Patents

Literature

1122 results about "Dimethylolpropionic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dimethylolpropionic acid is a free flowing white crystalline solid consisting of one tertiary carboxylic group and two hydroxyl groups. The carboxylic acid group is less reactive and hence, DMPA act as a diol.

Aqueous organosilicone-modified alkyd resin and preparing method thereof

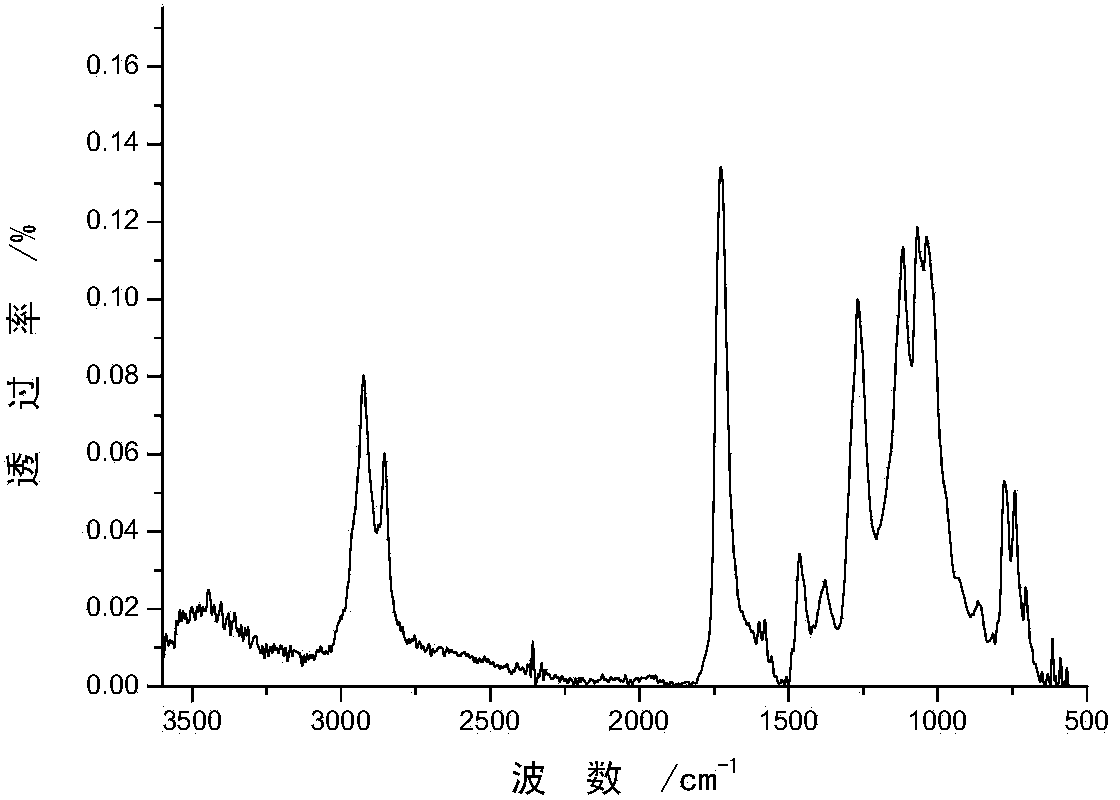

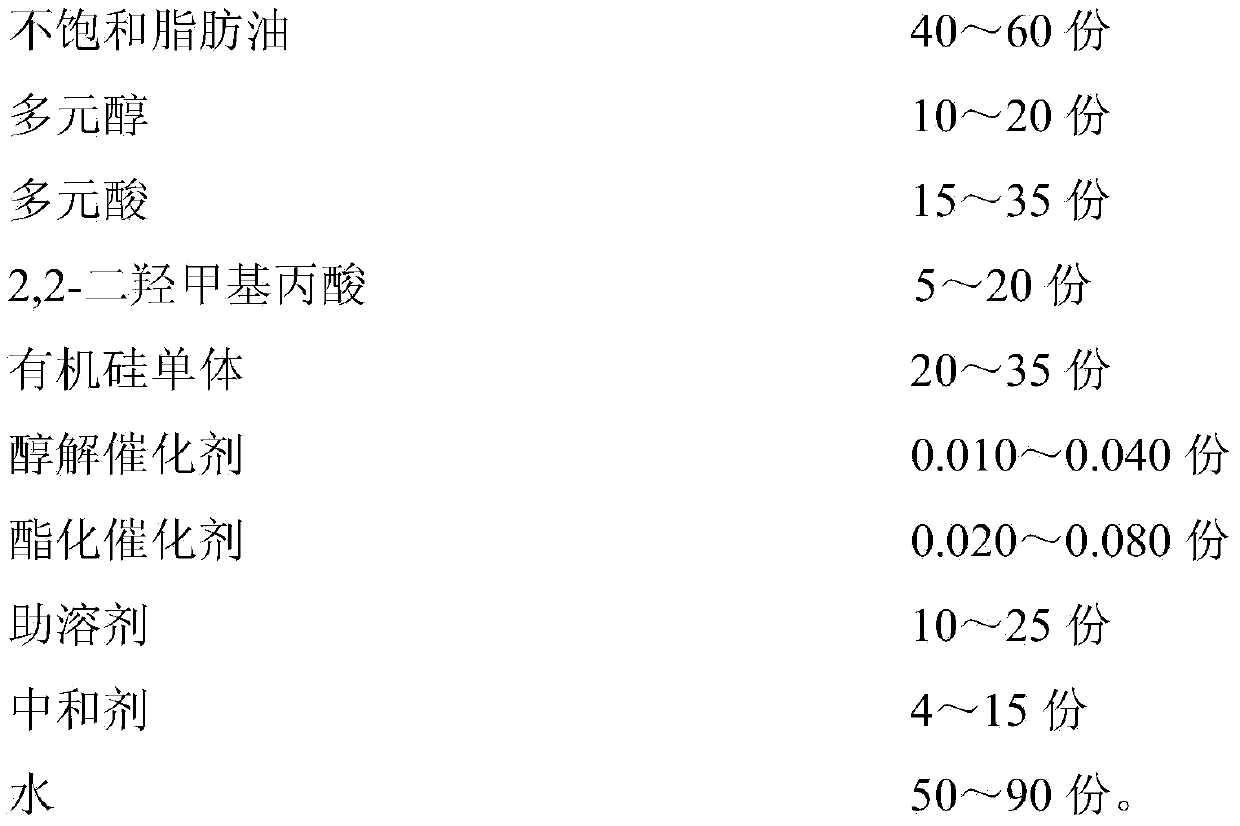

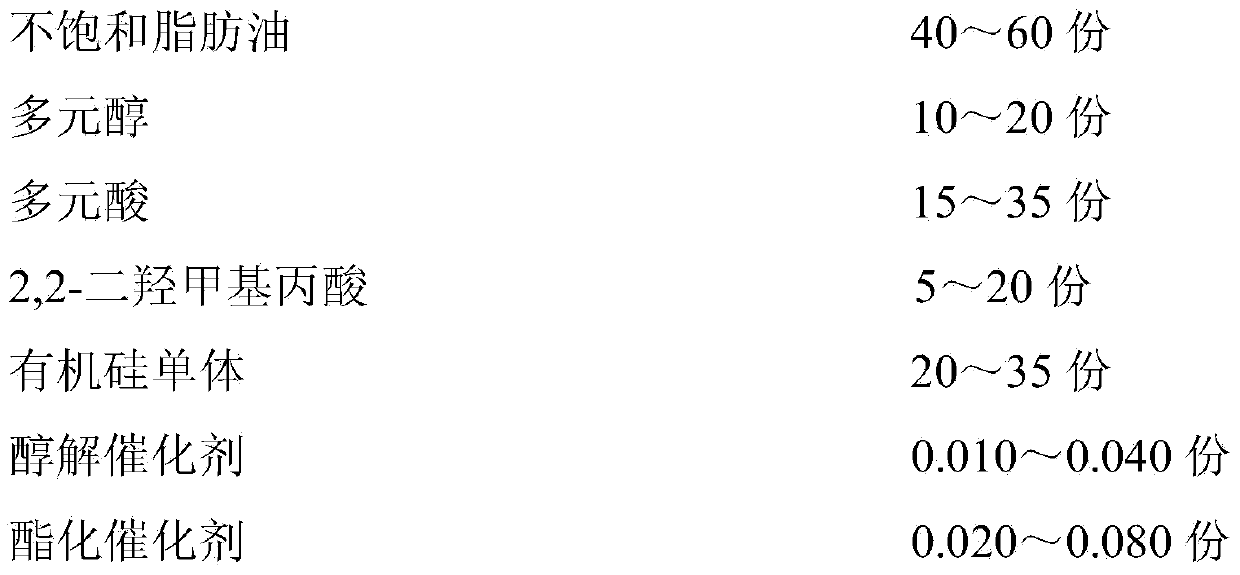

The invention belongs to the technical field of chemical engineering, and discloses aqueous organosilicone-modified alkyd resin and a preparing method thereof. The aqueous organosilicone-modified alkyd resin comprises following components by weight: 40-60 parts of nonsaturated fatty oil, 10-20 parts of polyol, 15-35 parts of polyatomic acid, 5-20 parts of 2,2-dimethylolpropionic acid, 20-35 parts of an organosilicon monomer, 0.010-0.040 part of an alcoholysis catalyst, 0.020-0.080 part of an esterification catalyst, 10-25 parts of a cosolvent, 4-15 parts of a neutralizer and 50-90 parts of water. The prepared alkyd resin has characteristics of clear appearance, good water solubility, good properties, no toxicity, no harm, and capability of meeting the environmental requirements.

Owner:SOUTH CHINA UNIV OF TECH

Polyurethane-polypeptide graft copolymer and preparation method thereof

The invention relates to a polyurethane-polypeptide graft copolymer and a preparation method thereof. The graft copolymer is a comb-shaped polymer, wherein the molecular weight of polyurethane is 10,000 to 100,000; and the molecular weight of the polypeptide chain segment is 500 to 5,000. The preparation method comprises the following steps of: 1) synthesis of polyurethane provided with lateral carboxyl on the molecular chain: adding diisocyanate, polypropylene glycol, polyethylene glycol, dibutyltin dilaurate catalyst and dimethyl formamide solvent into a dry reaction bottle, performing stirring reaction under inert atmosphere, adding dimethylolpropionic acid dissolved in dimethyl formamide to react, adding butanediol to react, finally adding butanol to react, and obtaining a target product; and 2) synthesis of the polyurethane-polypeptide graft copolymer: putting the polyurethane provided with lateral carboxyl on the molecular chain, a solvent and a condensation agent into a dry reactor, adding polypeptide homopolymer into the reactor, and performing stirring reaction under the inert atmosphere to obtain a target product with pH response.

Owner:SHANDONG UNIV OF TECH

One-component transparent waterborne polyurethane emulsion waterproof paint and preparation method thereof

InactiveCN105255348AImprove solubilityIncrease the amount of participationPolyurea/polyurethane coatingsSilicon dioxideTin

The invention discloses one-component transparent waterborne polyurethane emulsion waterproof paint and a preparation method thereof and relates to polyurethane waterproof paint. The waterproof paint comprises a resin phase and a nano-material phase. The preparation method comprises the following steps: diol and a hydrophilic chain extender are dried, and other prepolymerization monomers are dried; diol, diisocyanate, fluorine-containing acrylate monomers and hydroxyl-terminated siloxane after a dehydration process are added to a four-neck flask, the mixture is heated and added with an organic tin initiator for a reaction under the protection of nitrogen, and the mixture is heated and added with dimethylolpropionic acid for continuous reaction; after a reaction system is cooled, the chain extender and acrylate monomers are added for a reaction; after a prepolymer is cooled to the temperature lower than the room temperature, a neutralizer and a cross-linking agent are added; then deionized water is added for emulsification, and mixed liquor A is obtained; a silane coupling agent is dissolved in absolute ethyl alcohol, silica microspheres are added to absolute ethyl alcohol, and mixed liquor B is obtained; the mixed liquor B is added to the mixed liquor A, the mixture is heated, and a radical initiator is added for a reaction; an organic solvent is removed, and the one-component transparent waterborne polyurethane emulsion waterproof paint is obtained.

