Patents

Literature

705 results about "Dimethylethanolamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

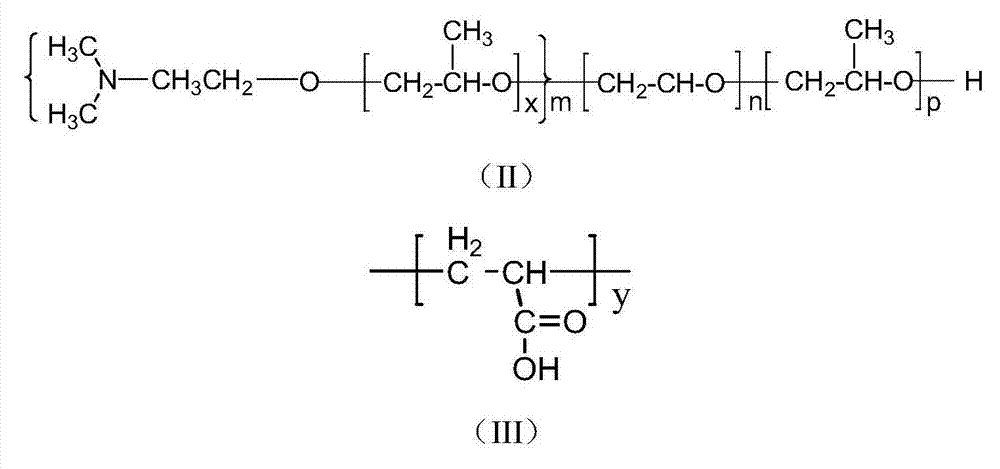

Dimethylethanolamine (DMAE or DMEA) is an organic compound with the formula (CH₃)₂NCH₂CH₂OH. It is bifunctional, containing both a tertiary amine and primary alcohol functional groups. It is a colorless viscous liquid. It is used in skin care products. It is prepared by the ethoxylation of dimethylamine.

Polyurethane rigid foam exterior wall thermal insulation material with high flame retardancy and preparation method thereof

InactiveCN101831168AImprove flame retardant performanceImprove mechanical propertiesEpoxyFire retardant

The invention provides a polyurethane rigid foam exterior wall thermal insulation material with high flame retardancy and a preparation method thereof. The polyurethane rigid foam exterior wall thermal insulation material with high flame retardancy comprises a component A and a component B, wherein the component A consists of phenolic resin, brominated epoxy resin, phosphorated flame retardant polyether polyol, organosilicon foam stabilizer, catalyst dimethylethanolamine, catalyst dibutyltin dilaurate, flame retardant and foaming agent 1,1-dichloro-1-fluoroethane, and the component B is flame retardant polyisocyanate curing agent. The invention also provides a preparation method of the exterior wall thermal insulation material. The polyurethane rigid foam exterior wall thermal insulation material has excellent mechanical property and high flame retardancy, overcomes the problem that the fireproof flame retardancy and the mechanical property of the traditional polyurethane rigid foam thermal insulation materials are mutually in contradiction and is suitable for exterior wall thermal construction of a building with higher fireproof level requirement.

Owner:SHANGHAI COLLODIN MATERIAL TECH DEV CO LTD

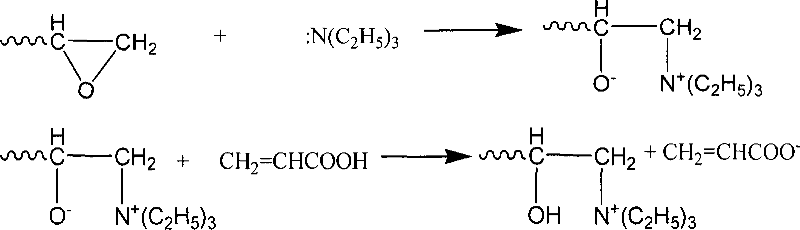

Preparation method of special epoxy resin for aqueous ultraviolet solidifying coating

A method of preparing special epoxy resin for water ultraviolet light curing coating includes steps: a) using bisphenol A type epoxy resin and acrylic acid as raw material, adding catalyst of triethylamine and inhibitor of p-hydroxyanisole, reacting at 70-100 DEG C, after mass concentration of acrylic acid lower than 40-50%, raising temperature to 110-120 DEG C until acid value of the system lower than 5mgKOH / 100g and generating epoxy acrylate; b) mixing the maleic anhydride and the epoxy acrylate according mole ratio of 0.8:1.05-0.8:1.05 and reacting water epoxy acrylate, adding catalyst triethylamine and inhibitor of p-hydroxyanisole under temperature of 60-100 DEG C and reacting for 1-3 h, adding dimethlyethanolamine to neutralizing, adding water and obtaining water epoxy acrylate with certain solid content.

Owner:CHINA PETROCHEMICAL CORP

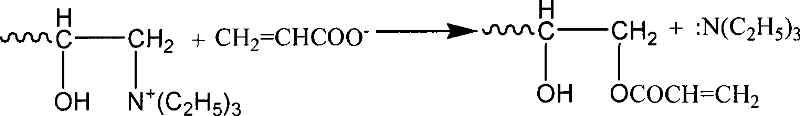

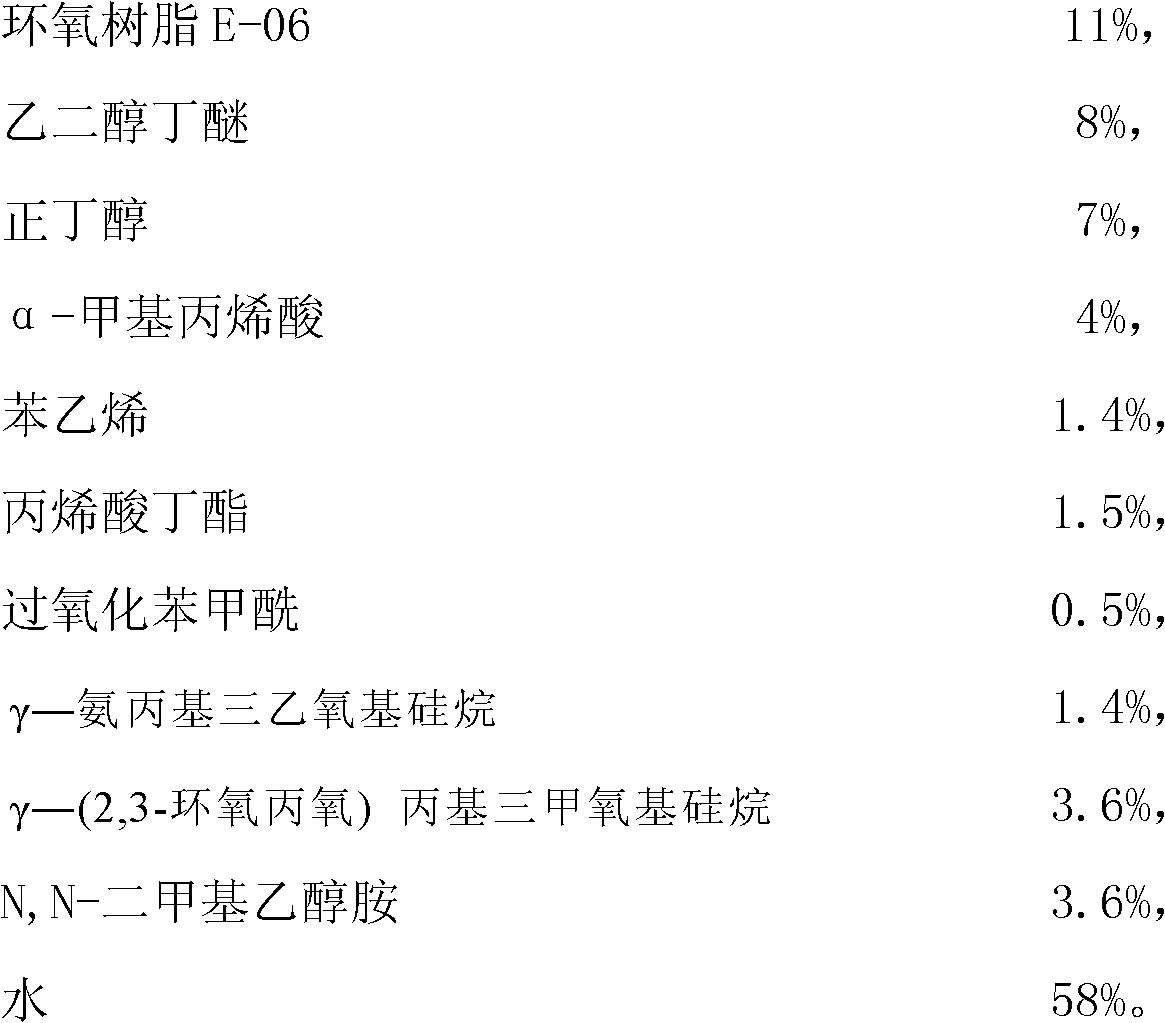

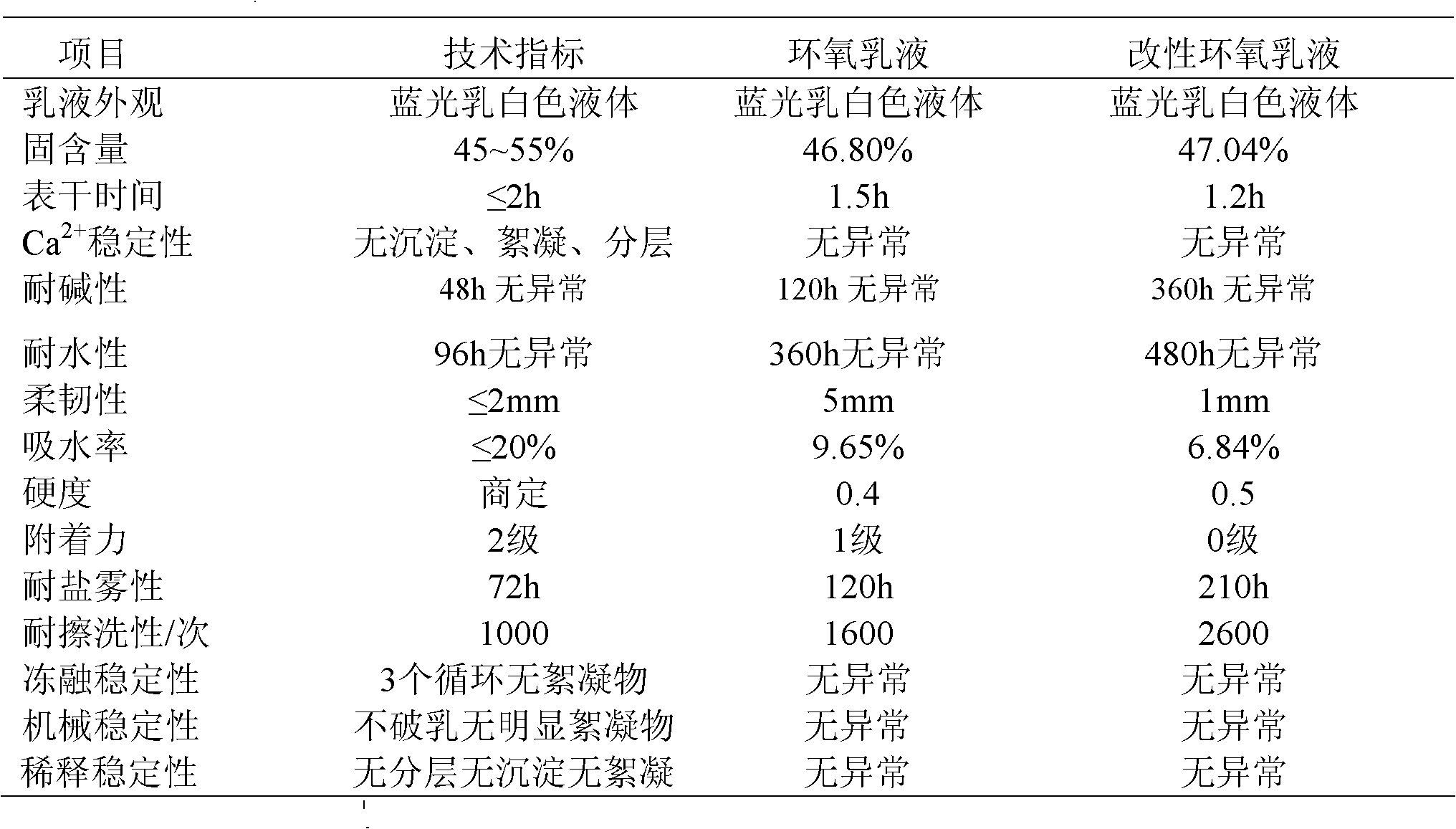

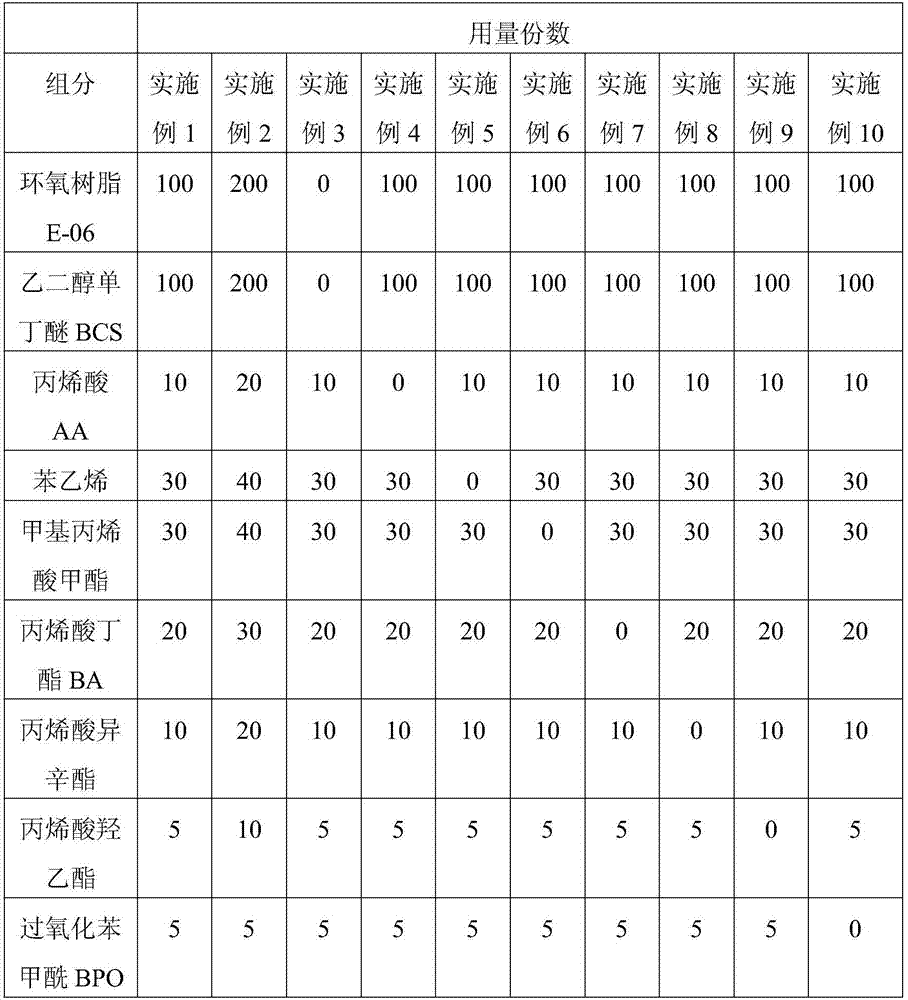

Modified epoxy emulsion and preparation method thereof

InactiveCN102585111AGood film formingGood physical and mechanical propertiesCoatingsHydrophilic monomerEpoxy

