Patents

Literature

4568results about How to "Increase roughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

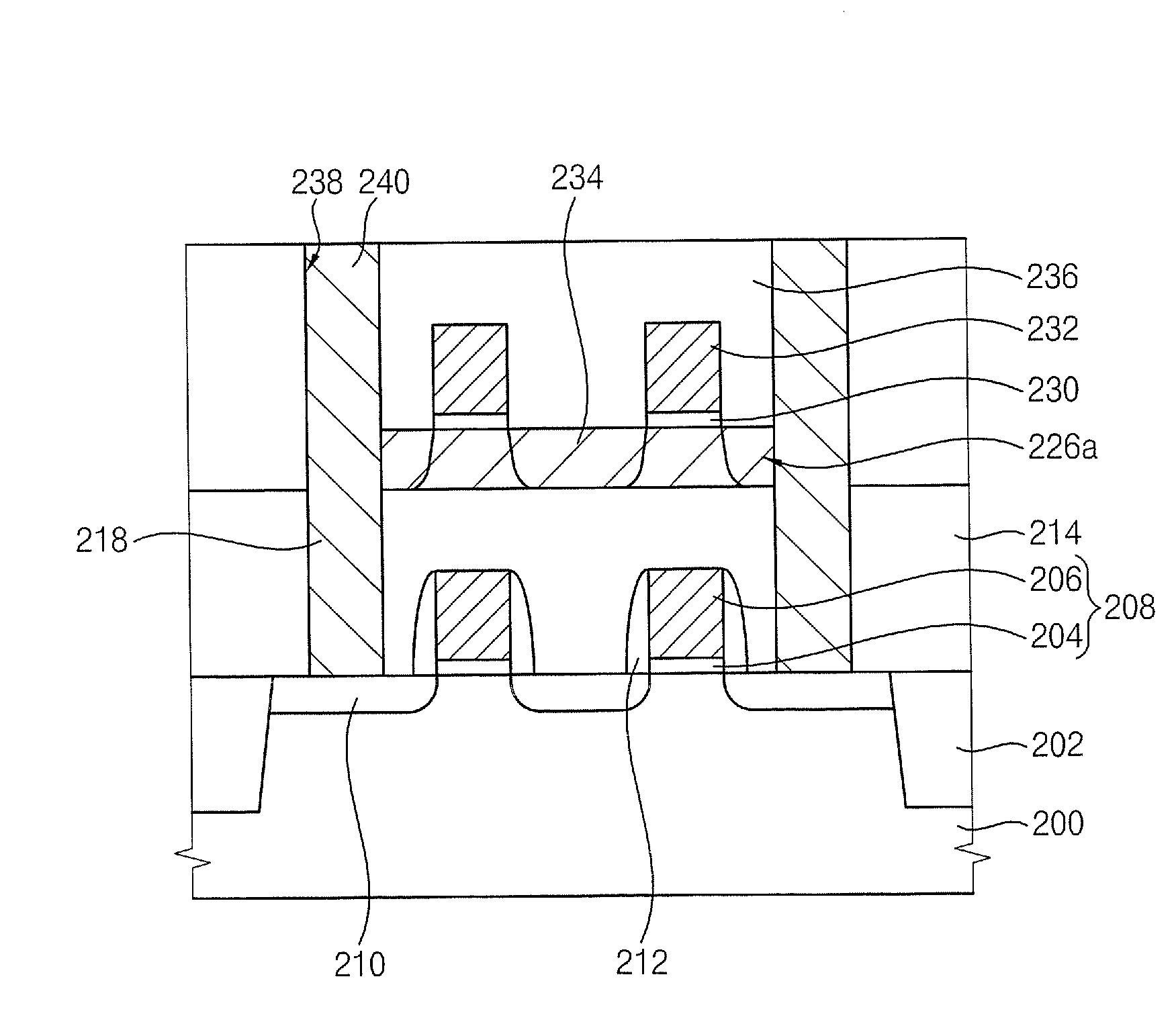

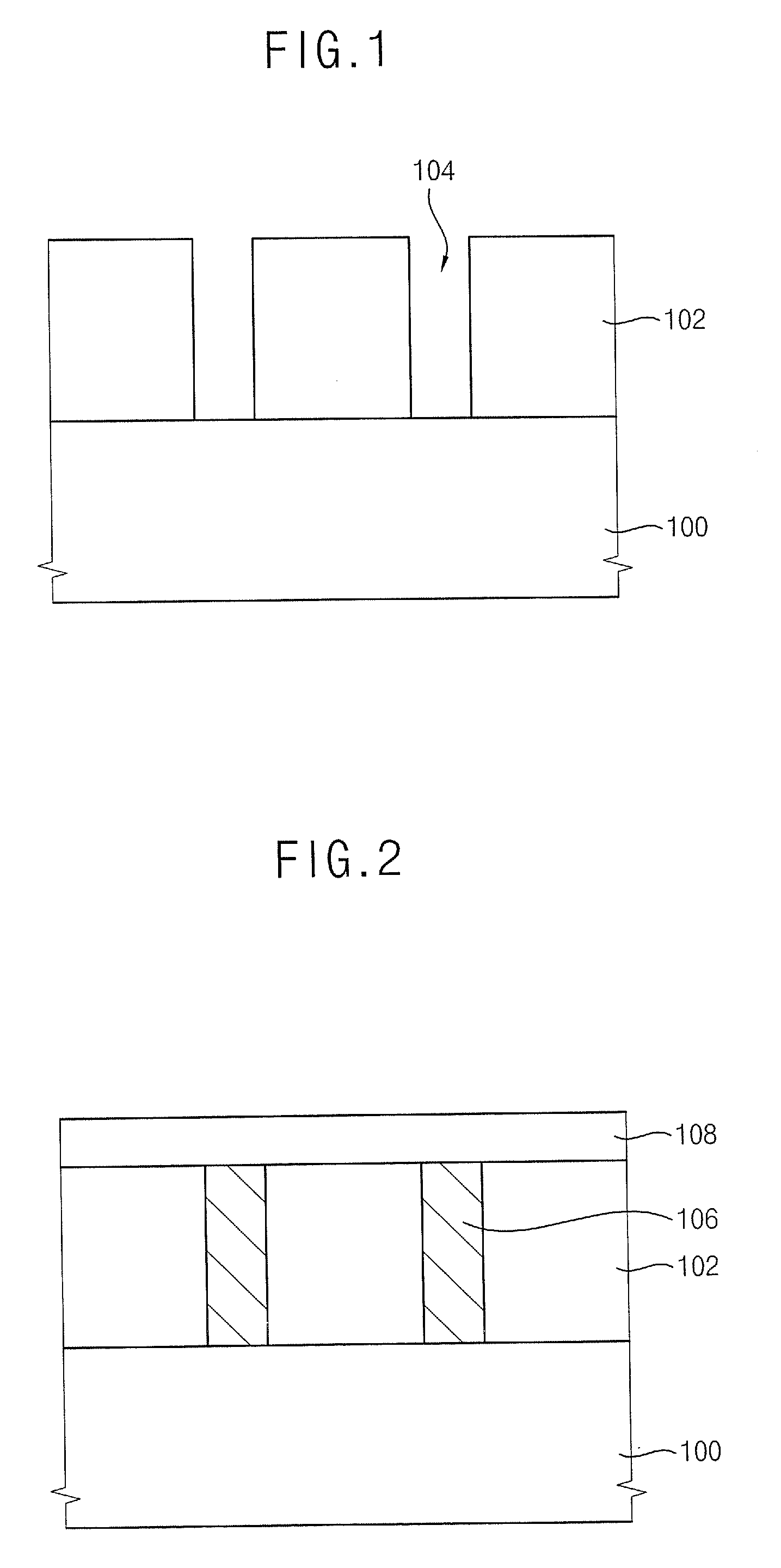

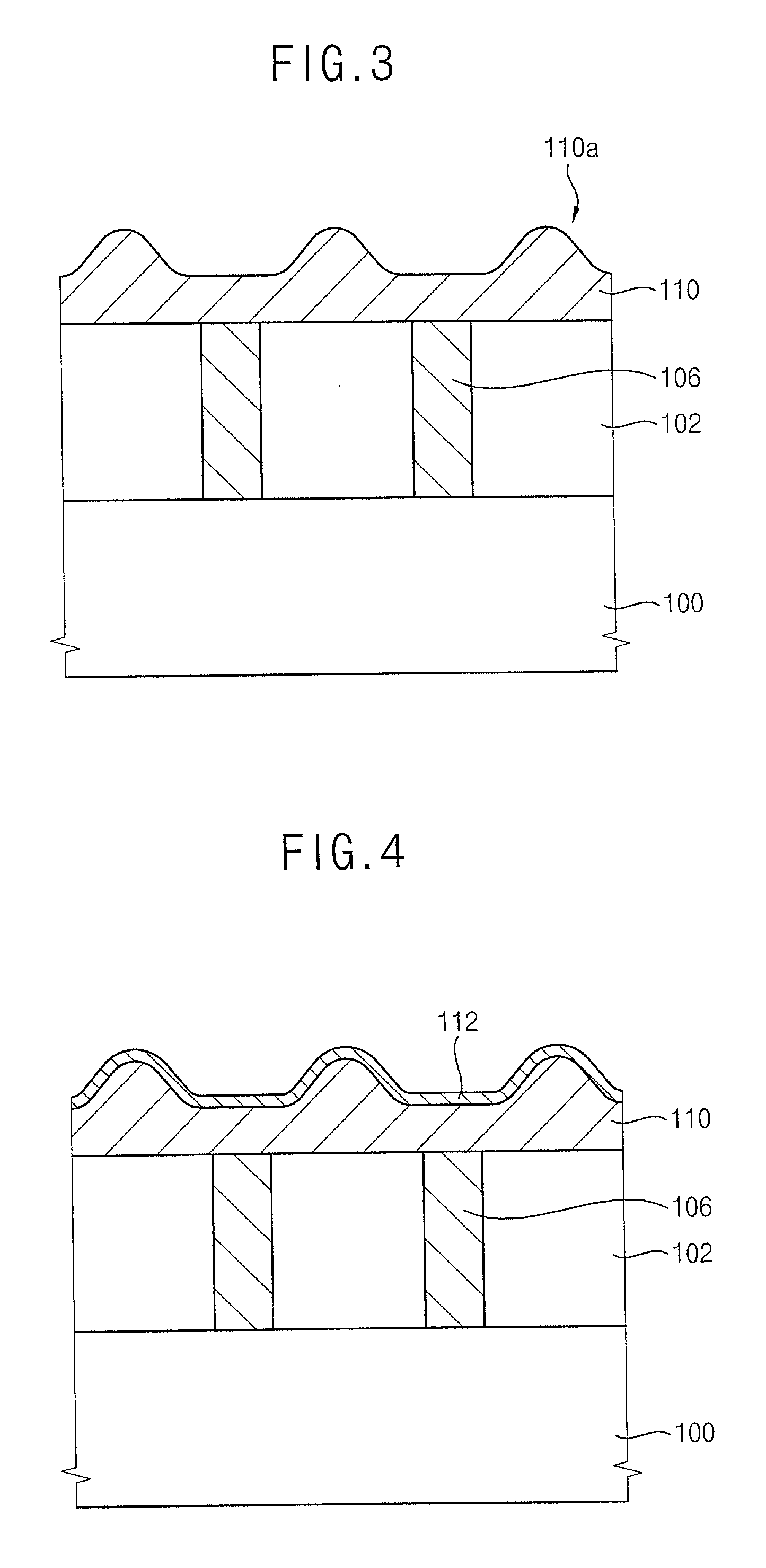

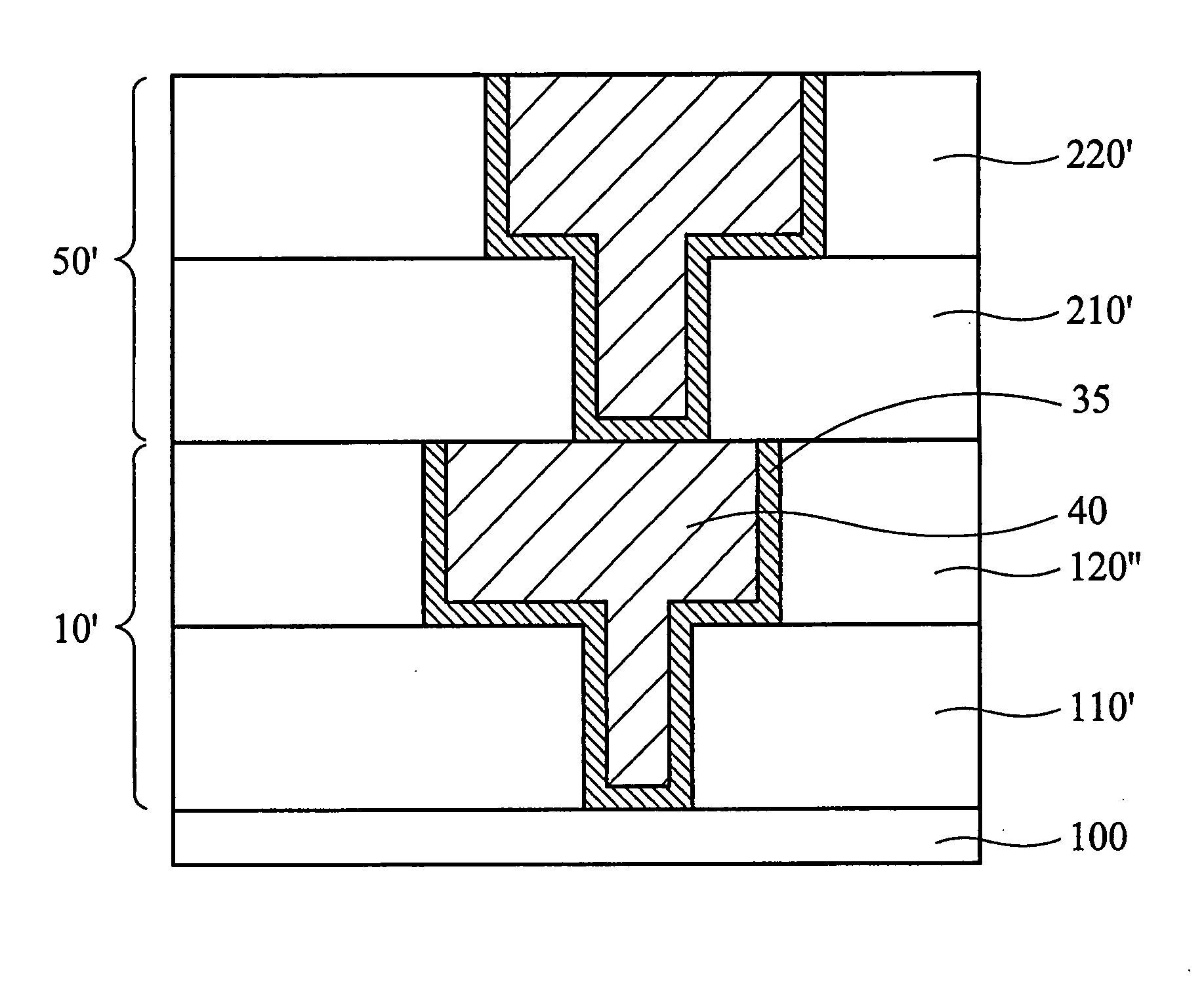

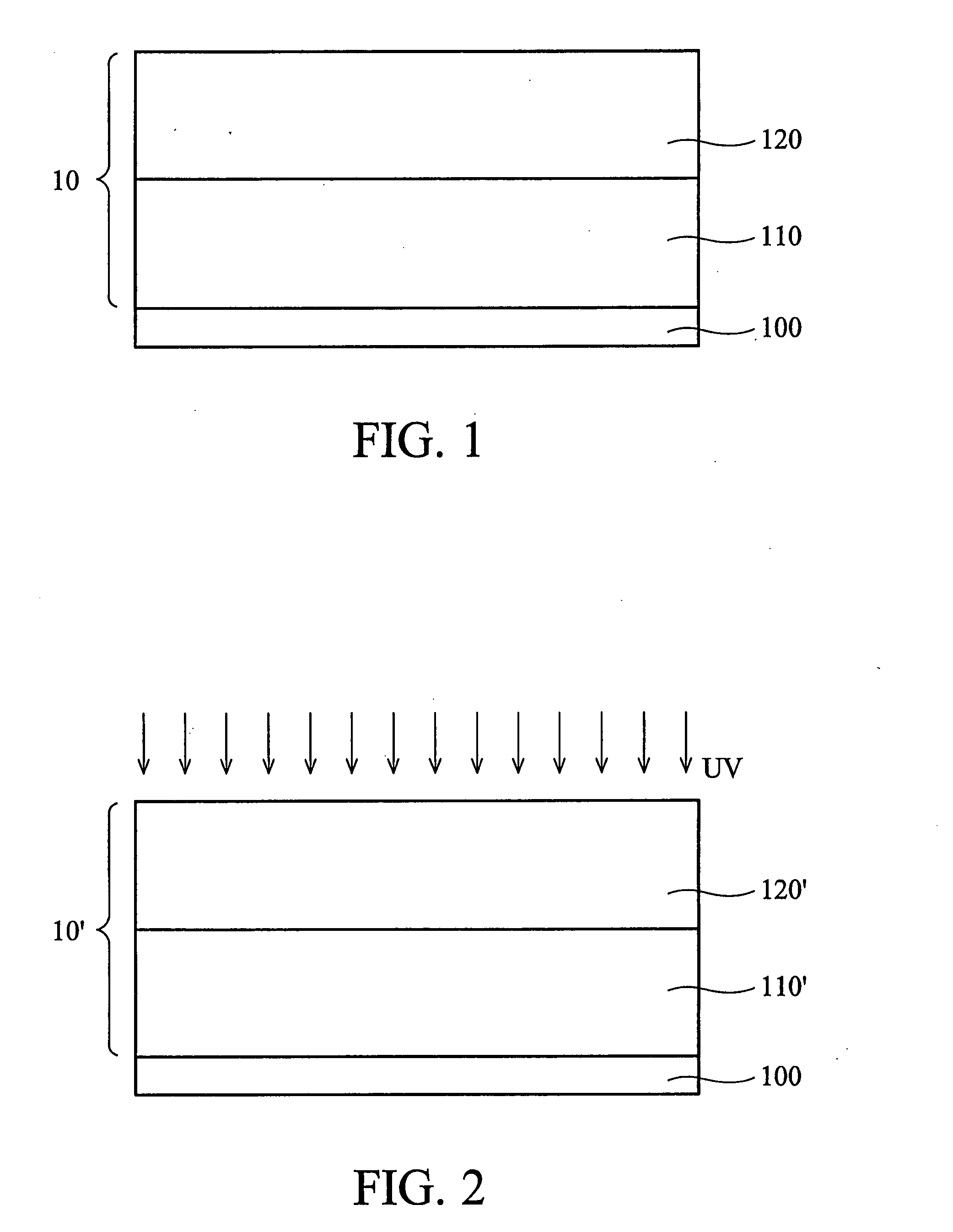

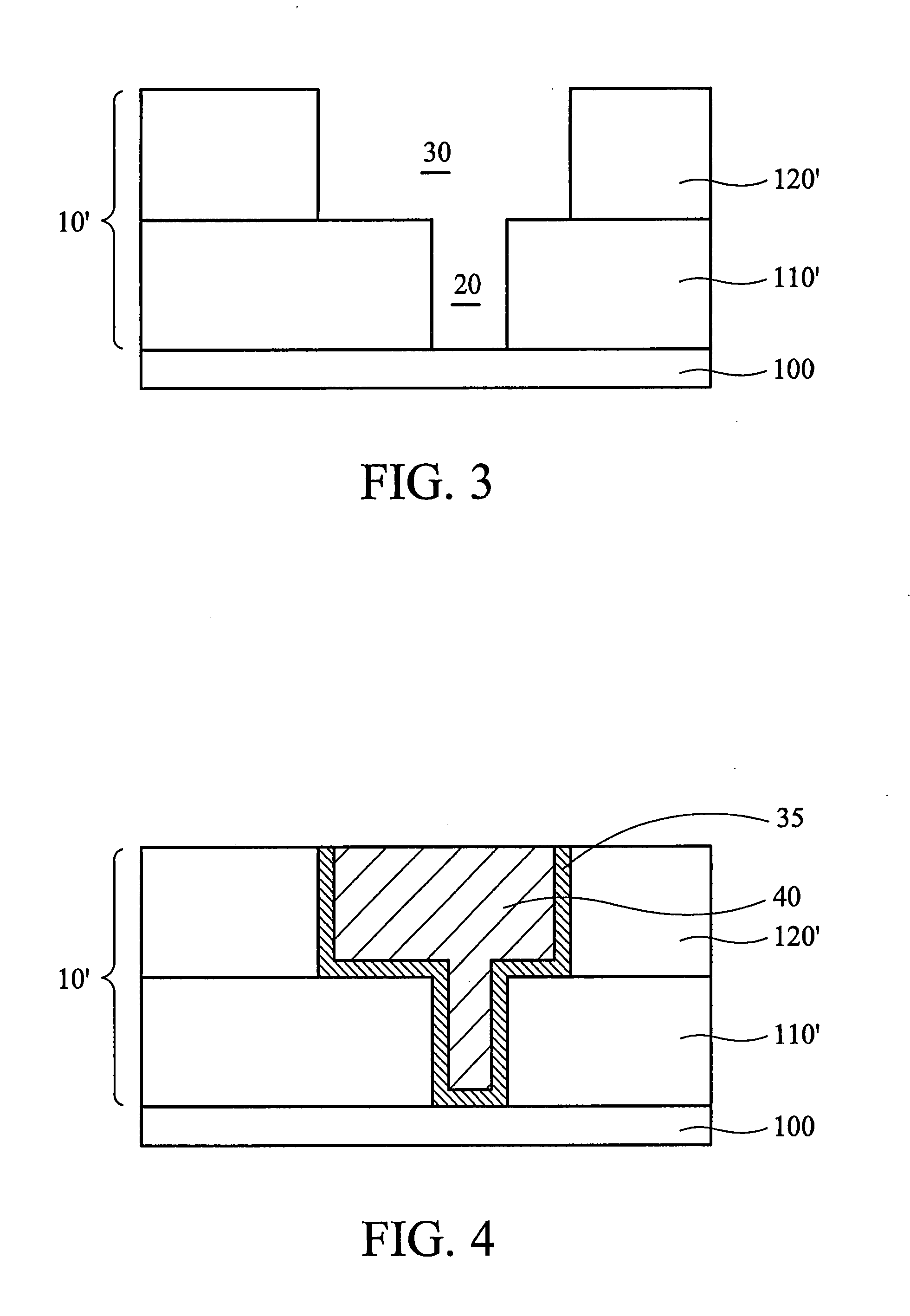

Methods of fabricating semiconductor devices including channel layers having improved defect density and surface roughness characteristics

ActiveUS20080160726A1Improved surface roughness characteristicUniform thicknessSemiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingSurface roughnessSingle crystal

A method of fabricating a semiconductor device including a channel layer includes forming a single crystalline semiconductor layer on a semiconductor substrate. The single crystalline semiconductor layer includes a protrusion extending from a surface thereof. A first polishing process is performed on the single crystalline semiconductor layer to remove a portion of the protrusion such that the single crystalline semiconductor layer includes a remaining portion of the protrusion. A second polishing process different from the first polishing process is performed to remove the remaining portion of the protrusion and define a substantially planar single crystalline semiconductor layer having a substantially uniform thickness. A sacrificial layer may be formed on the single crystalline semiconductor layer and used as a polish stop for the first polishing process to define a sacrificial layer pattern, which may be removed prior to the second polishing process. Related methods of fabricating stacked semiconductor memory devices are also discussed.

Owner:SAMSUNG ELECTRONICS CO LTD

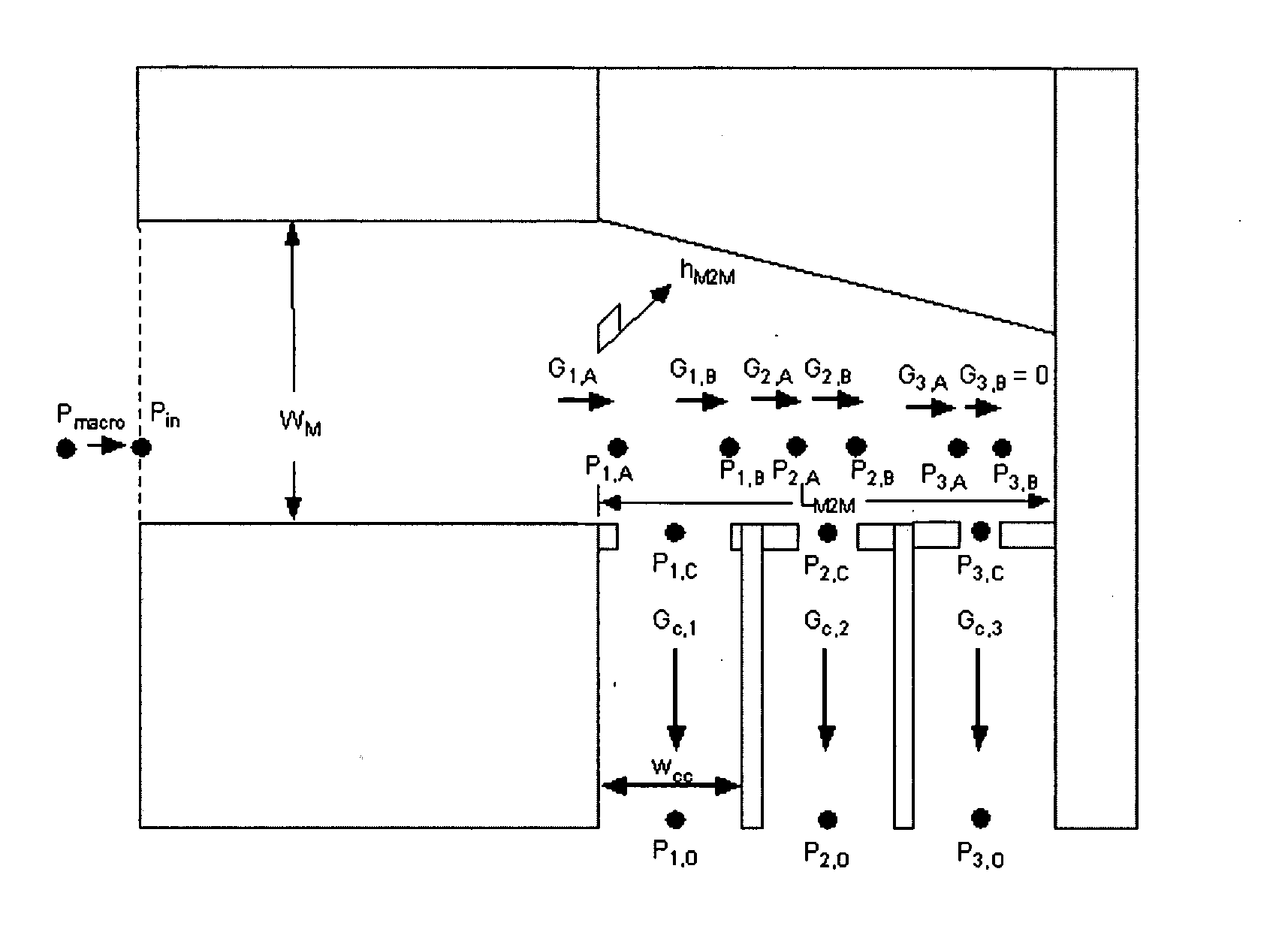

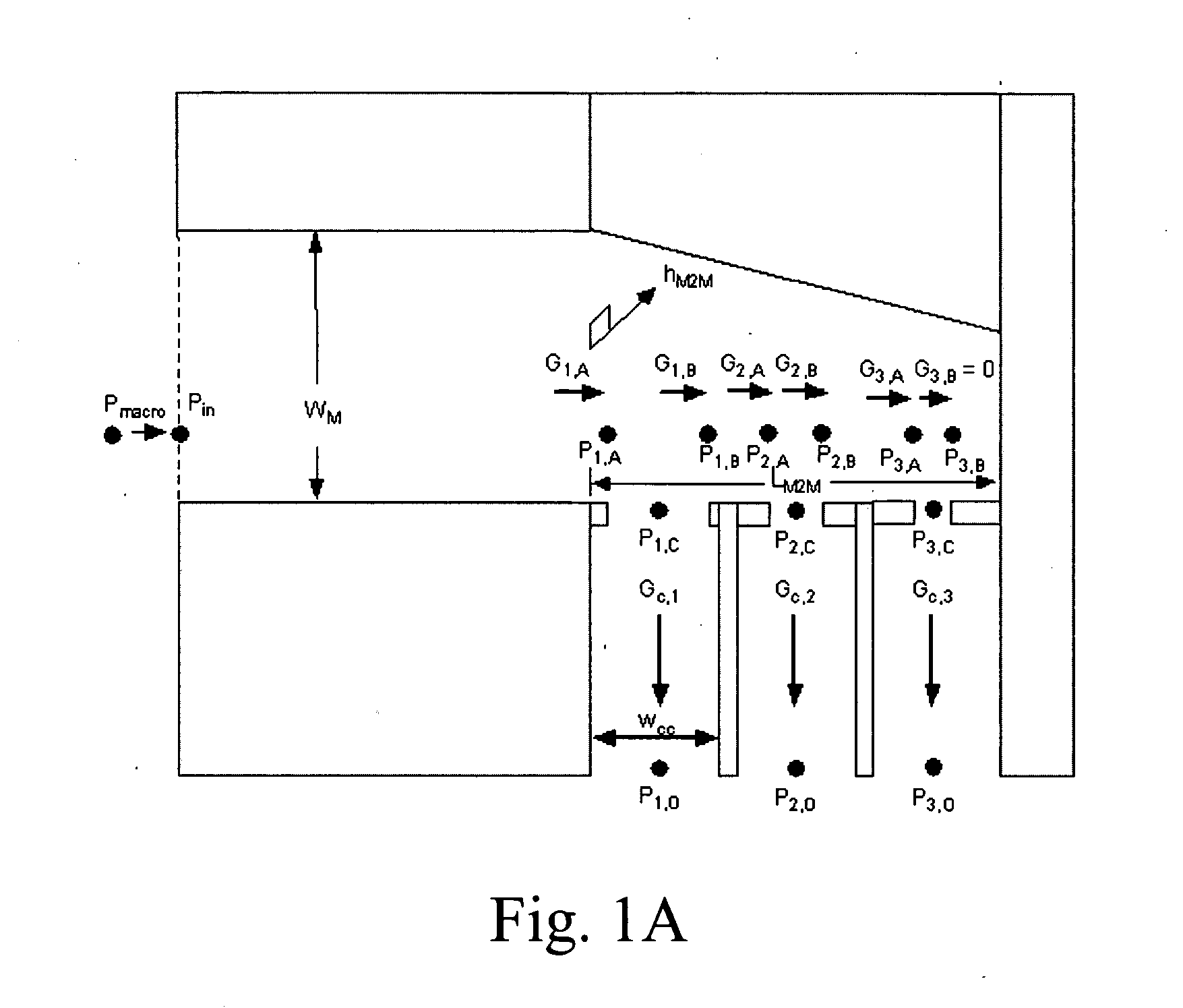

Manifold designs, and flow control in multichannel microchannel devices

InactiveUS20050087767A1Equally distributedLow costChemical/physical/physico-chemical microreactorsSemiconductor/solid-state device manufacturingEngineering

Owner:VELOCYS CORPORATION

Tunable dielectric compositions including low loss glass

InactiveUS6905989B2Lower sintering temperatureIncrease varietyFixed capacitor dielectricCeramic layered productsBreakdown strengthStrontium titanate

Tunable dielectric materials including an electronically tunable dielectric ceramic and a low loss glass additive are disclosed. The tunable dielectric may comprise a ferroelectric perskovite material such as barium strontium titanate. The glass additive may comprise boron, barium, calcium, lithium, manganese, silicon, zinc and / or aluminum-containing glasses having dielectric losses of less than 0.003 at 2 GHz. The materials may further include other additives such as non-tunable metal oxides and silicates. The low loss glass additive enables the materials to be sintered at relatively low temperatures while providing improved properties such as low microwave losses and high breakdown strengths.

Owner:NXP USA INC

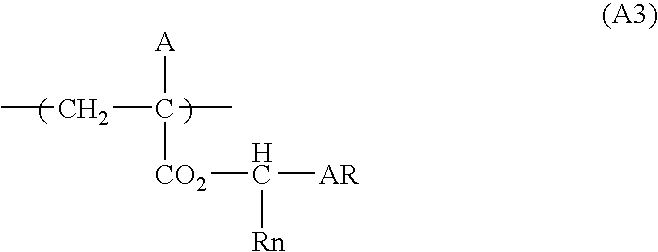

Resist composition and pattern forming method using the same

ActiveUS20070224539A1High resolutionImprove performancePhotosensitive materialsPhotomechanical apparatusResistNitrogen

A resist composition comprising at least one kind of a nitrogen-containing compound selected from the group consisting of an amine compound having a phenoxy group, an ammonium salt compound having a phenoxy group, an amine compound having a sulfonic acid ester group and an ammonium salt compound having a sulfonic acid ester group; and a pattern forming method using the composition.

