Patents

Literature

17926results about How to "Speed up the flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

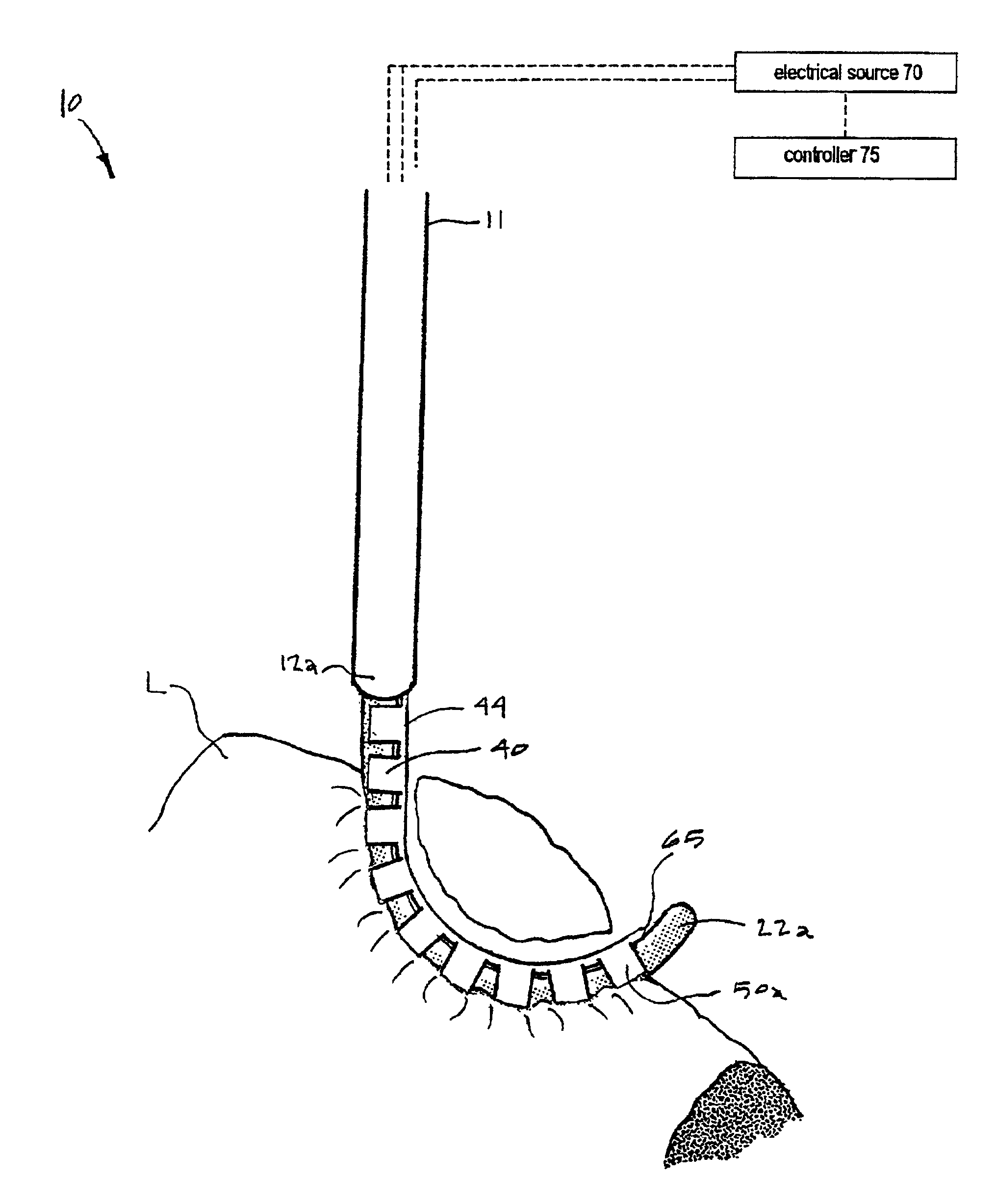

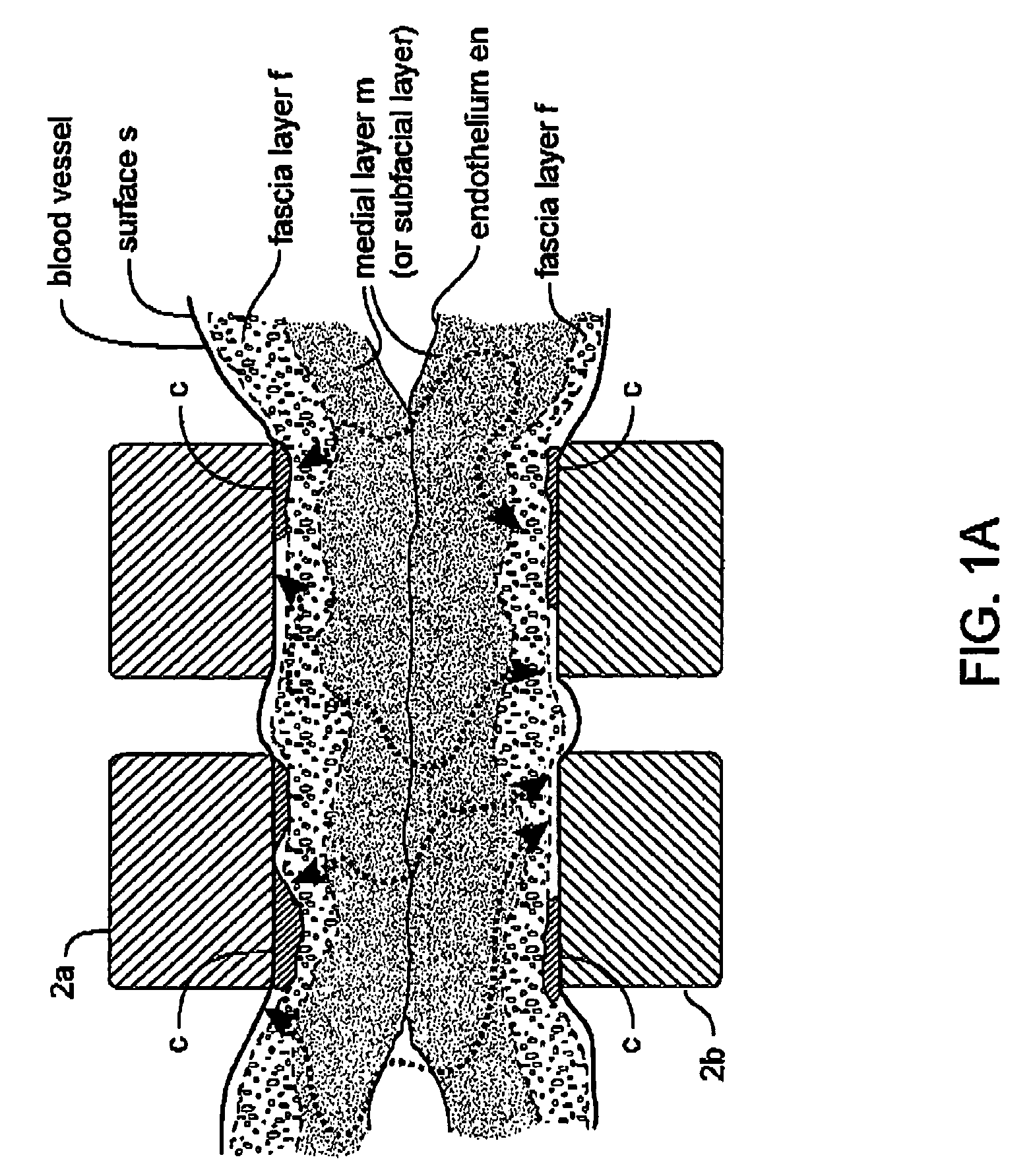

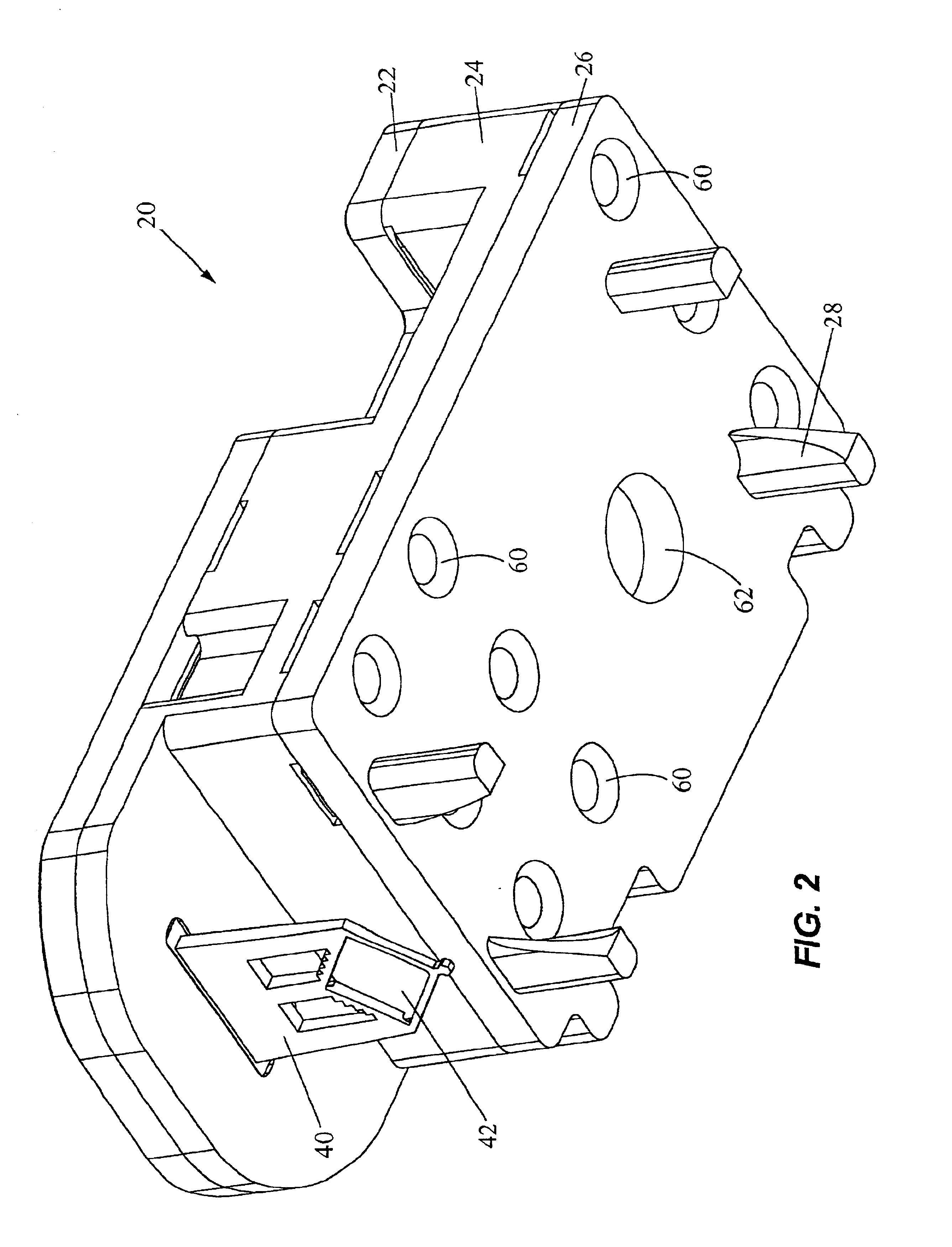

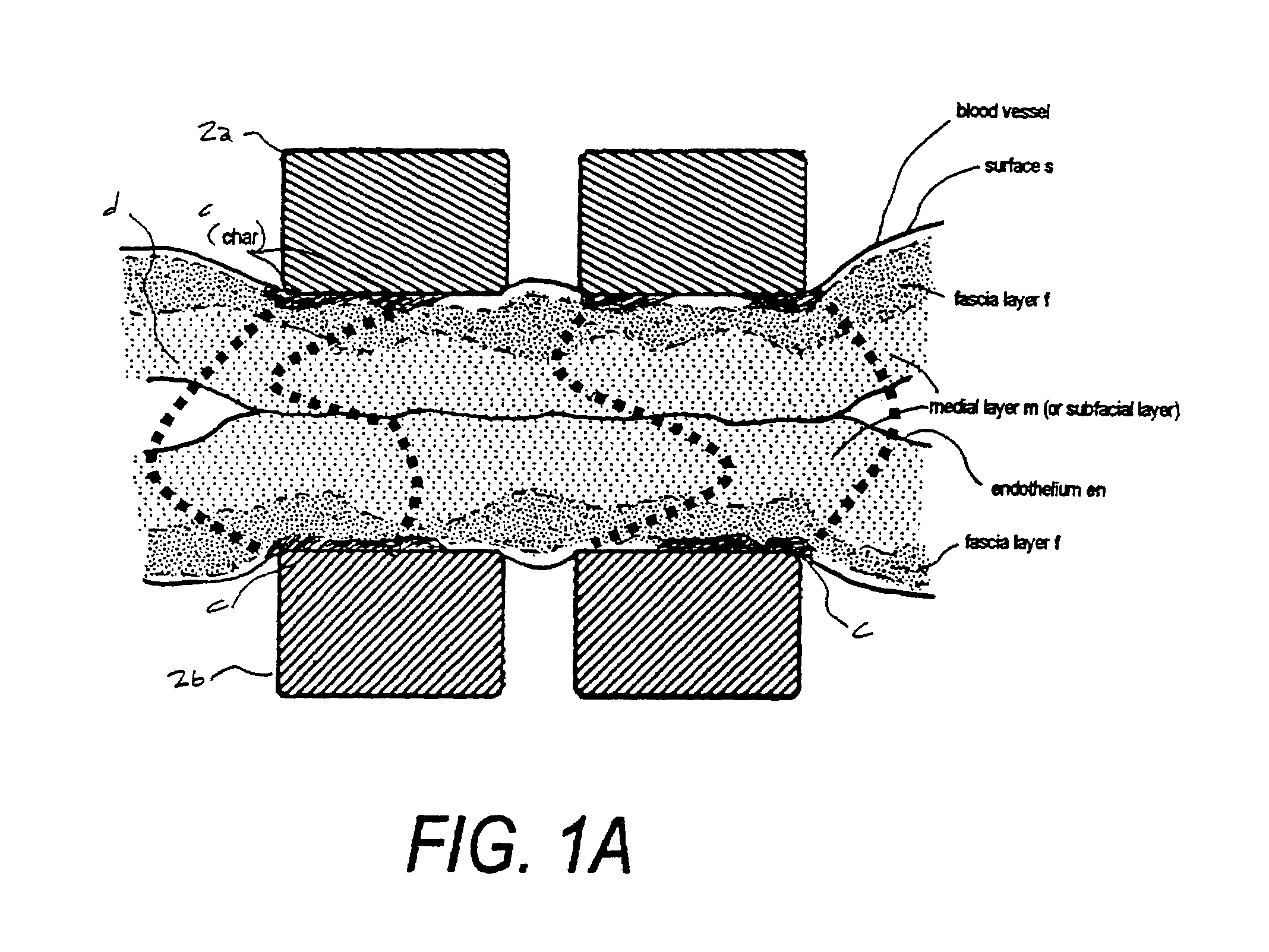

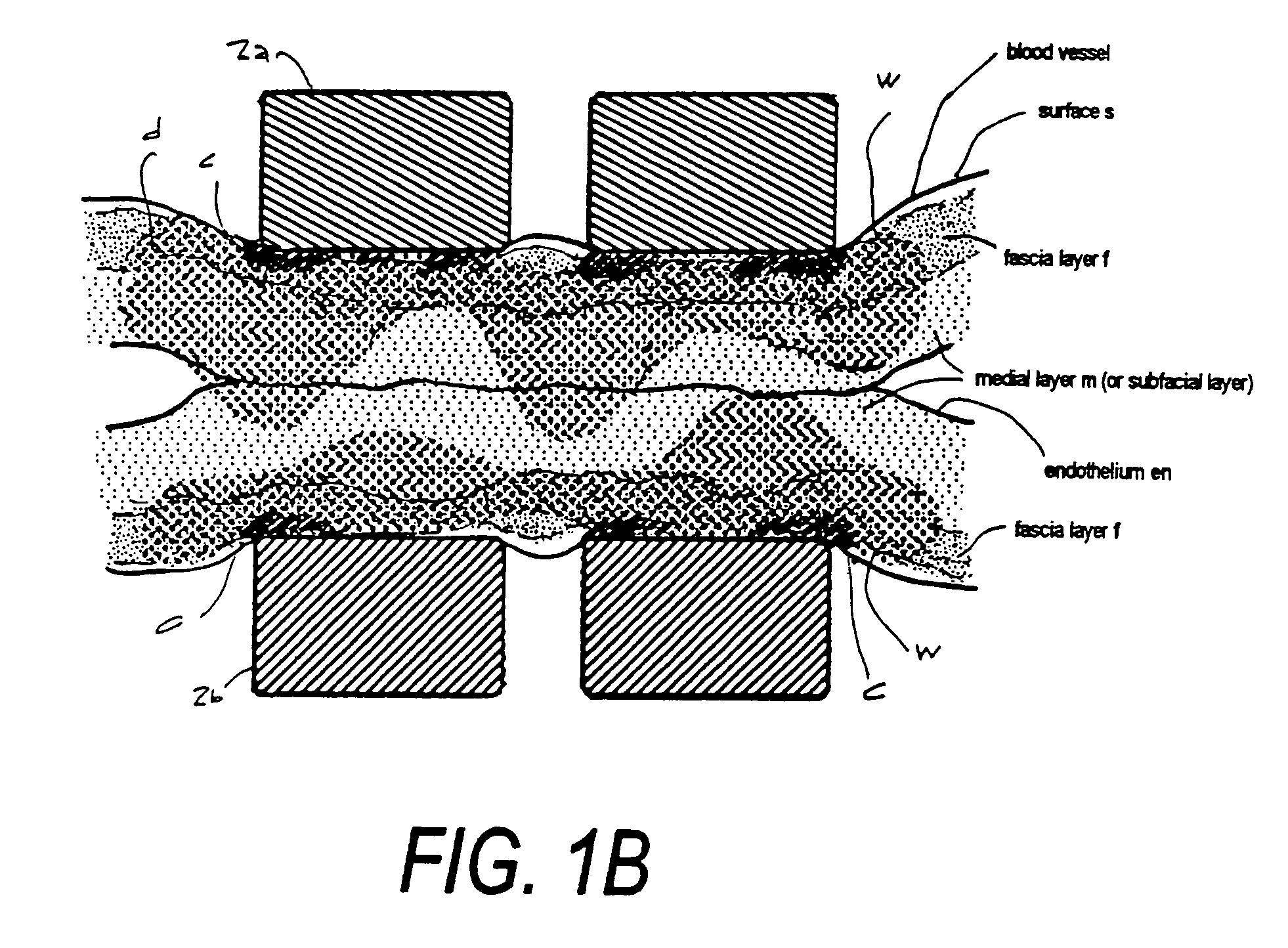

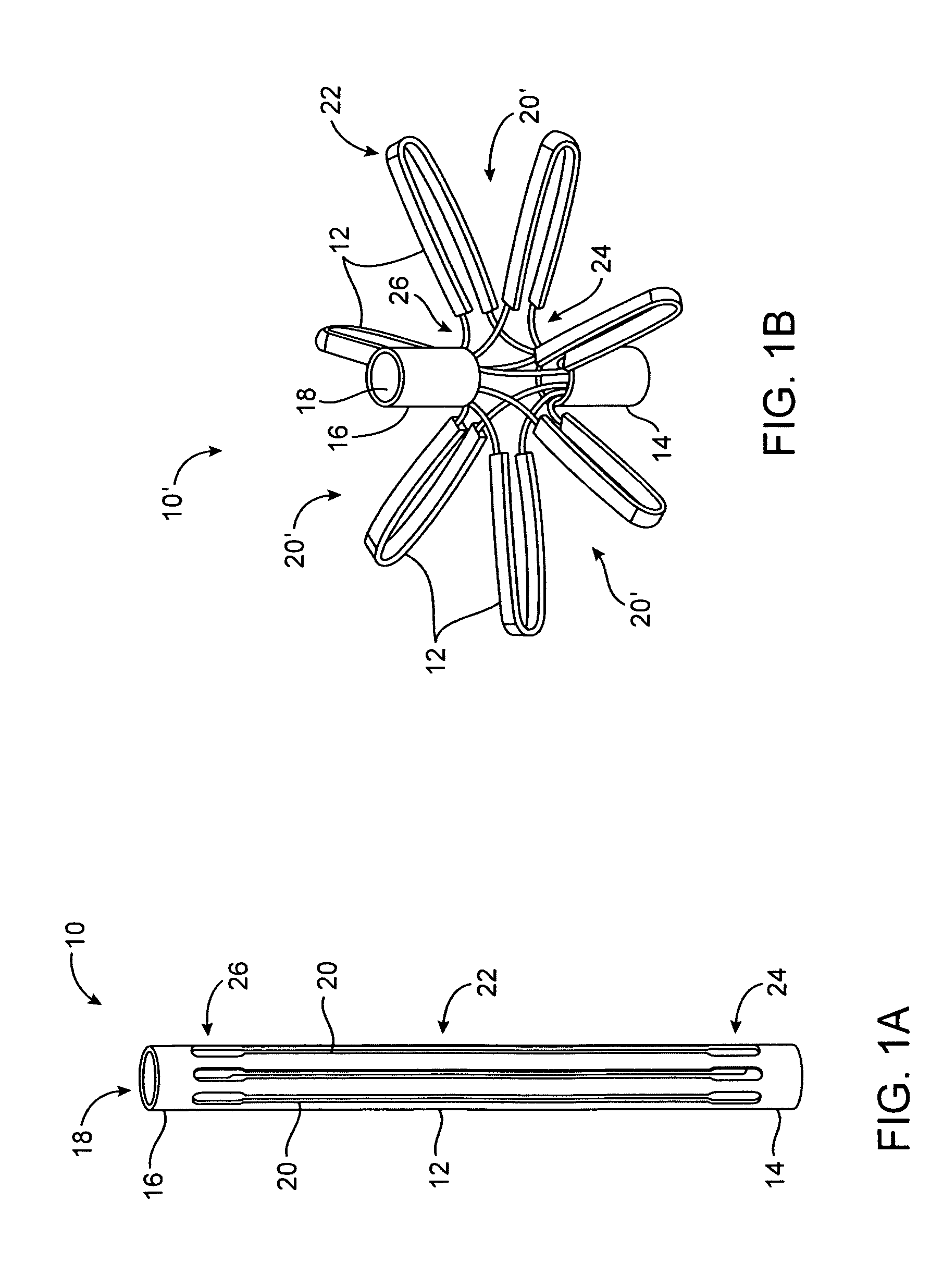

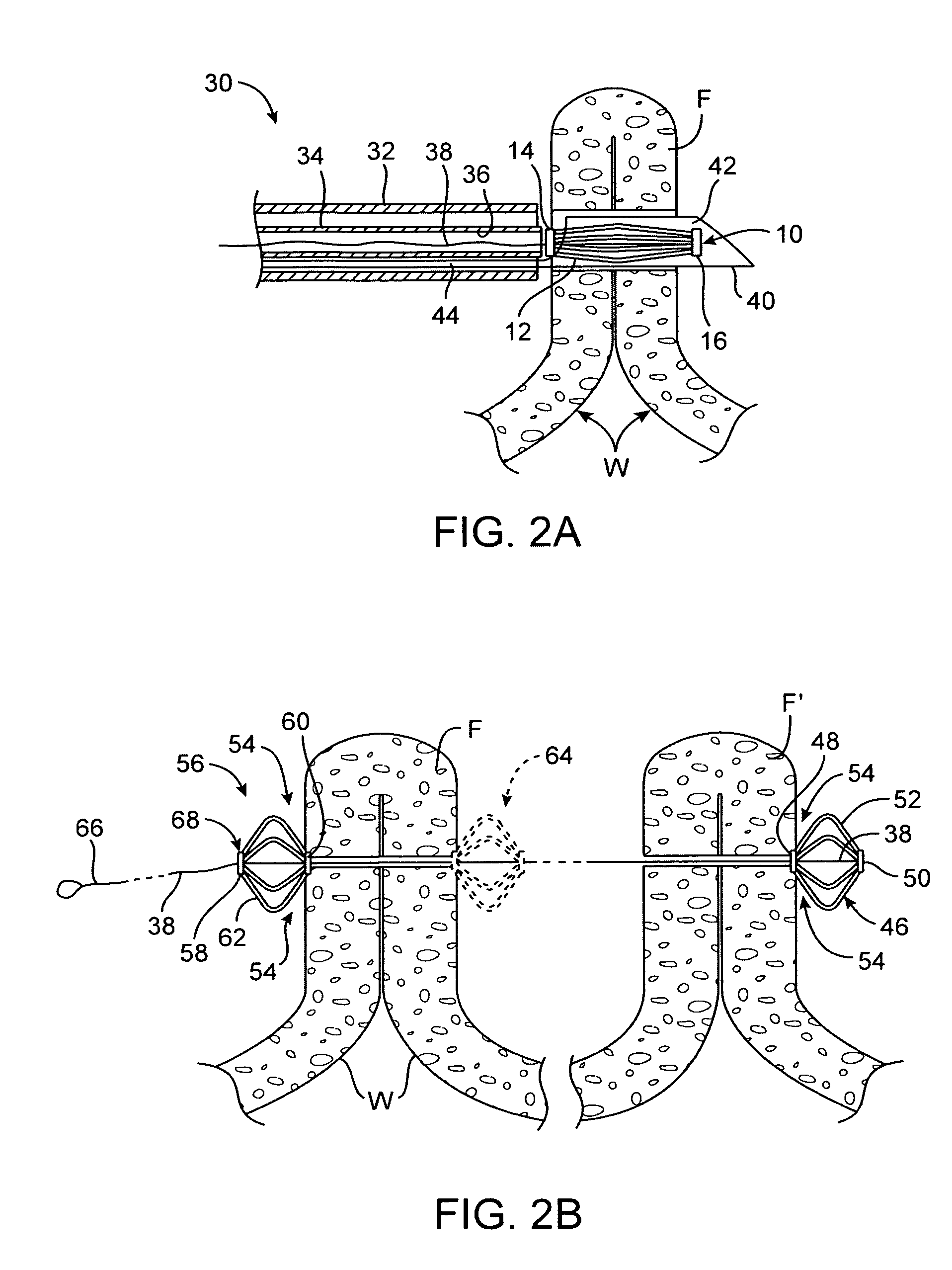

Electrosurgical working end and method for obtaining tissue samples for biopsy

InactiveUS6913579B2Speed up the flowHeating evenlyVaccination/ovulation diagnosticsSurgical instruments for heatingSurface layerTissue sample

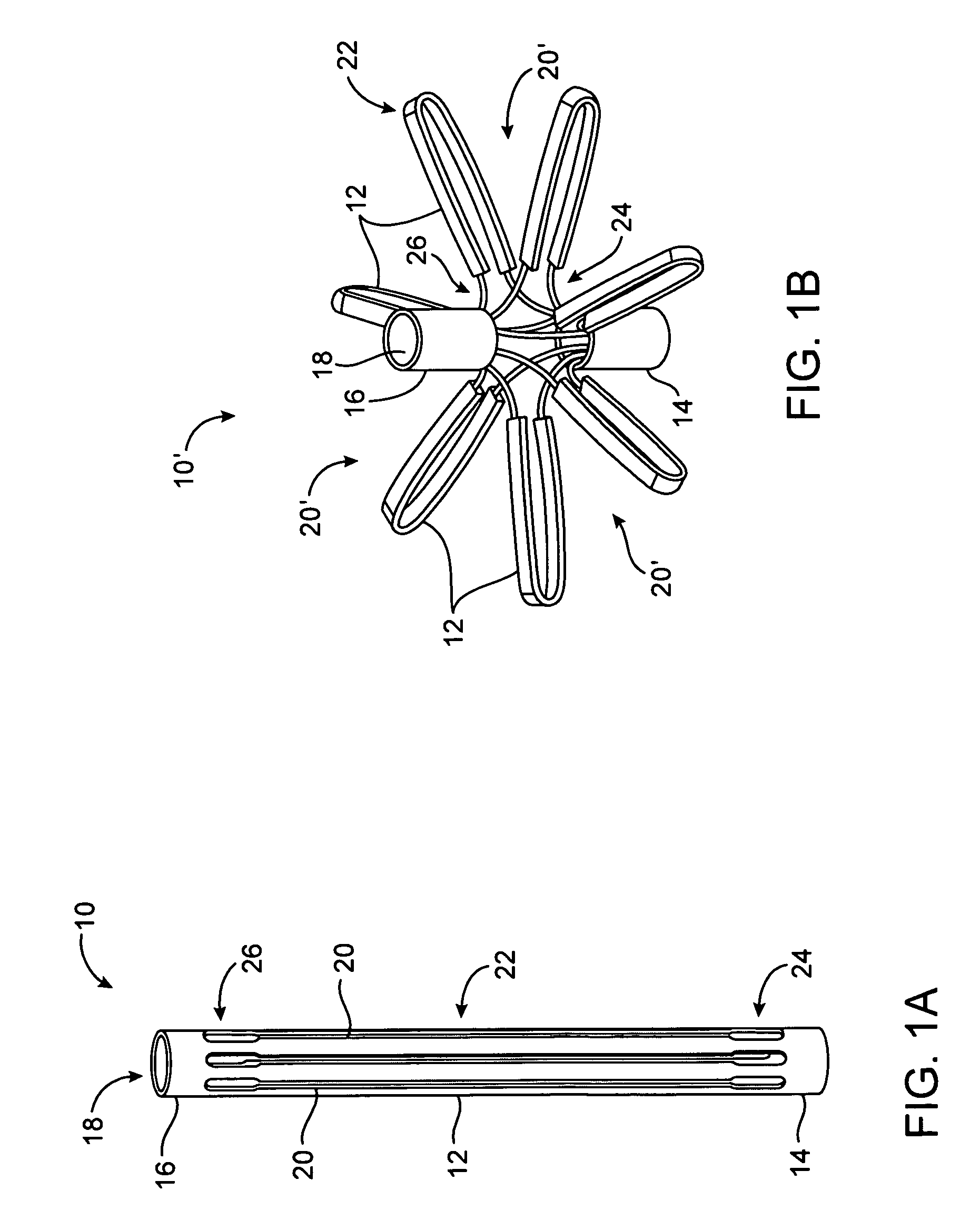

An electrosurgical working end and method for obtaining a tissue sample for biopsy purposes, for example, from a patient's lung or a liver. The working end provides curved jaw members that are positioned on opposing sides of the targeted anatomic structure. The working end carries a slidable extension member that is laterally flexible with inner surfaced that slide over the jaw members to clamp tissue therebetween. As the extension member advances, the jaws compress the tissue just ahead of the advancing extension member to allow the laterally-outward portion of the extension member to ramp over the tissue while a cutting element contemporaneously cuts the tissue. By this means, the transected tissue margin is captured under high compression. The working end carries a bi-polar electrode arrangement that engages the just-transected medial tissue layers as well as surface layers to provides Rf current flow for tissue welding purposes that is described as a medial-to-surface bi-polar approach.

