Patents

Literature

353 results about "Paint product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Real stone paint, and preparation method and construction method thereof

The invention provides a real stone paint. The real stone paint comprises, by weight, 90-130 parts of water, 2-5 parts of hydroxyethyl cellulose, 2-5 parts of a dispersant, 1-3 parts of a wetting agent, 4-8 parts of an antifoaming agent, 2-3 parts of an antiseptic, 100-150 parts of an emulsion, 5-12 parts of a film forming assistant, 1-3 parts of a pH adjusting agent, 5-20 parts of an antifreeze agent and 400-900 parts of a color sand component, wherein the color sand component comprises two or more than two natural stone flours with similar color. The invention further provides a preparation method of the real stone paint. The natural stone flowers with similar color in raw materials are blended in the embodiment of the invention to balance the color difference of all the natural stone flours, so even the color of one of the natural stone flours changes, the color difference of real stone paint products in batches is very small under the contrast of other natural stone flours with similar color, thereby the color difference change of the real stone paint is well controlled.

Owner:DRAGON BRAND COATINGS (BEIJING) CO LTD

Electrically-conducting paint based on TiB2 and its preparation method and application

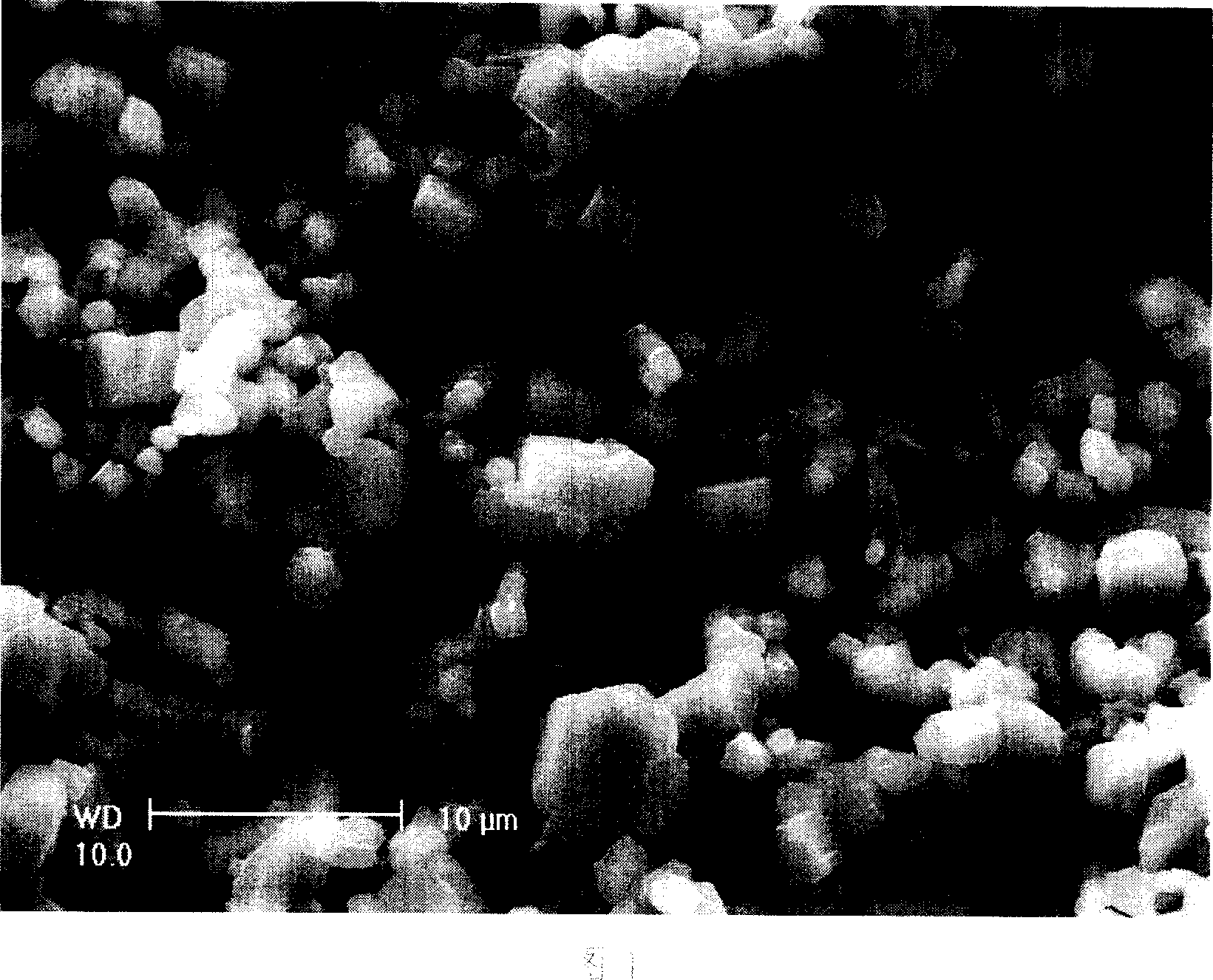

InactiveCN101148549AExcellent physical and chemical propertiesHigh melting pointPolyurea/polyurethane coatingsEpoxy resin coatingsDiluentRoom temperature

The present invention relates to conducting paint, and is especially one kind of TiB2 powder based conducting paint powder and its preparation process and application. The TiB2 powder based conducting paint powder consists of film forming material, coupling agent, diluent, assistants and curing agent; and conducting assistant consists of TiB2 powder as main component, carbon black, graphite, acetylene black and other conducting powder in certain proportion. It is prepared through adding the assistants into the film forming material and dispersing in a dispersing machine, adding coupling agent and conducting powder through stirring, adding mixed diluent through stirring to obtain paint product. The conducting paint coating is formed through brushing, spraying or dipping, and cured at room temperature or through heating. The present invention has the advantages of high conducting property, high hardness, high wear resistance, excellent protecting performance, etc.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

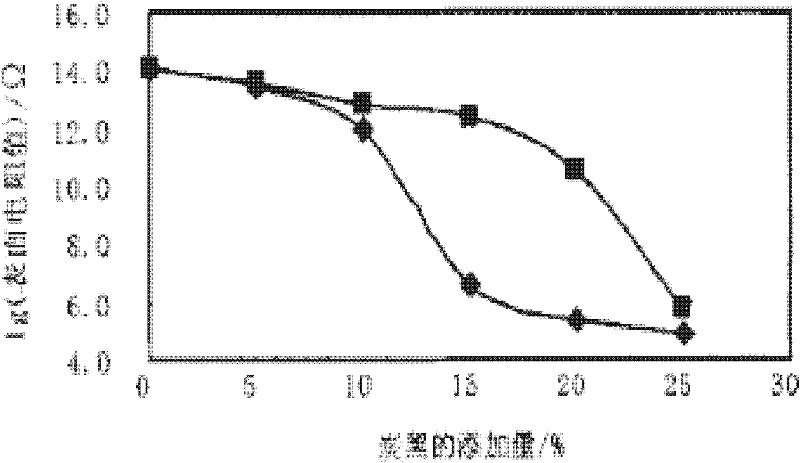

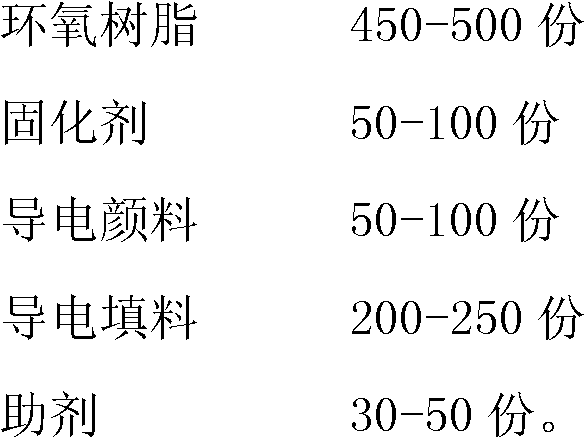

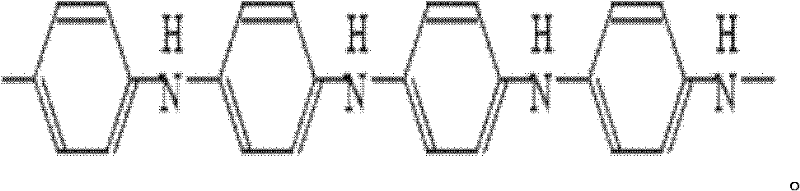

High-electric-conductivity heavy-anticorrosion wave-absorbing powder paint

ActiveCN102408813AImprove corrosion resistanceImprove bending resistanceAnti-corrosive paintsPowdery paintsEpoxyElectrical conductor

The invention relates to a high-electric-conductivity heavy-anticorrosion wave-absorbing powder paint which is prepared from the following raw materials in parts by weight: 450-500 parts of epoxy resin, 50-100 parts of curing agent, 50-100 parts of conductive pigment, 200-250 parts of conductive filler and 30-50 parts of assistant. The preparation method of the high-electric-conductivity heavy-anticorrosion wave-absorbing powder paint comprises the following steps: adding the materials into a high-speed mixer; after carrying out dry mixing, adding the mixture into an extruder, and melting, mixing, cooling and pelleting at the extrusion temperature of 80-90 DEG C; and pulverizing with a pulverizer, grading, screening and packaging to obtain the finished powder paint product. The invention has the characteristic of high electric conductivity, has an absorption action on certain electromagnetic waves, can be used as a preferred coating for electromagnetic shielding, and is applied to thefields of frequency converter shells, micro-current and light-current component shells and the like. In addition, the invention has excellent anticorrosion property and favorable electric conductivity (105 ohm), and the conducting power is almost approximate to that of a metallic conductor; and thus, the high-electric-conductivity heavy-anticorrosion wave-absorbing powder paint is an ideal antistatic coating, and can ensure safety in the aspects of fire resistance and explosion resistance.

