Patents

Literature

275 results about "Organoclay" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

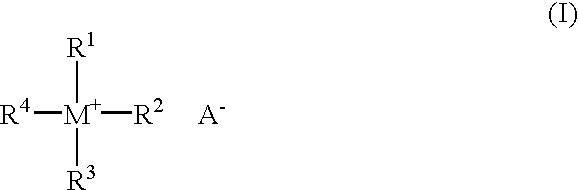

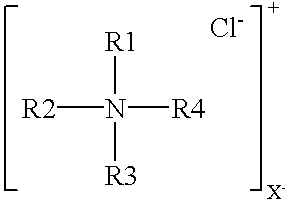

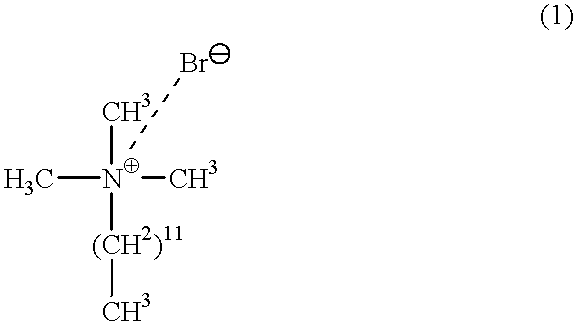

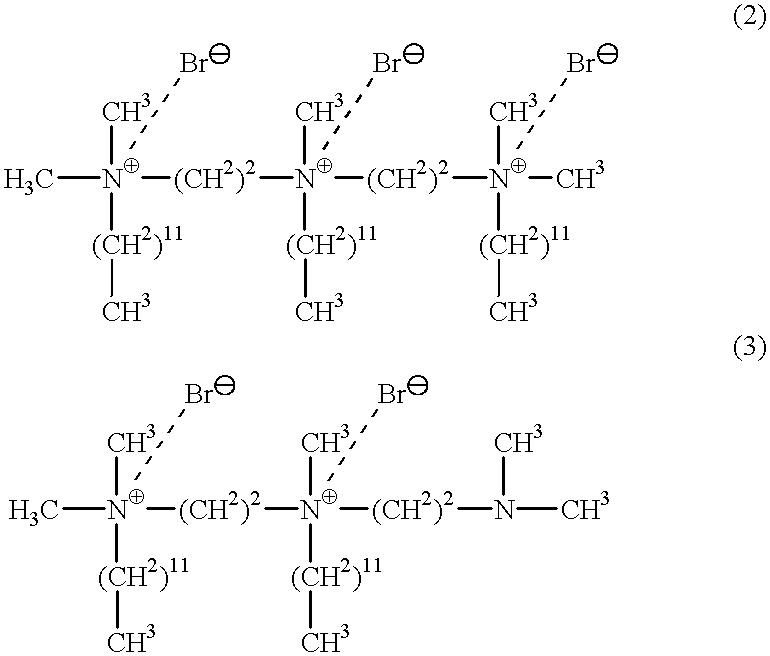

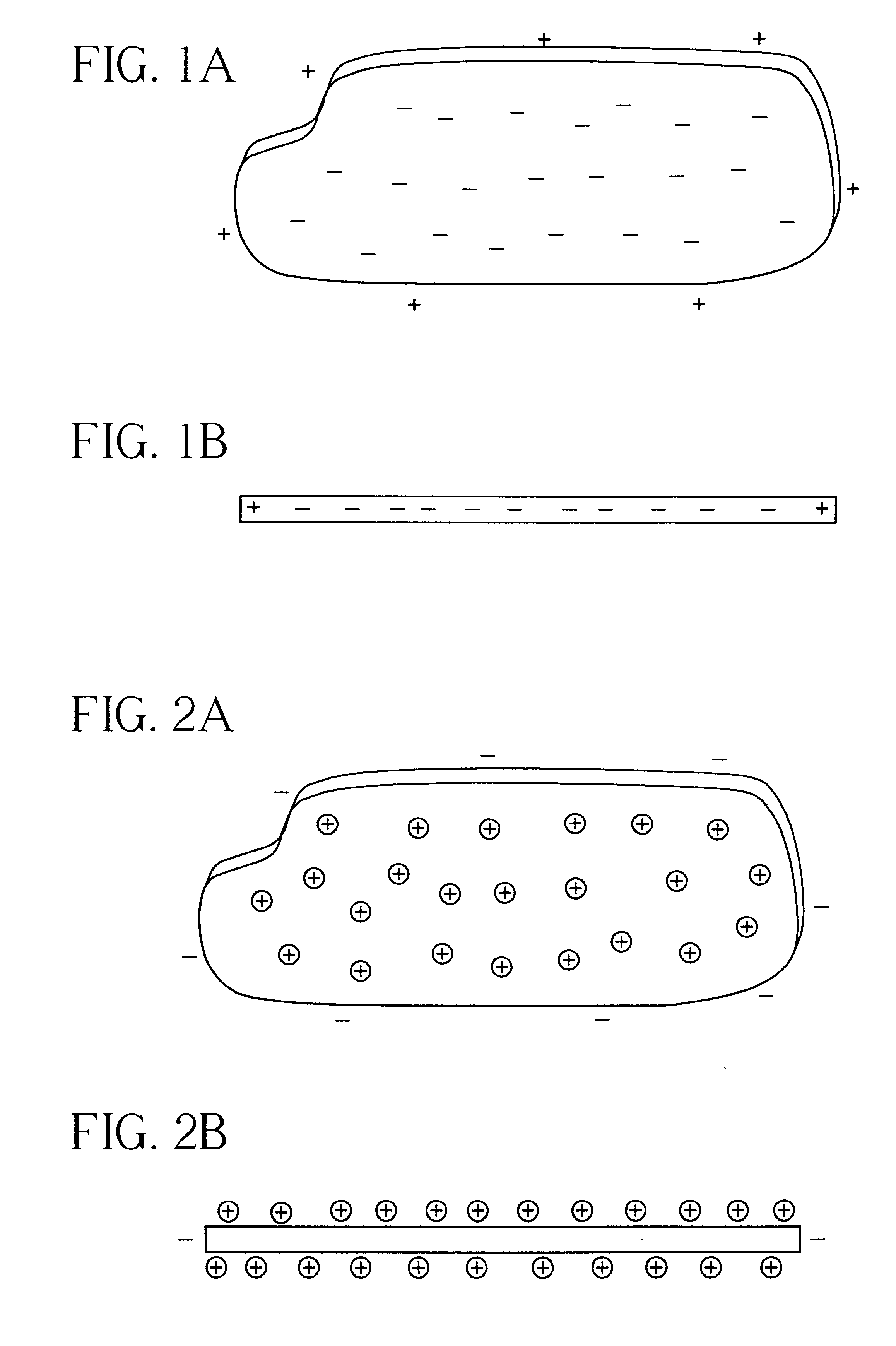

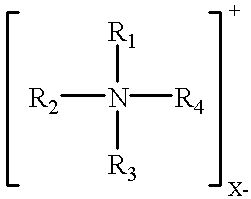

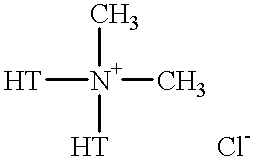

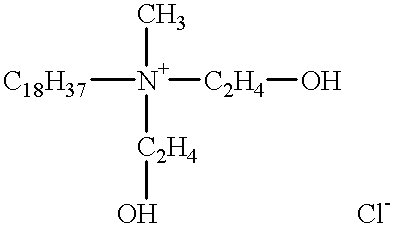

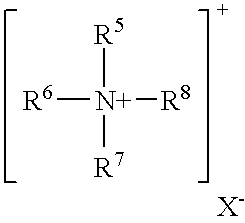

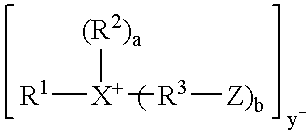

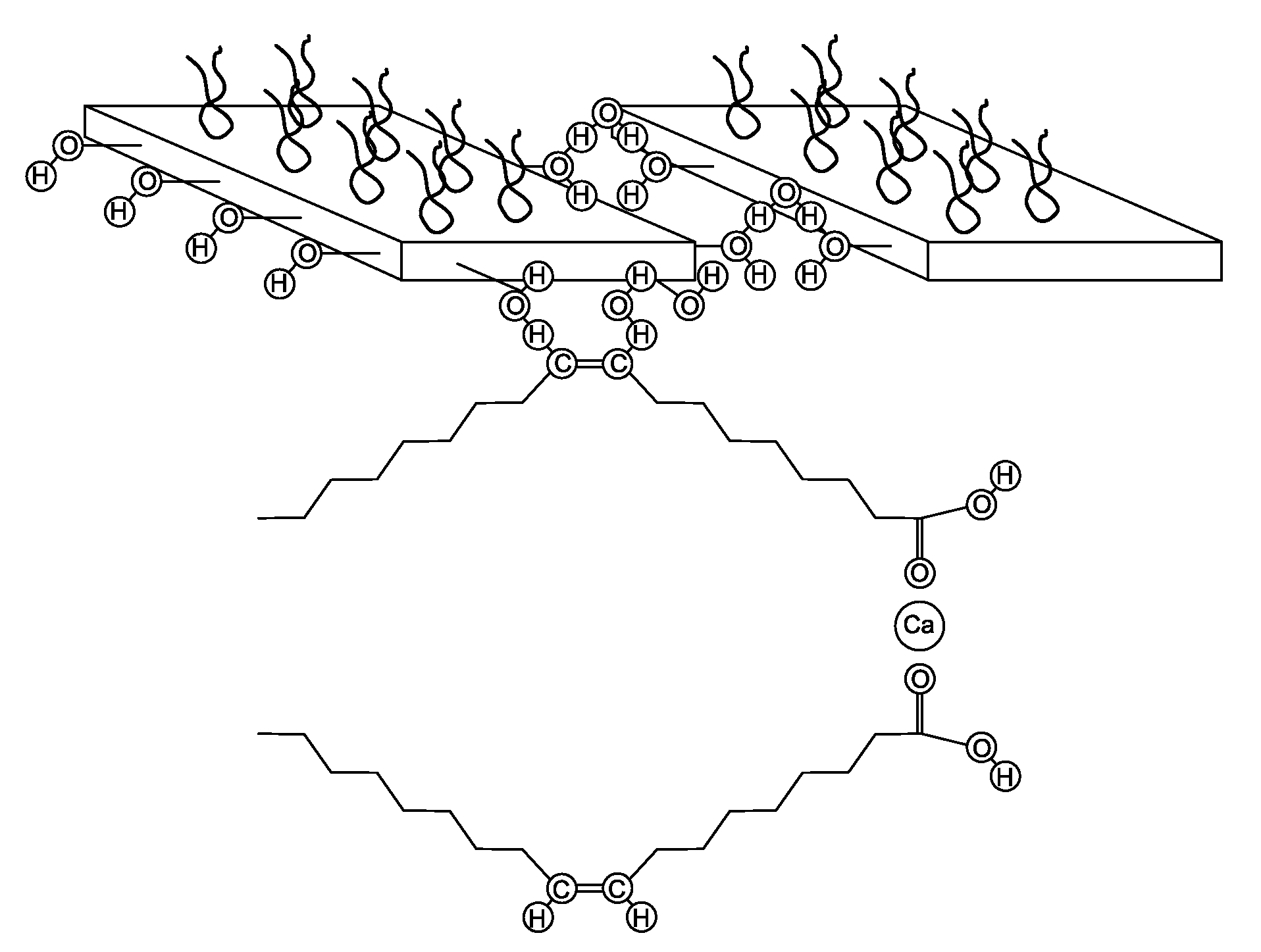

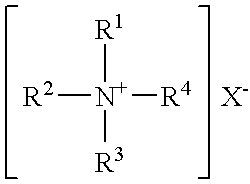

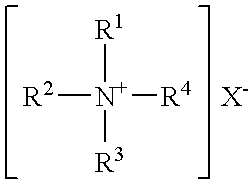

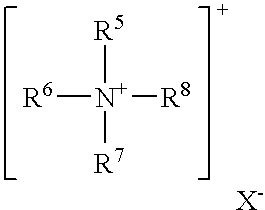

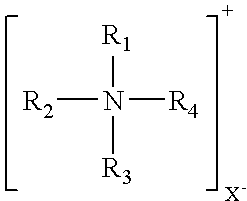

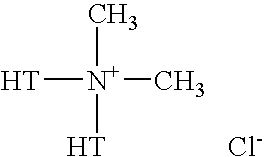

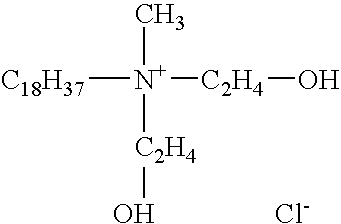

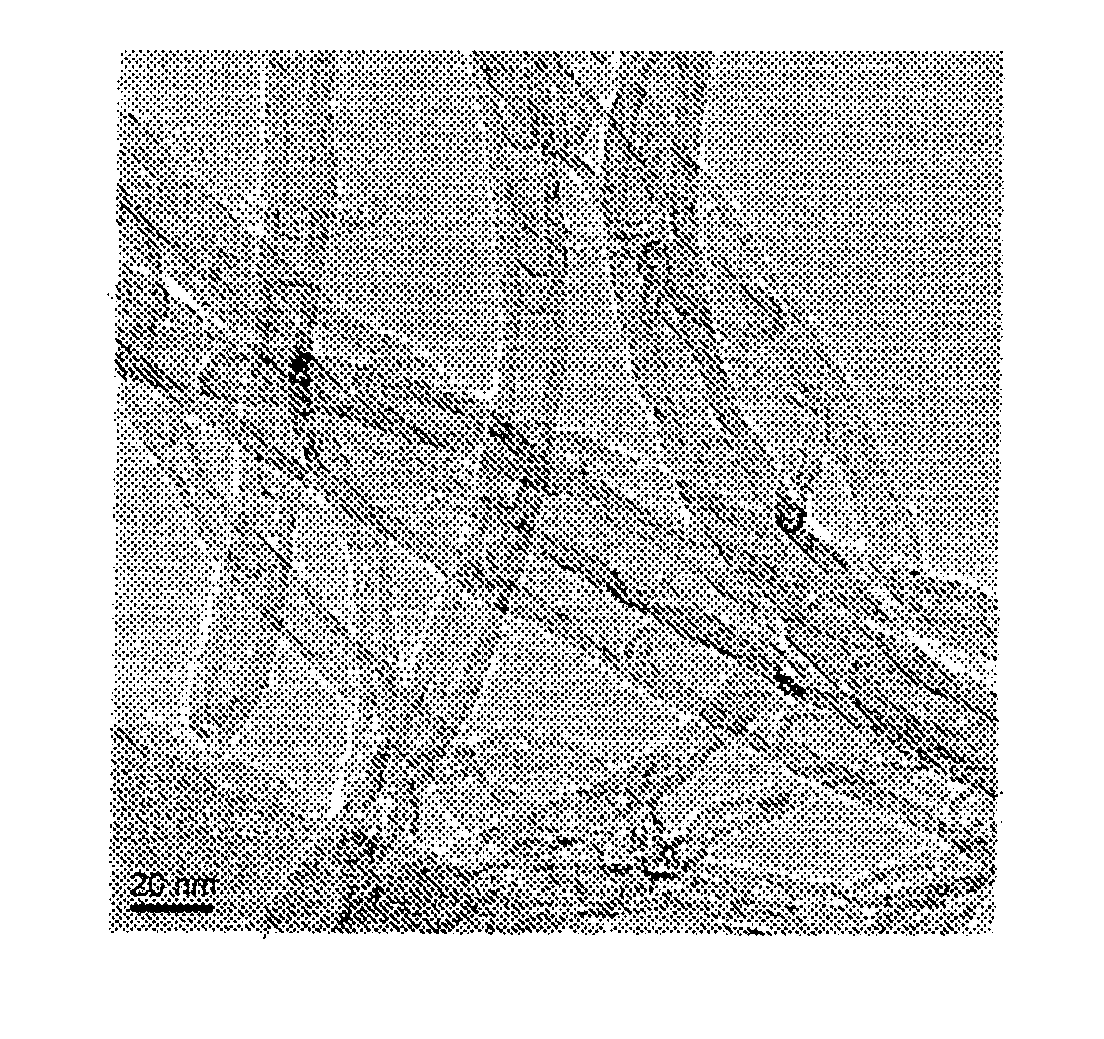

Organoclay is an organically modified phyllosilicate, derived from a naturally occurring clay mineral. By exchanging the original interlayer cations for organocations (typically quaternary alkylammonium ions) an organophilic surface is generated, consisting of covalently linked organic moieties. The lamellar structure remains analogous to the parent phyllosilicate.