Owner:ETHICON ENDO SURGERY INC

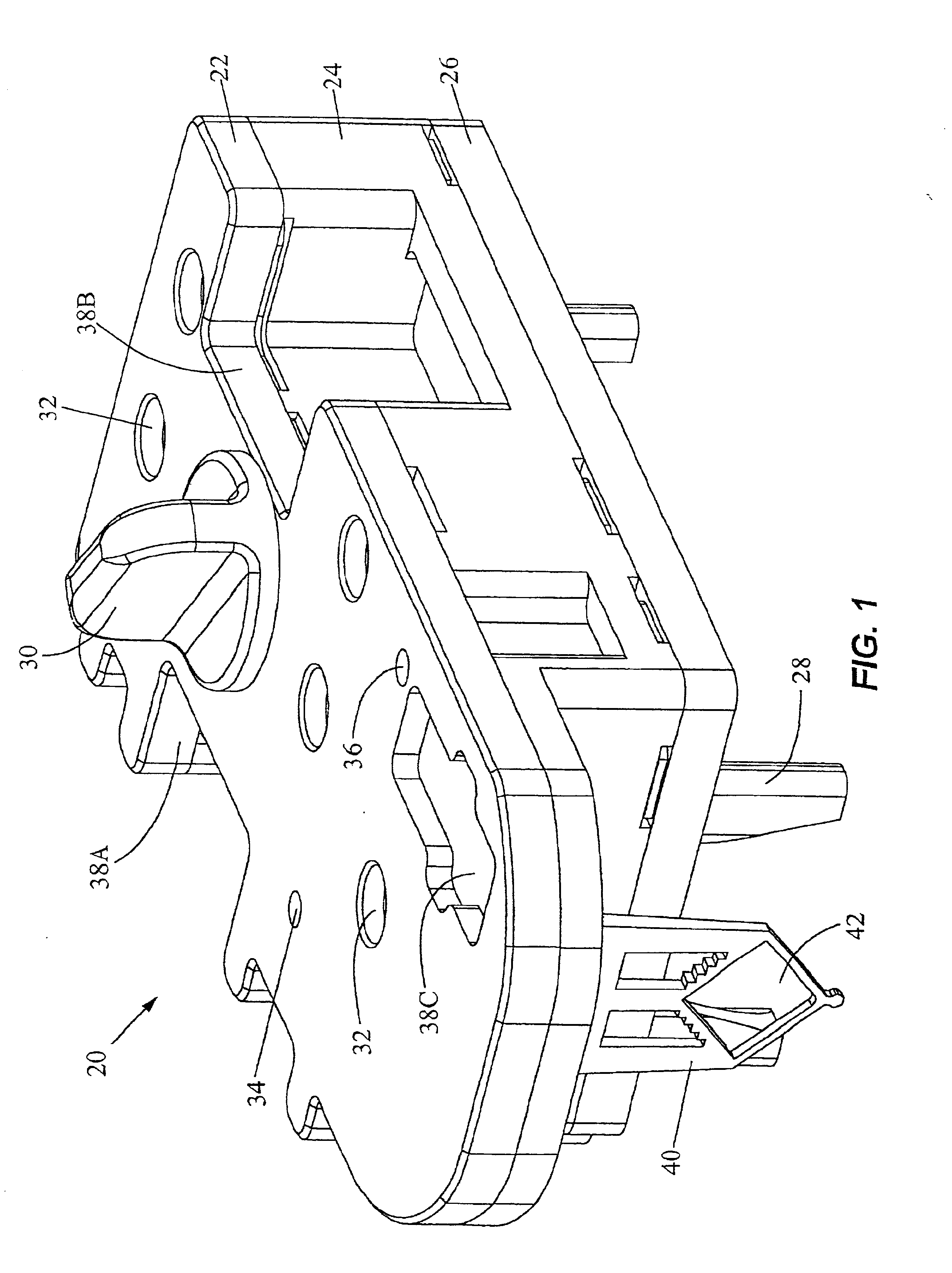

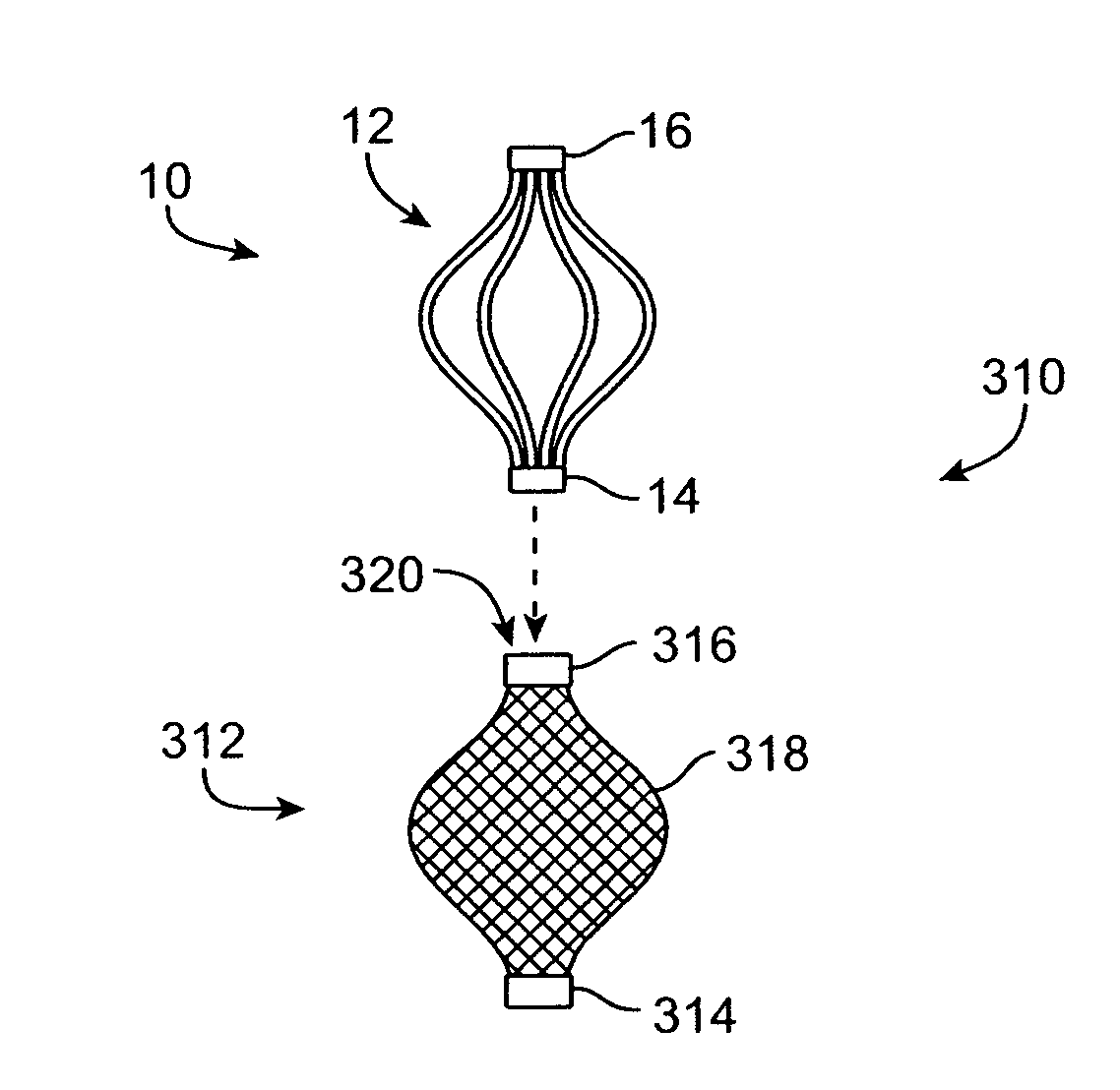

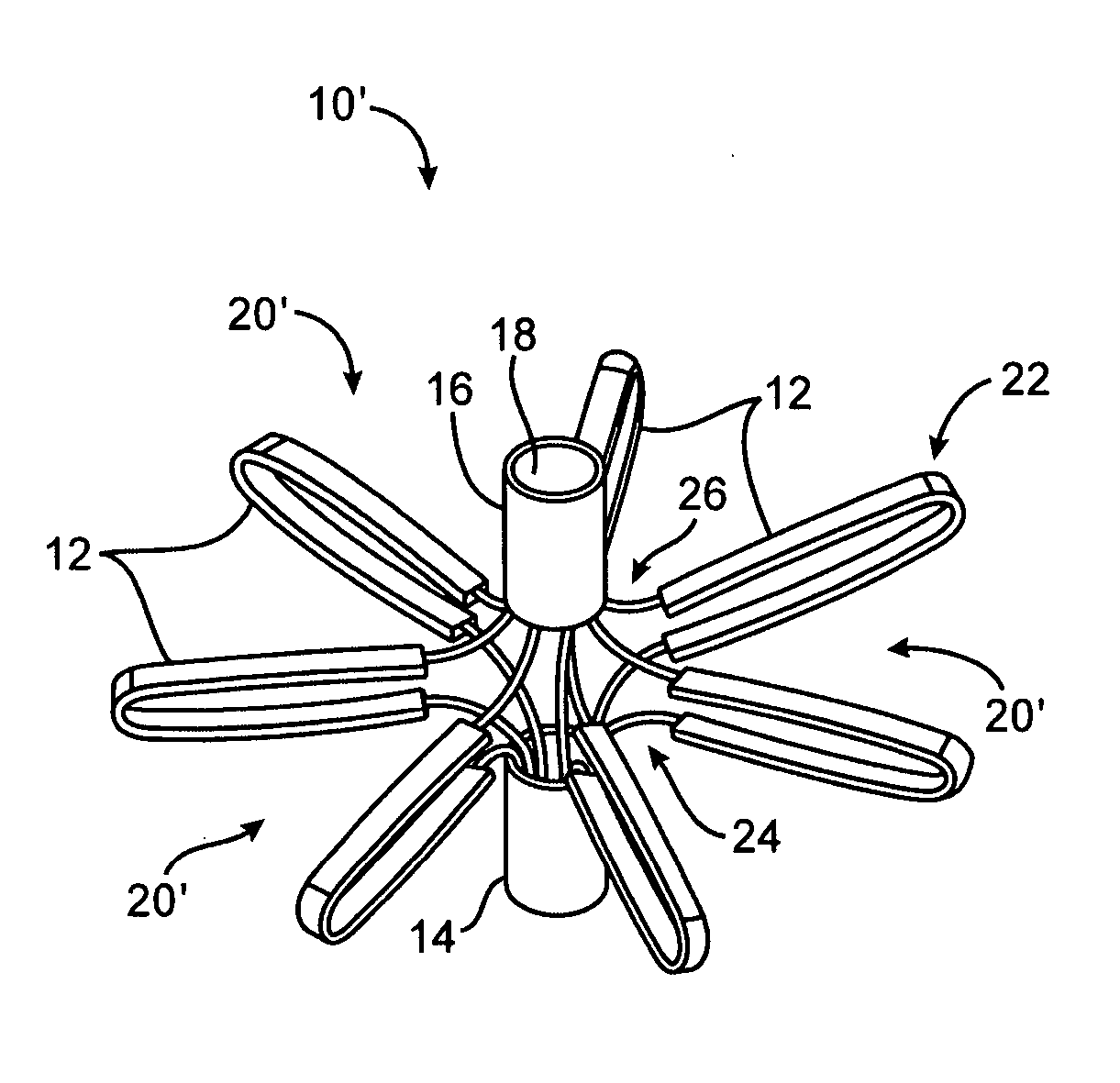

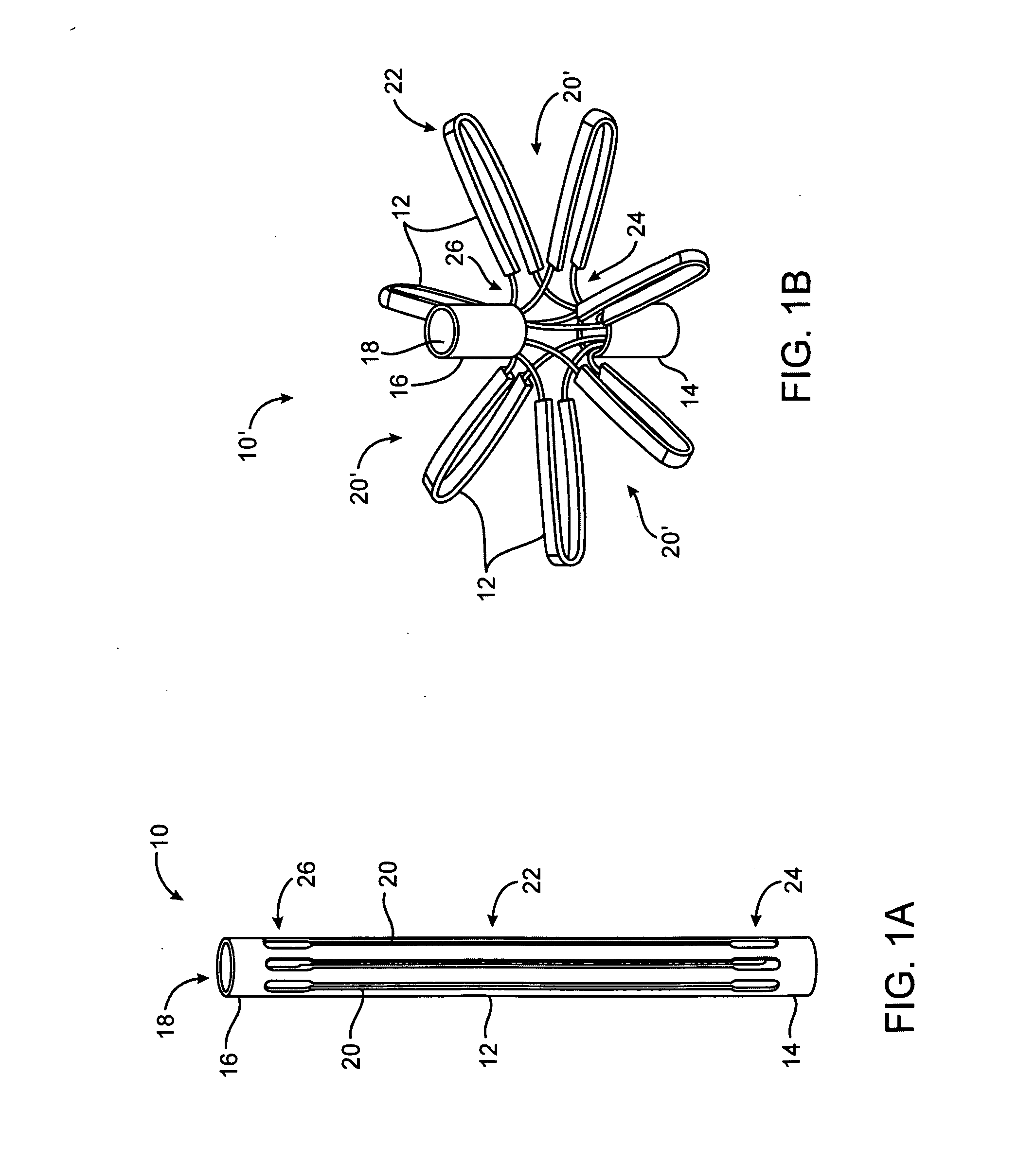

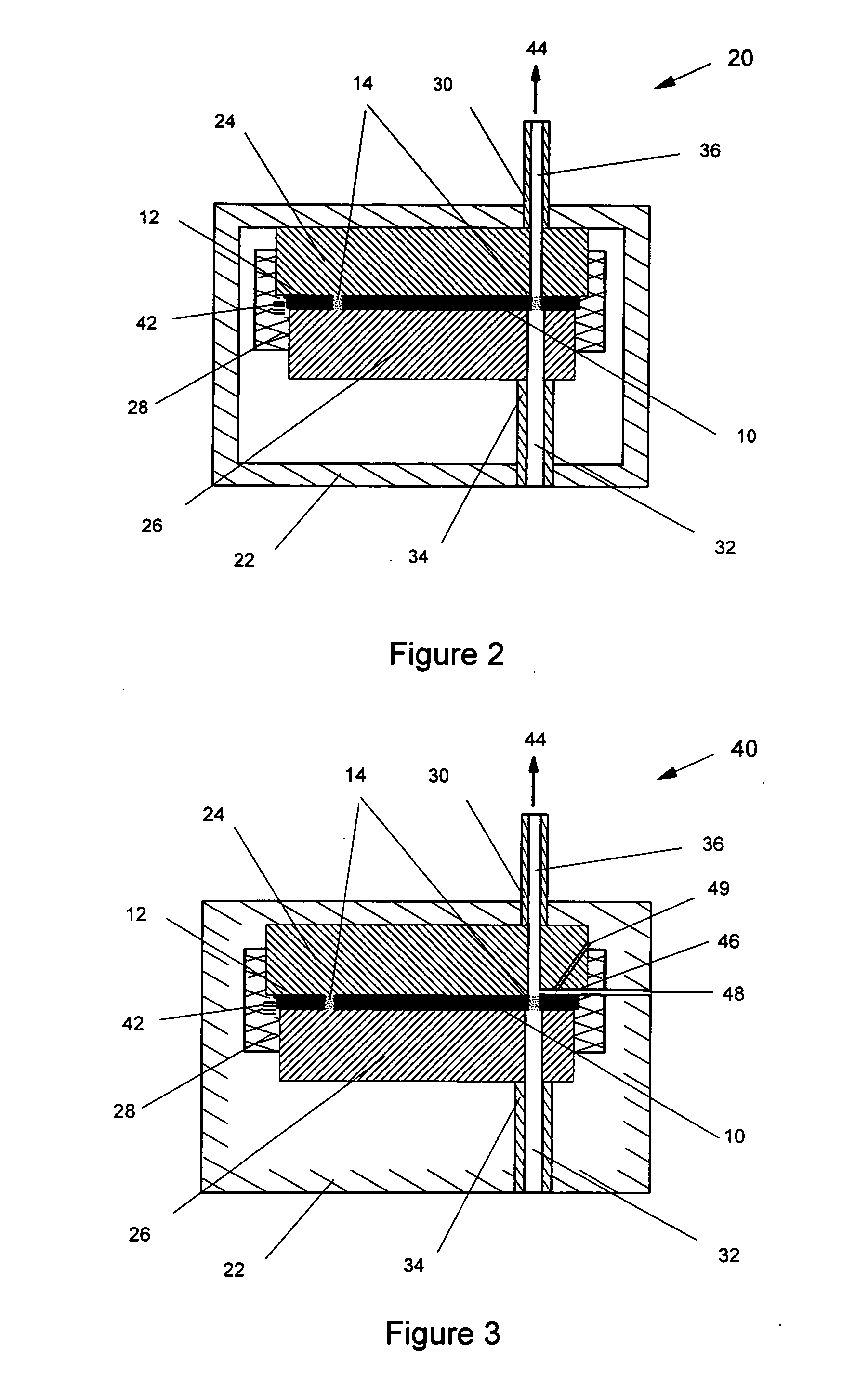

System for optimizing anchoring force

ActiveUS7695493B2Constant force against the tissuePrevent overcompressionSuture equipmentsDiagnosticsConstant forceStrain gauge

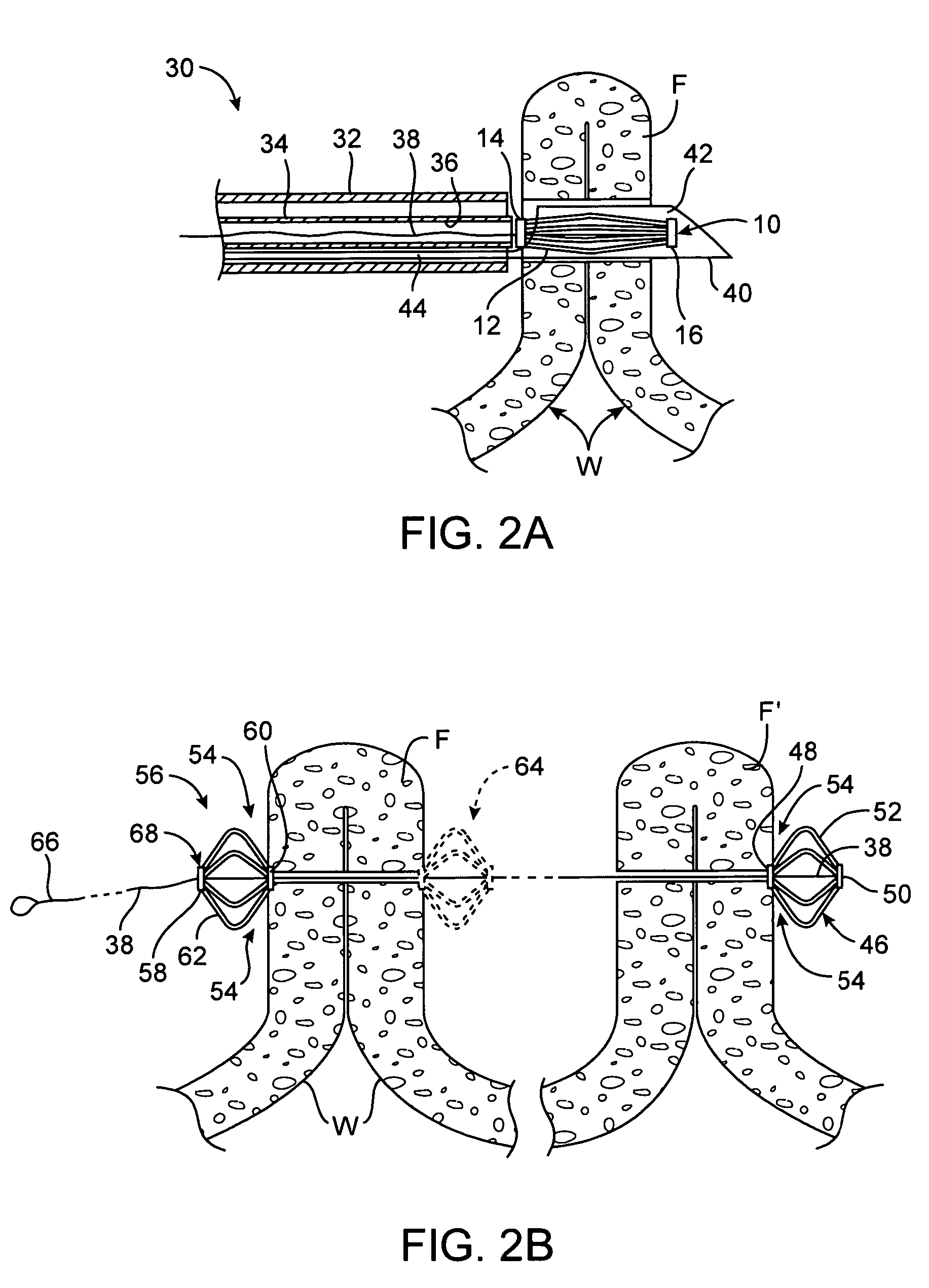

Systems for optimizing anchoring force are described herein. In securing tissue folds, over-compression of the tissue directly underlying the anchors is avoided by utilizing tissue anchors having expandable arms configured to minimize contact area between the anchor and tissue. When the anchor is in its expanded configuration, a load is applied to the anchor until it is optimally configured to accommodate a range of deflections while the anchor itself exerts a substantially constant force against the tissue. Various devices, e.g., stops, spring members, fuses, strain gauges, etc., can be used to indicate when the anchor has been deflected to a predetermined level within the optimal range. Moreover, other factors to affect the anchor characteristics include, e.g., varying the number of arms or struts of the anchor, positioning of the arms, configuration of the arms, the length of the collars, etc.

Owner:USGI MEDICAL

Power plug with a freely rotatable delivery point

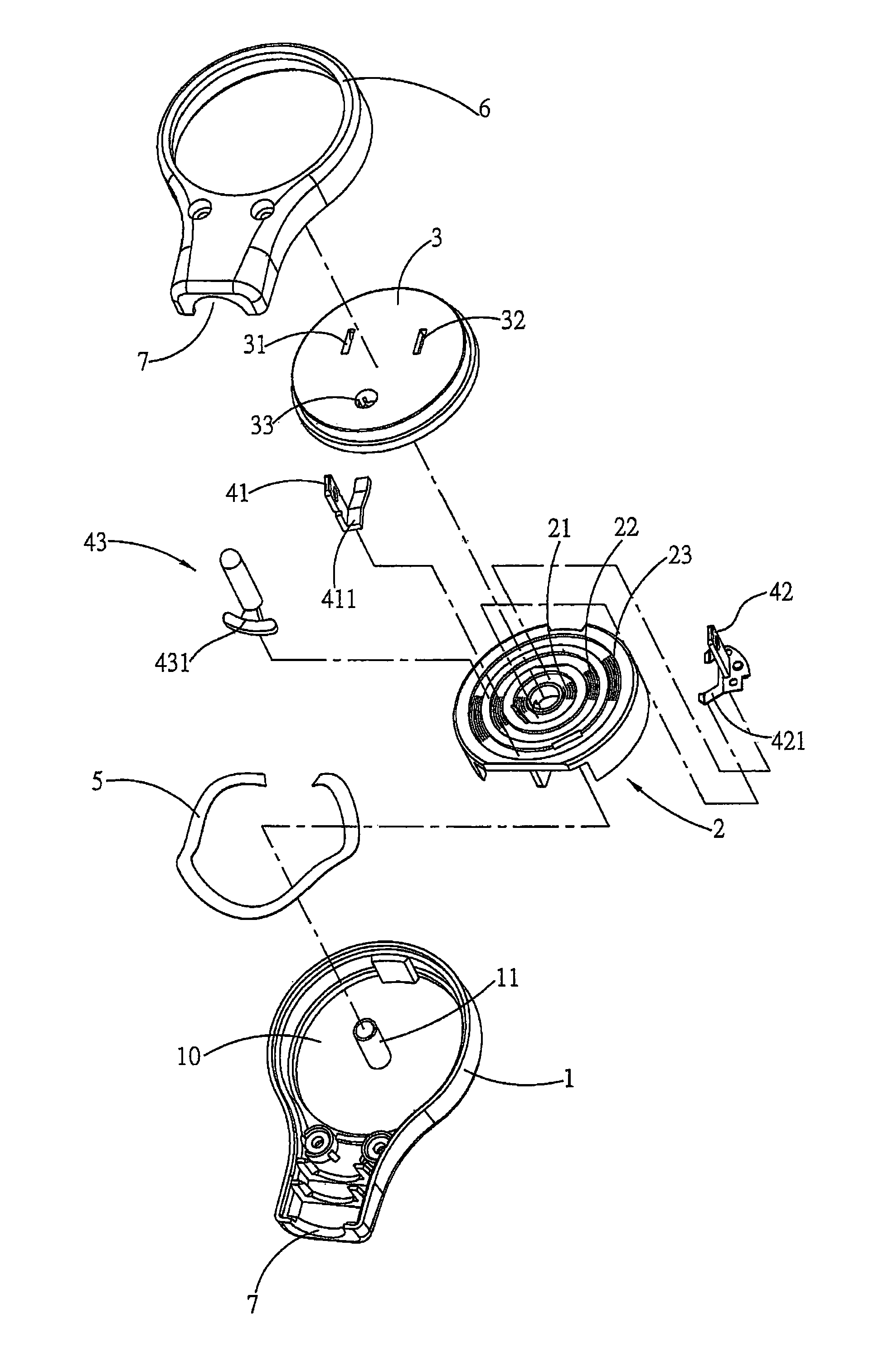

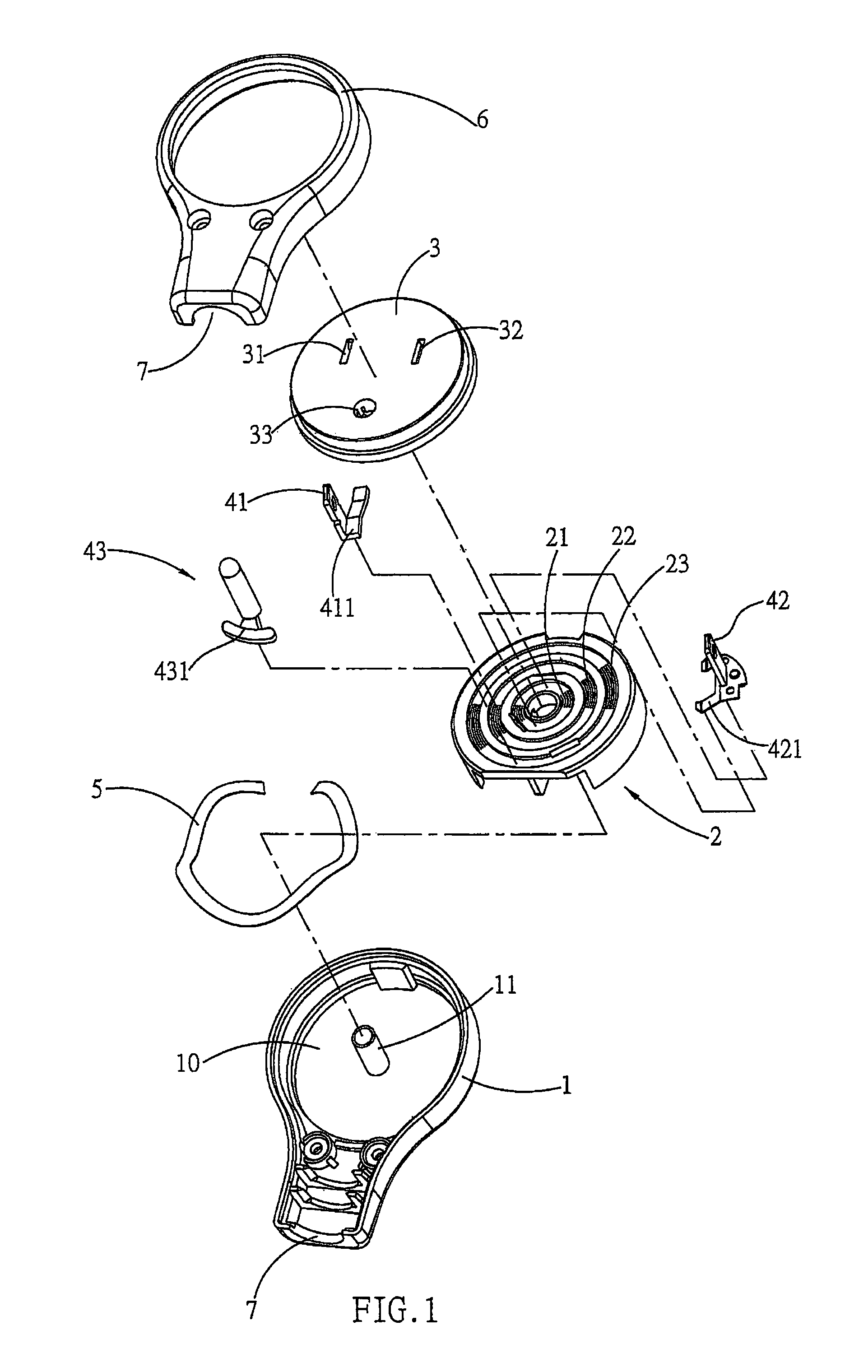

ActiveUS8167622B2Speed up the flowRotary current collectorTwo pole connectionsFree rotationElectric wire

A power plug with a freely rotatable delivery point is disclosed, wherein a relative orientation between a delivery point element (e.g. an electric wire) and insertion terminals of the plug can change freely on a plane. A plug seat includes an armature which displaces axially. An open end of the seat is loosely connected with a turntable which is coaxial with the armature. The turntable is assembled with the insertion terminals which loosely contact with the armature by relative rotation. Between the seat and the armature, an elastic arch element is axially provided and parts of the insertion terminals relative to the armature are indirectly provided with plate-shaped conducting probes with an elastic shear. By the elastic arch element and the conducting probes, a mechanical vibration wave occurring during rotation of the turntable is absorbed, such that the armature can actually contact with the terminals to avoid jump sparks.

Owner:MIG SURGE TECH

Intervertebral disc implant

InactiveUS6187048B1Speed up the flowReduce and eliminate any adverse effectJoint implantsSpinal implantsIntervertebral discProsthesis

An implant for forming an intervertebral disc nucleus pulposus prosthesis includes a conformable material adapted to fill cavities within the disc and to at least partially polymerize in-situ to form a shaped, resiliently deformable prosthesis.

Owner:HOWMEDICA OSTEONICS CORP

Device for surgical repair, closure, and reconstruction

InactiveUS20070021779A1Significant timeLarge skinSnap fastenersSuture equipmentsSurgical repairSurgical department

A device and technique for a sutureless wound closure, which limits the risks of rupture and scarring, is described. The device includes a one-piece surgical fastener generally shaped in a curve along the width of the surgical fastener. The fastener includes a tissue insertion tongue with a plurality of tissue attachment points for fixing the fastener to skin tissue. The fastener also includes a clasp for engaging an identical surgical fastener. The surgical fastener can also be a two-piece structure including a male connecting strap and a female connector. Both pieces include a tissue-connecting mechanism for fixing to skin tissue. The female connector includes an engagement clasp for securing the male connecting strap to the female connector.

