Patents

Literature

92results about How to "Improved melt processability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermoplastic olefin compositions, processes and articles

A thermoplastic olefin (TPO) composition comprises (1) a major amount by weight of (a) a substantially linear homopolymer or copolymer of a C2-C10 α-olefin in major proportion to (b) a long chain branched a linear homopolymer or copolymer of a C2-C10 α-olefin, (2) a minor amount by weight of a cross linkable elastomer, and (3) at least one thermally decomposing free radical generating agent present in an amount sufficient to promote an increase in melt strength of the composition over that of the melt strength of the linear homopolymer or copolymer of a C2-C10 α-olefin alone and insufficient to substantially degrade the α-olefinic polymers. The TPO composition is prepared by melt blending the components at a temperature sufficient to melt said homopolymers or copolymers of a C2-C10 α-olefin and thermally decompose said agent. Articles are thermoformed from the thermoplastic olefin.

Owner:EXOUSIA IP LLC

Method to prepare processable polyimides with reactive endogroups using 1,3-bis(3-aminophenoxy)benzene

InactiveUS6288209B1Improved solvent resistance and modulus and elevated use temperatureImproved melt processabilityNon-fibrous pulp additionSynthetic resin layered productsPolymer scienceBackbone chain

Polyimide copolymers were obtained containing 1,3-bis(3-aminophenoxy)benzene (APB) and other diamines and dianhydrides and terminating with the appropriate amount of reactive endcapper. The reactive endcappers studied include but should not be limited to 4-phenylethynyl phthalic anhydride (PEPA), 3-aminophenoxy-4'-phenylethynylbenzophenone (3-APEB), maleic anhydride (MA) and nadic anhydride (5-norbornene-2,3-dicarboxylic anhydride, NA). Homopolymers containing only other diamines and dianhydrides which are not processable under conditions described previously can be made processable by incorporating various amounts of APB, depending on the chemical structures of the diamines and dianhydrides used. By simply changing the ratio of APB to the other diamine in the polyimide backbone, a material with a unique combination of solubility, Tg, Tm, melt viscosity, toughness and elevated temperature mechanical properties can be prepared. The copolymers that result from using APB to enhance processability have a unique combination of properties that include low pressure processing (200 psi and below), long term melt stability (several hours at 300° C. for the phenylethynyl terminated polymers), high toughness, improved solvent resistance, improved adhesive properties, and improved composite mechanical properties. These copolyimides are eminently suitable as adhesives, composite matrices, moldings, films and coatings.

Owner:NASA

Biodegradable polymer

InactiveUS20040122135A1Significant comprehensive benefitsImproved melt processabilityFireproof paintsPigmenting treatmentUrea derivativesPolyester

A biodegradable polymer includes a) 20 to 60% of a mixture of starch and / or a modified starch, b) 8 to 22% of starch plasticisers and processing agents c) 30 to 70% of one or more biodegradable aliphatic polyesters d) 1 to 10% of a layered silicate clay mineral. The silicate mineral is an organoclay which has been formed by reacting clay with an intercalating chemical to compatibilise it with the polymers so that the clay is exfoliated and makes the blend amorphous. The polymers may also include the usual additives including e) from 0 to 20% by weight of a polyol plasticiser f) from 0.1 to 1.5% by weight of a C12-22 fatty acid or salt or a destructing agent preferably urea and / or urea derivatives, and g) from 0 to 12% by weight of added water. The polyester may be modified by reaction with maleic anhydride.

Owner:PLANTIC TECH

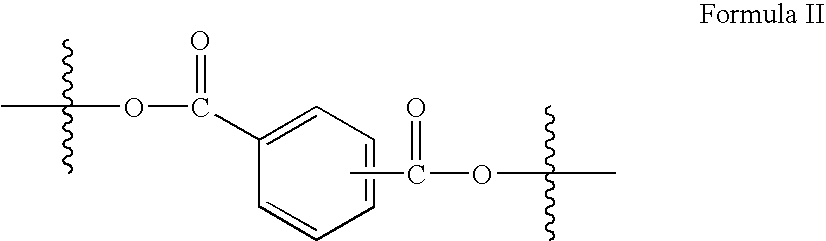

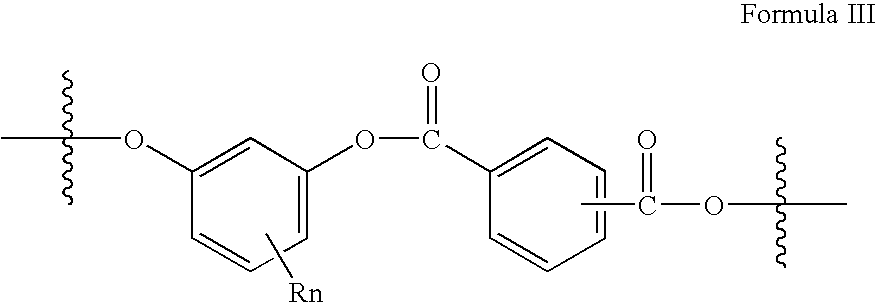

Miscible polyimide blends

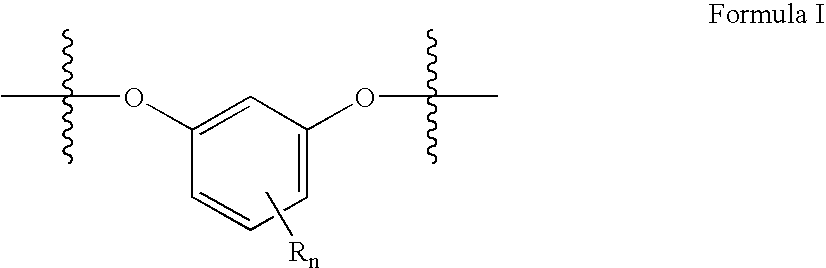

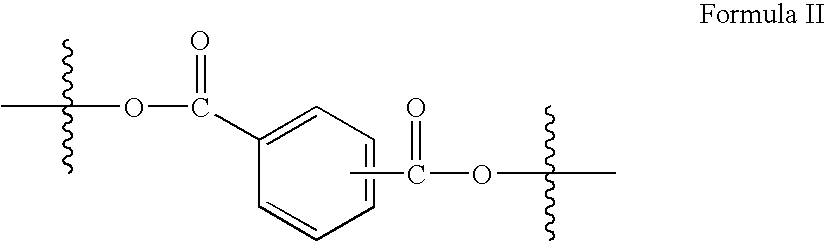

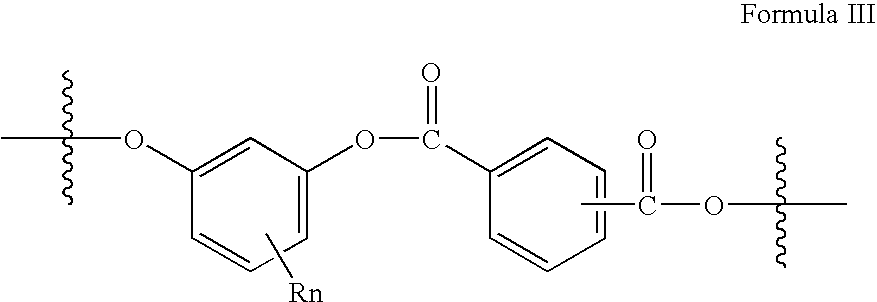

Compositions made from a polyarylate or polyester carbonate containing greater than about 50 mole % resorcinol based ester linkages give miscible blends with polyimide resins. The blends of polyimides and resorcinol based polyesters or resorcinol based polyester carbonates also give miscible blends when combined with other aryl alky polyester resins.

Owner:SHPP GLOBAL TECH BV

Release agent for transparent polymide blends

Compositions made from a polyarylate or polyester carbonate containing greater than about 50 mole % resorcinol based ester linkages give miscible blends with polyimide resins, addition of alkyl amide compounds improves mold release and melt flow while maintaining transparency. The blends also have high refractive index and low haze.

