Patents

Literature

31results about How to "Reduce mass flow rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

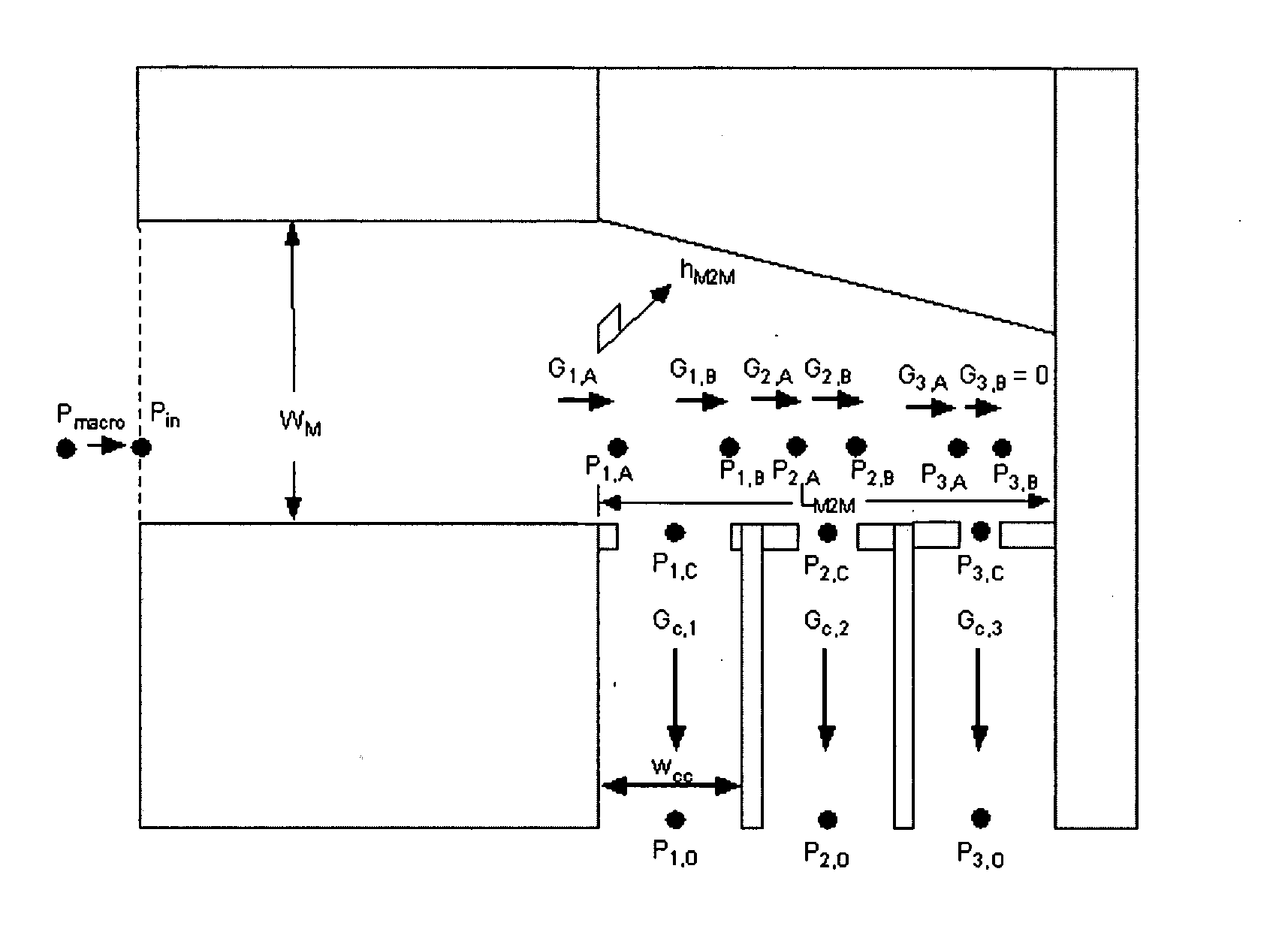

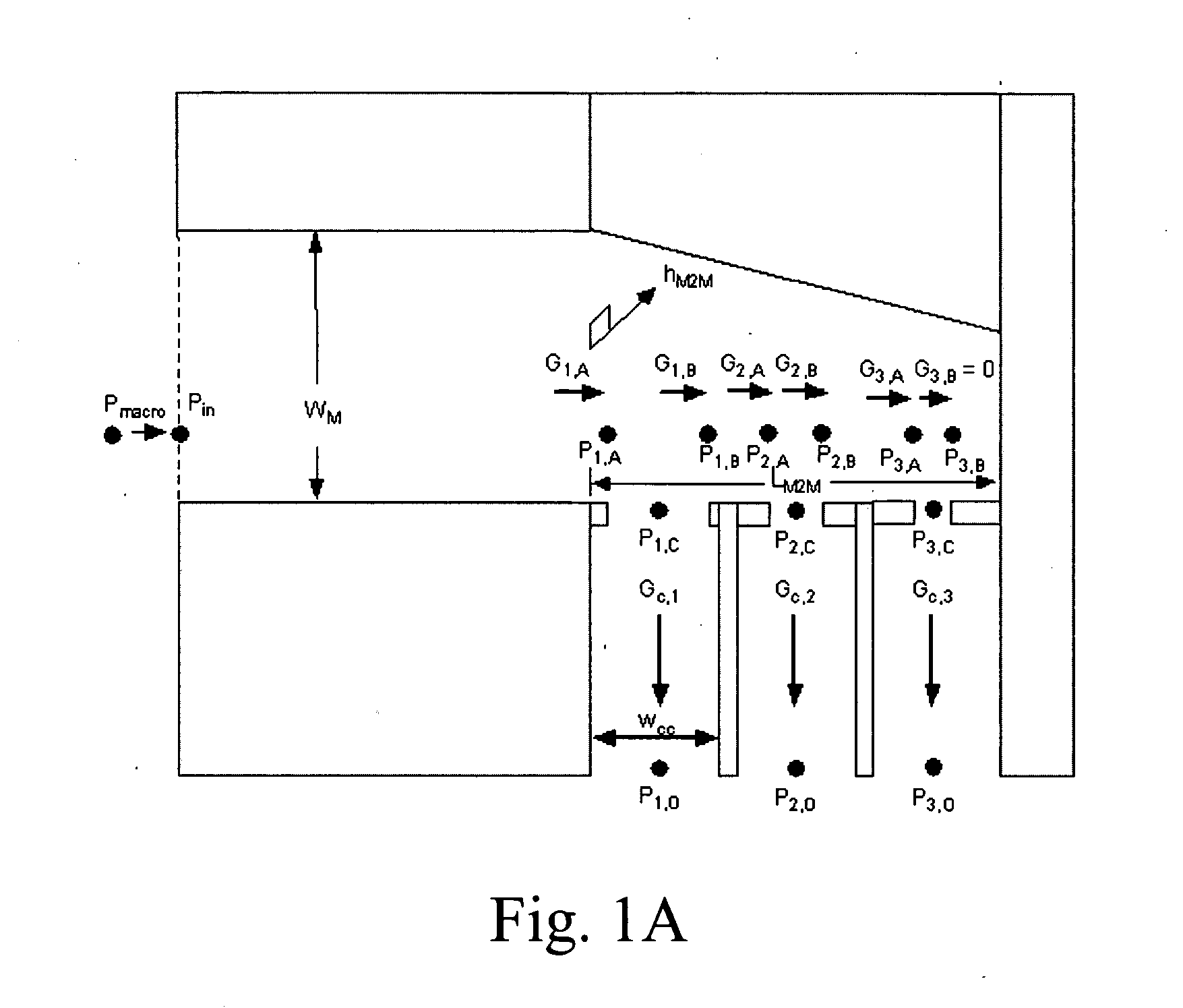

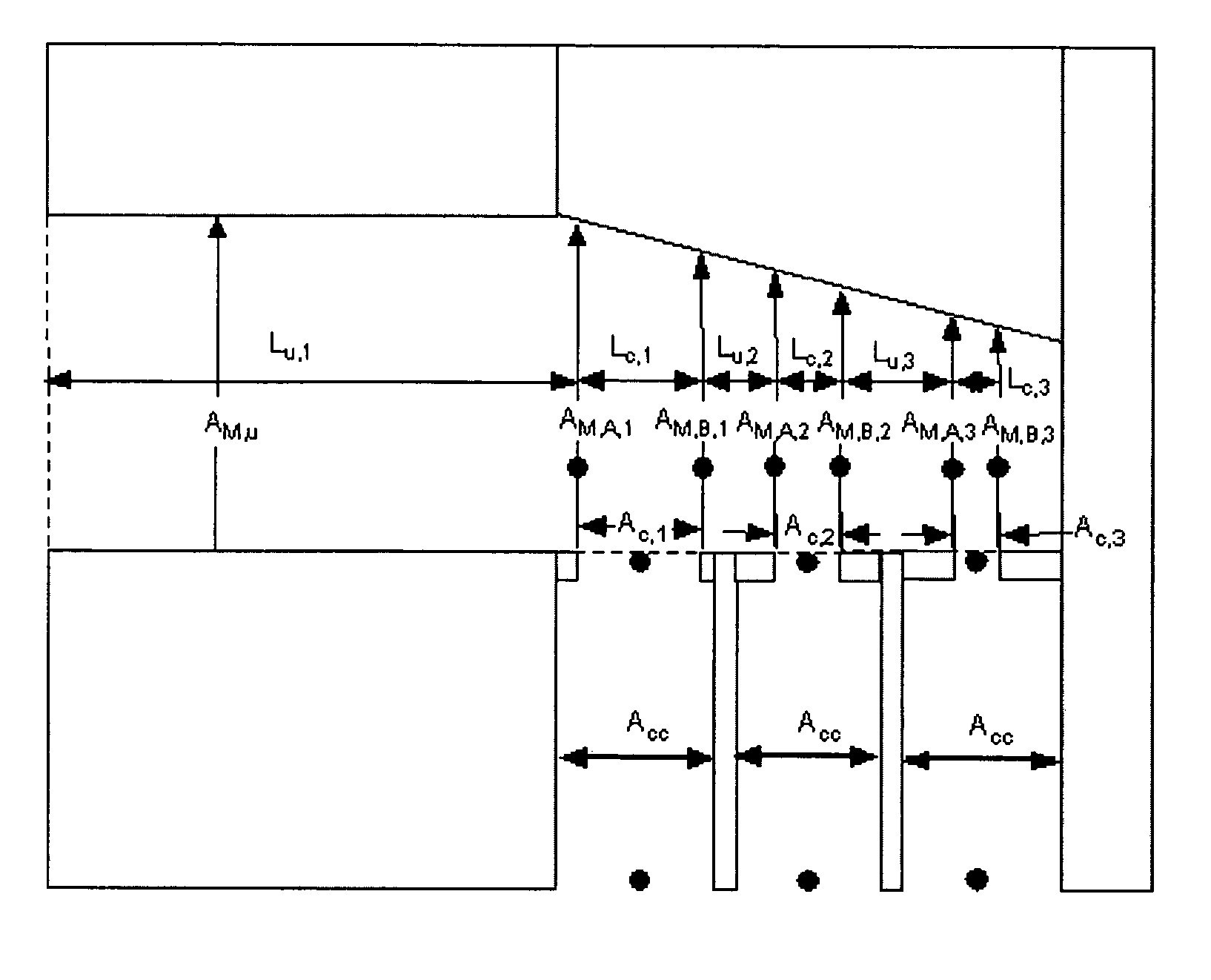

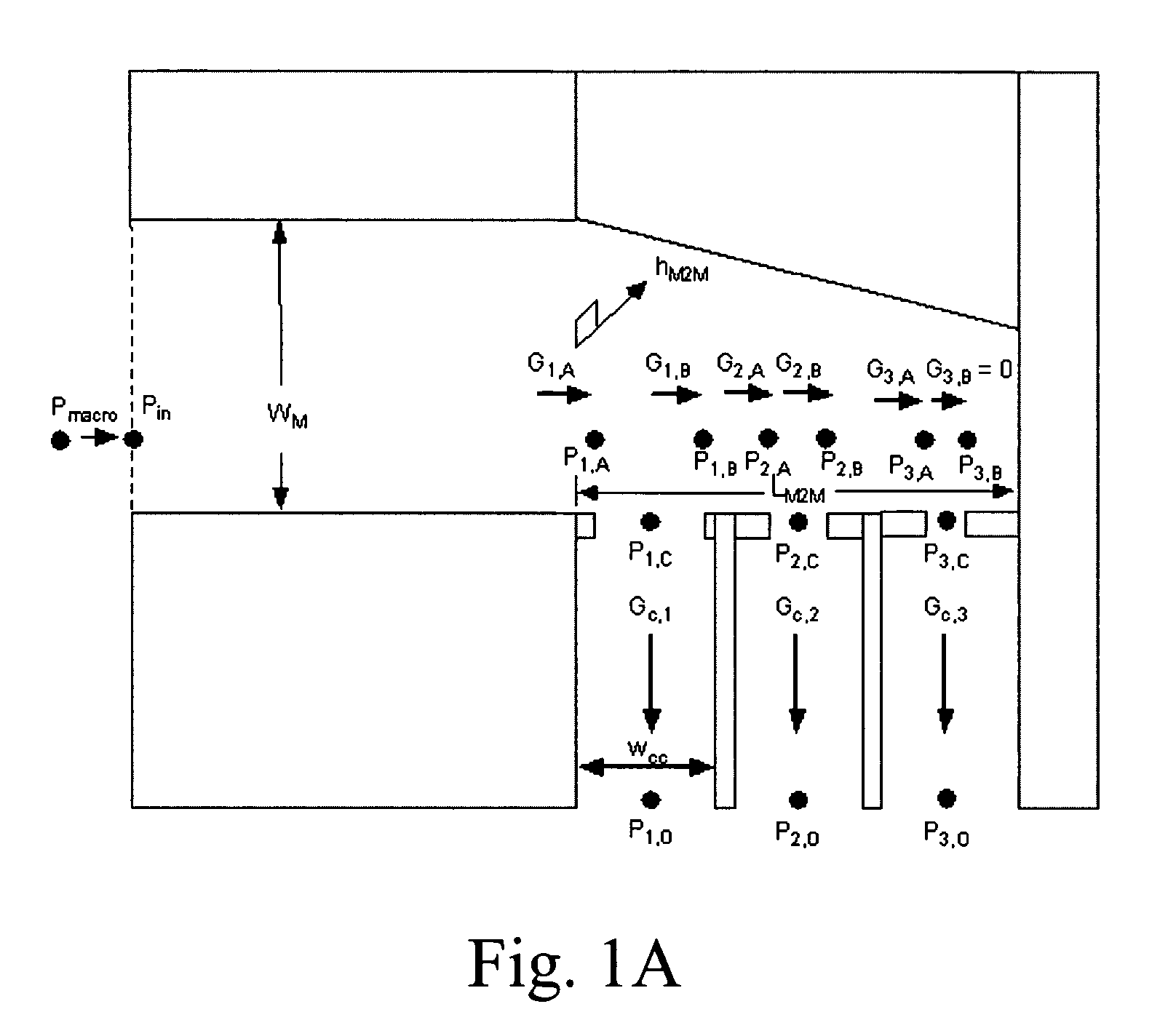

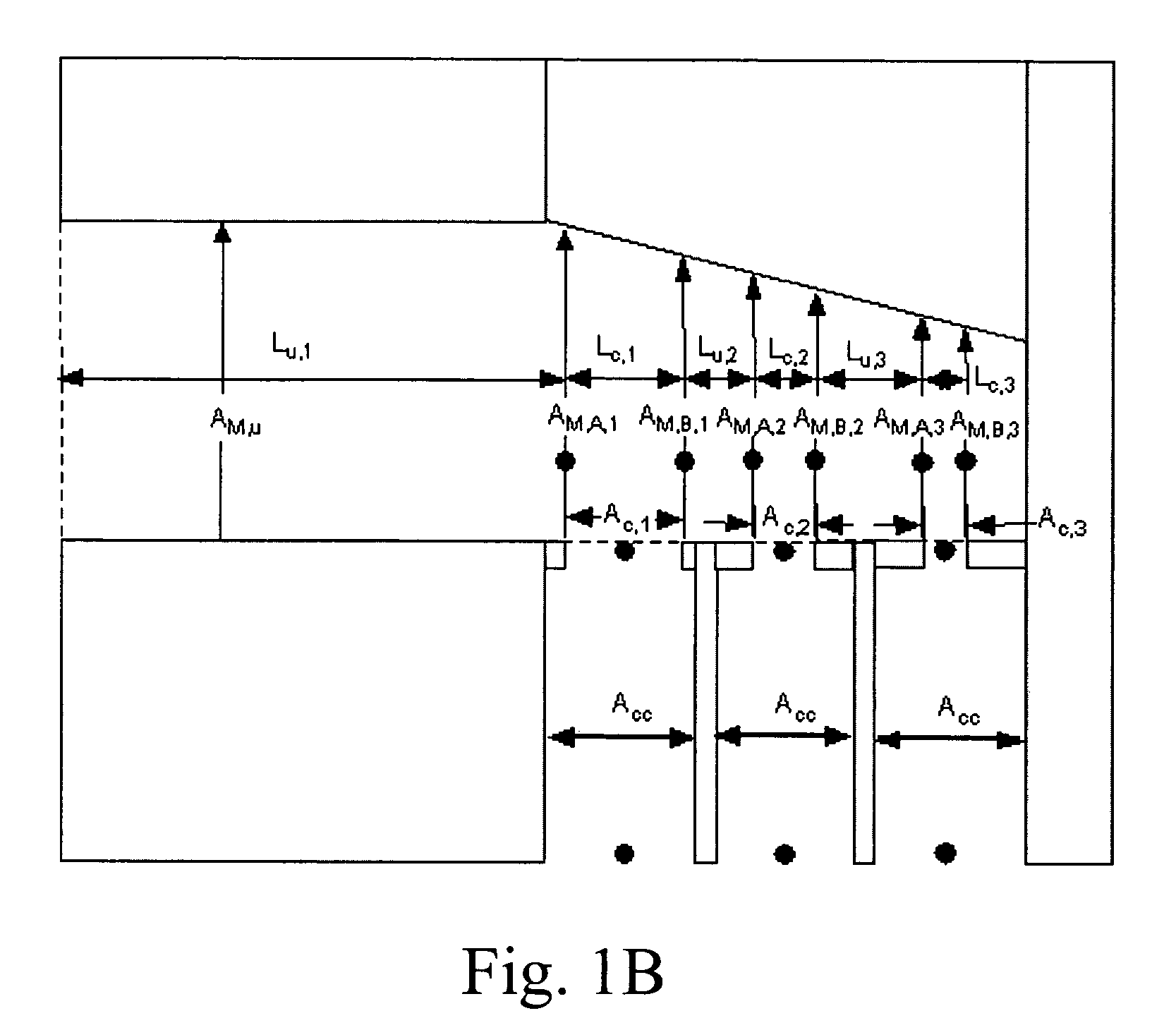

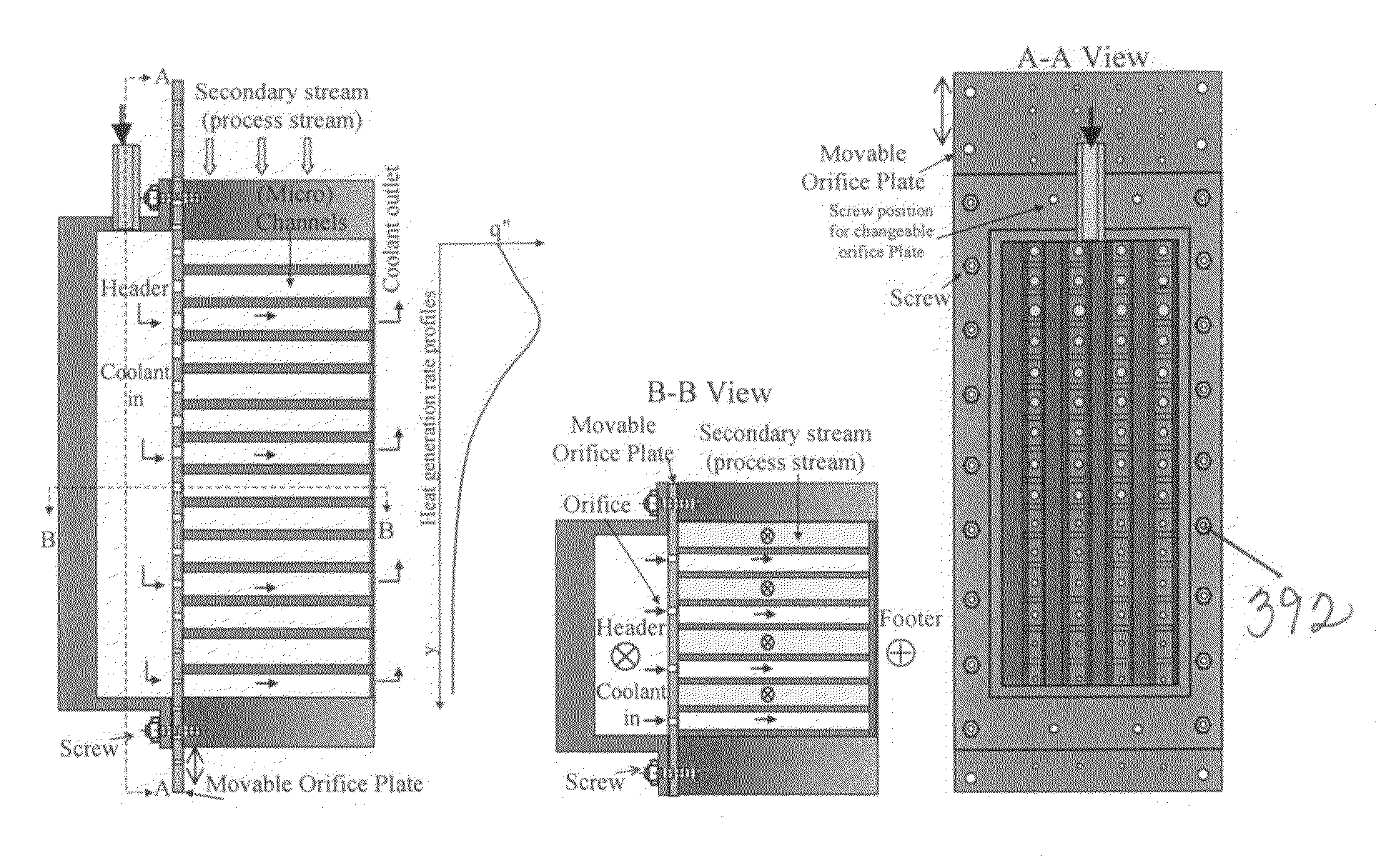

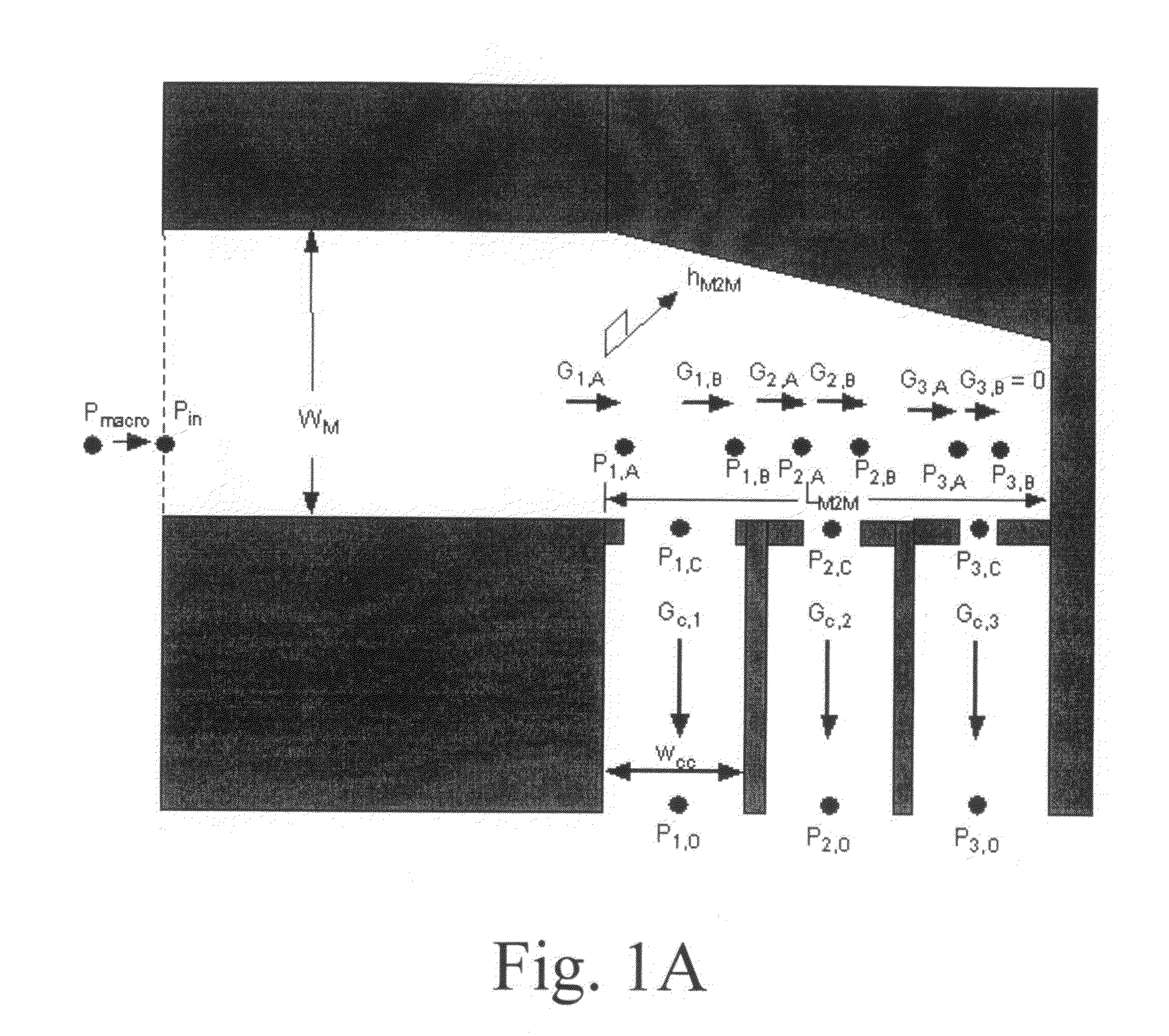

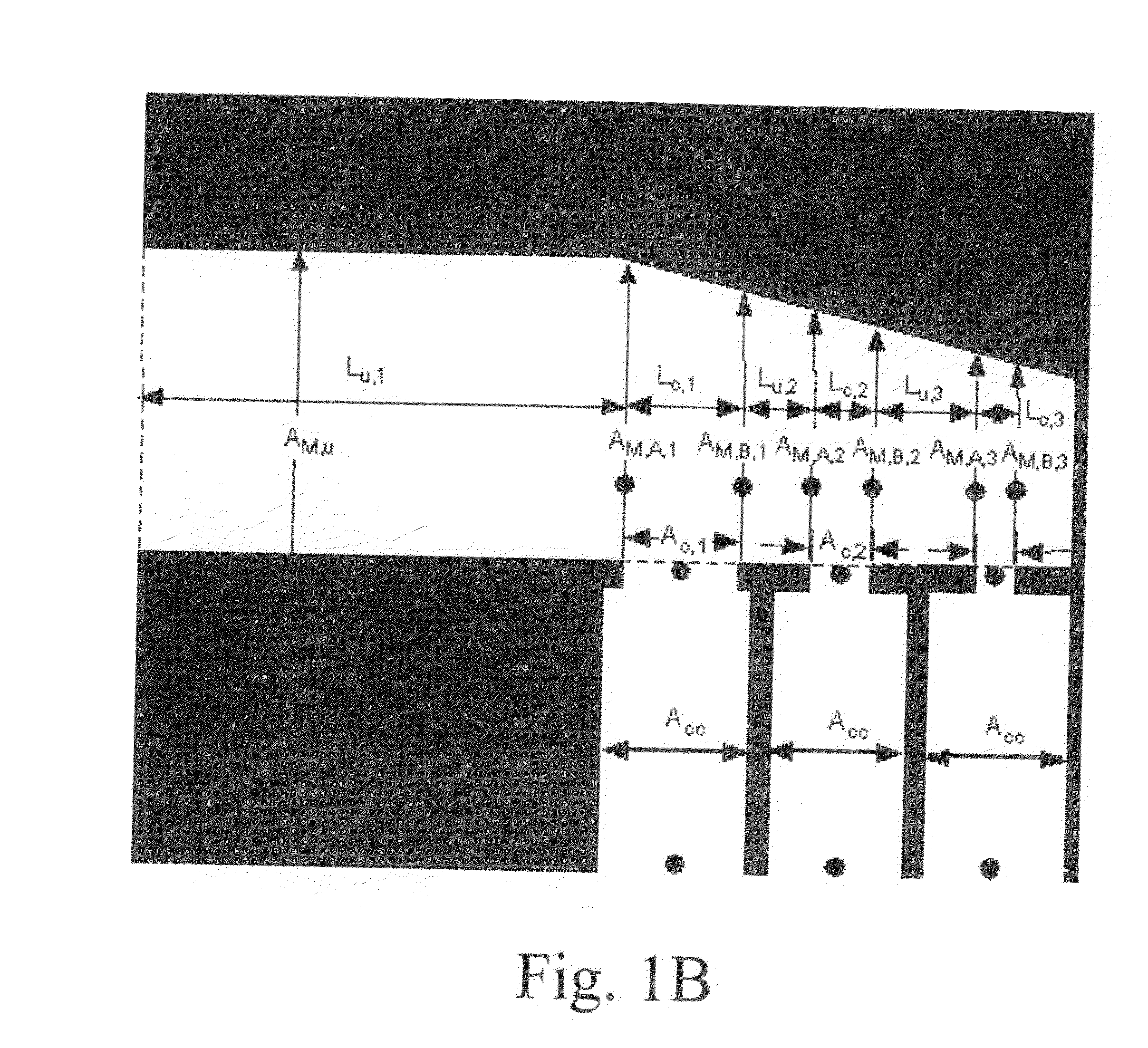

Manifold designs, and flow control in multichannel microchannel devices

InactiveUS20050087767A1Equally distributedLow costChemical/physical/physico-chemical microreactorsSemiconductor/solid-state device manufacturingEngineering

