Patents

Literature

2650results about "Boiler control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

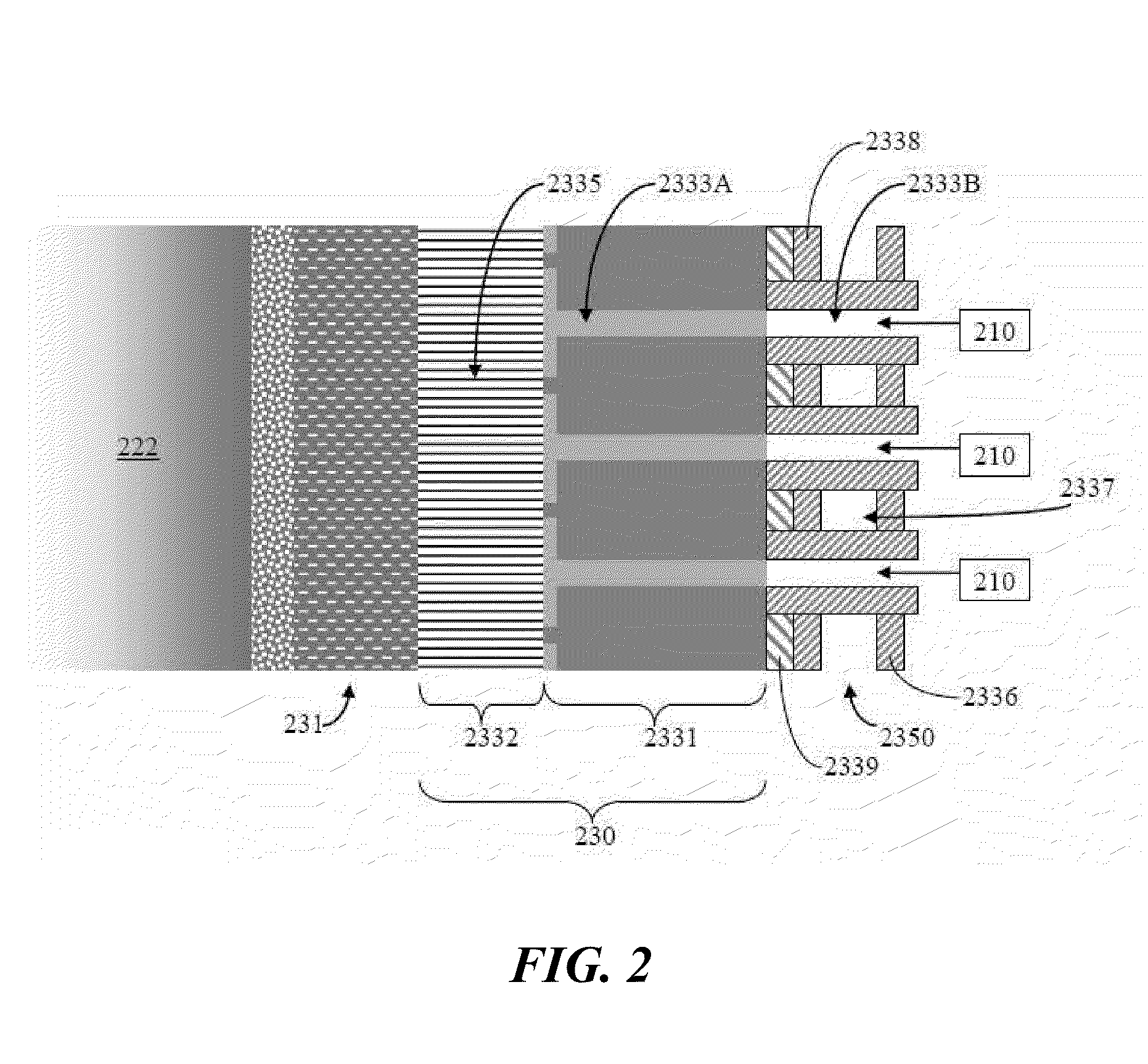

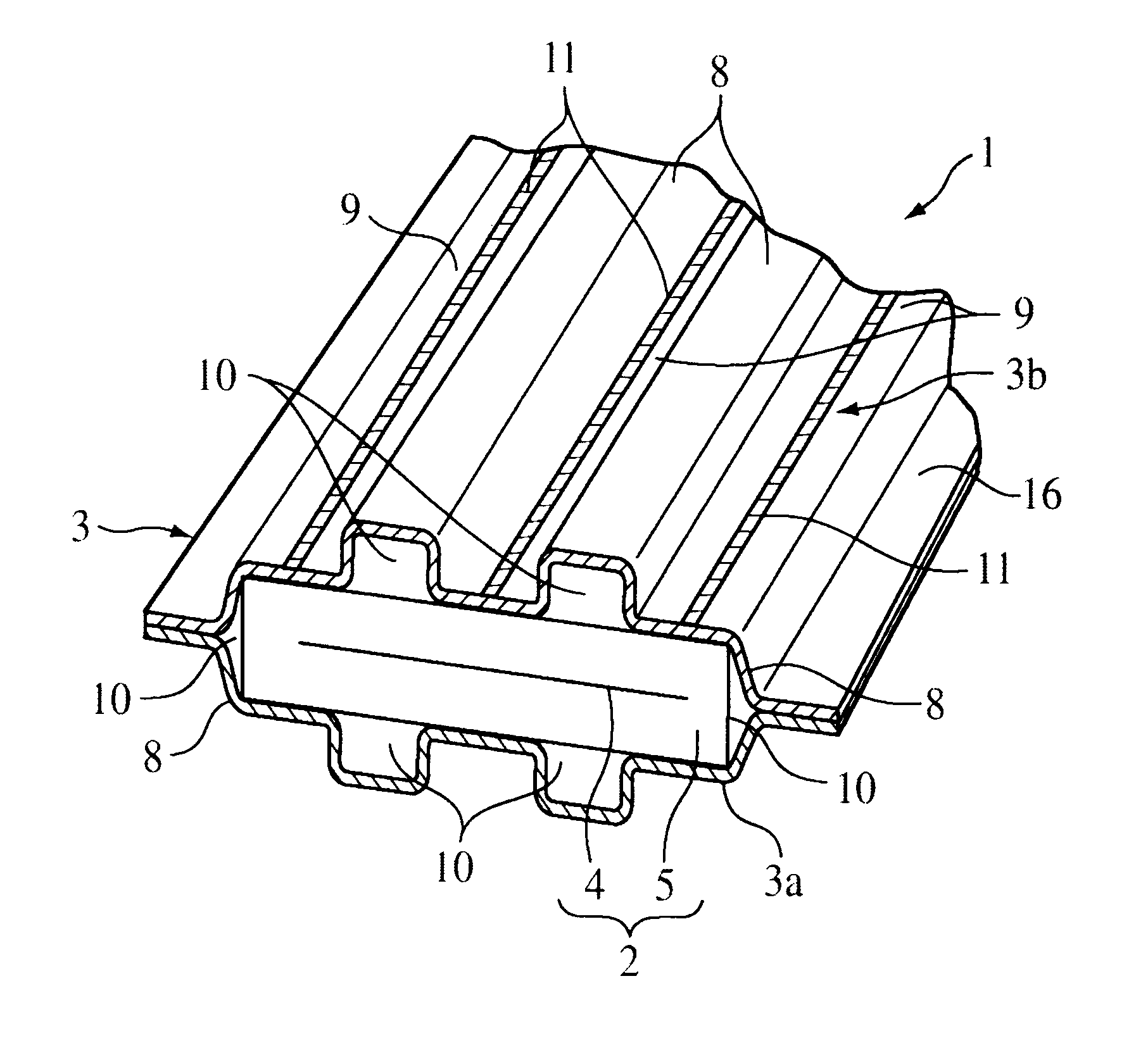

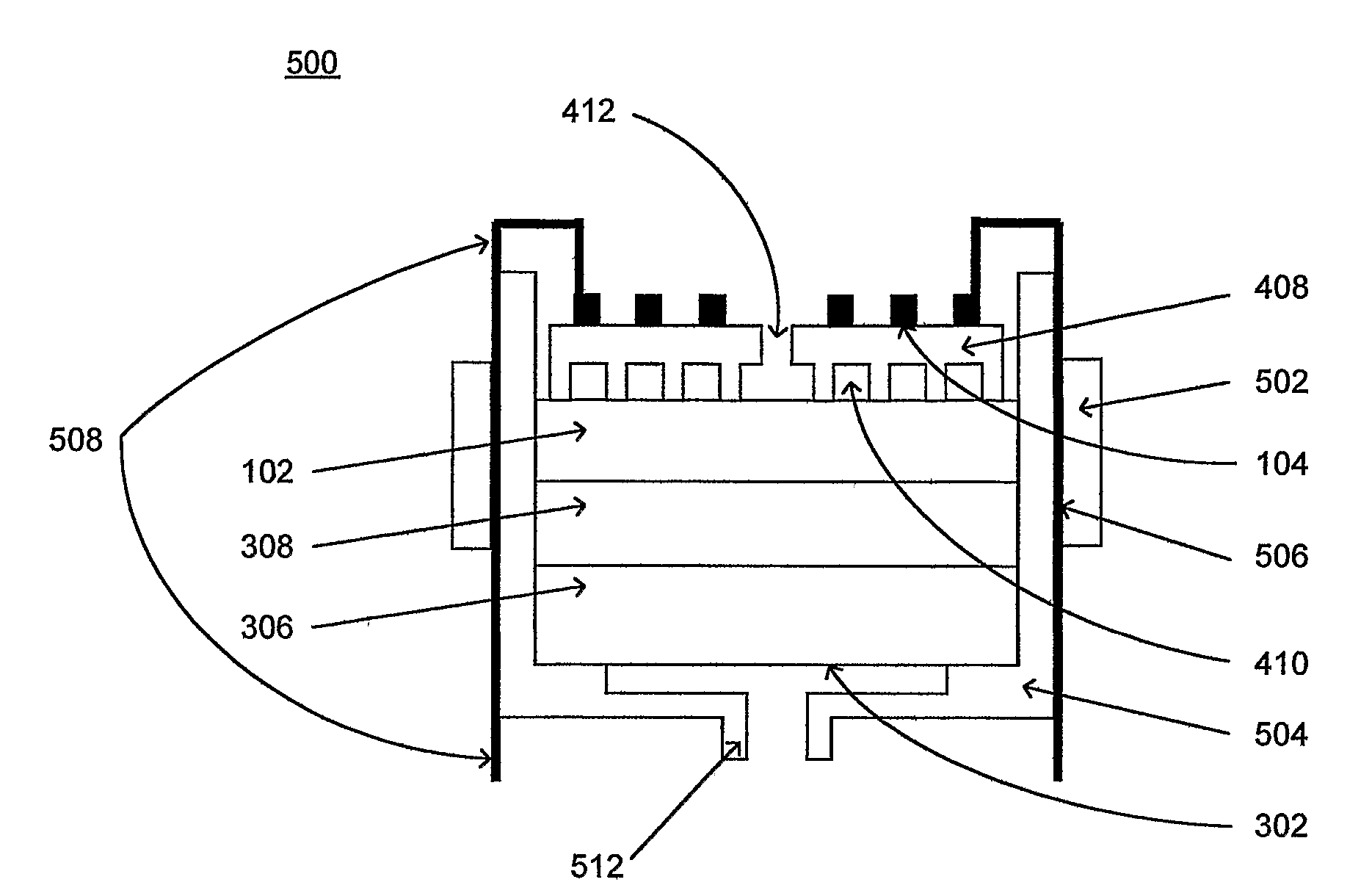

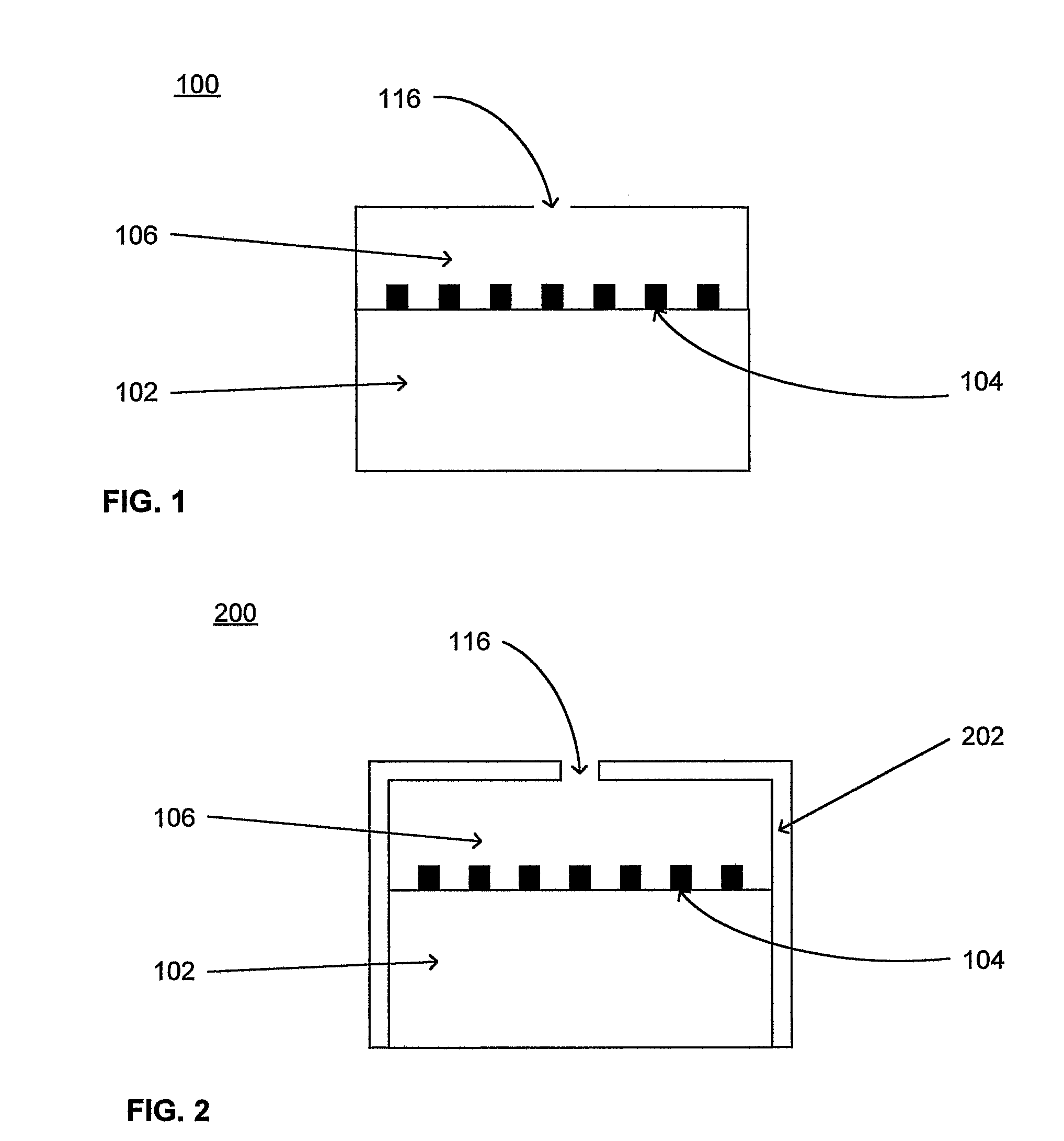

Heating elements formed from a sheet of a material and inputs and methods for the production of atomizers

The present disclosure relates to an input for production of atomizers and atomizers formed from a sheet of a material, and which may be employed in an aerosol delivery device such as a smoking article. The input may include a carrier and heating elements coupled thereto. The heating elements may include first and second ends and interconnected alternating loops disposed therebetween. The heating elements may be oriented parallel to a longitudinal axis of the carrier, or perpendicular thereto. The heating elements may be coupled to a liquid transport element by bending the interconnected loops at least partially around the liquid transport element. The ends of the heating element may be coupled to heater terminals. A related method for forming atomizers is also provided.

Owner:RAI STRATEGIC HLDG INC

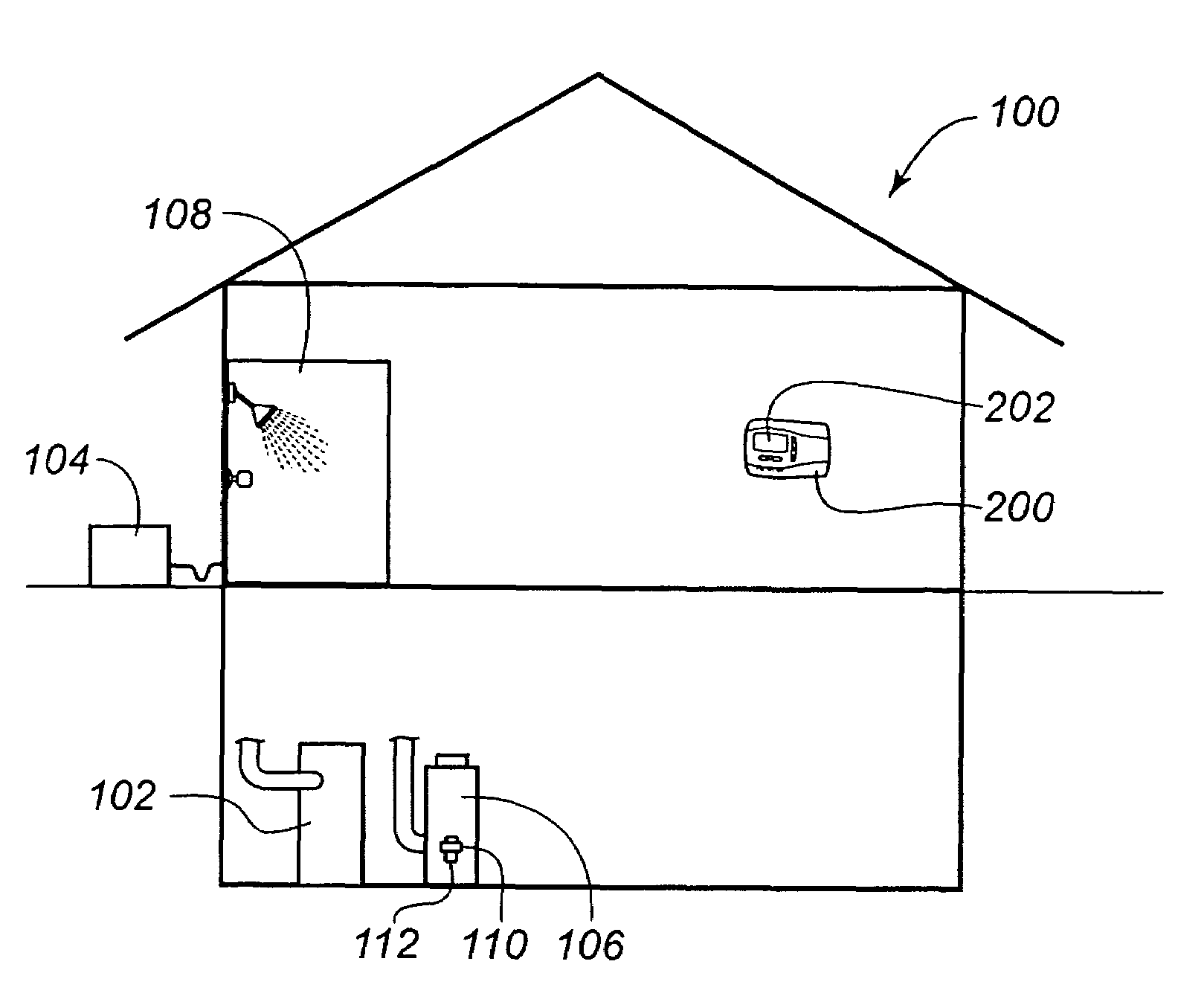

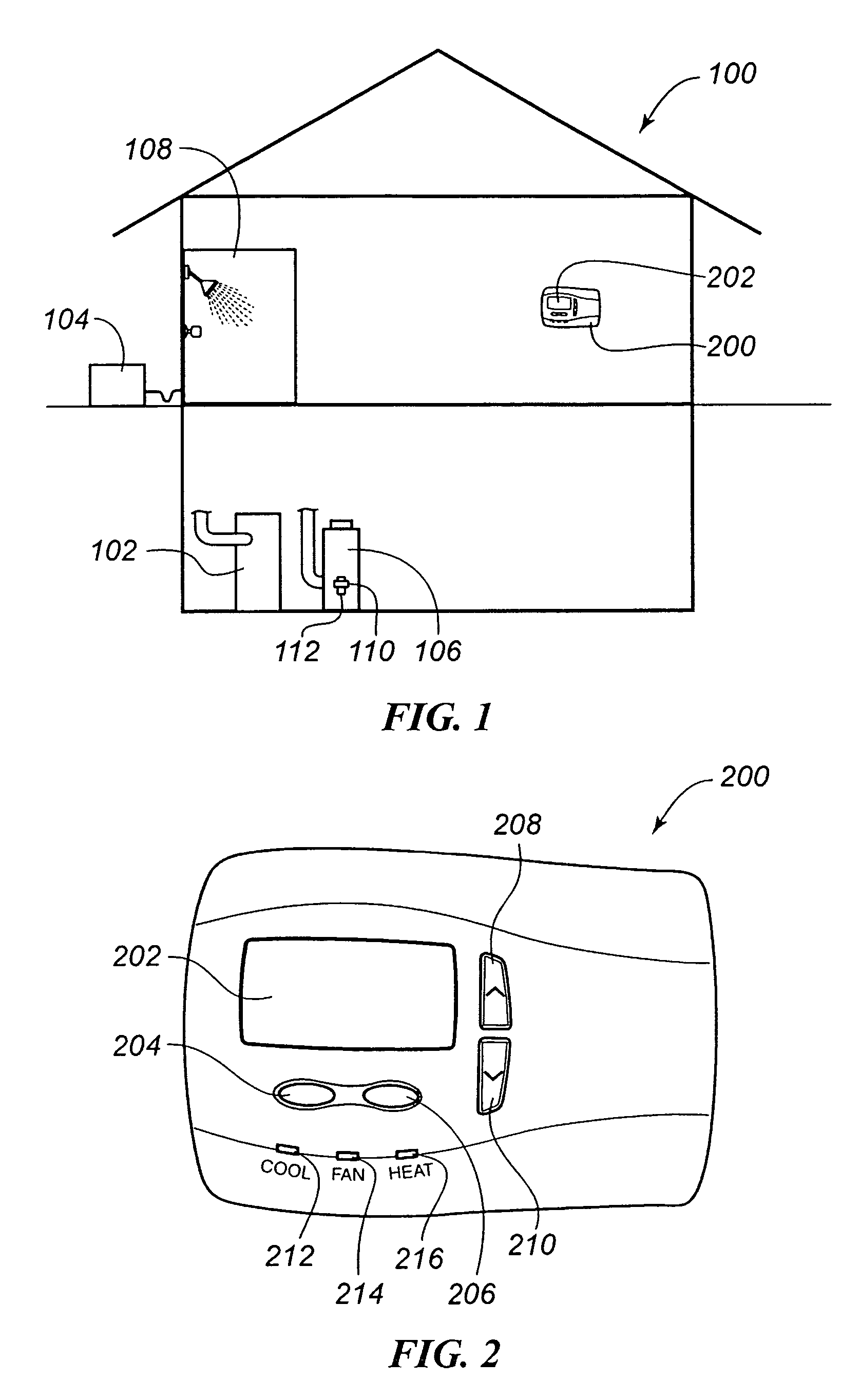

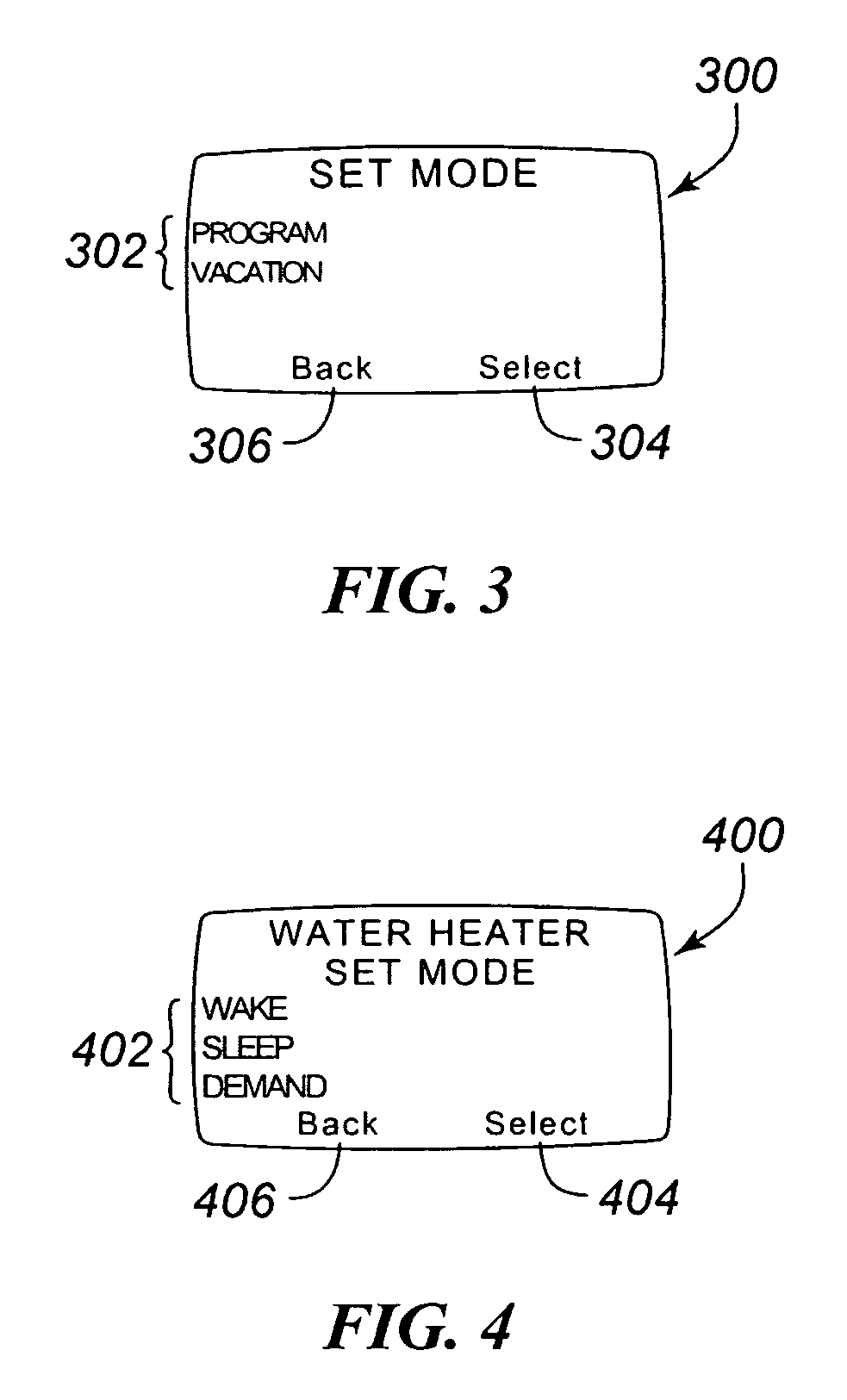

System and method for controlling appliances and thermostat for use therewith

InactiveUS7469550B2Save energySaving of operationTemperature control without auxillary powerMechanical apparatusThermostatEngineering

