Patents

Literature

244 results about "Proximity effect correction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

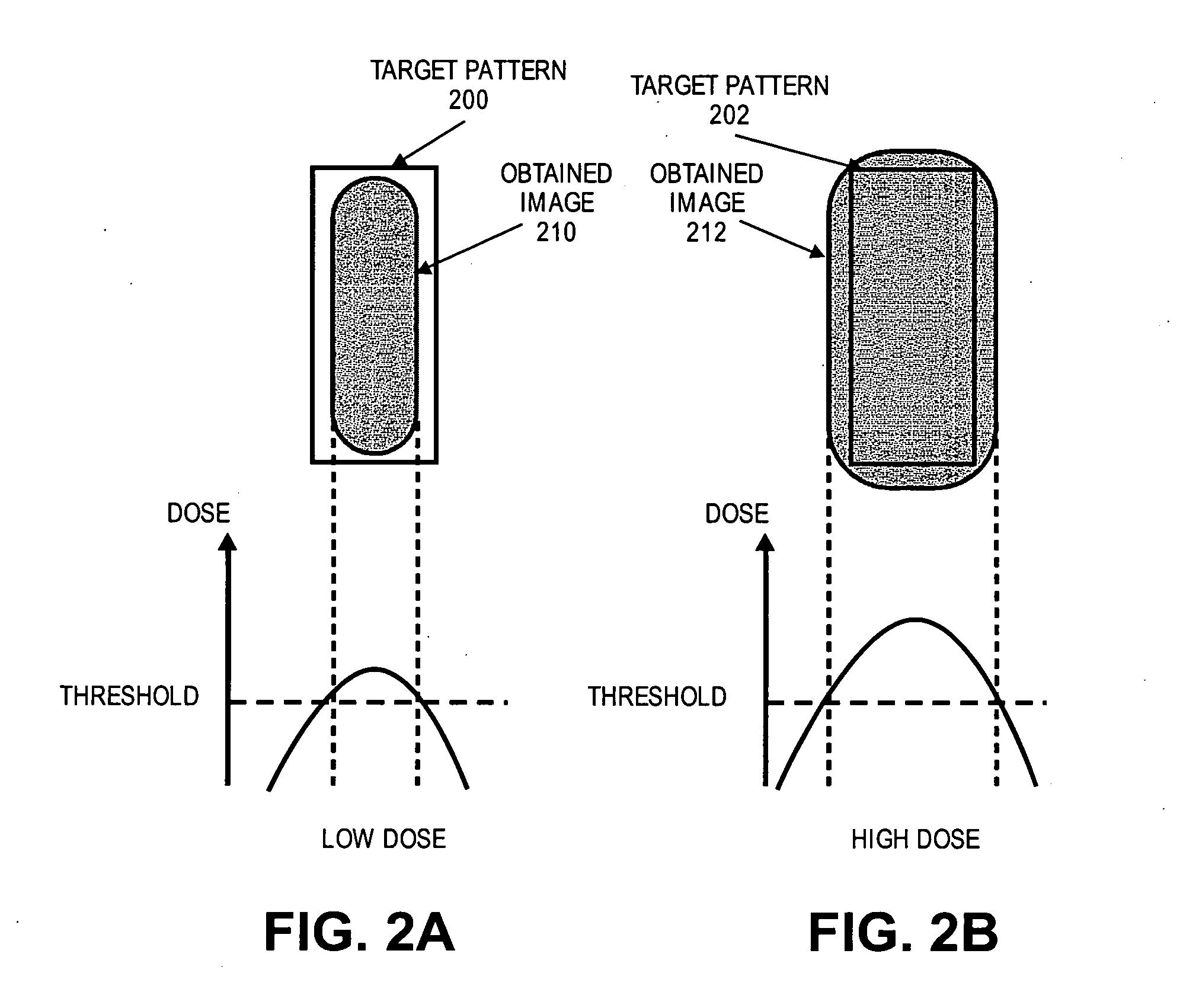

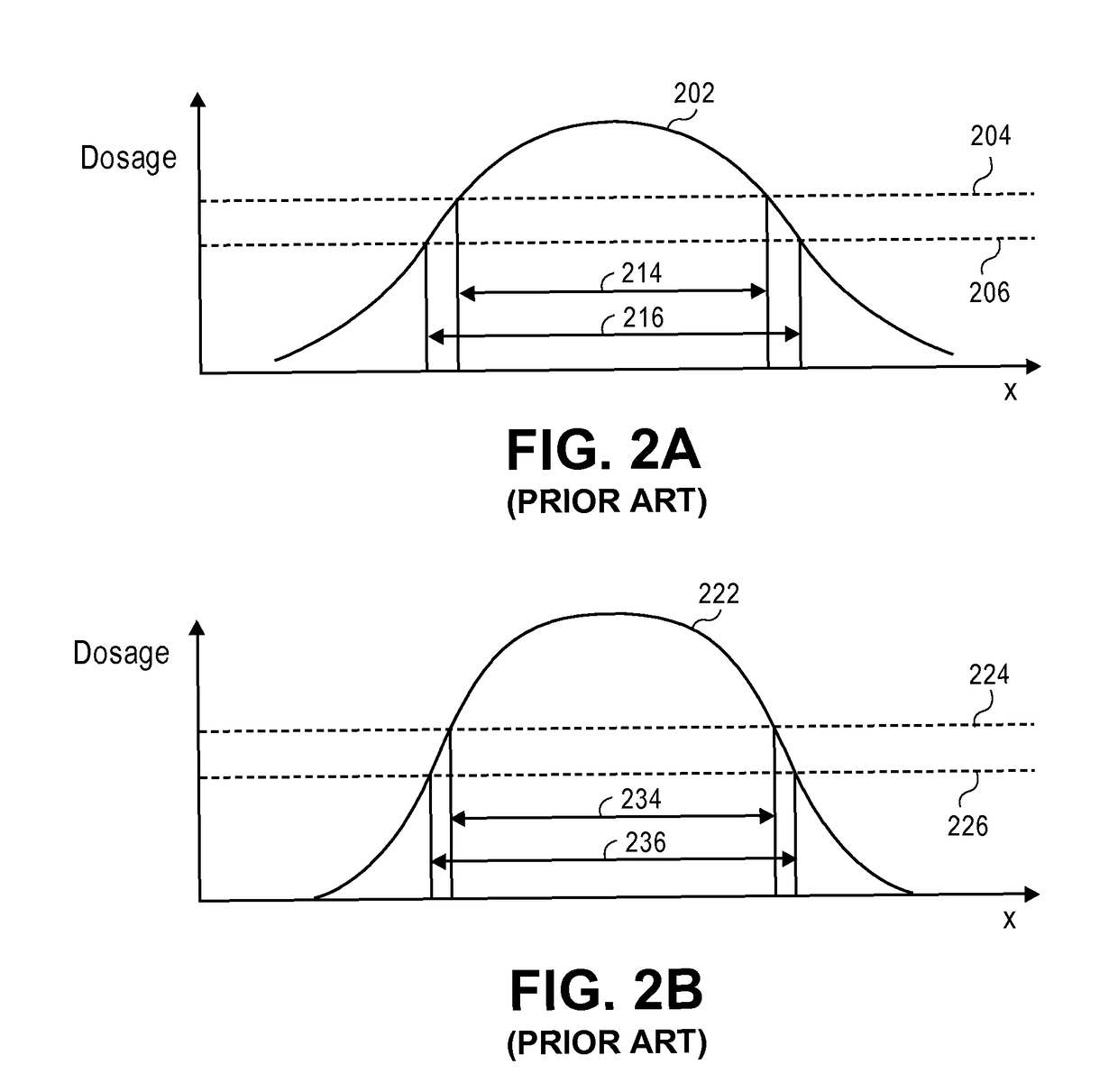

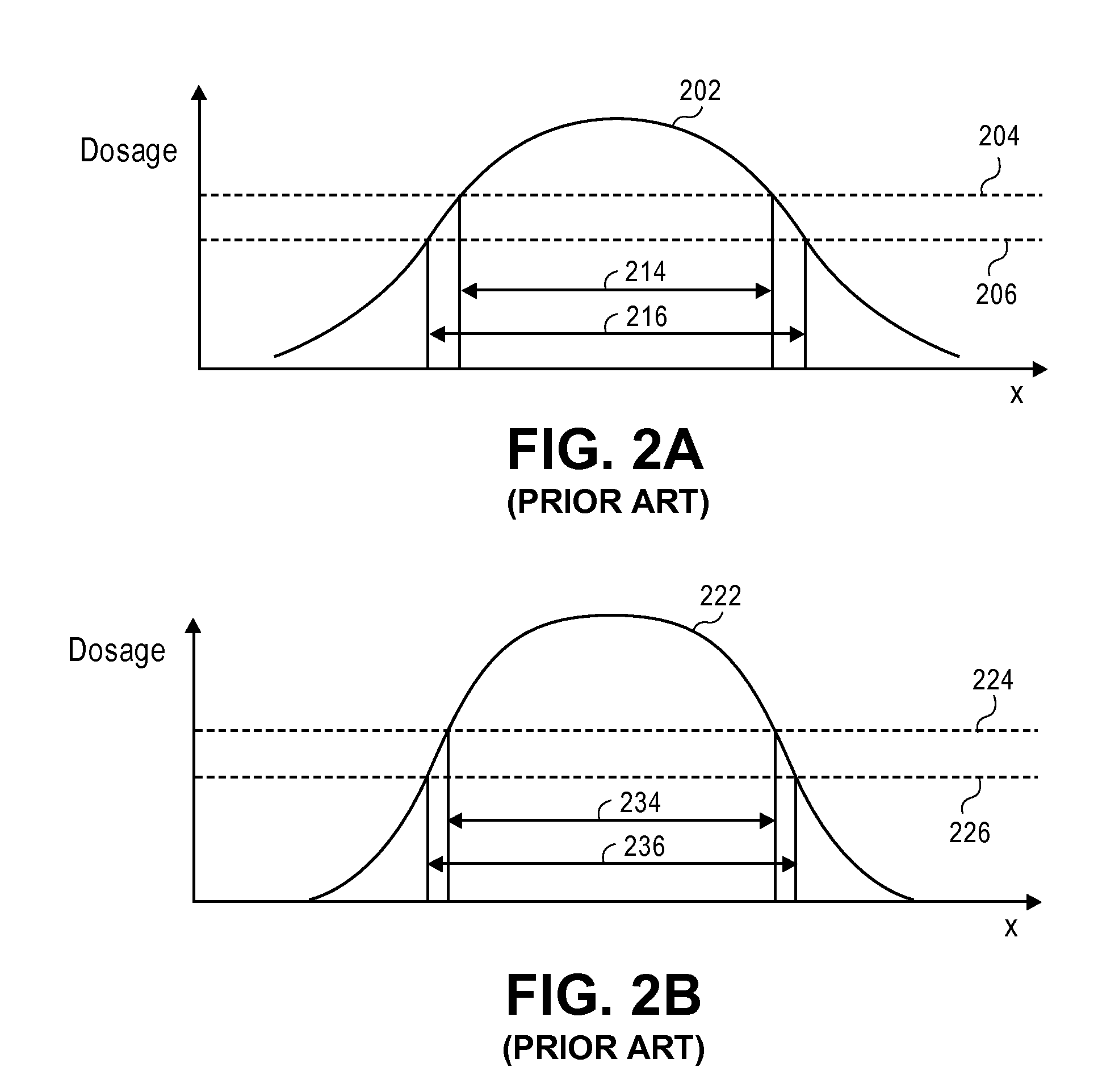

Proximity effect correction adjusts the exposure dose of localized areas of a pattern relative to an absolute Base Dose. The Base Dose in turn depends on the resist process (sensitivity, thickness, …), the underlying material stack composition and accelerating voltage.

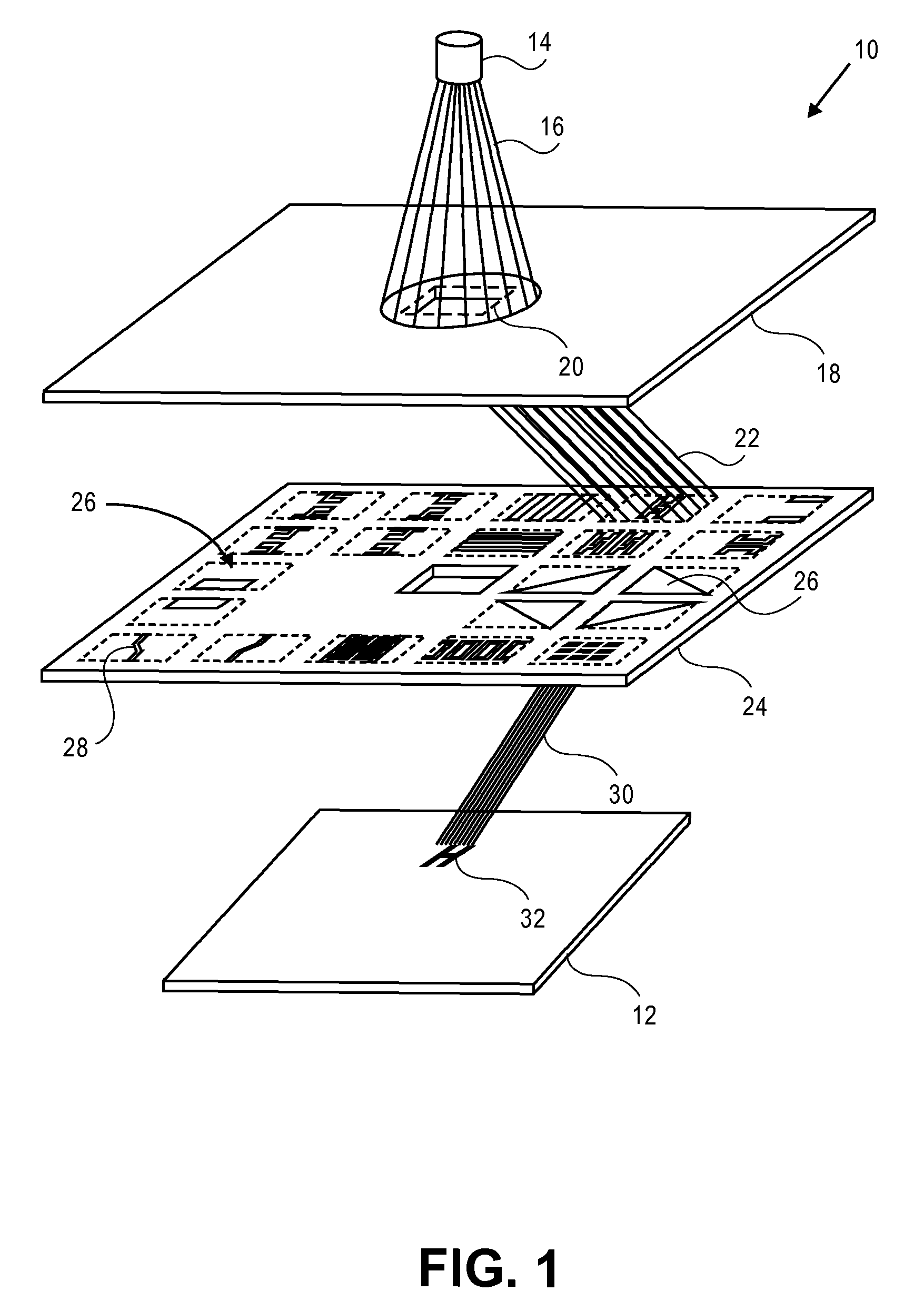

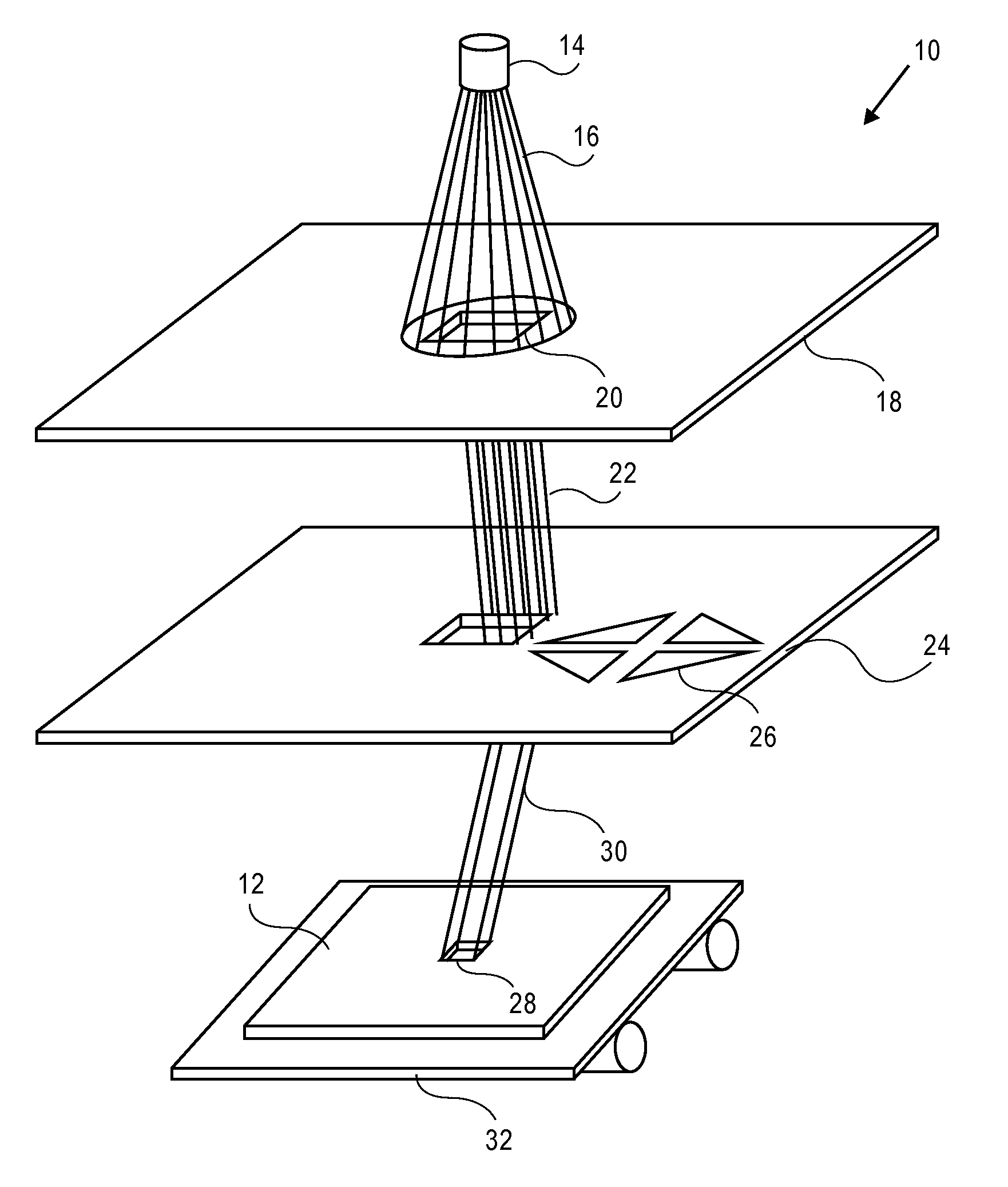

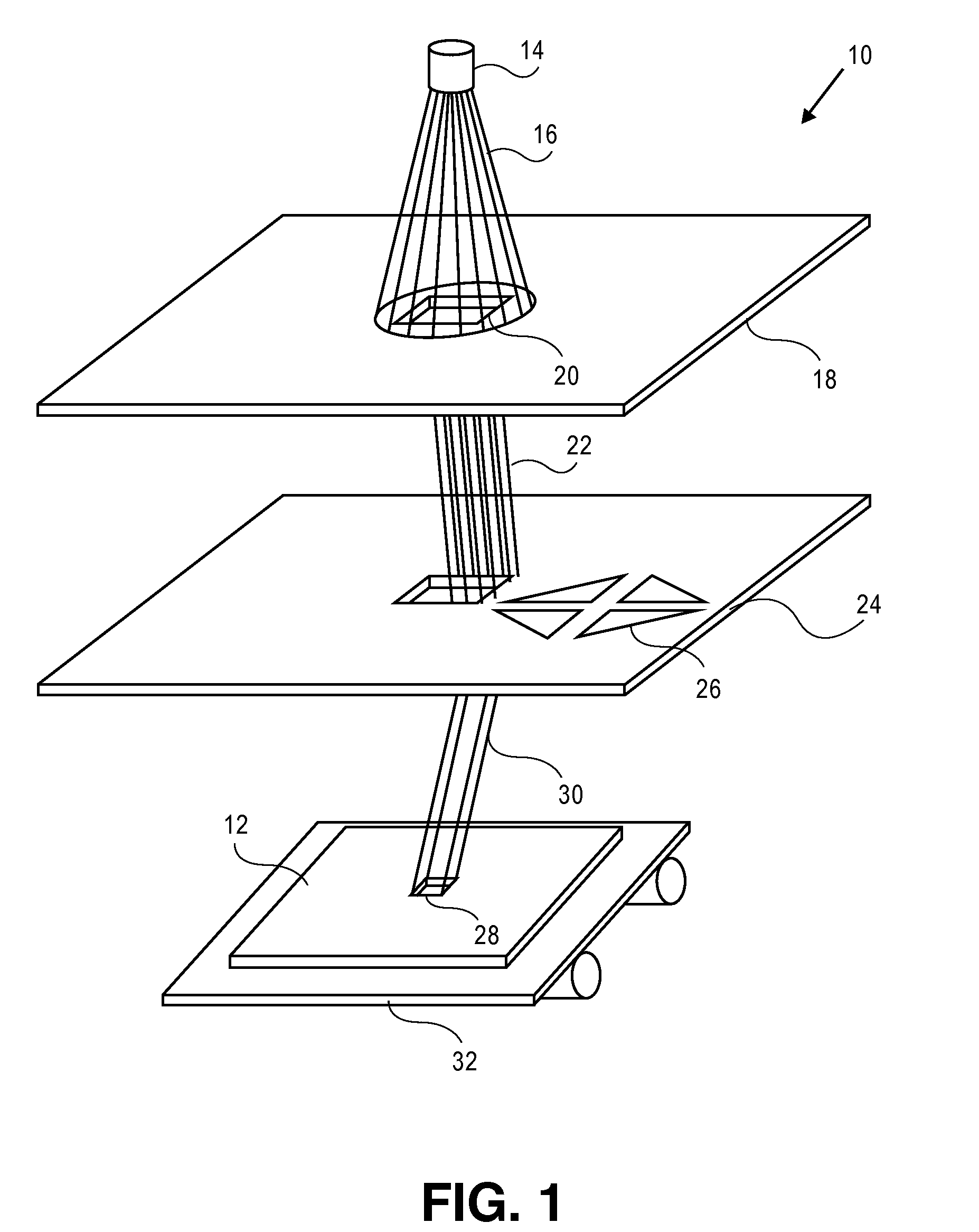

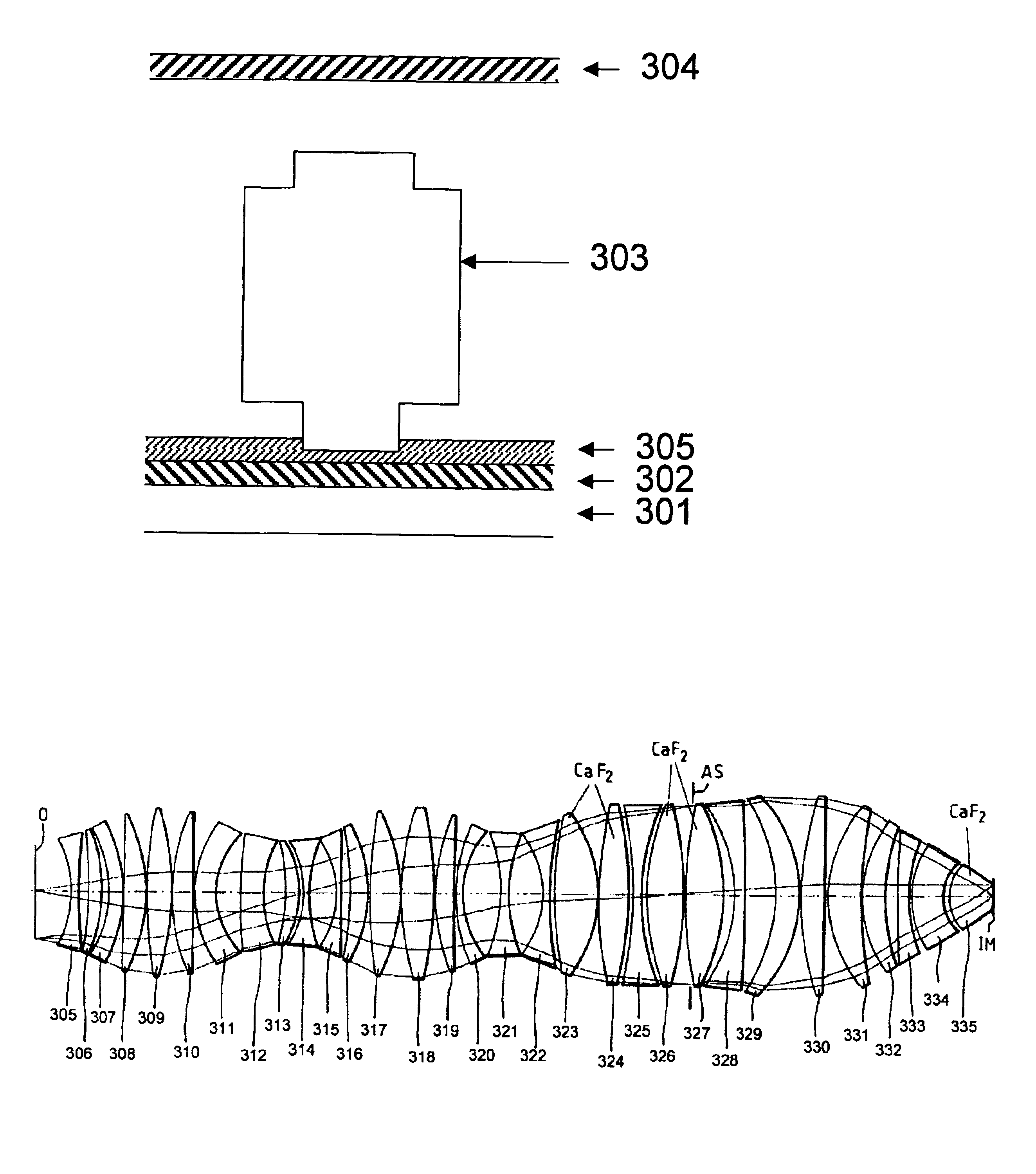

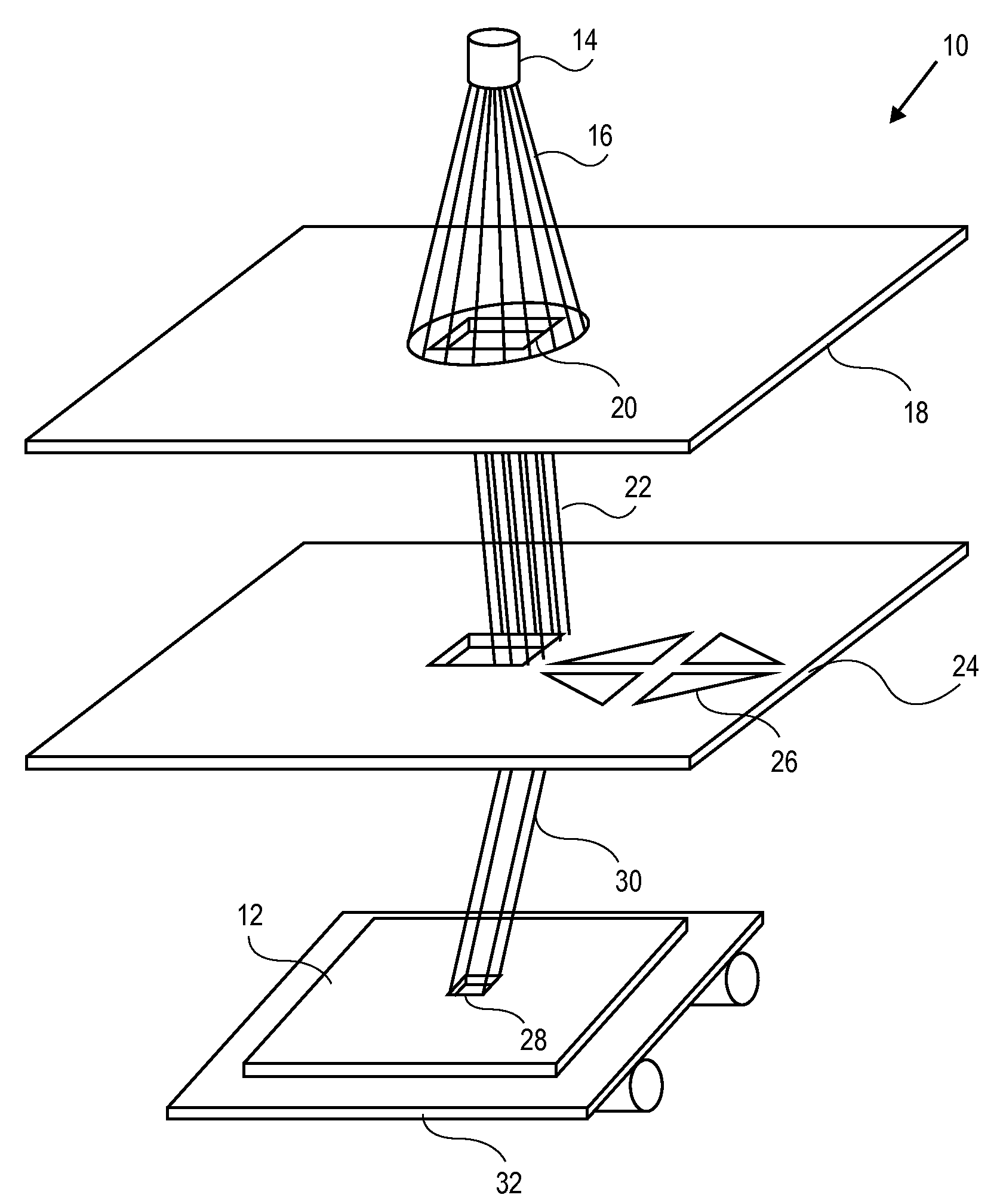

Contact printing using a magnified mask image

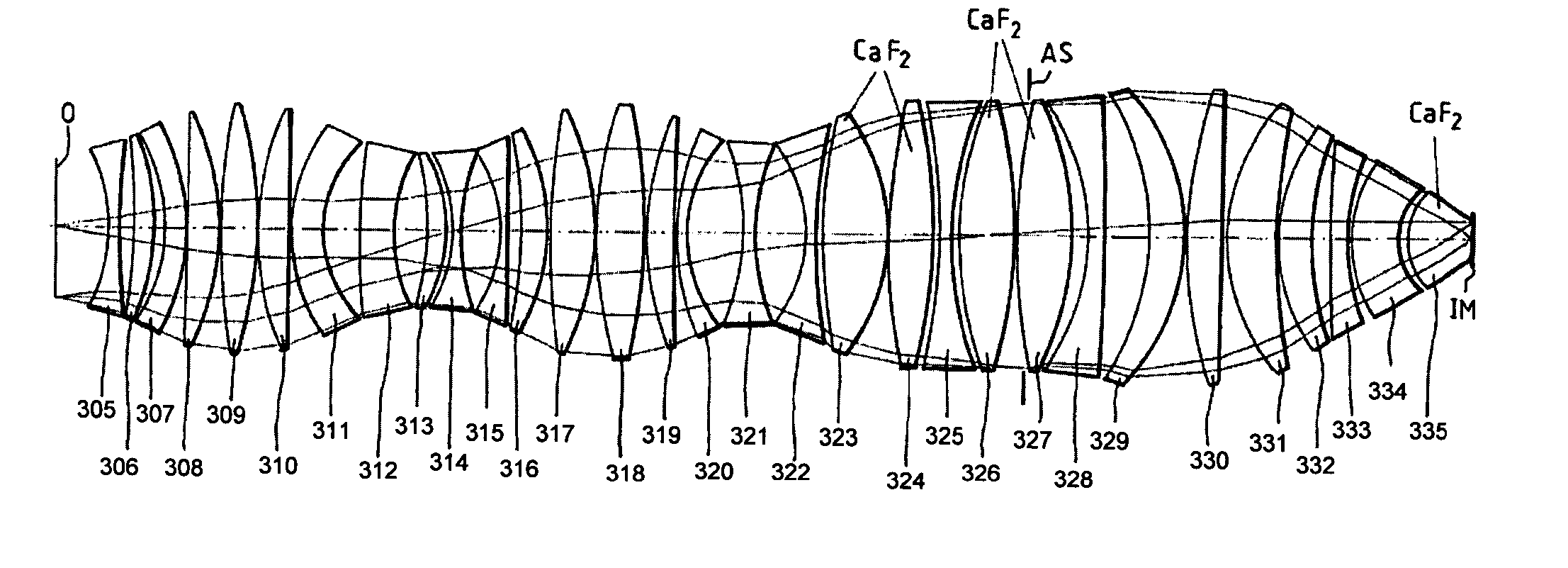

InactiveUS20050068639A1Avoid stickingPhotomechanical exposure apparatusMicrolithography exposure apparatusRefractive indexOff-axis illumination

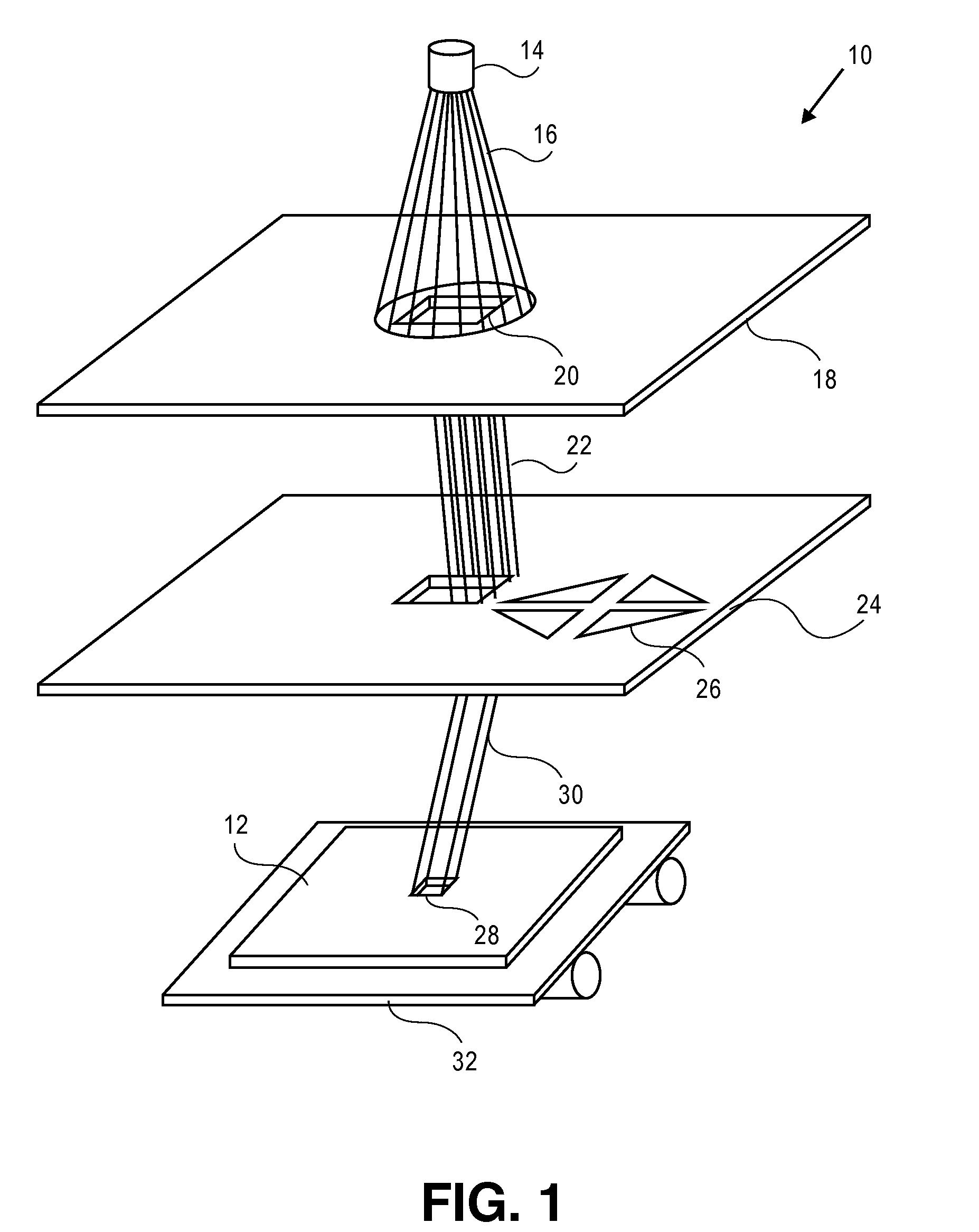

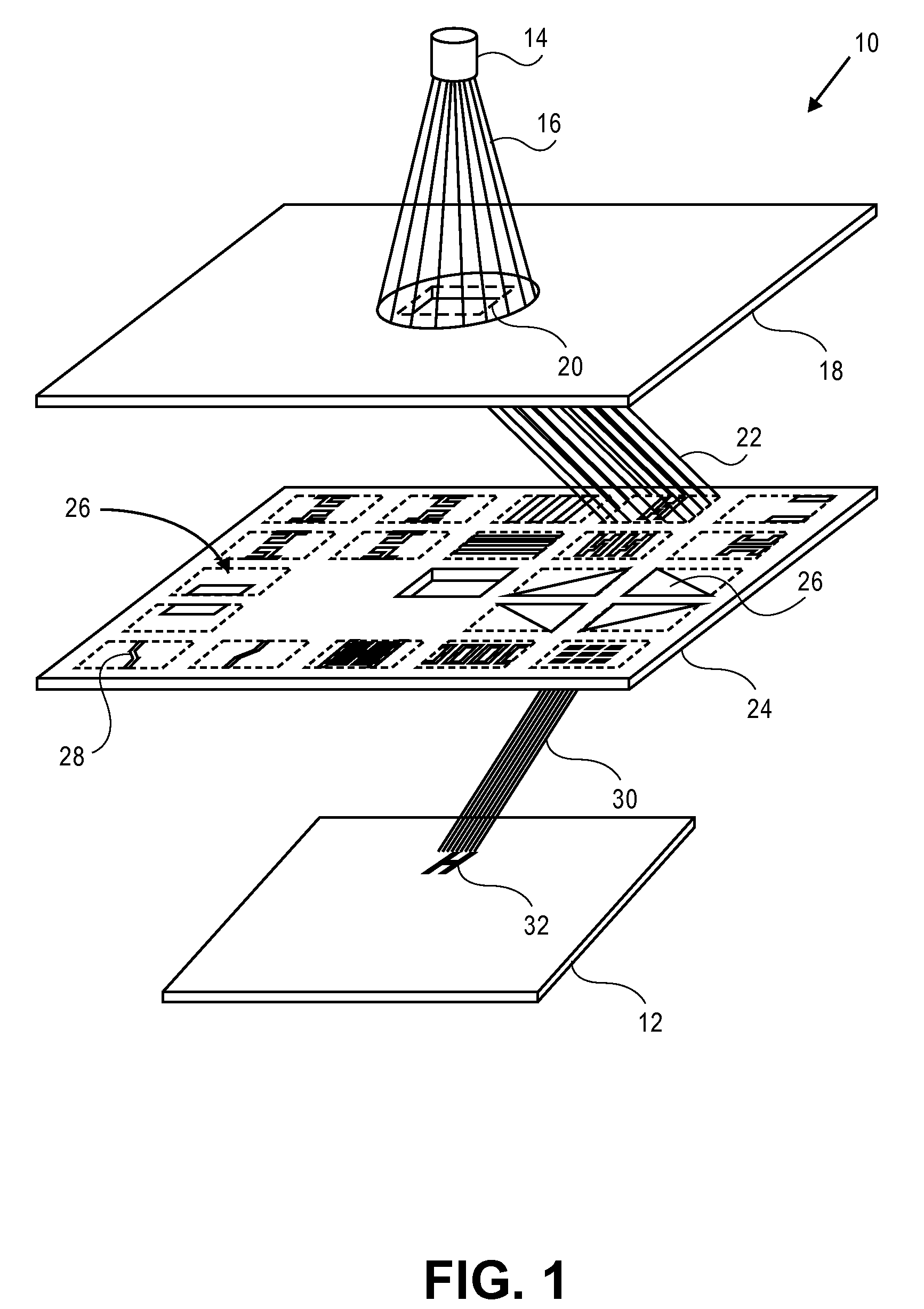

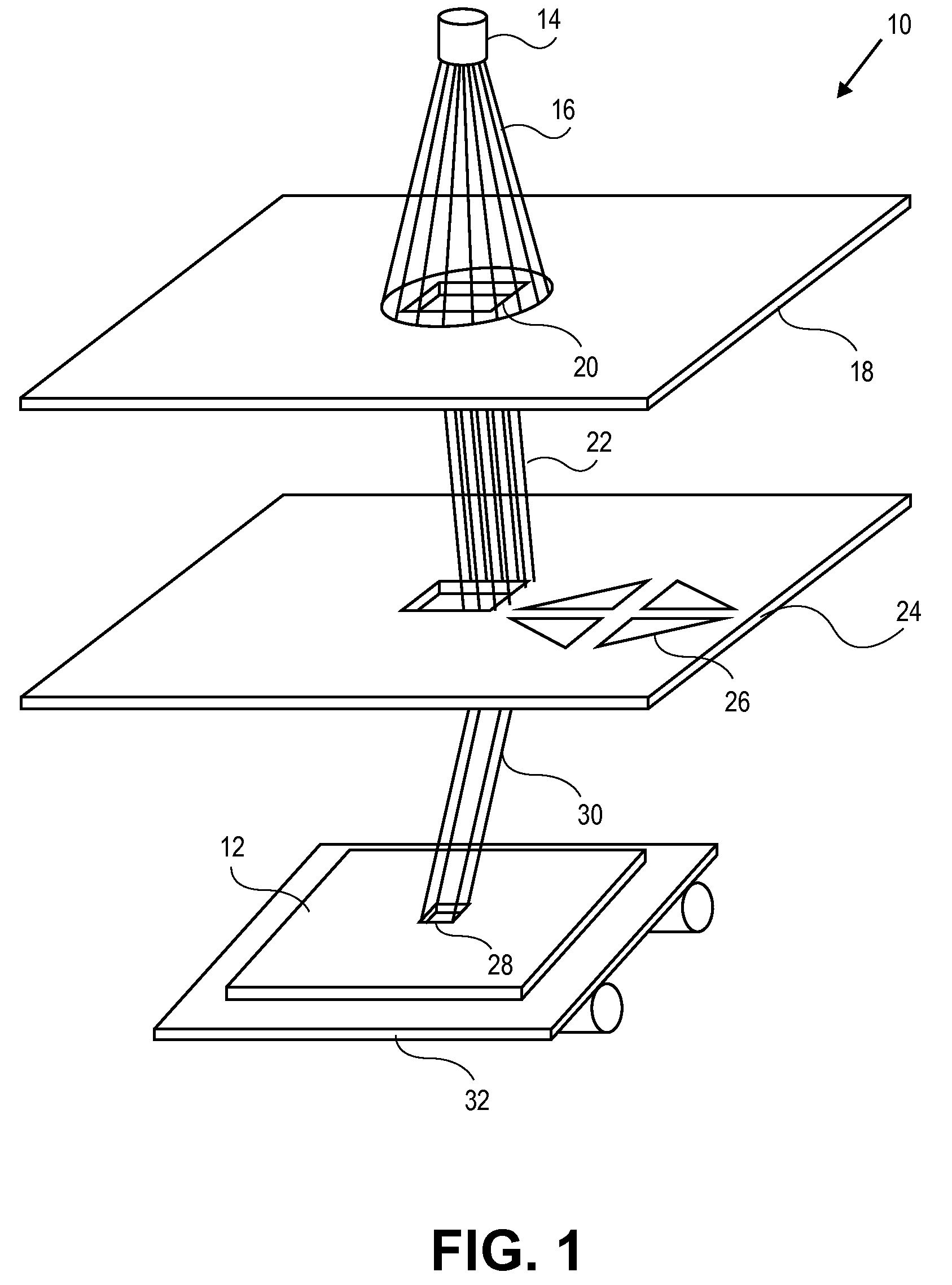

Improvements in the fabrication of integrated circuits are driven by the decrease of the size of the features printed on the wafers. Current lithography techniques limits have been extended through the use of phase-shifting masks, off-axis illumination, and proximity effect correction. More recently, liquid immersion lithography has been proposed as a way to extend even further the limits of optical lithography. This invention described a methodology based on contact printing using a projection lens to define the image of the mask onto the wafer. As the imaging is performed in a solid material, larger refractive indices can be obtained and the resolution of the imaging system can be increased.