Owner:国润恒科(天津)防腐工程技术有限公司

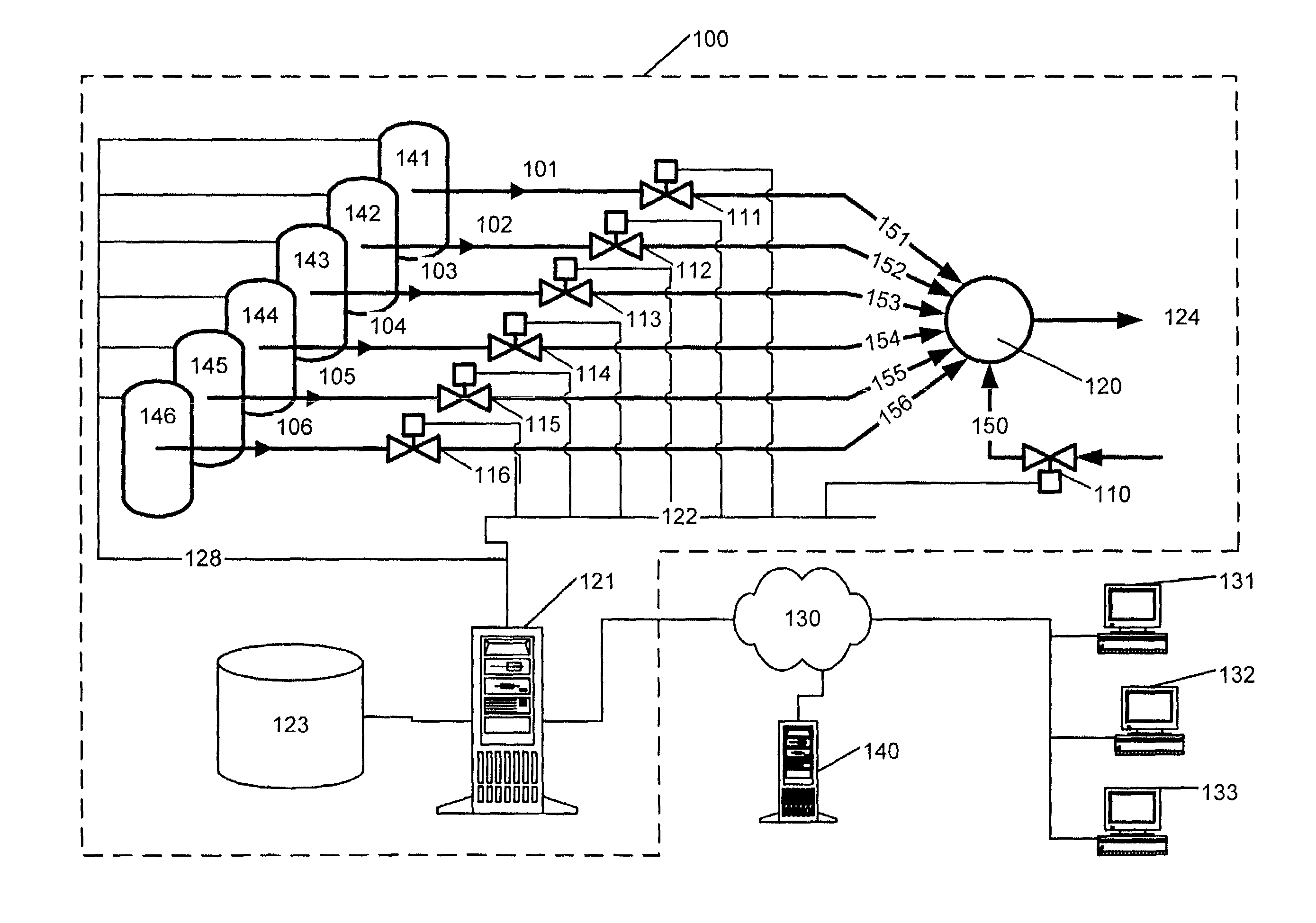

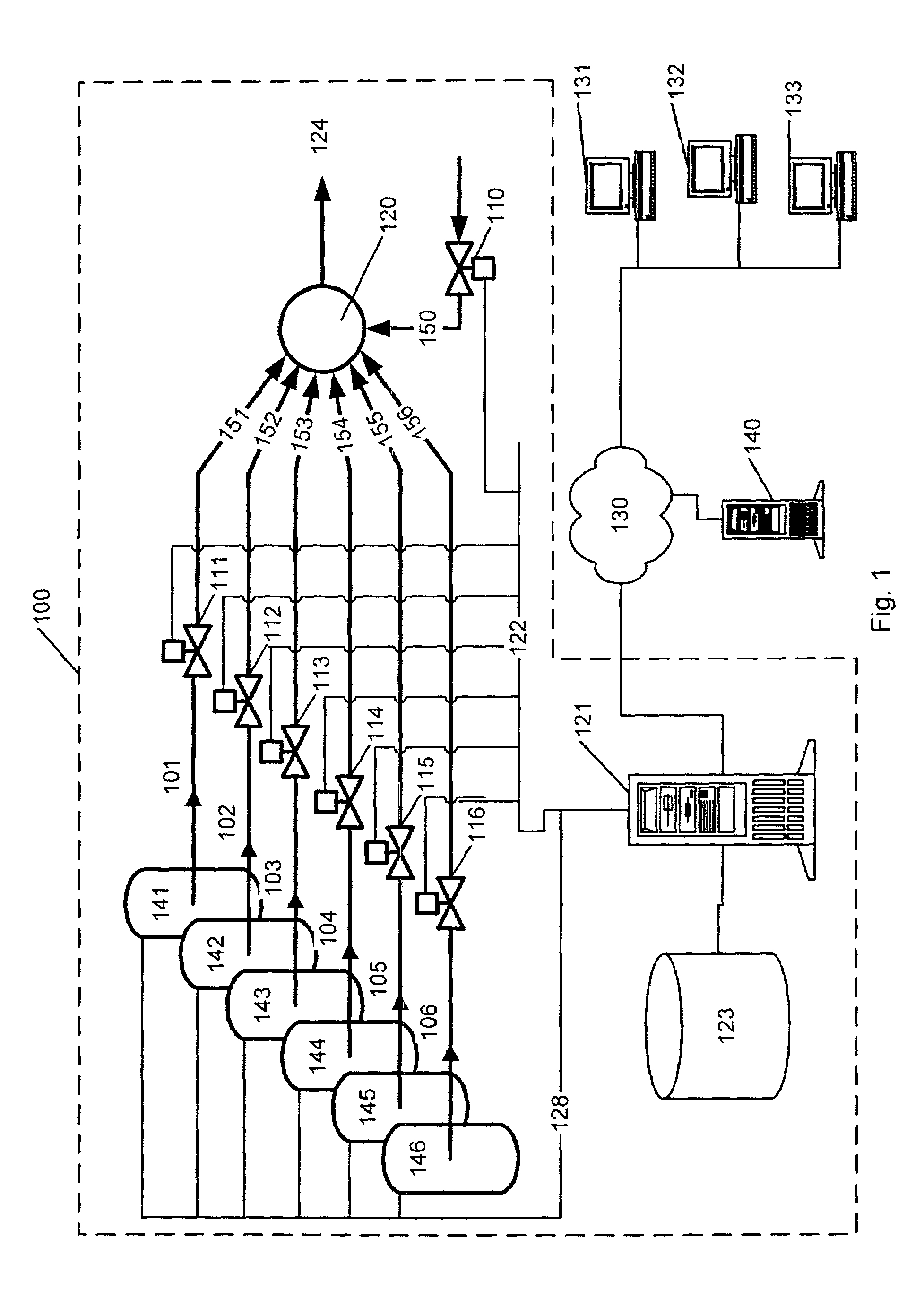

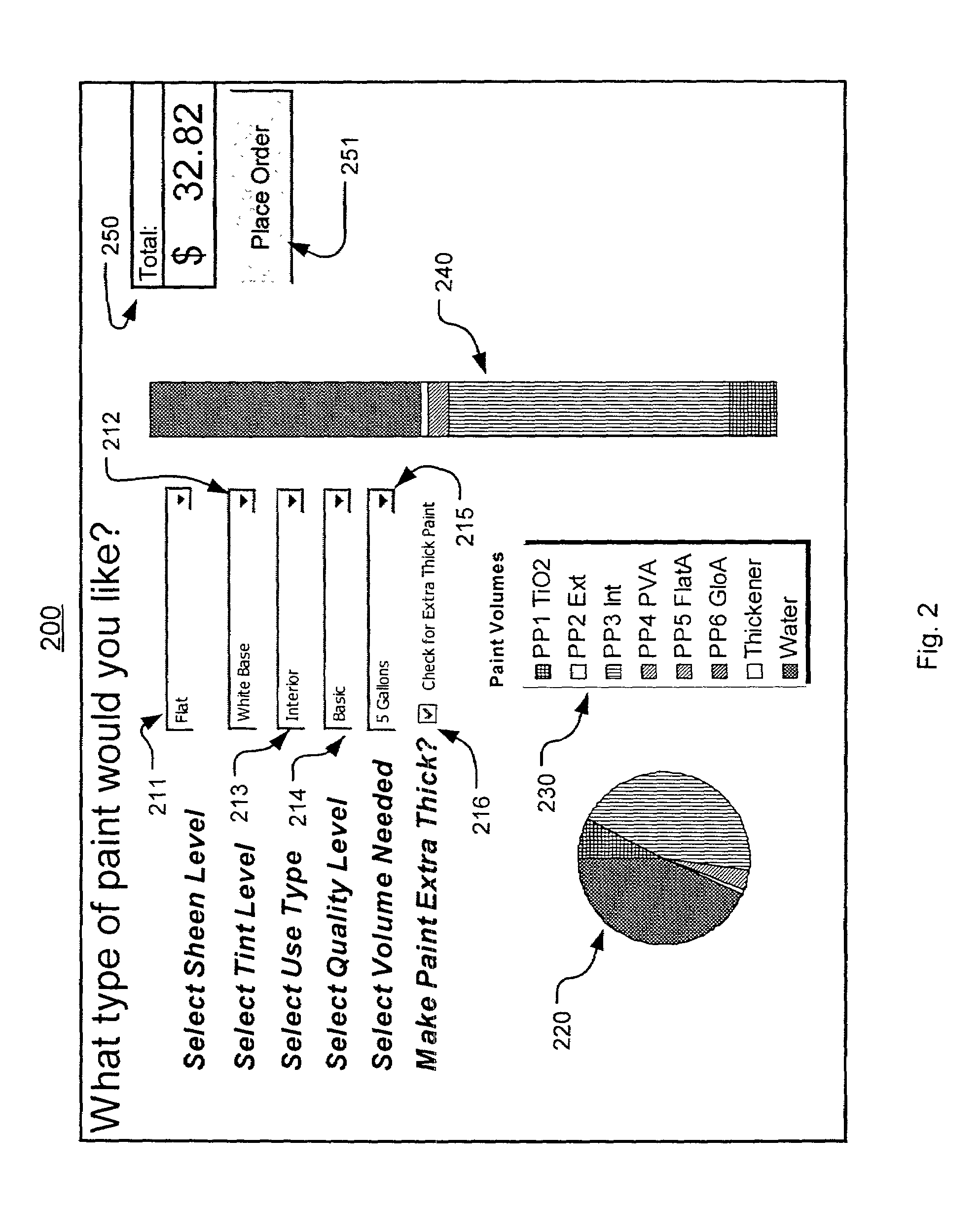

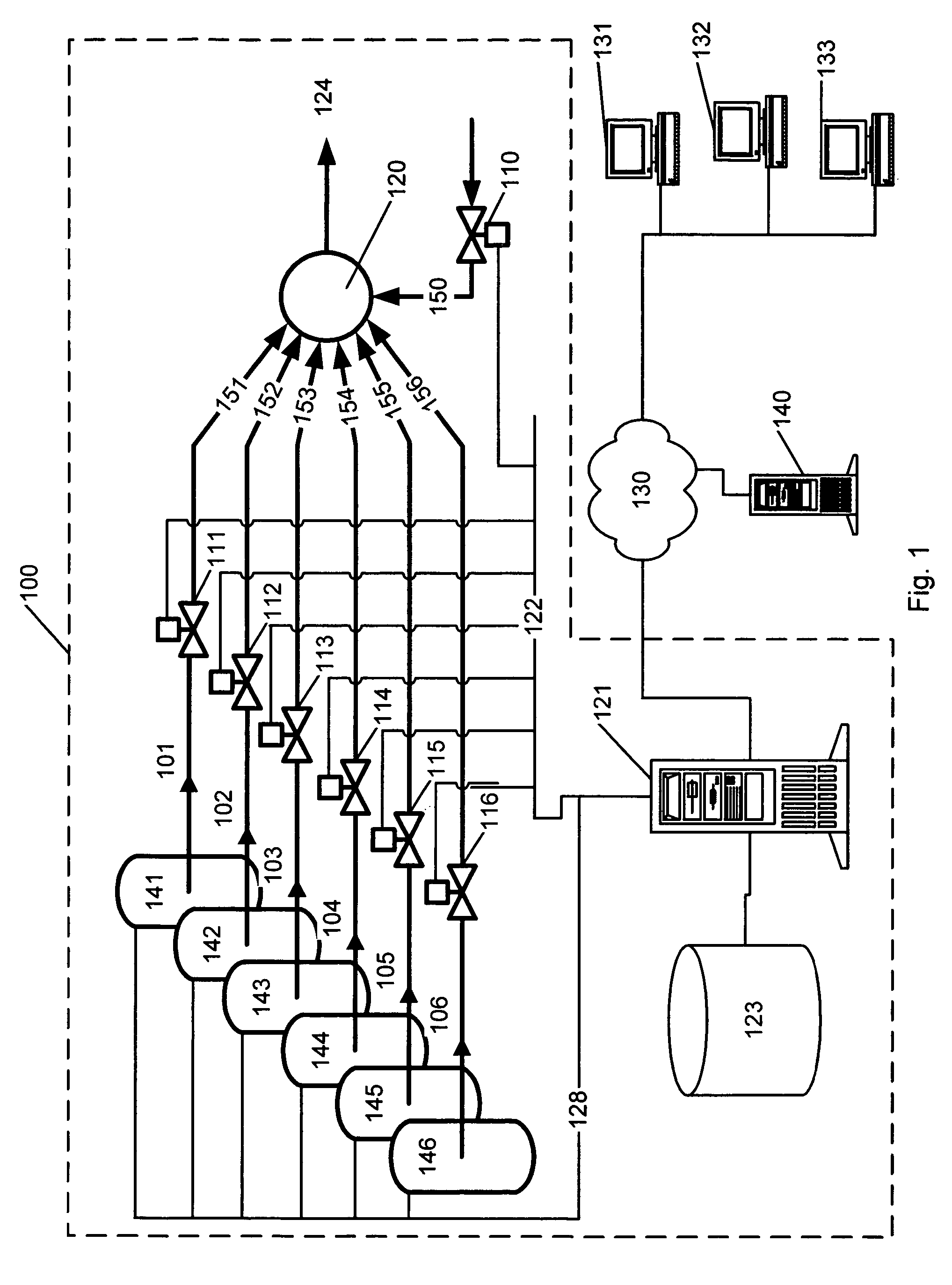

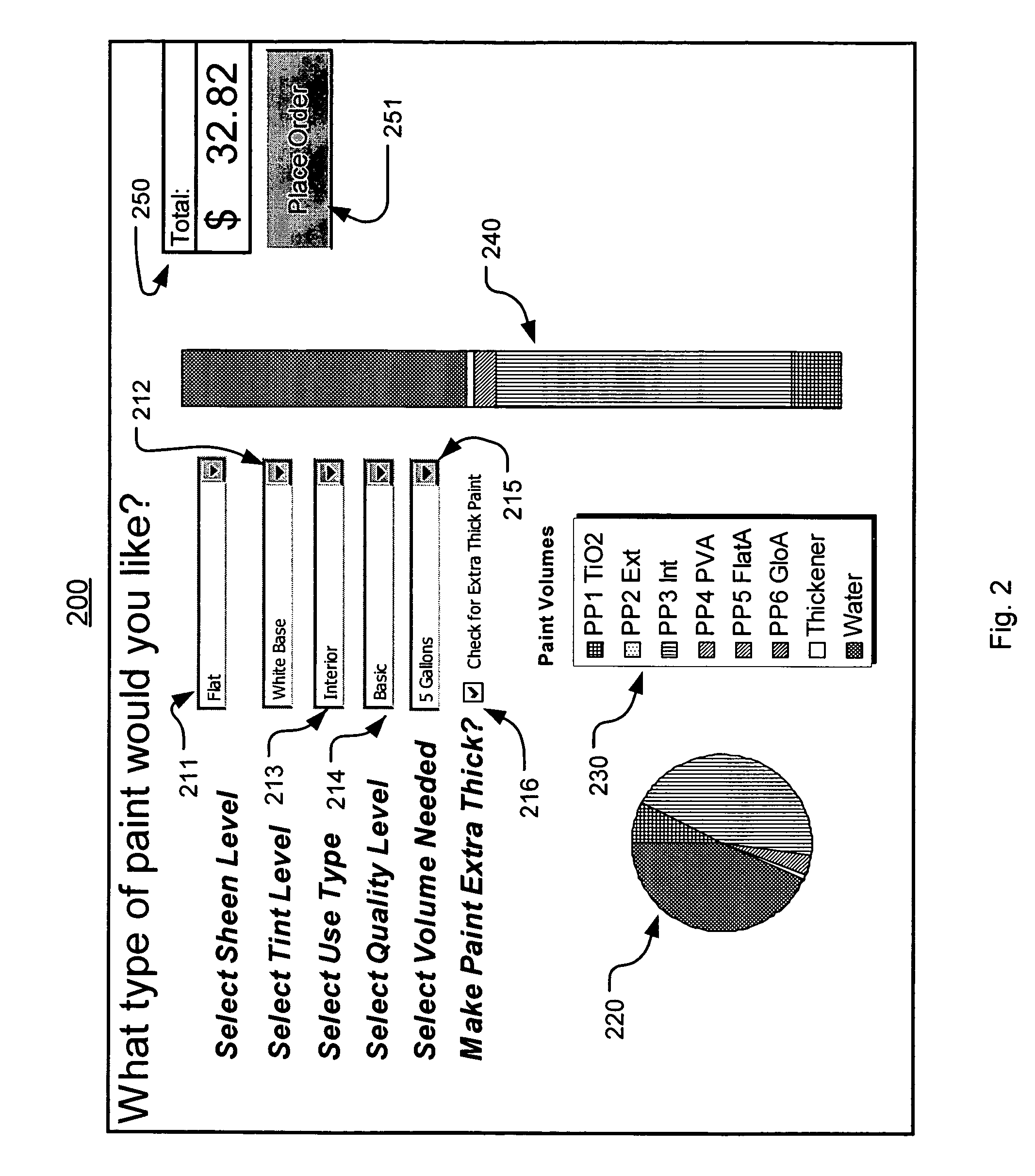

Distributed paint manufacturing system

InactiveUS7250464B2Less amountViscosity fluctuations are smallTransportation and packagingMixer accessoriesHybrid systemUser input

Owner:ROHM & HAAS CO

Products made with yellow mustard gum

Yellow mustard gum was used to produce varieties of new foods, cosmetics, paints, and industrial products including but not limited to the following products: nutraceutical beverages, nutraceutical sauces, nutraceutical salad dressings, nutraceutical confectionary products, cosmetics products, pharmaceutical products, paints products and chemical products and were claimed accordingly.

Owner:SHARAFABADI SOHEIL KHAJEH

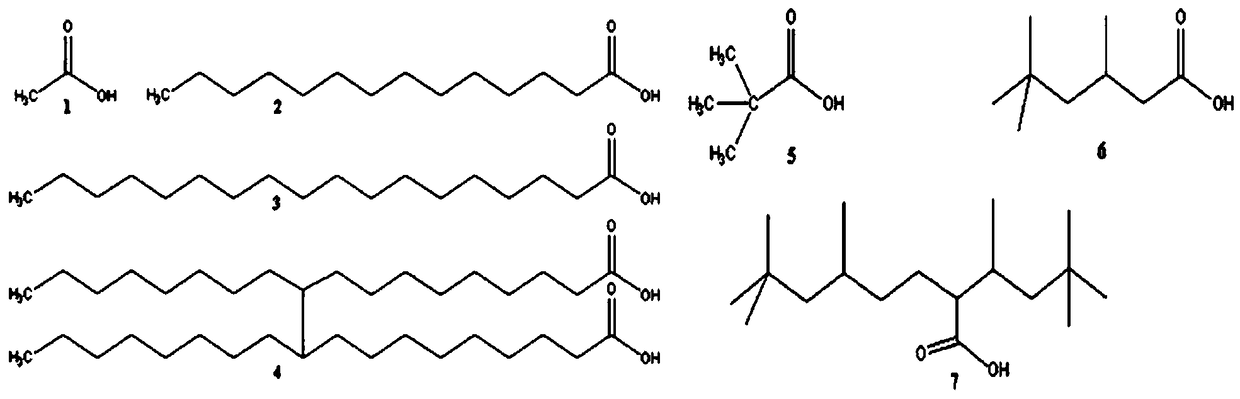

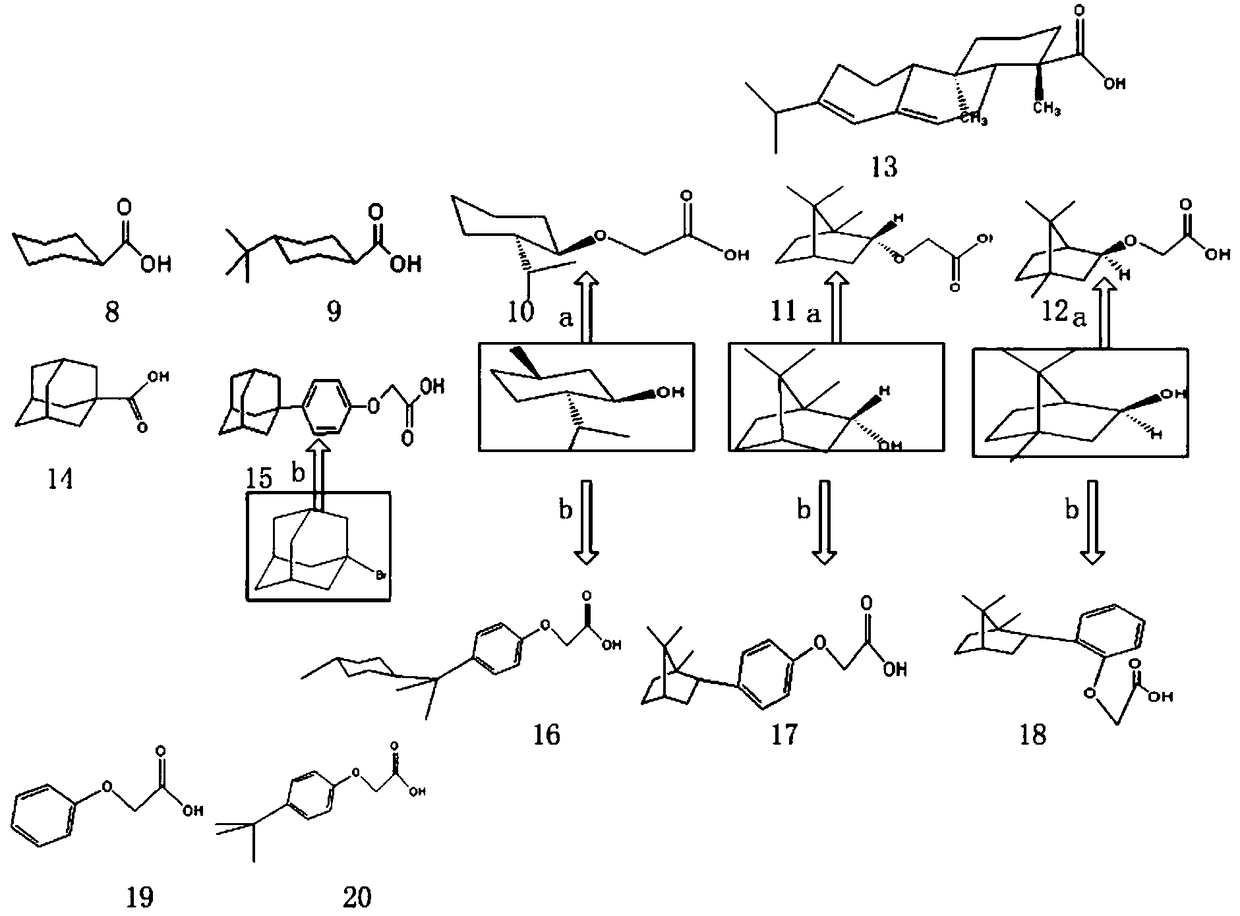

High solid content polyurethane emulsion containing alicyclic sulfonic acid type hydrophilic chain extending agent and preparation method thereof

The invention discloses a high solid content polyurethane emulsion containing an alicyclic sulfonic acid type hydrophilic chain extending agent and a preparation method thereof. The high solid content polyurethane emulsion containing alicyclic sulfonic acid type hydrophilic chain extending agent is prepared by the following substances in percentage by weight: 9.5-16.5 of diisocyanate, 78-88 of polyester polyol, 0.25-0.45 of dimethylol propionic acid, 0.25-0.45 of salifying reagent, 1.4-3.8 of alicyclic sulfonic acid type hydrophilic chain extending agent, 0.9-1.9 of diamine chain extending agent and 0.01-0.02 of organic tin catalyst. The high solid content polyurethane emulsion containing the alicyclic sulfonic acid type hydrophilic chain extending agent has the solid content above 50 percent and good heat resistance and hydrolyzing resistance, can be applied to paint and adhesive and particularly can meet aqueous polyurethane adhesive and paint products with high performance.