Owner:SHPP GLOBAL TECH BV

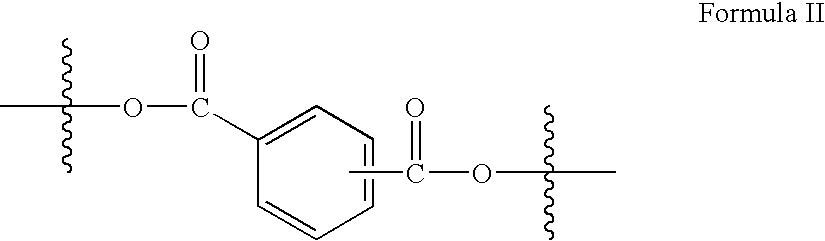

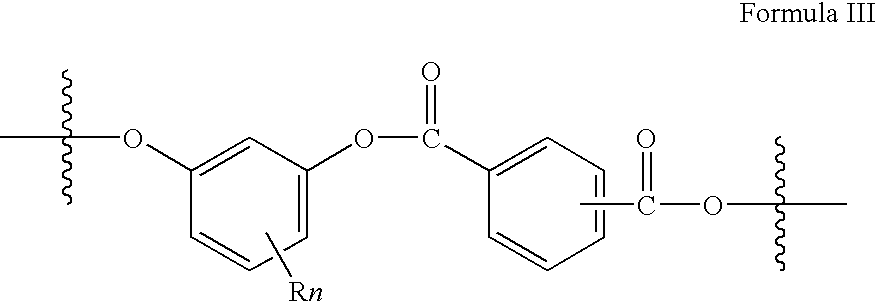

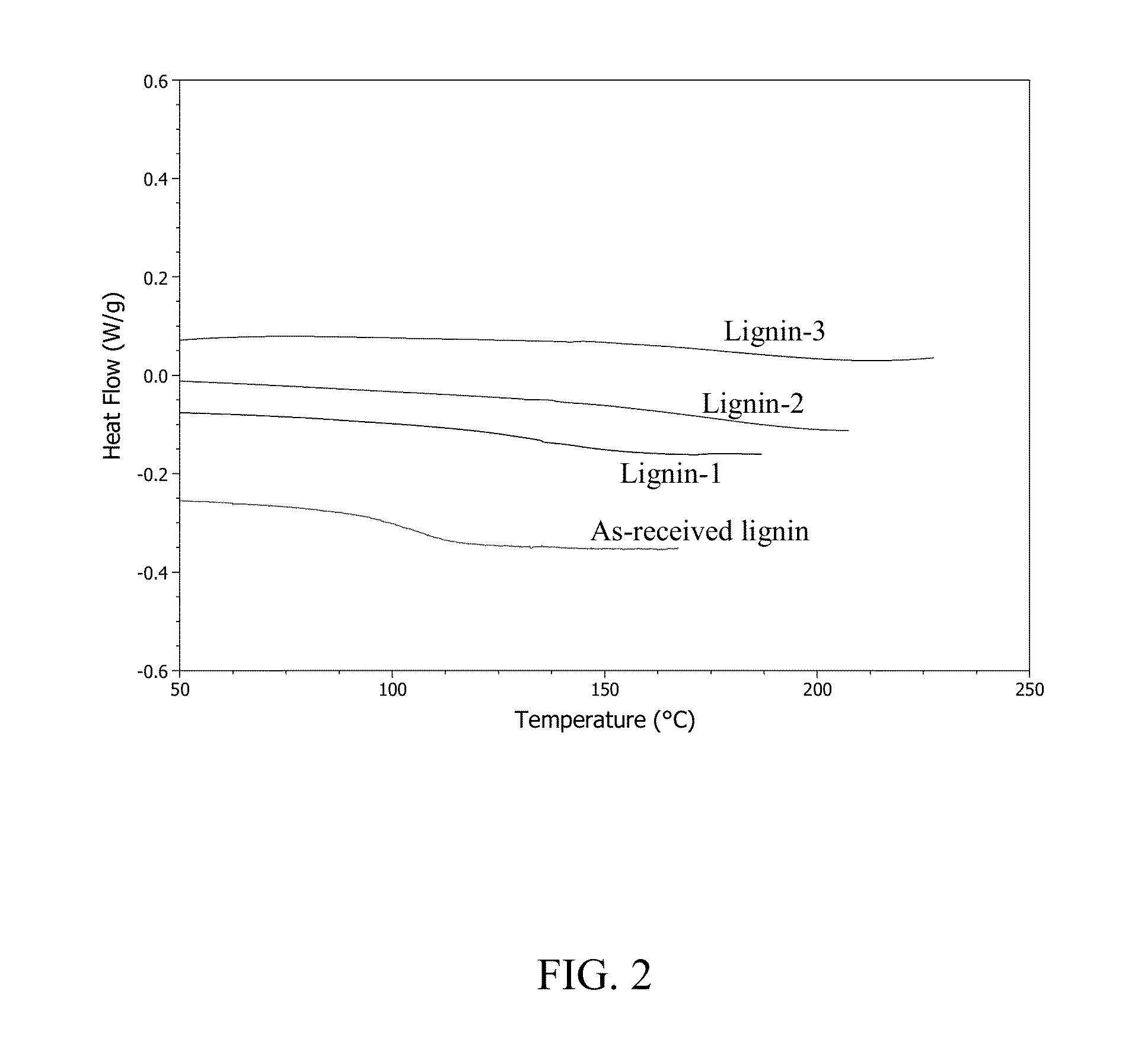

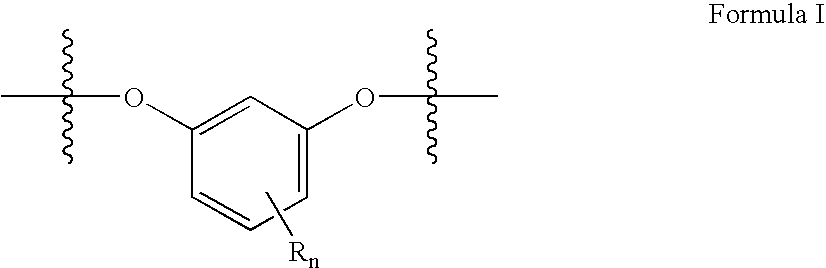

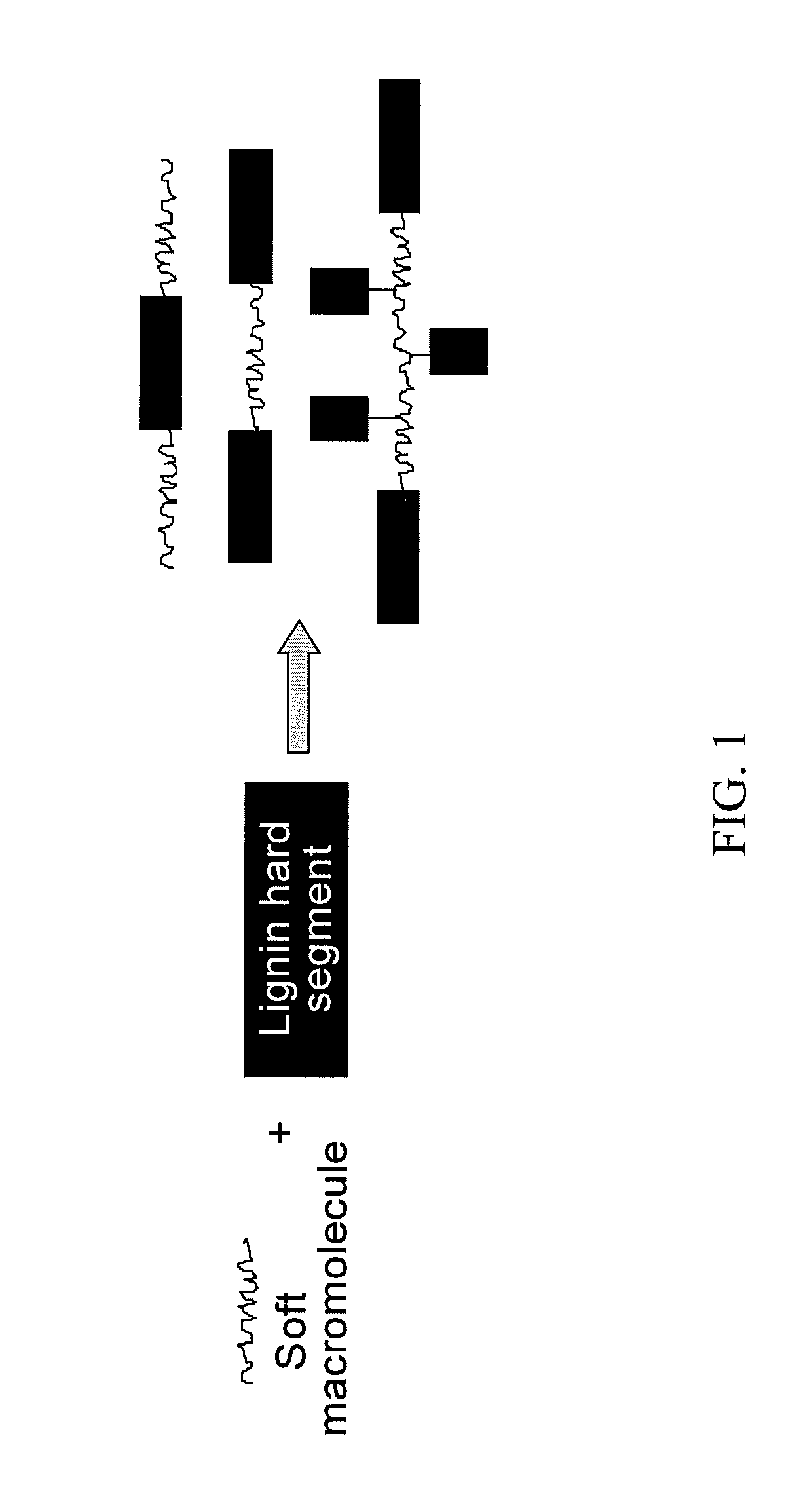

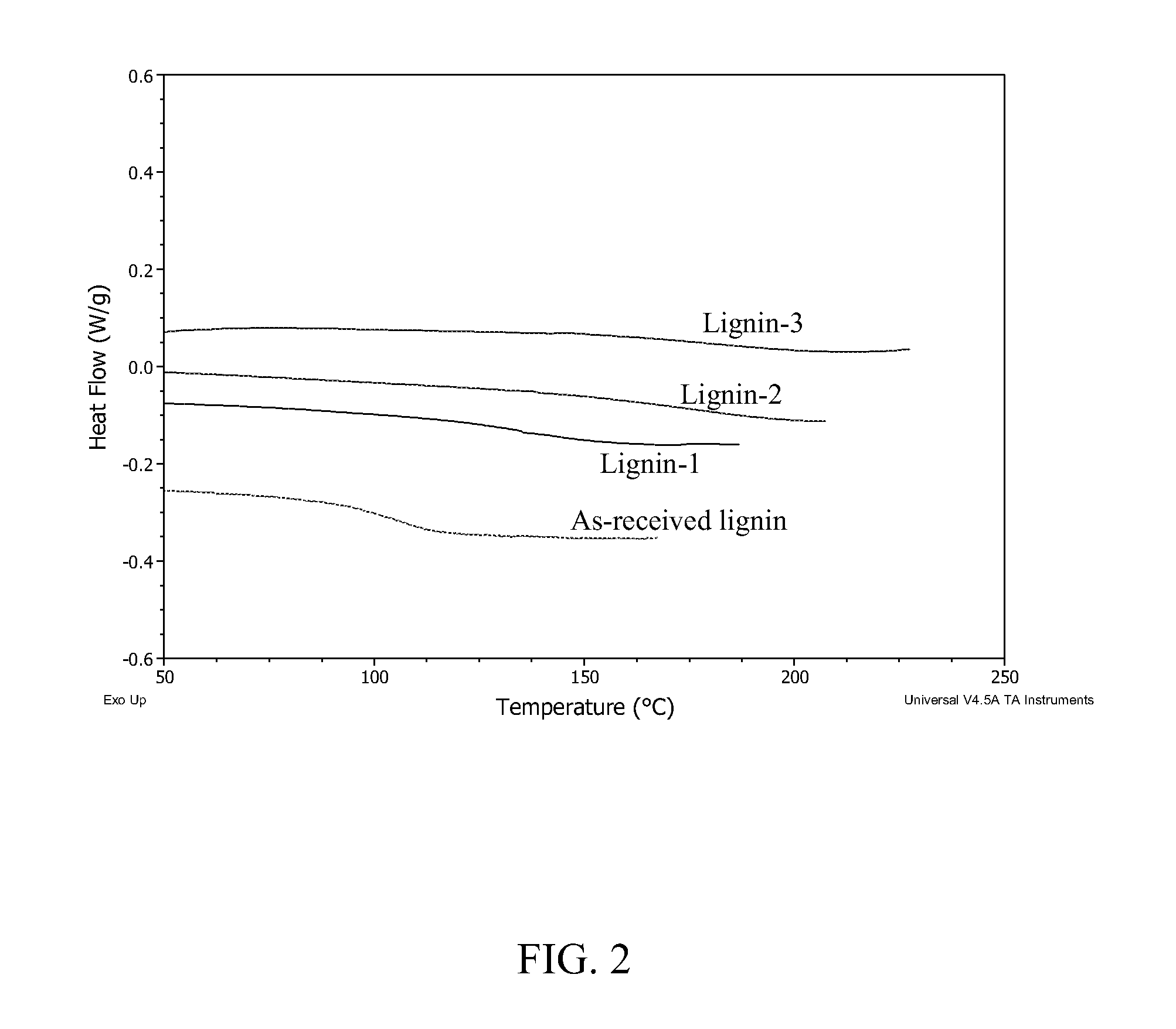

Lignin-derived thermoplastic co-polymers and methods of preparation

InactiveUS20130116383A1Reduce amountSignificant durabilityLignin derivativesThermoplasticCarbon atom

The present invention relates to a crosslinked lignin comprising a lignin structure having methylene or ethylene linking groups therein crosslinking between phenyl ring carbon atoms, wherein said crosslinked lignin is crosslinked to an extent that it has a number-average molecular weight of at least 10,000 g / mol, is melt-processible, and has either a glass transition temperature of at least 100° C., or is substantially soluble in a polar organic solvent or aqueous alkaline solution. Thermoplastic copolymers containing the crosslinked lignin are also described. Methods for producing the crosslinked lignin and thermoplastic copolymers are also described.

Owner:UT BATTELLE LLC

Miscible polyimide blends

Compositions made from a polyarylate or polyester carbonate containing greater than about 50 mole % resorcinol based ester linkages give miscible blends with polyimide resins. The blends of polyimides and resorcinol based polyesters or resorcinol based polyester carbonates also give miscible blends when combined with other aryl alky polyester resins.

Owner:SHPP GLOBAL TECH BV

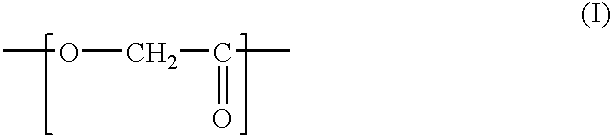

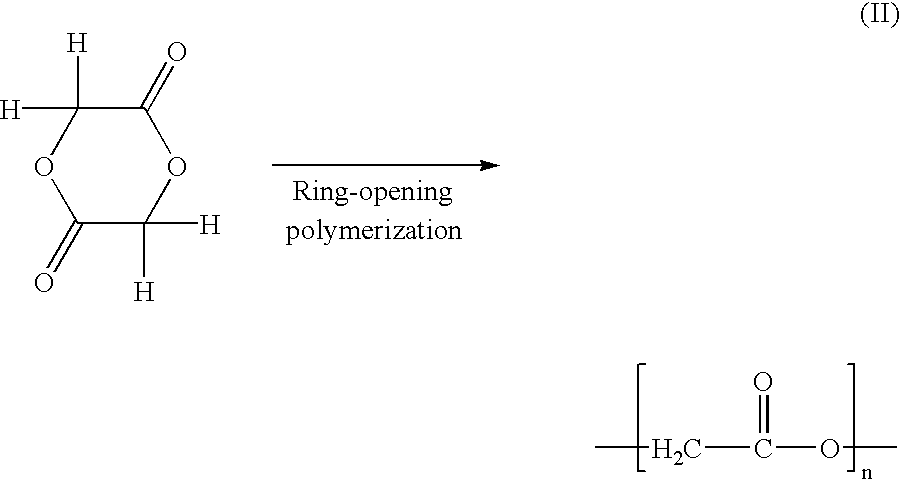

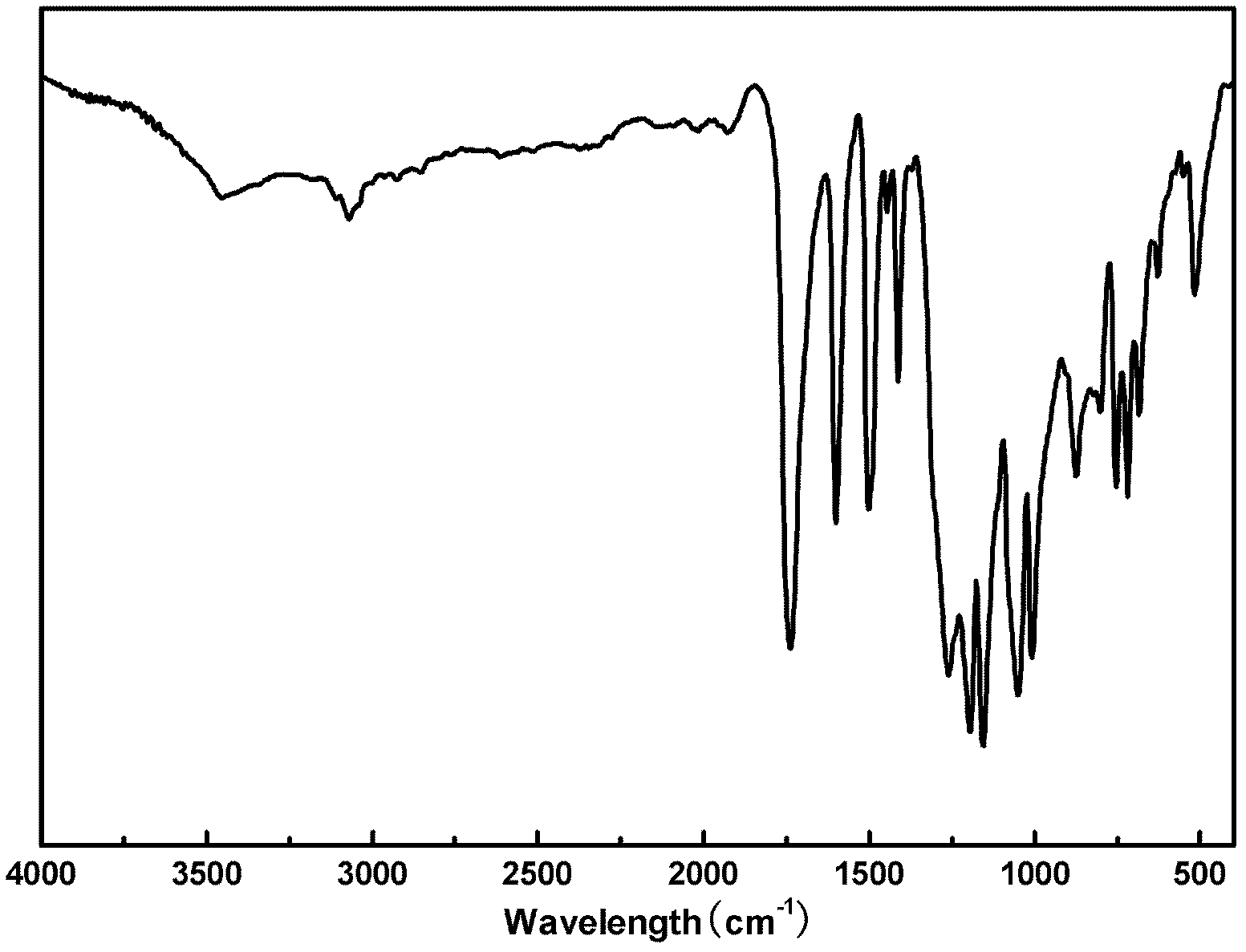

Crystalline polyglycolic acid, polyglycolic acid composition and production process thereof

InactiveUS20030125508A1Improved melt processabilityImproved melt stabilityOrganic chemistryBottlesVitrificationCrystallization temperature

Crystalline polyglycolic acid wherein a difference between the melting point Tm and the crystallization temperature Tc2 is not lower than 35° C., and a difference between the crystallization temperature Tc1 and the glass transition temperature Tg is not lower than 40° C. A production process of polyglycolic acid modified in crystallinity, comprising applying heat history to crystalline polyglycolic acid at a temperature of not lower than (the melting point Tm of the crystalline polyglycolic acid+38° C.). A polyglycolic acid composition comprising crystalline polyglycolic acid and a heat stabilizer, wherein a difference (T2-T1) between the temperature T2 at 3%-weight loss on heating of the polyglycolic acid composition and the temperature T1 at 3%-weight loss on heating of the crystalline polyglycolic acid is not lower than 5° C.

Owner:KUREHA KAGAKU KOGYO KK

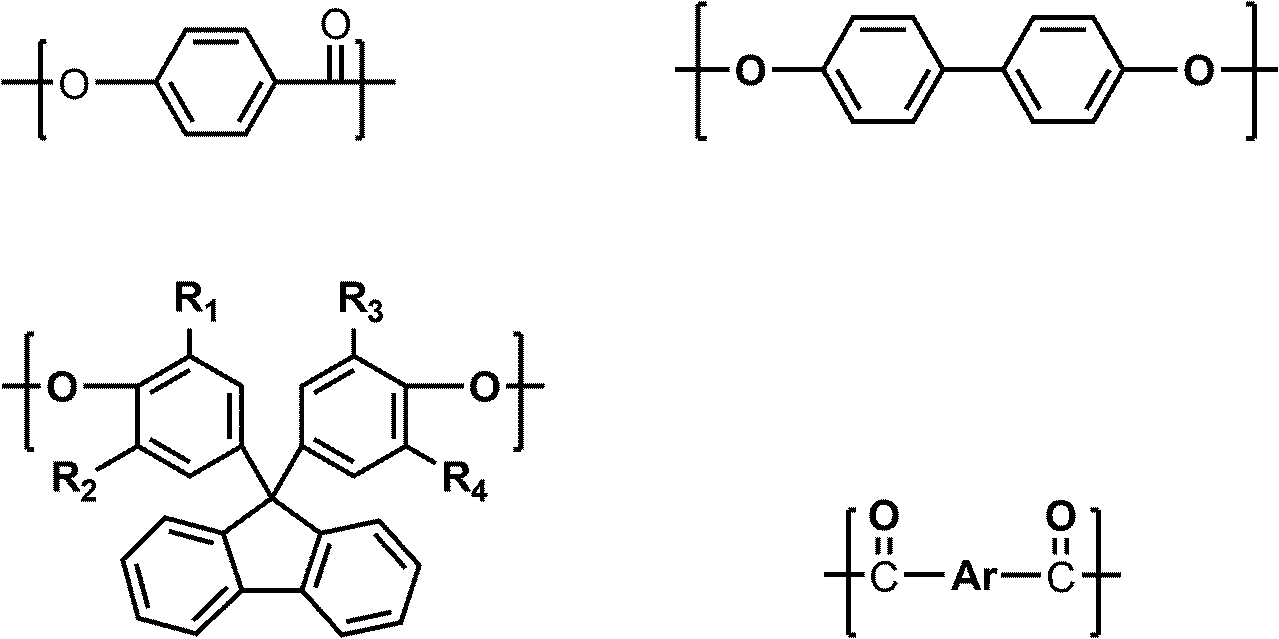

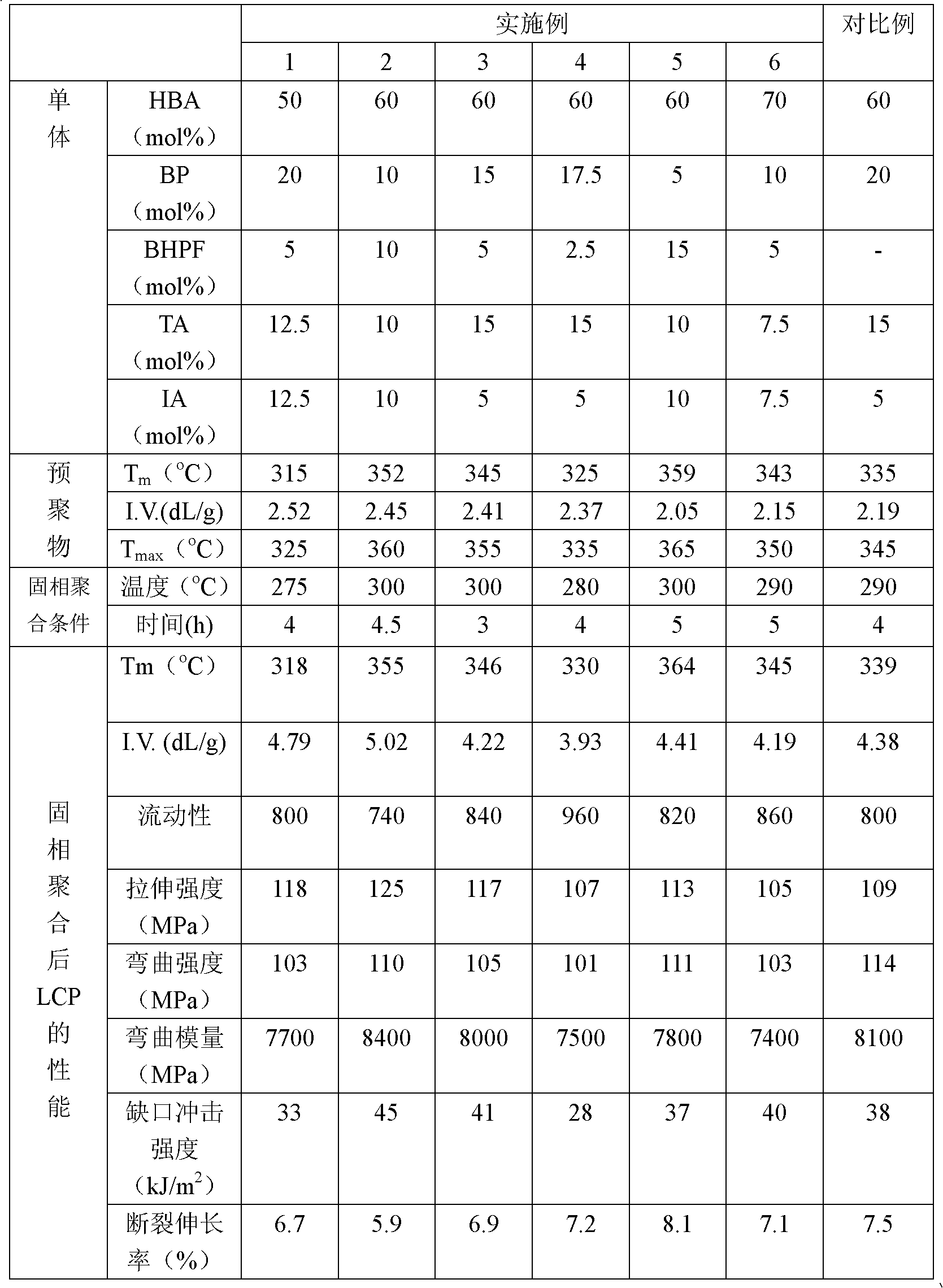

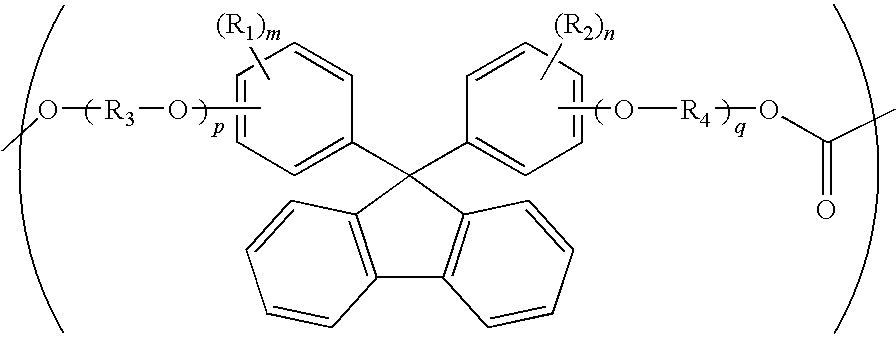

Liquid crystal polyester and its preparation method and use

ActiveCN103012759AImprove liquidityEasy to processLiquid crystal compositionsPolyesterChain structure

The invention belongs to the field of material engineering and discloses a liquid crystal polyester and its preparation method and use. The liquid crystal polyester is obtained by a condensation polymerization reaction of p-hydroxybenzoic acid, biphenol, diphenol with a fluorene skeleton and aromatic dicarboxylic acid. A unit with a fluorene skeleton side group is introduced into a chain structure of the liquid crystal polyester so that the liquid crystal polyester has a melting temperature of 310 to 360 DEG C, good fluidity and excellent melting processing performances.