Oil based compositions and method for temporarily sealing subterranean zones

InactiveUS6887833B2High viscosityLow viscosityOther chemical processesFlushingOrganoclayHydrochloric acid

The present invention provides oil based compositions and methods of using the compositions for temporarily sealing subterranean zones. The compositions are basically comprised of oil, a hydratable polymer, an organophilic clay, a water-swellable clay, and an acid soluble material such as calcium carbonate. These compositions will form a viscous gel when contacted with water. The gelled mass may then be dissolved with an acidic fluid, such as 15% hydrochloric acid.

Owner:HALLIBURTON ENERGY SERVICES INC

Cosmetic compositions having improved wear and beauty benefits

InactiveUS6503495B1Maintain integrityInhibit growthCosmetic preparationsImpression capsWater insolubleWater soluble

Owner:NOXELL CORP

Preparation of elastomer with exfoliated clay and article with composition thereof

Owner:THE GOODYEAR TIRE & RUBBER CO +1

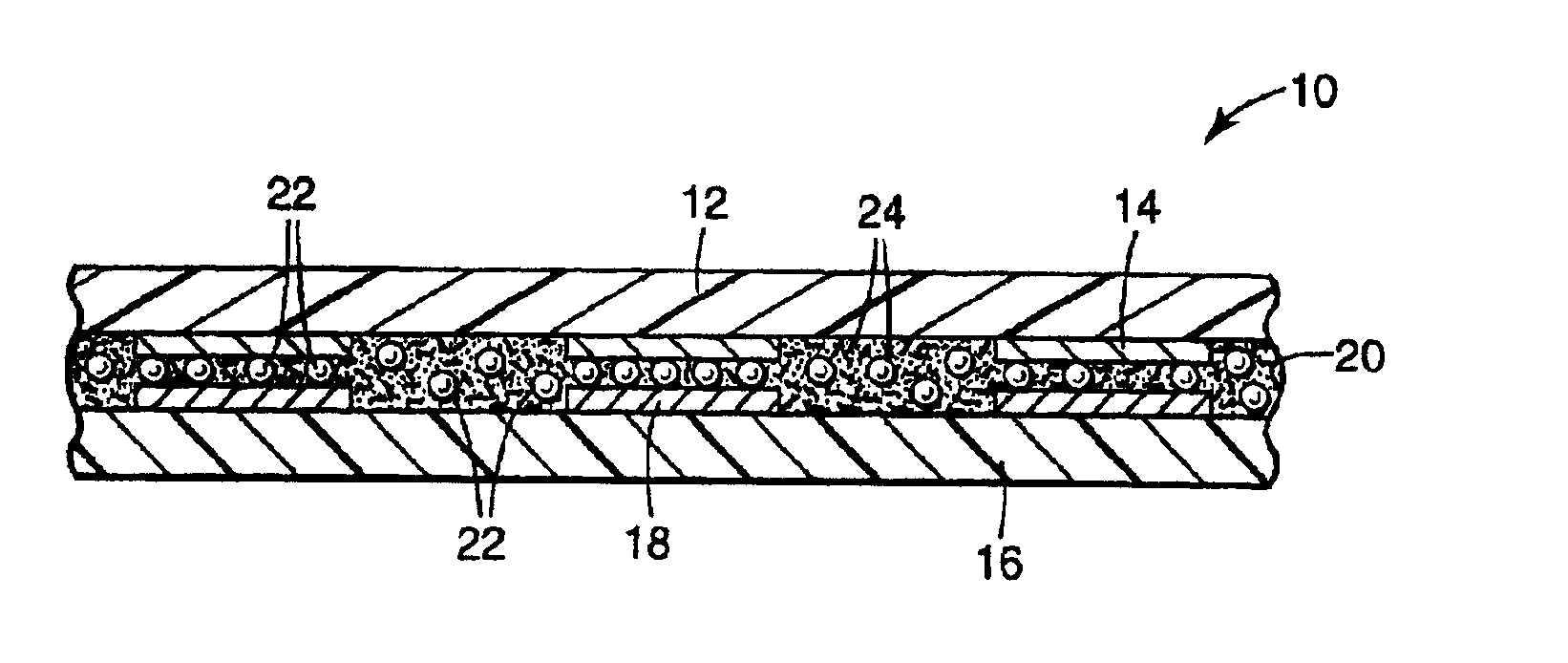

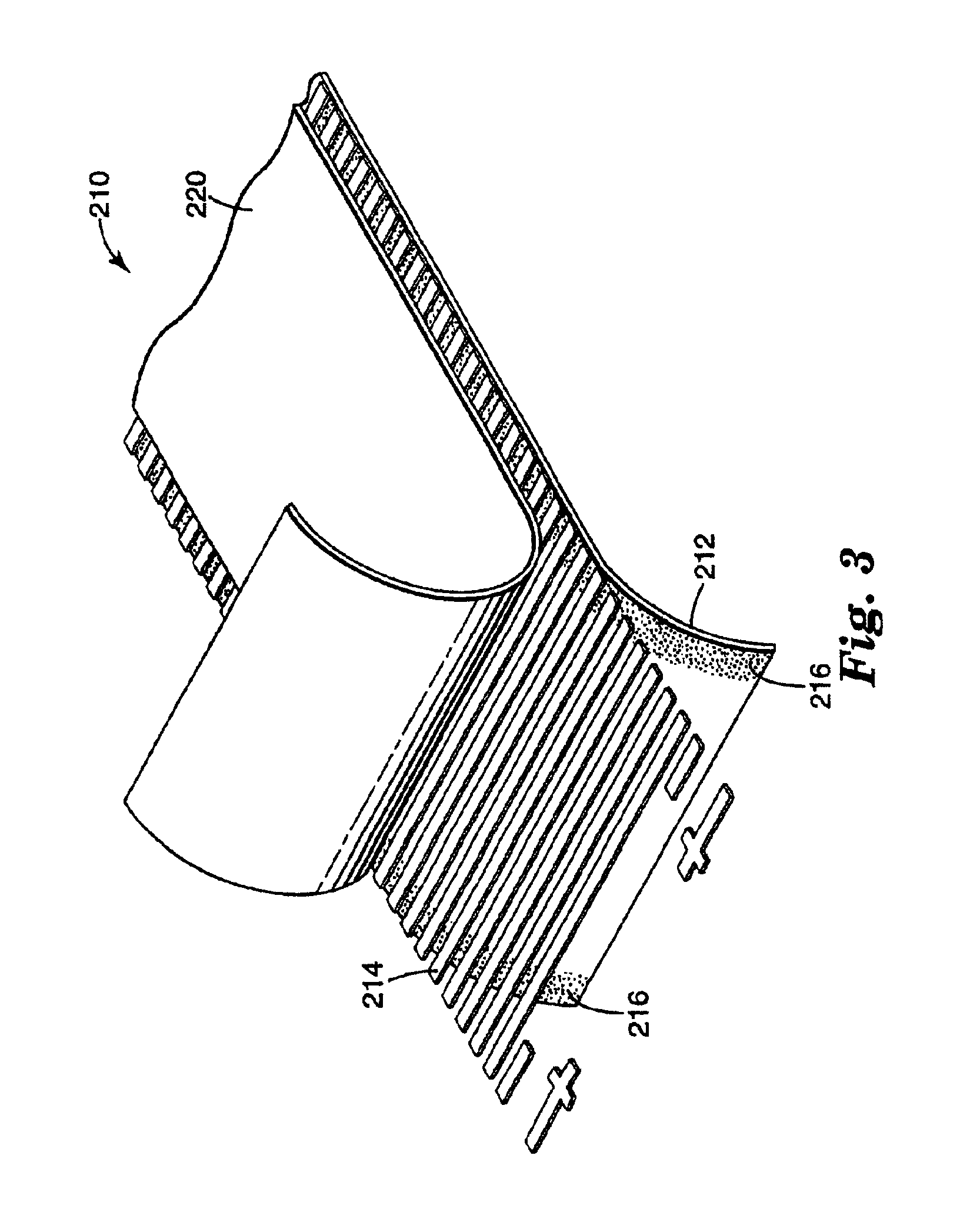

Devices, compositions, and methods incorporating adhesives whose performance is enhanced by organophilic clay constituents

InactiveUS6884833B2Faster build-upImprove adhesionPrinted circuit assemblingNon-insulated conductorsOrganoclayHot melt

Incorporating organophilic clay into hot melt adhesive compositions, particularly those comprising semi-crystalline, thermoplastic polymers, greatly improves the adhesive properties in many respects. Some of these improvements are particularly beneficial to the specific use of hot melt adhesives filled with electrically conductive particles for use as electrically conductive adhesives.

Owner:3M INNOVATIVE PROPERTIES CO

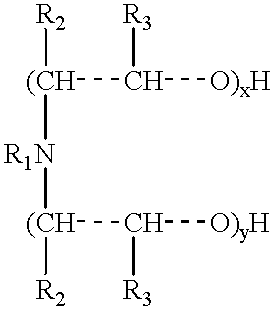

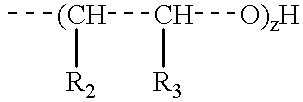

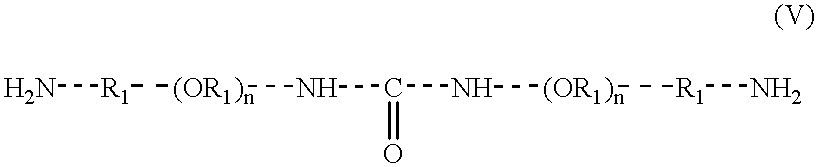

Oil and oil invert emulsion drilling fluids with improved anti-settling properties

InactiveUS6339048B1Dc level restoring means or bias distort correctionTelephonic communicationEmulsionOrganoclay

This invention is of a drilling fluid composition containing a liquid thixotrope, which thixotrope is free of solvents or any other diluent, and is in easily usable, liquid form, pourable at ambient temperatures, and which provides effective and efficient rheological properties when used at low levels in such compositions. In a specific aspect, the invention provides an oil or oil invert emulsion drilling fluid composition containing one or more organoclays, and in addition contains a additive which comprises the reaction product of an alkoxylated nitrogen containing compound or a diamine, and one or more polycarboxylic acids in a specified equivalent ratio.

Owner:ELEMENTIS SPECIALTIES INC

Organoclay/polymer compositions with flame retardant properties

InactiveUS6610770B1Cheap to makeIncrease risk of ignitionSilicon compoundsOrganoclayPolymer chemistry

The present invention is directed to polymer compositions with flame retardant properties that are made from a polymer blended using a defined process with a smectite clay that has been reacted with a specified mixture of organic materials.The inventive compositions have the property that when the organically modified clay is added to the polymer, a composite results which has flame-retardant properties and is based on the finding that degree of dispersion of a smectite organoclay in a polymer matrix will give the compositions flame-retardant properties. Further, it has been found that it is very important to proper functioning of the flame retardant polymer compositions that they have the organoclay dispersed in the polymer such that it is not completely exfoliated.

Owner:ELEMENTIS SPECIALTIES INC

Compatibilizer for immiscible polymer blends

The present invention is polymer blend, which includes at least two immiscible polymers, and a compatibilizer used to produce a substantially homogeneous blend. The compatibilizer is a functionalized nanocomposite which prevents segregation of the polymer components in the polymer blend. The nanocomposites are formed by combining an organoclay and an intercalation agent. The intercalation agent is a reaction product of a polyamine functionalized with an alkyl halide in a polar solvent. The compatibilized blends are used in thin films, which are especially useful in microlithographic applications and as lubricants in low tolerance magnetic disks.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

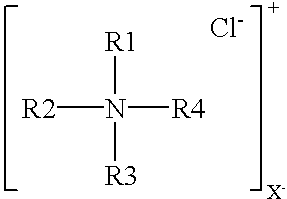

Clay/organic chemical compositions useful as additives to polymer, plastic and resin matrices to produce nanocomposites and nanocomposites containing such compositions

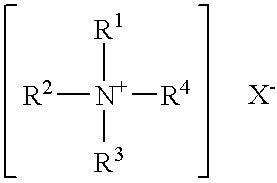

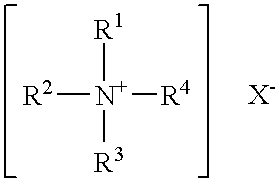

InactiveUS6380295B1Good dispersionImprove structural strengthCoatingsSilicon compoundsAmmonium compoundsWater dispersible

This invention is of a hybrid organoclay that consists of an organic chemical / phyllosilicate clay intercalate that has been ion-exchanged with quaternary ammonium compounds. Since this hybrid organoclay is hydrophobic, it can be washed in water to remove reaction salts and excess water soluble or water dispersible polymers to give a clean product via inexpensive means such as filtration. This allows a better dispersing composition to be prepared without the difficulties of isolation presented by prior art which uses energy intensive means to remove the bulk of the water from the final product and cannot be easily washed. In one aspect, the present invention provides a solid clay / chemical composition that comprises: (a) one or more smectite clays, (b) a quaternary ammonium compound which reacts via an ion exchange mechanism with the smectite clay, and (c) one or more non-anionic organic materials that intercalate with the clay. The invention is useful both as an ingredient to form nanocomposites and as a rheological additive.