Owner:XIAMEN UNIV

N-methylpyrrolidone-free polyurethane dispersions based on dimethylolpropionic acid

InactiveUS20060240264A1Synthetic resin layered productsPolyurea/polyurethane coatingsPolymer sciencePropanoic acid

The present invention relates to aqueous polyurethane dispersions that are free from N-methylpyrrolidone and other solvents and wherein the polyurethanes are the reaction products of A) a mixture of 25% to 90% by weight of 1-isocyanate-3,3,5,-trimethyl-5-isocyanatomethylcyclohexane (IPDI) and 10% to 75% by weight of 4,4′-diisocyanatodicyclohexylmethane, wherein the preceding percentages are based on the weight of component A), with B) one or more polyols having average molarcular weights (Mn) of 500 to 6000, C) one or more compounds which have at least one OH— or NH-functional group and contain a carboxyl and / or carboxylate group, wherein at least 50 mol % of the acid groups, based on the total moles of acid incorporated into the polyurethane, are incorporated by dimethylolpropionic acid, D) one or more polyols and / or polyamines having average molecular weights (Mn) of below 500, and E) optionally one or more monoalcohols and / or monoamines. The present invention also relates to a process for preparing the aqueous polyurethane dispersions and to the use of the polyurethane dispersions for preparing coatings or adhesives.

Owner:BAYER MATERIALSCIENCE AG

Preparation method of organic fluorosiloxane modified polyurethane emulsion containing short fluoroalkyl chain

ActiveCN103865026ANot easy to corrodeImprove water resistancePolyurea/polyurethane coatingsPolymer scienceSolvent

The invention relates to a preparation method of an organic fluorosiloxane modified polyurethane emulsion containing a short fluoroalkyl chain. The method comprises the following steps: by taking isophorone diisocyanate as a hard segment and a mixture of polytetrahydrofuran ether diol and hydroxyl silicone oil as a soft segment, heating to 70-110 DEG C to react for 1-8 hours; then, adding dimethylolpropionic acid and fluorine-containing diol as a chain extender for primary chain extension for 1-6 hours; cooling to 25-60 DEG C, adding a neutralizer, stirring for 0.5-1.5 hours, and transferring to a high speed disperser; adding neutralizer and a secondary chain extender, and dispersing for 0.5-3 hours at a high speed to obtain the emulsion which is uniform and stable in grain size. The prepared modified polyurethane emulsion coating not only has better temperature resistance, water resistance, solvent resistance and corrosion resistance, but also has good water repellency and oil repellency.

Owner:SHANDONG UNIV

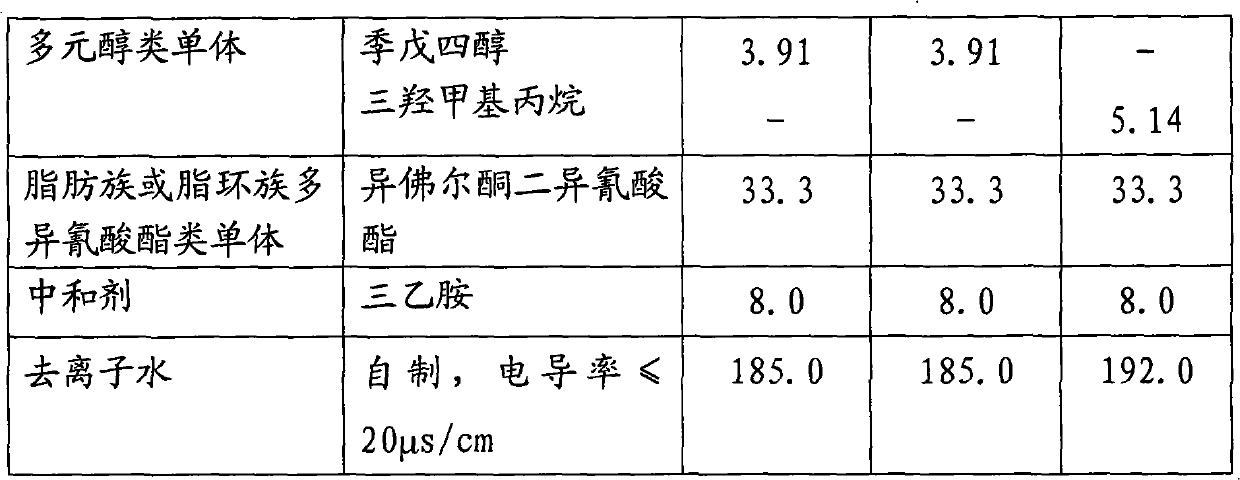

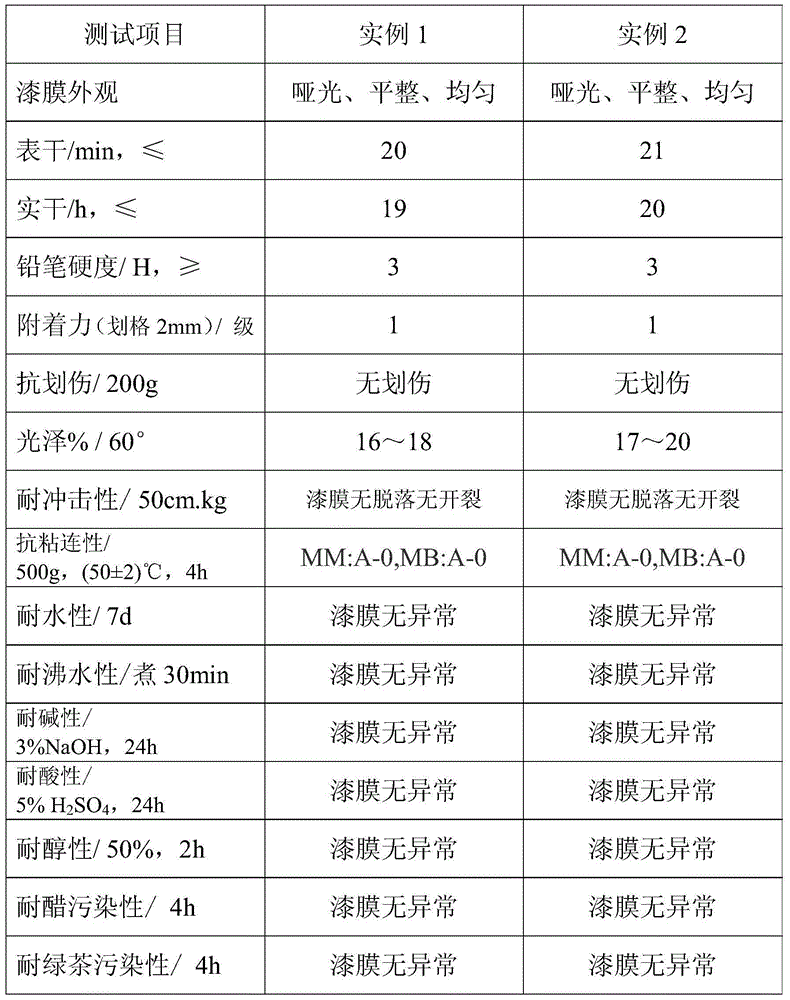

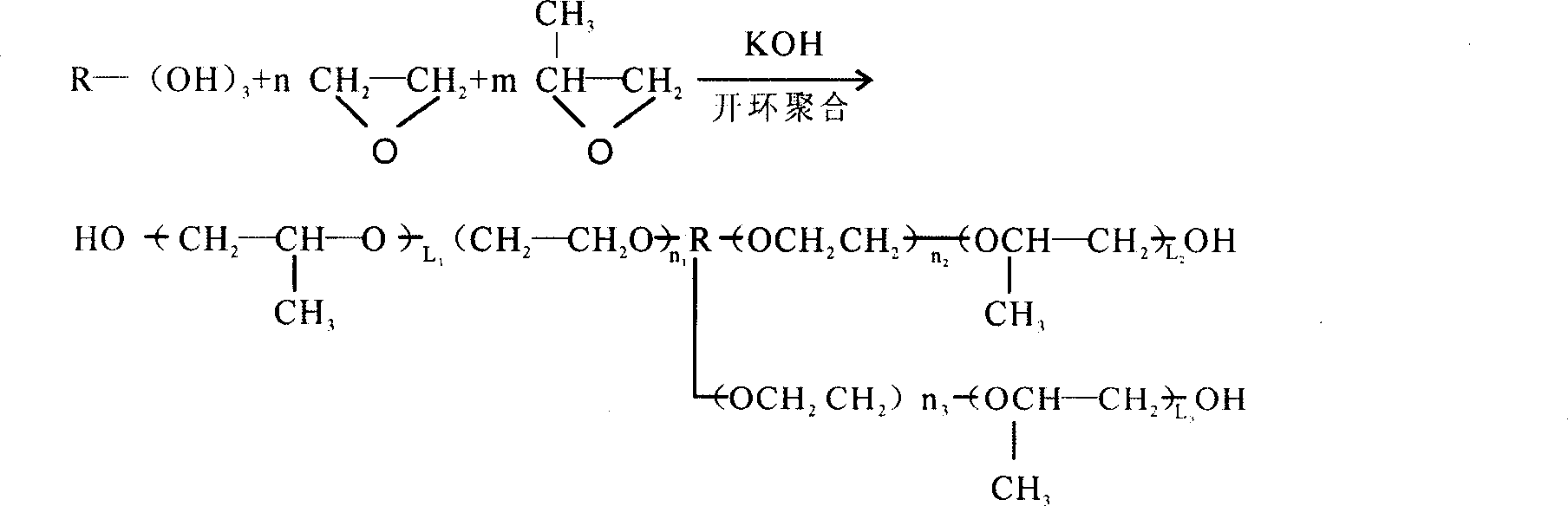

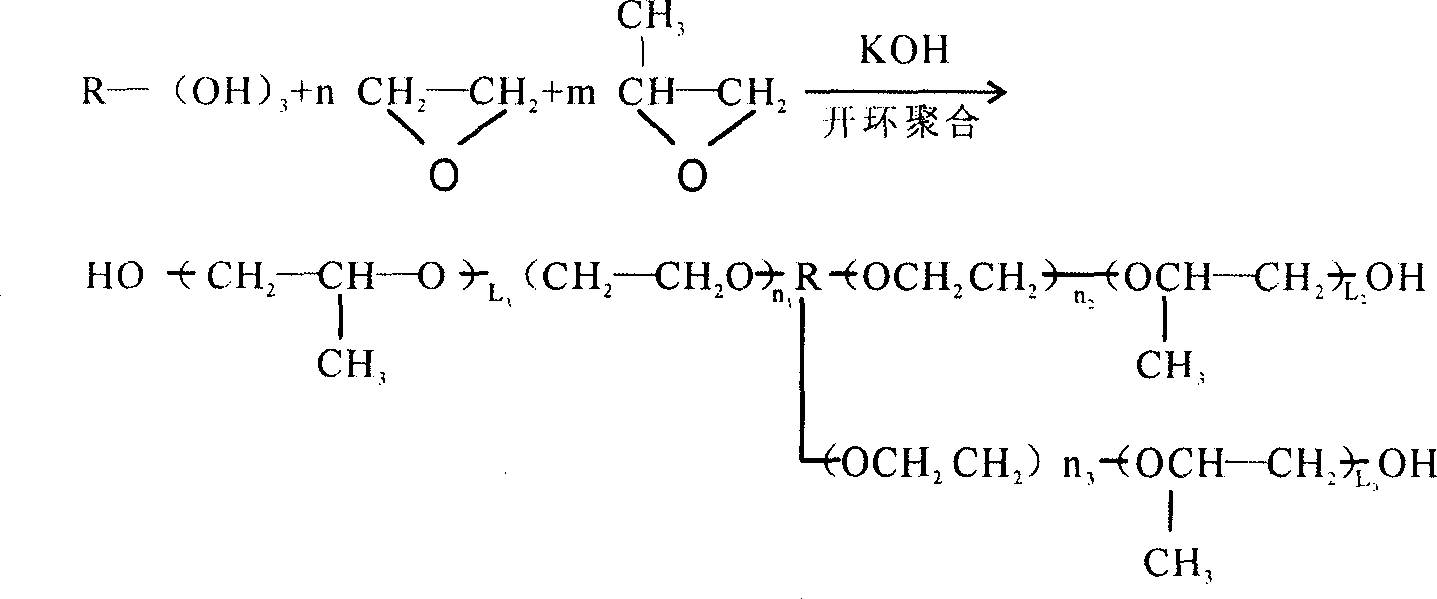

Hydroxylated polyurethane water dispersoid for waterborne soft-feel coating and preparation method thereof