Owner:FUJIFILM CORP

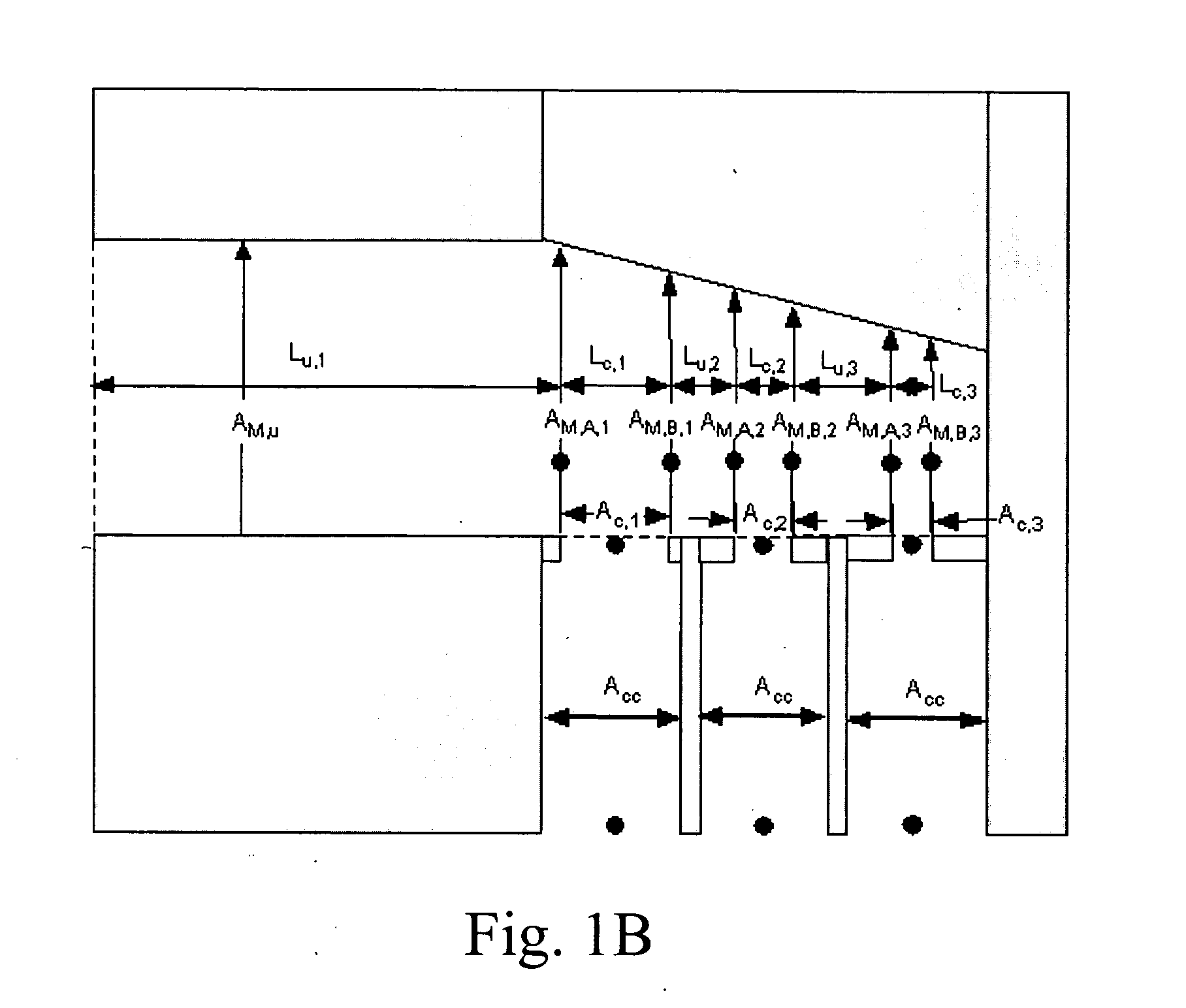

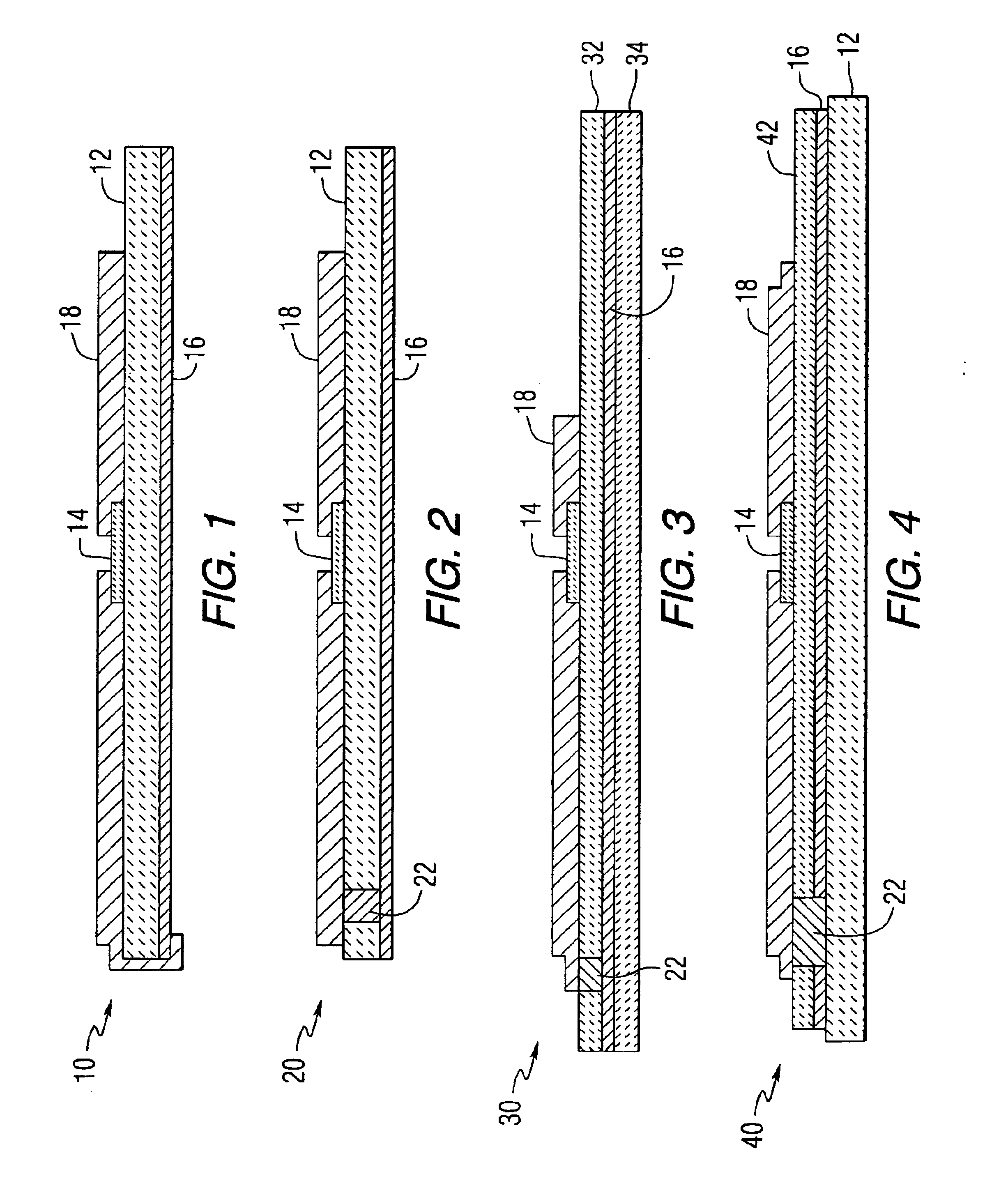

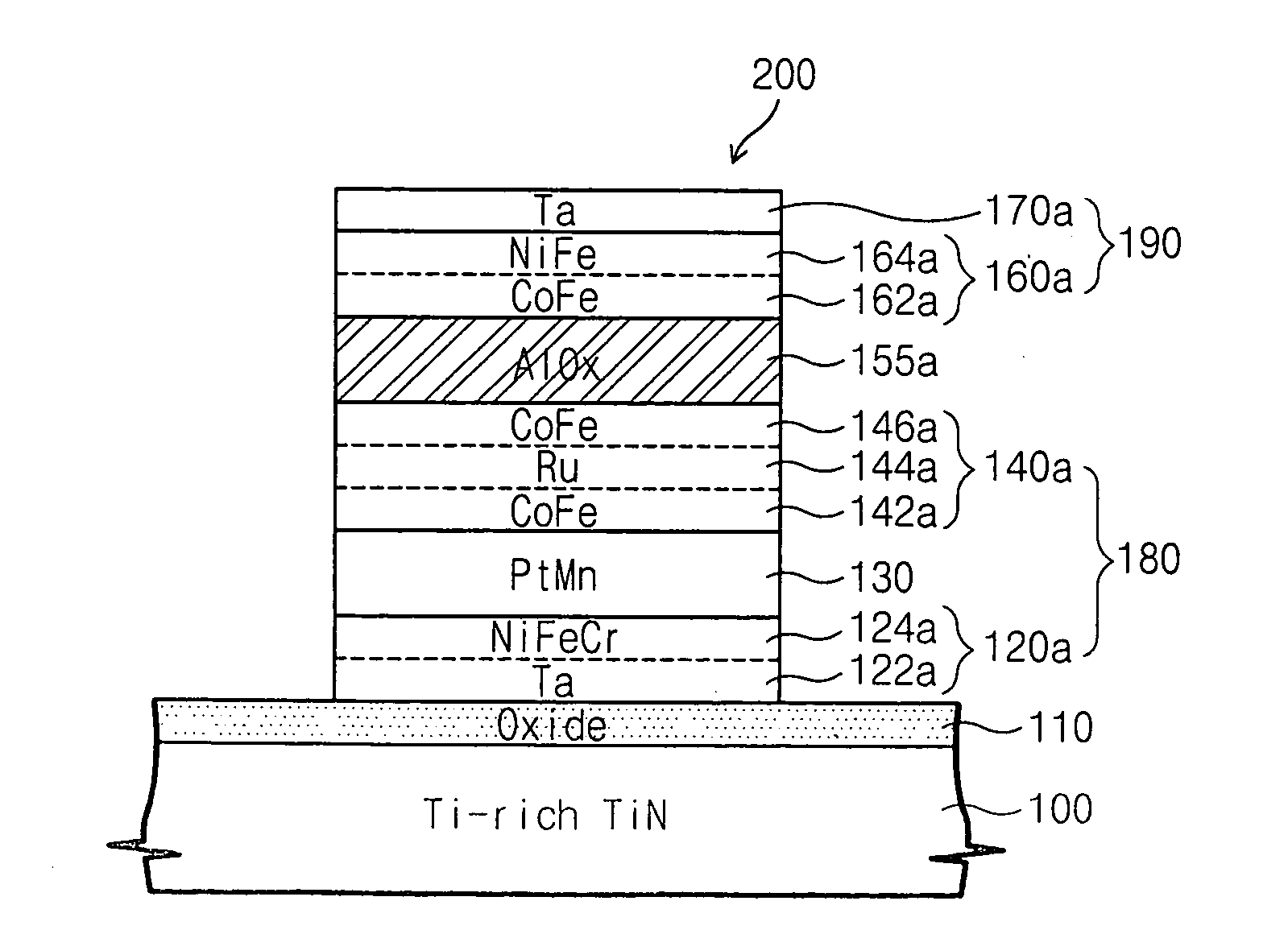

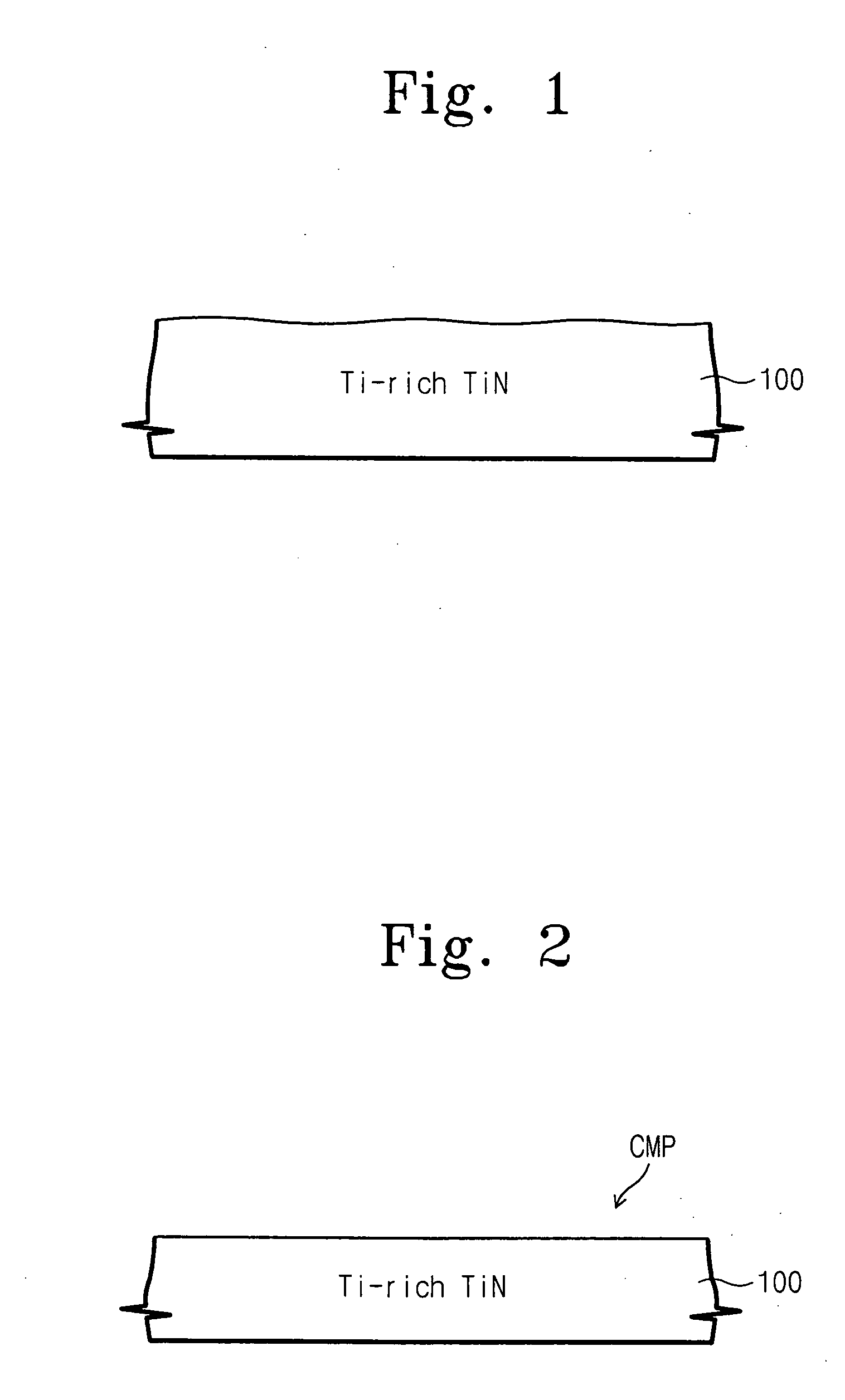

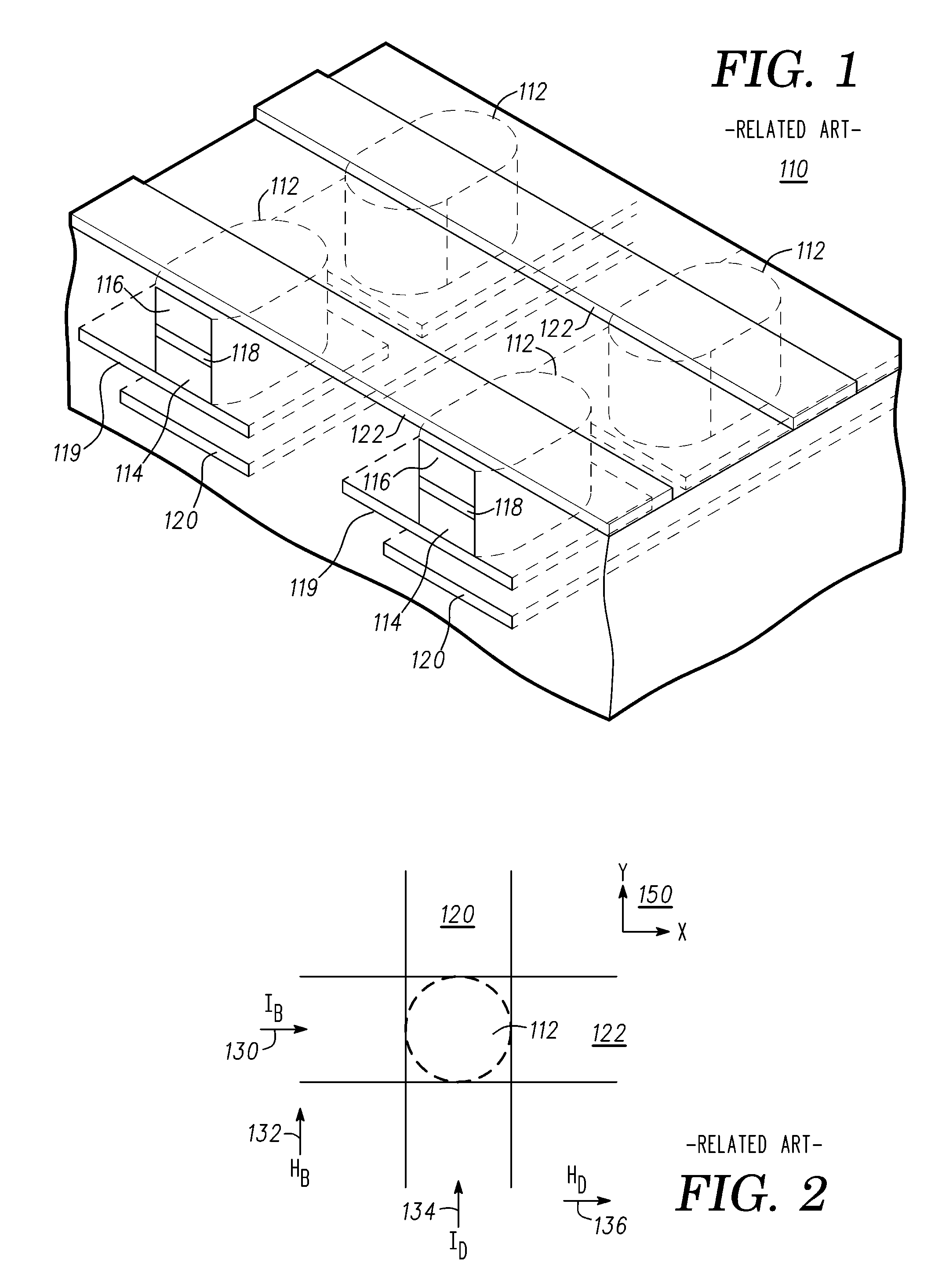

Magnetic random access memory devices having titanium-rich lower electrodes with oxide layer and oriented tunneling barrier, and methods for forming the same

ActiveUS20050006682A1Addressing Insufficient ControlLow polishing rateNanostructure applicationNanomagnetismRandom access memoryTitanium

Magnetic Random Access Memory (MRAM) devices include a lower electrode and a magnetic tunnel junction on the lower electrode. The magnetic tunnel junction includes a seed layer and a tunneling barrier that is oriented in a same direction as the most closely packed plane direction of the seed layer. An oxide layer may be provided between the lower electrode and the magnetic tunnel junction. The lower electrode may be a titanium-rich TiN layer having more than 50 atomic percent titanium content. Analogous fabrication methods are also described.