Owner:APPLIED MATERIALS INC

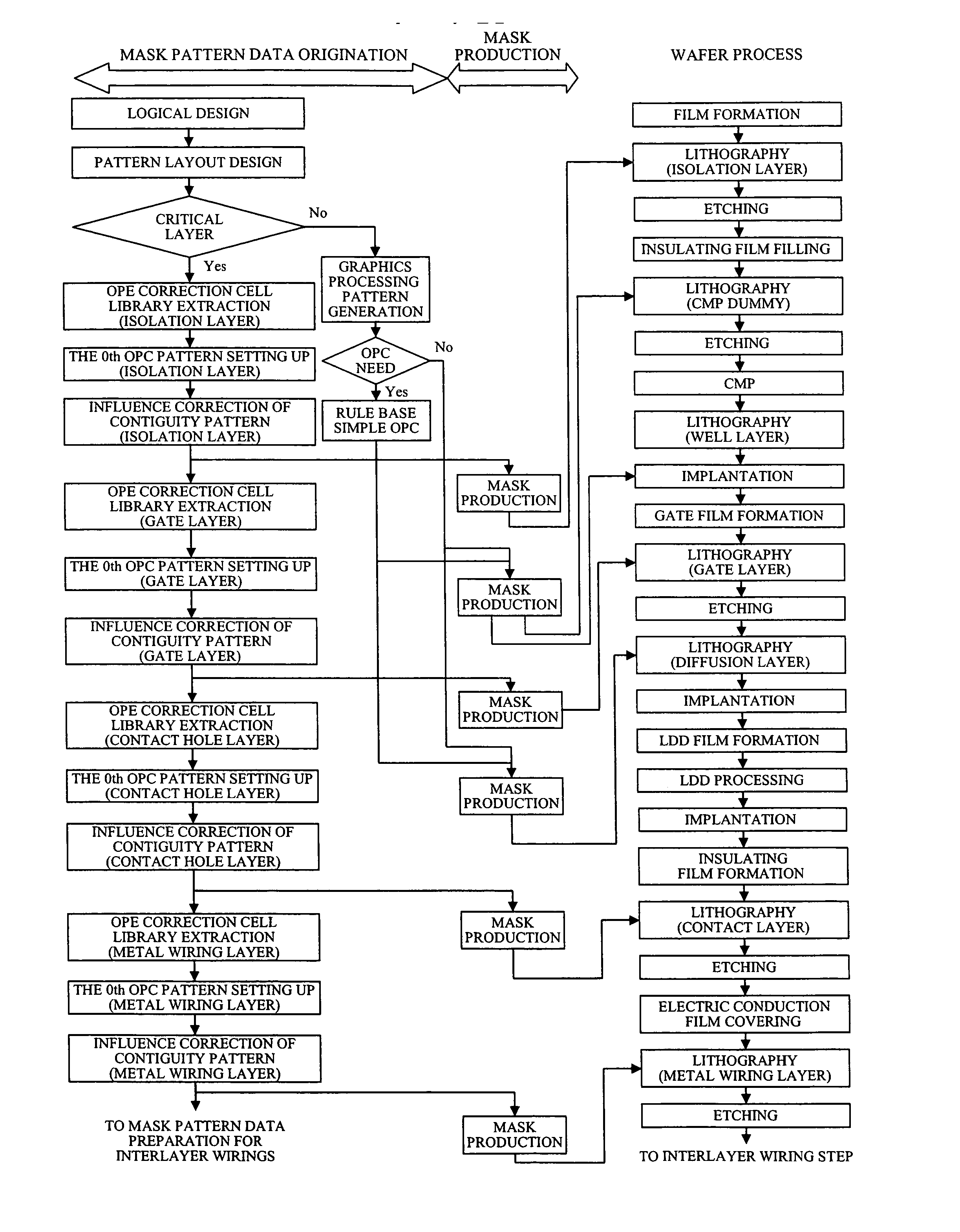

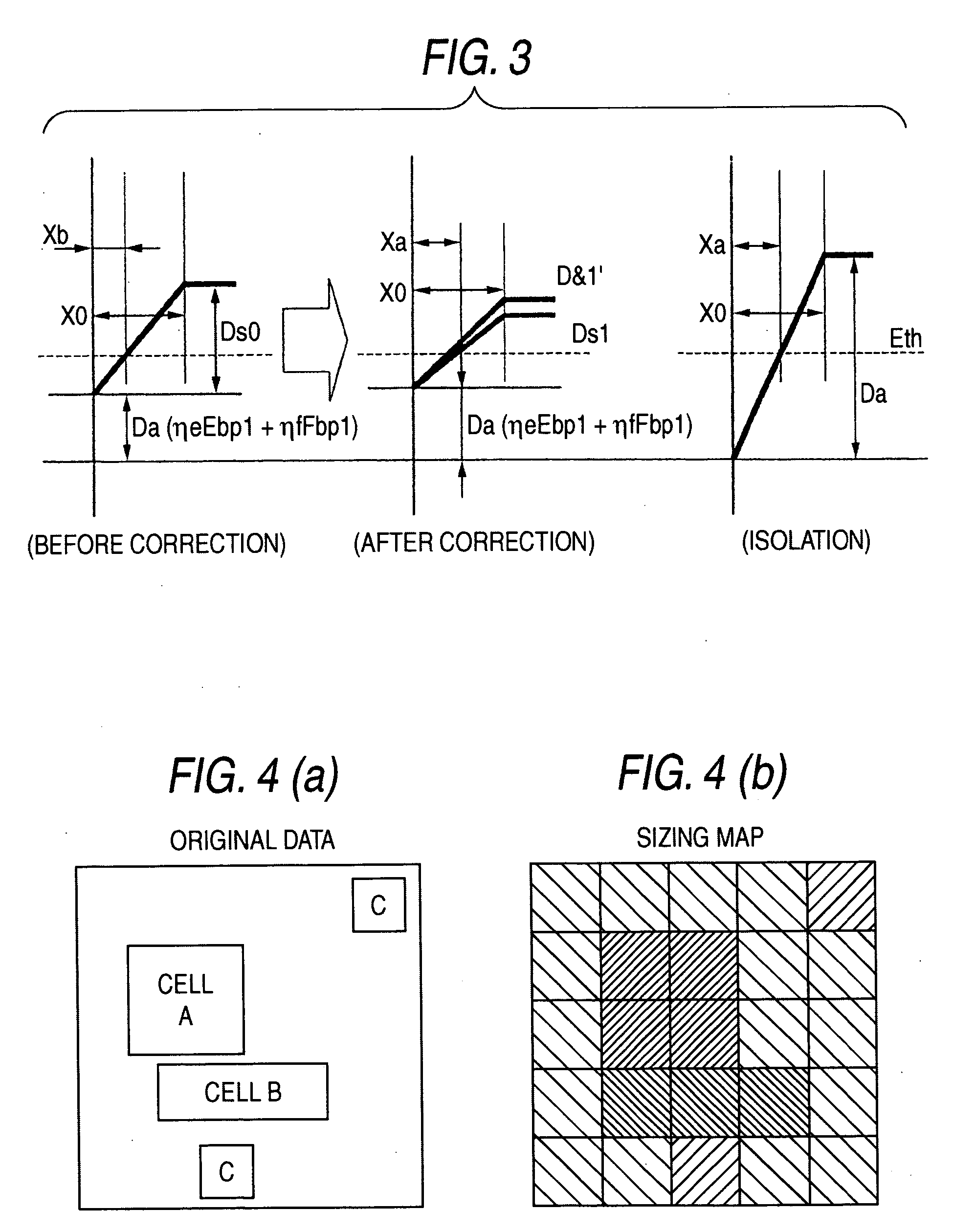

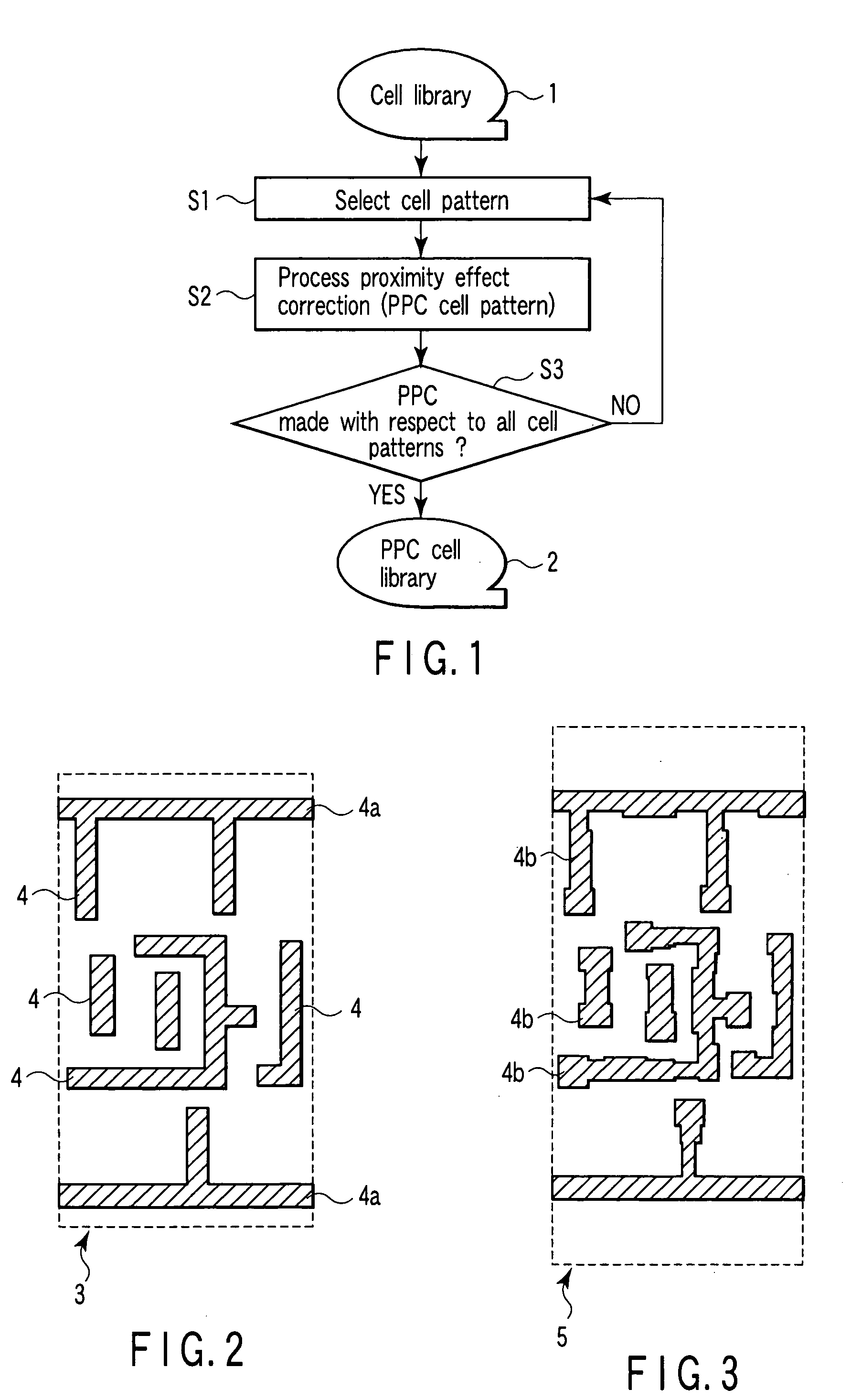

Mask pattern design method and manufacturing method of semiconductor device

InactiveUS20070074145A1Extended processing timeLower manufacturing requirementsOriginals for photomechanical treatmentSpecial data processing applicationsDevice materialSemiconductor chip

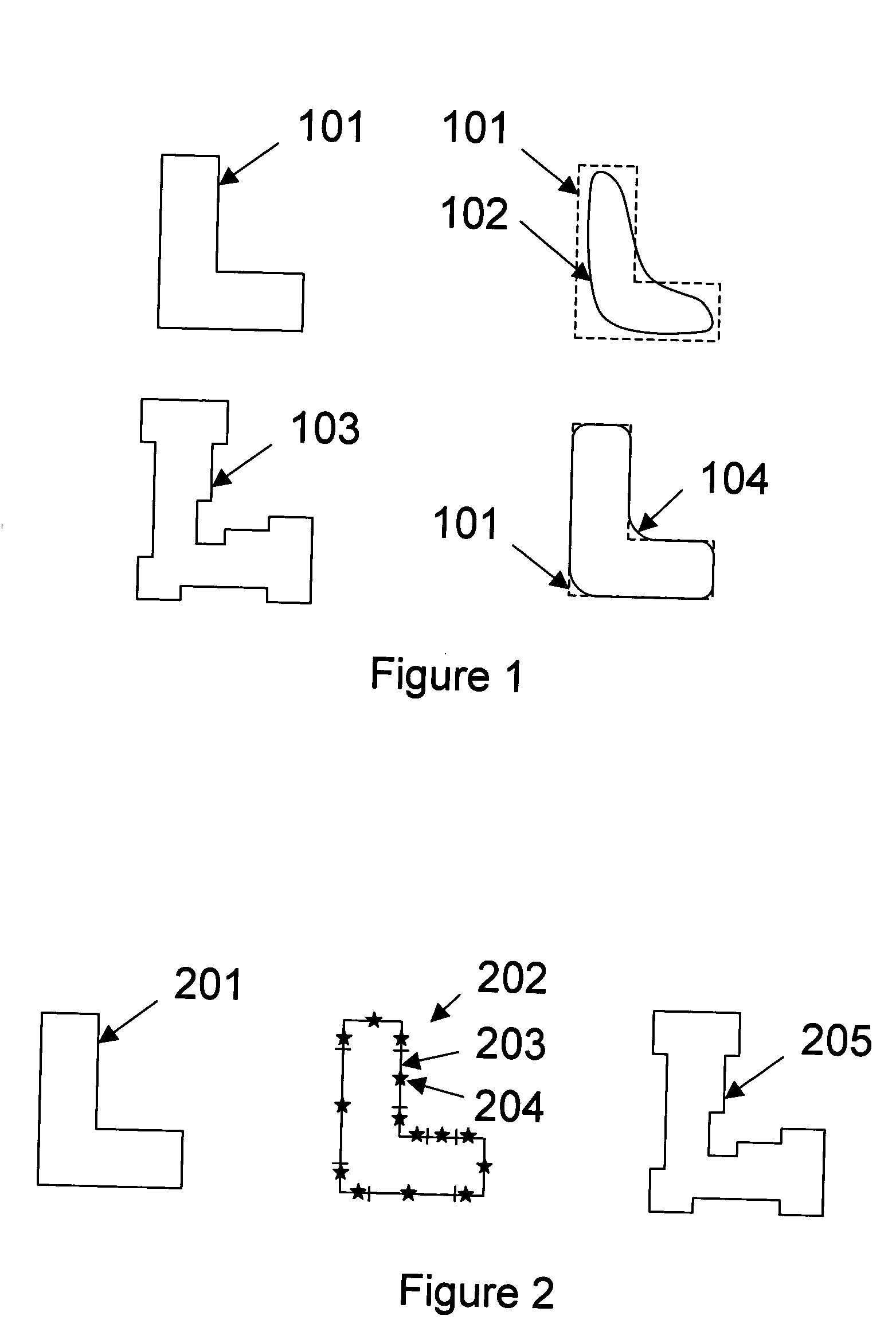

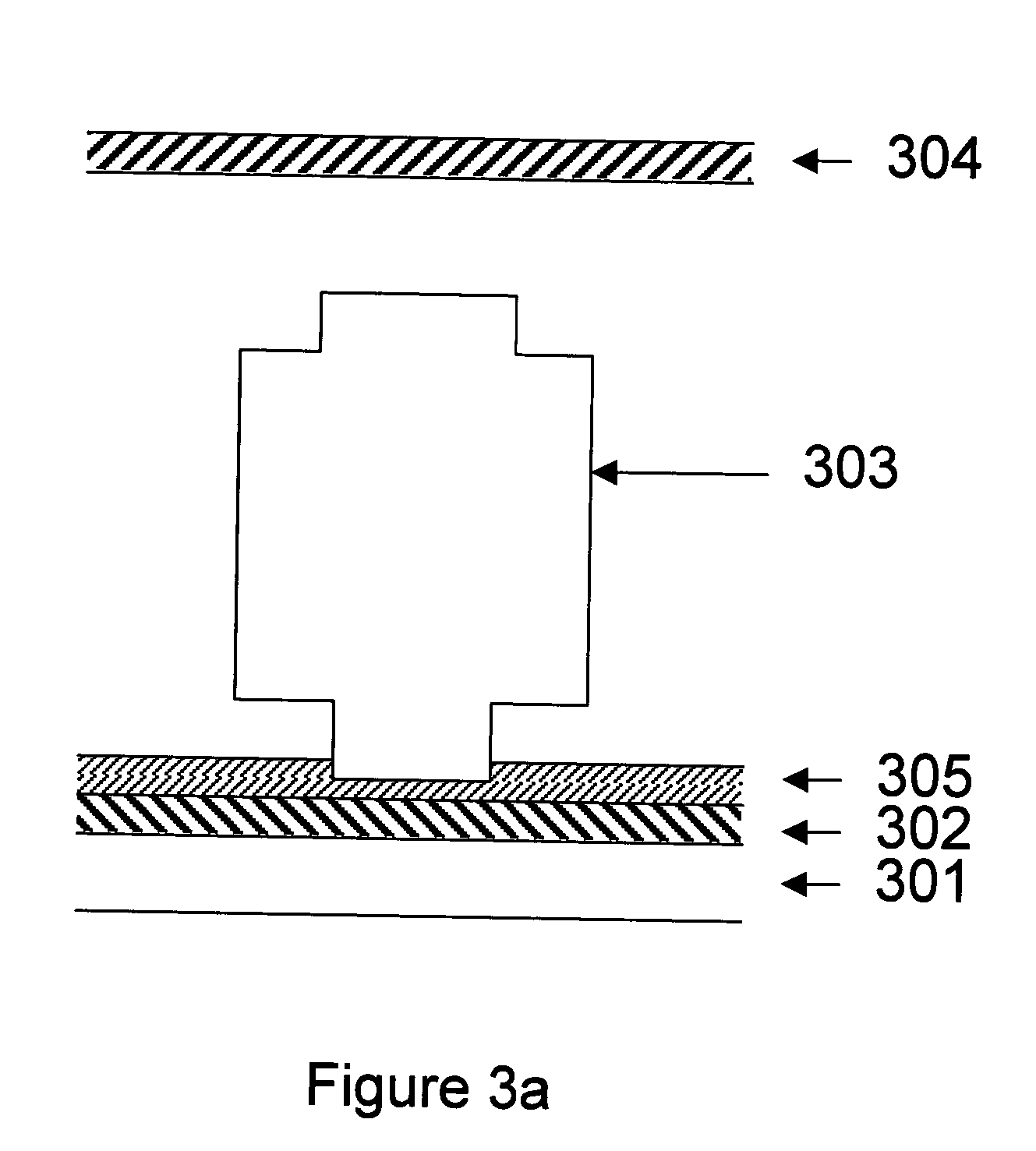

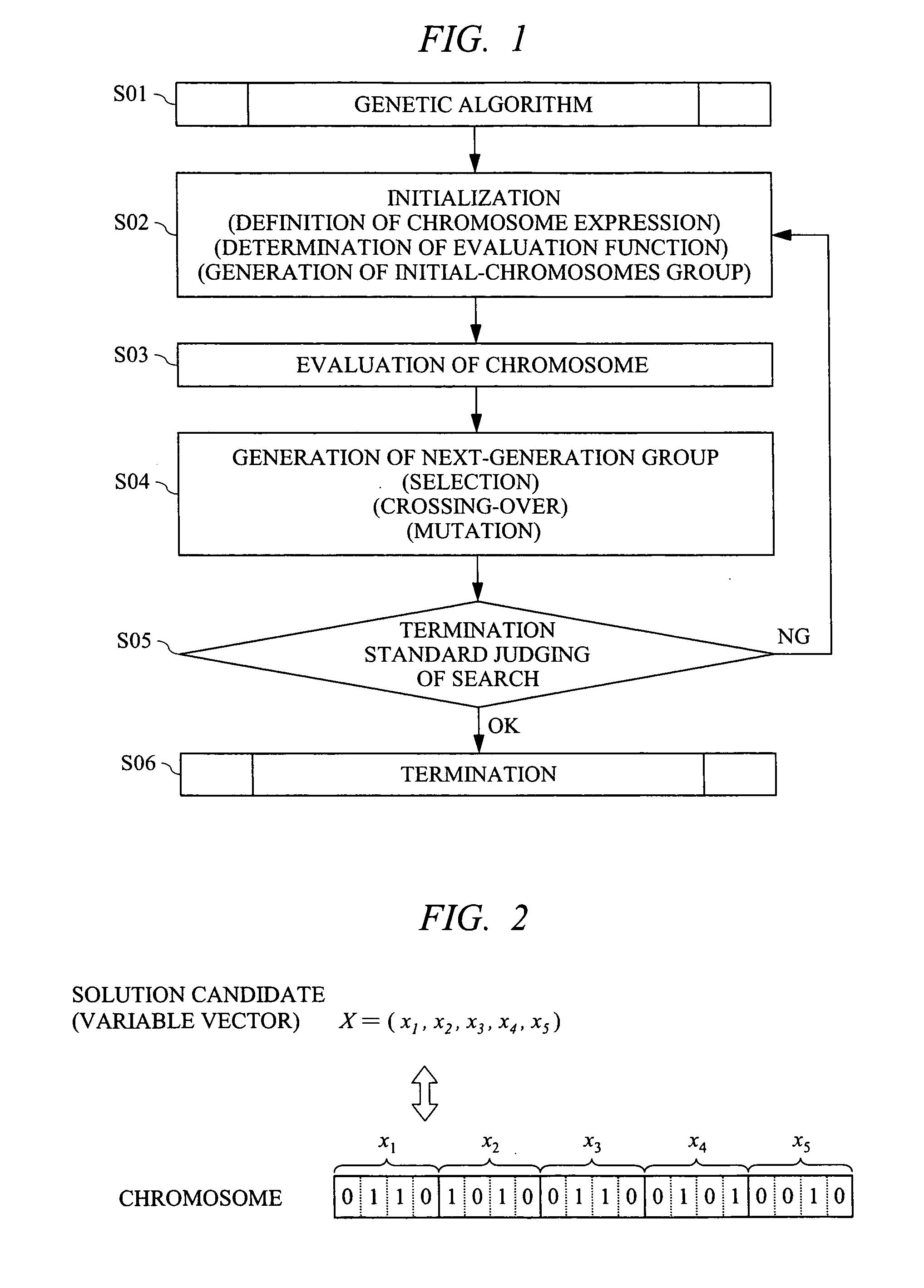

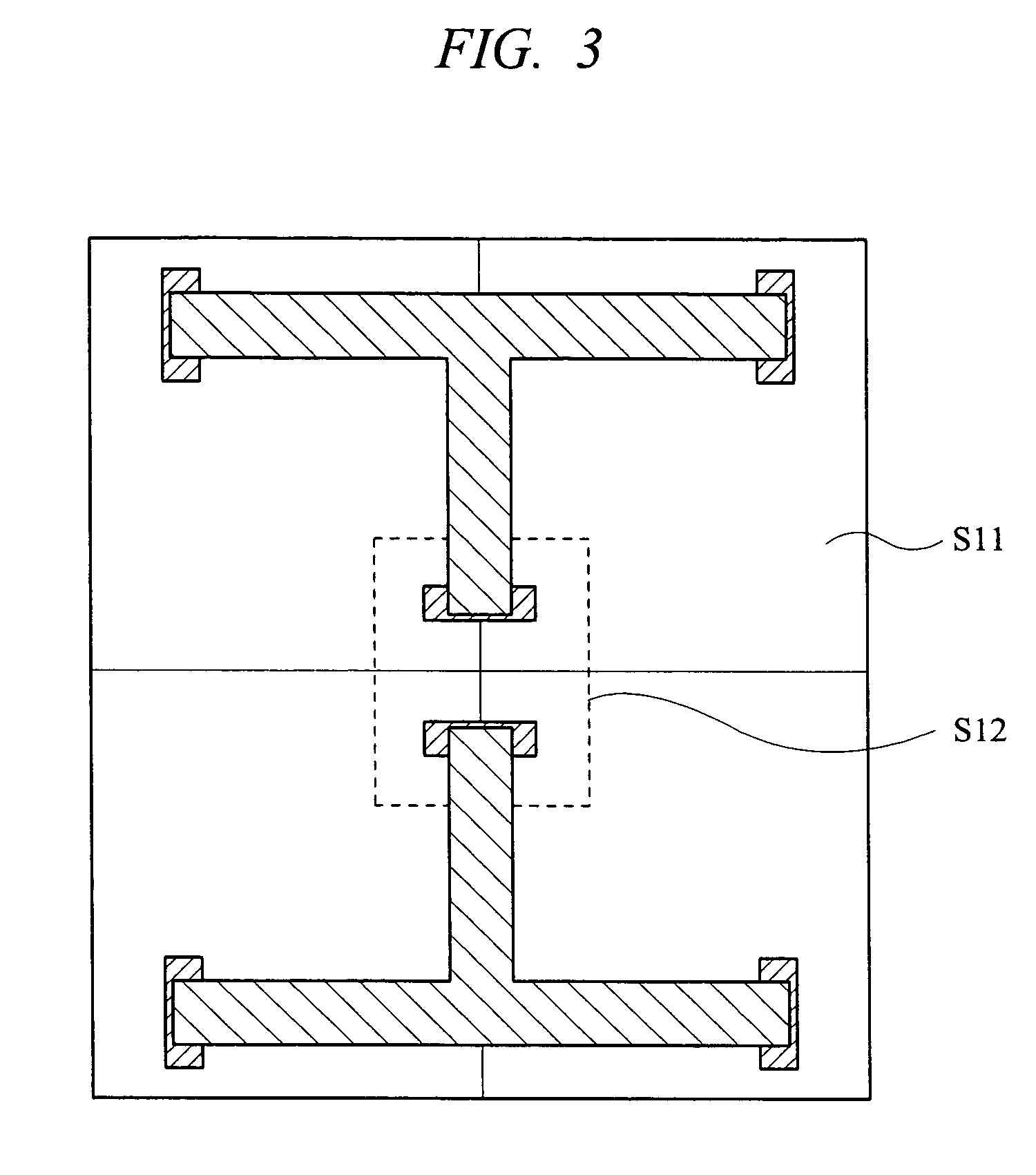

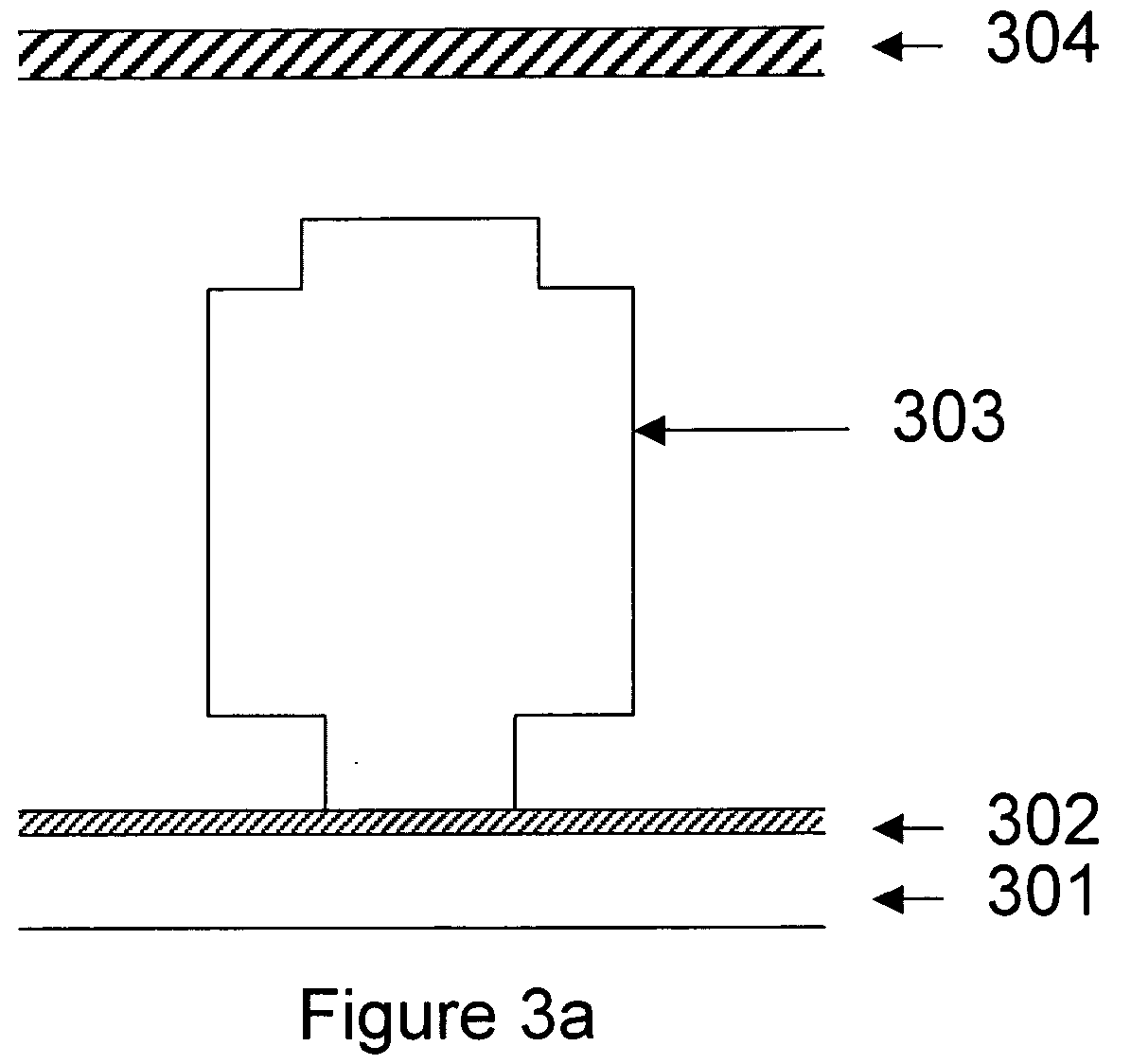

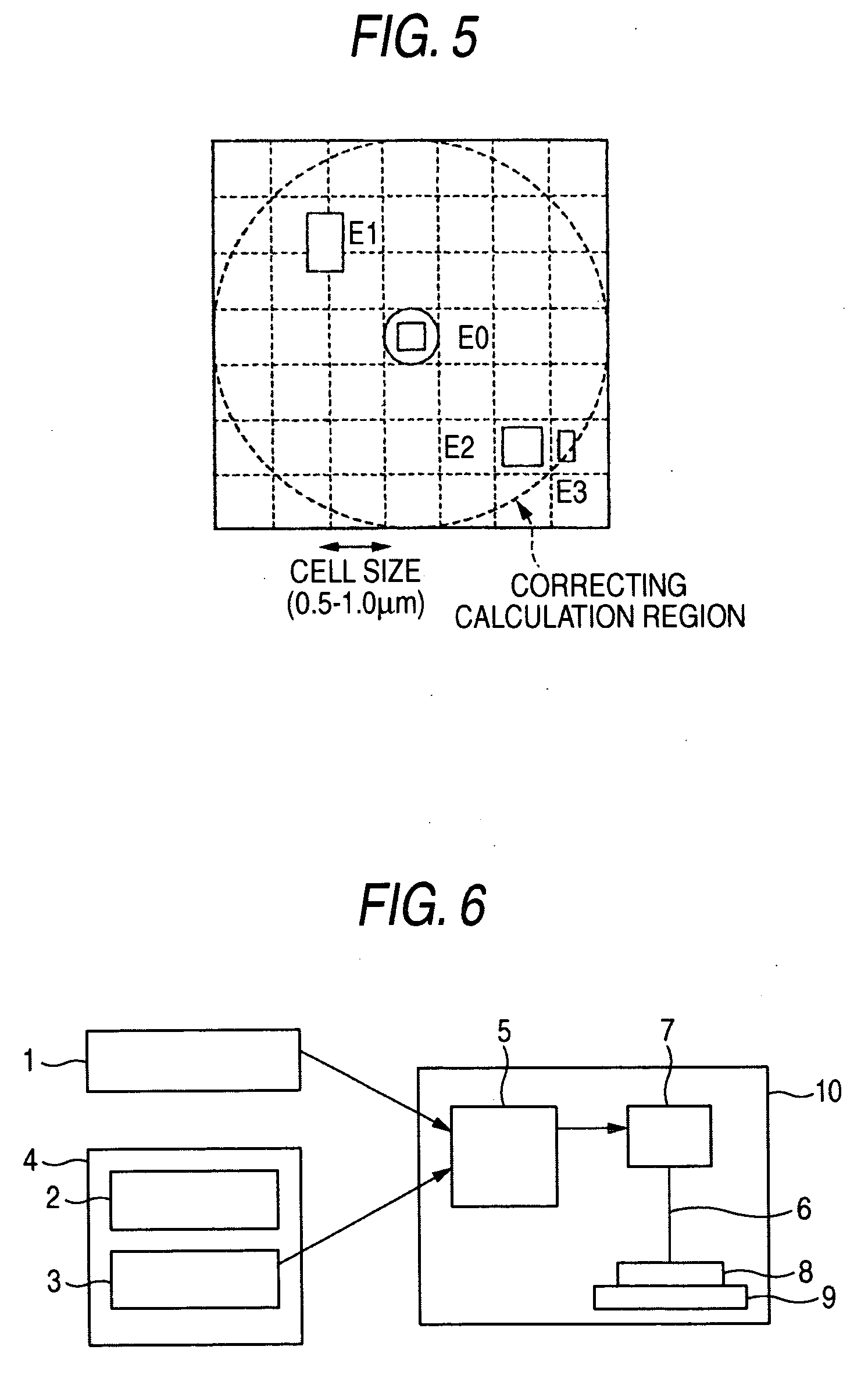

To a cell library pattern which makes the basic constitution of a semiconductor circuit pattern, OPC processing is performed beforehand, and a semiconductor chip is produced using this cell library pattern. Since it is influenced by the pattern of the cell arranged to the circumference and the pattern arranged around other cells at this time, correction processing (optimization processing) is performed. The part of this correction processing is a portion in which a pattern faces between cell boundaries in the inside of the region specified from the cell boundary, and proximity effect correction is performed by making the width, the length, and the position of this portion into variables. Or proximity effect correction is performed by making a polygon into a variable. Or sizing is done and proximity effect correction is performed.

Owner:RENESAS TECH CORP

Method and system for proximity effect and dose correction for a particle beam writing device

InactiveUS20080116398A1Reduce image qualityEffective estimateElectric discharge tubesRadiation applicationsCell patternLithographic artist

