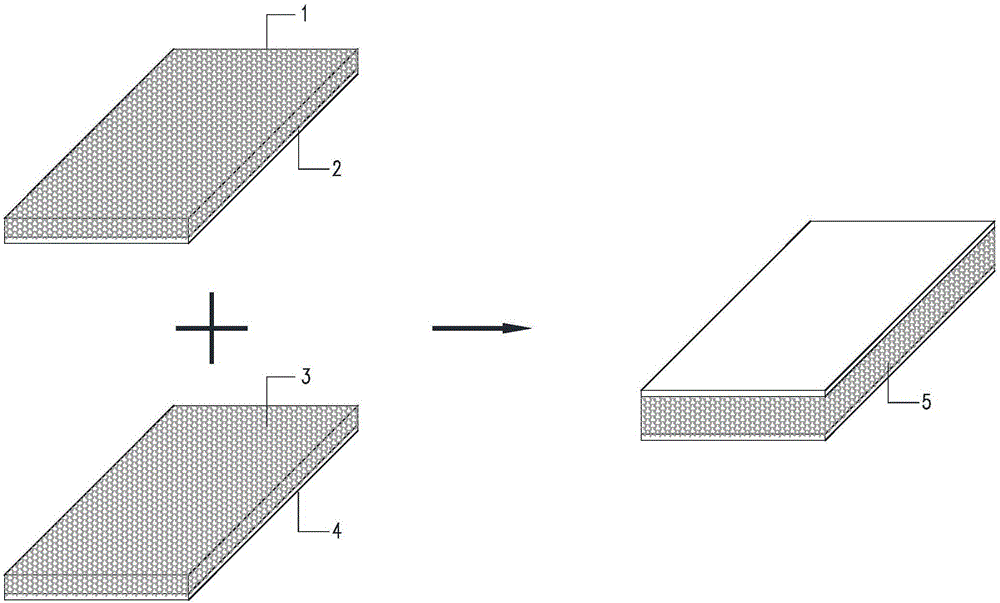

Assembly type magnesium-based cement foaming light board and preparation method thereof

ActiveCN106760149ASimple preparation routeLight weight high strengthConstruction materialSolid waste managementFiberSurface layer

The invention discloses an assembly type magnesium-based cement foaming light board and a preparation method thereof. The assembly type magnesium-based cement foaming light board comprises a first assembly light board body and a second assembly light board body. The first assembly light board body comprises a first magnesium-based cement fiber material surface layer and a first magnesium-based cement foaming layer, and the second assembly light board body comprises a second magnesium-based cement fiber material surface layer and a second magnesium-based cement foaming layer. The preparation method for the assembly type magnesium-based cement foaming light board comprises the following steps of (a) preparation of a magnesium-based cement foaming material; (b) preparation of a magnesium-based cement fiber material; (c) preparation of the first assembly light board body; (d) preparation of the second assembly light board body; and (e) preparation of the assembly type magnesium-based cement foaming light board. The assembly type magnesium-based cement foaming light board prepared through the preparation method is simple in preparation line, energy is saved, the environment is protected, waste is utilized, needed raw materials are cheap and easy to obtain, and the product is low in production cost.

Owner:王常清

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com