Owner:SAMSUNG ELECTRONICS CO LTD

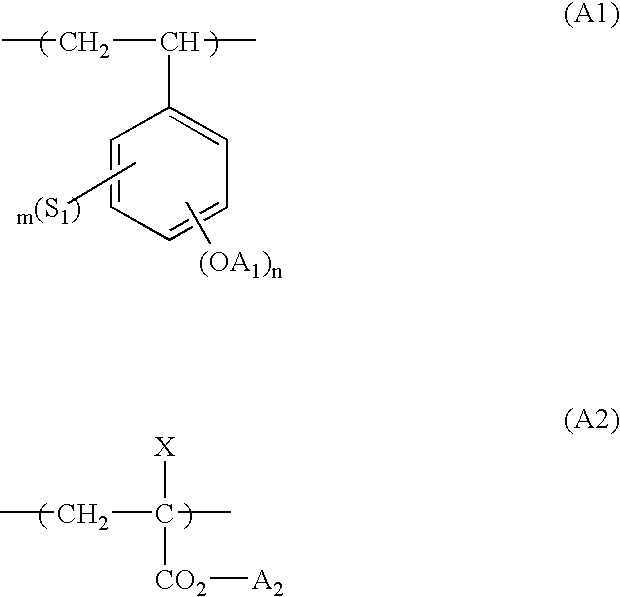

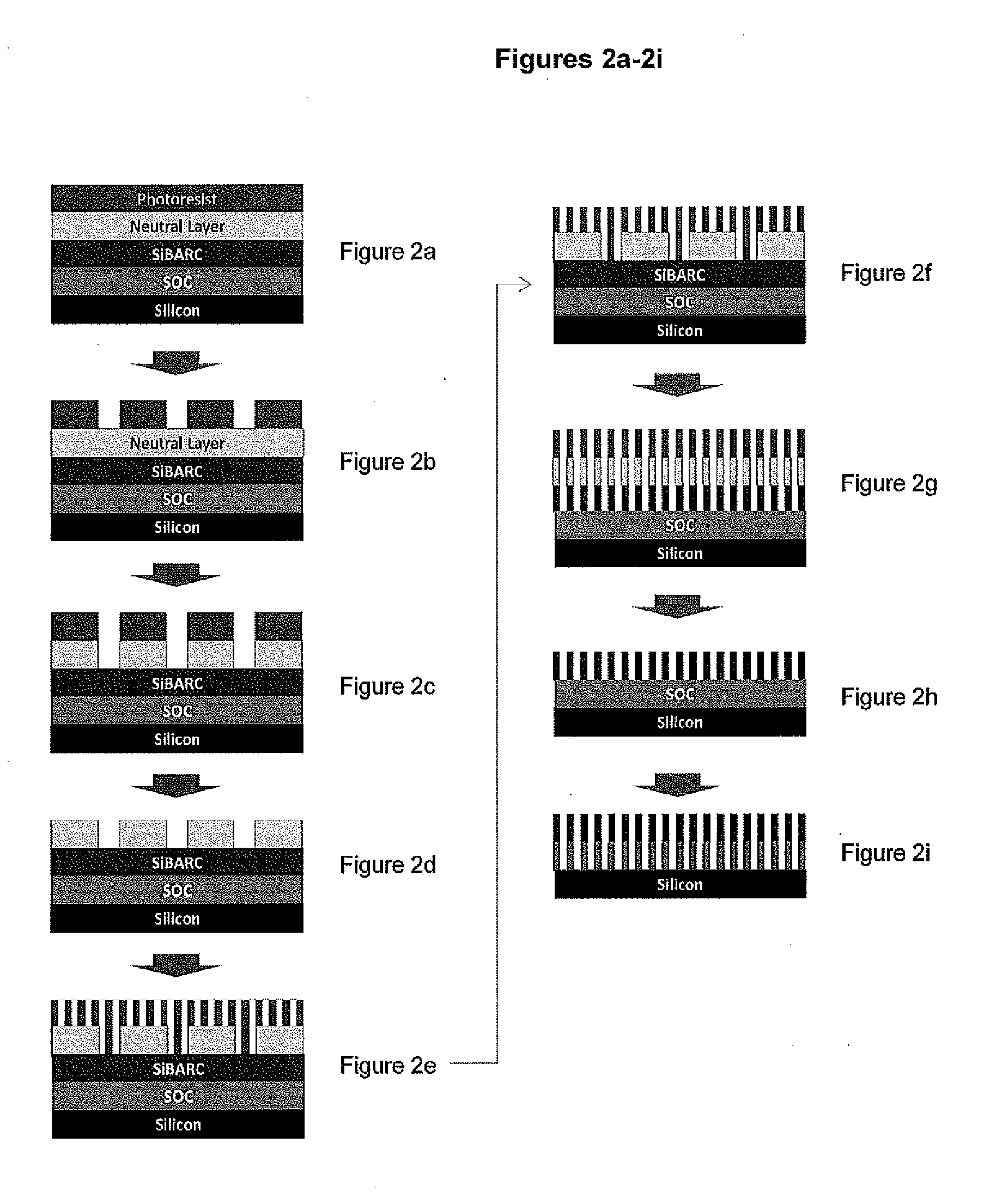

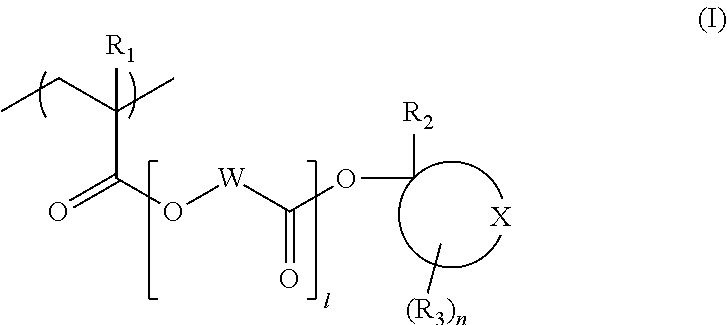

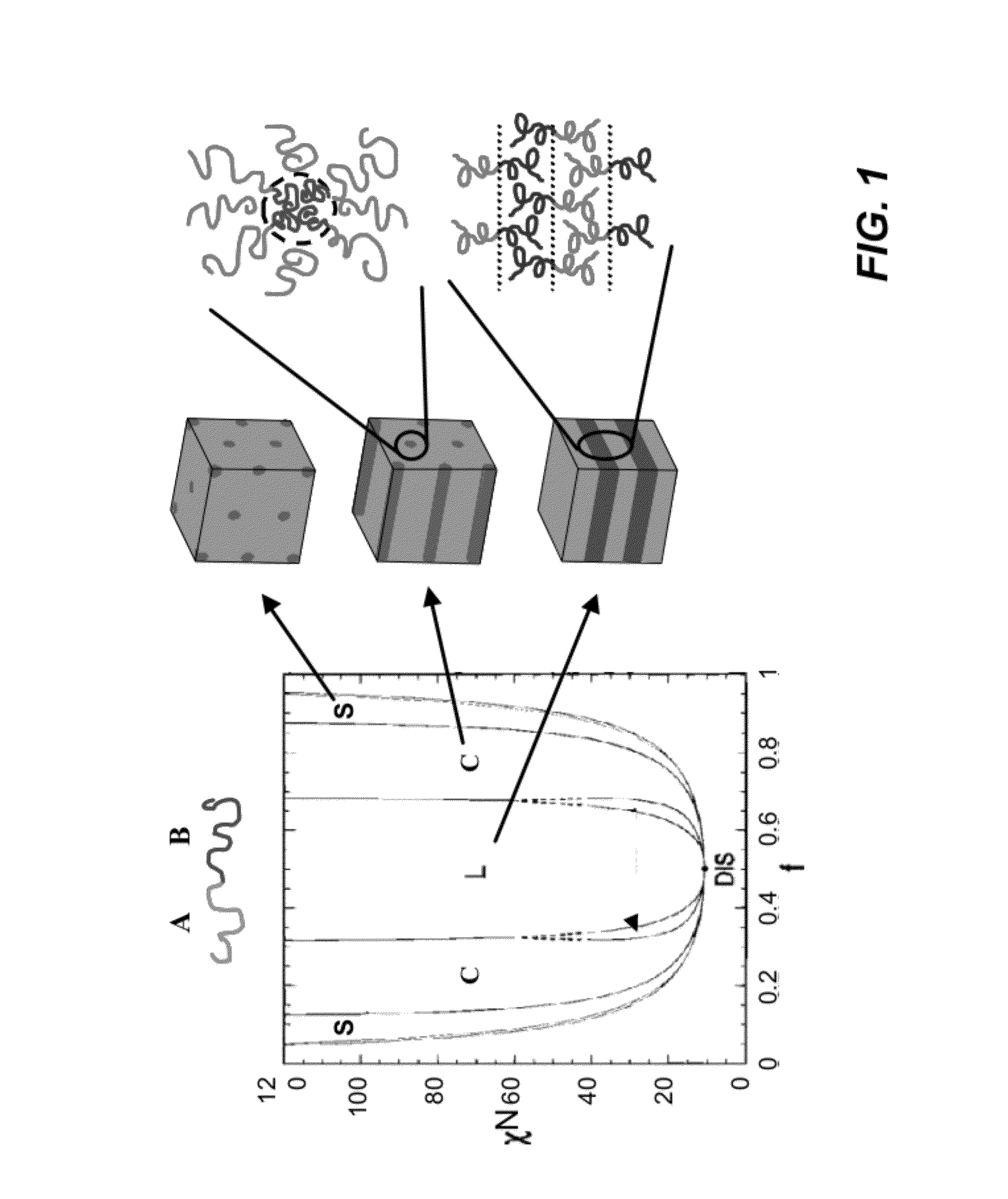

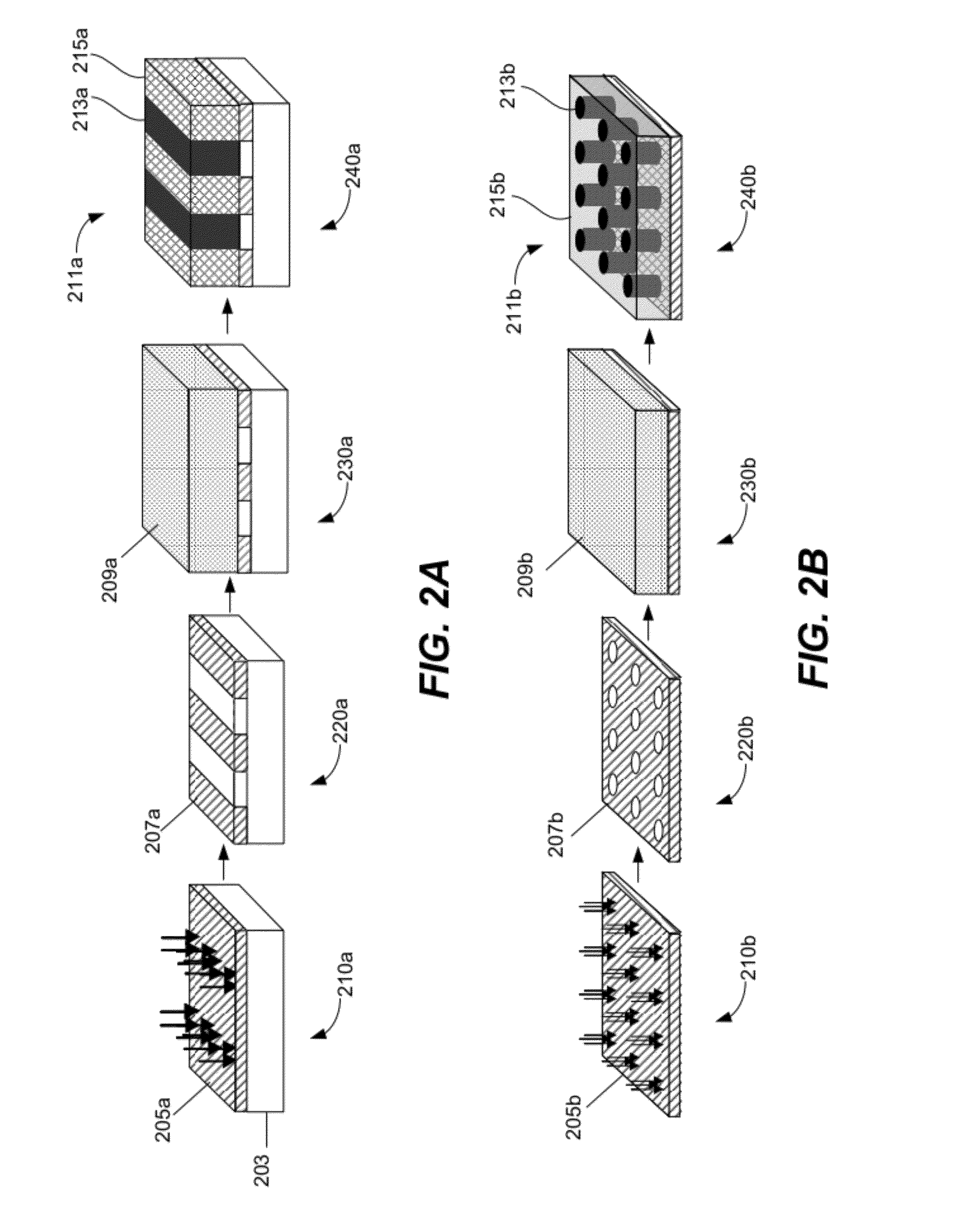

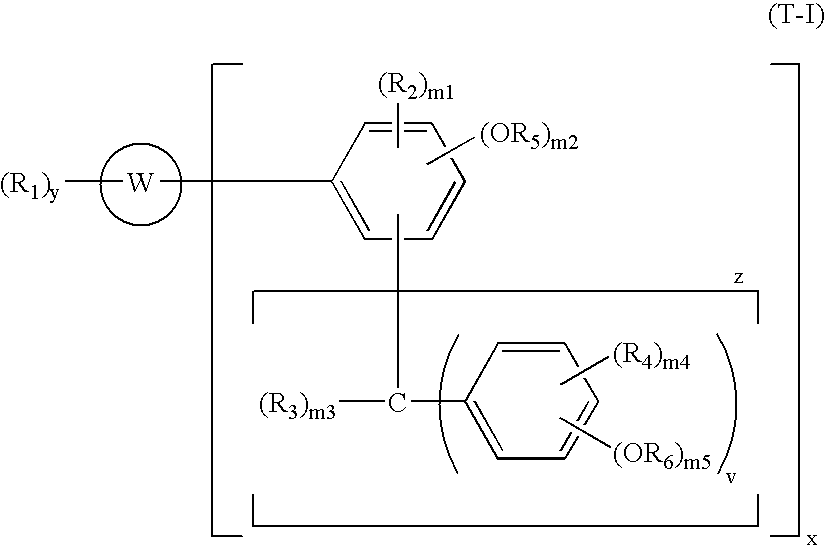

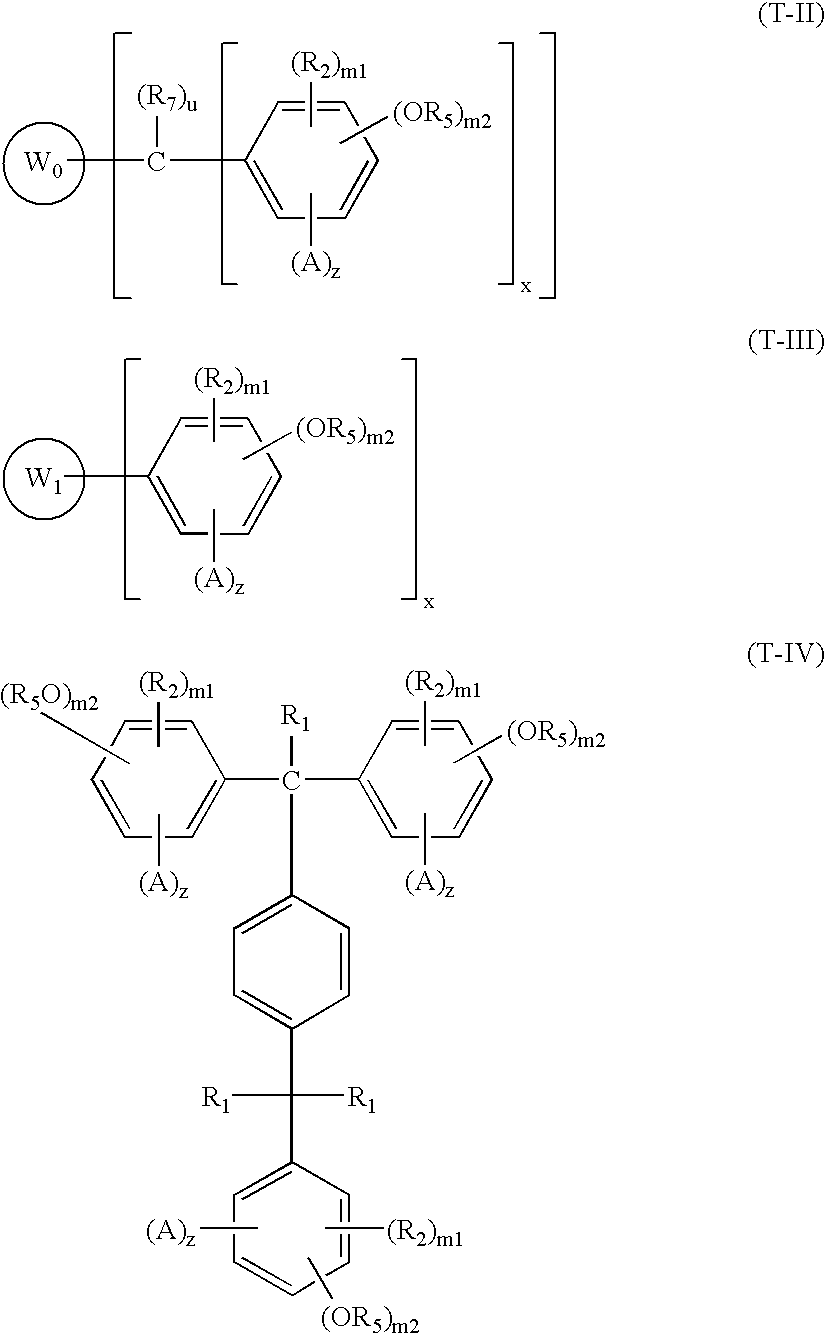

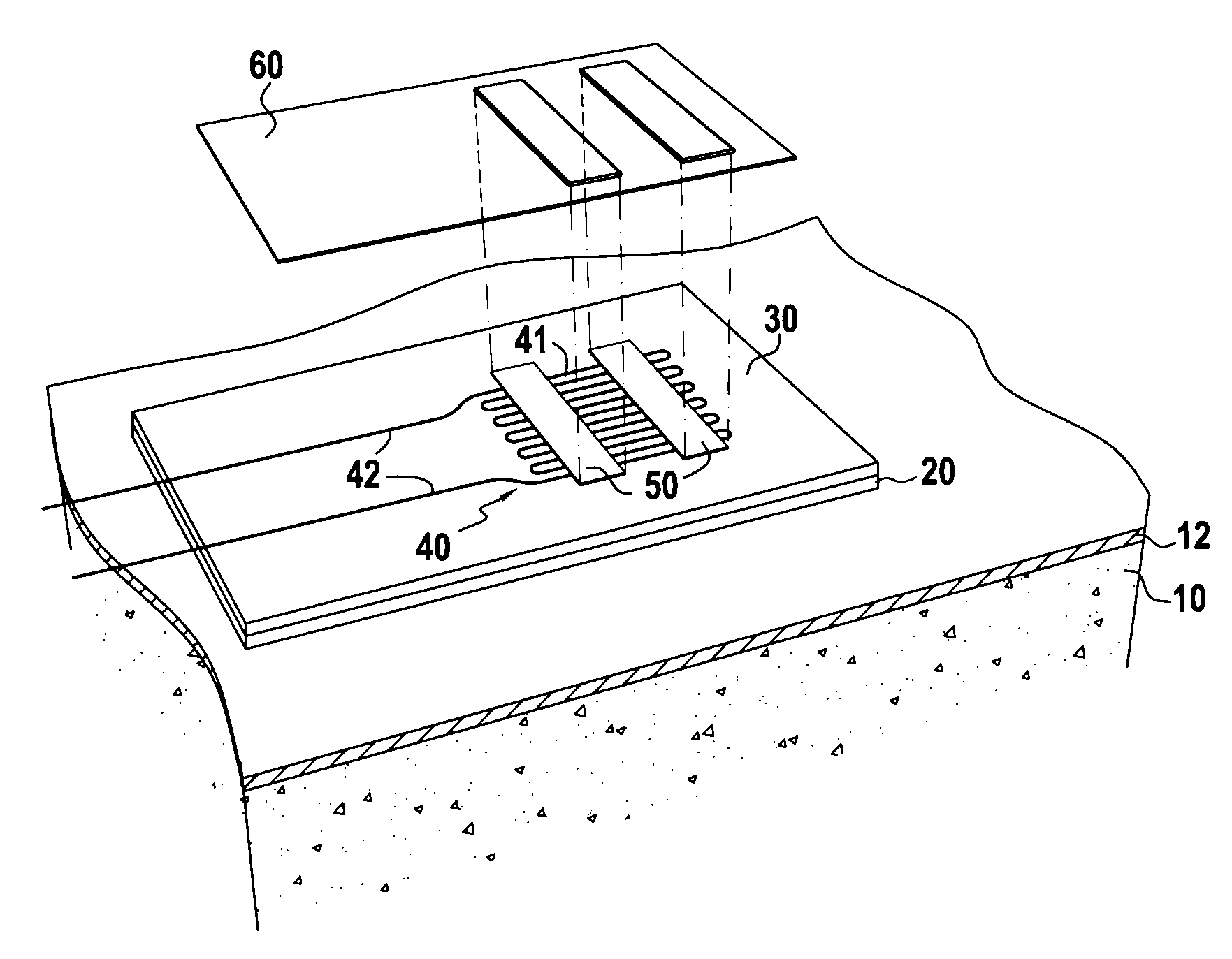

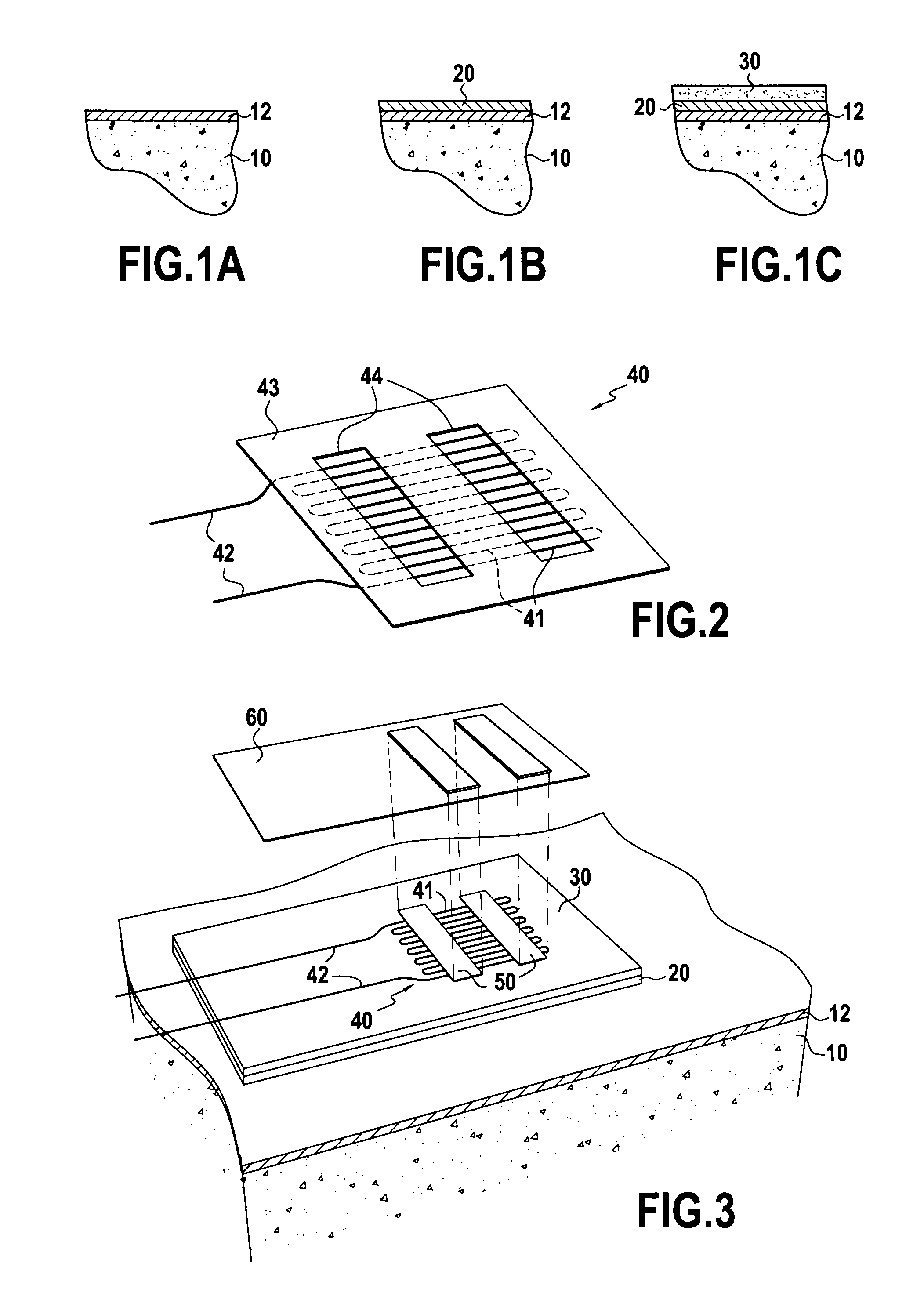

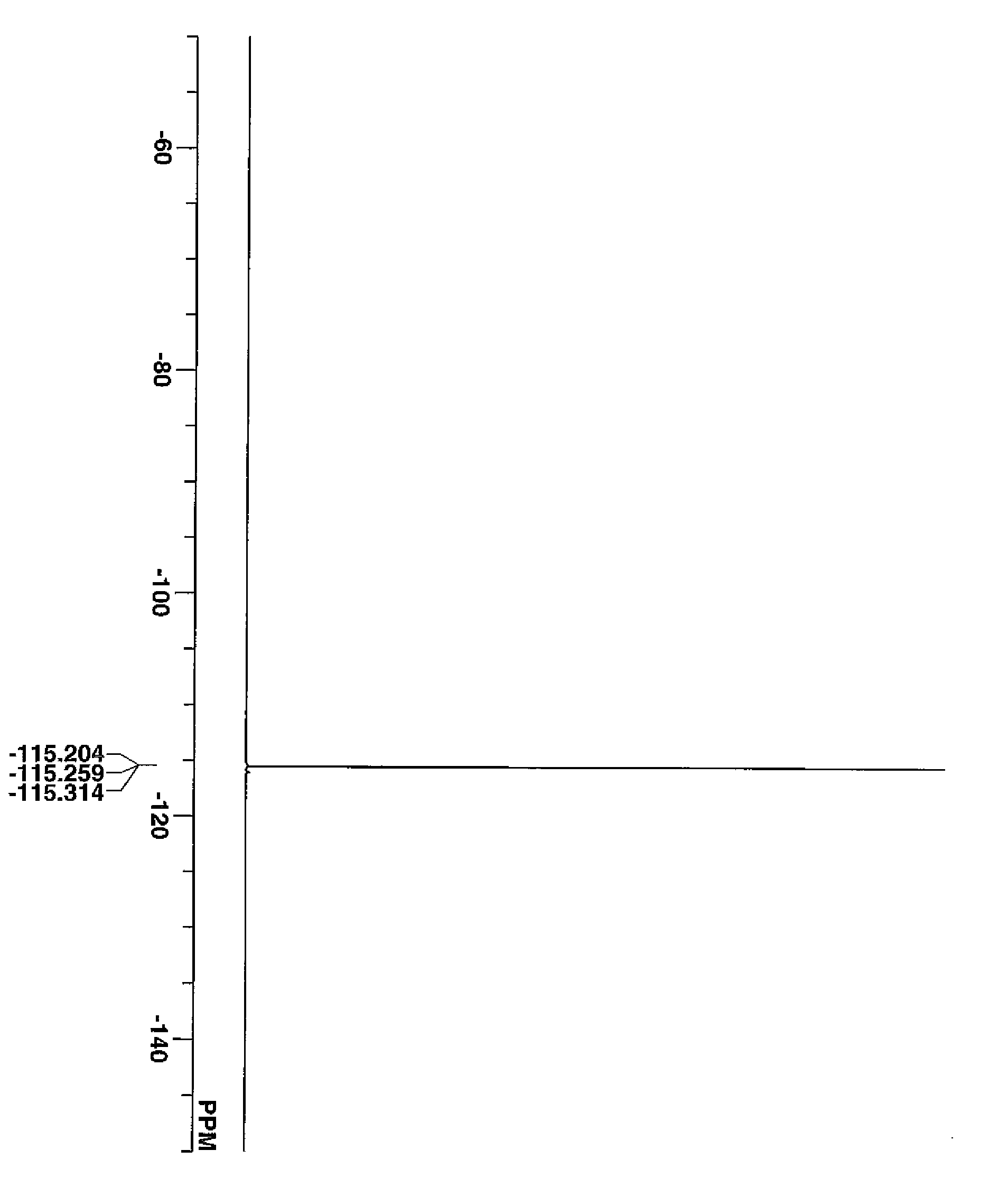

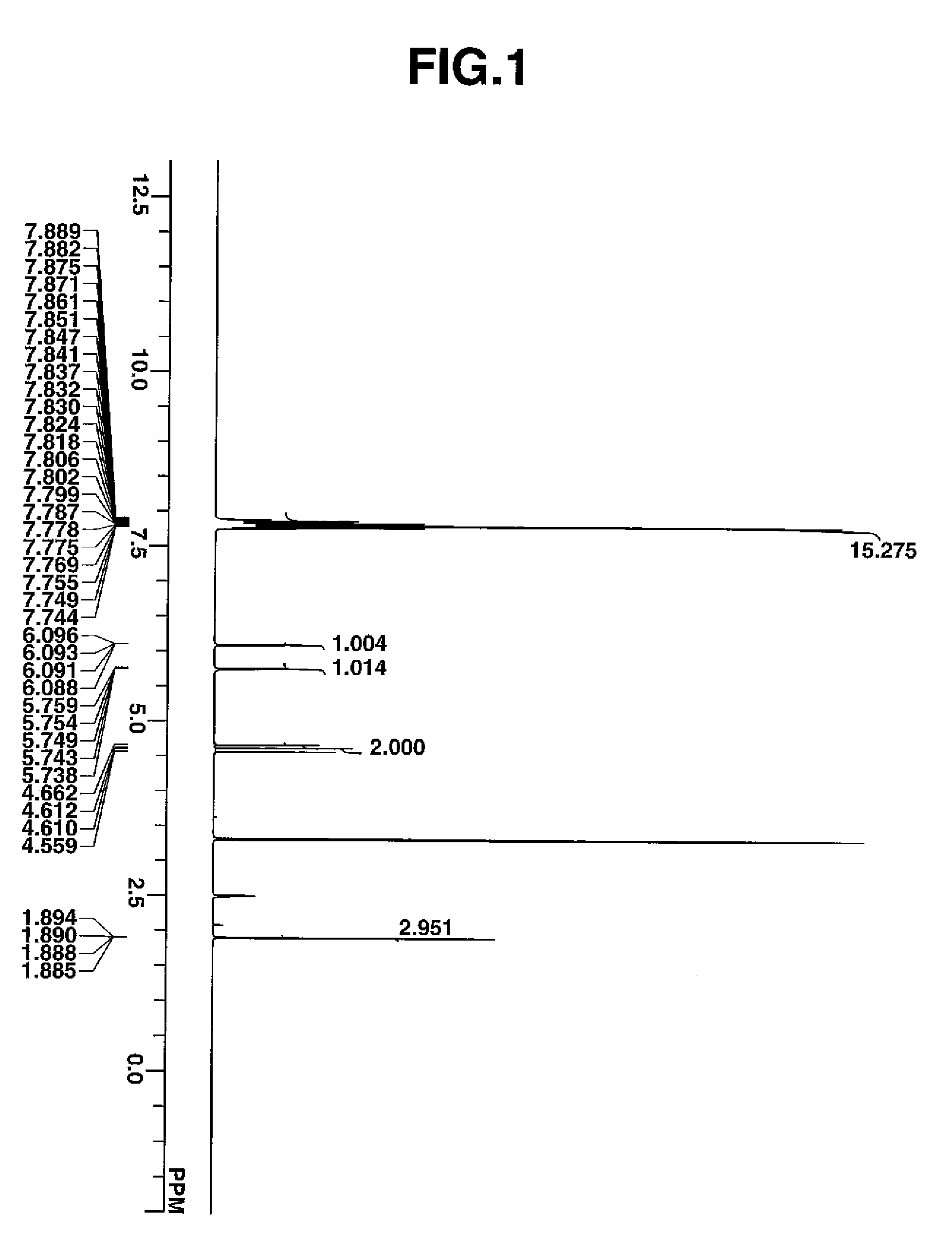

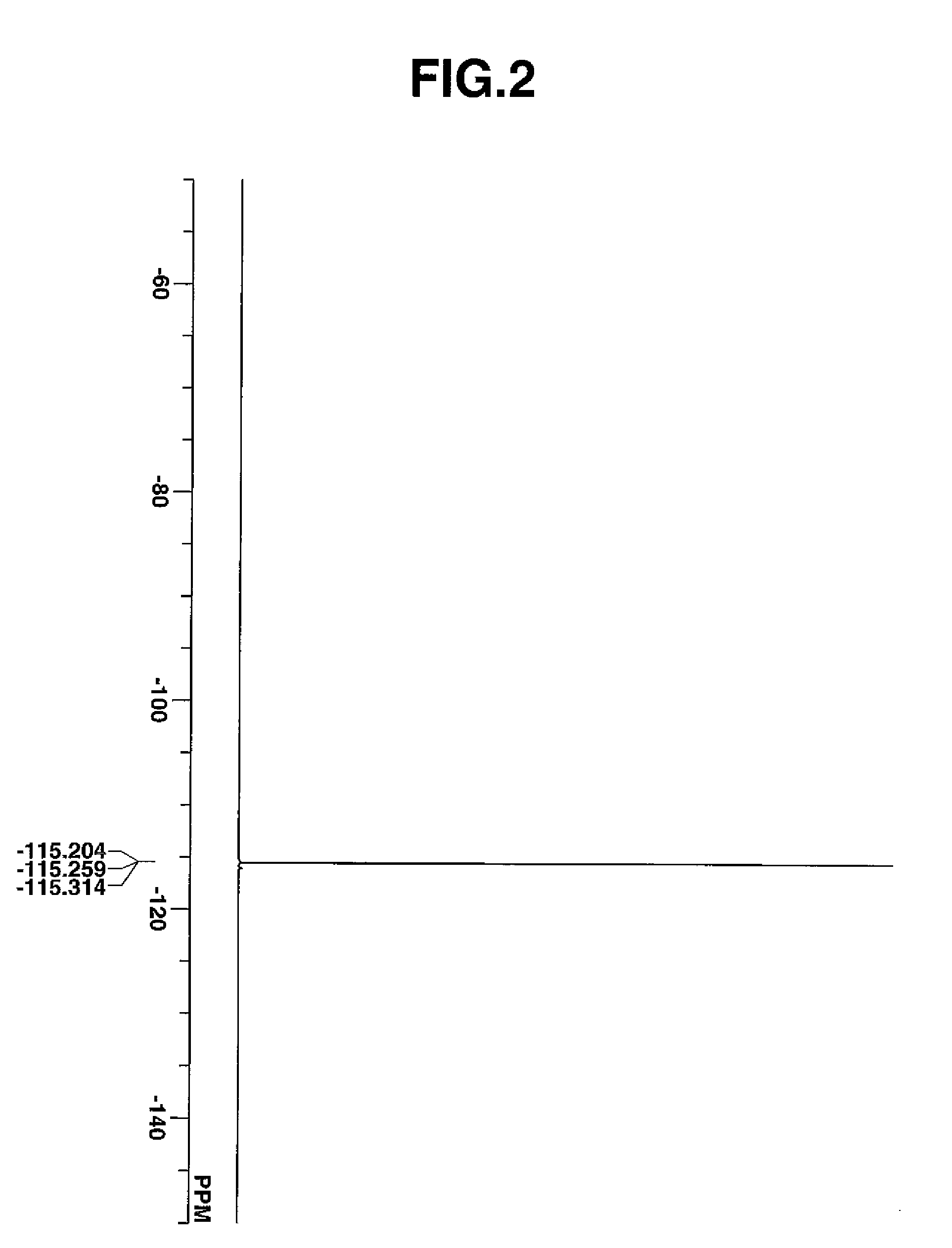

Compositions of neutral layer for directed self assembly block copolymers and processes thereof

ActiveUS20130078576A1High resolutionHigh pattern definitionElectric discharge tubesNanoinformaticsPolymer scienceMoiety

The present invention relates to novel neutral layer compositions and methods for using the compositions. The neutral layer composition comprises at least one random copolymer having at least one unit of structure (1), at least one unit of structure (2) and at least one unit of structure (3)where R1 is selected from the group consisting of a C1-C8 alkyl, C1-C8 fluoroalkyl moiety, C1-C8 partially fluorinated alkyl, C4-C8 cycloalkyl, C4-C8 cyclofluoroalkyl, C4-C8 partially fluorinated cycloalkyl, and a C2-C8 hydroxyalkyl; R2, R3 and R5 are independently selected from a group consisting of H, C1-C4 alkyl, CF3 and F; R4 is selected from the group consisting of H, C1-C8 alkyl, C1-C8 partially fluorinated alkyl and C1-C8 fluoroalkyl, n ranges from 1 to 5, R6 is selected from the group consisting of H, F, C1-C8 alkyl and a C1-C8 fluoroalkyl and m ranges from 1 to 3.

