Patents

Literature

812results about How to "Low VOC" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment friendly antibacterial waterborne paint and preparation thereof

InactiveCN101486861AImprove adhesionFull paint filmAntifouling/underwater paintsPaints with biocidesChemistryEmulsion

The invention provides an environment-friendly antibacterial water paint and a preparation method thereof. The components include deionized water, germicide, assistant for film forming, defoaming agent, wetting agent, dispersant, nanometer TiO2, emulsion or water dispersoid resin, filler, anti-settling agent, flatting agent, thickener, pH regulator, scratch resistance agent or slipping agent, pigment or coloring agent, additive with special function and the like. The preparation method includes the steps of: A. preparing the water dispersoid; B. adding the water dispersoid obtained in the step A into the stirred emulsion, then adding the assistant for film forming, the flatting agent, the thickener, the anti-settling agent, and the pH regulator and uniformly stirring and dispersing the components; C. adding the pigment or the coloring agent; and D. charging water and adjusting the Stormer viscosity at the temperature of 25 DEG C to be 65-90KU, thus obtaining the water paint. The water paint provided in the invention has good adhesion to wood materials, full paint films with certain hardness, low VOC, no heavy metal, and the antibacterial and mildewproof functions, and belongs to the environment-friendly and safe children woodwork water paint.

Owner:SHENZHEN OCEANPOWER NEW MATERIALS TECH

Dry-type heat-insulating waterproof coating

InactiveCN101648794AGood heat insulation and waterproof effectImprove waterproof performancePliabilityTalc

The invention relates to a dry-type heat-insulating waterproof coating which comprises the following raw materials in percentage by weight: 0-5.5 dispersible polymer powder, 10-20 hollow filling beads, 5-20 sepiolite powder, 5-10 mica powder, 5-30 heavy calcium carbonate powder, 5-15 light calcium carbonate powder, 0.5-1.5 rutile titanium dioxide, 10-20 talc powder and 10-40 white cement. A coat formed by the coating of the invention has favorable heat-insulating waterproof effect (lowers indoor temperature by 4-20 DEG C) and excellent flexibility, impermeability, weathering resistance and bonding strength to a substrate as well as high strength, good brightness, uniform luster, smooth and tender touch feeling, waterproof washing and rubbing, and the like. The dry-type coating has the advantages of simple production process, convenient transportation, long storage time, convenient construction, and the like, no toxicity or pollution, environment-friendly trend suitability, low cost, low VOC and high performance, thereby becoming a new-generation building coating product.

Owner:吕海涛

Coated substrate having enhanced scratch and mar resistance

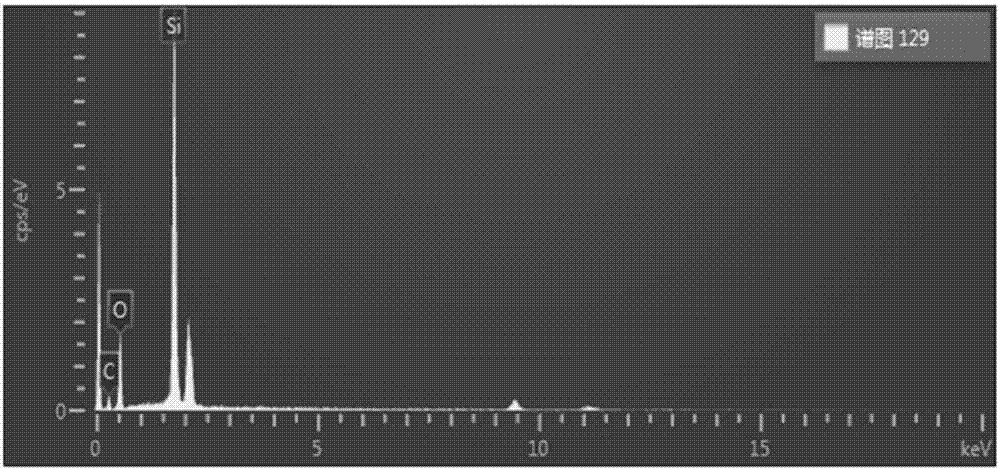

ActiveUS20080160289A1Good optical performanceImprove scratch resistanceMaterial nanotechnologyPigmenting treatmentAutomotive coatingSilicon dioxide

Disclosed herein is a substrate comprising a coating composition of silica nano-particles having enhanced mar and scratch resistance. In particular, the invention relates to a coating composition that contains silica nano-particle dispersion for use in automotive coating applications.

Owner:AXALTA COATING SYST IP CO LLC

Two component coating compositions and coatings produced therefrom

ActiveUS20040010091A1Reduce decreaseUnacceptable functionalityLiquid surface applicatorsLocks for portable objectsMethacrylateEpoxy

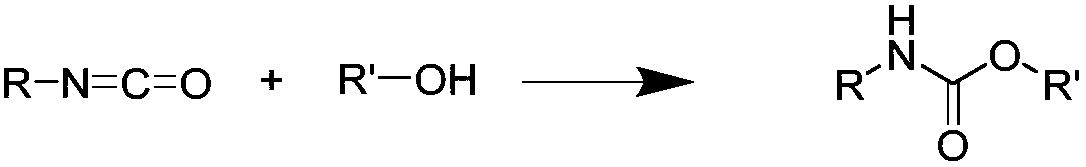

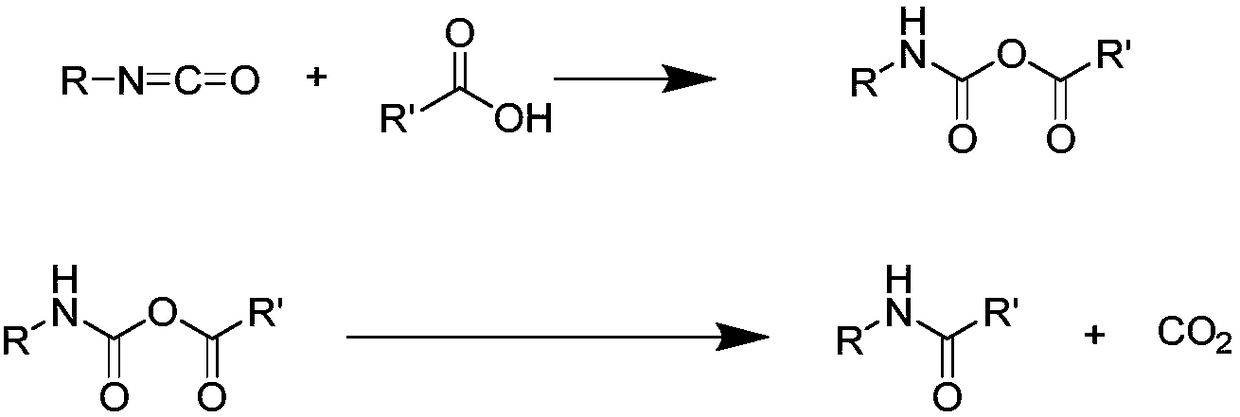

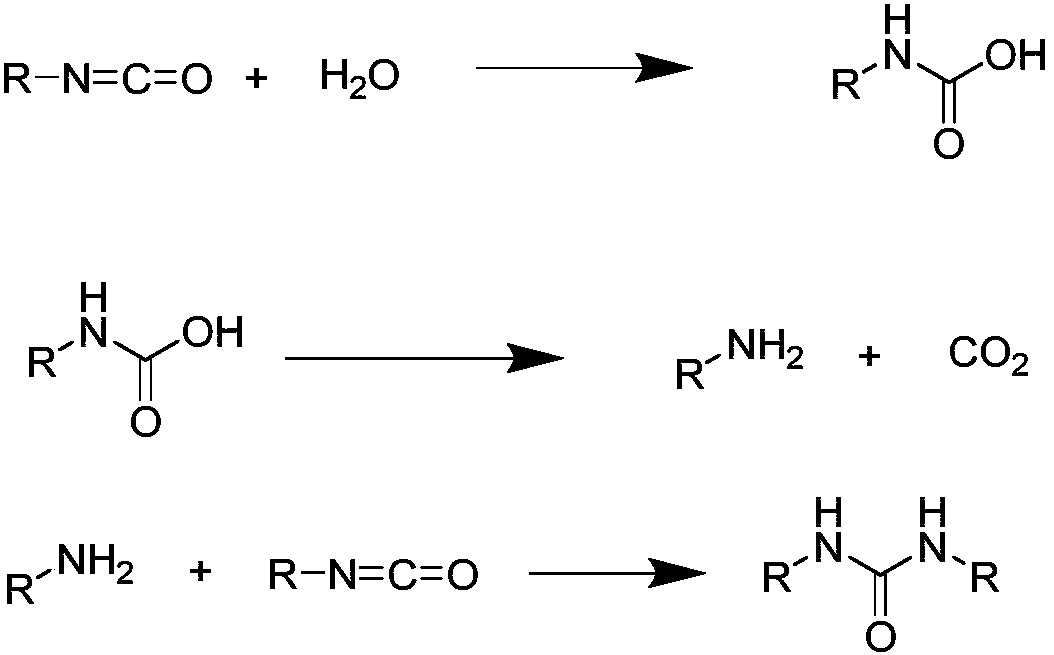

The present invention is directed to two component coating compositions that cure under ambient conditions and more particularly to those having low VOC (volatile organic content) that are suitable for use in automotive refinish and Original Equipment Manufacturing (OEM) applications. The coating composition includes crosslinkable and crosslinking components, wherein the crosslinkable component includes a low polydispersity, low molecular weight copolymer having on an average 2 to 25 functional groups, such as hydroxyl, carboxyl, acetoacetoxy, primary and secondary amine, and epoxy. The copolymer is polymerized from a monomer mixture that includes one or more non-functional acrylate monomers and one or more functional methacrylate monomers provided with the functional groups. The crosslinking component includes polyisocyanate, polyamine, ketimine, melamine, epoxy, polyacid or a combination thereof. The invention is also directed to coating produced from the coating composition.

Owner:AXALTA COATING SYST IP CO LLC

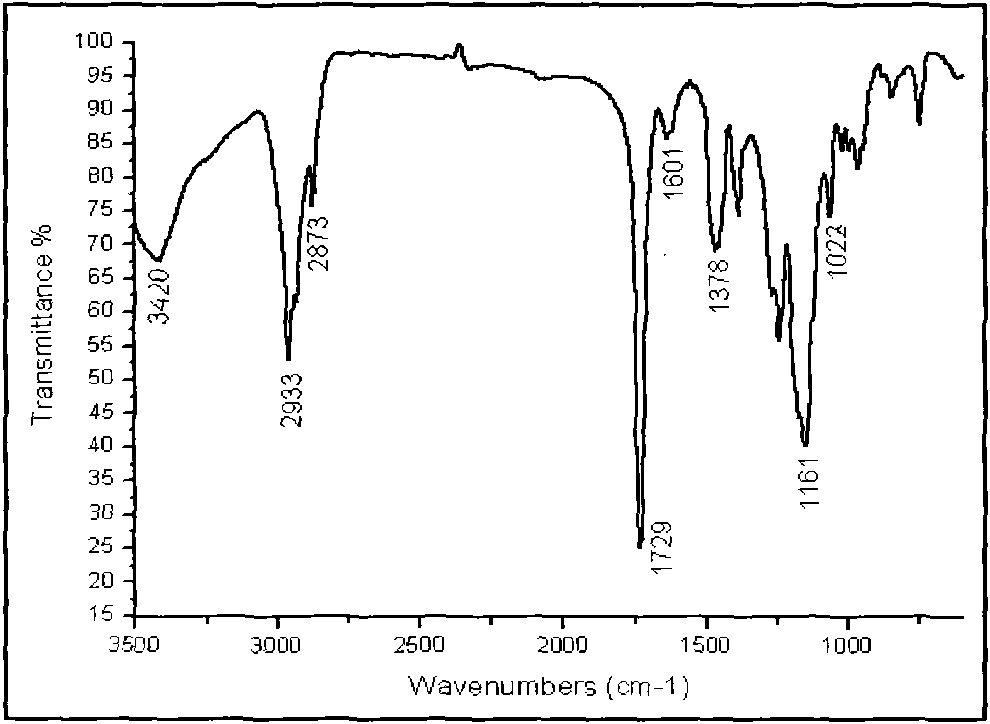

Preparation method of polyester acrylate hybrid aqueous dispersion

InactiveCN101824209AAchieve chemical modificationImprove stabilityPolyurea/polyurethane coatingsPolyesterOrganic solvent

The invention relates to a preparation method of polyester acrylate hybrid aqueous dispersion, which belongs to the field of chemical coatings, and the preparation method comprises four steps of synthesizing hydroxyl acrylate resin, preparing an intermediate, preparing polyester acrylate resin and dispersing with deionized water. The preparation method effectively combines the advantages of polyester and acrylic resin, the prepared stable dispersion can be used as the hydroxyl resin component of a dual-component polyurethane coating for preparing a high-performance waterborne dual-component polyurethane coating with hydrophilic polyisocyanate, and a coating film has excellent performance; in addition, the preparation of the dispersion does not use amine as a neutralizer, thereby avoiding the smell caused by the amine and simplifying the process; and only a small amount of cosolvent is adopted in the dispersion, and the content of an organic solvent in the coating is low.