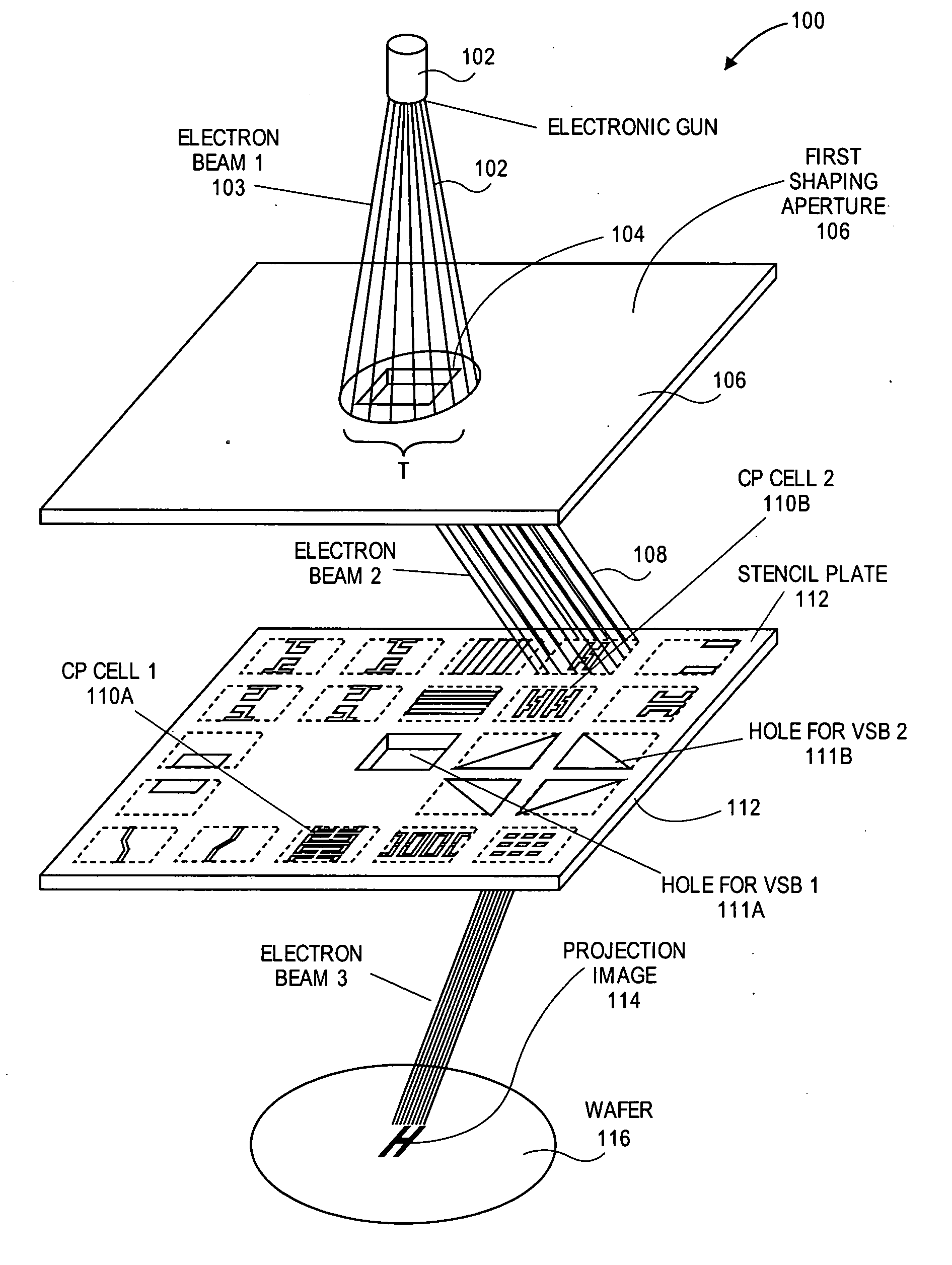

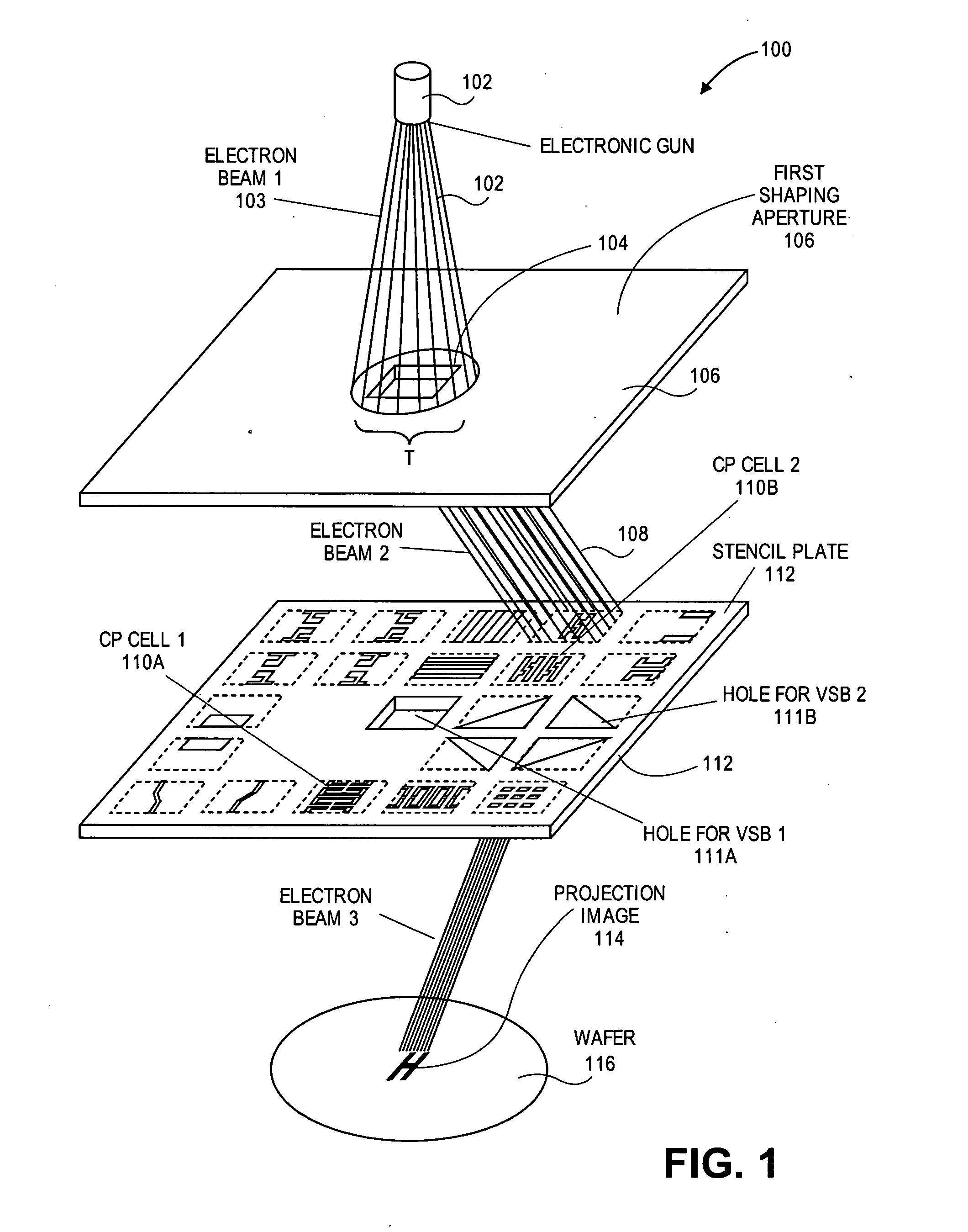

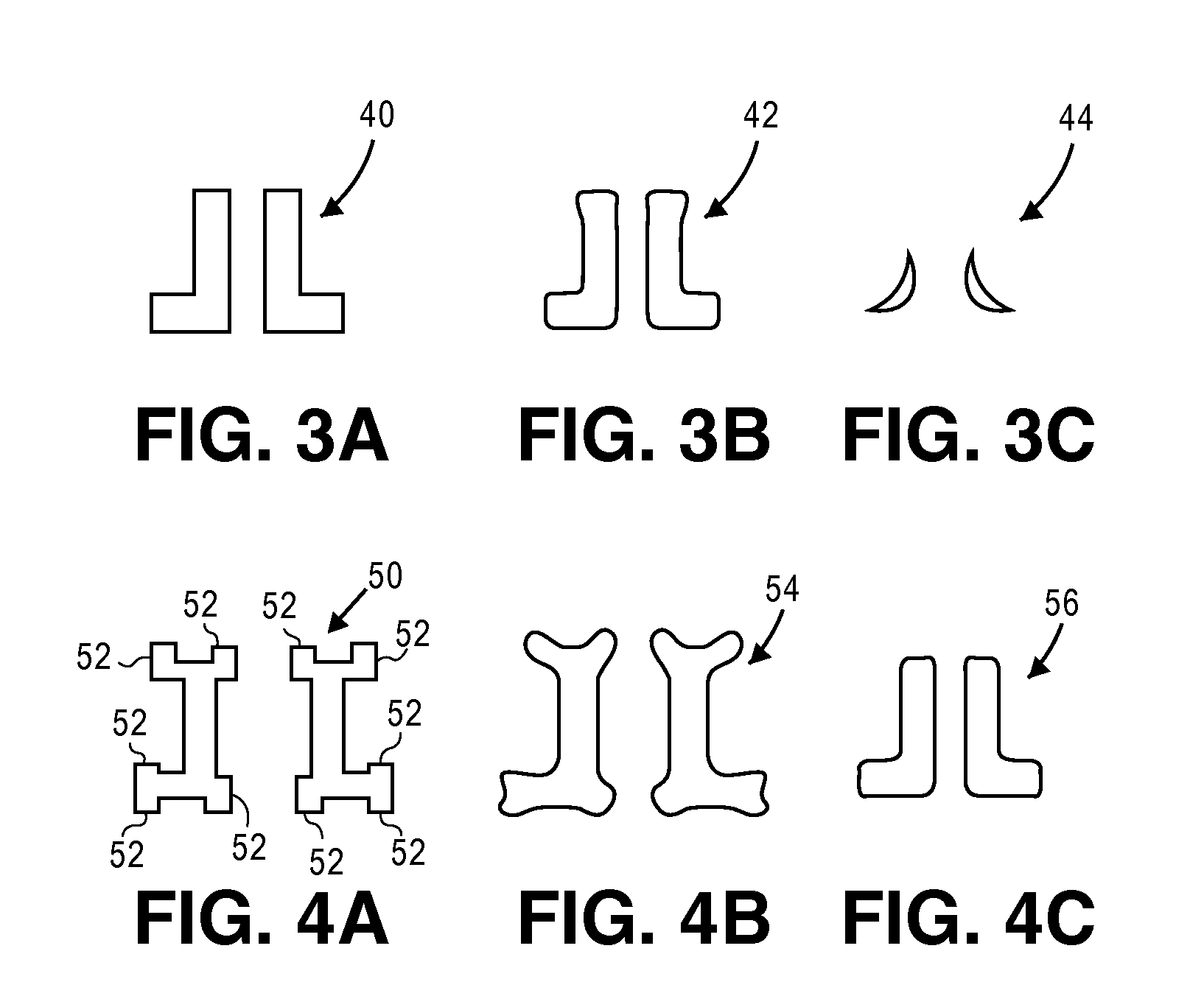

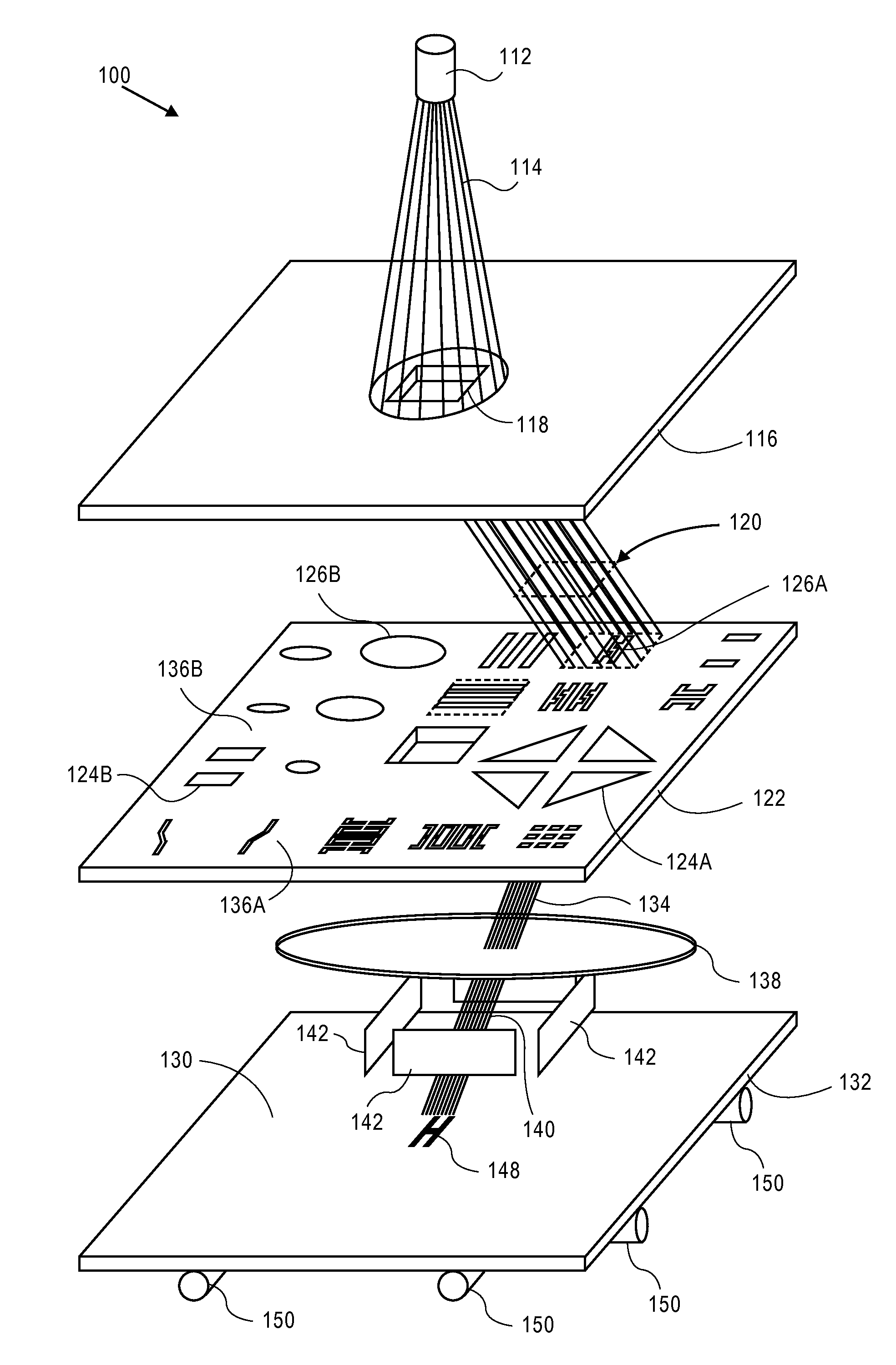

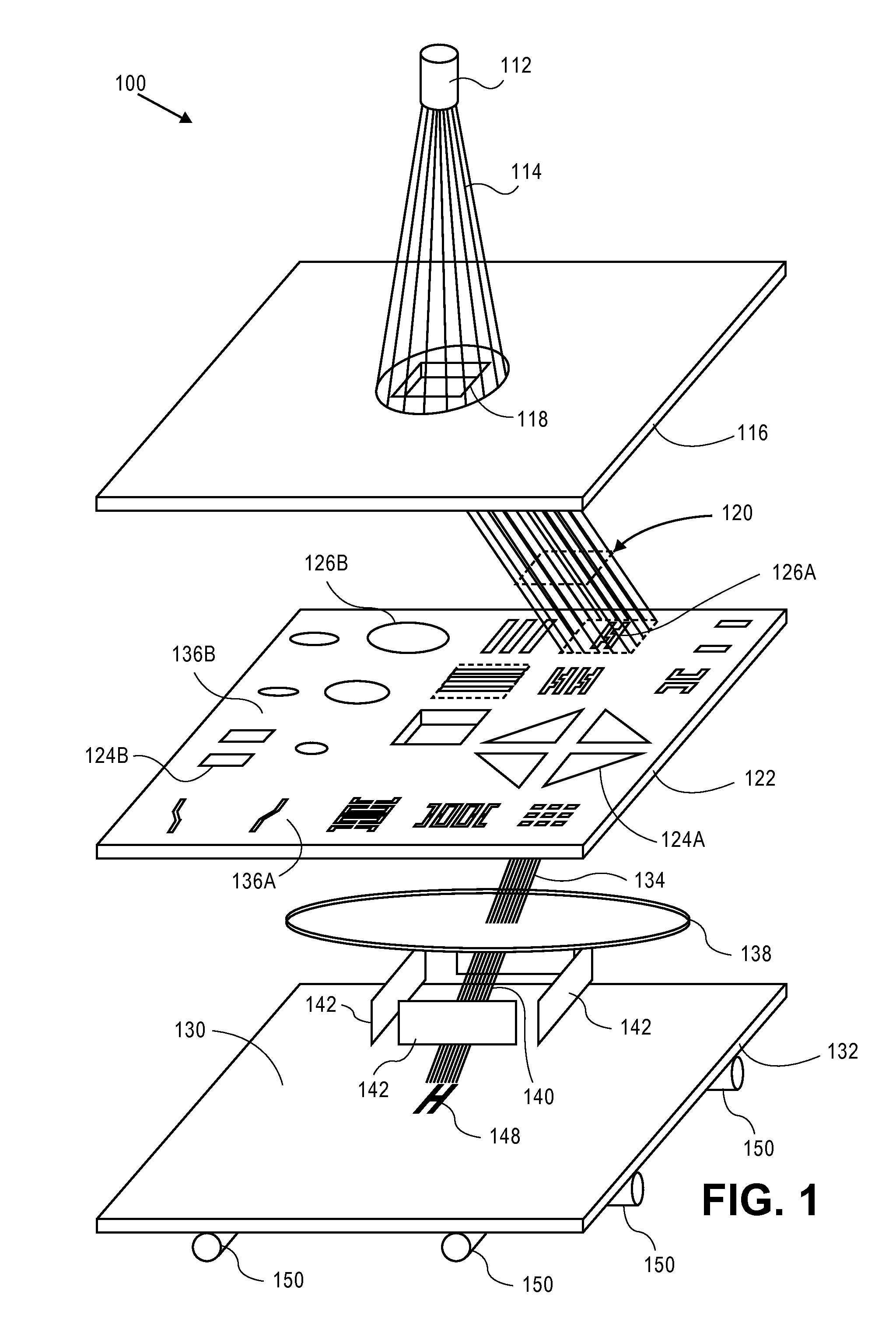

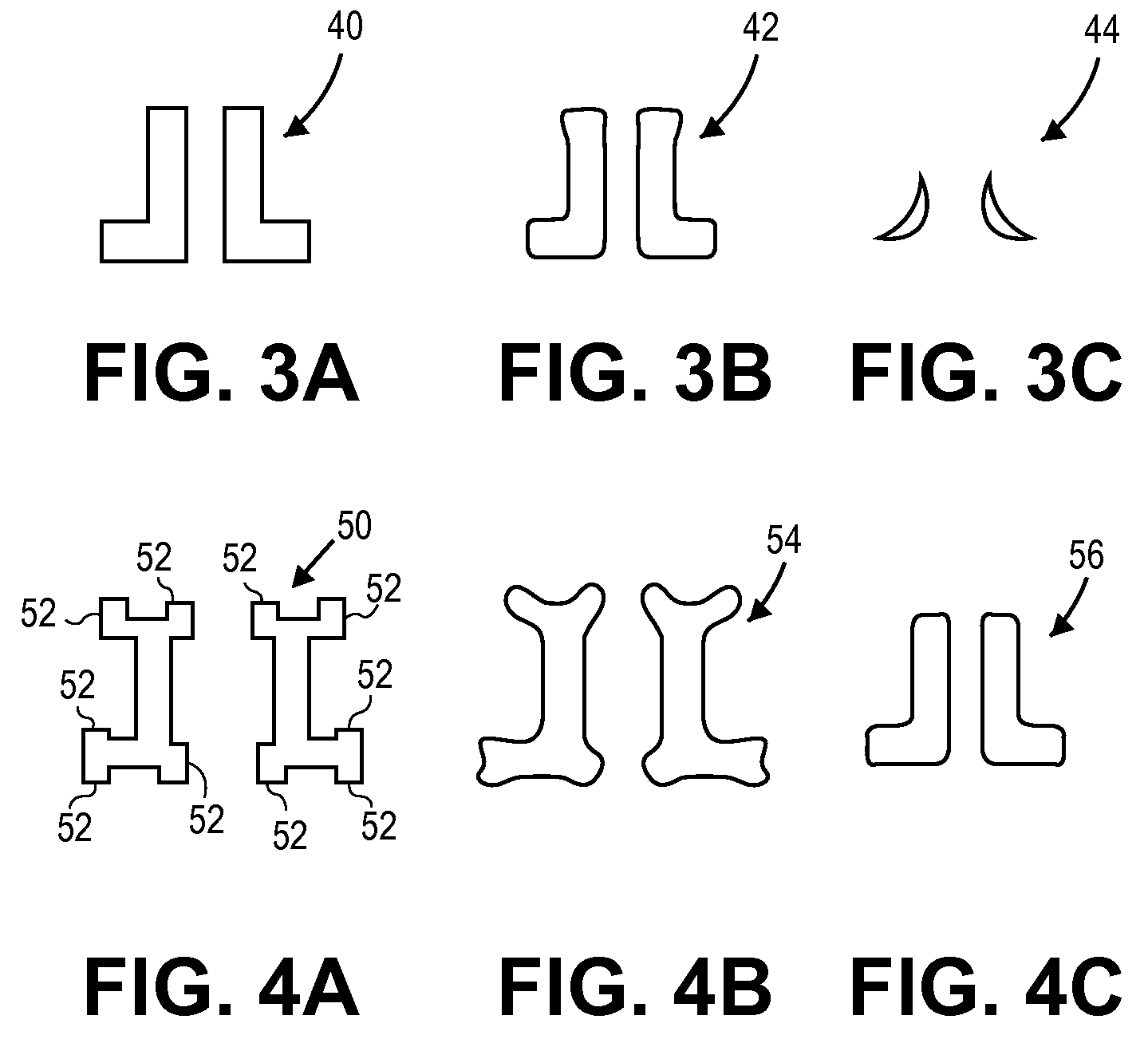

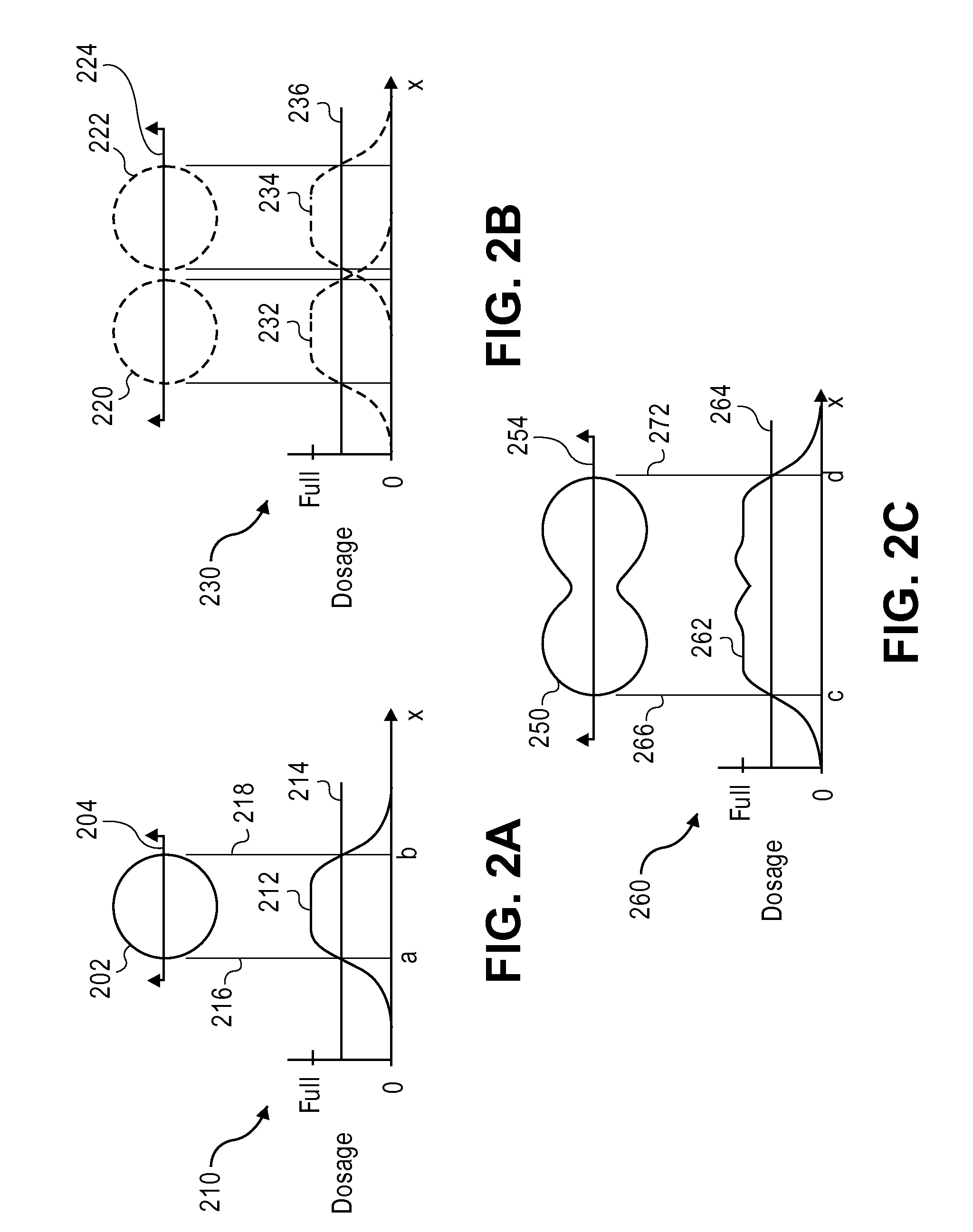

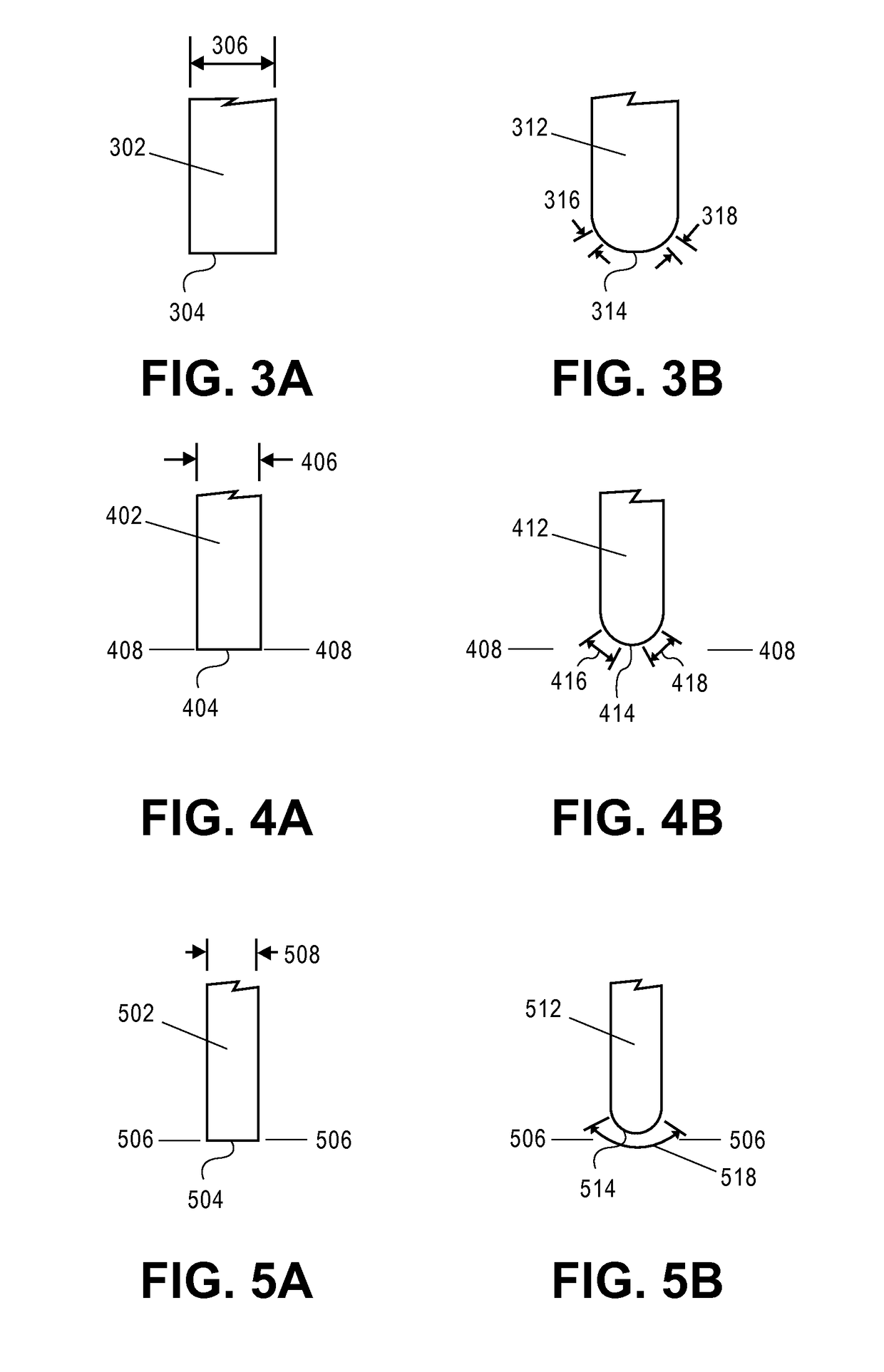

A method of particle beam lithography includes selecting at least two cell patterns from a stencil, correcting proximity effect by dose control and by pattern modification for the at least two cell patterns, and writing the at least cell two patterns by one shot of the particle beam after proximity effect correction (PEC).

Owner:CADENCE DESIGN SYST INC

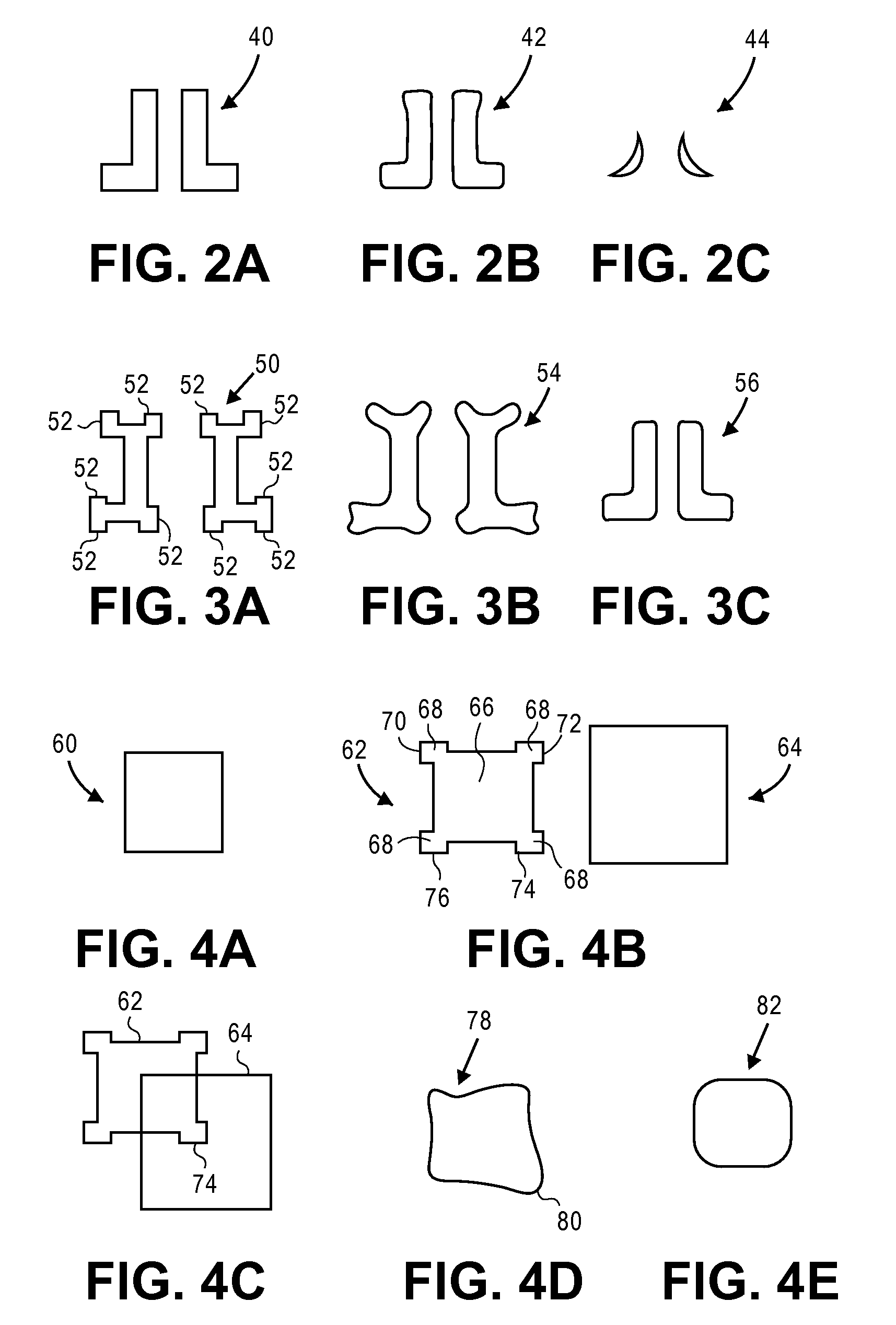

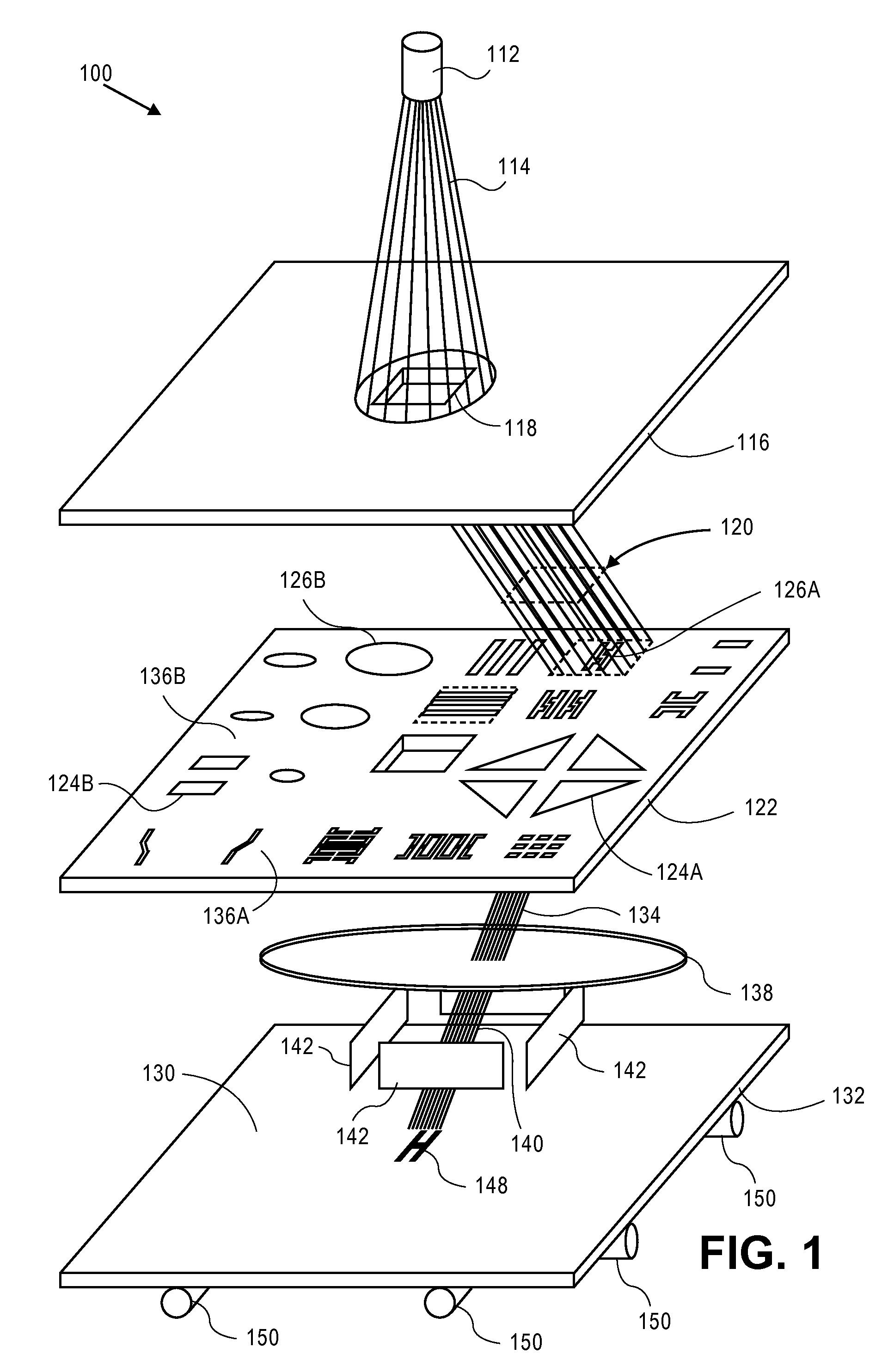

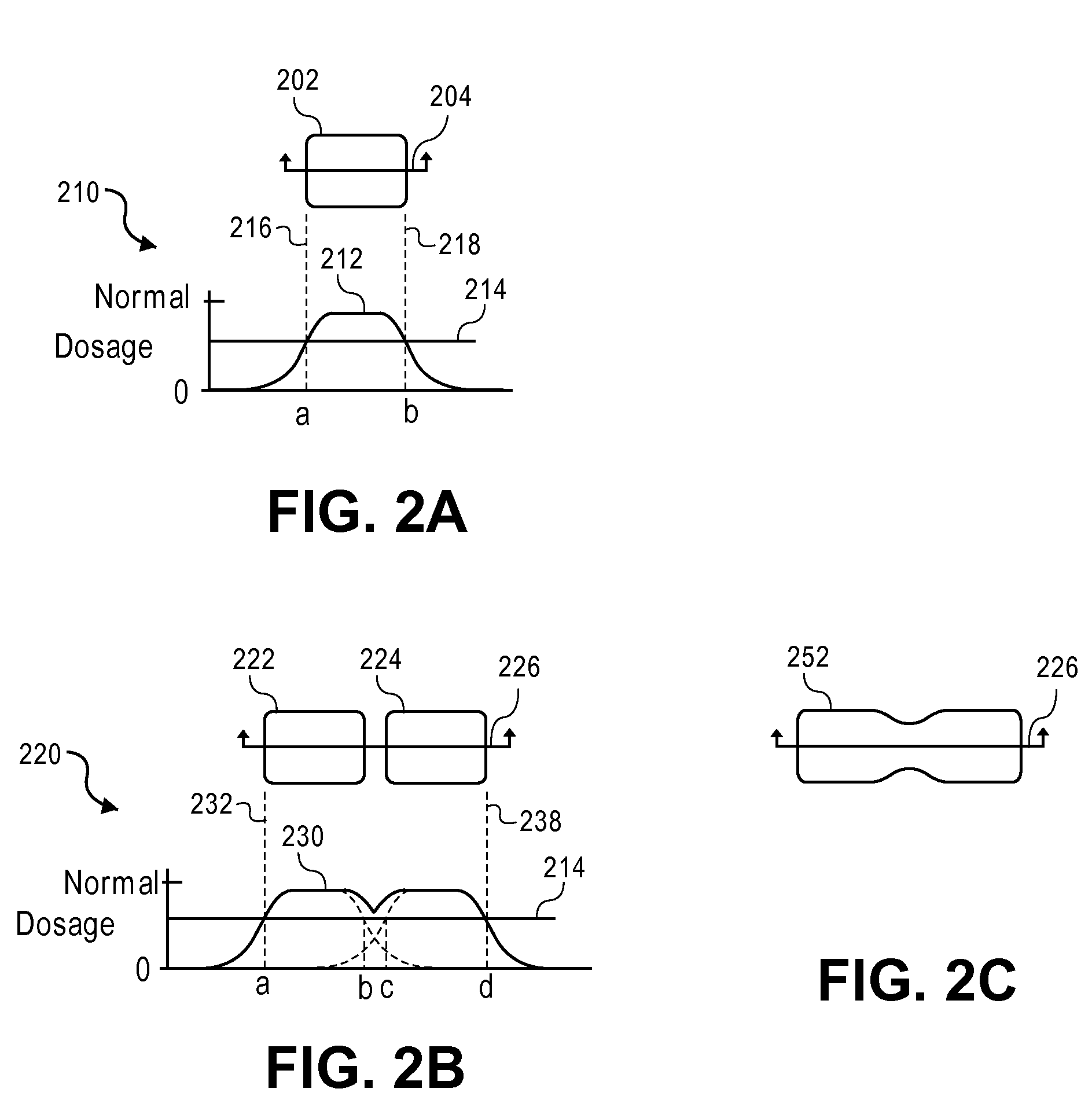

Method and system for design of a reticle to be manufactured using variable shaped beam lithography