An energy saving control for appliances via an intelligent thermostat is provided. This intelligent thermostat provides programmatic control over the HVAC system, and provides coordinated control over the appliances. This control over the appliances is accomplished via a communications network between the intelligent thermostat and the appliances. The appliances include occupancy sensors and transmit usage and occupancy information to the intelligent thermostat. The intelligent thermostat processes this information to determine the occupancy of the dwelling. The thermostat controls the HVAC system and the appliances according to the determined occupancy of the dwelling.

Owner:ROBERTSHAW CONTROLS CO

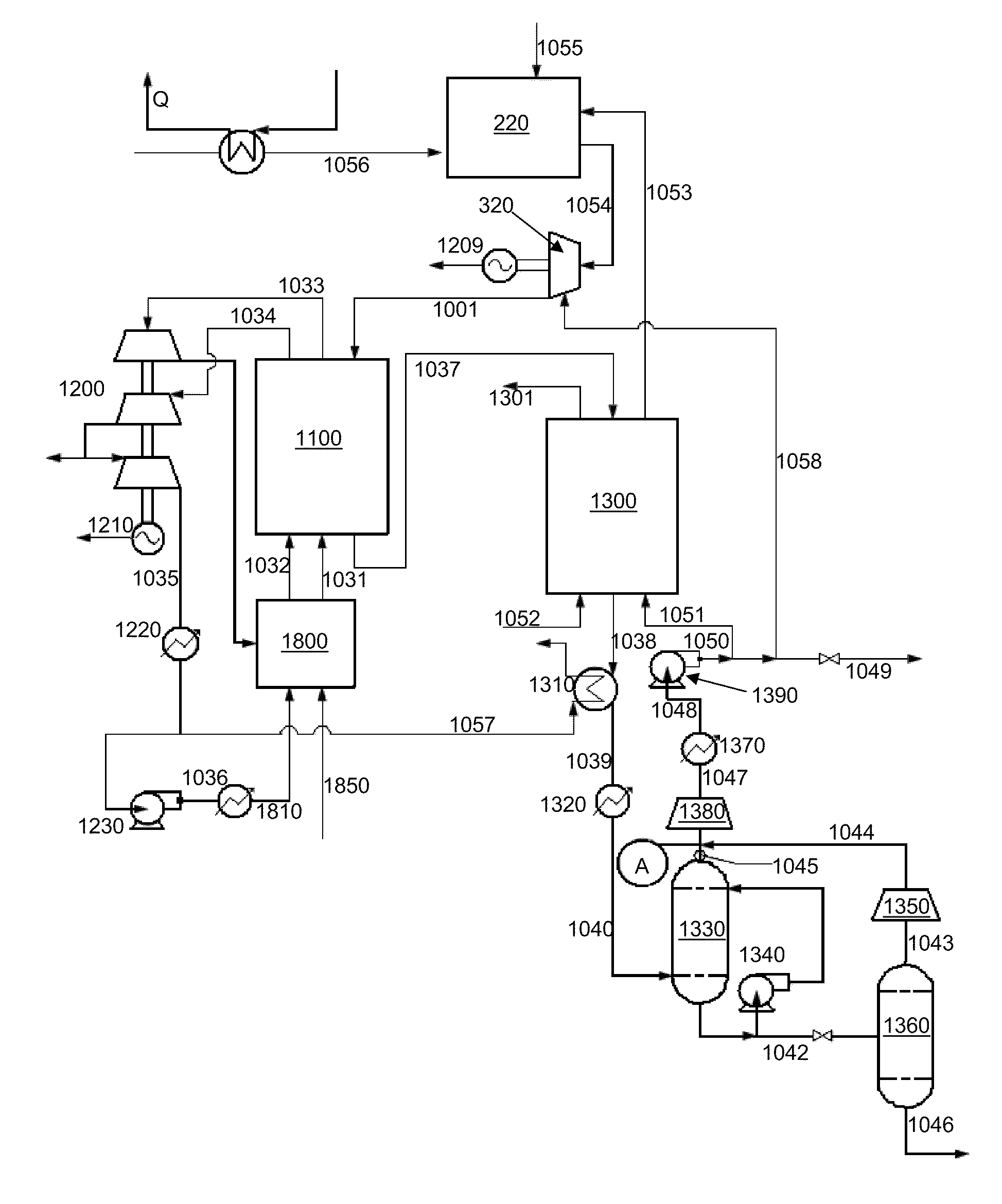

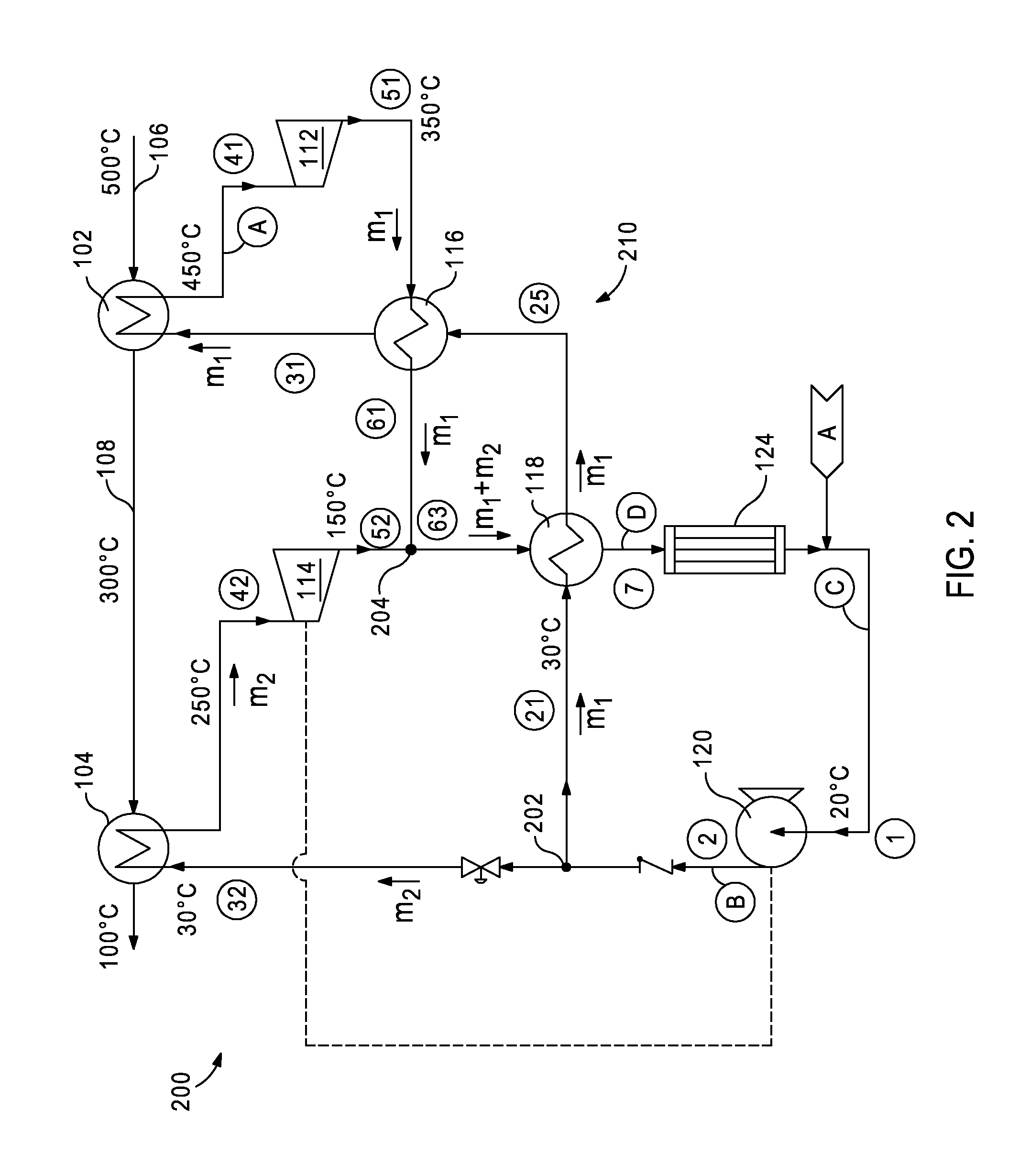

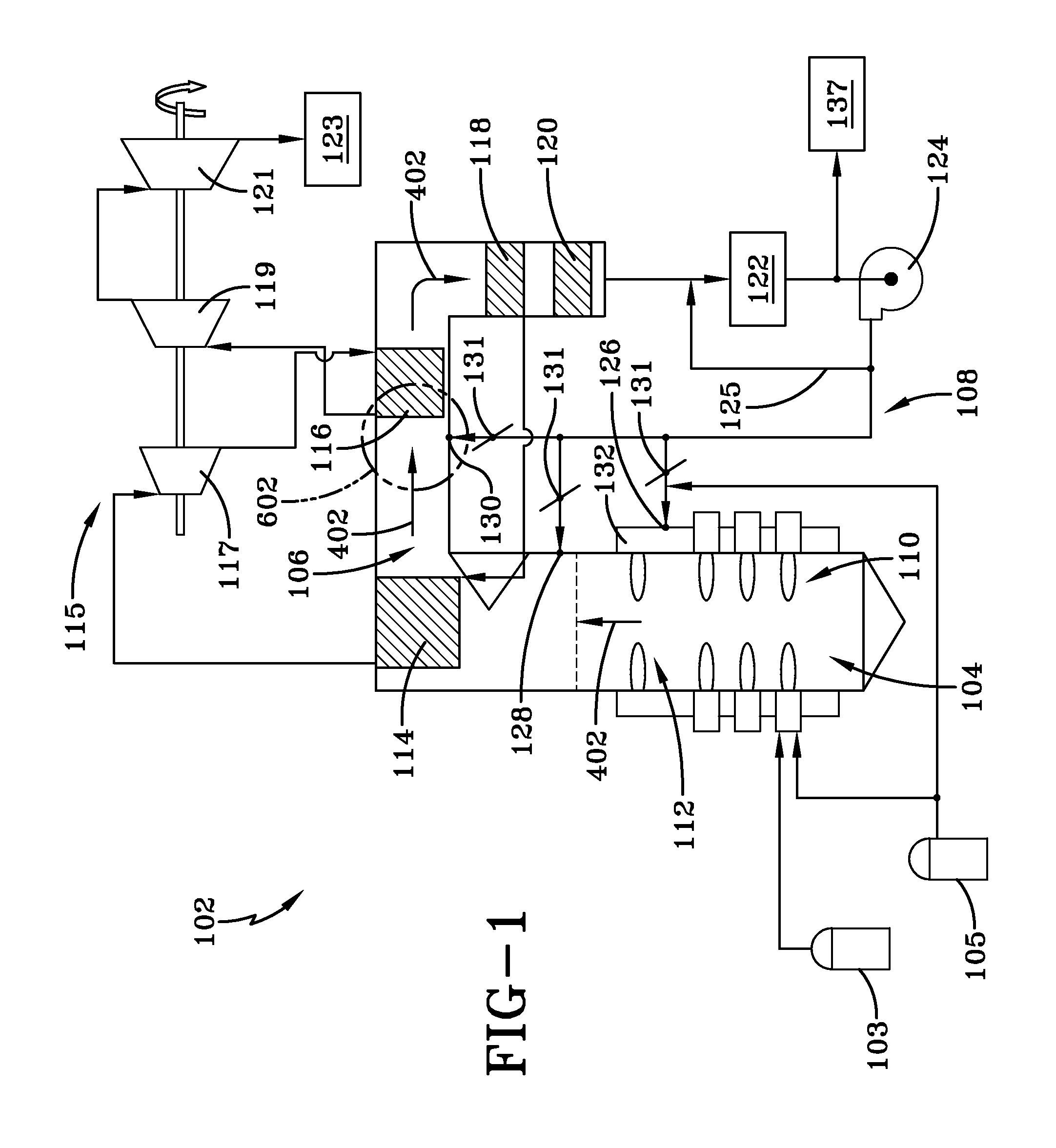

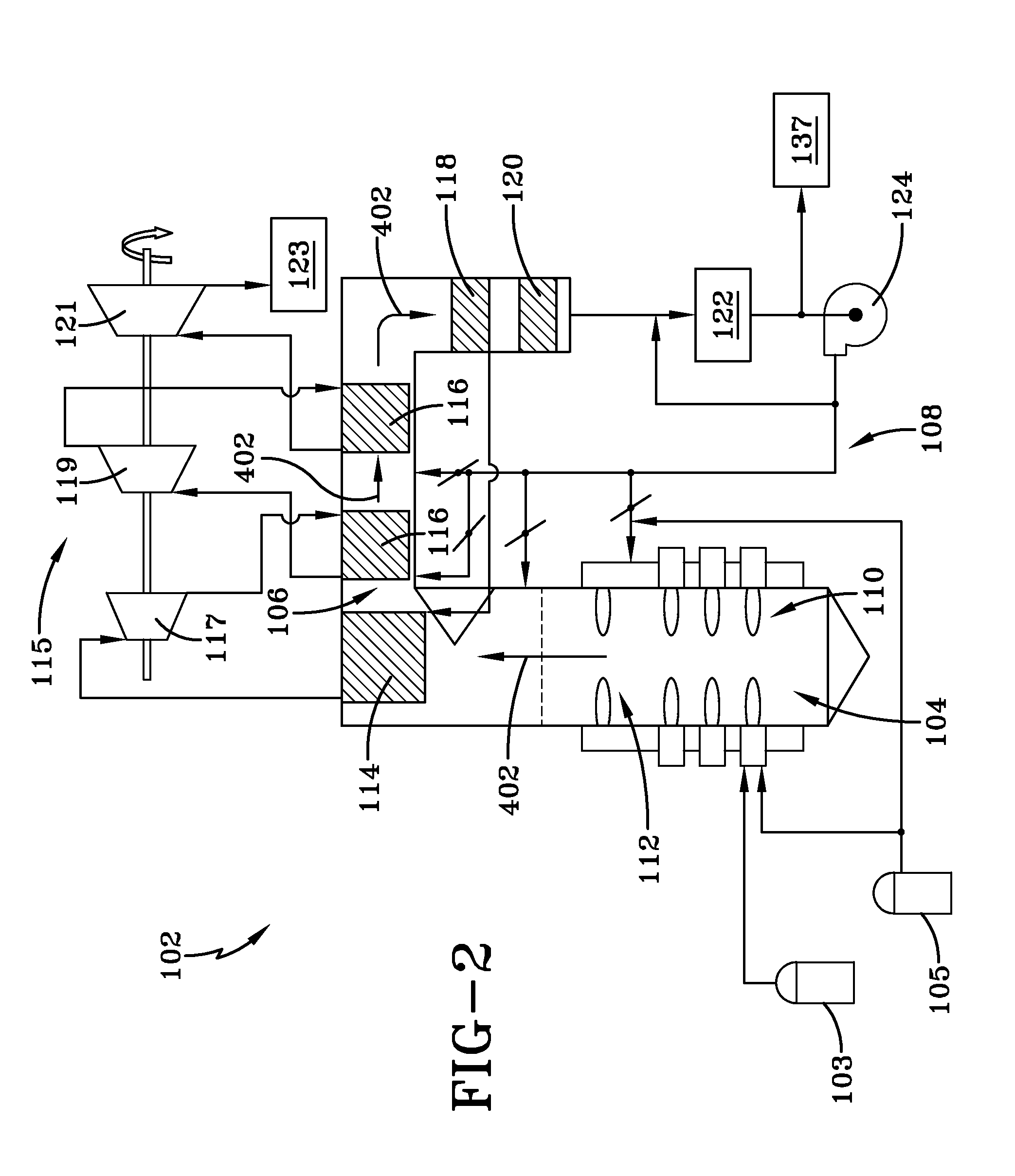

System and method for high efficiency power generation using a carbon dioxide circulating working fluid

ActiveUS20110179799A1Improve efficiencyIncrease pressure ratioSolidificationLiquefactionWorking fluidCombustor

The present invention provides methods and system for power generation using a high efficiency combustor in combination with a CO2 circulating fluid. The methods and systems advantageously can make use of a low pressure ratio power turbine and an economizer heat exchanger in specific embodiments. Additional low grade heat from an external source can be used to provide part of an amount of heat needed for heating the recycle CO2 circulating fluid. Fuel derived CO2 can be captured and delivered at pipeline pressure. Other impurities can be captured.