Owner:SURGICAL SECURITY

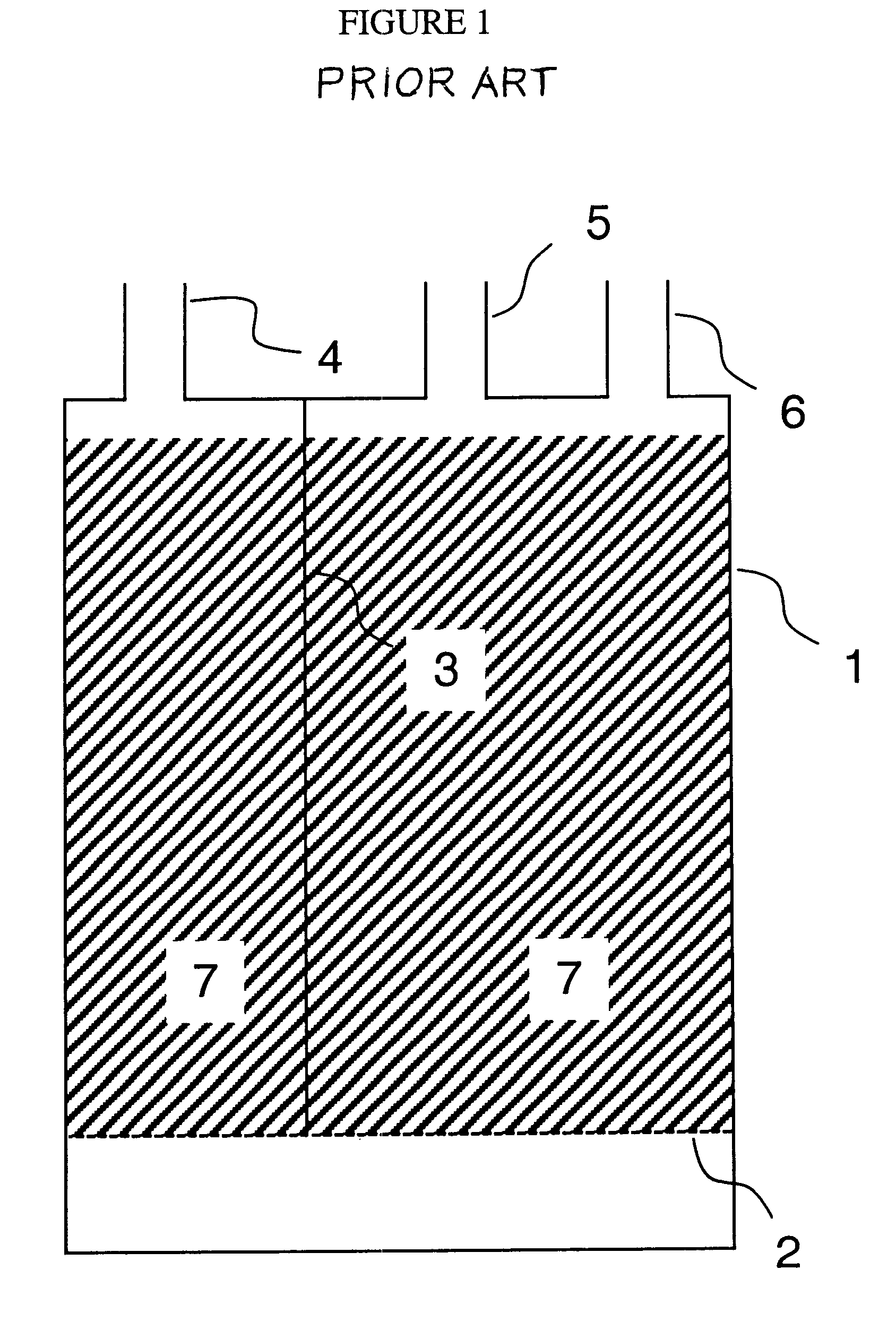

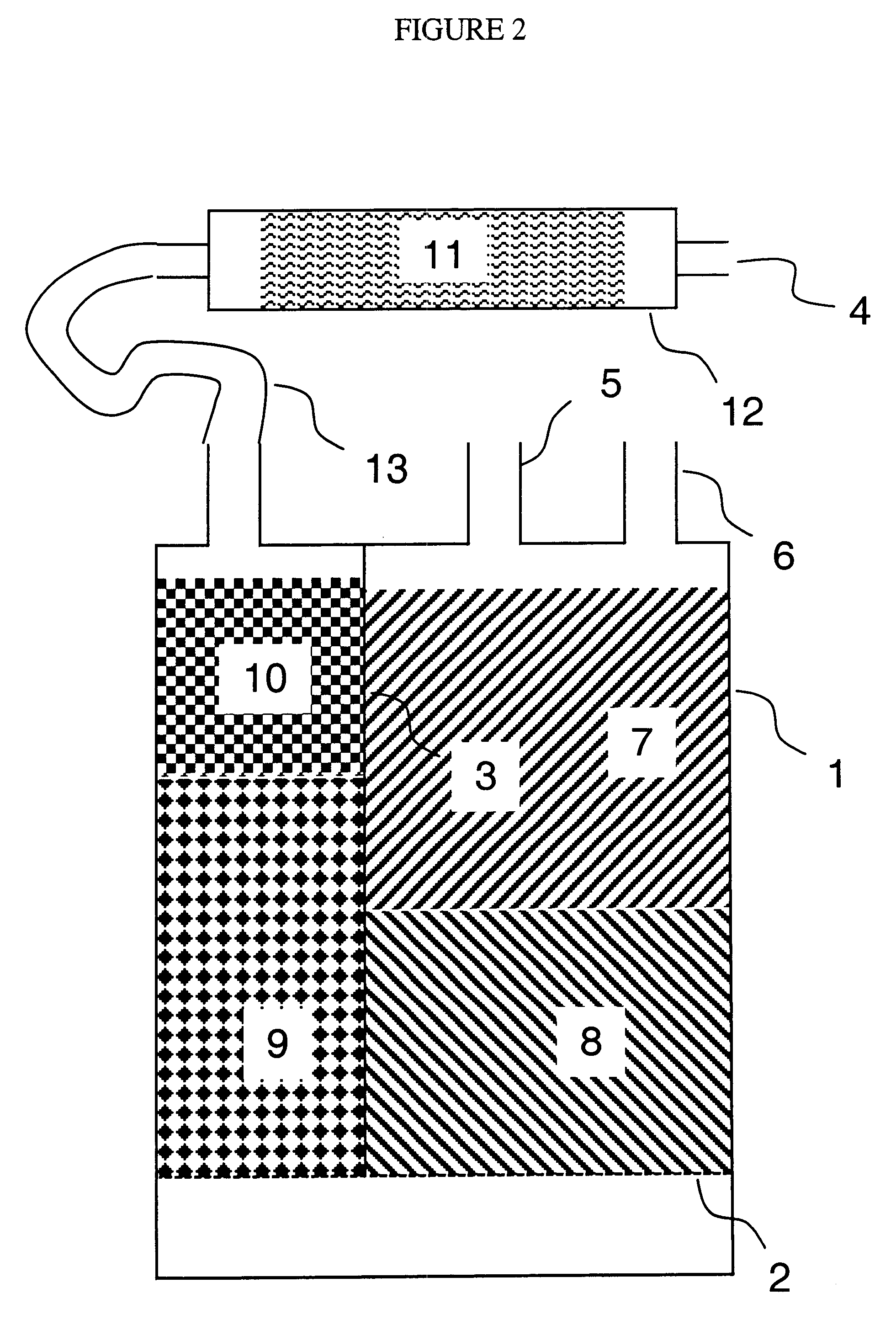

Lateral temperature equalizing system for large area surfaces during processing

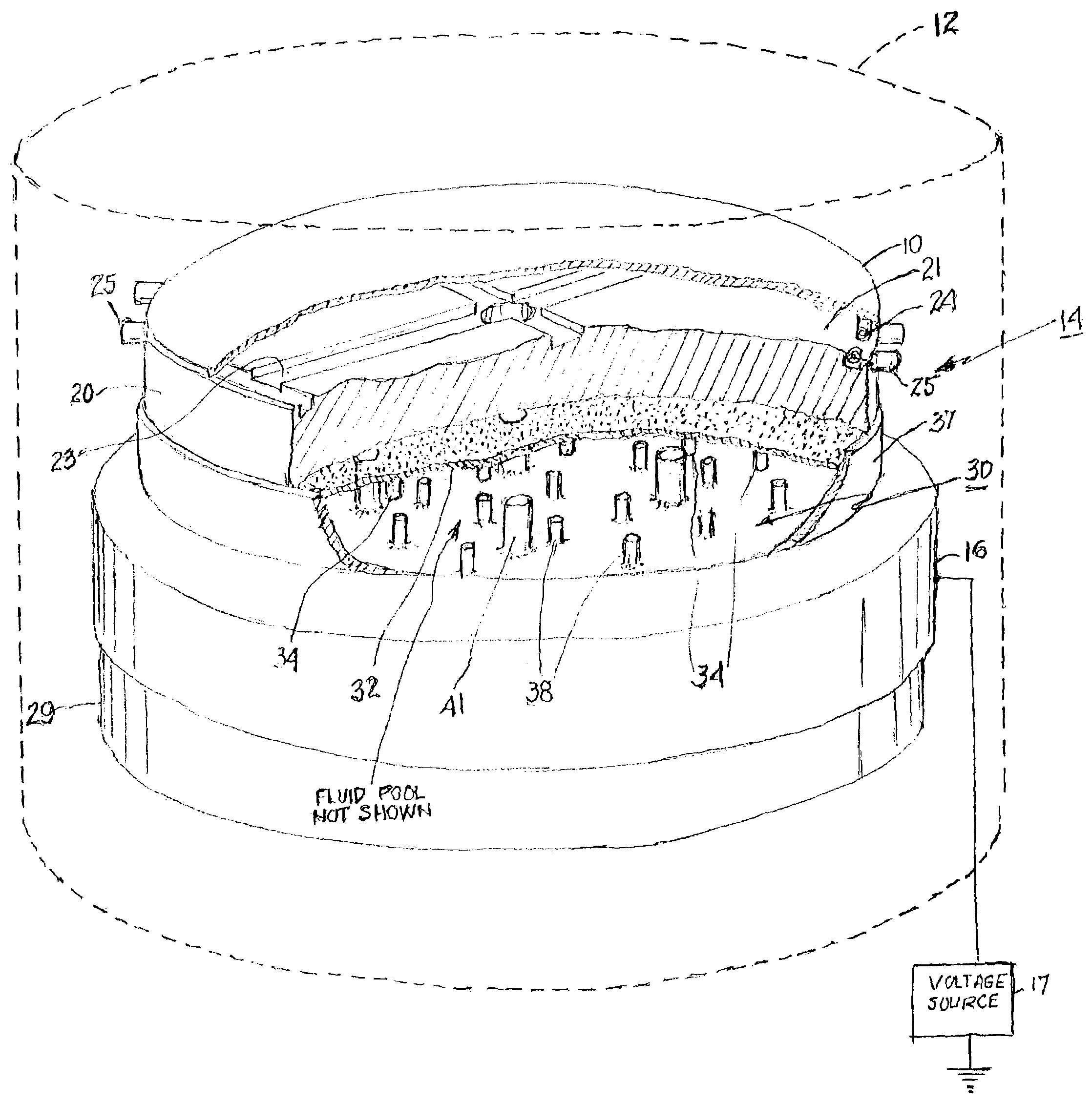

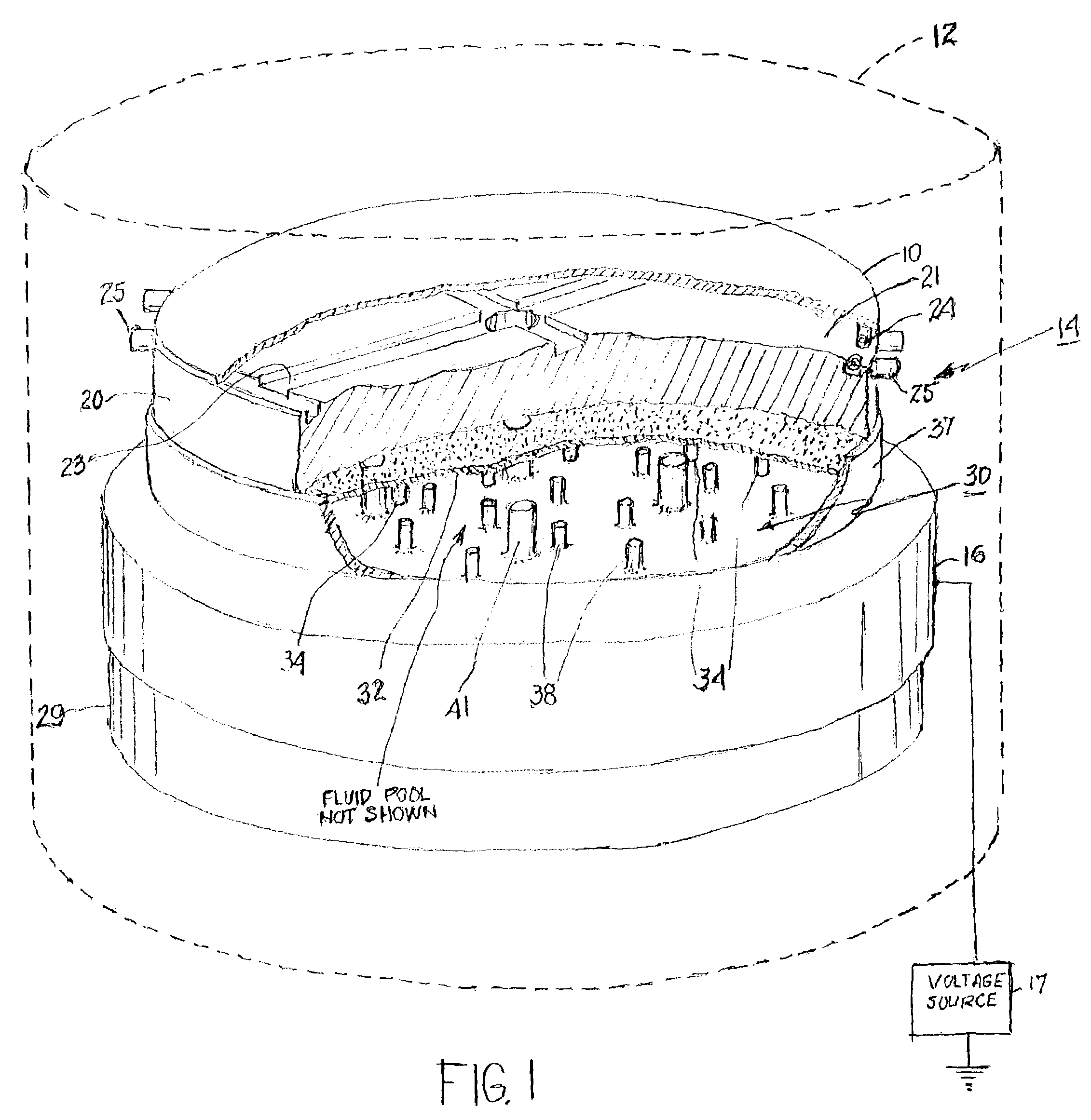

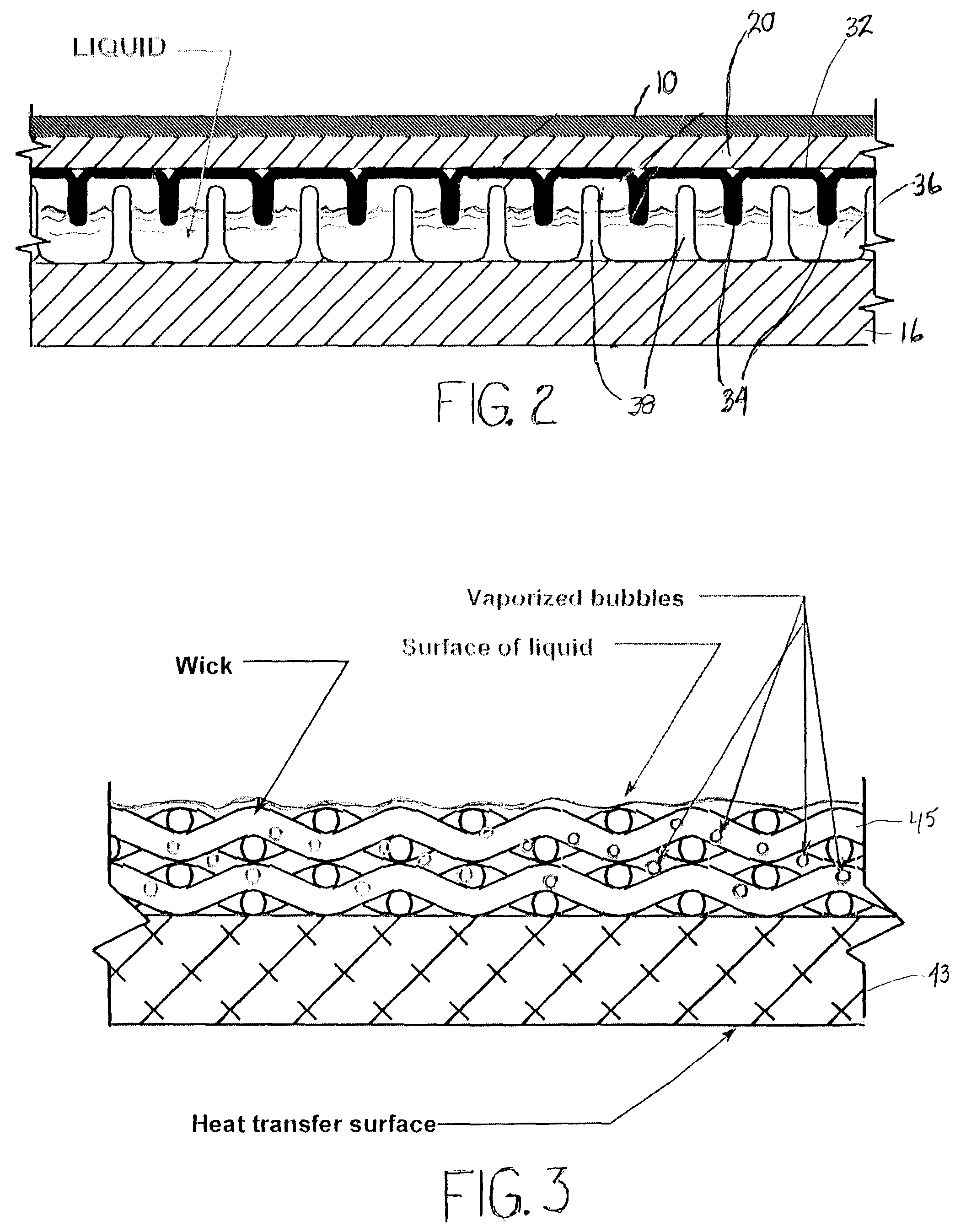

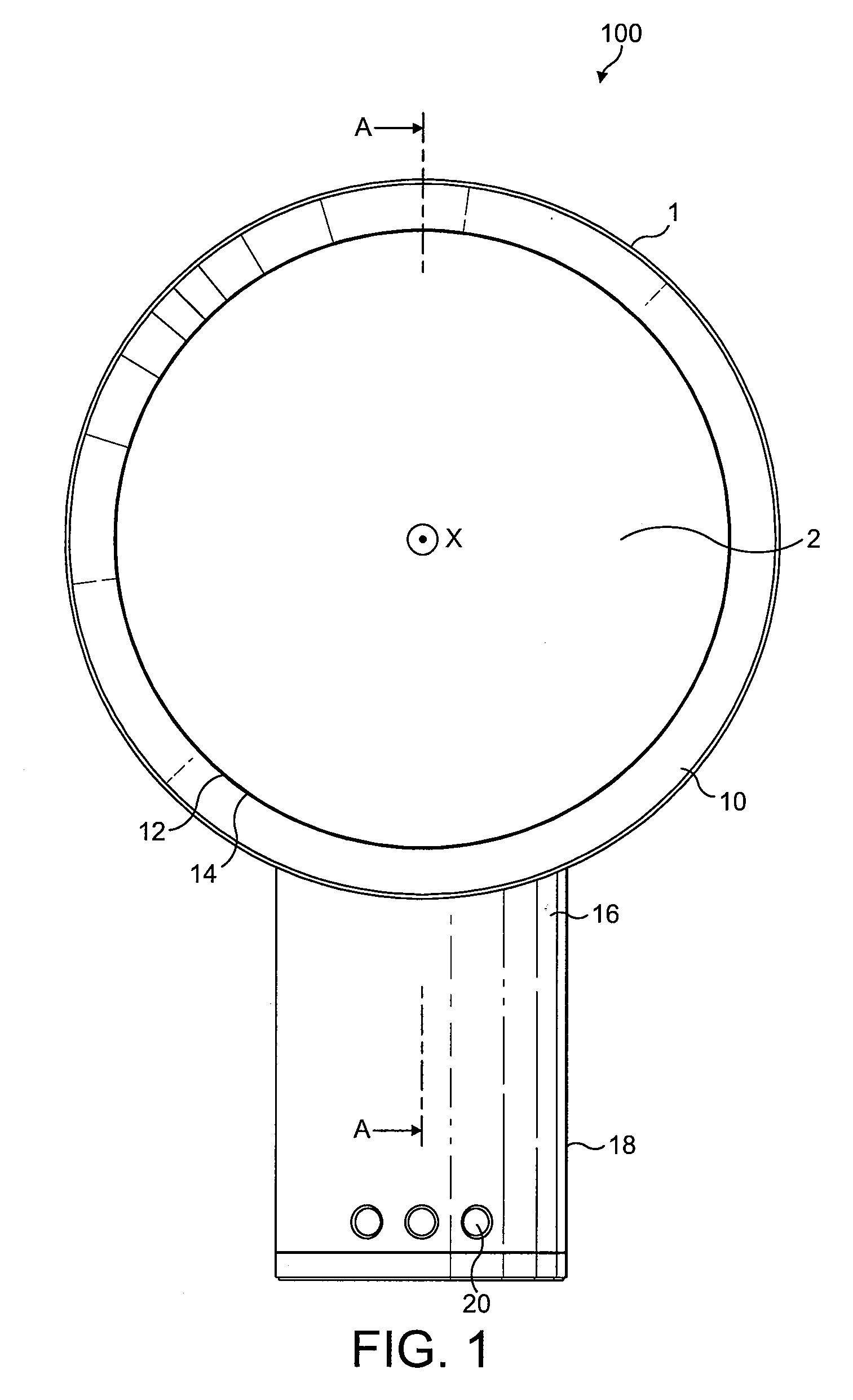

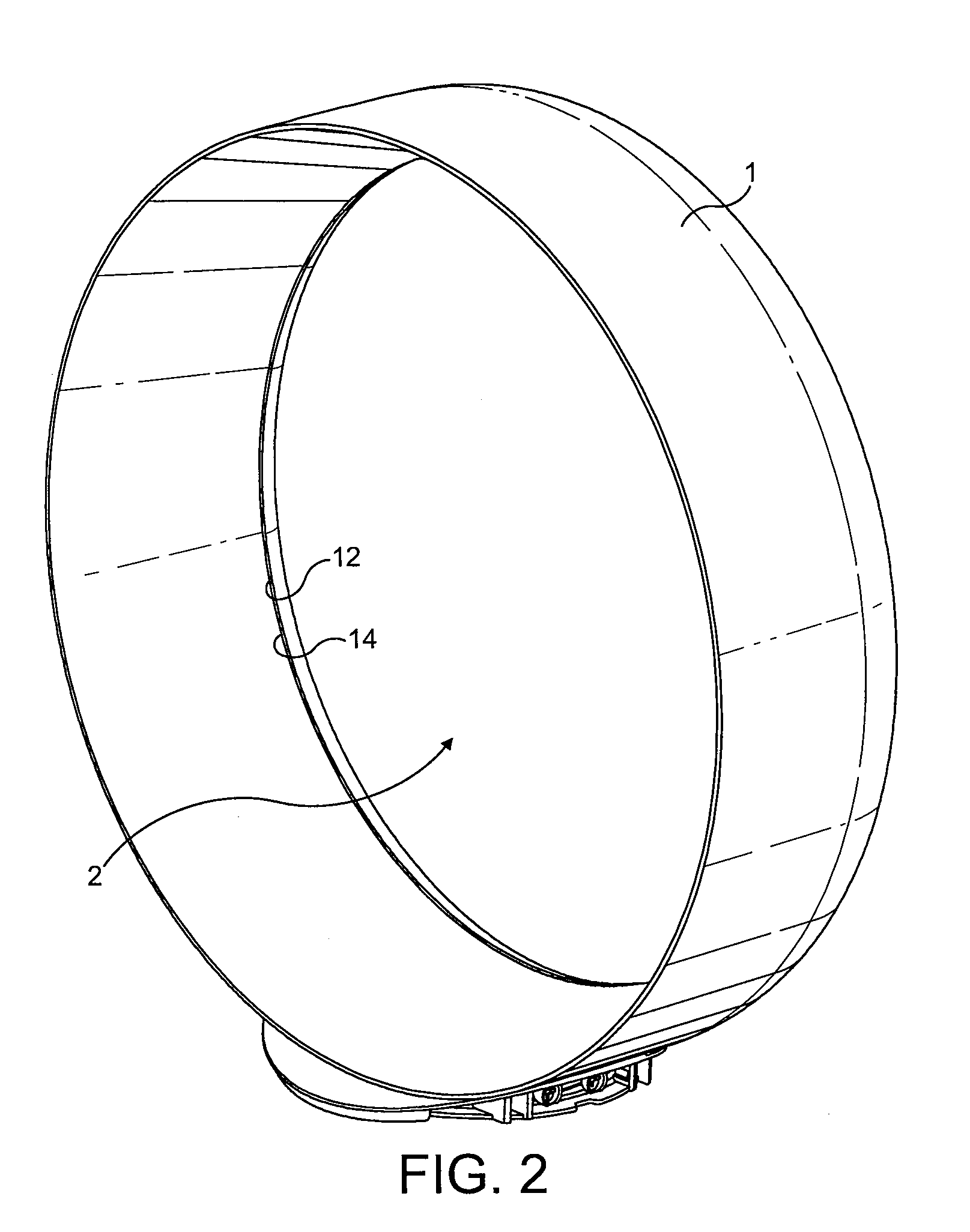

ActiveUS7195693B2Rapid temperature stabilizationLittle changeElectric discharge tubesSemiconductor/solid-state device manufacturingHigh energyShortest distance

In many processes used in fabricating semiconductors the wafer is seated on the top surface of a pedestal and heated in a high energy process step, such as plasma etching. The pedestal, chuck or platen may be cooling but the wafer gradually heats until the process can no longer continue. Where large, e.g. 300 mm diameter, wafers are being processed the temperature level across the wafer is difficult to maintain substantially constant. In this system and method the lateral temperature distribution is equalized by a heat sink structure in a chamber immediately under the wafer support on top of the pedestal. A number of spatially distributed wicking posts extend downwardly from a layer of wicking material across the top of the chamber, into a pool of a vaporizable liquid. At hot spots, vaporized liquid is generated and transported to adjacent condensation posts extending up from the liquid. The system thus passively extracts heat to equalize temperatures while recirculating liquid and assuring adequate supply. The free volume above and within the liquid, and the short distances between posts, assure adequate heat transfer rates.

Owner:BE AEROSPACE INCORPORATED

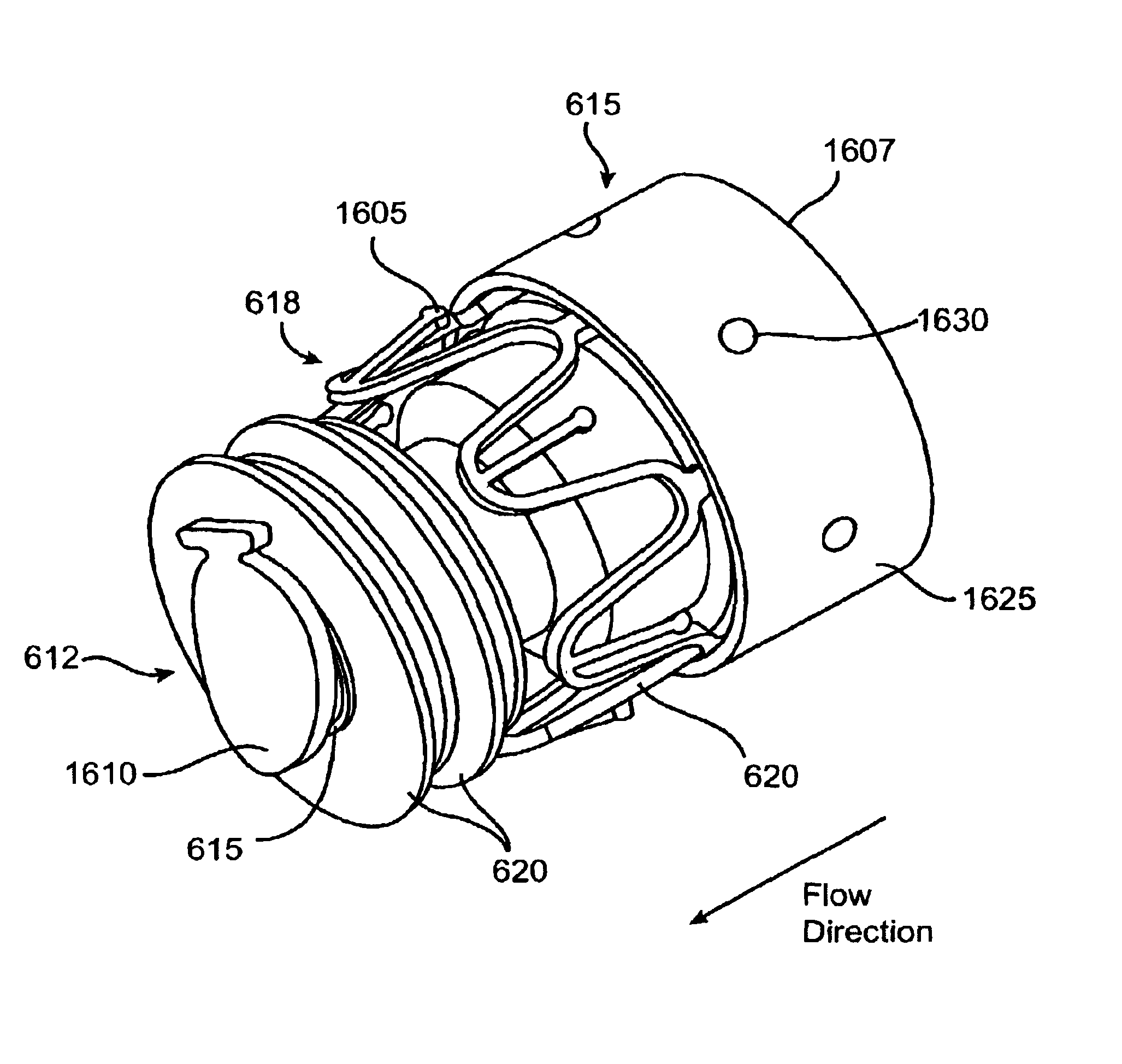

Electrosurgical systems and methods for recanalization of occluded body lumens

InactiveUS6855143B2Speed up the flowEliminate potentialSurgical instruments for heatingTherapeutic coolingCoronary arteriesDistal portion

The present invention comprises electrosurgical apparatus and methods for maintaining patency in body passages subject to occlusion by invasive tissue growth. The apparatus includes an electrode support disposed at a shaft distal end having at least one active electrode arranged thereon, and at least one return electrode proximal to the at least one active electrode. In one embodiment, a plurality of active electrodes each comprising a curved wire loop portion are sealed within a distal portion of the electrode support. The apparatus and methods of the present invention may be used to open and maintain patency in virtually any hollow body passage which may be subject to occlusion by invasive cellular growth or invasive solid tumor growth. Suitable hollow body passages include ducts, orifices, lumens, and the like, with exemplary body passages including the coronary arteries. The present invention is particularly useful for reducing or eliminating the effects of restenosis in coronary arteries by selectively removing tissue in-growth in or around stents anchored therein.

Owner:ARTHROCARE

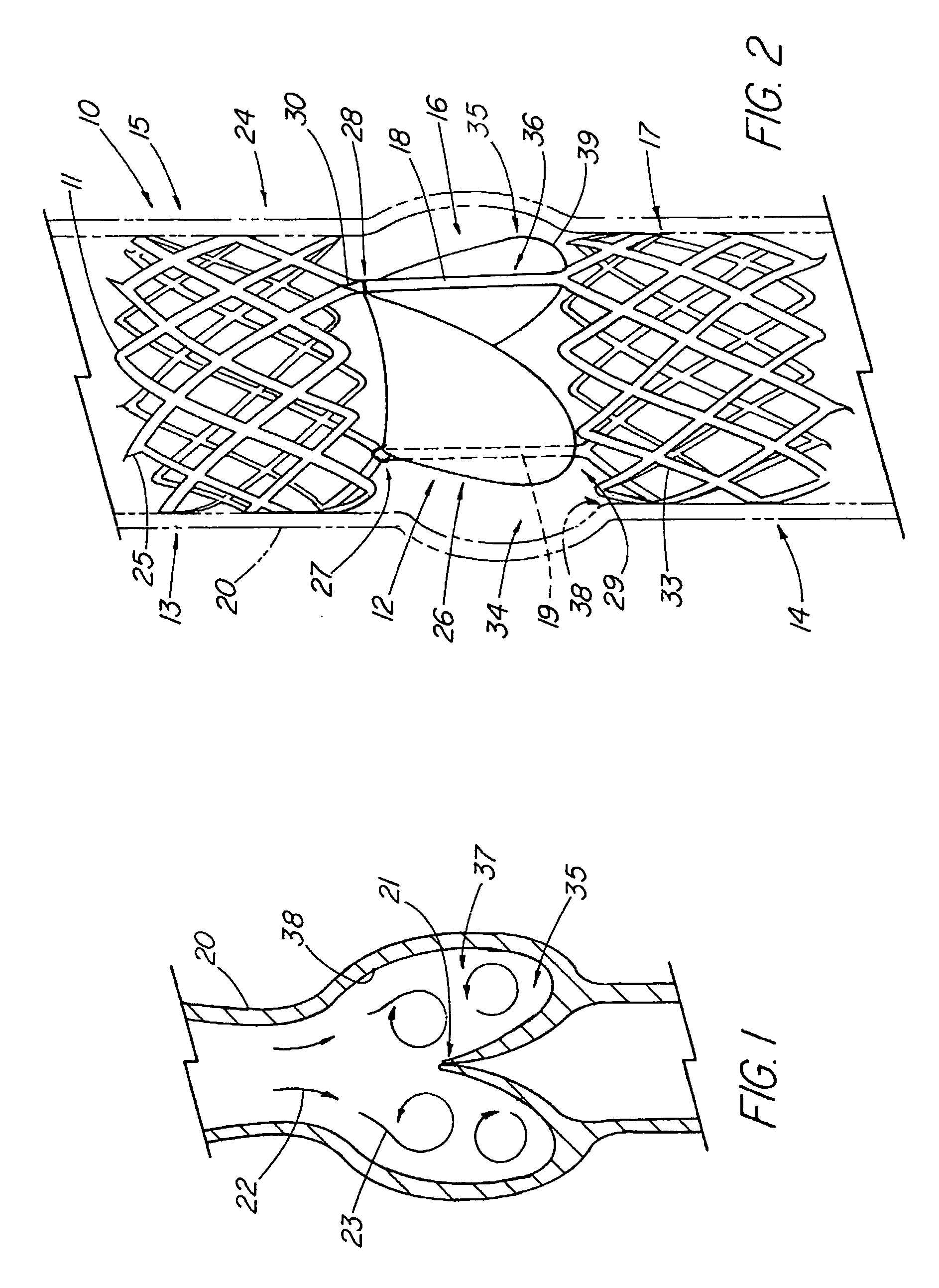

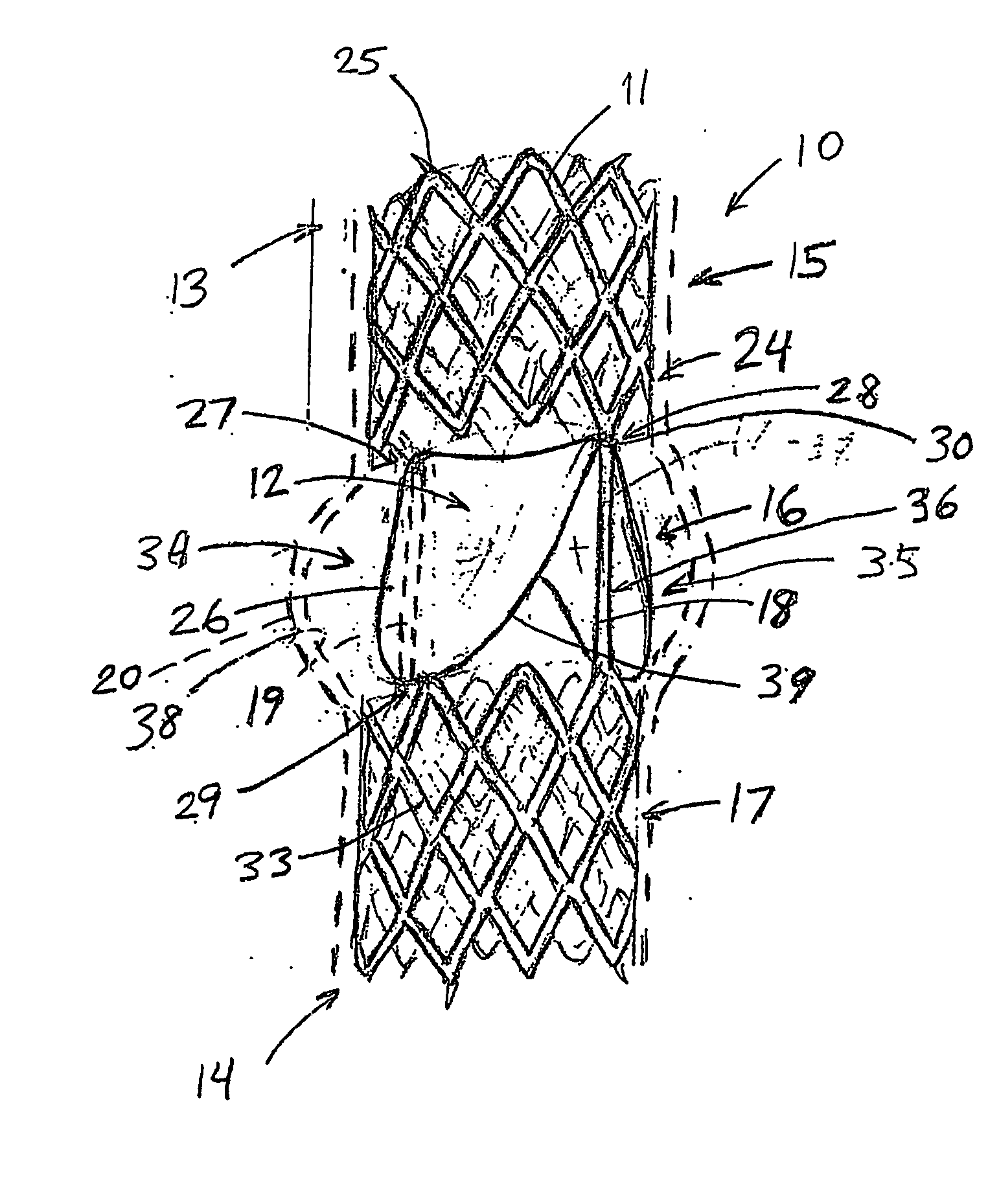

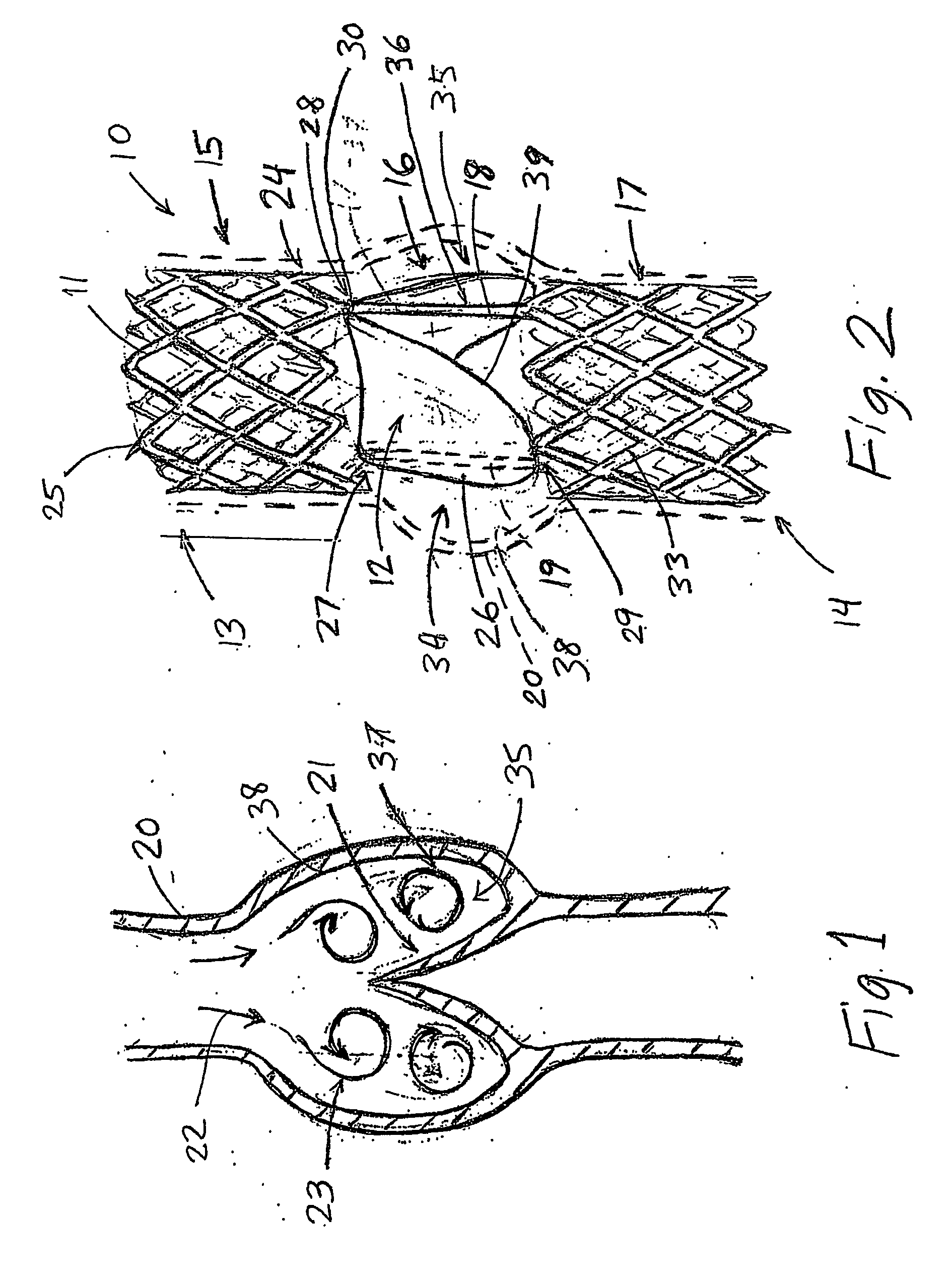

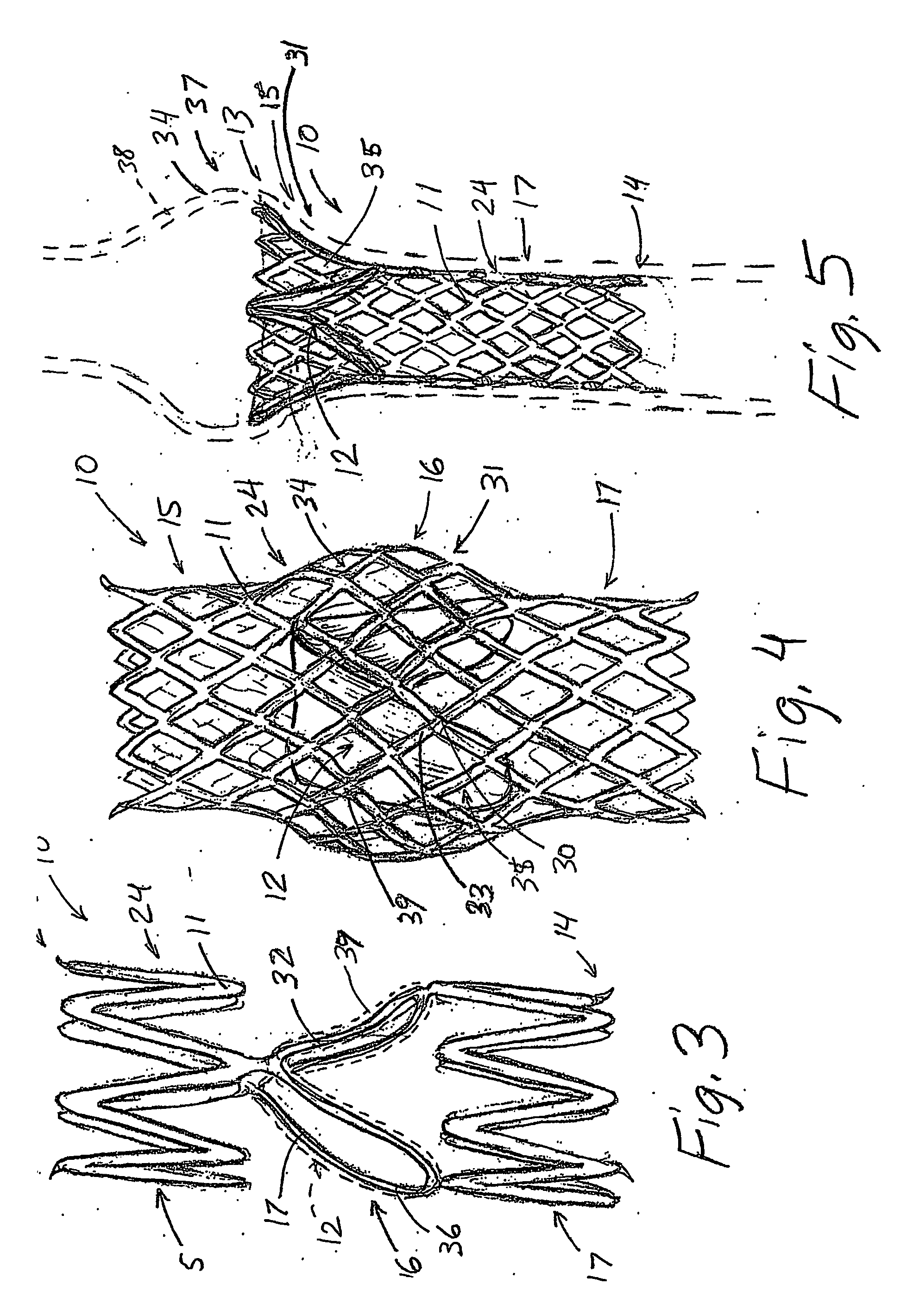

Artificial valve prosthesis with improved flow dynamics

ActiveUS7618447B2Easy to removeMore turbulent flowVenous valvesBlood vesselsVenous ValvesProsthetic valve

An expandable venous valve having a support structure that configured to enlarge the area adjacent to the valve structure such that the flow patterns of retrograde flow are modified in a way that facilitates the flushing of the pockets at the base of the valve area to prevent stagnation of bodily fluid, which in the venous system, can lead to thrombus formation. The enlarged pocket areas can be created by forming an artificial sinus adjacent the valve structure in an unsupported section of vessel wall between two support frame section or the support frame can comprise an expanded-diameter intermediate or proximal section that forms an artificial sinus adjacent the valve structure. In another group of embodiments, the attachment pathway between opposing leaflets and the support frame and / or vessel wall comprises a proximal portion that places the leaflets in extended contact with one another and a distal portion forms a large angle with respect to the adjacent walls such that a large pocket is created at the base of the leaflets. In one embodiment, the attachment pathway extends distally along a pair of substantially parallel longitudinal attachment struts to create an extended leaflet contact area, then angles circumferentially and distally from the former along distal attachment struts to define the bottom edge of the leaflets.

Owner:COOK MEDICAL TECH LLC

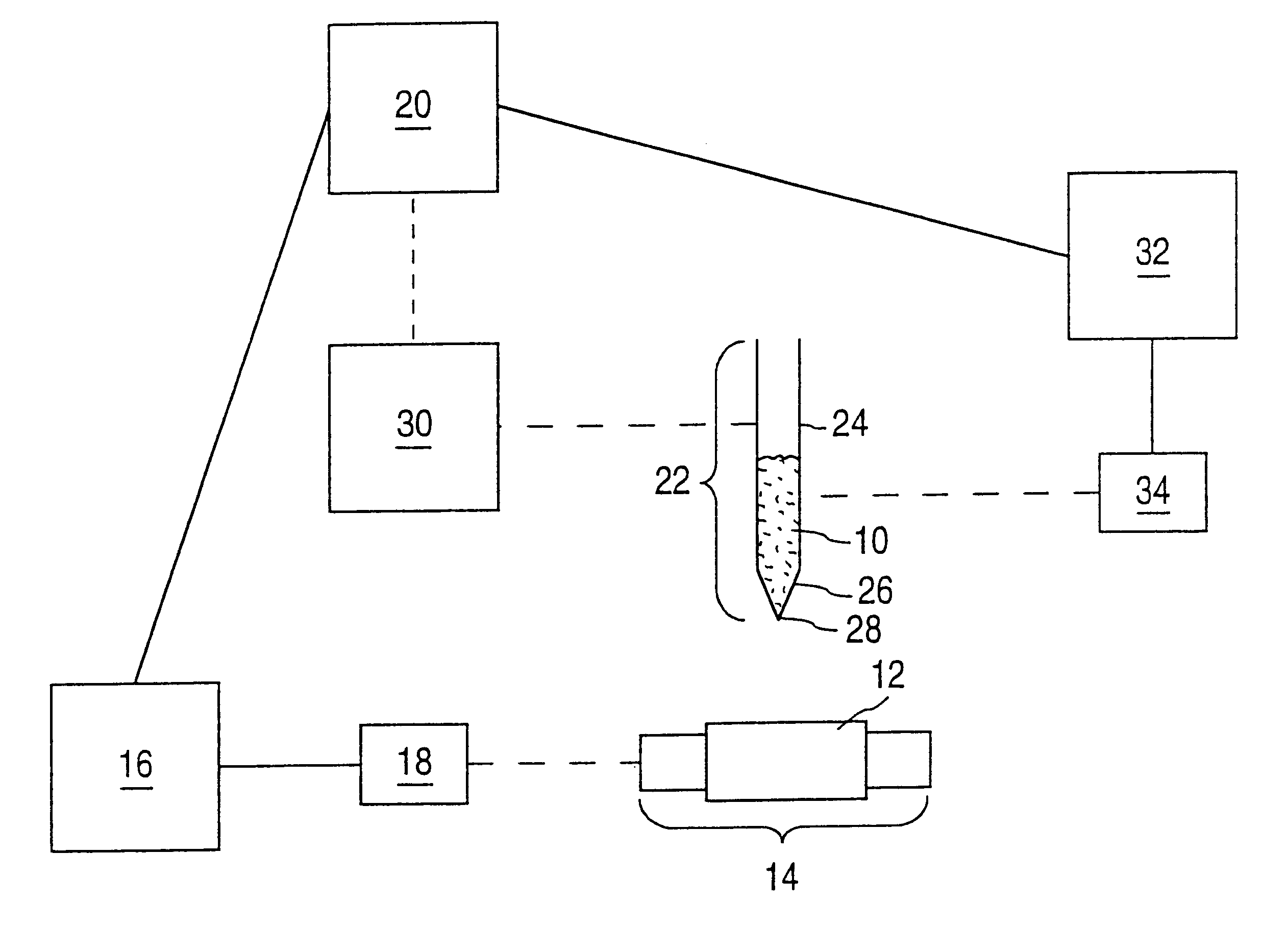

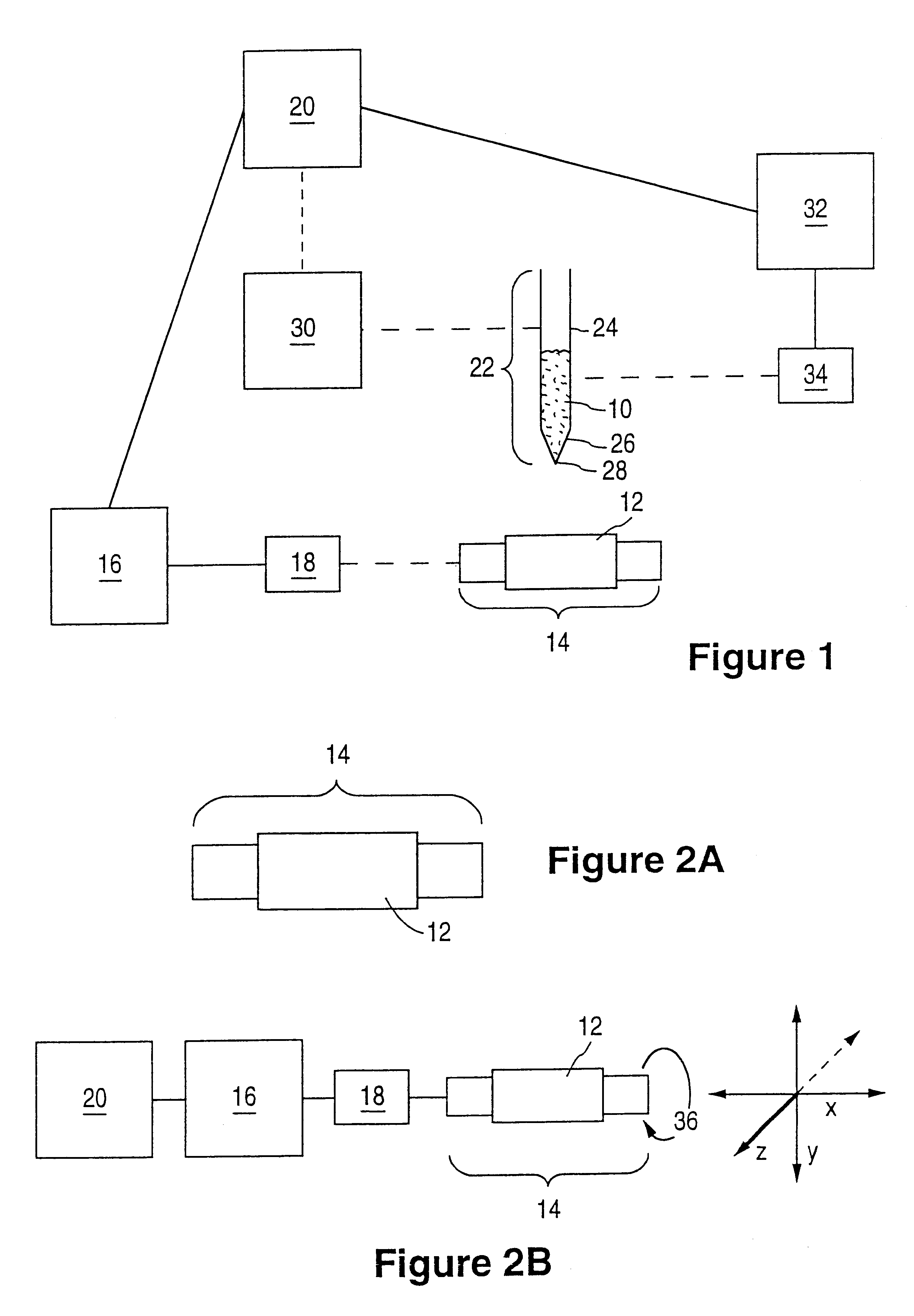

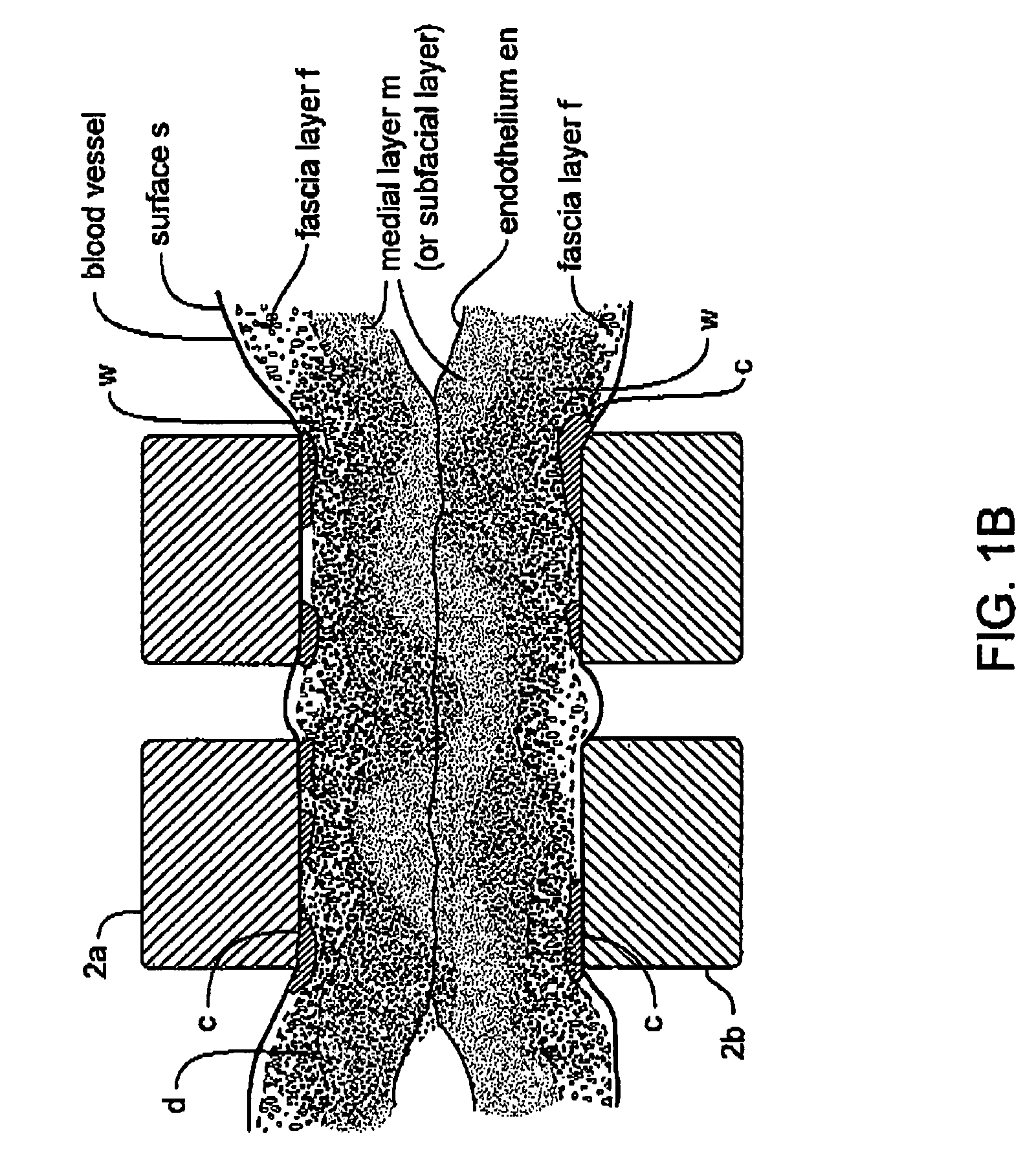

Apparatus and method for depositing a coating onto a surface of a prosthesis

A patterned coating on a prosthesis, for example a stent, and a method for forming the coating are disclosed. Additionally, an apparatus for forming the patterned coating is disclosed.

