Patents

Literature

64results about How to "Prevent clogging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for analyzing a fluid sample

InactiveUS6881541B2Small pore sizePrevent cloggingBioreactor/fermenter combinationsHeating or cooling apparatusBiologyReaction chamber

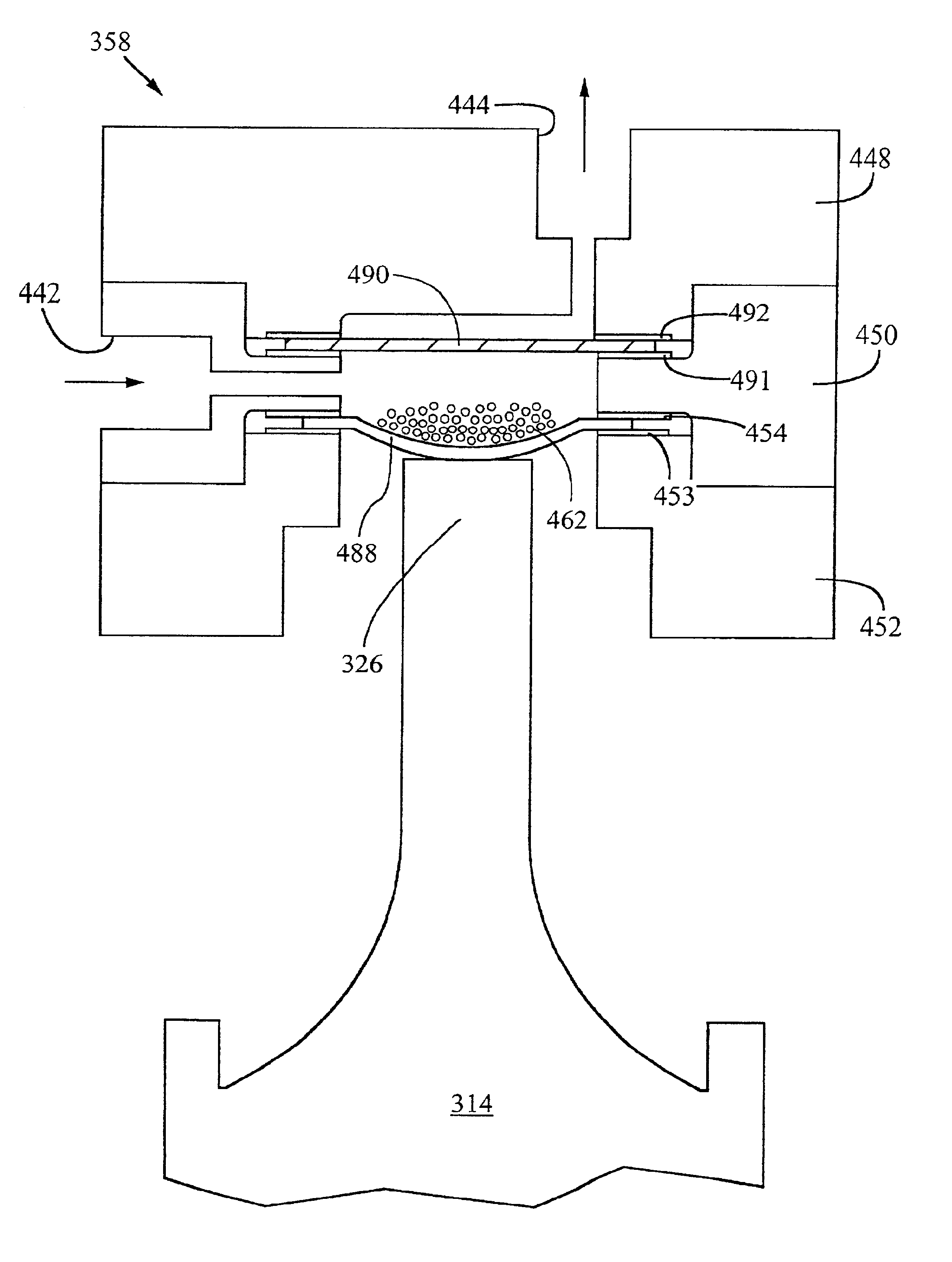

A method for extracting nucleic acid from a fluid sample comprises the steps of introducing the sample into a cartridge having a sample flow path and a lysing chamber in the sample flow path. The lysing chamber contains at least one filter for separating cells or viruses from the sample. The sample is forced to flow through the lysing chamber to capture the cells or viruses with the filter, while used sample fluid flows to waste. The captured cells or viruses are disrupted to release their nucleic acid, the nucleic acid is eluted from the lysing chamber, and optionally the nucleic acid is amplified and detected in a reaction chamber of the cartridge.

Owner:CEPHEID INC

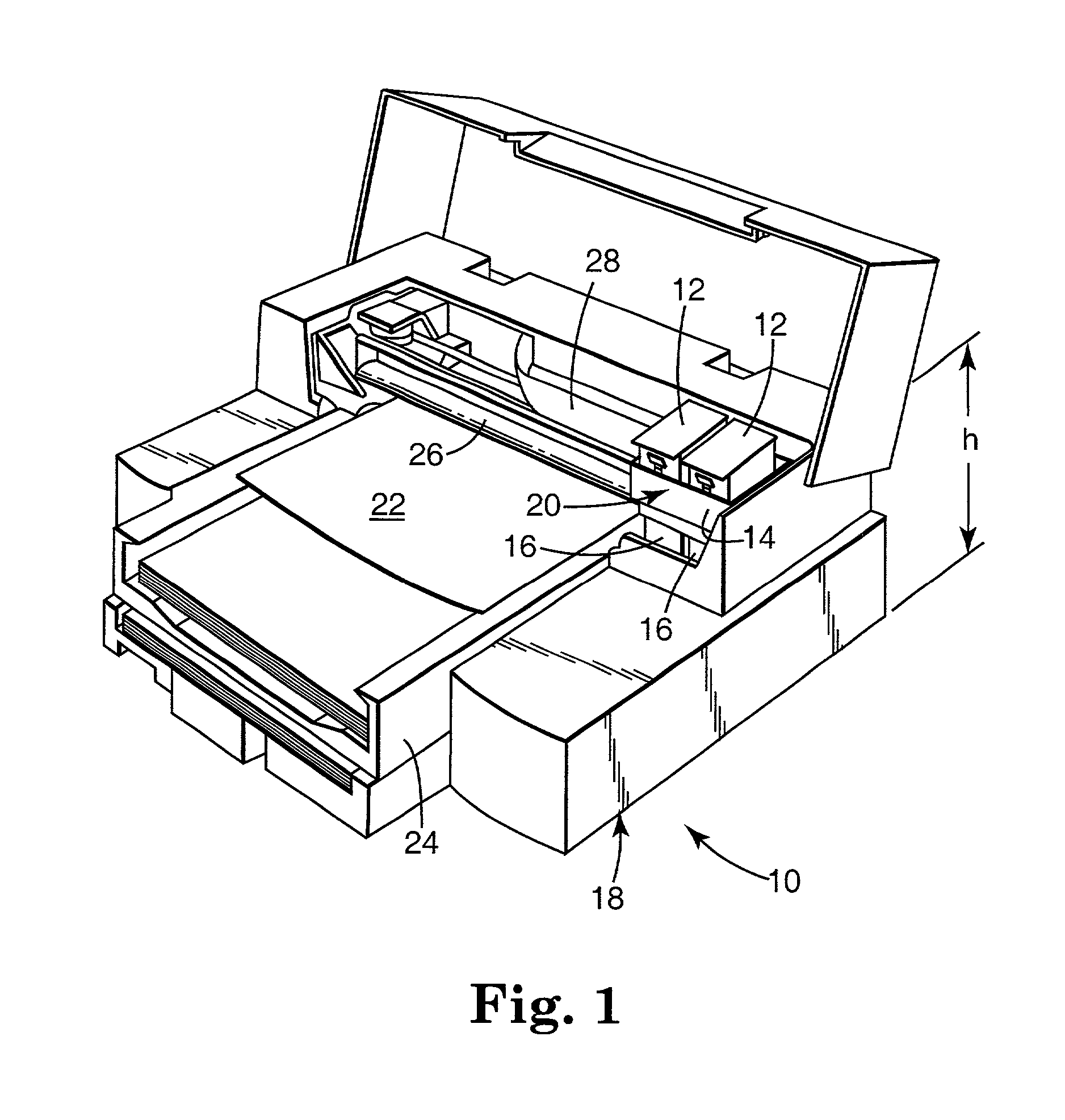

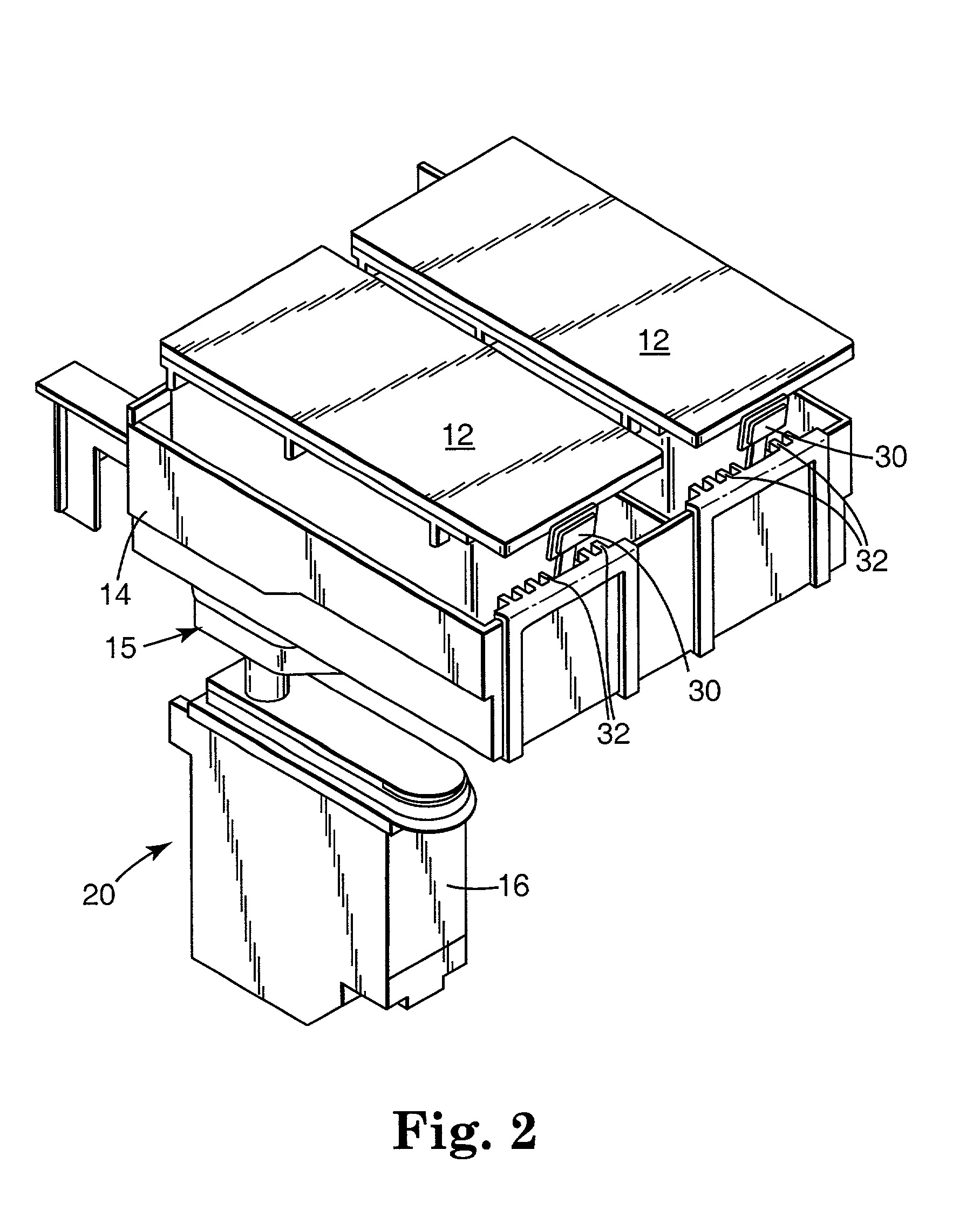

Inkjet printing system using filter fluid interconnects for pigmented inks

InactiveUS20020126188A1Prevent cloggingPrevent droolFiltration separationPrintingBiomedical engineeringInkjet printing

Disclosed is a pigmented fluid delivery system for an inkjet printing system. The pigmented fluid delivery system comprises a first printer component and at least a second printer component. The first printer component has a fluid outlet in fluid communication with a supply of pigmented fluid defined by particles suspended in a carrier fluid. The second printer component has a fluid inlet releasably connectable to the fluid outlet of the first printer component. The fluid inlet includes a filter compatible with the supply of pigmented fluid. The filter is an open weave screen defining a plurality of pores. The pores are sized to allow passage of the pigmented fluid while preventing clogging from flocculation of the particles and evaporation of the carrier fluid.

Owner:HEWLETT PACKARD DEV CO LP

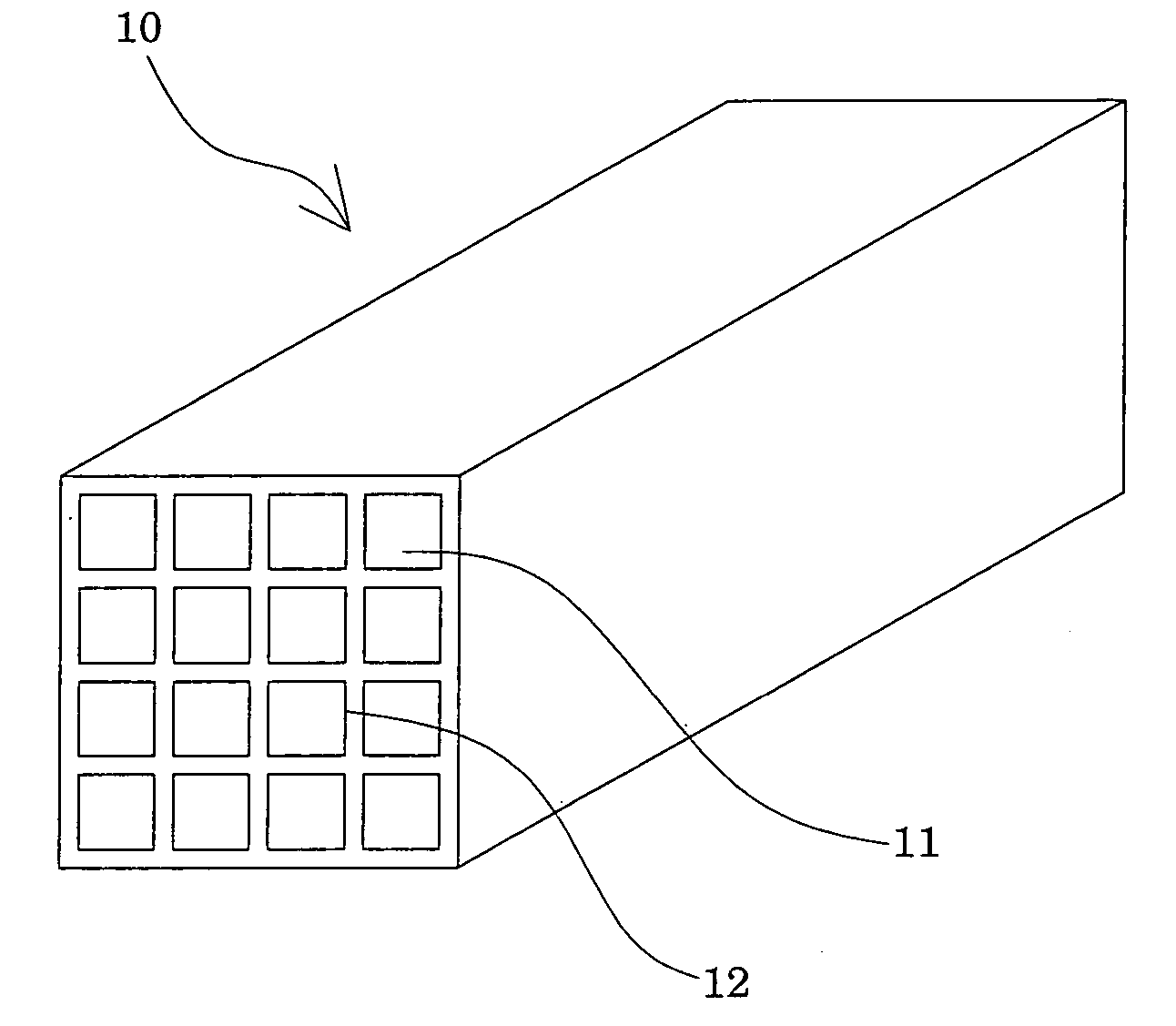

Method of producing a multi-microchannel, flow-through element and device using same

ActiveUS20120032366A1Prevent cloggingIncrease speedMaterial analysis by electric/magnetic meansProcess efficiency improvementBiomedical engineeringMicromixer

A method of producing a multi-microchannel, flow-through element, including the steps of providing a body of material, and producing multiple microchannels within the body, wherein the microchannels extend through the body to produce a multi-microchannel, flow-through element. Such an element can be used as a micromixer, a sensor element, a filter, a fuel element or a chromatographic element.

Owner:NEW MEXICO TECH RES FOUND

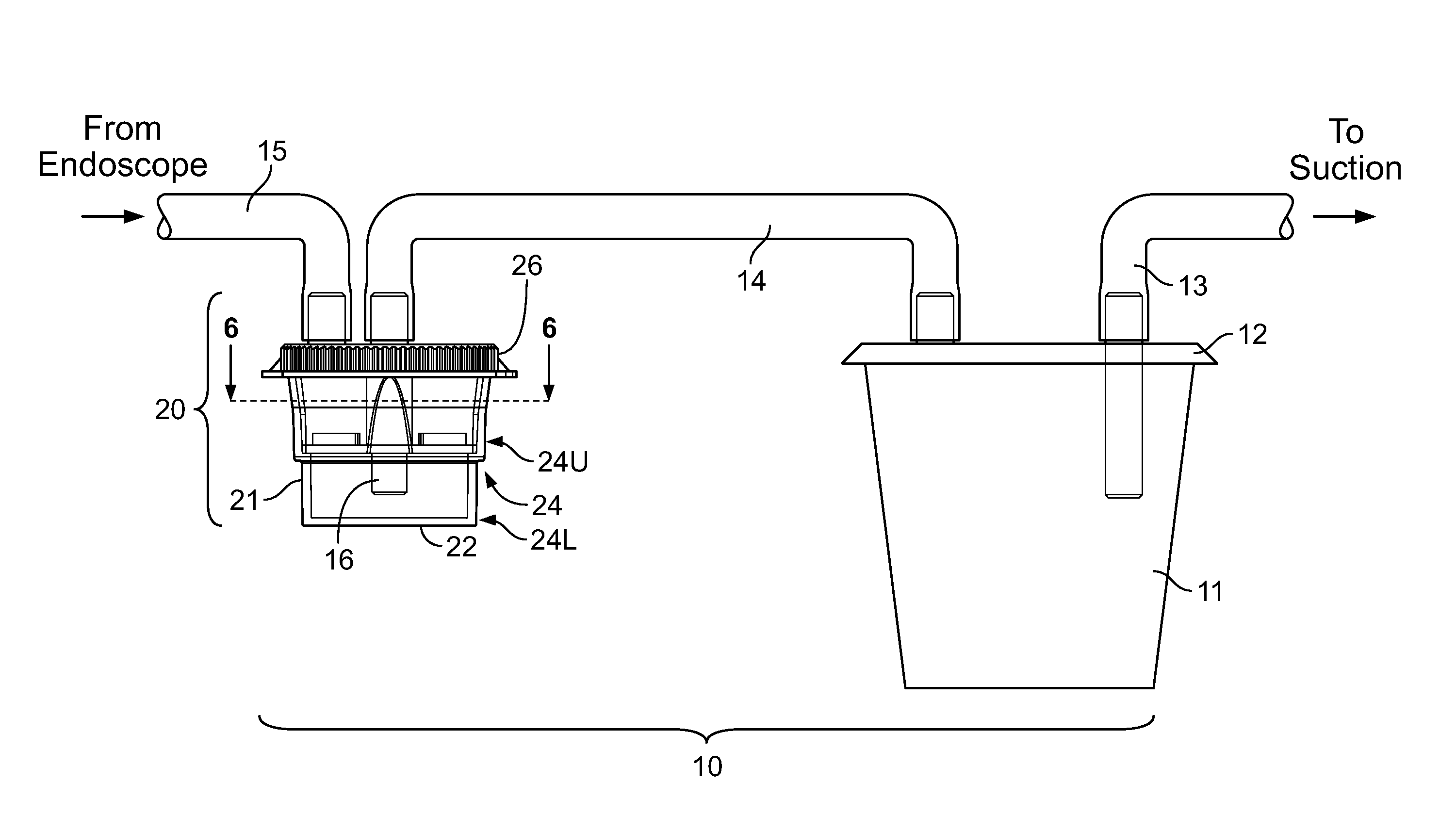

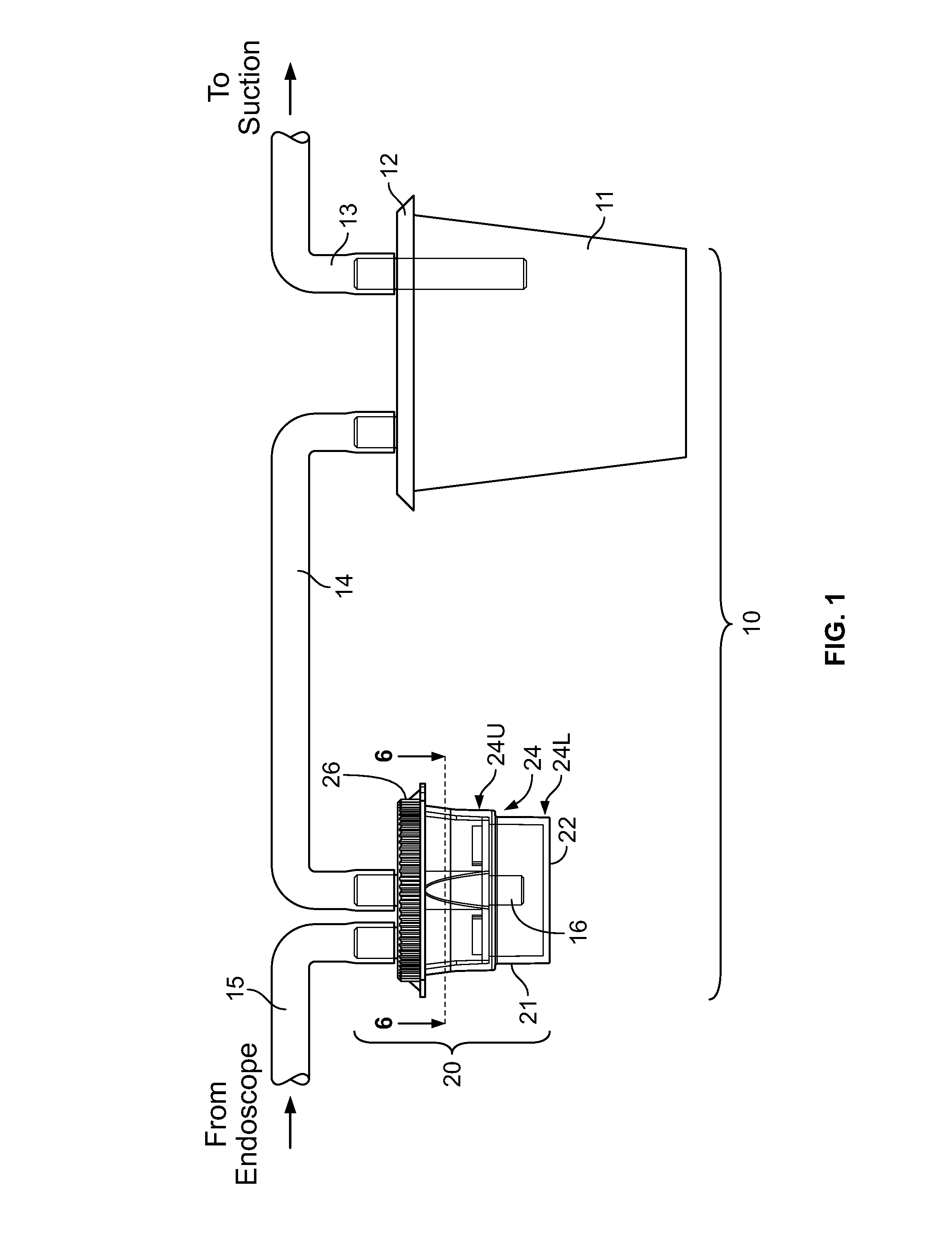

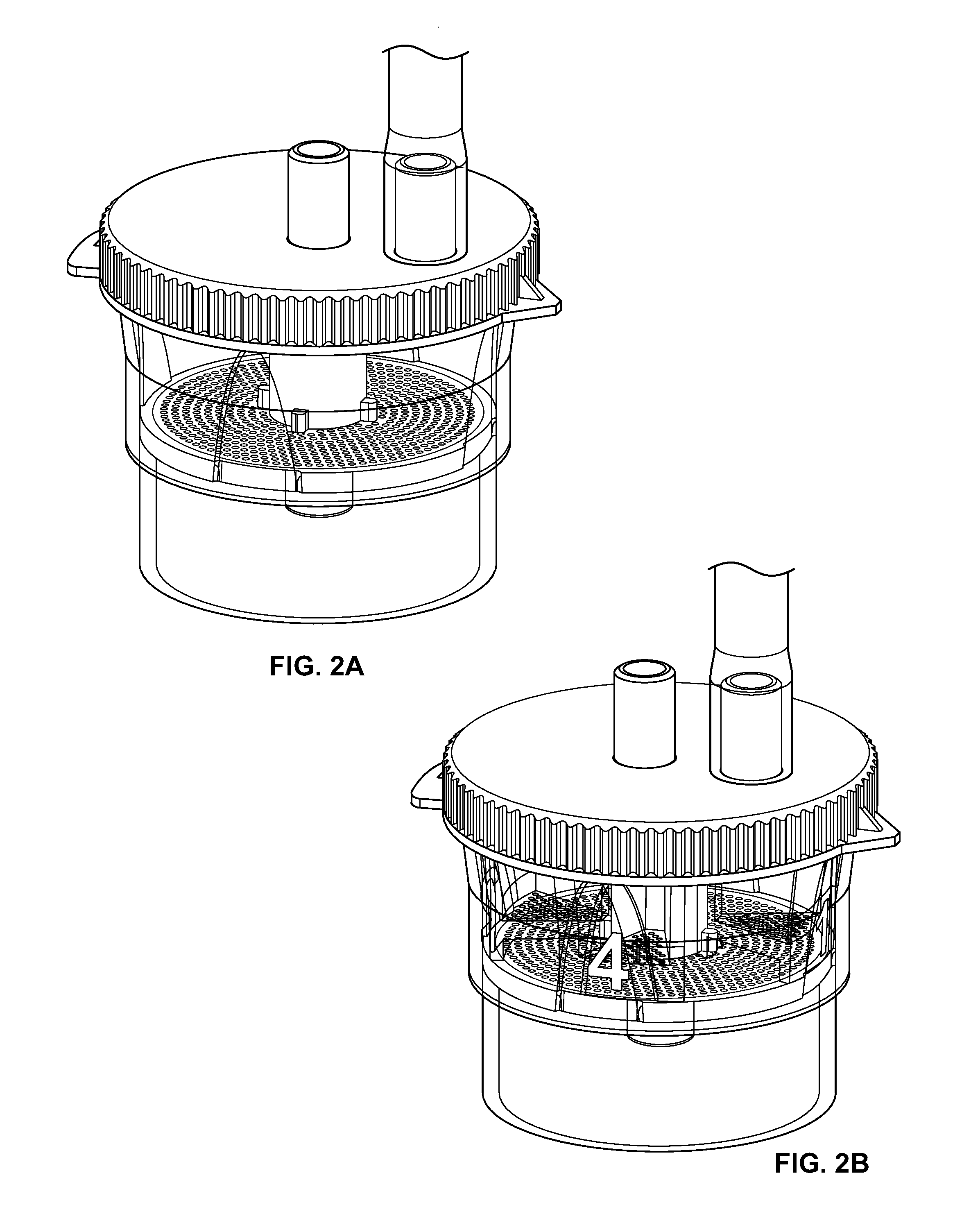

Tissue collection and separation device

ActiveUS20120053484A1Prevent cloggingPrevent positionSurgeryVaccination/ovulation diagnosticsBody fluidSolid particle