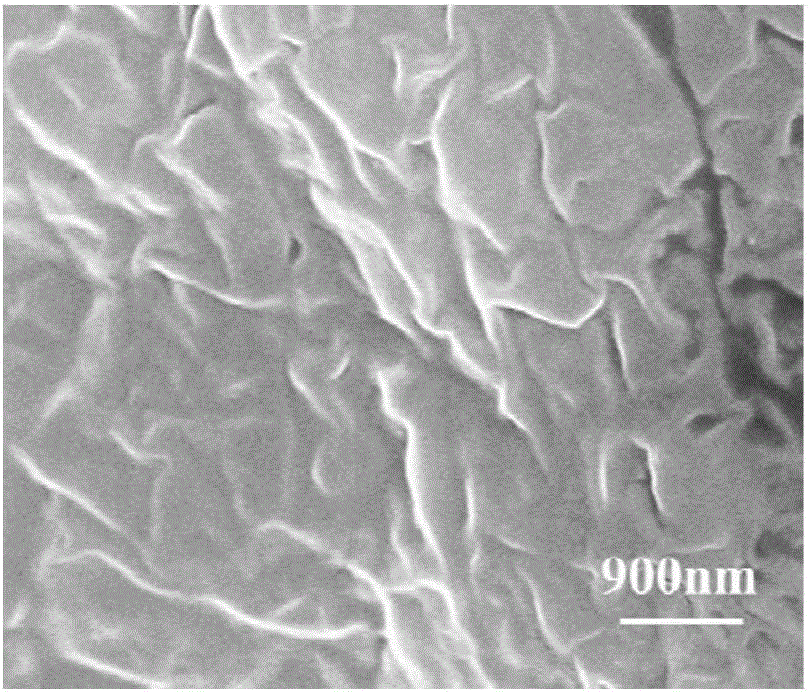

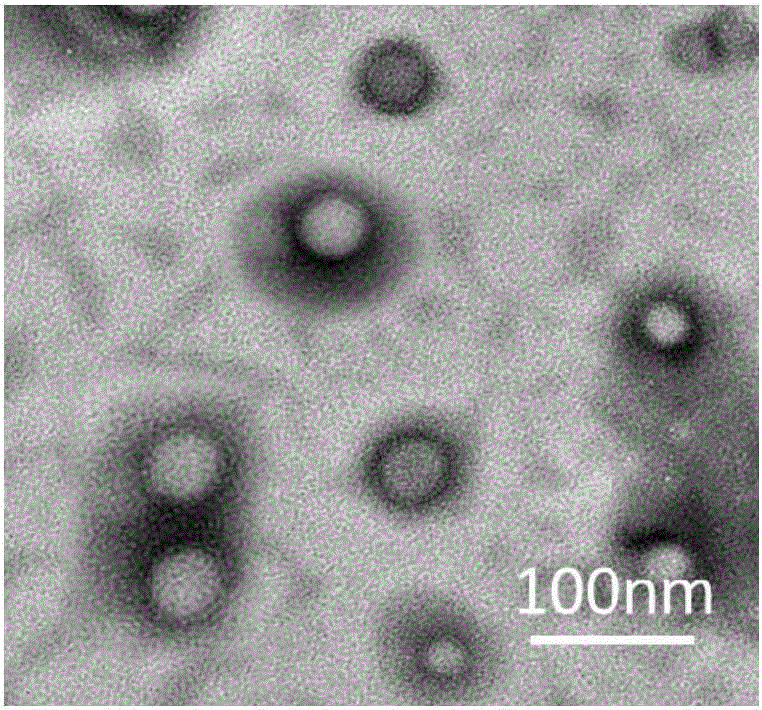

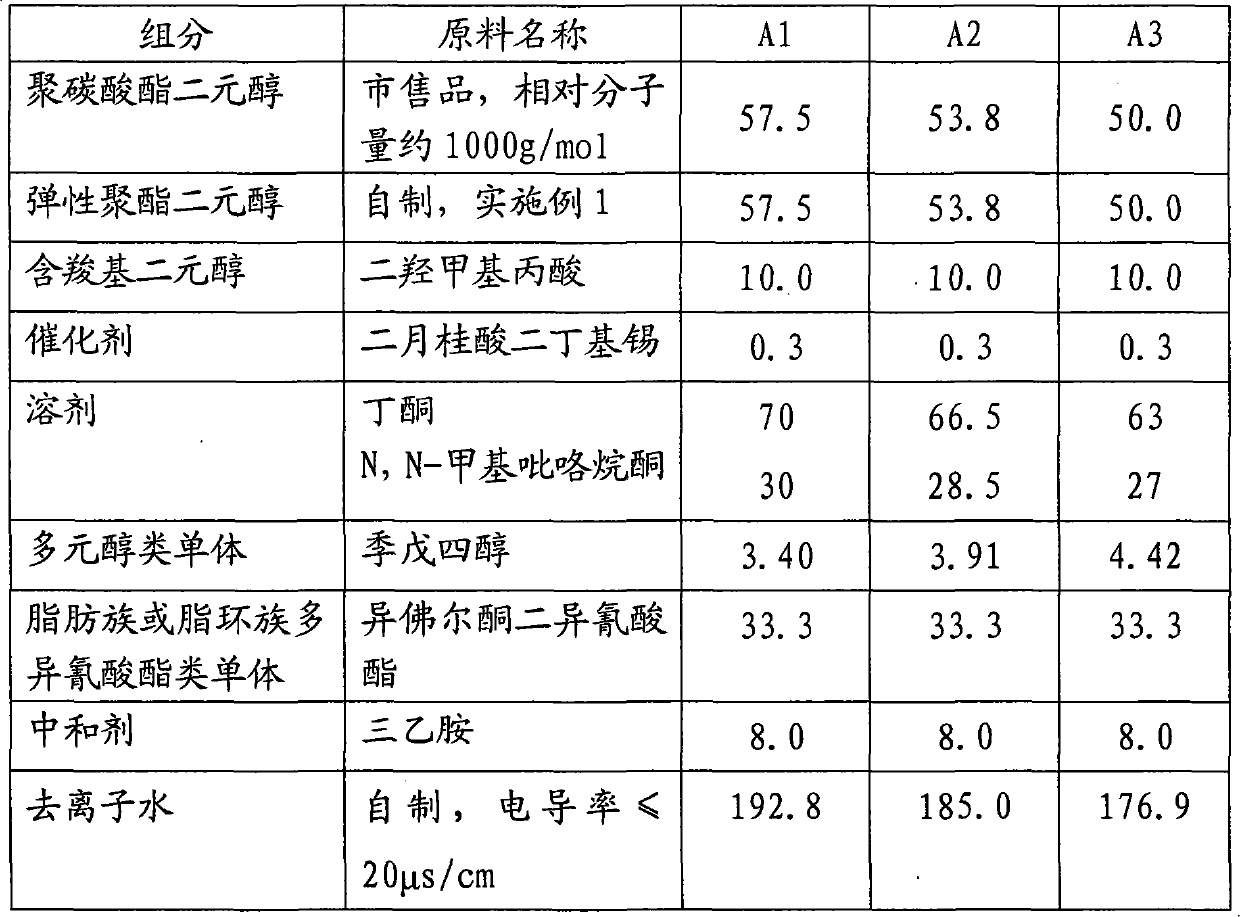

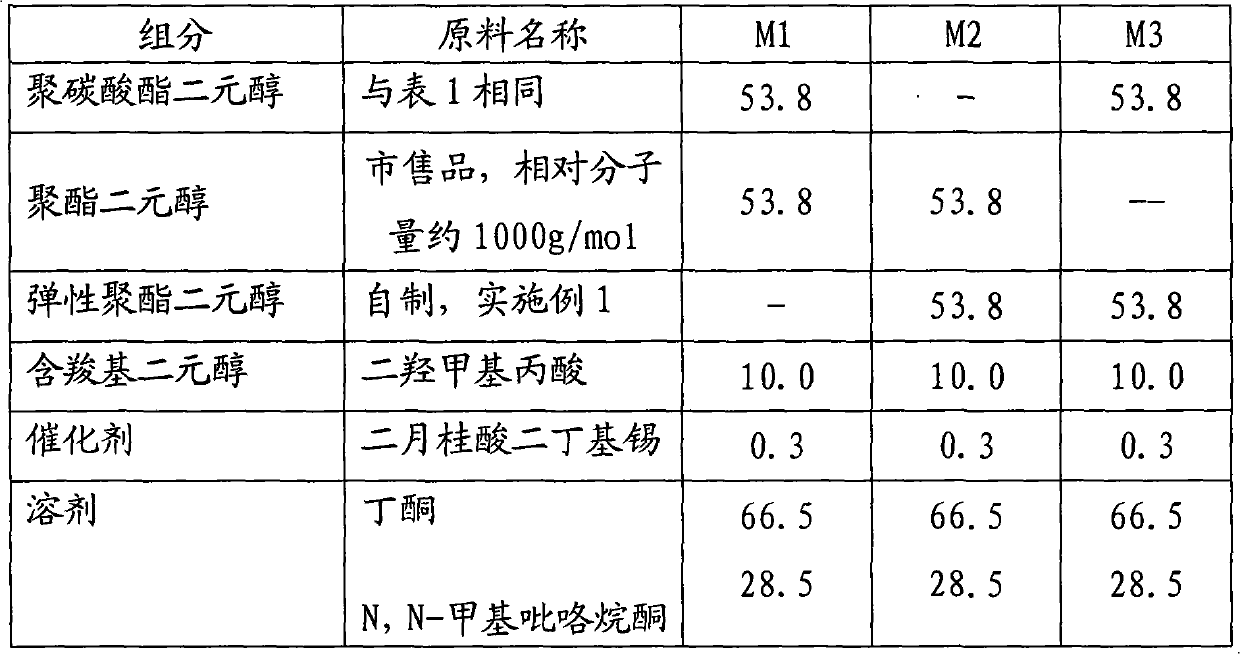

ActiveCN102002166AThe preparation process is simple and controllableEasy to operatePolyurea/polyurethane coatingsPolyesterFilm resistance

The invention relates to a hydroxylated polyurethane water dispersoid for a waterborne soft-feel coating and a preparation method thereof. The hydroxylated polyurethane water dispersoid is the water dispersoid formed by the following steps of: taking the raw materials in parts by weight: 15 to 20 parts of polycarbonate diols, 15 to 25 parts of elastic 4-butanediol, 1 to 5 parts of pentaerythritol, 2 to 5 parts of hydroxylated dimethylolpropionic acid or dihydroxymethyl butyric acid, 10 to 20 parts of fatty group or alicyclic group isocyanates monomers and 0.1 to 1.0 part of catalysts and solvents; carrying out heating polymerization to obtain hydroxylated urethane resin; and then neutralizing a water dispersoid formed after salt forming, self emulsifying and the solvent removing, wherein the coating-4 viscosity change of the coating stored for 6 months is smaller than 5 percent. After the hydroxylated polyurethane water dispersoid prepared by the method is prepared into a double-ingredient waterborne soft-feel coating, better balance is obtained between the coating film soft feel and the coating film resistance on alcohol and contaminants, and the effect of the hydroxylated polyurethane water dispersoid is proved.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Aqueous fluorine-containing acrylate modified polyurethane coating, preparation method and application thereof

The present invention belongs to the field of polymer material synthesis, relates to aqueous polyurethane acrylate emulsion modification, and especially to an aqueous fluorine-containing acrylate modified polyurethane coating, a preparation method and an application thereof. The preparation method comprises: dissolving polyether polyol in an N-methyl pyrrolidone solution of dimethylol propionic acid; adding diisocyanate in a dropwise manner; adopting dibutyltin dilaurate as a catalyst, and adding hydroxyethyl methacrylate to carry out end capping; adding triethylamine to form a salt, then adding deionized water to prepare an aqueous polyurethane acrylate prepolymer emulsion; and finally adding hexafluorobutyl acrylate and azodiisobutyronitrile to prepare the aqueous fluorine-containing acrylate modified polyurethane coating. The synthesized emulsion of the present invention has the following advantages that: dispersion is uniform; stability is good; water resistance and mechanical property of the cured film are substantially improved; elasticity and mechanical property of polyurethane are provided; ultraviolet resistance, nuclear radiation resistance, flexibility, excellent surface properties, water resistance and corrosion resistance of the fluorine-containing material are provided; and the coating can be adopted as coatings for building and furniture.

Owner:BOMEX CHEM SHANGHAI

Method for preparing organosilicon/acrylate double modified aqueous polyurethane

The invention relates to a method for preparing organosilicon / acrylate double modified aqueous polyurethane, which comprises the following steps: carrying out a reaction on isocyanate, polyhydric alcohol and dimethylolpropionic acid to obtain polyurethane prepolymer I; dropwise adding dimethylolpropionic acid into the polyurethane prepolymer I, and dropwise adding hydroxyethyl methacrylate containing a polymerization inhibitor into the polyurethane prepolymer I, thereby obtaining polyurethane prepolymer II containing double bonds; dropwise adding organosilane into the polyurethane prepolymer II to obtain silane-modified polyurethane; adding triethylamine into the silane-modified polyurethane to carry out salification reaction, adding deionized water, and stirring to obtain organosilicon-modified aqueous polyurethane emulsion; and finally, adding methyl methacrylate and butyl acrylate into the organosilicon-modified aqueous polyurethane emulsion to carry out emulsion polymerization, thereby obtaining the organosilicon / acrylate double modified aqueous polyurethane. The method has the advantages of convenient operation and simple technique; and the prepared polyurethane chain segment contains silane and acrylate and has the advantages of favorable water resistance and mechanical properties.