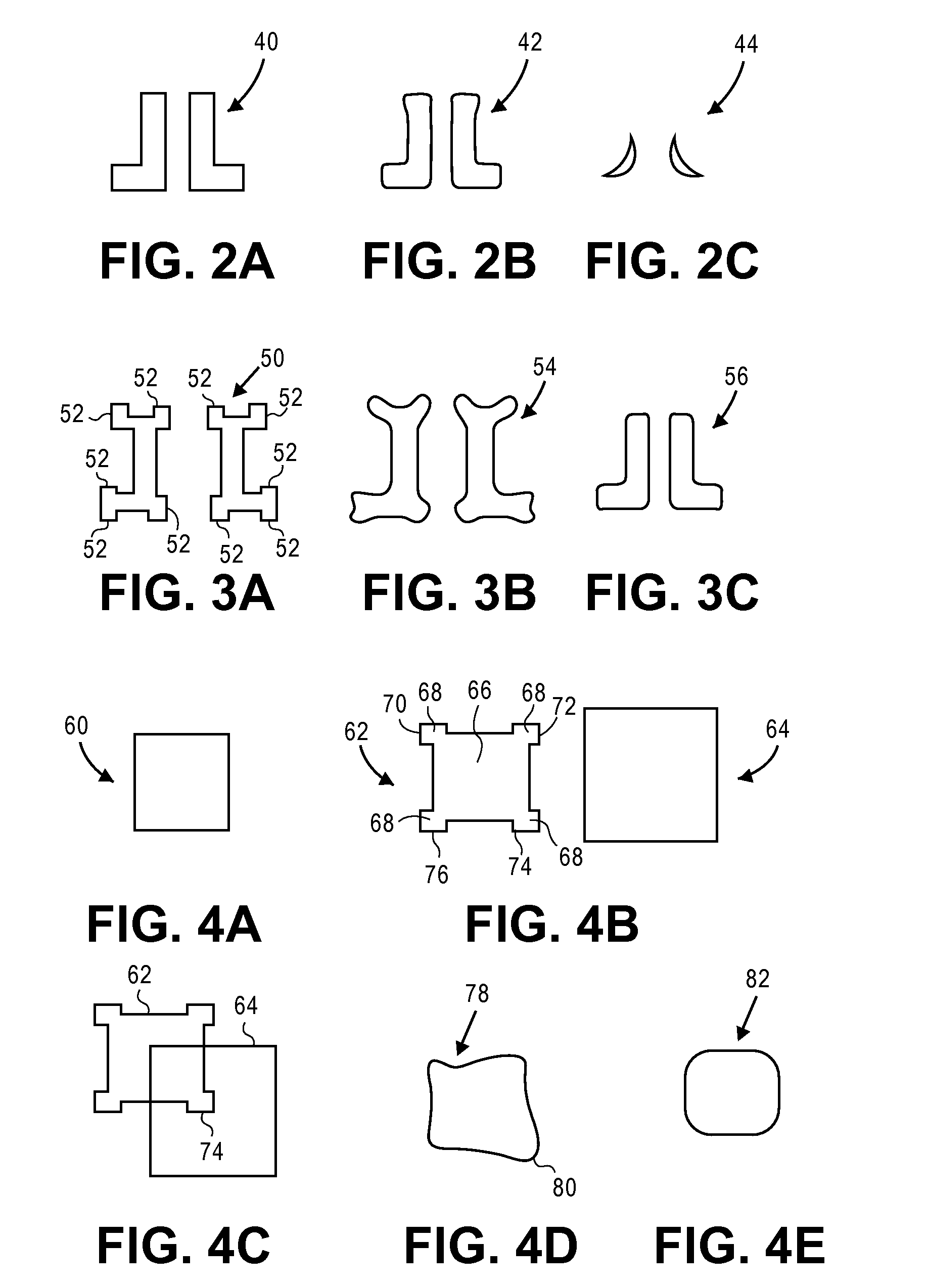

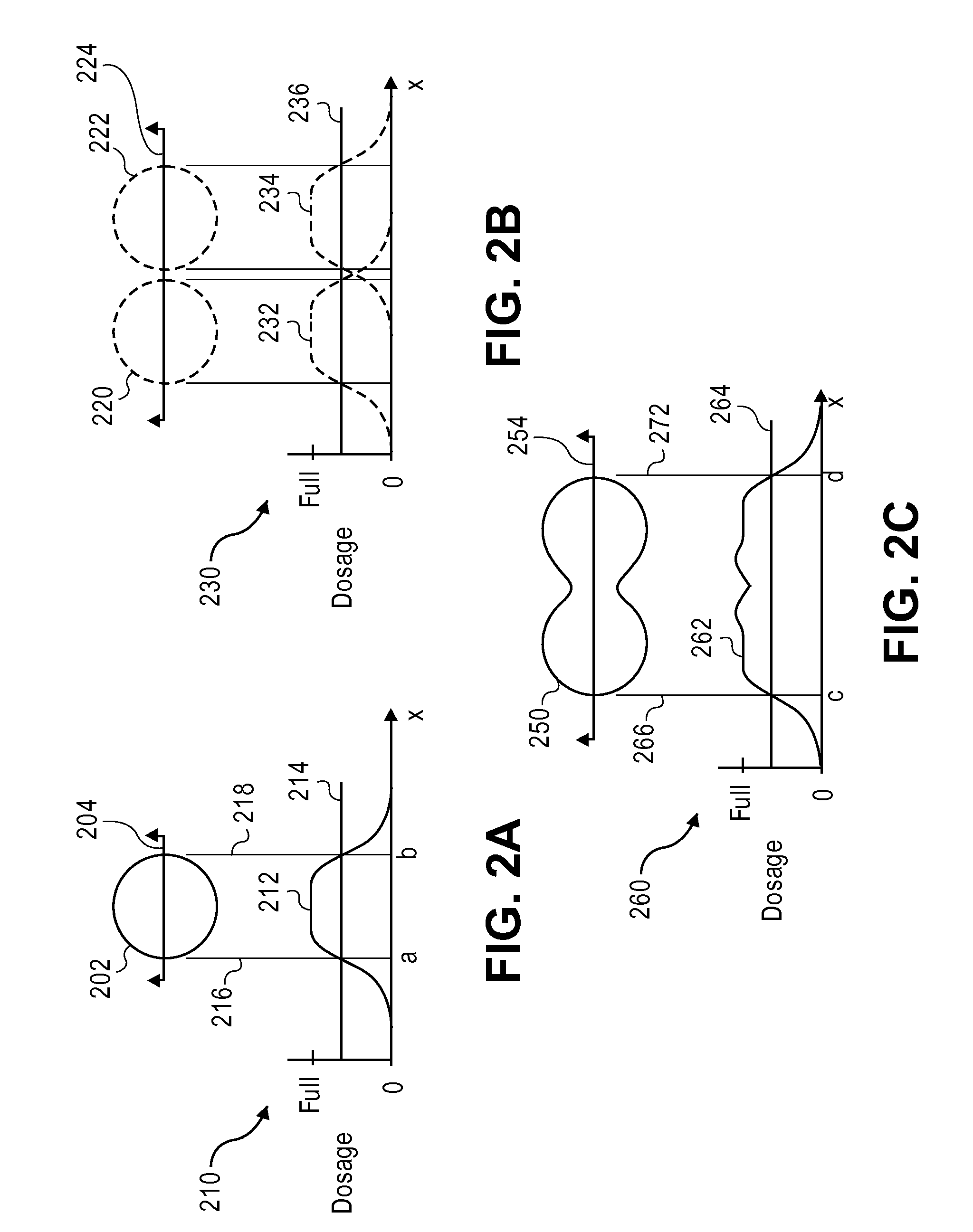

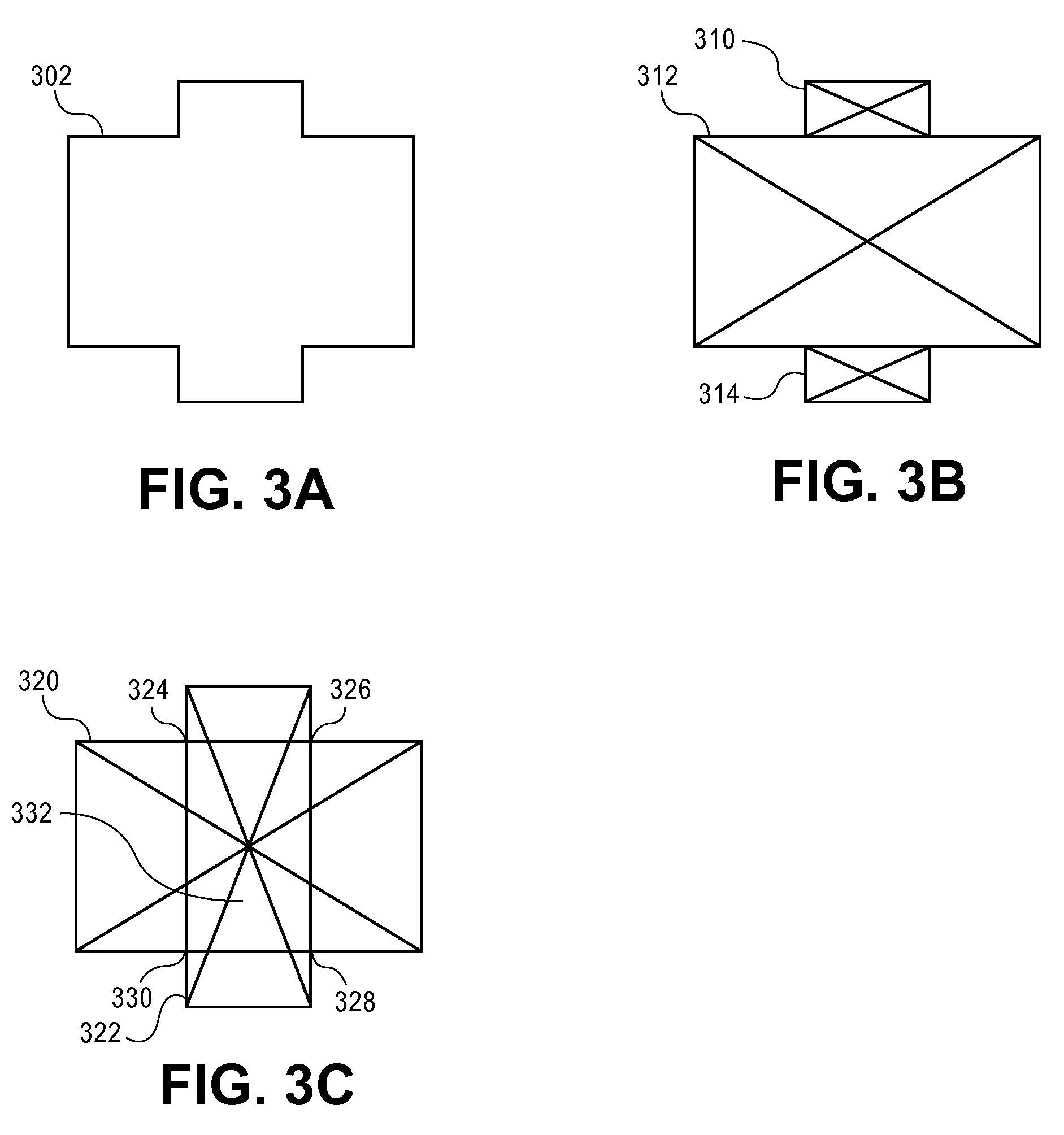

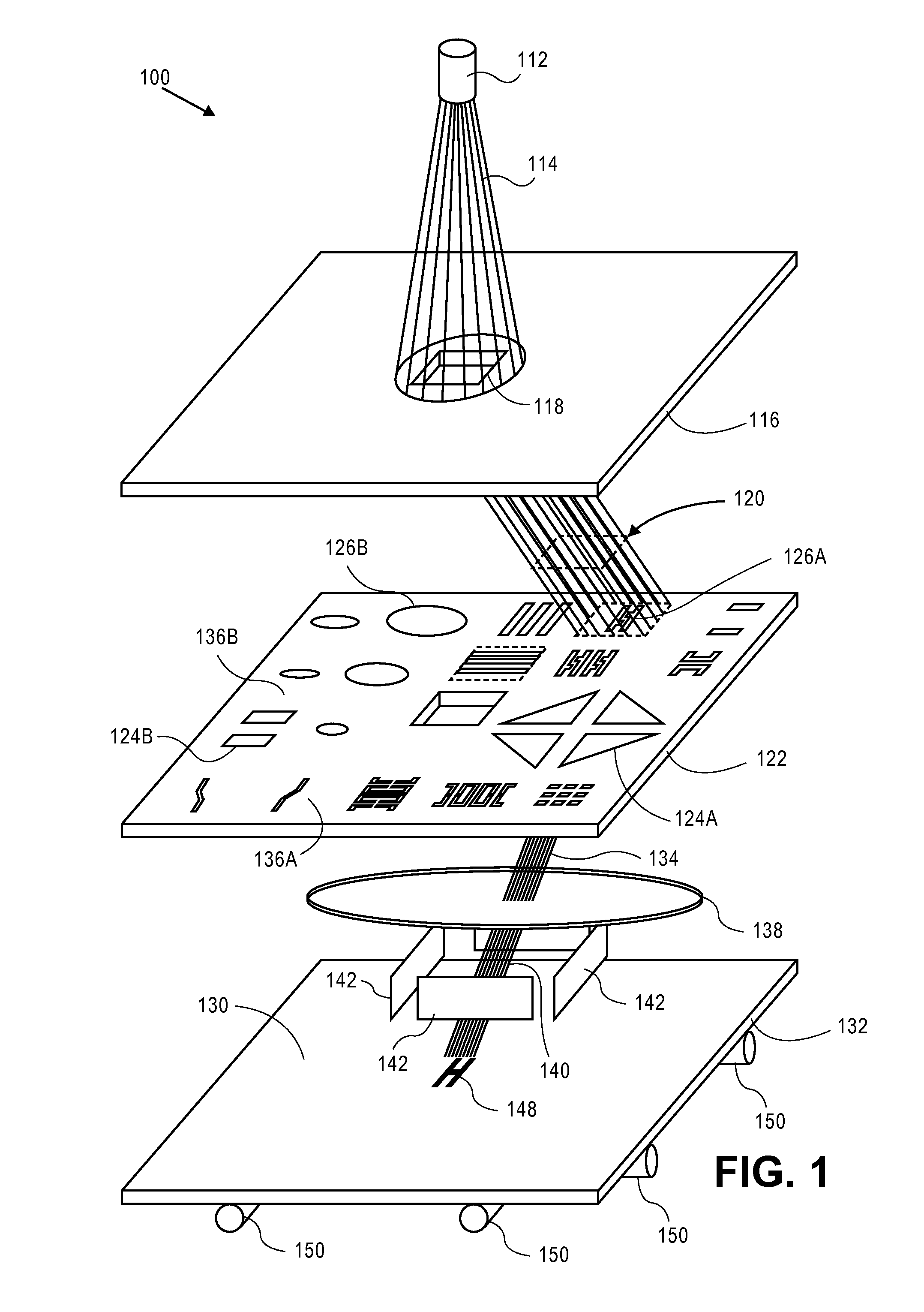

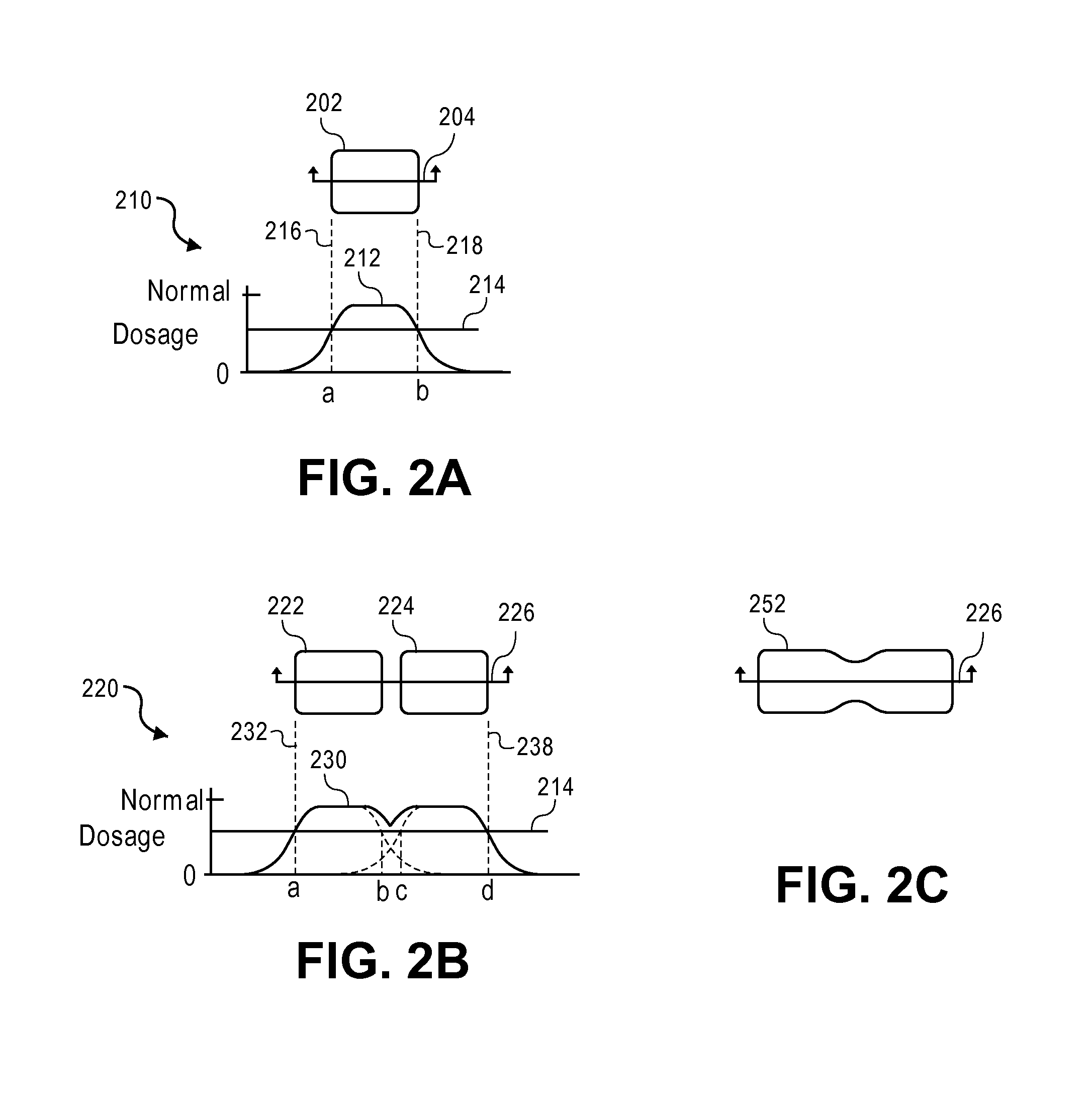

A method for fracturing or mask data preparation or proximity effect correction of a desired pattern to be formed on a reticle is disclosed in which a plurality of variable shaped beam (VSB) shots are determined which can form the desired pattern. Shots within the plurality of VSB shots are allowed to overlap each other. Dosages of the shots may also be allowed to vary with respect to each other. The union of the plurality of shots may deviate from the desired pattern. The plurality of shots may be determined such that a pattern on the surface calculated from the plurality of shots is within a predetermined tolerance of the desired pattern. In some embodiments, an optimization technique may be used to minimize shot count. In other embodiments, the plurality of shots may be optionally selected from one or more pre-computed VSB shots or groups of VSB shots.

Owner:D2S

Beam dose computing method and writing method and record carrier body and writing apparatus

A beam dose computing method includes specifying a matrix of rows and columns of regions as divided from a surface area of a target object to include first, second and third regions of different sizes, the third regions being less in size than the first and second regions, determining first corrected doses of a charged particle beam for correcting fogging effects in the first regions, determining corrected size values for correcting pattern line width deviations occurring due to loading effects in the second regions, using said corrected size values in said second regions to create a map of base doses of the beam in respective ones of said second regions, using said corrected size values to prepare a map of proximity effect correction coefficients in respective ones of said second regions, using the maps to determine second corrected doses of said beam for correction of proximity effects in said third regions, and using the first and second corrected doses to determine an actual beam dose at each position on the surface of said object.

Owner:NUFLARE TECH INC

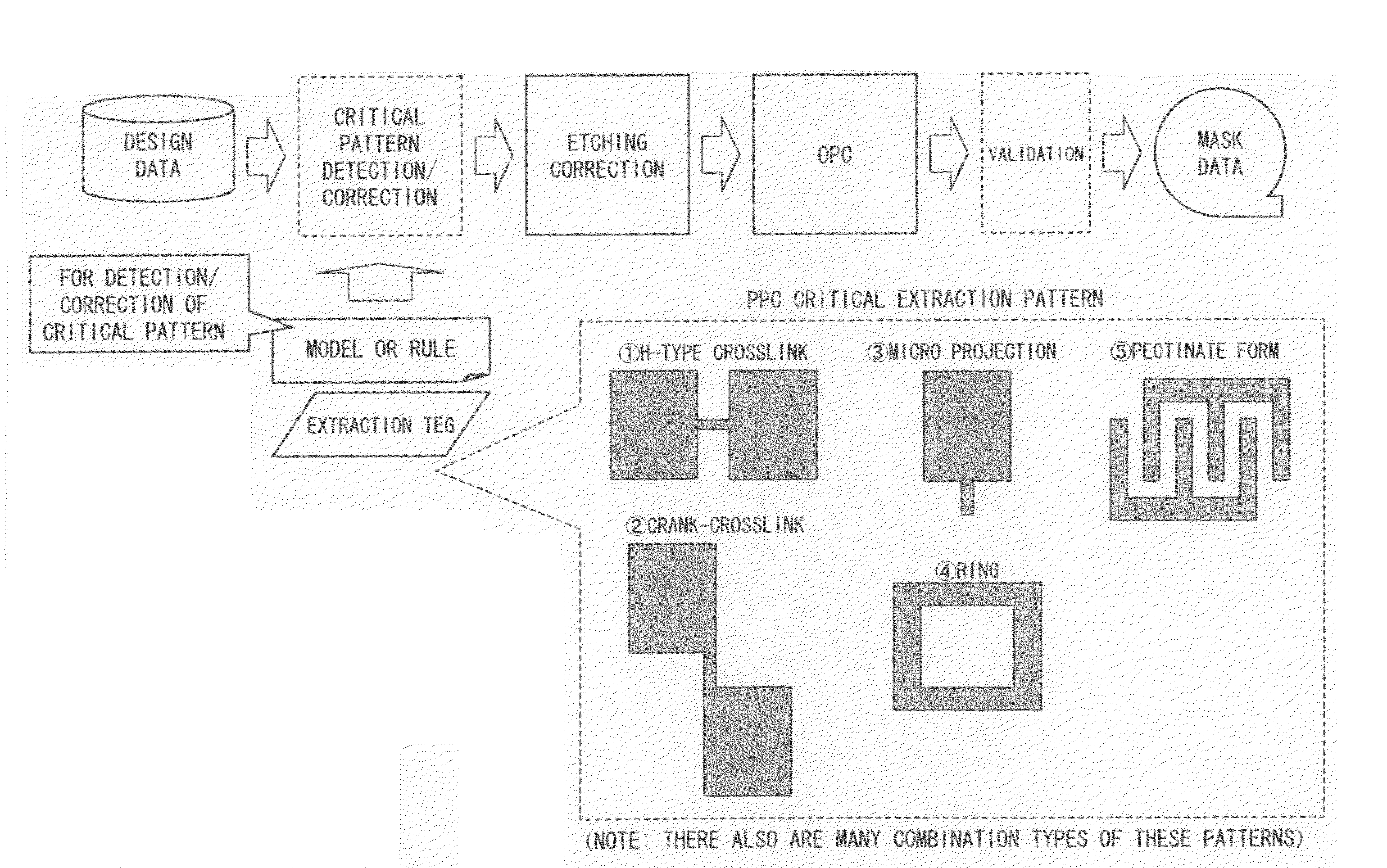

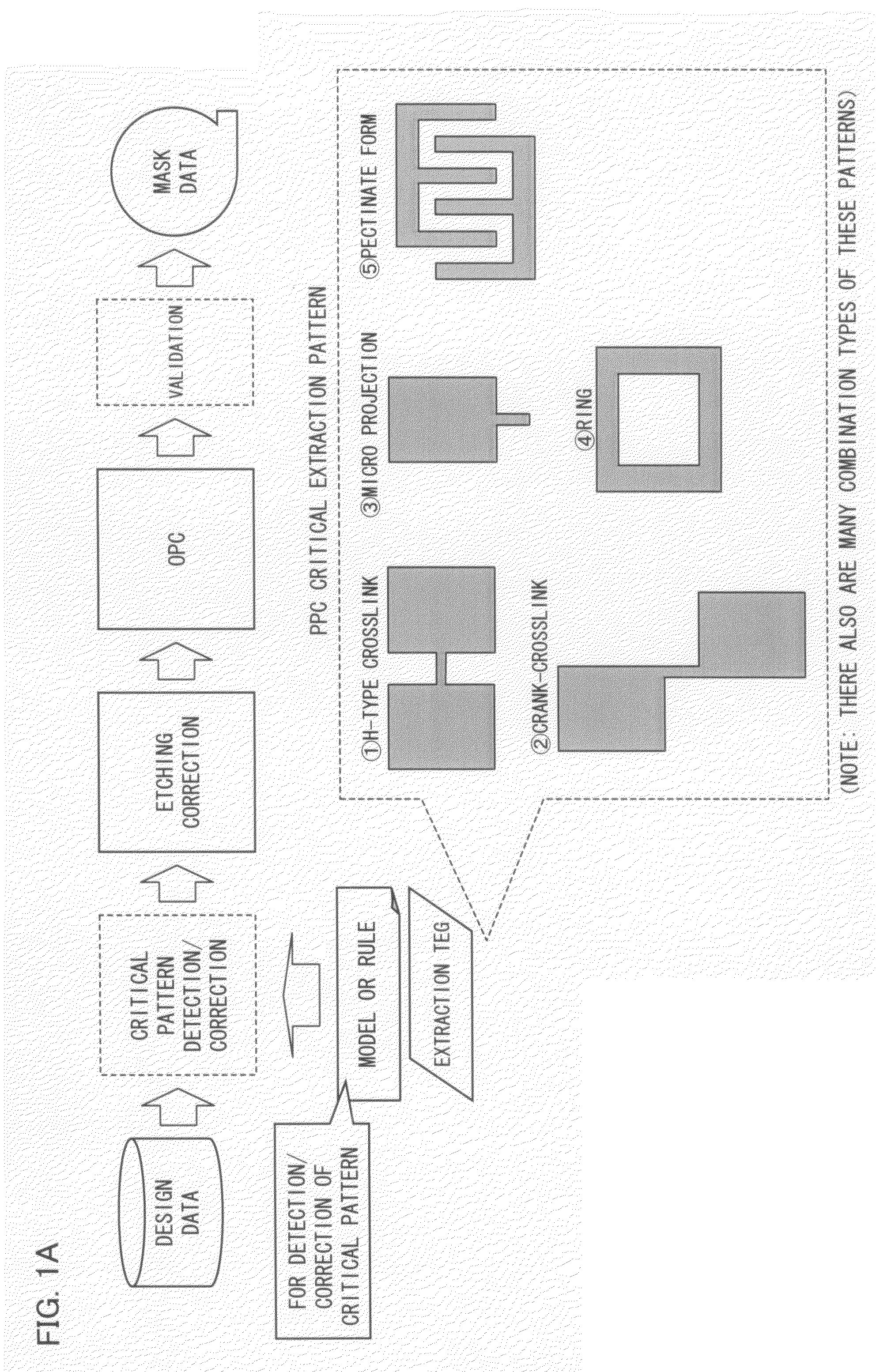

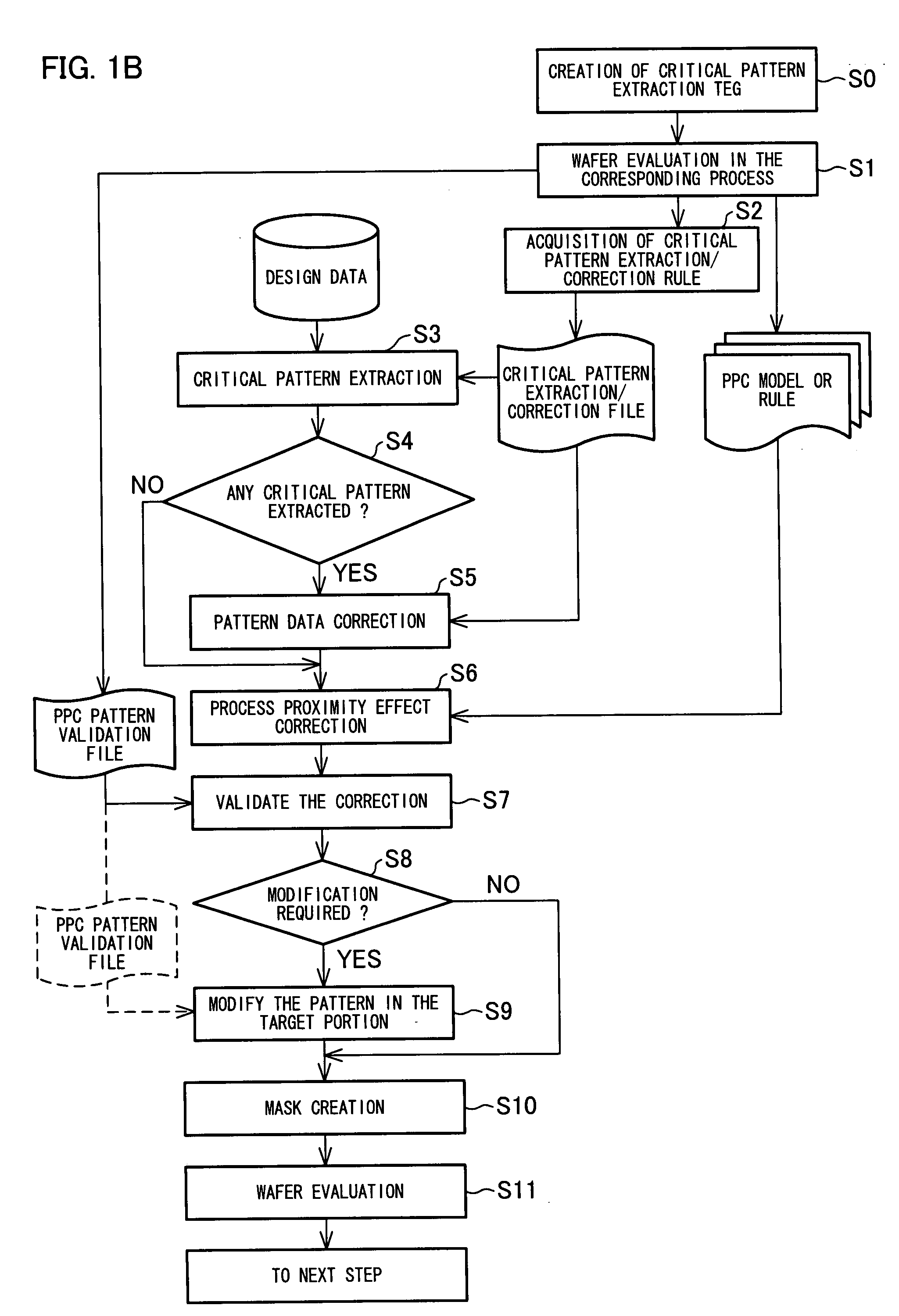

Correction method and correction system for design data or mask data, validation method and validation system for design data or mask data, yield estimation method for semiconductor integrated circuit, method for imporving design rule, mask production method, and semiconductor integrated circuit production method

InactiveUS20080003510A1Wastes in costWastes in development periodPhotomechanical apparatusSemiconductor/solid-state device manufacturingResistValidation methods

The subject invention provides a correction method for design data or mask data comprising the steps of:(i) carrying out PPC of design data or mask data;(ii) exposing and developing a resist with an evaluation mask including a critical pattern which becomes critical in a process, etching a circuit material using the resist having been developed, and measuring pattern sizes of the developed resist and the etched circuit material; (iii) extracting parameter numerical condition for preventing the design data or the mask data from being critical after OPC or PPC, as a rule or as a model based on the pattern sizes of the resist and the circuit material; (iv) extracting a critical pattern with a parameter not satisfying the foregoing rule or the model from the design data or the mask data; and (v) correcting the critical pattern.With this method, the present invention provides such as a validation / correction method for design data or mask data by which a pattern which becomes critical in a process is extracted in advance so that the pattern can be corrected. Consequently, the process spec is achieved in a short period of time after OPC or process proximity effect correction (PPC).

Owner:SHARP KK

Contact or proximity printing using a magnified mask image

InactiveUS20050007567A1Avoid stickingElectric discharge tubesPhoto-taking processesLithographic artistImage resolution

Improvements in the fabrication of integrated circuits are driven by the decrease of the size of the features printed on the wafers. Current lithography techniques limits have been extended through the use of phase-shifting masks, off-axis illumination, and proximity effect correction. More recently, liquid immersion lithography has been proposed as a way to extend even further the limits of optical lithography. This invention described a methodology based on contact or proximity printing using a projection lens to define the image of the mask onto the wafer. As the imaging is performed in a solid material, larger refractive indices can be obtained and the resolution of the imaging system can be increased.

Owner:TAKUMI TECH

Method and system for design of a reticle to be manufactured using character projection lithography

InactiveUS20100058282A1Reducing shot countShorten write timeElectric discharge tubesRadiation applicationsMask data preparationCamera lens

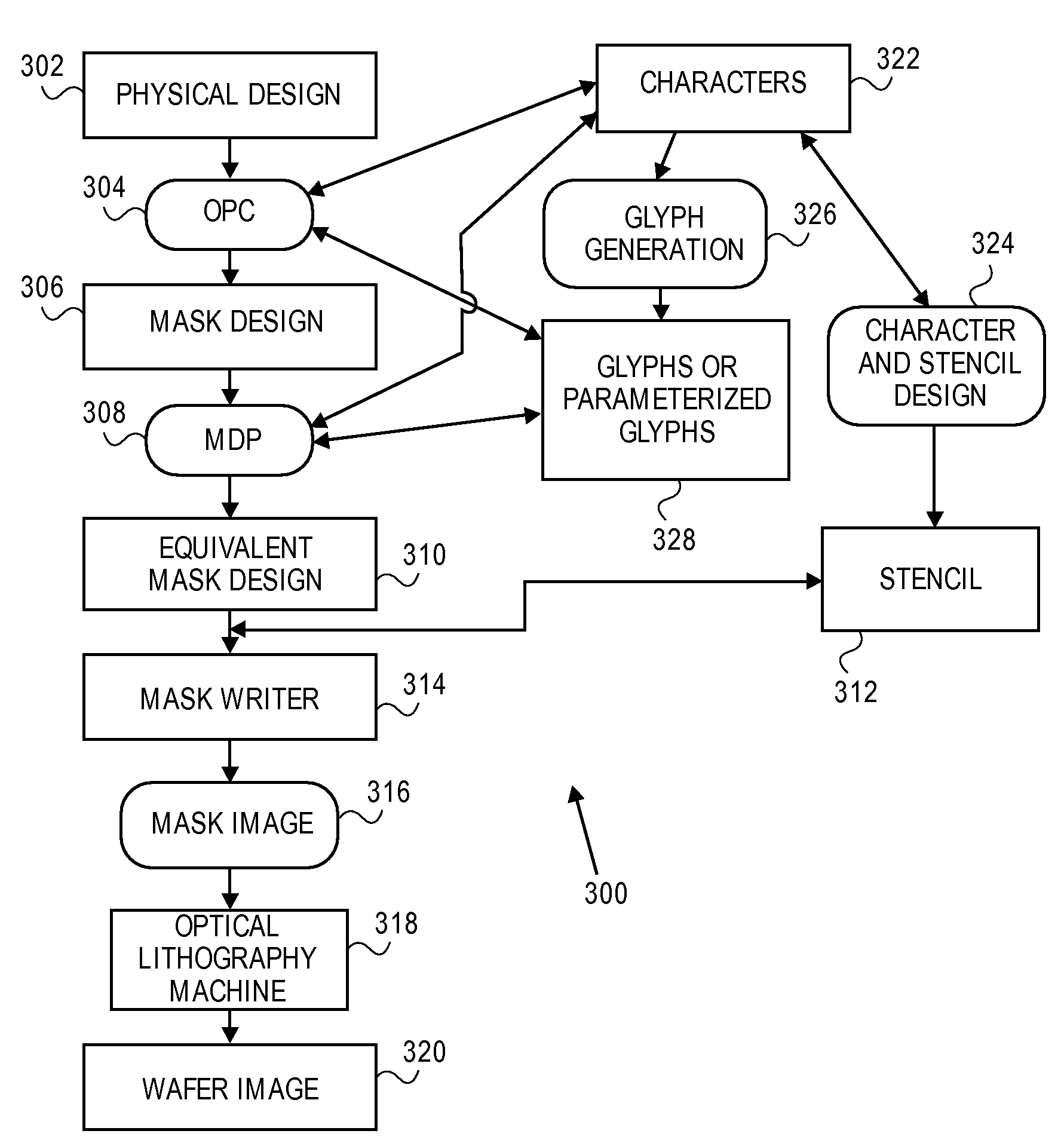

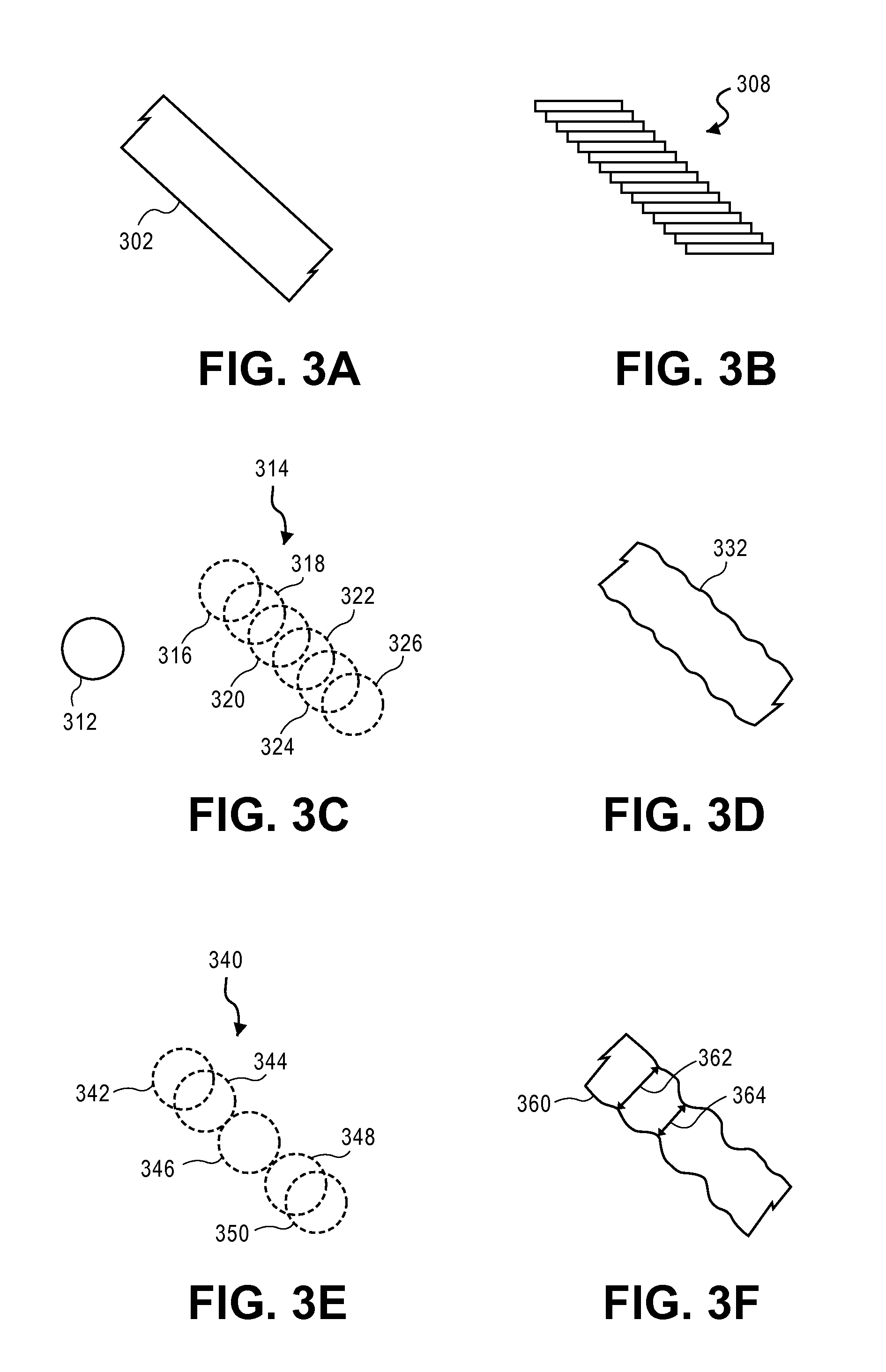

A method for fracturing or mask data preparation or proximity effect correction is disclosed which comprises the steps of inputting patterns to be formed on a surface, a subset of the patterns being slightly different variations of each other and selecting a set of characters some of which are complex characters to be used to form the number of patterns, and reducing shot count or total write time by use of a character varying technique. A system for fracturing or mask data preparation or proximity effect correction is also disclosed.

Owner:D2S

Method and system for design of a reticle to be manufactured using character projection lithography

InactiveUS7759027B2Reduce countShorten the timeElectric discharge tubesRadiation applicationsMask data preparationAlgorithm

A method for fracturing or mask data preparation or proximity effect correction is disclosed which comprises the steps of inputting patterns to be formed on a surface, a subset of the patterns being slightly different variations of each other and selecting a set of characters some of which are complex characters to be used to form the number of patterns, and reducing shot count or total write time by use of a character varying technique. A system for fracturing or mask data preparation or proximity effect correction is also disclosed.

Owner:D2S

Method and System for Design of a Reticle to be Manufactured Using Variable Shaped Beam Lithography

ActiveUS20100058279A1Minimize shot countElectric discharge tubesRadiation applicationsMask data preparationLithographic artist

A method for fracturing or mask data preparation or proximity effect correction of a desired pattern to be formed on a reticle is disclosed in which a plurality of variable shaped beam (VSB) shots are determined which can form the desired pattern. Shots within the plurality of VSB shots are allowed to overlap each other. Dosages of the shots may also be allowed to vary with respect to each other. The union of the plurality of shots may deviate from the desired pattern. The plurality of shots may be determined such that a pattern on the surface calculated from the plurality of shots is within a predetermined tolerance of the desired pattern. In some embodiments, an optimization technique may be used to minimize shot count. In other embodiments, the plurality of shots may be optionally selected from one or more pre-computed VSB shots or groups of VSB shots.

Owner:D2S

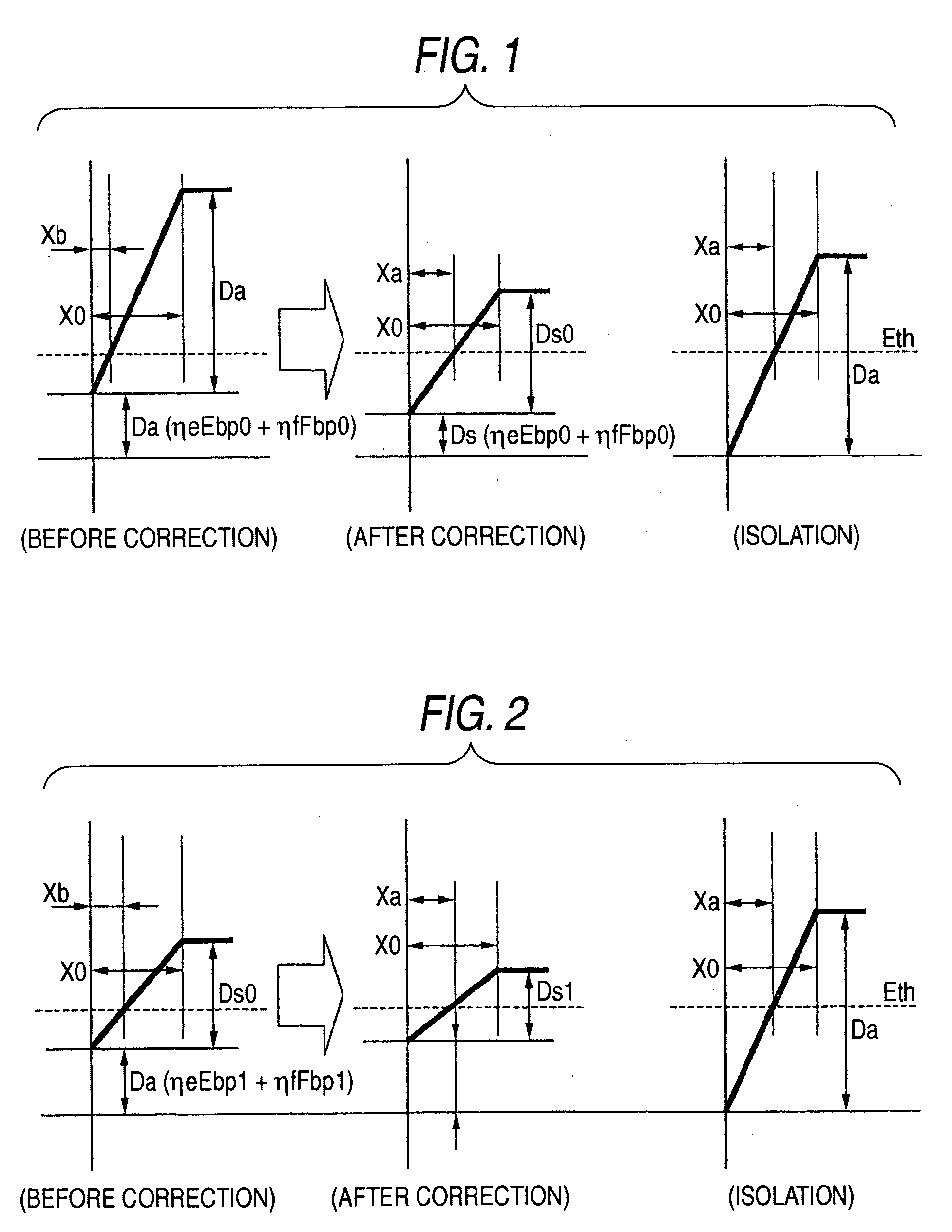

Electron beam writing method and lithography mask manufacturing method

ActiveUS20050221204A1Avoid volatilityImprove accuracyCellsElectric discharge tubesStored energyEnergy based

A writing pattern to be a correcting object is divided by a rough mesh for a Foggy effect correction and a fine mesh for a proximity effect correction, a rate of an area occupied by the pattern to be written for each of the meshes is obtained, a stored energy based on a Foggy effect and a proximity effect in execution of exposure in a state in which a correction for a calculating object mesh is not carried out at all is calculated, an dose in the fine mesh for a proximity effect correction is obtained by a first calculation in such a manner that an influence of the Foggy effect and the proximity effect is reduced and a pattern and a dimension which can disregard the influence of the Foggy effect and the proximity effect are coincident with each other by the stored energy which is calculated, are calculation is carried out in such a manner that the pattern and the dimension which can disregard the influence of the Foggy effect and the proximity effect are coincident with each other with the influence of the Foggy effect and the proximity effect fixed, and the recalculation is repeated until desirable precision in a dimension is reached.

Owner:HOYA CORP

Method for Fracturing and Forming a Pattern Using Curvilinear Characters with Charged Particle Beam Lithography

InactiveUS20110053056A1Photo-taking processesElectric discharge tubesMask data preparationCamera lens

In the field of semiconductor production using shaped charged particle beam lithography, a method and system for fracturing or mask data preparation or proximity effect correction is disclosed, wherein a series of curvilinear character projection shots are determined for a charged particle beam writer system, such that the set of shots can form a continuous track, possibly of varying width, on a surface. A method for forming a continuous track on a surface using a series of curvilinear character projection shots is also disclosed. Methods for manufacturing a reticle and for manufacturing a substrate such as a silicon wafer by forming a continuous track on a surface using a series of curvilinear character projection shots is also disclosed.

Owner:D2S

Contact printing using a magnified mask image

InactiveUS6961186B2Avoid stickingPhotomechanical exposure apparatusMicrolithography exposure apparatusLithographic artistSolid mass

Improvements in the fabrication of integrated circuits are driven by the decrease of the size of the features printed on the wafers. Current lithography techniques limits have been extended through the use of phase-shifting masks, off-axis illumination, and proximity effect correction. More recently, liquid immersion lithography has been proposed as a way to extend even further the limits of optical lithography. This invention described a methodology based on contact printing using a projection lens to define the image of the mask onto the wafer. As the imaging is performed in a solid material, larger refractive indices can be obtained and the resolution of the imaging system can be increased.