Owner:VELOCYS CORPORATION

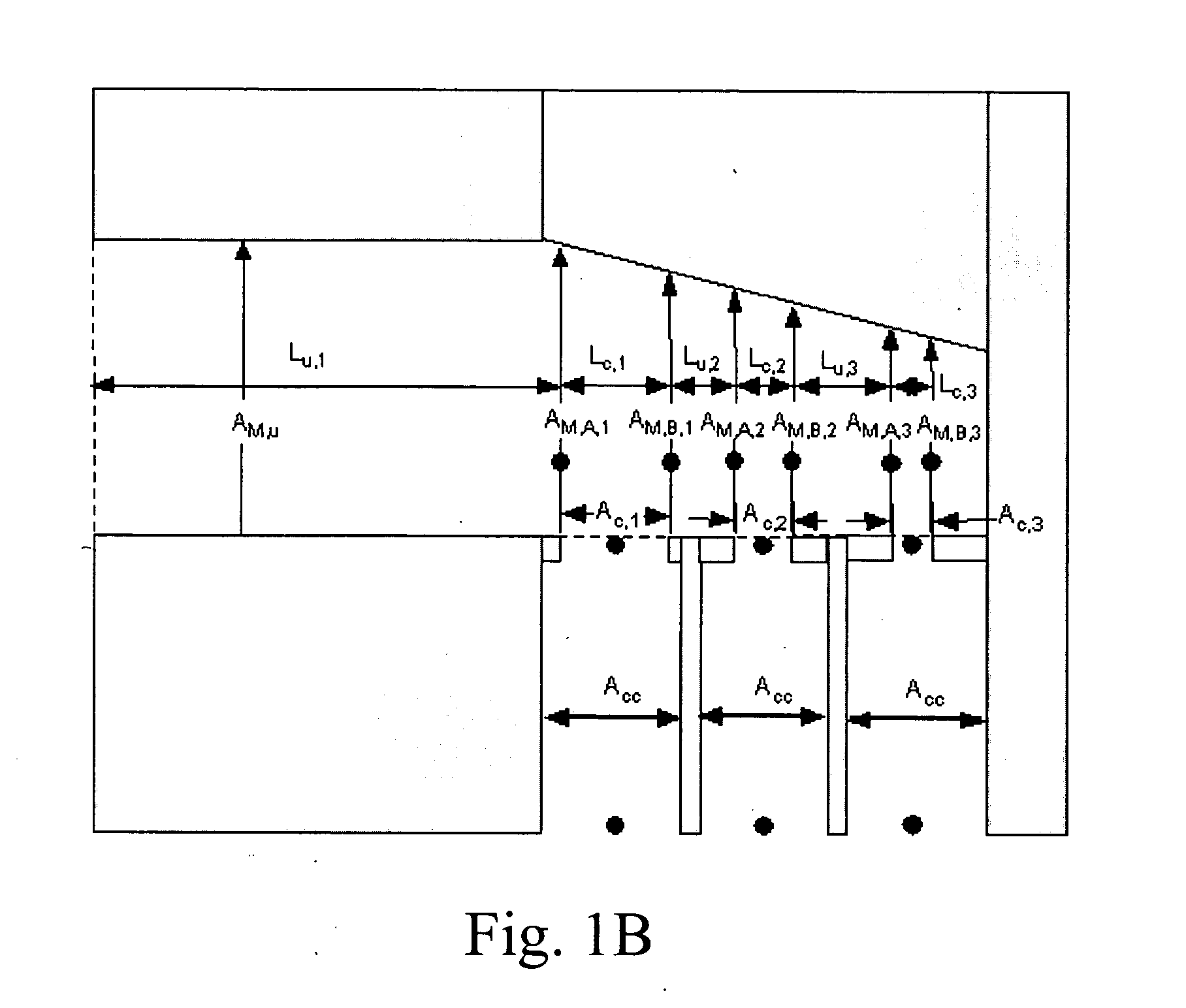

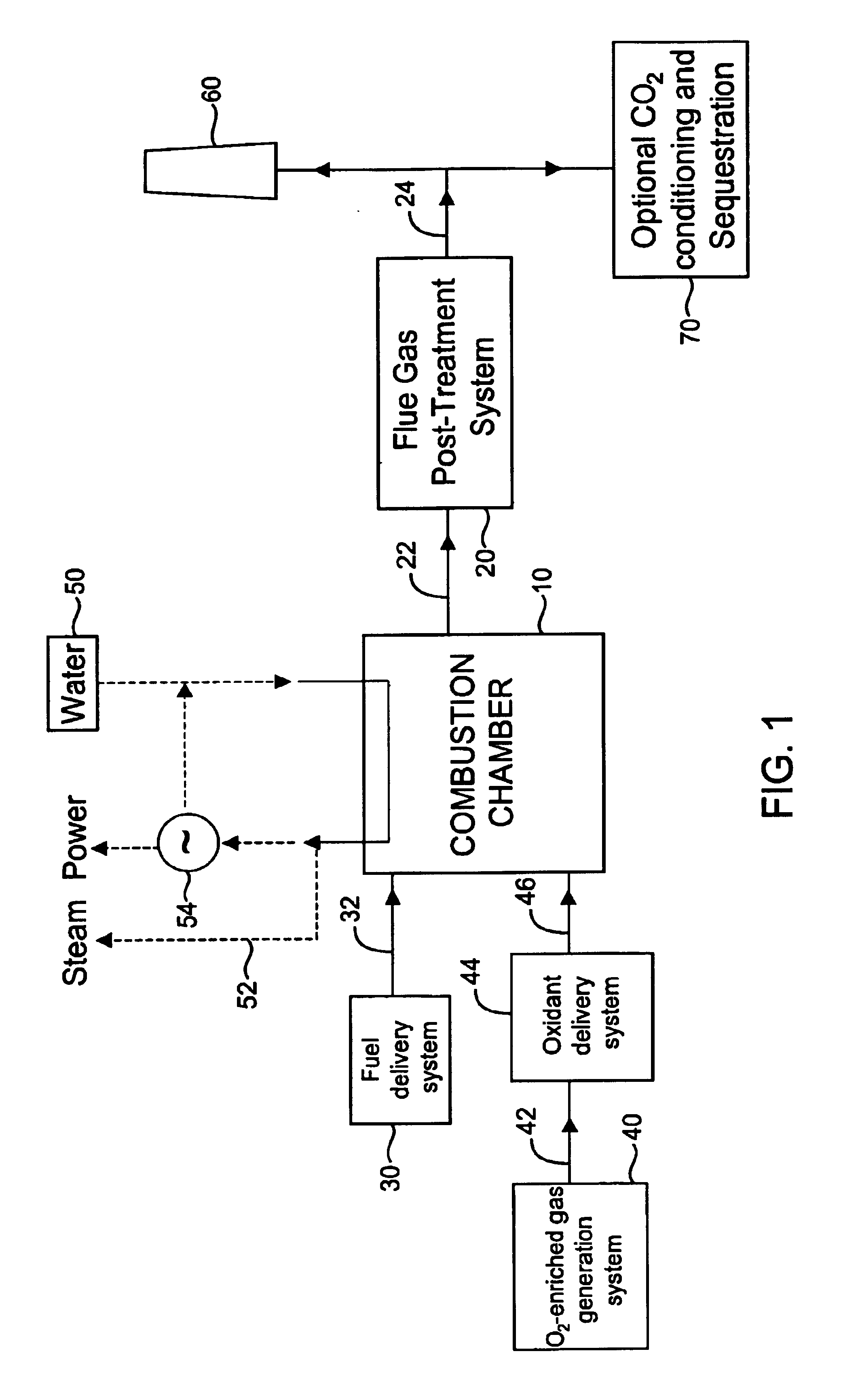

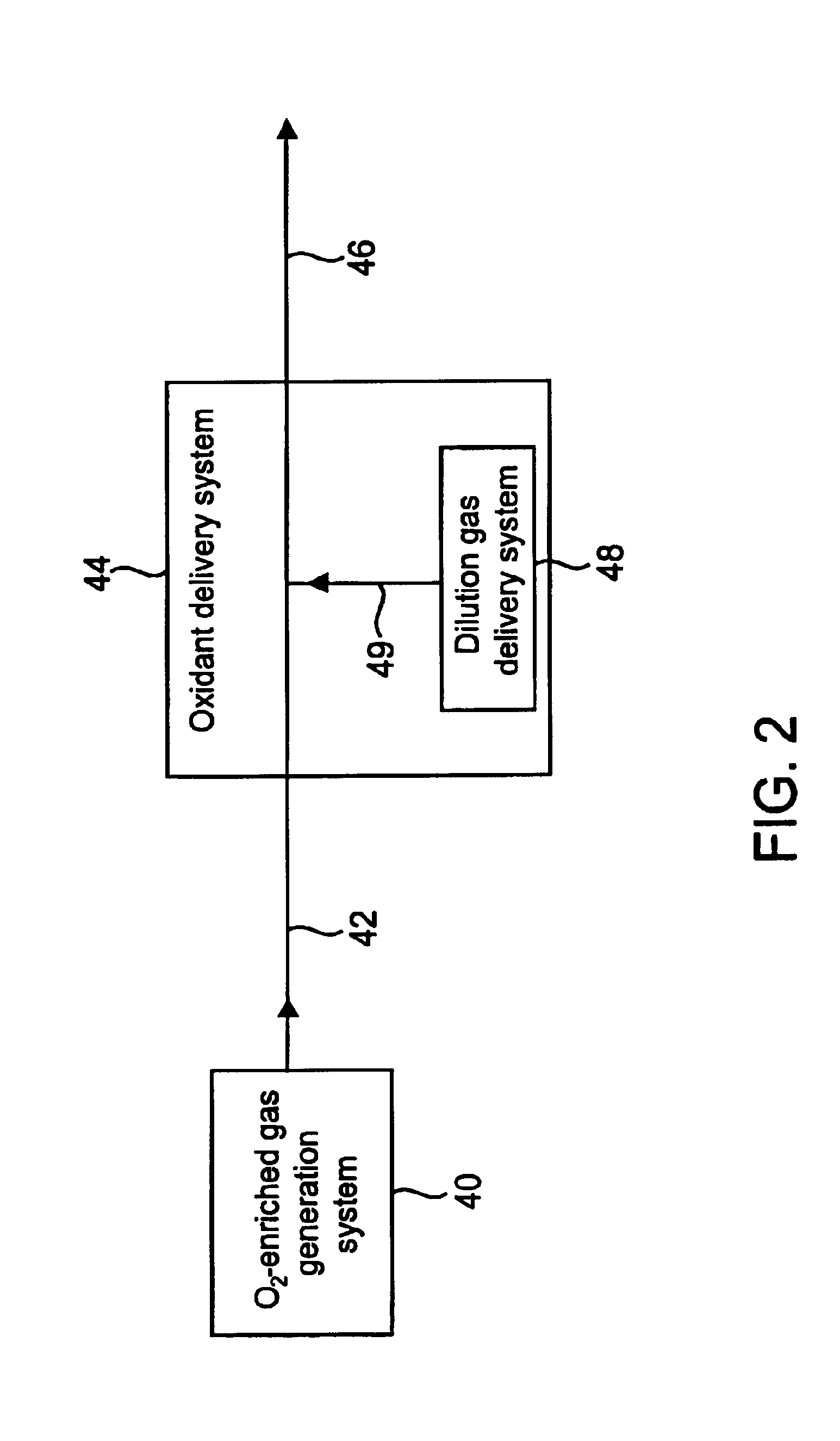

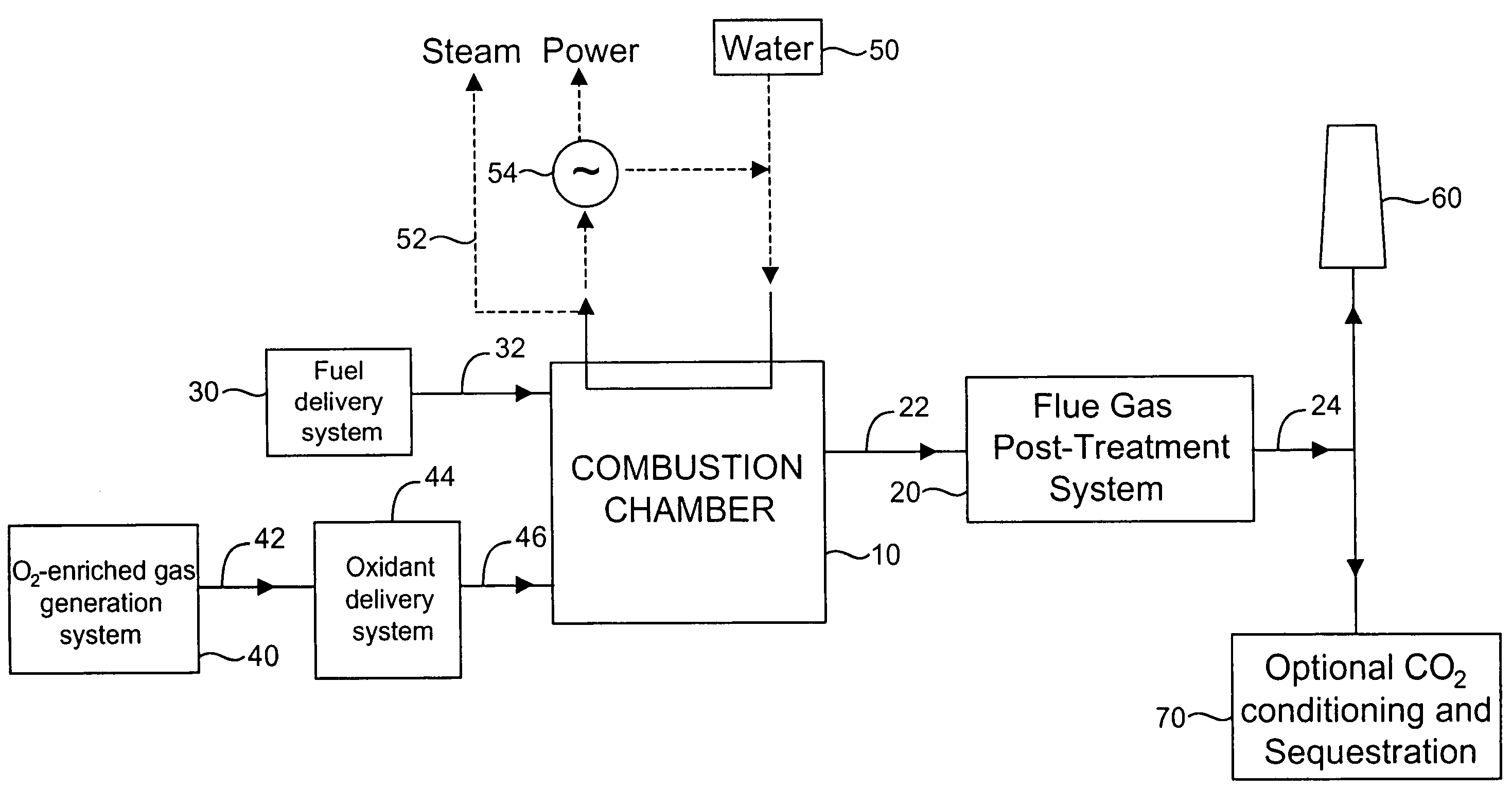

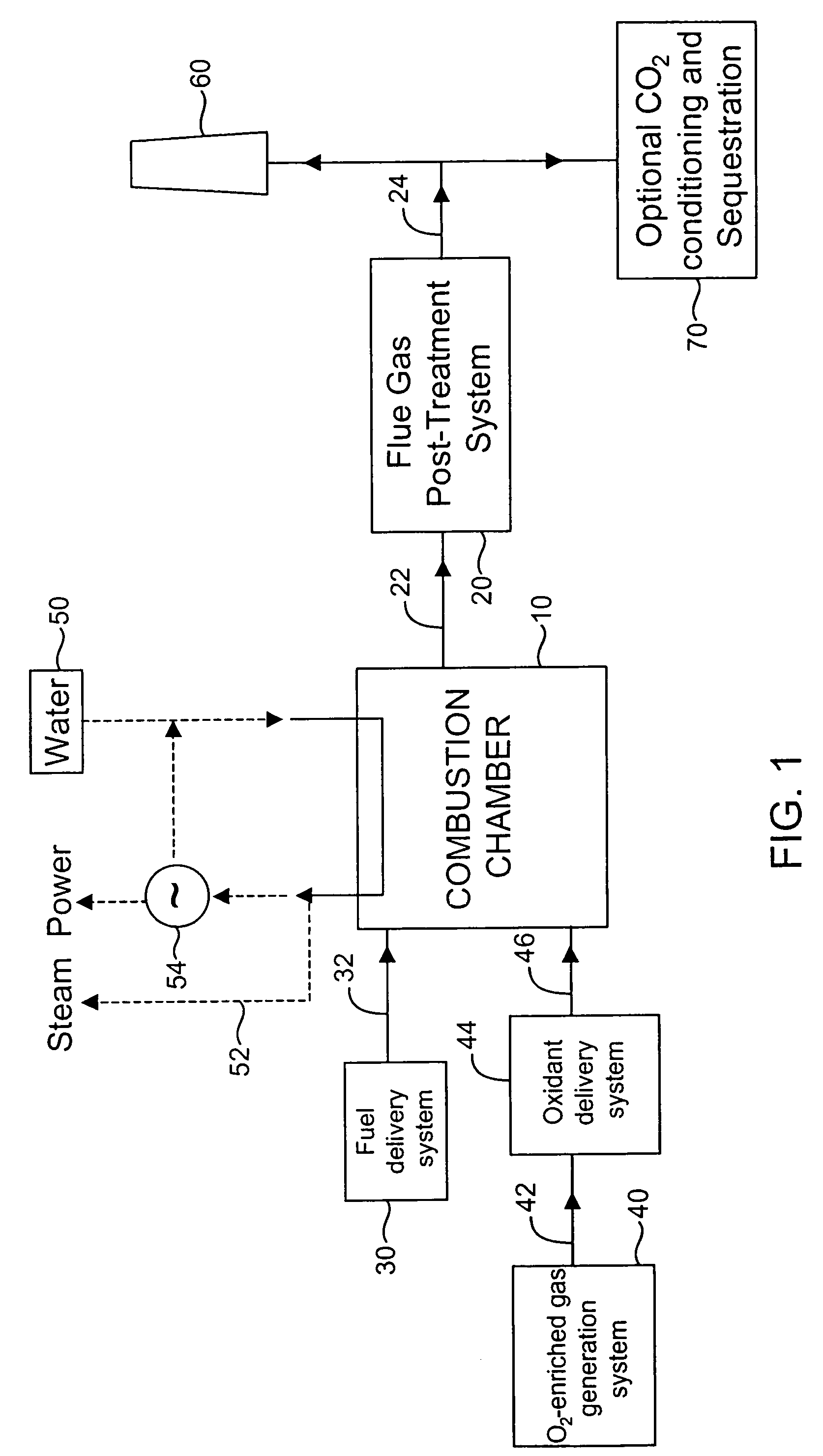

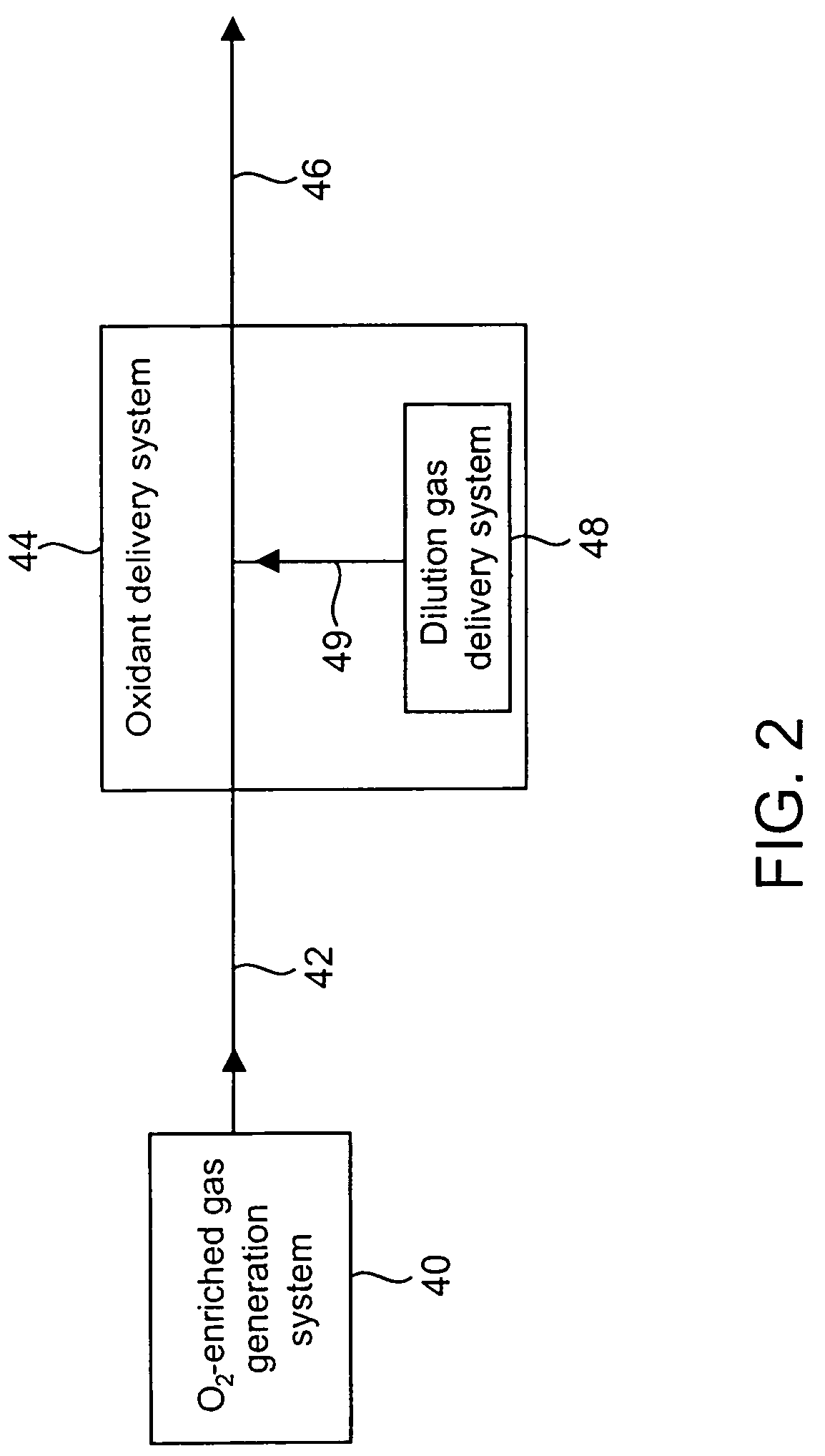

Steam-generating combustion system and method for emission control using oxygen enhancement

InactiveUS6935251B2Low costReduce mass flow rateUsing liquid separation agentEmission preventionParticulatesHigh concentration

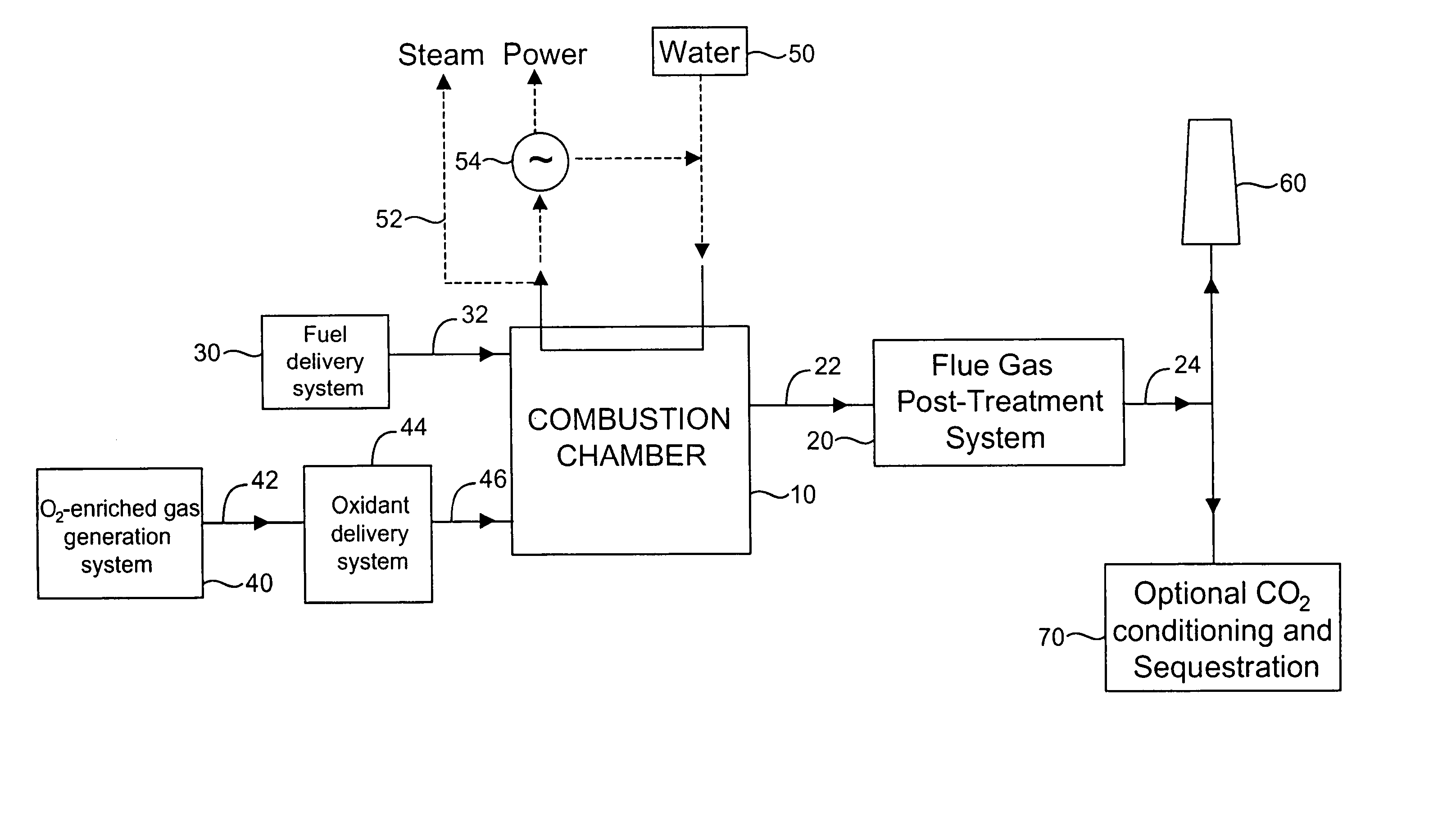

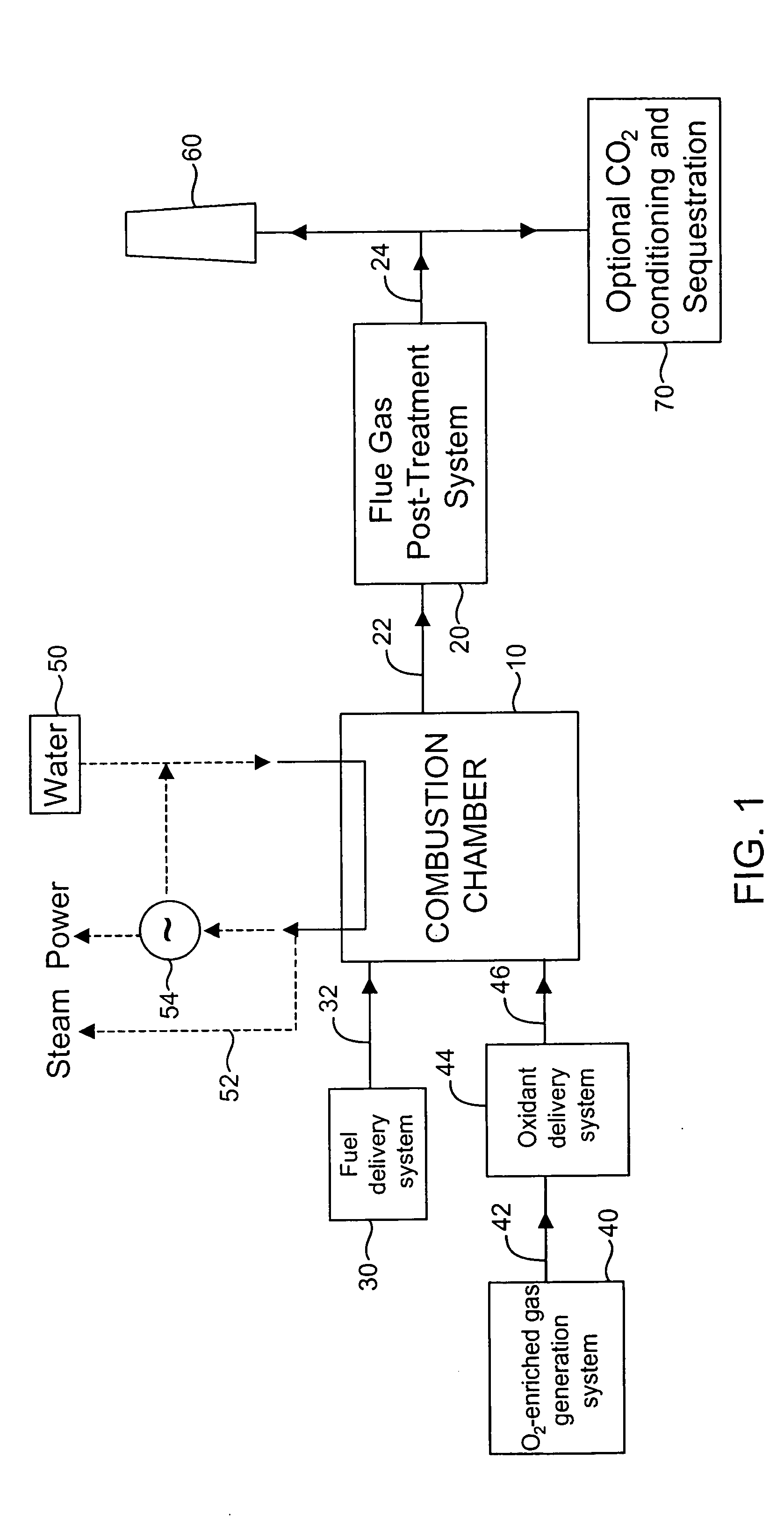

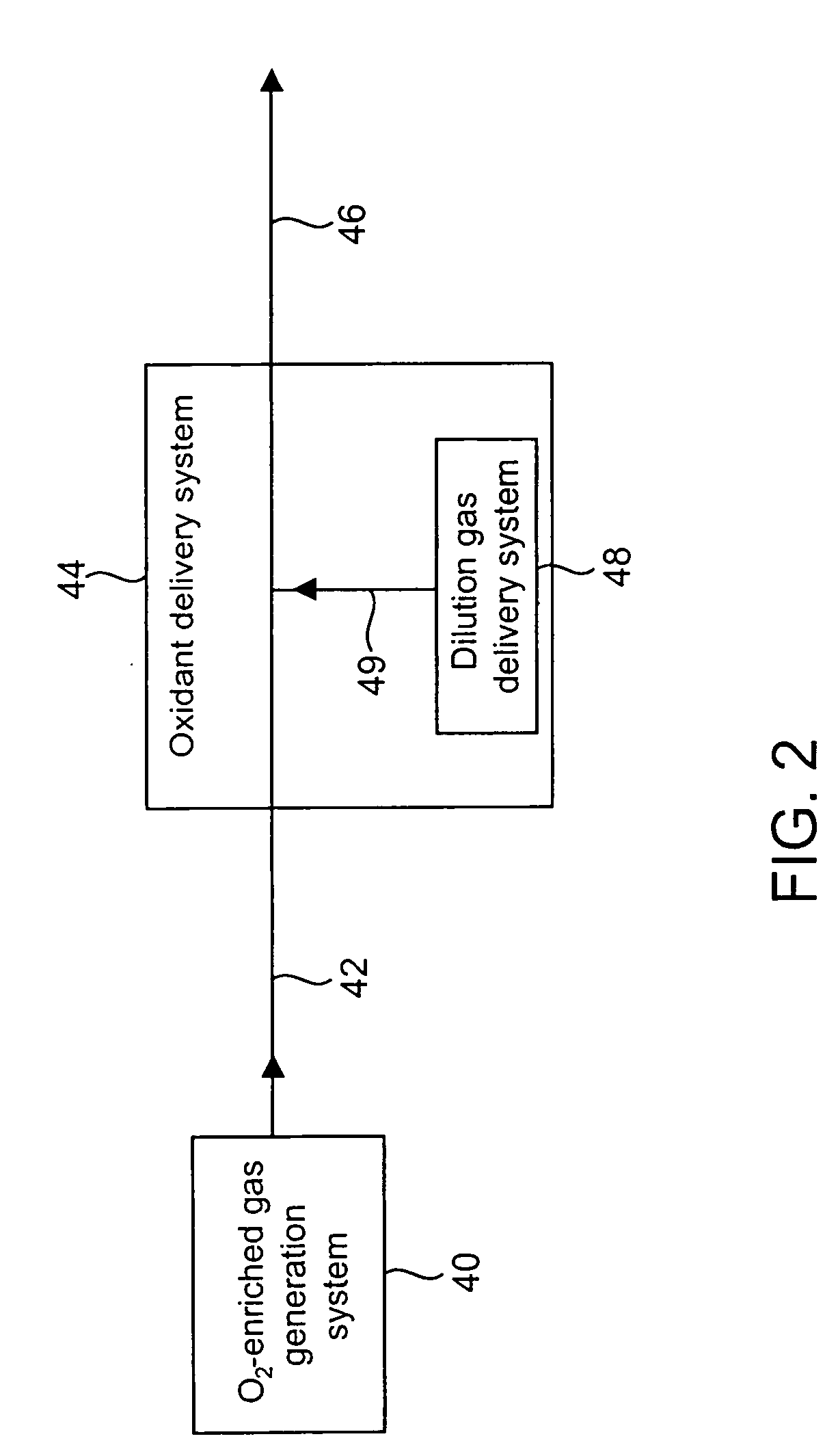

A steam-generating combustion system includes an oxygen enriched gas provided as at least part of an oxidant stream. A combustion chamber receives and combusts a fuel in the oxidant stream and generate steam. The combustion chamber generates flue gas having a flue gas volume which is smaller than a volume of flue gas generated by the combustion chamber when operated with air as the oxidant stream. A flue gas pollutant control system receives the flue gas from the combustion chamber and reduces at least one of particulate matter, SOx, NOx, and mercury. The reduction in flue gas volume allows the implementation of much smaller pollutant control equipment, since the size of the pollutant control units is mainly based on the volume or mass flow rate of flue gas to be treated. Moreover, the system including oxygen-enriched gas in the oxidant will lead to concentrated levels of the pollutants in the flue gas. The high concentrations of pollutants will enhance their absorption in the different pollutant control systems, improving removal efficiency for all species.