Owner:ZHUHAI YUTIAN CHEM PROD

Flake pigment, powder paint containing the same, powder-coated film obtained by coating with the powder paint using triboelectrification electrostatic coating apparatus, painted product on which film is formed, and method of manufacturing flake pigment

ActiveUS20110008613A1Good metal effectSerious disadvantageFibre treatmentSynthetic resin layered productsPhosphateElectrostatic coating

A flake pigment according to the present invention includes a flake particle, a single-layer or multiple-layer coat covering a surface of the flake particle, and a fine particle. An outermost layer of the coat includes a copolymer including one or more type of first bond unit originating from a fluoric polymerizable monomer having fluorine and one or more type of second bond unit originating from a polymerizable monomer having phosphate group. The fine particle is fixed with the outermost layer being interposed and has a characteristic to provide triboelectrification characteristics to the flake pigment.

Owner:TOYO ALUMINIUM KK

Environmentally-friendly aqueous spray paint and preparation method thereof

InactiveCN105907201AImprove atomization effectHigh ejection ratePolyurea/polyurethane coatingsEnvironmental resistanceHardness

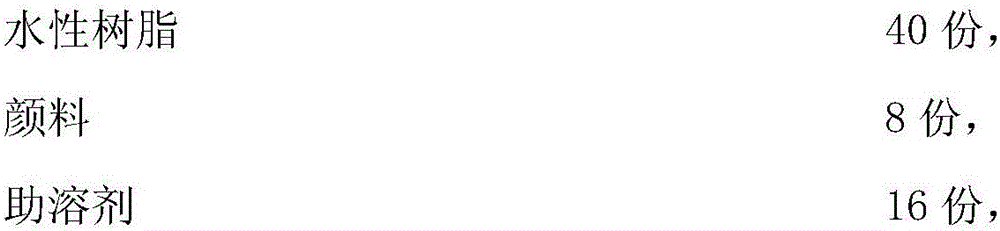

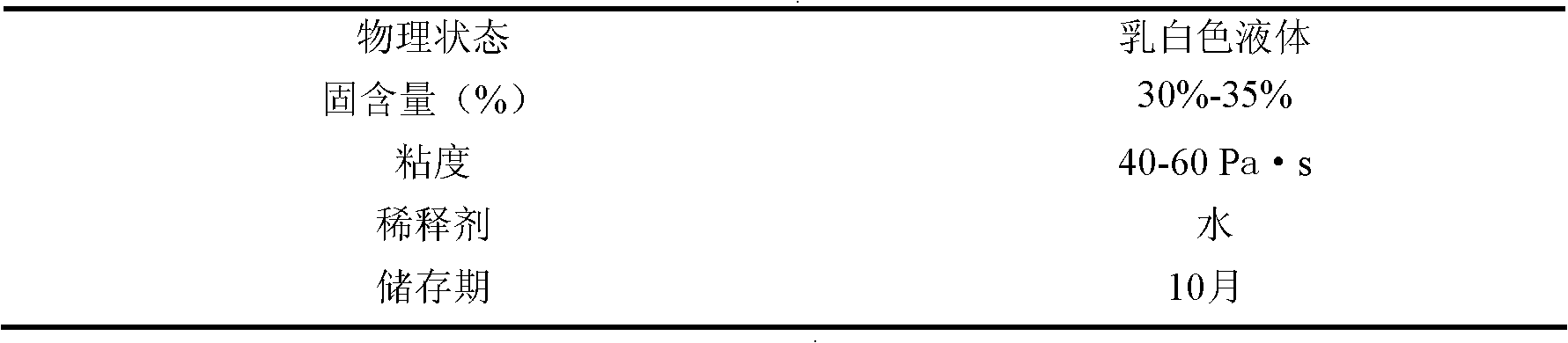

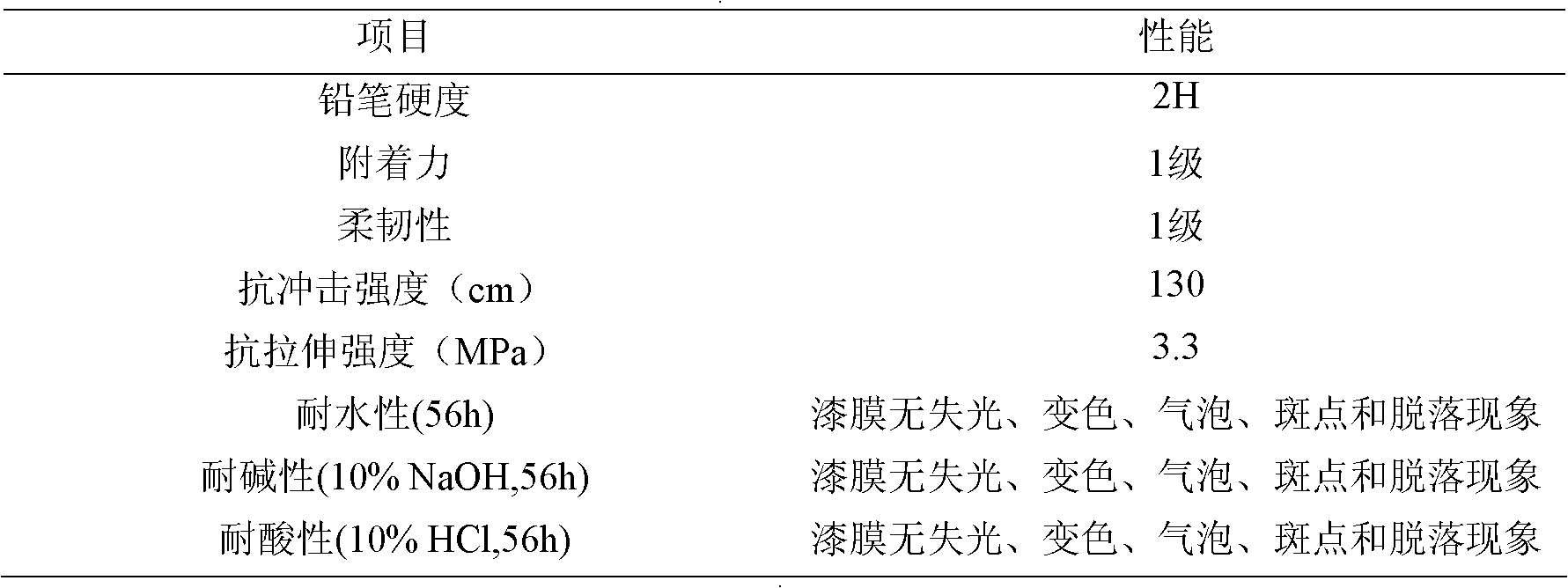

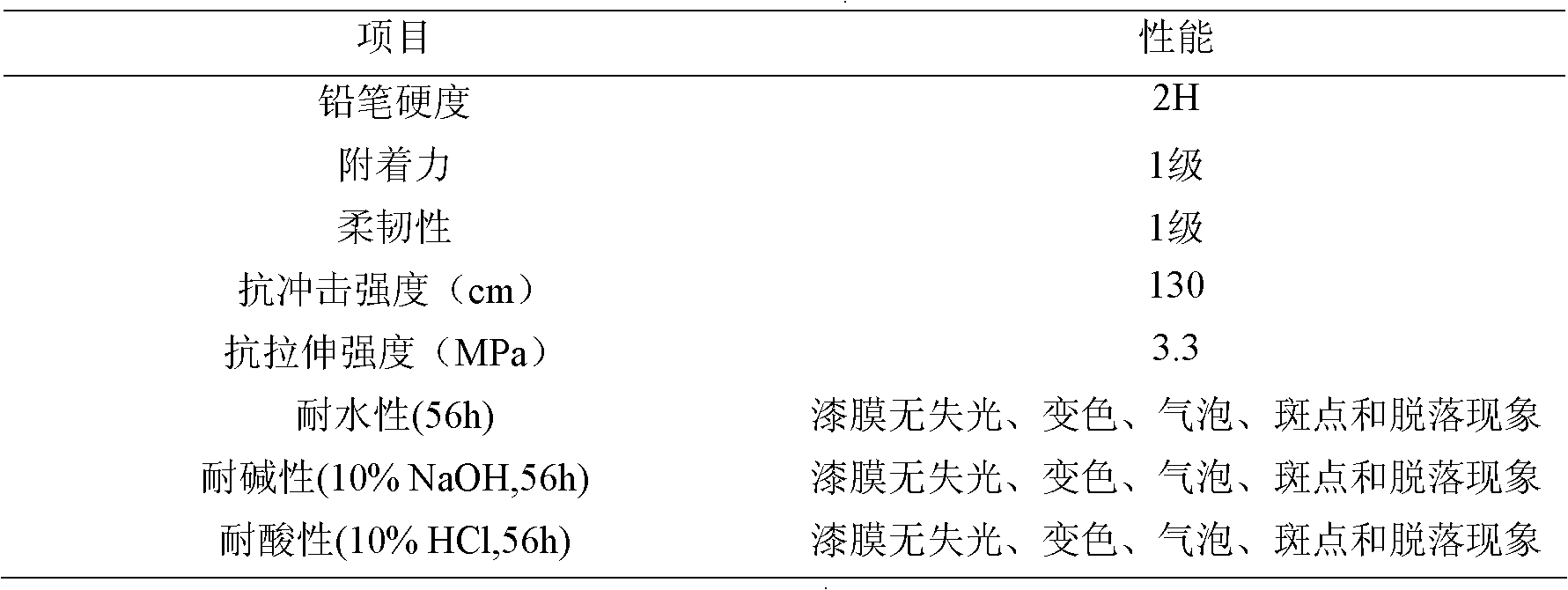

The invention provides an environmentally-friendly aqueous spray paint liquid, a propellent, an aerosol coated environmentally-friendly aqueous spray paint and a preparation method of the paint. The liquid comprises, by weight, 30-45 parts of aqueous resin, 5-15 parts of a pigment, 15-30 parts of a cosolvent, 20-35 parts of water and 0.5-2 parts of an assistant. The environmentally-friendly aqueous spray paint liquid adopts an aqueous resin system, so a whole paint film has a good hydrophobic and oleophobic effect, and improvement of the quality of spray paint products is facilitated; water is used to substitute parts of a solvent, so the VOC is reduced, and environmental protection is realized; and the produced environmentally-friendly aqueous spray paint has good sprayability and a high spray rate, and a film formed by the paint has high fullness, excellent hardness, adhesion, glossiness, flexibility and impact resistance, and has abundant and gorgeous colors, excellent decorative effect, good ageing resistance, and extremely good antirust and protection functions.

Owner:中山市润宜汽车用品有限公司

Method for preparing waterborne polyurethane taken as waterborne epoxy hardener

The invention relates to a method for preparing waterborne polyurethane taken as a waterborne epoxy hardener. The method comprises the following steps of: adding aliphatic polyisocyanate into low polymer polyalcohol; dissolving dimethylolpropionic acid taken as a hydrophilic chain extender in N-methylpyrrolidone; adding dibutyltin dilaurate taken as a catalyst into the mixture; stirring the mixture and raising the temperature to a certain extent to prepare a preformed polymer containing a terminated isocyanate group; cooling the prepared preformed polymer to room temperature; adding triethylamine into the preformed polymer to perform neutralization reaction for a certain period of time; and adding an appropriate amount of distilled water and violently stirring the mixture to emulsify the mixture; and adding a polyamine chain extender to perform chain extension reaction for a certain period of time to obtain amino-terminated waterborne polyurethane emulsion. The method has the advantages of preparing polyurethane emulsion which can be directly applied to curing epoxy resin, realizing a simple synthetic method and more easily controlled operation, enhancing the compatibility of epoxy resin emulsion with a curing agent, enabling a synthetized paint product to achieve the advantages of polyurethane and the epoxy resin and realizing high performance of paint.

Owner:TIANJIN UNIV

Heat-resistant phenolic resin produced by taking cresol residues as raw material and application of heat-resistant phenolic resin in heat-resistant anti-corrosion paint

InactiveCN102757620AFast dryingImprove adhesionAnti-corrosive paintsChemical reactionMechanical equipment

The invention provides a heat-resistant phenolic resin produced by taking cresol residues as a main raw material. The heat-resistant phenolic resin is obtained after a series of chemical reaction through utilizing the active functional groups of various compounds in the cresol residues. A heat-resistant anti-corrosion paint is produced by taking the heat-resistant phenolic resin as a main film forming matter and compounding with glass flakes and other lamellar inorganic mineral materials, has the advantages of high drying speed, good adhesion, high hardness, good heat resistance, strong water resistance and solvent resistance and the like, and is suitable for the heat-resistant anticorrosion coating of the surfaces of chemical mechanical equipment, pipelines, flues, storage tanks, heat dissipation devices and other devices. According to the heat-resistant phenolic resin, the cresol residues are comprehensively utilized, therefore, the pollution problem of the cresol residues is fundamentally solved, and the effects of comprehensive treatment and waste material recycle are realized; and moreover, new paint products are increased, and the application field of the phenolic paint is broadened.

Owner:LANZHOU PETROCHEM COLLEGE OF VOCATIONAL TECH

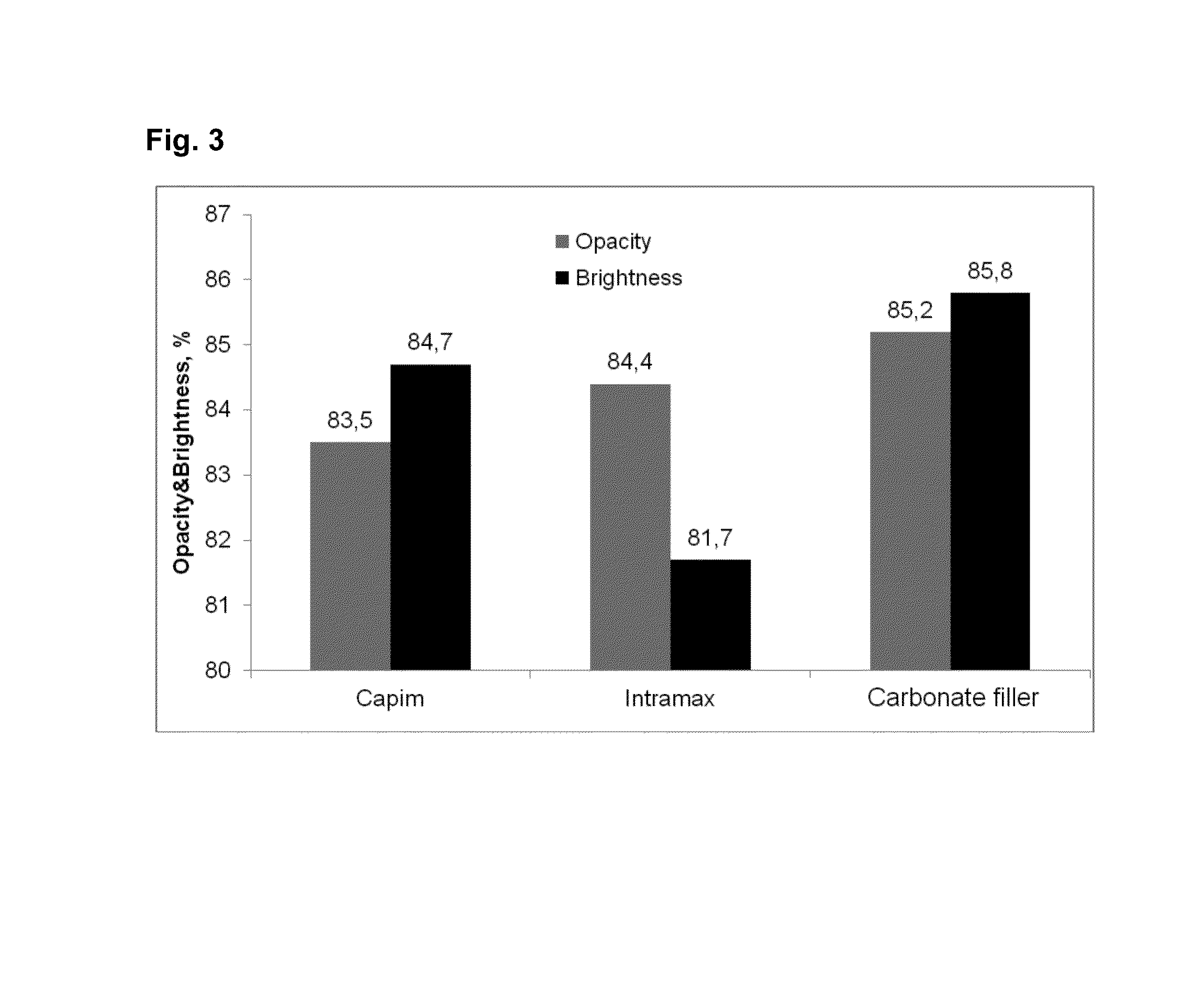

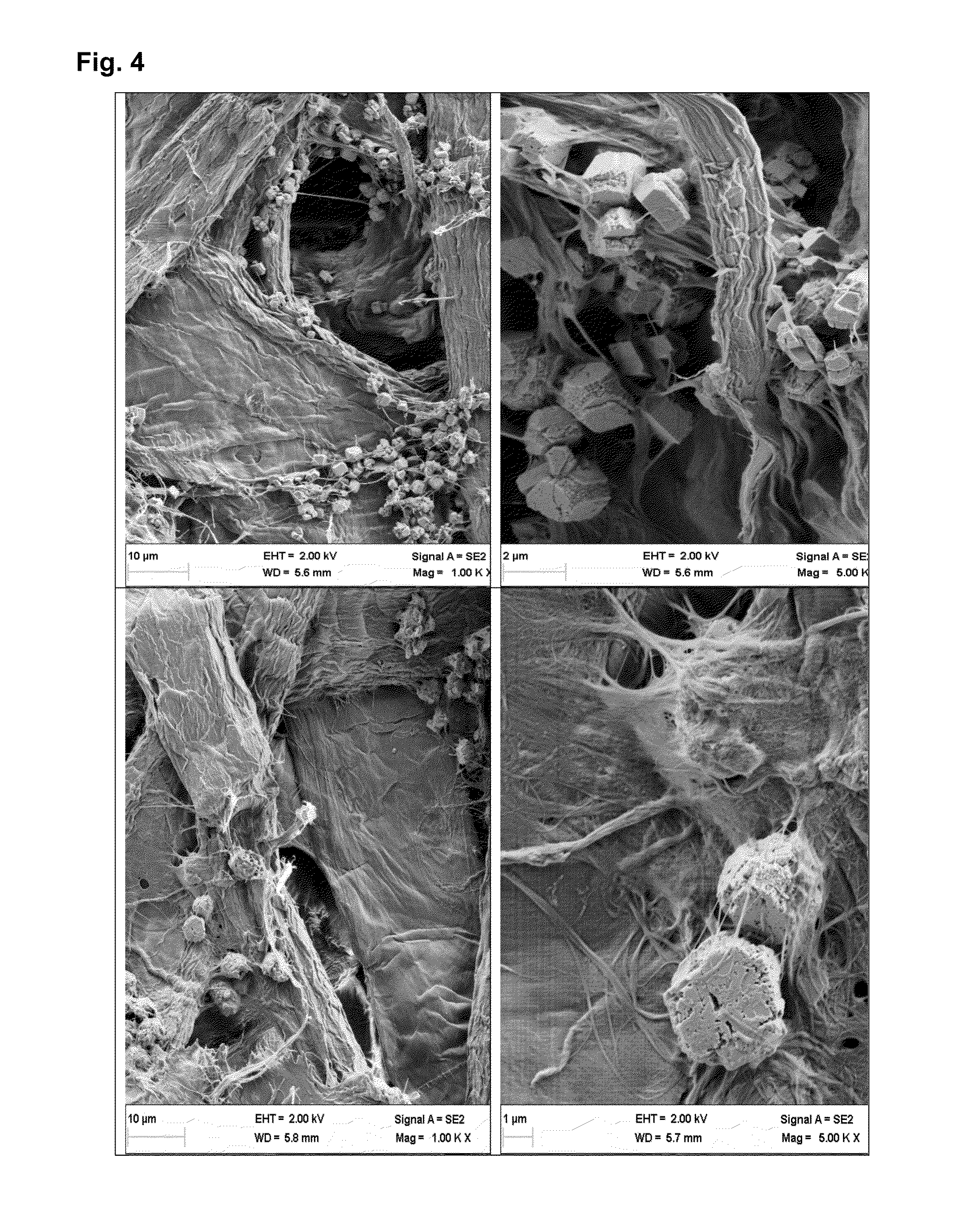

Use of precipitated carbonate in the manufacture of a fibre product

InactiveUS20140069302A1Good strength performanceImprove strength propertiesCalcium/strontium/barium carbonatesPigmenting treatmentCardboardFiber