Owner:APPLIED MATERIALS INC

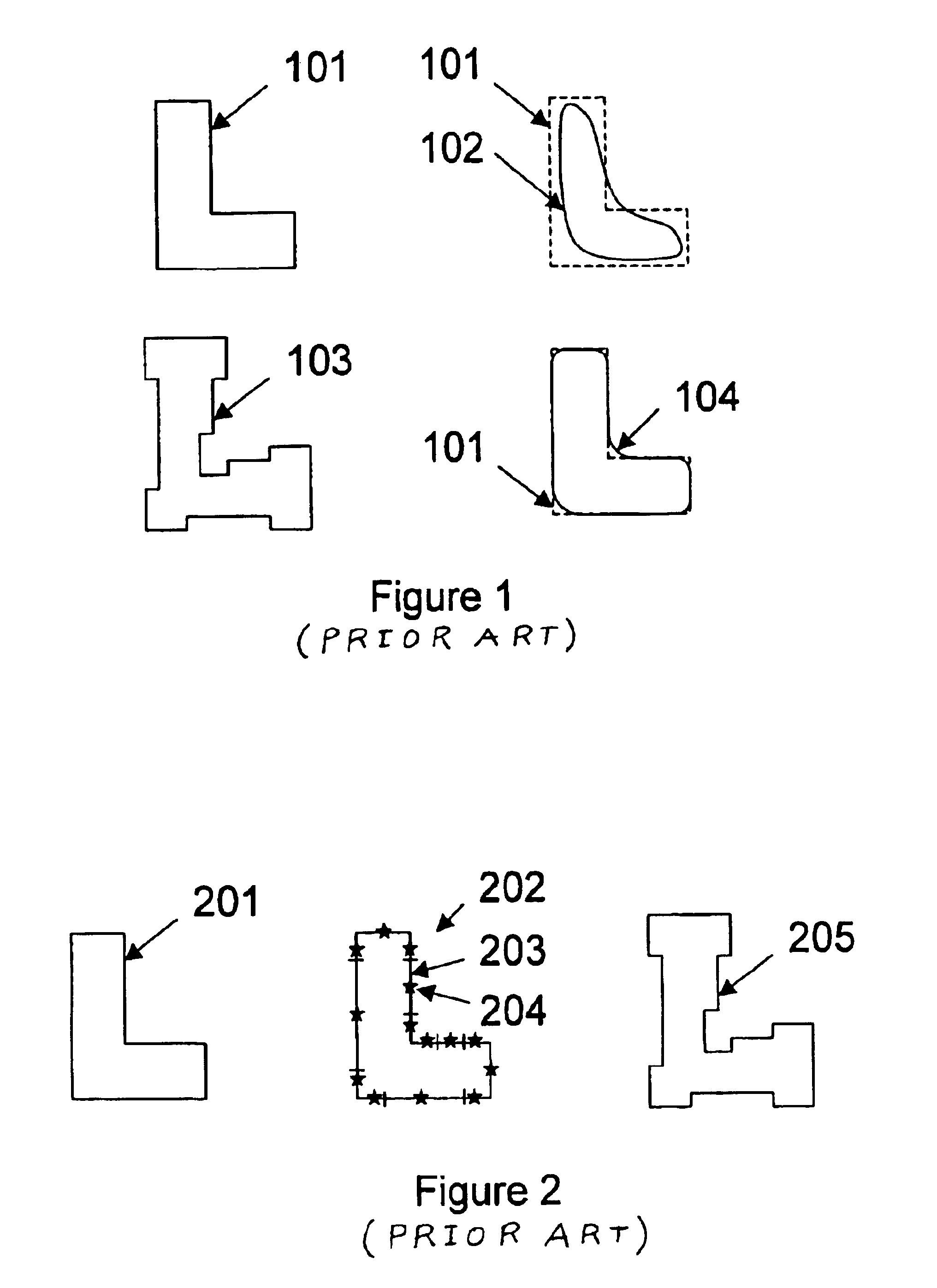

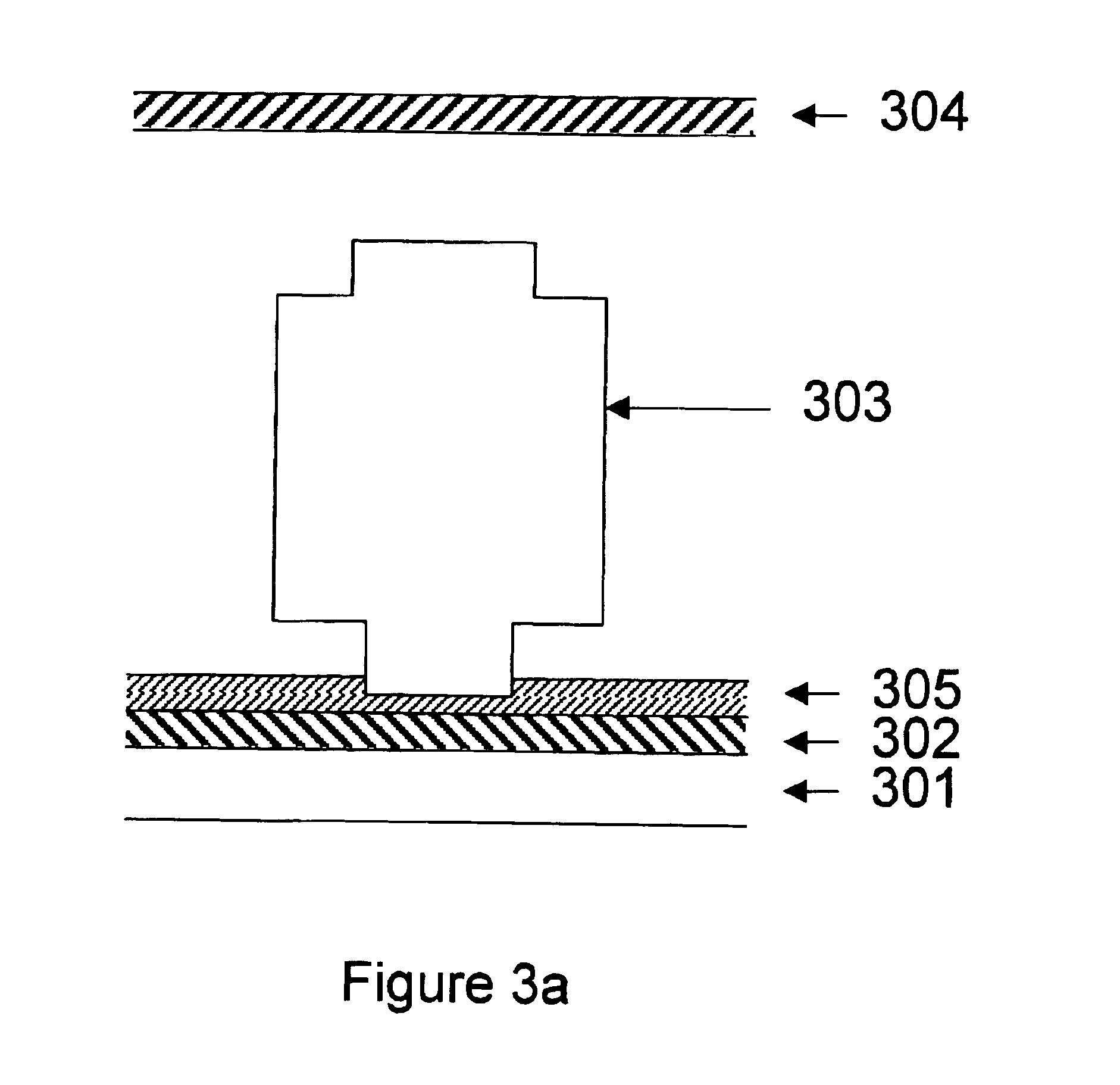

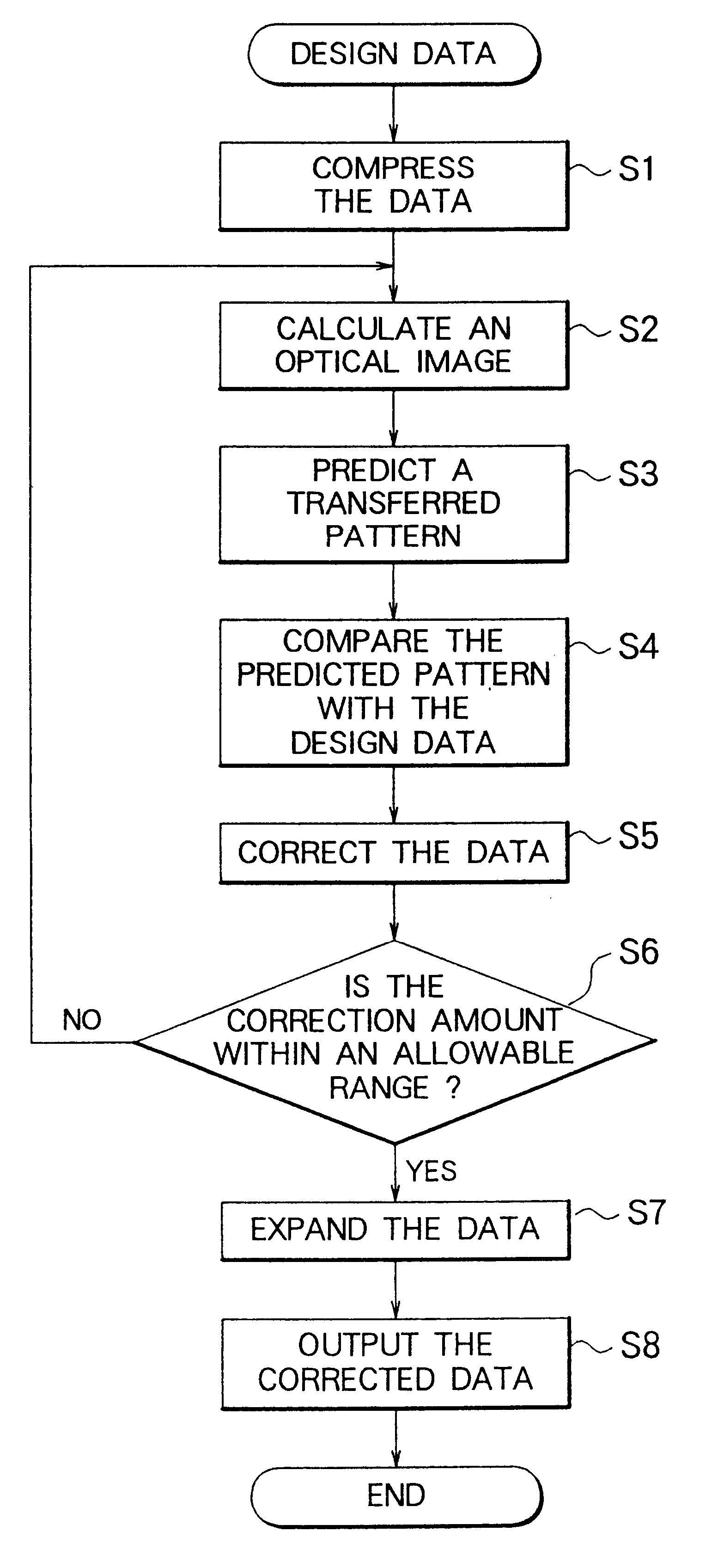

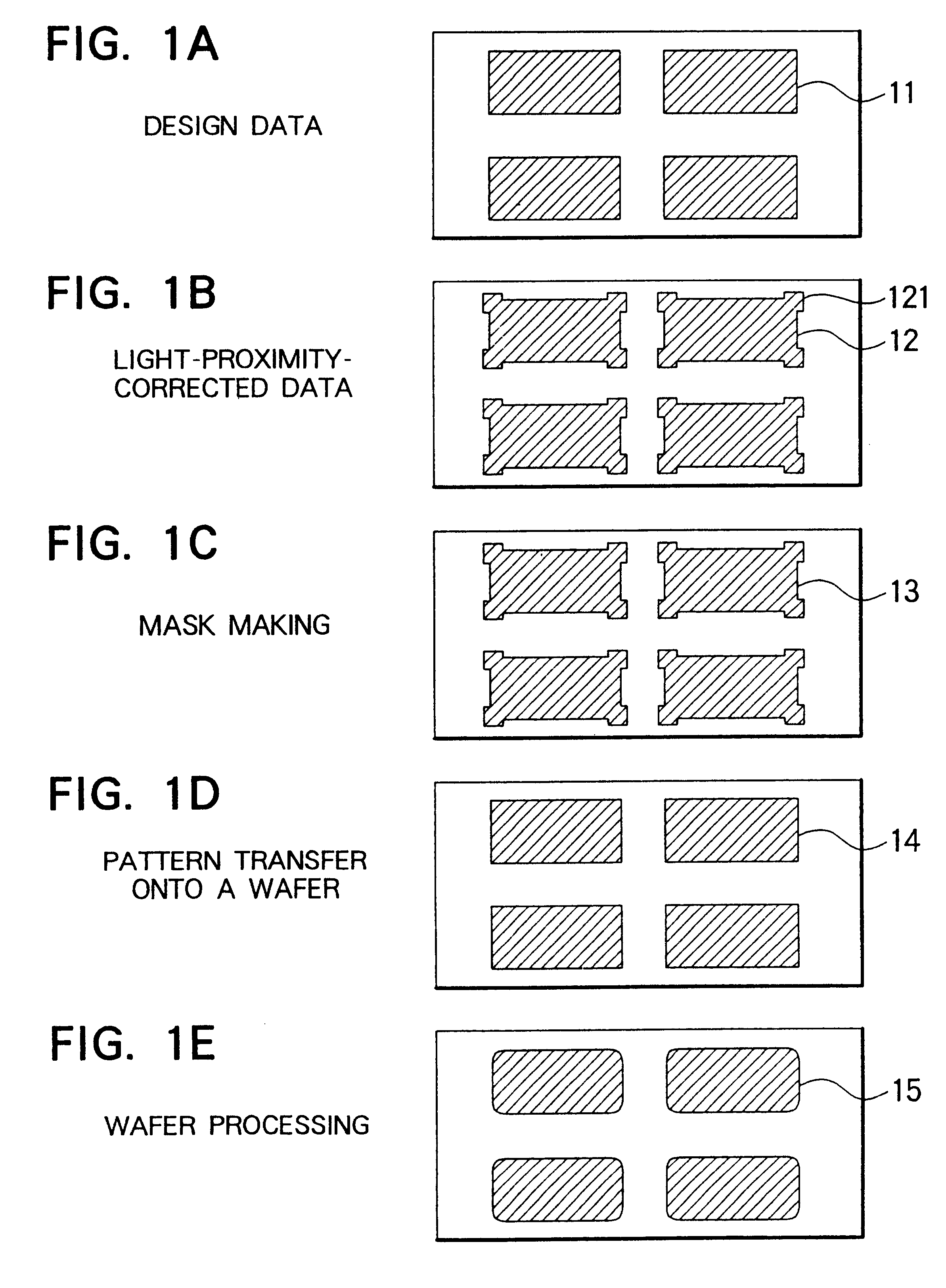

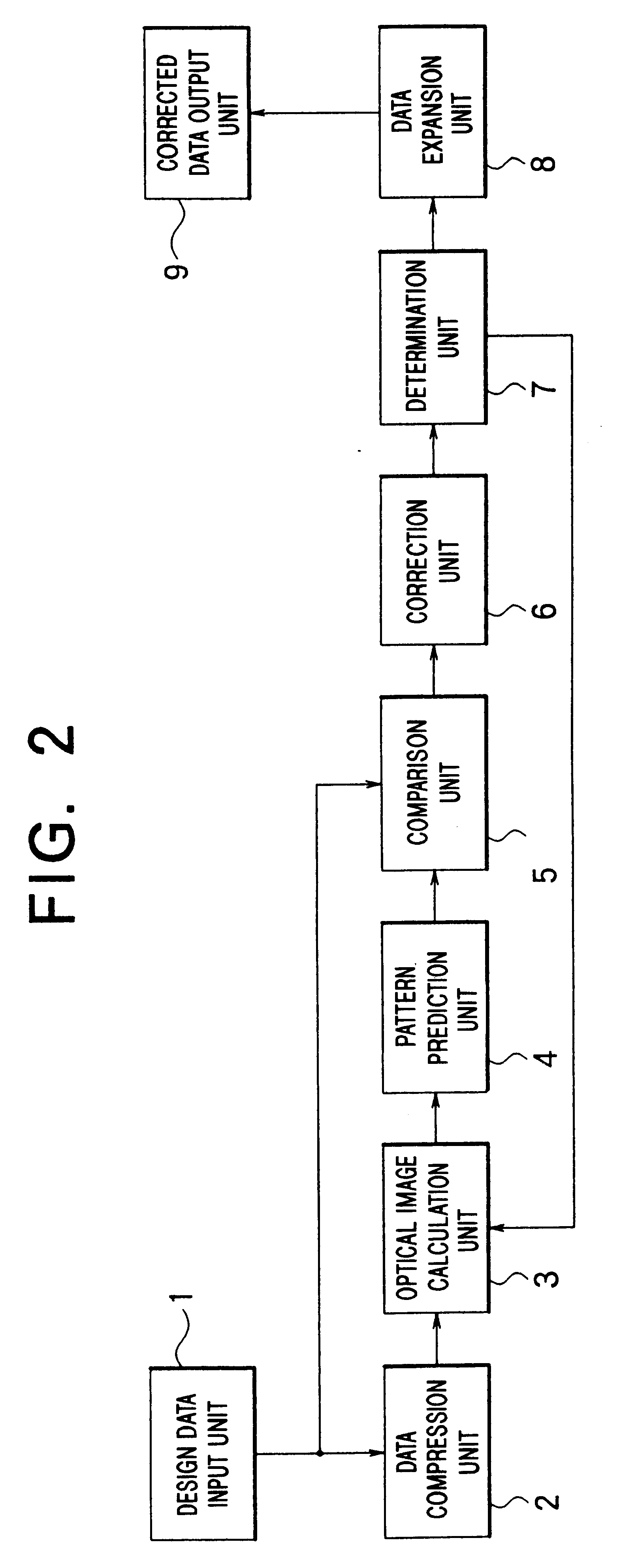

Method of forming a pattern using proximity-effect-correction

InactiveUS6453274B2Semiconductor/solid-state device manufacturingImage codingProjection imageDesign data

A method of correcting light proximity effects includes the steps of: compressing design data of a circuit pattern (step S1); generating a projection image which is formed during a process of transferring a pattern onto a wafer, the projection image being generated according to the design data (step S2); predicting the size of the transferred pattern, said prediction being performed from the projection image (step S3); calculating the difference between the predicted size of the transferred pattern and the pattern size designated by the design data (step S4); correcting the compressed design data by an amount equal to the above-described difference (step S5); judging whether the correction amount is within an allowable range (step S6); expanding the corrected data after the correction amount has fallen within the allowable range (step S7); and outputting the resultant data (step S8).

Owner:RENESAS ELECTRONICS CORP

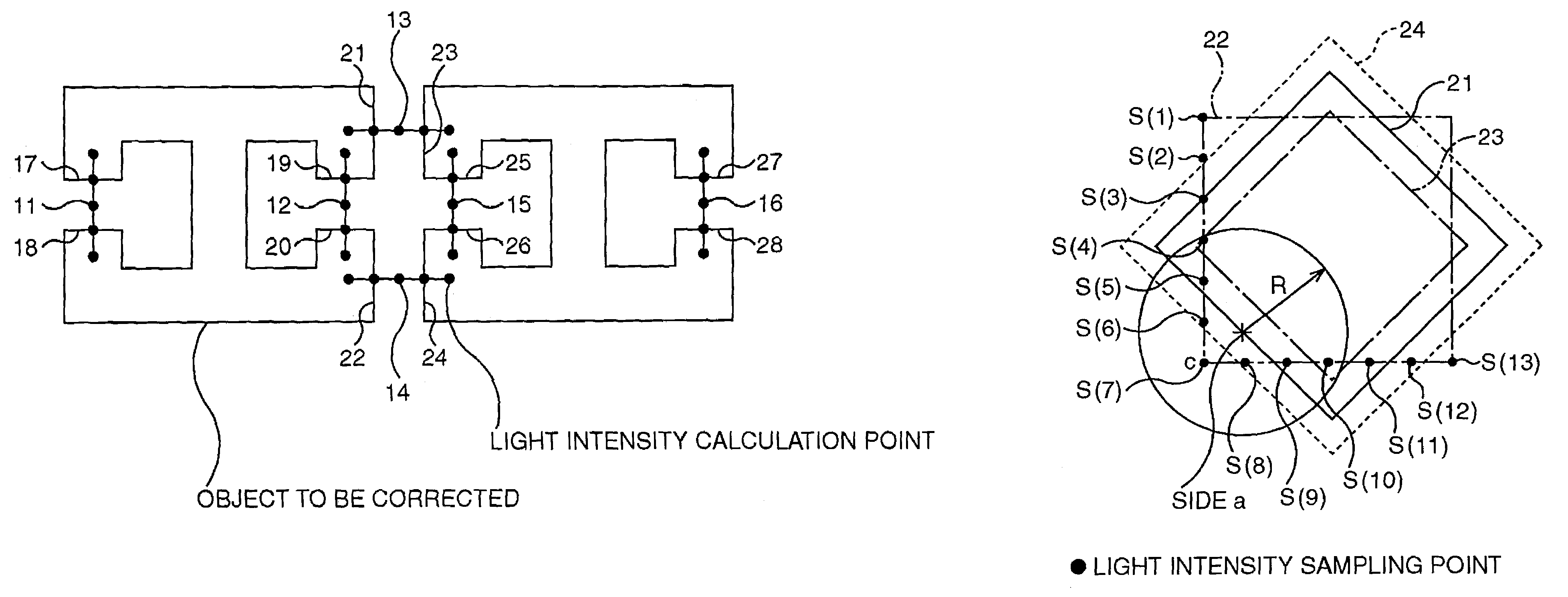

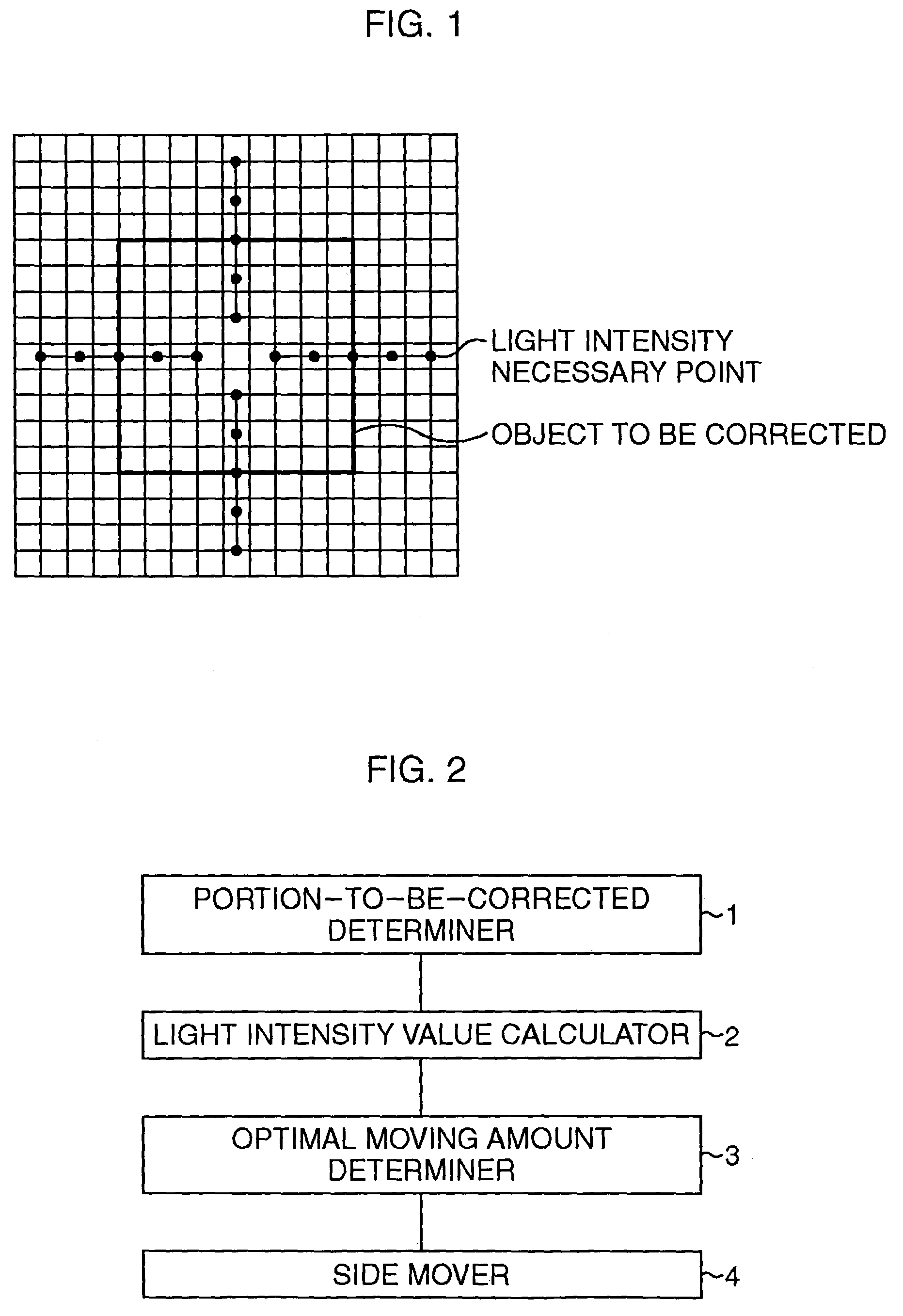

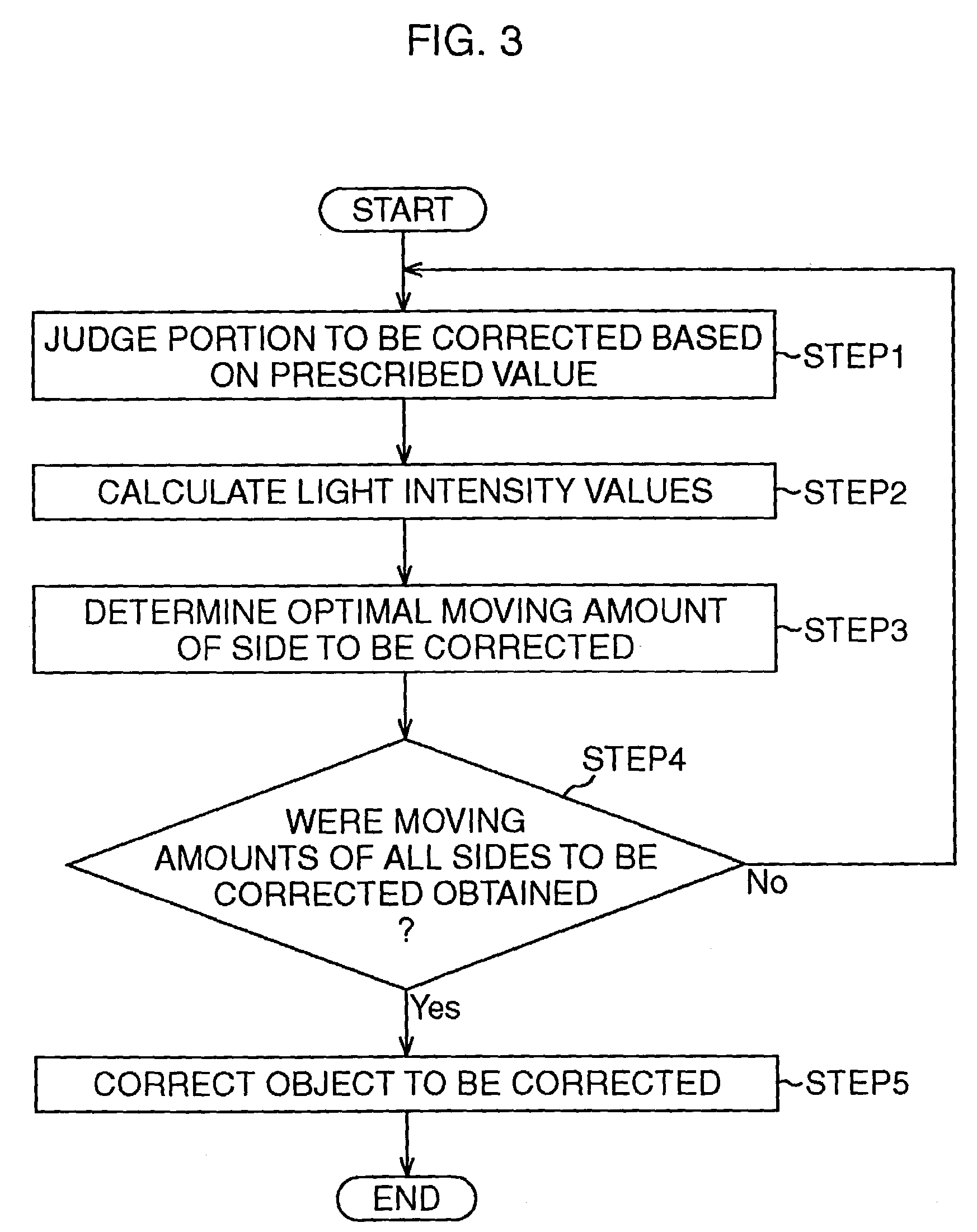

Proximity effect correction apparatus, proximity effect correction method, storage medium, and computer program product

InactiveUS7047516B2Improve reliabilityMeet needsDigital data processing detailsSemiconductor/solid-state device manufacturingComputer scienceComputer program

Light intensity values only of the vicinity of a specified portion, that is, for example, based on a prescribed value, an area where the distance between edges of an object to be corrected is equal to or shorter than the prescribed value are calculated, and the object to be corrected is corrected based on the light intensity values.

Owner:MIE FUJITSU SEMICON

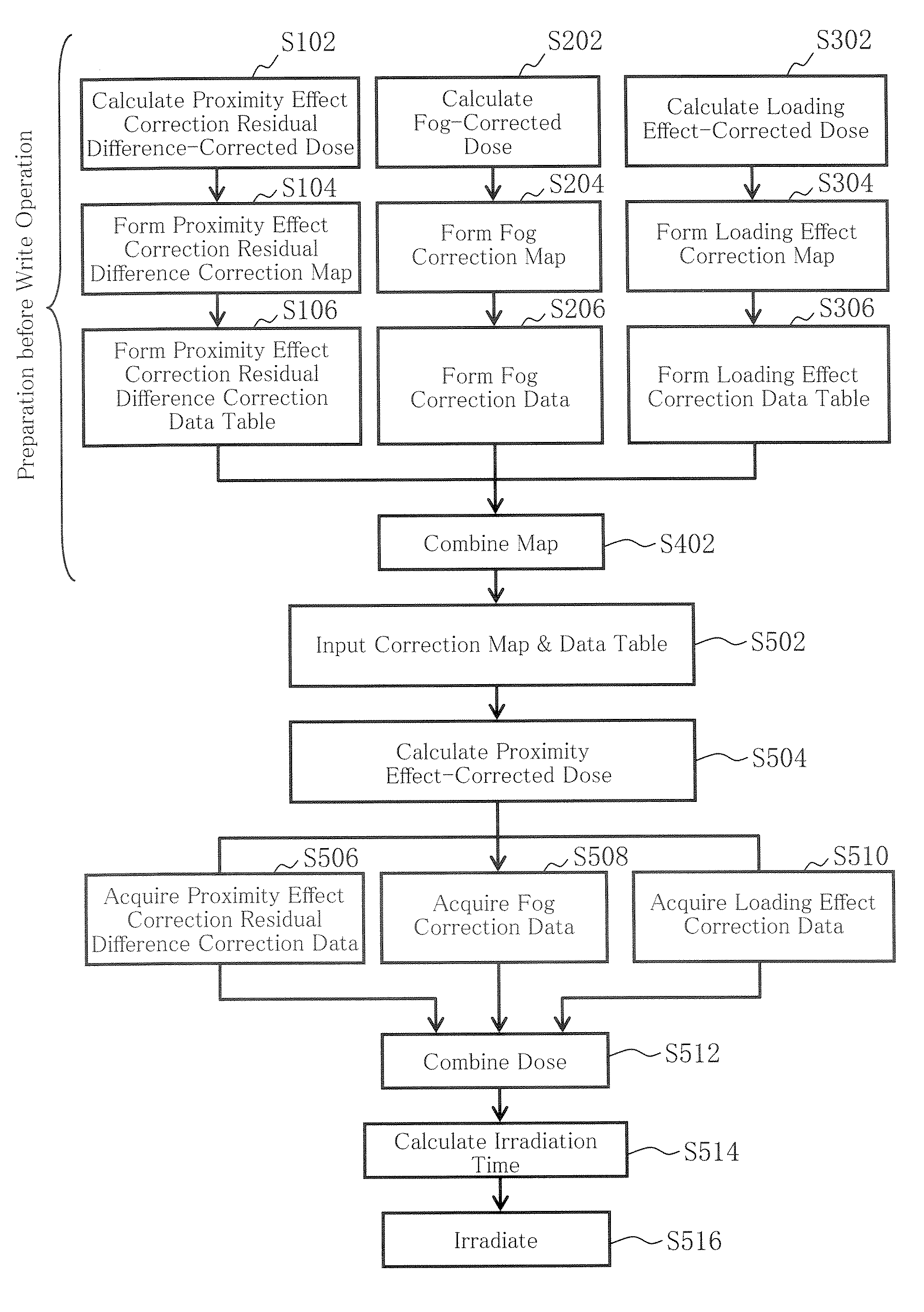

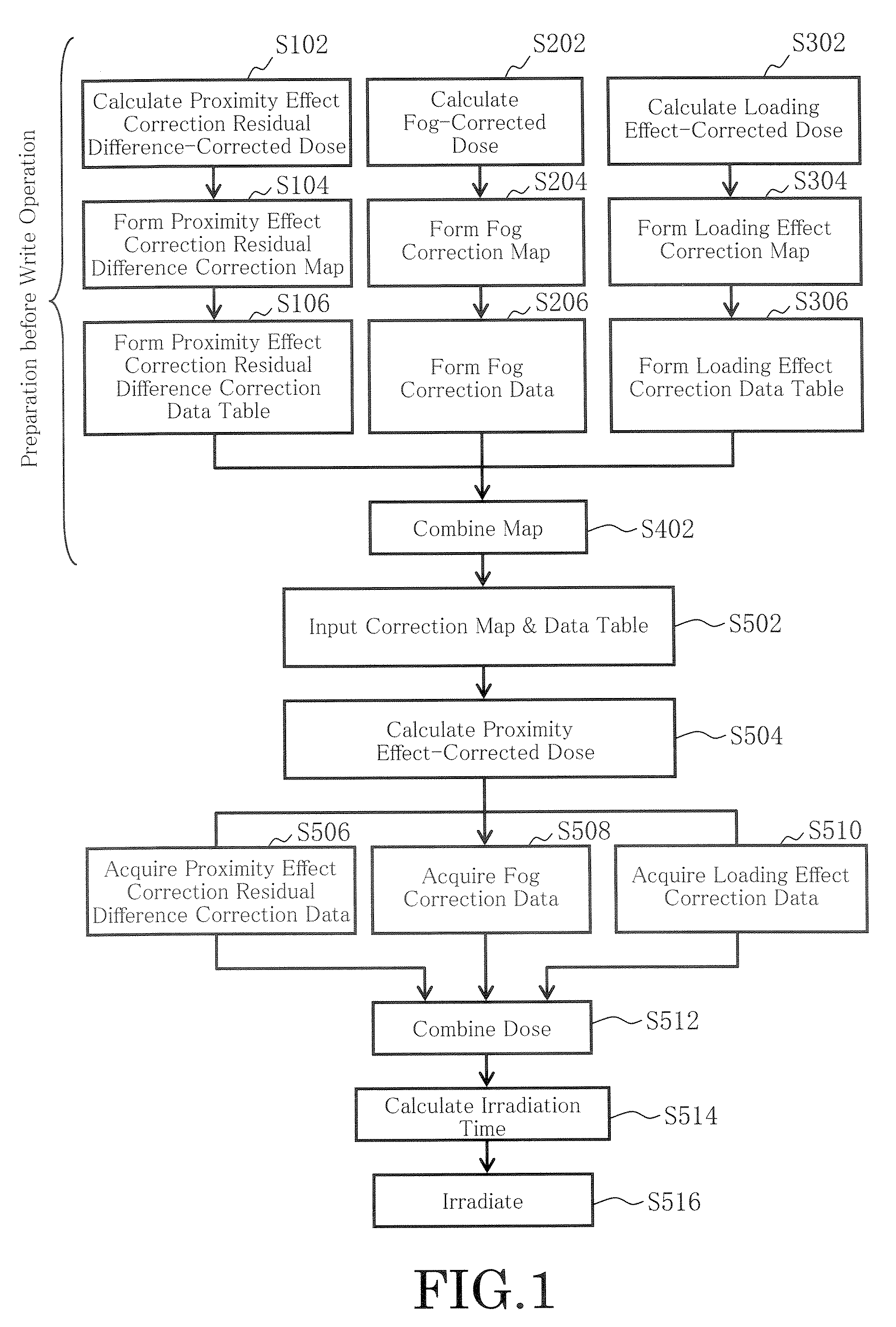

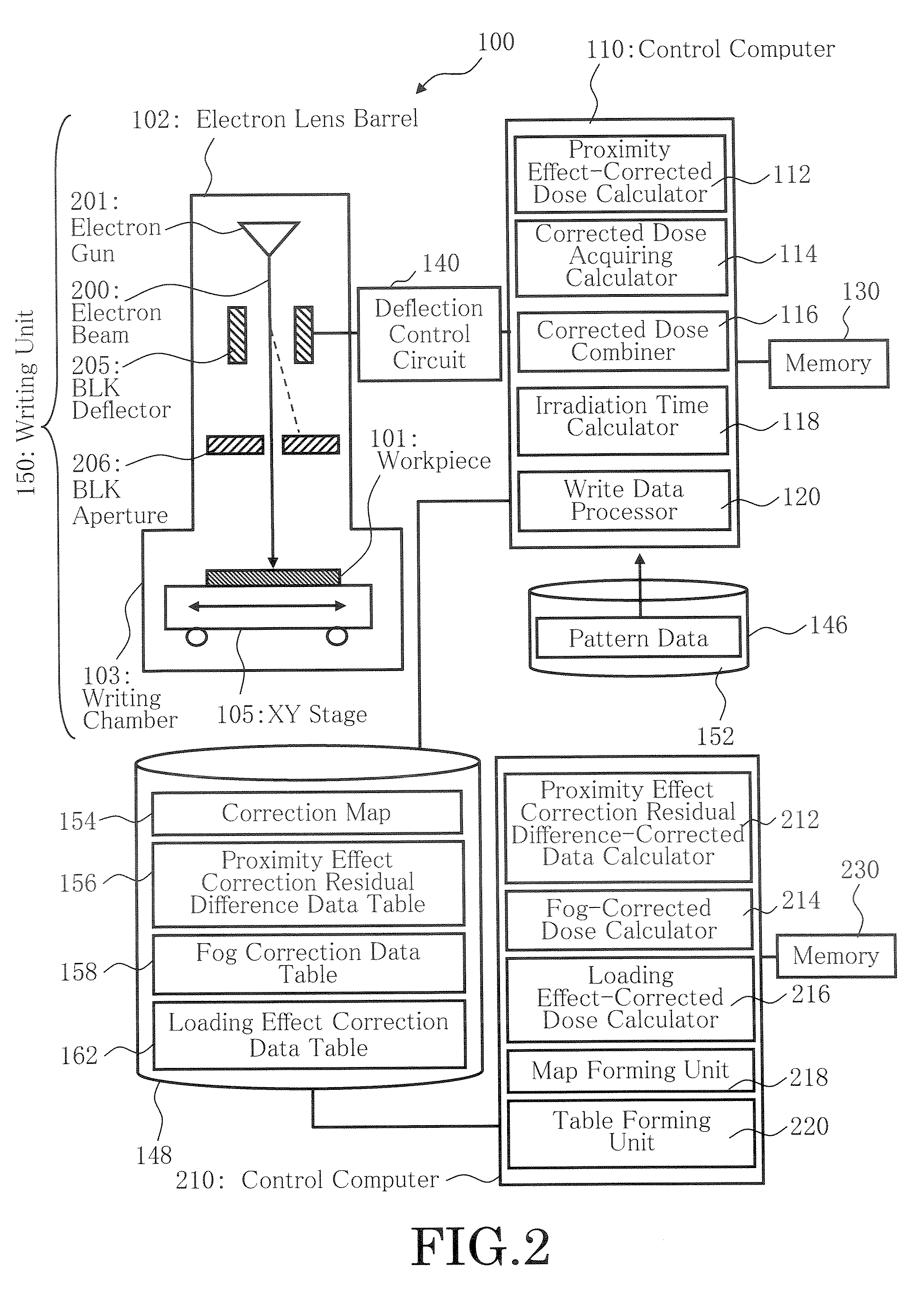

Charged particle beam writing method and apparatus

ActiveUS20070194250A1Improve accuracyElectric discharge tubesNanoinformaticsAtomic physicsCharged particle beam

A method for writing a pattern on a workpiece by use of a charged particle beam, the method includes calculating a corrected dose including at least a proximity effect correction dose for correction of proximity effect, calculating a corrected residual difference-corrected dose for correcting a correction residual difference of the corrected dose, calculating a exposure dose of the charged particle beam to be corrected by the corrected dose as corrected by the correction residual difference-corrected dose, and irradiating the charged particle beam onto the workpiece in such a way as to become the exposure dose.

Owner:NUFLARE TECH INC

Method for design and manufacture of a reticle using variable shaped beam lithography

A method is disclosed for using non-overlapping variable shaped beam (VSB) shots in the design and manufacture of a reticle, where the union of the plurality of shots deviates from the desired pattern. Methods are described for fracturing or mask data preparation or proximity effect correction of a desired pattern to be formed on a reticle; for forming a pattern on a reticle using charged particle beam lithography; and for optical proximity correction (OPC) of a desired pattern. Dosages of the shots may be allowed to vary with respect to each other. The plurality of shots may be determined such that a pattern on the surface calculated from the plurality of shots is within a predetermined tolerance of the desired pattern. In some embodiments, an optimization technique may be used to minimize shot count.

