Patents

Literature

2436 results about "Shaped beam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

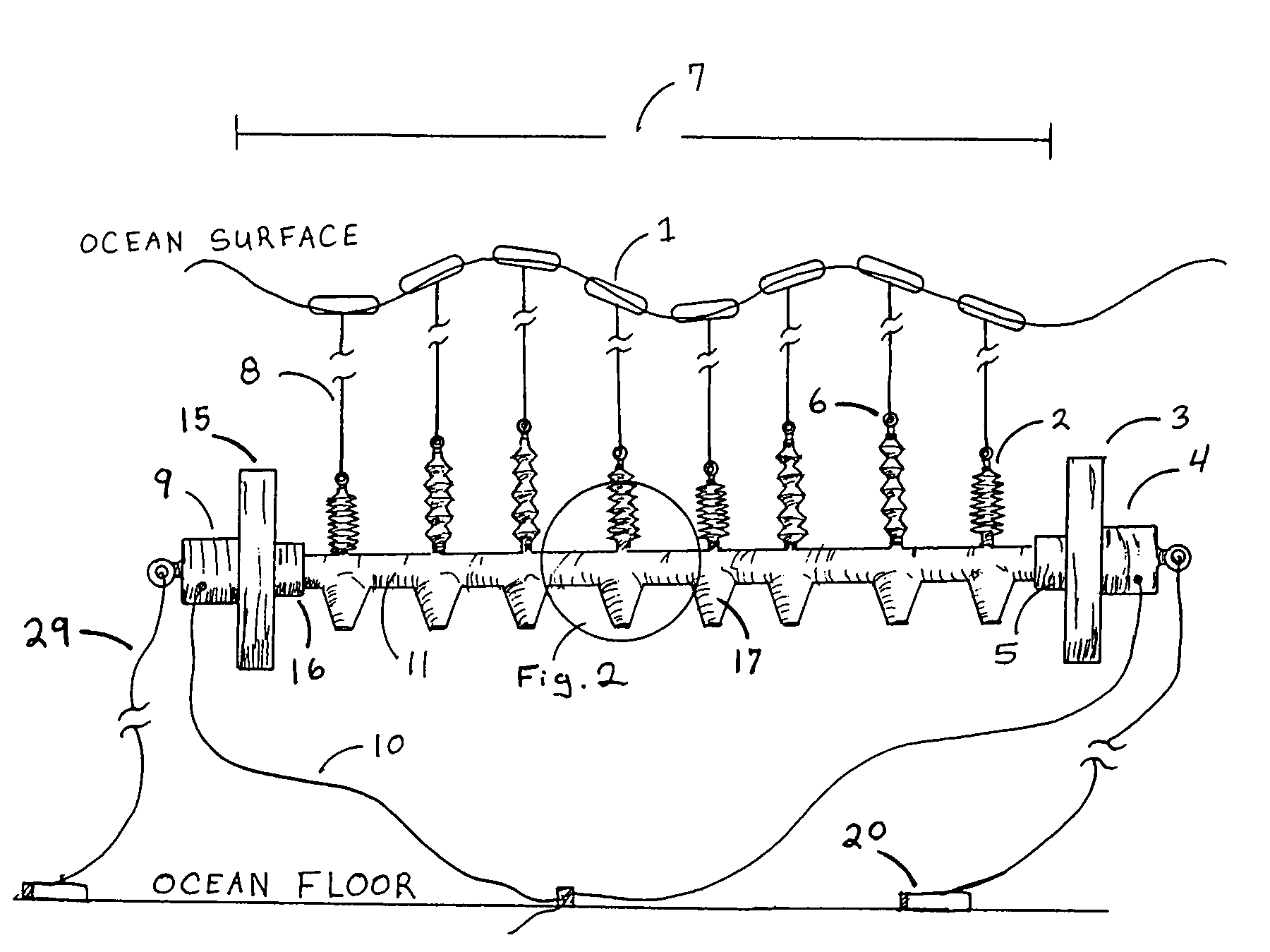

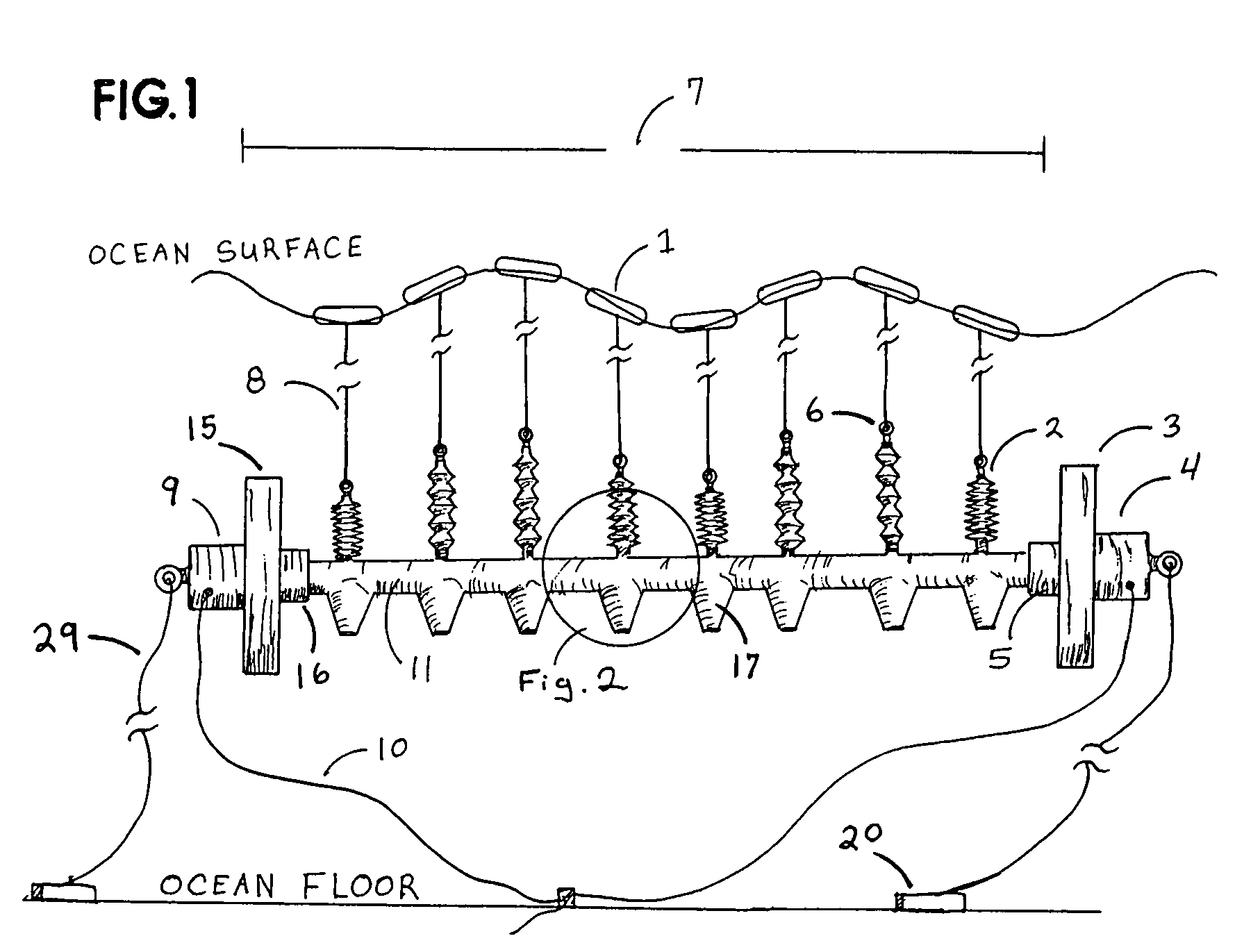

Ocean wave energy converter

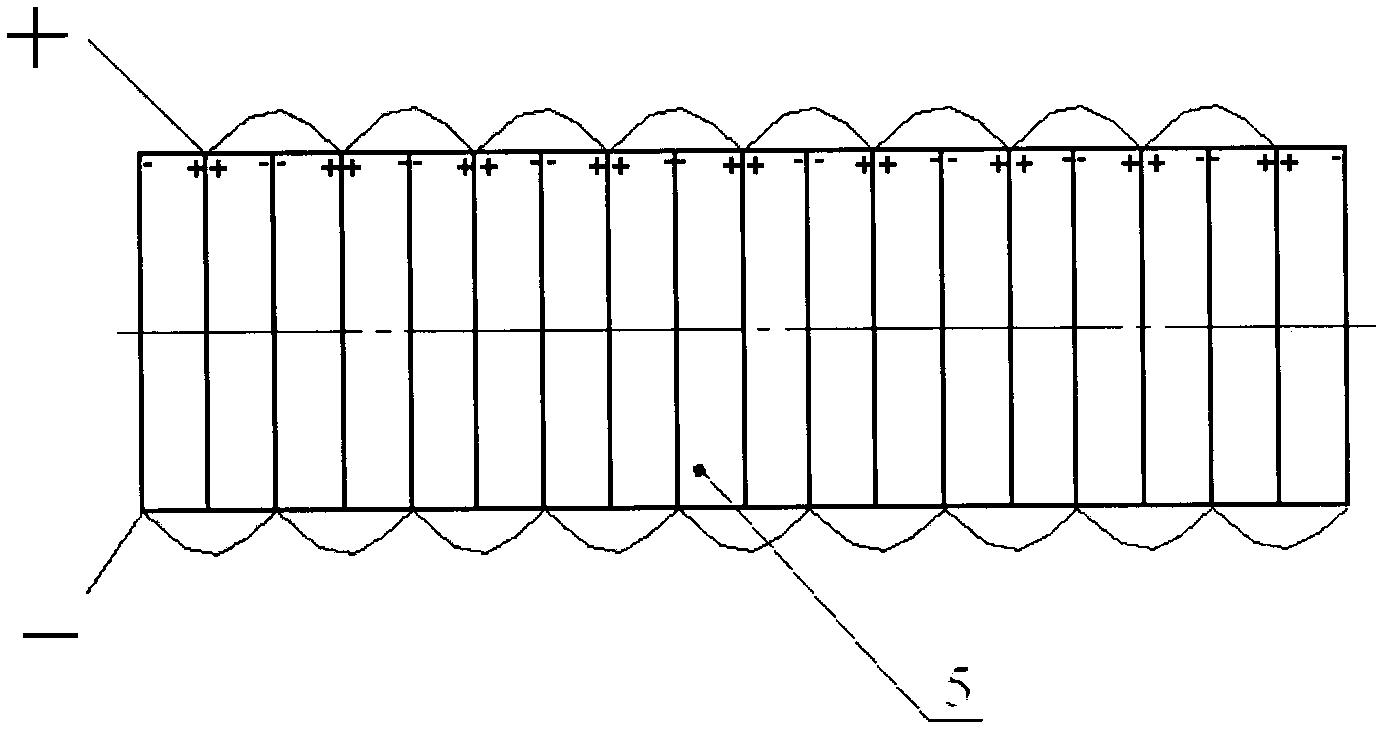

A long cylinder shaped beam is submerged in the ocean and suspended horizontally by multiple floats for converting ocean wave energy. The long length (at least the distance of the crest of two waves) and heavy weight of the beam, give the floats something stable to pull against. The weight of the beam pulling at the floats is transferred back and forth, as the ocean swells move over the beam, which activate machine components that may be installed in the beam, the floats or with rods connecting the floats to the beam. An individual float will not lift the beam except when the tide raises all the floats. The floats will pull and release the tension of the weight of the beam at randomly different times. The shape of the beam is straight. The ocean surface is continuously curving up and down and the beam will not bend to the shape of the ocean surface, but the floats will mimic the undulating or curvy shape of the ocean surface, and that motion actives the machine. The energy of the floats pulling against the elongated component is then turned into mechanical or hydraulic energy.