Owner:ELEMENTIS SPECIALTIES INC

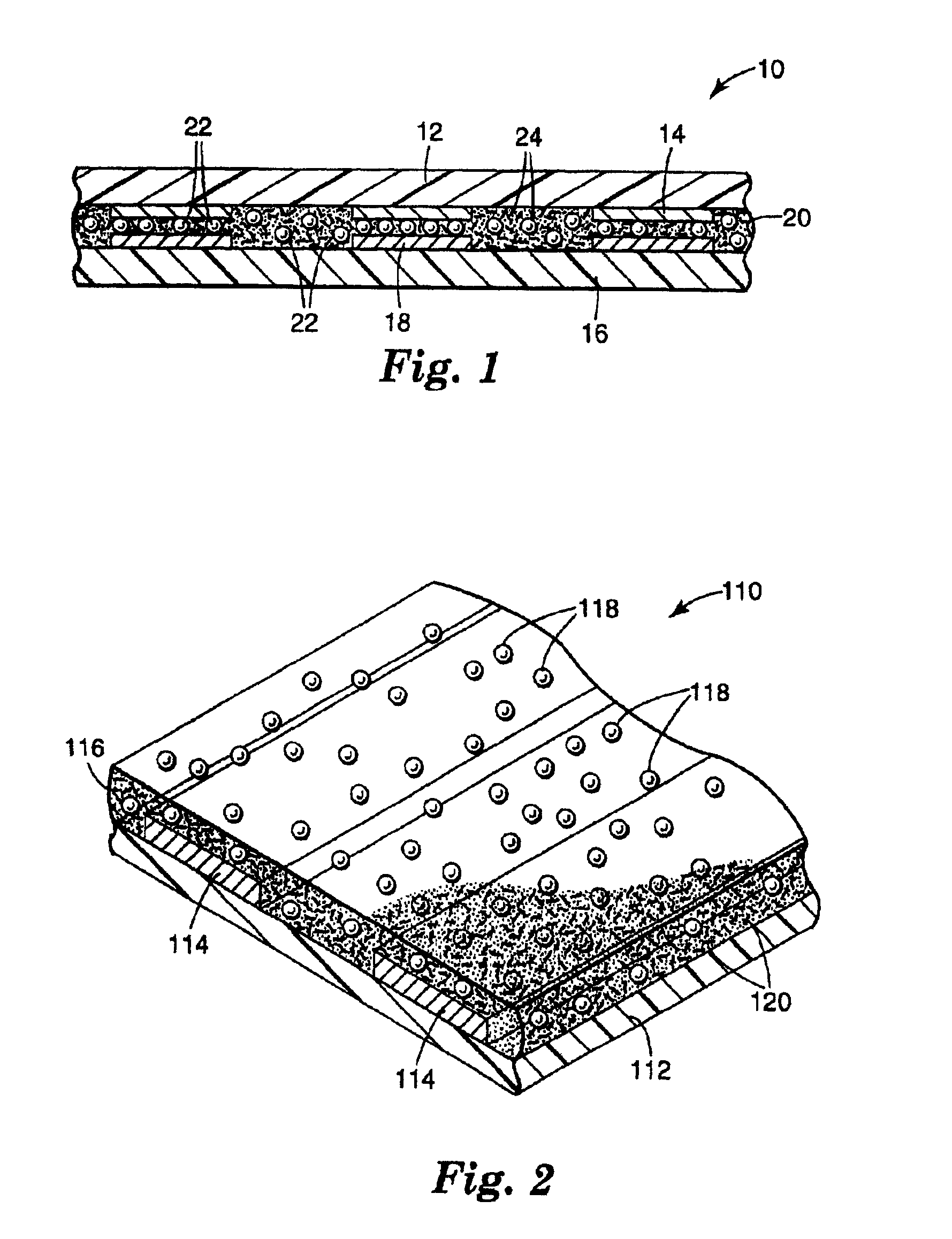

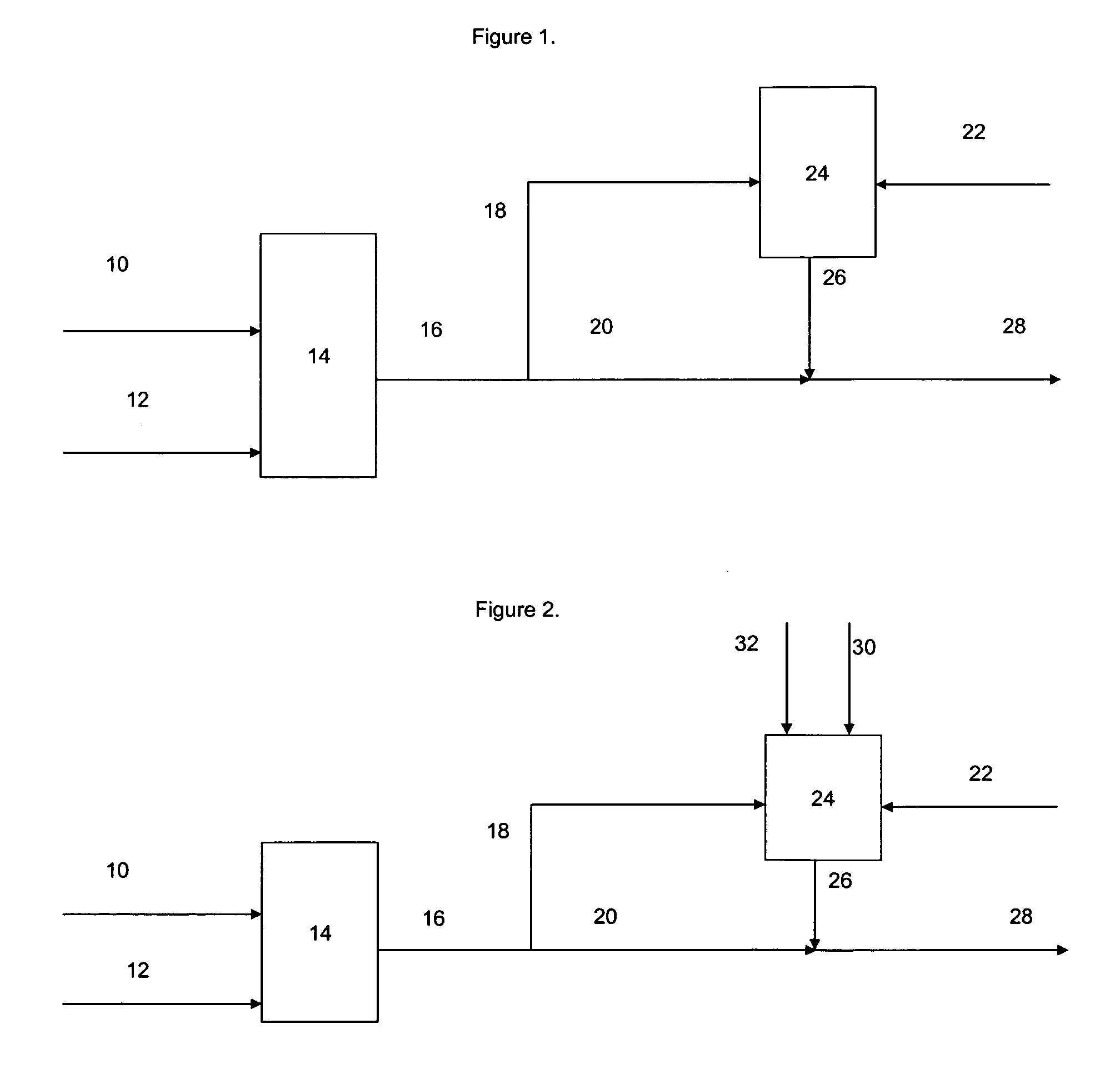

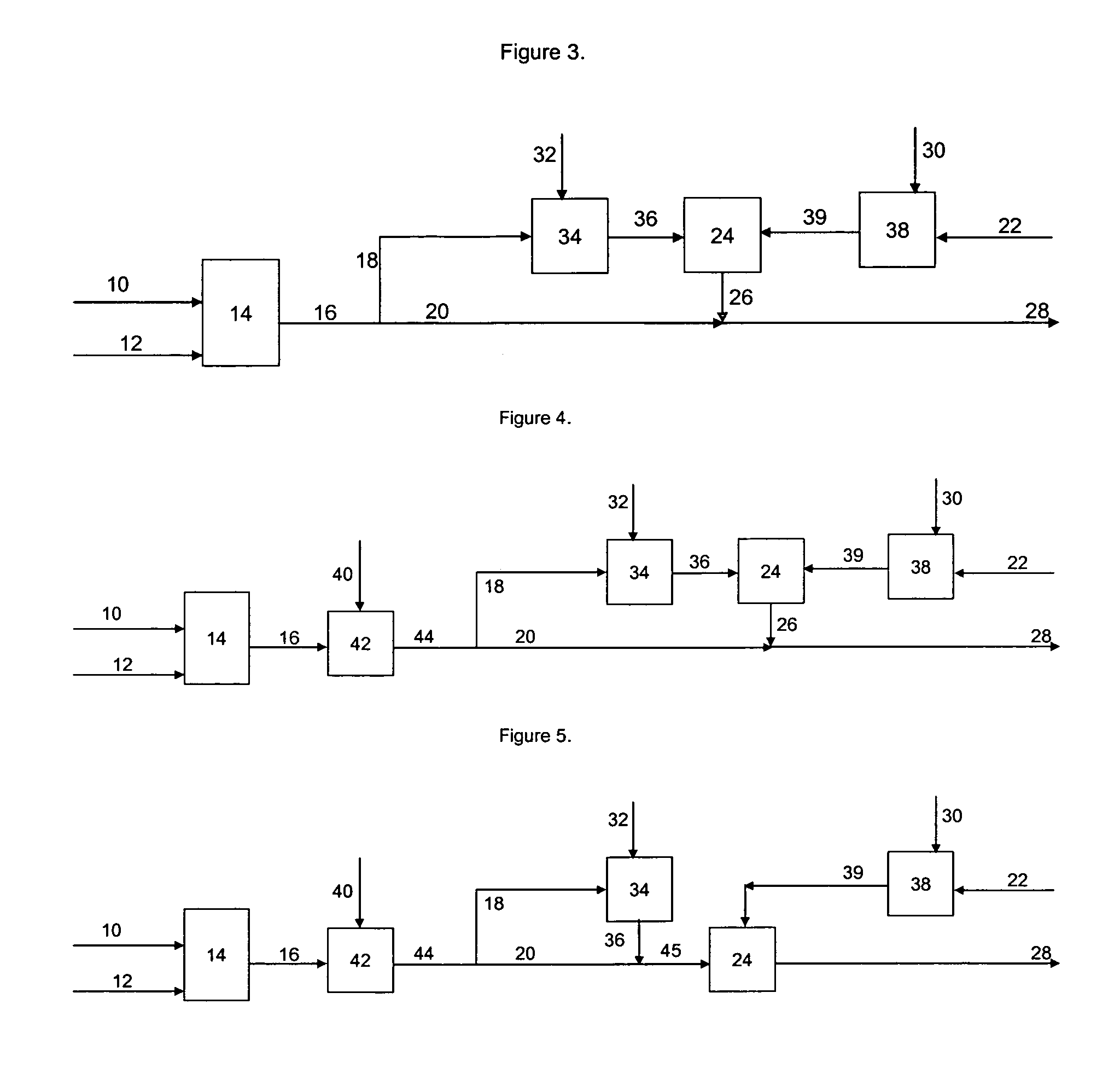

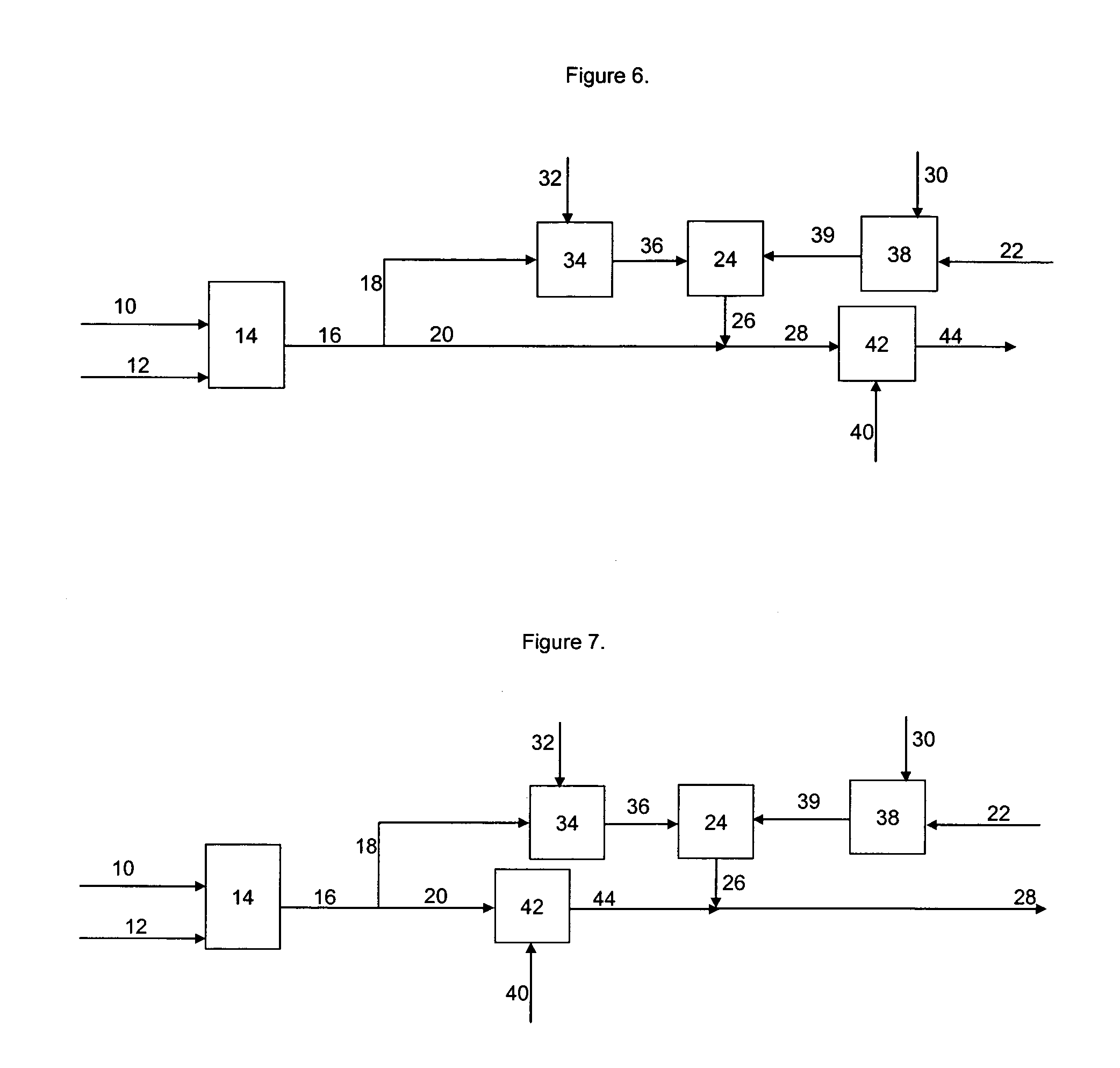

Split-stream process for making nanocomposites

ActiveUS7501460B1Adversely affect polymer propertyLess costlyPigmenting treatmentMaterial nanotechnologyElastomerMasterbatch

The present invention is a process to produce a nanocomposite of a elastomer and organic clay, e.g. an exfoliated clay, suitable for use as an air barrier. The process can include the steps of: (a) contacting a solution (10) of butyl rubber in an organic solvent with a halogen (12) to form a halogenated butyl rubber solution (16); (b) neutralizing the halogenated butyl rubber solution; (c) functionalizing at least a portion (18) of the halogenated butyl rubber; (d) mixing a dispersion (22) of clay with the functionalized butyl rubber (18) to form a masterbatch (26) comprising a polymer-clay nanocomposite; (e) combining the masterbatch (26) with the rest of the halogenated butyl rubber solution (20) to form a second mixture (28); (e) recovering the nanocomposite from the second mixture (28). The nanocomposite so formed has improved air barrier properties and is suitable for use as a tire innerliner or innertube.