Owner:KINGFA SCI & TECH CO LTD +2

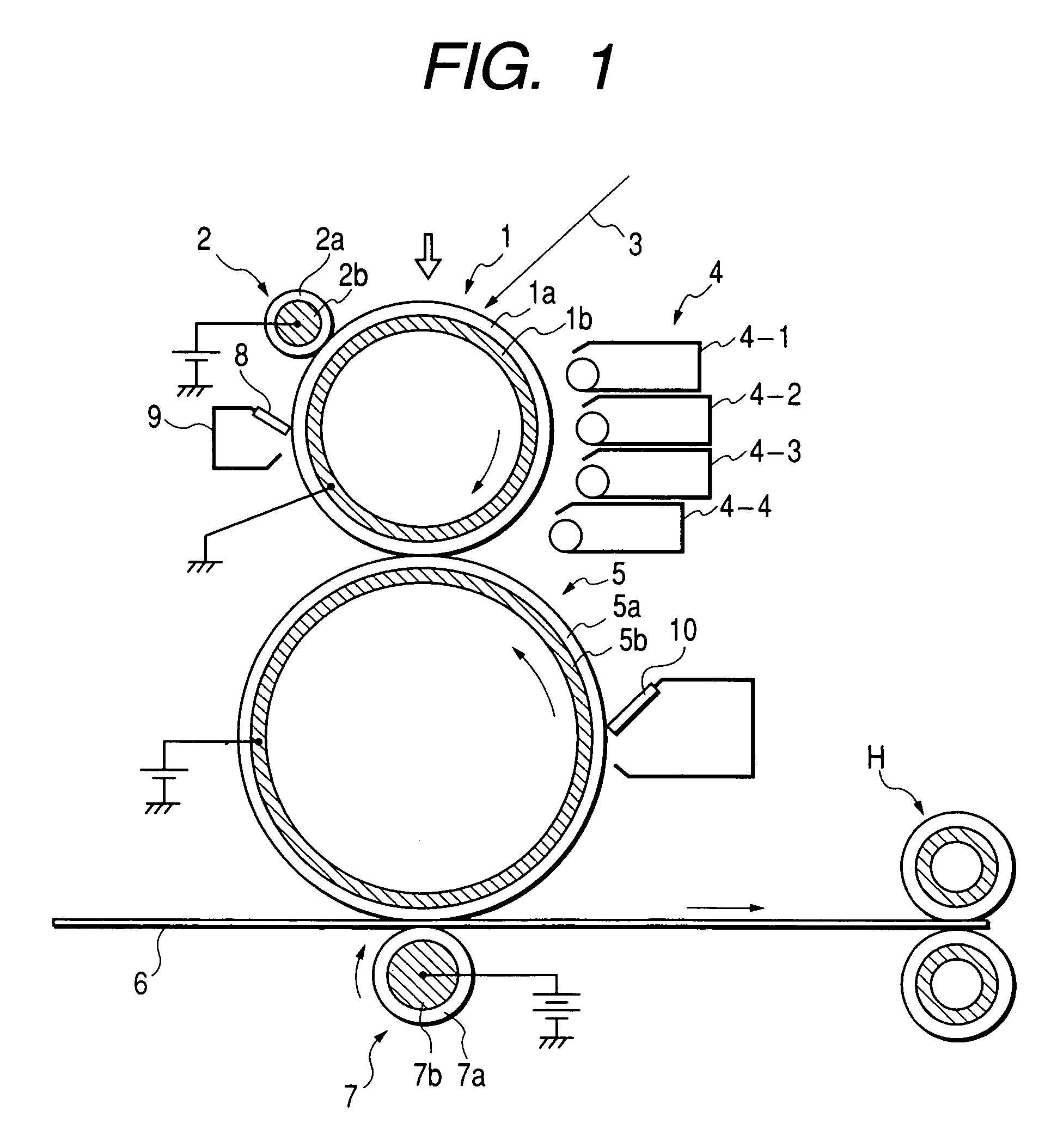

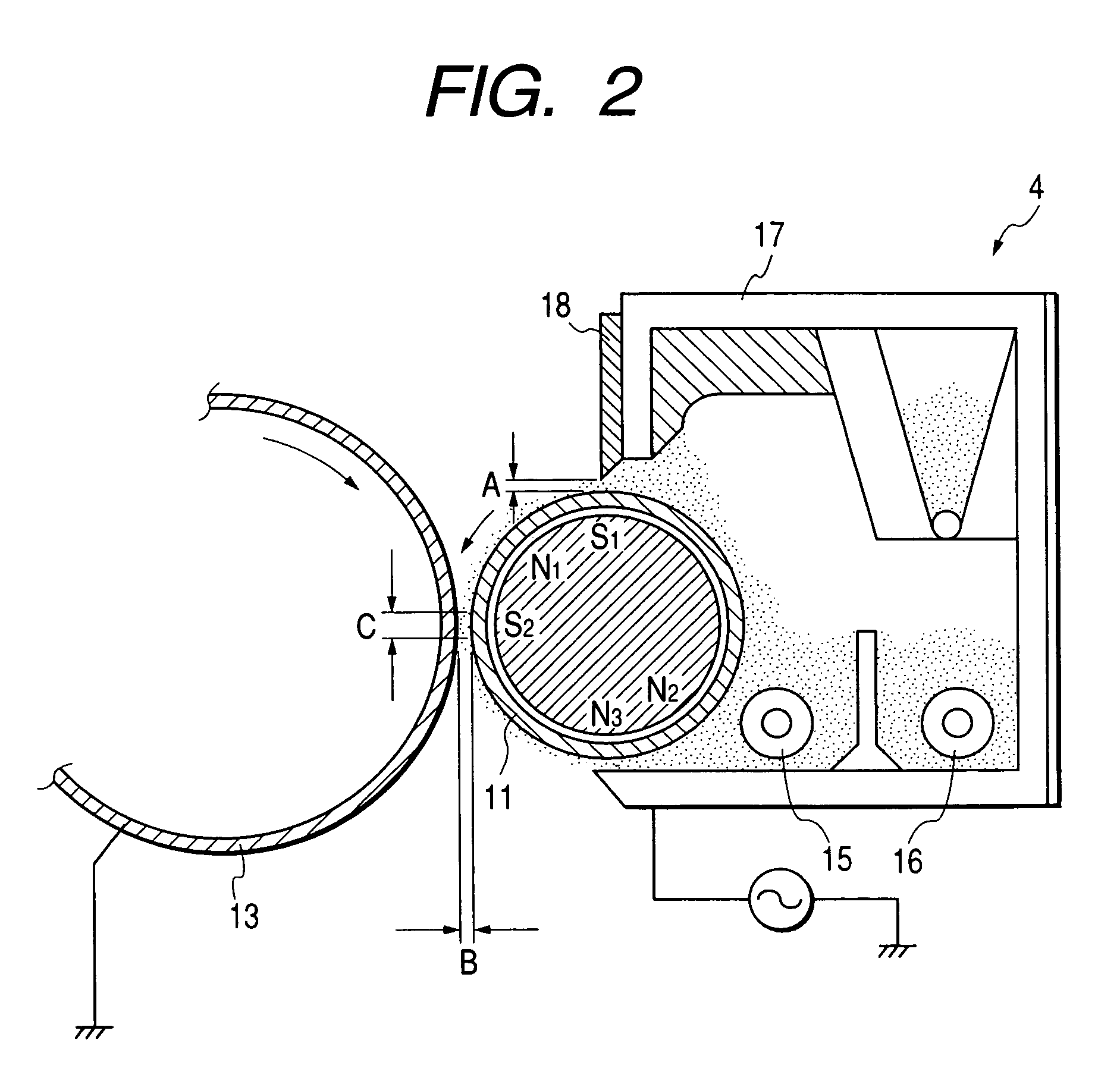

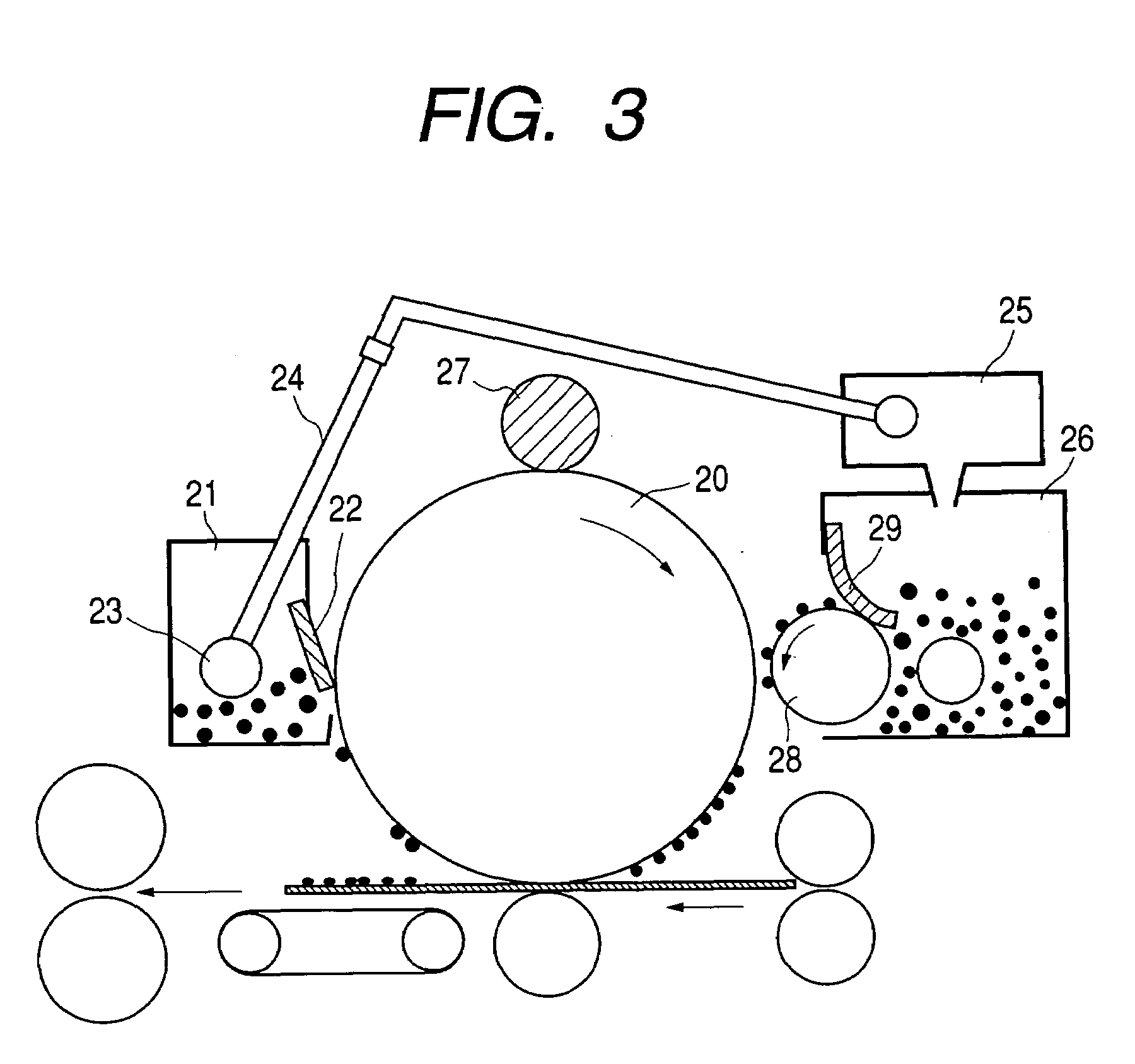

Polyhydroxyalkanoate containing amide group, sulfonic group, and sulfonate ester group, method for producing the same, and charge control agent, toner, image forming method, and image forming apparatus

InactiveUS7393912B2Improved melt processabilityImprove featuresOrganic active ingredientsDevelopersHalogenAliphatic hydrocarbon

A polyhydroxyalkanoate containing in a molecule at least one unit represented by the chemical formula (1). The polyhydroxyalkanoate is a biodegradable plastic with enhanced melt-processability and exhibits excellent charging stability, high chargeability, and enhanced dispersibility when used as a charge control agent of a toner in an electrophotographic process.(R denotes -A1(—SO2R1)x. R1 is selected from OH, a halogen atom, ONa, OK, and OR1a. R1a and A1 are selected from a substituted or unsubstituted aliphatic hydrocarbon structure, a substituted or unsubstituted aromatic ring structure, and a substituted or unsubstituted heterocyclic structure. Further, m and x are integers selected from 1 to 8, and when two or more units exist, each of R, R1R1a, A1, m, and x is defined as above independently for each of the units.)

