Patents

Literature

3057 results about "Adhesion force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Adhesion is the attraction force between molecules of different kinds. In other words, adhesion forces occur between different molecules. Adhesion can be defined as the preference to stick to other types of molecules. Adhesion forces include electrostatic forces between two different molecules.

Climbing with dry adhesives

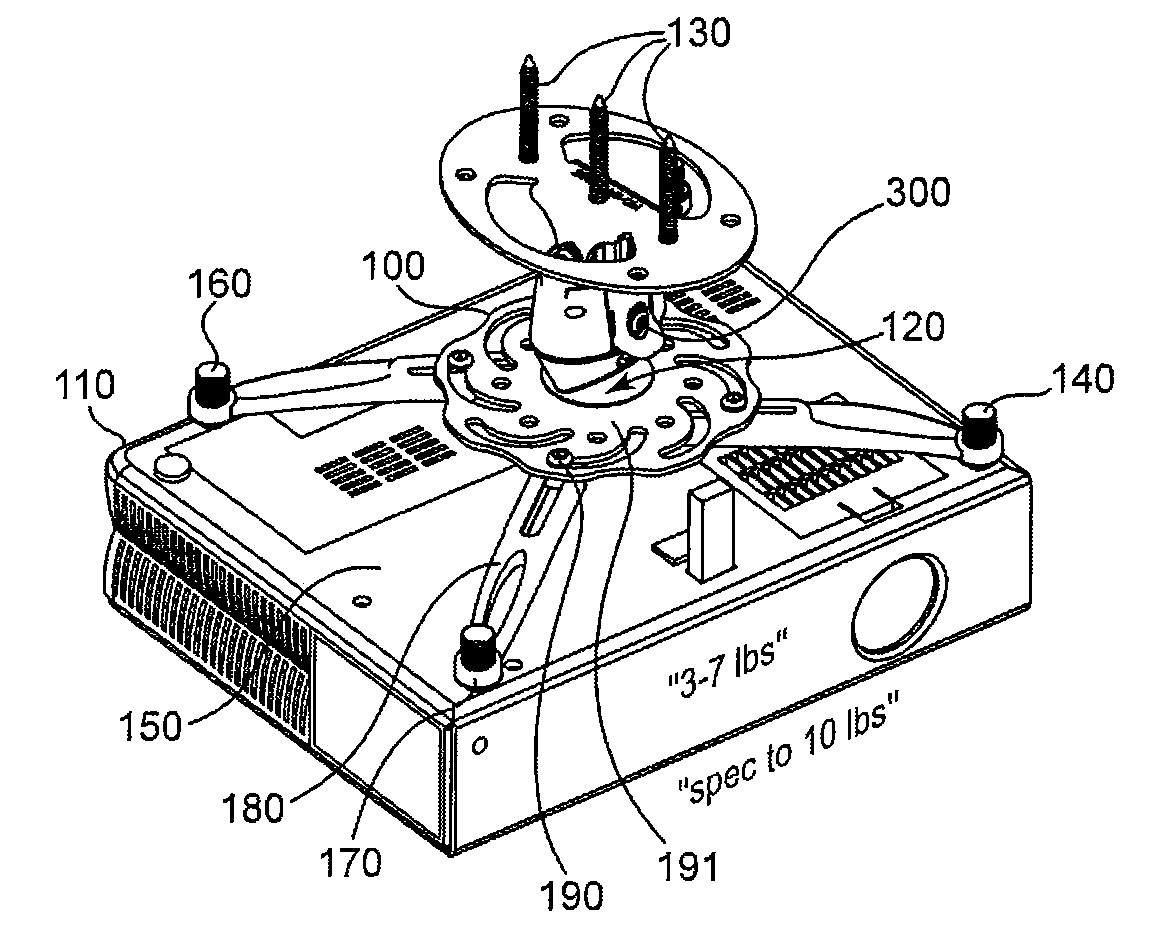

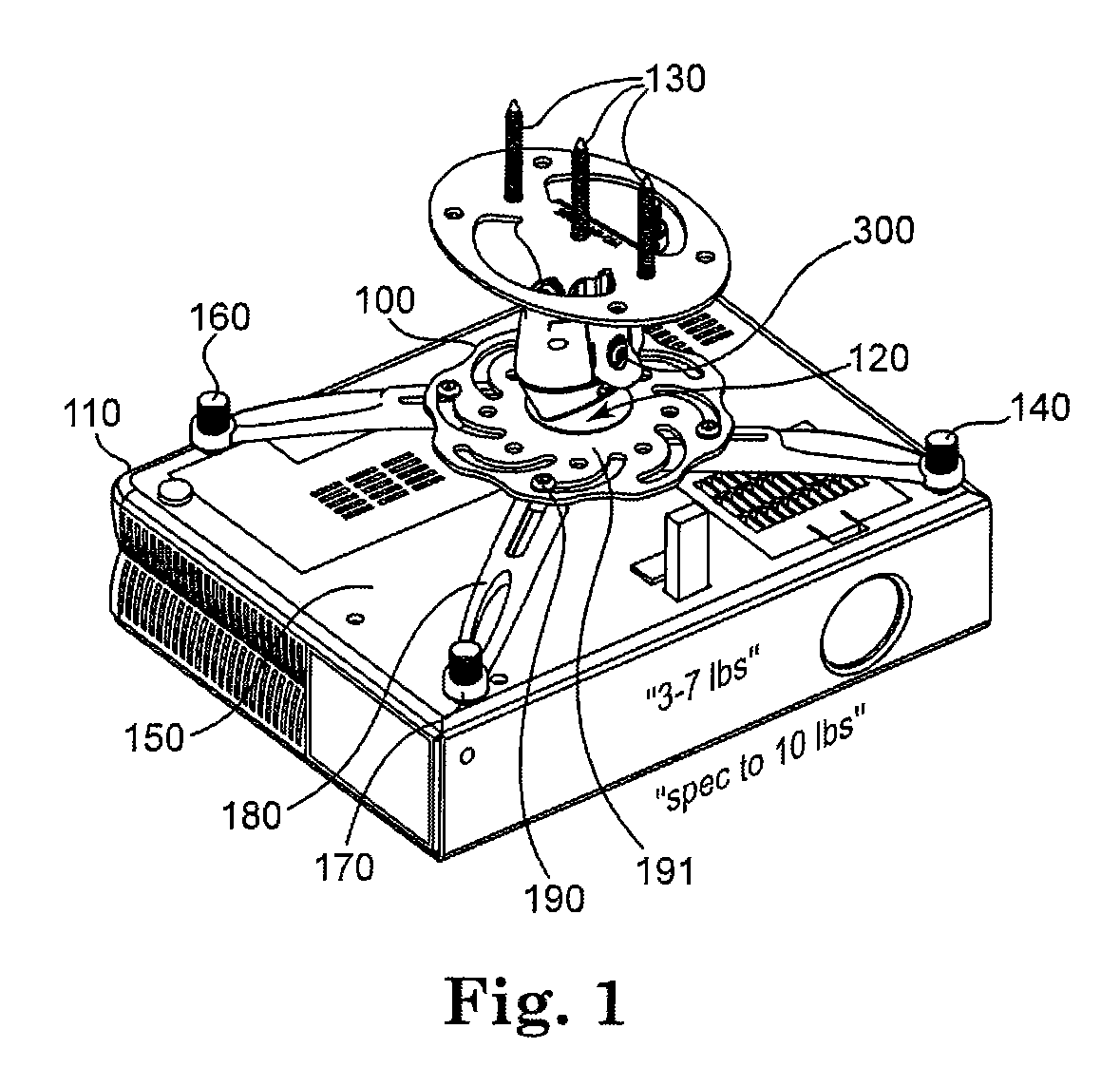

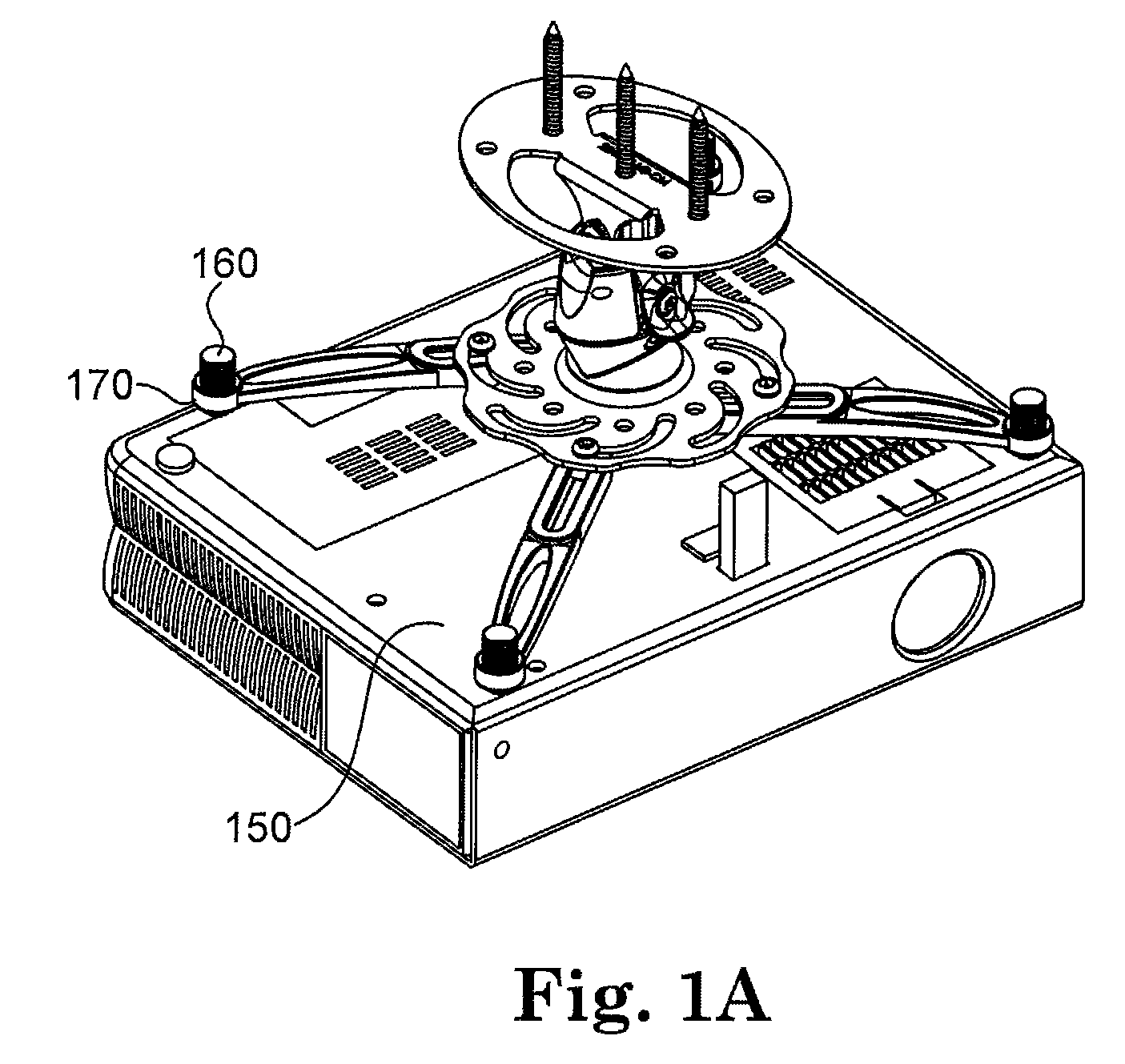

ActiveUS20070289786A1Facilitate disengagementSolve the lack of adhesionLifting devicesVehiclesStress distributionMicrometer

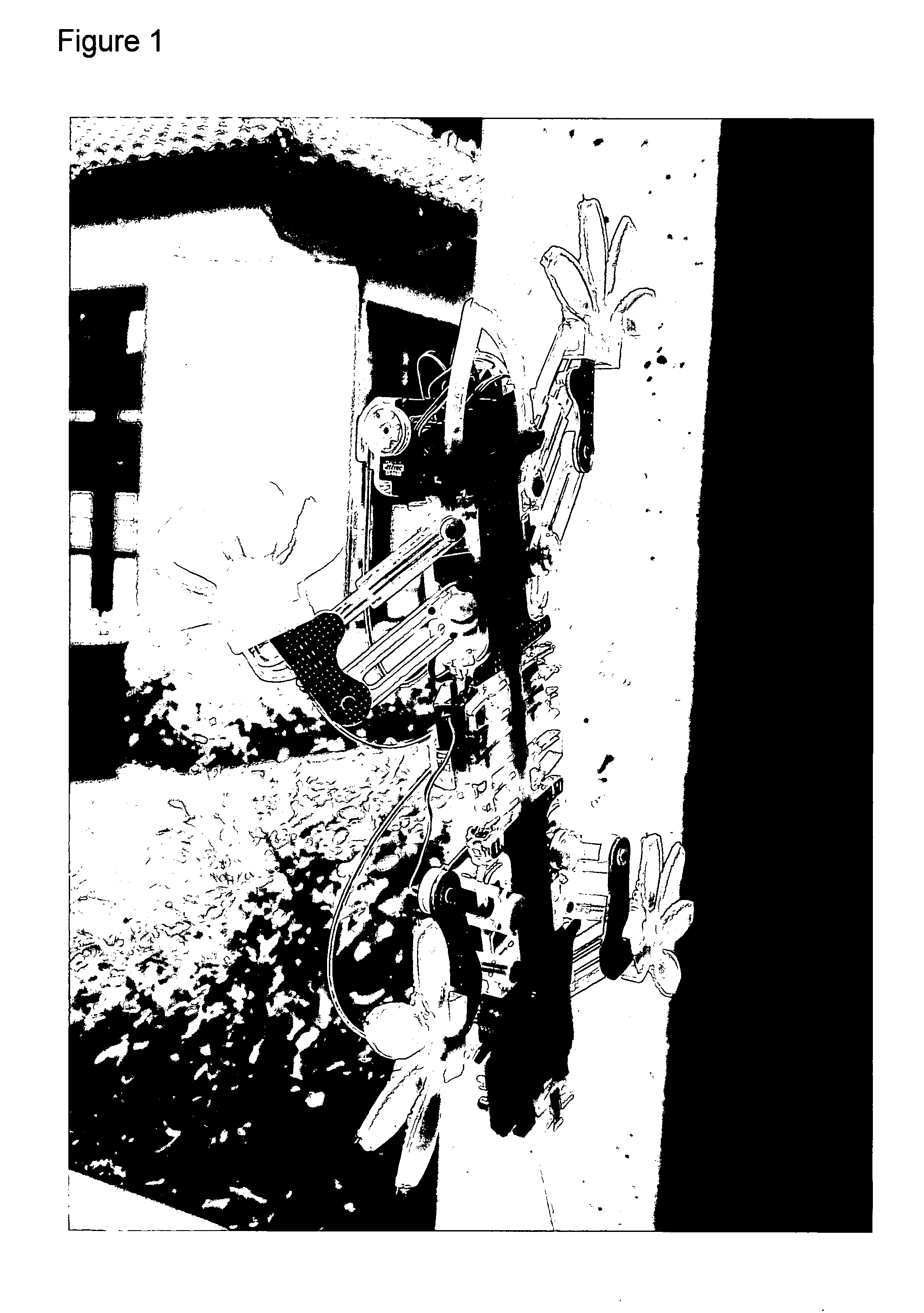

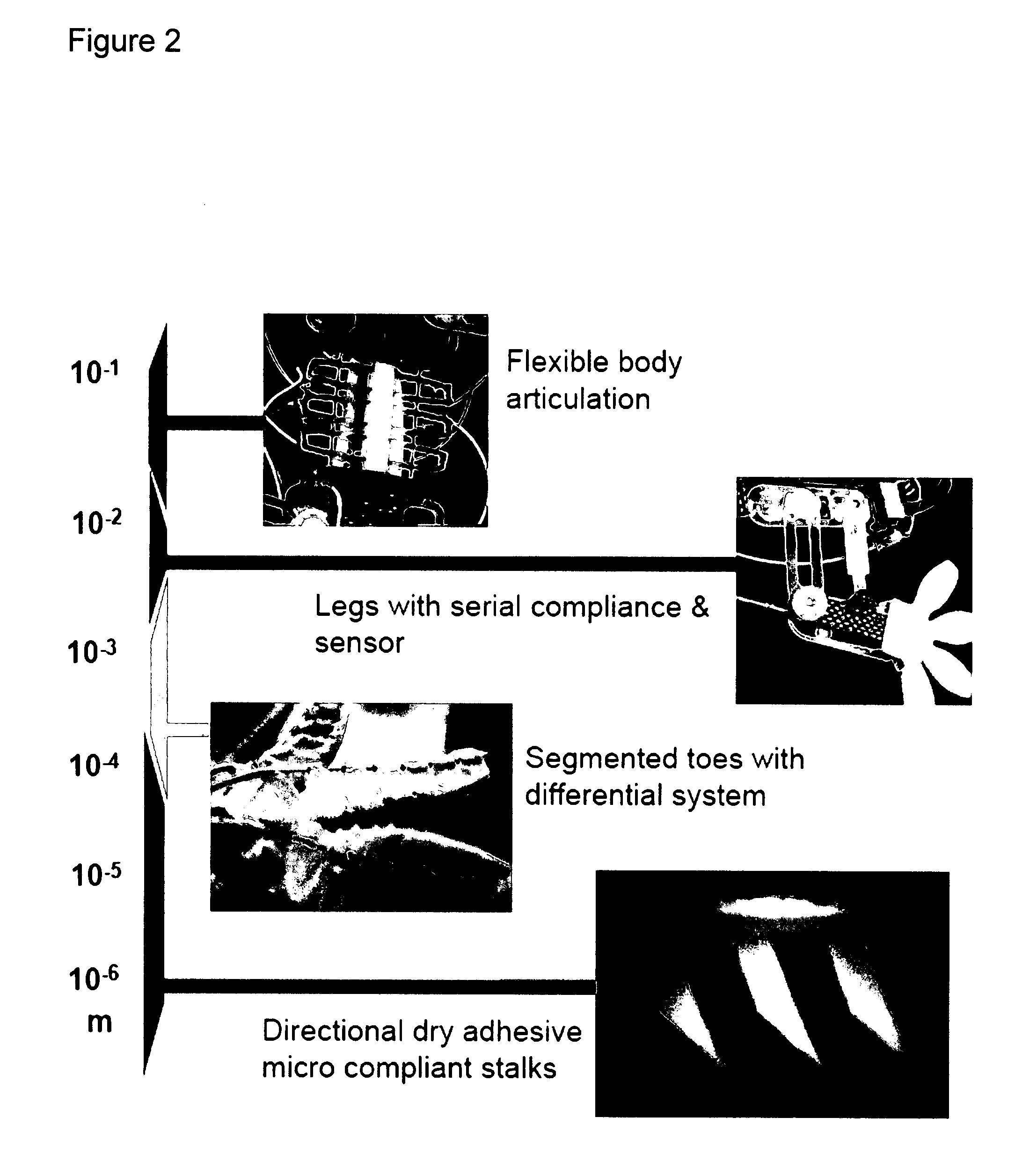

A bio-inspired device is provided designed to scale smooth vertical surfaces using anisotropic frictional materials. The device draws its inspiration from geckos and other climbing lizards and employs similar compliance and force control strategies to climb (or hang onto) smooth vertical surfaces including glass, tile and plastic panels. Foremost among the design features embodied in the device are multiple levels of compliance, at length scales ranging from centimeters to micrometers, to allow the device to conform to surfaces and maintain large real areas of contact so that adhesive forces can support it. Structures within the feet ensure even stress distributions over each toe and facilitate engagement and disengagement of the adhesive materials. A force control strategy works in conjunction with the anisotropic adhesive materials to obtain sufficient levels of friction and adhesion for climbing with low attachment and detachment forces.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Micro-nano coating material with low surface energy and preparation method thereof

ActiveCN106085070AEasy to control surface topographyEasy to control the size of the surface energyPolyurea/polyurethane coatingsPowdery paintsEtchingMicrosphere

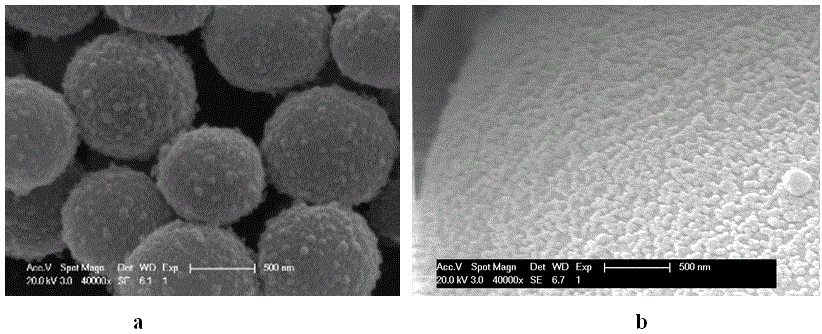

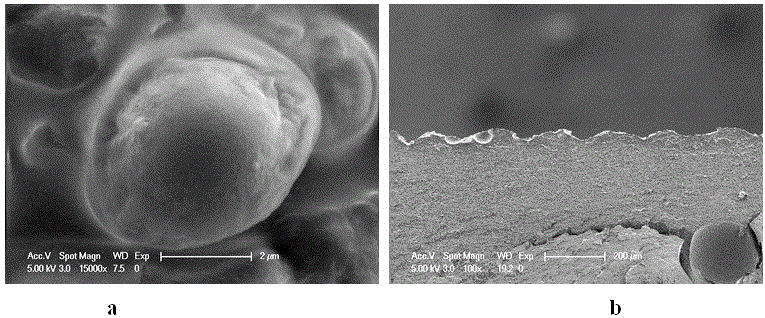

The invention belongs to the technical field of functional materials, and particularly relates to a micro-nano coating material with low surface energy and a preparation method thereof. The preparation method comprises the following steps of mixing composite microspheres with micro sodium structure and hydrophobic nature, matrix resin with contact angle more than 90 degrees with coating film, solvent, powder, and additive, and adopting a co-mixing method, an in-situ emulsion polymerizing method, an in-situ solution polymerizing method, an in-situ concentration and polymerizing method, an in-situ addition and polymerizing method and the like, so as to prepare the coating material with micro-nano structure; performing spraying, brushing, roll coating, photo-etching, 3D (three-dimensional) printing, mechanical processing and the like, drying and curing at the temperature of 0 to 1000 DEG C, and coating the coating material with micro-nano structure onto different matrix surfaces, so as to obtain the micro-nano coating material with low surface energy and groove structure. The micro-nano coating material has the advantages that the preparation technology is simple, the coating hardness is high, the water-resistant property is good, the adhesion force to different matrix surfaces is strong, and the micro-nano coating material can be used for self-cleaning, resistance-reducing, denoising, anti-icing and other functional materials.