Owner:8 RIVERS CAPTTAL LLC

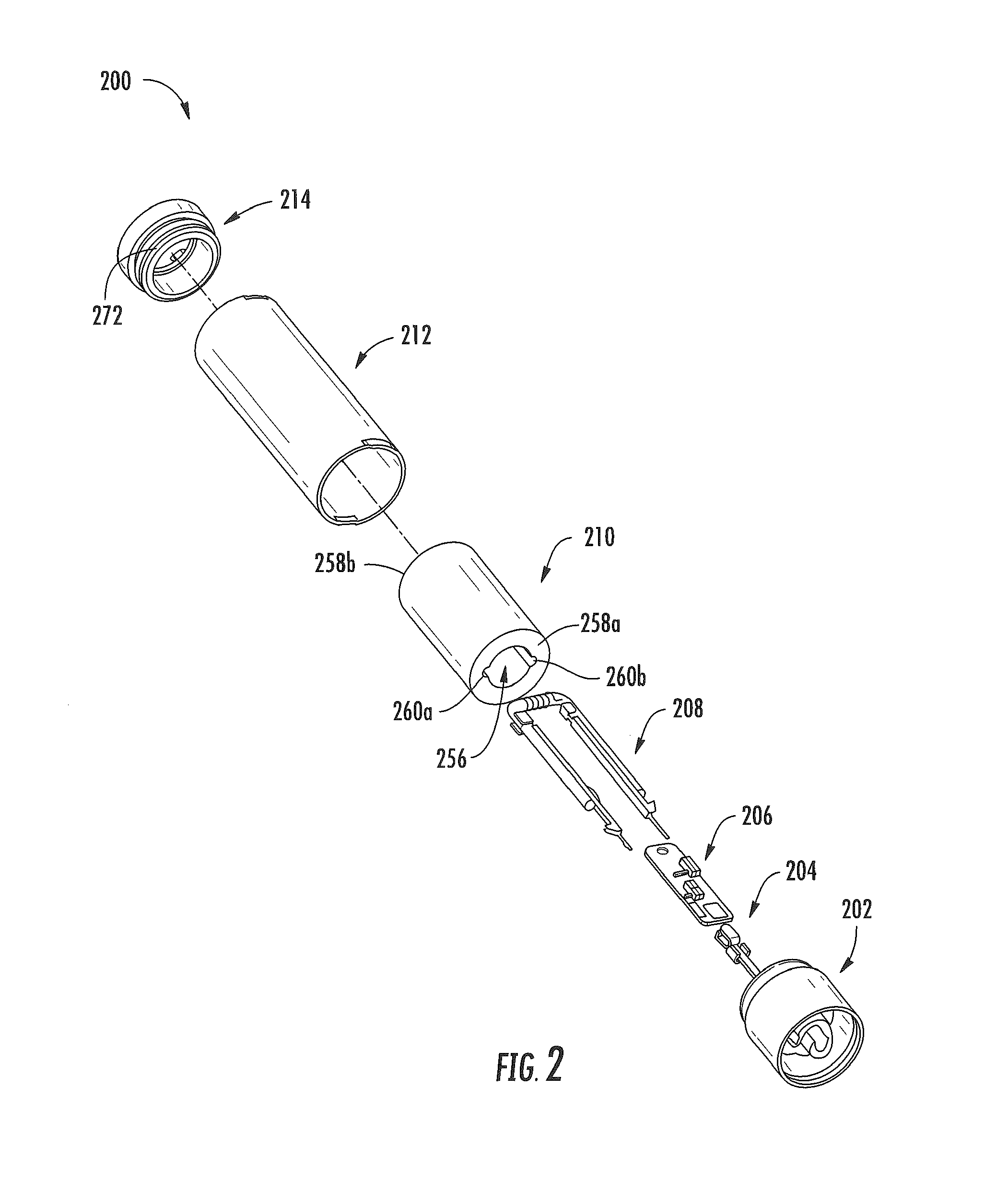

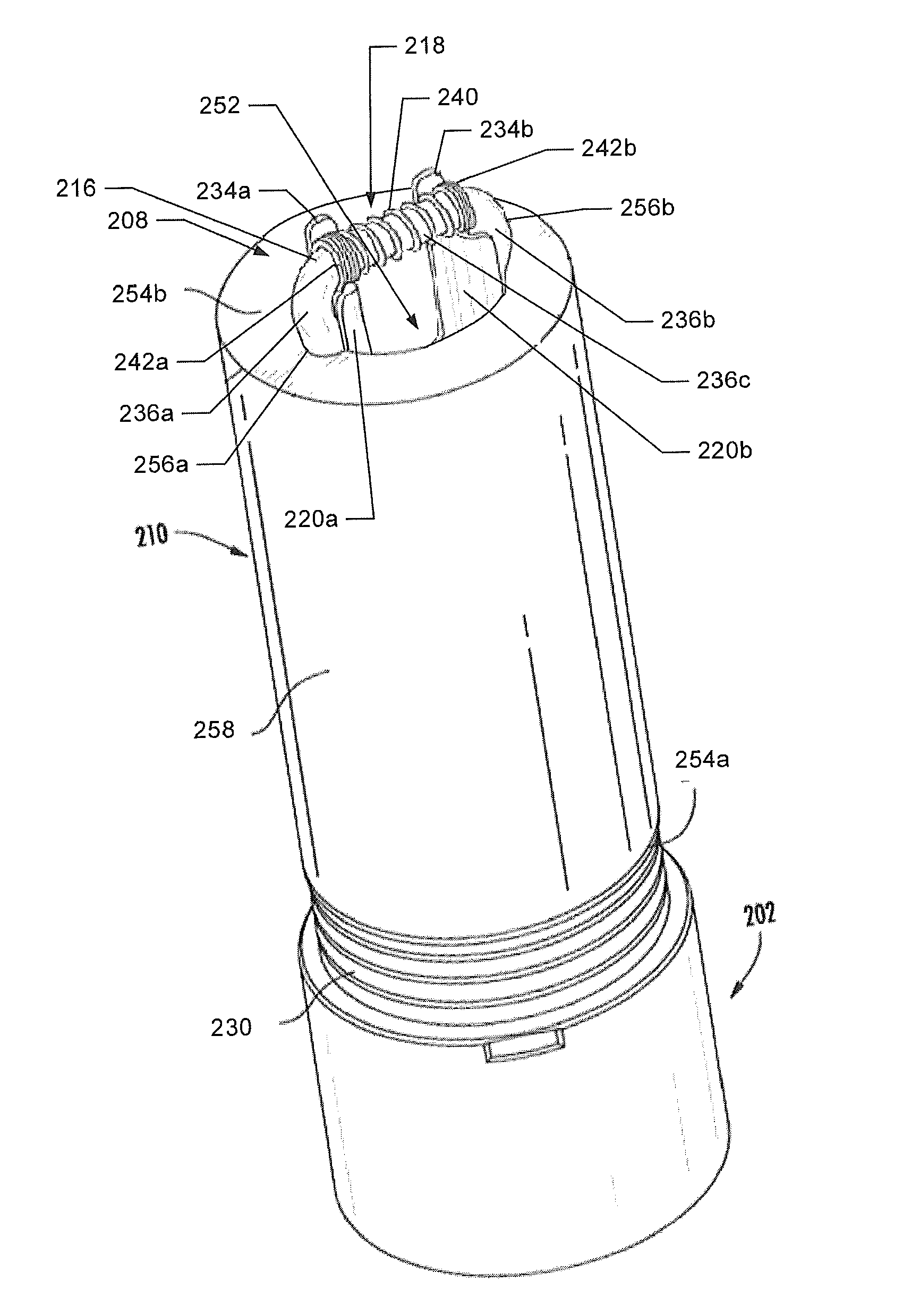

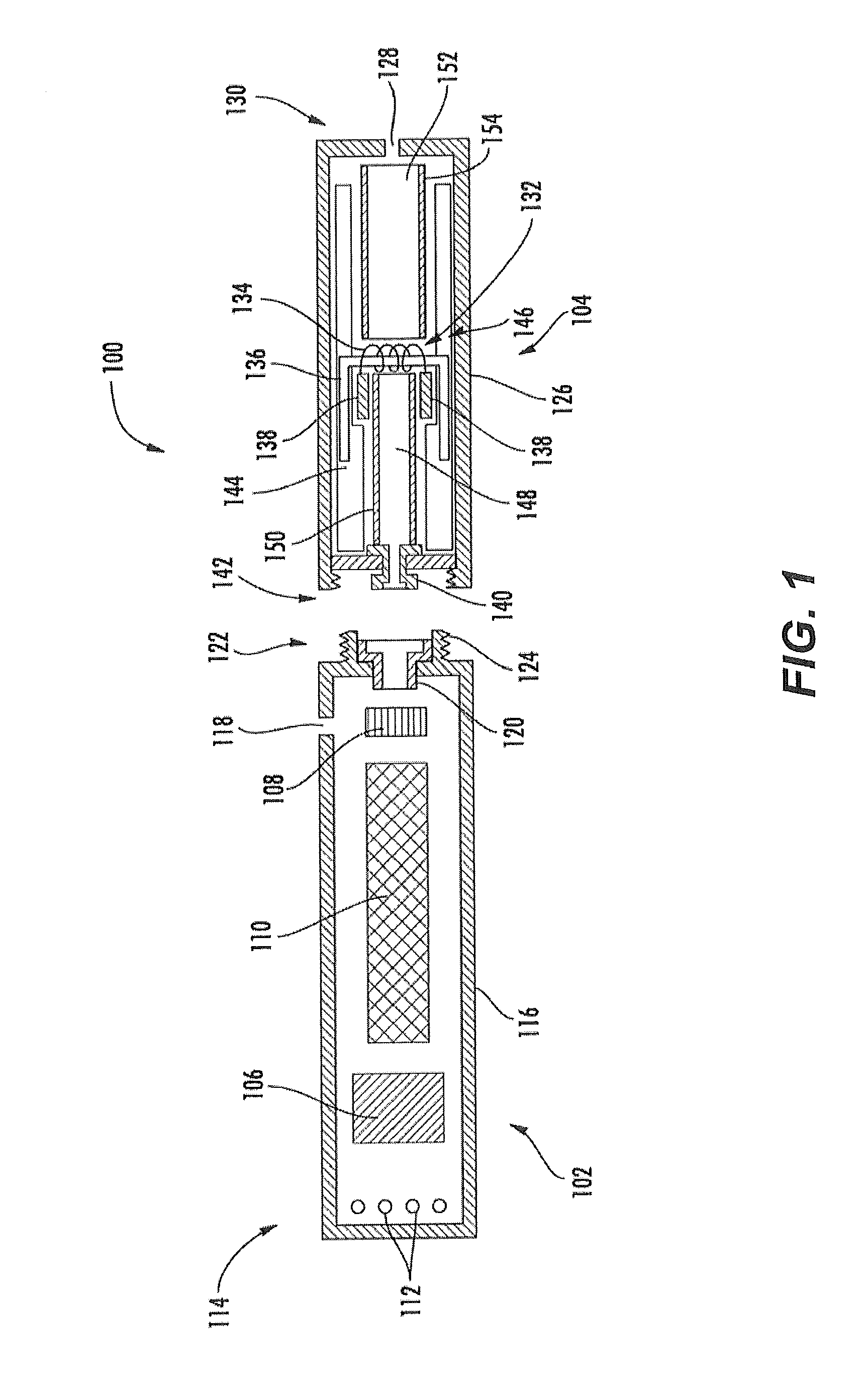

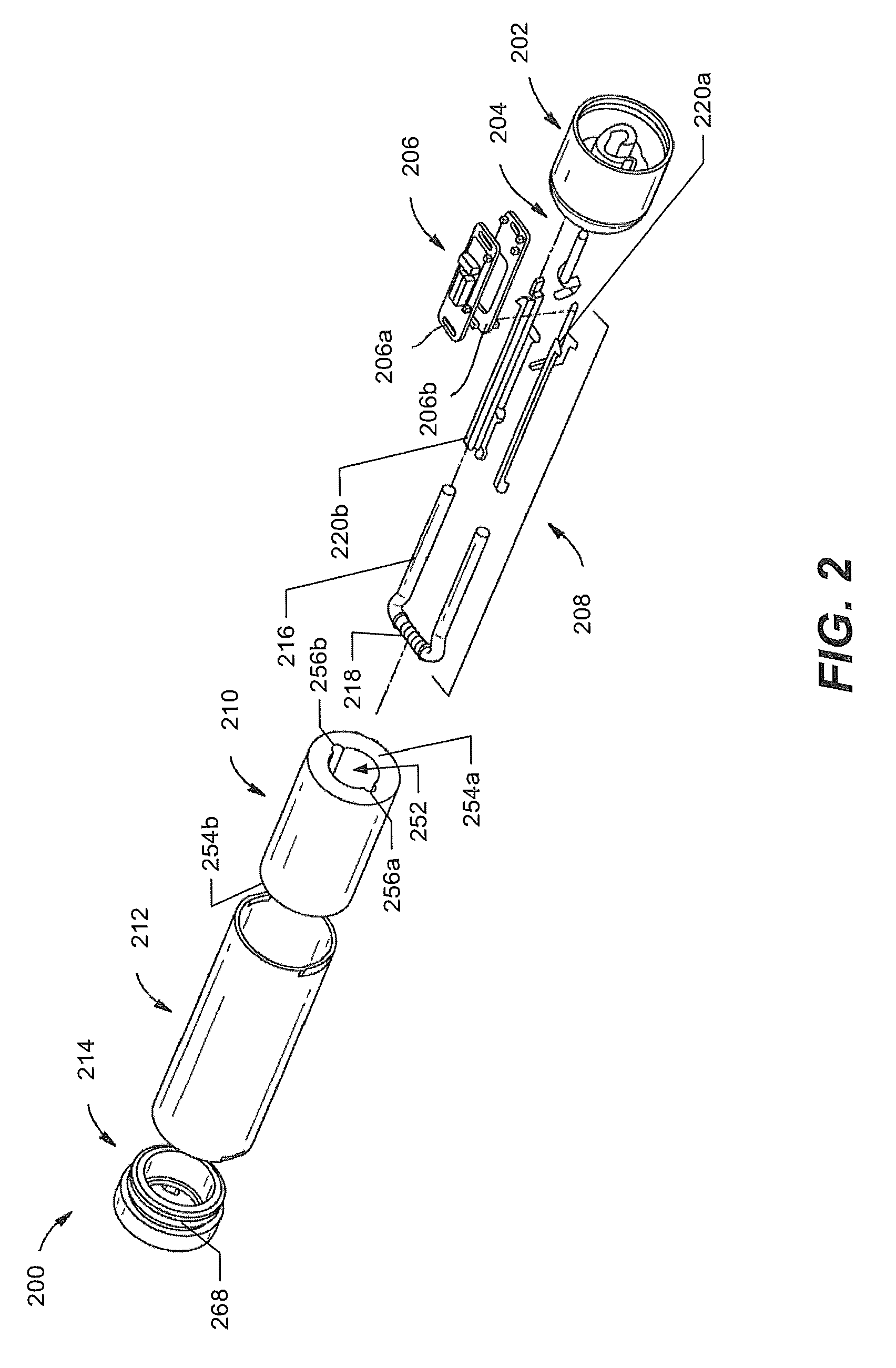

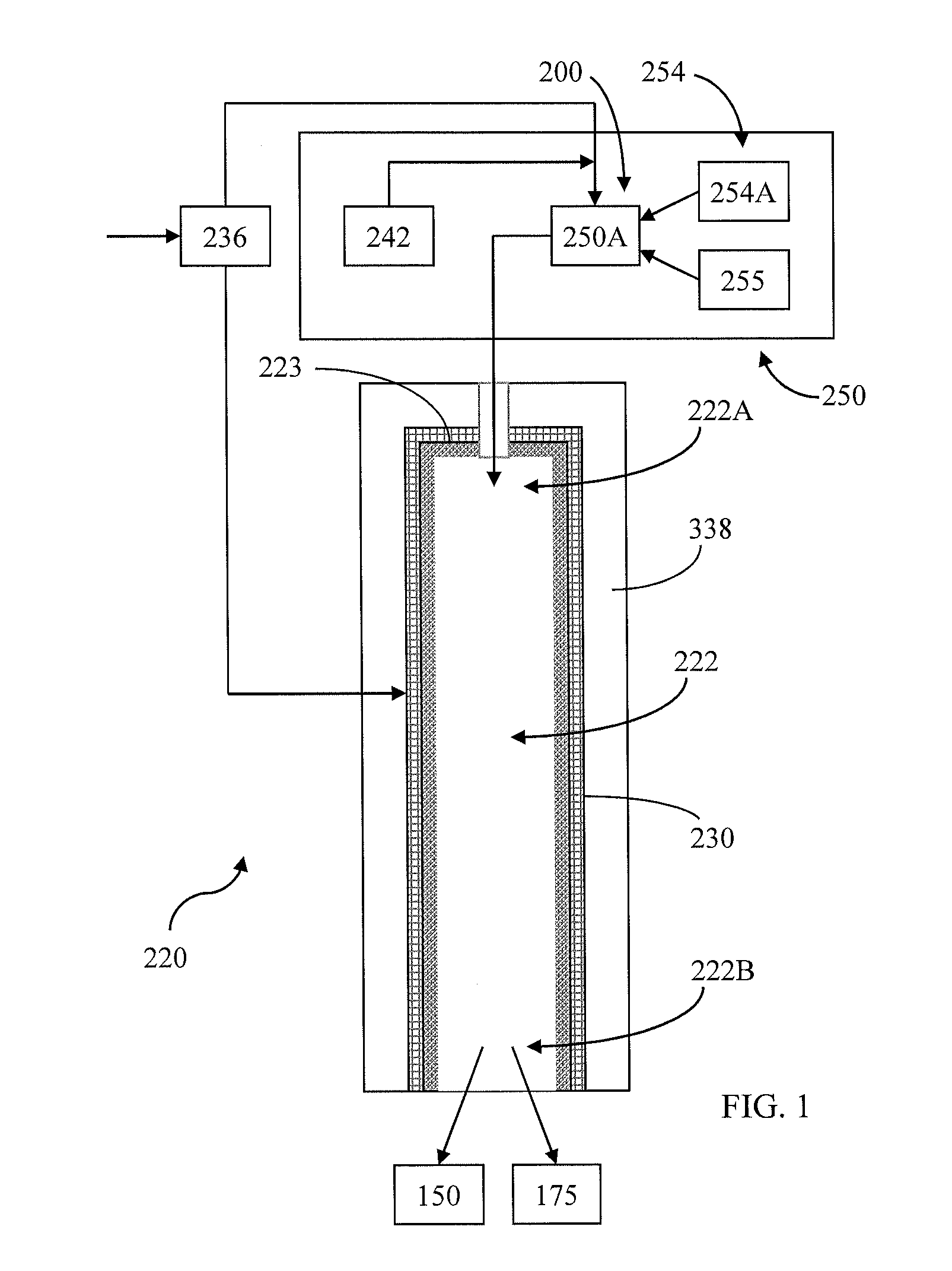

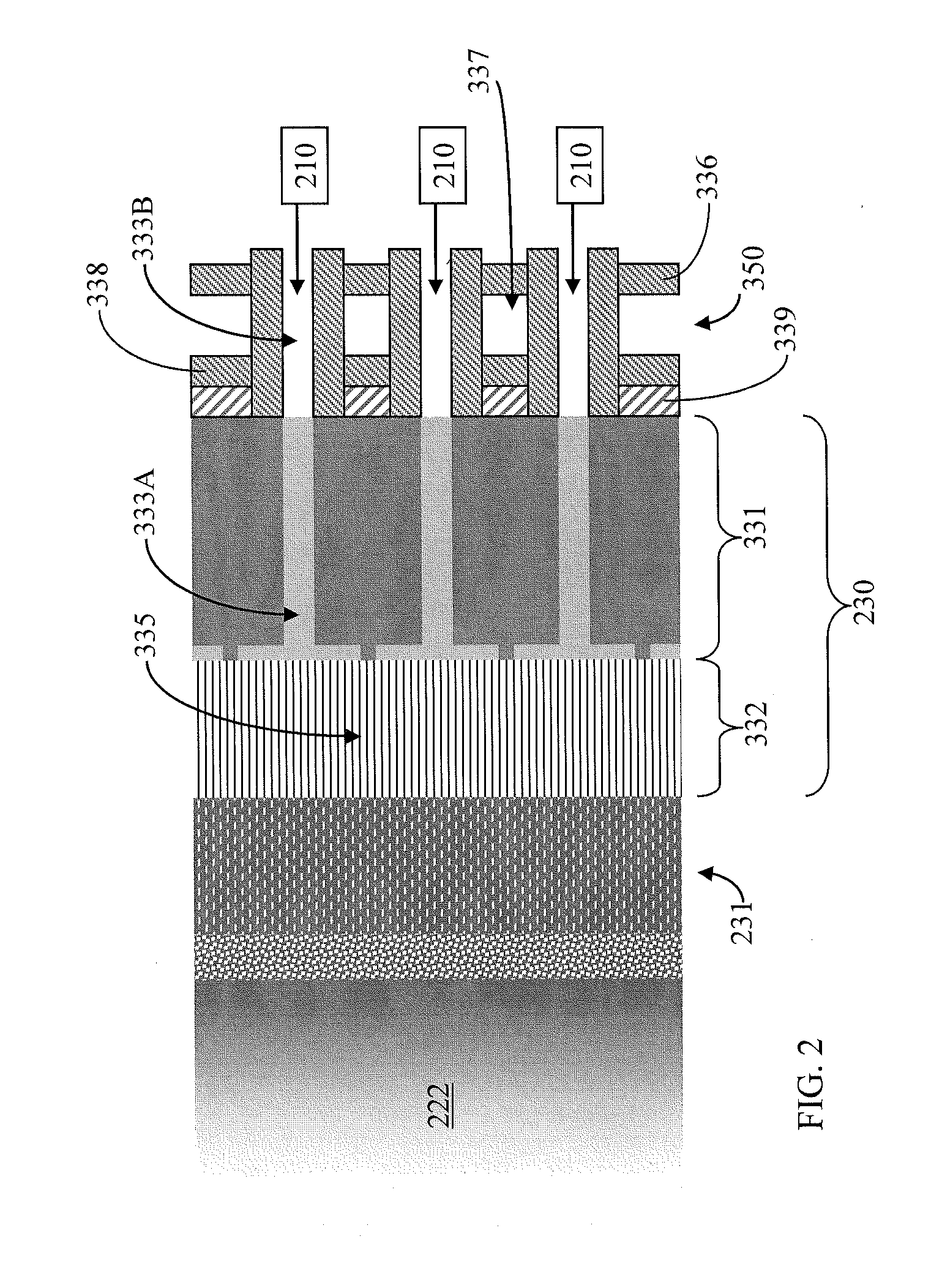

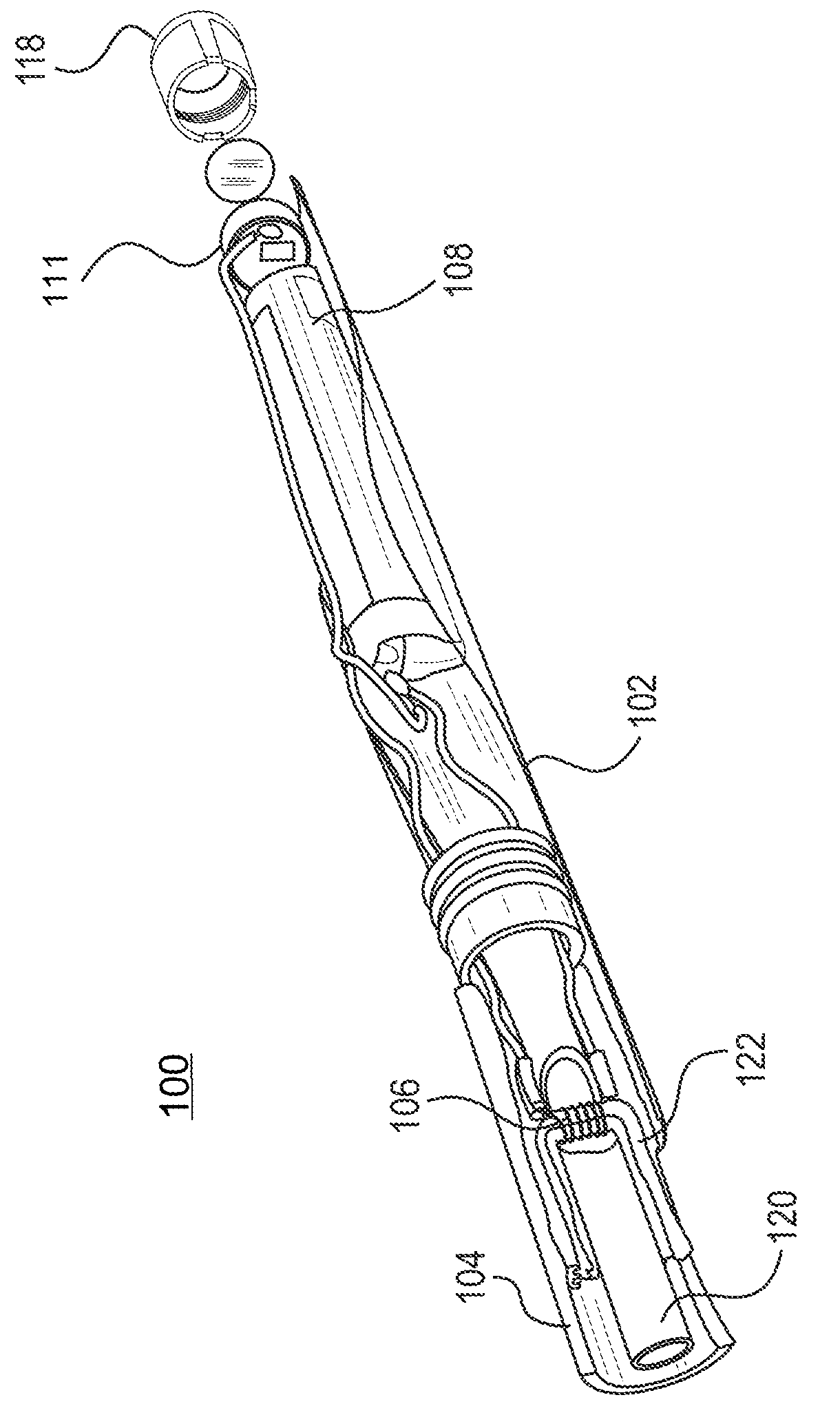

Atomizer for an aerosol delivery device and related input, aerosol production assembly, cartridge, and method

The present disclosure relates to atomizers for an aerosol delivery device such as a smoking article. The atomizer may include a liquid transport element and a wire extending along at least a portion of a longitudinal length thereof. The wire may define contact portions configured to engage heater terminals and a heating portion configured to produce heat. The heating portion may include a variable coil spacing. In other atomizers, the wire may extend at least partially through the liquid transport element proximate the contact portions. Related inputs, cartridges, aerosol production assemblies, and methods of forming atomizers are also provided.