Owner:AIR LIQUIDE AMERICA INC +1

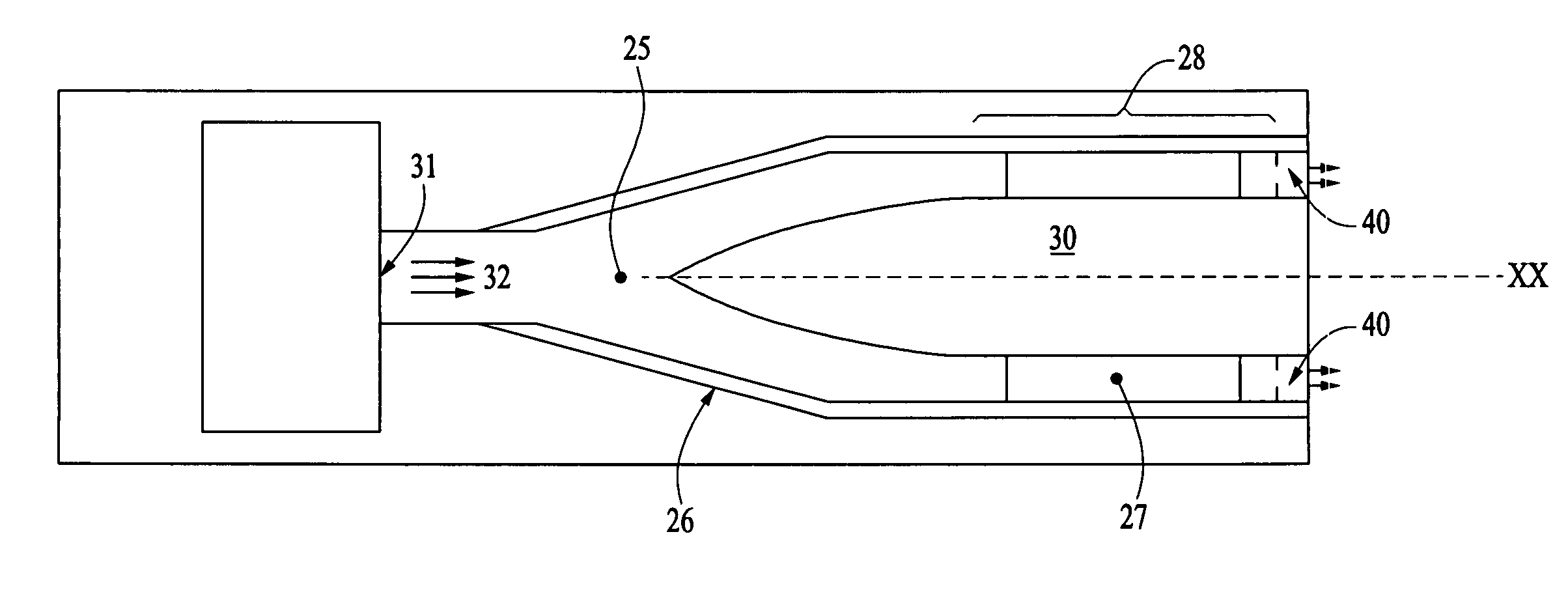

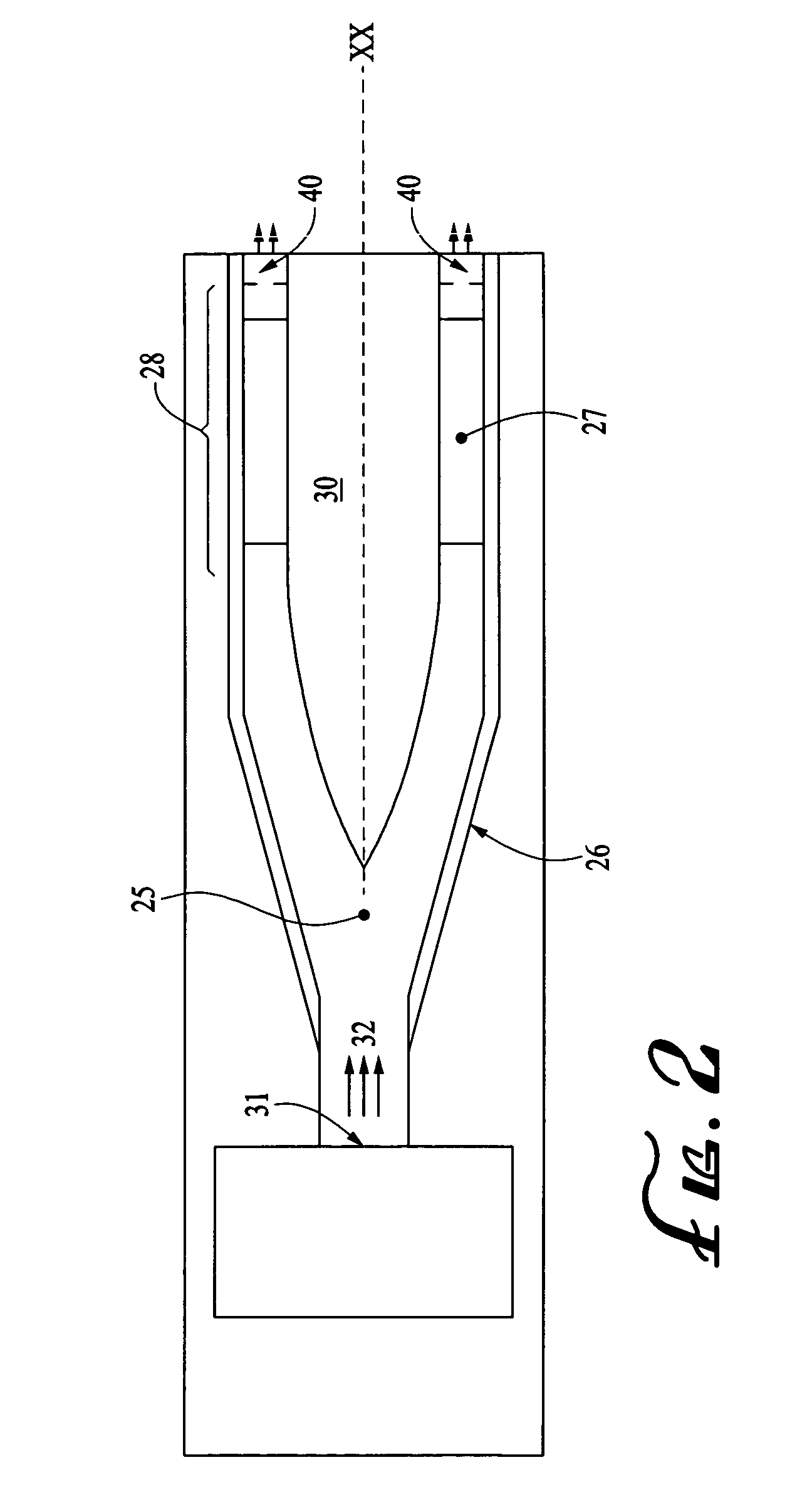

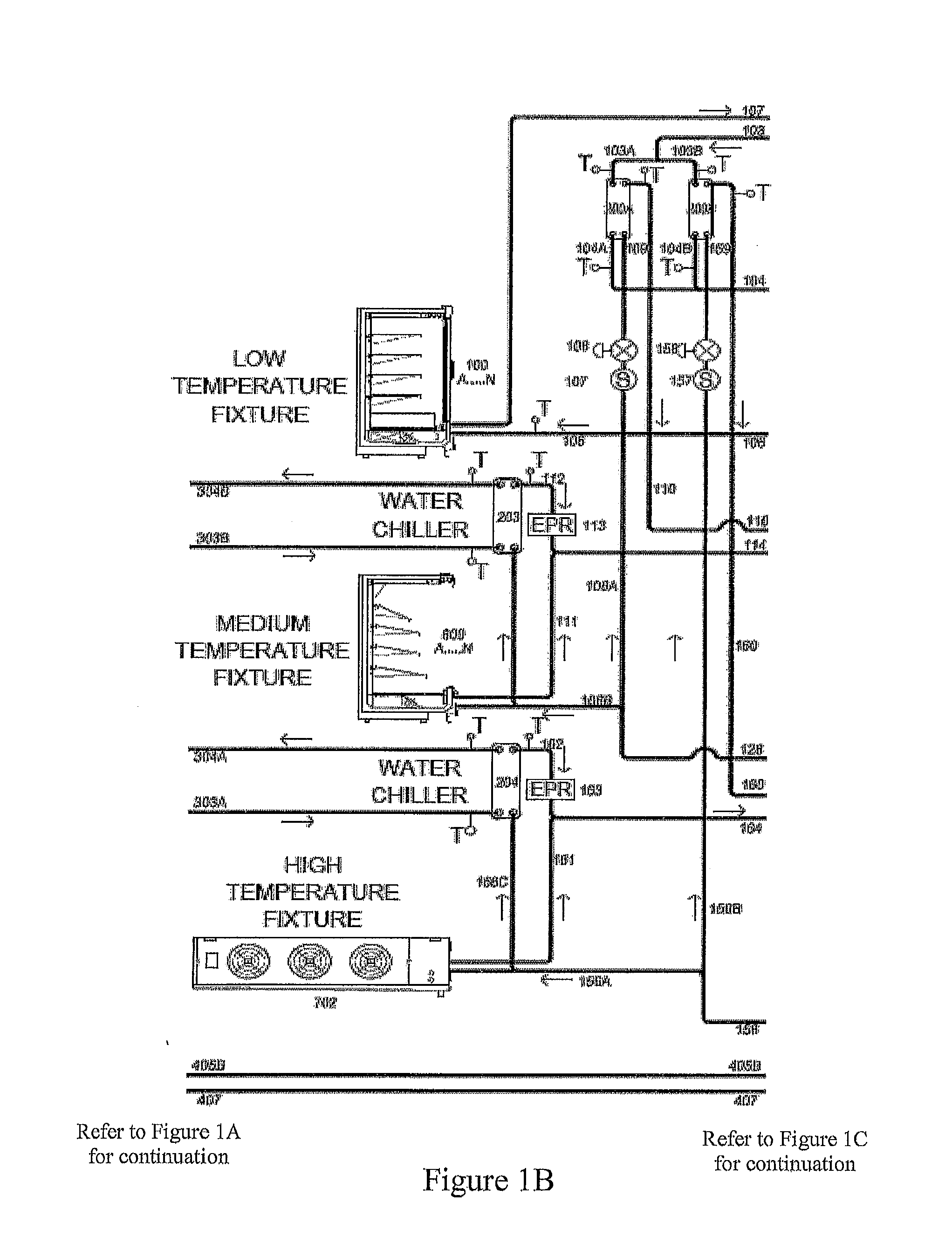

Low cost wind tunnel for supersonic and hypersonic aerothermal testing

The invention disclosed herein provides a subsonic wind tunnel capable for accurately maintaining a desired Mach number, pressure and temperature for use in aerothermal testing of materials. The invention allows the Mach number to be precisely controlled in the test section of the wind tunnel by employing a restricted outlet acting as a sonic throat for the wind tunnel. In the preferred embodiment, the restricted outlet is constructed to be variable in cross sectional area allowing a range of Mach numbers to be tested. The variable outlet is varied during the operation of the wind tunnel so that an actual trajectory with changing Mach numbers, pressure, and temperature is simulated.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