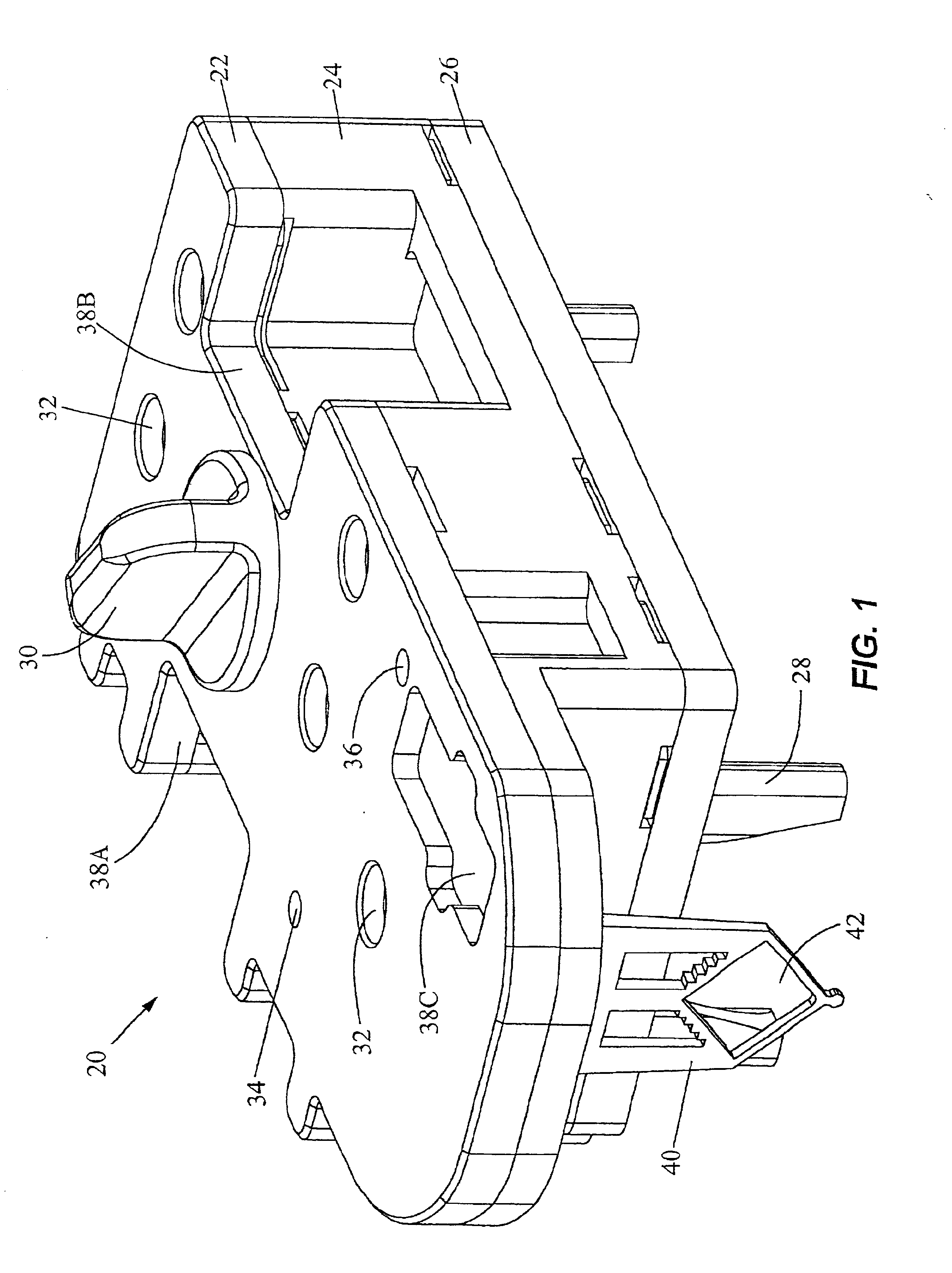

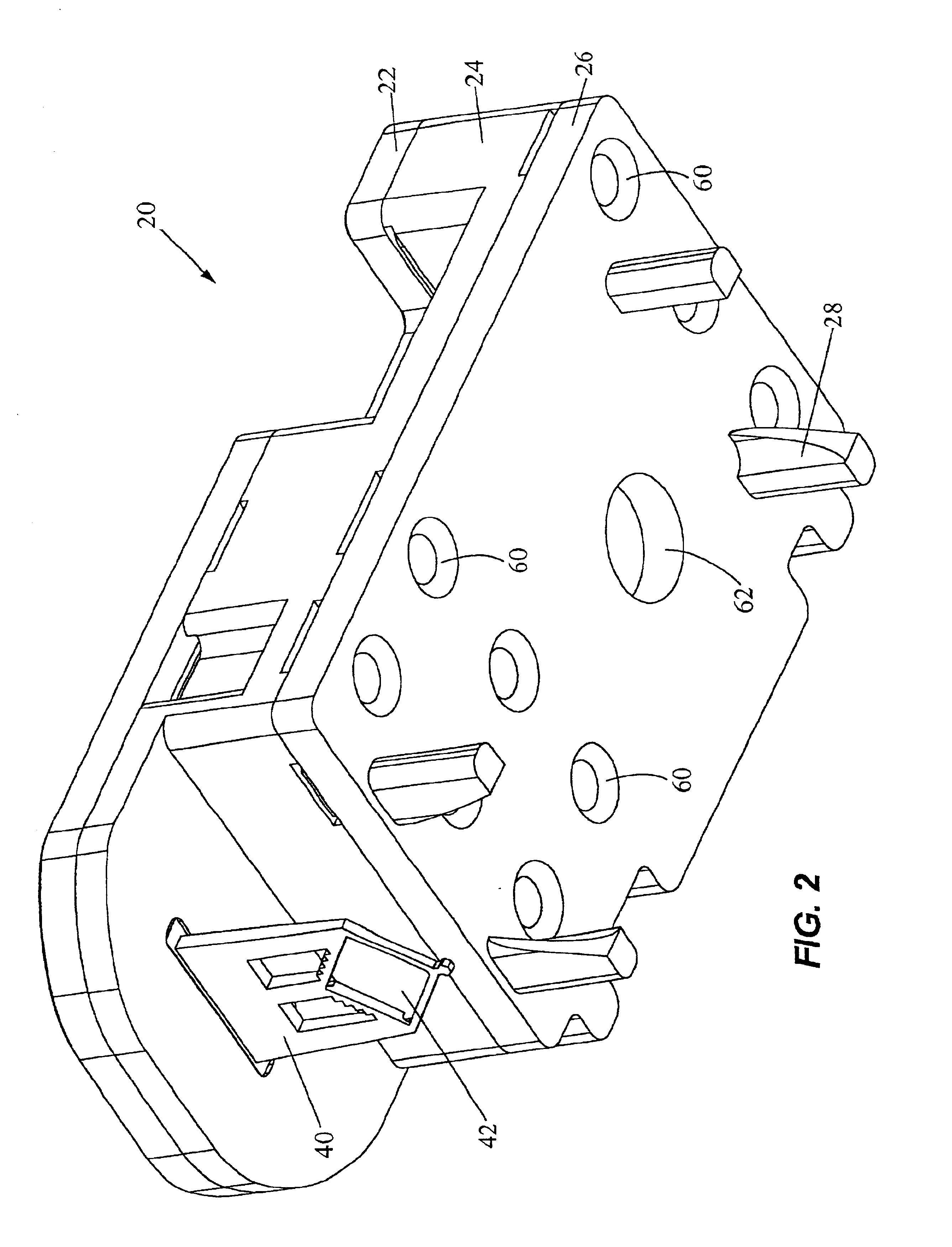

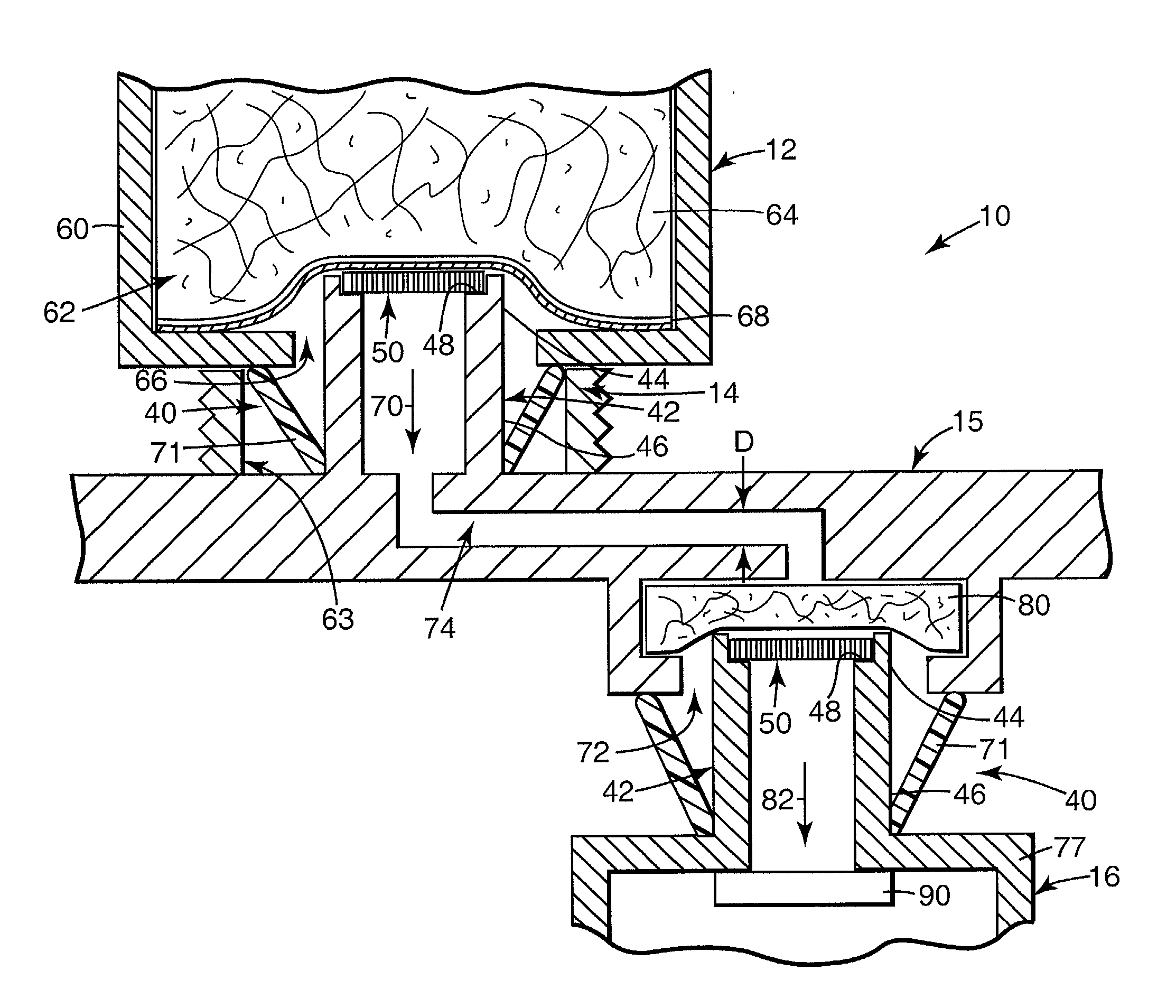

An improved tissue specimen trapping device for collecting and separating solid particles and materials from body fluids has a porous separator that rests on a shelf-like annular ledge between upper and lower portions of the tissue collection container. At least one tissue collection basket removably disposed in the tissue collection container above the separator shelf has a porous bottom surface to filter tissue specimens from body fluids and has downward projections to the tissue collection basket above the separator shelf to create a space therebetween. To ensure that each tissue collection basket is properly and securely positioned within the tissue collection container, a group of cooperating projections and recesses on the inside circumferential wall of the tissue collection container and on the outside arcuate walls of the tissue collection baskets, and / or on the outer surface of the central column within the tissue collection container and on the inner arcuate walls of the tissue collection baskets are used. At least one projection on the underside of the cover rubs against the upper edge of the side walls of the tissue collection baskets as the projection passes over the upper edges of the side walls of each tissue collection basket when the cover is rotated on the tissue collection container provides a tactile indication that the fluid / tissue inlet port is aligned with respect to a tissue collection basket within the tissue collection container.

Owner:BOSTON SCI SCIMED INC

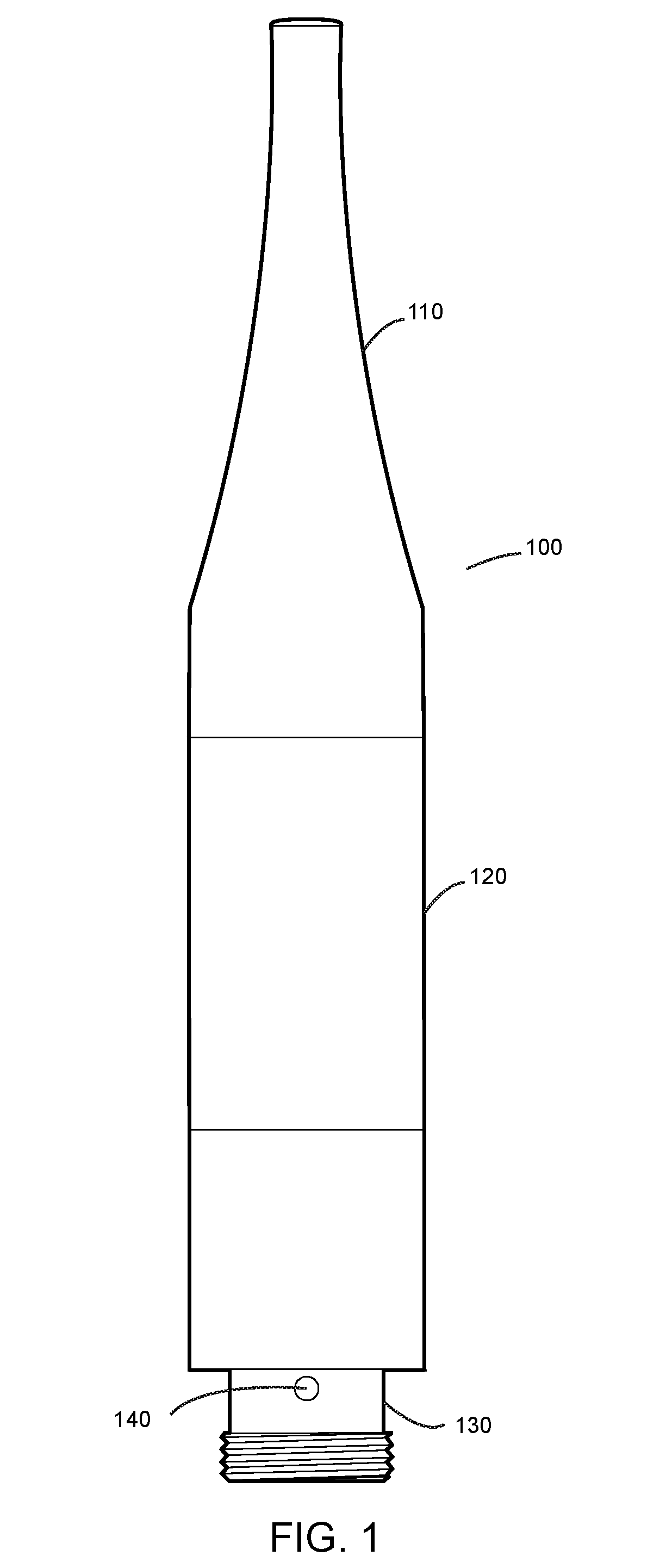

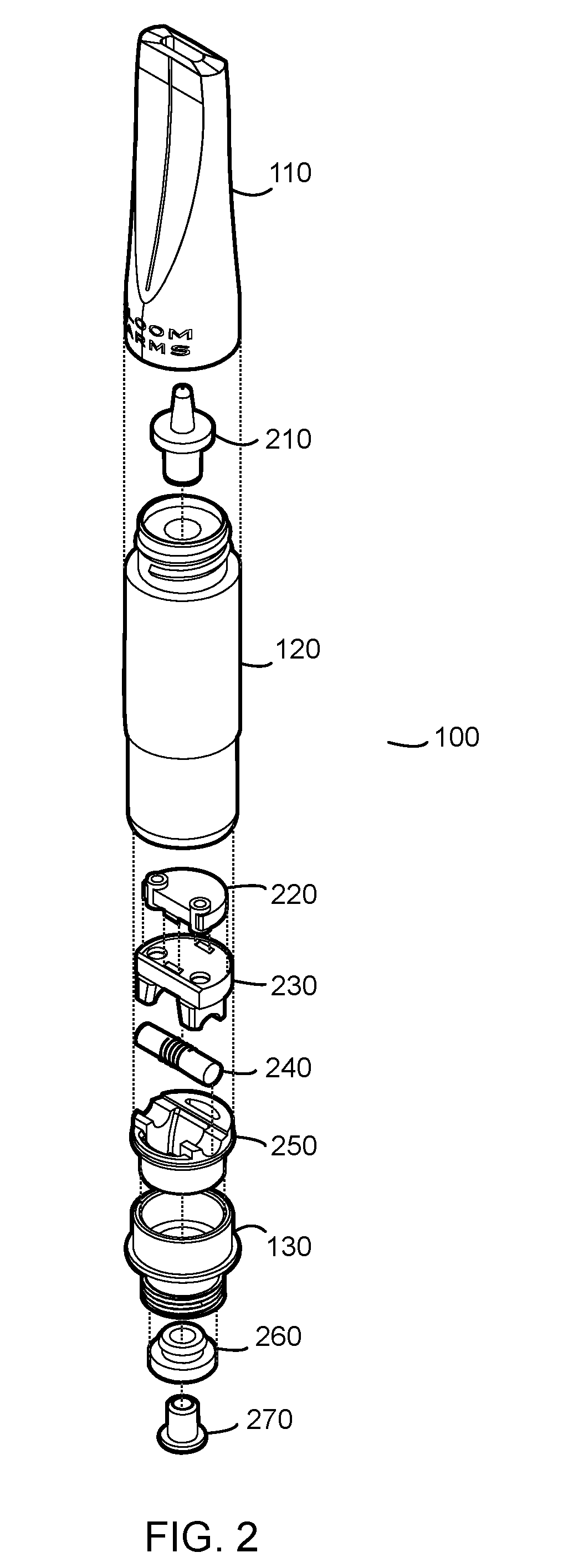

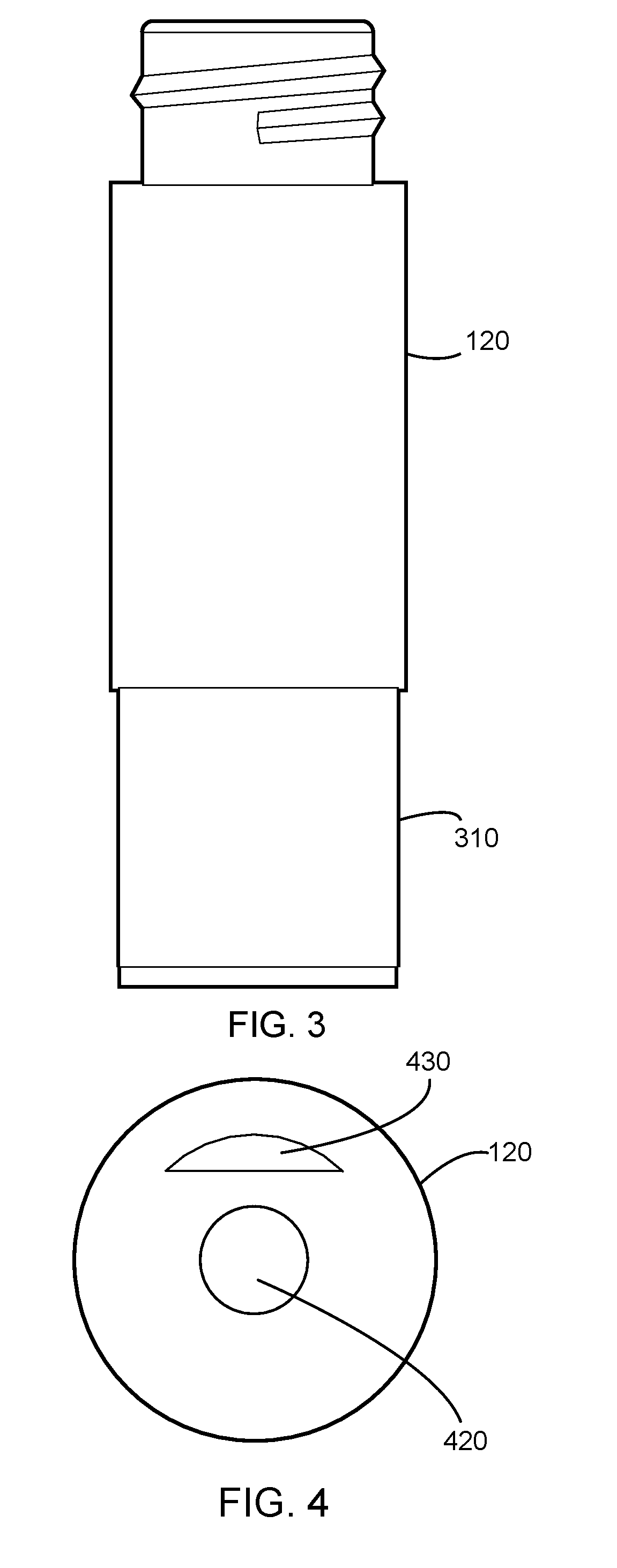

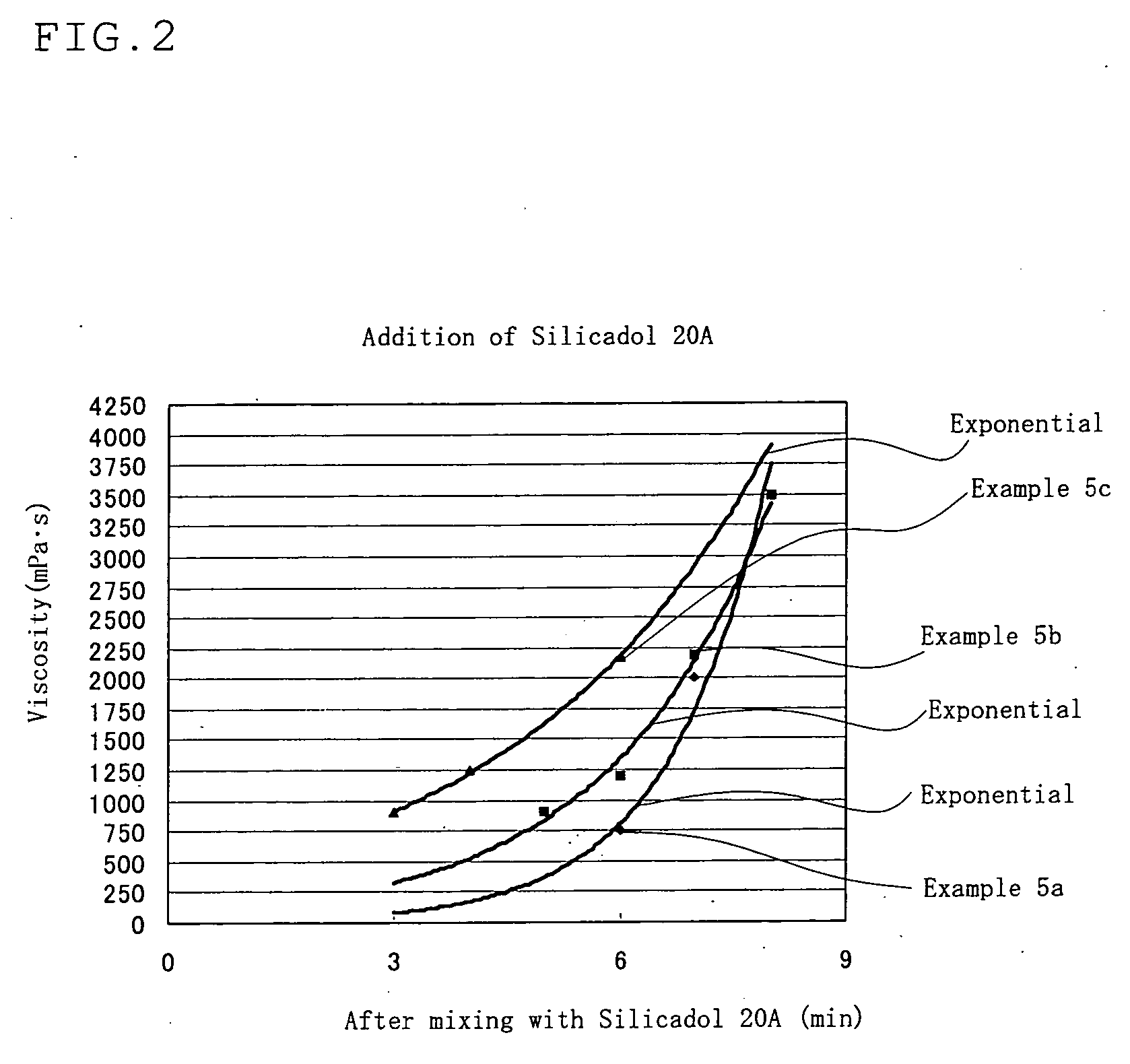

Variable Viscosity Vaporizer Cartridge

A vaporizer and vaporizer cartridge for inhaling vapors from vaporized oil. The vaporizer has a mouthpiece for use by a user to inhale the vapors. The mouthpiece is connected to a cartridge which contains the oil to be vaporized and the apparatus for vaporizing the oil. The vaporizer cartridge contains a reservoir of the oil which flows down to a wick, which is heated by a heating coil to a temperature necessary to vaporize the oil. Under the wick is a residue basin which collects any oil which fails to vaporize. The residue basin is placed at an optimal distance from the wick such that when the next user initiates another draw on the vaporizer, the un-vaporized oil in the residue basin is vaporized. Below the cartridge is a battery component that provides power to a heating coil which heats the wick to vaporize the oil. Air flows up from below the cartridge on one side, then cross-flows across the wick and residue basin, and up the other side of the cartridge to the mouthpiece.

Owner:ACROSS INFINITY LLC

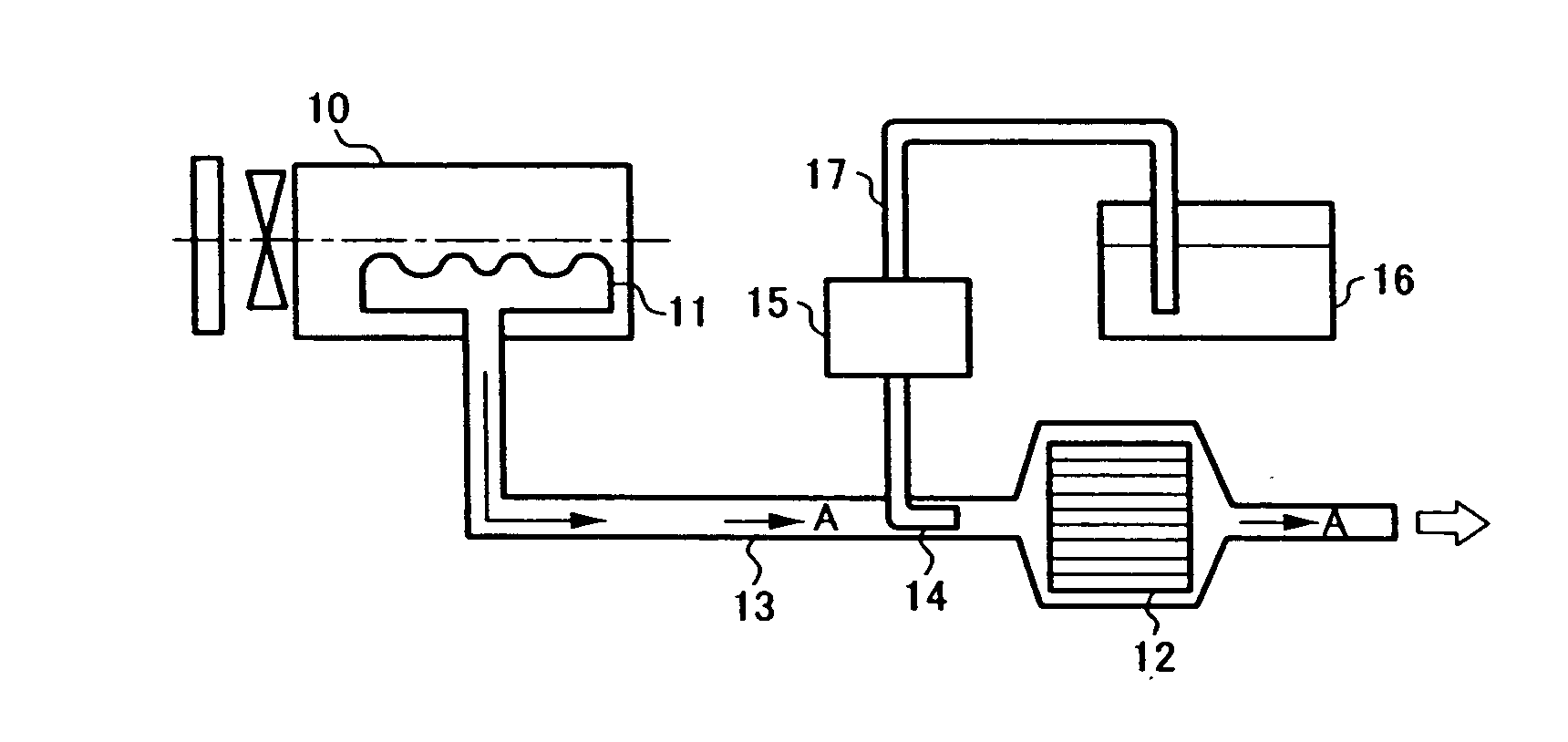

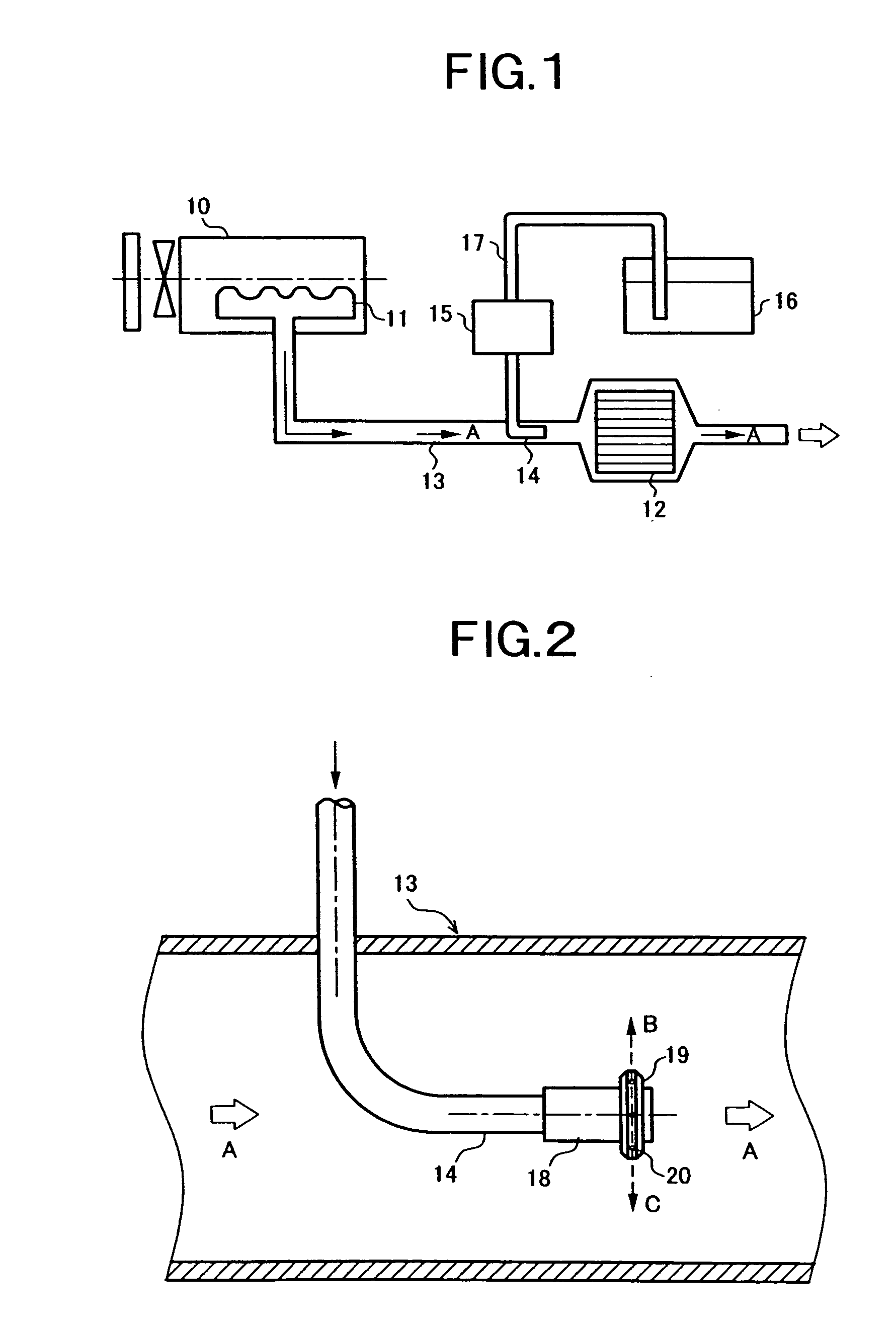

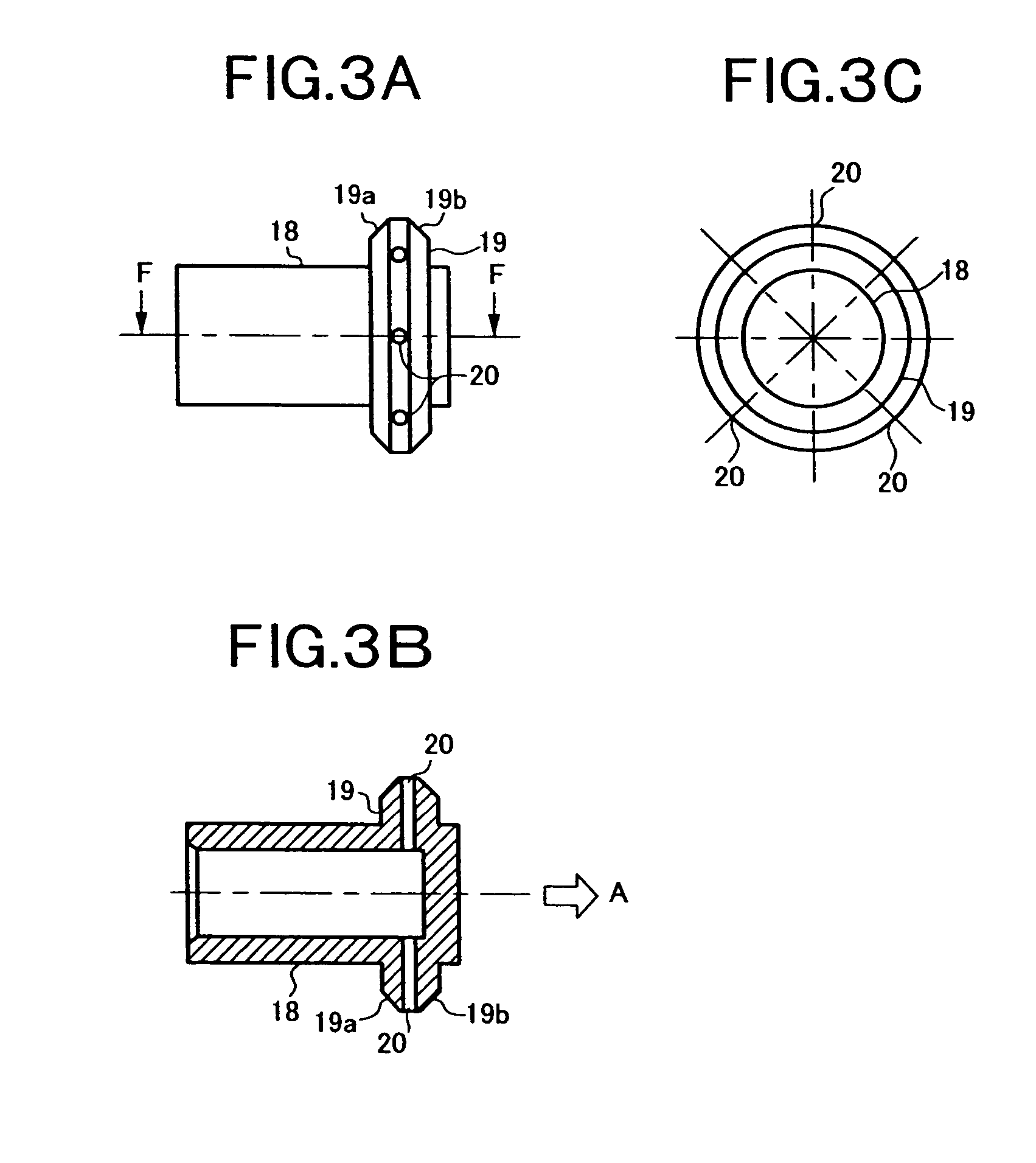

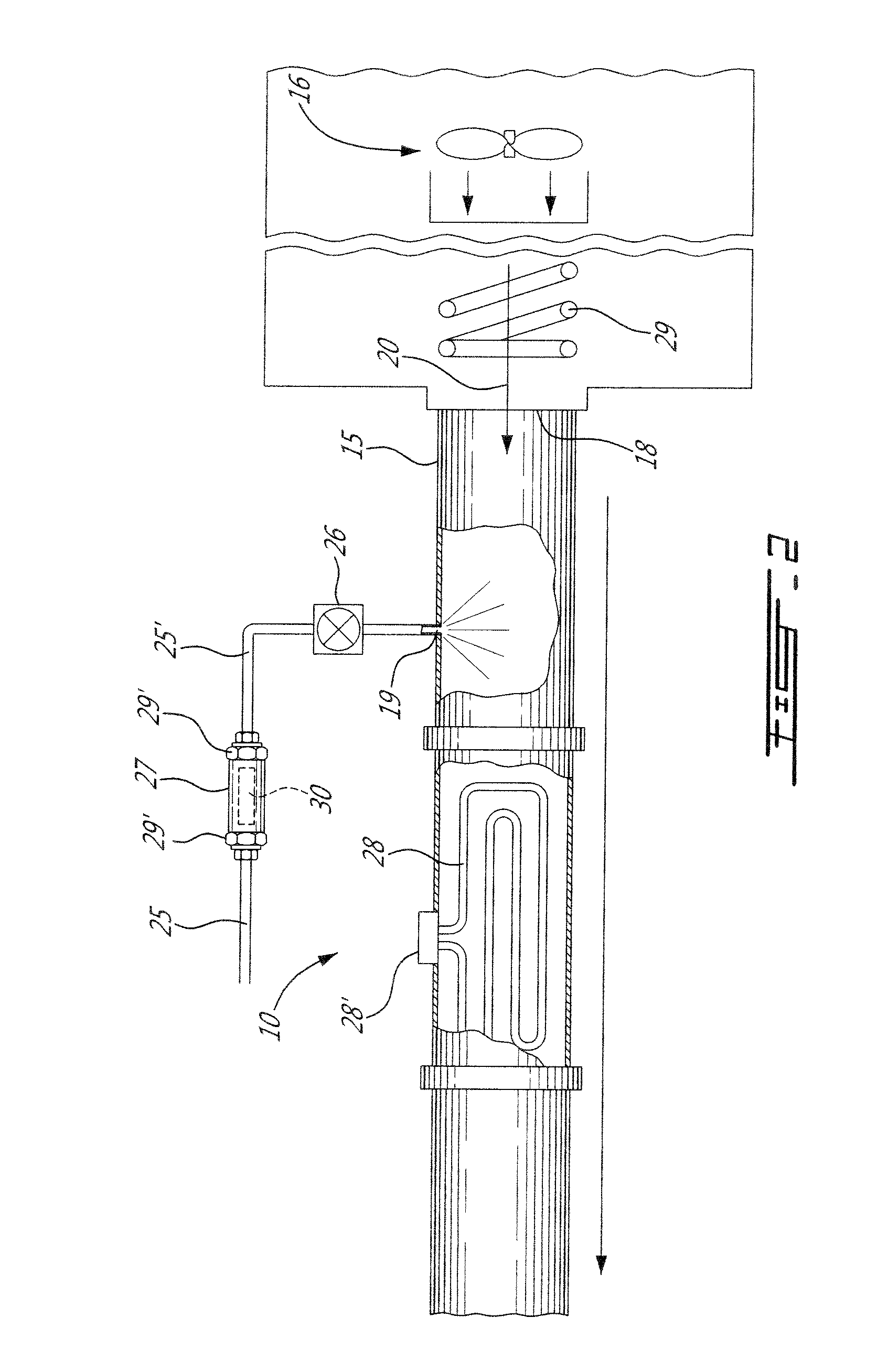

Exhaust gas purification apparatus of engine

ActiveUS20070101700A1Prevent cloggingMix proportion be improveInternal combustion piston enginesFlow mixersExhaust gasExhaust fumes

For preventing clogging in an injection nozzle for supplying a reducing agent to exhaust gas flow on an upstream side of a reducing catalyst and for improving the efficiency of NOx purification processing, the injection nozzle 14 has a tip end portion 18 provided with a ring shaped protruding ridge 19 disposed on an outer peripheral surface of an exhaust gas downstream side end portion of the tip end portion 18 that is arranged substantially in parallel with an exhaust gas flow direction A inside an exhaust pipe 13, the ring shaped protruding ridge 19 being provided with injection hole or holes 20 drilled outward from the central axis of the injection nozzle 14, so that the reducing agent is ejected on the exhaust gas upstream side of the reduction catalyst, from the injection holes 20. The injection holes 20 do not directly open on a wide outer peripheral surface of the injection nozzle 14, and then when injection stops, the reducing agent does not become attached to or does not remain around the injection holes 20, or the remaining amount thereof becomes small, so that clogging of the injection holes 20 of the injection nozzle 14 is prevented, and the efficiency of NOx purification processing is improved.