Owner:ZHUZHOU FEILU ADVANCED MATERIAL TECH CO LTD

Water-based two-component fluorosilicone acrylic anticorrosive paint and preparation method thereof

InactiveCN103320000AHigh resistivityGood weather resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsIonChemistry

The invention relates to a water-based two-component fluorosilicone acrylic anticorrosive paint. A film forming material component consists of 50-70 parts of water-based hydroxyl fluorosilicone acrylic resin, 20-40 parts of a pigment / filler, 1-10 parts of an auxiliary and 3-20 parts of de-ionized water, and a curing agent component comprises 5-10 parts of aqueous polyisocyanate and 1-5 parts of a thinner, wherein the weight ratio of the film forming material to the curing agent is 100: (5-15). The preparation method comprises the steps of dispersing and grinding the de-ionized water, the auxiliary and the pigment / filler, adding the water-based hydroxyl fluorosilicone acrylic resin, and uniformly stirring the prepared film forming material with the curing agent to obtain the paint. The anticorrosive paint has the advantages that a polysiloxane-polyurethane segmented copolymer is synthesized by taking the polysiloxane as a soft segment, thus enhancing water resistance, corrosion resistance and other performances; the shell raw material, which includes a fluorine-containing acrylic monomer, guarantees excellent ultraviolet and nuclear radiation resistance, flexibility, wear resistance and durability of coating. The paint is good in compatibility, self-dried at normal temperature, non-toxic and tasteless, low in volatile organic compound (VOC) and strong in coating adhesion, and can be widely applied to large steel structure, bridge, boat and other fields.

Owner:JIUQING PAINT SHANGHAI

Multifunctional aqueous adhesive and preparation method thereof

ActiveCN101058704AAvoid poisoningAvoid the chance of occupational diseasesMonocarboxylic acid ester polymer adhesivesNatural rubber adhesivesPolymer scienceAdjuvant

The invention discloses a multipurpose aqueous adhesive, which comprises the following parts: 10-35% thermoplastic rubber or emulsion, 0. 5-35% solvent, 28-45% emulsion, 20-80% viscosifying resin or its emulsion, 0. 5-5% functional adjuvant and 1-20% water. The making method comprises the following steps: putting the solvent into autoclave; stirring at middle speed and adding thermoplastic rubber and its modifying product until dissolving completely; or putting into copolymerized rubber emulsion directly; stirring to add the viscosifying resin or the viscosifying resin in the invention; blending evenly; adding emulsion; fetching the sample to test the viscosity; adding fitful quantity of water and corresponding functional adjuvant according to the purpose and viscosity; dispersing at high speed until even condition; cooling; filtering; packing; obtaining the product for shoe-making, hand pocket and decorative aspect with low cost.

Owner:林润强

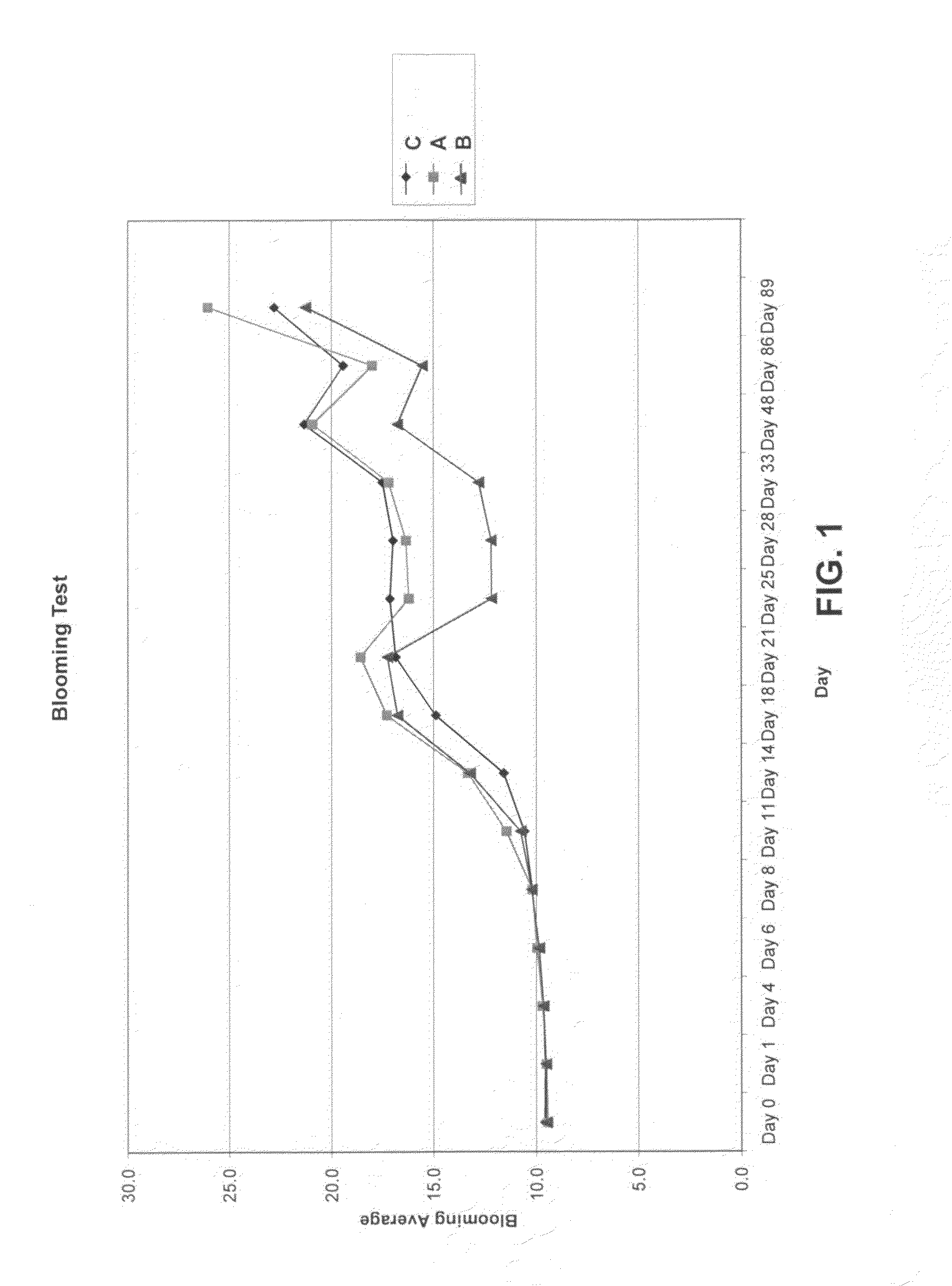

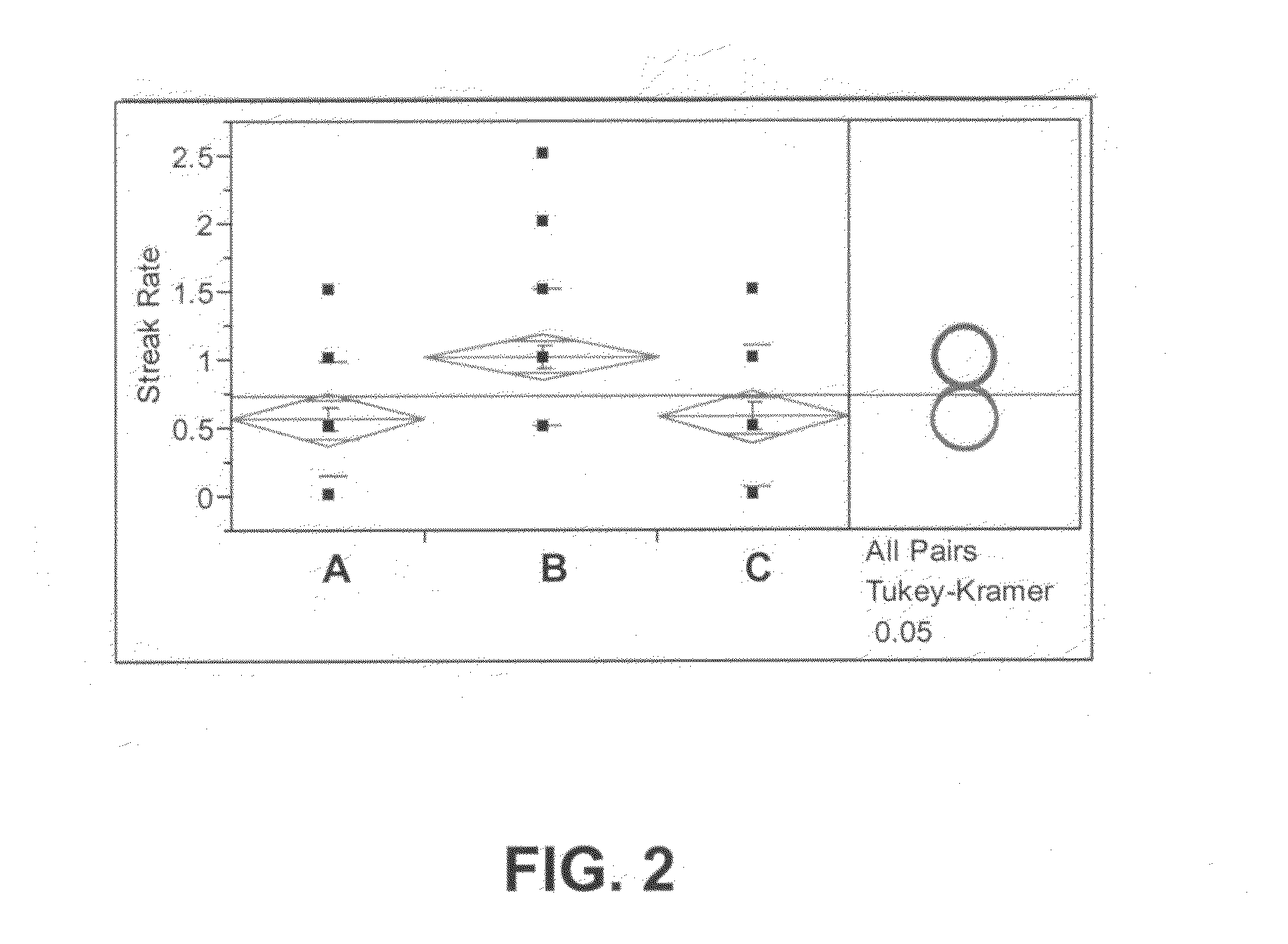

Low voc hard surface treating composition providing anti-fogging and cleaning benefits

ActiveUS20110098206A1Reduce environmental impactReduce complexityNon-ionic surface-active compoundsOrganic detergent compounding agentsPolymeric surfaceSURFACTANT BLEND

A multi-functional hard surface treating composition is described which includes (1) a surfactant system including at least two surfactants and (2) at least one alkylene glycol alkyl ether. The at least two surfactants include an anionic surfactant and either a polymer surfactant or a nonionic surfactant. The surfactant system and alkylene glycol alkyl ether have a synergistic effect to provide anti-fogging, anti-streaking, and cleaning benefits to a hard surface treated with the composition.