Owner:ABBOTT CARDIOVASCULAR

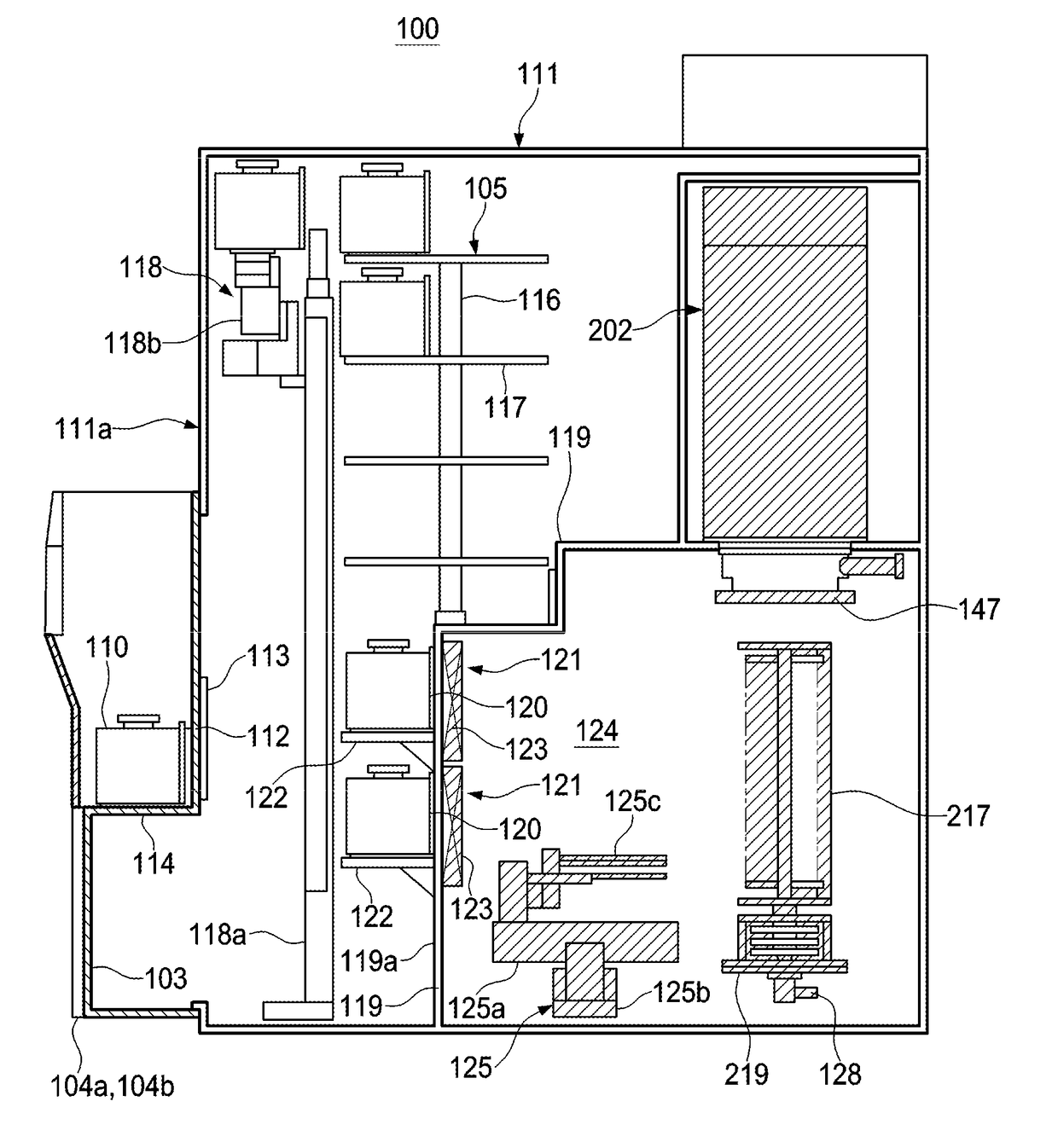

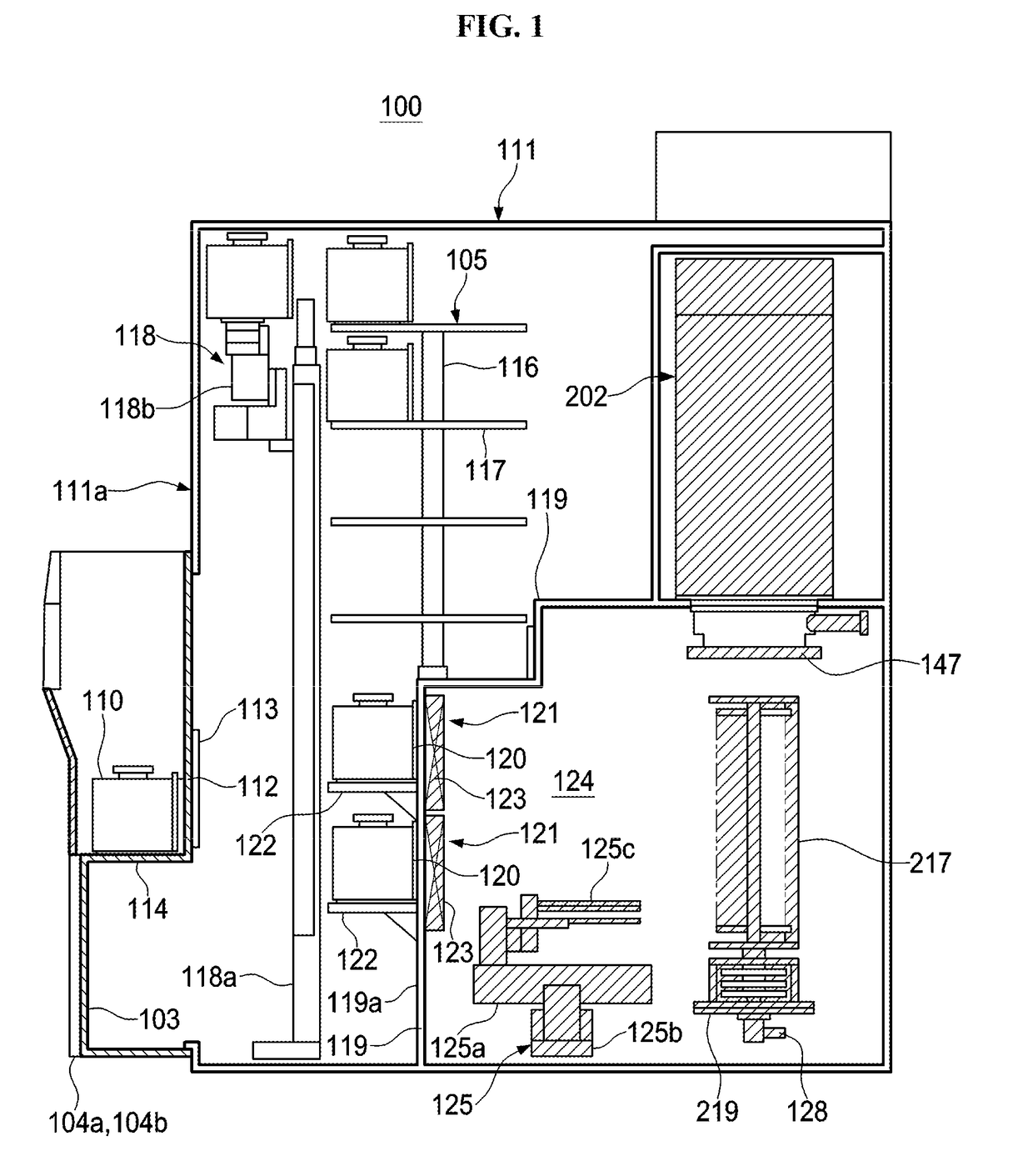

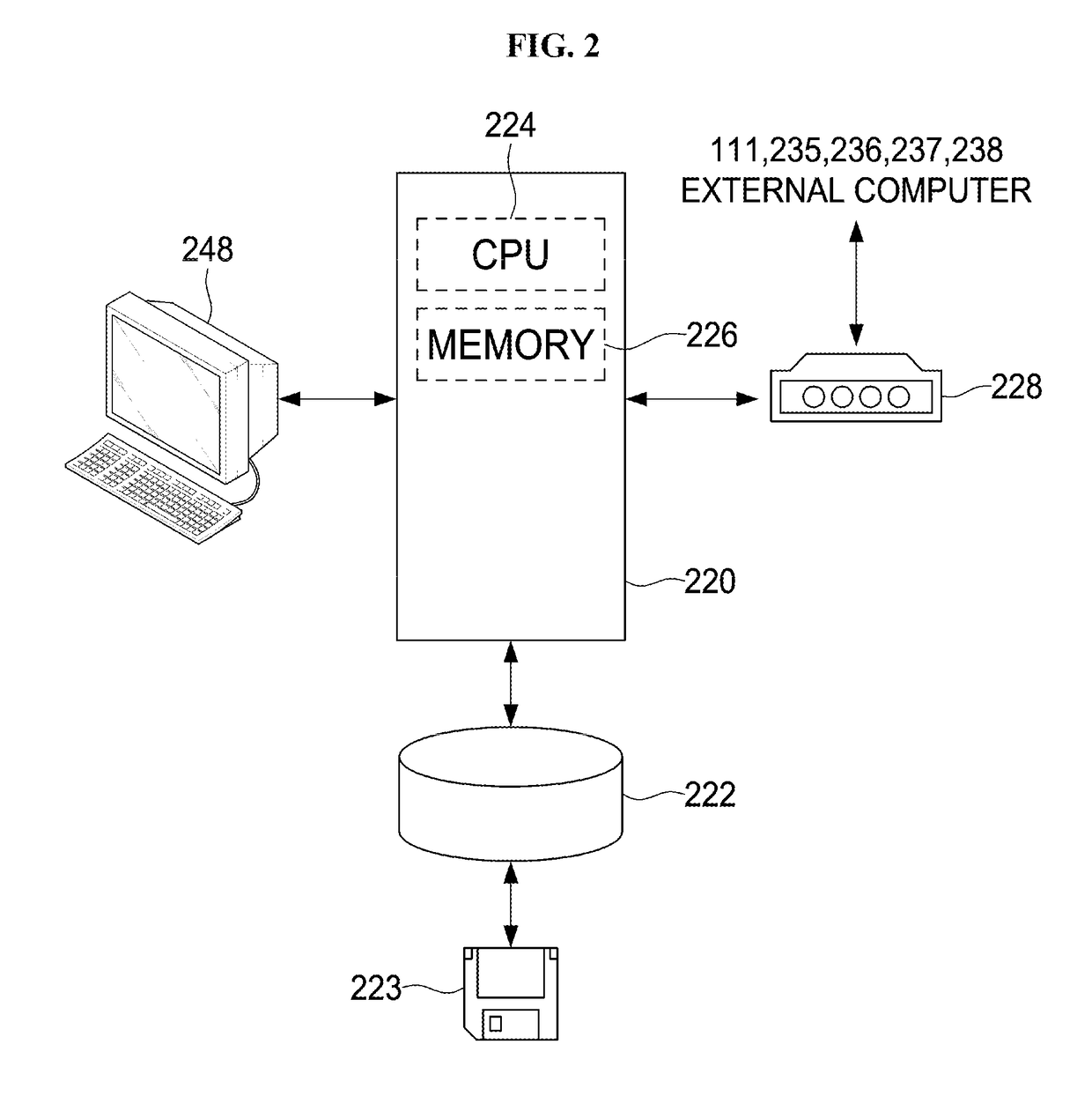

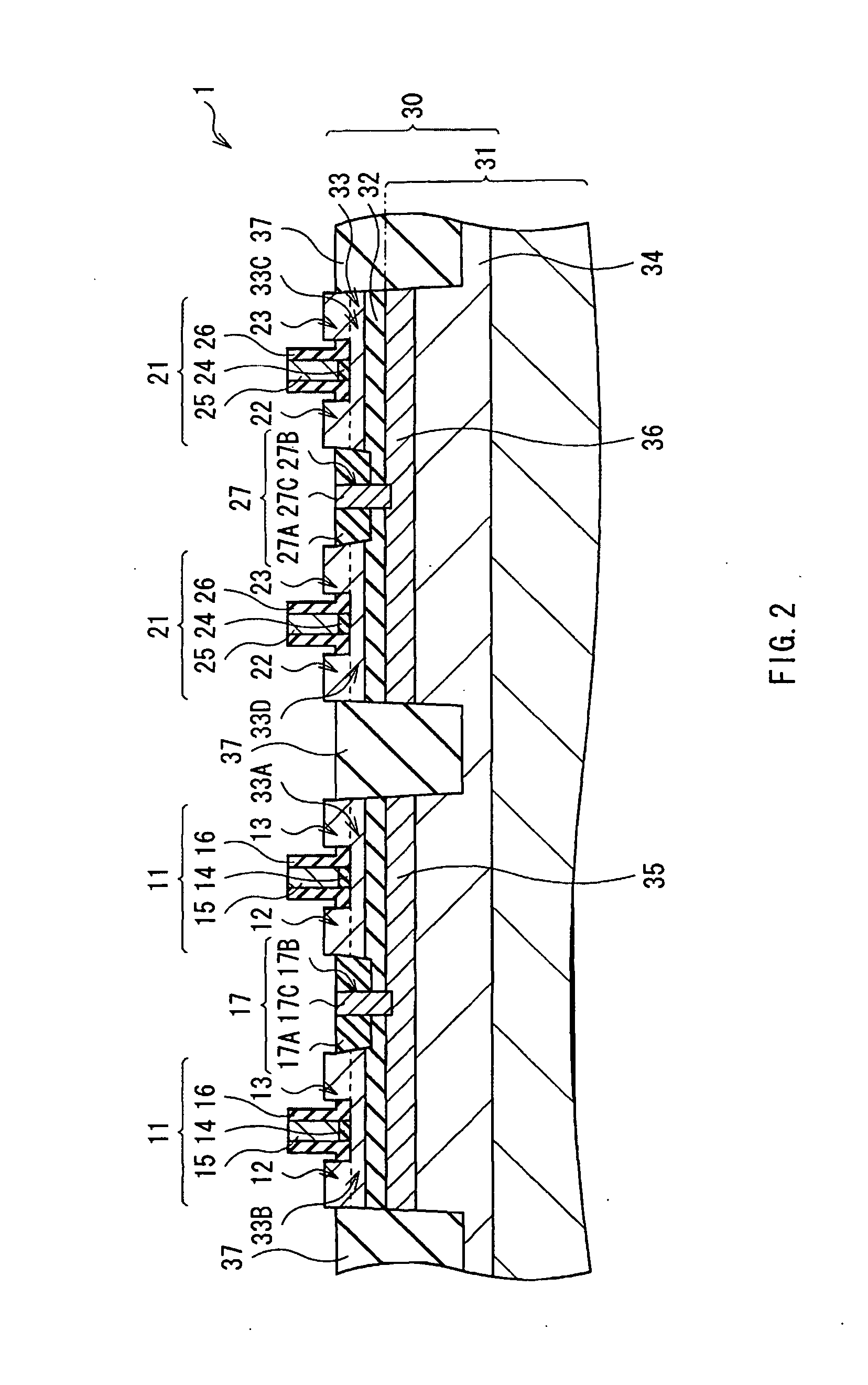

Reaction tube structure and substrate processing apparatus

ActiveUS20180142353A1Speed up the flowSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProcess engineeringGas supply

A substrate processing apparatus includes a reaction tube defining a substrate processing chamber; a gas inlet provided at a lower portion of the reaction tube to supply a process gas; a first buffer unit for temporarily retaining the process gas, the first buffer unit at a first side of an inner surface of the reaction tube and includes a plurality of gas supply holes; and a gas outlet provided at a second side of the inner surface of the reaction tube opposite to the first side, to exhaust the process gas from the process chamber. The gas supply holes are provided from an upper end portion of the first buffer unit to a lower end portion of the first buffer unit, and the process gas is supplied through the plurality of gas supply holes into the process chamber, passes through the process chamber, and exhausted through the gas outlet.

Owner:KOKUSA ELECTRIC CO LTD

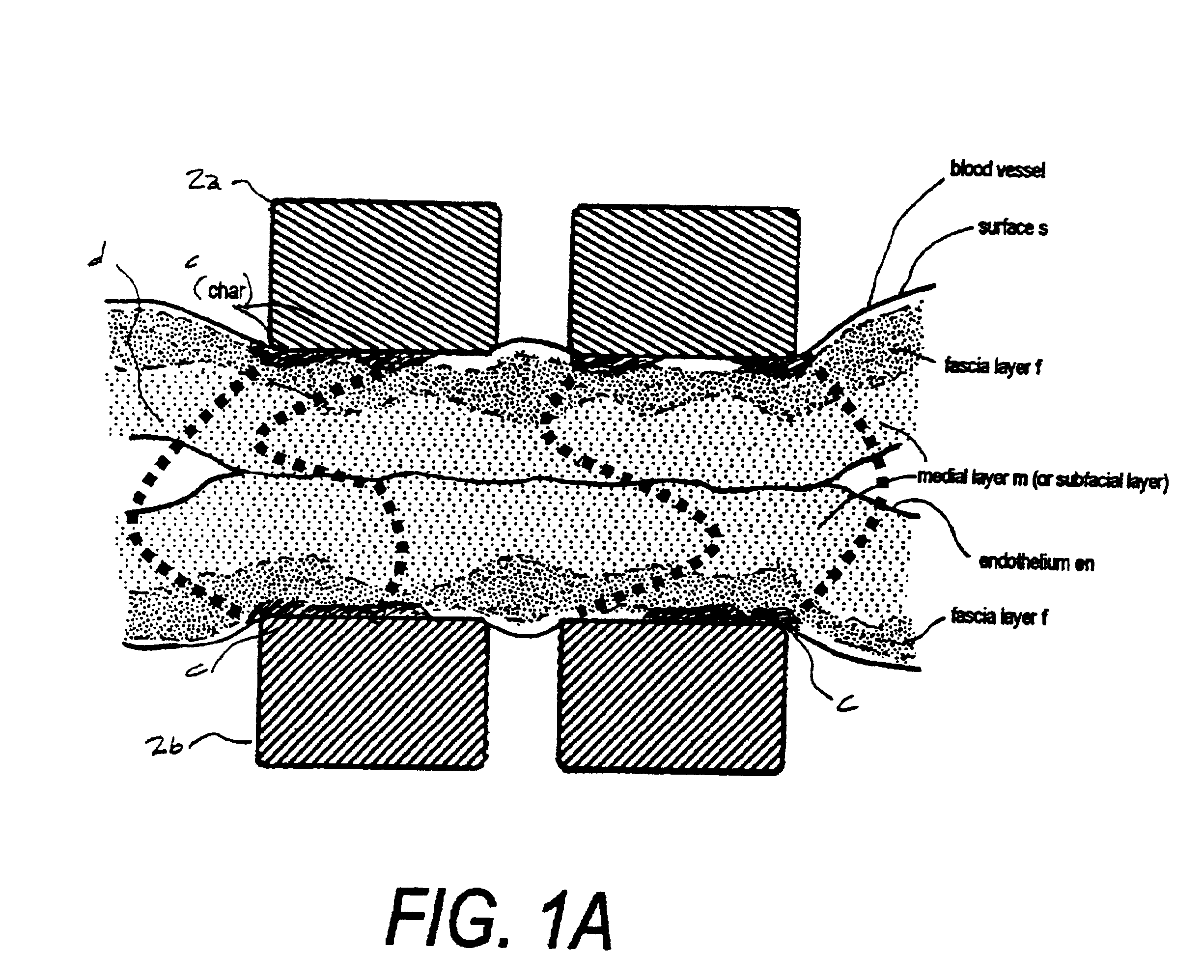

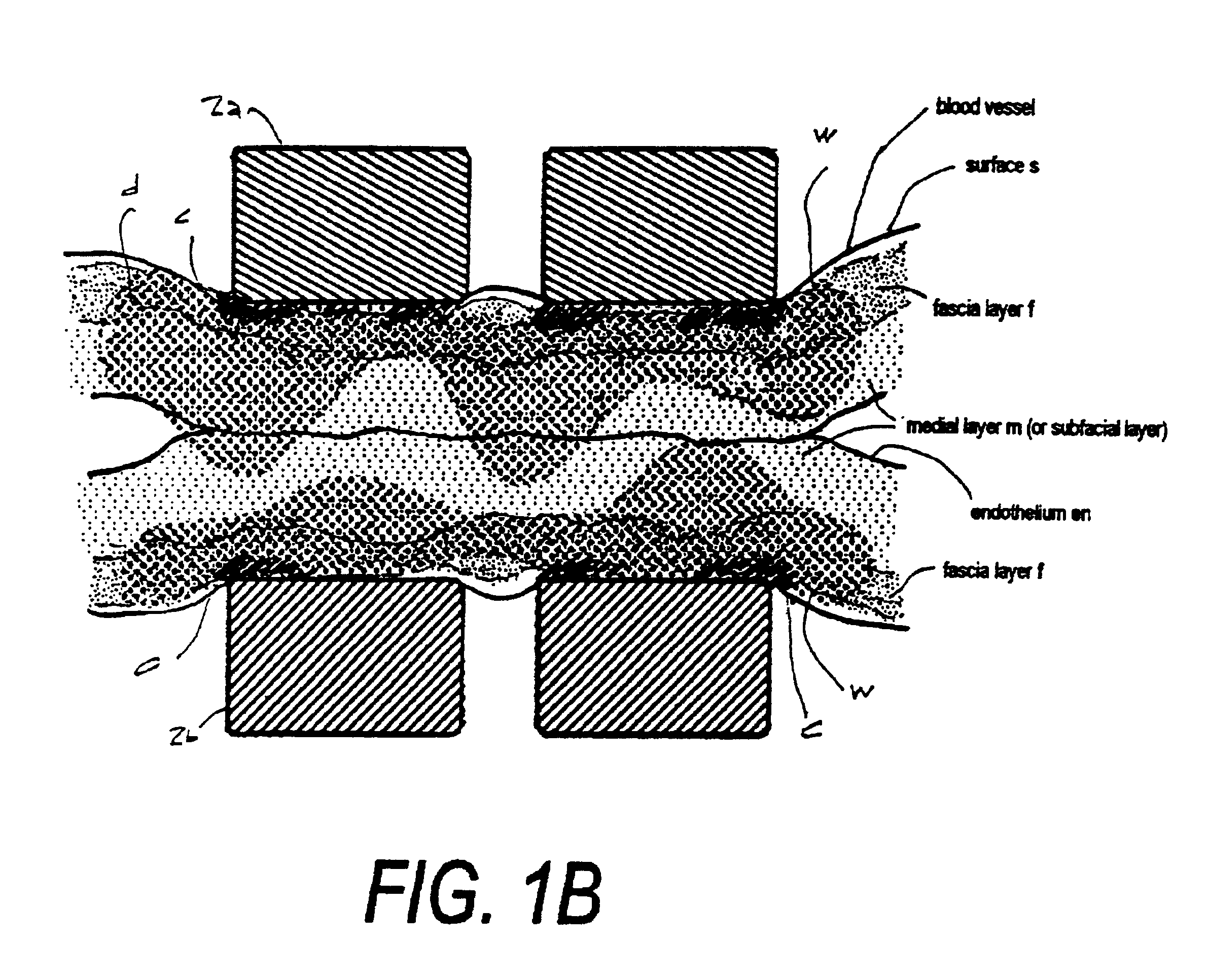

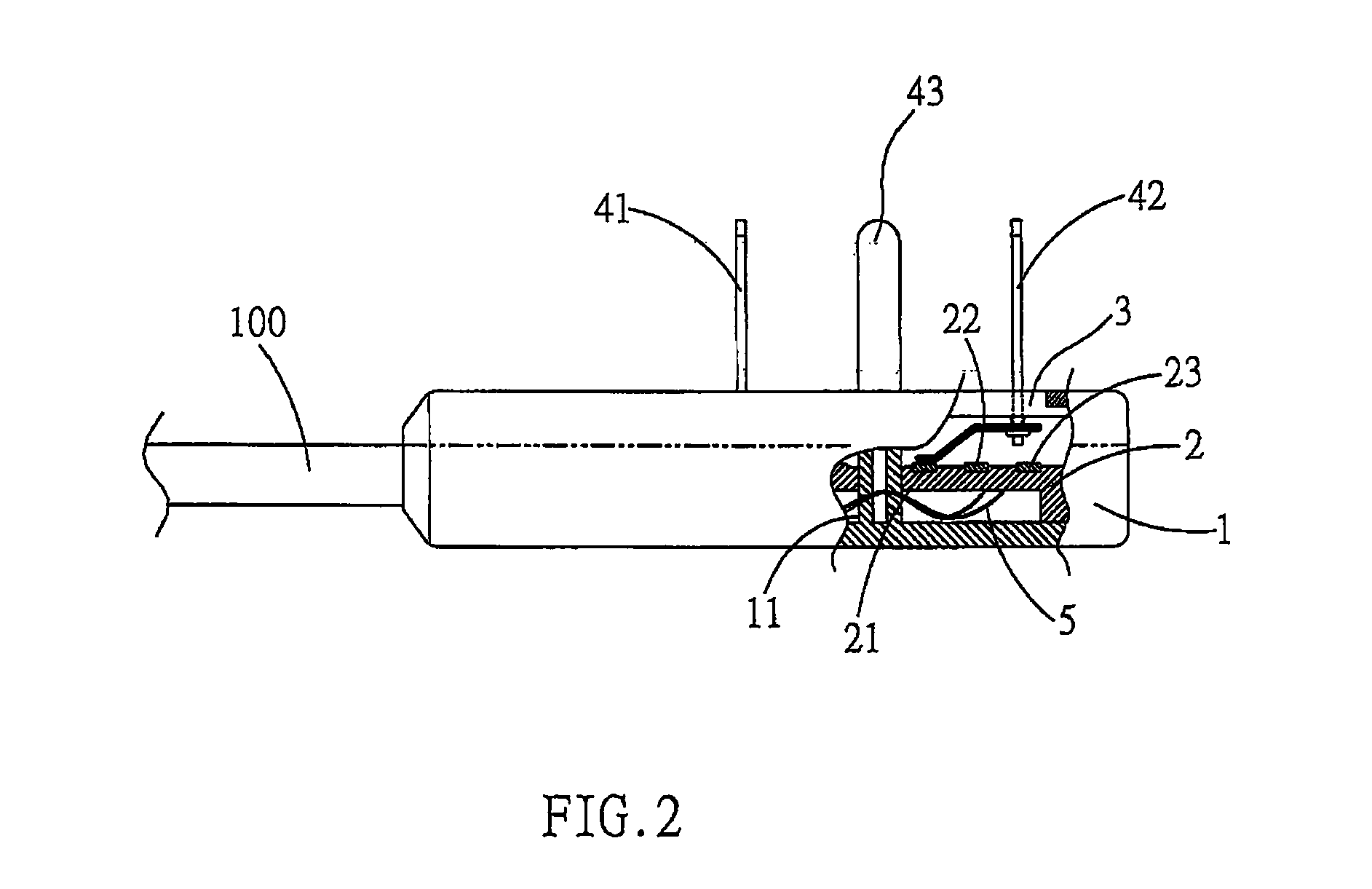

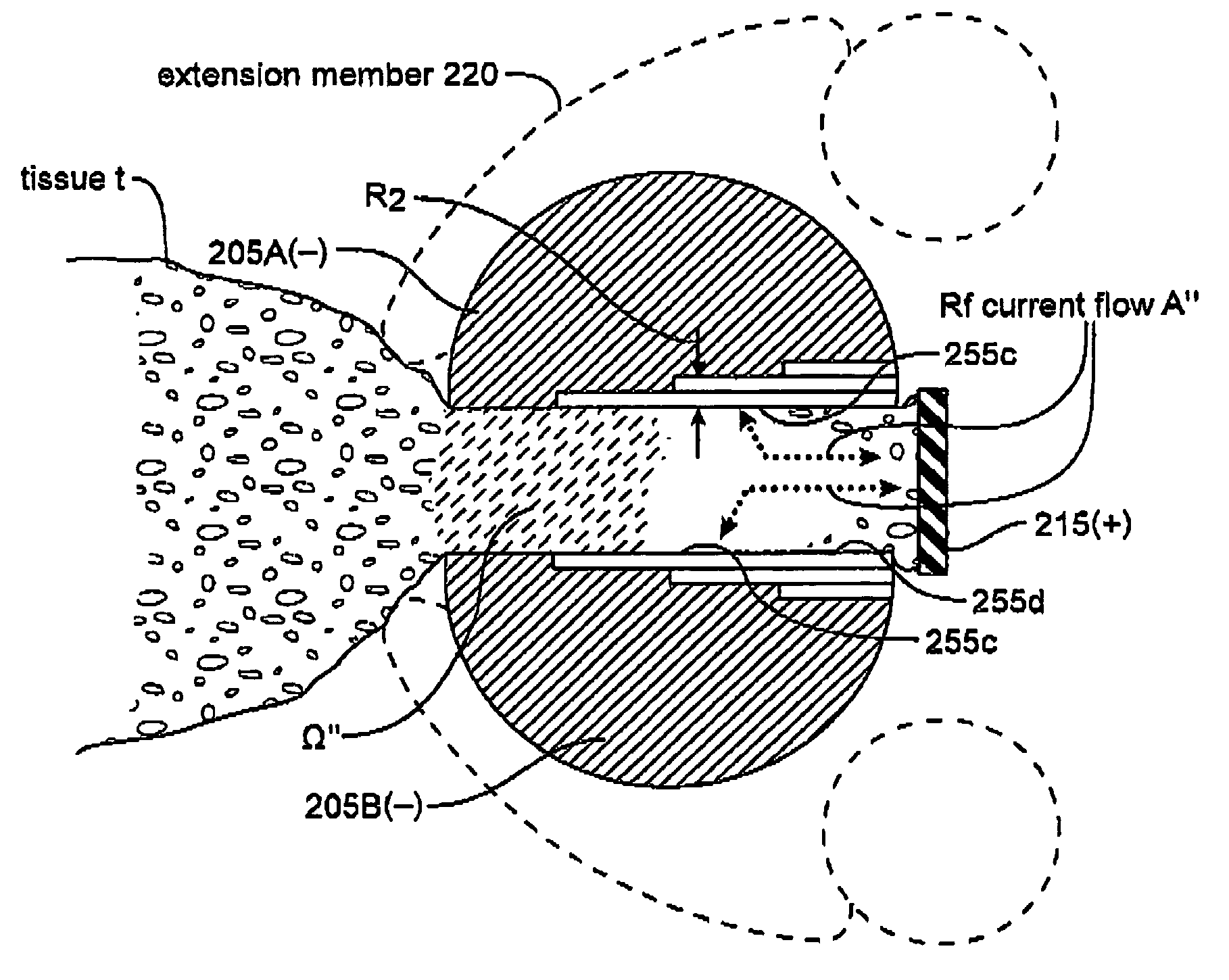

Electrosurgical instrument and method of use

InactiveUS20050267464A1Efficient weldingSpeed up the flowSurgical instruments for heatingSurgical forcepsElectrical resistance and conductanceEngineering

An embodiment of a method of the invention provides a method for welding tissue comprising providing a tissue welding device having first and second tissue engaging surfaces with at least one surface including an electrode surface that defines a plurality of surface portions having different resistances to electrical current flow therethrough. A target tissue volume is engaged with the tissue engaging surfaces. Rf energy is delivered to the target volume to create a substantially even temperature distribution across at least a portion of the target tissue volume to substantially uniformly weld at least a portion of the target tissue volume.

Owner:SURGRX

Method for analyzing a fluid sample

InactiveUS6881541B2Small pore sizePrevent cloggingBioreactor/fermenter combinationsHeating or cooling apparatusBiologyReaction chamber

A method for extracting nucleic acid from a fluid sample comprises the steps of introducing the sample into a cartridge having a sample flow path and a lysing chamber in the sample flow path. The lysing chamber contains at least one filter for separating cells or viruses from the sample. The sample is forced to flow through the lysing chamber to capture the cells or viruses with the filter, while used sample fluid flows to waste. The captured cells or viruses are disrupted to release their nucleic acid, the nucleic acid is eluted from the lysing chamber, and optionally the nucleic acid is amplified and detected in a reaction chamber of the cartridge.

