Processing method for impregnated paper surface decorated artificial board

A technology of impregnating adhesive film paper and a processing method, which is applied in the direction of manufacturing tools, wood processing utensils, and the joining of wooden veneers, can solve problems such as affecting human health, harm, irritating odor, etc. Easy to manufacture, no formaldehyde release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

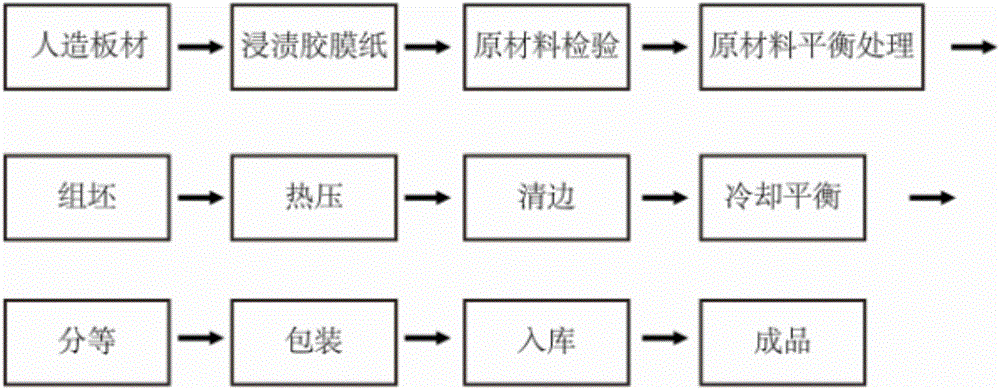

Image

Examples

Embodiment 1

[0026] 1. Wood-based panel processing: Take the wood-based panel and grind the surface. The grinding process uses a 200-mesh grinding wheel, and controls the grinding speed to be 45m / min, and the motor speed of the grinder is 1500r / s, for standby;

[0027] 2. Selection of impregnated film paper: the weight is 125g / m 2 impregnated film paper;

[0028] 3. Raw material inspection and balance treatment: in parts by weight, take 75 parts of melamine resin with a concentration of 50%, and 5 parts of magnesium oxide, mix them evenly, and perform balance treatment to obtain a balanced treatment glue;

[0029] 4. Blank assembly: according to the order of impregnated film paper, artificial board and impregnated film paper, the blanks are assembled;

[0030] 5. Hot pressing: Lay the preformed man-made panels and impregnated film paper on the lower steel formwork of each layer of the press through the board feeding device; take the impregnated film paper for dipping and drying treatment,...

Embodiment 2

[0035] 1. Wood-based panel processing: Take the wood-based panel and grind the surface. The grinding process uses a 300-mesh grinding wheel, and the speed of grinding the board is controlled to be 50m / min, and the motor speed of the grinder is 2000r / s. Reserve;

[0036] 2. Selection of impregnated film paper: the weight is 135g / m 2 impregnated film paper;

[0037] 3. Raw material inspection and balance treatment: in parts by weight, take 85 parts of melamine resin with a concentration of 54%, 10 parts of magnesium oxide, mix evenly, and perform balance treatment to obtain the glue of balance treatment;

[0038] 4. Blank assembly: according to the order of impregnated film paper, artificial board and impregnated film paper, the blanks are assembled;

[0039] 5. Hot pressing: Lay the preformed man-made panels and impregnated film paper on the lower steel formwork of each layer of the press through the board feeding device; take the impregnated film paper for dipping and drying ...

Embodiment 3

[0044] 1. Wood-based panel processing: Take the wood-based panel and grind its surface. The grinding process uses a 200-mesh grinding wheel, and controls the grinding speed to be 47m / min, and the motor speed of the grinder is 1800r / s, for standby;

[0045] 2. Selection of impregnated film paper: the weight is 130g / m 2 impregnated film paper;

[0046] 3. Raw material inspection and balance treatment: in parts by weight, take 80 parts of melamine resin with a concentration of 50%, and 8 parts of magnesium oxide, mix them evenly, and perform balance treatment to obtain a balanced treatment glue;

[0047] 4. Blank assembly: according to the order of impregnated film paper, artificial board and impregnated film paper, the blanks are assembled;

[0048]5. Hot pressing: Lay the preformed man-made panels and impregnated film paper on the lower steel formwork of each layer of the press through the board feeding device; take the impregnated film paper for dipping and drying treatment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com