Owner:QINGDAO UNIV OF SCI & TECH +1

A preparing method of water-based self-crosslinking acrylic acid modified polyurethane matte resin

The invention relates to a preparing method of water-based self-crosslinked acrylic acid modified polyurethane matte resin. The resin mainly comprises isocyanate tripolymer, polyether polyol or polyester polyol, dimethylolpropionic acid, acrylate, an alkali neutralizing agent and deionized water. The resin prepared by the method is low in VOC content, environmental friendly and free of pollution and is characterized by low-temperature curing performance, a high extinction efficiency, good transparency, protruding water proofness, protruding acid resistance, protruding alkali resistance, protruding stain resistance and protruding yellowing resistance. After modification, polyurethane and hydroxy in acrylic acid resin are crosslinked, thus enhancing the resin crosslinking density, and improving resin mechanical strength, wear resistance and scratch resistance. The matte resin is free of addition of a flatting agent and insensitive to electrolytes. Prepared coating is good in stability. The matte resin is widely used for water-based wood paint, water-based industrial paint, water-based plastic paint, and the like requiring matte effects.

Owner:常州市日新树脂有限公司

Polyurethane shape memory macromolecule material and synthetic technique thereof

A polyurethane shape memory polymer material and its synthesis are disclosed. The process is carried out by vacuum dewatering, pre-polymerization reacting 2,4-toluene diiso-cyanate with DMF under N2 protection, dripping into polyhydric alcohol to obtain pre-polymer, chain-extending reacting DMPA with 1,4-BDO, neutralization reacting TEA with DMPA carboxyl, and adding water 300-1000 ml to obtain final product. The final solution concentration is 15-25 mol%. It has excellent waterproof, gas-permeation performances and moisture-penetrability.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Method for preparing waterborne polyurethane taken as waterborne epoxy hardener

The invention relates to a method for preparing waterborne polyurethane taken as a waterborne epoxy hardener. The method comprises the following steps of: adding aliphatic polyisocyanate into low polymer polyalcohol; dissolving dimethylolpropionic acid taken as a hydrophilic chain extender in N-methylpyrrolidone; adding dibutyltin dilaurate taken as a catalyst into the mixture; stirring the mixture and raising the temperature to a certain extent to prepare a preformed polymer containing a terminated isocyanate group; cooling the prepared preformed polymer to room temperature; adding triethylamine into the preformed polymer to perform neutralization reaction for a certain period of time; and adding an appropriate amount of distilled water and violently stirring the mixture to emulsify the mixture; and adding a polyamine chain extender to perform chain extension reaction for a certain period of time to obtain amino-terminated waterborne polyurethane emulsion. The method has the advantages of preparing polyurethane emulsion which can be directly applied to curing epoxy resin, realizing a simple synthetic method and more easily controlled operation, enhancing the compatibility of epoxy resin emulsion with a curing agent, enabling a synthetized paint product to achieve the advantages of polyurethane and the epoxy resin and realizing high performance of paint.

Owner:TIANJIN UNIV

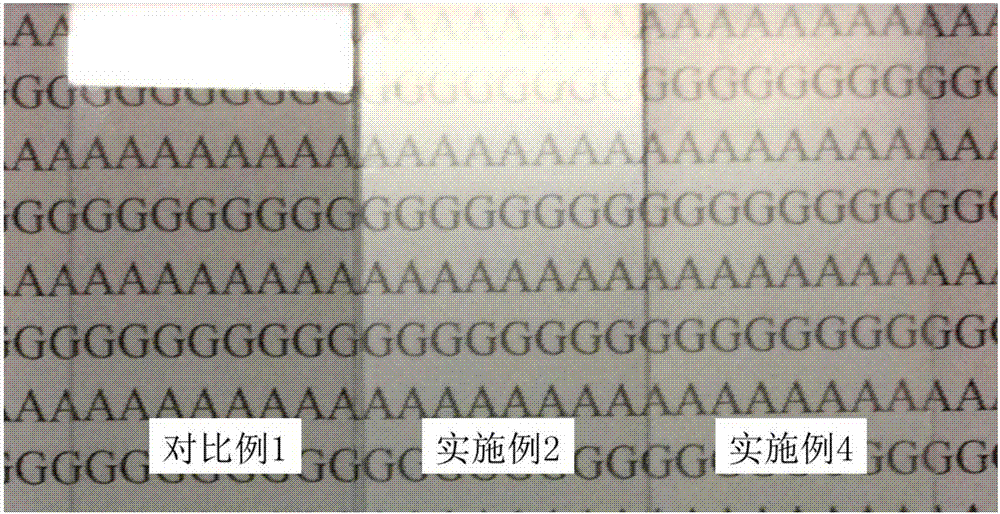

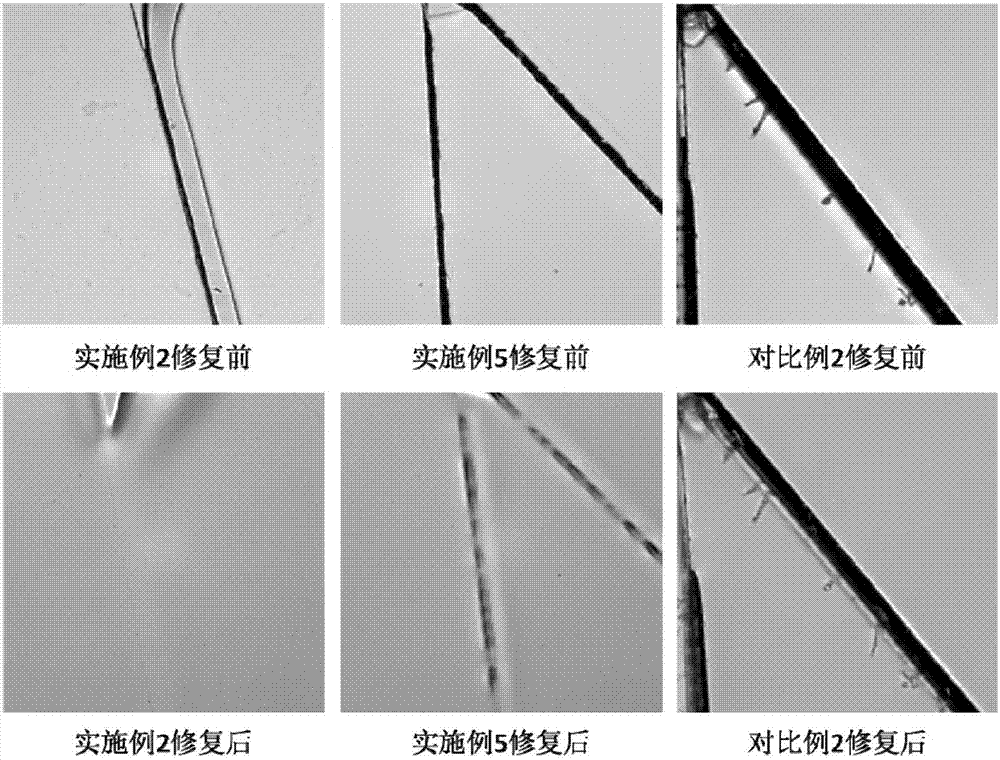

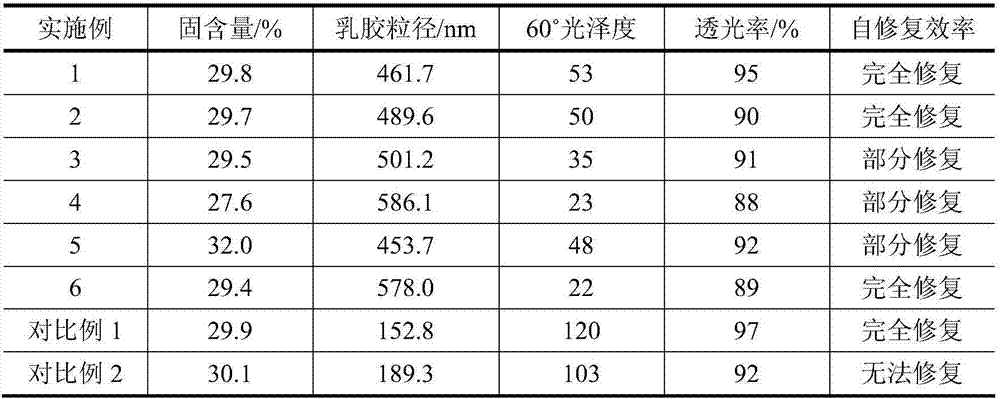

Self-repairing anti-glare waterborne polyurethane paint and preparation method thereof

ActiveCN106867388AGuaranteed transmission throughTo achieve the purpose of anti-glarePolyurea/polyurethane coatingsPolymer scienceCopolymer

The invention discloses anti-glare waterborne polyurethane paint with a self-repairing function and a preparation method thereof. The preparation method is characterized in that aliphatic polyether glycol subjected to dehydration treatment and diisocyanate are subjected to prepolymerization under the effect of organic tin catalyst; then, the aliphatic polyether glycol subjected to dehydration treatment is added to generate a segmented copolymer; primary chain extension is performed through dimethylolpropionic acid; neutralization is performed to form salt; deionized water and sodium sulfamate type chain extenders are subjected to emulsification and chain extension; sulfonic acid groups are introduced at a hard chain section; then, aliphatic diamine type or hydrazine chain extenders with higher reactivity is added, so that the rest isocyanate completely reacts; finally, the proper amount of auxiliary agents is mixed to obtain the waterborne polyurethane paint. The paint coating film has good diffusion performance and high transmissivity; the excellent anti-glare effect can be achieved without adding additional auxiliary agents or performing surface treatment; the coating film has the self repairing capability through a large number of reversible hydrogen bonds and sulfonic acid groups in polyurethane.

Owner:QINGYUAN YAKOO CHEM CO LTD

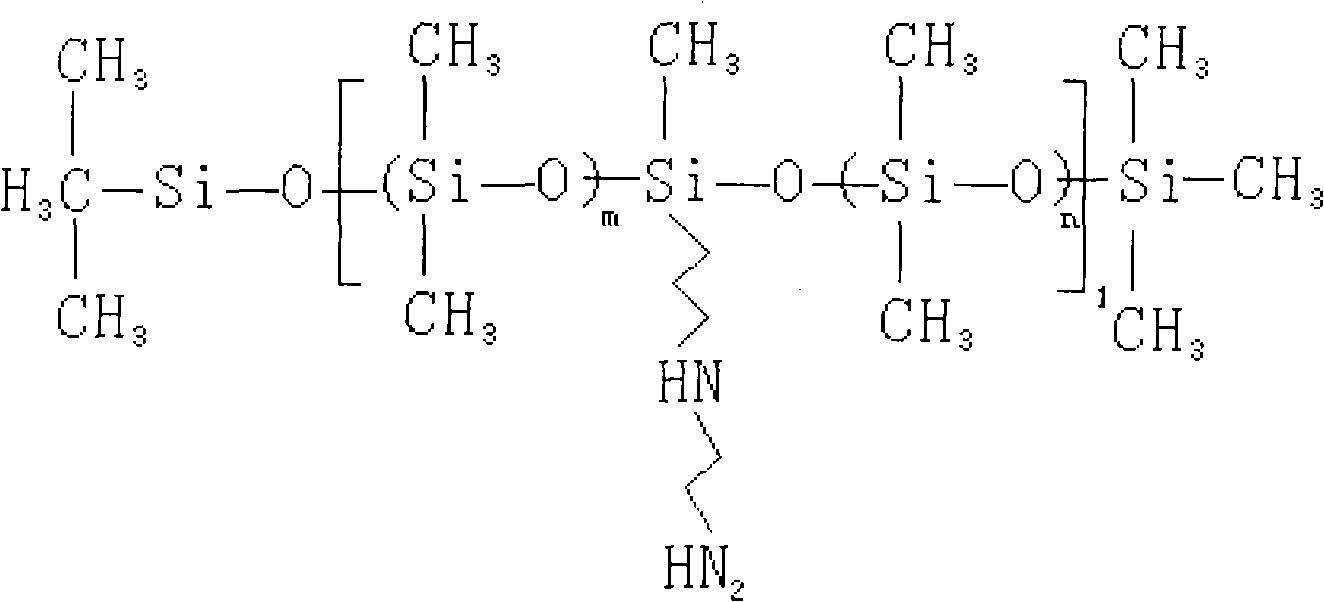

Amino silicone modified waterborne polyurethane and preparation method thereof

InactiveCN102167795AReduce joinLower surface energyPolyurea/polyurethane coatingsPropanoic acidSide chain

The invention discloses amino silicone modified waterborne polyurethane. The waterborne polyurethane is prepared from the following raw materials in parts by weight: 150-220 parts of polyether, 100-150 parts of isophorone diisocyanate, 15-20 parts of dimethylol propionic acid, 0.5-0.8 part of catalyst, 0-5 parts of trimethylolpropane, 15-30 parts of 1,4-butanediol, 4-5 parts of acetone, 10-15 parts of triethylamine, 5-10 parts of side chain amino silicone oil and 620-630 parts of deionized water. The preparation method of the amino silicone modified waterborne polyurethane is that side chain amino silicone oil is introduced in the aqueous phase chain extending process for modification; and the waterborne polyurethane has low preparation cost and good water resistance and adhesive force, is environmentally friendly and has no security threat.