Owner:VOLVO LASTVAGNAR AB

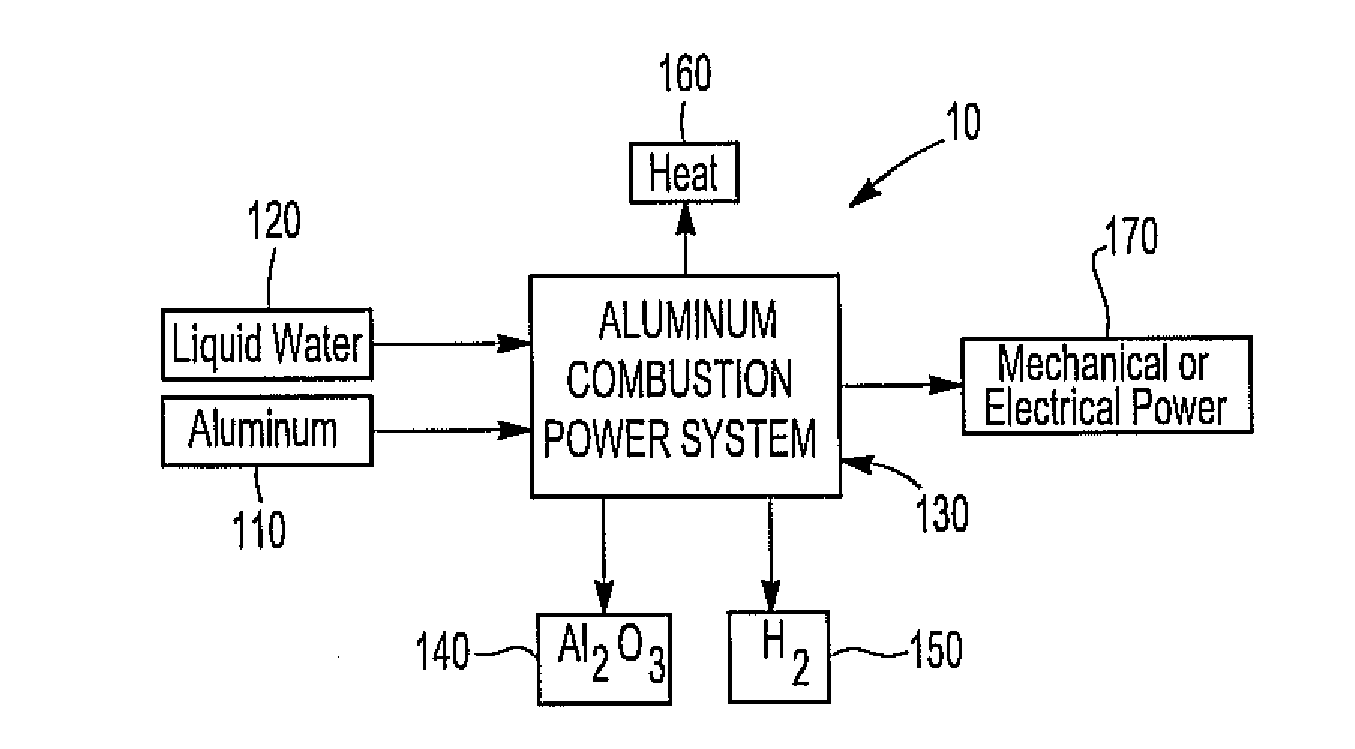

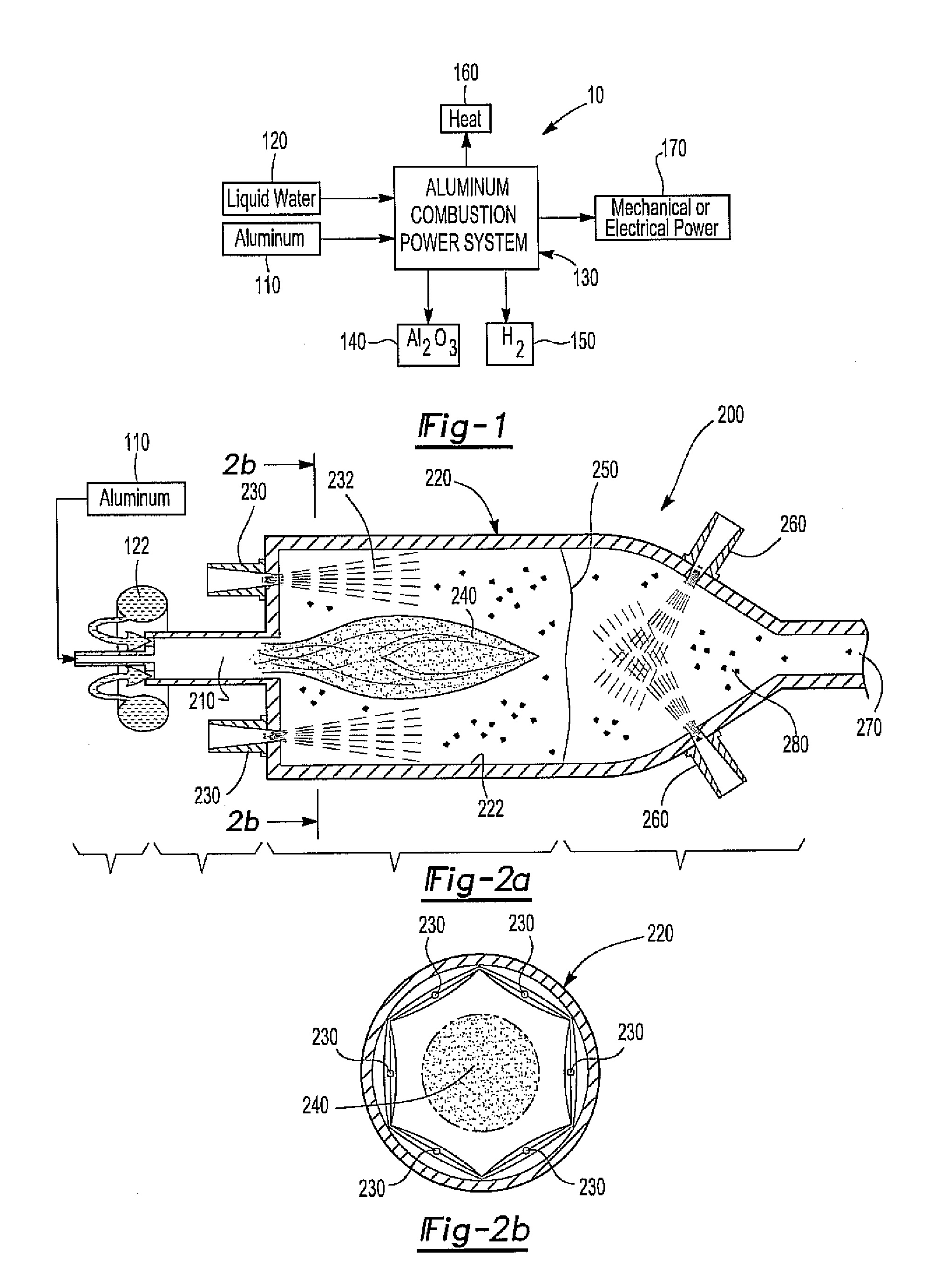

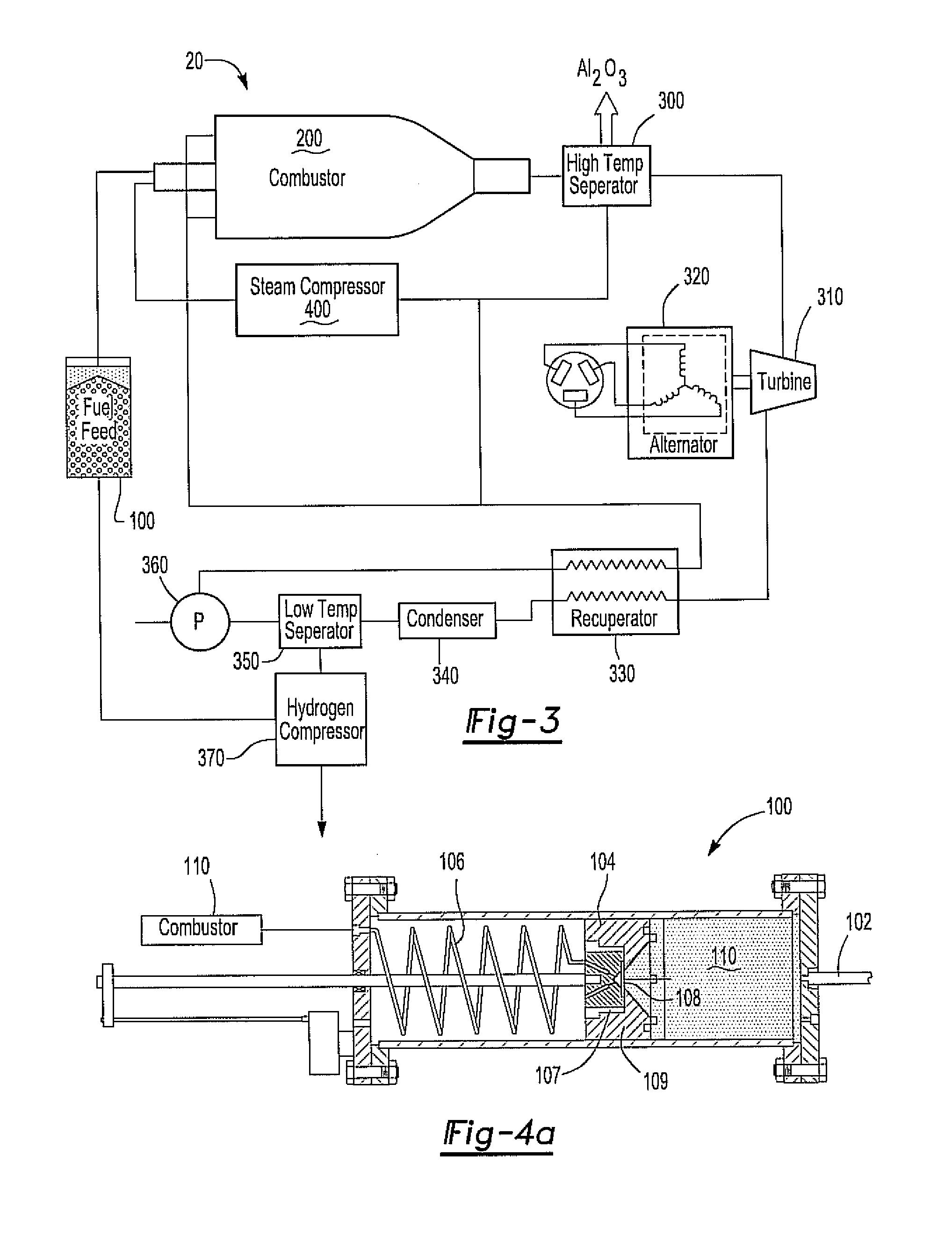

Aluminium combustion power system

An engine that oxidizes aluminum with water to produce electrical and / or mechanical power. The engine can include a fuel made at least partly from aluminum powder that flows like liquid under high pressure. The engine can also include a steam supply system, a combustor, a fuel feed system, a fuel injection system, and a water supply system.

Owner:PENN STATE RES FOUND

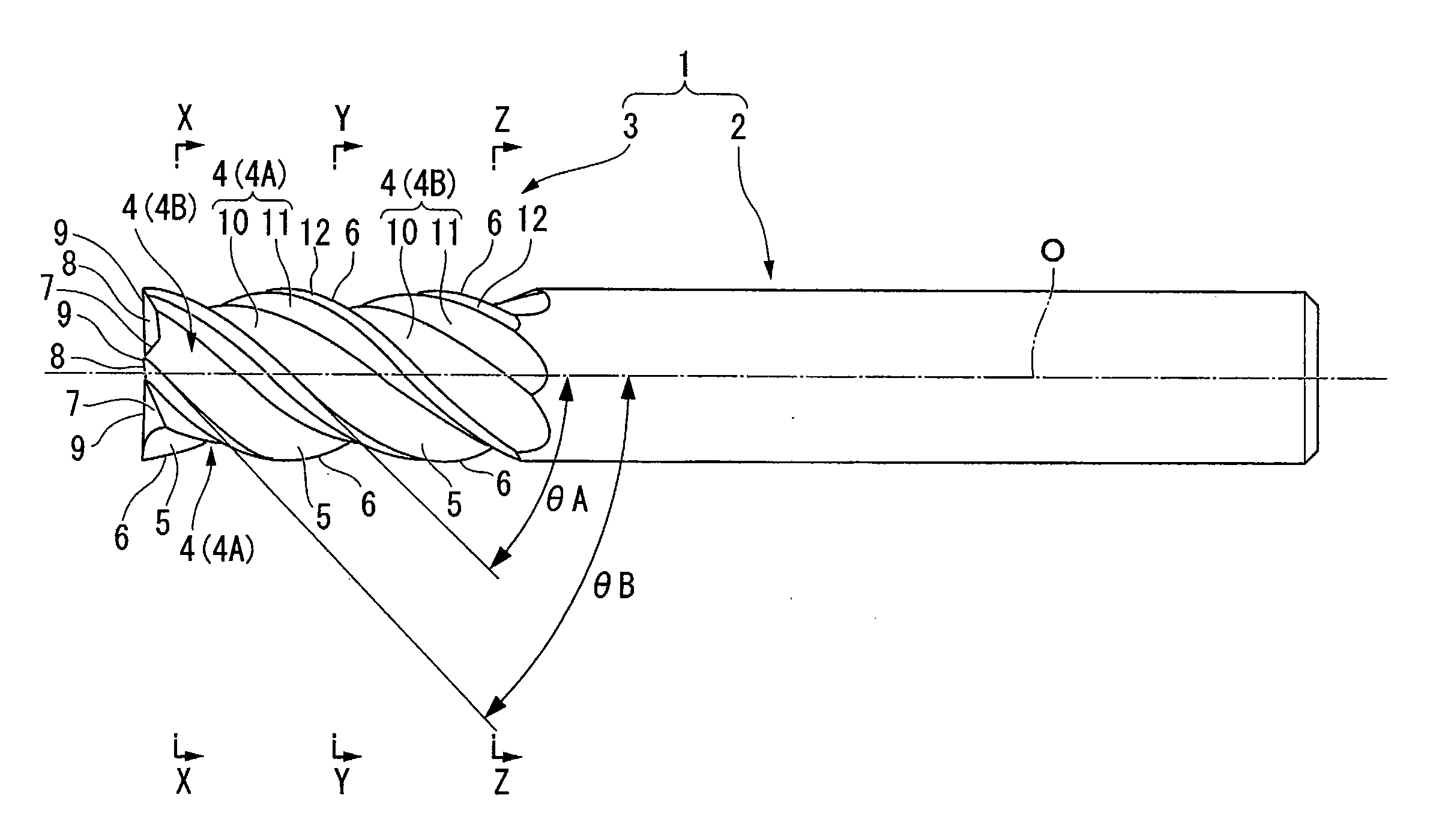

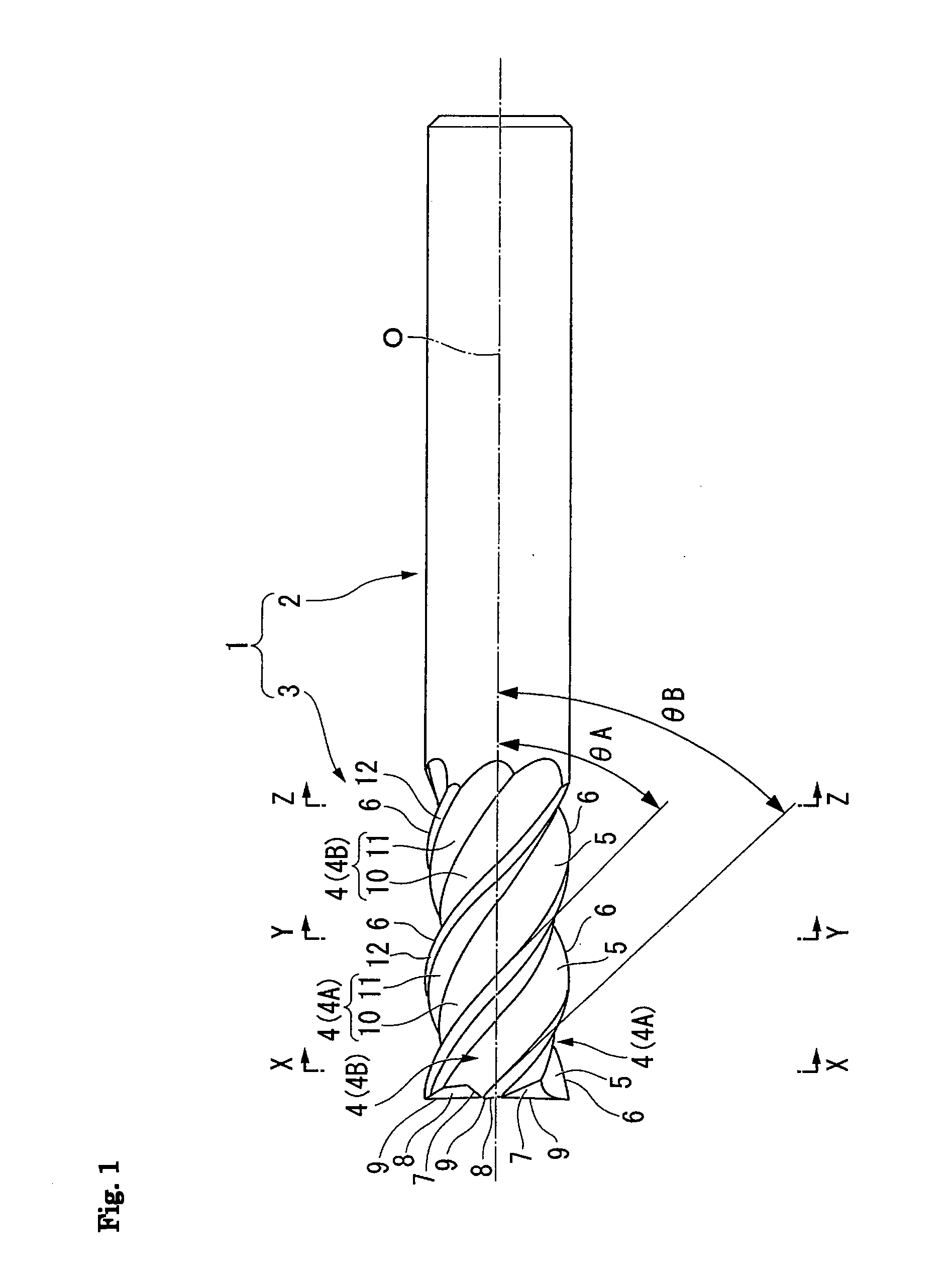

End mill

A plurality of chip discharge flutes are located on an outer periphery of a tip portion of the end mill body which rotates on its axis. Helix angles between the axis and the cutting edges in the chip discharge flutes, of which are at least one or more; are different from others. A cross-section perpendicular to the axis shows that a flute bottom face in a main flute portion forms a concavely curved shape from the rake face to a point where the flute bottom face, touches a web thickness circle of the end mill body, forms a linear shape, and goes toward the end mill rotating direction; and a flute bottom face in a sub-flute portion forms a linear shape, intersects with the flute bottom face in the main flute portion at an obtuse angle, goes further toward the end mill rotating direction.

Owner:MITSUBISHI MATERIALS CORP

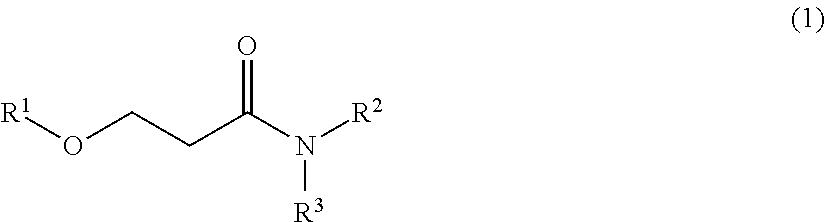

Nonaqueous ink composition for ink jet recording and ink jet recording method using nonaqueous ink composition

ActiveUS20120249666A1Prevent cloggingStabilize ejection of inkDuplicating/marking methodsInksSolventPolymer chemistry

A nonaqueous ink composition for ink jet recording contains a glitter pigment and a solvent represented by the following formula:wherein R1 represents an alkyl group containing one to eight carbon atoms and R2 and R3 represent a methyl group or an ethyl group.

Owner:SEIKO EPSON CORP

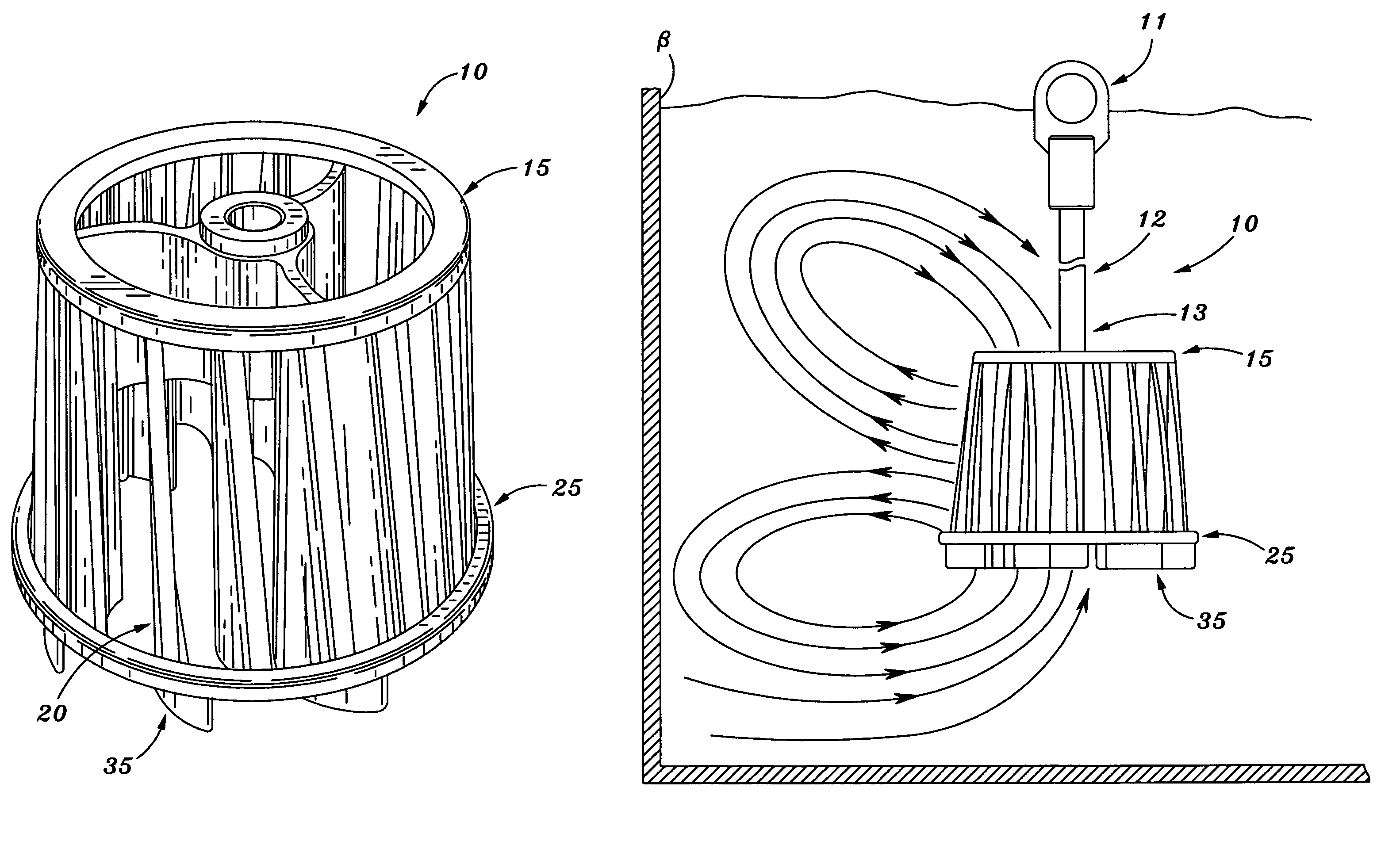

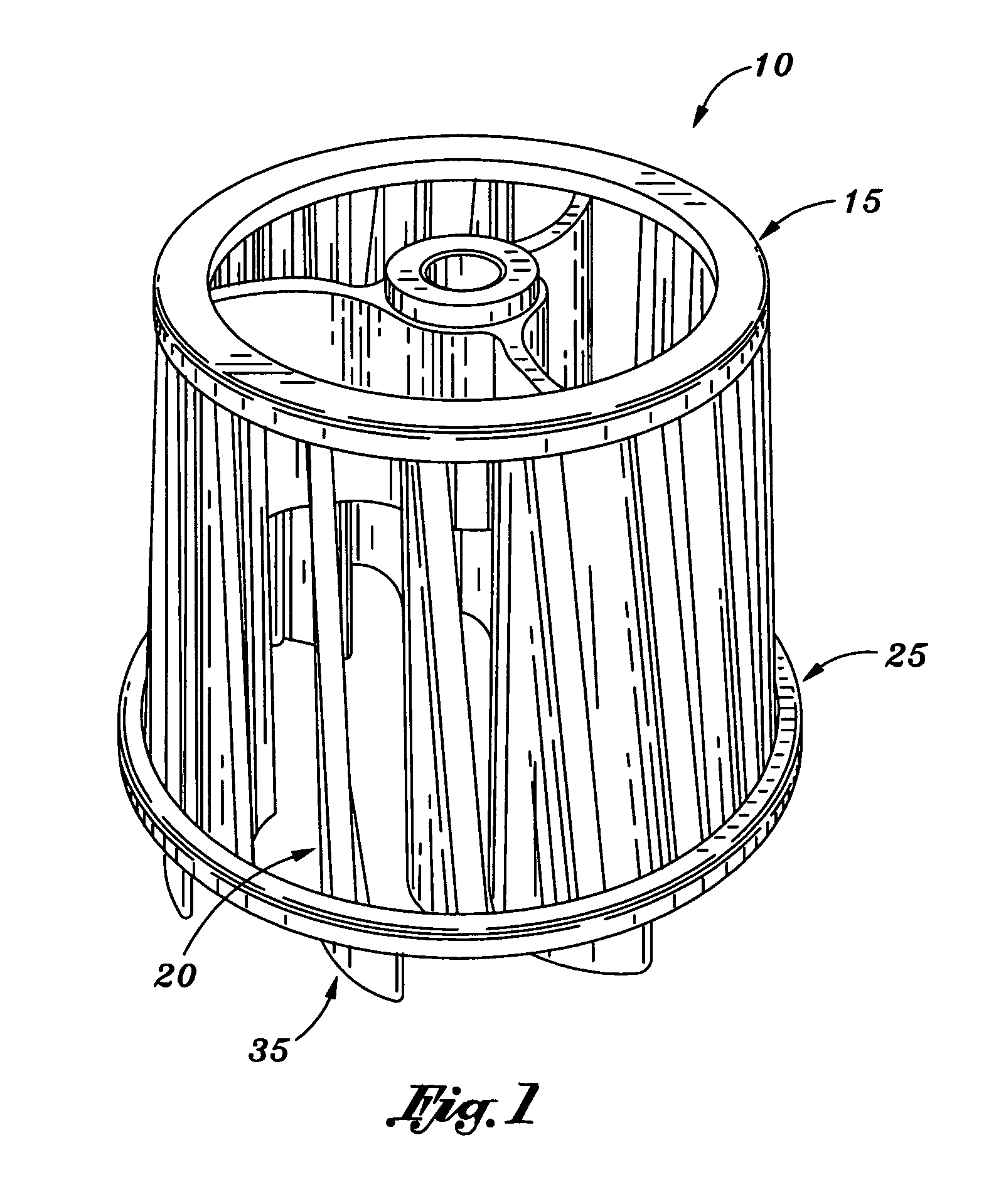

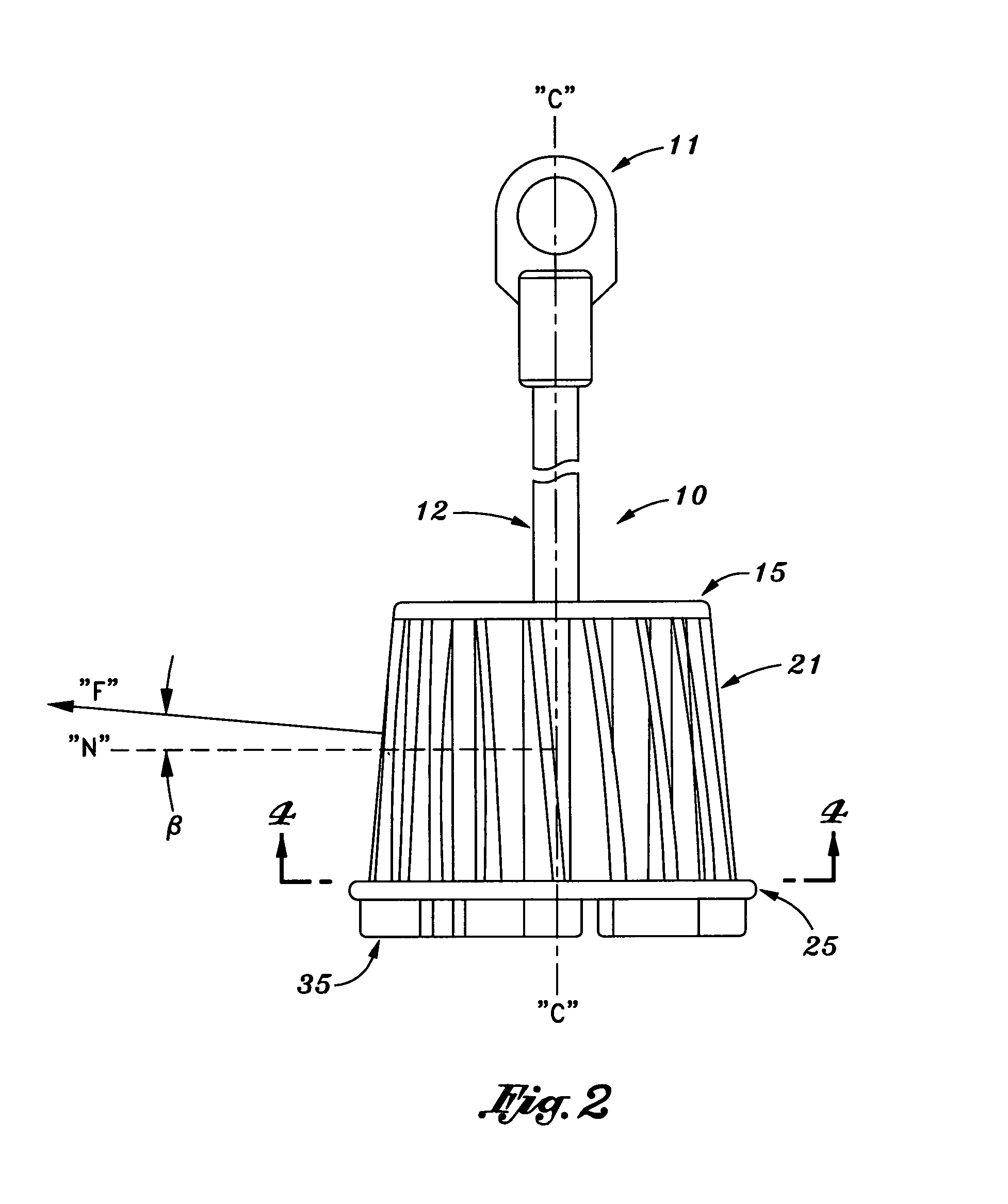

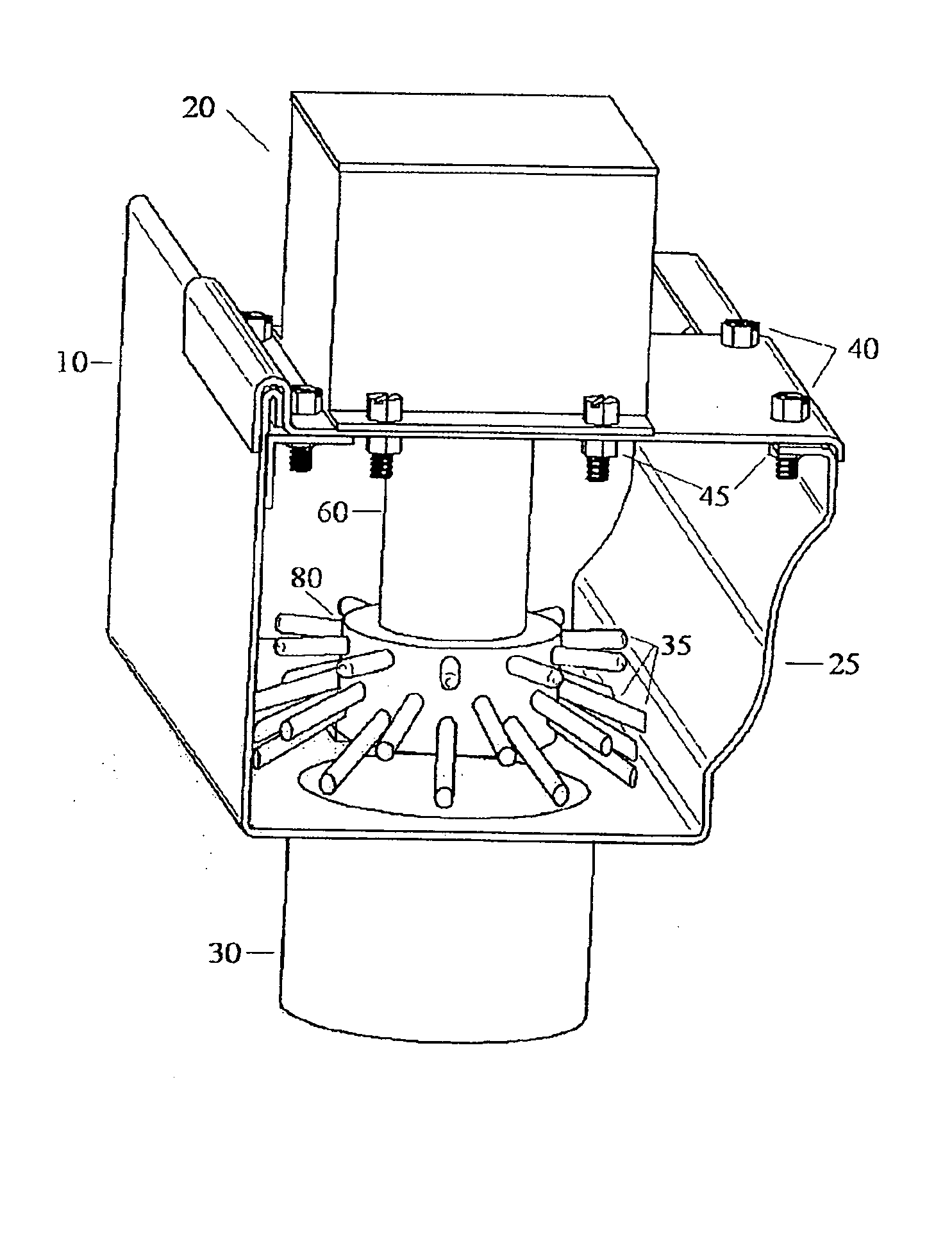

Fluid mixing device

InactiveUS6971788B1Prevent cloggingAvoid cloggingFlow mixersRotary stirring mixersEngineeringCircular cone

A mixing device includes vanes arranged so that the outer edges of the vanes define a frusto-conical surface in order to facilitate improved circulation of the liquid being mixed. Each vane is preferably curved, either lengthwise, widthwise, or both. In one embodiment, the outer edges of the vanes are tapered outward to form the frusto-conical surface. In an alternative embodiment, the inner and outer edges of the vanes are aligned with each other, and the vanes are tilted relative to a central axis to form the frusto-conical surface. The vanes may extend between upper and lower rims having the same or different diameters. Turbines extend between the vanes and shaft for rotating the mixing device. The turbines are arranged to avoid inhibiting entry of liquids through the top and bottom of the mixing device. Feet extend downward from the bottom edge of the mixing device to facilitate mixing of liquids on the bottom of the container. The inner edges of the vanes define a frusto-conical surface in order to prevent clogging of the mixing device.