Owner:SC JOHNSON & SON INC

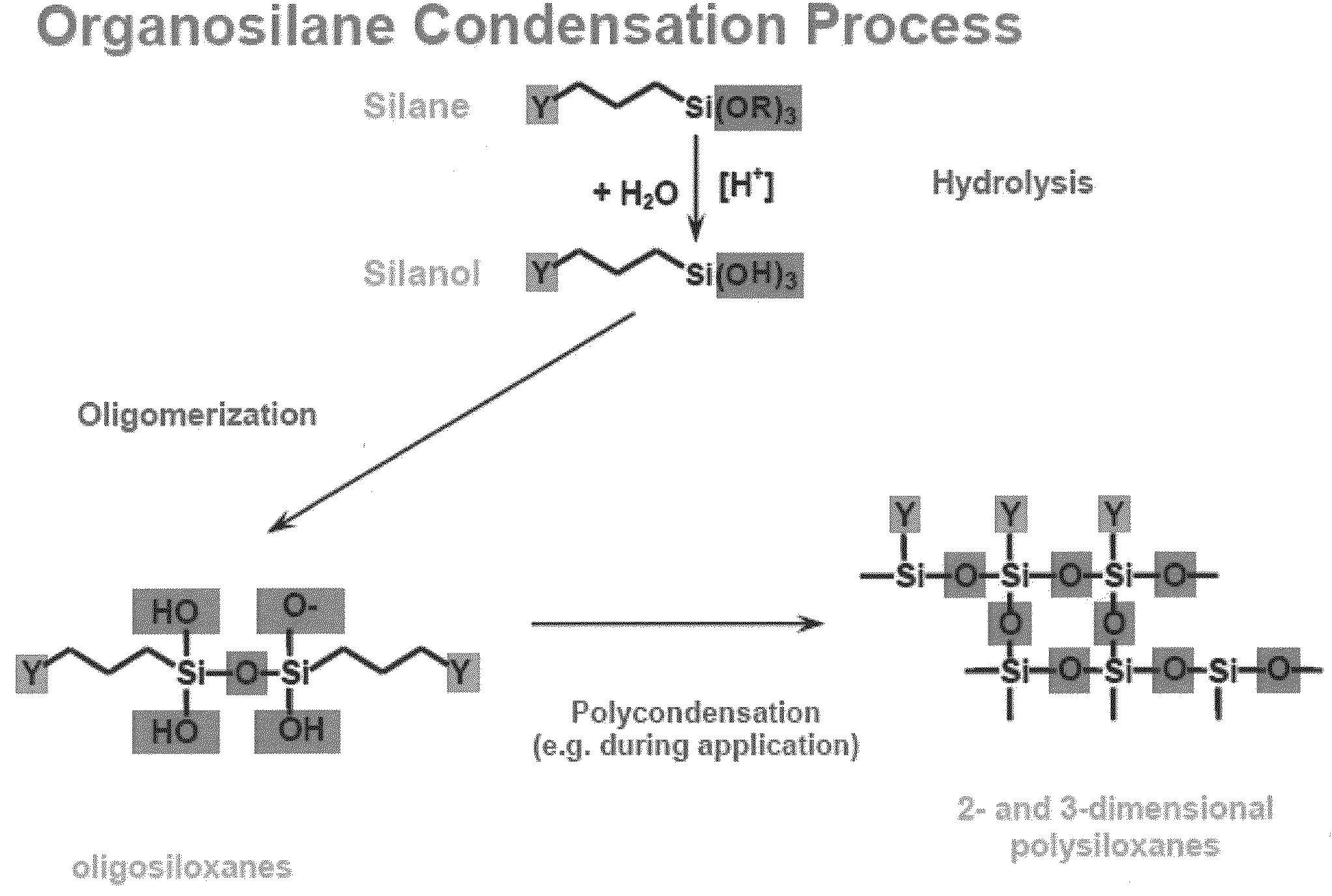

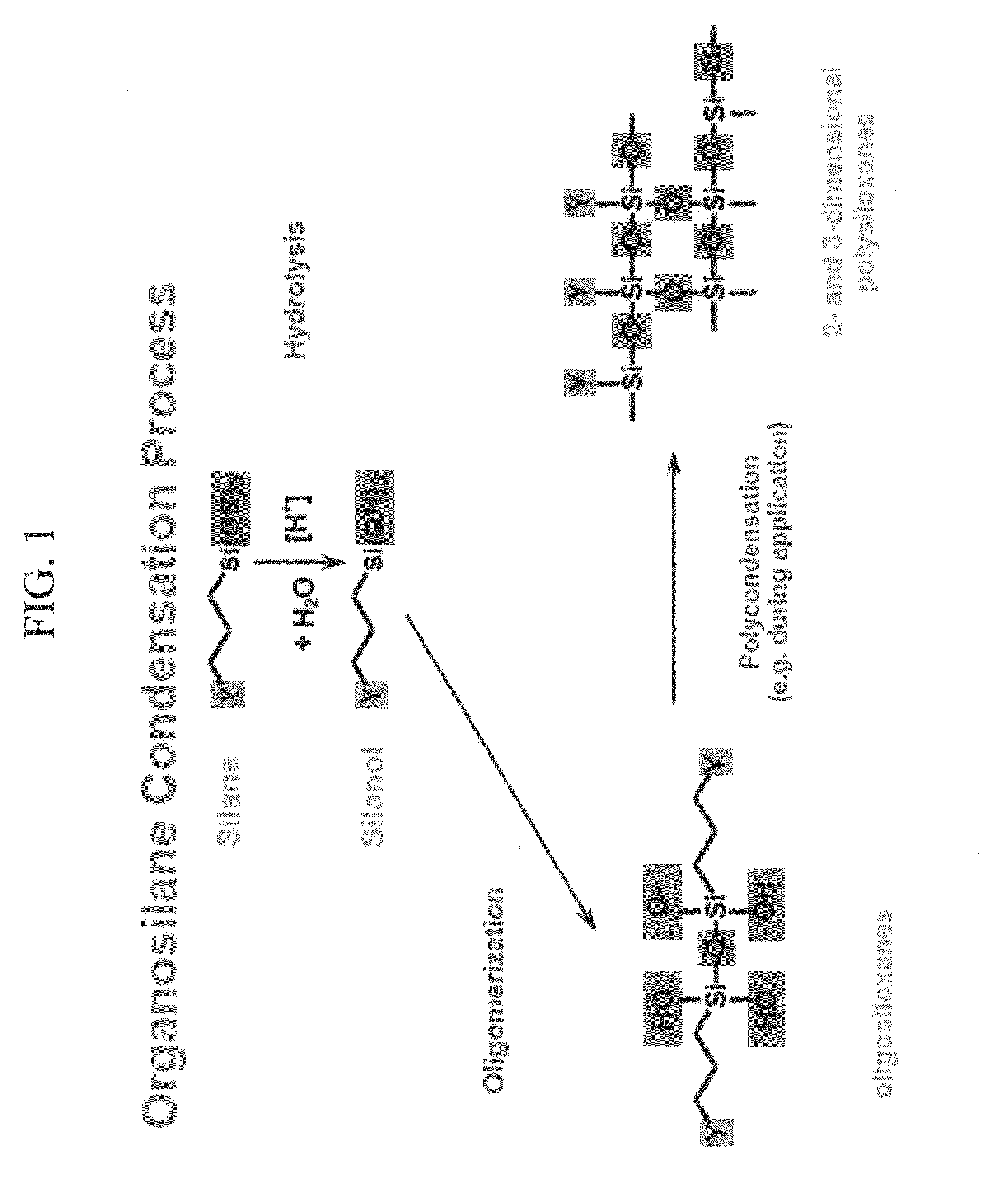

Silane-containing corrosion protection coatings

A metal surface can be corrosion protected by coating a corrosion protection composition on the metal surface, thereby obtaining a coating; and curing said coating at a temperature of from 20 to 120° C., to obtain a cured coating; wherein said corrosion protection composition comprises a condensated and hydrolyzed oligomer and / or polymer of at least one functionalized silane.

Owner:EVONIK DEGUSSA GMBH

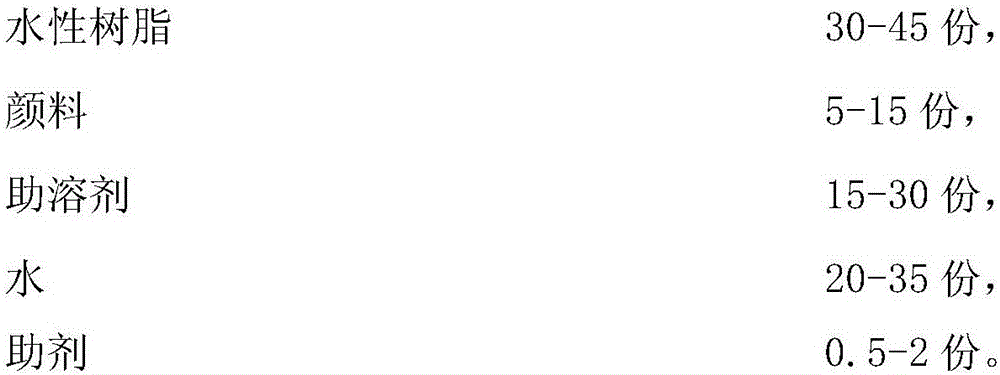

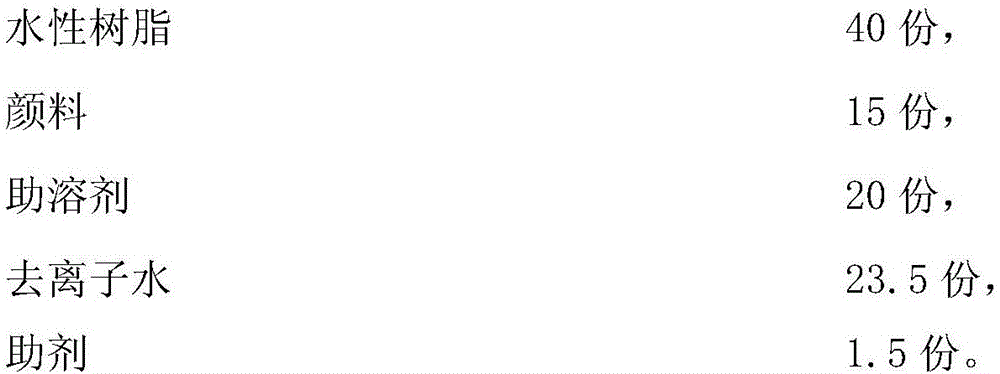

Environmentally-friendly aqueous spray paint and preparation method thereof

InactiveCN105907201AImprove atomization effectHigh ejection ratePolyurea/polyurethane coatingsEnvironmental resistanceHardness

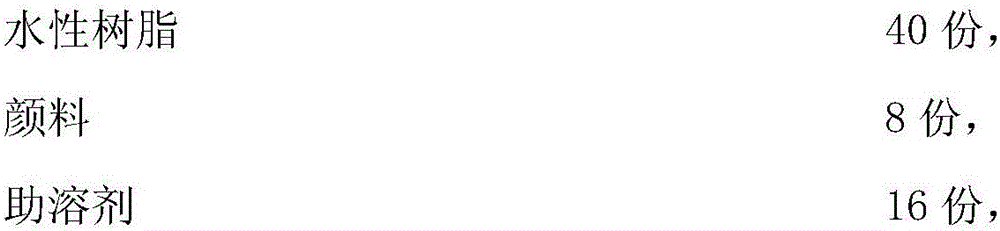

The invention provides an environmentally-friendly aqueous spray paint liquid, a propellent, an aerosol coated environmentally-friendly aqueous spray paint and a preparation method of the paint. The liquid comprises, by weight, 30-45 parts of aqueous resin, 5-15 parts of a pigment, 15-30 parts of a cosolvent, 20-35 parts of water and 0.5-2 parts of an assistant. The environmentally-friendly aqueous spray paint liquid adopts an aqueous resin system, so a whole paint film has a good hydrophobic and oleophobic effect, and improvement of the quality of spray paint products is facilitated; water is used to substitute parts of a solvent, so the VOC is reduced, and environmental protection is realized; and the produced environmentally-friendly aqueous spray paint has good sprayability and a high spray rate, and a film formed by the paint has high fullness, excellent hardness, adhesion, glossiness, flexibility and impact resistance, and has abundant and gorgeous colors, excellent decorative effect, good ageing resistance, and extremely good antirust and protection functions.