Owner:EXXONMOBIL CHEM PAT INC

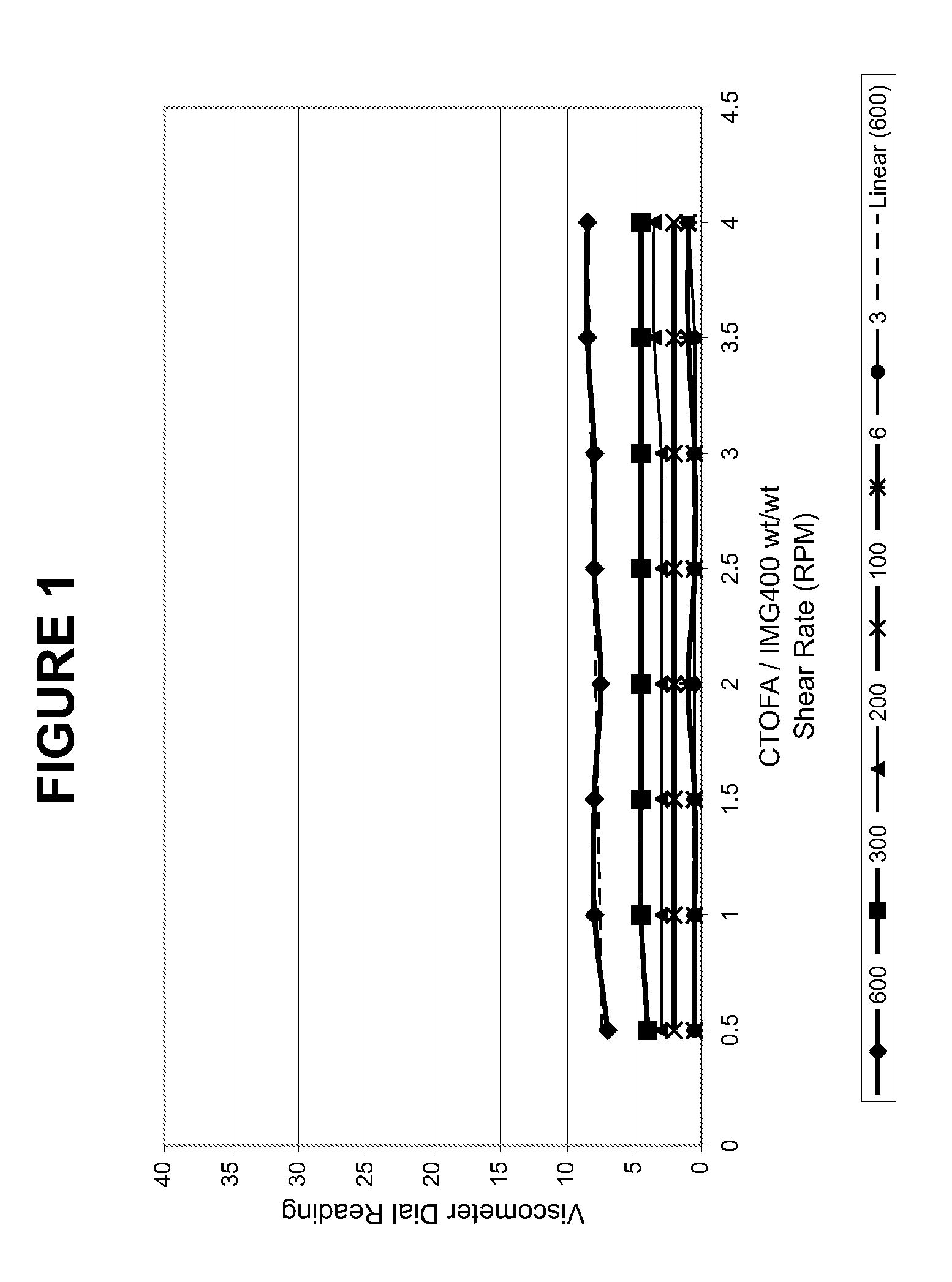

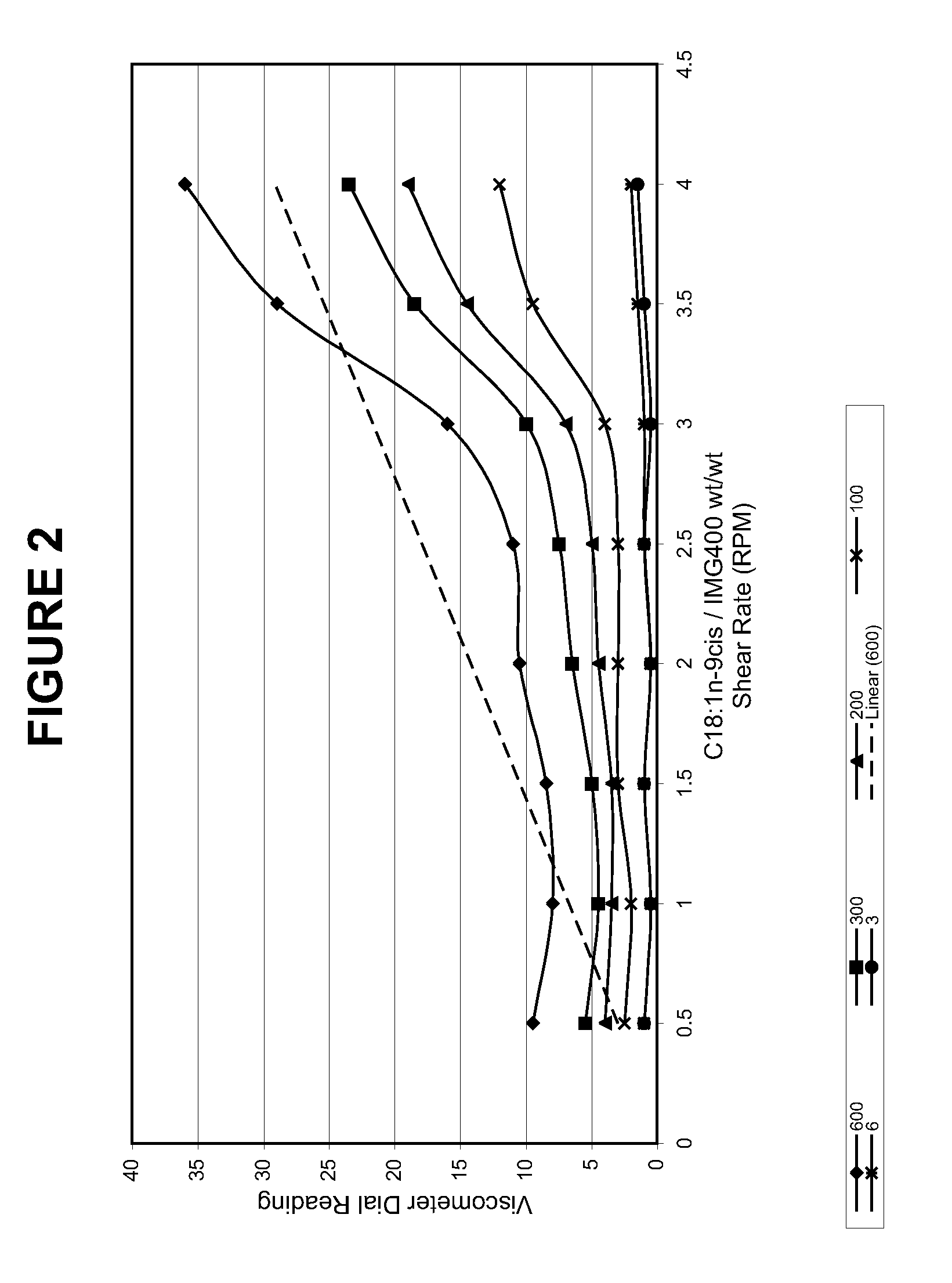

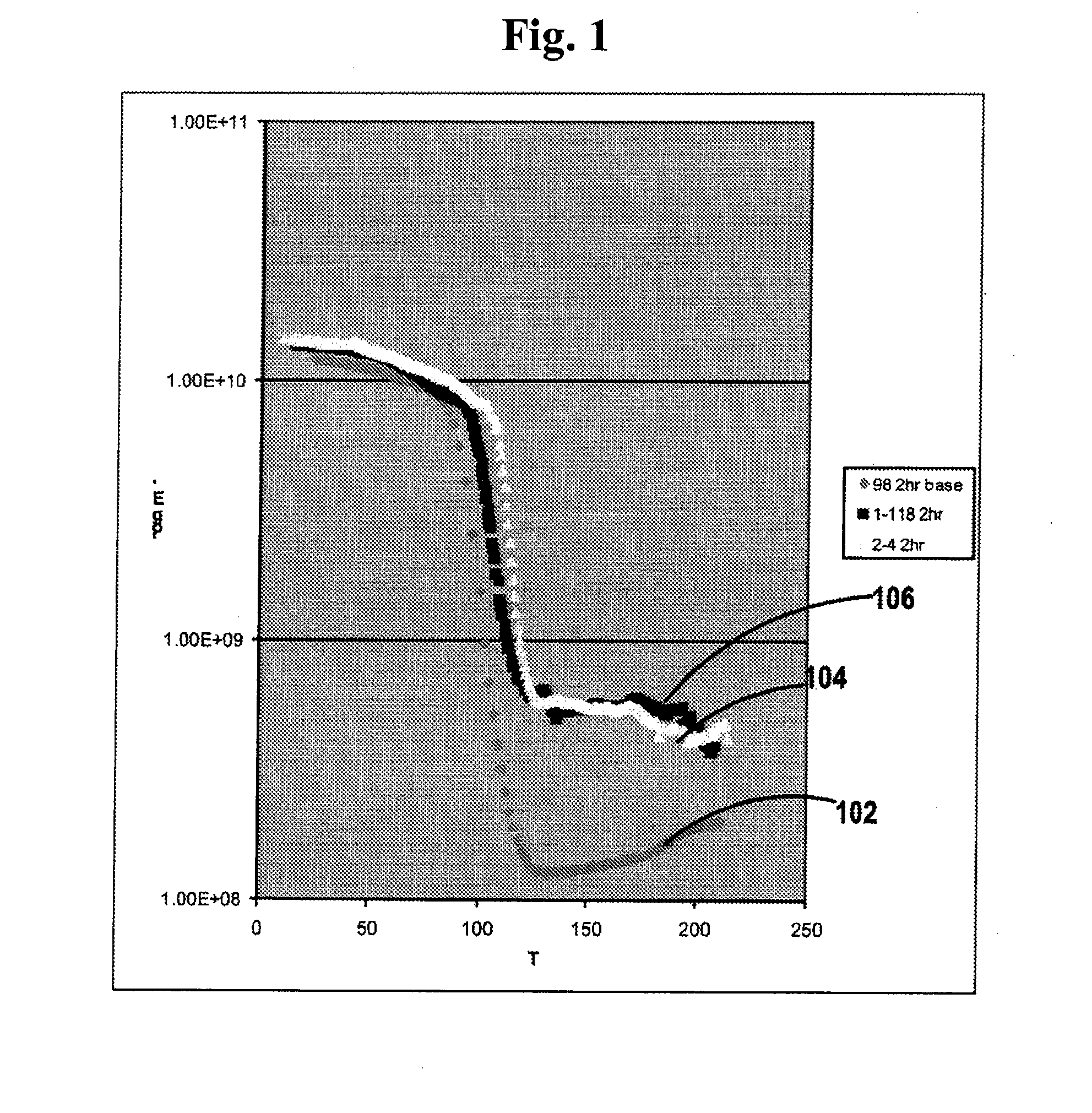

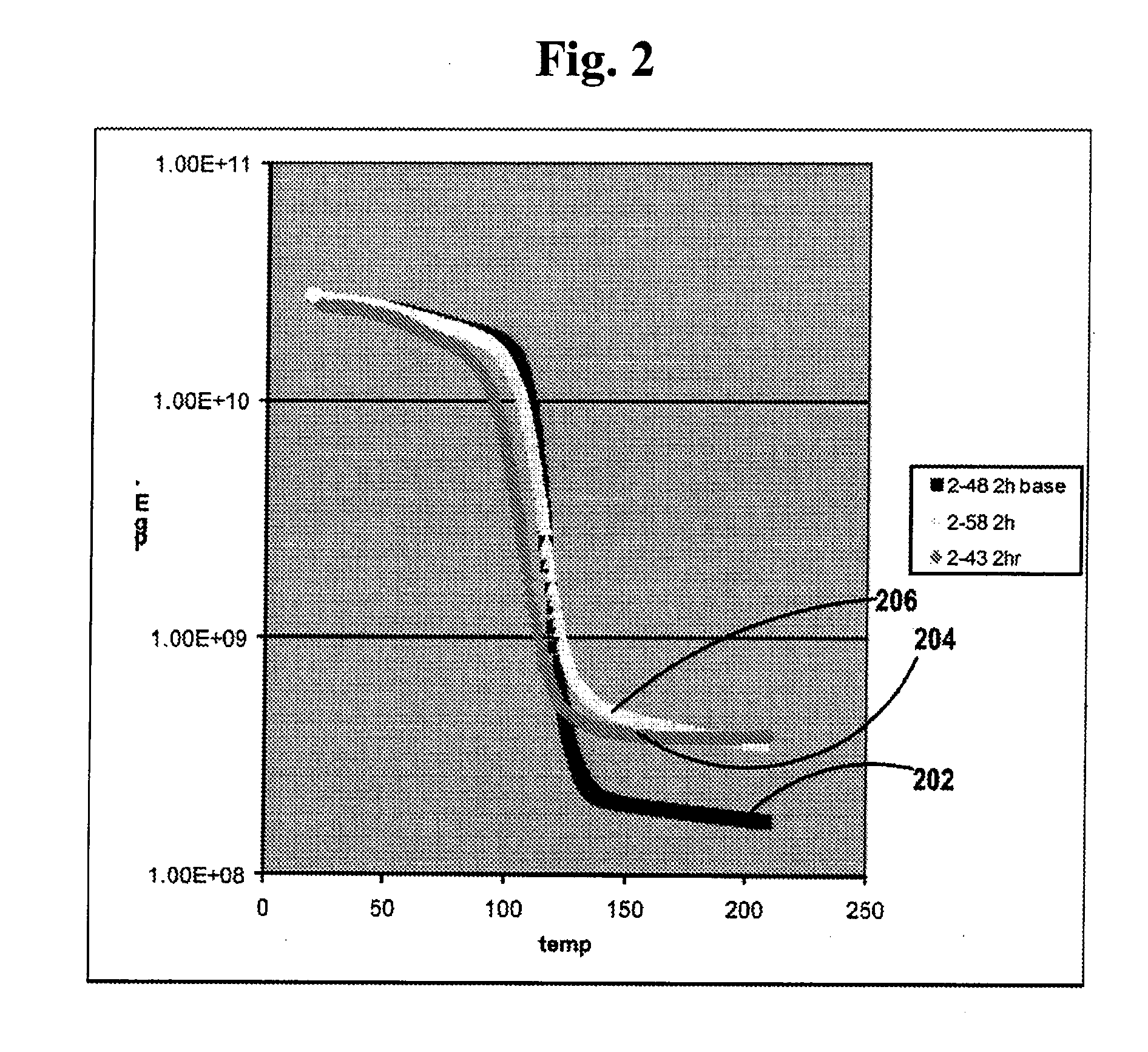

Organophilic clay additives and oil well drilling fluids with less temperature dependent rheological properties

Conventional organophilic clays, when used as rheological additives in oil and oil based invert muds, display marked viscosity loses in the mud when these muds are heated much above 350° F., whereas muds prepared according to the present invention are dramatically more viscosity-stable at temperatures through 400° F. The present invention relates to the discovery of oil and oil based invert emulsion drilling fluids that provides more stable drilling fluid viscosity and anti-settling performance over varying temperatures when compared to conventional fluids containing conventional organoclays. As a result, the inventive fluids of this invention are ideal candidates for high temperature applications. This invention in another aspect of this invention is a process for improving the rheological properties of oil well drilling fluids particularly useful for oil-based invert emulsion types of drilling fluids. The new process uses as a rheological viscosifer for such fluids a specific organoclay which when added to a drilling fluid at from about 0.5 and 5% by weight creates an inventive drilling fluid composition less sensitive to the very hot temperatures found in the drilling hole, and in the long stem of drilling pipe.

Owner:ELEMENTIS SPECIALTIES INC

Methods and compositions for sealing oil containing subterranean zones

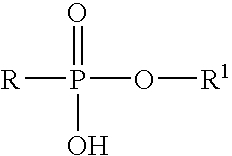

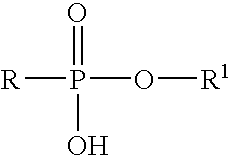

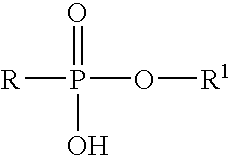

ActiveUS7026272B2Delayed additional viscosityHigh viscosityFluid removalFlushingIon releasePhosphonic Acid Esters

The present invention provides methods and compositions for sealing subterranean zones containing oil to prevent the uncontrolled flow of fluids into or from the zones. The compositions basically comprise water, a phosphonic acid ester, a multivalent metal ion releasing compound and an organophilic clay.