Owner:FUDAN UNIV

Aluminum pulp composition of crystal silicon solar cell and preparation method thereof

InactiveCN101728439AEasy to printImprove adhesionFinal product manufactureNon-conductive material with dispersed conductive materialAdhesion forceAdhesive

The invention discloses an aluminum pulp composition of a crystal silicon solar cell and a preparation method thereof, wherein an aluminum pulp is prepared by the following compositions in percentage by weight: 50-85 percent of spherical aluminum powder, 2-15 percent of lead-free glass adhesive, 10-35 percent of organic carrier and 0.5-6 percent of metal / nonmetal power additive. The prepared aluminum pulp is used for a single crystal silicon solar cell, can enable warpage of a silicon wafer to be small, and aluminum films are dense and uniform, have no aluminum pills, do not bulb and have strong adhesion force and high photoelectric conversion efficiency.

Owner:LUOYANG SHENJIA ELECTRONICS CERAMICS

Hydrolysis-resistant double-component polyurethane adhesive for structure adhesion

ActiveCN102559126AImprove hydrolysis resistanceHigh bonding strengthPolyureas/polyurethane adhesivesPolyesterAdhesion force

The invention relates to a hydrolysis-resistant double-component polyurethane adhesive for structure adhesion. The hydrolysis-resistant double-component polyurethane adhesive for structure adhesion consists of a component A and a component B, wherein the component A comprises the following components in part by weight: 30 to 70 parts of polyisocyanate resin, 5 to 20 parts of plasticizing agent, 0.25 to 5 parts of thixotropic agent, 10 to 50 parts of incremental filler and 0.25 to 1 part of water-removing agent; and the component B comprises the following components in part by weight: 5 to 30 parts of polyester polyol, 5 to 30 parts of vegetable oil polyol, 5 to 30 parts of polyether polyol, 3 to 15 parts of water-absorbing filler, 1 to 10 parts of thixotropic agent, 3 to 15 parts of incremental filler, 0.1 to 10 parts of pigment, 0.1 to 5 parts of adhesion force accelerator, 0.1 to 2 parts of chain extender and 0.01 to 0.2 part of catalyst. An adhesion system improves adhesion property, solves the problem that a thermosetting composite material is subjected to surface roughening treatment before adhesion and improves the using efficiency. Aiming at the problem of poor hydrolysis resistance of a polyester type polyurethane adhesive system, the hydrolysis resistance is improved through molecule design of polyurethane soft and hard sections.

Owner:TONSAN ADHESIVES INC

High-performance jet ink

The invention relates to a high-performance jet ink. The jet ink comprises the following components by weight percent: 20-80% of solvent, 1-45% of cosolvent, 4-20% of adhesive, 0.5-20% of colorant, 0-5% of adhesion force promoter, 0.01-2% of wax powder, 0-2% of brightening agent and 0-5% of other additives. As adhesion force promoter is added in the jet ink, the adhesion performance on base materials such as glass, metal, polypropylene or polyethylene is increased. In addition, wax is added to increase wear resistance and scratch resistance, and brightening agent is added to increase the lustrousness, brilliance and definition of the ink. The product has high adhesion force, good wear resistance, high lustrousness and definition and good compatibility, thus the defects of the existing ink such as low lustrousness, poor wear resistance and low definition can be greatly improved and the jet ink has good market prospect.

Owner:王学珍

Failsafe injected adhesive joint

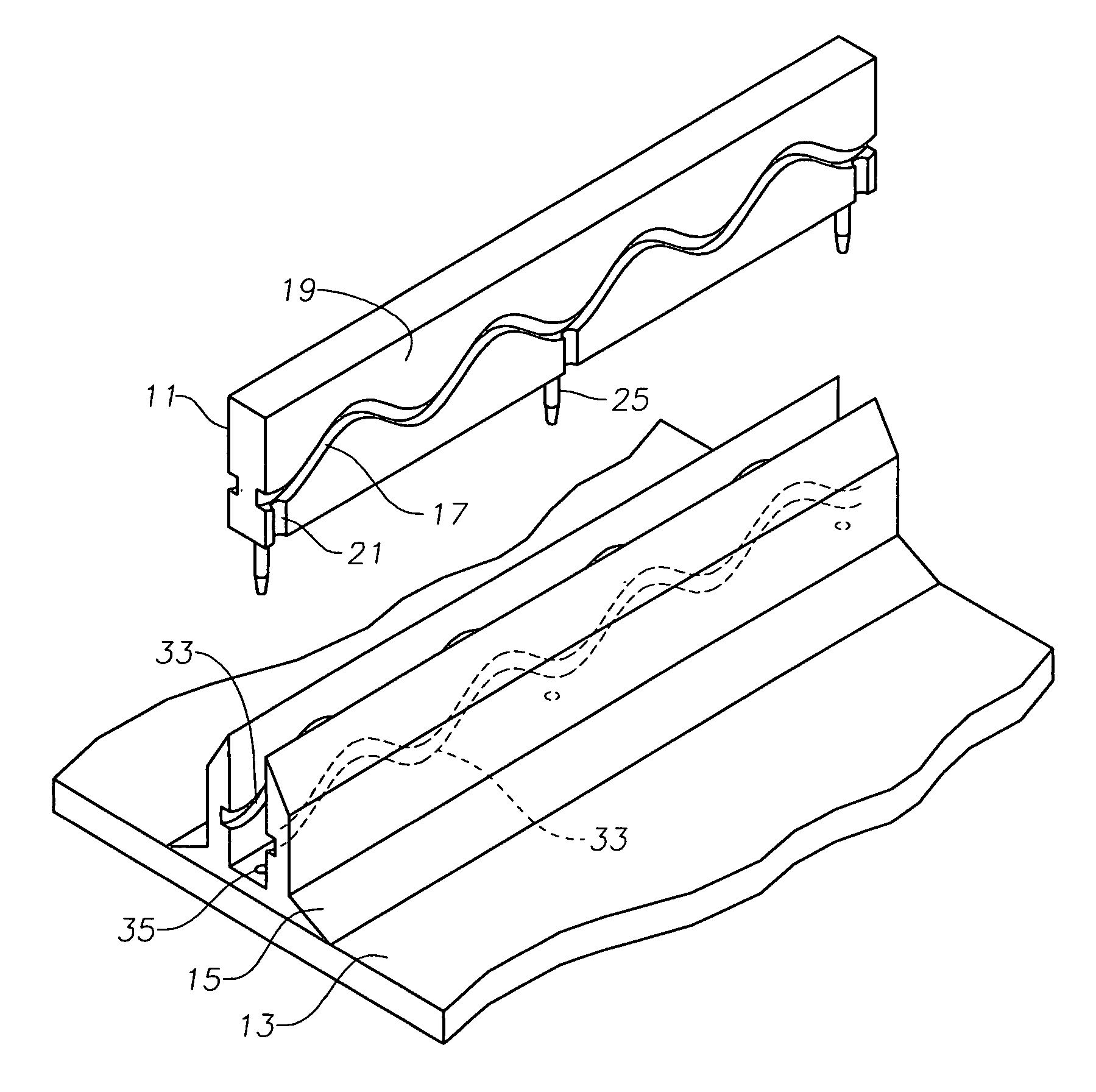

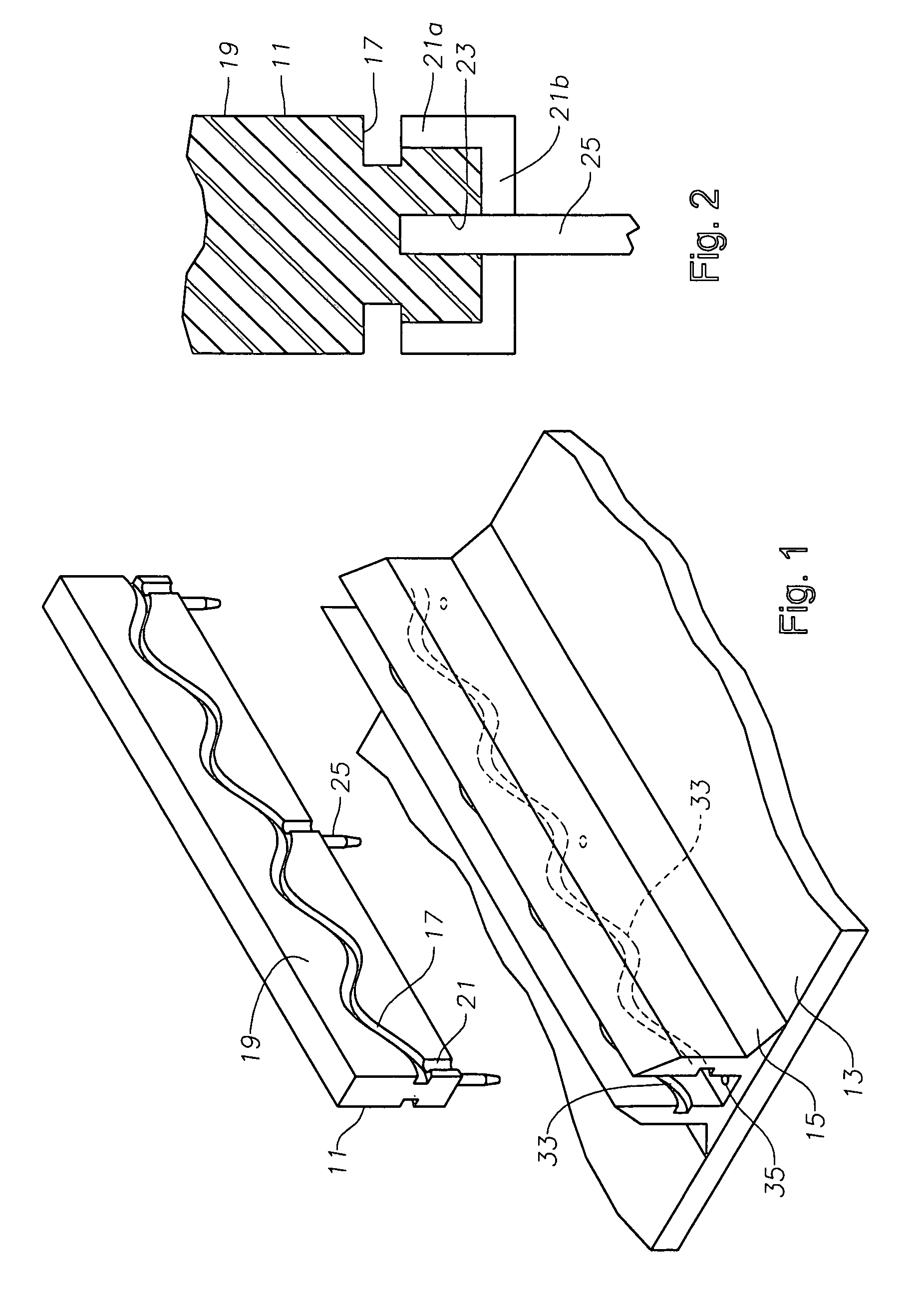

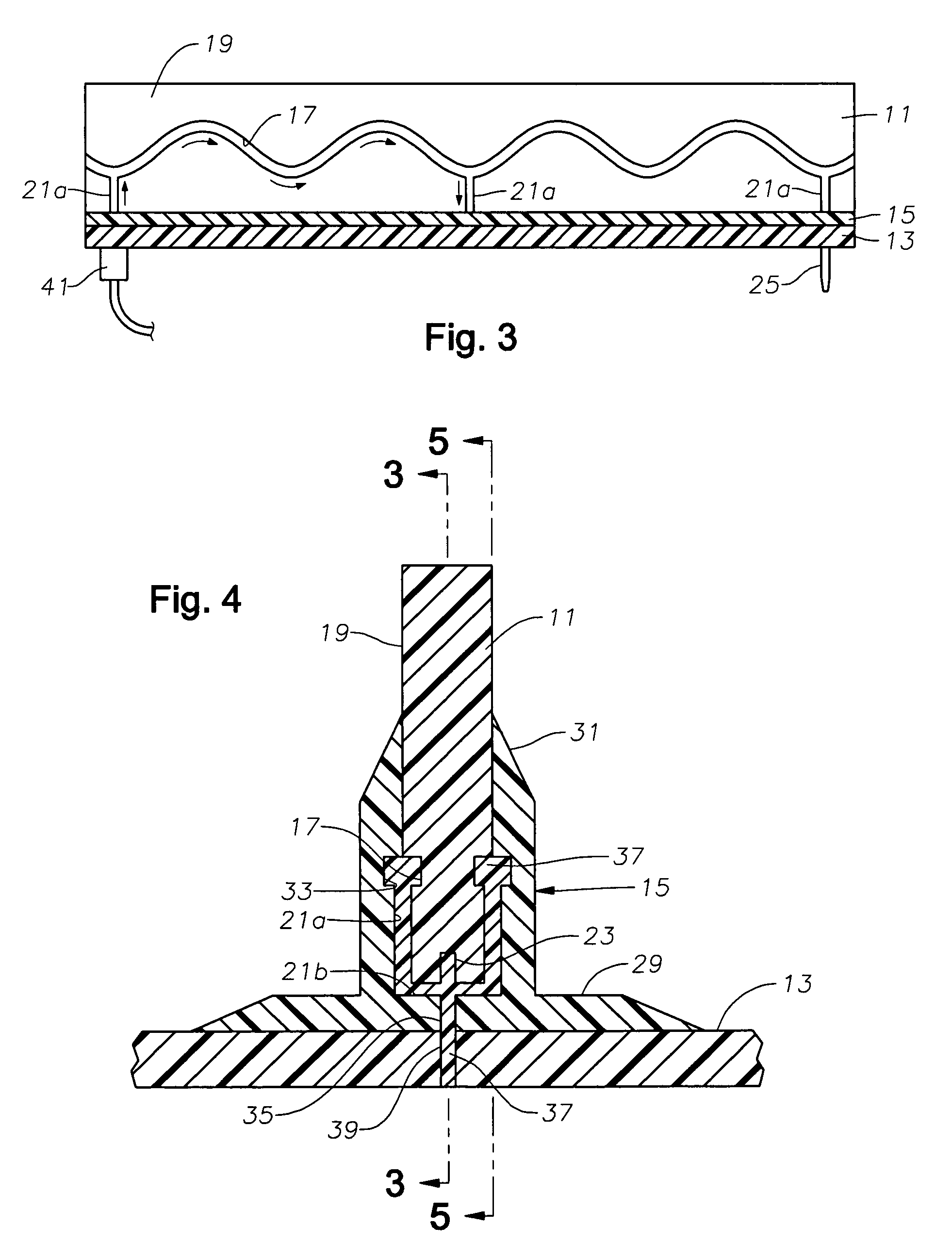

ActiveUS20070261787A1Convenient verificationCross sectional areaMaterial gluingCylinder headsAdhesion forceInjection port

A composite member is joined to another composite or noncomposite member, using liquid or paste adhesive resin that cures in the joint. The joint is configured in such a way that the adhesive forms an interlocking key within recesses in the joined members that prevents joint disassembly once the adhesive has cured and hardened. Both of the members are provided with recesses extending along their lengths in the joint. The recesses register with each other to define a cavity and may undulate. The recessed are designed in such a way as to take the full load capability if the joint, even if there is no adhesion to the joined members. Adhesive is injected into the cavity through injection ports spaced periodically along the length of the joint.

Owner:LOCKHEED MARTIN CORP

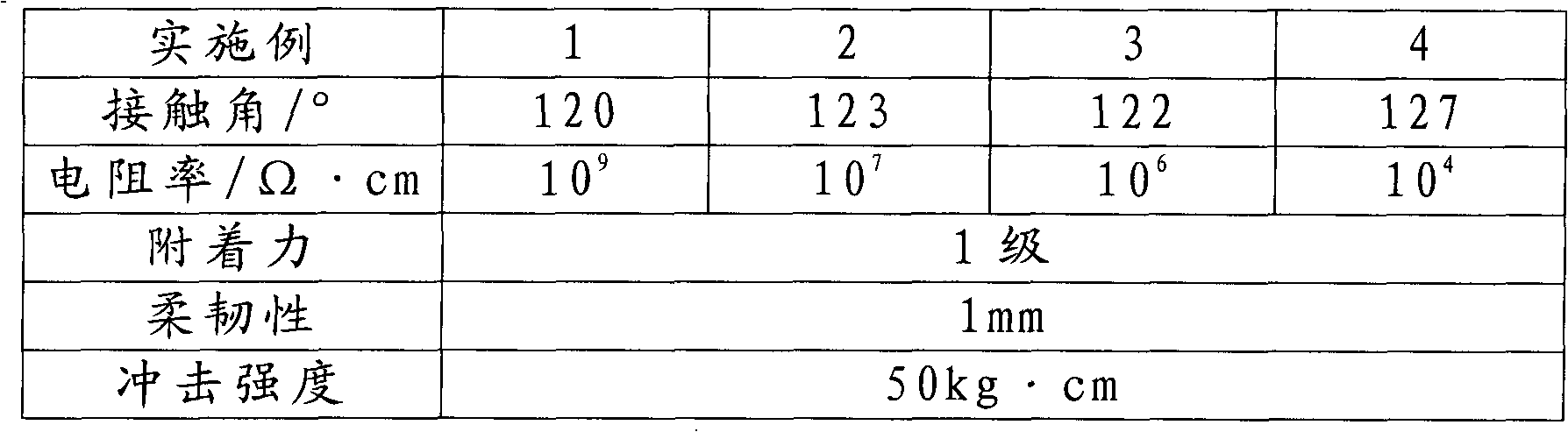

High hydrophobic static-electricity conducting anti-icing coating and method for producing same

ActiveCN101792631AHas electrostatic propertiesReduce formationInsulated cablesElectrically-conductive paintsElectric wireStatic electricity

The invention provides high hydrophobic static-electricity conducting anti-icing coating and a method for producing the same, aiming at solving the problem existing in the prior art that the common low surface energy coating can not balance both hydrophilic characteristic and static-electricity conducting function. According to the technical scheme adopted to solve the problem, the high hydrophobic static-electricity conducting anti-icing coating comprises component A and component B, wherein the weight ratio of the component A to the component B is 9-16:1. The component A comprises the following materials by weight percent: 35-60 percent of the fluorocarbon resin, 10-40 percent of conductive powder, 1-8 percent of organic silicon compound, 0.5-3 percent of anti-aging agent, 0.5-5 percent of dispersant, 0.5-3 percent of anti-sedimentation agent and 10-40 percent of organic solvent. The component B is aliphatic and / or aromatic curing agent. After being coated on the surface of an electric wire, the high hydrophobic static-electricity conducting low surface energy anti-icing coating can delay the icing and reduce the adhesion force of the ice and the surface of the electric wire. In addition, with the static-electricity conducting performance, the high hydrophobic static-electricity conducting low surface energy anti-icing coating can protect the electric wire against lightning stroke.

Owner:STATE GRID CORP OF CHINA +1

Mount with magnetic attachment and automatic safety latching

A system and method of releasably mounting a device, usually to a ceiling, is disclosed. The system has a ceiling mounted unit (200) and a device mounted unit (250), releasably joined preferably by an magnetic coupling (202) which engages a floating plate (252) allowing for positive coupling even if the units are misaligned. A safety latch (256) with a locking / latching claw (260) and ejection / disengagement prong (266) provide positive locking and a method of separating the units despite strong adhesion forces.