Owner:OLSON CHRIS F

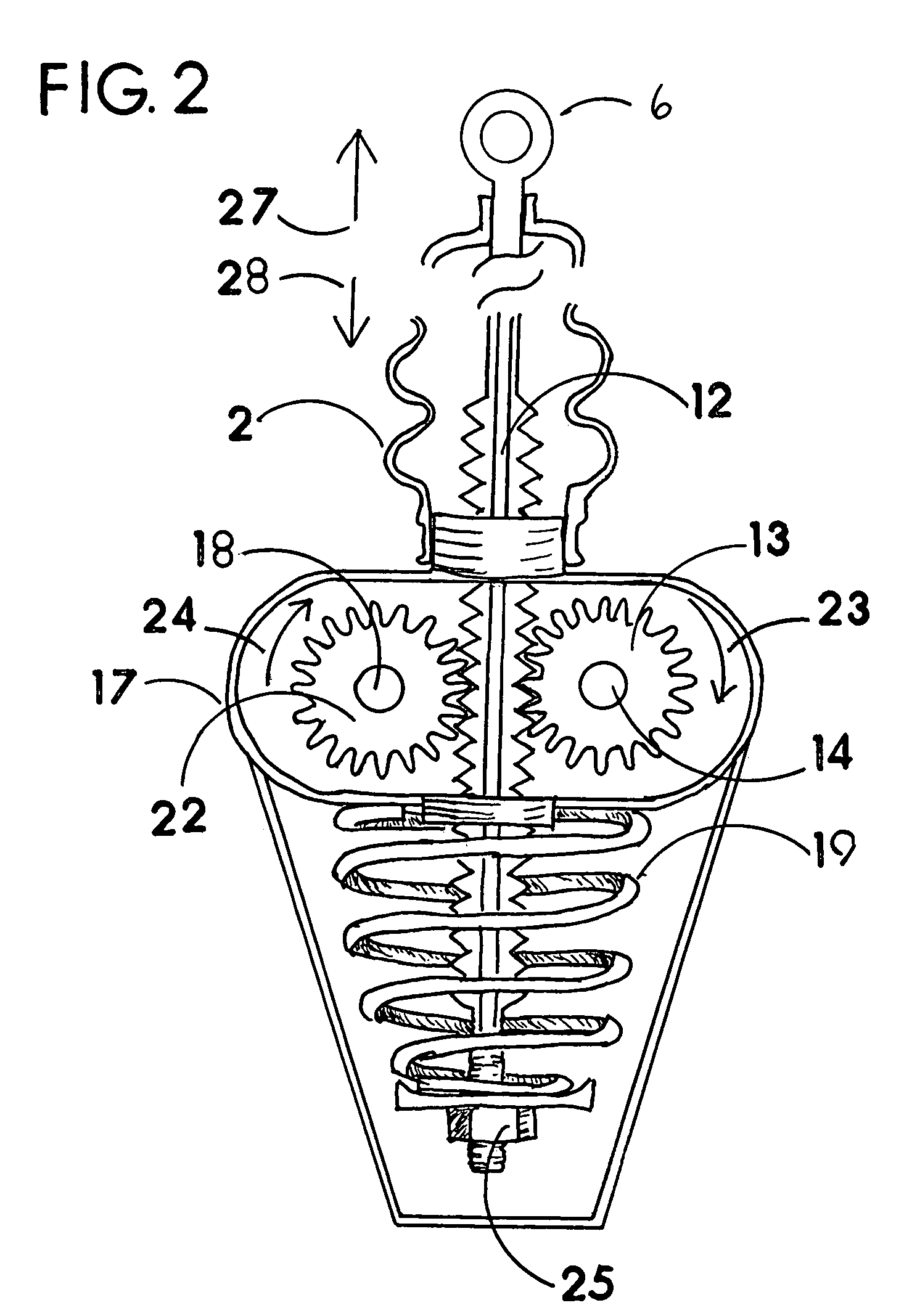

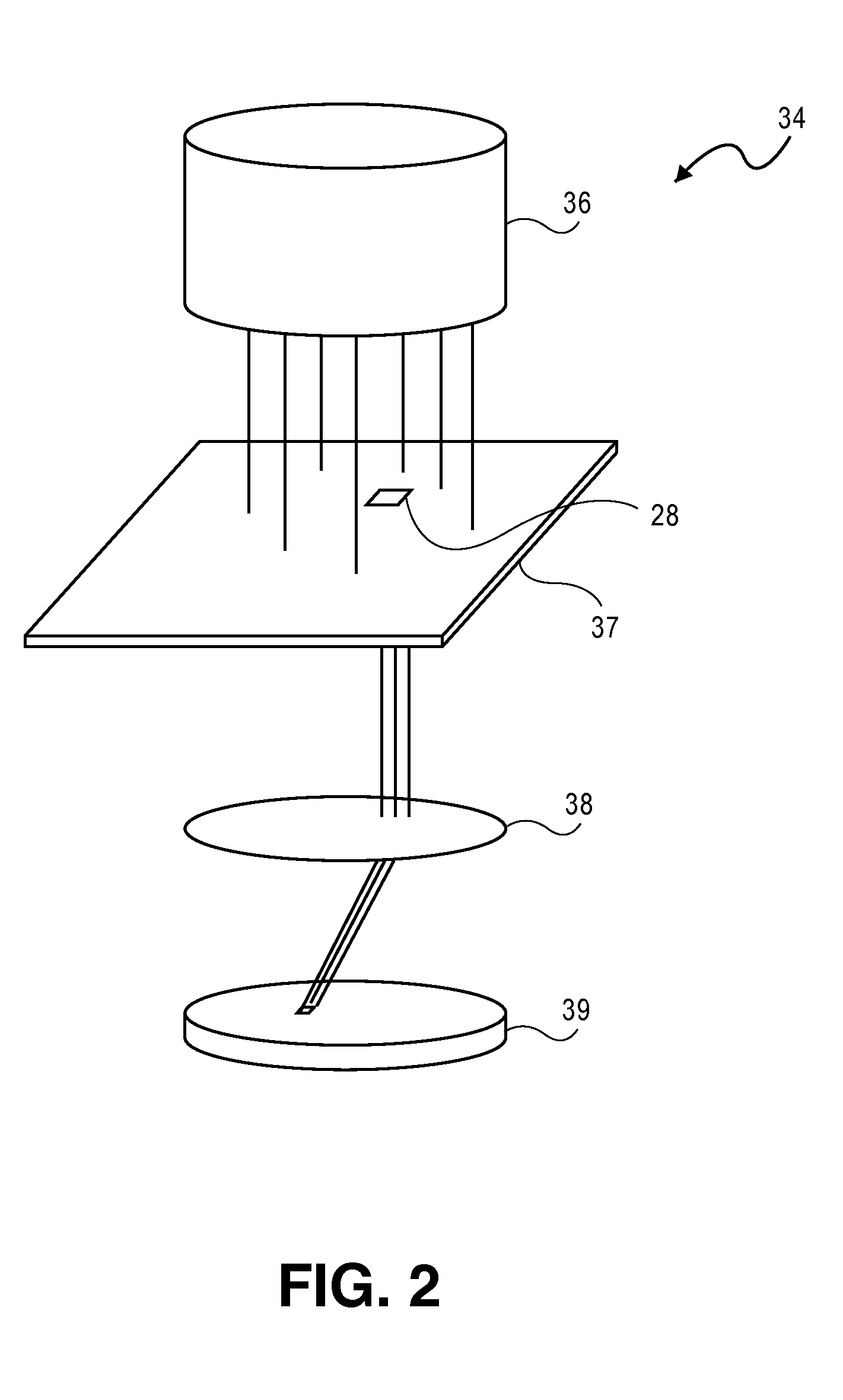

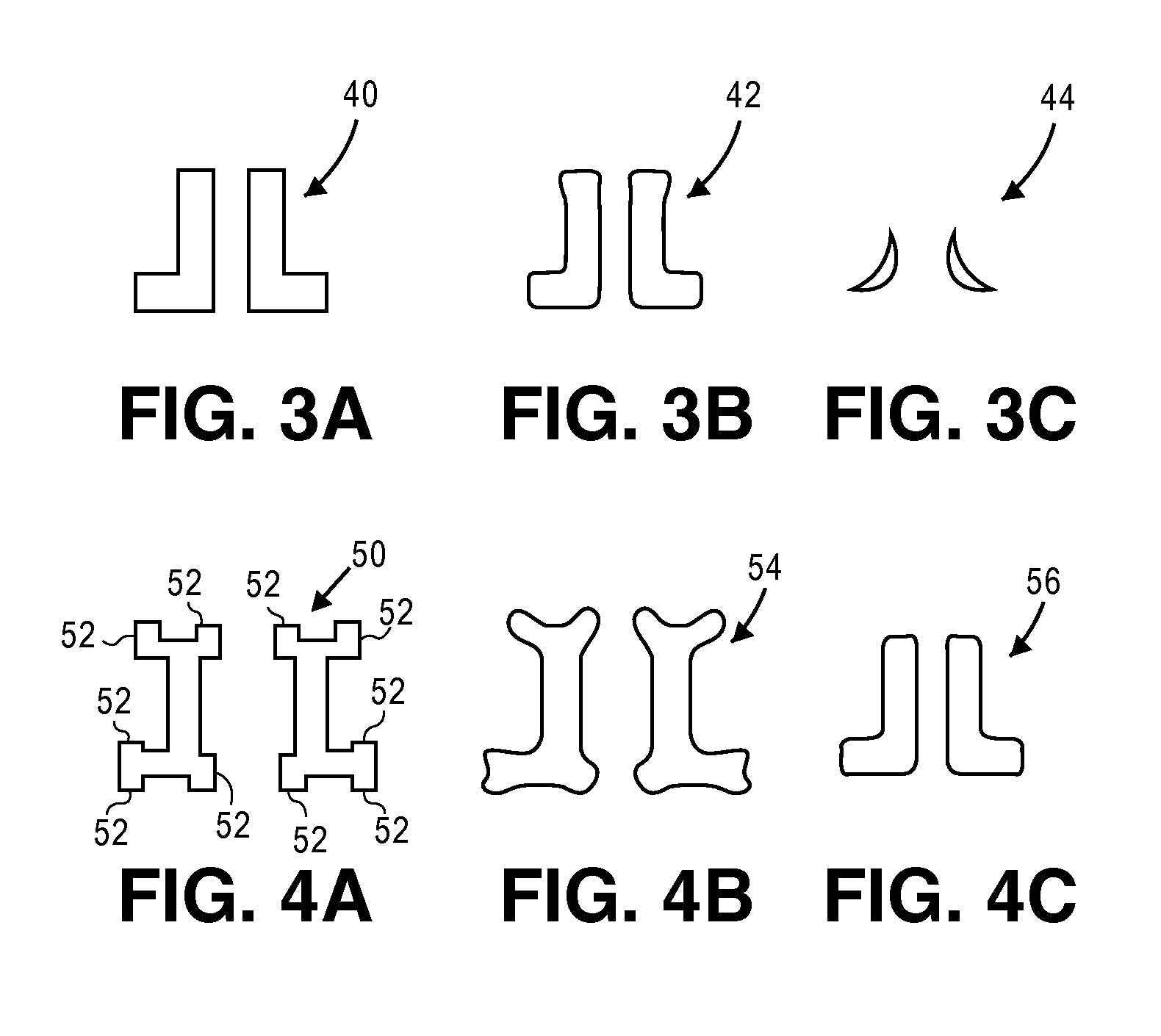

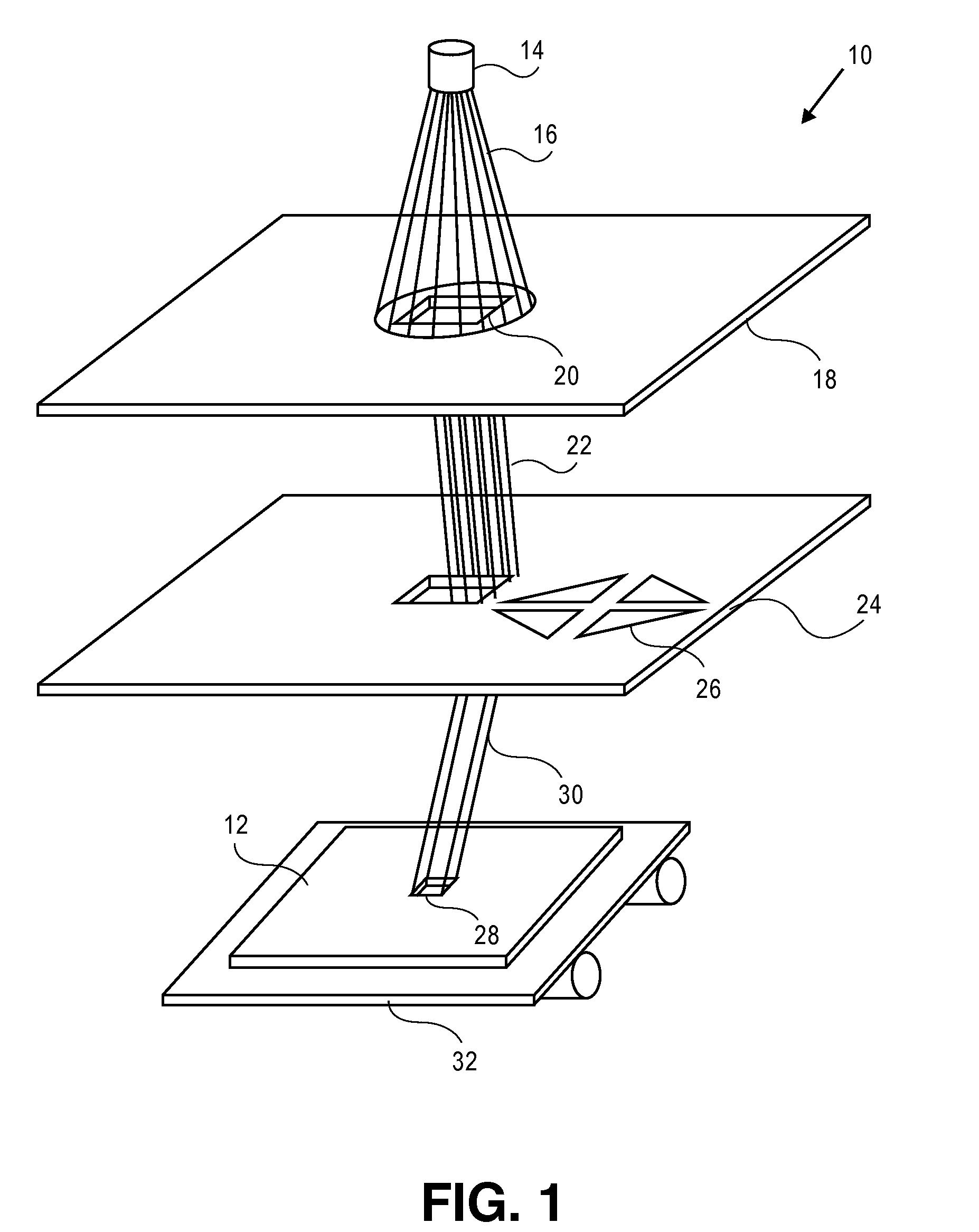

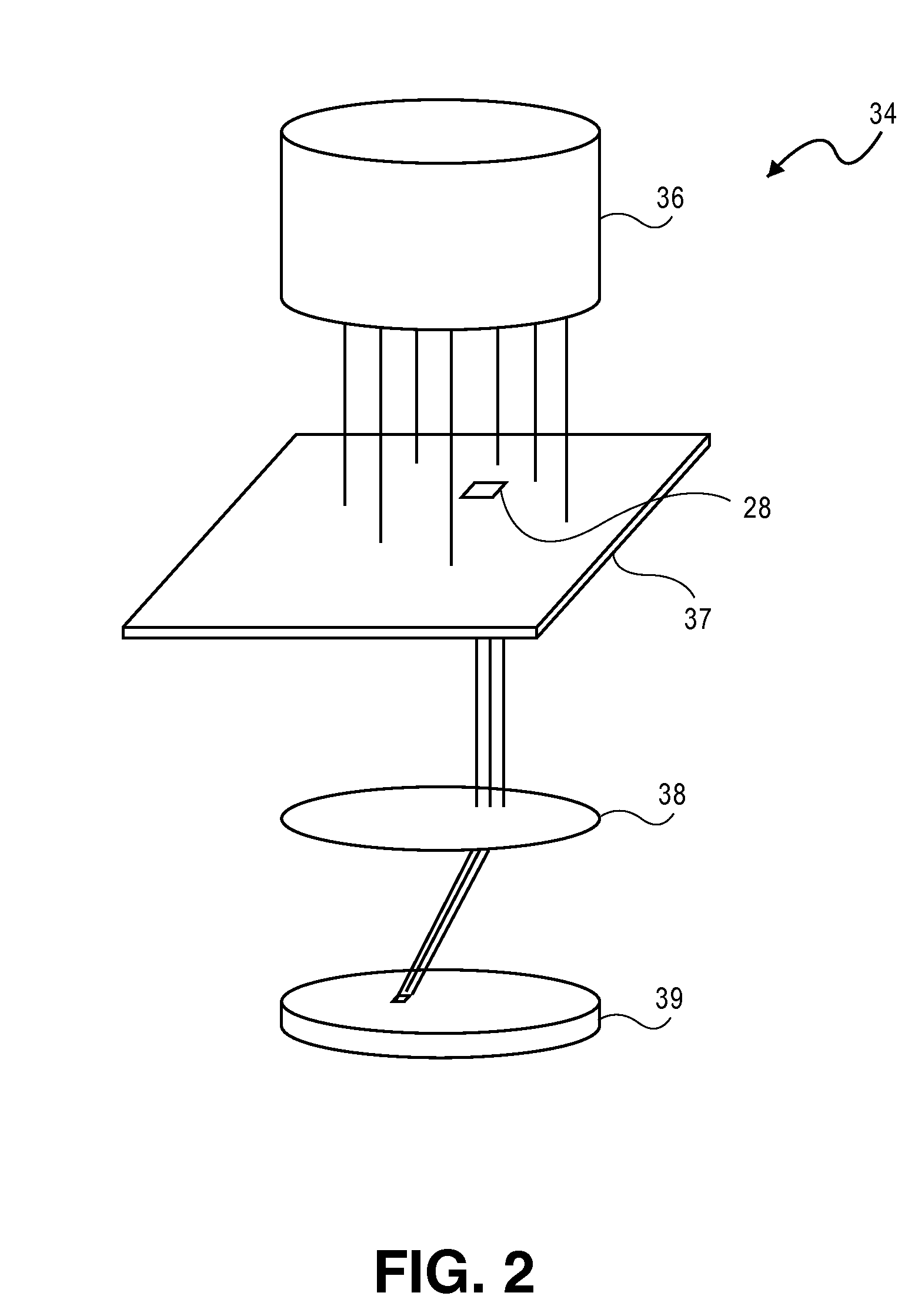

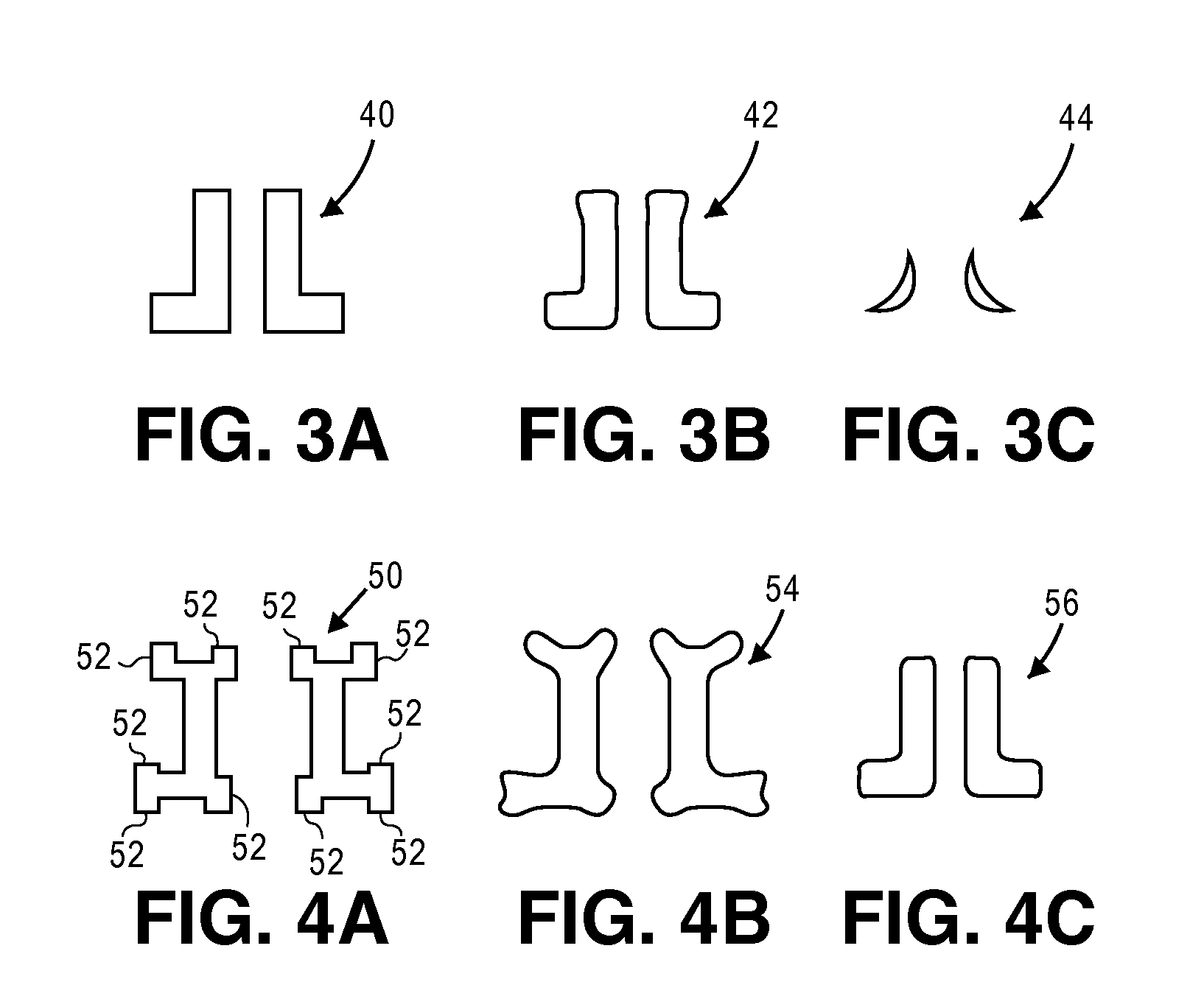

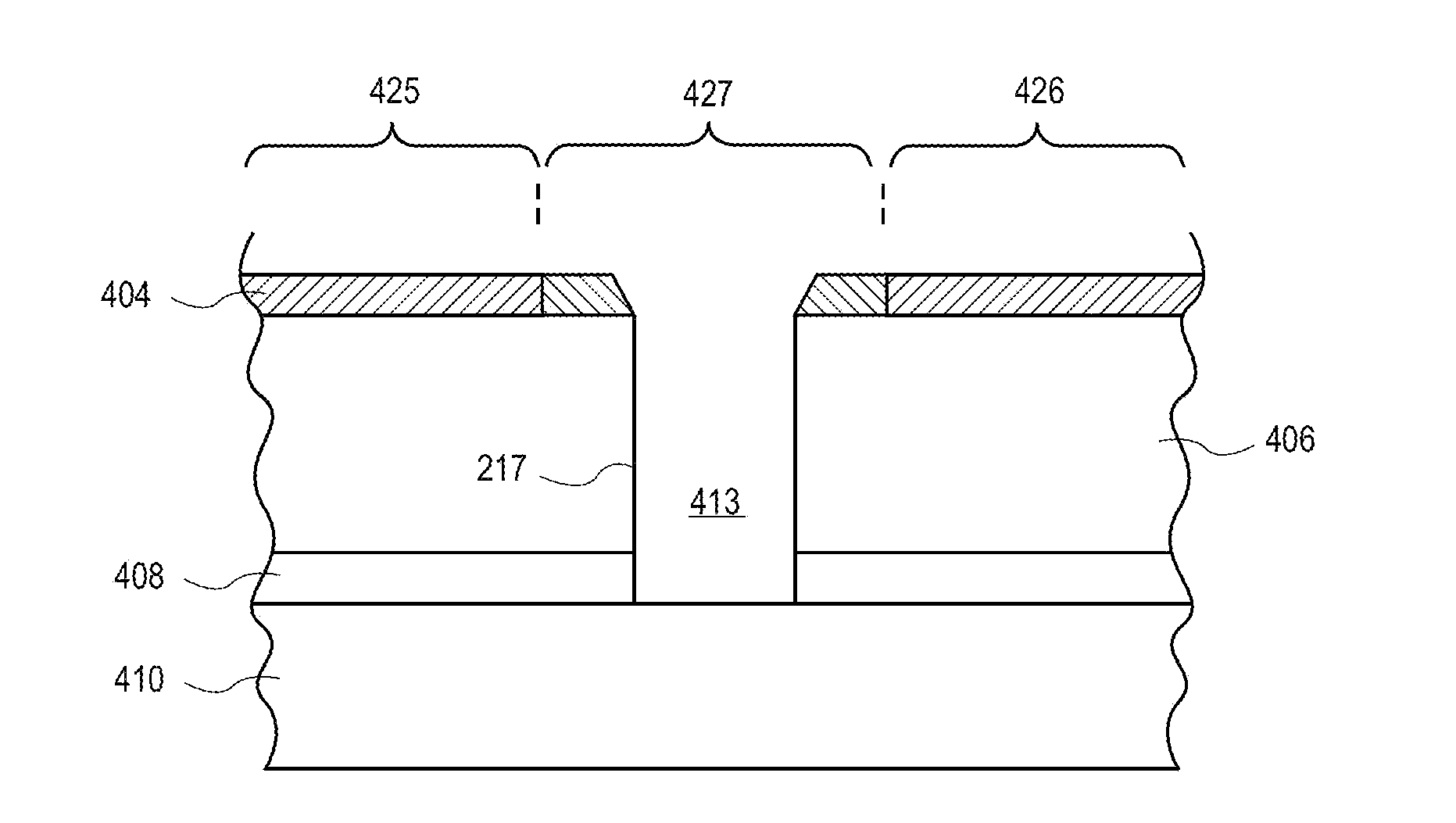

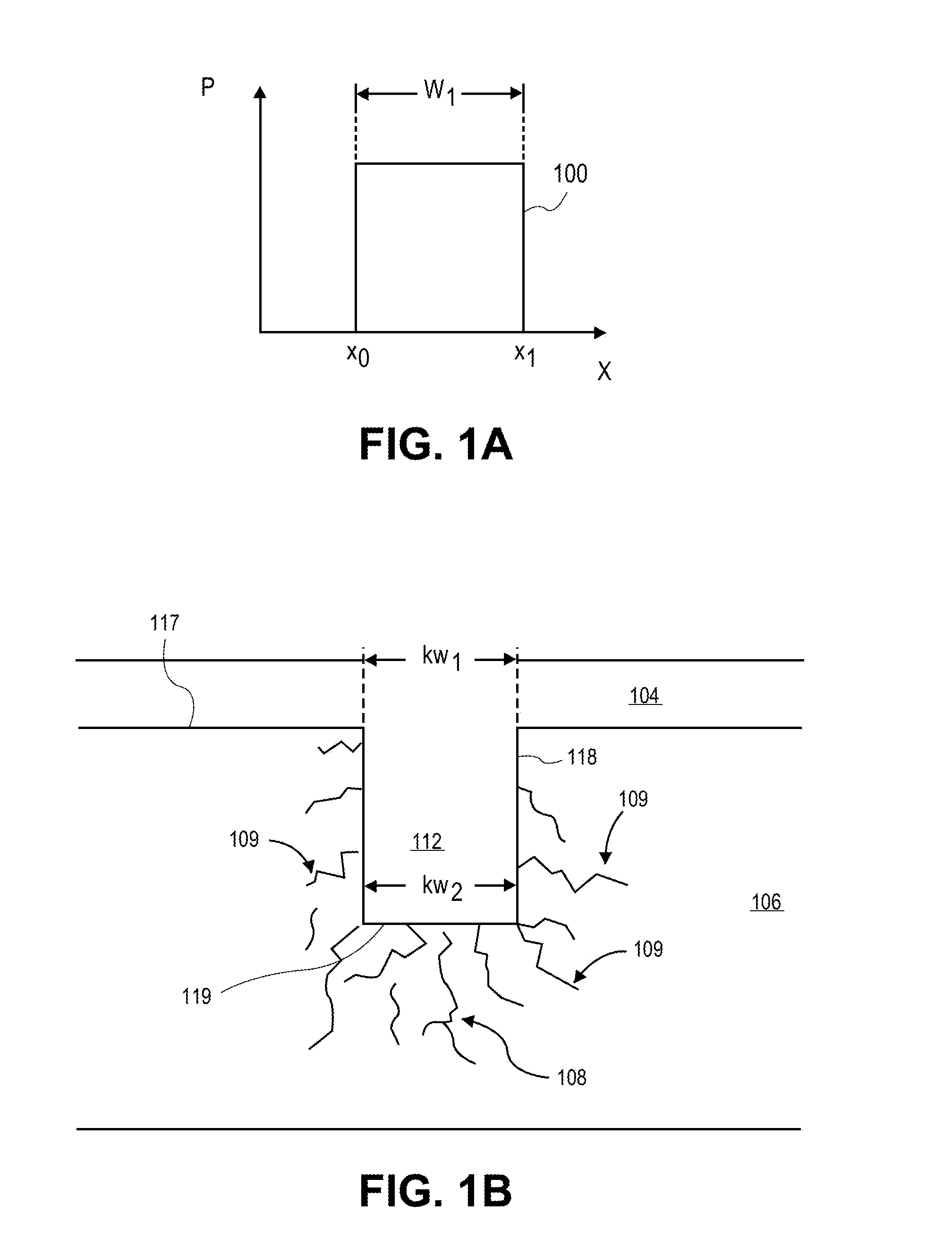

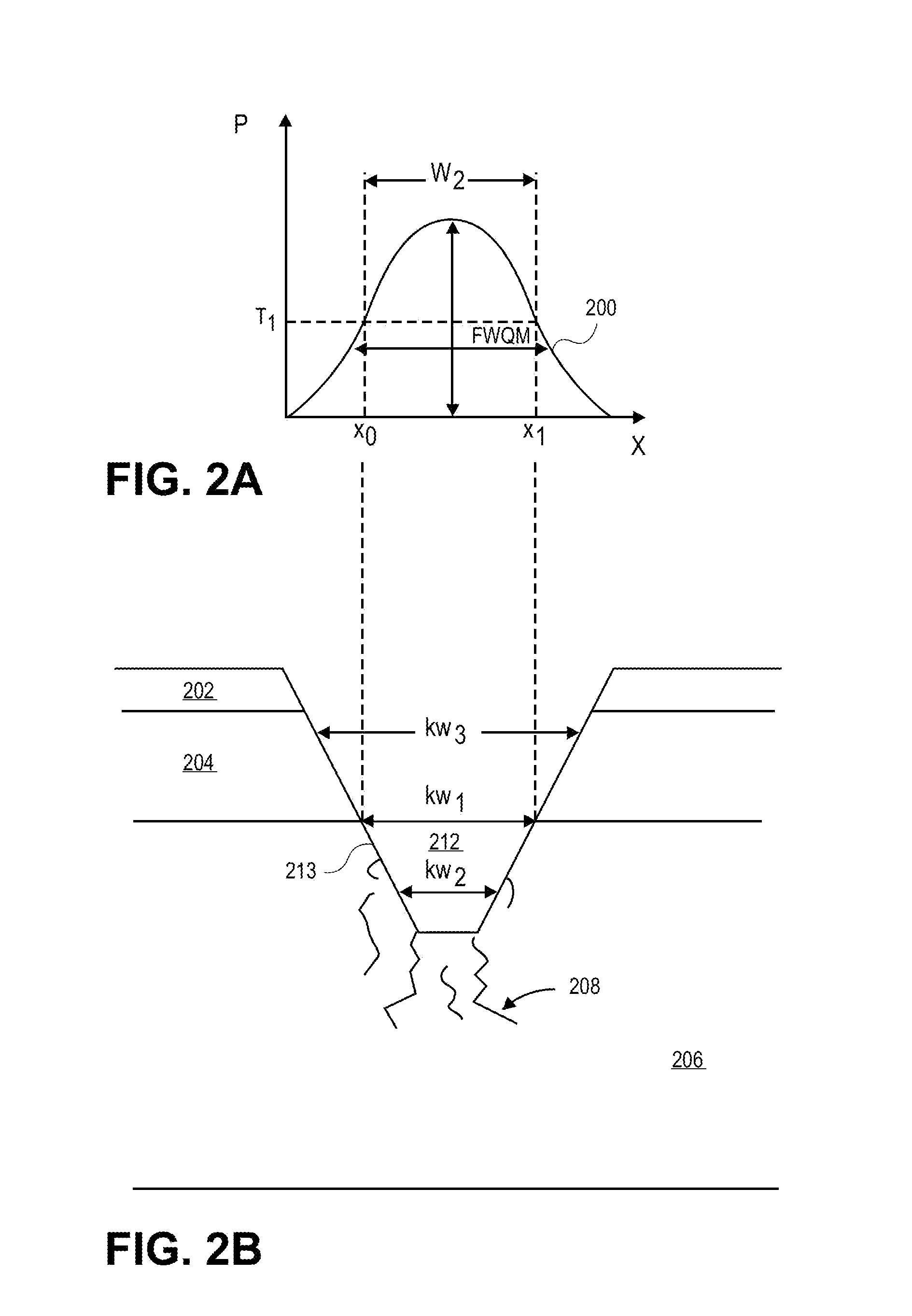

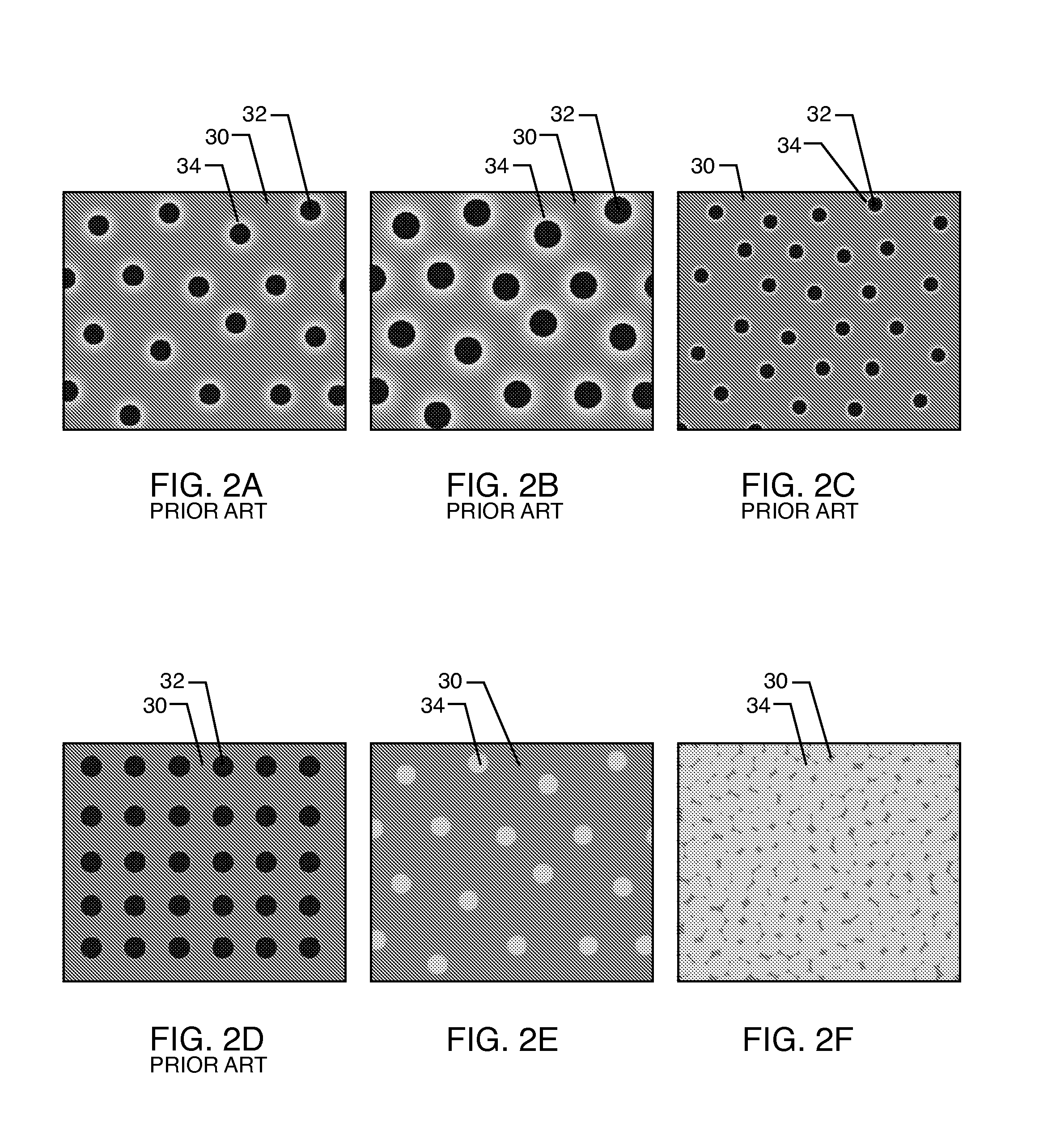

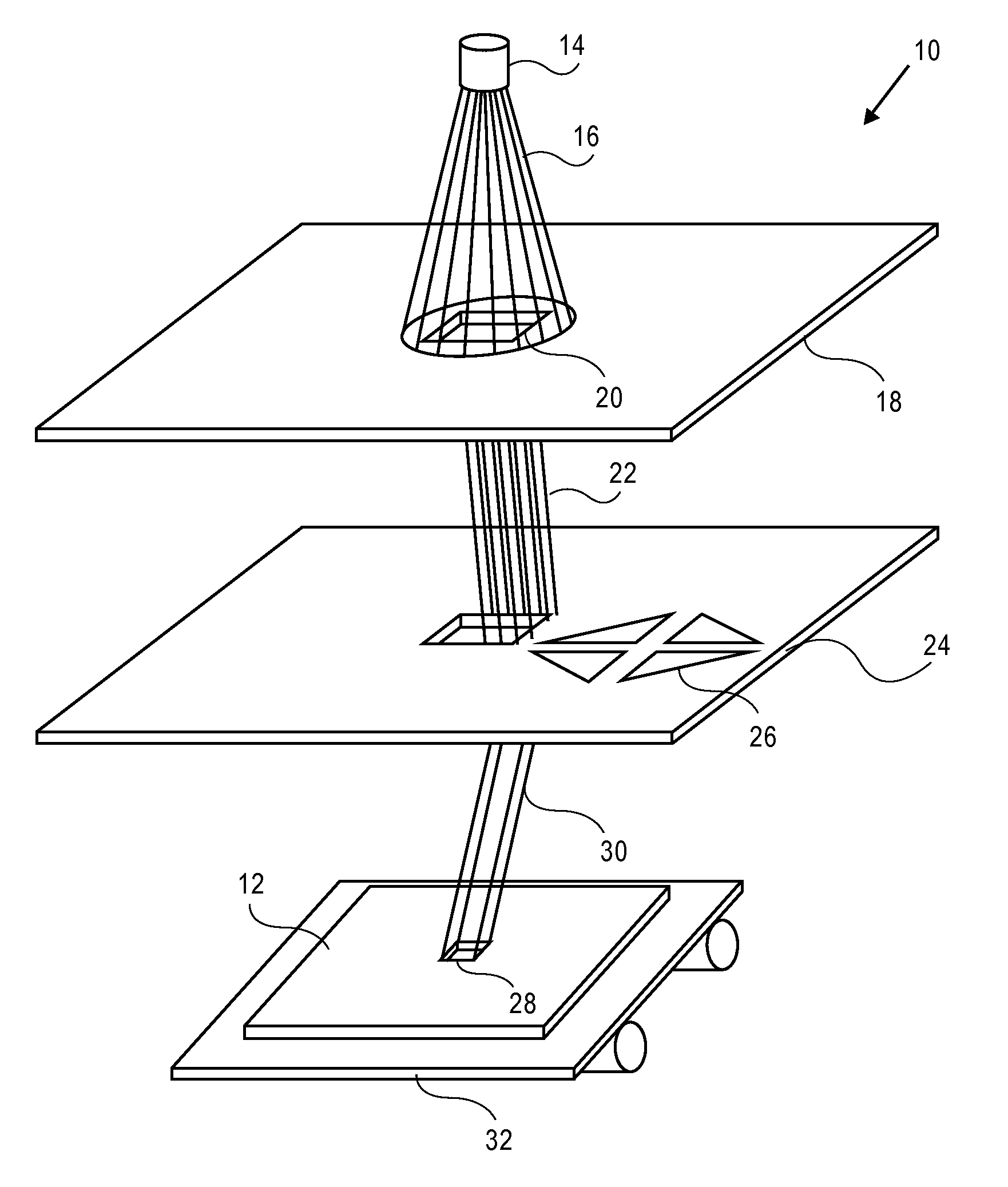

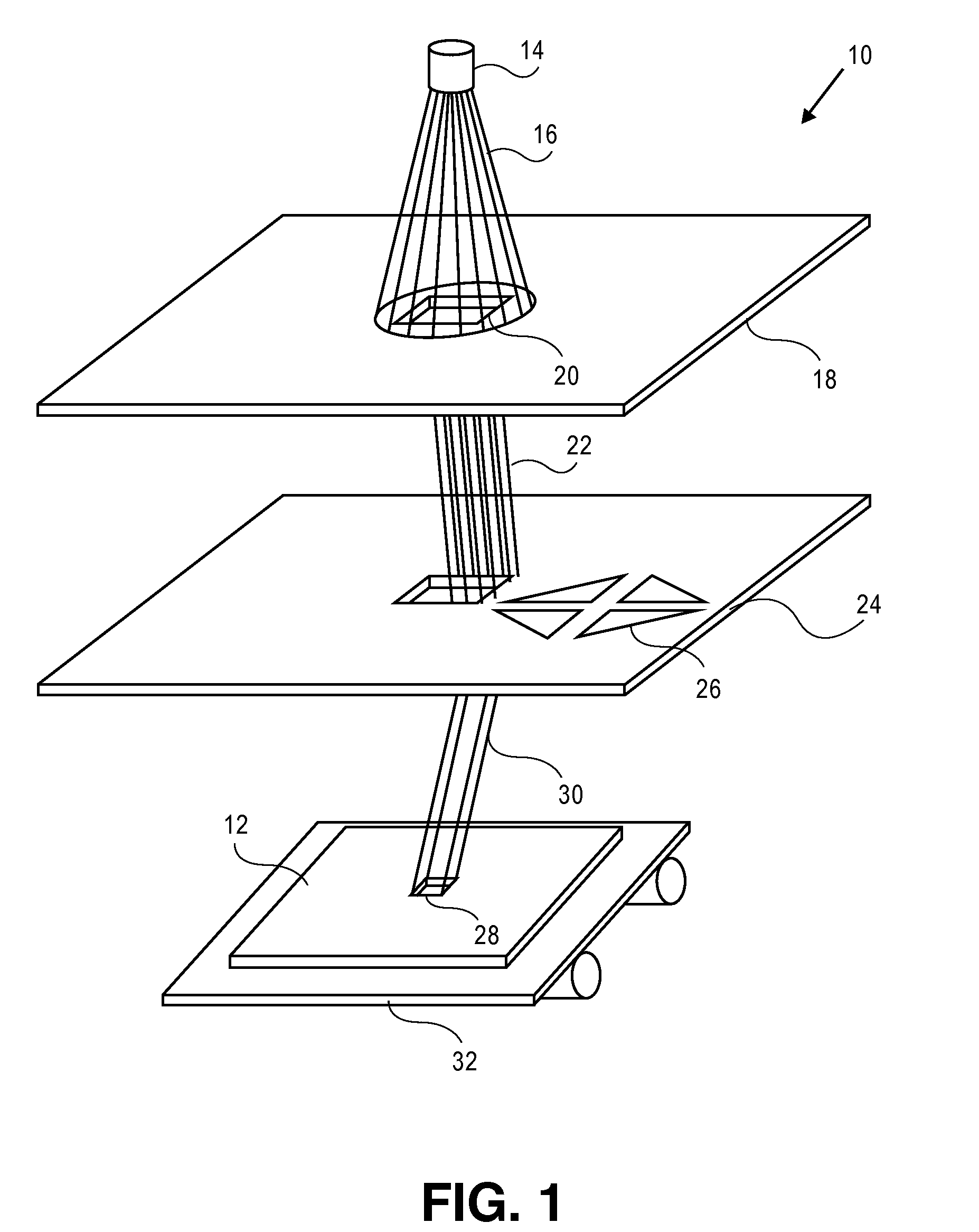

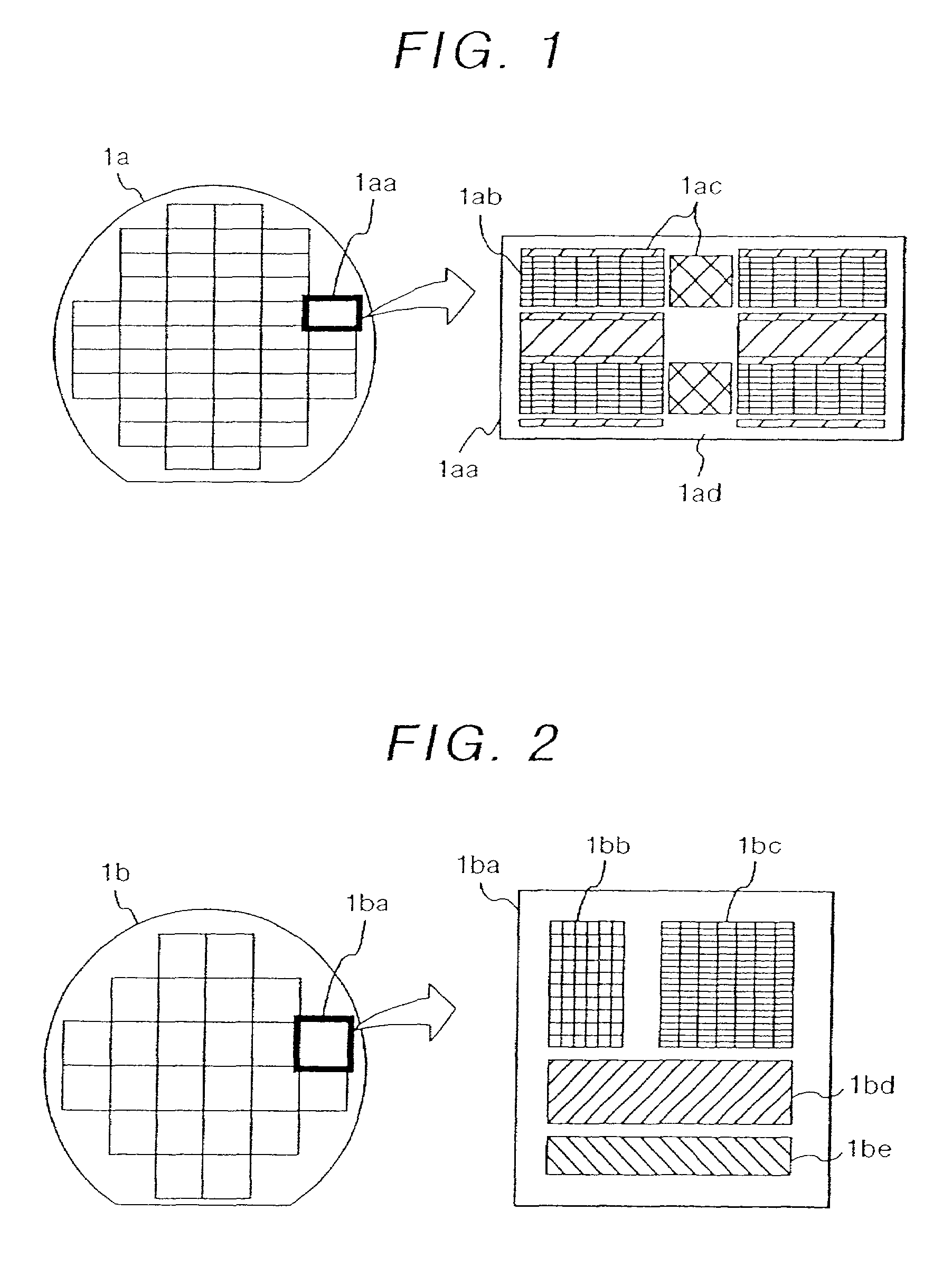

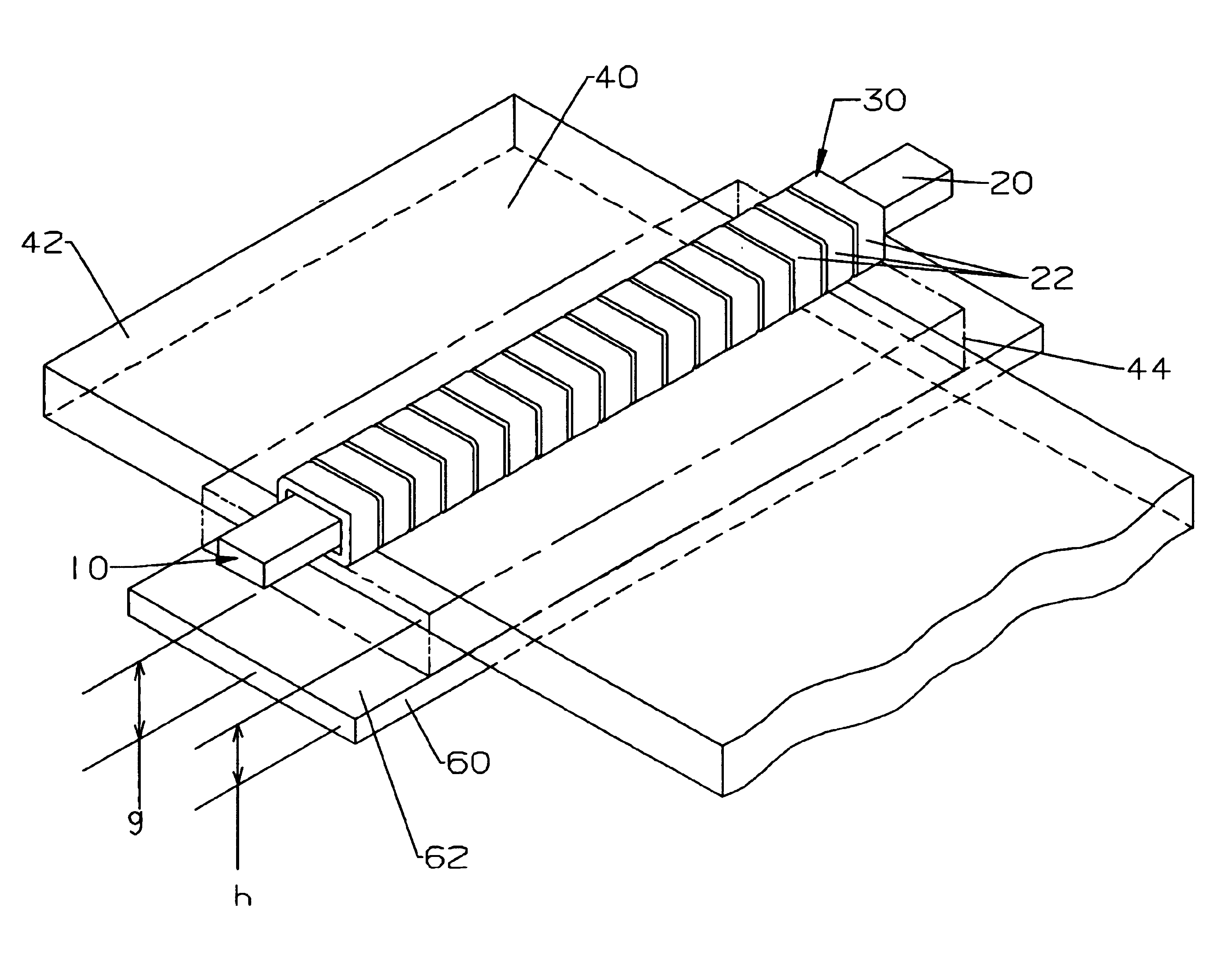

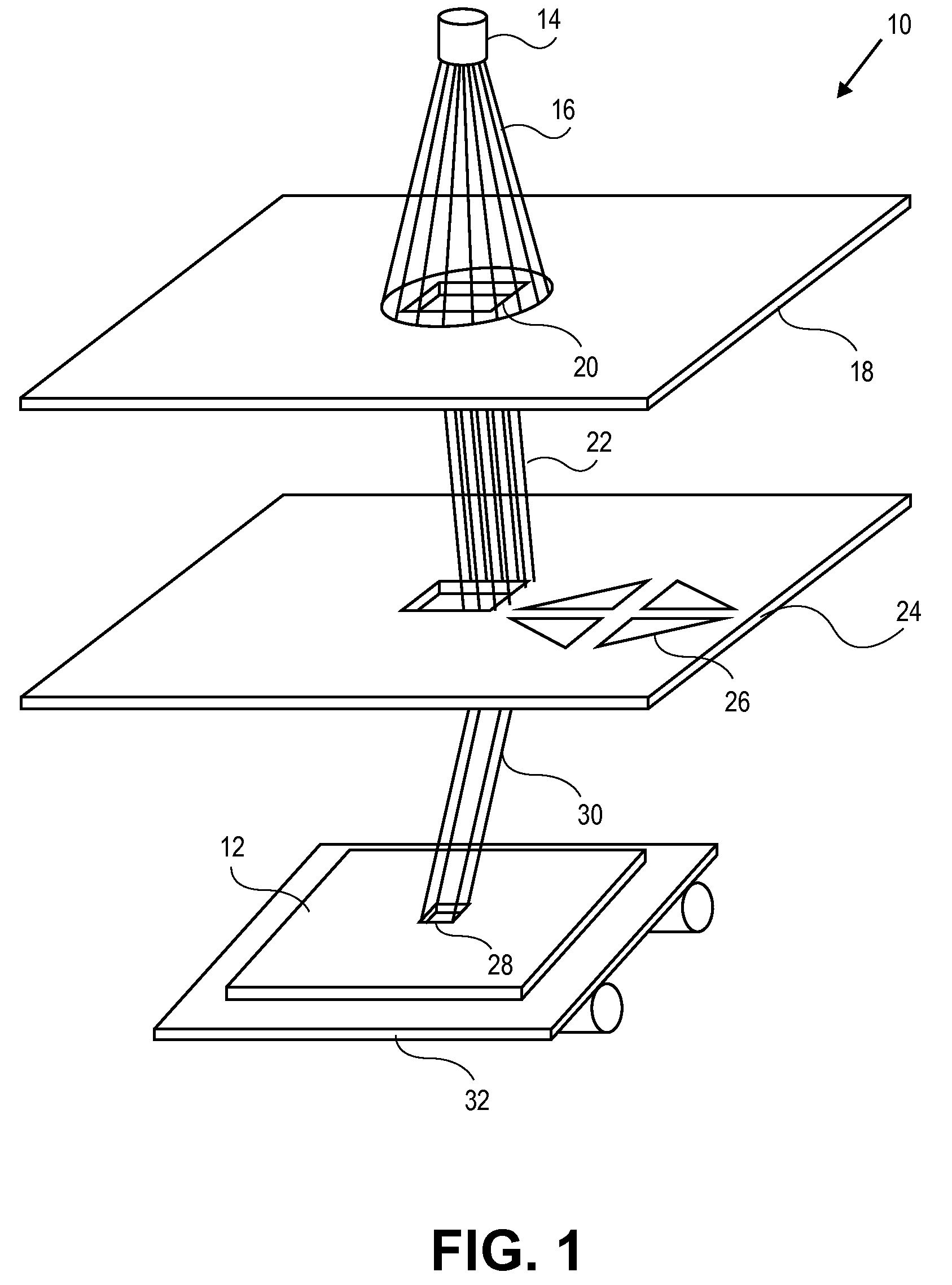

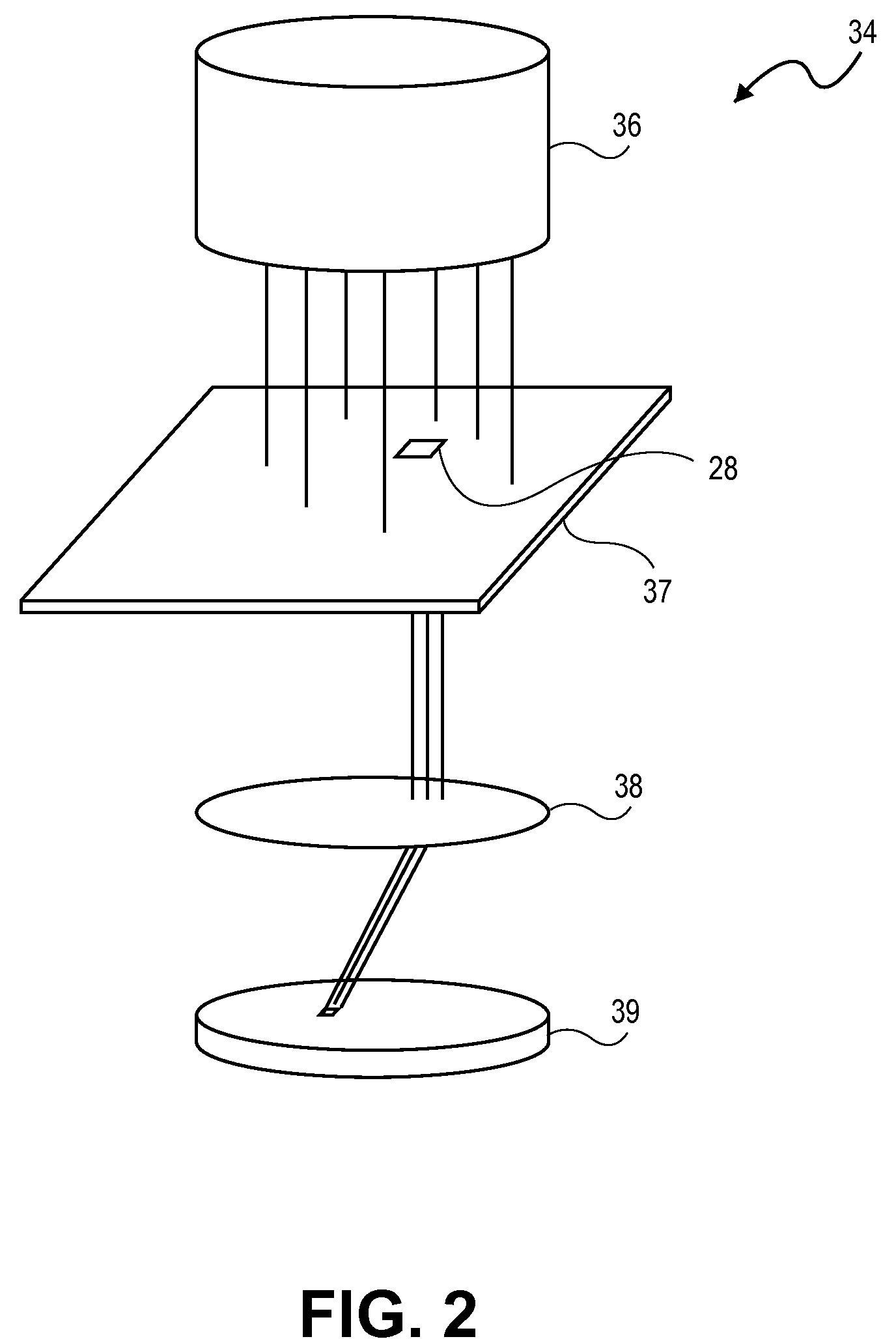

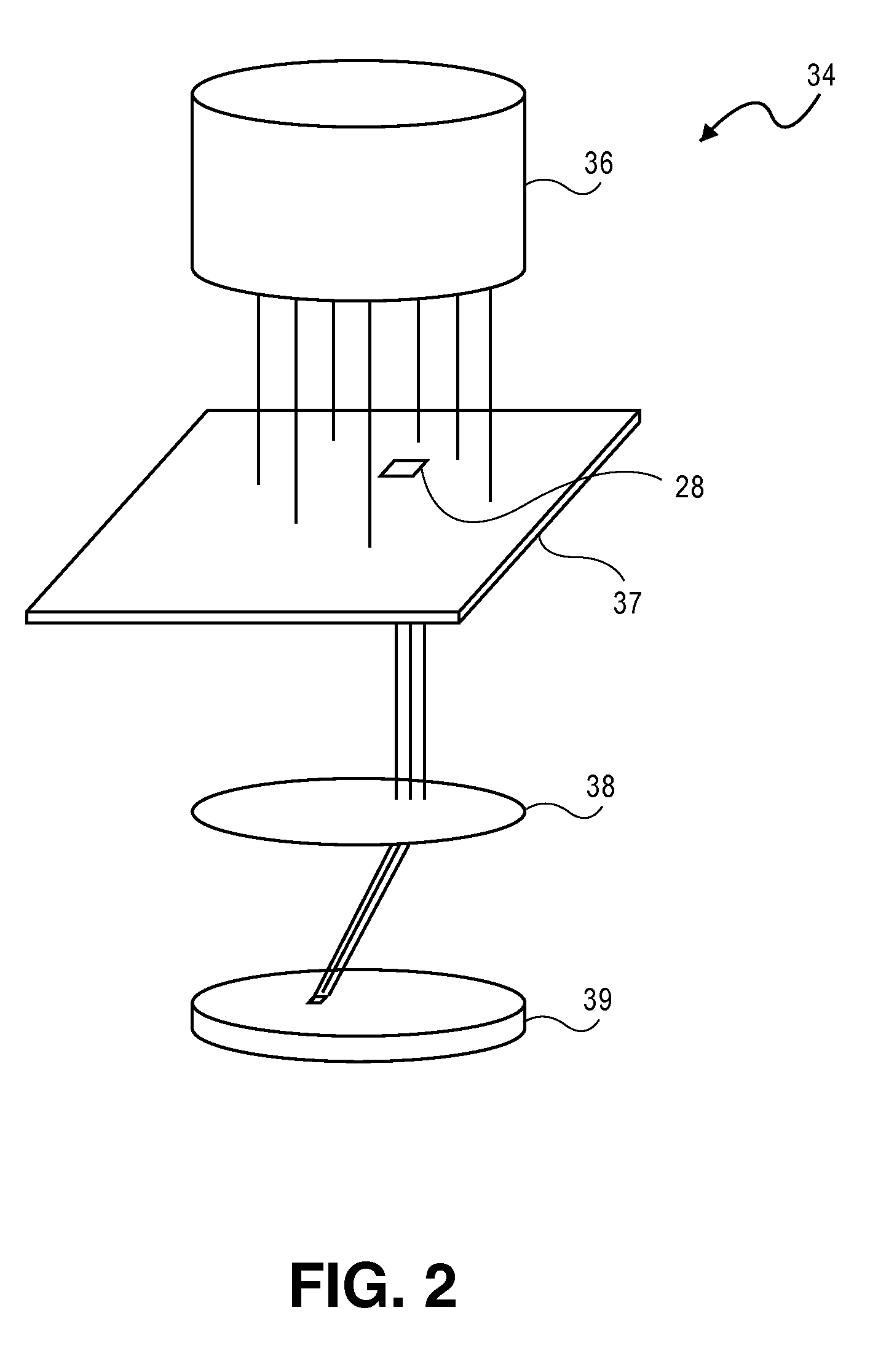

Method for manufacturing a surface and integrated circuit using variable shaped beam lithography

A method is disclosed in which a plurality of variable shaped beam (VSB) shots is used to form a desired pattern on a surface. Shots within the plurality of shots are allowed to overlap each other. Dosages of the shots may also be allowed to vary. The union of the plurality of shots may deviate from the desired pattern. The plurality of shots may be determined such that a pattern on the surface calculated from the plurality of shots is within a predetermined tolerance of the desired pattern. In some embodiments, an optimization technique may be used to minimize shot count. In other embodiments, the plurality of shots may be optionally selected from one or more pre-computed VSB shots or groups of VSB shots. The method of the present disclosure may be used, for example, in the process of manufacturing an integrated circuit by optical lithography using a reticle, or in the process of manufacturing an integrated circuit using direct write.

Owner:D2S

Method and system for design of a reticle to be manufactured using variable shaped beam lithography

A method for fracturing or mask data preparation or proximity effect correction of a desired pattern to be formed on a reticle is disclosed in which a plurality of variable shaped beam (VSB) shots are determined which can form the desired pattern. Shots within the plurality of VSB shots are allowed to overlap each other. Dosages of the shots may also be allowed to vary with respect to each other. The union of the plurality of shots may deviate from the desired pattern. The plurality of shots may be determined such that a pattern on the surface calculated from the plurality of shots is within a predetermined tolerance of the desired pattern. In some embodiments, an optimization technique may be used to minimize shot count. In other embodiments, the plurality of shots may be optionally selected from one or more pre-computed VSB shots or groups of VSB shots.

Owner:D2S

X-ray inspection using spatially and spectrally tailored beams

InactiveUS7010094B2High energyHandling using diaphragms/collimetersMaterial analysis by transmitting radiationShaped beamLight beam

A system and method for inspecting an object, the system and method comprising a source for generating a penetrating radiation beam for irradiating the object, the beam having, for each instant of time, an instantaneous energy spectrum of intensity, a shaper for modulating the generated beam, thereby creating a shaped beam, the shaper comprising at least a first section and a second section, the first section attenuating the intensity of a portion of the generated beam by a first attenuation factor and the second section attenuating the intensity of another portion of the generated beam by a second attenuation factor, and at least one detector for detecting the shaped beam after the shaped beam interacts with the object. The source may scan a beam across an object while the source and at least one detector are moving on a platform capable of highway travel or on an inspection module movable with respect to the object.

