Curing agent for water-based resin and preparation method thereof

A water-based resin and curing agent technology, used in coatings, polyurea/polyurethane coatings, etc., can solve the problems of short pot life of two-component polyurethane coatings, and achieve the effect of improved mechanical properties and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

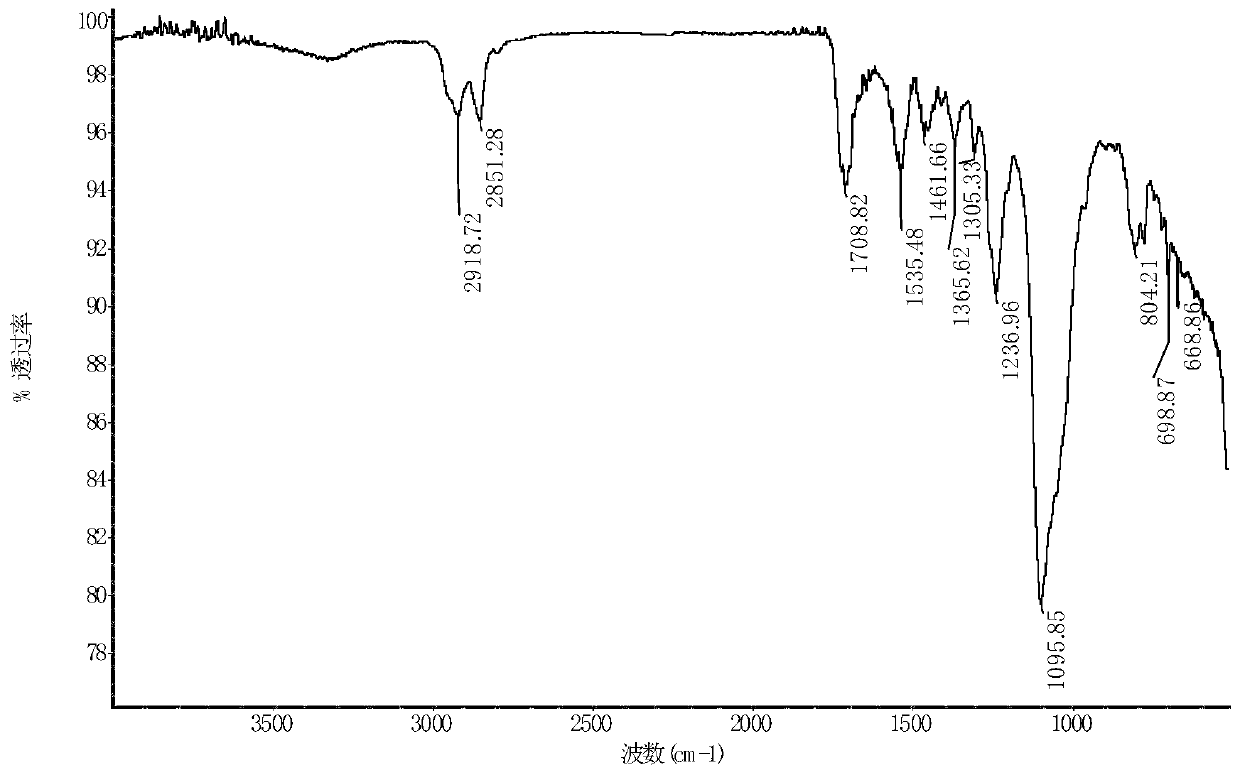

Image

Examples

Embodiment 1

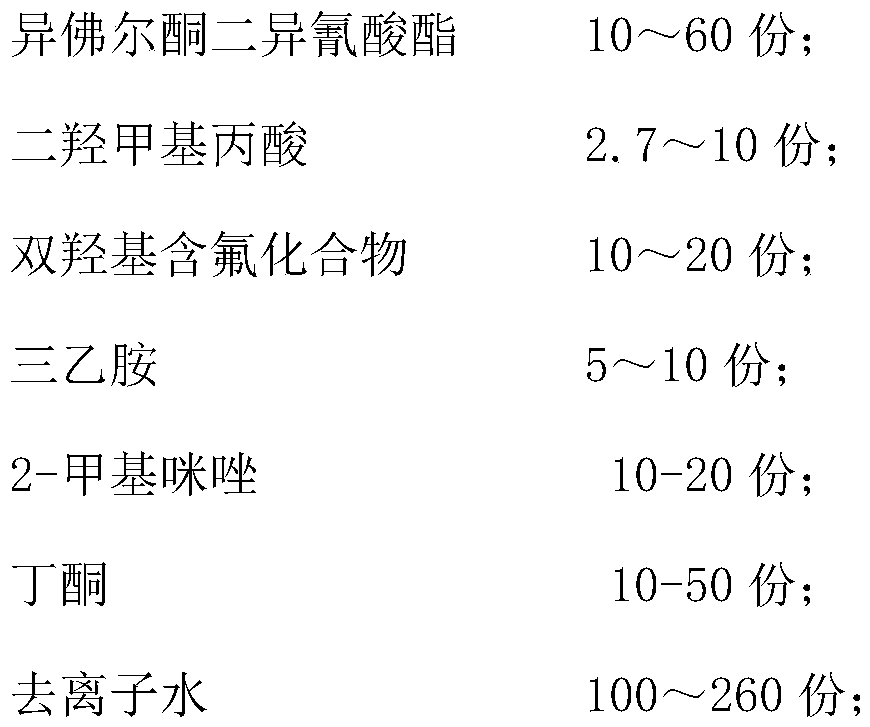

[0036] A curing agent for water-based resin, calculated in parts by weight, its preparation raw materials include:

[0037]

[0038] The raw materials for the preparation of the above-mentioned dihydroxyl fluorine-containing compound include: hexafluoroisopropanol, isophorone diisocyanate, trimethylolpropane, solvent and catalyst in a weight ratio of 100:100:60:10:0.01, wherein, The solvent is acetone; the catalyst is dibutyltin dilaurate.

[0039] The preparation method of above-mentioned a kind of water-based resin curing agent, the steps are as follows:

[0040] 1) Add hexafluoroisopropanol, isophorone diisocyanate, and the catalyst into the four-necked flask in sequence, raise the temperature to 30°C, and add the solvent into the four-necked flask at a rate of 0.05ml / s in proportion, React for 1 hour under stirring, then add trimethylolpropane in proportion, raise the temperature to 70°C, and react for 5 hours under stirring to obtain the dihydroxyl fluorine-containing...

Embodiment 2

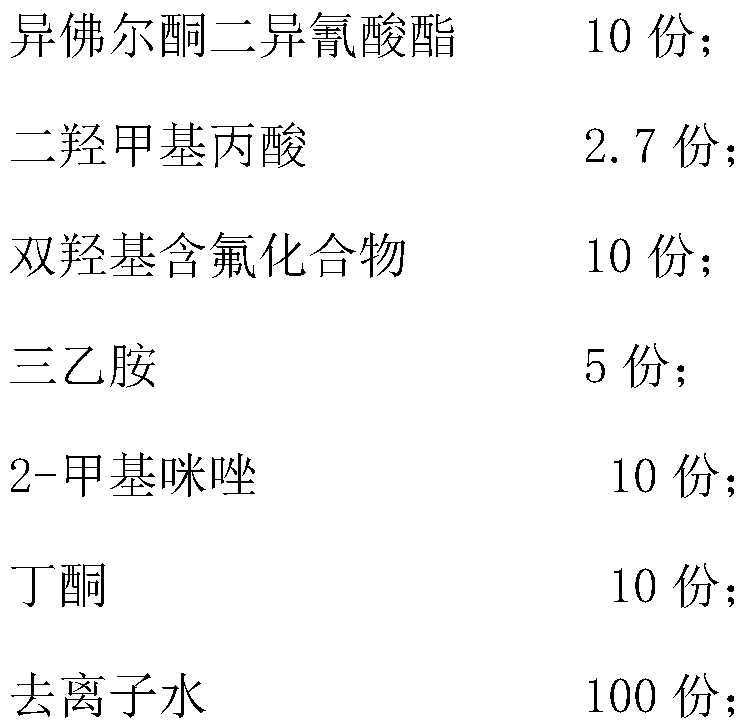

[0053] A curing agent for water-based resin, calculated in parts by weight, its preparation raw materials include:

[0054]

[0055] The raw materials for the preparation of the above-mentioned dihydroxyl fluorine-containing compound include: hexafluoroisopropanol, isophorone diisocyanate, trimethylolpropane, solvent and catalyst in a weight ratio of 200:200:100:100:0.02, wherein, The solvent is a mixture of acetone and ethyl acetate at a volume ratio of 1:1; the catalyst is dibutyltin dilaurate.

[0056] The preparation method of above-mentioned a kind of water-based resin curing agent, the steps are as follows:

[0057] 1) Add hexafluoroisopropanol, isophorone diisocyanate, and the catalyst to the four-necked flask in sequence, raise the temperature to 50°C, and add the solvent to the four-necked flask at a rate of 0.1ml / s in proportion, React for 1 hour under stirring, then add trimethylolpropane in proportion, raise the temperature to 90°C, and react for 1 hour under s...

Embodiment 3

[0064] A curing agent for water-based resin, calculated in parts by weight, its preparation raw materials include:

[0065]

[0066] The raw materials for the preparation of the above-mentioned dihydroxyl fluorine-containing compound include: hexafluoroisopropanol, isophorone diisocyanate, trimethylolpropane, solvent and catalyst in a weight ratio of 150:150:80:30:0.015, wherein, The solvent is ethyl acetate; the catalyst is dibutyltin dilaurate.

[0067] The preparation method of above-mentioned a kind of water-based resin curing agent, the steps are as follows:

[0068] 1) Add hexafluoroisopropanol, isophorone diisocyanate, and the catalyst into the four-necked flask in sequence, raise the temperature to 35°C, and add the solvent into the four-necked flask at a rate of 0.08ml / s in proportion, React for 2 hours under stirring, then add trimethylolpropane in proportion, raise the temperature to 80°C, and react for 2 hours under stirring to obtain the dihydroxyl fluorine-co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com