The present invention relates to a filler or a filler mixture containing carbonate, as well as to a process for manufacturing the same by precipitating the filler directly into the pulp or, as a separate process without the presence of fibres, particularly from the wire water of the paper or board manufacture. The invention also relates to a fibre product containing this filler, such as a paper or board product, or a plastic, rubber, concrete or paint product.

Owner:NORDKALK AB

Silicone modified polyacrylate and its prepn and application

InactiveCN1887926AImprove heat resistanceGood chemical resistanceCoatingsAcrylonitrileAcrylate polymer

The present invention relates to water soluble organosilicon modified polyacrylate and its preparation process. The organosilicon modified polyacrylate has number average molecular weight of 33,000-70,000, and is prepared through the first free radical polymerization with monomers, including (methyl) acrylate 15-85 wt%, hydroxyl group containing acrylate 6-18 wt%, (methyl) acrylic acid 5-17 wt%, styrene 0-25 wt%, acrylonitrile 0-15 wt%, Veova 0-30 wt% and vinyl siloxane 1-20 wt%, under the action of initiator inside alcohol or alcohol ether medium, and the subsequent neutralization with ammonia or organic amine to produce salt. The polymer of the present invention has high storage stability, high water resistance, high chemical resistance, excellent heat resistance and electric insulating performance, and may be used widely as filming material for various paint products.

Owner:SHENZHEN HANLONG TECH DEV

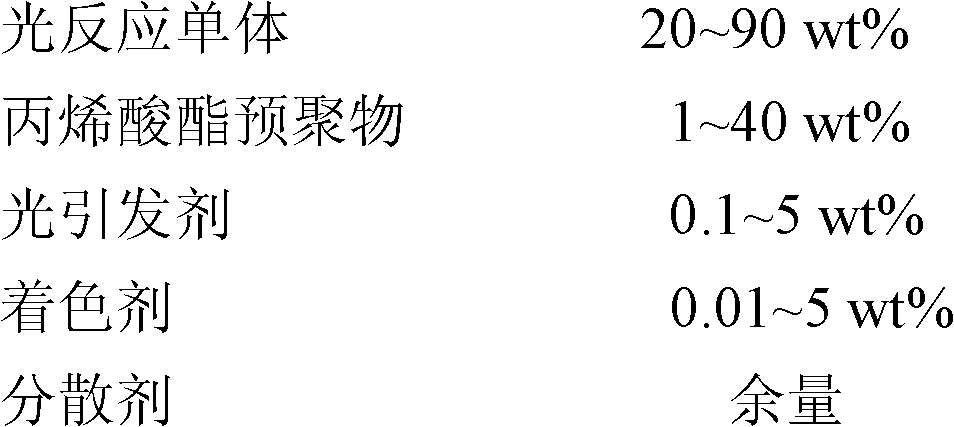

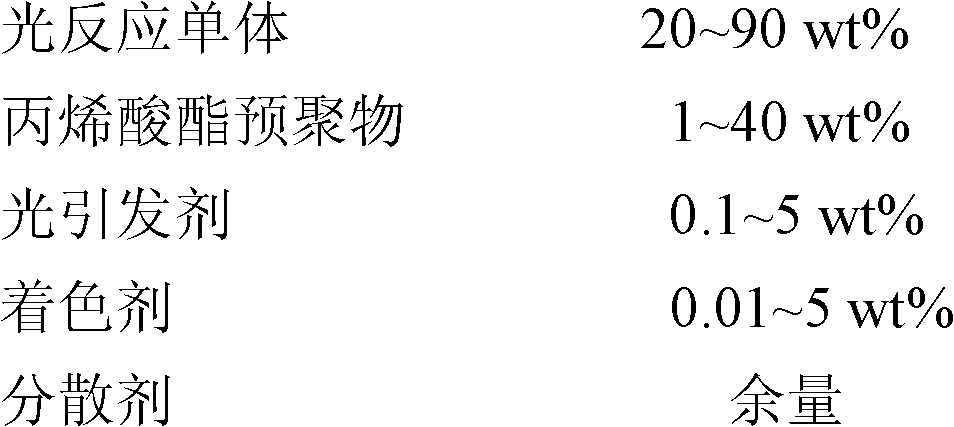

UV-curable ink used in inkjet printing direct-to-plate, and preparation method and application thereof

The invention relates to a UV-curable ink used in inkjet printing direct-to-plate, and a preparation method and an application thereof. According to the invention, according to a total weight of the UV-curable ink, 20-90wt% of a photoreactive monomer, 1-40wt% of an acrylic ester prepolymer, 0.1-5wt% of a photoinitiator, 0.01-5wt% of a coloring agent, and balance of a dispersing agent are mixed and grinded; the mixed liquid is filtered; and the filtrate is the UV-curable ink provided by the invention. The UV-curable ink used in inkjet printing direct-to-plate is sprayed on the surface of a blank plate base or a plate base with a coating by using an inkjet printer, such that patterns are formed; and the blank plate base or the coated plate base with the UV-curable ink used in inkjet printing direct-to-plate is cured for 1-60 seconds under ultraviolet light with a wavelength of 300-450nm. The curing speed of the obtained printing plate is high, and good printability and printing durability are provided when printing is carried out. A paint product resolution reaches 150 lines.

Owner:INST OF CHEM CHINESE ACAD OF SCI

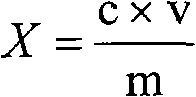

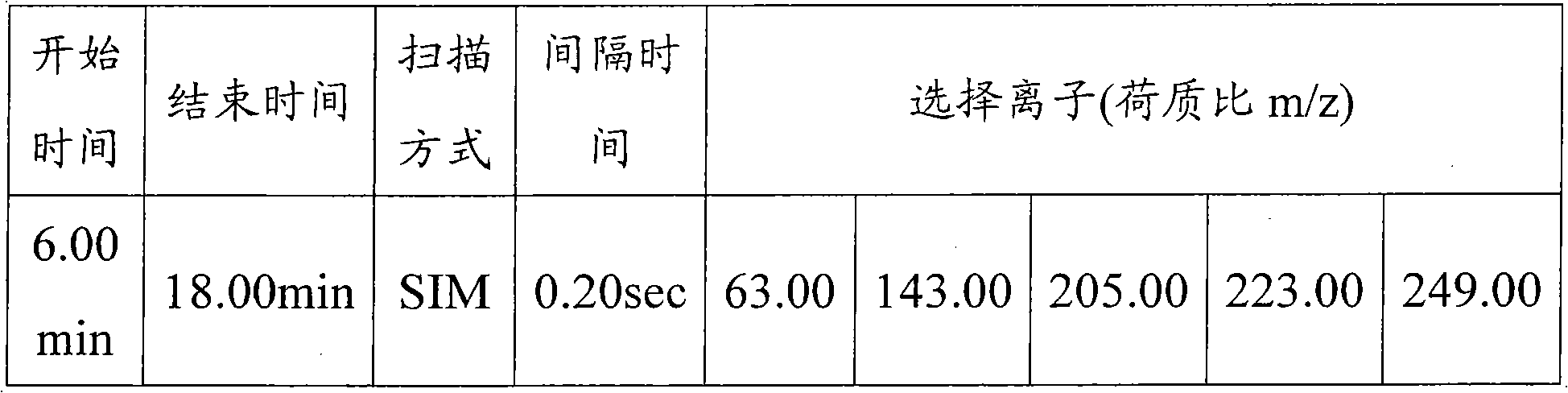

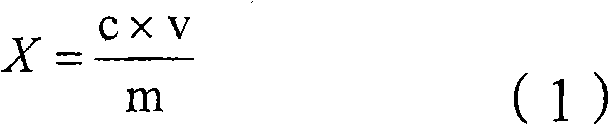

Method for determining content of tris (2-chloroethyl) phosphate

The invention provides a method for determining the content of tris (2-chloroethyl) phosphate, which comprises the following steps: a sample to be tested is extracted with an organic solvent extractant, the obtained extract is purified via a Waters Oasis HLB extraction column after being concentrated, is concentrated to a definite volume after leacheate which is the organic solvent is collected, and finally is filtered to prepare a specimen test solution; and then the specimen test solution is detected with a gas chromatograph-mass spectrometer according to an external standard method. When the sample to be tested is a solid sample, the sample to be tested is pulverized firstly and then is extracted by ultrasound; and when the sample to be tested is liquid, the sample is extracted by ultrasound. The method for determining the content of the tris (2-chloroethyl) phosphate is rapid and effective, the error rate of is not more than 5 percent, and the detection limit is 0.05mg / kg. The invention provides a reliable and conveniently implementary method for detecting the content of tris (2-chloroethyl) phosphate in rubber, plastics, printing ink and paint products and can meet the needs in research and production.

Owner:谱尼测试集团股份有限公司

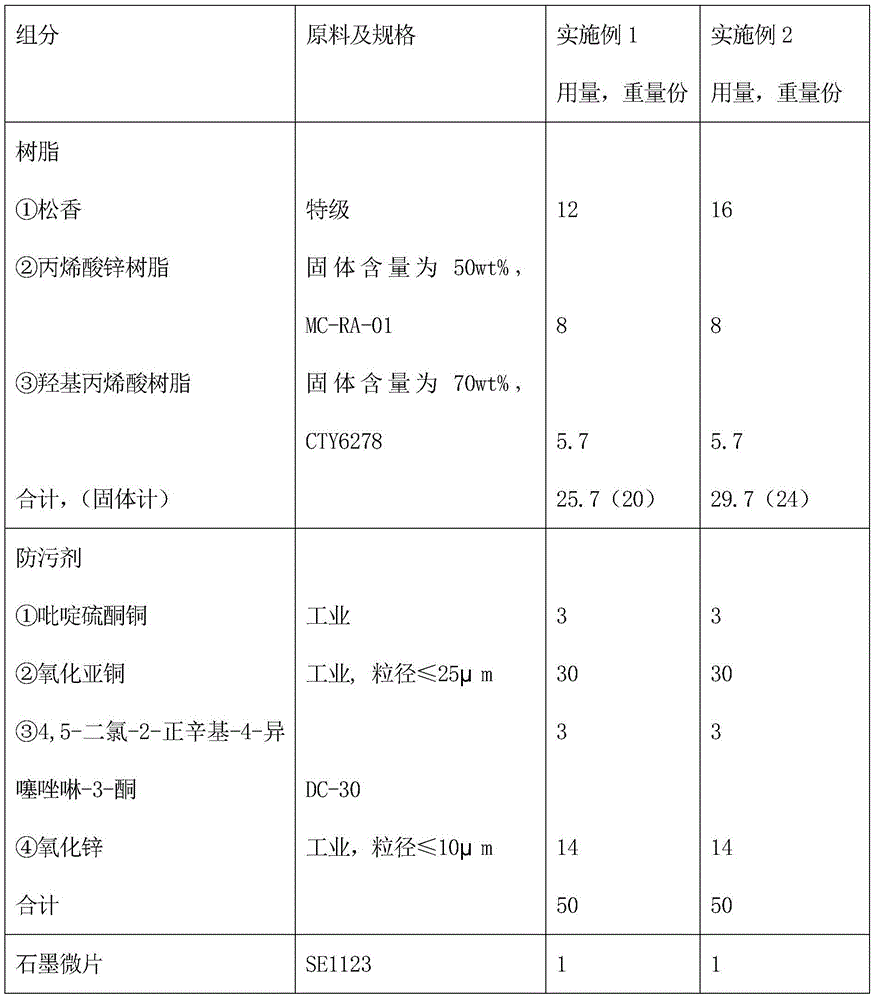

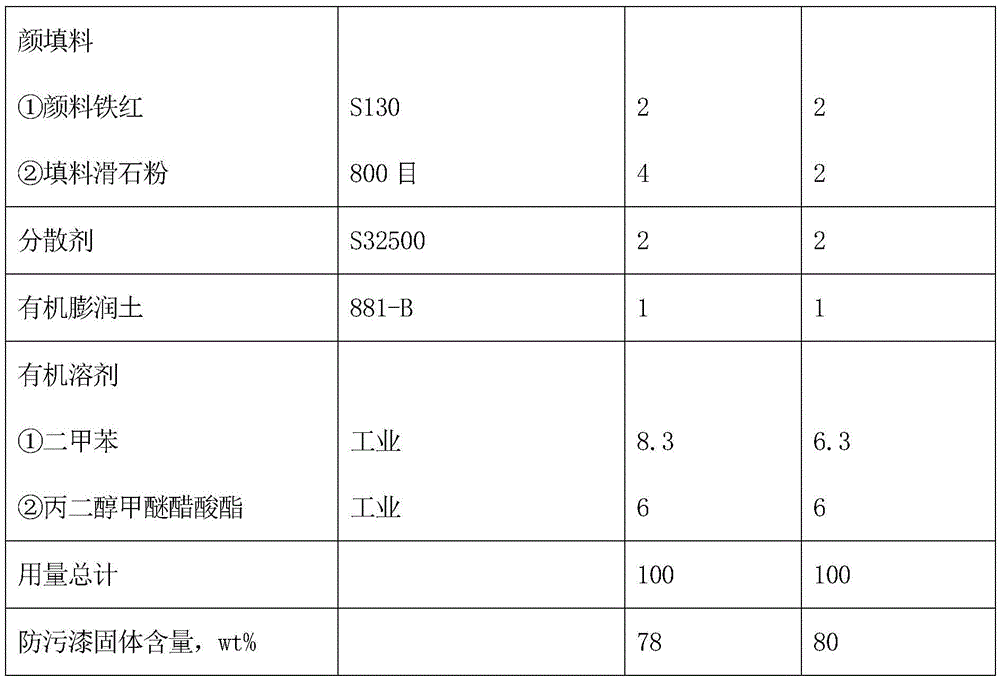

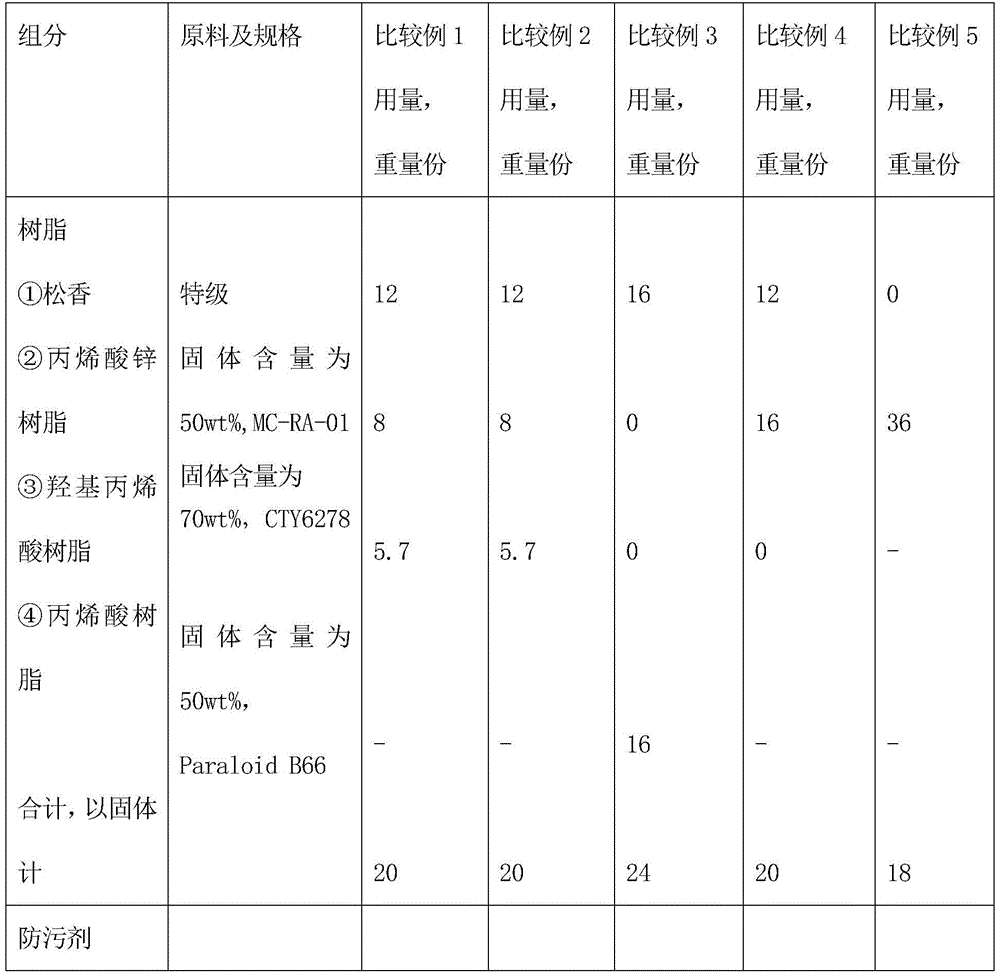

Self-polishing antifouling paint and preparation method thereof

ActiveCN105482702AHigh strengthImprove hydrophobicityAntifouling/underwater paintsRosin coatingsSodium PyrithioneCrack resistance

The invention relates to a self-polishing antifouling paint and a preparation method thereof. Every 100 parts by mass of the antifouling paint is composed of 18-24 parts of solid-based resin, 50-55 parts of antifouling compound, 0.5-1.5 parts of graphene microchip, 3-6 parts of pigment and filler, 1-2 parts of dispersing agent, 1-2 parts of organobentonite and the balance of organic solvent. The resin is composed of a hydroxy acrylic resin, a zinc acrylate resin and rosin. The antifouling compound is composed of zinc pyrithione, 4,5-dichloro-2-n-octyl-4-isothiazolinyl-3-one, cuprous oxide and zinc oxide. The preparation method comprises the following steps: respectively preparing the graphene microchip-zinc oxide-hydroxy acrylic resin slurry and cuprous oxide-rosin-zinc acrylate slurry, and mixing to obtain the self-polishing antifouling paint. The obtained self-polishing antifouling paint product has the advantages of stable quality, long antifouling period, favorable polishing effect, high strength, cracking resistance and low VOC (volatile organic compound).

