Patents

Literature

208 results about "Supercritical steam generator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

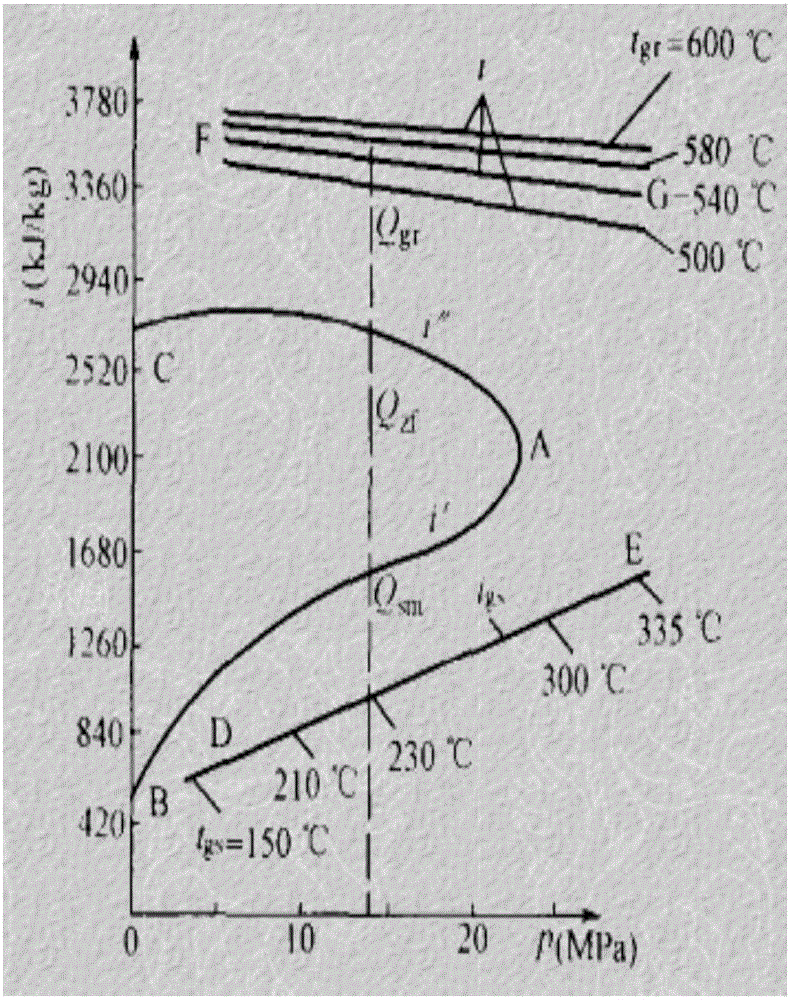

A supercritical steam generator is a type of boiler that operates at supercritical pressure, frequently used in the production of electric power. In contrast to a subcritical boiler in which bubbles can form, a supercritical steam generator operates at pressures above the critical pressure – 3,200 psi or 22 MPa. Therefore, liquid water immediately becomes steam. Water passes below the critical point as it does work in a high pressure turbine and enters the generator's condenser, resulting in slightly less fuel use.

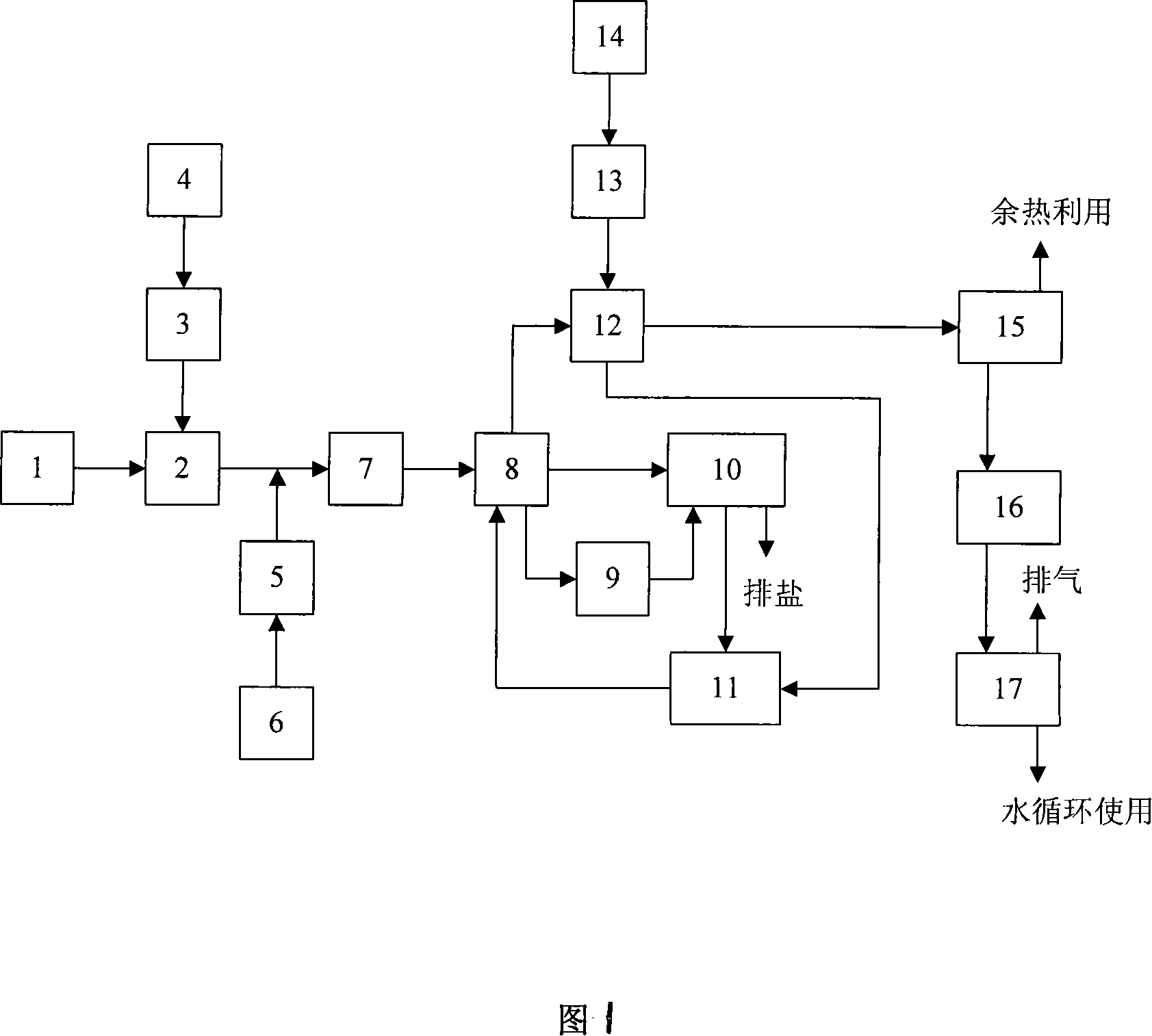

System for comprehensive utilization of three industrial wastes

InactiveCN101618292AAchieve energy saving and emission reductionReduce manufacturing costDispersed particle separationWater/sewage treatmentElectric powerToxic industrial waste

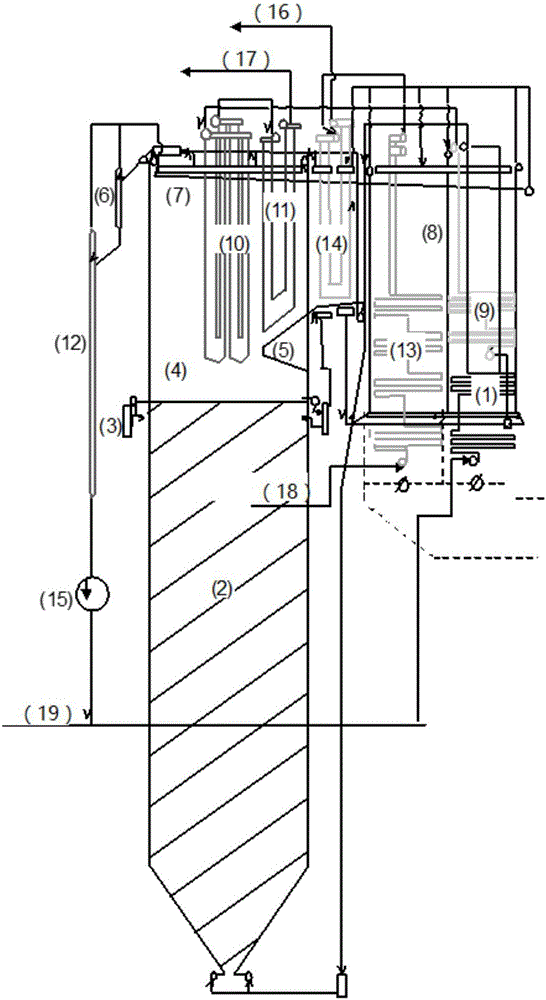

The invention provides a system for comprehensive utilization of three industrial wastes, mainly relating to the field of energy conservation and emission reduction, in particular to the comprehensive utilization of the three industrial wastes; to realize the objective of energy conservation and emission reduction required by the recycle economy, a system technology targeted at comprehensive utilization of the three industrial wastes of factories is adopted; in the invention, the reactor in the nuclear plant, the boiler in the coal-fired power plant and other types of supercritical boilers are utilized to provide a new cooling and turbine drive mode to solve the issue of industrial discharge of greenhouse gas and other polluting gases; in addition, collected emissions are utilized to produce nuclear fuel, compound chemical fertilizer or feedstuff and other chemical raw materials; moreover, to realize recycling of resources and sustainable utilization of energy, the original three wastes are innovatively applied to nuclear electric power generation. The system is characterized by comprising 10 major links and the beneficial effect thereof lies in utilizing new methods to realize energy conservation and emission reduction and production cost in the late stage of production can be reduced.

Owner:李元胜

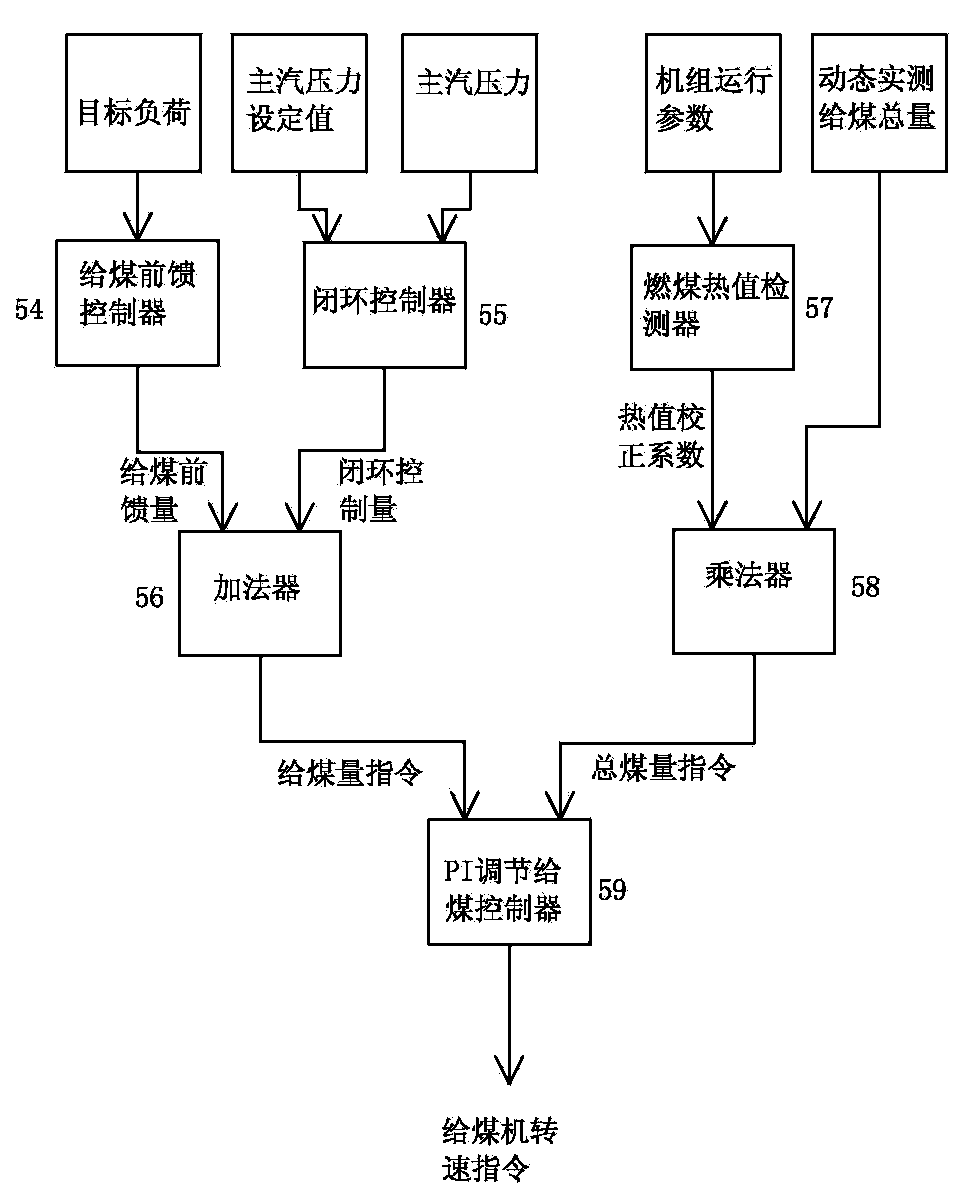

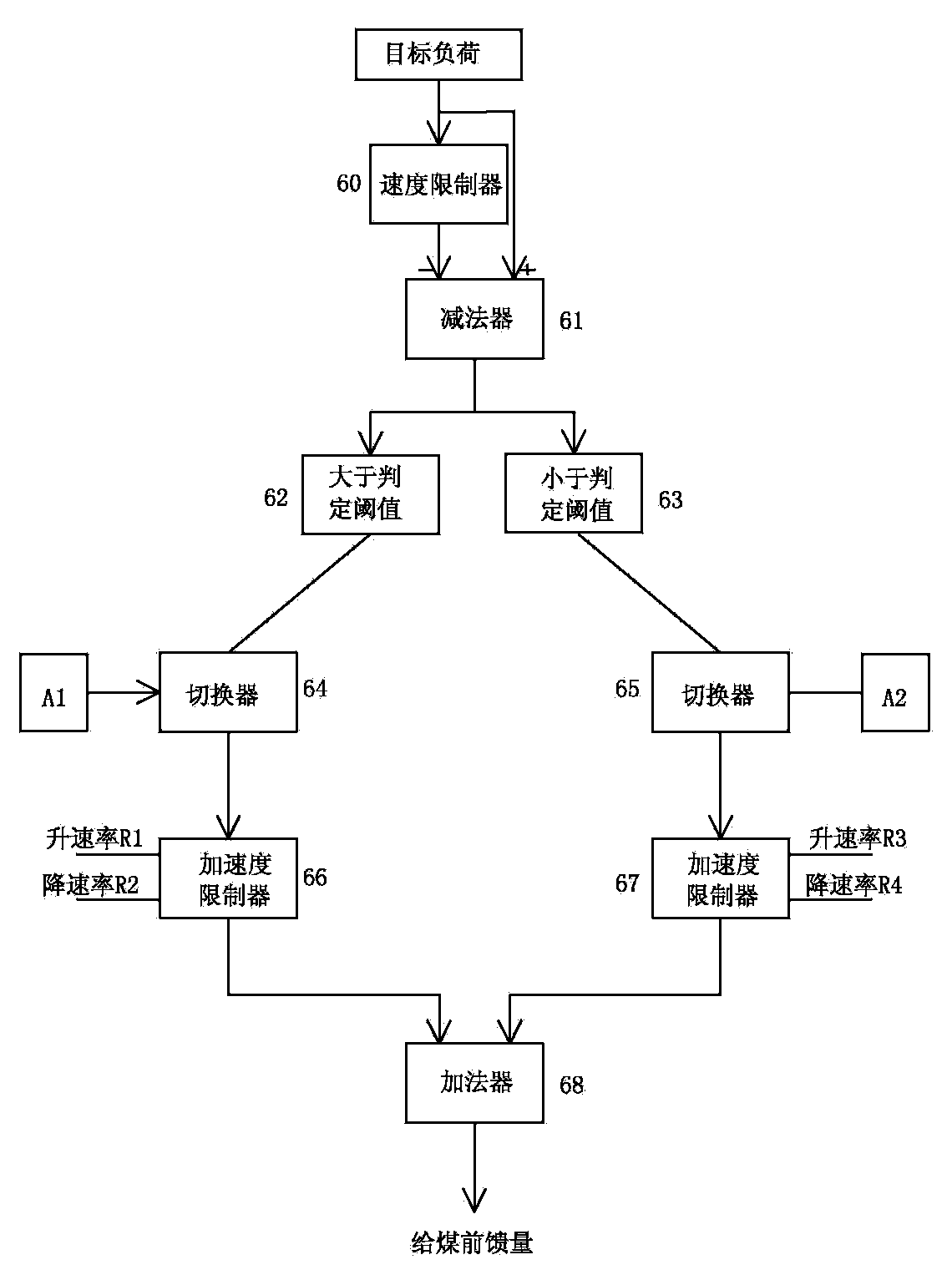

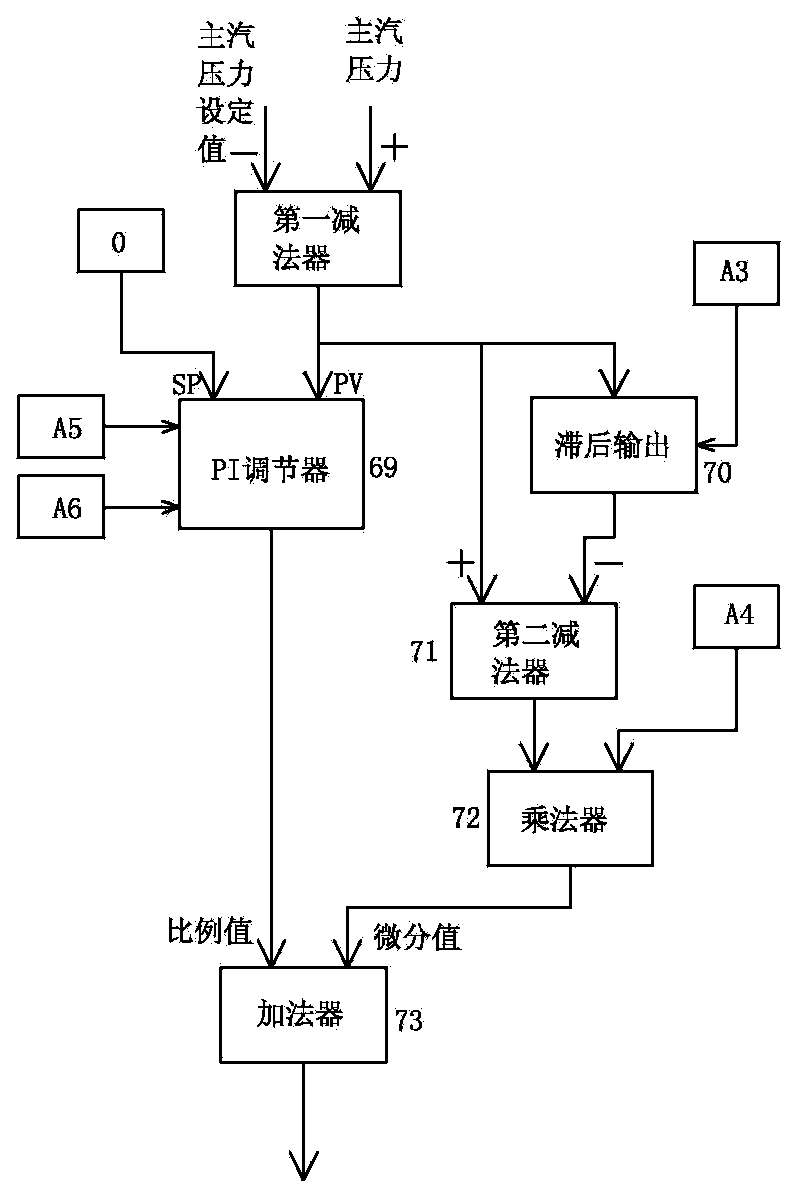

Supercritical boiler fire coal heat value self-balance control loop distributed control system implementation method

ActiveCN104238520AImprove running stabilityImprove operating economyProgramme total factory controlSupercritical steam generatorCombustion

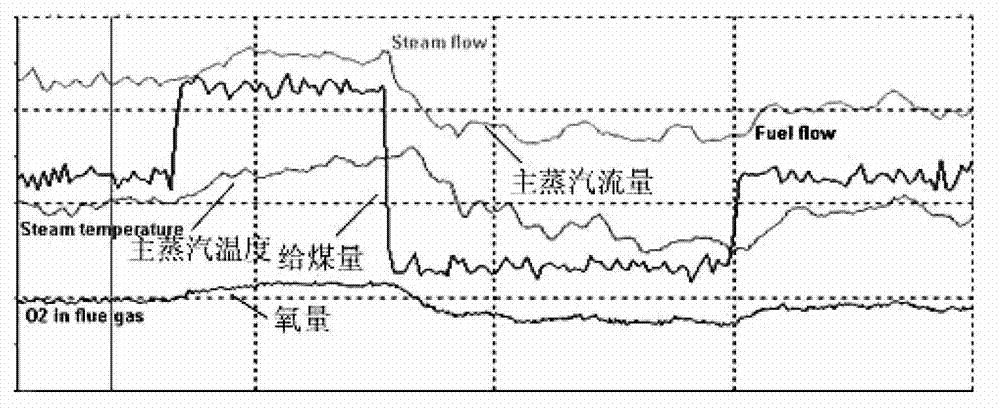

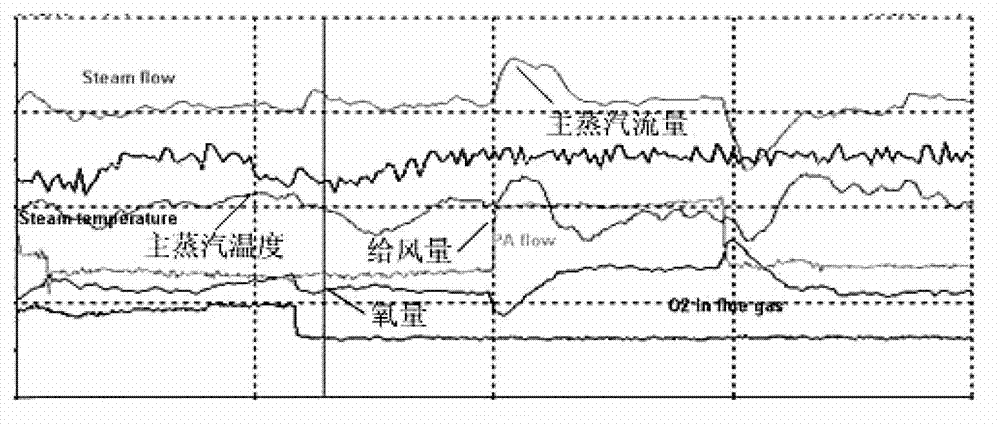

The invention discloses a supercritical boiler fire coal heat value self-balance control loop distributed control system implementation method. The method comprises the steps of outputting a final coal feeder rotation speed command after PID adjustment is carried out on a received coal feed quantity command and a total coal quantity command with a heat value corrected, wherein the total coal quantity command with the heat value corrected is a total coal quantity command output by multiplying a dynamically-measured total coal feed quantity by a heat value balance correction coefficient, and the heat value balance correction coefficient is a delayed heat value balance correction coefficient. According to the method, soft measurement of a fire coal heat value can be achieved based on a unit DCS platform, additional investment is not needed, and a soft measurement signal of the fire coal heat value makes it convenient for operating personnel to monitor the quality of fired coal in real time and guides boiler combustion adjustment. A fire coal heat value self-balance control loop is designed, and therefore a unit coordinated control system has the ability to adapt to various types of coal, and the operation stability and the economy of a unit are improved.

