Patents

Literature

82 results about "Mask data preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

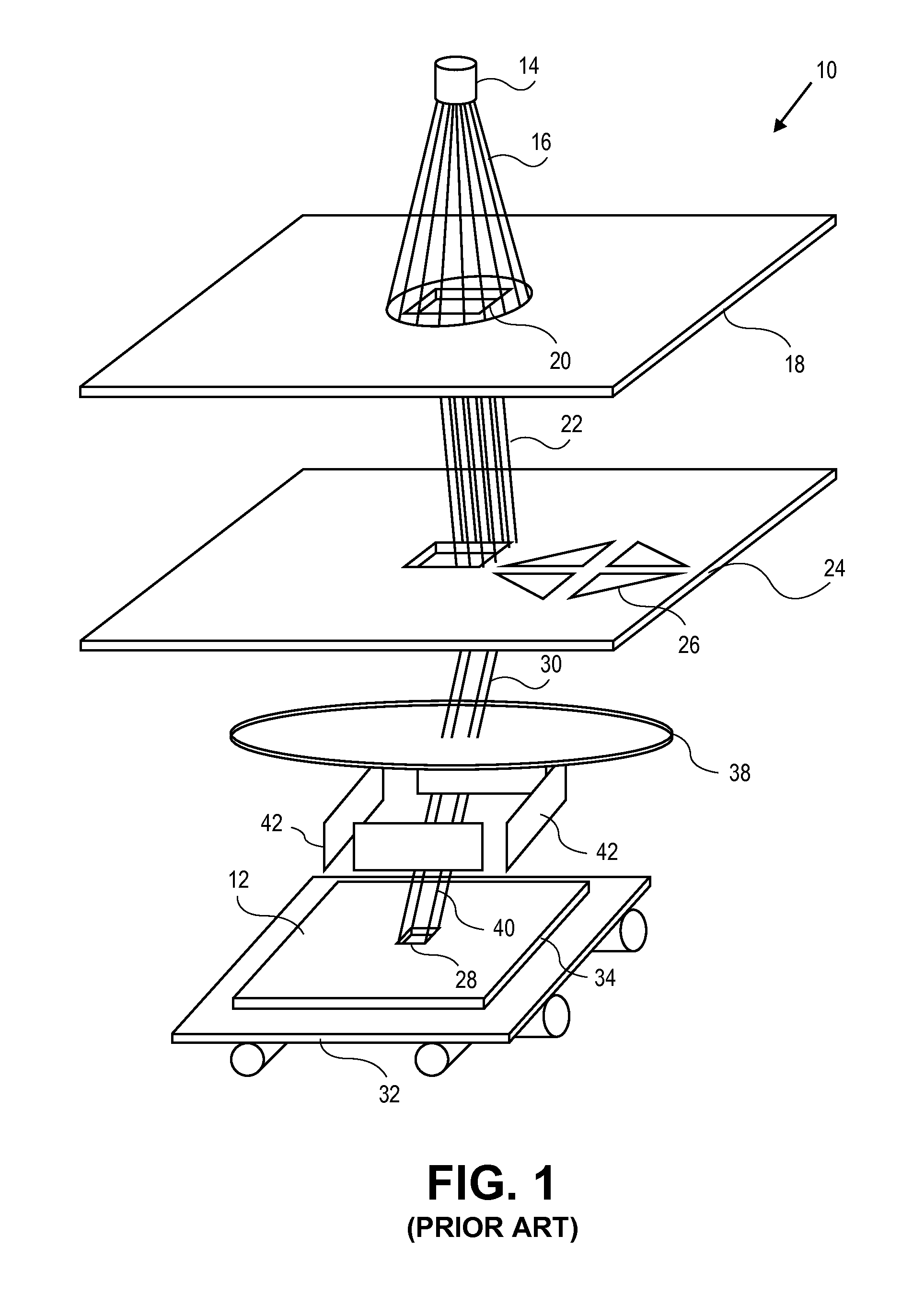

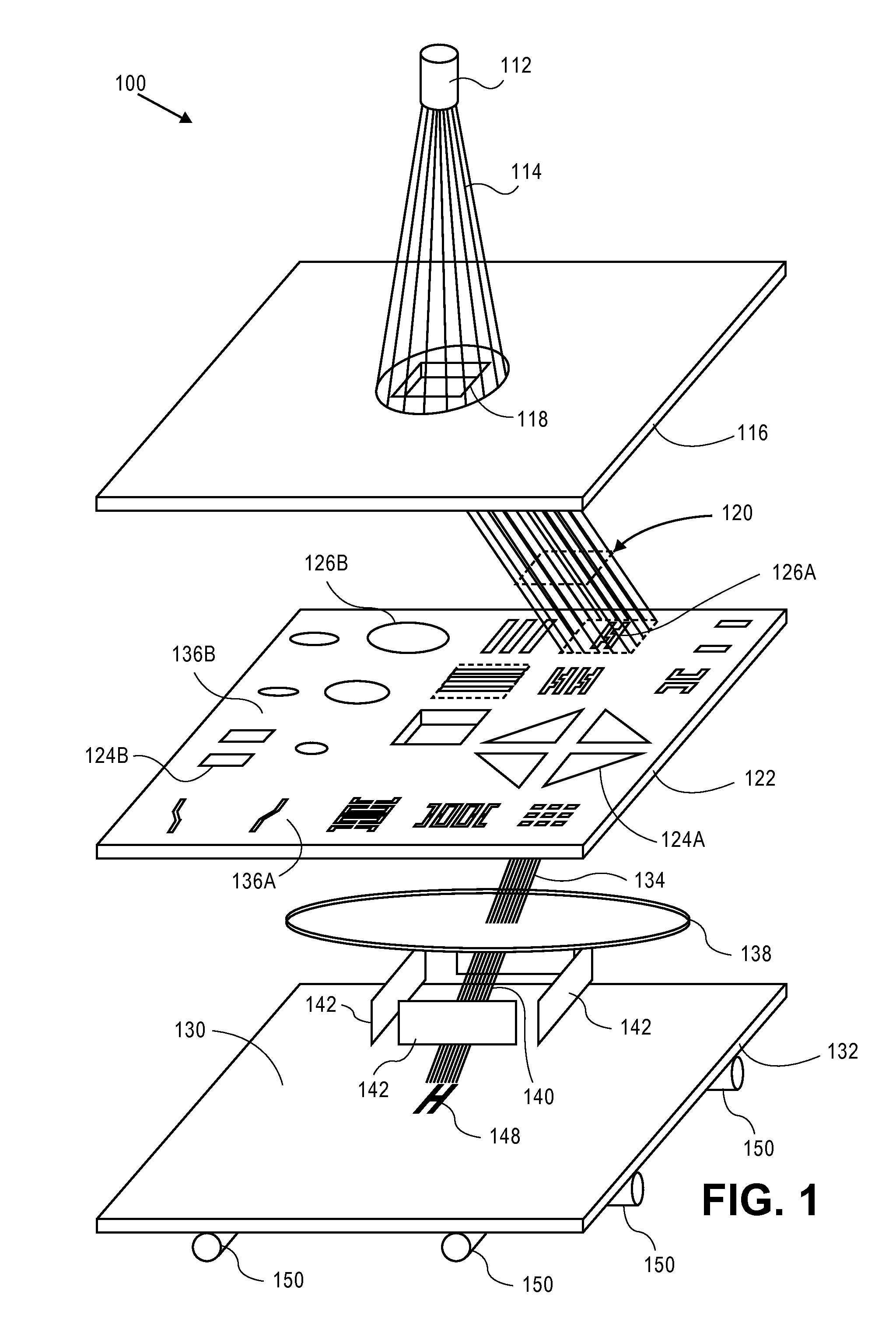

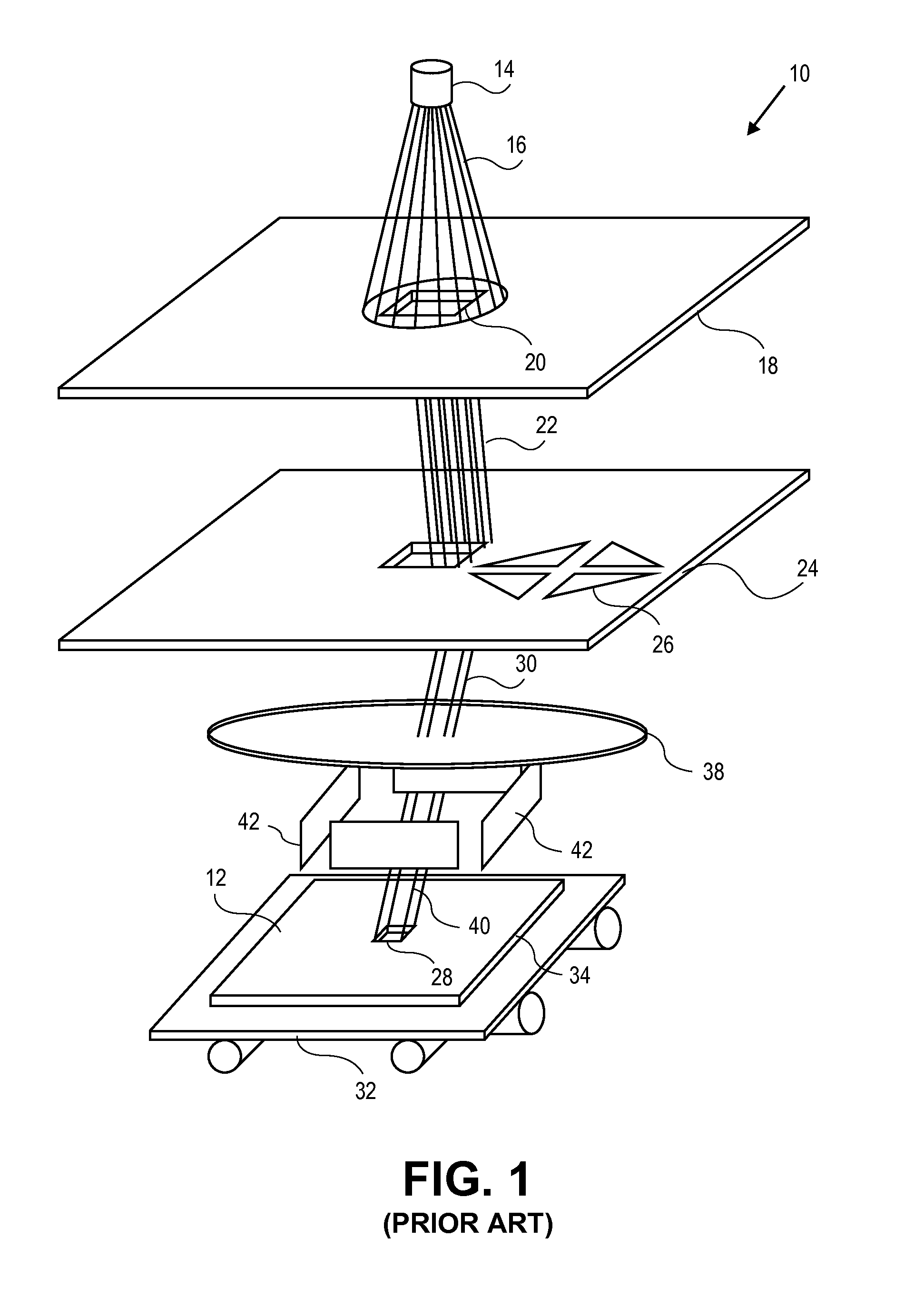

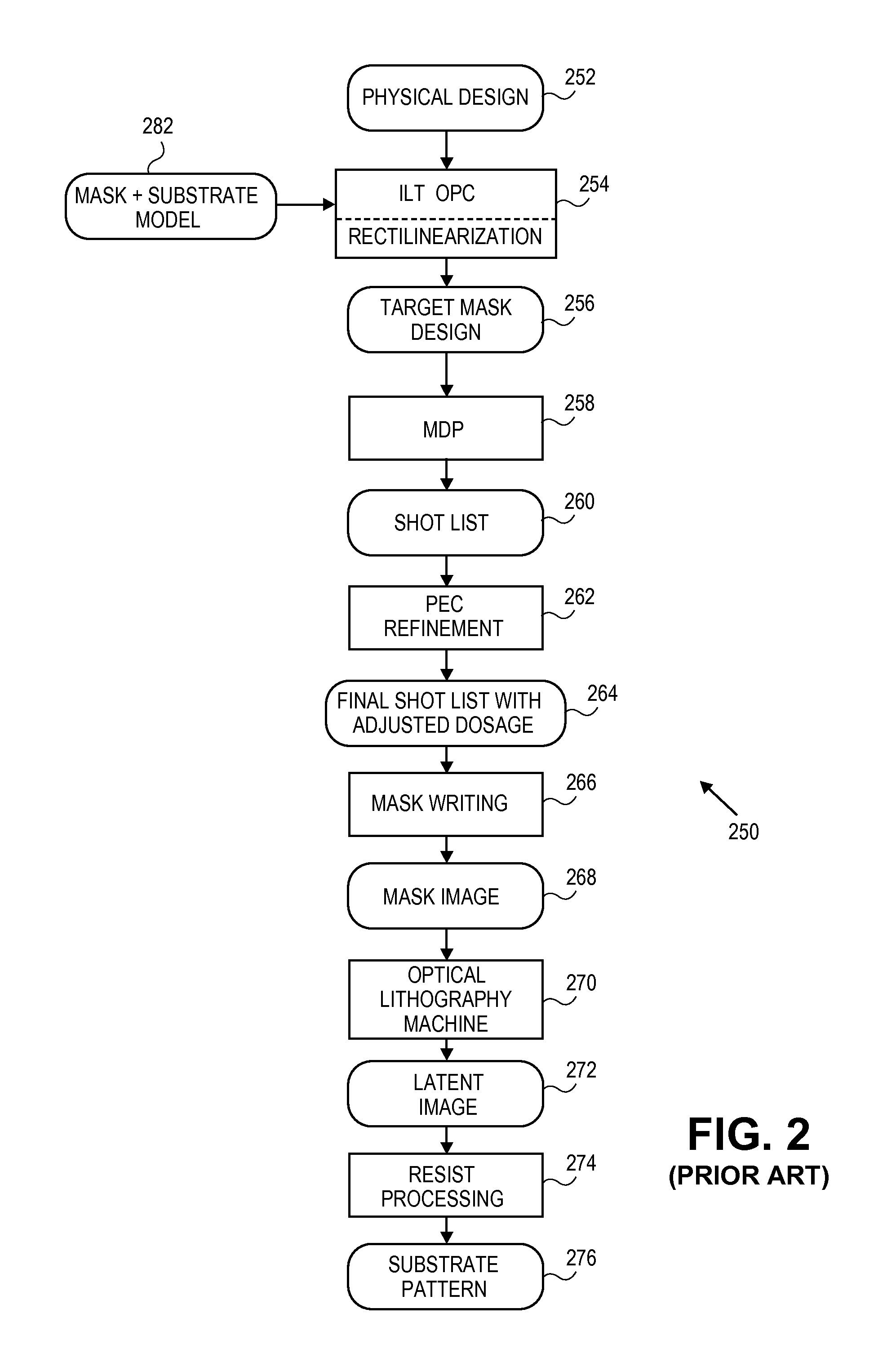

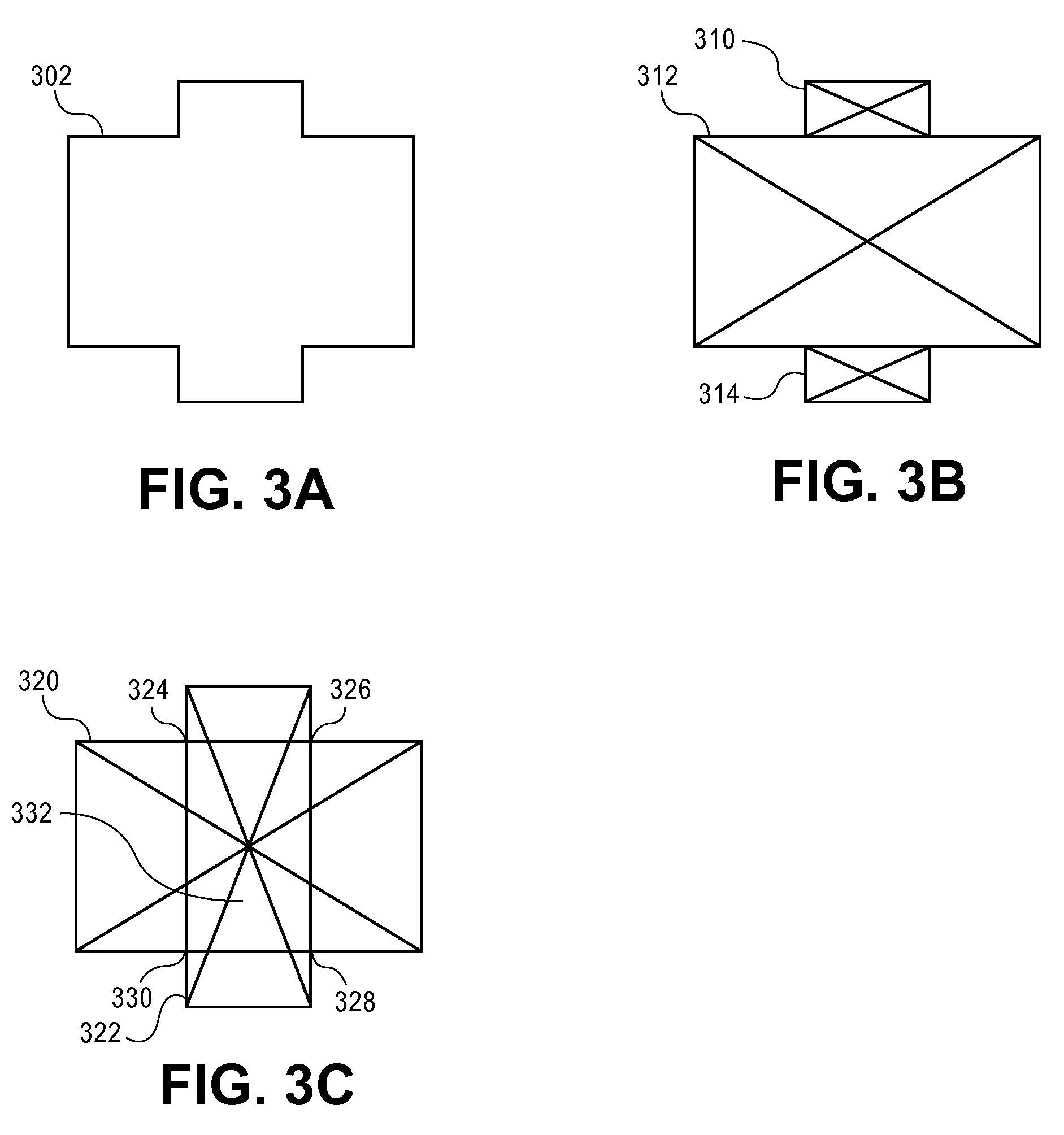

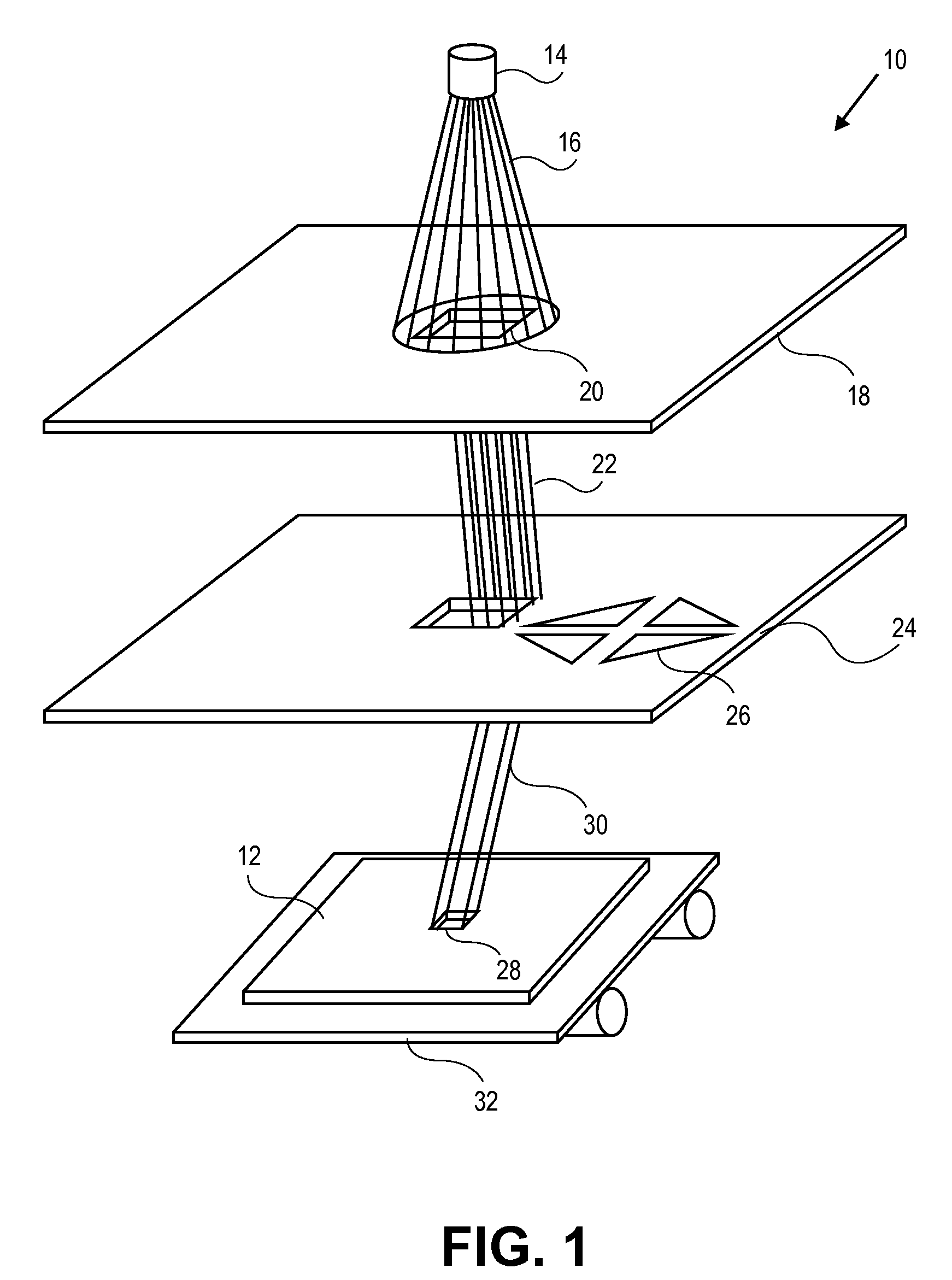

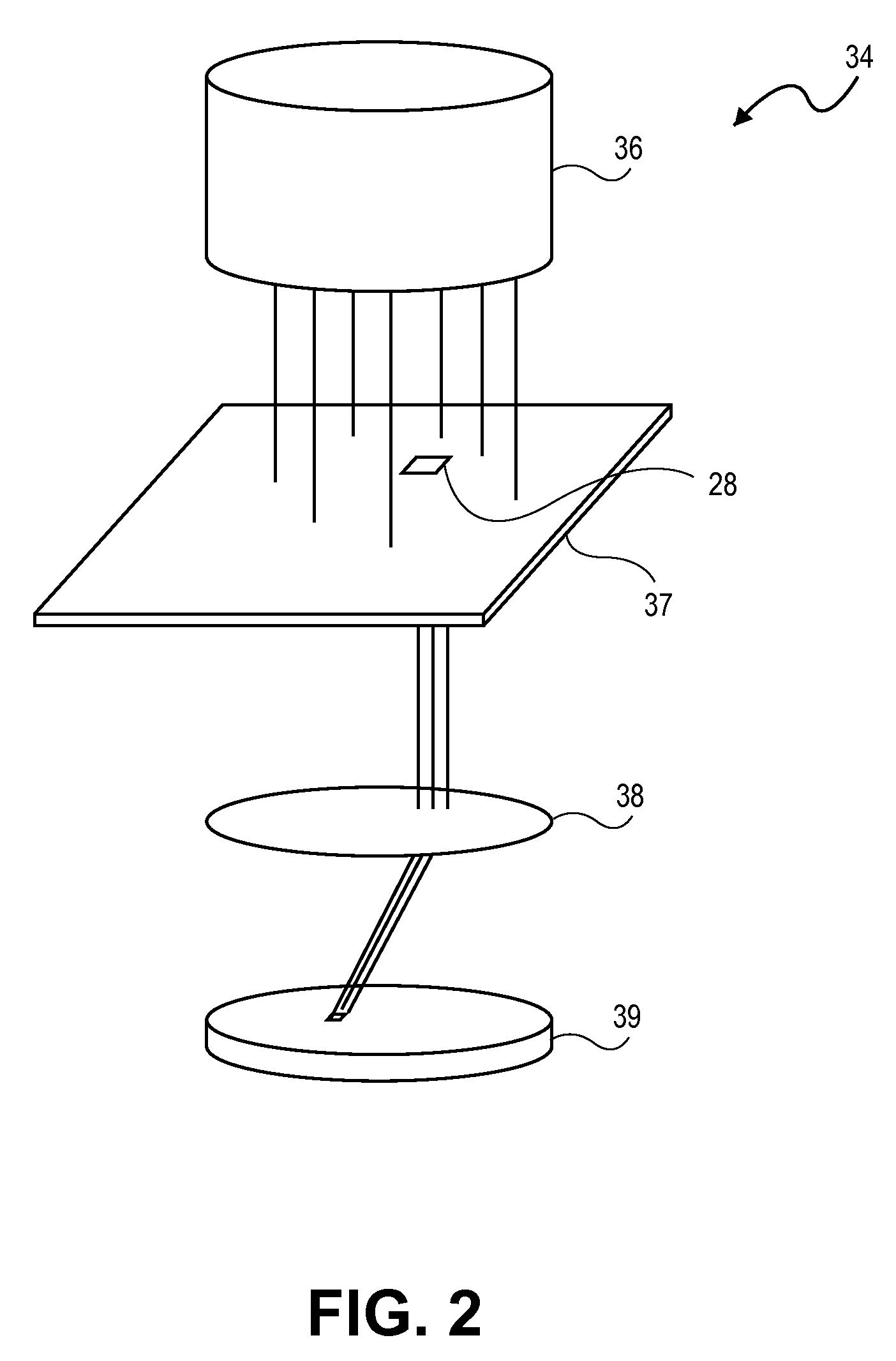

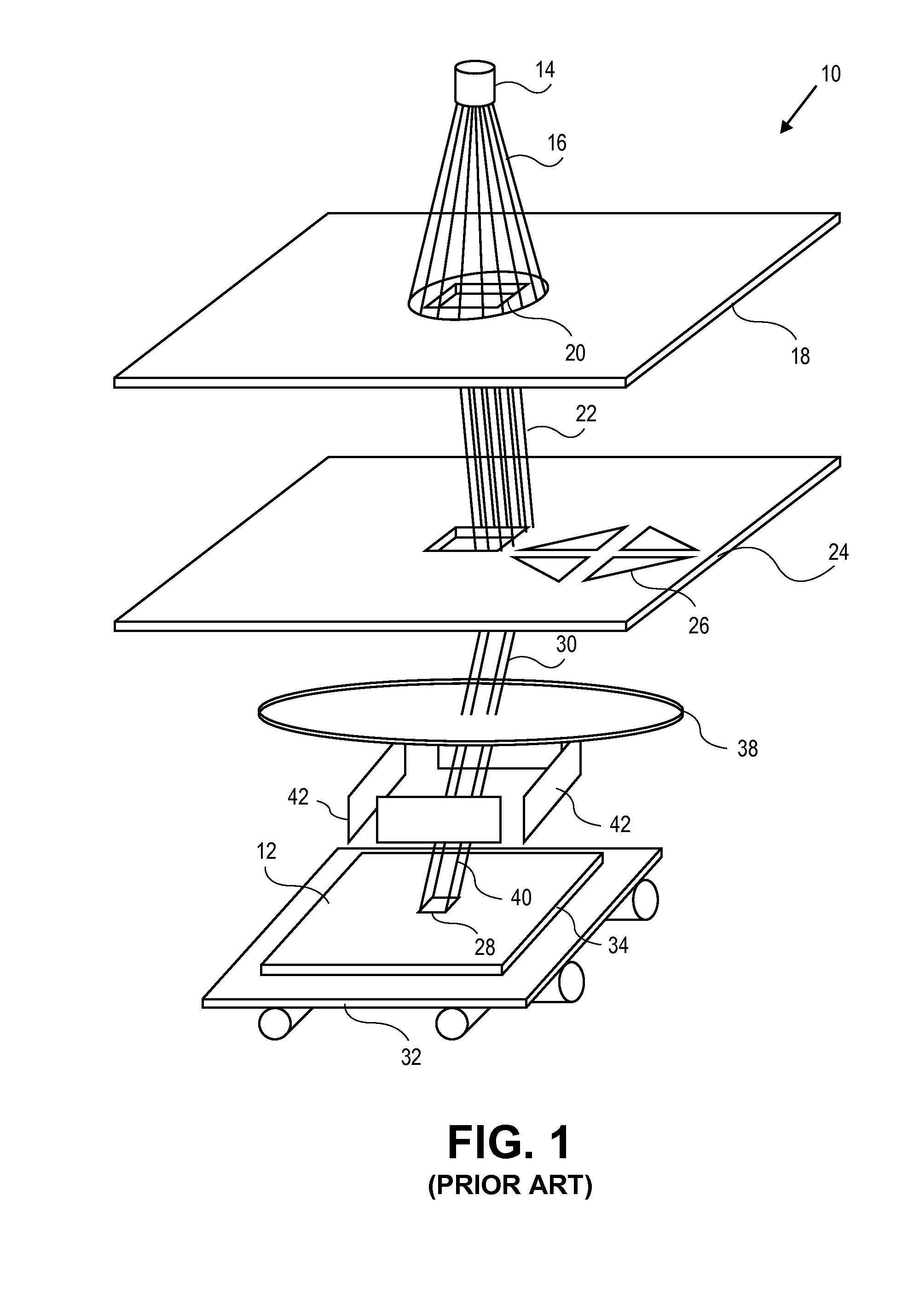

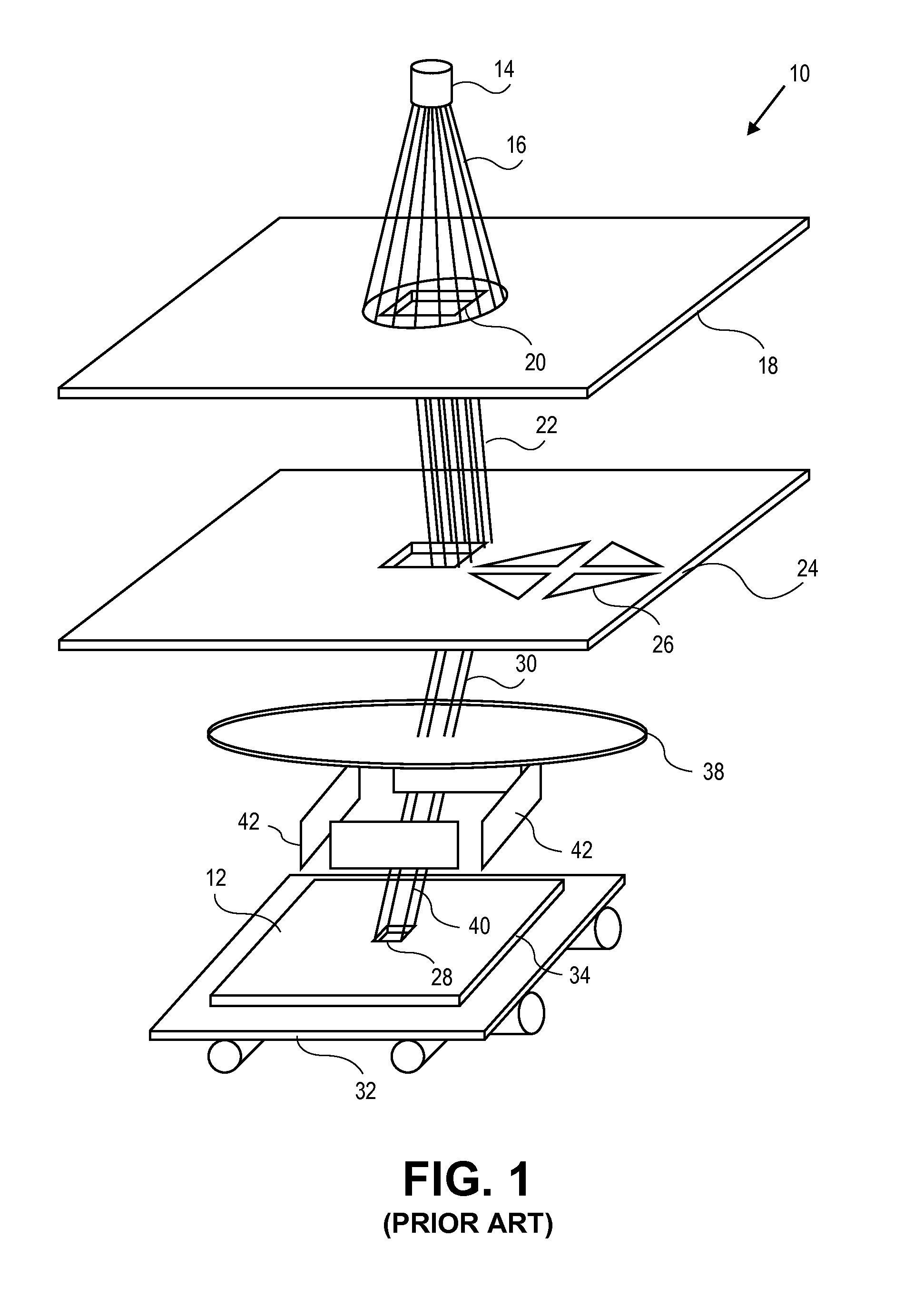

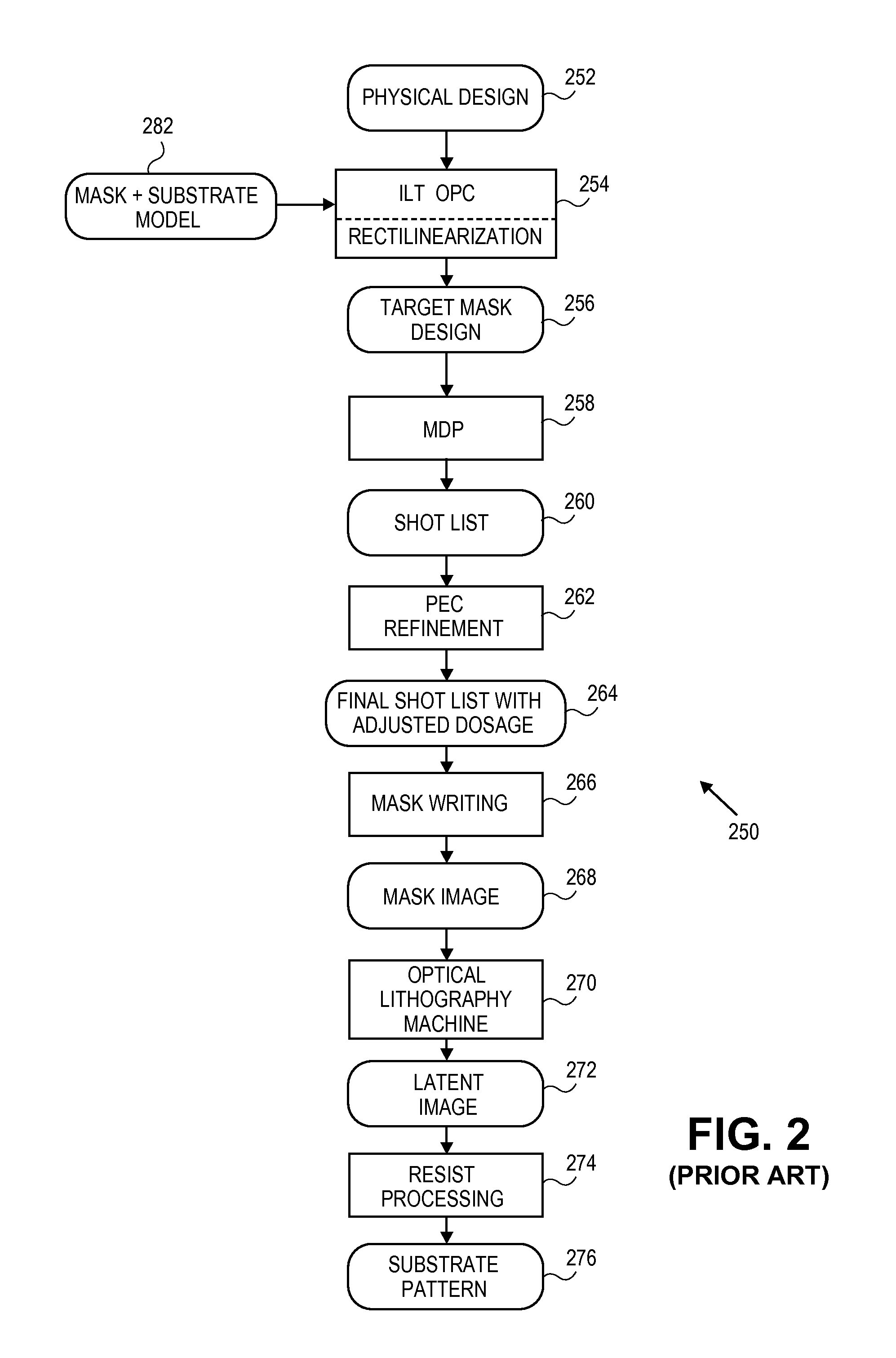

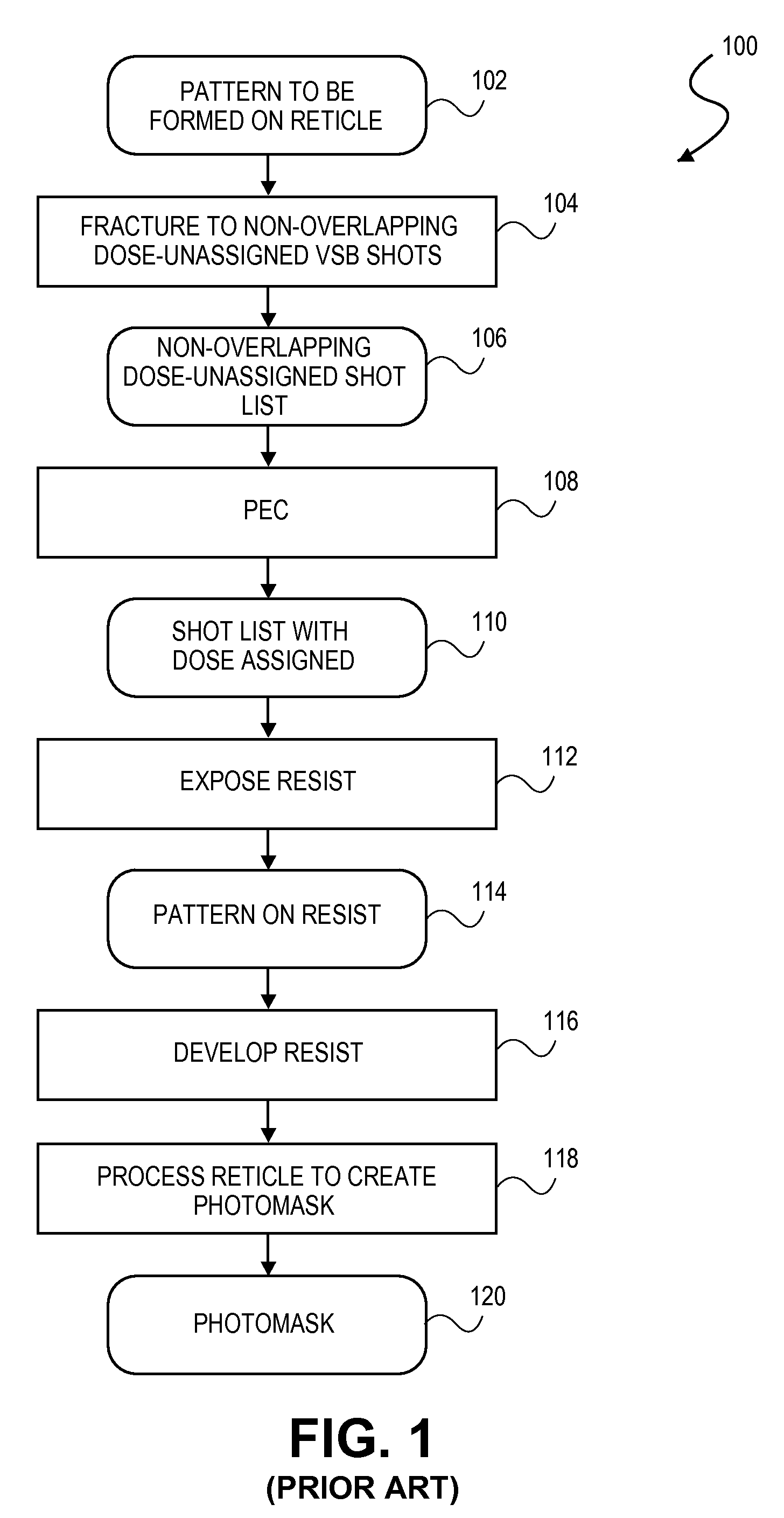

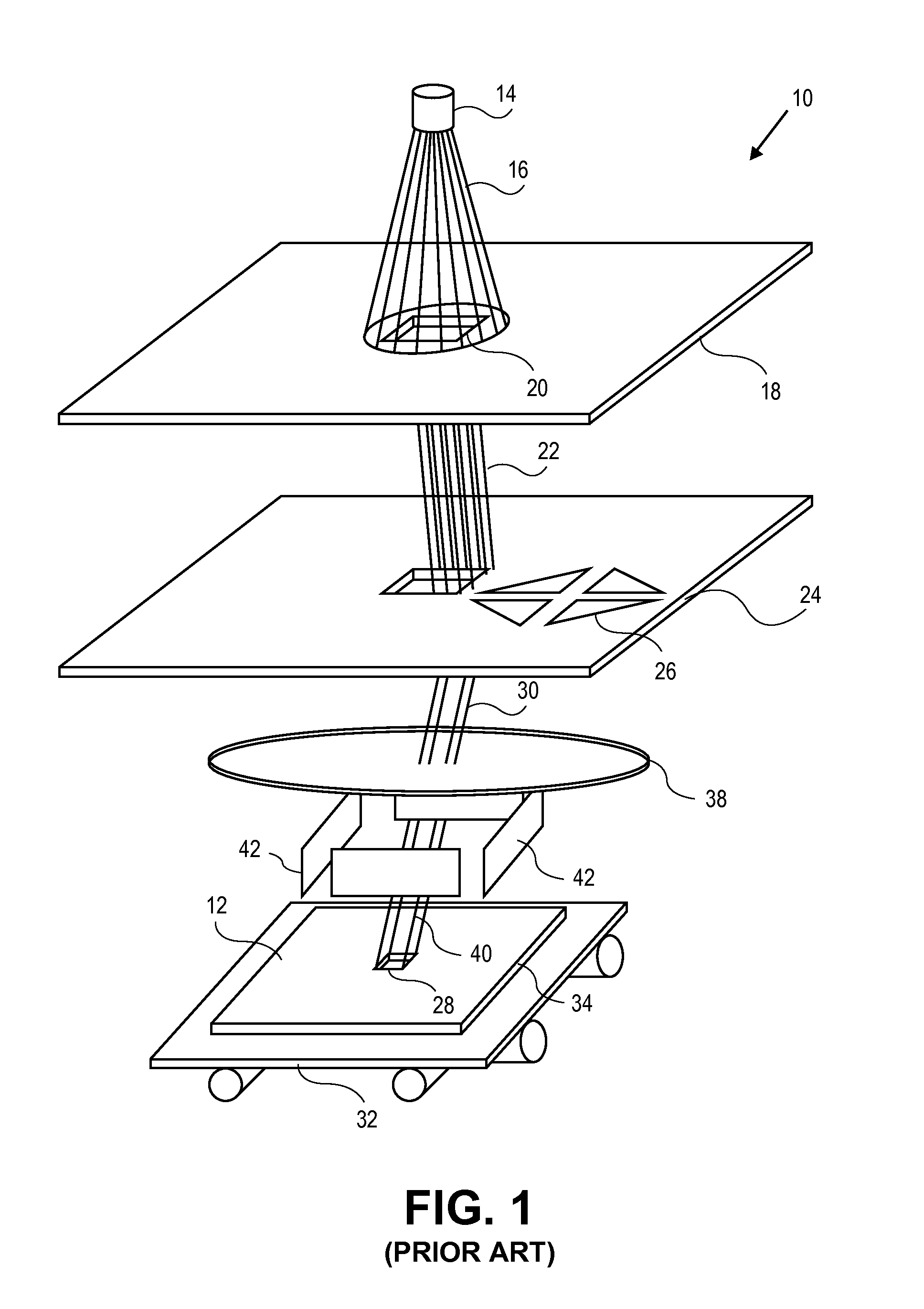

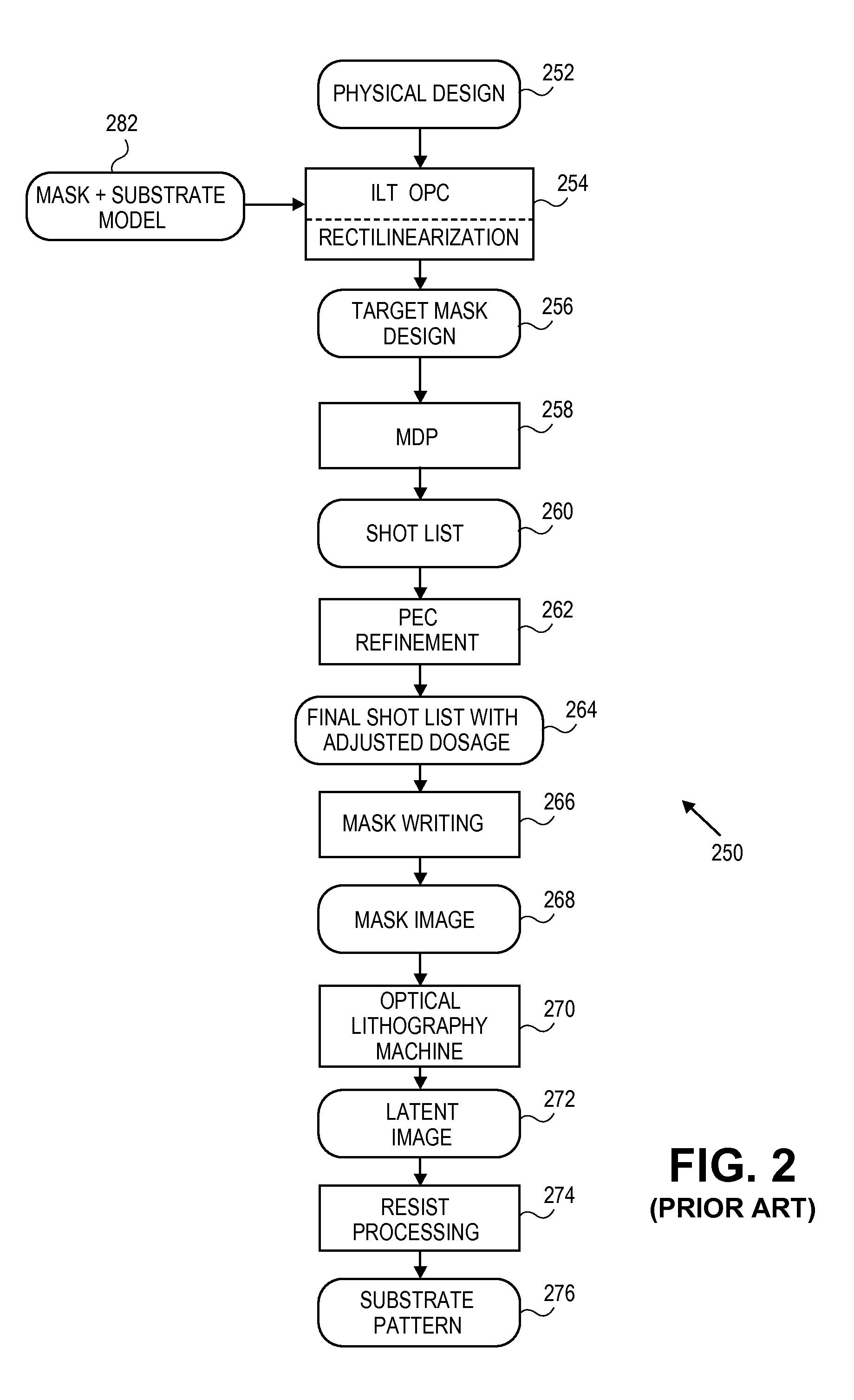

Mask data preparation (MDP) is the procedure of translating a file containing the intended set of polygons from an integrated circuit layout into set of instructions that a photomask writer can use to generate a physical mask. MDP usually involves mask fracturing where complex polygons are translated into simpler shapes, often rectangles and trapezoids, that can be handled by the mask writing hardware. Because mask fracturing is such a common procedure within the whole MDP, the term fracture, used as a noun, is sometimes used inappropriately in place of the term mask data preparation. The term fracture does however accurately describe that sub-procedure of MDP.