Owner:D2S

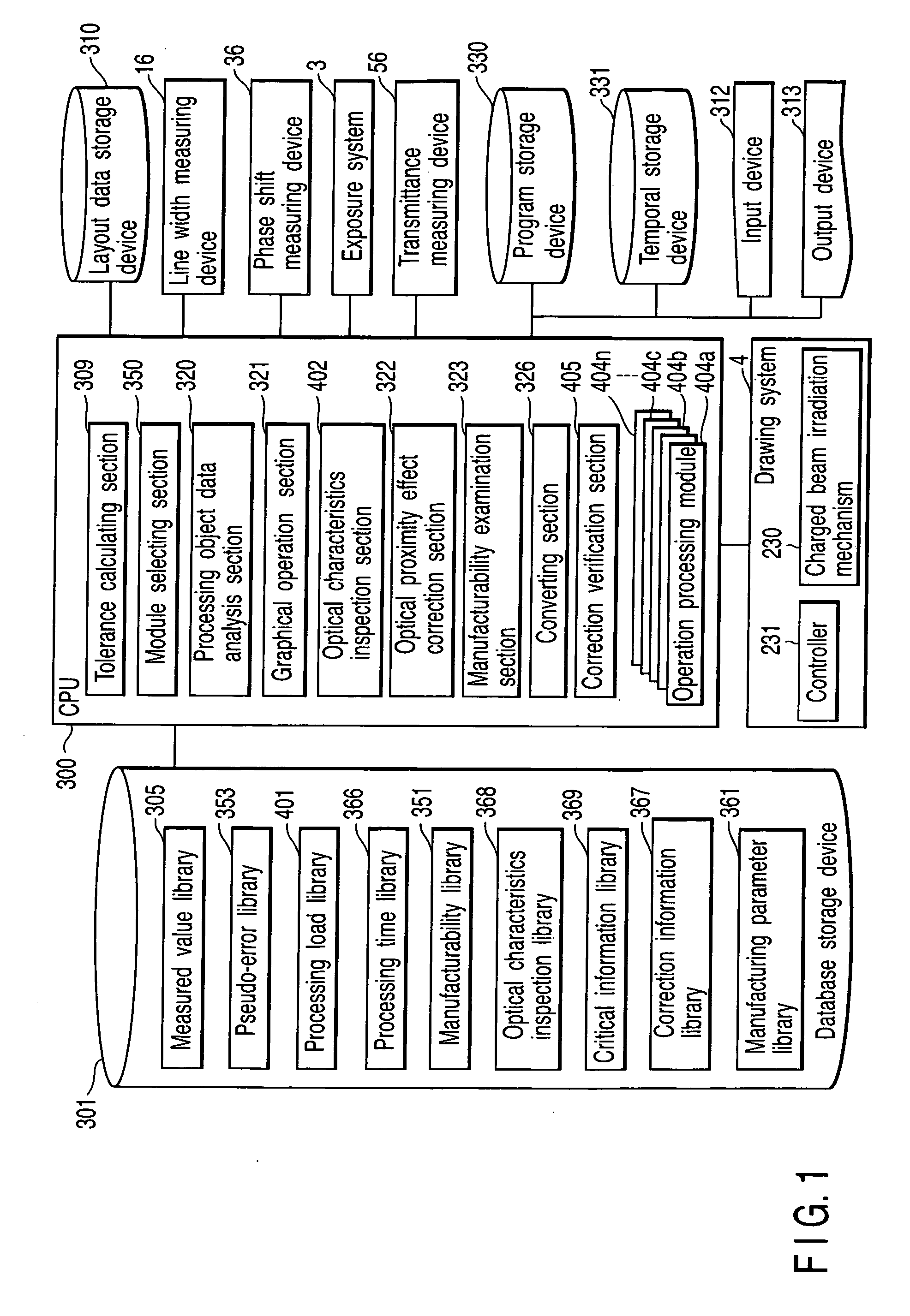

Mask manufacturing system, mask data creating method and manufacturing method of semiconductor device

InactiveUS20070124718A1Originals for photomechanical treatmentSpecial data processing applicationsDevice materialProcess information

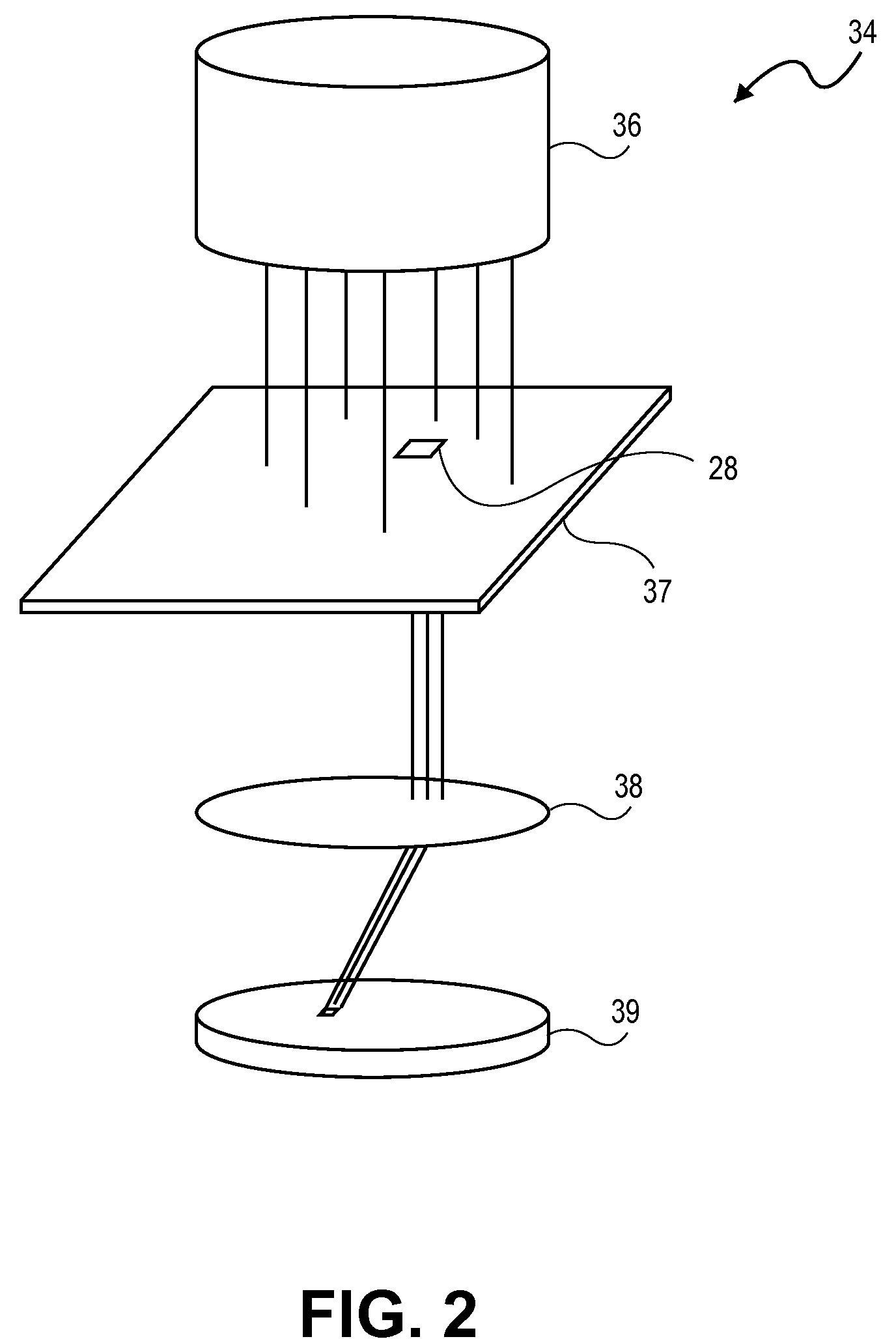

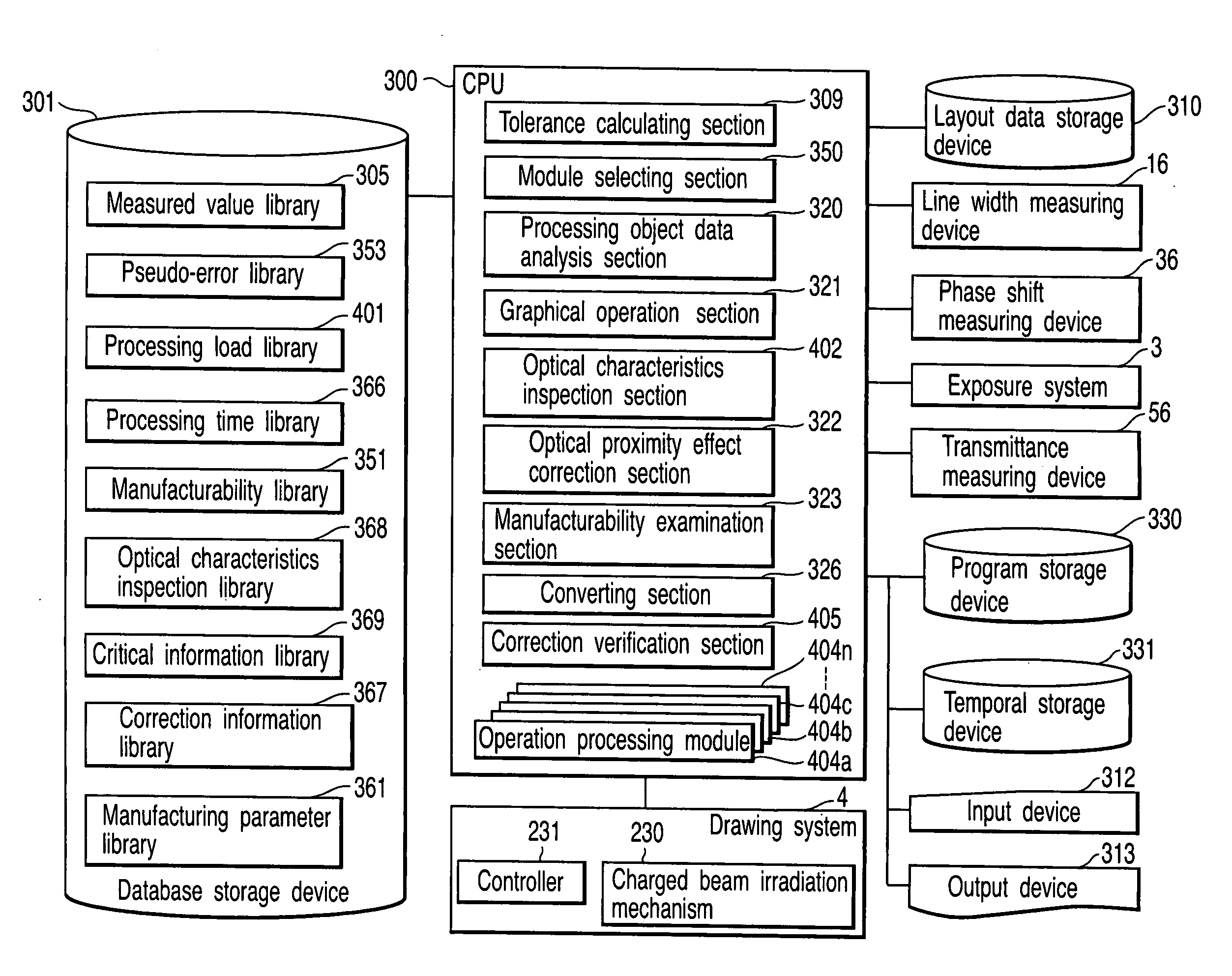

A mask manufacturing system and a mask data creating method reusing data for processing information and environment in the past to reduce a photomask developing period, and a manufacturing method of a semiconductor device are disclosed. According to one aspect of the present invention, it is provided a mask manufacturing system comprising a storage device storing processing data for semiconductor integrated circuits processed in the past, a plurality of operation processing modules, a module selecting section selecting at least one operation processing modules, an optical proximity effect correction section executing optical proximity effect correction to a processing object data and generating a correction data by utilizing past correction information applied for a stored data equivalent to the processing object data, a converting section converting the processing object data into mask data, and a drawing system drawing a mask pattern based on the mask data.

Owner:KK TOSHIBA

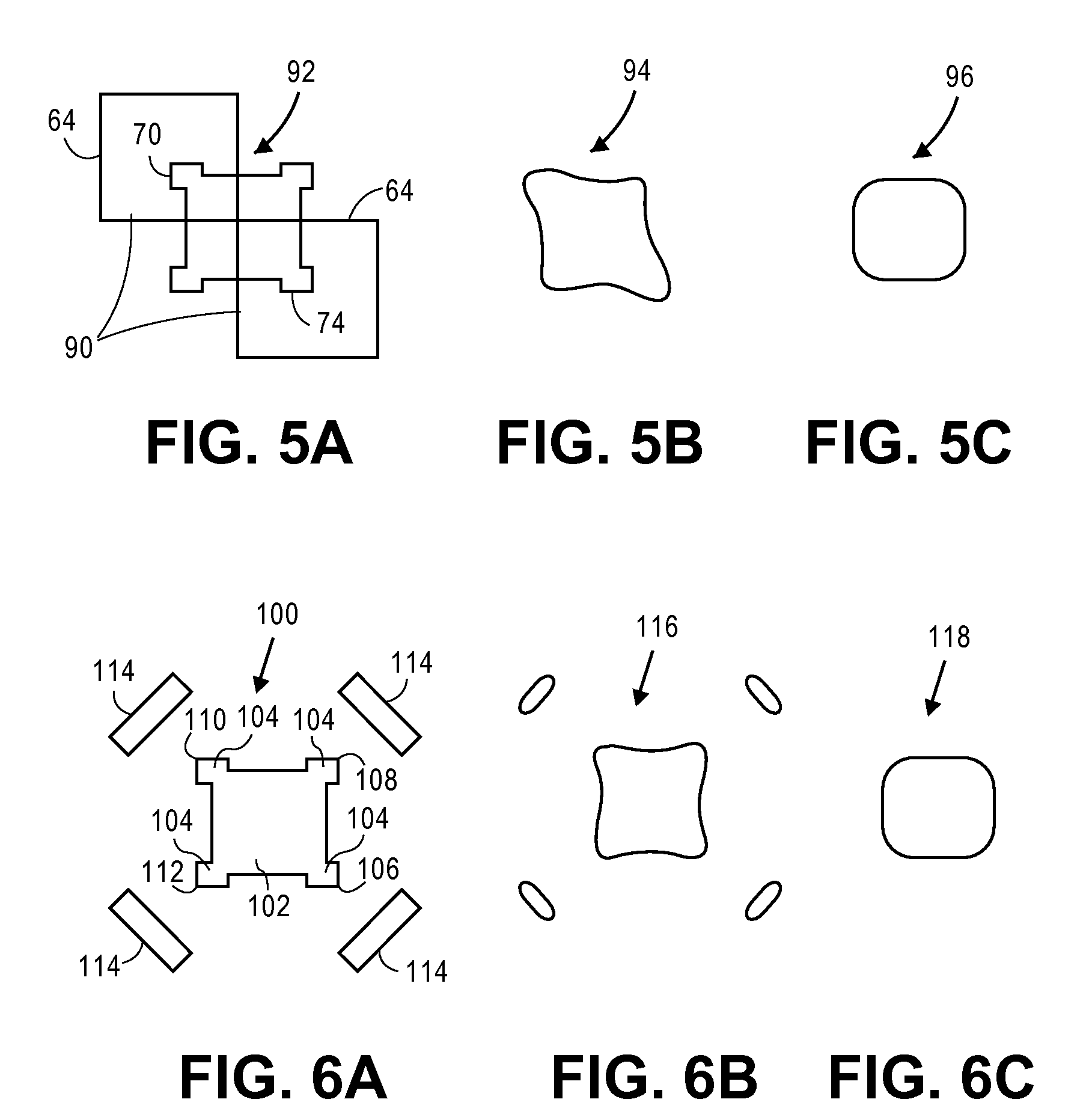

Method and system for fracturing a pattern using charged particle beam lithography with multiple exposure passes which expose different surface area

ActiveUS8137871B2Reduce in quantityElectric discharge tubesRadiation applicationsMask data preparationLithographic artist

In the field of semiconductor production using charged particle beam lithography, a method and system for fracturing or mask data preparation or proximity effect correction is disclosed, in which the union of shots from one of a plurality of exposure passes is different than the union of shots from a different exposure pass. Methods for manufacturing a reticle and for manufacturing an integrated circuit are also disclosed, in which the union of shots from one of a plurality of charged particle beam exposure passes is different than the union of shots from a different exposure pass.

Owner:D2S

Method for fracturing and forming a pattern using curvilinear characters with charged particle beam lithography

In the field of semiconductor production using shaped charged particle beam lithography, a method and system for fracturing or mask data preparation or proximity effect correction is disclosed, wherein a series of curvilinear character projection shots are determined for a charged particle beam writer system, such that the set of shots can form a continuous track, possibly of varying width, on a surface. A method for forming a continuous track on a surface using a series of curvilinear character projection shots is also disclosed. Methods for manufacturing a reticle and for manufacturing a substrate such as a silicon wafer by forming a continuous track on a surface using a series of curvilinear character projection shots is also disclosed.

Owner:D2S

Method and system for forming high accuracy patterns using charged particle beam lithography

ActiveUS8473875B2Increase roughnessImprove variationPhotomechanical apparatusComputer aided designMask data preparationLithographic artist

Owner:D2S

Method and system for fracturing a pattern using charged particle beam lithography with multiple exposure passes which expose different surface area

ActiveUS20110159435A1Reduce in quantityElectric discharge tubesRadiation applicationsMask data preparationLithographic artist

In the field of semiconductor production using charged particle beam lithography, a method and system for fracturing or mask data preparation or proximity effect correction is disclosed, in which the union of shots from one of a plurality of exposure passes is different than the union of shots from a different exposure pass. Methods for manufacturing a reticle and for manufacturing an integrated circuit are also disclosed, in which the union of shots from one of a plurality of charged particle beam exposure passes is different than the union of shots from a different exposure pass.

Owner:D2S

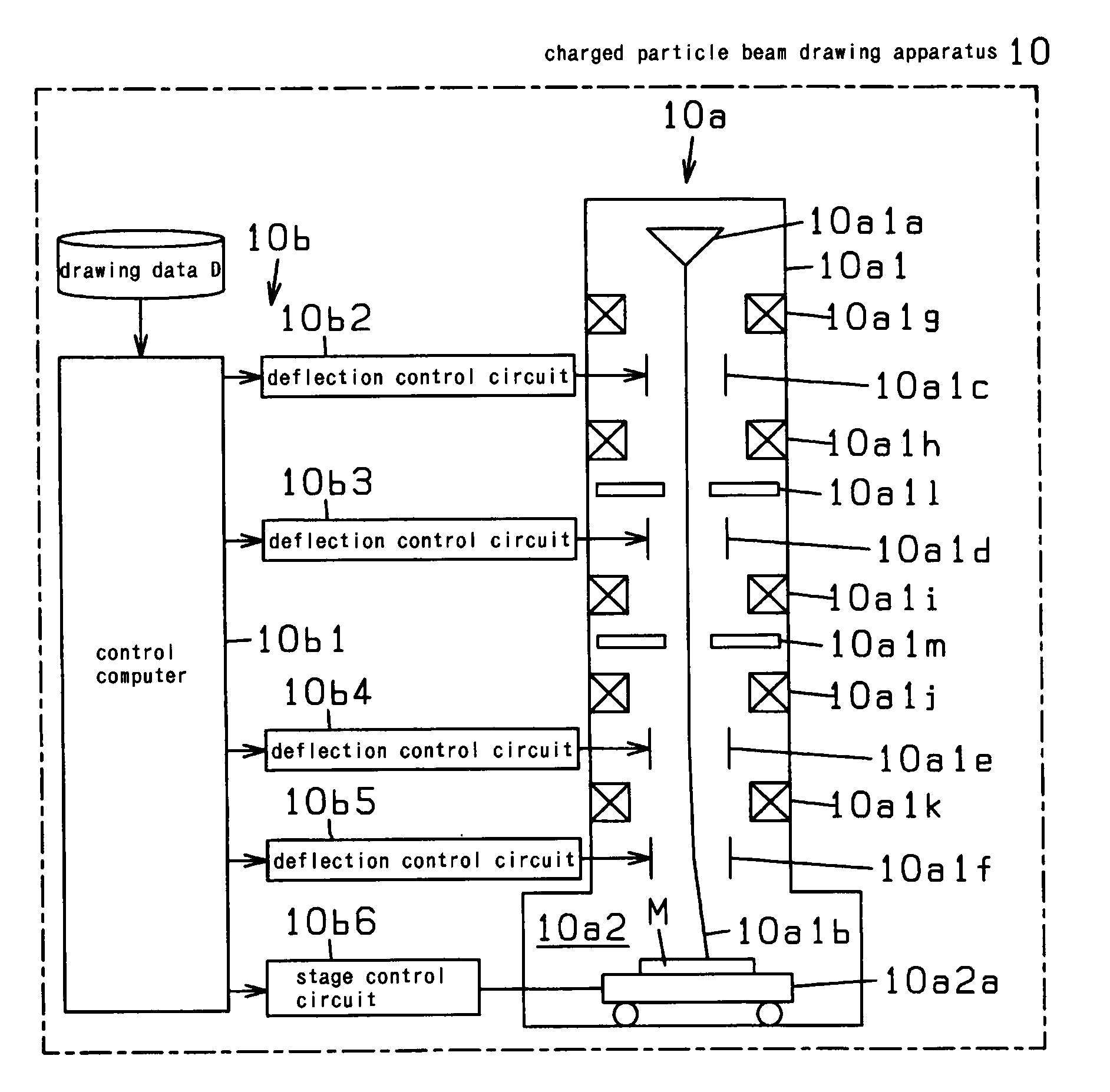

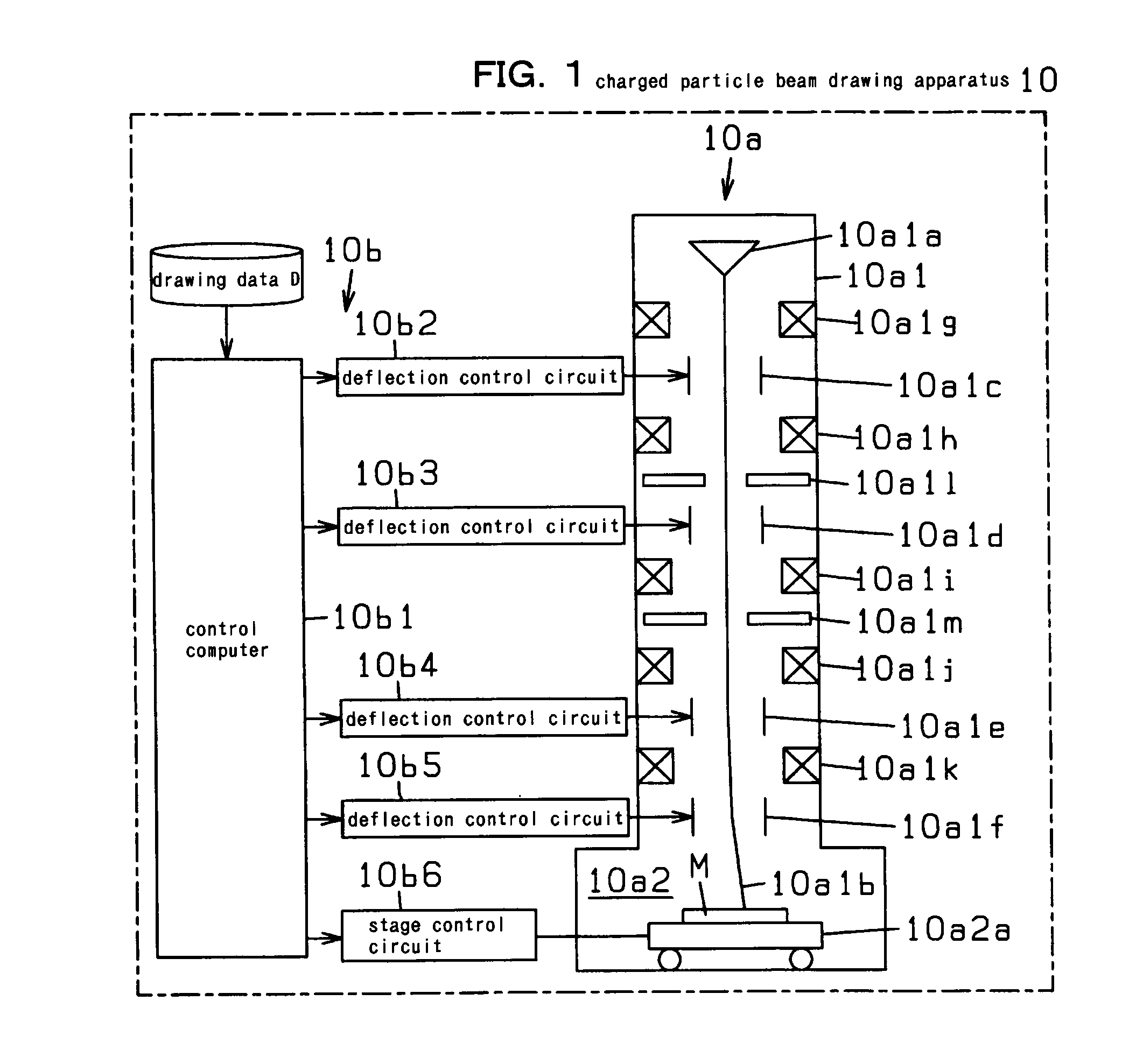

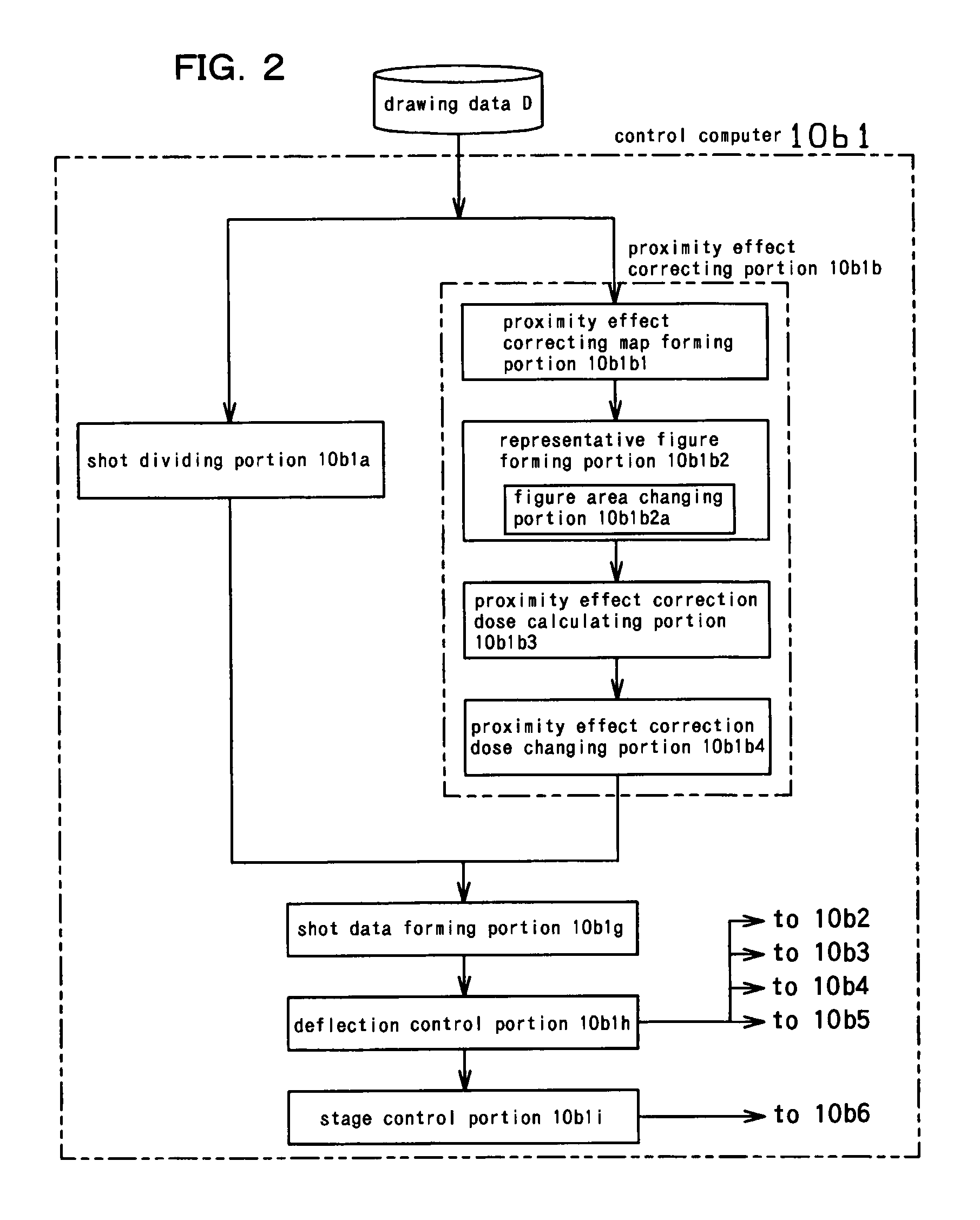

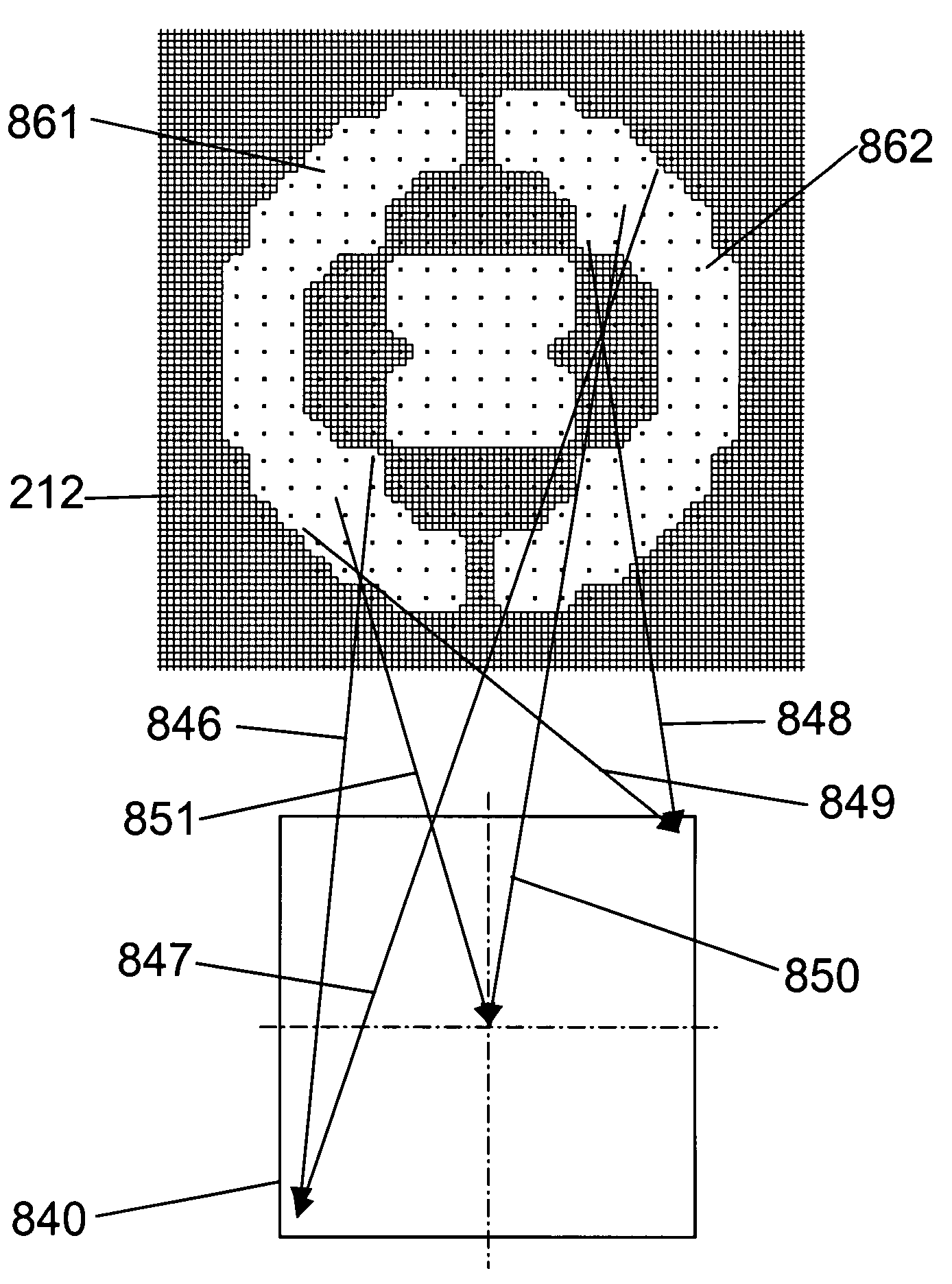

Charged particle beam drawing apparatus and proximity effect correction method thereof

ActiveUS20110068281A1Easy to solveElectric discharge tubesNanoinformaticsParticle physicsCharged particle beam

A charged particle beam drawing apparatus forms a map having meshes, forms representative figures, area of each representative figure in each mesh being equal to gross area of figures in each mesh, and calculates a proximity effect correction dose of the charged particle beam in each mesh on the basis of area of each representative figure in each mesh. If it is necessary to change the proximity effect correction dose of the charged particle beam for drawing at least one pattern corresponding to at least one figure, the charged particle beam drawing apparatus changes area of the at least one figure before the representative figures are formed by a representative figure forming portion, and changes the proximity effect correction dose of the charged particle beam for drawing the at least one pattern corresponding to the at least one figure, calculated by a proximity effect correction dose calculating portion.