Owner:CEPHEID INC

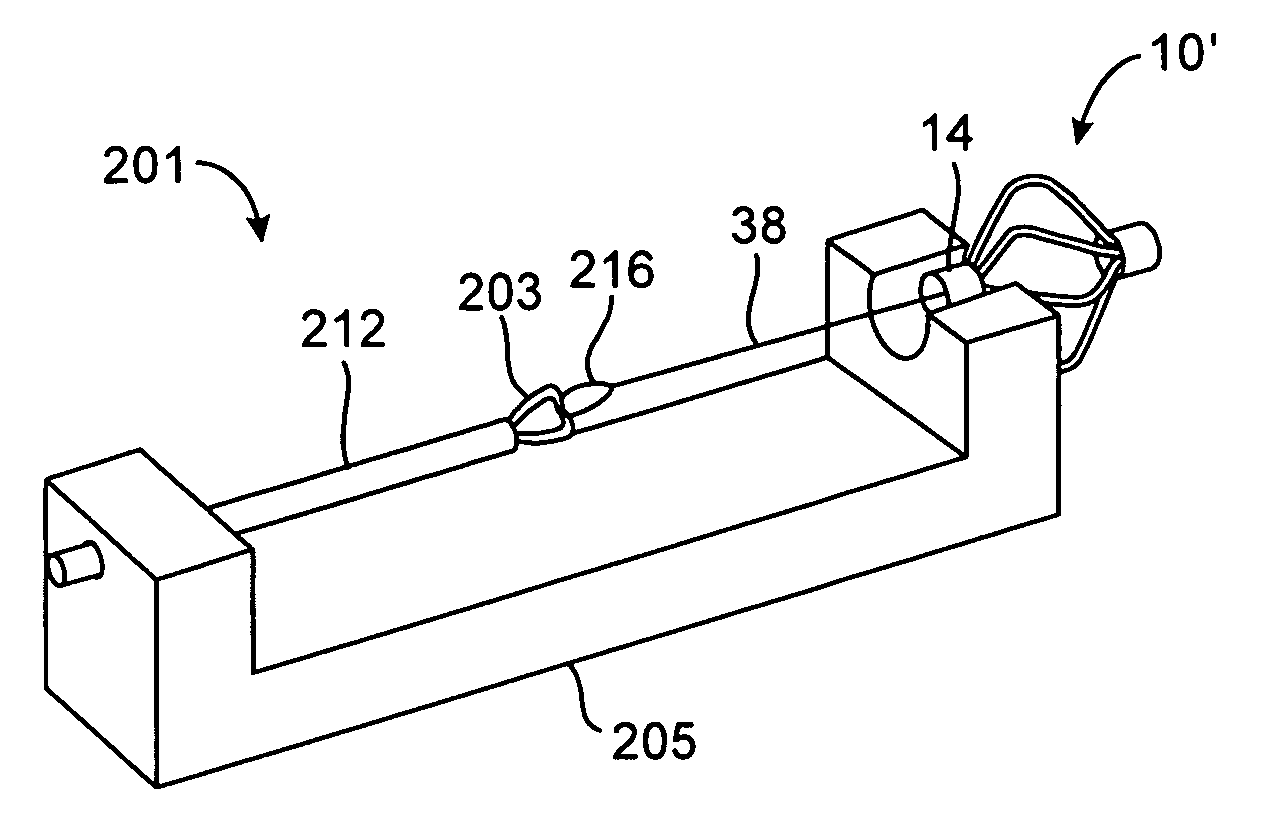

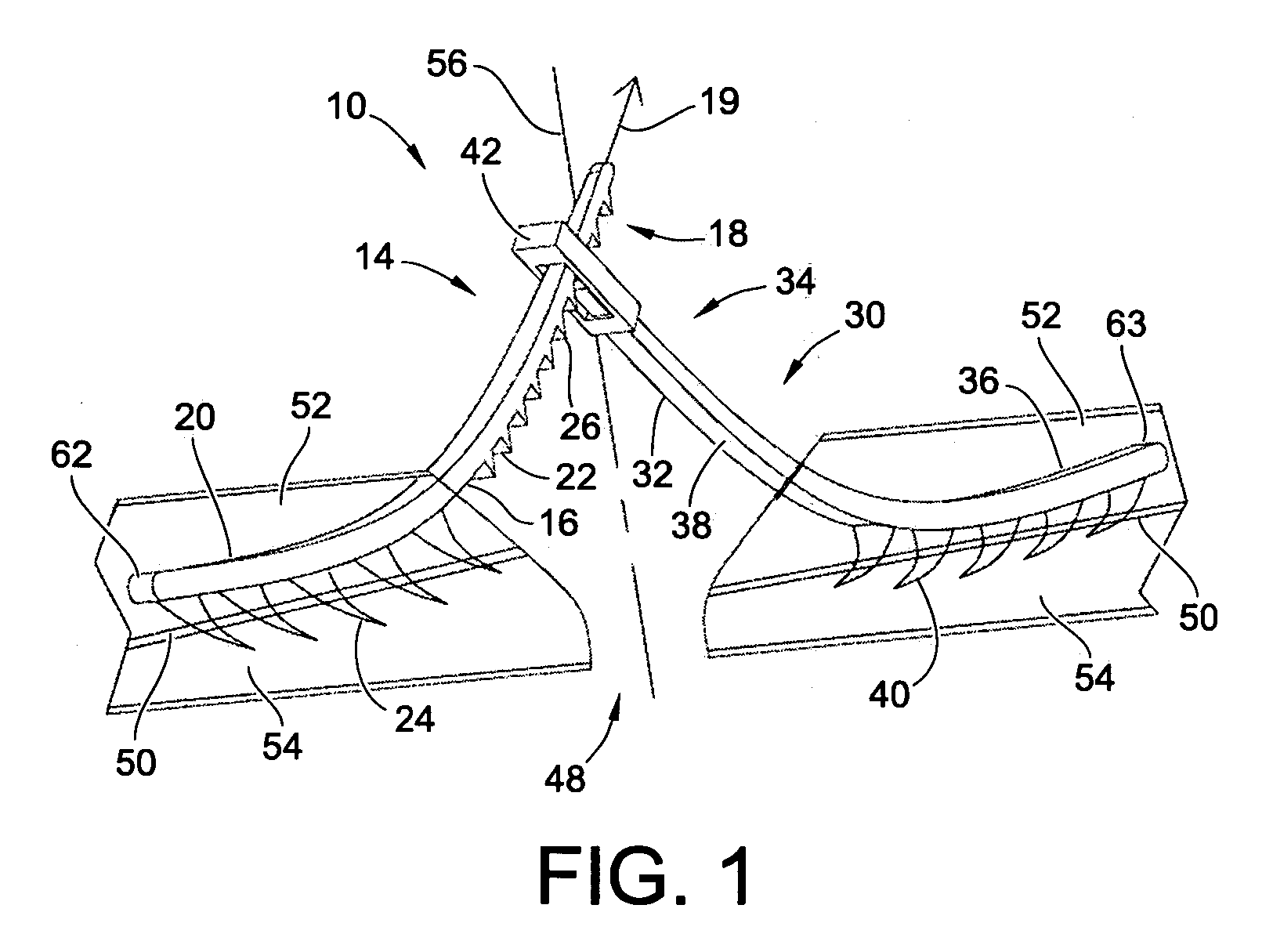

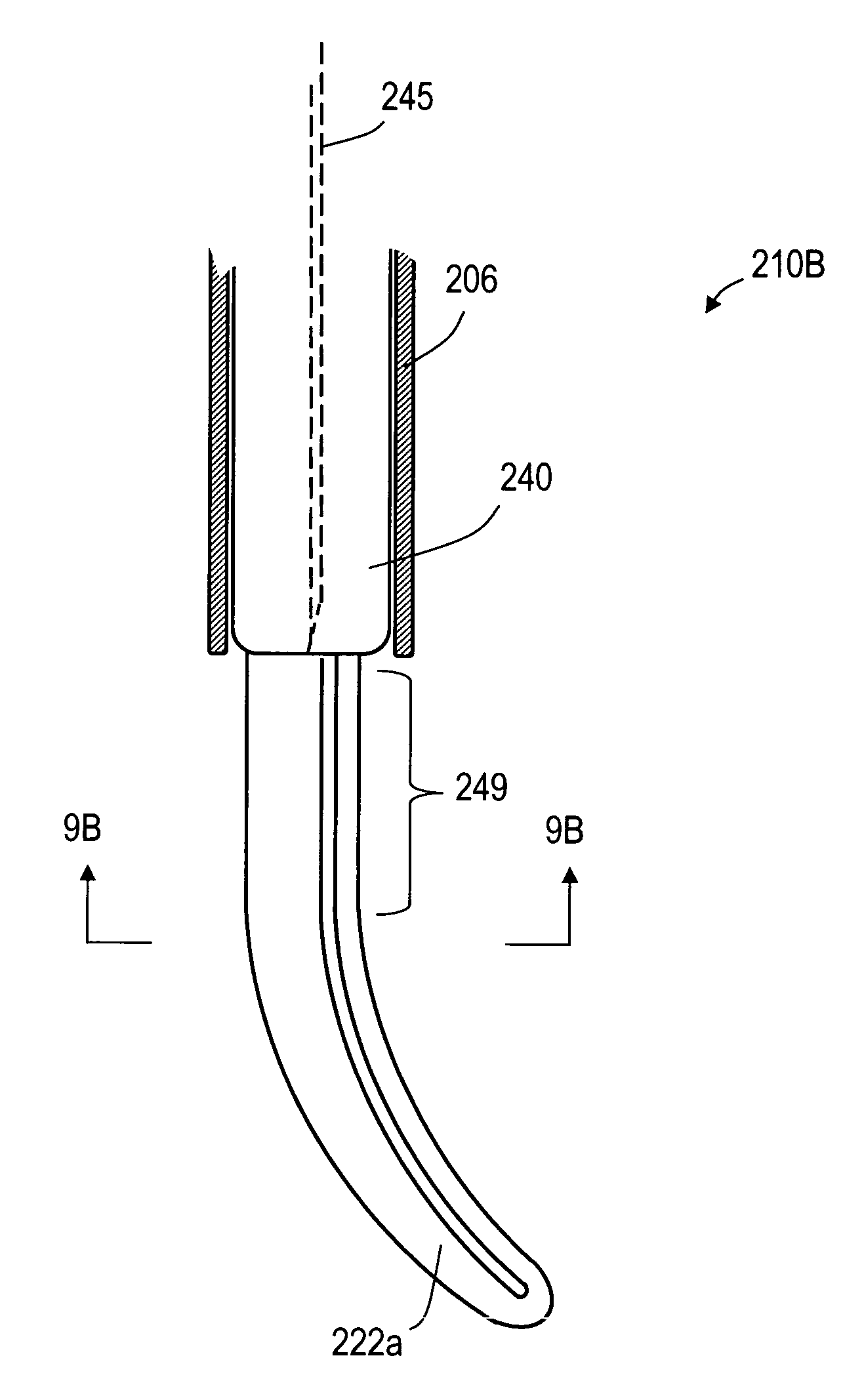

Electrosurgical instrument and method

ActiveUS8075558B2Speed up the flowHeating evenlySurgical scissorsSurgical instruments for heatingElectrical resistance and conductanceHigh intensity

An electrosurgical working end and method for sealing and transecting tissue. An exemplary working end provides curved jaw members that are positioned on opposing sides of the targeted anatomic structure. The working end carries a slidable extension member having flange portions with inner surfaces that slide over the jaw members to clamp tissue therebetween. The working end carries an independent slidable cutting member that is flexible to follow the curved axis of the jaws. The electrosurgical surfaces of the jaws include partially-resistive bodies for carrying a current or load which modulates ohmic heating in the engaged tissue to prevent charring and desiccation of tissue to create a high strength thermal seal.

Owner:ETHICON ENDO SURGERY INC

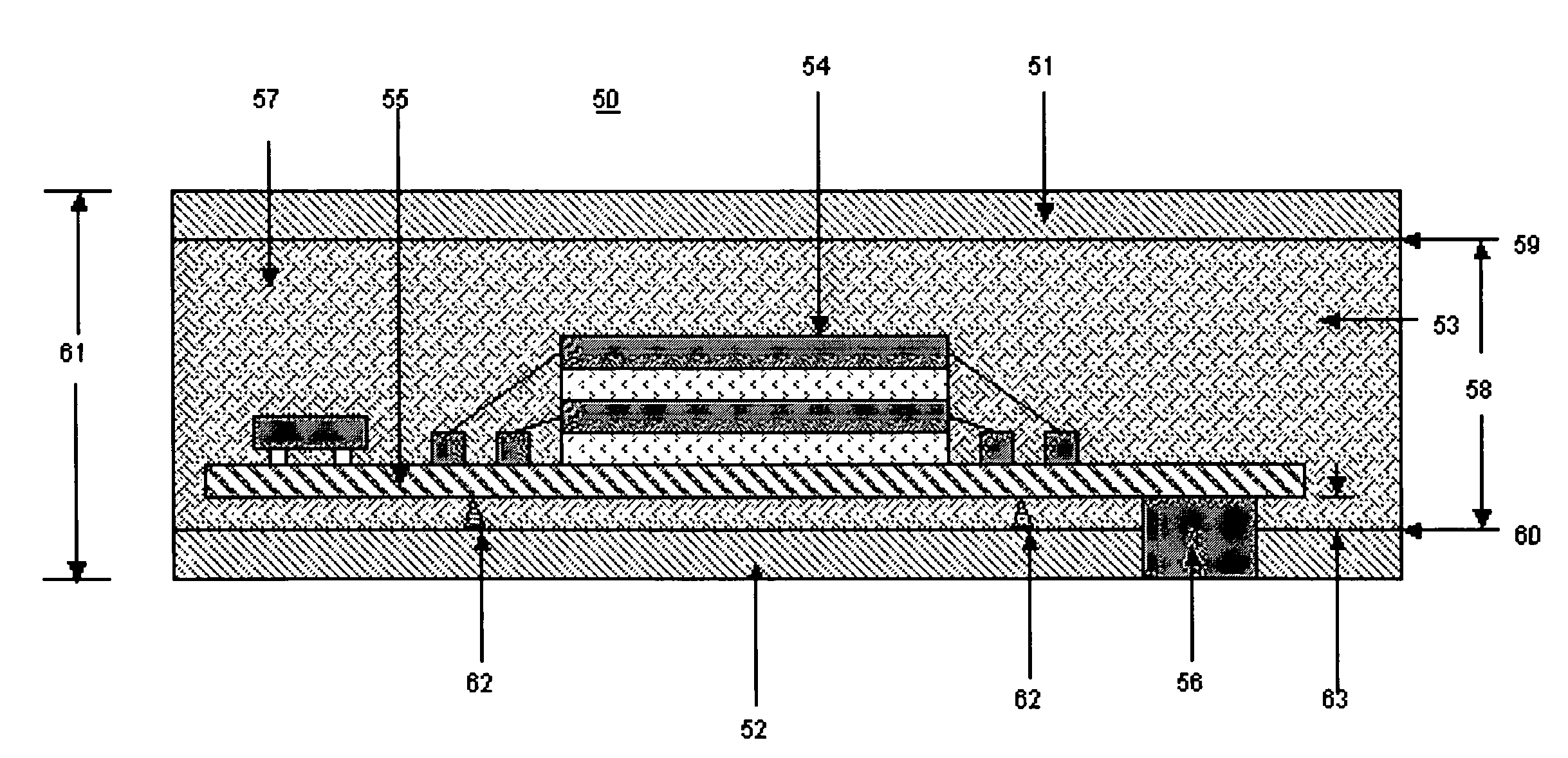

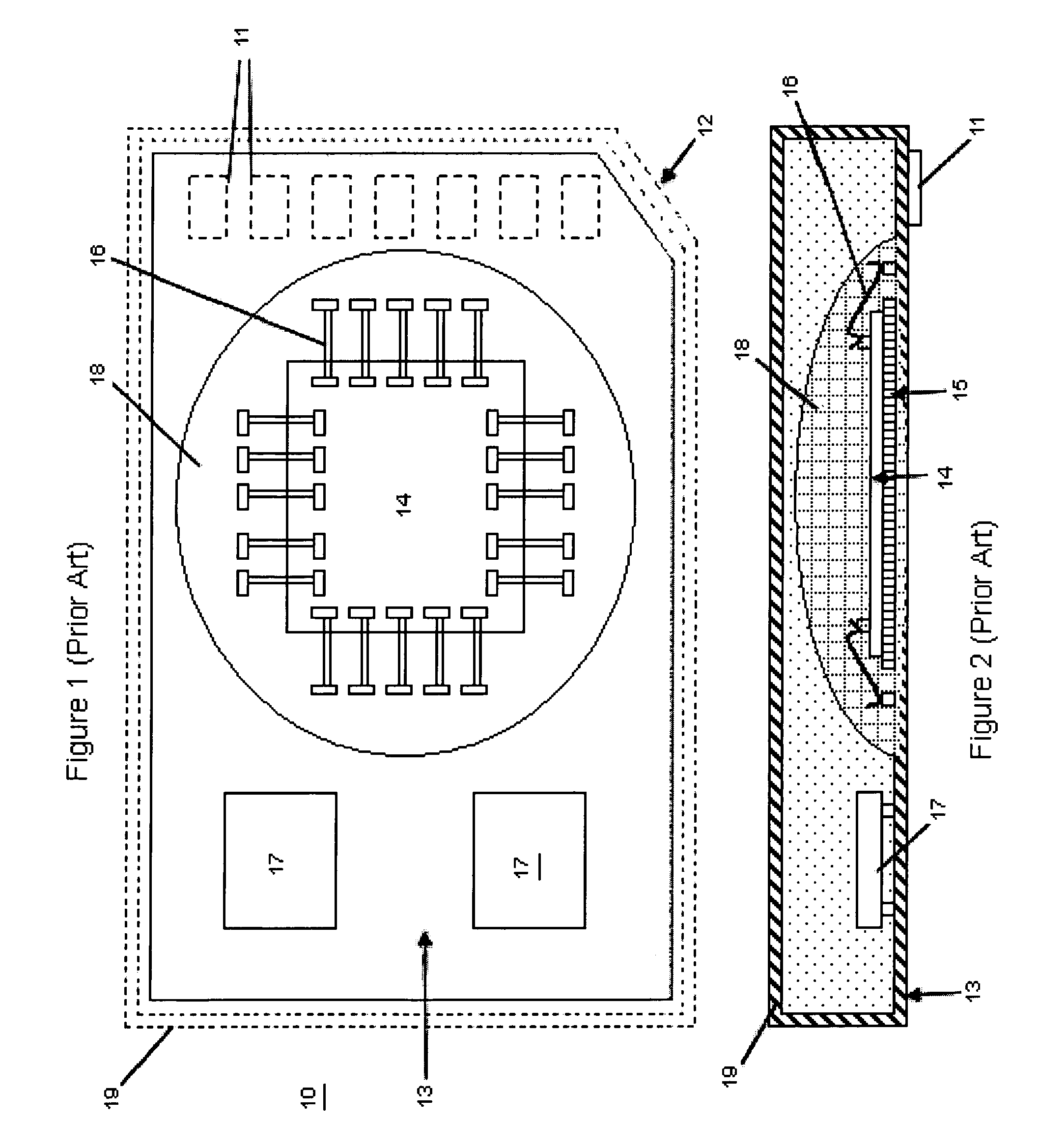

Method for making memory cards and similar devices using isotropic thermoset materials with high quality exterior surfaces

InactiveUS7225537B2Shorten the timeQuality improvementPrinted circuit assemblingLine/current collector detailsEngineeringInjection moulding

Memory Cards containing Integrated Circuits and other electronic components (e.g. resistors) in a variety of form factors having high quality external surfaces of polycarbonate, synthetic paper (e.g. Teslin), or other suitable material (e.g. PVC) can be made through use of injection molded thermoplastic material or thermosetting material that becomes the core layer of said Memory Cards and similar devices. The object of the invention is to provide the following properties to Memory Cards: rapid production cycle, high volume manufacturing throughput, security, electronics protection, better tamper resistance, durability, and highly reliable complex electronics encapsulation, achieved through a process utilizing low temperature and low pressure.

Owner:CARDXX

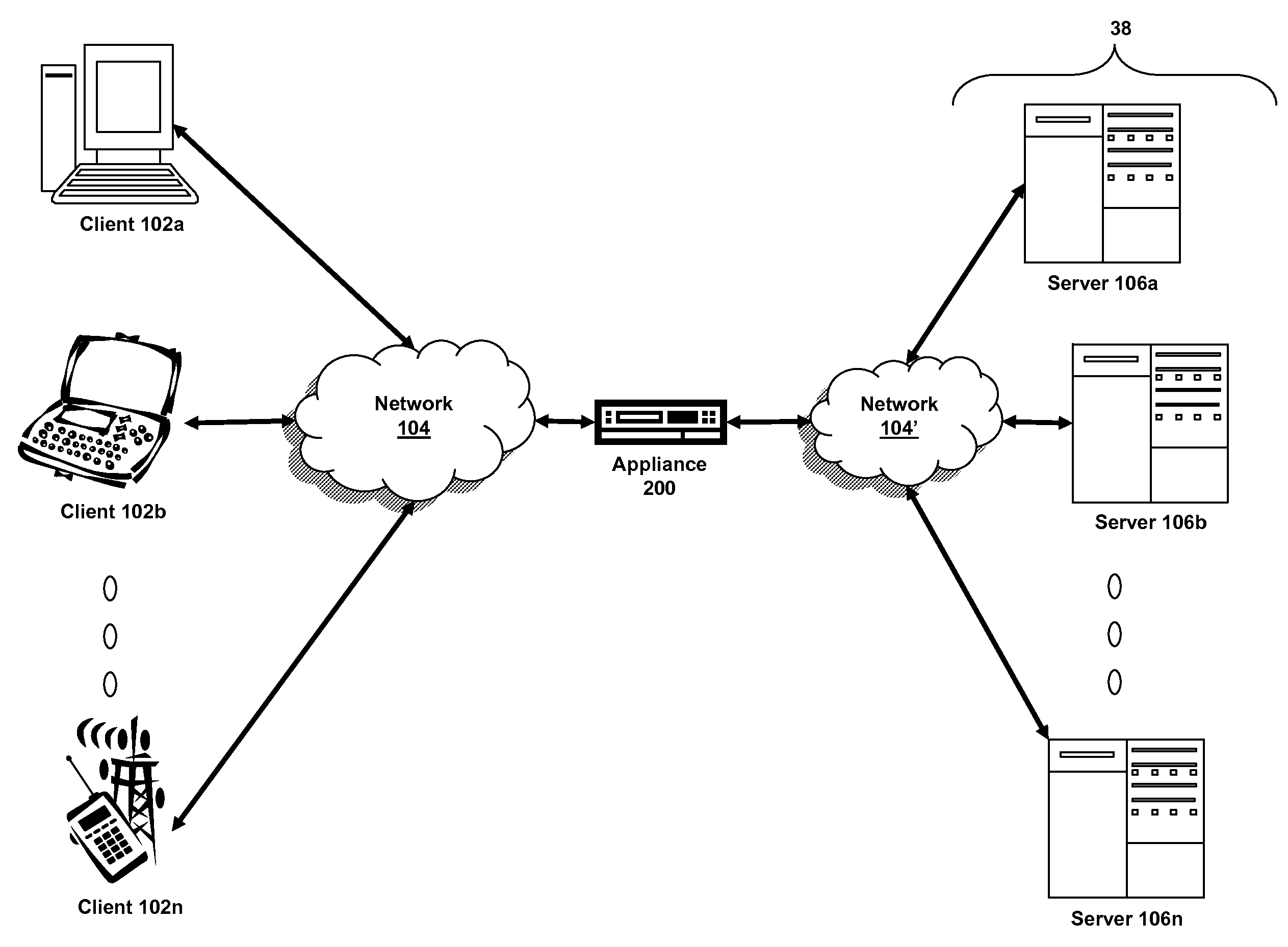

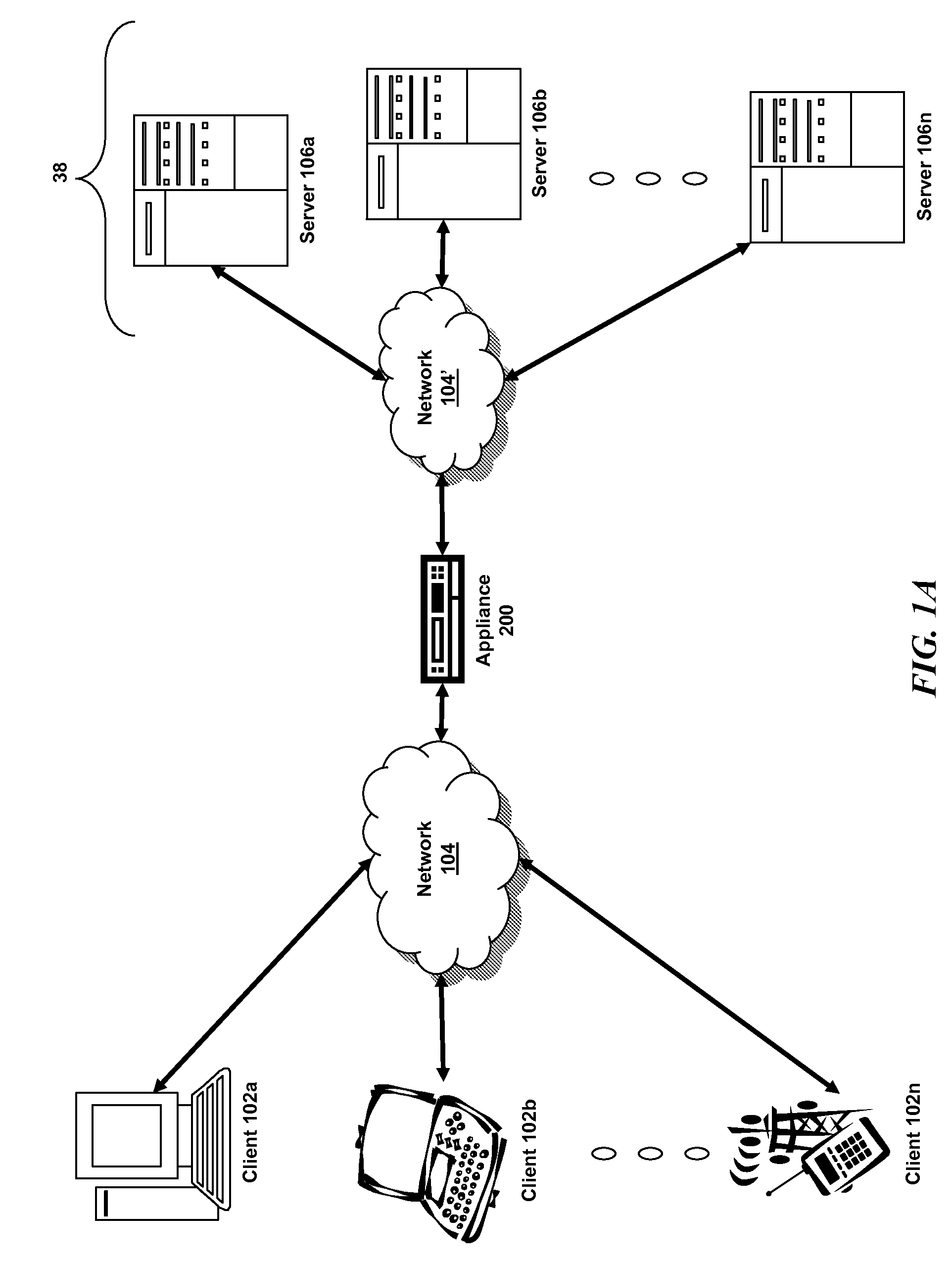

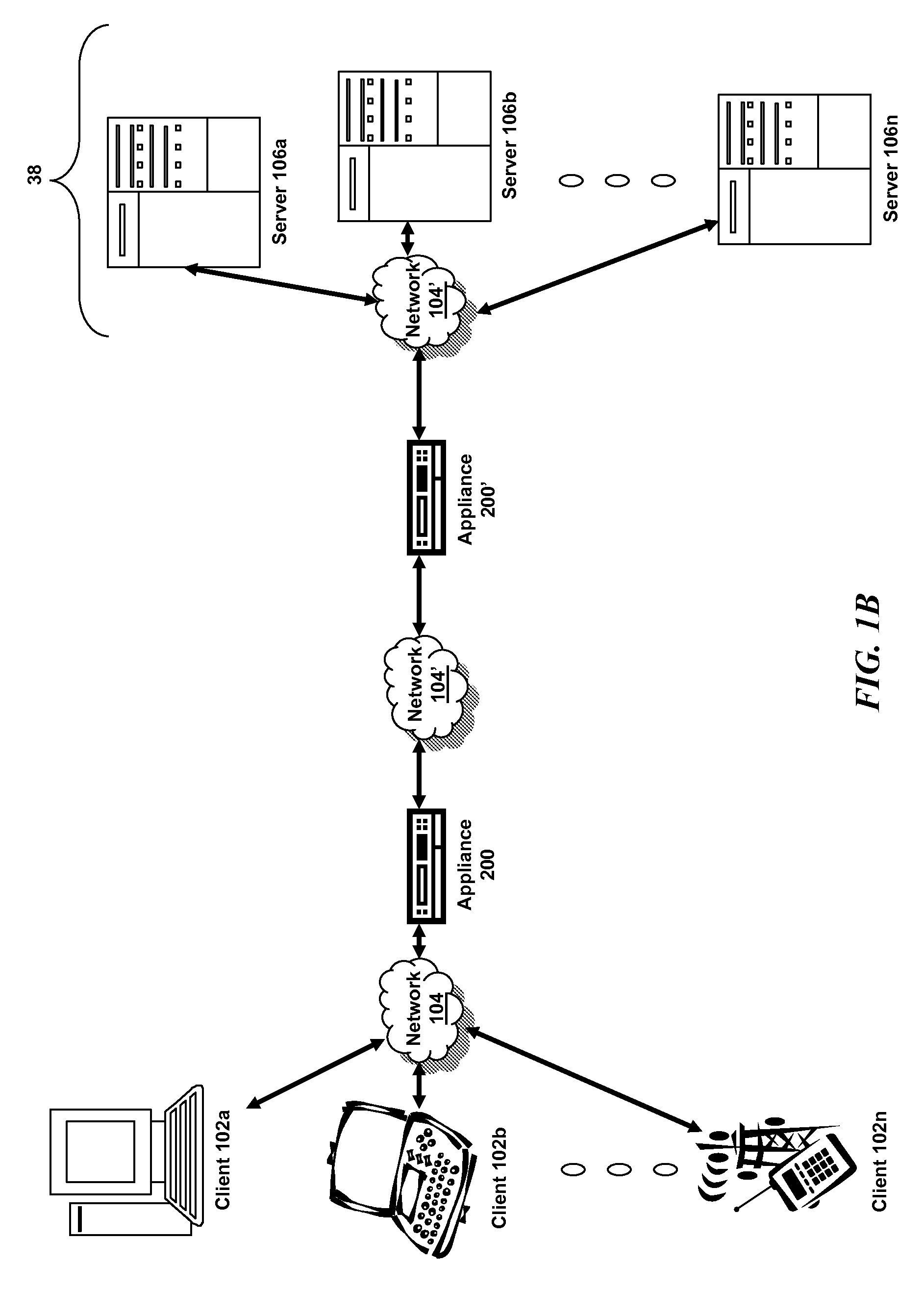

Systems and methods for packet steering in a multi-core architecture

InactiveUS20100284404A1Reduces unnecessary copying and cachingSpeed up the flowData switching by path configurationProgram controlNetwork packetIp address

Described herein is a method and system for distributing whole and fragmented requests and responses across a multi-core system. Each core executes a packet engine that further processes data packets and data packet fragments allocated to that core. A flow distributor executing within the multi-core system forwards client requests to a packet engine on a core that is selected based on a value generated when a hash is applied to a tuple comprising a client IP address, a client port, a server IP address and a server port identified in the request. The packet engine maintains each element of the tuple and forwards the request to the selected core. The packet engine can also process data packet fragments by assembling the fragments prior to transmitting them to the selected core, or by transmitting the data packet fragments to the selected core.

Owner:CITRIX SYST INC

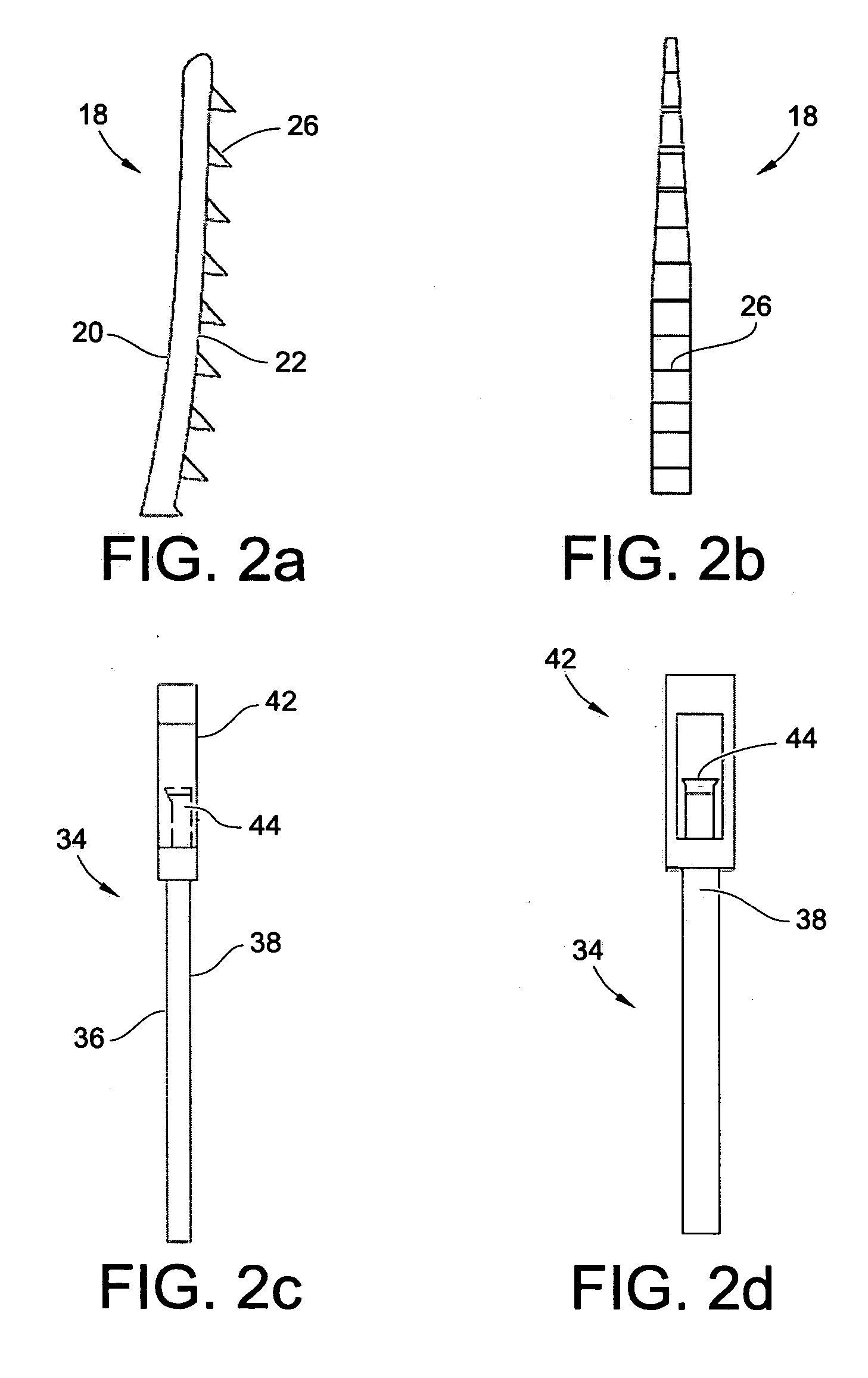

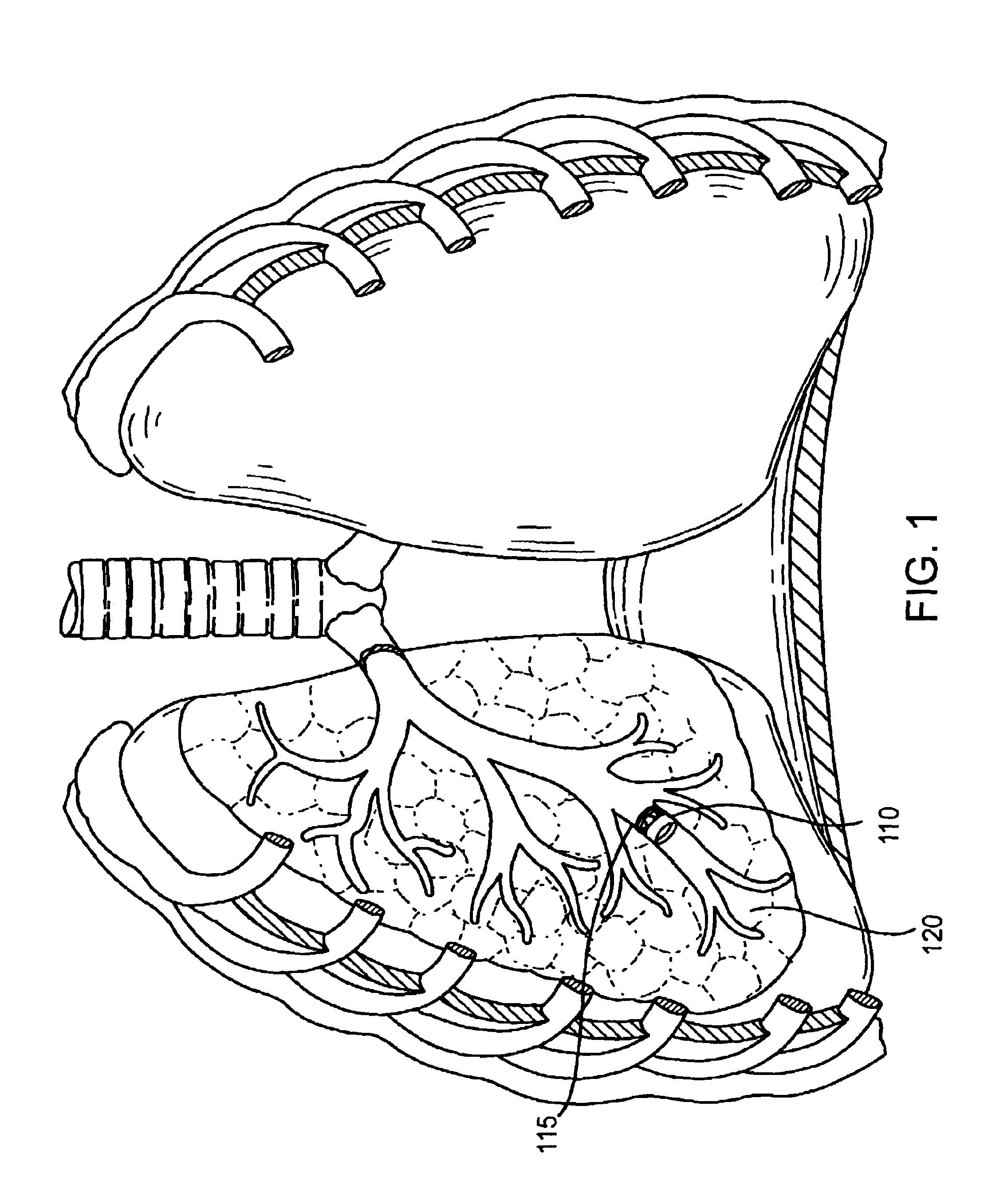

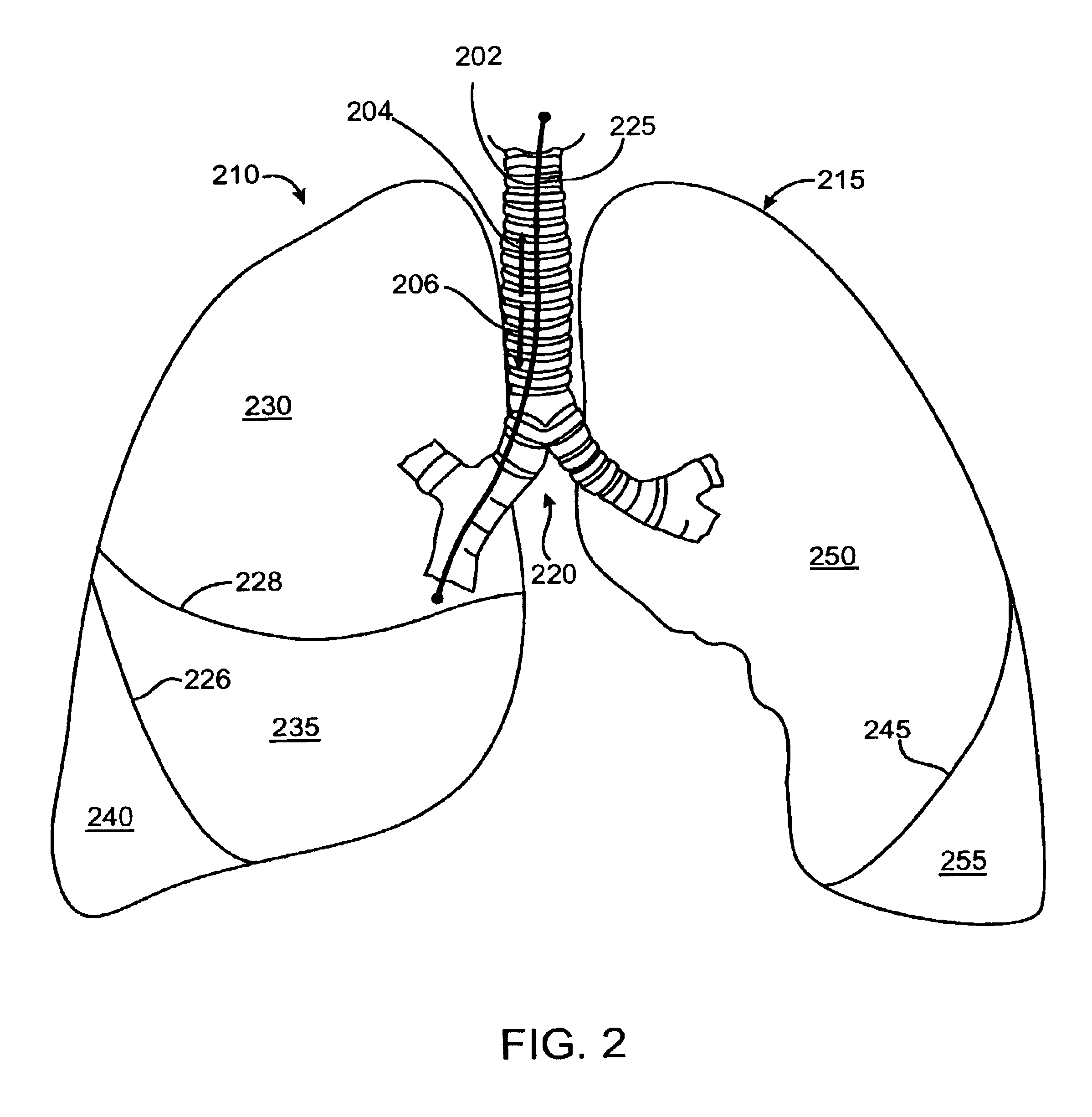

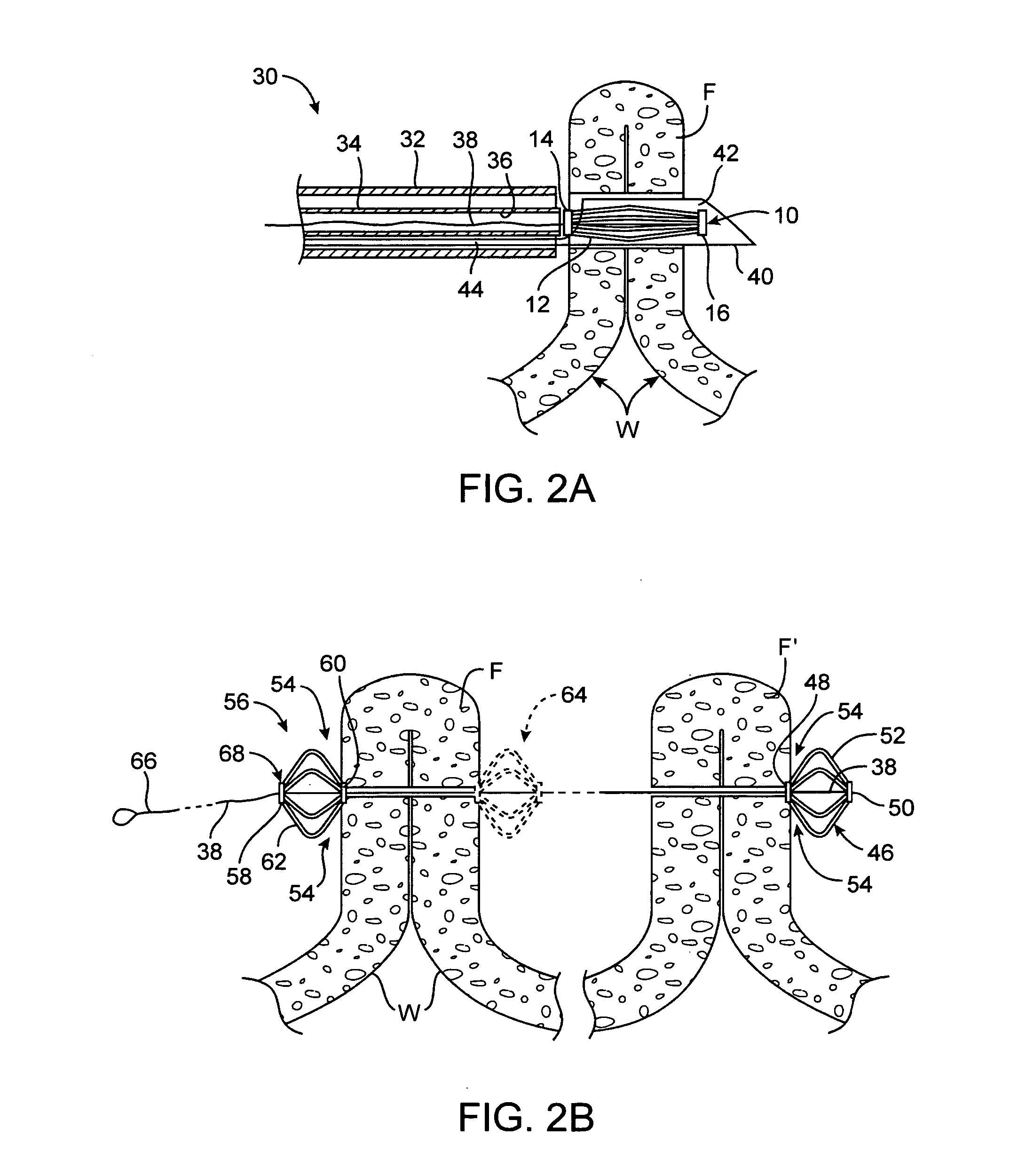

Bronchial flow control devices and methods of use

InactiveUS6941950B2Improved air flow dynamicSpeed up the flowBronchiEar treatmentRadiologyLung region

Disclosed are methods and devices for regulating fluid flow to and from a region of a patient's lung, such as to achieve a desired fluid flow dynamic to a lung region during respiration and / or to induce collapse in one or more lung regions. An identified region of the lung is targeted for treatment, such as to modify the flow to the targeted lung region or to achieve volume reduction or collapse of the targeted lung region. The targeted lung region is then bronchially isolated to regulate airflow into and / or out of the targeted lung region through one or more bronchial passageways that feed air to the targeted lung region. The bronchial isolation of the targeted lung region is accomplished by implanting a flow control device into a bronchial passageway that feeds air to a targeted lung region.