Owner:SILICON VALLEY BANK

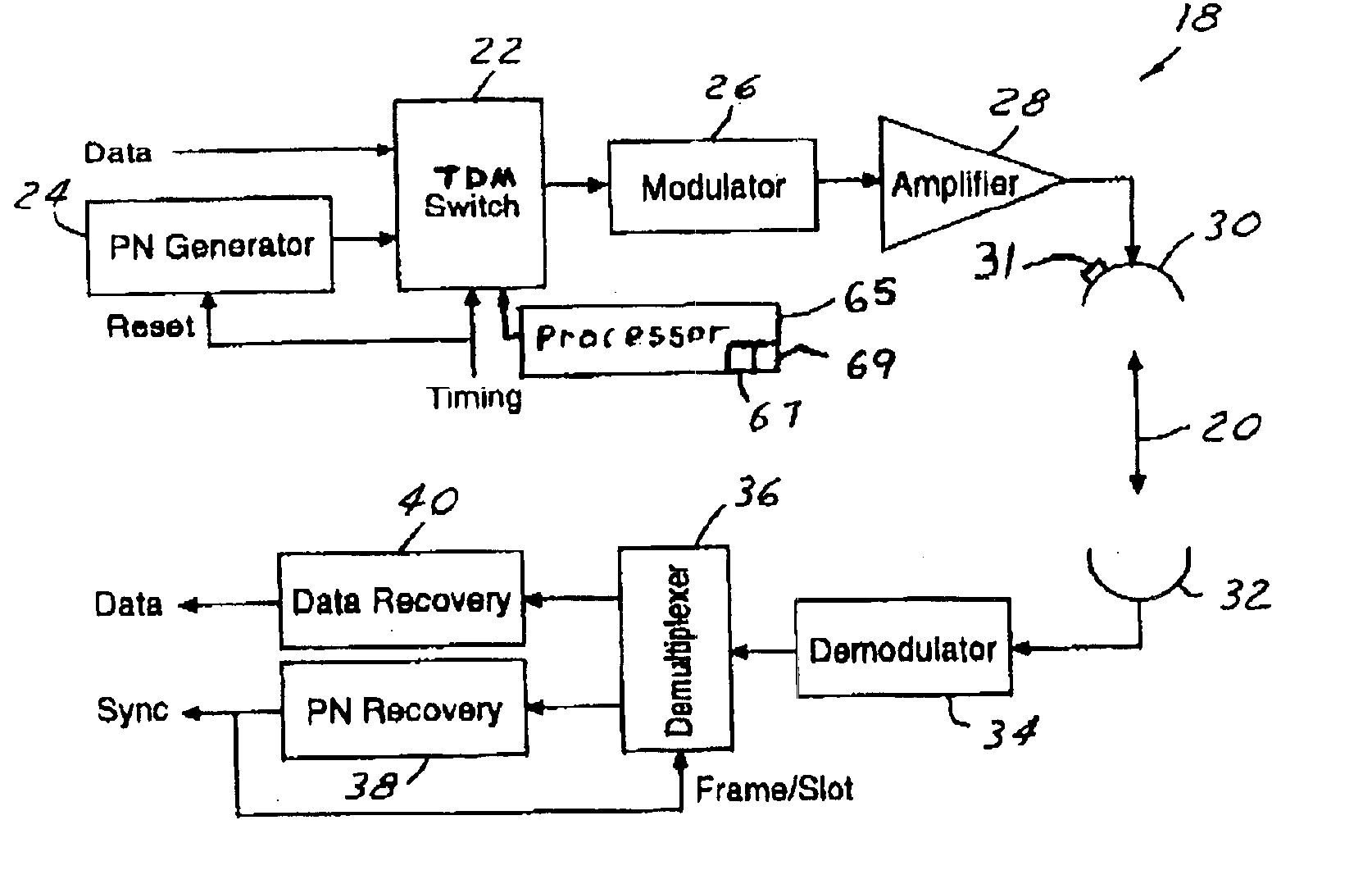

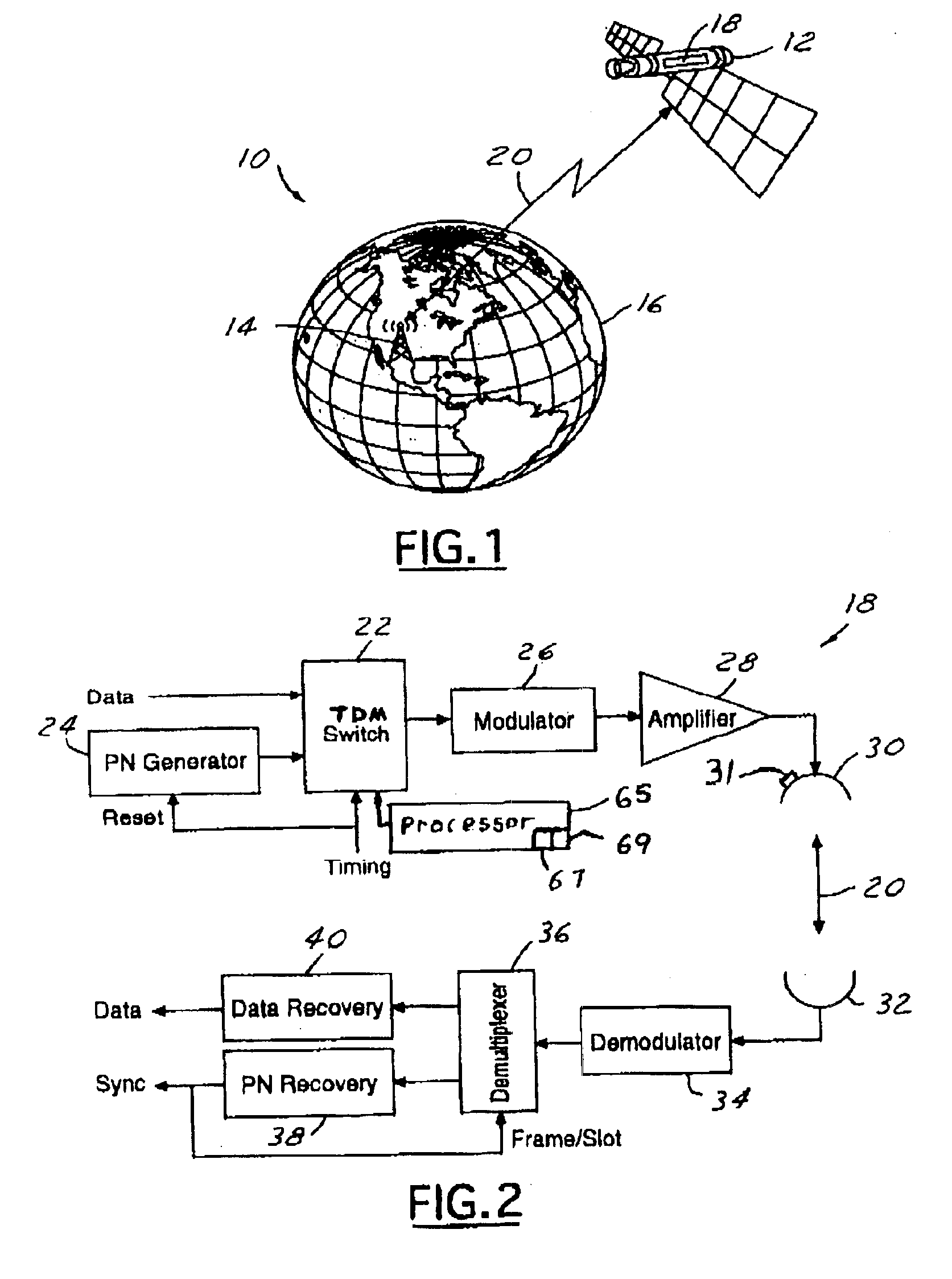

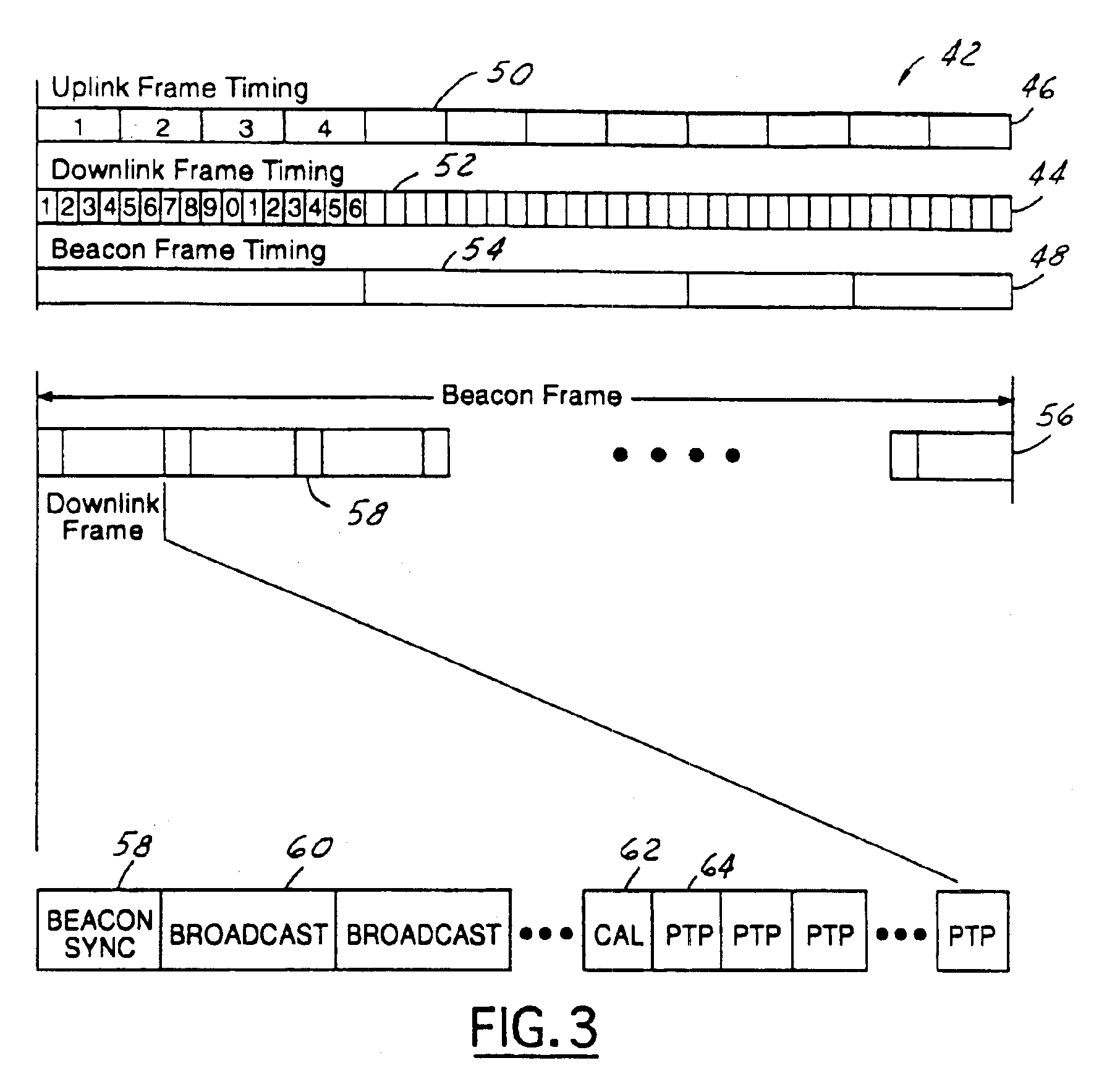

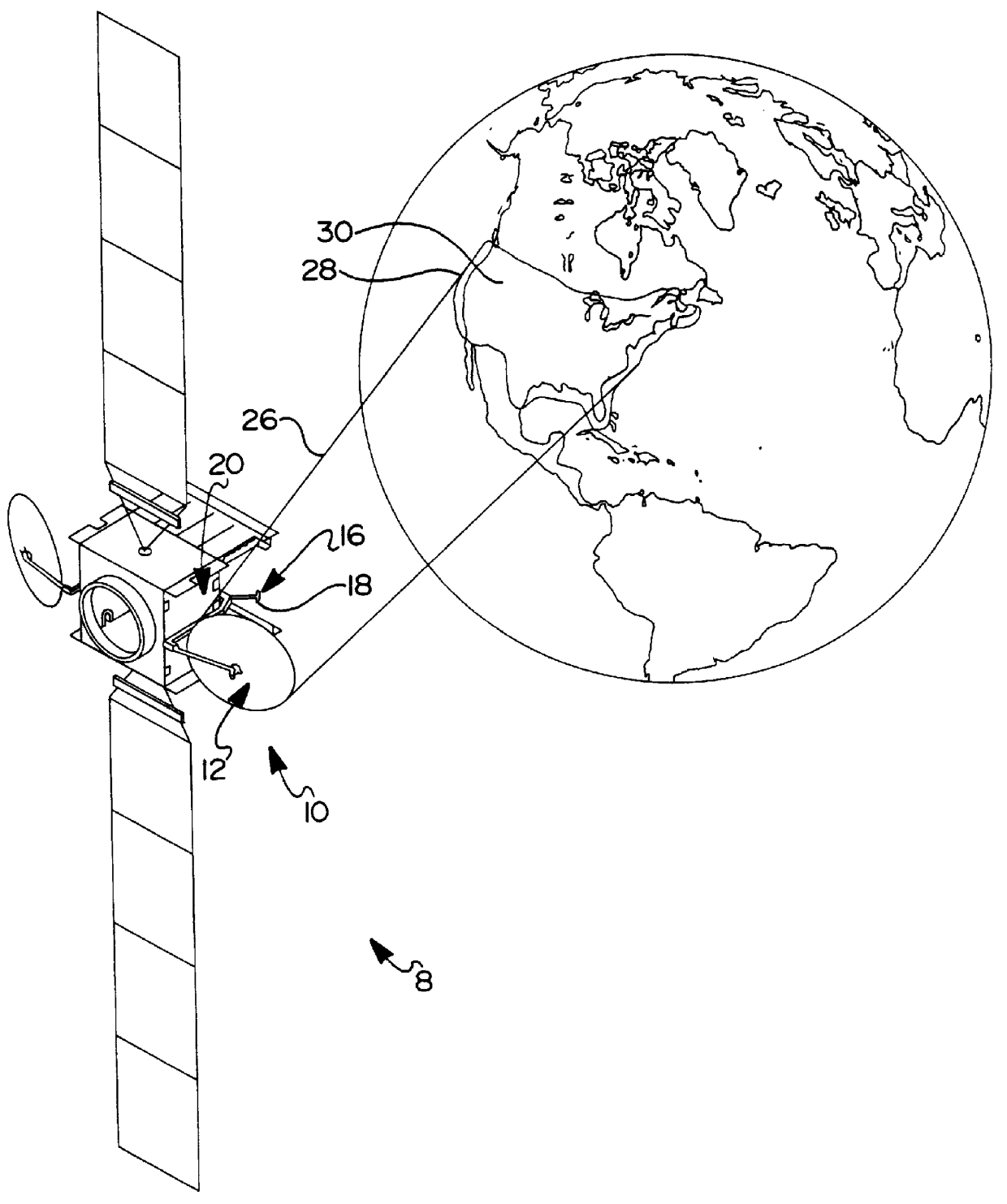

Multimode transmission system using TDMA

InactiveUS6975600B1Reduce in quantityImproved and reliableCircuit switching systemsRadio transmissionWide areaShaped beam

A multimode transmission system using TDMA provides a plurality of satellite services to a ground station terminal. These services include timing beacon synchronization, multi-cast / broadcast data service, calibration data, and point-to-point data service. The multimode transmission system uses a TDM switch to generate a TDMA signal having a plurality of TDMA transmission frames. Each TDMA transmission frame includes a plurality of downlink frame time slots. Each time slot may be of variable length and is dynamically allocated to an individual satellite service based upon demand. The TDMA signal is then broadcast using an advanced transmit antenna system, which requires beam-shaping and beam power control features, to enable TDMA switching between shaped beams and spot beam modes of the antenna. These antenna features allow for the dynamic partitioning of satellite system capacity between wide-area broadcasts and localized point-to-point service and efficient utilization of the satellite transmission power.

Owner:HUGHES ELECTRONICS

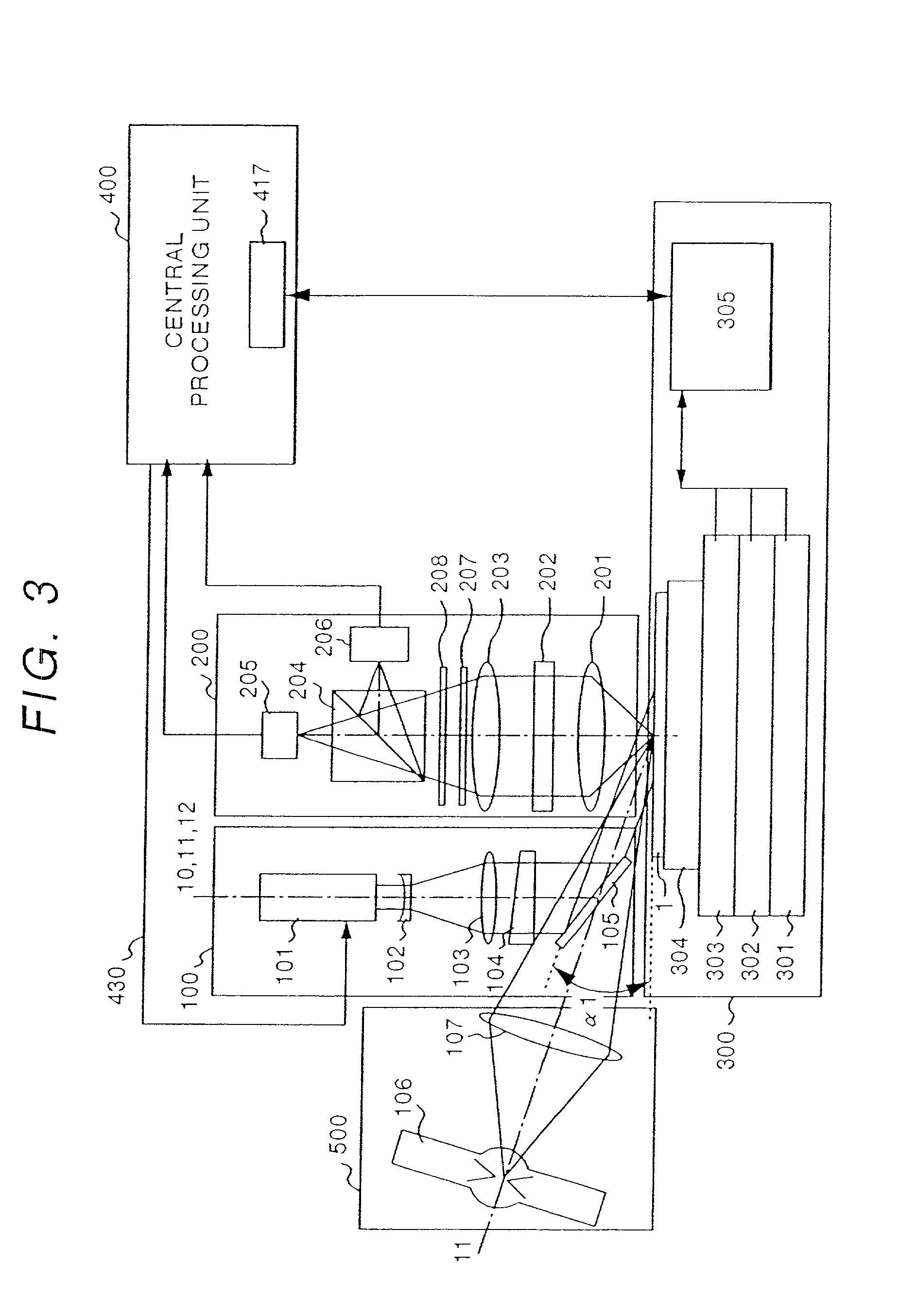

Apparatus for detecting information on object

ActiveUS20070195921A1Increase speedDecreasing accuracyMaterial analysis using wave/particle radiationMaterial analysis using microwave meansShaped beamLight beam

An apparatus for detecting information on an object includes an irradiating unit, a detecting unit, and an information-obtaining unit. The irradiating unit irradiates the object with electromagnetic waves as a rectangular shaped beam. The electromagnetic waves include a frequency component in (or range of) at least part of a frequency region of 30 GHz to 30 THz, and have variations in magnitude at intervals of 10−11 seconds or more or a temporally constant magnitude. The detecting unit detects the electromagnetic waves transmitted or reflected by the object through interaction therebetween. The information-obtaining unit obtains information on the object from information on the electromagnetic waves detected by the detecting unit.

Owner:CANON KK

Damage isolation by shaped beam delivery in laser scribing process

ActiveUS20120322240A1Electric discharge tubesSemiconductor/solid-state device manufacturingShaped beamOptoelectronics

Owner:APPLIED MATERIALS INC

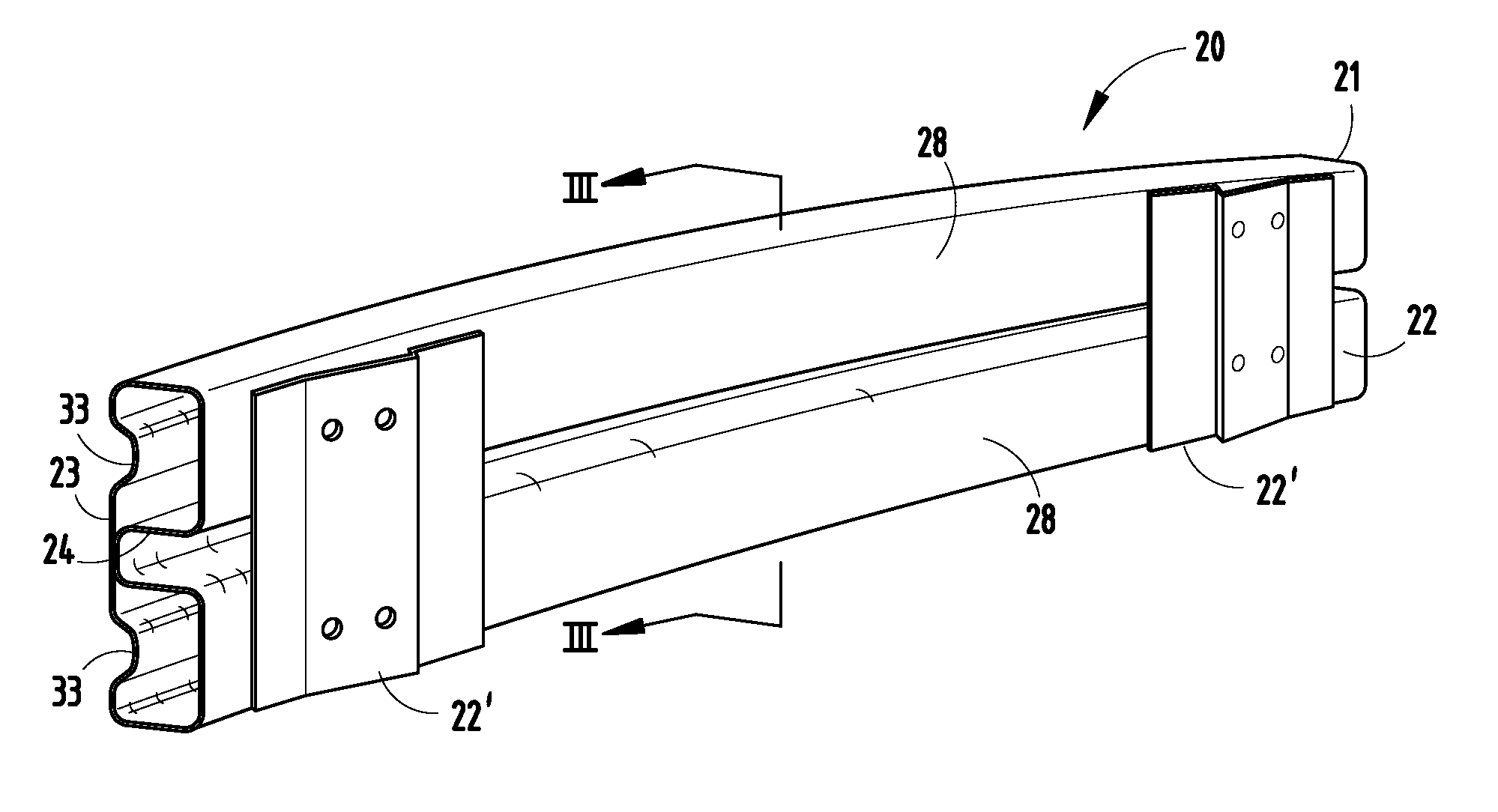

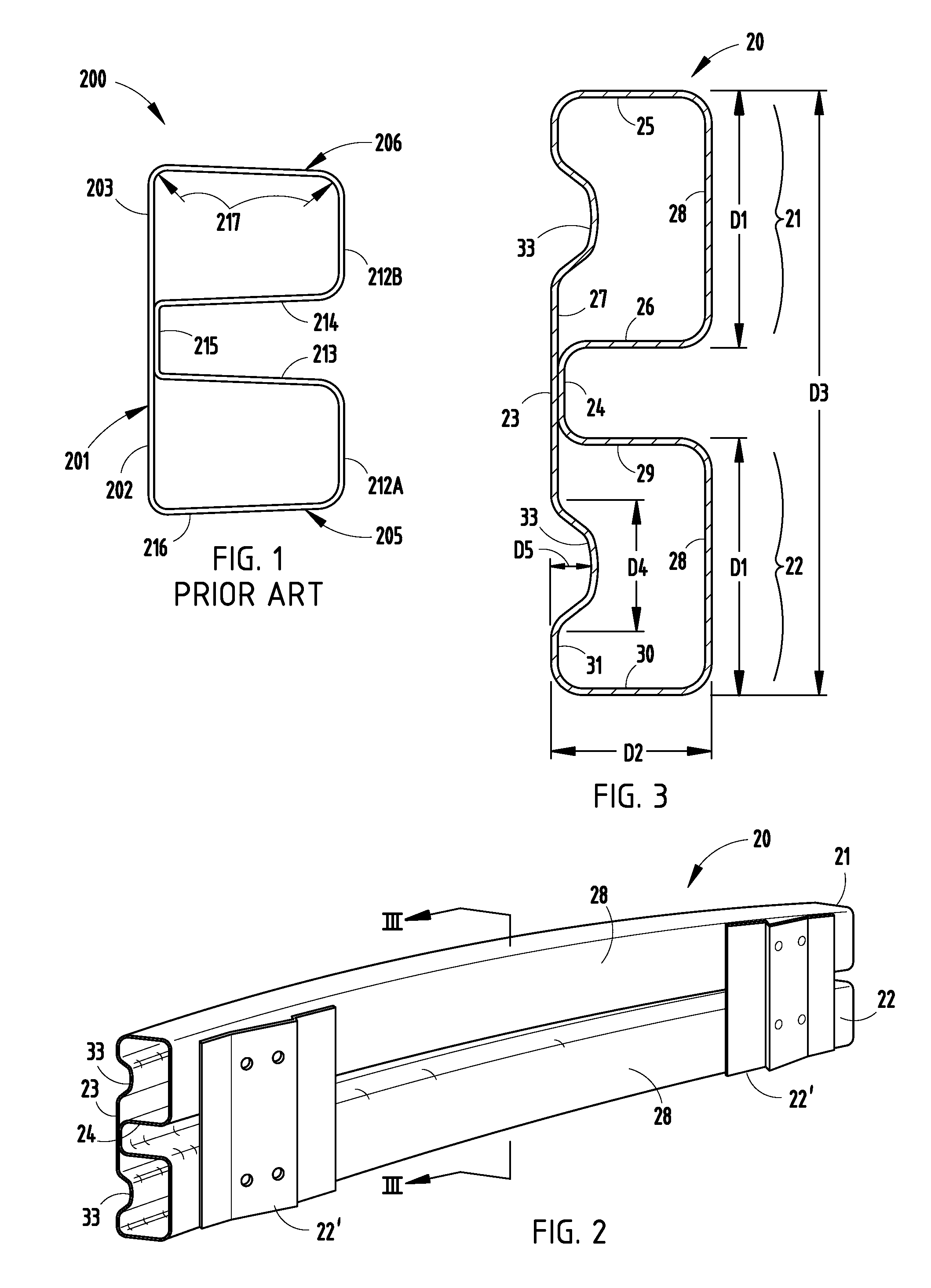

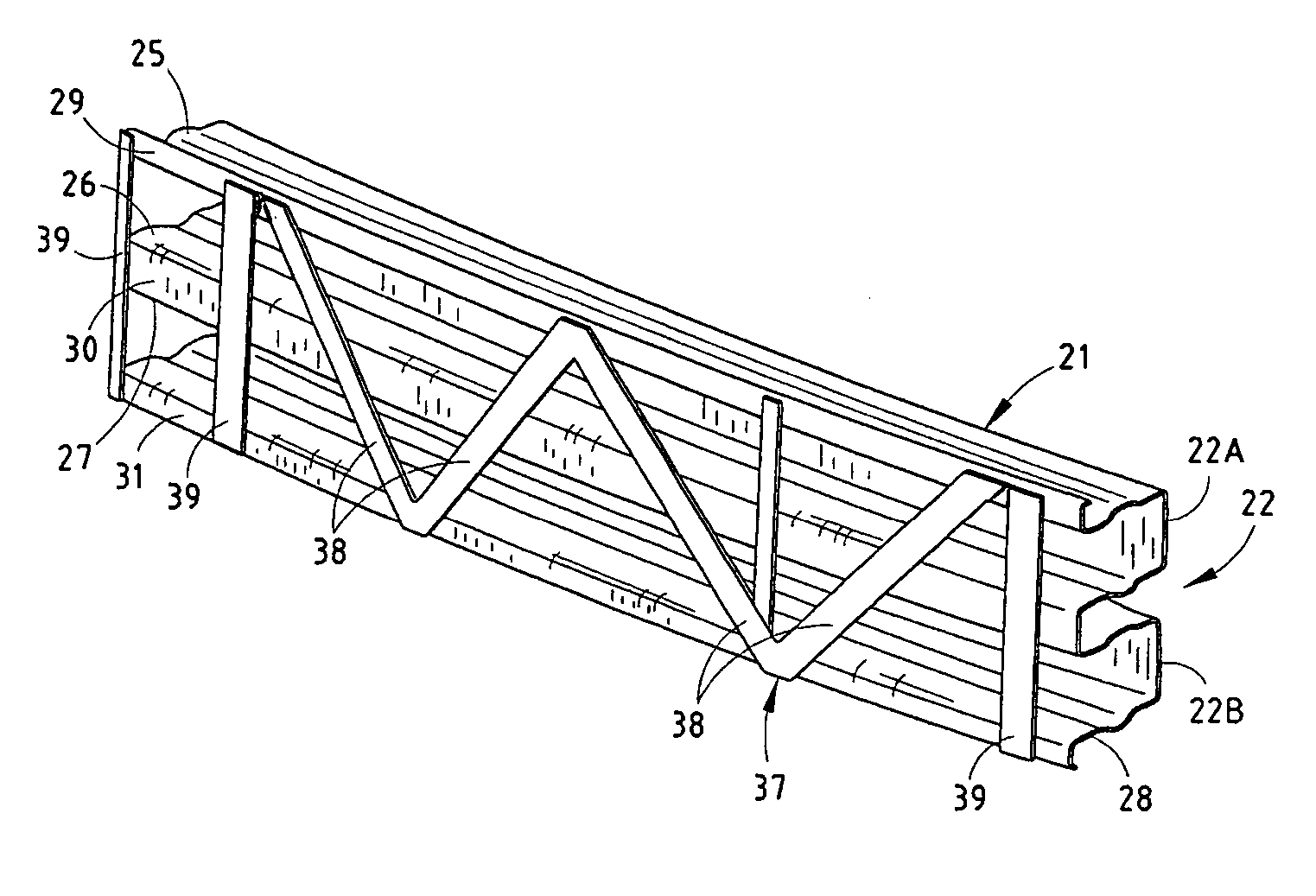

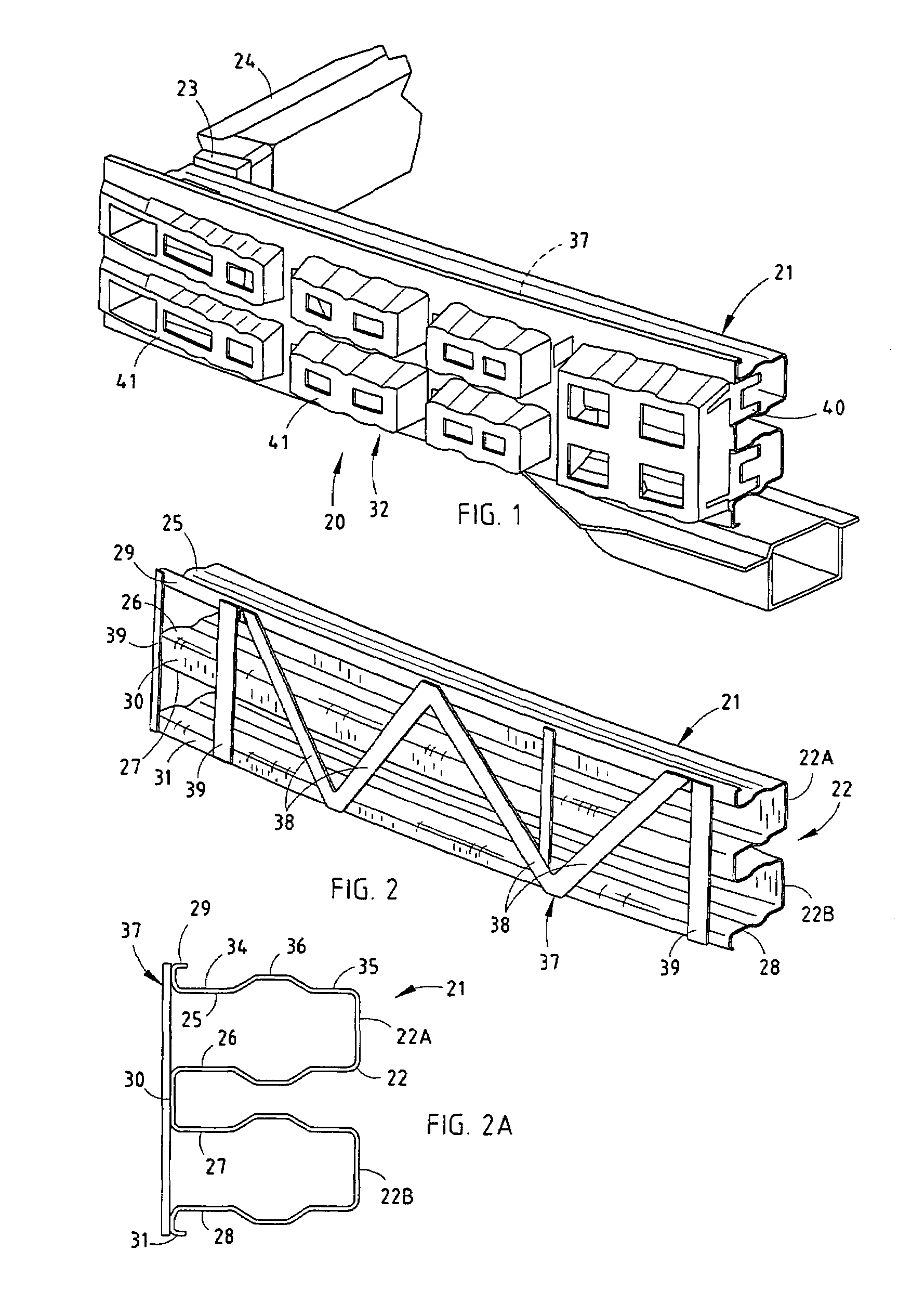

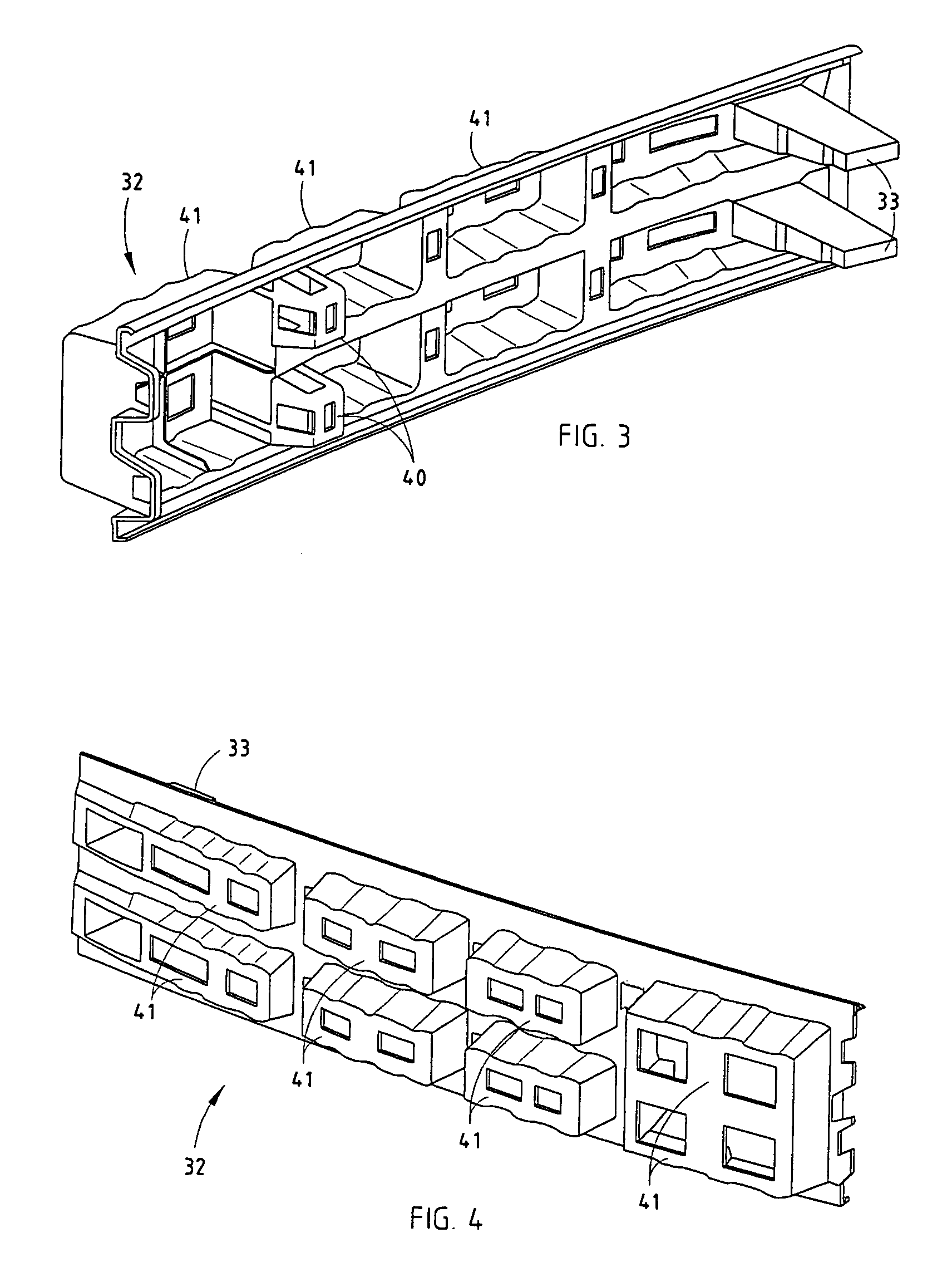

B-shaped beam with integrally-formed rib in face

InactiveUS20080093867A1Reduce “ offset ”Weight increaseBumpersMetal rolling arrangementsShaped beamEngineering