Owner:HALLIBURTON ENERGY SERVICES INC

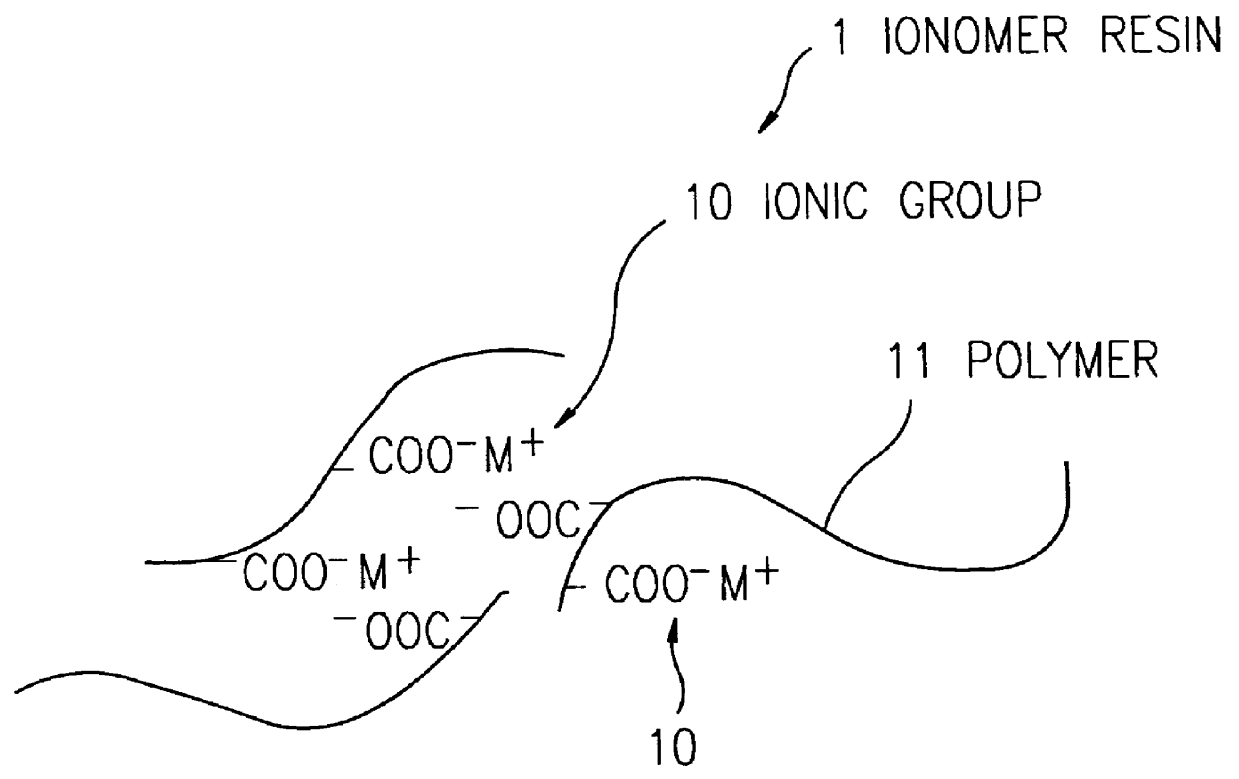

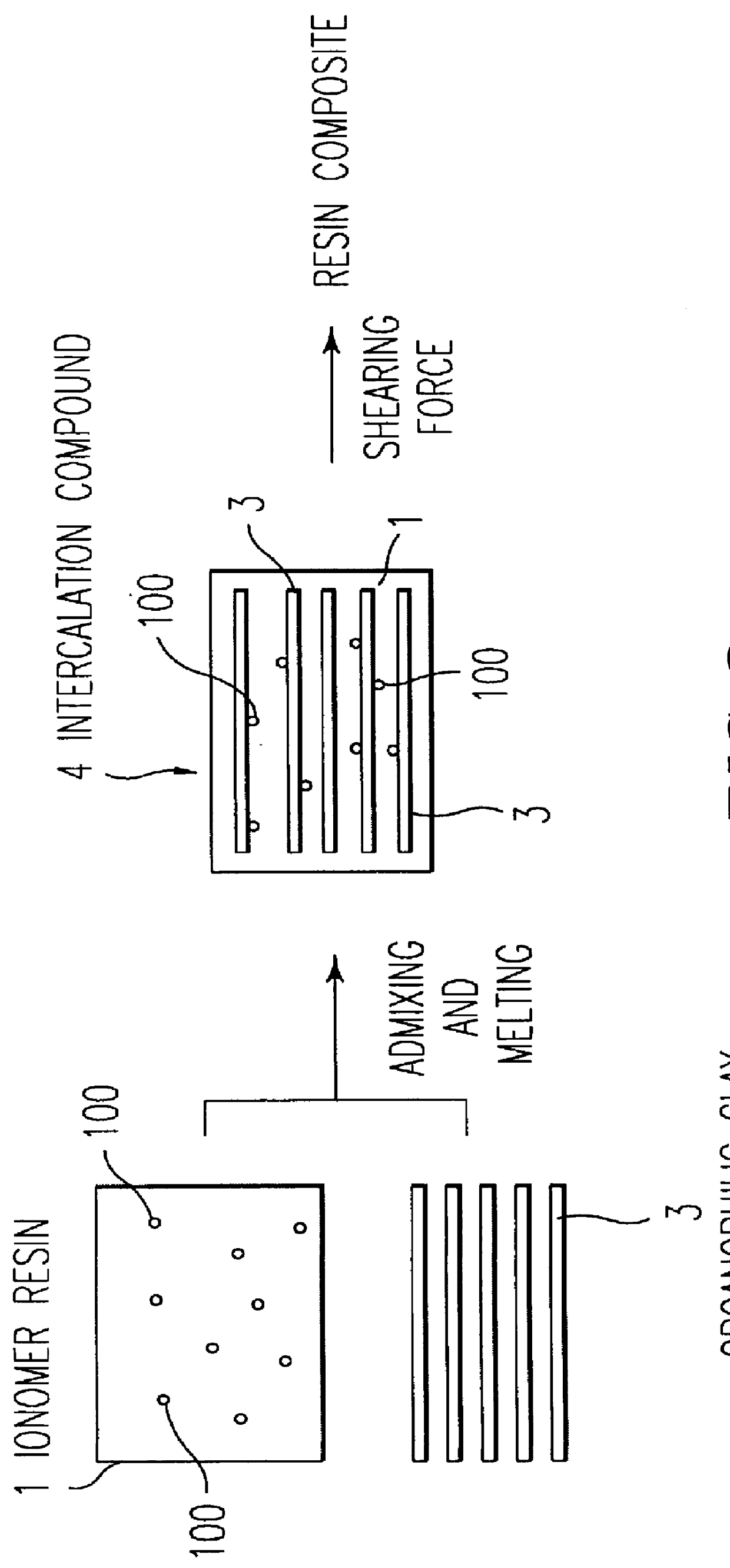

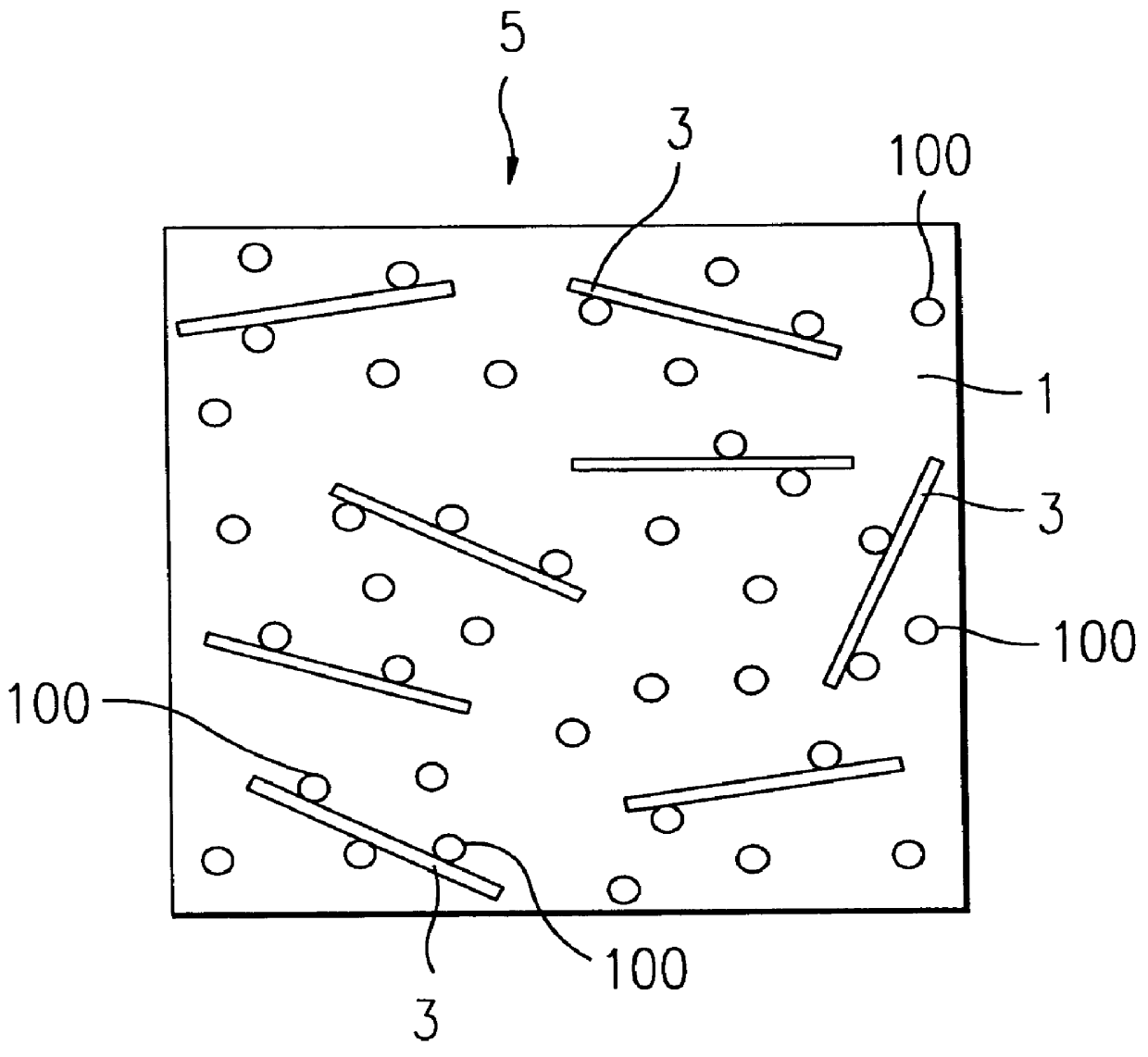

Resin composite and method for producing the same

A resin composite comprising an organophilic clay and an ionomer resin is provided. The organophilic clay is dispersed in the ionomer resin to have excellent mechanical properties. A method for producing a resin composite comprises the steps of adding an organophilic clay to an ionomer resin, melting the mixture of the clay and the ionomer resin by heating and shearing the mixture.

Owner:TOYOTA CENT RES & DEV LAB INC

Polymerized macrocyclic oligomer nanocomposite compositions

InactiveUS20050059768A1Excellent heat distortion temperature heatIncrease stiffnessMaterial nanotechnologyMicaOligomerOrganoclay

The invention relates to polymers derived from macrocyclic oligomers containing organo clay fillers. The invention also relates to processes for preparing such compositions. Furthermore, the invention relates to articles prepared from organoclay filled polymer compositions.

Owner:DOW GLOBAL TECH LLC

Polypropylene material with high bath strength and preparation method

This invention relates to a method for preparing propylene material with high melt strength. The propylene material is composed of: propylene 100 parts, organic peroxide initiator 0.002-4 parts, multifunctional monomer 0.005-5 parts, branching promoter 0.001-4 parts, and organic clay 0.1-10 parts. The dispersion degree of organic clay is 10-100 nm. The method comprises: uniformly mixing propylene, organic peroxide initiator, multifunctional monomer, branching promoter and organic clay, adding into a twin-screw extruder, melting, extruding and granulating with temperature, rotation speed and feeding rate controlled to obtain gel-free propylene material with high melt strength. During the in-situ intercalation process, organic clay is dispersed in the polymer matrix on nanoscale. Uniformly dispersed organic clay can control the formation of branching structure, and improve the melt strength and mechanical properties of the propylene material. The propylene material is suitable for extrusion foaming and other thermal molding processes.

Owner:河北福恩特电气设备集团有限公司

Suspended delayed borate cross-linker

A composition for delaying the cross-linking of water soluble polymer solutions includes a boron source suspended by an organophilic clay in a solution of a non-aqueous solvent. One process of manufacturing the composition includes the steps of first suspending the organophilic clay in the non-aqueous solvent and then suspending the boron source in the organophilic clay-non-aqueous solvent suspension. Another process of manufacturing composition includes the steps of first mixing the boron source and the organophilic clay to form a dry mixture and then suspending the dry mixture of the boron source and the organophilic clay in a non-aqueous solvent. In a method of hydraulically fracturing a formation, a water soluble polymer solution with a pH between about 8.5 and 12.5 and the boron source suspended by the organophilic clay in the solution of the non-aqueous solvent are pumped into the formation under sufficient pressure to cause a fracture in the formation rock.

Owner:BENCHMARK

Biodegradable polymer

A biodegradable polymer includes a) 20 to 60% of a mixture of starch and / or a modified starch, b) 8 to 22% of starch plasticisers and processing agents c) 30 to 70% of one or more biodegradable aliphatic polyesters d) 1 to 10% of a layered silicate clay mineral. The silicate mineral is an organoclay which has been formed by reacting clay with an intercalating chemical to compatibilise it with the polymers so that the clay is exfoliated and makes the blend amorphous. The polymers may also include the usual additives including e) from 0 to 20% by weight of a polyol plasticiser f) from 0.1 to 1.5% by weight of a C12–22 fatty acid or salt or a destructing agent preferably urea and / or urea derivatives, and g) from 0 to 12% by weight of added water. The polyester may be modified by reaction with maleic anhydride.

Owner:PLANTIC TECH

Biodegradable polymer

InactiveUS20040122135A1Significant comprehensive benefitsImproved melt processabilityFireproof paintsPigmenting treatmentUrea derivativesPolyester

A biodegradable polymer includes a) 20 to 60% of a mixture of starch and / or a modified starch, b) 8 to 22% of starch plasticisers and processing agents c) 30 to 70% of one or more biodegradable aliphatic polyesters d) 1 to 10% of a layered silicate clay mineral. The silicate mineral is an organoclay which has been formed by reacting clay with an intercalating chemical to compatibilise it with the polymers so that the clay is exfoliated and makes the blend amorphous. The polymers may also include the usual additives including e) from 0 to 20% by weight of a polyol plasticiser f) from 0.1 to 1.5% by weight of a C12-22 fatty acid or salt or a destructing agent preferably urea and / or urea derivatives, and g) from 0 to 12% by weight of added water. The polyester may be modified by reaction with maleic anhydride.