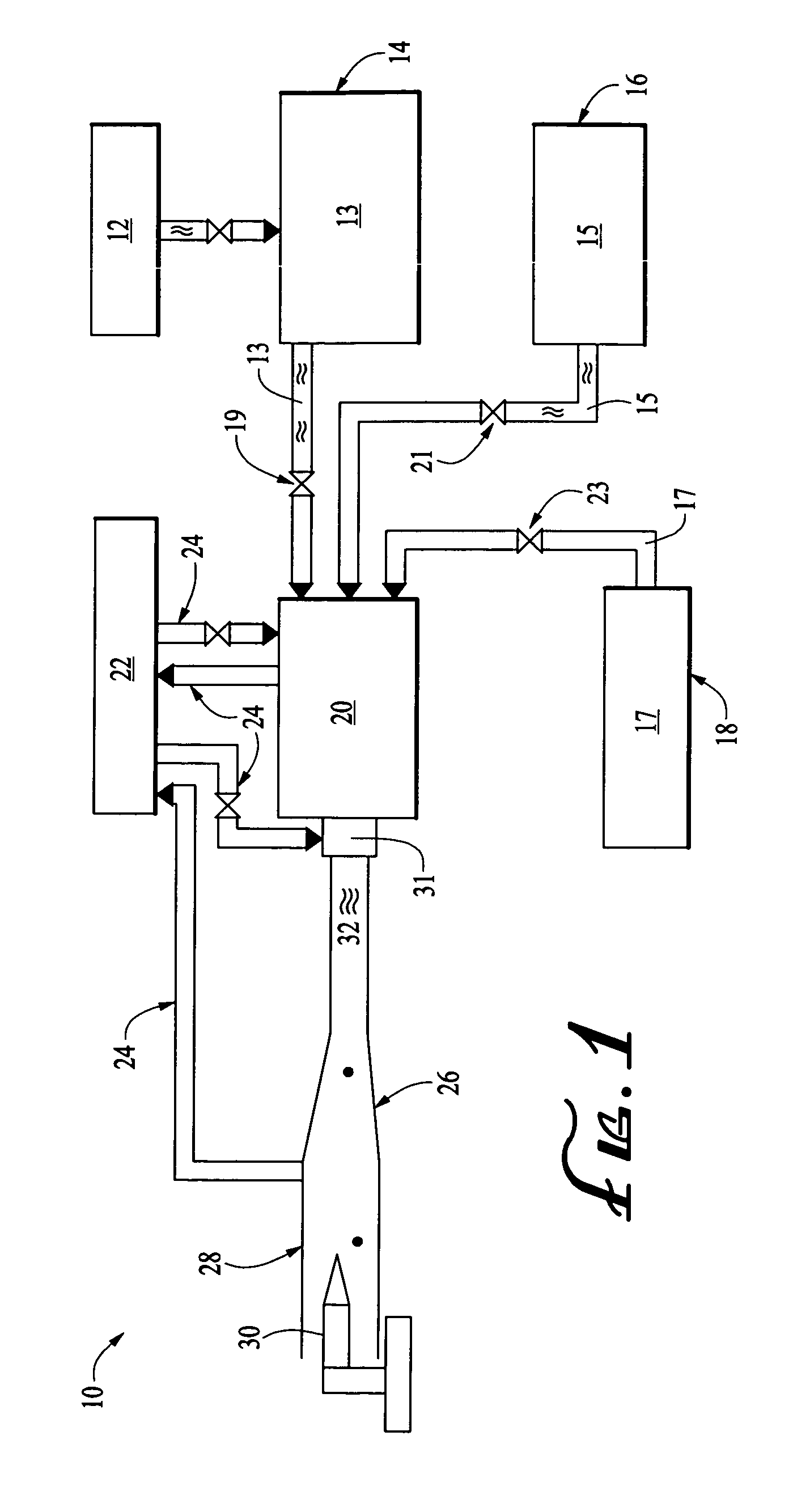

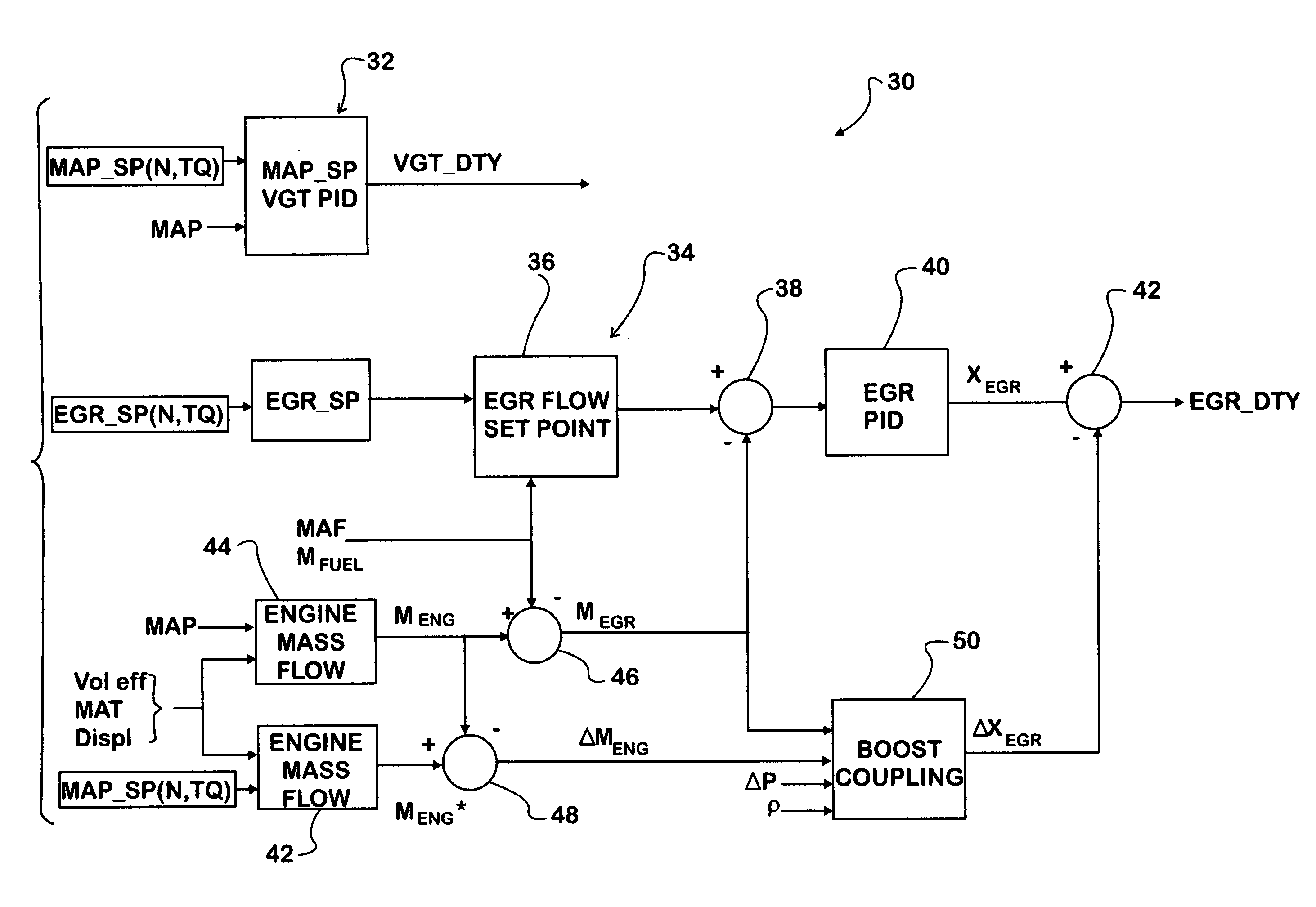

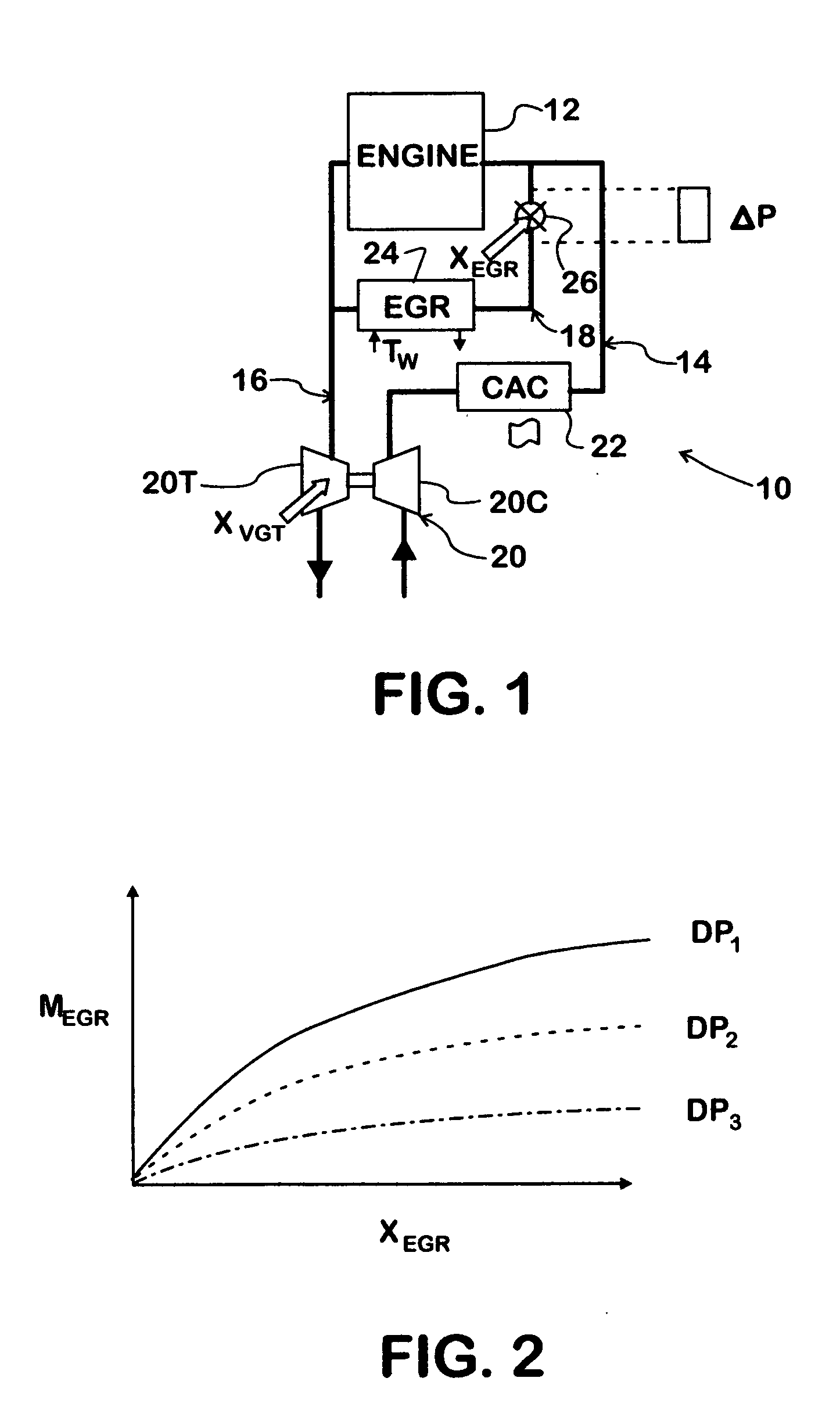

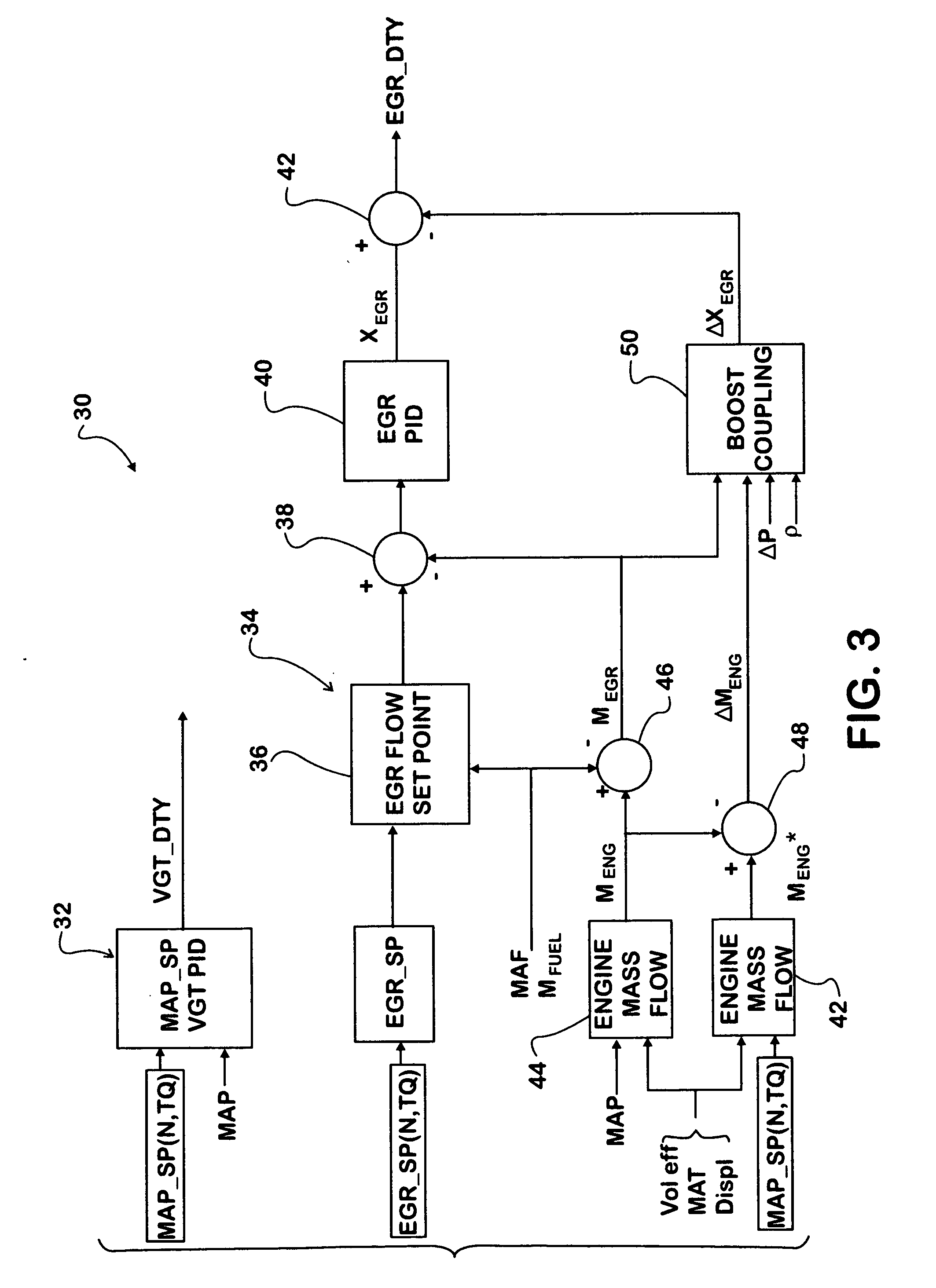

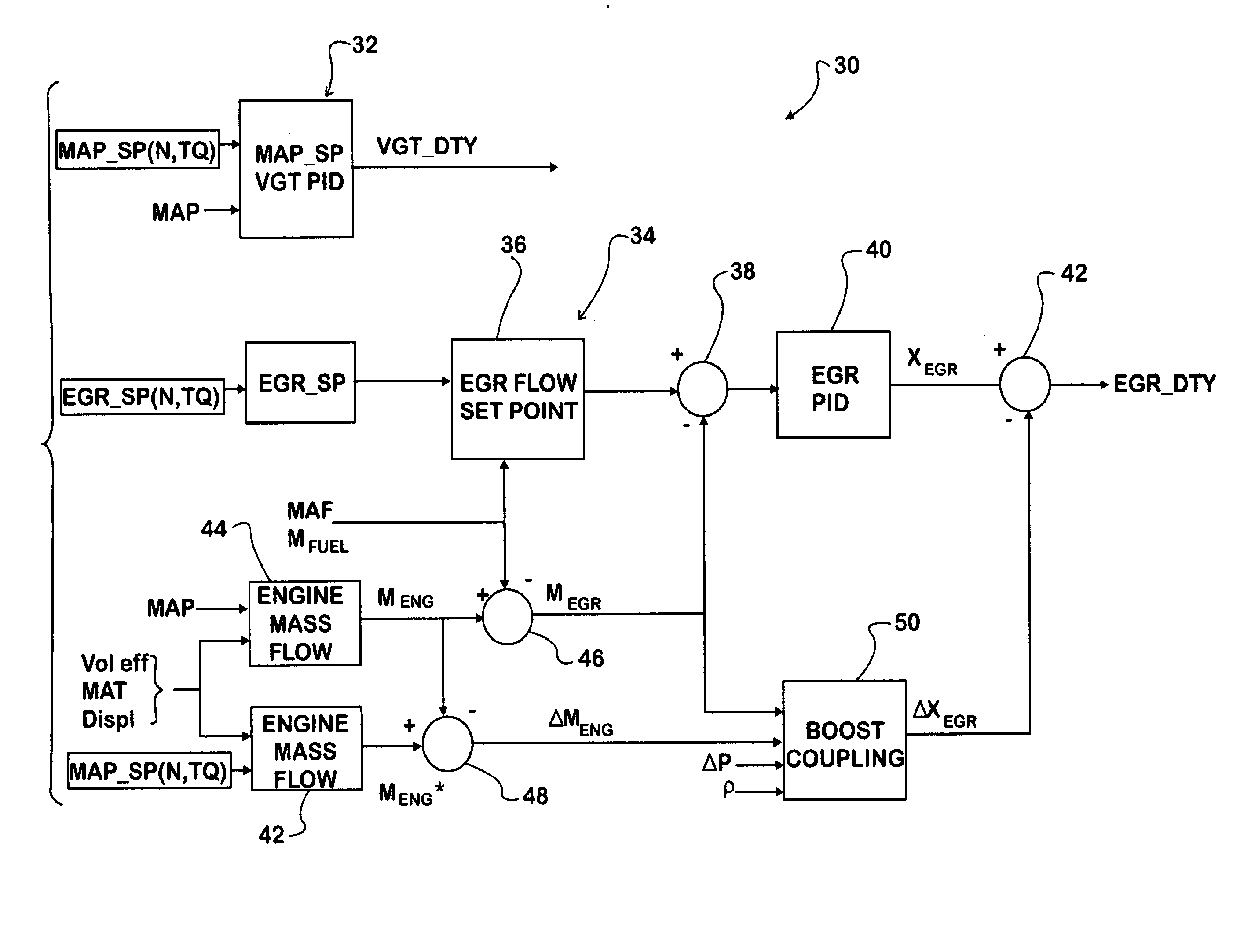

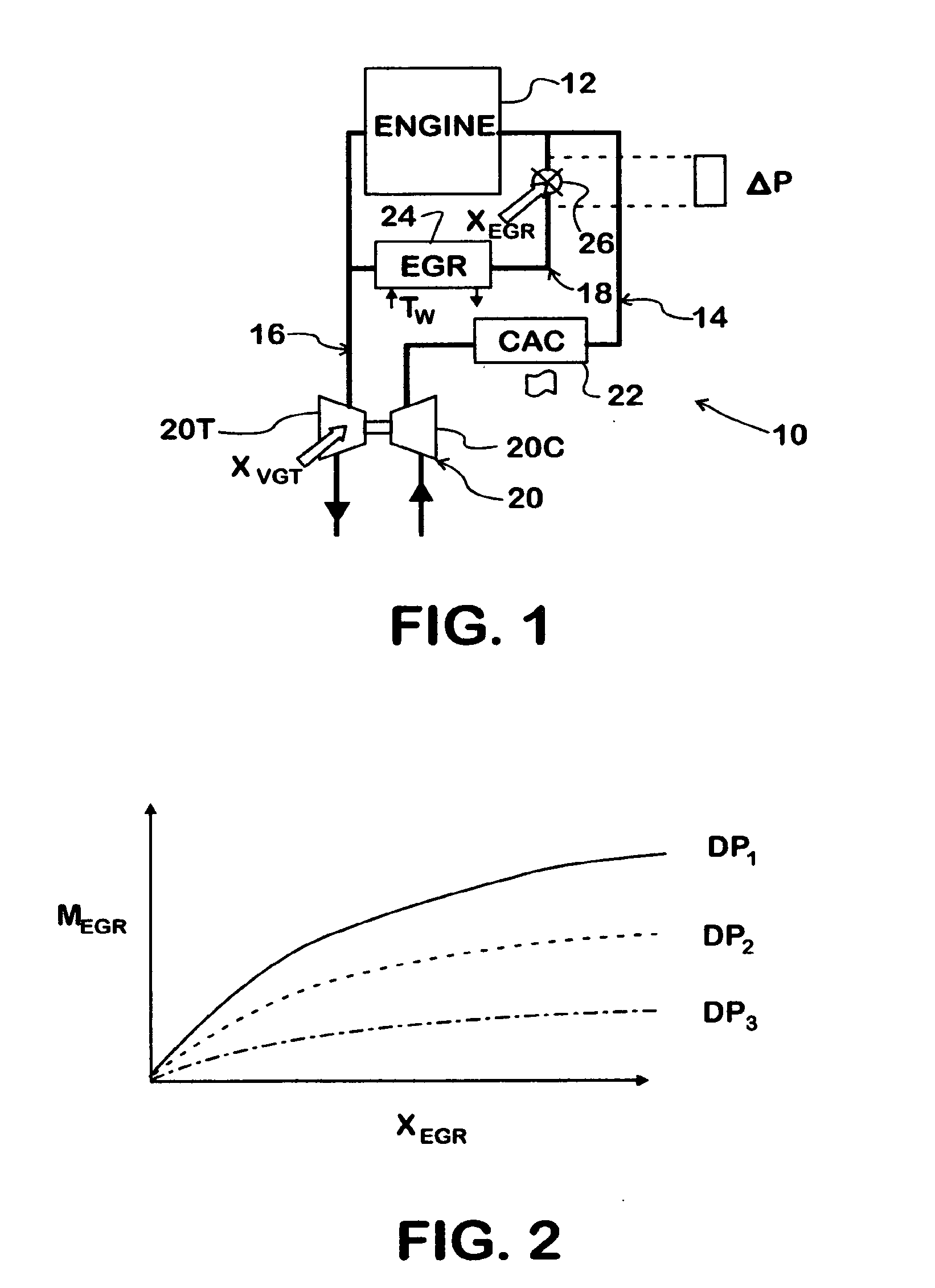

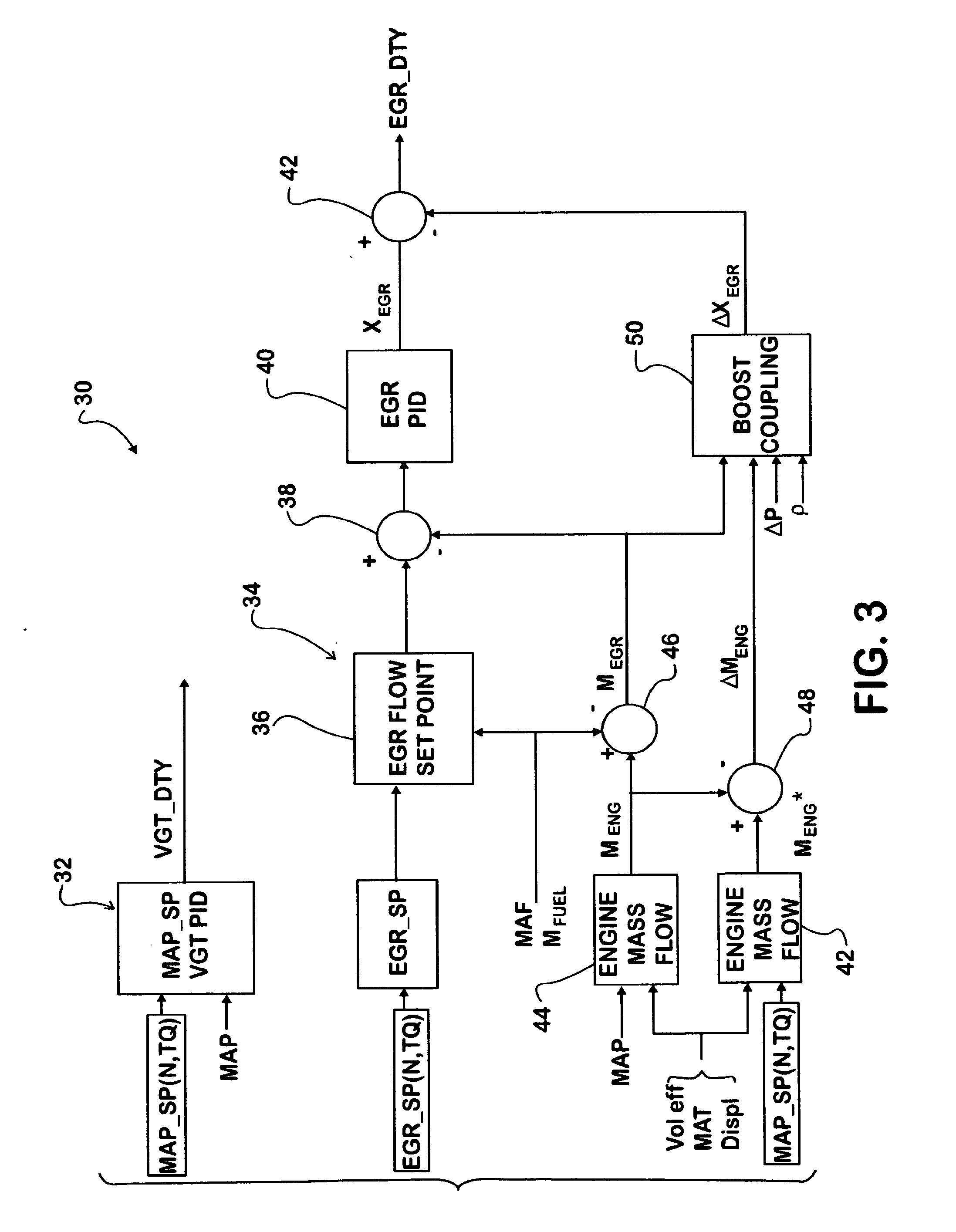

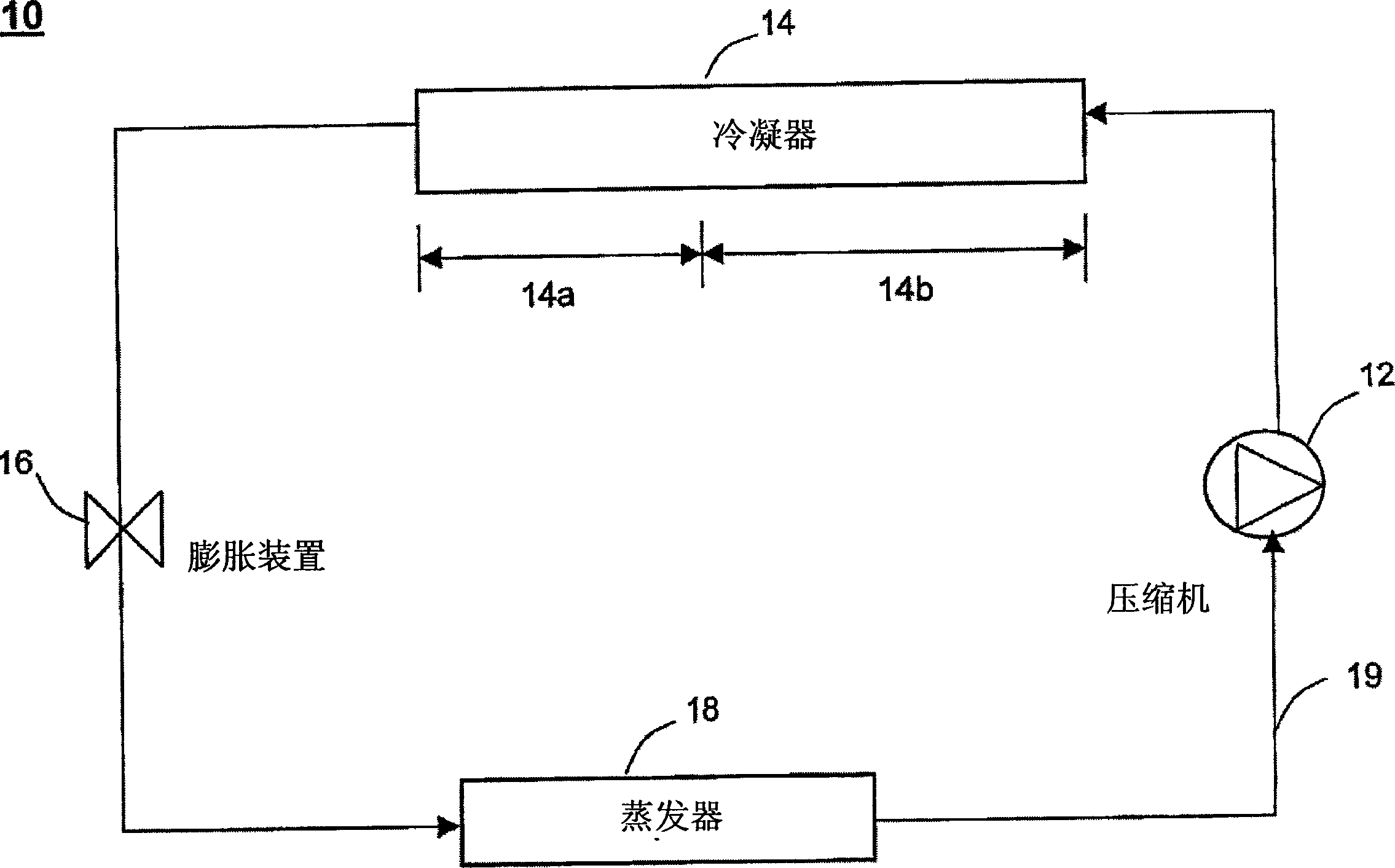

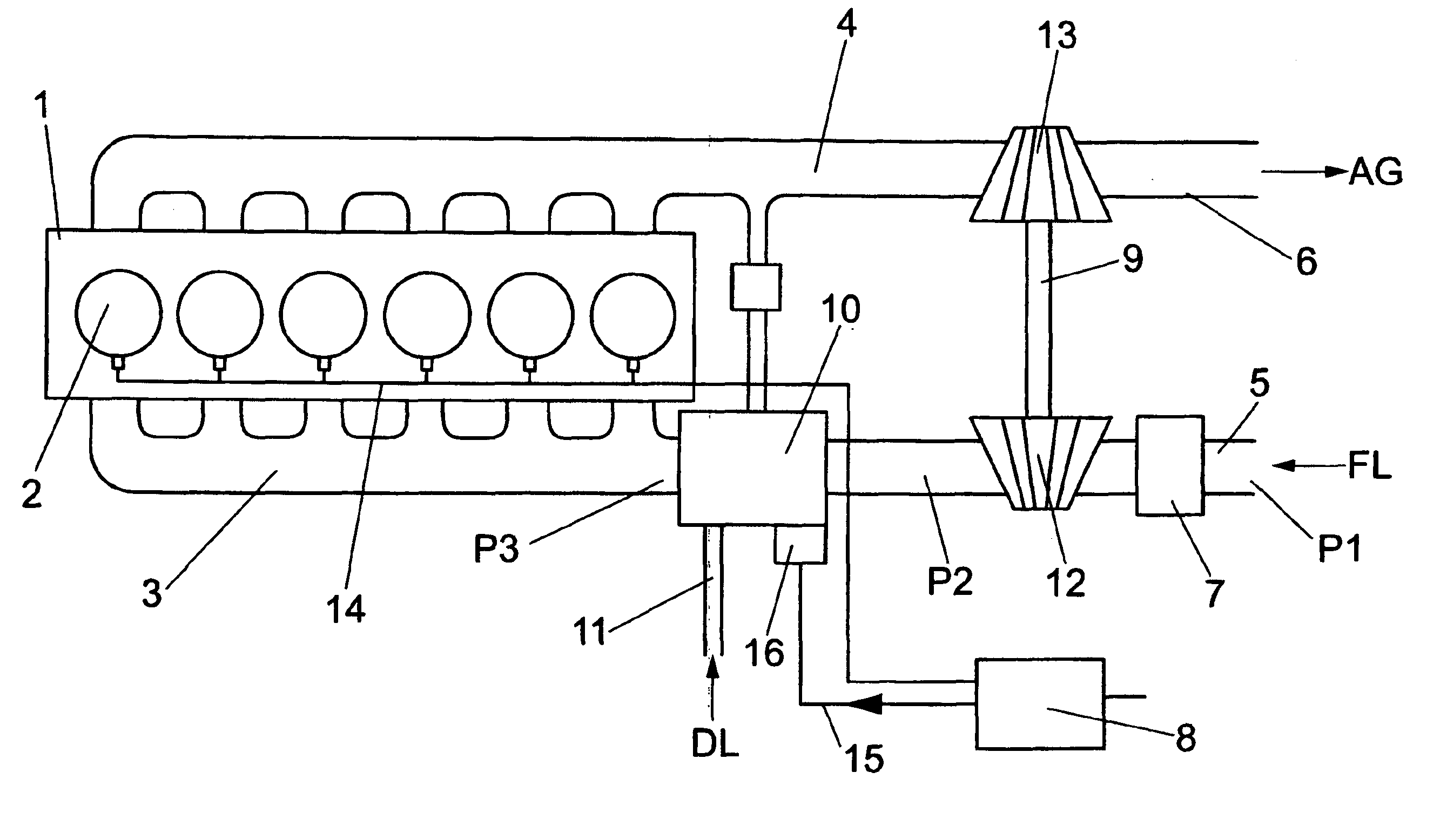

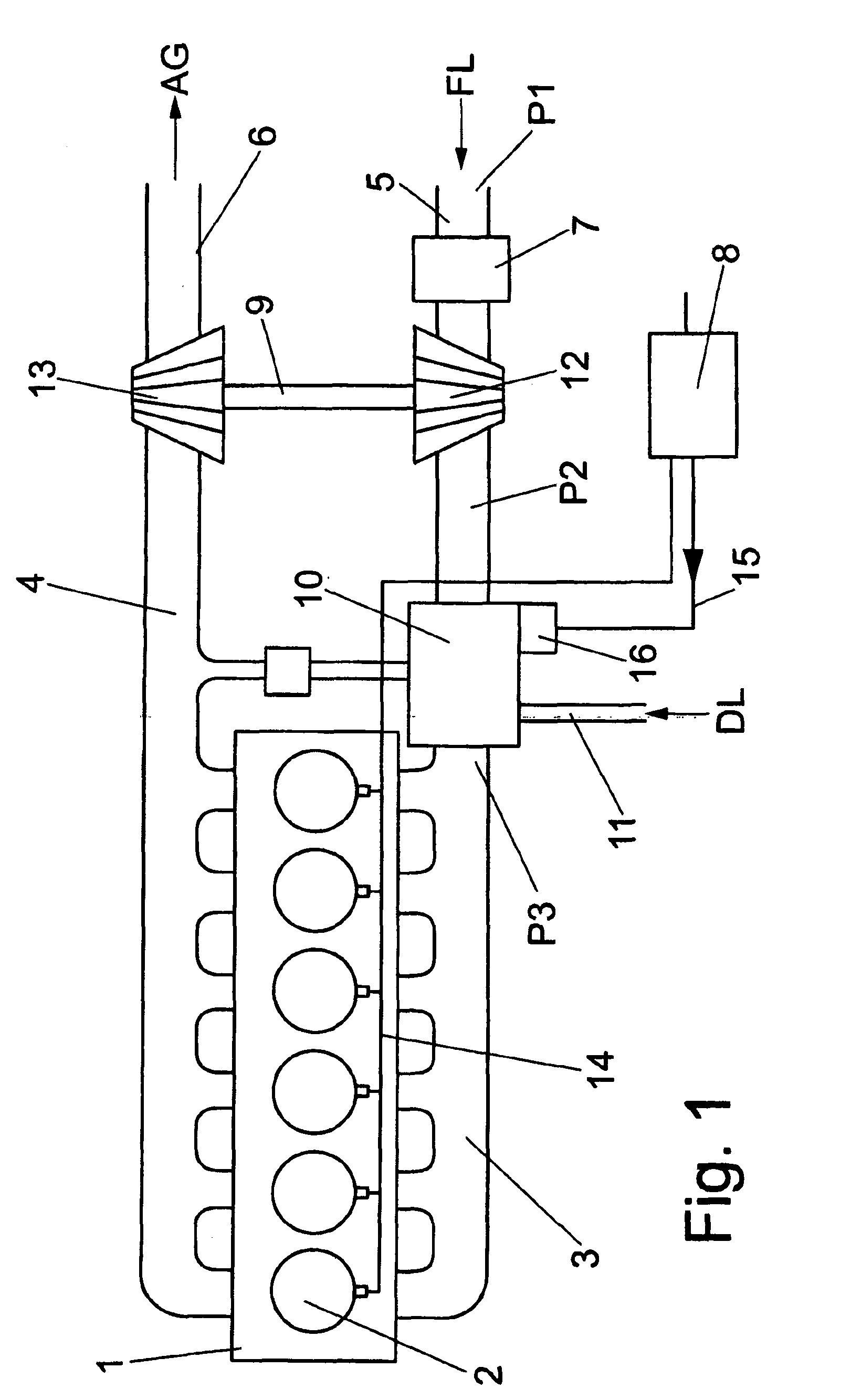

Strategy for control of recirculated exhaust gas to null turbocharger boost error

InactiveUS20080078176A1Increase mass flowLimit NOx formationElectrical controlInternal combustion piston enginesTurbochargerExhaust gas recirculation

A method for coordinating control of exhaust gas recirculation (18) in a turbocharged internal combustion engine (10) with control of engine boost. When actual boost deviates from a desired boost set-point developed by a boost control strategy (32), such as during a sudden acceleration or deceleration, the EGR control strategy (34) provides a prompt adjustment of exhaust gas recirculation (EGR) seeking to null out the boost disparity.

Owner:INT ENGINE INTPROP CO LLC

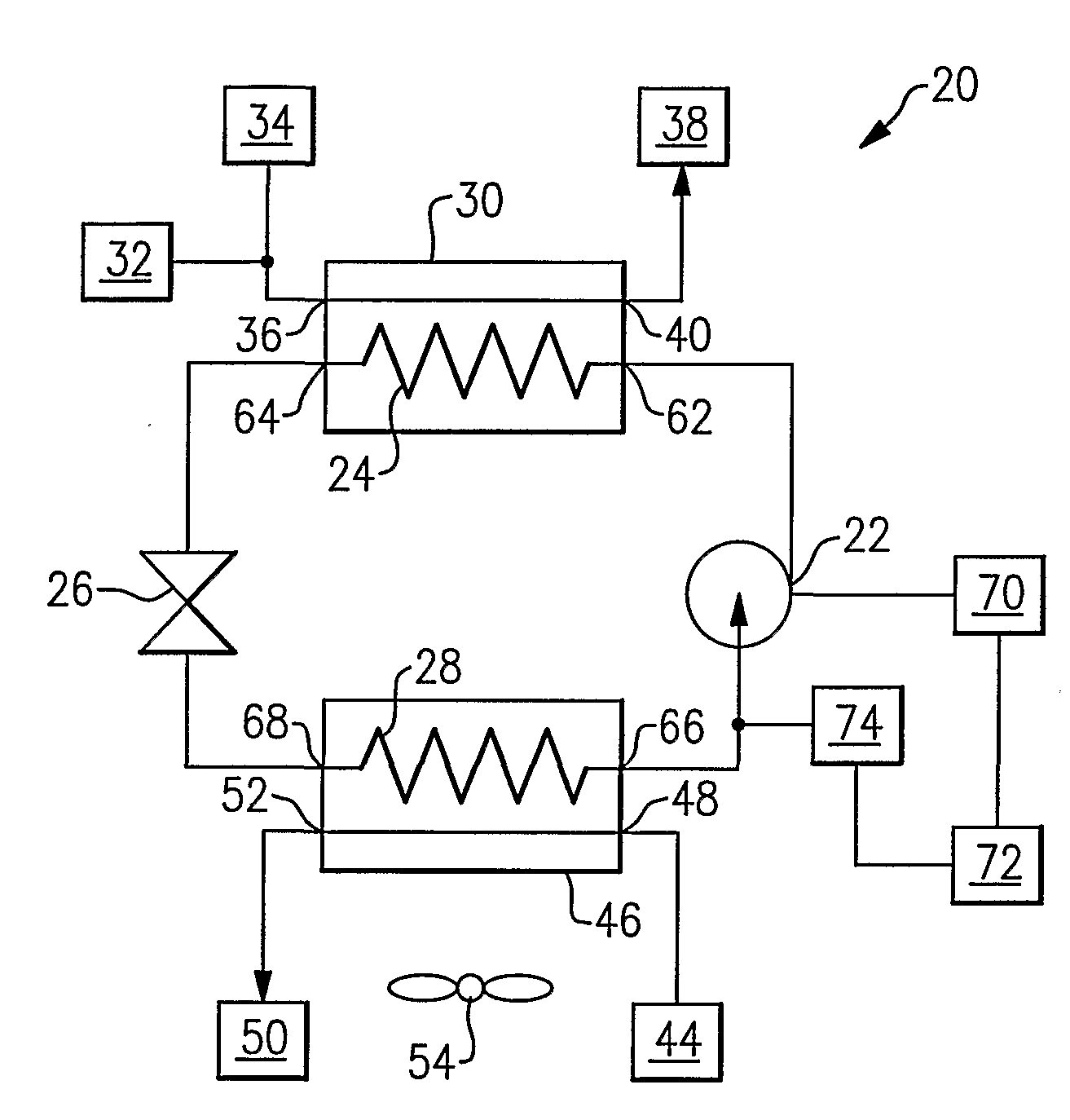

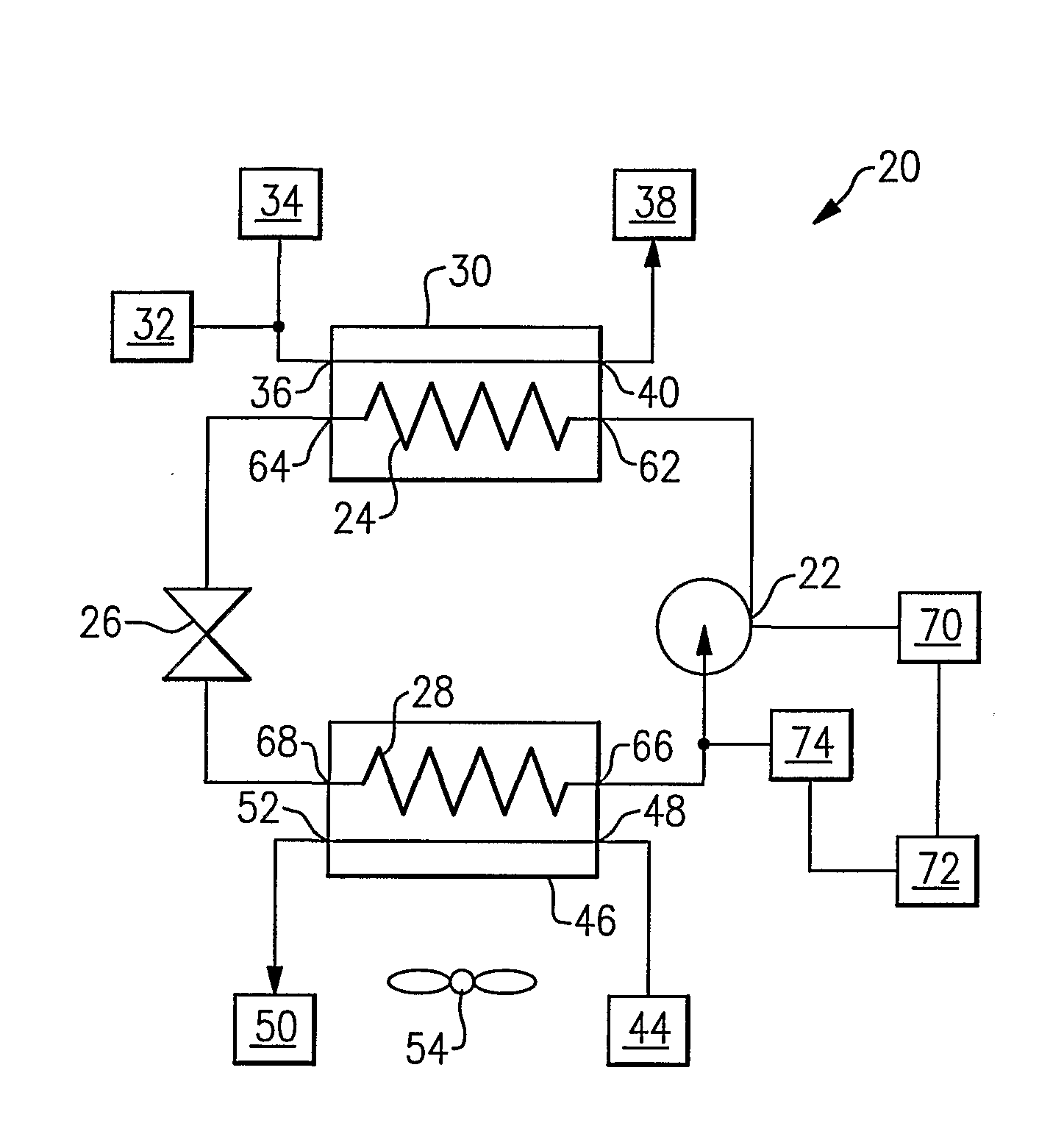

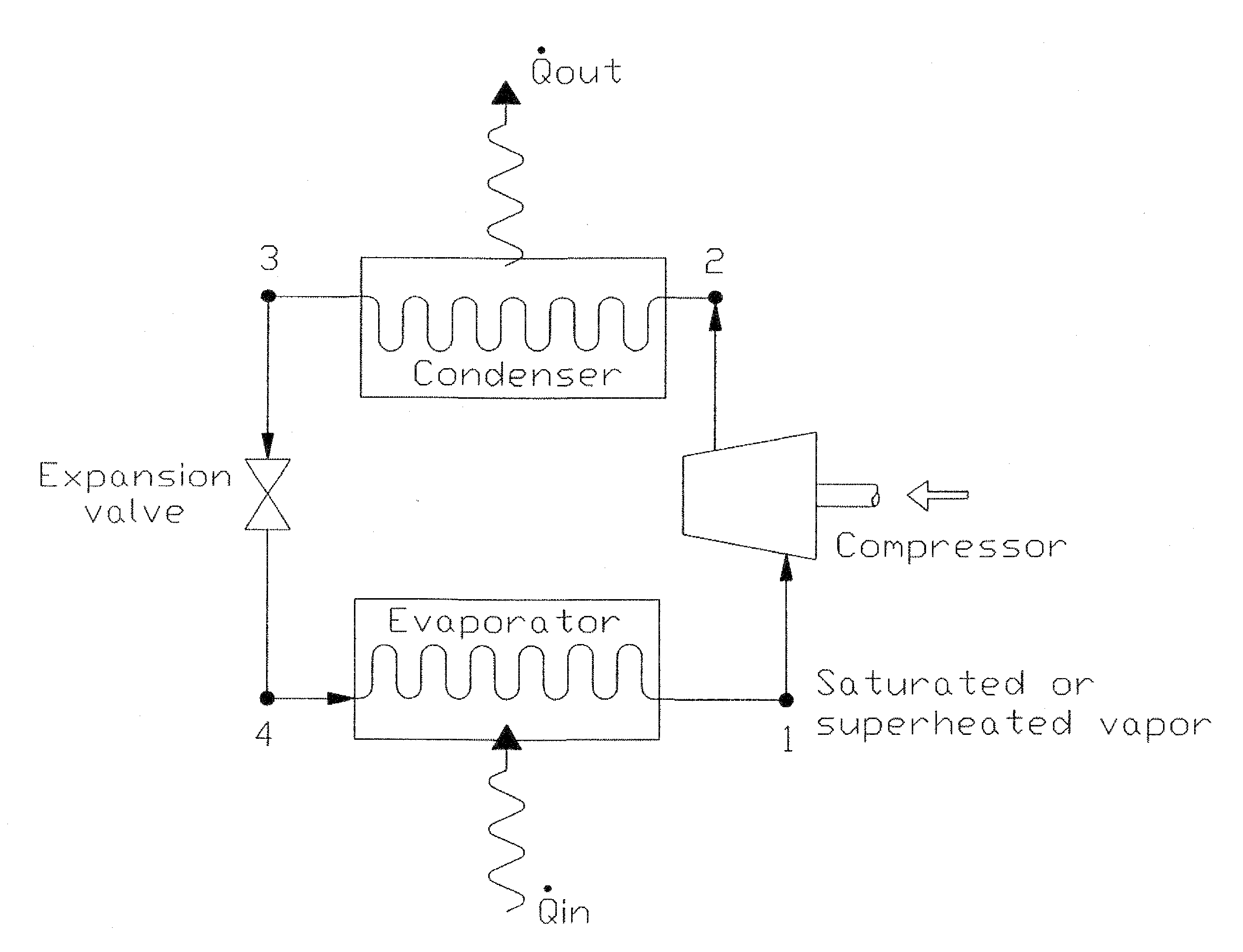

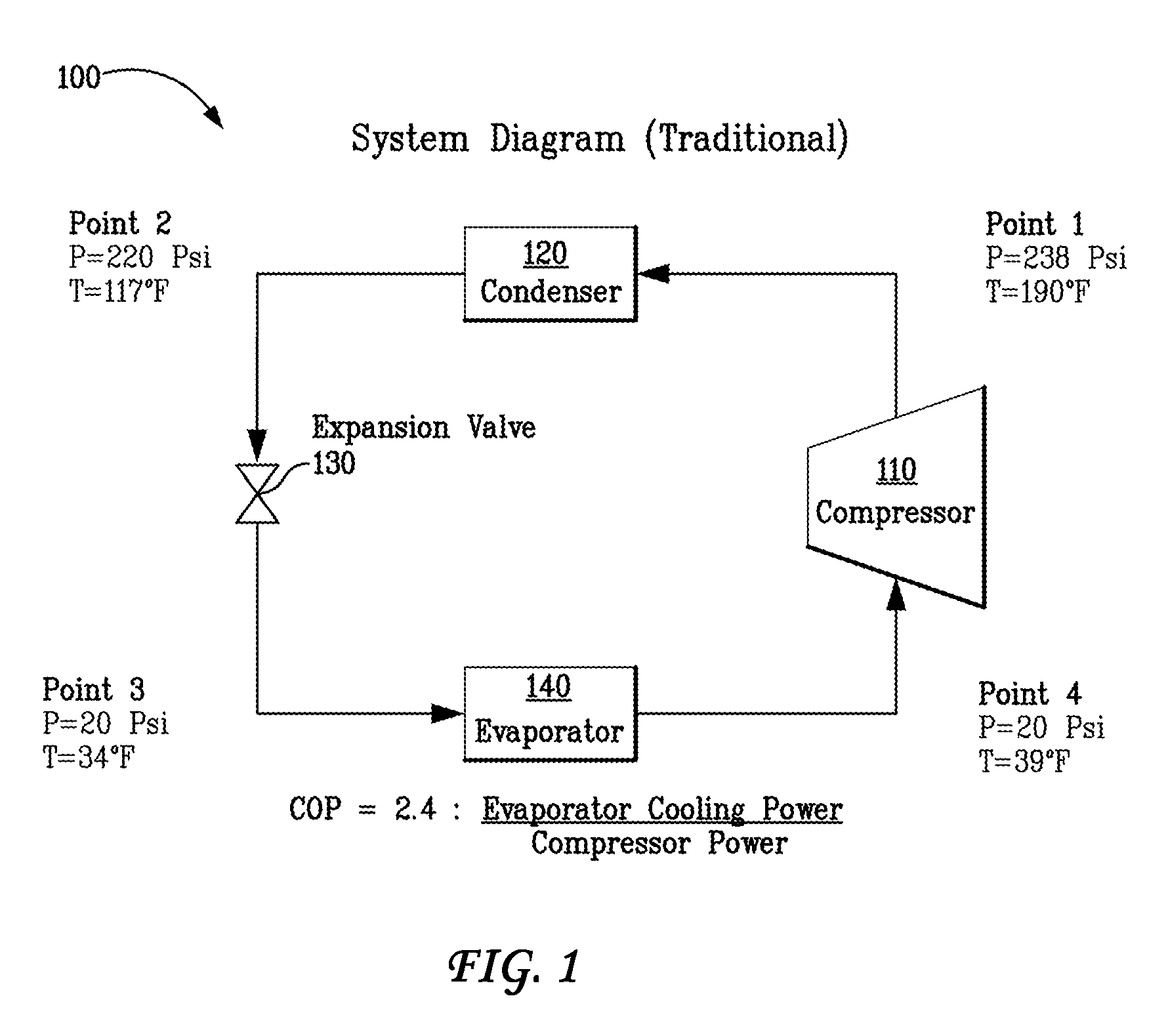

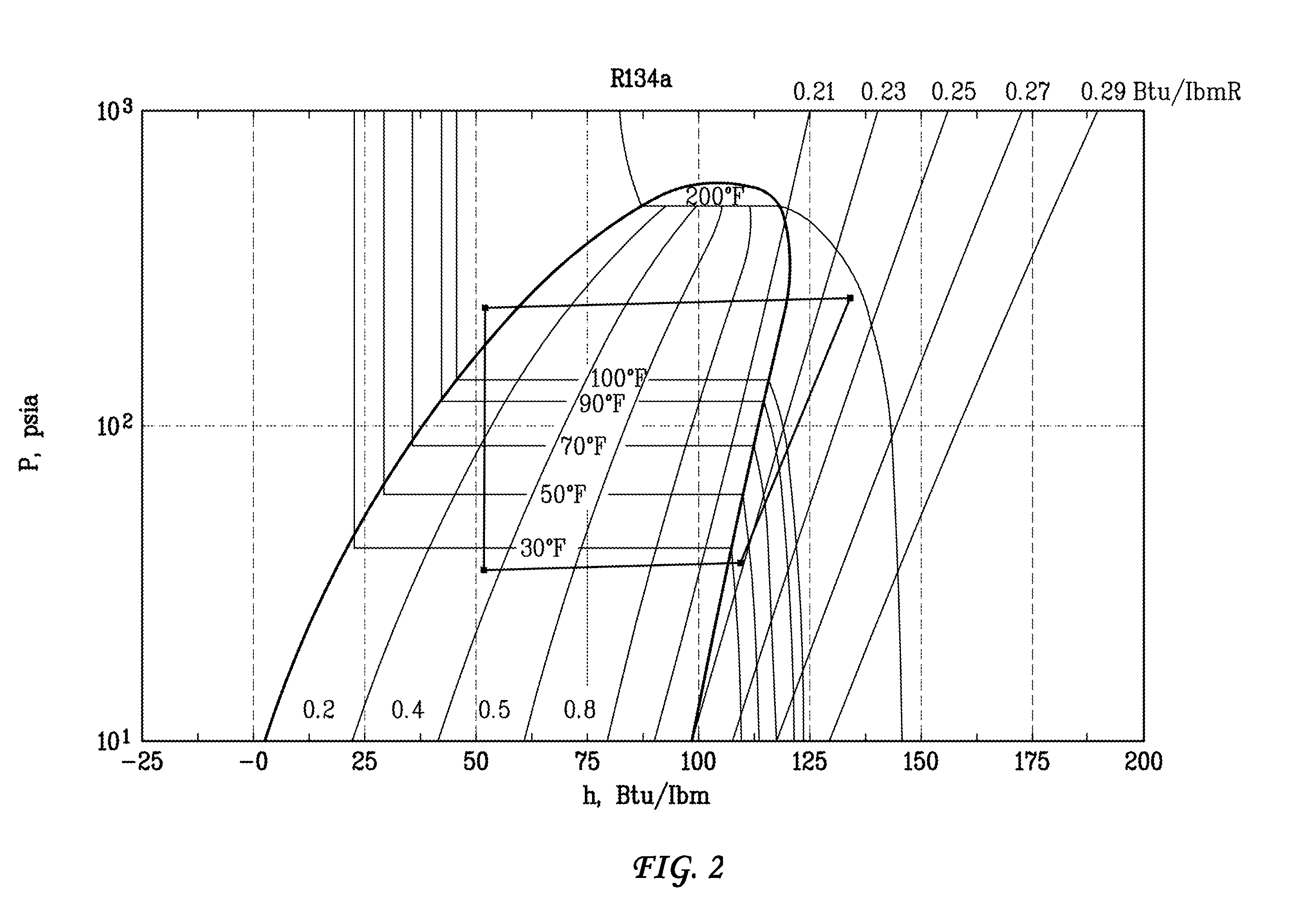

Heat Pump Water Heating System Using Variable Speed Compressor

InactiveUS20080302118A1Increasing energy exchanger per unit flow rateImprove performanceCompression machines with non-reversible cycleEvaporators/condensersGas coolerEngineering

A transcritical refrigeration system includes a compressor, a gas cooler, an expansion device, and an evaporator. Refrigerant is circulated though the closed circuit system. Preferably, carbon dioxide is used as the refrigerant. A variable speed drive controls the speed of the refrigerant flowing through the compressor. Varying the speed of the refrigerant flowing through the compressor changes the mass flow rate of the refrigerant in the system to optimize the coefficient of performance.

Owner:CARRIER CORP

Steam-generating combustion system and method for emission control using oxygen enhancement

InactiveUS7320288B2Accelerate emissionsLow costEmission preventionDispersed particle separationParticulatesHigh concentration

A steam-generating combustion system includes an oxygen enriched gas provided as at least part of an oxidant stream. A combustion chamber receives and combusts a fuel in the oxidant stream and generate steam. The combustion chamber generates flue gas having a flue gas volume which is smaller than a volume of flue gas generated by the combustion chamber when operated with air as the oxidant stream. A flue gas pollutant control system receives the flue gas from the combustion chamber and reduces at least one of particulate matter, SOx, NOx, and mercury. The reduction in flue gas volume allows the implementation of much smaller pollutant control equipment, since the size of the pollutant control units is mainly based on the volume or mass flow rate of flue gas to be treated. Moreover, the system including oxygen-enriched gas in the oxidant will lead to concentrated levels of the pollutants in the flue gas. The high concentrations of pollutants will enhance their absorption in the different pollutant control systems, improving removal efficiency for all species.

Owner:AIR LIQUIDE AMERICA INC

Manifold designs, and flow control in multichannel microchannel devices

InactiveUS7422910B2Equally distributedLow costChemical/physical/physico-chemical microreactorsSemiconductor/solid-state device manufacturingEngineering

Owner:VELOCYS CORPORATION

Manifold designs, and flow control in mulitchannel microchannel devices

InactiveUS20090074627A1Equally distributedLow costChemical/physical/physico-chemical microreactorsLaboratory glasswaresEngineeringStreamflow

Owner:VELOCYS INC

Strategy For Control Of Recirculated Exhaust Gas To Null Turbocharger Boost Error

InactiveUS20110079008A1Cost-effectiveImplemented cost-effectivelyElectrical controlNon-fuel substance addition to fuelTurbochargerExhaust fumes

A method for coordinating control of exhaust gas recirculation (18) in a turbocharged internal combustion engine (10) with control of engine boost. When actual boost deviates from a desired boost set-point developed by a boost control strategy (32), such as during a sudden acceleration or deceleration, the EGR control strategy (34) provides a prompt adjustment of exhaust gas recirculation (EGR) seeking to null out the boost disparity.