Owner:ANHUI XINLT POWER TECH CONSULTING +3

Technique for processing coking wastewater or organic wastewater by supercritical water oxidization technique

InactiveCN101209883AEmission reductionEfficient removalScale removal and water softeningMultistage water/sewage treatmentWater cyclingSolid particle

The invention relates to a process by adopting supercritical water oxidation technology to treat coking wastewater or organic wastewater. The invention is that: coking wastewater or organic wastewater is pretreated to obtain wastewater without solid granules; the wastewater is heated to 380-450 DEG C with a first interchanger and / or a supercritical boiler, and then enters demineralizing equipment to remove the salt in the wastewater by taking advantage of the property that supercritical inorganic matter is indissoluble; the wastewater after desalting is put in a reaction kettle to generate autothermal reaction with an heated and pressurized oxidant to obtain high-temperature gas-liquid mixture with higher temperature; the high-temperature gas-liquid mixture enters the first interchanger and acts as thermal medium to exchange heat with new coming coking wastewater or organic wastewater and then goes through a secondary interchanger to enter a cooler and is cooled to normal temperature, after pressure thereof is adjusted by a pressure regulation device, the high-temperature gas-liquid mixture enters a gas-liquid separator for separation, and then the air is discharged, while the liquid, namely the treated water is recycled. The organic contamination and oxidant are all dissolved in the wastewater; oxidation reaction is generated in homogeneous phase, in short reaction time, oxygenolysis of organic contamination is carried out quickly.

Owner:北京能泰高科环保技术有限公司

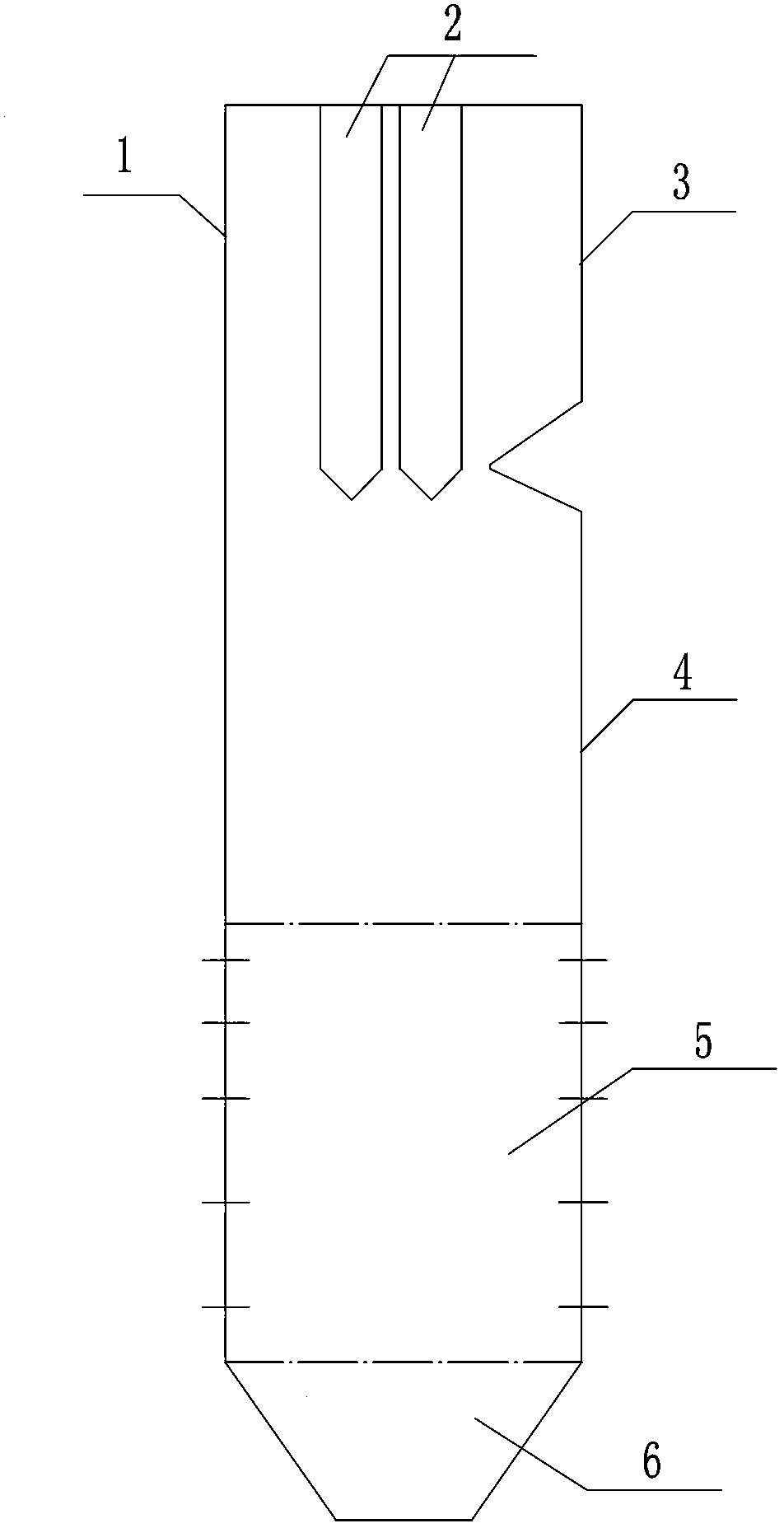

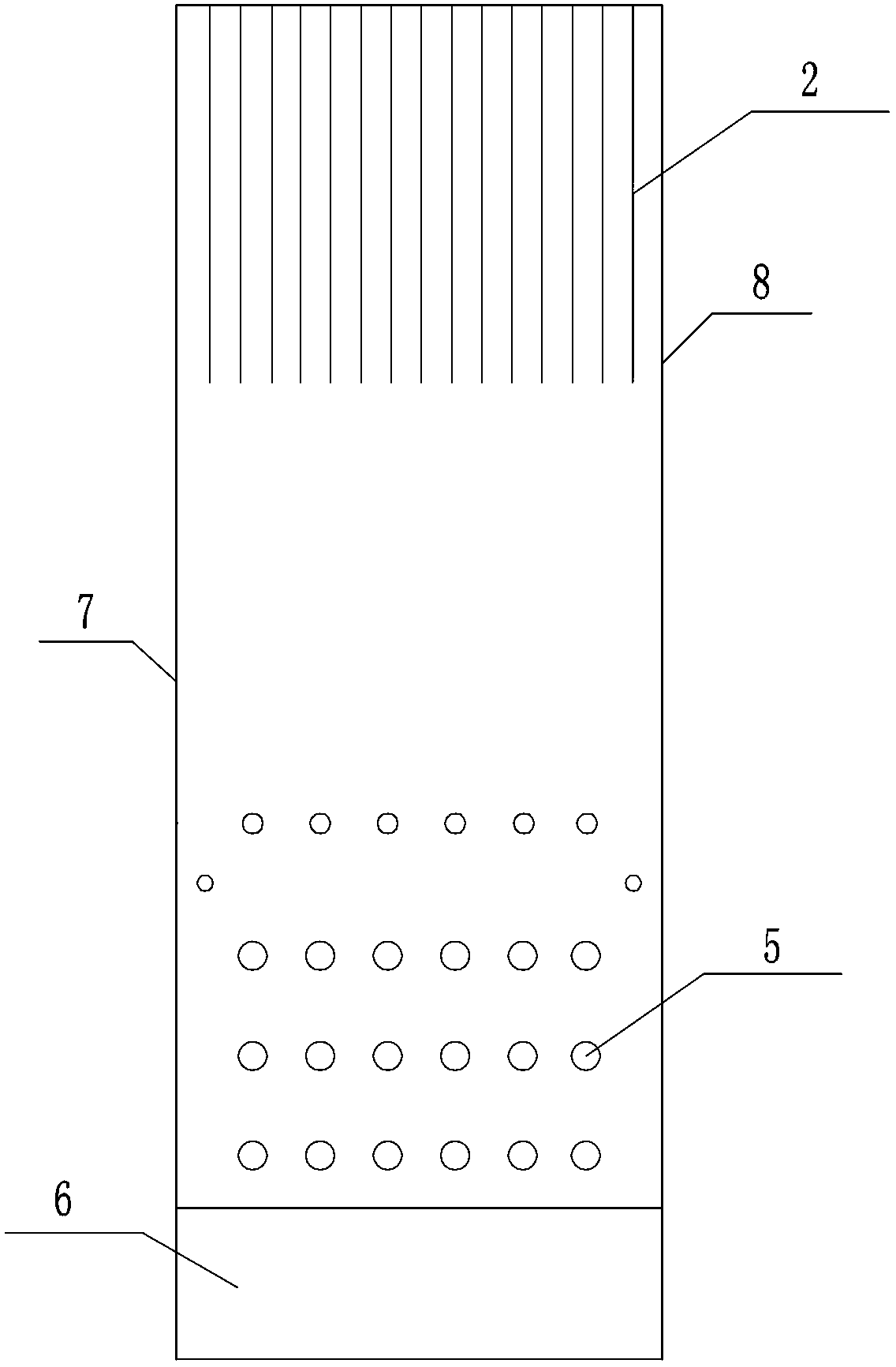

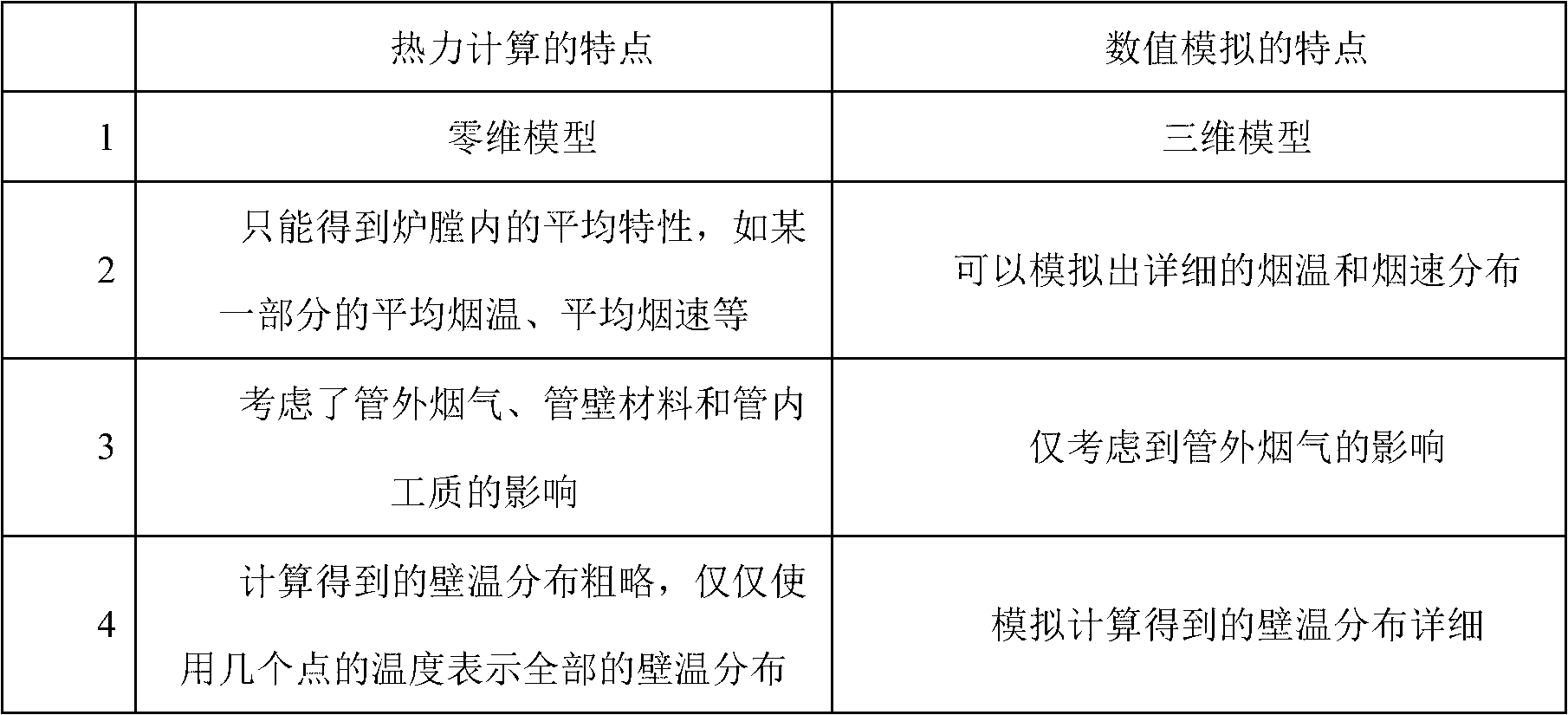

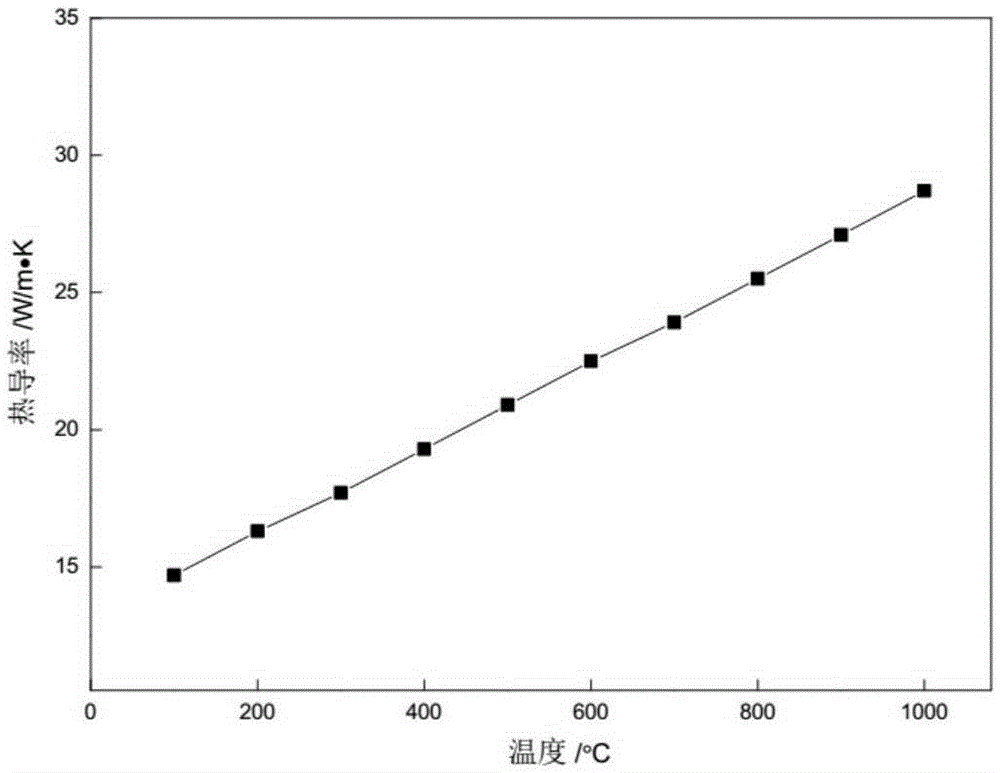

Method for calculating temperature of tube wall of platen superheater of ultra supercritical boiler by assistance of numerical simulation

ActiveCN102799775ACalculation detailsImprove accuracySpecial data processing applicationsSupercritical steam generatorTrombe wall

The invention discloses a method for calculating the temperature of the tube wall of a platen superheater of an ultra supercritical boiler by the assistance of numerical simulation. The method comprises the steps of: step (1) modeling the whole boiler containing the platen superheater, and constructing a mathematical model of a calculating method for the temperature of the tube wall of the superheater; step (2) conducting the numerical simulation on the constructed mathematical model to obtain the smoke temperature and smoke speed distribution nearby a platen superheater calculation area, selecting calculating data which are taken as initial conditions of the thermodynamic calculation and the hydrodynamic force calculation of the platen superheater; step (3) calculating the temperature of the wall of the platen superheater by utilizing the thermodynamic calculation and the hydrodynamic force calculation; step (4) checking and calculating the obtained tube wall of the whole platen superheater; and step (5) outputting a calculated result. According to the calculation method, the advantages of both the numerical simulation and the thermodynamic calculation can be considered, the detail wall temperature distribution in the boiler can be obtained, and meanwhile, the accuracy of the temperature wall result is also improved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