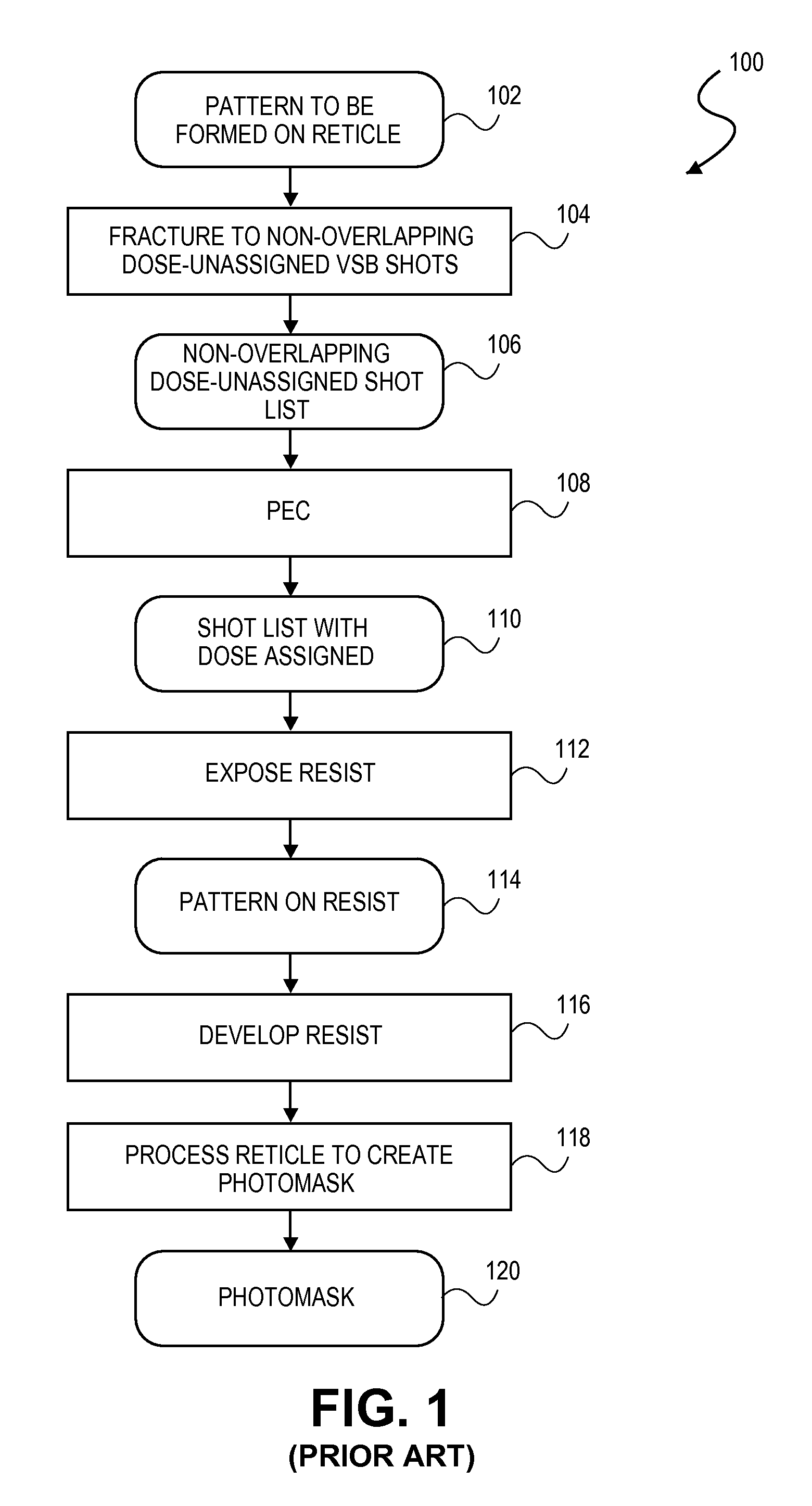

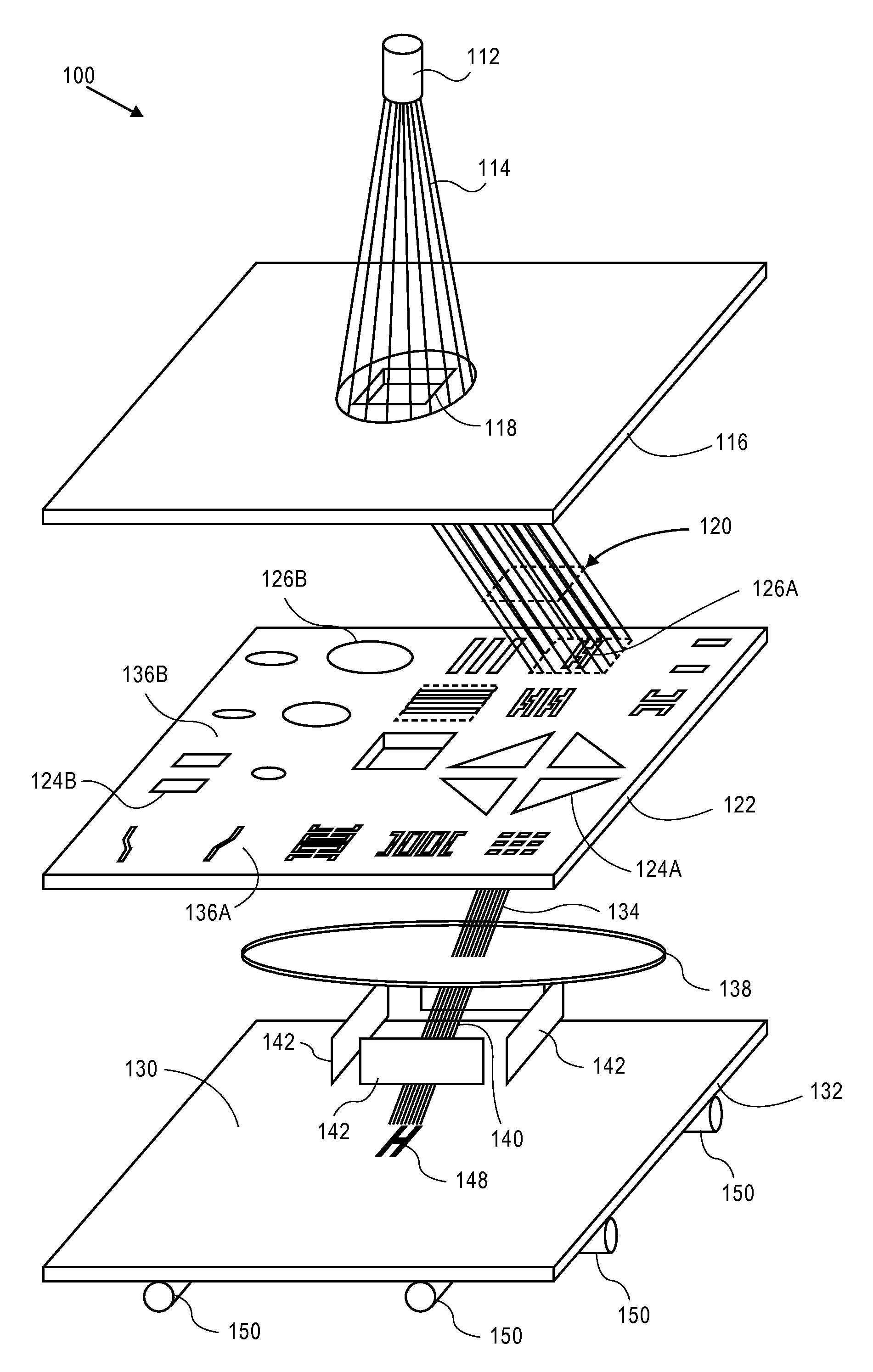

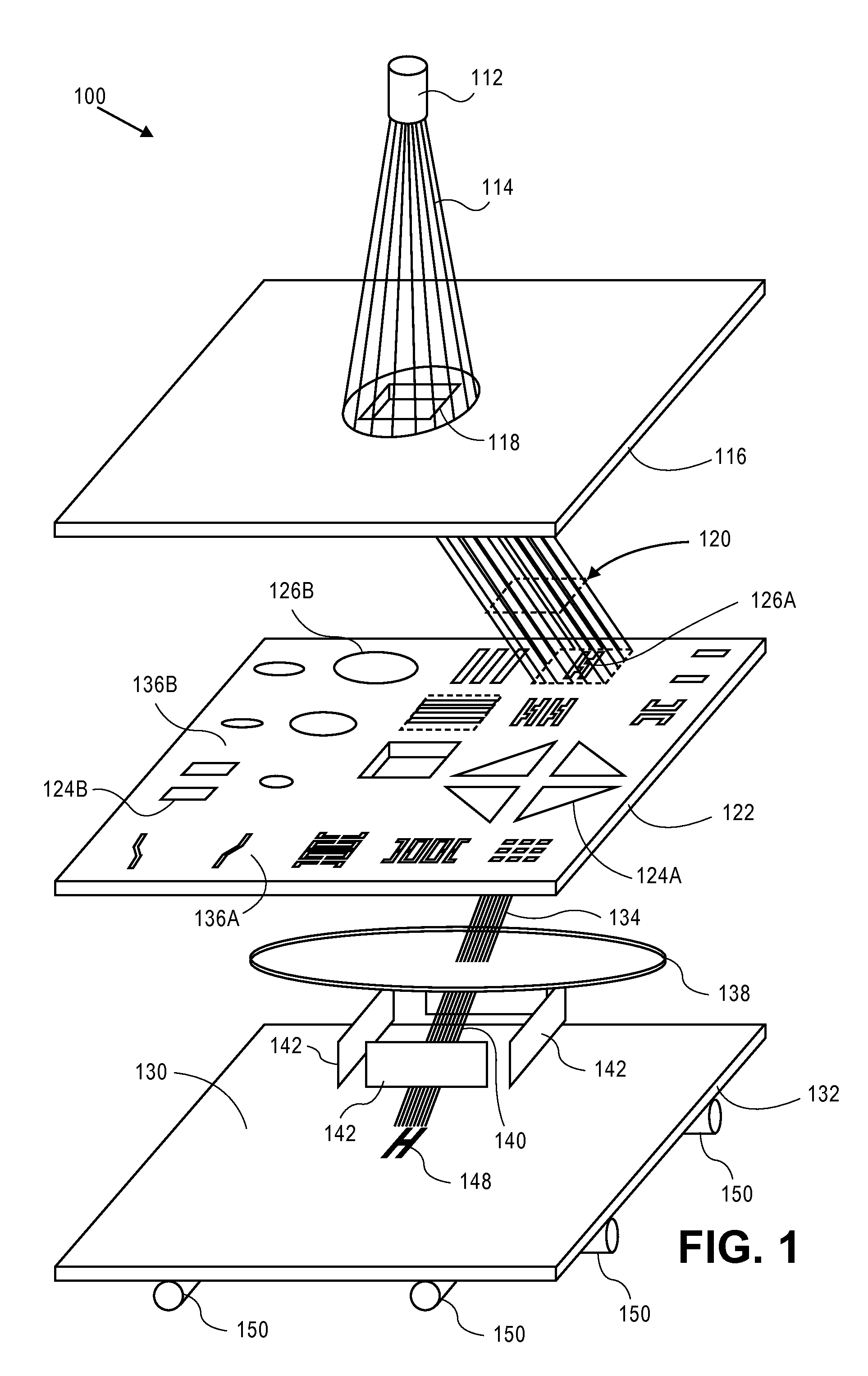

Method and system for design of a reticle to be manufactured using variable shaped beam lithography