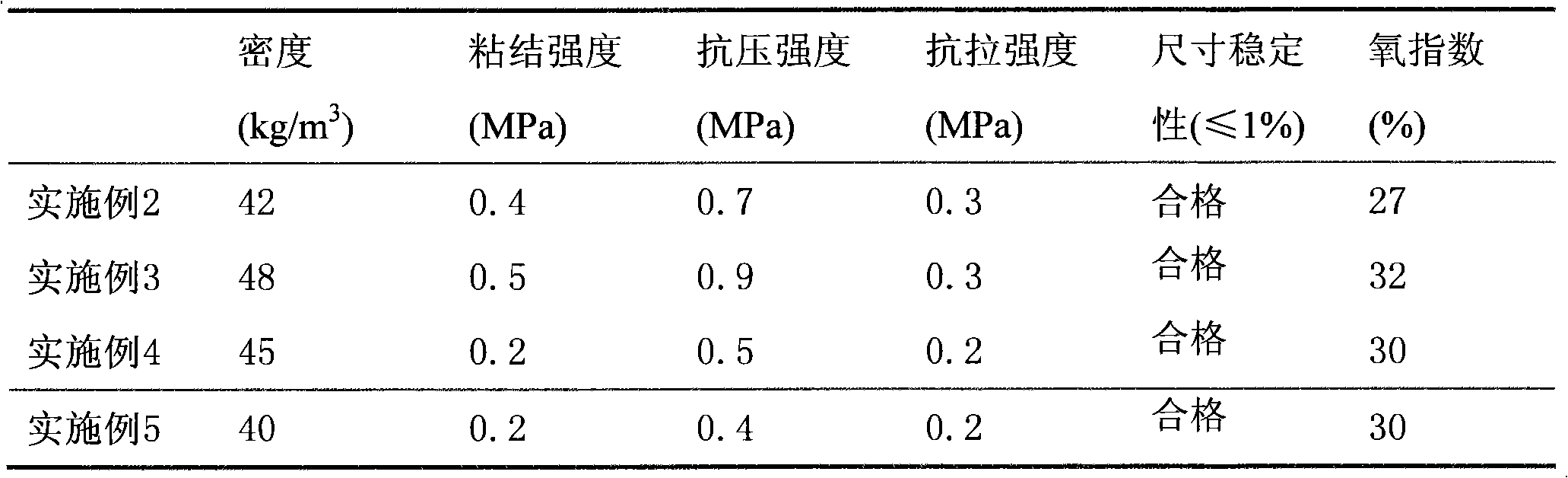

The invention discloses a modified epoxy emulsion and a preparation method thereof. The emulsion comprises the following components in percentage by weight: 10-15 percent of epoxy resin E-06, 8-10 percent of ethylene glycol monobutyl ether, 7-8 percent of n-butyl alcohol, 4-4.5 percent of alpha-methacrylic acid, 1-1.5 percent of styrene, 1-1.5 percent of butyl acrylate, 0.4-0.8 percent of benzoyl peroxide, 1-1.5 percent of gamma-aminopropyl triethoxy silane, 3.2-4 percent of gamma-trimethoxypropylsilane, 3.2-4.2 percent of N,N-dimethylethanolamine and 50-60 percent of water. The preparation method comprises the following steps of: preparing for graft copolymerization; then, introducing hydrophilic monomers by utilizing the graft copolymerization method; and adding a mixture for further modification to obtain the modified epoxy emulsion. The modified epoxy emulsion has the characteristics of strong adhesion, good flexibility, hardness, corrosion resistance, water resistance, alkali resistance, scrub resistance and simple preparation process.

Owner:JIANGSU UNIV OF SCI & TECH

Fireproof flame-retardant polyurethane external wall thermal-insulation system material

InactiveCN101851993AImprove fire and flame retardant performanceImprove heat resistanceFireproof paintsCovering/liningsFoaming agentPolyol

The invention relates to a fireproof flame-retardant polyurethane external wall thermal-insulation system material, which is characterized by comprising a moistureproof primer paint, a flame-retardant rigid polyurethane foam material, an interface agent, anti-crack mortar, a fireproof coating and a decorating coating which are arranged sequentially from inside to outside, wherein the flame-retardant rigid polyurethane foam material consists of an component A and a component B; the component A is prepared by mixing 80 to 50 parts by weight of phosphorous flame-retardant polyether polyol, 20 to 50 parts by weight of heterocyclic amine polyether polyol, 2 parts by weight of organic silicon foam stabilizer, 2 parts by weight of dimethylethanolamine catalyst, 1 part by weight of dibutyltin dilaurate catalyst, 20 to 50 parts by weight of flame retardant and 20 to 40 parts by weight of fluoro dichloroethane; the component B is a flame-retardant polyisocyanates curing agent; in the using process, the component A and the component B are mixed and foamed and an isocyanate index is between 1.05 and 1.10. The fireproof flame-retardant polyurethane external wall thermal-insulation system material of the invention has the advantage of having higher fireproof flame-retardant property.

Owner:SHANGHAI COLLODIN MATERIAL TECH DEV CO LTD

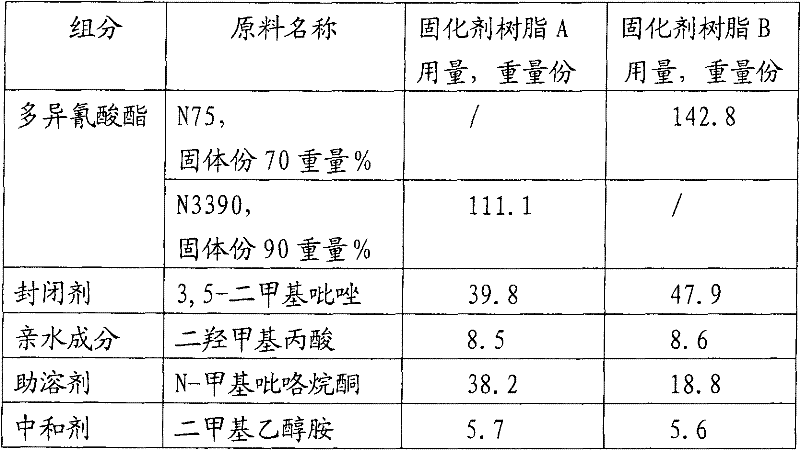

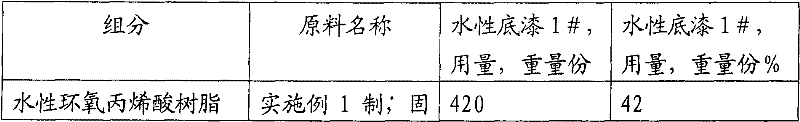

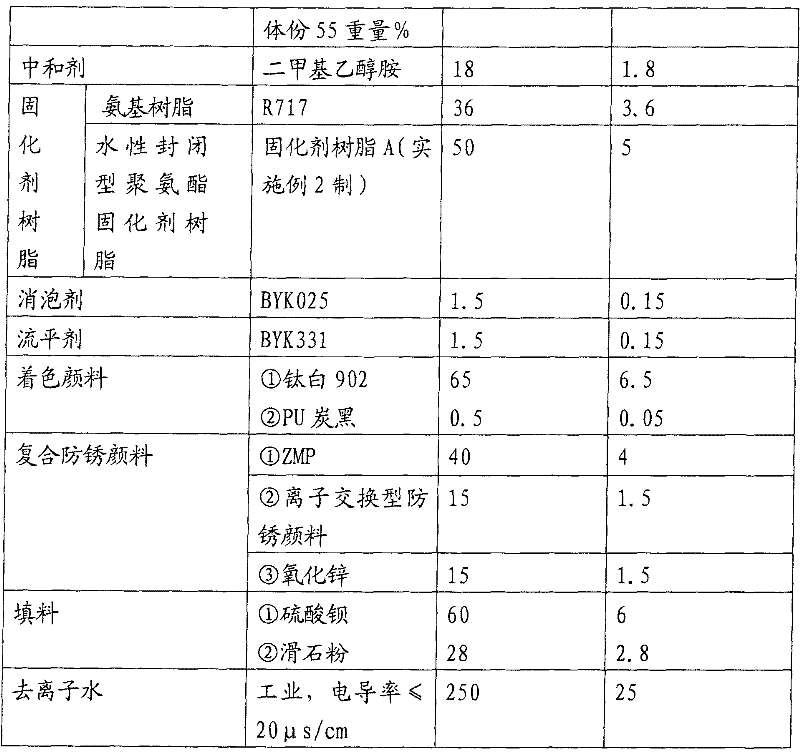

Aqueous primer used for bicycles

The invention relates to an aqueous primer used for bicycles, which comprises the following components in percentage by weight: 25-45% of aqueous epoxy acrylate resin, 2-10% of curing agent resin, 1-3% of neutralizing agent dimethylethanolamine, 2-10% of compound anticorrosive pigment, 5-20% of tinting pigment and filler, 0.1-0.5% of antifoaming agent, 0.1-0.5% of flatting agent and 20-40% of deionized water, wherein the sum of the content of all components is 100%. The aqueous epoxy acrylate resin accounts for 10-40% of the total mass of epoxy resin; the curing agent resin comprises aqueous closed-type polyurethane curing agent resin and amino curing agent resin, wherein the mass ratio of the aqueous closed-type polyurethane curing agent resin to the amino curing agent resin is 1:5-5:1; the aqueous closed-type polyurethane curing agent resin is decapsulated and solidified at the temperature of 130DEG C; the amino curing agent resin is carbinol or butylated amino melamine formaldehyderesin; and the compound anticorrosive pigment comprises modified zinc phosphate, zinc oxide and ion exchange type anticorrosive pigment. The aqueous primer disclosed by the invention is especially suitable for preventing rust and corrosion of structures, such as bicycles and the like.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

Aqueous polyurethane matting resin

ActiveCN103865031AGood physical propertiesLittle elasticityPolyurea/polyurethane coatingsSulfonateAlcohol

The invention provides aqueous polyurethane matting resin. According to the aqueous polyurethane matting resin, any matting material does not need to be added, coating is uniform, the matting effect is good and the service life is long. The aqueous polyurethane matting resin contains following components in parts by weight: 10-18 parts of diisocyanate, 0.5-5 parts of dimethylolpropionic acid (DMPA), 35-60 parts of dihydric alcohol, 0.05-1 part of organic bismuth catalyst, 0.5-5 parts of dimethylethanolamine, 0.5-10 parts of 2-[(2-aminoethyl)amino]sodium sulfonate, 0.5-5 parts of hydrazine hydrate, 1-10 parts of N-methylpyrrolidone catalyst and 104-180 parts of de-ionized water. The invention further provides a preparation method of the aqueous polyurethane matting resin.

Owner:ANQING HAOYE WATER PAINT

Water-based metallic flashing paint and preparation method of the flashing paint

ActiveCN102604497ASolve the permutation problemGood orientationPaints with free metalsWater basedEther

The invention relates to a water-based metallic flashing paint and a preparation method of the flashing paint. The water-based metallic flashing paint comprises the following components by weight: 30 to 50 parts of acrylic copolymer aqueous dispersion-1, 15 to 27 parts of amino resin, 0.1 to 0.9 parts of BYK-028, 2.0 to 3.6 parts of dimethylethanolamine, 10 to 22 parts of water, 3 to 5 parts of waterborne aluminum powder, 0.05 to 0.20 parts of a dispersant, 2 to 5 parts of ethylene glycol monobutyl ether, 0.1 to 0.9 parts of BYK-347, 1.7 to 2.8 parts of BYK-425, 2 to 4 parts of waterborne polyurethane, 1.5 to 2.5 parts of polyurethane dispersant and 3.5 to 5.5 parts of water-based CAB. The water-based metallic flashing paint causes low environment pollution, and has the characteristics of good luster and flashing effect.