Owner:DE OJEDA WILLIAM

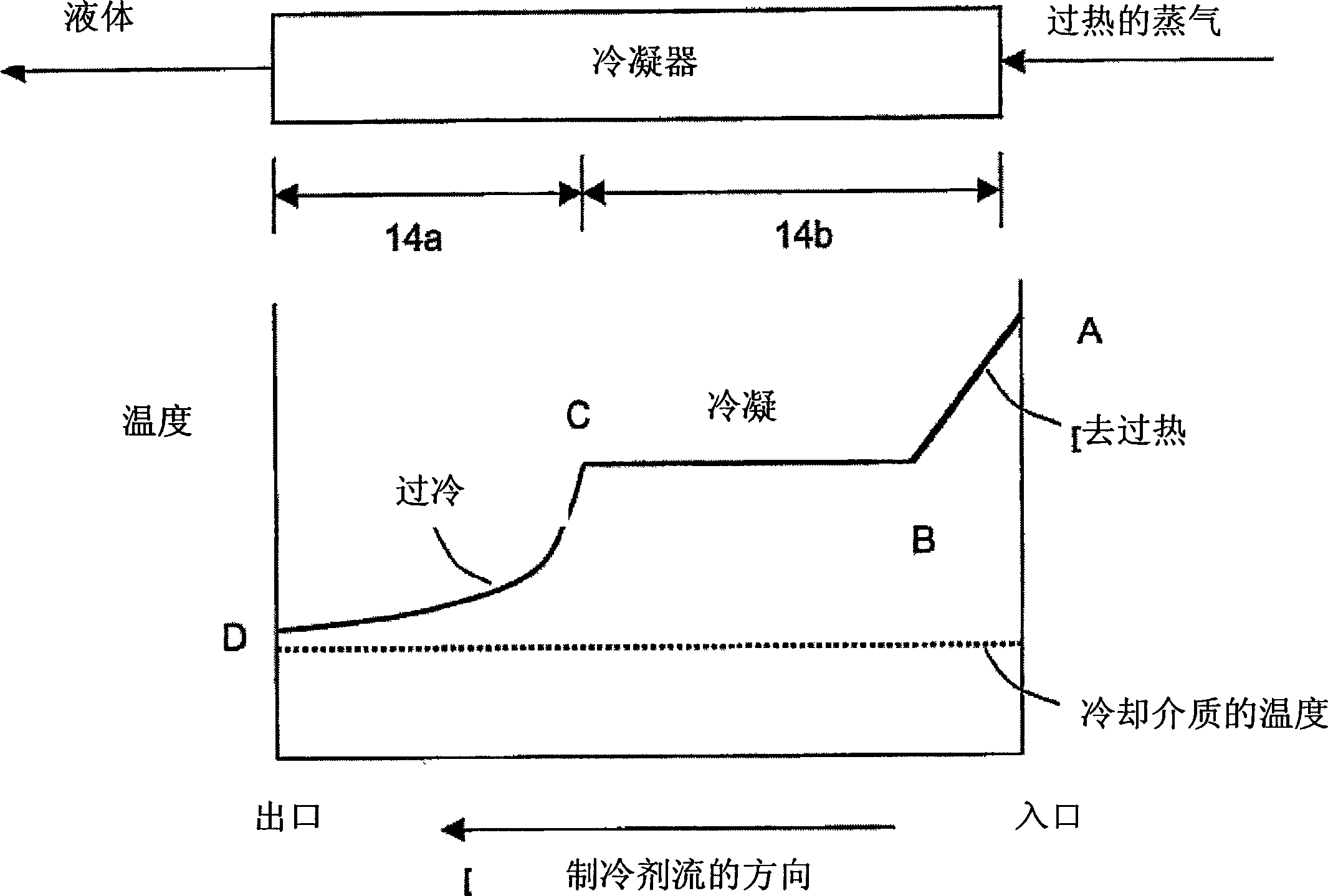

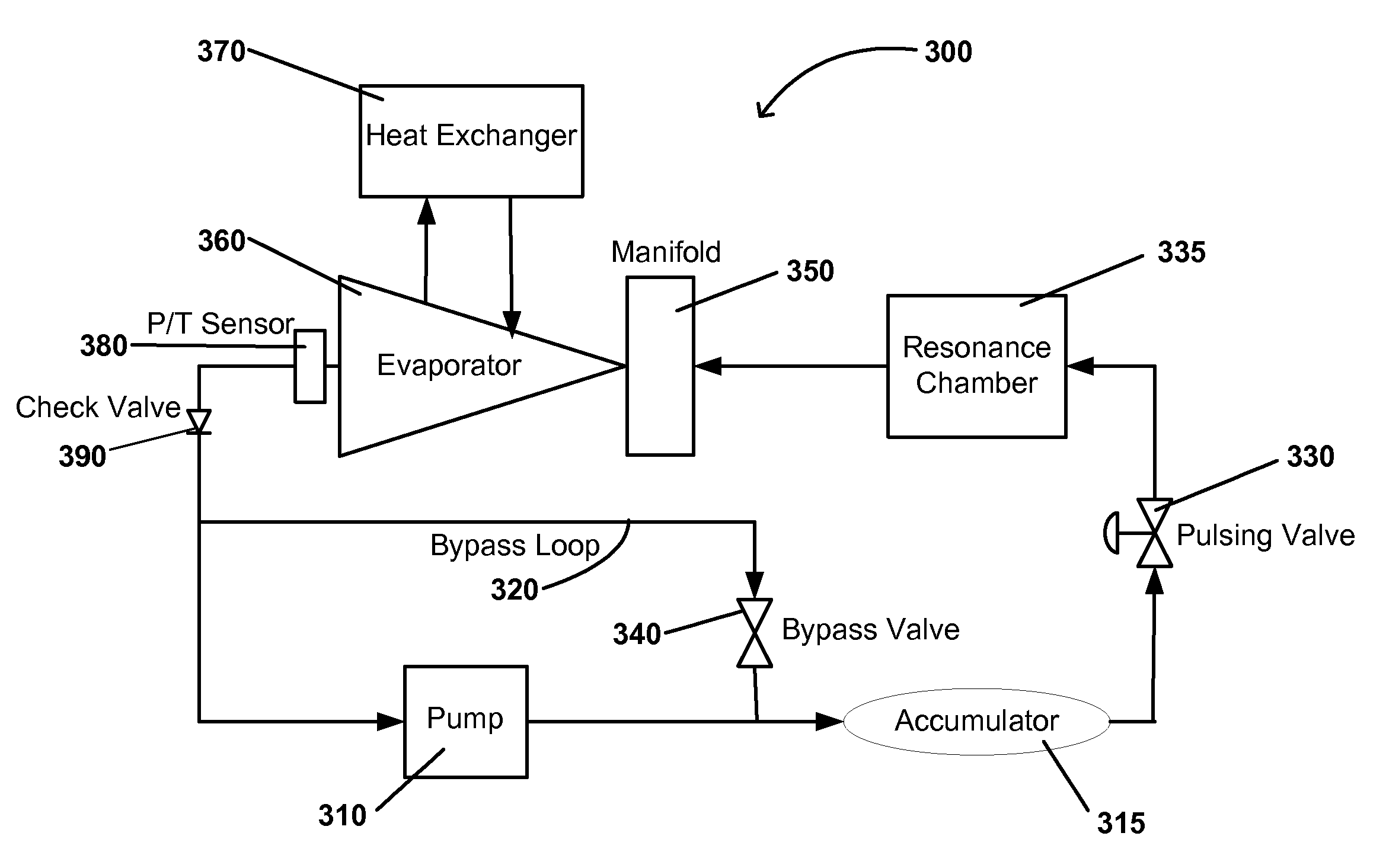

Refrigeration system with bypass subcooling and component size de-optimization

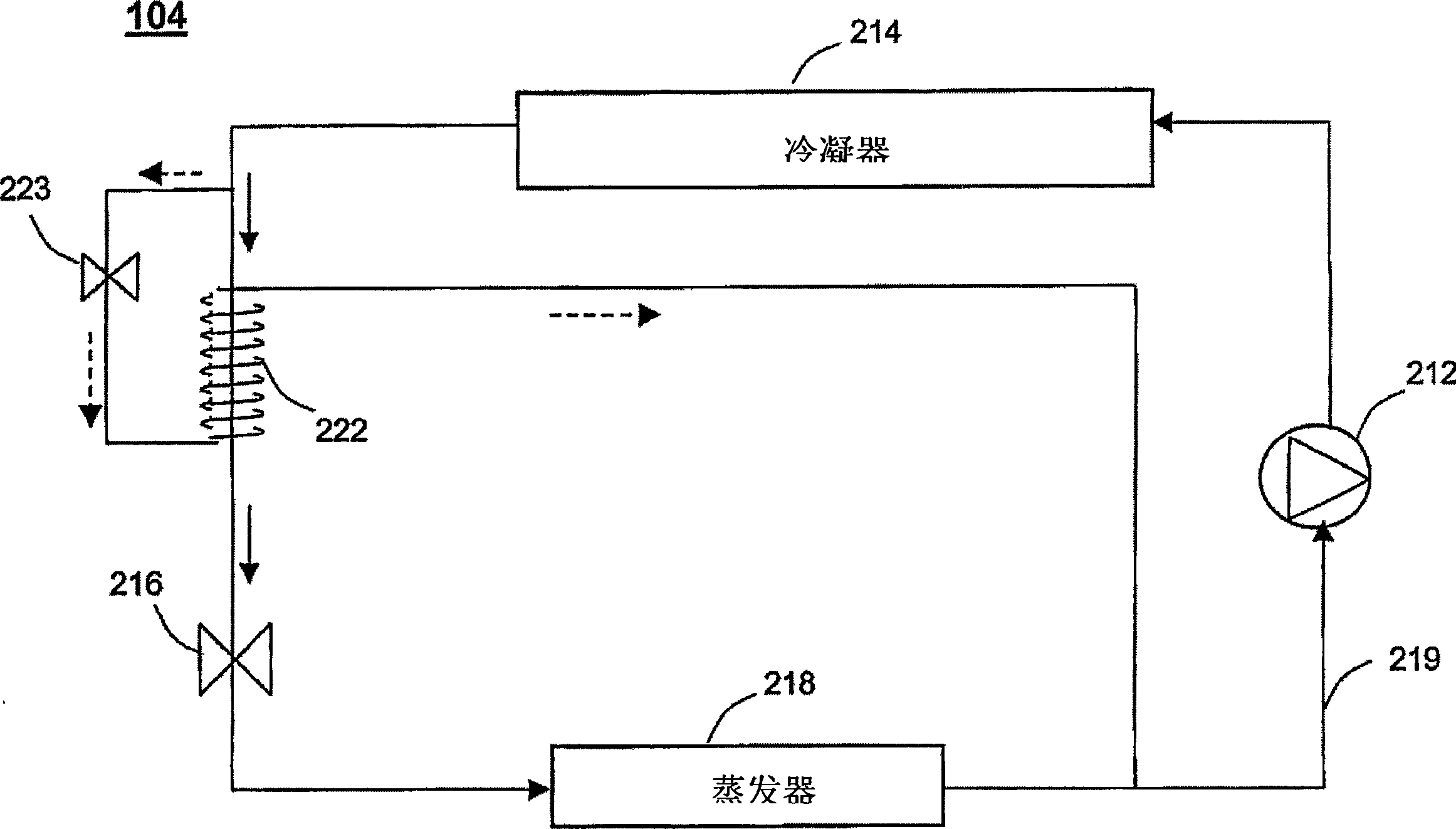

InactiveCN1732365AReduce mass flow rateReduce cooling effectCompression machines with several condensersCompression machines with several evaporatorsClosed loopEngineering

A refrigeration system having a primary refrigerant circuit comprising a compressor, a condenser, a primary expansion device and an evaporator connected together to form a refrigerant circuit in which A closed loop system; and a bypass line, which is connected to the outlet of the condensing device, the bypass line includes: a secondary expansion device; a heat exchange device, between the outlet of the condenser and the inlet of the primary expansion device The primary refrigerant path is thermally connected to absorb heat from the discharged refrigerant from the condenser. The condenser is reduced in size, lacking the heat transfer capacity to provide some or all of the subcooling according to conventional practice, and the heat exchanger provides some or all of the subcooling according to the capacity of the condenser. Pressure regulating means for mixing the vapors of two different pressures may also be provided to connect the outlet of the evaporator and heat exchanger with the inlet of the compressor. A method of operating a refrigeration system having a reduced volume condenser and a bypass line including a heat exchanger for providing subcooling.

Owner:沃特克斯·埃尔康公司

Method for preparing CuCrZr spherical powder based on VIGA process

ActiveCN110480024AUniform particle sizeUniform sizeAdditive manufacturing apparatusTransportation and packagingCrucibleBar stock

A method for preparing CuCrZr spherical powder based on a VIGA process comprises the following steps that (1) smelting is conducted according to the proportion and adding mode of each element, forgingis performed after pouring, and a CuCrZr bar blank is obtained; (2) a CuCrZr alloy bar stock is processed; (3) the CuCrZr alloy bar stock is placed into a crucible in a furnace for melting and then stirred through electromagnetic induction, pre-vacuumizing treatment is conducted on the whole set of equipment, and then inert protective gas is introduced; (4) the obtained alloy melt is introduced into an atomizing chamber through a guide pipe to be atomized and crushed into a large number of fine liquid drops, and the liquid drops are solidified into spherical powder particles in the flying process; (5) the CuCrZr spherical powder is obtained through a powder collecting device and then sieved and vacuum packaged as required after the powder is completely cooled. According to the preparationmethod of the CuCrZr alloy spherical powder, the powder is prepared by a VIGA process on the basis that the raw material requirements of metal additive manufacturing are met, so that the problem of domestication preparation of additive manufacturing raw materials of advanced copper-alloy complex cooling structural parts of an aerospace engine is solved.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Steam-generating combustion system and method for emission control using oxygen enhancement

InactiveUS20050233274A1Accelerate emissionsLow costEmission preventionDispersed particle separationCombustion systemCombustion chamber

A steam-generating combustion system includes an oxygen enriched gas provided as at least part of an oxidant stream. A combustion chamber receives and combusts a fuel in the oxidant stream and generate steam. The combustion chamber generates flue gas having a flue gas volume which is smaller than a volume of flue gas generated by the combustion chamber when operated with air as the oxidant stream. A flue gas pollutant control system receives the flue gas from the combustion chamber and reduces at least one of particulate matter, SOx, NOx, and mercury. The reduction in flue gas volume allows the implementation of much smaller pollutant control equipment, since the size of the pollutant control units is mainly based on the volume or mass flow rate of flue gas to be treated. Moreover, the system including oxygen-enriched gas in the oxidant will lead to concentrated levels of the pollutants in the flue gas. The high concentrations of pollutants will enhance their absorption in the different pollutant control systems, improving removal efficiency for all species.

Owner:AIR LIQUIDE AMERICA INC

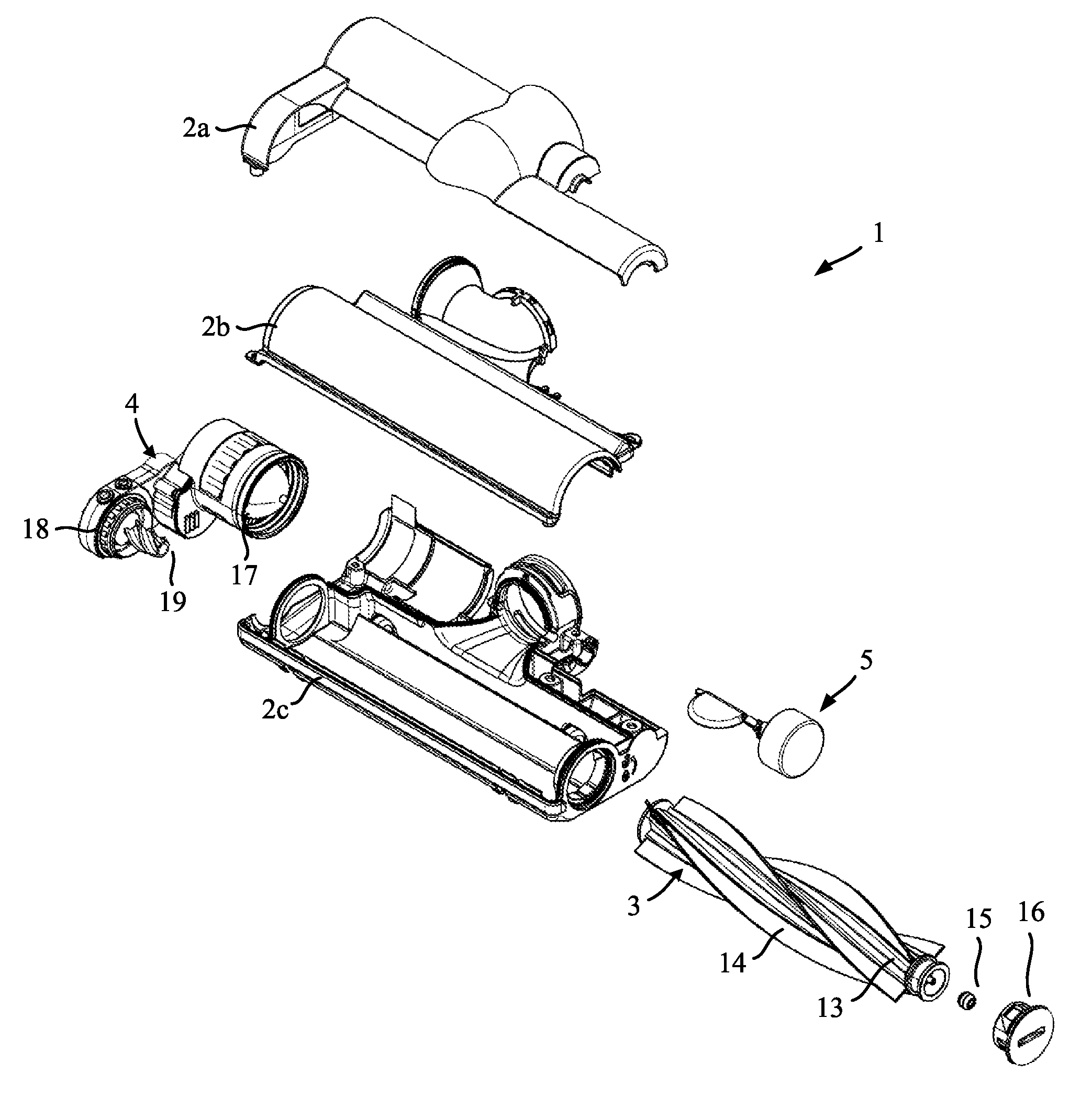

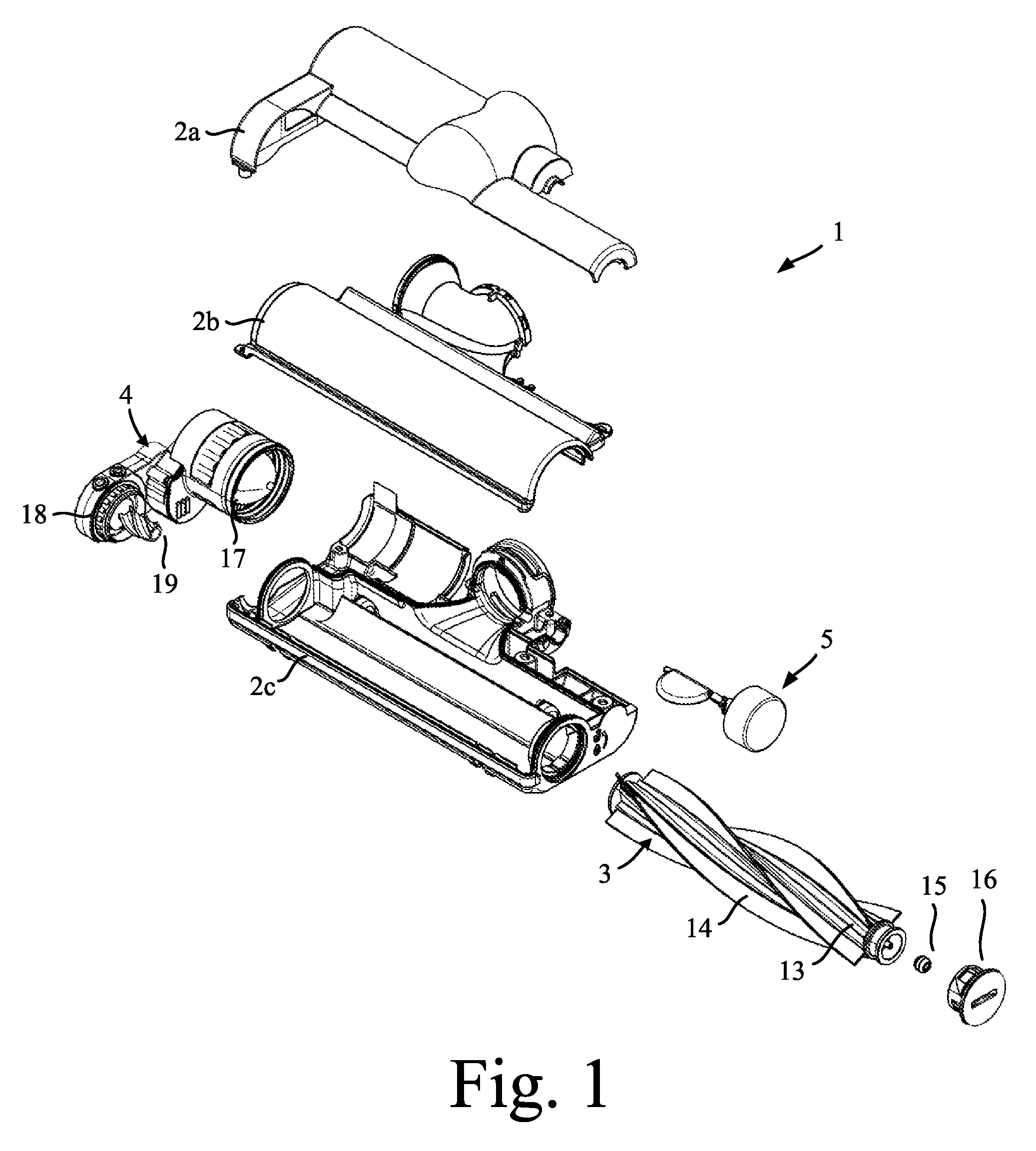

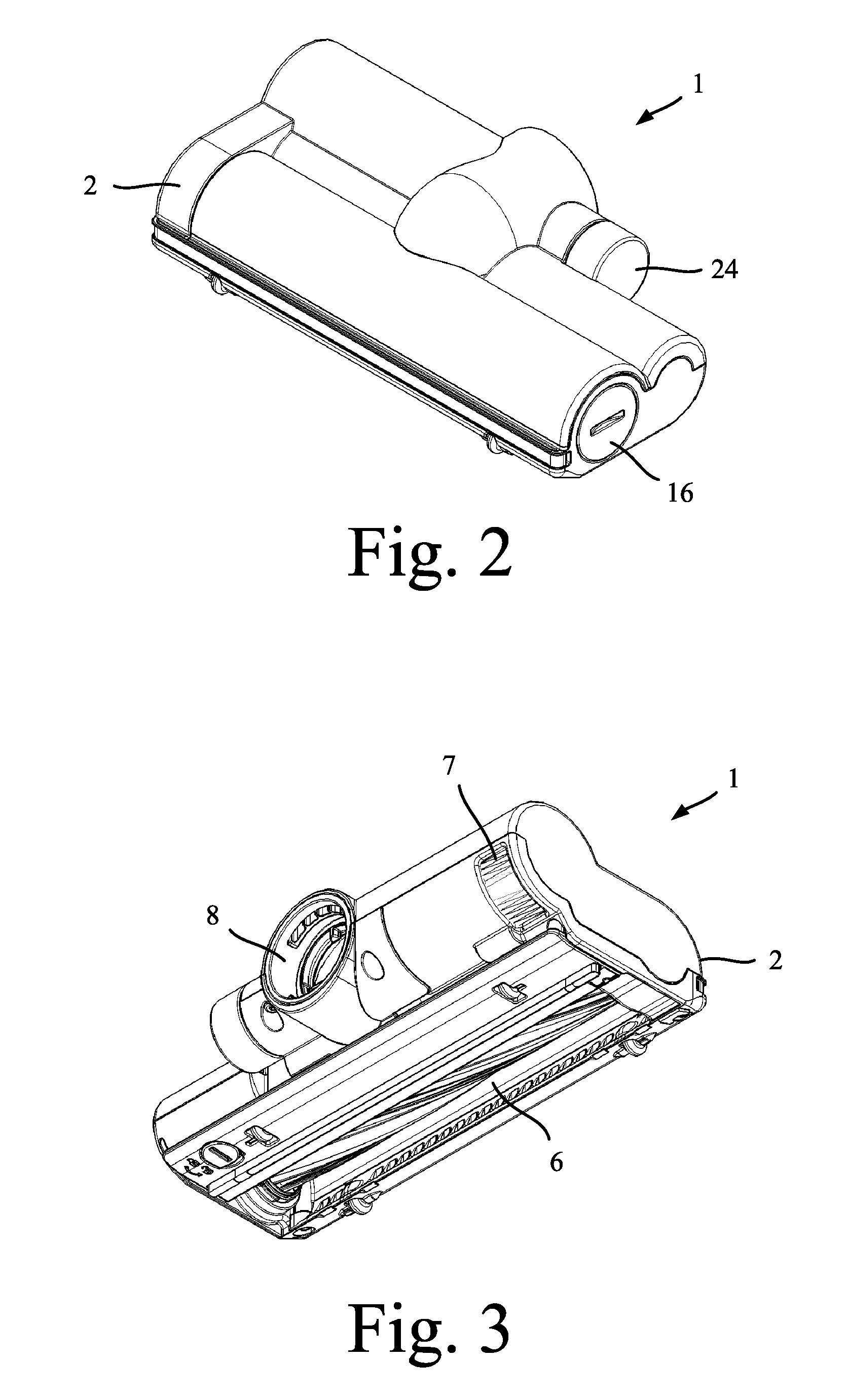

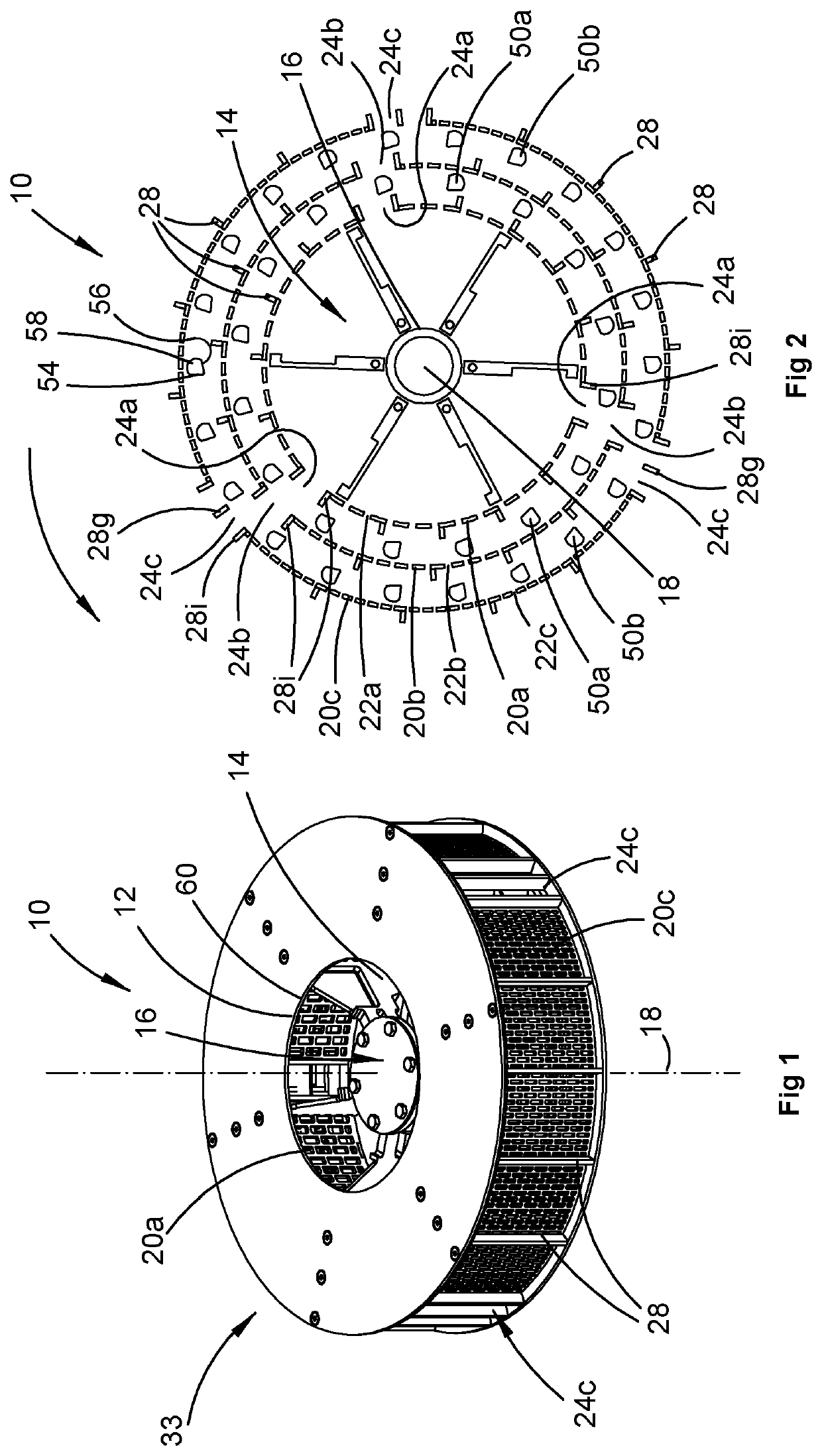

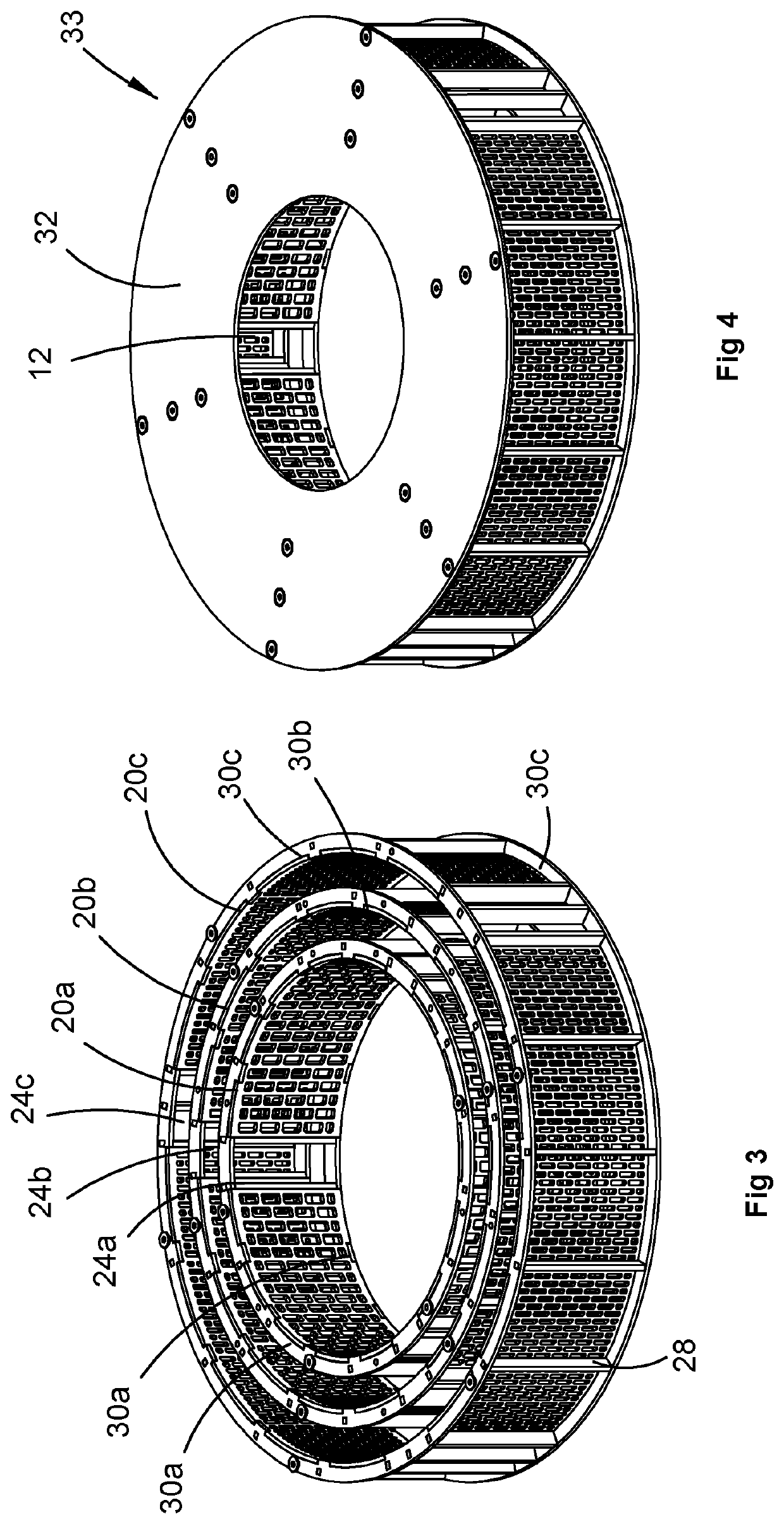

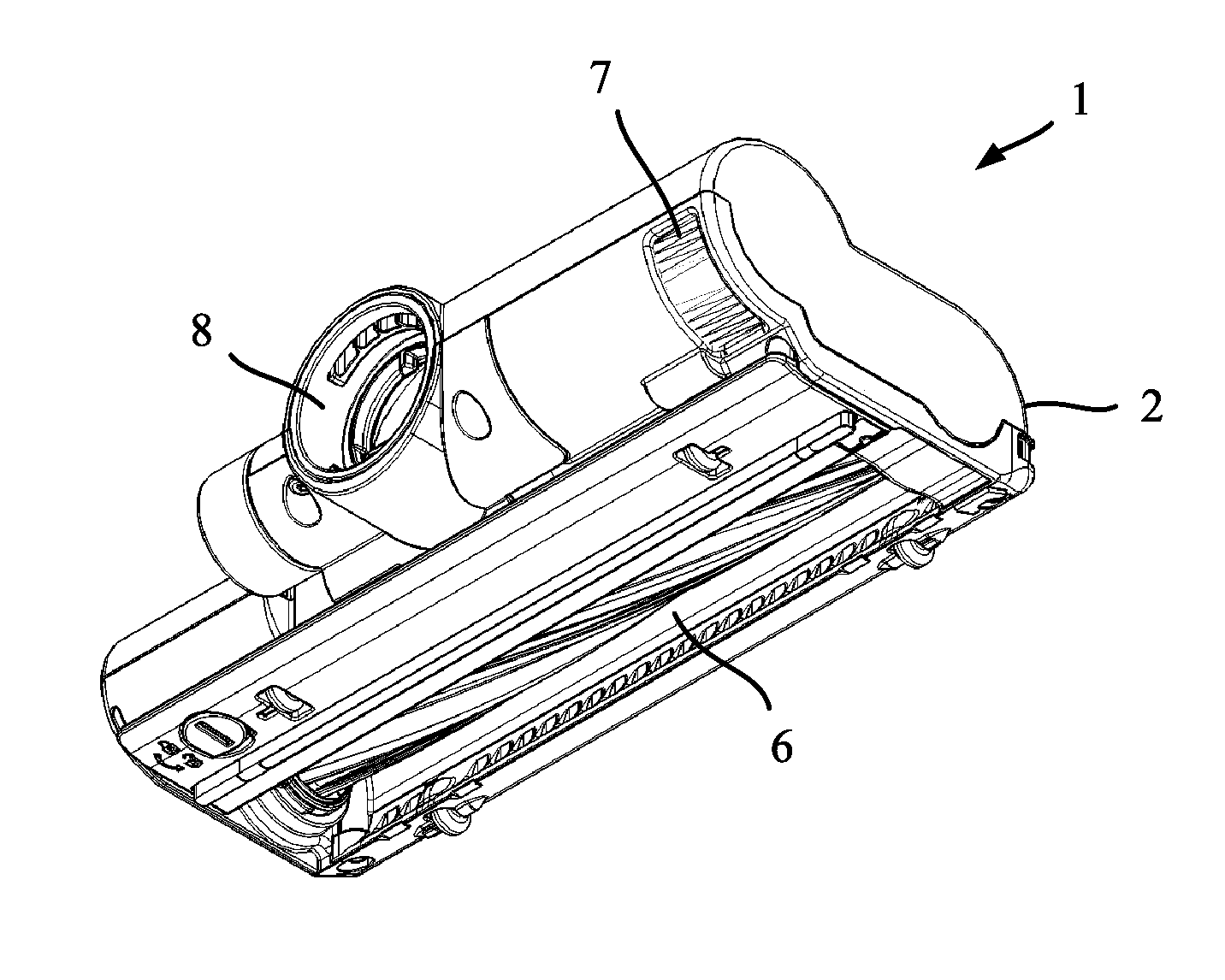

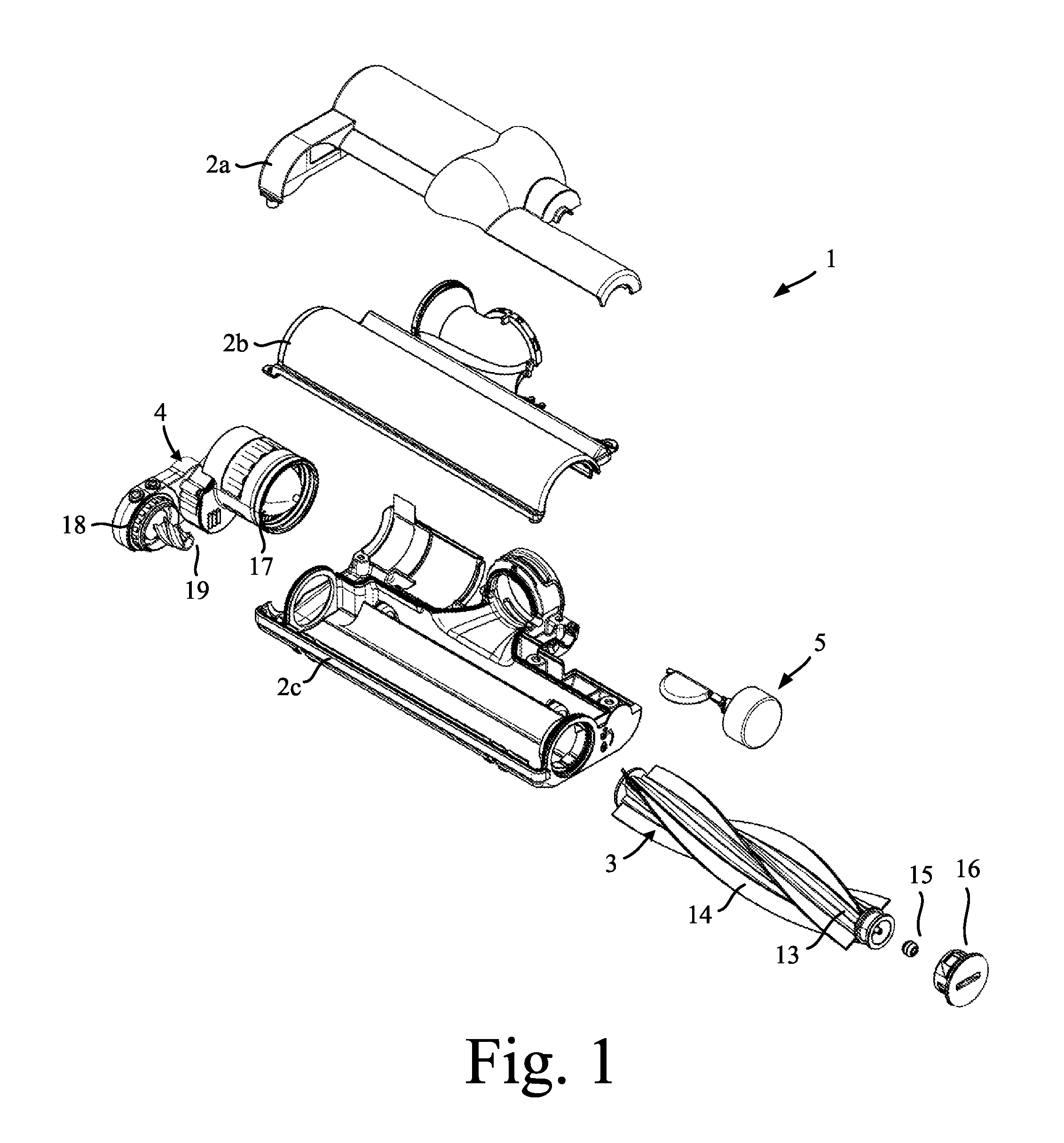

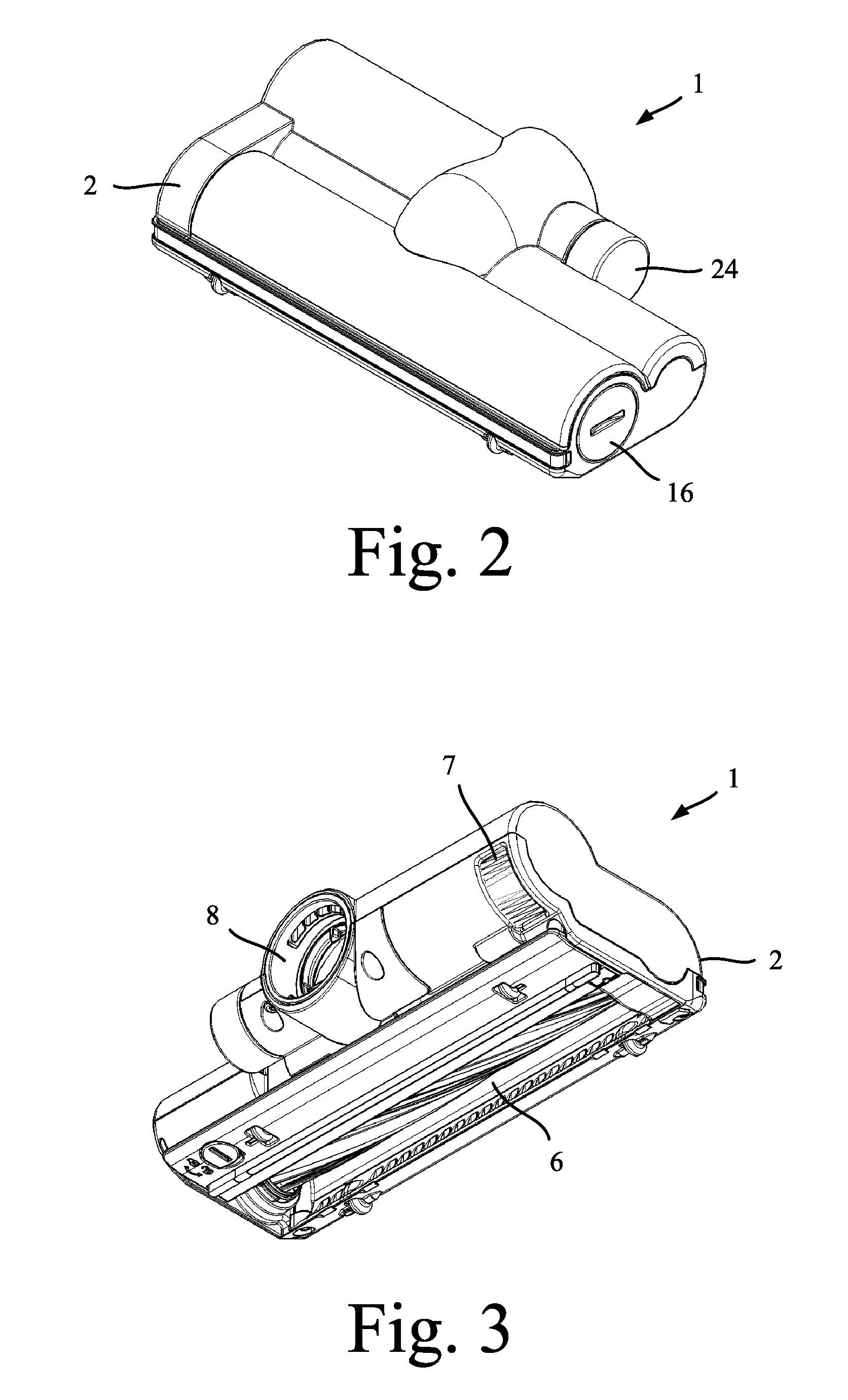

Cleaner head for a vacuum cleaner

InactiveUS8966709B2Reduce mass flow rateLow implementation costSuction nozzlesTurbineDynamic pressure

A cleaner head that includes a suction inlet for admitting a first airflow, a turbine inlet for admitting a second airflow, an outlet for discharging the first airflow and the second airflow and an agitator and its drive assembly. A first airflow path then carries the first airflow from the suction inlet to the outlet, and a second airflow path carries the second airflow from the turbine inlet to the outlet. The drive assembly includes a turbine that is driven by the second airflow. A baffle is located in the second airflow path and is movable between an open position in which the second airflow path is unrestricted and a closed position in which the second airflow path is restricted. The baffle is biased in the open position and moves to the closed position when the dynamic pressure of the second airflow at the baffle exceeds a threshold.