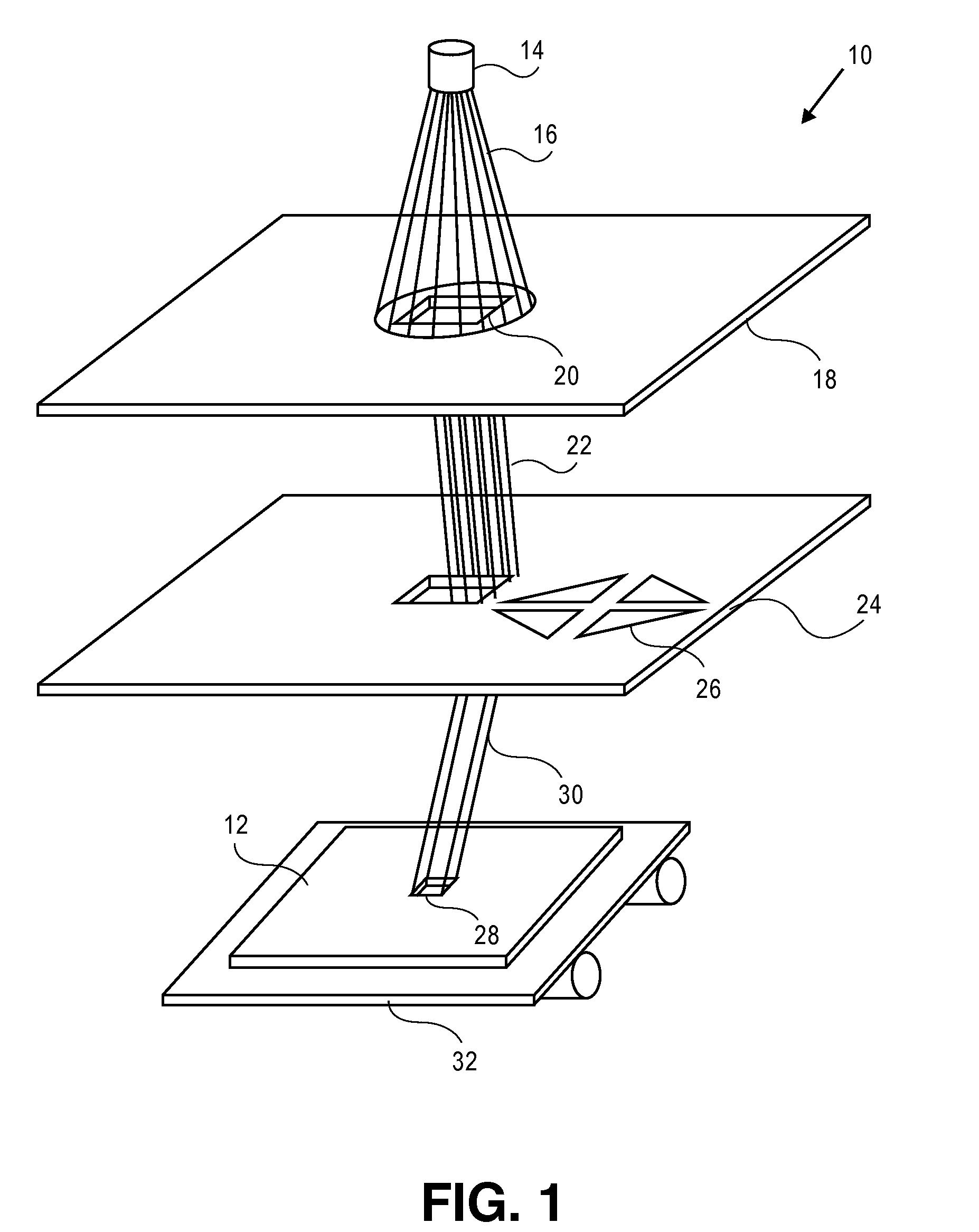

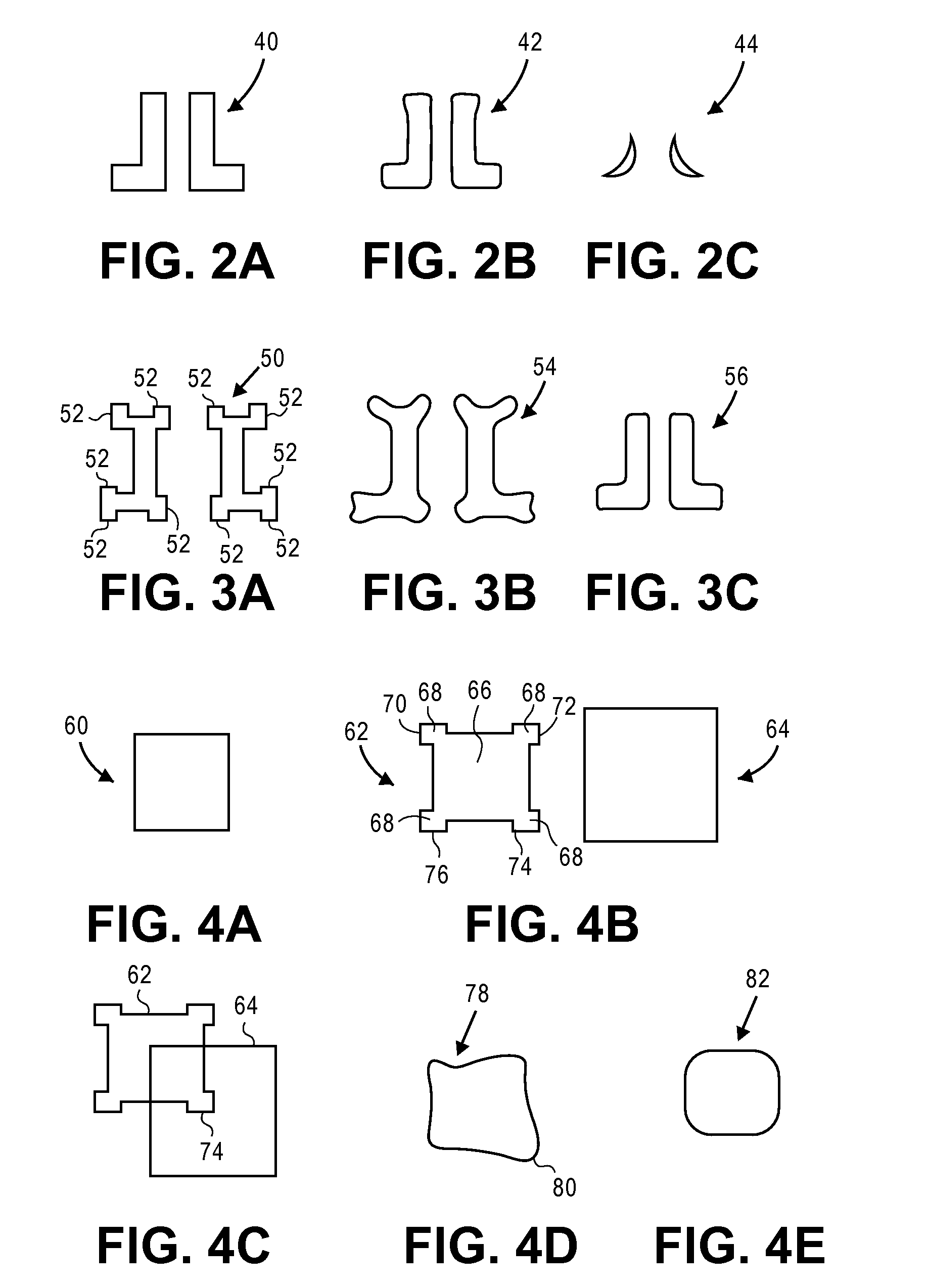

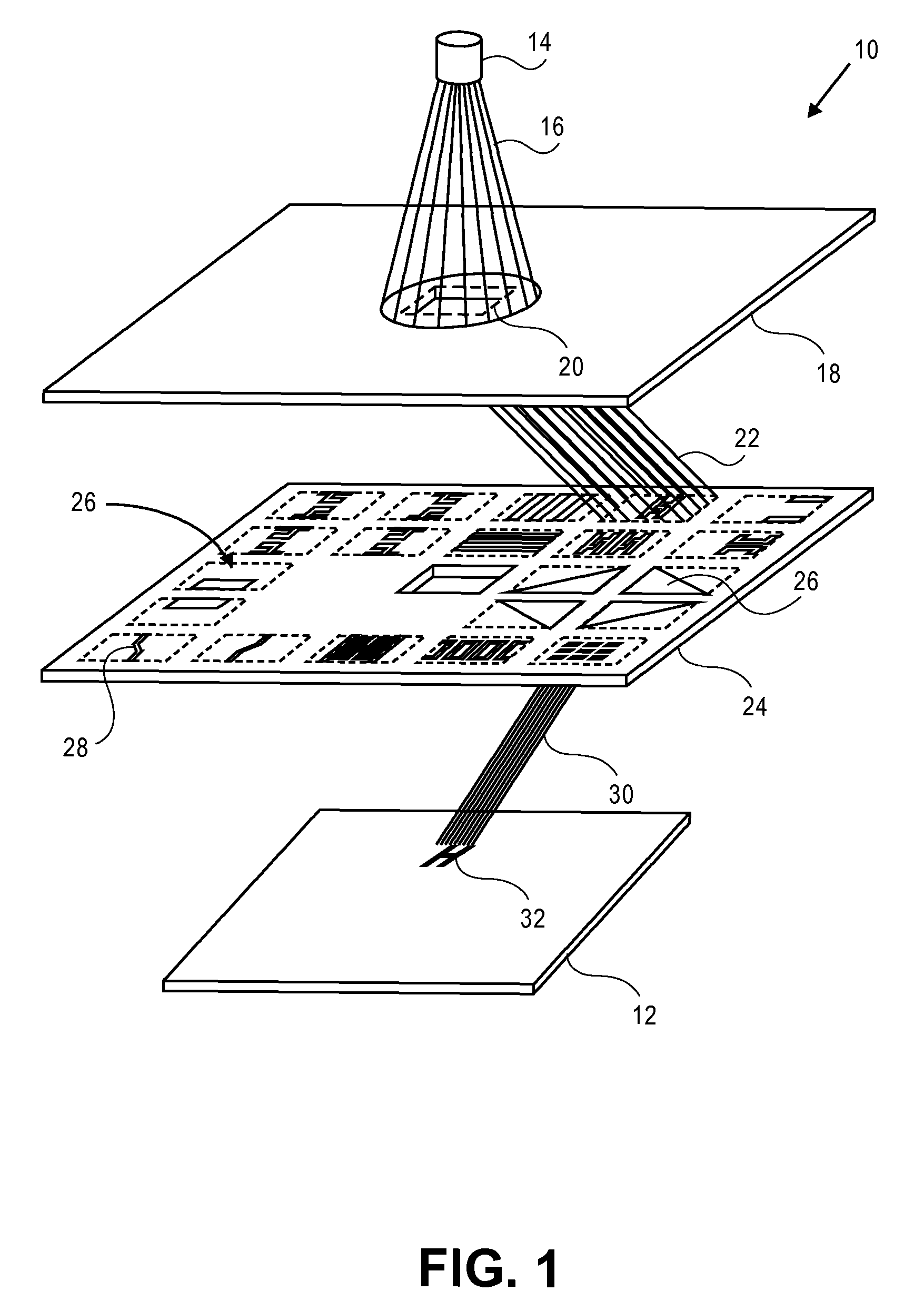

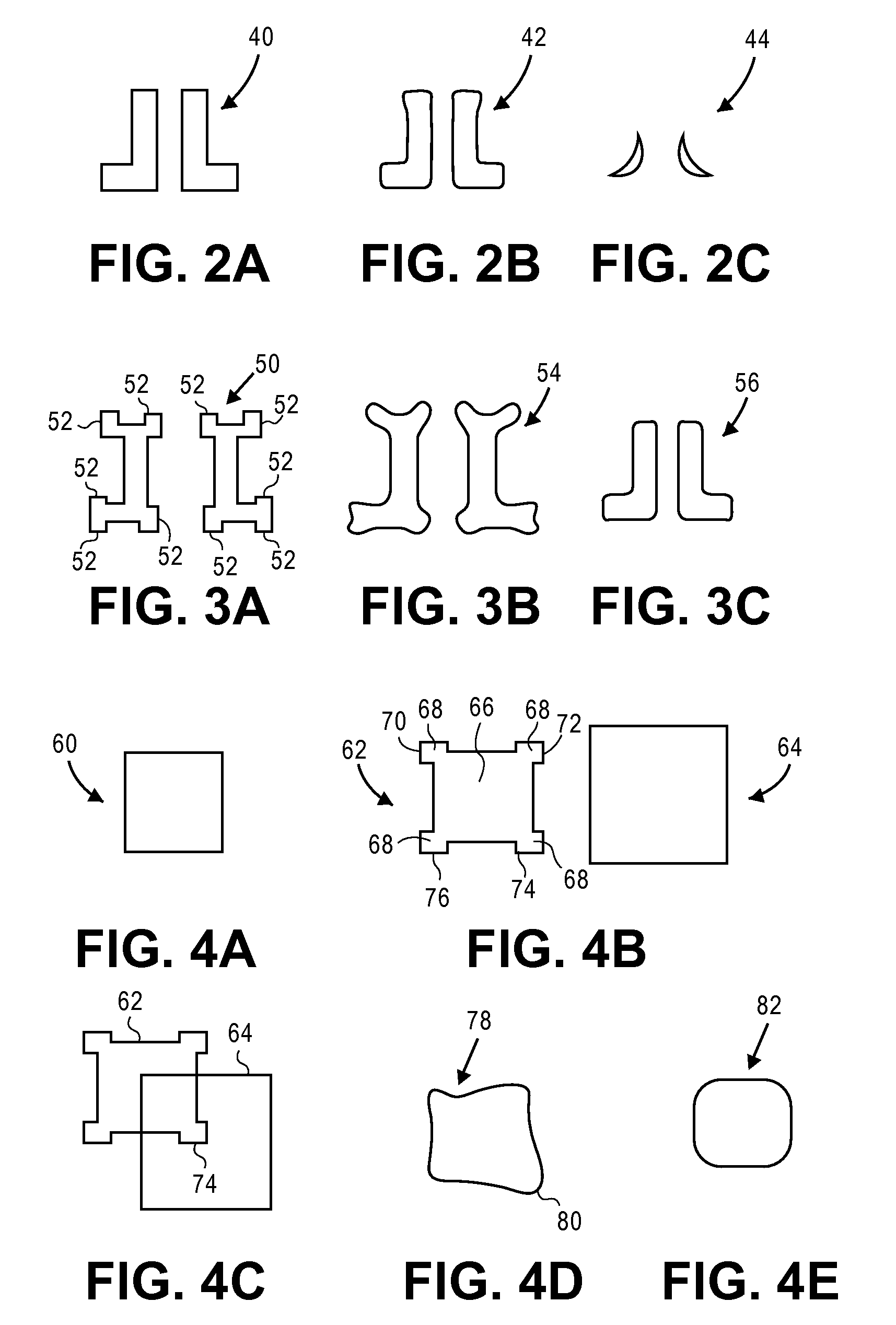

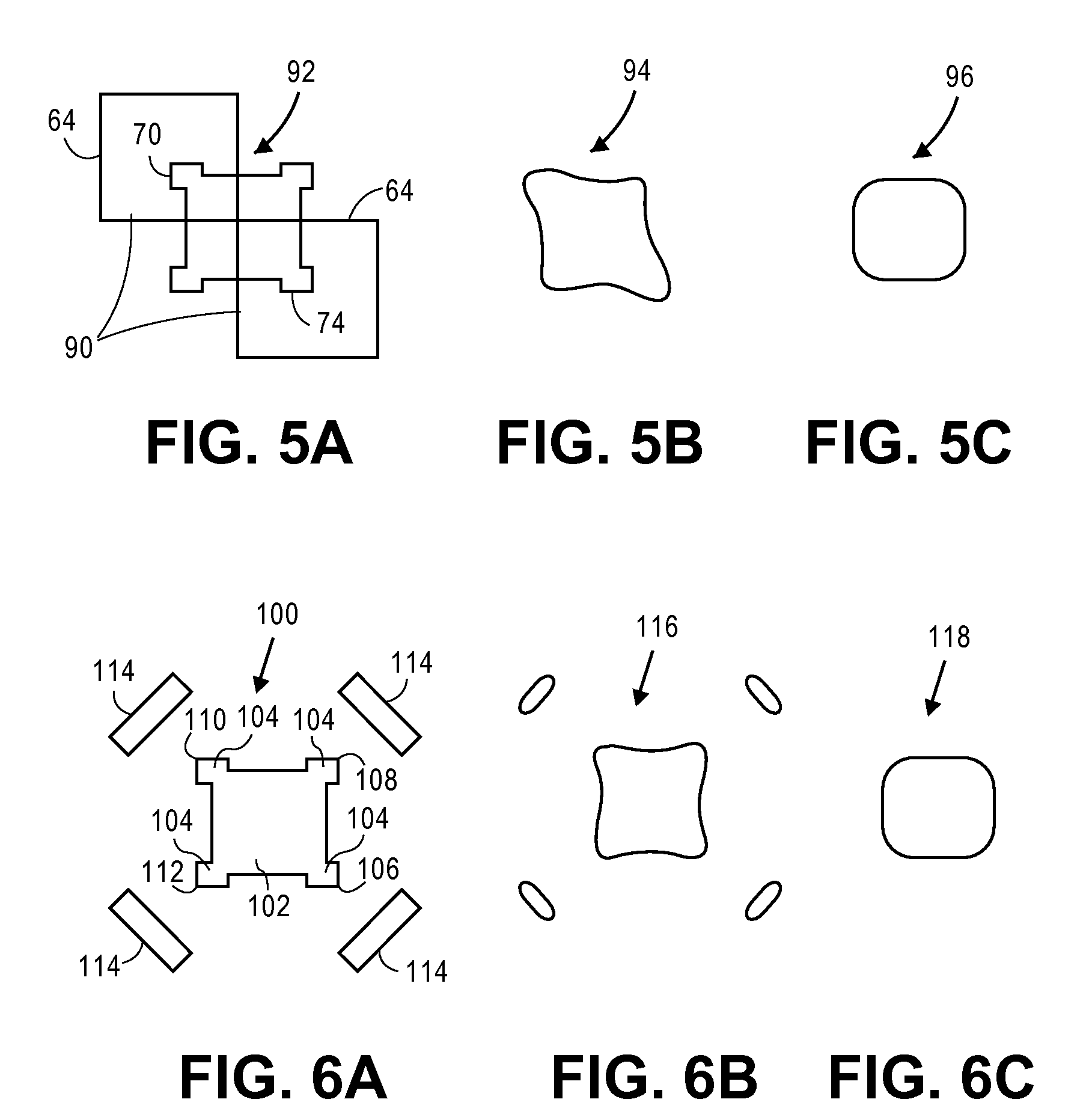

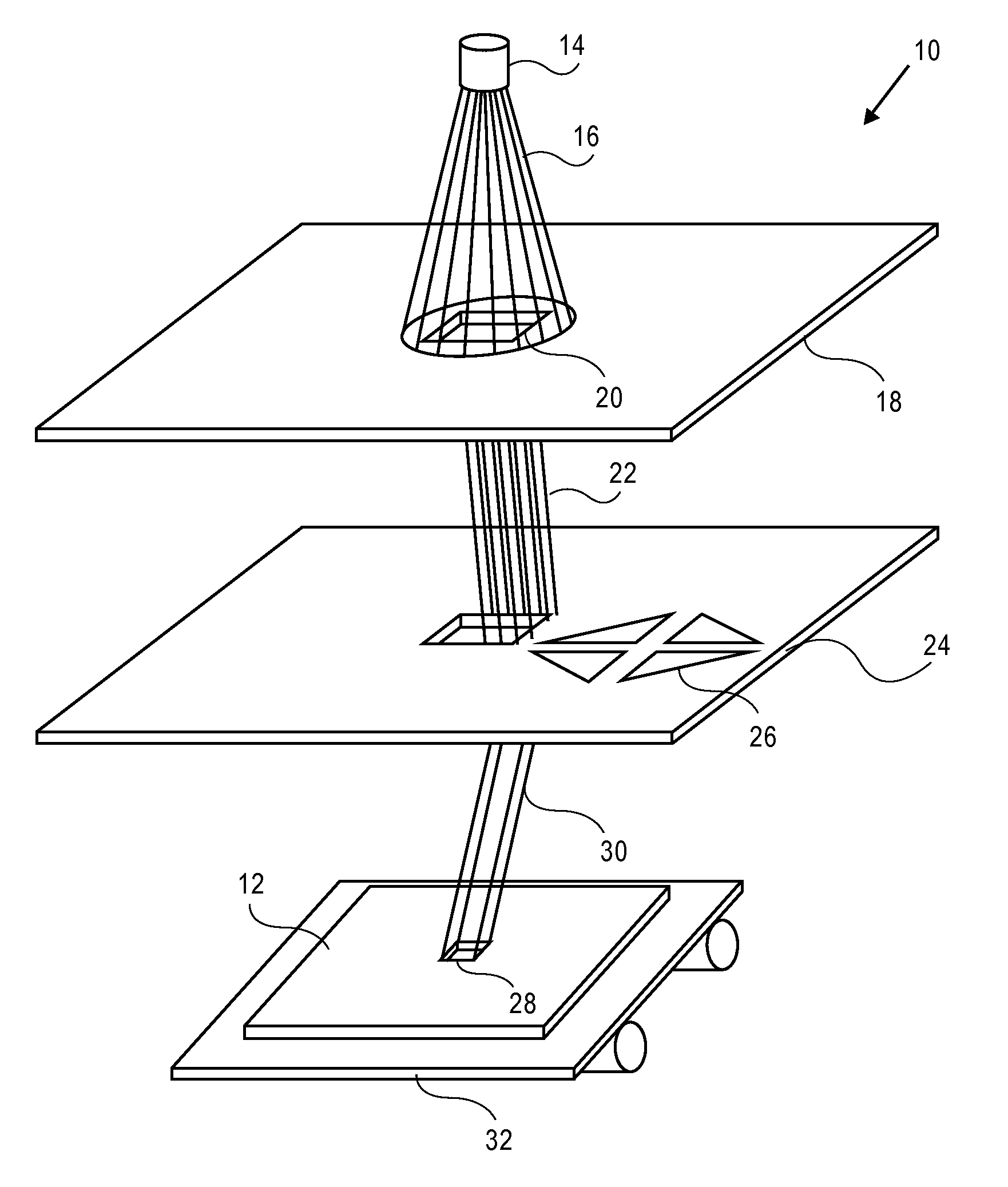

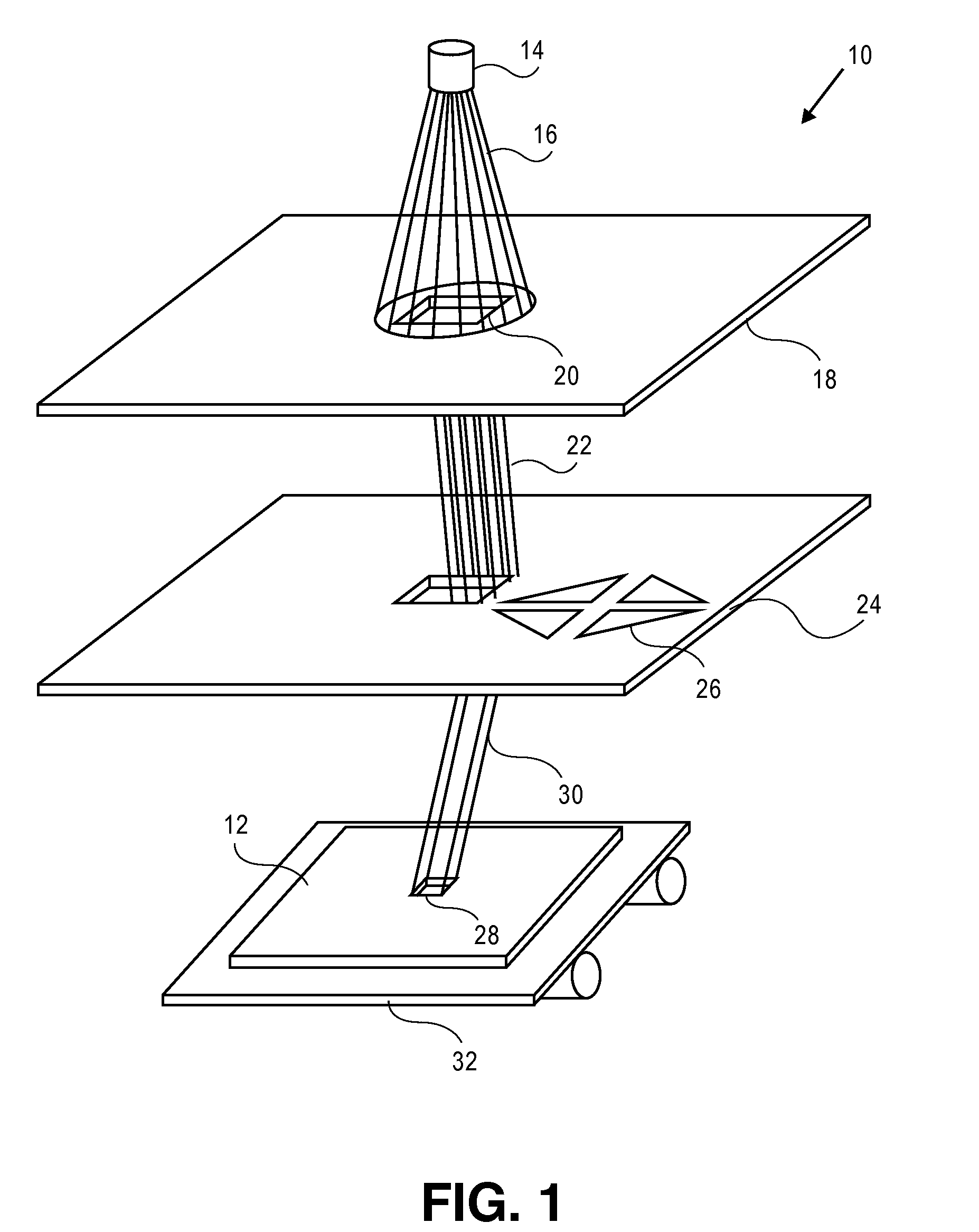

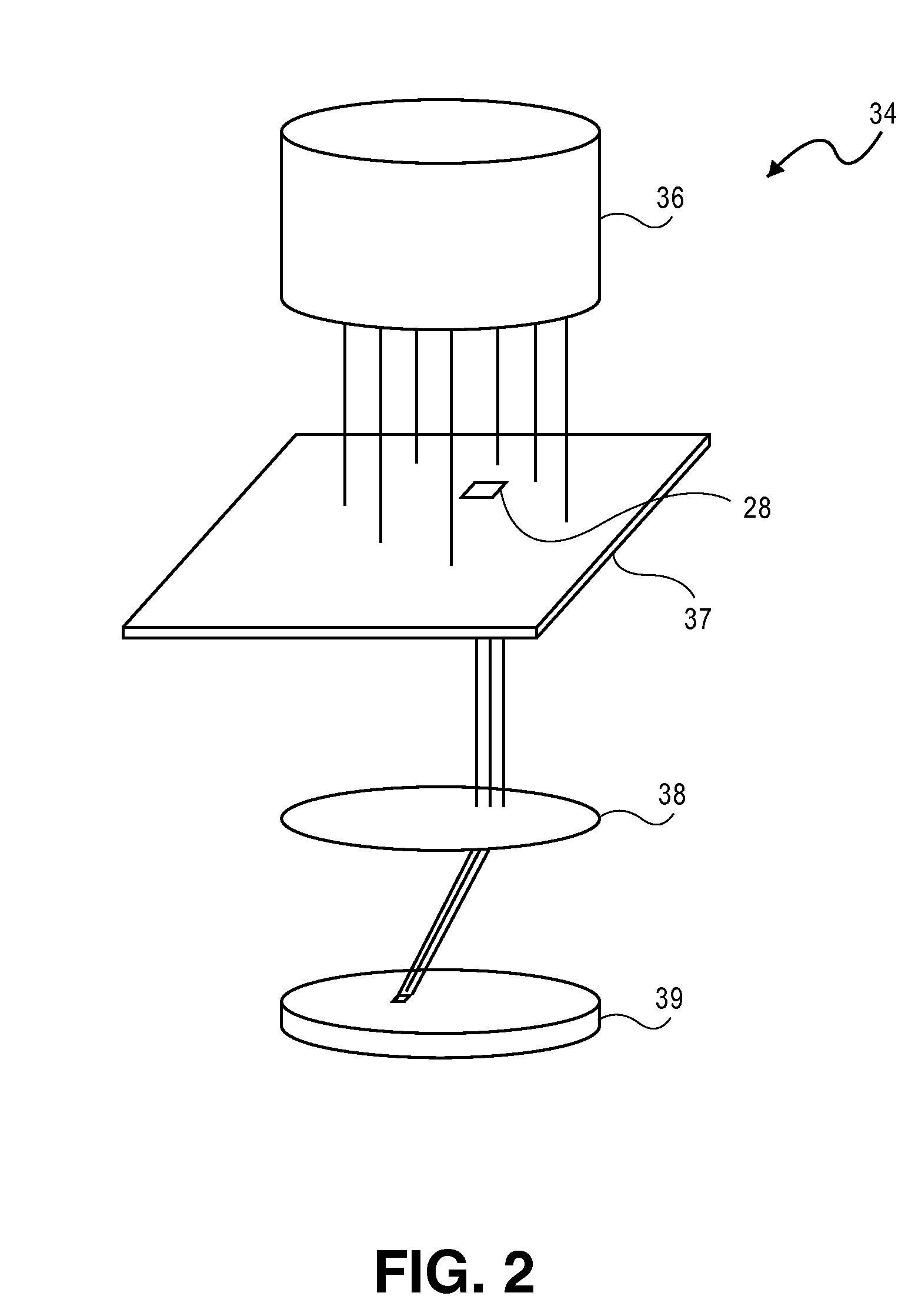

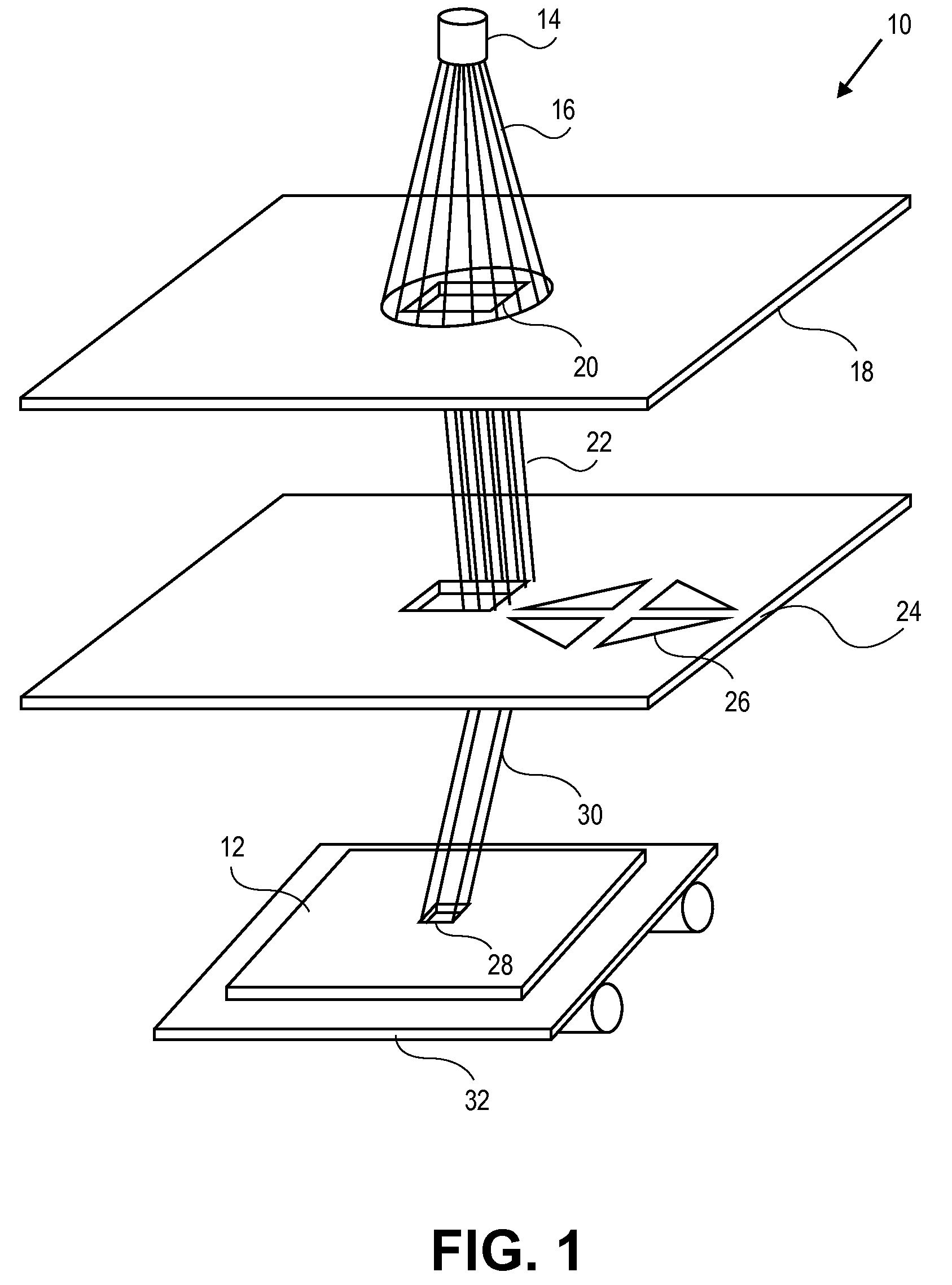

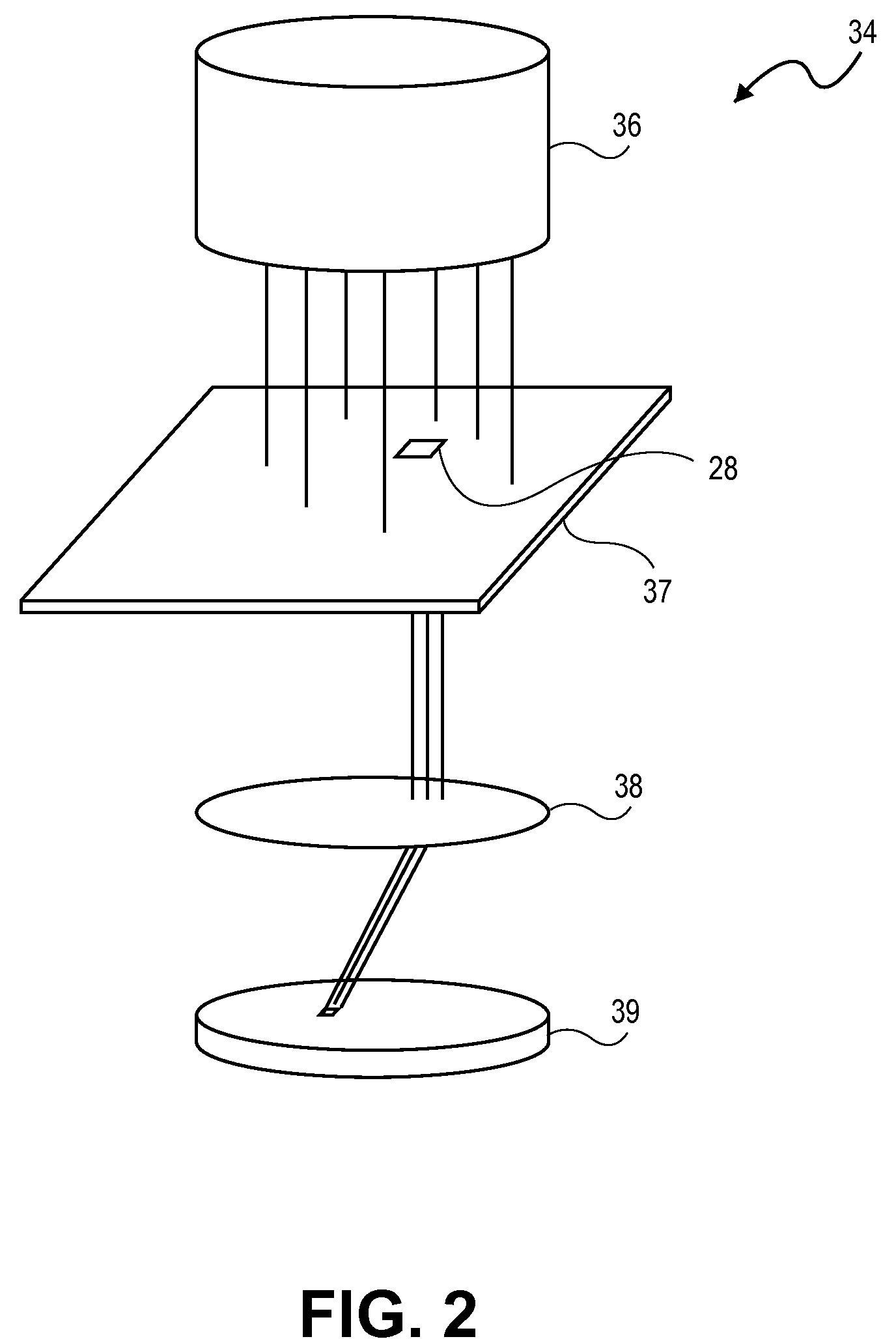

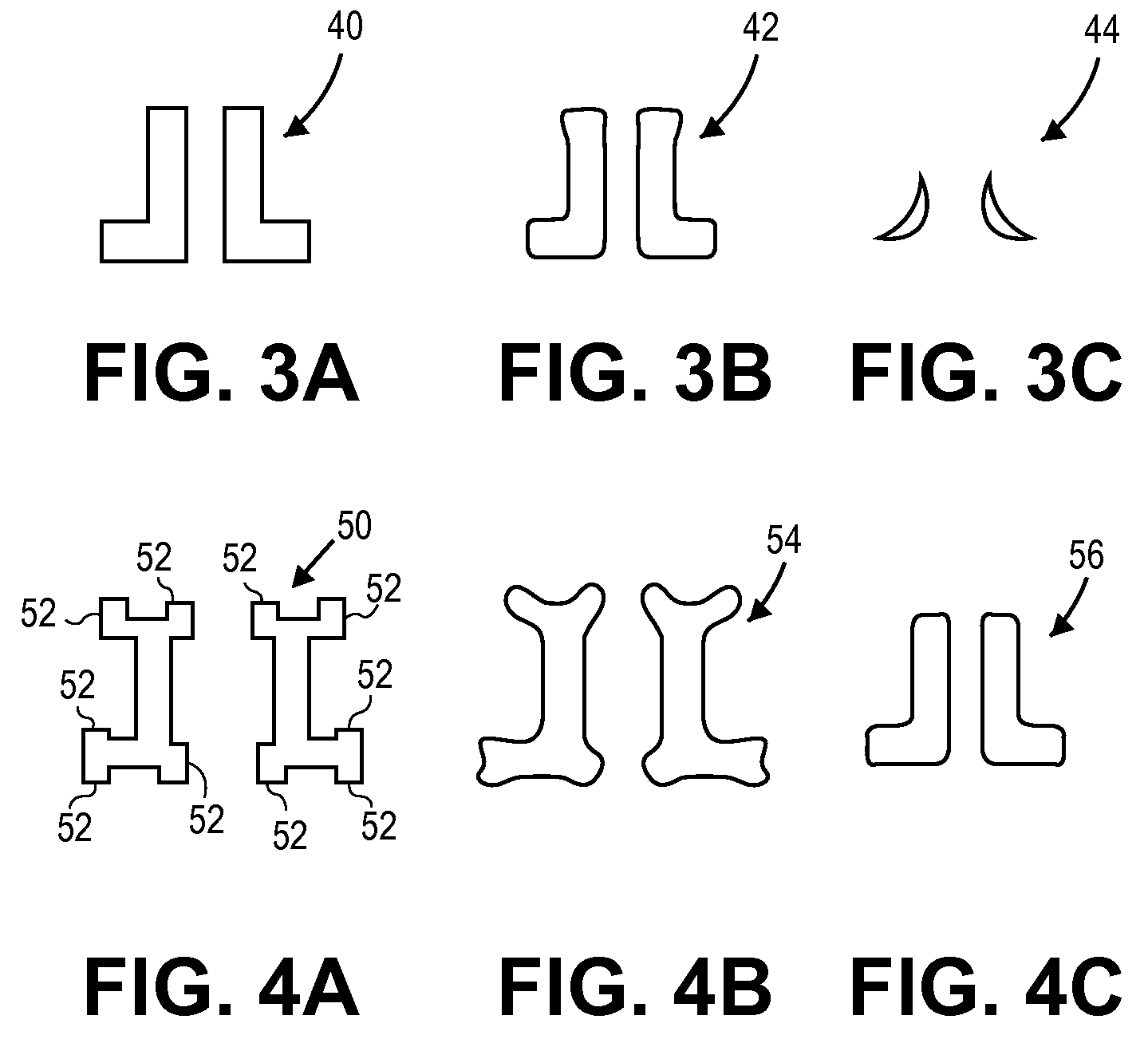

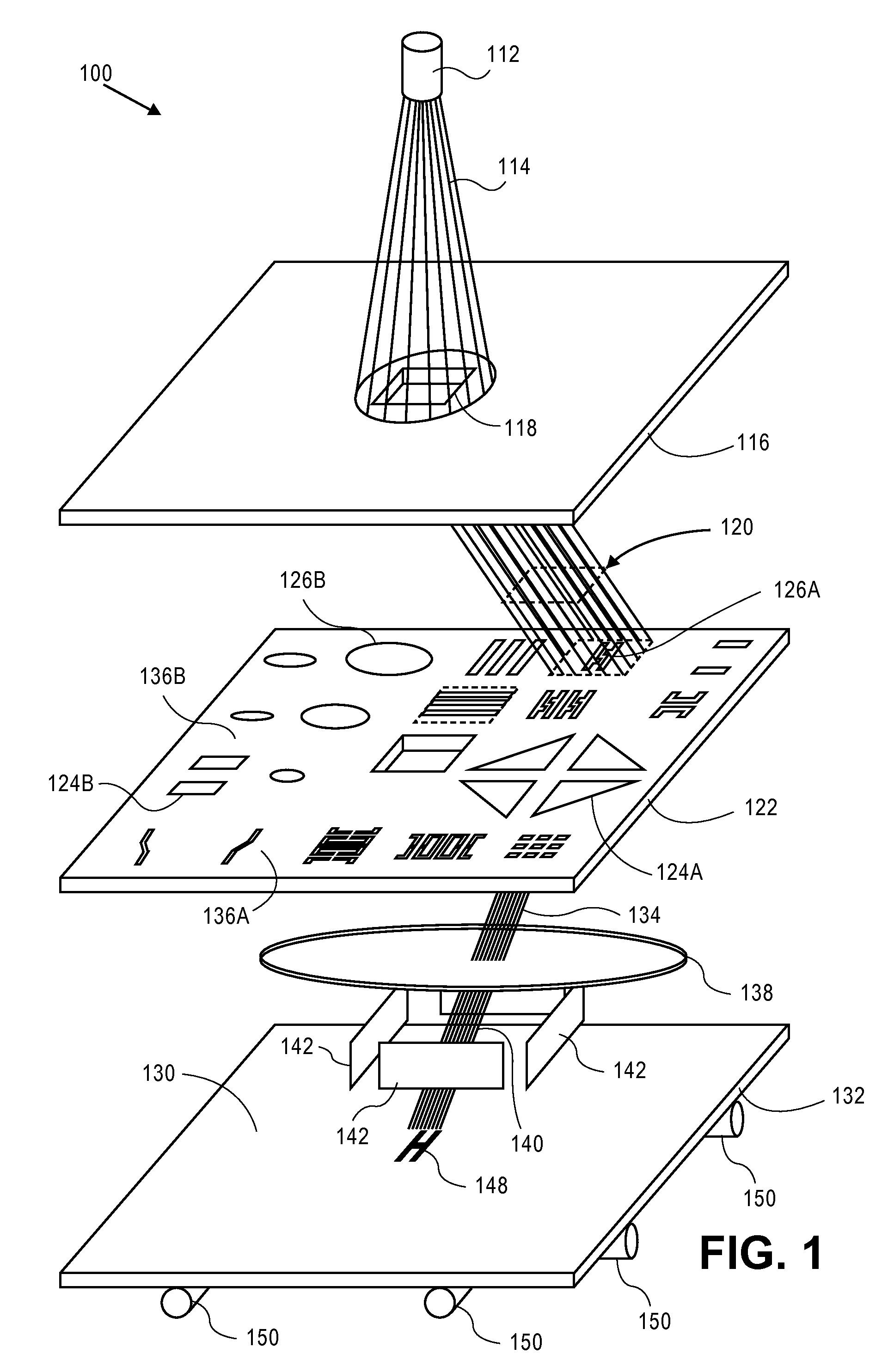

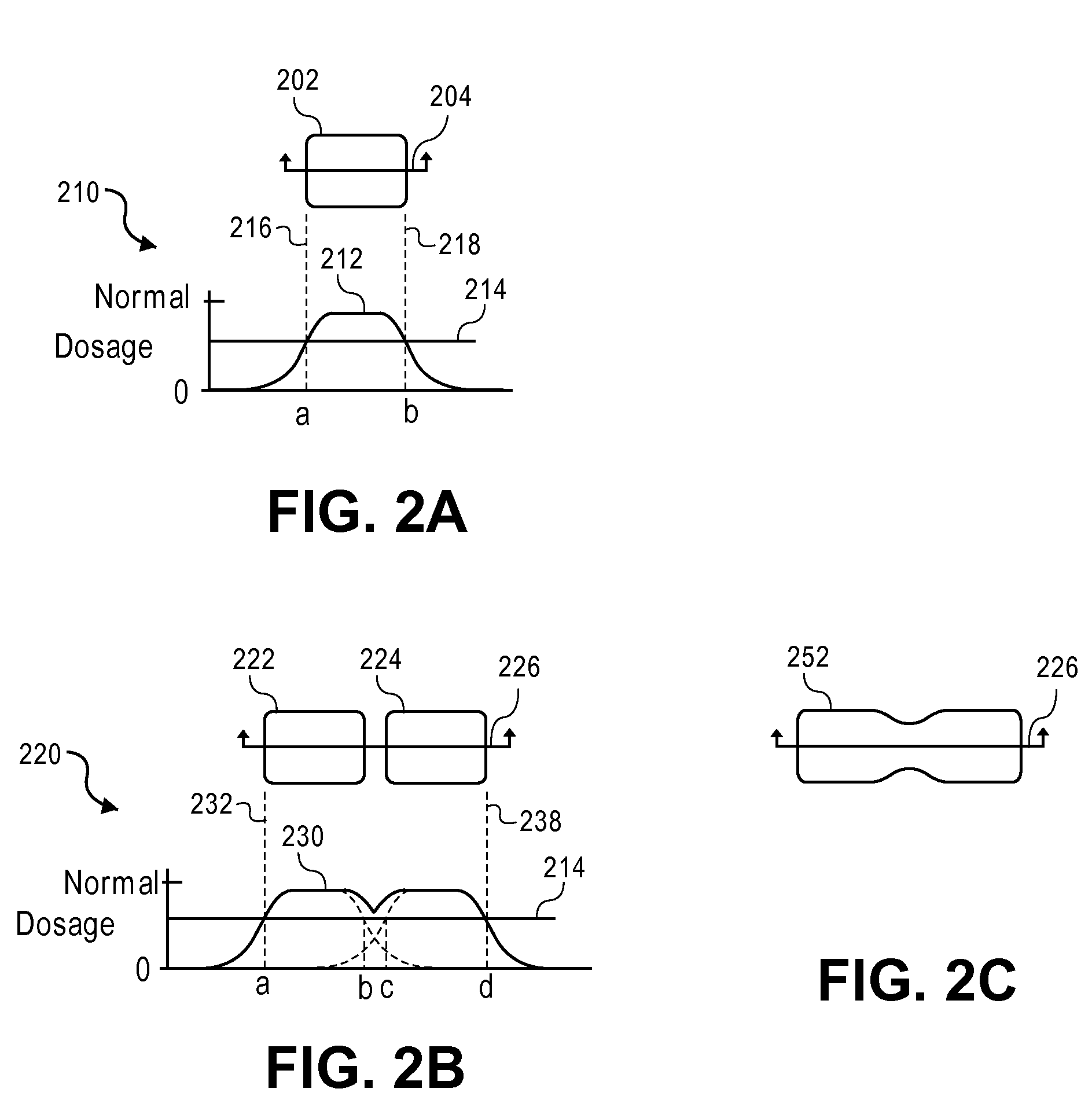

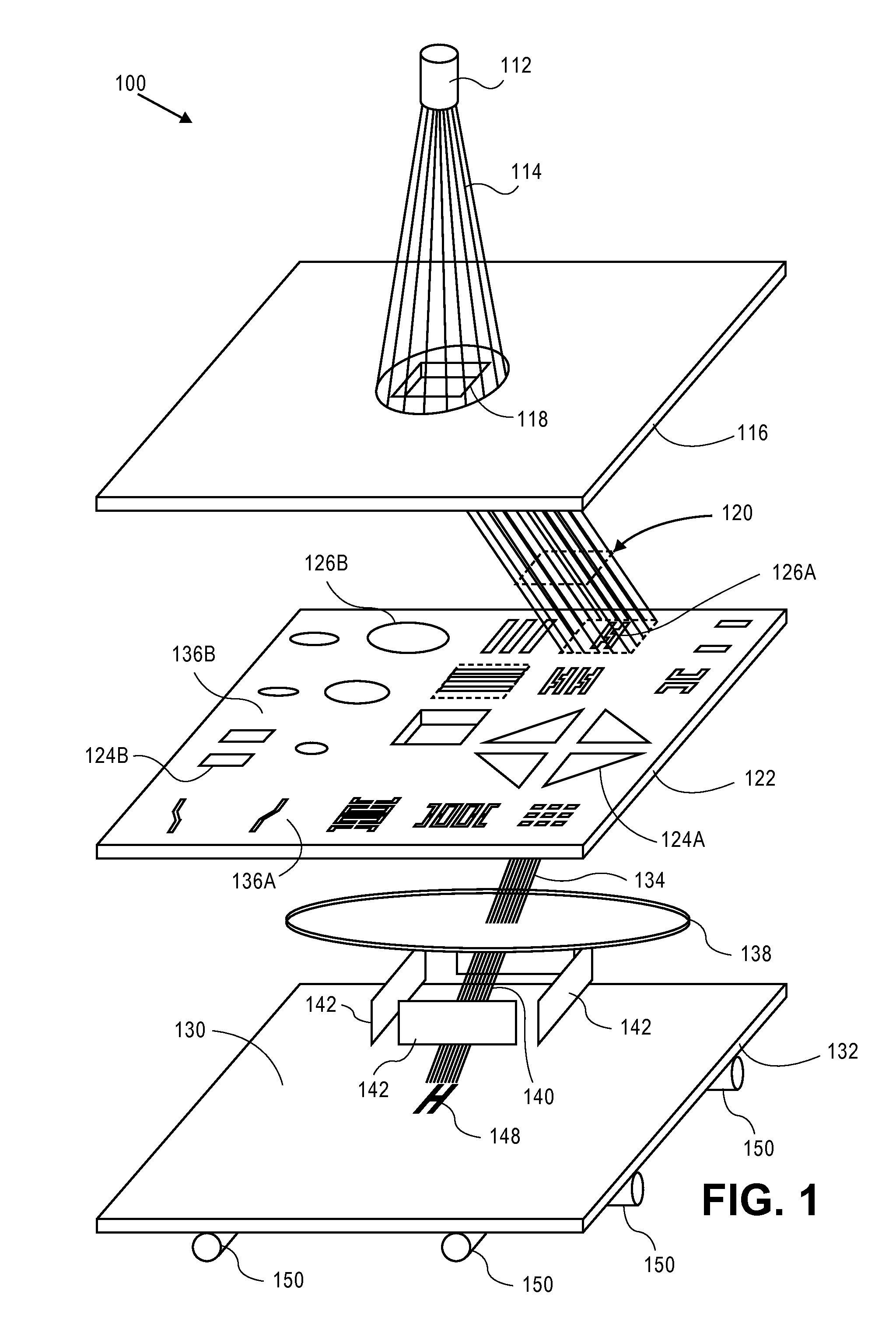

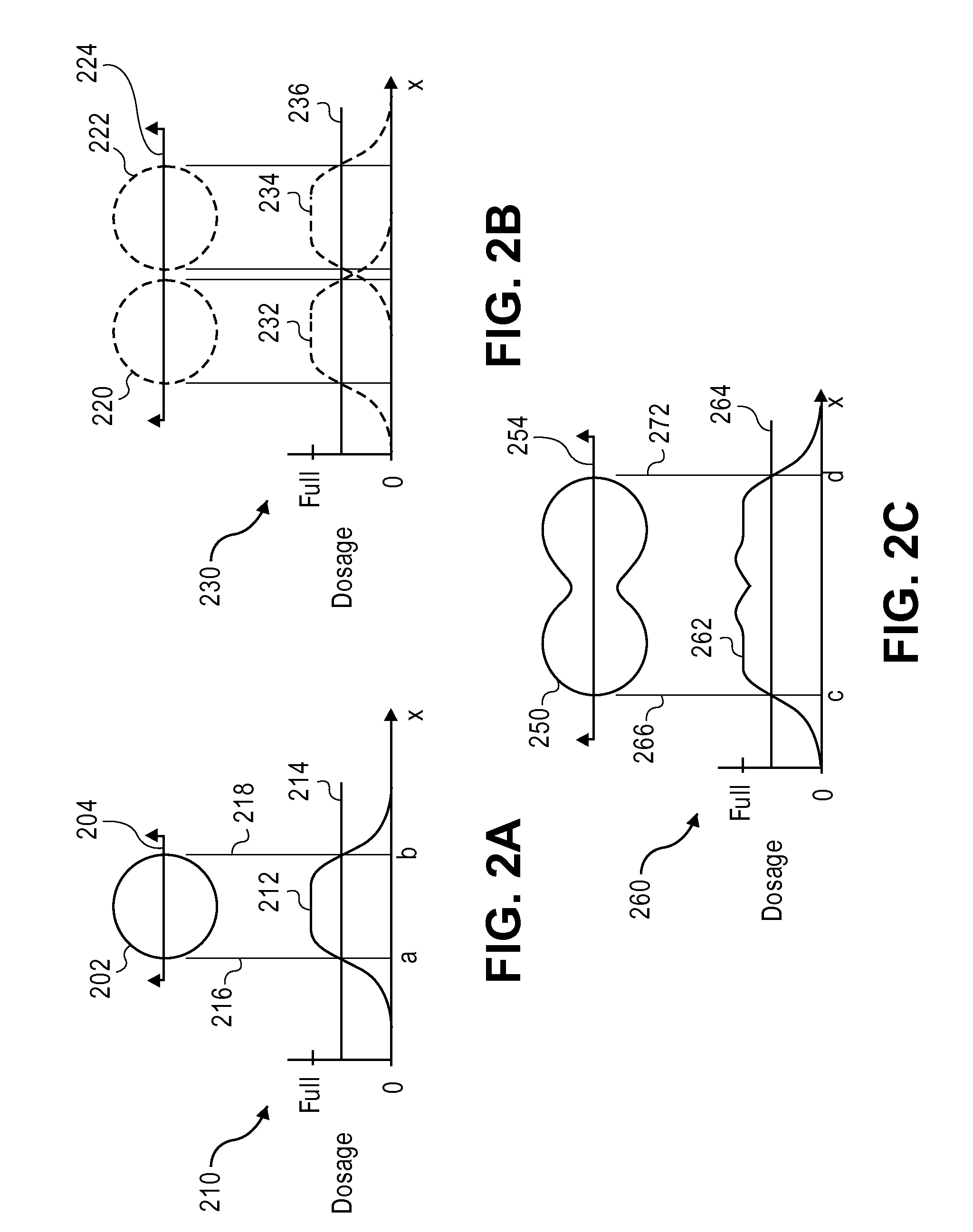

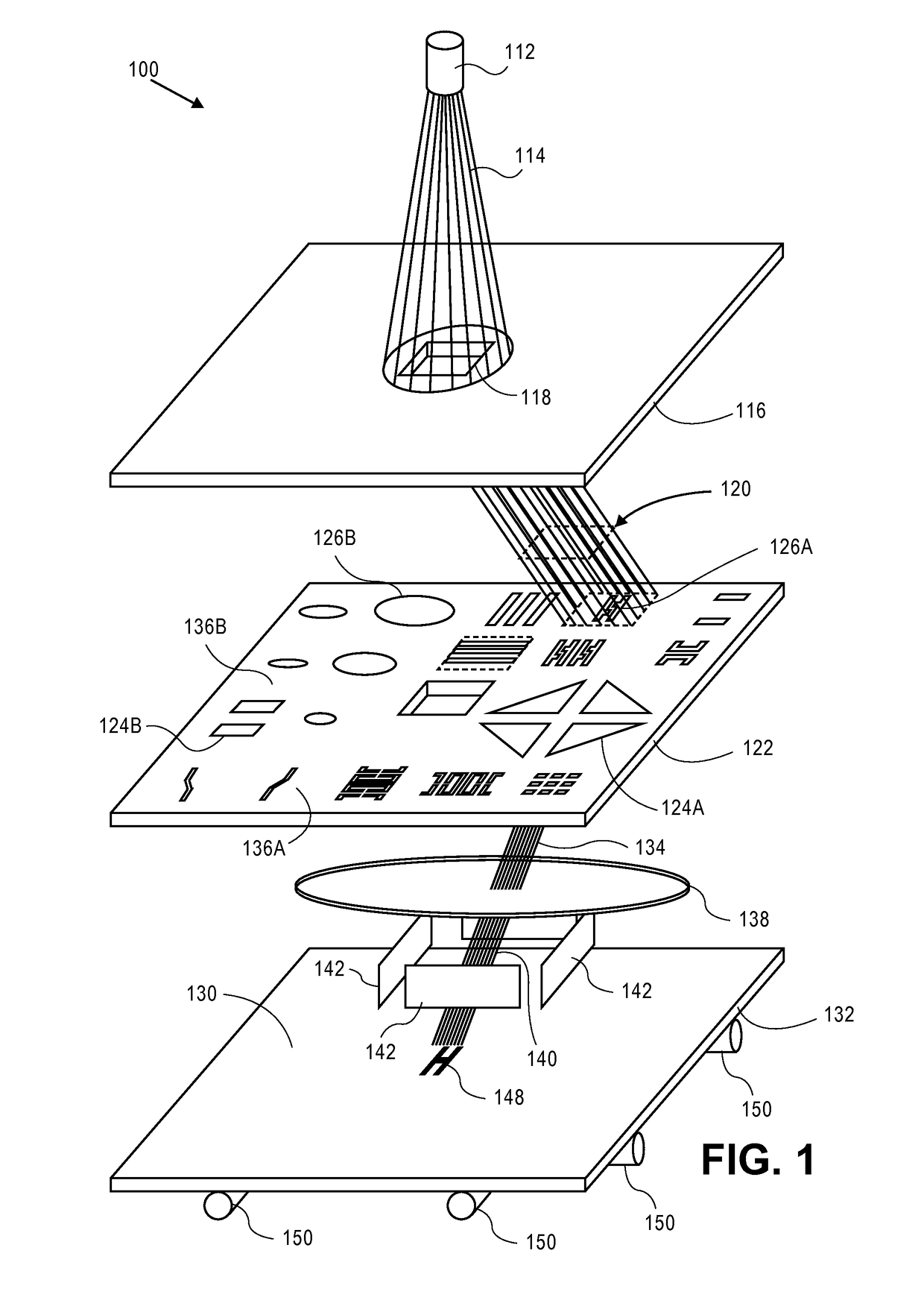

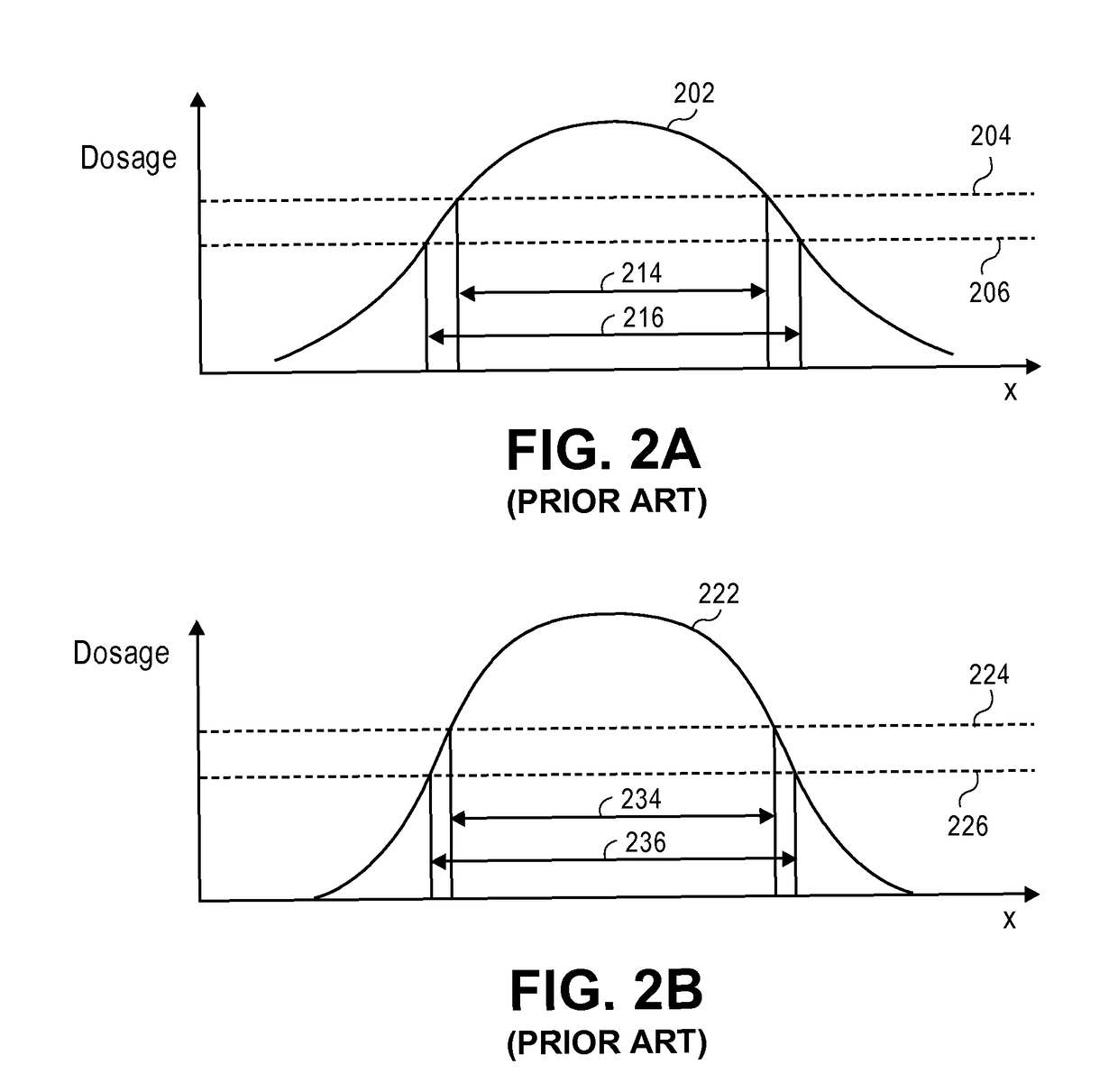

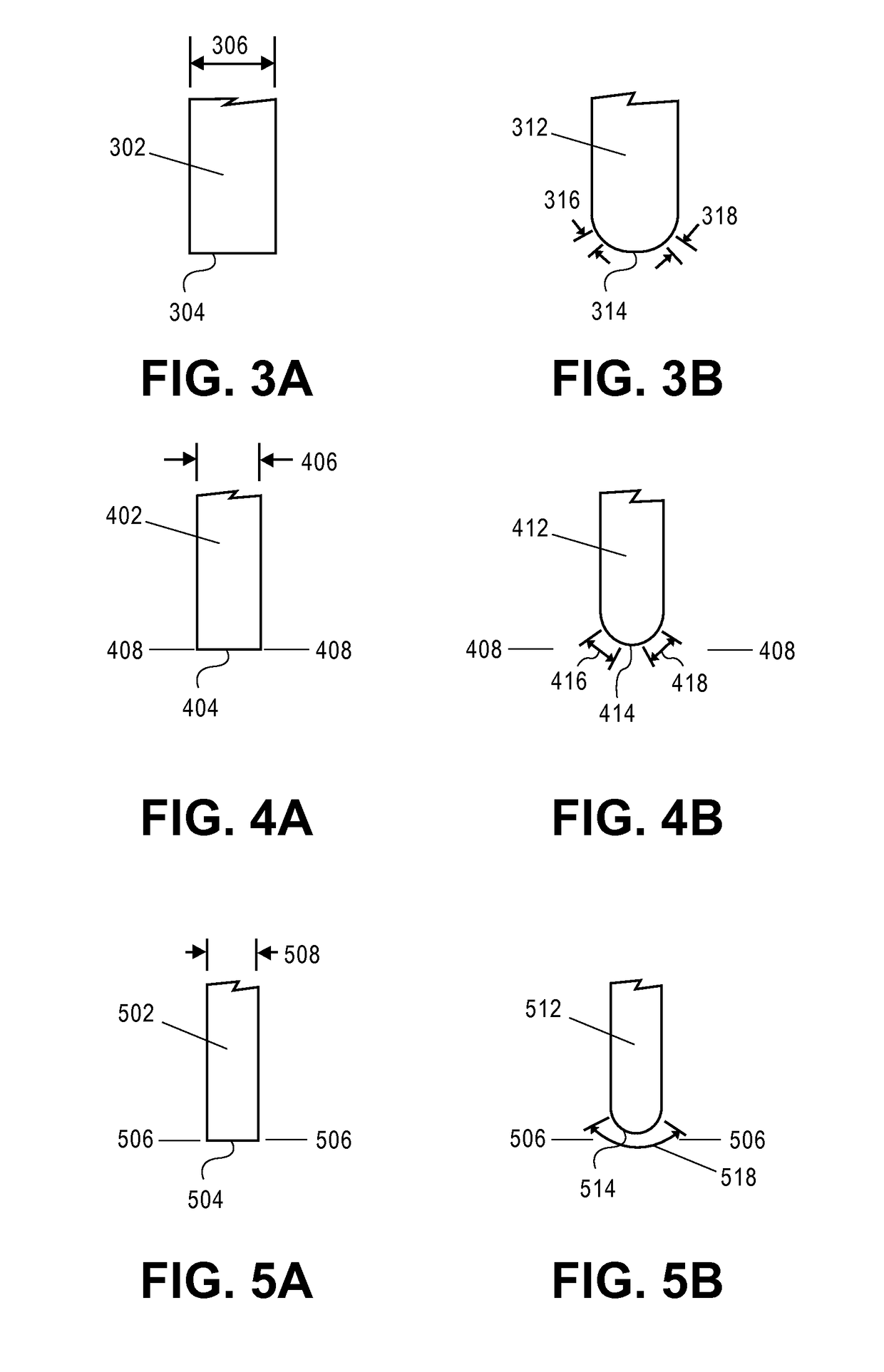

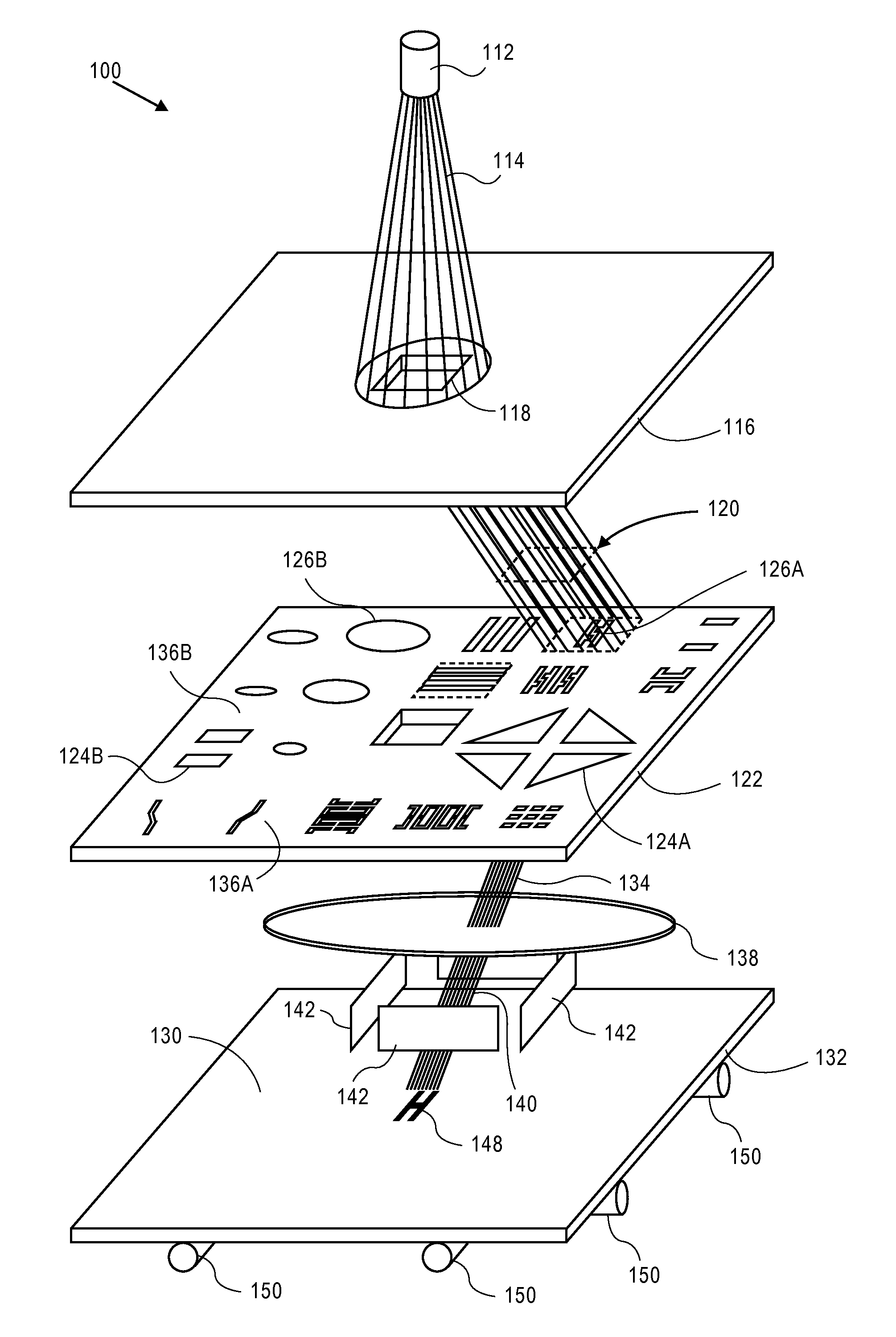

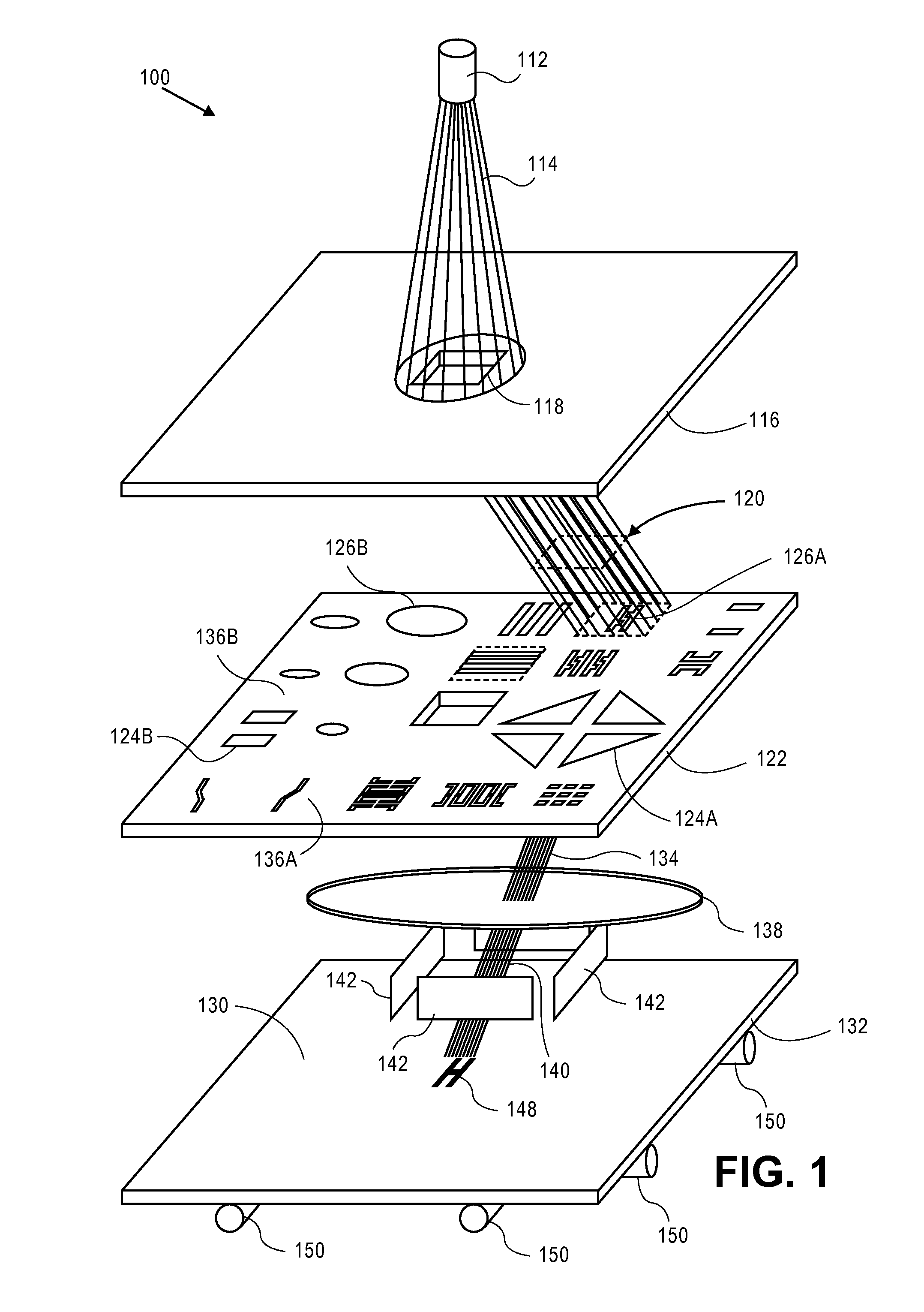

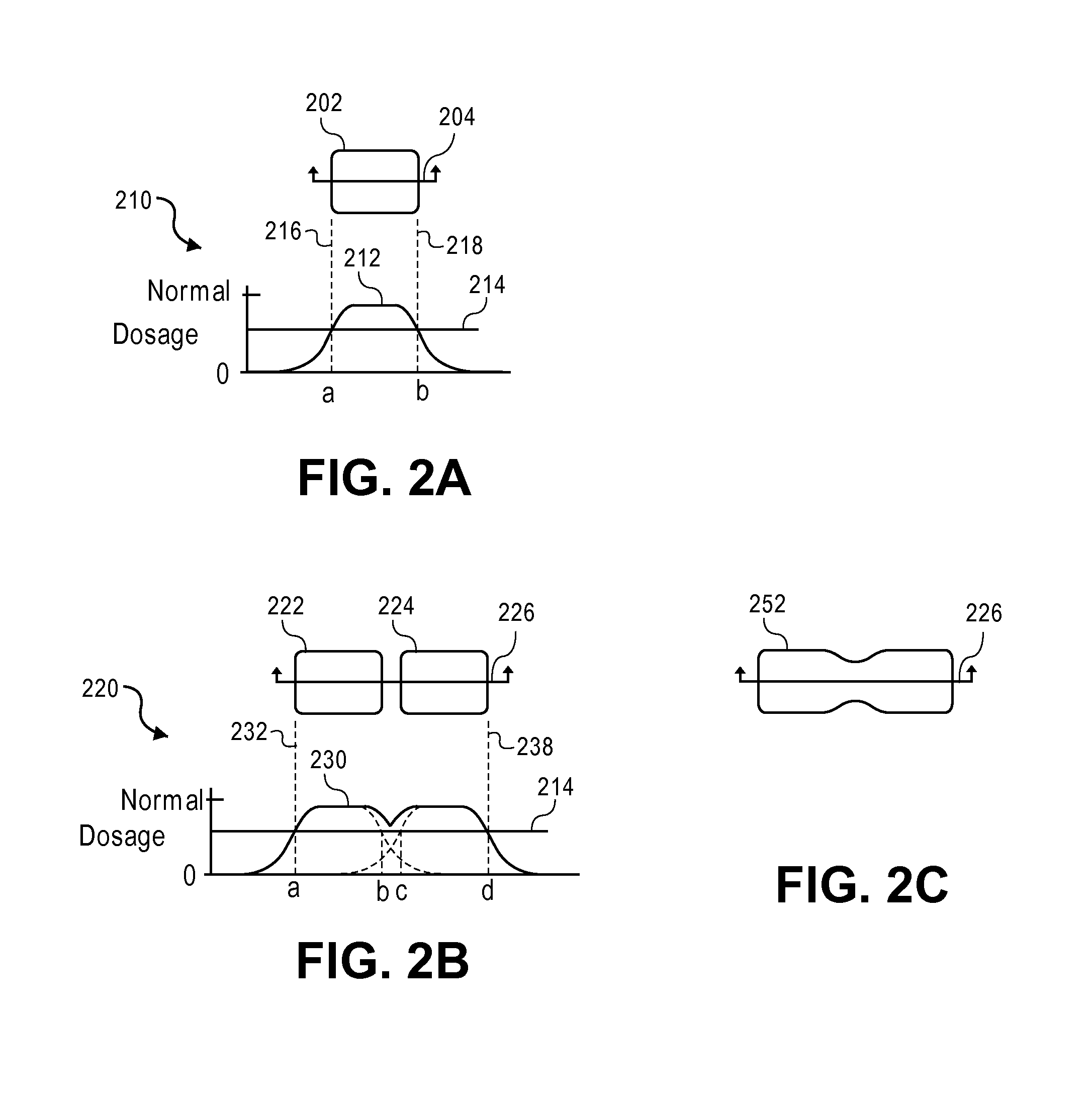

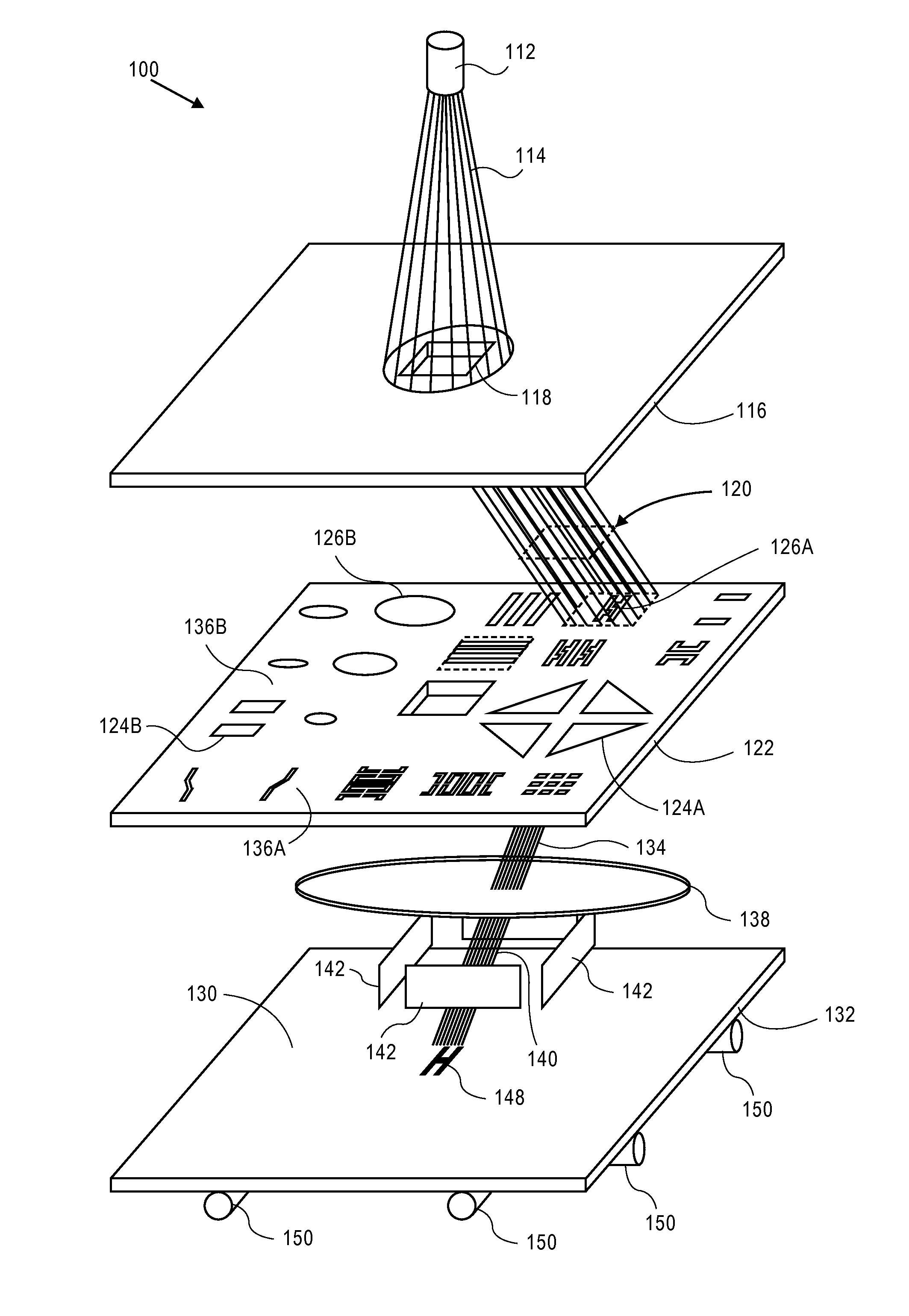

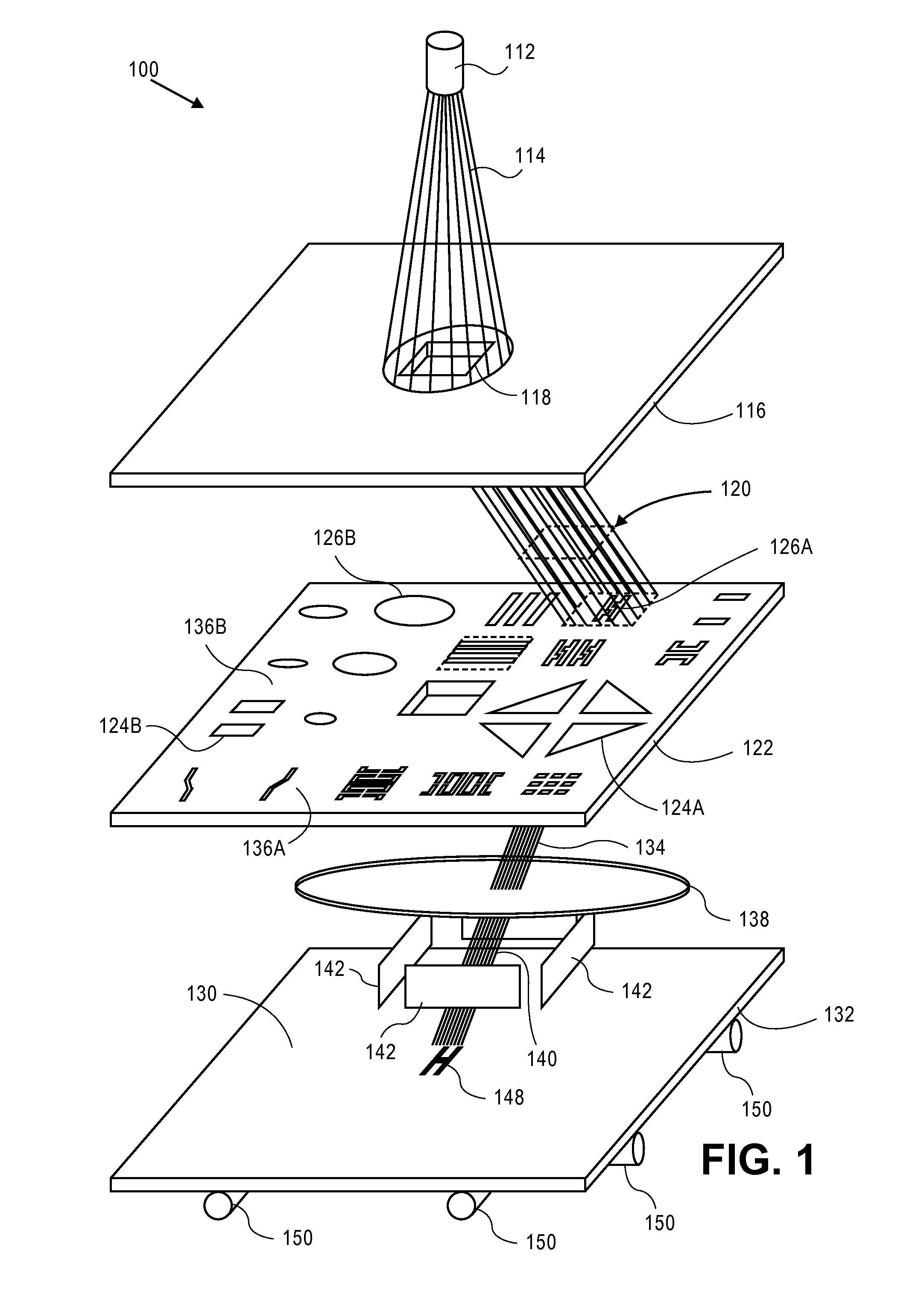

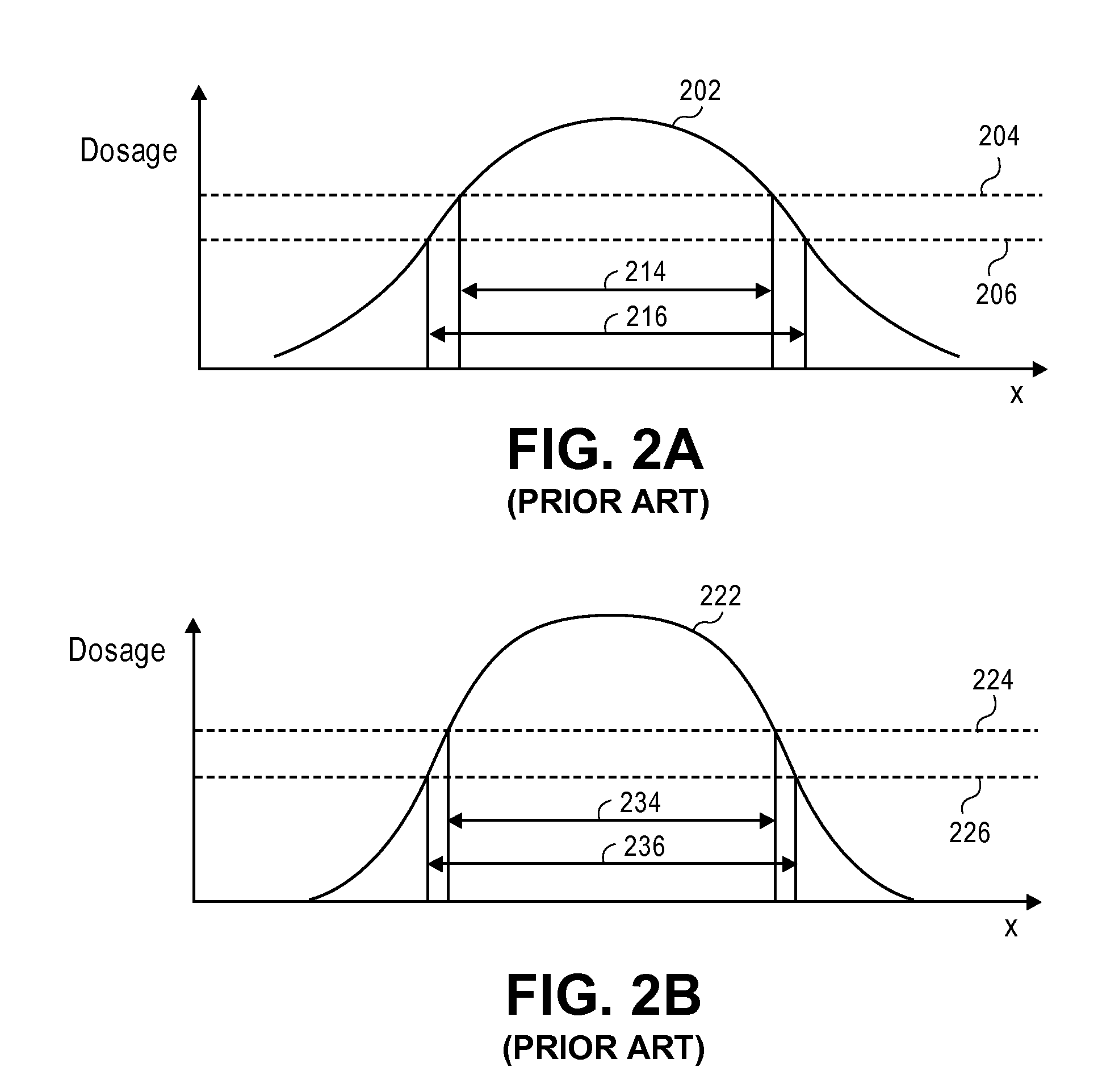

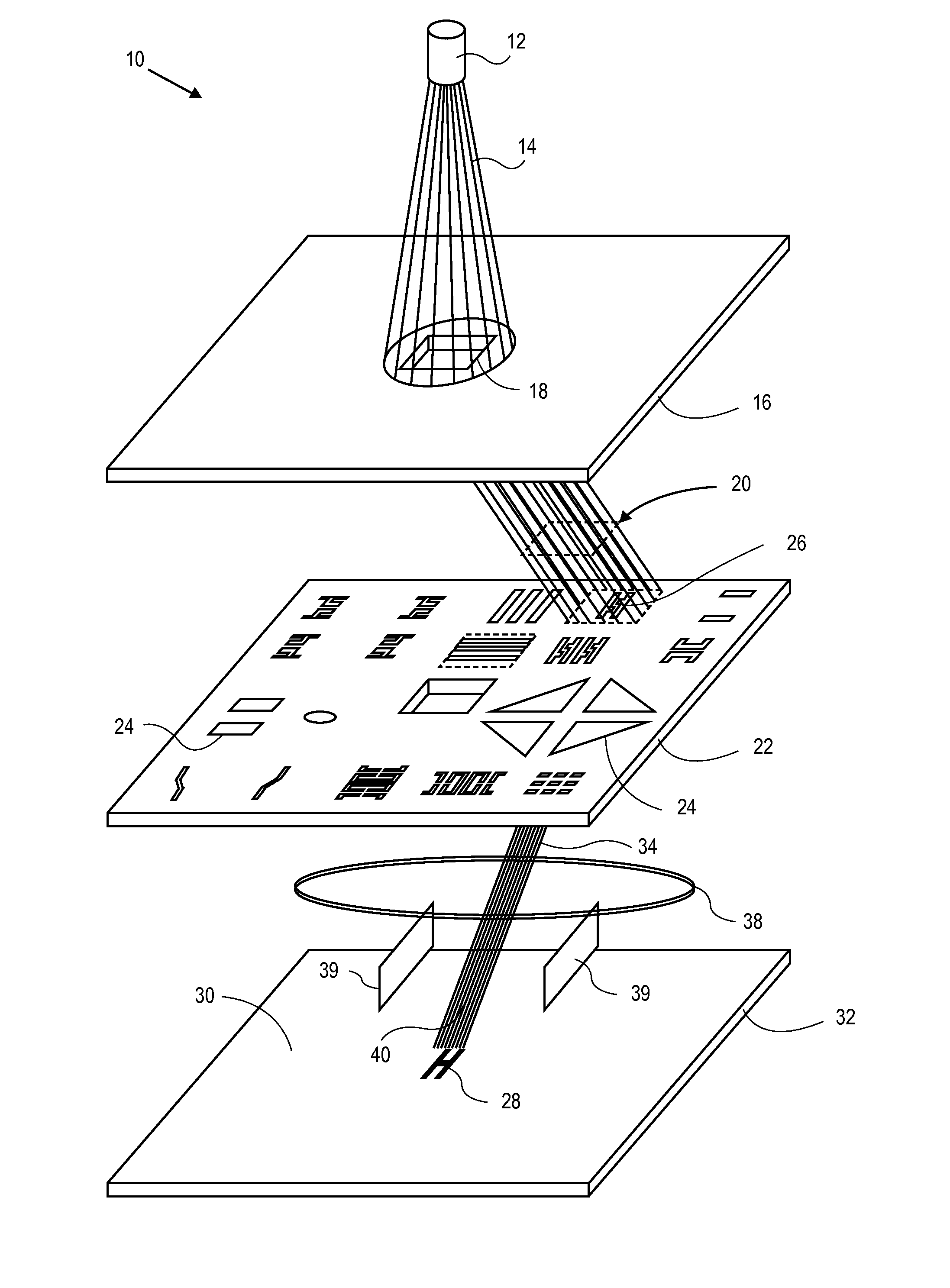

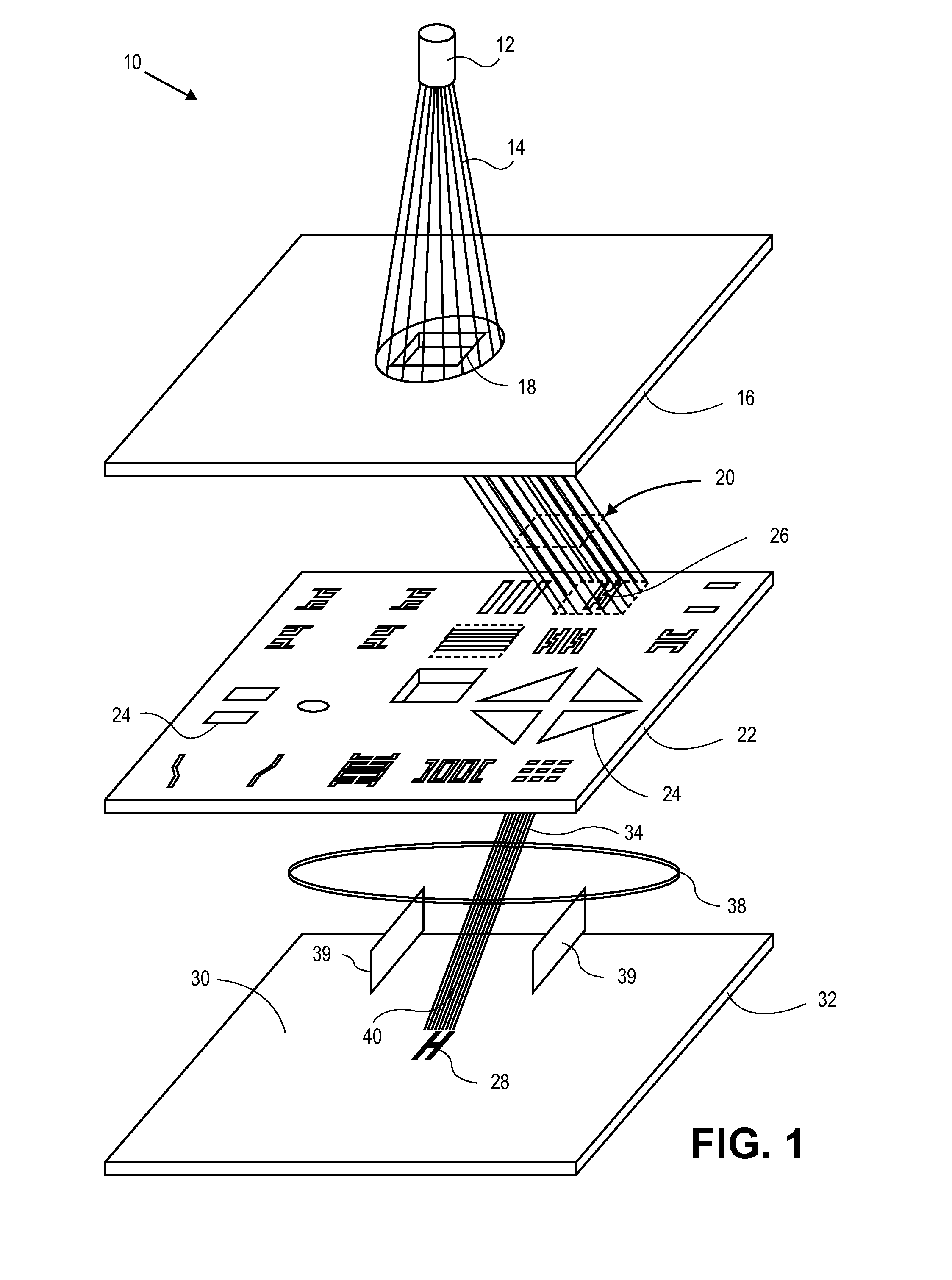

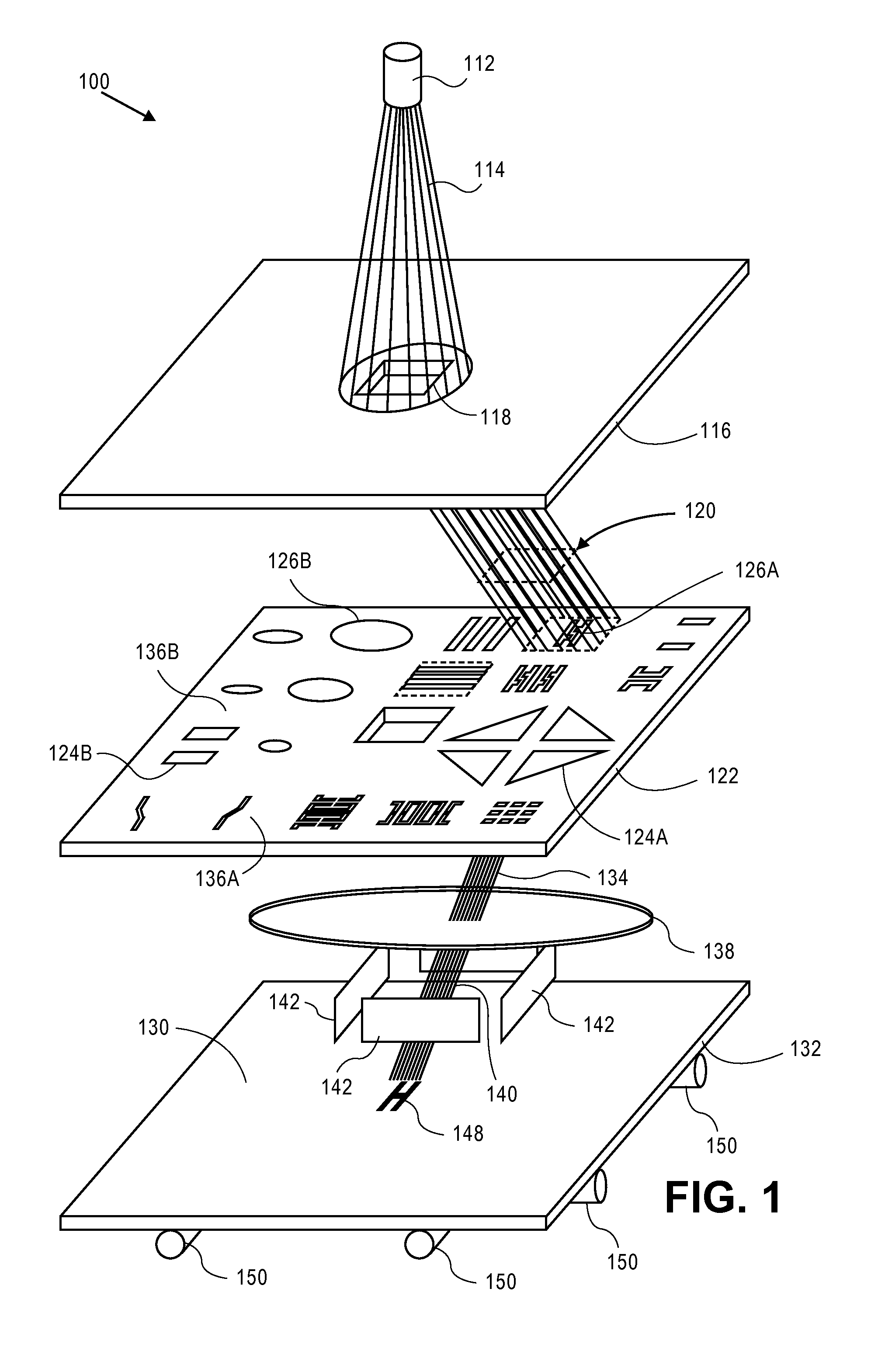

