High hydrophobic static-electricity conducting anti-icing coating and method for producing same

A technology of water conduction and static electricity, which is applied in the direction of conductive coatings, conductors, circuits, etc., can solve the problems of not being able to take into account the hydrophobic characteristics and conductive static electricity functions, and achieve the effects of shortening the residence time, reducing adhesion, and reducing surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

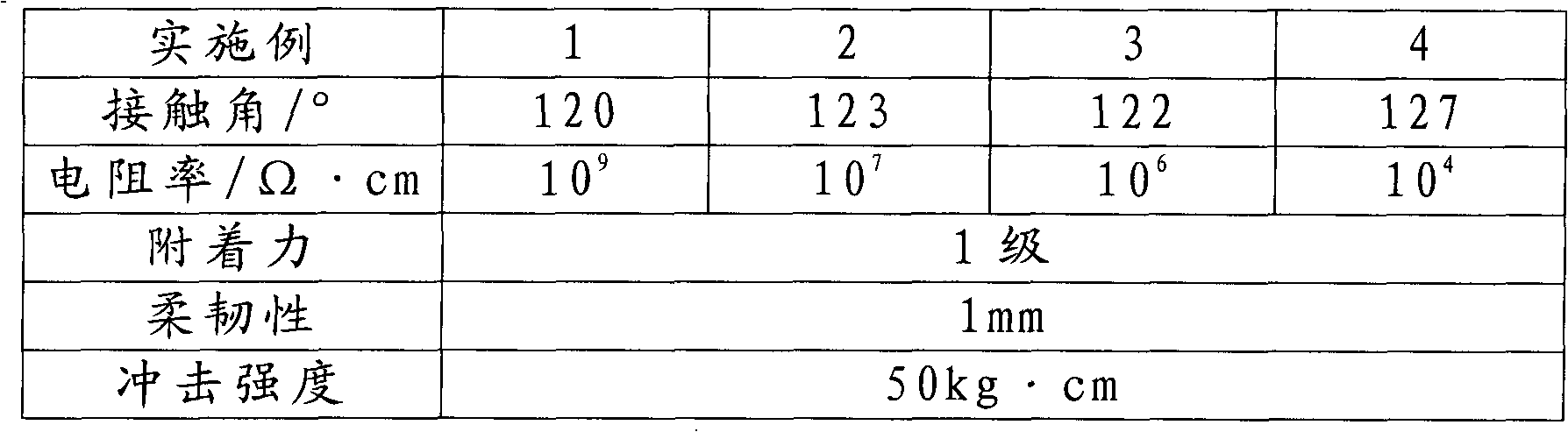

Examples

Embodiment 1

[0038] The weight ratio of A and B components is 15:1, and the formula of A component is as follows:

[0039] Fluorinated acrylic resin 38g, conductive mica 11g, iron red 3g, methyl siloxane copolymer 5g, UV-A 1g, 104S 1g, organic bentonite 1g, butyl acetate 20g, S100 10g.

[0040] Group B is Bayer's N75.

[0041]Prepare component A according to the following steps: dry the conductive mica and iron red in the formula of component A, and set aside. Weigh fluorinated acrylic resin, add iron red, organic bentonite, methyl siloxane copolymer, UV-A, 104S, butyl acetate, S100, add the above mixture into a basket sand mill and grind until fine The material is discharged after the temperature is 5-20 μm. Add the above mixture into the mixing tank, start stirring, add the metered sheet-shaped conductive mica, use a high-speed mixer to stir for 30 minutes at a speed of 2000rmp, filter with a 120-mesh filter, measure and pack, and test the viscosity of the coating at 86s (coating - 4 c...

Embodiment 2

[0044] The weight ratio of A and B components is 12:1, and the formula of A component is as follows:

[0045] Fluorinated acrylic resin 45g, nano-silicon nitride 12g, conductive titanium dioxide 8g, dimethylsiloxane copolymer 6g, UV-B 1g, 104 1g, organoclay 1g, xylene 20g, ethyl acetate 6g.

[0046] Group B is Bayer's N75.

[0047] Prepare component A according to the following steps: dry the conductive titanium dioxide and nano-silicon nitride in the formula of component A, and set aside. Weigh fluorinated acrylic resin, add nano-silicon nitride, conductive titanium dioxide, organic clay, UV-B, xylene, ethyl acetate, 104, dimethyl siloxane copolymer, and add the mixture to the basket sand mill Medium grinding, the grinding fineness is 5-20μm and the material is discharged. Filter with a 130-mesh filter, measure and pack, set aside, and test the viscosity at 105s (Tu-4 cups).

[0048] According to the ratio of 12:1, take the measured components A and B, mix them evenly, and...

Embodiment 3

[0050] The weight ratio of A and B components is 11:1, and the formula of A component is as follows:

[0051] Fluorinated acrylic resin 50g, conductive mica 17g, conductive barium sulfate 6g, acrylic modified organosiloxane 3g, UV-P 2g, 610S 1g, fumed silica 1g, xylene 10g, butyl glycol ether acetate 10g.

[0052] Group B is Bayer's N75.

[0053] Prepare component A according to the following steps: dry the conductive mica and conductive barium sulfate in the formula of component A, and set aside. Weigh fluorinated acrylic resin, add conductive barium sulfate, fumed silica, UV-P, xylene, ethylene glycol butyl ether acetate, 610S, acrylic modified organosiloxane, and add the mixture to the basket sand Grinding in the mill, the grinding fineness is 5-20μm and the material is discharged. Add the metered sheet-shaped conductive mica to the above materials, stir evenly with a high-speed mixer at a speed of 2200rmp, filter with a 140-mesh filter, measure and pack, and test the vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com