Owner:DYSON TECH LTD

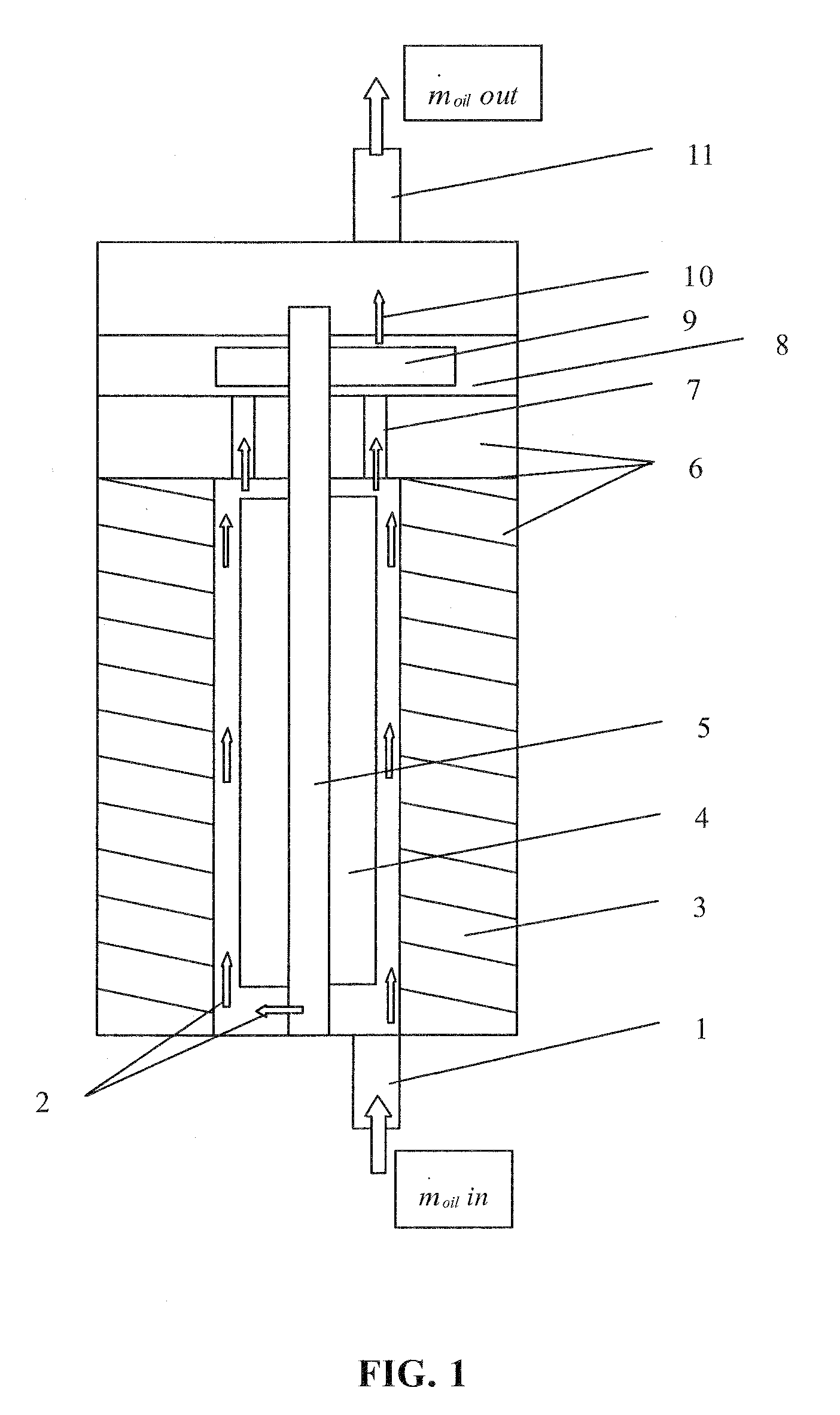

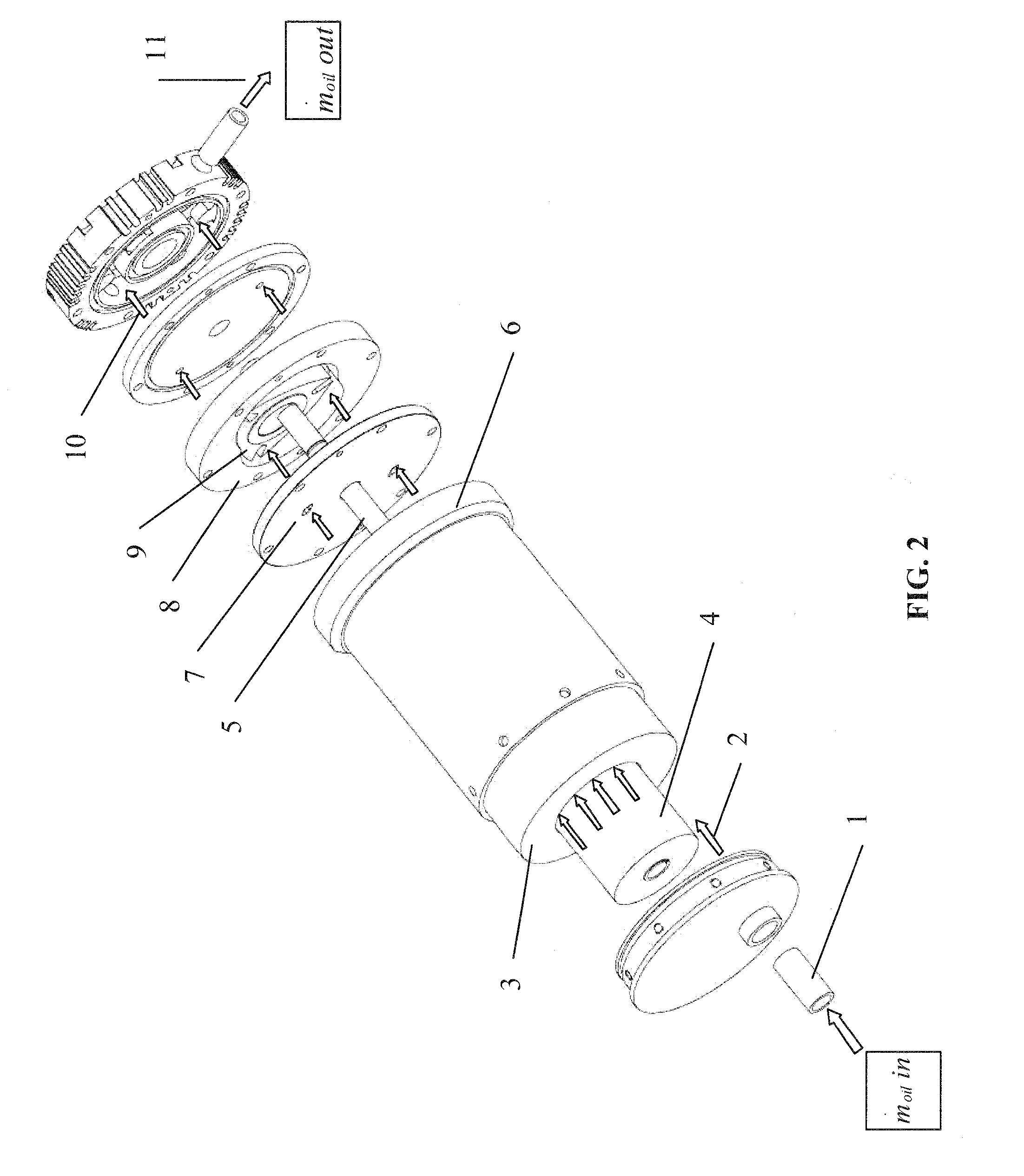

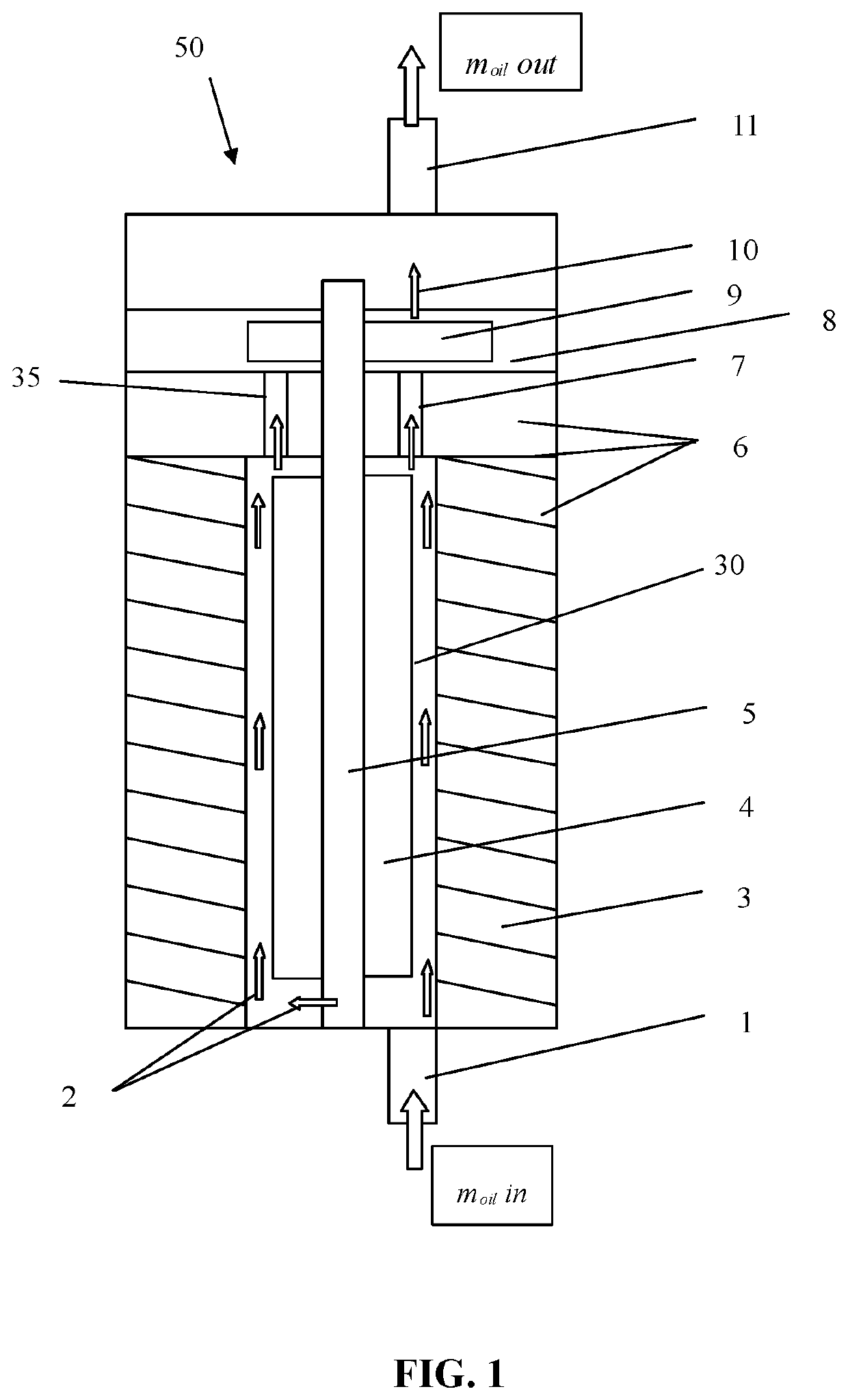

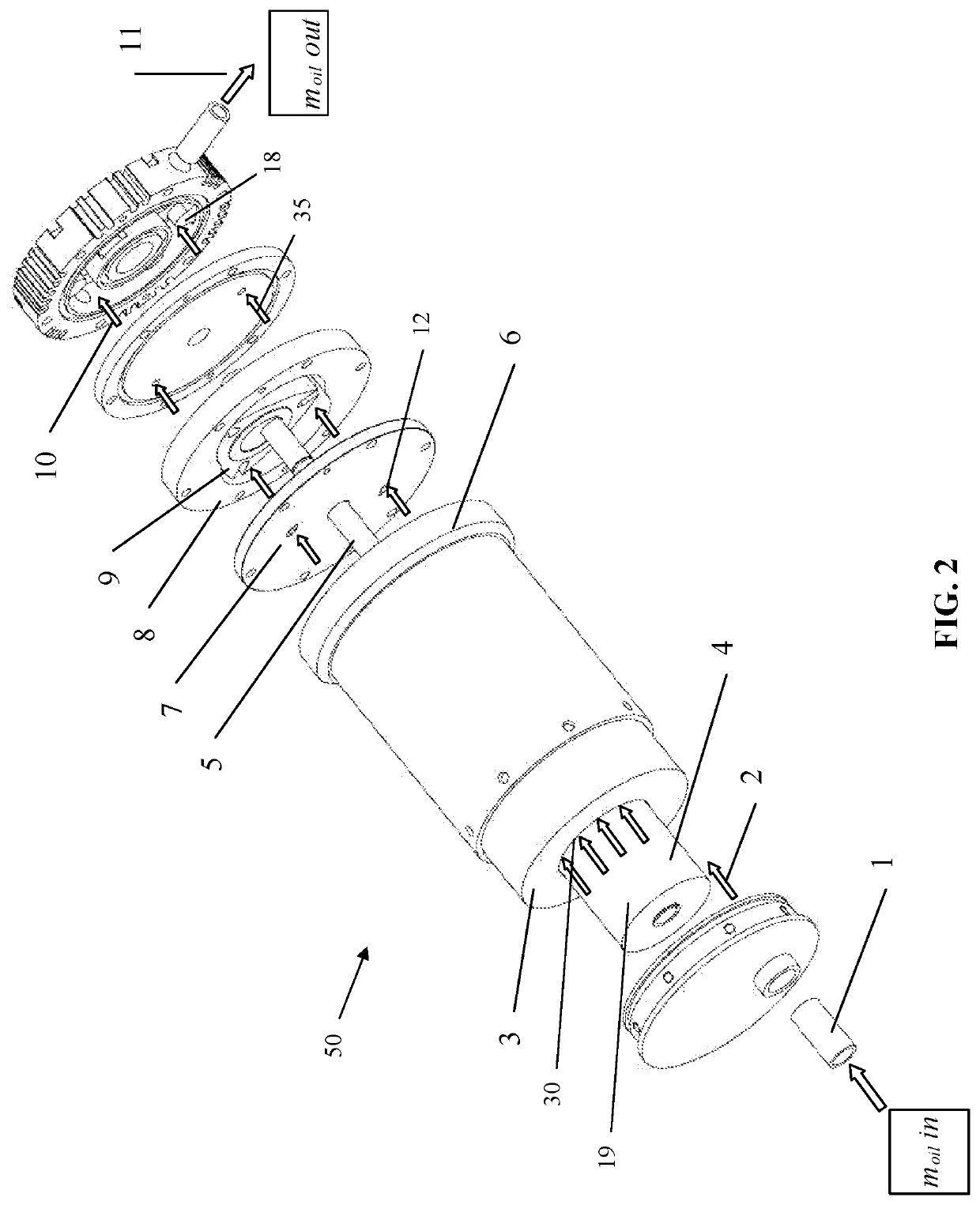

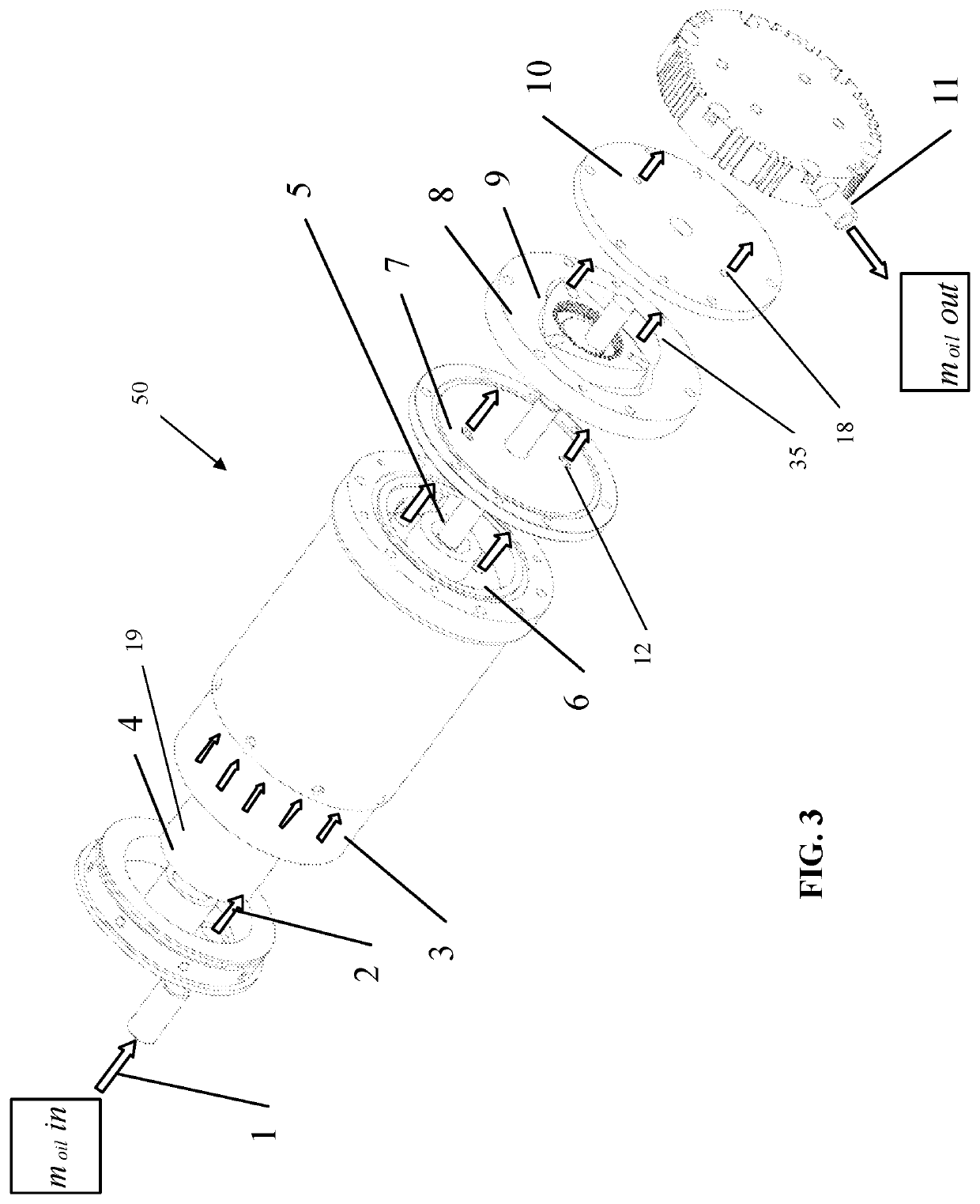

Method and apparatus for orientation independent compression

ActiveUS20100132382A1Adequate oil-vapor mixture velocityMinimizing internal volumeCompressorFlexible member pumpsPolyesterWorking fluid

The subject invention pertains to a method and apparatus for an orientation independent compressor. The subject compressor can be part of a vapor compression cycle system, and can use one or more of a variety of working fluids, including, but not limited to, refrigerants such as r-134a, r-22, CO2, and NH3. Embodiments of the compressor can utilize positive displacement means to compress the vapor. In a specific embodiment, the compressor can incorporate an oil-lubricated rotary lobed type positive displacement compressor. In a further specific embodiment, the working fluid can be a refrigerant, such as r-134a, incorporating entrained oil, such as miscible lubricating oils. An example of such a miscible lubricating oil that can be used is polyester (POE) oil.

Owner:RINI TECH

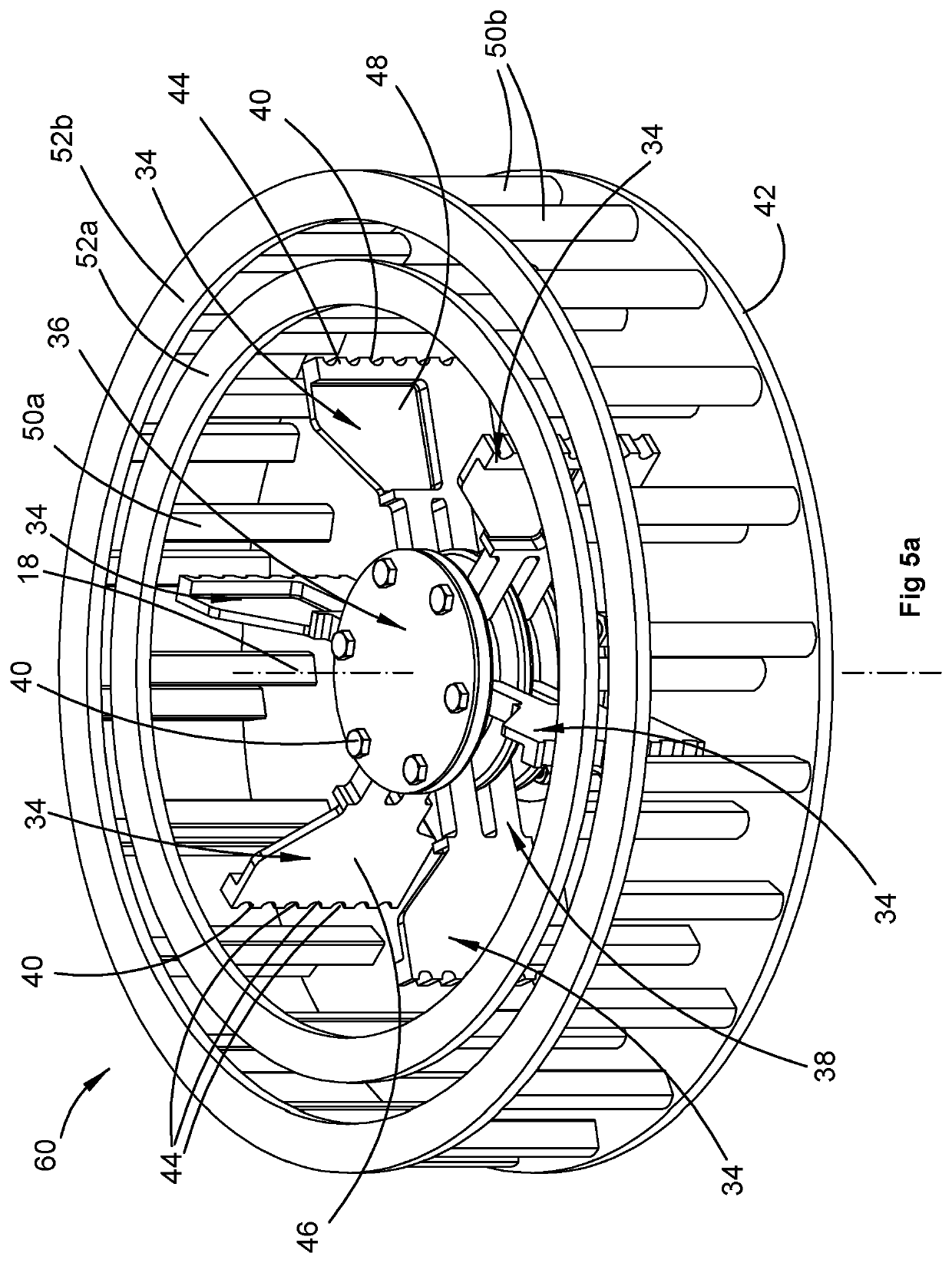

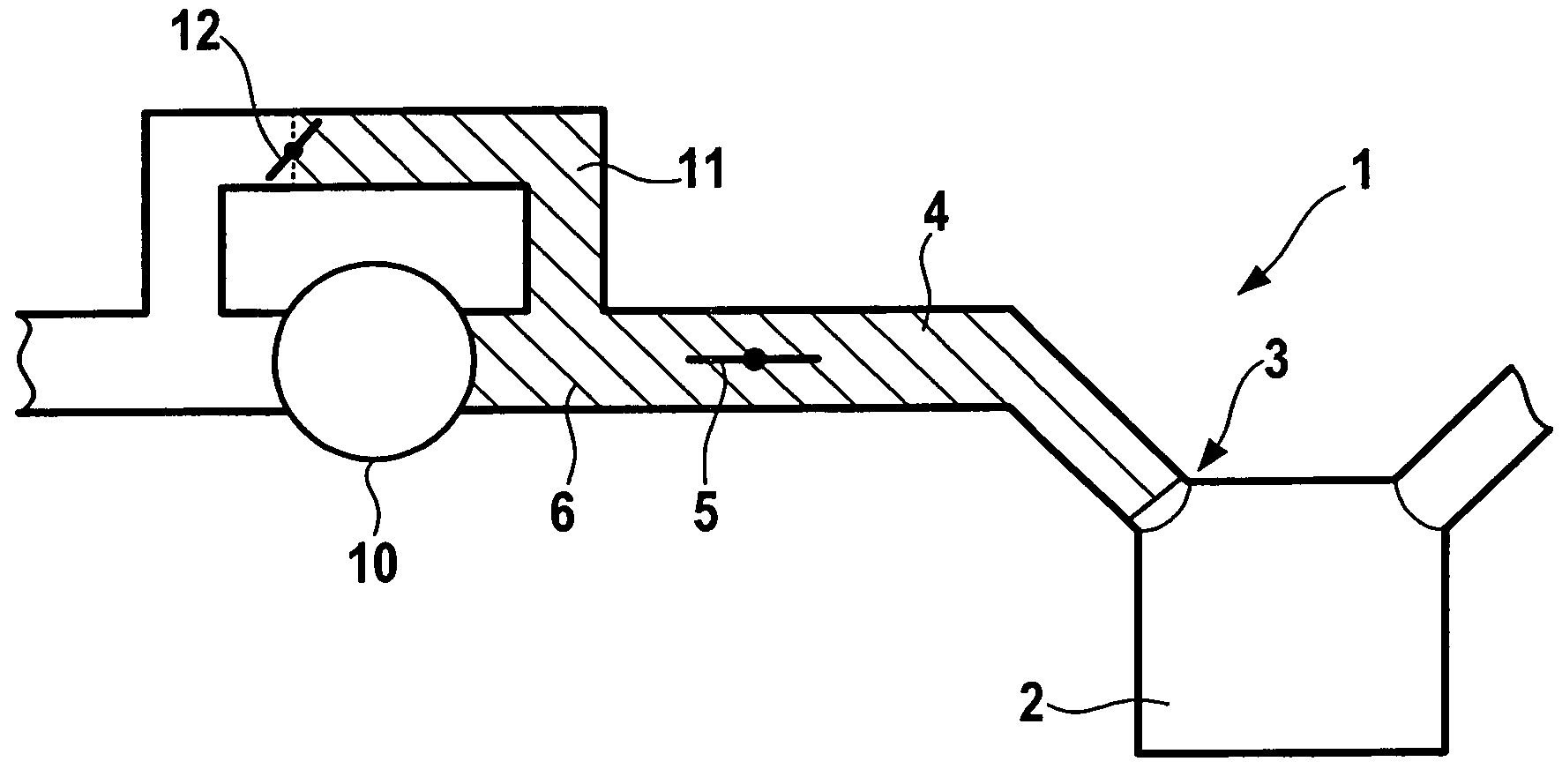

An impact mill and a residue processing system incorporating same

PendingUS20210022289A1Reduce mass flow rateShorten speedMowersThreshersRotational axisThermodynamics

An impact mill (10) has an inlet (12) for material to enter the mill, an impact mechanism (16, 50) arranged to rotate about a rotation axis and being operable to pulverise the material after entering through the inlet, and an outlet (154) for discharge of pulverised material. Blockage sensors (Bj), vibration sensors V, torque sensors Tn, temperature sensors and proximity sensors may be selectively incorporated into the mill.