Owner:PULMONX

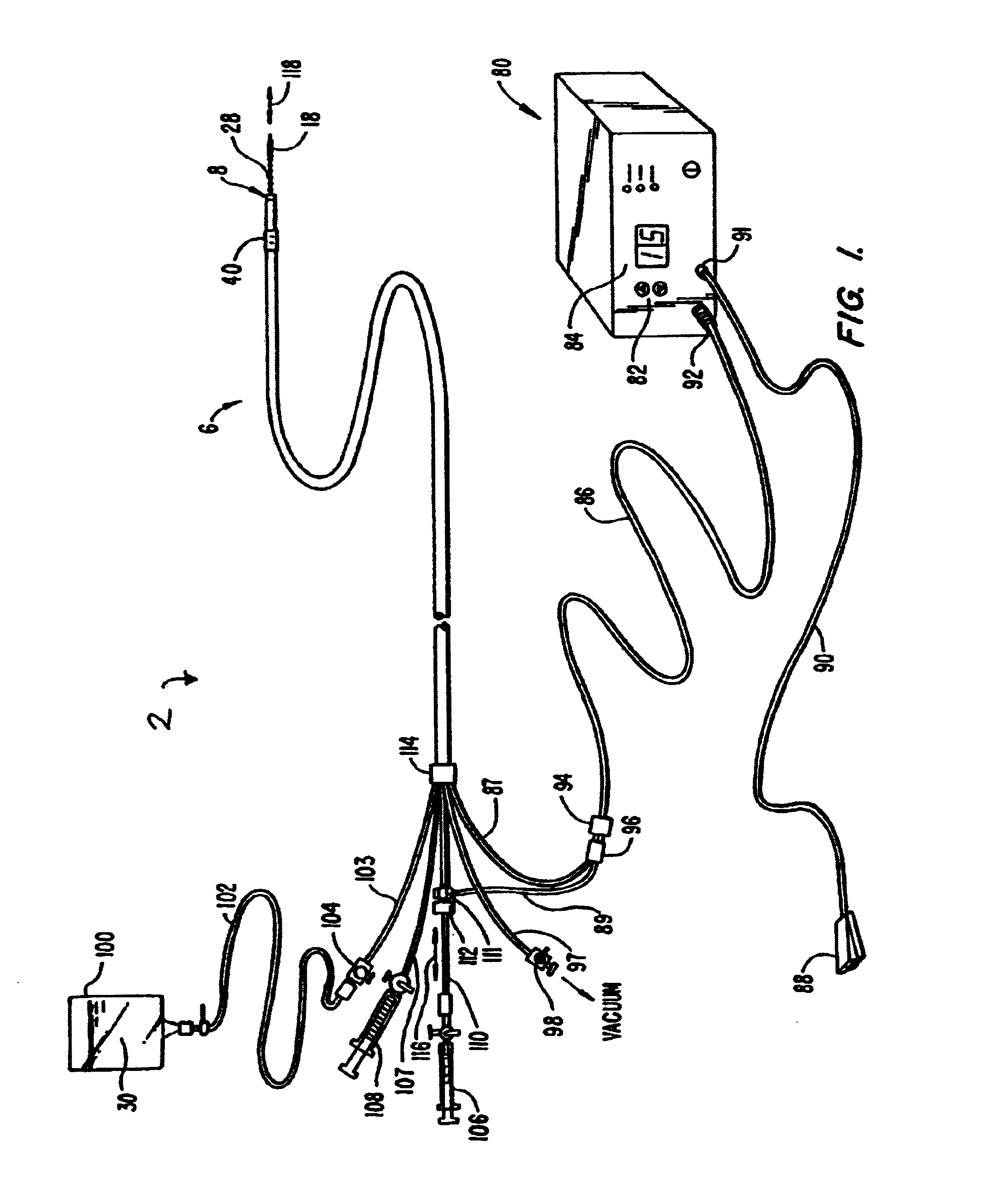

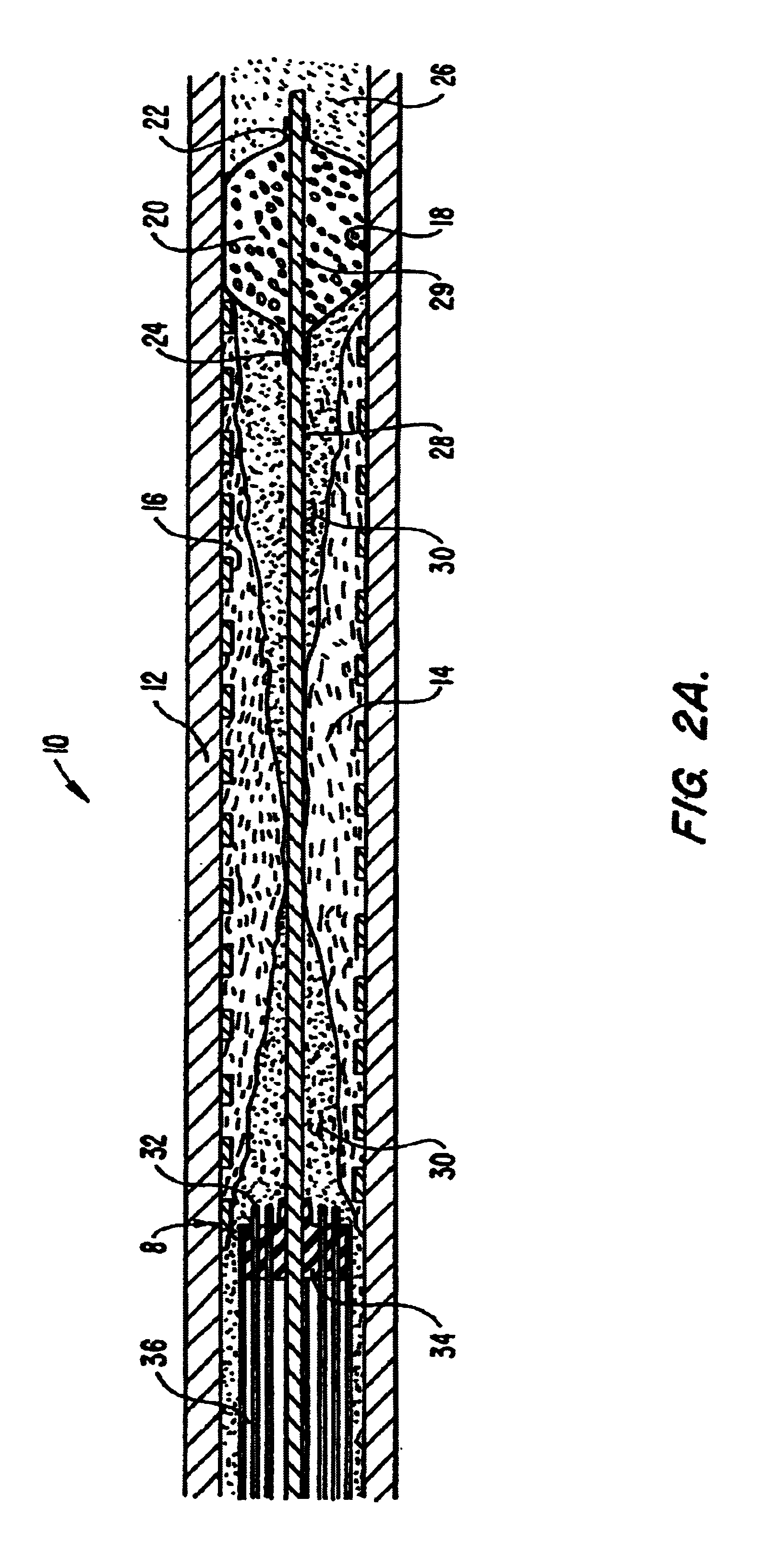

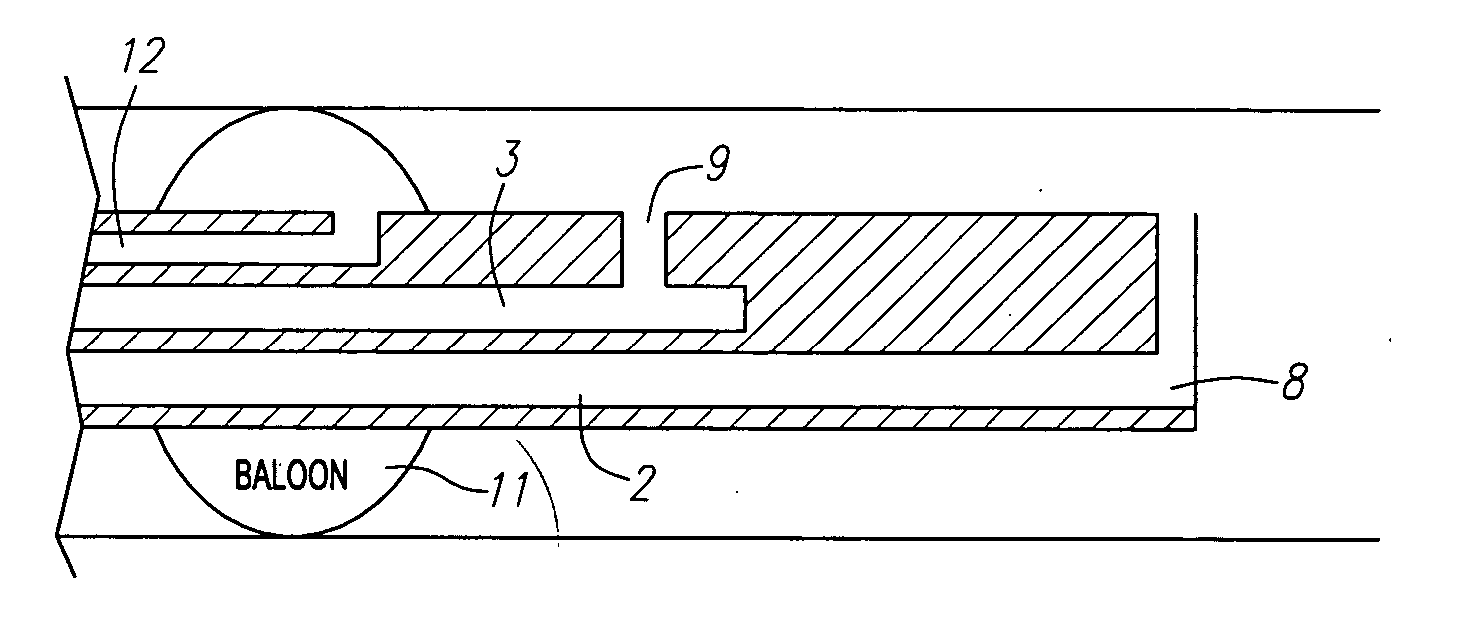

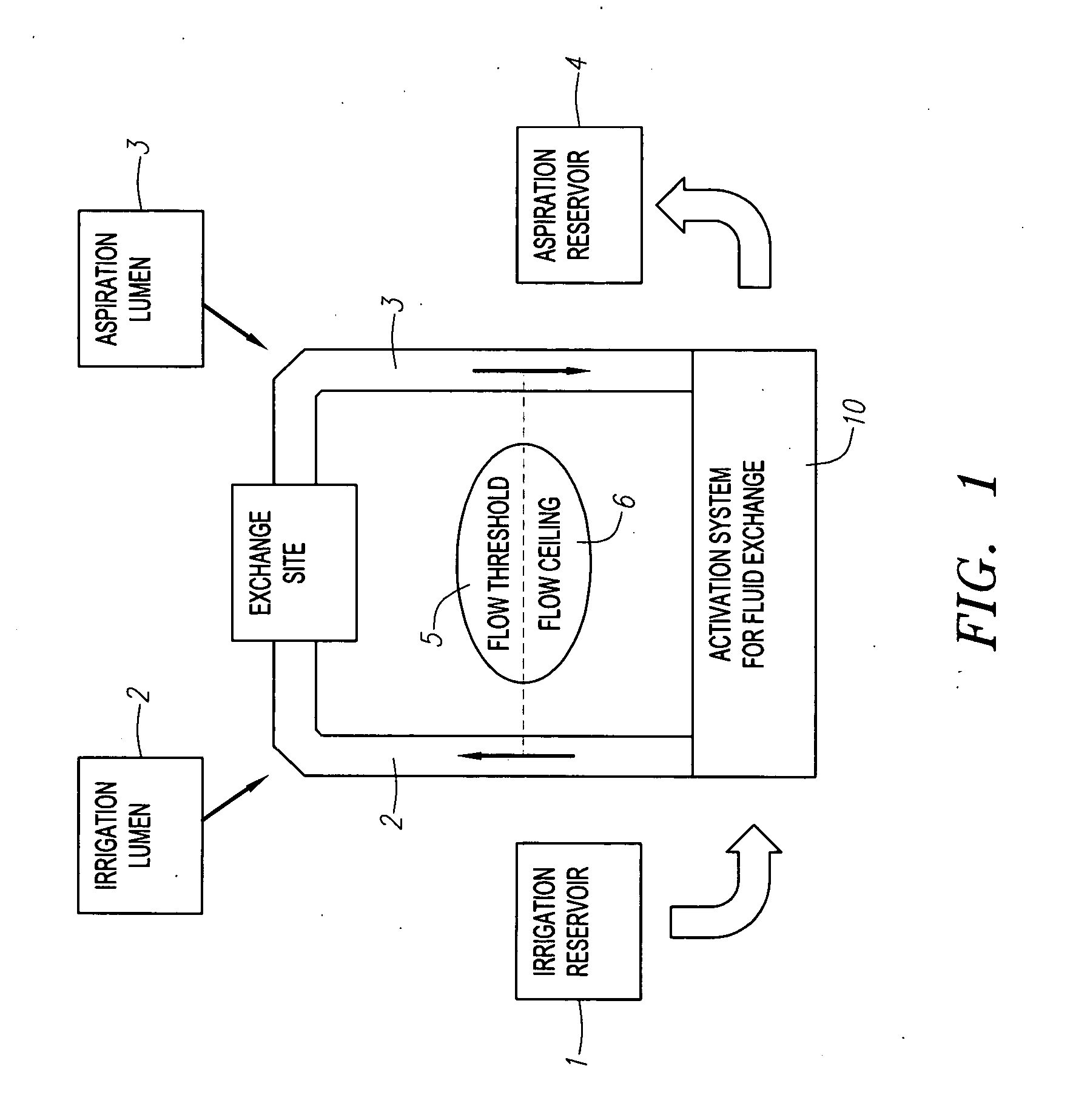

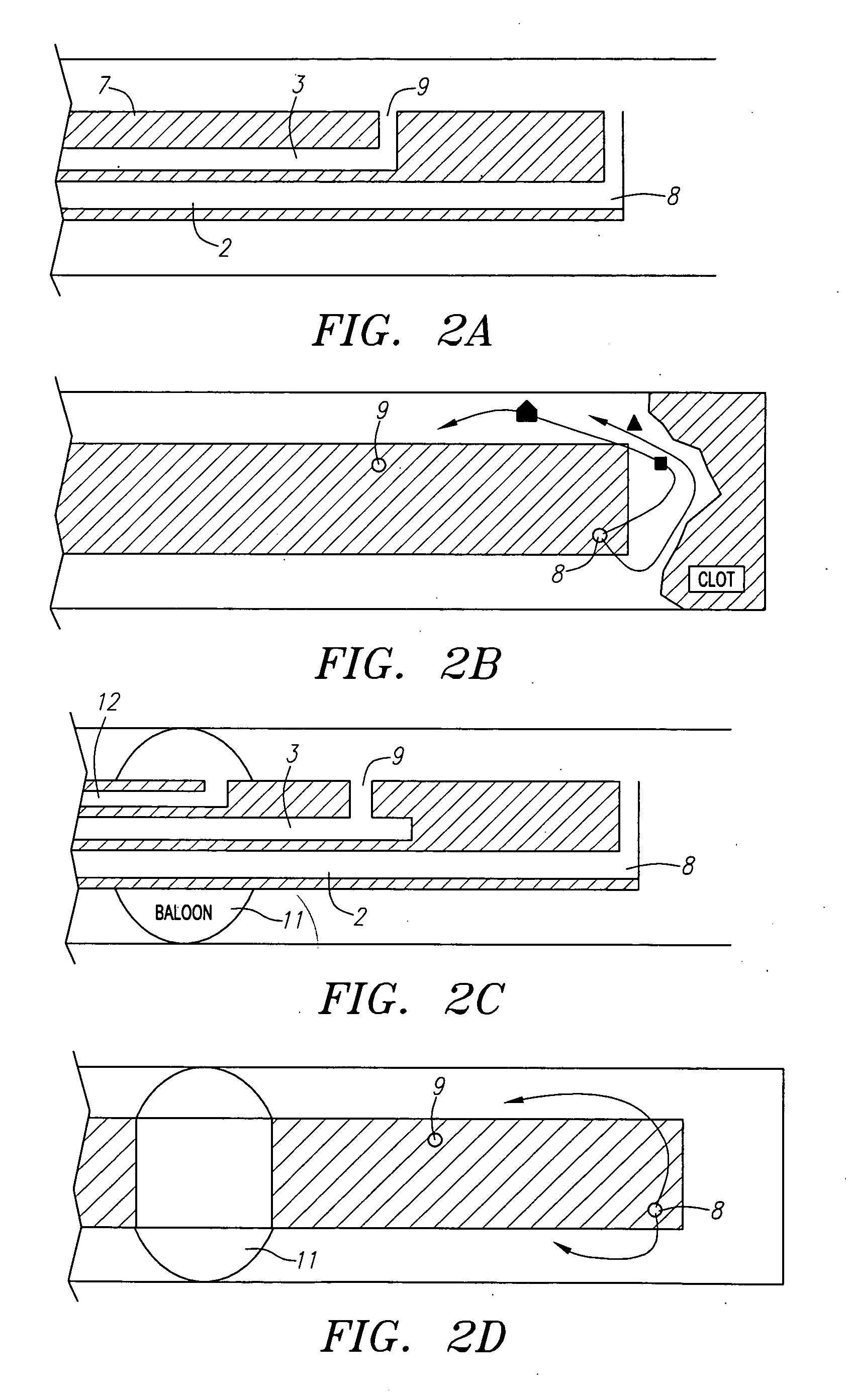

Fluid exchange system for controlled and localized irrigation and aspiration

InactiveUS20050085769A1Improved exchangeSpeed up the flowInfusion syringesSurgeryElectricityFluid management

The control of fluid introduction into and out of body conduits such as vessels, is of great concern in medicine. As the development of more particular treatments to vessels and organs continues it is apparent that controlled introduction and removal of fluids is necessary. Fluid delivery and removal from such sites, usually referred to as irrigation and aspiration, using fluid exchange devices that control also need to be considerate of potential volume and / or pressure in the vessel or organ are described together with catheter and lumen configurations to achieve the fluid exchange. The devices include several electrically or mechanically controlled embodiments and produce both controlled and localized flow with defined volume exchange ratios for fluid management. The applications in medicine include diagnostic, therapeutic, imaging, and uses for the introduction or removal of concentrations of emboli within body cavities.

Owner:FOX HOLLOW TECH

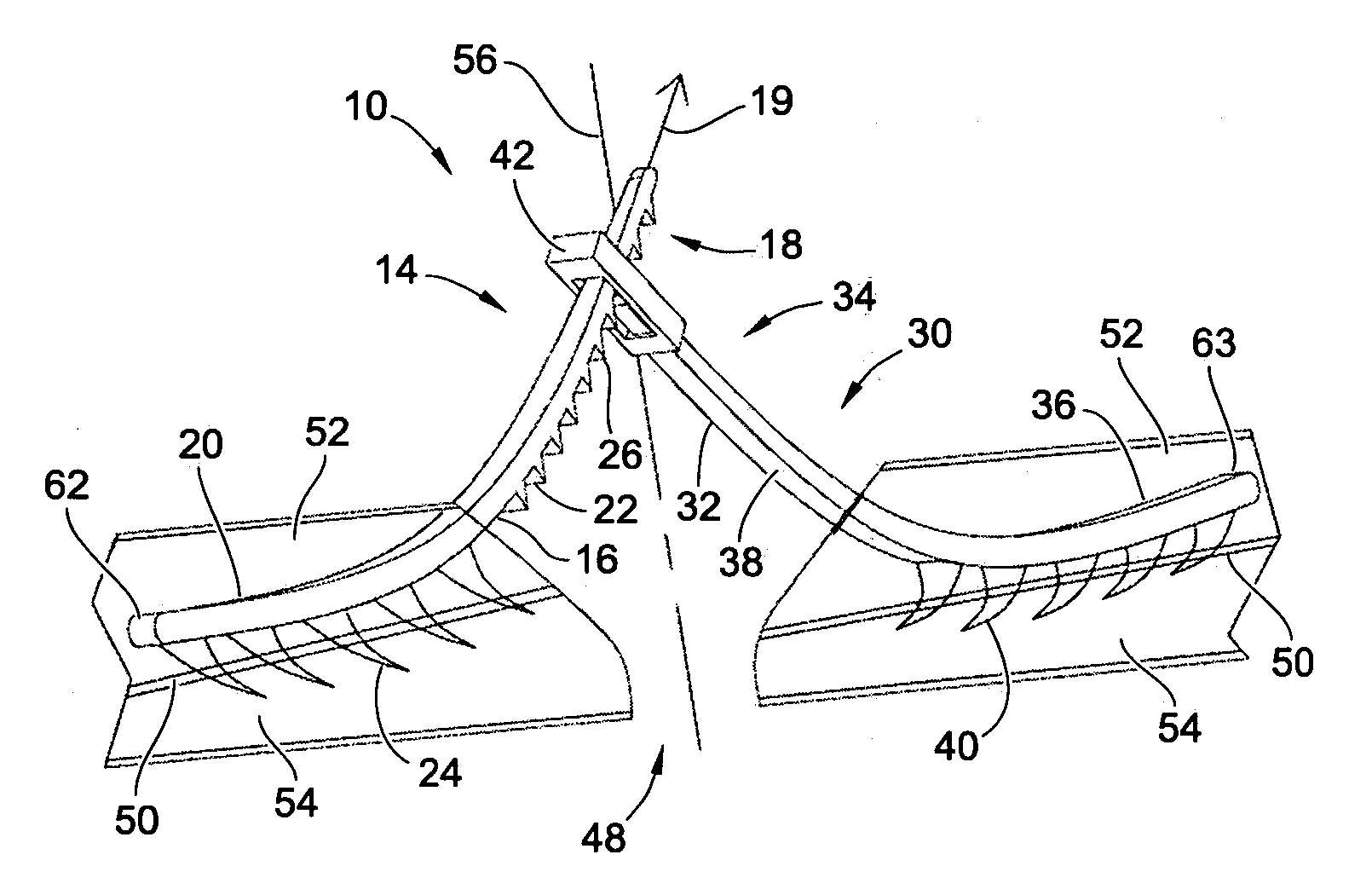

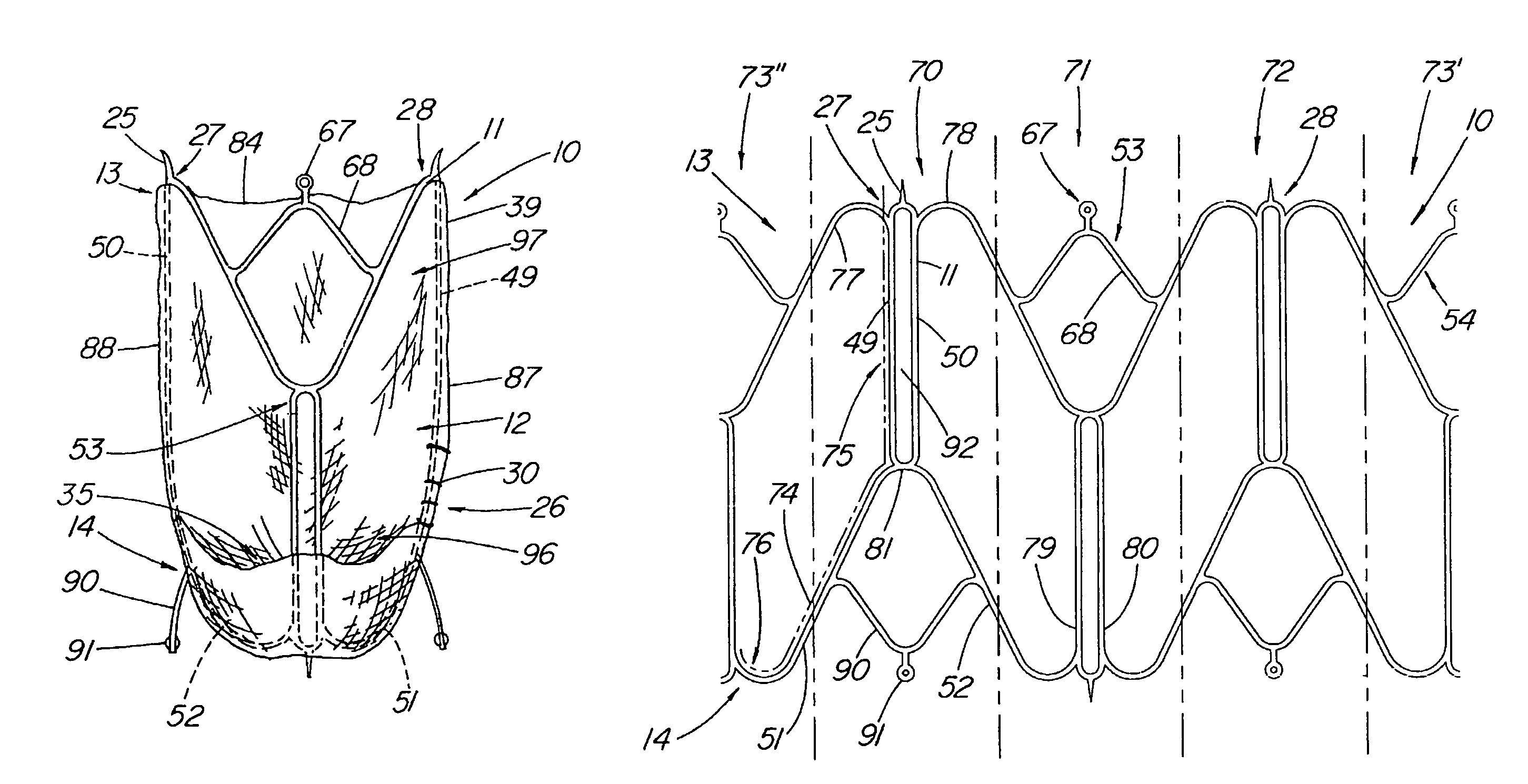

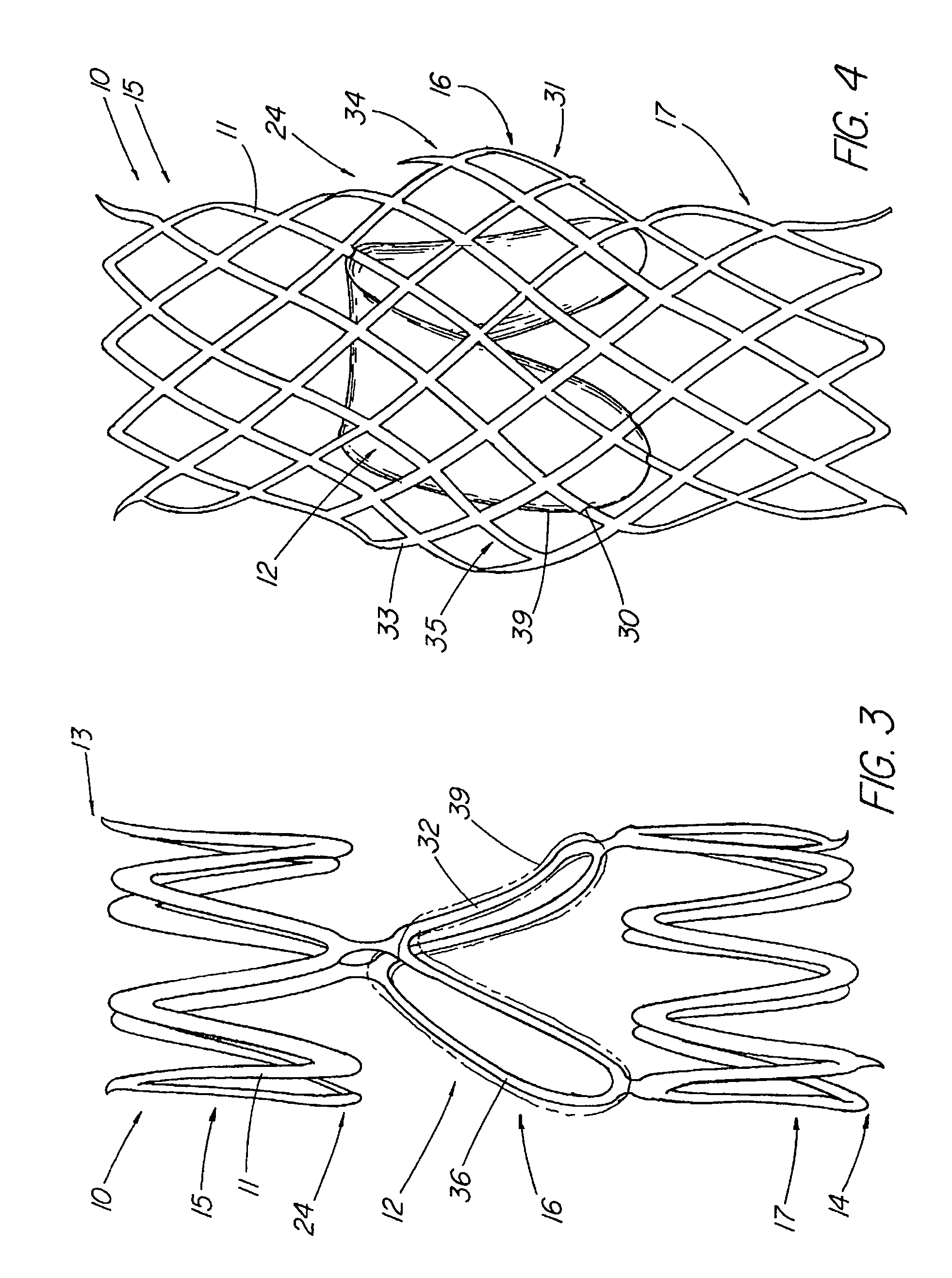

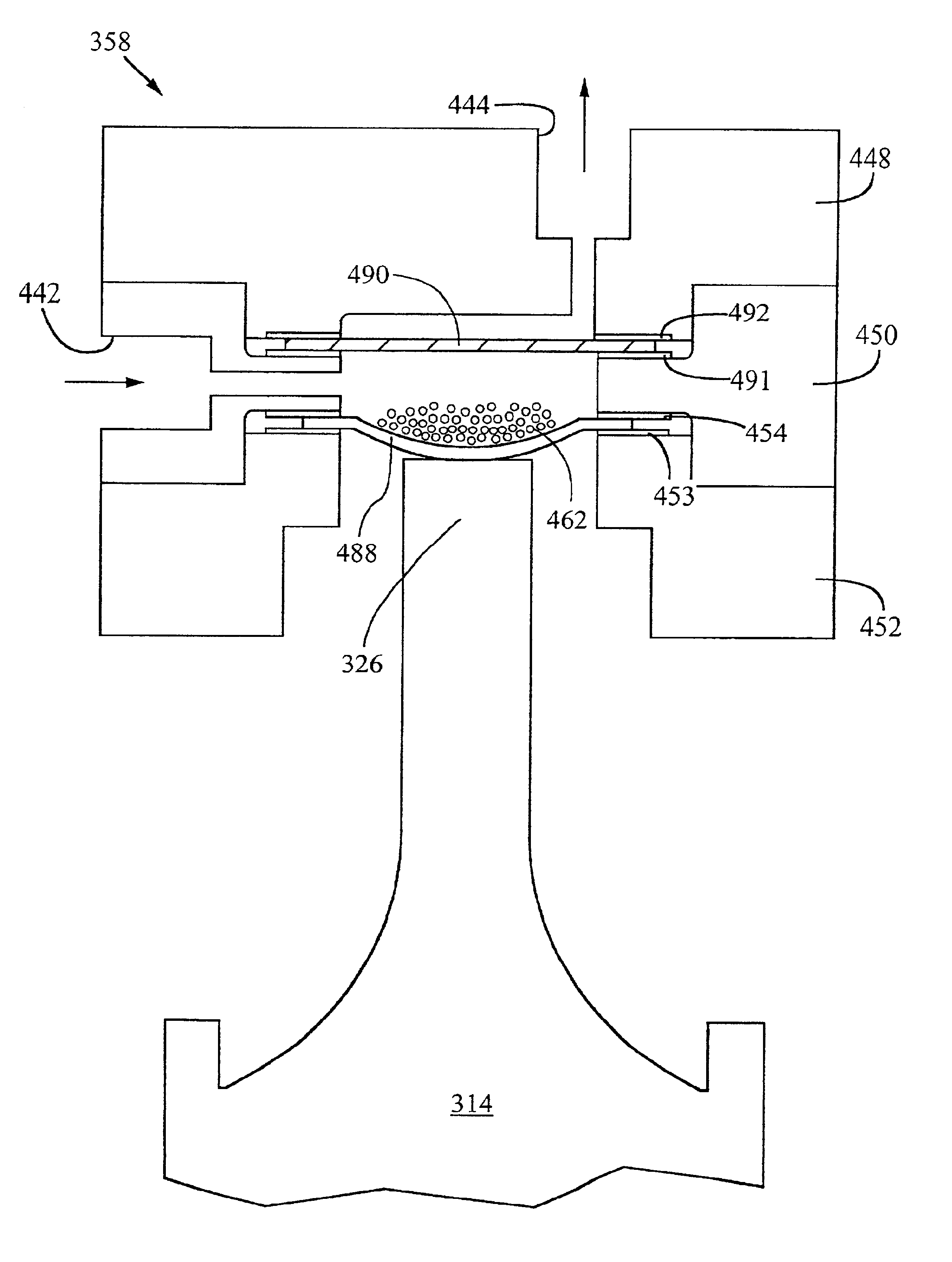

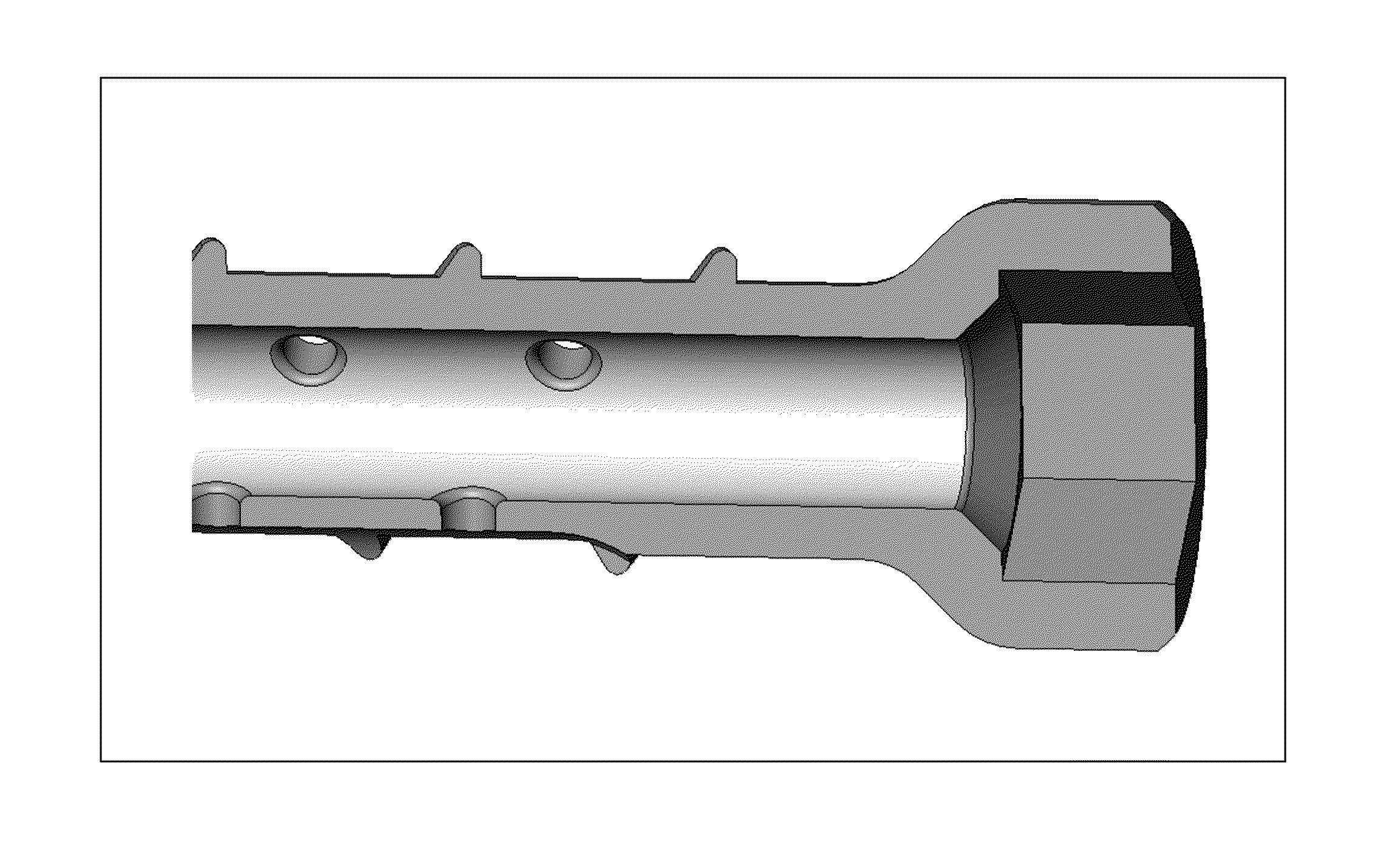

Compressible tissue anchor assemblies

ActiveUS7736379B2Constant force against the tissuePrevent overcompressionSuture equipmentsDiagnosticsConstant forceStrain gauge

Apparatus & methods for optimizing anchoring force are described herein. In securing tissue folds, over-compression of the tissue directly underlying the anchors is avoided by utilizing tissue anchors having expandable arms configured to minimize contact area between the anchor and tissue. When the anchor is in its expanded configuration, a load is applied to the anchor until it is optimally configured to accommodate a range of deflections while the anchor itself exerts a substantially constant force against the tissue. Various devices, e.g., stops, spring members, fuses, strain gauges, etc., can be used to indicate when the anchor has been deflected to a predetermined level within the optimal range. Moreover, other factors to affect the anchor characteristics include, e.g., varying the number of arms or struts of the anchor, positioning of the arms, configuration of the arms, the length of the collars, etc.