Owner:PPG ARCHITECTURAL FINISHES INC

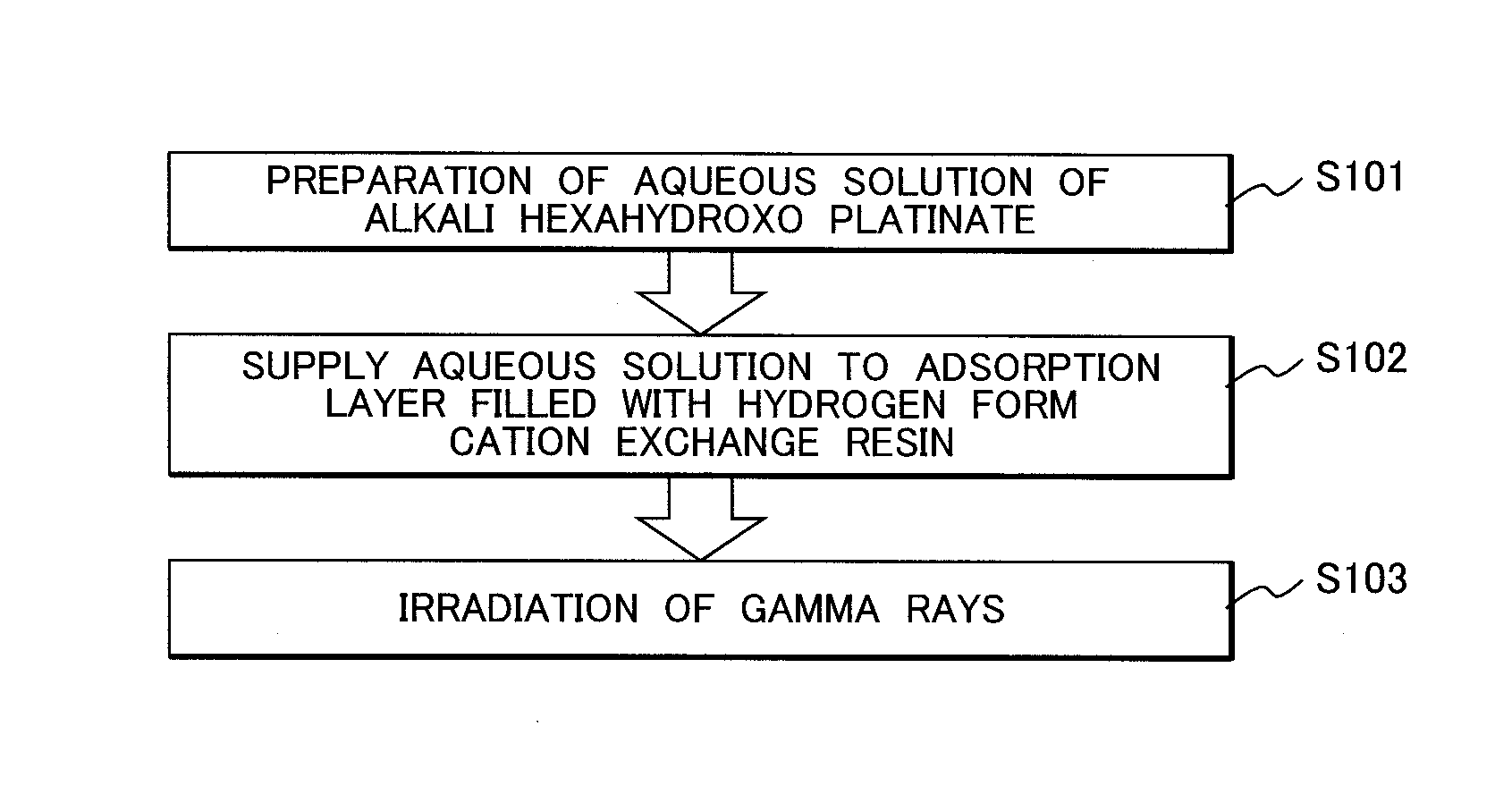

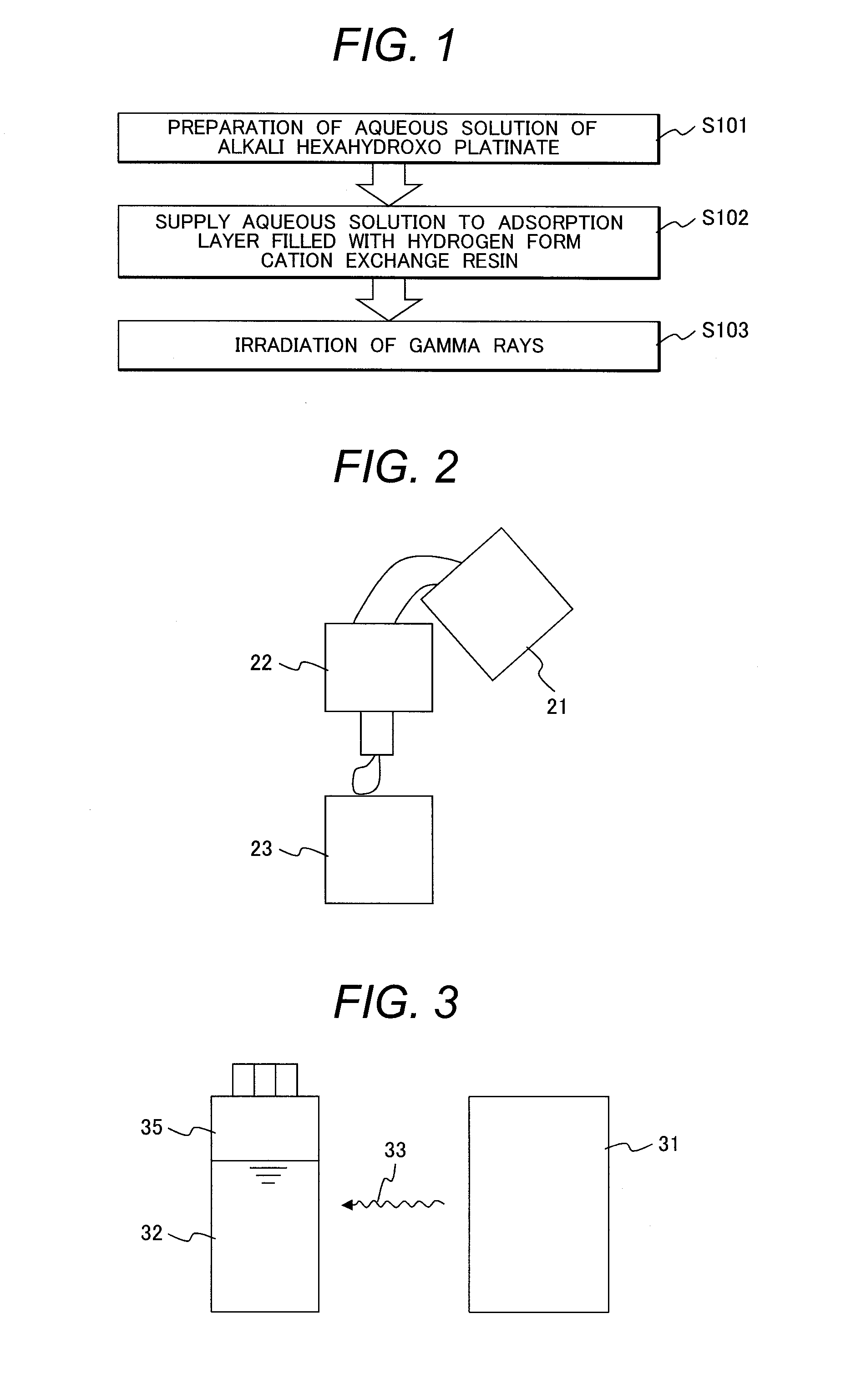

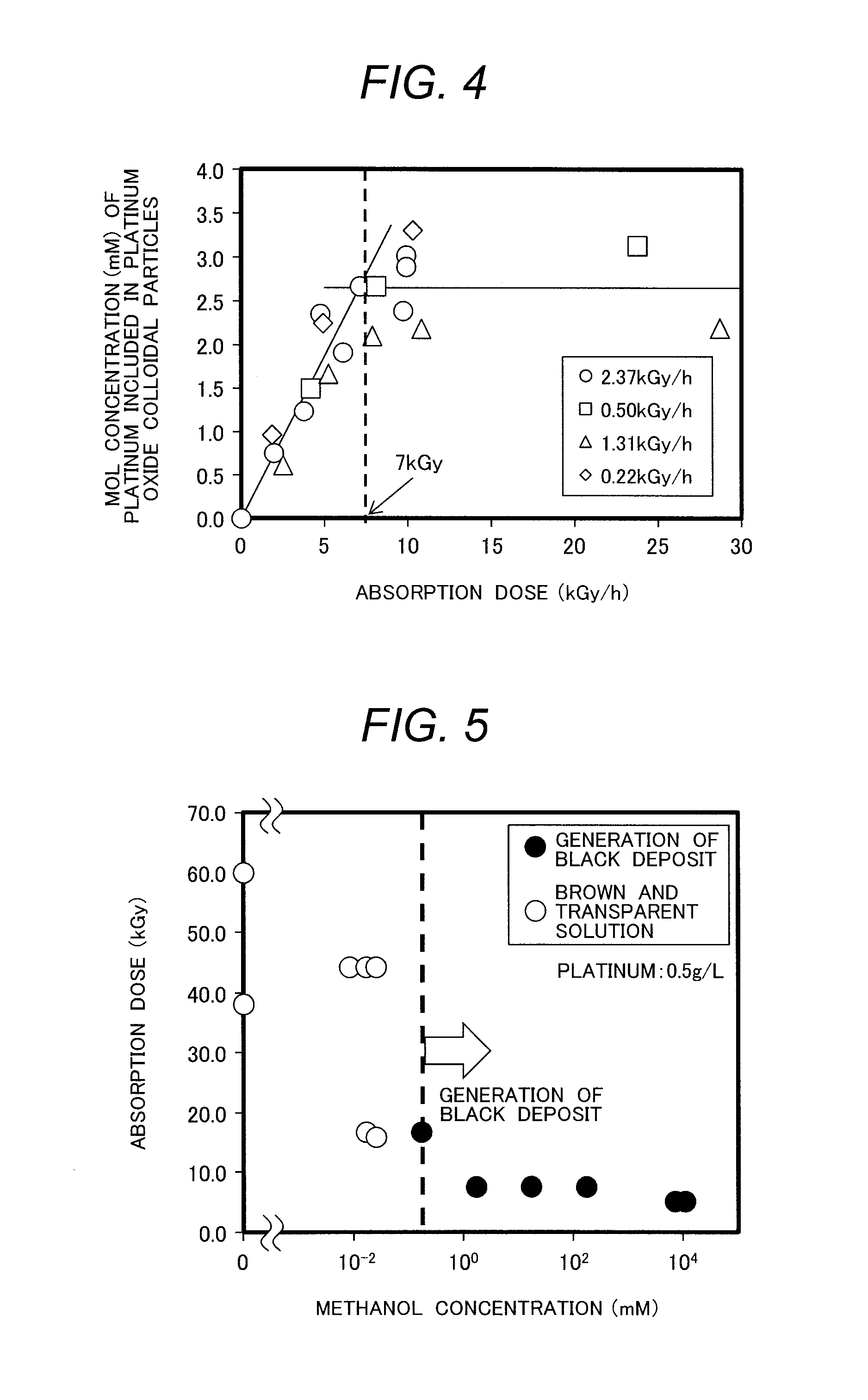

Platinum Oxide Colloidal Solution, Manufacturing Method Therefor, Manufacture Apparatus Thereof, and Method of Injection Noble Metal of Boiling Water Nuclear Power Plant

InactiveUS20140140465A1Prevent cloggingIncreased electrical conductivityNuclear energy generationOrganic-compounds/hydrides/coordination-complexes catalystsNuclear power plantColloidal Solution

An aqueous solution of alkali hexahydroxo platinate is produced. As a alkali hexahydroxo platinate, sodium hexahydroxoplatinate or potassium hexahydroxoplatinate is used. The aqueous solution of alkali hexahydroxo platinate is passed through a hydrogen form cation exchange resin layer in a cation exchange resin tower. The aqueous solution of alkali hexahydroxo platinate makes contact with the hydrogen form cation exchange resin of the hydrogen form cation exchange resin layer, thus a suspension of hexahydroxo platinic is generated. If gamma rays are irradiated to the suspension, a platinum oxide colloidal solution in which colloidal particles including a platinum dioxide, a platinum monoxide, and a platinum hydroxide exist is generated. In a platinum oxide colloidal solution, the content of impurities is little and a noble metal compound is dispersed stably in water.

Owner:HITACHI-GE NUCLEAR ENERGY LTD

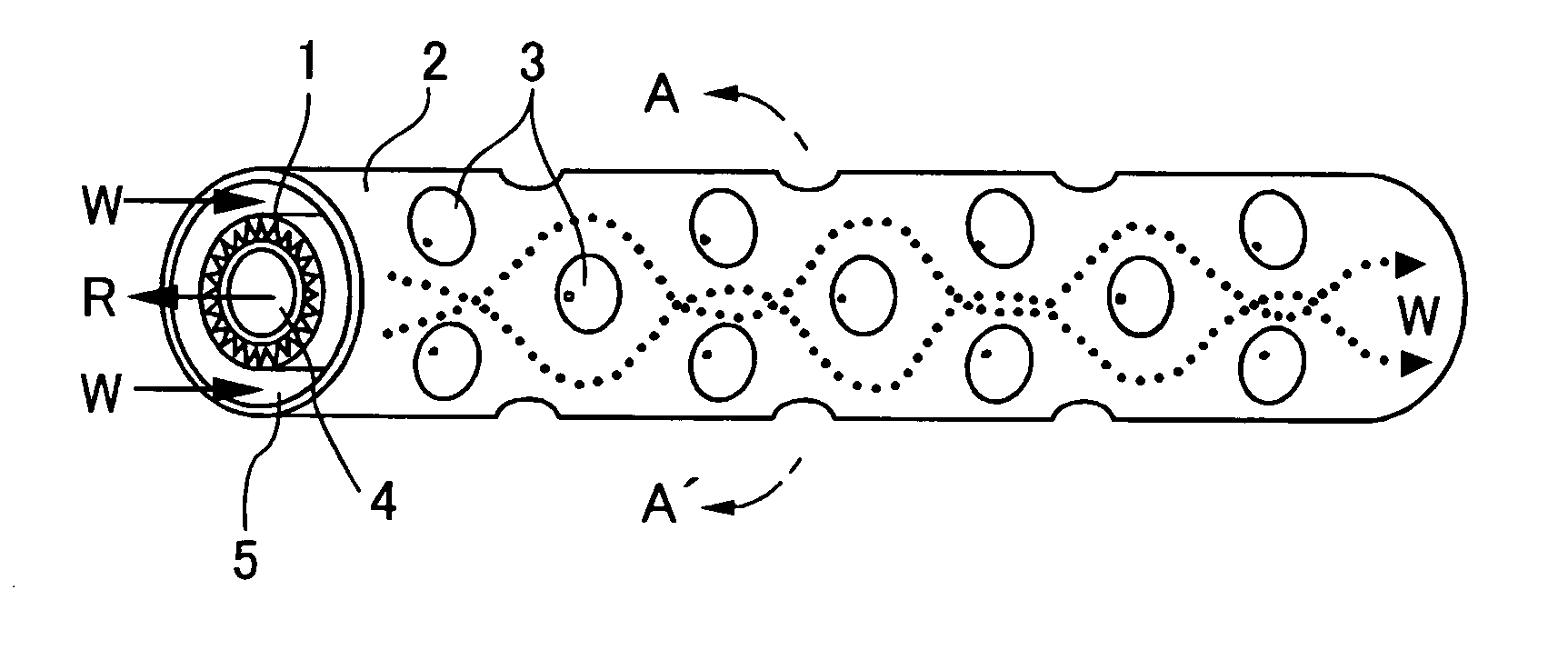

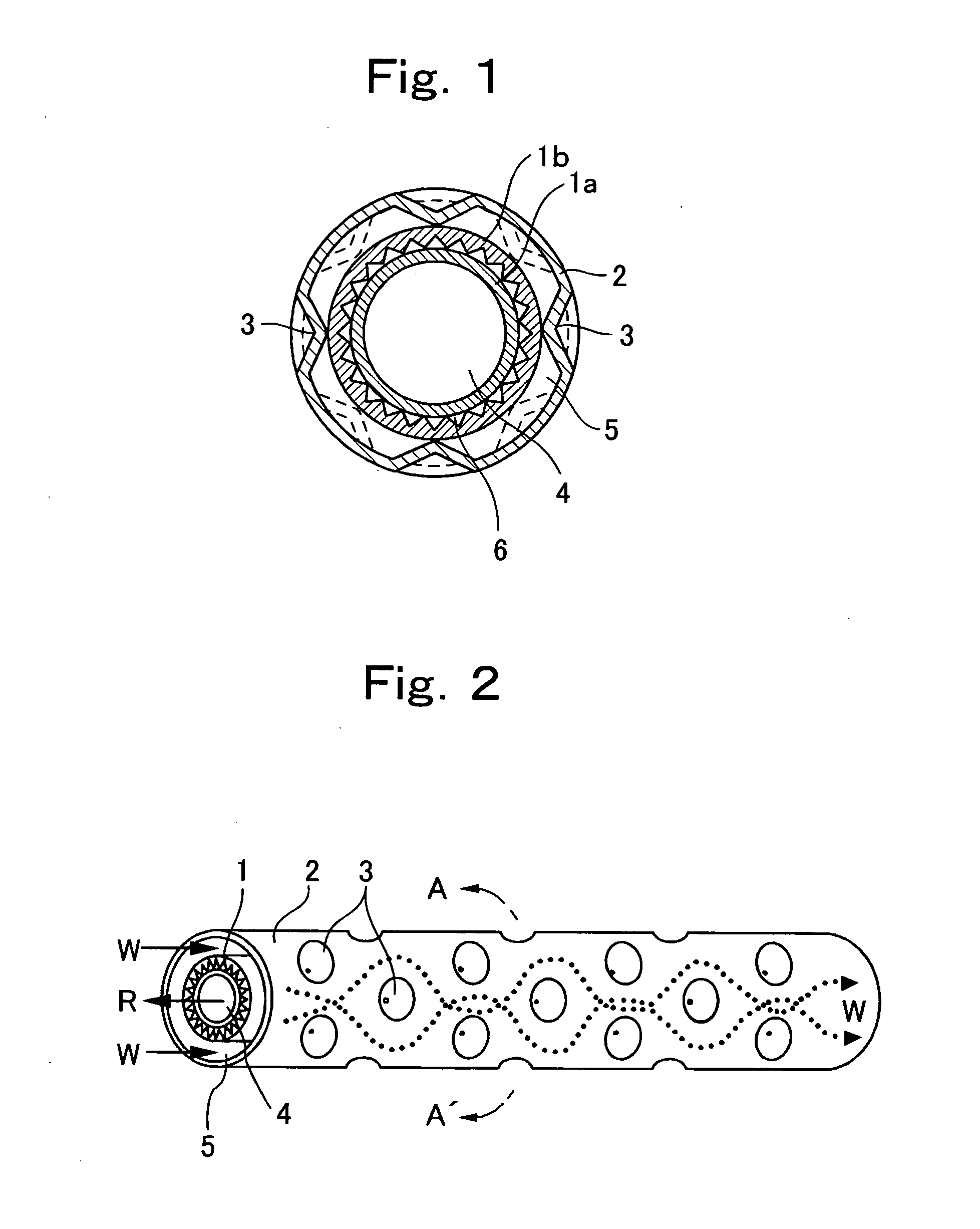

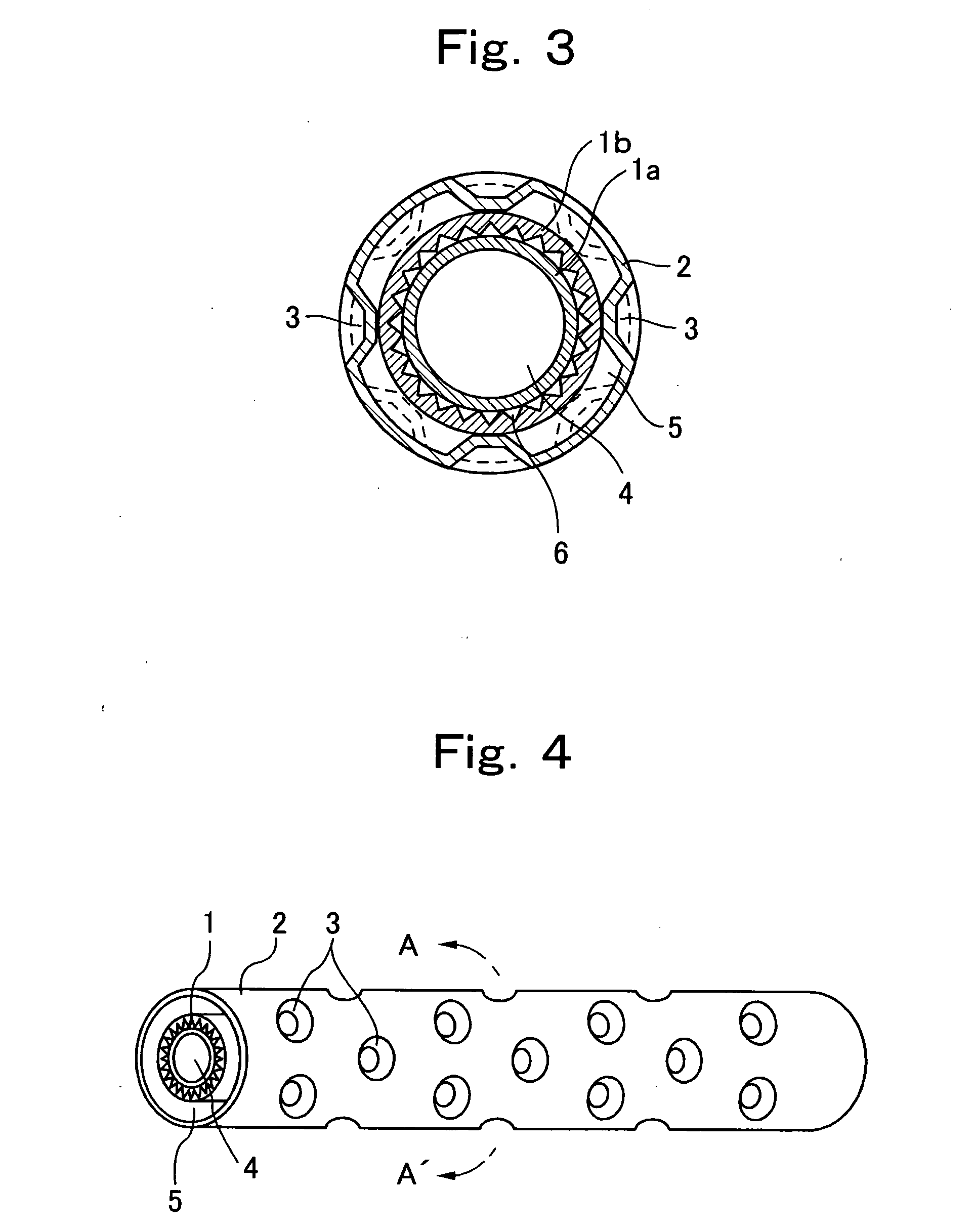

Double-pipe heat exchanger

InactiveUS20050051310A1Prevent cloggingIncreased turbulenceHeat exhanger sealing arrangementStationary tubular conduit assembliesEllipseEngineering

It is an object of the invention to provide an inexpensive double-pipe heat exchanger having high performance and comprising an inner pipe and an outer pipe which constitute a double pipe without adding a heat-transfer facilitating material such as an inner fin. In the double-pipe heat exchanger having the inner pipe and the outer pipe, the outer pipe is dented from its outside toward its inside, thereby forming a plurality of projections which are dented toward the inner pipe. Examples of shapes of the projection are substantially conical shape, substantially truncated shape, substantially spherical surface shape, substantially cylindrical shape, substantially elliptic cylindrical shape and the like. The projections are disposed helically or in a staggered configuration such as to surround the inner pipe. With this structure, only by subjecting the outer pipe to simple working such as press working, it is possible to increase the turbulent flow of fluid flowing between the inner pipe and the outer pipe, and to facilitate heat transfer from fluid flowing in the inner pipe to fluid flowing between the inner pipe and the outer pipe.