Owner:上海金力泰化工股份有限公司

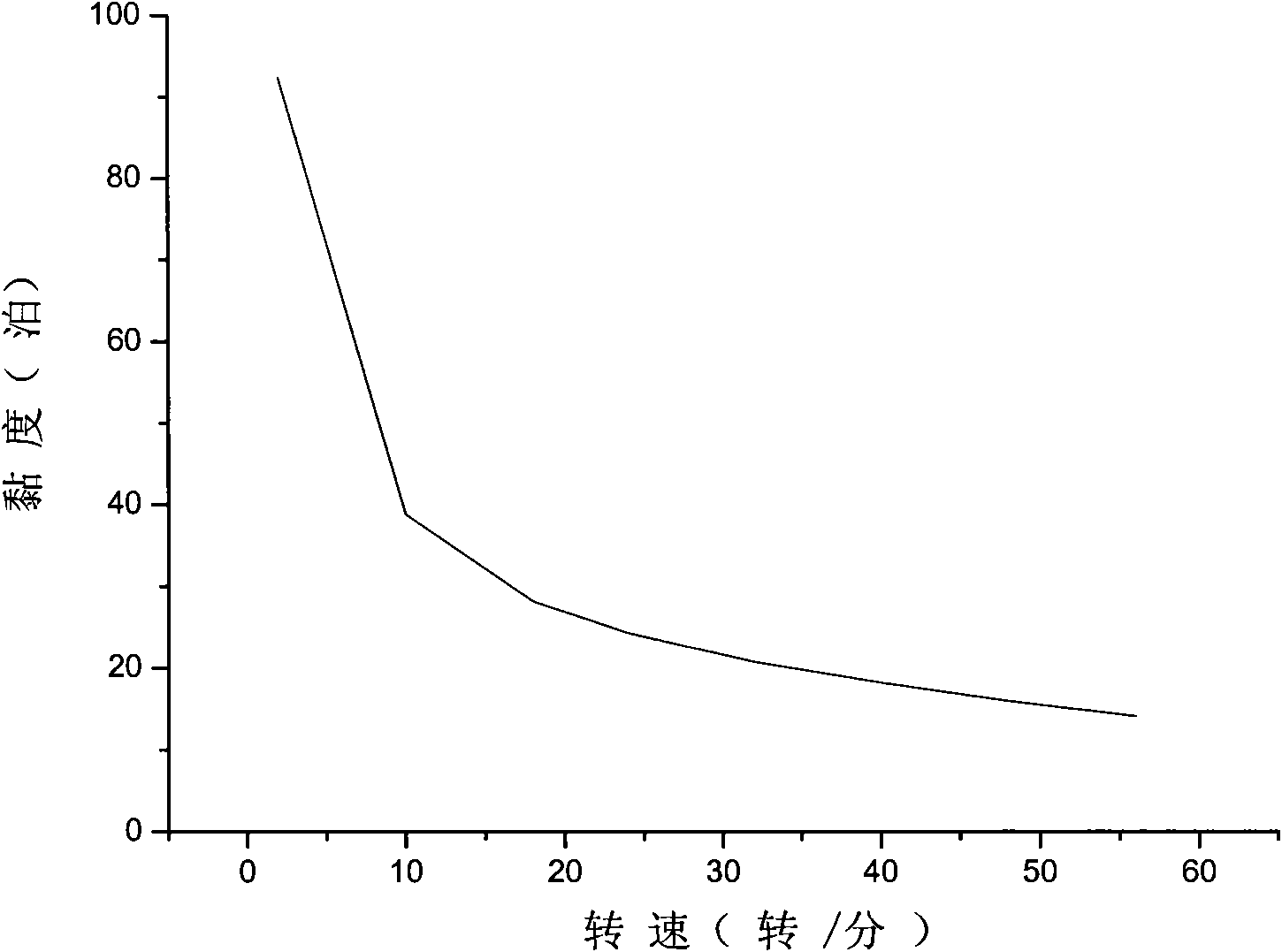

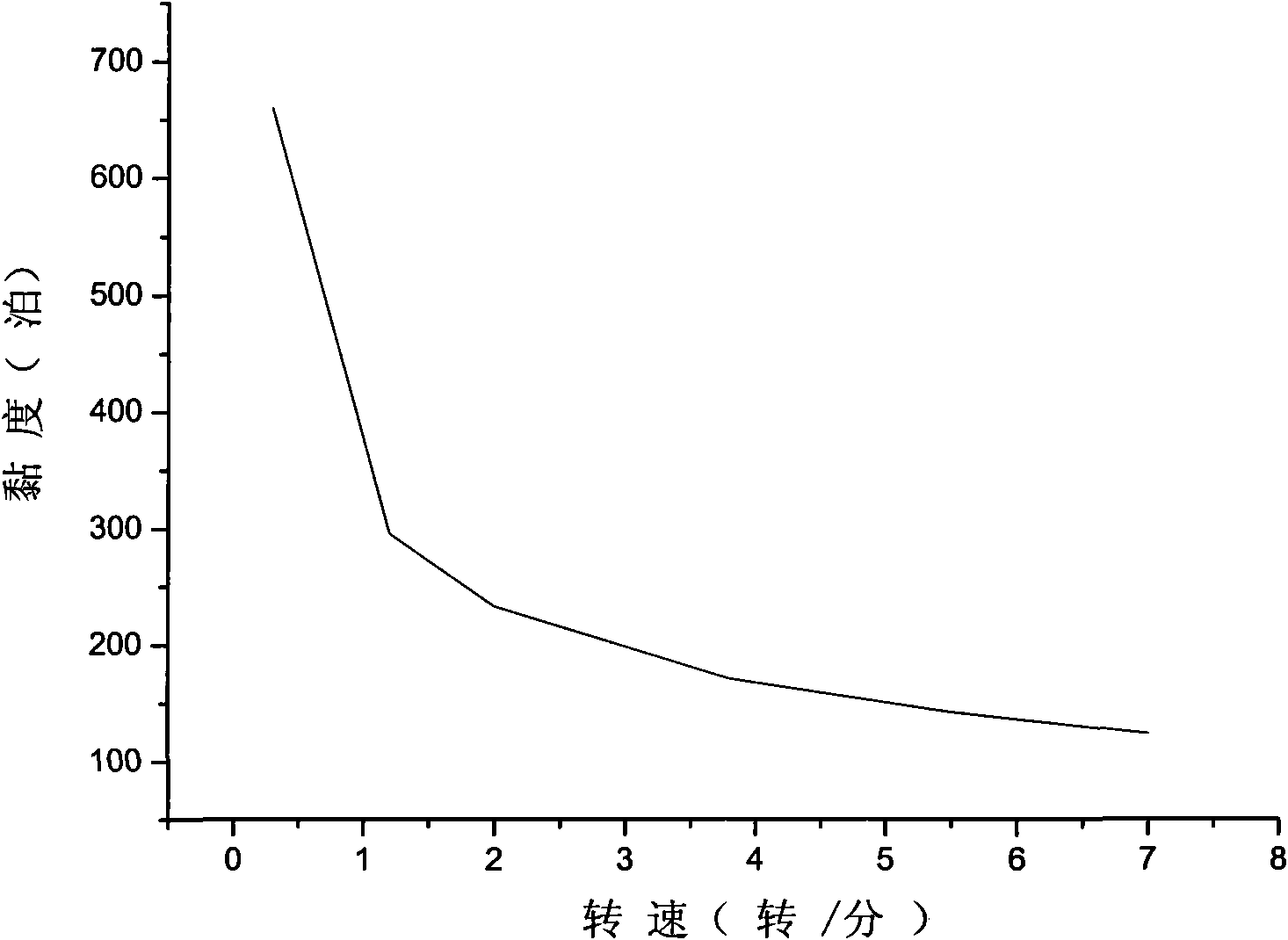

Reverse-phase demulsifying agent for treating polymer flooding produced liquid of oil fields and preparation method thereof

InactiveCN103755884AImprove water qualityDewatering/demulsification with chemical meansPolymer scienceWater quality

The invention discloses a reverse-phase demulsifying agent for treating polymer flooding produced liquid of oil fields and a preparation method thereof, and relates to the technical field of oil industries. According to the preparation method, the reverse-phase demulsifying agent for treating the polymer flooding produced liquid of the oil fields is prepared by using ethylene oxide and propylene oxide block polyether taking N,N-dimethylethanolamine as an initiating agent and acrylic acid as raw materials and adding a catalyst and the initiating agent. When the polymer flooding produced liquid is treated by the reverse-phase demulsifying agent compounded with a conventional demulsifying agent for the oil fields, the quality of water obtained by dehydration is good.

Owner:SOUTHWEST PETROLEUM UNIV

Topical composition for anti-aging skin treatment using dual DNA repair mechanism and method of use

InactiveUS8911774B2Reduction of degreeReduce pigmentationBiocideCosmetic preparationsSkin colorMethylsulfonylmethane

A topical composition for anti-aging treatment of the skin includes water soluble extract of Uncaria species, Arabidopsis thaliana extract, lipoic acid, dimethylethanolamine, tetrahexyldecyl ascorbate, dimethyl sulfoxide, Glycyrrhiza Glabra(Licorice) root extract, methylsulfonylmethane, phytosterols, D-ribose, tocotrienol, tocopherol, glucosamine hydrochloride, Pisum sativum extract; Bambusa vulgaris extract, and a dermatologically acceptable liposomal delivery medium. Further disclosed is a method using the topical composition for anti-aging skin treatment utilizing DNA repair in both the nucleus and the mitochondria. The topical composition can be applied on the skin of a person daily, and can also be applied in a dermal infusion treatment, with or without micro-dermal abrasion or skin suction. Topical application of the composition achieves effective reduction of pigmentation spots and degree of winkles, and improvement of skin color tone.

Owner:LIFE SCI INT

Heat-resisting waterproof wallpaper and production method thereof

InactiveCN106703311AImprove waterproof performanceImprove heat resistanceCovering/liningsFibre treatmentMaterials scienceGlycerol Ethers

The invention discloses a heat-resisting waterproof wallpaper. The heat-resisting waterproof wallpaper comprises a base material layer, a waterproof layer and a heat-resisting layer, wherein the heat-resisting layer is made of waterborne silicon-acrylate resin, hydroxyl-polyacrylate emulsion, cellulose acetate butyrate solution, amino resin, iron oxide red, iron oxide yellow, pearl powder, lauryl mercaptan, dimethylethanolamine, thiethylamine, triethanolamine, 2-amino-2-methylpropanol, ammonium hydroxide, acrylic glycidyl ether, ethylene glycol monobutyl ether, waterborne aluminum powder, charcoal powder, talcum powder, sodium bicarbonate, glass fiber, vermiculite powder, perlite powder, EVA (ethylene-vinyl acetate copolymer) wax, polyethylene wax, nano titanium dioxide, waterborne polyisocyanate curing agent, wetting agent, magnesium stearate, polyoxypropylene glycerol ether, carboxymethyl cellulose and anti-setting agent. The invention also discloses a preparation method of the heat-resisting waterproof wallpaper. The prepared heat-resisting waterproof wallpaper is excellent in heat-resisting and waterproof performance.

Owner:安徽易有墙纸有限公司

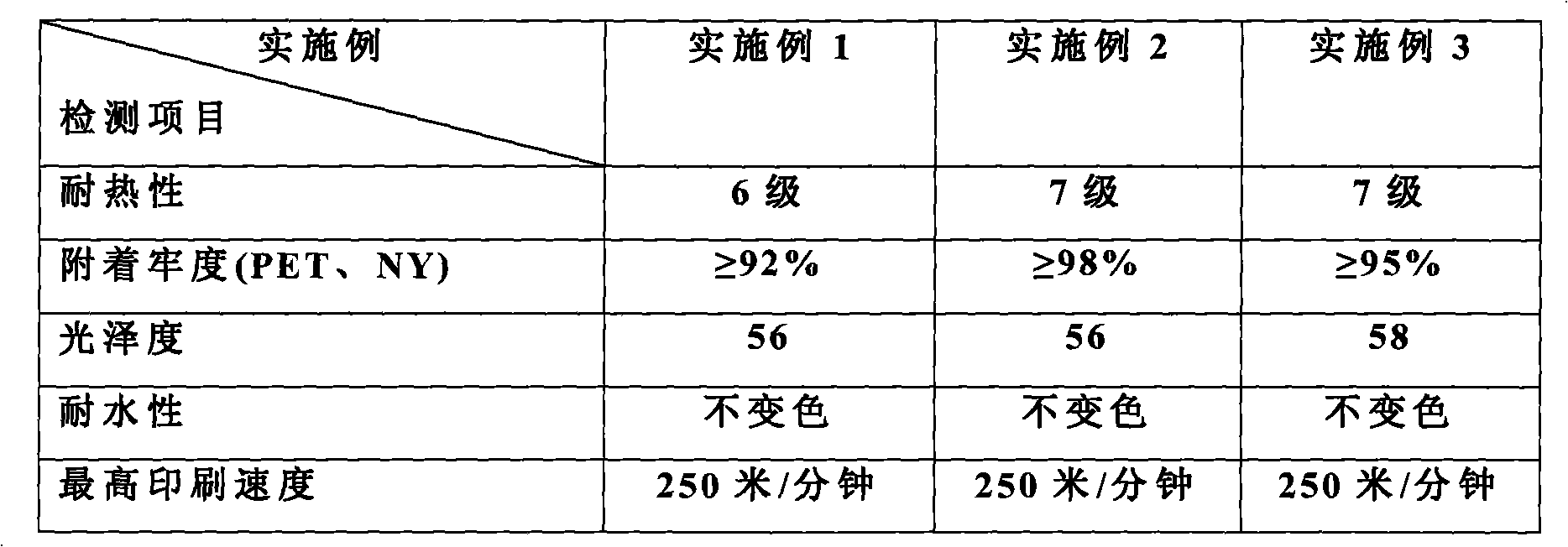

Aqueous ink

ActiveCN101665639AGood printing adaptabilitySuitable for high speed printingInksAdhesion forceDimethylethanolamine

The invention relates to an aqueous ink comprising following components by weight proportion: 30-35 parts of waterborne polyurethane resin, 30-35 parts of aqueous pigment, 3-5 parts of propanediol, 1-1.5 parts of dimethylethanolamine and 20-30 parts of water. The aqueous ink of the invention has excellent printing adaptability, is suitable for high-speed printing, meanwhile, has high temperature resistance, excellent gloss, and excellent adhesion force and water resistance.

Owner:英科·卡乐油墨(苏州)有限公司

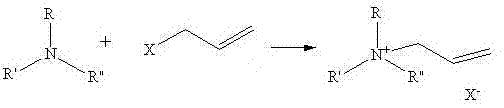

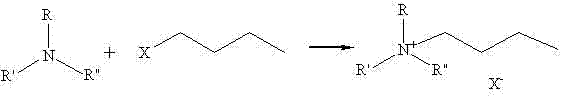

Method for synthesizing quaternary ammonium salt ionic liquid by microwave radiation heating

InactiveCN102344377AGood acid and alkali resistanceReduce volumeOrganic compound preparationAmino compound preparationHalohydrocarbonButyl chloride

The invention provides a method for synthesizing quaternary ammonium salt ionic liquid by microwave radiation heating, which comprises the following steps: mixing tertiary amine compounds (N,N-dimethylethanolamine, trimethylamine or triethanolamine) and halohydrocarbon compounds (allyl chloride, n-butyl chloride, n-butyl bromide, octadecyl chloride) with a molar ratio of 1:1.05-1:2 under a microwave radiation heating condition, putting the mixture into a microwave reactor to perform a microwave reaction with an adjusted microwave power of 100 W-400 W, a heating temperature of 30 DEG C-80 DEG C, and reaction time of 1 min-15 min so as to obtain a crude product, removing residual halohydrocarbon compounds in the crude product to obtain quaternary ammonium salt ionic liquid with halogens as anions; the halohydrocarbon compounds are chlorinated hydrocarbon compounds or brominated hydrocarbon compounds. The preparation method of the invention is simple, does not require the addition of any solvent except reaction raw materials, and can prepare high-purity quaternary ammonium salt ionic liquid simply, efficiently, rapidly, and economically.