Owner:CHINA NAT OFFSHORE OIL CORP +3

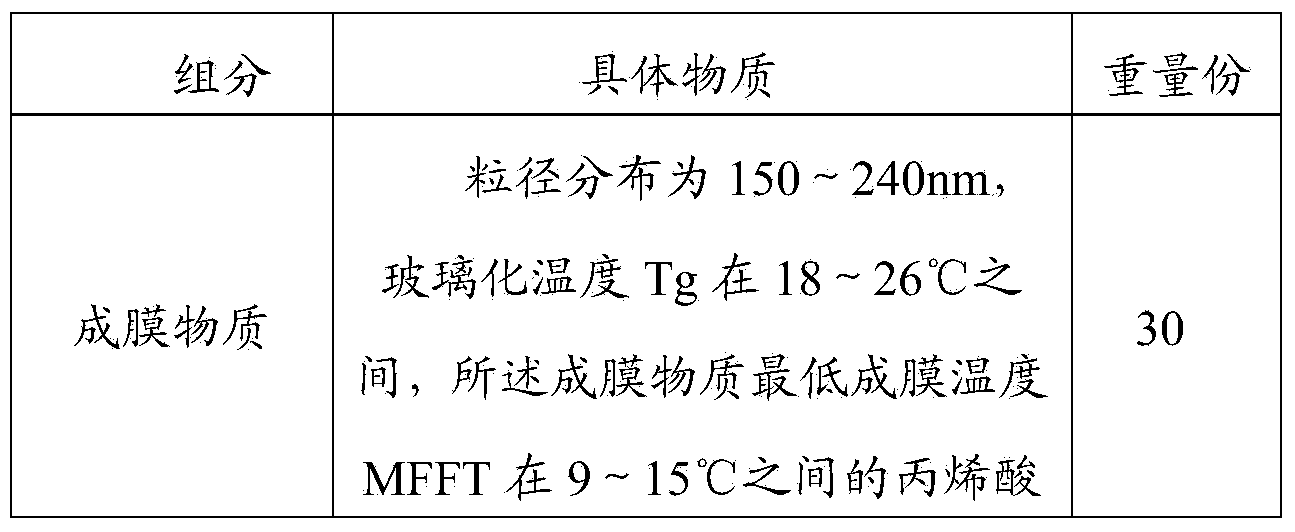

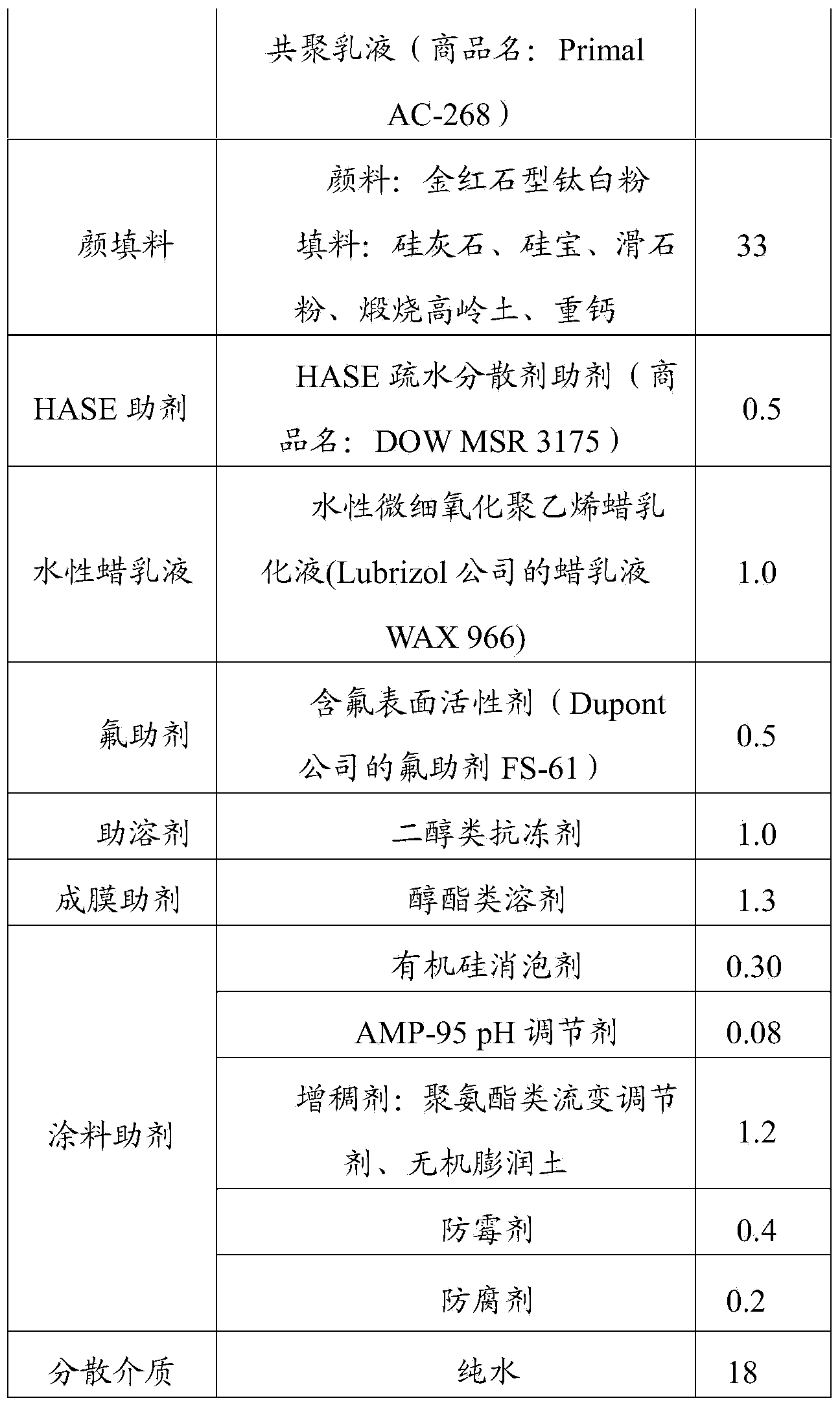

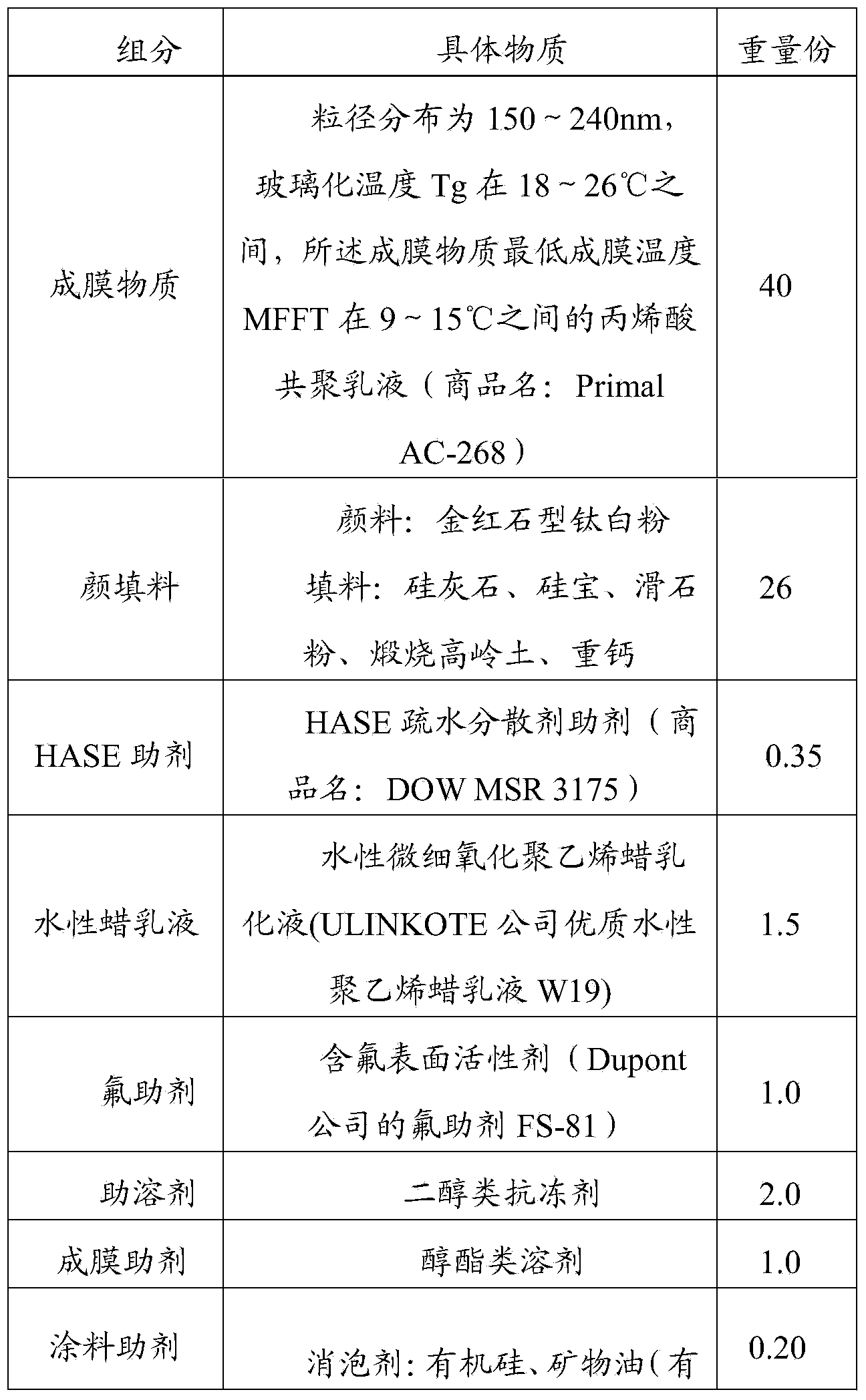

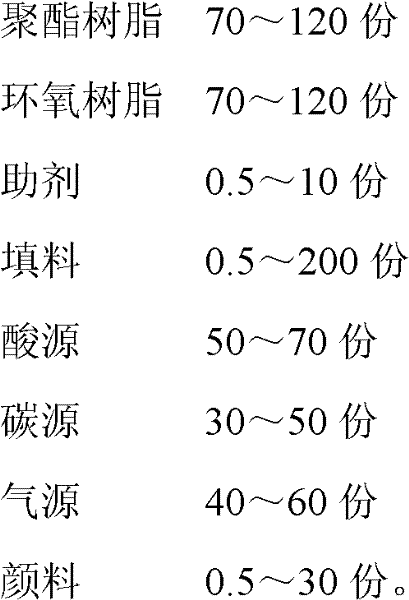

Water-based paint composition and preparation method thereof

ActiveCN103849267AWater and oil amphobic effect is goodImprove qualityAntifouling/underwater paintsPaints with biocidesWaxWater based

The invention provides a water-based paint composition. The water-based paint composition comprises the following components in parts by weight: 30-50 parts of film-forming substances, 26-40 parts of pigment filler, 0.3-0.5 part of HASE hydrophobic dispersing agent auxiliaries, 1.0-2.0 part of water-based fine oxidized polyethlene wax emulsion, 0.3-1.0 part of fluorine-containing surfactant, 1.0-2.0 parts of cosolvent, 1.0-2.0 parts of coalescing agents, 2.0-3.0 parts of other auxiliaries, and acceptable amount of water. Pigment volume concentration of the water-based paint composition is 30%-50%. A paint film formed by the paint composition is better in water-oil amphiphobic effect, beneficial to improving quality of an interior-wall paint product; meanwhile, a novel application field is developed, high environment-friendly requirements are combined with high-quality anti-staining characteristic, so that the product can serve for the interior decoration market better.

Owner:NIPPON PAINT CHINA

Water-based finishing paint for plastics and preparation method and application thereof

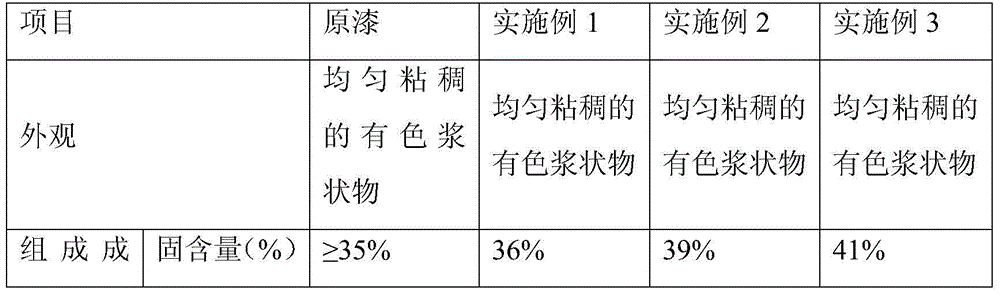

The invention relates to a water-based finishing paint for plastics and a preparation method and application thereof; the water-based finishing paint comprises a hydroxylated acrylic resin, a wetting agent, a flatting agent, a deforming agent, deionized water and an aliphatic polyisocyanate curing agent; the preparation method comprises the following steps of: firstly, weighing the hydroxylated acrylic resin according to a formula dosage, then adding the wetting agent, the flatting agent and the deforming agent under high-speed stirring, uniformly mixing and stirring, then adding the deionized water to dilute a mixture, slowly adding the aliphatic polyisocyanate curing agent under the stirring state, stirring till the raw materials are uniformly mixed, adjusting viscosity to be 13-22 seconds (testing under a 25-DEG C normal temperature by using an NK-2 IWATA cup), filtering, discharging, and preparing the water-based finishing paint for plastics; and when being applied, the water-based finishing paint for plastics is coated on a priming paint of a plastic shell such as a shell of a cell phone, a shell of a panel personal computer and the like. The water-based finishing paint is non-corrosive as water is used as a dispersion medium and solves the problem of difficulty to adhere of the water-based finishing paint by adopting the hydroxylated acrylic resin; and the large-batch production of the water-based finishing paint is easily realized, and the properties of the water-based finishing paint product are stable.

Owner:GUANGDONG JANUS SMART GRP CO LTD

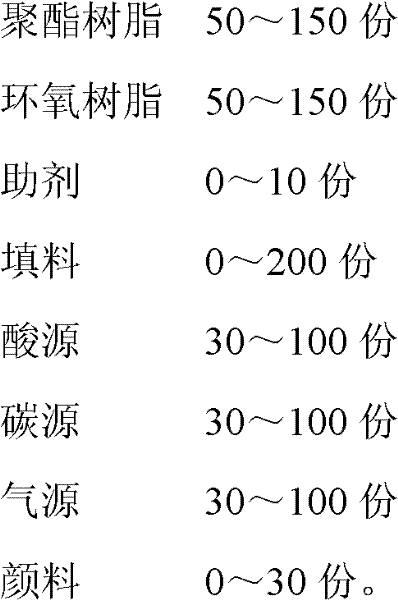

Low-temperature curing flame-retardant finishing powder paint and preparation method thereof

InactiveCN102391764ASimple recipeImprove the decorative effectPowdery paintsEpoxy resin coatingsEpoxyPolyester

The invention discloses a low-temperature curing flame-retardant finishing powder paint. The paint comprises the following components in part by weight: 50 to 150 parts of polyester alkyd, 50 to 150 parts of epoxy resin, 0 to 10 parts of aid, 0 to 200 parts of filler, 30 to 100 parts of acid source, 30 to 100 parts of carbon source, 30 to 100 parts of gas source and 0 to 30 parts of pigment. The invention also discloses a preparation method for the finishing powder paint. The powder paint has the characteristics of simple formula, high decoration, and capacity of obviously improving the flame retarding capacity of base materials after being painted on heat sensitive base materials, can be painted on combustible heat sensitive base materials such as medium density fiberboard (MDF), sandwich plates, bakelite plates and the like, and belongs to energy-saving environmentally-friendly paint products.