Owner:GAMBER JOHNSON

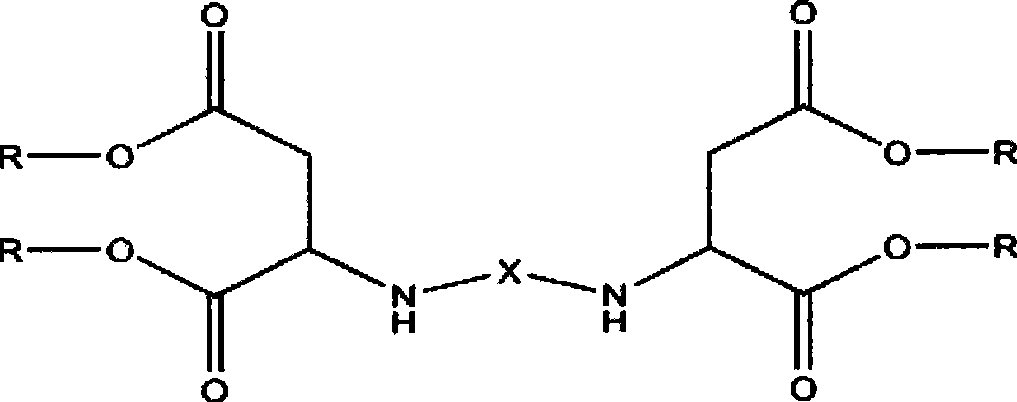

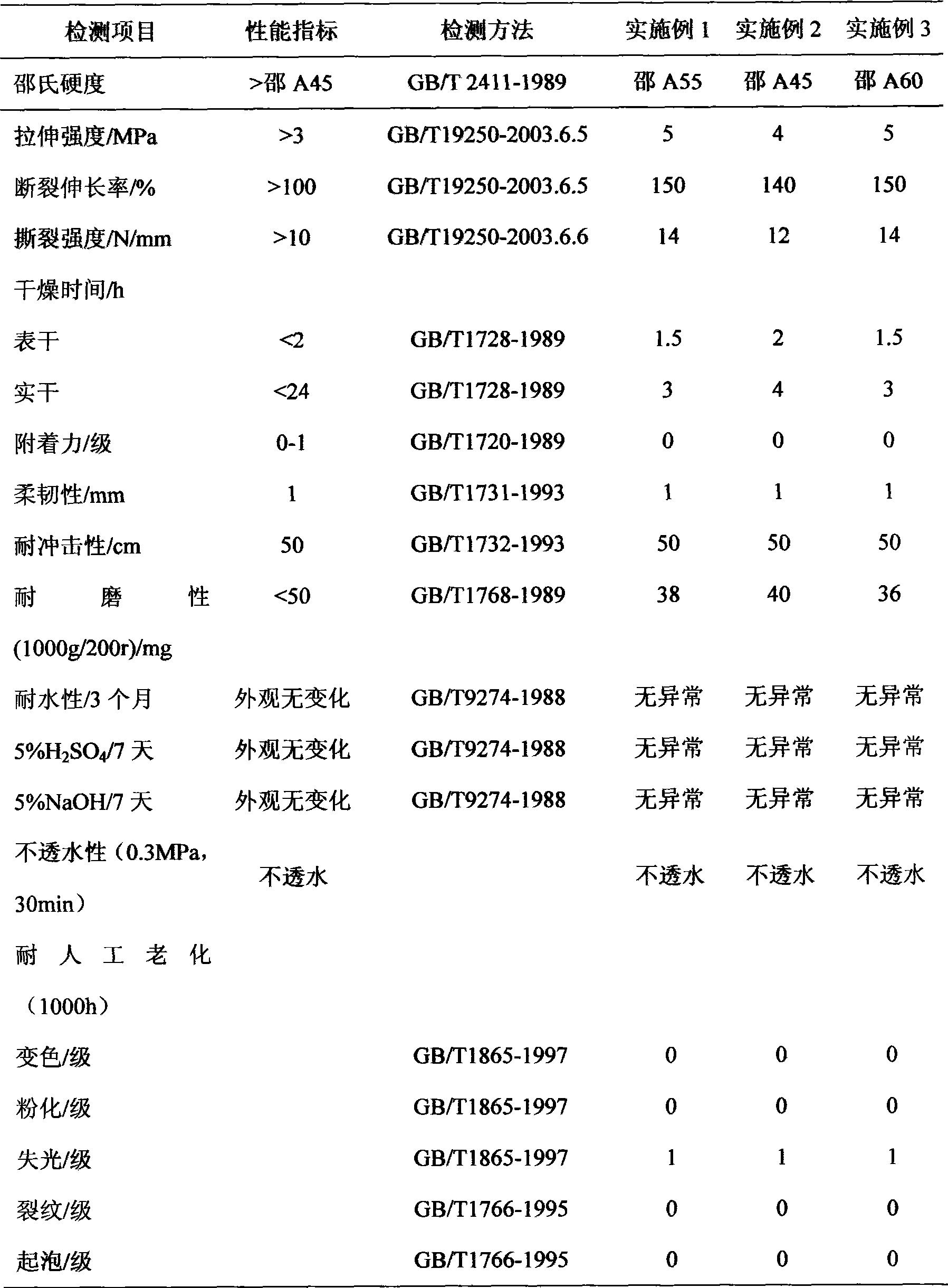

Preparation of polyaspartate polyurea waterproof coating material

InactiveCN101469246AStrong adhesionImprove toughnessAntifouling/underwater paintsPaints with biocidesAdhesion forceSpray coating

The invention discloses a method for preparing a polyaspartate polyurea waterproof coating, which is characterized in that the coating is based on polyaspartate polyurea and takes polyisocyanates as a curing agent. The coating material maintains the excellent performance of the prior polyurea coating, and also overcomes the disadvantages that the prior polyurea has overquick gelation time and needs special equipment for construction at the same time. The coating has the advantages of strong adhesion force, good toughness and wear resistance, good weather performance and so on, does not contain a solvent, is green and environment-friendly, and can reach the needed thickness through spray coating at one time.

Owner:SHANGHAI HUAYI FINE CHEM CO LTD

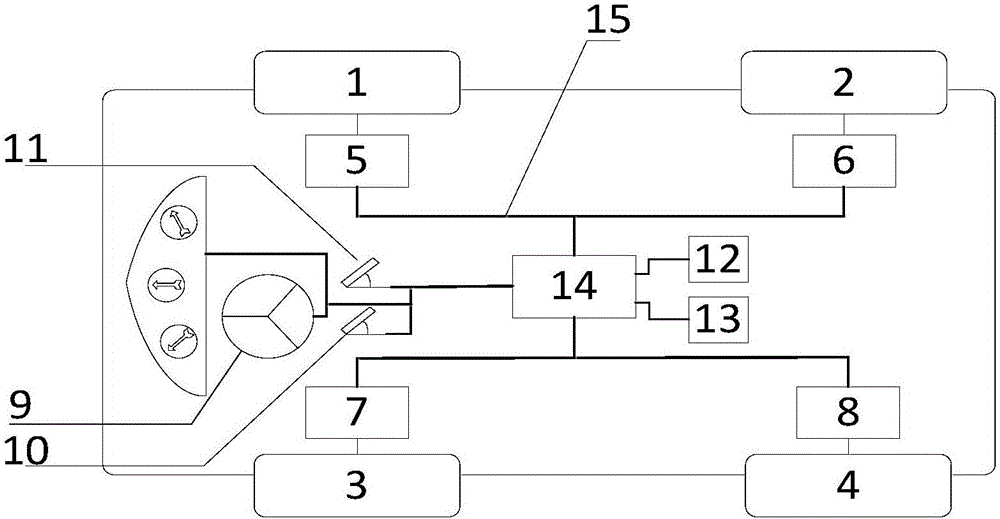

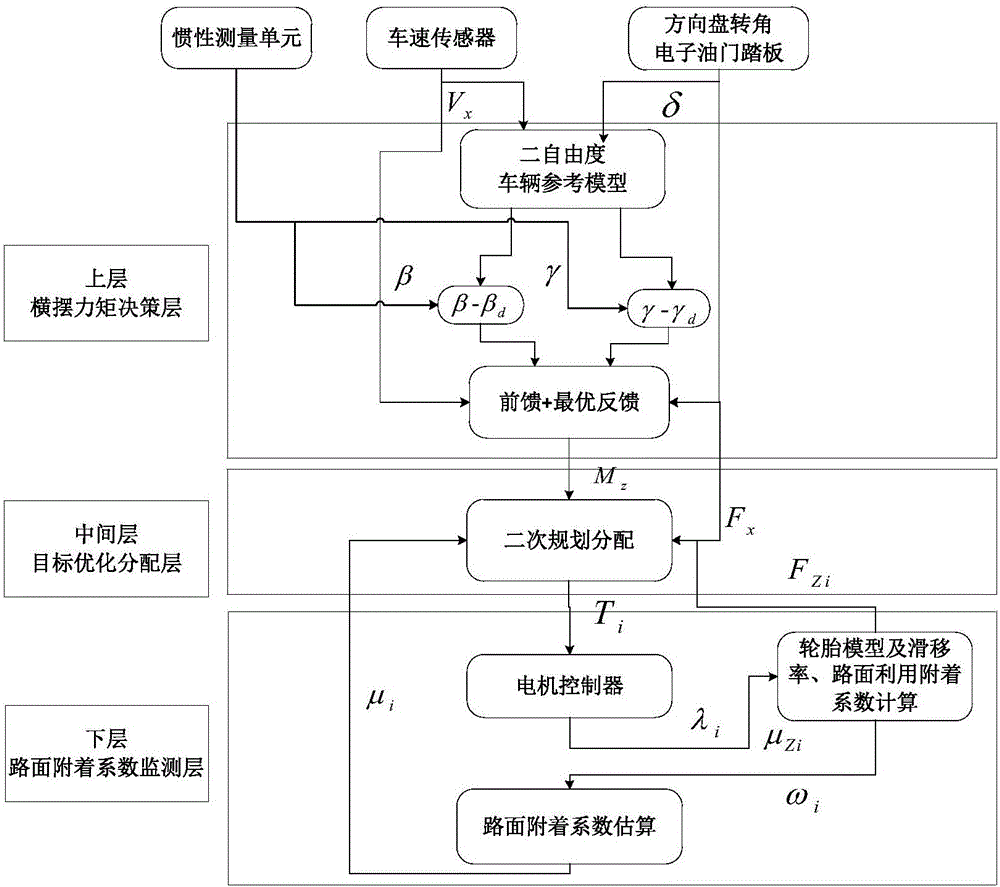

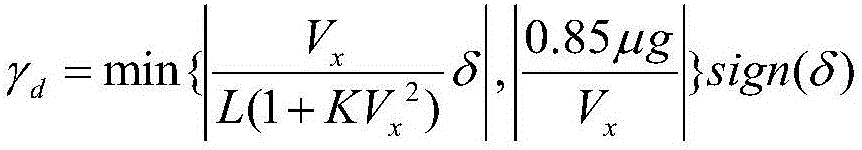

Hierarchical system used for four-wheel-hub motor-driven electric automobile, and control method

InactiveCN106585425AImprove stabilityImprove maneuverabilitySpeed controllerElectric devicesRoad surfaceEngineering

The invention discloses a hierarchical system used for a four-wheel-hub motor-driven electric automobile, and a control method. First of all, yaw moment is calculated as a yaw moment decision-making layer according to a vehicle speed sensor, a steering wheel rotary angle transmitter, an electronic throttle sensor and an inertia measurement unit; then according to automobile longitudinal force constraints, yaw moment constraints, a maximum adhesion force which can be provided by a pavement and restrictions of motor maximum output moment, target torque of each wheel hub motor is calculated as a target optimization analysis layer; and finally, degrees of similarity to six standard pavements are obtained by inputting two parameters, i.e., an adhesion coefficient and a wheel slip rate into a pavement adhesion coefficient estimation fuzzy controller by means of a current pavement, and an adhesion coefficient estimated value of the current pavement is obtained as a pavement adhesion coefficient monitoring layer after weighted averaging is performed. According to the invention, whole-vehicle stability is taken as a control target, motor torque is reasonably distributed according to operation working conditions, and the controllability, the stability and the economic property of vehicles are improved.

Owner:XI AN JIAOTONG UNIV

Organosilicon modified aqueous polyurethane resin and preparation thereof

An organosilicon modified aqueous polyurethane resin comprises the following raw materials in percentage by weight: 10 to 20 percent of isocyanate, 20 to 40 percent of polyester polyol, 0.1 to 5 percent of organic silicon oil, 2 to 5 percent of a hydrophilic chain extender, 2 to 5 percent of a polyol chain extender, 1 to 3 percent of a polybasic amine chain extender, 0.01 to 1 percent of a catalyst, 1 to 4 percent of a salifying agent, 5 to 8 percent of a solvent and the rest of water. The emulsion made by the organosilicon modified aqueous polyurethane resin is obviously better than the emulsion made by a non-modified aqueous polyurethane resin regarding adhesion force, abrasion resistance, heat tolerance, smoothness, etc. The polyurethane emulsion made by the organosilicon modified aqueous polyurethane resin can be applied to the surface of a product through spray coating, brush coating, roller coating and dip coating. At present, the polyurethane emulsion is mainly used for the coating of the surfaces of gloves, condoms, medical ducts, etc.

Owner:SHANDONG INOV POLYURETHANE

Preparation method of silicon dioxide super-hydrophobic thin film and super-hydrophobic material

InactiveCN103359954AImprove surface hydrophobicityImprove stabilityOther chemical processesCoatingsAdhesion forcePtru catalyst

The invention provides a preparation method of a silicon dioxide super-hydrophobic thin film. The preparation method comprises the following steps of: step one. preparing alkaline colloidal sol, namely mixing orthosilicate ester, a basic catalyst, a solvent and water to prepare the SiO2 alkaline colloidal sol; step two. adding hexamethyl disilazane to the SiO2 alkaline colloidal sol for reaction to obtain modified SiO colloidal sol; and step three. coating the modified SiO colloidal sol on the surface of a substrate, and drying to obtain the silicon dioxide super-hydrophobic thin film. The invention also provides a super-hydrophobic material. The silicon dioxide super-hydrophobic thin film prepared by the method has strong adhesion force with a substrate and a good dewatering effect; complicated equipment is not needed; the process is simple; the preparation cycle is shortened; the cost is saved; and the application range is wide.