Owner:CANON KK

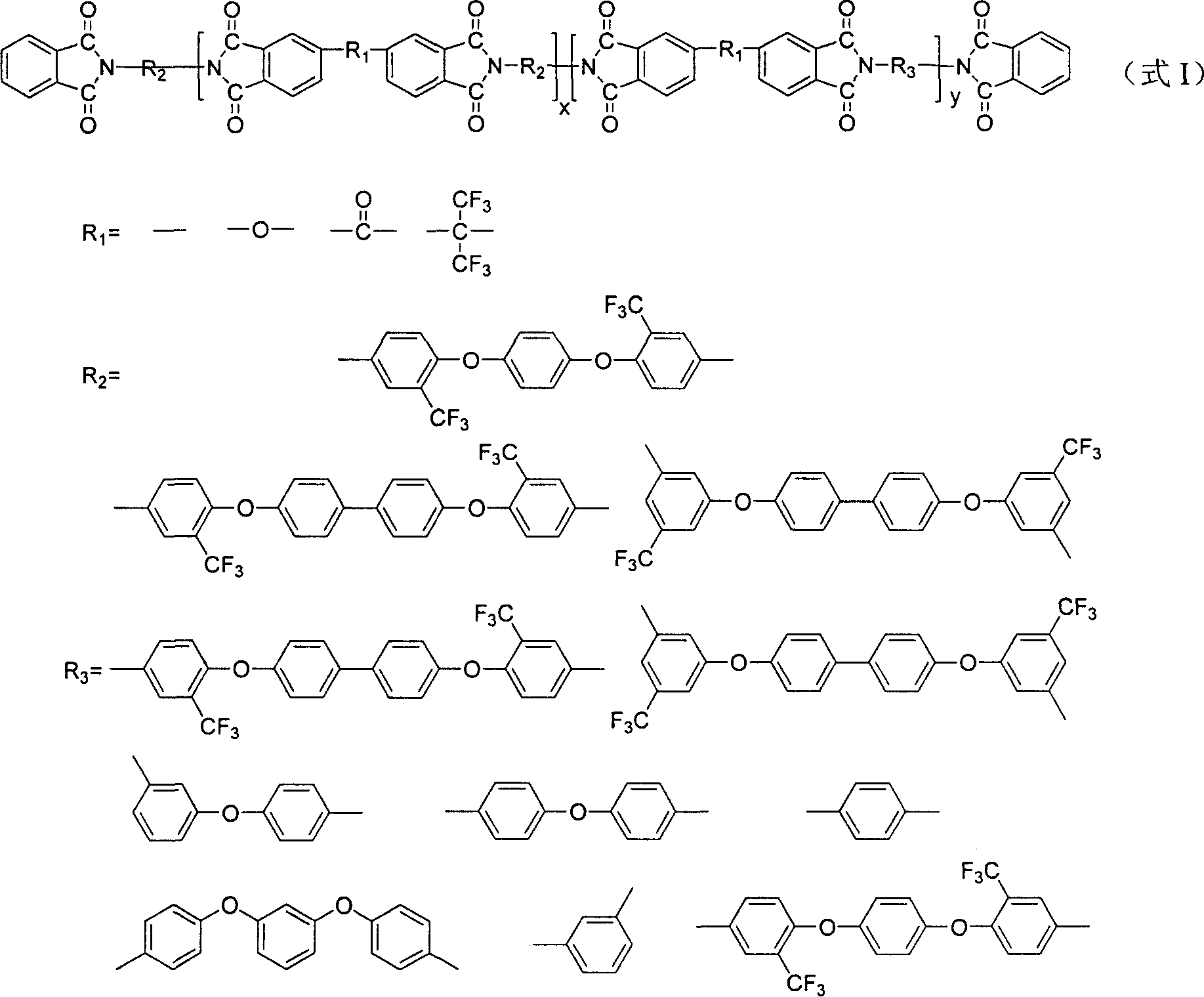

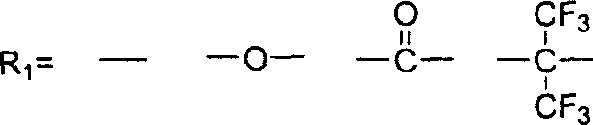

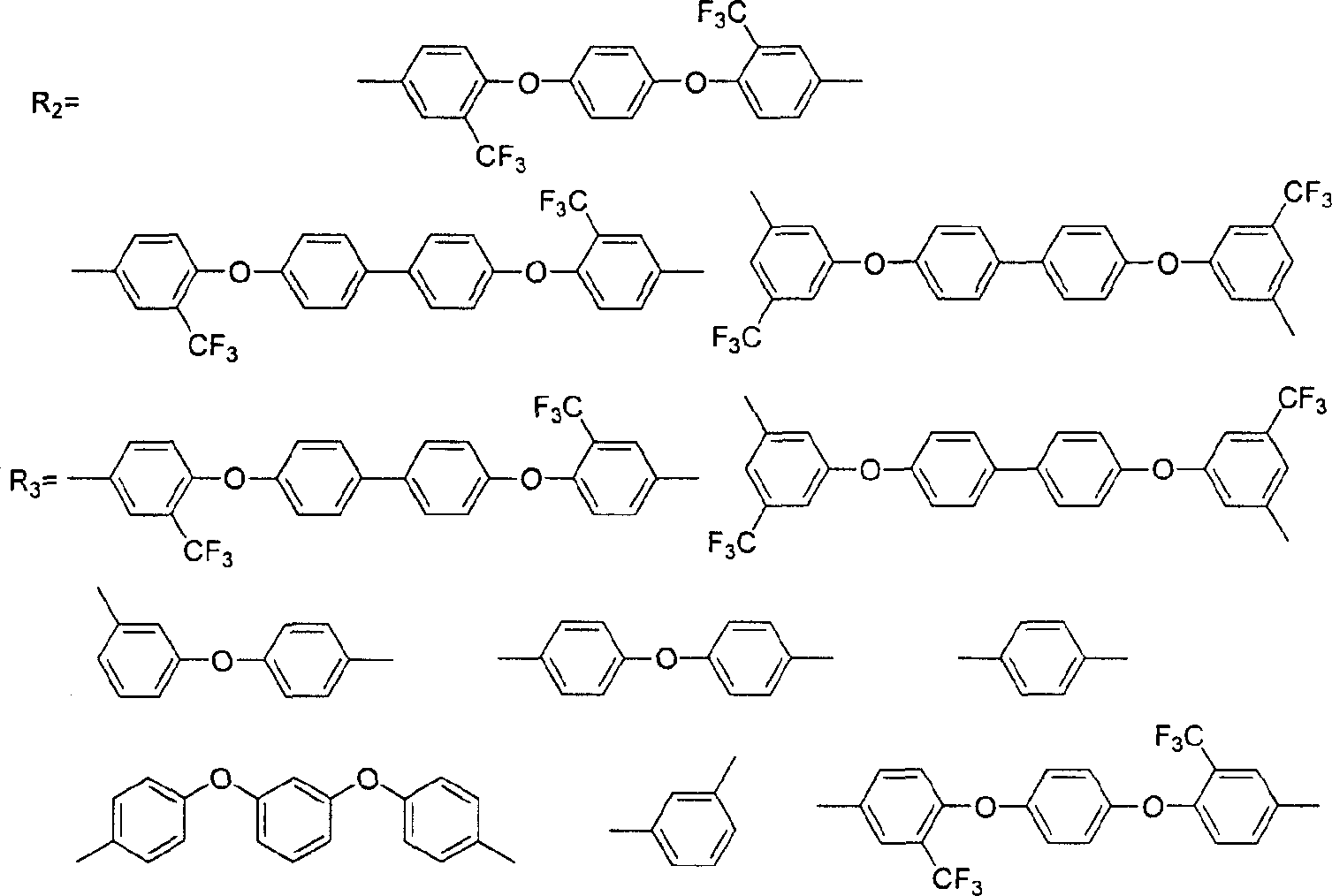

Fluorine-containing thermoplastic polyimide polymer and preparation method thereof

The invention discloses a thermoplastic polyimide polymer with fluorine and preparing method, which is characterized by the following: setting the structural formula as formula I; proceeding condensed and polymeric reaction with aromatic dianhydride, aromatic diamine and sealing end agent; synthesizing thermoplastic polyimide; introducing fluorine-containing group and flexible ether link in polyimide backbone structure; decreasing molecular chain rigidity and acting force of molecular chain; possessing good function to improve dissolving property and flux processability of polyimide; decreasing specific absorption of the material through introduction of fluorine-containing group; increasing stability of thermal oxidation. This product possesses good heat endurance and mechanics mechanical property, which can be used to outer-space, electron, micro electron, petrochemical, car and so on domain.

Owner:INST OF CHEM CHINESE ACAD OF SCI

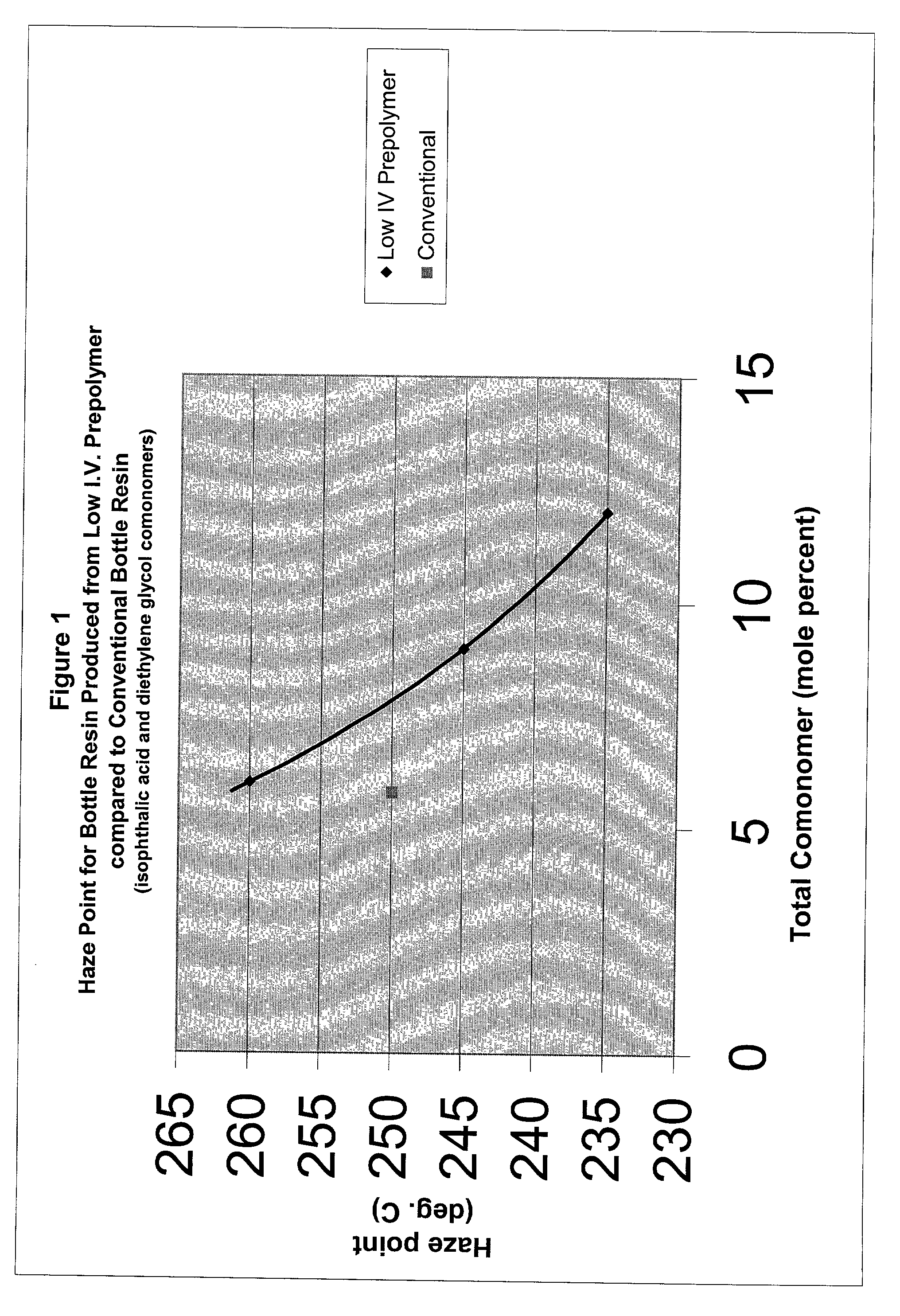

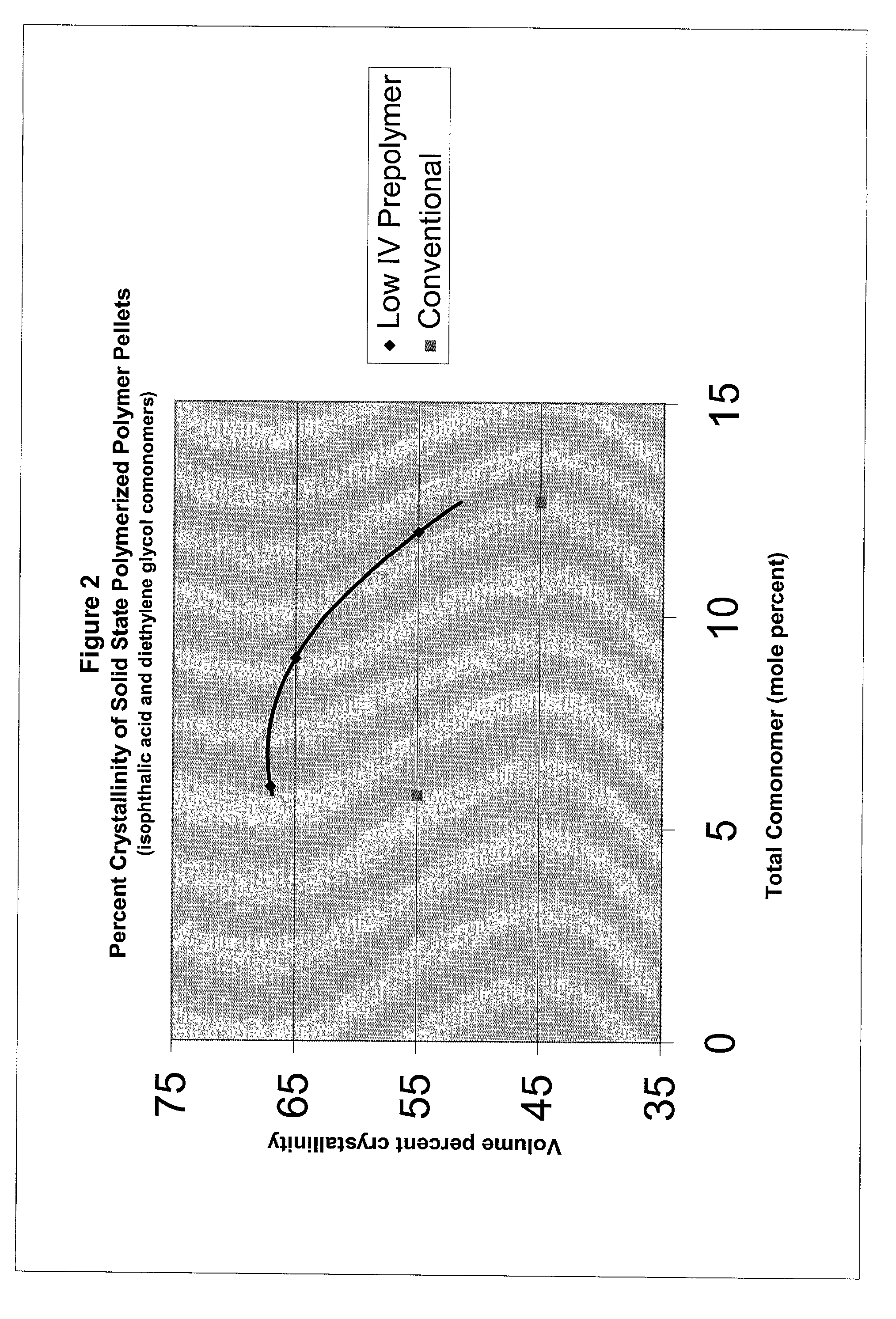

Method of preparing modified polyester bottle resins

InactiveUS20010034431A1Maintain good propertiesCost-effectiveThin material handlingHollow articlesDimethyl terephthalatePolyethylene terephthalate

Owner:WELLMAN INC

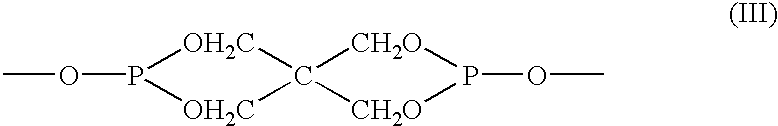

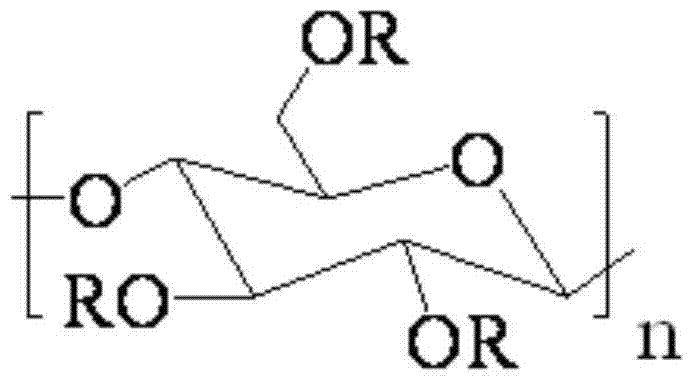

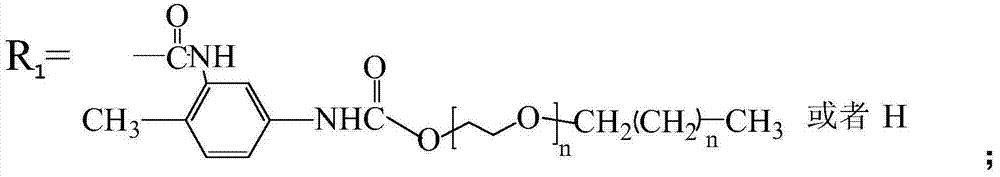

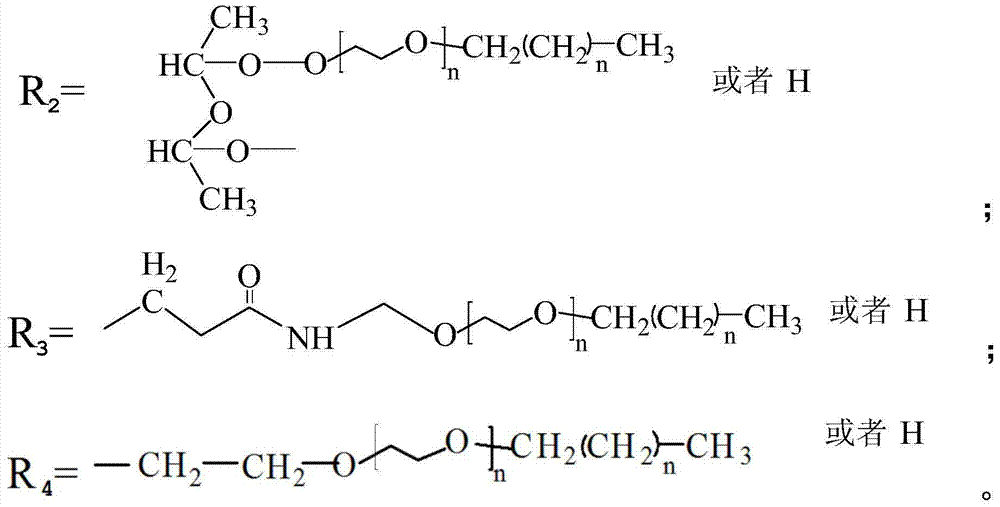

Thermoplastic cellulose-based solid-solid phase transition material and preparation method thereof

The invention discloses a thermoplastic cellulose-based solid-solid phase transition material and a preparation method thereof. The preparation method comprises the following steps: 1, drying cellulose or a cellulose derivative; 2, respectively dissolving a cross-linking agent and polyethylene glycol alkyl ether in an organic solvent I to obtain a cross-linking agent solution and a polyethylene glycol alkyl ether solution, adding the polyethylene glycol alkyl ether to the cross-linking agent solution in a dropwise manner, adding a catalyst, and reacting for 0.5-10h to obtain a prepolymer solution, wherein a mole ratio of the polyethylene glycol alkyl ether to the cross-linking agent is 1:1; and 3, dissolving cellulose in an ionic liquid to obtain a cellulose solution, adding the prepolymer solution, acid anhydride and a catalyst to the above obtained cellulose solution, carrying out a polymerization reaction for 2-24h to obtain a finally obtained mixture, adding the finally obtained mixture to deionized water or an organic solvent II for precipitation, repeatedly washing the above obtained precipitate with deionized water 2-3 times, and carrying out vacuum drying to obtain the thermoplastic cellulose-based solid-solid phase transition material. The phase transition material has a good thermal stability and a melting processing performance, and can be blended with a thermoplastic copolymer matrix for melting processing.