Owner:SOUTH CHINA UNIV OF TECH

Compound concrete anti-corrosion and rust-resistant agent

The invention discloses a compound concrete anti-corrosion and rust-resistant agent which comprises the following components in parts by weight: 15-30 parts of a polycarboxylic acid water reducing agent, 3-12 parts of sodium dodecyl sulfate, 15.7-20.6 parts of N-dimethylethanolamine, 1-5 parts of sodium molybdate, and 50-60 parts of water. The compound concrete anti-corrosion and rust-resistant agent can block capillary holes in the concrete, improves the chloride ion permeability resistance of concrete, can significantly alleviate the damage of chloride ions on a reinforcing steel bar passivation film, enhances the sulfate corrosion resistant ability of the concrete, has excellent rust-resistant performance and good repair performance, can enhance durability of the concrete and the comprehensive anti-corrosion ability of the concrete, and significantly improves the durability of buildings.

Owner:HUNAN CONSTR ENG GRP COR +1

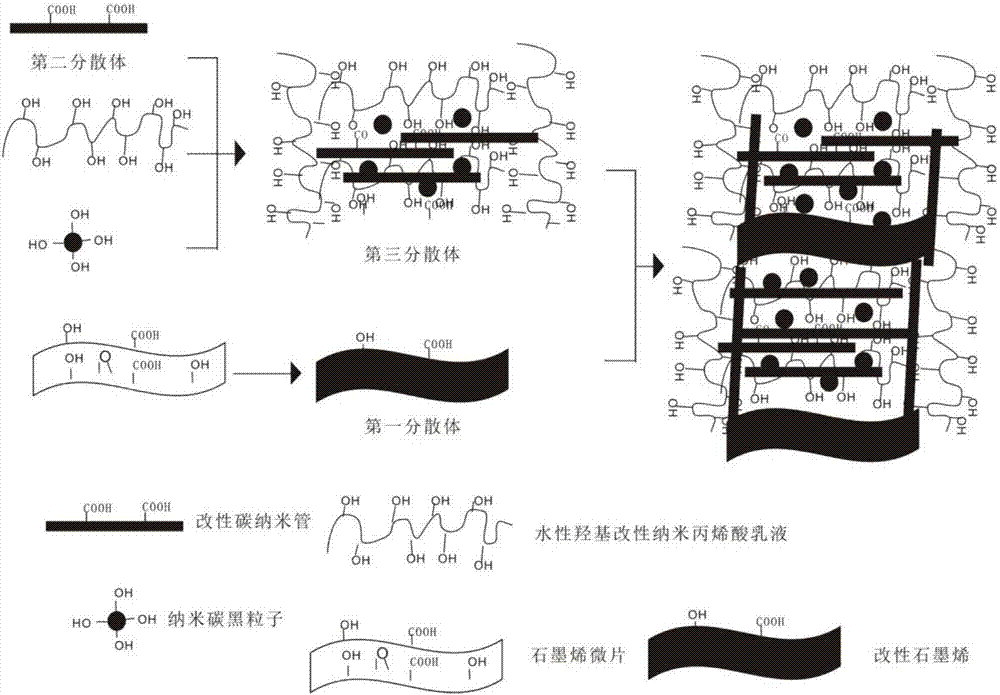

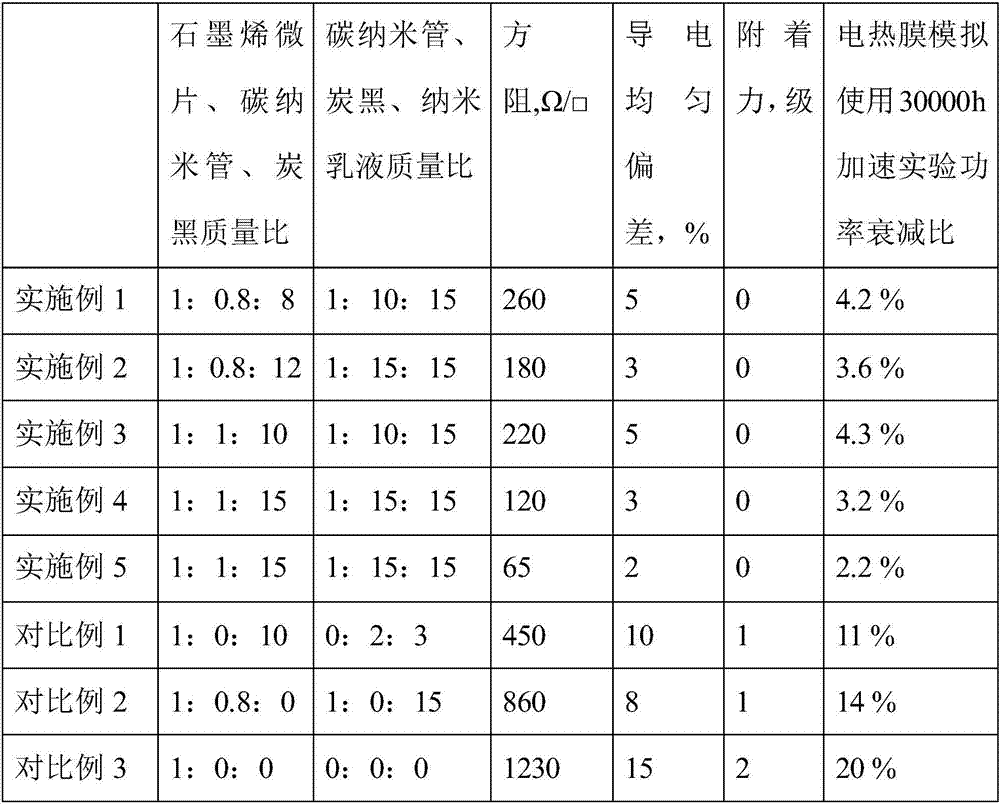

Water-based graphene/carbon nanotube composite electric-heating conversion printing ink and preparation method thereof

The invention discloses water-based graphene / carbon nanotube composite electric-heating conversion printing ink and a preparation method thereof. The preparation method comprises the following steps: uniformly stirring a graphene microchip, a water-based non-ionic high-polymer dispersant and water, and then dispersing so as to obtain a first dispersion; putting one-dimensional nano-powder into inorganic strong acid, carrying out heating reflux, carrying out ultrasonic treatment, washing with water, and drying, so as to obtain a second dispersion; uniformly mixing the second dispersion with carbon black powder, a water-based anionic dispersant, sodium dodecyl benzene sulfonate, a water-based hydroxyl-modified nano-acrylic emulsion and dimethylethanolamine, and then dispersing so as to obtain a third dispersion; and mixing the first dispersion, the third dispersion and water-based resin, grinding, adding a flatting agent, a defoamer, a pH adjusting agent, a preservative and an anti-settling agent, and uniformly mixing, so as to obtain the water-based graphene / carbon nanotube composite electric-heating conversion printing ink. The invention further discloses the water-based graphene / carbon nanotube composite electric-heating conversion printing ink.

Owner:安徽华惠福科技有限公司

Multifunctional organic rust inhibitor and preparation method thereof

The invention relates to a multifunctional organic rust inhibitor prepared by reaction of an organic acid and a hydroxyl compound, the molar ratio of organic acid to hydroxyl compound is 1:1-1:2.5; the organic acid is an arbitrary proportion mixture of one or more than two substance of lauric acid, palmitic acid, stearic acid, benzoic acid, p-tert-butyl benzoic acid, lauroyl sarcosine and oleoyl sarcosine, the hydroxyl compound is an arbitrary proportion mixture of one or more than two substance of n-butyl alcohol, lauryl alcohol, ethanolamine, diethanolamine, triethanolamine, N-methyldiethanolamine, N, N-dimethylethanolamine, and 2-amino-2-methyl-1 - propanol. The multifunctional organic rust inhibitor can protect steel bar and concrete from erosion of chloride and sulfate and other corrosion mediums, plays a dual role of concrete self protection and steel bar corrosion protection, greatly improves the service life of a reinforced concrete structure, and is simple in synthesis process and easy to implement.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