Owner:PANASONIC CORP

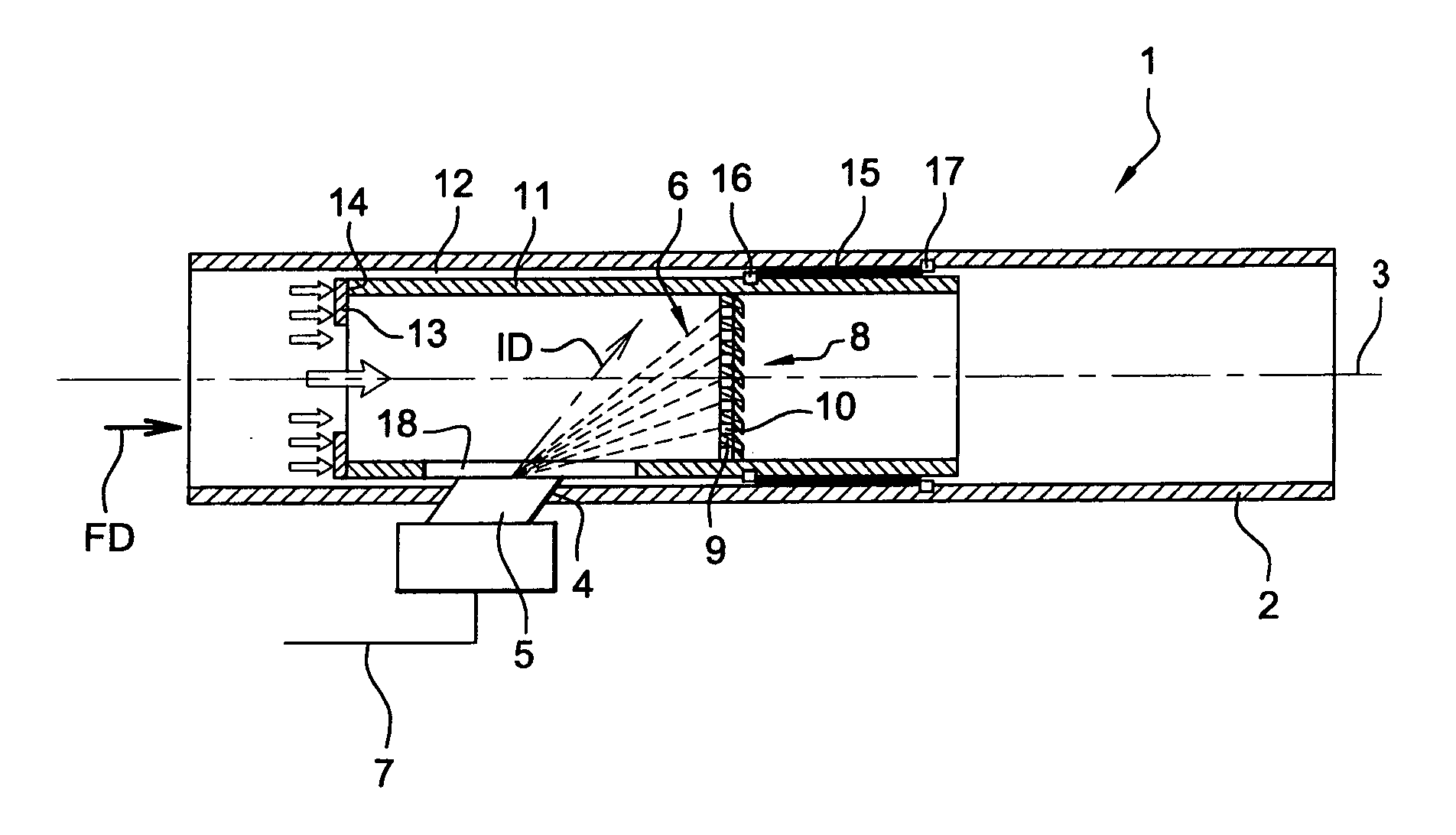

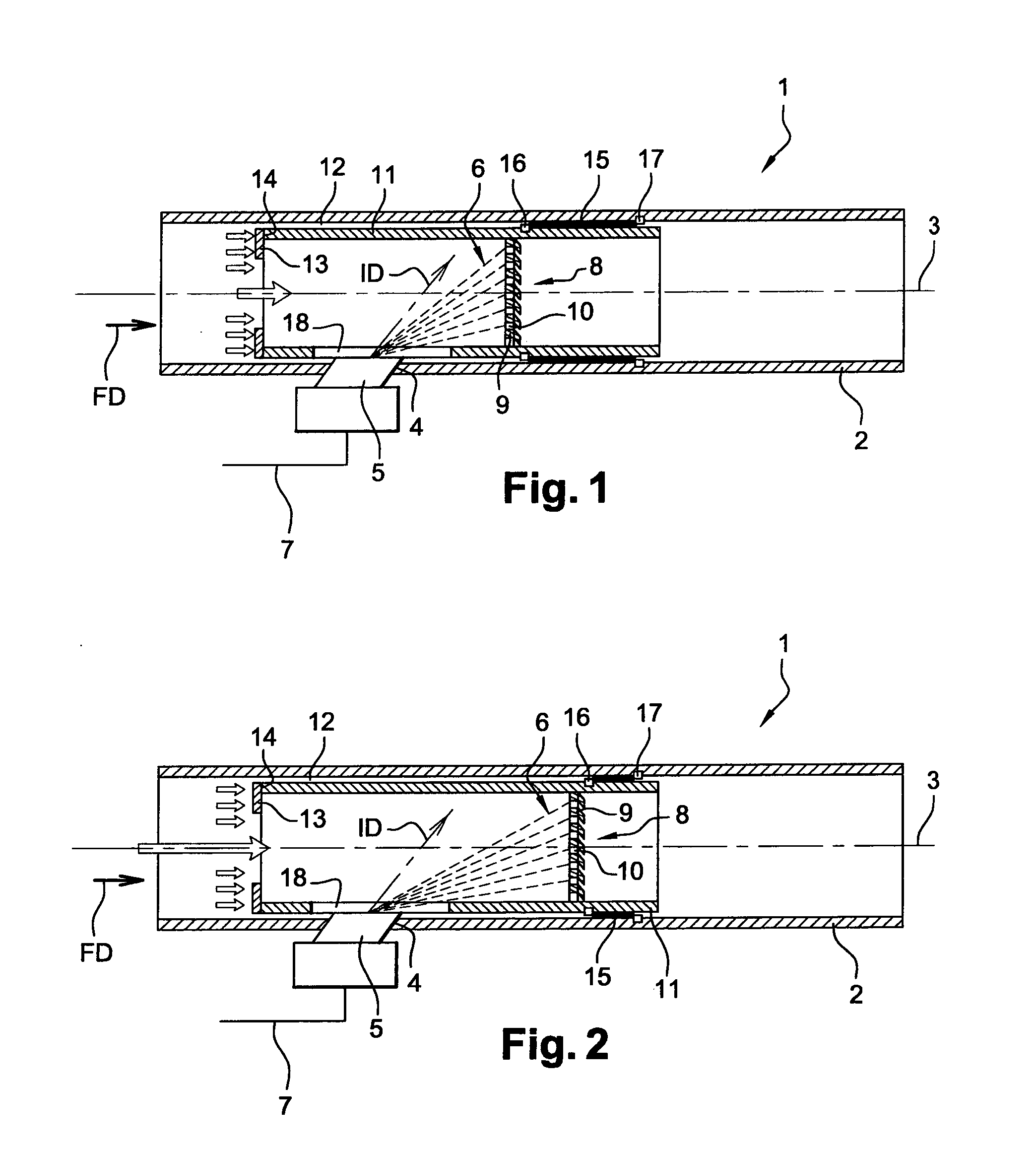

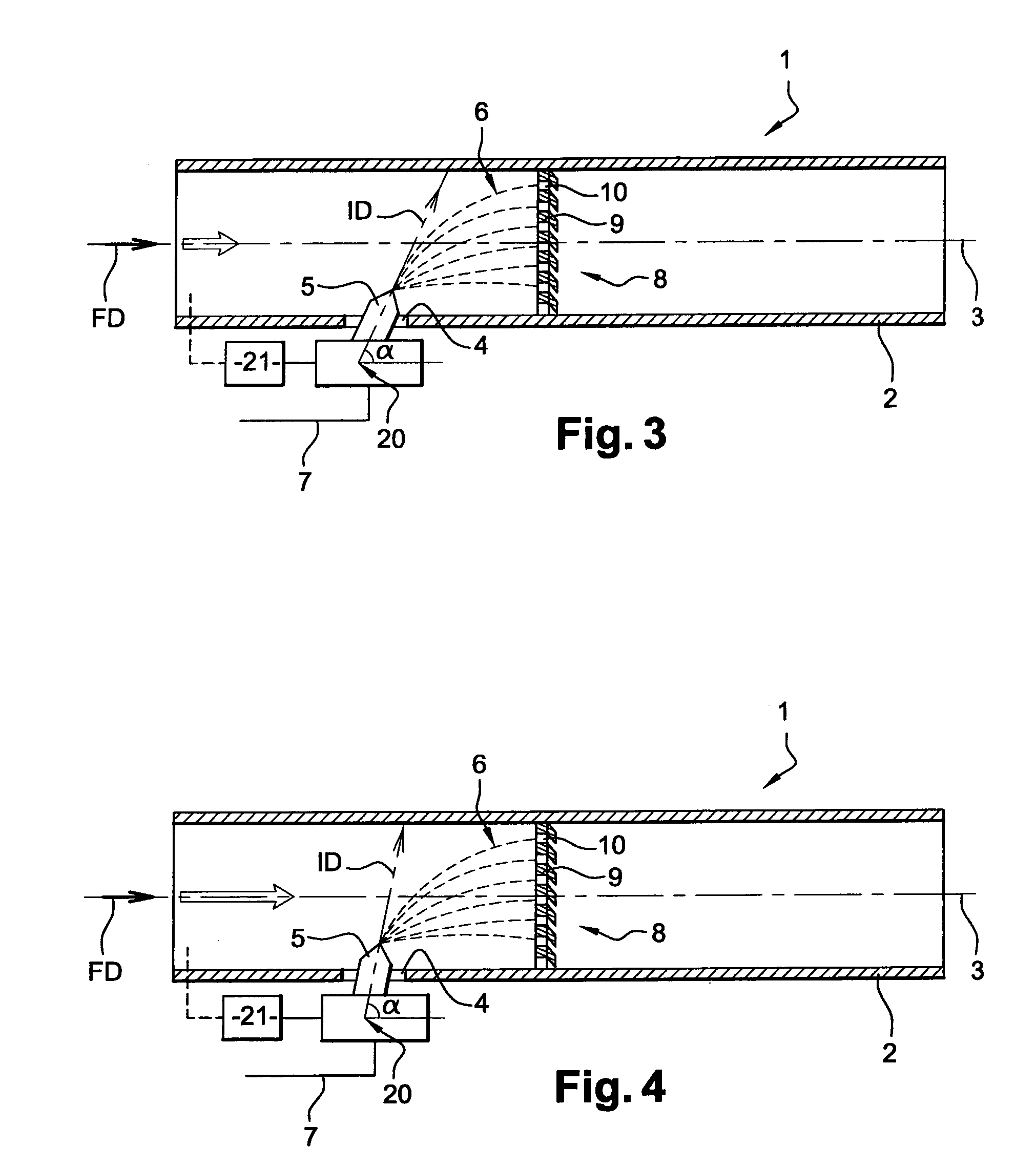

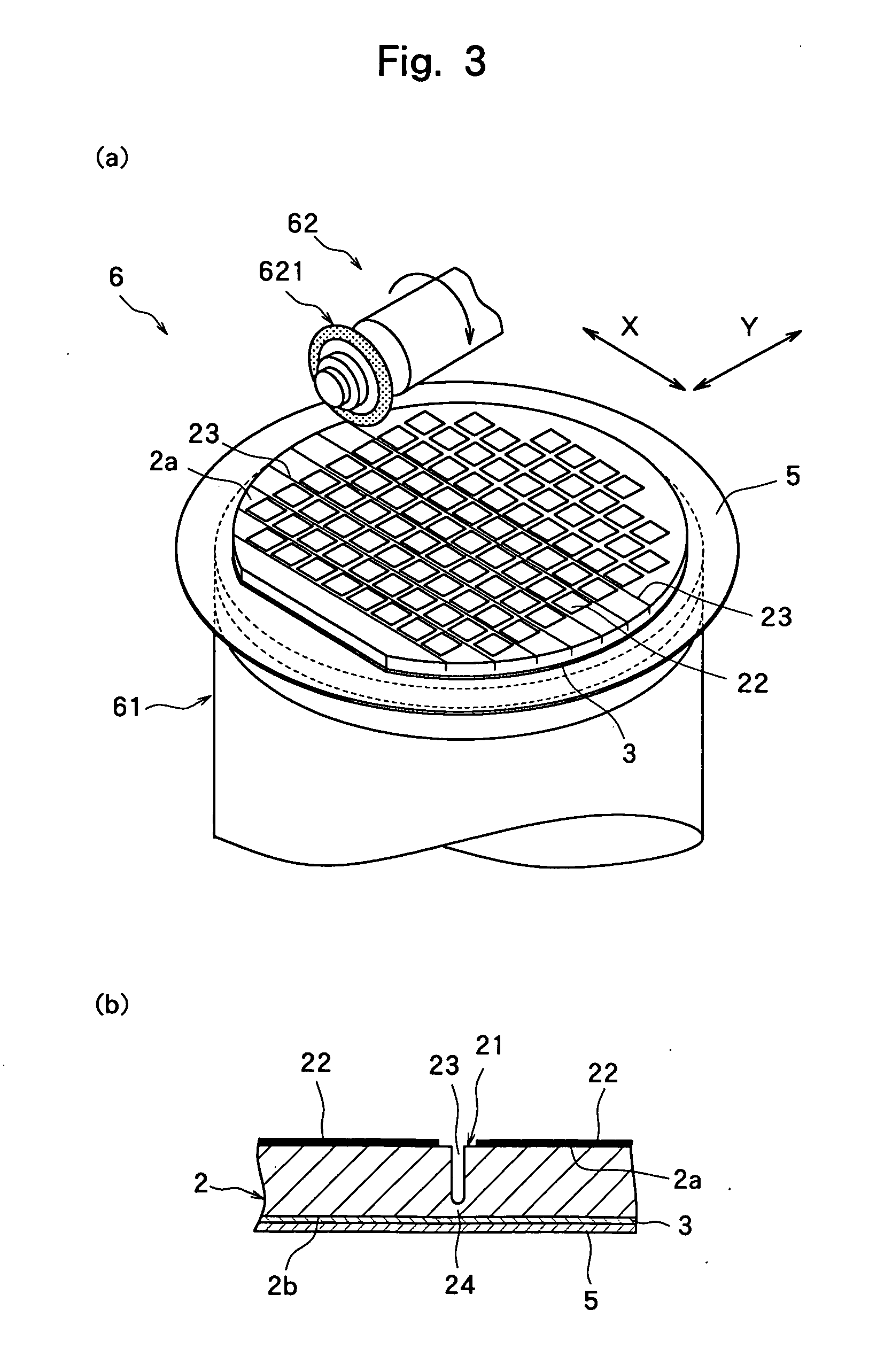

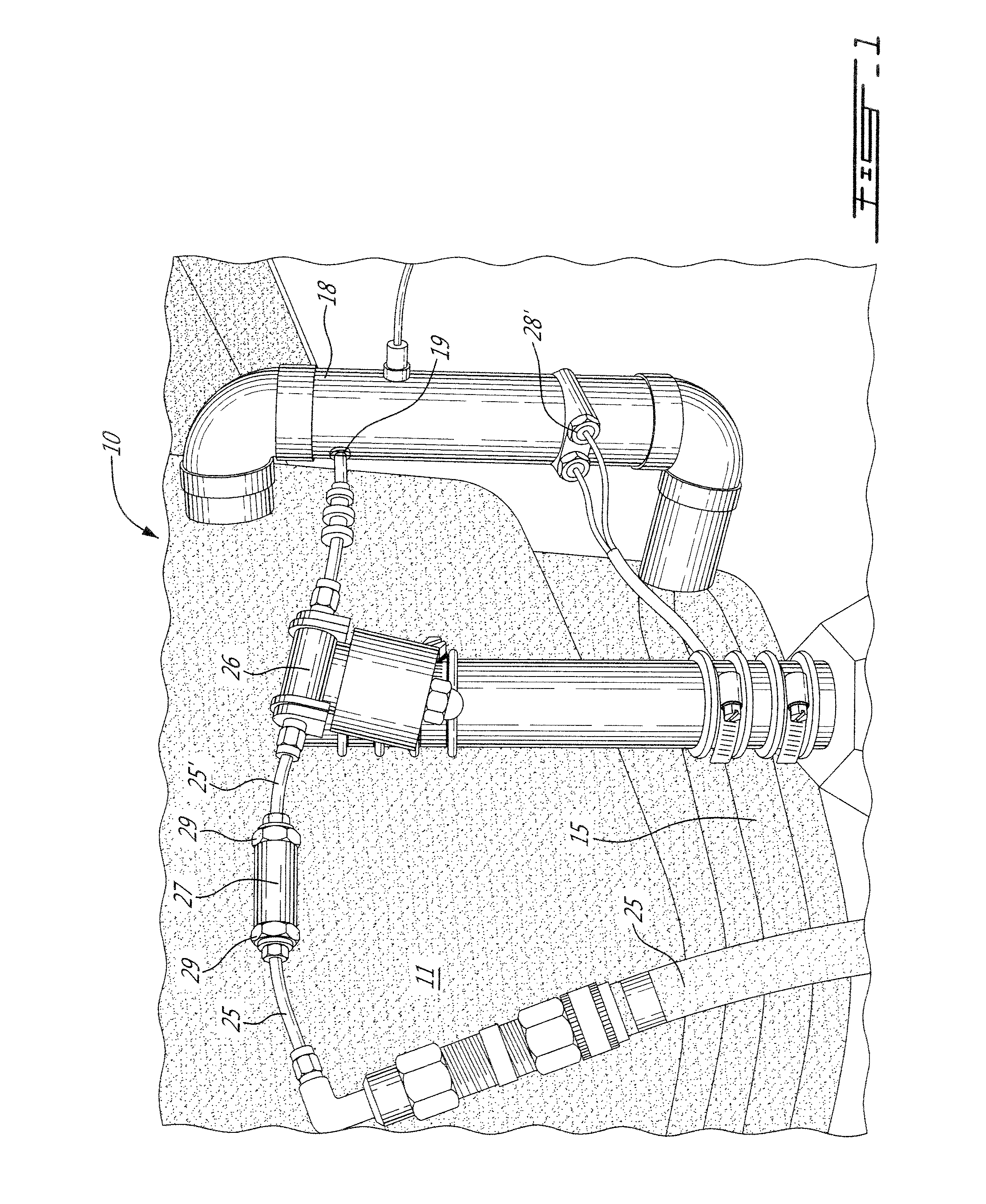

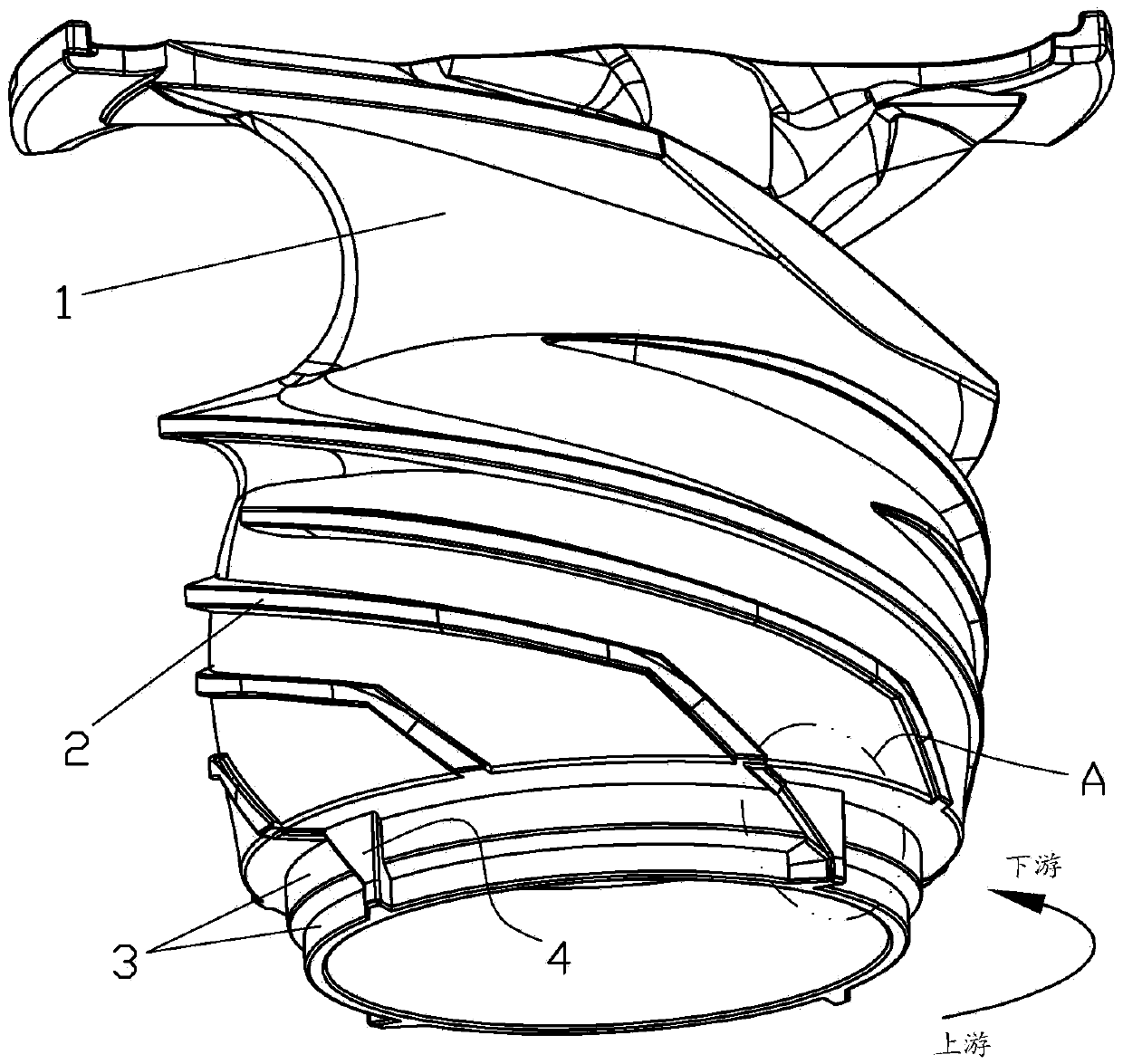

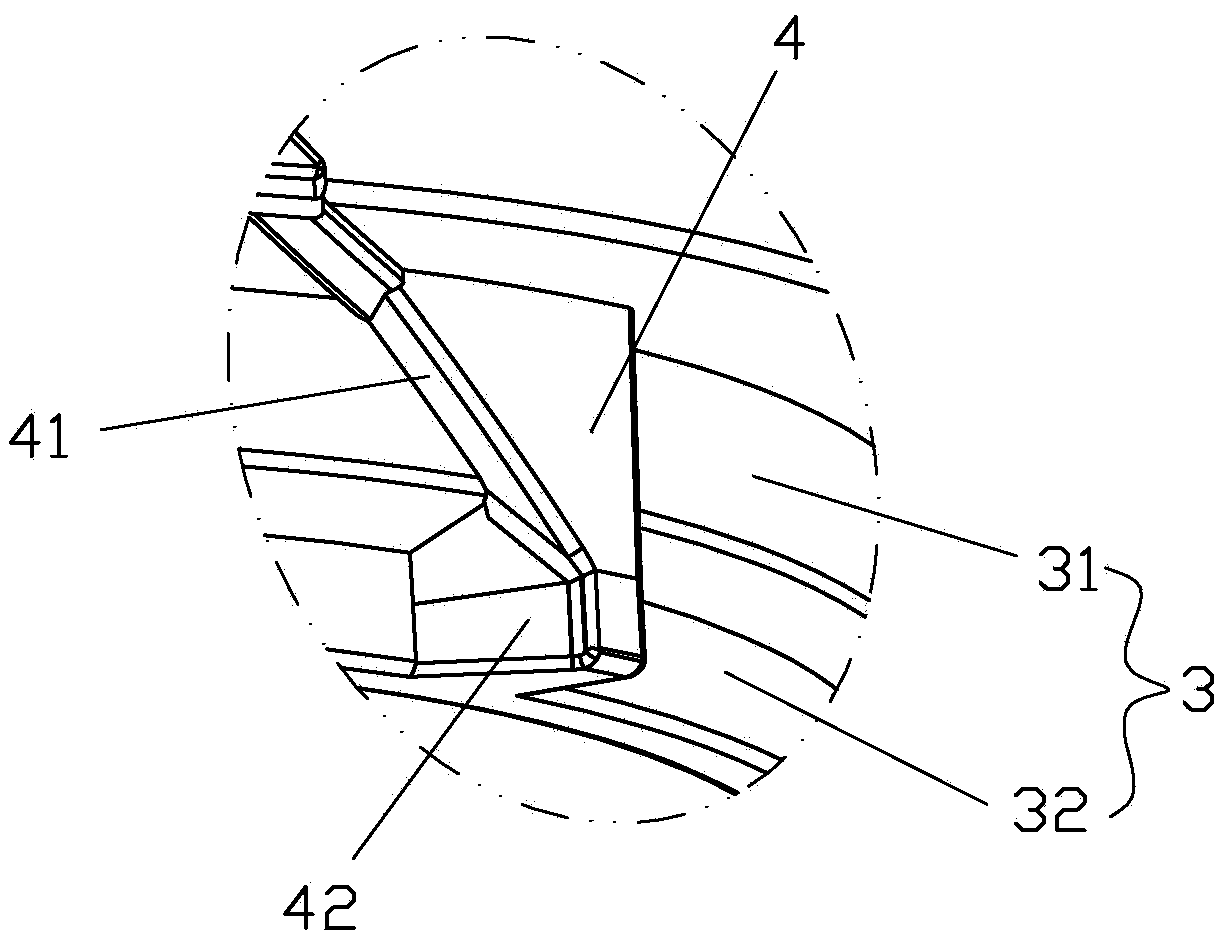

Mixing system in an exhaust gas mixing chamber

InactiveUS20120073272A1Enhance mixingPrevent cloggingInternal combustion piston enginesFlow mixersExhaust gasMixing chamber

The mixing system includes a mixing chamber in which exhaust gases can flow in a flow direction, a nozzle designed to inject a fluid inside the mixing chamber, according to an injection direction, and an evaporating device positioned inside the mixing chamber, downstream from the injection inlet. The nozzle and the evaporating device are movable one with respect to the other, so that a substantial portion of the flow of the fluid injected into the mixing chamber hits the evaporating device regardless of the flow rate of the exhaust gases.

Owner:RENAULT TRUCKS

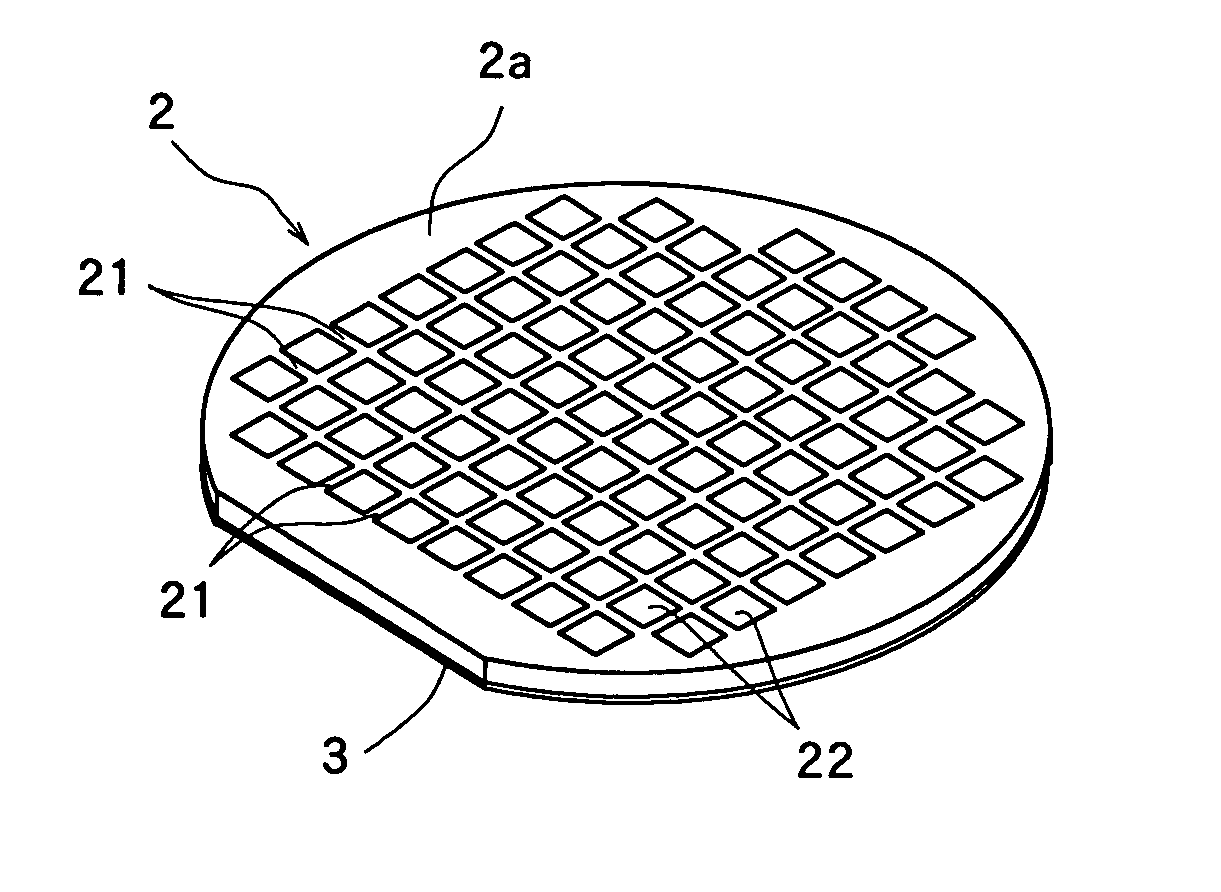

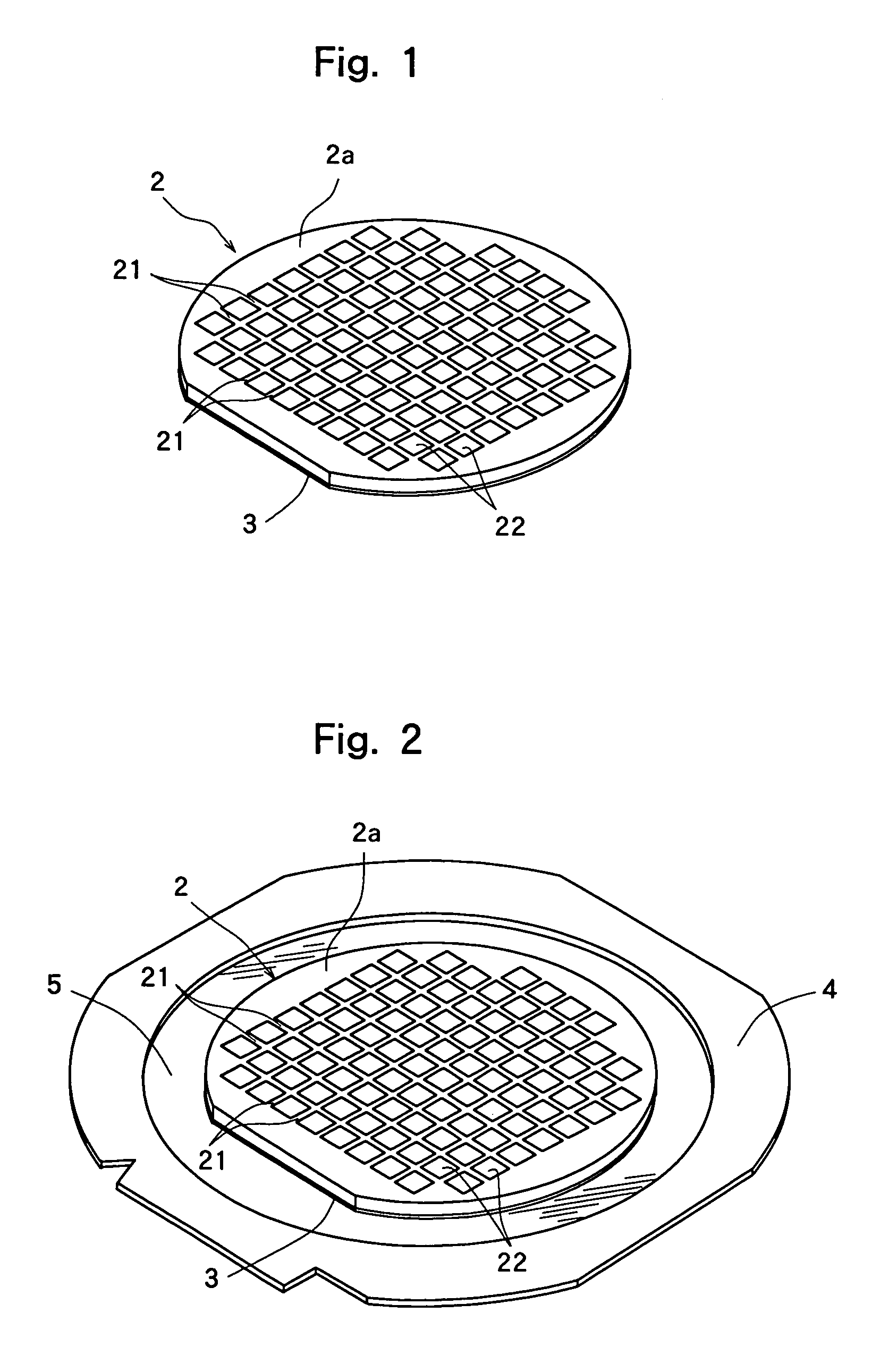

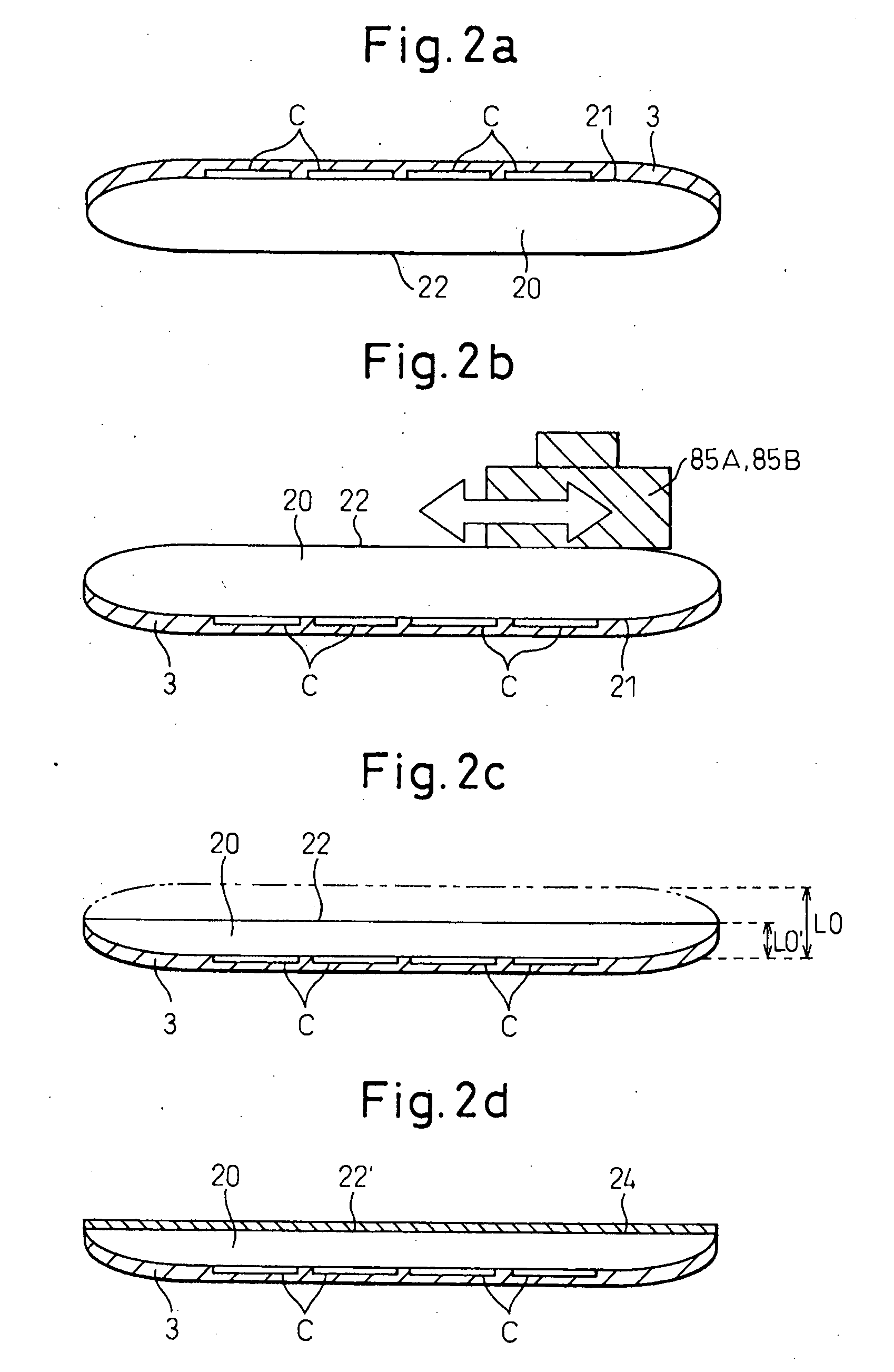

Wafer dividing method

InactiveUS20060045511A1Prevent cloggingCausing cloggingSemiconductor/solid-state device manufacturingExposure controlEngineeringLaser beams

A method of dividing a wafer having a plurality of streets formed on the front surface in a lattice pattern, devices formed in a plurality of areas sectioned by the plurality of streets, and a metal film formed on the back surface, into individual chips, comprising: a street cutting step for cutting the front surface of the wafer along the streets to form grooves, leaving an uncut portion having a predetermined thickness on the back surface side; and a cutting-off step for cutting off the uncut portion and the metal film by applying a laser beam to the uncut portion of the groove formed along the streets.