Owner:GUANGZHOU QINGTIAN INDAL

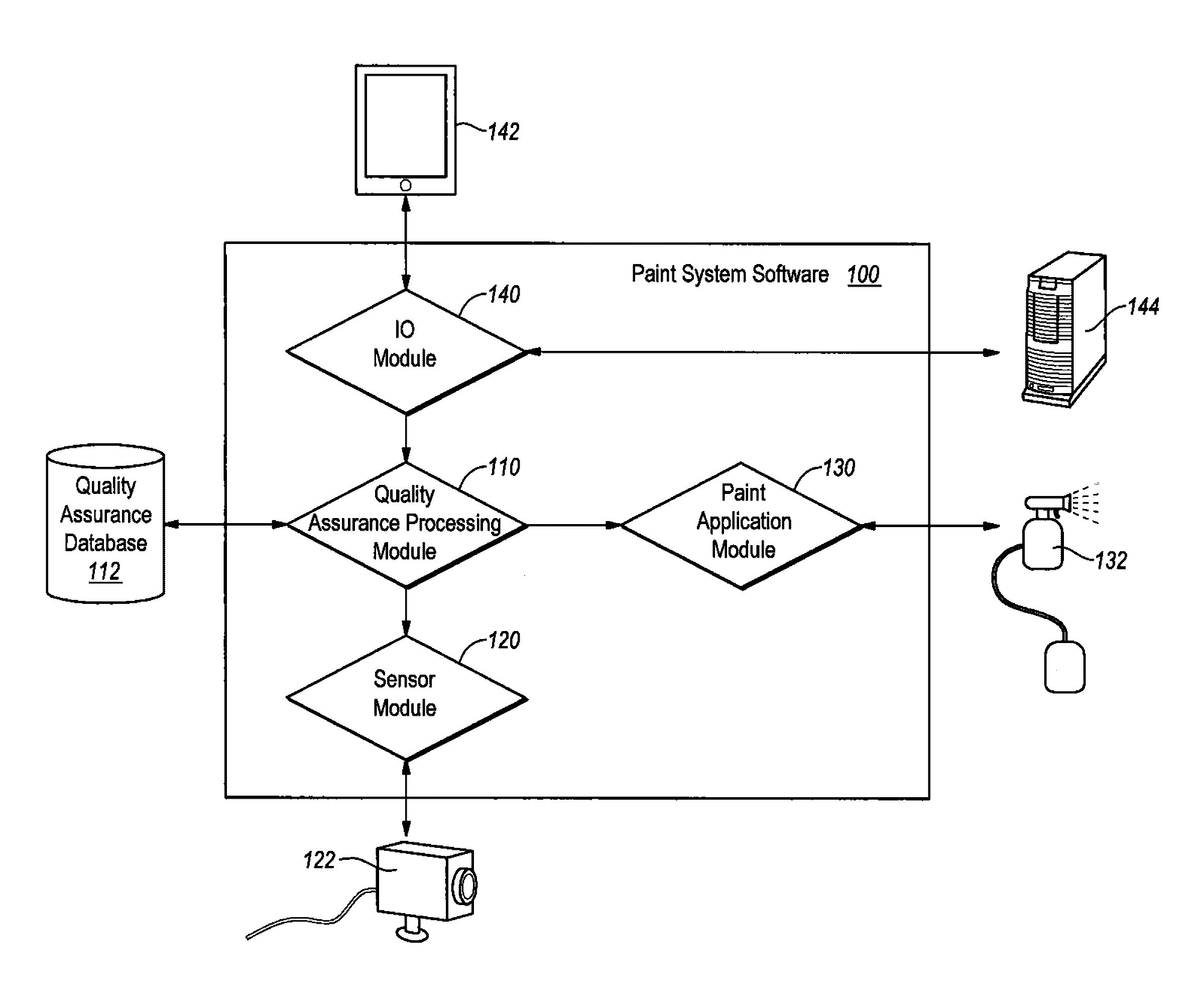

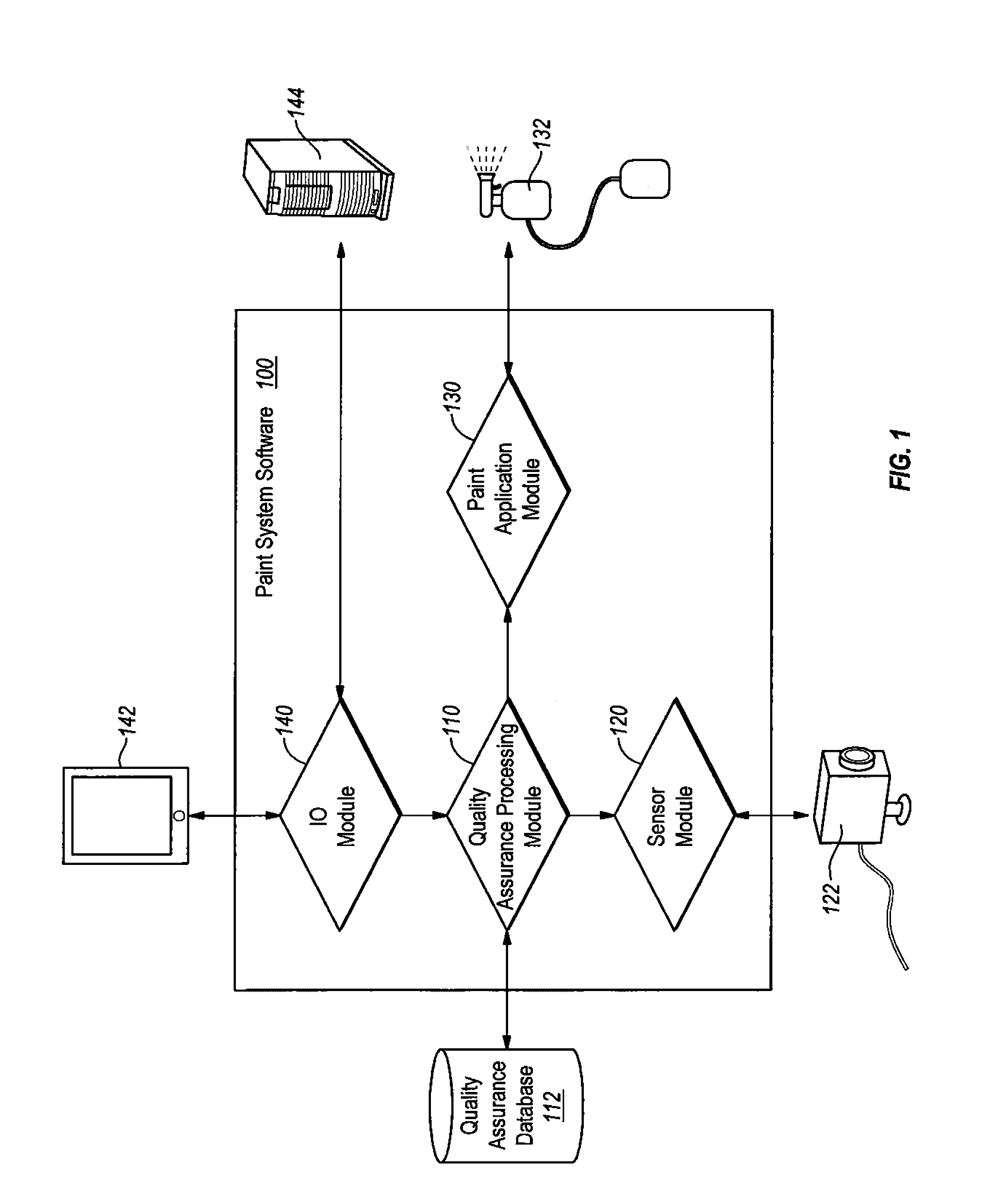

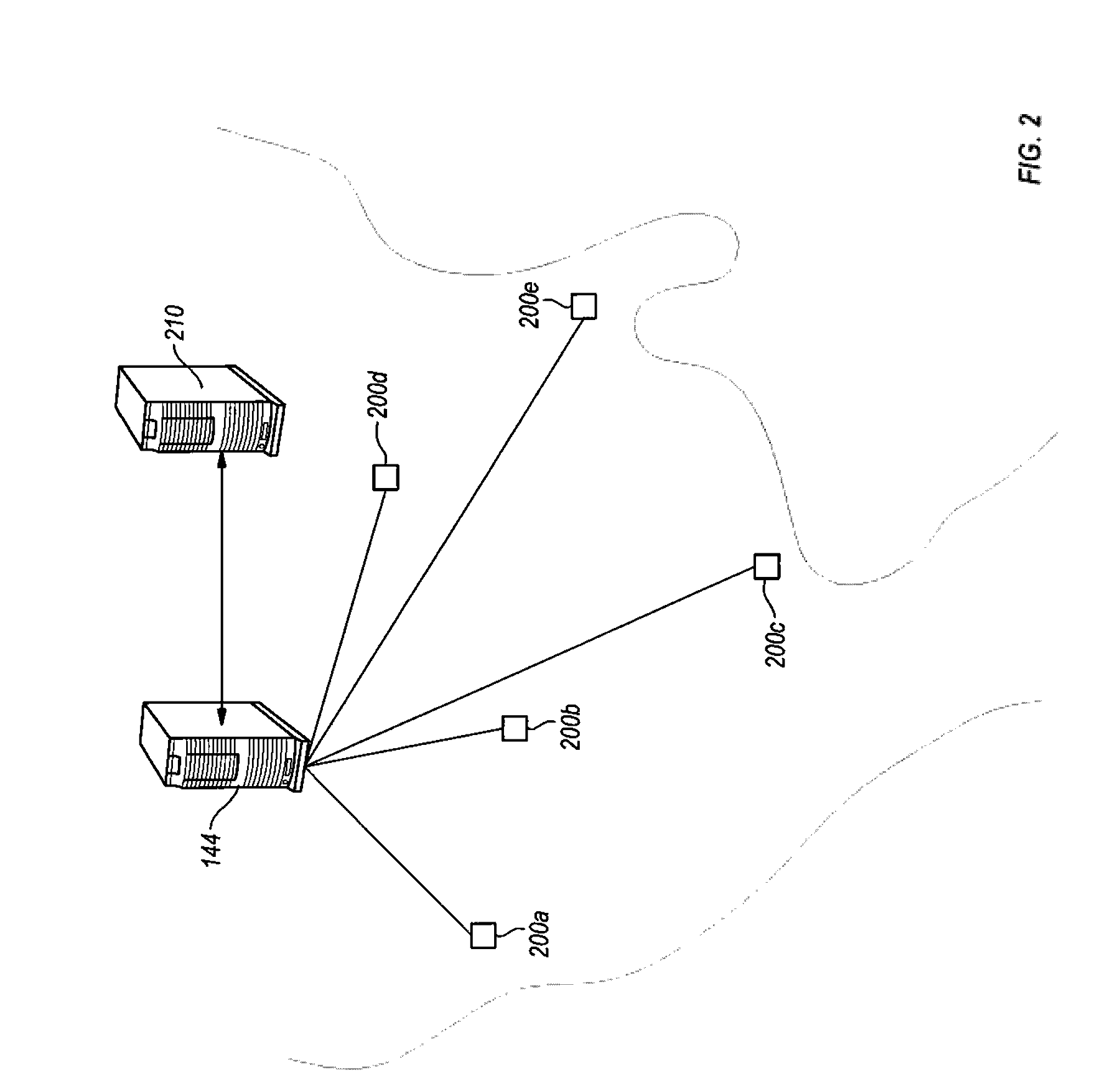

Integrated and intelligent paint management

ActiveUS20160313294A1Testing/monitoring control systemsSpraying apparatusQuality controlDatabase access

Methods, systems, and computer readable-medium with instructions for receiving data and providing calculated adjustments to a paint application process can comprise receiving at the server a first operating parameter associated with a first paint processing machine at a first painting facility. The method can also comprise receiving at the server a first quality control measurement from an analysis of a finished first paint product. Additionally, the method can comprise accessing from a database a set of historical operating parameters associated with the first painting processing machine. Further, the method can comprise automatically identifying a deficiency in the finished first paint product based upon the first quality control measurement. Further still, the method can comprise transmitting to a mobile computing device screen a proposed adjustment to the first operating parameter that will correct the deficiency.

Owner:PPG IND OHIO INC

Method for recycling waste paint slag of water-soluble paint

The invention discloses a method for recycling waste paint slag of water-soluble paint. The method comprises the following steps of: (1) collecting a mixed paint slag solution, adjusting the pH value to be 3-5, standing for 12-24 hours, filtering and taking filter residue, adjusting the pH value of the filter residue to be 8-11, standing for 2-3 hours, filtering and collecting filtrate and filter residue respectively, drying the filter residue to obtain recycled pigment, and concentrating the filtrate to obtain a recycled resin solution; and (2) compounding the recycled pigment and the recycled resin solution with a dispersing agent, grinding resin, a water-soluble alcohol solvent, deionized water, a defoaming agent, a thickening agent and a pH regulator to obtain regenerated water-soluble paint. According to the method disclosed by the invention, pigment particles and resin which are dispersed into an emulsion system are settled by a demulsification method by adjusting the pH value, and the resin is separated from the pigment particles from the sediment by utilizing the alkali solubility characteristic of the resin, so that the pigment particles and the resin component are recycled, and the recycled pigment particles and the recycled resin component are further applied to production of water-soluble paint products with the same physicochemical properties and application performance.

Owner:YONGKANG HONGYI TRADE

Multi-colored texture paint

Owner:RUST OLEUM CORP

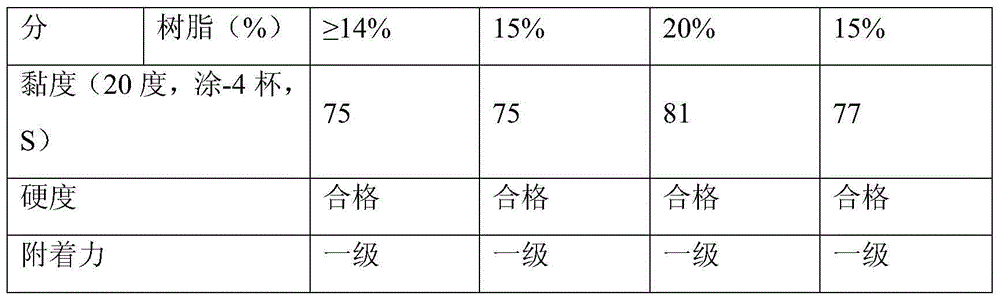

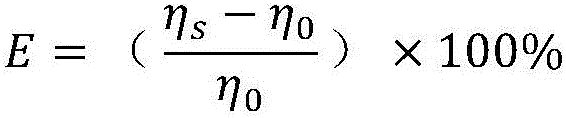

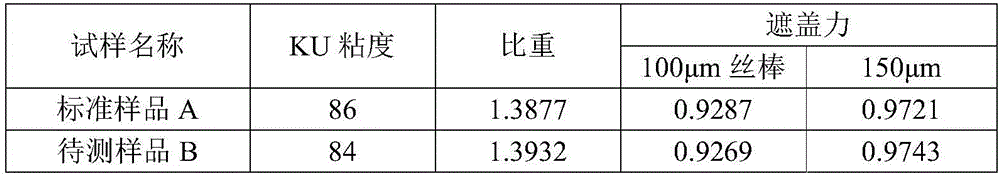

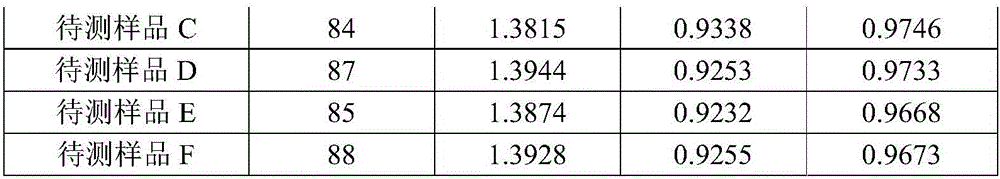

Method measuring inter-batch stability of latex paint by using rotational rheometer

ActiveCN105758766AQuality improvementReaction feeding accuracyFlow propertiesPaint productViscosity measurement

The invention discloses a method measuring inter-batch stability of latex paint by using a rotational rheometer, comprising the following steps: (1), providing the rotational rheometer, a standard latex paint sample and a latex paint sample to be tested; (2), measuring viscosity of the standard latex paint sample at a preset shearing rate by using the rotational rheometer; (3), preparing the homogenously disposed latex paint sample to be detected; (4), measuring viscosity of the latex paint sample to be detected, at a preset shearing rate by using the rotational rheometer; (5), comparing the viscosity measurement of the latex paint sample to be detected with that of the standard latex paint sample, and calculating a deviation of the latex paint sample to be detected with respect to the standard latex paint sample so as to evaluate production stability of sample latex paint.The method enables feeding accuracy in the production process of latex paint products to be accurately reflected, thus improving total quality of paint production.