Owner:中山市润宜汽车用品有限公司

Environmentally friendly hot melt adhesive membrane for automotive interior products, preparation method and application

ActiveCN107151539AHigh strengthEffective bondingNon-macromolecular adhesive additivesFilm/foil adhesivesOrganic solventElastic component

The invention discloses an environmentally friendly hot melt adhesive membrane for automotive interior products, a preparation method and application. The environmentally friendly hot melt adhesive membrane for the automotive interior products comprises the following components in parts by mass: 100 parts of an elastic component, 0.1-50 parts of a non-elastic component and 0.1-20 parts of composite filler. The melt index of the elastic component is 0.9-30 g / 10 min (190 DEG C, 2.16 kg), the melt index of the non-elastic component is 0.2-10 g / 10 min (190 DEG C, 2.16 kg), and the melt index of the elastic component is greater than that of the non-elastic component. The composite filler comprises bamboo charcoal fibers and flame-retardant filler. The environmentally friendly hot melt adhesive membrane is used for adhesion of the automotive interior products, does not contain any organic solvents, does not produce toxic or harmful gas, and has antibacterial property and flame retardancy. Compared with a common antibacterial or flame-retardant product, the environmentally friendly hot melt adhesive membrane for the automotive interior products is simple and convenient to process.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

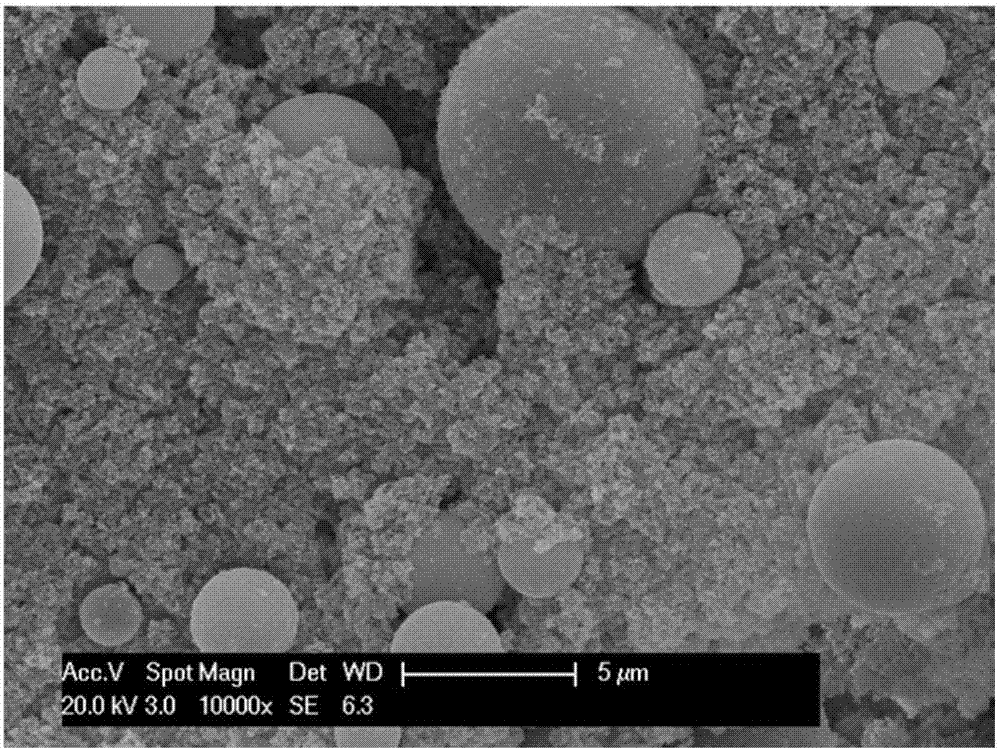

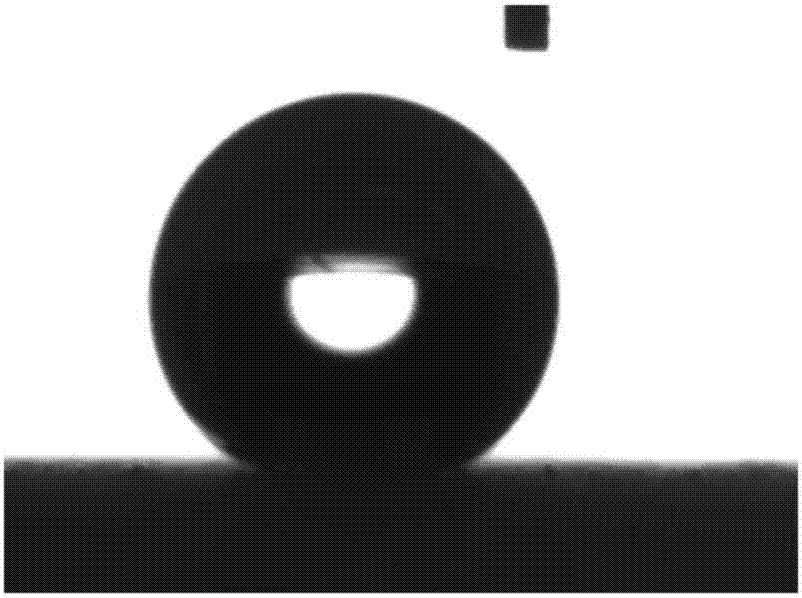

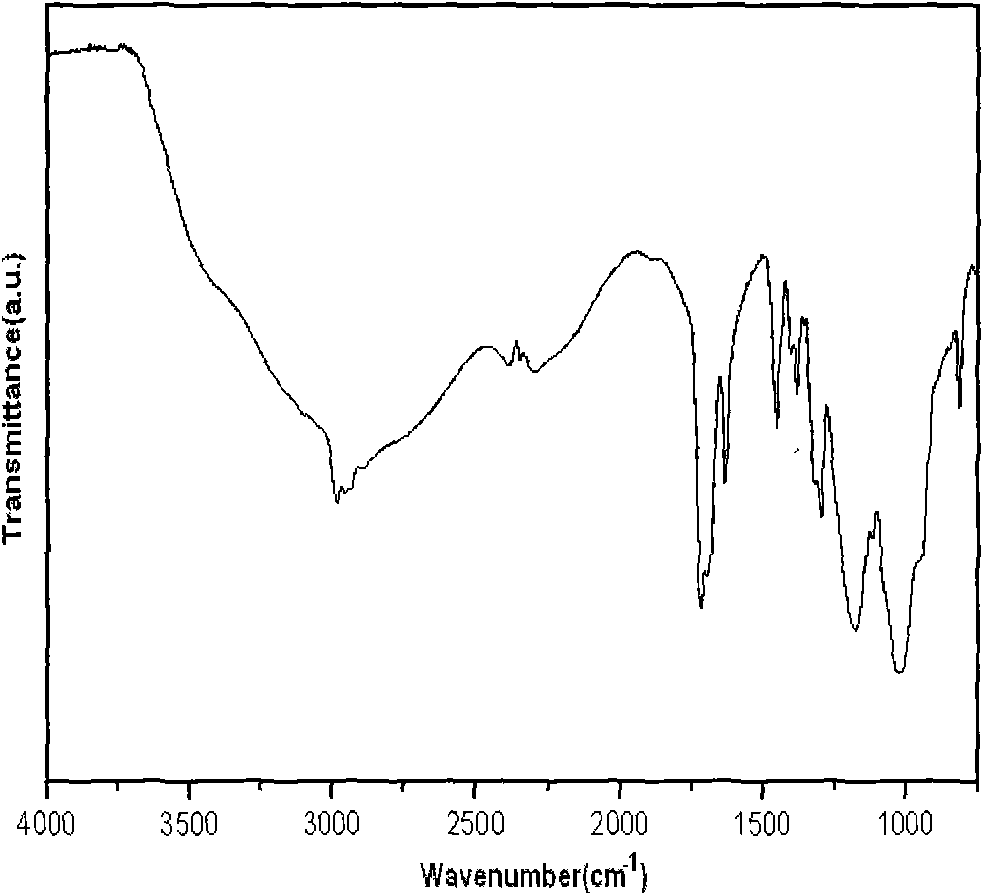

Aqueous transparent super-hydrophobic paint and preparation method thereof

The invention provides aqueous transparent super-hydrophobic paint and a preparation method thereof. The preparation method comprises the steps that firstly, deionized water is added into a reaction still, and the pH value is adjusted; secondly, aqueous colloidal silica is added under the conditions of water-bath heating and stirring, then micro composite SiO2 powder is added, tetraethyl orthosilicate, siloxane and aqueous organosilicone or silicone-modified resin are added, and the aqueous super-hydrophobic paint can be obtained after mechanical stirring is conducted for a certain time. In the preparation and use processes of the paint, no fluorine-containing substance is involved, the solvent is water, and the paint is green and environmentally friendly, free of toxins and harmless. The paint is widely used in the aspects of self-cleaning, corrosion prevention, mould prevention, condensation resistance, freezing resistance, oil water separation and the like.

Owner:SOUTHEAST UNIV

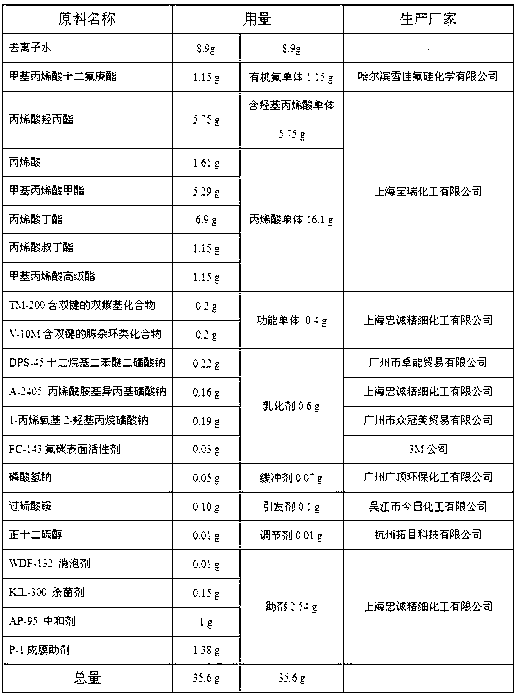

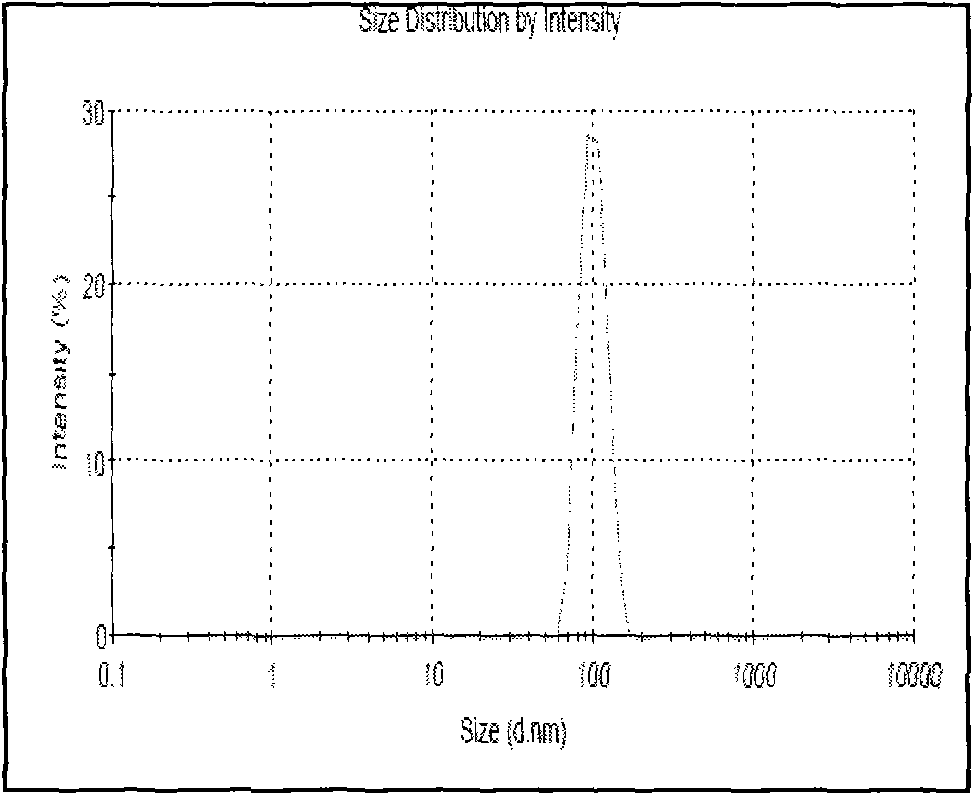

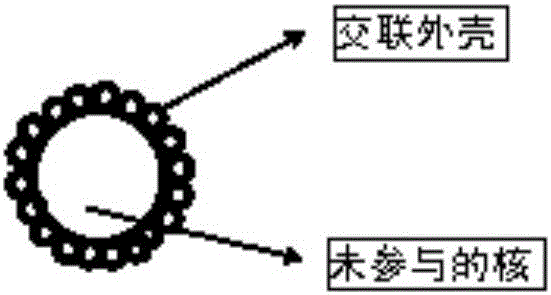

Preparation method of core-shell acrylic acid elastic emulsion containing phosphate group

InactiveCN102757523ASimple processEasy to operateAnti-corrosive paintsPolymer scienceFunctional monomer

Owner:BEIJING UNIV OF CHEM TECH

Single-component, high-solid-content and low-volatility organic compound and environment-friendly type varnish composition and preparation method and application of varnish composition

The invention discloses a single-component, high-solid-content and low-volatility organic compound (VOC) and environment-friendly type varnish composition. The varnish composition comprises at least one polymer with a hyper-branched or tree-shaped structure, at least one hydroxyl acrylic resin or hydroxyl methacrylic resin, at least one cross-linking curing agent, at least one acid catalyst, at least one rheology control agent and at least one auxiliary agent. With the adoption of the varnish composition and application of the varnish composition, disclosed by the invention, the viscosity of a varnish coating system can be effectively reduced, and the solid content of the construction can be easily improved to be 58 percent or above; construction VOC emission is reduced to be smaller than or equal to 420g / L; varnish film shrinkage caused in a curing process can also be effectively reduced and a cured multi-coating varnish film has better appearance effect; particularly, the effect in a wet-on-wet process, a three-coating and one-drying process of curing three coatings together or an IPP system of primers, paints and varnishes is obvious.