Owner:PLANTIC TECH

Polyolefin nanocomposites

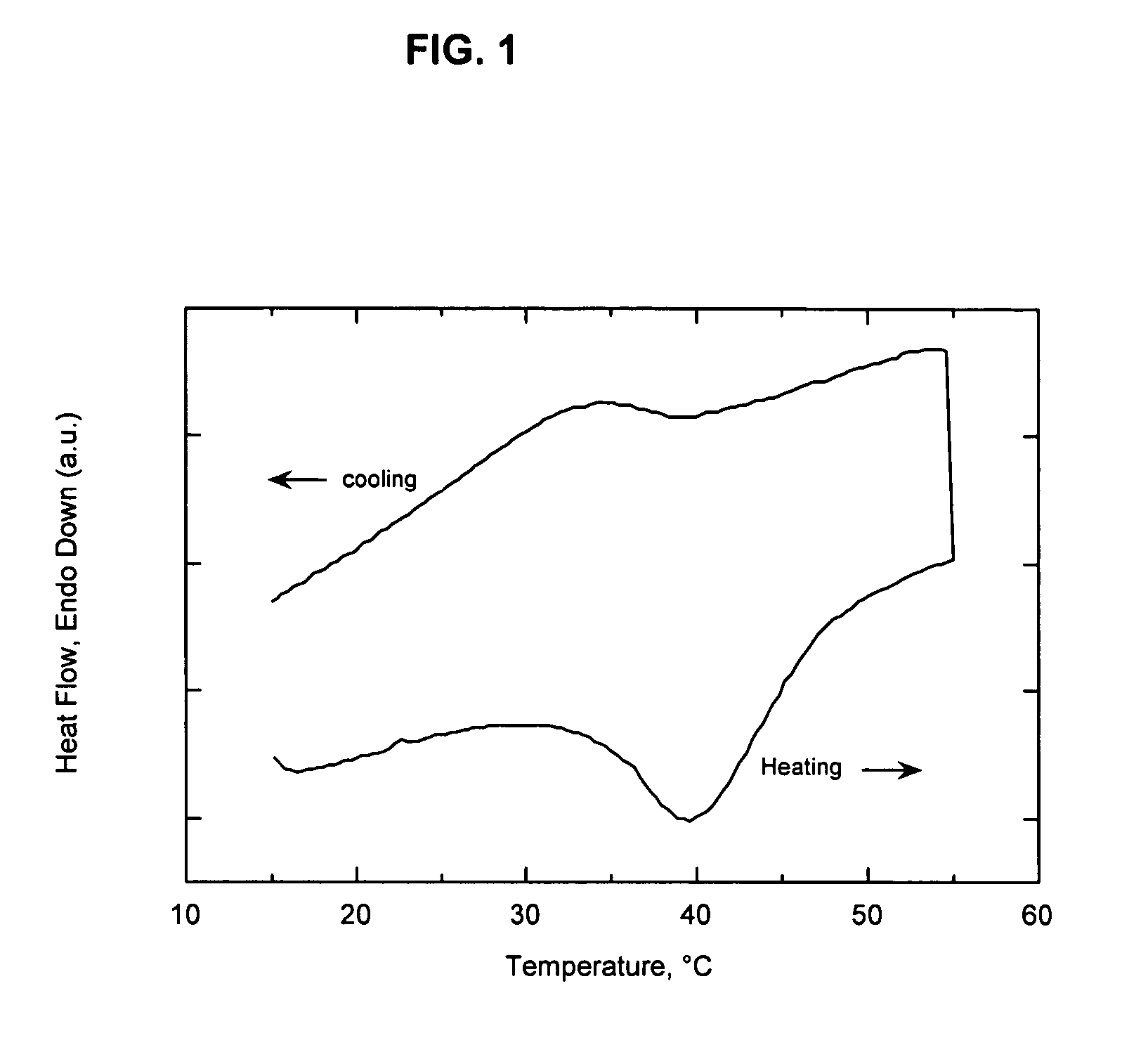

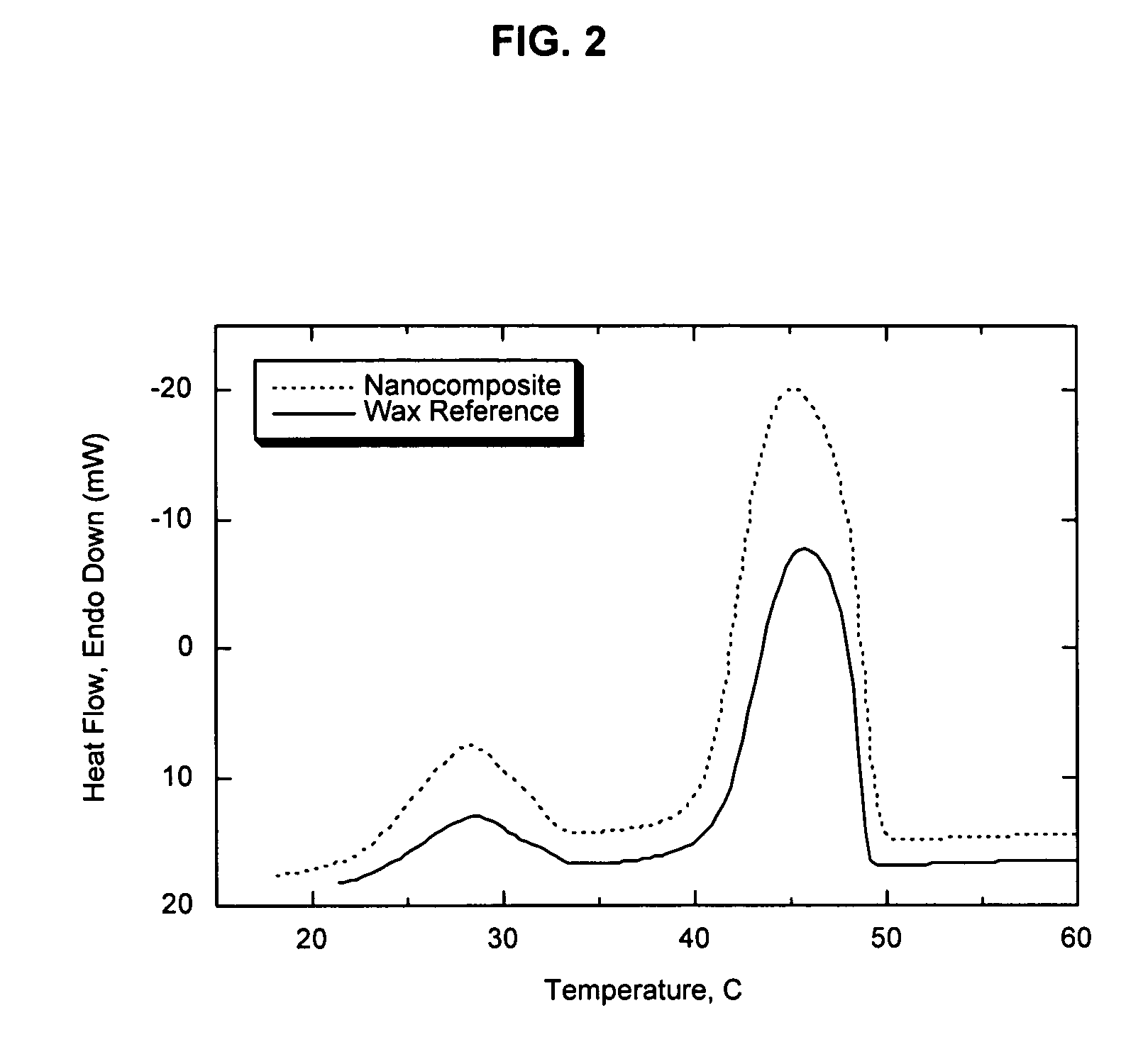

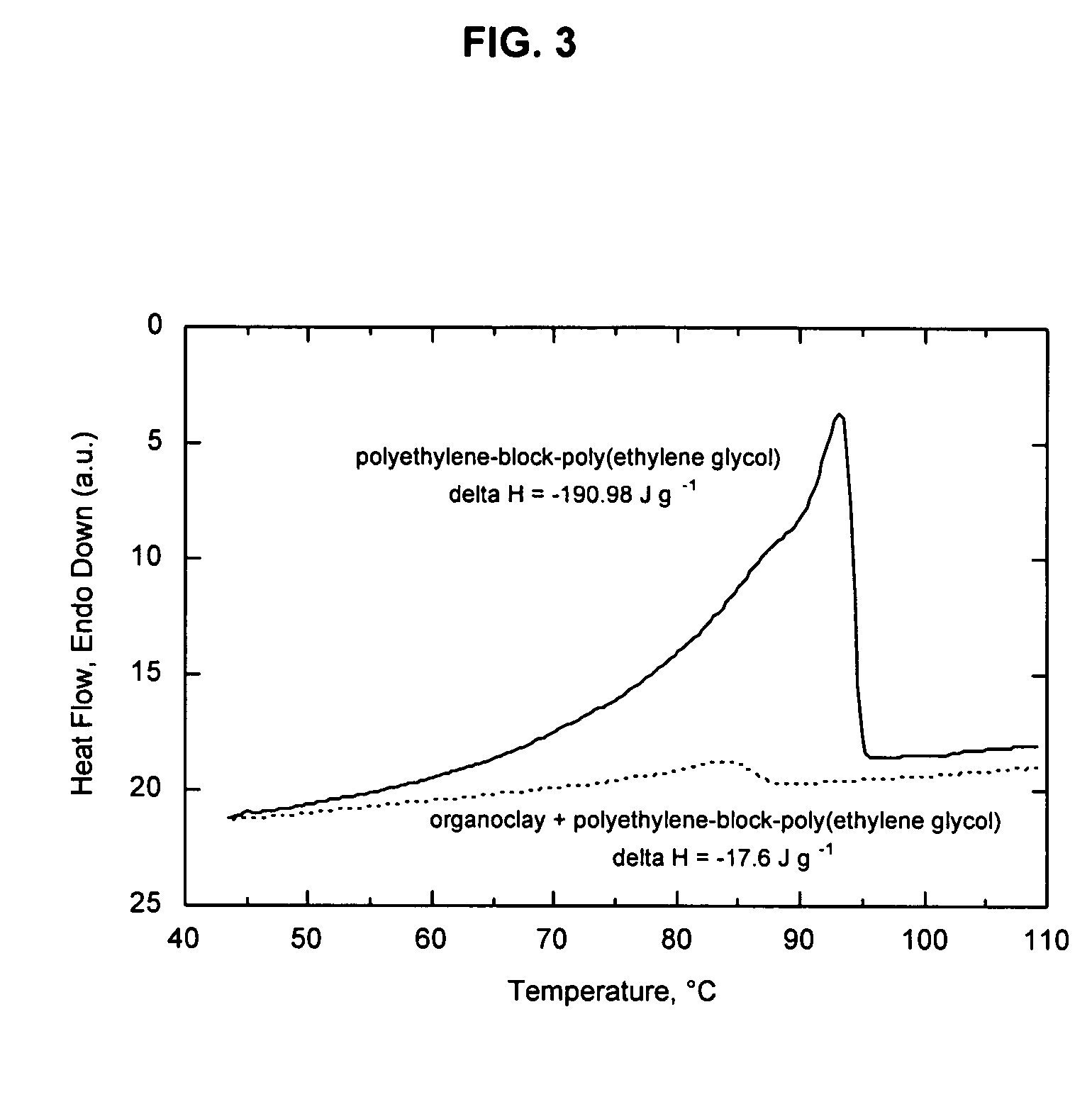

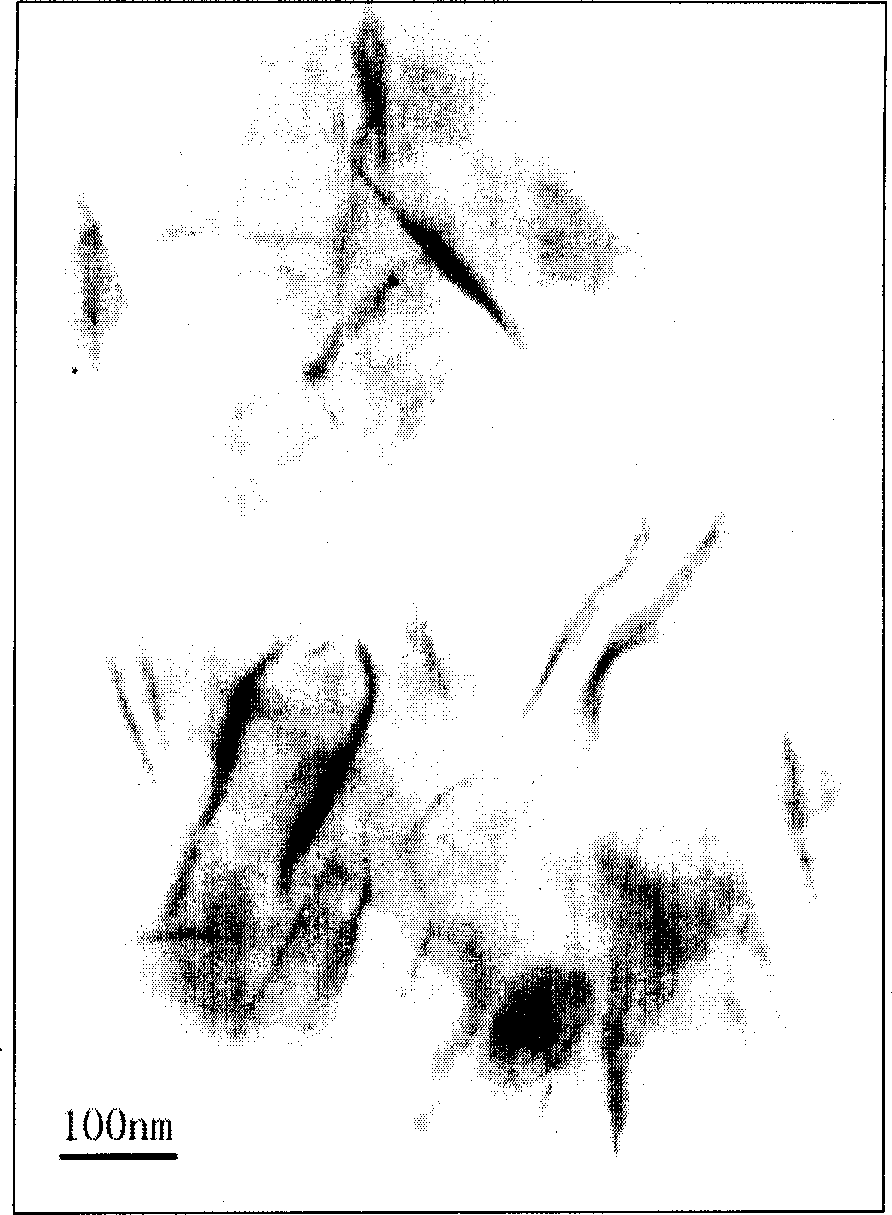

InactiveUS7157516B2Growth of polymer is lessenedIncrease in sizeMaterial nanotechnologyPigmenting treatmentVitrificationPolyolefin

The present invention relates to methods for the preparation of clay / polymer nanocomposites. The methods include combining an organophilic clay and a polymer to form a nanocomposite, wherein the organophilic clay and the polymer each have a peak recrystallization temperature, and wherein the organophilic clay peak recrystallization temperature sufficiently matches the polymer peak recrystallization temperature such that the nanocomposite formed has less permeability to a gas than the polymer. Such nanocomposites exhibit 2, 5, 10, or even 100 fold or greater reductions in permeability to, e.g., oxygen, carbon dioxide, or both compared to the polymer. The invention also provides a method of preparing a nanocomposite that includes combining an amorphous organophilic clay and an amorphous polymer, each having a glass transition temperature, wherein the organophilic clay glass transition temperature sufficiently matches the polymer glass transition temperature such that the nanocomposite formed has less permeability to a gas than the polymer.

Owner:UCHICAGO ARGONNE LLC

Process for preparing organic modified clay and styrene butadiene rubber nano composite material

The process of preparing nanometer composite material of organically modified clay and styrene butadiene rubber includes the first mixing organic modifier aqua and water clay suspension, the subsequent mixing with styrene butadiene latex, demulsifying and flocculating, drying, pugging and final vulcanizing to obtain the composite material. The organic modifier is alkyl ammonium salt and has the weight ratio to the clay of 0.1-0.5. The composite material has large rubber molecule entering the clay lamella to form obvious intercalation, nanometer scale dispersing of clay lamella in rubber base to result in excellent strengthening effect, and obviously raised mechanical performance, especially stretching strength, of the vulcanized rubber.

Owner:BEIJING UNIV OF CHEM TECH

Methods Of Preparing Hydrocarbon, Water And Organophilic Clay Emulsions And Compositions Thereof

InactiveUS20090260885A1Low viscosityPerformance maximizationTransportation and packagingMixingPolyesterFoundry

This invention relates to compositions and methods for improving the performance of organophilic organic-clay complexes, which are dispersible in organic liquids to form a gel therein. Depending on the composition of the gel, such gels may be useful as lubricating greases, oil-based muds, oil base packer fluids, paint-varnish-lacquer removers, paints, foundry molding sand binders, adhesives and sealants, inks, polyester laminating resins, polyester gel coats, cosmetics, detergents, and the like.

Owner:ENGINEERED DRILLING SOLUTIONS

Use of organoclay in HDPE nanocomposites to provide barrier properties in containers and film

InactiveUS7629406B2Effective oxygen barrier propertyReduce the amount requiredSpecial tyresWater vaporOrganoclay

HDPE nanocomposite is made by mixing HDPE with organoclay. Such HDPE nanocomposite contains concentrations of organoclay less than 4 weight percent. Unexpectedly, using less organoclay than that conventionally recommended, results in superior oxygen and water vapor transmission rates for HDPE compounds. The HDPE nanocomposite is useful for packaging films and containers for food or other perishables.