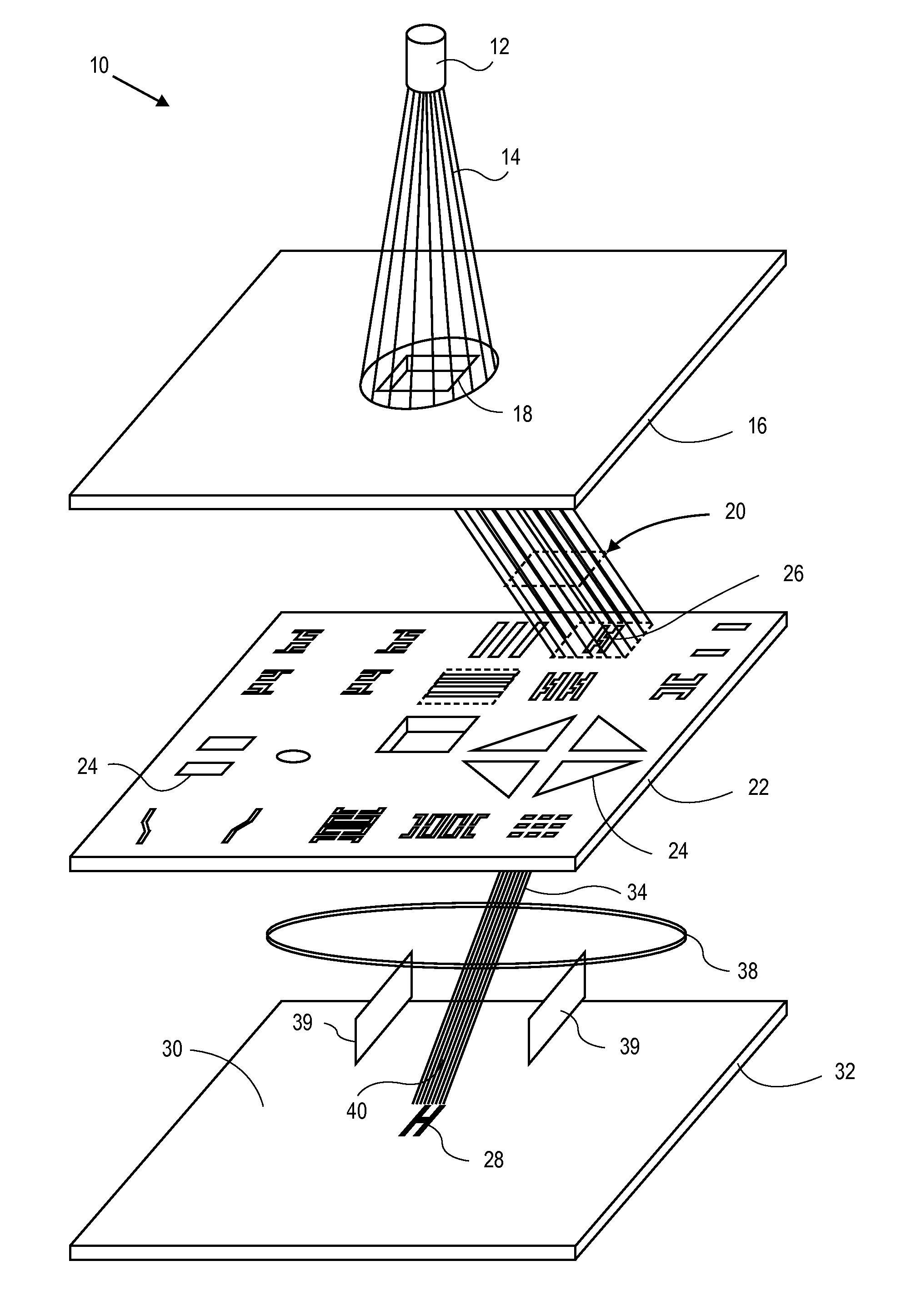

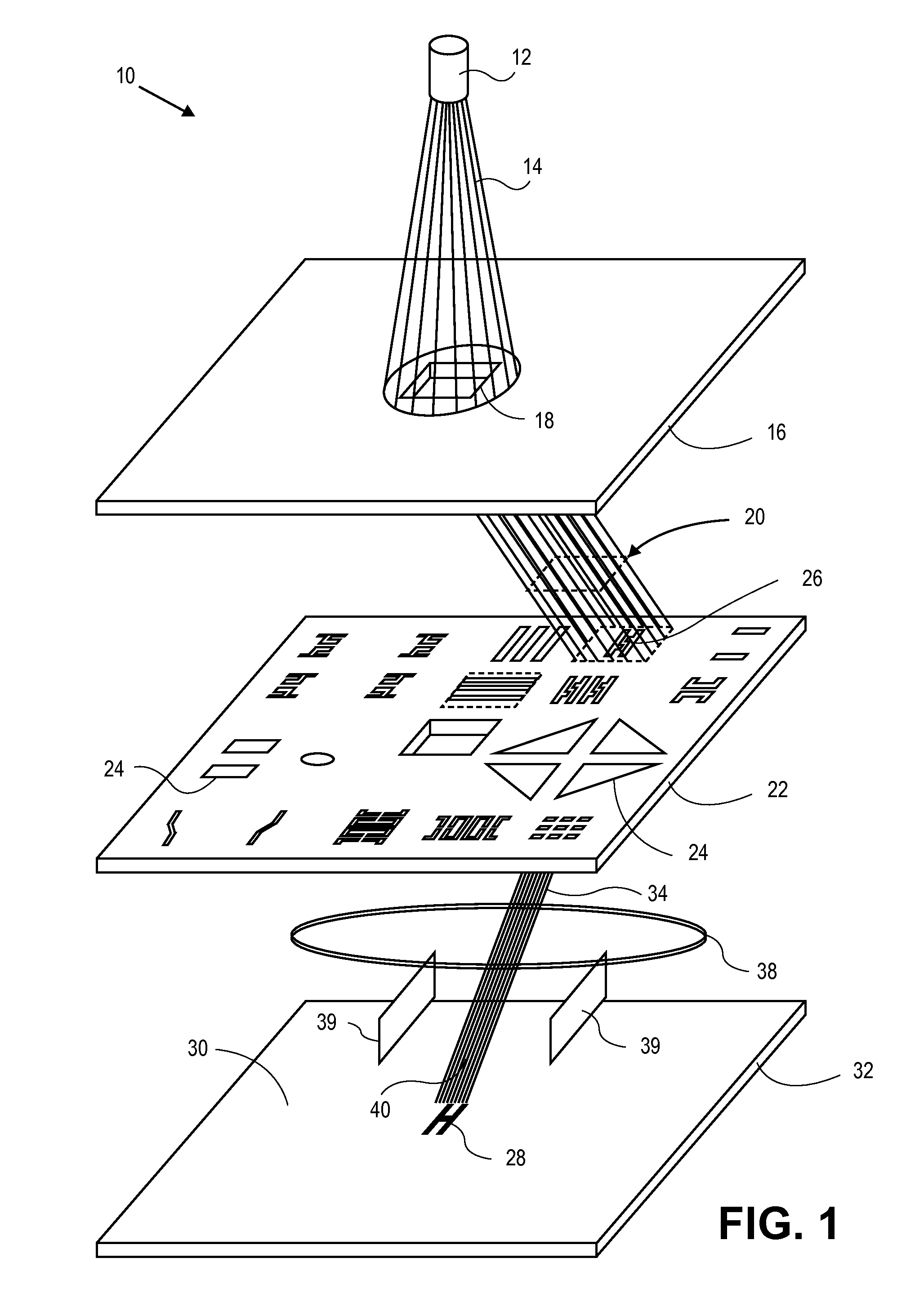

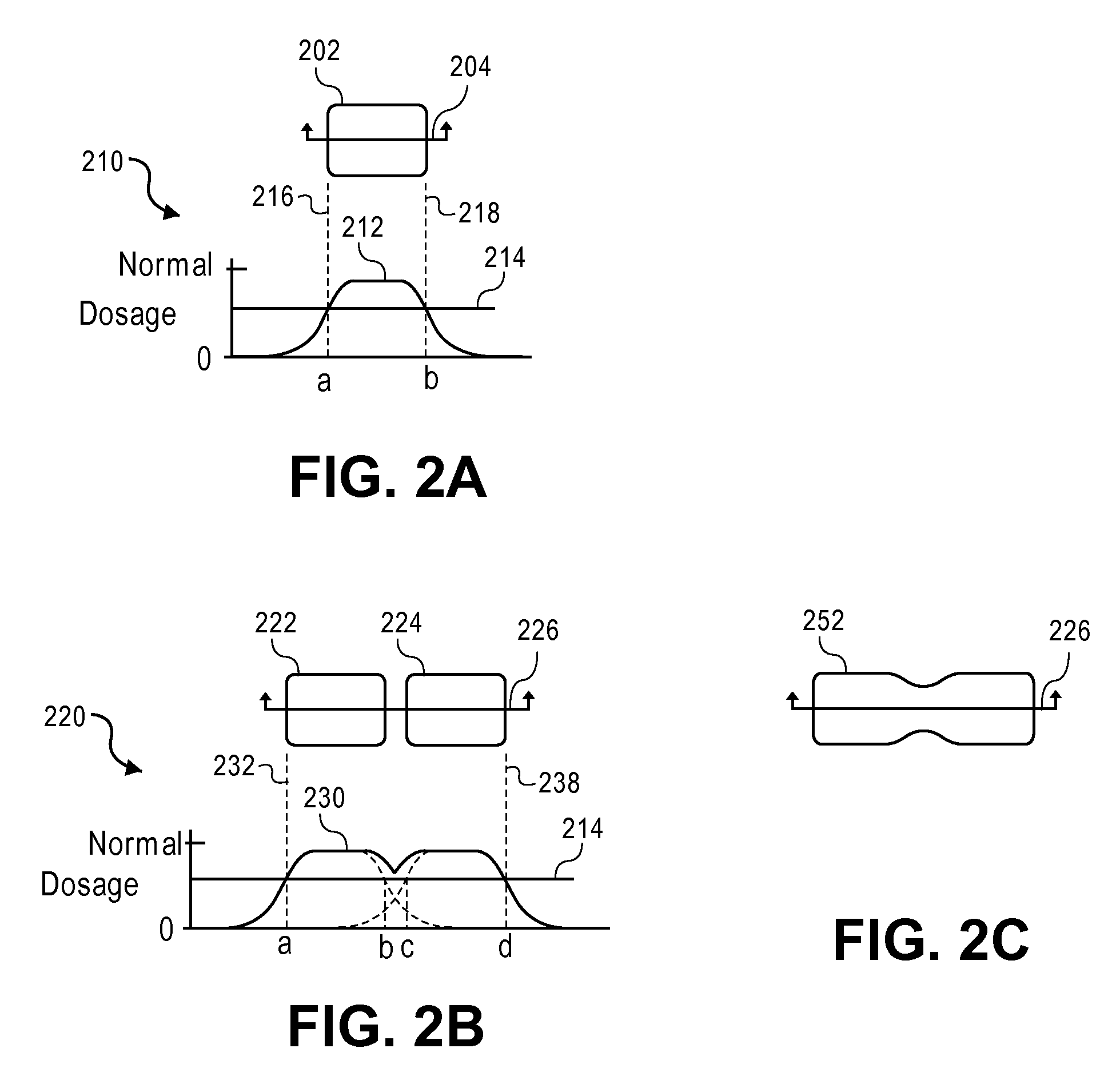

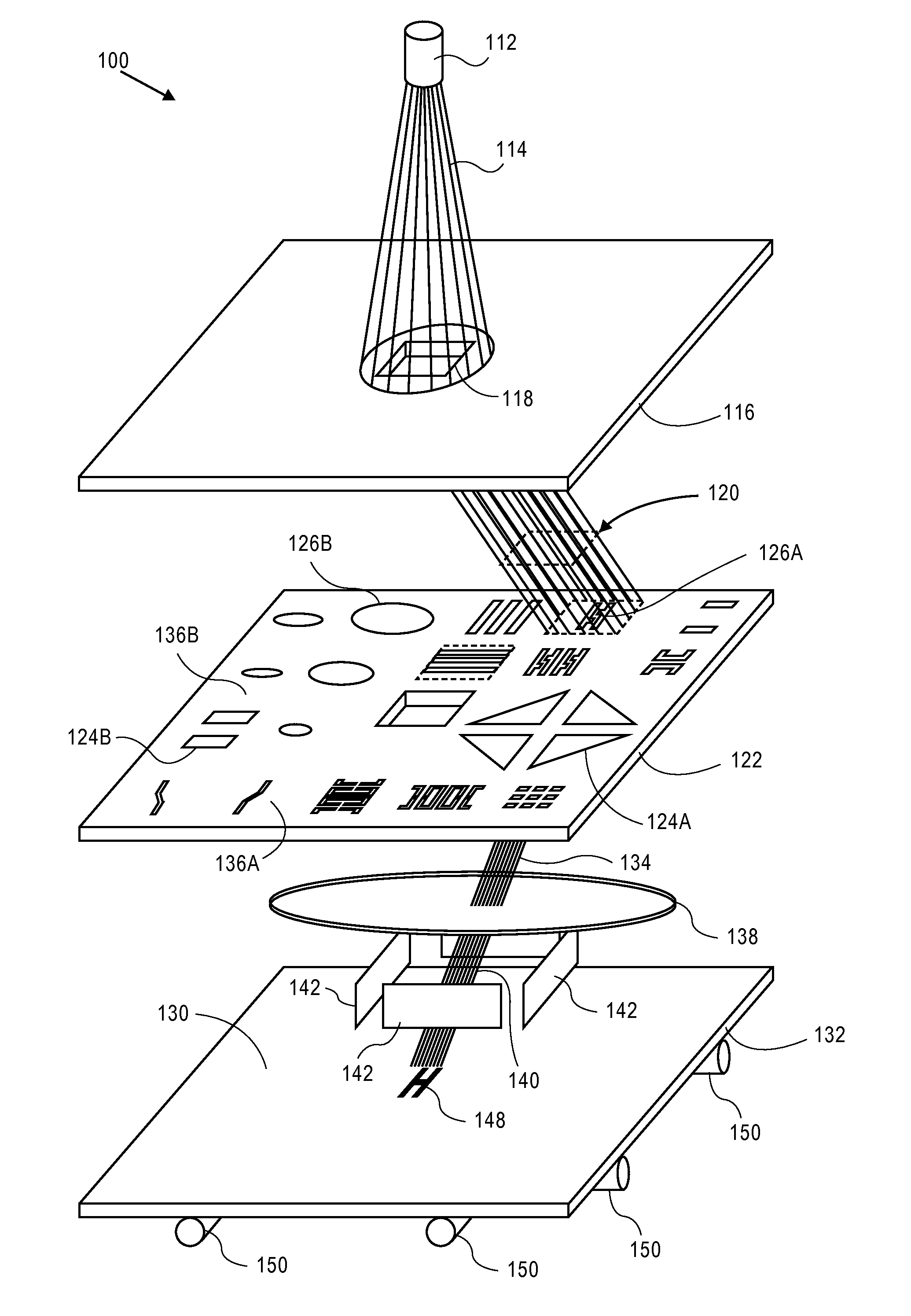

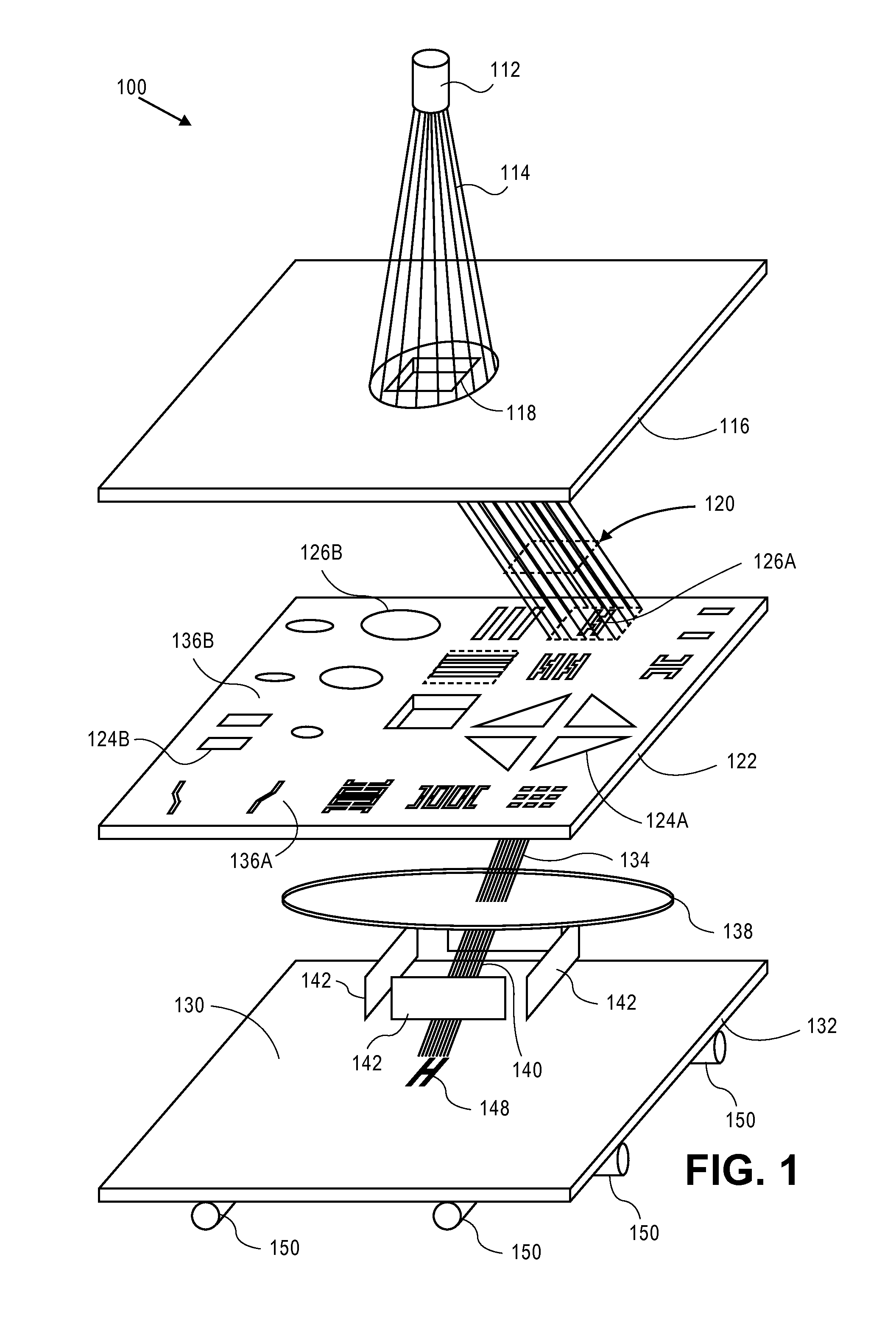

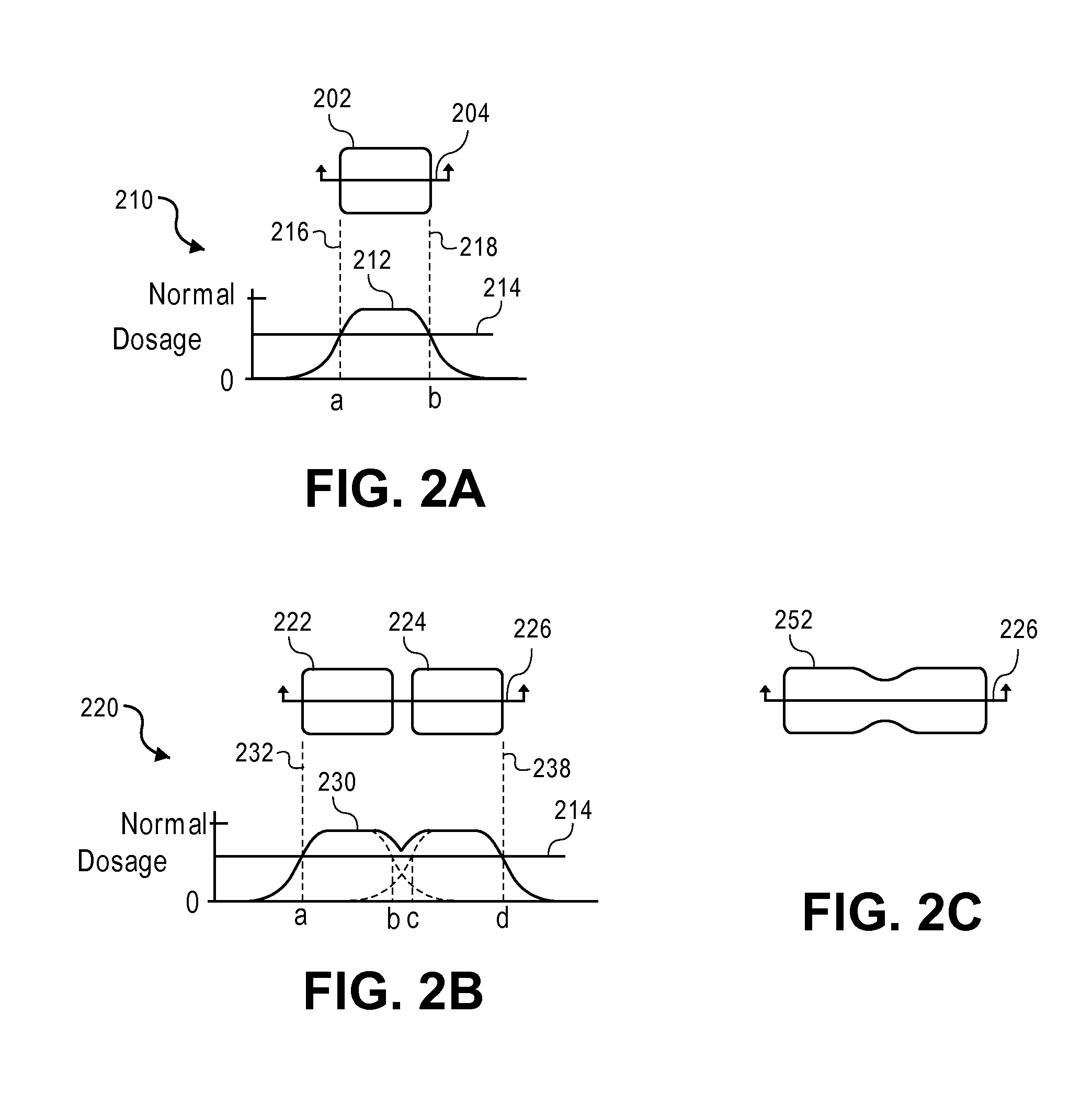

A method for fracturing or mask data preparation or proximity effect correction of a desired pattern to be formed on a reticle is disclosed in which a plurality of variable shaped beam (VSB) shots are determined which can form the desired pattern. Shots within the plurality of VSB shots are allowed to overlap each other. Dosages of the shots may also be allowed to vary with respect to each other. The union of the plurality of shots may deviate from the desired pattern. The plurality of shots may be determined such that a pattern on the surface calculated from the plurality of shots is within a predetermined tolerance of the desired pattern. In some embodiments, an optimization technique may be used to minimize shot count. In other embodiments, the plurality of shots may be optionally selected from one or more pre-computed VSB shots or groups of VSB shots.

Owner:D2S