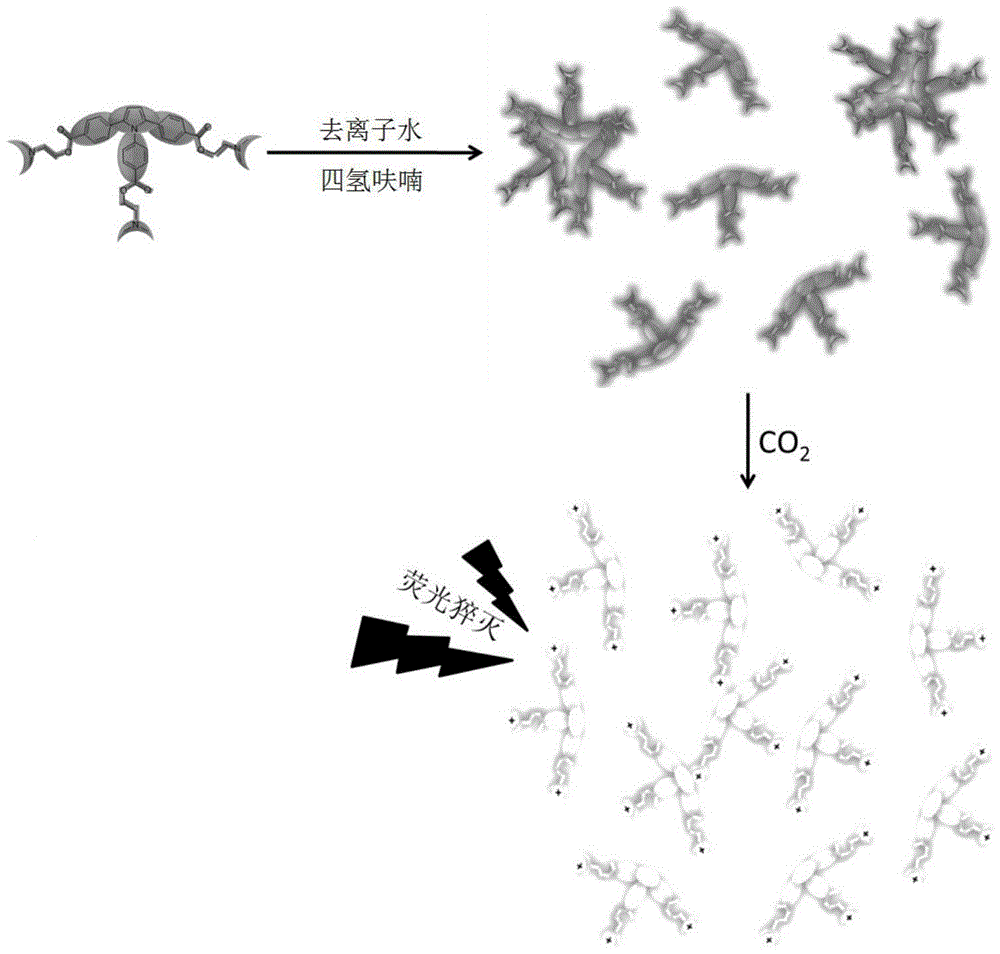

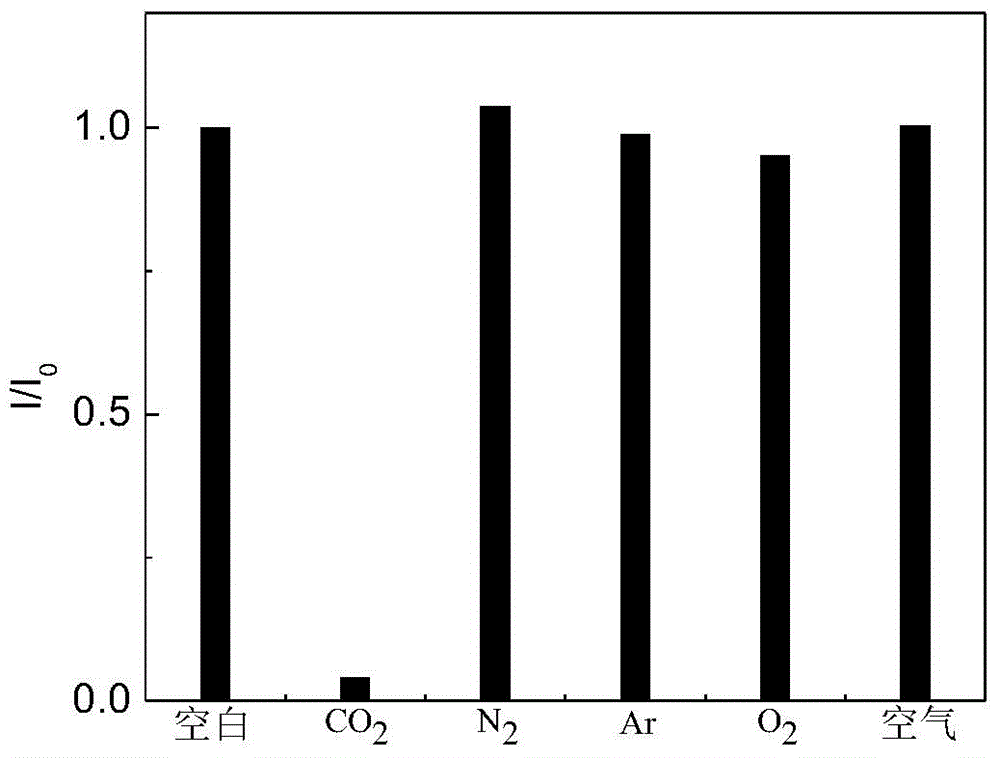

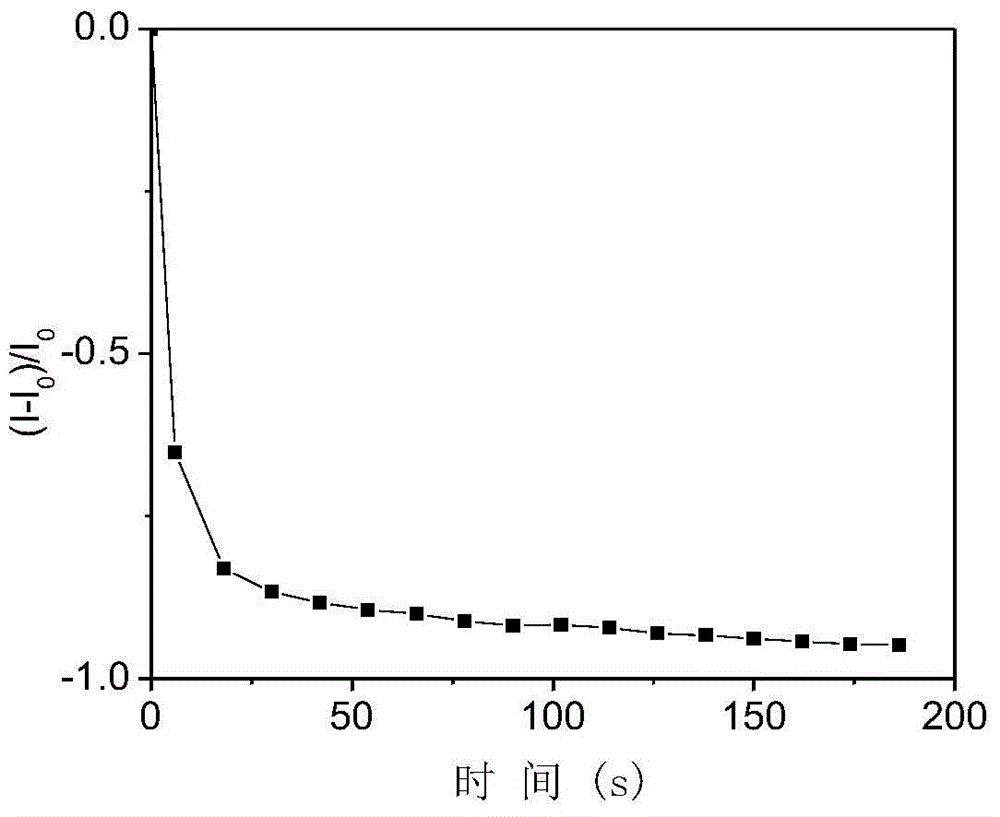

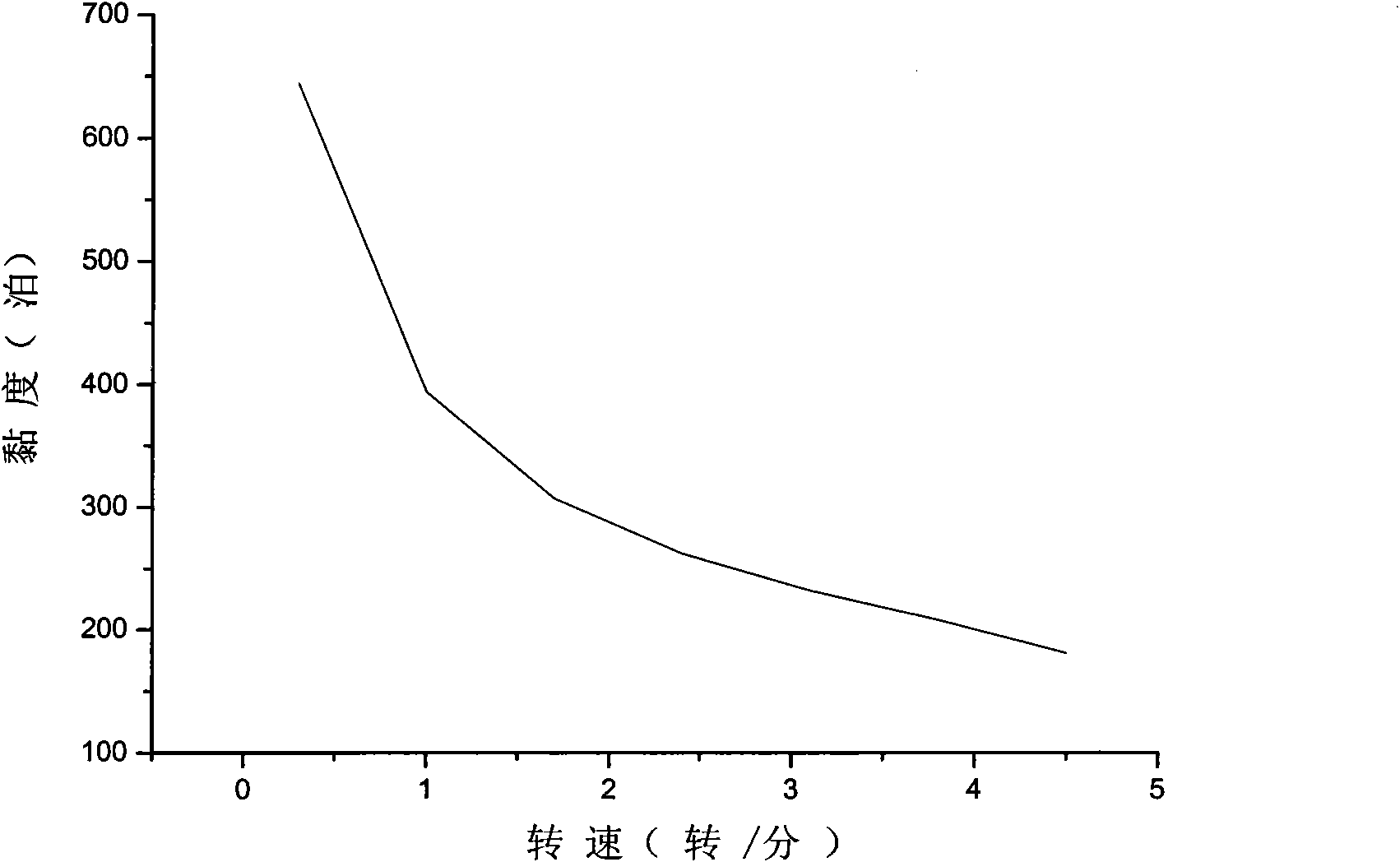

Fluorescent reagent for detecting trace carbon dioxide and preparation method thereof

InactiveCN104059632AHigh sensitivityDecreased fluorescence intensityOrganic chemistryFluorescence/phosphorescenceEthyl esterSolvent

The invention discloses a fluorescent reagent for fluorescent detection of trace carbon dioxide and a preparation method thereof, belonging to the field of fluorescent sensors. The fluorescent reagent is composed of ethyl 4,4',4''-(1H-pyrryl-1,2,5-triyl)tri(2-dimethylamino)benzoate (TPP-DMAE for short), deionized water and a good solvent. The preparation method comprises the following steps: dissolving the TPP-DMAE in N,N-dimethylethanolamine, adding a catalyst, and reacting to obtain the TPP-DMAE; and dissolving the TPP-DMAE in a mixed solvent composed of the deionized water and good solvent to obtain the fluorescent reagent. The fluorescent reagent can quantitatively detect carbon dioxide, has the advantages of high response speed, high sensitivity and high selectivity, has favorable visual detection signals, can be completely independent from high-precision instruments according to actual demands, and can satisfy the requirements of current people for carbon dioxide detection to great extent. The preparation method is simple and convenient to operate.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Aqueous composite coating for plastic

InactiveCN105385250AHigh hardnessImprove adhesionPolyurea/polyurethane coatingsPolyolefinAcrylic resin

The invention discloses aqueous composite coating for plastic. The aqueous composite coating is prepared from the following raw materials in parts by weight: 20 to 40 parts of aqueous chlorinated polyolefin resin, 20 to 40 parts of aqueous acrylic resin, 15 to 30 parts of aqueous polyurethane dispersoid, 2 to 5 parts of silane coupling agent, 20 to 40 parts of nano calcium carbonate, 5 to 10 parts of ultrafine talcum powder, 10 to 20 parts of nano silicon dioxide, 5 to 15 parts of aluminum silicate, 1 to 6 parts of barium sulfate, 1 to 3 parts of titanium dioxide, 1 to 4 parts of zinc phosphate, 1 to 4 parts of adhering force accelerant, 0.5 to 2.5 parts of dimethylethanolamine, 1 to 2 parts of flatting agent, 1 to 2 parts of antibacterial agent, 1 to 2 parts of de-foaming agent, 1 to 2 parts of mildew preventive and 1 to 2 parts of wetting agent. The aqueous composite coating has great hardness and strong adhering force.

Owner:ANHUI JINDUN PAINT

Electroconductive polymer printing ink and preparation method thereof

InactiveCN101624490AImprove printing accuracyImprove stabilityInksOther printing apparatusWater basedScreen printing

The invention relates to an electroconductive polymer printing ink for offset printing, gravure printing and screen printing. A conductive substance of the ink adopts a conducting polymer based on poly-ethylene-dioxythiophene. The electroconductive polymer printing ink comprises water-based polymer resin, conductive polymer aqueous dispersion solution, propanetriol, dimethyl sulfoxide, N,N-dimethylethanolamine and a water-based thickening agent. The invention also relates to a method for preparing the electroconductive polymer printing ink for offset printing, gravure printing and screen printing, which comprises the following steps: mixing the conducting polymer aqueous dispersion solution based on the poly-ethylene-dioxythiophene with the dimethyl sulfoxide according to the proportion; and mixing the water-based polymer resin with the water-based thickening agent according to the proportion for standby; adjusting pH of the mixture to be between 7.5 and 9.5; evenly mixing the mixture with the water-based resin; and adding the propanetriol into the mixture. The electroconductive polymer printing ink and the method have the advantages of thin thickness of an ink film, high printing precision and high printing speed, and also have the advantages of environmental protection, good electroconductive performance, high stability and the like.

Owner:HESHAN ASTROS PRINTING

Polyurethane flame-retardant thermal-insulation material and preparation method thereof

The invention provides a polyurethane flame-retardant thermal-insulation material and a preparation method thereof. The polyurethane flame-retardant thermal-insulation material is composed of a component A and a component B, wherein the component A is composed of phenol formaldehyde resin, a brominated epoxy resin, phosphorous flame-retardant polyether glycol, an organosilicon foam stabilizer, a catalyst dimethylethanolamine, a catalyst dibutyltin dilaurate, a flame retardant and a foaming agent monofluorodichloroethane; and the component B is a flame-retardant polyisocyanate curing agent. The invention also provides a preparation method of the outer wall thermal-insulation material. The thermal-insulation material has excellent mechanical properties and high flame retardancy, solves the problem of contradiction between the flame retardancy and mechanical properties of the original polyurethane hard foam thermal-insulation material, and is suitable for outer wall thermal-insulation construction with higher requirements for fire-protection rating.

Owner:广西宾阳县荣良农业科技有限公司

Waterborne epoxy anticorrosive paint with modified vermiculite being used as functional filler and preparation method thereof

InactiveCN104004440ASimple structureImprove thermal stabilityAnti-corrosive paintsEpoxy resin coatingsEpoxyRust

The invention relates to waterborne epoxy anticorrosive paint with modified vermiculite being used as functional filler and a preparation method thereof. The anticorrosive paint is composed of waterborne epoxy resin emulsion, rust resisting pigment, modified vermiculite, normal filler, a dispersing agent, a flatting agent, an antifoaming agent, a pH modifier N, N-dimethylethanolamine, a thickening agent and the balance deionized water according to the mass percent, wherein the rust resisting pigment is zinc phosphate or aluminium triphosphate or ferrotitanium powder or iron oxide red, and the normal filler is talcum powder or barium sulfate or carbon black. The monified vermiculite is used for preparation, the steps for preparing the waterborne expoxy anticorrosive paint are achieved, the modified vermiculite is used as anticorrosive functional filler, the nano stratified structure and heat stability are used for improving the anticorrosive performance and the heat resistance performance of the coat. The waterborne epoxy anticorrosive paint is excellent in comprehensive performance and capable of meeting the demand for corrosion prevention of a storage tank, a pipeline, a bridge and the like.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Topical Composition For Anti-Aging Skin Treatment Using Dual DNA Repair Mechanism and Method of Use

InactiveUS20100291190A1Reduction of pigmentation spotImprove skin toneBiocideCosmetic preparationsSkin colorSativum

A topical composition for anti-aging treatment of the skin includes water soluble extract of Uncaria species, Arabidopsis thaliana extract, lipoic acid, dimethylethanolamine, tetrahexyldecyl ascorbate, dimethyl sulfoxide, Glycyrrhiza Glabra(Licorice) root extract, methylsulfonylmethane, phytosterols, D-ribose, tocotrienol, tocopherol, glucosamine hydrochloride, Pisum sativum extract; Bambusa vulgaris extract, and a dermatologically acceptable liposomal delivery medium. Further disclosed is a method using the topical composition for anti-aging skin treatment utilizing DNA repair in both the nucleus and the mitochondria. The topical composition can be applied on the skin of a person daily, and can also be applied in a dermal infusion treatment, with or without micro-dermal abrasion or skin suction. Topical application of the composition achieves effective reduction of pigmentation spots and degree of winkles, and improvement of skin color tone.