Owner:NUFLARE TECH INC

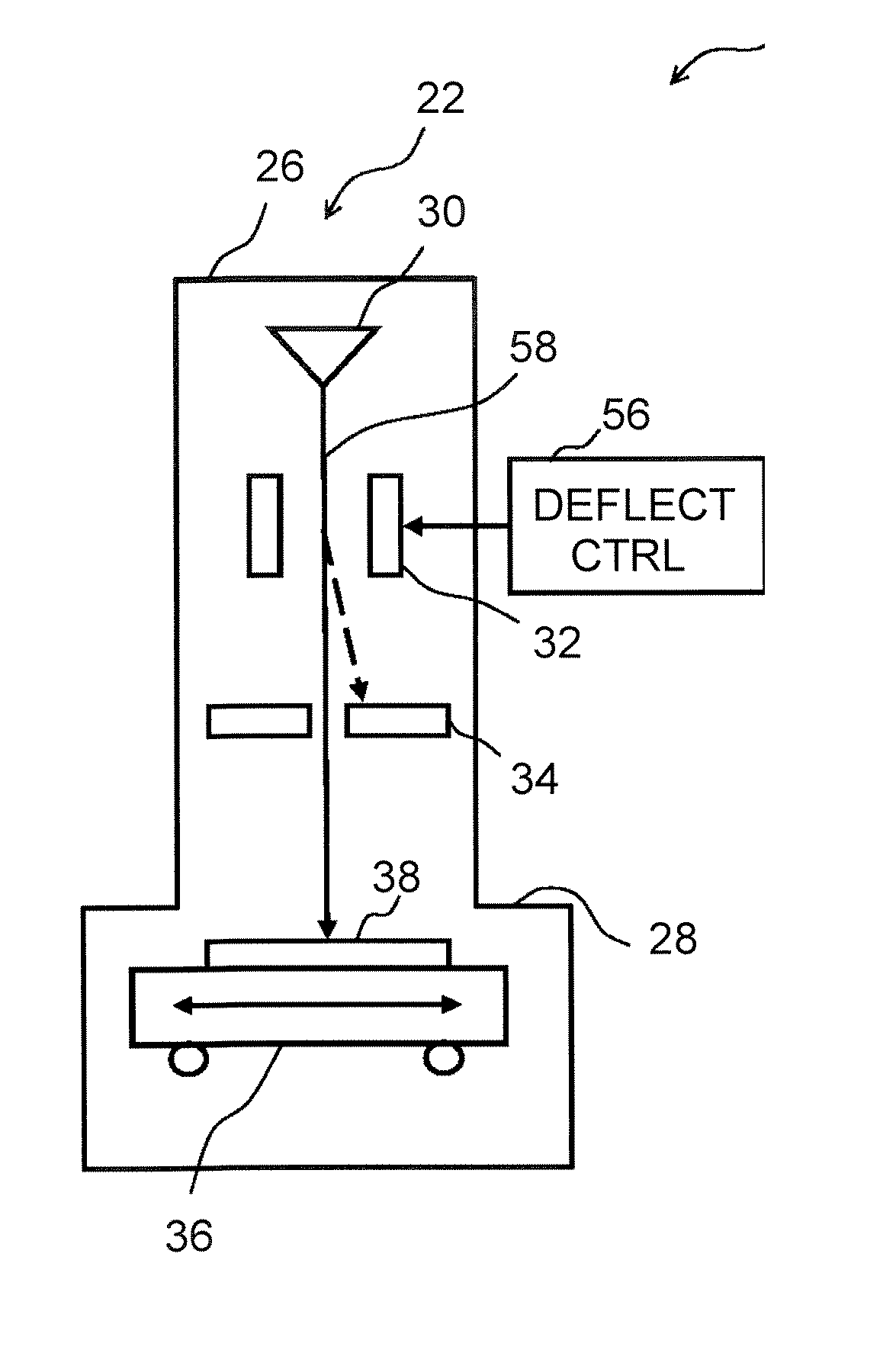

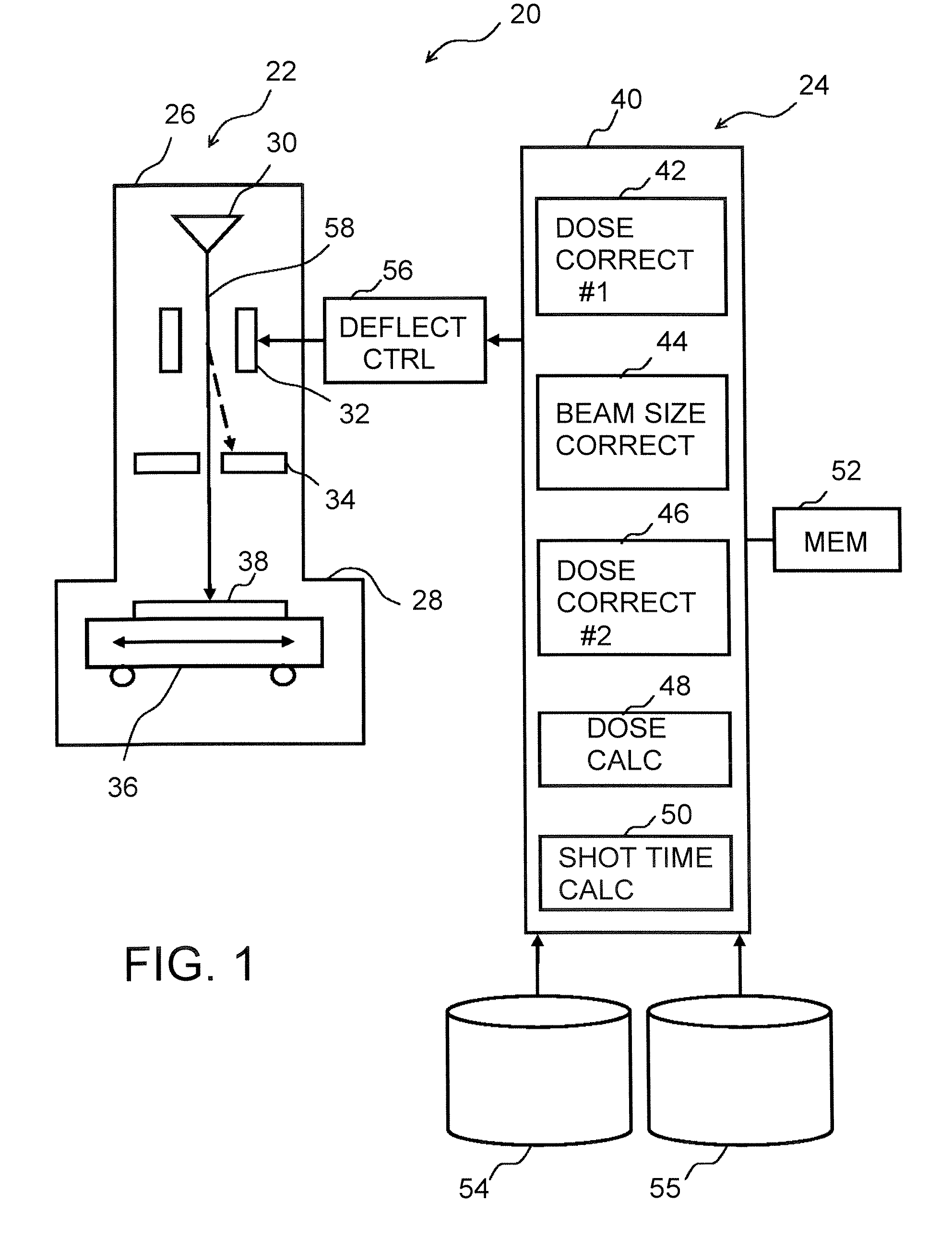

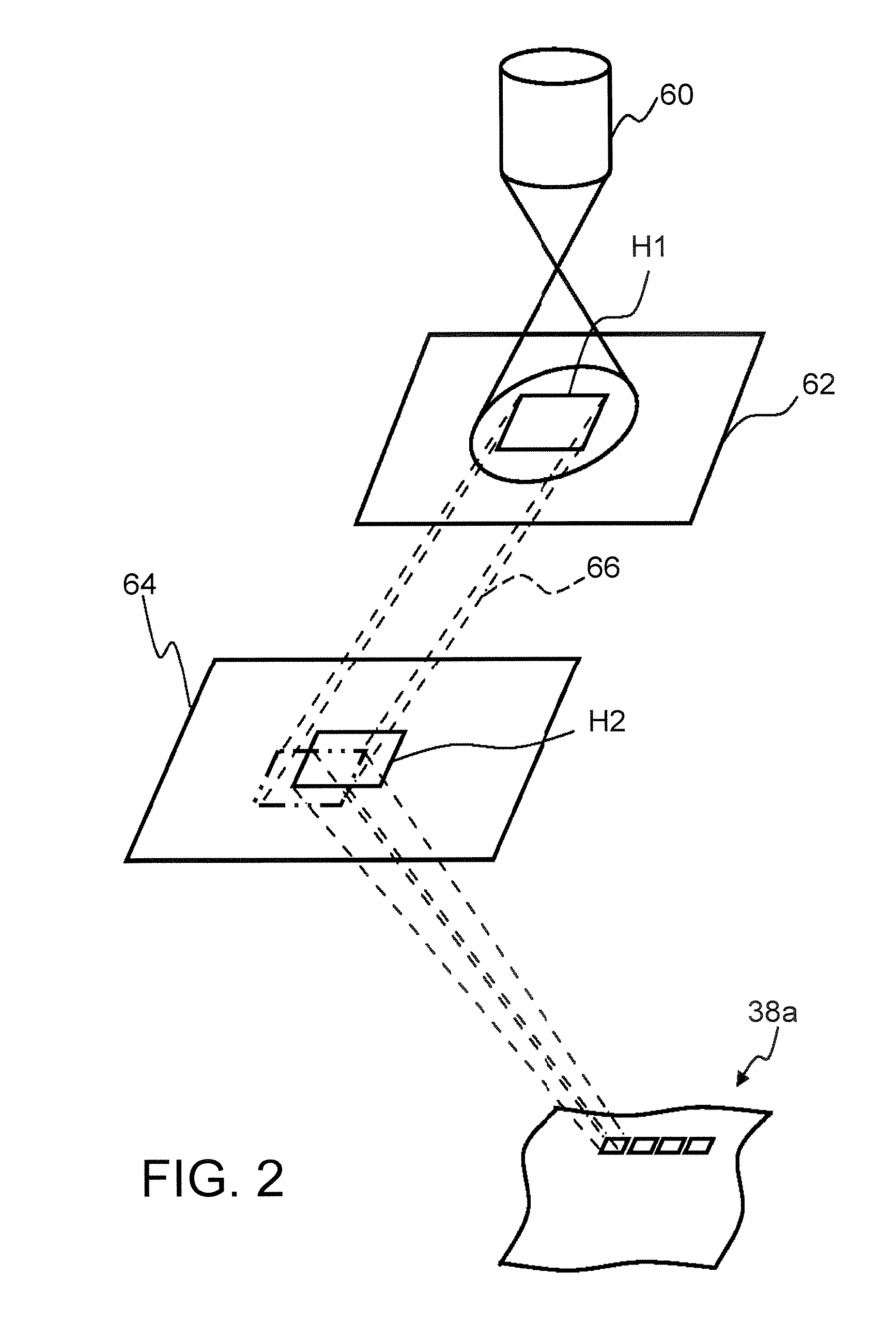

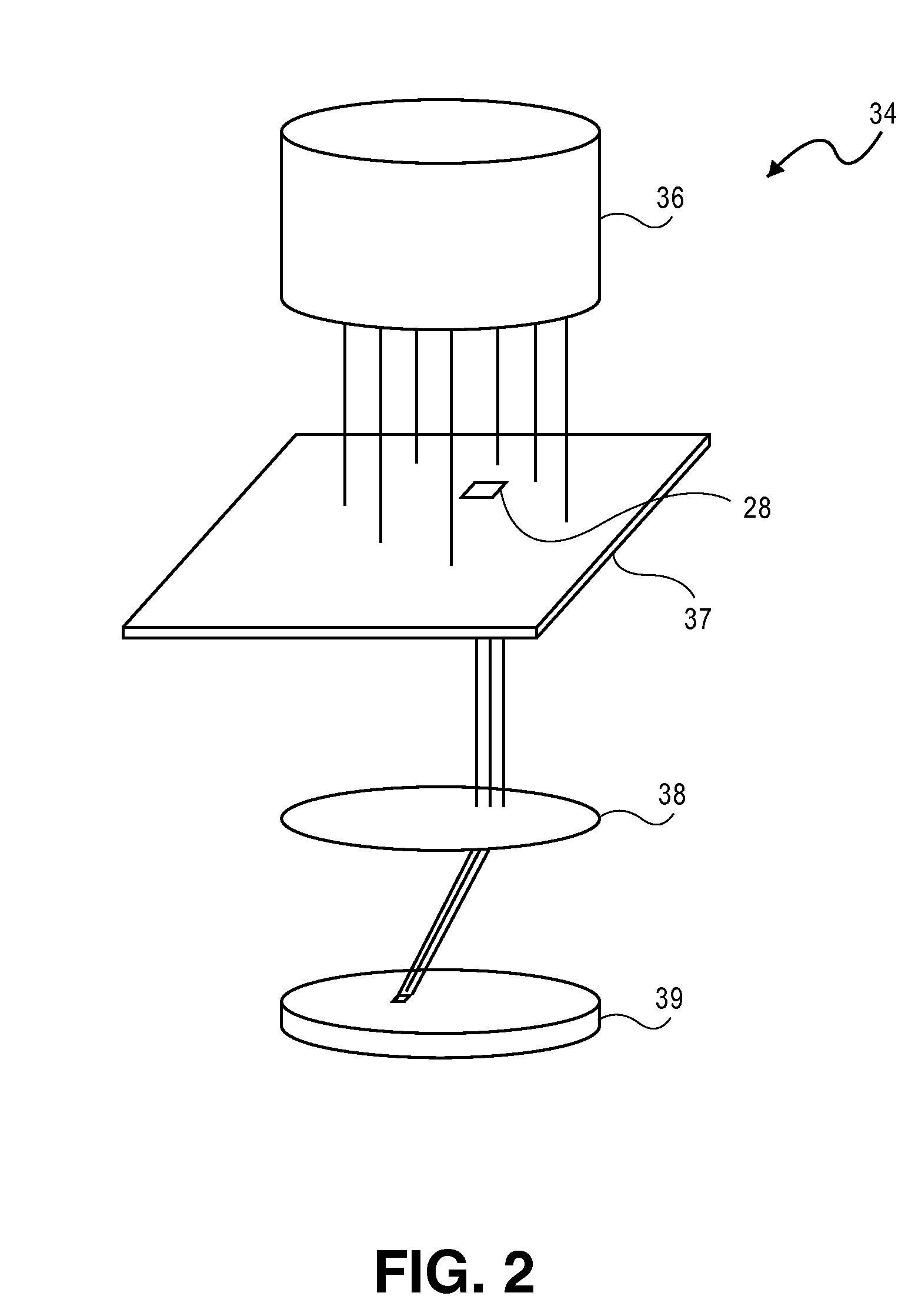

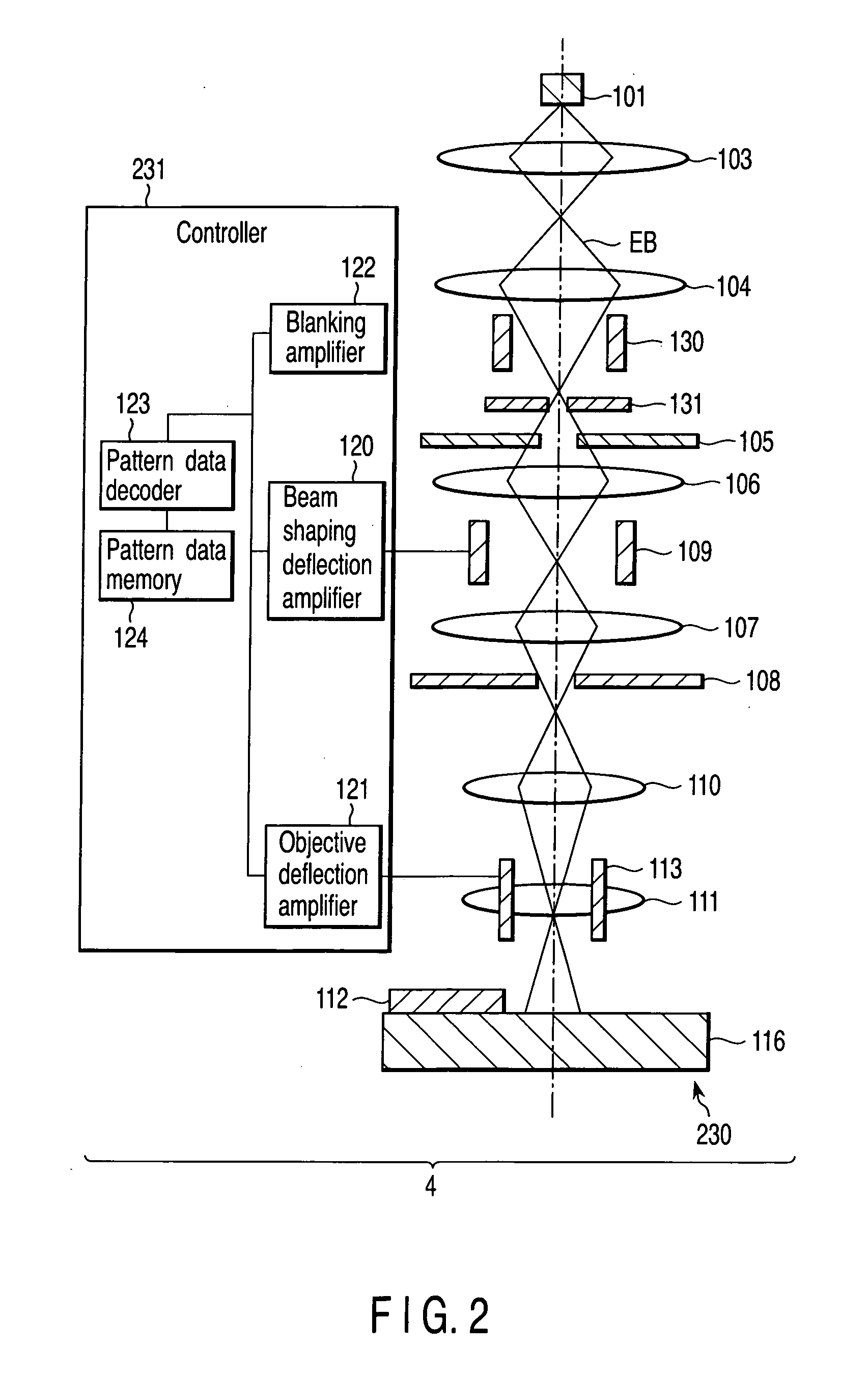

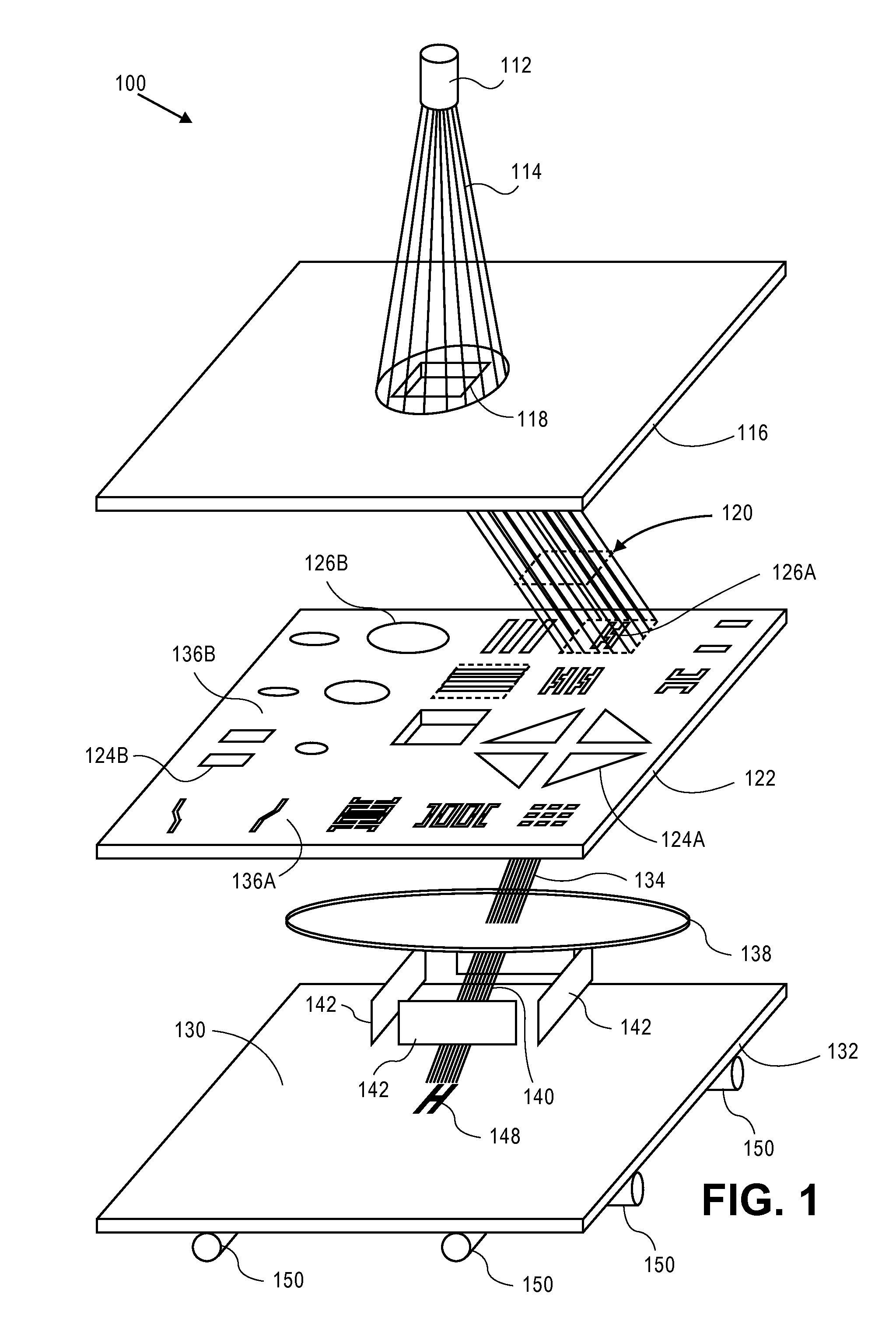

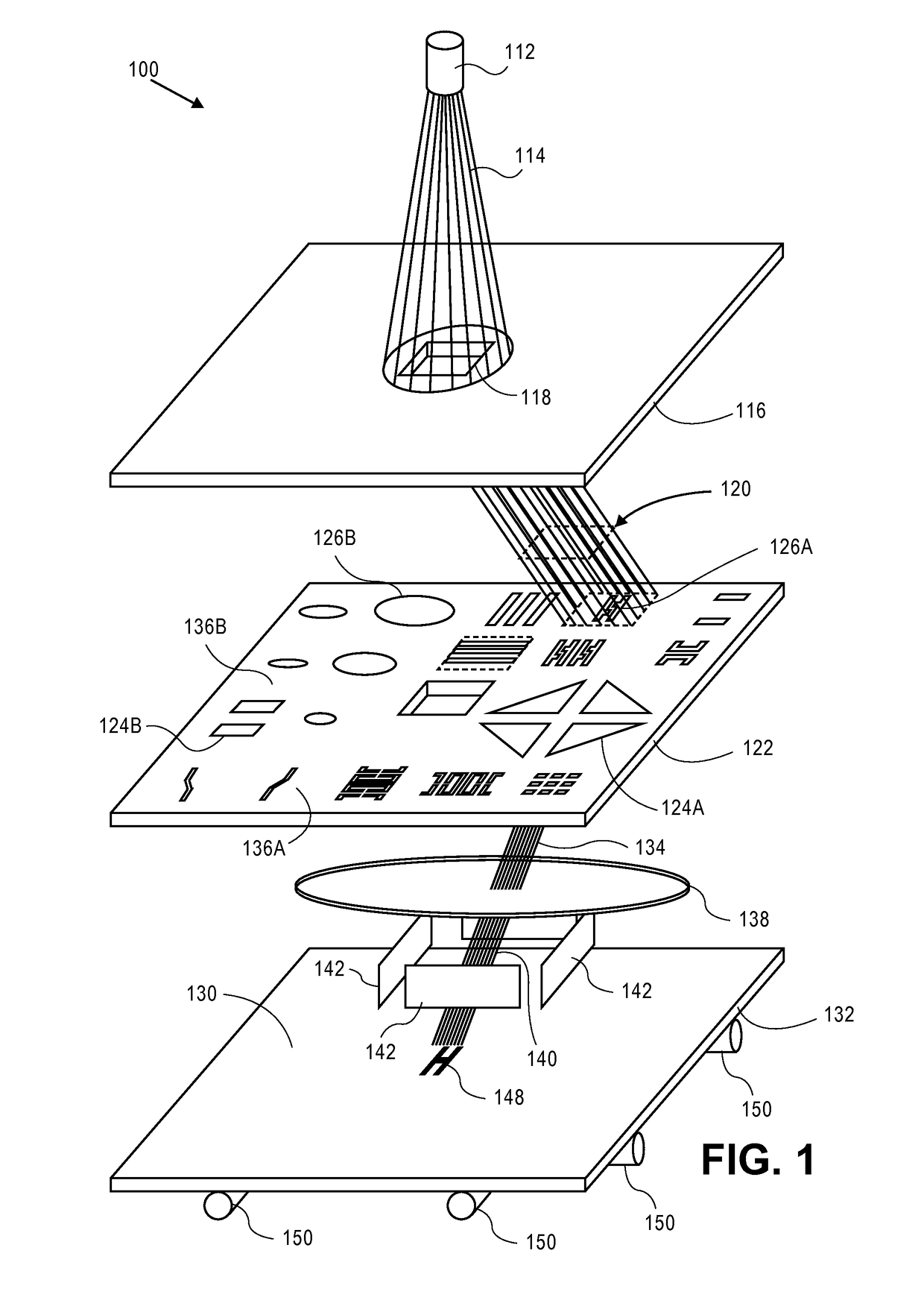

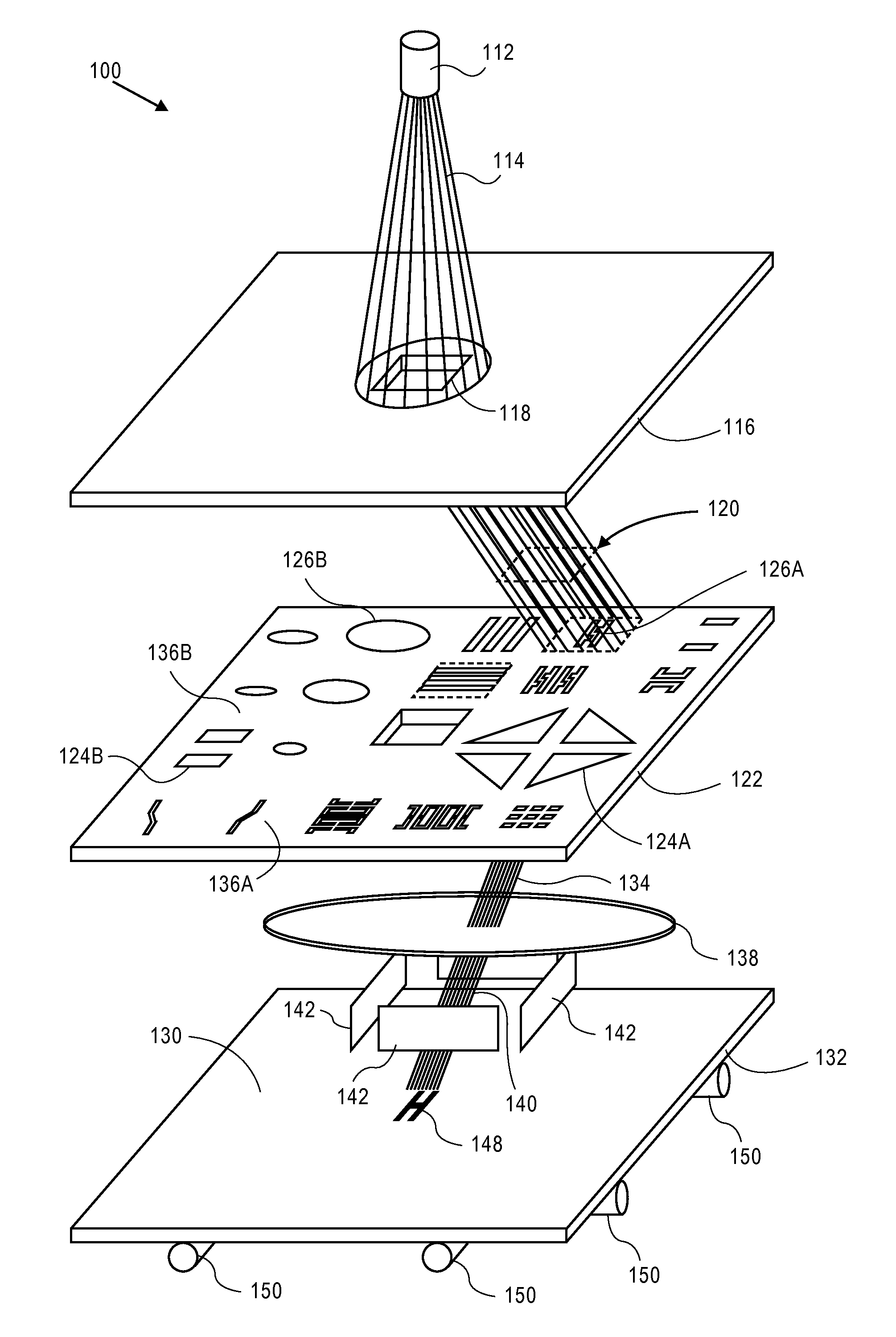

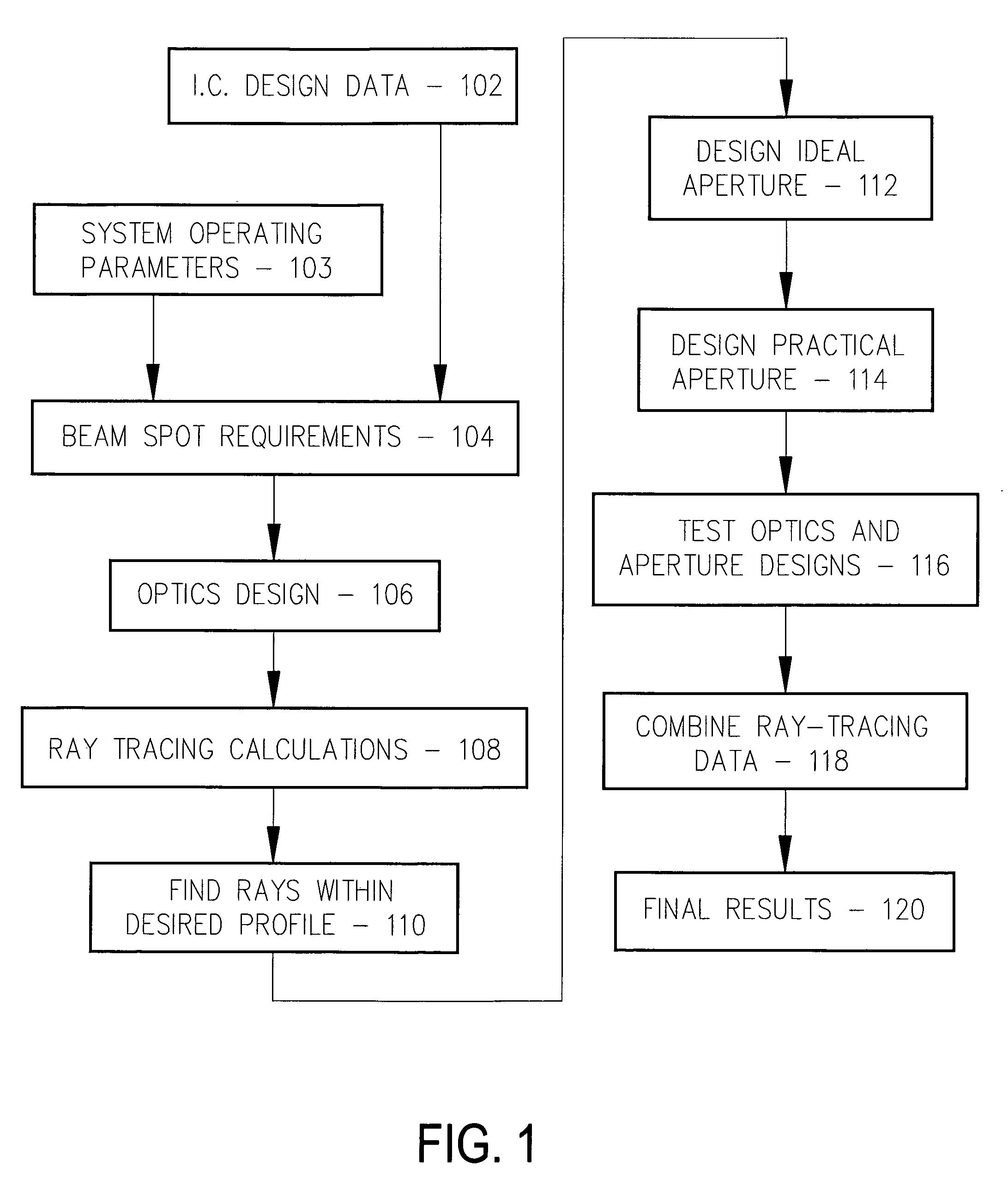

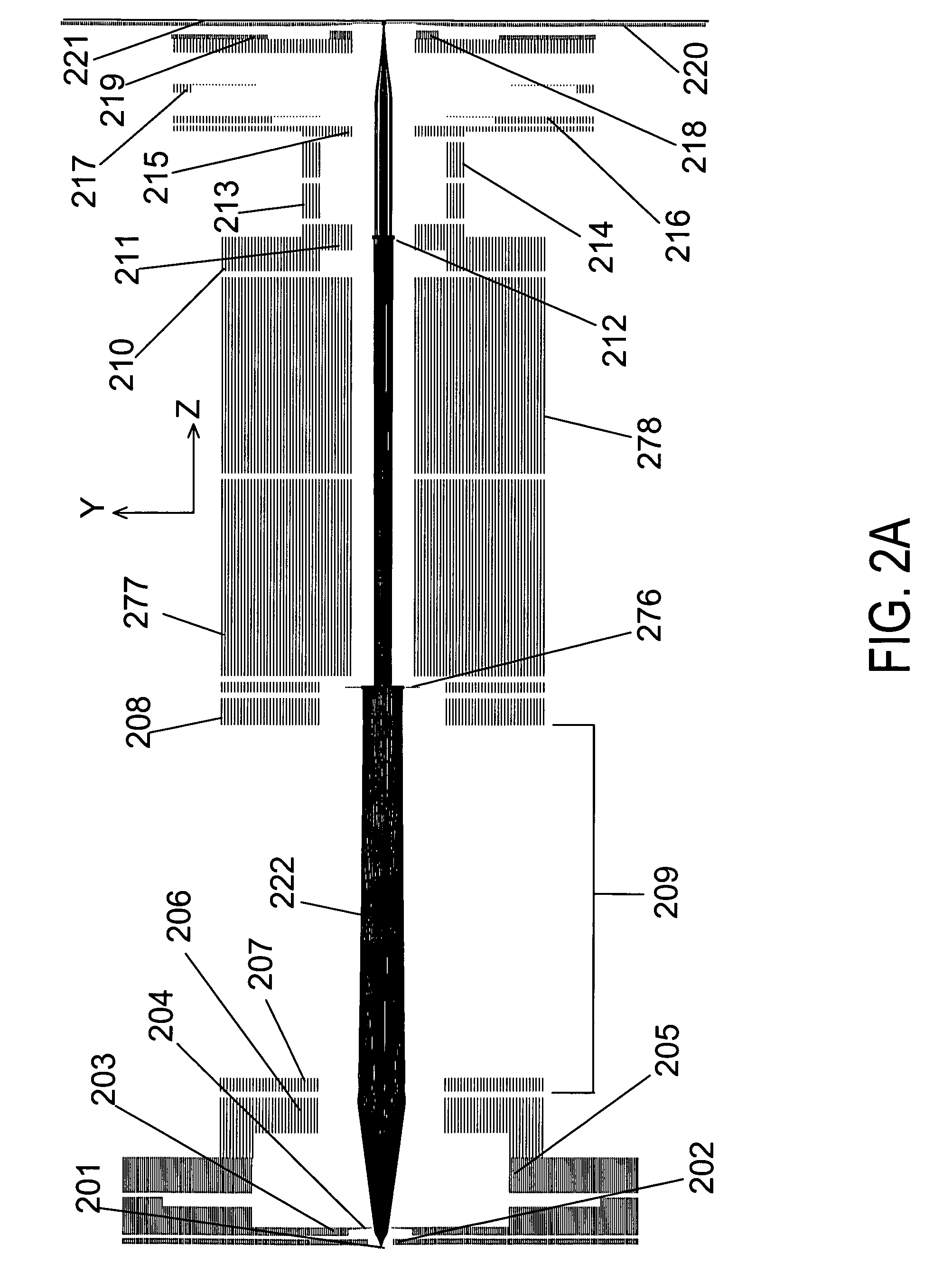

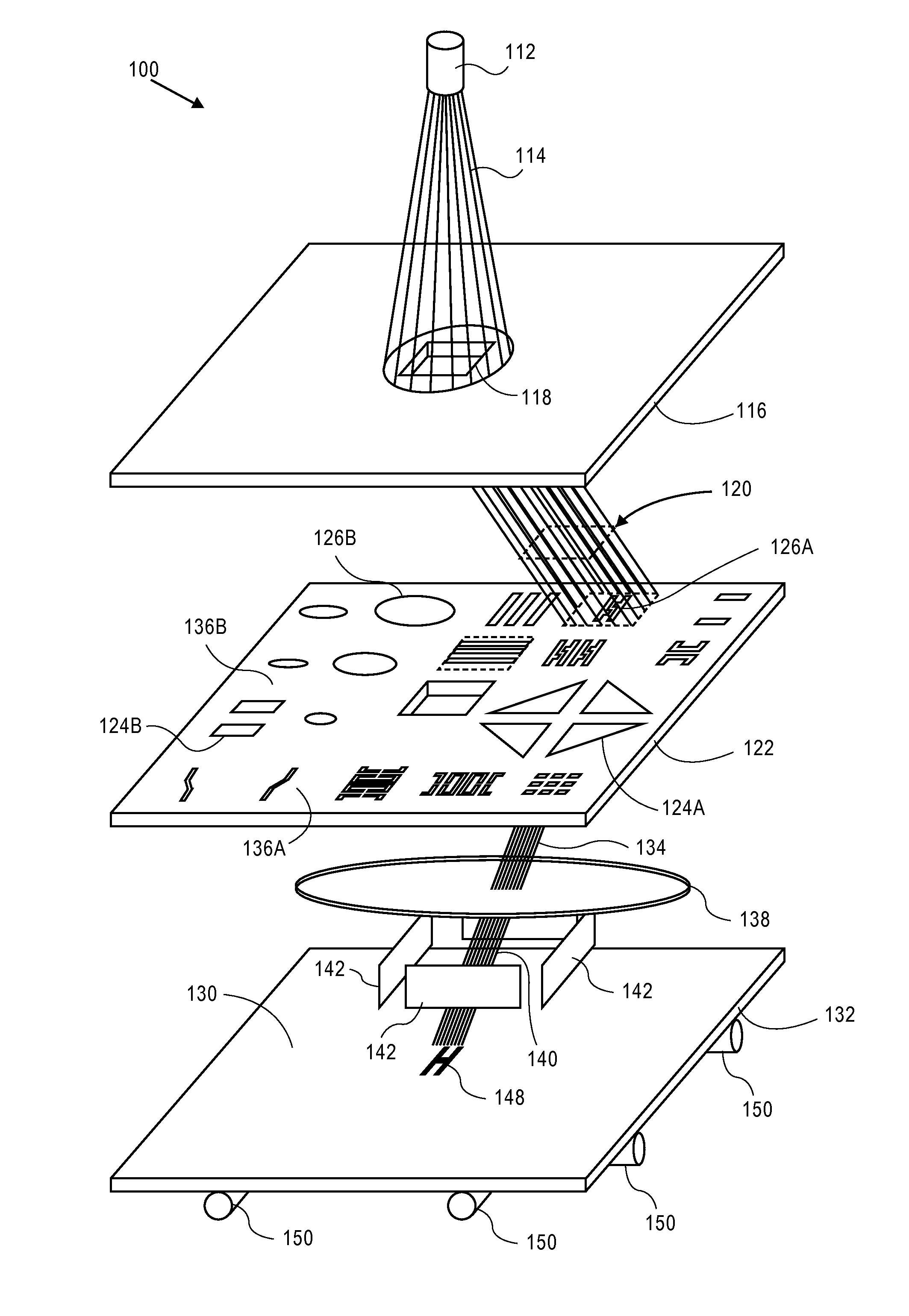

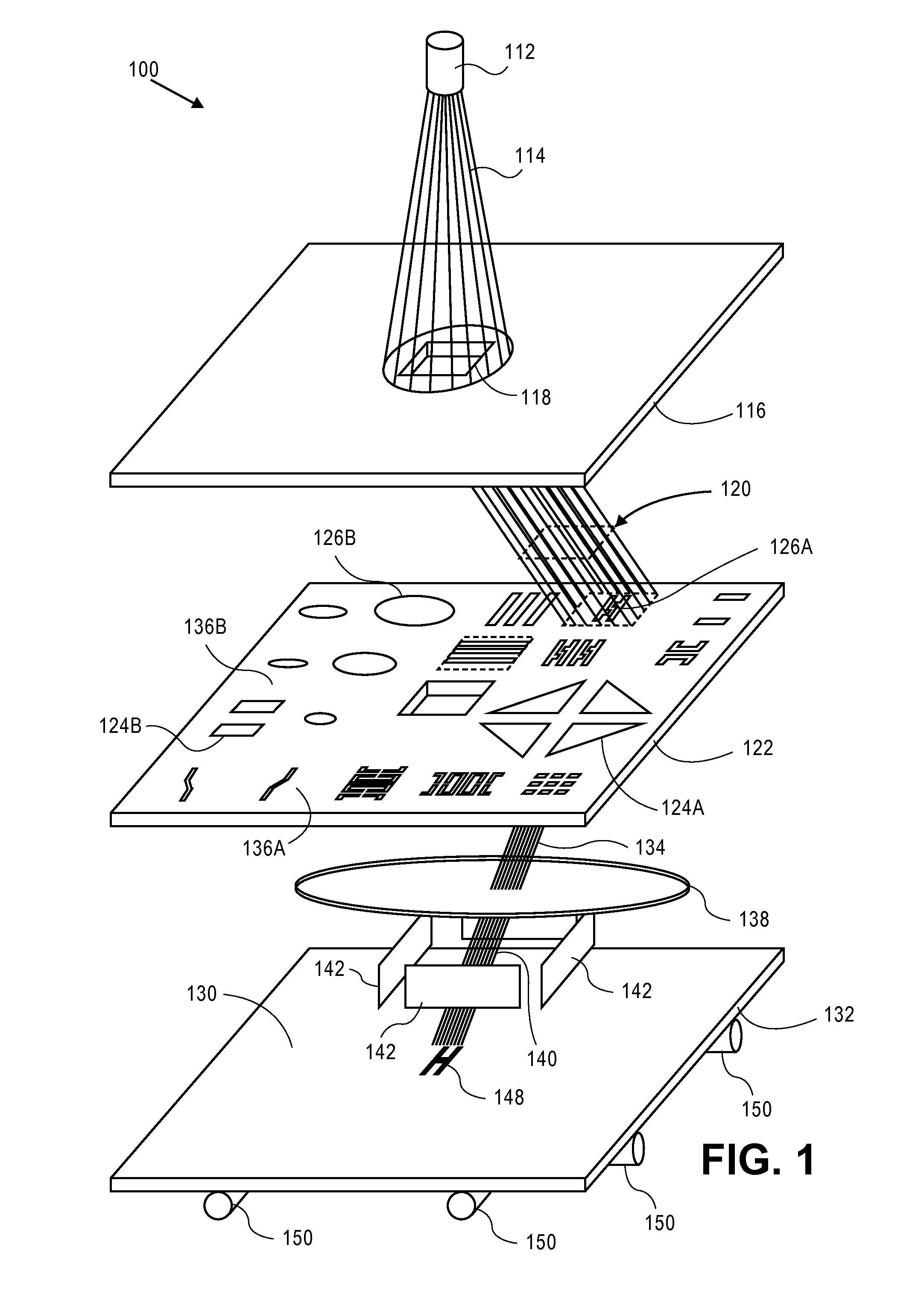

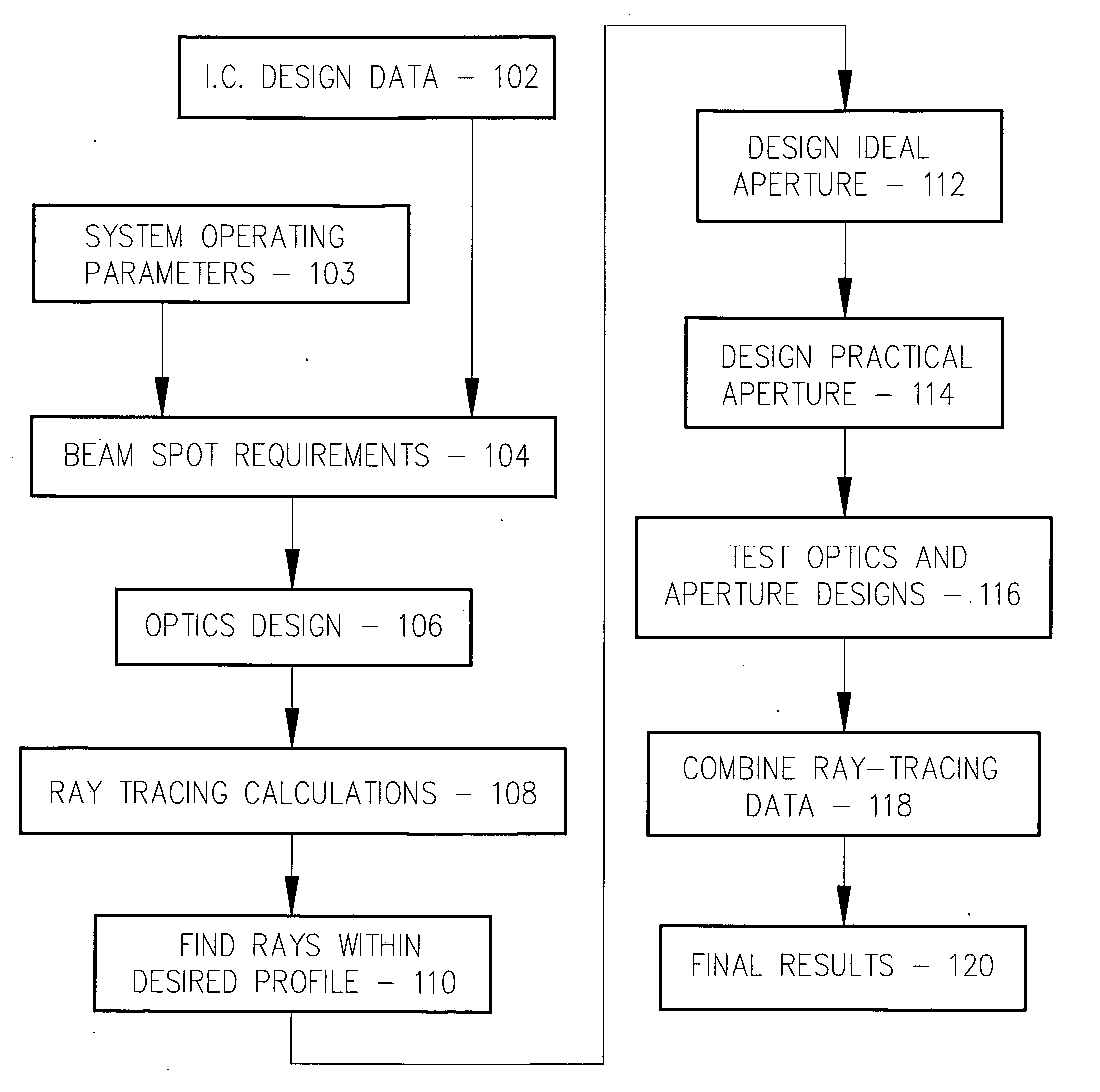

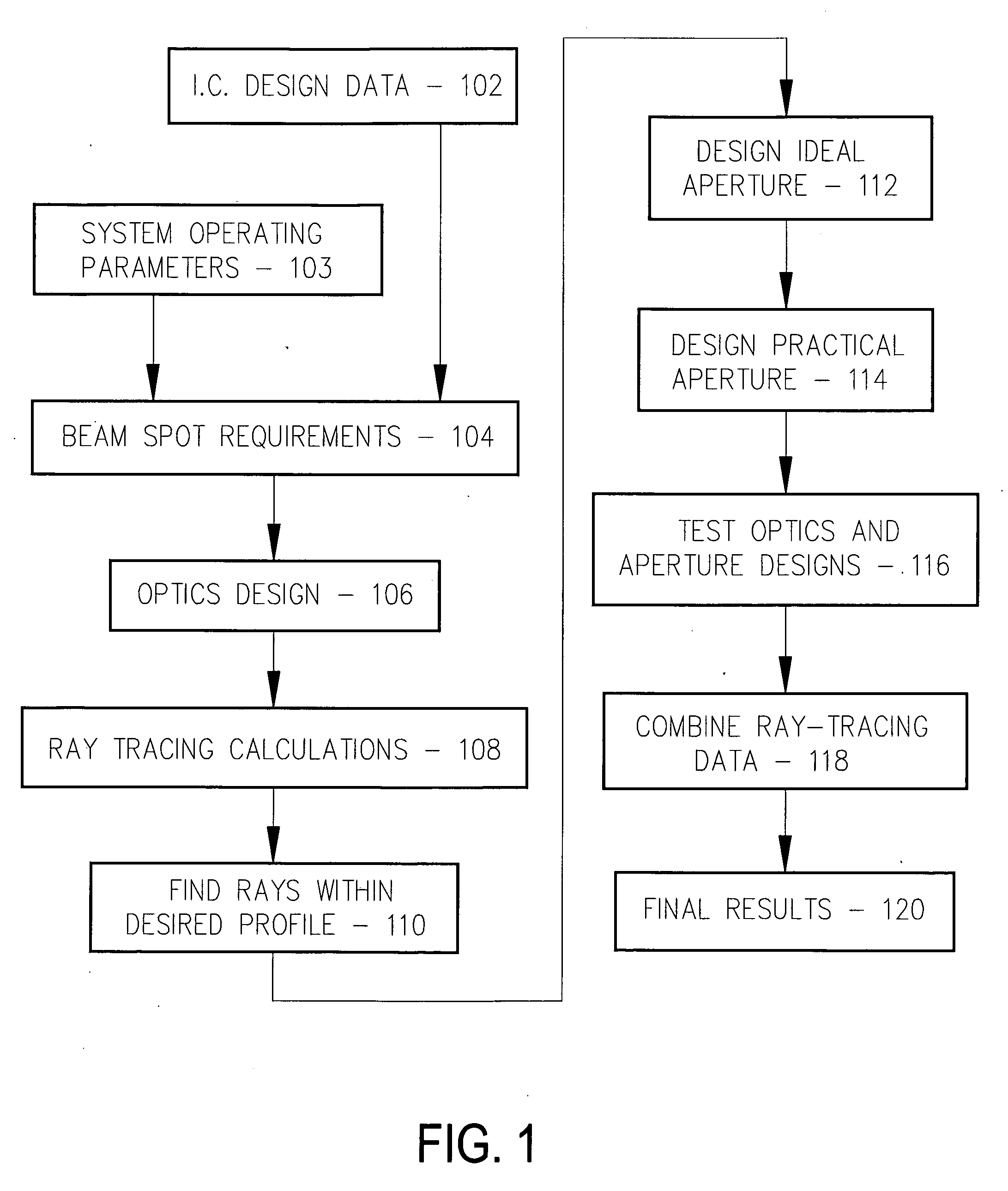

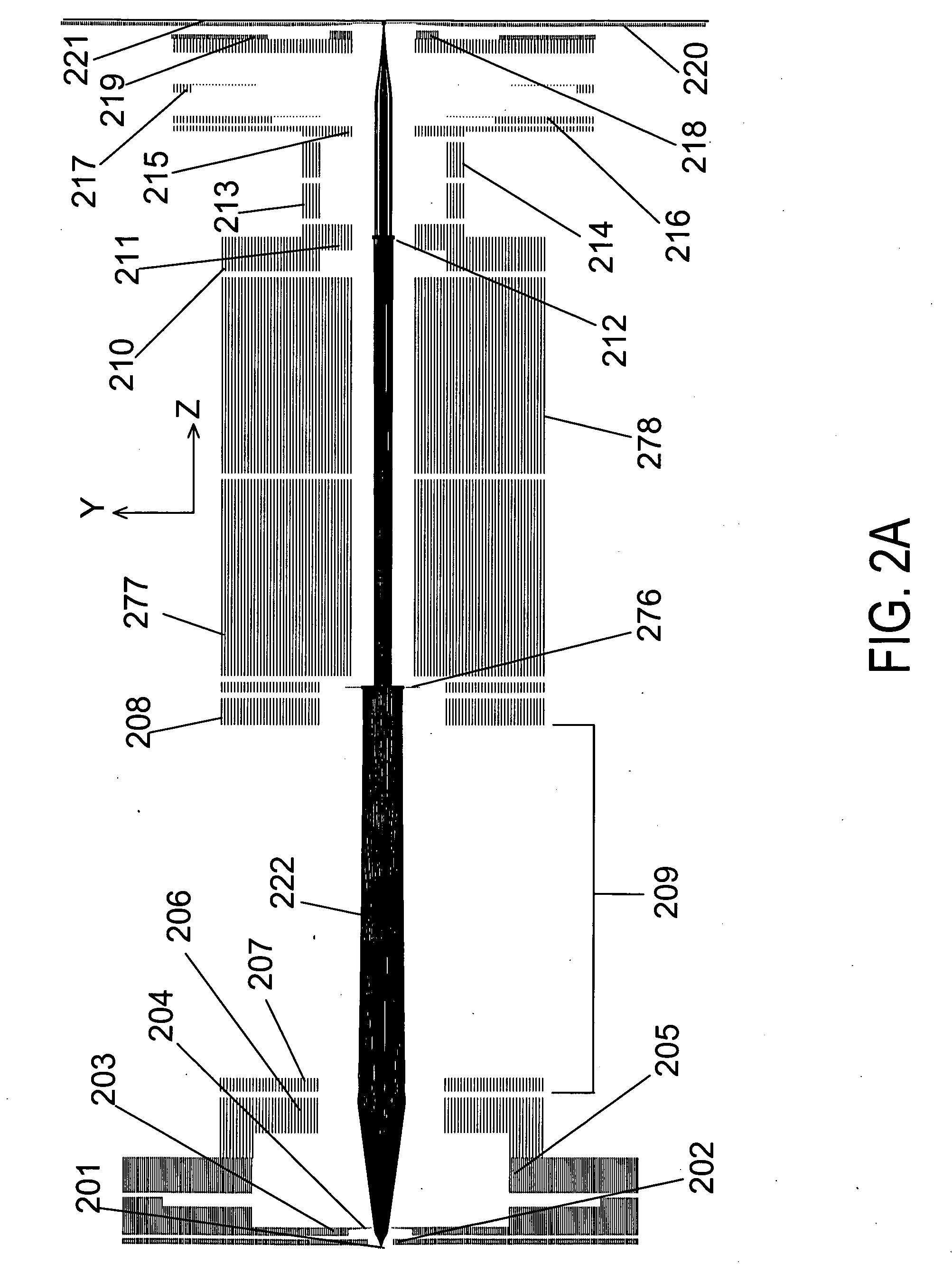

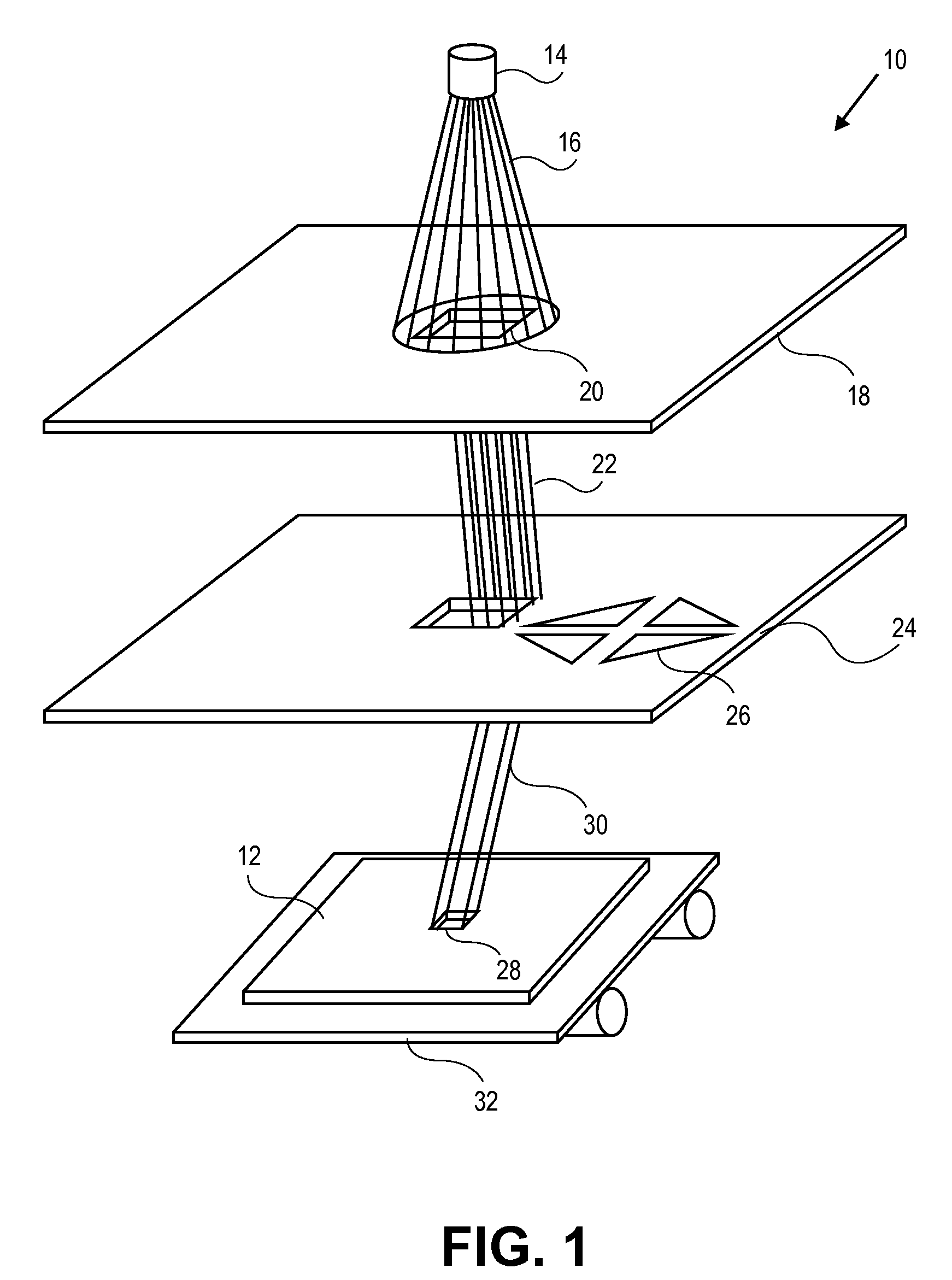

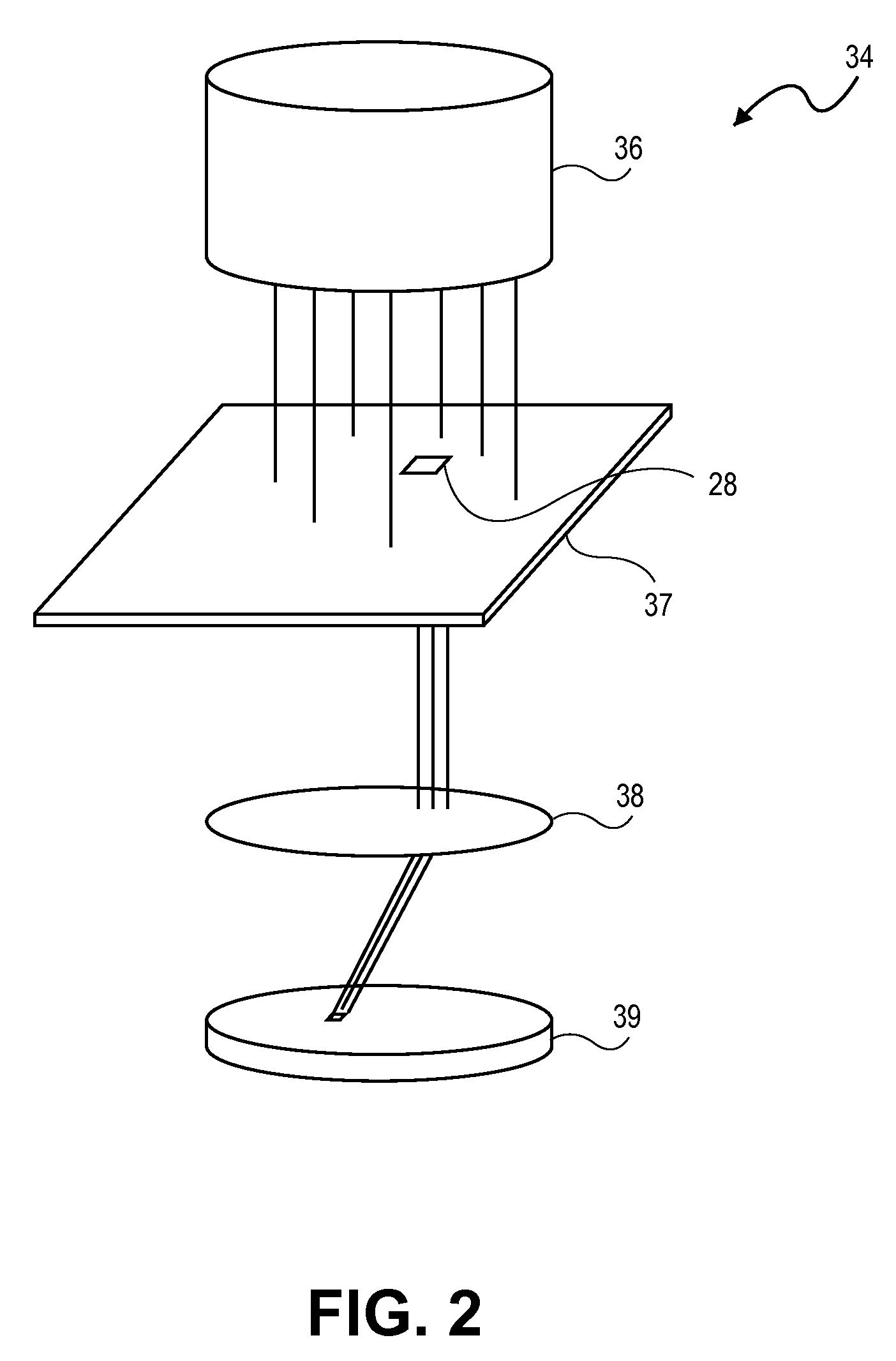

Optics for generation of high current density patterned charged particle beams

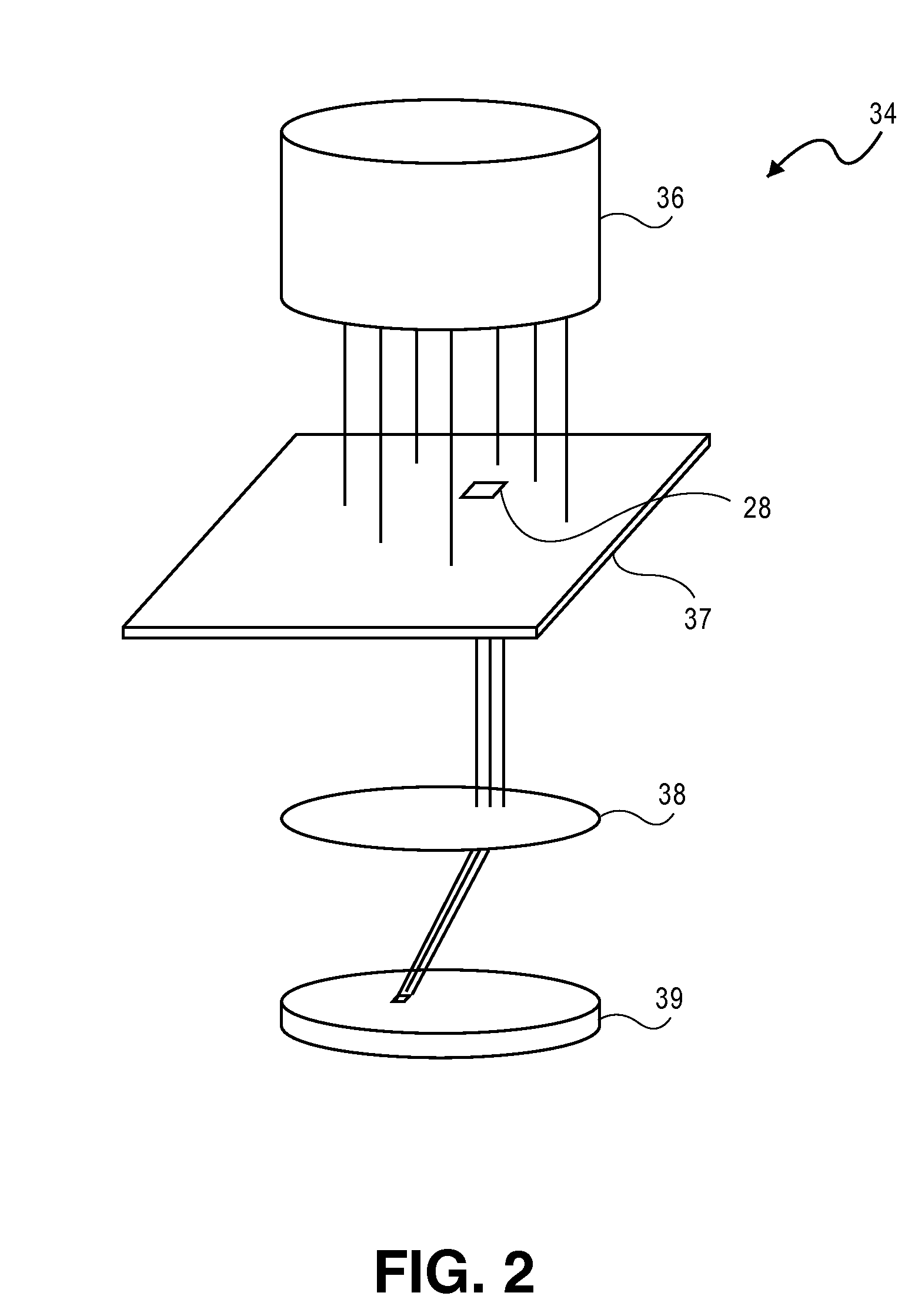

ActiveUS7462848B2Improve edge sharpnessResist exposure timeElectric discharge tubesNanoinformaticsHigh current densityShaped beam

A direct-write electron beam lithography system employing a patterned beam-defining aperture to enable the generation of high current-density shaped beams without the need for multiple beam-shaping apertures, lenses and deflectors is disclosed. Beam blanking is accomplished without the need for an intermediate crossover between the electron source and the wafer being patterned by means of a double-deflection blanker, which also facilitates proximity effect correction. A simple type of “moving lens” is utilized to eliminate off-axis aberrations in the shaped beam. A method for designing the patterned beam-defining aperture is also disclosed.

Owner:MULTIBEAM CORP +1

Method and System for Forming High Accuracy Patterns Using Charged Particle Beam Lithography

ActiveUS20120096412A1Increase roughnessImprove variationPhotomechanical apparatusComputer aided designCamera lensMask data preparation

A method and system for fracturing or mask data preparation for charged particle beam lithography are disclosed in which accuracy and / or edge slope of a pattern formed on a surface by a set of charged particle beam shots is enhanced by use of partially-overlapping shots. In some embodiments, dosages of the shots may vary with respect to each other before proximity effect correction. Particle beam simulation may be used to calculate the pattern and the edge slope. Enhanced edge slope can improve critical dimension (CD) variation and line-edge roughness (LER) of the pattern produced on the surface.

Owner:D2S

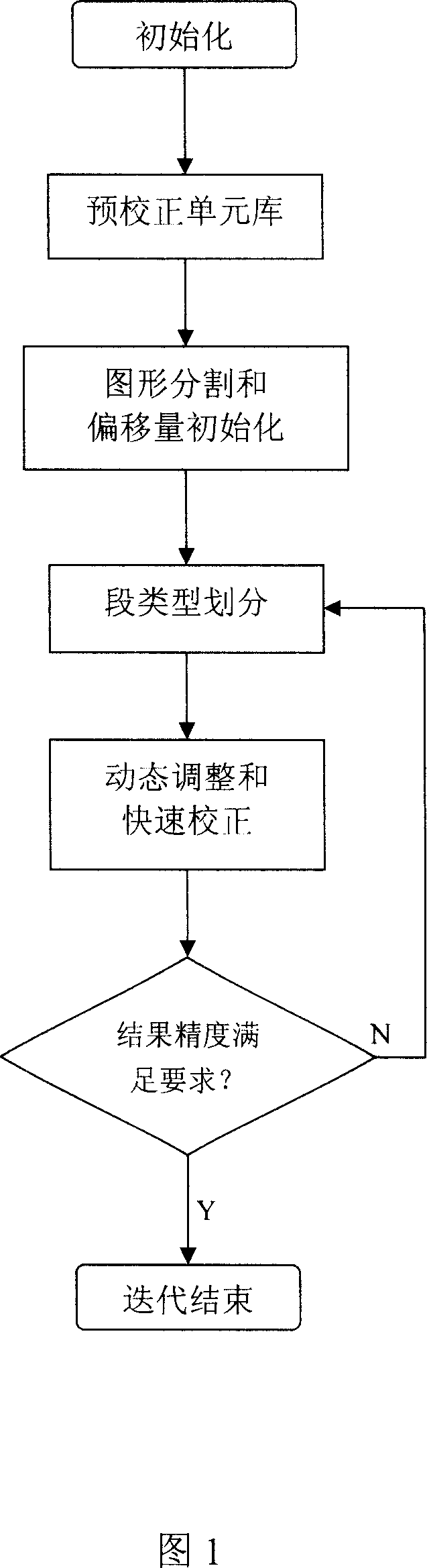

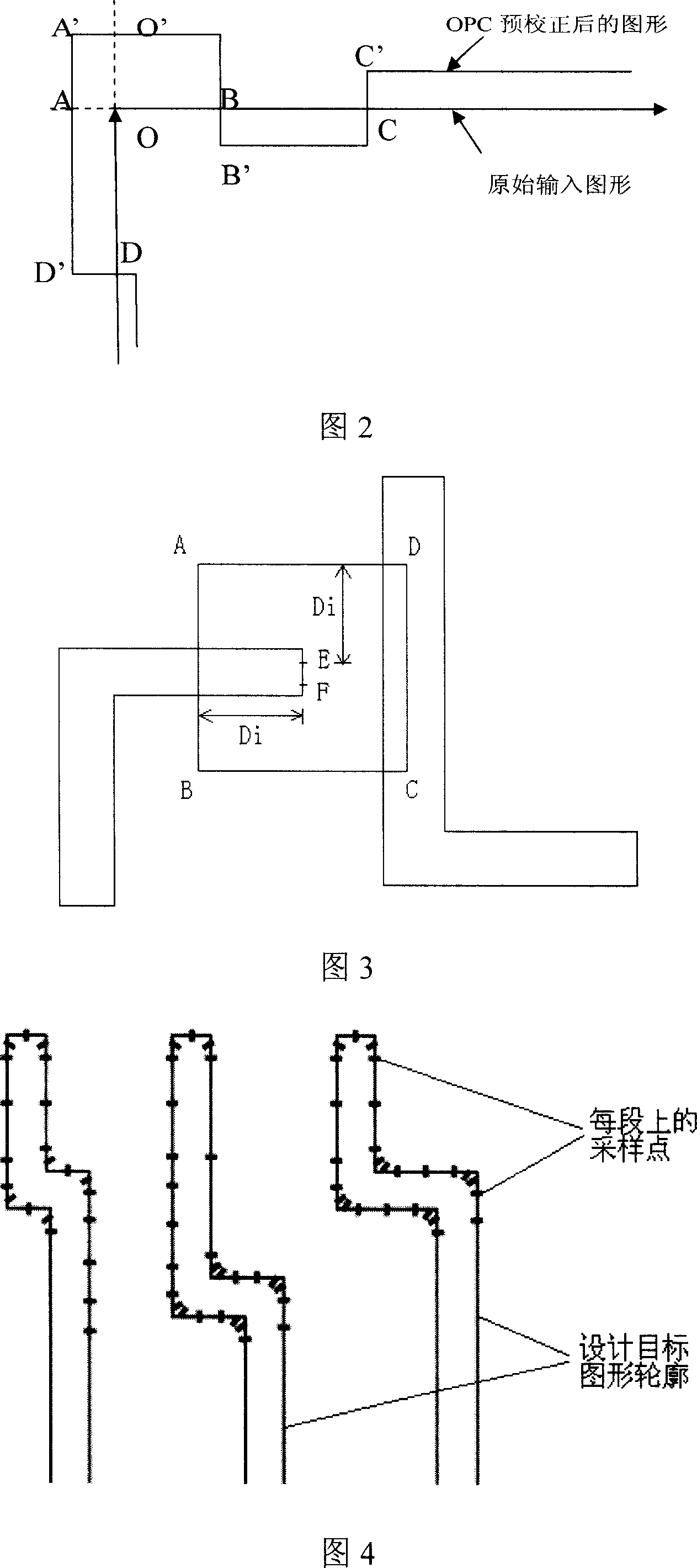

Method for correcting layering optical proximity effect

InactiveCN101013271AHigh speedImprove predictabilitySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusGraphicsDesign engineer

The invention discloses a hierarchical optical proximity effect correction method, including the preparation of the pre-correction module library, the initialization of the mask graphic offset and the step using dynamic adjustment algorithm for rapid computation, and it provides a method to make full use of the territory hierarchical structure in the optical proximity effect correction, and under the deep submicron conditions, the high precision mask process is considered as high costs for too big calculation quantities, and the computational complexity can be greatly reduced under the help of the new algorithm, and meanwhile, the new approach provides the module library with pre-correction results to IC design process, making the design engineer more flexible and effective to check the design. The method of the invention can be used for aided high-precision IC mask board, to increase the results predictability in IC design process, and OPC correction computational speed, lower costs, and increase IC production yield and reduce production cycle.

Owner:ZHEJIANG UNIV

Optics for generation of high current density patterned charged particle beams

ActiveUS20060145097A1Minimize beam writing doseMaximize process latitudeElectric discharge tubesNanoinformaticsHigh current densityShaped beam