Owner:SHAPE CORP

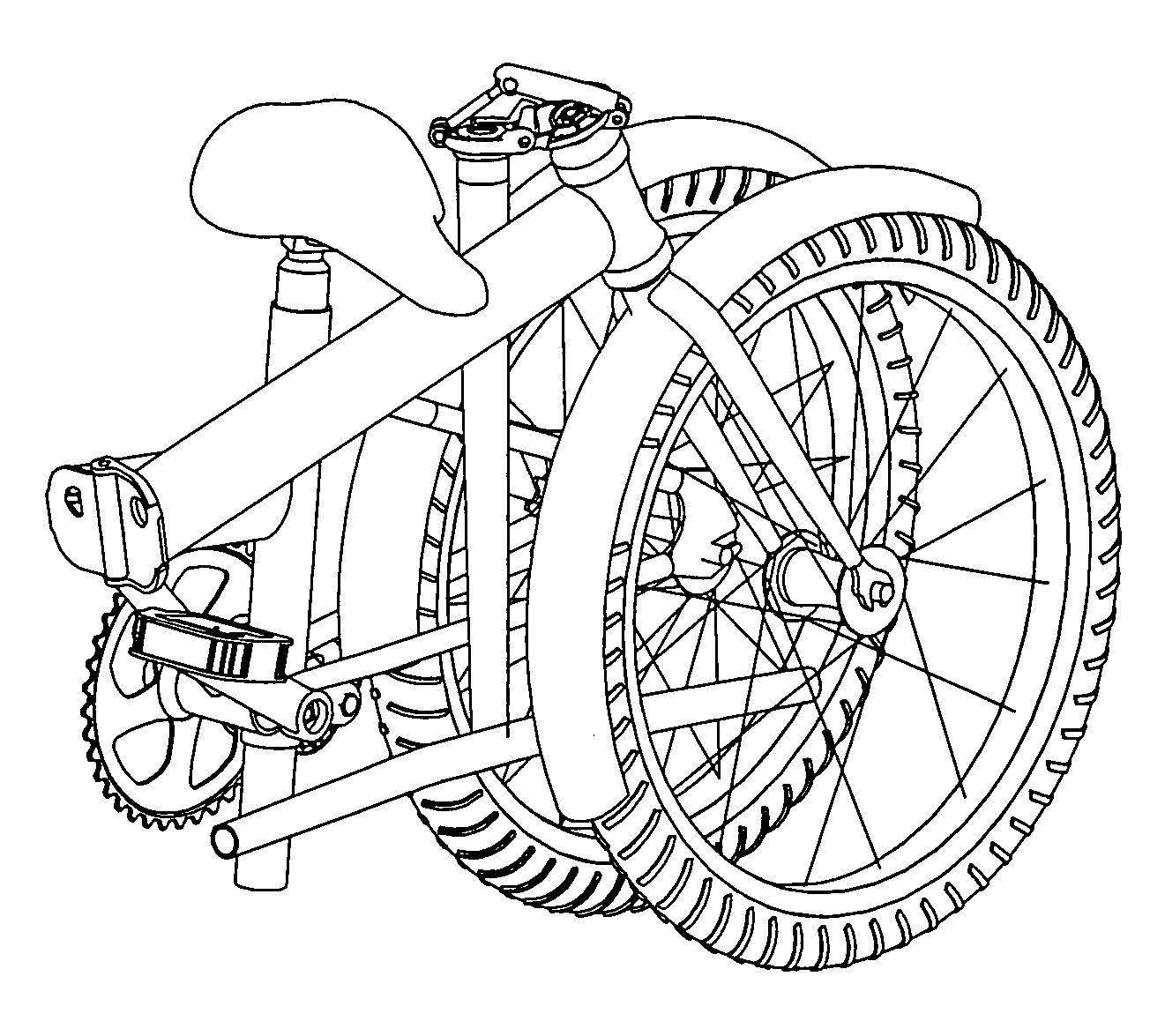

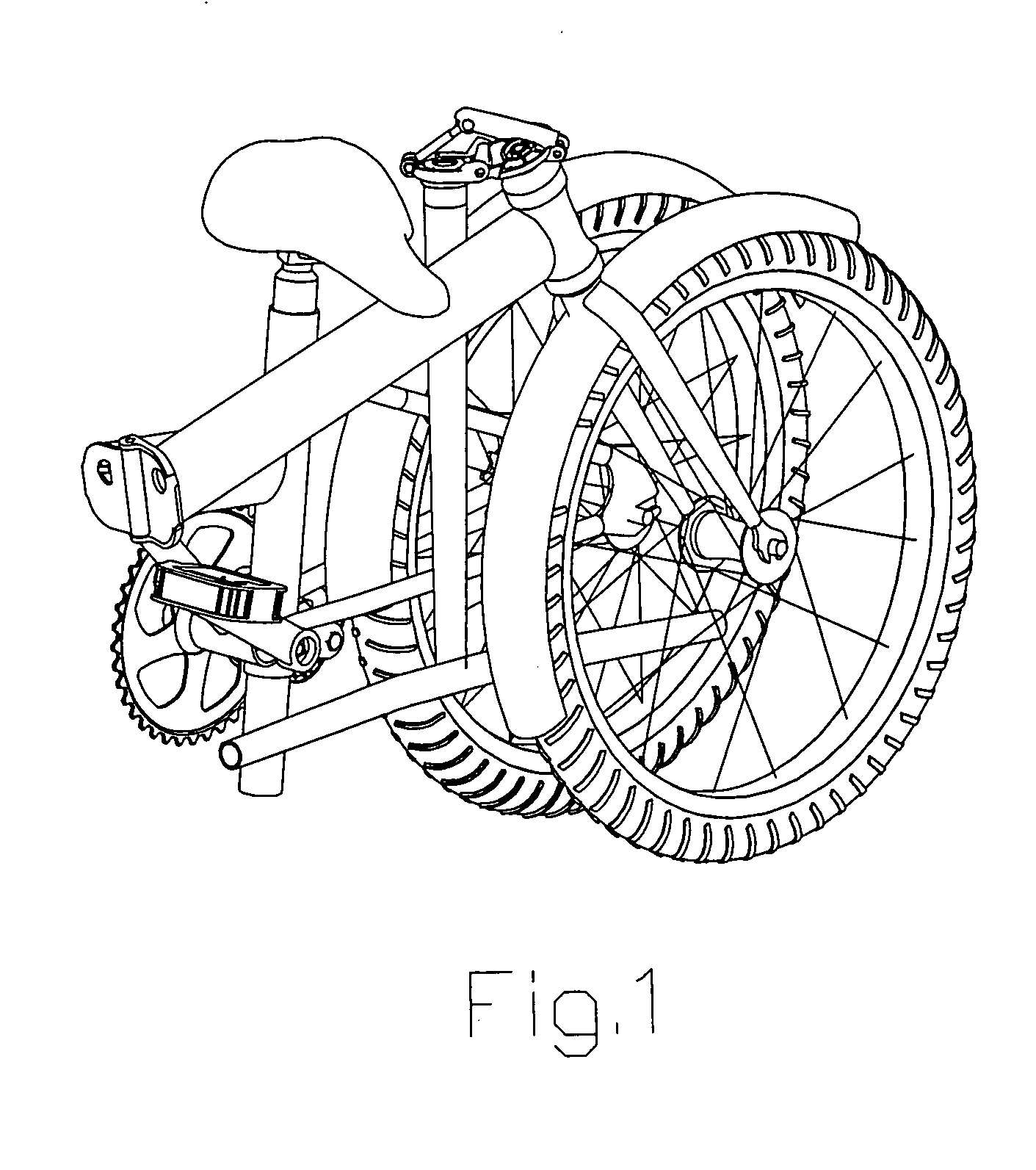

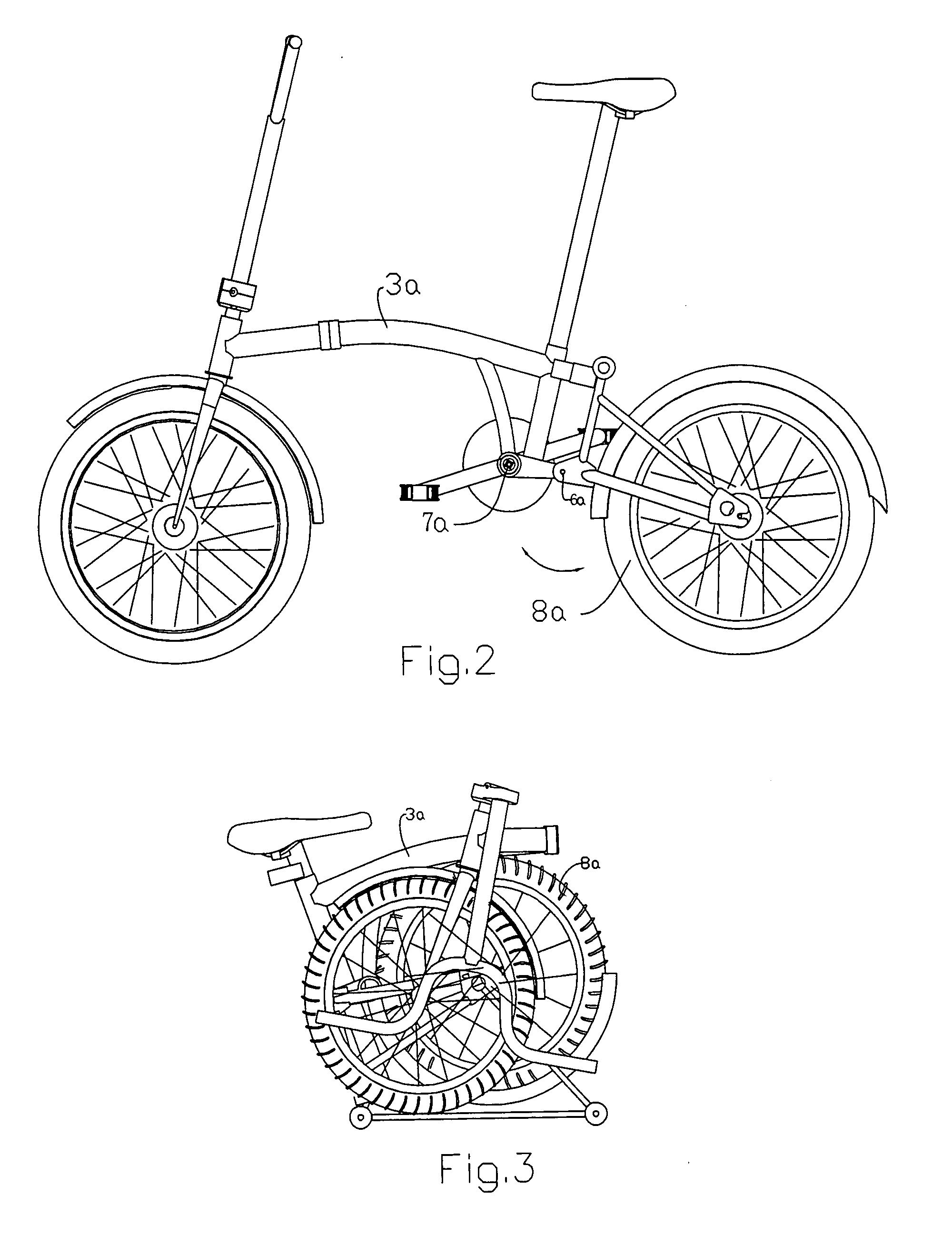

Folding bicycle

InactiveUS20070210556A1Avoid excessive widthAvoid excessive heightPassenger cyclesWheel based transmissionShaped beamAcute angle

The present invention discloses a folding bicycle, wherein a folding joint is installed on the beam, and the rear fork is hinged with the frame via a hinge axle, on the rear fork is installed a support bar which rests against the frame; and wherein the beam is S-shaped, and the hinge axle is tilted by an acute angle with respect to the central axle of the frame. When the bicycle is folded, the front and rear wheels are located separately, each at one side of the beam and within the concave section of the S-shaped beam, so that the bicycle is more compact and has a less width after being folded.

Owner:TAK WEI HON DAVID

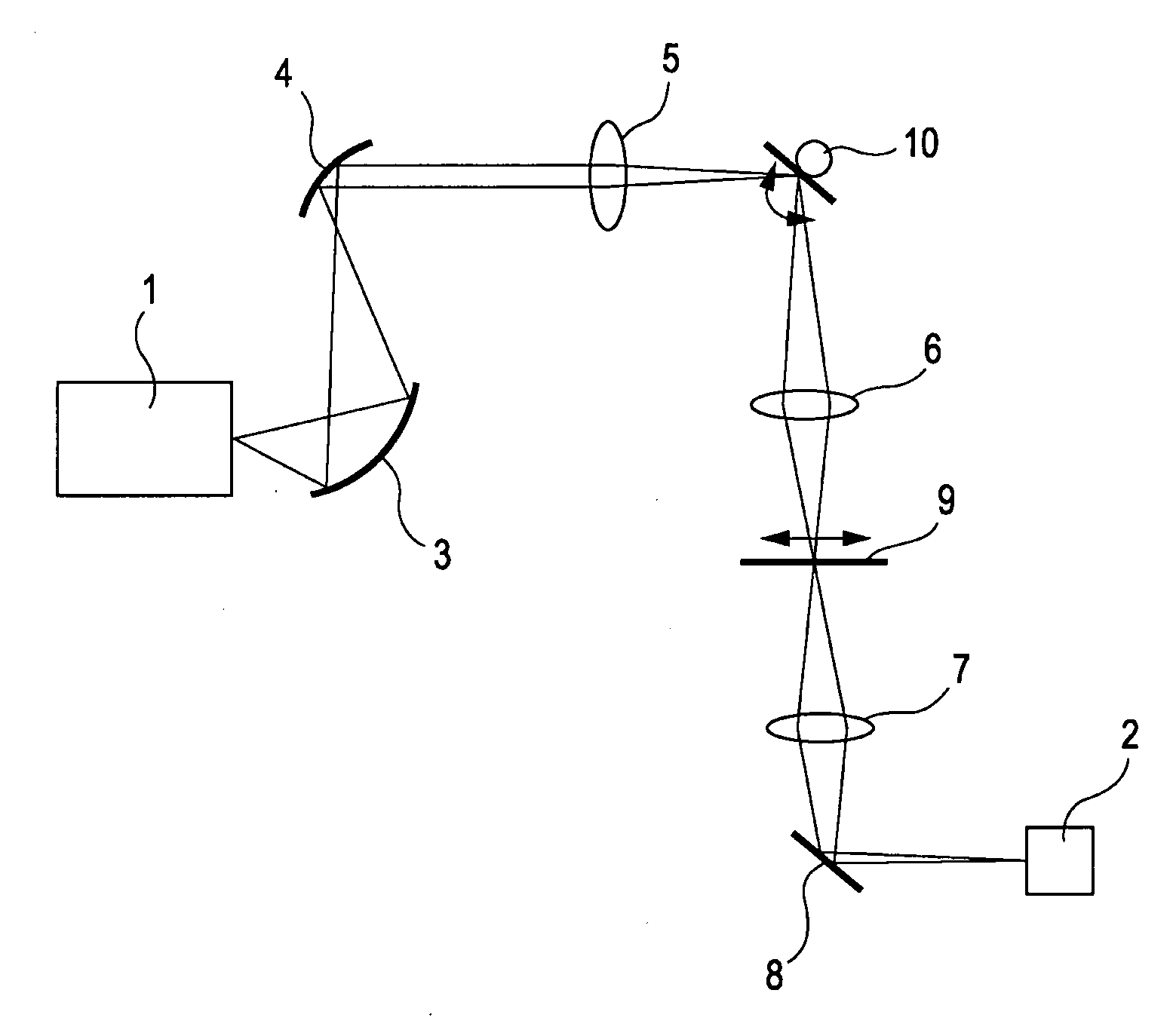

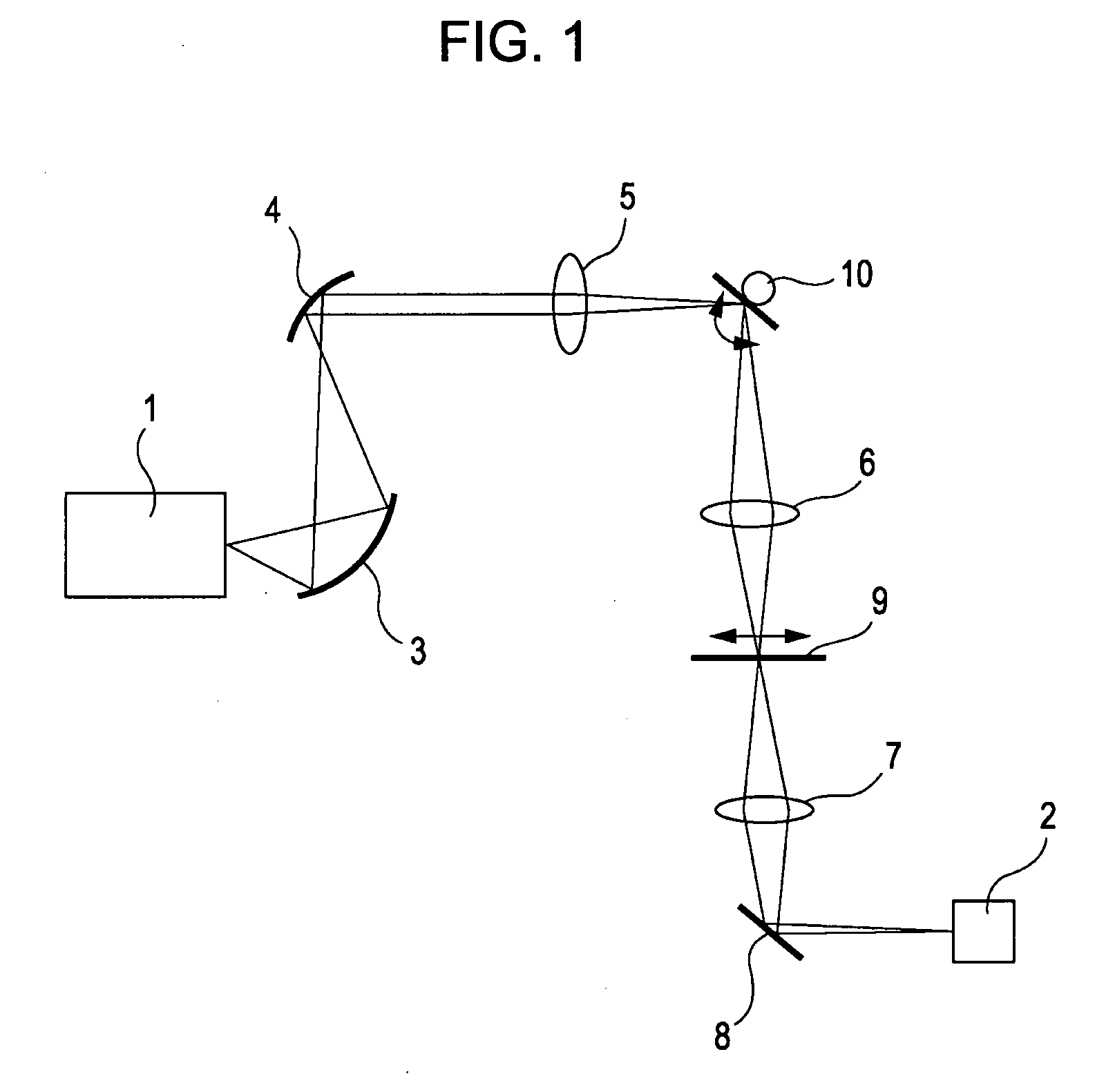

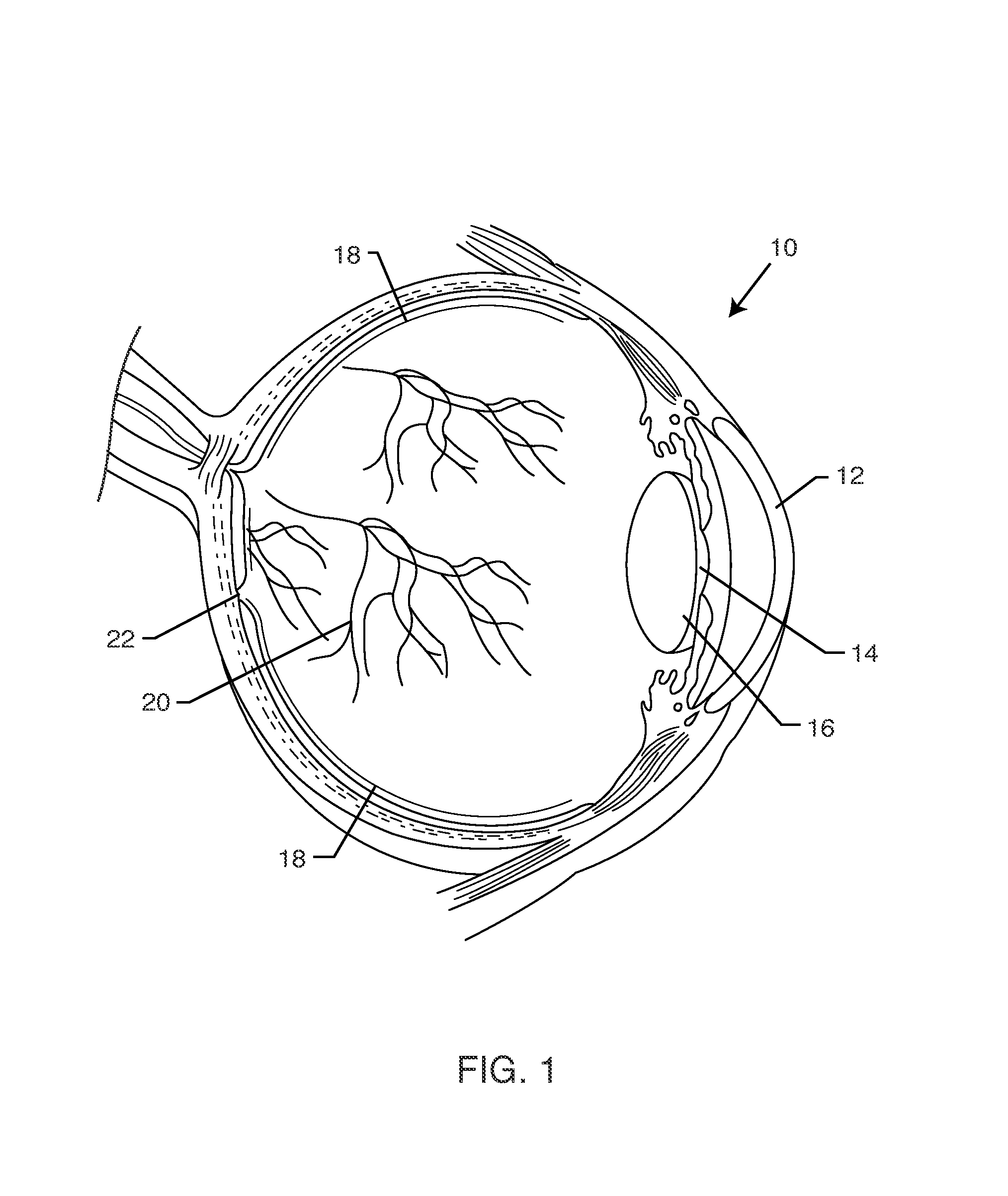

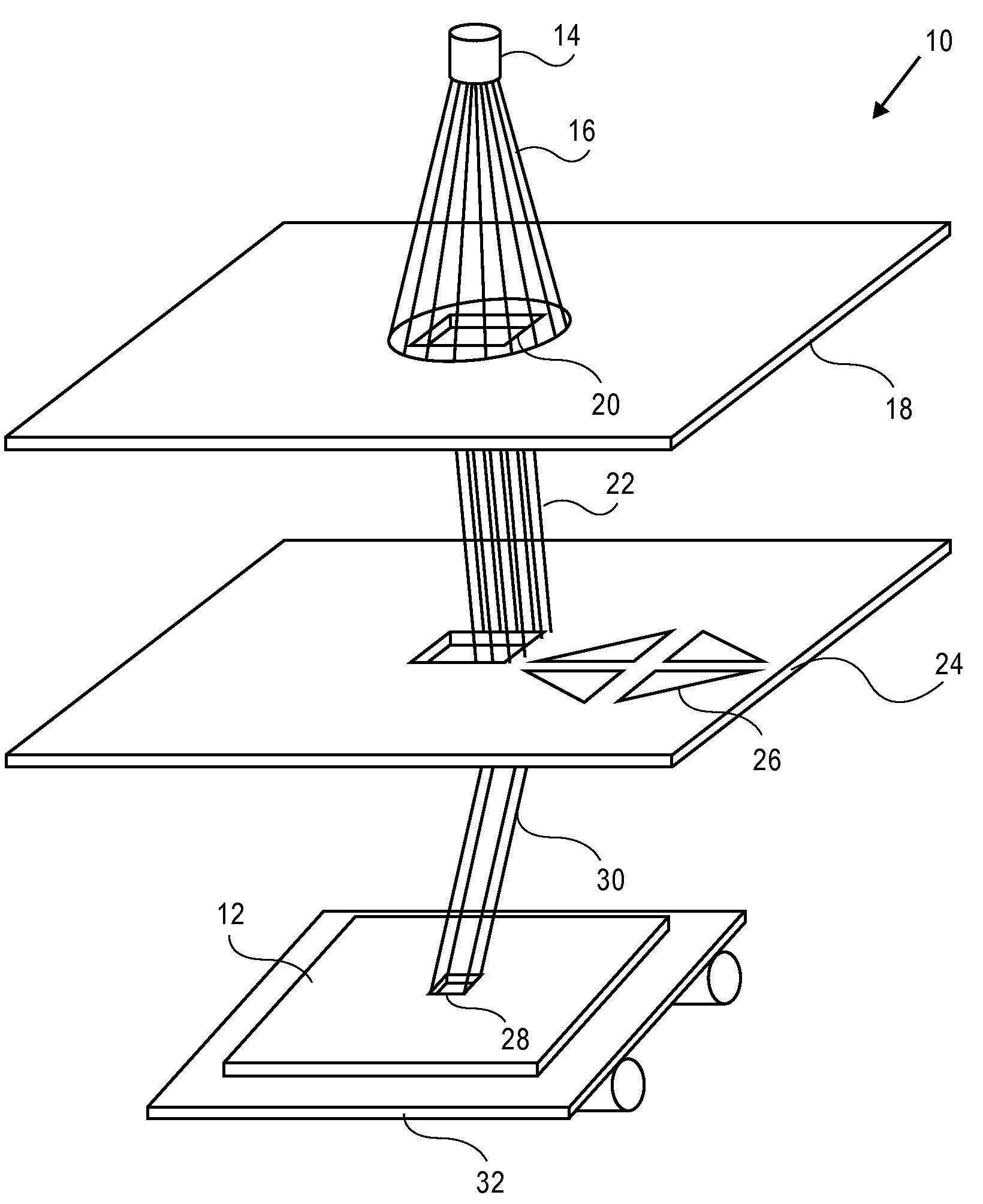

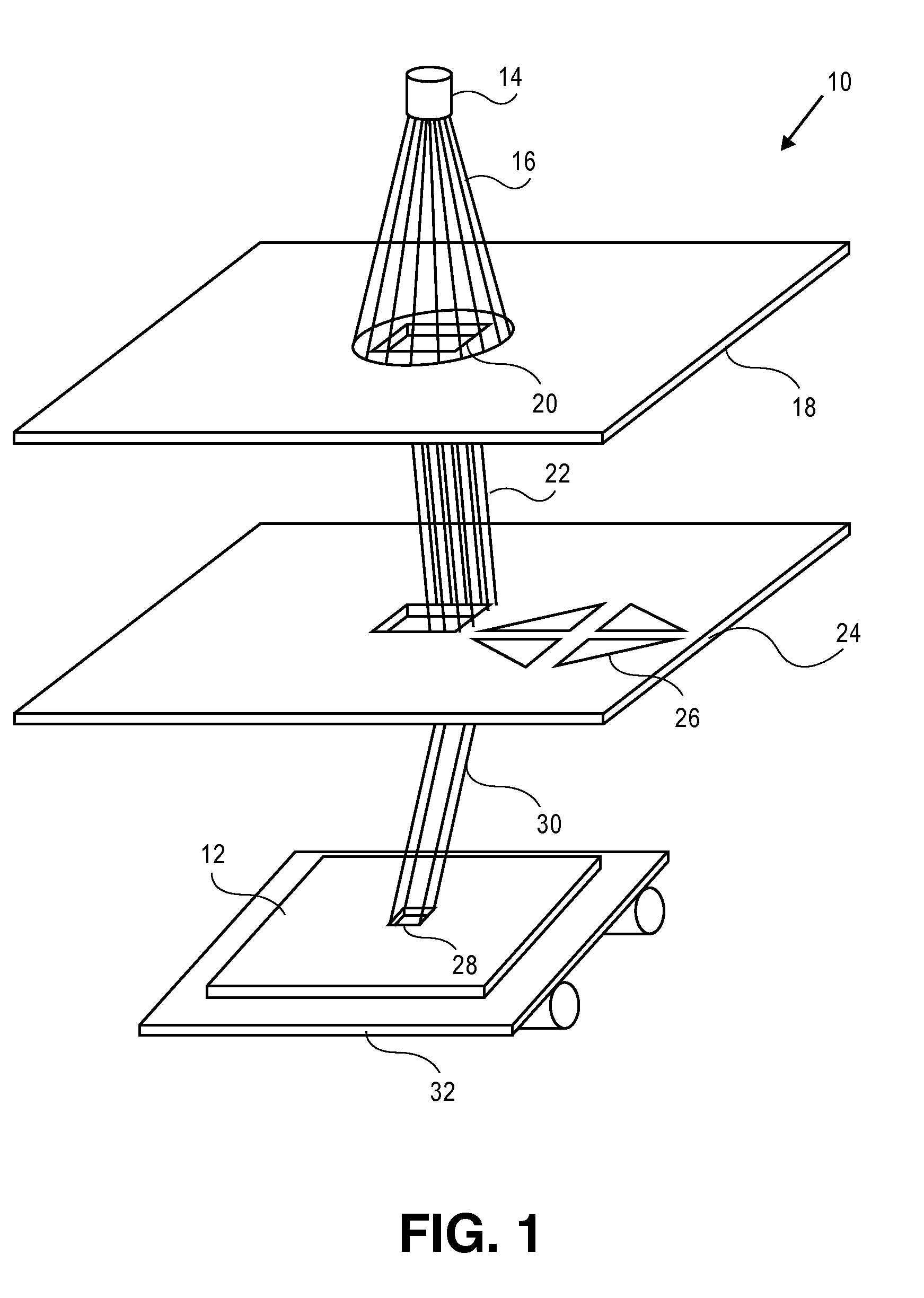

System and process for retina phototherapy

ActiveUS20130317487A1Avoid treatmentReduce areaLaser surgerySurgical instrument detailsDiseaseShaped beam

A system and process for treating retinal diseases includes passing a plurality of radiant beams, i.e., laser light beams, through an optical lens or mask to optically shape the beams. The shaped beams are applied to at least a portion of the retina. Due to the selected parameters of the beams—pulse length, power and duty cycle—the beams can be applied to substantially the entire retina, including the fovea, without damaging retinal or foveal tissue, while still attaining the benefits of retinal phototherapy or photostimulation.