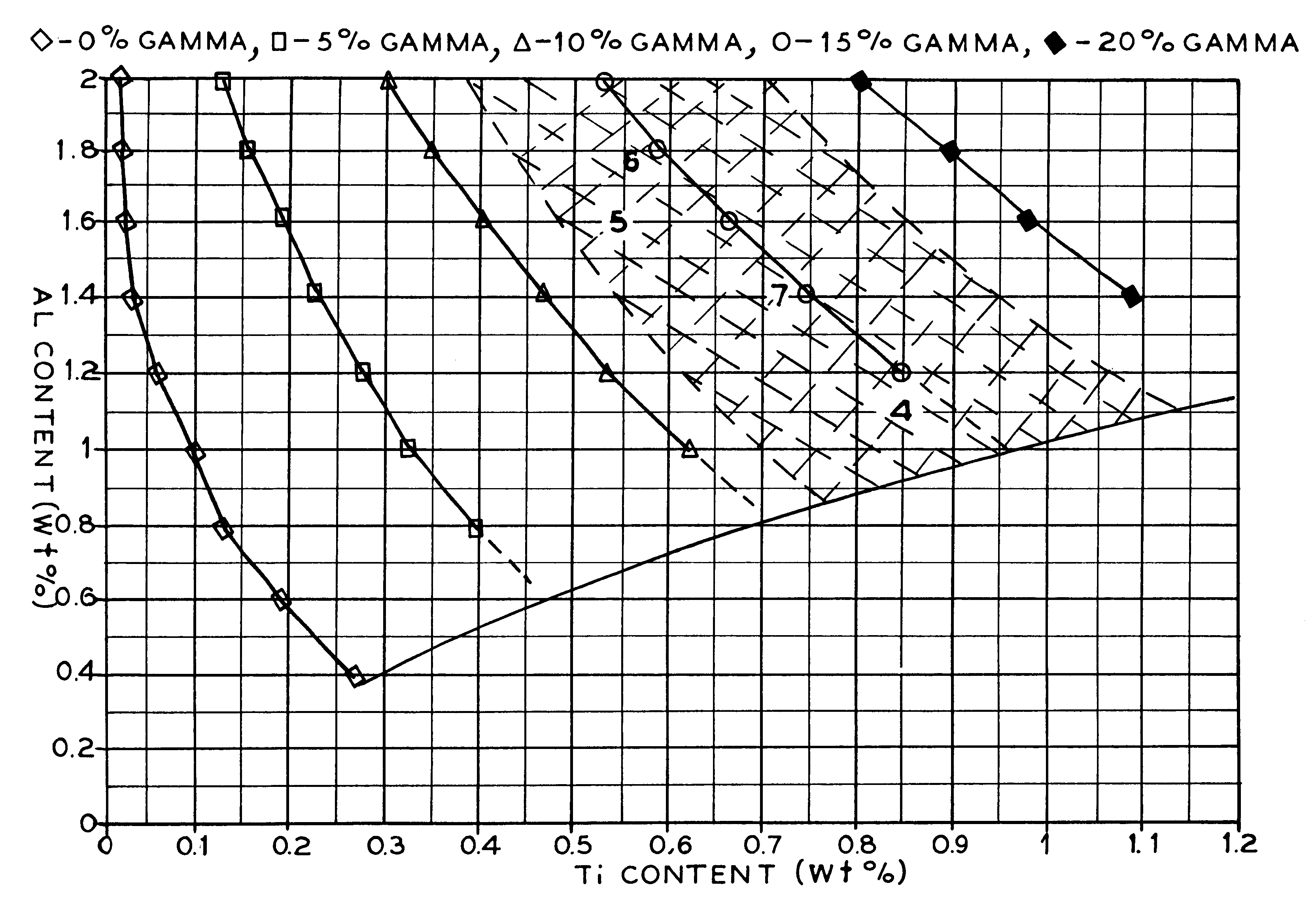

Advanced ultra-supercritical boiler tubing alloy

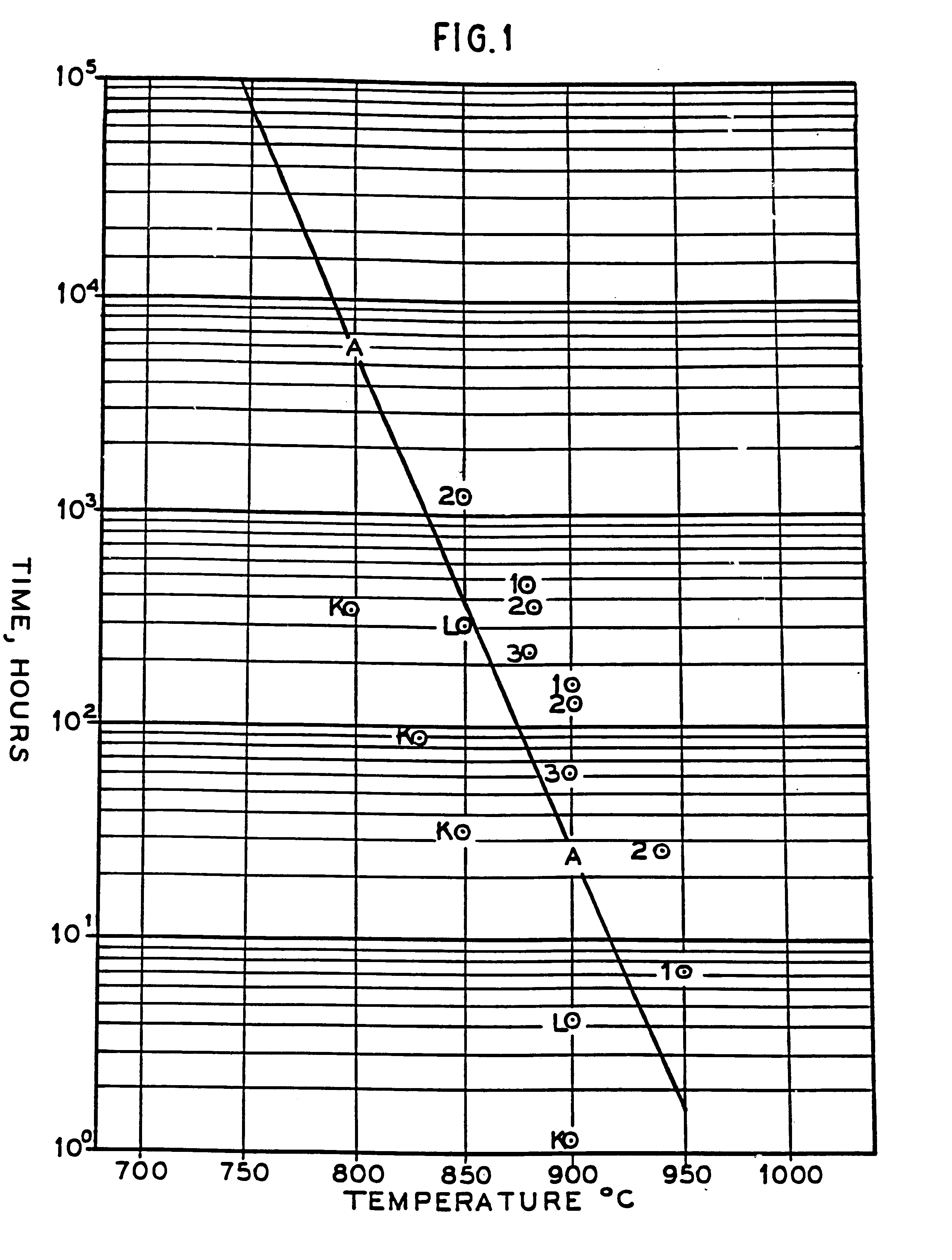

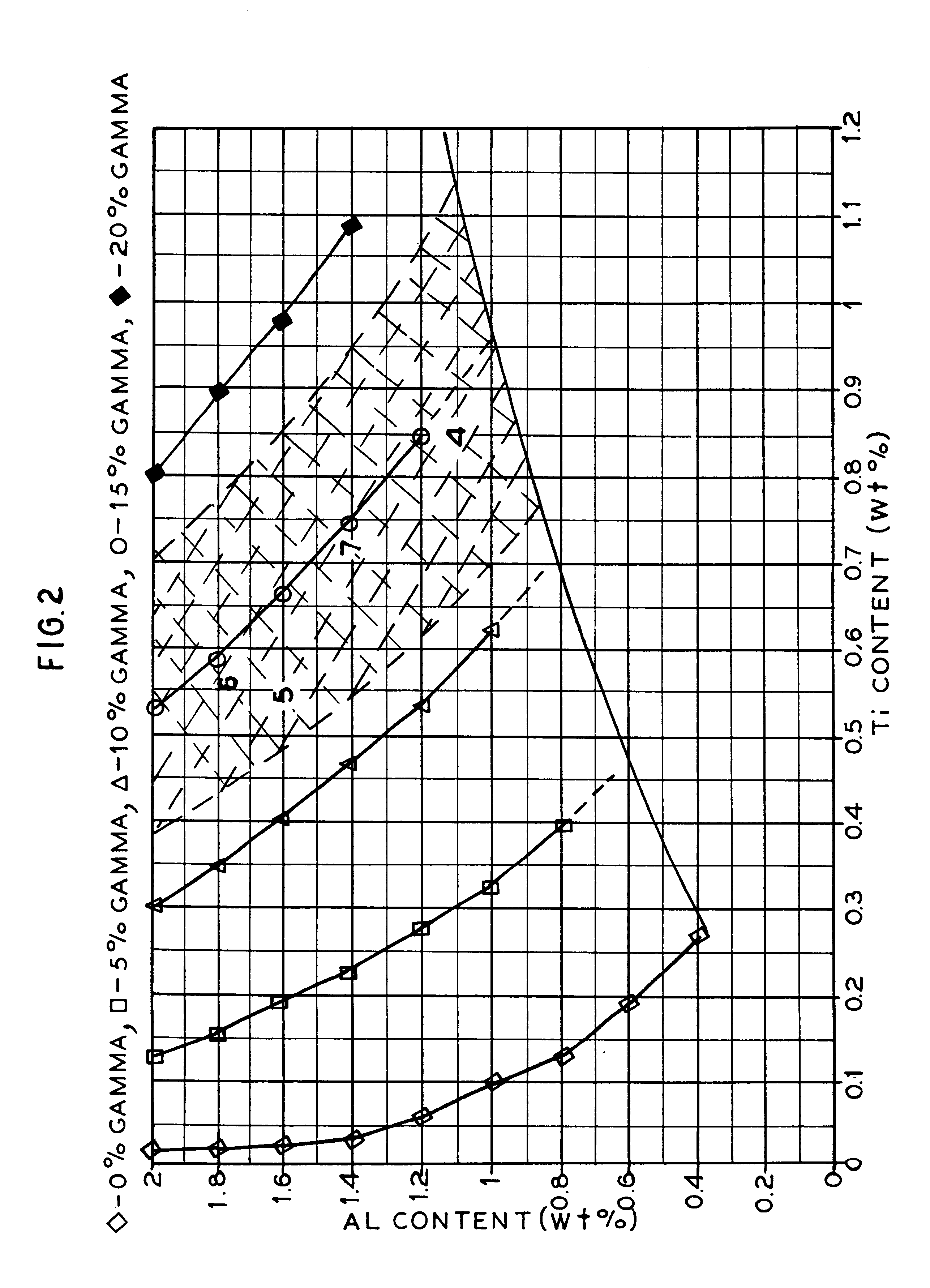

An ultra supercritical boiler tubing alloy characterized by a microstructure stabilized and strengthened for 375 bar / 700.degree. C. steam, in weight percent, service and alloyed to resist coal ash / flue gas corrosion for 200,000 hours consisting of 10 to 24 cobalt, 22.6 to 30 chromium, 2.4 to 6 molybdenum, 0 to 9 iron, 0.2 to 3.2 aluminum, 0.2 to 2.8 titanium, 0.1 to 2.5 niobium, 0 to 2 manganese, 0 to 1 silicon, 0.01 to 0.3 zirconium, 0.001 to 0.01 boron, 0.005 to 0.3 carbon, 0 to 4 tungsten, 0 to 1 tantalum and balance nickel and incidental impurities.

Owner:HUNTINGTON ALLOYS CORP (US)

Monitoring method and optimal control method for supercritical circulating fluidized bed (CFB) boiler combustion signals

InactiveCN103115356ACalculation speedAccurate measurementFluidized bed combustionApparatus for fluidised bed combustionCombustionFluidized bed

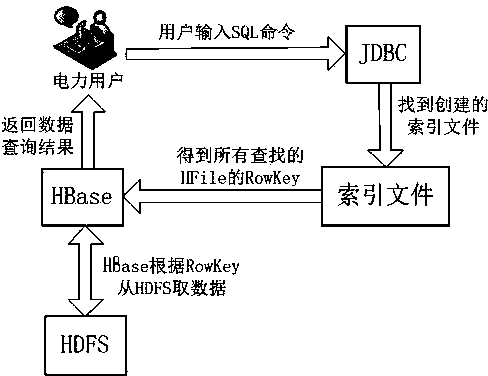

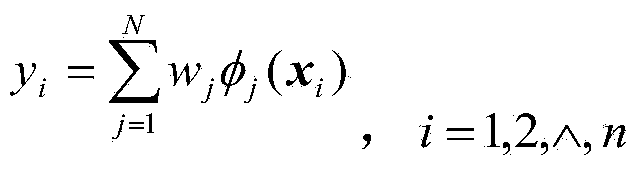

The invention discloses a monitoring method and an optimal control method for supercritical circulating fluidized bed (CFB) boiler combustion signals. The monitoring method comprises the following steps of: step 1, acquiring and pre-processing field data, and determining an auxiliary variable of an instant combustion carbon quantity model; step 2, building the instant combustion carbon quantity model based on mechanism modeling and data analysis hybrid modeling, and estimating the storage amount of instant combustion carbon in a hearth through a generalized Kalman filter information fusion technology, wherein the instant combustion carbon quantity model is shown in the description; and step 3, building a dynamic heat signal model, a hearth bed temperature signal model and a hearth outlet oxygen signal model through the instant combustion carbon quantity, and predetermining heat, bed temperatures and oxygen. The methods provided by the invention can accurately measure signals of heat, bed temperatures, oxygen and the like of a supercritical CFB boiler in real time, so that the optimal control on supercritical CFB boiler combustion is realized, and the combustion stability of the supercritical CFB boiler is improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

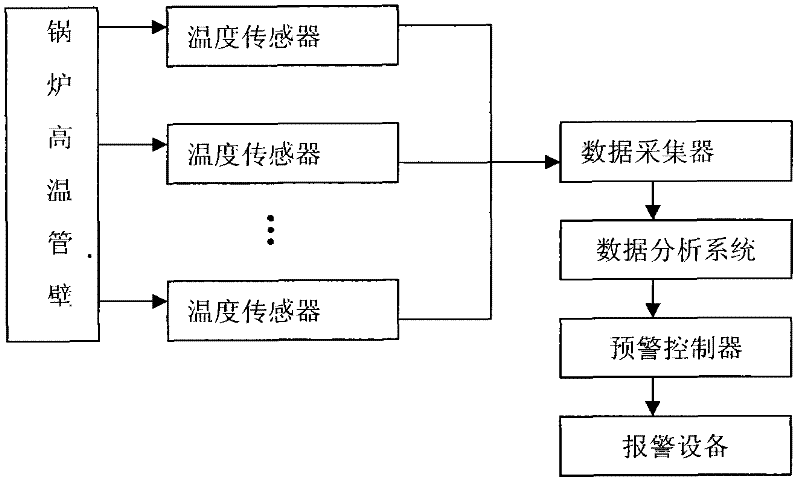

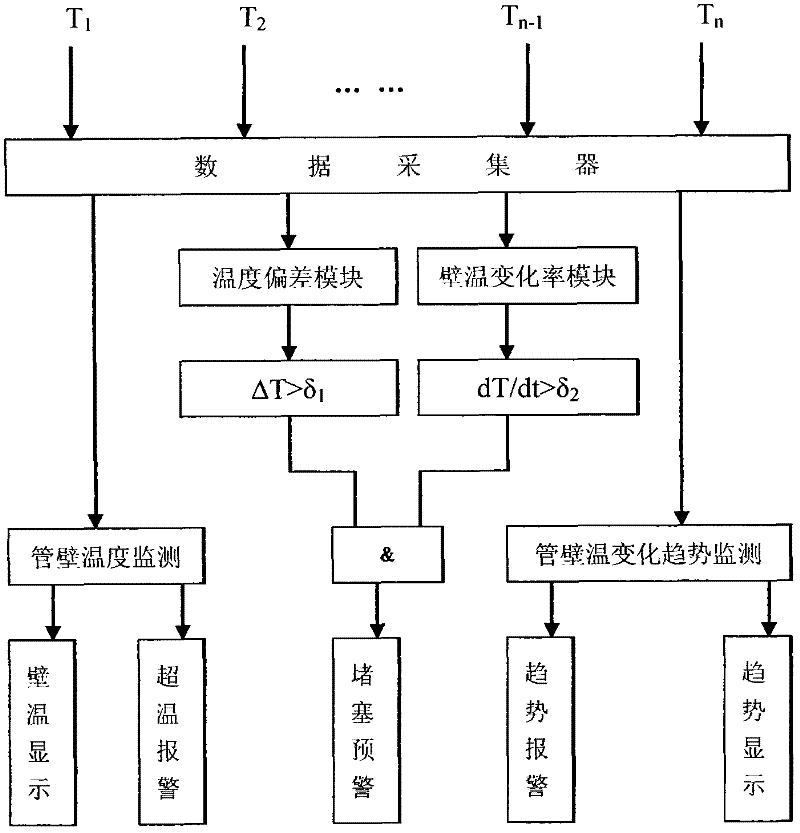

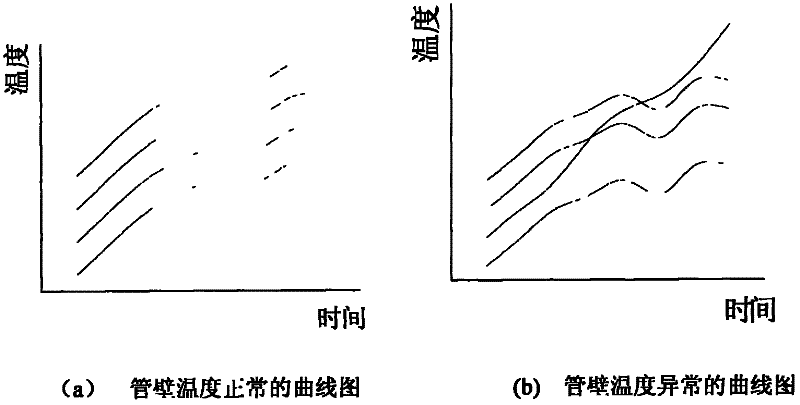

On-line prewarning device and prewarning method for iron scale blockage in high-temperature pipeline of super-critical boiler

ActiveCN102052662APrevent over-temperature pipe explosion accidentsImprove securityBoiler controlSteam boilersSupercritical steam generatorReal-time data

The invention discloses an on-line prewarning device and a prewarning method for iron scale blockage in a high-temperature pipeline of a super-critical boiler. The on-line prewarning device comprises temperature sensors, a data collector, a data analysis system, a prewarning controller and alarm equipment which are in signal connection in sequence, wherein the temperature sensors are distributed on high-temperature pipelines near an outlet header of the boiler. Since the wall temperature of a pipeline of the super-critical boiler and the iron scale blockage in the pipeline have strong coupling relationship, when the temperature departure of the pipeline is greater than a preset value delta 1, and the wall temperature change rate is greater than a preset value delta 2, i.e. iron scale blockage existing in the pipeline can be forecast, and a blockage prewarning signal is sent. The prewarning device can also display the temperature of different high-temperature tube panels and pipeline walls of the super-critical boiler and the real-time data, history data of the change rate of the super-critical boiler, and has the functions of overtemperature alarm and trend alarm. By adopting the invention, the phenomenon of iron scale blockage in high-temperature pipelines can be forecast quickly, so that the purpose of on-line real-time monitoring and prewarning iron scale blockage in high-temperature pipelines of the super-critical boiler can be achieved.

Owner:SOUTH CHINA UNIV OF TECH

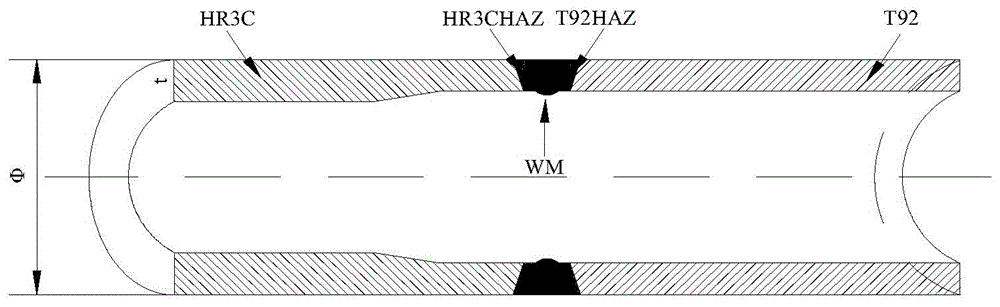

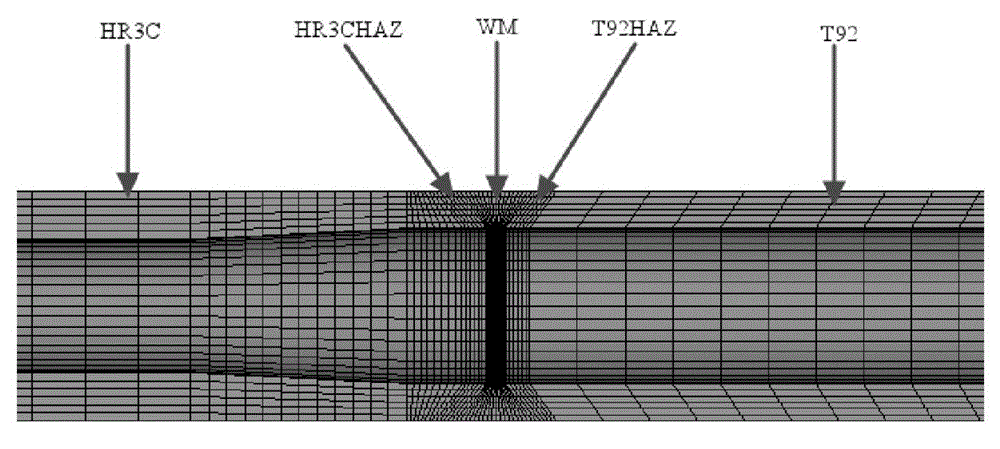

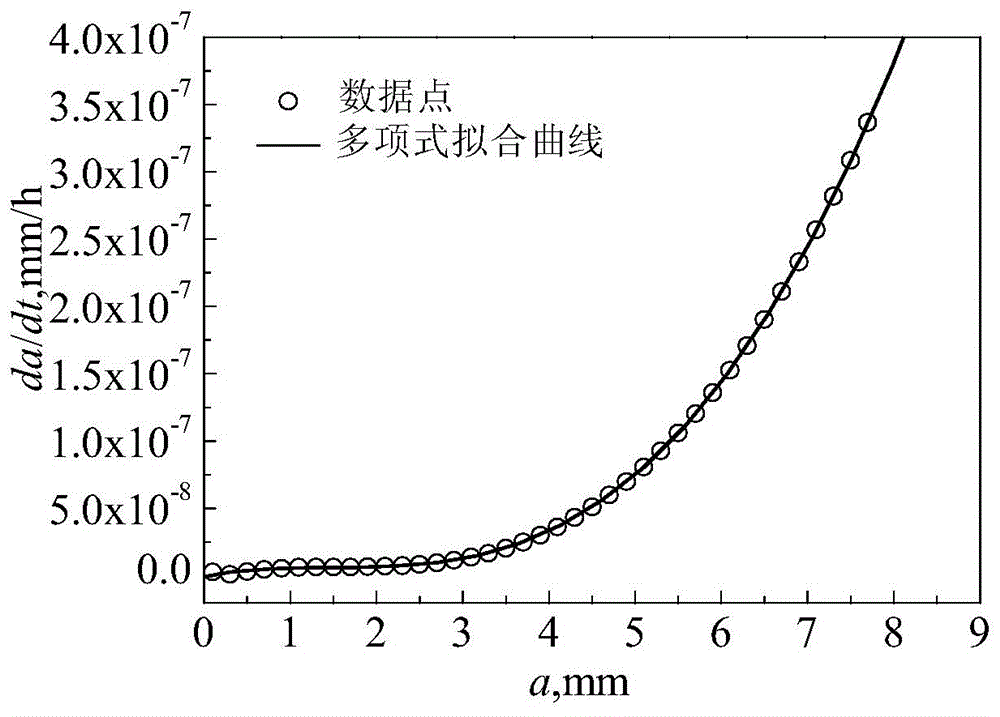

Service life evaluation method of ultra-supercritical boiler special steel pipe welding connector

InactiveCN104156577AAvoid the problem of too much errorSpecial data processing applicationsSupercritical steam generatorEngineering

The invention relates to a service life evaluation method of an ultra-supercritical boiler special steel pipe welding connector. The method includes the steps of firstly: using an NSW-MOD theoretical model to determine mathematic relation between a creep damage accumulation process and crack growth rate on the basis of a crack tip creep damage accumulation process; secondly, using a polynomial to fit a da / dt-a curve to obtain a maximum curvature point, namely the turning point a of creep crack growth; thirdly, calculating to obtain the ratio a / (S-a0), namely the creep crack growth service life loss a / (S-a0) of the special steel pipe welding connector under high temperature and high pressure, of special steel pipe welding connector pipeline wall thickness S to the difference (S-a0) of S and initial crack length a0; acquiring the creep crack growth residual service life of the special steel pipe welding connector under high temperature and high pressure by numerical integration between the crack length a at the turning point and the pipe wall thickness S. The method has strict physical and theoretical basis, and service life predication is highly matched with actual service life.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

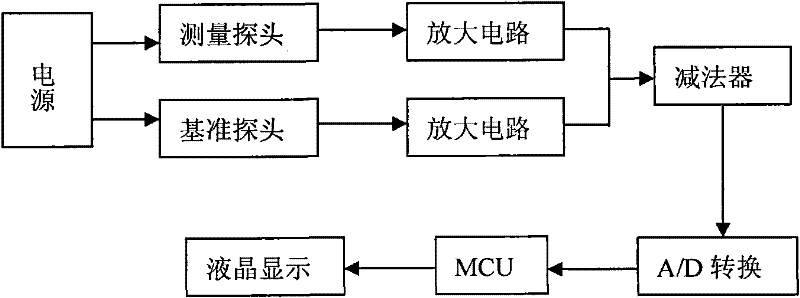

Scale detecting instrument in tube on high-temperature heating surface of supercritical boiler and detection method

InactiveCN101750011AWide detection rangeBaseline consistentElectrical/magnetic thickness measurementsSupercritical steam generatorMicrocontroller

The invention discloses a scale detecting instrument in a tube on a high-temperature heating surface of a supercritical boiler and a detection method. The detecting instrument comprises a measuring probe, a reference probe, an amplifying circuit, a subtracter, an A / D converter, a singlechip and a display. In the detection method, magnetic signals from a position to be detected and a scale-free position of the detected tube are respectively converted into voltage signals by the measuring probe and the reference probe; after the two voltage signals are amplified by the amplifying circuit, differential voltage signals are acquired through the subtracter and converted into digital signals by the A / D converter; and the digital signals are sent to the display for displaying after being processed by the singlechip. According to the difference value of magnetic flux density detected by the measuring probe and the reference probe, the scale detecting instrument can detect the thickness of scales in the tube on the heating surface quantitatively, and thus the scale detecting instrument can perform quantitative detection quickly and conveniently on the accumulation thickness of the scales in the tube on the high-temperature heating surface of the boiler.