Owner:LIFE SCI INT

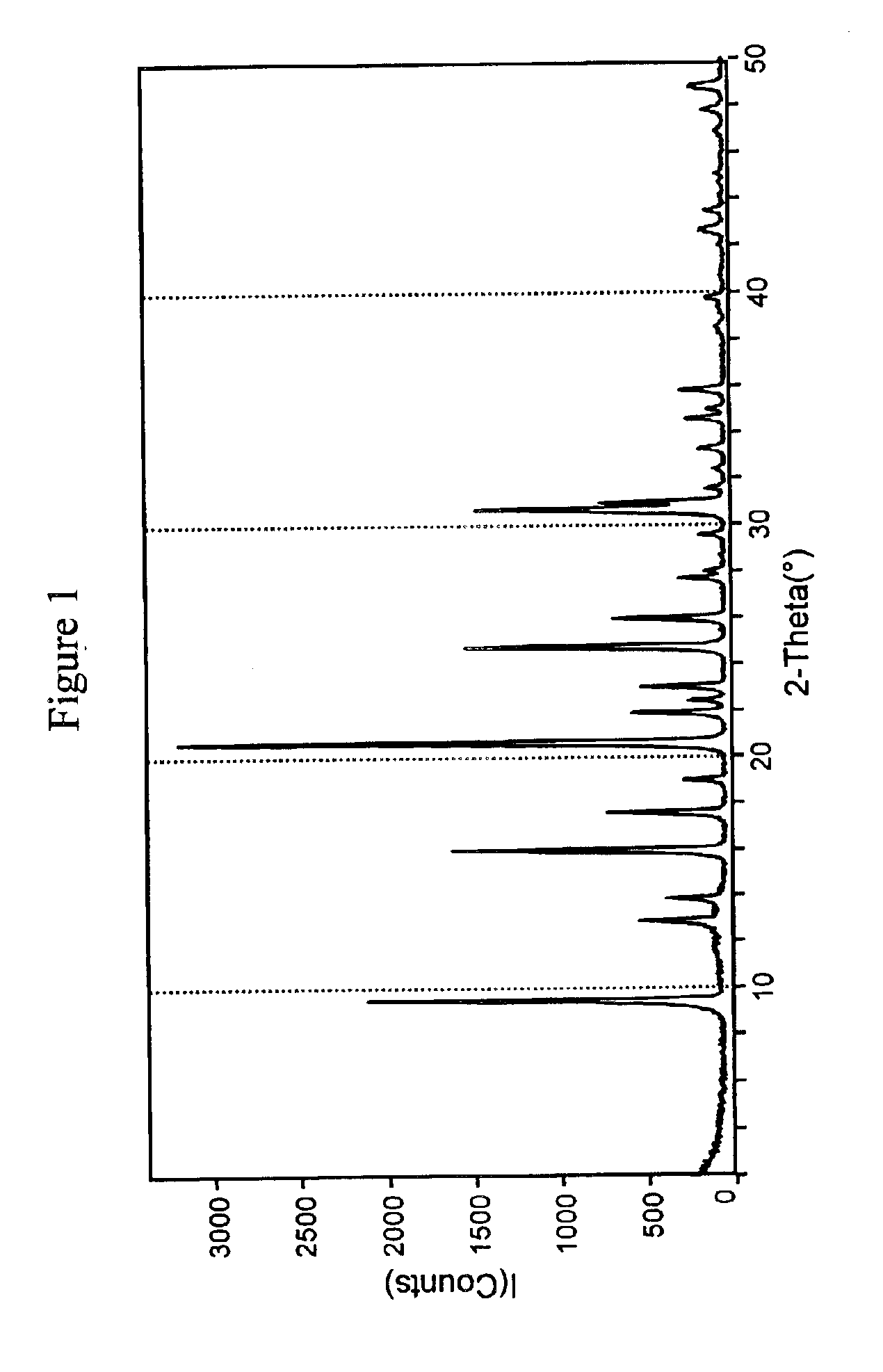

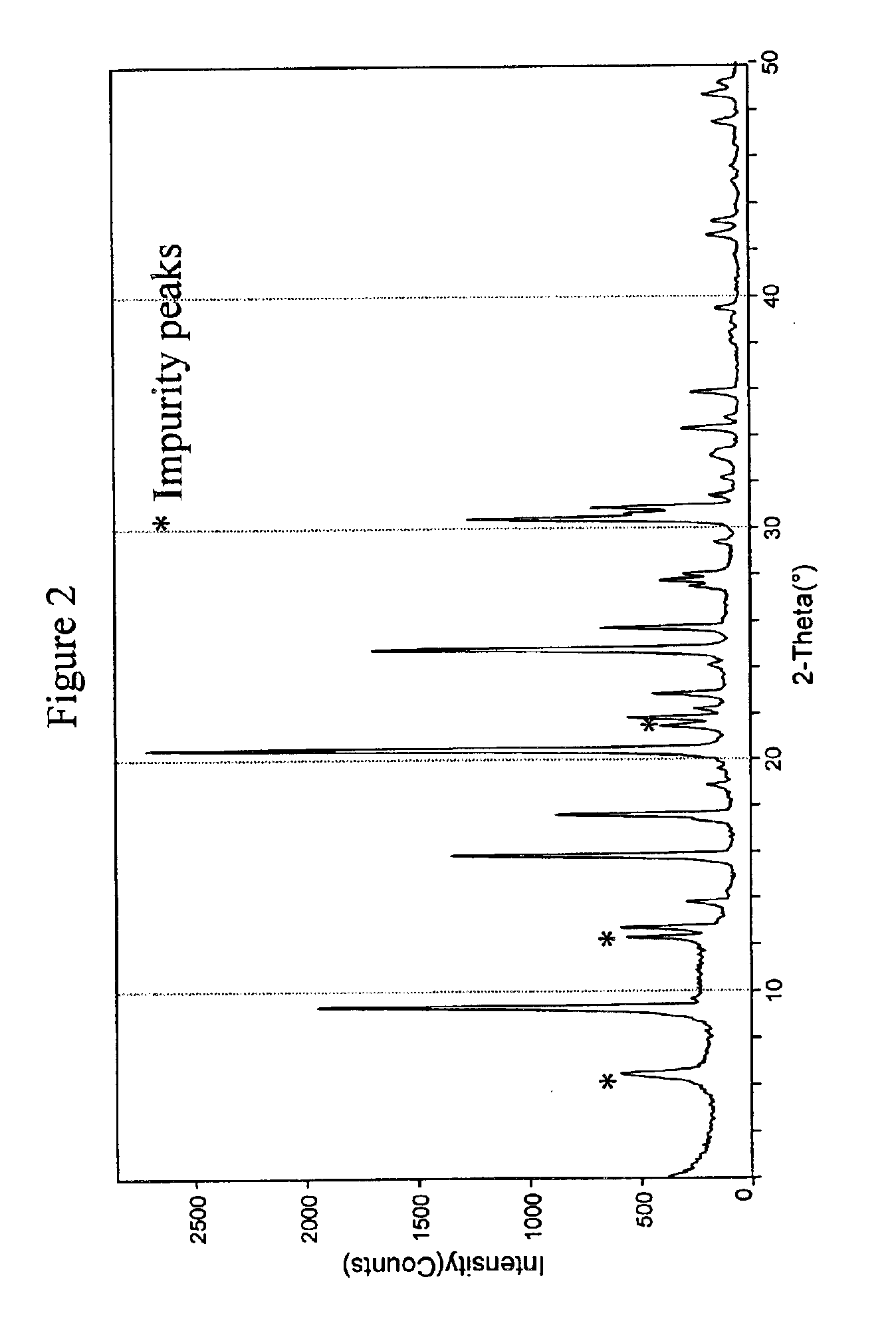

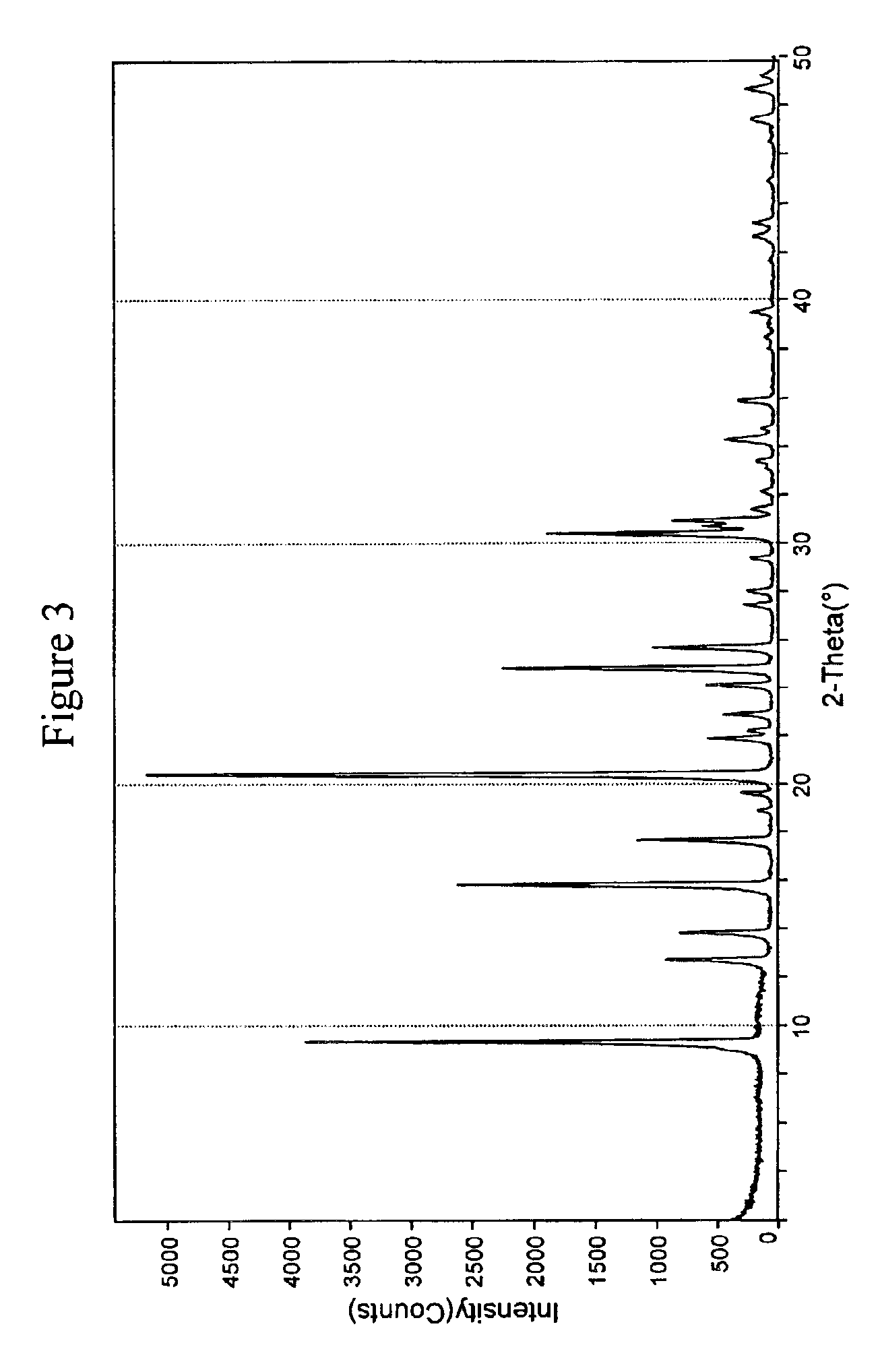

Synthesis of silicoaluminophosphates

The invention is directed to a method of synthesizing silicoaluminophosphate molecular sieves using synthesis templates that contain at least one dimethylamino moiety, selected from one or more of N,N-dimethylethanolamine, N,N-dimethylpropanolamine, N,N-dimethylbutanolamine, N,N-dimethylheptanolamine, N,N-dimethylhexanolamine, N,N-dimethylethylenediamine, N,N-dimethylbutylenediamine, N,N-dimethylheptylenediamine, N,N-dimethylhexylenediamine 1-dimethylamino-2-propanol, N,N-dimethylethylamine, N,N-dimethylpropylamine, N,N-dimethylpentylamine, N,N-dimethylhexylamine and N,N-dimethylheptylamine. The use of dimethylamino moiety containing templates results in good quality SAPO molecular sieves of CHA framework type.

Owner:EXXONMOBIL CHEM PAT INC

Triphenylmethane polymeric colorant having sterically hindered amine counter ion

Novel triphenylmethane dyes or colorants with sterically hindered fugitive amine counter ions are provided as durable, storage-stable, and excellent coloring and shading printing inks. Ink compositions are disclosed which provide improvements in long-term storage capabilities, particularly within alkaline environments, extremely effective colorations of cellulose-based substrates, and lower cost over those of the prior art. The preferred dyes or colorants are triphenylmethane polymeric colorants which are capped with cyclic anhydride and the preferred sterically hindered amine counter ions are those based on low molecular weight fugitive tertiary amines, such as N,N-dimethylethanolamine. Compositions comprising water soluble or emulsion resins as diluents for lowered viscosity and lower overall cost are also contemplated. Furthermore, compositions comprising the inventive colorant and other pigments, dyes, surfactants, preservatives, and other colorants are contemplated. A method of making such an inventive ink composition and a cellulose-based substrate contacted with such an inventive ink composition are also disclosed.