Owner:BYD CO LTD

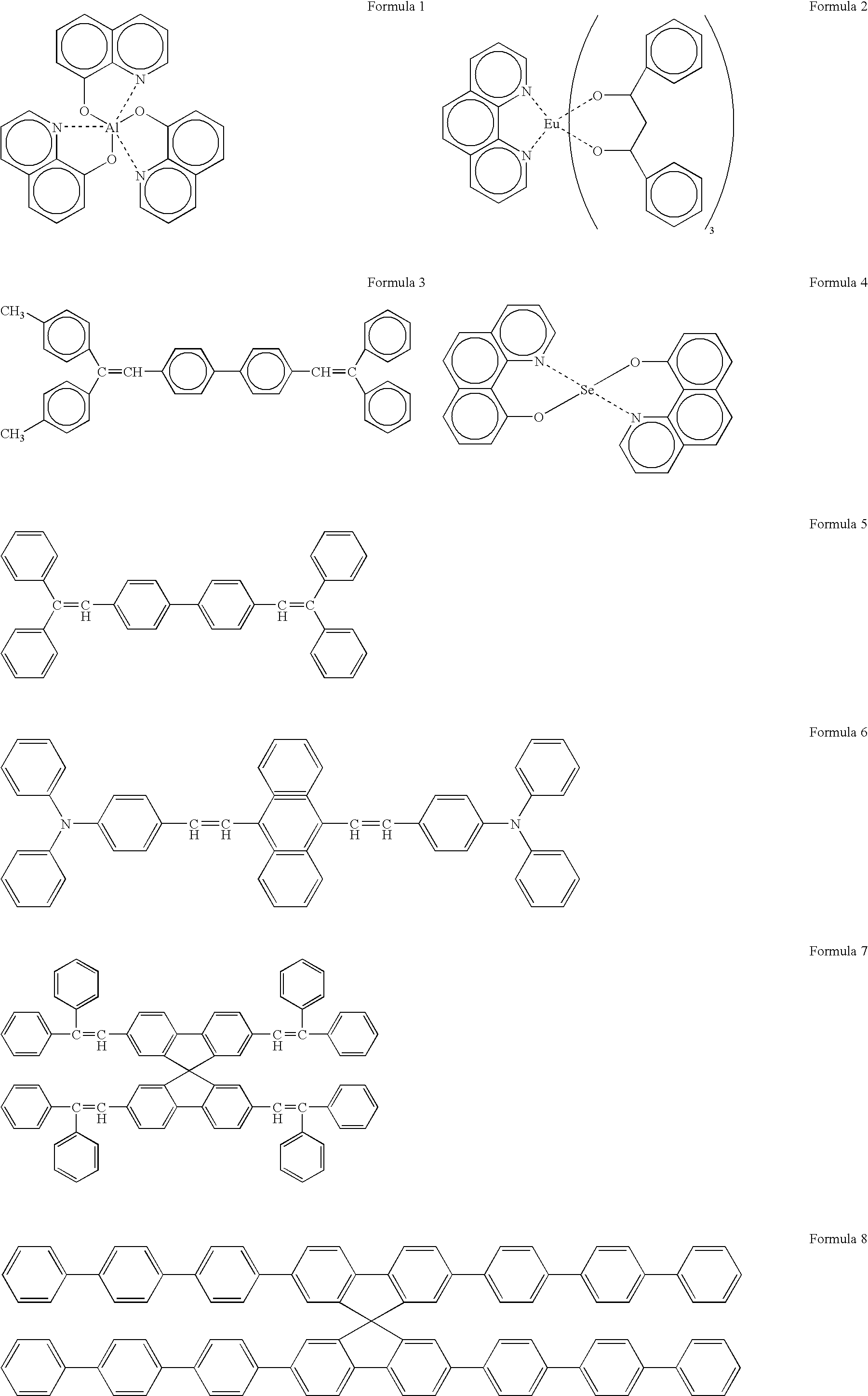

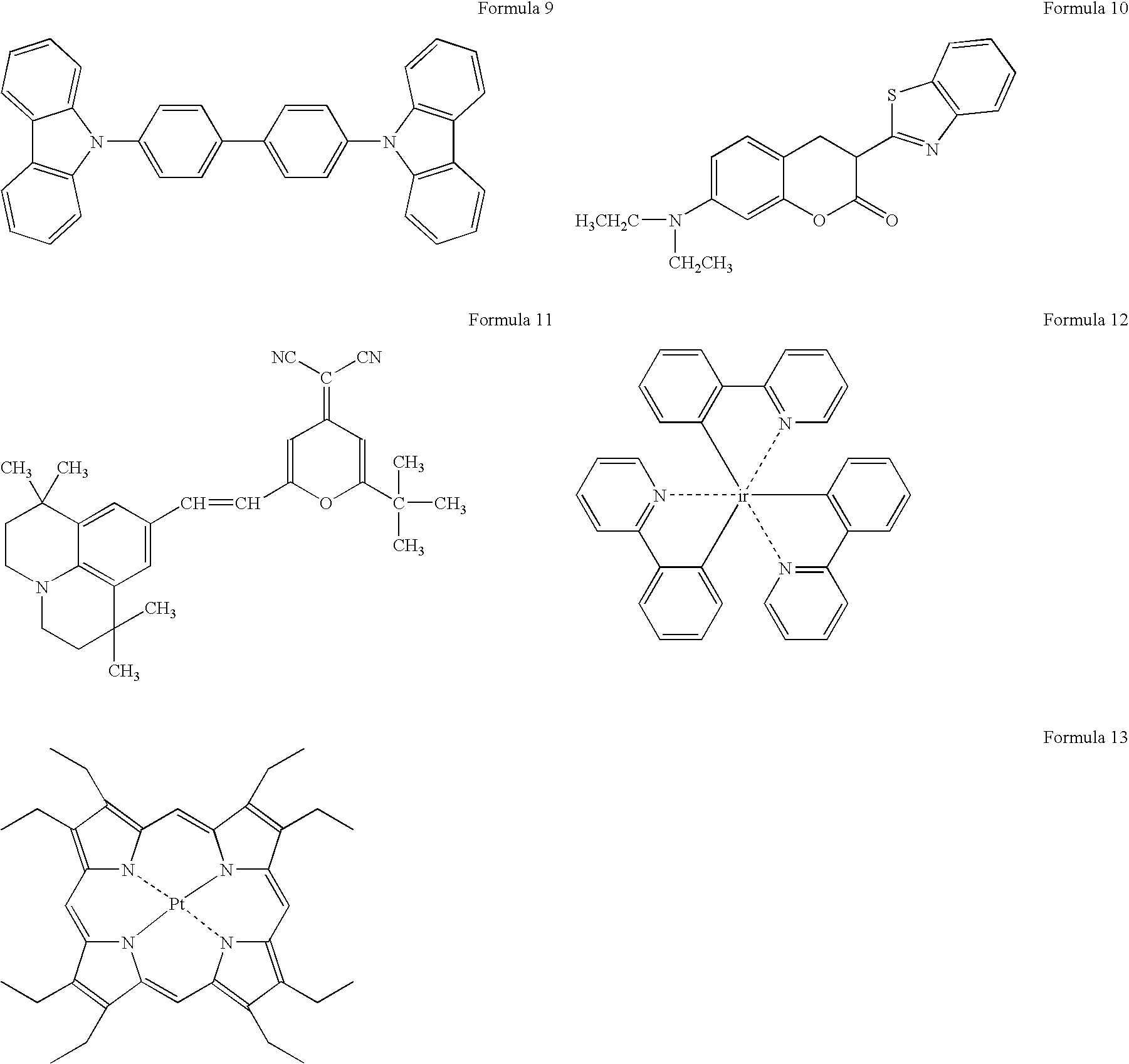

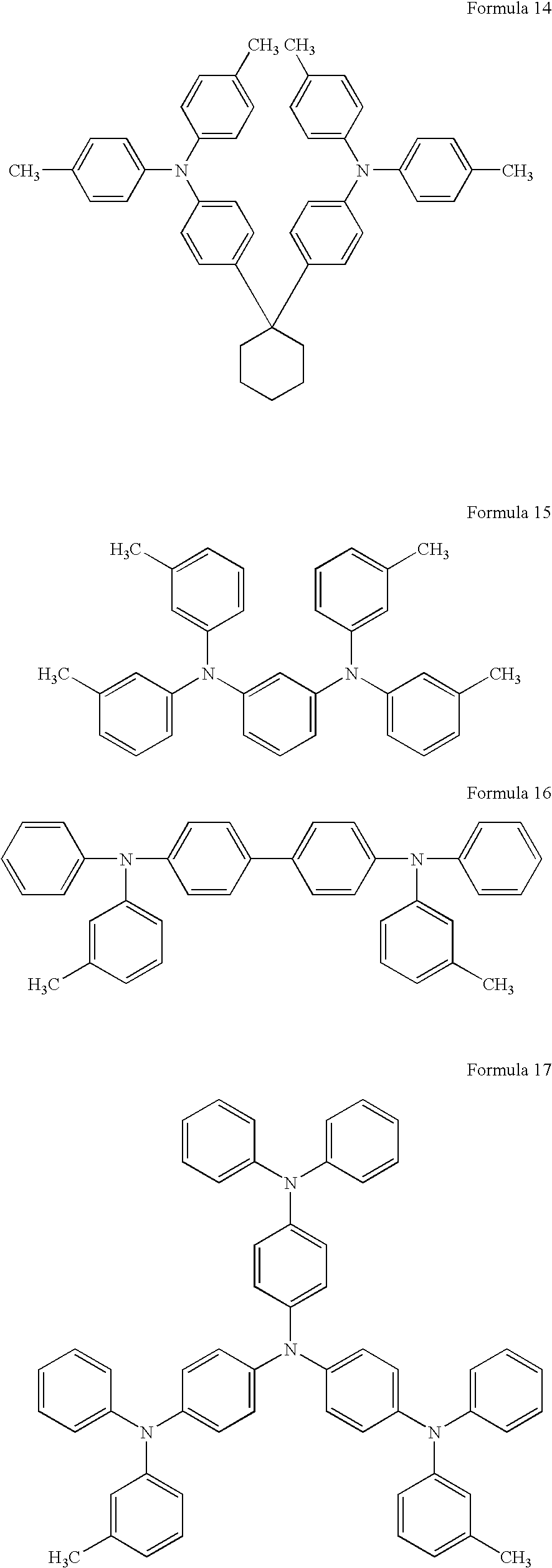

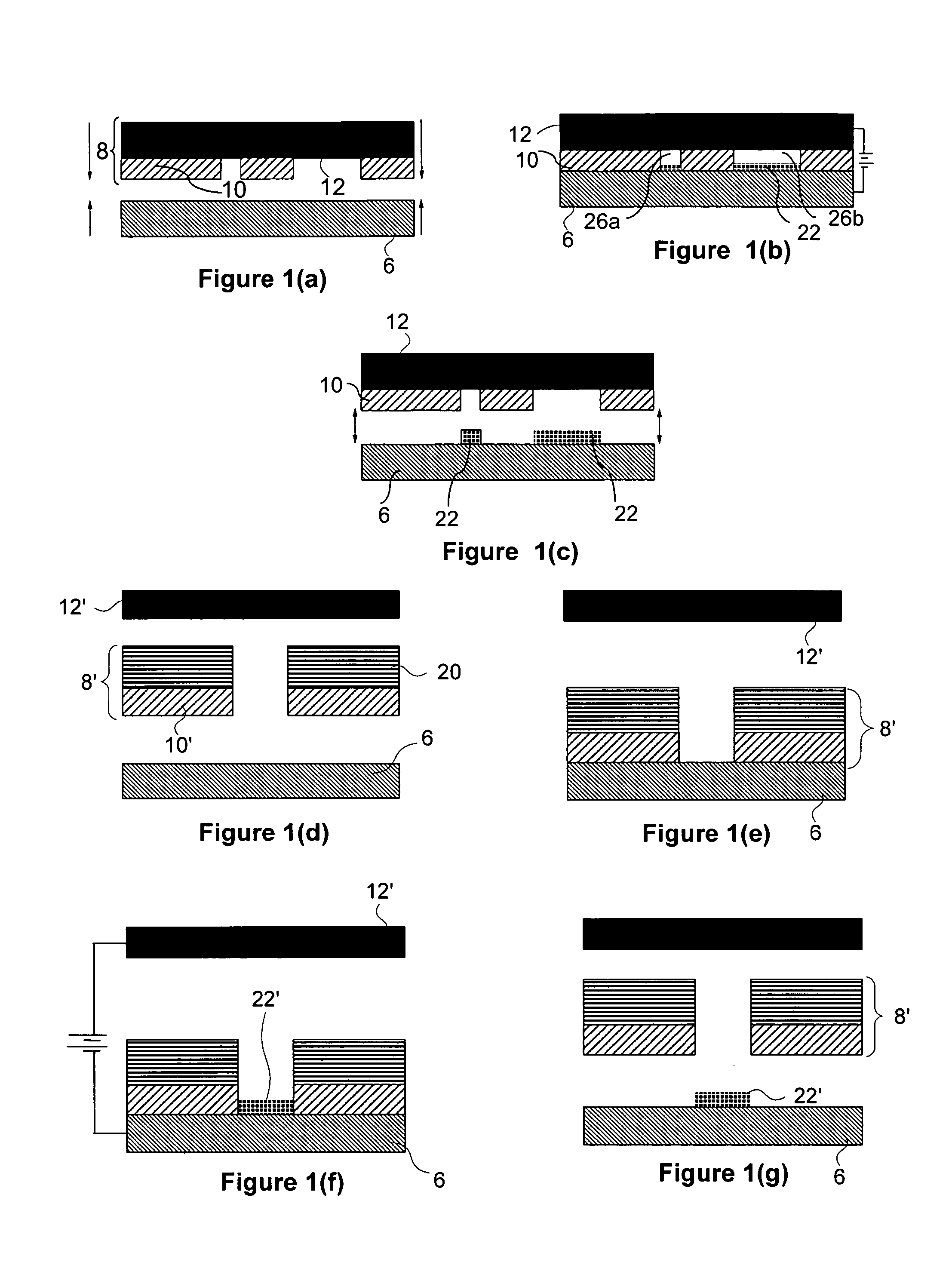

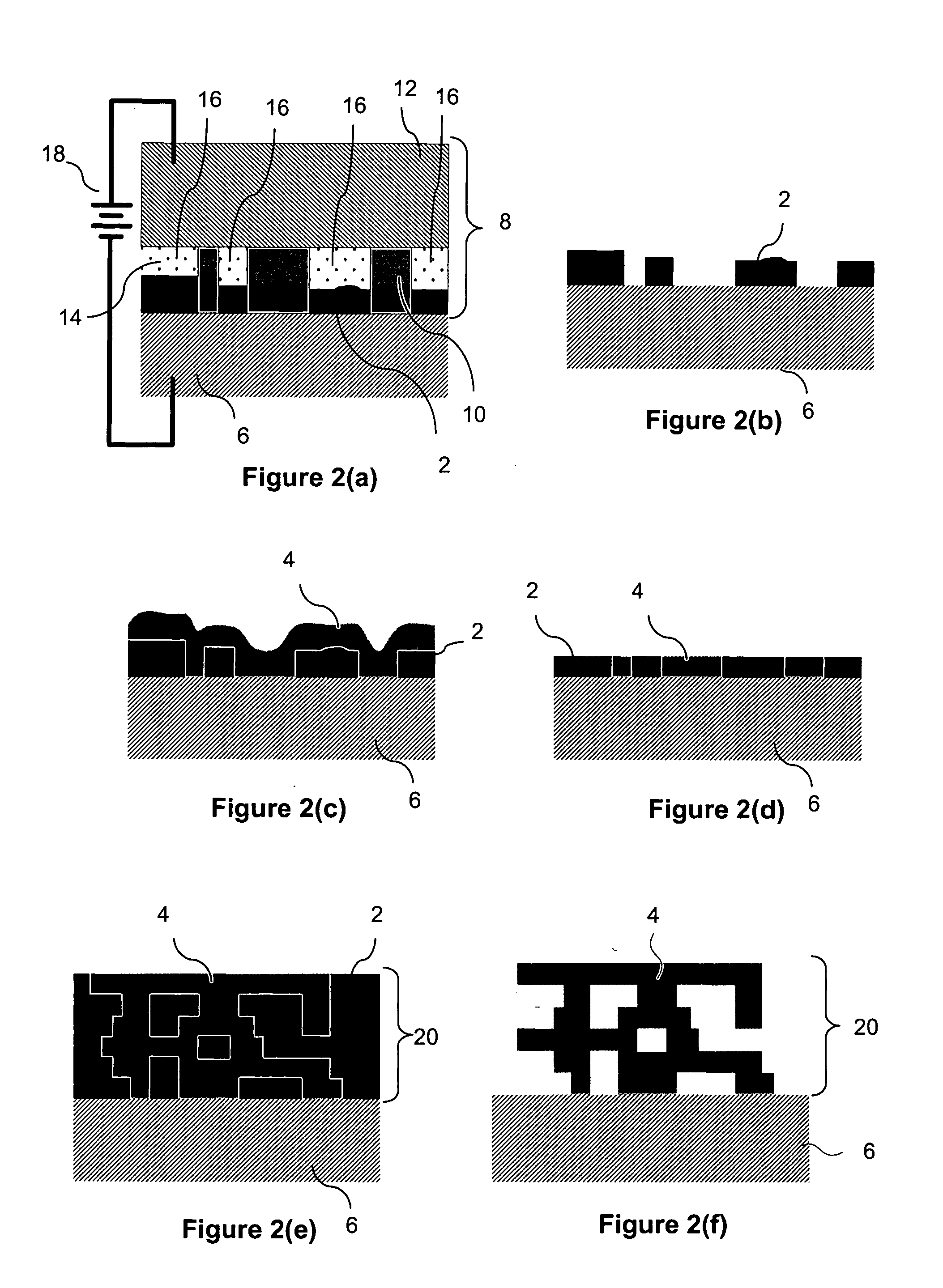

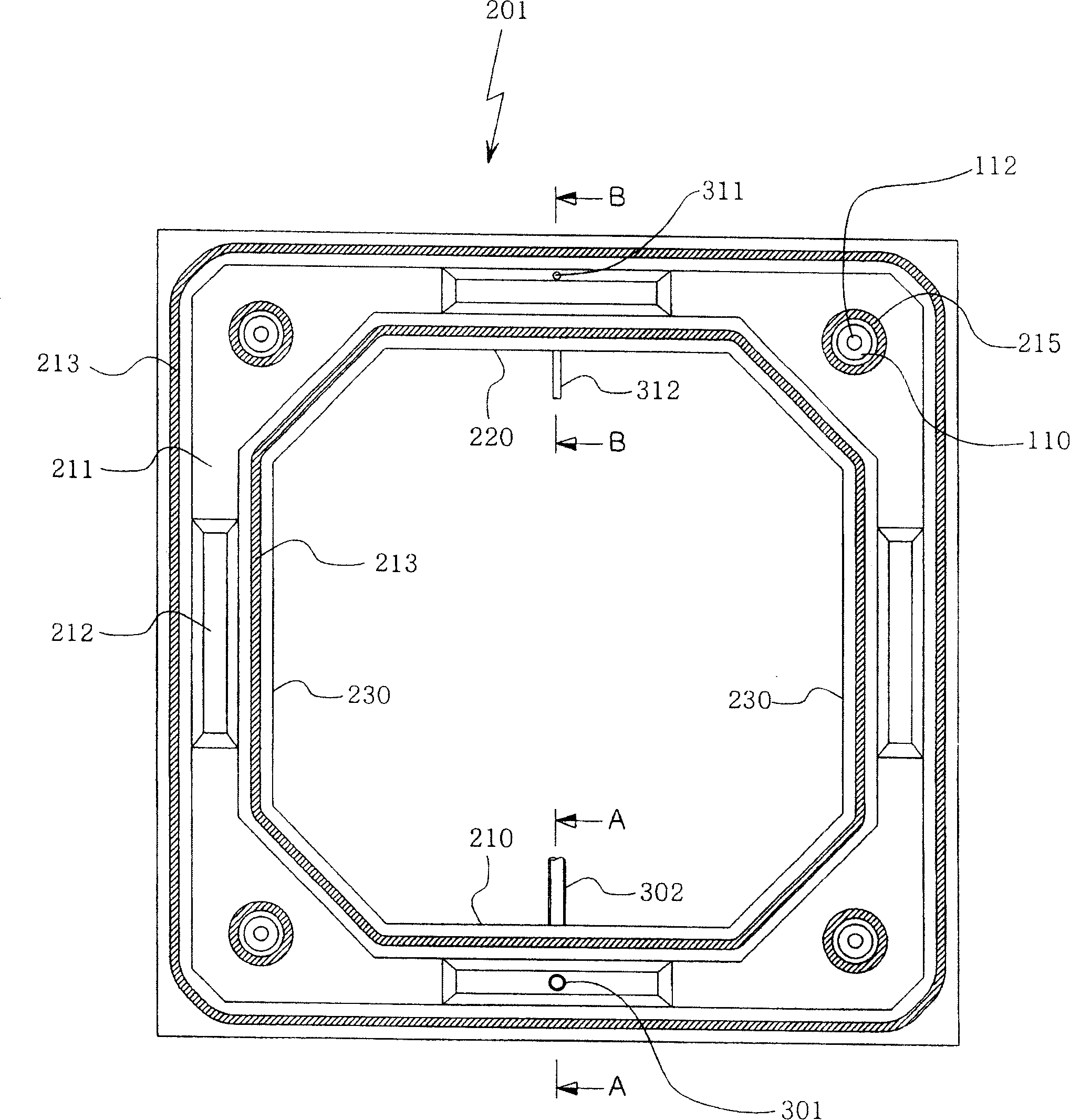

Donor film for low molecular weight full color organic electroluminescent device using laser induced thermal imaging method and method for fabricating low molecular weight full color organic electroluminescent device using the film

InactiveUS20040191564A1Reduce molecular weightElectroluminescent light sourcesSolid-state devicesAdhesion forcePhotothermal conversion

A low molecular weight full color organic electroluminescent device and a method to fabricate the low molecular weight full color organic electroluminescent device enable scale-up and mass-production of an organic electroluminescent device of high resolution by providing a donor film of a low molecular weight full color organic electroluminescent device, the donor film including a substrate film; a photothermal conversion layer formed on the upper part of the substrate film; and a transfer layer formed on the upper part of the photothermal conversion layer and formed of a low molecular weight material. A part of the transfer layer that is irradiated and heated by a laser is separated from the photothermal conversion layer according to a change of an adhesion force of the transfer layer with the photothermal conversion layer, while part of the transfer layer which is not irradiated by the laser is fixed to the photothermal conversion layer.

Owner:SAMSUNG MOBILE DISPLAY CO LTD

Lead-free and cadmium-free electrode silver slurry for piezoelectric ceramics and preparation method thereof

ActiveCN102751000AAchieve lead-freeImprove adhesionNon-conductive material with dispersed conductive materialCable/conductor manufactureAdhesion forceSlurry

The invention discloses a lead-free and cadmium-free electrode silver slurry for piezoelectric ceramics. The lead-free and cadmium-free electrode silver slurry for piezoelectric ceramics is prepared from the following raw materials in percentage by weight: 50 to 75 percent of conducting silver micro powder, 0.5 to 5 percent of inorganic additive, 1 to 15 percent of lead-free glass powder and 15 to 45 percent of organic carrier. The lead-free and cadmium-free electrode silver slurry is technologically advantaged in that a boron-bismuth-silicon-zinc-titanium glass system is designed, the traditional lead-containing glass can be completely substituted, a lead-free product is realized, the system glass can react with a piezoelectric ceramic substrate to form a firm interface between an electrode and the substrate, and the adhesion force of the interface is more than 15N / mm<2>.