Owner:LANGFANG NIPPON PAINT

Antibacterial water color ink and method for preparing same

The invention relates to an antibacterial water color ink for printed matters for packaging children products and a method for preparing the same. The method comprises the following steps: firstly, according to the stated weight percentage, evenly mixing and stirring part of a water soluble resin dispersoid, an amine stabilizer, a latent solvent, a bactericidal agent, deionized water and an antifoaming agent, then adding a pigment into the mixture, and dispersing the pigment at a rotating speed of between 500 and 1,200 rpm to prepare an even water soluble dispersed slurry; and secondly, pumping the water soluble dispersed slurry obtained in the step A into a sand mill by a pump, grinding the slurry until the fineness is less than or equal to 10 microns, then adding the remaining water soluble resin dispersoid, a wetting agent and a rheology modifier to the slurry, stirring the mixture until the materials are dispersed and mixed evenly, and adjusting the viscosity to prepare the antibacterial water color ink. The antibacterial water color ink prepared by the method has good adhesive force to various base materials or textiles, and the varnish thereof is full and has certain flexibility; besides, the antibacterial water color ink has low smell and ultra-low VOC without PAE and heavy metals, and has good antibacterial and antifungus functions.

Owner:SHENZHEN OCEANPOWER NEW MATERIALS TECH

Waterborne epoxy anticorrosive paint and preparation method thereof

InactiveCN104231866AImprove mechanical propertiesImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsEpoxyEmulsion

The invention belongs to the technical field of chemical materials and environment protection, and in particular relates to waterborne epoxy anticorrosive paint and a preparation method thereof. The waterborne epoxy anticorrosive paint comprises components A and B; the component A comprises water, waterborne epoxy emulsion, anticorrosive pigment, packing and assistant; the component B comprises water, amino silane, nanosilicon dioxide and waterborne epoxy hardener. The preparation method comprises the steps of: mixing water and part of the assistant and stirring to uniformity, gradually adding the anticorrosive pigment and other packing, dispersing at high speeds, stirring the waterborne epoxy resin with part of the assistant to uniformity, and thereby obtaining the component A; mixing the water, the amino silane and the nanosilicon dioxide and dispersing at high speeds, further adding waterborne epoxy hardener to continuing dispersion, ball-milling, and thereby obtaining the component B. The waterborne epoxy anticorrosive paint has very low VOC, excellent physical and mechanical properties and good anticorrosion performance, and is applicable to using as anticorrosive paint for metal.

Owner:JIANGSU YICHENG BARRIER SCI & TECH +1

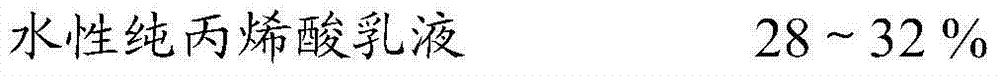

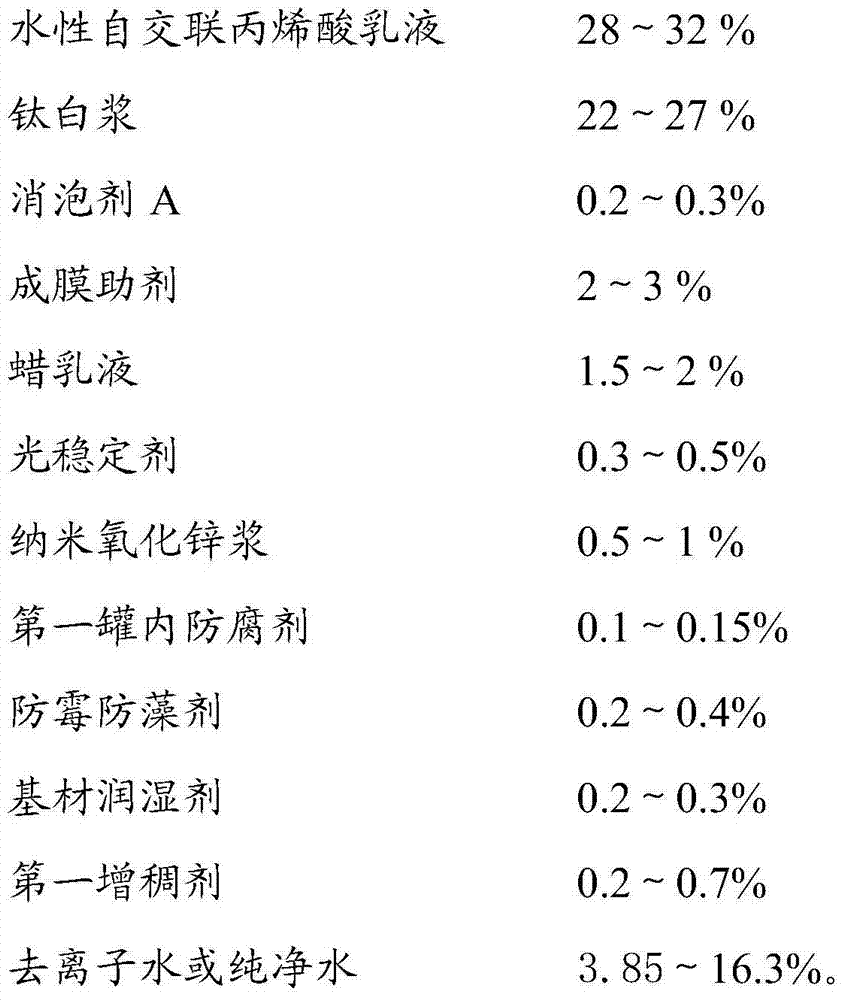

High-weather-resistance high-stain-resistance white paint for outdoor woodware and preparation method of paint

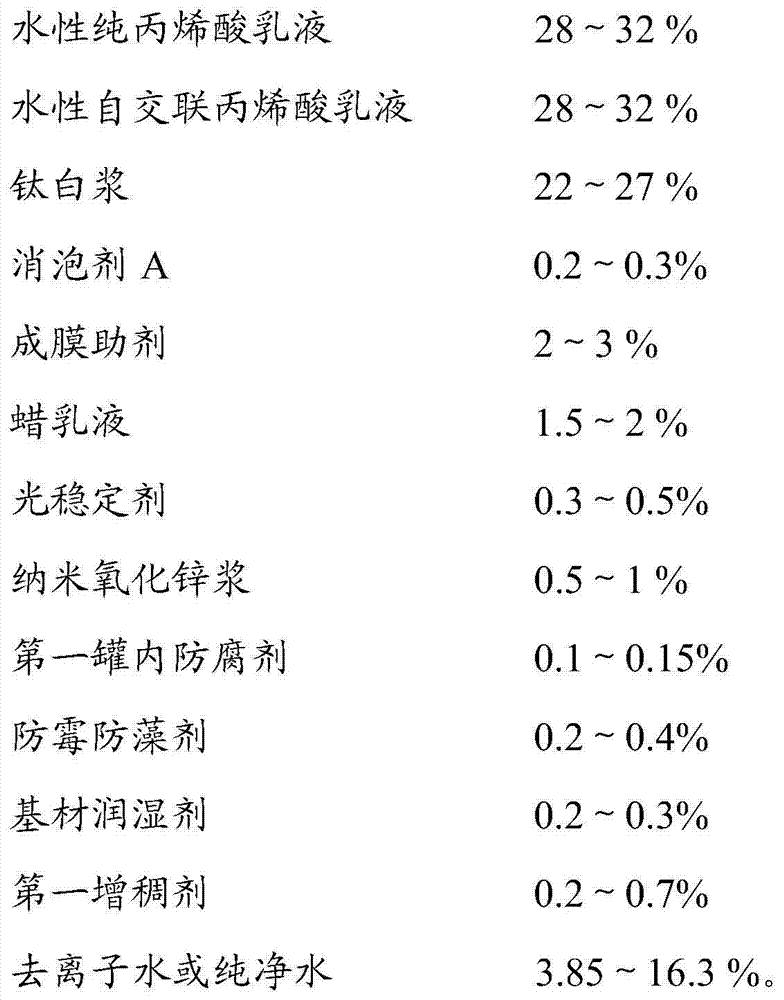

The invention discloses high-weather-resistance high-stain-resistance white paint for outdoor woodware and a preparation method of the paint. The high-weather-resistance high-stain-resistance white paint for the outdoor woodware comprises the following components in percentage by weight: 28-32% of water-based pure acrylic emulsion, 28-32% of water-based self-crosslinking acrylic emulsion, 22-27% of titanium dioxide pulp, 0.2-0.3% of a defoaming agent A, 2-3% of a film forming additive, 1.5-2% of wax emulsion, 0.3-0.5% of a light stabilizer, 0.5-1% of nanometer zinc oxide pulp, 0.1-0.15% of a first in-tank preservative, 0.2-0.4% of mildew-proof algaecide, 0.2-0.3% of a substrate wetting agent, 0.2-0.7% of a first thickening agent and 3.85-16.3% of deionized water or purified water. The high-weather-resistance high-stain-resistance white paint for the outdoor woodware is resistant to weather, stain and water, low in smell and VOC and excellent in environmental protection and safety comprehensive performances; the preparation method is simple in process and low in cost.

Owner:CHINA PAINT MFG CO SHENZHEN

Low volatile organic content lubricant

ActiveUS7524797B1Low VOCEfficient use ofPretreated surfacesBearing componentsWater basedAcrylic resin

A water-based lubricant composition, comprising: water, molybdenum disulfide, polytetrafluoroethylene, and a polymeric binder, wherein the binder is an acrylic resin or a polyurethane resin.

Owner:TEXAS RES INT

High-performance water-based two-component finish paint composition as well as preparation method and use thereof

InactiveCN108864918AHigh hardnessImprove water resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedAcrylic resin

The invention discloses a high-performance water-based two-component finish paint composition, which is prepared finish paint and a curing agent, wherein the finish paint is prepared from the following components in parts by weight: 60-75 parts of water-based hydroxyl acrylic resin, 0.3-1.1 parts of a flatting agent, 0.3-1 part of an antifoaming agent, 1-4 parts of a dispersing agent, 2-30 parts of pigment, 5-15 parts of deionized water, 0-0.5 part of a pH regulating aid and 0-11.6 parts of other additives; the curing agent is prepared from the following components in parts by weight: 55-75 parts of isocyanate, 25-45 parts of a solvent and 0-1 part of a water removal agent. The finish paint composition provided by the invention has good construction performance and paint film property, andis lower in content of volatile organic compounds (VOCs), thus being used for finish paint for buses.

Owner:NIPPON PAINT CHINA

Process for forming a dispersion of silica nano-particles

InactiveUS20080021147A1Good optical performanceImprove scratch resistancePigmenting treatmentMaterial nanotechnologyOligomerSilanes

Disclosed herein is a process for preparing a dispersion of silica nano-particles. The dispersions are prepared from silica nano-particles having reactive silane groups of 1-500 nm particle size, and least 0.001 parts by weight of oligomer having at least two groups reactive with the silica nano-particles, or oligomer in combination with a film forming polymer, a low molecular weight coupling agent, or a combination of a film forming polymer and a low molecular weight coupling agent.