Owner:TIANJIN POLYTECHNIC UNIV +1

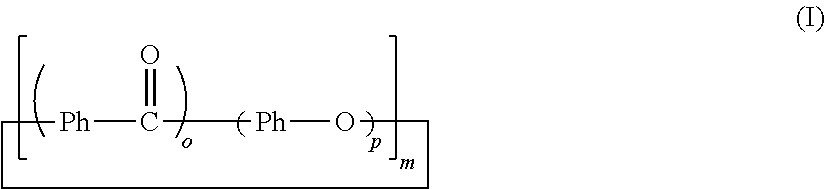

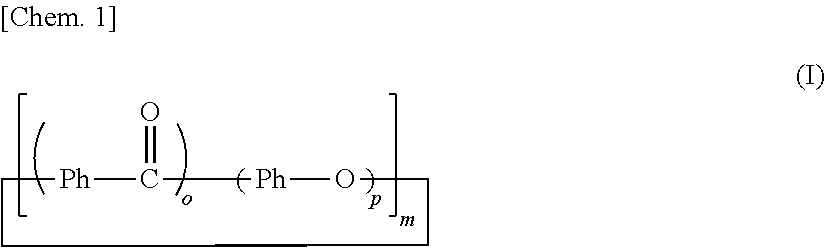

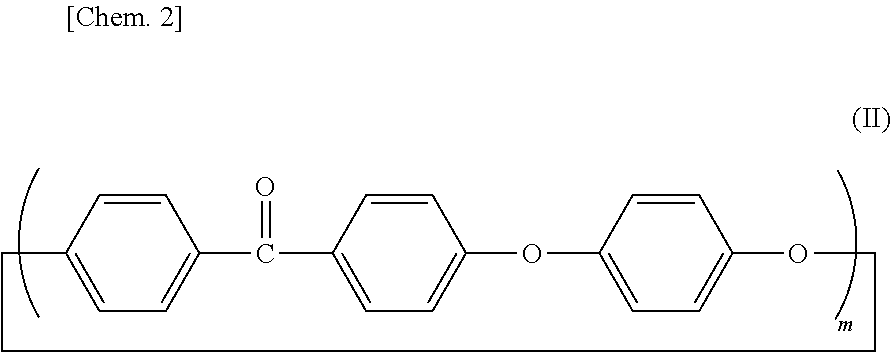

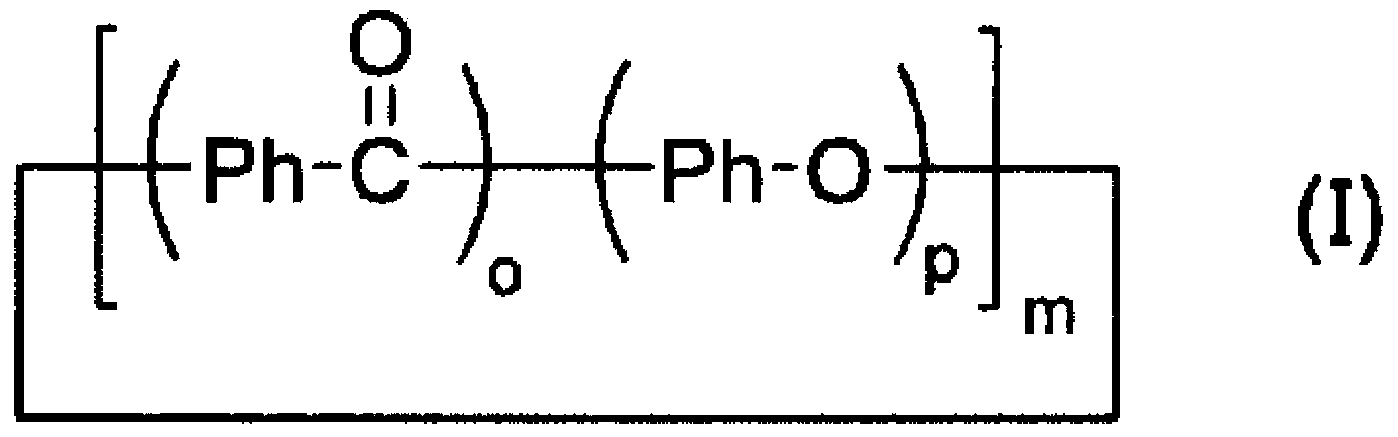

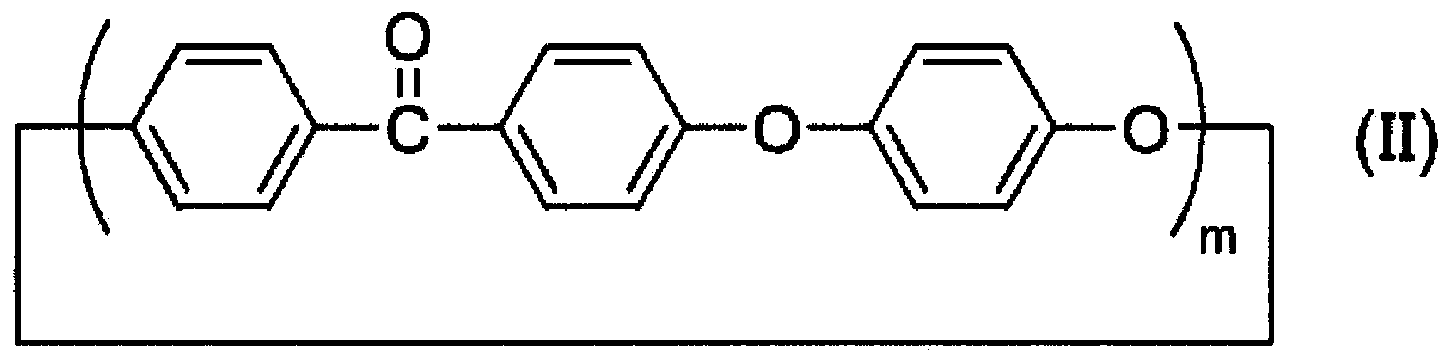

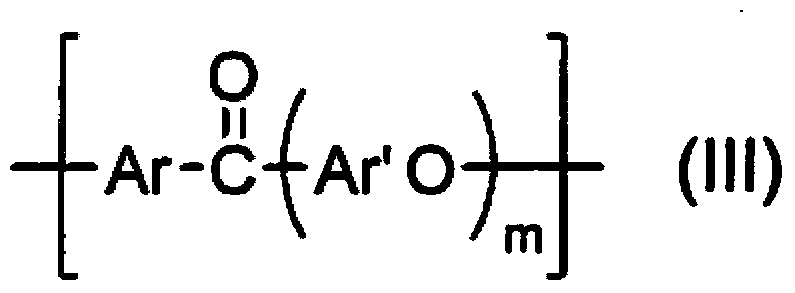

Thermoplastic resin composition, and molded product thereof

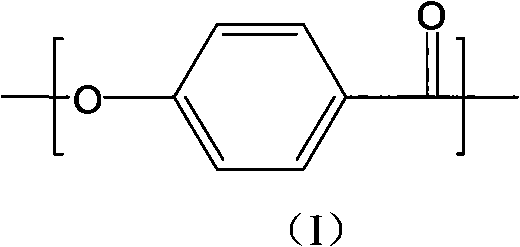

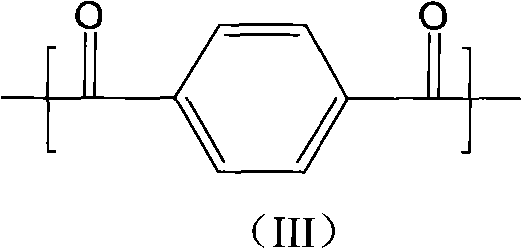

A thermoplastic resin composition is provided having excellent flowability, high crystallization characteristics, high transparency and excellent processability in melt processing to resin molded products, sheets, films, fibers and pipes. The thermoplastic resin composition includes 100 parts by weight of (A) a thermoplastic resin; and 0.5 to 50 parts by weight of (B) a cyclic poly(phenylene ether ketone) that is expressed by General Formula (I) given below and has phenylene ketone shown by -Ph-CO— and phenylene ether shown by -Ph-O— as are repeating structural unit:wherein Ph in Formula represents a para-phenylene structure; o and p are respectively integral numbers of not less than 1; and m is an integral number of 2 to 40.

Owner:TORAY IND INC

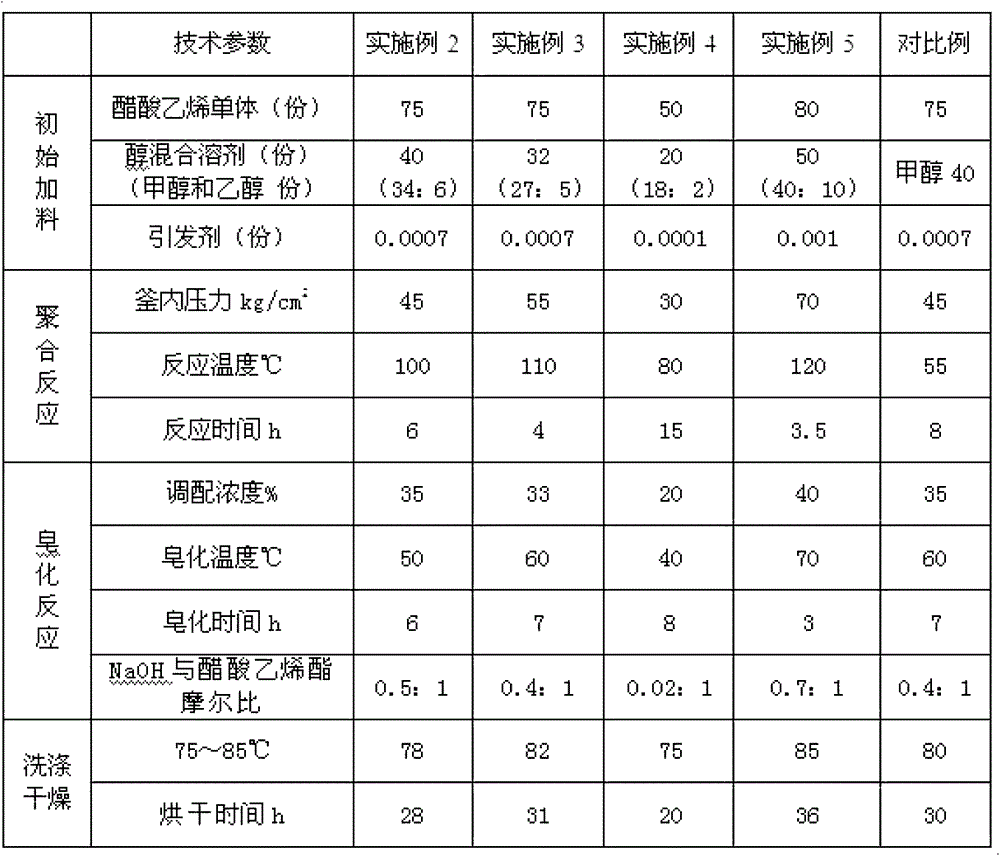

Composition containing ethylene-vinyl alcohol copolymer, and preparation method thereof

The invention relates to a composition containing an ethylene-vinyl alcohol copolymer, and a preparation method thereof. The composition comprises 90-95wt% of the ethylene-vinyl alcohol copolymer and 5-10wt% of an ethylene-vinyl alcohol micro-molecular oligopolymer, and the molecular structure of the ethylene-vinyl alcohol copolymer contains 1-2%mol of a 1,2-glycol structure. The preparation method of the composition comprises the following steps: polymerizing 50-80 parts of a vinyl acetate monomer, 20-50 parts of an alcoholic solvent and 0.0001-0.001 parts of an initiator at 80-140DEG C under 30-70kg / cm<2>, and carrying out a saponification reaction to obtain the composition. The molecular structure of the composition contains 1-2%mol of the 1,2-glycol structure having a viscosity reducing effect, and also contains 5-10mol% of the micro-molecular oligopolymer having a plasticising effect, so it is in favor of the melting processing property of the ethylene-vinyl alcohol copolymer, and the problems of the bad repeated utilization of the routine ethylene-vinyl alcohol copolymer, the easy migration of inorganic salt additives to the surface of the polymer, and environment pollution are overcome. The preparation method has the advantages of simple process, safety, environmental protection, high product quality, and suitableness for industrial production.