Owner:王奇

Poly(carbonate-ether) aqueous polyurethane, aqueous polyurethane adhesive and preparation method thereof

ActiveCN103483539AReduce usageHigh solid contentPolyureas/polyurethane adhesivesPolyurethane adhesiveEther

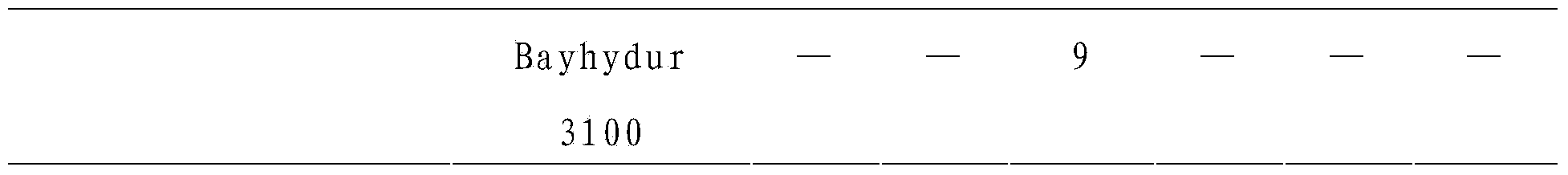

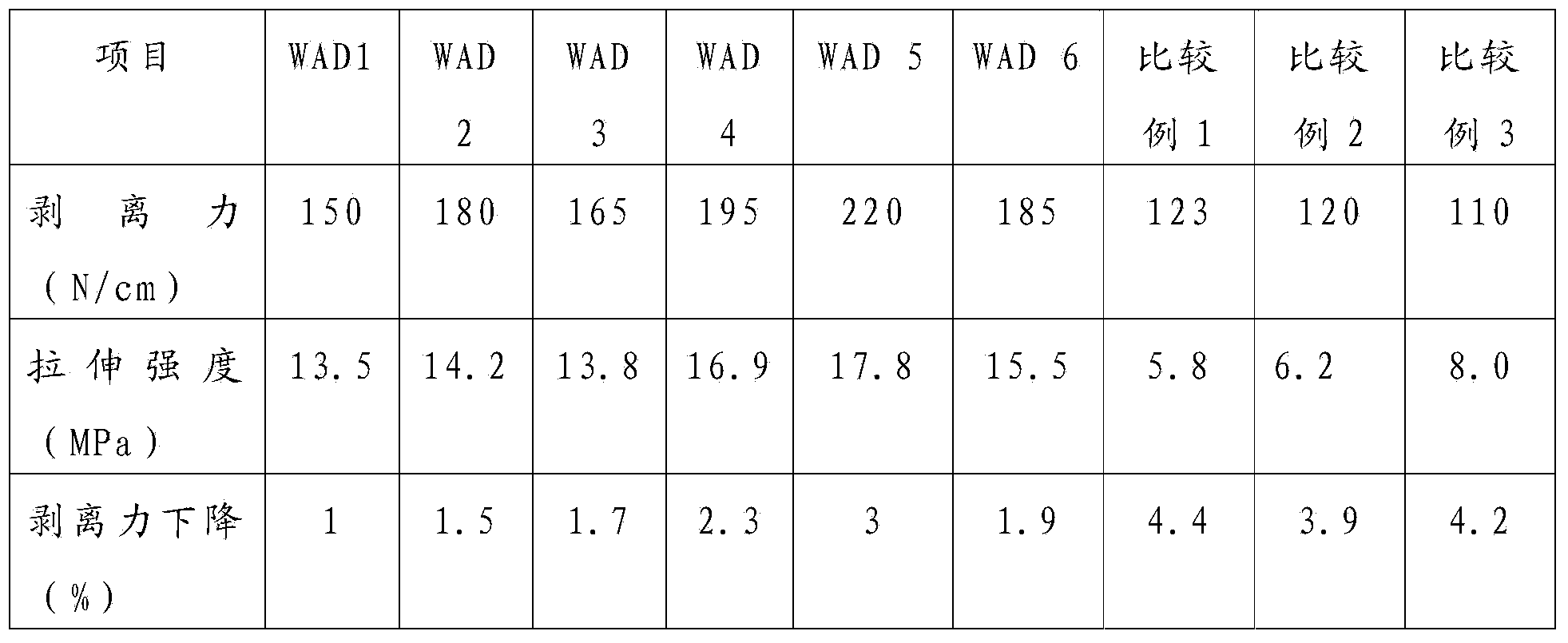

The invention provides a poly(carbonate-ether) aqueous polyurethane emulsion, an aqueous polyurethane adhesive having the poly(carbonate-ether) aqueous polyurethane emulsion as the main component and a preparation method of the aqueous polyurethane adhesive. According to the invention, dimethylolpropionic acid and diaminosulfonate are commonly used as hydrophilic chain extenders; with introduction of diaminosulfonate, the use amount of dihydroxytoluene is reduced, therefore, the phase inversion time is in advance; the solid content of the finally prepared poly(carbonate-ether) aqueous polyurethane emulsion is increased; when the poly(carbonate-ether) aqueous polyurethane emulsion is used as the adhesive, water in the poly(carbonate-ether) aqueous polyurethane emulsion does not need to be removed; the utilization efficiency of the poly(carbonate-ether) aqueous polyurethane emulsion is increased; the aqueous polyurethane adhesive prepared by the step of mixing the poly(carbonate-ether) aqueous polyurethane emulsion with other additives has excellent release force and tensile strength; and experimental results show that: the release force of the aqueous polyurethane adhesive provided by the invention is 150-220N / cm; and the tensile strength is up to 13.5-17.8MPa.

Owner:HUAFON GROUP +1

Waterborne polyurethane dispersion liquid serving as high-molecular material, and preparation method thereof

InactiveCN103601867AGood adhesionGood film formingPolyureas/polyurethane adhesivesInksLiquid productPolyester

The invention relates to a waterborne polyurethane dispersion liquid serving as a high-molecular material. A preparation method comprises the steps of: according to the mole ratio of polyols to isocyanate being 1:(1-5), complexing polyester polyol and polyether polyol with an isocyarnate mixture containing tetramethylbenzene dimethyl diisocyanate, 1,6-hexon diisocyanate and other polyisocyanate, reacting for 1-2 hours at 50-100DEG C to obtain a prepolymer, then adding micromolecular alcohol and hydrophilic group-containing dimethylolpropionic acid, reacting for 0.5-1.5 hours, neutralizing with triethylamine, preserving heat for one hour at 70-80DEG C, dispersing into water, adding an amine chain extender to obtain a waterborne dispersion body. For the waterborne polyurethane dispersion liquid, the solid content is 35%-45%, PH is 7.0-8.5, the viscosity is 30-100mpa.s, and the PVC (Polyvinyl Chloride) / PVC speeling strength is 4-6kg / cm. The waterborne polyurethane dispersion liquid product has excellent binding property, film forming performance and excellent mixing property with acrylic resin. The waterborne polyurethane dispersion liquid is widely applied in the fields of a binding agent, paint and waterborne ink.

Owner:SHANGHAI XINGUANG CHEM

Aqueous polyurethane matting resin

ActiveCN103865031AGood physical propertiesLittle elasticityPolyurea/polyurethane coatingsSulfonateAlcohol

The invention provides aqueous polyurethane matting resin. According to the aqueous polyurethane matting resin, any matting material does not need to be added, coating is uniform, the matting effect is good and the service life is long. The aqueous polyurethane matting resin contains following components in parts by weight: 10-18 parts of diisocyanate, 0.5-5 parts of dimethylolpropionic acid (DMPA), 35-60 parts of dihydric alcohol, 0.05-1 part of organic bismuth catalyst, 0.5-5 parts of dimethylethanolamine, 0.5-10 parts of 2-[(2-aminoethyl)amino]sodium sulfonate, 0.5-5 parts of hydrazine hydrate, 1-10 parts of N-methylpyrrolidone catalyst and 104-180 parts of de-ionized water. The invention further provides a preparation method of the aqueous polyurethane matting resin.

Owner:ANQING HAOYE WATER PAINT

Water-soluble polyurethane for wood lacquer and preparation method thereof

ActiveCN102070768AGood yellowing resistanceHigh molecular weightPolyurea/polyurethane coatingsEthylenediaminePropanoic acid

The invention discloses water-soluble polyurethane for the wood lacquer and a preparation method thereof. The water-soluble polyurethane comprises the following raw materials in parts by weight: 165-175 parts of polycarbonate diol, 131-132 parts of isophorone diisocyanate, 0.4-0.6 part of catalyst, 16.5-17.5 parts of dihydromethyl propionic acid, 2.7-3 parts of dihydroxyacetone, 18.5-19.5 parts of 1,4-butanediol, 4-5 parts of acetone, 12.5-13 parts of triethylamine, 6-7 parts of ethylenediamine, 628-638 parts of deionized water and 5-6 parts of adipic acid dihydrazide. The preparation method adopts the preparation technology combining the acetone method with pre-polymer dispersion method, thus effectively reducing the dosage of acetone and increasing the molecular weight of the generated polyurethane; and when the prepared water-soluble polyurethane dispersion forms a film, with the volatilization of water and the reduction of the pH value, the self-crosslinking reactions of ketonic carbonyl and hydrazide group can be performed, thus the after crosslinking density of the film can be increased and the hardness and water resistance of the the film can be increased.

Owner:安徽好思家涂料股份有限公司

Preparation method of aqueous polyurethane dispersion and application of aqueous polyurethane dispersion

InactiveCN103193954AHas self-matting propertiesEasy to preparePolyurea/polyurethane coatingsEthylenediaminePolymer science

The invention discloses a preparation method of an aqueous polyurethane dispersion and application of the aqueous polyurethane dispersion. The preparation method of the aqueous polyurethane dispersion comprises the following steps of: adding an isocyanate monomer to a hydroxyl styrene butadiene rubber along with stirring under the protection of inert gas; reacting for 0.5 to 2 hours; heating to 70 to 90 DEG C; adding dimethylolpropionic acid and polyether polyol; reacting for 3 to 5 hours; cooling to 40 to 60 DEG C; adding triethylamine to carry out neutralization reaction for 0.1 to 2 hours; adding deionized water; shearing and dispersing at rotational speed of 700 to 900 revolutions per minute; and adding ethylenediamine to carry out chain extension for 1 to 3 hours, thus obtaining aqueous polyurethane dispersion. The aqueous polyurethane dispersion disclosed by the invention has the advantages that a butyl rubber fragment is introduced, thus a molecular chain can be separated in a microphase separation way, and the intramolecular extinction is caused accordingly, and as the result, the product has the automatic matte performance. A coating prepared through the aqueous polyurethane dispersion disclosed by the invention is high in transparency and great in hand feel.