Owner:MERCK PATENT GMBH

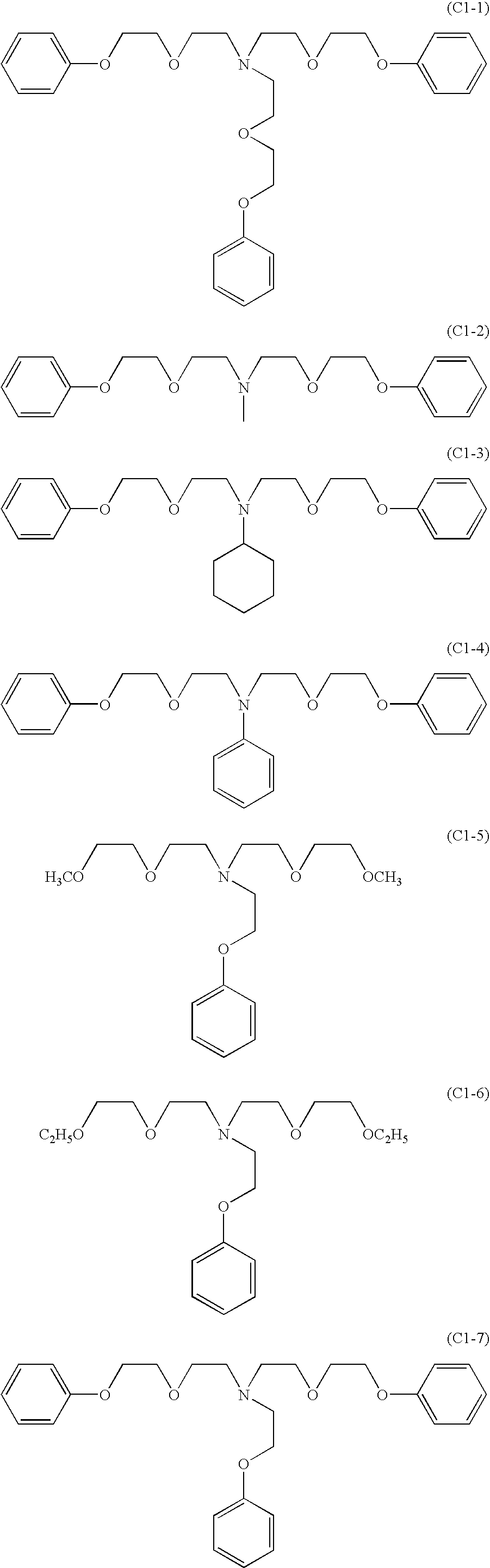

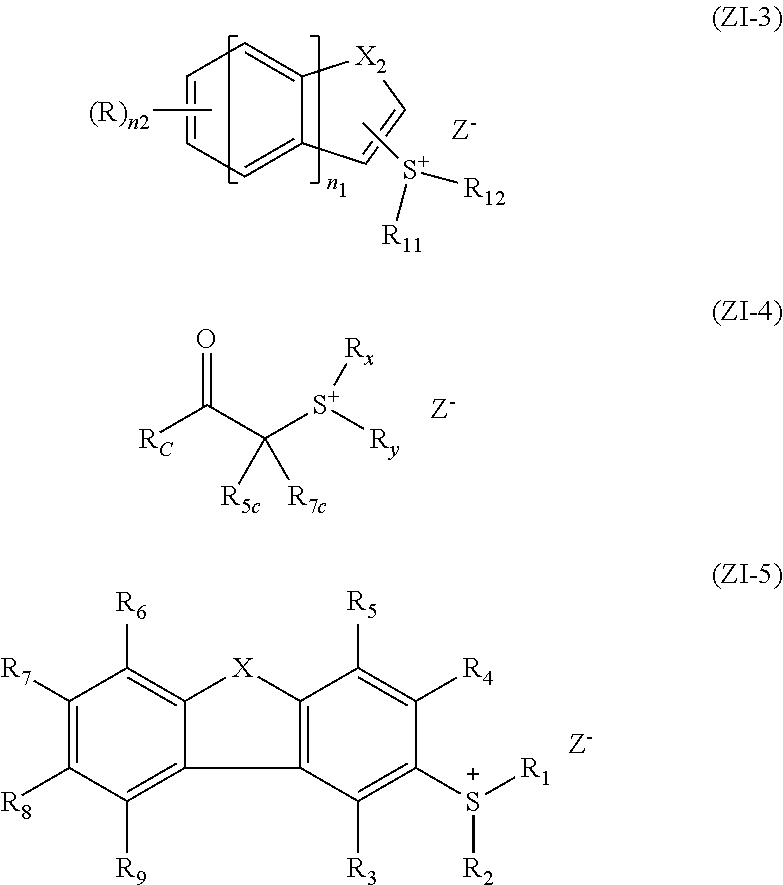

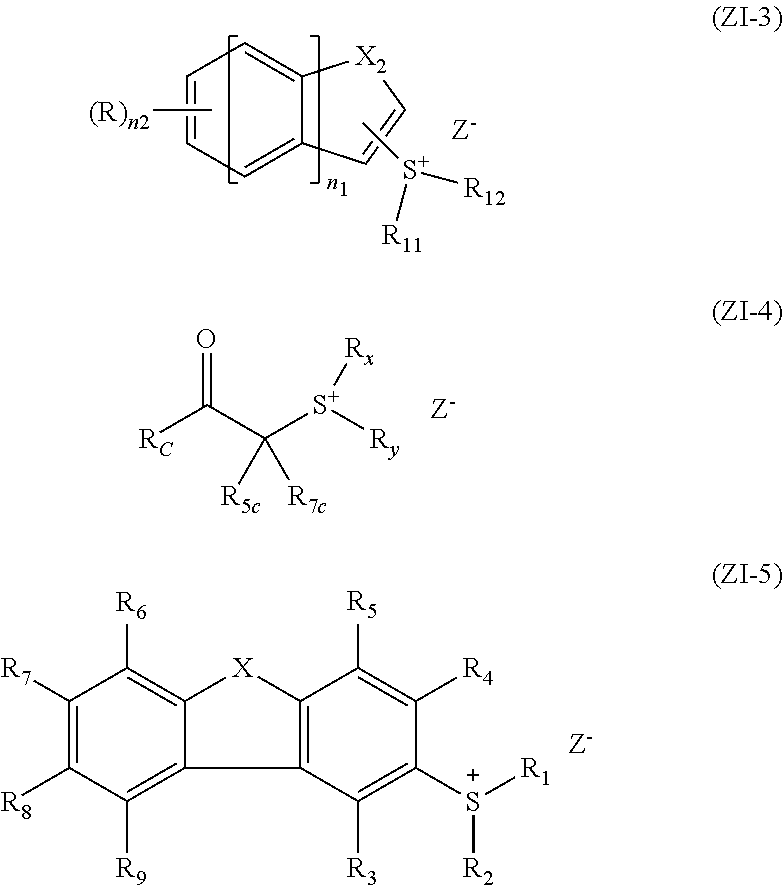

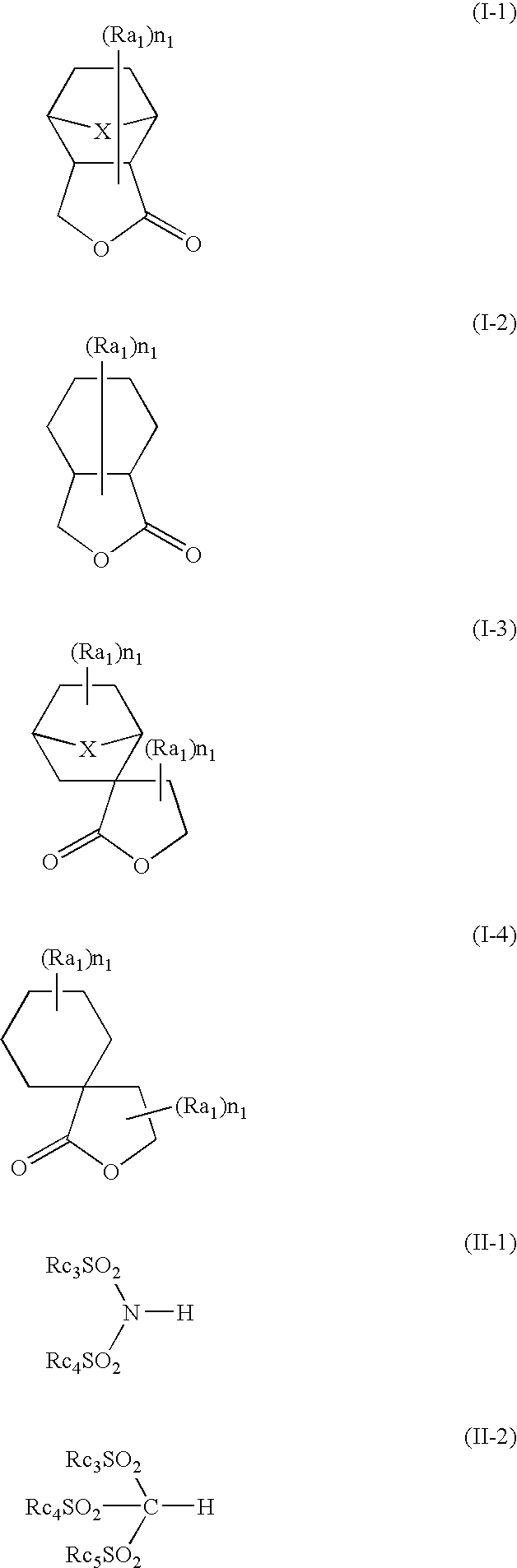

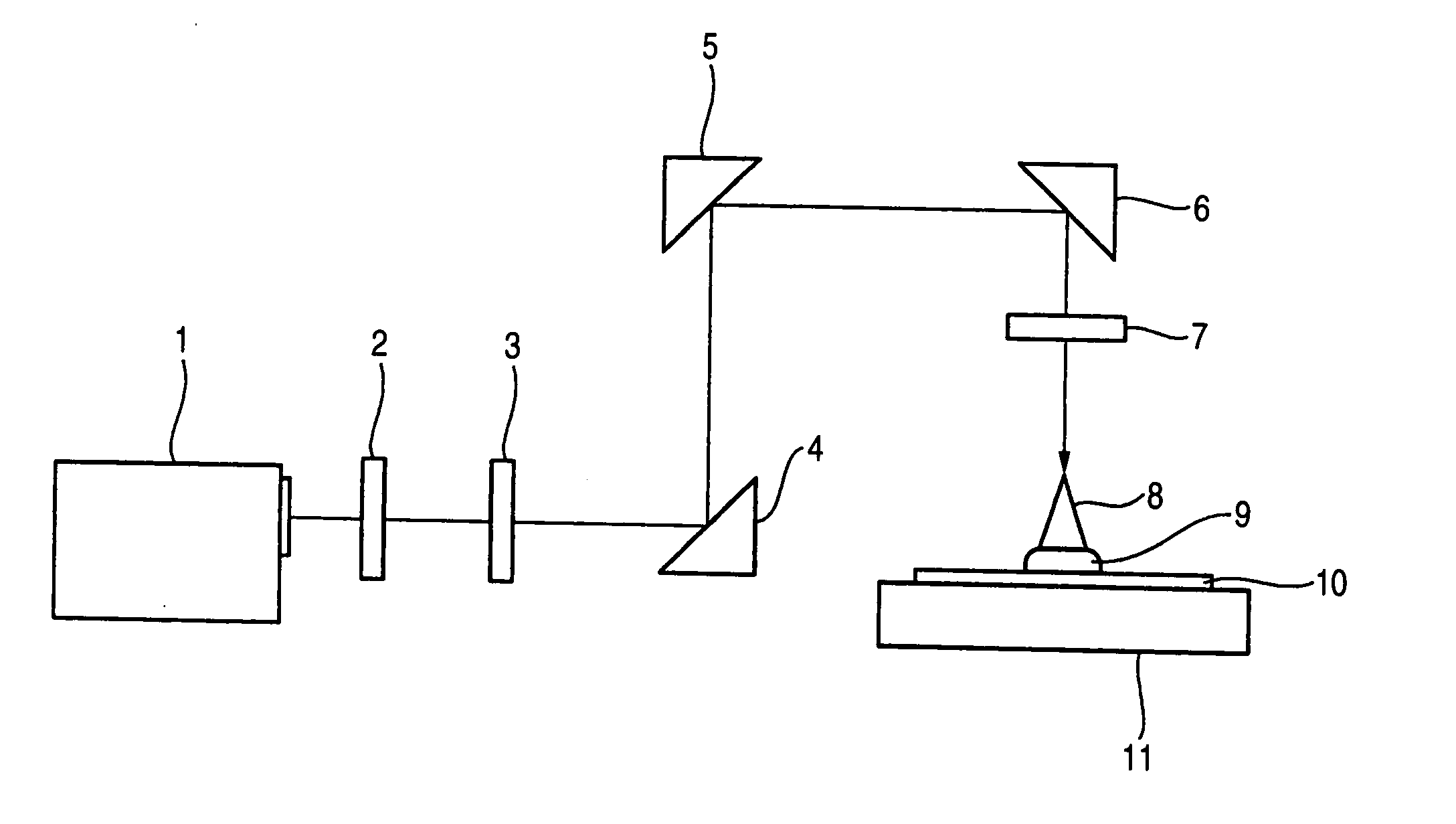

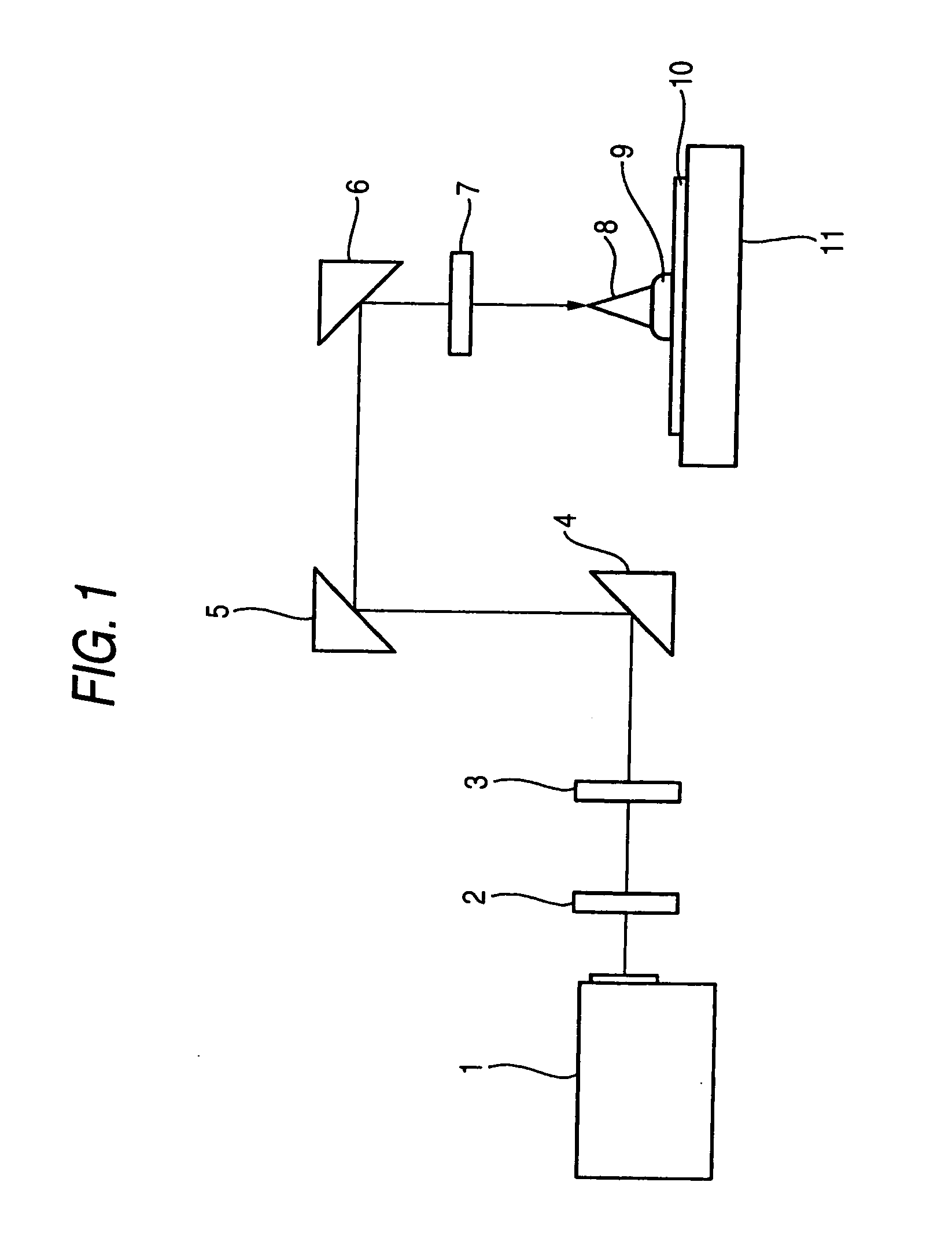

Actinic ray-sensitive or radiation-sensitive resin composition, and actinic ray-sensitive or radiation-sensitive film and pattern forming method using the same composition

InactiveUS20120251948A1Increase roughnessPhotosensitive materialsRadiation applicationsActinic RaysLeaving group

The actinic ray-sensitive or radiation-sensitive resin composition of the present invention contains (A) a resin capable of increasing the solubility in an alkaline developer by the action of an acid, and (C) at least one selected from the group of compounds represented by the following formula (ZI-3), (ZI-4) or (ZI-5) and capable of generating an acid upon irradiation of actinic rays or radiation, wherein the resin (A) contains at least one repeating unit having a group capable of decomposing by the action of an acid to leave a leaving group having a ring structure, and the leaving group having a ring structure has at least one of a polar group as a substituent and a polar atom as a part of the ring structure, and a compound derived from the leaving group having a ring structure has a log P value of not less than 0 and less than 2.8.