Owner:MILLIKEN & CO

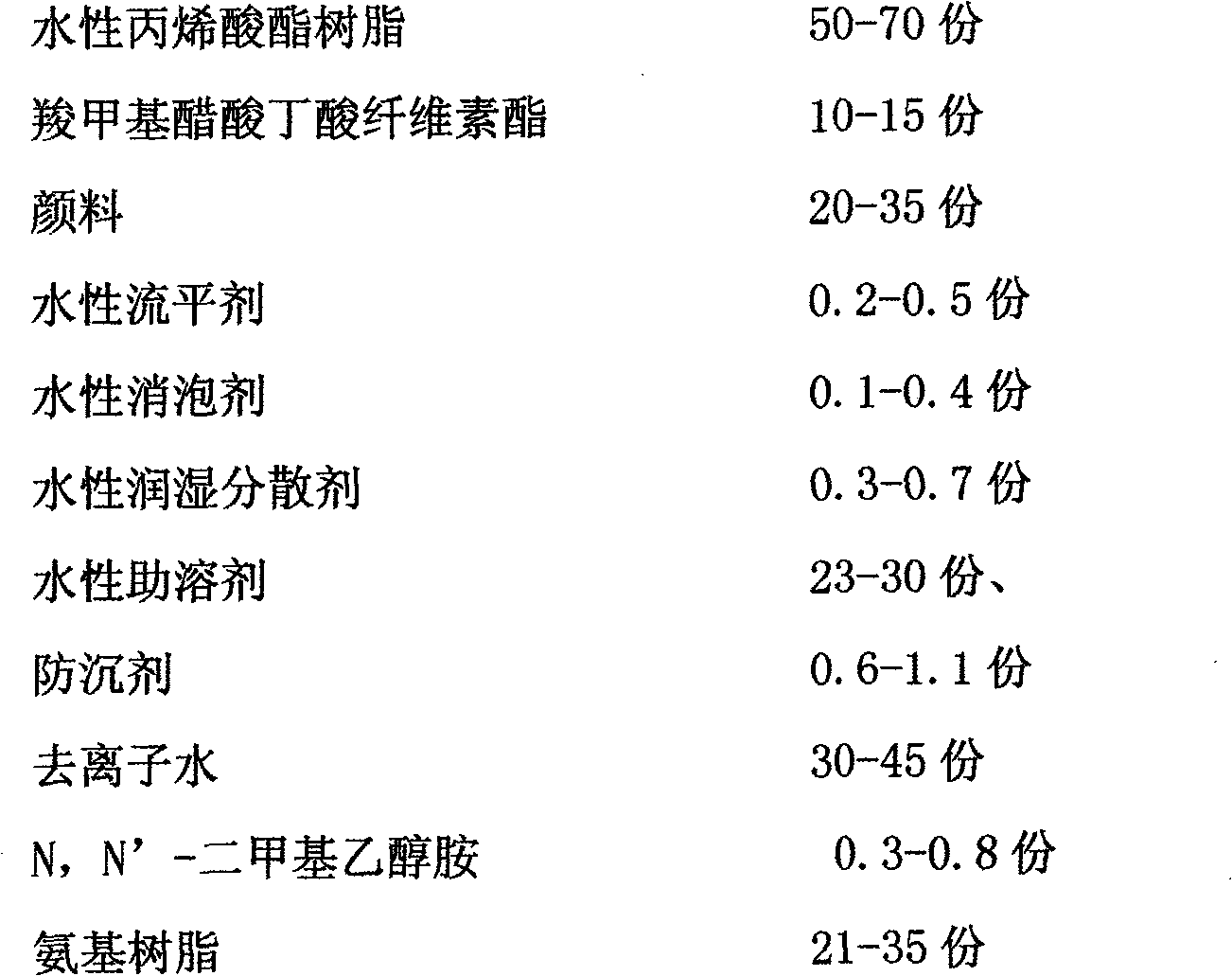

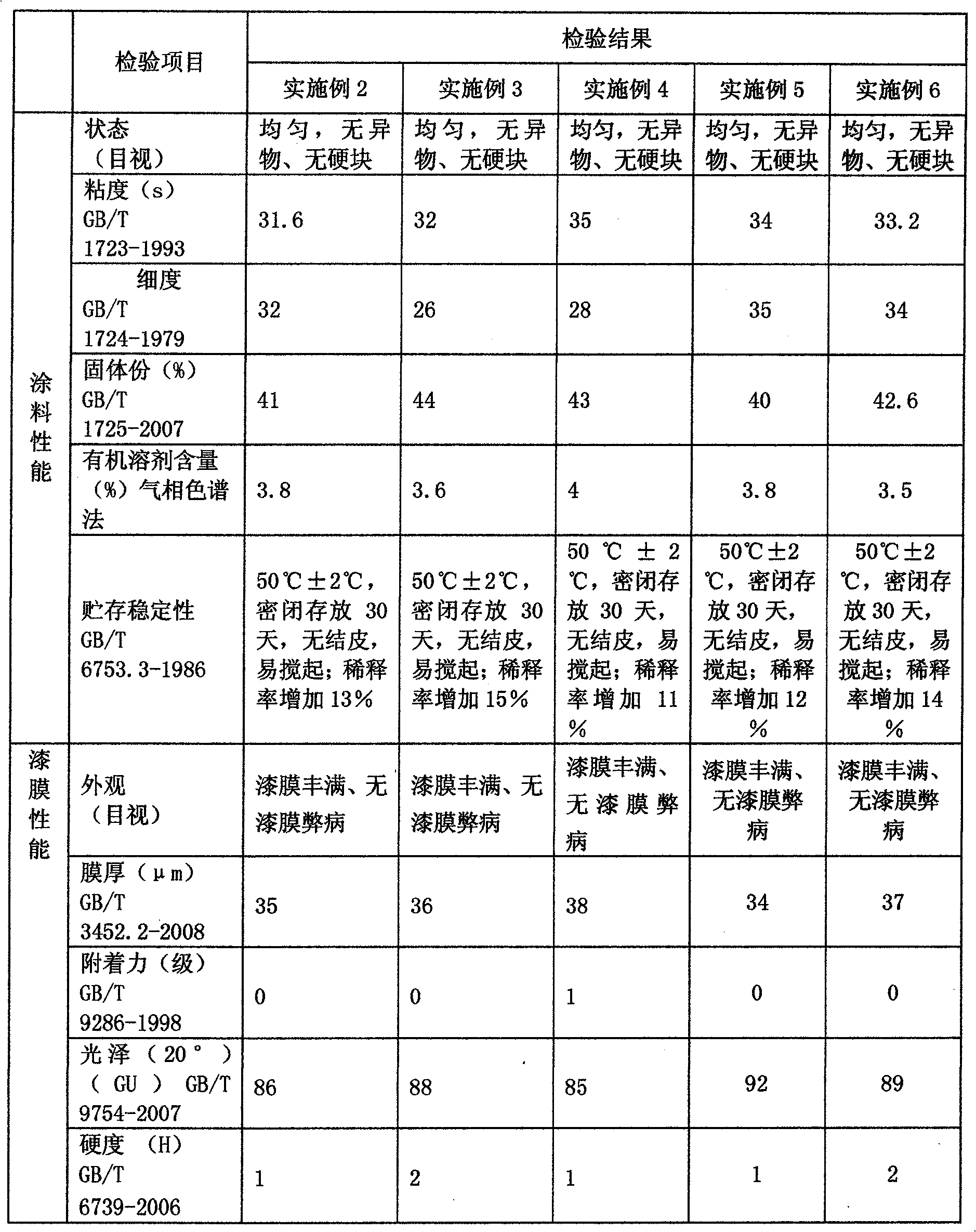

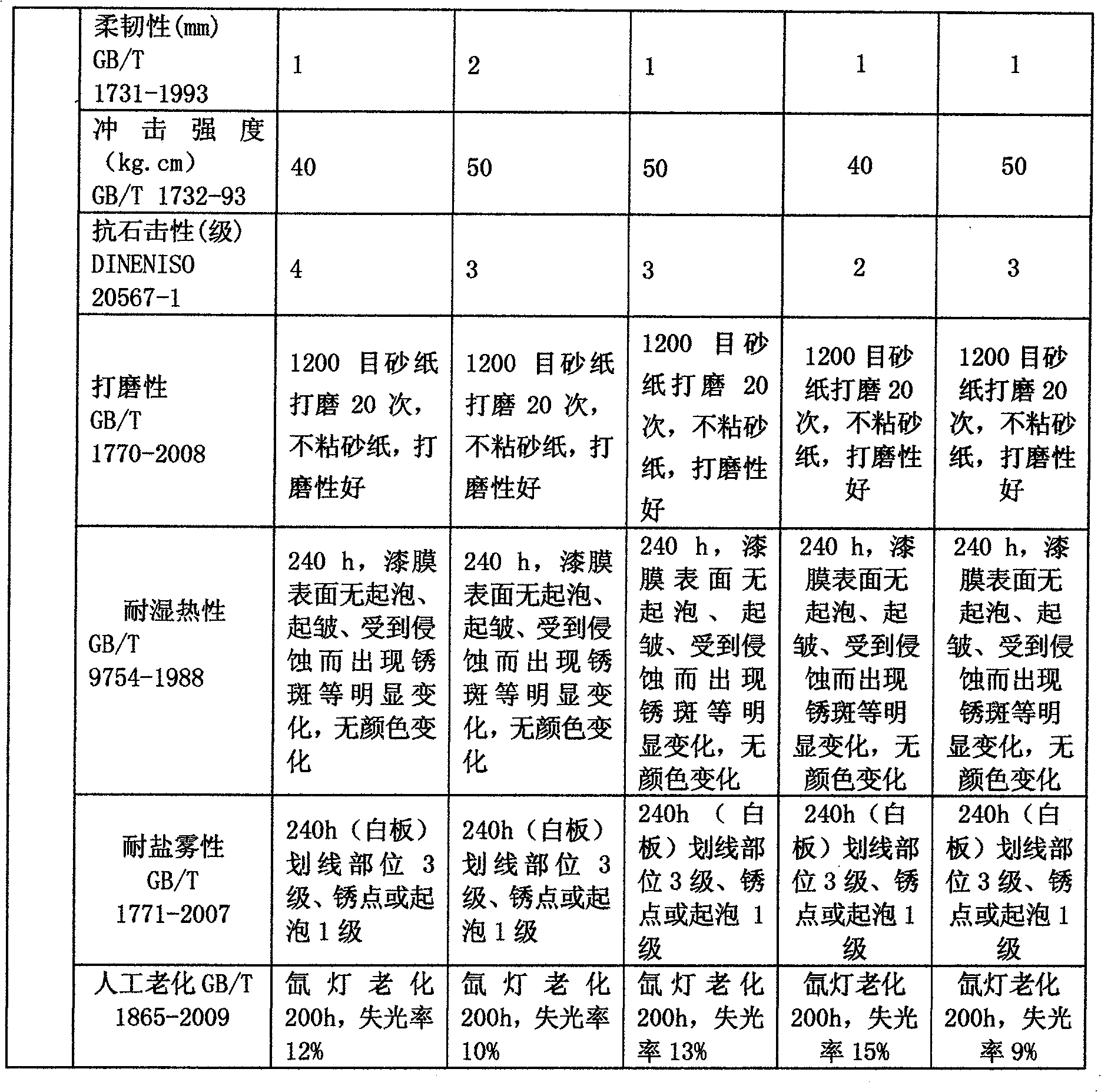

Water-based automobile finish and preparation method thereof

The invention discloses water-based automobile finish and a preparation method thereof. The water-based automobile finish comprises the following components in parts by weight: 50-70 parts of water-based acrylate resin, 10-15 parts of carboxymethyl cellulose acetate butyrate ester, 20-35 parts of pigment, 0.2-0.5 part of water-based levelling agent, 0.1-0.4 part of water-based defoaming agent, 0.3-0.7 part of water-based moistening dispersing agent, 23-30 parts of water-based cosolvent, 0.6-1.1 parts of anti-settling agent, 30-45 parts of deionized water, 0.3-0.8 part of N,N'-dimethylethanolamine and 21-35 parts of amino resin. Compared with the traditional solvent type finish, the water-based automobile finish has the advantages that no organic solvent is contained and an obtained paint film has extremely strong adhesive force, good humidity resistance, good ageing resistance and high glossiness.

Owner:CHANGCHUN SANHUA IND

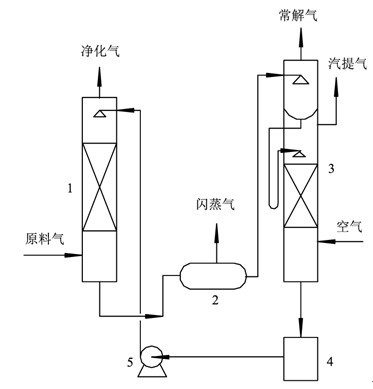

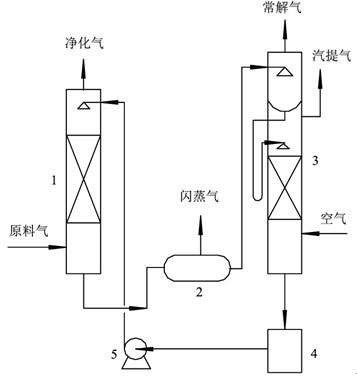

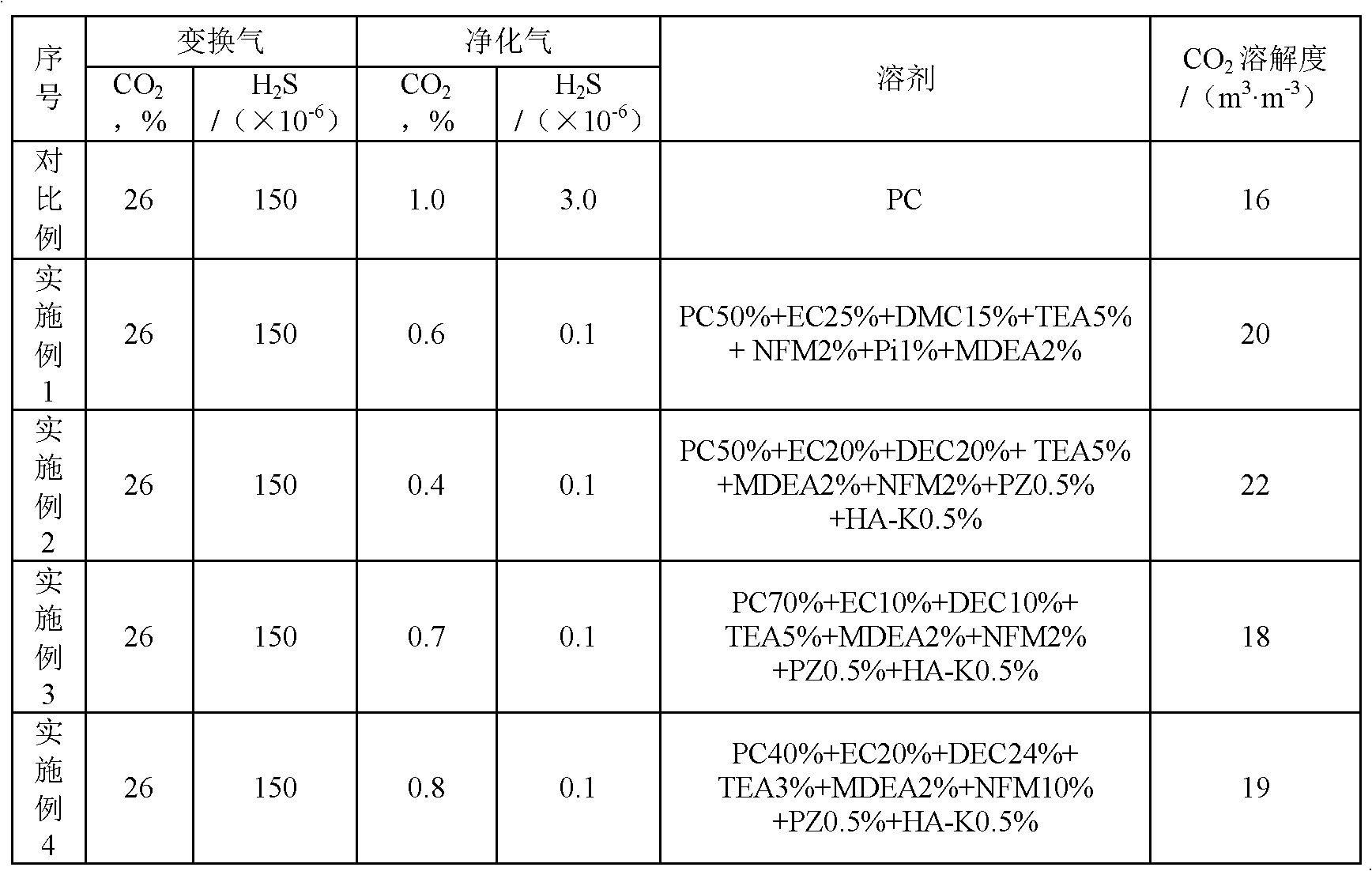

Mixed solvent for removing acid gas

InactiveCN102657998AFlexibleOptimized formulaDispersed particle separationAbsorption capacityMethyl carbonate

The invention discloses a mixed solvent for removing acid gas, which belongs to the technical field of gas separation and is characterized by being composed of two or more than two of main absorption components, assisting absorption components and active components in mixing mode, wherein the main absorption components comprise propylene carbonate (PC), ethylene carbonate (EC), dimethyl carbonate (DMC), diethyl carbonate (DEC) and N-methyl-2-pyrrolidone (NMP), the assisting absorption components comprise N-methyldiethanolamine (MDEA), triethanolamine (TEA), diglycolamine (DGA) and dimethylethanolamine (DMEA), and the active components comprise phosphoric acid (Pi), piperazine (PZ), urotropin (HA-K), N-Formylmorpholine formylmorpholine (NFM), 2-amino-2methyl-1-propyl alcohol (AMP) and morpholine by-products. By means of the mixed solvent for removing acid gas, on one hand, absorption capacity and purification of CO2 are improved, and on the other hand, desulfuration accuracy is greatly improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Waterborne epoxy resin for stoving varnish and preparation method and application

InactiveCN107141425ALow VOCStrong environmental protectionEpoxy resin coatingsIsooctyl acrylateEpoxy

The invention discloses waterborne epoxy resin for stoving varnish. The waterborne epoxy resin is prepared from epoxy resin, acrylic acid, butyl acrylate, iso-octyl acrylate, hydroxyethyl acrylate, methyl methacrylate, styrene, benzoyl peroxide, ethylene glycol monobutyl ether, dimethylethanolamine and deionized water. The best raw material ratio is obtained through screening of a large number of experiments, the environmental friendliness is high, and epoxy resin can be dispersed into water; in the whole preparation technology, a large quantity of organic solvent can be prevented from being adopted, only a small quantity of environment-friendly solvent is adopted, deionized water is adopted for replacing the large quantity of organic solvent, the prepared water dispersion epoxy resin is low in VOC, the performance of the epoxy resin is the same as that of solvent type epoxy resin, and the waterborne epoxy resin has the excellent hardness, shock resistance and adhesive force and has the good technical effect.