Owner:OJAI RETINAL TECH

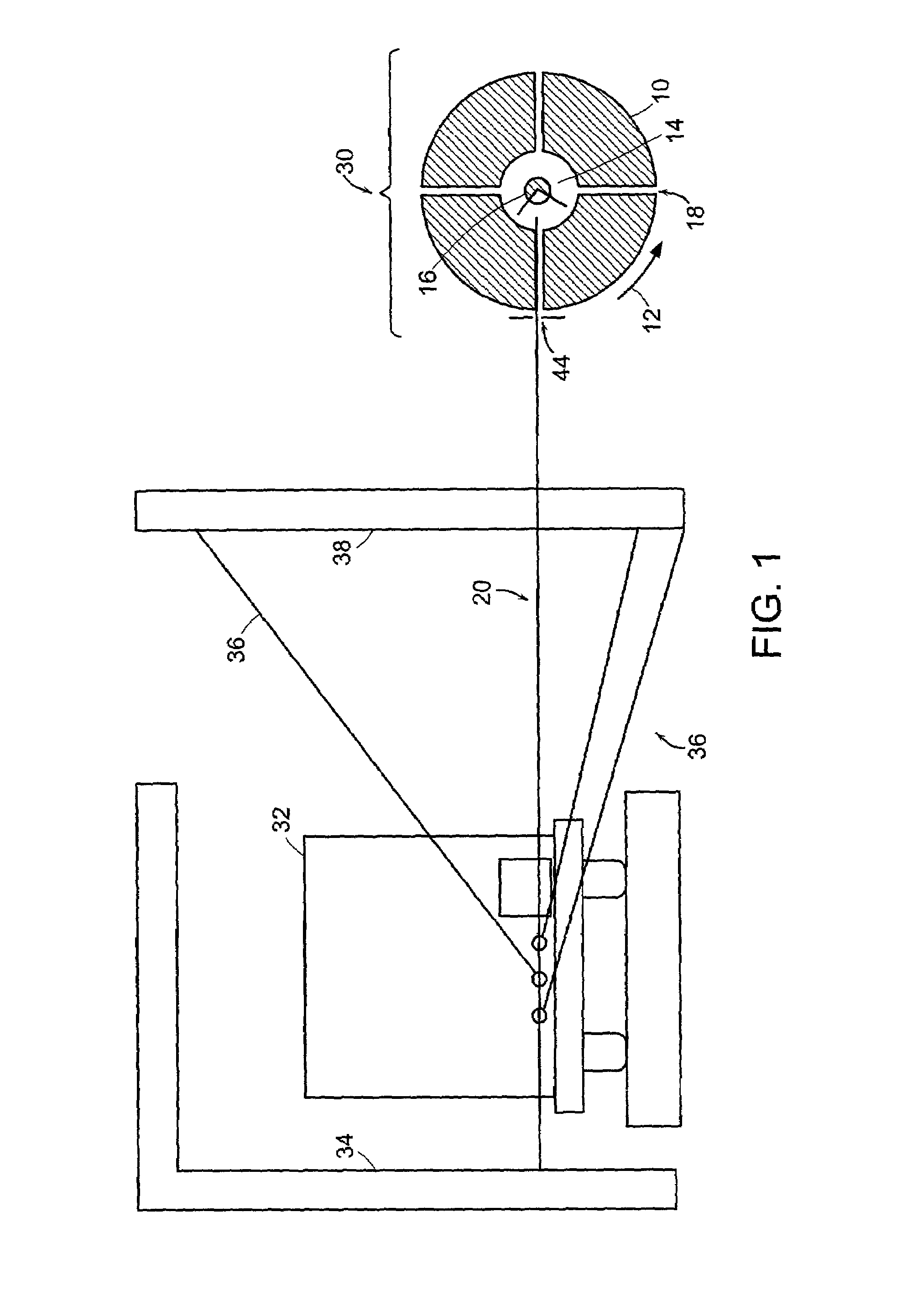

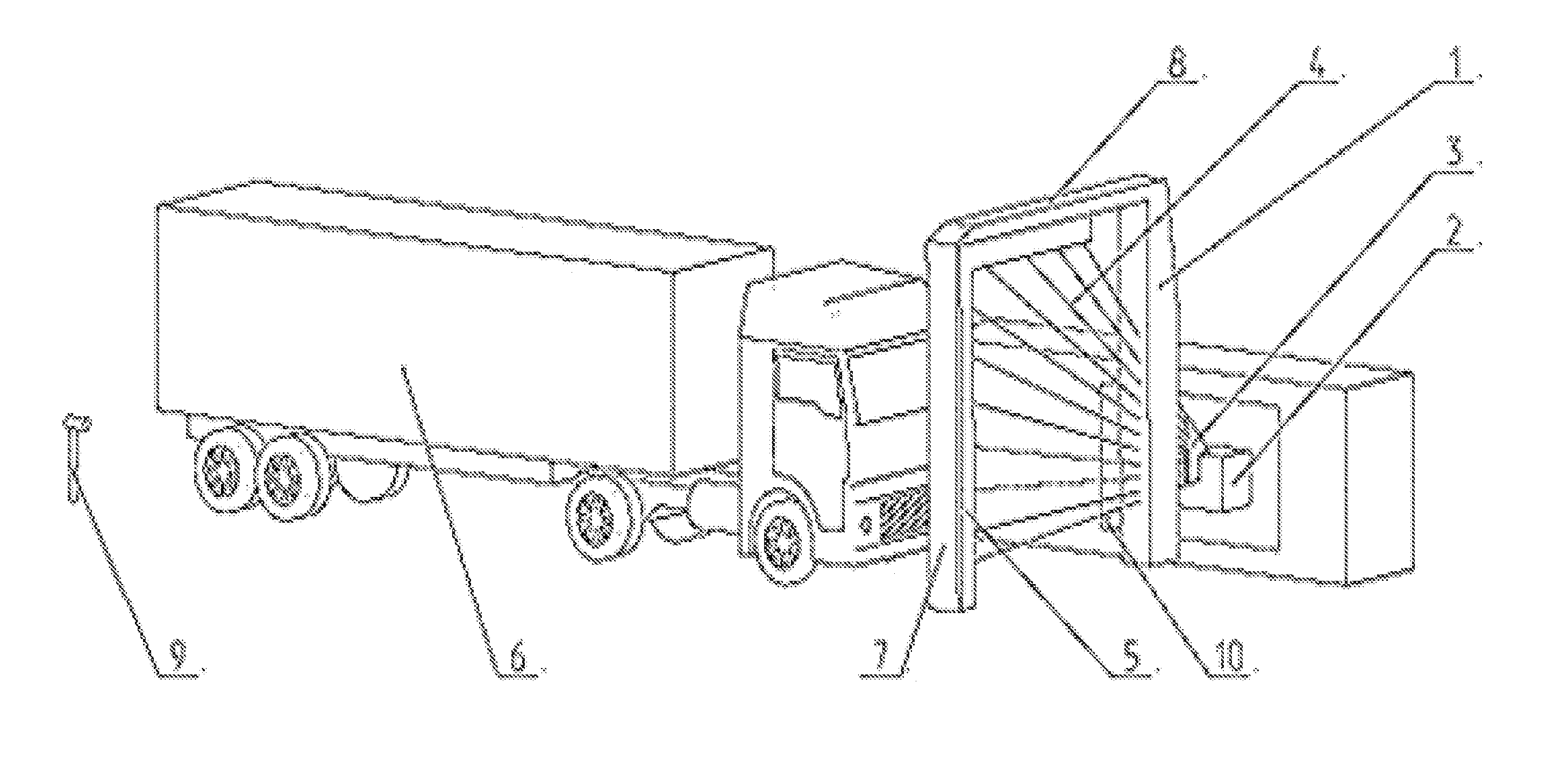

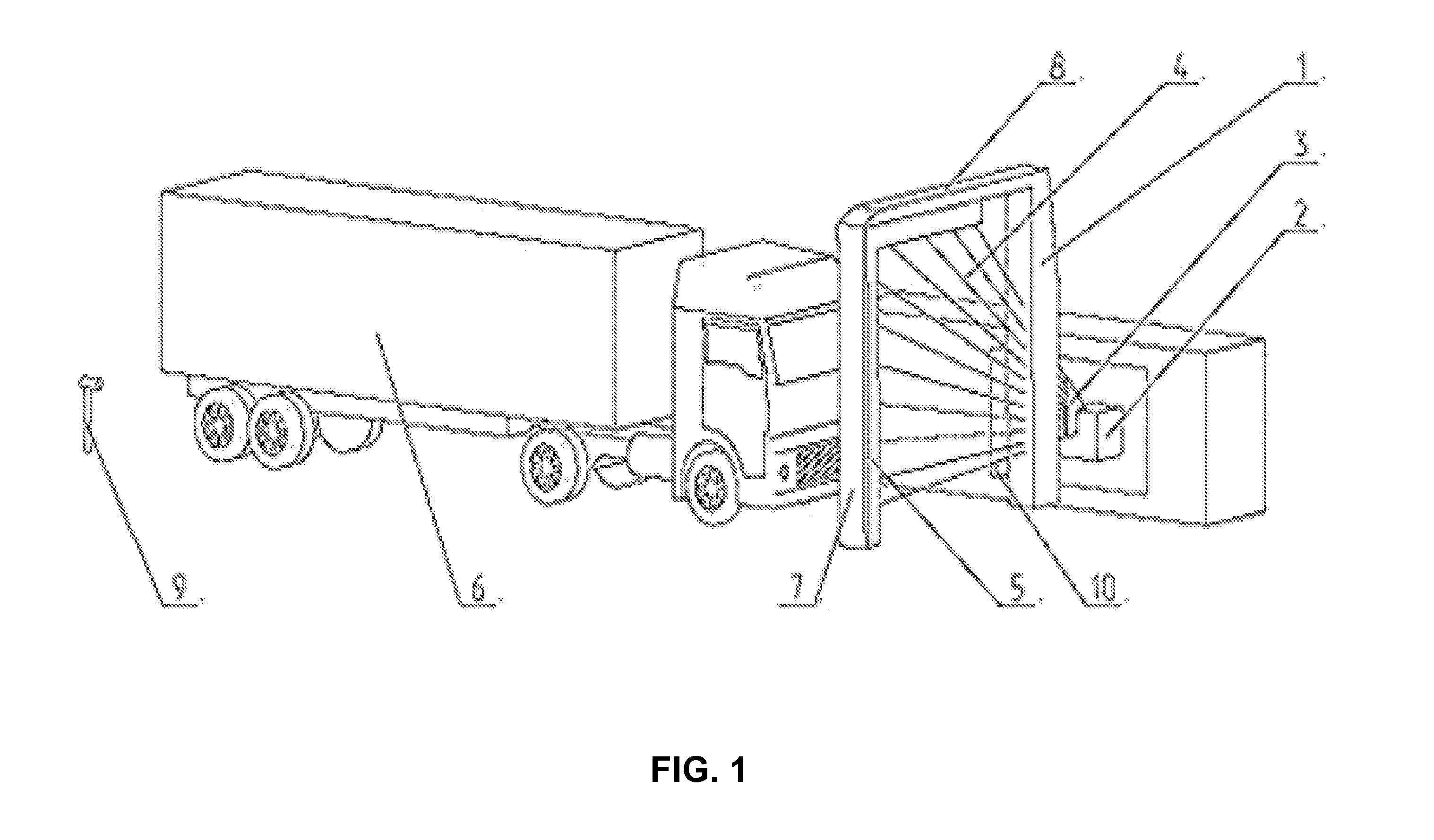

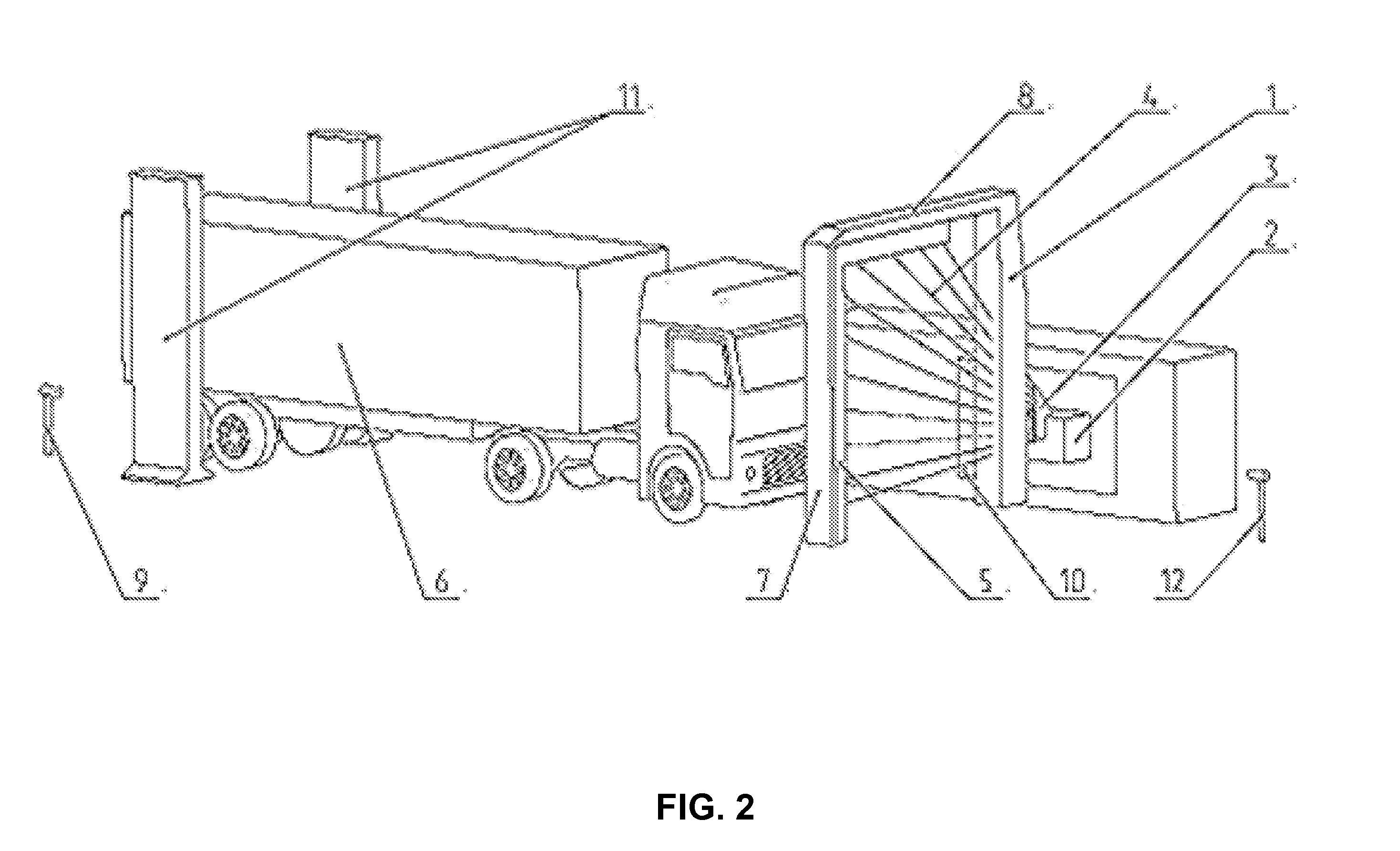

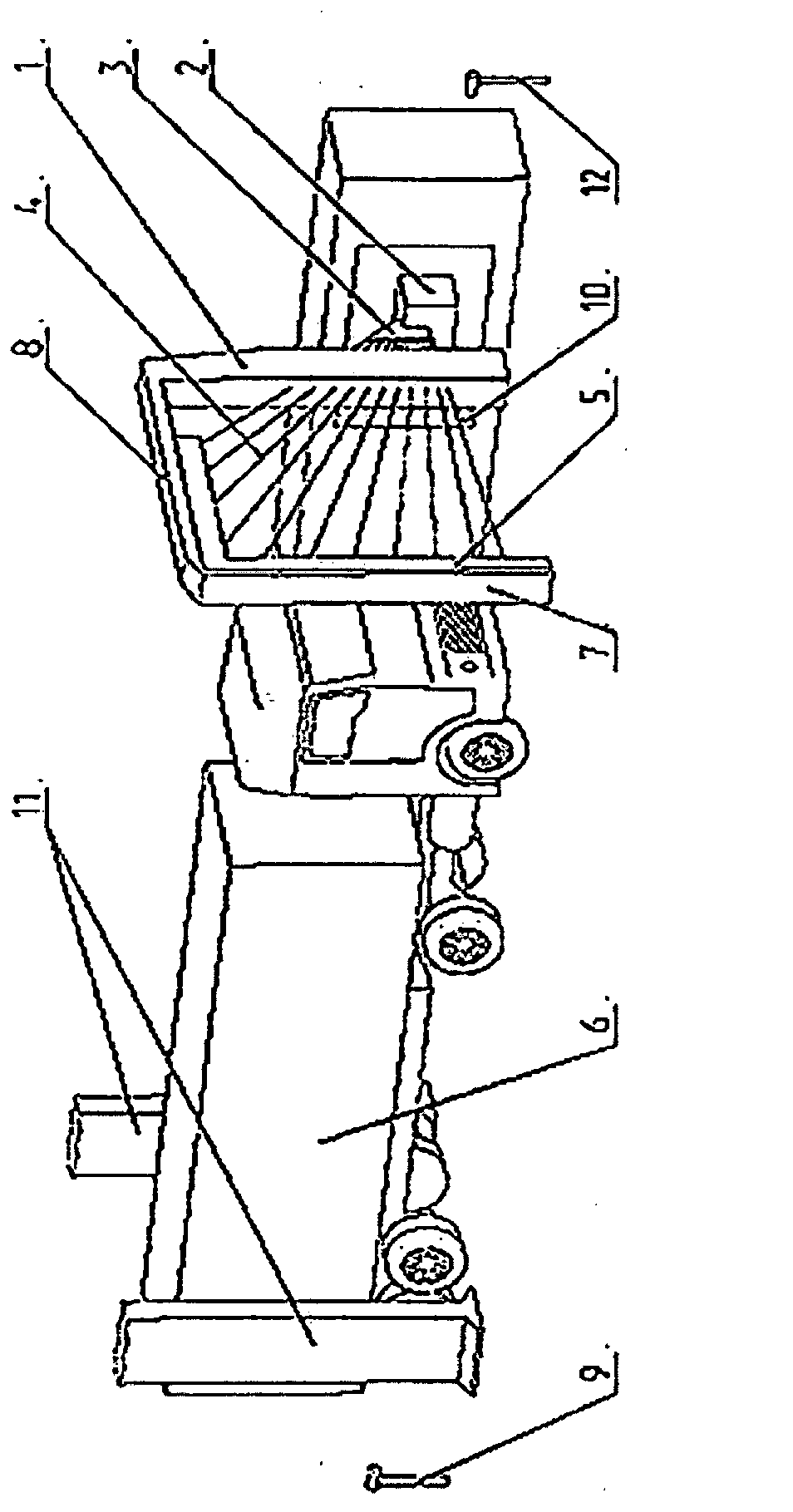

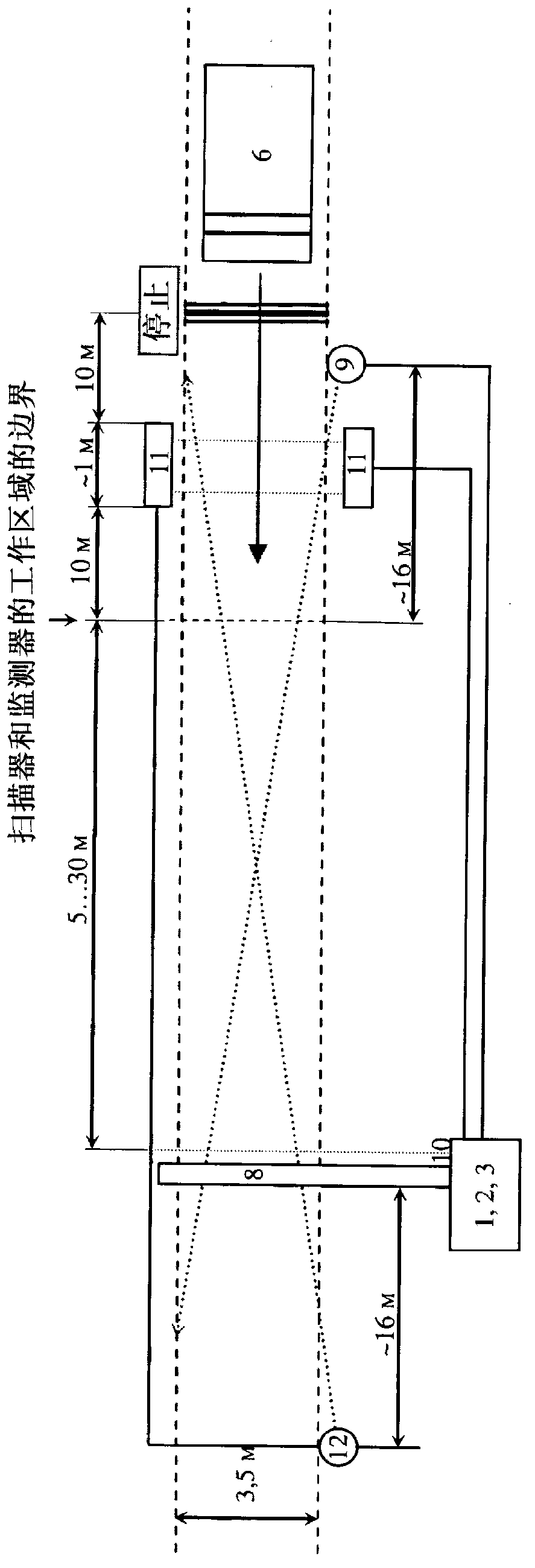

Cargo and vehicle inspection system

ActiveUS20110274242A1Reliable detectionReduce frequencyRadiation beam directing meansMaterial analysis by transmitting radiationElectricityShaped beam

An apparatus for X-ray scanning of vehicles includes a pulsed X-ray source generating X-rays. A collimator forms a fan-shaped beam from the X-rays. A detector detects the fan-shaped beam after it passes through a vehicle. A speed sensor measures a speed of the vehicle passing through the apparatus and providing an electrical output corresponding to the speed. An image formation module converts an output of the detector into an image of the vehicle, based on the measured speed of the vehicle. A cross-section of the fan-shaped beam is substantially similar to a width of the detector. The X-rays comprise primarily photons with energy between 2.5 and 9 MeV. A filter is adjacent to the collimator for filtering out low energy X-ray photons. A vehicle presence sensor can be used, whose output is used to turn the X-ray source on and off. An alignment platform can be used for aligning the fan-shaped beam with the detector. A frequency of the pulses is adjusted based on the speed of the vehicle. The X-ray source is turned off if the speed of the vehicle is below a predetermined threshold.

Owner:NAUCHNO PROIZVODSTVENNOE CHASTNOE UNITARNOE PREDPRIYATIE ADANI

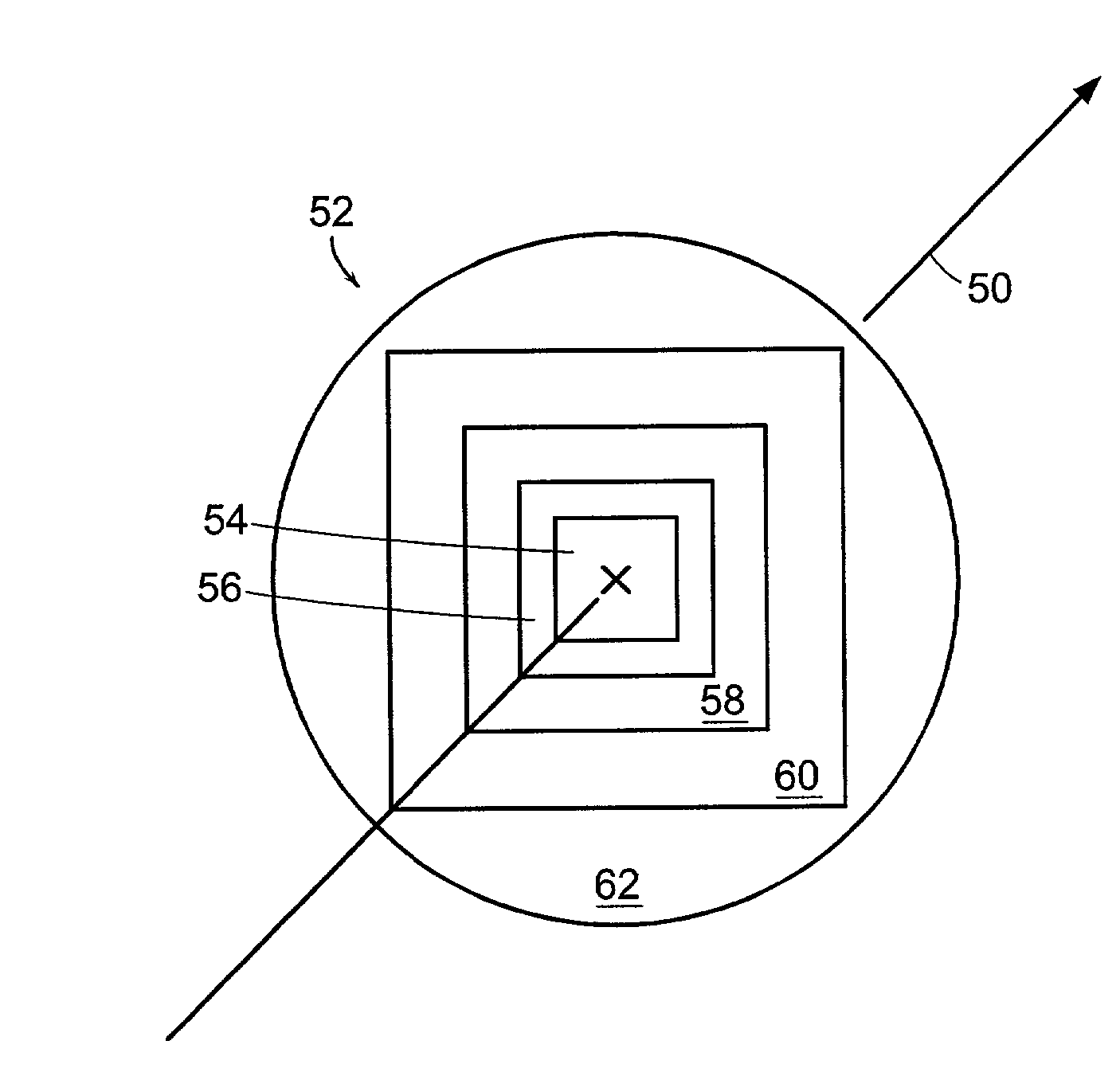

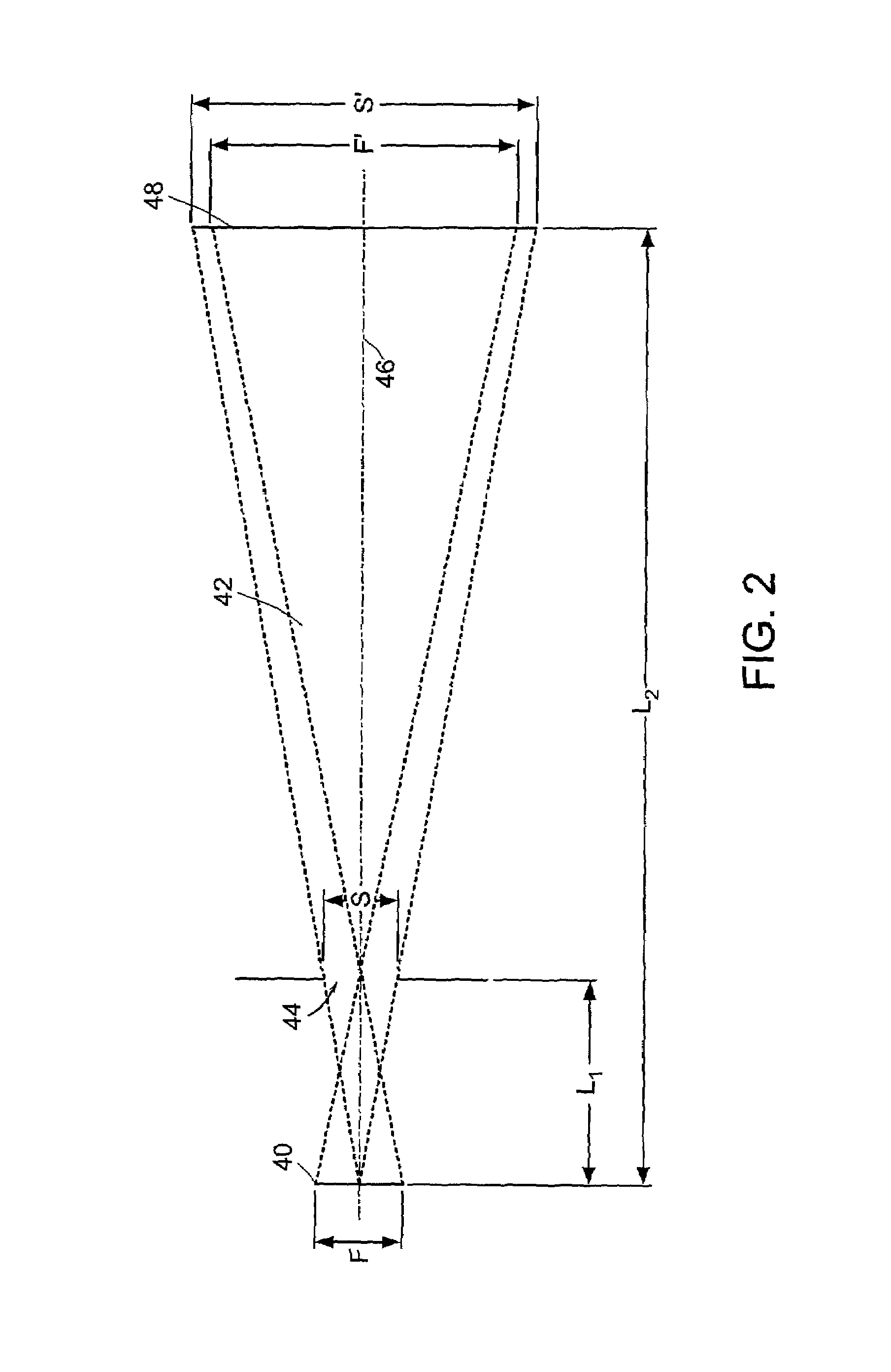

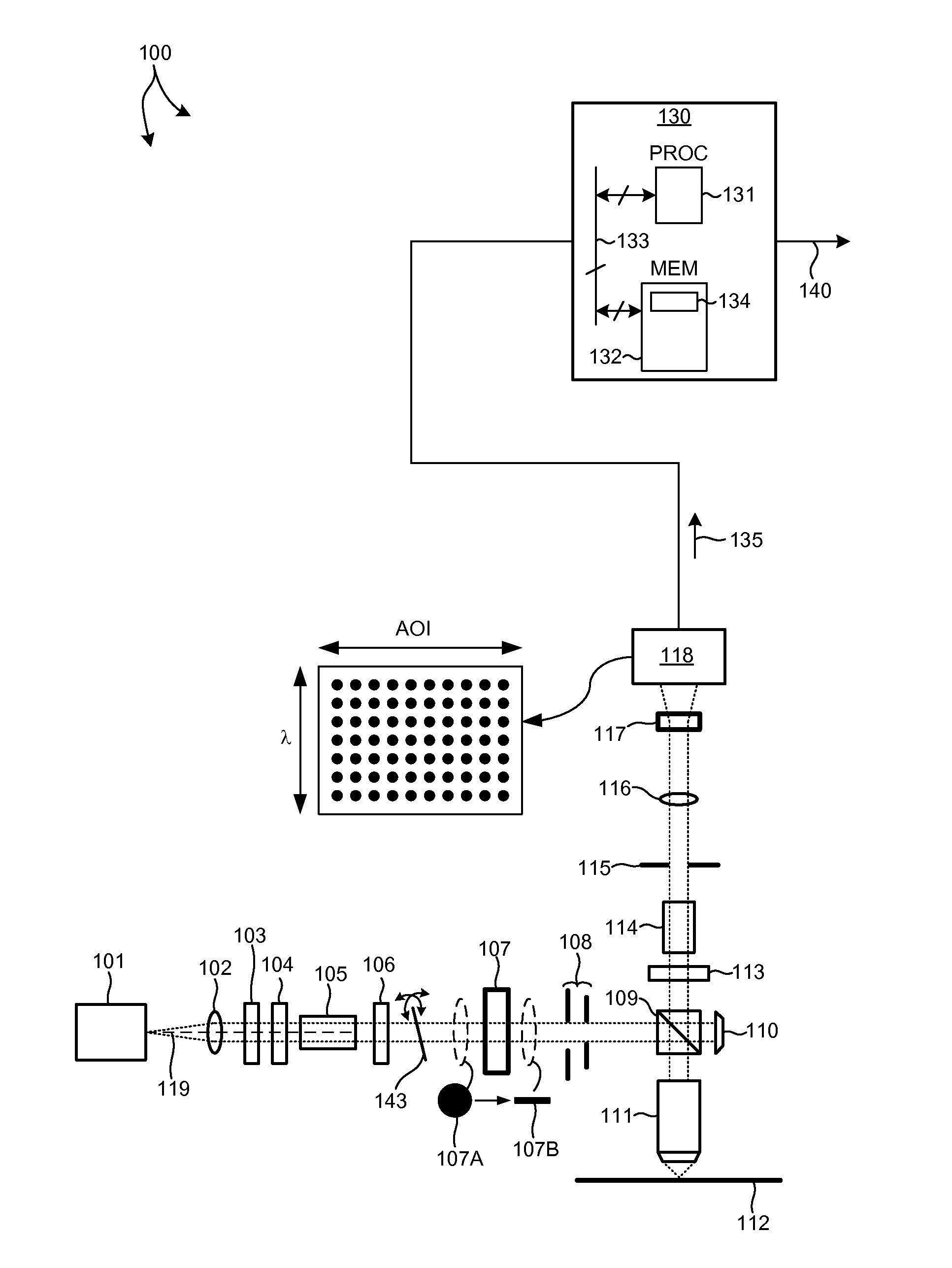

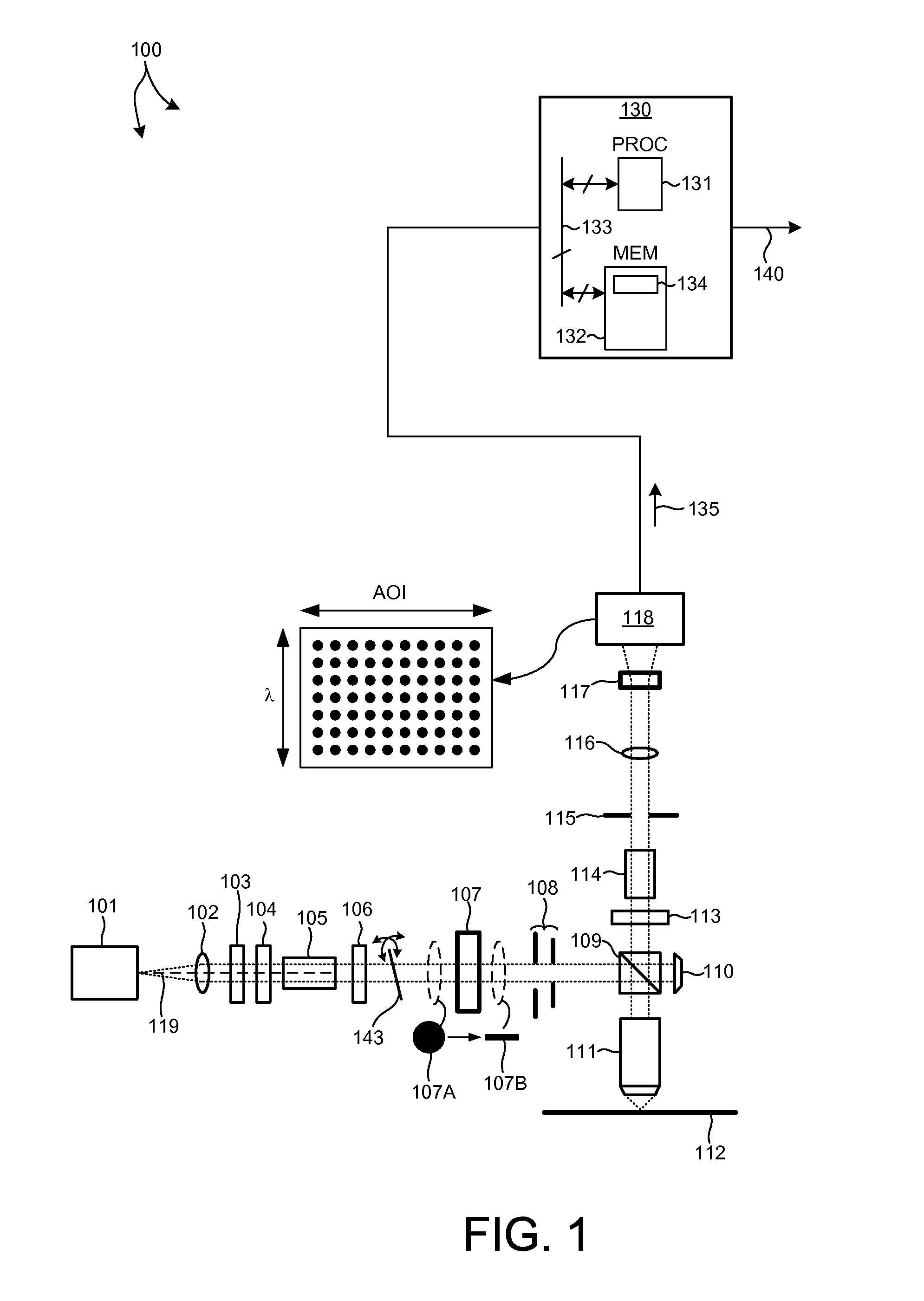

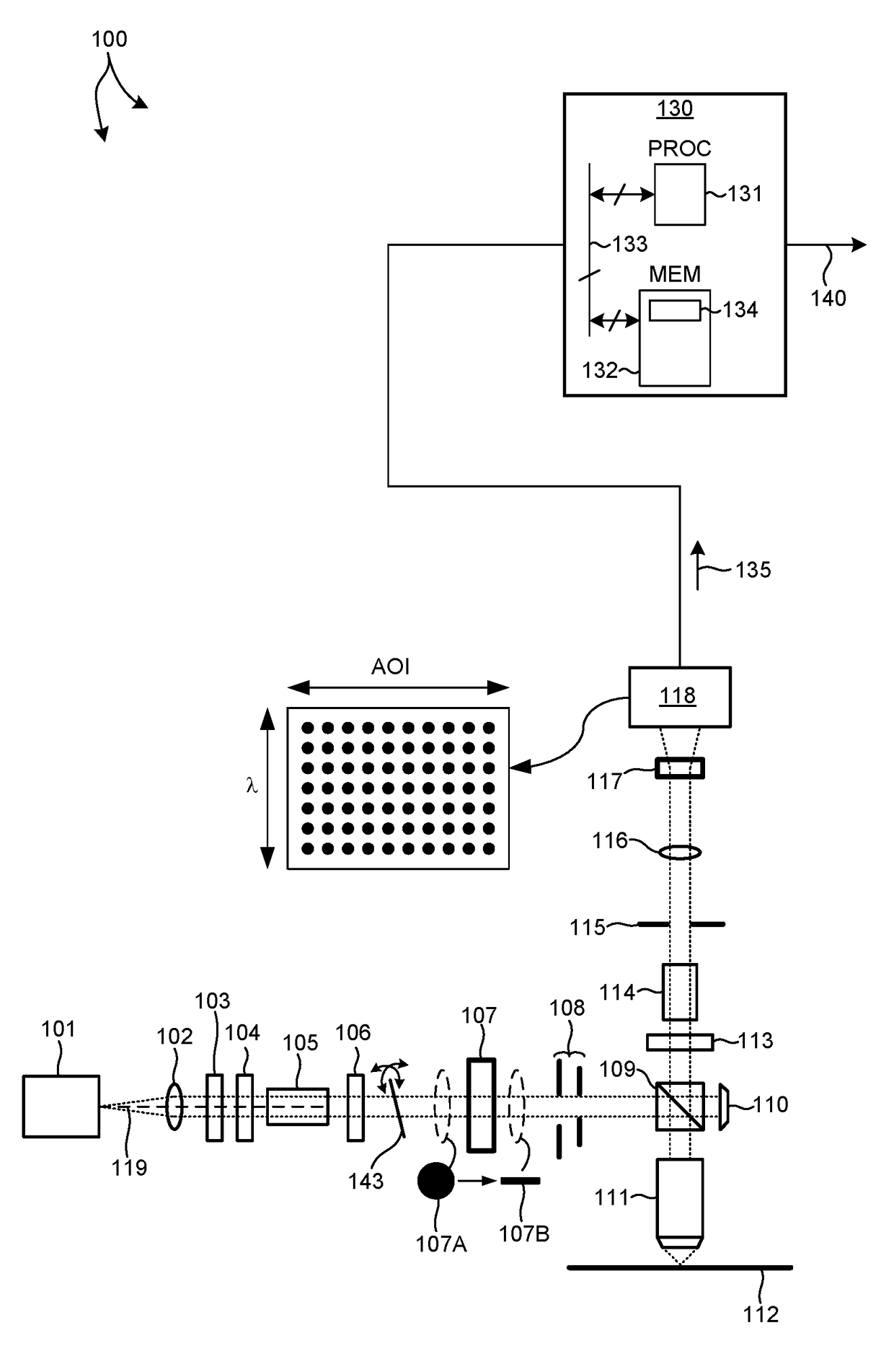

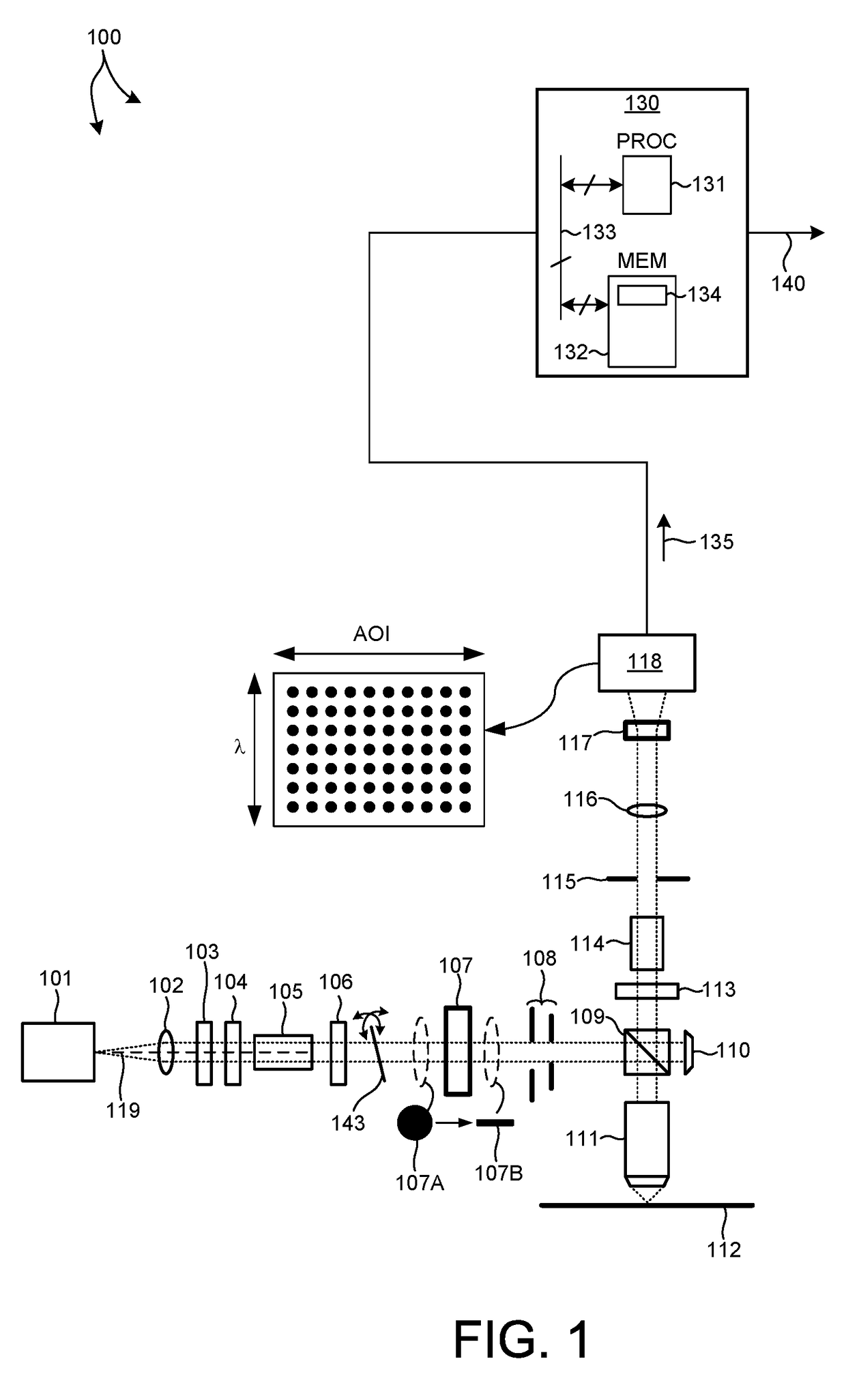

Spectroscopic Beam Profile Metrology

ActiveUS20160161245A1High measurement sensitivityReduction of coherence effectPhotomechanical apparatusMaterial analysis by optical meansTwo dimensional detectorAngle of incidence

A spectroscopic beam profile metrology system simultaneously detects measurement signals over a large wavelength range and a large range of angles of incidence (AOI). In one aspect, a multiple wavelength illumination beam is reshaped to a narrow line shaped beam of light before projection onto a specimen by a high numerical aperture objective. After interaction with the specimen, the collected light is passes through a wavelength dispersive element that projects the range of AOIs along one direction and wavelength components along another direction of a two-dimensional detector. Thus, the measurement signals detected at each pixel of the detector each represent a scatterometry signal for a particular AOI and a particular wavelength. In another aspect, a hyperspectral detector is employed to simultaneously detect measurement signals over a large wavelength range, range of AOIs, and range of azimuth angles.

Owner:KLA TENCOR TECH CORP

Method and System for Design of a Reticle to be Manufactured Using Variable Shaped Beam Lithography

ActiveUS20100058279A1Minimize shot countElectric discharge tubesRadiation applicationsMask data preparationLithographic artist

A method for fracturing or mask data preparation or proximity effect correction of a desired pattern to be formed on a reticle is disclosed in which a plurality of variable shaped beam (VSB) shots are determined which can form the desired pattern. Shots within the plurality of VSB shots are allowed to overlap each other. Dosages of the shots may also be allowed to vary with respect to each other. The union of the plurality of shots may deviate from the desired pattern. The plurality of shots may be determined such that a pattern on the surface calculated from the plurality of shots is within a predetermined tolerance of the desired pattern. In some embodiments, an optimization technique may be used to minimize shot count. In other embodiments, the plurality of shots may be optionally selected from one or more pre-computed VSB shots or groups of VSB shots.