Owner:DISCO CORP

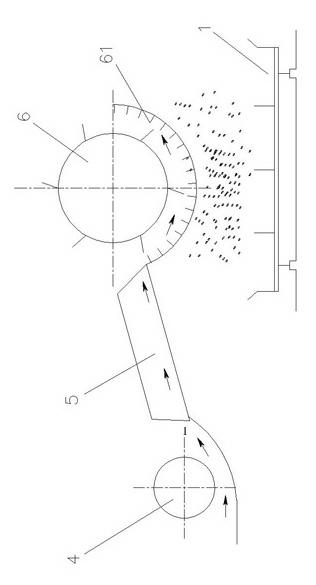

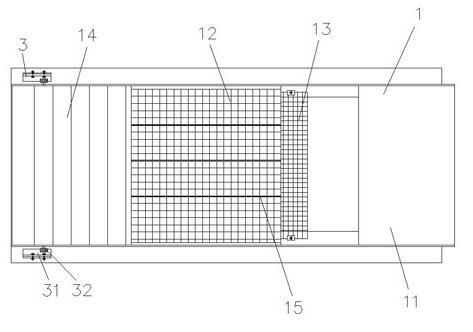

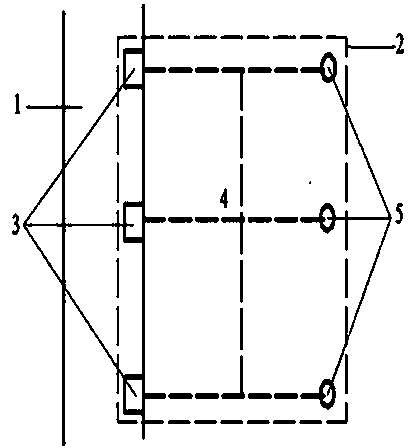

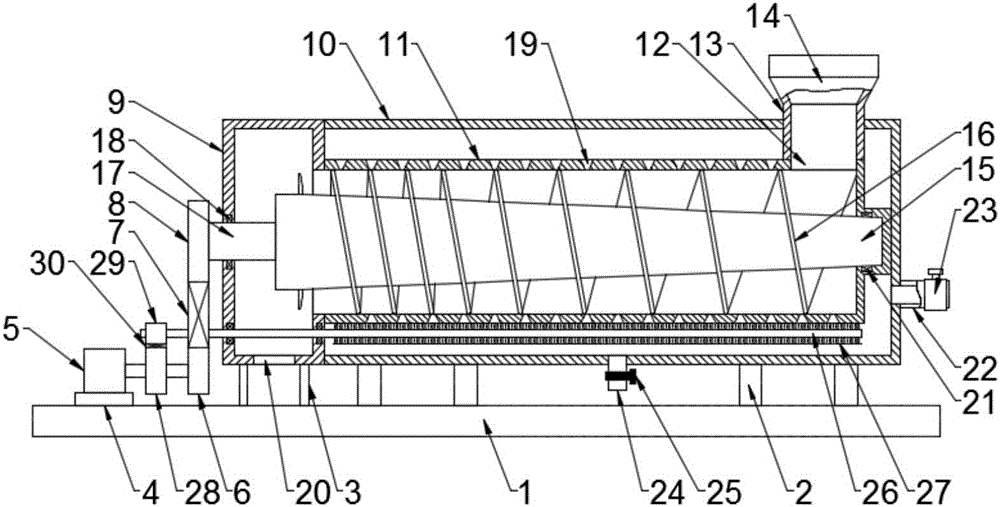

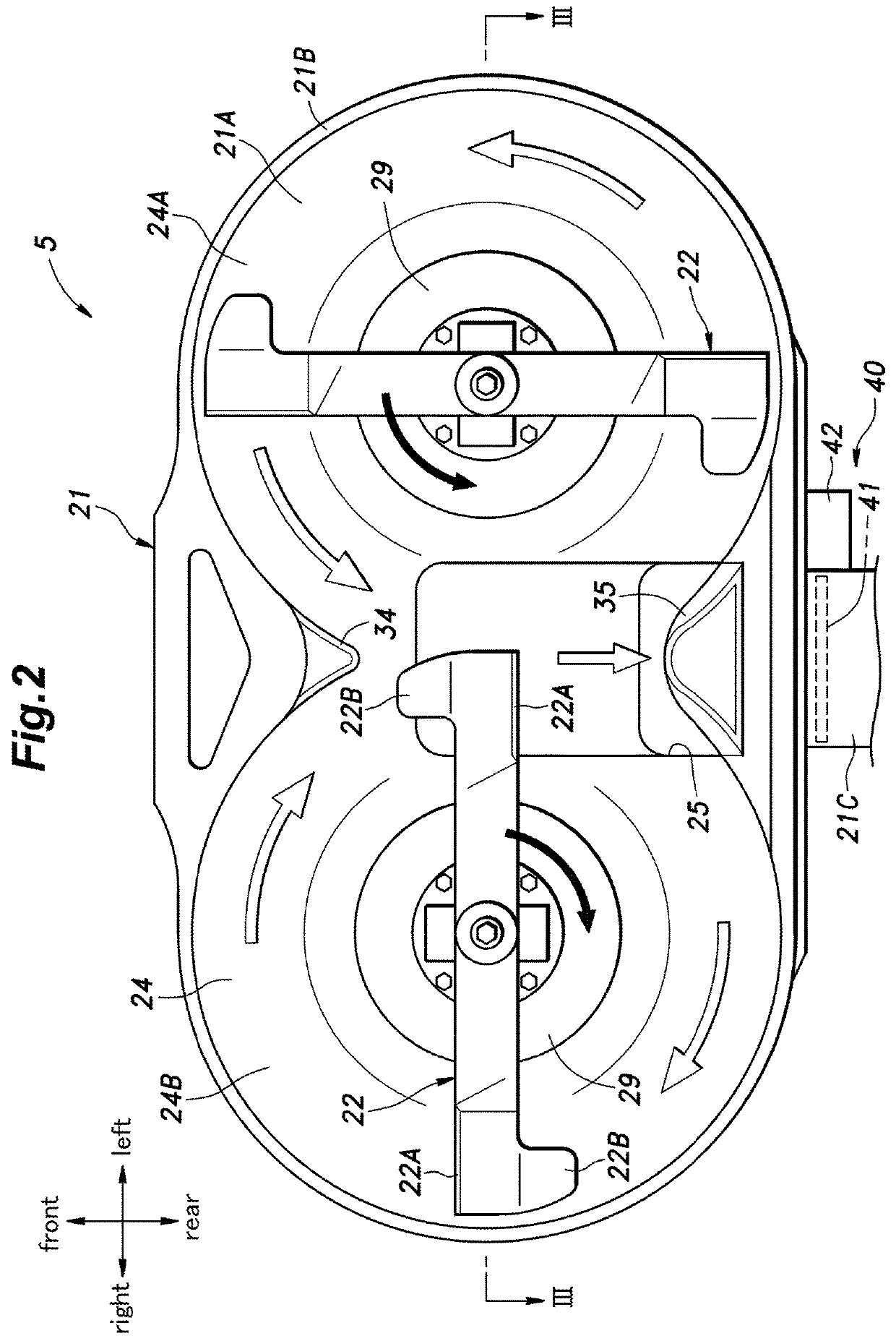

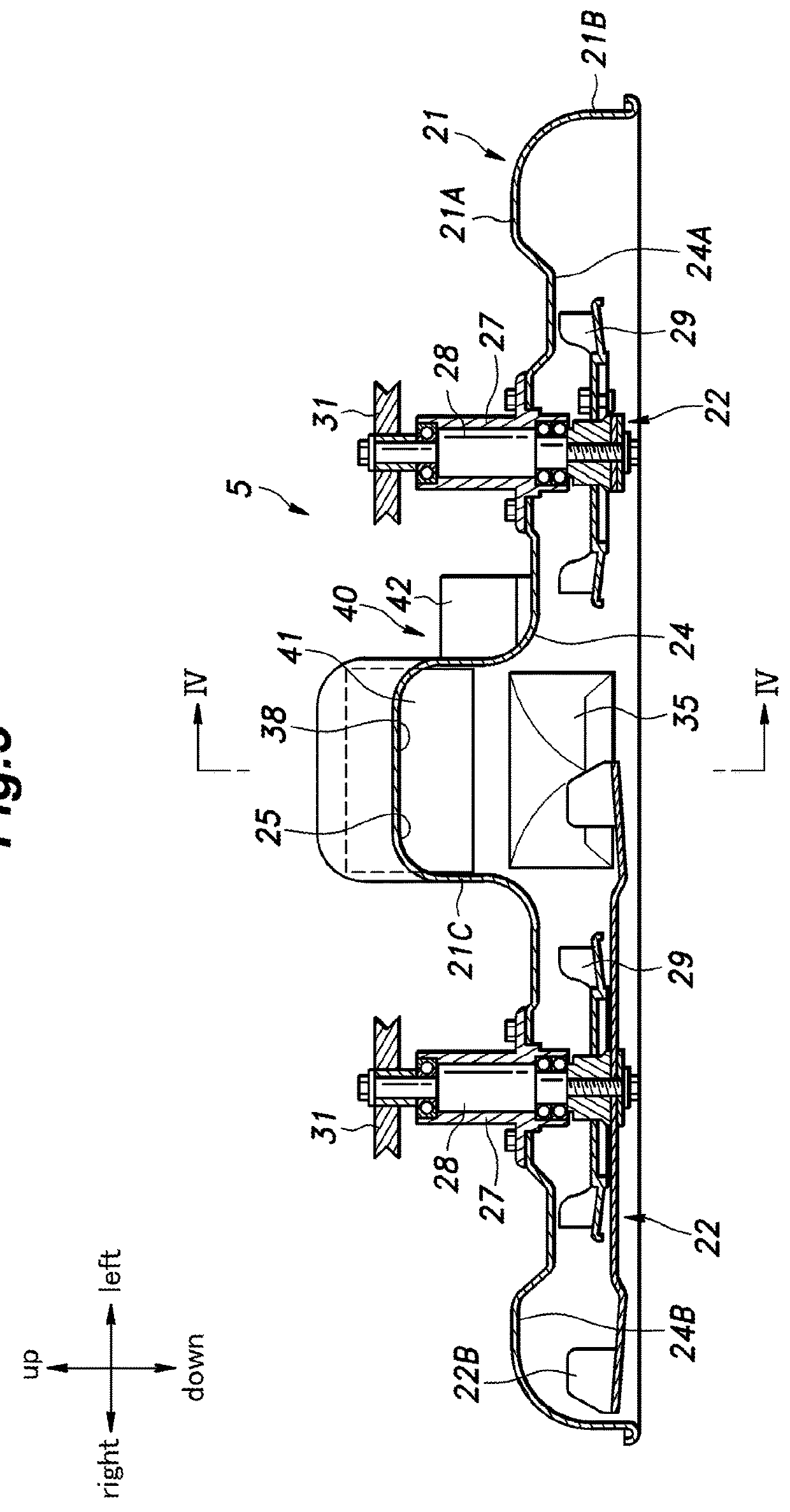

Sorting screen of combine harvester

The invention discloses a sorting screen of a combine harvester, which comprises a screen body, an eccentric drive mechanism and sliding mechanisms, wherein the eccentric drive mechanism is disposed below one end of a screen body, and the sliding mechanisms are symmetrically disposed on two sides of the other end of the screen body. The screen body comprises a screen frame, an upper mesh screen, a lower mesh screen, a corrugated plate and a plurality of sorting baffles. The eccentric drive mechanism comprises a crankshaft, a pair of connecting plates and a pair bearing blocks, wherein two ends of the crankshaft are supported inside the bearing blocks through bearings respectively, a crankshaft journal is fixedly respectively connected with the lower end of every one of the connecting plates in one pair, and the upper ends of the connecting plates in one pair are fixedly connected with the front bottom and the rear bottom of the screen frame respectively. The sliding mechanisms comprise sliding seats and rollers, wherein the rollers supported at the front and the rear of the screen frame are inlaid inside the sliding seats. The sorting screen is simple and compact in structure, threshed grains fall onto the whole screen surface and flow from the left to the right, and the left and the right of the screen are evenly stressed so that the screen is less prone to damage. The screen is small in size and large in sorting area, so that the overall weight of the harvester is lowered greatly, the overall reliability of the harvester is improved, and the grains are sorted effectively and efficiently.

Owner:JIANGSU WORLD AGRI MACHINERY

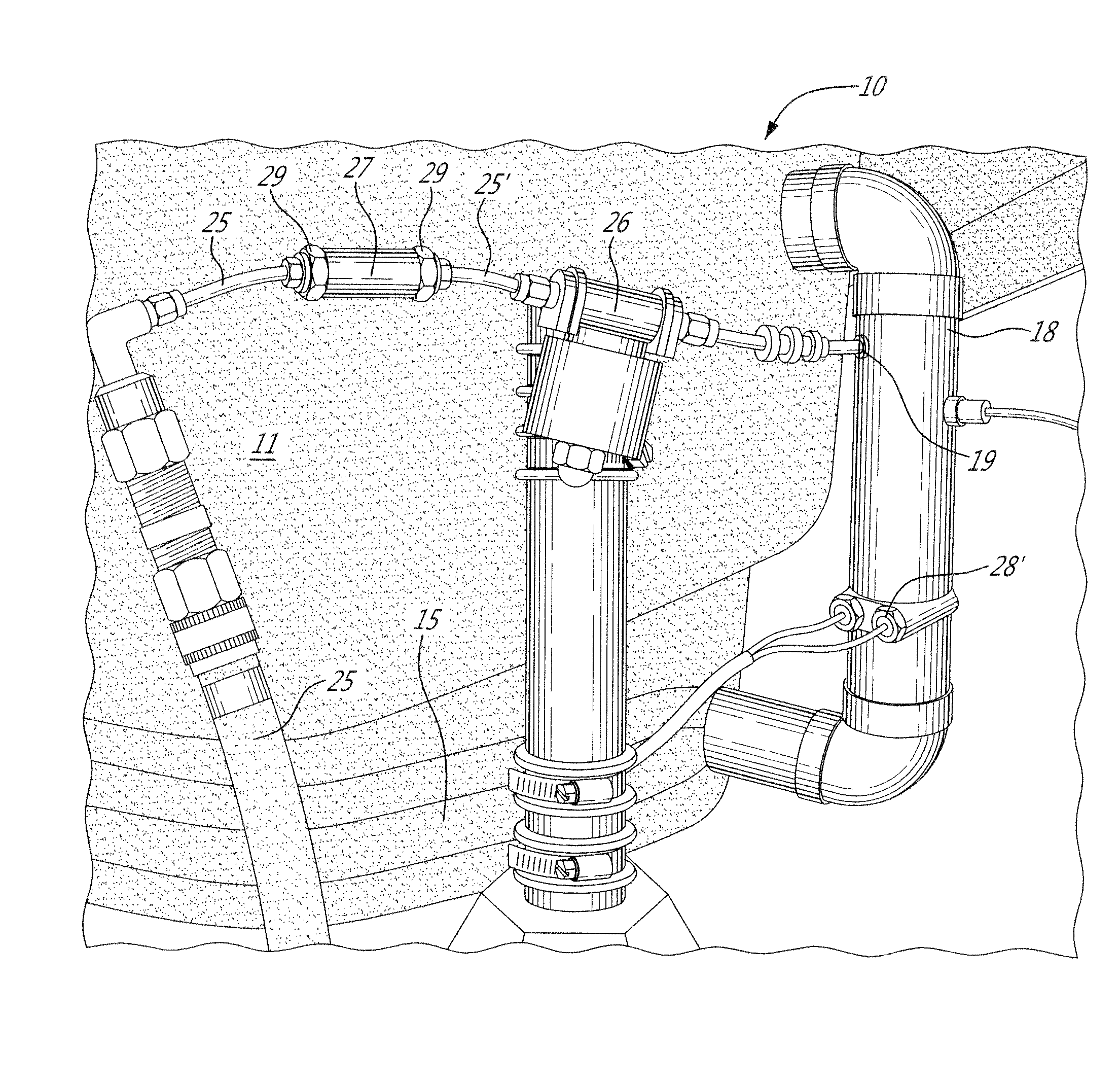

Air injection system for a hydro-massaging bath

An air injection system for a hydro-massaging bath is described. An air convecting conduit is in communication with a plurality of injecting orifices formed in a peripheral wall of the bath. An air blower injects air under pressure in an entry opening of the air convecting conduit. A water spray injector is located downstream of the entry opening and upstream of the air injecting orifices to inject a spray of a predetermined volume of water in the injected air under pressure. A water supply conduit is connected to the water spray injector and has a flow regulating valve to regulate the volume of water spray injected in the heated air to saturate the air with water. A shut-off valve is provided in the water supply conduit, and a heater is disposed in the air convecting conduit downstream of the water spray injector and upstream of the air injecting orifices wherein heated, humidified air injected in the water contained within the bathtub does not produce a cool sensation on the body of a user person.

Owner:GESTION ULTRA INT

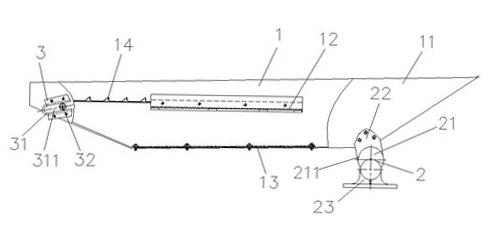

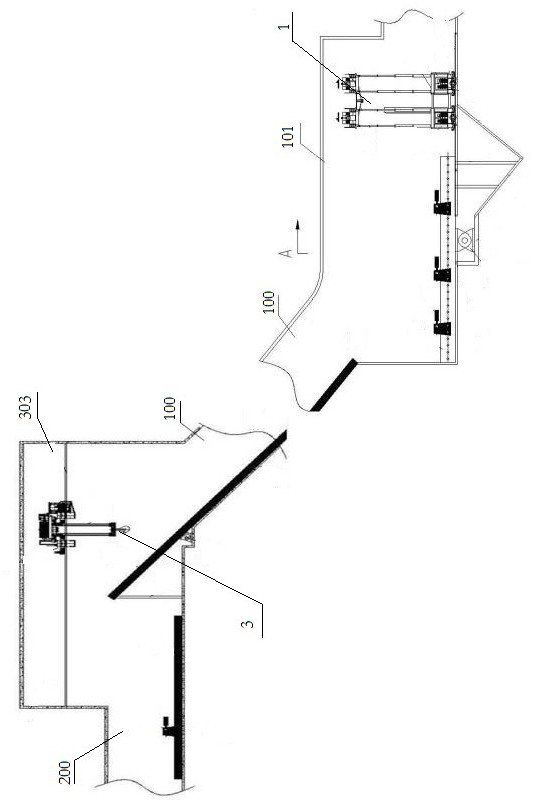

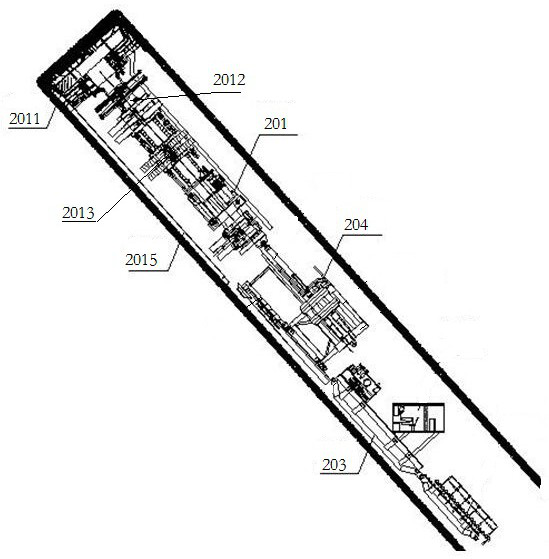

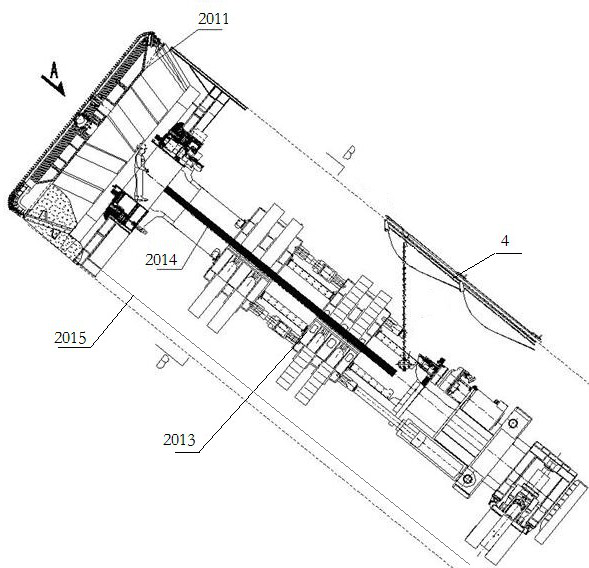

Tunnel inclined shaft construction system and construction method

The invention discloses a tunnel inclined shaft construction system and a construction method. The tunnel inclined shaft construction system involves a starting device, an inclined shaft TBM and a receiving device, wherein a follow-up transportation system is arranged inside an inclined shaft excavated by the inclined shaft TBM, the inclined shaft TBM comprises a tunneling main machine and a rearmatching part, and a safety anti-running device is arranged between the tunneling main machine and the rear matching part; and the tunneling main machine comprises a cutterhead, a main drive, a star-shaped beam and a muck discharging mechanism, the main drive is arranged on the star-shaped beam and connected with the cutterhead, a cutter conveying tool is arranged inside the star-shaped beam, andthe muck discharging mechanism corresponds to the cutterhead. The structural design of the tunnel inclined shaft construction system is suitable for large-gradient inclined shafts, and the construction method is simple and effective, improves efficient and safe starting of the inclined shaft TBM, is a great innovation of inclined shaft construction and has high popularization value.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

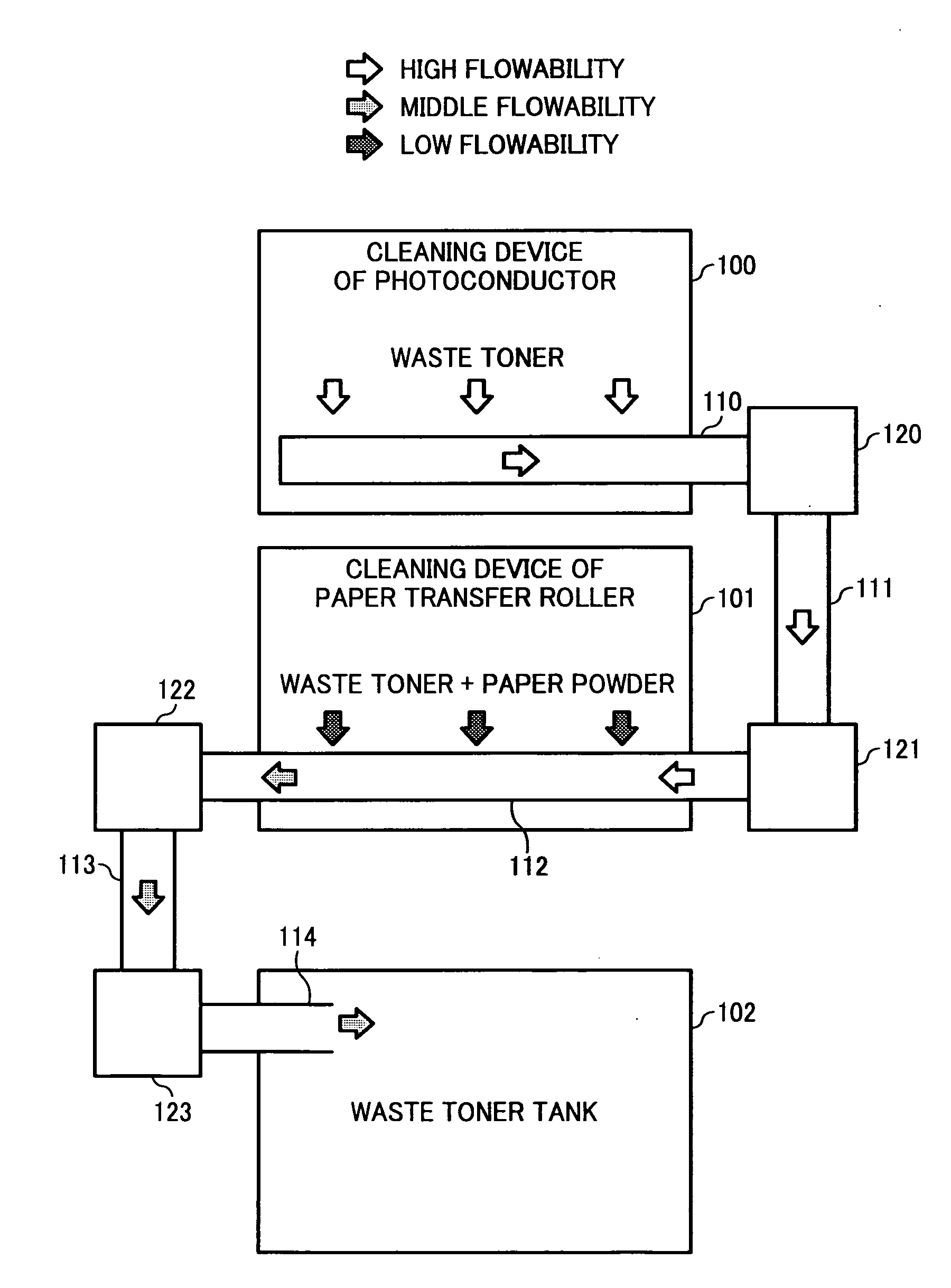

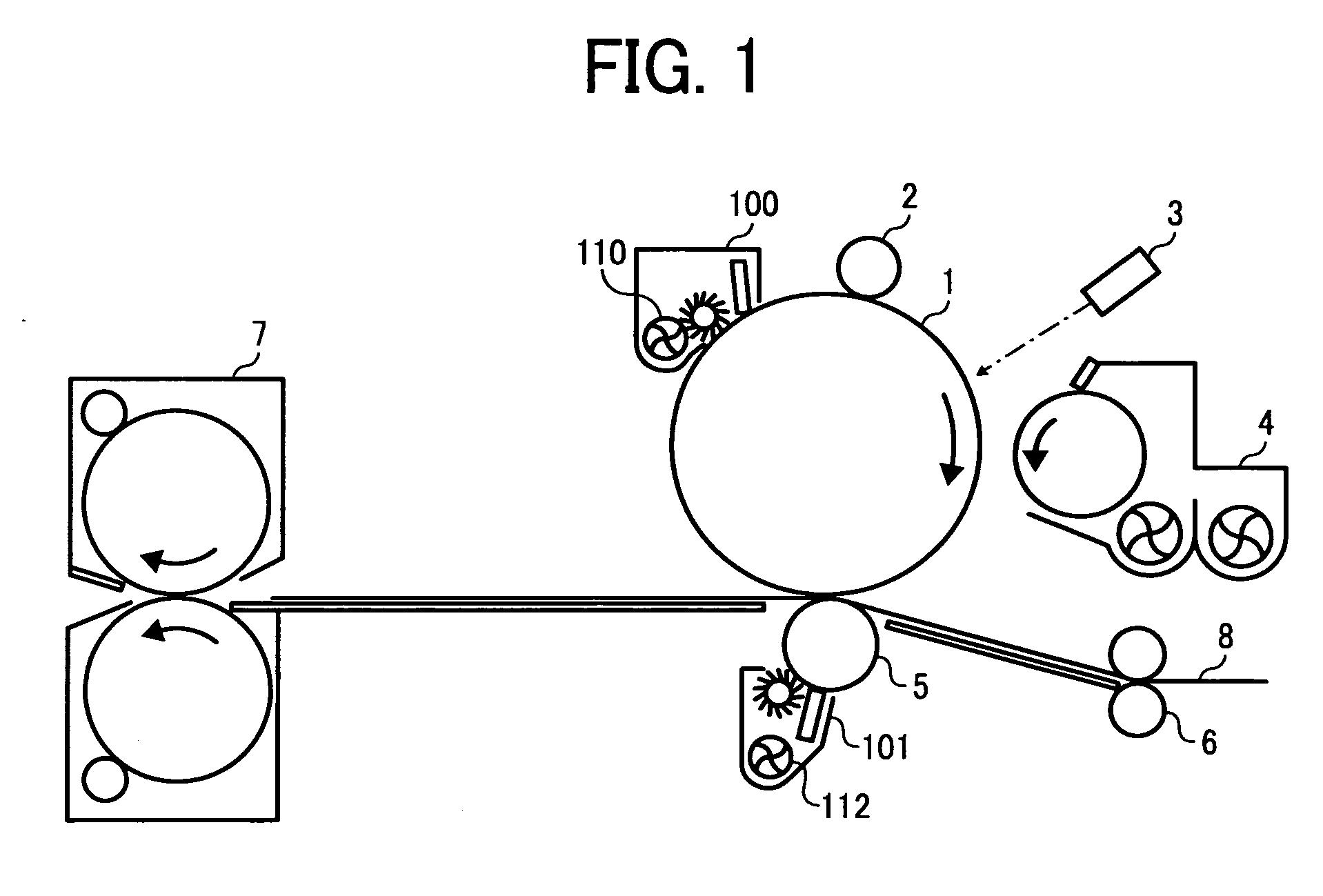

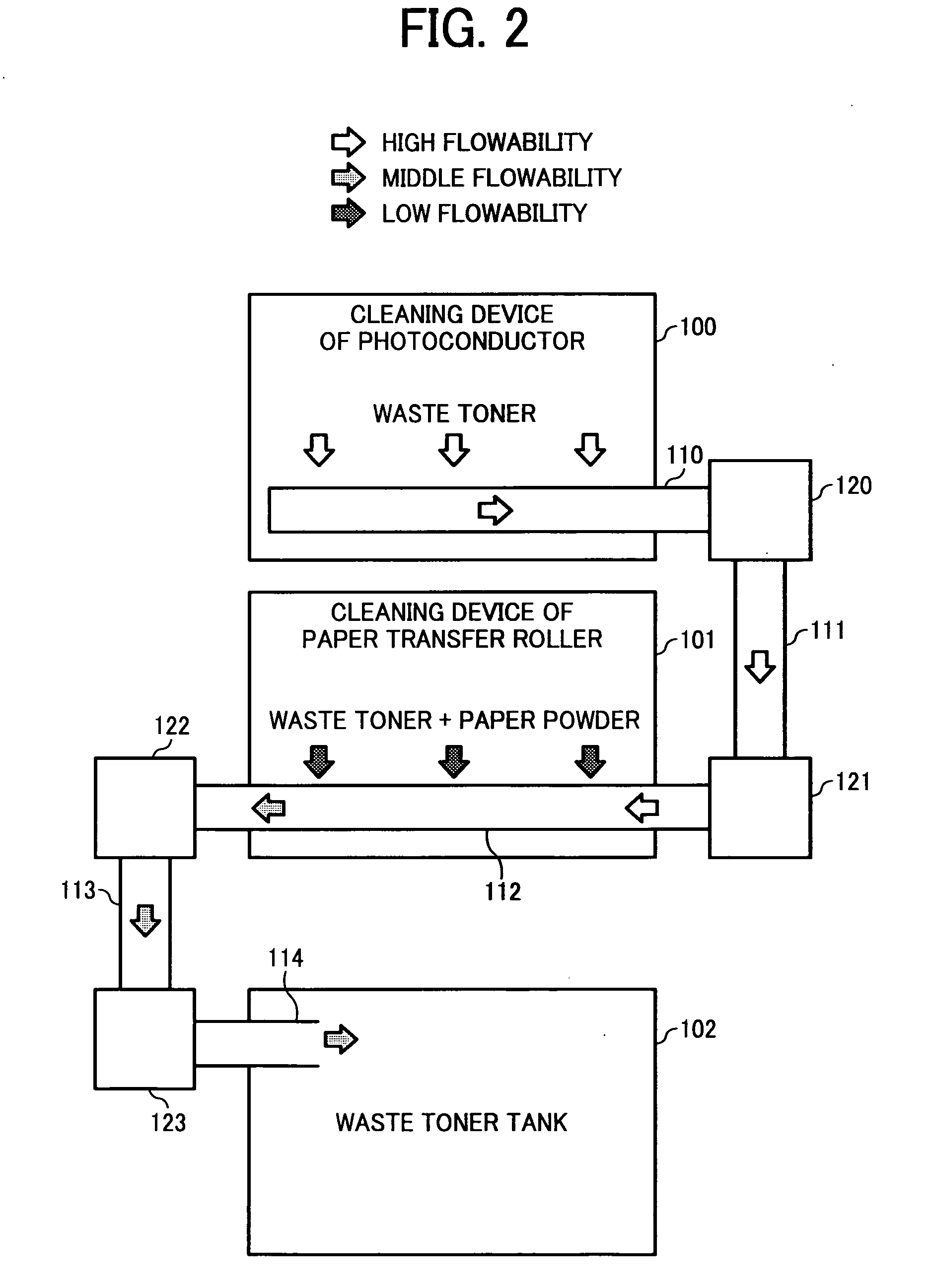

Waste toner conveying device and image forming apparatus

InactiveUS20090232570A1High flowabilityPrevent cloggingElectrographic process apparatusWaste management

A waste toner conveying device includes a first conveying path configured to convey waste toner having paper powder at a low mixed ratio, which is stored in a first cleaning device, outside the first cleaning device, a second conveying path configured to convey second waste toner having a paper powder at a high mixed ration, which is stored in a second cleaning device, outside the second cleaning device, and at least one forwarding path configured to convey the first waste toner conveyed from the first cleaning device through the first conveying path and the second waste toner conveyed from the second cleaning device through the second conveying path are conveyed to a waste toner storage device. The at least one forwarding path is configured to convey the first waste toner conveyed from the first cleaning device through the first conveying path to the waste toner storage device via the second conveying path.

Owner:RICOH KK

Deodorant material and process for producing the same

InactiveUS20050172813A1Prevent cloggingEffect be exertGas treatmentOther chemical processesGypsumDeodorant

The invention provides a deodorizing article which can be used semi-permanently and maintains sufficient mechanical strength under usual conditions of use and a method for producing the deodorizing article. The deodorizing article of the invention is produced by dispersing in a medium a clay mineral having meso-pores, gypsum series, a mineral having a pore size greater than that of the gypsum series, and a white inorganic filler, and molding the formed dispersion.

Owner:MIDORI ANZEN

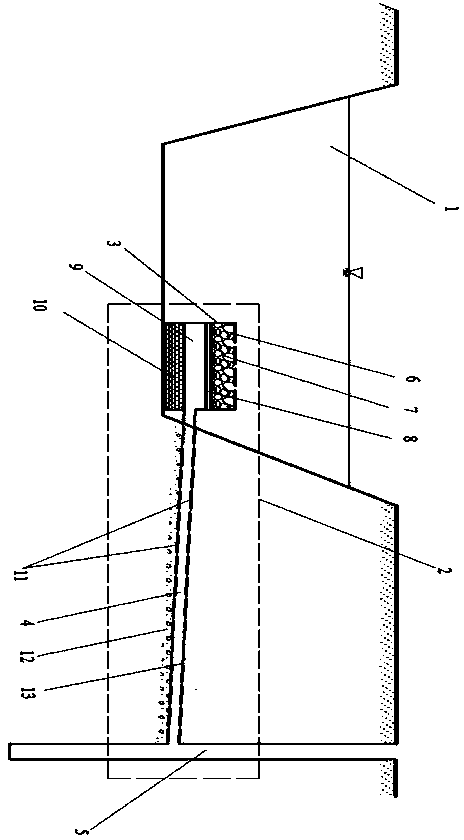

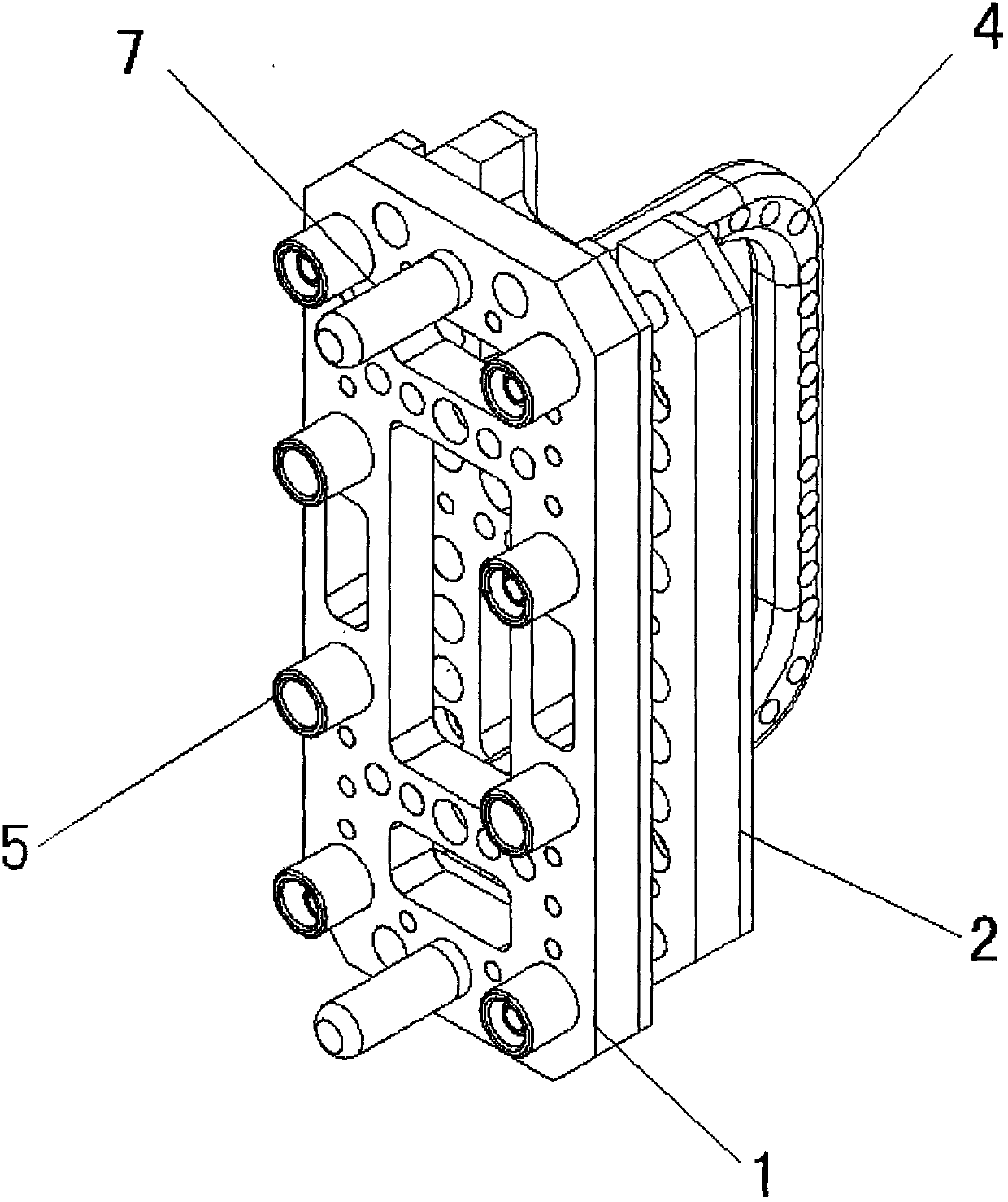

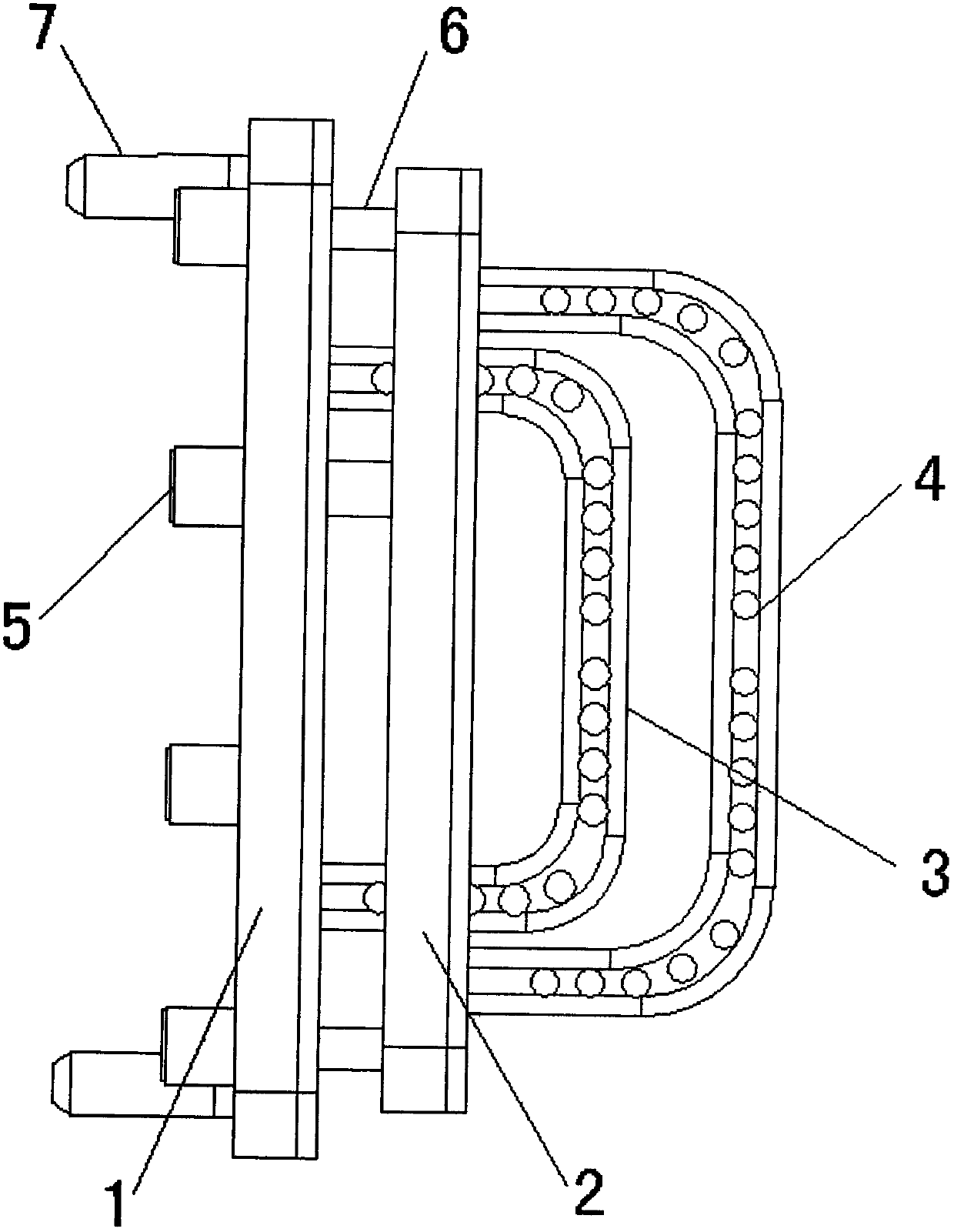

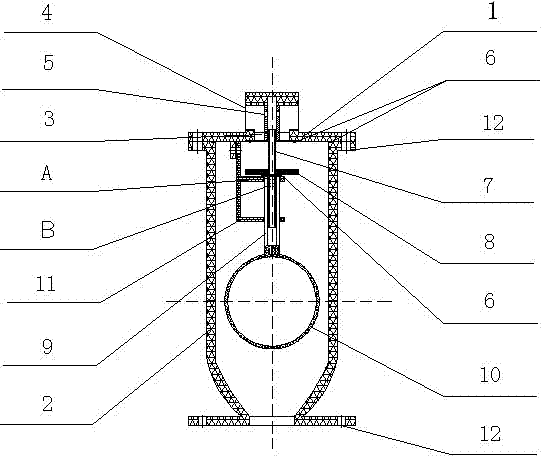

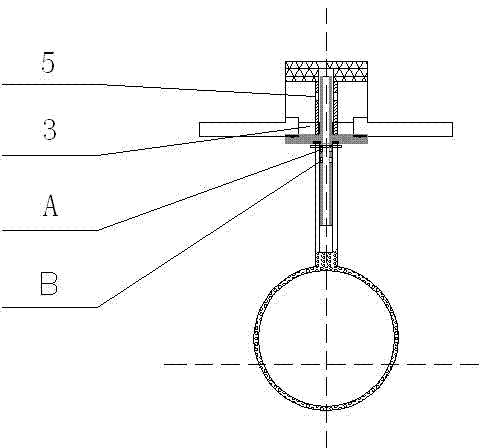

Efficient and anti-blocking water-bearing stratum supply device

InactiveCN104196005APrevent cloggingImprove recharge efficiencyLoose filtering material filtersGravity filtersWater pipeEngineering