Owner:CHINA PETROCHEMICAL CORP +1

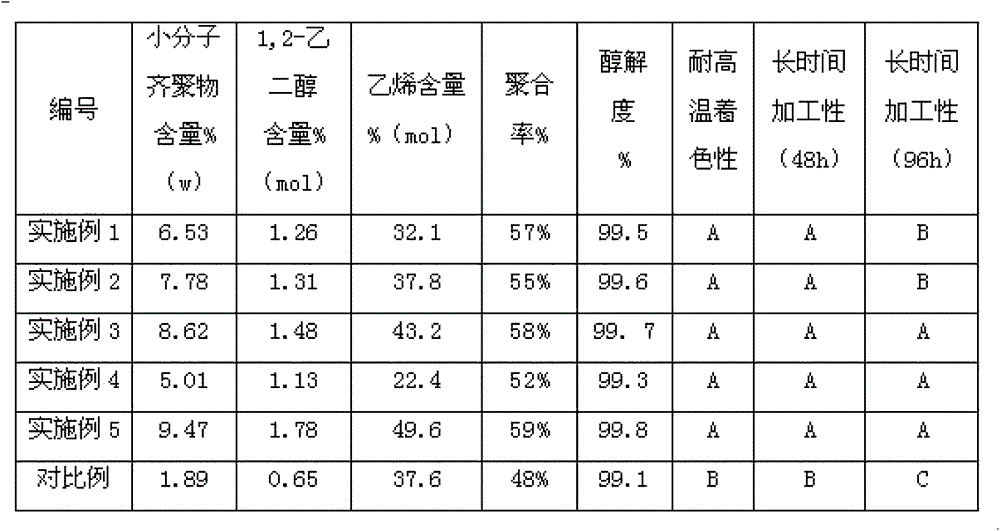

Optical film

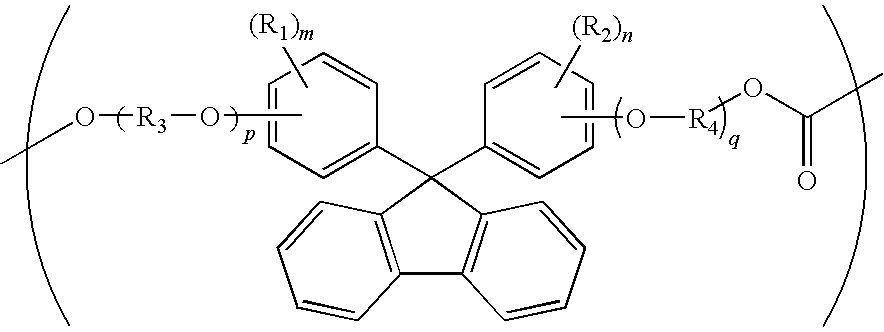

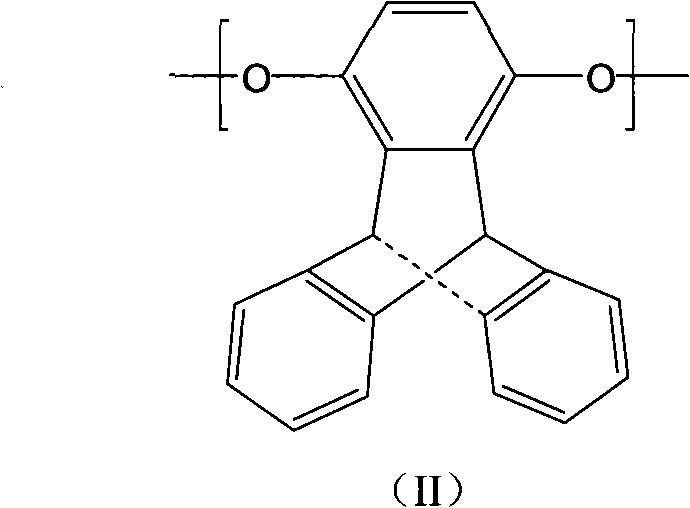

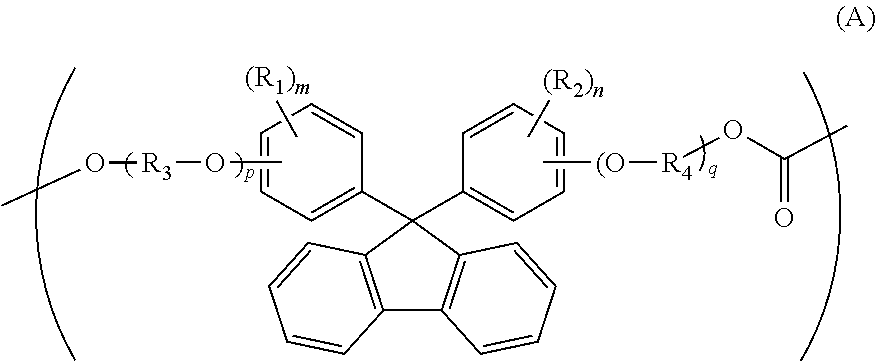

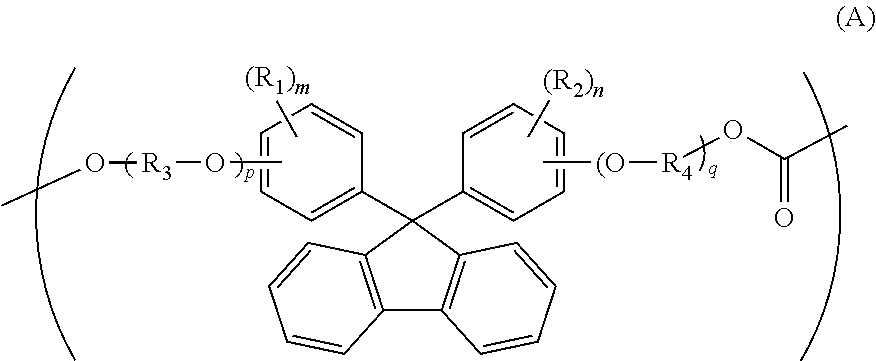

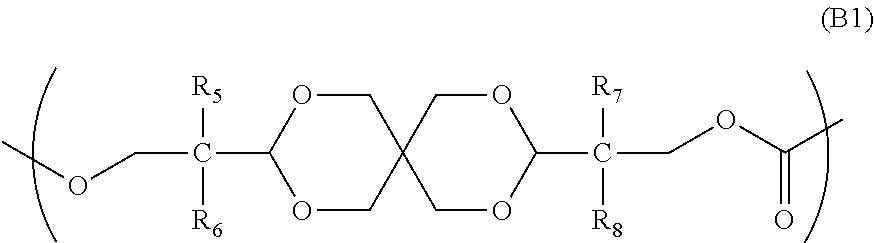

ActiveUS20100104777A1Low photoelastic constantSmall retardationLiquid crystal compositionsPolarising elementsPolycarbonateBisphenol-A-polycarbonate

It is an object of the present invention to provide an optical film which has reverse chromatic dispersibility that its retardation becomes smaller as the wavelength becomes shorter and a low photoelastic constant.The optical film is made of a polycarbonate copolymer containing a unit (A) represented by the following formula:wherein R1 and R2 are each independently a hydrogen atom, hydrocarbon group having 1 to 10 carbon atoms or the like, R3 and R4 are each independently a hydrocarbon group having 1 to 10 carbon atoms or the like, “m” and “n” are each independently an integer of 0 to 4, and “p” and “q” are each independently an integer of 0 or more,and a unit (B) represented by the following formula:wherein R5 to R8 are each independently a hydrogen atom or alkyl group having 1 to 10 carbon atoms,the (A / B) molar ratio of the unit (A) to the unit (B) is 10 / 90 to 90 / 10 and which satisfies the following expression (1):R(450)<R(550)<R(650) (1)wherein R(450), R(550) and R(650) are retardation values within the plane of the film at wavelengths of 450 nm, 550 nm and 650 nm, respectively.

Owner:TEIJIN CHEM LTD

Method for producing crystallized polyester

ActiveUS20120065342A1Improved melt processabilitySatisfactory crystallization propertyPolyesterCrystallinity

A method for producing a crystallized polyester comprises the crystallization step of applying a shear and / or a pressure to a polyester selected from an aliphatic polyester and a polyalkylene terephthalate at a temperature of (Tm−70° C.) to (Tm+20° C.), where Tm is a melting point of the polyester, thereby converting the polyester into a state having a crystallinity of 10% or more and fluidity.

Owner:NATUREWORKS LLC

Thermoplastic resin composition, and molded product thereof

A thermoplastic resin composition is provided having excellent flowability, high crystallization characteristics, high transparency and excellent processability in melt processing to resin molded products, sheets, films, fibers and pipes. The thermoplastic resin composition includes 100 parts by weight of (A) a thermoplastic resin; and 0.5 to 50 parts by weight of (B) a cyclic poly(phenylene ether ketone) that is expressed by General Formula (I) given below and has phenylene ketone shown by -Ph-CO- and phenylene ether shown by -Ph-O- as are repeating structural unit: wherein Ph in Formula represents a para-phenylene structure; o and p are respectively integral numbers of not less than 1; and m is an integral number of 2 to 40.

Owner:TORAY IND INC

Wholly aromatic liquid crystal polymer and preparation method thereof

InactiveCN101649044AExcellent melt processing propertiesExcellent performanceLiquid crystal compositionsChemistrySteric effects

The invention discloses a wholly aromatic liquid crystal polymer and a preparation method thereof. The wholly aromatic liquid crystal polymer is obtained by the condensation polymerization reaction offour monomers: para-hydroxybenzoic acid, triptycene quinhydrone, terephthalic acid and m-phthalic acid. By introducing a triptycene unit with a space steric effect, the melting temperature of homopolymerizing para-hydroxybenzoic acid is reduced, a nematic liquid crystal polymer with excellent melting processing performance is obtained and the performance of fiber members is good; the triptycene unit is introduced into a rigid chain so as to have double functions of space steric hindrance and a benzene ring substitutional group, thereby increasing the molecule width of the polymer and reducingthe action force among the molecules and a melting point; however, the extension direction of the rigid chain is not changed and therefore, a copolymer still keeps good liquid crystal performance andgood mechanical performance. The thermal melting temperature of the liquid crystal polymer is from 280 DEG C to 370 DEG C and mostly from 290 DEG C to 350 DEG C. The liquid crystal polymer can be widely used for electronic electric appliances and parts and components of other precise equipment.

Owner:KINGFA SCI & TECH CO LTD +1

Polyamide Resin

A polyamide resin is a polymer comprising (A) aliphatic diamine; and (B) dicarboxylic acid, wherein the (A) aliphatic diamine includes (a1) a first aliphatic diamine monomer including a C4, C6, C8 or C10 aliphatic diamine or a combination thereof, and (a2) a second aliphatic diamine monomer including a C12, C14, C16 or C18 aliphatic diamine or a combination thereof. The polymer can have good melt processability, low absorbency, and / or excellent brightness.

Owner:CHEIL IND INC

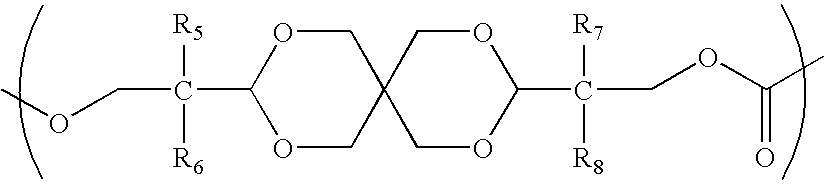

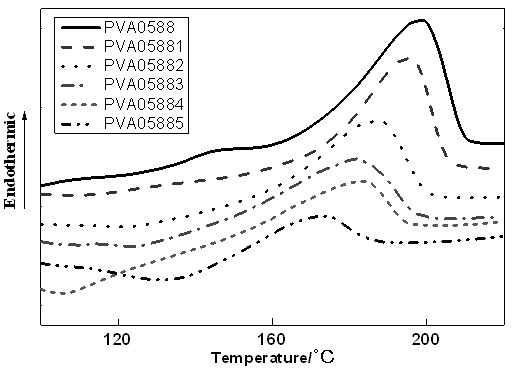

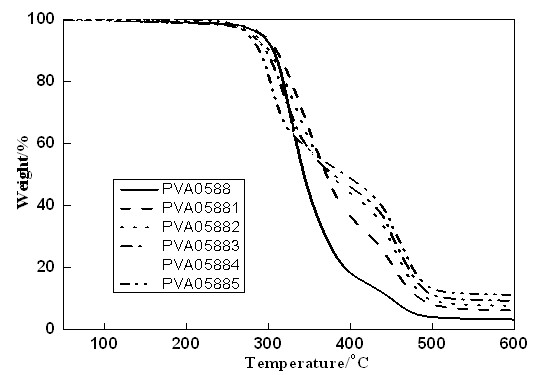

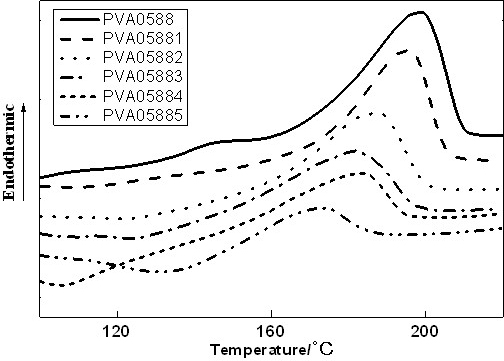

Polyvinyl alcohol material suitable for melt processing and preparation method thereof

InactiveCN102321325ALower melting temperatureHigh thermal decomposition temperatureLithium chlorideChloride

The invention discloses a polyvinyl alcohol material suitable for melt processing, which comprises 90-100 parts of polyvinyl alcohol and 1-5 parts of calcium chloride or lithium chloride. According to the invention, by adding calcium chloride or lithium chloride in polyvinyl alcohol, the polyvinyl alcohol material is prepared by melt blending in common plastic processing equipment. Calcium chloride or lithium chloride can reduce intermolecular force of polyvinyl alcohol, decrease the melting temperature, facilitate the improvement of the melt processing characteristics of polyvinyl alcohol, and make the melt processing be realized better; the method adopted by the invention has the advantages of simplicity, environmental protection, low cost, and easy industrialization, and the prepared polyvinyl alcohol material can meet the requirements for food packaging industry and the like.

Owner:贵州省复合改性聚合物材料工程技术研究中心

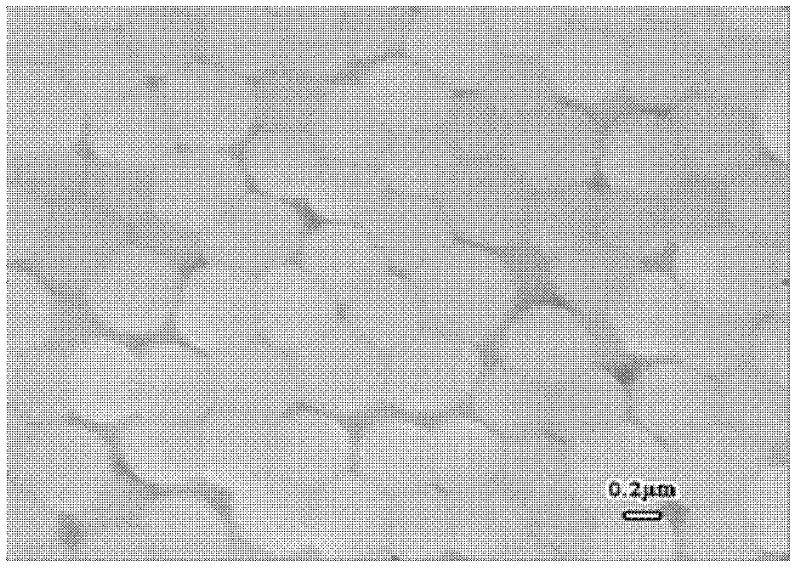

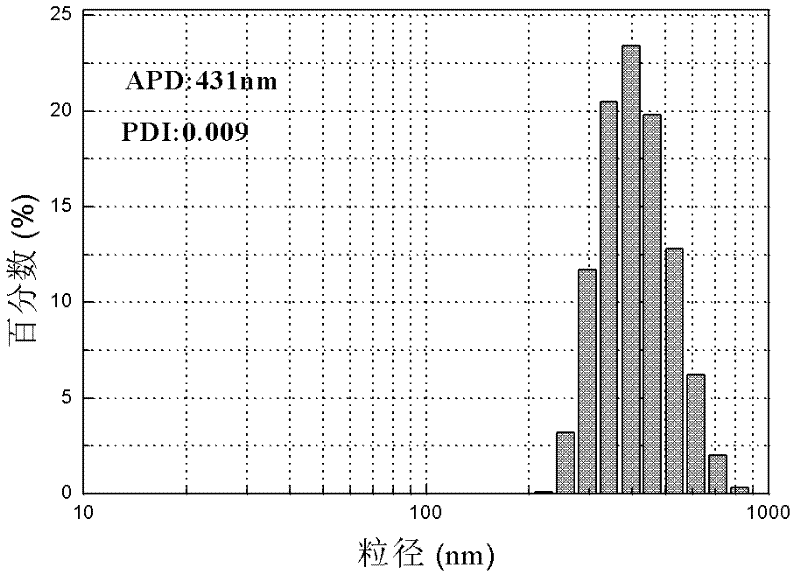

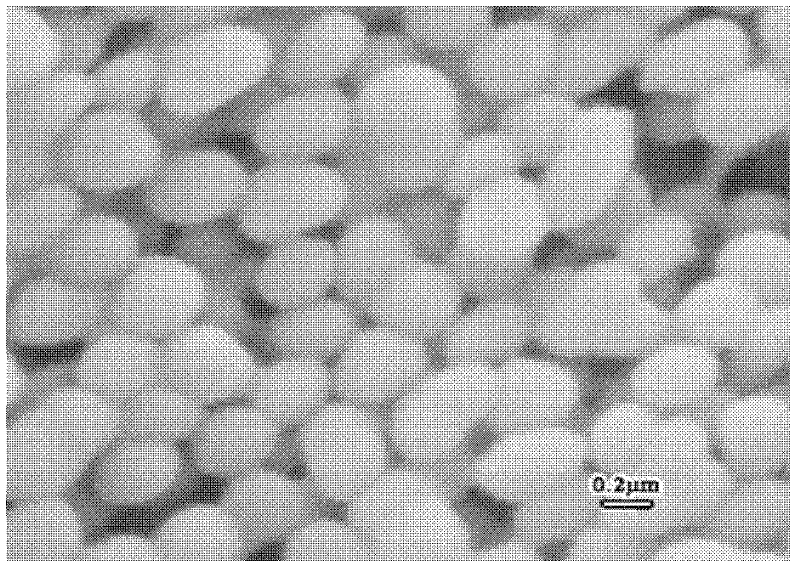

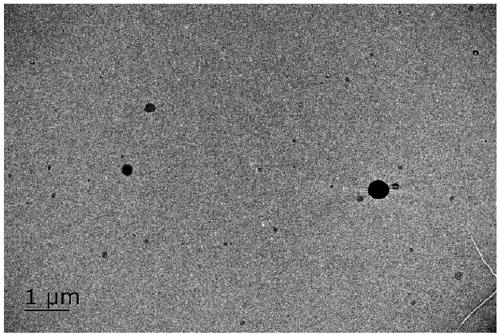

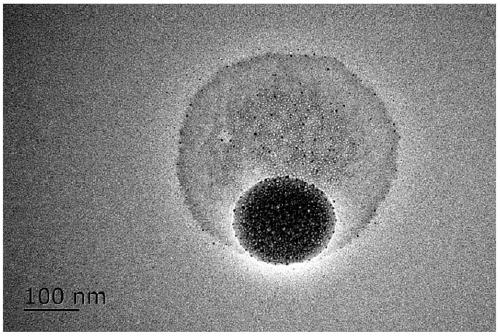

Method for preparing polyvinylidene fluoride (PVDF)-constructed composite particles with nuclear shell interpenetrating network structure

The invention discloses a method for preparing polyvinylidene fluoride (PVDF)-constructed composite particles with a nuclear shell interpenetrating network structure. The method comprises the following steps of: adding deionized water into PVDF seed emulsion, performing ultrasonic dispersion, adding monomers, after the temperature of a system is raised to reaction temperature, adding initiator, and polymerizing; and decompressing the emulsion, drying at low temperature until the weight of the emulsion is constant to prepare the composite particles with the nuclear shell interpenetrating network structure. The composite particles with the nuclear shell interpenetrating network structure are formed based on PVDF seeds, effectively combine the respective characteristics of two polymers, and have complementary advantages of the two polymers; the crystallization temperature of PVDF can be reduced from 142.5 DEG C to 71.4 DEG C in differential scanning calorimetry (DSC); and melting processability of the PVDF, and the compatibility between the PVDF and other polymers which are not compatible with the PVDF are improved, the dielectric performance, piezoelectric performance, ferroelectric performance and other performance of the PVDF can be improved, and the composite particles can be widely applied to the fields of optical fiber coating, outdoor painting and coating, dental repairing and the like.