Owner:HEFEI SHENGDA ELECTRONIC TECH IND CO LTD

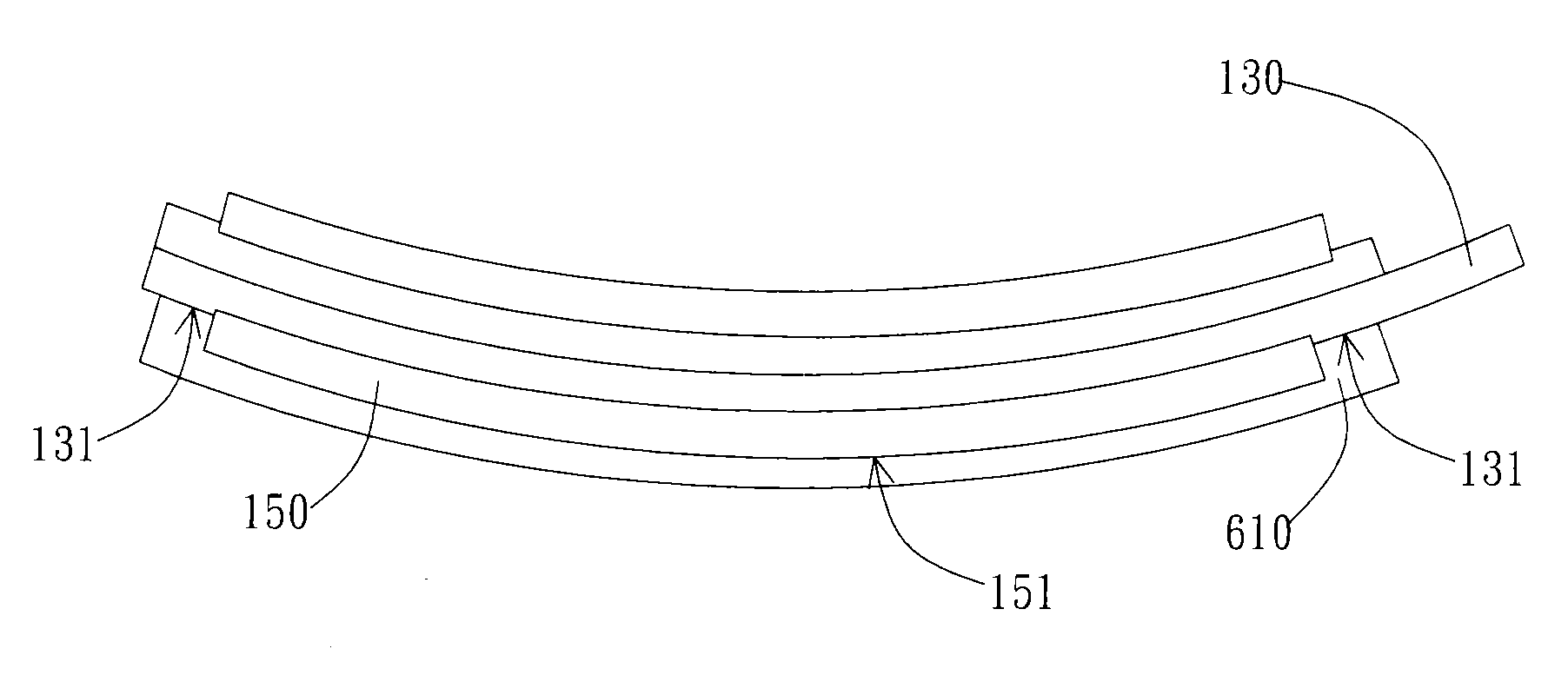

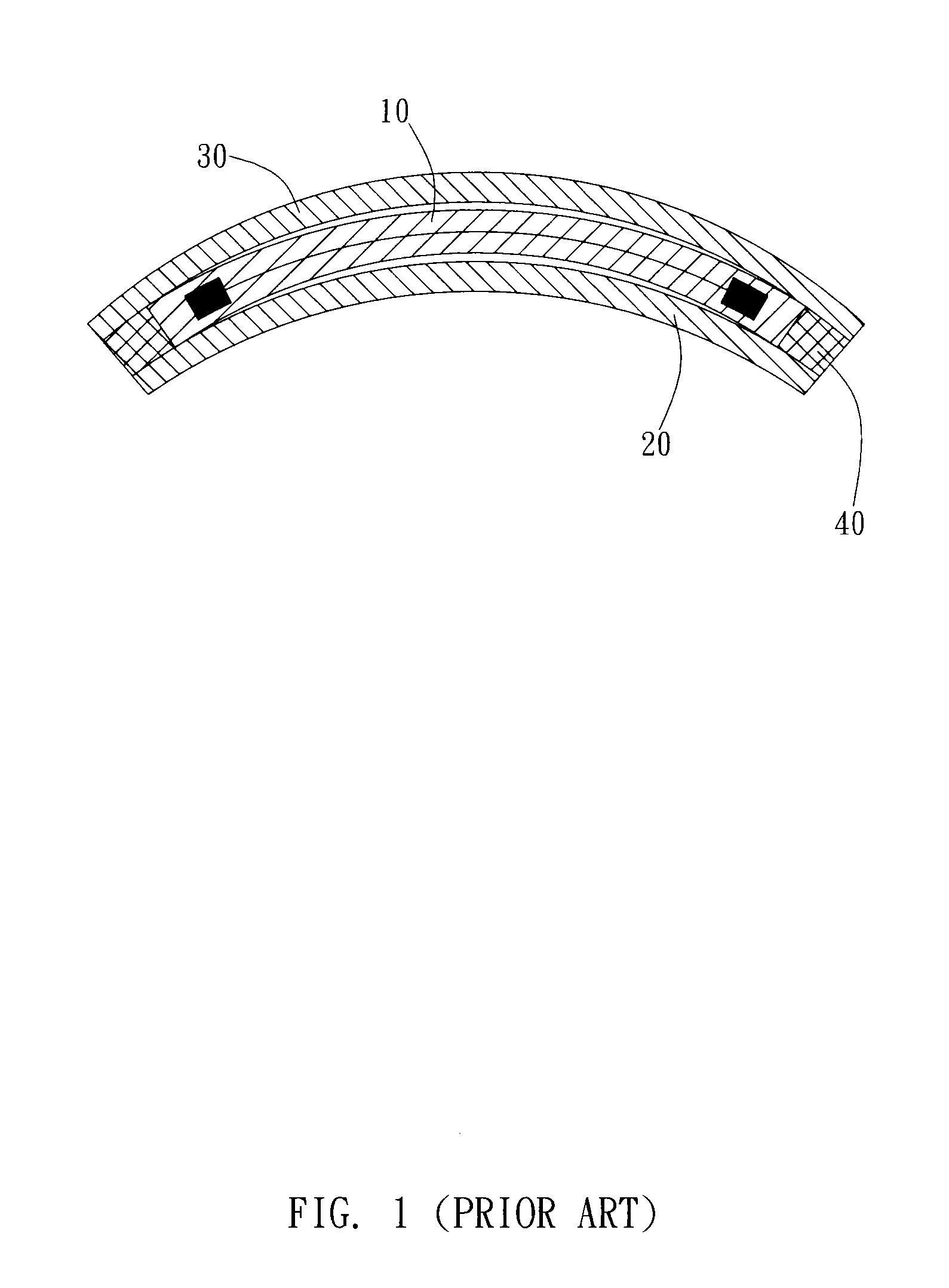

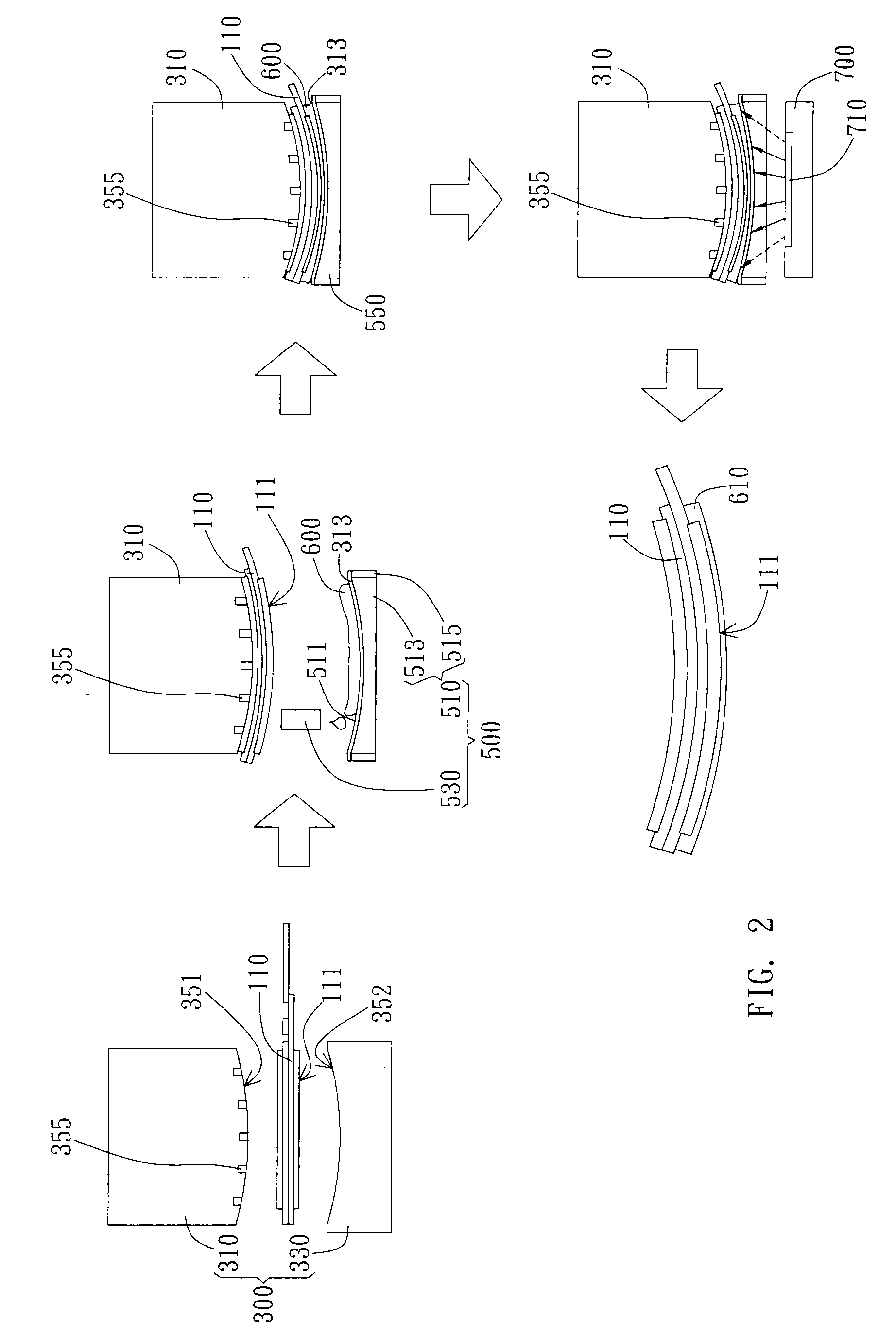

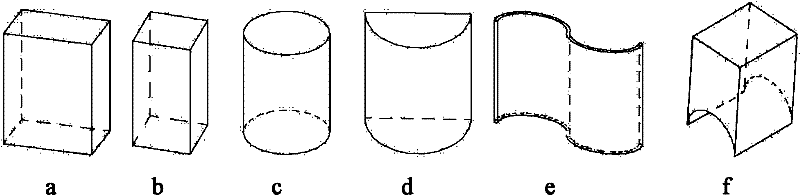

Curve-Shaped Display Module, Manufacture Method Thereof, and Manufacture Apparatus for Manufacturing the Same

ActiveUS20120044618A1Improve structural stabilityDomestic articlesElectrical apparatus contructional detailsAdhesion forceCurve shape

A curve-shaped display module, a manufacture method thereof, and a manufacture apparatus for manufacturing the same are provided. The manufacture apparatus includes a curve-forming mold, a curable material-dispensing device, and a curing device. The manufacture method includes the following steps: pressing the display panel to make the display panel have a curved shape and a first curved surface by using the curve-forming mold; distributing a curable material on the first curved surface by using the dispensing device; and curing the curable material to form a cured casing by using the curing device. The display module has the display panel having the first curved surface and the cured casing formed from the curing of the curable material. The cured casing covers and is closely attached to the first curved surface with an adhesion force therebetween to sustain the curved shape of the display panel.

Owner:AU OPTRONICS CORP

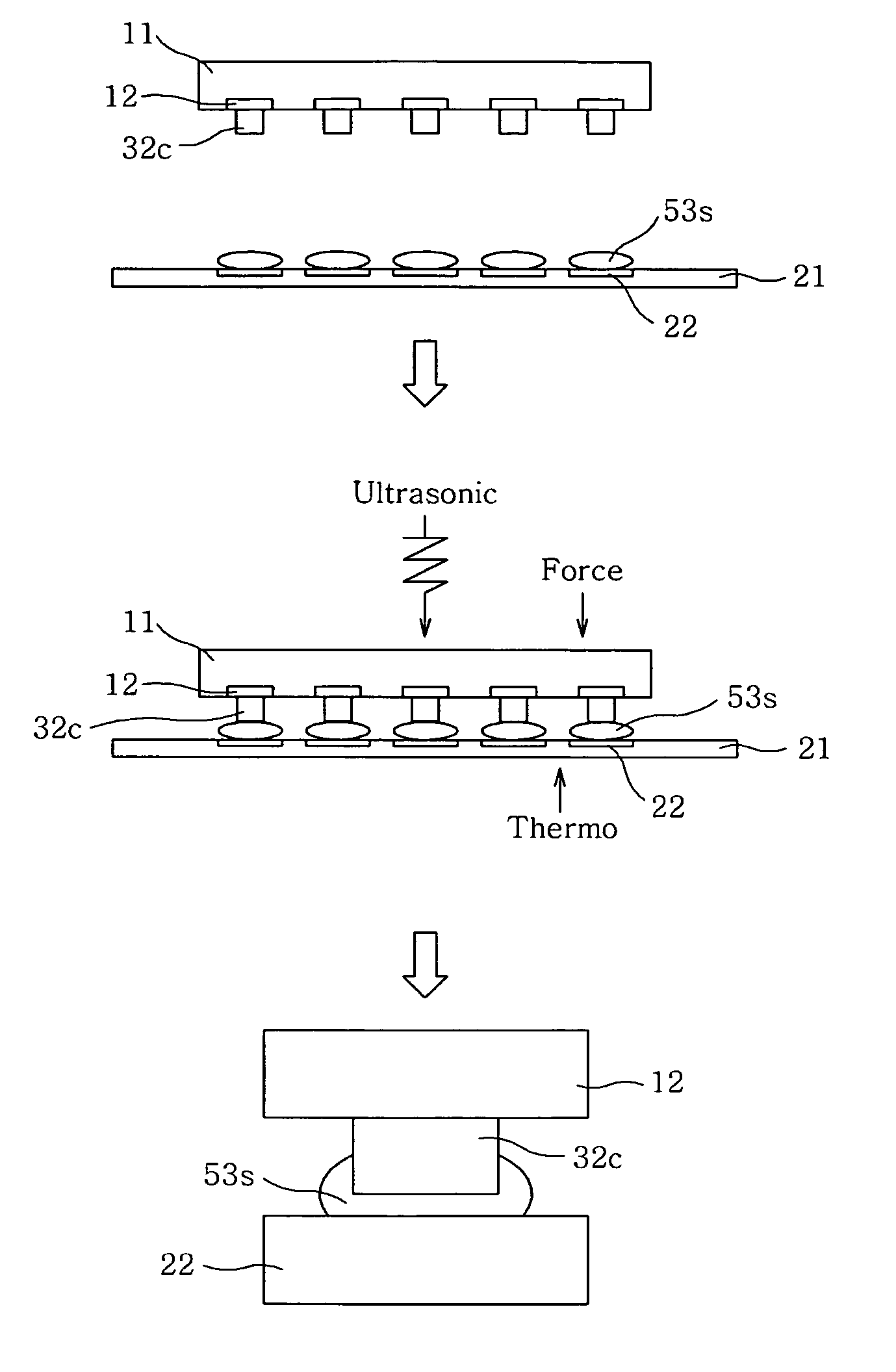

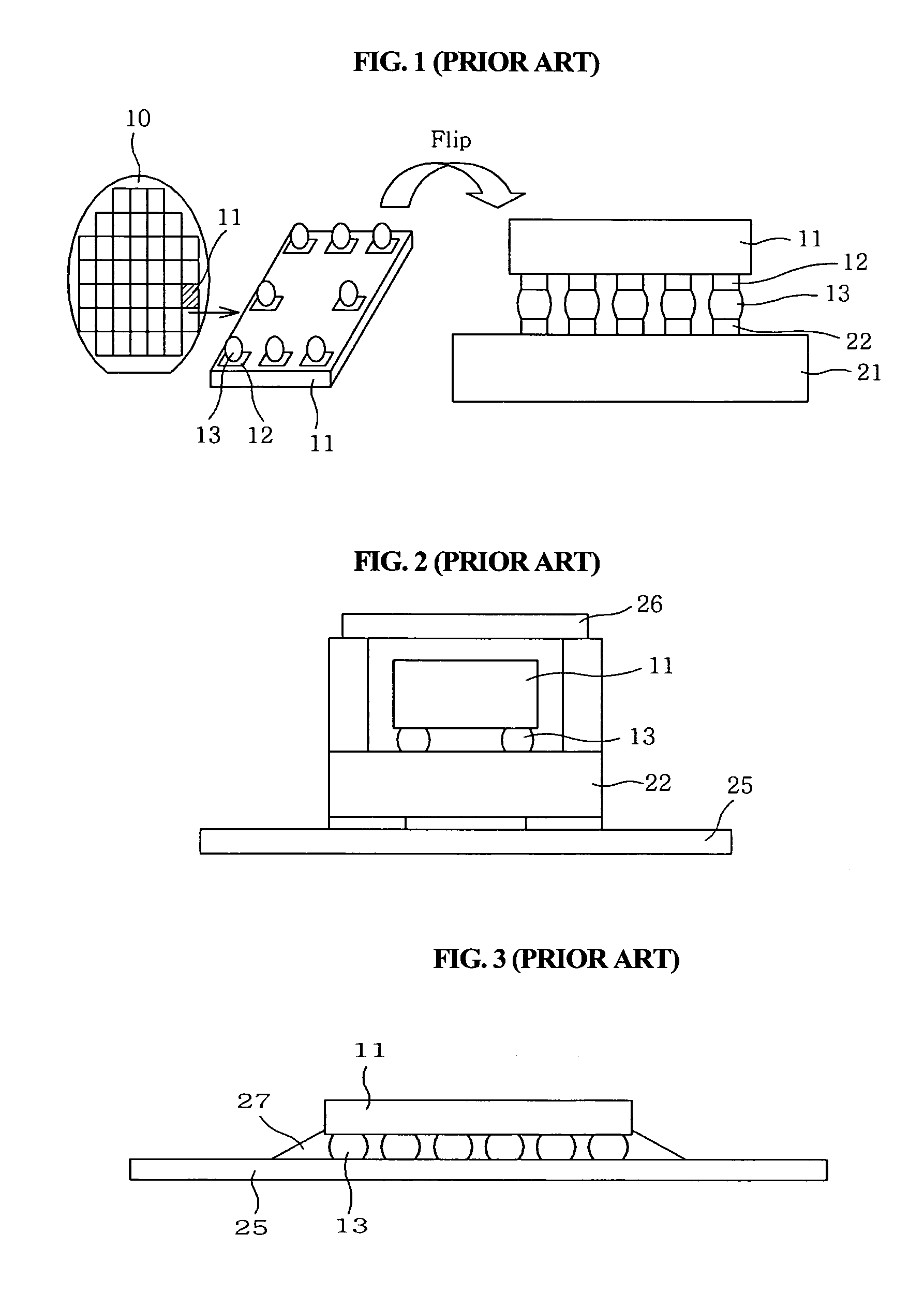

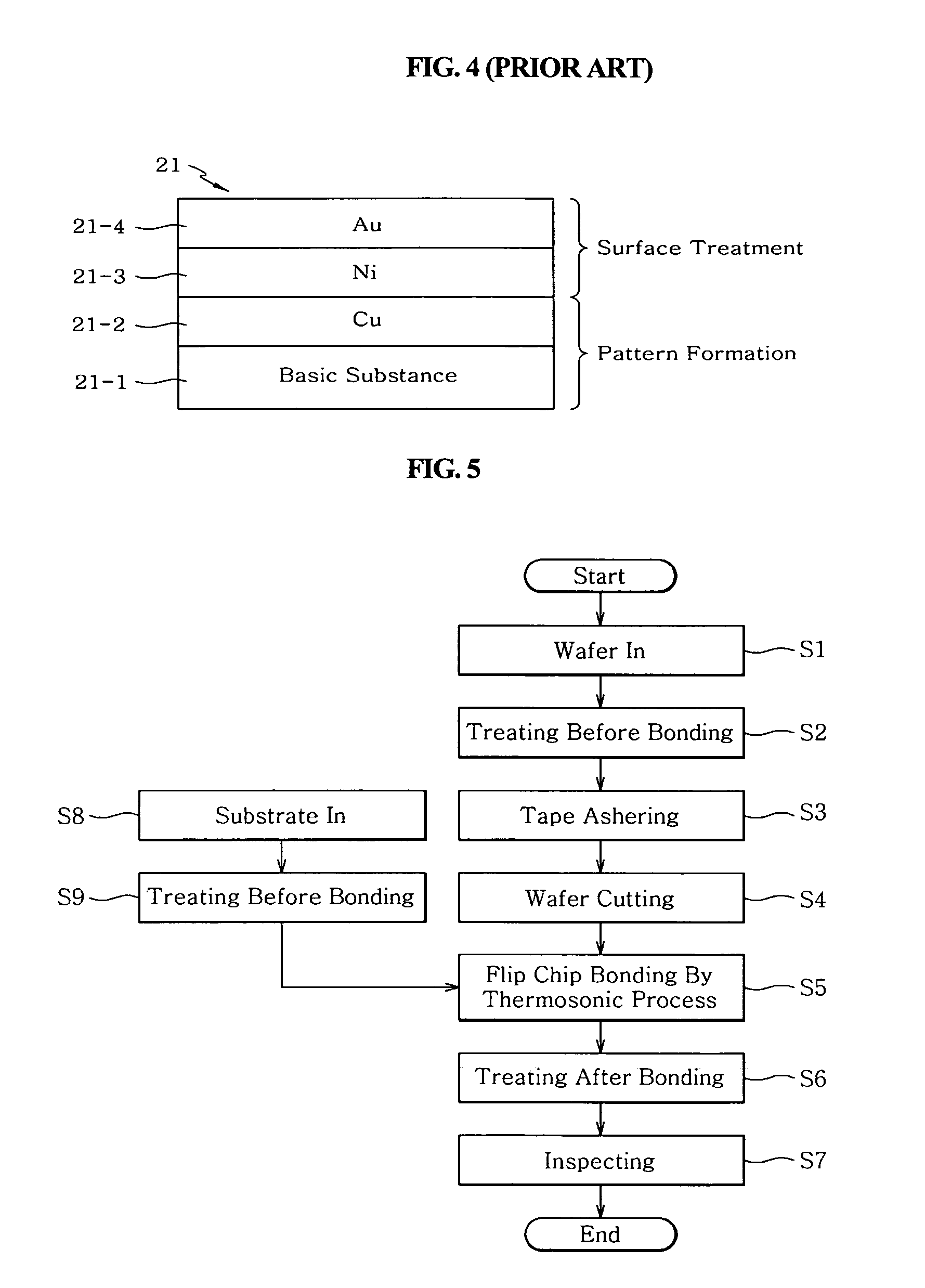

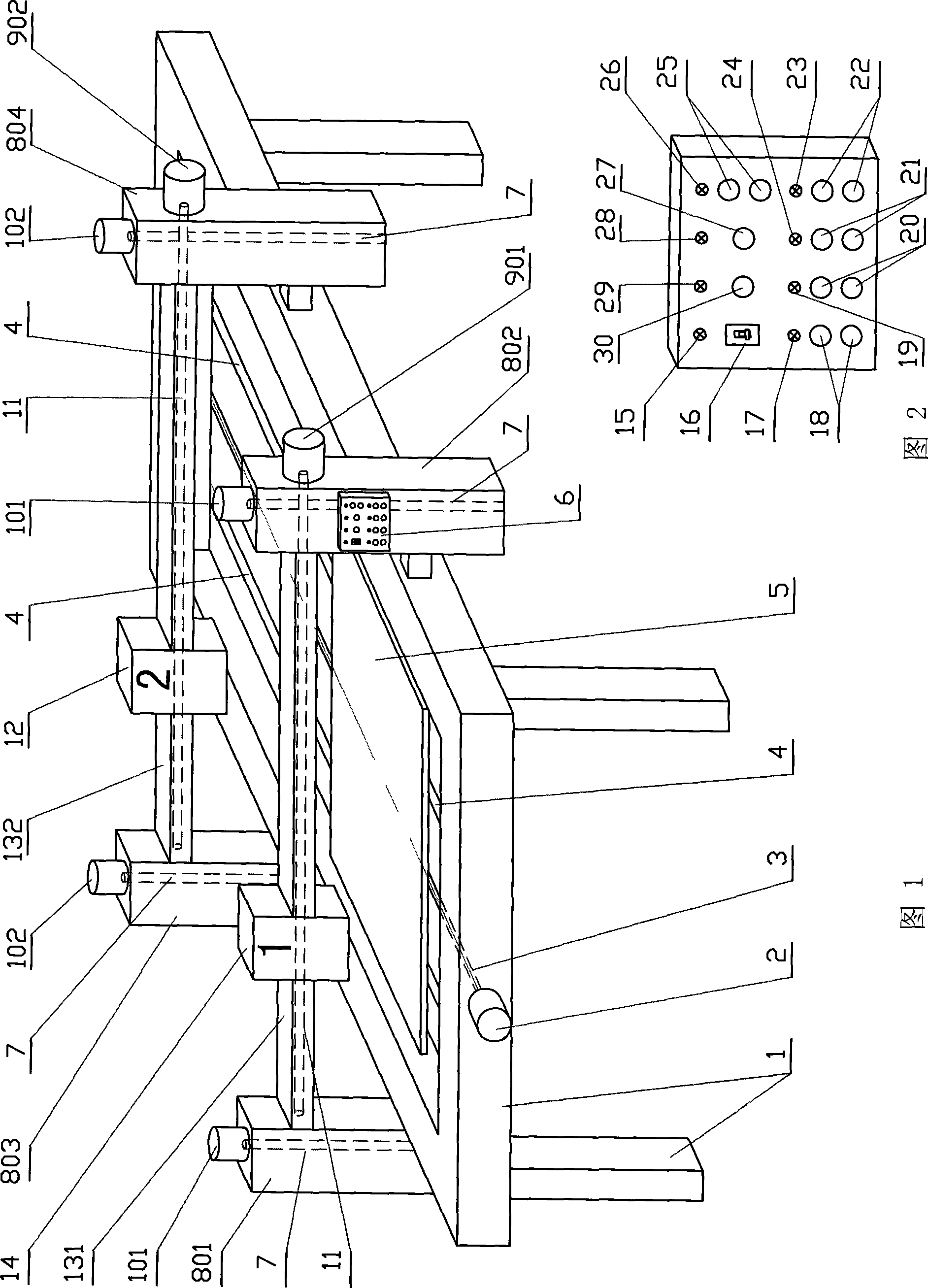

Flip chip bonding method for enhancing adhesion force in flip chip packaging process and metal layer-built structure of substrate for the same

InactiveUS7115446B2Increase productivityImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesAdhesion forceWafering

A flip chip bonding method and substrate architecture are disclosed for enhancing bonding performance between a chip and a substrate by forming a bump on the chip or the substrate. The flip chip bonding method includes performing pretreatment of a wafer having chips, dicing, and obtaining the pretreated individual chip; performing pretreatment of a substrate; aligning the pads of the pretreated chip with the pads of the pretreated substrate, and bonding the chip and the substrate together by applying an ultrasonic wave and heat using a collet and simultaneously applying pressure. Post treatment is performed by filling or molding resin after bonding. The chip or the substrate is formed with a plated bump, a stud bump or a wedge bump. The stud bump or the wedge bump can be additionally formed on the plated bump.