Owner:EI DU PONT DE NEMOURS & CO

Water-borne inflation type refractory coating and preparation method thereof

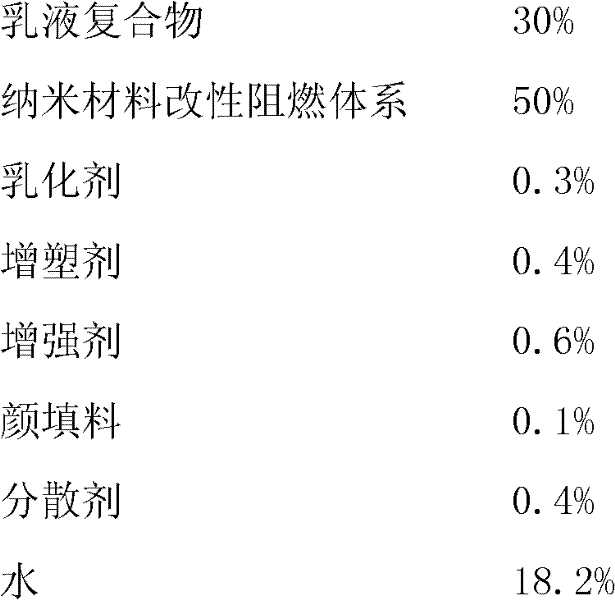

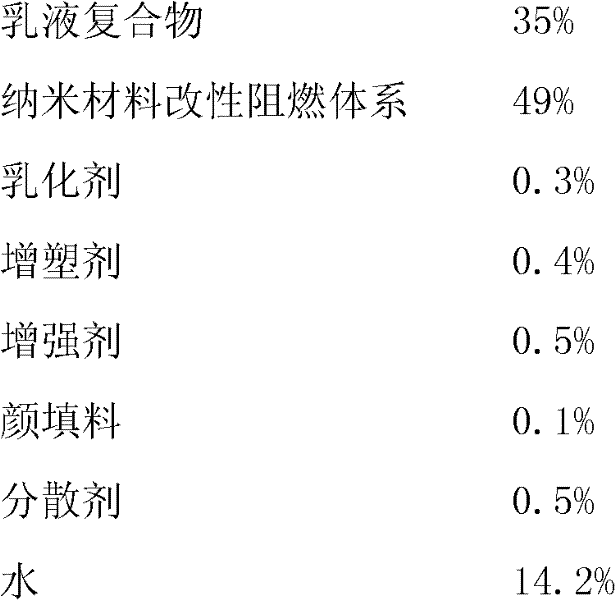

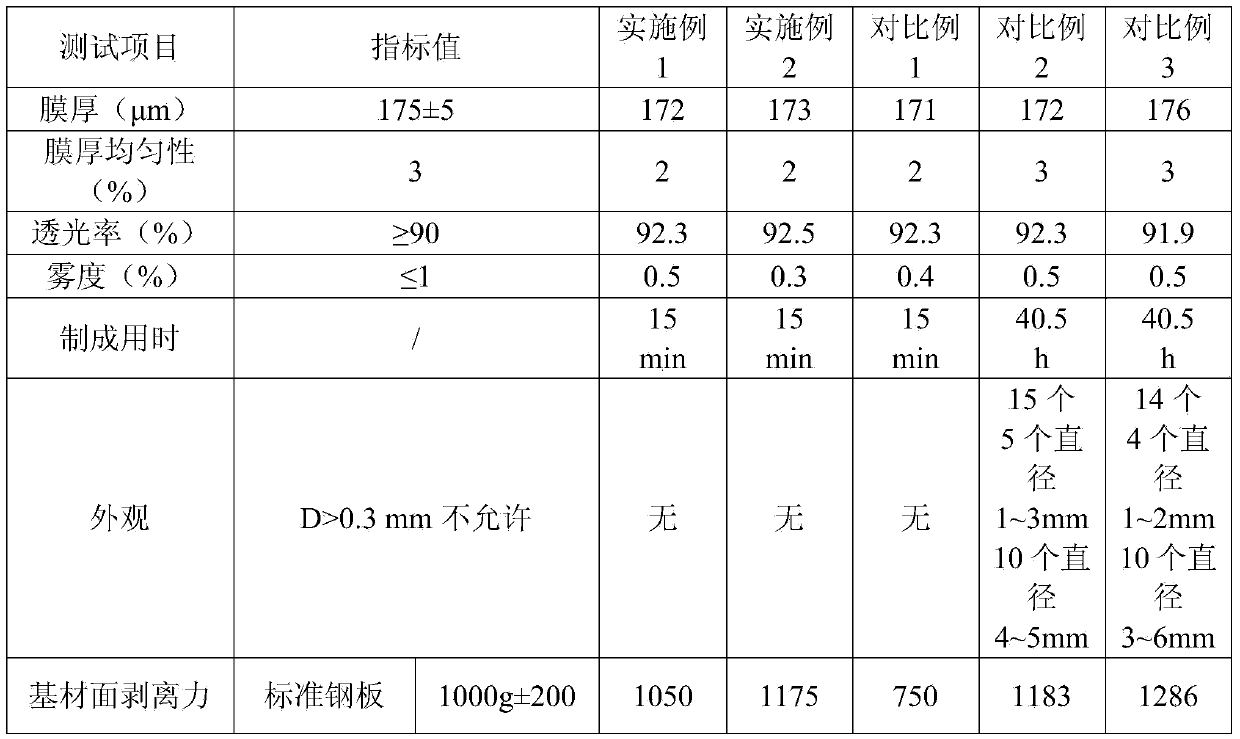

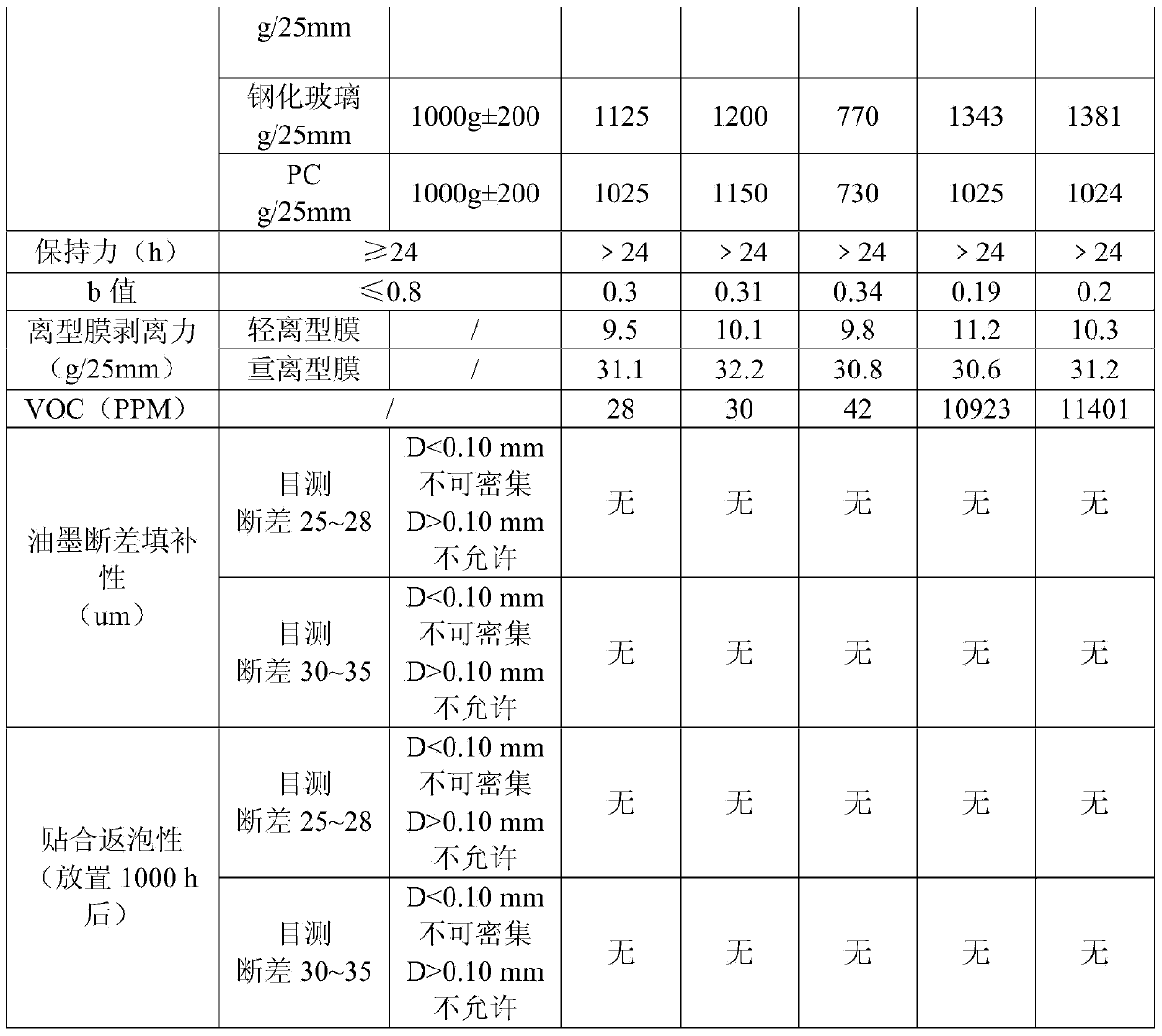

The invention discloses a water-borne inflation type refractory coating and a preparation method thereof. The refractory coating is prepared from the following components: 30-40% of emulsion compound, 40-58% of modified antiflaming system of a nanometer material, 0.3-0.6% of emulsifying agent, 0.2-0.4% of plasticizer, 0.4-0.8% of reinforcing agent, 0.1-0.15% of pigment filler, 0.2-0.6% of dispersing agent and the balance of water. Compared with the prior art, the water-borne inflation type refractory coating has the advantages of excellent environmental performance, simple technology, sufficient raw material resources, proper price and the like and can be widely applied.

Owner:湖南新纪元建设发展有限公司

Pure-acrylic emulsion with low VOC and preparation method thereof

The invention discloses a pure-acrylic emulsion with low VOC and a preparation method thereof. The pure-acrylic emulsion is mainly used for preparing indoor paint and the formulation thereof comprises: 20-25% of methyl methacrylate, 10-15% of butyl acrylate, 7-10% of ethyl hexyl acrylate, 0.5-1% of crylic acid, 1-5% of emulsifier, 0.3-0.5% of persulfate, 0.2-0.3 of oxidant, 0.15-0.25% of reducing agent and 53% of water. The preparation method comprises the following steps: selecting monomers with similar reactivity ratio to carry out emulsion polymerization, and then adopting a redox system to carry out after-treatment on the emulsion so as to further reduce the content of residual monomers. According to measurement, the VOC content of the polymerization emulsion is less than or equal to 30(g / L) and far below the national regulation.

Owner:上海巴德富实业有限公司

Solvent-free UV (ultraviolet) curing glue for optical transparent adhesive tape and preparation method and application thereof

ActiveCN103725245ALow VOCGood flexibilityNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceSolvent free

The invention belongs to the technical field of UV (ultraviolet) curing glue, and discloses solvent-free UV curing glue for an optical transparent adhesive tape and a preparation method and application thereof. The glue comprises the following components in parts by mass: 20-60 parts of aliphatic polyurethane acrylate, 5-15 parts of hyperbranched polyester acrylate, 10-25 parts of acrylate monomer, 1-10 parts of thiol, 1-10 parts of tackifying resin, 0.1-1 part of leveling agent, 0.5-2 parts of antifoaming agent and 0.5-2 parts of photoinitiator. In the invention, the colloid crosslinking density and colloid strength are improved by preferentially adopting aliphatic polyurethane acrylate with low functionality degree and adding hyperbranched polyester acrylate; the acrylate monomer adjusts the viscosity and enhances the colloid strength; the caking property is improved by adding the thiol containing an ether structure; the prepared non-solvent UV curing glue for an optical transparent adhesive tape has high toughness, high light transmittance, low haze, high colloid strength, high viscosity, high thickness and low VOC (volatile organic compound) content.

Owner:广州慧谷功能材料有限公司

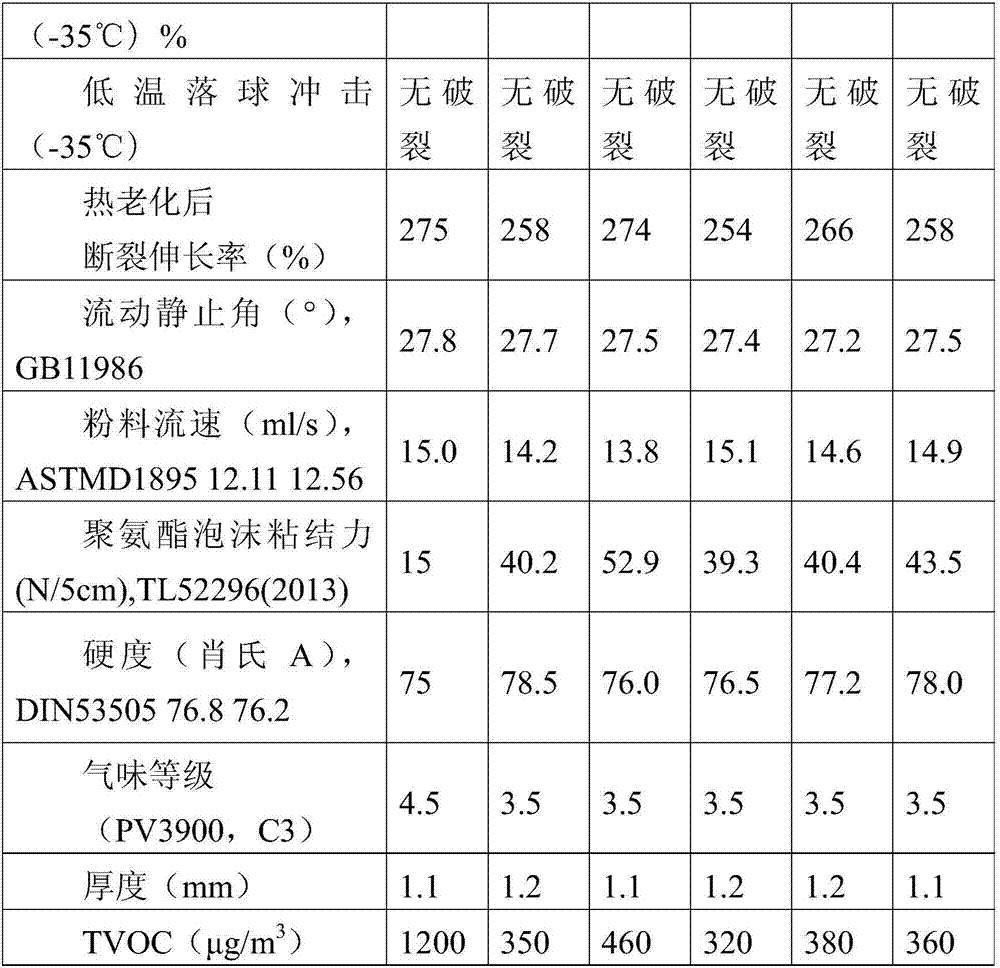

Low-odor PVC powder for automotive upholstery and preparing method thereof

The invention relates to low-odor PVC powder. The low-odor PVC powder comprises 100 parts of PVC resin, 35-50 parts of plasticizer, 5-10 parts of heat stabilizer, 0.2-1.0 part of light stabilizer, 0.3-1.0 part of antioxidant, 3-5 parts of dispersant and 1-5 parts of deodorant. The deodorant is formed by at least one of nano calcium carbonate, nano zinc oxide, fumed silica, precipitated silica and hot-melt rubber powder. The low-odor PVC powder further comprises a coupling agent formed by at least one of an aluminate coupling agent, a borate coupling agent, an aluminum-titanium coupling, a titanate coupling and dispersible rubber powder, and the mass ratio of the coupling agent to the deodorant is (1-5):100. The invention further provides a preparing method of the low-odor PVC powder. The surface of the deodorant is modified by the coupling agent, and the compatibility between the deodorant and the PVC matrix is improved.