Owner:GUANGDONG TOPKEY POWER TECHN DEV +1

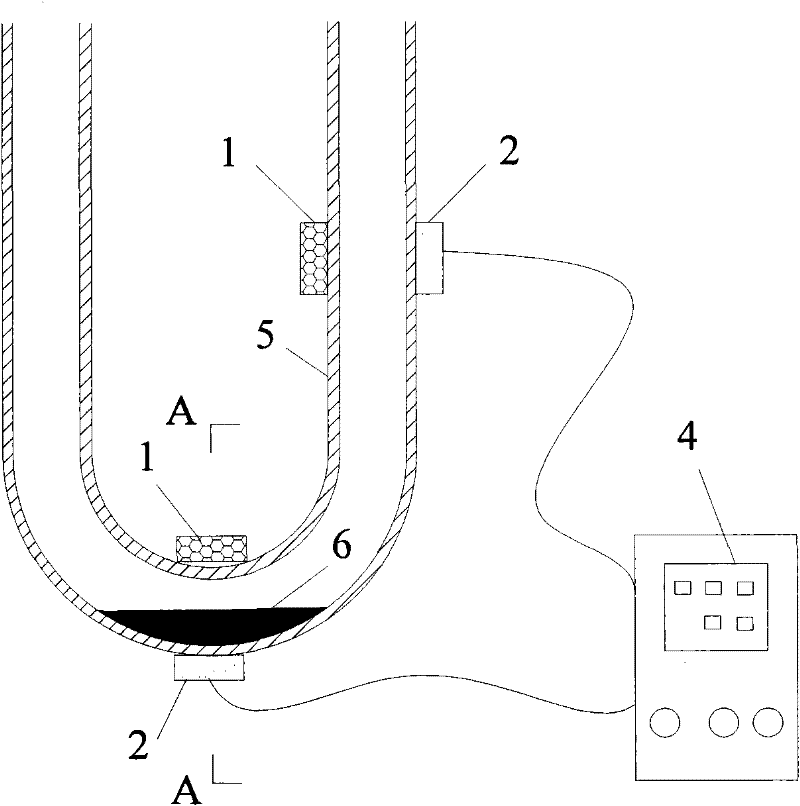

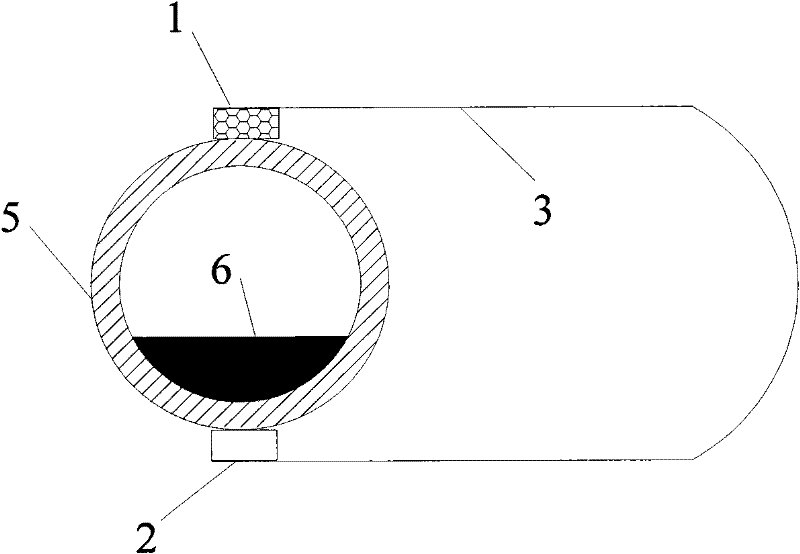

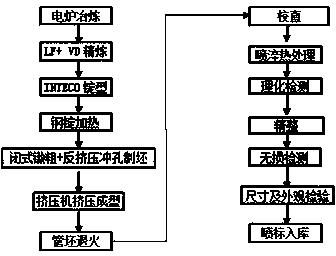

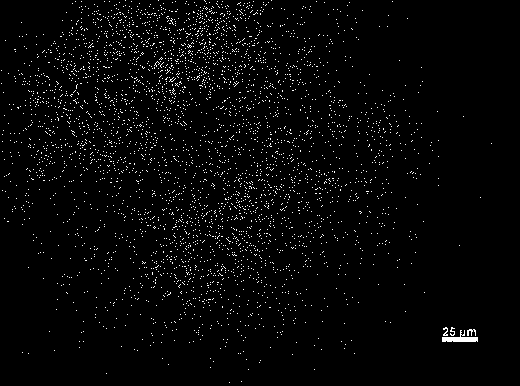

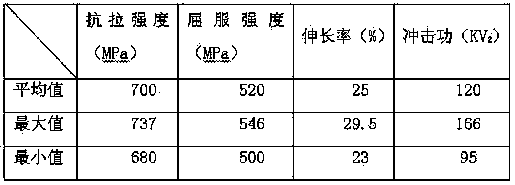

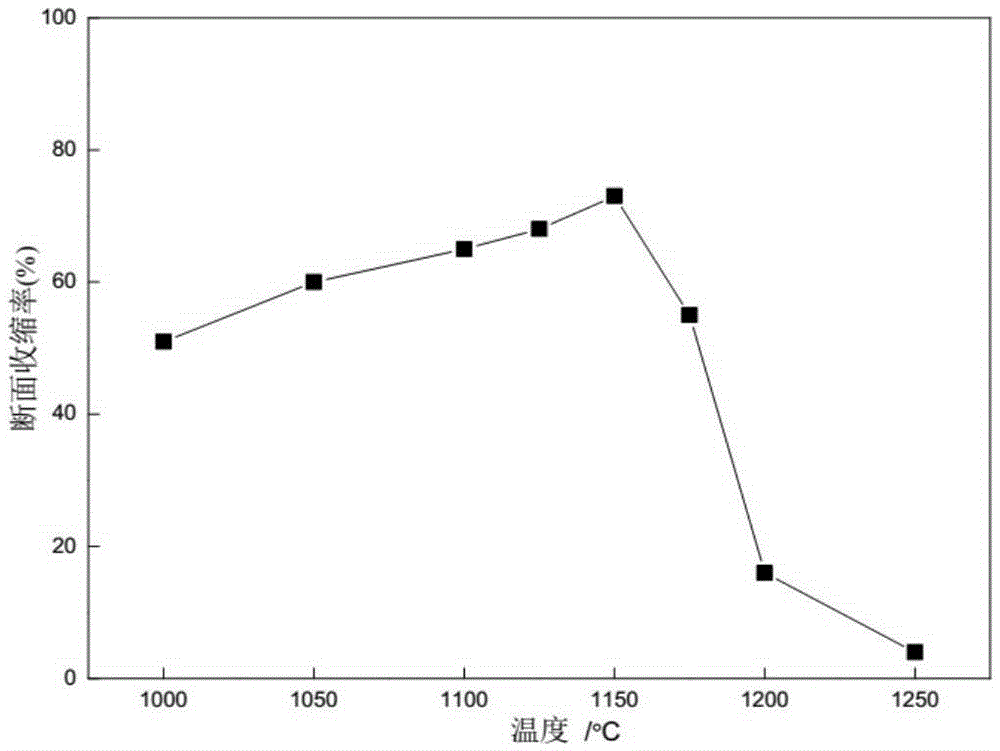

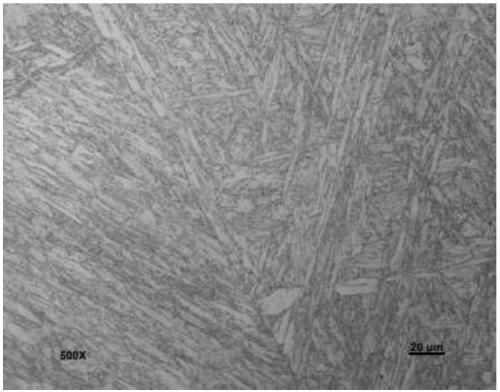

Manufacturing method of high-quality P92 large-aperture thick-wall seamless steel pipe of ultra-supercritical unit

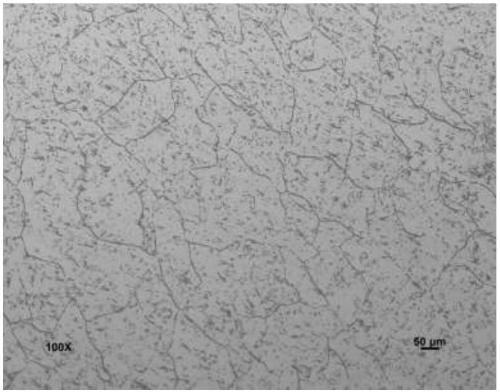

The invention relates to a manufacturing method of a high-quality P92 large-aperture thick-wall seamless steel pipe of an ultra-supercritical unit and belongs to the field of heat-resistant steel tubing manufacture. The manufacturing method realizes dynamic combination of internal control of steel chemical components, improvement of steel purity, steel ingot casting, enclosed upsetting, reverse extrusion punching, extrusion molding and spraying quenching, the steel tube obtained by the manufacturing method satisfies ASMESA335, EN10216-2 and GB5310 standard requirements, the microstructure of the steel tube is completely tempered martensite and satisfies the requirement of clear martensite lath orientation in the 400x view field, delta-ferrite content is less than or equal to 1% and less than or equal to 3% in the most serious field, and comprehensive performance indexes satisfy the international advanced level. The manufacturing method can produce different specifications of P92 large-aperture thick-wall seamless steel pipes having the external diameter of 325-1200mm, wall thickness of 20-180mm and length less than or equal to 12500mm, and can be used in different fields of an ultra-supercritical boiler and power-station four-pipes. The manufacturing method can effectively guarantee product quality and the high-quality P92 large-aperture thick-wall seamless steel pipe obtained by the manufacturing method can replace an imported product.

Owner:INNER MONGOLIA NORTH HEAVY INDS GROUP

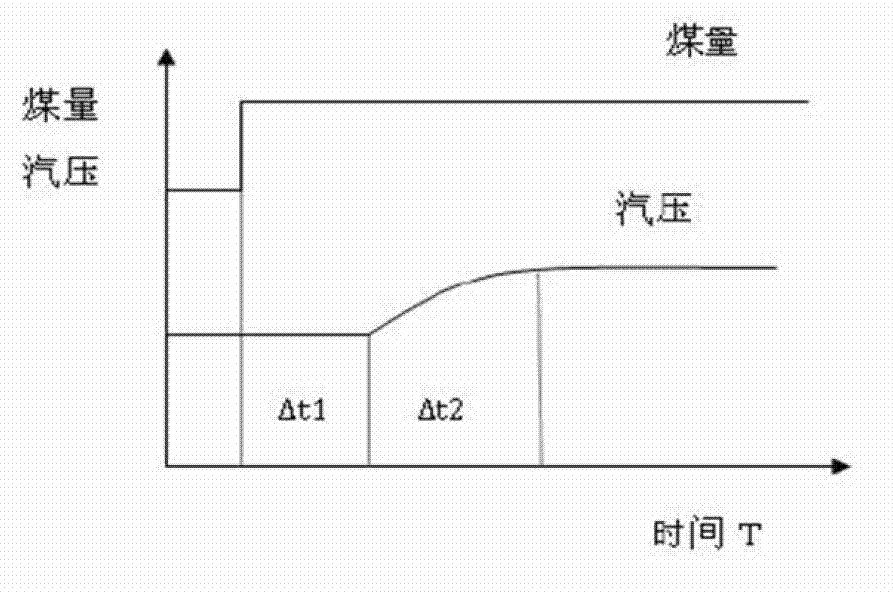

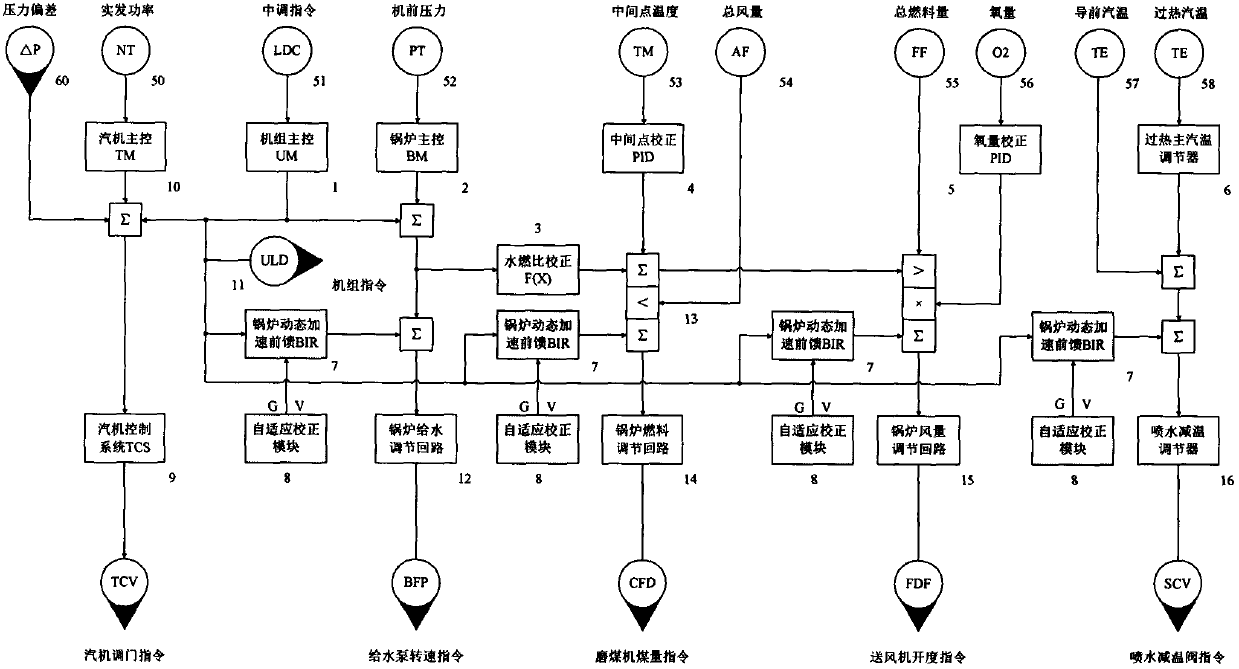

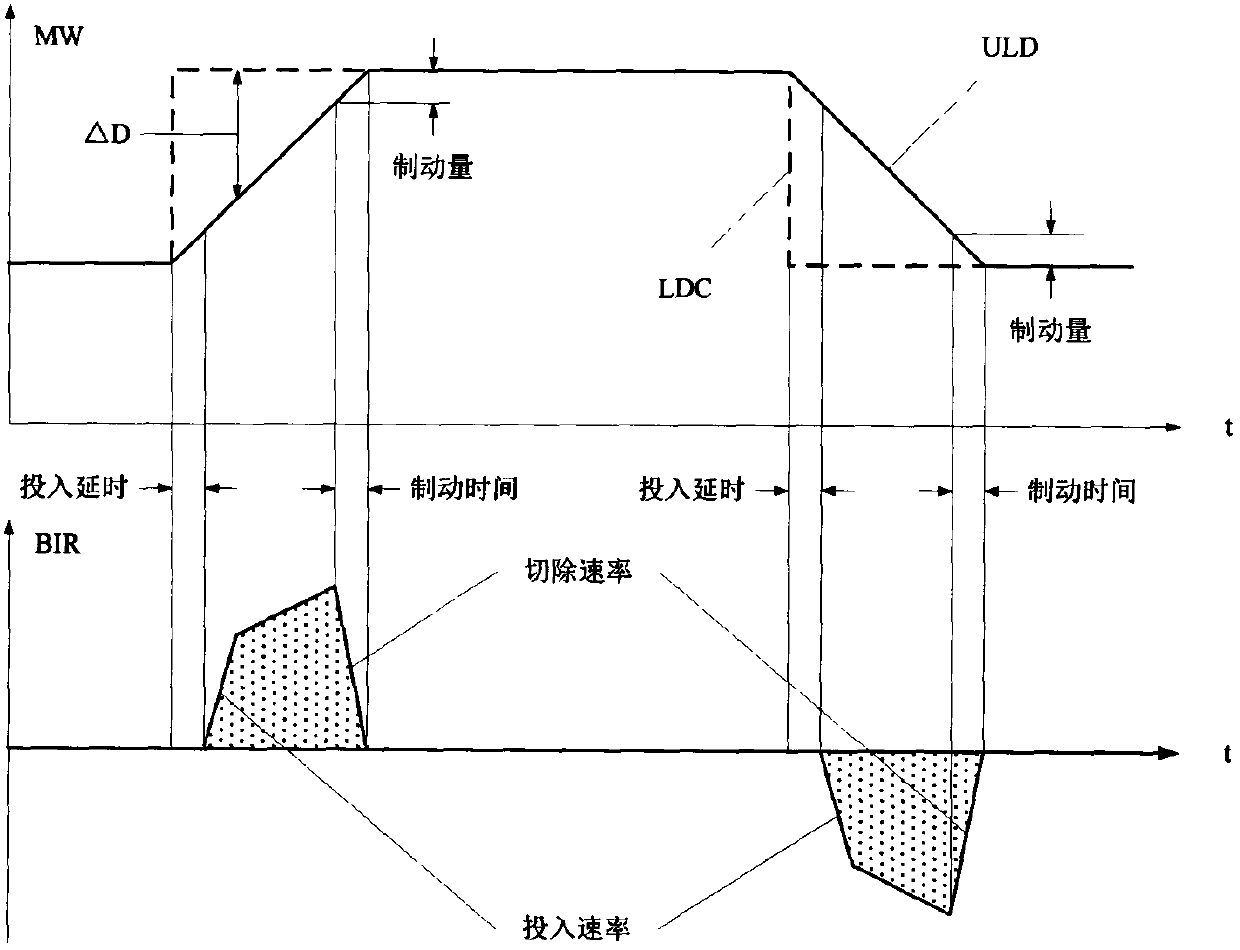

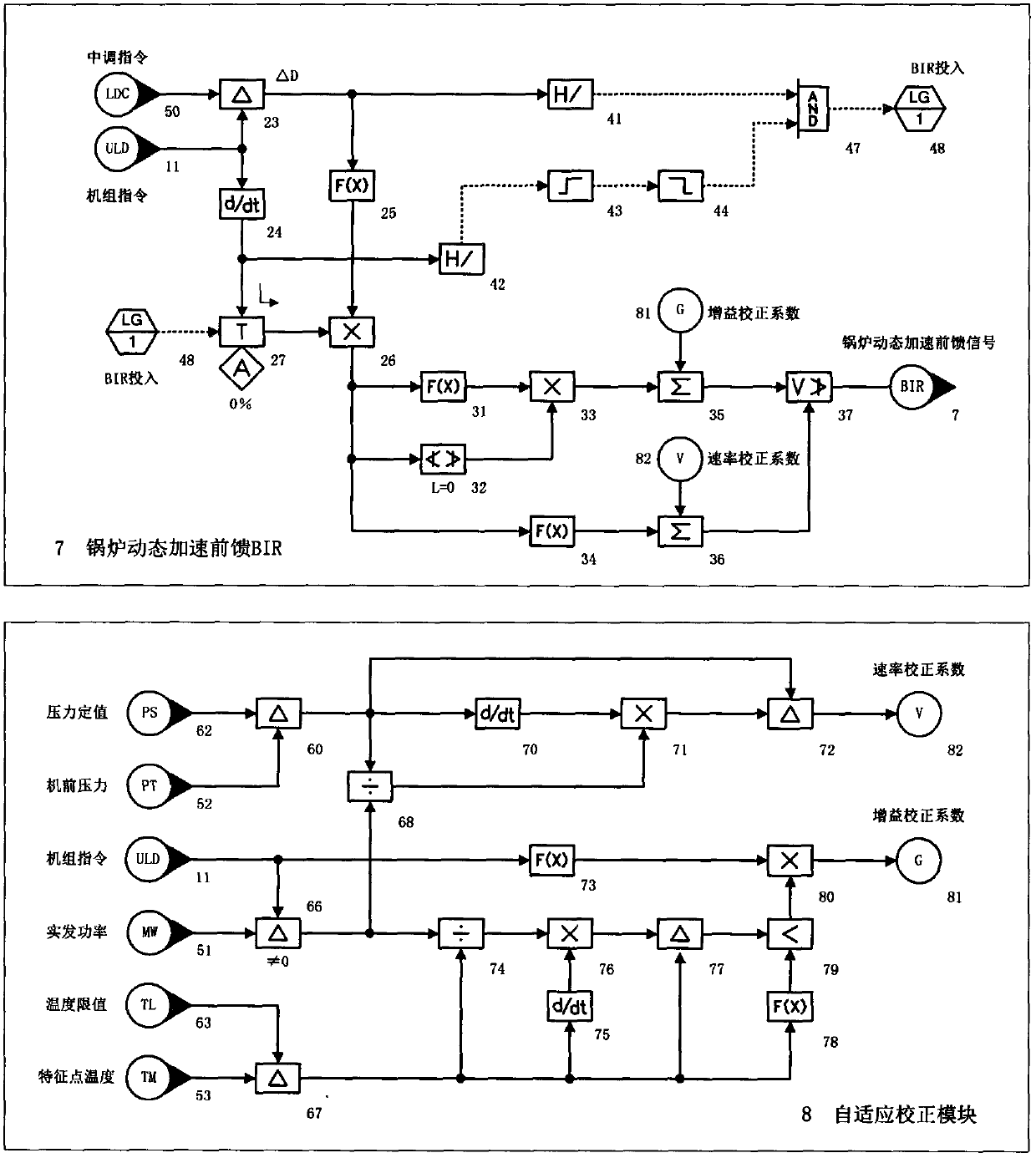

Self-adaptive correcting method for dynamic accelerating feedforward of supercritical boiler

InactiveCN102679314AImprove dynamic response characteristicsImprove stabilityBoiler controlSupercritical steam generatorControl theory

The invention discloses a self-adaptive correcting method for dynamic accelerating feedforward signals of a supercritical boiler. By adopting the method, the dynamic accelerating feedforward signals of the supercritical boiler during the load verifying process of the supercritical boiler can be intelligently and self-adaptively adjusted according to the real-time load deviation, the change rate of the temperature along with the load and time and the change rate of the pressure along with the load and the time, and the dynamic accelerating feedforward signals can be amplitude limited according to the safety allowance of the intermediate point temperature, as a result, the compensating precision of the dynamic accelerating feedforward signals is effectively improved, and overcompensation and boil overtemperature are avoided.