Owner:KOO JA UK +1

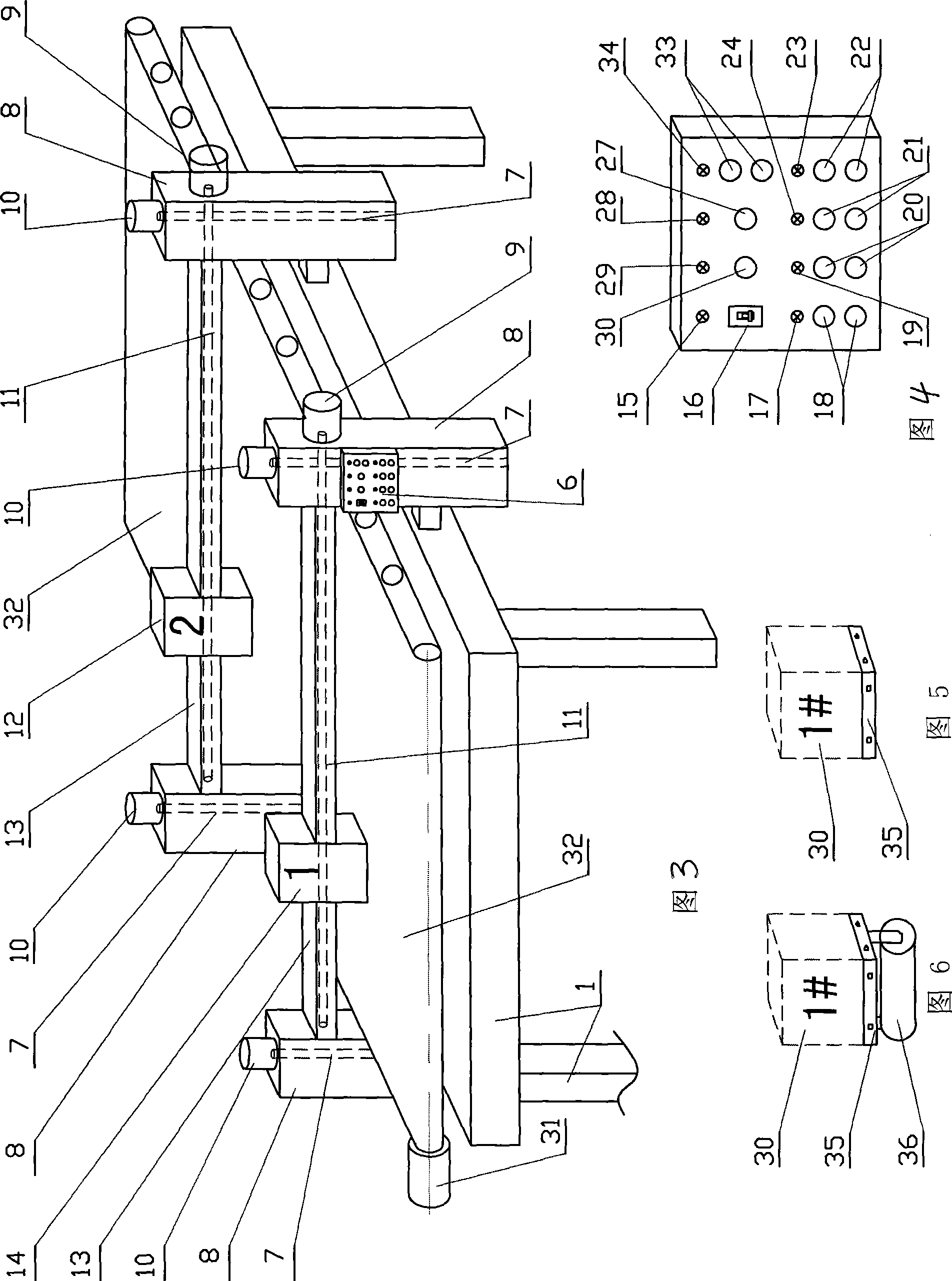

Color jet printing machine and jet printing method

InactiveCN101367296AImprove ergonomicsLow costTypewritersPower drive mechanismsScreen printingAdhesion force

The invention relates to a color jet printer and a jet printing method thereof. The color jet printer comprises a machine frame, an upright post, a horizontal beam, a jet printing worktable and an electric cabinet, wherein the structure of the jet printing worktable comprises a parallelly traveling worktable and a rotary conveyer belt; textile to be printed is tiled on the parallelly traveling worktable or the rotary conveyer belt; and pattern areas of the textile are sprayed with white bottom layers by a computer programmed NO. 1 inking box and white bottom areas are sprayed with colored patterns by a computer programmed NO. 2 inking box. By utilization of the prior computer programmed color jet printing technology to perform jet printing of patterns on the textile such as T-shirts and so on or planar carriers, the jet printing method improves the work efficiency, reduces the cost and strengthens the viewing effect compared with the prior printing method. The white bottom layers are printed on the pattern areas of the textile at first and then sprayed with patterns, thereby the jet printing method can improve the adhesion force of the patterns and the textile, guarantee that the patterns are not fallen off and strengthen the jet printing effect of the patterns. Moreover, the white bottom layers of the textile can be respectively printed by the jet printing technique, the hot transfer printing technique or the silk-screen printing technique.

Owner:徐中九

Ultrathin section steel structure fire-resisting paint and preparation thereof

The invention discloses an ultra-thin fireproof coating for a steel structure and a preparation method thereof. The coating has the characteristics of high gloss, good water resistance, strong adhesion force and so on of a solvent based ultra-thin fireproof coating, also has the advantages of water-based coatings by taking water as a medium, and satisfies the direction of developing low-pollution and environment-friendly coatings of the coating industry. The technical proposal comprises that the ultra-thin fireproof coating for the steel structure is prepared from the following components by weight portion: 10 to 35 portions of acrylic hybrid emulsion, 10 to 25 portions of dehydration and carbon-forming catalyst, 10 to 25 portions of carbon forming agent, 5 to 20 portions of foaming agent, 5 to 20 portions of flame retardant, 5 to 25 portions of pigment and filler, 3 to 10 portions of reinforcing agent, 5 to 10 portions of latent solvent, 1 to 5 portions of dispersant, 0.1 to 1 portion of foam killer, 0.2 to 2 portions of flatting agent, 0.2 to 2 portions of thickening agent, 1 to 5 portions of film forming additive, and the balance being water.

Owner:MARINE CHEM RES INST

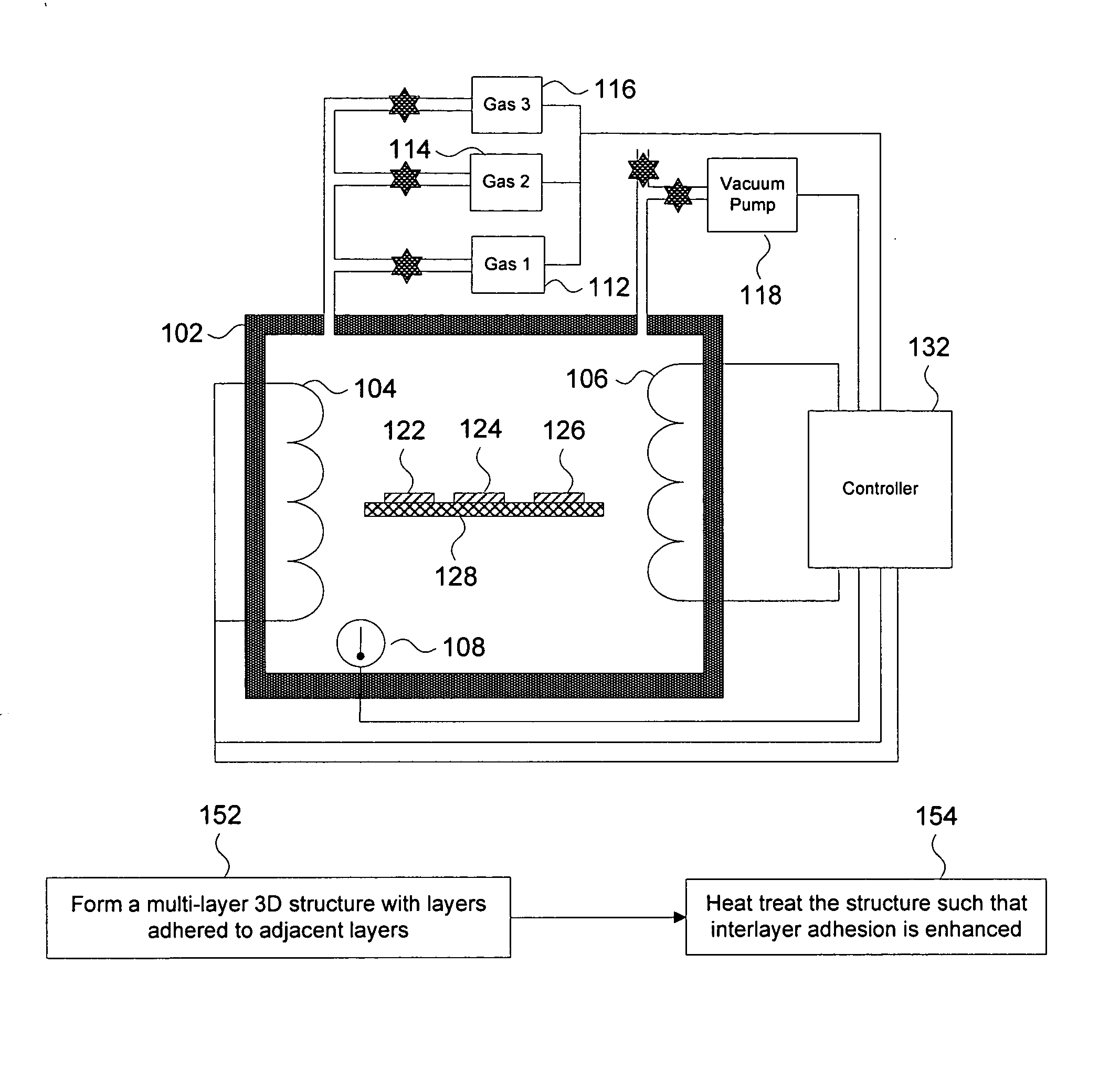

Method of electrochemically fabricating multilayer structures having improved interlayer adhesion

InactiveUS20050045585A1Improve propertiesImprove interlayer adhesionDecorative surface effectsSemiconductor/solid-state device manufacturingReducing atmosphereHeat treating

Multi-layer microscale or mesoscale structures are fabricated with adhered layers (e.g. layers that are bonded together upon deposition of successive layers to previous layers) and are then subjected to a heat treatment operation that enhances the interlayer adhesion significantly. The heat treatment operation is believed to result in diffusion of material across the layer boundaries and associated enhancement in adhesion (i.e. diffusion bonding). Interlayer adhesion and maybe intra-layer cohesion may be enhanced by heat treating in the presence of a reducing atmosphere that may help remove weaker oxides from surfaces or even from internal portions of layers.

Owner:UNIV OF SOUTHERN CALIFORNIA

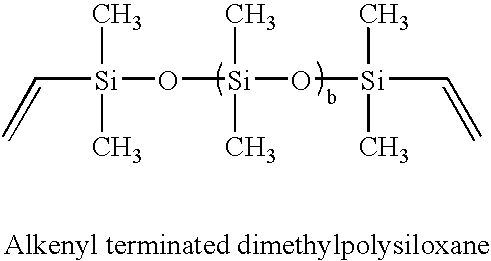

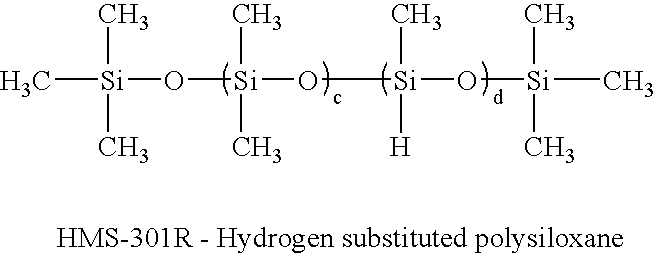

Photocured silicone sealant having improved adhesion to plastic

InactiveUS6908682B2Improve adhesionExtended service lifeOther chemical processesCouplings bases/casesAdhesion forceHydrogen

A curable composition for use as a sealant, in which the curable composition comprises a silicone fluid in an amount from about 80 wt % to about 90 wt %, a vinyl group containing polyorganosiloxane in an amount from about 10 wt % to about 20 wt %, a hydrogen containing polysiloxane in an amount from about 0.5 wt % to about 2.0 wt %, and a hydrosilation photocatalyst in an amount from about 5 ppm to about 100 ppm. The sealant cures in about 1 second to about 20 seconds during reaction of the vinyl group containing polydiorganosiloxane and the hydrogen containing polysiloxane, by exposure to ultraviolet radiation, in the presence of the hydrosilation photocatalyst. The sealant has an adhesion force to plastic from about 2.0 N / 100 mm to about 4.0 N / 100 mm.

Owner:3M INNOVATIVE PROPERTIES CO

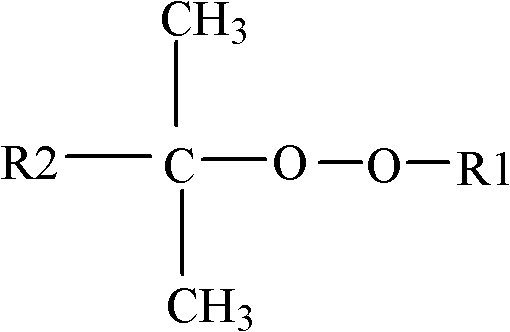

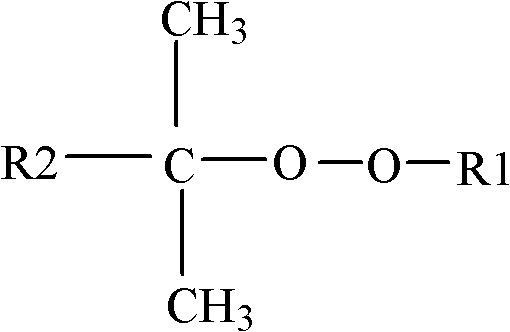

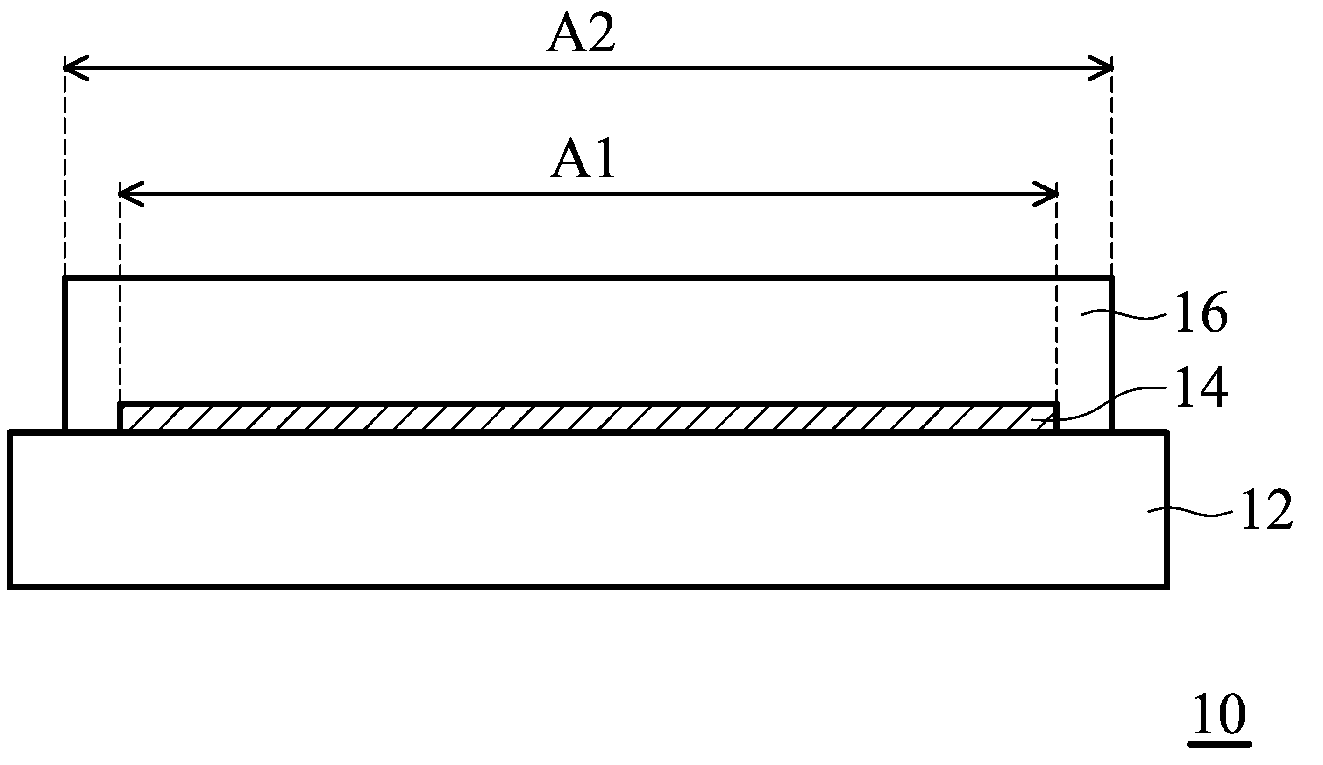

Halogen-free low dielectric resin composition and prepreg and copper clad laminate made of same