Owner:RAI STRATEGIC HLDG INC

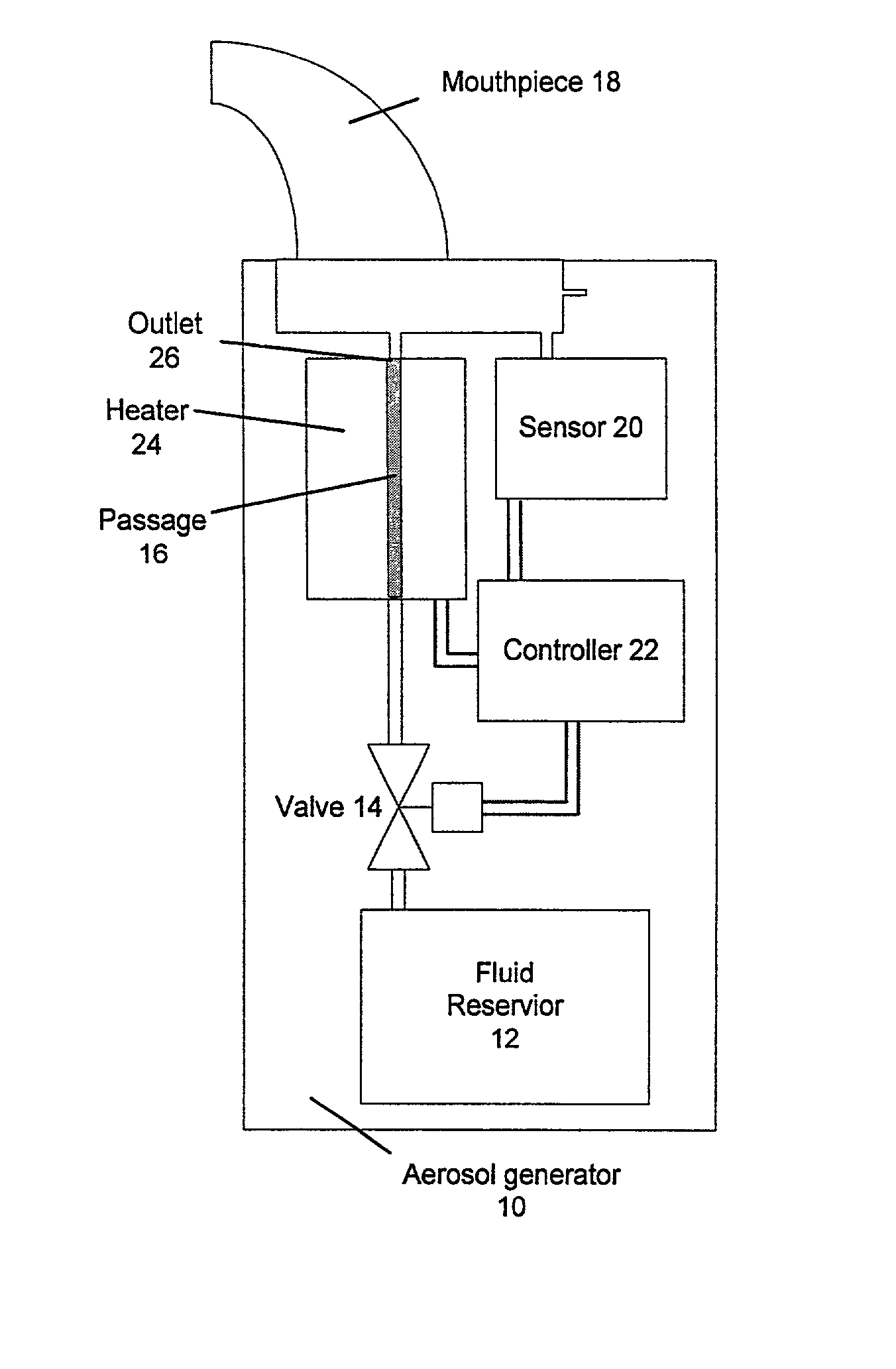

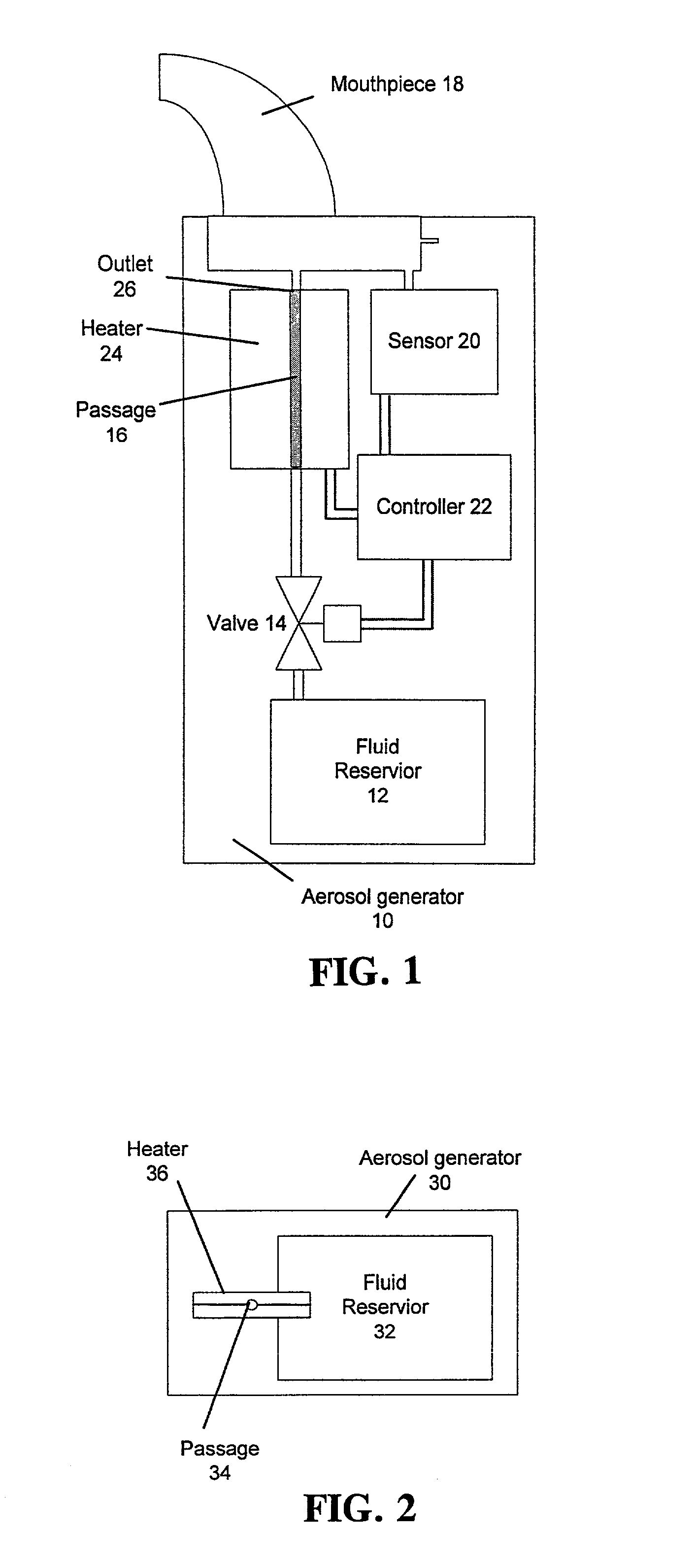

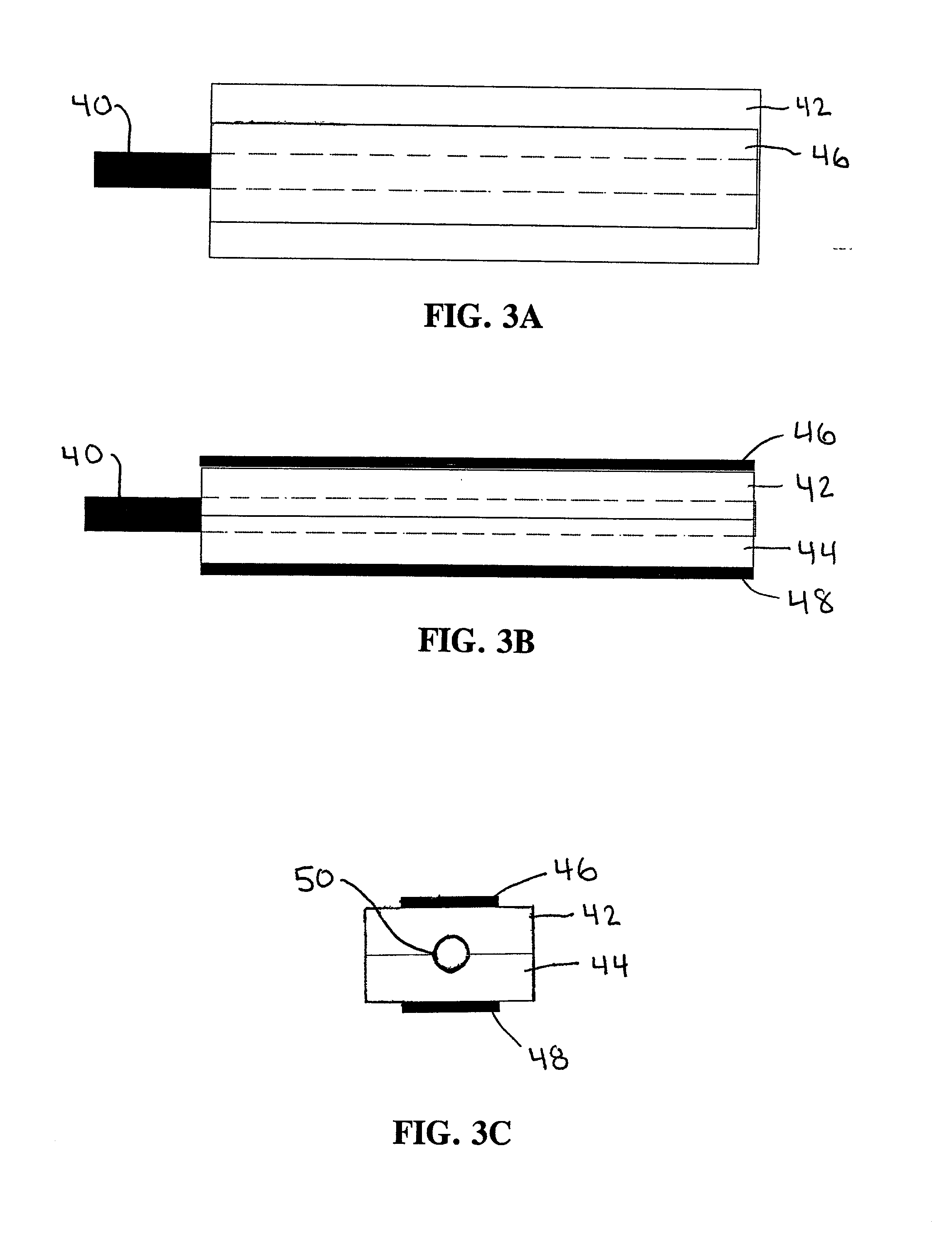

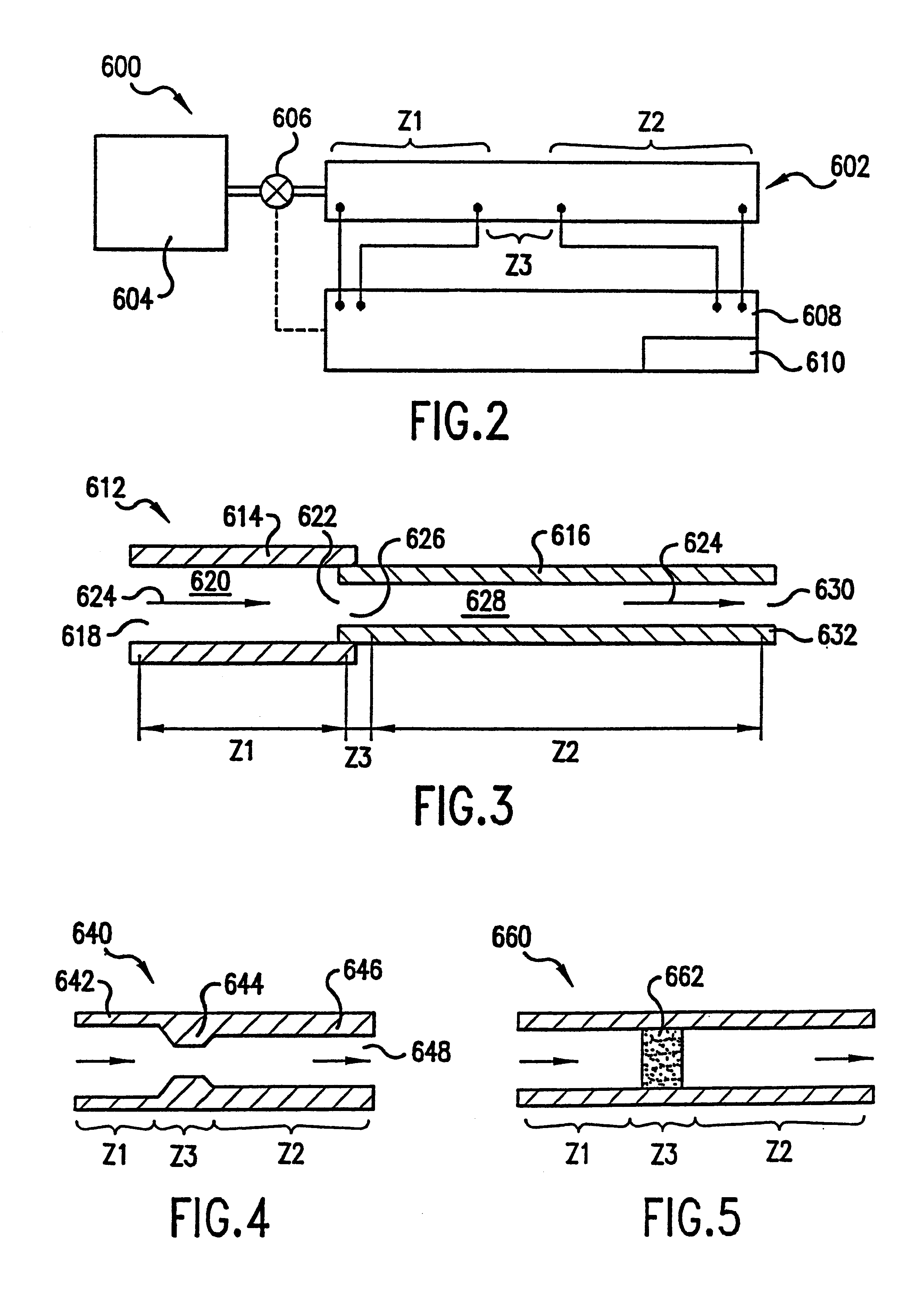

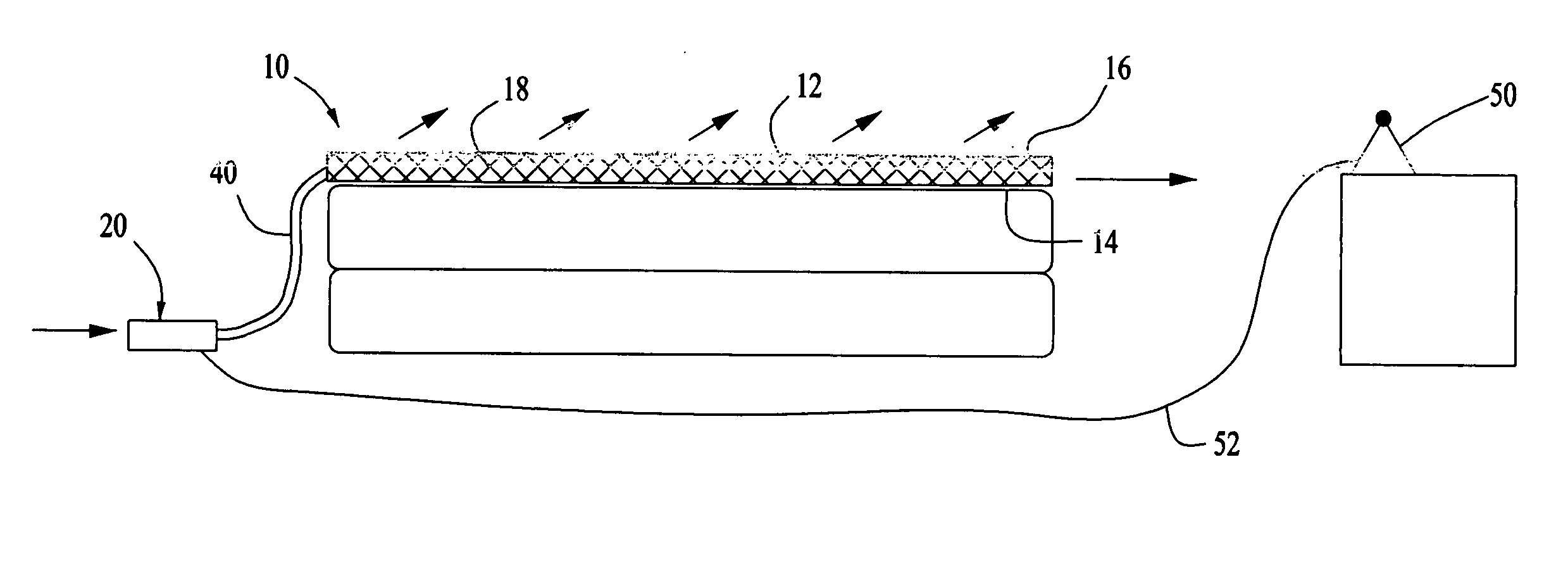

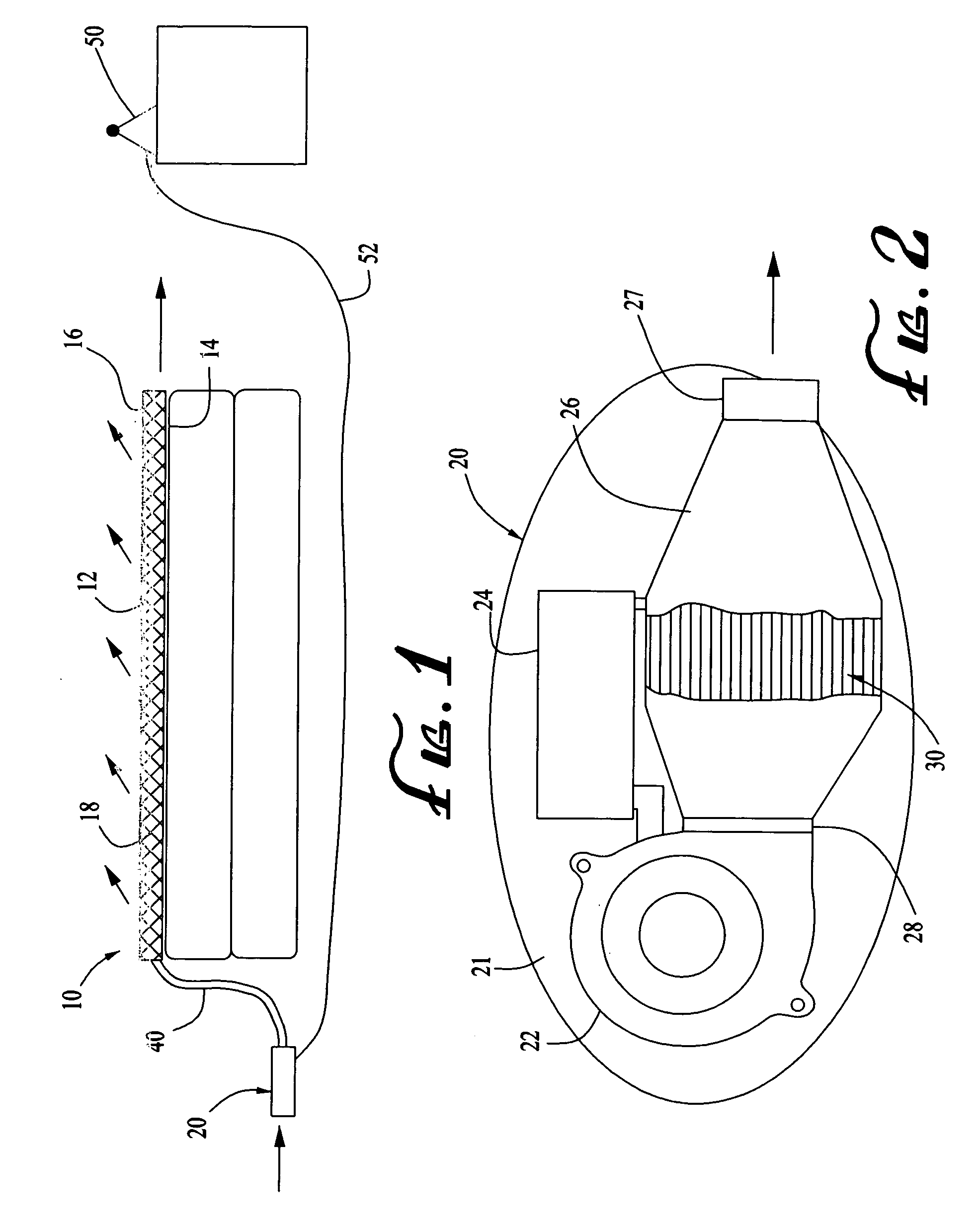

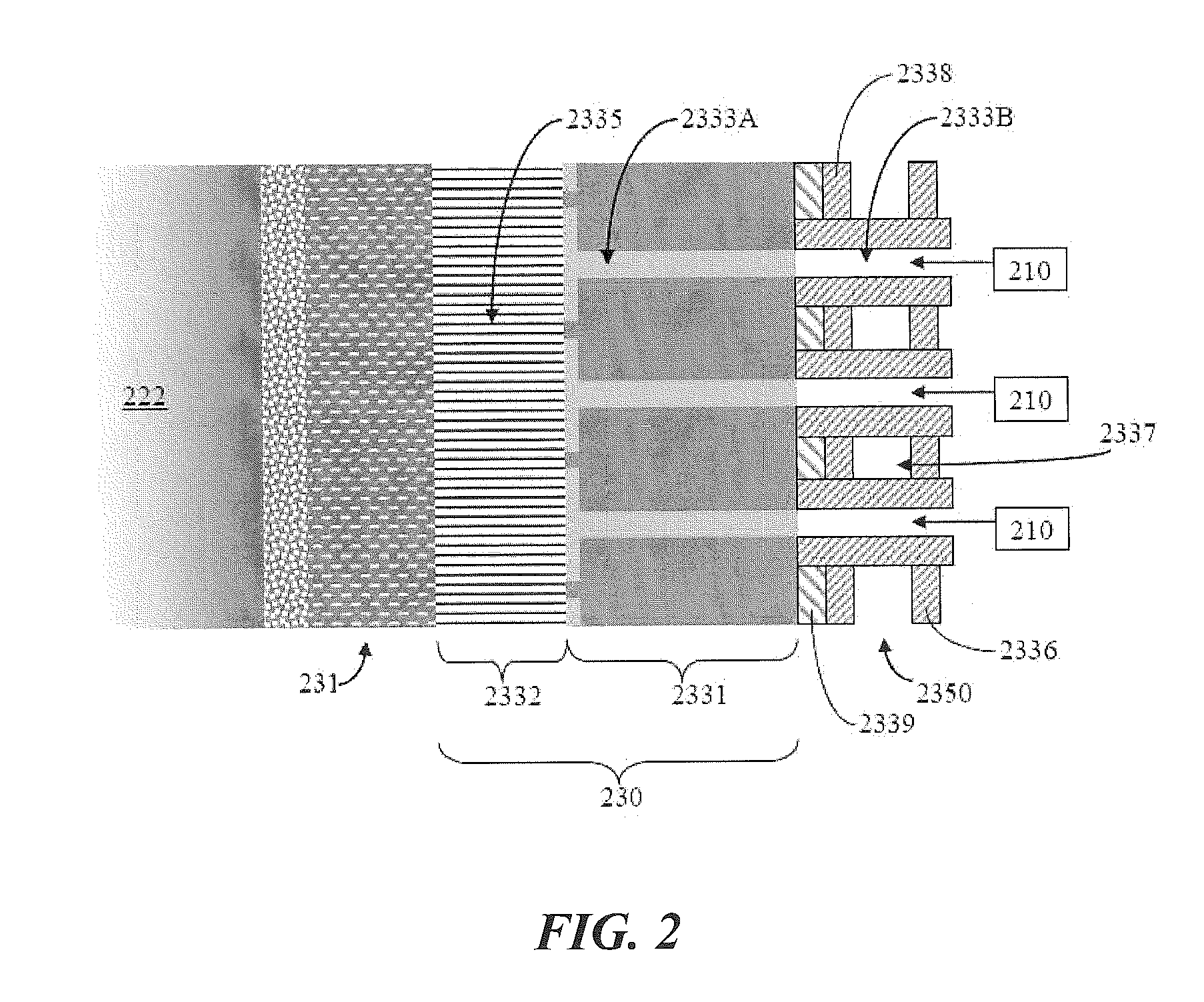

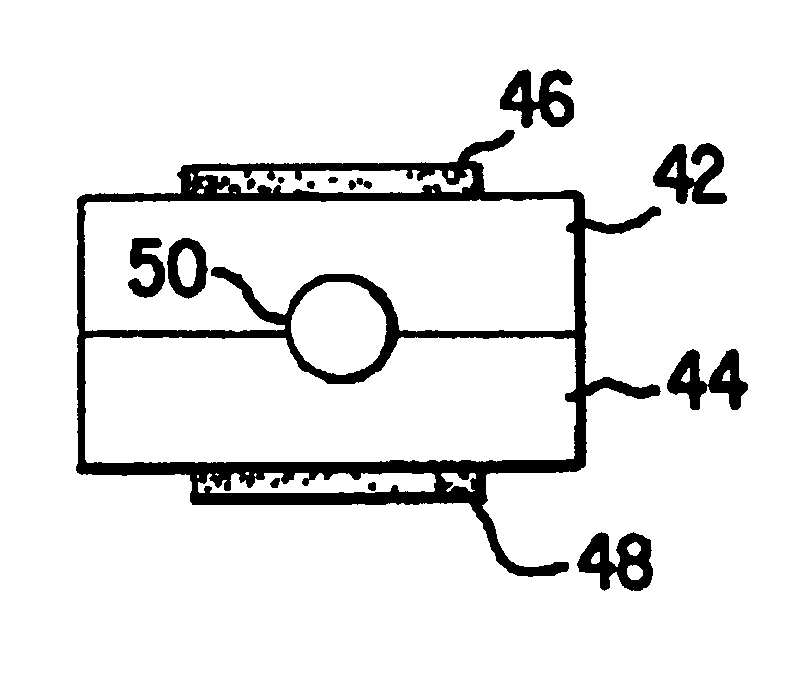