Owner:SHANGHAI WATERBASED CHEM CO LTD

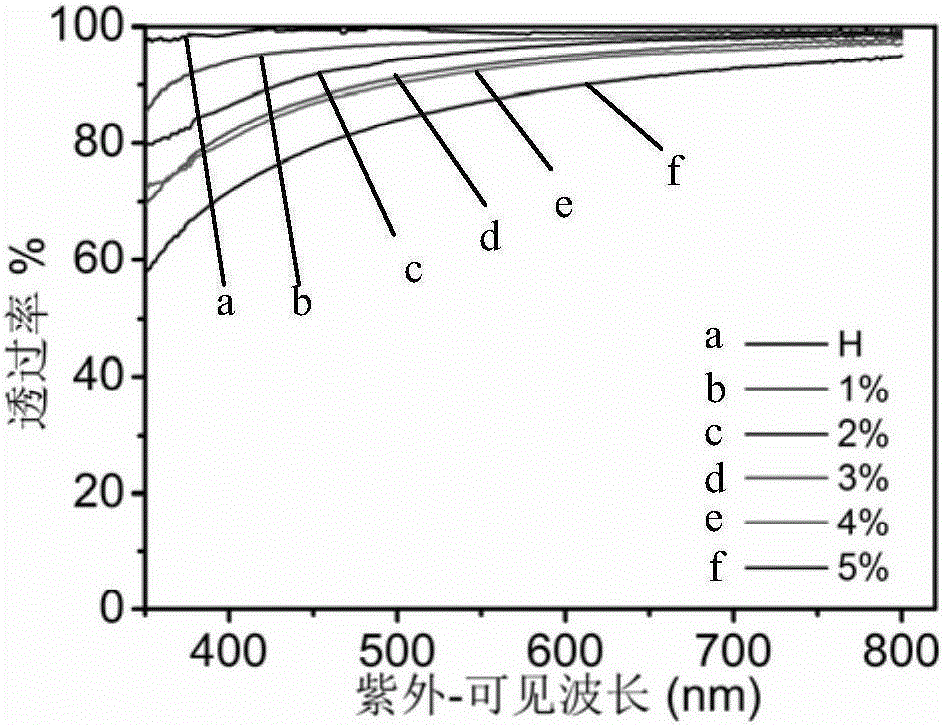

Preparation method for antifogging thin film coating with high light transmission

ActiveCN103709927APolyurea/polyurethane coatingsPigment treatment with organosilicon compoundsSolventDibutyltin dilaurate

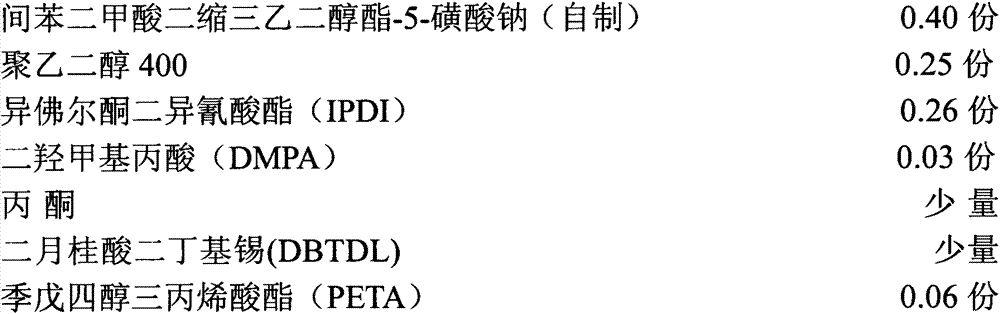

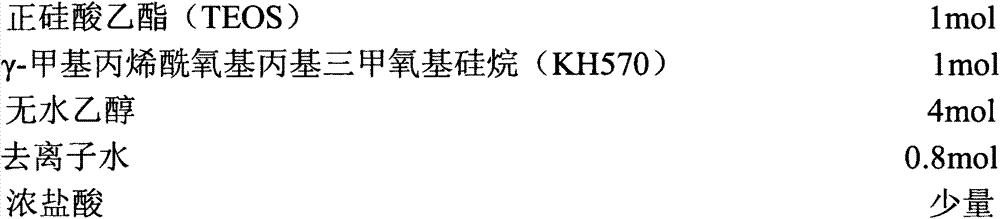

Provided is a preparation method for an antifogging thin film coating with high light transmission. M-phthalic acid triethylene glycol ester-5-sodium sulfonate (self made), polyethylene glycol 400, isophorone diisocyanate and pentaerythritol triacrylate are employed as main raw materials, dibutyltin dilaurate is employed as a catalyst, dimethylolpropionic acid is employed as a chain extender, acetone is employed as a solvent, and hydrophilic UV prepolymers are prepared; ethyl orthosilicate is employed as a precursor, gamma-methacryloxy propyl trimethoxysilane is employed as a modifier, a sol-gel method is employed, and uniform and stable modified SiO2 sol is prepared; the hydrophilic UV prepolymers and the modified SiO2 sol are subjected to hybridization through a UV curing way, and a thin film coating is obtained. The prepared thin film coating has good hardness and adhesive force, water resistance and high light transmission and good antifogging effects, and can be used for antifog of surfaces of glass and eyeglass. The preparation technology of the thin film coating accords with green environmental protection concepts, curing and film forming are fast, and comprehensive performances are good. The antifogging thin film coating has good market prospect and is suitable for popularization and application.

Owner:JIANGNAN UNIV

Heparan polyurethane blended modified polyethersulfone hollow fiber membrane and preparation method and application thereof

ActiveCN103055725AGood physical and chemical stabilityNot easy to precipitateDialysisFiberHollow fibre membrane

The invention discloses a preparation method and application of a heparan polyurethane blended modified polyethersulfone hollow fiber membrane. The preparation method is characterized by comprising the following steps of: adding 10 to 25 weight parts of diphenylmethane diisocyanate, 5 to 13 weight parts of dimethylolpropionic acid and 62 to 85 weight parts of solvent into a dissolving kettle, performing reaction for 4 to 12 hours at a temperature of 70 to 90 DEG C, washing the product with methanol and distilled water and drying to obtain carboxyl-containing polyurethane; adding 10 weight parts of polyurethane into 100 weight parts of concentrated sulfuric acid to carry out sulfonation to obtain polyurethane containing carboxyl and a sulfonic acid group; adding 1 to 10 weight parts of heparan polyurethane, 10 to 25 weight parts of polyethersulfone and 70 to 89 weight parts of solvent into the dissolving kettle to dissolve for 2 to 24 hours at a temperature of 75 to 95 DEG C so as to obtain hollow fiber membrane spinning dope; and preparing the hollow fiber membrane with excellent blood compatibility, permanent hydrophilicity, capacity of resisting to protein pollution and an anticoagulation function by adopting a dry spraying and wet spinning technology.

Owner:SICHUAN UNIV

Preparation method of paint aqueous polyurethane/amino resin composite emulsion

ActiveCN104212330AEmission reductionIncrease the degree of cross-linkingPolyurea/polyurethane coatingsCross-linkEnvironmental resistance

The invention discloses a preparation method of an aqueous polyurethane / amino resin composite emulsion base on amino resin for manufacturing aqueous paint. The method is characterized by comprising, firstly, combining polypropylene carbonate dihydric alcohol with common macromolecular dihydric alcohol to partially or totally substitute the common macromolecular dihydric alcohol; performing reactions with diisocyanate, dimethylolpropionic acid, micromolecular chain extender and cross-linking agent; performing end capping with end-capping reagent; performing neutralization and emulsification to obtain a polyhydric end-capped aqueous polyurethane preformed polymer emulsion; compounding the polyhydric end-capped aqueous polyurethane preformed polymer emulsion with amino resin, catalyst, coating additive and deionized water to obtain the aqueous polyurethane / amino resin composite emulation. The preparation method of the paint aqueous polyurethane / amino resin composite emulation does not need organic cosolvent, and meanwhile, due to the fact of taking the polypropylene carbonate as one of the raw materials and performing end capping through the end-capping reagent containing secondary amino and hydroxyl, achieves high hydroxyl functionality and hydroxyl value; solidified paint molecular chains are high in crosslinking degree; the water-resistant and corrosion-resistant performance of coating can be improved, and obvious cost and environmental advantages can be obtained.

Owner:UNIV OF SCI & TECH OF CHINA +1

Method for preparing visible light self-repairing waterborne polyurethane coating material with double selenium bonds on main chain

ActiveCN106497385AAchieve self-healingAchieve brokenPolyurea/polyurethane coatingsPhotochemistryDiselenide

The invention discloses a method for preparing a visible light self-repairing waterborne polyurethane coating material with double selenium bonds on a main chain. The method comprises the following steps: firstly, preparing an isocyanate end capped polyurethane prepolymer with double selenium bonds on a main chain from raw materials of diisocyanate, dihydroxyethyl diselenide, macromolecule dihydric alcohol and dimethylolpropionic acid; secondly, adding triethylamine for neutralization, further adding a proper amount of deionized water for rapid emulsification, slowly adding a diamine chain extender which is diluted with water, and performing emulsification chain expansion under a condition that the rotation speed is greater than 1200r / min, thereby obtaining the visible light self-repairing waterborne polyurethane coating material with the double selenium bonds on the main chain. On the basis of the visible light reversibility characteristic of double-selenium dynamic covalent bonds, the waterborne polyurethane coating material with the double selenium bonds on the main chain is capable of achieving self-repairing of cracks and broken parts under radiation of gentle visible illumination, so that the service life of the material can be greatly prolonged, the potential safety hazard in use can be reduced, and a relatively long service life can be achieved for the waterborne polyurethane coating material. The waterborne polyurethane coating material with double selenium bonds on the main chain is applicable to coating of leather, textiles, paper, furniture, wall surfaces and the like, and has wide application prospects.

Owner:SICHUAN UNIV

Ultraviolet light curable waterborne polyurethane acrylate and preparation method thereof

The invention discloses ultraviolet light curable waterborne polyurethane acrylate and a preparation method thereof. The method comprises the following steps: synthesizing a polyurethane prepolymer: carrying out a reaction on diisocyanate, polyester polyol, dimethylolpropionic acid and a catalyst to obtain the polyurethane prepolymer; adding a polymerization inhibitor, an antioxidant and multi-group acrylate with hydroxyl to the polyurethane prepolymer to react to obtain partially blocked urethane acrylate; neutralization and dispersion: adding organic amine to the partially blocked urethane acrylate to realize neutralization, and then performing dispersion; and amine chain extension: adding polyamine to perform a chain extension reaction to obtain the ultraviolet light curable waterborne polyurethane acrylate. The product prepared by the preparation method provided by the invention has the advantages of high solid content, high hardness, free of organic solvent, good adhesive force, capability of air drying or ultraviolet light curing, the product can be applied to UV curable wood paper coatings, UV curable plastic coatings, UV curable ink, UV curable adhesives and the other fields.

Owner:广东昊辉新材料有限公司

Preparation method for polyfunctional urethane acrylate aqueous UV resin

ActiveCN103232585AHigh carbon-carbon double bond contentIncreased double bond contentInksPolyurea/polyurethane coatingsPolyesterPolymer science

The invention discloses a preparation method for a polyfunctional urethane acrylate aqueous UV resin. According to the invention, diisocyanate reacts with polyester (ether) polyol to form a main chain, and a ratio of 1,4-butylene glycol to 2,2-dimethylol propionic acid to (methyl)hydroxy acrylate is adjusted so as to prepare the polyfunctional urethane acrylate aqueous UV resin which is allowed to have high cross-linking density and excellent comprehensive properties; considerable organic solvents are not needed in preparation of the resin, so unnecessary solvent evaporation and raw material waste are avoided; high solid content can guarantee that complex procedures like hot drying or infrared drying are reduced after film coating of the resin, so production time is reduced, and production efficiency is improved; and termination of unsaturated acrylic acid ester guarantees cross-linking density after photocuring of a polymer, and the cured polymer has excellent glossiness, mechanical performance, water resistance and solvent resistance.