Owner:HEBEI UNIV OF TECH

Lignin/polyvinyl alcohol composite material and preparation method thereof

The invention belongs to the technical field of high molecular materials, and discloses a lignin / polyvinyl alcohol composite material and a preparation method thereof. The composite material comprisesthe following components by mass percentage: 70-99.4% of polyvinyl alcohol, 0.5-30% of lignin and 0.1-10% of additive, wherein the additive comprises at least one of 3-amino-1,2,4 triazole, 4-aminopyridine, 1-(3-aminopropyl) imidazole, 4-(2-ethylamino) benzene-1,2-diphenol, 2-amino-3-imidazolylpropionic acid, tannic acid, 3,3,3',3'-tetramethyl-1,1-helix biindolyl-5,5',6,6'-tetraol, zinc chloride,zinc acetate, ferric chloride, calcium chloride, copper chloride, iron oxide, and sodium chloride. The present invention also provides a composite material preparation method. The tensile strength ofthe lignin / polyvinyl alcohol composite material can reach up to 140 MPa, and the elongation at break of the lignin / polyvinyl alcohol composite material can reach up to 800%.

Owner:SOUTH CHINA UNIV OF TECH

Thermoplastic olefin compositions and articles

A thermoplastic olefin (TPO) composition comprises (1) a major amount by weight of (a) a substantially linear homopolymer or copolymer of a C2–C10 α-olefin in major proportion to (b) a long chain branched a linear homopolymer or copolymer of a C2–C10 α-olefin, (2) a minor amount by weight of a cross linkable elastomer, and (3) at least one thermally decomposing free radical generating agent present in an amount sufficient to promote an increase in melt strength of the composition over that of the melt strength of the linear homopolymer or copolymer of a C2–C10 α-olefin alone and insufficient to substantially degrade the α-olefinic polymers. The TPO composition is prepared by melt blending the components at a temperature sufficient to melt said homopolymers or copolymers of a C2–C10 α-olefin and thermally decompose said agent. Articles are thermoformed from the thermoplastic olefin.

Owner:EXOUSIA IP LLC

Optical film

InactiveUS20120120356A1Desired wavelength dispersion characteristicLow photoelastic constantPolarising elementsNon-linear opticsPhotoelasticityThin membrane

An optical film having a desired wavelength dispersion characteristic, a low photoelastic coefficient and a desired Nz coefficient.The optical film is formed from a copolymer and meets the following conditions (i) to (v):(i) the thickness (d) is 20 to 80 μm;(ii) the following formulas (1) and (2) are satisfied:0.6<R(450) / R(550)<1 (1)1.01<R(650) / R(550)<1.40 (2)(R(450), R(550) and R(650) are retardations within the plane of the film at respective wavelengths);(iii) R(550) is 120 to 160 nm;(iv) the birefringence (Δn) is not less than 1.5×10−3; and(v) the Nz coefficient represented by the following formula (4) is 1.18 to 2.40:Nz=(nx−nz) / (nx−ny) (4)(nx, ny and nz are 3-dimensional birefringences of the film).

Owner:TEIJIN KASEK KK

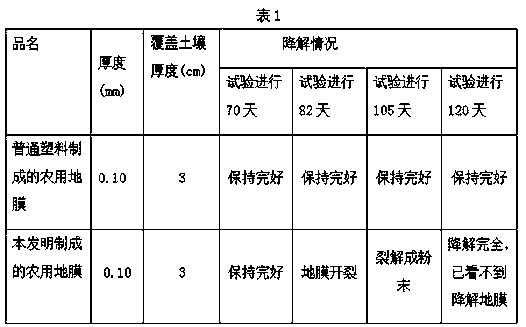

Corn field special-purpose degradable environmental protection mulch film, and preparation method thereof

InactiveCN109181090ASmall particle sizeLarge specific surface areaPlant protective coveringsChemistryPlasticizer

The invention belongs to the technical field of agricultural plastic mulching film, and more specifically relates to a corn field special-purpose degradable environmental protection mulch film, and apreparation method thereof. The corn field special-purpose degradable environmental protection mulch film comprises, by weight, 90 to 100 parts of linear low density polyethylene, 10 to 15 parts of low density polyethylene, 40 to 50 parts of modified cassava starch, 7 to 12 parts of modified nanometer calcium carbonate, 5 to 10 parts of bagasse powder, 2 to 3 parts of polyvinyl alcohol, 0.08 to 0.2 part of photosensitizer iron stearate, 0.05 to 0.1 part of a phosphite ester type anti-oxidant, 0.3 to 0.5 part of a thermal degradation promoter, 1 to 3 parts of a compatibilizer, and 2 to 5 partsof a plasticizer. The corn field special-purpose degradable environmental protection mulch film is invented based on corn growth rules and light illumination and temperature climate factors; photosensitizer iron stearate, the phosphite ester type anti-oxidant, and the thermal degradation promoter are introduced, so that problems in the prior art that degradation of mulch film in soil is difficultto realize, and degradation induction period is difficult to control are solved; the obtained corn field special-purpose degradable environmental protection mulch film is easily degradable, is green,is friendly to the environment; no white pollution is caused; and field pollution is reduced.

Owner:袁志平

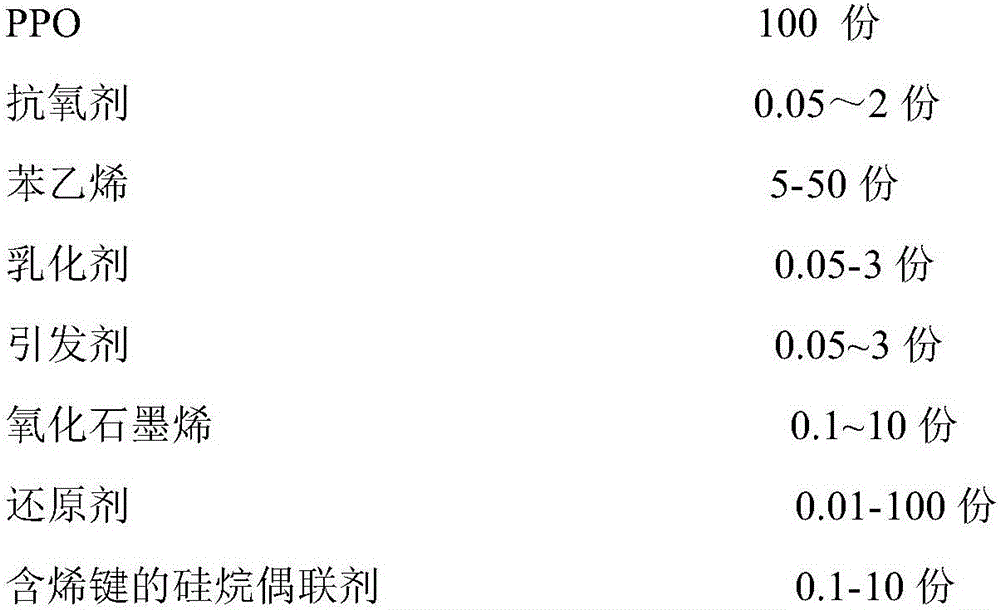

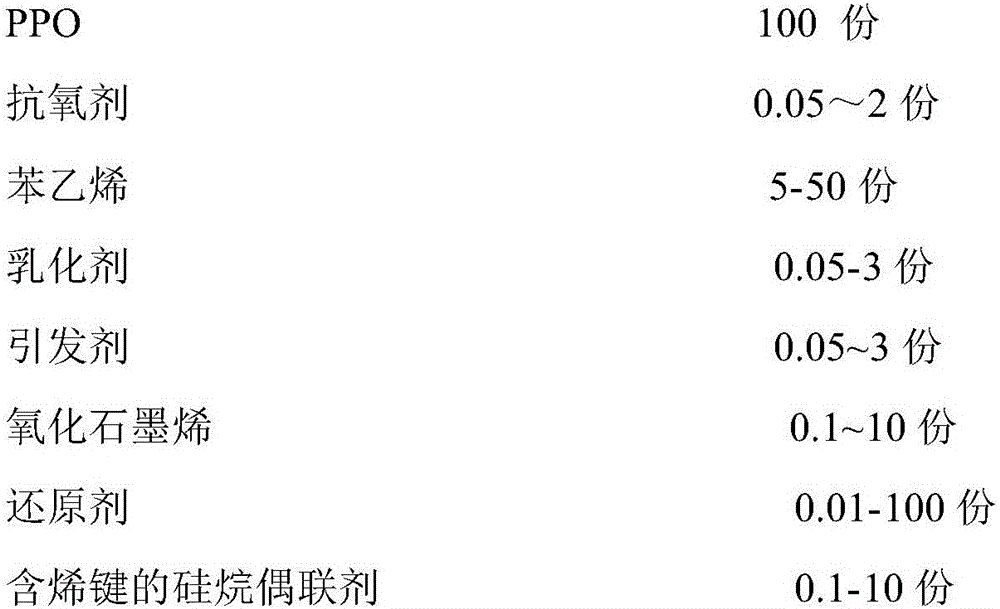

Preparation method of high-performance polyphenylene oxide/graphene nano composite material

ActiveCN106118018AImproved melt processabilityImprove mechanical propertiesGraphene nanocompositesPolystyrene

The invention discloses a high-performance polyphenylene oxide (PPO) / graphene nano composite material and a preparation method thereof. The preparation method is characterized by comprising the following steps: dispersing 0.1 to 10 parts of graphene oxide into 100 to 1000 parts of de-ionized water; adding 0.1 to 10 parts of a silane coupling agent containing an ethylenic bond and stirring uniformly at a room temperature; ultrasonically dispersing for 10min to 200min, wherein the ultrasonic power is 100w to 5000w, the frequency is 10000HZ to 100000HZ and the ultrasonic temperature is 40 DEG C to 100 DEG C; adding 0.05 to 3 parts of an emulsifier at 40 DEG C to 90 DEG C and stirring to dissolve the emulsifier; then adding 5 to 50 parts of styrene and introducing nitrogen to remove oxygen for 30min, so as to emulsify the styrene sufficiently; adding 0.05 to 3 parts of an initiating agent, uniformly stirring and reacting for 4h to 8h; continually adding 0.01 to 100 parts of a reducing agent and carrying out a reduction reaction in an oil bath at 50 DEG C to 100 DEG C for 2h to 10h; filtering a product and washing the product with distilled water; drying at 90 DEG C until the weight is constant; crushing to obtain polyphenylene oxide / graphene nano composite powder; furthermore, adding 100 parts of PPO, 0.05 to 2 parts of an antioxygen and 5 to 50 parts of the polyphenylene oxide / graphene nano composite powder into a high-speed mixer and mixing; fusing and mixing by adopting a double-screw extruder; extruding and granulating under the conditions that the rotary speed of screws is 50rpm to 200rpm and the temperature of a charging barrel is 270 DEG C to 340 DEG C, so as to obtain the PPO / graphene nano composite material.

Owner:WUXI JIAHONG PLASTICS TECH +1

Lignin-derived thermoplastic co-polymers and methods of preparation

The present invention relates to a crosslinked lignin comprising a lignin structure having methylene or ethylene linking groups therein crosslinking between phenyl ring carbon atoms, wherein said crosslinked lignin is crosslinked to an extent that it has a number-average molecular weight of at least 10,000 g / mol, is melt-processible, and has either a glass transition temperature of at least 100° C., or is substantially soluble in a polar organic solvent or aqueous alkaline solution. Thermoplastic copolymers containing the crosslinked lignin are also described. Methods for producing the crosslinked lignin and thermoplastic copolymers are also described.

Owner:UT BATTELLE LLC

Preparation method of ultrahigh-conductivity 3D printing carbon fiber composite wire

InactiveCN106317767AHigh temperature resistantFriction-resistantAdditive manufacturing apparatusFiberEpoxy

The invention discloses a preparation method of an ultrahigh-conductivity carbon fiber composite wire for 3D printing. The formula comprises the following components: 60-70 parts of HKT800 carbon fiber, 60-64 parts of thermoplastic resin, 5-8 parts of boron trifluoride monoethylamine, 1-4 parts of AG80 epoxy resin, 1-3 parts of antioxidant, 2-5 parts of nanoparticle carrier type catalyst, 2-8 parts of color masterbatch and 4-10 parts of processing aid; and the preparation method comprises the following steps of: preparing the materials according to the formula, and mixing for 2-4min in a high-speed kneading machine; drying for 3-5h in a vacuum drum drying oven at 150 DEG C; and performing extrusion, strip casting, drafting and rolling through a twin-screw extruder to obtain 3D printing carbon fiber composite wires different in wire diameter. The material printed by the 3D printing carbon fiber composite wire has the characteristics of high-temperature resistance, friction resistance, heat conductivity, corrosion resistance and ultrahigh conductivity; the preparation technology is simple and feasible while the cost is low.

Owner:SUZHOU POLYKING COMPOSITE +2

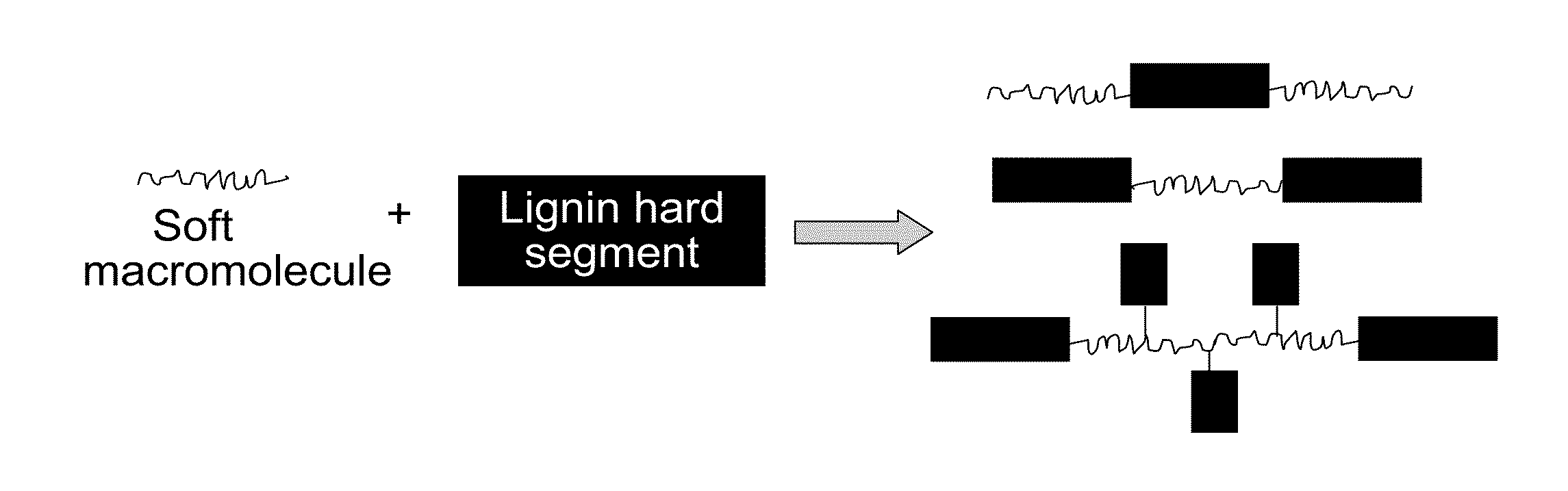

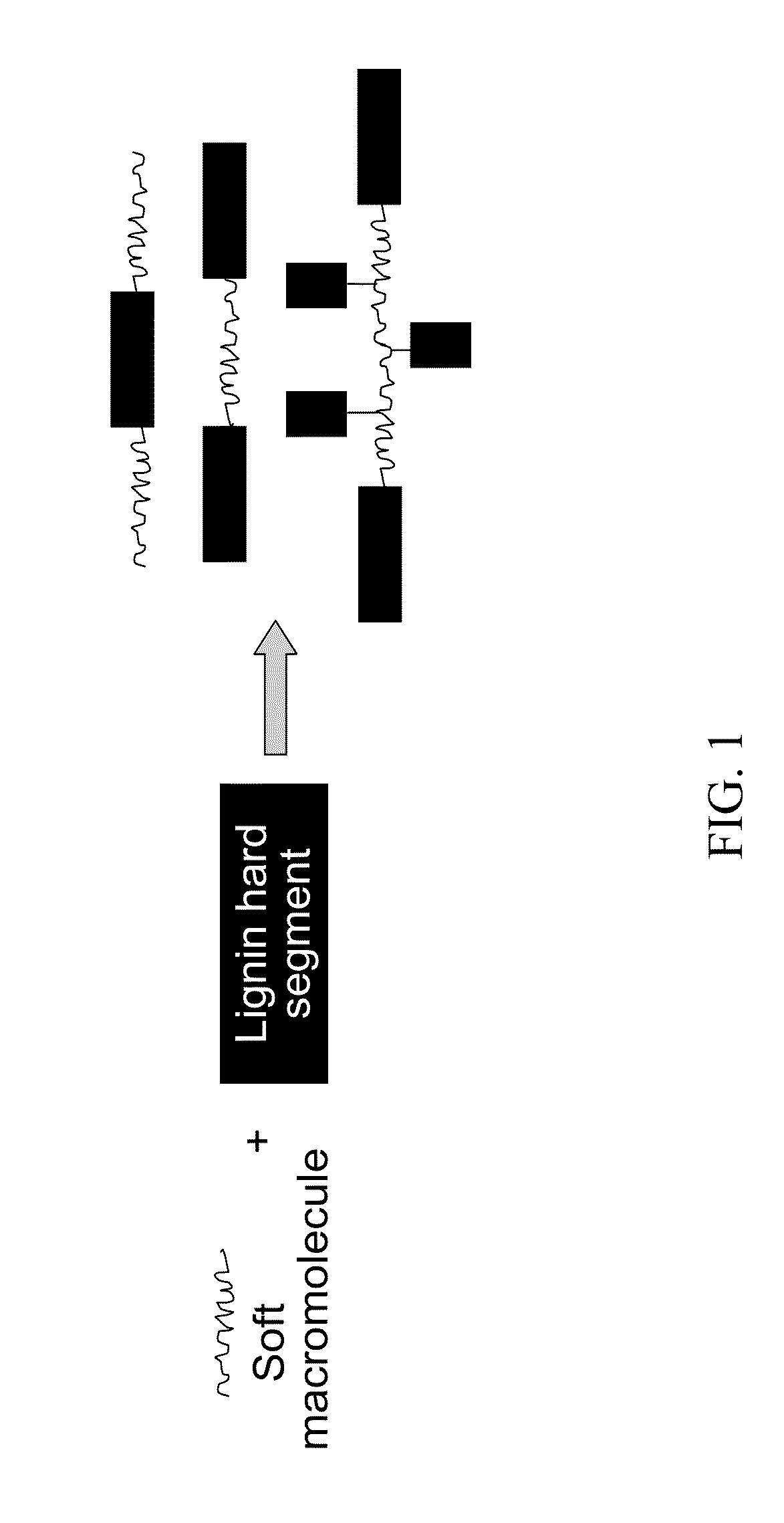

Melt processible polyureas and polyurea-urethanes, method for the production thereof and products made therefrom