Owner:江苏三木化工股份有限公司 +1

Composition For Cosmetic And Health Improvement

InactiveUS20140212388A1Good for healthPromotes skin healthBiocideInorganic active ingredientsMedicineBiotin

The invention relates to compositions in a form of health drinks, capsules, tablets or powders. In particular the compositions improve individual's general health, maintain and improve regeneration of human connective tissue and simultaneously provide positive cosmetic effects for a better life and more happiness for all, male, female, young and old. The composition may include compounds such as silica compound, biotin, carnosine, hyaluronic acid, methylsulfonyl methane (MSM), dimethylethanolamine (DMEA) and omega-3-oil along with other components.

Owner:PRIETO MARIA ALVAREZ

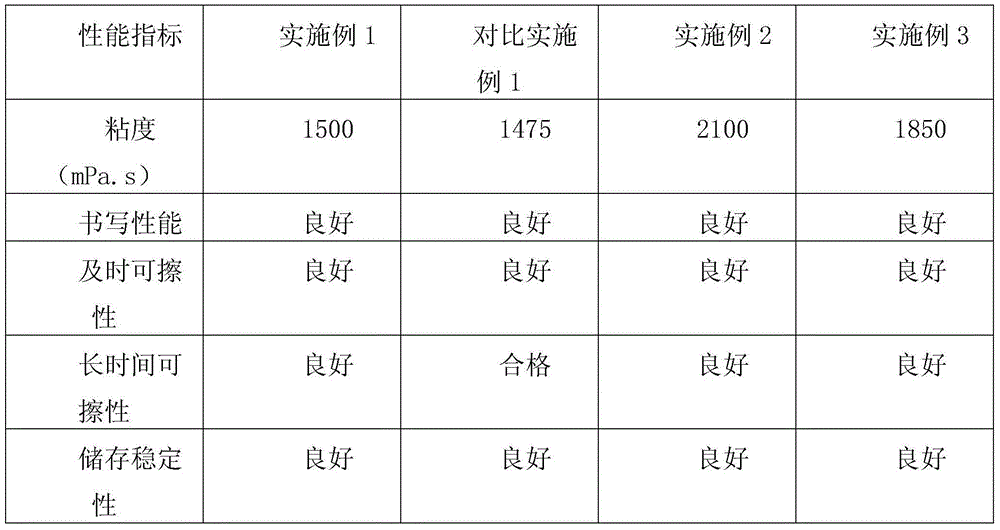

Erasable neutral ink and preparation method thereof

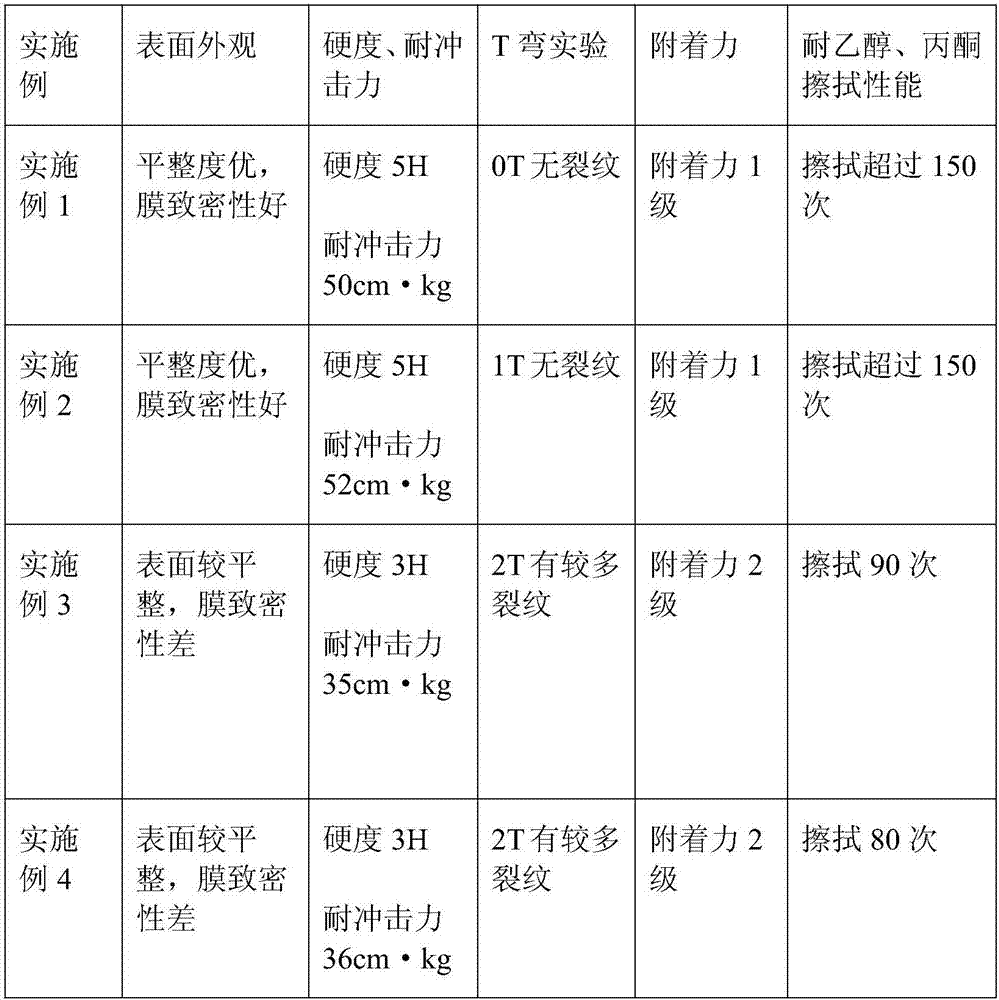

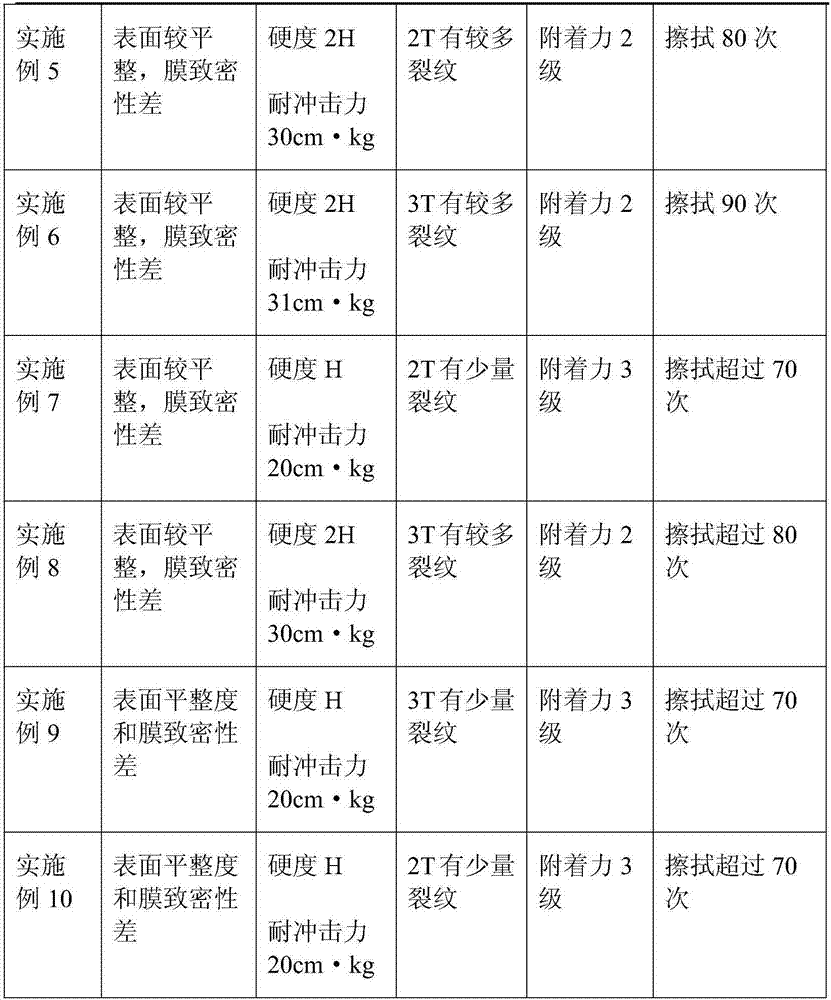

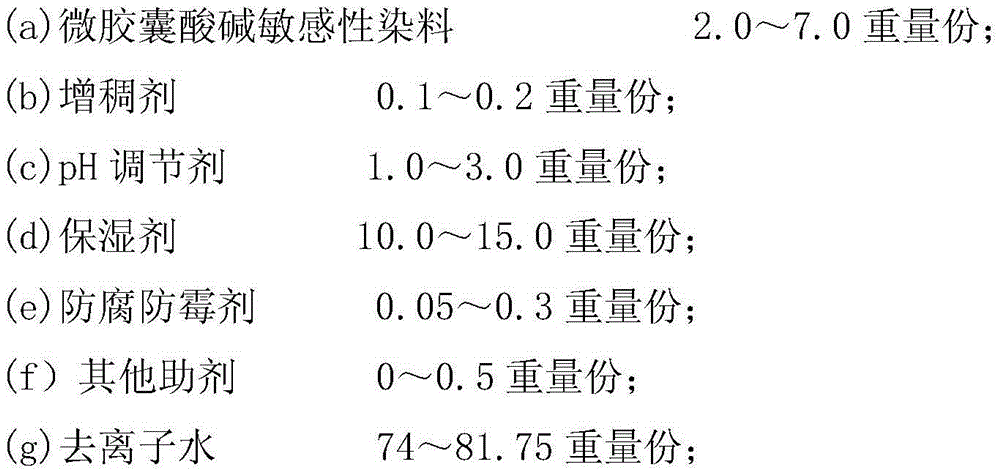

The invention provides an erasable neutral ink composition comprising a neutral ink component (A) and an erasable liquid component (B), wherein the component (A) comprises the following components in parts by weight: 2.0-7.0 parts of a microcapsule acid-alkali sensitive dye (a), 0.1-0.2 part of a thickening agent (b), 1.0-3.0 parts of a pH regulator (c), 10.0-15.0 parts of a humectant (d), 0.05-0.3 part of an antiseptic and anti-mildew agent (e), 0-0.5 part of other auxiliary agents (f) and 74-81.75 parts of deionized water (g), wherein the total weight of the components (a)-(g) accounts for 95-100% of the total weight of the composition, the viscosity of the neutral ink component is 1500-3000mPa.s, and the thixotropic value is more than or equal to 2.5; and the component (B) is an alkaline solution comprising an aqueous solution of one or more of sodium hydroxide, 2-amino-2-methyl-1-propanol, N-methylethanolamine, dimethylethanolamine, monoethanolamine, diethanolamine, triethanolamine, butyl ethanolamine, butyl diethanolamine, 2-amino-2-ethyl-1,3-propylene glycol and N-aminopropyl-methylethanolamine.

Owner:LOTUS STATIONERY

Antifouling scale-inhibiting anti-aging exterior wall coating and preparation method thereof

The invention provides an exterior wall coating which is composed of the following raw materials in parts by weight: 84-90 parts of water-based acrylic emulsion, 10-15 parts of styrene-acrylic emulsion, 16-50 parts of hydrotalcite powder, 4-6 parts of nano silicon dioxide, 0.1-0.2 part of triallyl isocyanurate, 3-4 parts of acrylic acid, 1-2 parts of aluminium nitride, 1-2 parts of dimethylethanolamine, 0.7-1 part of ureidopropyltriethoxysilane, 1-2 parts of sodium tripolyphosphate, 1-2 parts of polyvinylpyrrolidone, 1-2 parts of para toluene sulfonamide, 1-2 parts of ammonium dihydrogen phosphate, 0.4-0.6 part of triphenyl phosphite, 2-3 parts of absolute ethyl alcohol, 3-5 parts of coalescing agent, 0.1-0.2 part of polyoxypropylene glycerol ether and 10-20 parts of deionized water. The coating provided by the invention has the advantages of low raw material loss, low gel production, simple process, hard coating film, good glossiness, strong impact resistance, low cracking rate, soft texture, excellent decorative property, high weather resistance, scrubbing resistance, high adhesion force and long service life; and the coating is free of special smell and contains no heavy metals such as mercury and lead and also does not contain formaldehyde volatile, and thus the coating meets the technical requirements of an environment-friendly coating.

Owner:CHUZHOU MAISITE NEW BUILDING MATERIAL

Water-soluble band tape paint and method of producing the same

The invention provides a water soluble tape paint, which belongs to the technical field of paint. The water soluble tape paint comprises water soluble acrylic resin, an aqueous and oily dispersant, a polyether modified siloxane defoamer, a nano-gas phase silicon dioxide anti-settling agent, a paint, dimethylethanolamine, de-ionized water, a cosolvent, a fluorocarbon modified polyacrylate flatting agent, and water soluble amino-acid resin through proportioning. The content of organic solvent in the water soluble tape paint is low; all of the organic solvents are friendly to the environment, which fall beyond the scope of solvents restricted by the state. The lacquer films can be cured quickly and have excellent physical and mechanical properties without needing catalyzers, which can reach and be higher than the index of the traditional solvent.

Owner:无锡市南雅化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com