Owner:D2S

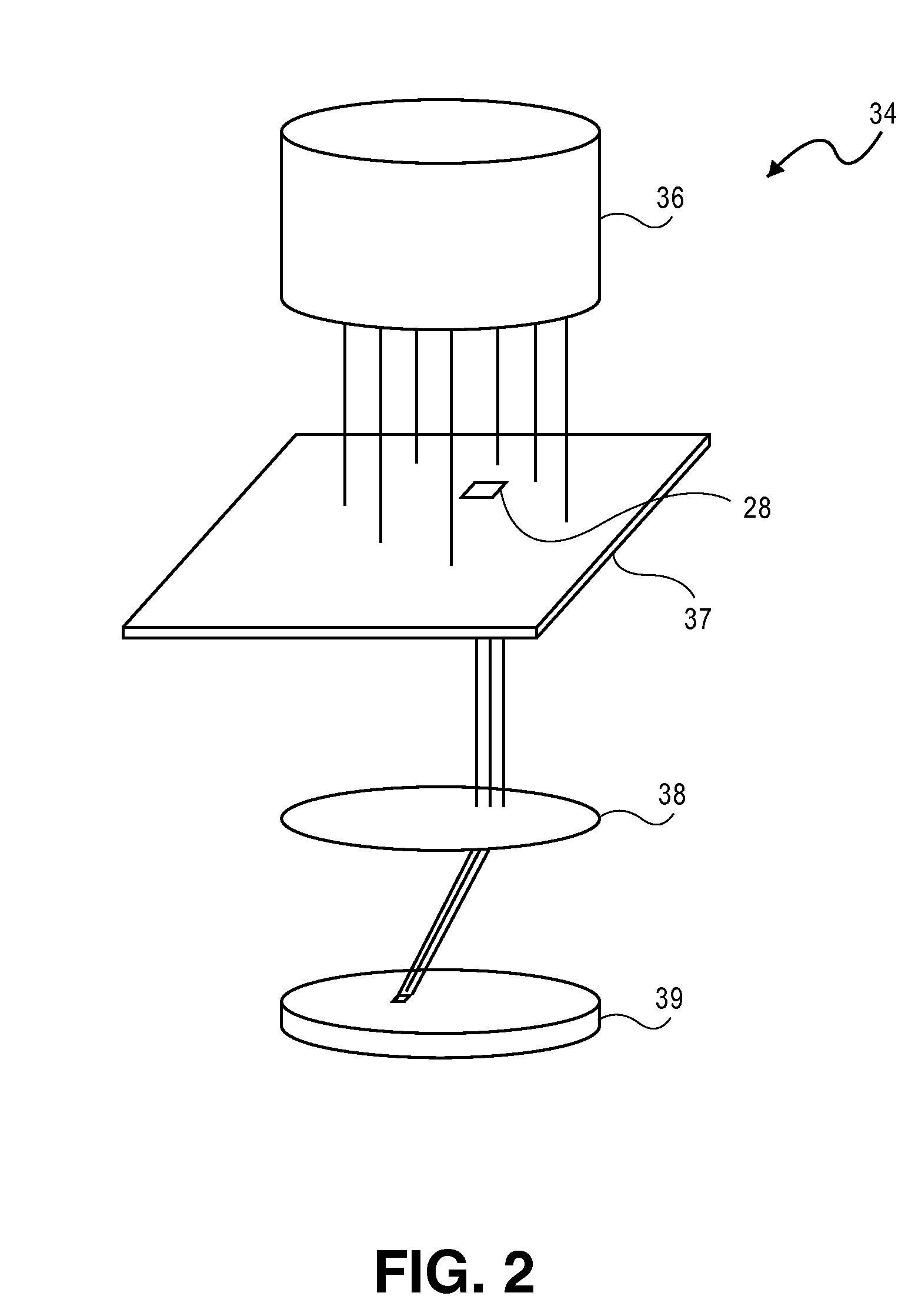

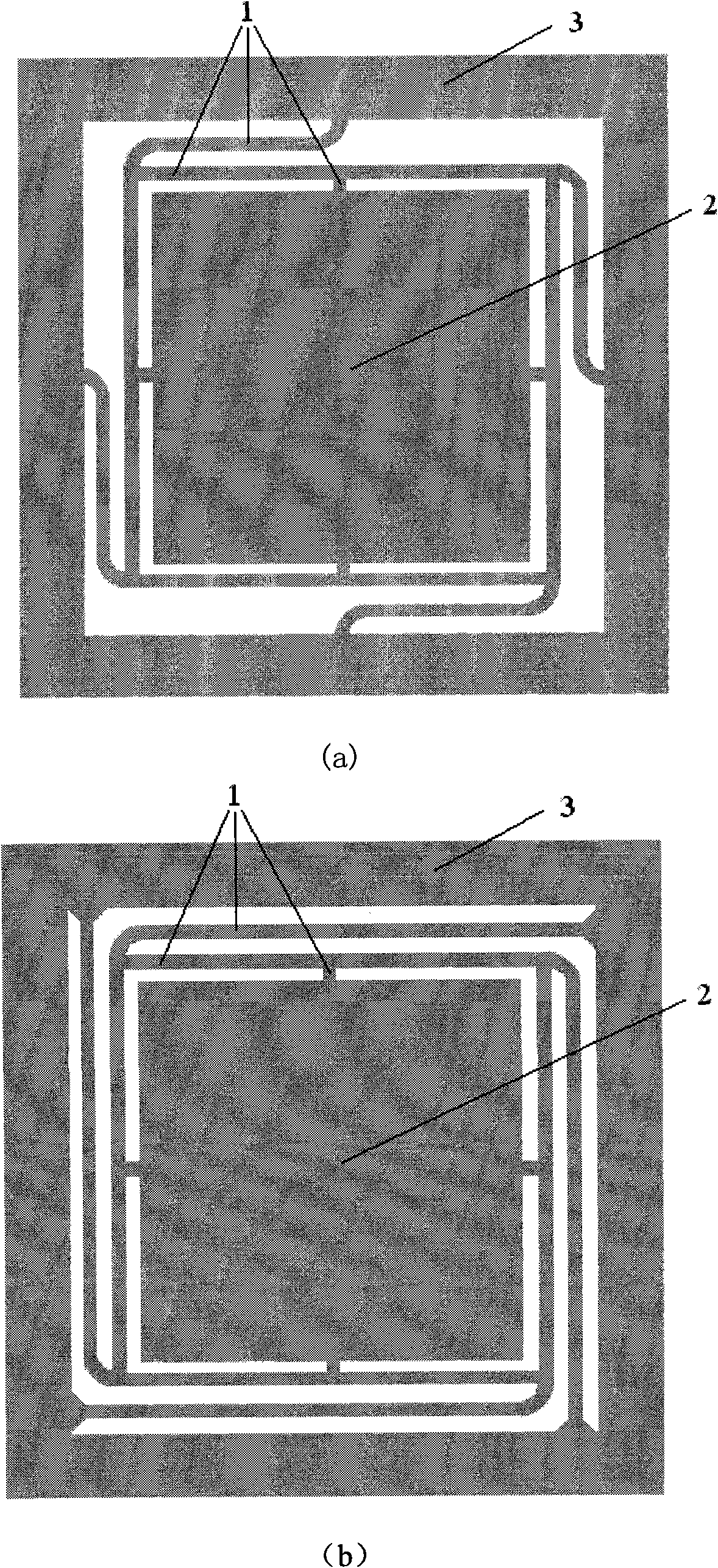

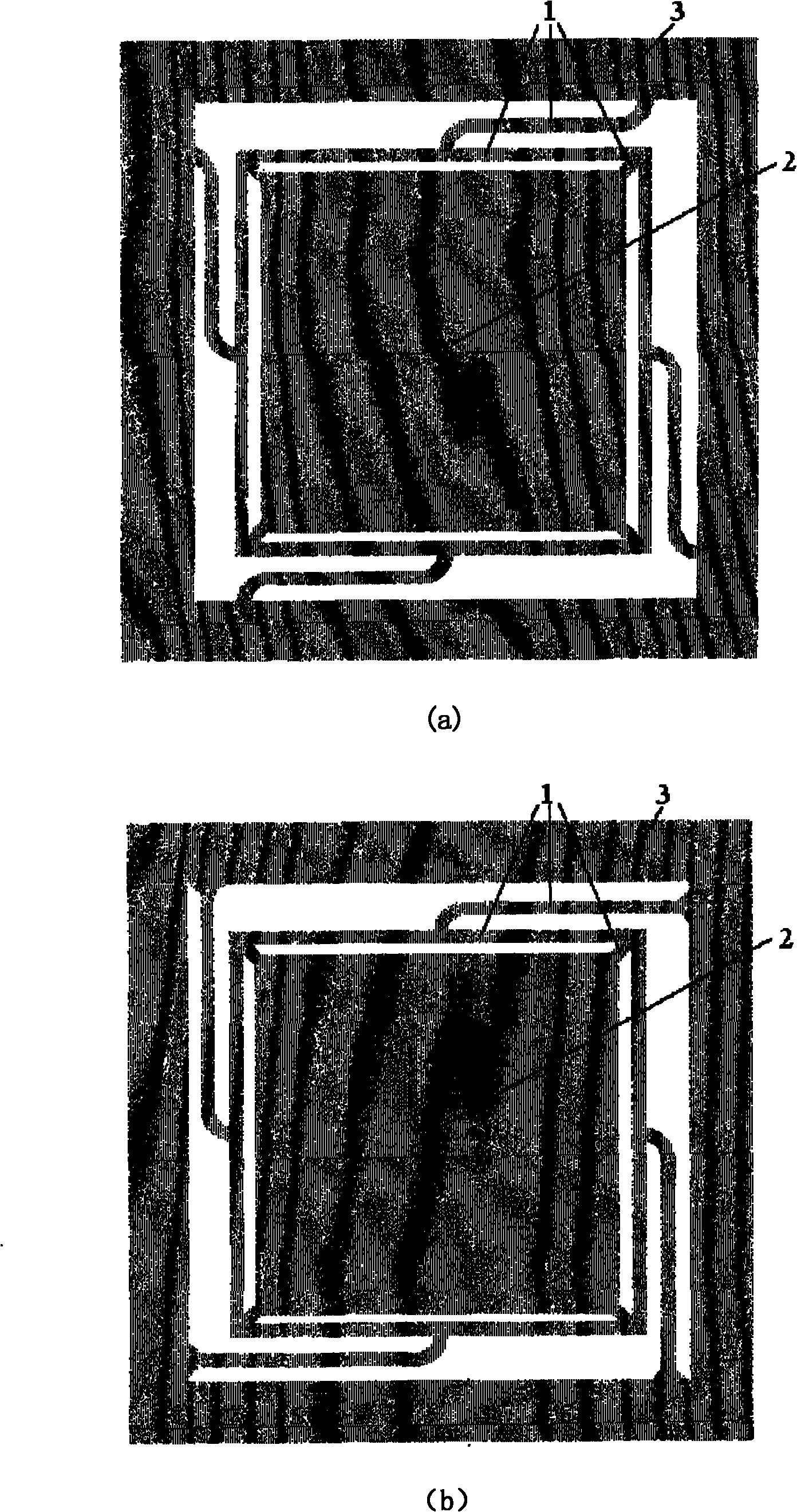

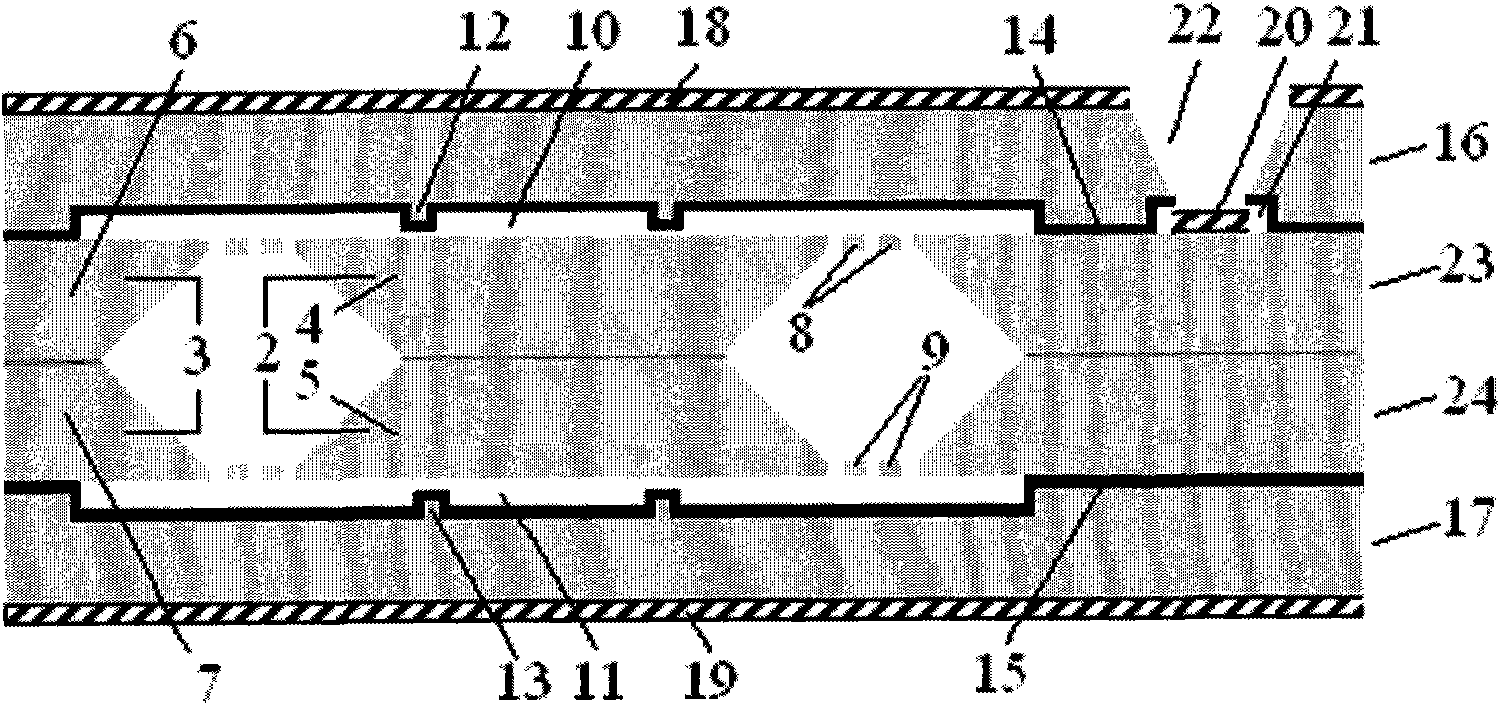

Capacitive micro-acceleration sensor with symmetrically combined elastic beam structure and production method thereof

ActiveCN101858929AReduce sensitivityGreat lateral sensitivityPrecision positioning equipmentPiezoelectric/electrostriction/magnetostriction machinesCross sensitivityShaped beam

The invention relates to a capacitive micro-acceleration sensor with a symmetrically combined elastic beam structure and a production method thereof. The acceleration sensor comprises a symmetric center mass block, an external support frame, eight symmetric straight beams, two symmetric frame beams, a combined elastic beam structure, an upper cover plate and a lower cover plate, wherein the eight symmetric straight beams are used for connecting the center mass block with the external support frame, and the combined elastic beam structure is formed by connecting eight symmetric L-shaped beams together; and the other end of each straight elastic beam connected with the frame beams is connected to the middle or a vertex angle at the top end and the bottom end of the lateral face of the center mass block, and the other end of each L-shaped beam connected with the frame beams is connected to the inner side face of the external support frame. The acceleration sensor adopts the combined elastic beam structure which is formed by connecting the symmetric straight beams, the frame beams and the L-shaped beams together, has high symmetry and can remarkably reduce the cross-sensitivity of the sensor; and the sensor is produced by adopting a microelectronic mechanical system technology and is the capacitive micro-acceleration sensor with high sensitivity.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

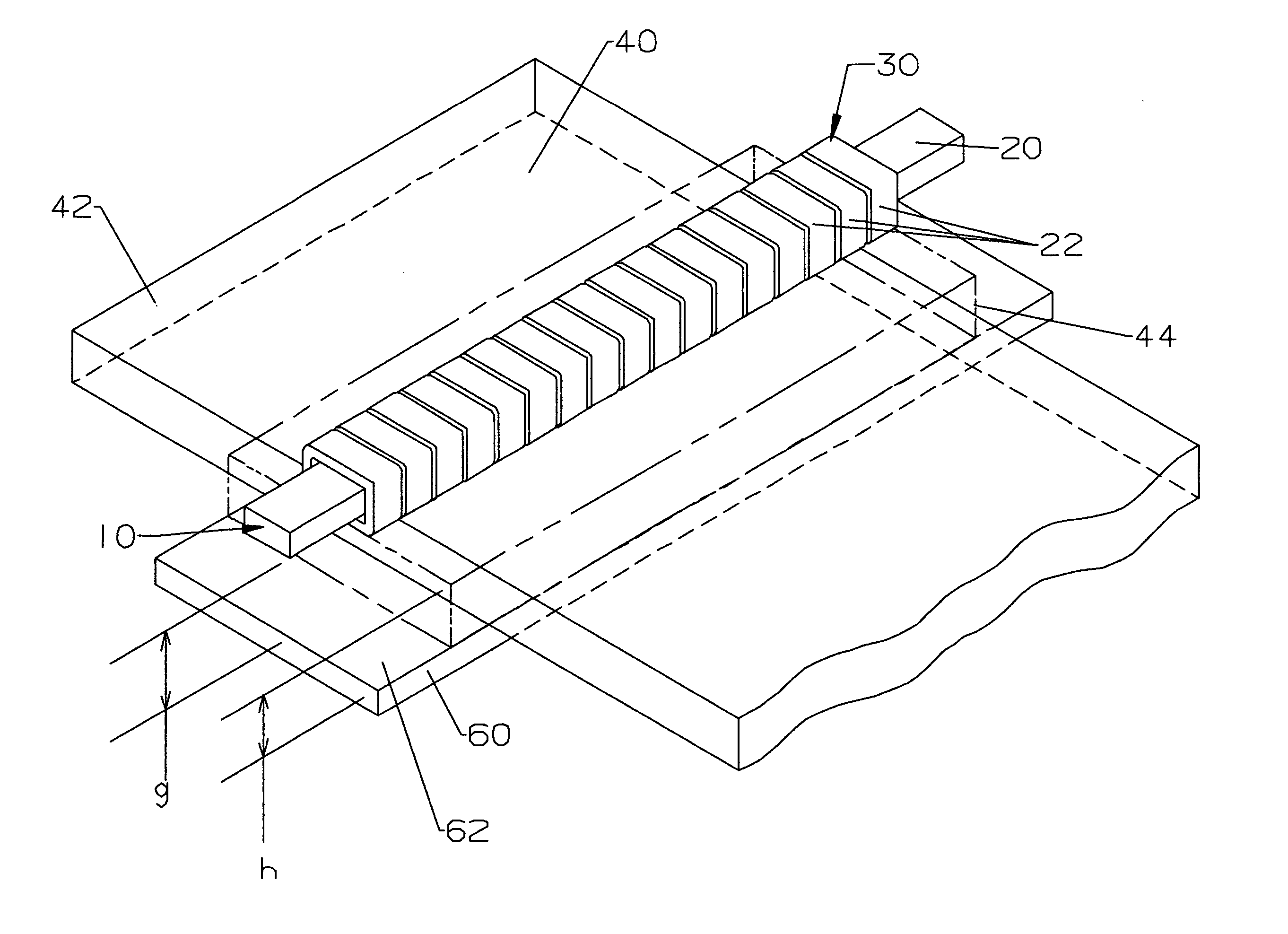

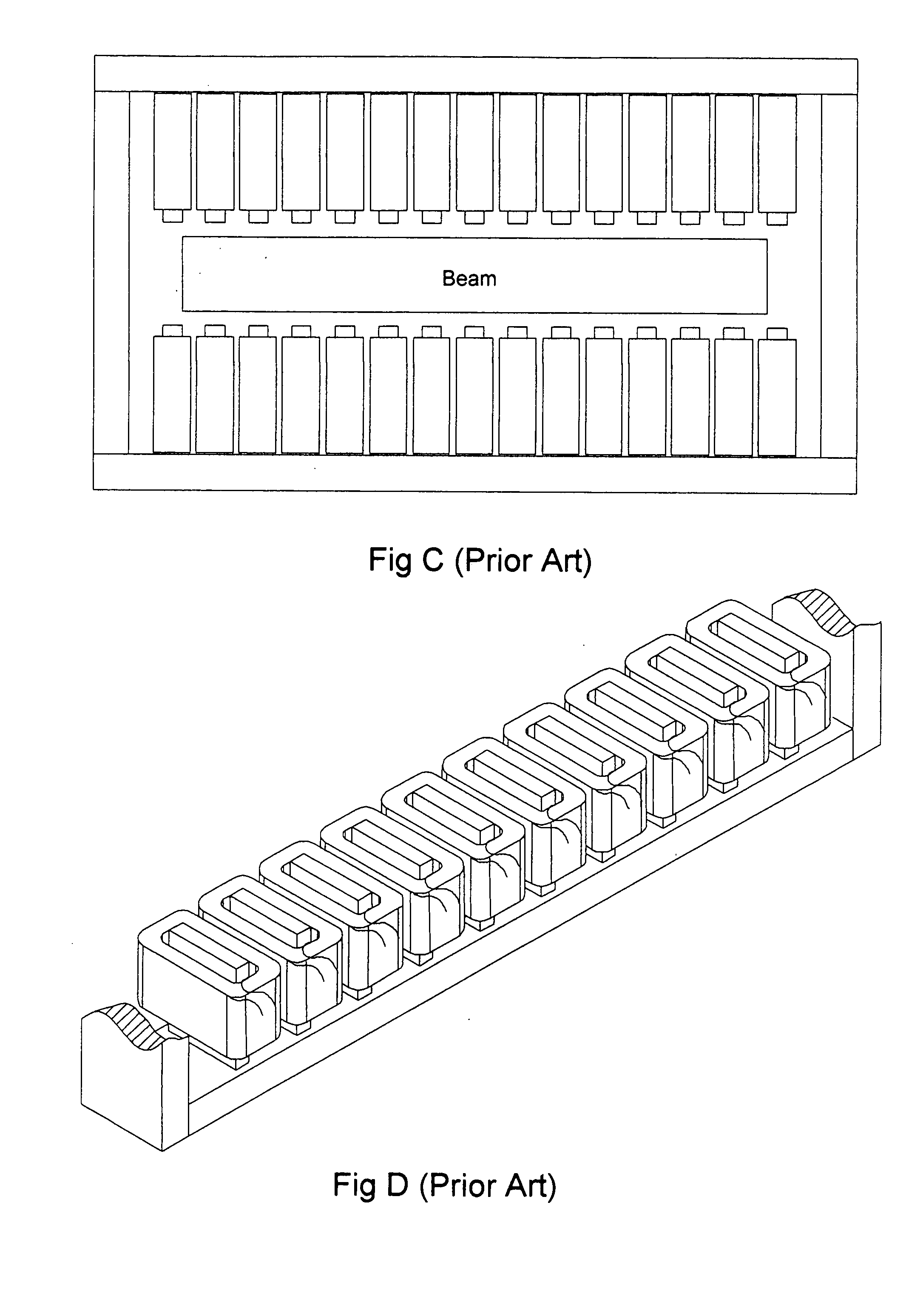

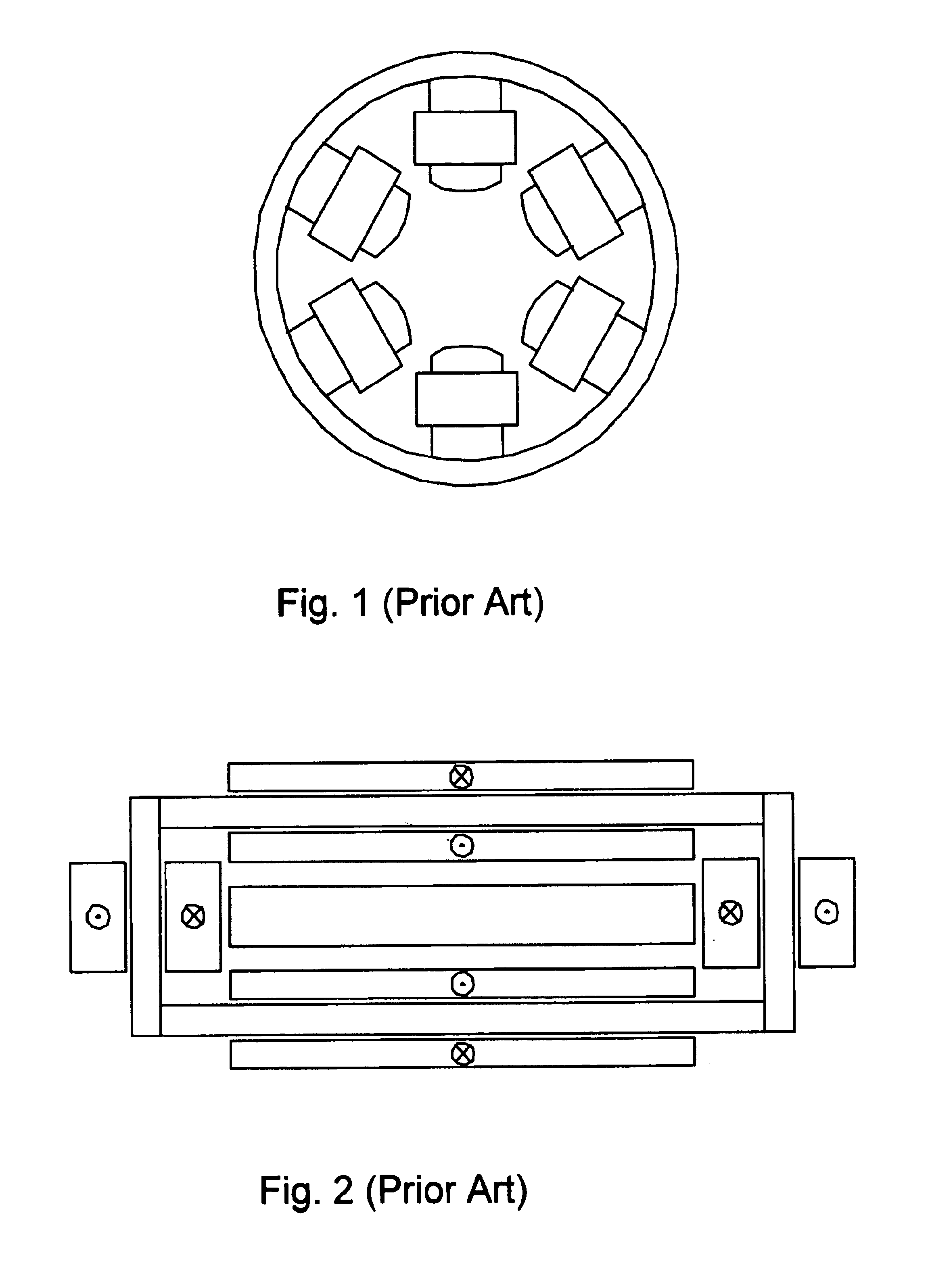

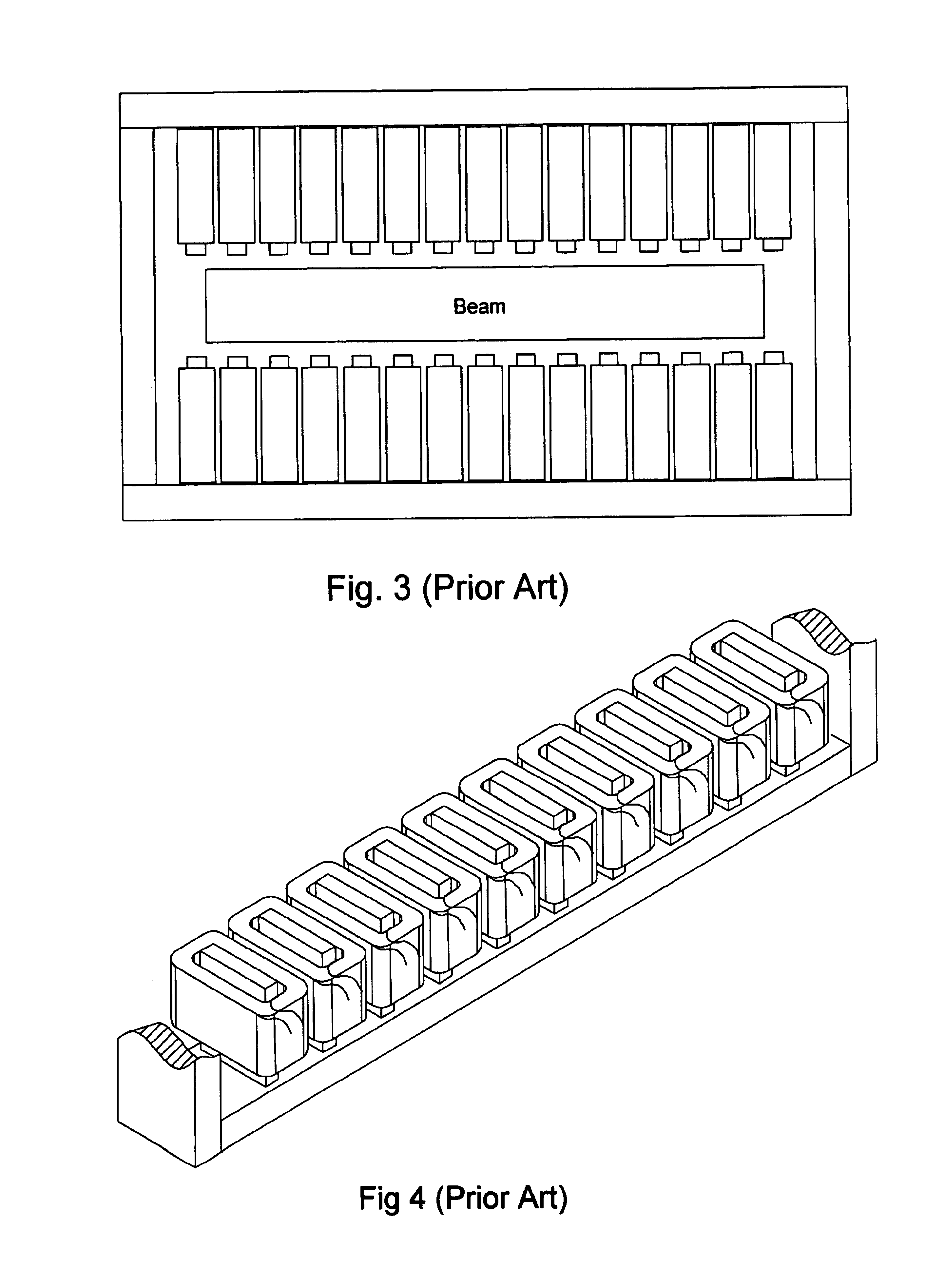

Electromagnetic regulator assembly for adjusting and controlling the current uniformity of continuous ion beams

An electromagnetic regulator assembly for the production of contiguous magnetic fields which are applied to a continuous ion beam is described. The assembly is structured for controlling the uniformity of traveling continuous ribbon-shaped beams; and allows for direct adjustment of the magnetic field gradient of the magnetic field as the parameter for increasing the current uniformity.

Owner:WHITE NICHOLAS R

Focal prostate cancer conformal radiofrequency ablation electrode

InactiveCN101006939AEffective treatmentSafe and effective treatmentElectrotherapySurgical instruments for heatingShaped beamRf ablation

The invention discloses a conformal RF ablation electrode of focal prostate cancer, which is composed of conductor and sleeve, wherein the conductor moves in the sleeve pipe, which mates mutually and strictly; the conductor is hollow pipe with multiple fine-hollow core needles on one end; the sub-needles constitutes fan shaped beam with memory ability, which are recessed into sleeve; the handle is loaded on the rear end of conductor and sleeve.

Owner:SHANGHAI JIAO TONG UNIV

Apparatus and method for testing defects

InactiveUS7037735B2Improve efficiencySemiconductor/solid-state device testing/measurementElectric discharge tubesShaped beamLight beam

Owner:HITACHI HIGH-TECH CORP

Bumper system with "W" beam and energy absorber

A bumper system includes a “W” or “C” shaped beam having a back wall and mounts along the back wall adapted for attaching the beam to rails of a vehicle frame. An energy absorber engages a face of the beam and has rearwardly-extending energy-absorbing sections that extend through the face into contact with the back wall at each of the mounts for improved energy absorption. The horizontal walls of the beam have front and rear sections that align, but also have a U-shaped intermediate section that weakens the walls for promoting a more uniform and predictable collapse. A one-piece brace includes diagonal straps that hold free ends of top and bottom walls together to prevent premature spreading apart upon impact. The energy absorber includes energy-absorbing sections that extend past the straps to detentingly engage the intermediate sections of the beam.

Owner:NETSHAPE INT LLC

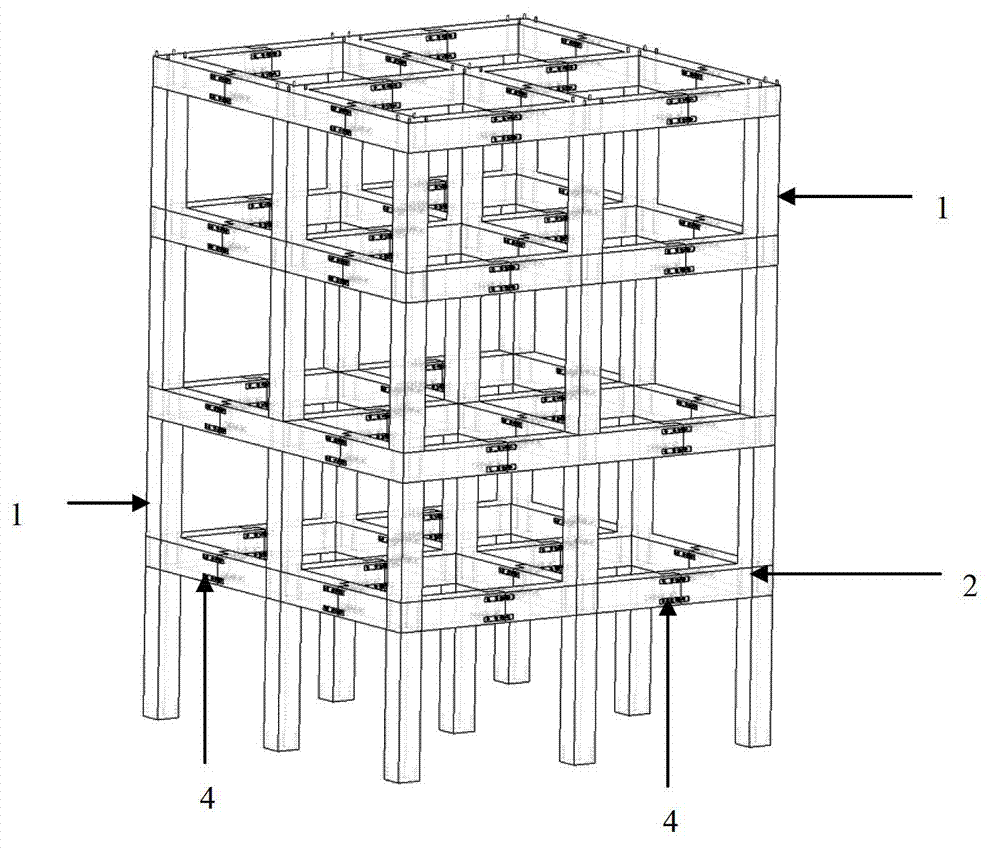

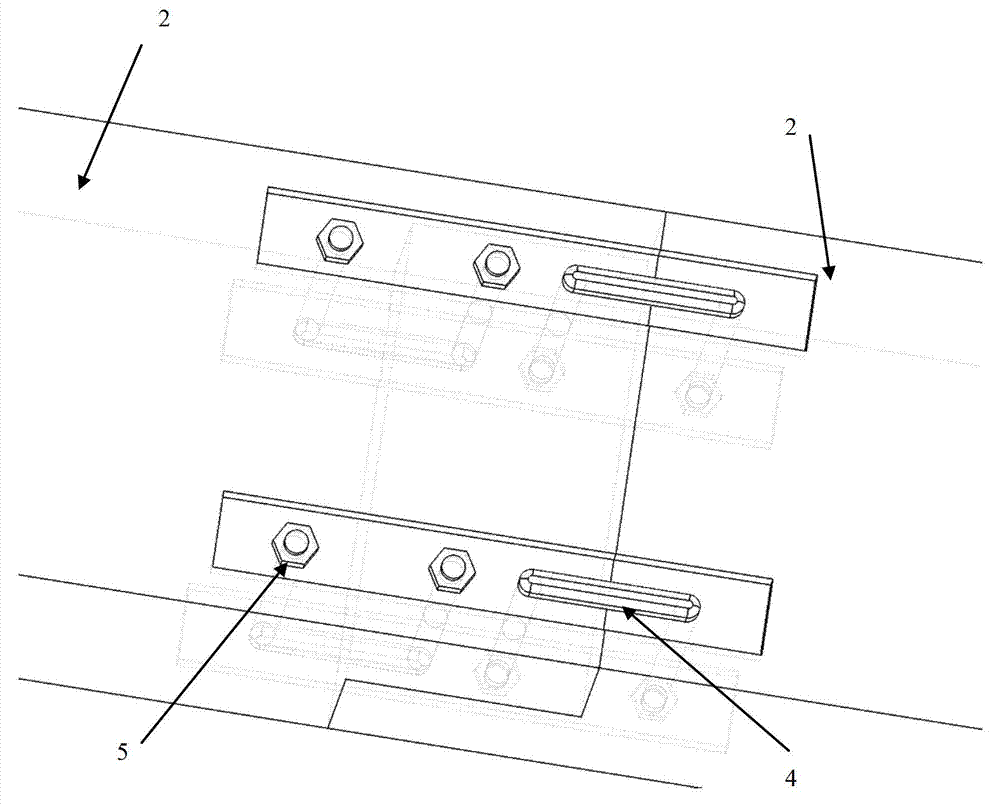

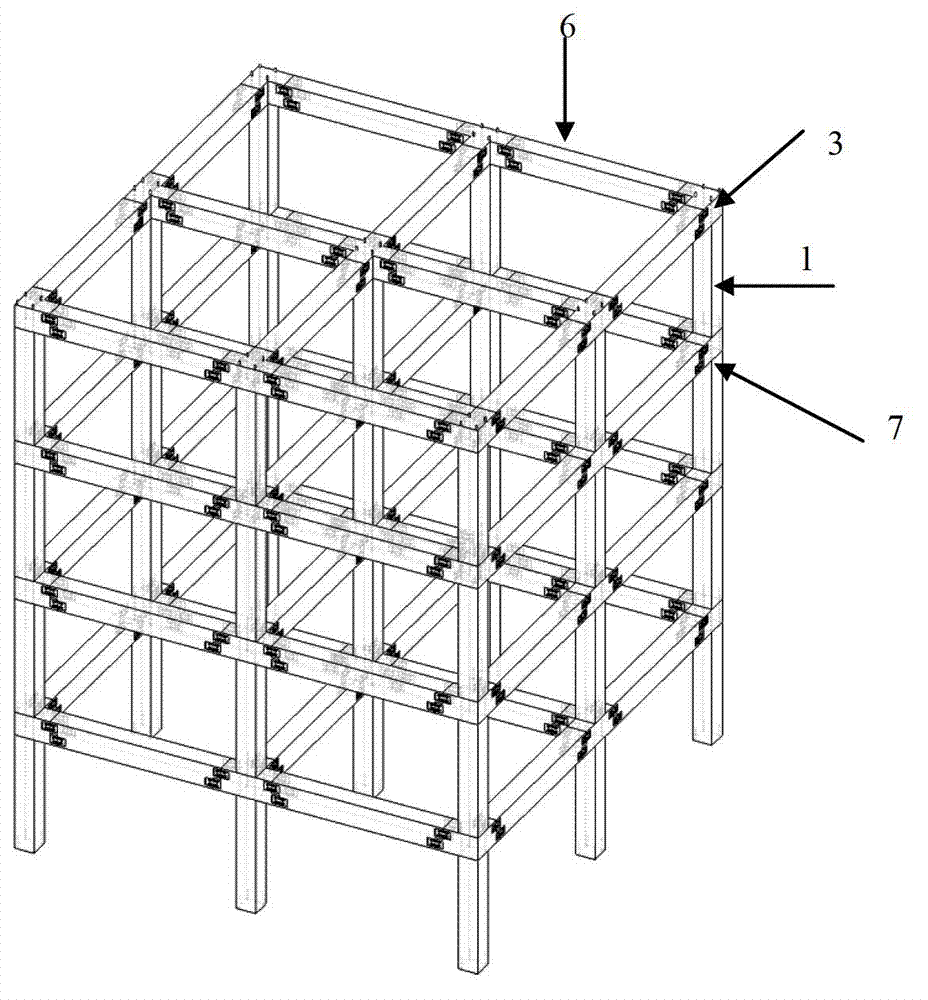

Prefabricated reinforced concrete frame structure system

The invention discloses a prefabricated reinforced concrete frame structure system. The system comprises a prefabricated column and beam structures, wherein the beam structures comprise a beam middle connecting prefabricated structure and a beam end connecting prefabricated structure; the beam middle connecting prefabricated structure comprises a prefabricated special-shaped beam, a U-shaped bolt and a nut; the beam end connecting prefabricated structure comprises a node splicing device, a nut, a prefabricated beam, a dissipation connecting plate and an embedded lateral bolt; reinforcing steel bars are reserved at the upper end of the prefabricated column, a vertical hole path is reserved at the lower end of the prefabricated column, and the prefabricated column, a foundation and the prefabricated special-shaped beam or the node splicing device are connected into a whole. Standardized production of the prefabricated column, the prefabricated special-shaped beam, the node splicing device and the prefabricated beam can be performed in factories, wet construction in construction fields is avoided, and the house building speed is accelerated. Forms of all prefabricated parts are relatively simple, transportation is facilitated, and the dissipation capacity of the prefabricated structure is improved due to use of the dissipation connecting plate.