Owner:AMCOL INTERNATIONAL CORPORATION

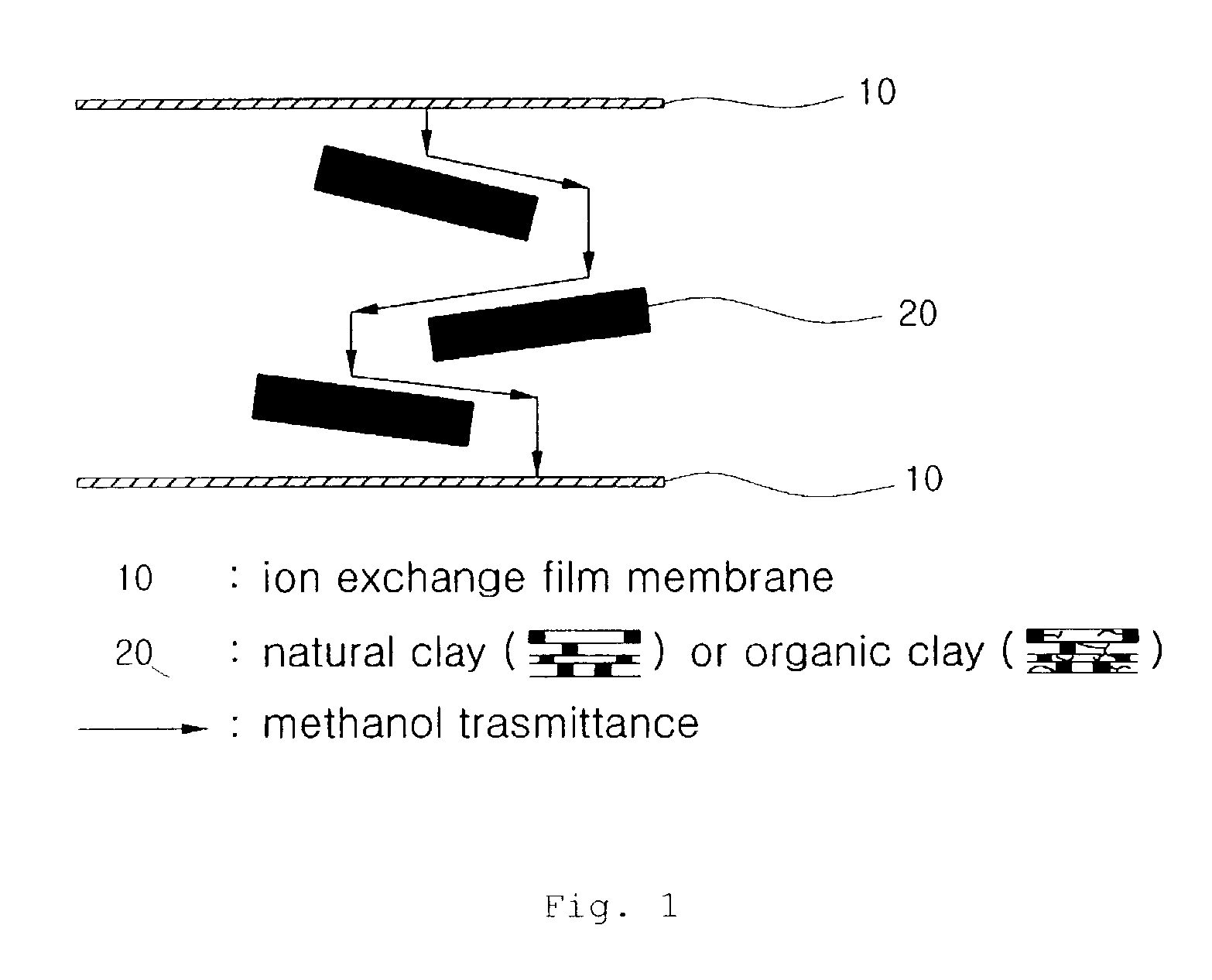

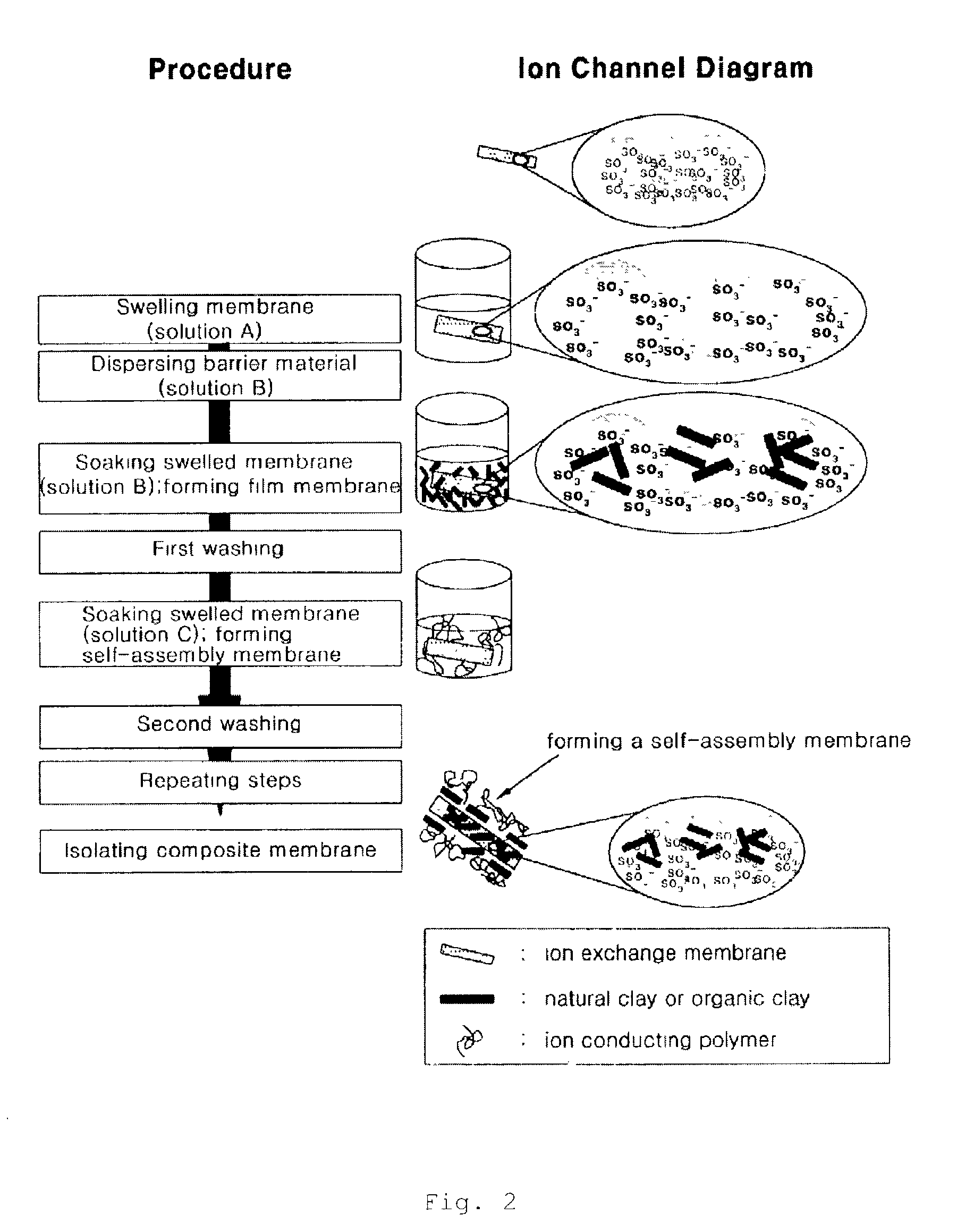

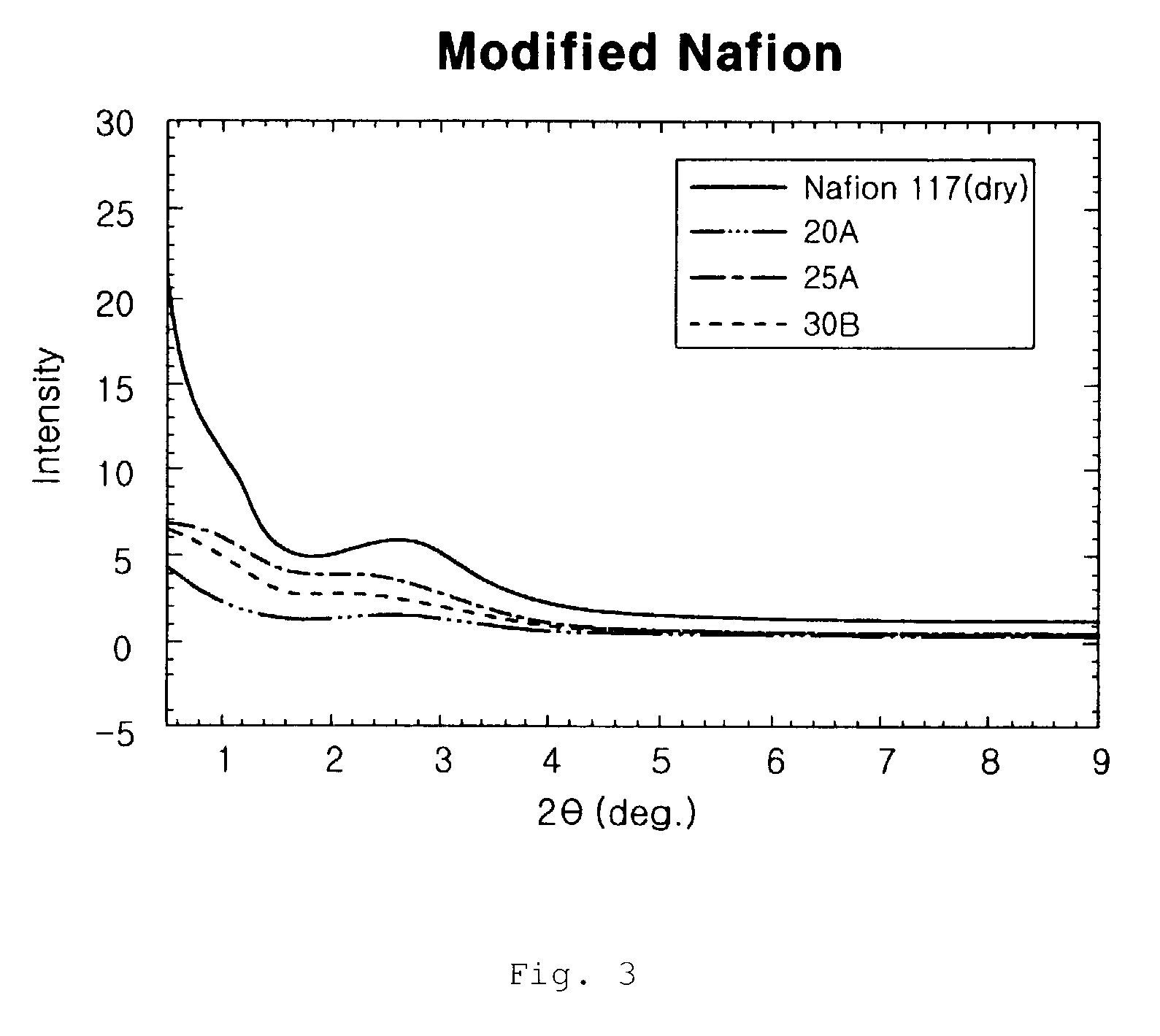

Proton exchange composite membranes, composite solutions, and method for manufacturing and fuel cell using the same

InactiveUS7029559B2Effective blockingImprove proton conductivityIon-exchange process apparatusNon-metal conductorsFuel cellsOrganoclay

An ion exchange composition membrane is made up of dispersed natural clay and / or organized clay in ion conducting polymeric film as a methanol barrier material. The membrane exhibits low methanol crossover, high proton conductivity and is thus suitable for use in direct methanol fuel cells with low costal advantage.

Owner:KOREA INST OF SCI & TECH

High efficiency master gels for thickening oil based compositions

InactiveUS20070071703A1Pronounced effect rheological propertyIncrease loadCosmetic preparationsHair removalOrganoclaySilicone fluid

The composition, preparation and use of a thickening system or master gel for oil based compositions, especially cosmetic compositions is described. These highly efficient master gels include: i) greater than about 10% to about 40% of an organoclay, ii) from about 70% to less than about 90% of a carrier oil comprising a substantially dissolved mixture of at least one silicone fluid and at least one organic oil wherein the total silicone fluids comprise from about 10% to about 90% of the carrier based on the total weight of the carrier, and ii) from 0.5% to about 6% of a polar activator. In a preferred embodiment the master gel contains from about 15% to about 30% of an organoclay and is chosen so that the viscosity of the master gel composition is at least 2.5 million cP as measured with a Brookfield viscometer at 1 rpm.

Owner:LIN SAMUEL QCHENG SUN

Organophilic clay additives and oil well drilling fluids with less temperature dependent rheological properties

An additive composition including a synergistic combination of a hectorite organoclay composition and an attapulgite organoclay composition. The hectorite organoclay composition includes (i) a first organic cation provided by an alkoxylated quaternary ammonium salt; and ii) a second organic cation wherein such second organic cation is not provided by an alkoxylated quaternary ammonium salt. The attapulgite organoclay composition includes (iii) a third organic cation provided by an alkoxylated quaternary ammonium salt; and (iv) a fourth organic cation wherein such third organic cation is not provided by an alkoxylated quaternary ammonium salt.

Owner:ELEMENTIS SPECIALTIES INC

Biocidal organoclay

A bentonite based organoclay, when mixed with a biocidal quaternary amine containing a benzyl molecule within its structure, acts as a reasonably effective biocide. When this organoclay is further treated with iodine and iodide compounds, its efficiency is greatly enhanced.

Owner:BIOMIN

Clay/organic chemical compositions useful as additives to polymer, plastic and resin matrices to produce nanocomposites and nonocomposites containing such compositions

InactiveUS6794437B2Good dispersionImprove structural strengthCoatingsSilicon compoundsWater dispersibleAmmonium compounds

This invention is of a hybrid organoclay that consists of an organic chemical / phyllosilicate clay intercalate that has been ion-exchanged with quaternary ammonium compounds. Since this hybrid organoclay is hydrophobic, it can be washed in water to remove reaction salts and excess water soluble or water dispersible polymers to give a clean product via inexpensive means such as filtration. This allows a better dispersing composition to be prepared without the difficulties of isolation presented by prior art which uses energy intensive means to remove the bulk of the water from the final product and cannot be easily washed.In one aspect, the present invention provides a solid clay / chemical composition that comprises: (a) one or more smectite clays, (b) a quaternary ammonium compound which reacts via an ion exchange mechanism with the smectite clay, and (c) one or more non-anionic organic materials that intercalate with the clay.The invention is useful both as an ingredient to form nanocomposites and as a rheological additive.