Owner:FUJIFILM CORP

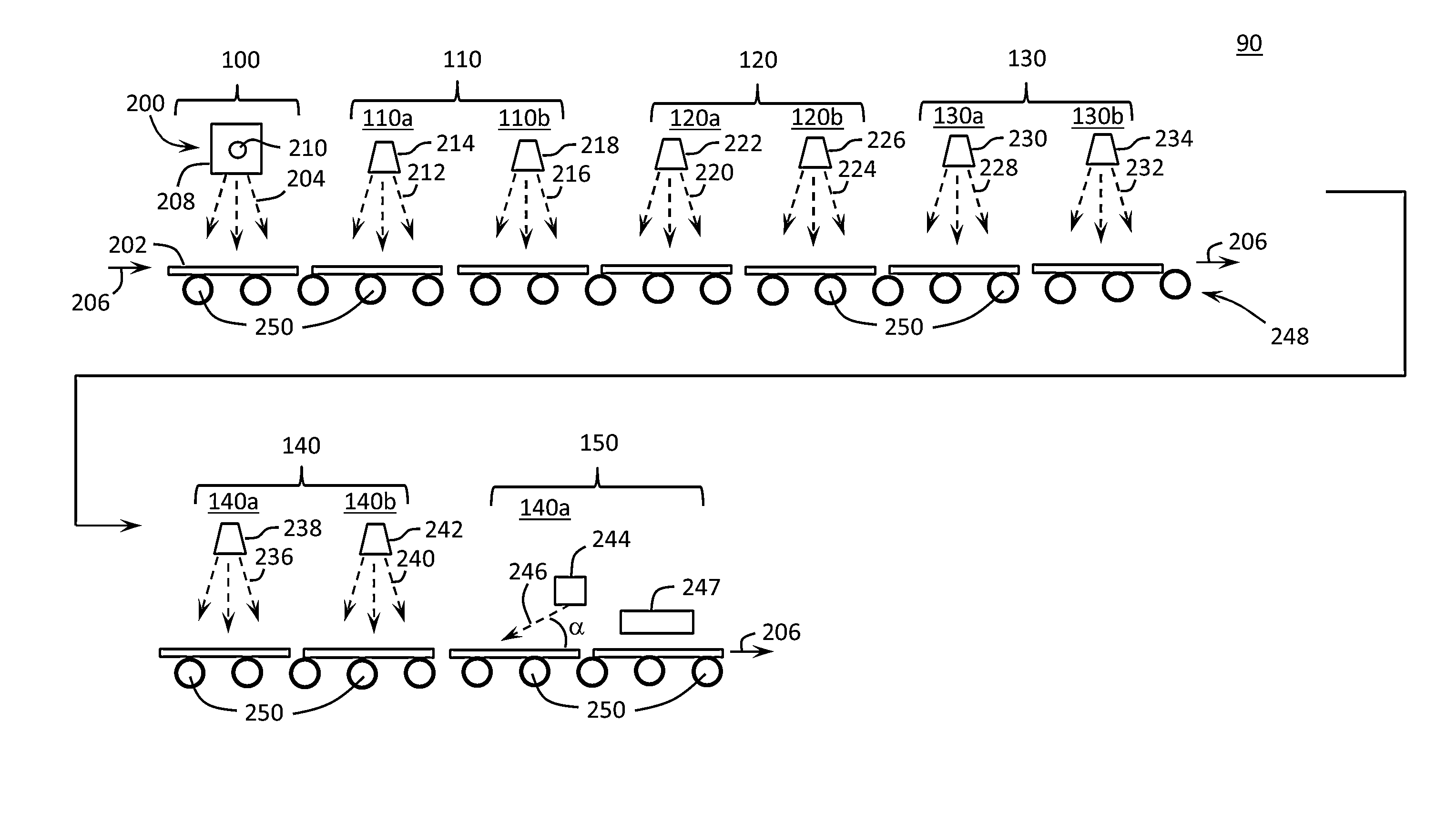

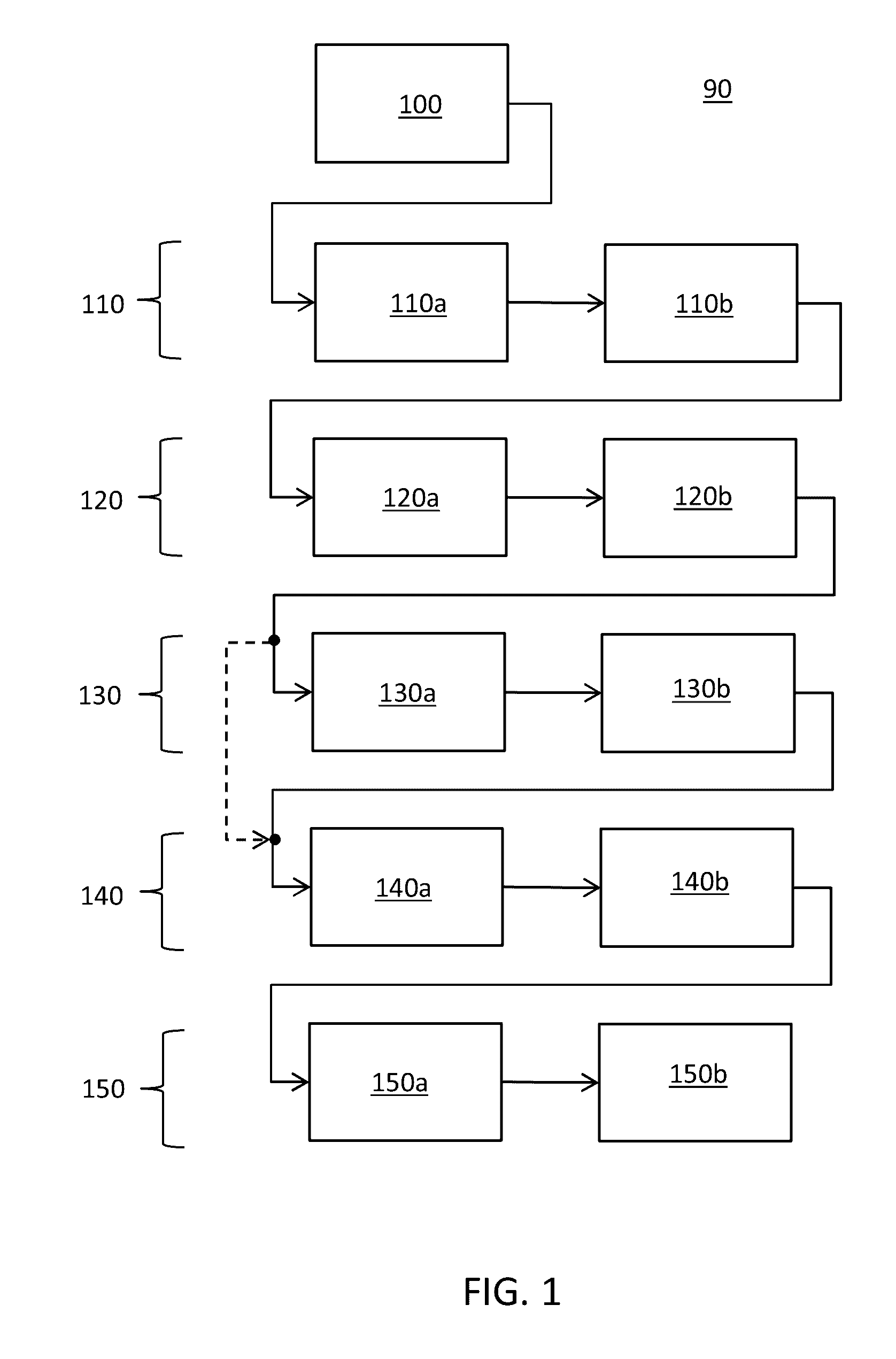

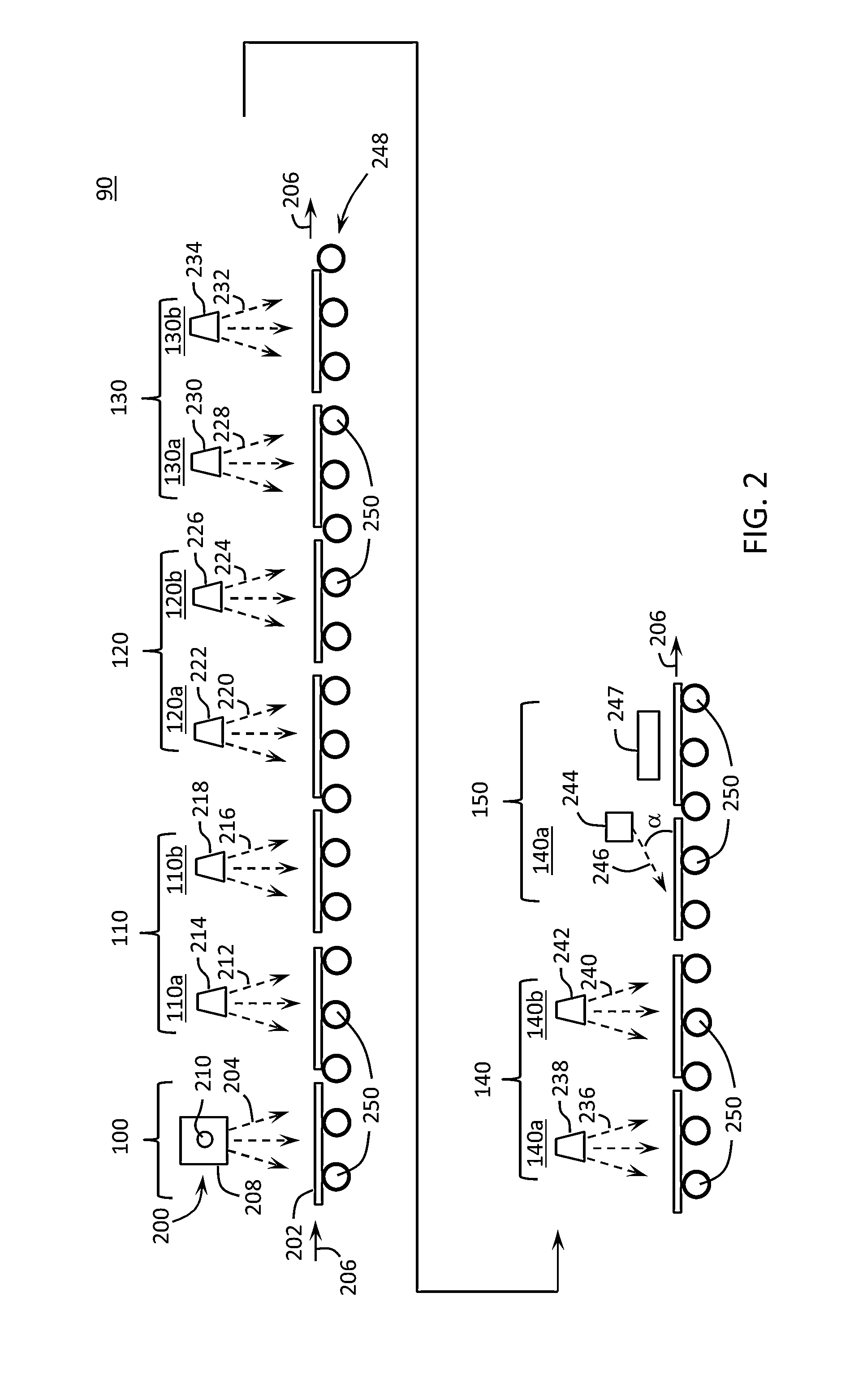

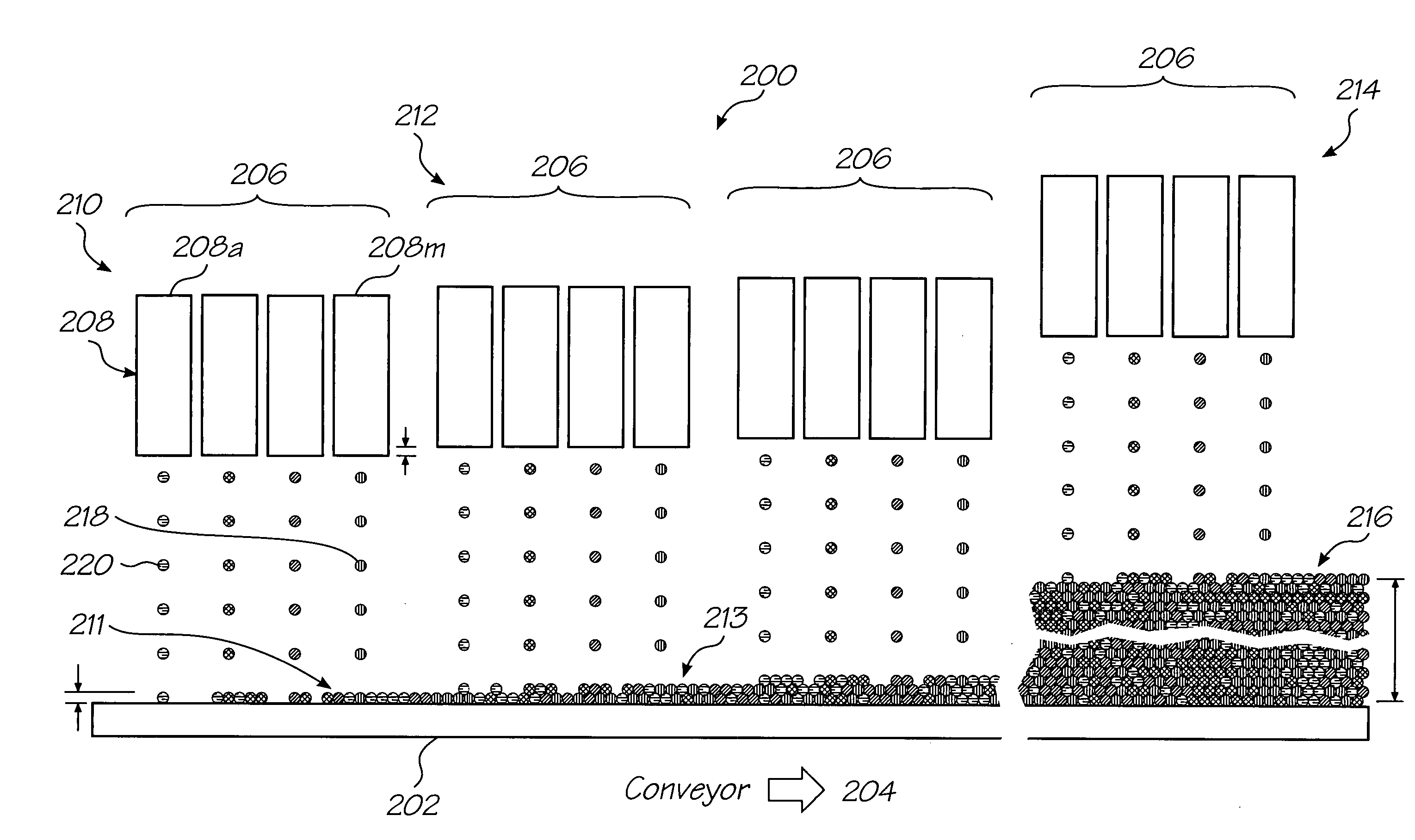

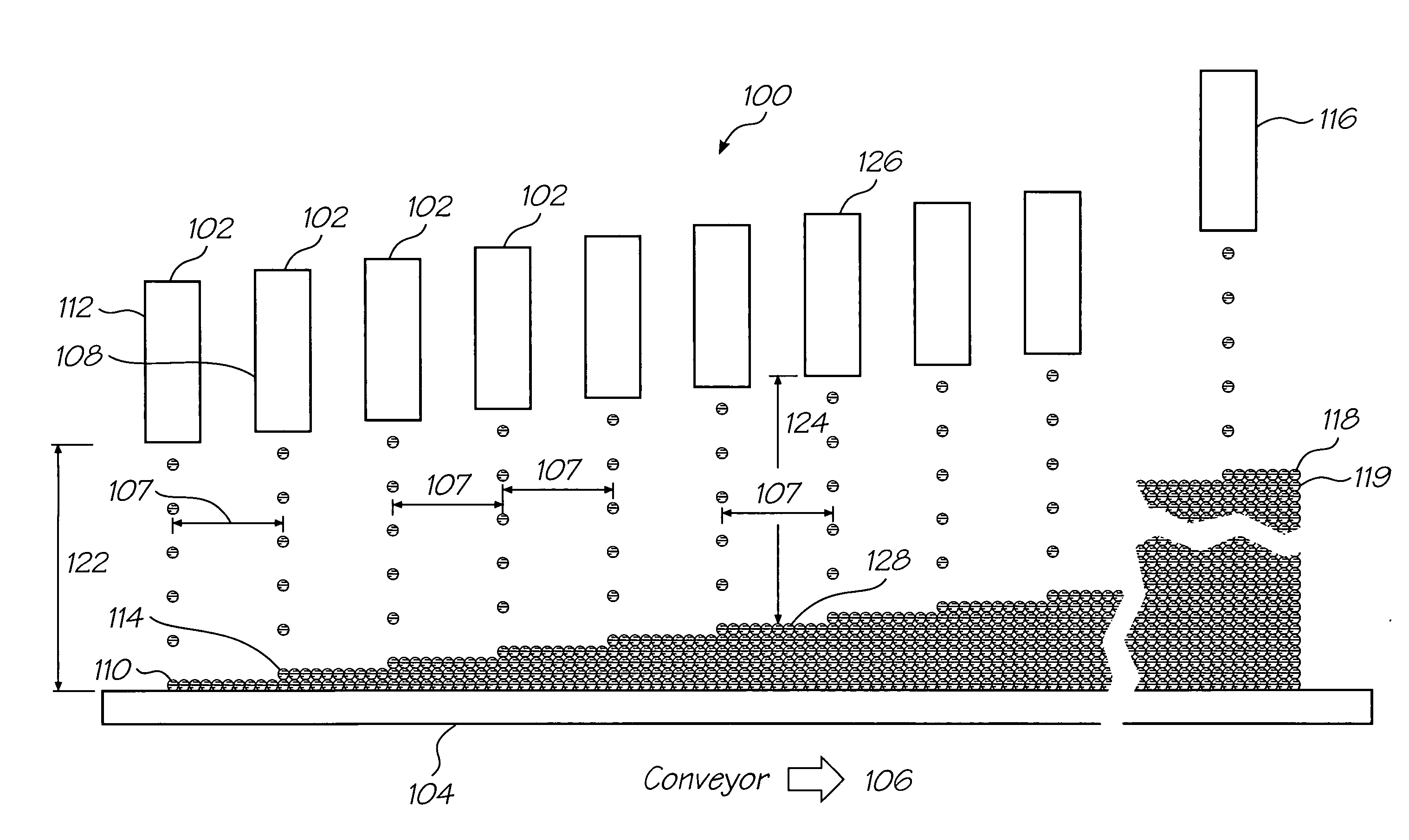

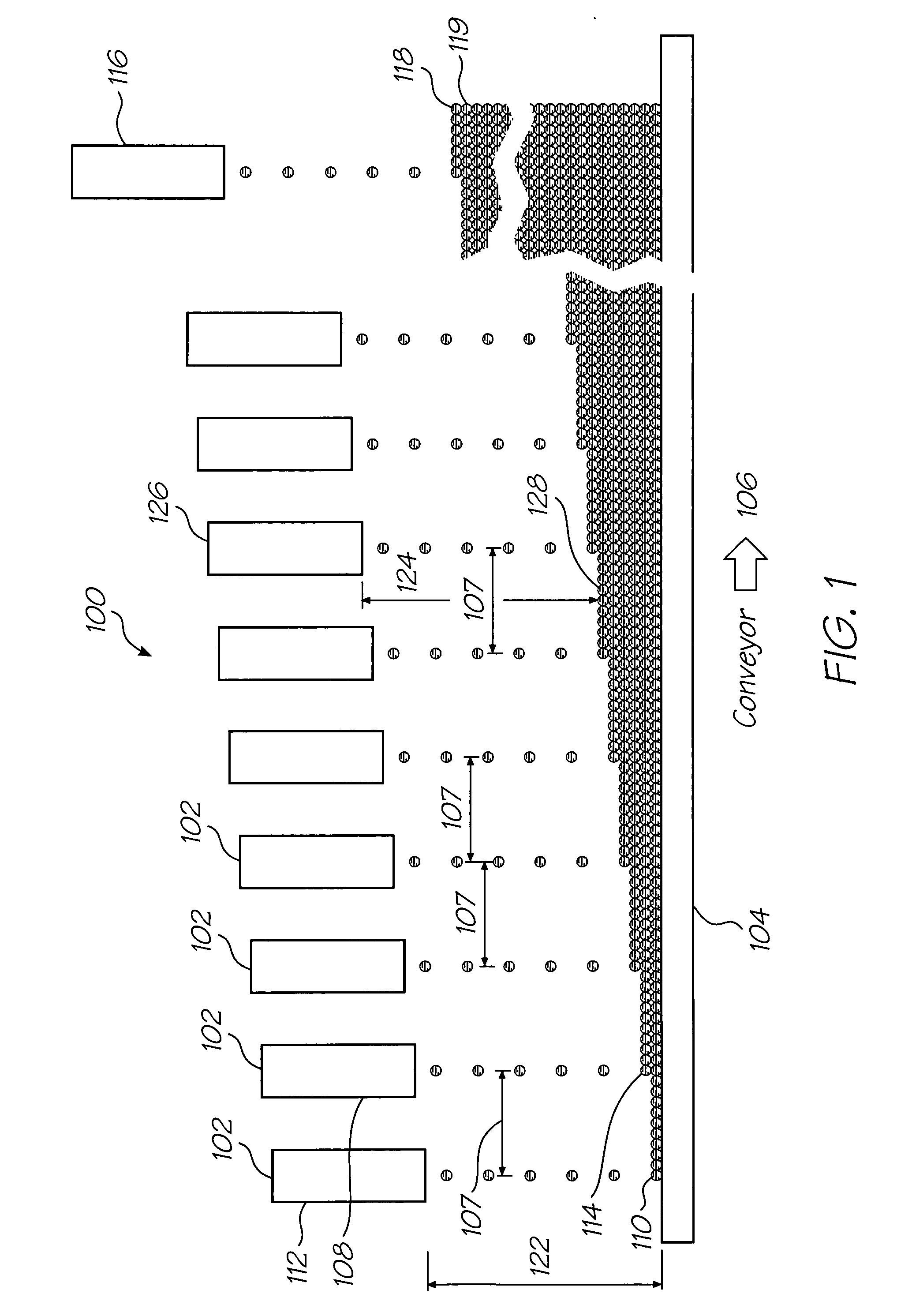

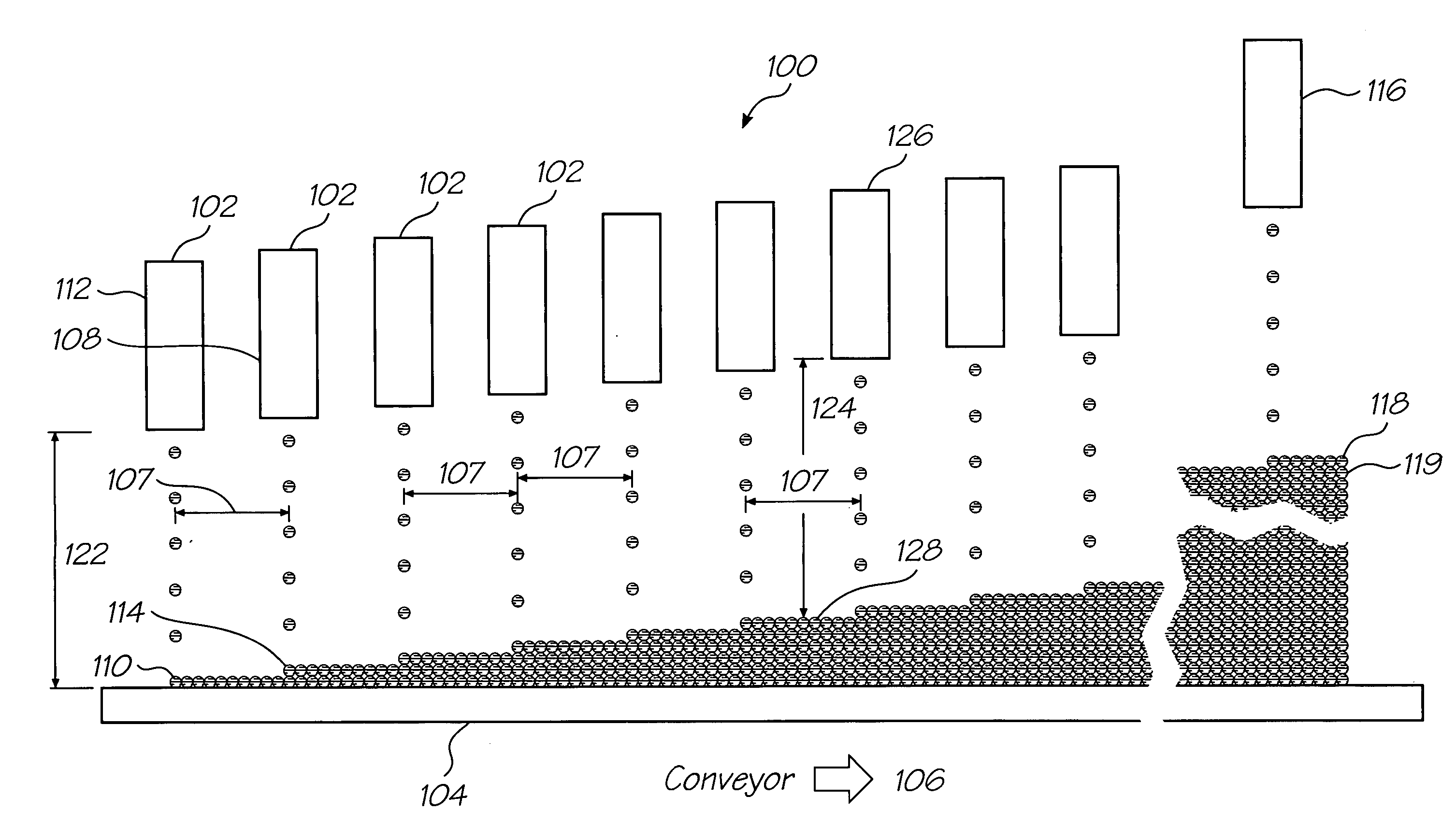

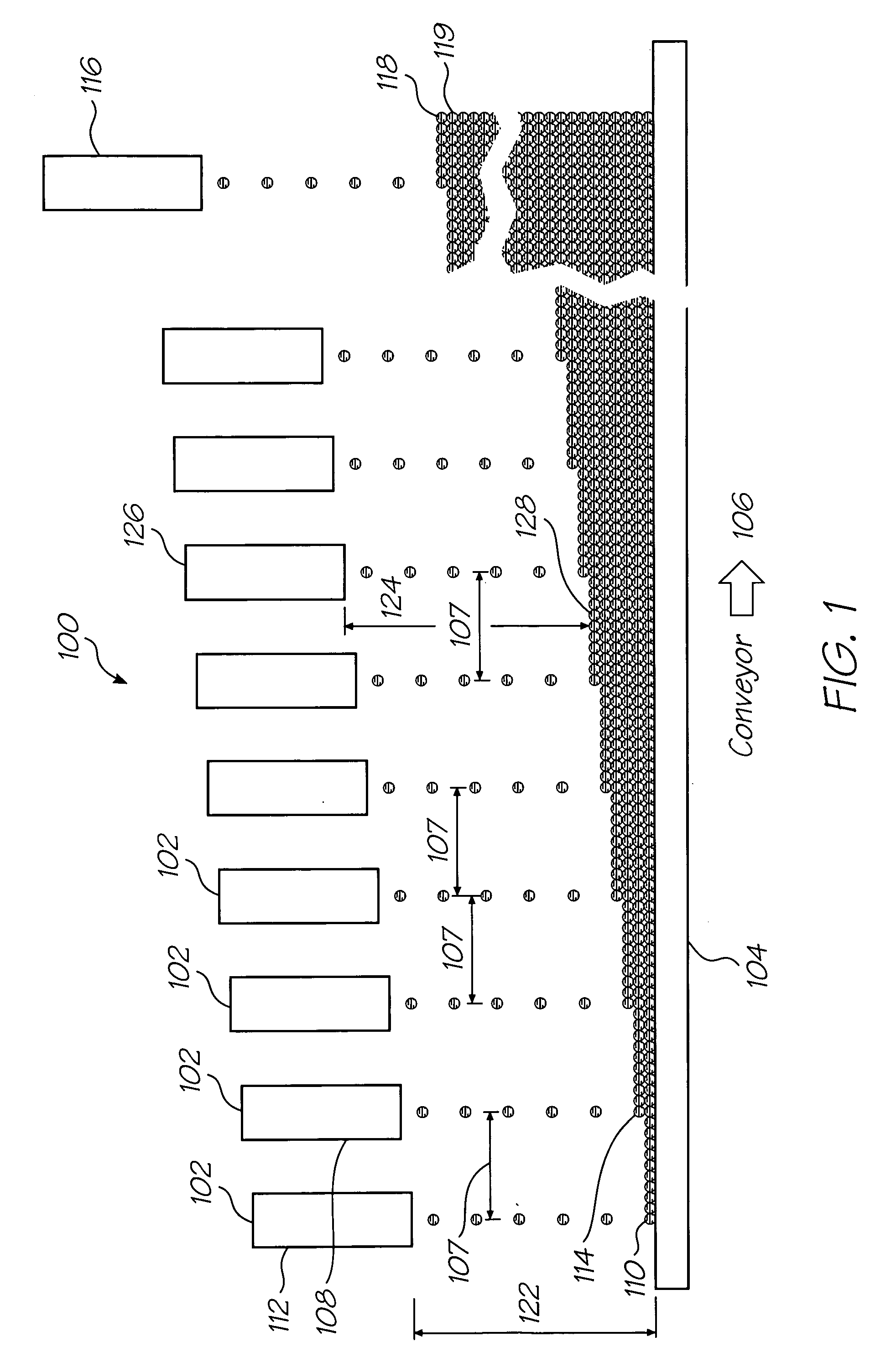

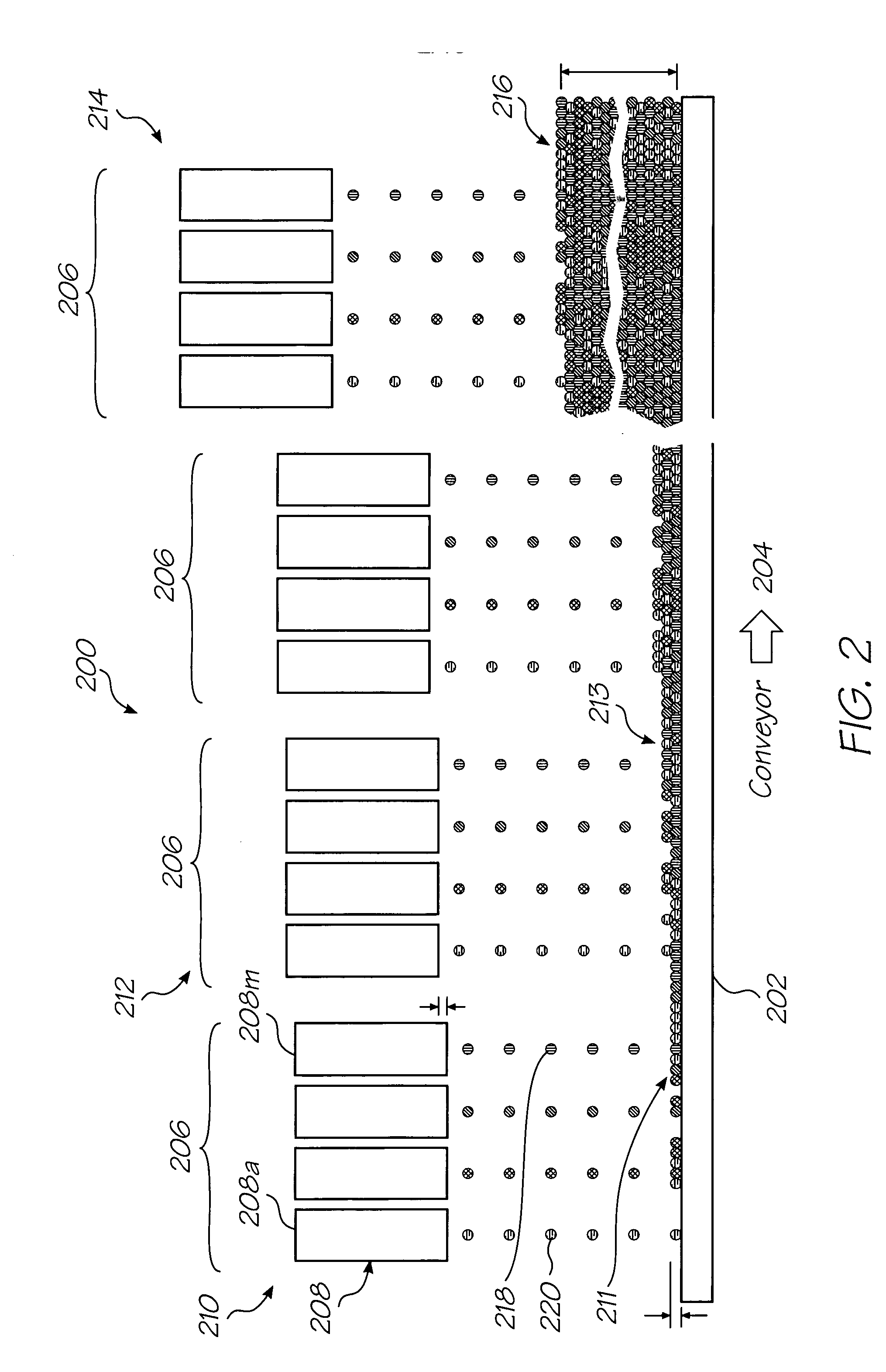

Method of cleaning glass substrates

InactiveUS9561982B2Low levelEnhance electrostatic interactionSemiconductor/solid-state device manufacturingFlexible article cleaningThin glassElectrostatic discharge

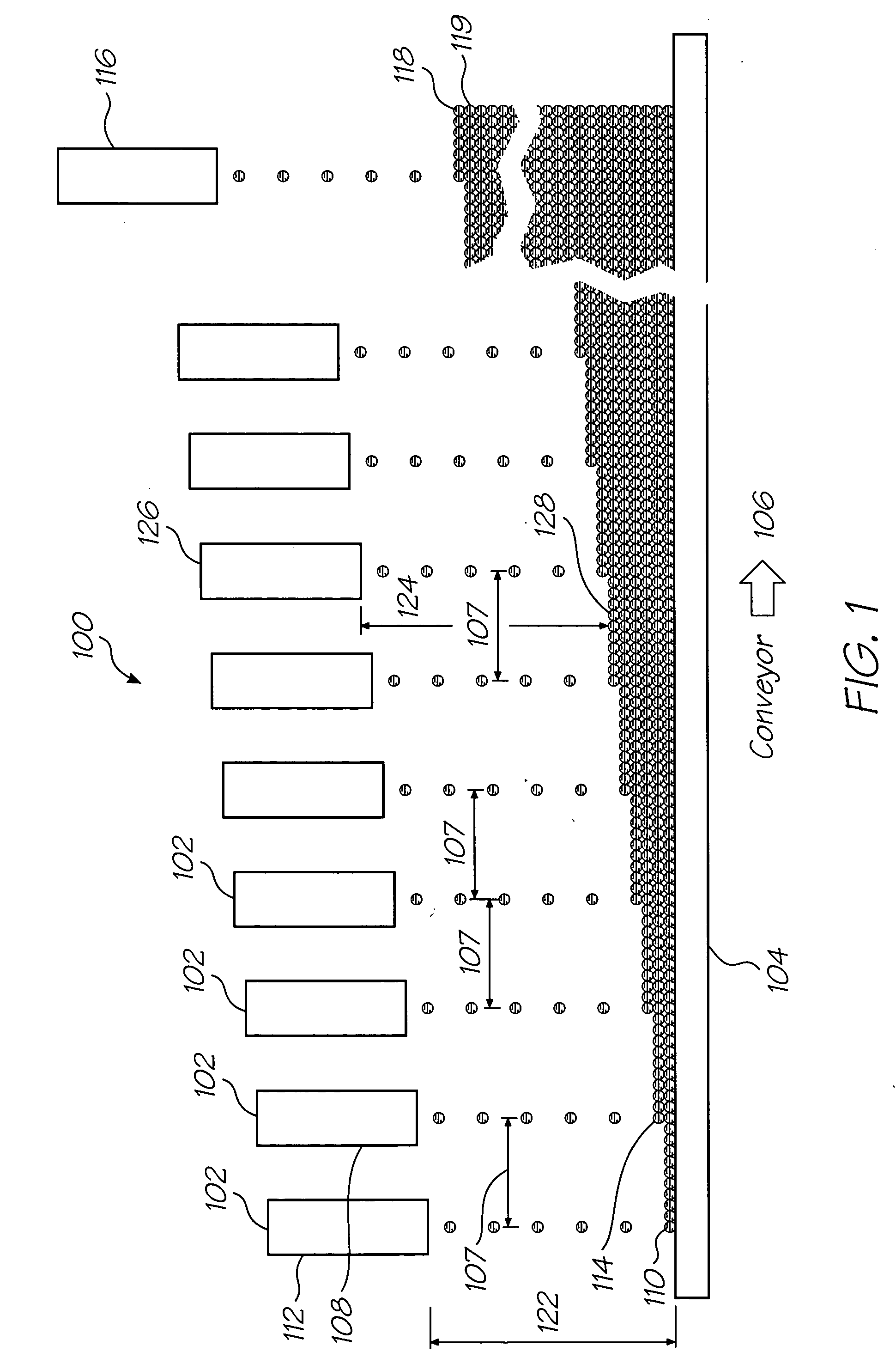

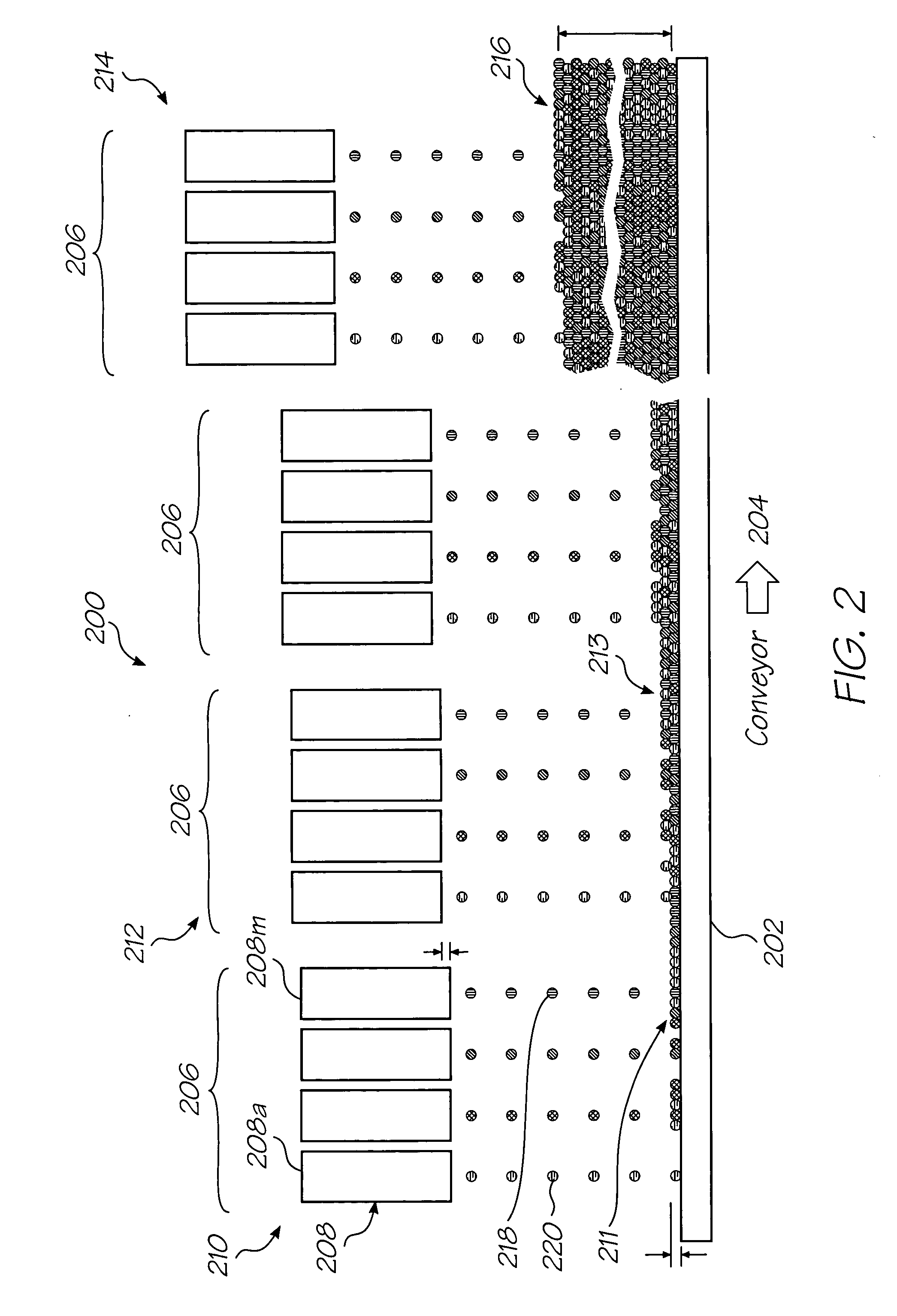

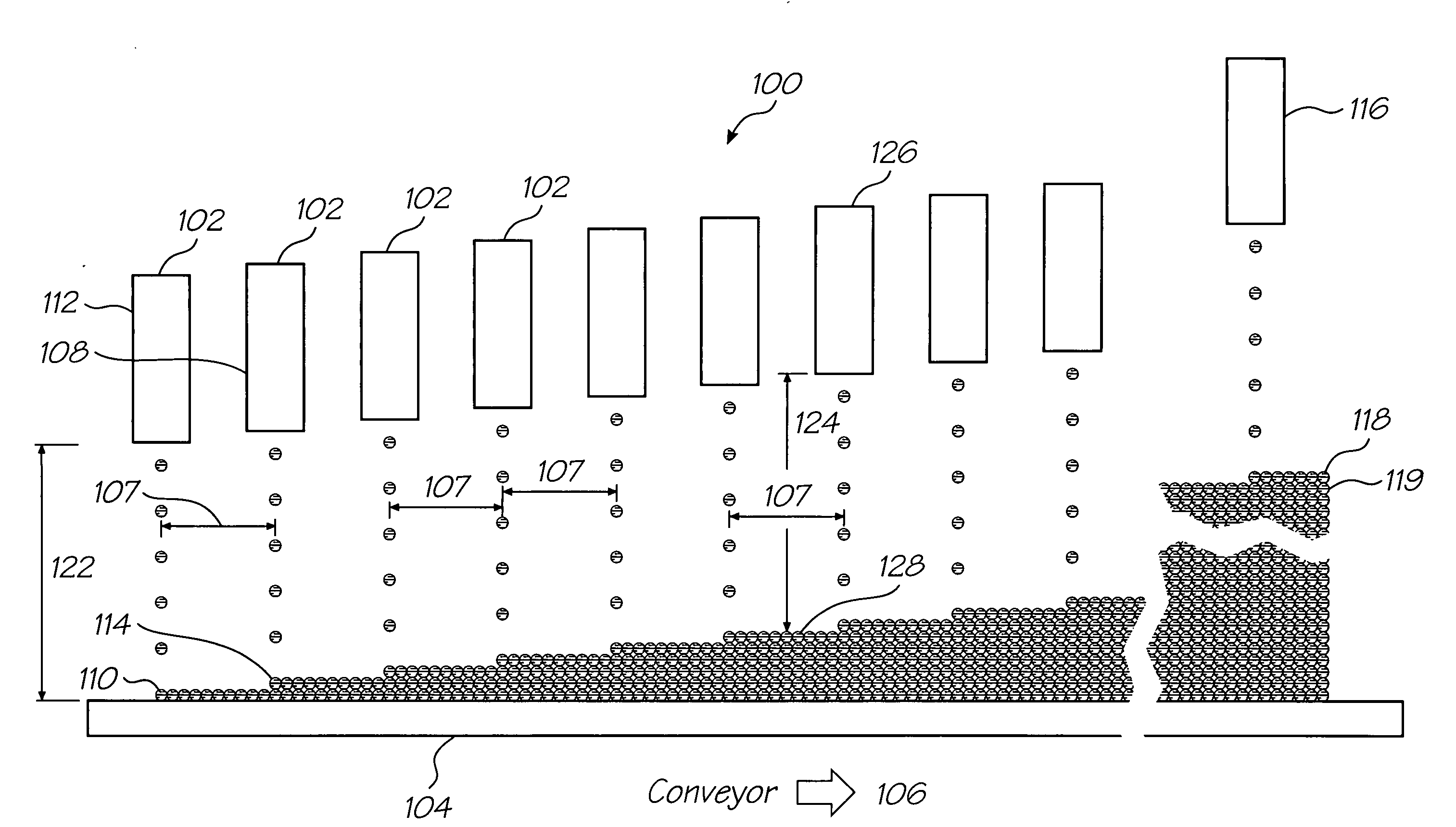

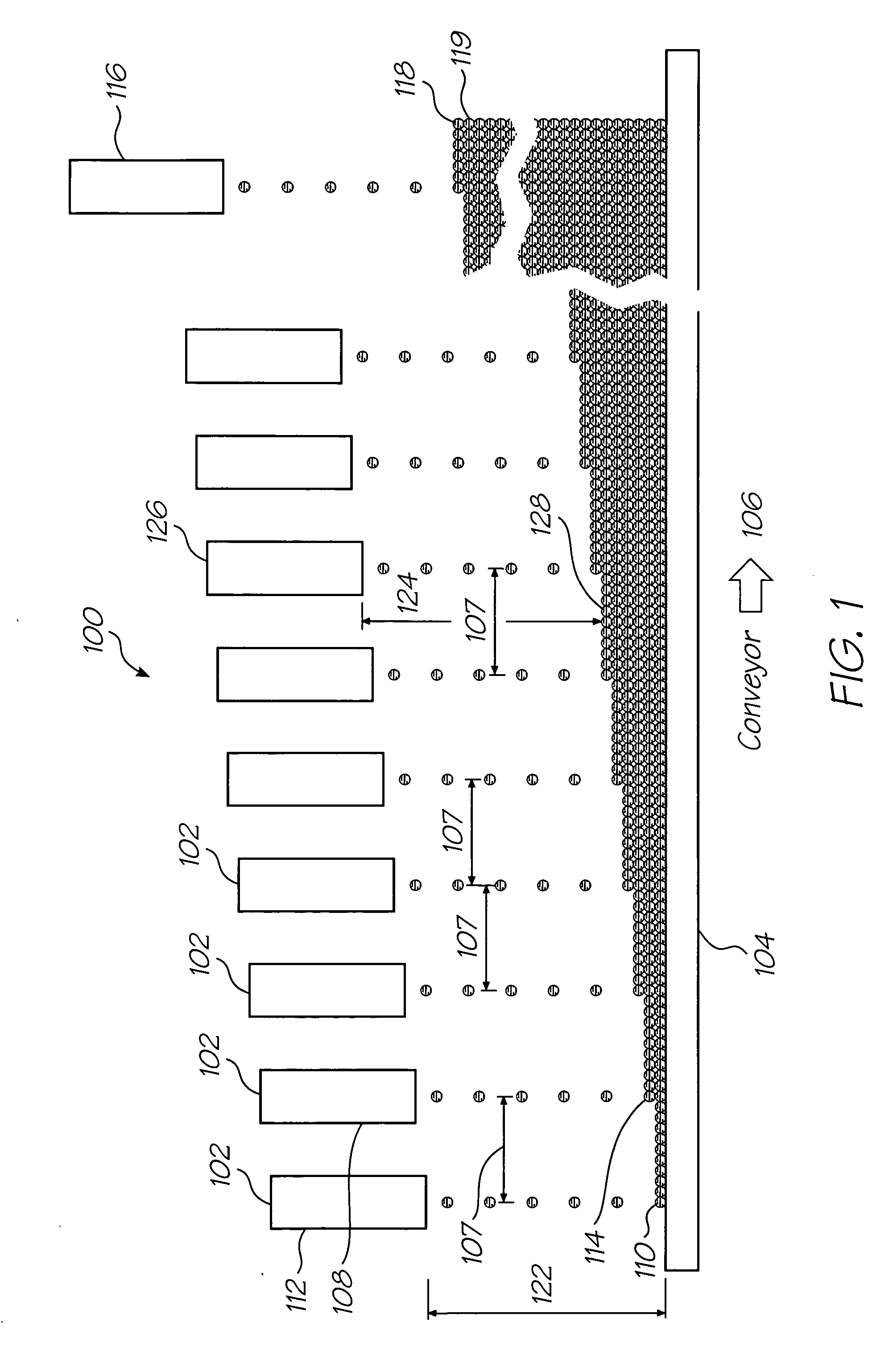

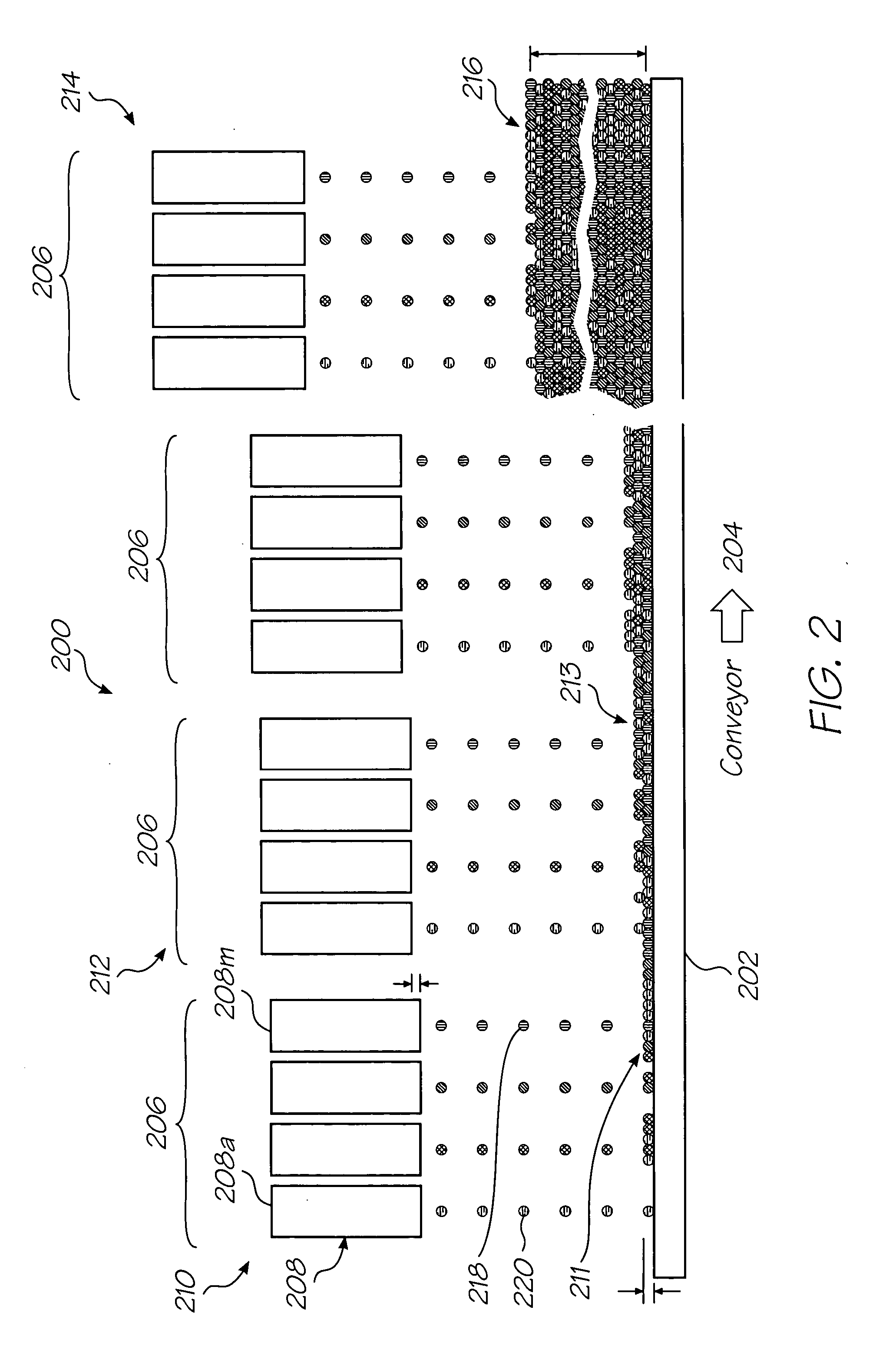

A method of cleaning thin glass substrates comprises applying a sequence of chemical washing steps as the thin glass substrate is being conveyed in a conveyance direction. In addition, surfaces of the glass substrate may be treated to enhance electrostatic discharge properties of the glass substrates.

Owner:CORNING INC

Printed product incorporating inorganic semiconductors

ActiveUS20040145629A1Constant speedIncrease speedAdditive manufacturing apparatusLiquid surface applicatorsSemiconductorManufacturing engineering

A printing system including at least one printhead for printing material to create a printed product, and an object incorporation device that incorporates inorganic semiconductors into the product being printed whilst the at least one printhead prints the product.