Owner:CHINA RAILWAY CONSTR GROUP +1

Electromagnetic regulator assembly for adjusting and controlling the current uniformity of continuous ion beams

ActiveUS7078713B2Stability-of-path spectrometersBeam/ray focussing/reflecting arrangementsMagnetic field gradientBand shape

An electromagnetic regulator assembly for the production of contiguous magnetic fields which are applied to a continuous ion beam is described. The assembly is structured for controlling the uniformity of traveling continuous ribbon-shaped beams; and allows for direct adjustment of the magnetic field gradient of the magnetic field as the parameter for increasing the current uniformity.

Owner:WHITE NICHOLAS R

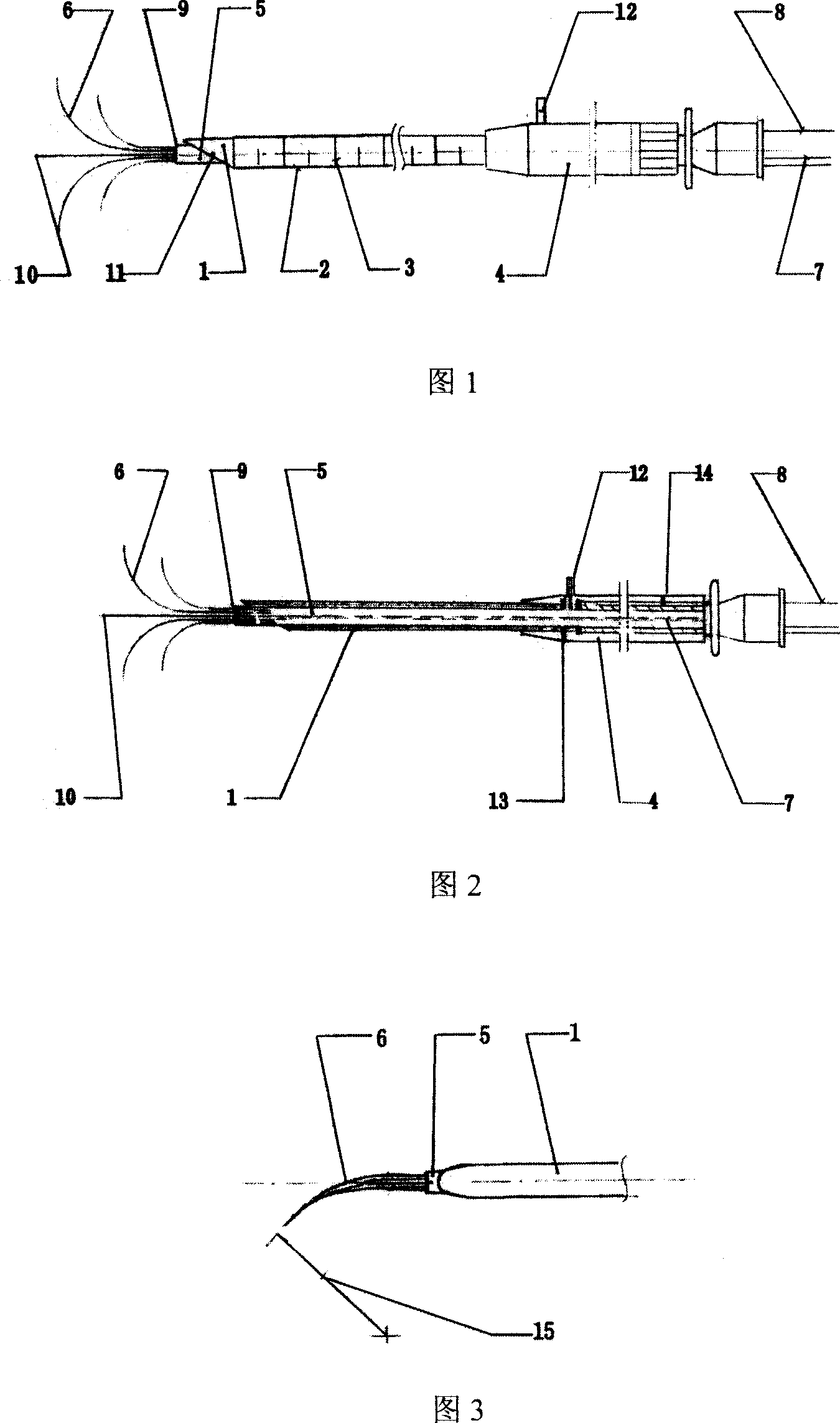

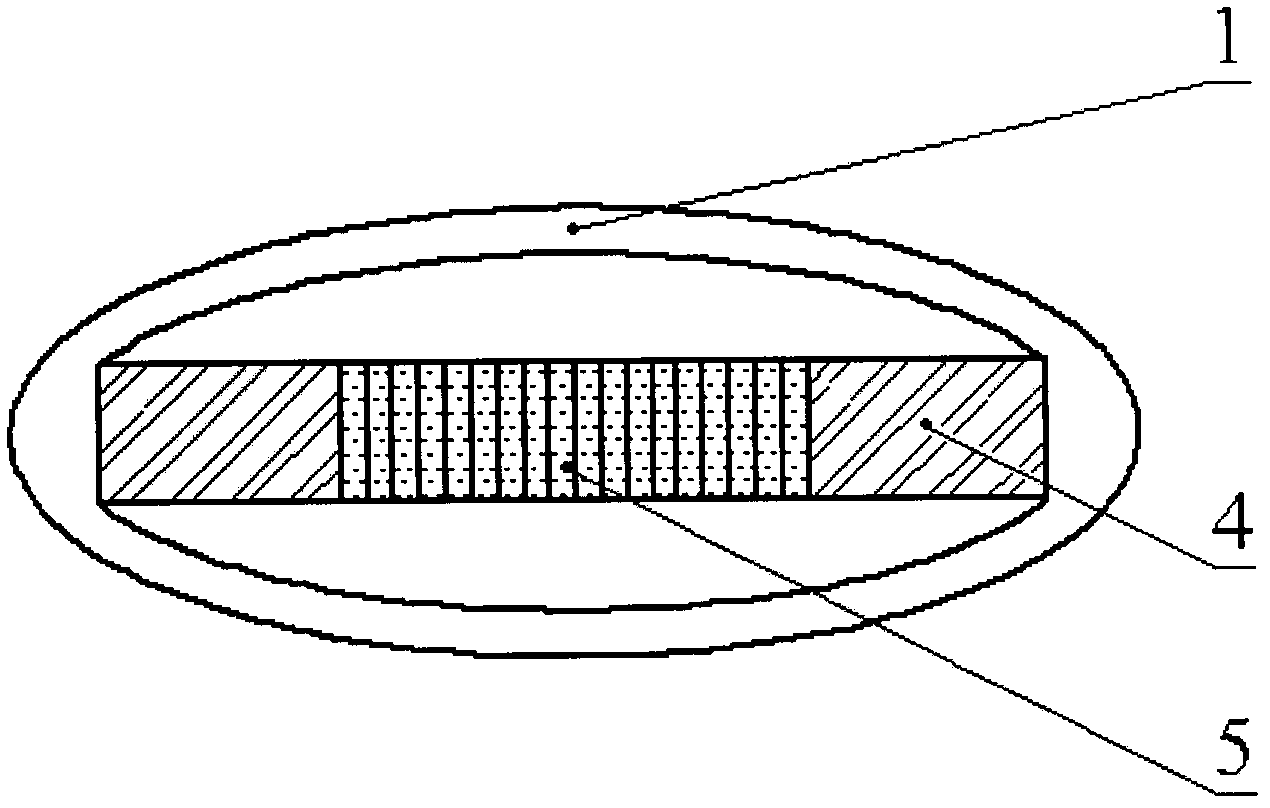

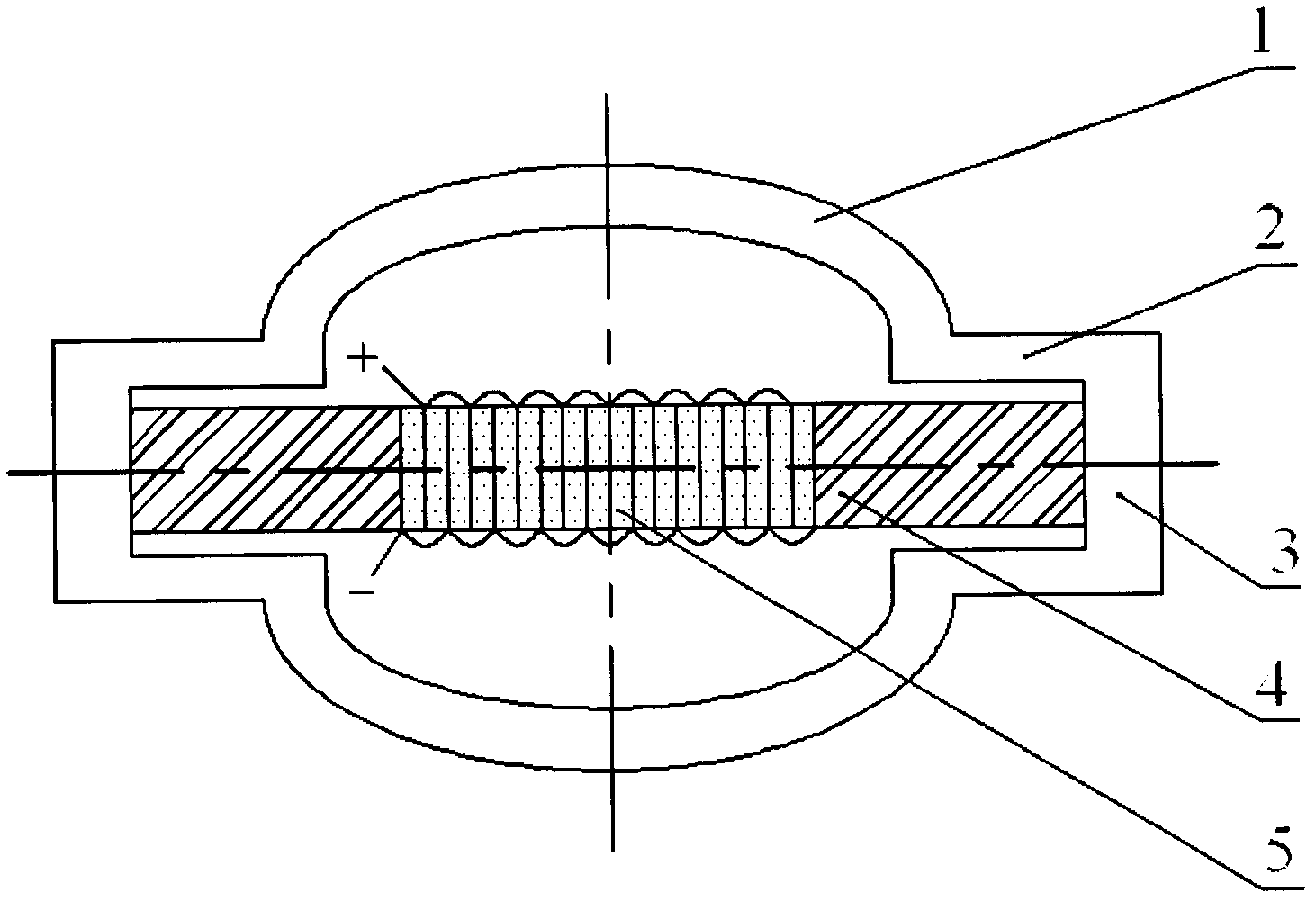

Ultra-wideband underwater acoustic transducer

InactiveCN101964185AAchieving ultra-wideband transmissionIncrease the dimension along the major axisSound producing devicesUltra-widebandShaped beam

The invention provides an ultra-wideband underwater acoustic transducer, which comprises an arc beam, a U-shaped beam, a transition block and a driving element, wherein the arc beam is a cylindrical shell, the section of which is elliptical arc; the U-shaped beam is a U-shaped curved translation body; the arc beam and the U-shaped beam form a flextensional shell, and two end faces of the flextensional shell are closed by cover plates; and the driving element and the transition block form a vibrator assembly, and the vibrator assembly is arranged in the flextensional shell and rigidly connected with the inner wall of the U-shaped beam. The ultra-wideband underwater acoustic transducer has the characteristics of low frequency, high power, compact structure, small size and light weight, and can be applied in the fields of underwater acoustic detection, antagonism, communication, measurement, marine resource exploration and the like.

Owner:HARBIN ENG UNIV

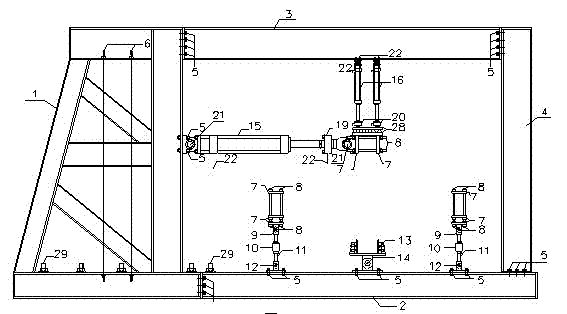

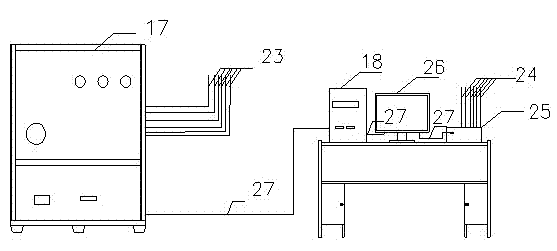

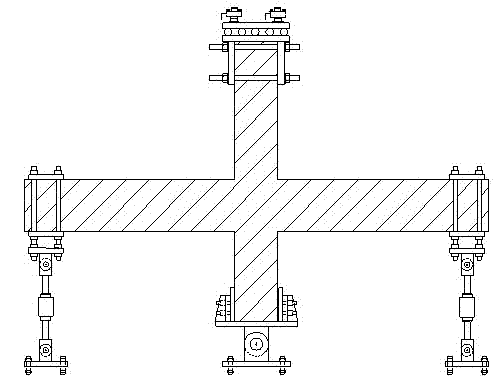

Portable performance test device for automatic control of combined action of bidirectional load of beam-column joint and determination method

InactiveCN103076192AFlexible stroke adjustmentPrevent movementStructural/machines measurementShaped beamAutomatic control

The invention discloses a portable performance test device for automatic control of a combined action of a bidirectional load of a beam-column joint and a determination method. The test device comprises an outer frame fixing device, a test piece fixing device, a test piece loading device and a data acquisition system, wherein the outer frame fixing device comprises a trapezoidal horizontal counter-force frame, an I-shaped girder bearing platform, an I-shaped beam, an I-shaped upright and a prestress wire rope; the test piece loading device comprises a horizontal actuator, two vertical actuators, a hydraulic oil source, a horizontal load sensor and a vertical load sensor; the test piece fixing device comprises two steel splints, an anchor bolt rod, a column fixing base and a column bottom hinge support; and the data acquisition system comprises a controller, a multi-channel strain collector and a computer. The device, provided by the invention, has the advantages of simple structure, convenience for assembly and disassembly, and few required materials, and is suitable for testing hysteretic behavior of a node test piece at scientific research and construction sites.

Owner:HOHAI UNIV +1

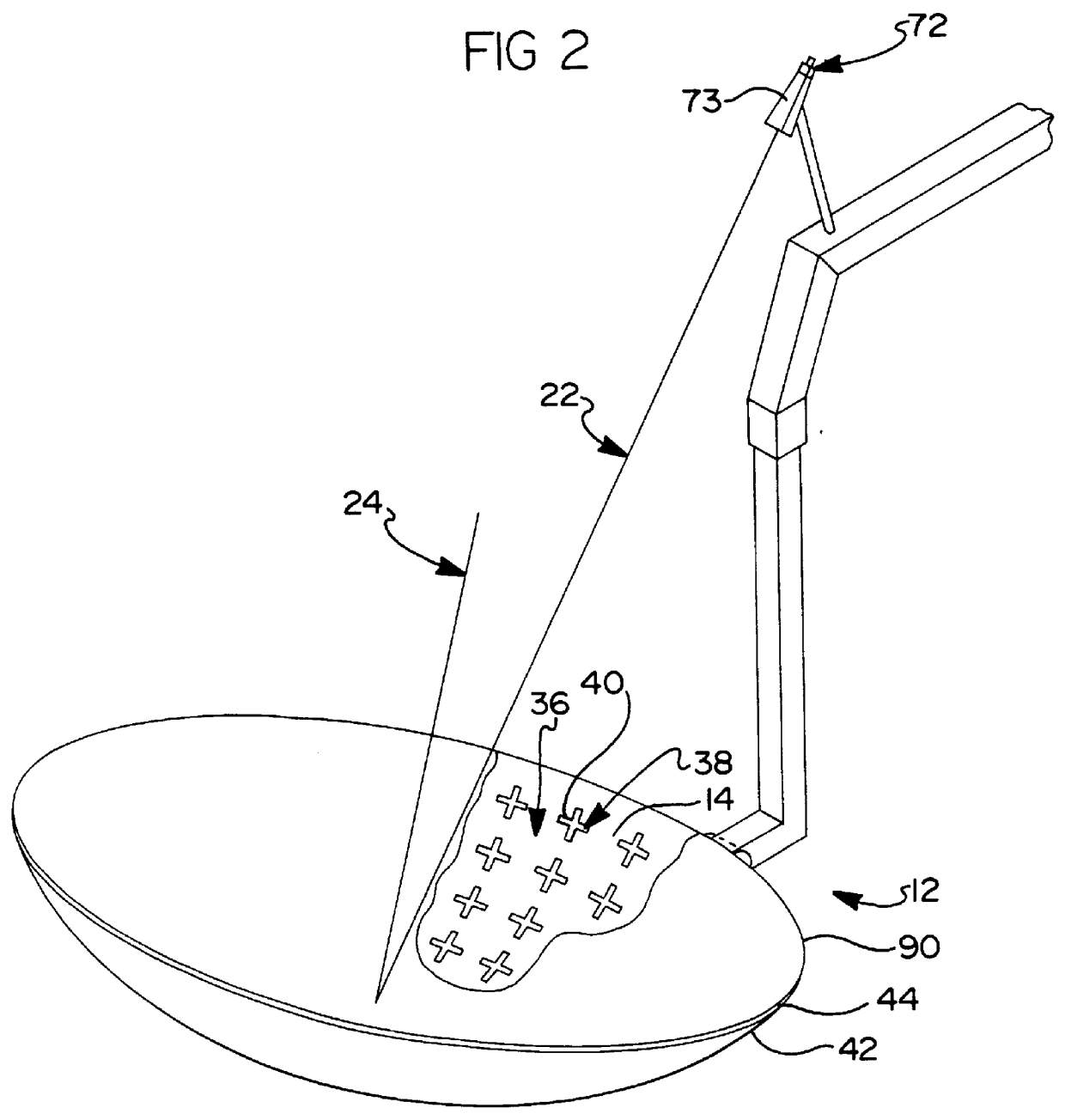

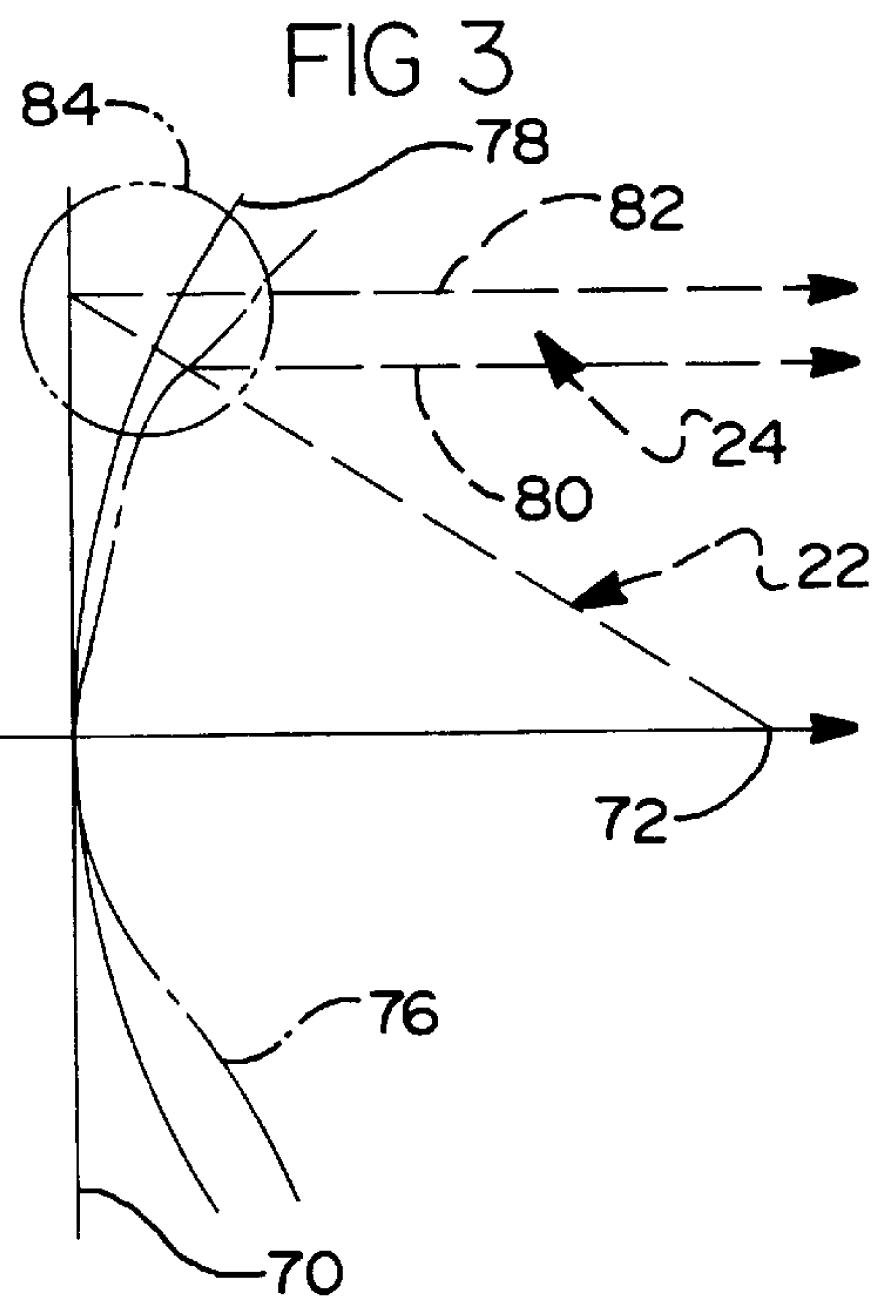

Method for improving pattern bandwidth of shaped beam reflectarrays

InactiveUS6031506AImproving pattern bandwidthReduce beamshape variationSimultaneous aerial operationsRadiating elements structural formsShaped beamGeosynchronous satellite

A method for shaping reflected radio frequency signals includes geometrically shaping a reflector surface of an antenna to focus the beam, and reflectively shaping the reflector surface with phasing elements that emulate geometric shaping to configure the beam to a predetermined shape. In the preferred embodiment, the antenna comprises a geosynchronous satellite antenna conveying signals from a wave guide horn to or from a predetermined geographic area on earth. The use of a parabolic-approaching surface of reflectarray phasing elements for shaping the beam substantially improves the beam pattern bandwidth over the performance of previously known shaped beam reflectarrays.

Owner:HUGHES ELECTRONICS

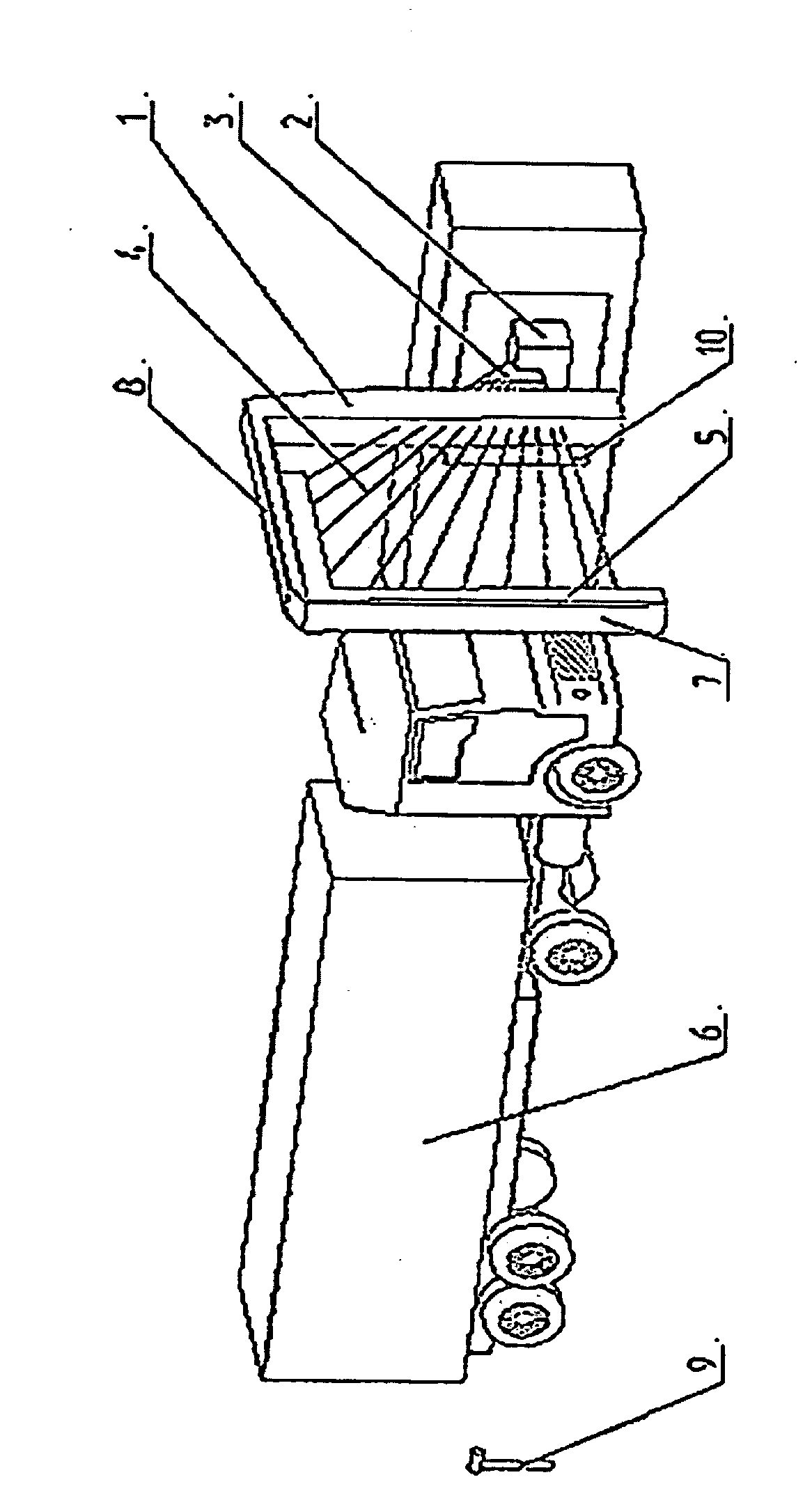

Cargo and vehicle inspection system

An apparatus for X-ray scanning of vehicles includes a pulsed X-ray source (2) generating X-rays. A collimator forms (3) a fan -shaped beam from the X-rays. A detector (5) detects the fan- shaped beam after it passes through a vehicle (6). A speed sensor (9) measures a speed of the vehicle passing through the apparatus and providing an electrical output corresponding to the speed. An image formation module converts an output of the detector into an image of the vehicle, based on the measured speed of the vehicle. The width of the fan- shaped beam is substantially similar to the width of the detector. The X-rays comprise primarily photons with energy between 2.5 and 9 MeV. A filter (19) is adjacent to the collimator for filtering out low energy X-ray photons. A vehicle presence sensor (10) can be used, whose output is used to turn the X-ray source on and off. An alignment platform (13, 17) can be used for aligning the fan -shaped beam with the detector. A frequency of the pulses is adjusted based on the speed of the vehicle. The X-ray source is turned off if the speed of the vehicle is below a predetermined threshold.

Owner:NAUCHNO PROIZVODSTVENNOE CHASTNOE UNITARNOE PREDPRIYATIE ADANI

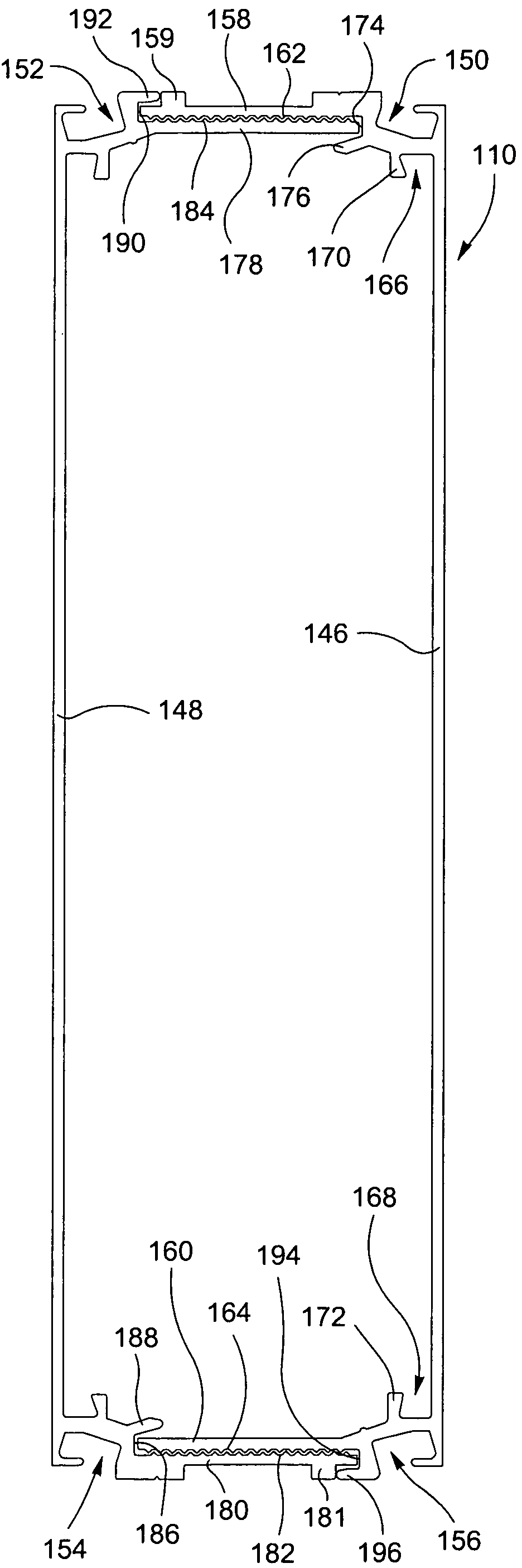

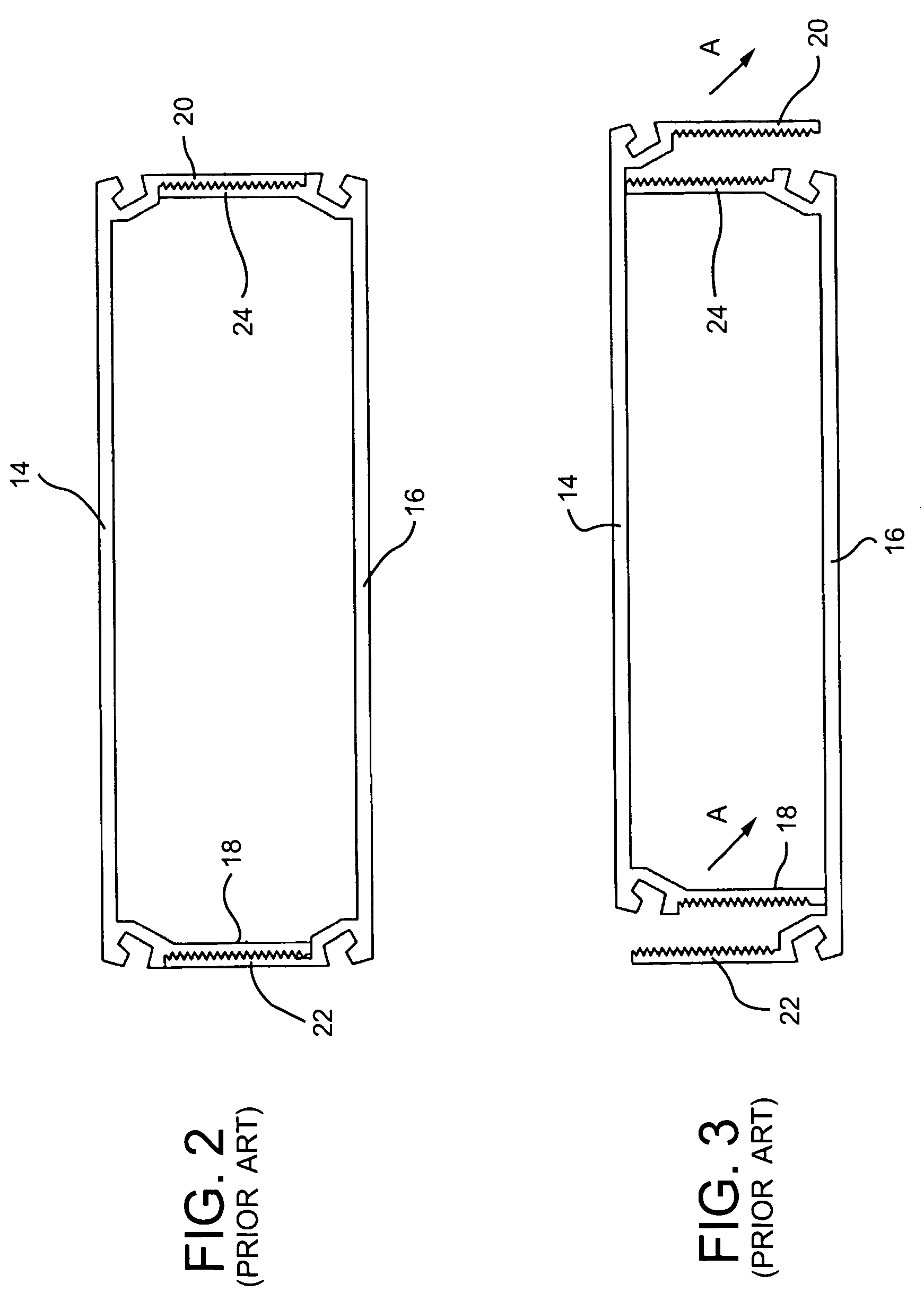

Lap and lock beam

Two U-shaped beam half sections are attached together by having nesting ledges / receptacles on the flanges of the half sections. While the flanges of each beam half overlap against each other, the nesting ledges / receptacles hold the beam half flanges to fixed locations. Fasteners such as screws can be driven through the sides of the beam half flanges to fixedly lock the beam half sections to one another.

Owner:THE HONG KONG UNIV OF SCI & TECH +2

Method for design and manufacture of a reticle using variable shaped beam lithography

A method is disclosed for using non-overlapping variable shaped beam (VSB) shots in the design and manufacture of a reticle, where the union of the plurality of shots deviates from the desired pattern. Methods are described for fracturing or mask data preparation or proximity effect correction of a desired pattern to be formed on a reticle; for forming a pattern on a reticle using charged particle beam lithography; and for optical proximity correction (OPC) of a desired pattern. Dosages of the shots may be allowed to vary with respect to each other. The plurality of shots may be determined such that a pattern on the surface calculated from the plurality of shots is within a predetermined tolerance of the desired pattern. In some embodiments, an optimization technique may be used to minimize shot count.