Owner:ELEMENTIS SPECIALTIES INC

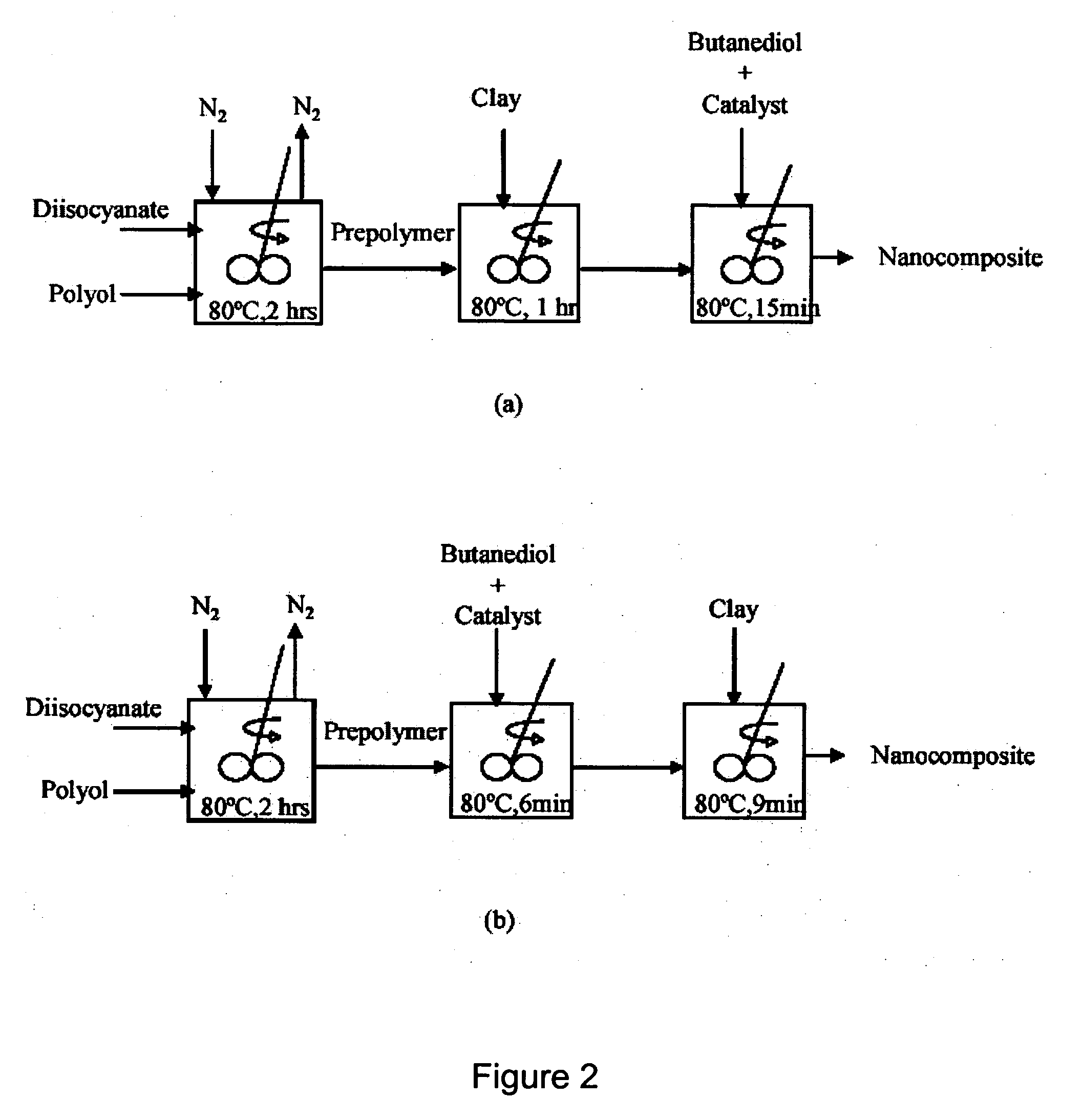

Synthesis of thermoplastic polyurethane composites

The present invention relates to nanocomposites and methods to produce nanocomposites. More particularly, the present invention relates to nanocomposites of thermoplastic polyurethanes that include one or more nanoparticles therein, and to methods to produce such nanocomposites. In one embodiment, the present invention relates to polyurethane nanocomposites wherein organoclay particles are tethered to the polyurethane. In one embodiment, a polymer-particle composite comprising: at least one polyurethane polymer; and particles of at least one modified and / or functionalized compound, wherein the particles of at least one modified and / or functionalized compound contain at least one site that will react with one or more isocyanate groups contained in the polyurethane polymer, and wherein the particles of at least one modified and / or functionalized compound become tethered to one or more isocyanate groups of the polyurethane polymer thereby yielding the polymer-particle composite.

Owner:THE UNIVERSITY OF AKRON

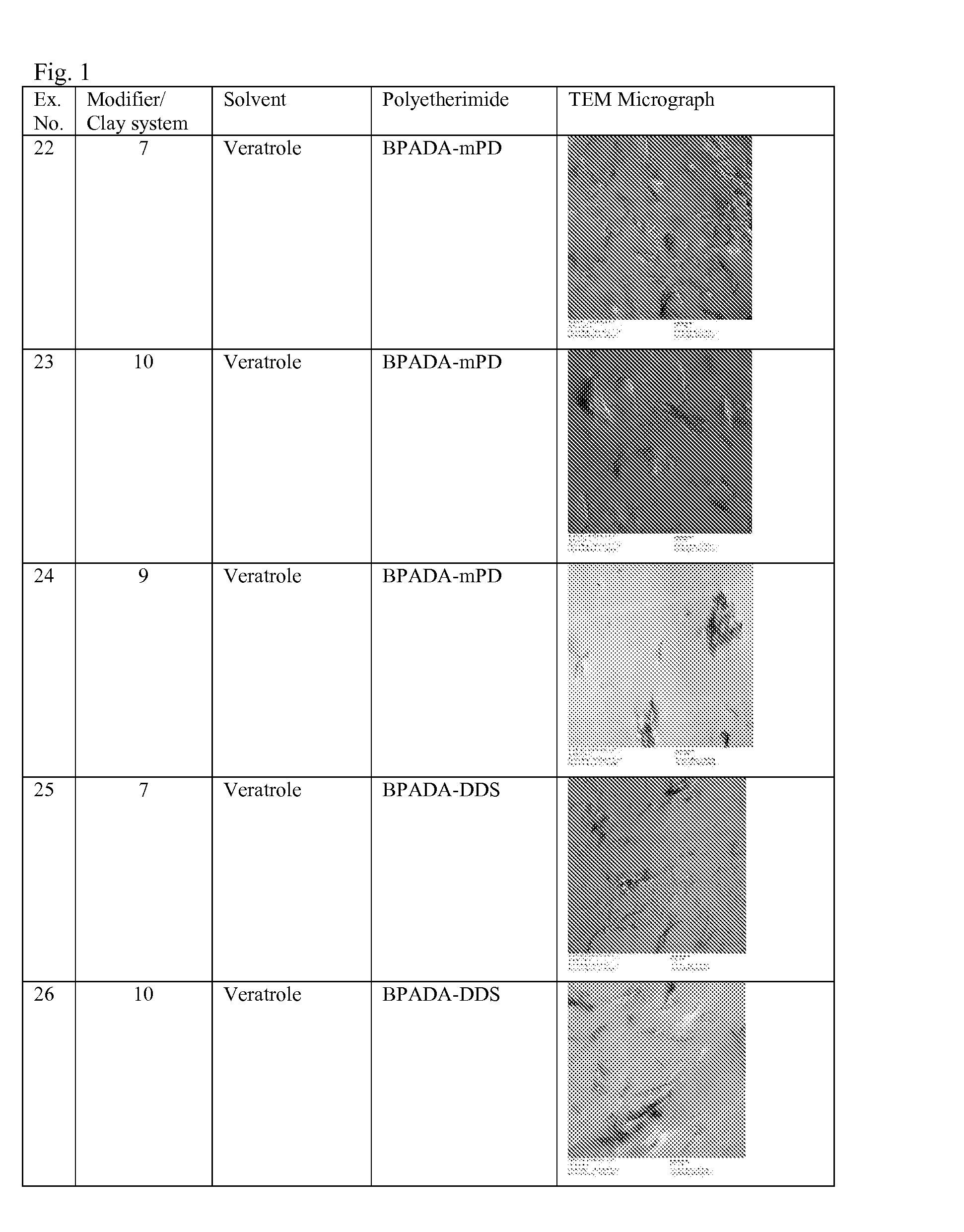

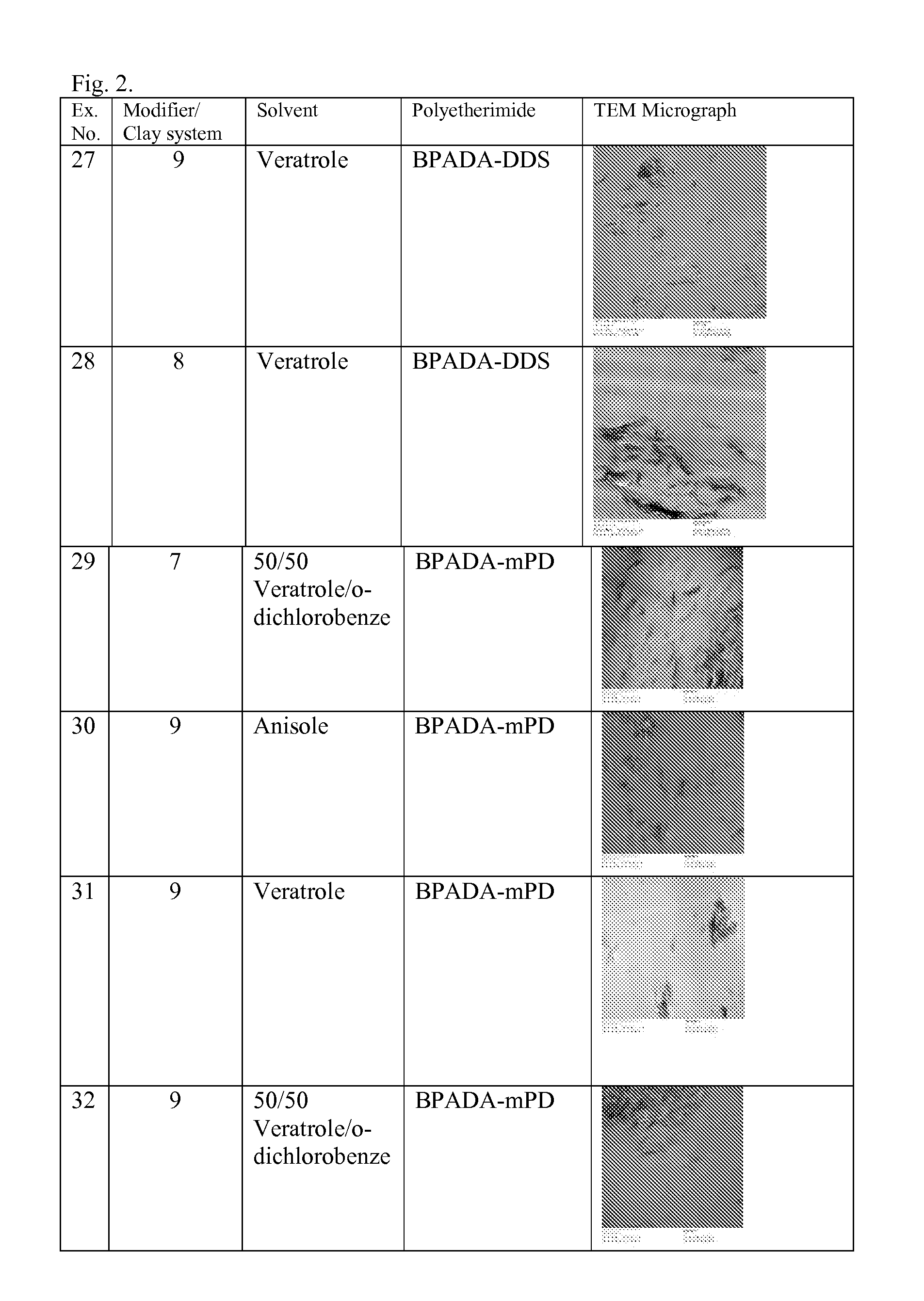

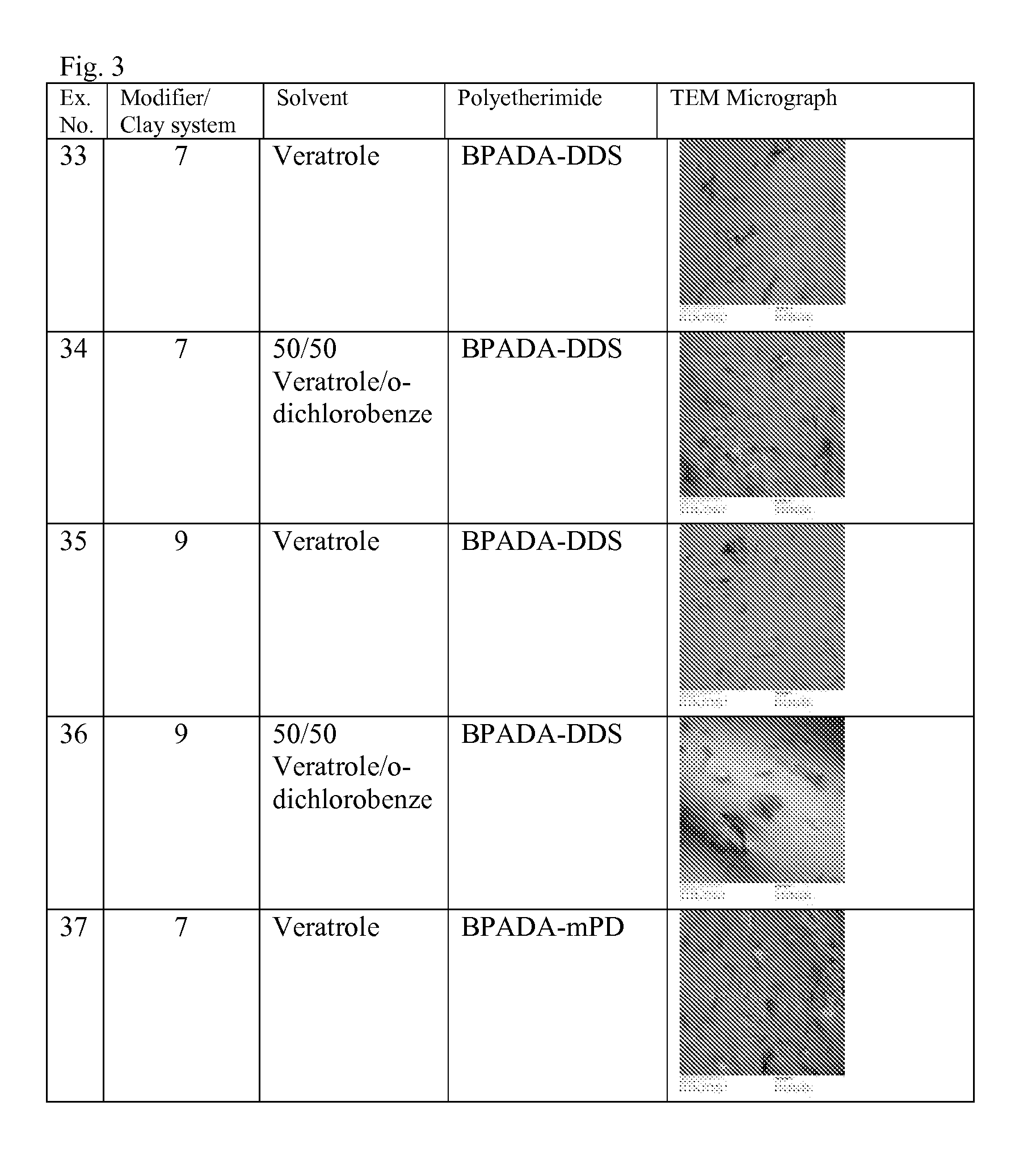

Methods of preparing polymer-organoclay composites and articles derived therefrom

A method for preparing a polymer-organoclay composite composition comprises combining a solvent and an unexfoliated organoclay to provide a first mixture, wherein the unexfoliated organoclay comprises alternating inorganic silicate layers and organic layers, and has an initial spacing between the silicate layers; exposing the first mixture to an energized condition of a sufficient intensity and duration to increase the initial spacing of the inorganic silicate layers, to provide a second mixture; contacting the second mixture with a polymer composition so that the polymer composition fills at least one region located between at least one pair of silicate layers, wherein the polymer composition is at least partially soluble in the solvent; and removing at least a portion of the solvent from the second mixture, wherein the inorganic silicate layers remain separated by the polymer after removal of the solvent.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Organoclay compositions for gelling unsaturated polyester resin systems

InactiveUS6534570B2Satisfactory gelling propertyPigmenting treatmentSpecial tyresAmmonium compoundsOrganoclay

An organoclay composition for gelling unsaturated polyester resin / monomer systems comprising a mineral clay mixture which has been treated with an alkyl quaternary ammonium compound. The mineral clay mixture comprises two components; mineral clay (a) comprising greater than 50 wt. %, based on the weight of the mineral clay mixture, of a mineral clay selected from the group consisting of sepiolite, palygorskite and mixtures of sepiolite and palygorskite; and mineral clay (b) comprising less than 50 wt. %, based on the weight of the mineral clay mixture, of a smectite.

Owner:BYK ADDITIVES

Underfill for high density interconnect flip chips

InactiveUS20120172495A1Improved propertyImproved crash protectionMaterial nanotechnologyNon-macromolecular adhesive additivesFilling materialsSiloxane

Underfill materials include inorganic fill materials (e.g., functionalized CNT's, organo clay, ZnO) that are functionalized reactive with other organic constituents (e.g., organics with epoxy groups, amine groups, or PMDA). The underfill materials also beneficially include polyhedral oligomeric silsesquioxane and / or dendritic siloxane groups that are functionalized with a reactive group (e.g., glycidyl) that reacts with other components of an epoxy system of the underfill.

Owner:NAMICS CORPORATION

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com