Owner:3D SYST INC

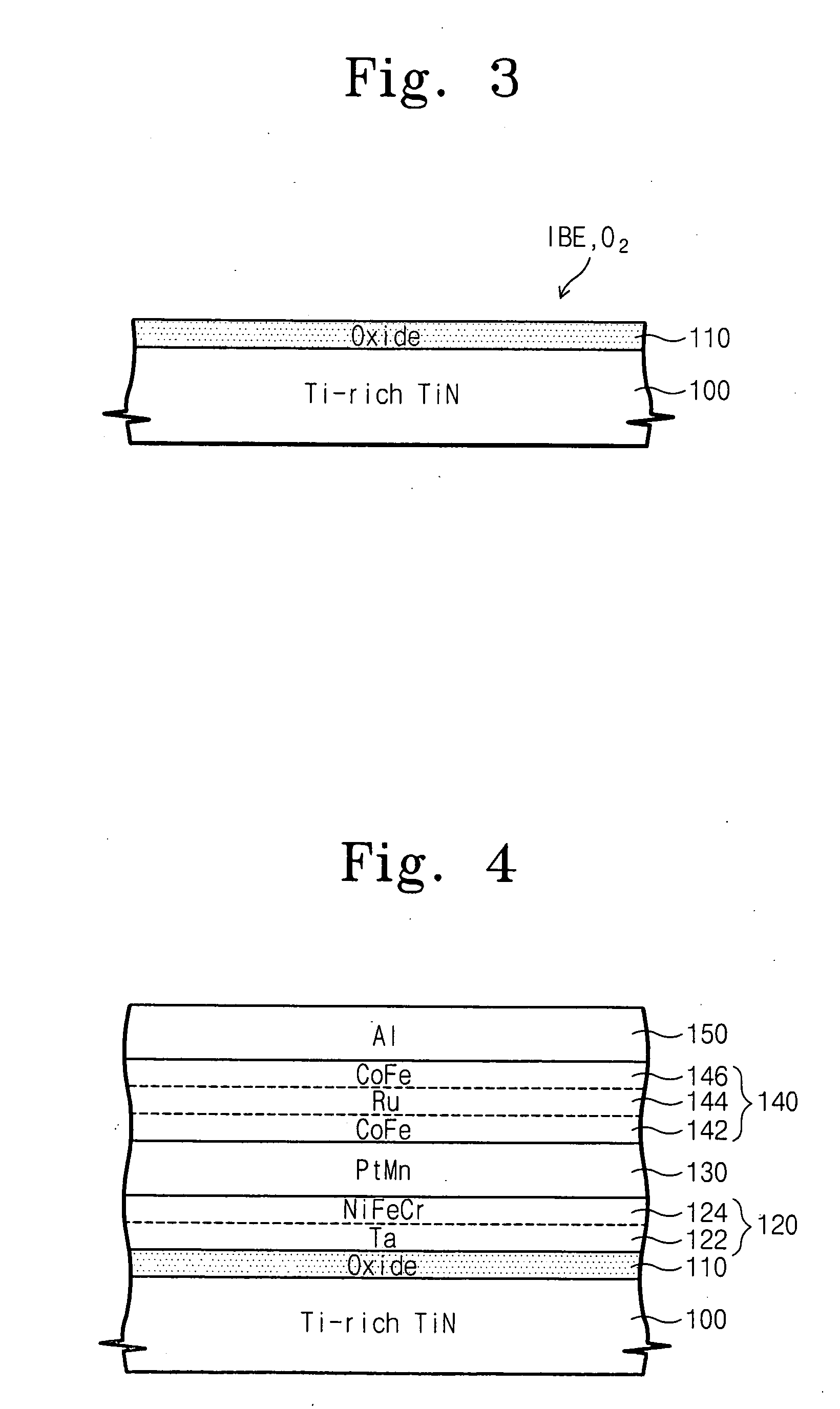

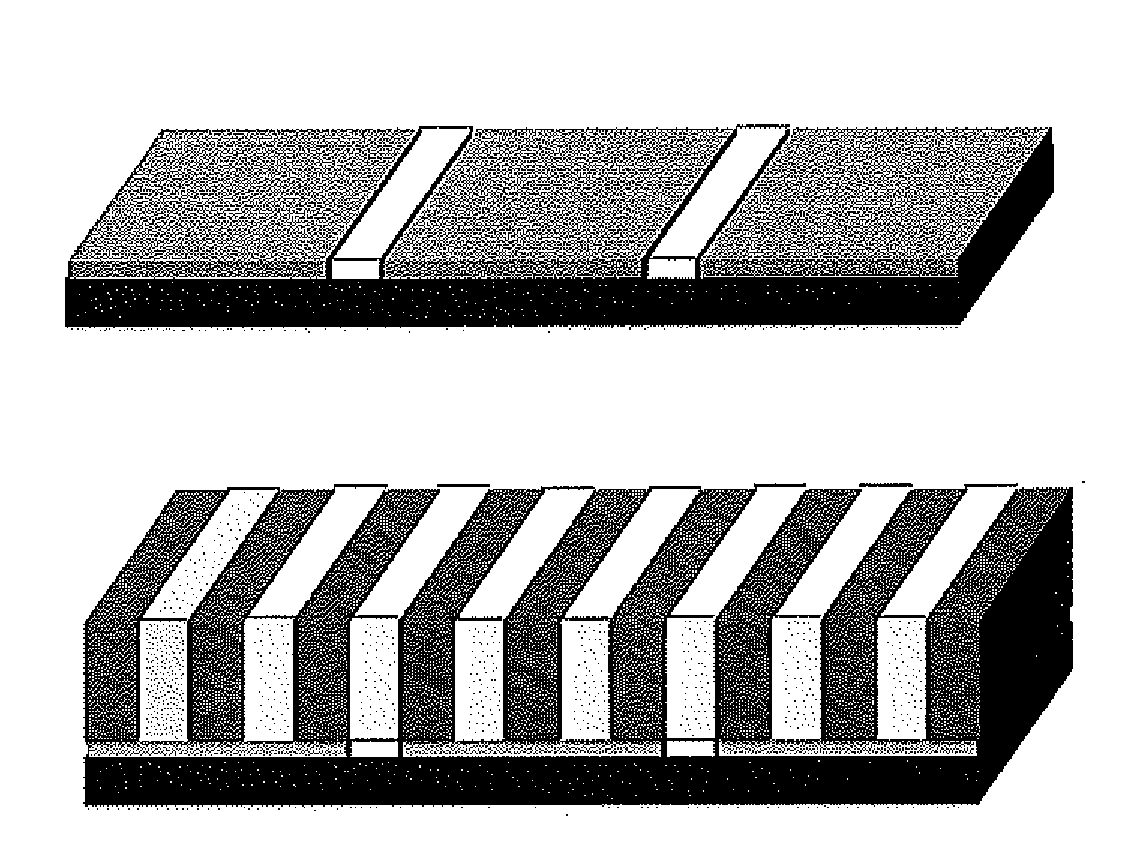

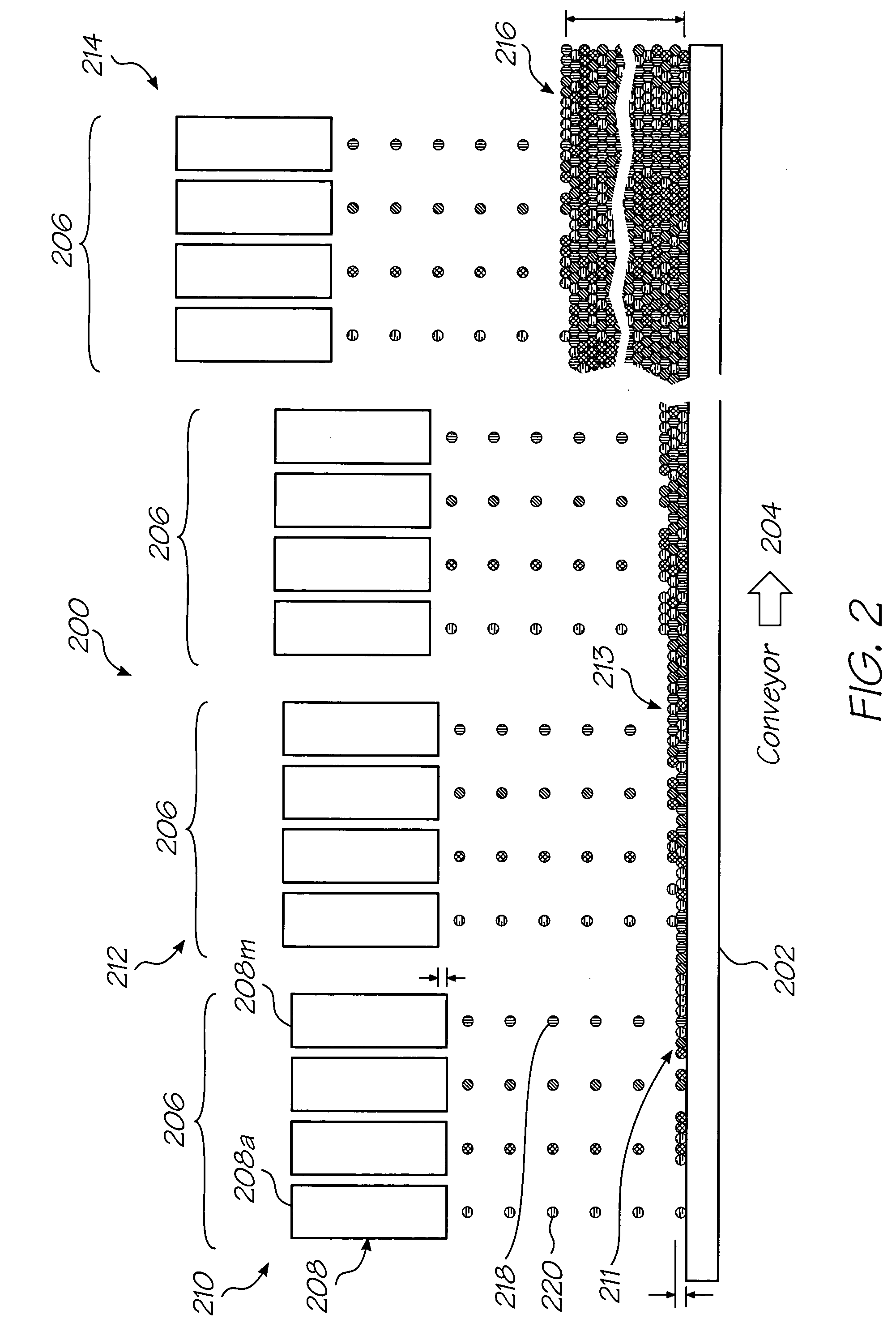

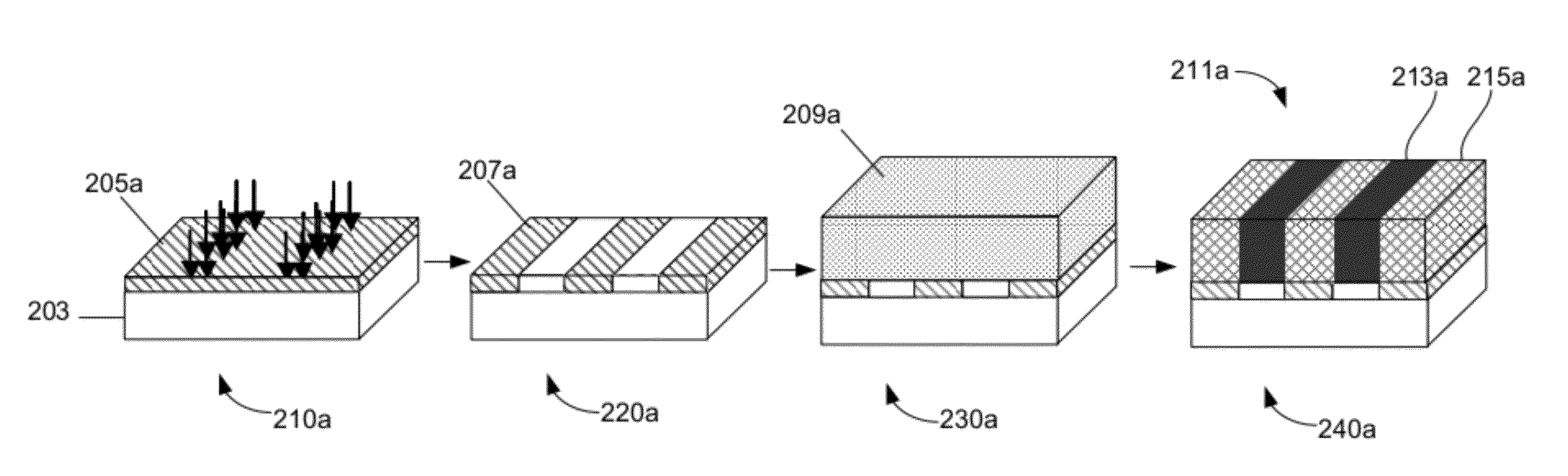

Solvent annealing block copolymers on patterned substrates

ActiveUS20120202017A1High degreeImproved size controlMaterial nanotechnologyDecorative surface effectsImage resolutionLine width

Provided herein are block copolymer thin film structures and methods of fabrication. Aspects described herein include methods of directed self-assembly of block copolymers on patterns using solvent annealing, and the resulting thin films, structures, media or other compositions. According to various embodiments, solvent annealing is used direct the assembly of block copolymers on chemical patterns to achieve high degrees of pattern perfection, placement of features at the precision of the lithographic tool used to make the chemical pattern, improved dimensional control of features, improved line edge and line width roughness, and resolution enhancement by factors of two to four or greater.

Owner:WISCONSIN ALUMNI RES FOUND

Resist composition, resin for use in the resist composition, compound for use in the synthesis of the resin, and pattern-forming method using the resist composition

ActiveUS20080081290A1Improve line edge roughnessAvoid it happening againPhotosensitive materialsRadiation applicationsActinic RaysCompound (substance)

A resist composition comprises: (A) a resin capable of increasing its solubility in an alkali developer by action of an acid; (B) a compound capable of generating an acid upon irradiation with actinic ray or radiation; (C) a resin having at least one of a fluorine atom and a silicon atom; and (D) a solvent, wherein the resin (C) has a degree of molecular weight dispersion of 1.3 or less and a weight average molecular weight of 1.0×104 or less.

Owner:FUJIFILM CORP

Positive photosensitive composition and pattern-forming method using the same

ActiveUS20060204890A1Simple compositionImprove line edge roughnessRadiation applicationsPhotomechanical apparatusActinic RaysSide chain

A positive photosensitive composition comprising: (A) a resin having at least one repeating unit having a specific lactone structure at a side chain and being capable of decomposing by the action of an acid to increase the solubility in an alkali developer; and (B) a compound capable of generating a specific acid upon irradiation with an actinic ray or a radiation, and a pattern-forming method using the positive photosensitive composition, are provided.

Owner:FUJIFILM HLDG CORP +1

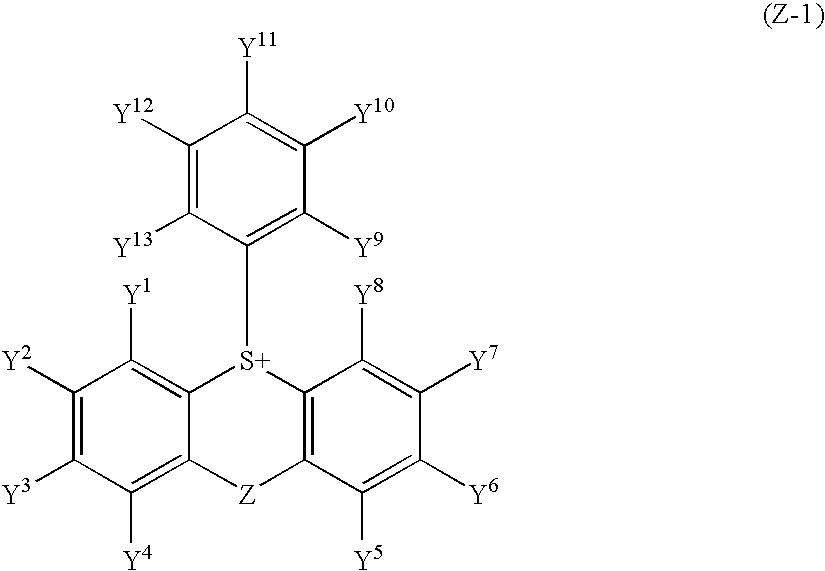

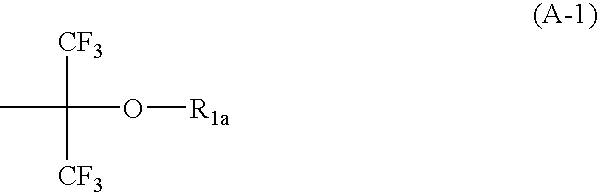

Positive resist composition and pattern formation method using the same

InactiveUS20070224540A1Improve performanceHigh sensitivityPhotosensitive materialsRadiation applicationsActinic RaysSulfonium

A positive resist composition containing a compound including a sulfonium cation having a structure represented by the formula (Z-I) as defined herein, a low molecular weight compound which increases solubility in an alkali developing solution by an action of an acid, and a compound which generates a compound having a structure represented by the formula (A-I) as defined herein upon irradiation of an actinic ray or a radiation.

Owner:FUJIFILM CORP

Positive photosensitive composition and method of forming resist pattern

ActiveUS20050019690A1High sensitivityImproved profileRadiation applicationsPhotosensitive material auxillary/base layersActinic RaysChemical compound

A positive photosensitive composition comprises: (A) 5 to 20 parts by weight of the total amount of at least one compound that generates an acid upon irradiation with an actinic ray; and (B) 100 parts by weight of the total amount of at least one fluorine atom-containing resin having a group that increases a solubility of the resin in an alkaline developer by the action of an acid.

Owner:FUJIFILM HLDG CORP +1

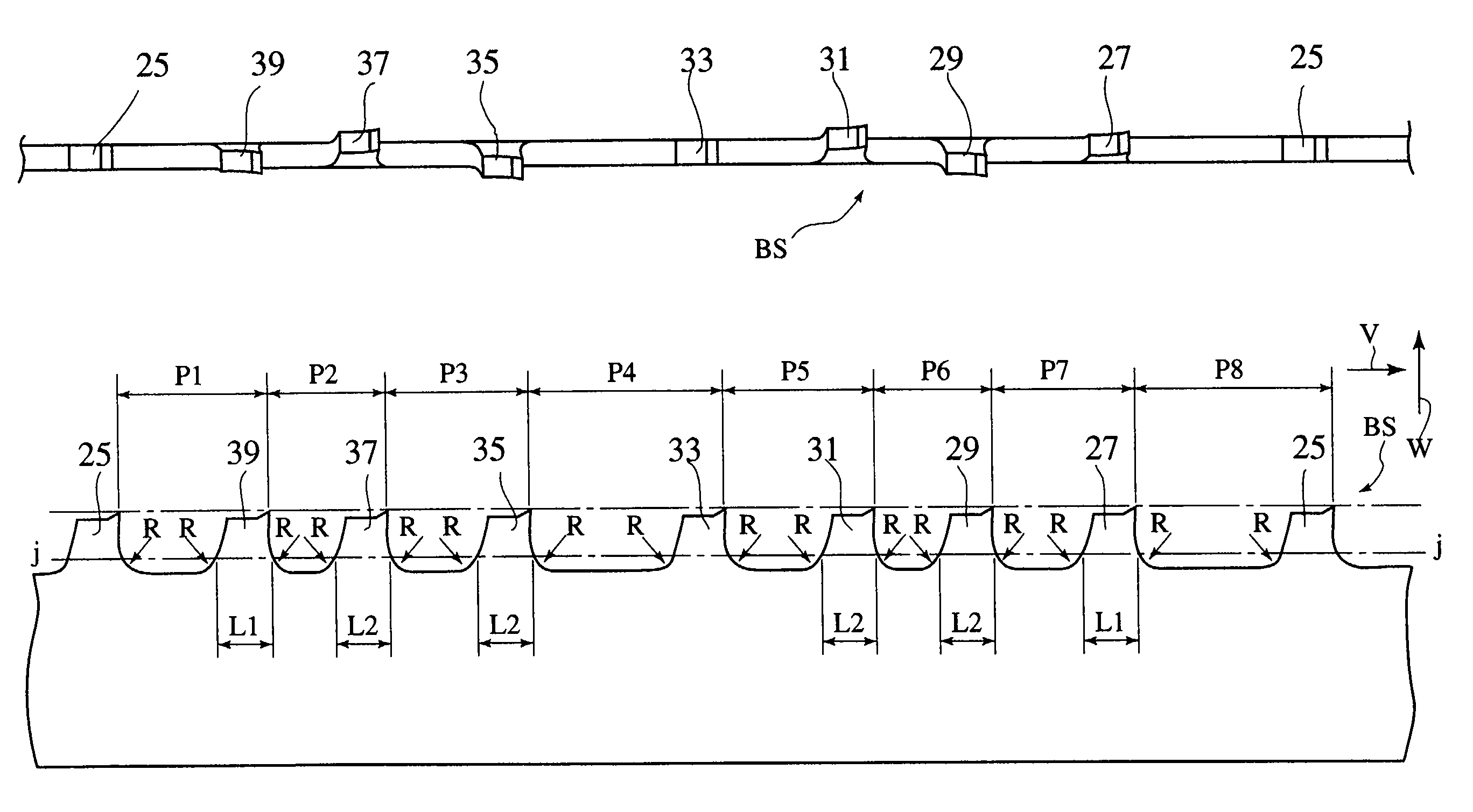

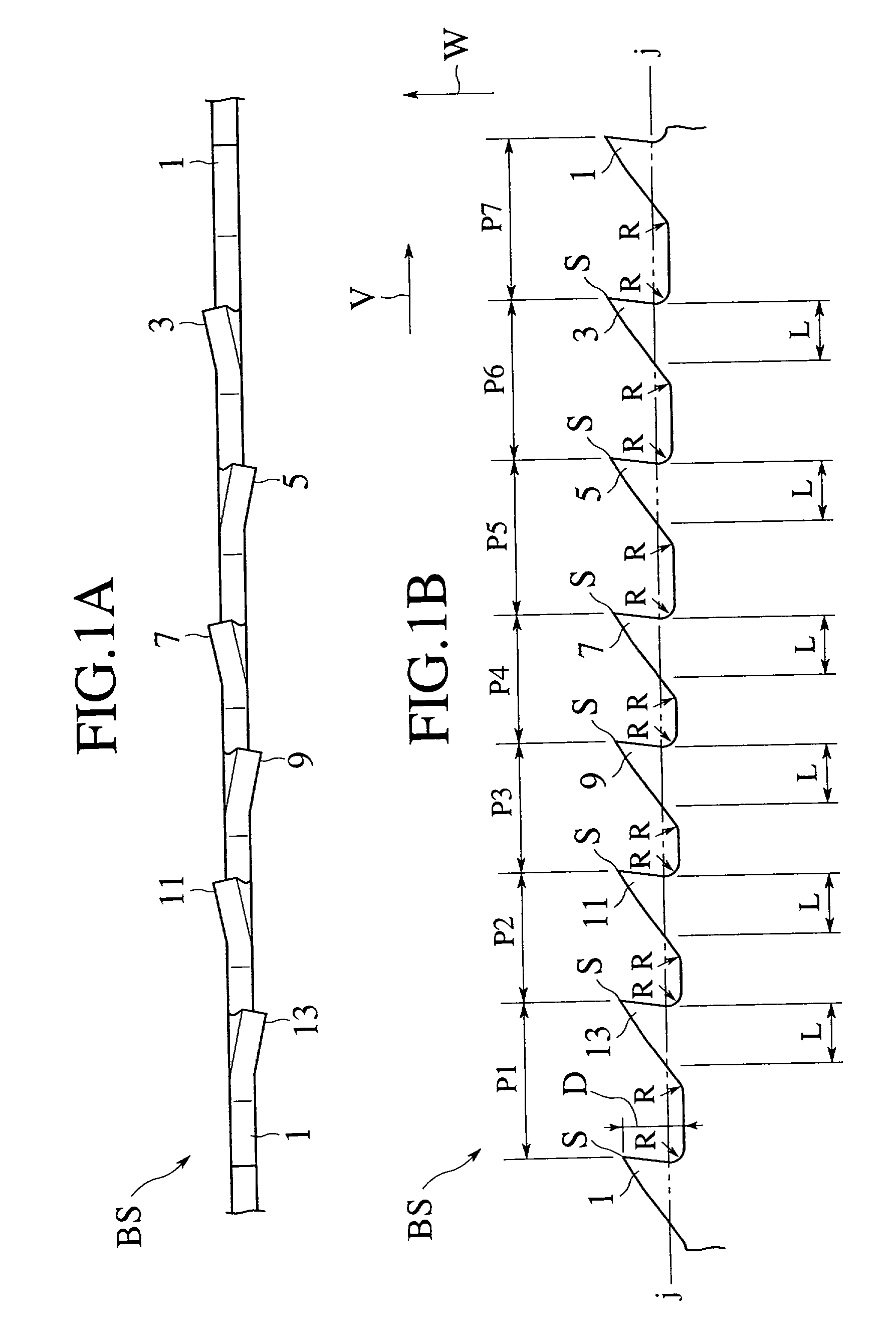

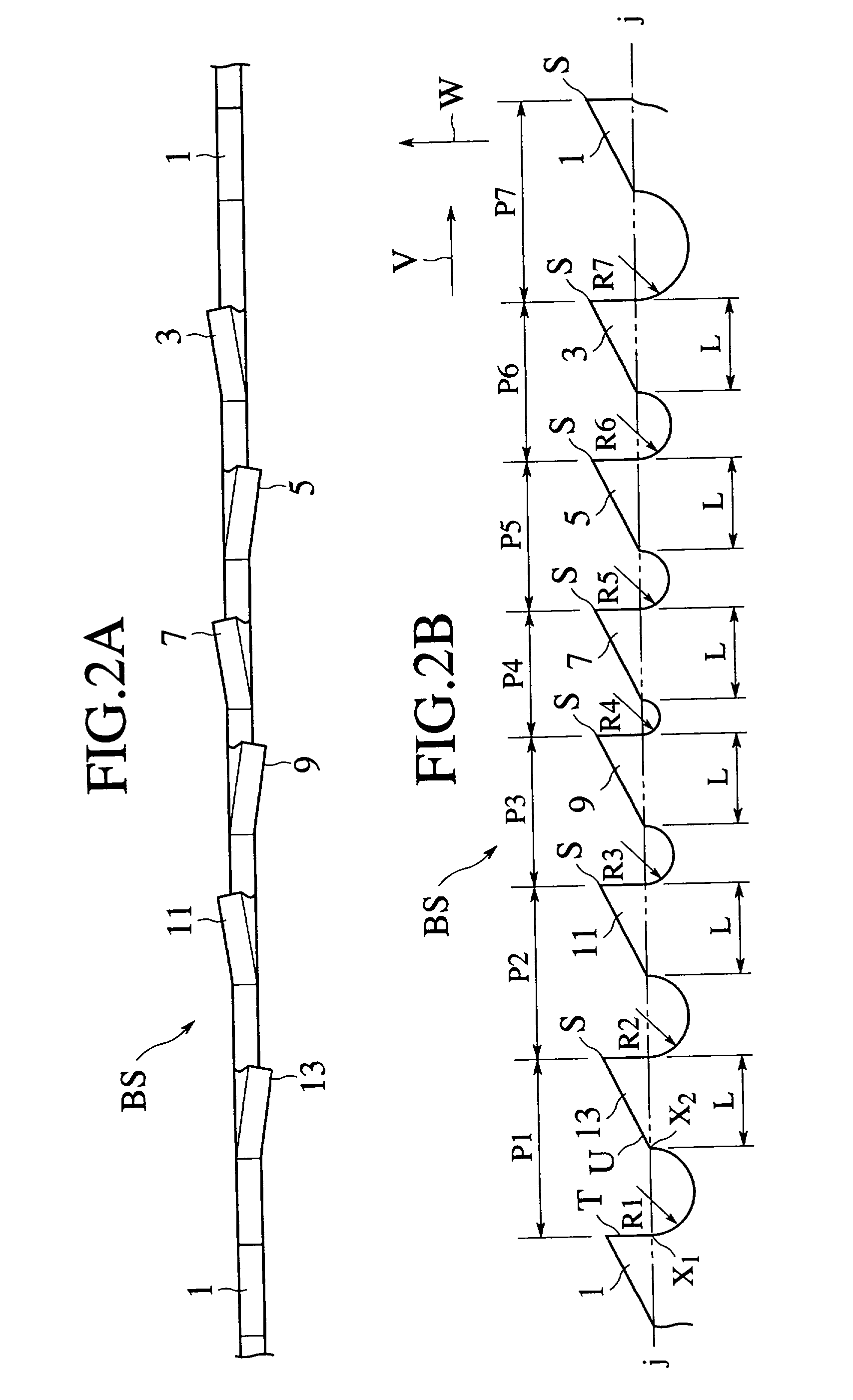

Band saw blade

InactiveUS7036415B2Easy to performImprove roughnessMetal sawing devicesMetal sawing toolsEngineeringMechanical engineering

Owner:AMADA CO LTD

Water-soluble total-synthesis metal working fluid and application thereof

The invention discloses a water-soluble total-synthesis metal working fluid and application thereof. The working fluid is prepared from the following raw materials in percentage by weight: 1wt%-30wt% of a lubricant, 1wt%-40wt% of a corrosion inhibitor, 1wt%-40wt% of organic amine, 1wt%-20wt% of a cleaning agent, 1wt%-20wt% of a coupling agent, 0.5wt%-5wt% of an antifoaming agent and the balance of water. The working fluid can form water-based steam with anti-rust property in an induction manner in the use procedure, so that the problem of rusting caused by steam which is easily generated by a closed machine tool is solved, and therefore, the working fluid is suitable for a high-precision machine tool, especially a numerical control machine tool with a closed structure.

Owner:TSINGHUA UNIV

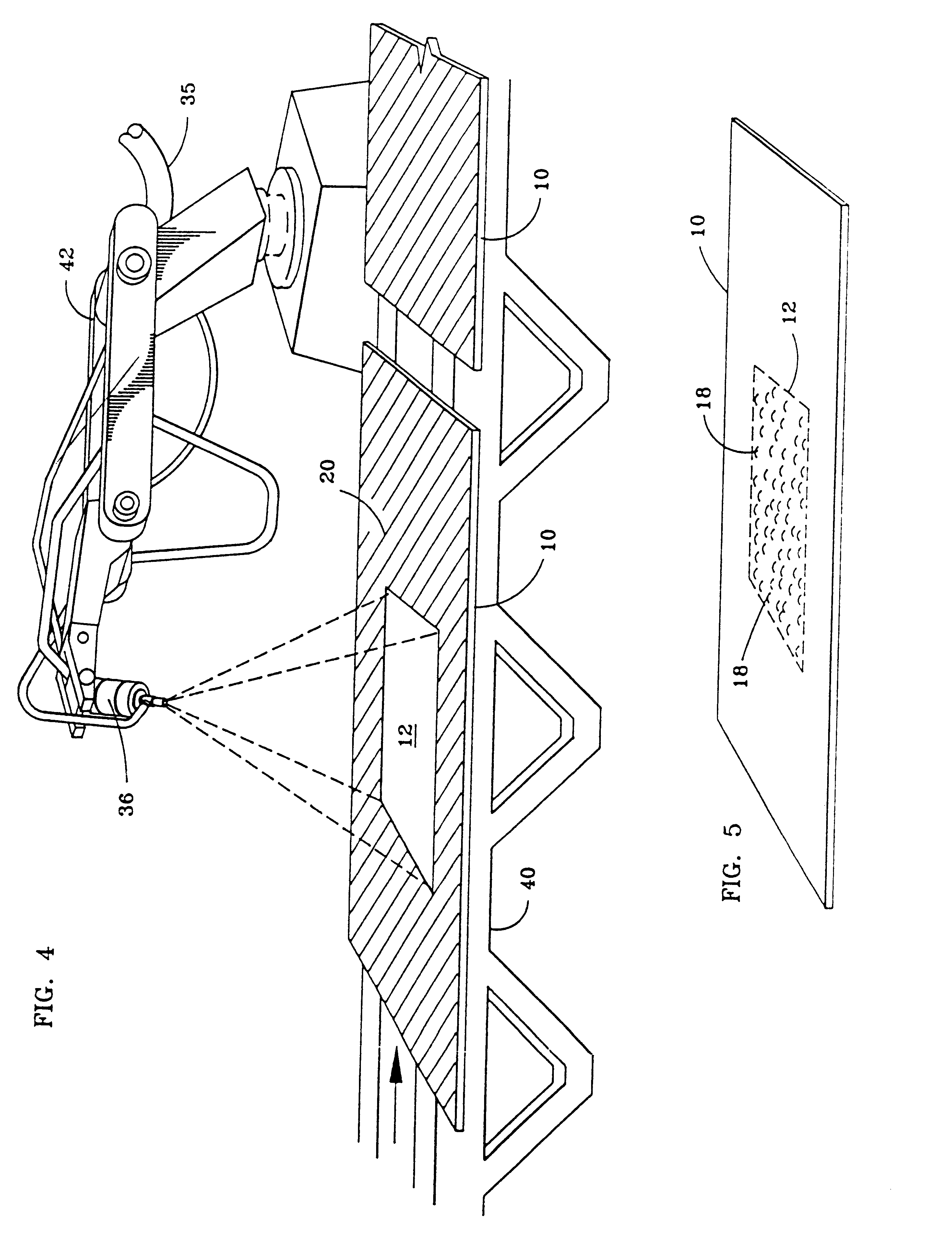

Thermoplastic products having antislip surfaces

InactiveUS6509084B2Effective antislip surface propertyGood adhesion and durability and wearabilityKitchenware cleanersCleaning machinesEngineeringVolcano

Thermoplastic products such as vehicle cargo area liners, floor mats, recreational and playground equipment, cargo pallets, and wet area walking surfaces are provided with an antislip surface treatment. The antislip surface is made up of individual non-interconnected asperities of an antislip polymer material, which do not form a continuous film over the surface of the thermoplastic product. The thermoplastic product is especially made of high density polyethylene. The antislip polymer is preferably a thermoset polymer, and most particularly is a polyurea / isocyanate polymer. The antislip polymer is preferably applied by spraying, and then the product is heat treated at a temperature in the range from 100 to 200° F., or is thermoformed at a temperature in the range from 250 to 550° F. The antislip asperities are durably bonded onto the thermoplastic base material, and provide a significantly increased coefficient of friction. The asperity size, height, and hardness can be controlled by adjusting the processing conditions. The asperities may have an increased surface relief due to a so-called "moth effect" and an increased surface roughness due to cratering as a result of a so-called "volcano effect" in the process using thermoforming.