A direct-write electron beam lithography system employing a patterned beam-defining aperture to enable the generation of high current-density shaped beams without the need for multiple beam-shaping apertures, lenses and deflectors is disclosed. Beam blanking is accomplished without the need for an intermediate crossover between the electron source and the wafer being patterned by means of a double-deflection blanker, which also facilitates proximity effect correction. A simple type of “moving lens” is utilized to eliminate off-axis aberrations in the shaped beam. A method for designing the patterned beam-defining aperture is also disclosed.

Owner:MULTIBEAM CORP +1

Method for design and manufacture of a reticle using variable shaped beam lithography

ActiveUS20100055581A1Minimize shot countElectric discharge tubesRadiation applicationsMask data preparationCamera lens

A method is disclosed for using non-overlapping variable shaped beam (VSB) shots in the design and manufacture of a reticle, where the union of the plurality of shots deviates from the desired pattern. Methods are described for fracturing or mask data preparation or proximity effect correction of a desired pattern to be formed on a reticle; for forming a pattern on a reticle using charged particle beam lithography; and for optical proximity correction (OPC) of a desired pattern. Dosages of the shots may be allowed to vary with respect to each other. The plurality of shots may be determined such that a pattern on the surface calculated from the plurality of shots is within a predetermined tolerance of the desired pattern. In some embodiments, an optimization technique may be used to minimize shot count.

Owner:D2S

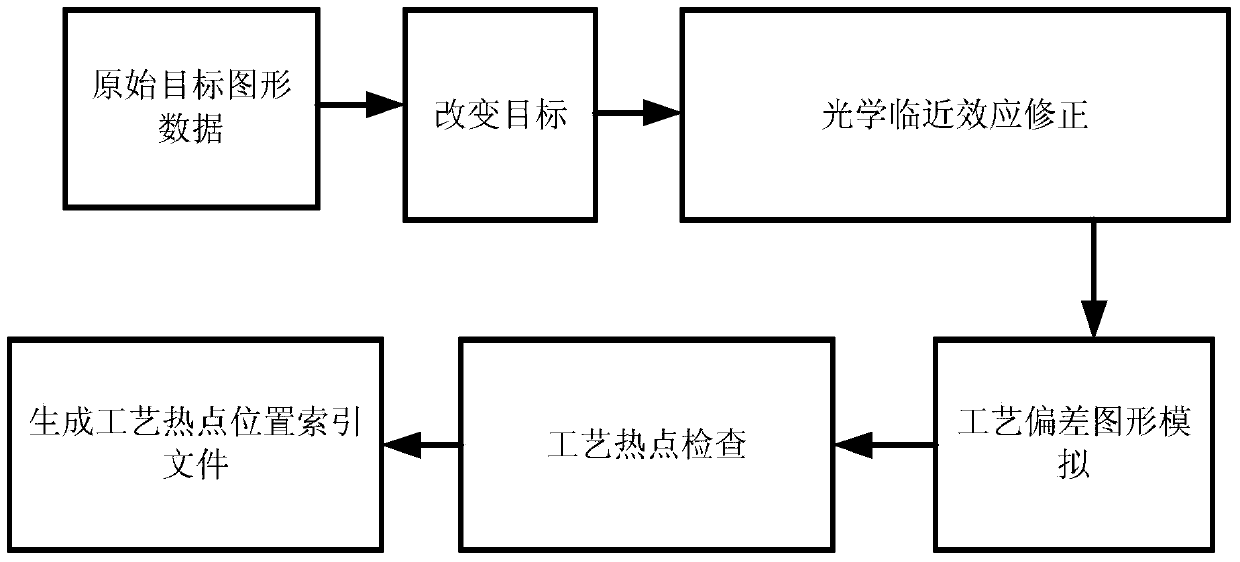

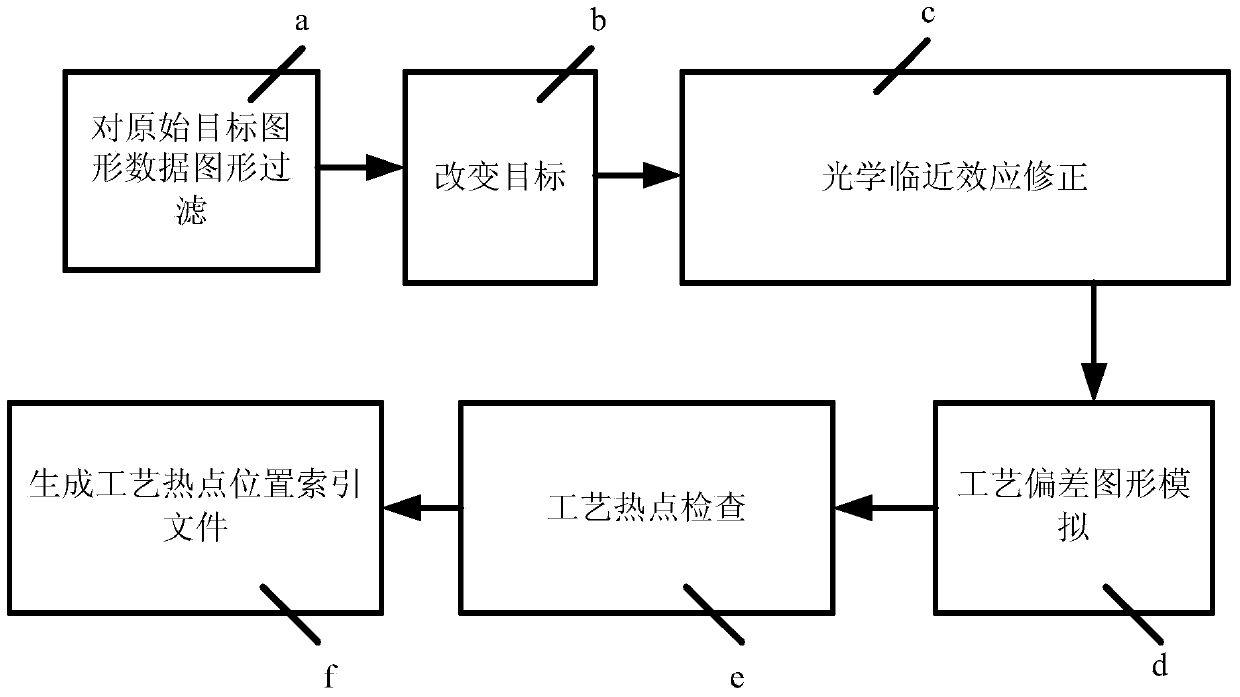

Layout design photoetching technology friendliness detection method based on regular figure filtering

ActiveCN103744267AAdded filtering stepsReduce use costPhotomechanical exposure apparatusMicrolithography exposure apparatusProcess deviationsAlgorithm

The invention provides a layout design photoetching technology friendliness detection method based on regular figure filtering. According to the layout design photoetching technology friendliness detection method based on regular figure filtering, by adding a step of filtering original object figure data before steps of performing optical proximity effect correction and technological error figure simulation, the time consumption of layout design photoetching technology friendliness detection is shortened, the usage cost of software and hardware is reduced, and also the extremely good matching between a detection result and a method of prior art can be realized, and thus the rapid accurate search for technological hot-spot areas in layout design is realized.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

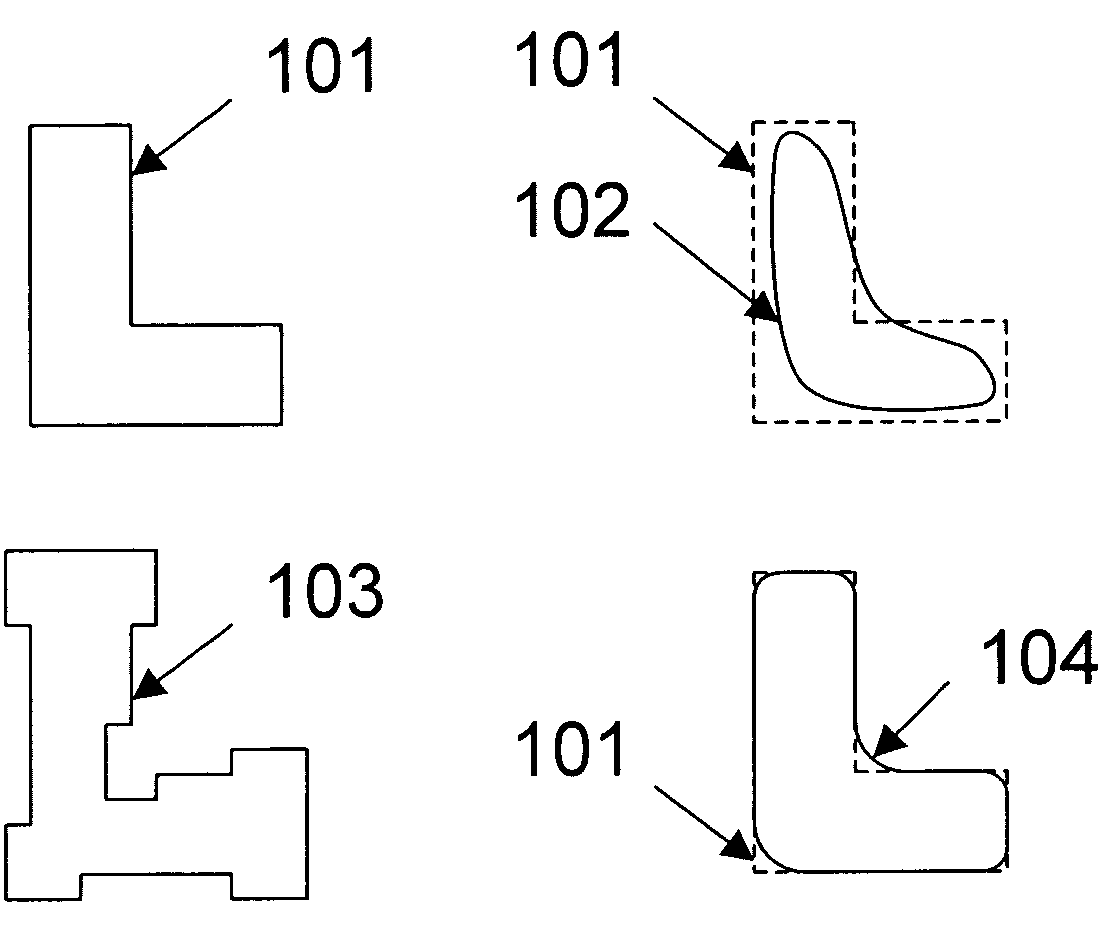

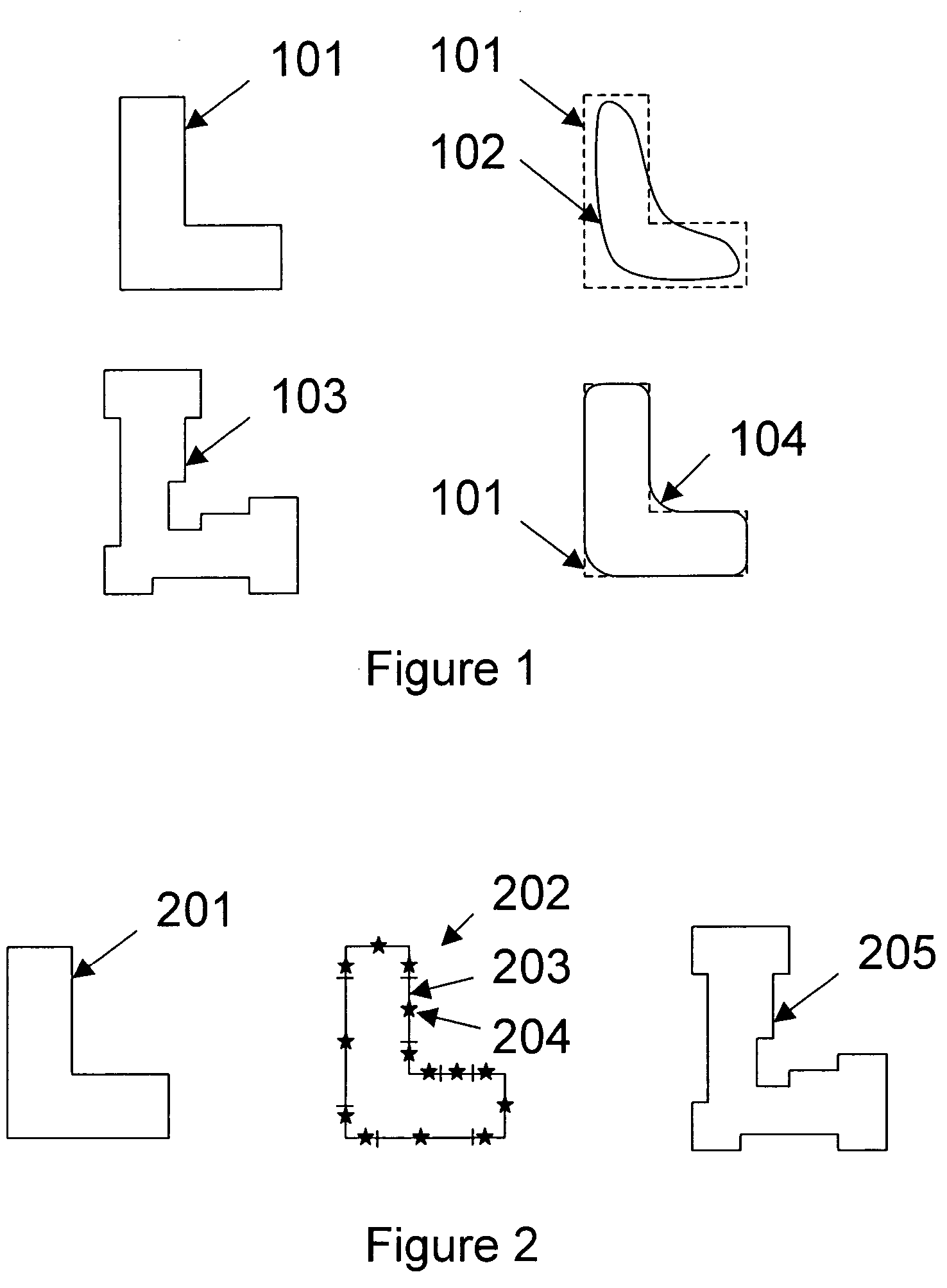

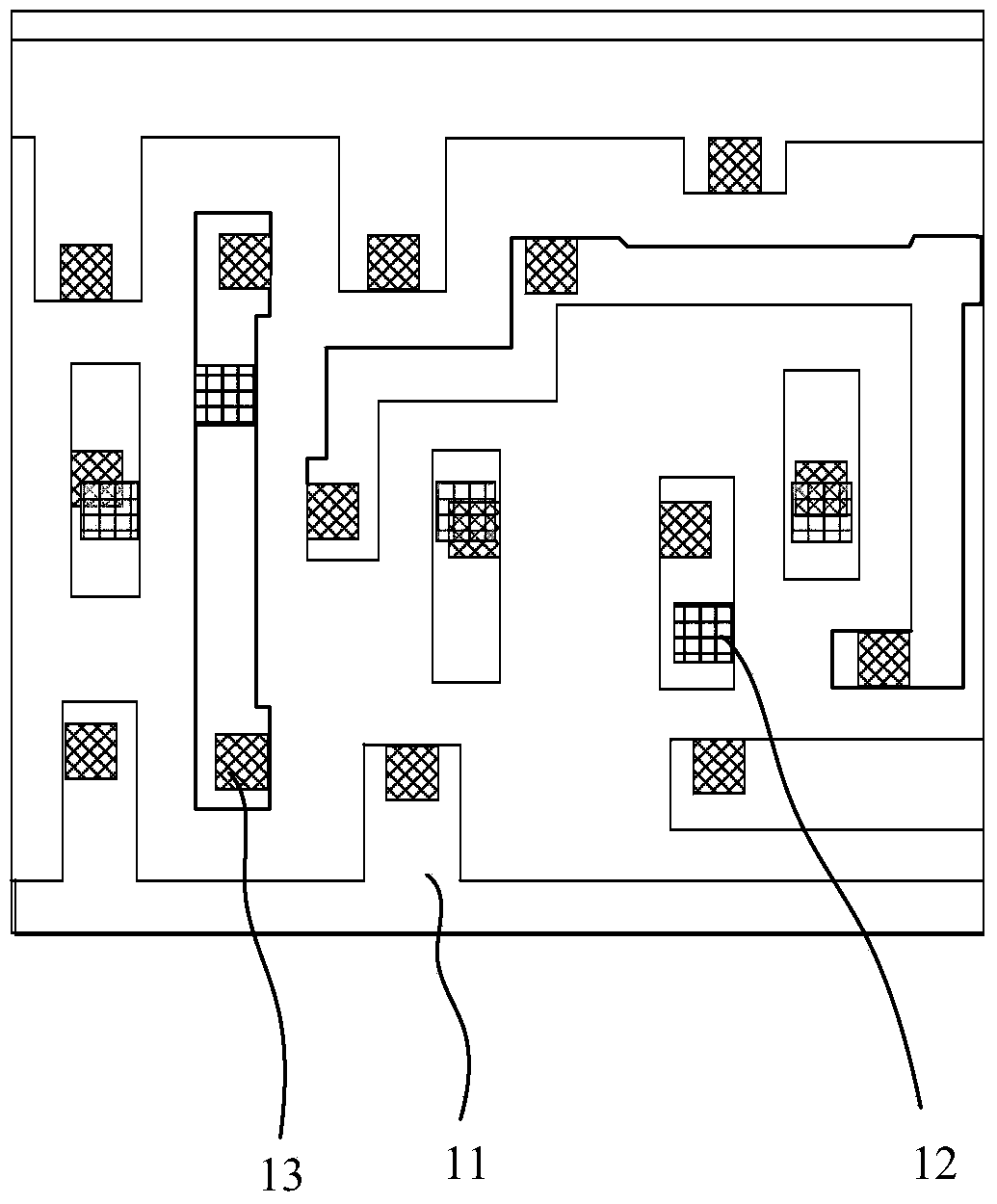

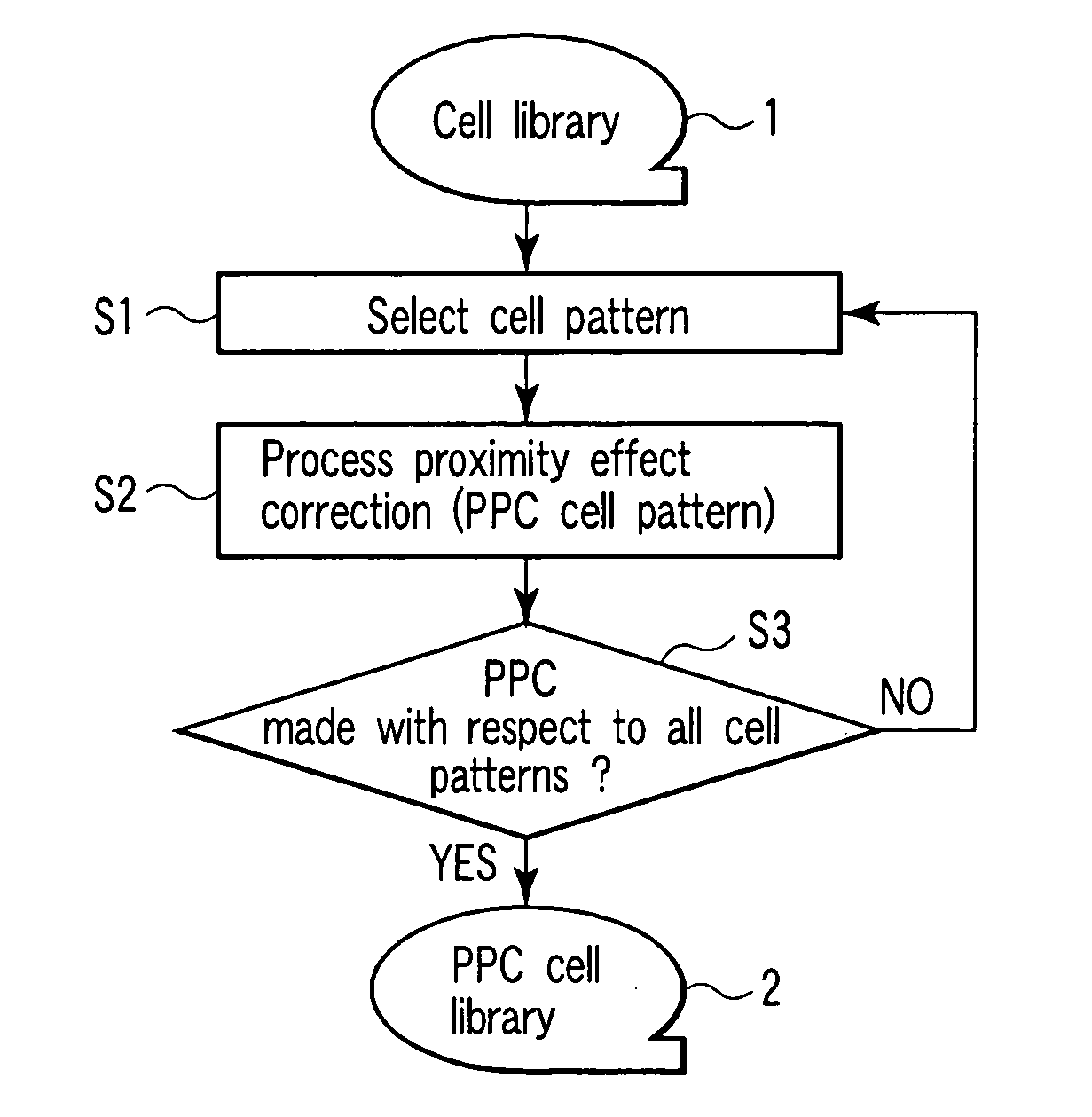

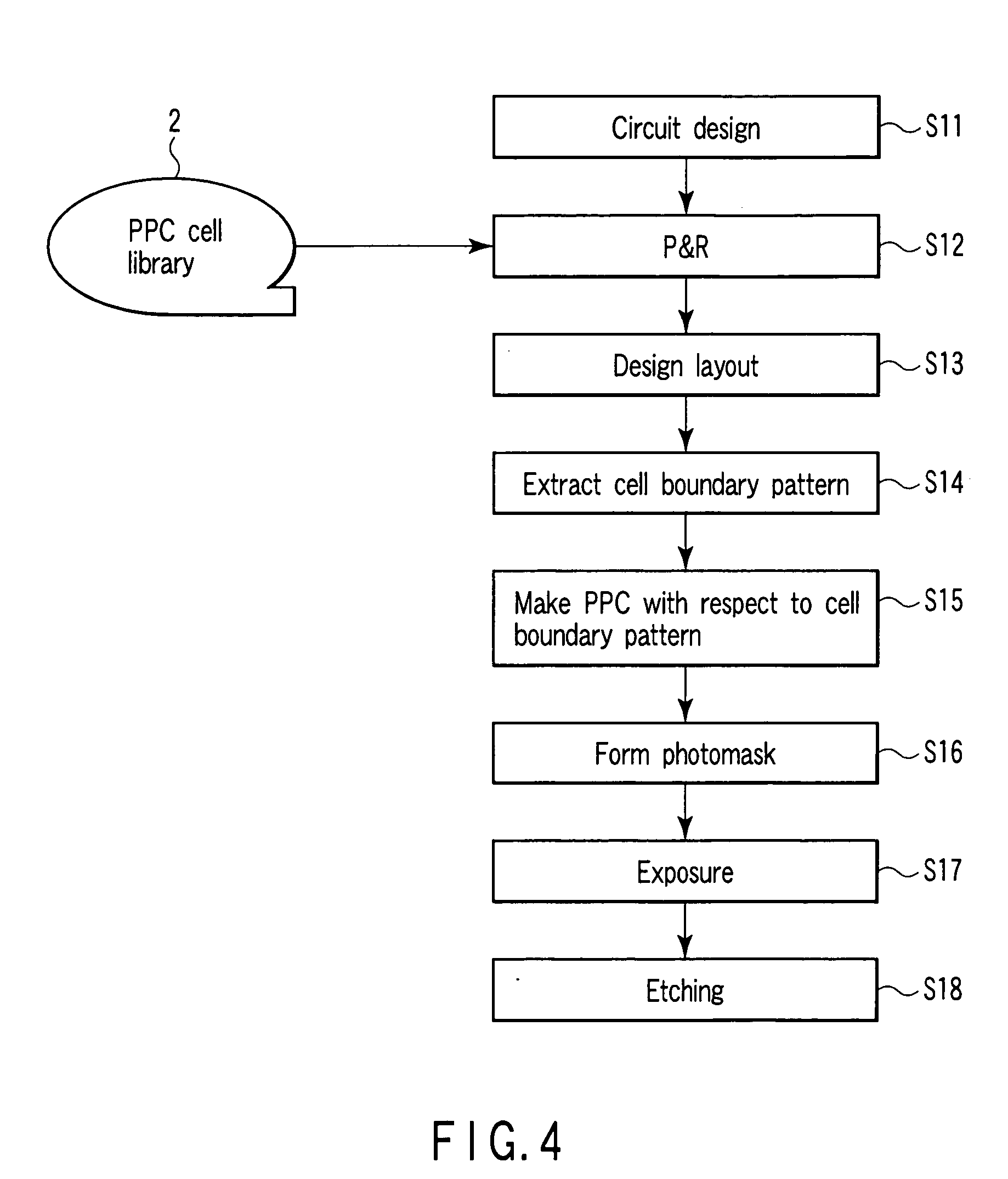

Method and system for forming a mask pattern, method of manufacturing a semiconductor device, system forming a mask pattern on data, cell library and method of forming a photomask

A method of forming a mask pattern comprises the following steps. A second cell library is prepared by making process proximity effect correction with respect to cell patterns stored in a first cell library. The second cell library stores corrected cell patterns. A first corrected cell pattern and a second corrected cell pattern of the corrected cell patterns are placed so that an edge of the first corrected cell pattern and an edge of the second corrected cell pattern contact or come close to or overlap each other. A boundary pattern at the boundary neighborhood between the first corrected cell pattern and the second corrected cell pattern is extracted. Process proximity effect correction is made with respect to the boundary pattern.

Owner:KK TOSHIBA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com