Owner:SEED TERMINATOR HLDG PTY LTD

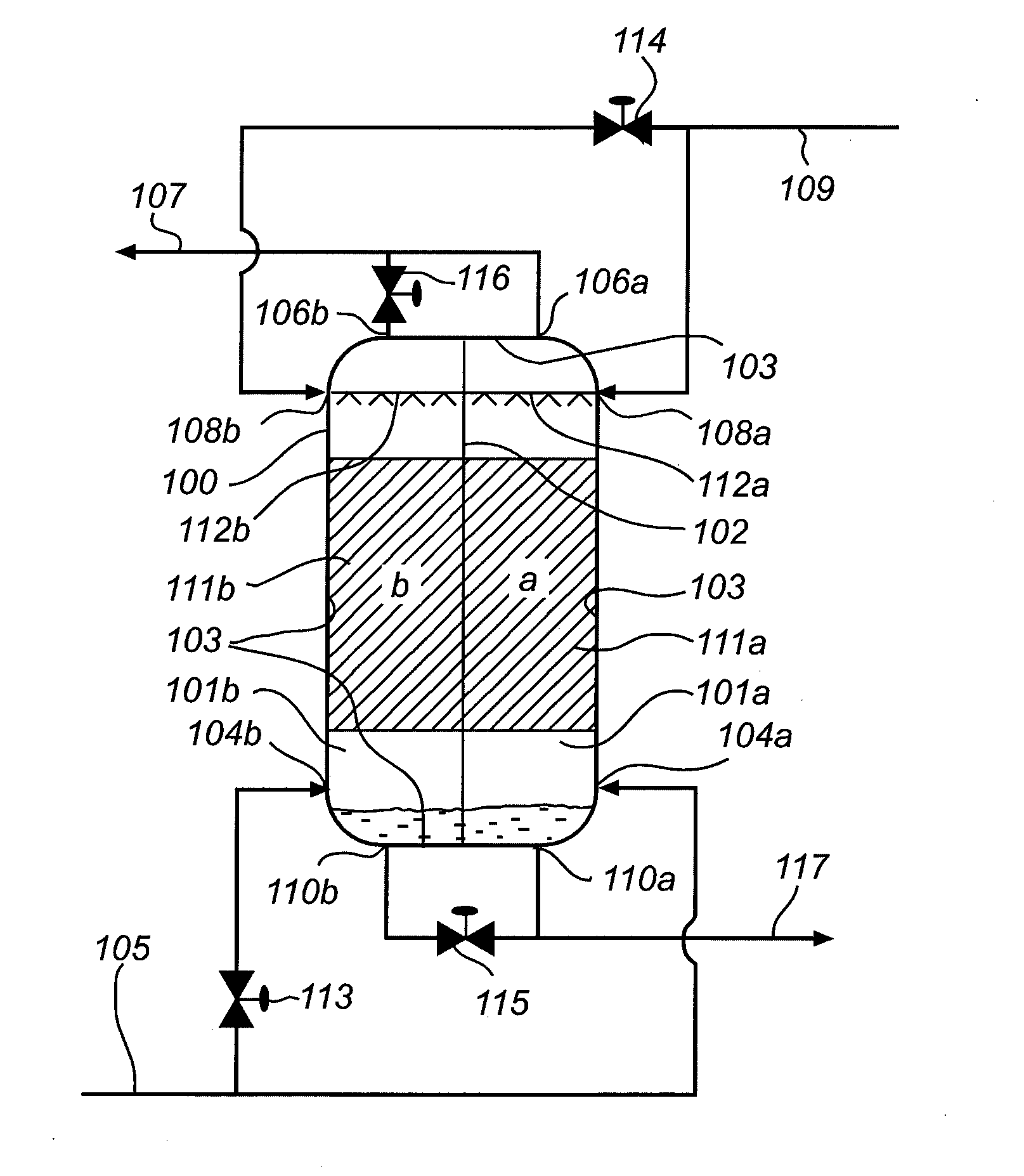

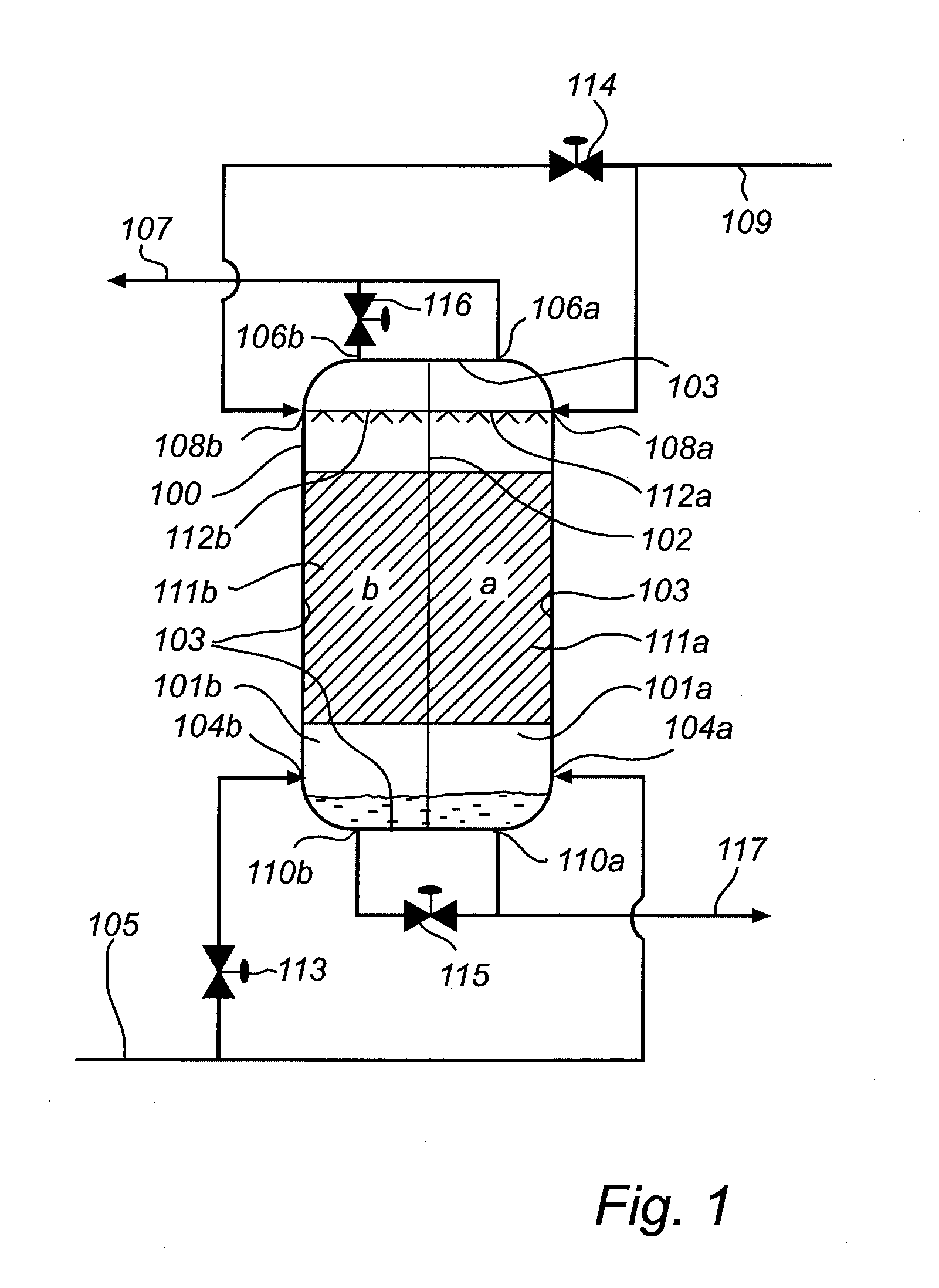

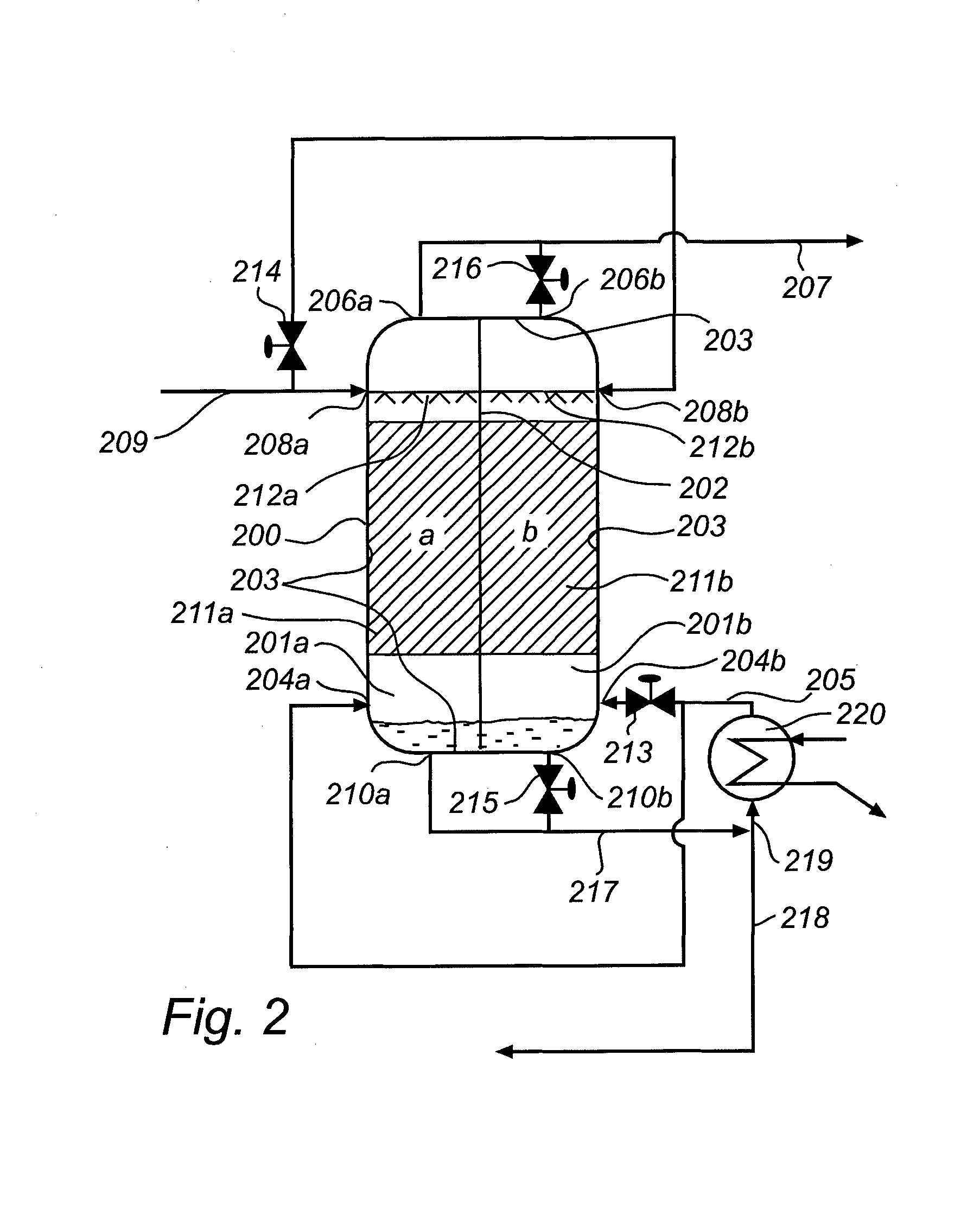

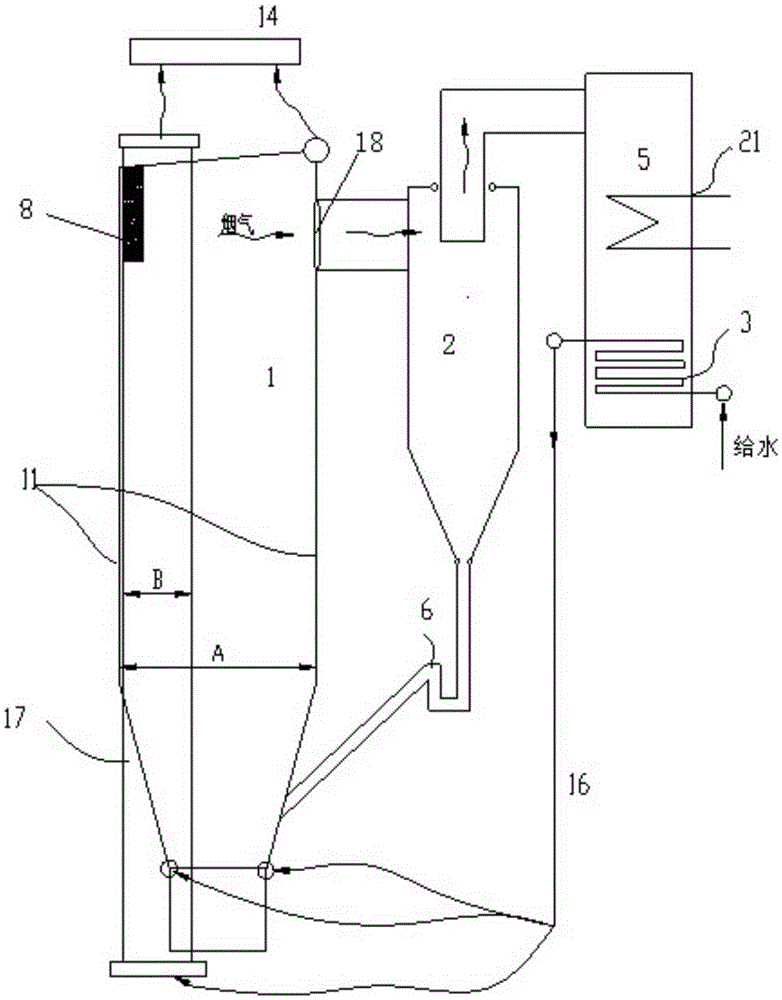

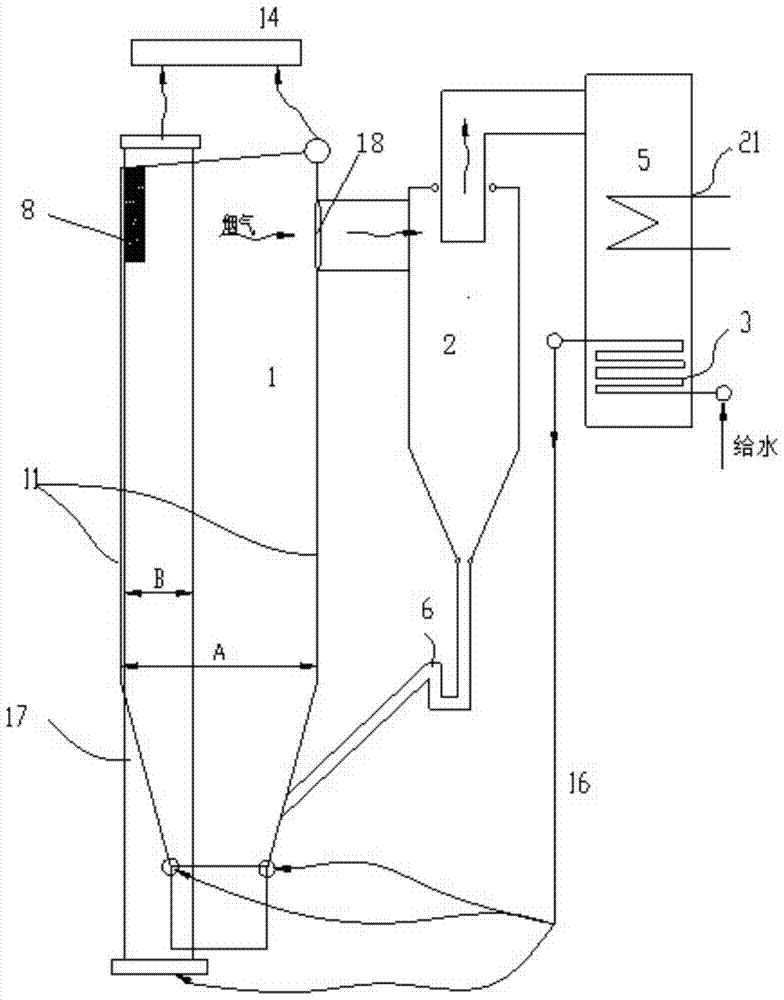

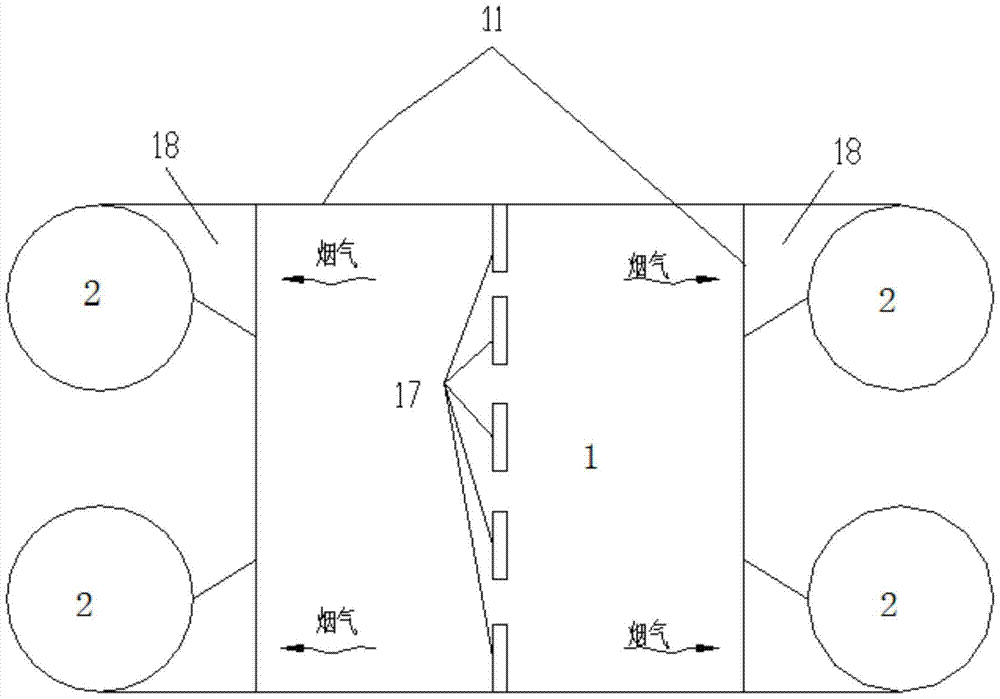

Gas/liquid contacting vessel and the use thereof in a flue gas treatment system

InactiveUS20140116252A1Improve efficiencyReduce mass flow rateGas treatmentUsing liquid separation agentFlueCarbon dioxide

The proposed invention relates to a gas / liquid contacting vessel (100) for treatment of a gas stream at varying mass flow rates, said vessel comprising at least two distinct gas / liquid contacting compartments (101a, 101b) separated from each other by a substantially vertical partition (102), each compartment having a gas inlet (104a, 104b) and a liquid outlet (110a, 110b) near a bottom end thereof and a gas outlet (106a, 106b) and a liquid inlet (108a, 108b) near a top end thereof, and a mass transfer device (111a, 111b) arranged between said bottom end and top end, wherein one of said compartments is operable for gas / liquid contacting independently of another of said compartments. The proposed invention further relates to a flue gas treatment system for removal of carbon dioxide (CO2) from a flue gas using a liquid absorbent and to a power plant comprising such a gas / liquid contacting vessel or flue gas treatment system.

Owner:GENERAL ELECTRIC TECH GMBH

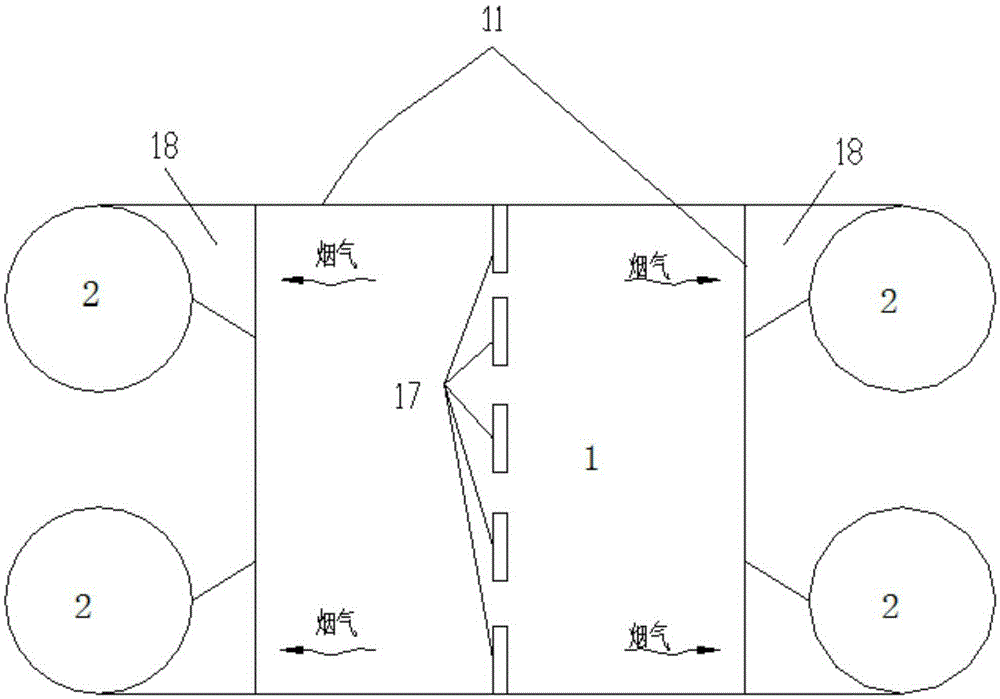

Supercritical circulating fluid bed boiler water wall having high flow stability under low load

ActiveCN105299634ASolve the problem of decreased flow stabilitySolve highFluidized bed combustionBoiler water tubesNegative feedbackEngineering

The invention discloses a method enabling a supercritical circulating fluid bed (CFB) boiler water wall to realize low mass velocity and a low-mass-velocity supercritical CFB boiler water wall having high flow stability under low load and relates to a circulating fluid bed boiler. The circulating fluid bed boiler comprises a low-mass-velocity hearth circumferential water wall and a water partition board, and the flow of a working medium is associated on the circumferential water wall and the water partition board. The inner diameters of, positions that the steam ratio is larger than 50%, of pipes of the hearth circumferential water wall and the water partition board are larger than the inner diameters of the pipes in lower positions, and the cross section of the large inner diameter parts of the pipes is 1.05 to 3 times of that of the small inner diameter parts. The supercritical CFB boiler water wall realizes low mass velocity, and meanwhile, the problem that water wall area and hearth height are increased at low mass velocity is solved. Particularly, the problem that the flow stability of the low-mass-velocity supercritical CFB boiler water wall declines under low load is solved, and the negative feedback of the water wall system is prevented from occurring.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Cleaner head for a vacuum cleaner

A cleaner head that includes a suction inlet for admitting a first airflow, a turbine inlet for admitting a second airflow, an outlet for discharging the first airflow and the second airflow and an agitator and its drive assembly. A first airflow path then carries the first airflow from the suction inlet to the outlet, and a second airflow path carries the second airflow from the turbine inlet to the outlet. The drive assembly includes a turbine that is driven by the second airflow. A baffle is located in the second airflow path and is movable between an open position in which the second airflow path is unrestricted and a closed position in which the second airflow path is restricted. The baffle is biased in the open position and moves to the closed position when the dynamic pressure of the second airflow at the baffle exceeds a threshold.

Owner:DYSON TECH LTD

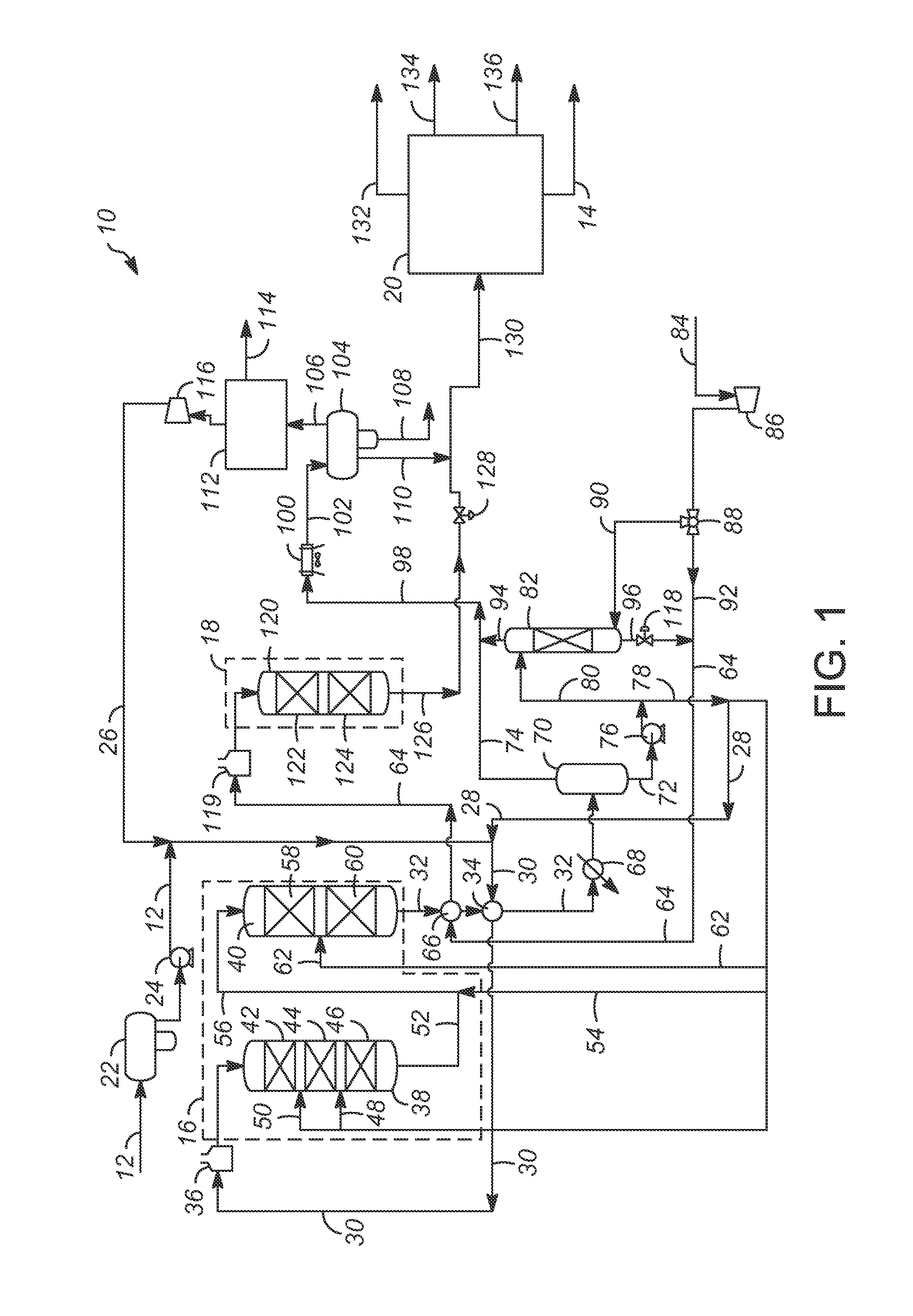

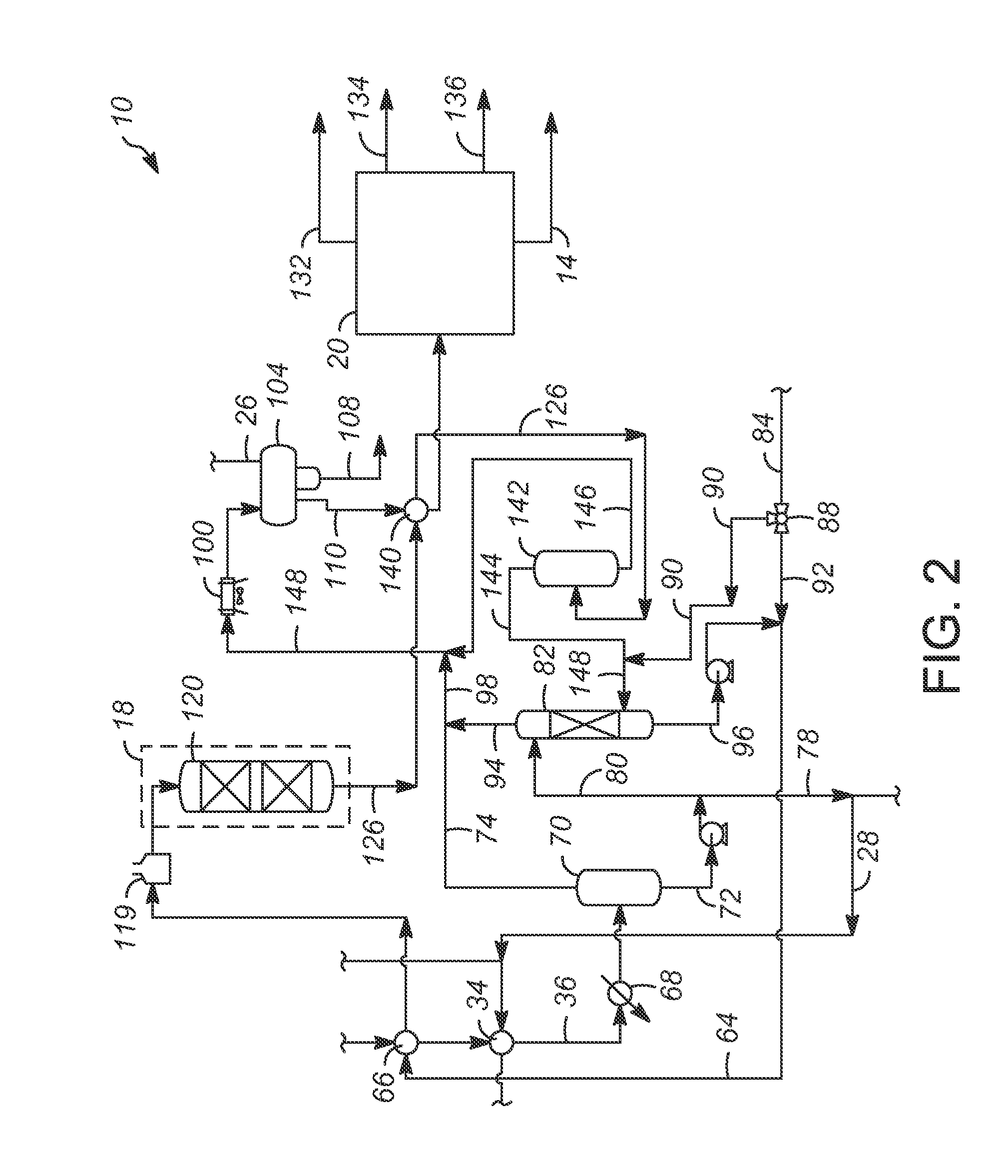

Methods and apparatuses for processing renewable feedstocks

InactiveUS20140296590A1Reduce mass flow rateRefining to change hydrocarbon structural skeletonLiquid hydrocarbon mixture productionIsomerizationReaction zone

Embodiments of methods and apparatuses for processing a renewable feedstock are provided herein. In one example, a method comprises dividing a H2-rich make-up stream into a first H2-rich portion and a second H2-rich portion. The second H2-rich portion has a lower mass flow rate than the first H2-rich portion. The renewable feedstock is deoxygenated in the presence of the first H2-rich portion at hydroprocessing conditions effective to form a deoxygenating reaction zone effluent that contains normal paraffins. At least a portion of the deoxygenating reaction zone effluent is isomerized in the presence of the second H2-rich portion at isomerization conditions effective to form an isomerization reaction zone effluent that contains branched paraffin. The isomerization conditions include a first hydrogen partial pressure of about 4,140 kPa gauge or less.

Owner:UOP LLC

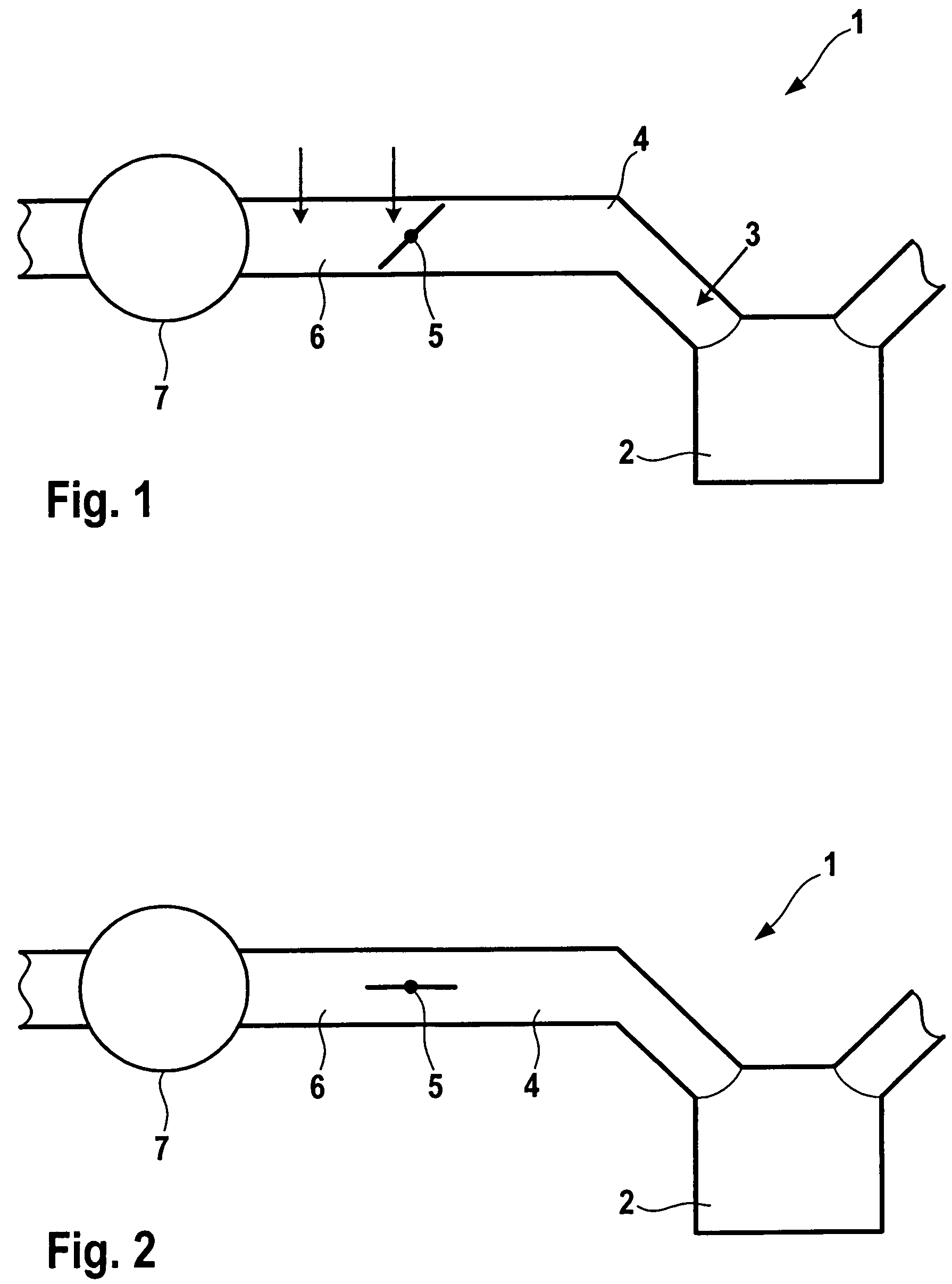

Method and device for controlling a charging device of an internal combustion engine during a charging mode

ActiveUS7529615B2Increase consumptionQuickly reachElectrical controlInternal combustion piston enginesExternal combustion engineControl system

A method for setting a mass flow rate of air to be provided in a charging mode; in the charging mode (where a throttle valve is open), the pressure prevailing in an induction pipe only being set via an adjustable mass flow rate of supplied air; a requested torque corresponding to a mass flow rate of air into a cylinder, the mass flow rate of air into the cylinder being adjustable via the pressure in the induction pipe; to set the mass flow rate of air into the cylinder, the pressure in the induction pipe being adjusted by a control system in accordance with a specifiable dynamic charge response characteristic.