The invention discloses an efficient and anti-blocking water-bearing stratum supply device, and belongs to the technical field of water-bearing stratum supply, namely artificial underground water recharge. The device comprises a channel (1) and a plurality of water filtering and dredging devices (2) vertically distributed along the channel (1). Each water filtering and dredging device (2) comprises a front-arranged filter unit (3), a rear-arranged dredging well (5) and an underground filter pipe (4) densely provided with water through holes and communicating the front-arranged filter unit (3) and the rear-arranged dredging well (5). The front-arranged filter unit (3) is arranged at the bottom of the channel (1), and the rear-arranged dredging well (5) is arranged at the other end of the filter pipe (4). The efficient and anti-blocking water-bearing stratum supply device has the remarkable advantages of being simple in design structure, small in occupied space, high in underground water supply efficiency, free of energy consumption, convenient to construct, low in cost and the like.

Owner:UNIV OF JINAN

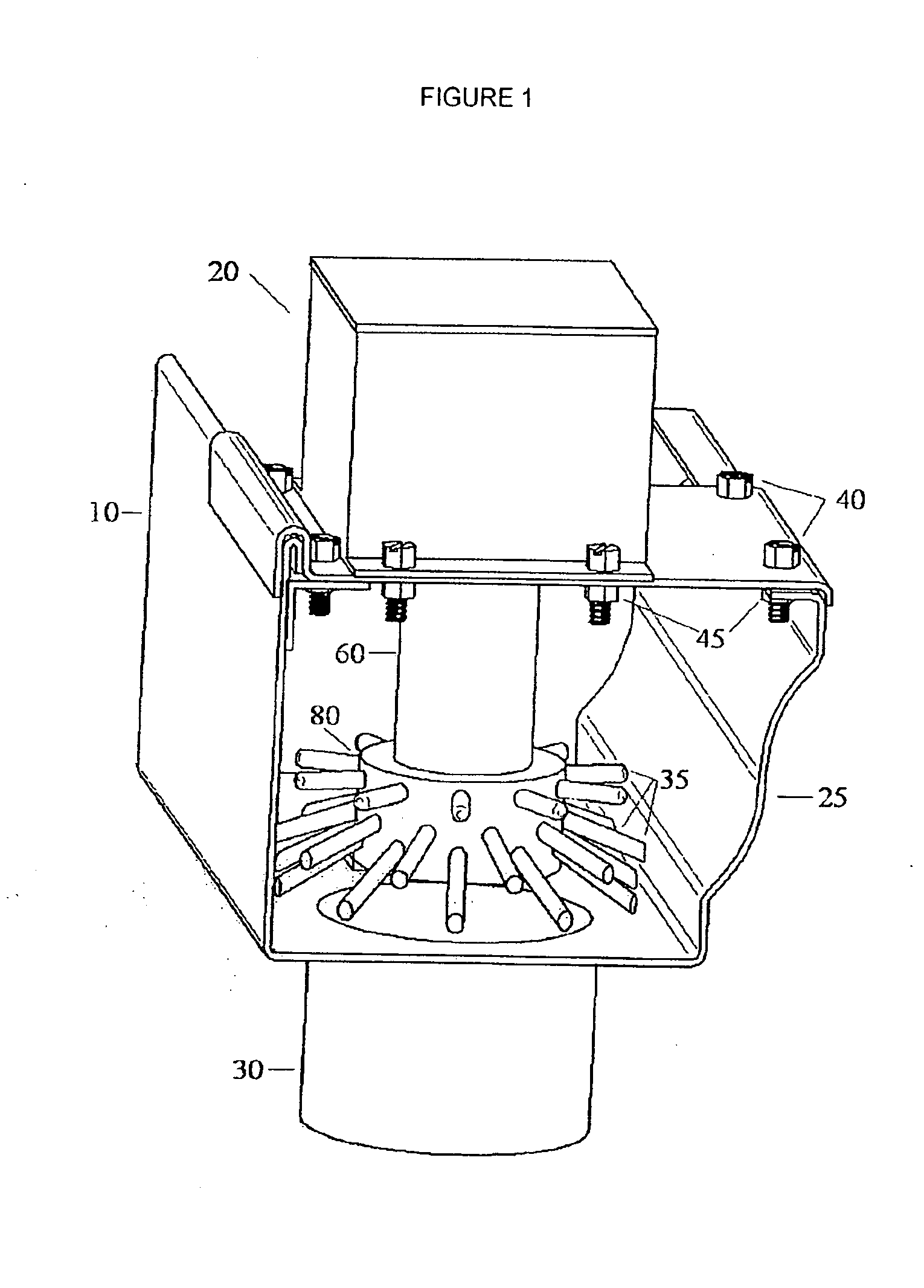

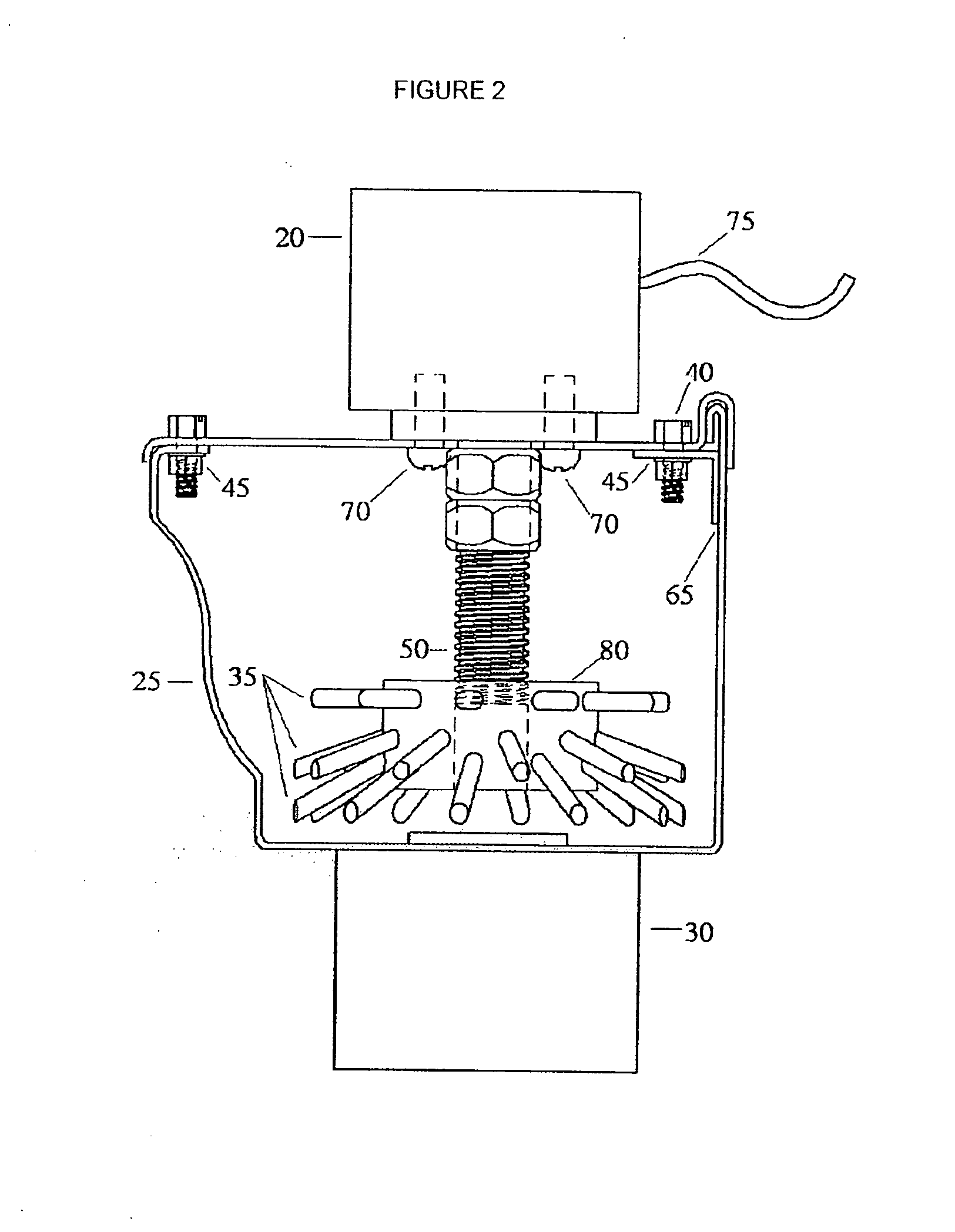

Method and apparatus for removal of gutter debris

Owner:RADEMACHER GEORGE

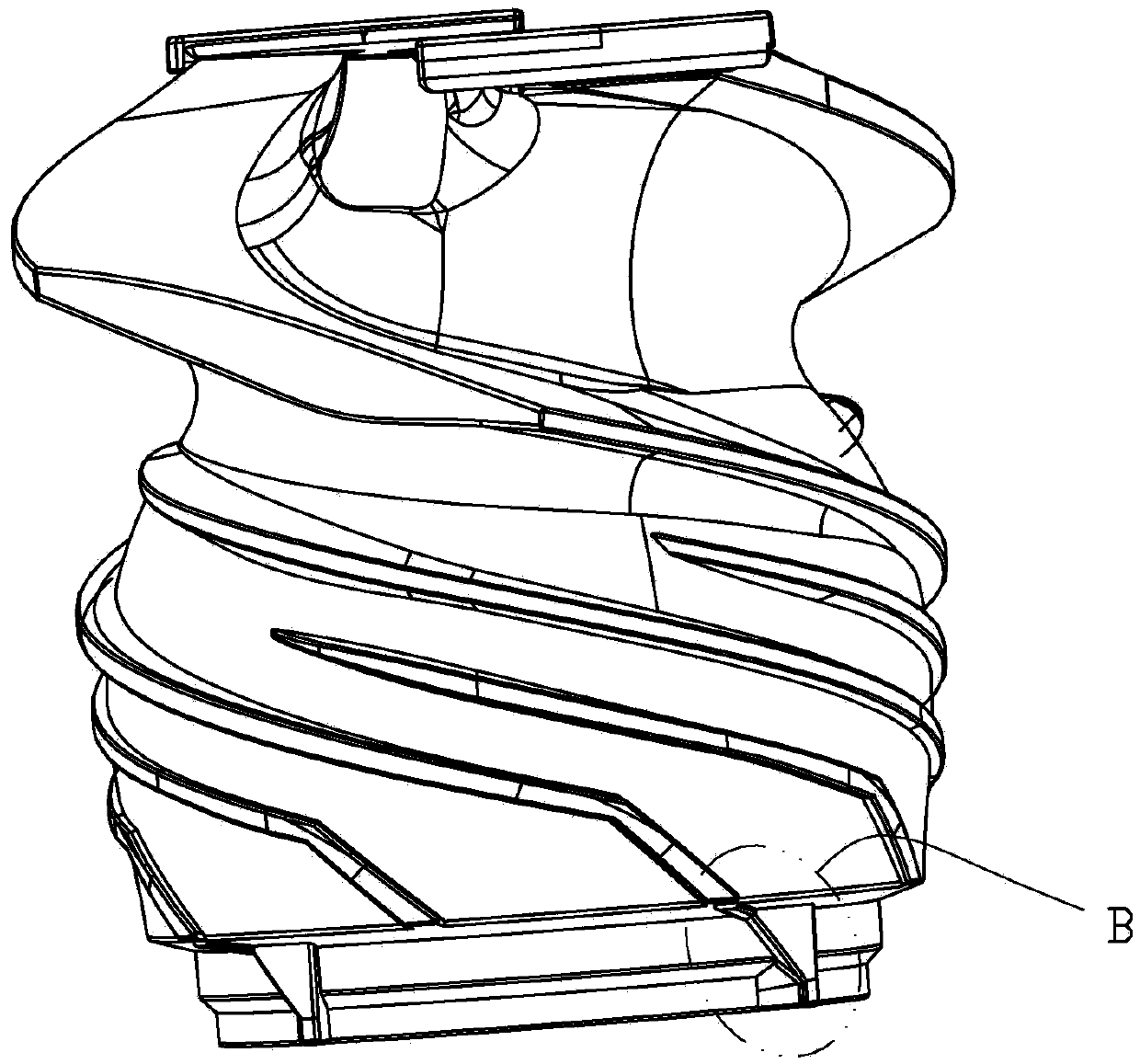

Juicer screw structure with material scrapers

The invention discloses a juicer screw structure with material scrapers. The juicer screw structure comprises a screw provided with a thread which spirally extends downwards from the top end of the screw, a skirt is arranged at the position, below the thread, of the bottom end of the screw, and the scrapers are arranged on the skirt and used for scraping and pushing residues of fruits and vegetables. The juicer screw structure with the material scrapers has the advantages that the juicer screw structure is simple; since accumulated residues can be effectively scraped and pushed to be discharged easily, residue blockage is avoided, wear of juicing parts due to the residues can be reduced, and service life of the juicing parts is prolonged.

Owner:江门市贝尔斯顿电器有限公司

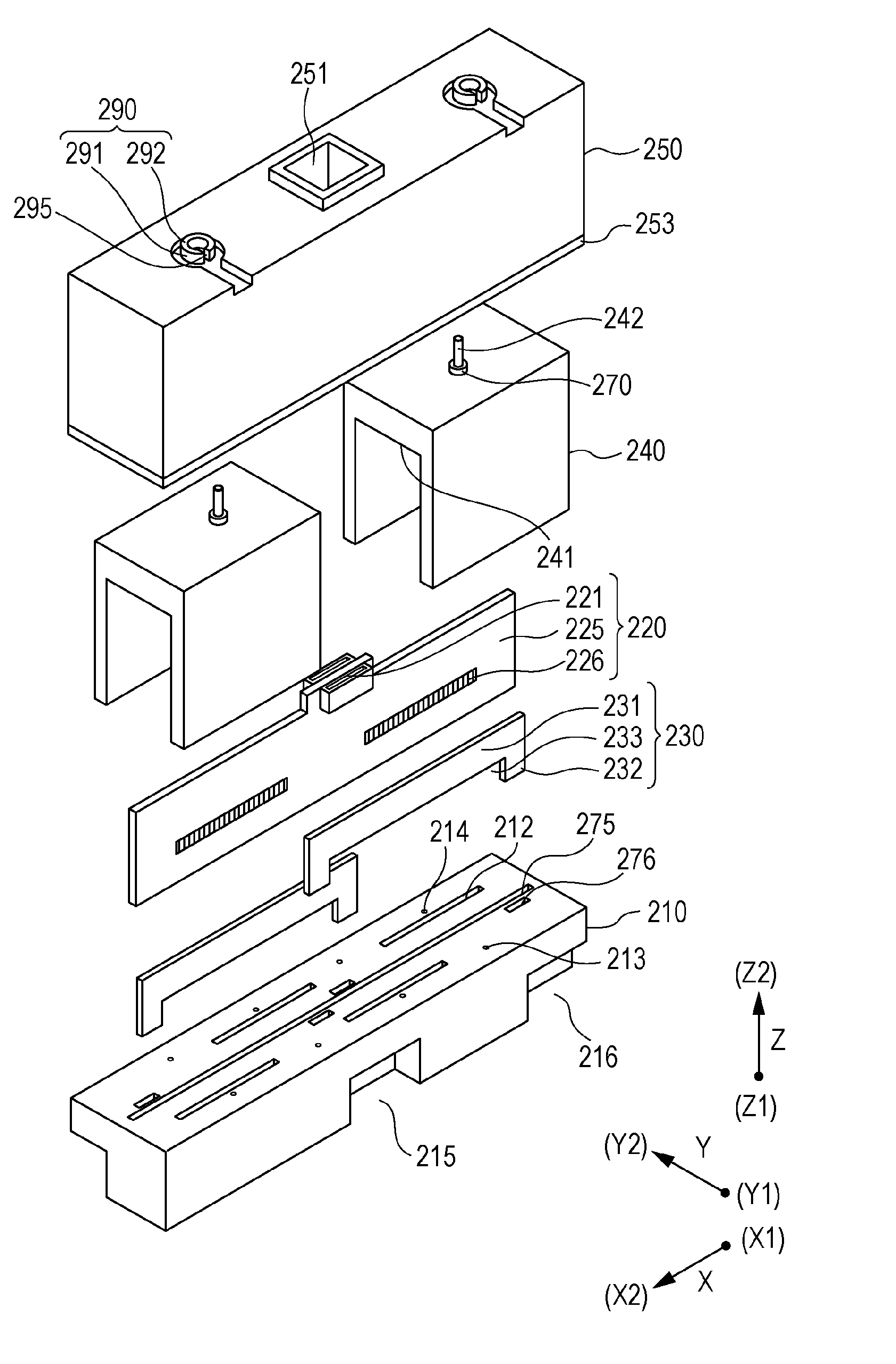

Flow path member, liquid ejecting head and liquid ejecting apparatus

The invention is to provide a liquid ejecting head including a flow path member which allows a capacity of an air bubble chamber to be increased as much as possible and in which a filter is not clogged even when the variation of a liquid consumption amount is large, and a liquid ejecting apparatus including the flow path member. Alternatively, the invention is to provide a liquid ejecting head including a flow path member which allows a capacity of an air bubble chamber to be increased as much as possible while being miniaturized in a transporting direction and a liquid ejecting apparatus including the flow path member.

Owner:SEIKO EPSON CORP

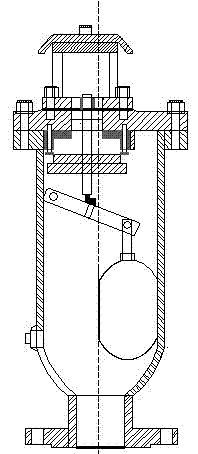

Self-cleaning solid-liquid separation device

InactiveCN106696333APrevent cloggingAvoid cloggingSludge treatment by de-watering/drying/thickeningPressesMotor shaftEngineering

The invention discloses a self-cleaning solid-liquid separation device. The self-cleaning solid-liquid separation device comprises a base, a blowdown tank and a support shell, wherein the blowdown tank is fixed to the top end of the base through second supporting legs; the support shell is fixed to the top end face of the base through first supporting legs; a screen drum is arranged in the support shell; a rotating shaft is arranged in the screen drum; a large diameter end of the rotating shaft is fixedly connected with a transmission shaft; an extrusion spiral fin matched with the screen drum is arranged on the rotating shaft in a sleeving manner; a substrate is arranged on the left side of the top end of the base; a motor is fixedly connected on the substrate; a first driving wheel and a second driving wheel are arranged on a motor shaft of the motor in a sleeving manner; a drainage pipe is connected at the bottom of the right side end of the support shell in a penetrating manner; a washing shaft is arranged at the bottom of an inner cavity of the support shell; and a fur brush matched with the screen drum is arranged at the other side end of the washing shaft in a sleeving manner. According to the self-cleaning solid-liquid separation device, sieve holes are of cone-shaped structures, extruded sludge can hardly block the sieve holes during the extrusion process, the washing shaft rotates at a high speed under the driving of the motor, the fur brush is driven to clean the sieve holes, and the sieve holes can be effectively prevented from being blocked.