Method and system for critical dimension uniformity using charged particle beam lithography

ActiveUS20130283216A1Semiconductor/solid-state device manufacturingOriginals for photomechanical treatmentMask data preparationCritical dimension

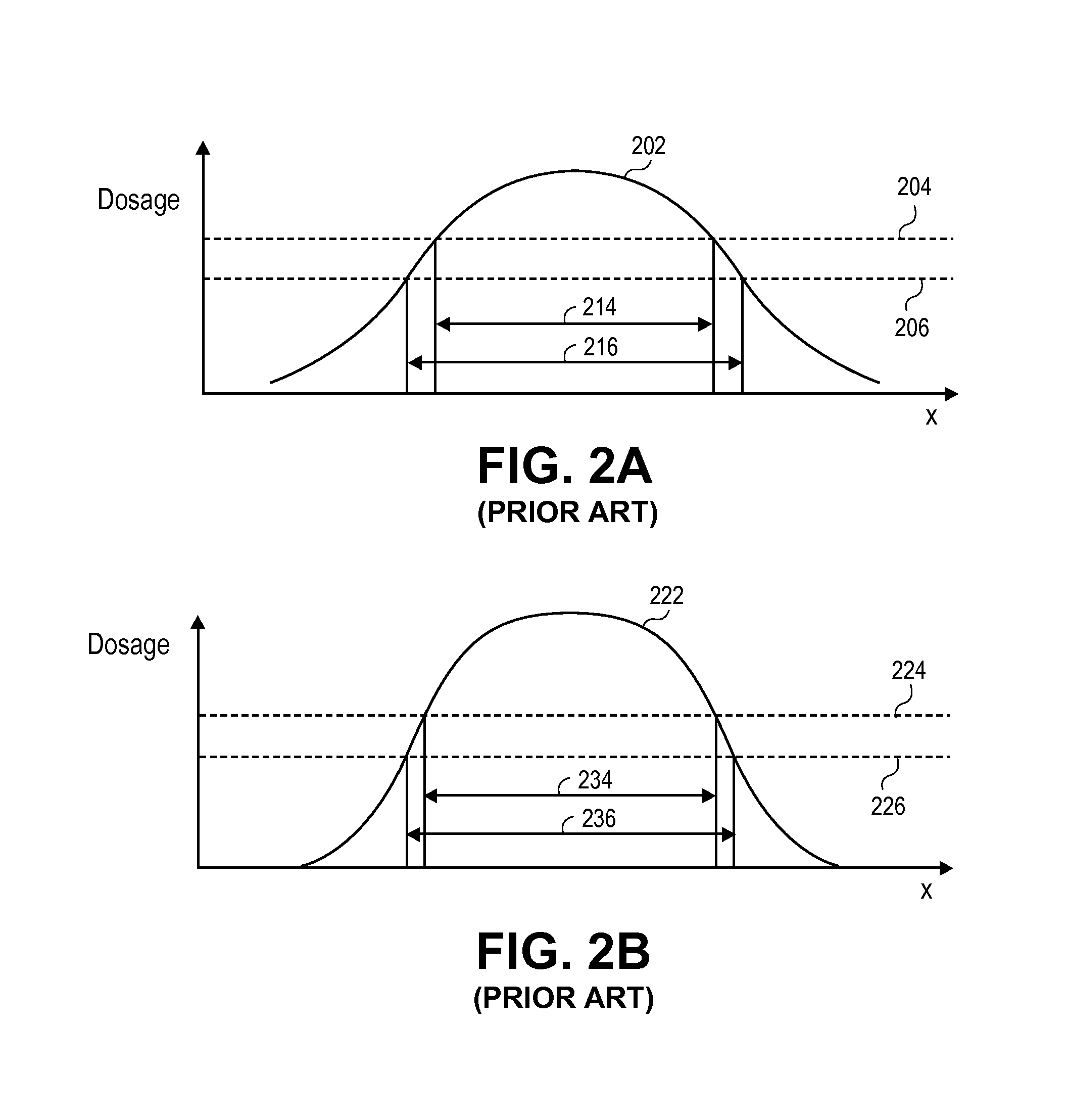

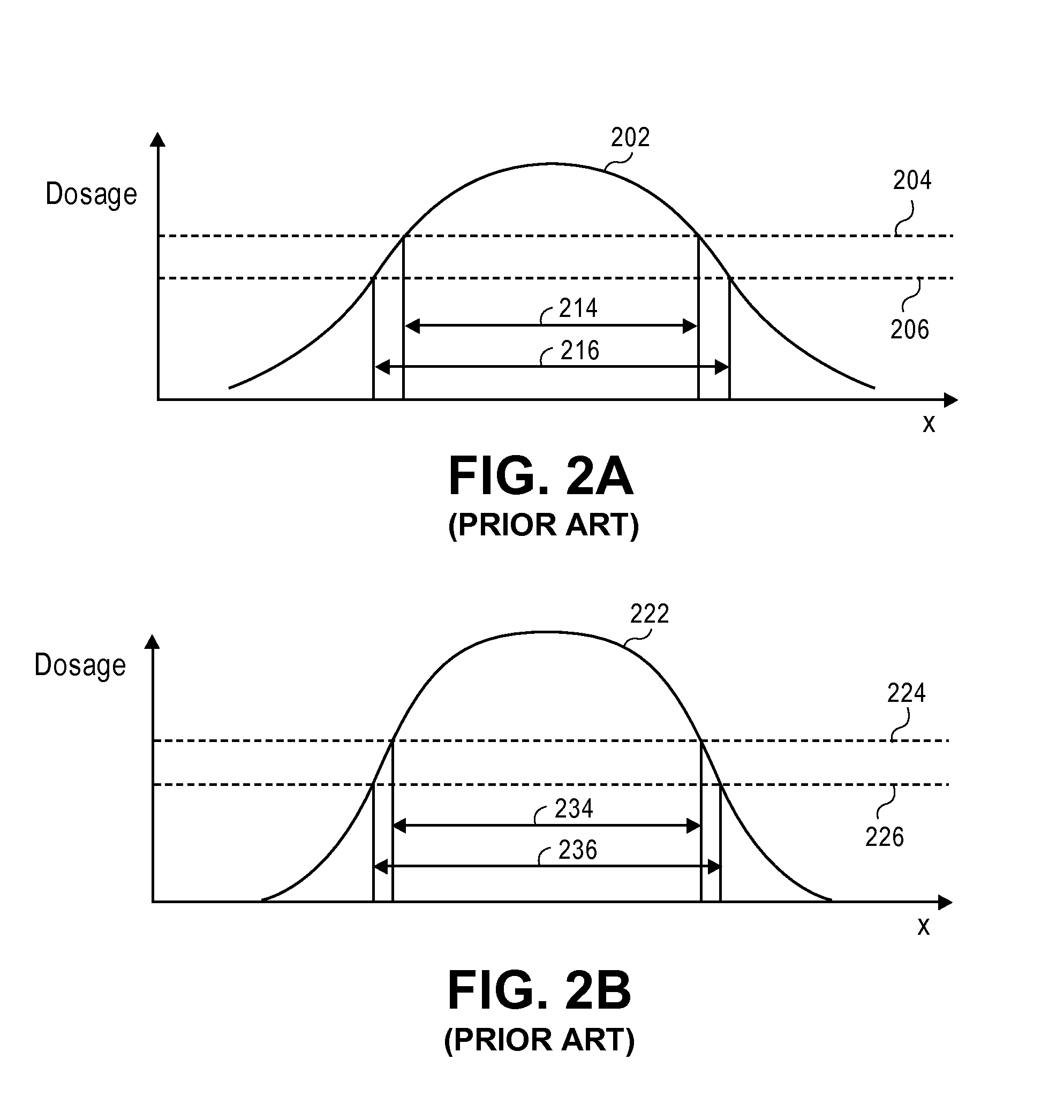

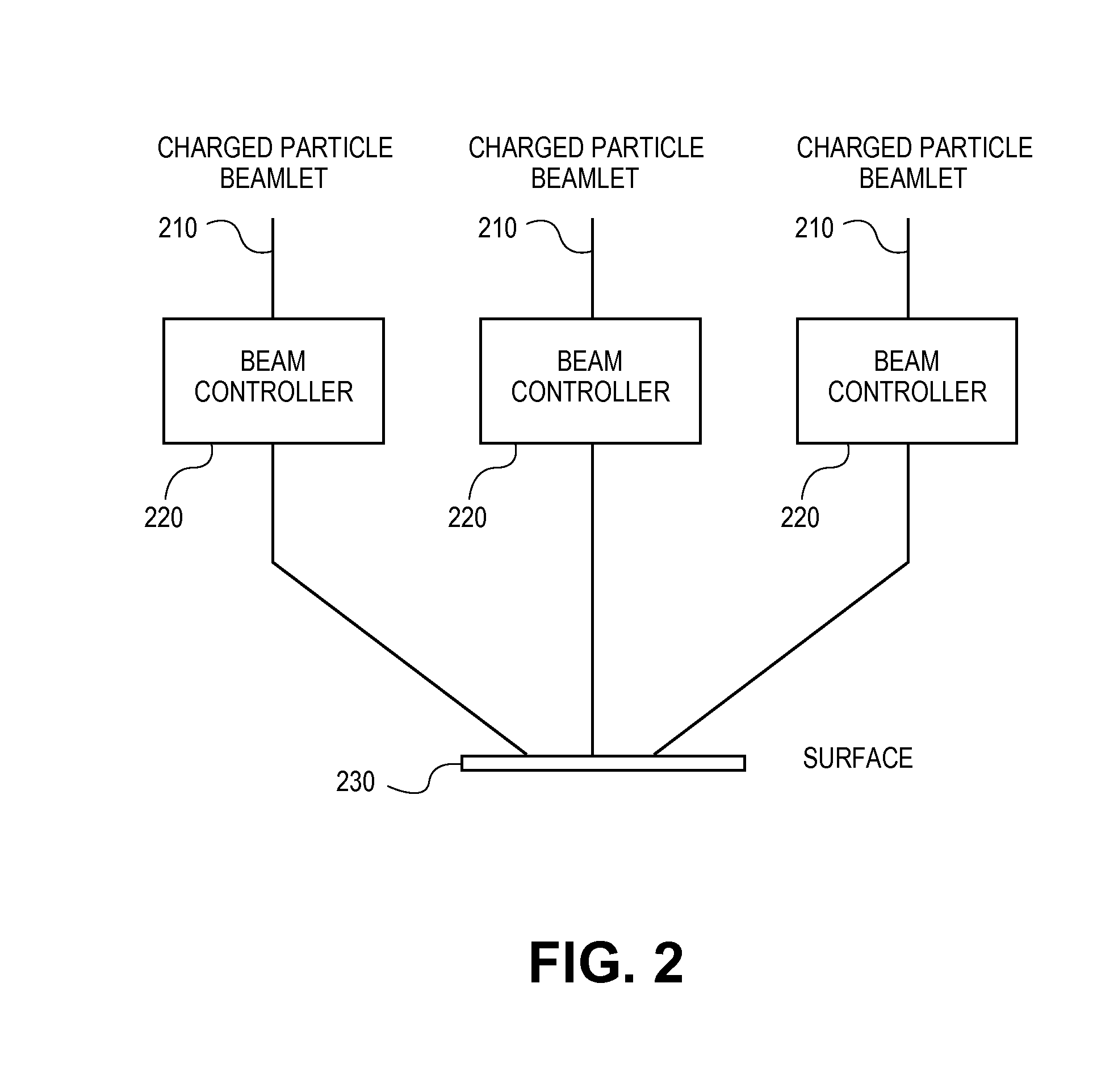

A method for mask data preparation or mask process correction is disclosed in which a set of charged particle beam shots is determined which is capable of forming a pattern on a surface, wherein critical dimension uniformity (CDU) of the pattern is optimized. In some embodiments the CDU is optimized by varying at least two factors. In other embodiments, model-based techniques are used. In yet other embodiments, the surface is a reticle to be used in an optical lithographic process to form a pattern on a wafer, and CDU on the wafer is optimized.

Owner:D2S

Method and system for design of a reticle to be manufactured using character projection lithography

InactiveUS20100058282A1Reducing shot countShorten write timeElectric discharge tubesRadiation applicationsMask data preparationCamera lens