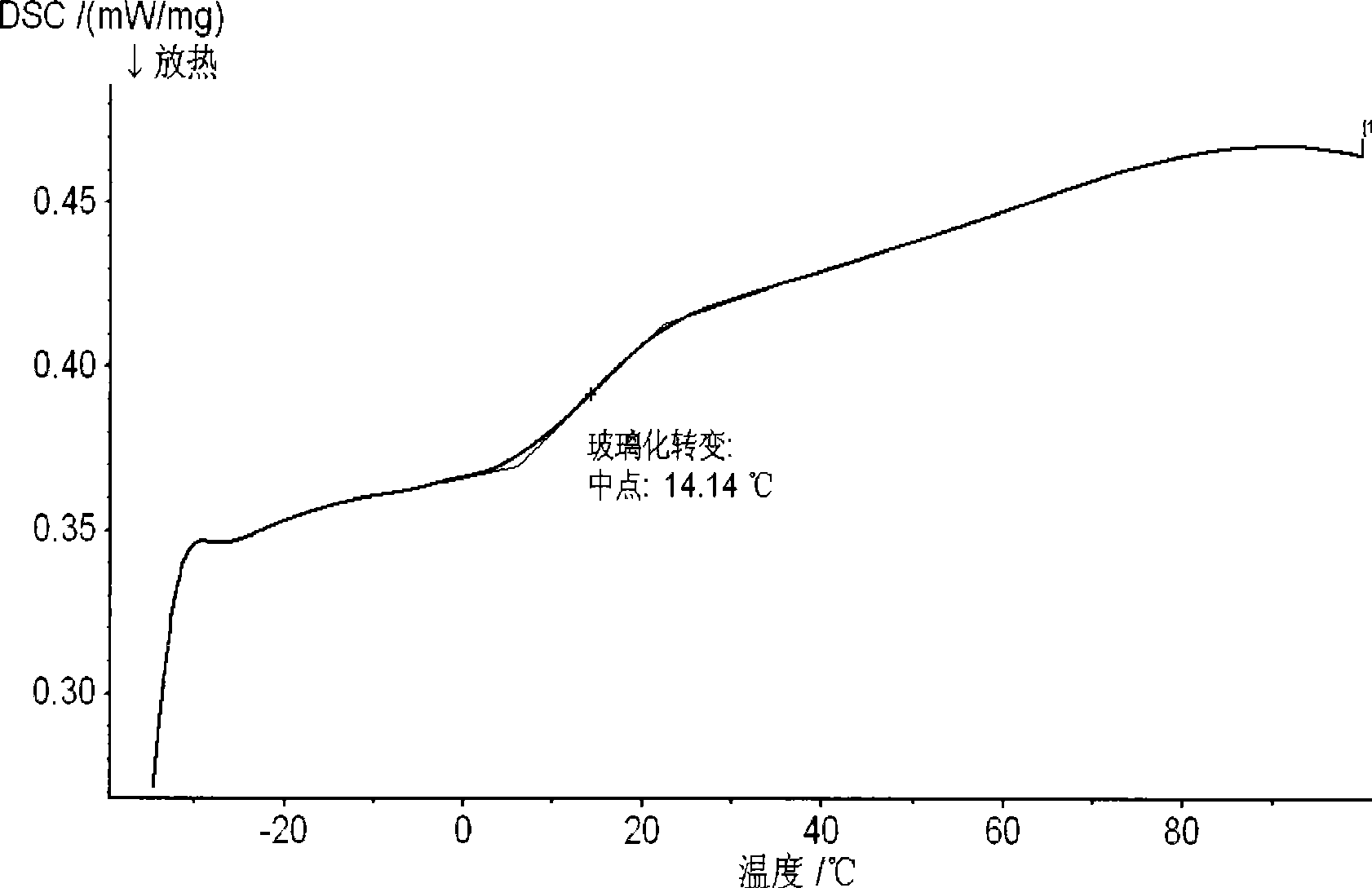

ActiveCN102504532AImprove shortcomingsHigh glass transition temperatureSynthetic resin layered productsCircuit susbtrate materialsDielectricEpoxy

The invention relates to a halogen-free low dielectric resin composition and a prepreg and copper clad laminate made of the same. The halogen-free low dielectric resin composition comprises the following components in part by weight of organic solid content: 5 to 90 parts by weight of epoxidized polybutadiene resin, 10 to 90 parts by weight of benzoxazine resin, 10 to 90 parts by weight of epoxy resin, 1 to 50 parts by weight of curing agent, 10 to 50 parts by weight of organic flame retardant, 0.001 to 1 part by weight of curing accelerator, 0.1 to 10 parts by weight of initiator and 10 to 100 parts by weight of fillings. Due to the adoption of the epoxidized polybutadiene in the halogen-free low dielectric resin composition disclosed by the invention, not only are the defects of polybutadiene improved, but also the advantages on the aspects of dielectric and flexibility are well kept and the adhesion force between the halogen-free low dielectric resin composition and a copper foil is improved; and the prepreg and copper clad laminate for a printed circuit board, which is made of the resin composition, has excellent dielectric performance, good heat resistance and high glass transition temperature and the requirements on the high frequency of transmission of an electronic signal and high speed of information processing in the industry of the printed circuit copper clad laminate can be met.

Owner:GUANGDONG SHENGYI SCI TECH

Self-crosslinking acrylic ester composition emulsion for plastic printing ink and preparation thereof

A self-crosslink acrylic ester compound emulsion for plastic ink and a preparation method thereof belong to the technical field of macromolecular synthesis. In order to solve the problems of the'ink shrinking' of the plastic ink on the surface of plastics and the adhesion force, the invention provides the self-crosslink acrylic ester compound emulsion for the plastic ink. The latex is a product obtained through emulsion polymerization which is carried out by a functional monomer with low polymerization shrinkage, low surface tension and higher permeability and other vinyl monomers. The invention also discloses the preparation method for the emulsion. The preparation method which is carried out through the pre-emulsification nucleocapsid emulsion technology mainly comprises the following two steps: 1. preparing a seed nucleus emulsion; and 2. preparing the nucleocapsid emulsion based on the seed nucleus emulsion to finally obtain the self-crosslink acrylic ester compound emulsion for the plastic ink. The emulsion which is bright and transparent after film forming has good adhesion force to a plastic base material, and the adhesion force to PP, PE films is particularly excellent.

Owner:PEKING UNIV +1

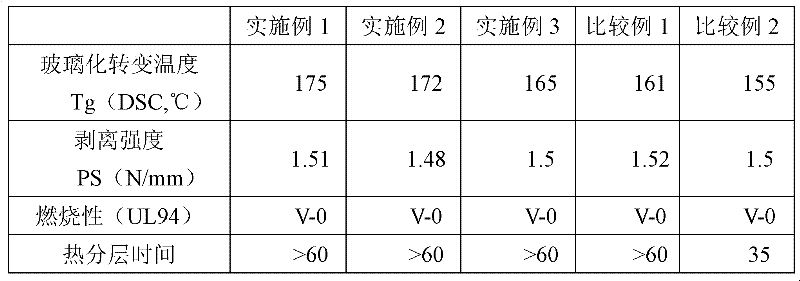

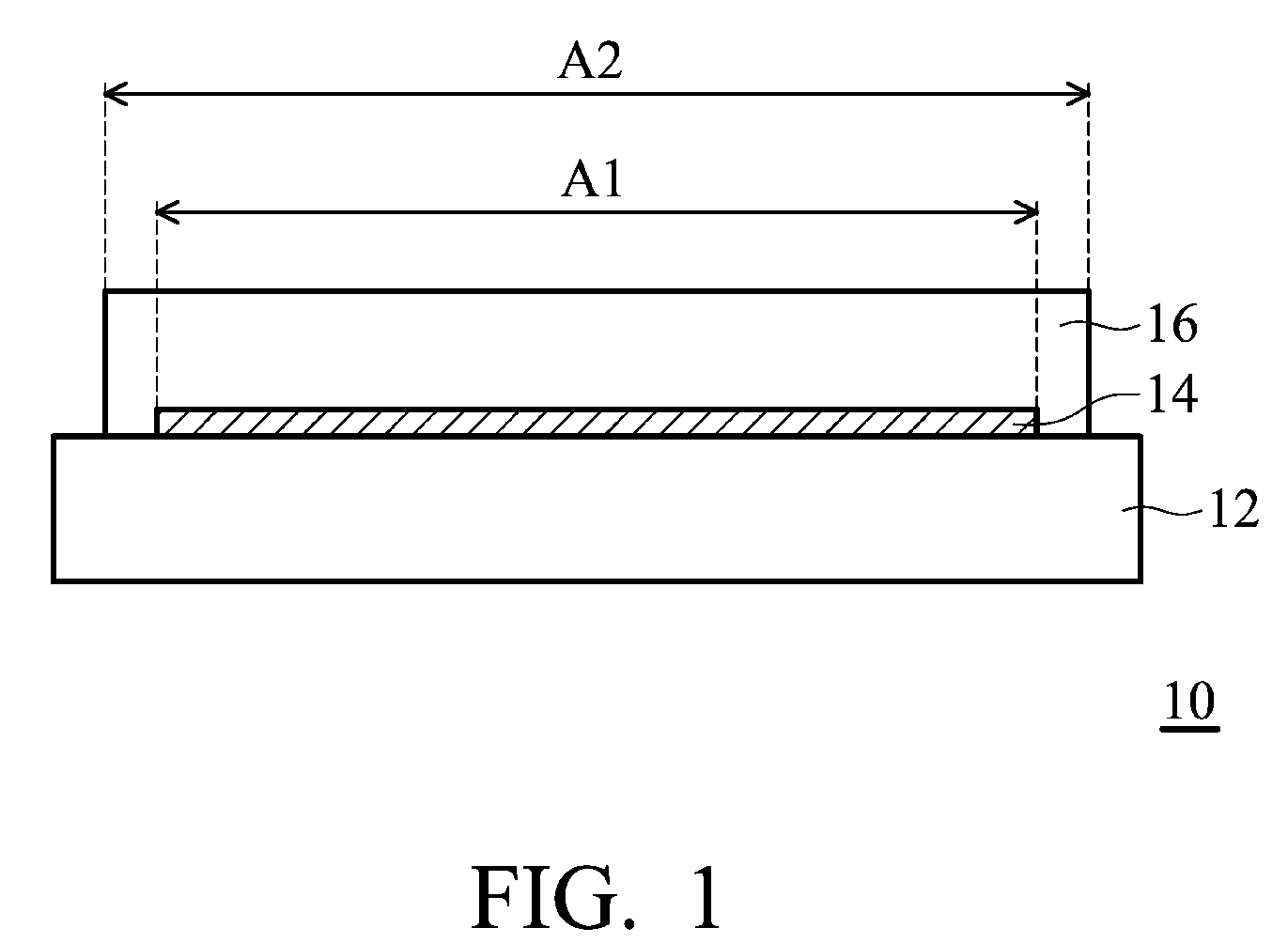

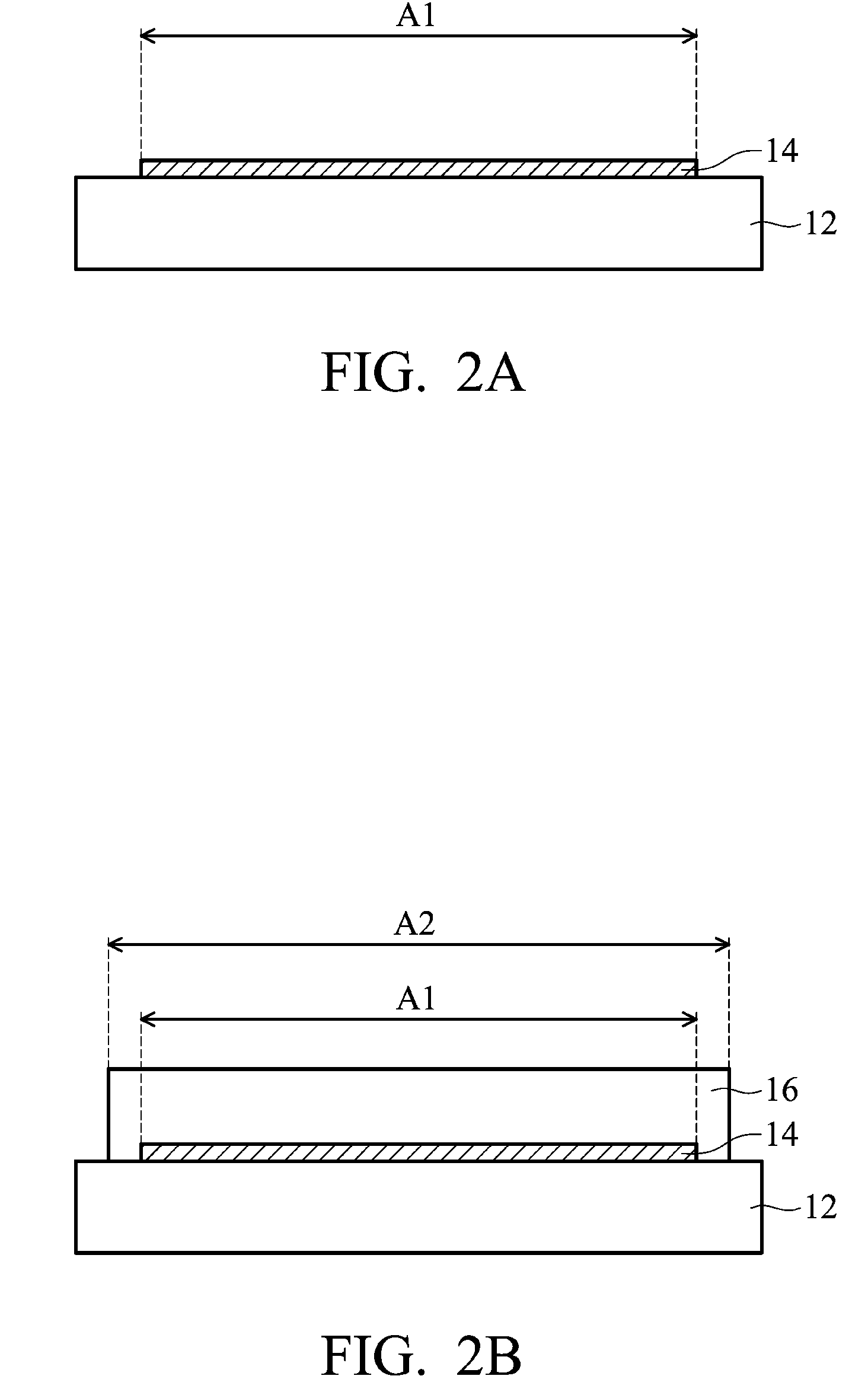

Substrate structures applied in flexible electrical devices and fabrication method thereof

ActiveUS20100068483A1Improve adhesionReduce adhesionSynthetic resin layered productsSolid-state devicesAdhesion forceElectrical devices

A substrate structure applied in flexible electrical devices is provided. The substrate structure includes a carrier, a release layer overlying the carrier with a first area and a flexible substrate overlying the release layer and the carrier with a second area, wherein the second area is larger than the first area and the flexible substrate has a greater adhesion force than that of the release layer to the carrier. The invention also provides a method for fabricating the substrate structure.

Owner:IND TECH RES INST

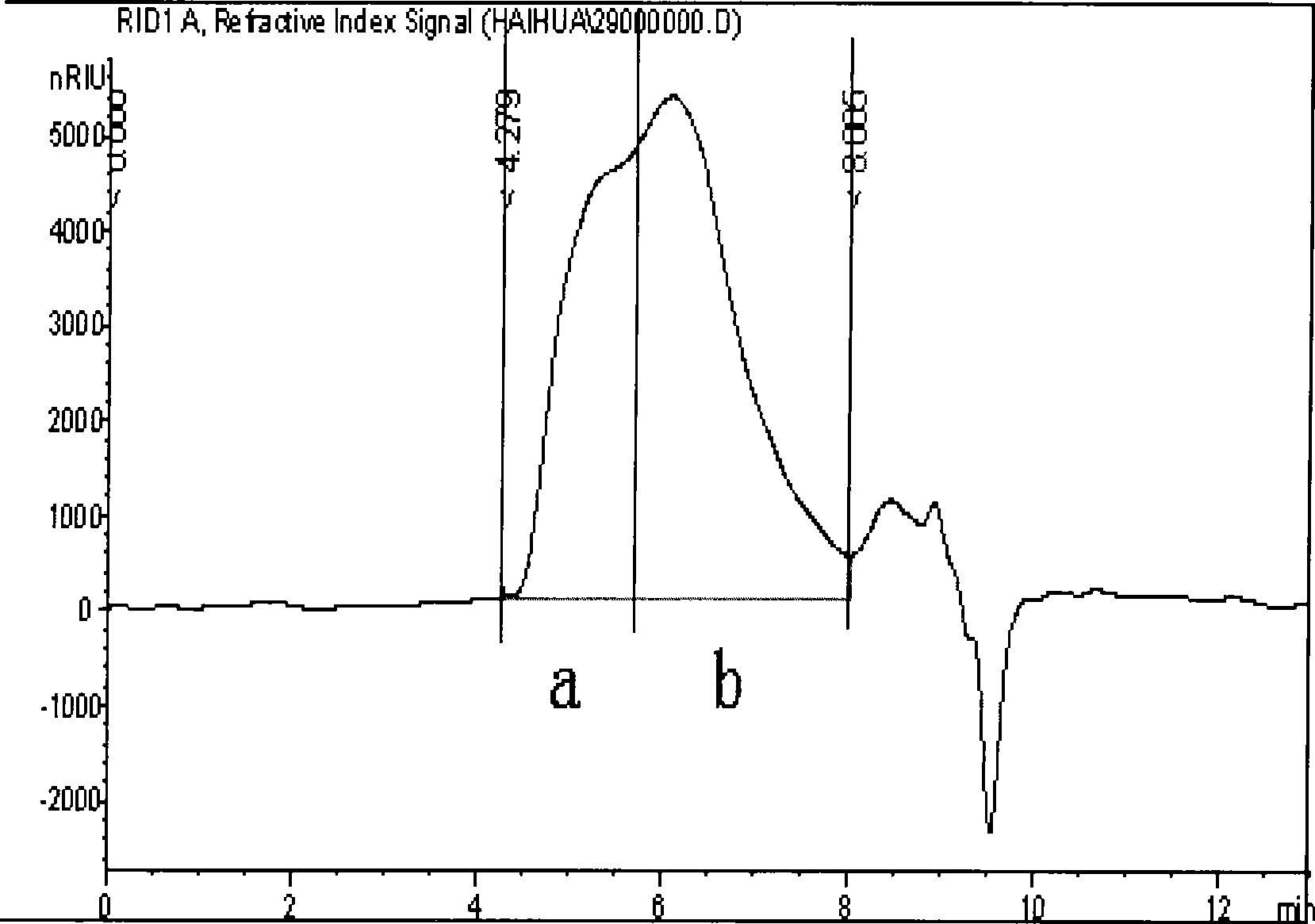

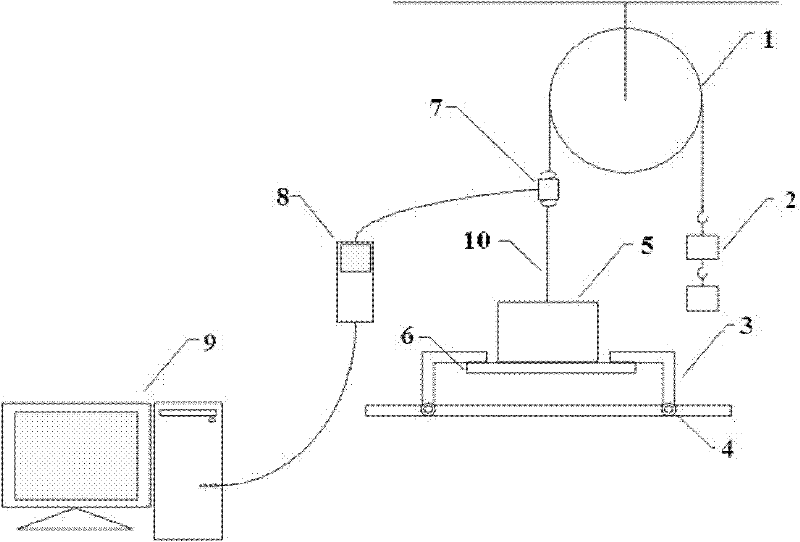

System and method for measuring ice coating adhesion strength on material surface

InactiveCN102288542ASimple structureEasy to operateUsing mechanical meansMaterial analysisAdhesion forceEngineering

The invention discloses a system and a method for measuring the adhesion strength of ice coating on a material surface, belonging to the field of ice coating measurement. The system comprises a force applying poise, a tension gauge, an icing mold, a fixing device, a pulling rope, a fixed pulley and a computer, wherein the icing mold is connected with a sample to be measured through ice coating; the sample to be measured is fixed by the fixing device; one end of the pulling rope is connected with the icing mold through the tension gauge, and the other end of the pulling rope is connected with the force applying poise through the fixed pulley; and the data output end of the tension gauge is connected with the computer through a data transmission line. The system for measuring the adhesion strength of ice coating on the material surface disclosed by the invention has a simple structure, the method is easy to operate, and the system and the method are suitable for measuring and analyzing the adhesion force of ice coating on different material surfaces in units such as plants, laboratories and the like.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

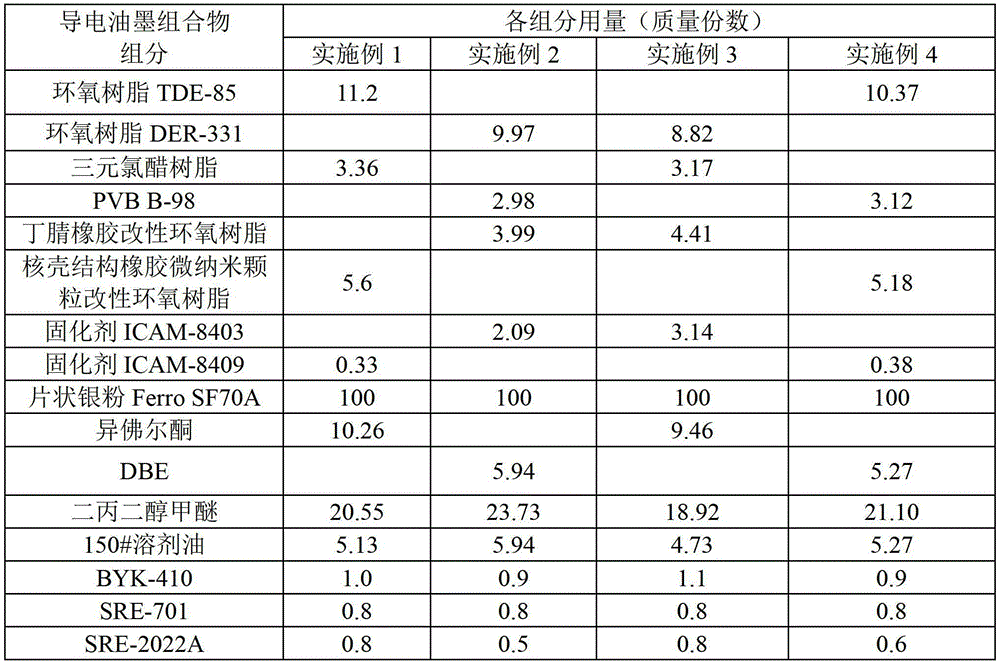

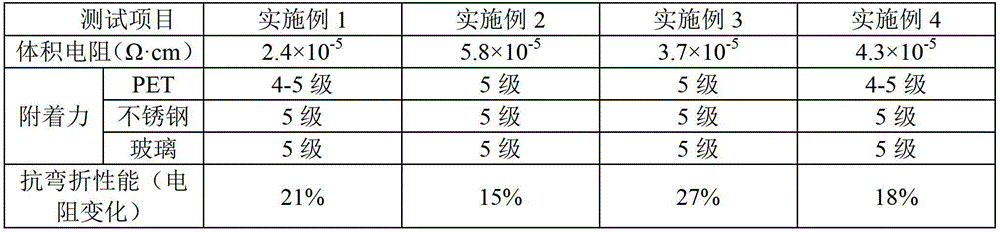

Screen printing conductive printing ink composition and preparation method thereof

The invention discloses a screen printing conductive printing ink composition which comprises the following components in percentage by mass: 20-70 percent of conductive material powder, 1-20 percent of epoxy resin, 0.2-15 percent of epoxy resin latent curing agent, 1-30 percent of thermoplastic resin, 5-60 percent of organic solvent and 0-5 percent of epoxy resin flexibilizer. The preparation method comprises the following steps: mixing the thermoplastic resin powder and the organic solvent, mixing the epoxy resin, the epoxy resin flexibilizer and the epoxy resin latent curing agent to obtain a thermoplastic resin system, adding the conductive material powder to the thermoplastic resin system, mixing the conductive material powder with the thermoplastic resin system; and finally, adding the organic solvent to regulate the viscosity, thus obtaining the screen printing conductive printing ink composition. The product has the advantages of high mechanical strength, stable electrical properties, excellent chemical resistance, high base material adhesion force, low volatile organic compound (VOC) content and the like.