Owner:D2S

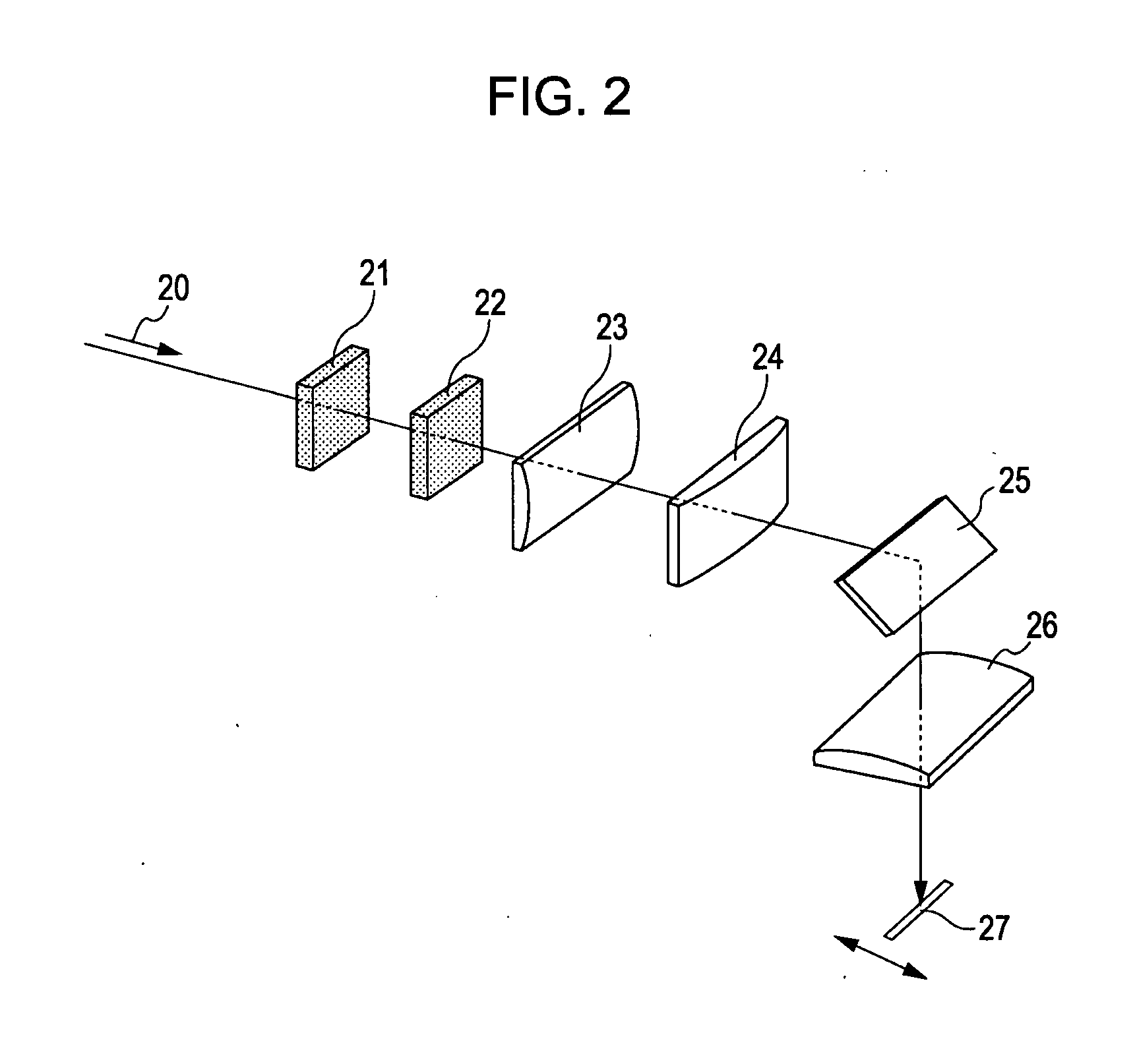

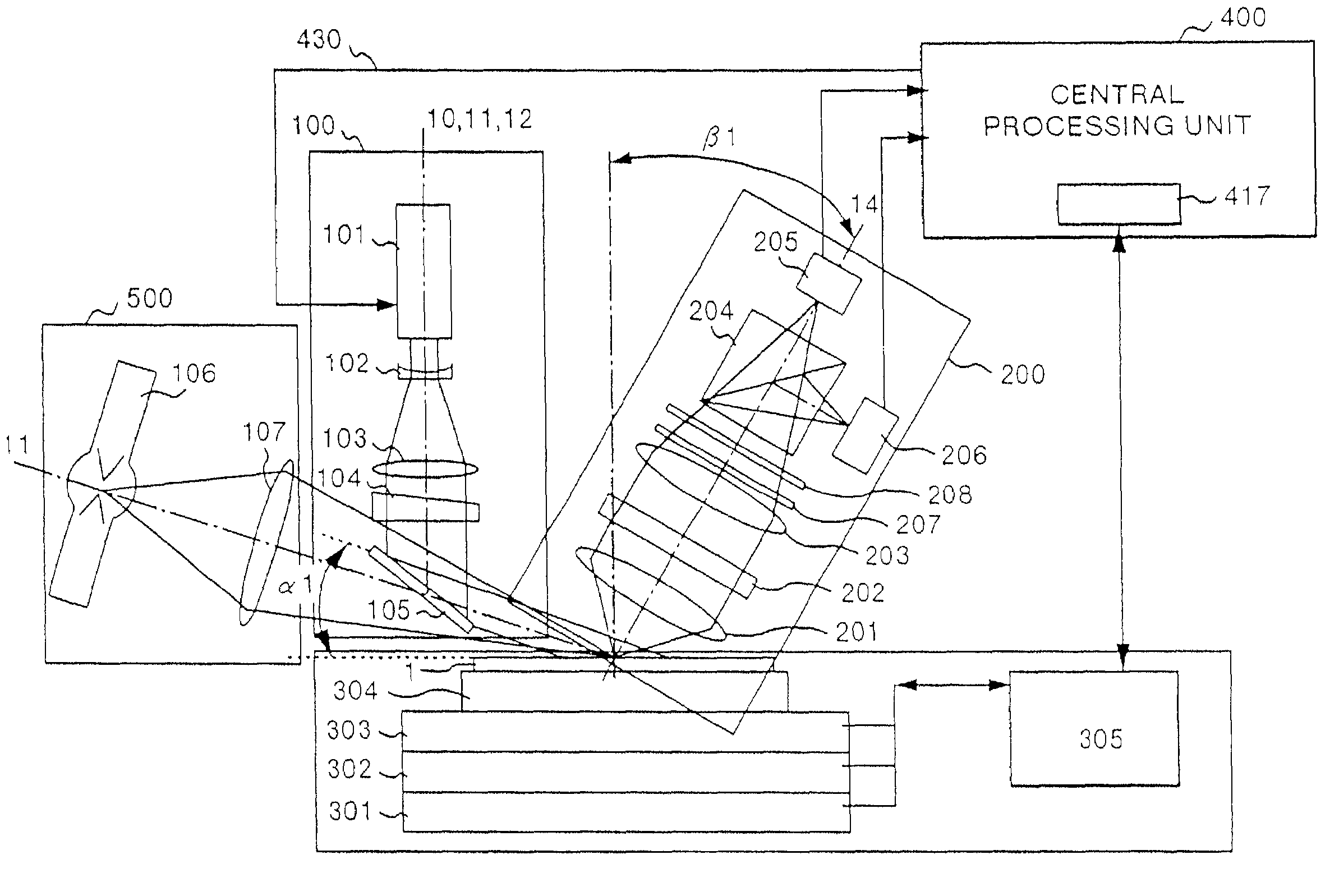

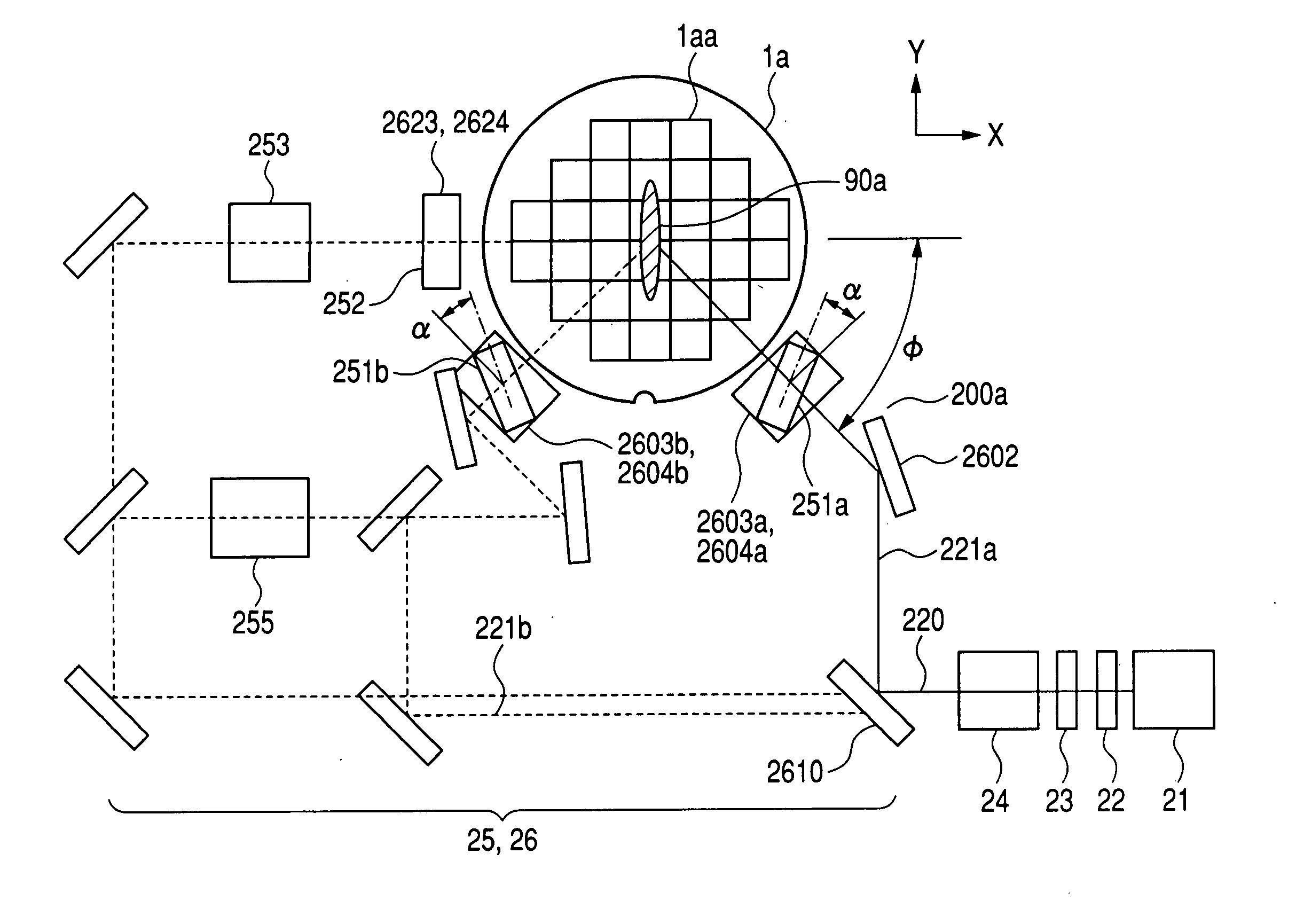

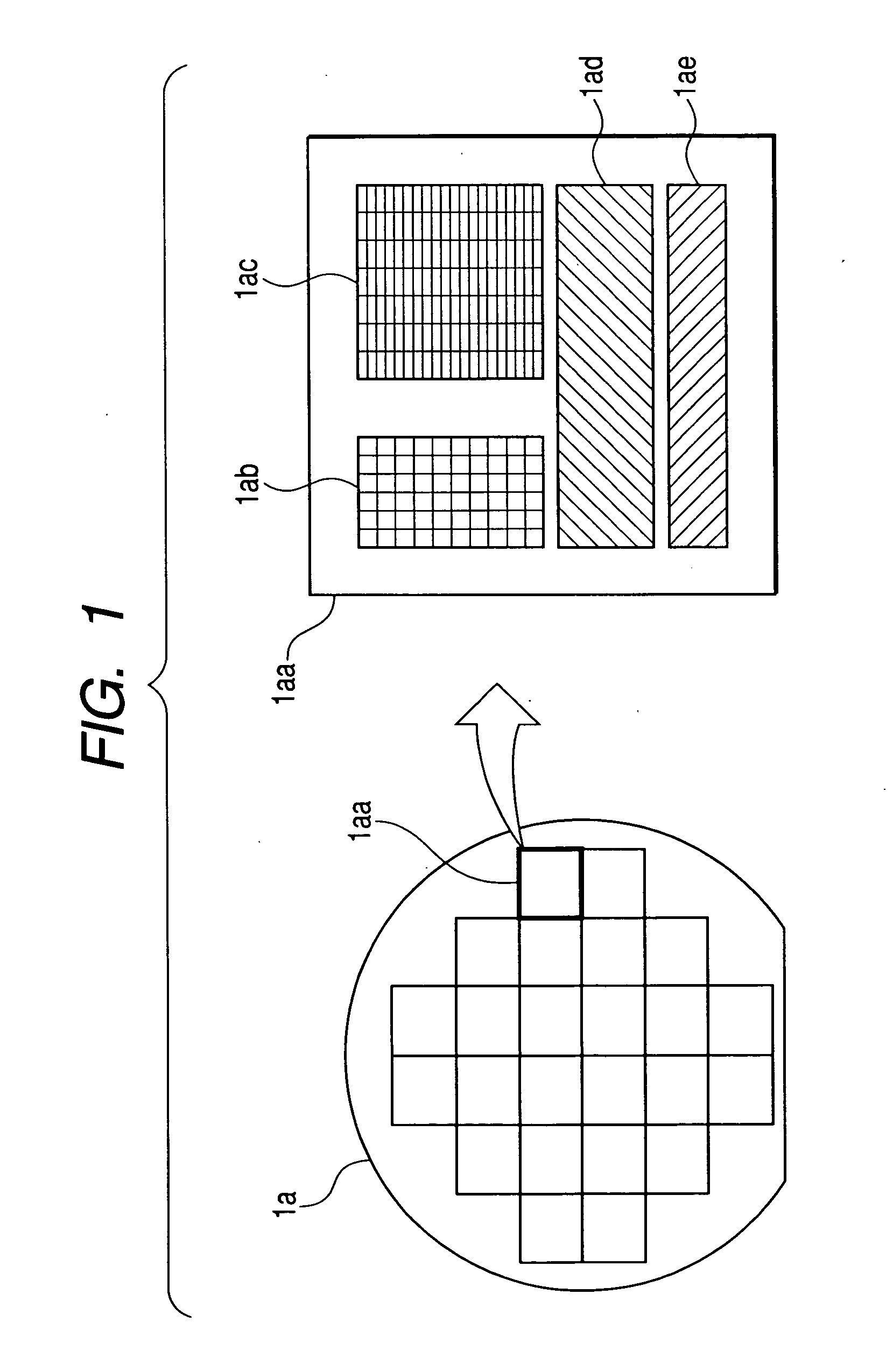

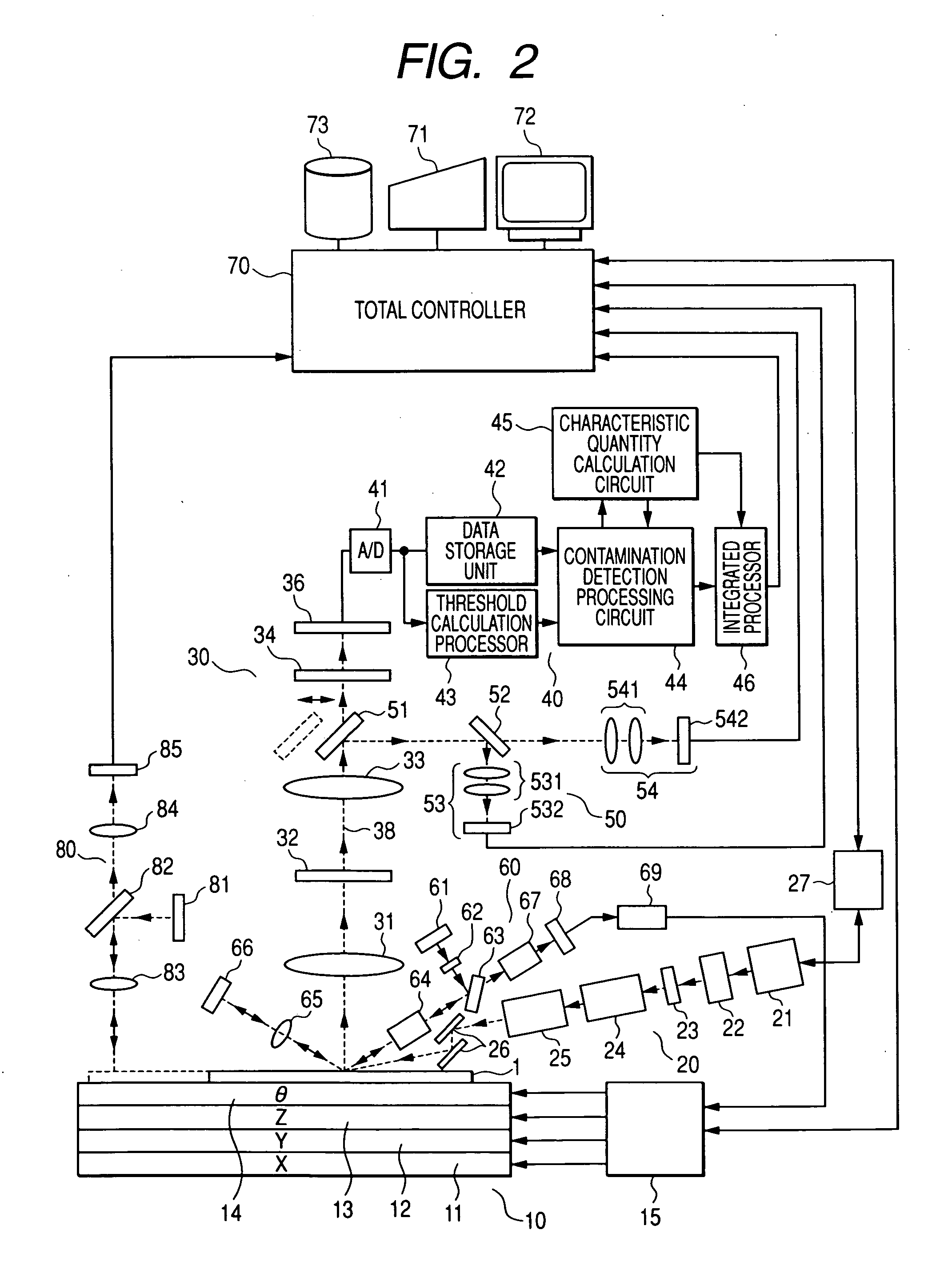

Apparatus and method for inspecting defects

InactiveUS20070177136A1Highly efficient manufacturing lineEfficient preparationSemiconductor/solid-state device testing/measurementOptically investigating flaws/contaminationShaped beamLight beam

A defect inspection apparatus includes an irradiation optical system 20, a detection optical system 30, and an image processor 40. In the irradiation optical system, a mirror 2603 is disposed to reflect downward a beam flux that has been guided to a first or second optical path, and a cylindrical lens 251 and an inclined mirror 2604 are disposed to focus the beam flux that has been directed downward by the mirror, at an inclination angle from a required oblique direction extending horizontally, onto a substrate 1 to be inspected, as a slit-shaped beam 90.

Owner:HITACHI HIGH-TECH CORP

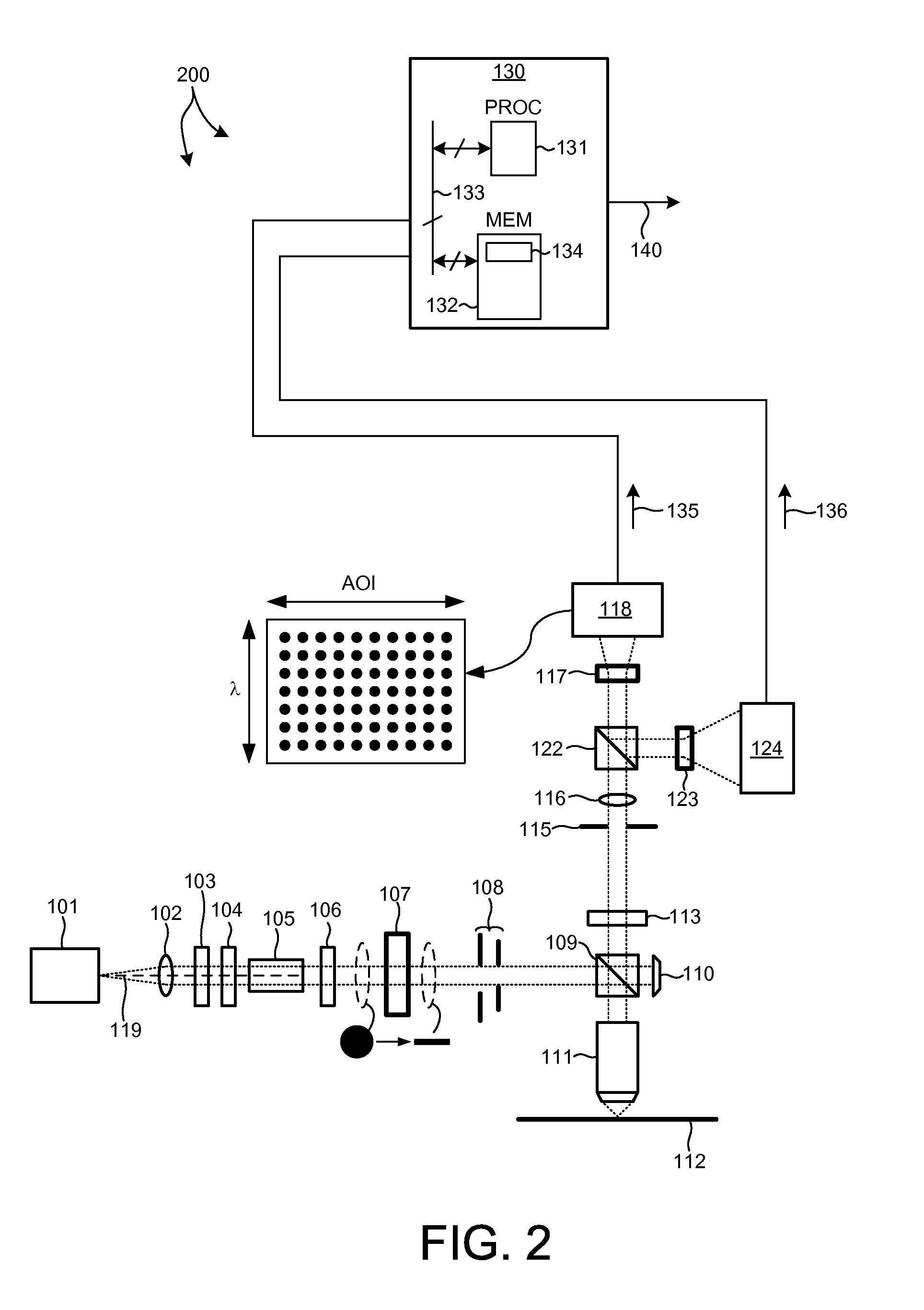

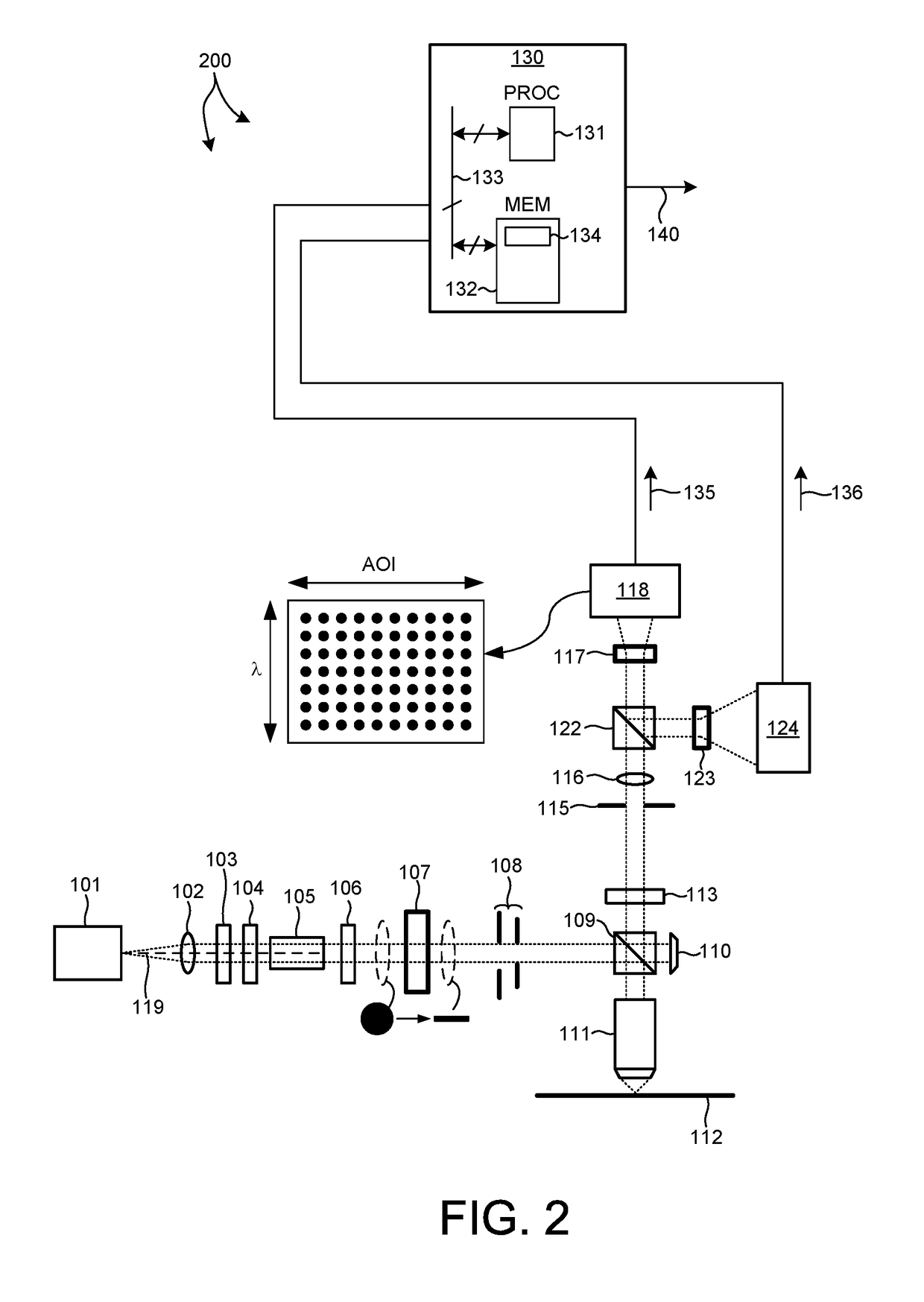

Spectroscopic Beam Profile Overlay Metrology

ActiveUS20170082932A1Improve accuracyImprove precisionSemiconductor/solid-state device testing/measurementPhotomechanical apparatusMetrologyShaped beam

A spectroscopic beam profile metrology system simultaneously detects measurement signals over a large wavelength range and a large range of angles of incidence (AOI). In one aspect, a multiple wavelength illumination beam is reshaped to a narrow line shaped beam of light that is projected onto an overlay metrology target such that the direction of the line shaped beam is aligned with the direction of extent of a grating structure of the overlay metrology target. Collected light is dispersed across a detector according to AOI in one direction and according to wavelength in another direction. The measured signal at each detector pixel is associated with a particular AOI and wavelength. The collected light includes first order diffracted light, zero order diffracted light, or a combination thereof. In some embodiments, first order diffracted light and zero order diffracted light are detected over separate areas of the detector.

Owner:KLA TENCOR TECH CORP

Method for Optical Proximity Correction of a Reticle to be Manufactured Using Variable Shaped Beam Lithography

ActiveUS20100055585A1Minimize shot countElectric discharge tubesRadiation applicationsCamera lensLithographic artist

A method for optical proximity correction (OPC) of a desired pattern for a substrate is disclosed in which a plurality of variable shaped beam (VSB) shots are determined which can form on a surface an OPC-corrected version of the desired substrate pattern. Shots within the plurality of VSB shots are allowed to overlap each other. Dosages of the shots may also be allowed to vary with respect to each other. The union of the plurality of shots may deviate from the OPC-corrected version of the desired pattern for the substrate. In some embodiments, optimization may be used to minimize shot count. In other embodiments, the plurality of shots may be optionally selected from one or more pre-computed VSB shots or groups of VSB shots, that is, glyphs. A method for creating glyphs is also disclosed, in which patterns that would result on a surface from one or a group of VSB shots are pre-calculated.

Owner:D2S

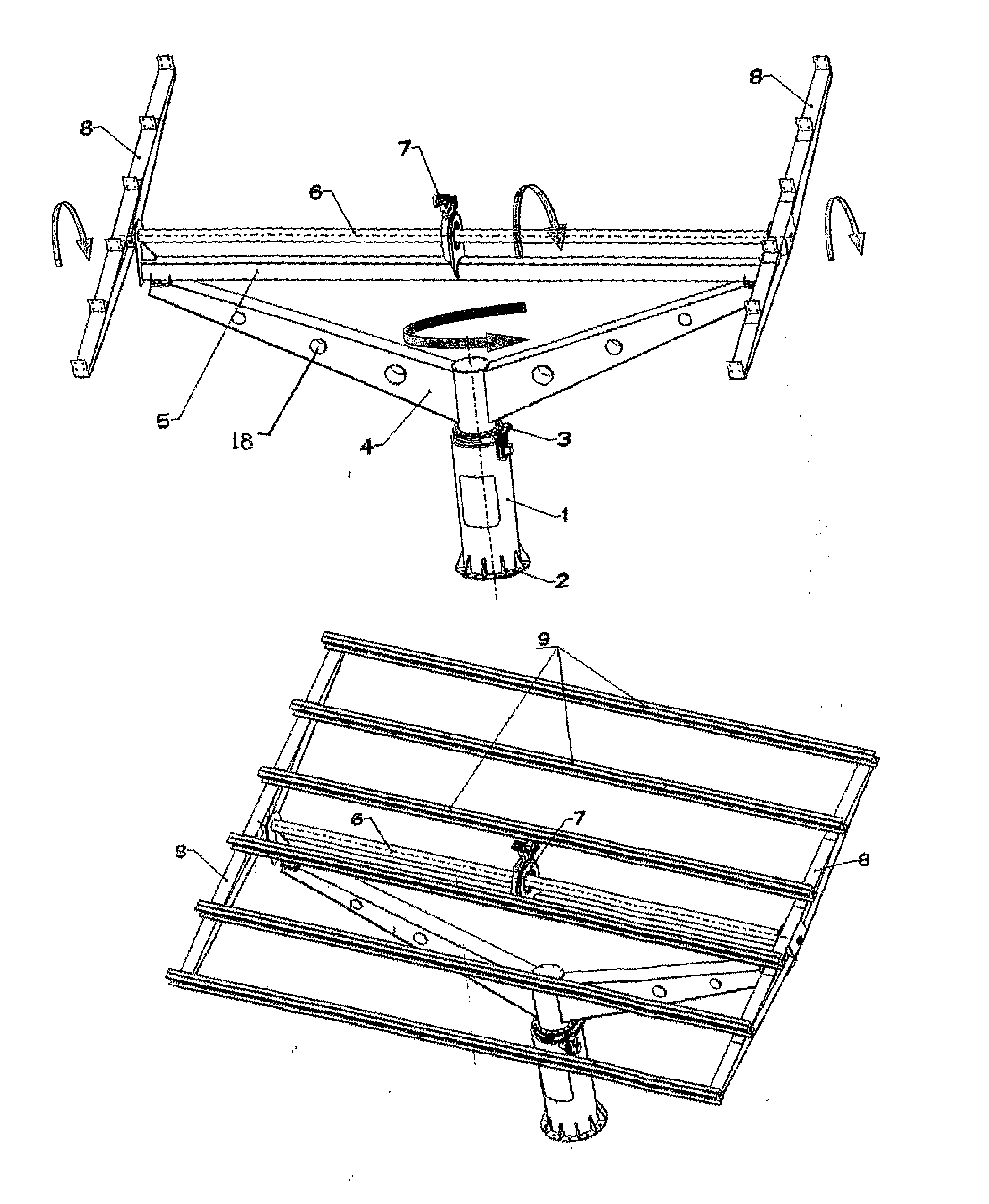

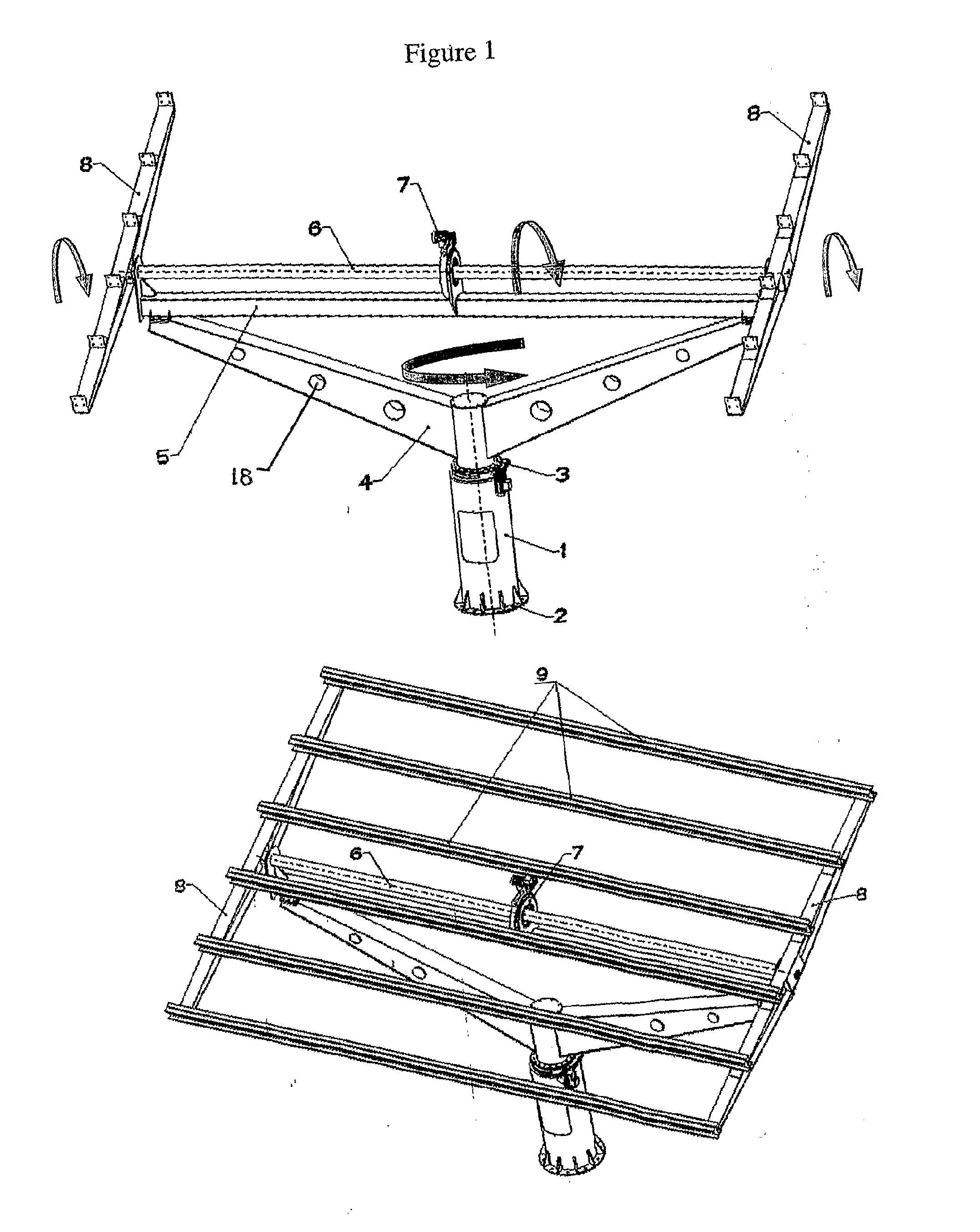

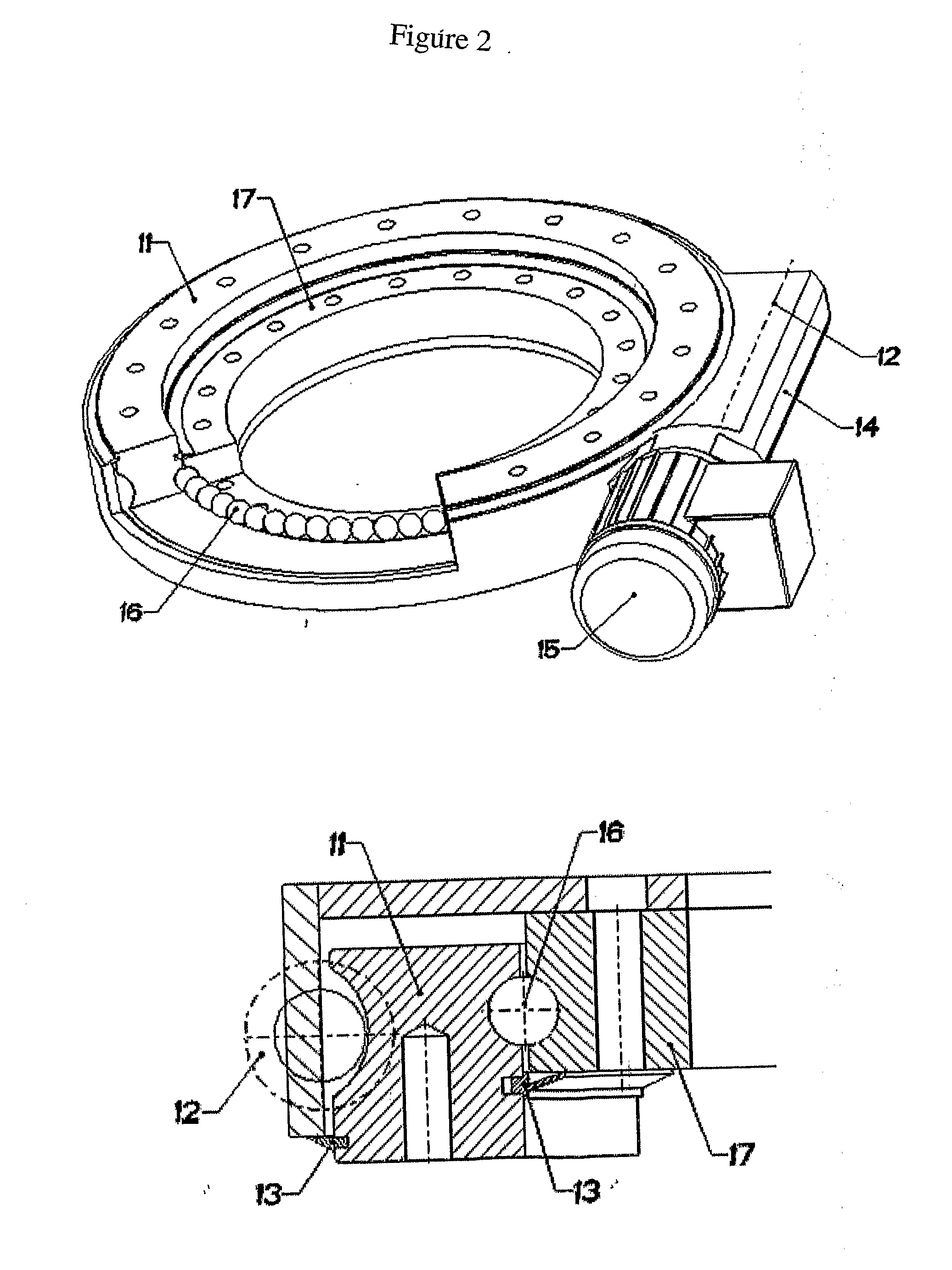

Photovoltaic panel support base rotating simultaneously around a horizontal and a vertical axis

InactiveUS20110126884A1Guaranteed smooth receptionPhotovoltaic supportsSolar heating energyBall bearingShaped beam

A Photovoltaic panel support base rotating simultaneously around two axes, i.e. around an horizontal axis (North-South direction) for the continuous correction of the swivel angle (β), and around a vertical axis (East-West direction) for the continuous correction of the hour angle (ω), the solar deviation (δ) and the azimuthal surface (γ). The assembly comprises the tower (1), the base (2) with round profile, used for the anchorage and the seat of the assembly, the first drive mechanism (3) with ball bearings (16) for the rotation of the upper part around a vertical axis, the cantilevers' support assembly (4) of V shape, the rod (5), the second mechanism (7) for the rotation of the photovoltaic panels plane around an horizontal axis, the rotation axis (6) of the photovoltaic panels plane, the beams (8) of changing thin walled profile H and the series of transverse thin walled beams (9) of U profile. The frames of the photovoltaic panels rest on the frame formed by the U-shaped beams. The strong wind which falls at the photovoltaic panel plane is received and transmitted to the inner part of the construction, from one hand by the beams assembly (8) of shape H and from the other by the V-shaped assembly of the cantilevers (4). The strong forces' flow to the increasing profiles of the two assemblies (8) and (4) significantly decreases their strength to the inner part of the construction and as a result the two rotating drive mechanisms (3) and (7) substantially receive minimum dynamic stressing having the form of contact voltages (Hertz) created to their ball bearings (16). The electric motors of the two rotation mechanisms are driven by means of satellite control in order for the combination of β, ω, δ and γ to provide the instantly desired result cos θ=1 or Θ=0, i.e. the incident solar radiation to always be vertical with regard to the panels plane.

Owner:DRITSAS VASILEIOS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com