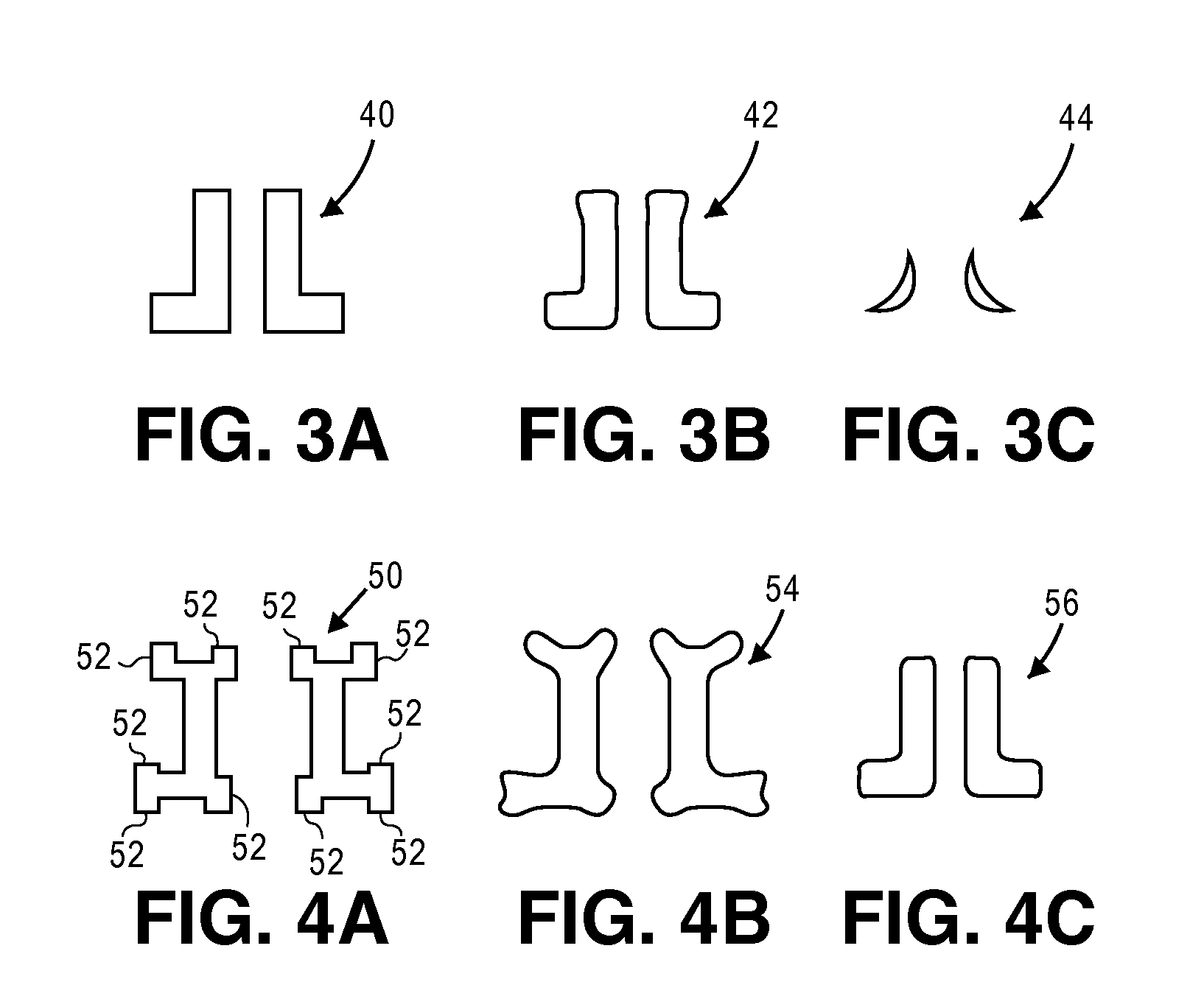

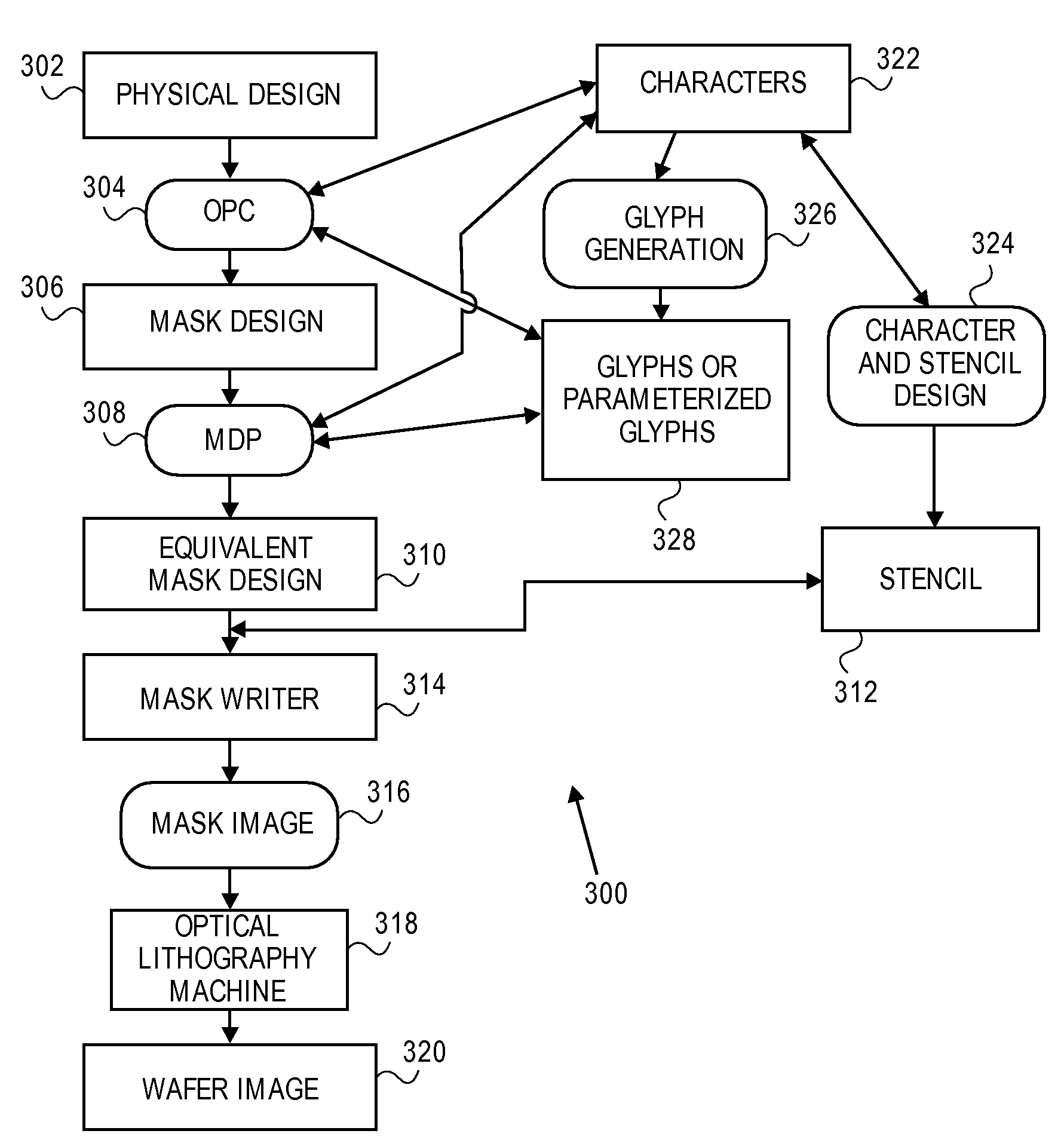

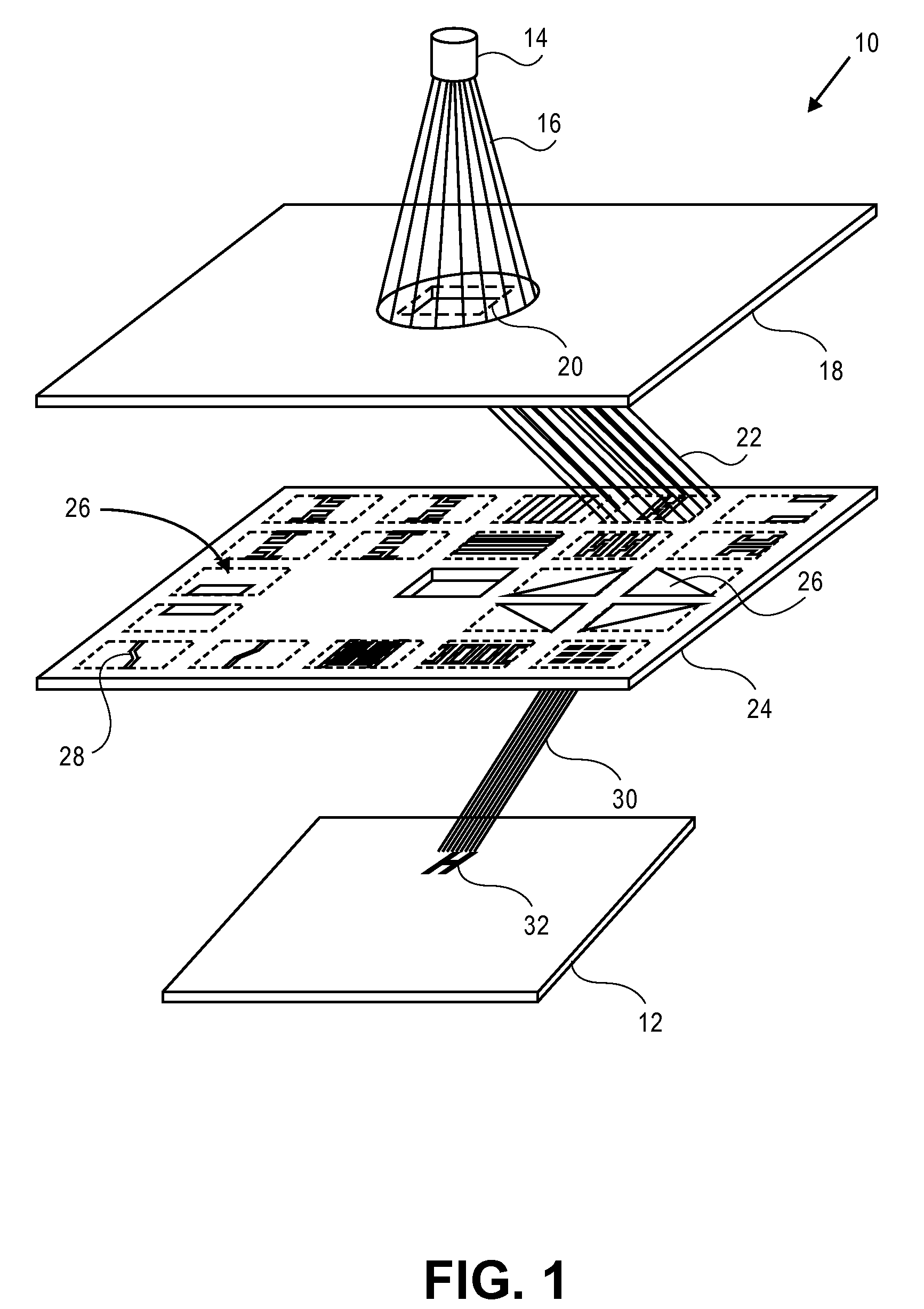

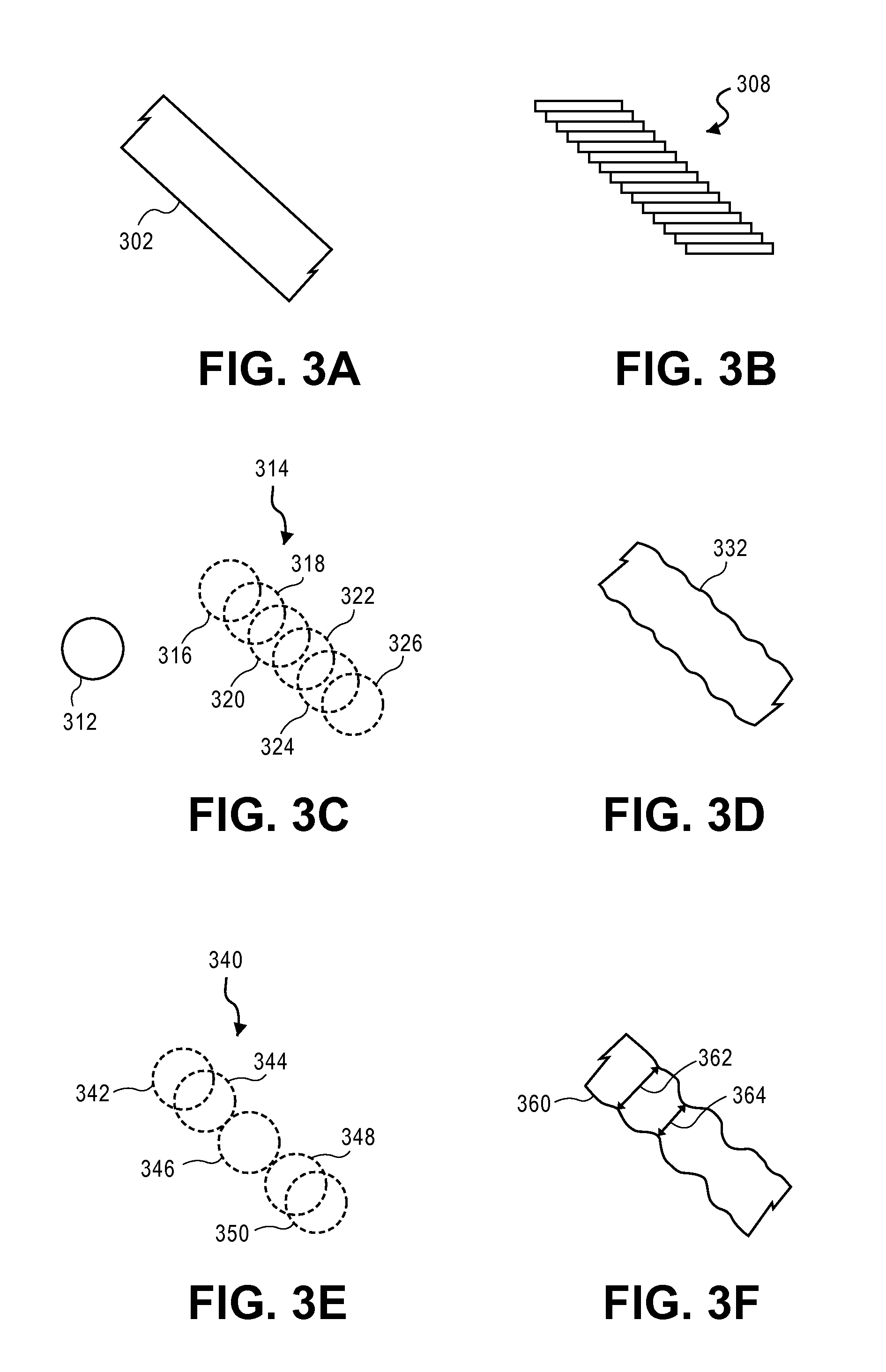

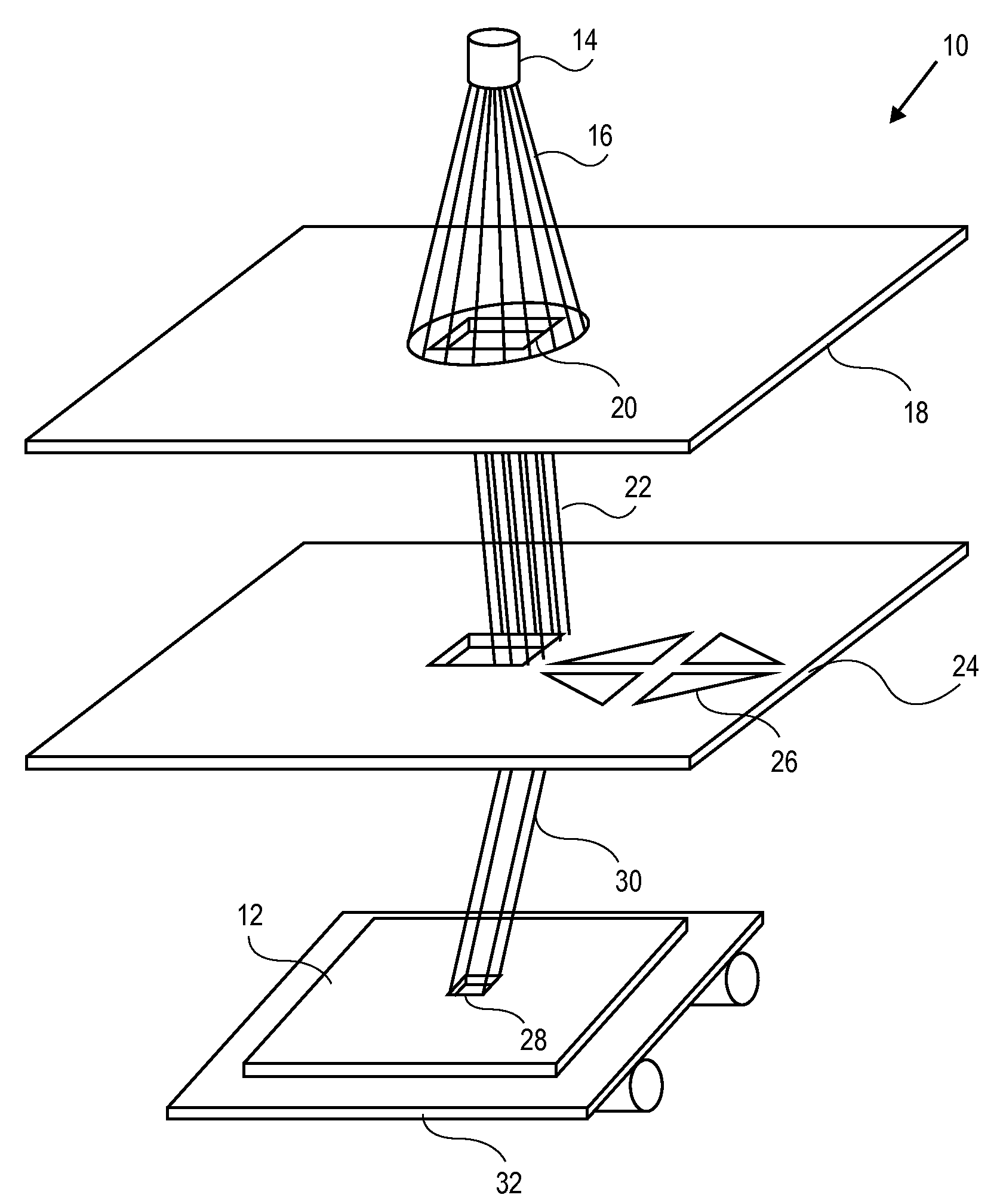

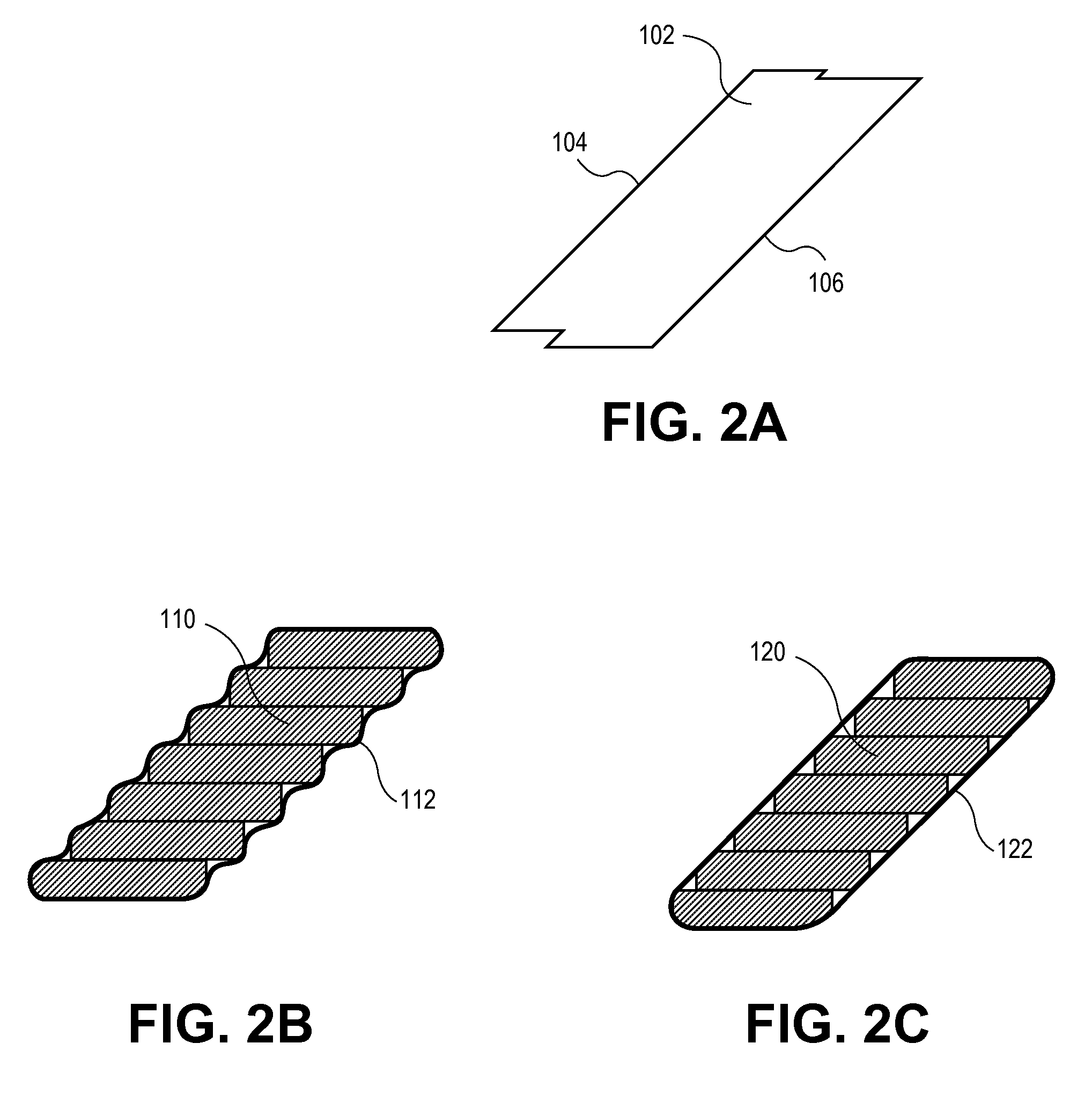

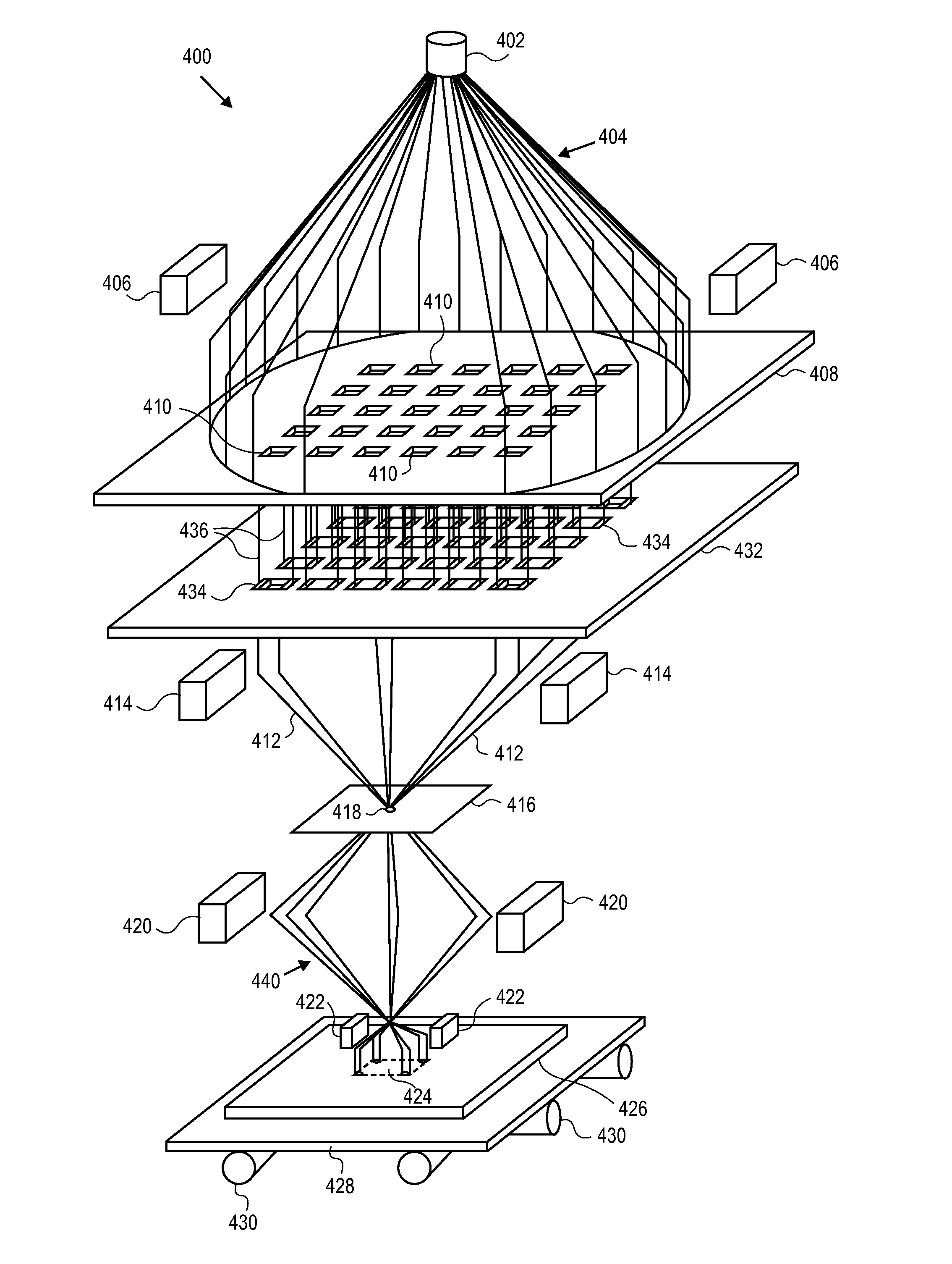

A method for fracturing or mask data preparation or proximity effect correction is disclosed which comprises the steps of inputting patterns to be formed on a surface, a subset of the patterns being slightly different variations of each other and selecting a set of characters some of which are complex characters to be used to form the number of patterns, and reducing shot count or total write time by use of a character varying technique. A system for fracturing or mask data preparation or proximity effect correction is also disclosed.

Owner:D2S

Method and system for design of a reticle to be manufactured using character projection lithography

InactiveUS7759027B2Reduce countShorten the timeElectric discharge tubesRadiation applicationsMask data preparationAlgorithm

A method for fracturing or mask data preparation or proximity effect correction is disclosed which comprises the steps of inputting patterns to be formed on a surface, a subset of the patterns being slightly different variations of each other and selecting a set of characters some of which are complex characters to be used to form the number of patterns, and reducing shot count or total write time by use of a character varying technique. A system for fracturing or mask data preparation or proximity effect correction is also disclosed.

Owner:D2S

Method and System for Design of a Reticle to be Manufactured Using Variable Shaped Beam Lithography

ActiveUS20100058279A1Minimize shot countElectric discharge tubesRadiation applicationsMask data preparationLithographic artist

A method for fracturing or mask data preparation or proximity effect correction of a desired pattern to be formed on a reticle is disclosed in which a plurality of variable shaped beam (VSB) shots are determined which can form the desired pattern. Shots within the plurality of VSB shots are allowed to overlap each other. Dosages of the shots may also be allowed to vary with respect to each other. The union of the plurality of shots may deviate from the desired pattern. The plurality of shots may be determined such that a pattern on the surface calculated from the plurality of shots is within a predetermined tolerance of the desired pattern. In some embodiments, an optimization technique may be used to minimize shot count. In other embodiments, the plurality of shots may be optionally selected from one or more pre-computed VSB shots or groups of VSB shots.

Owner:D2S

Mask data preparation

ActiveUS20050091632A1Electrical apparatusOriginals for photomechanical treatmentMask data preparationCritical zone

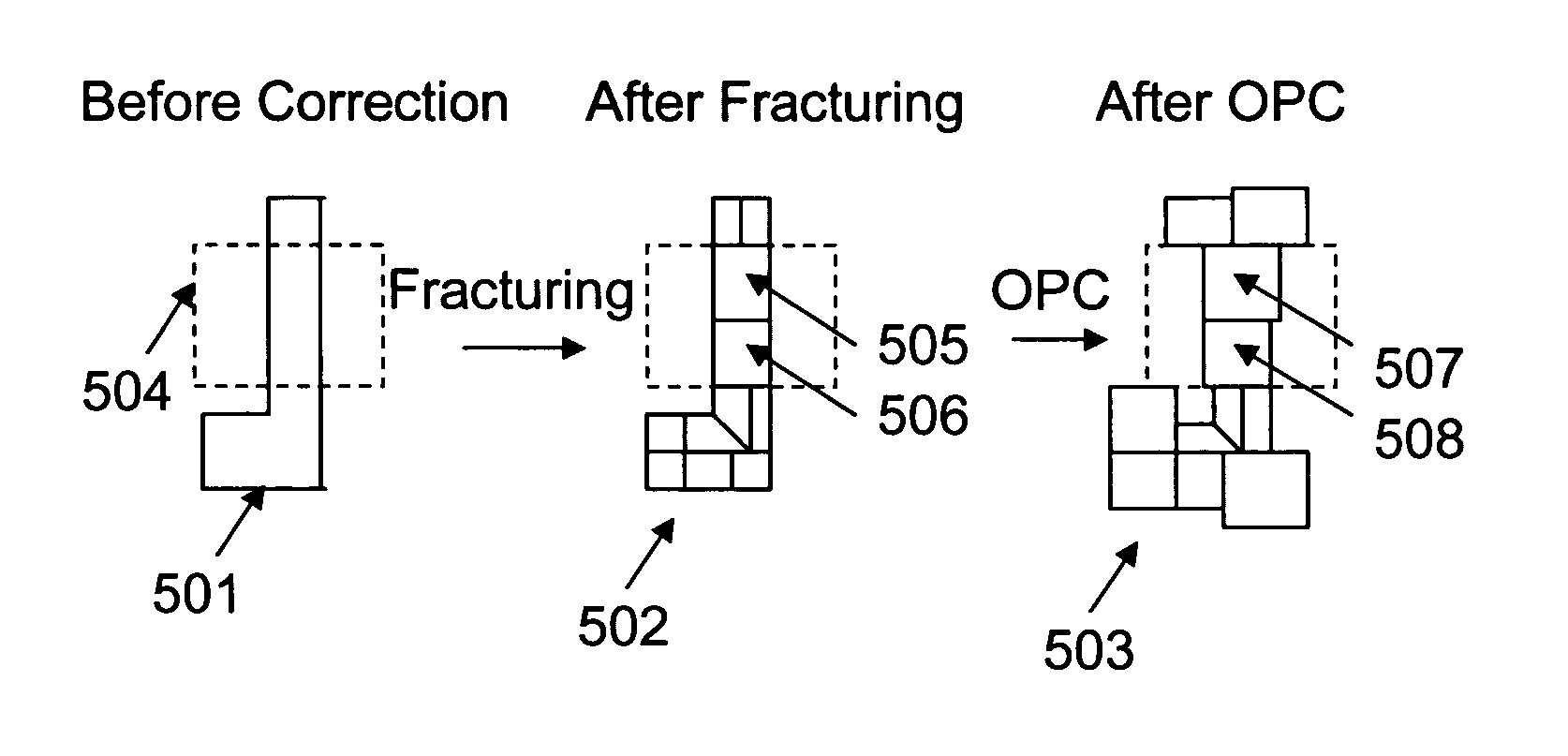

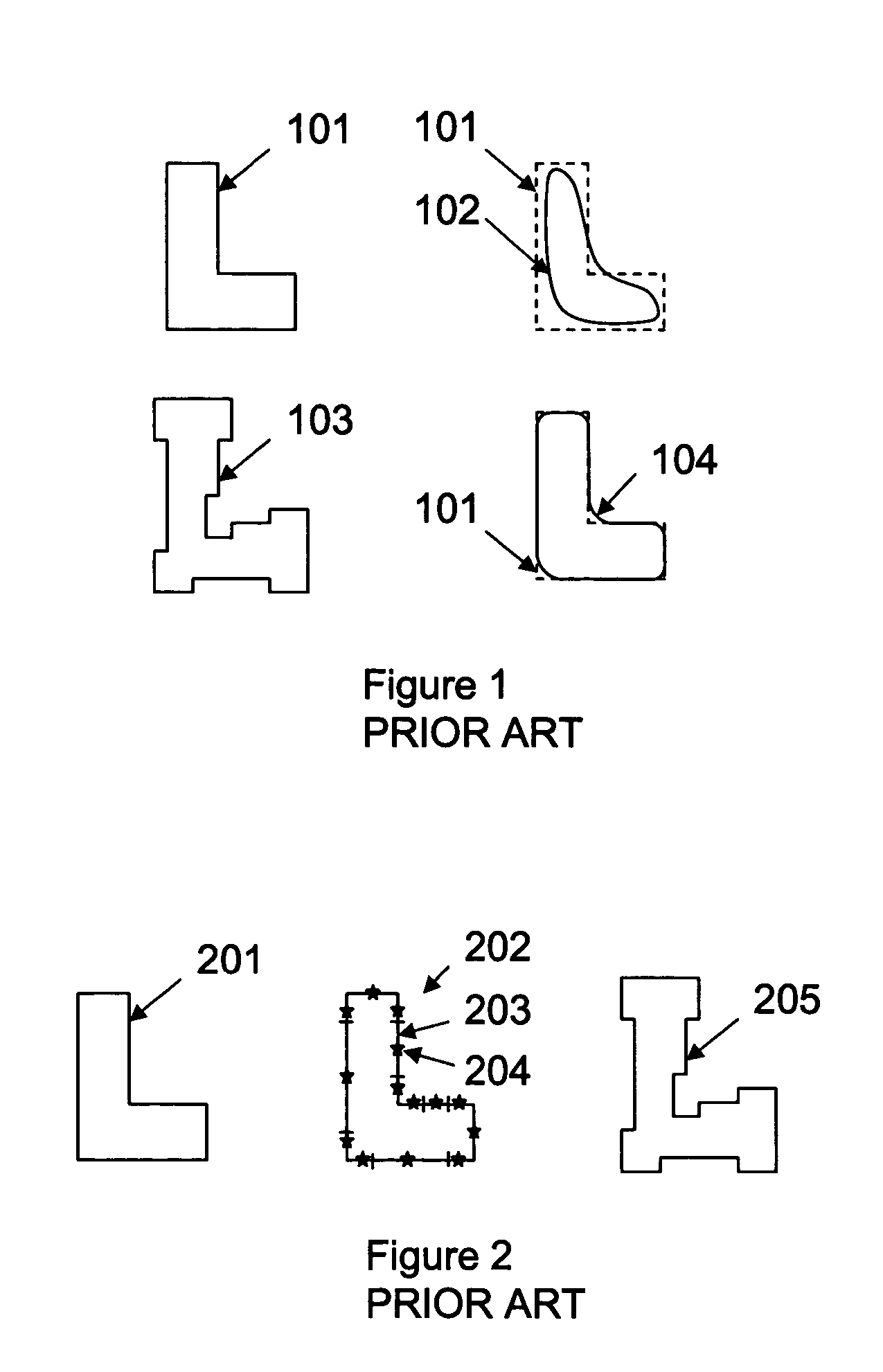

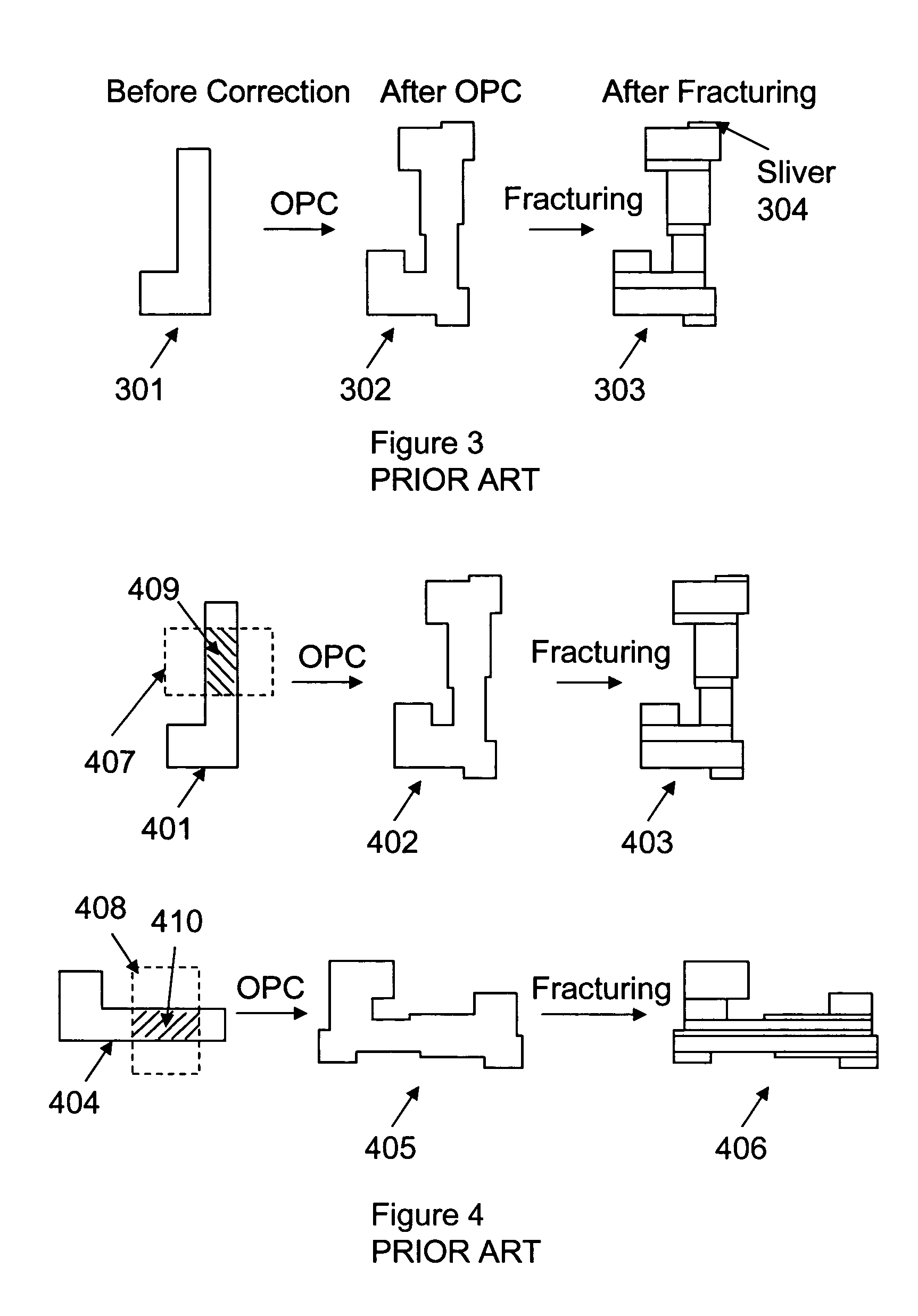

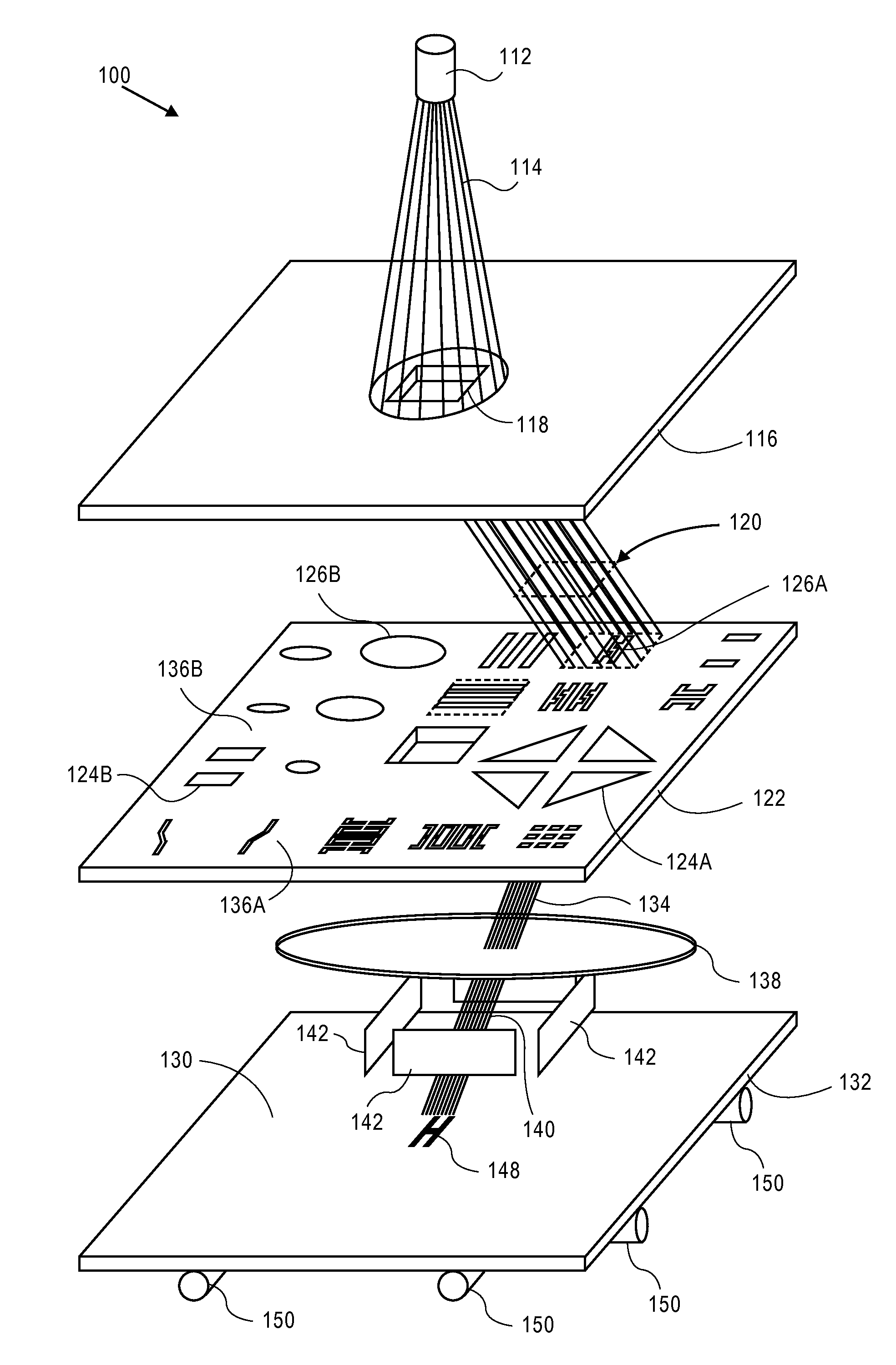

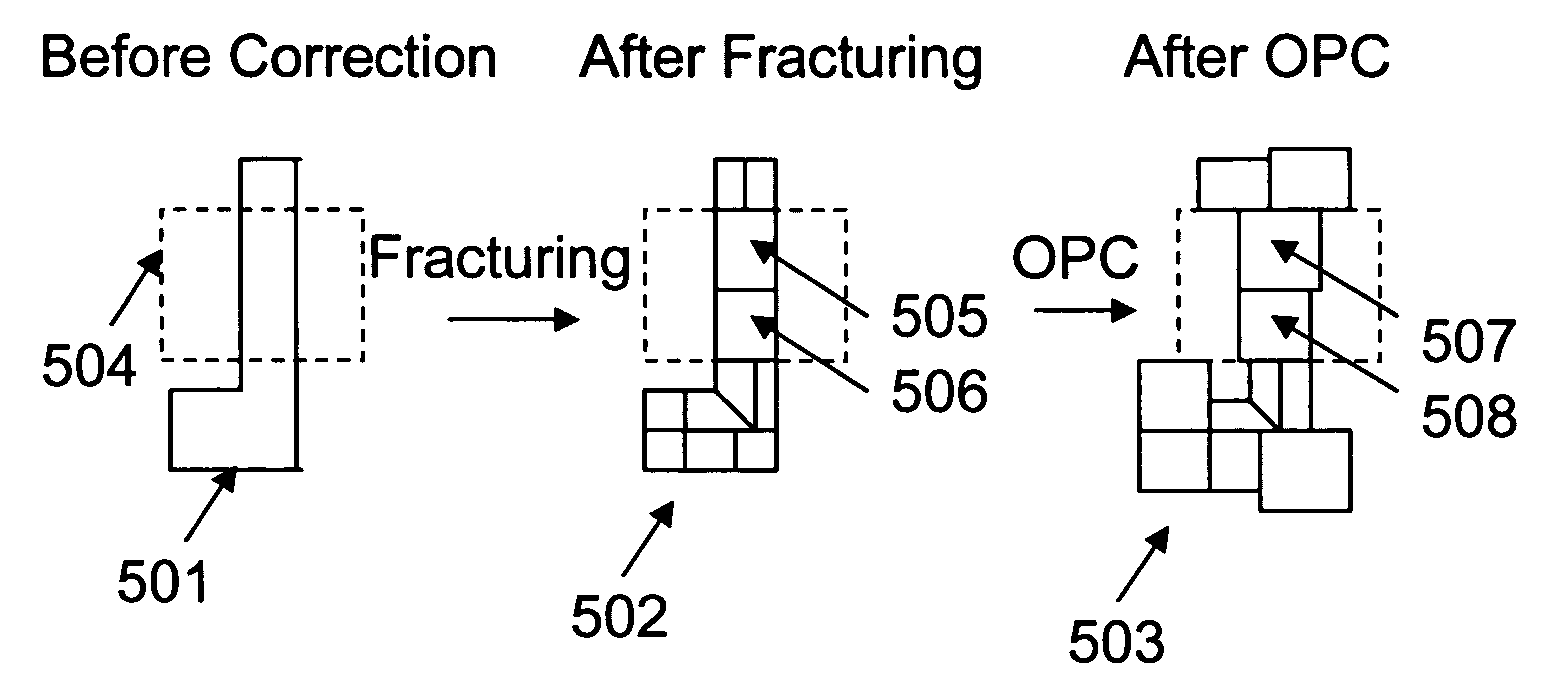

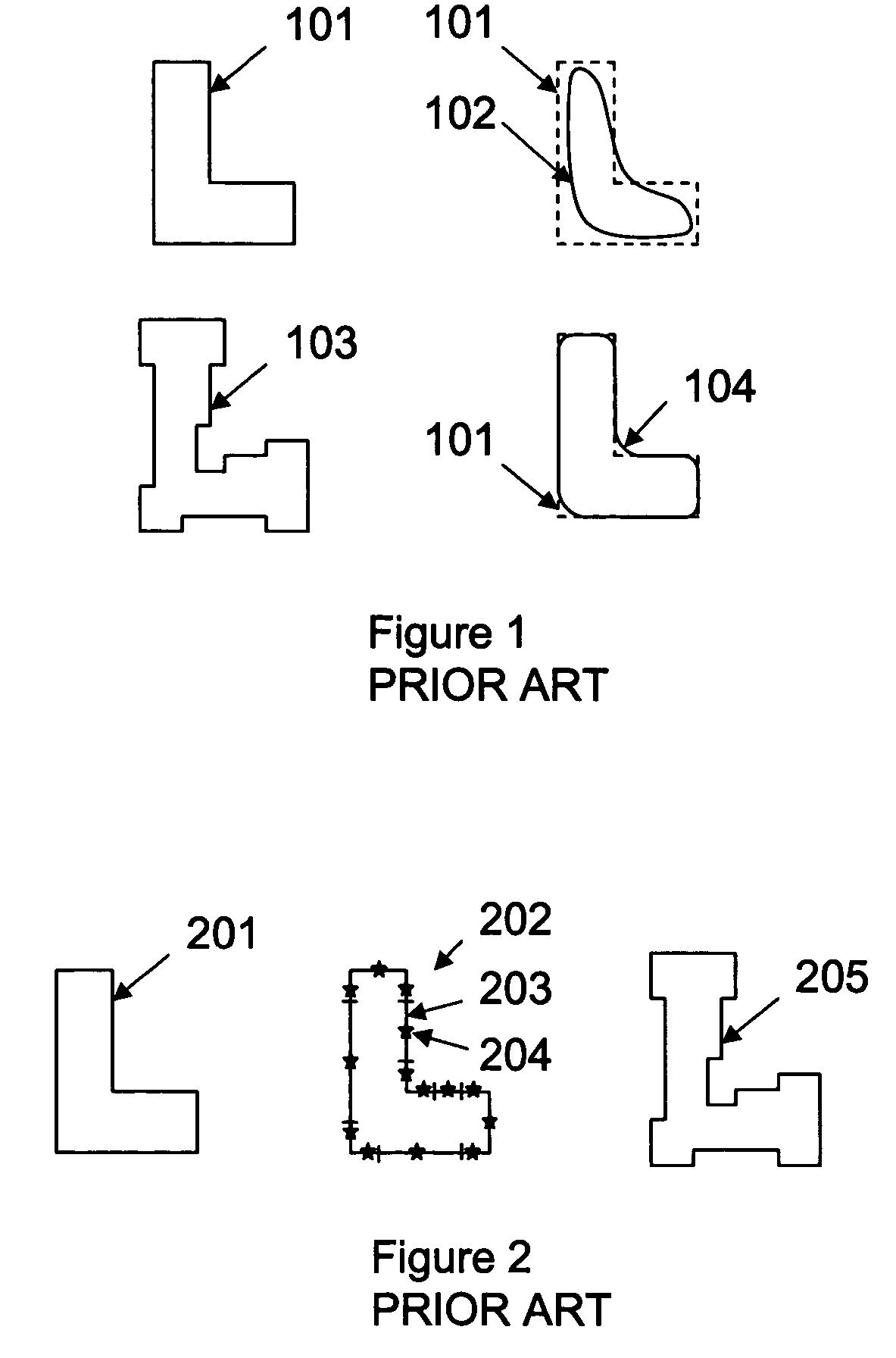

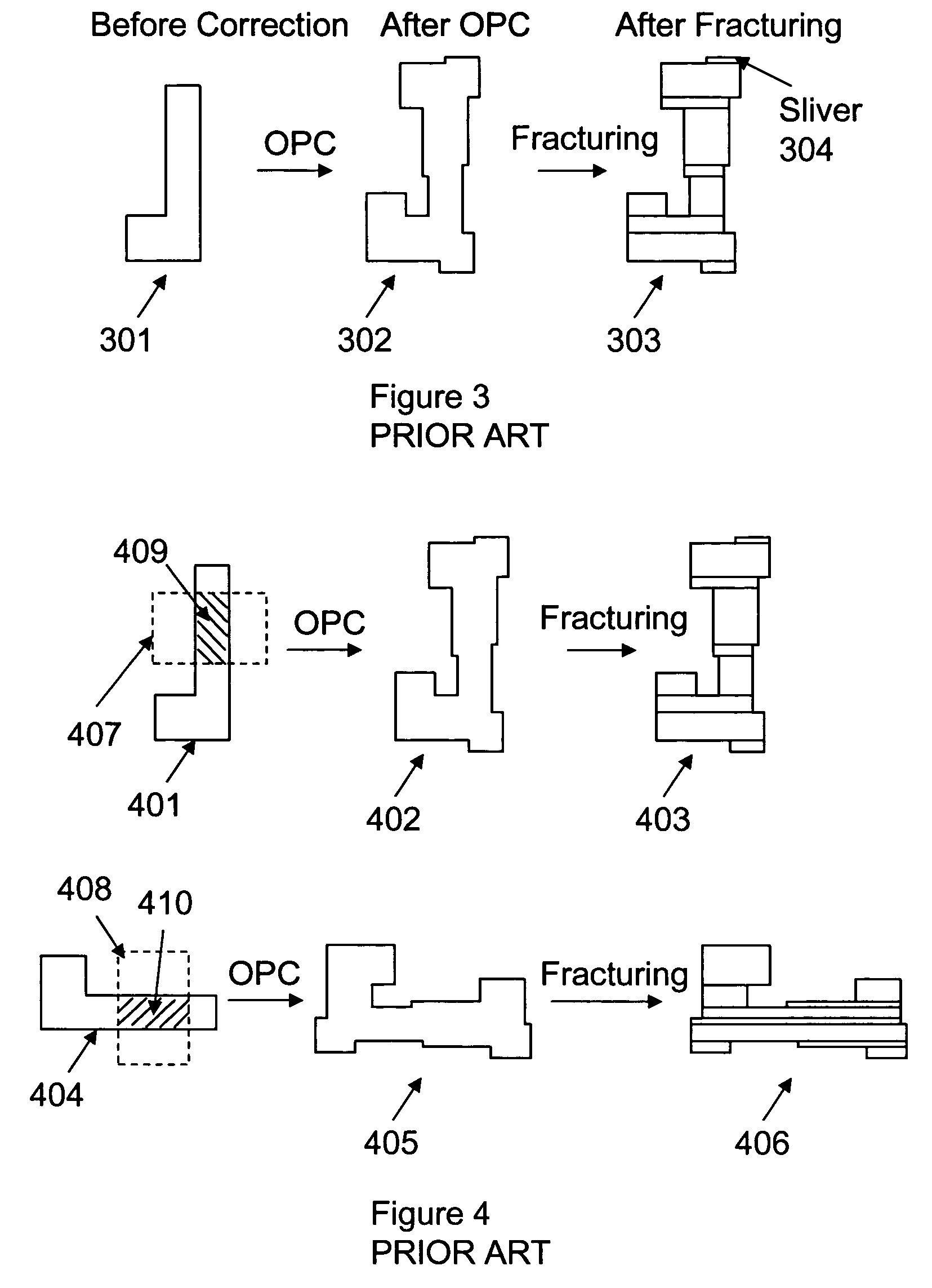

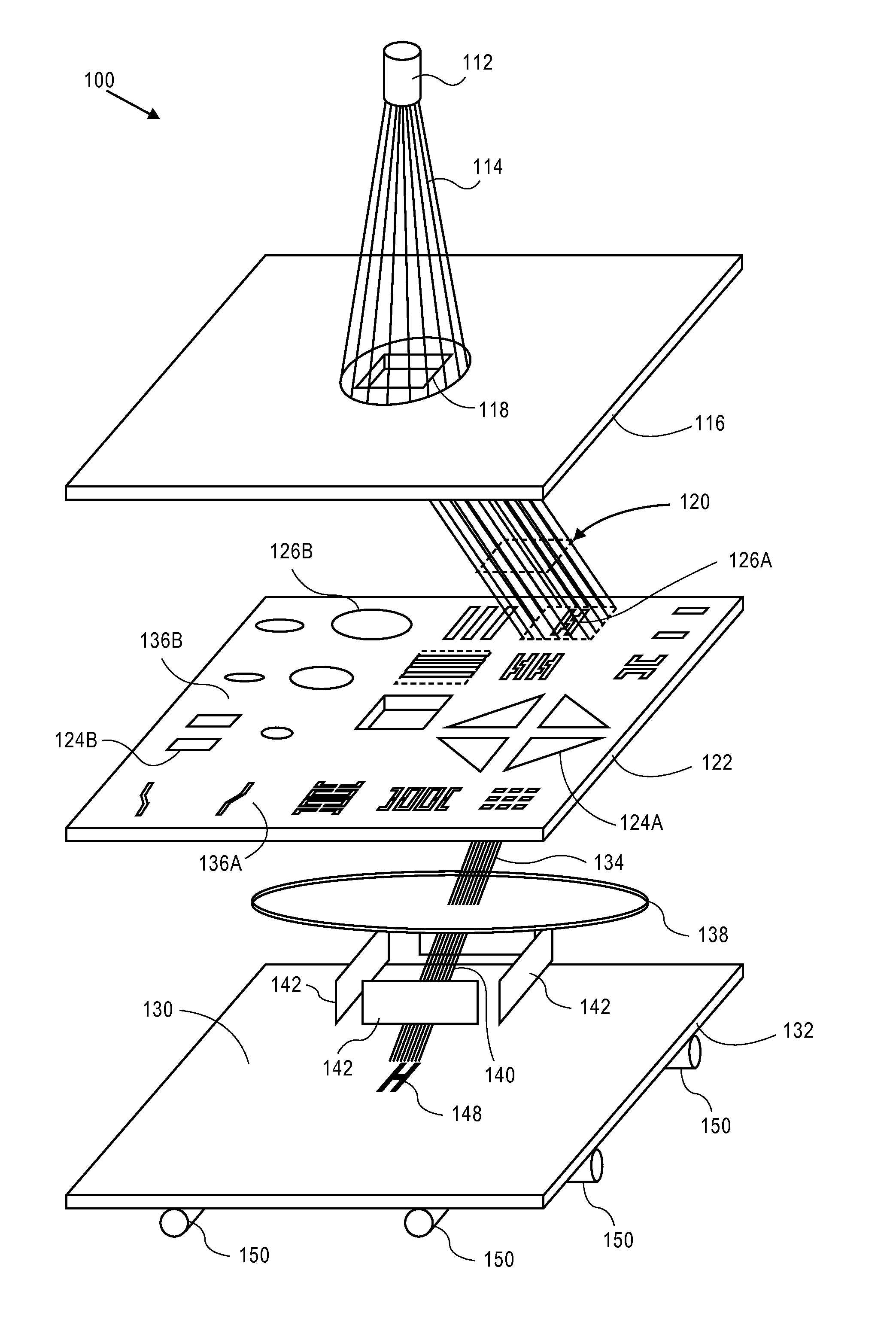

The manufacturing of integrated circuits relies on the use of optical proximity correction (OPC) to correct the printing of the features on the wafer. The data is subsequently fractured to accommodate the format of existing mask writer. The complexity of the correction after OPC can create some issues for vector-scan e-beam mask writing tools as very small slivers are created when the data is converted to the mask write tool format. Moreover the number of shapes created after fracturing is quite large and are not related to some important characteristics of the layout like for example critical areas. A new technique is proposed where the order of the OPC and fracturing steps is reversed. The fracturing step is done first in order to guarantee that no slivers are created and that the number of shapes is minimized. The shapes created can also follow the edges of critical zones so that critical and non-critical edges can be differentiated during the subsequent OPC step.

Owner:APPLIED MATERIALS INC

Method for Fracturing and Forming a Pattern Using Curvilinear Characters with Charged Particle Beam Lithography

InactiveUS20110053056A1Photo-taking processesElectric discharge tubesMask data preparationCamera lens

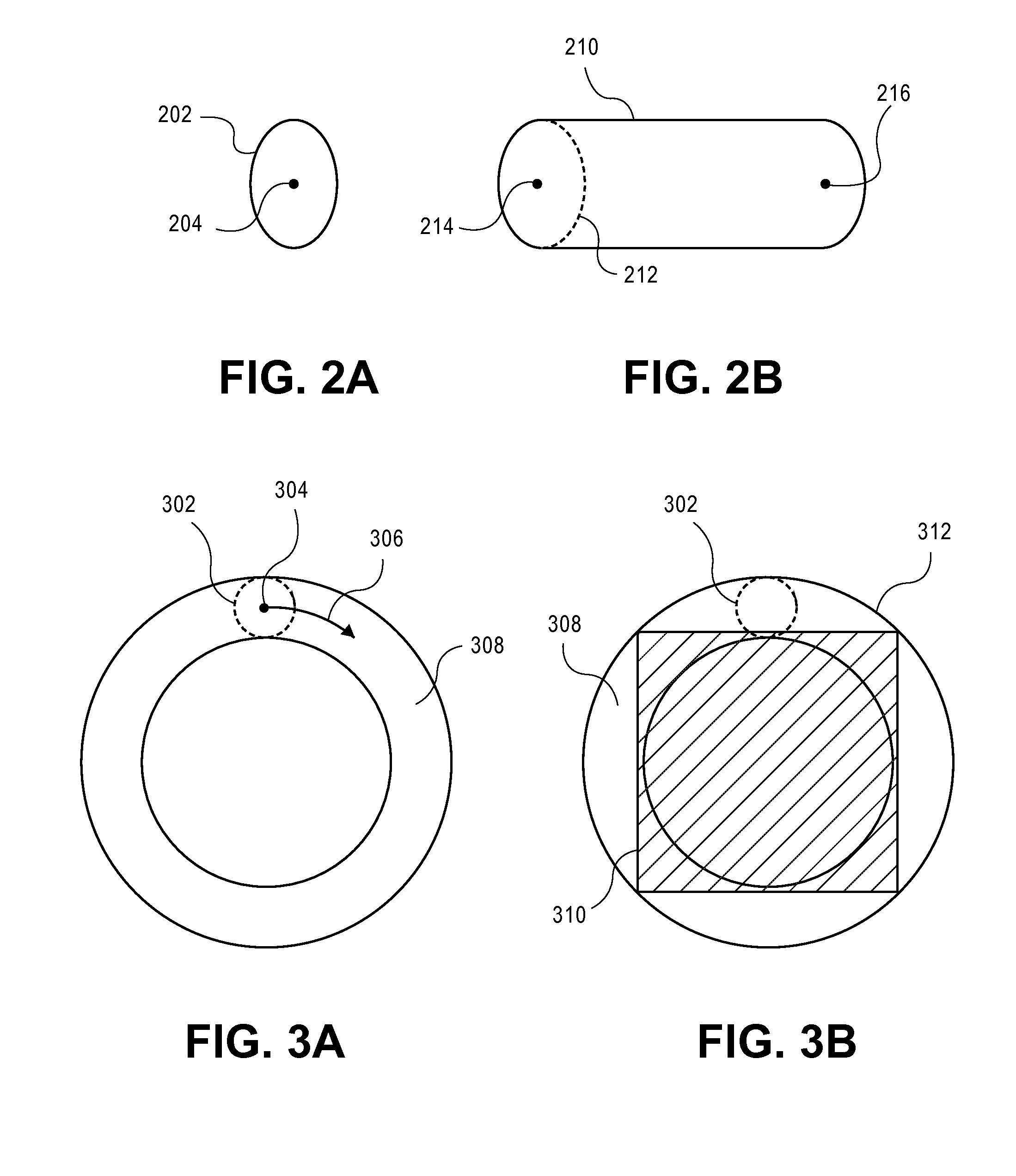

In the field of semiconductor production using shaped charged particle beam lithography, a method and system for fracturing or mask data preparation or proximity effect correction is disclosed, wherein a series of curvilinear character projection shots are determined for a charged particle beam writer system, such that the set of shots can form a continuous track, possibly of varying width, on a surface. A method for forming a continuous track on a surface using a series of curvilinear character projection shots is also disclosed. Methods for manufacturing a reticle and for manufacturing a substrate such as a silicon wafer by forming a continuous track on a surface using a series of curvilinear character projection shots is also disclosed.