Owner:USGI MEDICAL

Fan

ActiveUS20090060710A1Facilitate manufacturingEfficiently manufacturePump componentsJet pumpsAirflowEngineering

A fan assembly for creating an air current includes a bladeless fan assembly including a nozzle and a device for creating an air flow through the nozzle. The nozzle includes an interior passage and a mouth receiving the air flow from the interior passage. A Coanda surface located adjacent the mouth and over which the mouth is arranged to direct the air flow. The fan provides an arrangement producing an air current and a flow of cooling air created without requiring a bladed fan, that is, the air flow is created by a bladeless fan.

Owner:DYSON TECH LTD

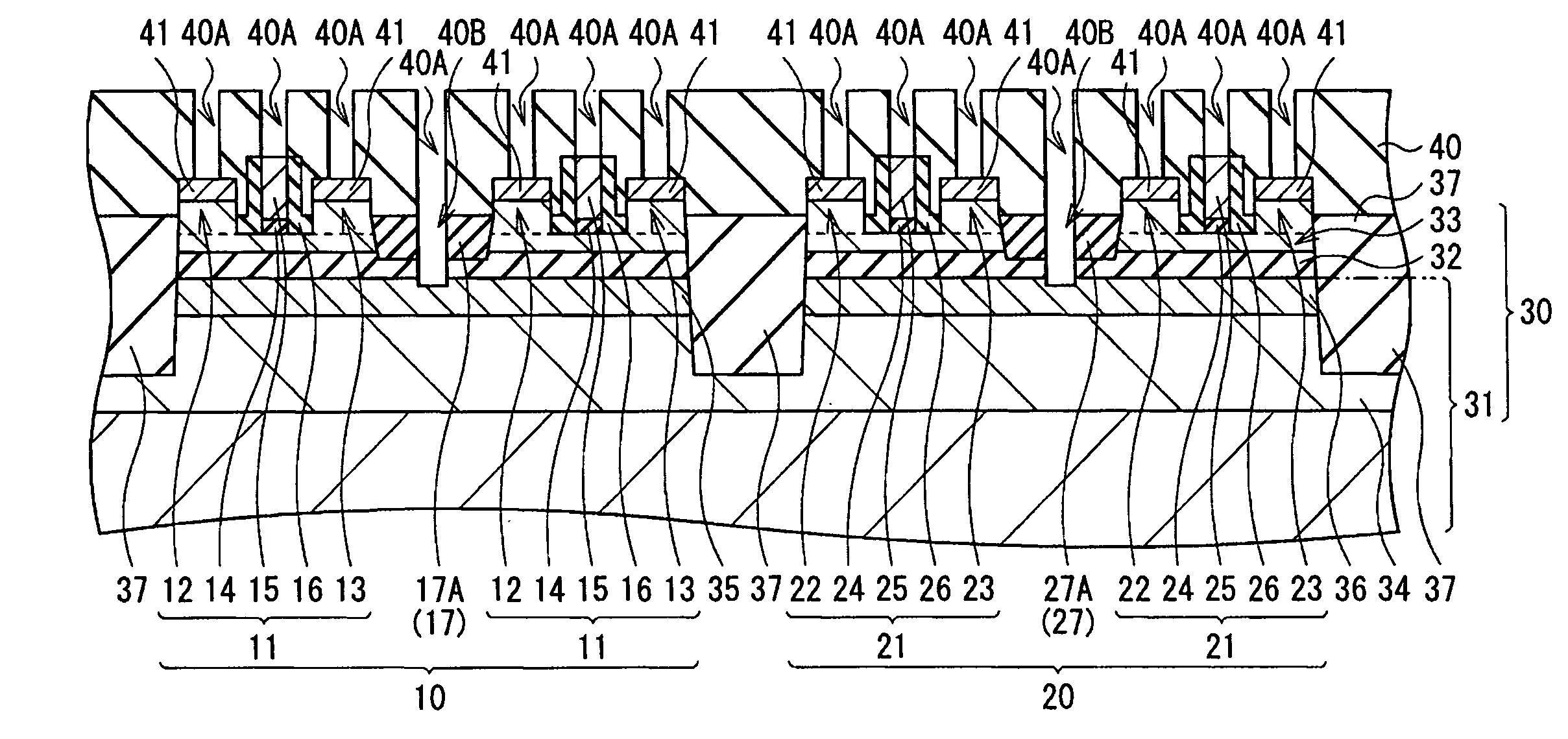

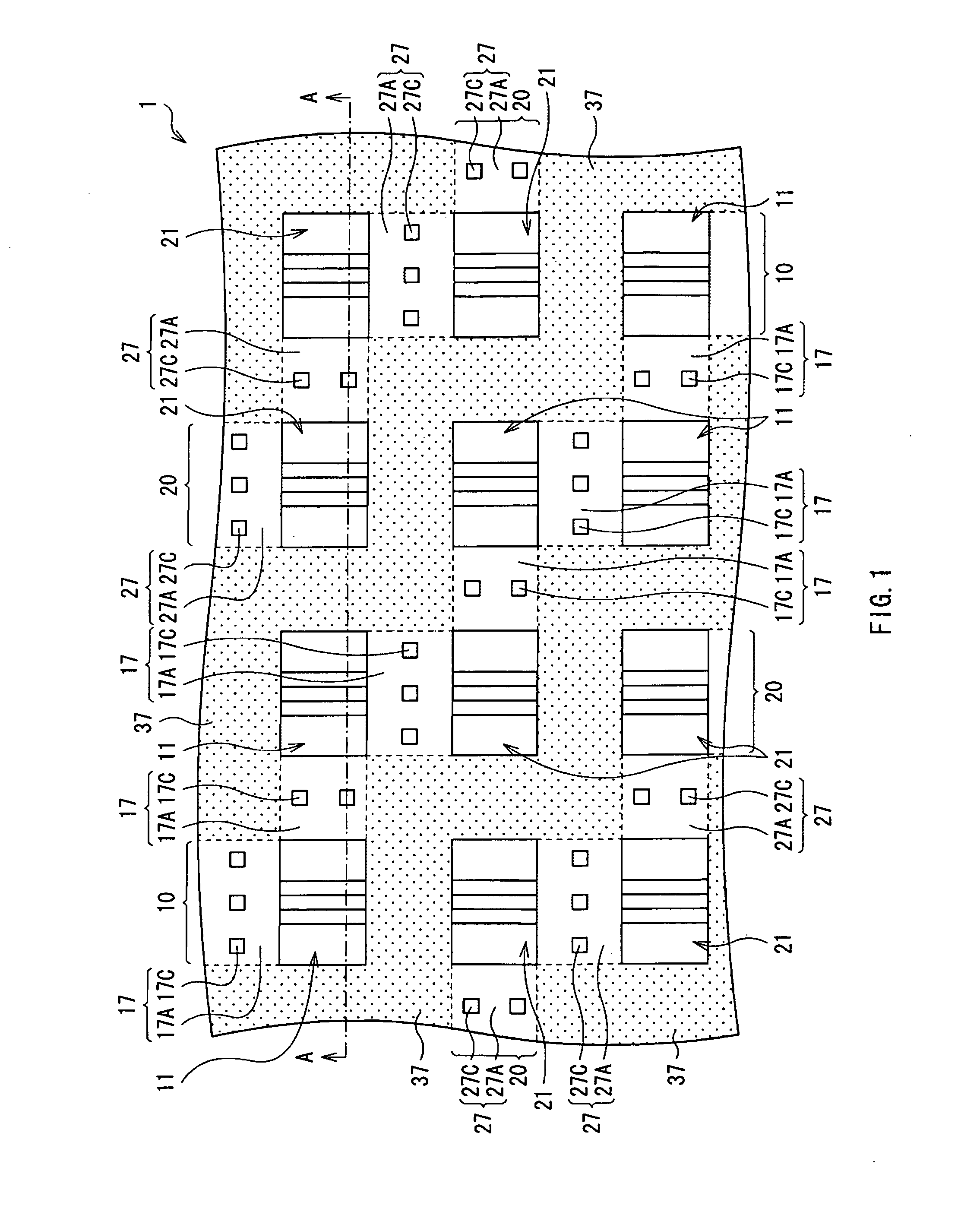

Semiconductor device

ActiveUS20100200919A1Suppression of short channel effectsSpeed up the flowTransistorSemiconductor/solid-state device detailsSemiconductor packageImpurity

The invention provides a semiconductor device capable of suppressing a short channel effect and fluctuation in a threshold. The semiconductor device includes: a plurality of first transistors formed in a first region in a semiconductor layer in a multilayer substrate having, on a semiconductor substrate, an insulating layer and the semiconductor layer in order from the semiconductor substrate; a plurality of second transistors formed in a second region in the semiconductor layer; a first impurity layer formed in a region opposed to the first region in the semiconductor substrate; a second impurity layer formed in a region opposed to the second region in the semiconductor substrate; and a first isolation part that isolates the first and second regions from each other and electrically isolates the first and second impurity layers from each other to a degree that at least current flowing between the first and second impurity layers is interrupted.

Owner:SONY CORP

Acid coated sand for gravel pack and filter cake clean-up

InactiveUS20040055747A1Enhances filter cake removalSpeed up the flowCleaning apparatusFluid removalCarboxylic acidGlycollic acid

A method of the preparation and utilization of polymerized alpha-hydroxycarboxylic-acid-coated proppants for gravel pack and removal of filter cake that was deposited by reservoir drilling fluid. In a preferred example, polyglycolic-acid-coated sand is used to replace conventional gravel pack sand typically used for gravel packing. Under downhole conditions, the acidic by-product generated from the hydration of polyglycolic-acid-coated sand can break down acid-soluble and / or acid-breakable components embedded in the filter cake. This reaction enhances the filter cake removal and the flow of hydrocarbon from the producing formation. The polyglycolic-acid-coated sand may be produced by polymerizing a glycolic acid with a natural or synthetic proppant like 20-40 mesh commercial sand, at temperatures of about 210° F. or higher.

Owner:MI

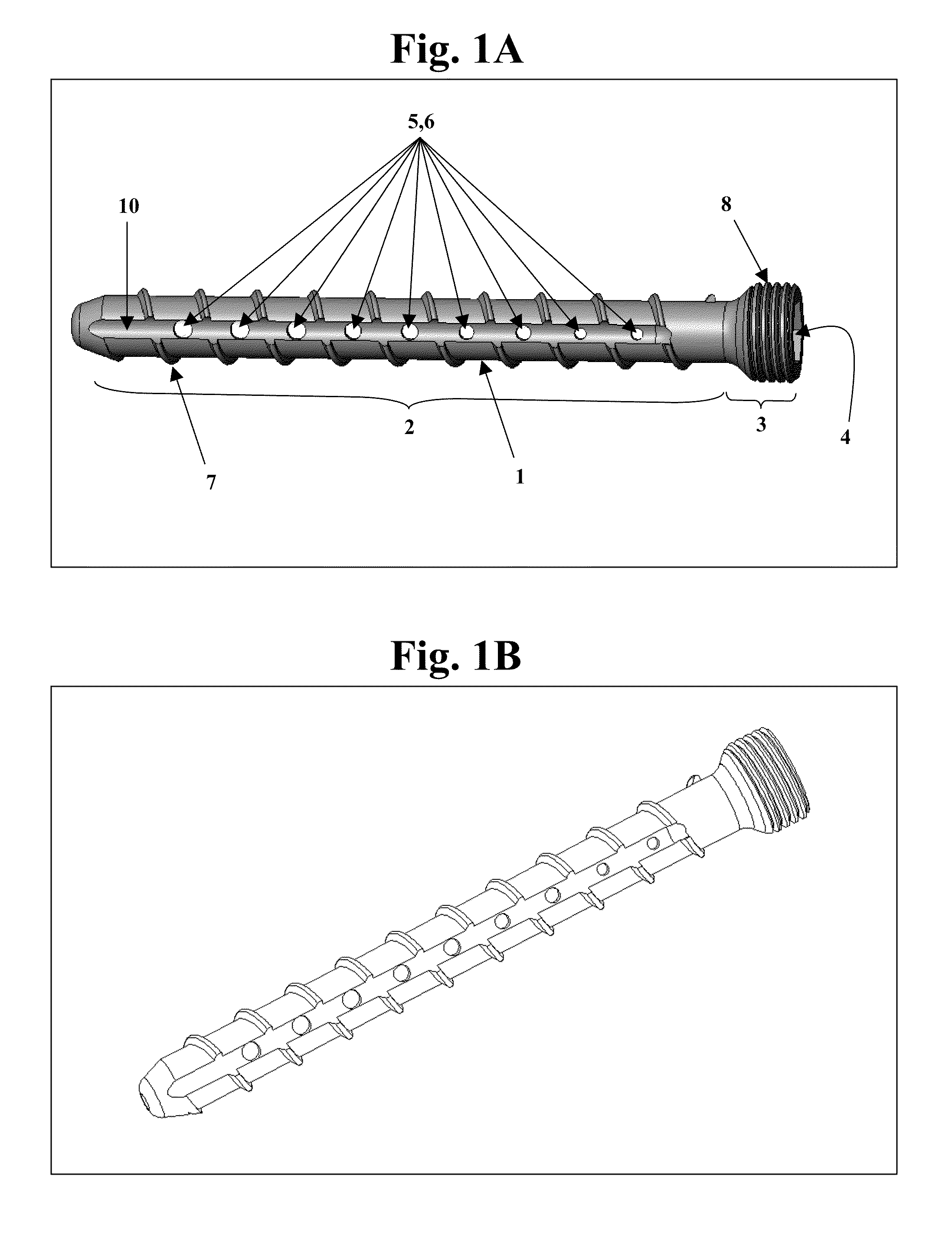

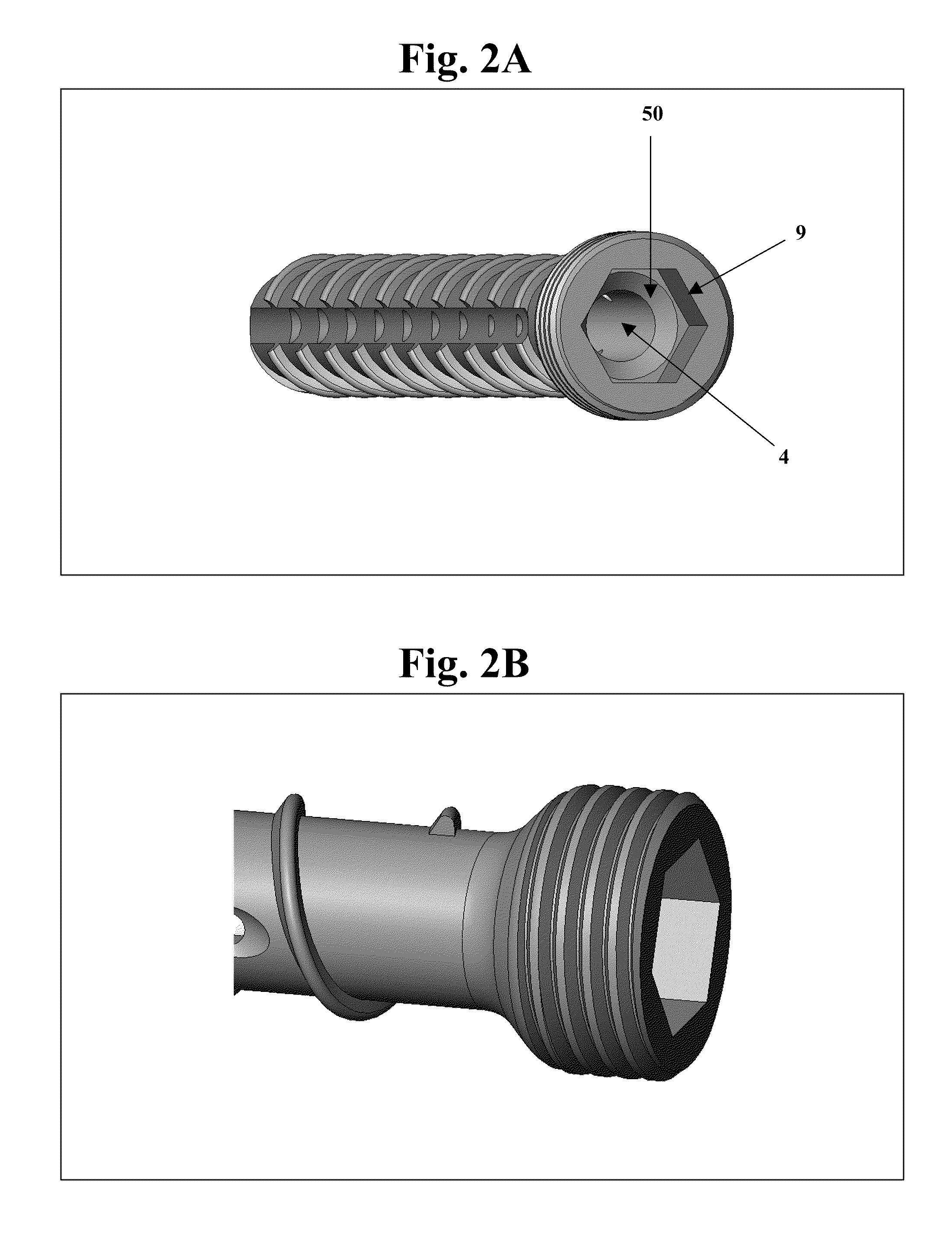

Bone screws and methods of use thereof

ActiveUS20110060373A1Prevent escapeFaster advanceSuture equipmentsDental implantsBone defectBiomedical engineering

The invention features bone screws having a threaded screw body and a screw head attached to one end of the screw body, the bone screw further including: a) an interior channel extending longitudinally through the screw head and through at least a portion of the screw body, wherein the interior channel has a width of less than 5.0 millimeters; and b) a plurality of radially-disposed delivery channels connecting the interior channel to the exterior of the screw body, each delivery channel having exterior openings. The invention further features devices that include a bone screw and a delivery manifold detachably attached to the screw head of the bone screw. In addition, the invention features methods of treating a patient having a bone defect by using a bone screw described herein.

Owner:INNOVISION CO LTD

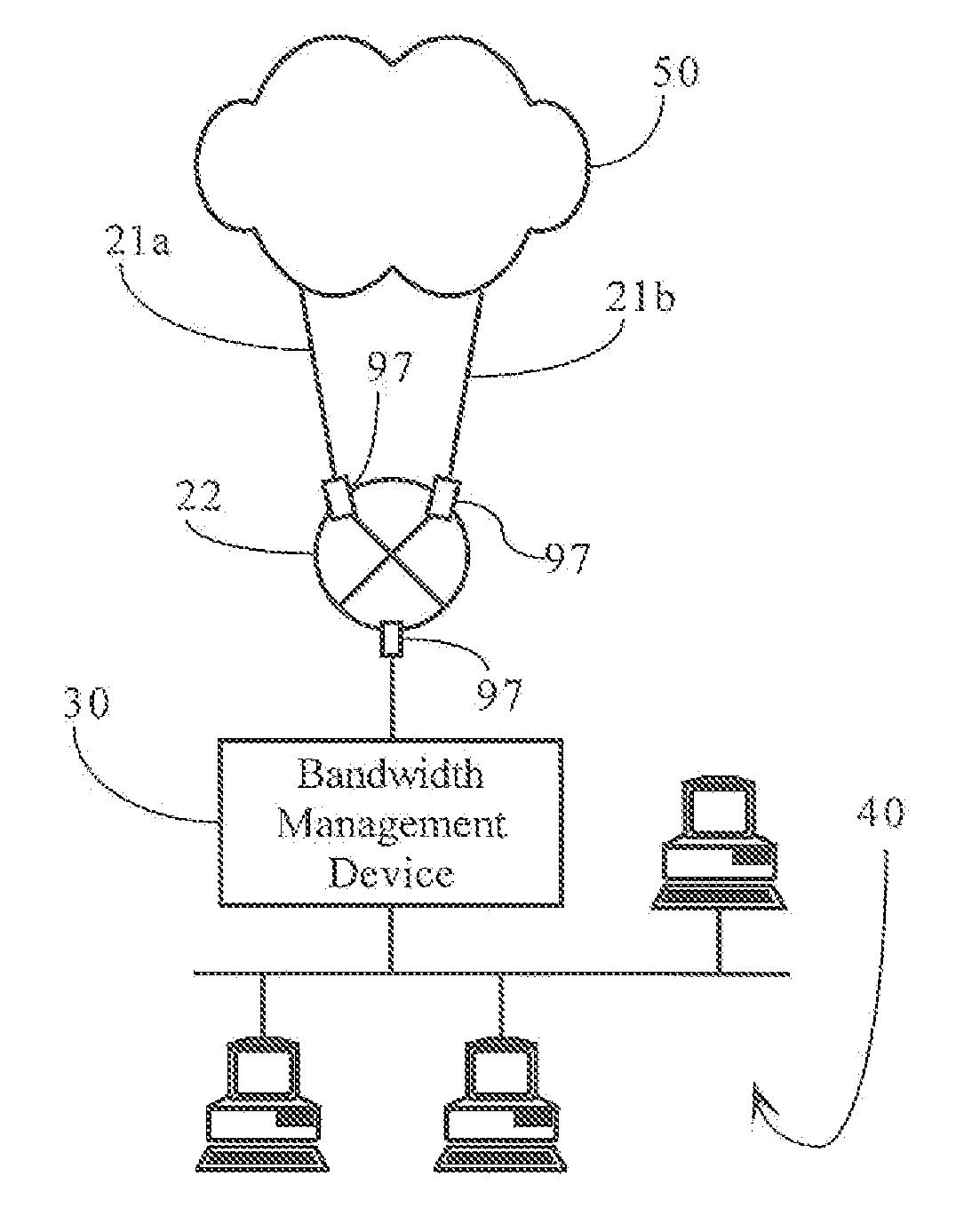

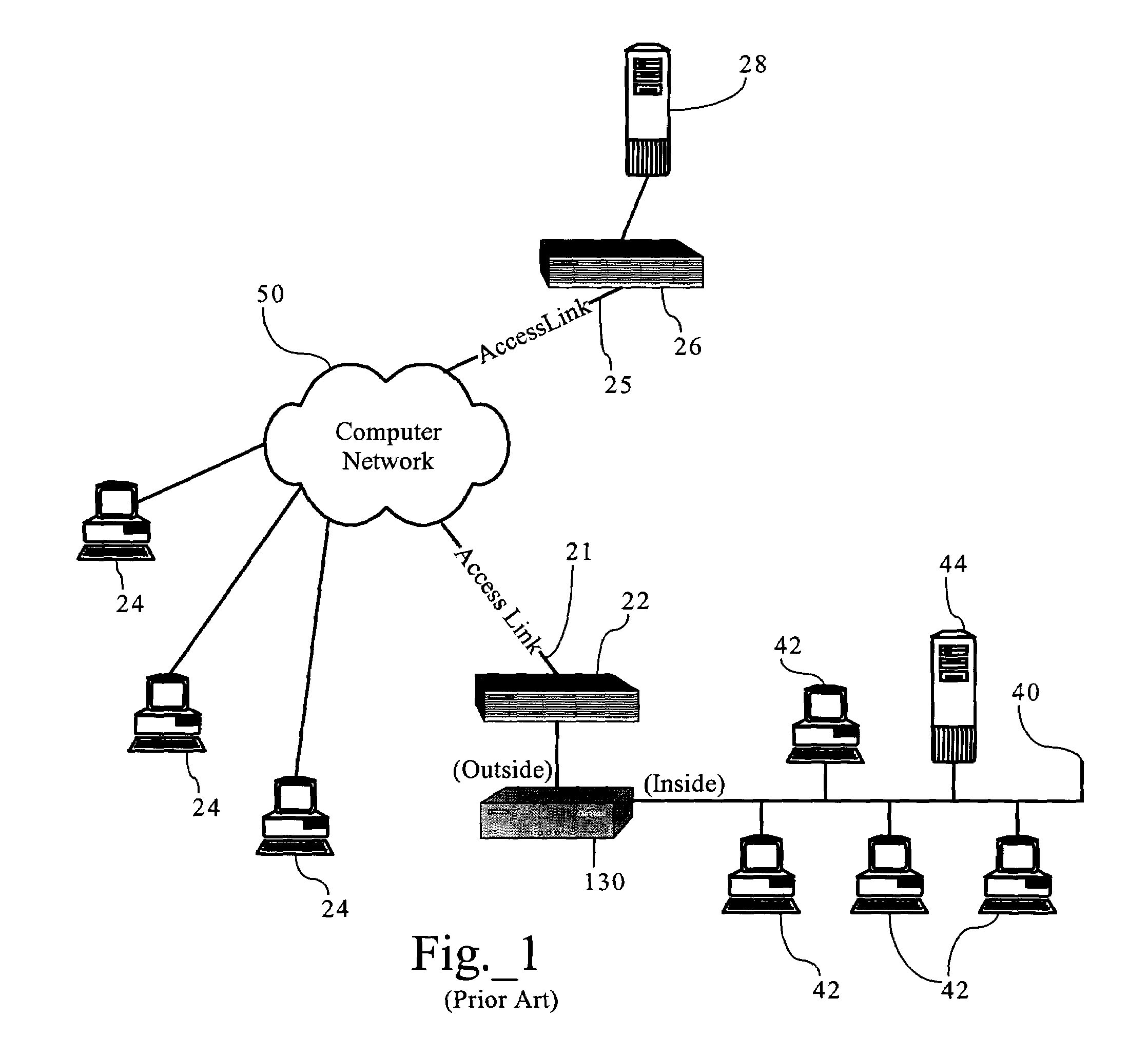

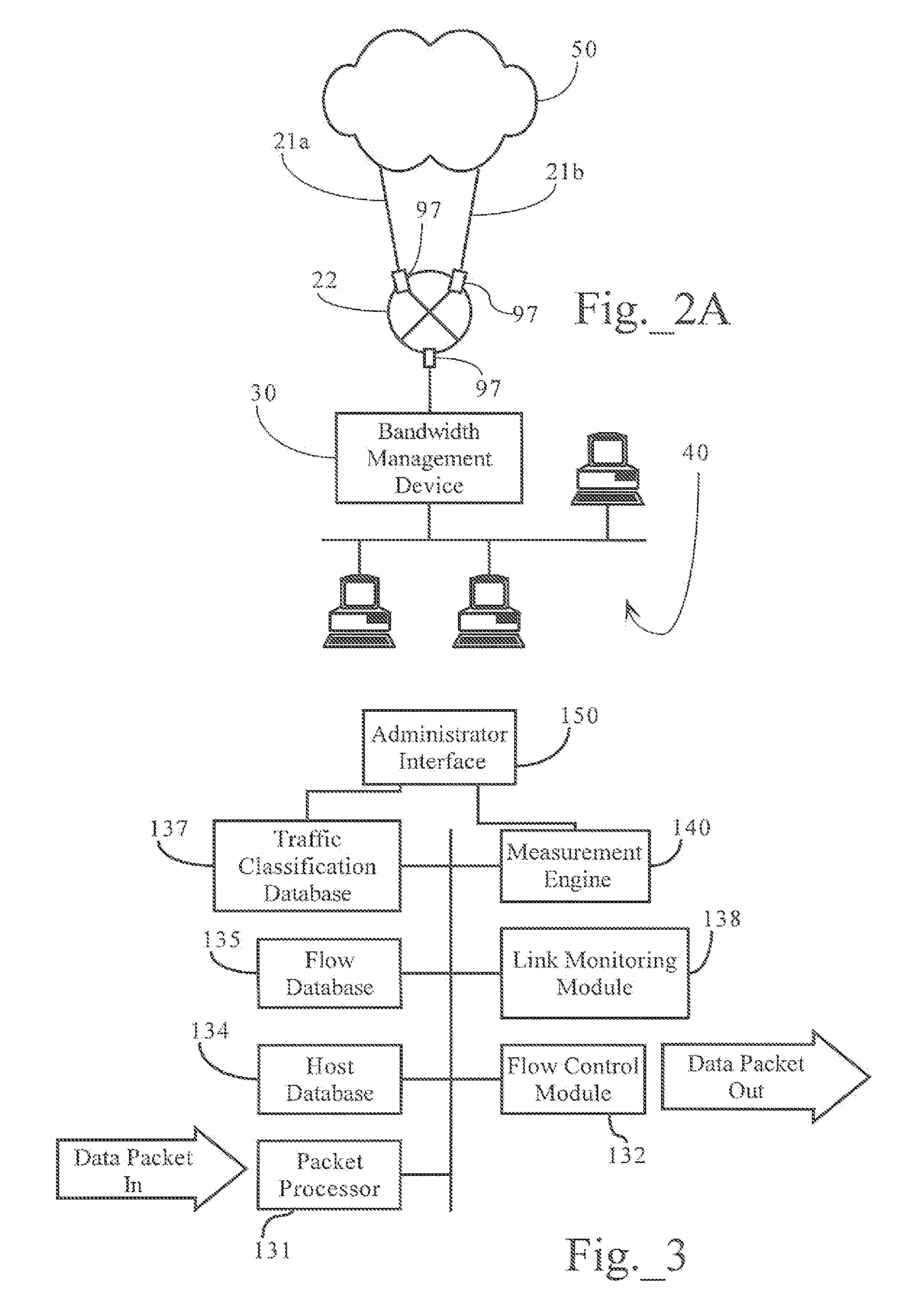

Dynamic bandwidth management responsive to access link state in redundant network topologies

ActiveUS7324553B1Improve network efficiencyEnsure smooth networkError preventionFrequency-division multiplex detailsTraffic capacityBandwidth management

Methods, apparatuses and systems allowing for dynamic bandwidth management schemes responsive to the state of a plurality of access links in redundant network topologies. In one embodiment, the present invention provides a bandwidth management device that periodically queries routing systems associated with access links, conceptually grouped into a virtual access link, to monitor that load of the access links and, depending on the detected load, adjust the configuration of the bandwidth management device to avoid overloading one or more of the access links. Embodiments of the present invention increases network efficiency and help network traffic to flow more smoothly with higher throughput. In one embodiment, the dynamic link control functionality is invoked when any given access link reaches a threshold capacity level. Assuming that network traffic will scale in the same ratio as presently observed, the present invention calculates the maximum traffic that can be let through so that no network interface or access link is overloaded.

Owner:CA TECH INC

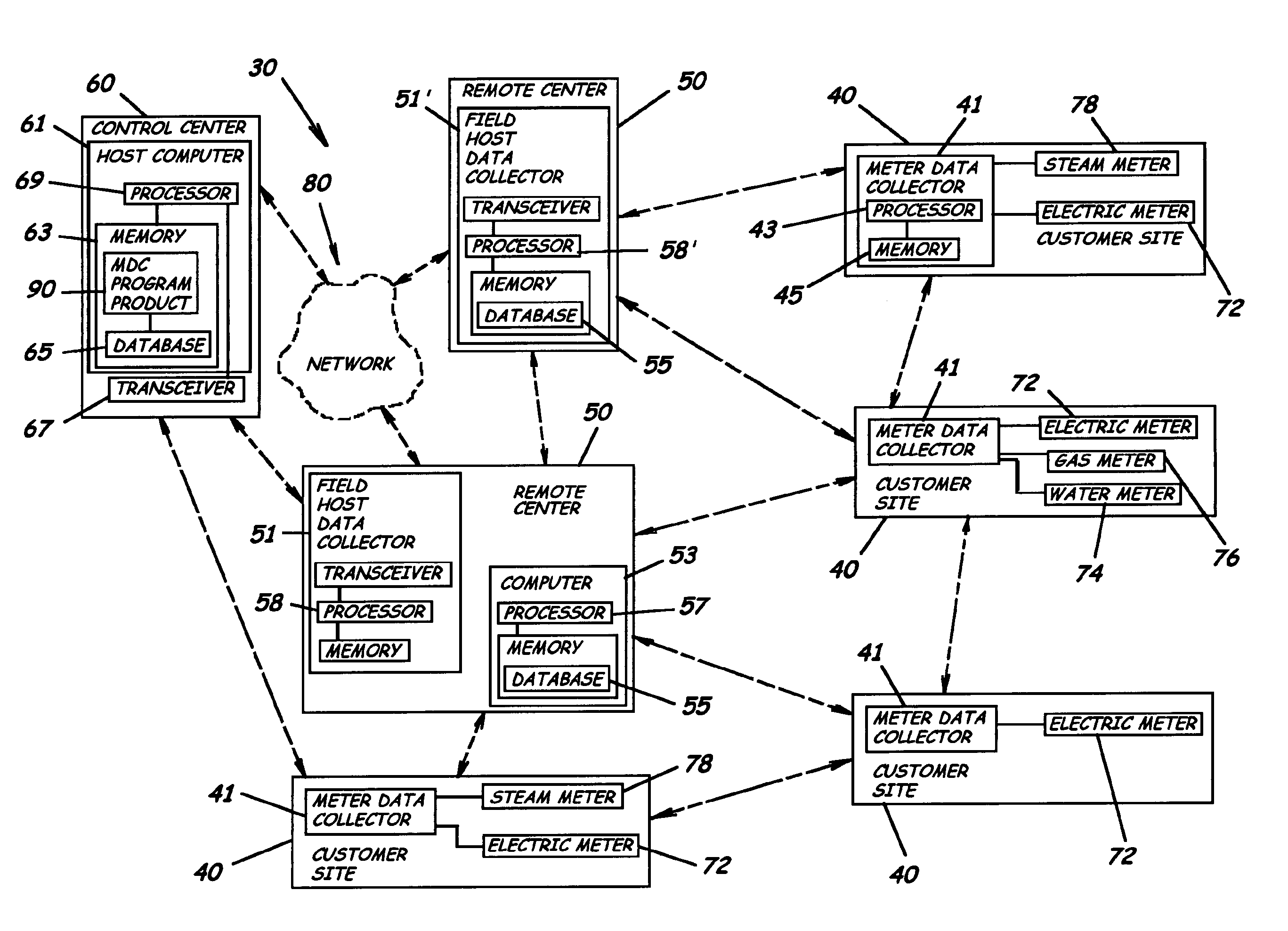

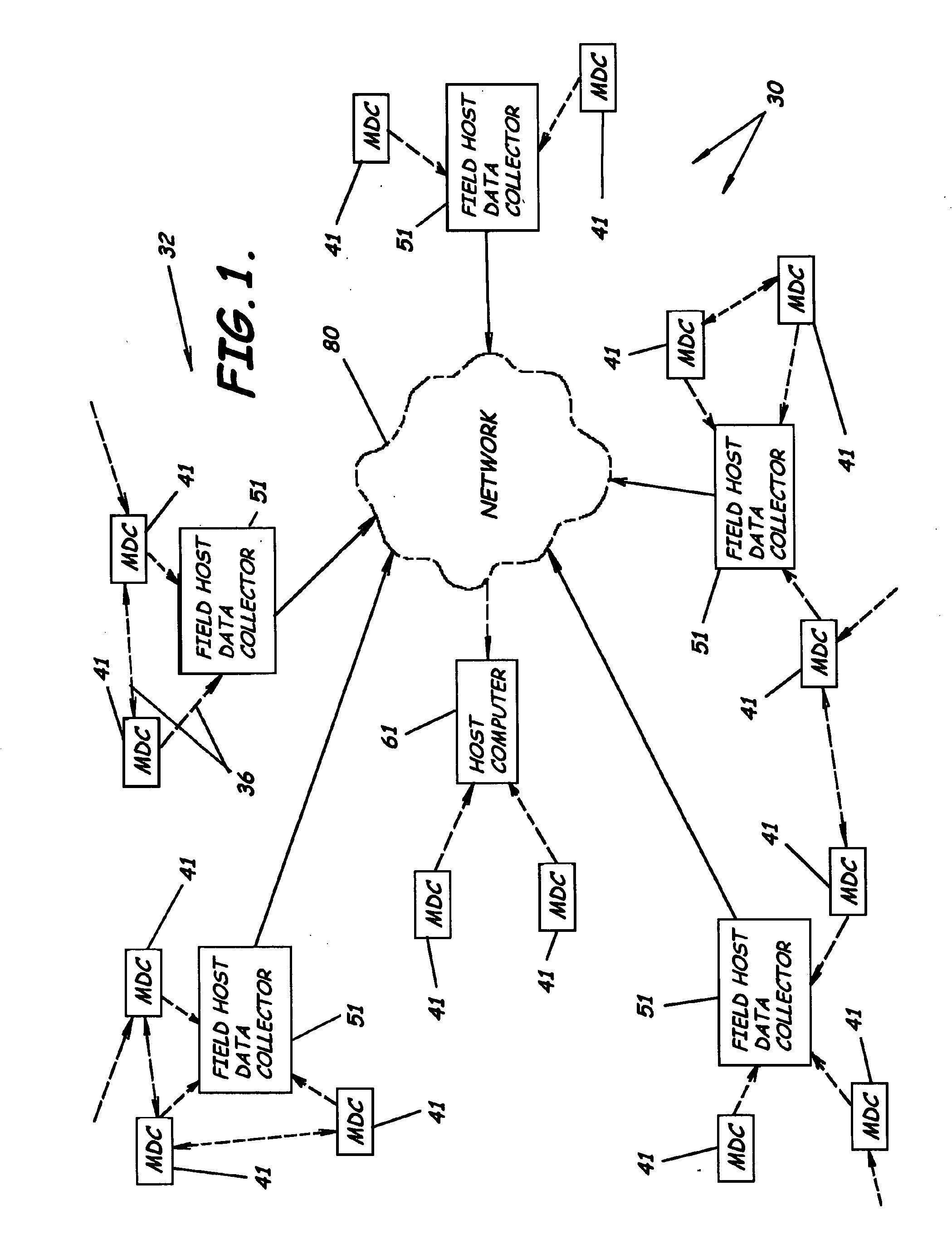

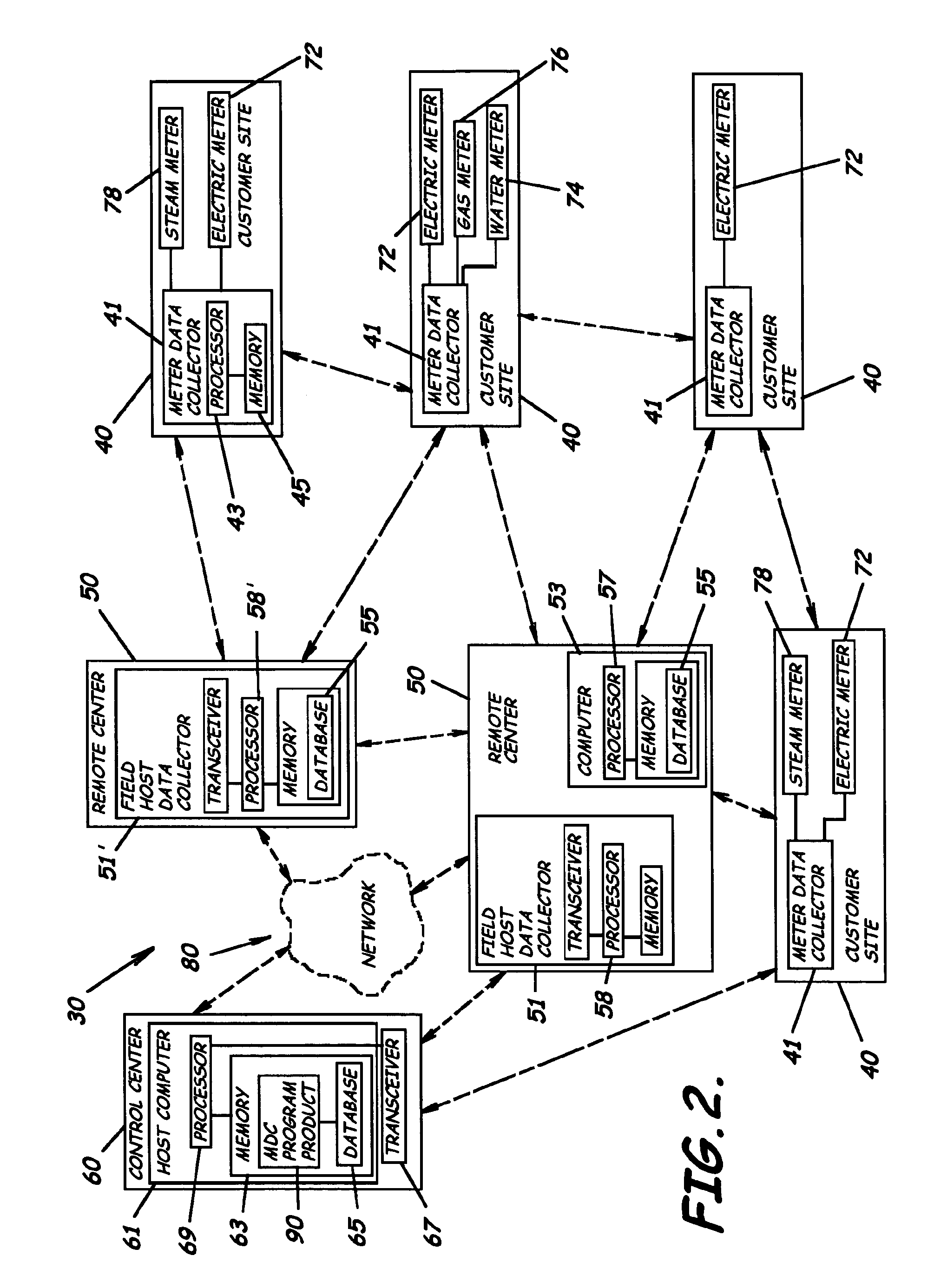

Automated meter reading system, communication and control network for automated meter reading, meter data collector program product, and associated methods

InactiveUS20050270173A1Enhance mesh communication network performanceEasy to detectElectric signal transmission systemsUtility meters data arrangementsFrequency-hopping spread spectrumData acquisition

An automated meter reading network system to collect utility usage data from multiple utility meters having utility meter sensors is provided. The system includes multiple meter data collectors each in communication with one or more utility meters to collect utility usage data and forming a wireless mesh communications network characterized by having a varying frequency mode of operation. The system also includes a host computer in communication with the meter data collectors either directly or through multiple field host data collectors, which can be connected to the host computer through a wide area network. The system also includes a meter data collector program product at least partially stored in the memory of the host computer adapted to manage the mesh communication network that is adapted to vary the frequency mode of at least portions of the mesh communication network between a fixed frequency mode and a frequency hopping spread spectrum mode to enhance network performance.