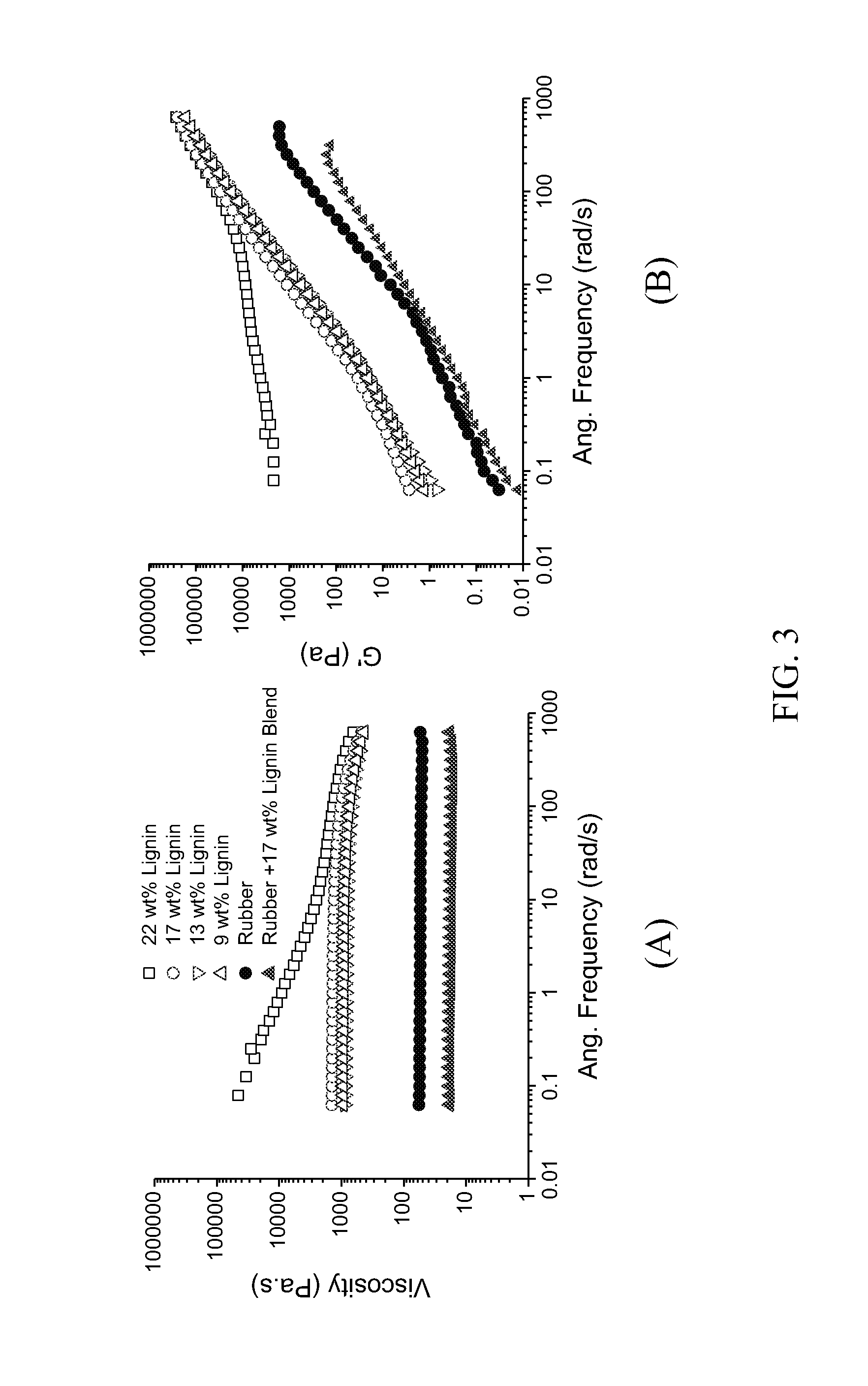

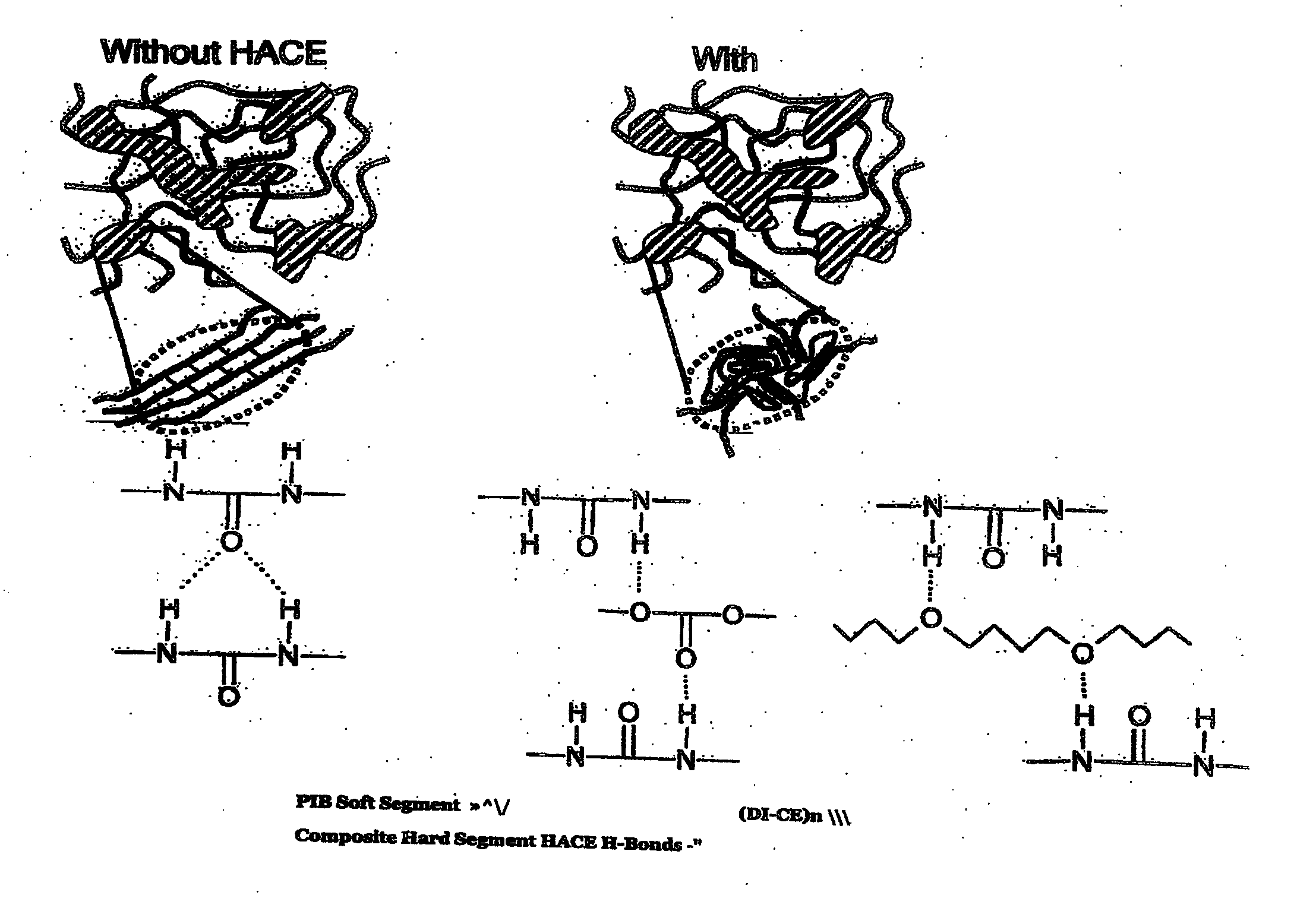

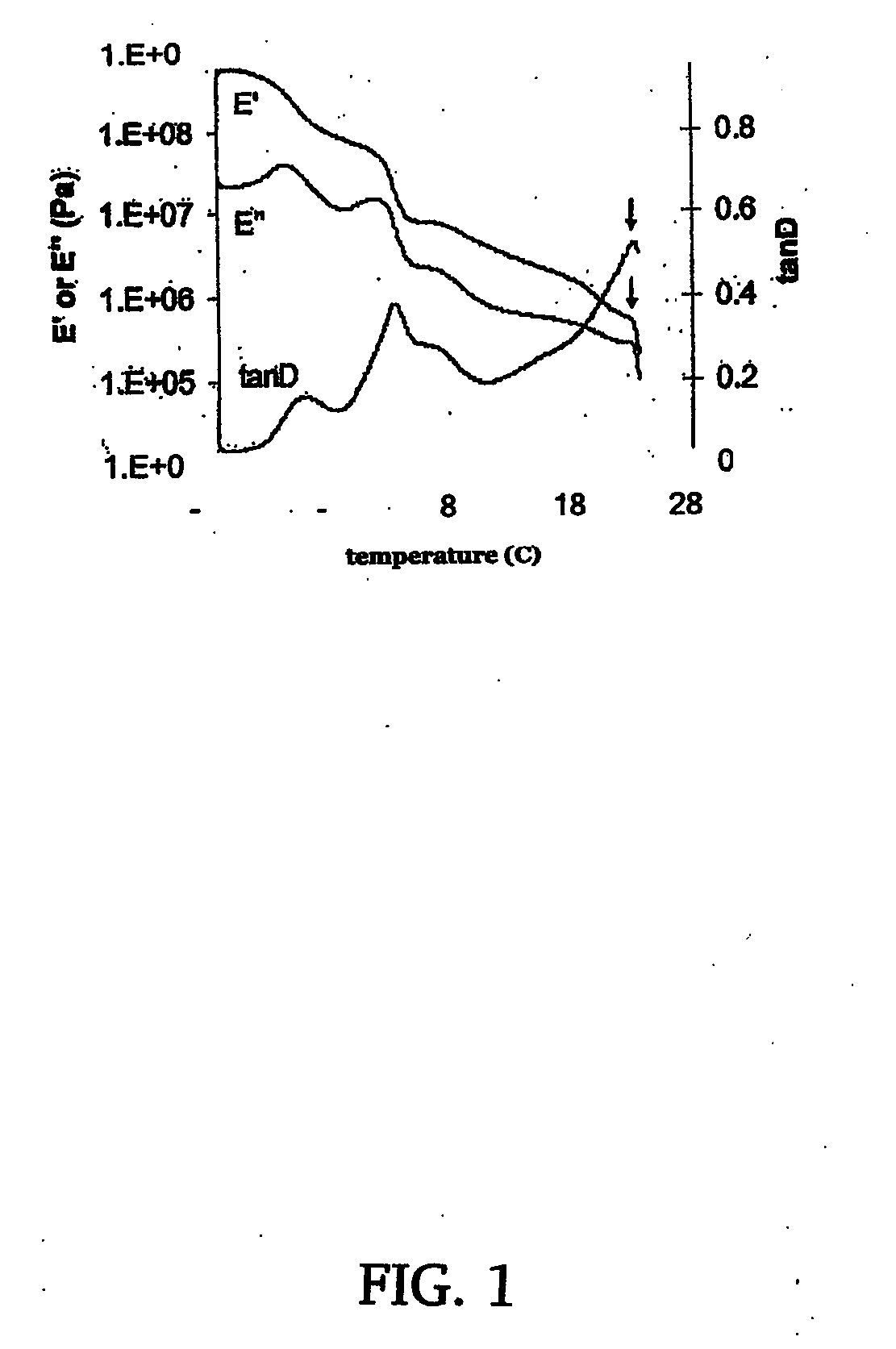

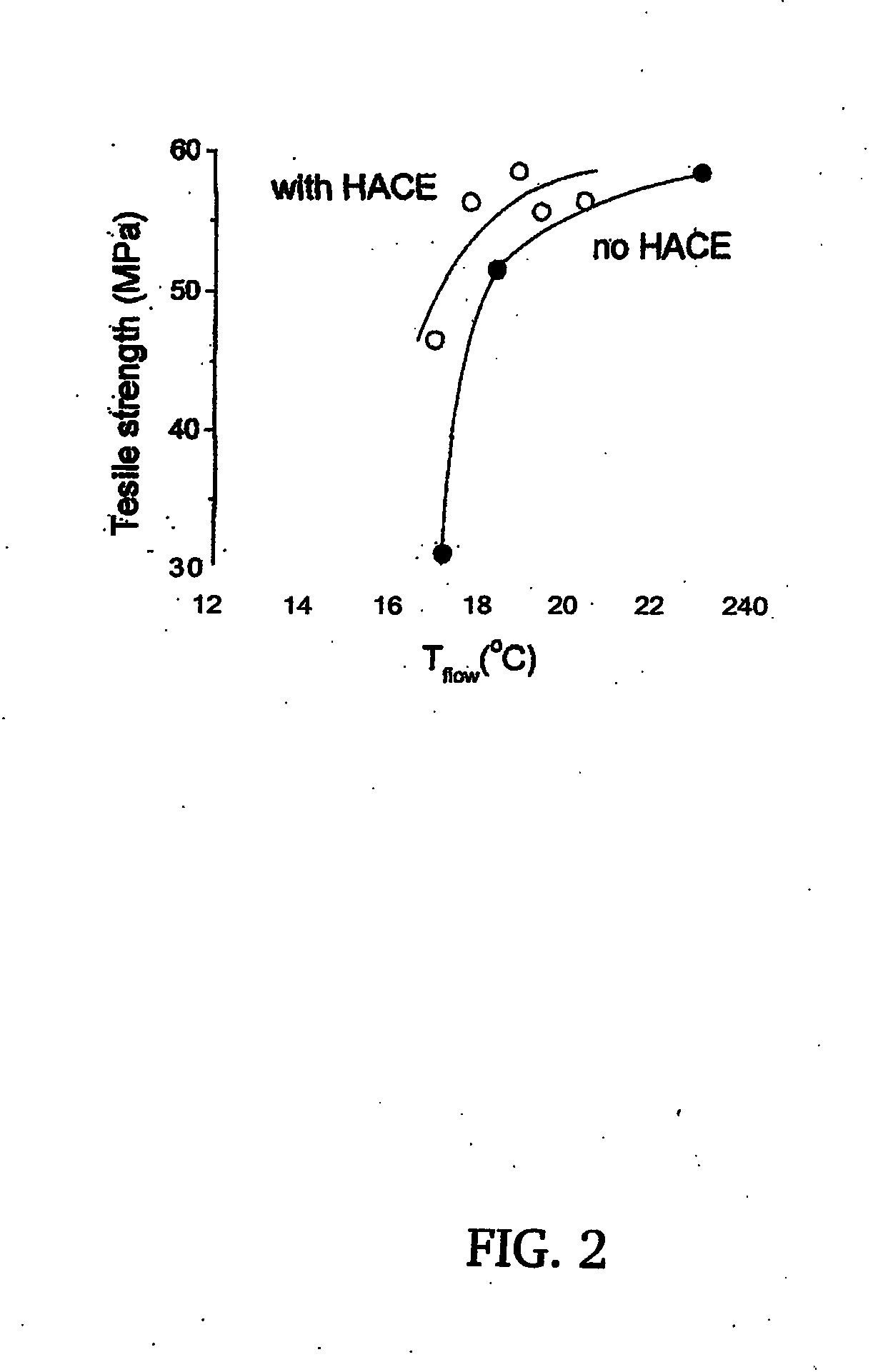

A polyurea or polyurea-urethane elastomer comprises a soft polymer segment and a hard polymer segment, wherein the hard polymer segment includes polyurea groups in combination with H-bond accepting chain extenders (HACEs) to reduce the flow temperature (Tflow) while maintaining the excellent mechanical properties such that the resulting polyurea elatomer is rendered melt-processable.

Owner:THE UNIVERSITY OF AKRON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com