Owner:GUANGDONG UNIV OF TECH

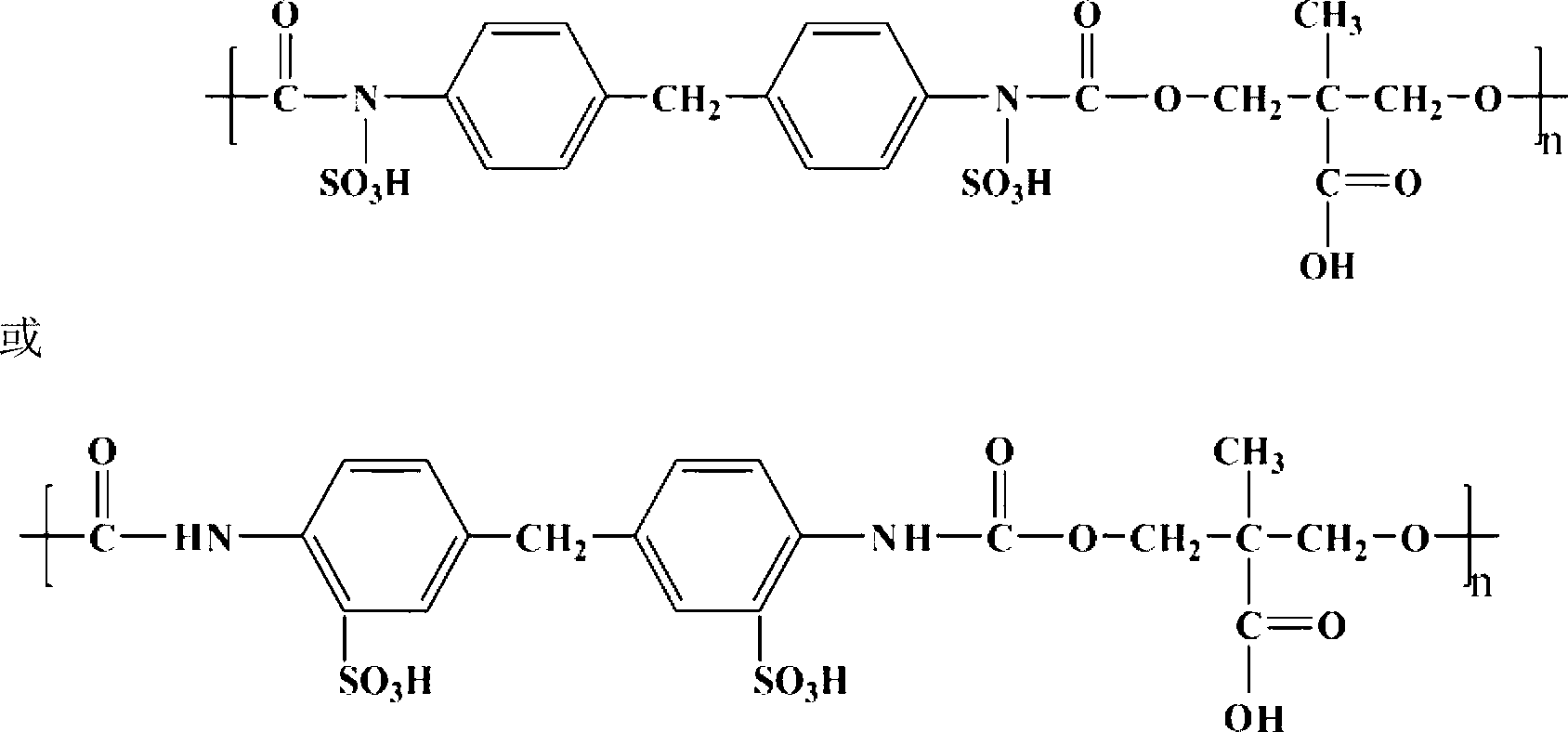

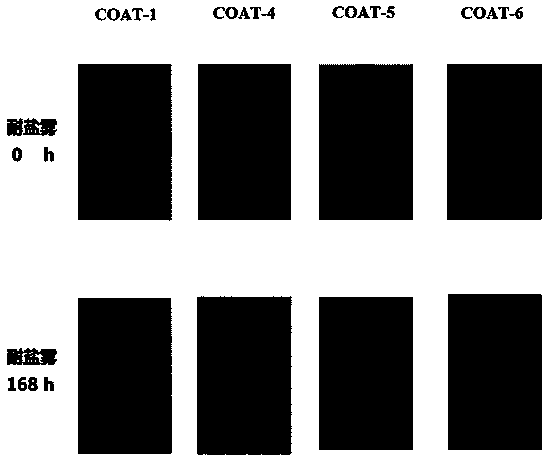

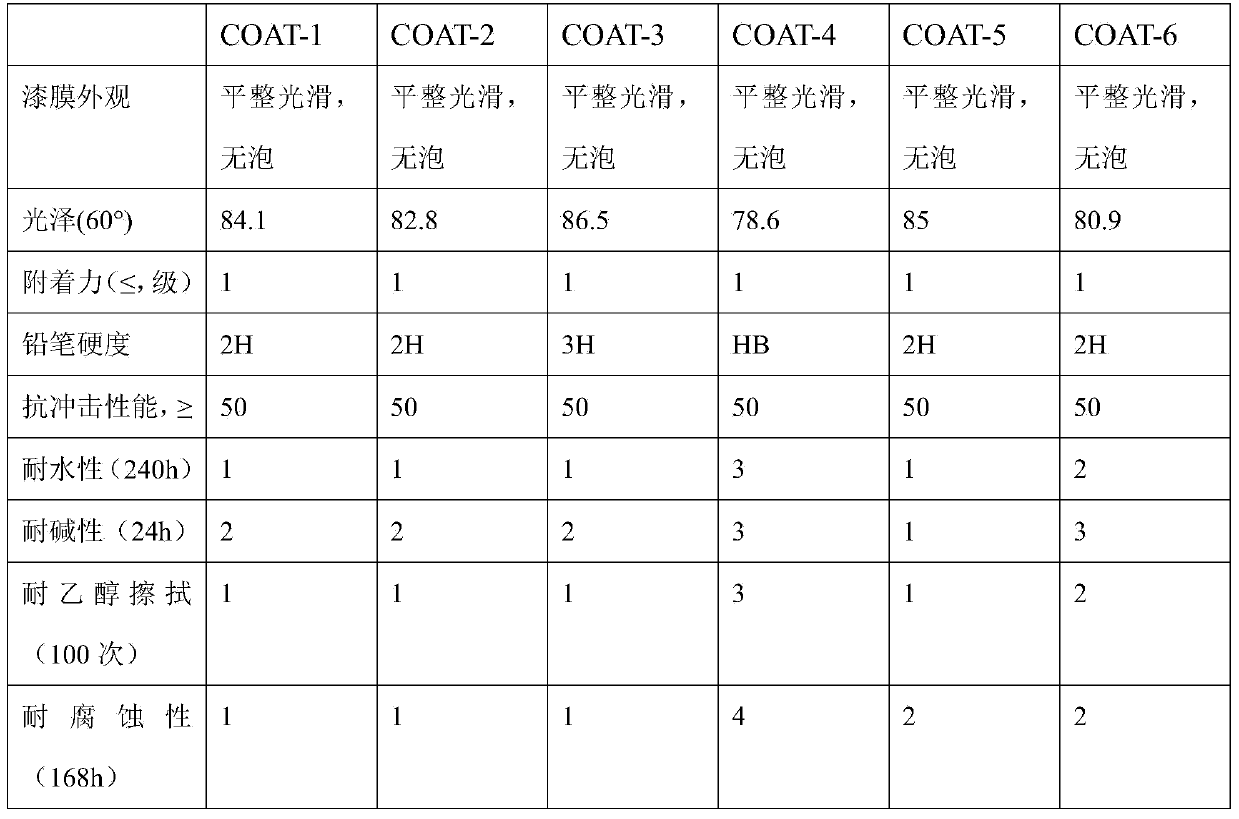

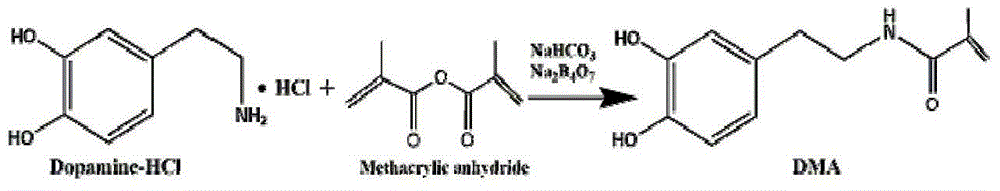

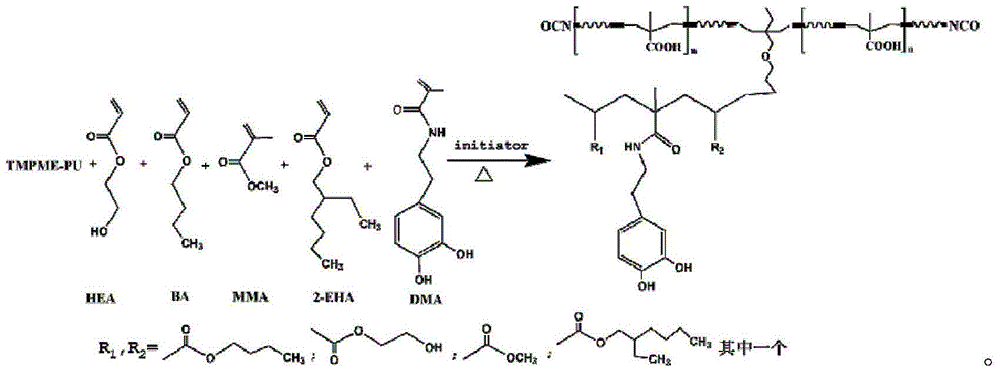

Bionically designed waterborne polyacrylate modified polyurethane composite emulsion and preparation method thereof

The invention discloses a bionically designed waterborne polyacrylate modified polyurethane composite emulsion and a preparation method thereof. The method is characterized by: using acetone or butanone and acrylic monomer as the solvent, subjecting diisocyanate HDI and IPDI, mixed polyester polyol, dimethylolpropionic acid, 1, 4-butanediol, trimethylolpropane monoallyl ether, hydroxypropy, and hydroxyethyl acrylate to polymerization to obtain polyurethane with carboxyl, and conducting neutralization with tertiary amine, removing the solvent to obtain self-emulsifying waterborne polyurethane anionic emulsion containing double bonds; then taking the emulsion as seed, adding acrylate monomer, dopamine methacrylamide and a proper amount of crosslinking agent monomer to carry out pre-emulsification, then performing seeded emulsion polymerization to obtain the bionically designed waterborne polyacrylate modified polyurethane composite emulsion. The composite emulsion provided by the invention has the advantages of energy saving and environmental protection, adaptation to various material surfaces, safe and reliable process, and stable product quality.

Owner:广东多正树脂科技有限公司

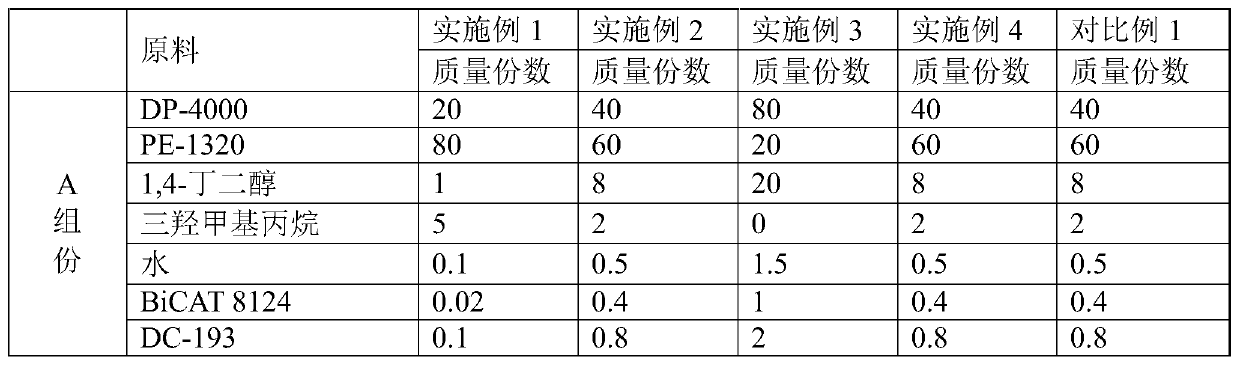

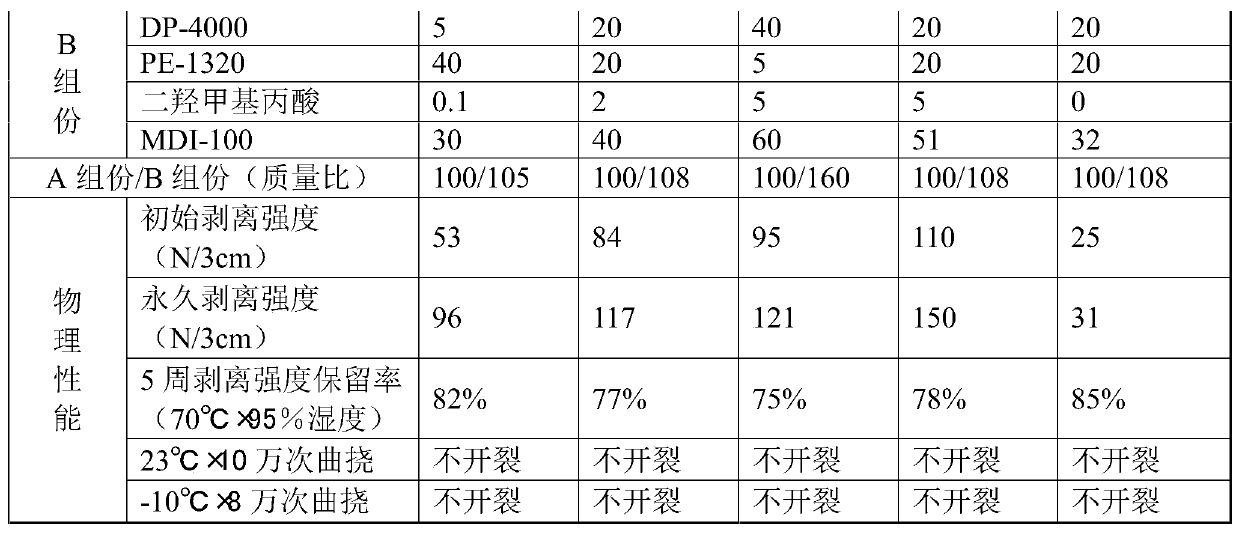

Solvent-free polyurethane resin for synthetic leather, preparation method thereof and application thereof in aqueous/solvent-free polyurethane synthetic leather