Owner:上海迪吉特控制系统有限公司

Heat-resisting alloy for 700-DEG C ultra-supercritical boiler water-cooling wall and tubing manufacturing method

ActiveCN105420638ASimple designMeet service environment requirementsSupercritical steam generatorAlloy

The invention provides a heat-resisting alloy for a 700-DEG C ultra-supercritical boiler water-cooling wall and a tubing manufacturing method, and belongs to the technical field of heat-resisting alloys. The alloy comprises the following chemical components in percentage by weight: 0.03 to 0.05% of C, 22 to 24% of Cr, 12 to 14% of Co, 8.3 to 8.8% of Mo, 0.5 to 1.0% of W, 0.003 to 0.005% of B, 0.05 to 0.12% of Zr, less than 0.1% of Mn, less than 0.05% of Si, not greater than 0.15% of Cu, not greater than 0.002% of P, not greater than 0.001% of S, not greater than 0.01% of N, not greater than 0.01% of O, not greater than 0.01% of Ca, not greater than 0.001% of Pb, not greater than 0.001% of Sb, not greater than 0.001% of Sn, not greater than 0.0001% of Bi, not greater than 0.001% of As, and the balance Ni and inevitable impurity elements. The manufacturing method comprises the following steps: smelting; homogenizing; cogging; thermally extruding; performing cold rolling; performing solid solution heat treatment. The alloy and the manufacturing method have the advantages that the endurance strength extrapolation number of a produced tubing under 600 DEG C and 105 hours is not less than 130MPa, which is far more than that of a T92 material, thus the requirement of a service environment of the 700-DEG C ultra-supercritical boiler water-cooling wall can be met, and postweld heat treatment is avoided.

Owner:CENT IRON & STEEL RES INST

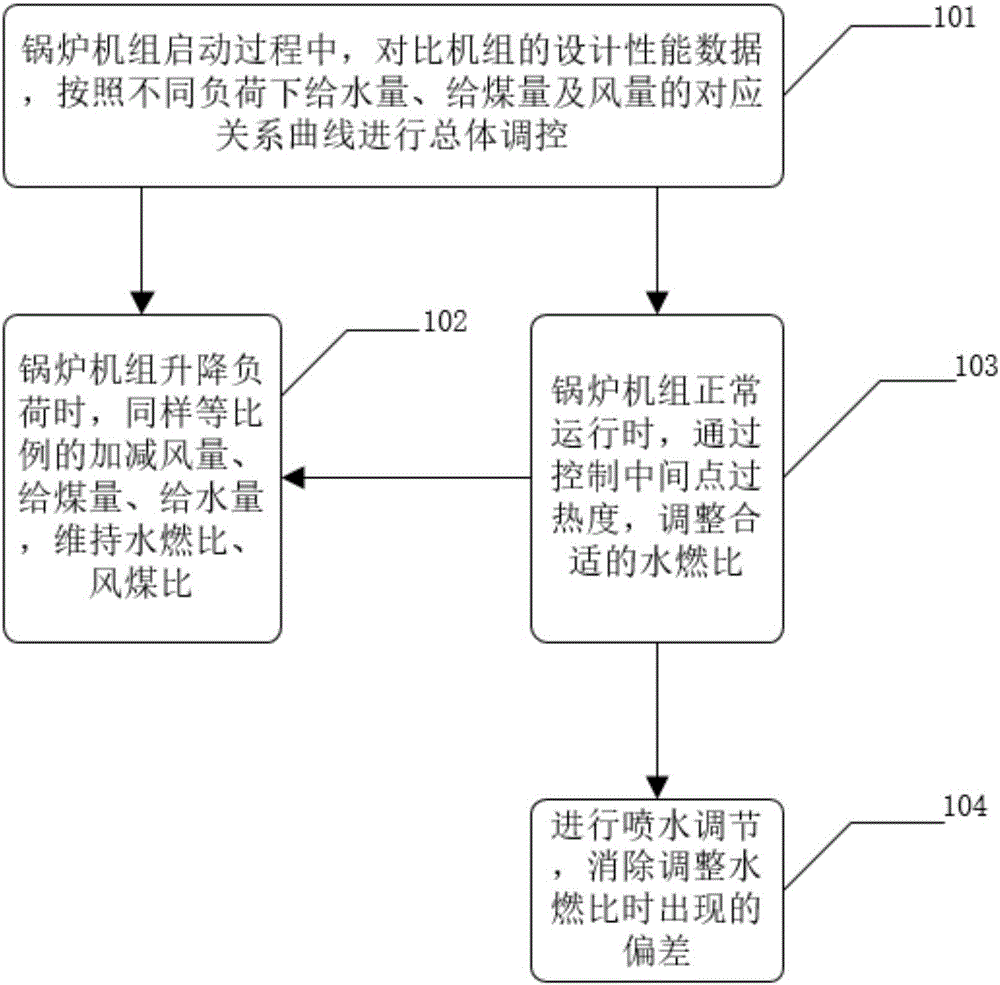

Control method for steam temperature of meager coal boiler of 1045MW ultra supercritical unit

ActiveCN106439770AGuaranteed uptimeEliminate biasSuperheating controlSteam separation arrangementsSupercritical steam generatorAir volume

The embodiment of the invention discloses a control method for the steam temperature of a meager coal boiler of a 1045MW ultra supercritical unit. The control method is used for solving the technical problems that because mature ultra supercritical steam temperature control technologies capable of being applied to actual production fields lack currently, heating surface over-temperature pipe explosion is frequently caused by unreasonable steam temperature control of a field ultra supercritical boiler, large potential safety hazards are caused to safe and stable operation of a power plant, and severe economic loss of a large thermal power plant is caused. The control method includes the steps that in the boiler unit starting process, design performance data of the unit are compared, and overall regulation and control are conducted according to the corresponding relation curve of water supply quantity, coal supply quantity and air volume under different loads; when the load of the boiler unit is increased or decreased, the air volume, coal supply quantity and water supply quantity are increased or decreased with the same ratio; when the boiler unit normally operates, the superheat degree of the intermediate point is controlled to regulate the water-fuel ratio to be proper; and water spraying adjustment is carried out, so that deviation in regulation of the water-fuel ratio is eliminated.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

Ultra supercritical boiler with parameter of more than 700 DEG C having secondary re-heating function

InactiveCN102364244ALower the elevationShorten the lengthSteam boilersFeed-water heatersSupercritical steam generatorCombustor

The invention discloses an ultra supercritical boiler with a parameter of more than 700 DEG C having a secondary re-heating function. A chamber of the boiler is horizontally placed, and a combustor is arranged on a front wall. A high temperature super-heater, a high temperature primary re-heater, a high temperature secondary re-heater, a low temperature super-heater, a low temperature secondary re-heater and a low temperature primary re-heater are sequentially arranged in a horizontal flue along the flow direction of the smoke; a coal economizer is arranged in two stages of a tail vertical flue; and a platen super-heater is arranged in the chamber of the boiler. Through the arrangement mode of the boiler disclosed by the invention, secondary re-heating of the unit can be realized; moreover, the temperature of the steam can be increased to more than 700 DEG C. The length of a high temperature steam pipeline is shortened to the maximum to reduce the construction cost while the efficiency of the unit is obviously improved. Through the invention, the efficiency of thermal power generating units in China is possibly improved to more than 50%.

Owner:XIAN THERMAL POWER RES INST CO LTD

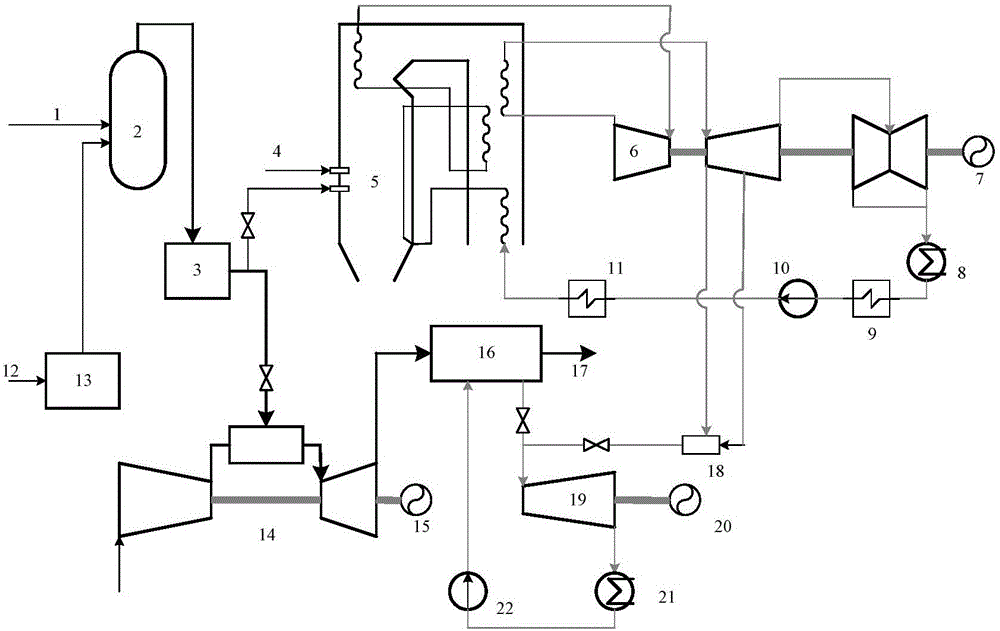

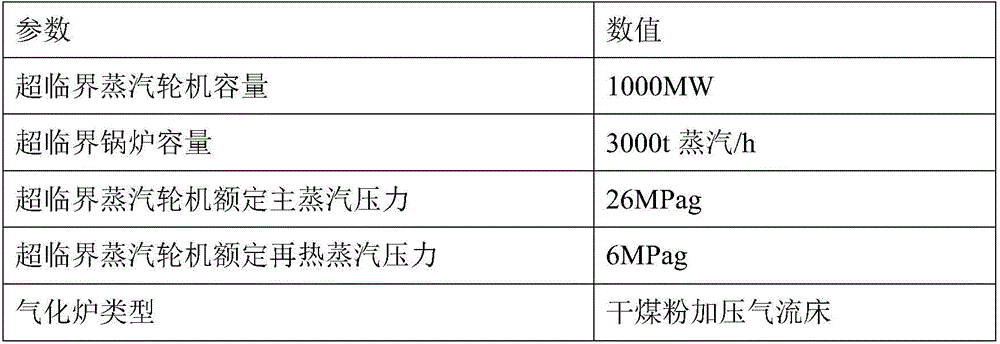

Peak-regulating power station integrating IGCC and supercritical unit, and peak regulating method

ActiveCN106246252AGuaranteed Ignition DemandImprove power generation efficiencyCombustion using gaseous and pulverulent fuelGas turbine plantsSyngasSupercritical steam generator

The invention discloses a peak-regulating power station integrating IGCC and a supercritical unit, and a peak regulating method. The peak-regulating power station comprises an IGCC power generator set and a supercritical power generator set, wherein a gasifier outlet in the IGCC power generator set is connected with a purification unit synthesized gas inlet, a purification unit outlet is divided into two ways, one way is connected with a combustion chamber of a gas turbine to implement the quick variable load of the peak-regulating power station by regulating the synthesized gas inlet volume of the gas turbine, and the other way is connected with a synthesized gas burner of the supercritical boiler in the supercritical power generator set; an extraction pipeline in steam cylinder of the supercritical steam turbine which is provided with steam by the supercritical boiler is connected with a steam regulator, an outlet of the steam regulator is connected with a combined cyclic steam turbine inlet pipeline in the IGCC power generator set; the two ways are organically fused through the connection and coordinated matching of pipelines among the systems, the quick and deep peak regulating capability of the power station can be realized, and the relatively high power generation efficiency can be kept.

Owner:CHINA HUANENG GRP CO LTD +1

RBF (Radial Basis Function) neural network based supercritical boiler nitric oxide discharging dynamic predication method

ActiveCN104331736AEfficient integrationFull inclusion of dynamic featuresBiological neural network modelsDynamic modelsNitric oxide

The invention discloses an RBF (Radial Basis Function) neural network based supercritical boiler nitric oxide discharging dynamic predication method and belongs to the technical field of environmental protection discharging parameter measurement. According to the technical scheme, the RBF neural network based supercritical boiler nitric oxide discharging dynamic predication method comprises the following steps of SS1 selecting a static auxiliary variable and a dynamic auxiliary variable; SS2 performing RBF neural network structure fitting on the static auxiliary variable and the dynamic auxiliary variable to obtain an RBF neural network structure based training boiler nitric oxide discharging dynamic predication model; adjusting RBF neural network parameters and obtaining an RBF neural network structure based supercritical boiler nitric oxide discharging dynamic predication model. According to the RBF neural network based supercritical boiler nitric oxide discharging dynamic predication method, under conditions that a same training error is set and the like, the number of interior nerve cells of the dynamic model is obviously smaller than that of a static model, the model structure is simple, the training time is short, and the generalization ability is strong.

Owner:STATE GRID CORP OF CHINA +2

Austenitic stainless steel excellent in high temperature strength and corrosion resistance, heat resistant pressurized parts, and the manufacturing method thereof

InactiveUS20030198567A1Excellent in high-temperature strength and thermal fatigue resistance propertySupercritical steam generatorThermal fatigue

An austenitic stainless steel suited for ultra supercritical boilers, which consists of C: 0.03-0.12%, Si: 0.1-1%, Mn: 0.1-2%, Cr: not less than 20% but less than 28%, Ni: more than 35% but not more than 50%, W: 4-10%, Ti: 0.01-0.3%, Nb: 0.01-1%, sol. Al: 0.0005-0.04%, B: 0.0005-0.01%, and the balance Fe and impurities; and also characterized by the impurities whose contents are restricted to P: not more than 0.04%, S: not more than 0.010%, Mo: less than 0.5%, N: less than 0.02%, and O (oxygen): not more than 0.005%. Heat resistant pressurized parts excellent in thermal fatigue properties and structural stability at high temperatures, which have a coarse grain whose grain size number is 6 or less, and whose mixed grain ratio is 10% or less.

Owner:NIPPON STEEL CORP

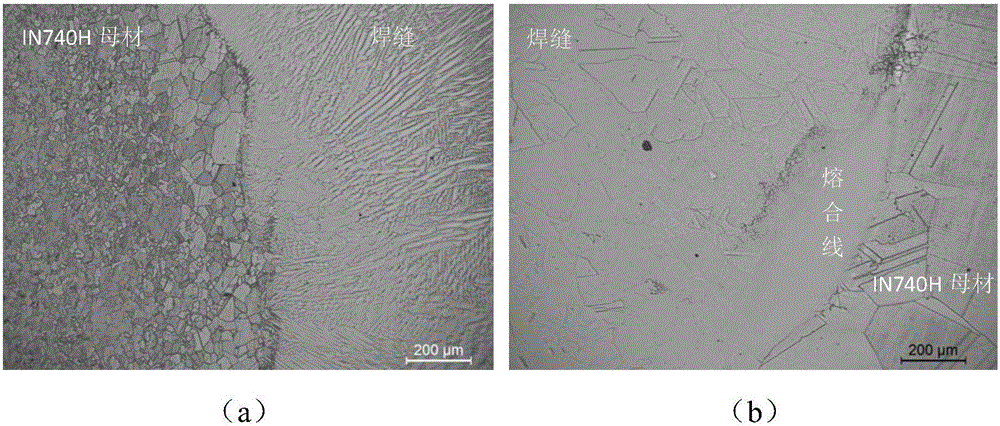

Nickel base alloy welding wire with weld deposit metal capable of being recrystallized

ActiveCN105689919AGood high temperature plasticityLess prone to welding cracksArc welding apparatusWelding/cutting media/materialsWelding residual stressImpurity

The invention belongs to the field of ultra-supercritical power station welding materials and particularly relates to a solution strengthening type nickel base alloy welding wire high in plasticity. The solution strengthening type nickel base alloy welding wire is suitable for welding of ultra-supercritical boiler superheaters / reheater pipes, welding between the superheaters and boiler gas collection headers (including connecting pipe seats) and welding between the reheater pipes and the boiler gas collection headers (including the connecting pipe seats). The solution strengthening type nickel base alloy welding wire is mainly characterized in that after the welding wire is used in welding conducted through TIG welding (argon tungsten-arc welding), weld deposit metal can be recrystallized after being subjected to postweld heat treatment at the temperature of 1000 DEG C or higher, and dendrite and columnar crystal tissue in an original weld is removed; the hardness of a weld area after welding is 300 HV, and the hardness is reduced to 210 HV after recrystallization; and weld residual stress and component segregation are eliminated, and the welding wire is basically consistent with base metal in appearance. The chemical components of the nickel base alloy welding wire include, by weight percent, smaller than 3% of Fe, 14%-18% of Cr, smaller than or equal to 0.45% of Al and Ti, smaller than 0.9% of Ti / Al, 1.0%-1.5% of Nb, 7.0%-9.8% of Mo, smaller than 0.4% of W, smaller than or equal to 1.0% of Si, 0.5%-1.0% of Mn, smaller than or equal to 0.1% of C, 0.003%-0.005% of B, smaller than or equal to 0.03% of Zr, the balance Ni and smaller than 0.1% of the sum of other impurity elements.

Owner:HUANENG POWER INTERNATIONAL +1

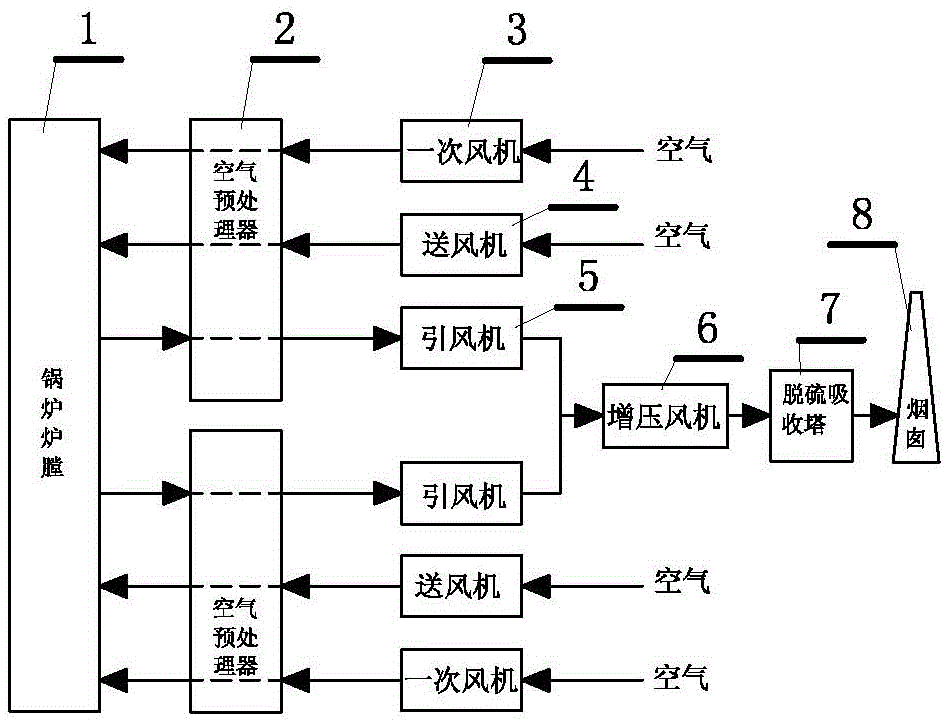

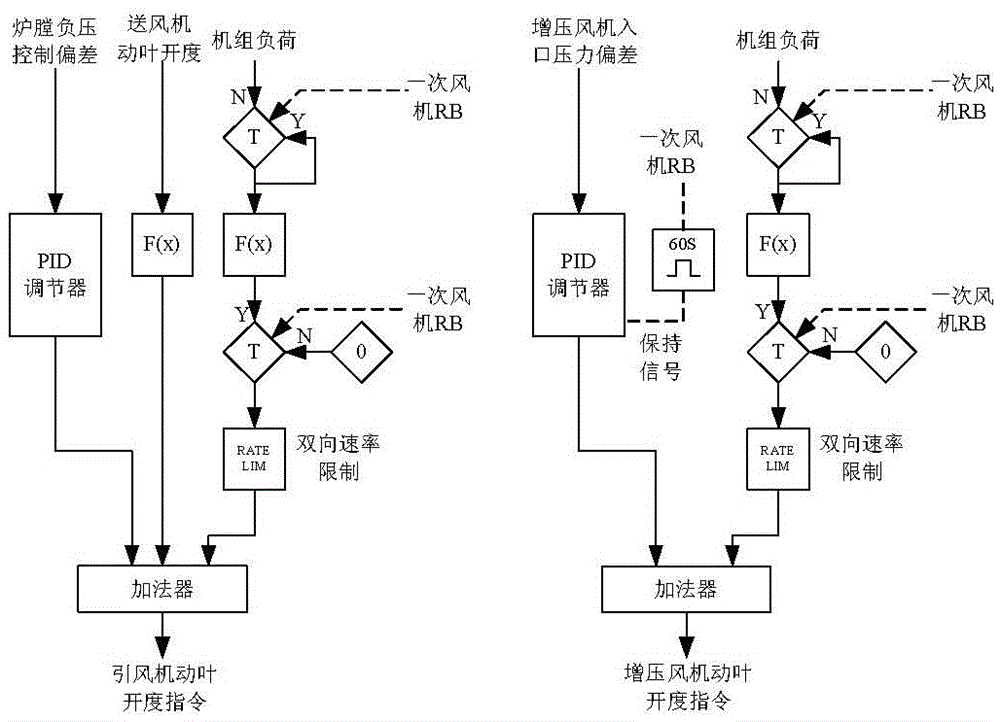

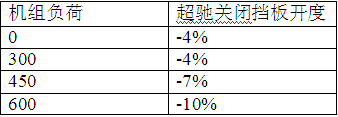

Quick control method of negative pressure of hearth during primary air fan RB process of supercritical once-through boiler

ActiveCN105650674ASolve unmanageable problemsSolve control problemsAir supply regulationSupercritical steam generatorHearth

The invention discloses a quick control method of the negative pressure of a hearth during the primary air fan RB process of a supercritical once-through boiler. The quick control method is used for controlling induced draft fans and a booster fan when an RB command is given, which is caused by the fact that one of two primary air fans in a system trips due to failure. Under different operation conditions and different loads, induced draft fan baffle commands and booster fan baffle commands are given when the primary air fan RB of the supercritical once-through boiler happens, so as to avoid the severe disturbance of the negative pressure of the hearth during the RB process, the control problem of the negative pressure of the hearth during the primary air fan RB process is solved, the negative pressure of the hearth can be quickly stabilized within the appropriate range after the primary air fan on one side trips, and disturbing again, which is caused by feedforward signal variation, is avoided during the RB process and after the RB is ended.