Owner:HEFEI ZHIHUI LONGTUTENG INTPROP CO LTD

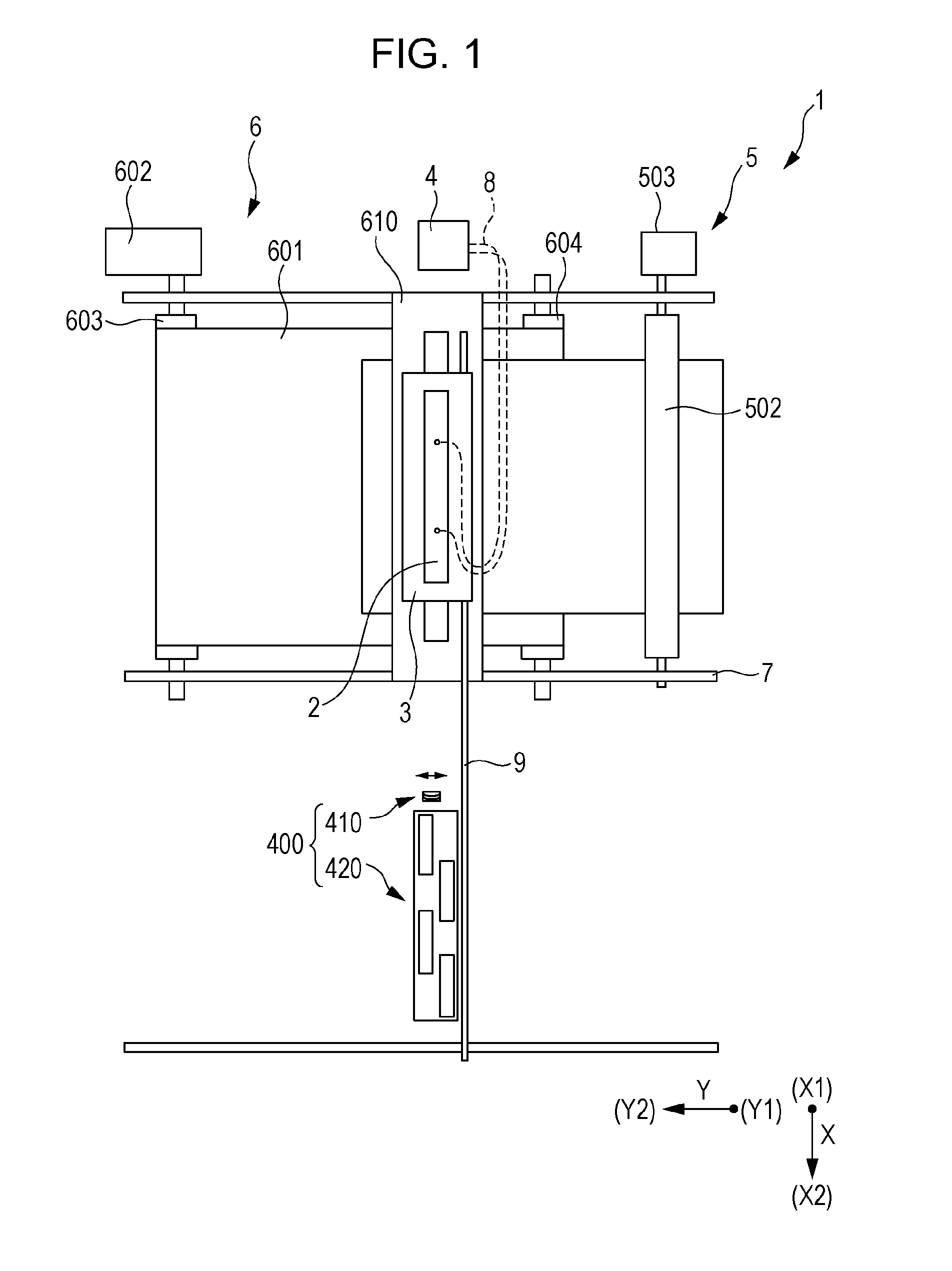

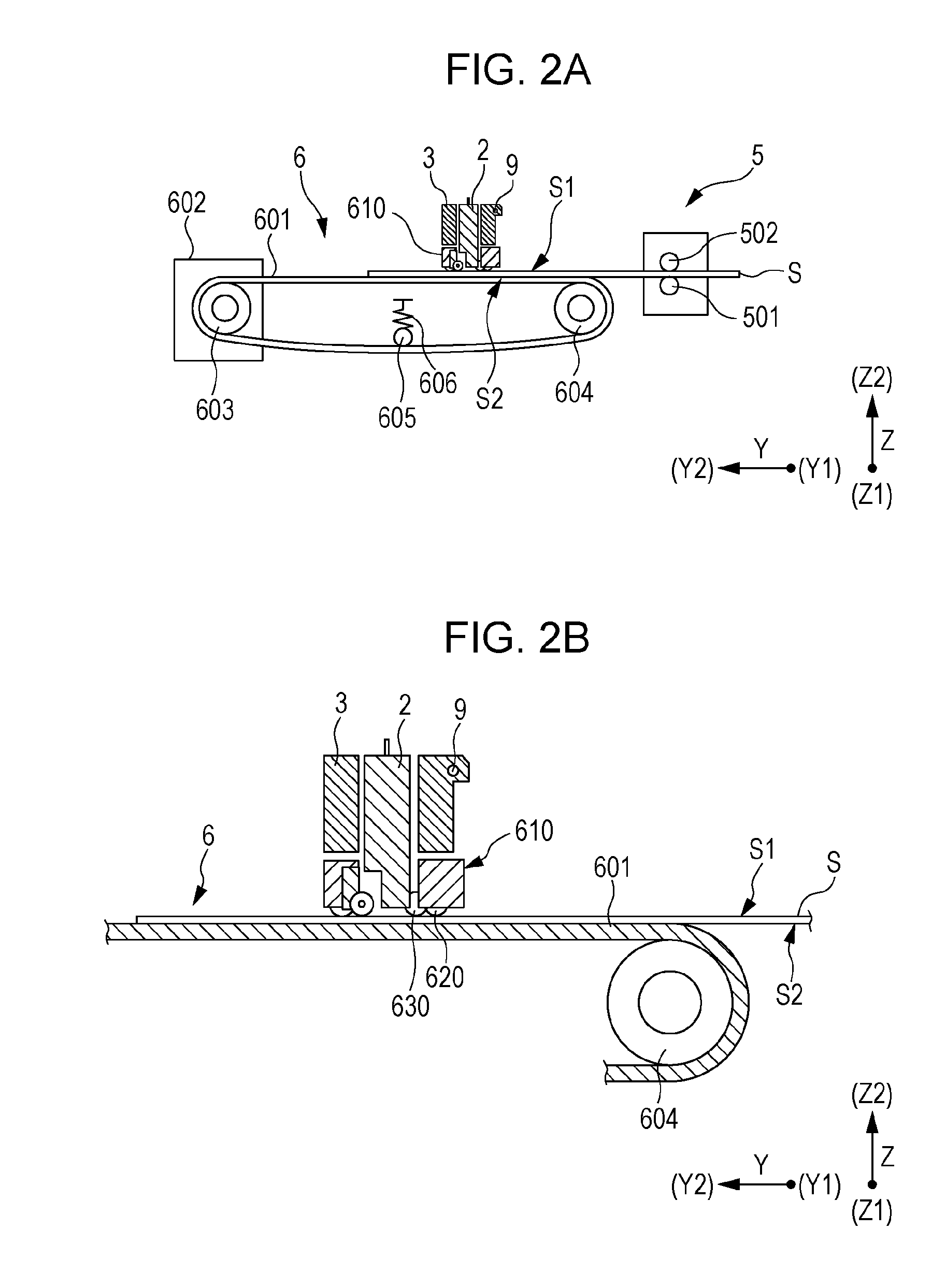

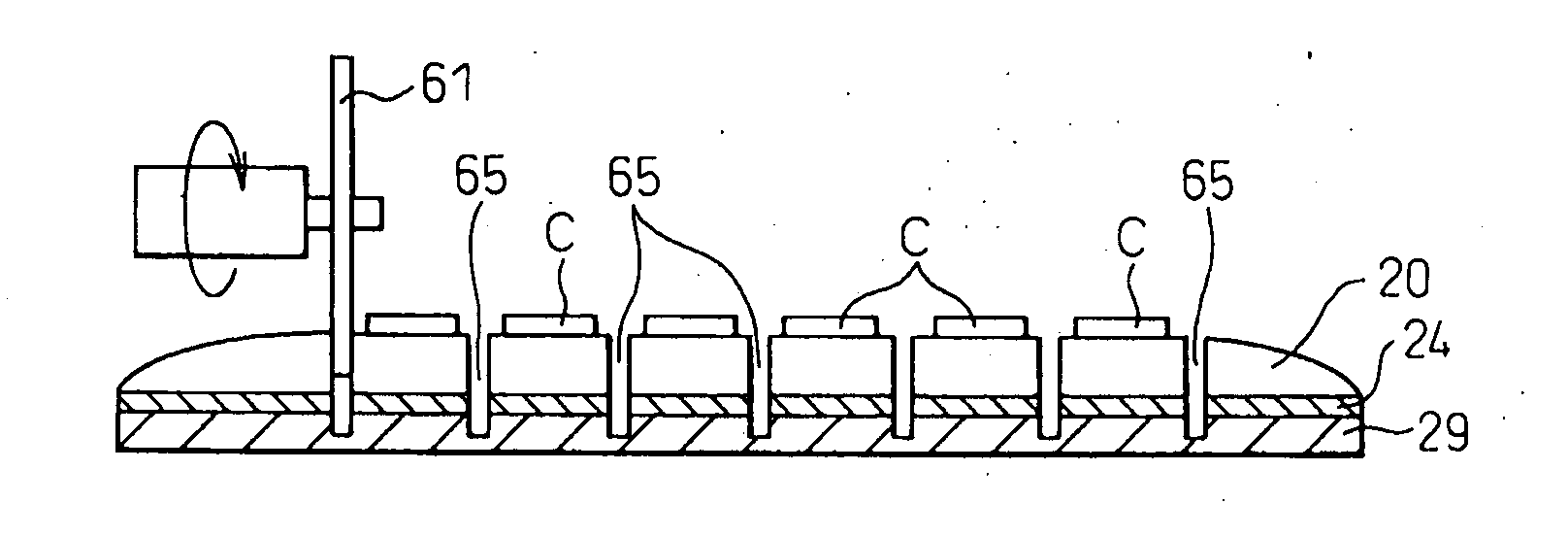

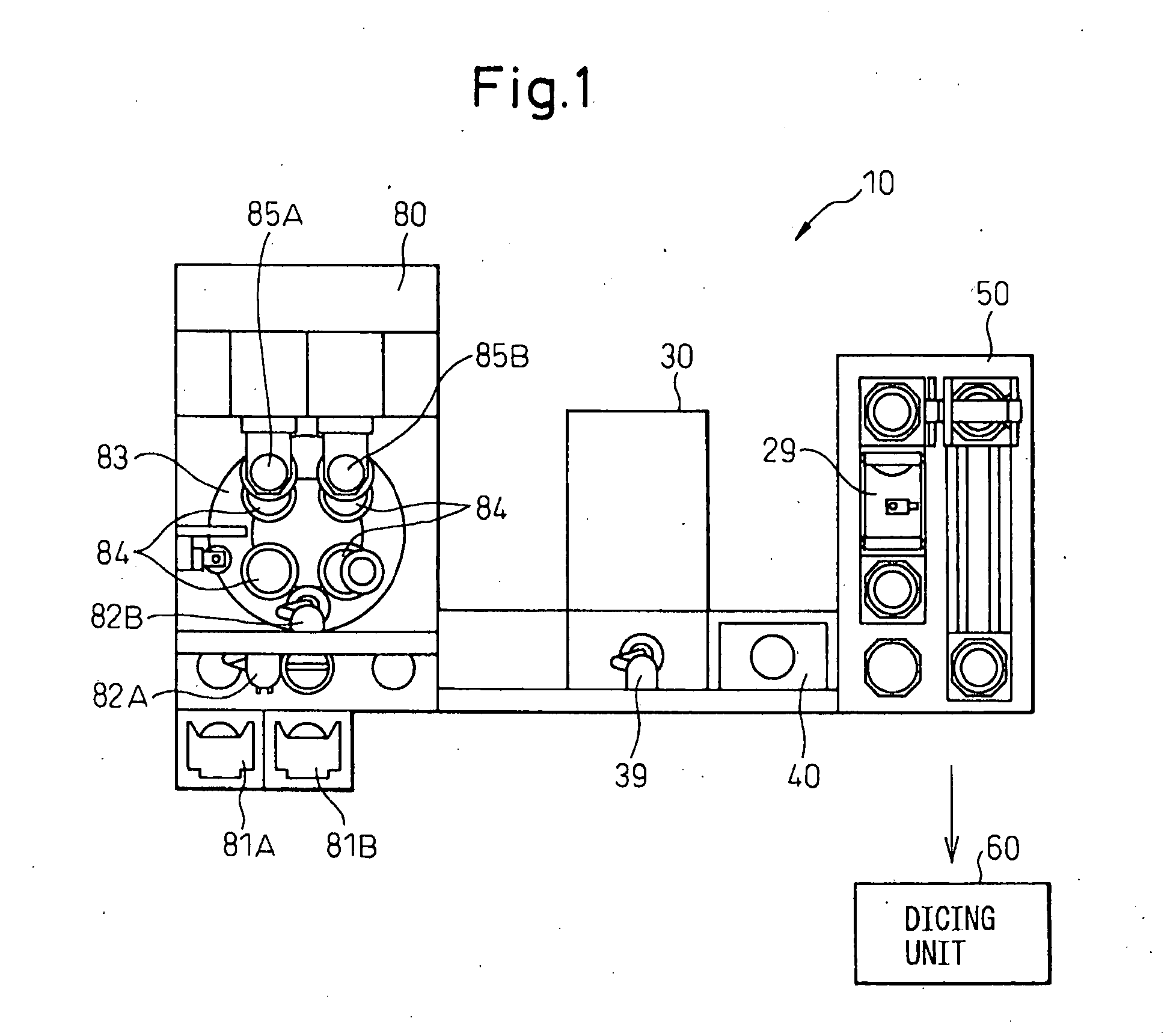

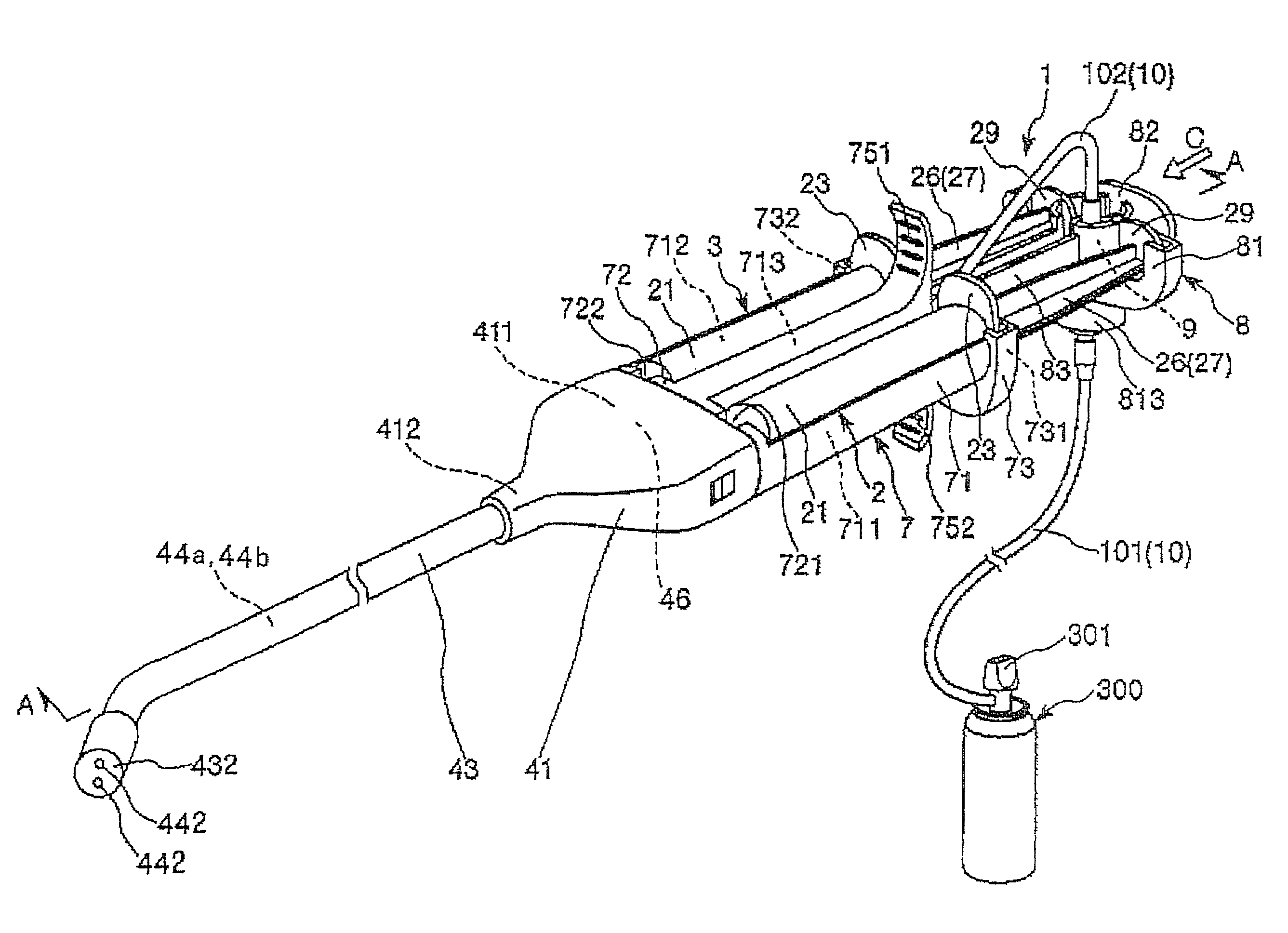

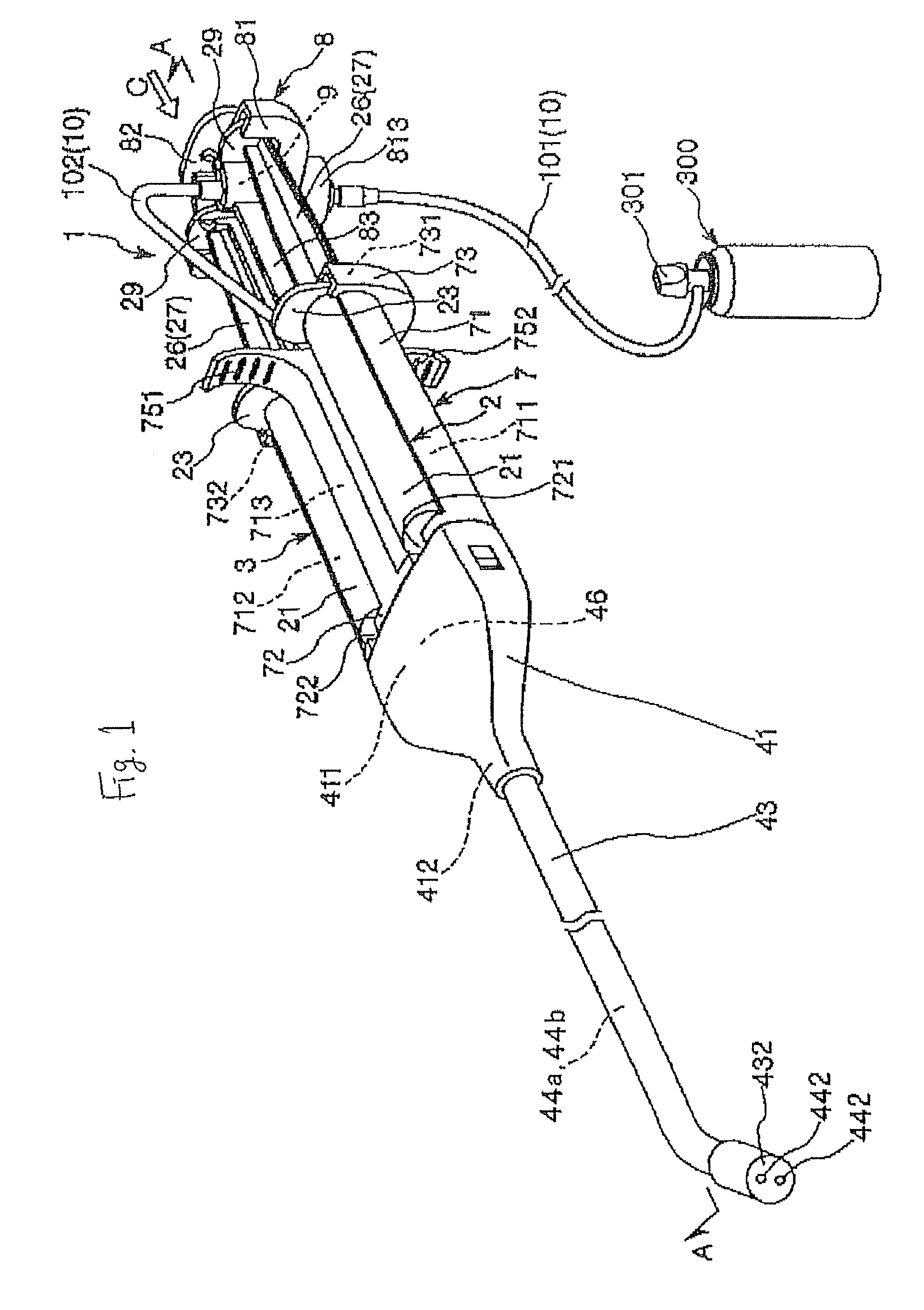

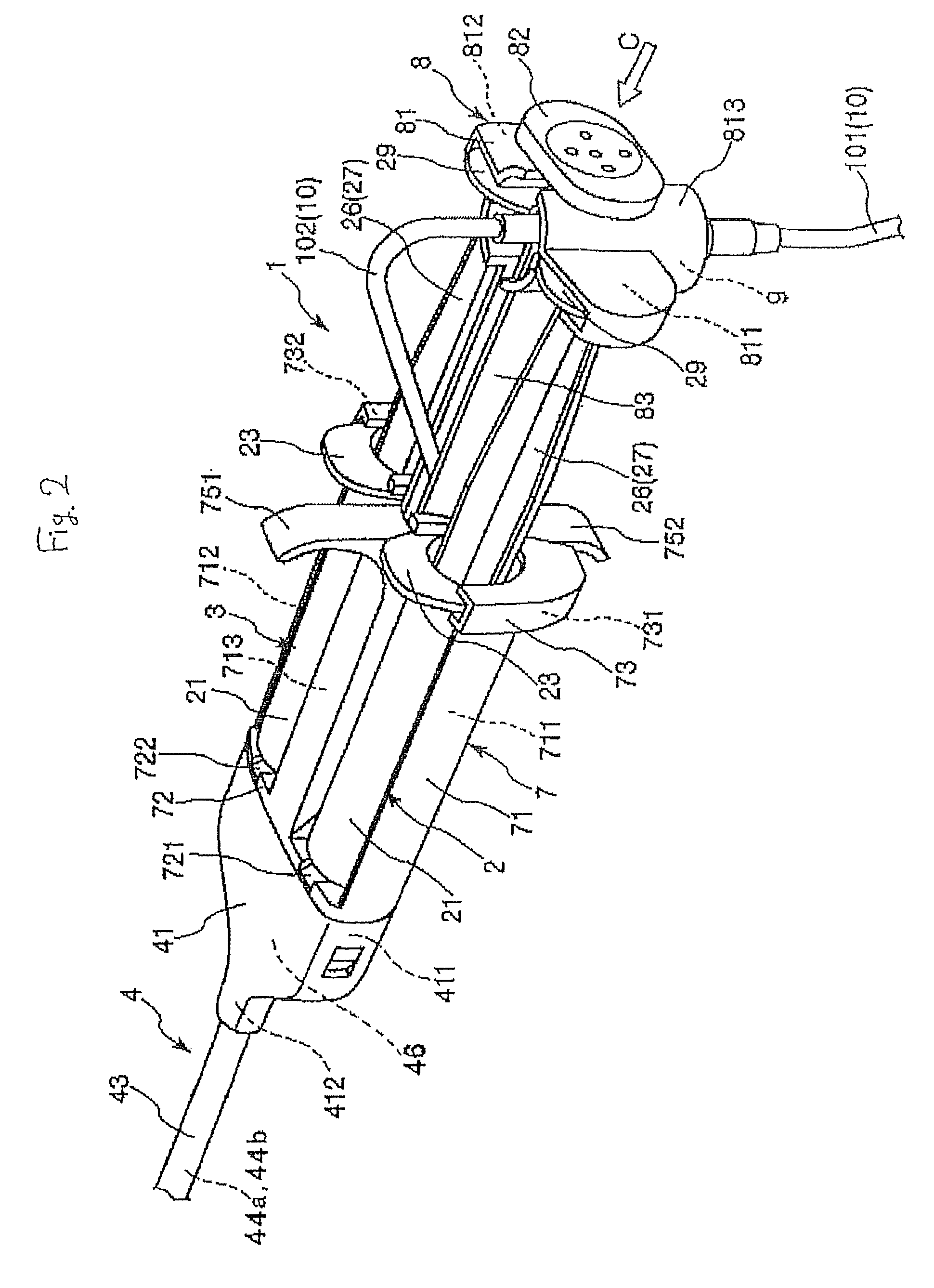

Wafer processing method and wafer processing apparatus

InactiveUS20080064188A1Cut capability be reducePrevent cloggingLiquid surface applicatorsLamination ancillary operationsEngineeringElectrical and Electronics engineering

A wafer processing apparatus (10) has a grinder (80) for grinding the back surface (22) of a wafer (20) on whose front surface (21) a circuit pattern (C) has been formed, and a die attachment paste applicator (30) for applying die attachment paste on the entire back surface of the wafer ground by the grinder. With this arrangement, die attachment paste can be applied to a wafer in a short period of time without using a film. The die attachment paste applicator is either a spin-coater (30A) that spin-coats die attachment paste supplied on the back surface of a wafer, or a screen-printing device (30B) that screen-prints die attachment paste on the back surface of a wafer.

Owner:TOKYO SEIMITSU

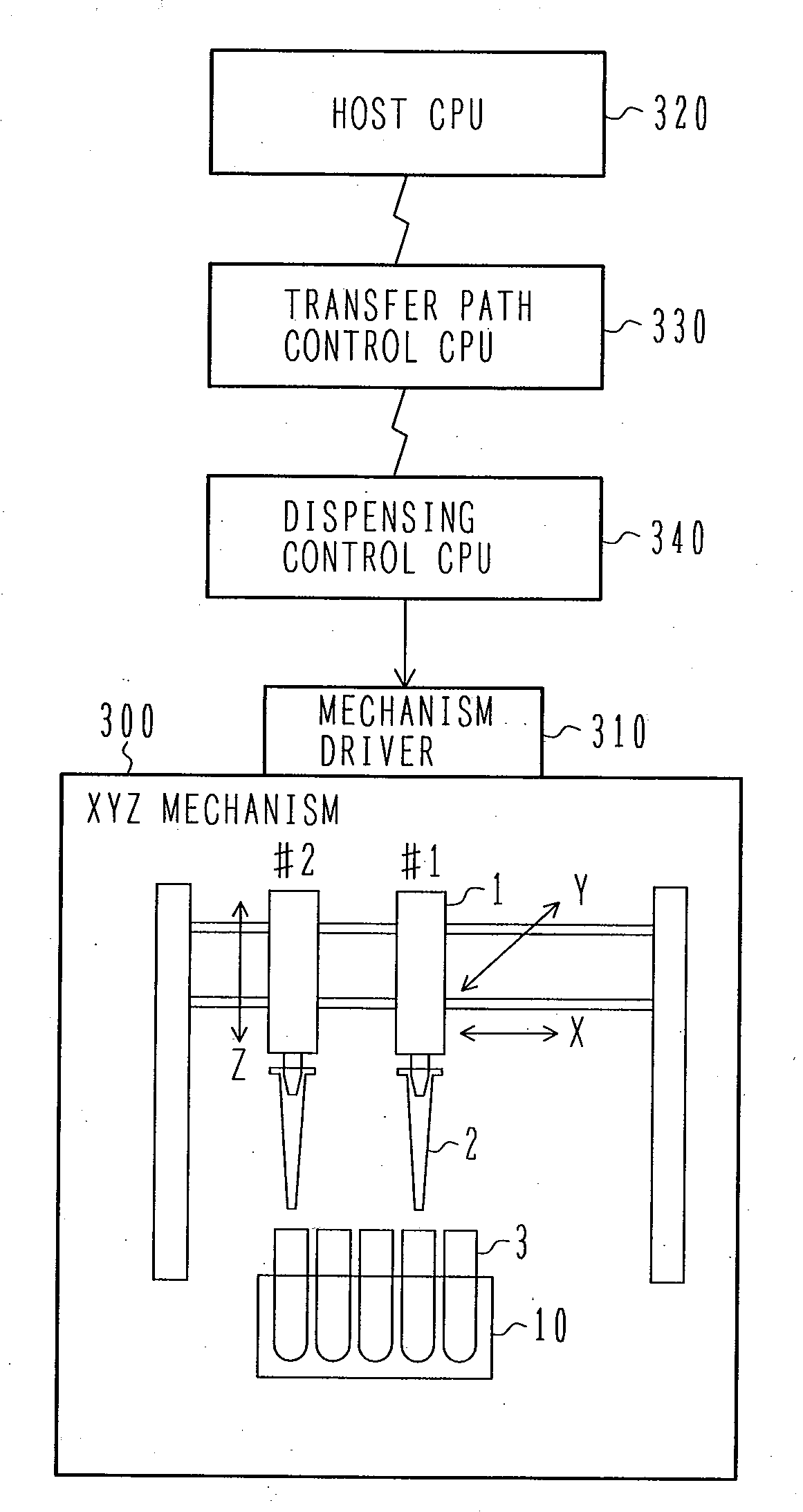

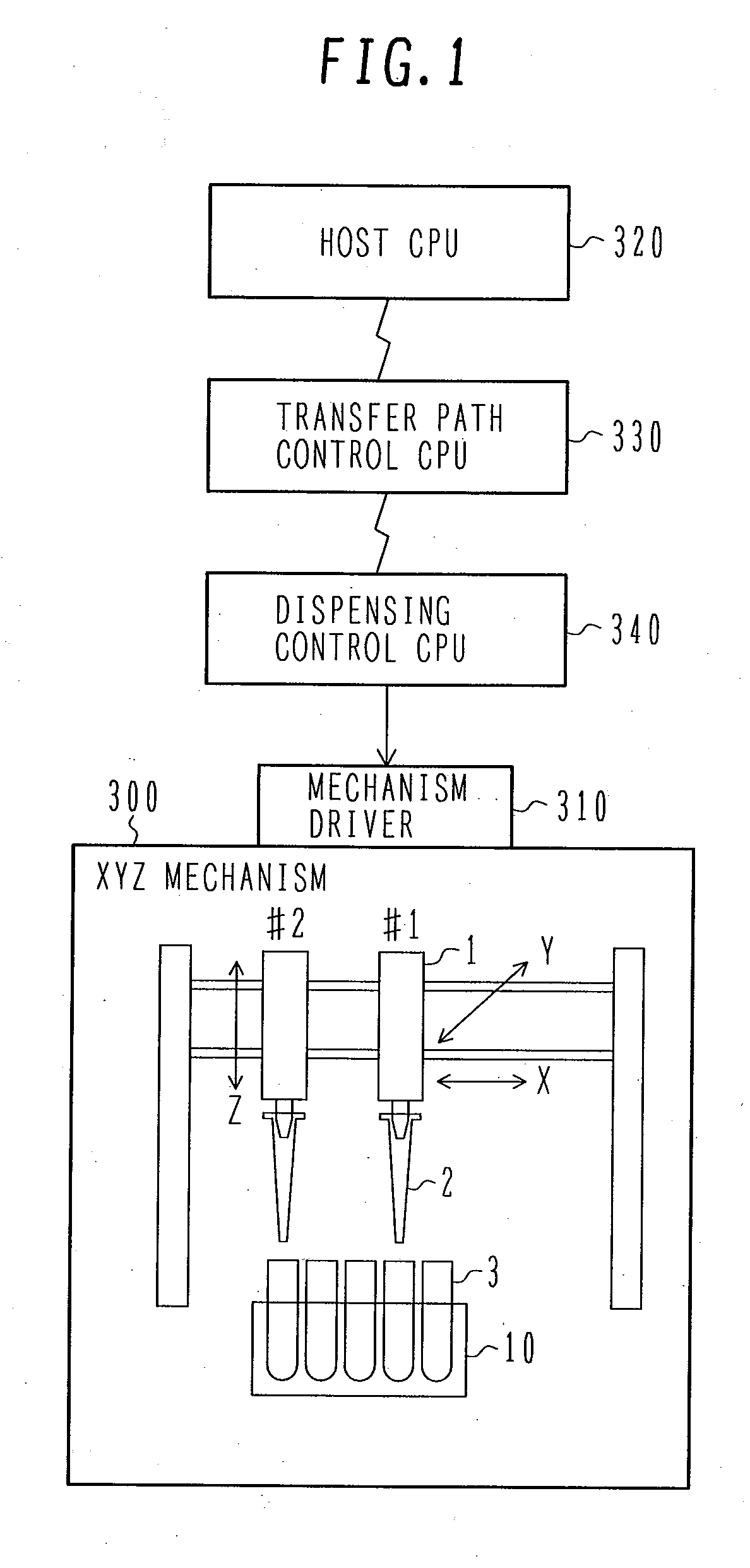

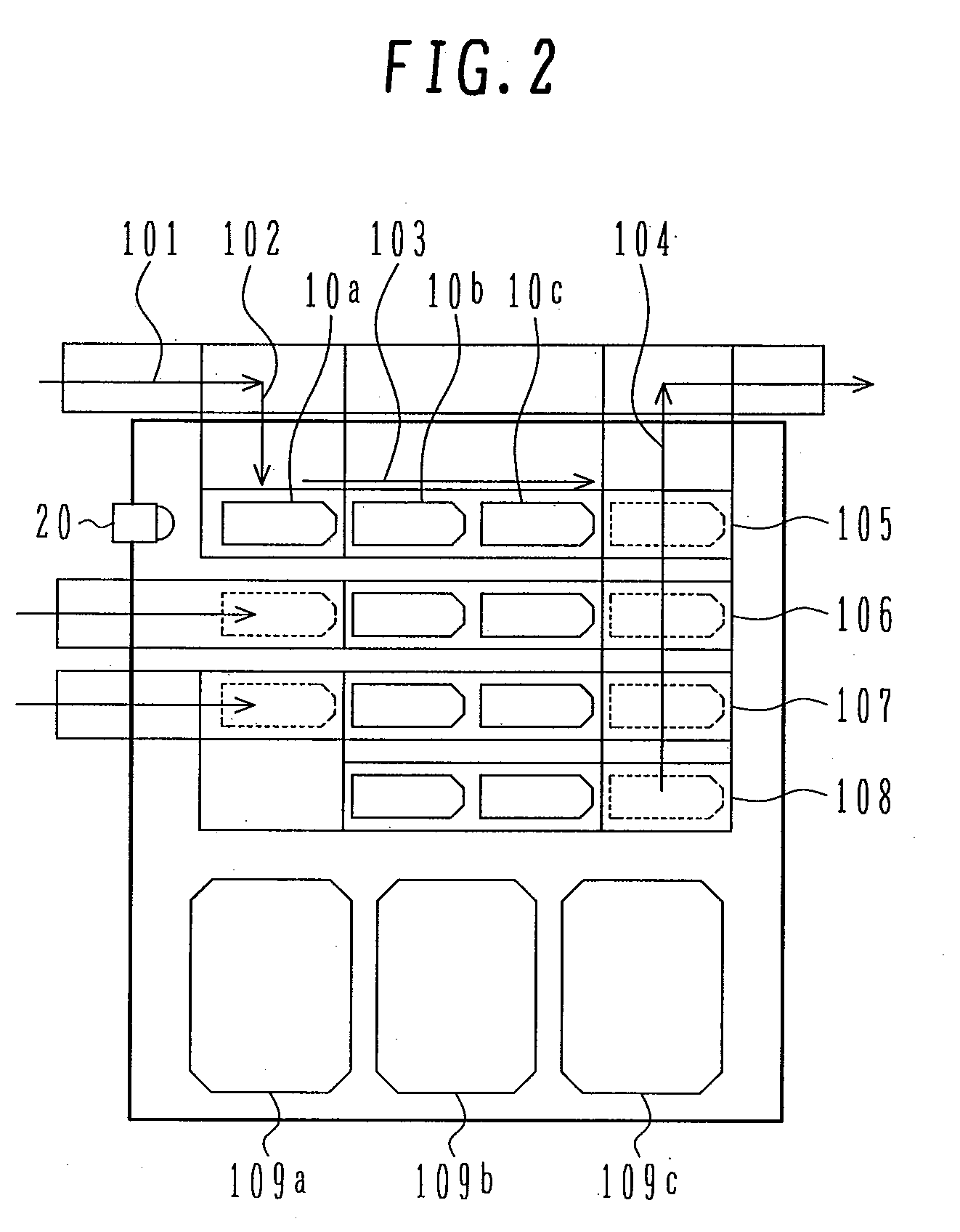

Sample dispensing apparatus

ActiveUS20080156118A1Prevent cloggingNegative effectWithdrawing sample devicesBurettes/pipettesBiomedical engineeringContamination

A sample dispensing apparatus dispenses a sample from a container accommodating a sample such as blood or urea sampled for checking. This sample dispensing apparatus can prevent internal contamination of the apparatus due to dripping of the sample and abnormal sucking operations caused by drainage, condensation and fixing of the sample. The sample dispensing apparatus according to the present invention comprises a dispensing device for dispensing a sucked sample, a dispensing head provided in the dispensing device, and a disposable nozzle chip dismountably set on the dispensing head. In this apparatus, dispensing of a sample to child sample containers is performed exchanging the child sample containers with new ones. When the state, in which dispensing to the child container cannot be carried out, is continued for a prespecified period of time, the nozzle chip is automatically released from the dispensing head.

Owner:HITACHI HIGH-TECH CORP

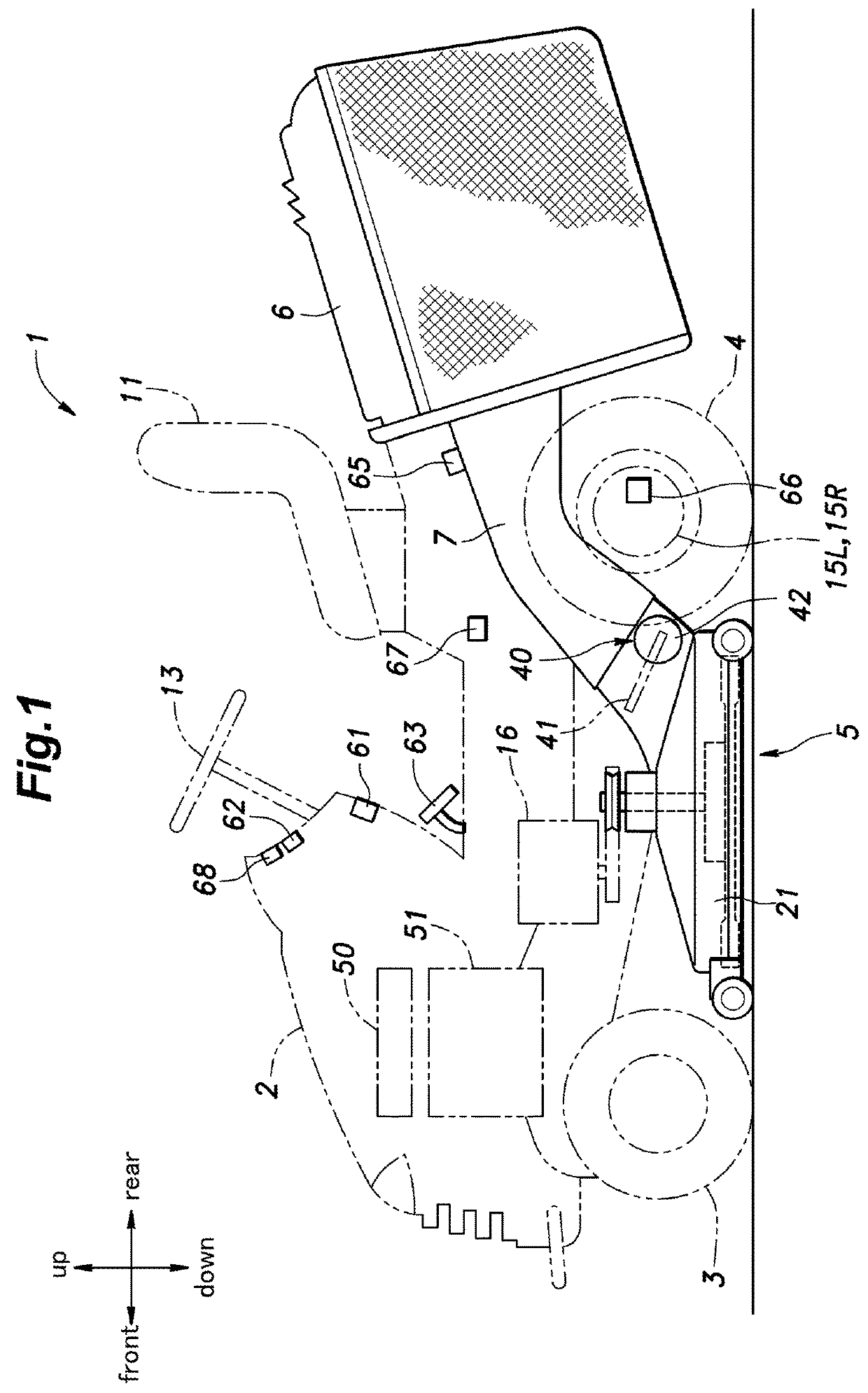

Lawn mower

ActiveUS20180177128A1Prevent cloggingPrevents uneven distributionLawn-mowersLawn mowerPressure sensor

A lawn mower contains: a work unit including a housing having a downward-facing opening and a cutter blade rotatably provided in the housing such that when rotated, the cutter blade cuts grass and generates a transport air flow flowing from the opening of the housing to inside; a grass clippings receptacle configured to receive grass clippings cut by the work unit; a grass clippings transport passage connecting an interior of the housing with the grass clippings receptacle; a shutter device including a shutter configured to selectively open and close the grass clippings transport passage and an actuator configured to drive the shutter; a controller configured to control the shutter device; and a pressure sensor provided in the grass clippings transport passage to detect a pressure in the grass clippings transport passage, wherein the controller is configured to control the shutter device in accordance with the pressure detected by the pressure sensor.

Owner:HONDA MOTOR CO LTD

Multi-cavity injection mould hardware mould inputting jig

The invention discloses a multi-cavity injection mould hardware mould inputting jig which comprises an element taking plate and an installation plate in parallel arrangement; the installation plate is installed above the element taking plate; the element taking plate and the installation plate are elastically connected through a plurality of elastomers; a first grip is arranged on the element taking plate; a second grip is installed on the installation plate; the element taking plate is provided with a plurality of embedding element clamp heads which are in uniform distribution; the embedding element clamp heads penetrate through the element taking plate and extend from the bottom surface of the element taking plate; the embedding clamp heads are of a hollow cylindrical shape matched with the shape of a hardware element; and the bottom surfaces (corresponding to the installation plate) of the embedding clamp heads are provided with a plurality of ejection columns inserted into the embedding element clamp heads. The multi-cavity injection mould hardware mould inputting jig has the characteristics that leisure time of operators can be reasonably utilized, the injection molding cycle is shortened, and the injection molding efficiency is improved; the invalid time of the operation of an injection molding machine is shortened, and blocking and chewing can be prevented; hardware can be safely enters a mold by utilizing the jig; and within the original effective time, hardware with the number four times, eight times or even more that of the original hardware can be input.

Owner:KENTA ELECTRONIC MFG KUNSHAN CO LTD

Sprayer

ActiveUS8545457B2Prevent cloggingAvoid cloggingLiquid surface applicatorsFlow mixersInjectorEngineering

A sprayer which inhibits or prevents clogging from occurring in a nozzle when a liquid is ejected from the nozzle includes a nozzle having a first internal tube through which a first liquid passes, and a second internal tube through which a second liquid passes. An external tube is provided in which the first internal tube and the second internal tube are positioned so that the gas passes therebetween. In the sprayer, each distal end part of the first internal tube and the second internal tube includes a gas permeable film impermeable to each liquid, and permeable to the gas.

Owner:TERUMO KK

A kind of intake and exhaust valve for sewage with many impurities and large gas volume

InactiveCN102261513AIncrease sizePrevent cloggingOperating means/releasing devices for valvesSewageMechanical engineering

The invention relates to a sewage inlet / exhaust valve, specifically to an inlet / exhaust valve for sewage containing lots of impurities and gases. The exhaust valve is provided with a gas vent having an enlarged size, which is advantageous for the exhausting of a large quantity of gases in the sewage, and simultaneously capable of preventing blockage; the gas vent is under the protection of a guide rod on a floating ball without contacting with bubbles easily incrusted in the sewage gases, thereby reducing blockage and ensuring long-term operation; besides, the position of the floating ball is in the middle position, so that the diameter of the whole valve body is reduced; and a circular floating ball is employed so that the contact area thereof with the liquid level can be widened and the length of the valve body can be also reduced. The exhaust valve overcomes the defects of impurity blockage and low gas output caused by a small gas outlet of the existing sewage inlet / exhaust valve.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com