The invention provides a solvent-free polyurethane resin for synthetic leather, a preparation method thereof and an application thereof in aqueous / solvent-free polyurethane synthetic leather. The invention provides the solvent-free polyurethane resin for the synthetic leather, which is prepared by mixing and reacting a component A and a component B according to a mass ratio of 1:2-2:1; wherein thecomponent A comprises polyhydric alcohol, a small molecular chain extender, a cross-linking agent, water, a catalyst and a foam stabilizer; the component B comprises polyhydric alcohol, isocyanate and dimethylolpropionic acid. The solvent-free polyurethane resin for the synthetic leather does not contain any organic solvent, has low energy consumption and high production efficiency, and when thesolvent-free polyurethane resin is used for aqueous / solvent-free polyurethane synthetic leather, the obtained aqueous / solvent-free polyurethane synthetic leather product is environment-friendly, softand plump in hand feeling and high in peeling strength.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD +1

Breathable polyurethane synthetic leather preparation method

InactiveCN106087451AImprove breathabilityComfortable to wearTextiles and paperPolymer scienceGluconacetobacter

The invention belongs to the technical field of synthetic leather preparation and relates to a breathable polyurethane synthetic leather preparation method. The method includes: subjecting octamethyl cyclotetrasiloxane and gamma-aminoethyl aminopropyl trimethoxysilane to ring opening and polymerization to obtain amino modified silicon oil; reacting with polytetrahydrofuran glycol to obtain polyether modified amino silicon oil; reacting with isophorone diisocyanate to obtain a prepolymer; reacting with 2,2-dimethylolpropionic acid and the like, and carrying out operations such as neutralizing to obtain polyether amino silicon oil modified polyurethane; fermenting gluconacetobacter and polyether amino silicon oil modified polyurethane to obtain bacterial cellulose; mixing with part of polyether amino silicon oil modified polyurethane, adding additives, stirring, coating, and performing operations of solidifying, washing, drying and the like to obtain breathable polyurethane synthetic leather. The breathable polyurethane synthetic leather prepared according to the method is higher than 720mL / cm<2>.h in air permeability and light and comfortable to wear and is excellent in water permeability which is higher than 952g / m<2>.24h.

Owner:周荣

Method for preparing mono-component normal-temperature self-crosslinking water-based polyurethane

InactiveCN103012733ASelf-crosslinking propertiesWater resistance Enhanced solvent resistanceWater basedPolyethylene glycol

The invention discloses a method for preparing mono-component normal-temperature self-crosslinking water-based polyurethane. The method comprises the following steps: taking diol 3-[bis-(2-hydroethyl)] amine-N (1,1-dimethyl-3-butanone) propionamide (DHPA) containing ketone carbonyl as a crosslinking chain extender for preparing polyurethane from isophorone diisocyanate (IPDI) and polyethylene glycol (PEG 3000), adding a hydrophilic chain extender of dimethylolpropionic acid (DMPA), neutralizing the mixture with triethylamine, and adding water for emulsification and separation to obtain the mono-component normal-temperature self-crosslinking water-based polyurethane. The emulsion has the function of self-crosslinking and the characteristics of excellent water and solvent resistances.

Owner:QINGDAO PENGHAI SOFT CO LTD

Water-based polyurethane and organosilicon, organofluorine copllymerized water-proof air-moisture-permeable antibacterial adhesive coating preparing method

InactiveCN1935919AImprove the bactericidal effectHigh waterproof, breathable and moisture permeable performanceBiocideAntifouling/underwater paintsWater basedPropanoic acid

The invention relates to aquosity polyurethane, organic silicon, and organic fluorine copolymerization water proof gasper drenching antibiotic coating adhesive preparing method. It includes the following steps: using diisocyanate to react with diatomic alcohol compound, alkyl silicol, hydroxyl group fluoro-silicon oil, dioxy methyl propionic acid to produce performed polymer with -NCO end group, enlarging chain by 1, 4 butylene glycol; using amine to adjust pH value to neutrality; adding de-ionized water contains anti-bacterial agent to stir at high speed; adding water to adjust viscosity. It can be coated at the fabric surface to realize water proof gasper drenching, and kill mold.

Owner:江阴市诺科科技有限公司

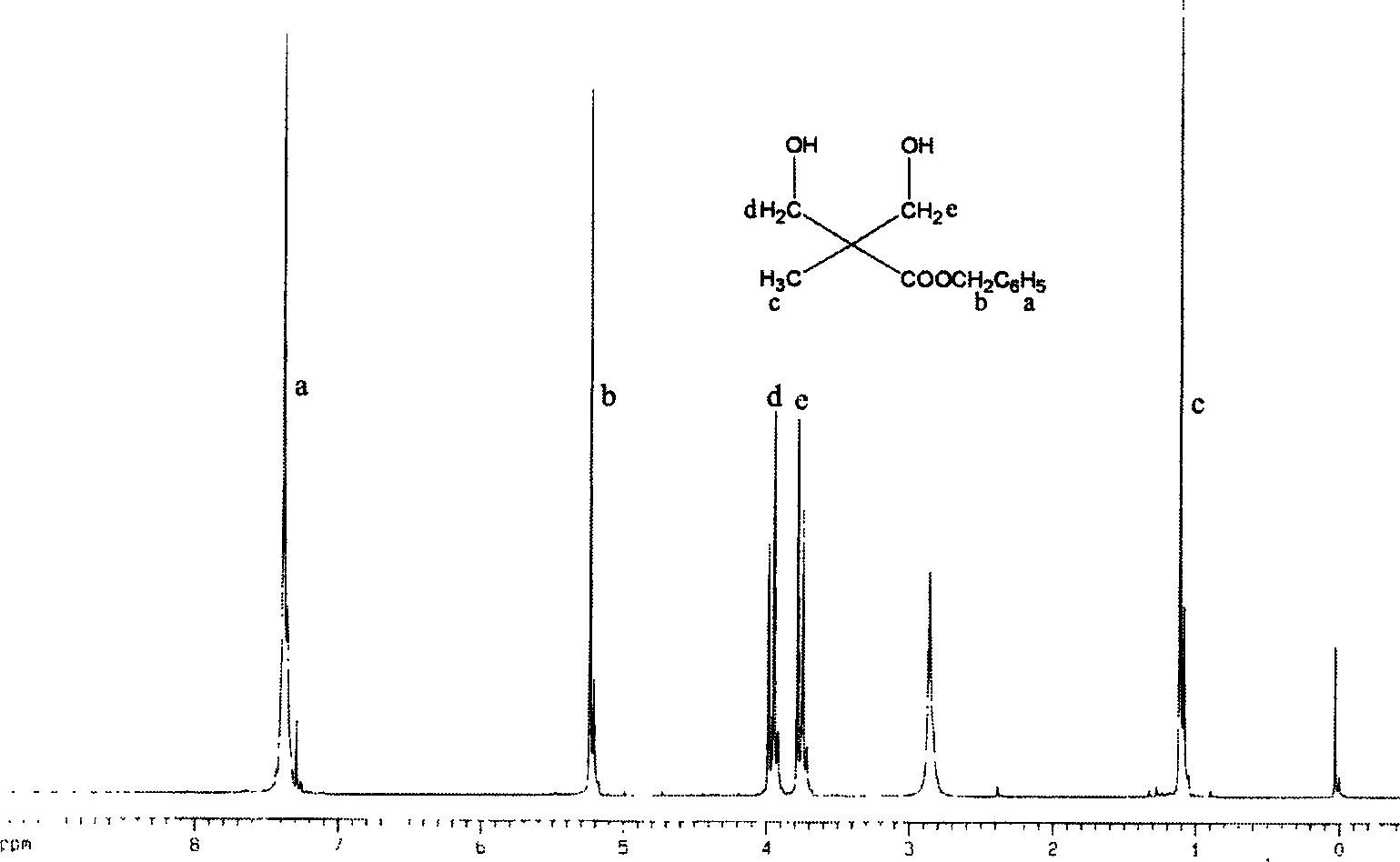

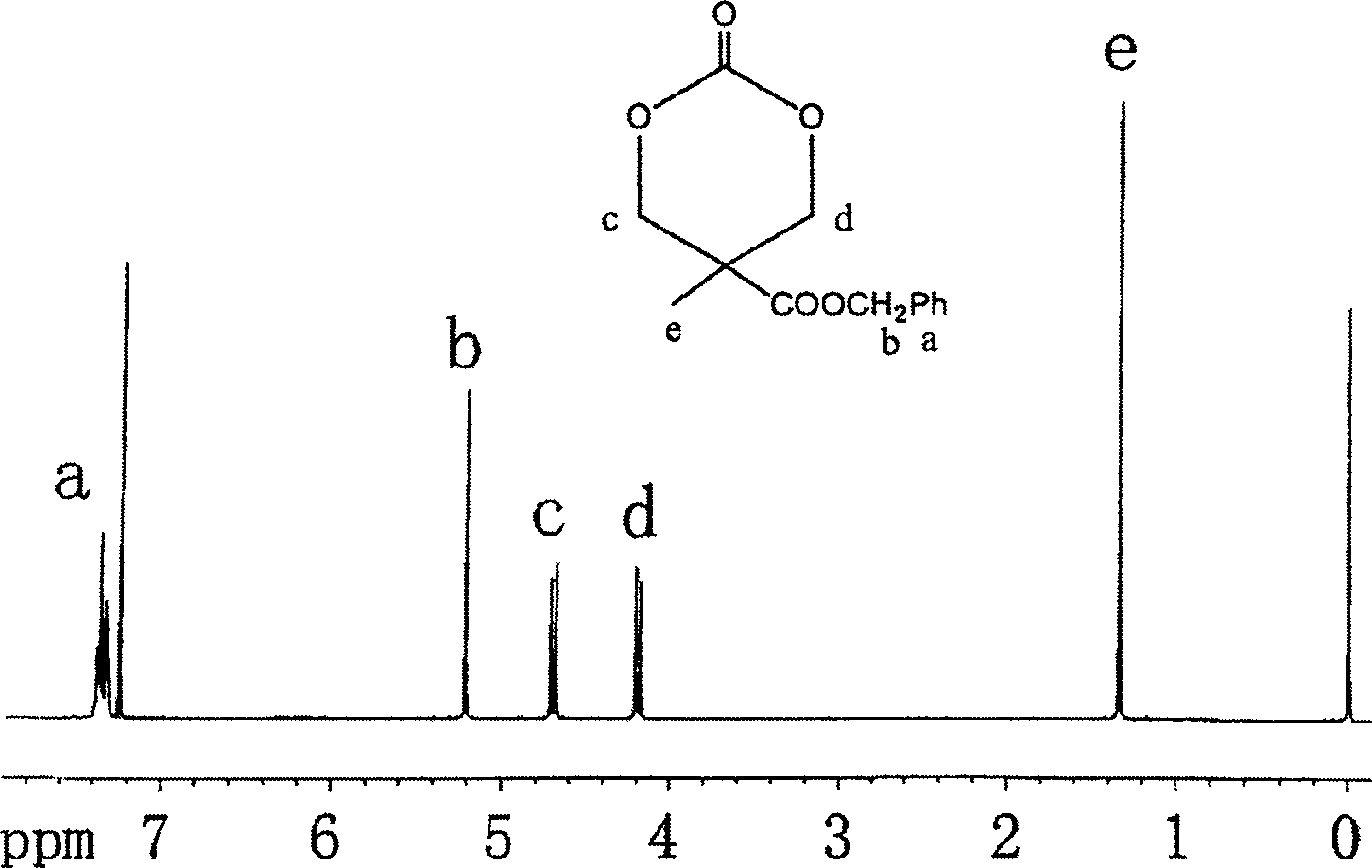

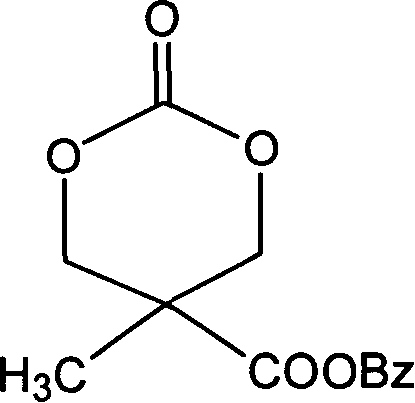

Fat ester carbonate polymer with side carboxy, its synthesis and use thereof

A fatty carbonate ester polymer with side carboxy, its synthesis and use are disclosed. The process is carried out by taking 2,2-dimethylolpropionic acid as raw material, synthesizing 2-methyl-2-carbobenzoxy trimethylene-carbonic ether, ring-opening polymerizing or having copolymerization with fatty cyclic ester monomer, catalyzing, hydrogenating, and removing protection to obtain fatty polycarbonate with side chain or copolymer of fatty cyclic ester and carbonic ester. It has biological degradation and non-toxic products, better biological compatibility and activity. It can be used for medicine release, high polymer medicine and tissue engineering.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com