Owner:SHANGHAIK YANFENG JINQIAO AUTOMOTIVE TRIM SYSTEMS CO LTD

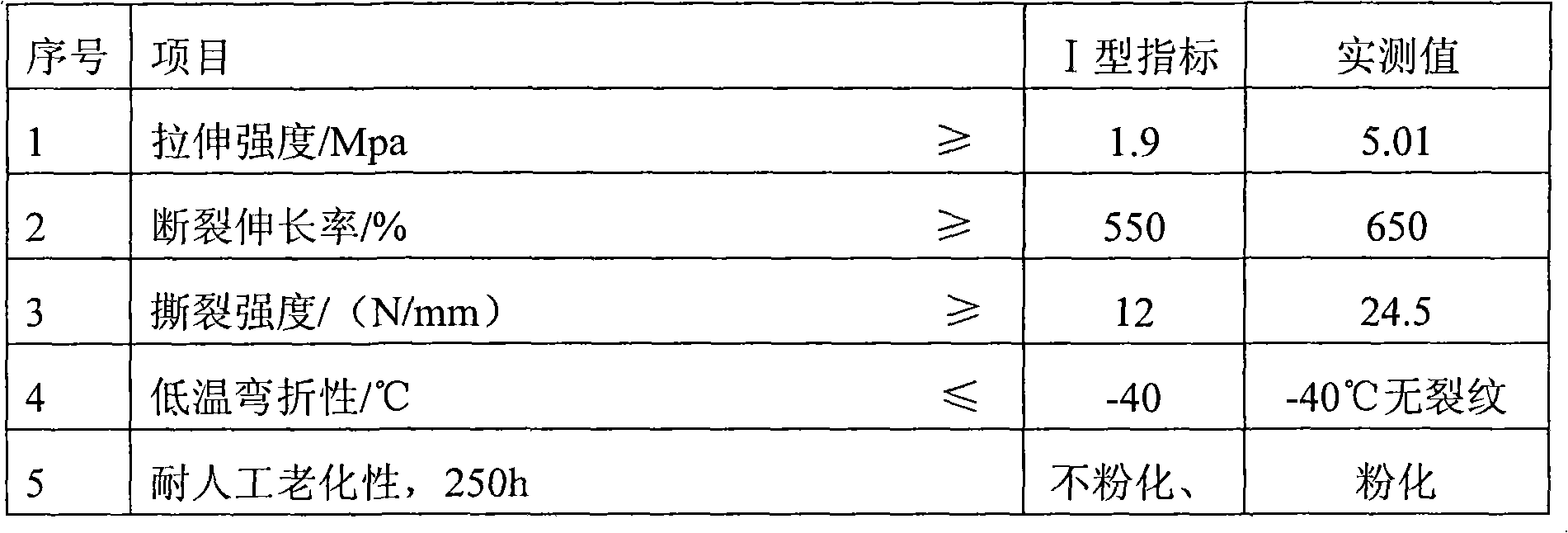

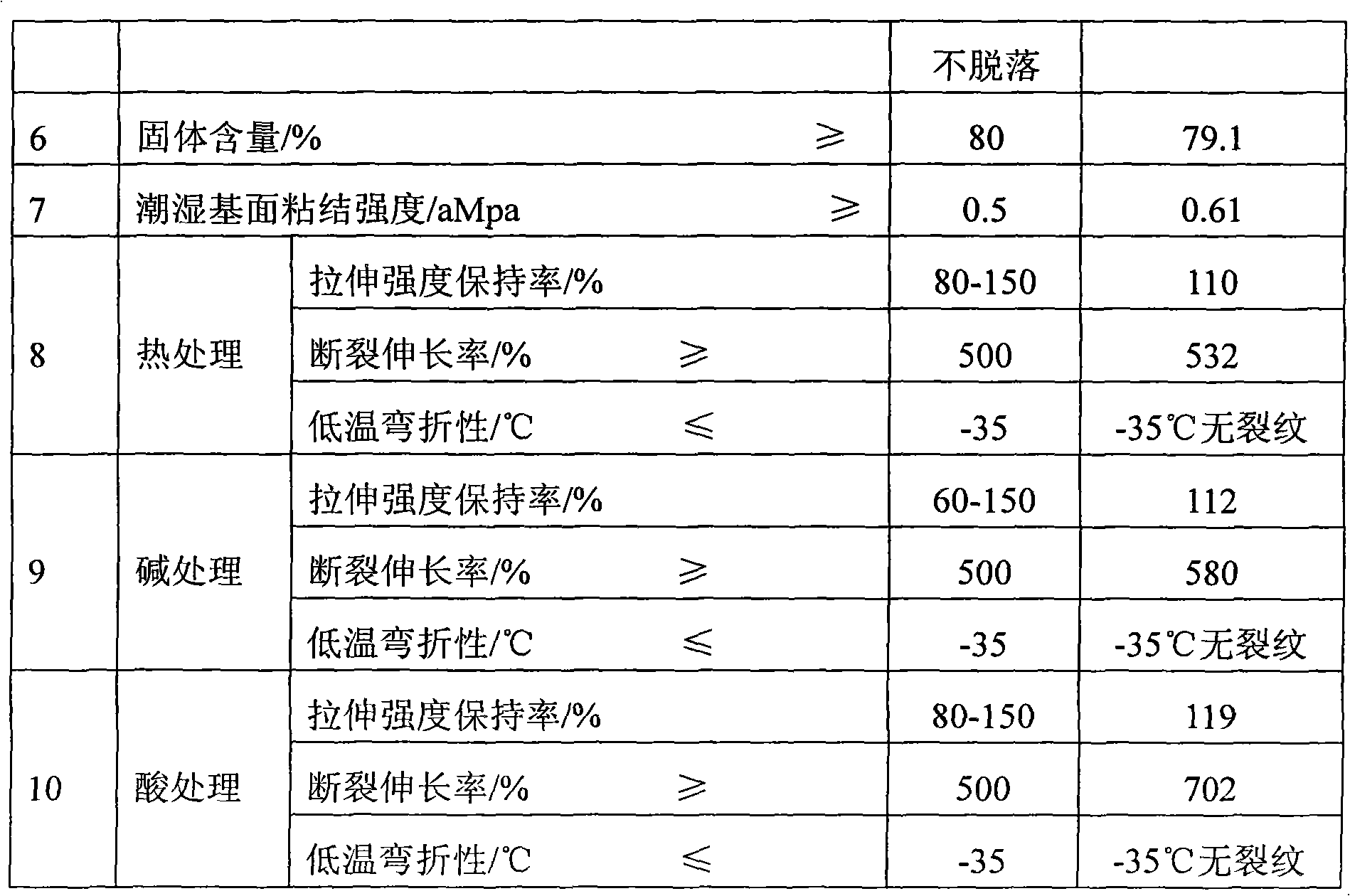

Single-component polyurethane waterproof coating and preparation method thereof

InactiveCN101985543ALow VOCSmall smellPolyurea/polyurethane coatingsExternal applicationToluene diisocyanate

The invention discloses a single-component polyurethane waterproof coating which is prepared by polyether polyol, chloroparaffin, pigment, a filler, toluene diisocyanate, a curing agent, xylene and a catalyst. The coating has low VOC (volatile organic compounds), low odor, excellent application property and good weatherability, and is applicable to external application. The invention further discloses a preparation method of the single-component polyurethane waterproof coating.

Owner:SHANGHAI HUILI PAINT

Underground gas plugging coating in coal mine

This invention provides an underground gas plugging coating in coal mine, consisting of an individually packaged liquid material and a powder material in the weight ratio of 0.3 to 0.45: 1; wherein the powder material comprises the following components by weight percentage: 30% to 45% of concrete, 30% to 40% of quartz powder, 5% to 10% of talcum powder, 5% to 10% of flyash, 7% to 13% of aluminium hydroxide, 0% to 4% of magnesium hydroxide, 2% to 4% of ammonium polyphosphate, 1% to 2% of melamine, 1% to 2% of pentaerythritol and 1% to 1.5% of carbon fiber; the liquid material is flexible styrene-acrylate emulsion or flexible pure acrylic emulsion. The coating is characterized by flame retardancy, antistatic property, watertightness, tight bonding with the coal wall and elasticity, further more, can prevent the gas from leaking after being sprayed on the coal wall, and reduce the gas concentration in the laneway.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV +1