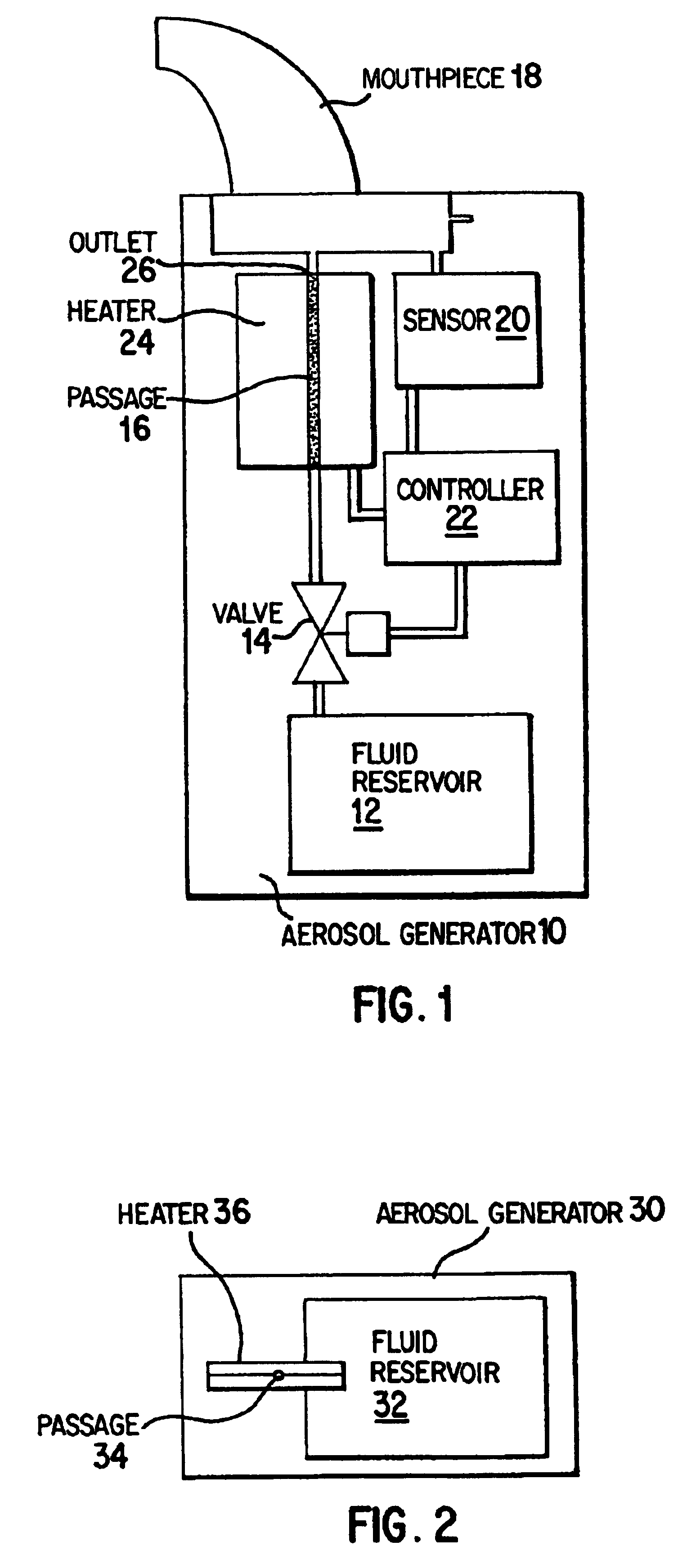

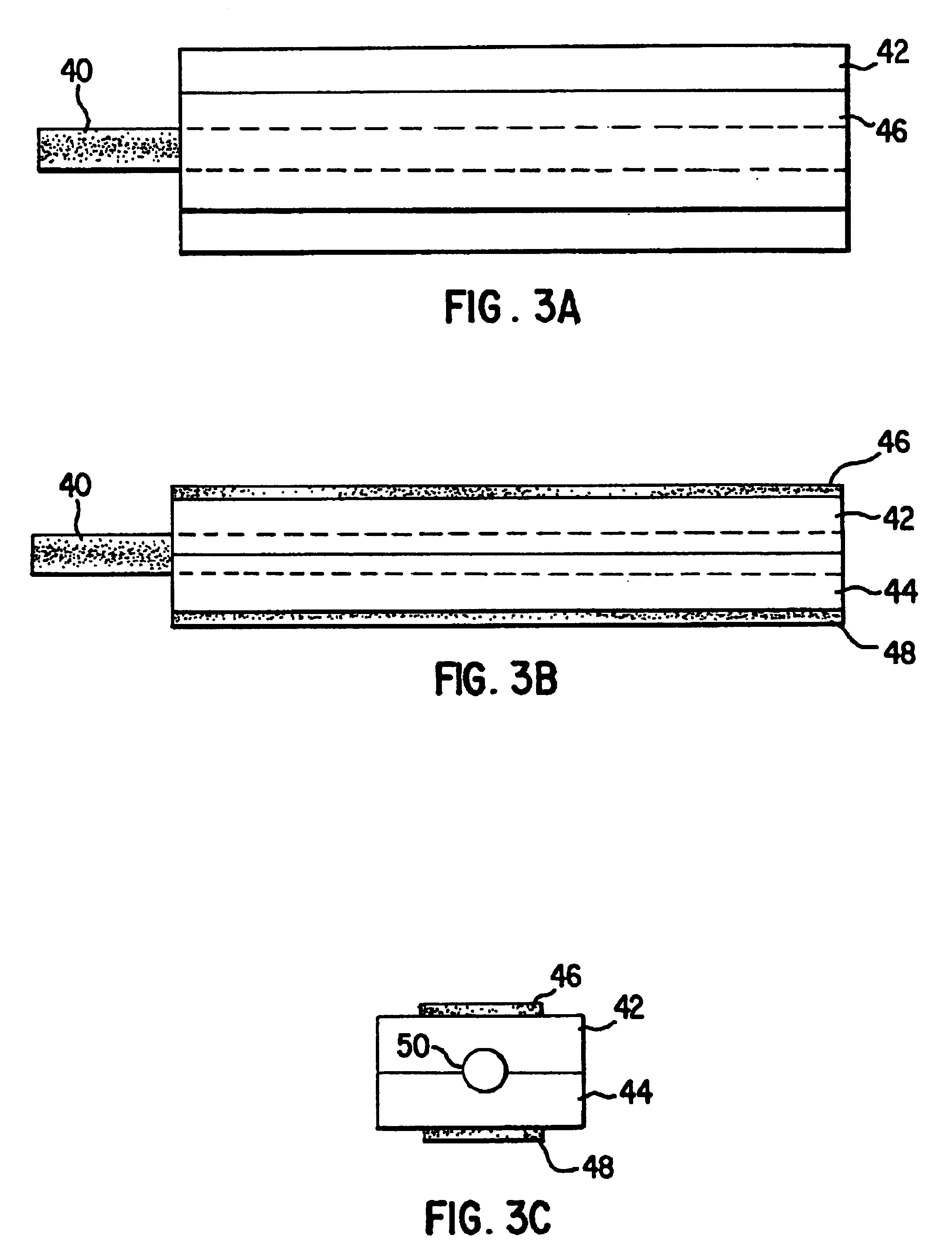

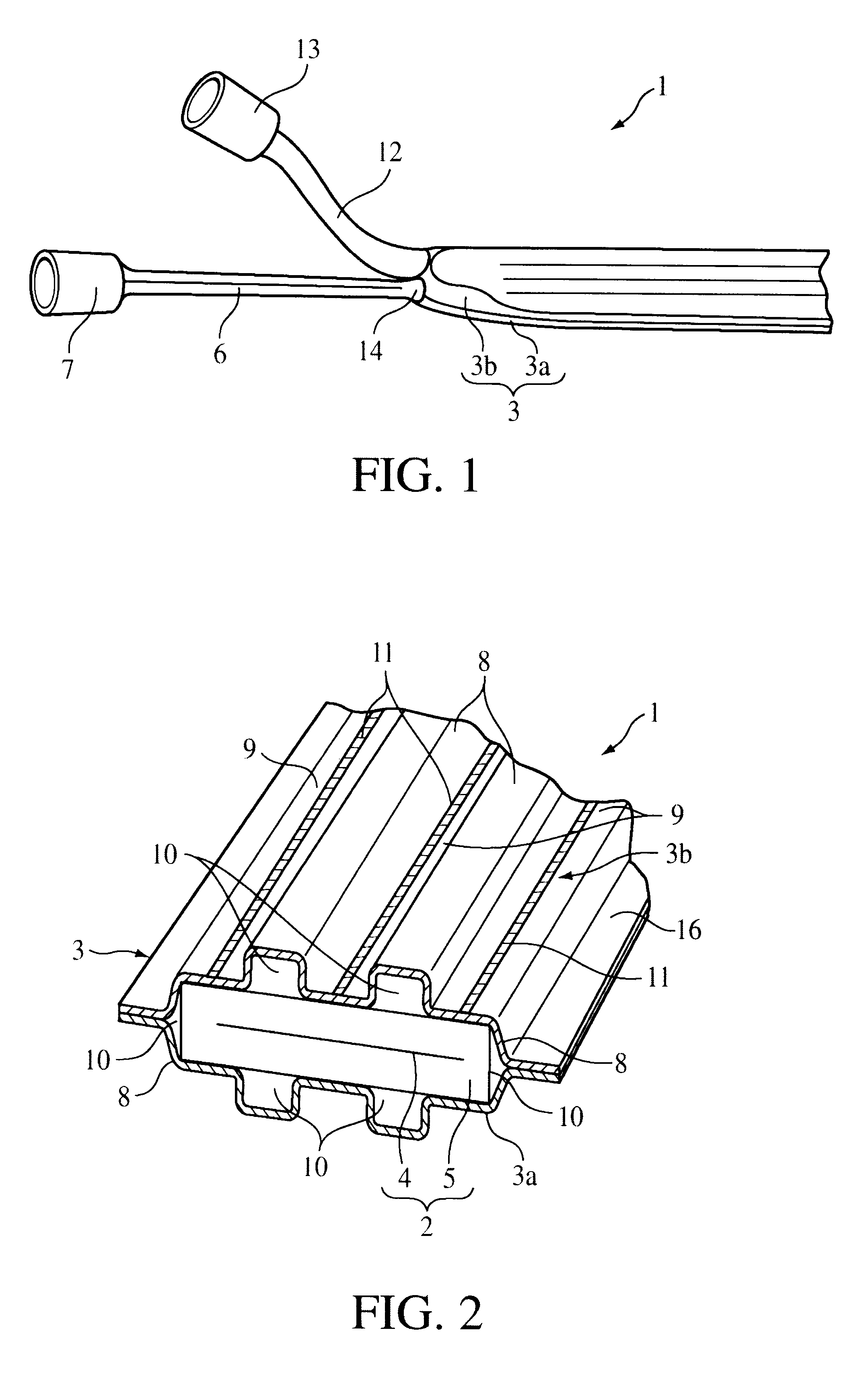

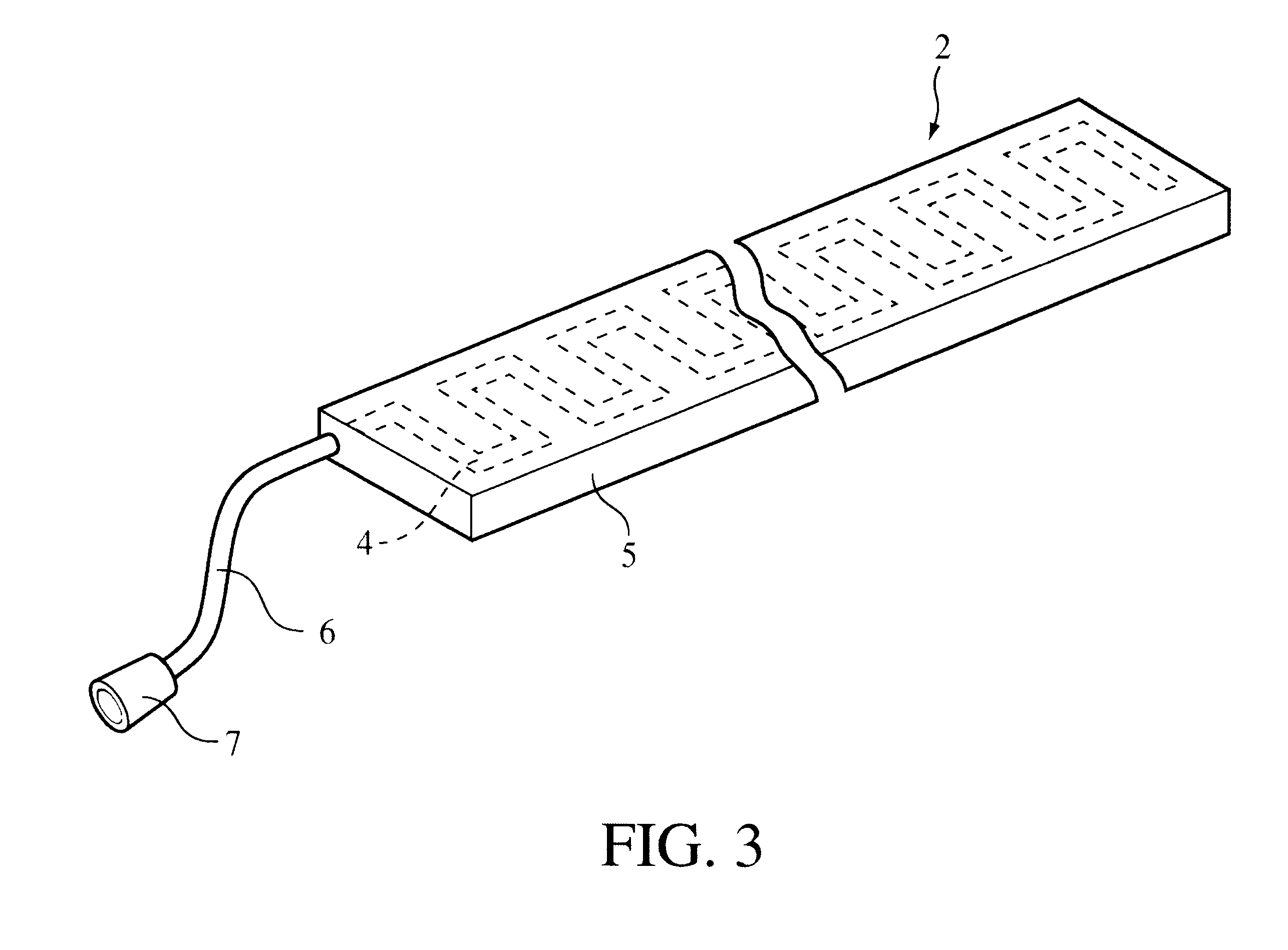

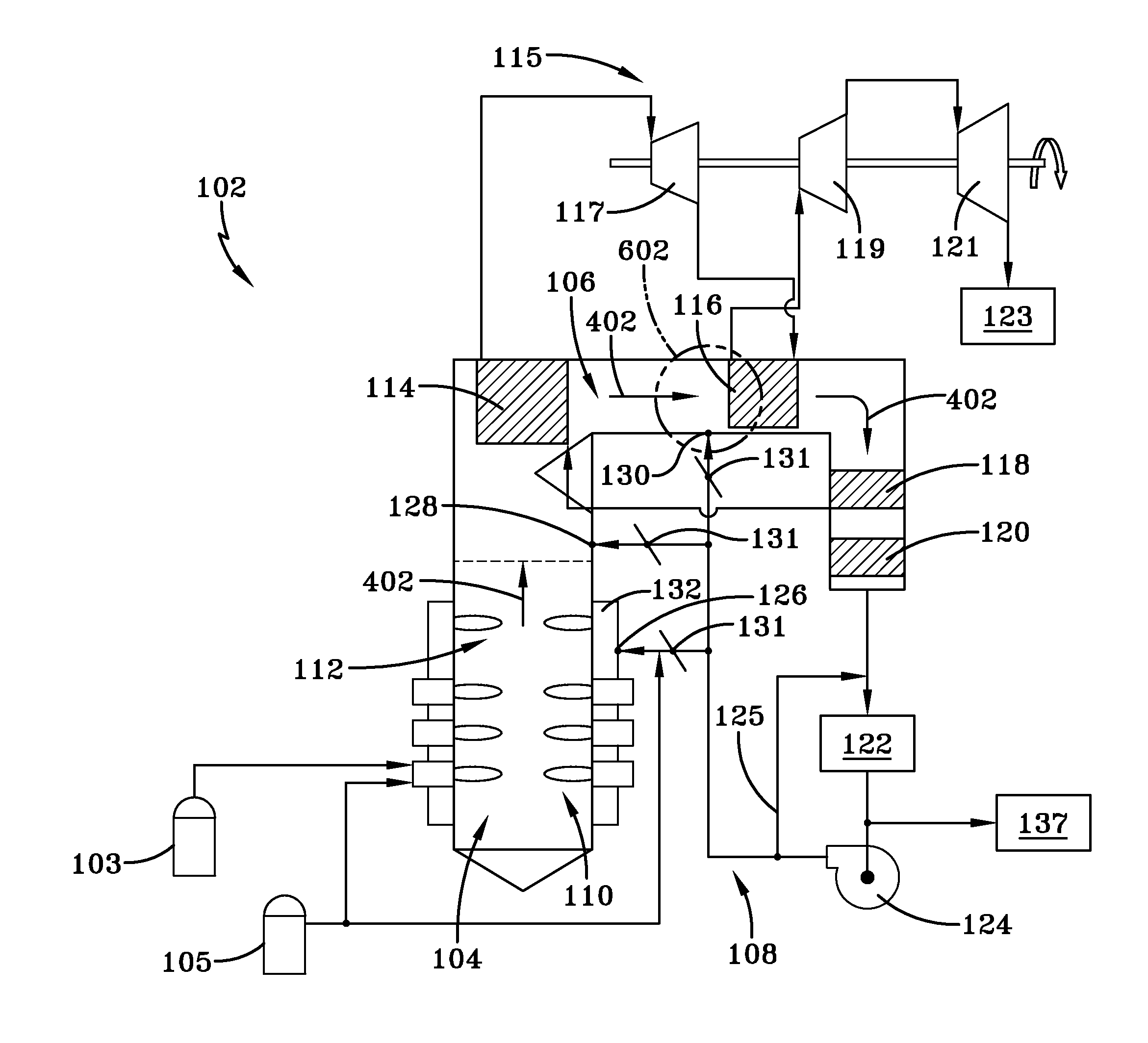

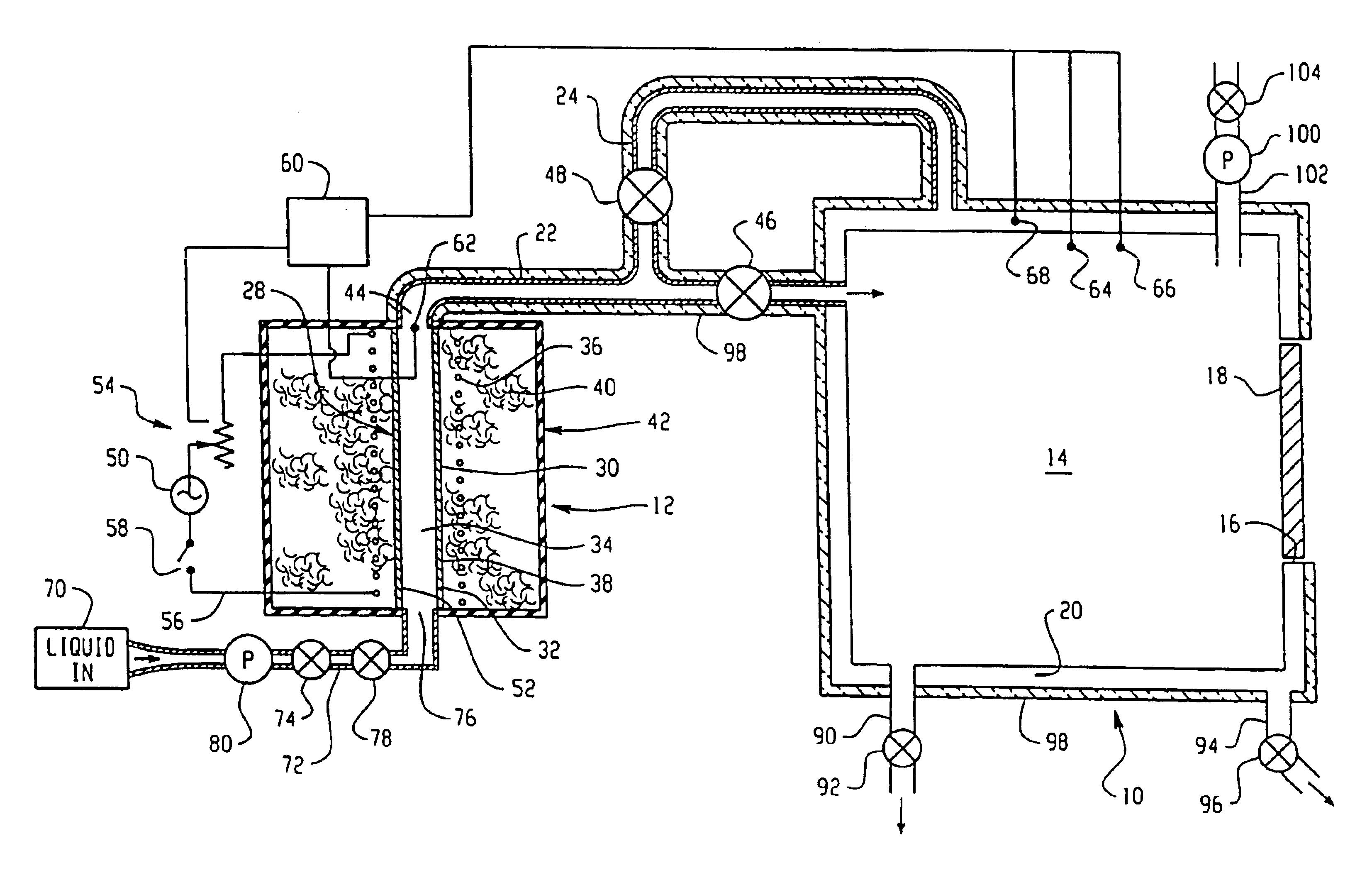

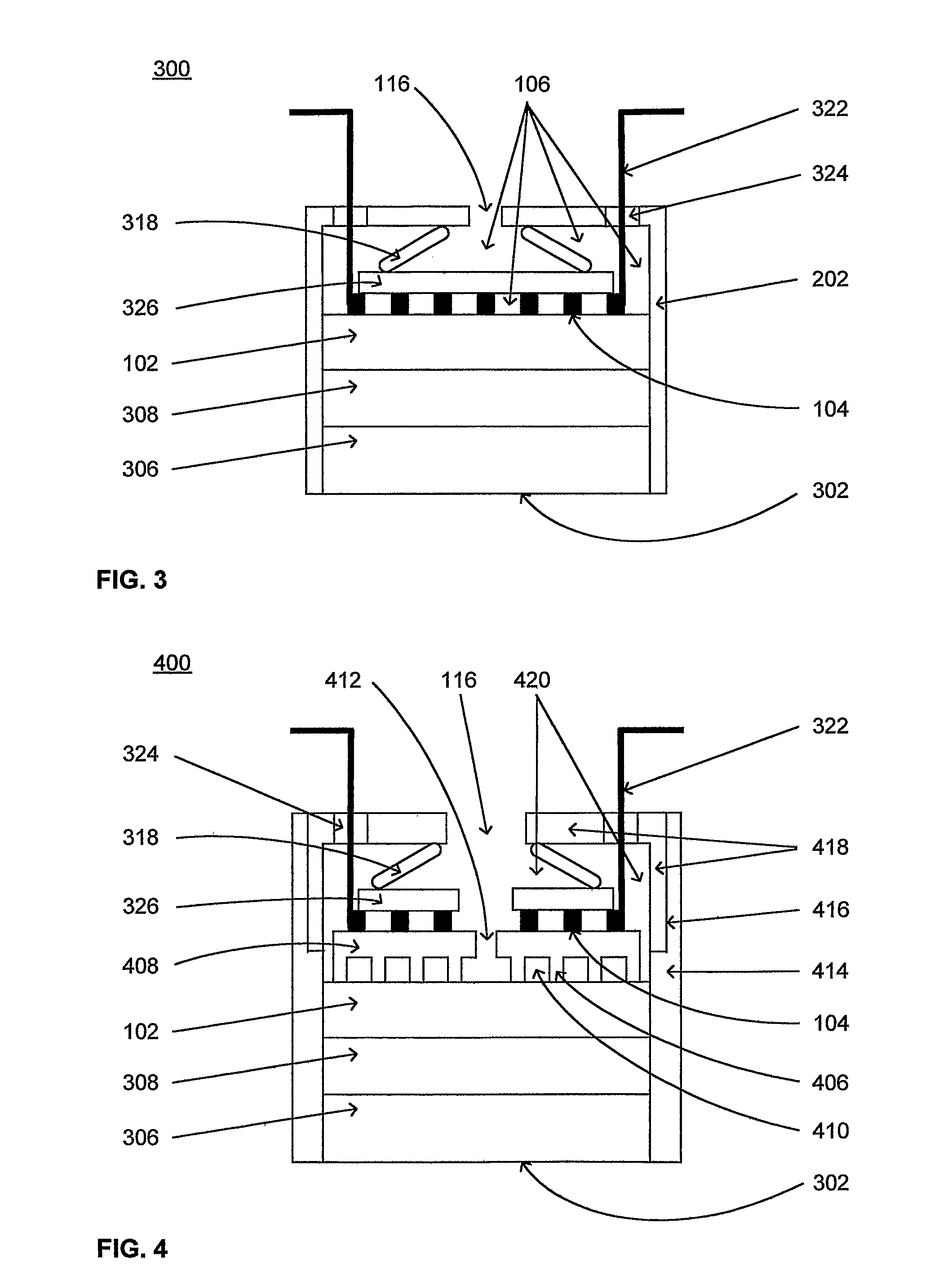

Aerosol generator having heater arranged to vaporize fluid in fluid passage between bonded layers of laminate