Owner:NAT UNIV OF DEFENSE TECH +1

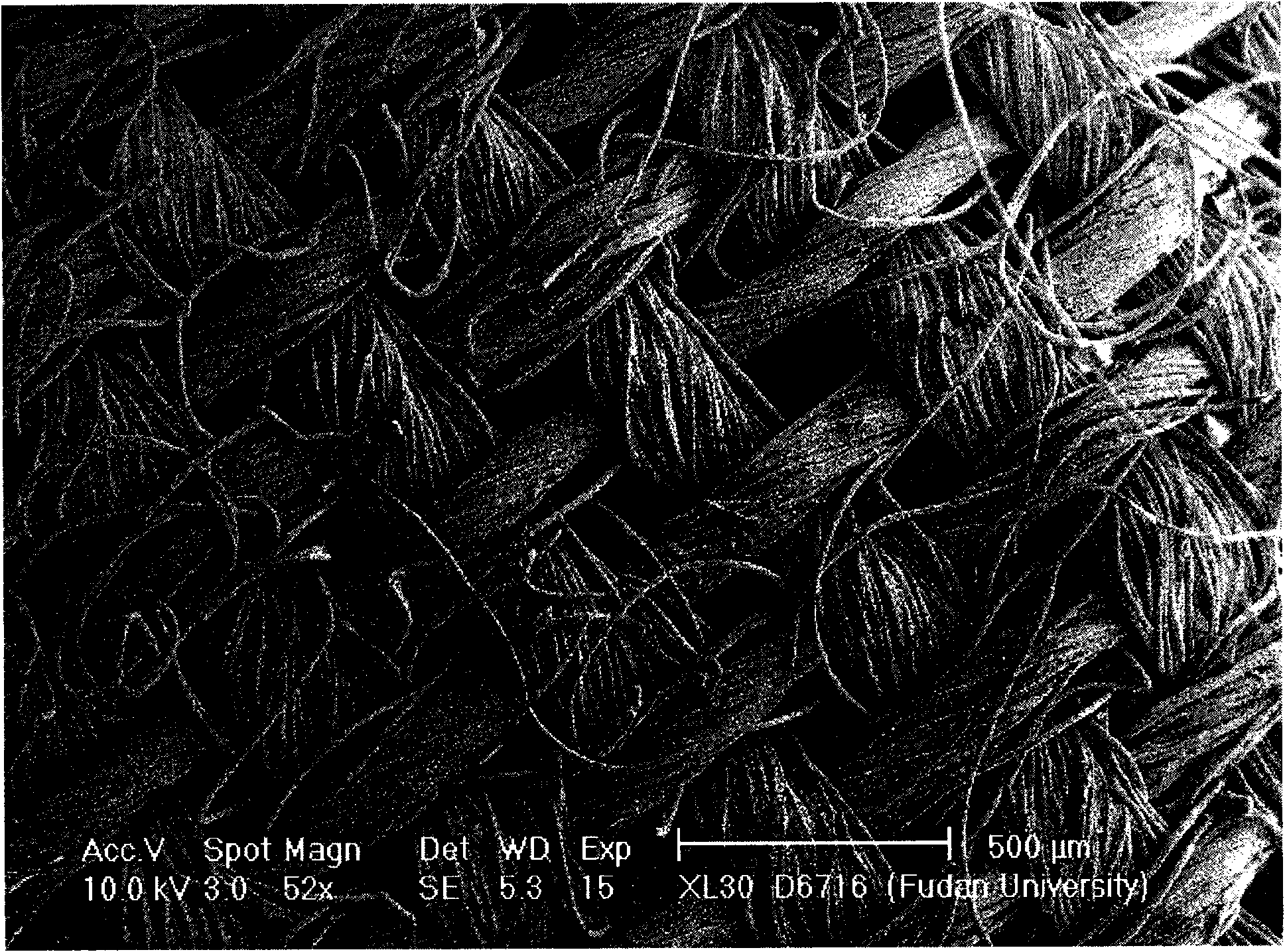

Low-silver-loaded electromagnetic wave shielding fabric preparation method

InactiveCN101613931AHigh bonding strengthImprove conductivityMagnetic/electric field screeningFibre typesPolyesterUltrasound - action

The invention belongs to the technical field of electromagnetic wave shielding material and relates to a low-silver-loaded electromagnetic wave shielding fabric preparation method, comprising the following specific steps: modifying the surface of polyester fabric, introducing an active group--sulphydryl under the premise of not increasing the surface area of the fabric, and then plating silver with ultrasonic wave; wherein, Ag-S chemical bond is formed between sulphydryl and silver so that the compactness of the silver coating and the adhesion force of the fabric substrate are increased; in the process of chemical plating, fresh plating solution is always on the surface of the fabric and the materials which are absorbed on the surface of the fabric through physical adsorption are removed timely owning to the action of ultrasonic wave so that the continuity and compactness of the silver coating can be improved further; the silver loading content of the prepared silver-loaded electromagnetic wave shielding fabric is 6.7-7.0% by weight; the fabric is more resistant to the corrosion of the air and water, the electromagnetic shielding effectiveness is more than 32dB in the range of 0.01-18GHz, namely the anti-electromagnetic radiation rate is more than 99.9%; the fabric can be widely used in electromagnetic wave antiradiation clothes and in the field of electromagnetic wave shielding for special departments such as military, national defense and the like.

Owner:FUDAN UNIV

High-pressure high-temperature edge sealing method for vacuum glass

ActiveCN103145325AImprove adhesionImprove the level ofGlass reforming apparatusAdhesion forceMetallurgy

The invention relates to a high-pressure high-temperature edge sealing method for vacuum glass. The high-pressure high-temperature edge sealing method for the vacuum glass comprise the steps of (1) of coating one circle of closed low-melting-point glass powder onto the edge periphery of a lower glass piece with a support object, and combining an upper glass piece with the lower glass piece; (2) putting the combined glass into a high-pressure high-temperature heating pot in a manner of vertically arranging the glass or flatly putting the glass on a bracket; and (3) increasing the temperature in the high-pressure high-temperature heating pot to the melting point of the glass powder 350 DEG C to 480 DEG C, increasing the pressure 0.1MPa to 5MPa into the pot by an air compressor, keeping the temperature and the pressure for 0.2 hour to 2 hours, and decreasing the pressure and the temperature to obtain a vacuum glass finished product. With the adoption of the high-pressure high-temperature edge sealing method for the vacuum glass, the low-melting-point glass powder is put between the edges of the two glass pieces; the temperature is increased to 350 DEG C to 480 DEG C under the normal pressure in the high-pressure pot; after the low-melting-point glass powder is molten, the pressure increase is performed, so that the two glass pieces are extruded in a vacuum way; therefore, the molten low-melting-point glass powder contacts with the upper glass piece and the lower glass piece fully and closely; the heat conduction speed and the heat conduction amount are increased; the adhesion force and the leveling performance of the molten powder are enhanced; the sealing quality of edges sealed with the low-melting-point glass powder is improved; and the technical difficulty of air leakage after the edge sealing is effectively solved.

Owner:TIANJIN GUSHANG VACUUM GLASS MFG

Metal surface vitrification agent and application method thereof

ActiveCN102747355AImprove corrosion resistanceStrong impact resistanceMetallic material coating processesSilanesConversion coating

The invention provides a metal surface vitrification agent and an application method thereof, aiming for solving the problem of possibility of environmental pollution caused by waste water discharge in a treatment process or after treatment in the existing metal surface phosphating treatment technology. According to the invention, the metal surface vitrification agent comprises 2.0-38.0% of zirconium titanium salt, 0.1-8.0% of silane, 0.5-18.0% of a buffer agent, 0.01-5.00% of film forming assistant, 0.1-6.1% of an anti-rust agent and 0.2-7.0% of a complexing agent, wherein the surface appearance is clear transparent liquid and no suspended matter exists; pH value is 1-2, and the specific gravity is 1.05+ / -0.02 g / cm<3>. The metal surface vitrification agent has the advantages that an embedded hybrid indissolvable nanometer ceramic conversion coating is formed on the metal surface at normal temperature and is excellent in impact resistance, the adhesion force of the coating is improved, and the corrosion resistance of the metal surface is enhanced. In addition, the metal surface vitrification agent, provided by the invention, contains no component capable of causing environmental pollution, and can be directly discharged without environmental pollution.

Owner:CHOGNQING CHANGYU METAL SURFACE TREATMENT TECH

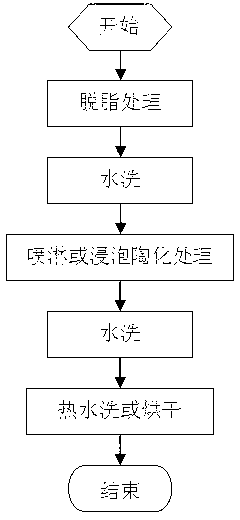

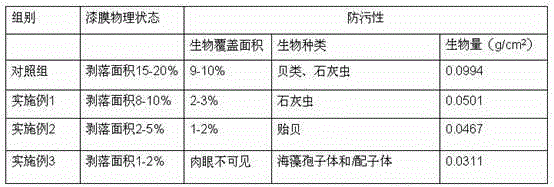

Ship anti-pollution method

InactiveCN104549961ANo toxic effectsNot volatileAntifouling/underwater paintsPretreated surfacesAdhesion forceDefect repair

The invention discloses a ship anti-pollution method. The ship anti-pollution method comprises the following steps of surface pretreatment of a steel plate, sanding treatment of a substrate, defect repair and sand blasting of welding seams and other structures, spraying of a primer, spraying of a reinforced paint, and subsequent servicing. Before coating, the surface of the steel plate is pretreated; during integral coating, the bottom part of a ship is sprayed with bionic marine anti-pollution coating, the coating contains a pure natural biological anti-pollution agent, the aversion function on marine organisms is realized, the adhesion force of the marine organisms is damaged, the pollution preventing purpose is realized, any poisonous influence on the marine environment is avoided, any damage on the marine organisms is avoided, and the coating is pure natural and is free from public nuisance; the adhesion force, anti-corrosive and strain-proof properties are excellent, the requirements of semi-gloss and matte of an anti-rust paint of a ship cabin are met, the spraying for multiple times is easy, the easiness in volatizing of moisture is avoided, the adhesion capability is higher, and the flash rust is avoided; the process flow is short, and the produced ship has excellent anti-pollution, anti-corrosive and anti-rust properties.

Owner:QINGDAO WUWEI THERMAL INSULATION MATERIAL

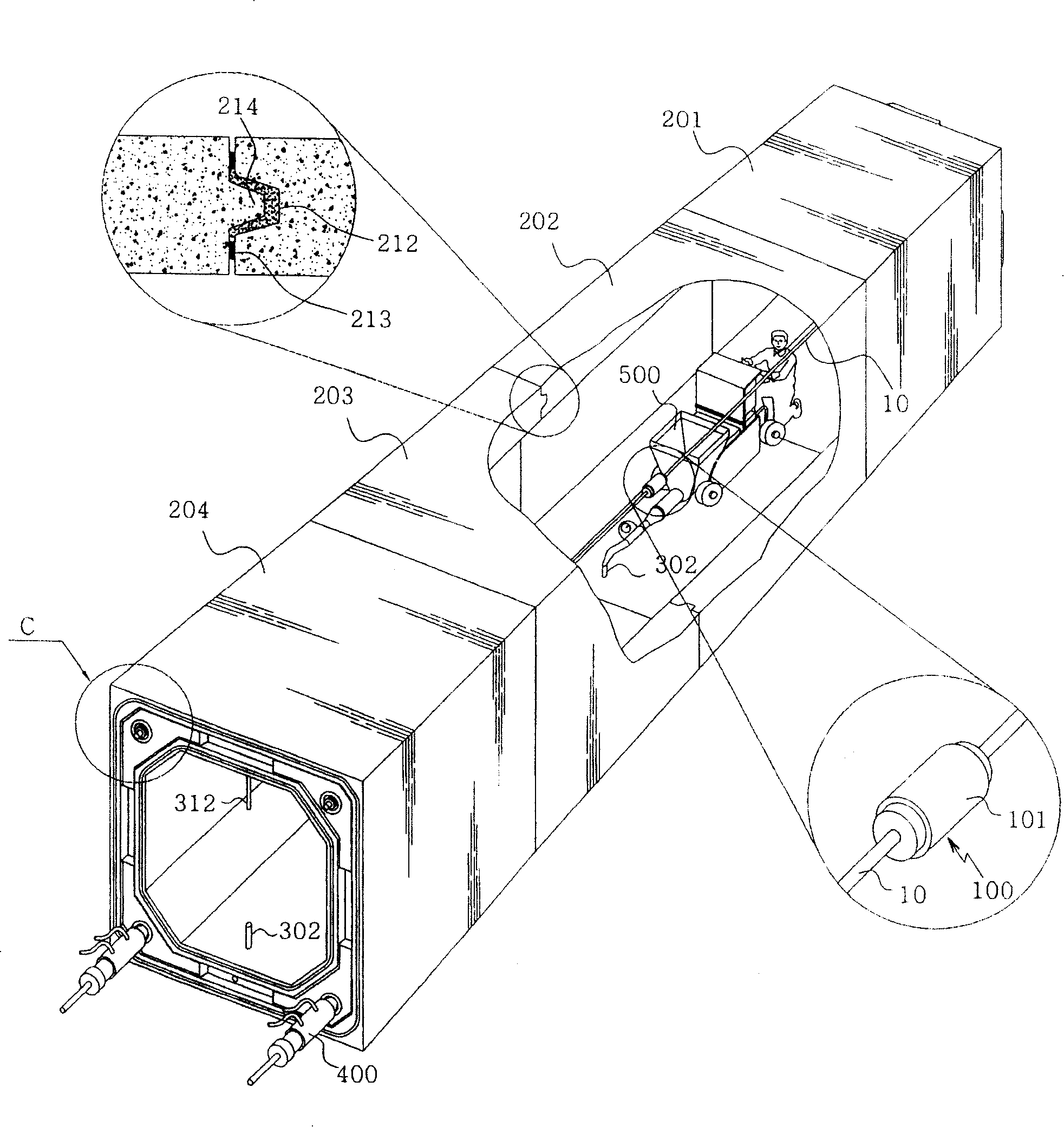

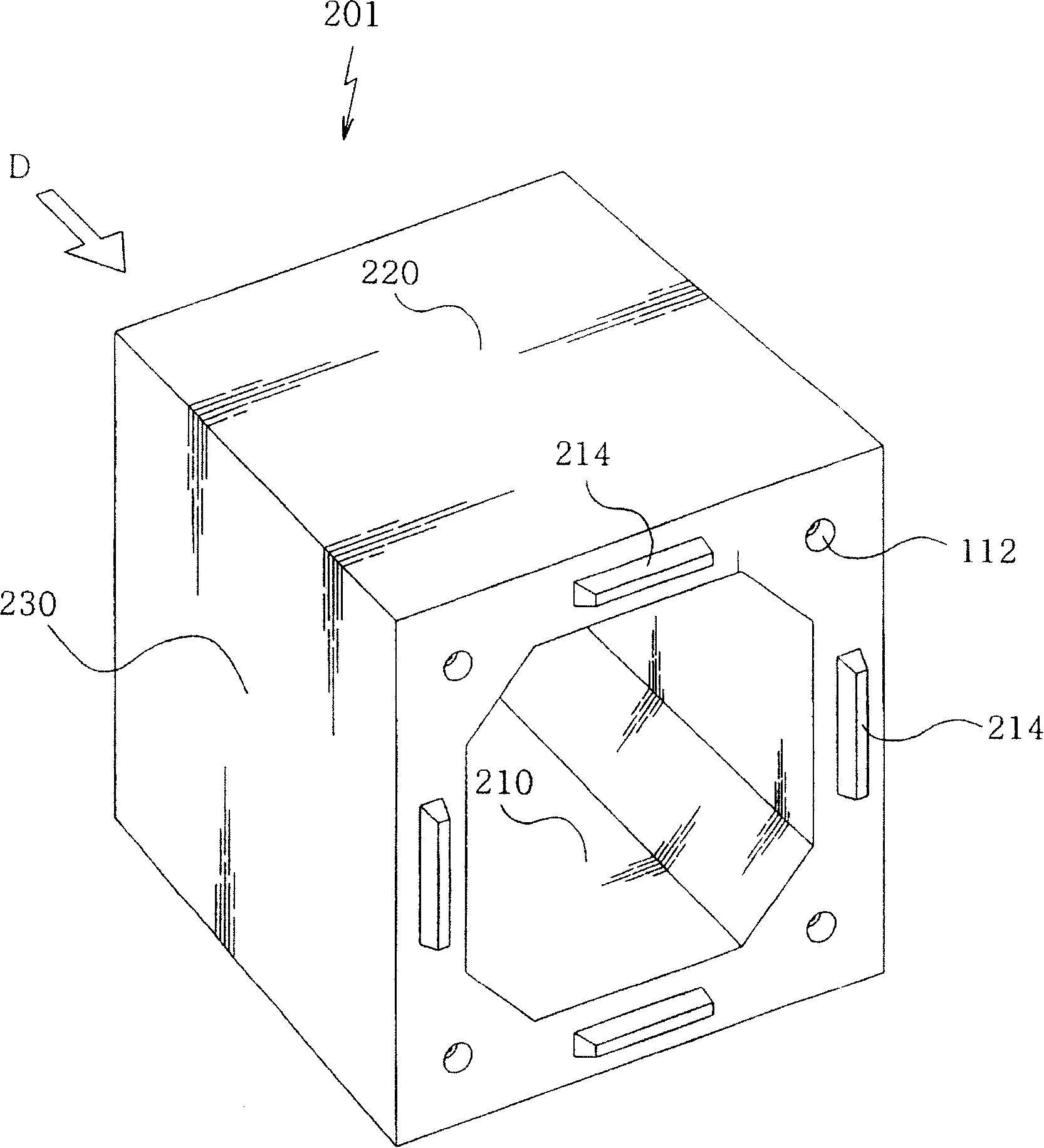

Prefabricated concrete box culvert using grouting method and bidirectional anchoring system as well as mounting structure and method thereof

InactiveCN101205724AAvoid damageReduce lossesArtificial islandsUnderground chambersAdhesion forcePre stress

The invention discloses a pre-fabricated concrete box culvert, the assembly structure thereof and an assembly method. The invention can ensure that the mortar is completely filled on a connecting surface of the pre-fabricated concrete box culvert, thereby furthest reducing the pre-stress damage caused by the sliding when the reinforcing steel bar is fixed, and allowing the pre-fabricated concrete box culvert to be assembled into a structure with extremely strong adhesion force, firmness and reliability, furthest reducing the loss of the bundled reinforcing steel bars and avoiding the damage to the structure.

Owner:朴斗绪 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com