Owner:ENERGY TECH GROUP

Compressible tissue anchor assemblies

ActiveUS20060217762A1Constant force against the tissuePrevent overcompressionSuture equipmentsDiagnosticsStrain gaugeBiomedical engineering

Apparatus & methods for optimizing anchoring force are described herein. In securing tissue folds, over-compression of the tissue directly underlying the anchors is avoided by utilizing tissue anchors having expandable arms configured to minimize contact area between the anchor and tissue. When the anchor is in its expanded configuration, a load is applied to the anchor until it is optimally configured to accommodate a range of deflections while the anchor itself exerts a substantially constant force against the tissue. Various devices, e.g., stops, spring members, fuses, strain gauges, etc., can be used to indicate when the anchor has been deflected to a predetermined level within the optimal range. Moreover, other factors to affect the anchor characteristics include, e.g., varying the number of arms or struts of the anchor, positioning of the arms, configuration of the arms, the length of the collars, etc.

Owner:USGI MEDICAL

Artificial Valve Prosthesis with Improved Flow Dynamics

ActiveUS20070260327A1Easy to removePrevent stagnantVenous valvesBlood vesselsProsthetic valveVenous Valves

An expandable venous valve having a support structure that configured to enlarge the area adjacent to the valve structure such that the flow patterns of retrograde flow are modified in a way that facilitates the flushing of the pockets at the base of the valve area to prevent stagnation of bodily fluid, which in the venous system, can lead to thrombus formation. The enlarged pocket areas can be created by forming an artificial sinus adjacent the valve structure in an unsupported section of vessel wall between two support frame section or the support frame can comprise an expanded-diameter intermediate or proximal section that forms an artificial sinus adjacent the valve structure. In another group of embodiments, the attachment pathway between opposing leaflets and the support frame and / or vessel wall comprises a proximal portion that places the leaflets in extended contact with one another and a distal portion forms a large angle with respect to the adjacent walls such that a large pocket is created at the base of the leaflets. In one embodiment, the attachment pathway extends distally along a pair of substantially parallel longitudinal attachment struts to create an extended leaflet contact area, then angles circumferentially and distally from the former along distal attachment struts to define the bottom edge of the leaflets.

Owner:COOK MEDICAL TECH LLC

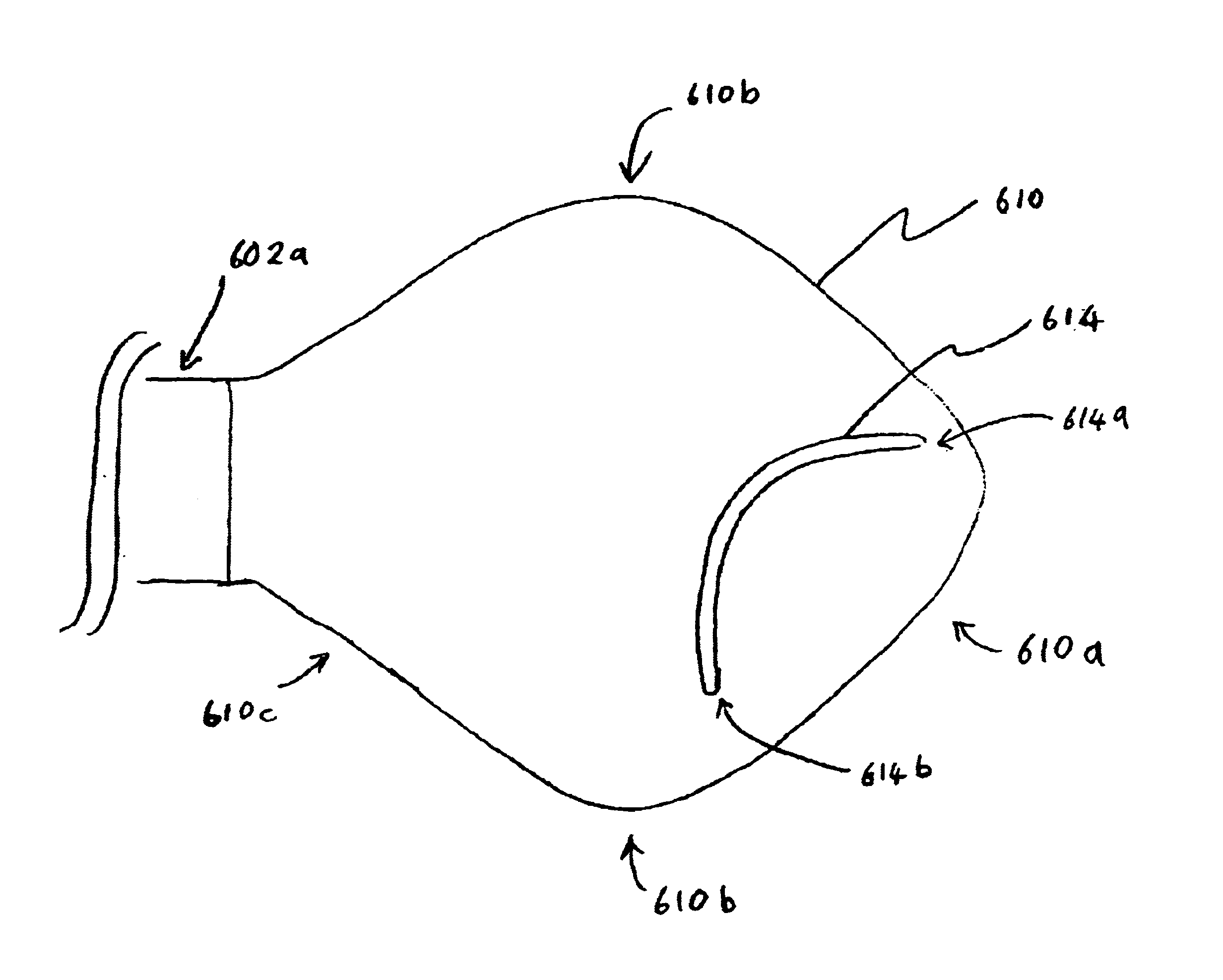

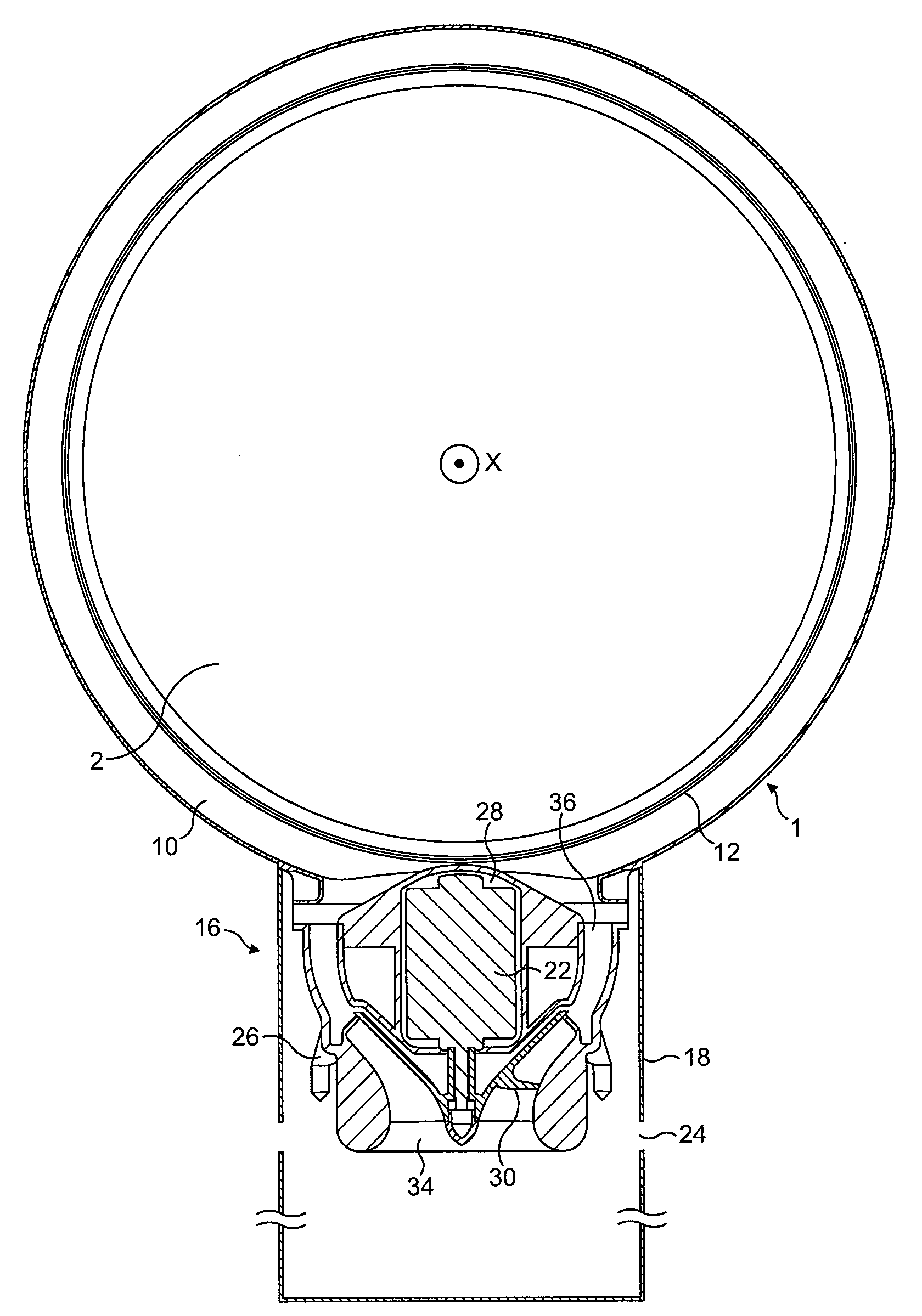

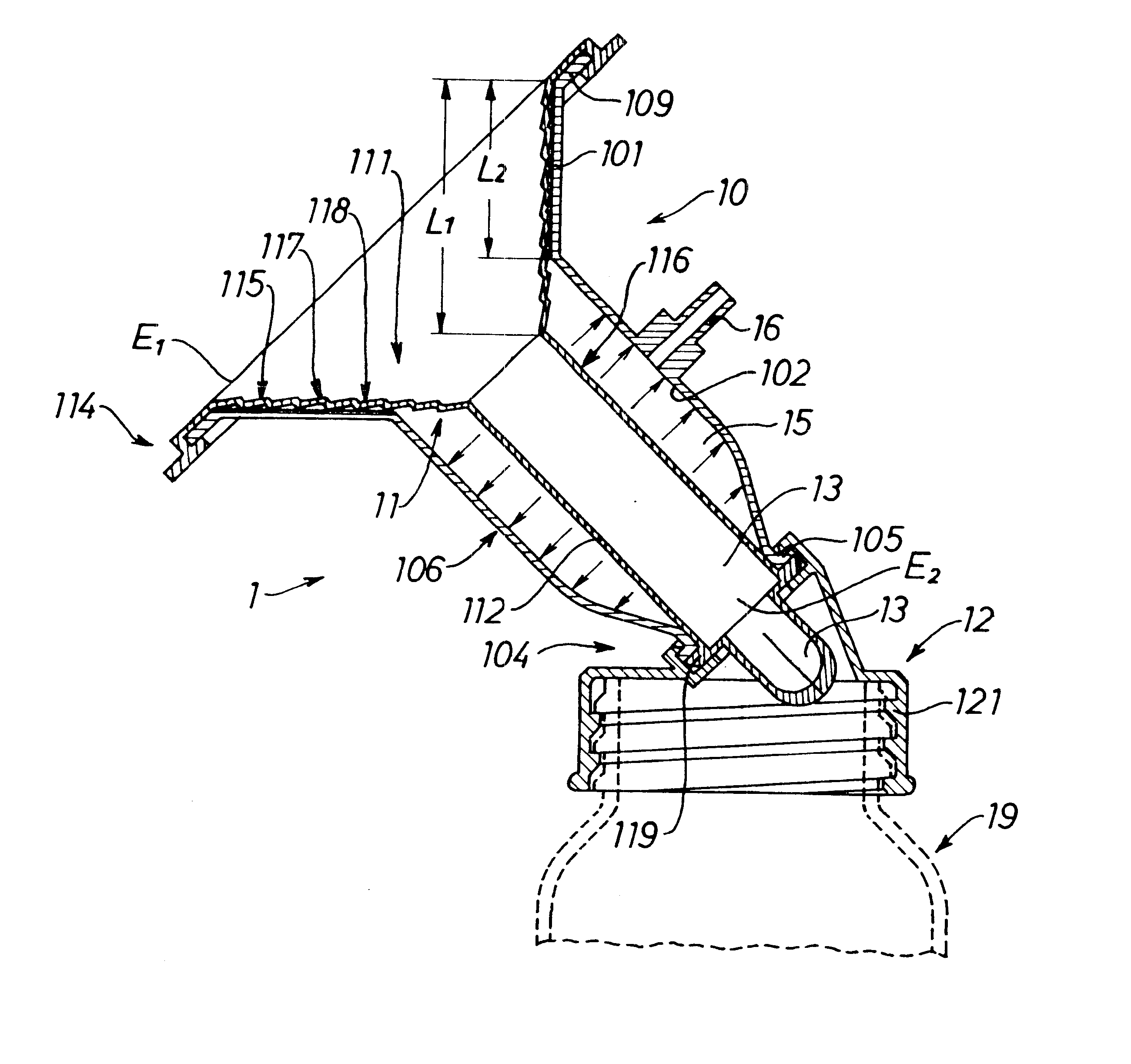

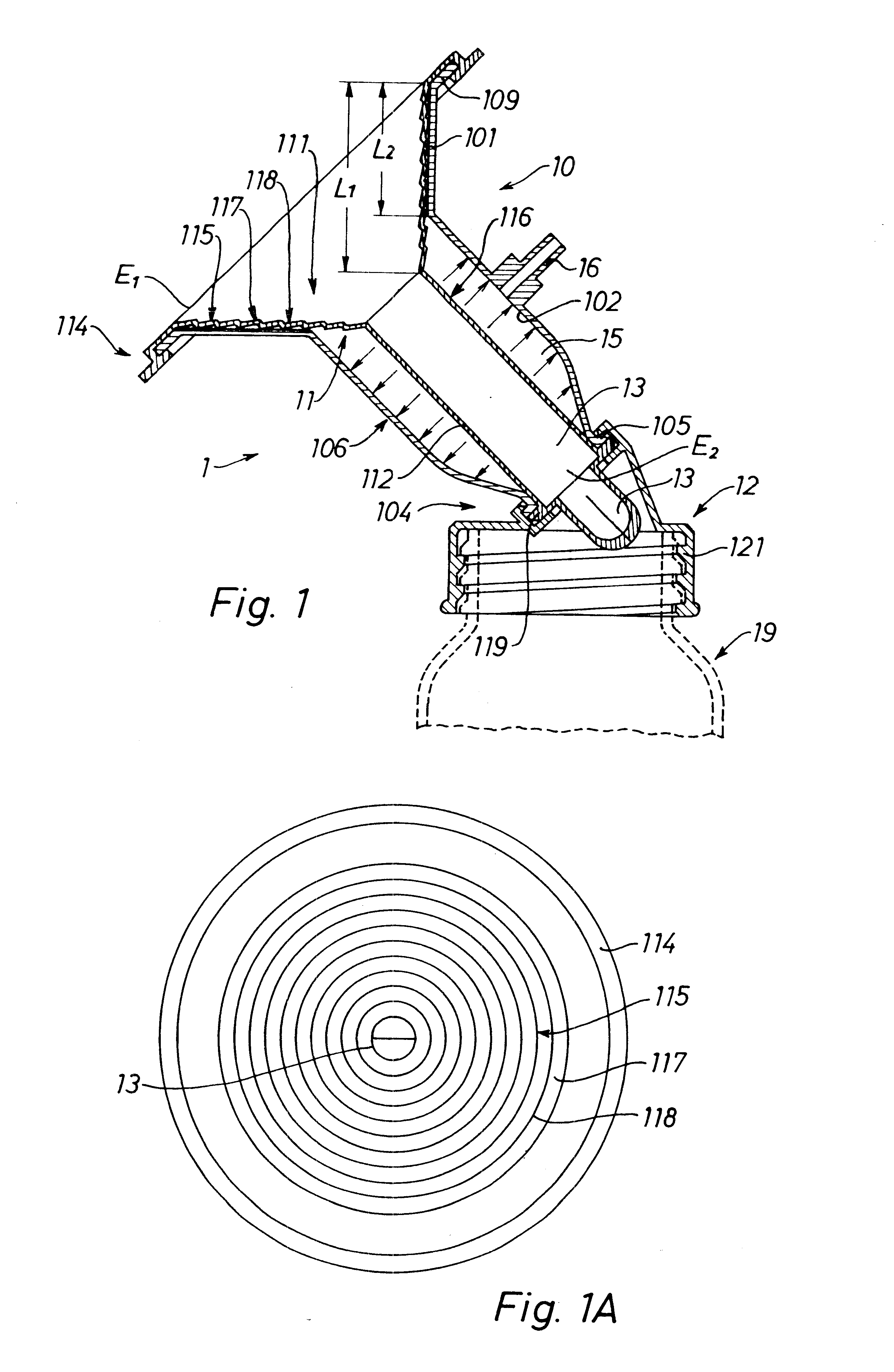

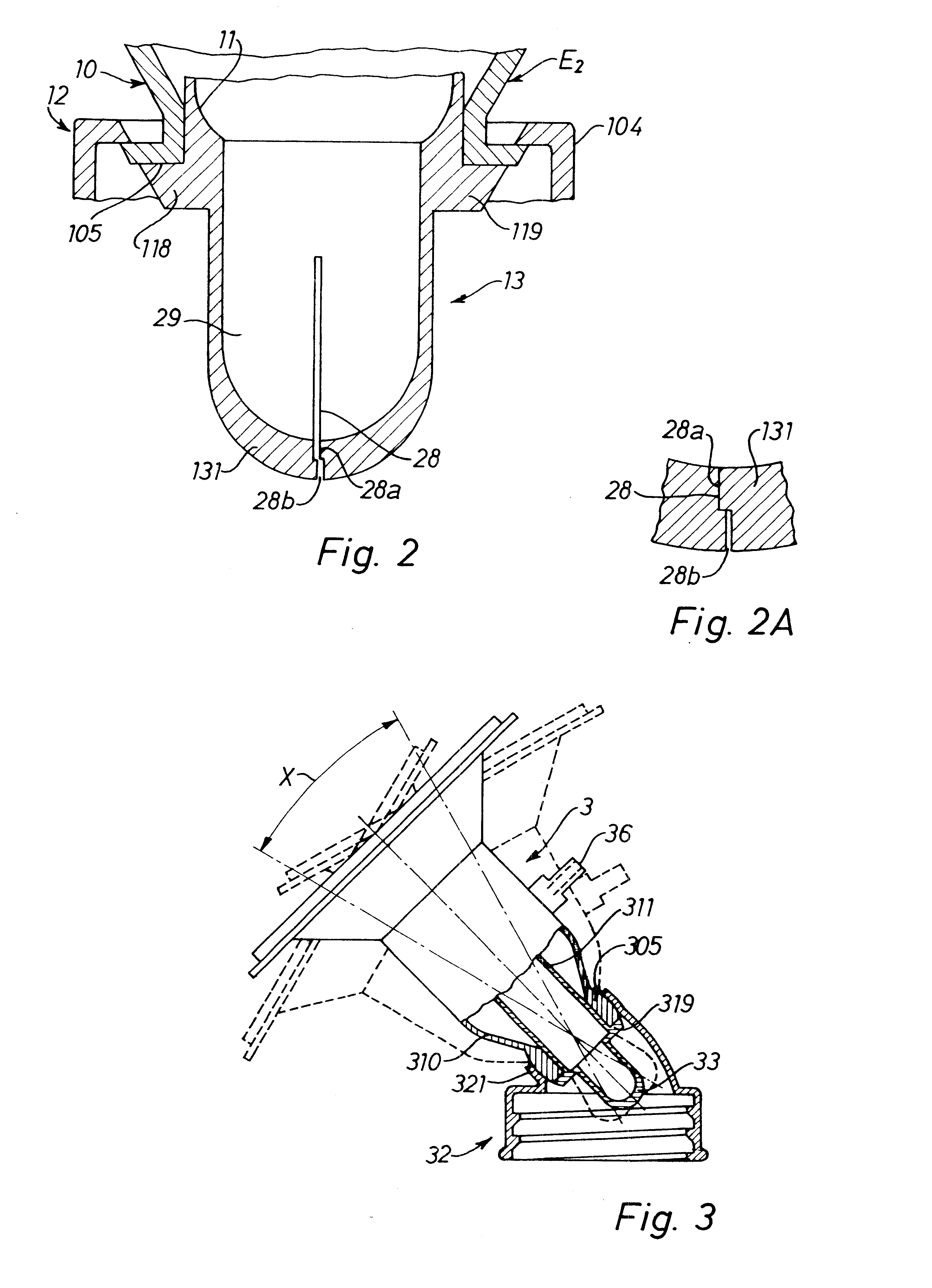

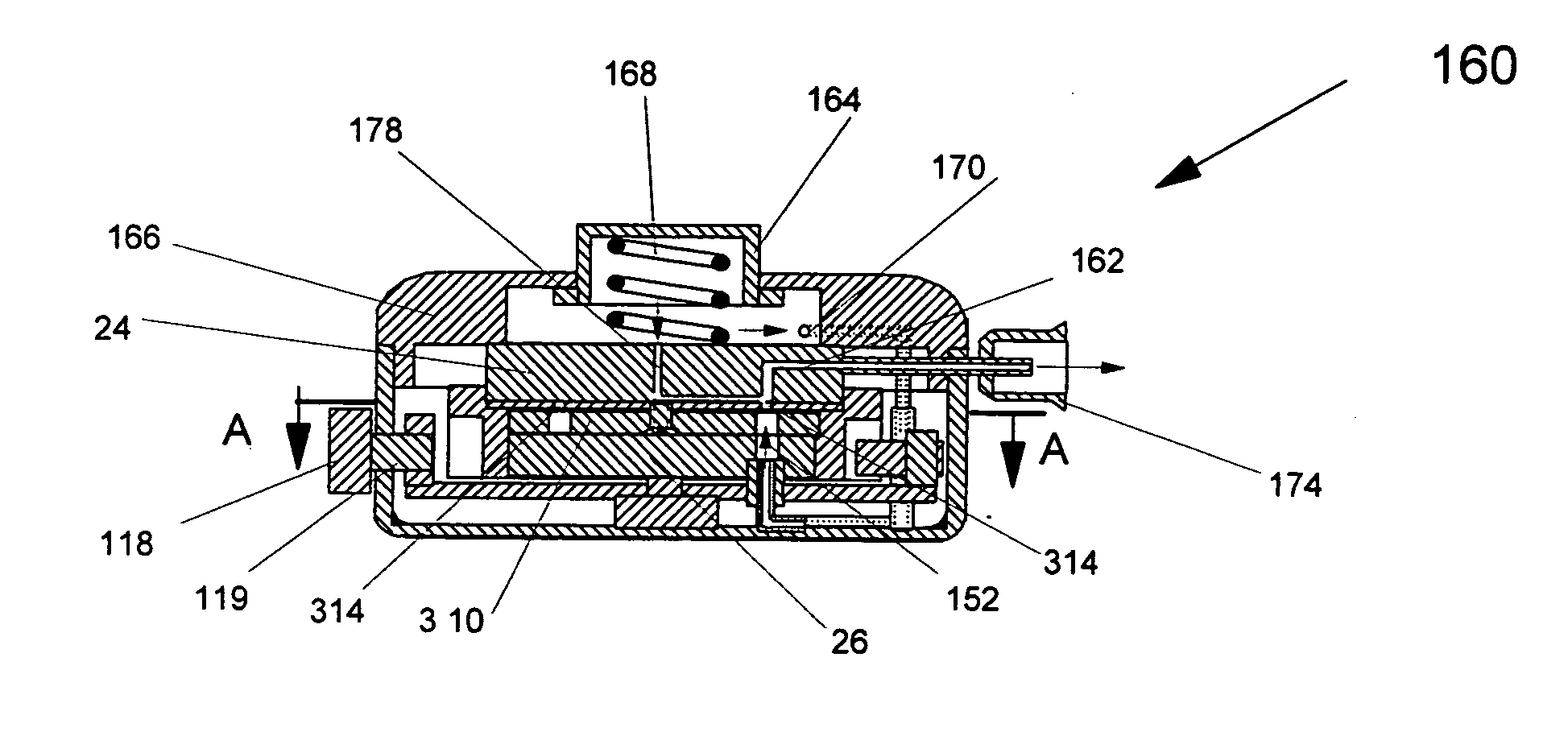

Suction bell for breast pump

InactiveUS6461324B1The process is simple and effectiveEasy to disassembleMilking pumpIntravenous devicesBottleConoid

A suction bell assembly, and an elastomeric liner therefor, are disclosed in which the bell includes a rigid outer shell (10,310) of generally Y-shaped axial cross section with a conical top portion (101) and a cylindrical body portion (106). A thin, flexible, elastic liner (11) is disposed within the shell and has a conical and preferably corrugated upper portion (111) disposed within the conical top portion of the shell and a peripheral lip (114) for sealingly engaging a rim (19) extending about the shell's top portion. The liner also includes an elongated tubular portion 112 spaced normally inwardly from the shell's inner surface, the tubular portion including a resilient annular flange (119) that sealingly engages a shoulder at the lower end of the shell to maintain the liner in an axially stretched and tensioned state. one-way valve means (13,43) is formed integrally with the liner and is disposed at the lower end of the tubular portion below the flange (119). The valve means (13,43) includes a calotte-shaped closure portion (131) having at least one slit (28,438,439) to permit the passage of milk downwardly through the lower end of the liner. In preferred embodiments, each slit (28,438,439) has offset but communicating inner and outer portions (28a,28b,438a,438b, 439a,439b). Means are also disclosed for allowing swivel action of the shell (310) in relation to a connector (32) for detachably connecting the suction bell to a milk-collecting bottle.

Owner:AMEDA

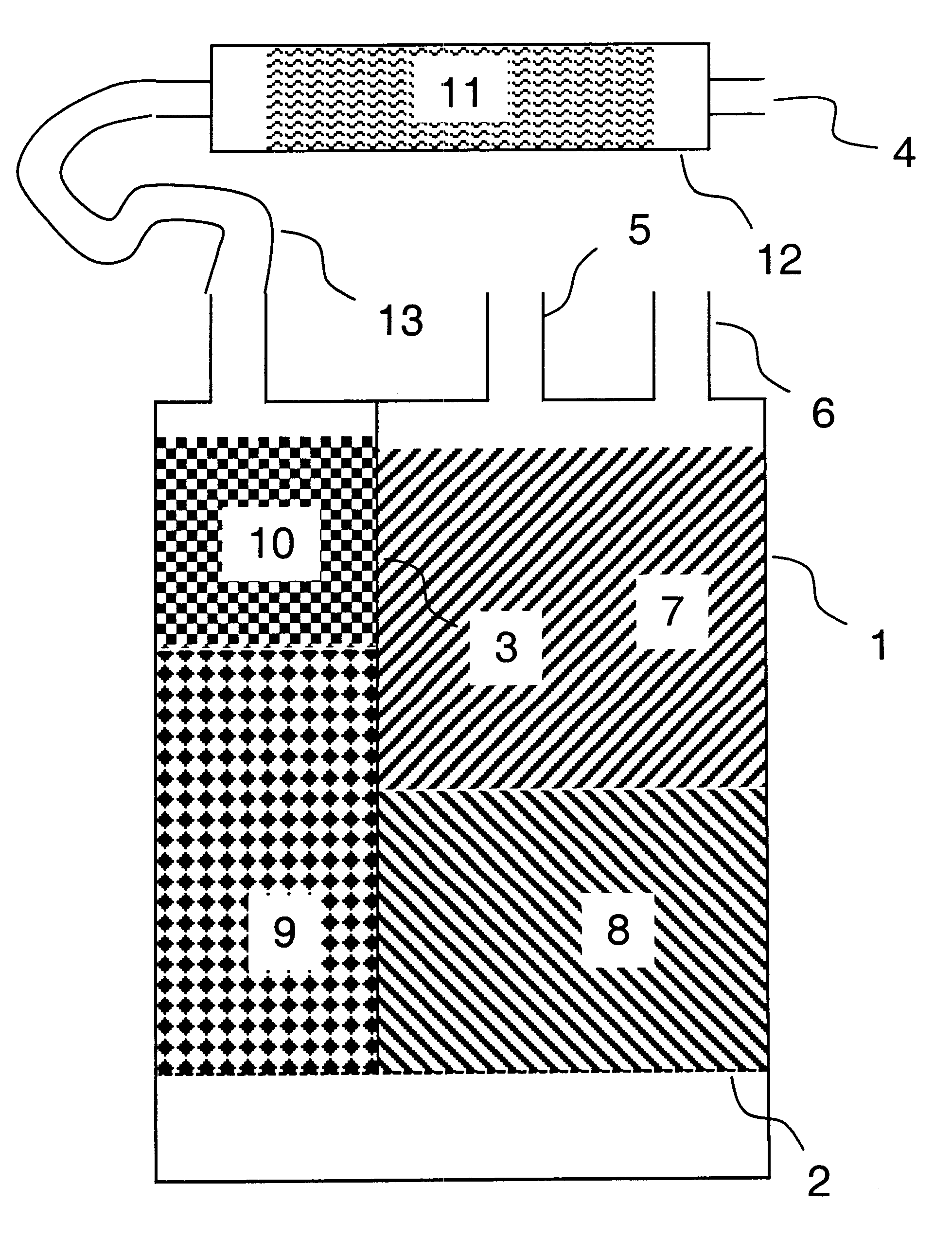

Method for reducing emissions from evaporative emissions control systems

InactiveUS6540815B1Loss in working capacityEmission reductionGas treatmentNon-fuel substance addition to fuelHigh concentrationSorbent

Disclosed is a method for sharply reducing diurnal breathing loss emissions from automotive evaporative emissions control systems by providing multiple layers, or stages, of adsorbents. On the fuel source-side of an emissions control system canister, high working capacity carbons are preferred in a first canister (adsorb) region. In subsequent canister region(s) on the vent-side, the preferred adsorbent should exhibit a flat or flattened adsorption isotherm on a volumetric basis and relatively lower capacity for high concentration vapors as compared with the fuel source-side adsorbent. Multiple approaches are described for attaining the preferred properties for the vent-side canister region. One approach is to use a filler and / or voidages as a volumetric diluent for flattening an adsorption isotherm. Another approach is to employ an adsorbent with the desired adsorption isotherm properties and to process it into an appropriate shape or form without necessarily requiring any special provision for dilution. The improved combination of high working capacity carbons on the fuel source-side and preferred lower working capacity adsorbent on the vent-side provides substantially lower diurnal breathing emissions without a significant loss in working capacity or increase in flow restriction compared with known adsorbents used in canister configurations for automotive emissions control systems.

Owner:INGEVITY SOUTH CAROLINA

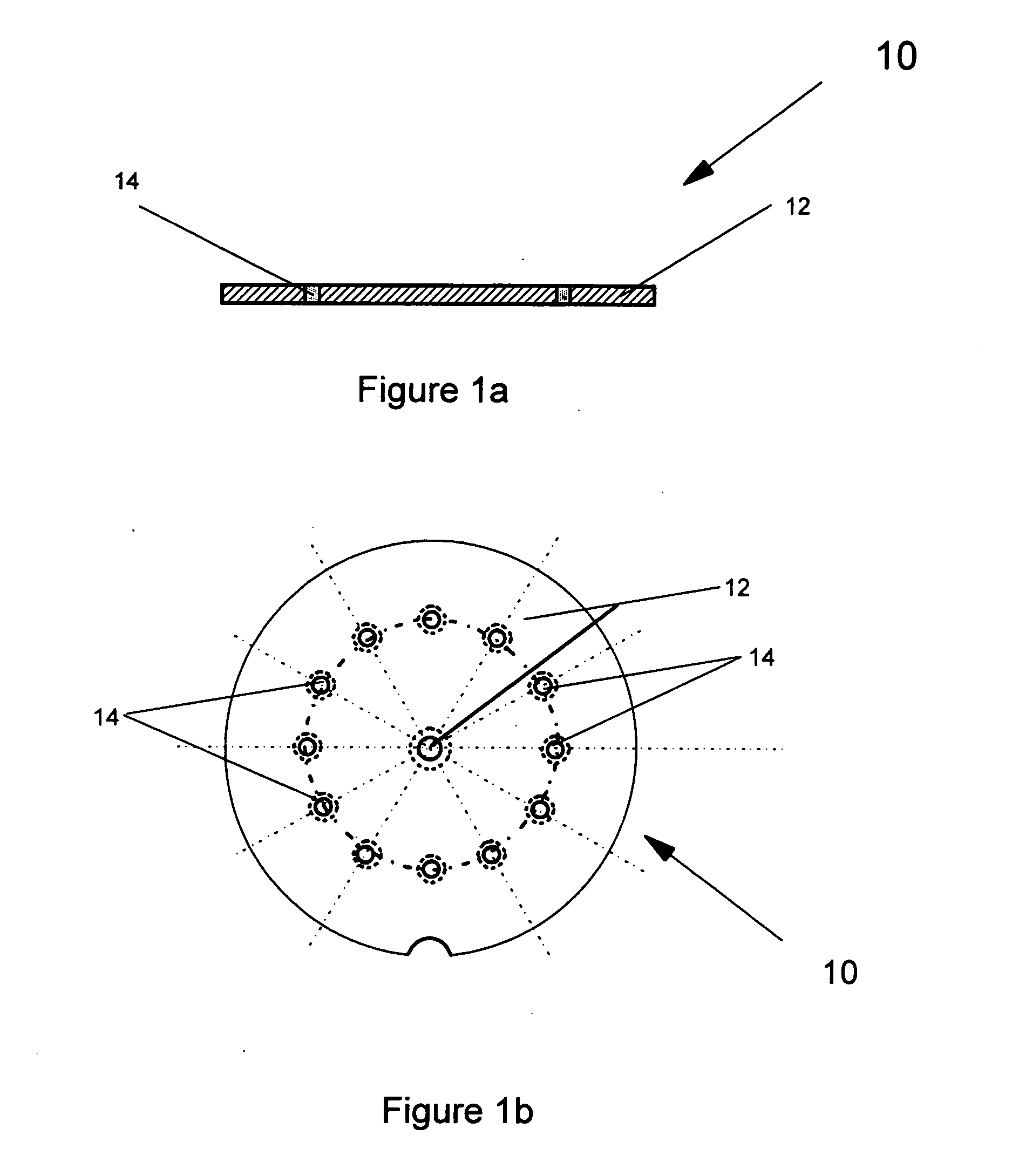

Dry powder inhaler

ActiveUS20070235029A1Small accurate volumePrecise deliveryRespiratorsLiquid surface applicatorsMicroDoseAerosolize

A new dry powder inhaler is developed as a pulmonary medicine delivery device for dispersing precise tiny dosages (10 μg-50 mg) of pure carrier-free ultra-fine powdered medicament (<5 μm aerodynamics particle size) into a patient's lung. The powder is drawn from the blister cell and dispersed through an outlet tube assisted by two air streams. The first air stream goes through a the blister cell from its upstream side, to significantly fluidize the medicament in the dose to flow upward. The second one extracts the fluidized powder from downstream of the blister cell for further deagglomeration and dispersion of the medicament powder by shear force. The rotating multi-dose blister can hold up to 60 doses, which are pre-metered with pure ultra-fine powdered medicament. So that it has higher drug loading capability in small volumes, compared to most current dry powder inhalers, which usually use some excipient. The inhaler efficiently disperse the aerosolized medicament in the air stream to the deep interior of patient's lung. The fine particle fraction (<4.7 μm) is reported to reach as high as 80% using this inhaler.

Owner:NINGBO INHAL PHARMA CO LTD

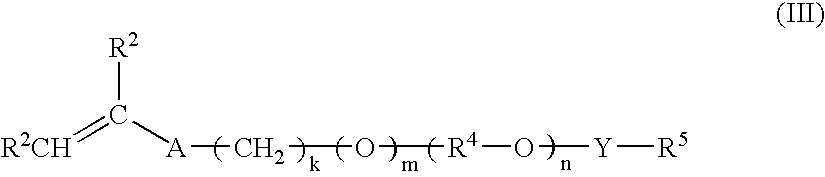

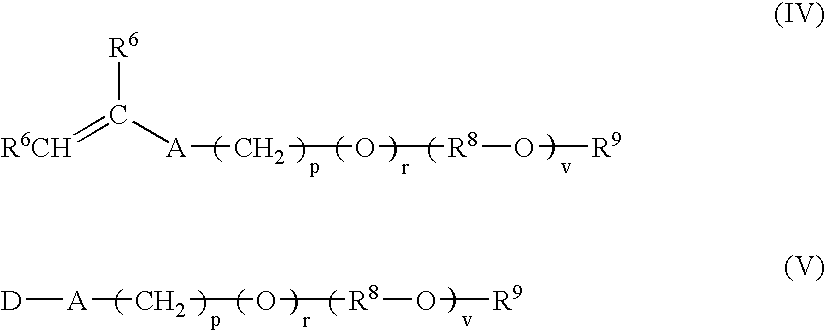

Multi-purpose polymers, methods and compositions

ActiveUS7378479B2Enhancing efficacy and deposition and deliveryImproved aesthetic propertyCosmetic preparationsHair cosmeticsStabilizer for polymersPersonal care

Disclosed are multi-purpose polymers that are the polymerization product of a monomer mixture comprising at least one amino-substituted vinyl monomer; at least one nonionic vinyl monomer; at least one associative vinyl monomer; at least one semihydrophobic vinyl surfactant monomer; and, optionally, comprising one or more hydroxy-substituted nonionic vinyl monomer, crosslinking monomer, chain transfer agent or polymeric stabilizer. These vinyl addition polymers have a combination of substituents, including amino substituents that provide cationic properties at low pH, hydrophobic substituents, hydrophobically modified polyoxyalkylene substituents, and hydrophilic polyoxyalkylene substituents. The polymers provide surprisingly beneficial rheological properties in acidic aqueous compositions, and are compatible with cationic materials. The multi-purpose polymers are useful in a variety of products for personal care, health care, household care, institutional and industrial care, and industrial applications.

Owner:LUBRIZOL ADVANCED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com