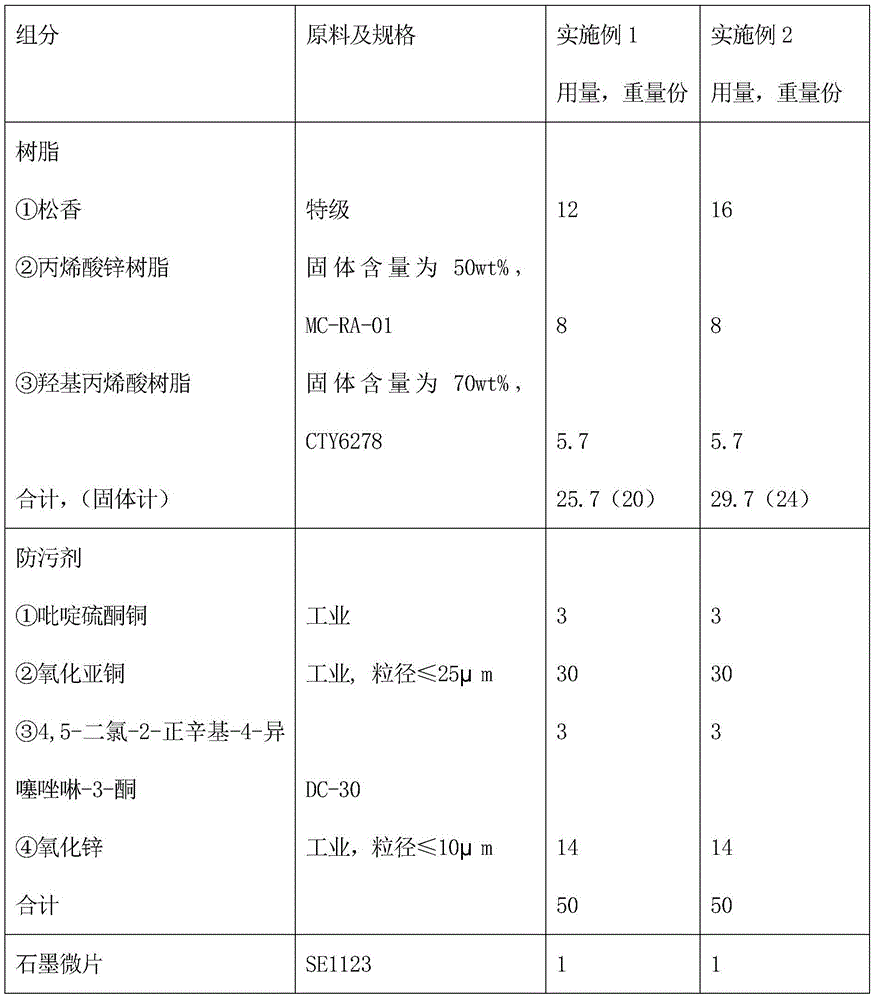

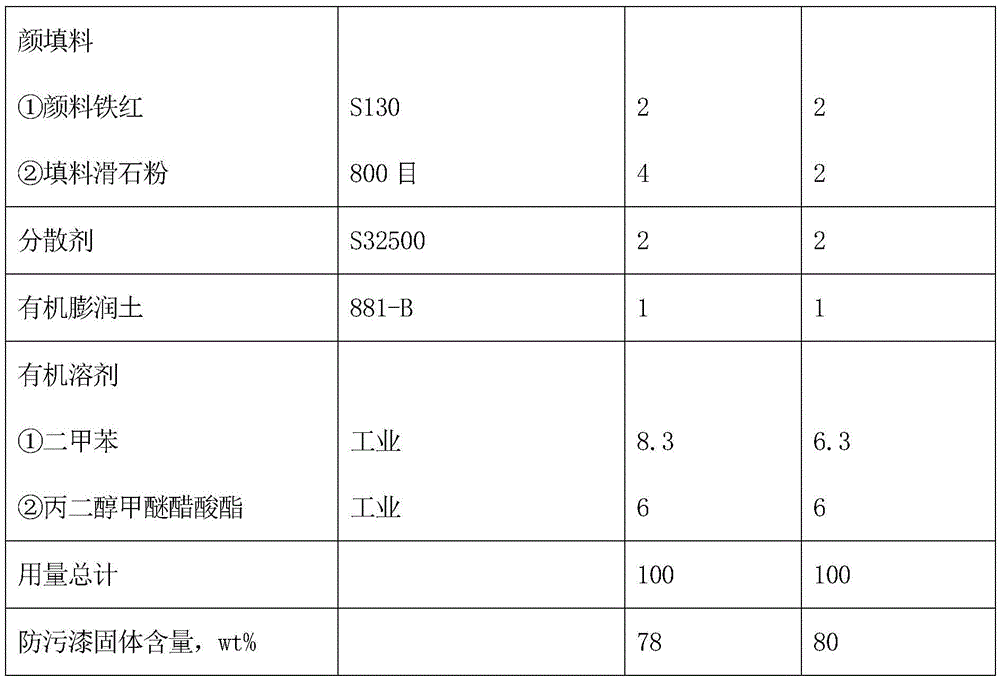

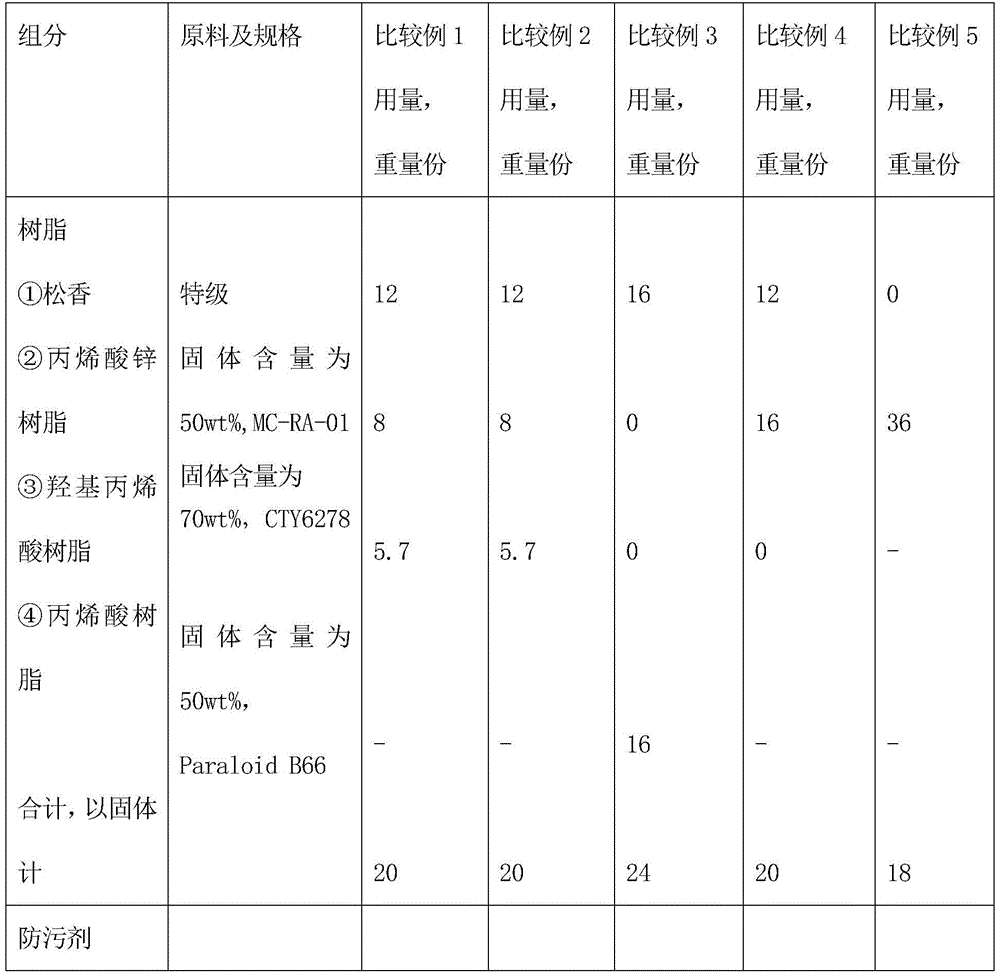

Self-polishing antifouling paint and preparation method thereof

ActiveCN105482702AHigh strengthImprove hydrophobicityAntifouling/underwater paintsRosin coatingsSodium PyrithioneCrack resistance

The invention relates to a self-polishing antifouling paint and a preparation method thereof. Every 100 parts by mass of the antifouling paint is composed of 18-24 parts of solid-based resin, 50-55 parts of antifouling compound, 0.5-1.5 parts of graphene microchip, 3-6 parts of pigment and filler, 1-2 parts of dispersing agent, 1-2 parts of organobentonite and the balance of organic solvent. The resin is composed of a hydroxy acrylic resin, a zinc acrylate resin and rosin. The antifouling compound is composed of zinc pyrithione, 4,5-dichloro-2-n-octyl-4-isothiazolinyl-3-one, cuprous oxide and zinc oxide. The preparation method comprises the following steps: respectively preparing the graphene microchip-zinc oxide-hydroxy acrylic resin slurry and cuprous oxide-rosin-zinc acrylate slurry, and mixing to obtain the self-polishing antifouling paint. The obtained self-polishing antifouling paint product has the advantages of stable quality, long antifouling period, favorable polishing effect, high strength, cracking resistance and low VOC (volatile organic compound).

Owner:CHINA NAT OFFSHORE OIL CORP +3

Method for preparing low VOC polyester-acrylic graft resin compositions

A method is disclosed for the preparation of a water-based graft copolymer of a carboxyl functional polyester and an ethylenically unsaturated monomer having a low level of volatile organic compounds.

Owner:BP CORP NORTH AMERICA INC

Environmental Cold-mix Adjustable-modulus Pavement Material and Manufacturing Method thereof

An environmental protection cold mixing type modulus-adjustable pavement material and preparation method thereof. Equal components of waterborne epoxy resin and waterborne curing agent are added in a container to obtain a waterborne epoxy resin mixture. Emulsified bitumen, the waterborne epoxy resin mixture, an emulsifying agent, a defoaming agent and a stabilizing agent are prepared according to a certain mass ratio; the emulsified bitumen is first added in the container, and the pH is regulated with hydrochloric acid to be 5.0 to 6.5, the above-mentioned other materials are added and stirred to make mixed liquid; a stator of a high-speed shearing machine is put into the mixed liquid, and the rotational speed is set as 350 to 500 rpm for about 20 to 40 min to obtain waterborne epoxy emulsified bituminous emulsion. B. Coarse aggregate, fine aggregate, fillers, cement and the waterborne epoxy emulsified bitumen obtained from the above-mentioned preparation are selected in proportion; and after the coarse aggregate, the fine aggregate and rubber powder are added in a stirring machine of asphalt mixture and stirred and the waterborne epoxy emulsified bitumen is added and stirred, the cement is added and stirred.

Owner:SHENZHEN TRAFFIC CONSTR ENG TEST & DETECTION CENT

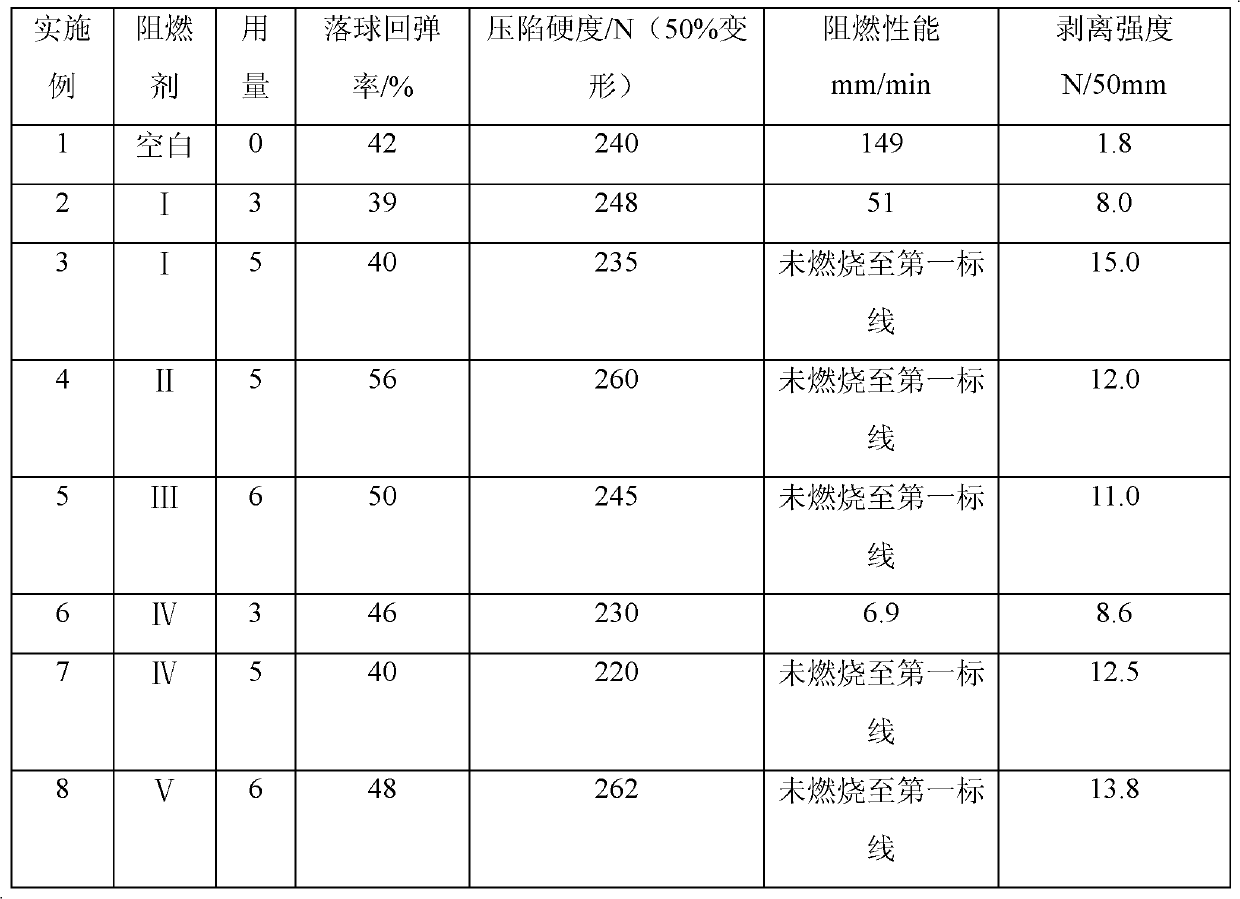

Reaction type flame retardant for soft polyurethane foam and application

The invention discloses a reaction type flame retardant for soft polyurethane foam and an application, belonging to the technical field of the flame retardants. The reaction type flame retardant contains three components, namely a phosphorus-containing polyhydroxy compound, a halogen-containing polylol and a chain extender with two degrees of functionality. When the flame retardant is in use, the reaction type flame retardant can be directly added into polyether polylol and is good in compatibility with the polyether polylol, and the precipitation can be avoided. The polyurethane foam prepared by the reaction type flame retardant is lasting in flame retarding effect and further has the characteristics of low VOC (volatile organic compounds) and low atomization, the flame retarding effect can not be reduced after aging, and adverse impacts on physical properties of the foam can be avoided. The soft foam using the flame retardant has excellent flame laminating performance and great peeling strength, and is suitable for being used as an interior trimming material for automobiles and airplanes.

Owner:北京万博汇佳科贸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com