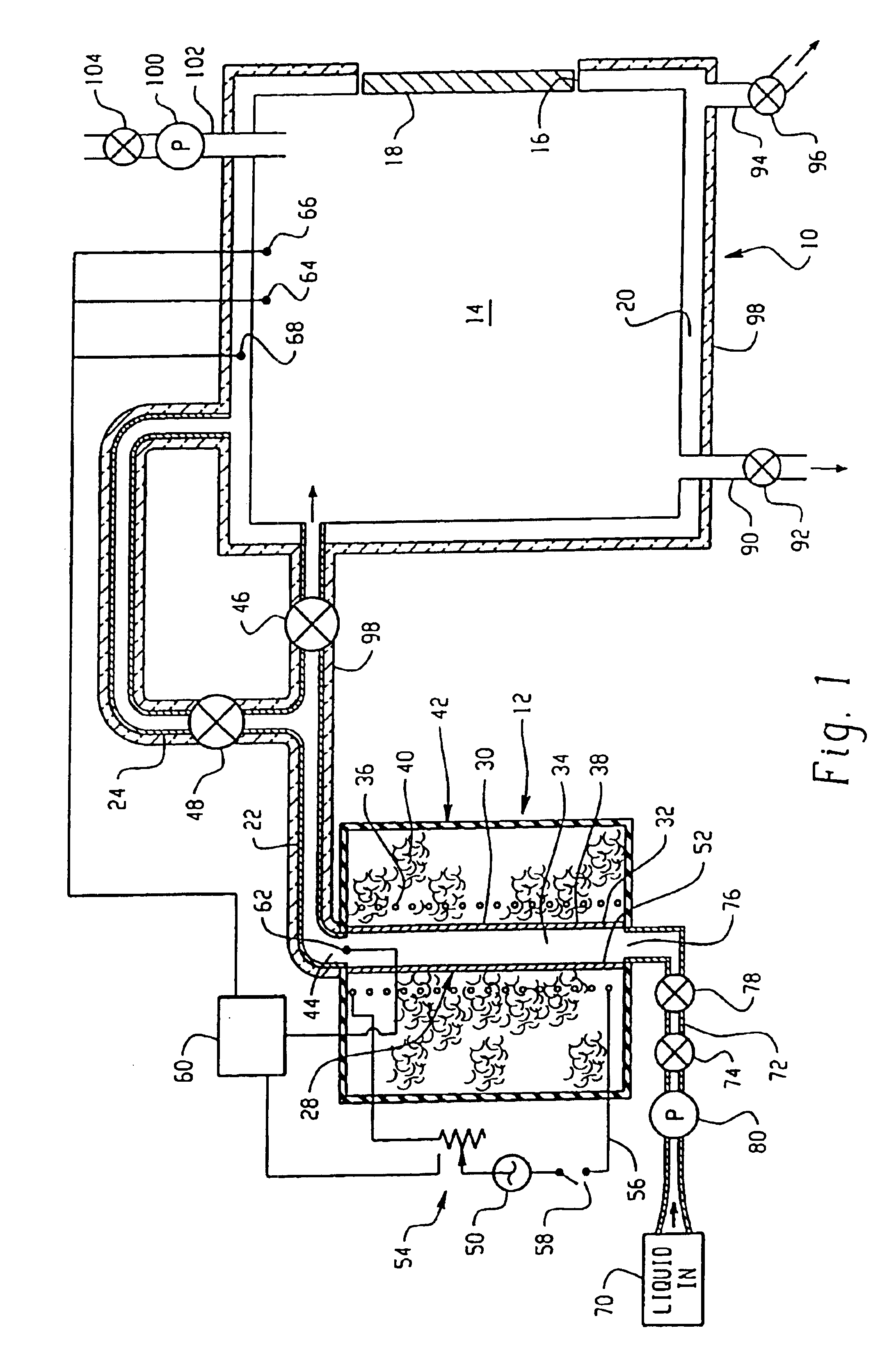

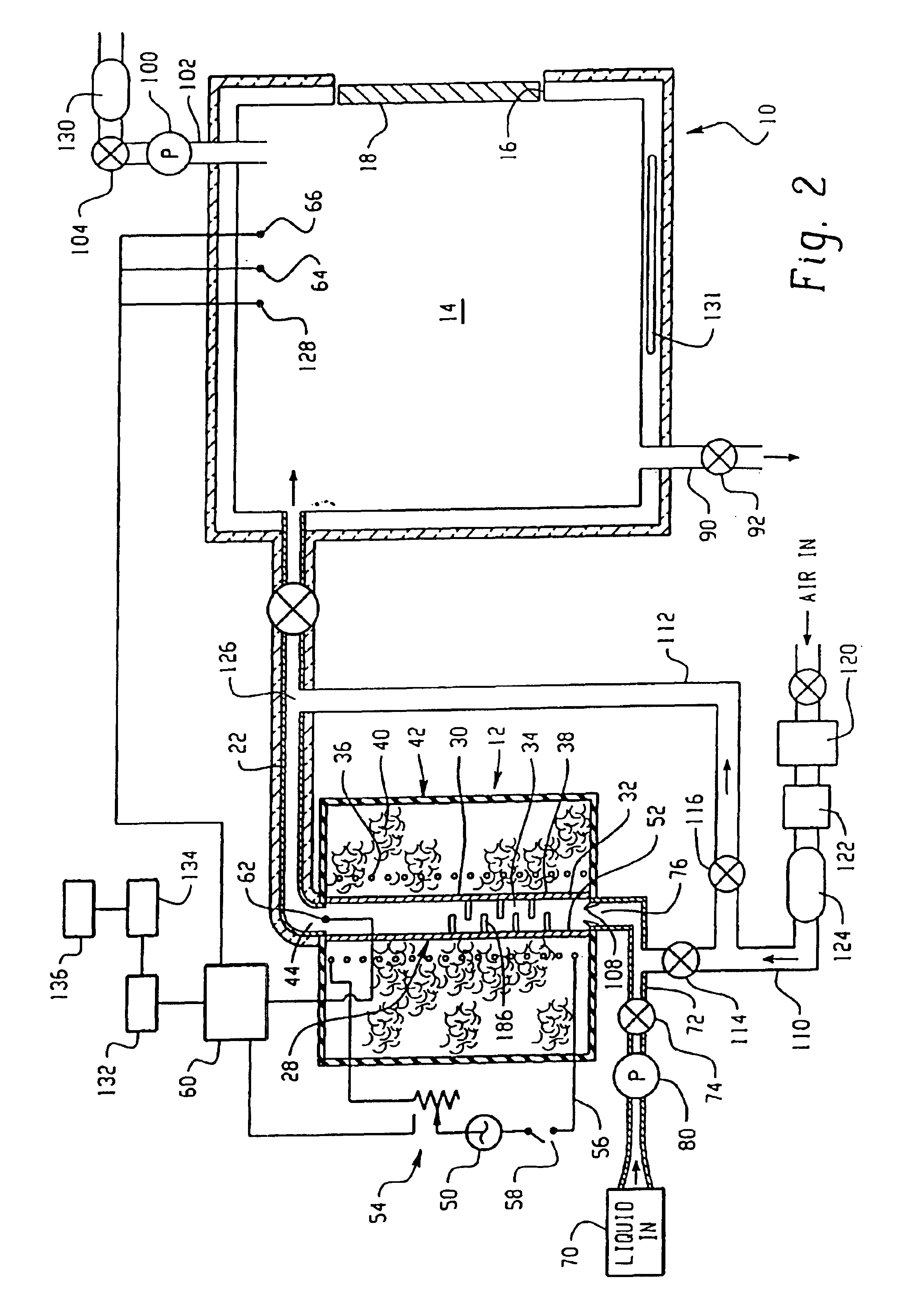

InactiveUS20030108342A1Internal combustion piston enginesWater-tube boilersCapillary TubingEngineering

An aerosol generator includes a fluid supply which supplies fluid to a fluid passage and a heater which heats the fluid into a gaseous state, the fluid passage being located between opposed layers of a laminate. The fluid passage can be a capillary sized passage formed by locating a mandrel between opposed layers of the laminate, bonding the layers together and removing the mandrel such that the space previously occupied by the mandrel forms the fluid passage. The opposed layers of the laminate can be copper sheets and ceramic layers can be provided on the outside of the copper layers. The aerosol generator can be used to generate aerosols containing medicated materials.