Owner:CHINA DATANG CORP SCI & TECH RES INST CO LTD EAST CHINA BRANCH

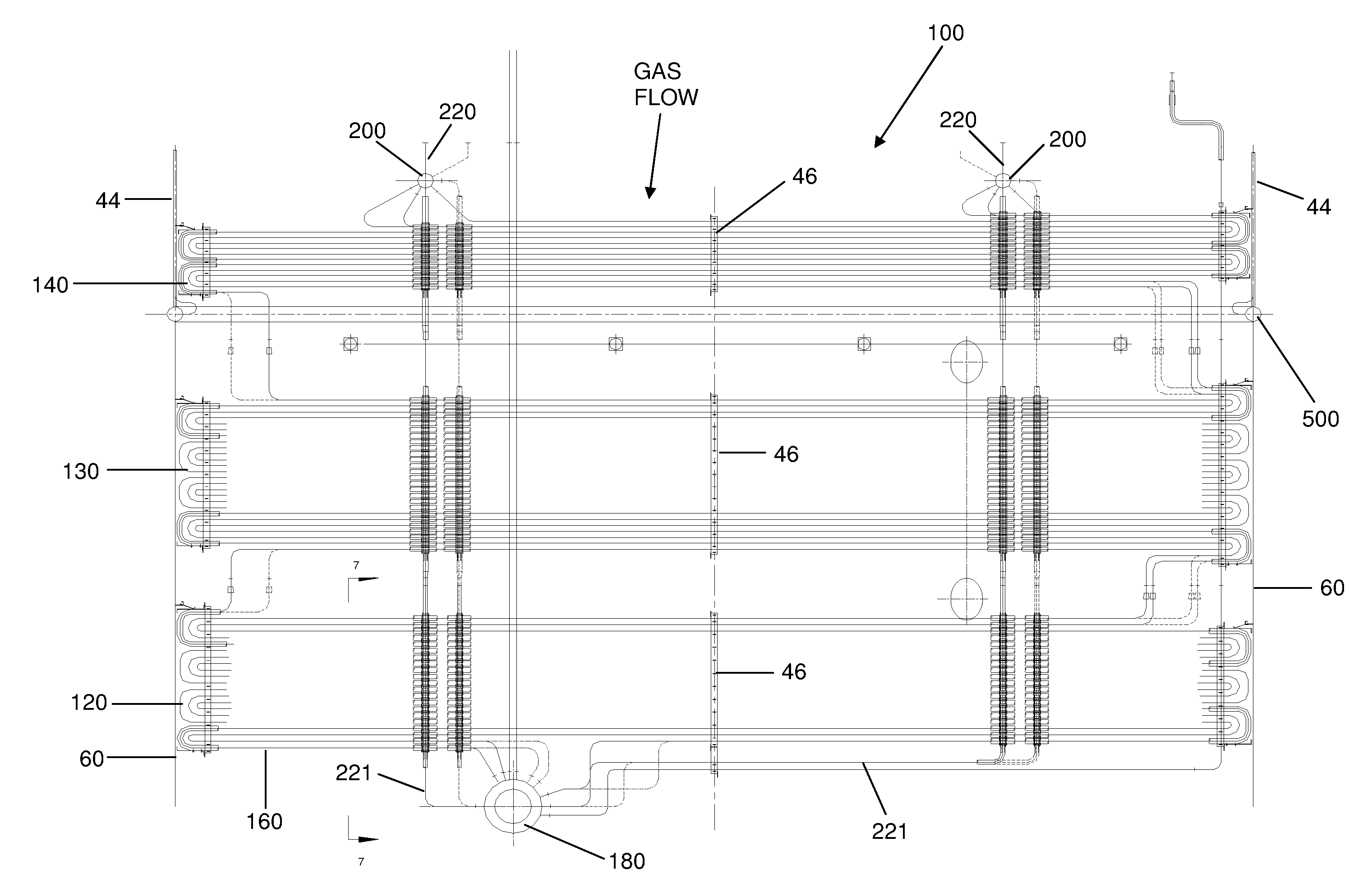

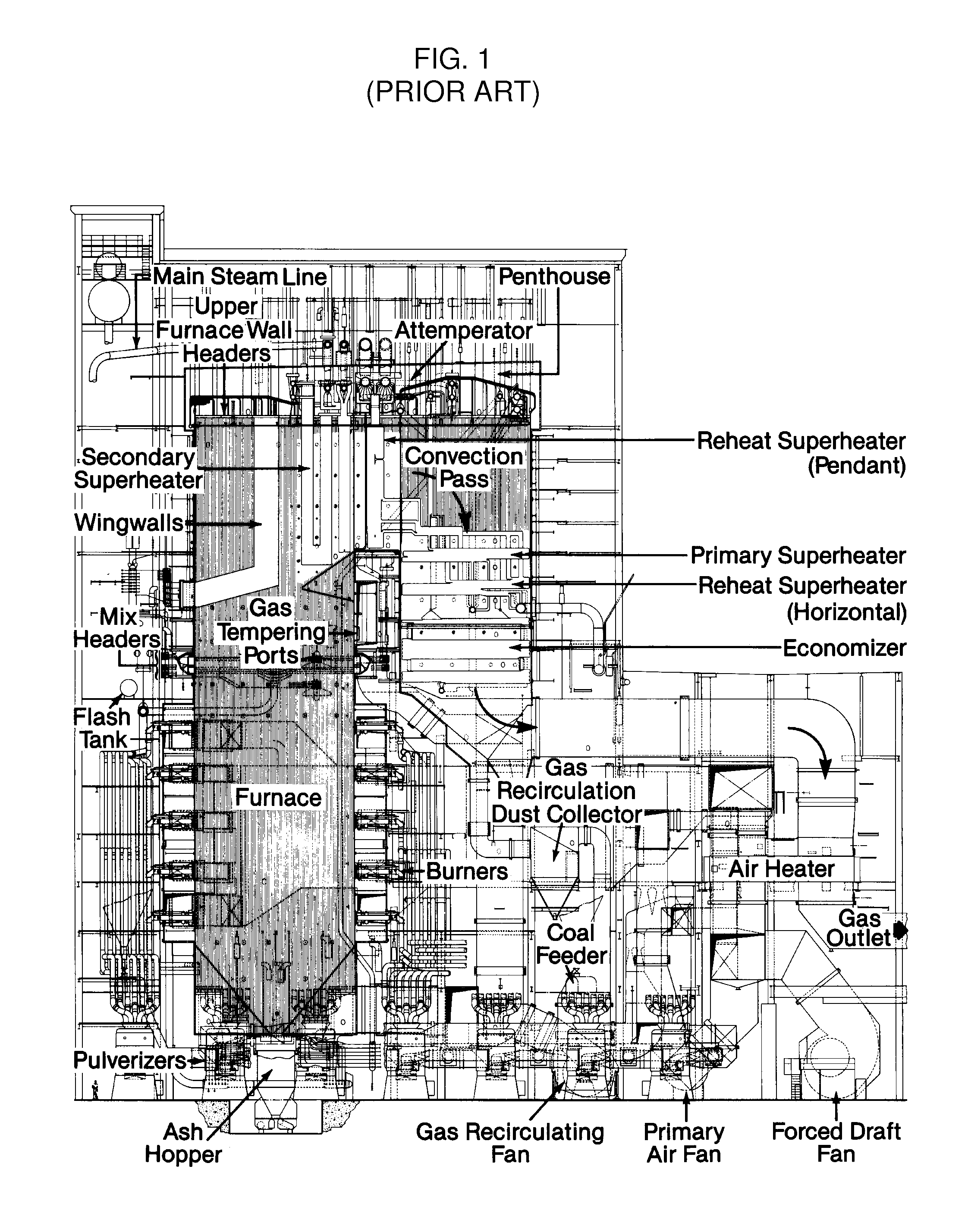

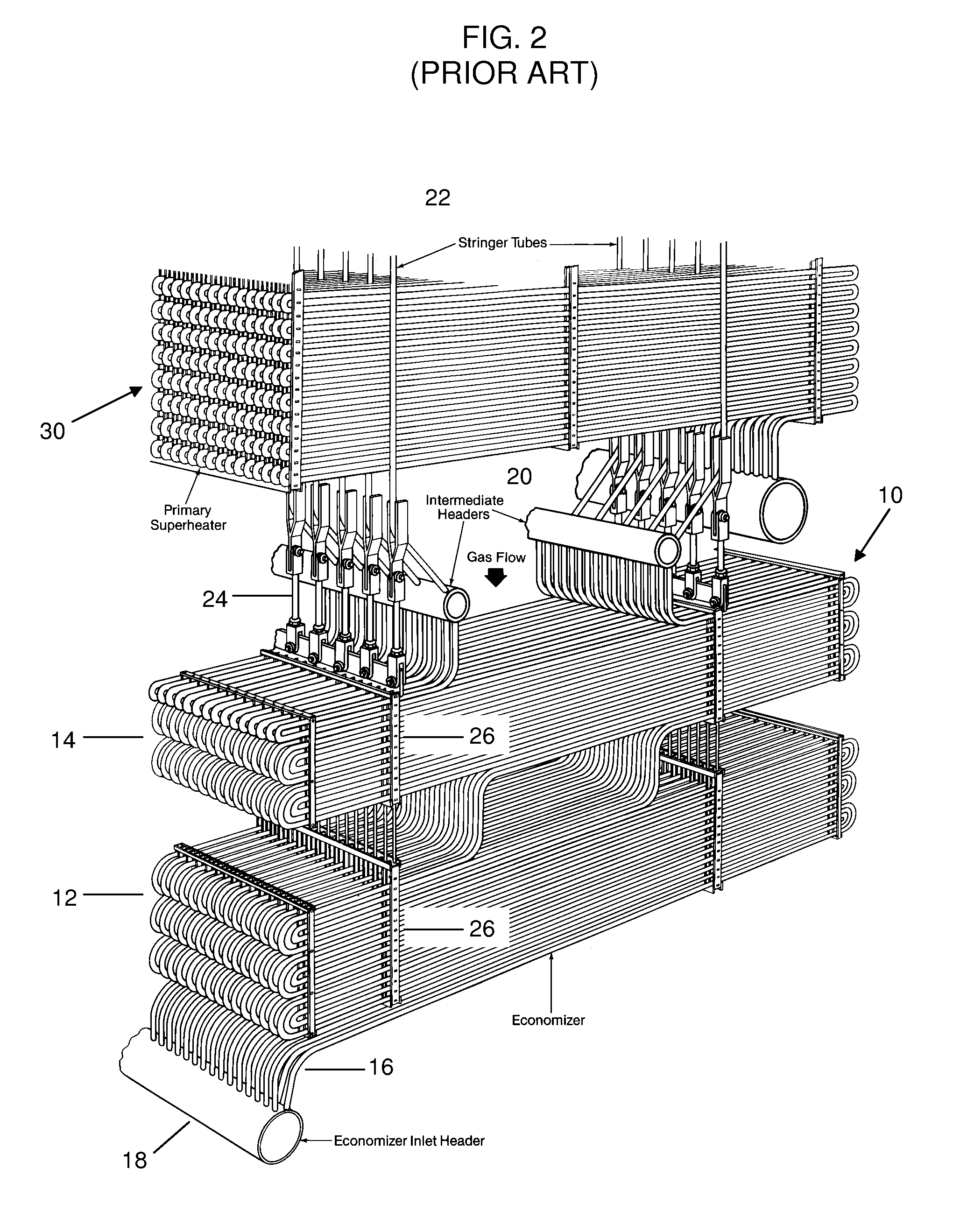

Economizer arrangement for steam generator

InactiveUS20080282997A1Simple designDifferent rate of erosionBoiler supporting/setting arrangementsSteam boilersSupercritical steam generatorFlue gas

An economizer arrangement particularly suitable for new or retrofit application to existing steam generators provides a water cooled stringer support tube system which can accommodate firing a wide range of fuels with varying characteristics in the steam generator. The economizer arrangement according to the present invention is particularly suited for retrofit applications to large supercritical steam generators. The use of water cooled stringer tube supports allows for higher flue gas temperatures in comparison to conventional non-cooled mechanical economizer supports. These features are provided in a design which fits within the existing economizer envelope of the steam generator.

Owner:THE BABCOCK & WILCOX CO

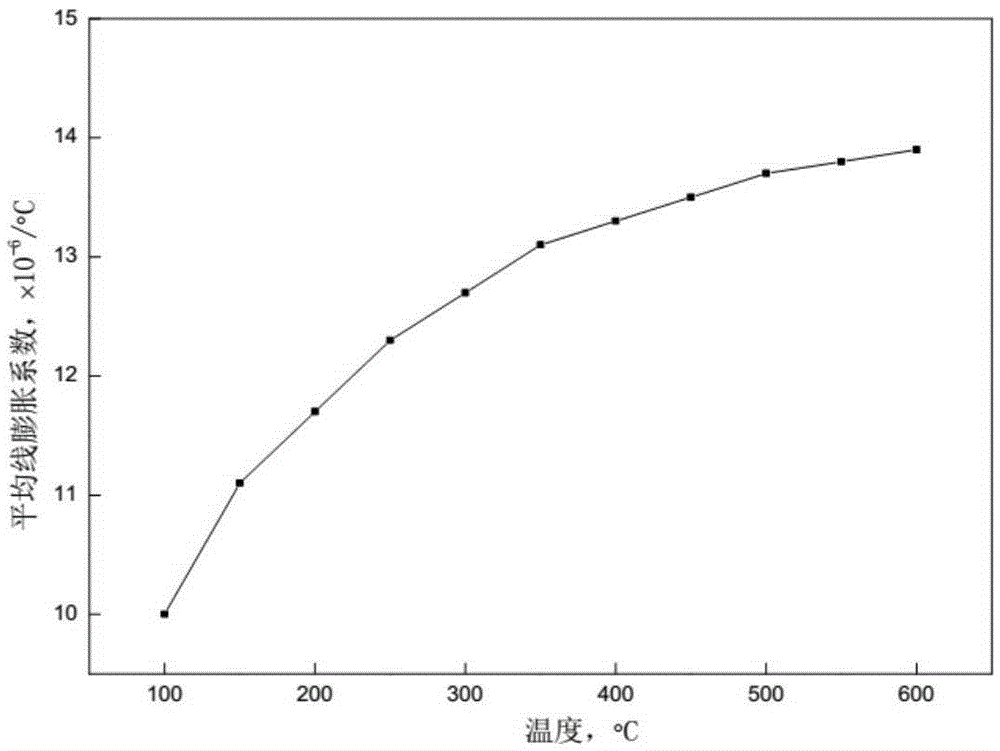

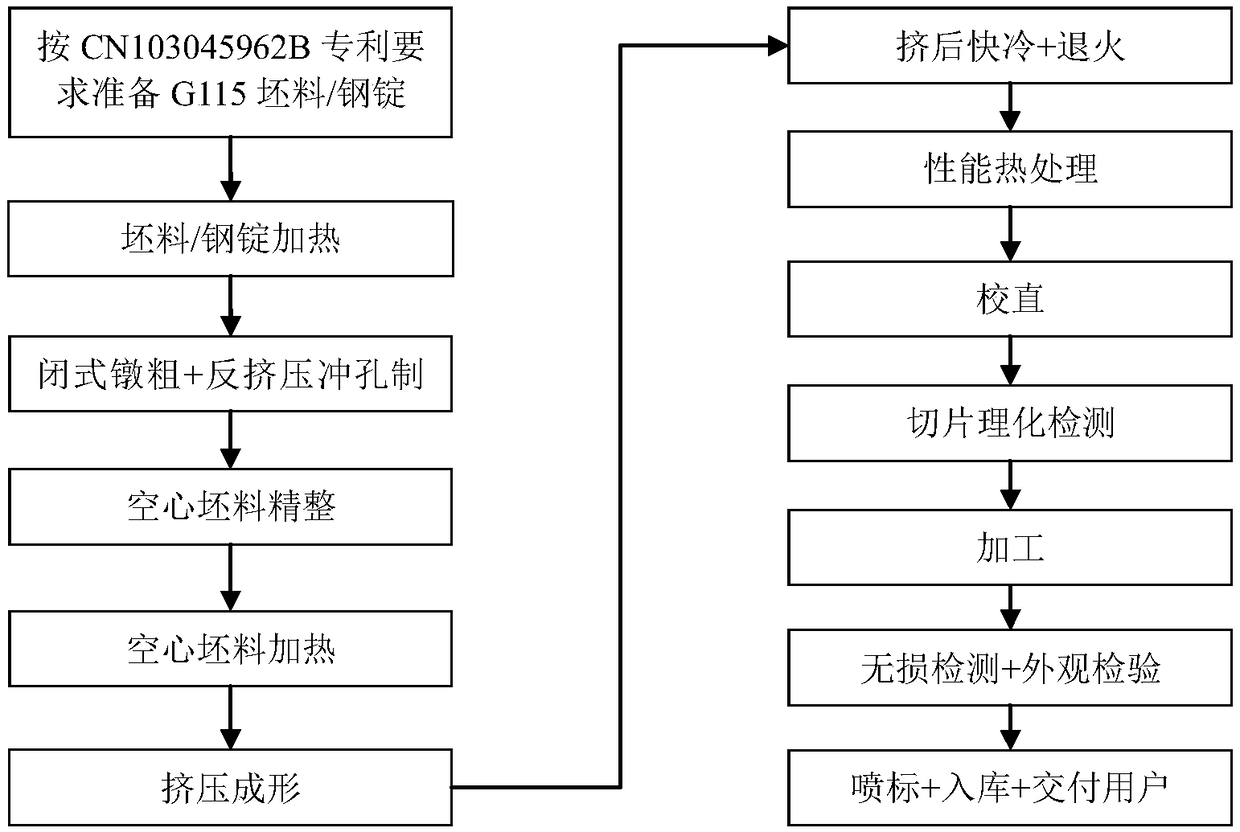

Manufacturing method for G115 large-caliber thick-wall seamless steel pipe of 630 DEG C ultra-supercritical unit

ActiveCN108998650AImprove impact toughnessSolve the problem of insufficient impact toughnessFurnace typesHeat treatment furnacesSupercritical steam generatorPunching

The invention relates to a manufacturing method for a G115 large-caliber thick-wall seamless steel pipe of a 630 DEG C ultra-supercritical unit, and belongs to the field of manufacturing of heat resistant steel pipes. In the method, for the long-term problem of weak impact toughness in production of the G115 large-caliber thick-wall seamless steel pipe, the following processes of preparation of araw material (forging stocks / steel ingots), closed upsetting, backward extrusion punching, extrusion moulding, heat treatment (rapid cooling and annealing) after extrusion and property heat treatmentare organically combined, and technological parameters of the patent CN103045962B are broken through, so that the impact toughness after heat treatment is performed on the steel pipe is greatly improved, and all properties can meet standard requirements of a T / CISA 003-2017 standard. Different specifications of G115 large-caliber thick-wall seamless steel pipes with the outer diameter of 325-1,200mm, the wall thickness of 20-180mm and the length of 12,500mm or below 12,500mm can be produced by adopting the method and can be applied to different fields of four major pipelines of an advanced ultra-supercritical boiler, a power station and the like. The steel ingots are adopted as the raw material, so that the production cost can be greatly reduced.