Owner:D2S

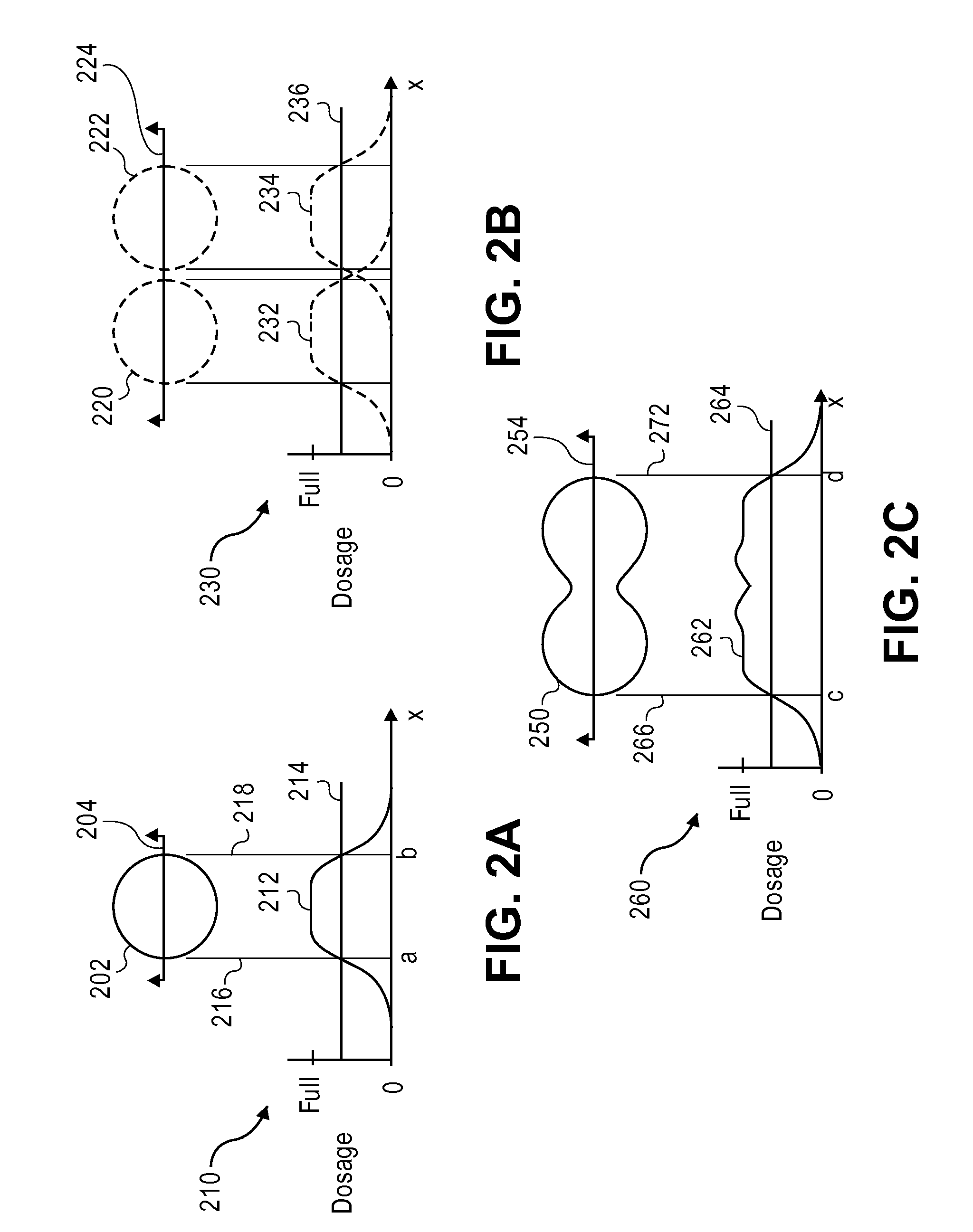

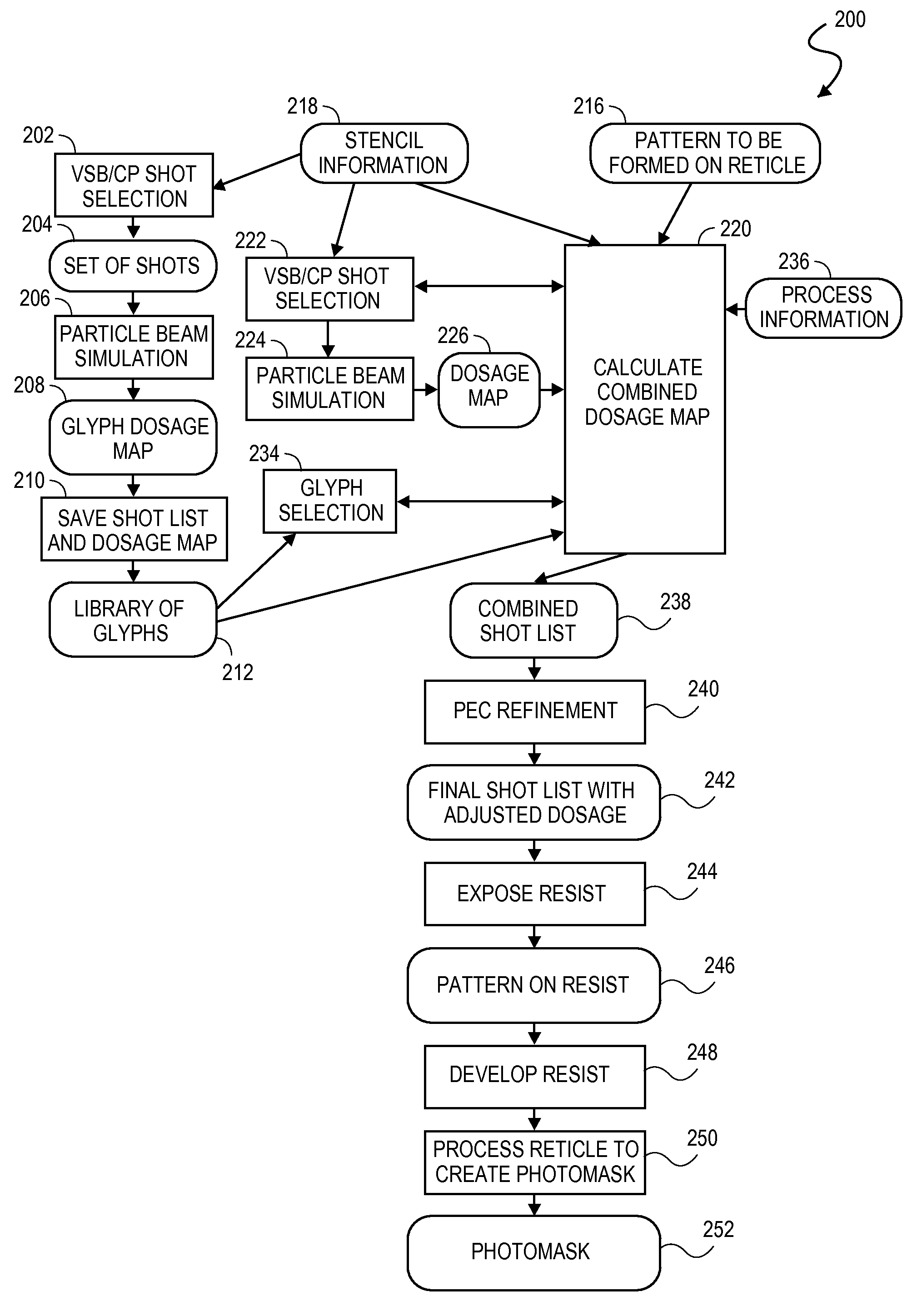

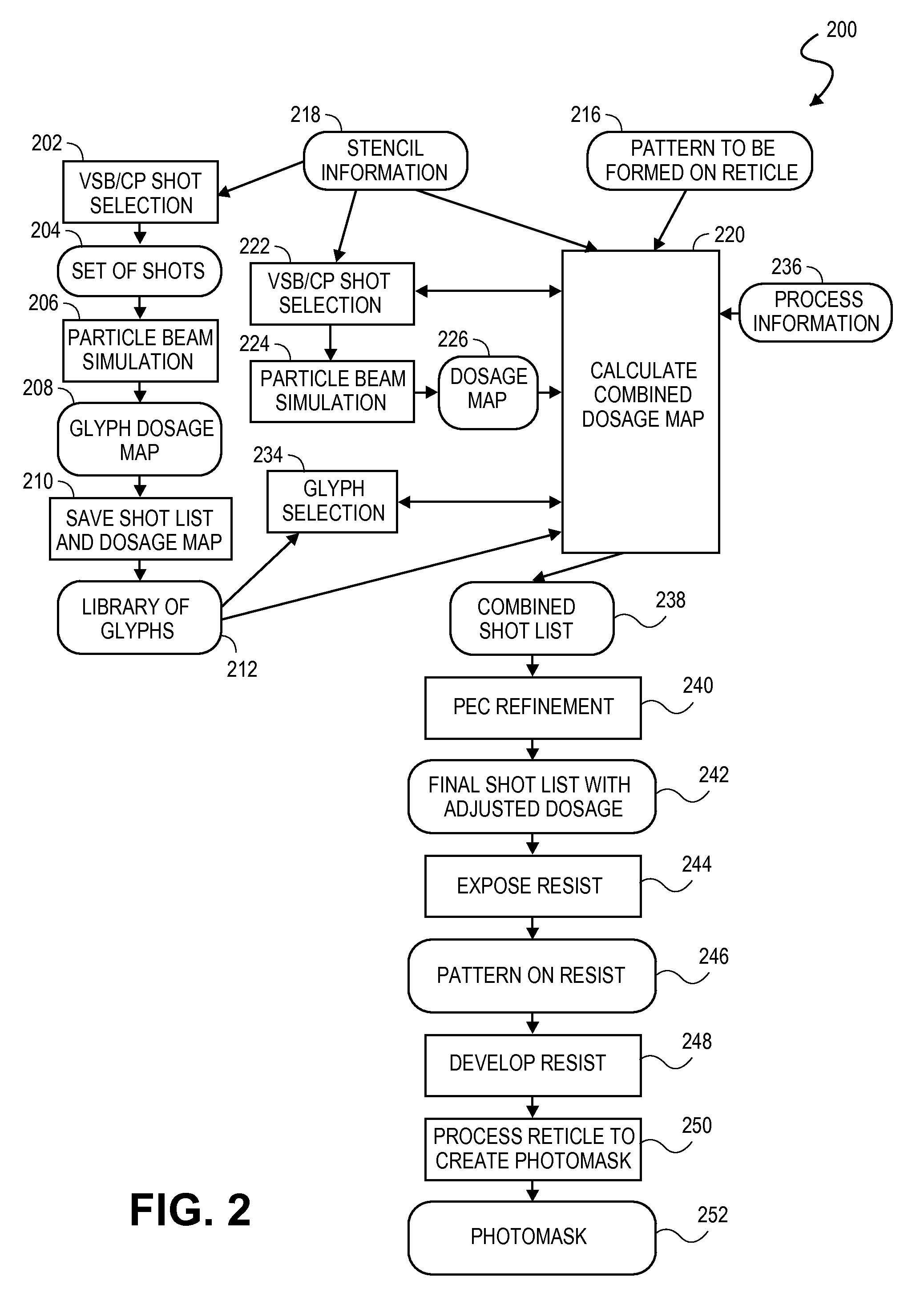

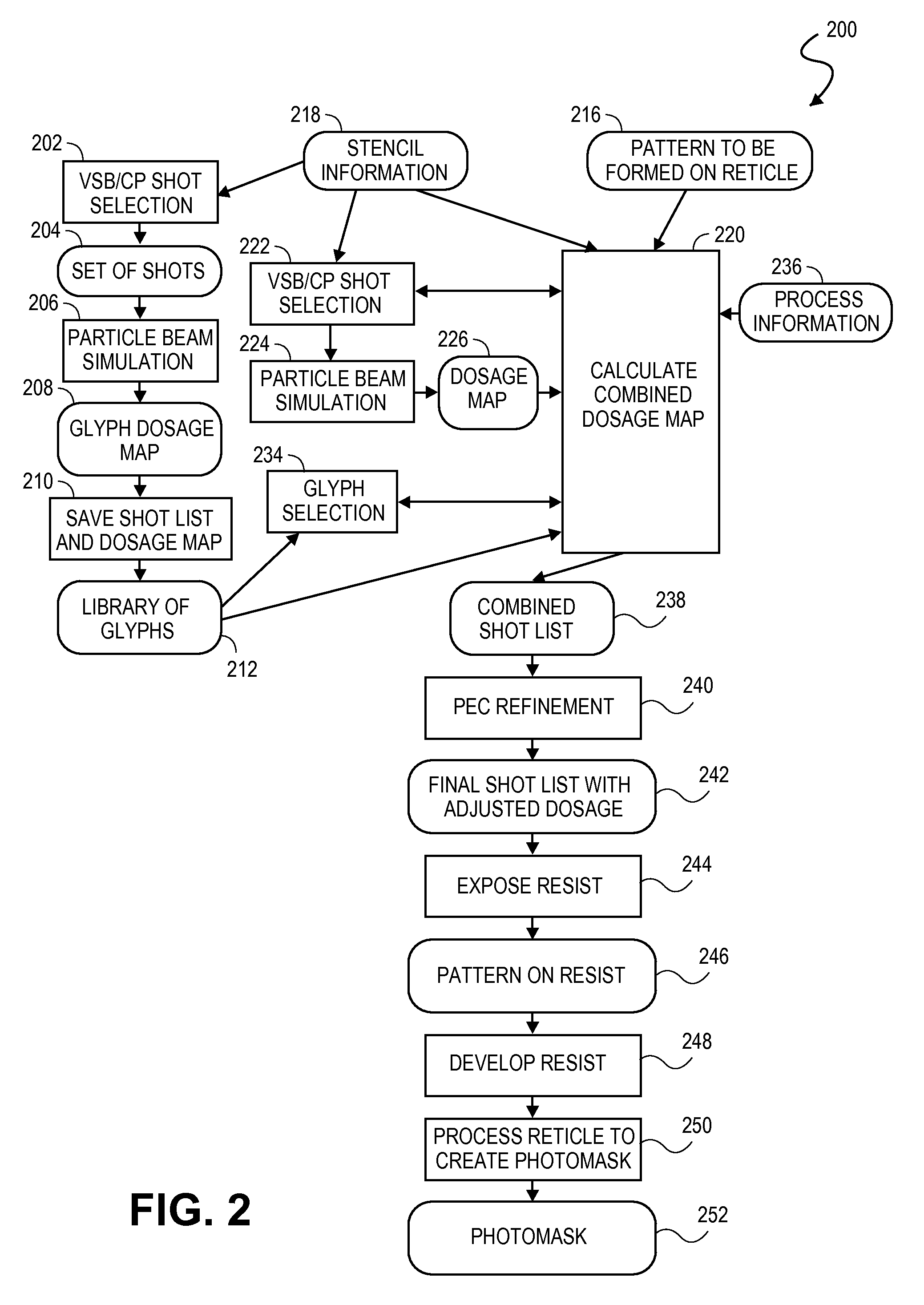

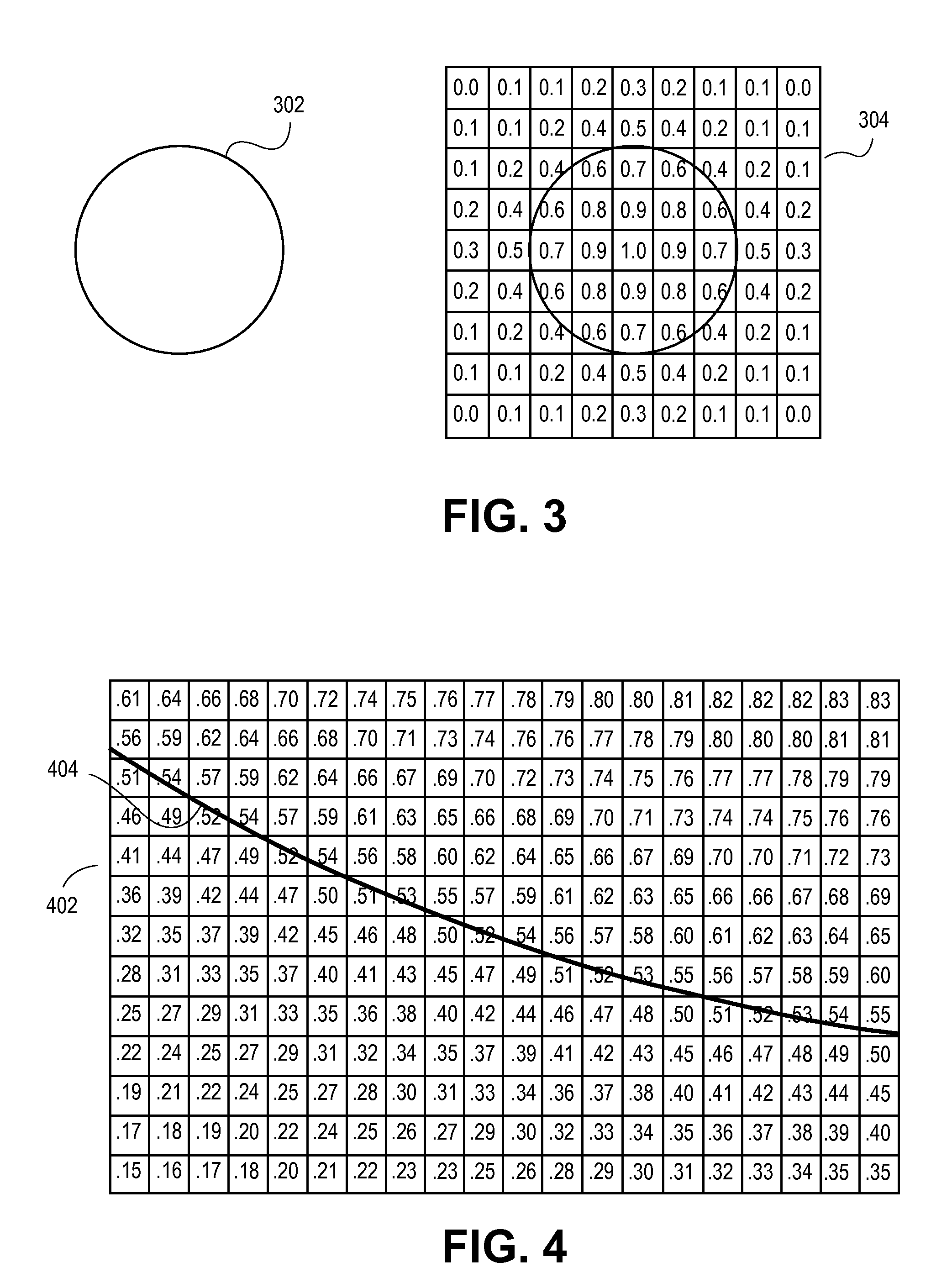

Method for design and manufacture of a reticle using a two-dimensional dosage map and charged particle beam lithography

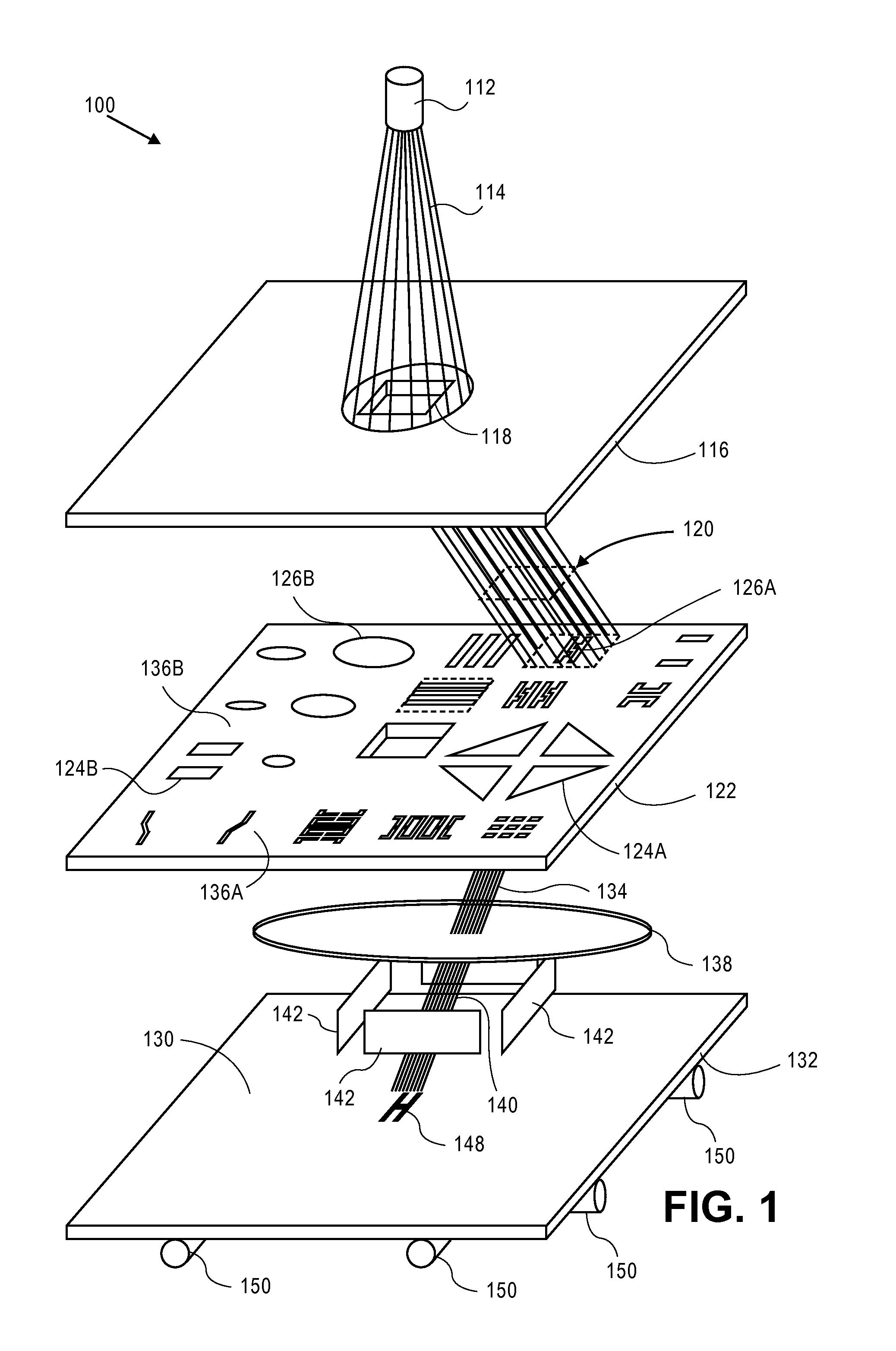

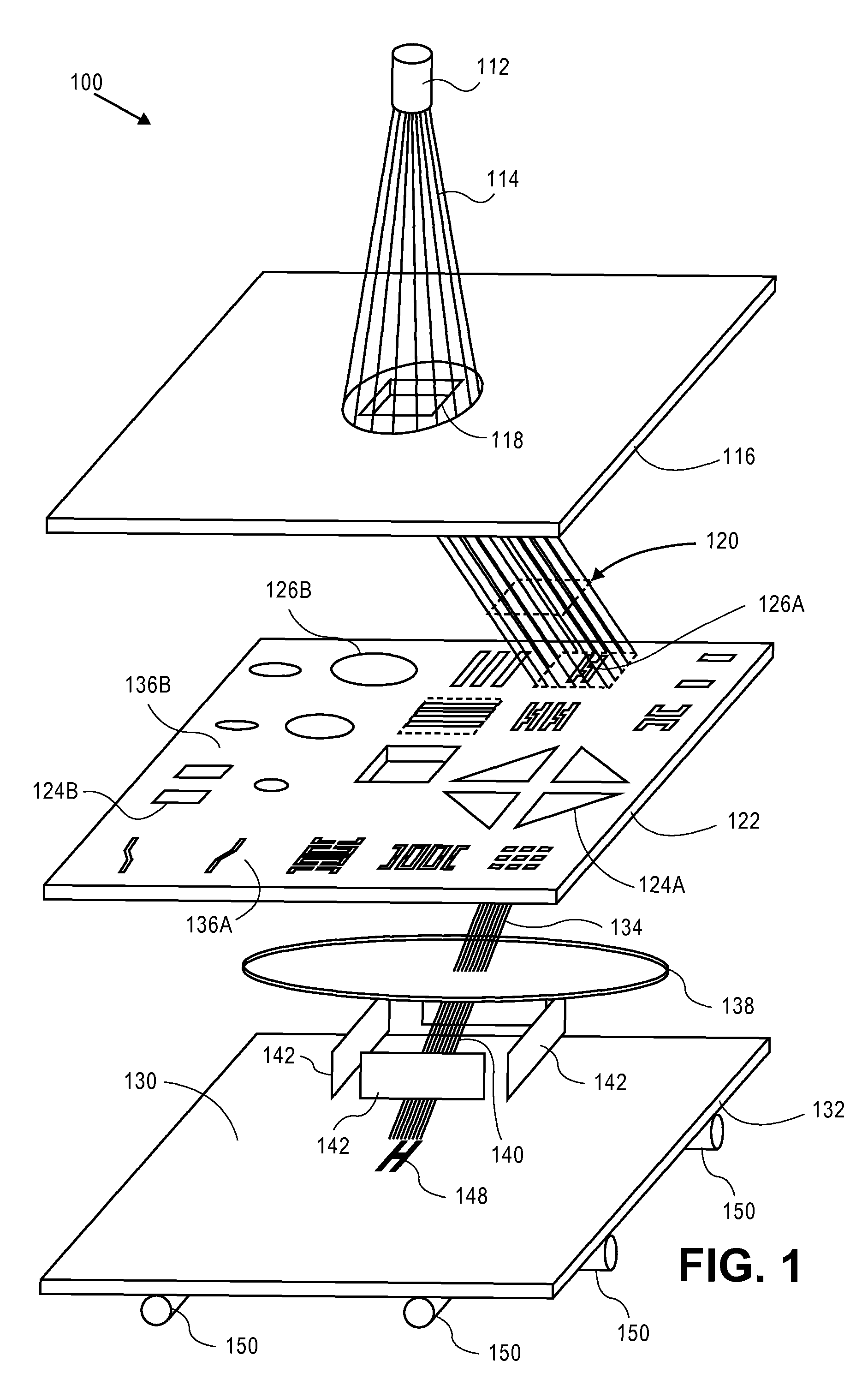

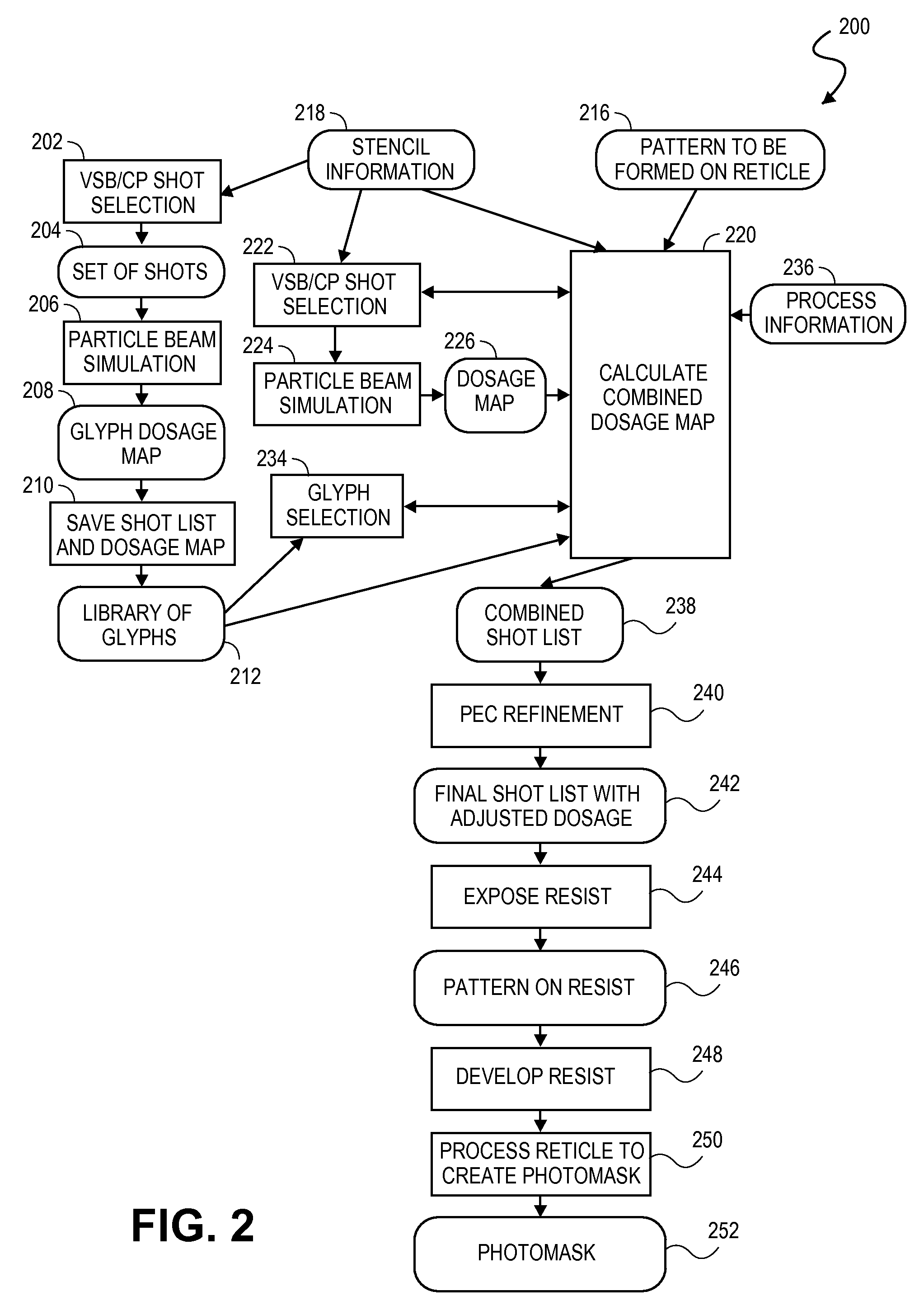

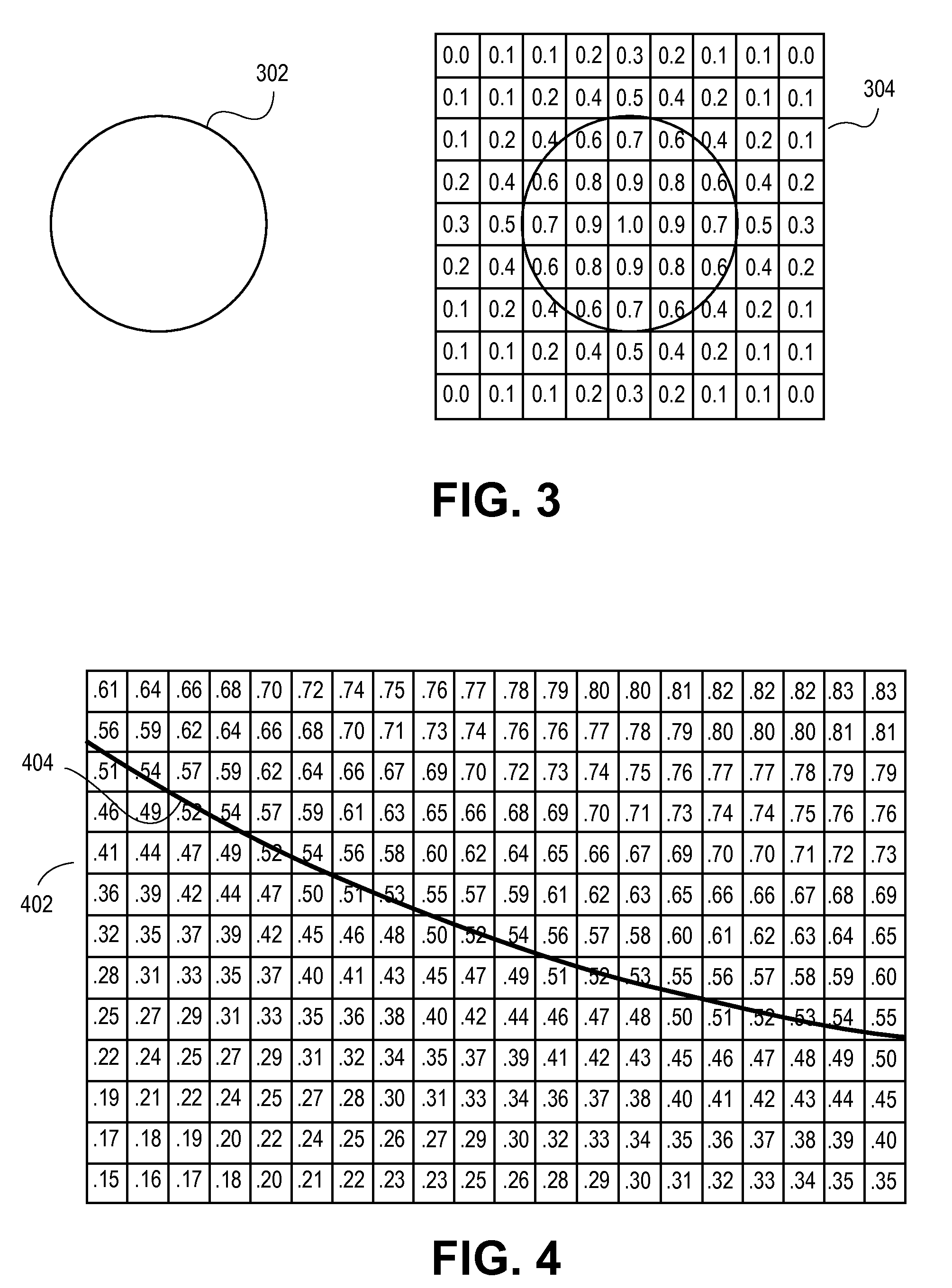

In the field of semiconductor device production, a method for manufacturing a surface using two-dimensional dosage maps is disclosed. A set of charged particle beam shots for creating an image on the surface is determined by combining dosage information such as dosage maps for a plurality of shots into the dosage map for the surface. A similar method is disclosed for fracturing or mask data preparation of a reticle image.

Owner:D2S

Method for design and manufacture of a reticle using variable shaped beam lithography

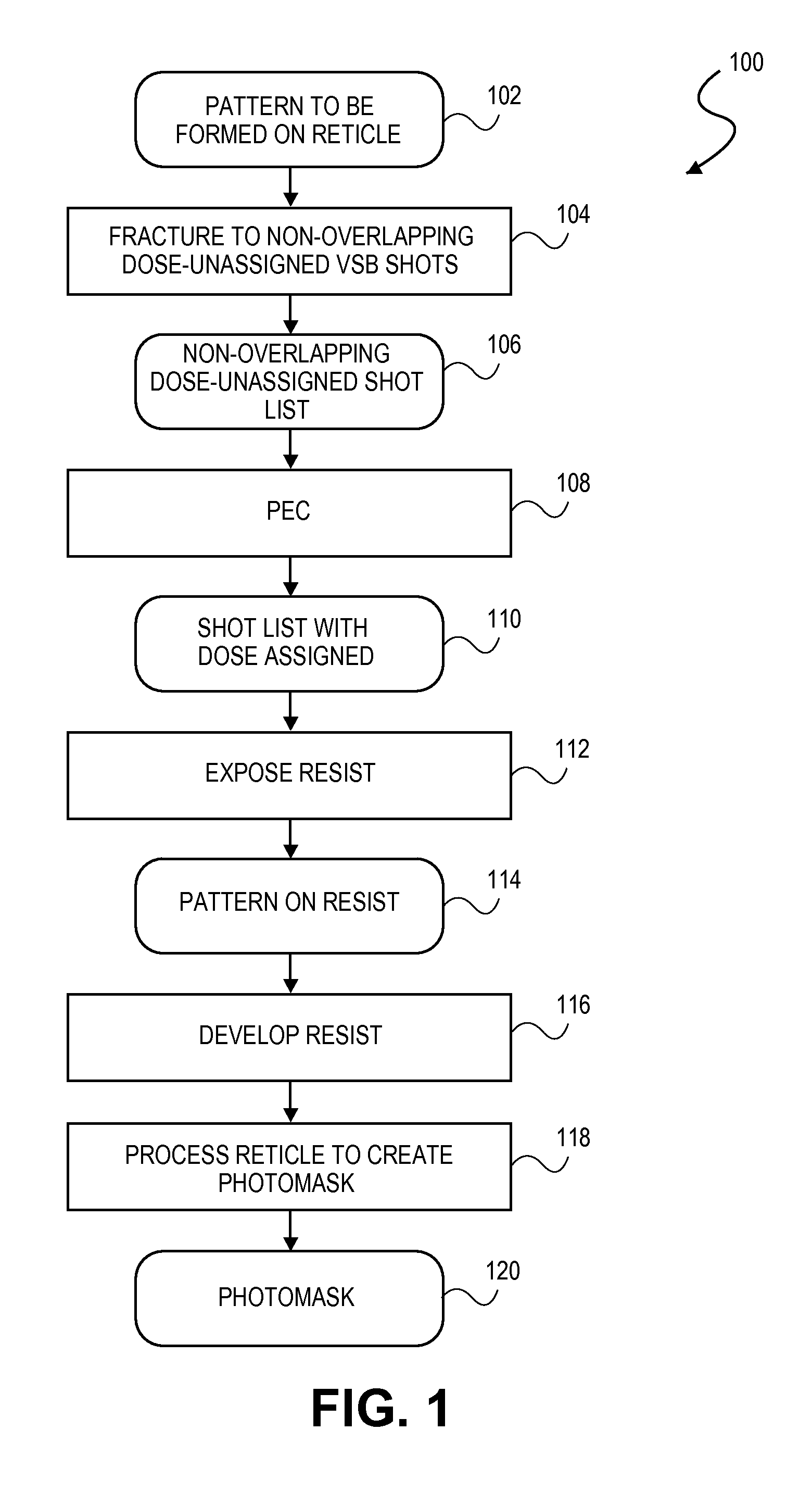

A method is disclosed for using non-overlapping variable shaped beam (VSB) shots in the design and manufacture of a reticle, where the union of the plurality of shots deviates from the desired pattern. Methods are described for fracturing or mask data preparation or proximity effect correction of a desired pattern to be formed on a reticle; for forming a pattern on a reticle using charged particle beam lithography; and for optical proximity correction (OPC) of a desired pattern. Dosages of the shots may be allowed to vary with respect to each other. The plurality of shots may be determined such that a pattern on the surface calculated from the plurality of shots is within a predetermined tolerance of the desired pattern. In some embodiments, an optimization technique may be used to minimize shot count.