Owner:PHILIP MORRIS USA INC

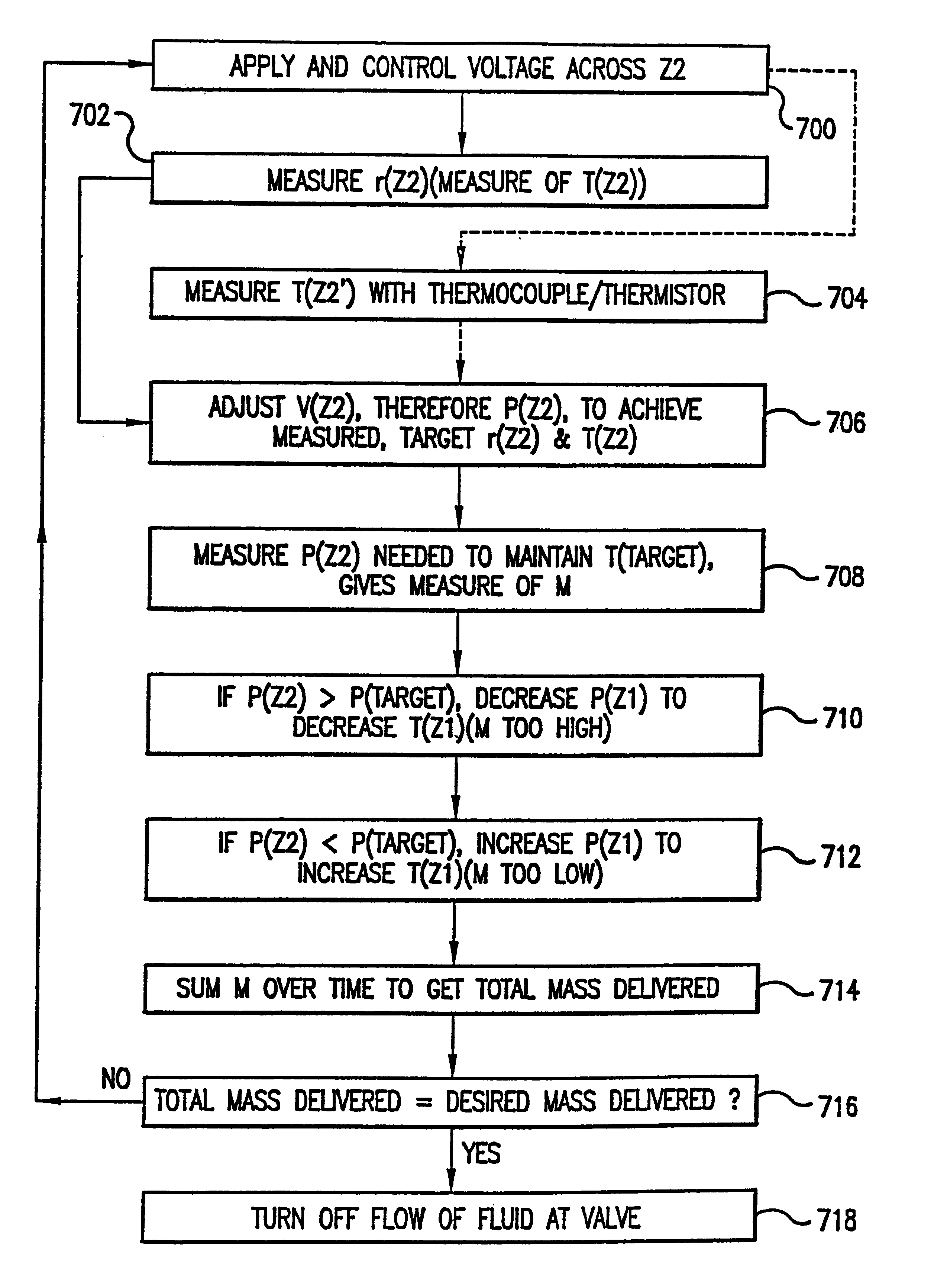

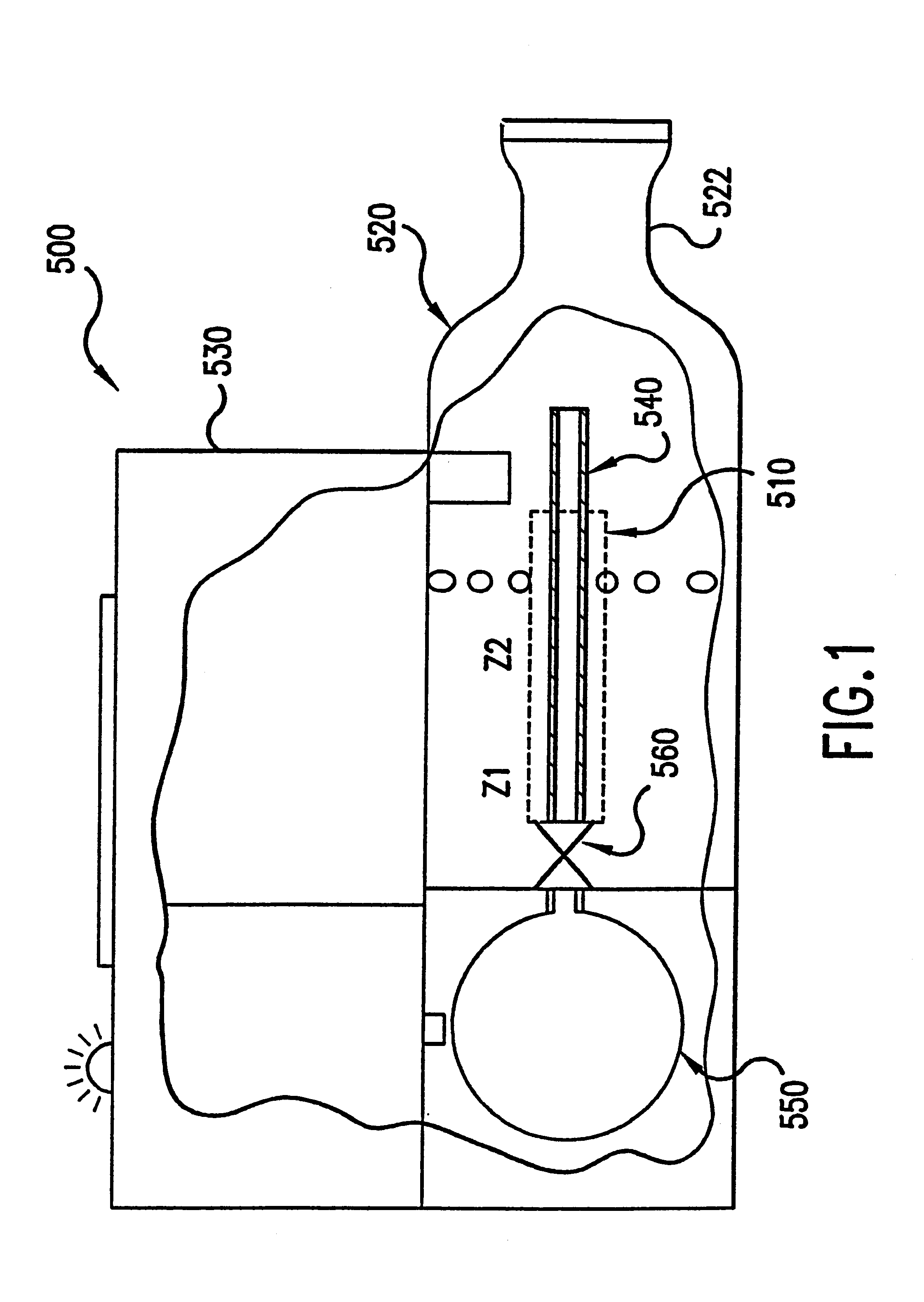

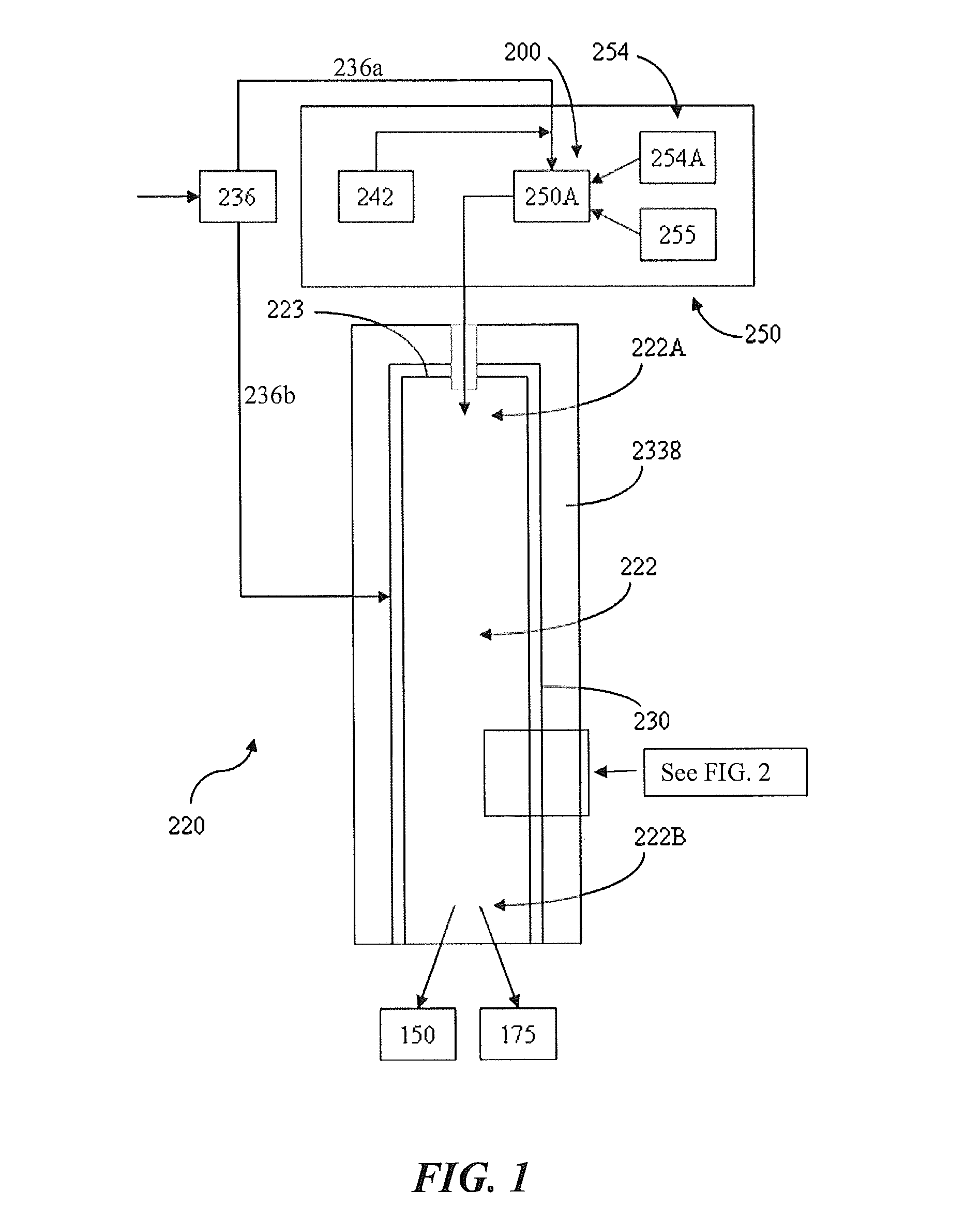

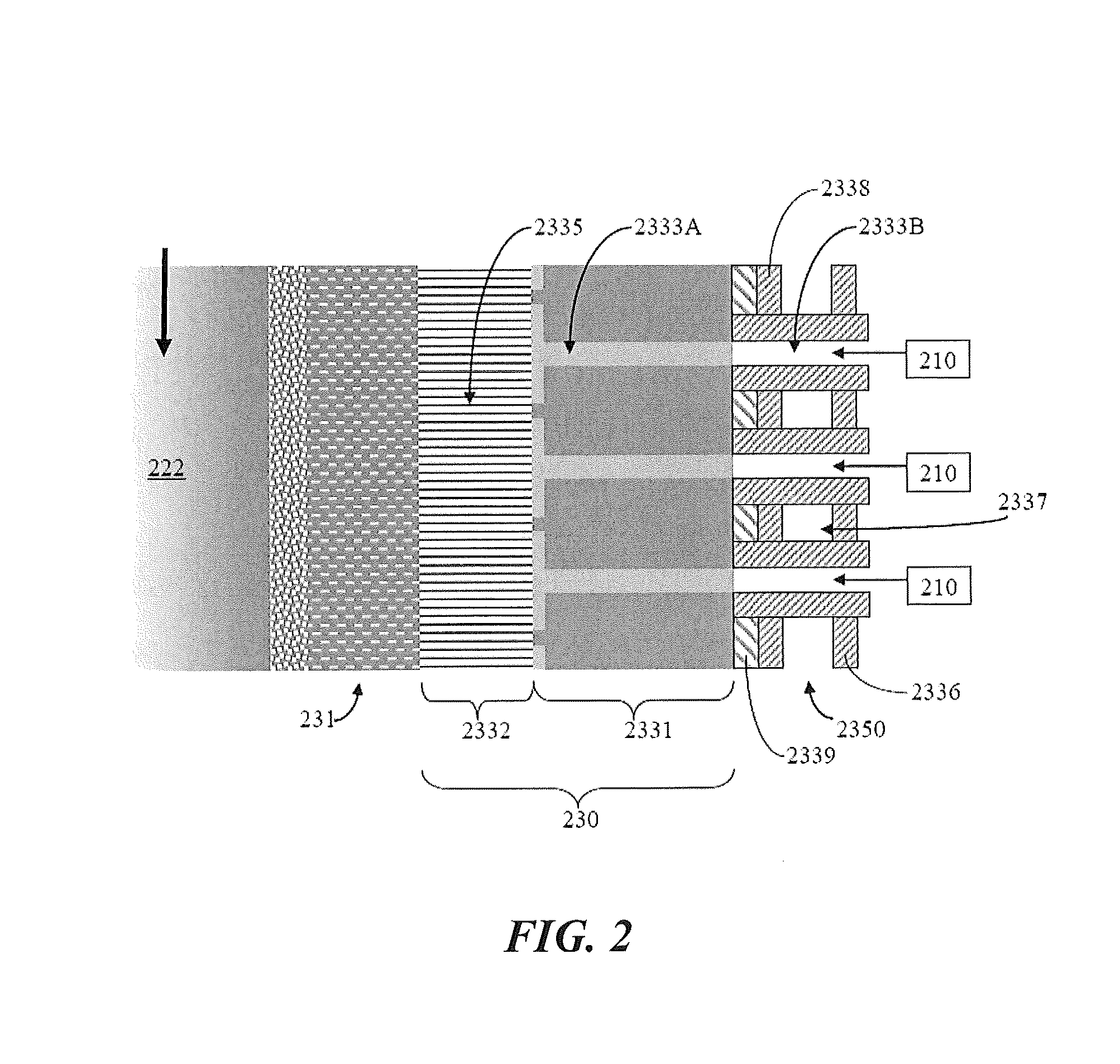

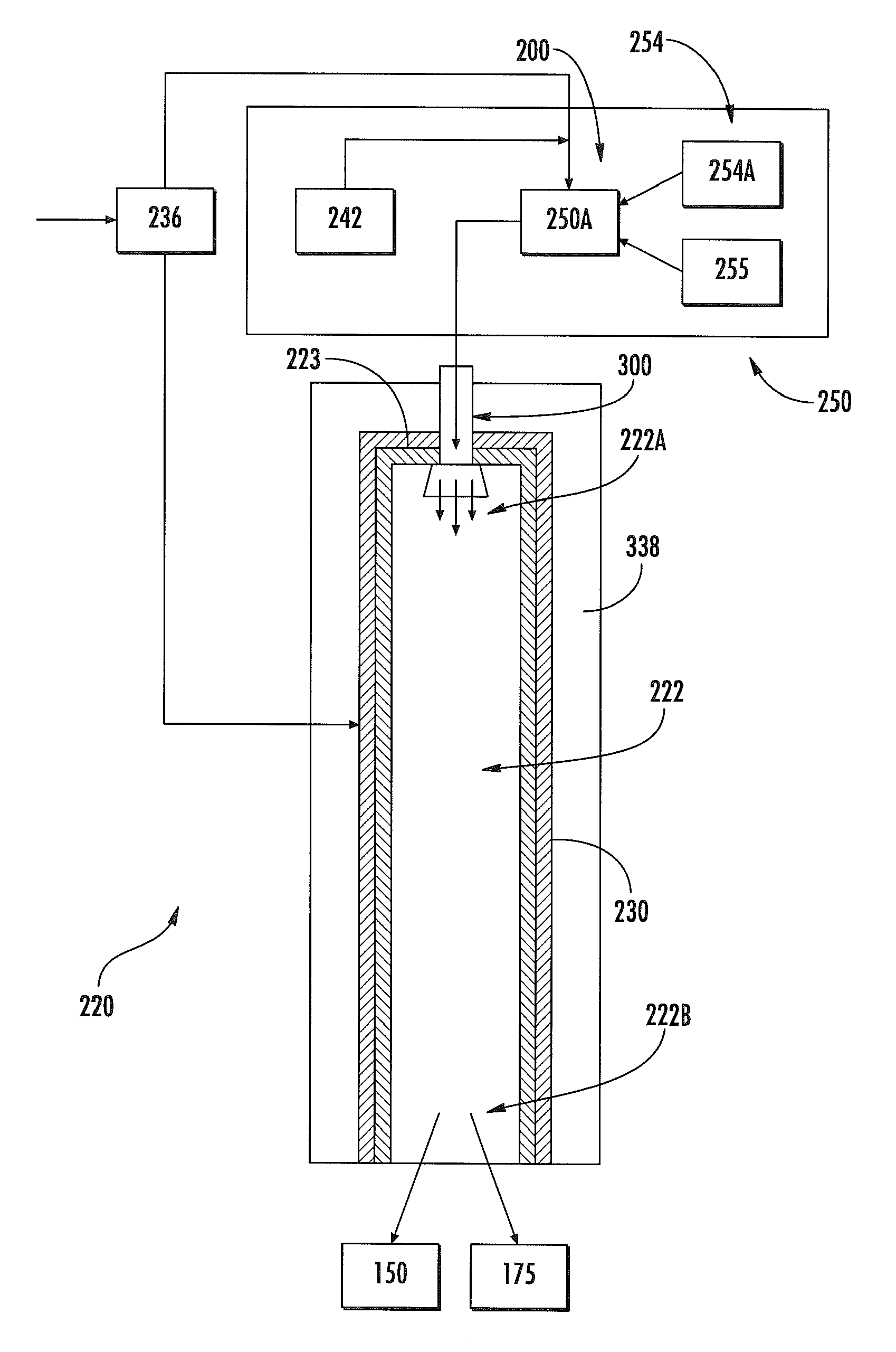

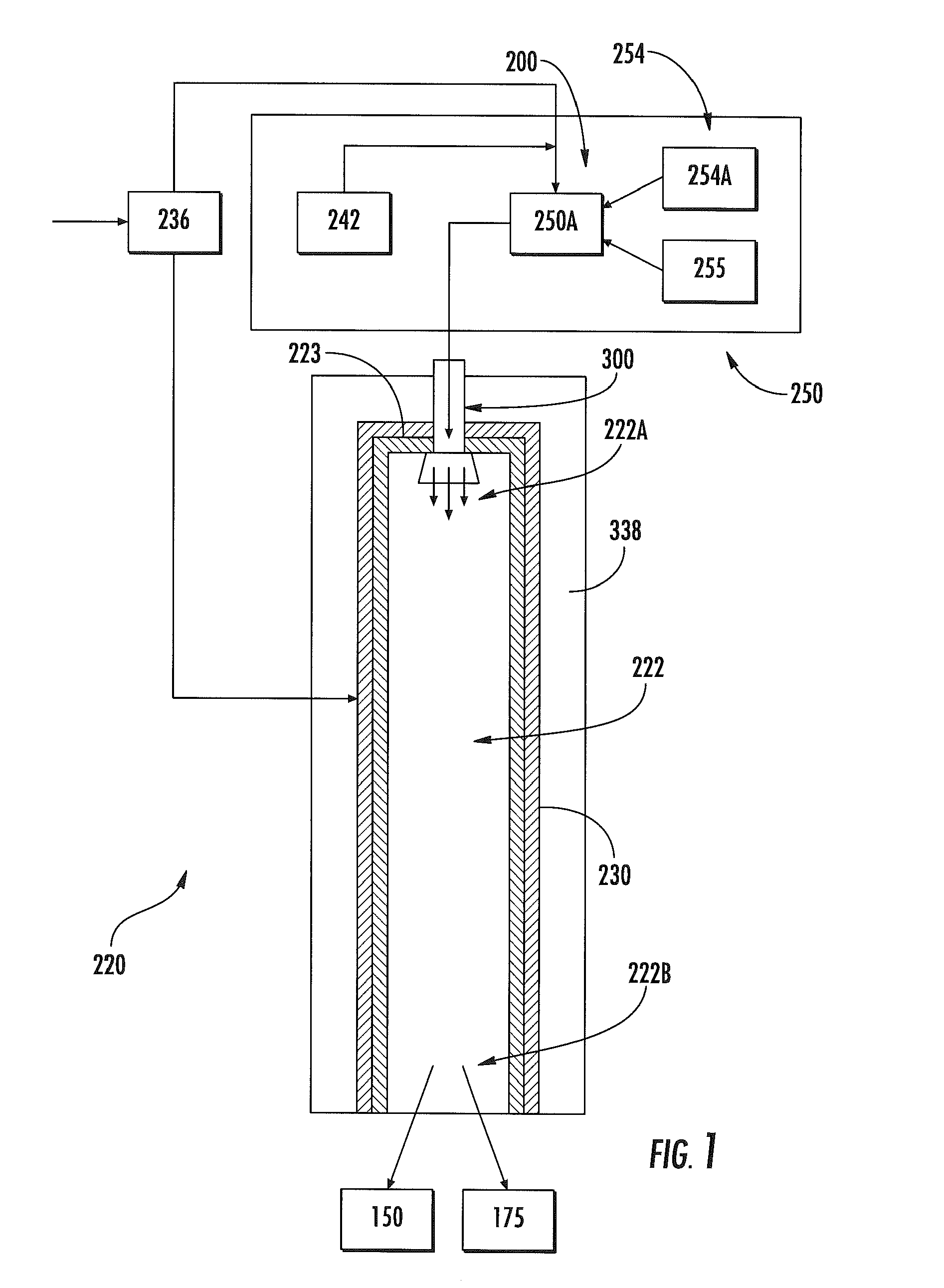

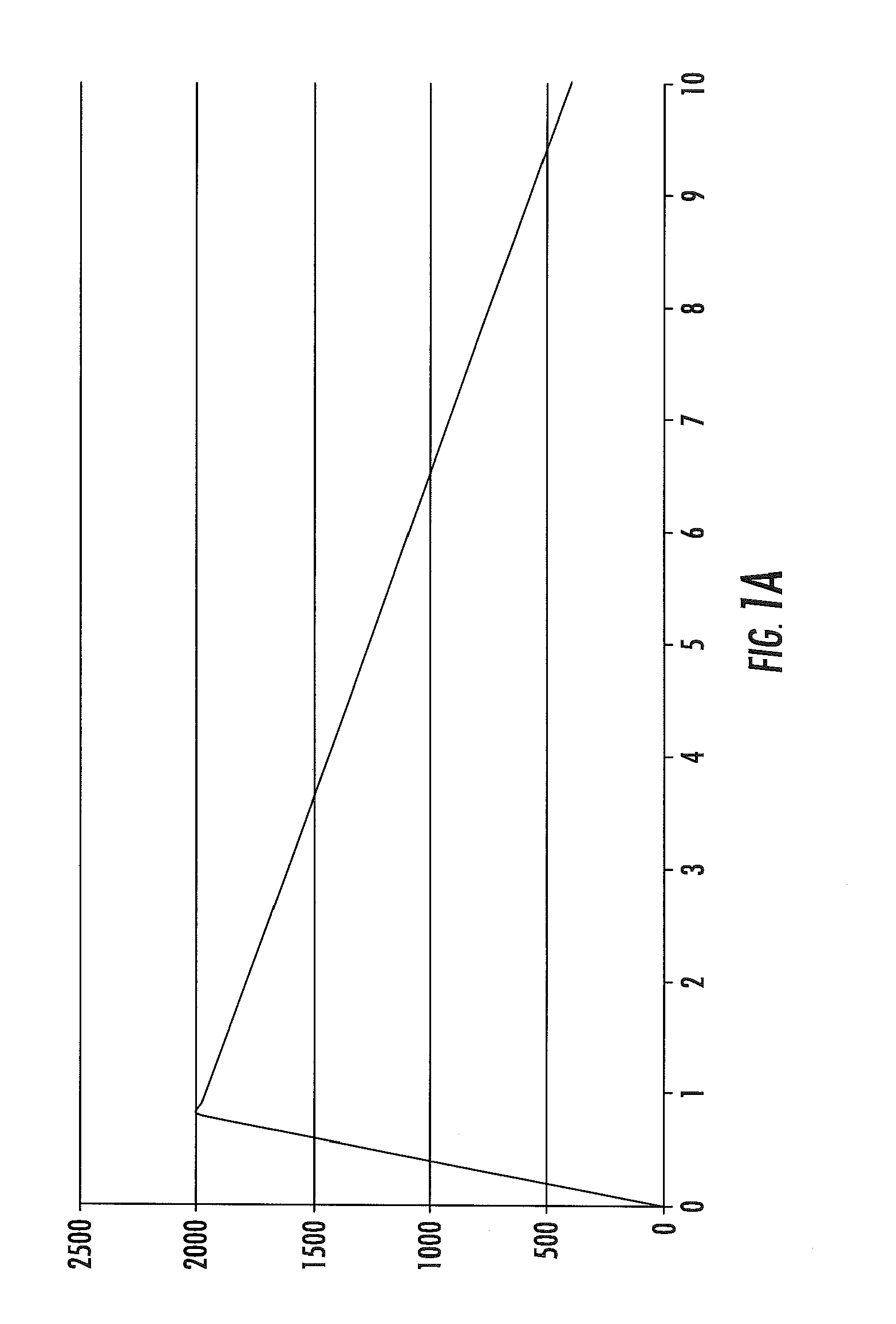

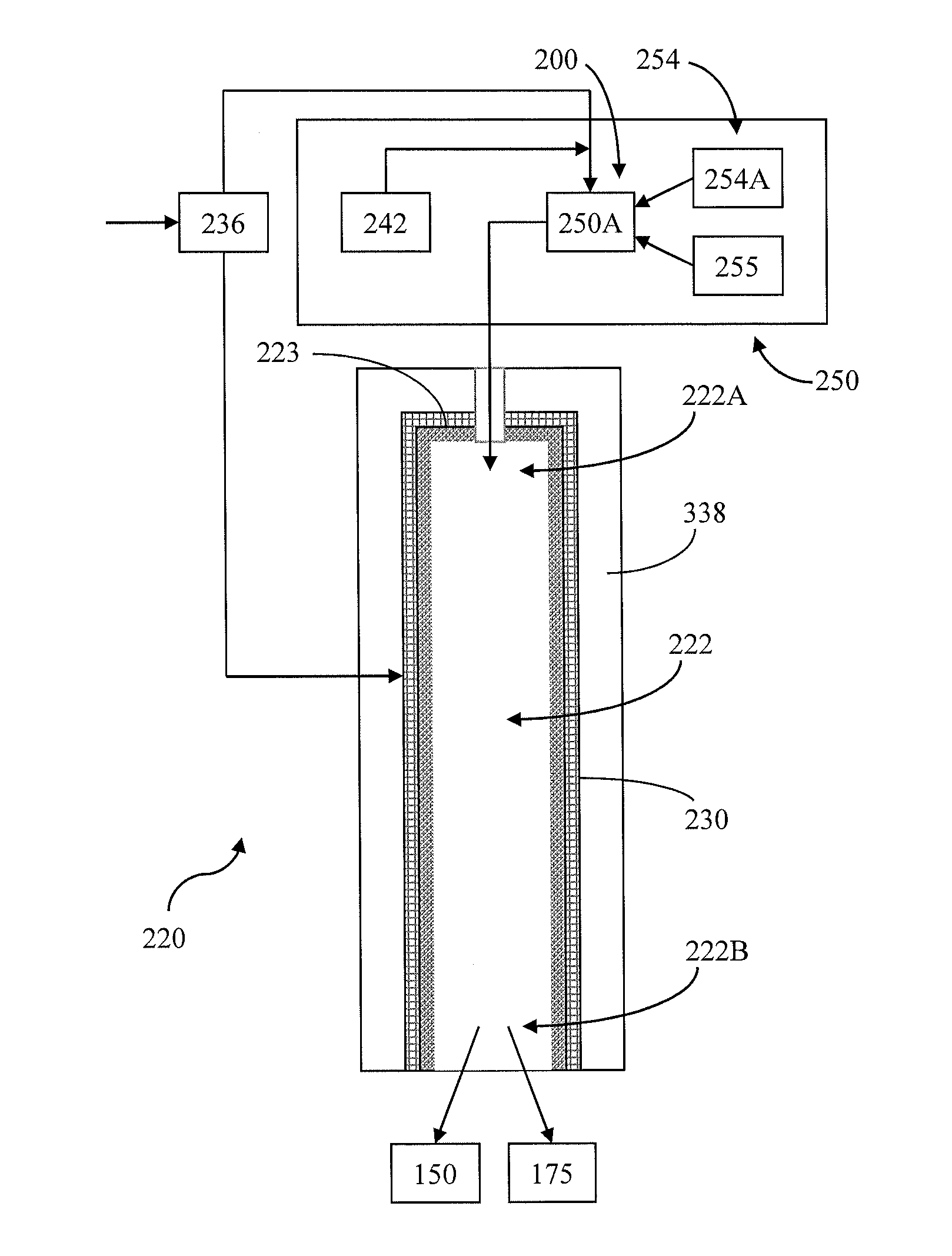

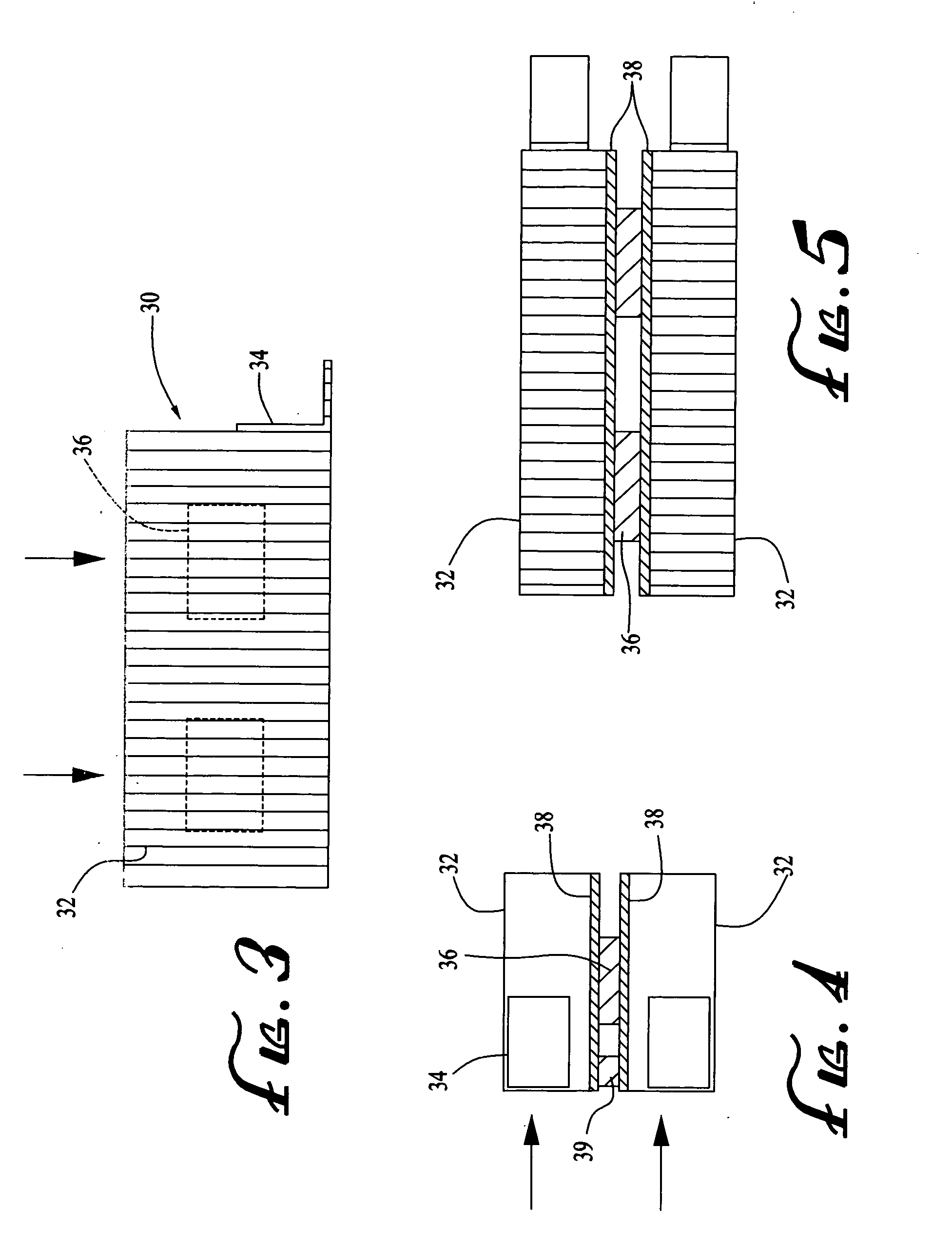

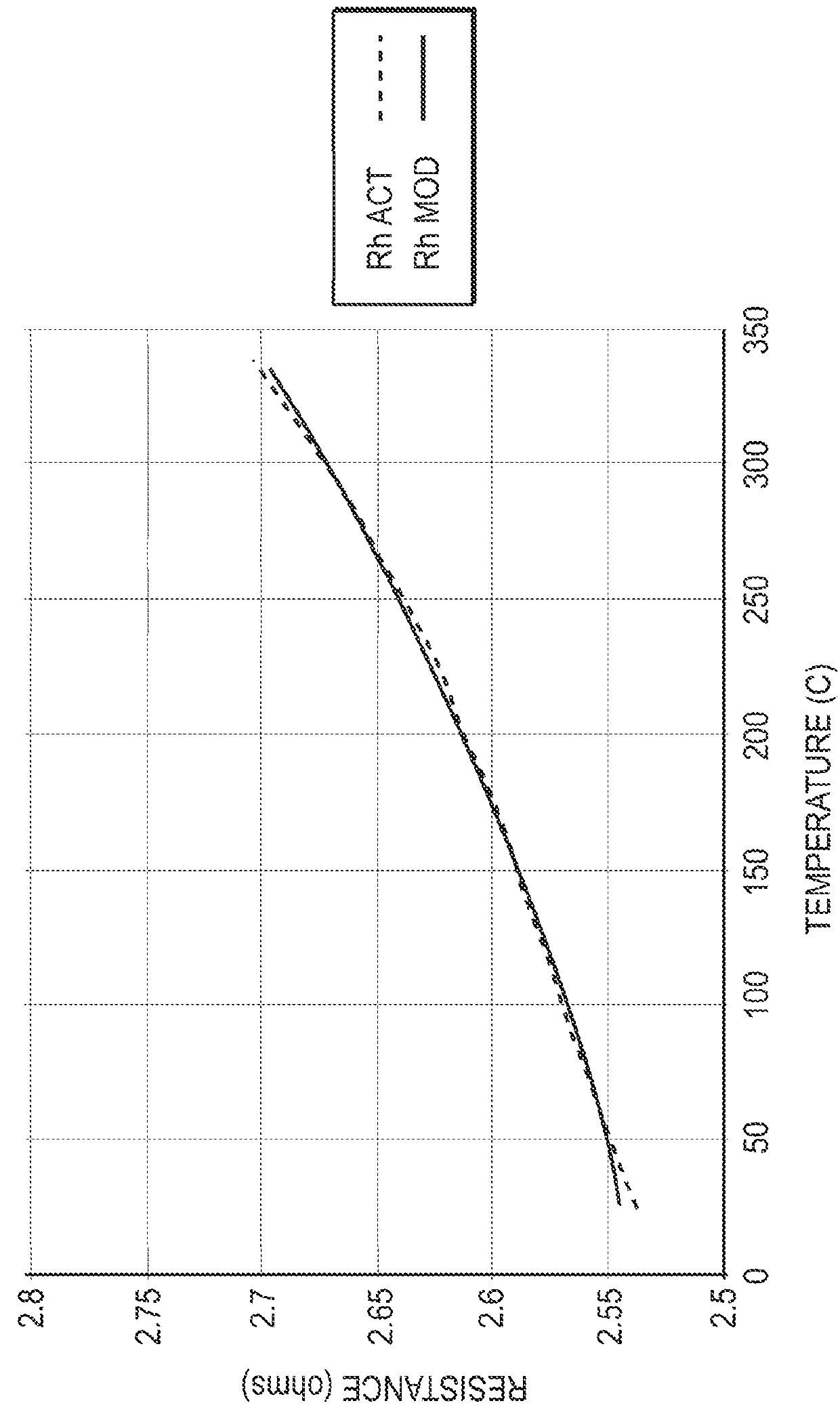

Aerosol generator having temperature controlled heating zone and method of use thereof

InactiveUS7173222B2Medical devicesBoiler controlTemperature controlElectrical resistance and conductance

A temperature and flow rate controlled capillary aerosol generator includes two heating zones optionally separated by a region in which a pressure drop is induced. Power is metered or applied to the downstream, second zone to achieve a target resistance, and therefore a target temperature, while power is metered or applied to the upstream, first zone to achieve a target mass flow rate exiting the second zone. A target temperature is achieved in the second zone to generate an aerosol from the liquid flowing through the generator at the desired mass flow rate.