Owner:LANGFANG NIPPON PAINT

Thermal conductive insulation paint and preparation method thereof

Disclosed are thermal conductive insulation paint and a preparation method thereof. The thermal conductive insulation paint is used for solving the problem that the thermal conductive property and the insulating property of existing high-power electronic components are dissatisfactory. The thermal conductive insulation paint comprises, by mass, 40-60% of epoxy-modified organic silicone resin wherein a curing agent accounts for 3-6% of the total mass of the epoxy-modified organic silicone resin, 15%-25% of silicon carbide, 5-10% of composite fire retardant, 3-8% of titanium dioxide, 5-15% of boron nitride and 1-3% of auxiliary agents. The preparation method comprises: drying the silicon carbide, the composite fire retardant, the titanium dioxide and the boron nitride in a drying oven with the mass ratio; adding the composite fire retardant, the titanium dioxide, the silicon carbide, the boron nitride and the auxiliary agent to the epoxy-modified organic silicone resin; mixing the mixture uniformly by a high-speed ball milling method and to obtain a paint product with the thermal conduction coefficient being high and the insulation and medium-resistance performance being excellent. The preparation method is simple and reasonable and is easy to carry out. The paint can be widely applied to various electronic devices with the temperature ranging from -55 DEG C to 300 DEG C.

Owner:TIANJIN DYLAN POWER TECH +1

Silicon-fluorin acrylic acid ternary polymerization latex and method for preparation thereof

The present invention is one kind of ternary silicofluoroacrylic acid copolymer emulsion and its preparation process. Organic fluororic pre-polymer is emulsified and activated to prepare seed emulsion, and organic silicon compound and acrylic ester monomer are then added to perform copolymerization to obtain the ternary silicofluoroacrylic acid copolymer emulsion. The present invention has excellent weather resistance, durability, water resistance and antifouling property, and may be used as paint directly or as intermediate product for compounding other paint product.

Owner:曹晓利

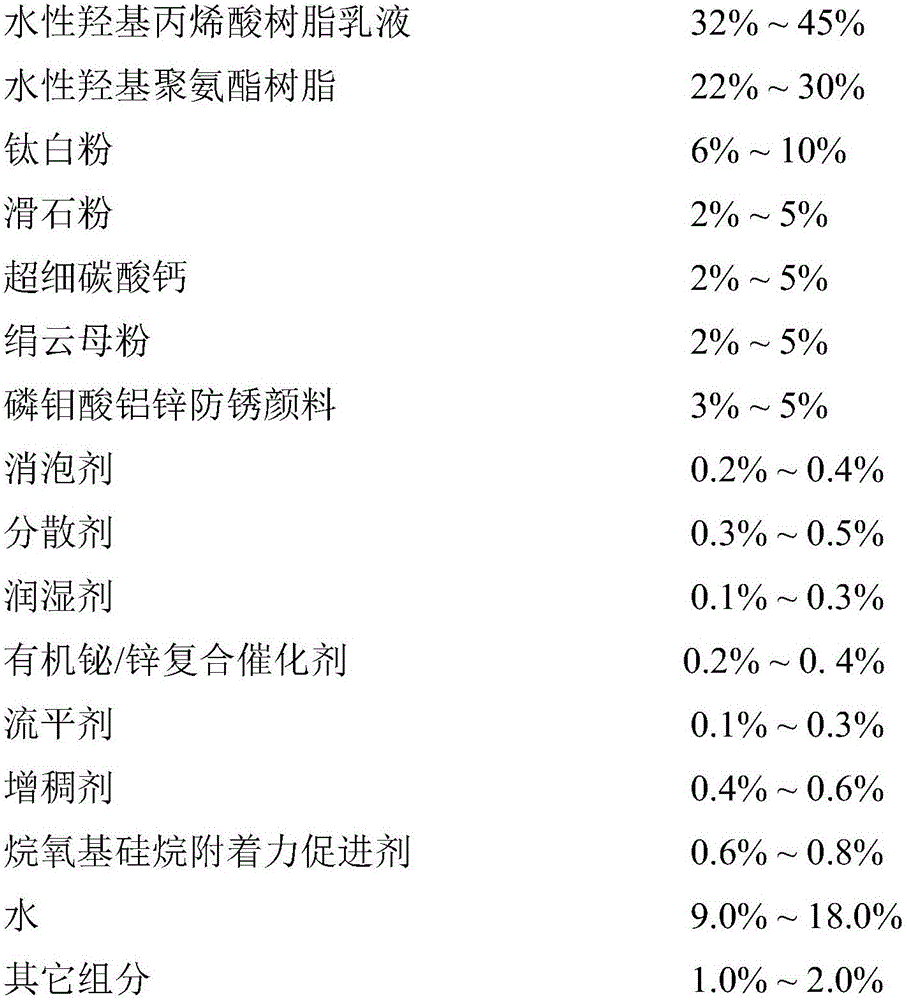

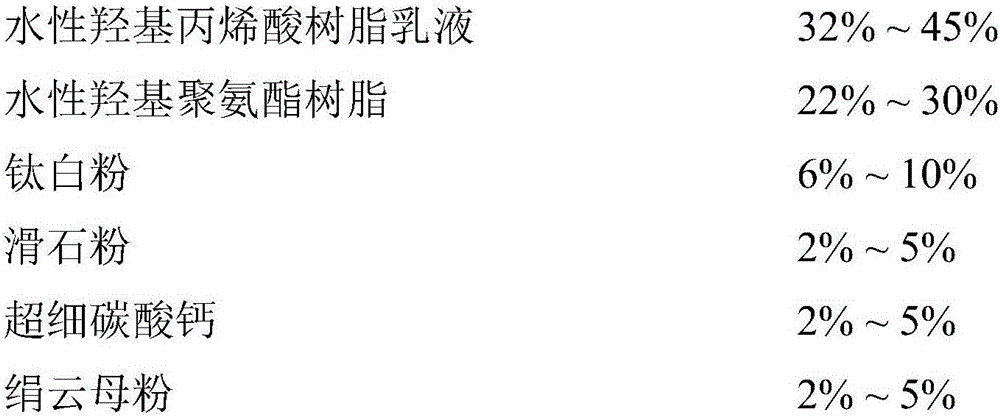

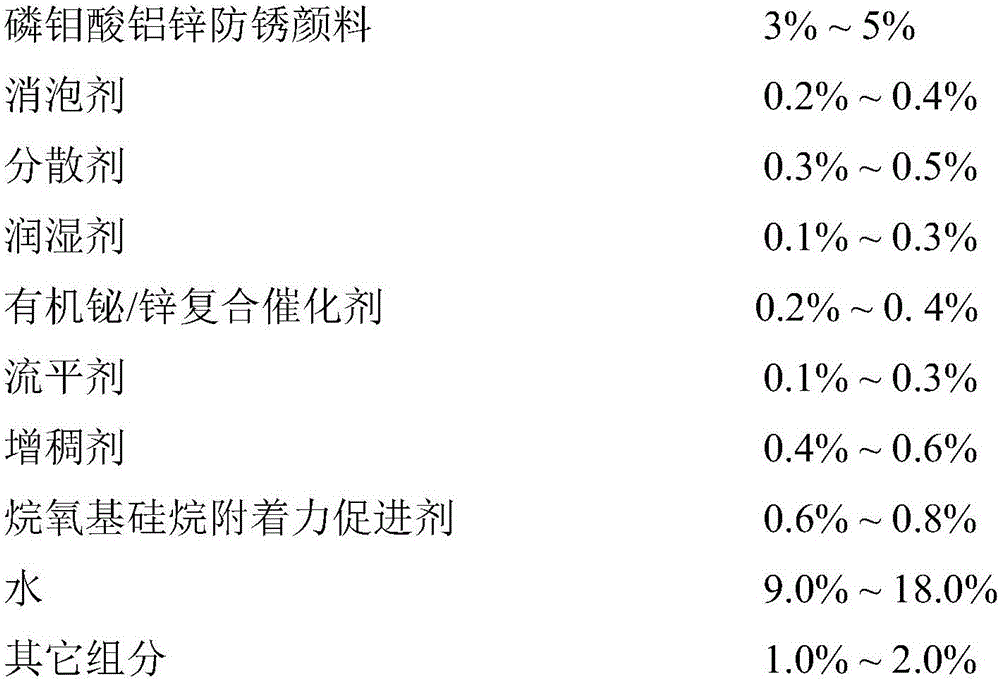

Two-component waterborne polyurethane industrial paint with excellent physical performance and preparation method thereof

InactiveCN106497377AImprove scratch resistanceStrong paint film adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsEmulsionAcrylic resin

The invention provides a two-component waterborne polyurethane industrial paint with the excellent physical performance. According to the industrial paint, mixed hydroxyl resin of waterborne acrylic resin emulsion and waterborne polyurethane resin is adopted as a main film forming agent, an environment-friendly organic bismuth and organic zinc composite catalyst and other auxiliaries are adopted, a sulfonate modification HDI trimer is adopted as a curing agent, uniform dispersion can be achieved without hydrotropy agents, an obtained paint film is excellent in hardness and scratch resistance, and the ultra-strong adhesive force and impact resistance are achieved. The two-component waterborne polyurethane industrial paint is a quick-drying waterborne two-component polyurethane coating, the drying speed is increased by three times compared with the drying speed of general industrial paint products, the outstanding environment-friendly advantage is achieved, and TVOC can be controlled to be 65 g / L or below. The invention further provides a preparation method of the two-component waterborne polyurethane industrial paint with the excellent physical performance.

Owner:中山蓝海洋水性涂料有限公司

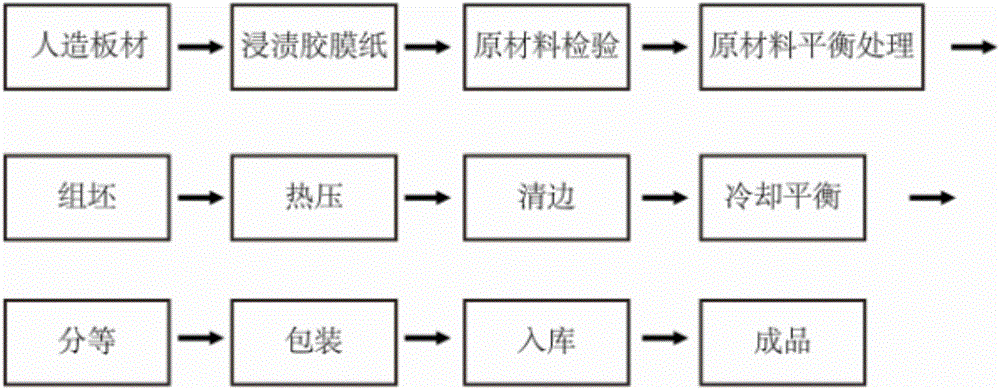

Processing method for impregnated paper surface decorated artificial board

InactiveCN106217508AImprove scratch resistanceHigh glossPaper/cardboard layered productsWood veneer joiningWear resistantPulp and paper industry

The invention relates to a melamine board and belongs to the processing field of artificial boards, and particularly relates to a processing method for an impregnated paper surface decorated artificial board. The surface decorated artificial board comprises a base plate and an impregnated paper decorative layer, wherein the surface decorated artificial board successively comprises an impregnated paper layer, the base plate and an impregnated paper layer in sequence. The bonding strength of the impregnated paper surface decorated artificial board obtained by the method provided by the invention can reach over 1.35Mpa. Compared with the surface of a conventional paint product with high brightness, the scratch resistance is effectively improved, and the glossiness can be increased by 10-20 degrees, so that the quality is effectively enhanced. Moreover, the product not only is attractive in appearance and wear-resistant and free of deformation, but also is simple in structure, easy to manufacture, low in cost, formaldehyde-free and suitable for interior wall decoration and outside surface decorative of various buildings, and meanwhile, the impregnated paper surface decorated artificial board can be applied to producing and manufacturing various frames, mobile houses, refuse channels and the like as alternative products of materials such as timbers.

Owner:KUNMING ZHENCHU IND TRADE

Water-based normal-temperature-curable peelable paint for safekeeping and protection of instrument and equipment

InactiveCN102816508AWide variety of sourcesWith cleaner productionPolyurea/polyurethane coatingsWater basedEngineering

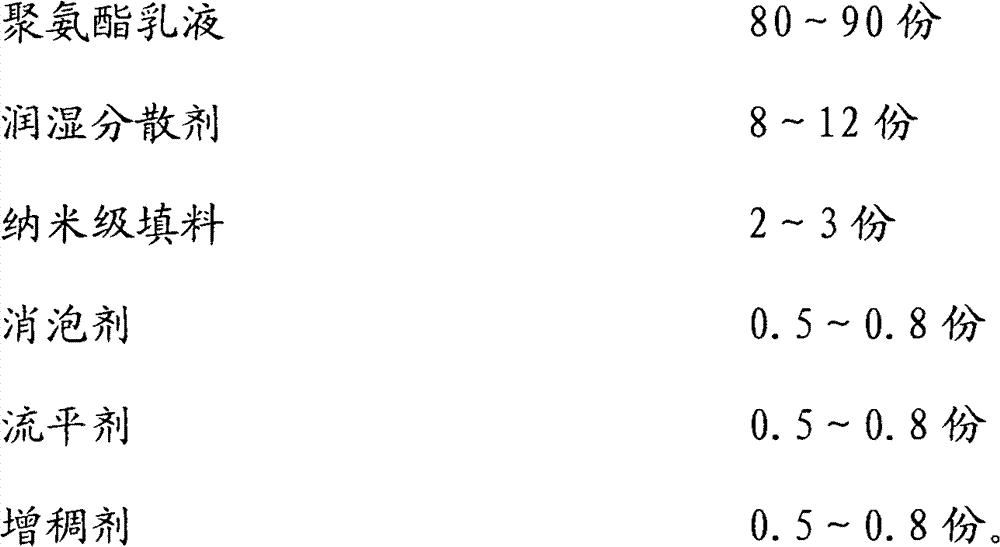

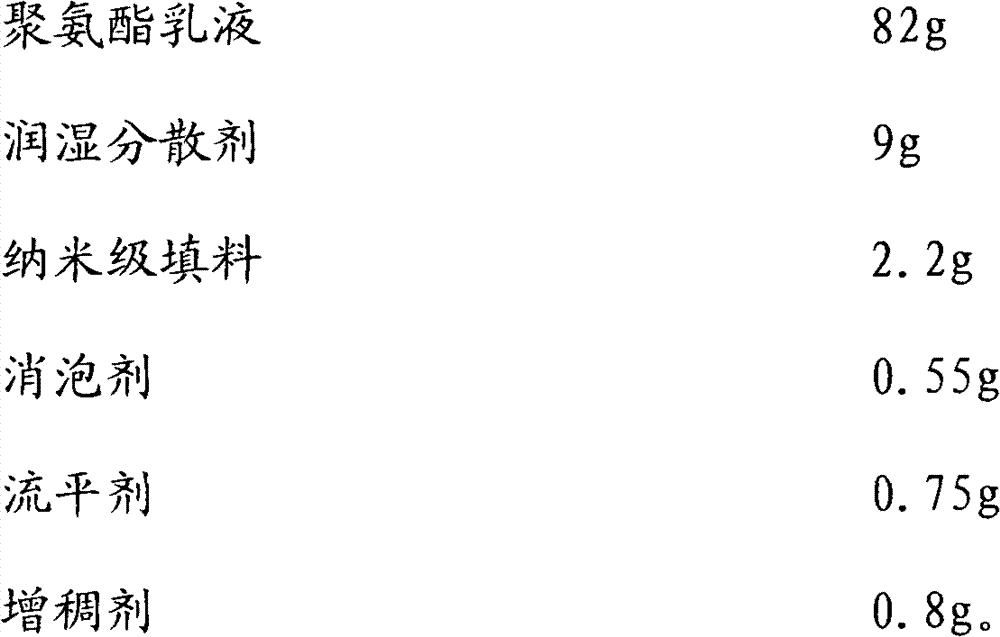

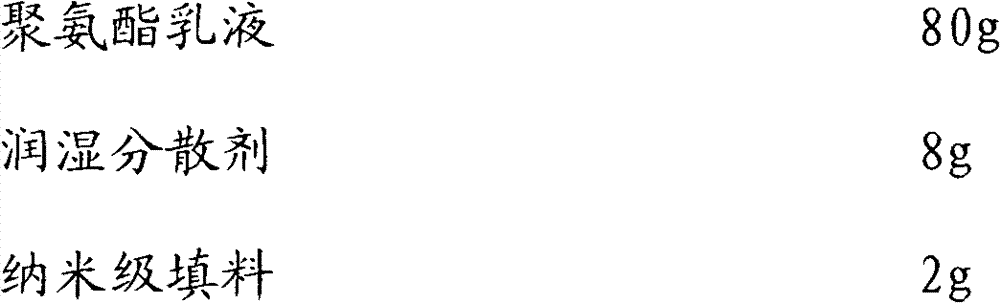

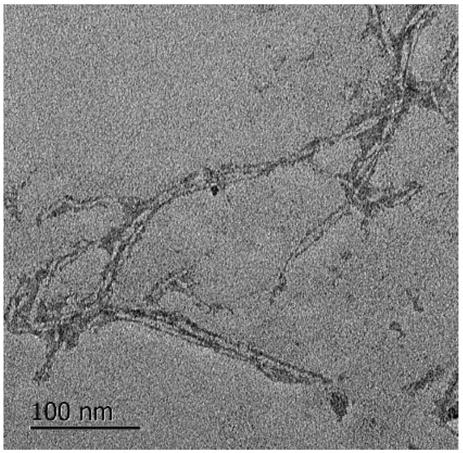

The invention discloses a water-based normal-temperature-curable peelable paint which is applicable to the safekeeping and protection of instrument and equipment. The water-based normal-temperature-curable peelable paint for the safekeeping and protection of instrument and equipment comprises the following raw materials in parts by weight: 80-90 parts of polyurethane emulsion, 8-12 parts of wetting dispersant, 2-3 parts of nano filler, 0.5-0.8 part of defoaming agent, 0.5-0.8 part of leveling agent and 0.5-0.8 part of thickener. The water-based normal-temperature-curable peelable paint product disclosed by the invention fundamentally contains no organic solvent component, is environment-friendly and pollution-free, is short in film-forming time and has good leveling property. The product is convenient to construct, the formed film is uniform, the bonding force exerted on the basal body is moderate, and the paint can be peeled easily. The detection through a test shows that when the coating thickness is 0.13-0.14mm (coated twice), the average tensile strength of the coating is up to 9.51Mpa, the average elongation at break is up to 274.54%, and the peeling property is the best.