Owner:D2S

Method and system for forming patterns using charged particle beam lithography

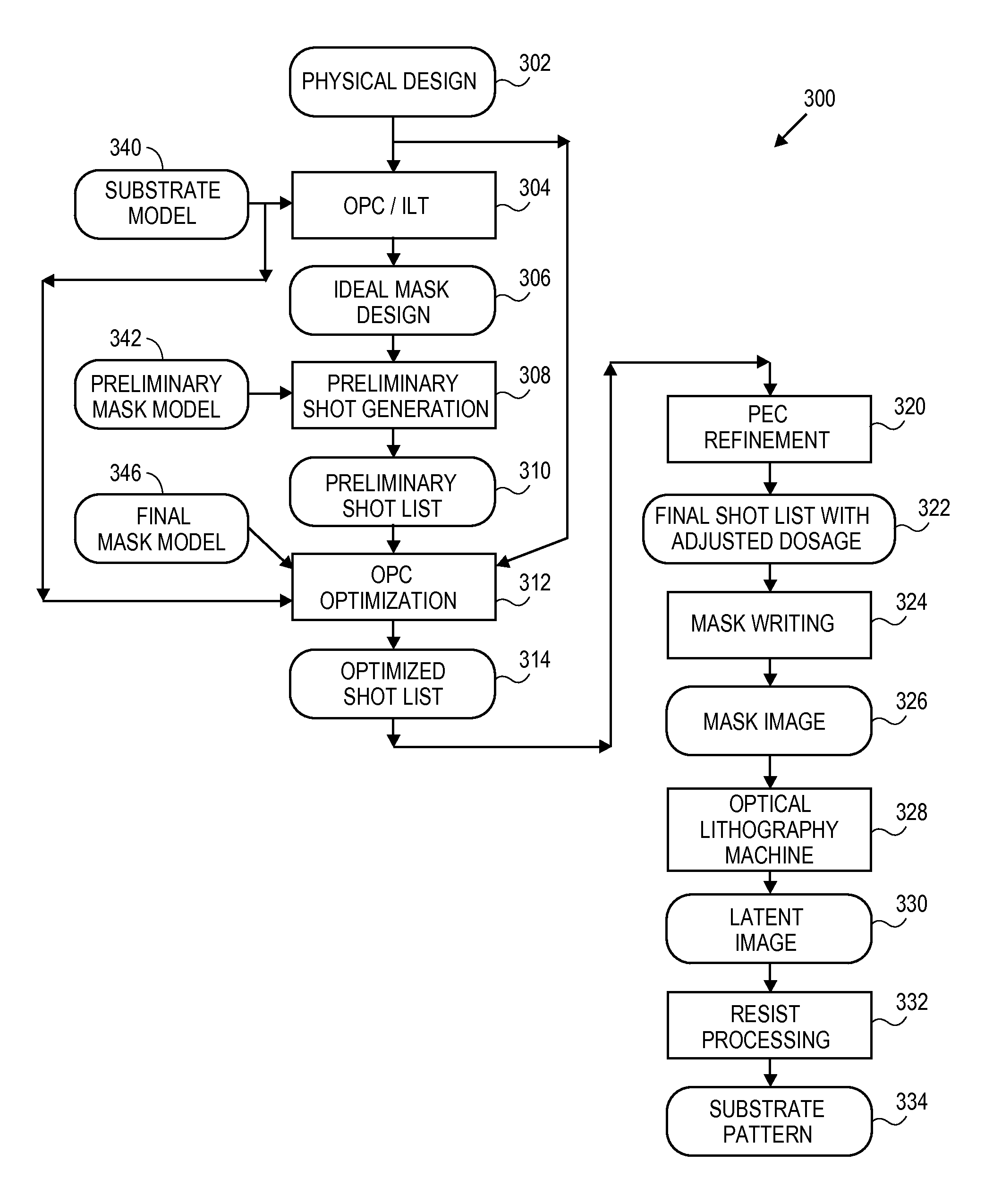

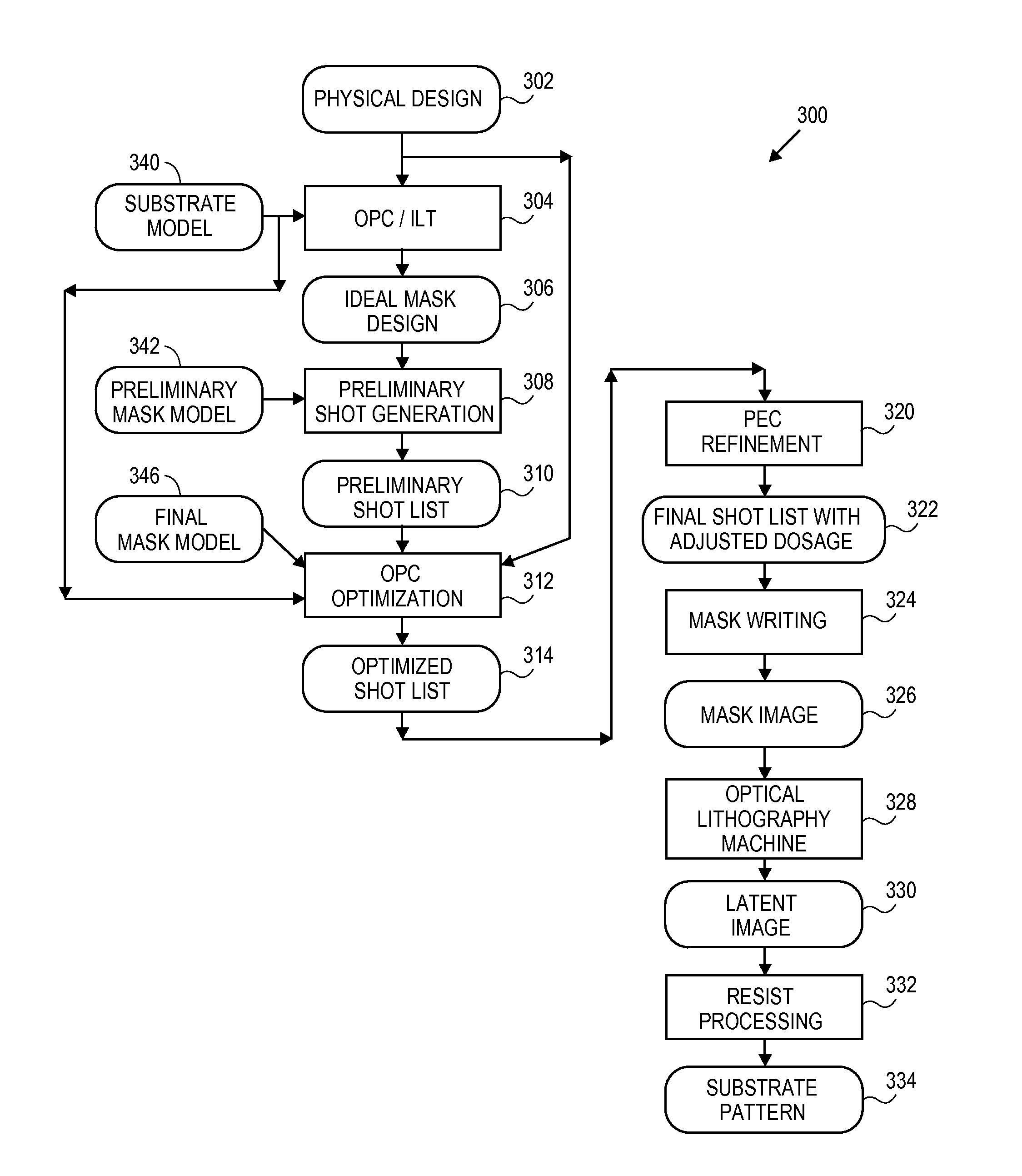

ActiveUS20130283218A1Photomechanical apparatusSemiconductor/solid-state device manufacturingMask data preparationLithographic artist

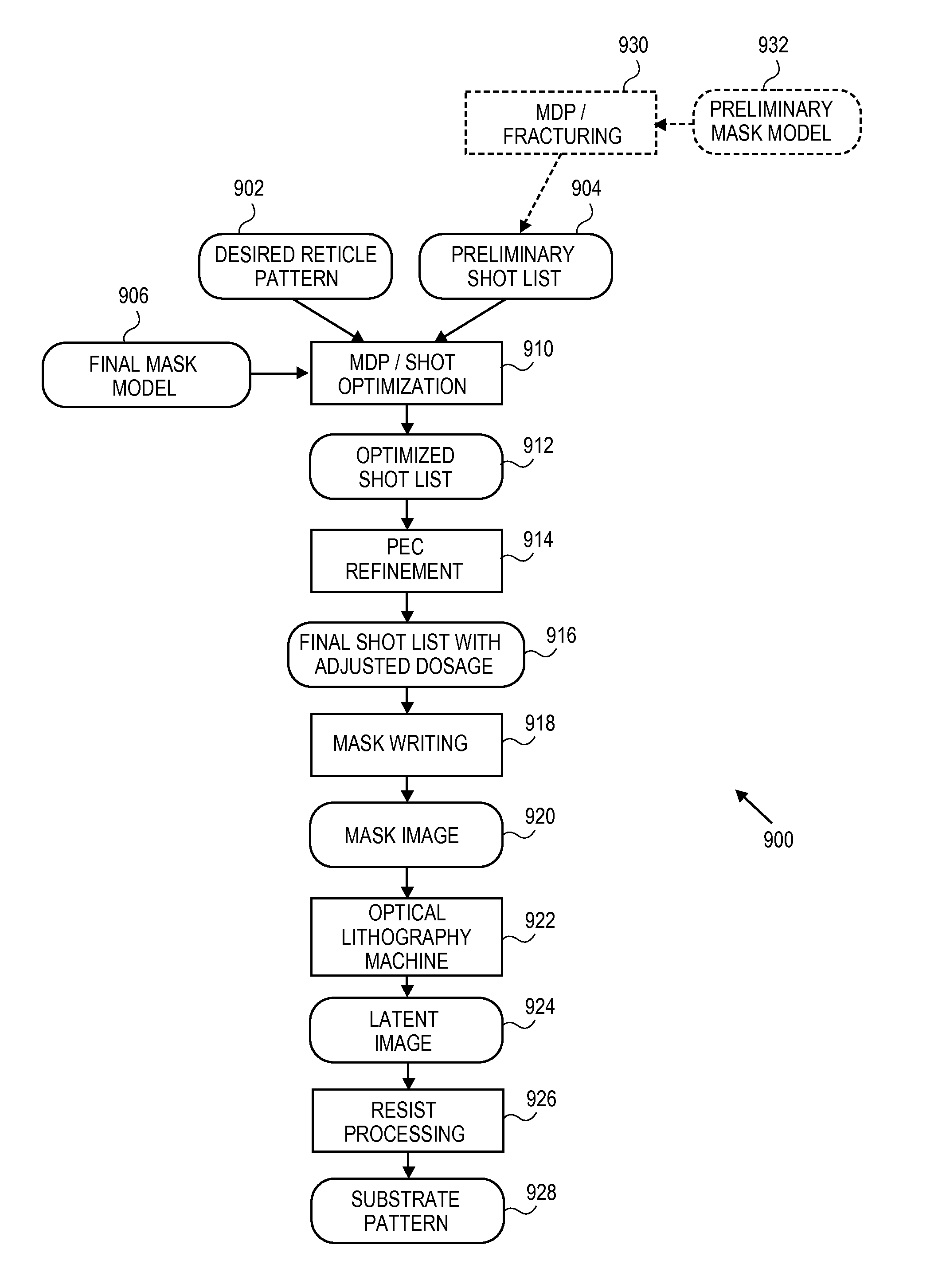

A method for mask data preparation (MDP) is disclosed, in which a set of shots is determined that will form a pattern on a reticle, where the determination includes calculating the pattern that will be formed on a substrate using an optical lithographic process with a reticle formed using the set of shots. A method for optical proximity correction (OPC) or MDP is also disclosed, in which a preliminary set of charged particle beam shots is generated using a preliminary mask model, and then the shots are modified by calculating both a reticle pattern using a final mask model, and a resulting substrate pattern. A method for OPC is also disclosed, in which an ideal pattern for a photomask is calculated from a desired substrate pattern, where the model used in the calculation includes only optical lithography effects and / or substrate processing effects.

Owner:D2S

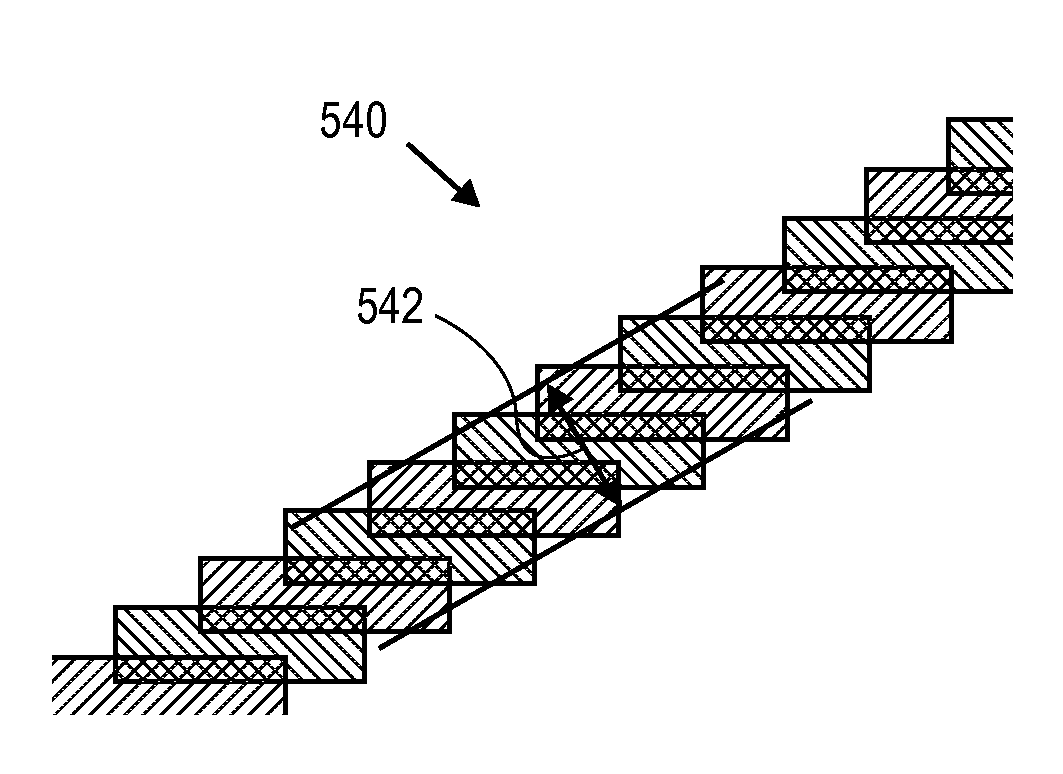

Method and system for fracturing a pattern using charged particle beam lithography with multiple exposure passes which expose different surface area

ActiveUS8137871B2Reduce in quantityElectric discharge tubesRadiation applicationsMask data preparationLithographic artist

In the field of semiconductor production using charged particle beam lithography, a method and system for fracturing or mask data preparation or proximity effect correction is disclosed, in which the union of shots from one of a plurality of exposure passes is different than the union of shots from a different exposure pass. Methods for manufacturing a reticle and for manufacturing an integrated circuit are also disclosed, in which the union of shots from one of a plurality of charged particle beam exposure passes is different than the union of shots from a different exposure pass.

Owner:D2S

Pattern Transfer Modeling for Optical Lithographic Processes

InactiveUS20110138343A1Photomechanical apparatusSpecial data processing applicationsTransfer modelMask data preparation

Various implementations of the invention provide for the optimization of etch induced pattern transfer across a significant portion of a design. In various implementations, an entire design, that is a “full-chip” may be optimized. With some implementations, the invention may be employed to detect etch hotspots. Further implementations may be employed in either or both a mask data preparation process (“MDP”) or to determine the etch effects of including various patterns in a design.

Owner:GRANIK YURI

Method for fracturing and forming a pattern using curvilinear characters with charged particle beam lithography

In the field of semiconductor production using shaped charged particle beam lithography, a method and system for fracturing or mask data preparation or proximity effect correction is disclosed, wherein a series of curvilinear character projection shots are determined for a charged particle beam writer system, such that the set of shots can form a continuous track, possibly of varying width, on a surface. A method for forming a continuous track on a surface using a series of curvilinear character projection shots is also disclosed. Methods for manufacturing a reticle and for manufacturing a substrate such as a silicon wafer by forming a continuous track on a surface using a series of curvilinear character projection shots is also disclosed.

Owner:D2S

Method and system for forming high accuracy patterns using charged particle beam lithography

ActiveUS8473875B2Increase roughnessImprove variationPhotomechanical apparatusComputer aided designMask data preparationLithographic artist

Owner:D2S

Method and system for fracturing a pattern using charged particle beam lithography with multiple exposure passes which expose different surface area

ActiveUS20110159435A1Reduce in quantityElectric discharge tubesRadiation applicationsMask data preparationLithographic artist

In the field of semiconductor production using charged particle beam lithography, a method and system for fracturing or mask data preparation or proximity effect correction is disclosed, in which the union of shots from one of a plurality of exposure passes is different than the union of shots from a different exposure pass. Methods for manufacturing a reticle and for manufacturing an integrated circuit are also disclosed, in which the union of shots from one of a plurality of charged particle beam exposure passes is different than the union of shots from a different exposure pass.

Owner:D2S

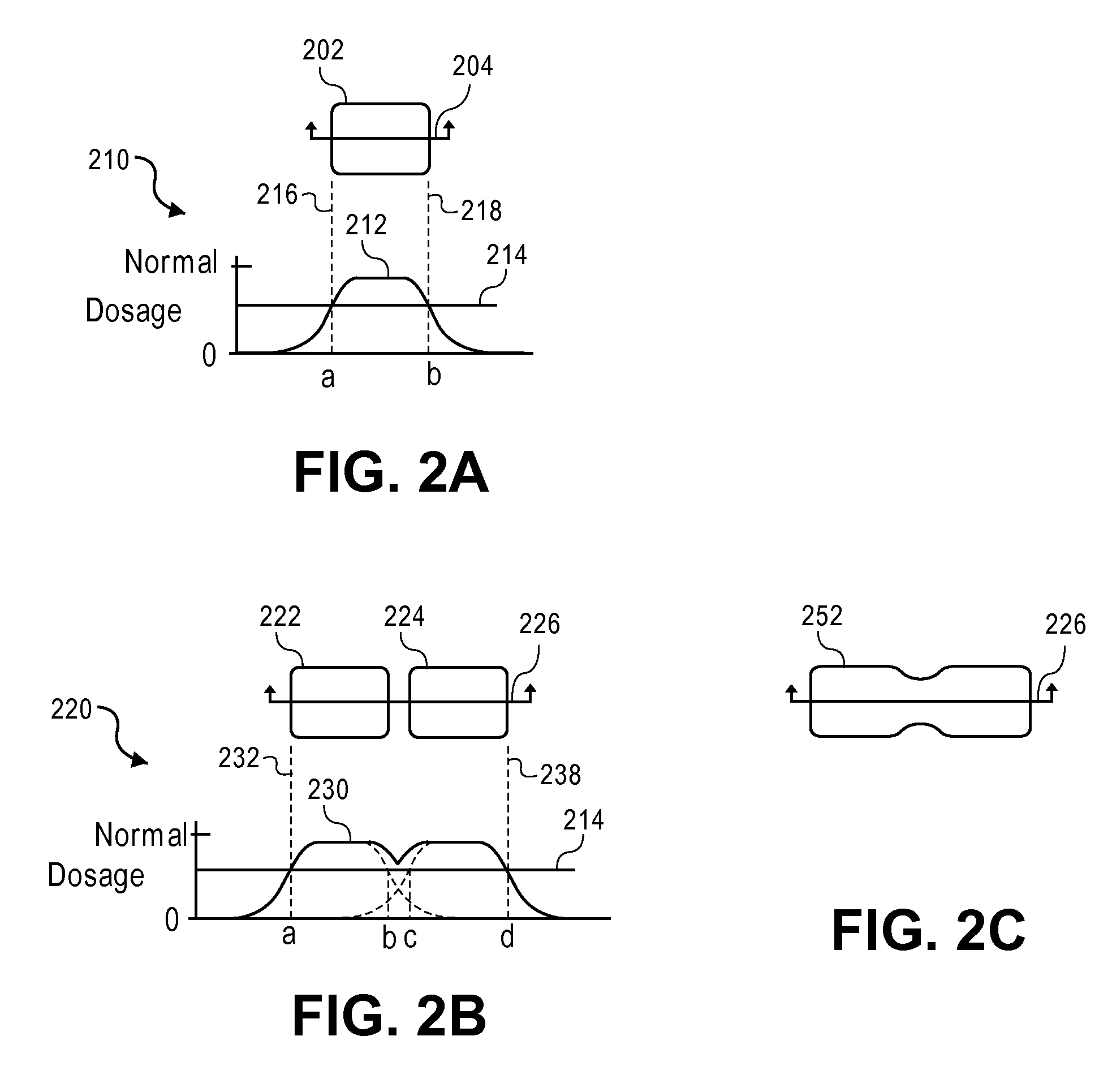

Method and System for Forming High Accuracy Patterns Using Charged Particle Beam Lithography

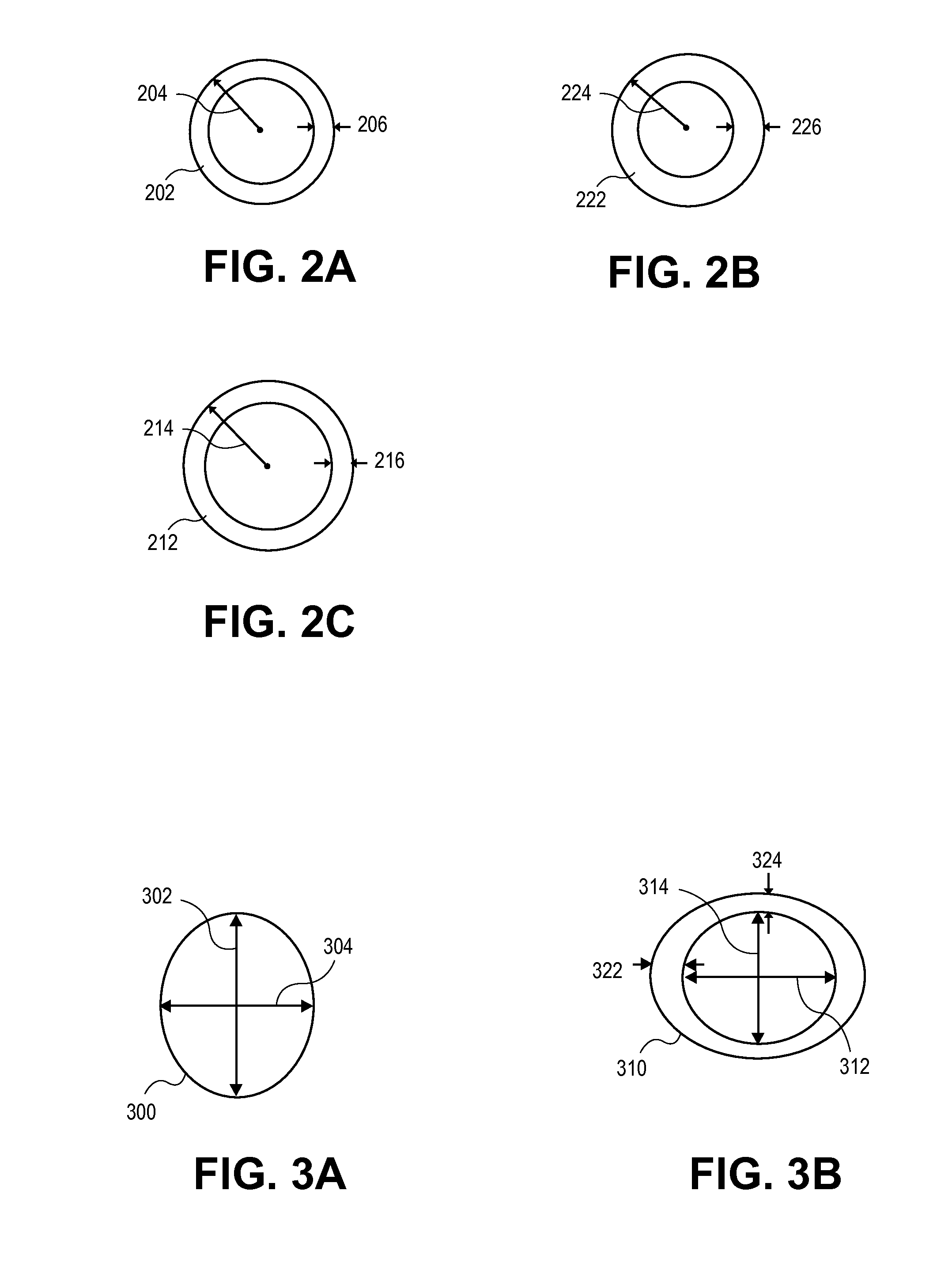

ActiveUS20120096412A1Increase roughnessImprove variationPhotomechanical apparatusComputer aided designCamera lensMask data preparation

A method and system for fracturing or mask data preparation for charged particle beam lithography are disclosed in which accuracy and / or edge slope of a pattern formed on a surface by a set of charged particle beam shots is enhanced by use of partially-overlapping shots. In some embodiments, dosages of the shots may vary with respect to each other before proximity effect correction. Particle beam simulation may be used to calculate the pattern and the edge slope. Enhanced edge slope can improve critical dimension (CD) variation and line-edge roughness (LER) of the pattern produced on the surface.

Owner:D2S

Method for design and manufacture of a reticle using a two-dimensional dosage map and charged particle beam lithography

ActiveUS8062813B2Electric discharge tubesRadiation applicationsMask data preparationLithographic artist

In the field of semiconductor device production, a method for manufacturing a surface using two-dimensional dosage maps is disclosed. A set of charged particle beam shots for creating an image on the surface is determined by combining dosage information such as dosage maps for a plurality of shots into the dosage map for the surface. A similar method is disclosed for fracturing or mask data preparation of a reticle image.

Owner:D2S

Method for design and manufacture of a reticle using variable shaped beam lithography

ActiveUS20100055581A1Minimize shot countElectric discharge tubesRadiation applicationsMask data preparationCamera lens

A method is disclosed for using non-overlapping variable shaped beam (VSB) shots in the design and manufacture of a reticle, where the union of the plurality of shots deviates from the desired pattern. Methods are described for fracturing or mask data preparation or proximity effect correction of a desired pattern to be formed on a reticle; for forming a pattern on a reticle using charged particle beam lithography; and for optical proximity correction (OPC) of a desired pattern. Dosages of the shots may be allowed to vary with respect to each other. The plurality of shots may be determined such that a pattern on the surface calculated from the plurality of shots is within a predetermined tolerance of the desired pattern. In some embodiments, an optimization technique may be used to minimize shot count.

Owner:D2S

Mask data preparation

ActiveUS7055127B2Electrical apparatusOriginals for photomechanical treatmentMask data preparationData preparation

The manufacturing of integrated circuits relies on the use of optical proximity correction (OPC) to correct the printing of the features on the wafer. The data is subsequently fractured to accommodate the format of existing mask writer. The complexity of the correction after OPC can create some issues for vector-scan e-beam mask writing tools as very small slivers are created when the data is converted to the mask write tool format. Moreover the number of shapes created after fracturing is quite large and are not related to some important characteristics of the layout like for example critical areas. A new technique is proposed where the order of the OPC and fracturing steps is reversed. The fracturing step is done first in order to guarantee that no slivers are created and that the number of shapes is minimized. The shapes created can also follow the edges of critical zones so that critical and non-critical edges can be differentiated during the subsequent OPC step.

Owner:APPLIED MATERIALS INC

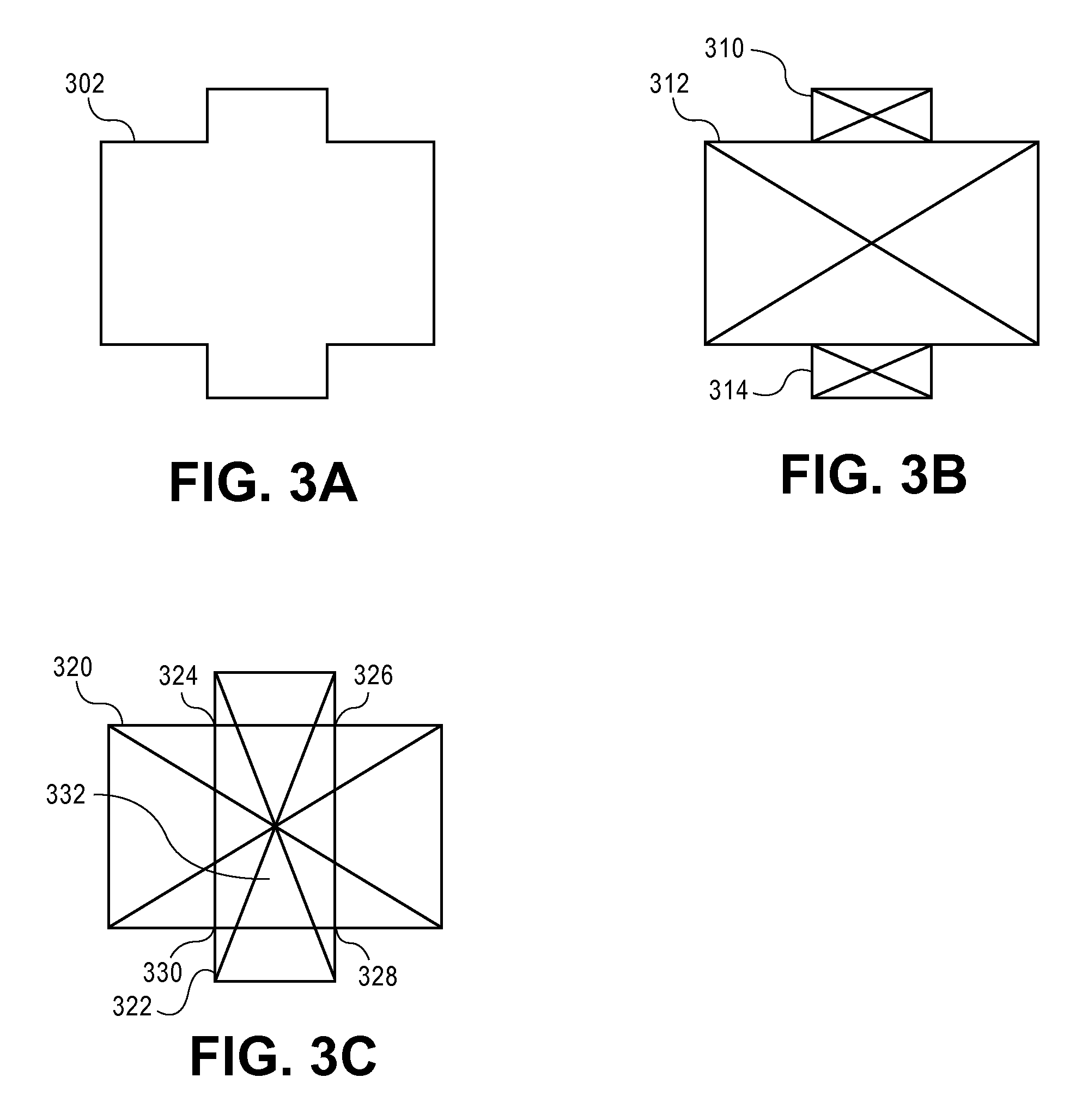

Method for Integrated Circuit Manufacturing and Mask Data Preparation Using Curvilinear Patterns

ActiveUS20120094219A1Photomechanical apparatusOriginals for photomechanical treatmentResistMask data preparation

A method for manufacturing a semiconductor device is disclosed, wherein during the physical design process, a curvilinear path is designed to represent an interconnecting wire on the fabricated semiconductor device. A method for fracturing or mask data preparation (MDP) is also disclosed in which a manhattan path which is part of the physical design of an integrated circuit is modified to create a curvilinear pattern, and where a set of charged particle beam shots is generated, where the set of shots is capable of forming the curvilinear pattern on a resist-coated surface.

Owner:D2S

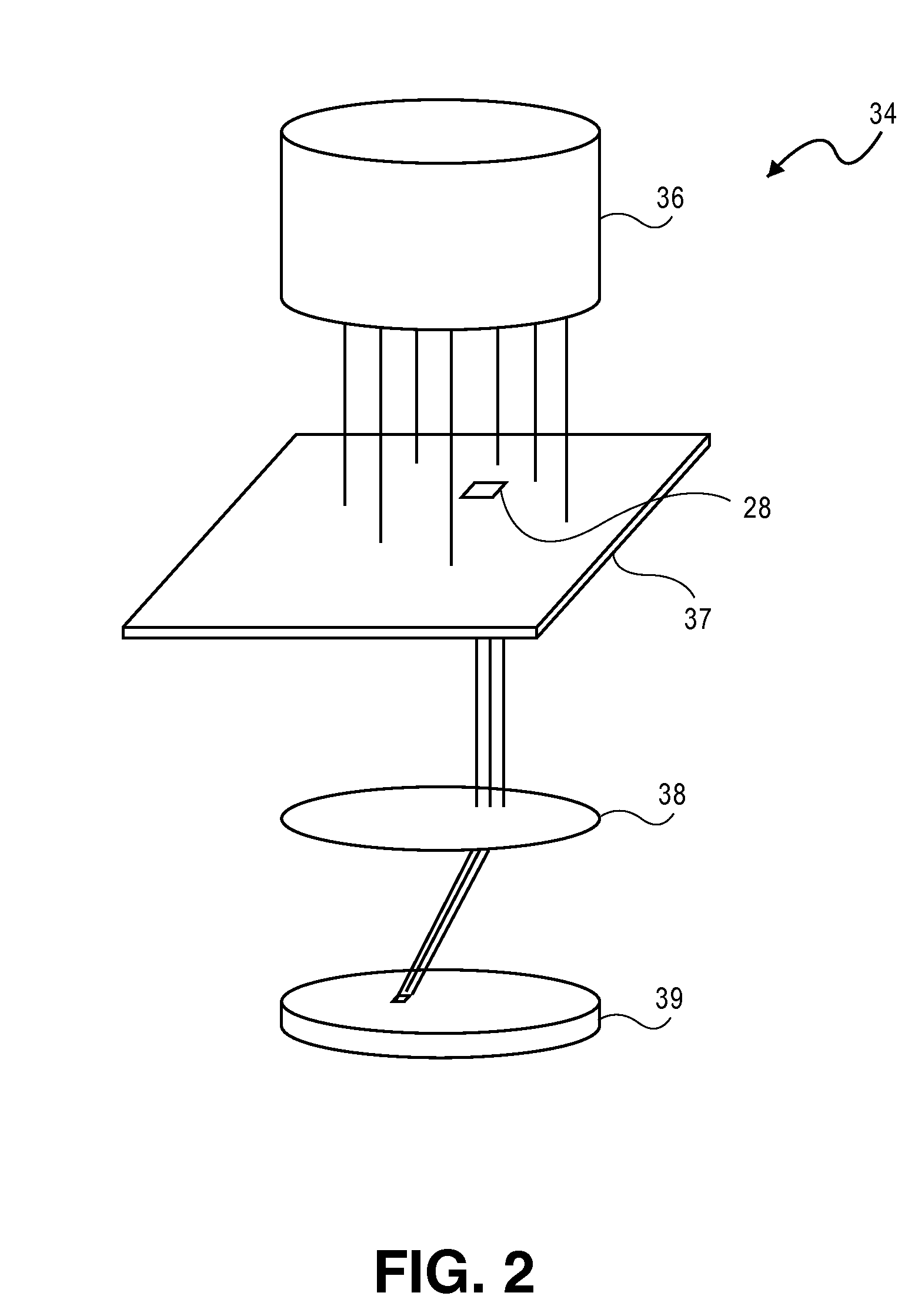

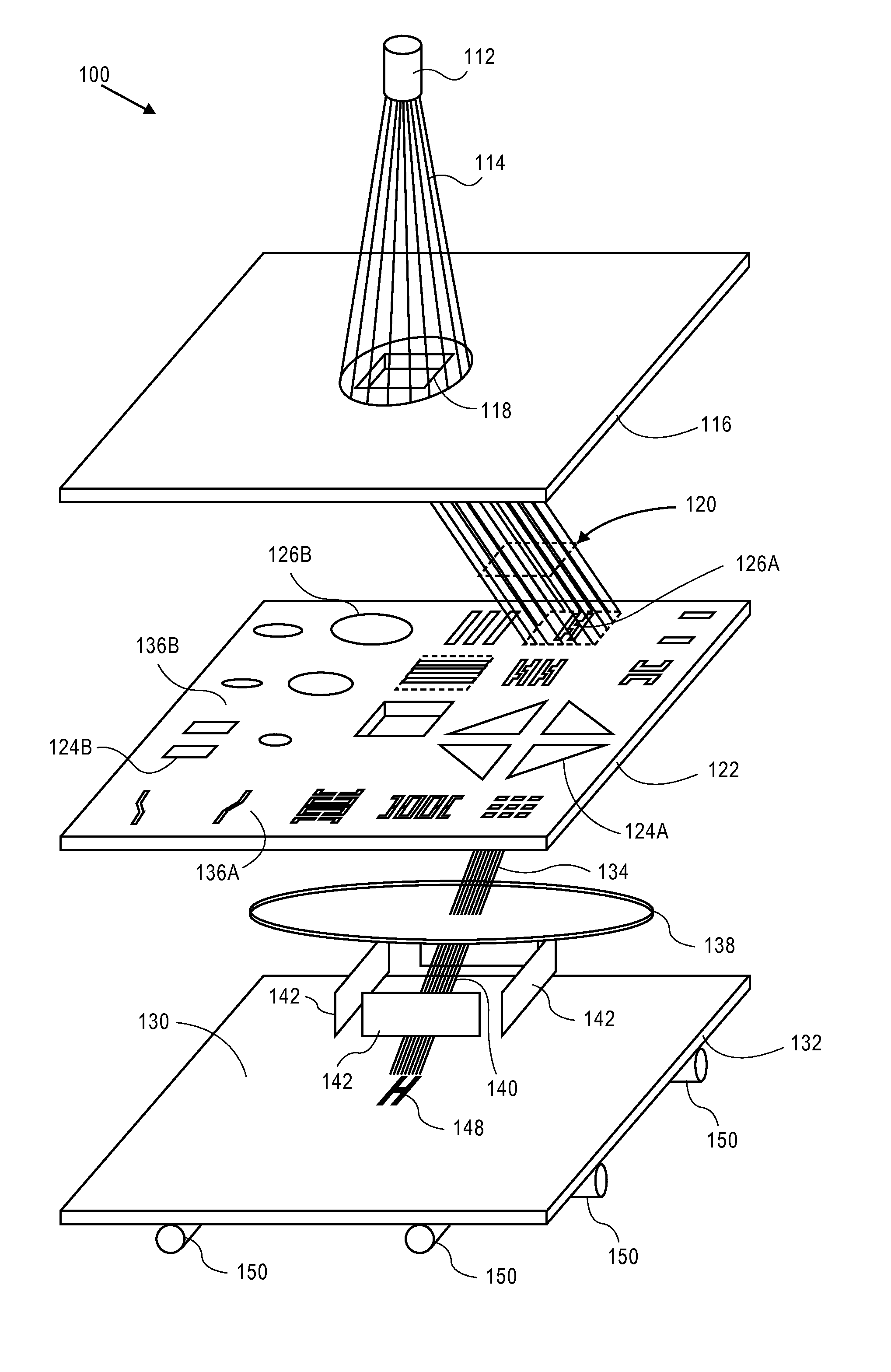

Method and system for manufacturing a surface using character projection lithography with variable magnification

A character projection charged particle beam writer system is disclosed comprising a variable magnification reduction lens which will allow different shot magnifications on a shot by shot basis. A method for fracturing or mask data preparation or optical proximity correction is also disclosed comprising assigning a magnification to each calculated charged particle beam writer shot. A method for forming a pattern on a surface is also disclosed comprising using a charged particle beam writer system and varying the magnification from shot to shot. A method for manufacturing an integrated circuit using optical lithography is also disclosed, comprising using a charged particle beam writer system to form a pattern on a reticle, and varying the magnification of the charged particle beam writer system from shot to shot.

Owner:D2S

Method for Fracturing a Pattern for Writing with a Shaped Charged Particle Beam Writing System Using Dragged Shots

InactiveUS20110089344A1Electric discharge tubesPhoto-taking processesMask data preparationShaped beam

In the field of semiconductor production using shaped charged particle beam lithography, a method and system for fracturing or mask data preparation or proximity effect correction is disclosed, wherein a shot determined for a shaped charged particle beam writer system comprises dragging the charged particle beam across a surface during the shot, so as to form a complex pattern in a single, extended shot. The dragging may be done with either variable shaped beam (VSB) or character projection (CP) shots. Methods for specifying in the shot data the path for the dragged shot are also disclosed. Other embodiments include using dragged shots with partial projection, varying the dragging velocity during a shot, and combining dragged shots with conventional shots. A method and system for creating glyphs which contain dragged shots is also disclosed.

Owner:D2S

Method and system for manufacturing a surface using charged particle beam lithography with variable beam blur

A charged particle beam writer system is disclosed comprising a generator for a charged particle beam having a beam blur radius, wherein the beam blur radius may be varied from shot to shot, or between two or more groups of shots. A method for fracturing or mask data preparation or optical proximity correction is also disclosed comprising assigning a beam blur radius variation to each calculated charged particle beam writer shot. A method for forming a pattern on a surface is also disclosed comprising using a charged particle beam writer system and varying the beam blur radius from shot to shot. A method for manufacturing an integrated circuit using optical lithography is also disclosed, comprising using a charged particle beam writer system to form a pattern on a reticle, and varying the beam blur radius of the charged particle beam writer system from shot to shot.

Owner:D2S

Method and system for fracturing a pattern using charged particle beam lithography with multiple exposure passes having different dosages

ActiveUS8221939B2Increase the number ofReduce in quantityElectric discharge tubesRadiation applicationsMask data preparationLithographic artist

In the field of semiconductor production using charged particle beam lithography, a method and system for fracturing or mask data preparation or proximity effect correction is disclosed, wherein base dosages for a plurality of exposure passes are different from each other. Methods for manufacturing a reticle and manufacturing an integrated circuit are also disclosed, wherein a plurality of charged particle beam exposure passes are used, with base dosage levels being different for different exposure passes.

Owner:D2S

Method and system for fracturing a pattern using charged particle beam lithography with multiple exposure passes having different dosages

ActiveUS20110159434A1Increase the number ofReduce in quantityElectric discharge tubesRadiation applicationsMask data preparationLithographic artist

In the field of semiconductor production using charged particle beam lithography, a method and system for fracturing or mask data preparation or proximity effect correction is disclosed, wherein base dosages for a plurality of exposure passes are different from each other. Methods for manufacturing a reticle and manufacturing an integrated circuit are also disclosed, wherein a plurality of charged particle beam exposure passes are used, with base dosage levels being different for different exposure passes.

Owner:D2S

Method and system for forming patterns with charged particle beam lithography

ActiveUS20140229904A1Reduce sensitivitySensitivity to change is reducedElectric discharge tubesRadiation applicationsMask data preparationPattern sensitivity

In a method for fracturing or mask data preparation or mask process correction for charged particle beam lithography, a plurality of shots are determined that will form a pattern on a surface, where shots are determined so as to reduce sensitivity of the resulting pattern to changes in beam blur (βf). In some embodiments, the sensitivity to changes in βf is reduced by varying the charged particle surface dosage for a portion of the pattern. Methods for forming patterns on a surface, and for manufacturing an integrated circuit are also disclosed, in which pattern sensitivity to changes in βf is reduced.

Owner:D2S

Method and system for forming patterns using charged particle beam lithography

ActiveUS8719739B2Photomechanical apparatusSemiconductor/solid-state device manufacturingMask data preparationLithographic artist

A method for mask data preparation (MDP) is disclosed, in which a set of shots is determined that will form a pattern on a reticle, where the determination includes calculating the pattern that will be formed on a substrate using an optical lithographic process with a reticle formed using the set of shots. A method for optical proximity correction (OPC) or MDP is also disclosed, in which a preliminary set of charged particle beam shots is generated using a preliminary mask model, and then the shots are modified by calculating both a reticle pattern using a final mask model, and a resulting substrate pattern. A method for OPC is also disclosed, in which an ideal pattern for a photomask is calculated from a desired substrate pattern, where the model used in the calculation includes only optical lithography effects and / or substrate processing effects.

Owner:D2S

Method and system for design of enhanced accuracy patterns for charged particle beam lithography

InactiveUS20120221980A1Electric discharge tubesNanoinformaticsMask data preparationLithographic artist

A method and system for fracturing or mask data preparation are presented in which overlapping shots are generated to increase dosage in selected portions of a pattern, thus improving the fidelity and / or the critical dimension variation of the transferred pattern. In various embodiments, the improvements may affect the ends of paths or lines, or square or nearly-square patterns. Simulation is used to determine the pattern that will be produced on the surface.

Owner:D2S

Method for design and manufacture of a reticle using a two-dimensional dosage map and charged particle beam lithography

InactiveUS8017286B2Electric discharge tubesRadiation applicationsMask data preparationLithographic artist

In the field of semiconductor device production, a method for manufacturing a surface using two-dimensional dosage maps is disclosed. A set of charged particle beam shots for creating an image on the surface is determined by combining dosage maps for a plurality of shots into the dosage map for the surface. A similar method is disclosed for fracturing or mask data preparation of a reticle image. A method for creating glyphs is also disclosed, in which a two-dimensional dosage map of one or more shots is calculated, and the list of shots and the calculated dosage map are stored for later reference.

Owner:D2S

Method and system for forming patterns using charged particle beam lithography

InactiveUS20130283217A1Photomechanical apparatusSemiconductor/solid-state device manufacturingMask data preparationLithographic artist

A method for mask data preparation (MDP) is disclosed, in which a set of shots is determined that will form a pattern on a reticle, where the determination includes calculating the pattern that will be formed on a substrate using an optical lithographic process with a reticle formed using the set of shots. A method for optical proximity correction (OPC) or MDP is also disclosed, in which a preliminary set of charged particle beam shots is generated using a preliminary mask model, and then the shots are modified by calculating both a reticle pattern using a final mask model, and a resulting substrate pattern. A method for OPC is also disclosed, in which an ideal pattern for a photomask is calculated from a desired substrate pattern, where the model used in the calculation includes only optical lithography effects and / or substrate processing effects.

Owner:D2S

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com