Owner:INNER MONGOLIA NORTH HEAVY INDS GROUP

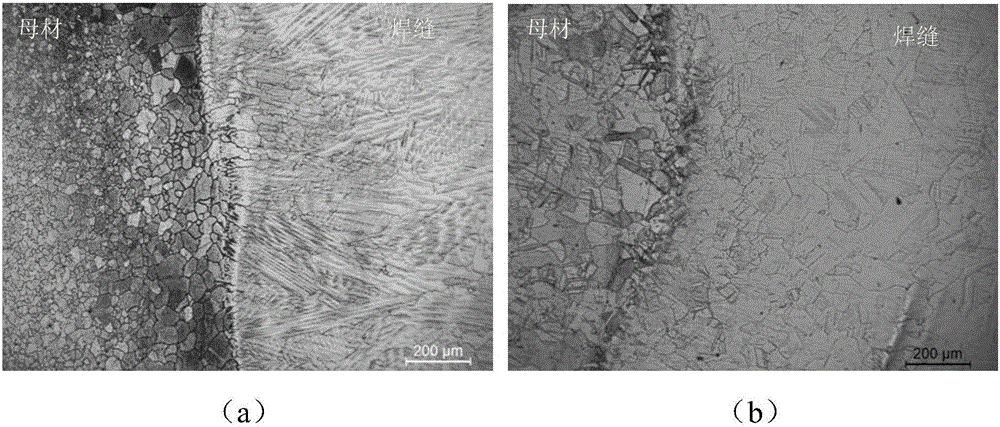

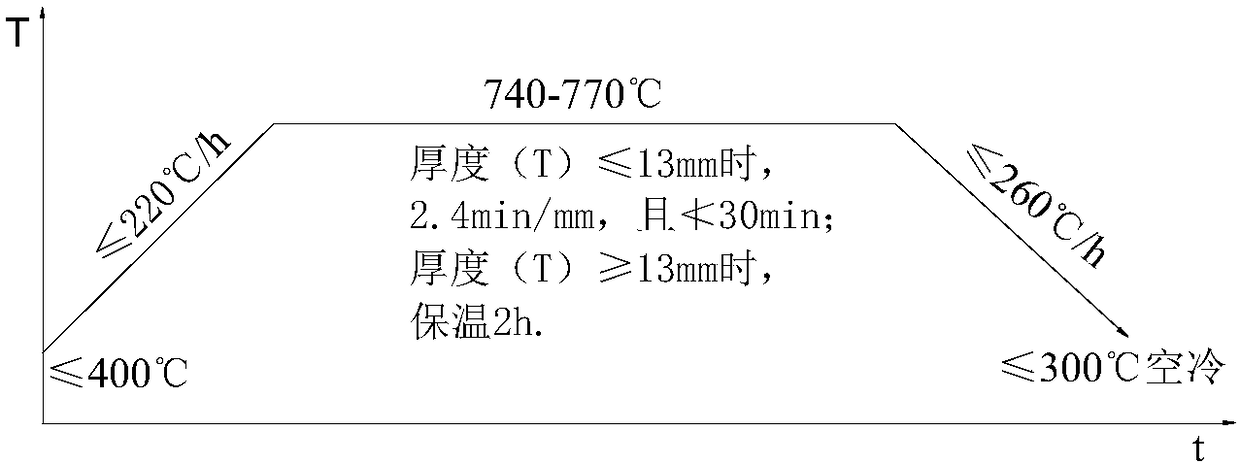

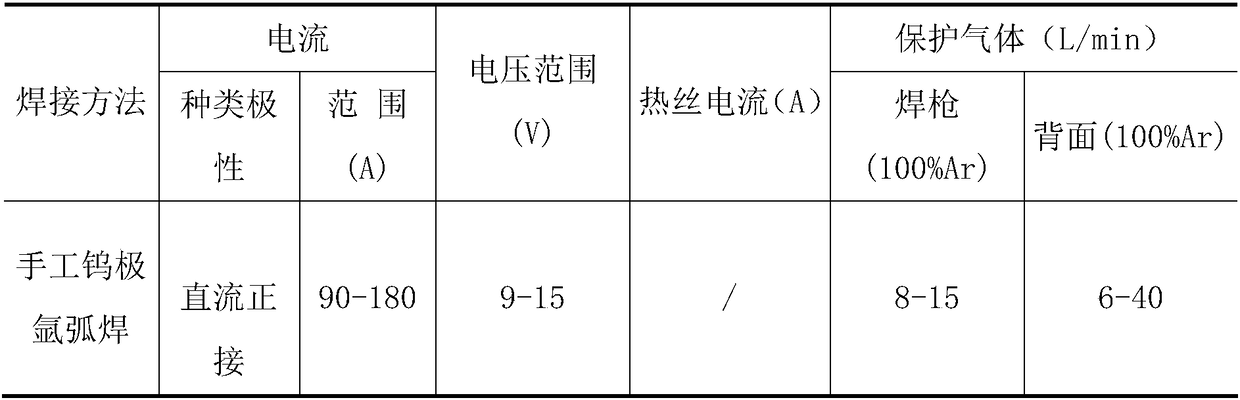

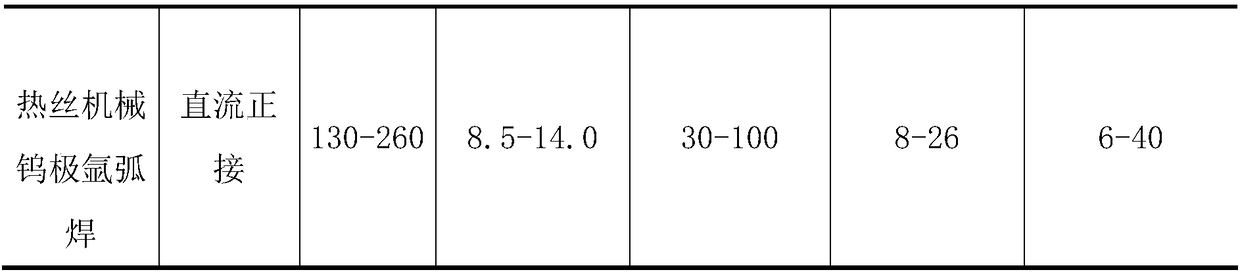

Welding method of dissimilar material pipes for advanced ultra-supercritical boiler

The invention discloses a welding method of dissimilar material pipes for an advanced ultra-supercritical boiler, and belongs to the field of welding of the dissimilar material pipes for boilers. Thetechnical essentials of the welding method comprise the following steps: a, performing pre-welding preparation; b, preparing welding materials; c, pre-heating welding joints of two pipes; d, performing interlayer temperature control by adopting a way of spraying and cooling through a water cooling device in a welding process; and e, performing post-welding inspection: inspecting the welding jointsaccording to standard after welding is carried out. According to the welding method of the dissimilar material pipes for the advanced ultra-supercritical boiler disclosed by the invention, when the two dissimilar material pipes are welded, a nickel-based alloy is selected as a filling material, and the interlayer temperature control is carried out by adopting a way of spraying and cooling throughthe water cooling device in a hot-filament tungsten argon arc welding process, so that the welding efficiency cannot be affected when the welding quality is ensured at the same time; whether thermaltreatment is needed or not and how to choose post-welding thermal treatment regime after welding are determined according to chemical components, tissue mechanical performance and the like of materials, and the problem of welding of dissimilar materials among candidate materials for the advanced ultra-supercritical boiler is solved.

Owner:HARBIN BOILER

Steel continuous casting process for ultra supercritical high-pressure boiler tube

The invention relates to a steel continuous casting process for an ultra supercritical high-pressure boiler tube. The steel continuous casting process is characterized in that a process control method is adopted for a continuous casting working procedure, totally protective casting is adopted for continuous casting; elongated nozzle argon seal protective casting is adopted in a process from a ladle to a tundish; integral built-in submerged nozzle protective casting is adopted in a process from the tundish to a crystallizer; a covering agent is adopted for molten steel in the tundish; the tundish is subjected to continuous temperature measurement; in the continuous casting process, full-automatic liquid level detection is carried out on the liquid level of the crystallizer; the pulling rate of continuous casting is automatically controlled according to the superheat degree of the tundish; automatic water distribution is adopted for the crystallizer and secondary cooling; and protecting slag used in the crystallizer during the casting process comprises the following components: 1.0+ / -0.15% of R, 36+ / -3% of SiO2, 36.0+ / -4% of CaO, less than or equal to 7.5% of Al2O3, less than or equal to 3.0% of Fe2O3, less than or equal to 3.0% of MgO, less than or equal to 3.9+ / -2.5% of F, 5.2+ / -2.0% of K2O+Na2O and 3.9+ / -2.0% of solid C. The steel continuous casting process provided by the invention can be used for effectively preventing surface cracks caused by transverse and longitudinal recessions of peritectic reaction corner parts during the casting process, effectively reducing the element segregation, improving the low-power quality of a casting blank and improving the quality of steel casting blank for the ultra supercritical high-pressure boiler tube.

Owner:NANJING IRON & STEEL CO LTD

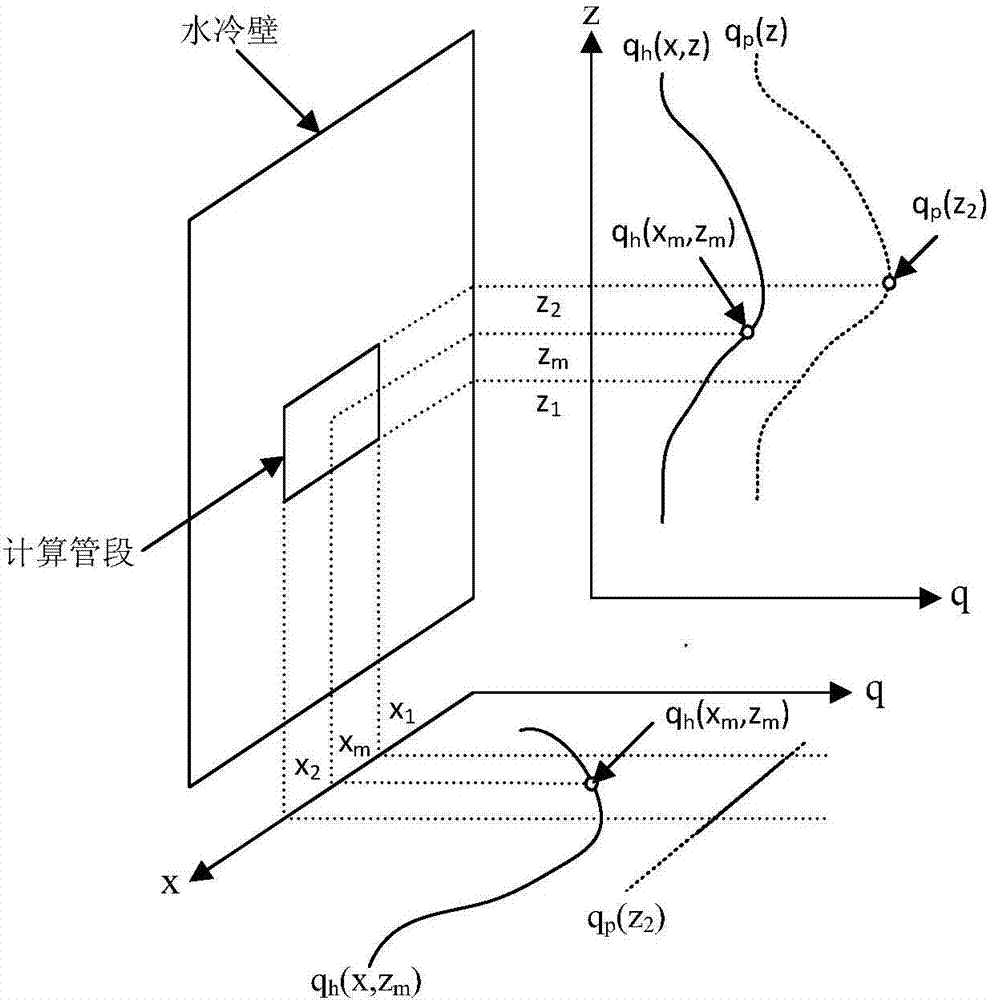

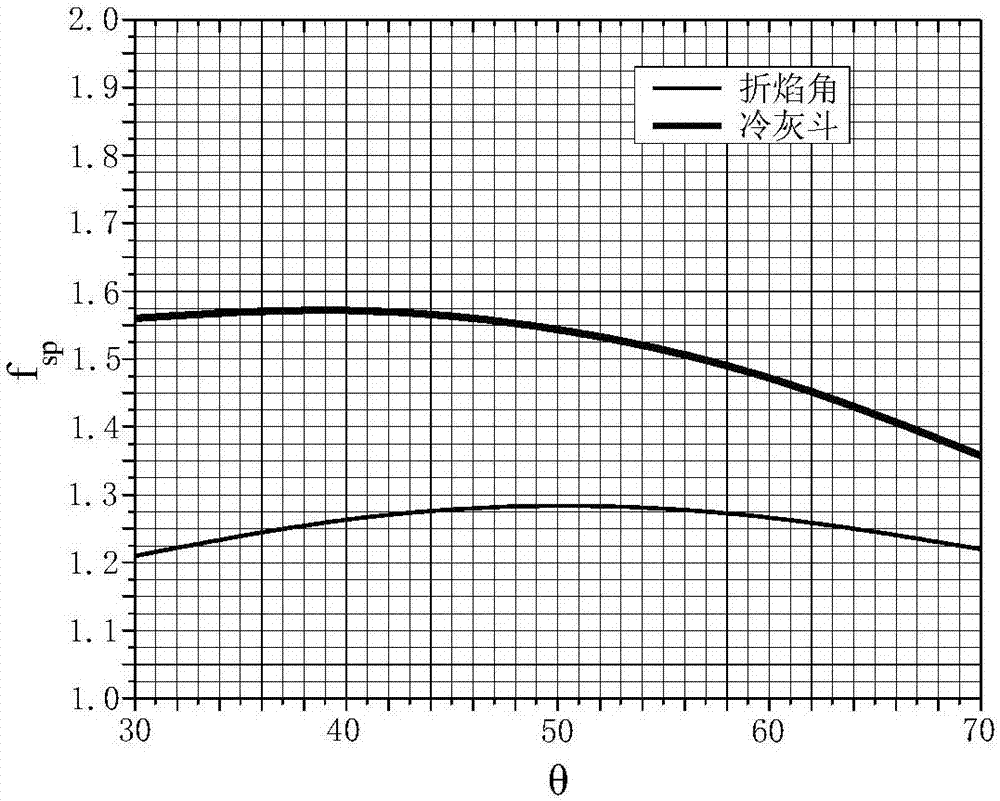

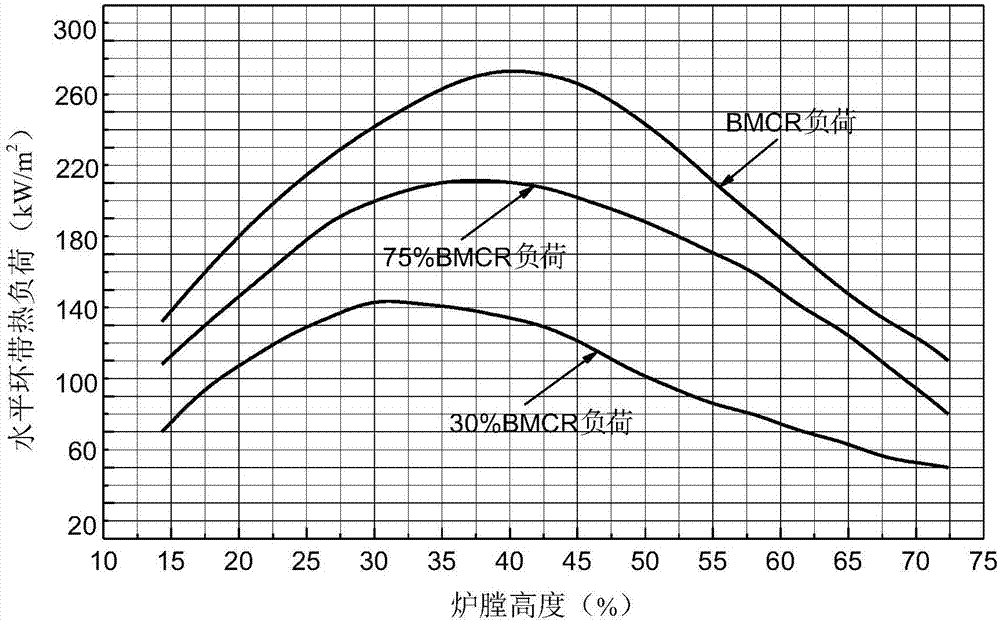

General hydrodynamic calculation method for ultra-supercritical boiler

ActiveCN106897547AFit closelyInformaticsSpecial data processing applicationsSupercritical steam generatorCombustion

The invention discloses a general hydrodynamic calculation method for an ultra-supercritical boiler, and provides a flow network system method consisting of a nonlinear model applied to a computer. The calculation method is suitable for hydrodynamic calculation and wall temperature safety analysis of the ultra-supercritical once-through boiler under various boiler overall arrangement forms, various pipe coil forms, various combustion technologies and various mass velocity combinations. The method comprises the steps of simplifying a water wall into a flow network system consisting of elements such as a connecting pipe loop, a heated loop, a pressure node and the like according to structure characteristics of the water wall and heat load distribution of a furnace chamber; and building the nonlinear calculation model of flow distribution according to a mass conservation equation, a momentum conservation equation and an energy conservation equation. Through direct solving of a nonlinear equation set, flow distribution and node pressure distribution in the heated loop and a connecting pipe are determined, and based on this, boiler water wall flow and metal wall temperature are subjected to safety check, so that guidance calculation can be performed for design and safety check of the boiler.

Owner:XI AN JIAOTONG UNIV +2

Super critical boiler wear resistant anticorrosion paint and its production method

ActiveCN1786085AEasy spray applicationDelicate appearanceAnti-corrosive paintsBulk chemical productionPyrophylliteWear resistant

The present invention relates to a production technique of wear-proof anti-corrosion paint, in particular, it relates to a supercritical boiler wear-proof anti-corrosion paint and its production method. Said wear-proof anti-corrosion paint is made up by using nano-grade alumina, titanium carbide, silicon oxide and zirconium oxide, pyrophyllite powder, metal aluminum powder, calcium oxide, magnesium oxide, potassium oxide and sodium oxide and making them undergo the processes of mixing, ball-grinding, adding high-temperature binding agent and fully stirring to obtain uniform slurry material, namely, the invented wear-proof anti-corrosion paint which can be extensively used in the high-temperature application fields of coal-fired power plant boiler pipeline, chemical equipment and metallurgical industry, etc.

Owner:上海瀚昱环保材料有限公司

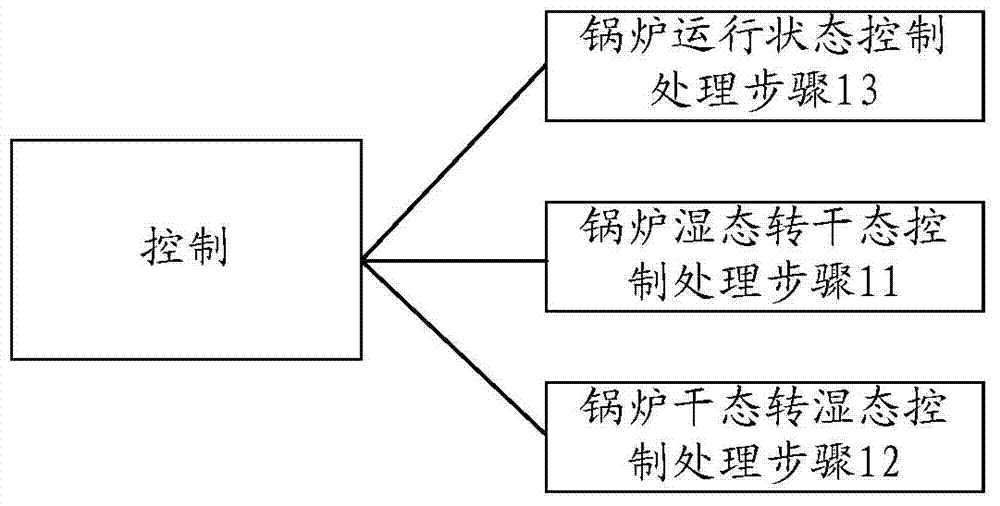

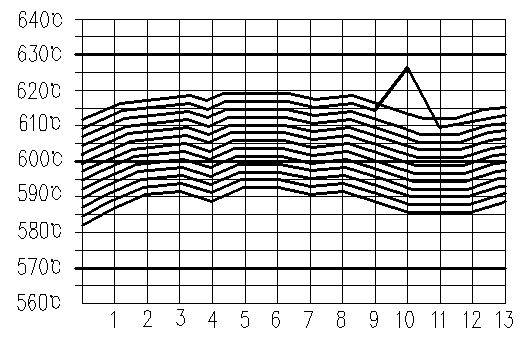

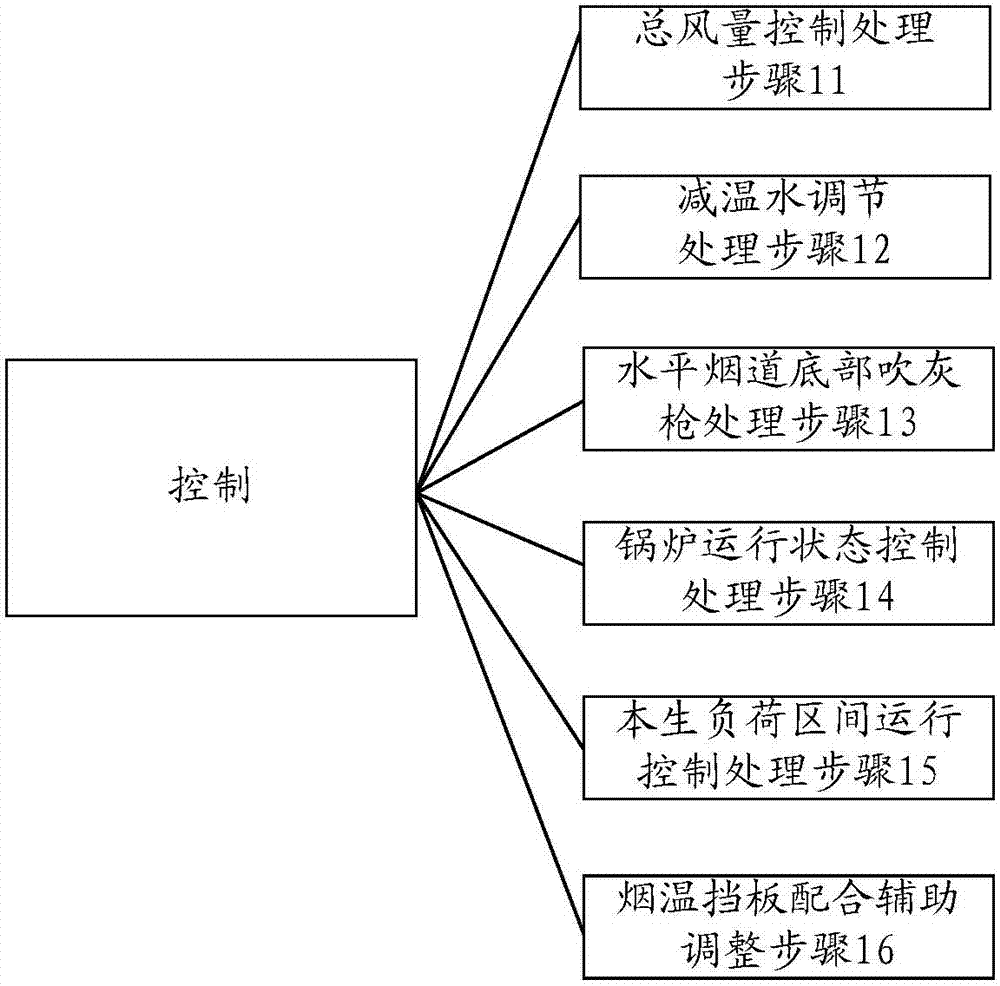

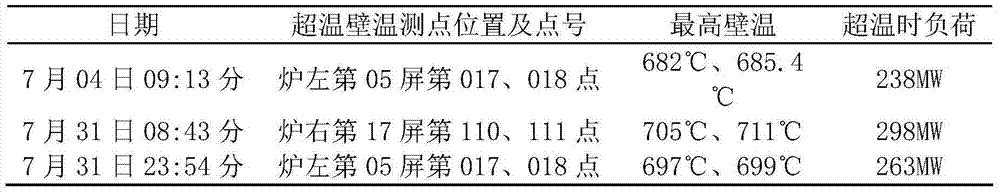

Tube wall overtemperature control method for platen superheater in 1045-megawatt ultra supercritical boiler