Owner:合肥华清高科表面技术股份有限公司

Nanometer cellulose functional doped modified paint and preparation method thereof

ActiveCN109054584AImprove toughnessHigh hardnessAntifouling/underwater paintsPaints with biocidesWater basedNanometer size

The invention discloses nanometer cellulose functional doped modified paint and a preparation method thereof. According to the nanometer cellulose functional doped modified paint and the preparation method thereof, the nanometer cellulose functional doped modified paint with one-dimensional nanometer dimensions (5-100 nm) is adopted for forming a compound system composed of a soft resin macromolecular chain structure and a hard nanometer cellulose structure with an ultra-high length-diameter ratio, surface functionalization of nanometer cellulose, a principle of the nanometer cellulose of interface structure toughening and the advantage that the one-dimensional nanometer cellulose and a macromolecular chain form a cross net are used, the tenacity, the impact resistance, the hardness and the surface strength of a paint surface layer are greatly improved, and the defects of cracks, chaps and the like, of a pant surface, caused by high or low temperature in a use process of the paint subjected to curing are overcome. The preparation method of the nanometer cellulose functional doped modified paint can be suitable for water-based paint or oil paint, and a paint product which is modified and prepared through a technology has excellent tenacity, hardness and surface strength, is low in cost, and can be applied in the field of multiple materials of woodware, metal, automobiles, plastic, glass, building surfaces and the like on a large scale.

Owner:清远粤绿新材料技术有限公司

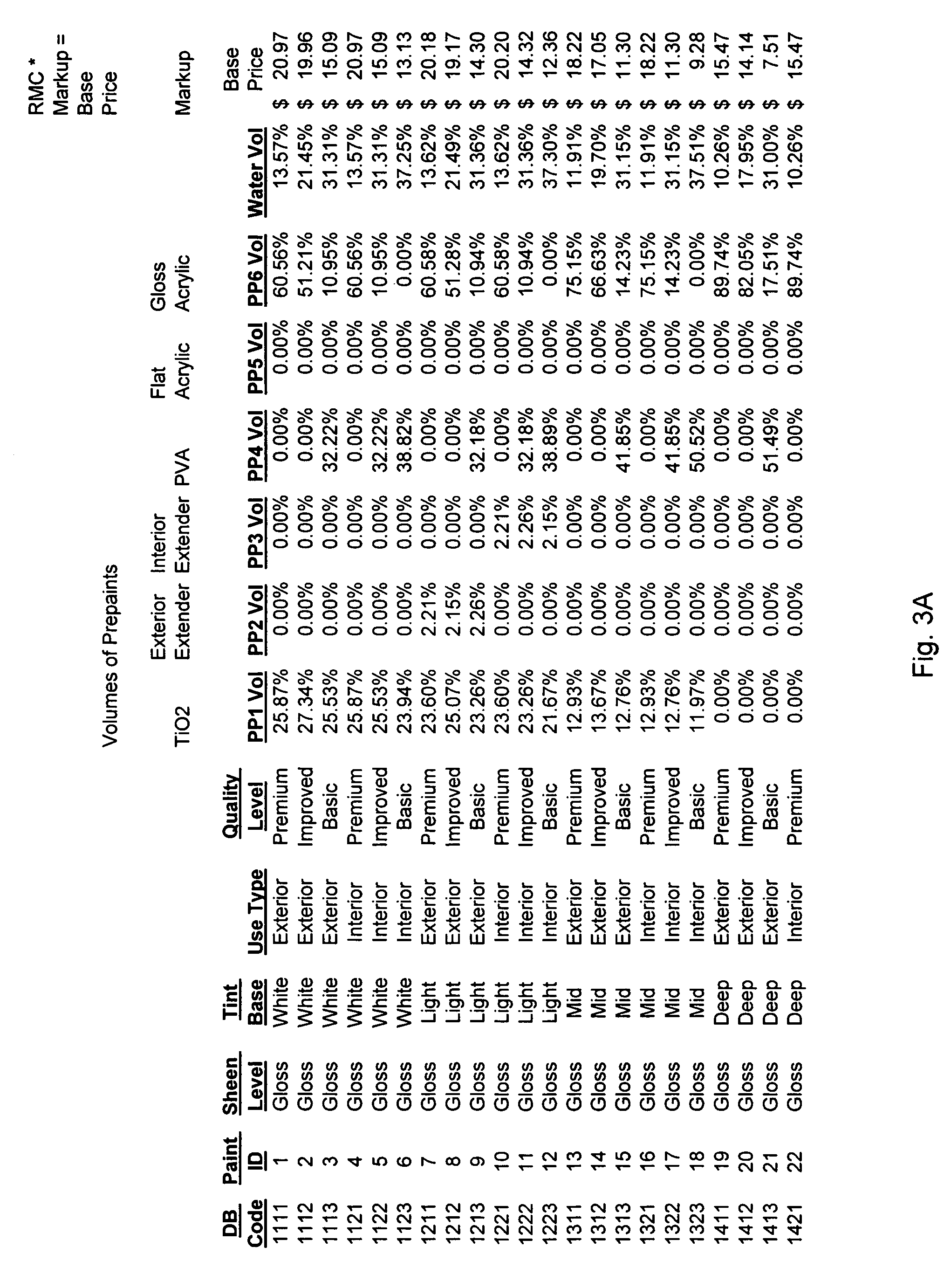

Distributed paint manufacturing system

InactiveUS7612129B2Less amountViscosity fluctuations are smallPigmenting treatmentTransportation and packagingHybrid systemUser input

A paint manufacturing method includes receiving each of a group of fluid prepaints at different inputs of a fluid component mixing system, determining at a computer system a first fluid prepaint ratio, and mixing the fluid prepaints in accordance with the first ratio to form a base paint at an output of the mixing system. A paint manufacturing system includes a computer-controlled prepaint mixing system. The prepaint mixing system includes multiple fluid inputs providing for computer-controllable flow of prepaints into the mixing system. The computer system includes a memory storing software instructions that configured the computer system to receive user input selecting a base paint to be produced, determine a ratio of fluid prepaints needed to produce the base paint, and regulate each fluid flow control to establish, in the determined ratio, a flow of fluid prepaints entering the fluid mixing system. A paint manufacturing system includes multiple paint manufacturing sites that can each produce paint products. Each manufacturing site includes a site control computer to control a paint manufacturing process at the site and the system also includes a coordinating computer system that can exchange manufacturing operations data with each of the site control computers.

Owner:ROHM & HAAS CO

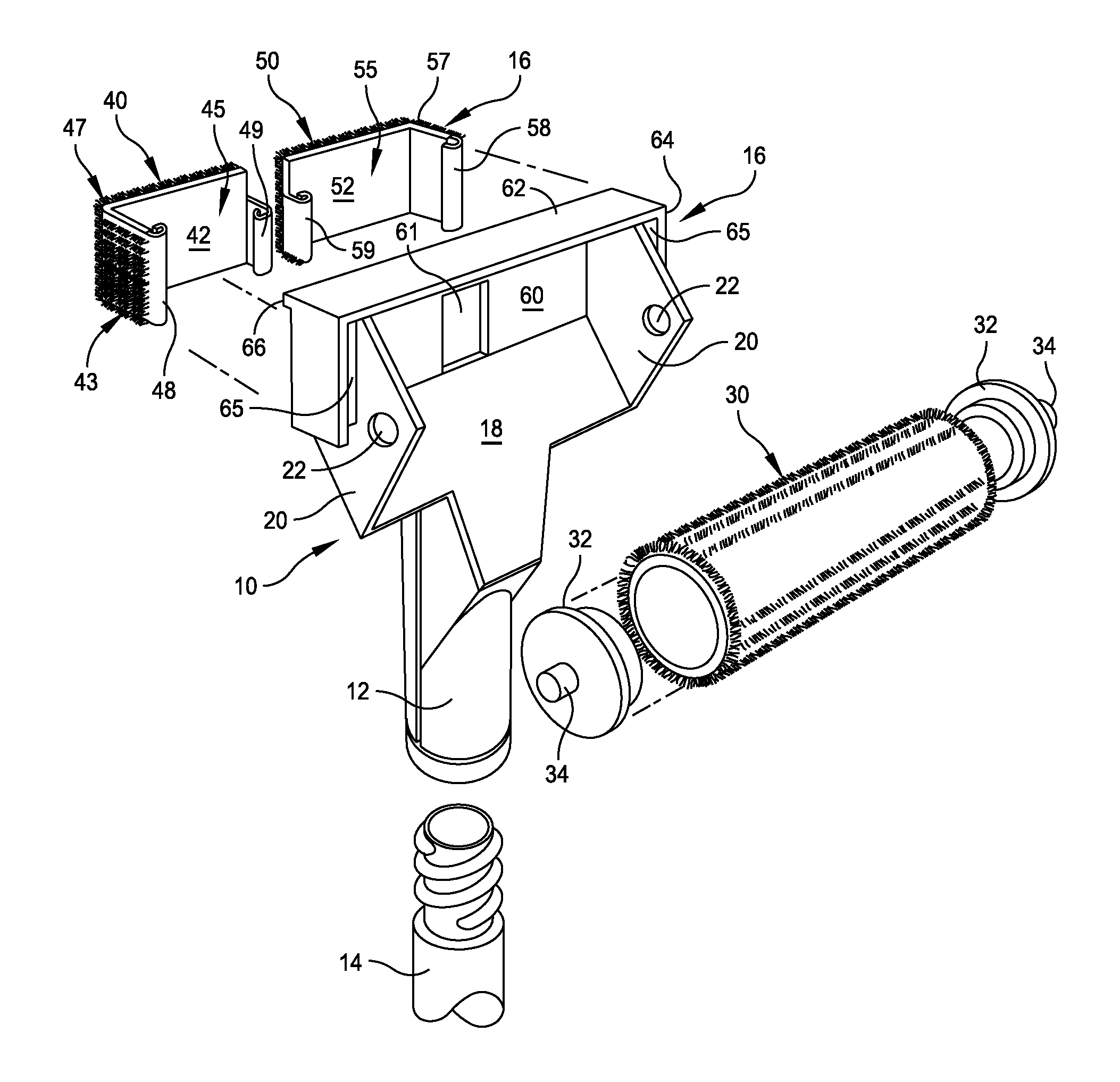

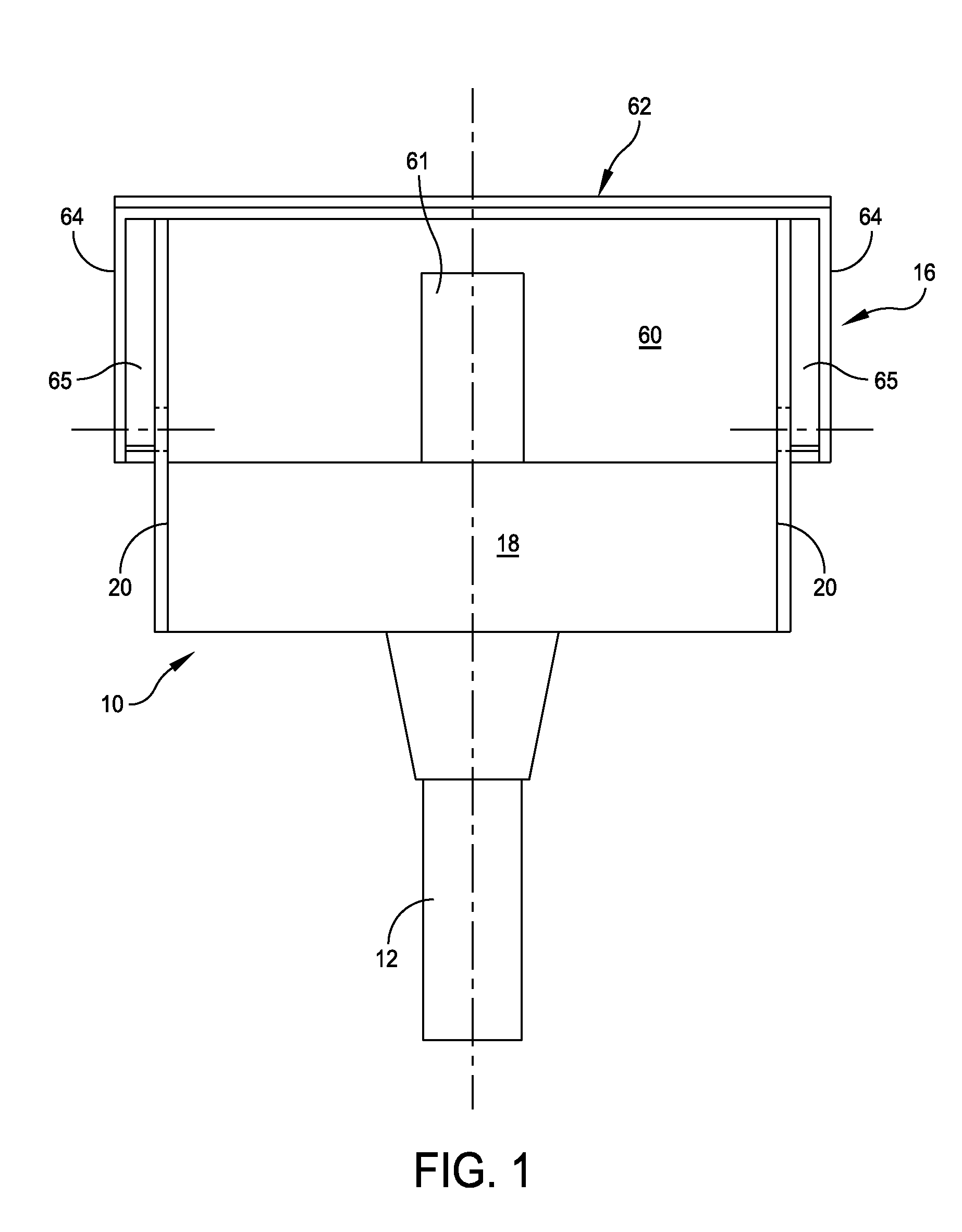

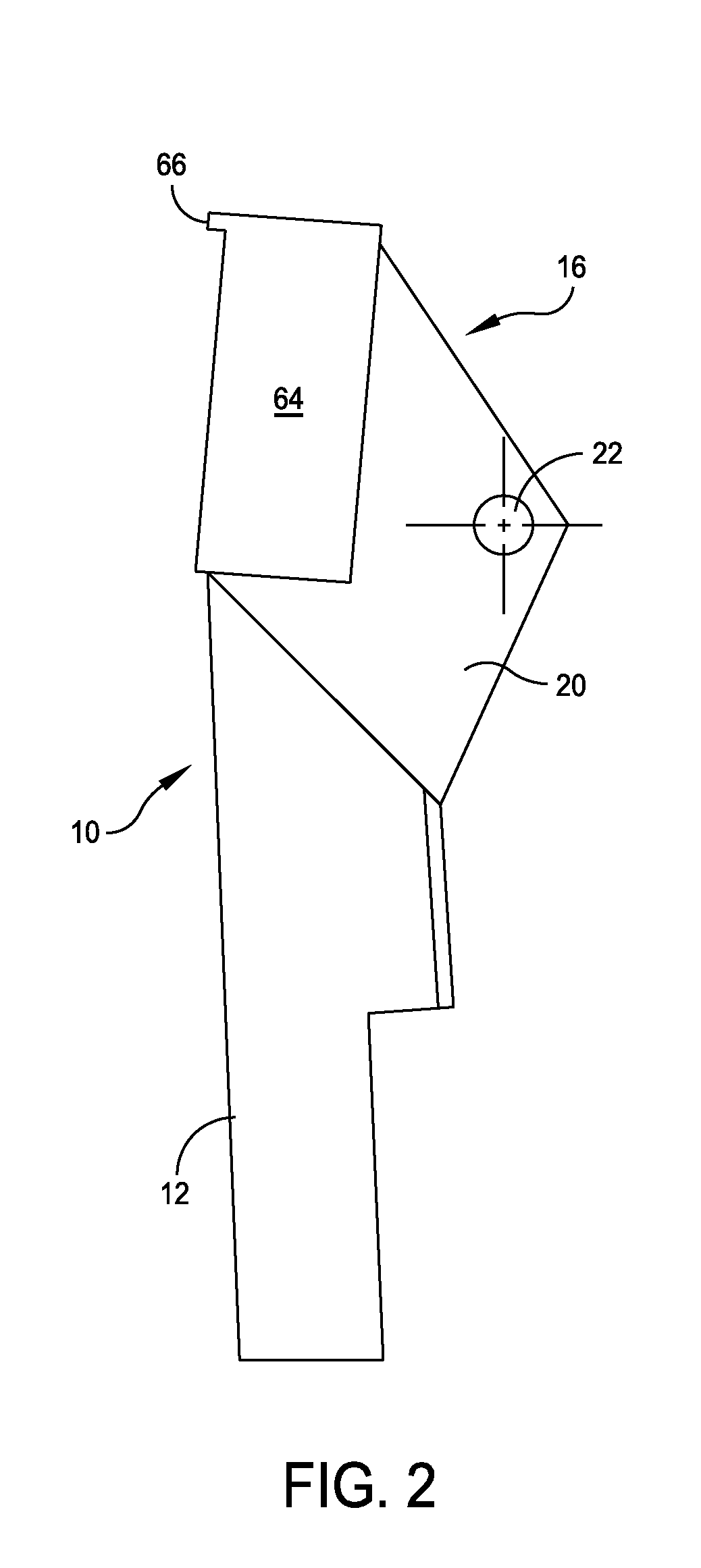

Painting device

A painting device for applying a paint product and that includes a frame with a handle end and a support end and that has one and another sides. The one side of the support end of the frame includes spaced apart flanges that retain therebetween a paint roller and the another side of the support end of the frame includes a wall member and opposed end wall surfaces that together retain a paint pad device.

Owner:MORRIS LAMONT C

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com