Owner:CUSTOM PLASTICS MOLDING

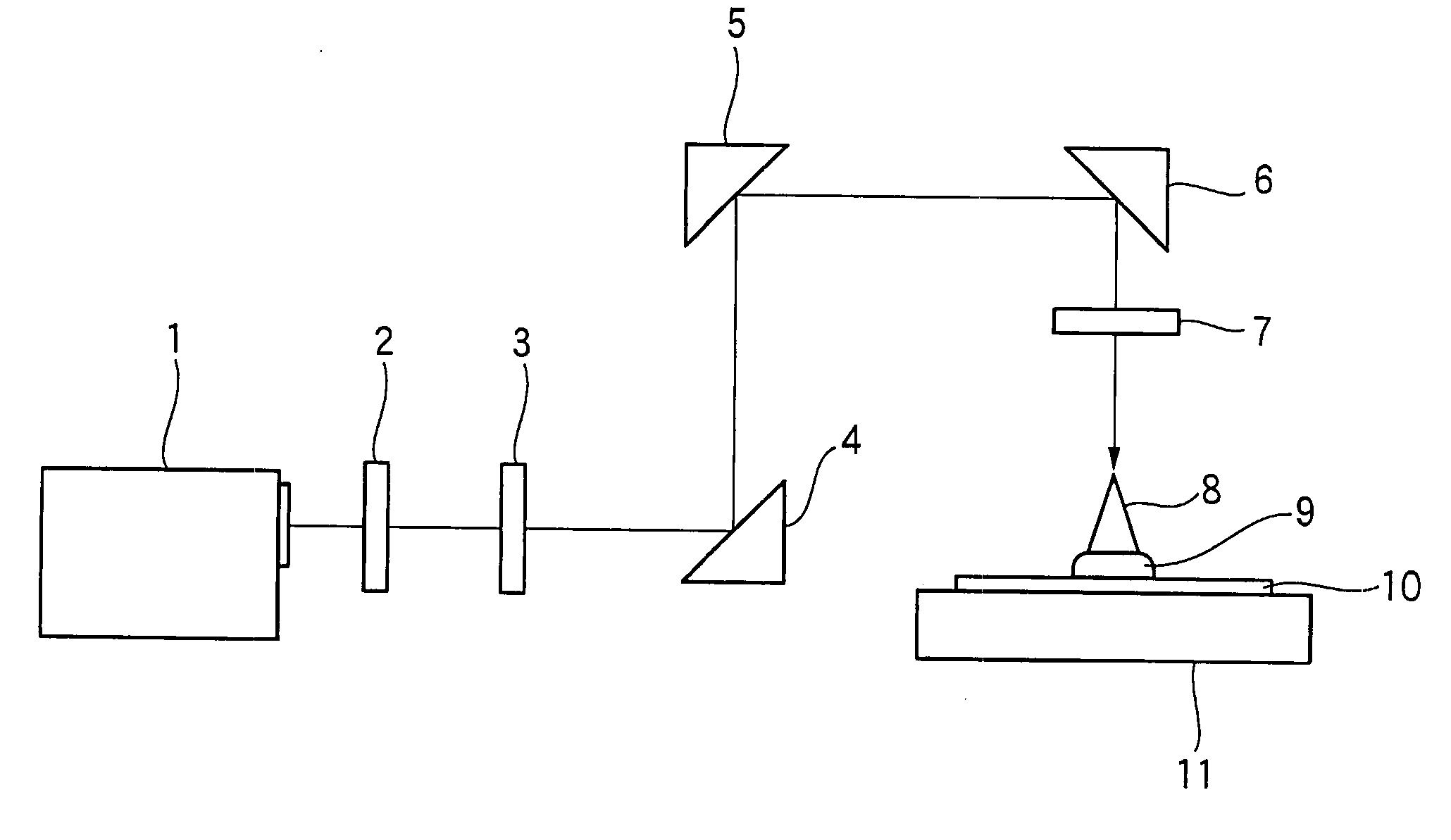

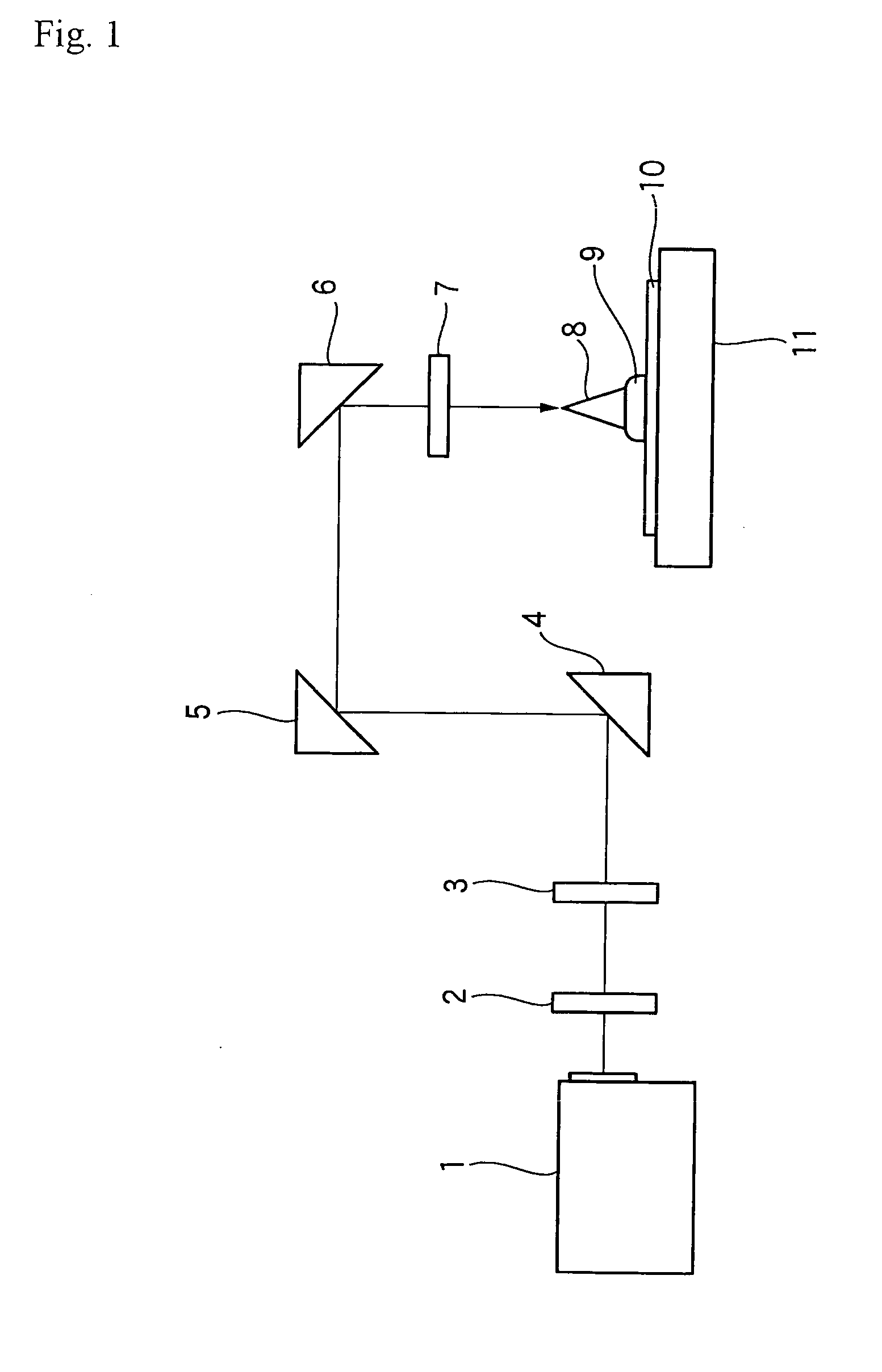

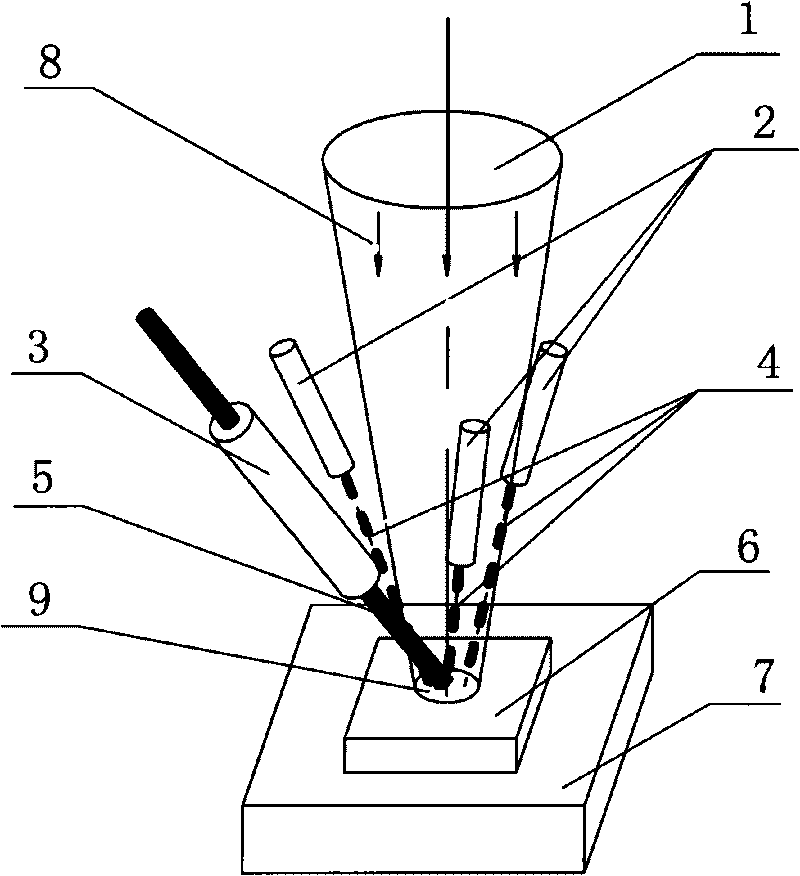

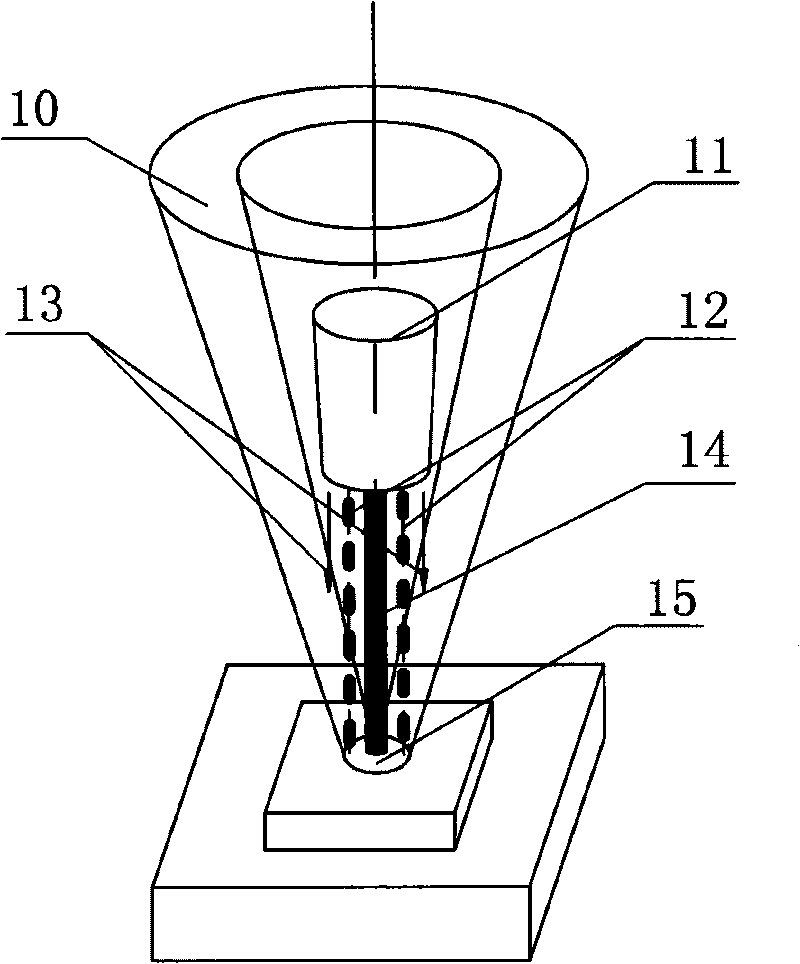

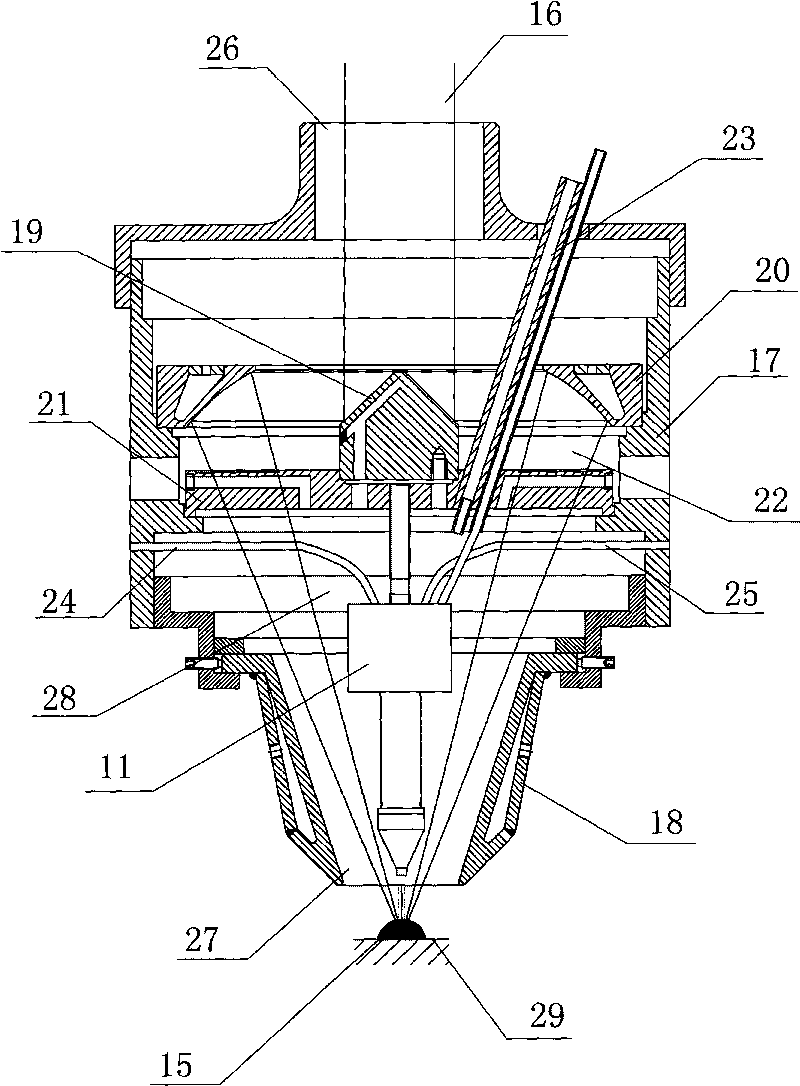

Welding wire sending and pulverized solder sending laser cladding forming method and device

InactiveCN101733550AIncrease peripheral light intensityOvercoming the deficiency of undermeltingLiquid spraying apparatusWelding/cutting media/materialsLight beamLaser beams

The invention discloses a welding wire sending and pulverized solder sending laser cladding forming method. The method is characterized in that a conscope is used to change a solid laser beam transmitted by a laser to an annular light beam through light path transformation, then an annular focus lens is used to focus the annular light beam to an annular conical light beam, a hollow conical aphotic zone is formed in the annular conical light beam, a welding wire sending and pulverized solder sending protective gas composite nozzle is arranged in the aphotic zone and has the same axis of the annular conical light beam, a welding wire sending hole is arranged in the center, parallel pulverized solder sending holes are around the welding wire sending hole, collimating protective gas holes are parallel to and around the pulverized solder sending holes, wire is sent to a molten pool through the welding wire sending hole along the axial direction of the light beam and vertically to a machining face, airborne pulverized solder is sent to the molten pool through the pulverized solder sending holes at the same time, and collimating protective gas surrounds the welding wire and pulverized solder and is blown to the molten pool. The invention adopts the welding wire sending and pulverized solder sending protective gas composite nozzle to realize welding wire, pulverized solder and protective gas composite cladding and solve the defects of the prior art.

Owner:SUZHOU UNIV

Method of making an alumina deposit on a substrate covered in sic

ActiveUS20080264176A1Improve toughnessEnhancing mechanical anchoringMolten spray coatingWave amplification devicesThermal sprayingStrain gauge

The invention relates to a method of depositing an alumina coating on a part having a silicon carbide surface. The method comprises the following steps:a) depositing a silicon adhesion underlayer on the SiC surface by chemical vapor spraying; andb) depositing a coating on the silicon adhesion underlayer by atmospheric thermal spraying.The invention also provides a device for measuring deformation, which device comprises a first alumina coating obtained by atmospheric thermal spraying onto the silicon adhesion underlayer deposited on the silicon carbide layer covering the substrate of the part, a free filament strain gauge placed on the coating, and an additional alumina coating obtained by atmospheric thermal spraying onto the strain gauge.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Digitally active 3-D object creation system

ActiveUS20040141030A1Increased substrate speedIncrease speedLiquid surface applicatorsConfectioneryEngineeringMultiple layer

Owner:3D SYST INC

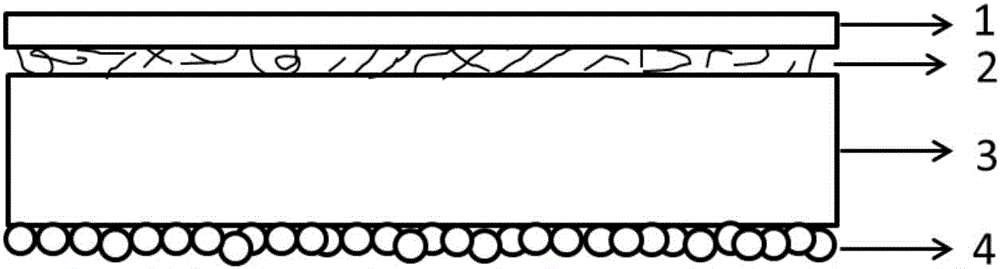

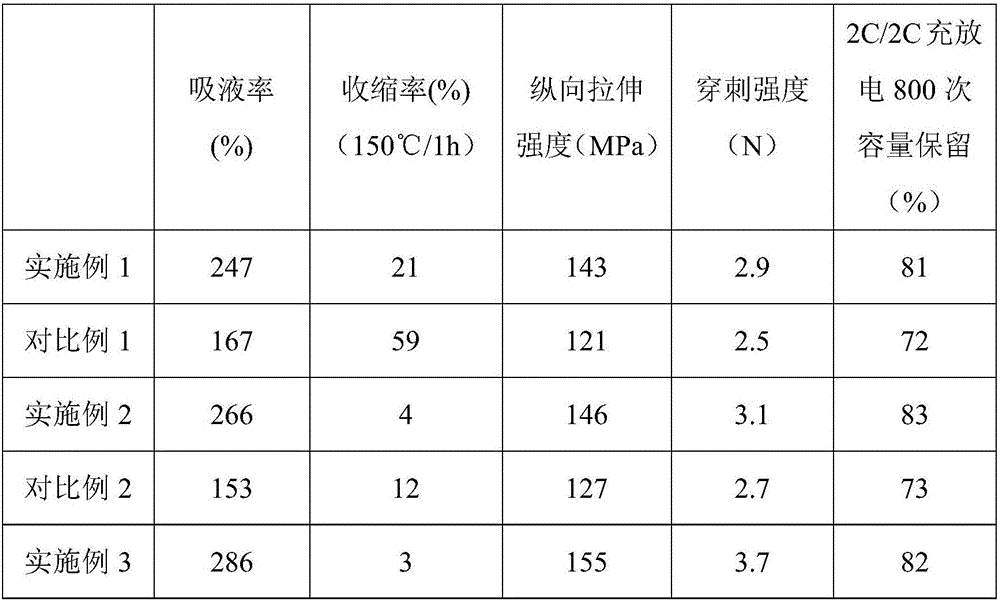

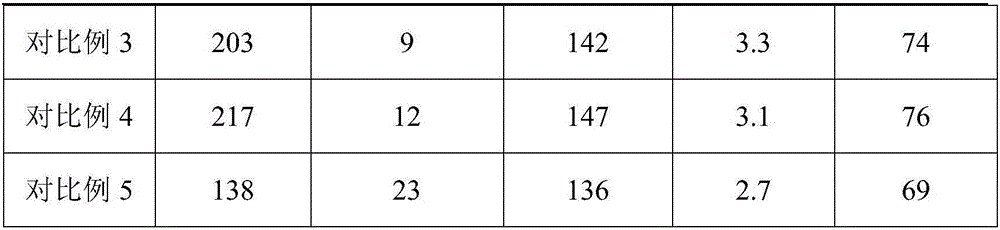

Lithium-ion battery separator subjected to composite coating treatment and preparation method thereof

ActiveCN106252565ATight bondIncrease volumetric energy densityFireproof paintsCell component detailsLithium-ion batteryAramid

The invention discloses a lithium-ion battery separator subjected to composite coating treatment and a preparation method thereof. The lithium-ion battery separator comprises a basement membrane, a polymer coating coated at one side of the basement membrane, and an inorganic particle coating coated at the other side of the basement membrane; the polymer coating is composed of an aramid coating coated on the basement membrane and a polyvinylidene fluoride coating coated on the aramid coating, and the thickness of the polymer coating is 0.3 to 5 [mu] m; and the inorganic particle coating is composed of inorganic particles of different particle sizes and a binding agent, and the thickness of the inorganic particle coating is s 0.5 to 5 [mu] m. The lithium-ion battery separator provided by the invention has the characteristics of being excellent in mechanical property and heat resistant property, having good wettability and solution preserving property to electrolyte, and excellent in cycle performance and high in safety performance.

Owner:深圳市鼎泰祥新能源科技有限公司

Interconnects containing bilayer porous low-k dielectrics using different porogen to structure former ratio

InactiveUS20080171431A1High strengthHigh hardnessRadiation applicationsSemiconductor/solid-state device detailsAtomic compositionDielectric permittivity

A bilayer porous low dielectric constant (low-k) interconnect structure and methods of fabricating the same are presented. A preferred embodiment having an effective dielectric constant of about 2.2 comprises a bottom deposited dielectric layer and a top deposited dielectric layer in direct contact with the former. The bottom layer and the top layer have same atomic compositions, but a higher dielectric constant value k. The bottom dielectric layer serves as an etch stop layer for the top dielectric layer, and the top dielectric layer can act as CMP stop layer. One embodiment of making the structure includes forming a bottom dielectric layer having a first porogen content and a top dielectric layer having a higher porogen content. A curing process leaves lower pore density in the bottom dielectric layer than that left in the top dielectric layer, which leads to higher dielectric value k in the bottom dielectric layer.

Owner:TAIWAN SEMICON MFG CO LTD

Fluorinated resins having a surface with high wettability

InactiveUS6432510B1Improve wettabilityIncrease roughnessSemi-permeable membranesSynthetic resin layered productsPolymer scienceCompatibilization

A fluorinated resin having enhanced wettability to water prepared by roughening a surface of the fluorinated resin such that a central line roughness average (Ra) of the surface is increased to at least 0.1 mum, and then depositing thereon a thin hydrophilic film while maintaining the central line roughness average (Ra) of at least 0.1 mum, the thin hydrophilic film being formed from a hydrophilic substance having a contact angle of water of less that 90°, and the resulting fluorinated resin having up to 20° of contact angle of water. The fluorinated resins are able to maintain high hydrophilicity even after prolonged exposure to the atmosphere and can be used in various fields that require bio-compatibility and in permeable membranes or filters.