Owner:ROBERT BOSCH GMBH

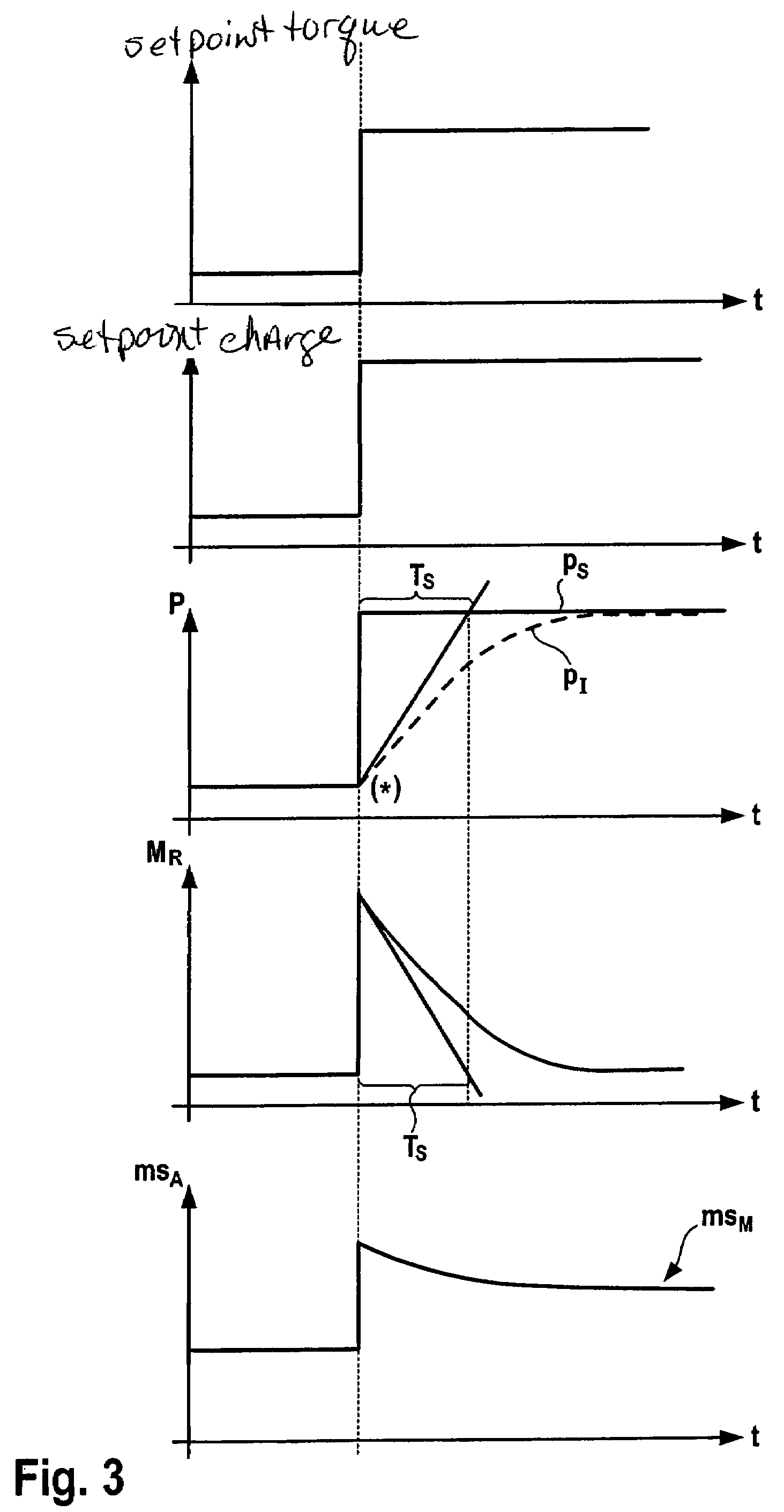

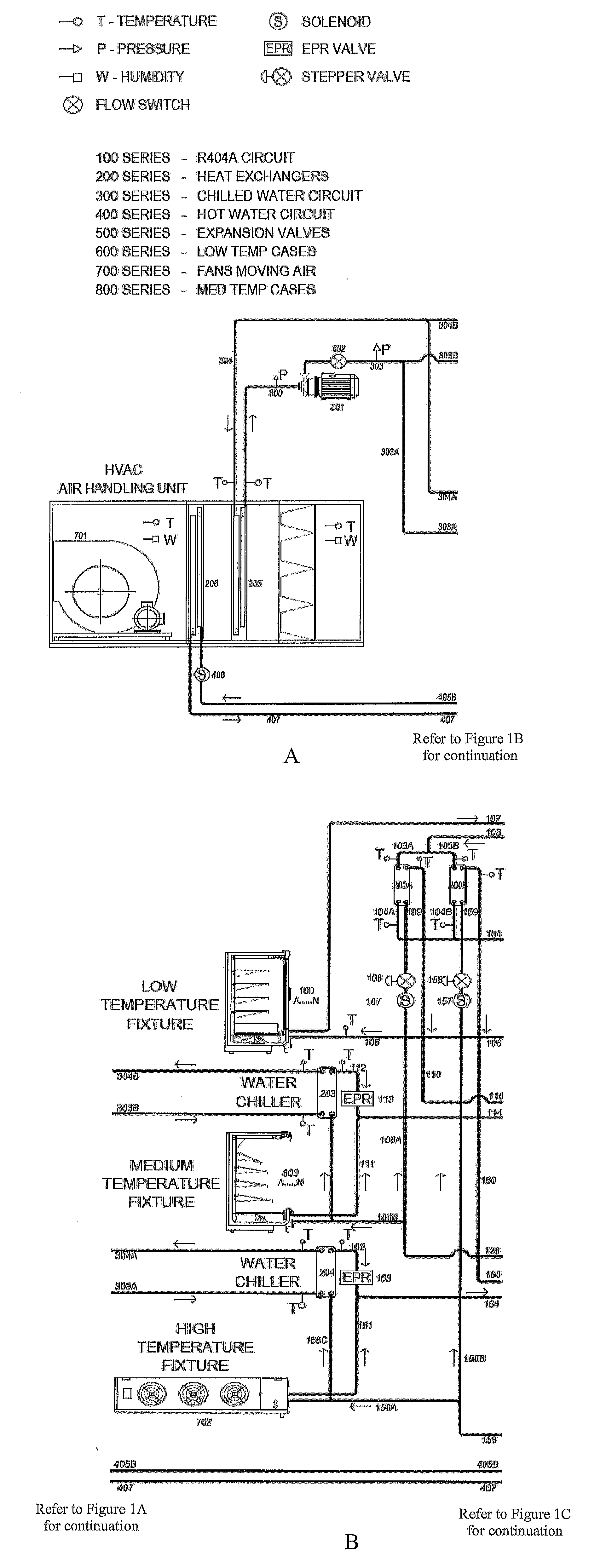

Cascading Plant

InactiveUS20140144166A1Small compressorHigh latent heatDomestic refrigeratorsEvaporators/condensersIceboxProcess engineering

An integrated refrigeration and air conditioning plant working in a cascade cycle with two different refrigerants for the low and high temperature circuits. The low temperature segment works with an ozone friendly synthetic refrigerant with a minimal amount of refrigerant charge, while the upper stage operates with another ozone friendly refrigerant with much lesser global warming potential than the one in the low stage. The upper and / or medium temperature circuit also services the air conditioning needs of the environment where the refrigerated equipment is located, such as the shop floor of a supermarket or a laboratory housing the cabinets that keep refrigerators.

Owner:CITY HLDG AUS

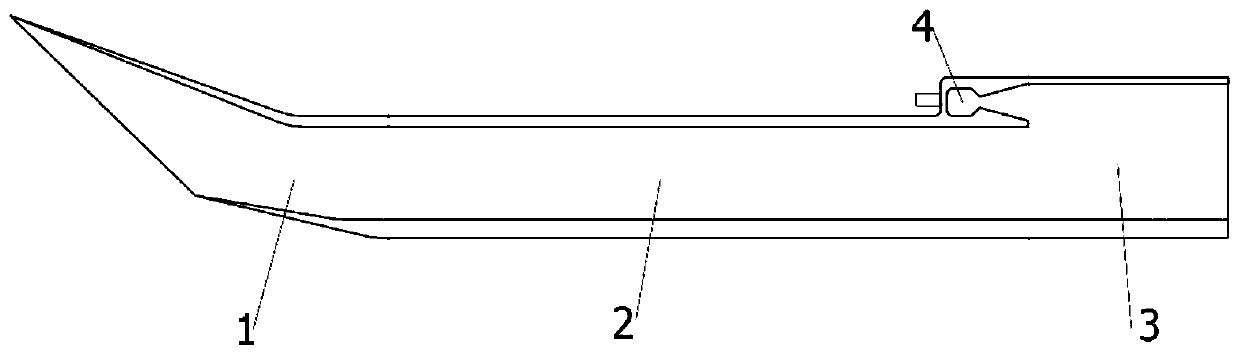

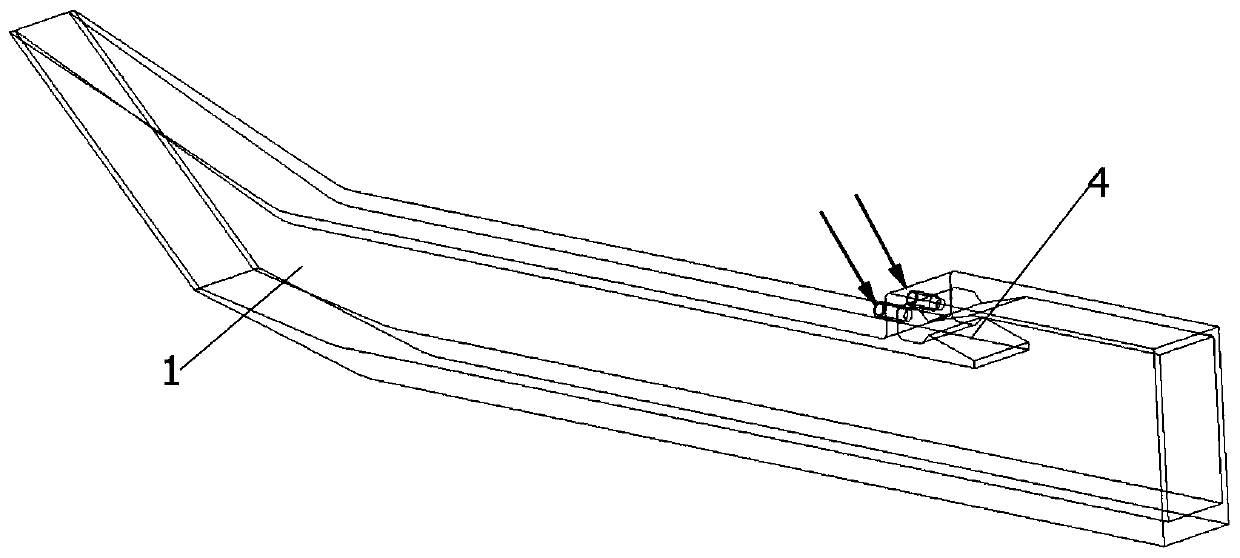

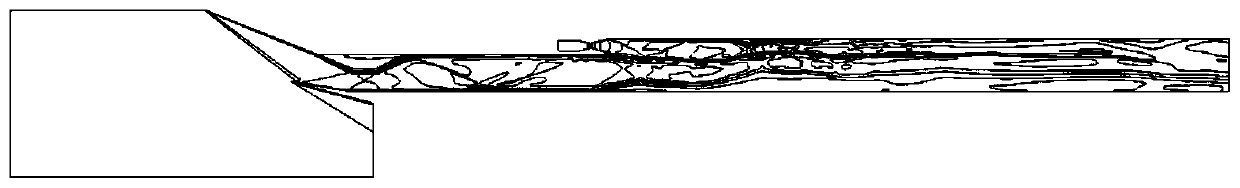

Starting control method of rocket-based combined cycle engine inlet

ActiveCN111594348AInhibition does not startImprove control abilityTurbine/propulsion fuel controlTurbine/propulsion air intakesThermodynamicsCombustor

The invention provides a starting control method of a rocket-based combined cycle engine inlet. Whether indoor pressure of a combustor is greater than a first pressure threshold value and smaller thanor equal to a second pressure threshold value or not is judged, if yes, the mass flow rate of an internally-installed rocket is reduced, and the secondary fuel injection quantity is reduced, so thatthe indoor pressure of the combustor is reduced. When the indoor pressure of the combustor is reduced to be smaller than the first pressure threshold value, the mass flow rate of the internally-installed rocket is improved, and the secondary fuel injection quantity is improved, so that the indoor pressure of the combustor is improved to the first pressure threshold value. By changing a working state of the internally-installed rocket, the jet flow radius of the internally-installed rocket is changed, so that the practical equivalent internal shrinkage ratio of the inlet is adjusted; and meanwhile, the combustor pressure is correspondingly reduced due to reduced fuel flow, and the inlet can be restrained to be not started through the purging action of the high-speed jet of the internally-installed rocket on low-energy boundary layers.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

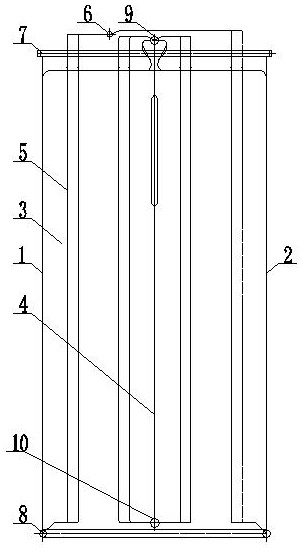

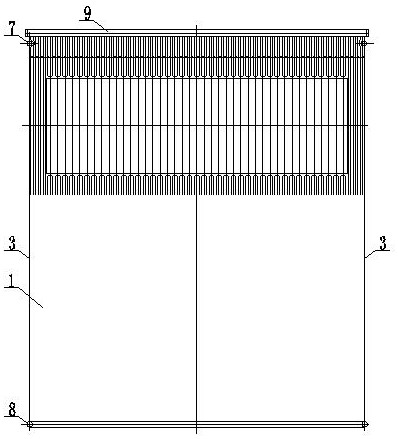

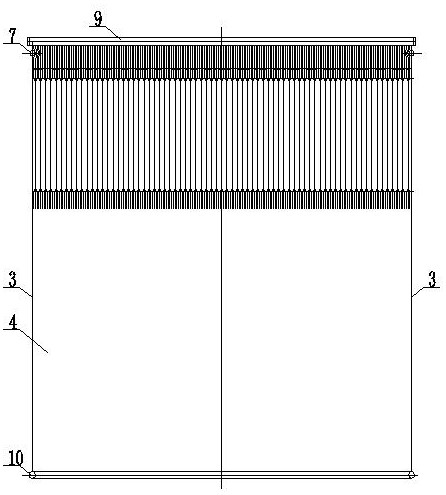

Wall enclosure superheater for supercritical circulating fluid bed (CFB) boiler and wall enclosure method

PendingCN112128735AReduce resistanceWater temperature is easy to controlSteam superheatersSupercritical steam generatorMechanical engineering

The invention discloses a wall enclosure superheater for a supercritical circulating fluid bed (CFB) boiler and a wall enclosure method. The number of side enclosure walls and the number of middle partition wall pipes are limited, so that the resistance of two descending processes is high, and the total resistance of a whole wall enclosure superheater system is high. The wall enclosure superheaterfor the supercritical CFB boiler comprises a front wall enclosure superheater (1), a rear wall enclosure superheater (2), a side wall enclosure superheater (3), a middle partition wall superheater (4), superheater hanging pipes (5), a hanging pipe upper header (6), a side wall enclosure upper header (7), a wall enclosure lower header (8), a front and rear wall enclosure upper header (9) and a middle partition wall lower header (10). The superheater hanging pipes are arranged in the tail flue in four rows: the two rows of hanging pipes close to the front wall enclosure superheater and the rearwall enclosure superheater are connected with the side enclosure walls in parallel to form a group of descending loops in the wall enclosure superheater system; and the two rows of hanging pipes close to the middle partition wall superheater are connected with the middle partition wall superheater in parallel to form the other group of descending loops in the wall enclosure superheater system. The invention discloses the wall enclosure superheater for the supercritical CFB boiler.

Owner:HARBIN BOILER

Method and Device for Controlling a Suction Pressure of an Internal Combustion Engine

ActiveUS20100228464A1Cutting costsReliable transmissionElectrical controlInternal combustion piston enginesExternal combustion engineTurbocharger

A method device for controlling a suction pressure of an internal combustion engine, particularly a diesel engine having an exhaust gas turbocharger. The compressor is connected to a suction line of the internal combustion engine via an actuating section having an actuating element for changing a cross-section of the actuating section. In the first step, the current suction pressure in the suction line of the internal combustion engine is determined. A compressor pressure of the compressor is determined by pressure sensors and compared to the suction pressure. Values corresponding to current operating data of the internal combustion engine are identified and an actuation signal is generated using a controller, based on the comparison; and changing the cross-section of the actuating section is adjusted by adjusting the actuating element using the actuating signals.

Owner:KNORR-BREMSE SYST FUER NUTZFAHRZEUGE GMBH

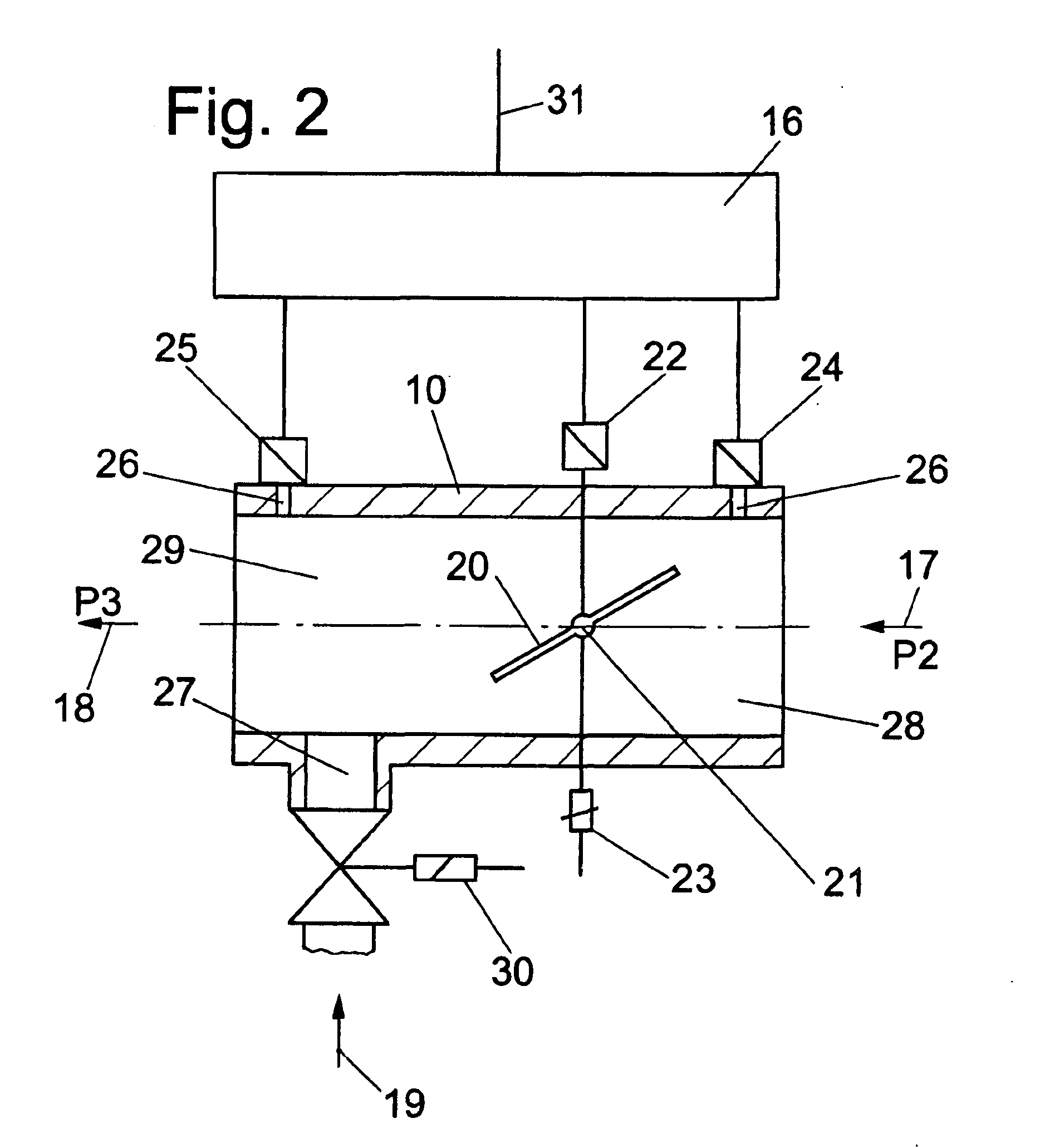

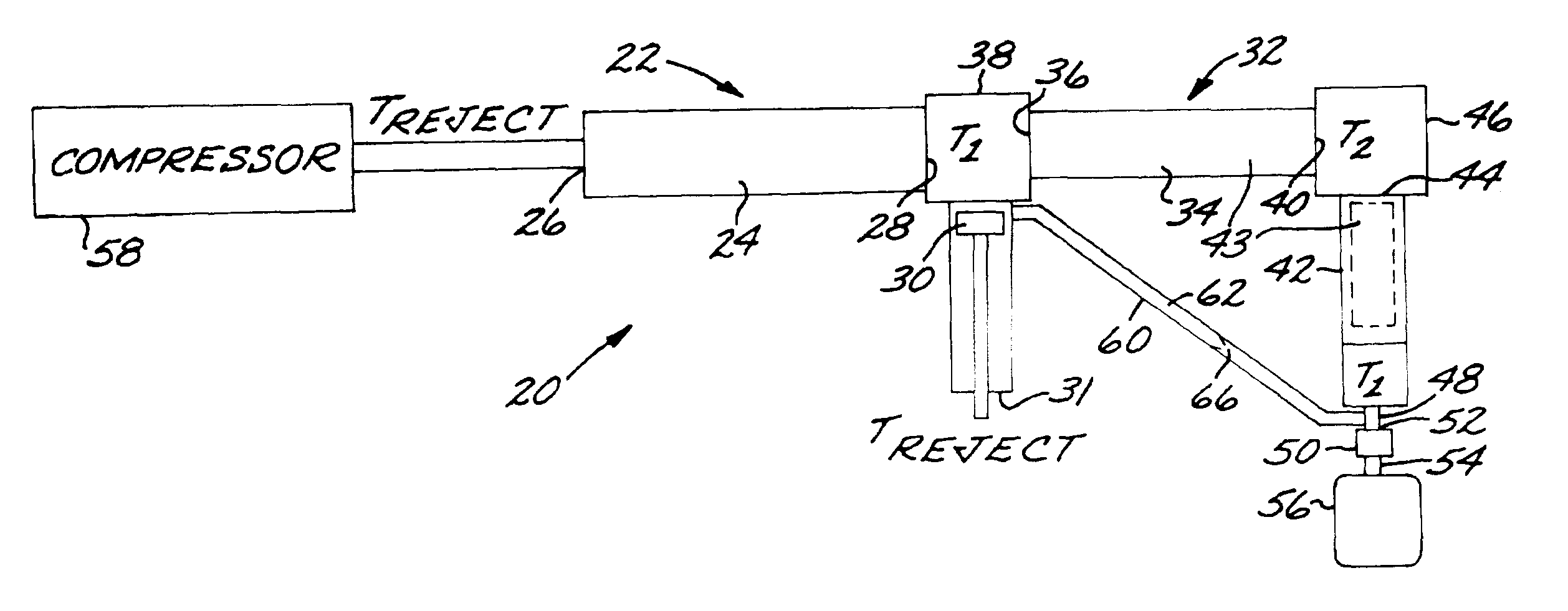

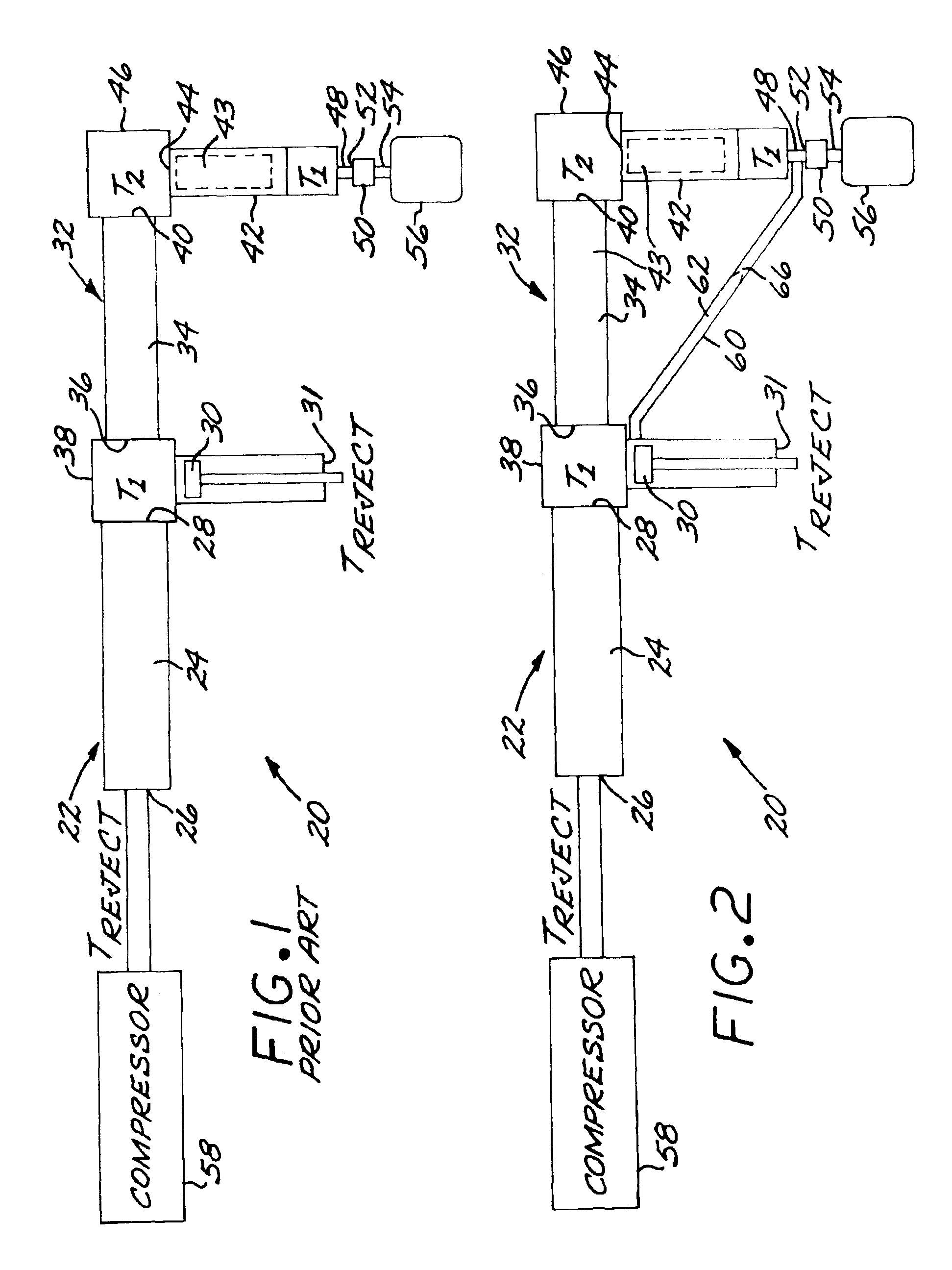

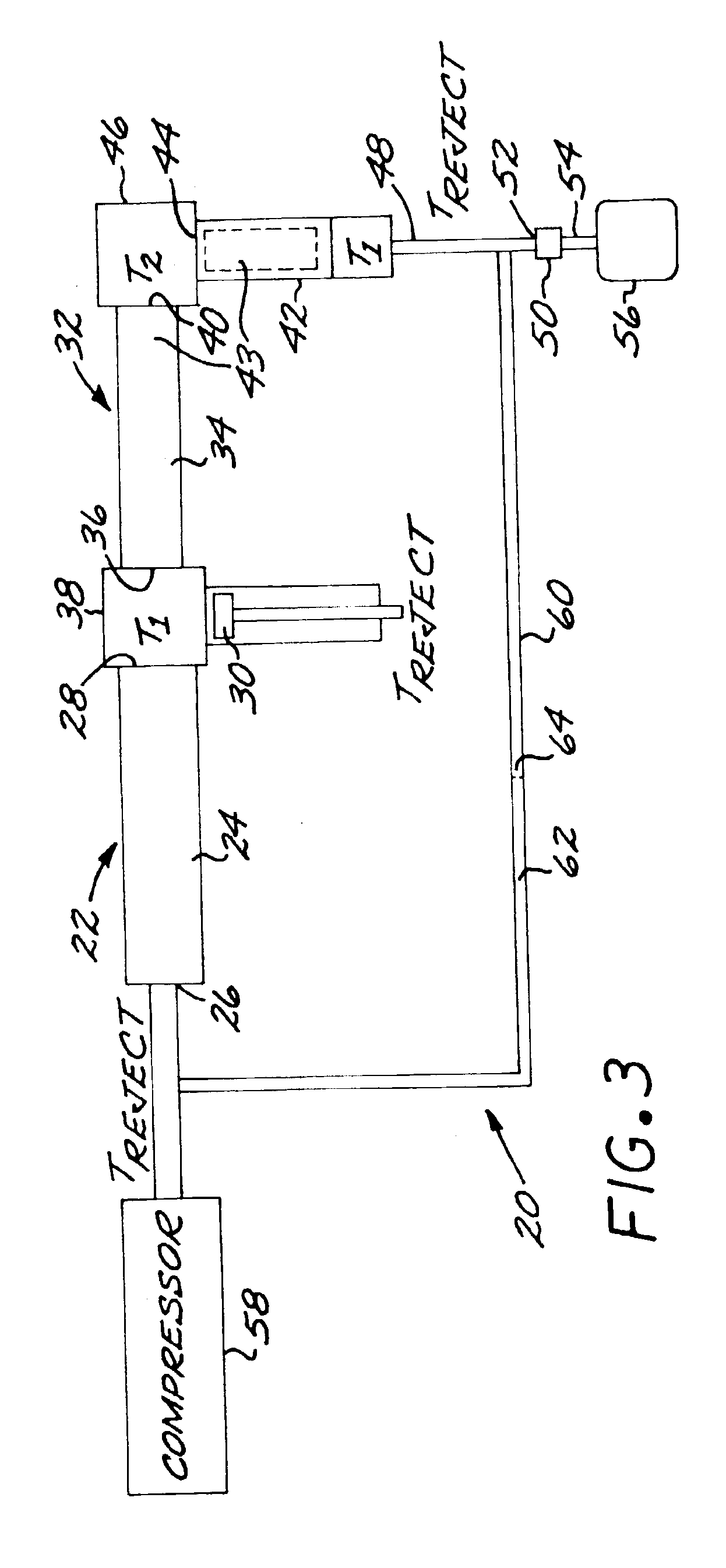

Supersonic Cooling With Pulsed Inlet and Bypass Loop

InactiveUS20120301268A1Reduce mass flow rateFacilitate flowPump componentsCompression machines with non-reversible cycleCooling powerEvaporator

A supersonic cooling system operates by pumping liquid without the need of a condenser. An inlet of the system may be pulsed to reduce energy required of a pump and to increase the cooling power of the system. The supersonic cooling system utilizes a compression wave in the generation of the cooling effect. The formation of the compression wave may be assisted by a resonance chamber. An evaporator of the cooling system operates in the critical flow regime.

Owner:CAITIN

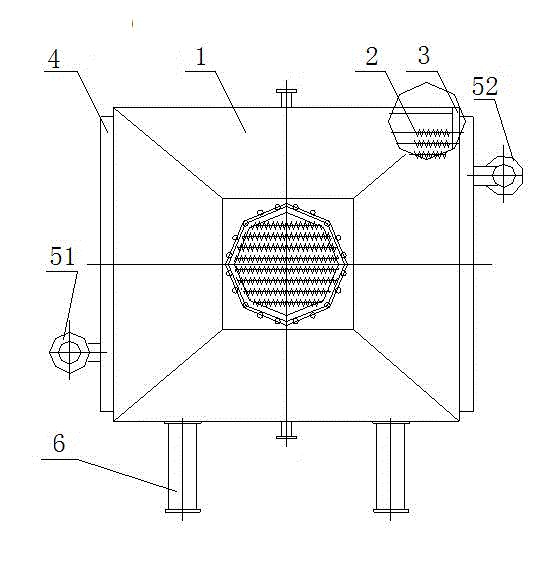

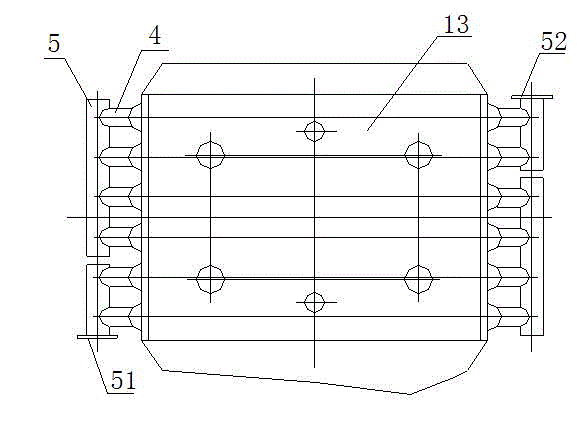

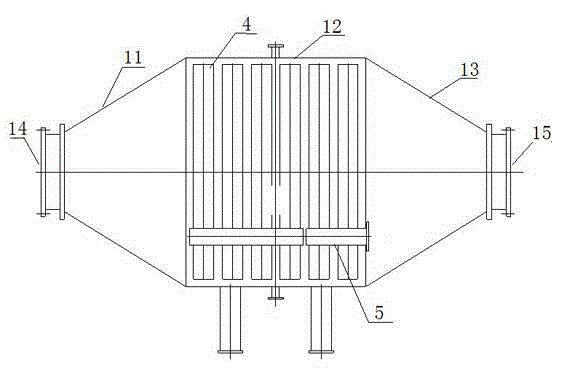

Fin cooler

InactiveCN104677145AImprove cooling effectImprove heat transfer coefficientStationary tubular conduit assembliesCooling effectEngineering

The invention relates to a fin cooler. The cooler comprises a shell, wherein the shell is divided into an air inlet part, an air outlet part and a heat exchange part; an air inlet and an air outlet are respectively formed in the ends of the air inlet part and the air outlet part; the heat exchange part of the shell is transversely provided with a fin tube; the two ends of the fin tube are welded with a tube plate; and a water box is arranged in the welded position of the fin tube and the tube plate, and is communicated through a connecting tube. The cooler can cool compressed air with a temperature of 129 DEG C and a pressure of 0.25 MPa. As the compressed air and a fluid are vertically staggered, the cooling effect is better.

Owner:SIPING TENGDA HEAT EXCHANGE EQUIP MFG

Stirling/pulse tube hybrid cryocooler with gas flow shunt

ActiveUS7093449B2Low efficiencyReduce adverse effectsCompression machines with cascade operationGas cycle refrigeration machinesDrop structureEngineering

A two-stage hybrid cryocooler includes a first-stage Stirling expander having a first-stage regenerator having a first-stage-regenerator inlet and a first-stage-regenerator outlet, and a second-stage pulse tube expander. The second-stage pulse tube expander includes a second-stage regenerator having a second-stage regenerator inlet in gaseous communication with the first-stage regenerator outlet, and a second-stage regenerator outlet, and a pulse tube having a pulse-tube inlet in gaseous communication with the second-stage regenerator outlet, and a pulse-tube outlet. The second-stage regenerator and the pulse tube together provide a first gas-flow path between the first-stage regenerator and the pulse-tube outlet. A pulse tube pressure drop structure has a pulse-tube-pressure-drop inlet in gaseous communication with the pulse-tube outlet, and a pulse-tube pressure-drop outlet, and a gas volume is in gaseous communication with the pulse-tube pressure-drop outlet. A gas flow shunt provides gaseous communication between the first-stage regenerator and the pulse-tube outlet. The gas flow shunt provides a second gas-flow path between the first-stage regenerator and the pulse-tube outlet.

Owner:RAYTHEON CO

A kind of method for preparing cucrzr spherical powder based on viga process

ActiveCN110480024BUniform particle sizeUniform sizeAdditive manufacturing apparatusTransportation and packagingCrucibleManufactured material

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Supercritical circulating fluidized bed boiler water wall with high flow stability under low load

ActiveCN105299634BSolve the problem of decreased flow stabilitySolve highFluidized bed combustionBoiler water tubesNegative feedbackFluidized bed

A water wall of a supercritical circulating fluidized bed boiler having high flow stability at a low load, and method of providing a low mass flow rate. The circulating fluidized bed boiler comprises a surrounding water wall (11) and a mid-partition water wall (17) of a furnace (1) having a low mass flow rate, and a working medium flows in the surrounding water wall (11) and the mid-partition water wall (17) connected in parallel. Tubes of the surrounding water wall (11) and the mid-partition water wall (17) have a greater inner diameter at locations having a steam content greater than 50% than locations having a steam content less than 50%, and the portion of the tubes having the greater inner diameter has a cross section area 1.05-3 times of a cross section area of the portion of the tubes having the smaller inner diameter. The water wall of the supercritical circulating fluidized bed boiler realizes a low mass flow rate, and addresses the problems of an increased water wall area and furnace height when the mass flow rate is low. In addition, the water wall of the supercritical circulating fluidized bed boiler addresses the problem of lower flow stability at a low load, thus preventing a negative feedback from happening in a water wall system.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Method and apparatus for orientation independent compression

ActiveUS11047381B2Reduce mass flow rateMinimizing internal volumeCompressorFlexible member pumpsPolyesterWorking fluid

Owner:RINI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com