ActiveCN103574589AInfluencing factors to avoid overheatingPrevent over-temperature pipe explosion accidentsSuperheating controlBoiler controlSupercritical steam generatorUnit operation

The invention discloses a tube wall overtemperature control method for a platen superheater in a 1045-megawatt ultra supercritical boiler. Control processing steps of converting a wet sate to a dry state of the boiler and converting the dry state to the wet state of the boiler are executed, so that alternating fluctuation of parameters of the steam specific volume and the like in a dry state-wet state conversion process is smaller, and the flow deviation is reduced. Besides, the processing steps can be controlled through the operation state of the boiler, and controlling is performed before the wet state is converted to the dry state or the dry state is converted to the wet state, so that overtemperature influence factors of the platen superheater of the 1045-megawatt ultra supercritical boiler are avoided, overtemperature tube burst accidents of the platen superheater can be effectively prevented, the labor intensity of operation staff is reduced, and the safety and the economy of unit operation are improved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

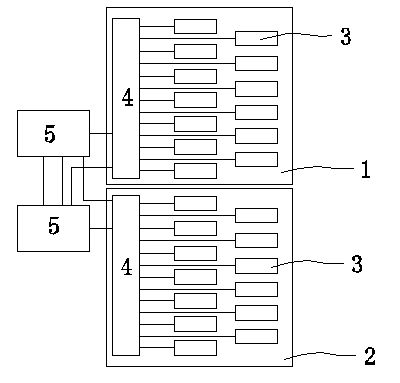

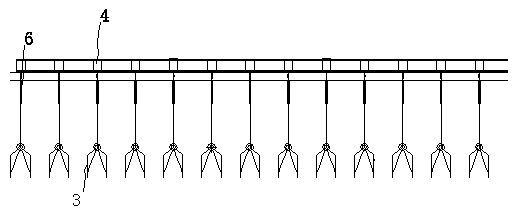

Ultra-supercritical boiler heating-surface wall-temperature monitoring system and monitoring method

InactiveCN101975389AShorten the lengthLow costBoiler controlSupercritical steam generatorData acquisition

The invention relates to ultra-supercritical boiler heating-surface wall-temperature monitoring system and monitoring method, aiming to solve the problems of long thermocouples and ultrahigh price caused when the thermocouples are led out from both sides of a boiler. The ultra-supercritical boiler heating-surface wall-temperature monitoring system comprises the thermocouples, data acquisition systems and a monitoring system, wherein the input ends of the data acquisition systems are connected with the thermocouples, and the output ends of the data acquisition systems are connected with the monitoring system. The ultra-supercritical boiler heating-surface wall-temperature monitoring system is characterized in that the thermocouples are led out from the top of the boiler, the data acquisition systems are placed at the top of the boiler, each data acquisition system comprises a heat-collecting block, and the thermocouples and the heat-collecting blocks are directly welded and connected. The thermocouples are led out from the top of the boiler, the length of the thermocouples is reduced, and the cost of the thermocouples is greatly lowered, so that each pipeline of a boiler platen superheater and a finishing superheater can be comprehensively monitored, and the monitoring reliability is greatly enhanced.

Owner:国能浙江北仑第三发电有限公司

Tube wall overtemperature control method for platen superheater in 1045-megawatt ultra supercritical boiler

The invention discloses a tube wall overtemperature control method for a platen superheater in a 1045-megawatt ultra supercritical boiler. At a low-load stage of 200-350 megawatts of the 1045-megawatt ultra supercritical boiler, the total air volume of the boiler is controlled to be more than 1600 tons per hour, and the oxygen quantity is 7%-9%; the regulation lead of desuperheating water is set, and when first-level desuperheating water automatic control doesn't meet the requirement, a manual mode is switched to, and controlling is performed; when the boiler operates in a low-load section, on the premise that the superheat degree is smaller than 10 DEG C after first-level temperature reduction, the first-level desuperheating water quantity is increased, and the outlet steam temperature of the platen superheater is controlled to be within 550 DEG C; and by means of control processing of an ash gun at the bottom of a horizontal flue and control processing of the operation state of the boiler, overtemperature tube burst accidents of the 1045-megawatt ultra supercritical boiler can be effectively prevented, the labor intensity of operation staff is reduced, and the safety and the economy of unit operation are improved.

Owner:GUANGDONG ELECTRIC POWER SCI RES INST ENERGY TECH CO LTD

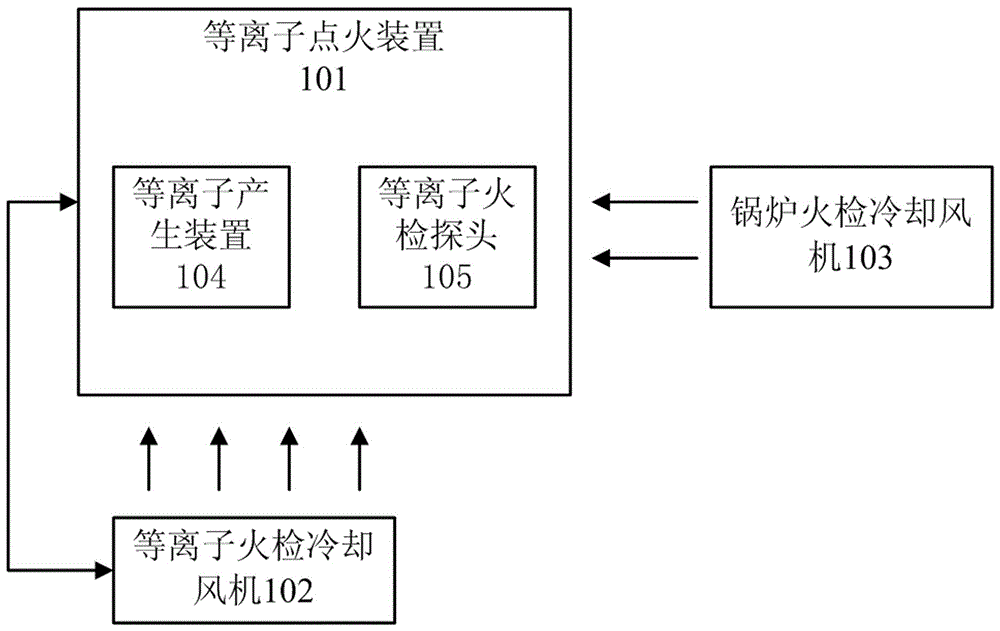

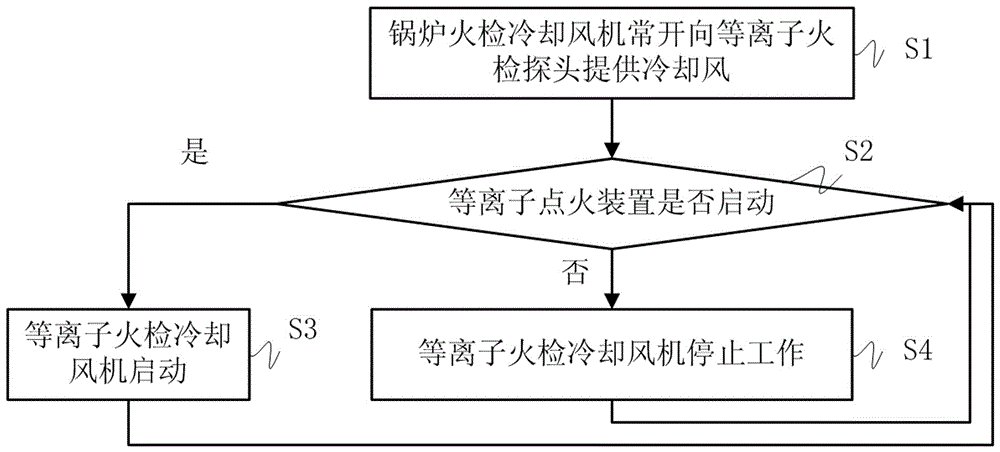

Plasma ignition system, control method, and applicable ultra-supercritical boiler

InactiveCN106196165ALower runReduce maintenanceIncandescent ignitionSupercritical steam generatorStopped work

The invention discloses a plasma ignition system which comprises a plasma ignition device, a plasma flame detection cooling fan and a boiler flame detection cooling fan, wherein the plasma ignition device comprises an ignition burner, a plasma generation device and a plasma flame detection probe; the plasma generation device and the plasma flame detection probe are arranged corresponding to the ignition burner; the input end of the plasma flame detection cooling fan is in communication connection with the plasma ignition device; the plasma flame detection cooling fan blows wind towards the plasma generation device; when the plasma ignition device and the plasma generation device are started up, the plasma flame detection cooling fan is triggered to start working and to supply plasma carrier wind; when the plasma generation device is shut down, the plasma flame detection cooling fan is controlled to stop working; and the boiler flame detection cooling fan is kept in a normally open state and blows wind towards the plasma flame detection probe. According to the plasma ignition system disclosed by the invention, the plasma flame detection cooling fan and the plasma ignition device are started up and shut down in a linked manner, thereby reducing the equipment operation, lowering the energy consumption, and reducing the maintenance.

Owner:JIANGSU DATANG INT LUSIGANG POWER GENERATION

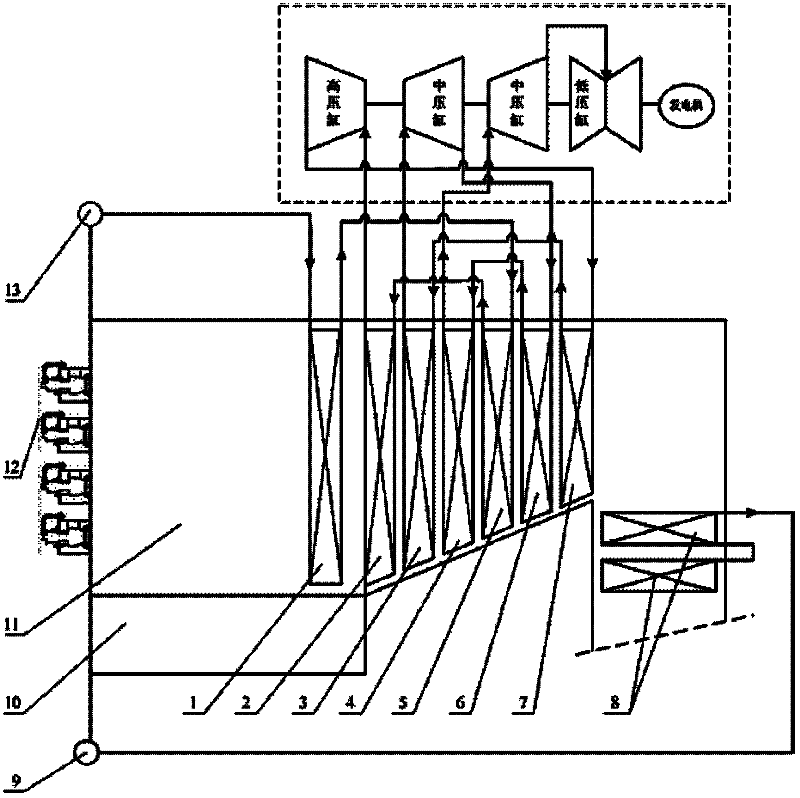

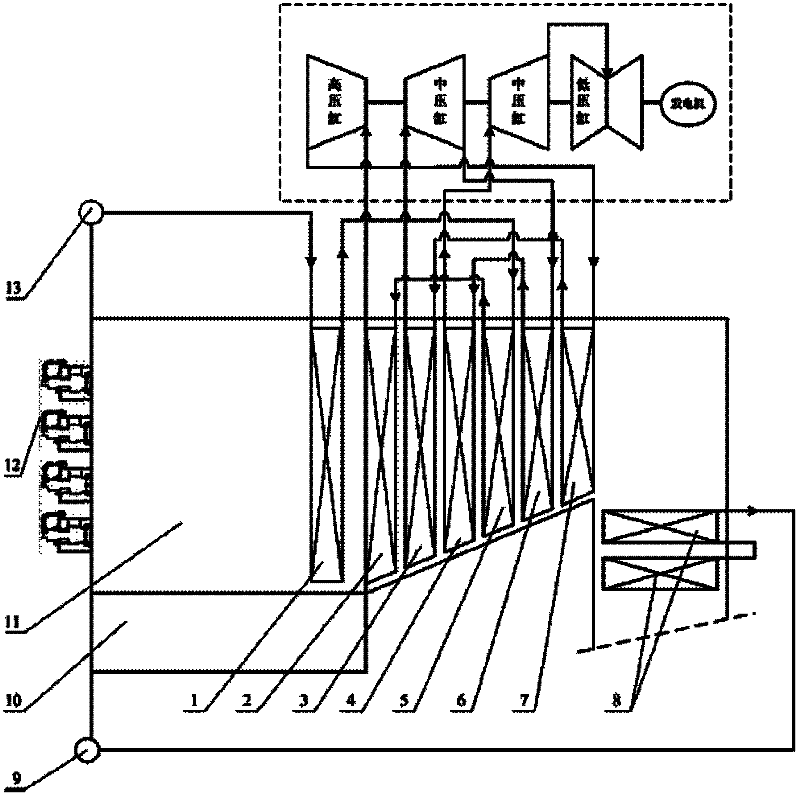

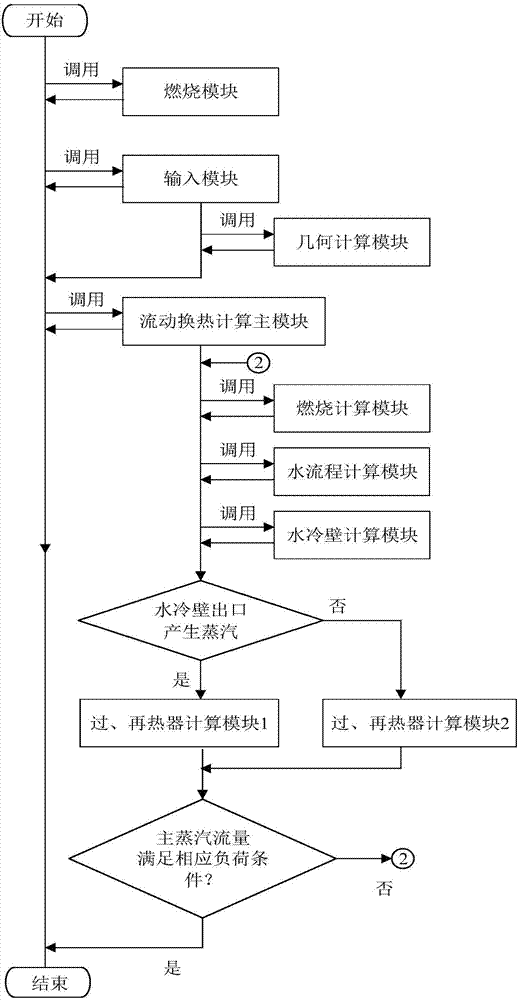

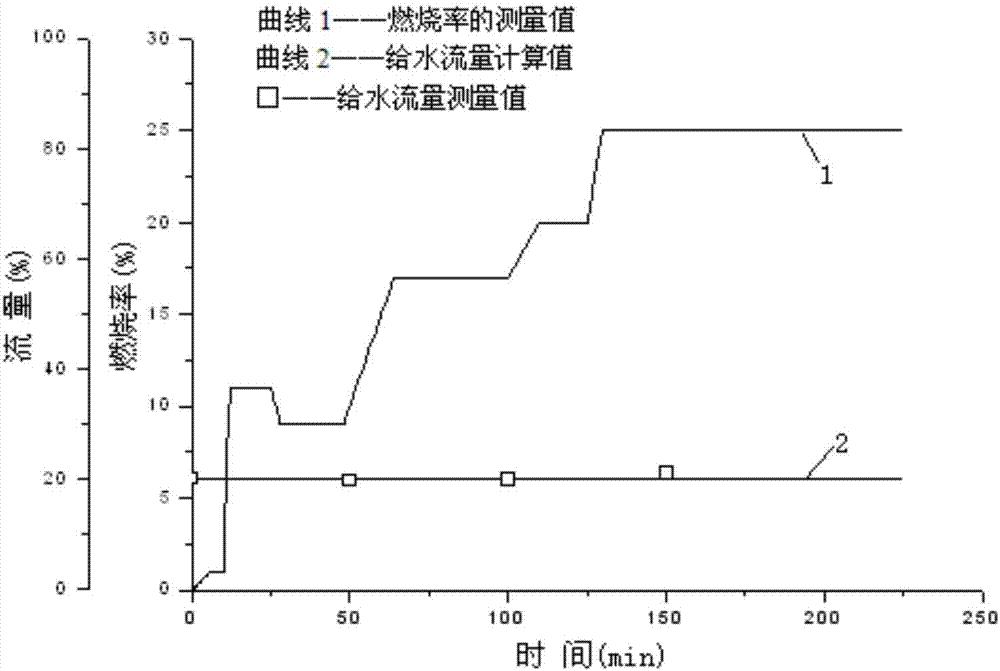

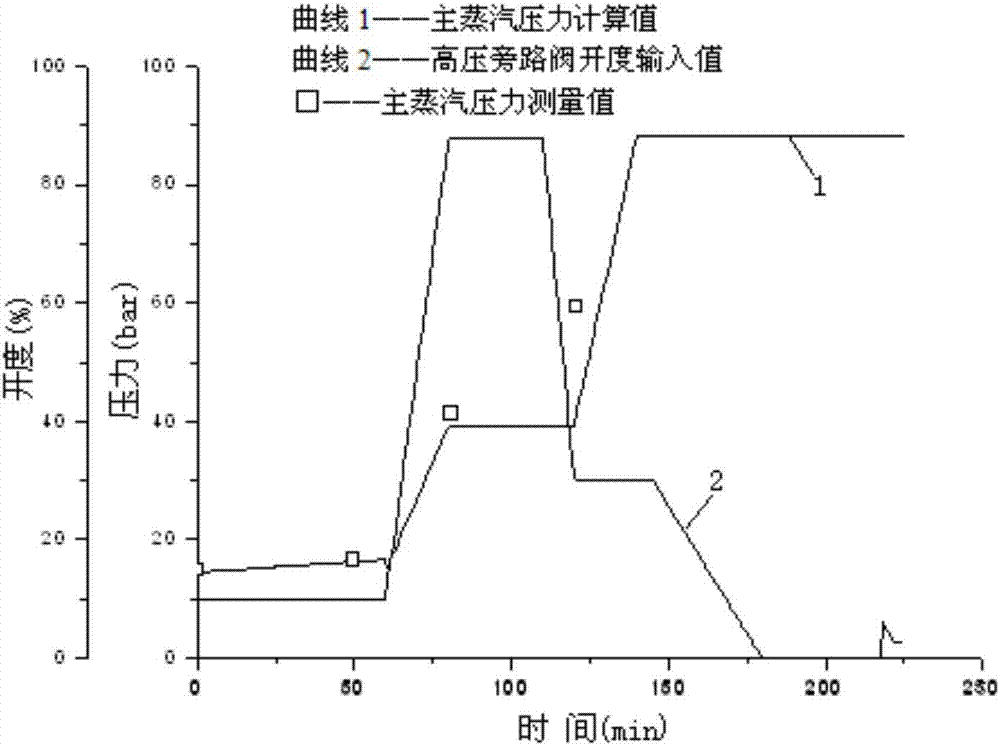

Start calculation method and system for supercritical boiler

ActiveCN107292006AOptimal Start CurveBest BoostDesign optimisation/simulationSpecial data processing applicationsMathematical modelEngineering

The invention discloses a start calculation method and system for a supercritical boiler. According to the method, first, furnace combustion calculation is performed, wherein a furnace is divided into two parts, namely a radiation heat exchange area and a radiation convection area, and calculation is performed on the two parts respectively to obtain furnace outlet smoke temperature, furnace heat absorption percentage and smoke specific heat under different combustion rates; and second, boiler heating surface heat exchange calculation is performed, wherein on the basis of analyzing and simplifying flowing heat transfer characteristics of an in-pipe working medium side and an out-pipe smoke side in a heating surface in the boiler starting process, a distributed parameter model considering changes of thermal parameters along with position coordinate changes is adopted, mathematic models of change laws of working medium temperature, pressure, enthalpy values, heating surface metal temperature and smoke temperature in the starting process are established according to a mass conservation equation, a momentum conservation equation, an energy conservation equation, a metal heat reservation equation and a complementary equation, and solving is performed. Through the start calculation method and system, arrangement forms of different boiler starting systems can be calculated and compared, and an optimal boiler starting system can be provided for a user.

Owner:XI AN JIAOTONG UNIV +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com