Owner:SAMSANG CORP

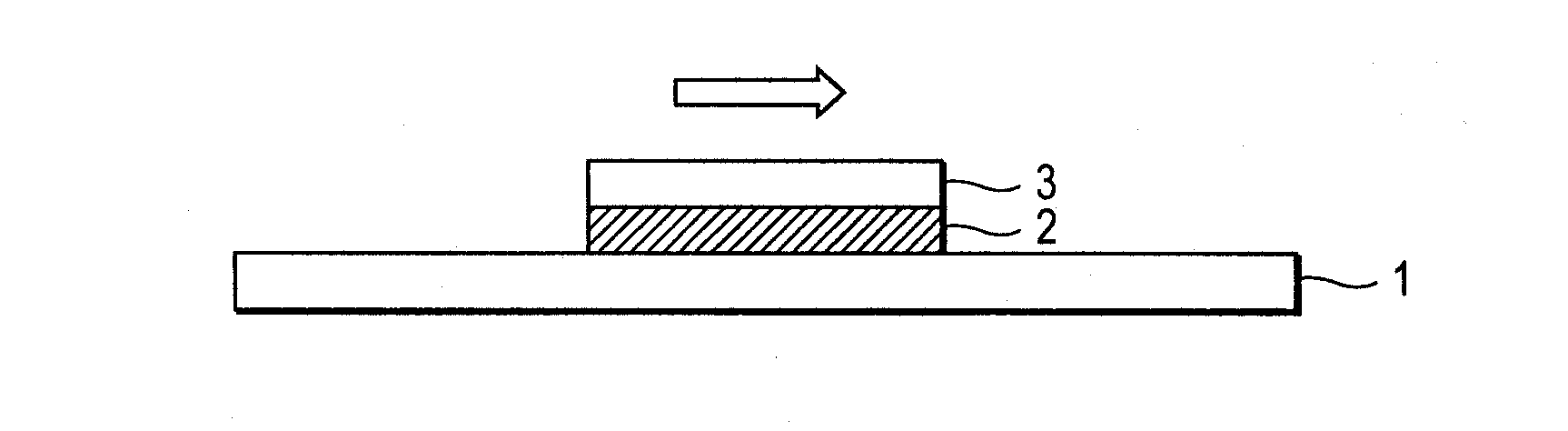

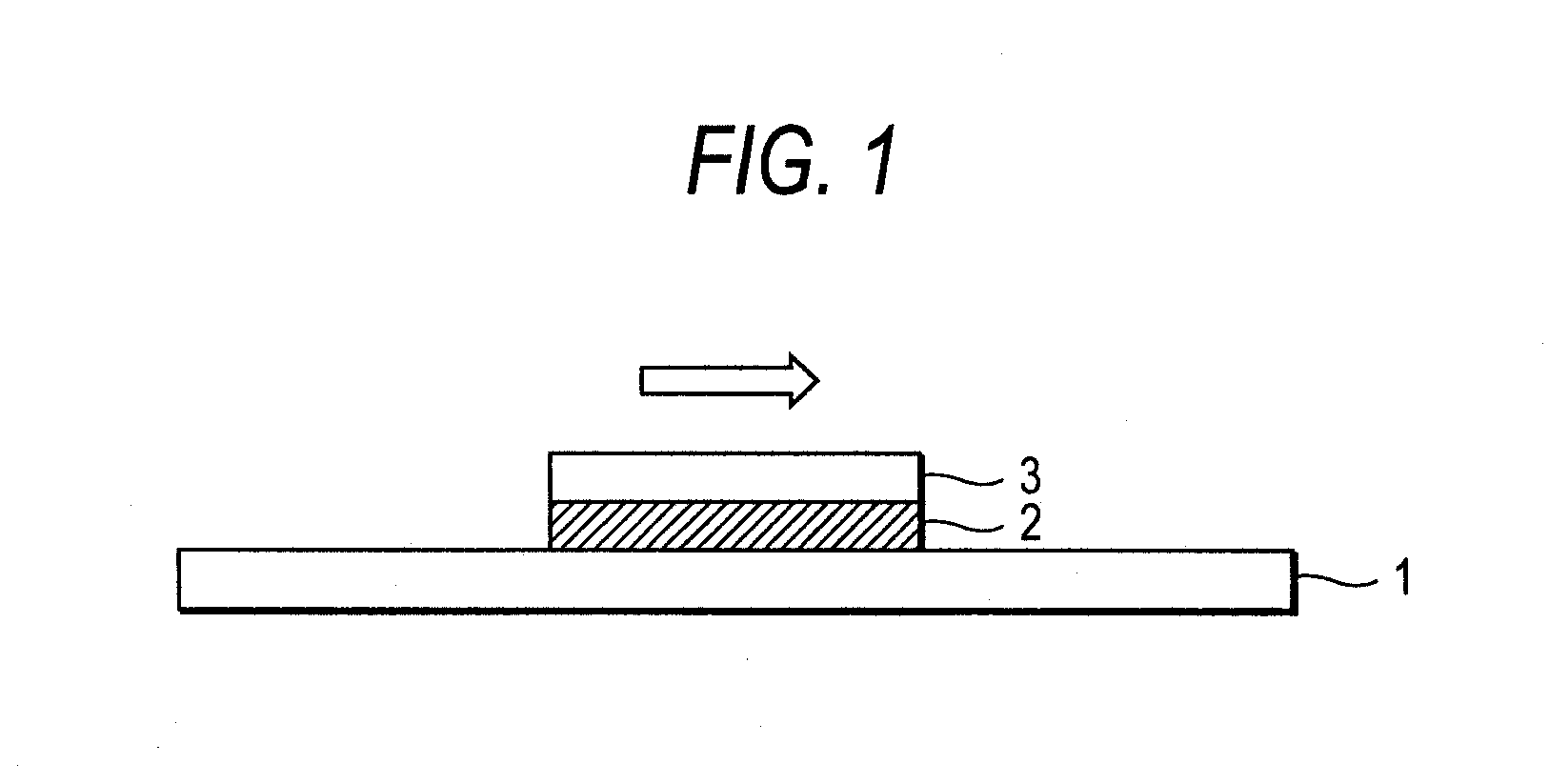

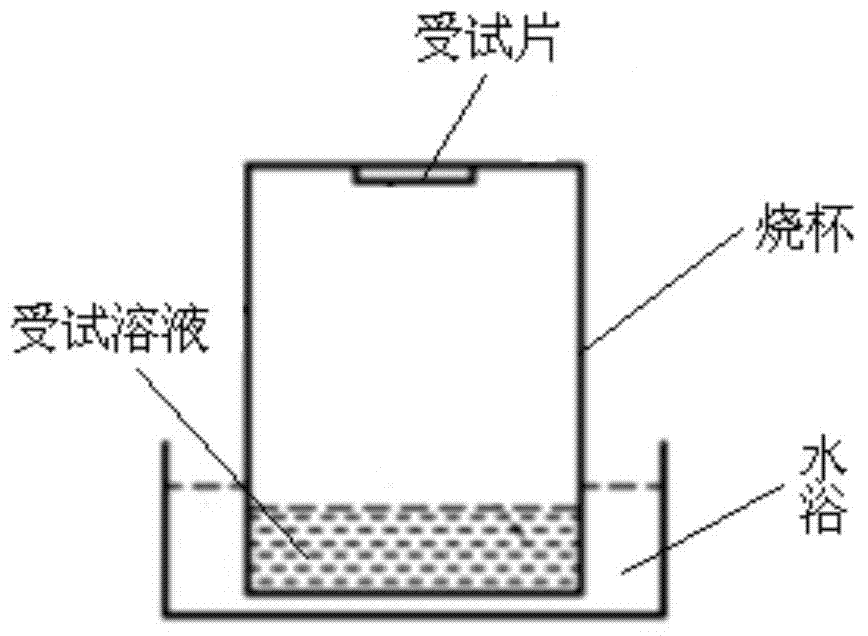

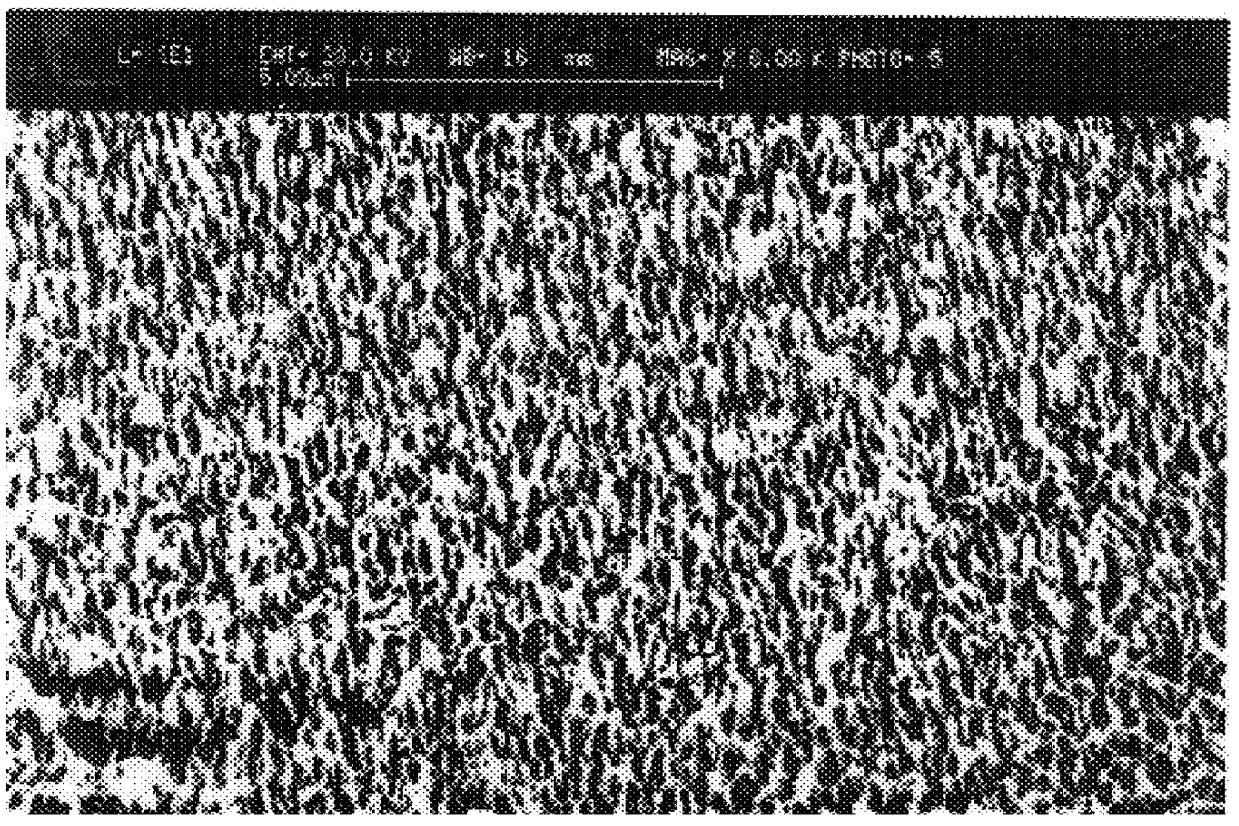

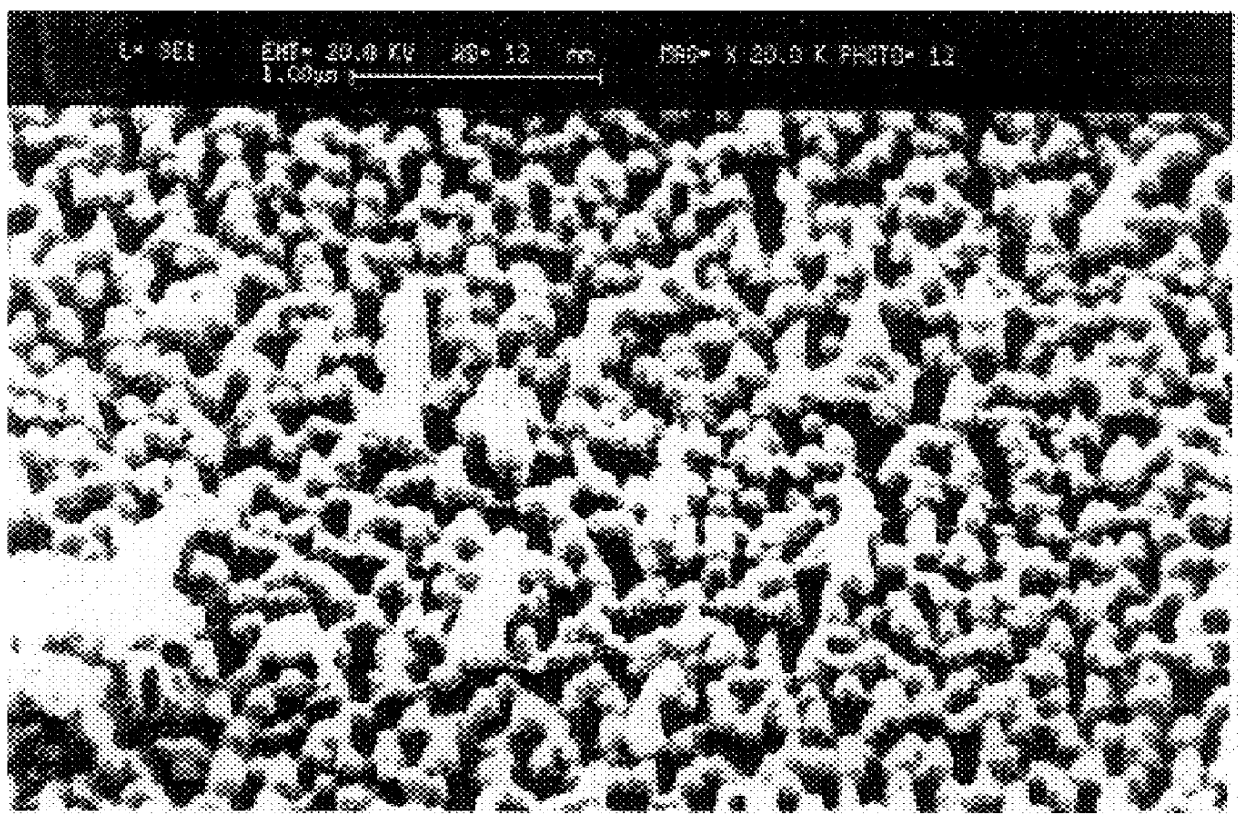

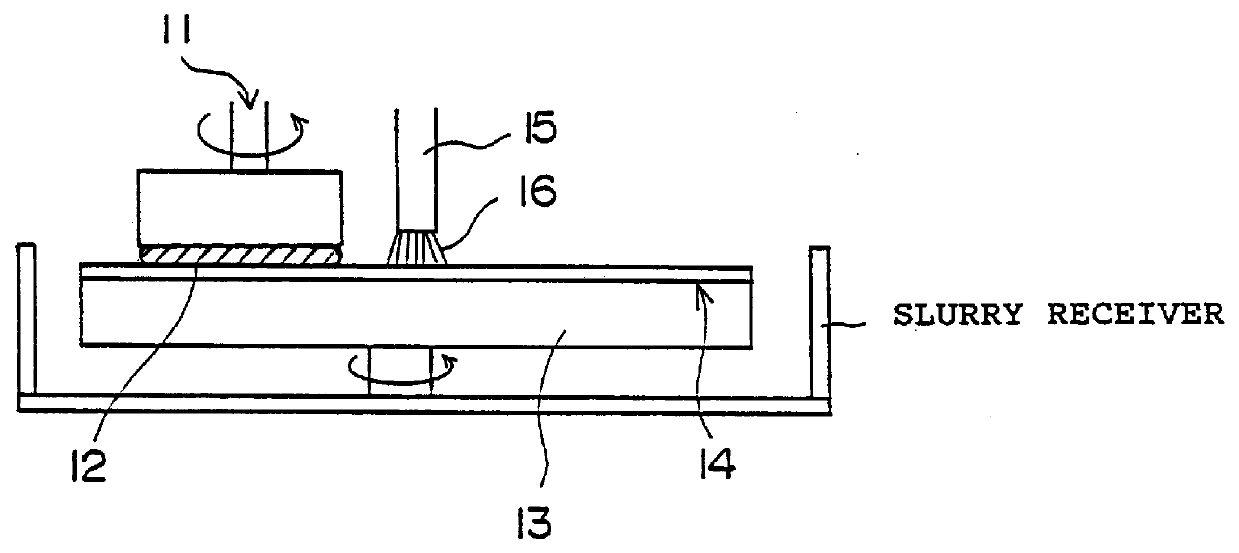

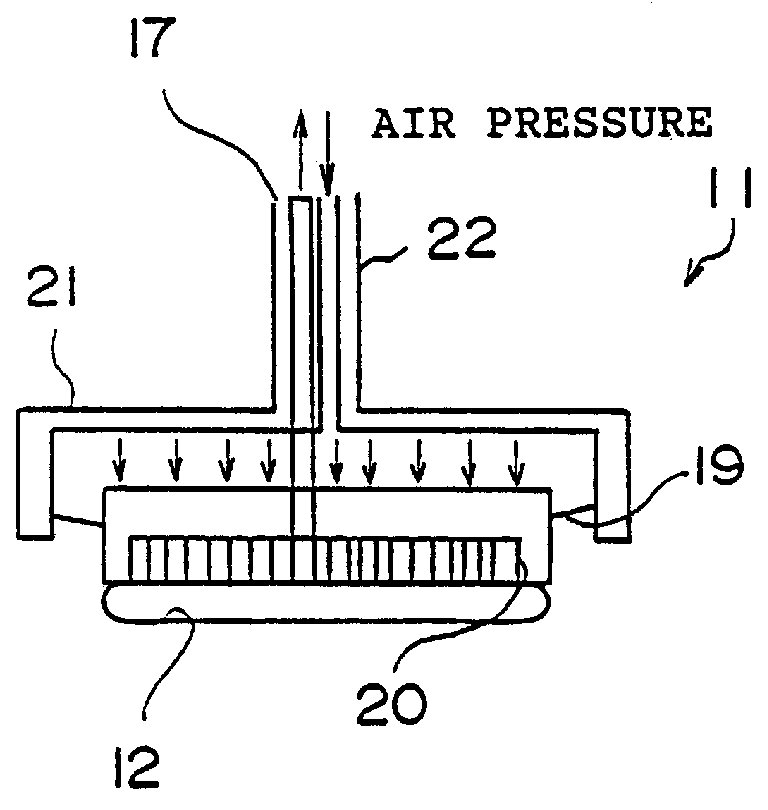

Polishing method for semiconductor wafer and polishing pad used therein

InactiveUS6120353AGood haze levelIncrease roughnessLapping machinesFlexible-parts wheelsEngineeringSemiconductor

In a polishing method for a semiconductor wafer in which polishing slurry is interposed between the semiconductor wafer and a polishing pad and the semiconductor wafer is mirror-polished by a polishing step for planarization, when polishing is conducted using a suede-like foam urethane resin polishing pad having physical properties of low compressibility lower than 9 % and high pore density equal to or higher than about 150 pores / cm.sup.2 as the polishing pad used in the polishing step, a mirror silicon wafer with good surface roughness of 50 bits in haze can be manufactured.

Owner:SHIN-ETSU HANDOTAI CO LTD

Fluorine-free superhydrophobic finishing agent containing modified nano silicon dioxide hydrosol and application thereof

ActiveCN102021819AExcellent water repellencyBasic physical and mechanical propertiesSilicon compoundsVegetal fibresOrganic solventHYDROSOL

The invention relates to a fluorine-free superhydrophobic finishing agent containing modified nano silicon dioxide hydrosol and application thereof. The finishing agent is prepared by the following steps of: (1) mixing a precursor, an anionic surfactant and water and stirring violently at the temperature of between 20 and 50 DEG C; and (2) slowly adding ammonia water serving as a catalyst dropwise, stirring, adding long-chain alkylsiloxane serving as a modifier and stirring continually so as to obtain modified SiO2 hydrosol. The finishing agent has a stable property, avoids the pollution of an organic solvent and has high water repellency when used for performing superhydrophobic finishing on textiles.

Owner:DONGHUA UNIV +1

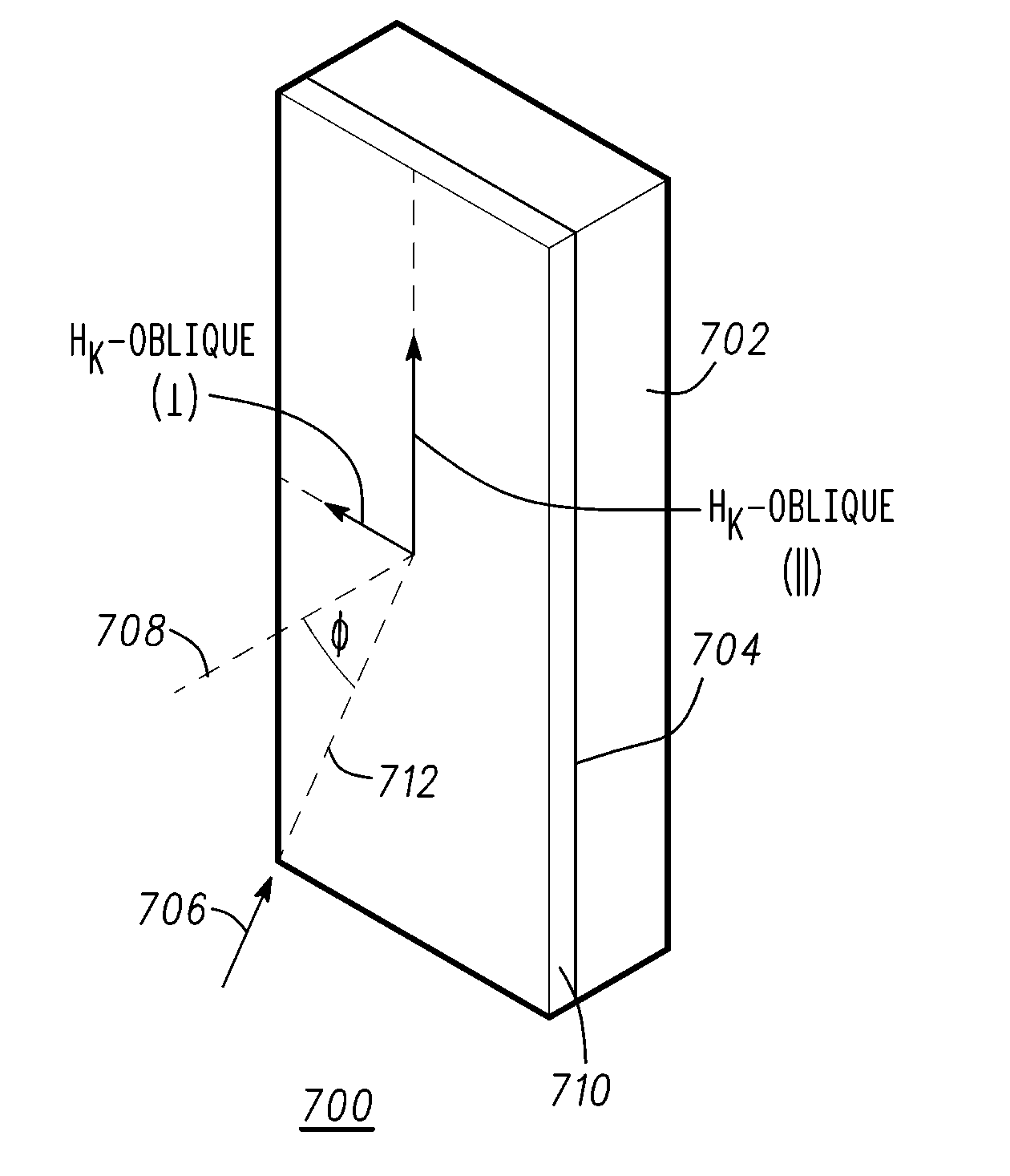

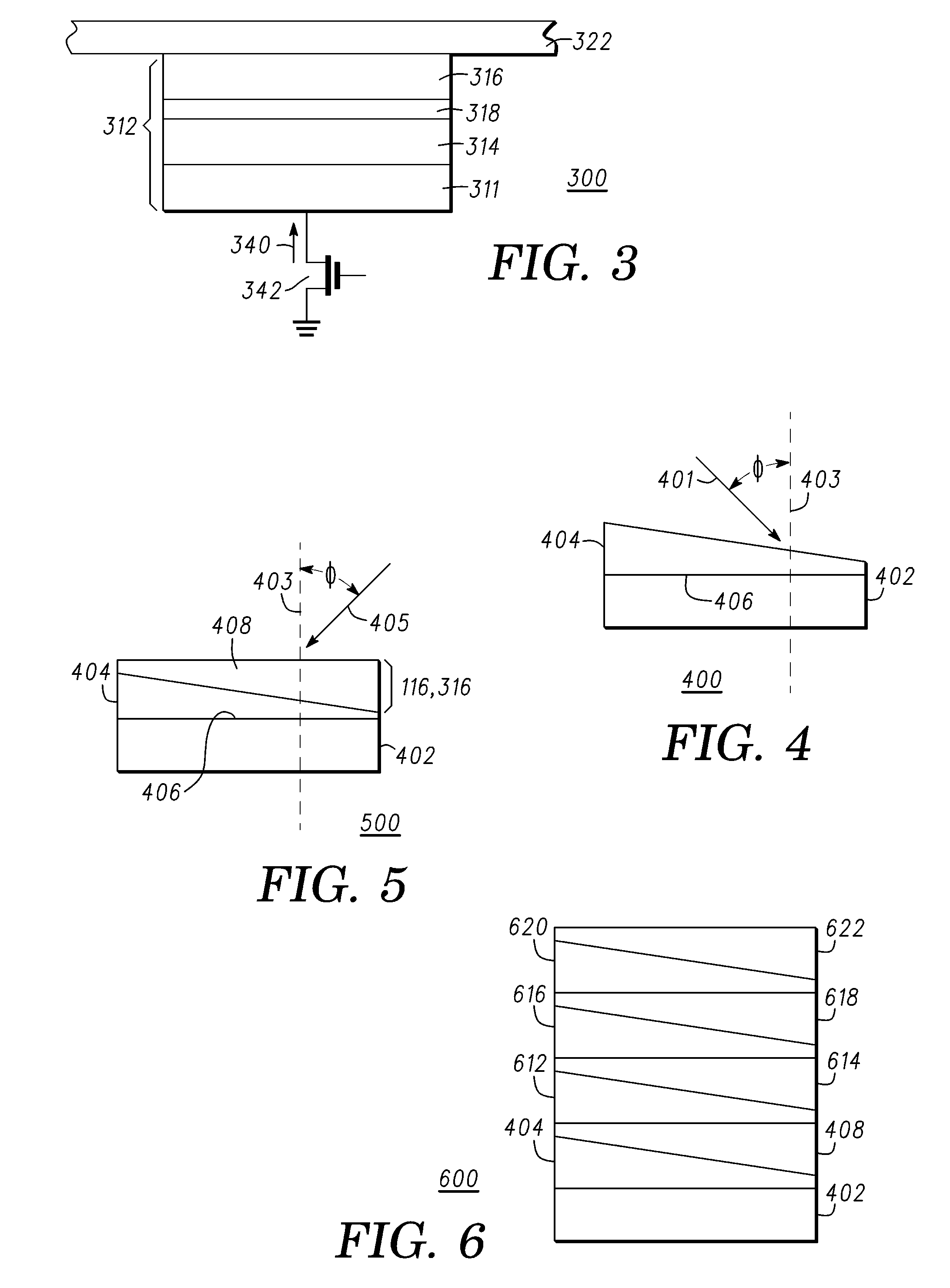

Structure and method for fabricating a magnetic thin film memory having a high field anisotropy

InactiveUS20120015099A1High magnetic materialLow critical currentNanomagnetismInductances/transformers/magnets manufactureDiffusionHigh energy

A method for depositing uniform and smooth ferromagnetic thin films with high deposition-induced microstructural anisotropy includes a magnetic material deposited in two or more static oblique deposition steps from opposed directions to form a free layer having a high kink Hk, a high energy barrier to thermal reversal, a low critical current in spin-torque switching embodiments, and improved resistance to diffusion of material from adjacent layers in the device. Nonmagnetic layers deposited by the static oblique deposition technique may be used as seed layers for a ferromagnetic free layer or to generate other types of anisotropy determined by the deposition-induced microstructural anisotropy. Additional magnetic or non-magnetic layers may be deposited by conventional methods adjacent to oblique layer to provide magnetic coupling control, reduction of surface roughness, and barriers to diffusion from additional adjacent layers in the device.

Owner:EVERSPIN TECHNOLOGIES

3-d product printing system

InactiveUS20040141018A1Increased substrate speedIncrease speedAdditive manufacturing apparatusLiquid surface applicatorsManufacturing engineeringSoftware engineering

Owner:SILVERBROOK RES PTY LTD

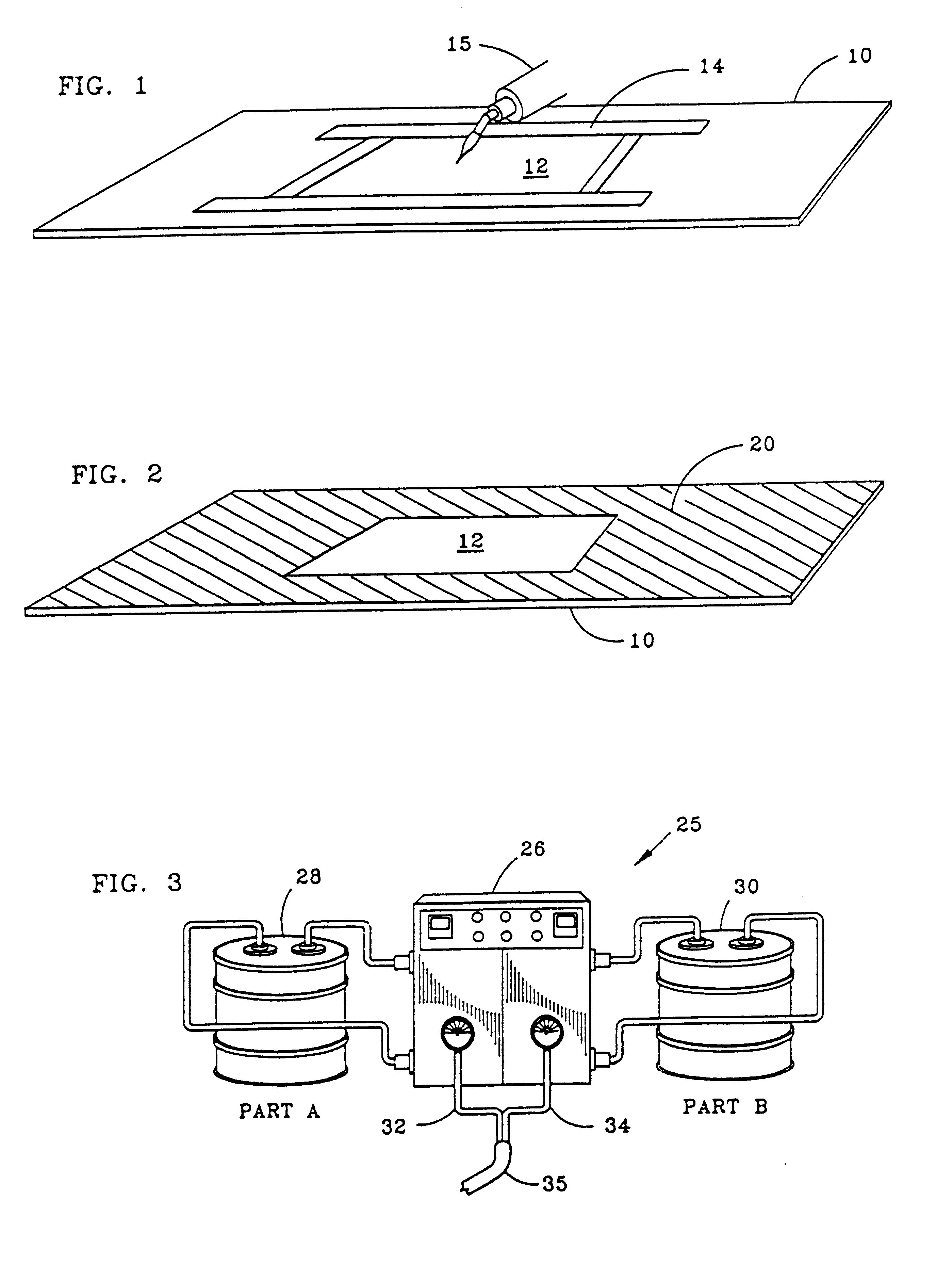

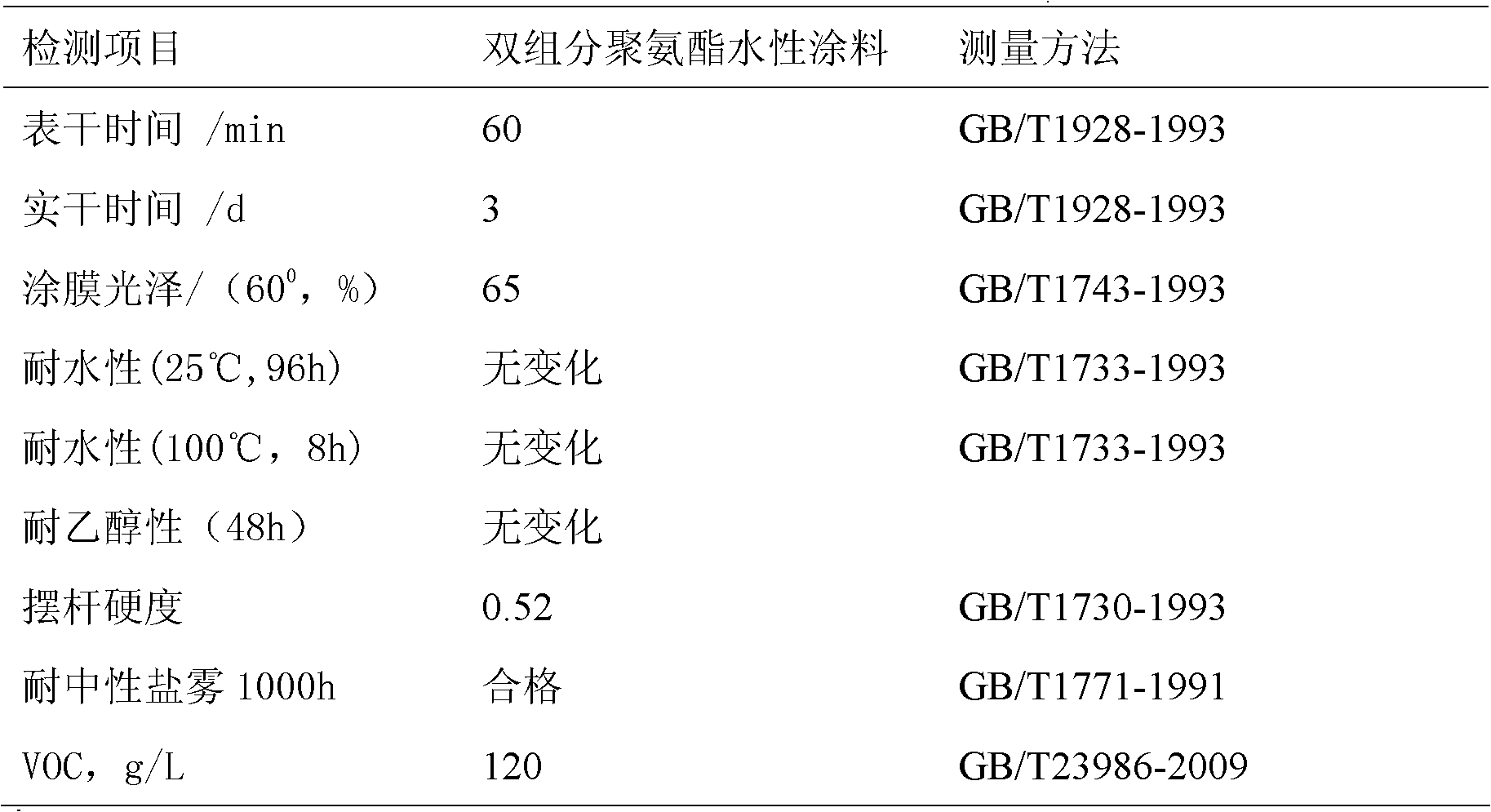

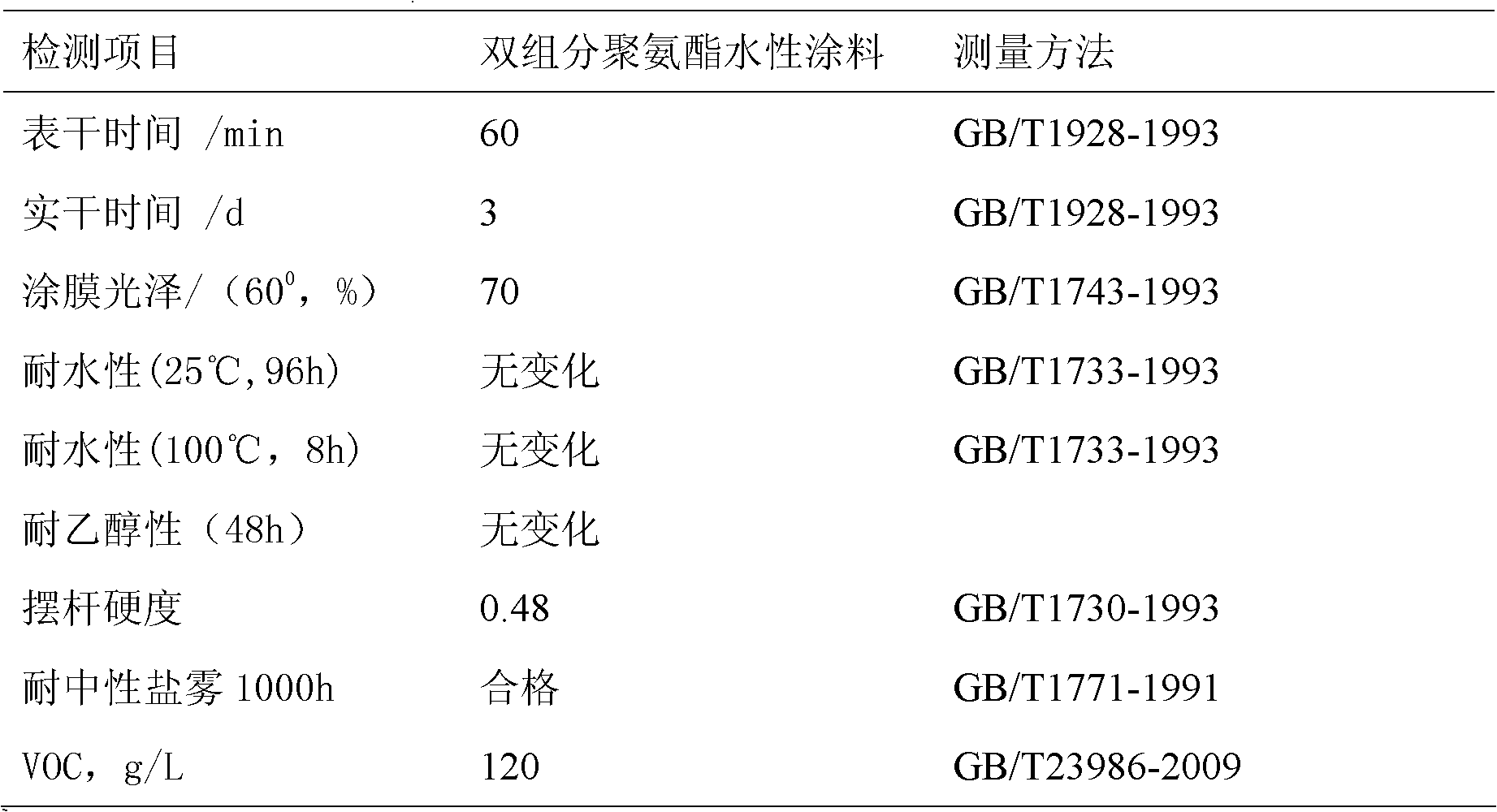

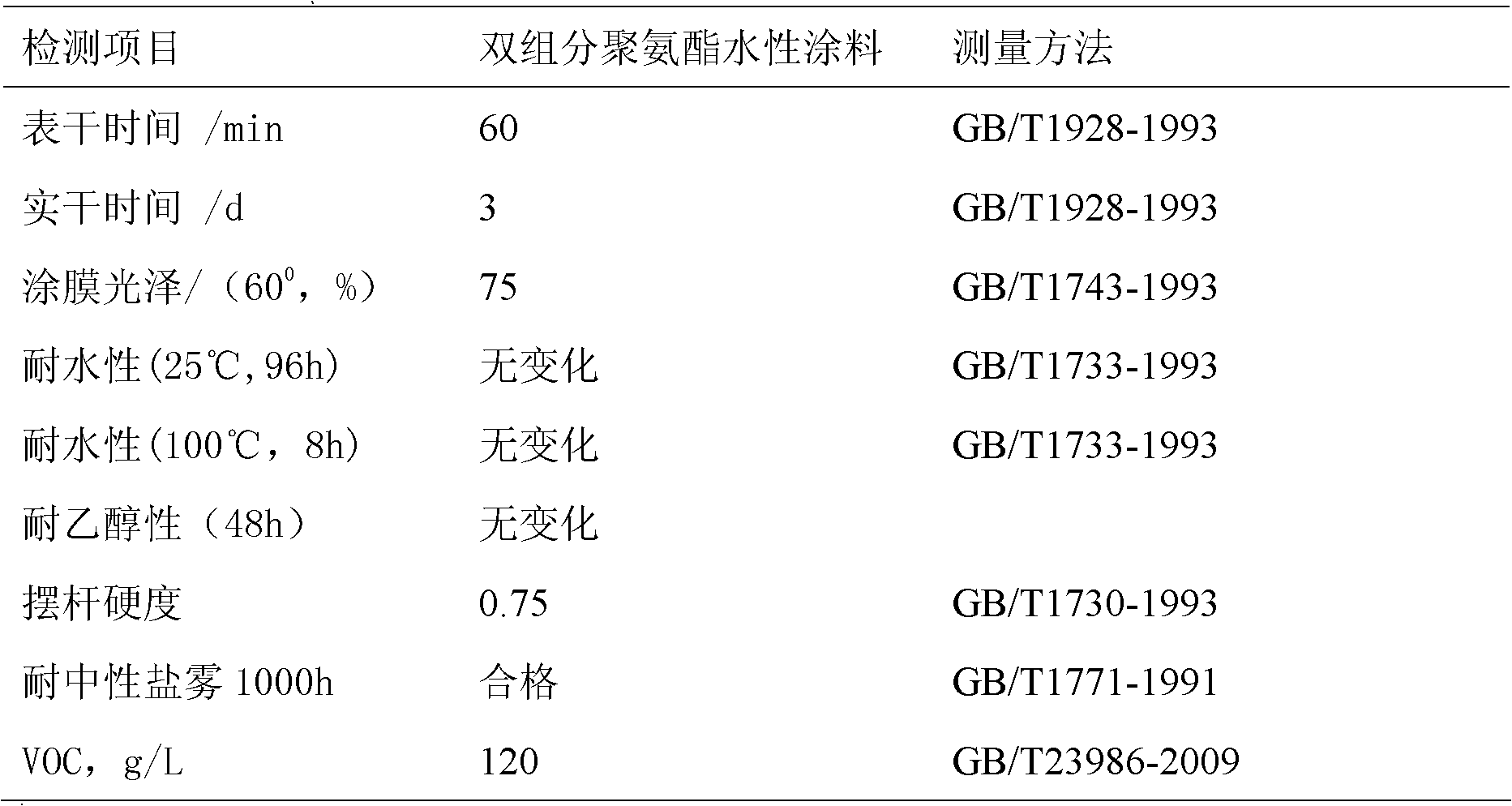

Double-component polyurethane water-based paint

InactiveCN102108246AIncrease roughnessImprove flatnessPolyurea/polyurethane coatingsWater basedPolymer science

The invention provides a double-component polyurethane water-based paint, belonging to the field of organic polymer compounds. The double-component polyurethane water-based paint comprises isocyanate curing agents component A and component B, wherein the molar ratio of OH groups of a polymer in the component A to NCO groups in the component B is 1: (1-2.2); and the component A contains polymer aqueous dispersion and polymer emulsion, wherein the content of OH in the polymer aqueous dispersion is 2.0-5.0% and the grain size of latex in the polymer aqueous dispersion is 10-100nm, the weight of the polymer emulsion is 0.05-16 times that of the polymer aqueous dispersion, the content of OH in the polymer emulsion is 0-2.0%, and the grain size of the latex in the polymer emulsion is 80-500nm. In the invention, the polymer aqueous dispersion which has small average grain size and contains -OH and the polymer emulsion which has large average grain size are compounded, wherein the latex with a large grain size can increase the roughness and unevenness of a film and reduce the gloss of the film, and the emulsion with small particles promotes the latex with the large grain size to aggregate, reduces the lowest film-forming temperature of the film, improves the film-forming capability of the film and decreases the usage amount of a film-forming additive; and the hardness, chemical-resistance and wear-resistance of the film are improved by using two different water-based polymers are used for compounding.

Owner:SOUTH CHINA UNIV OF TECH +1

Positive resist composition and patterning process

ActiveUS20090202943A1Feature size of to decreaseSmall feature sizePhotosensitive materialsRadiation applicationsResistHigh energy

A positive resist composition comprises a polymer comprising recurring units having a sulfonium salt incorporated therein as a base resin which becomes soluble in alkaline developer under the action of acid. The polymer generates a strong sulfonic acid upon exposure to high-energy radiation so as to facilitate effective scission of acid labile groups in the resist composition.

Owner:SHIN ETSU CHEM IND CO LTD

3-D object creation system employing voxels

ActiveUS20040141024A1Increased substrate speedIncrease speedDigitally marking record carriersDough shapingVoxelRegular array

A three dimensional object creation system that prints objects layer by layer, the system printing at least part of each of multiple layers simultaneously, wherein each layer is defined by a plurality of voxels arranged in a regular array and wherein the voxels of each layer are printed so as to be offset by half a voxel relative to the voxels of adjacent layers in a first direction, a second direction perpendicular to the first direction or both the first and second directions.

Owner:3D SYST INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com