Owner:PHILIP MORRIS USA INC

System and method for high efficiency power generation using a carbon dioxide circulating working fluid

ActiveUS8959887B2Improve efficiencyIncrease pressure ratioSolidificationLiquefactionWorking fluidCombustor

The present invention provides methods and system for power generation using a high efficiency combustor in combination with a CO2 circulating fluid. The methods and systems advantageously can make use of a low pressure ratio power turbine and an economizer heat exchanger in specific embodiments. Additional low grade heat from an external source can be used to provide part of an amount of heat needed for heating the recycle CO2 circulating fluid. Fuel derived CO2 can be captured and delivered at pipeline pressure. Other impurities can be captured.

Owner:8 RIVERS CAPTTAL LLC

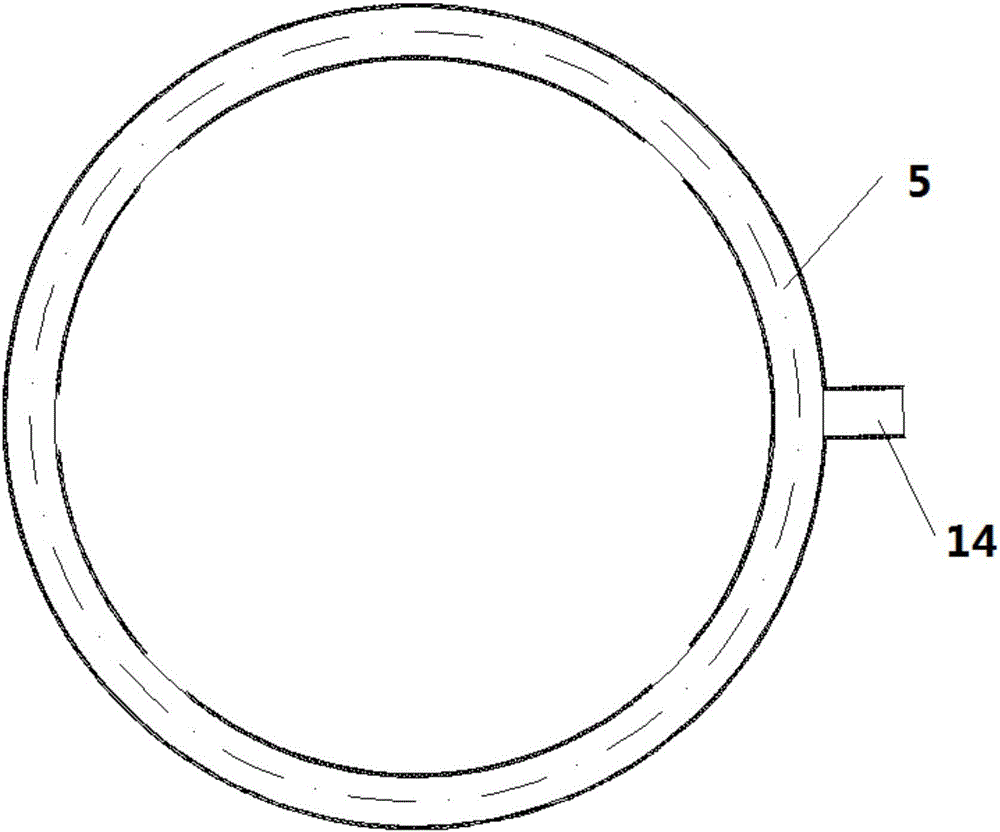

Apparatus for combusting a fuel at high pressure and high temperature, and associated system

ActiveUS8986002B2Reducing and eliminating needEliminate damage to and build-upContinuous combustion chamberGas turbine plantsWorking fluidCombustor

A combustor apparatus is provided, comprising a mixing arrangement for mixing a carbonaceous fuel with enriched oxygen and a working fluid to form a fuel mixture. A combustion chamber is at least partially defined by a porous perimetric transpiration member, at least partially surrounded by a pressure containment member. The combustion chamber has longitudinally spaced apart inlet and outlet portions. The fuel mixture is received by the inlet portion for combustion within the combustion chamber at a combustion temperature to form a combustion product. The combustion chamber directs the combustion product longitudinally toward the outlet portion. The transpiration member is configured to substantially uniformly direct a transpiration substance therethrough toward the combustion chamber, such that the transpiration substance is directed to flow helically about the perimeter and longitudinally between the inlet and outlet portions, for buffering interaction between the combustion product and the transpiration member. Associated systems are also provided.

Owner:8 RIVERS CAPTTAL LLC

Apparatus and Method for Combusting a Fuel at High Pressure and High Temperature, and Associated System and Device

ActiveUS20100300063A1Enhanced overall recoveryReducing and eliminating needSolidificationLiquefactionWorking fluidCombustion chamber

A combustor apparatus is provided, comprising a mixing arrangement for mixing a carbonaceous fuel with enriched oxygen and a working fluid to form a fuel mixture. A combustion chamber is at least partially defined by a transpiration member. The transpiration member is at least partially surrounded by a pressure containment member. The combustion chamber has opposed inlet and outlet portions. The inlet portion of the combustion chamber is configured to receive the fuel mixture for the fuel mixture to be combusted at a combustion temperature. The combustion chamber is further configured to direct the resulting combustion product toward the outlet portion. The transpiration member directs a transpiration substance therethrough toward the combustion chamber for buffering interaction between the combustion product and the transpiration member. Associated systems, apparatuses, and methods are also provided.

Owner:8 RIVERS CAPTTAL LLC

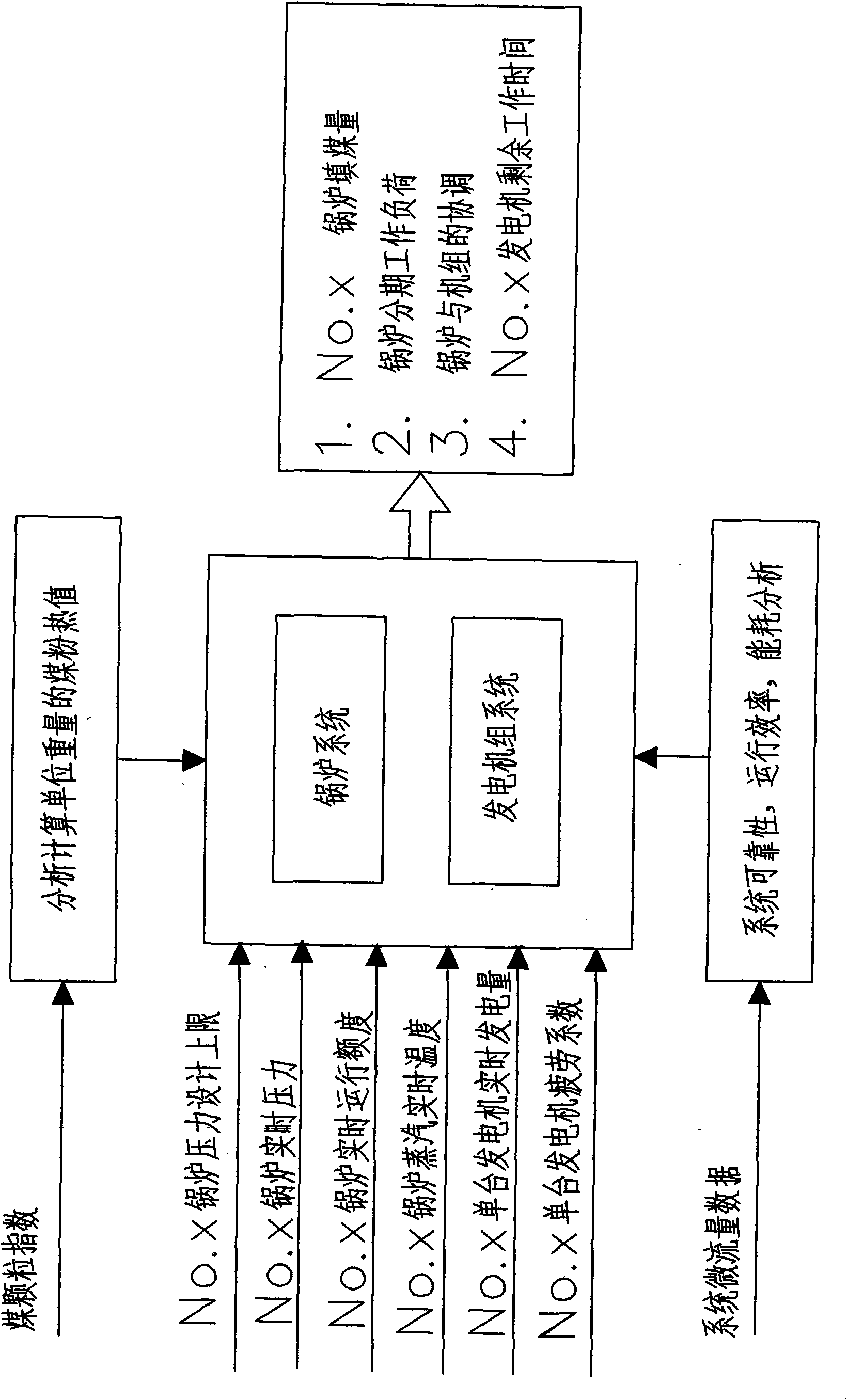

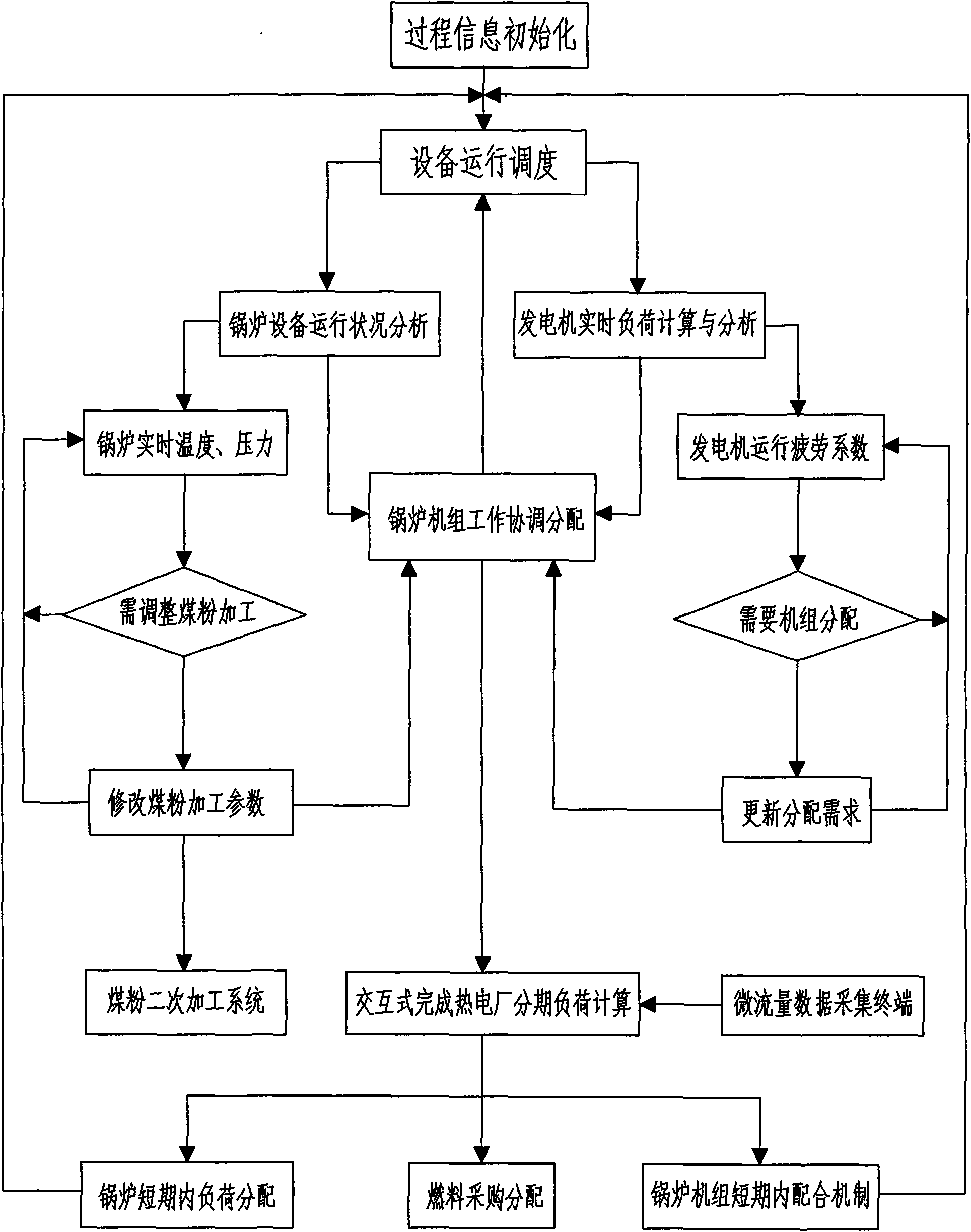

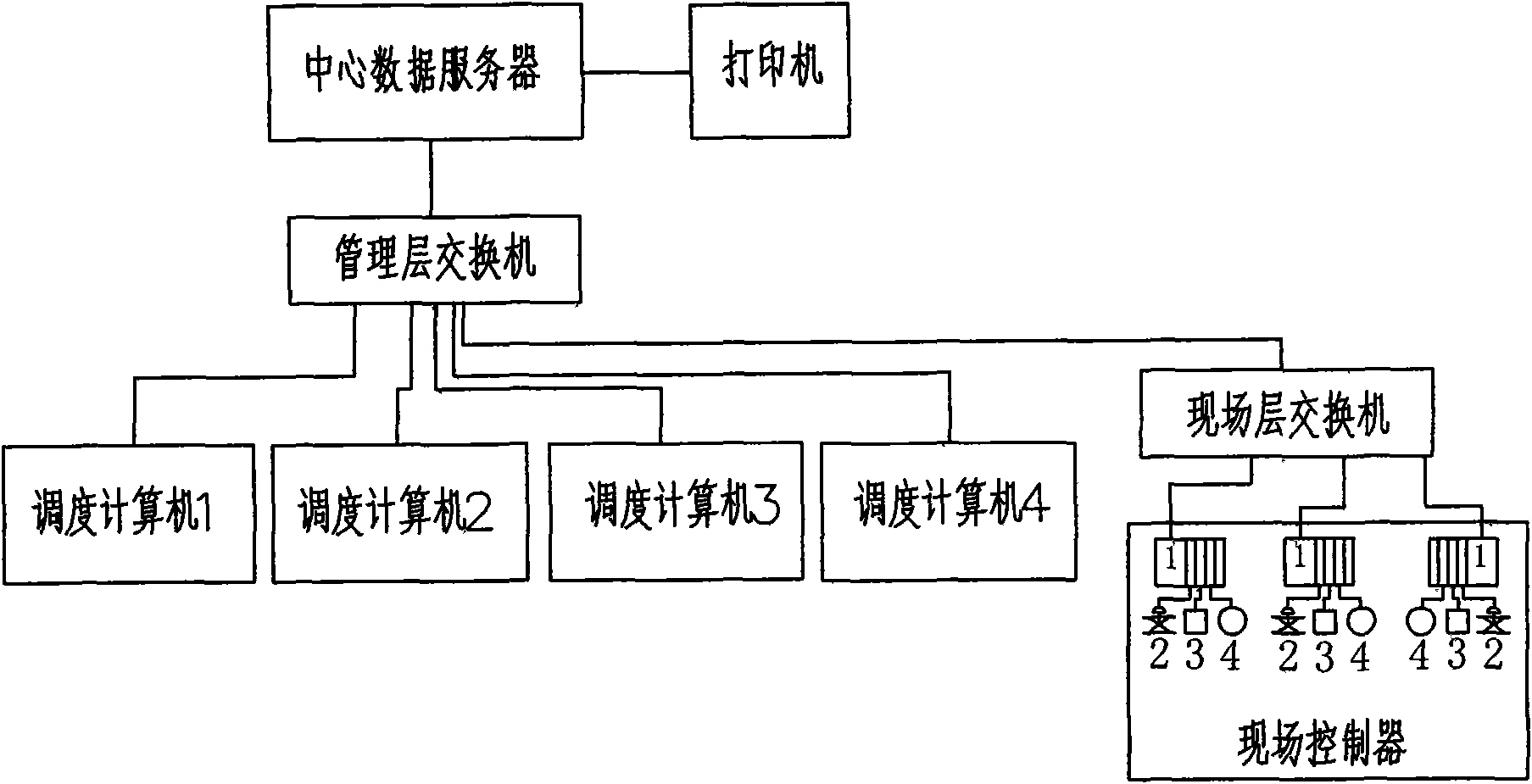

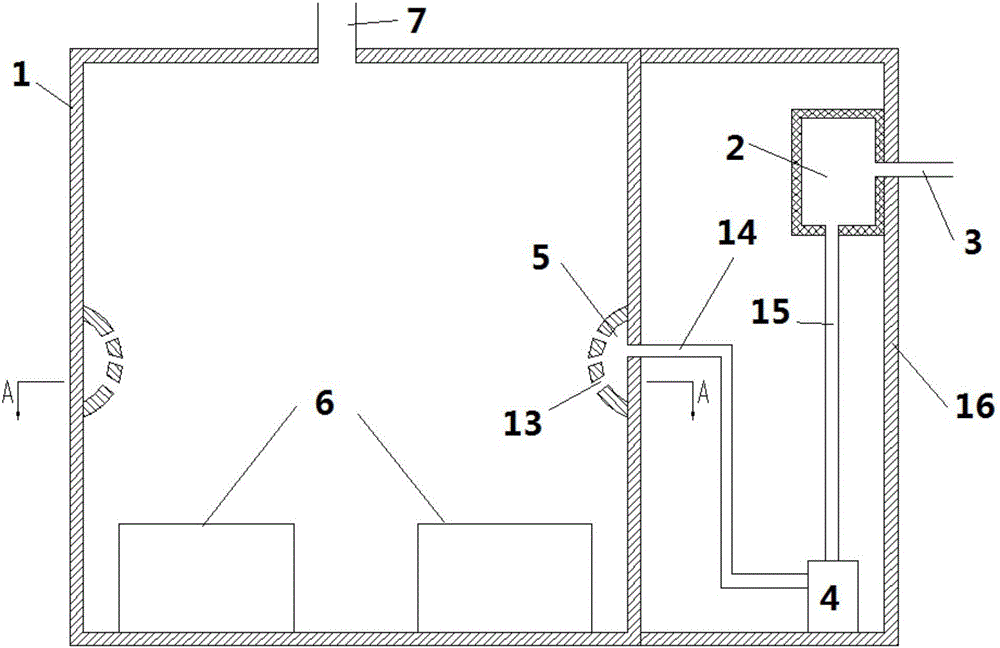

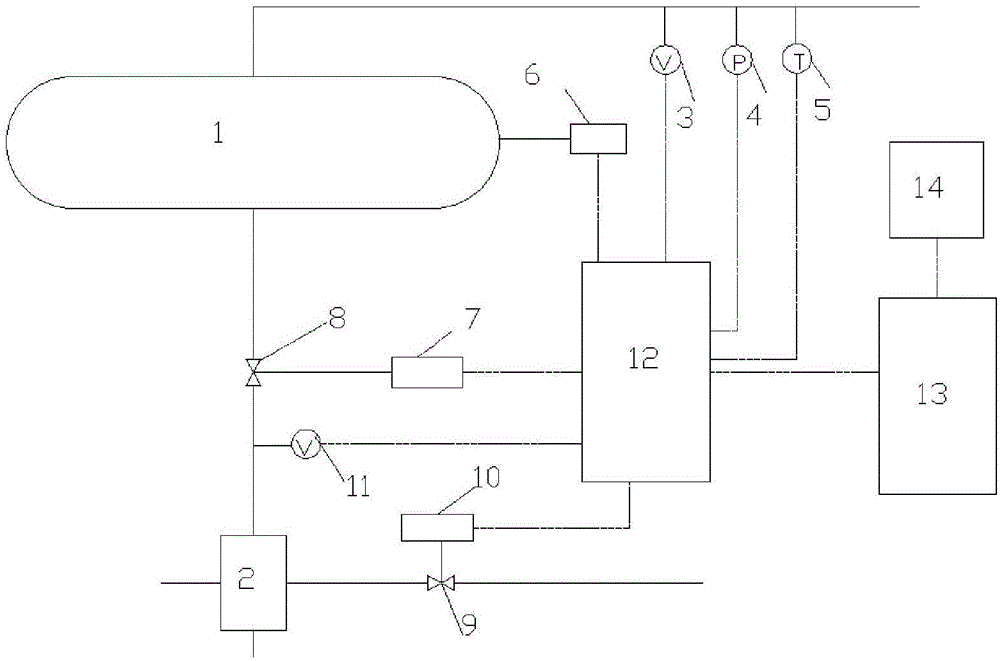

Dispatching method and dispatching system based on load online forecasting of thermoelectric power system

InactiveCN101619850AImprove production and operation efficiencyState switching is smoothEnergy industryBoiler controlLoad forecastingData acquisition

The invention discloses a dispatching method and a dispatching system based on load online forecasting of a thermoelectric power system. The dispatching method has the main objects of a boiler and a vapor generating set which are the core equipment of a thermoelectric power generation system. The dispatching process comprises the following steps: a. acquiring data; b. creating a real-time database and a historical database; c. analyzing data and making a dispatching decision, creating a decision dispatching knowledge base to obtain a corresponding operation decision in the current optimal state to be reached and in the recent optimal dispatching state, comparing the expectation effect of the dispatching decision with an actual effect, taking the result as the condition of load forecasting, and finally obtaining the optimal dispatching decision through human-computer interaction. The dispatching system comprises a field data acquiring terminal, a field production layer DCS, a management layer ERP, a center data server and a manufacture execution and management layer MES. The invention overcomes the defects existing in the prior art; and based on the production capacity and the distribution forecast of a thermoelectric plant, the dispatching method and the dispatching system facilitate improving the production operation efficiency of enterprises, lowering the source consumption and reducing the pollution discharge.

Owner:HANGZHOU PANGU AUTOMATION SYST

Convective cushion with positive coefficient of resistance heating mode

InactiveUS20070086757A1Eliminate useUse minimizedVehicle seatsStuffed mattressesElectrical resistance and conductanceRemote control

A cushion that is heated convectively using a positive temperature coefficient of resistance type resistive heating element that is provided with heat exchanging surfaces, includes a mattress pad, seat or the like with a bottom surface secured around its perimeter to an air permeable top surface, forming a plenum and containing tubular spacer material or other air flow structure therein. The plenum is connected to a power unit housing a blower, a heating module and a controller unit. The heating module includes a PTC type heating element in conduction with a base plate and a number of heat exchanger fins. Preferably the heating element is sandwiched between a pair of the base plates and the heat exchanger fins, and there is a seal between the base plates to minimize air flow from the blower from passing there between. A remote control for the user's convenience may be provided, and a foldable antenna attachable to the convective unit facilitates wireless communication between the remote control and controller unit. The user resting atop the cushion is able to control the blower and heating module to deliver air of a desired temperature and quantity to the cushion and through the top surface. The invention advantageously replaces the current carrying, conductive wires and insulation found inside prior art heated mattresses, enhancing safety and performance while at the same time offering a cooled or ventilated capability.

Owner:FEHER STEVE

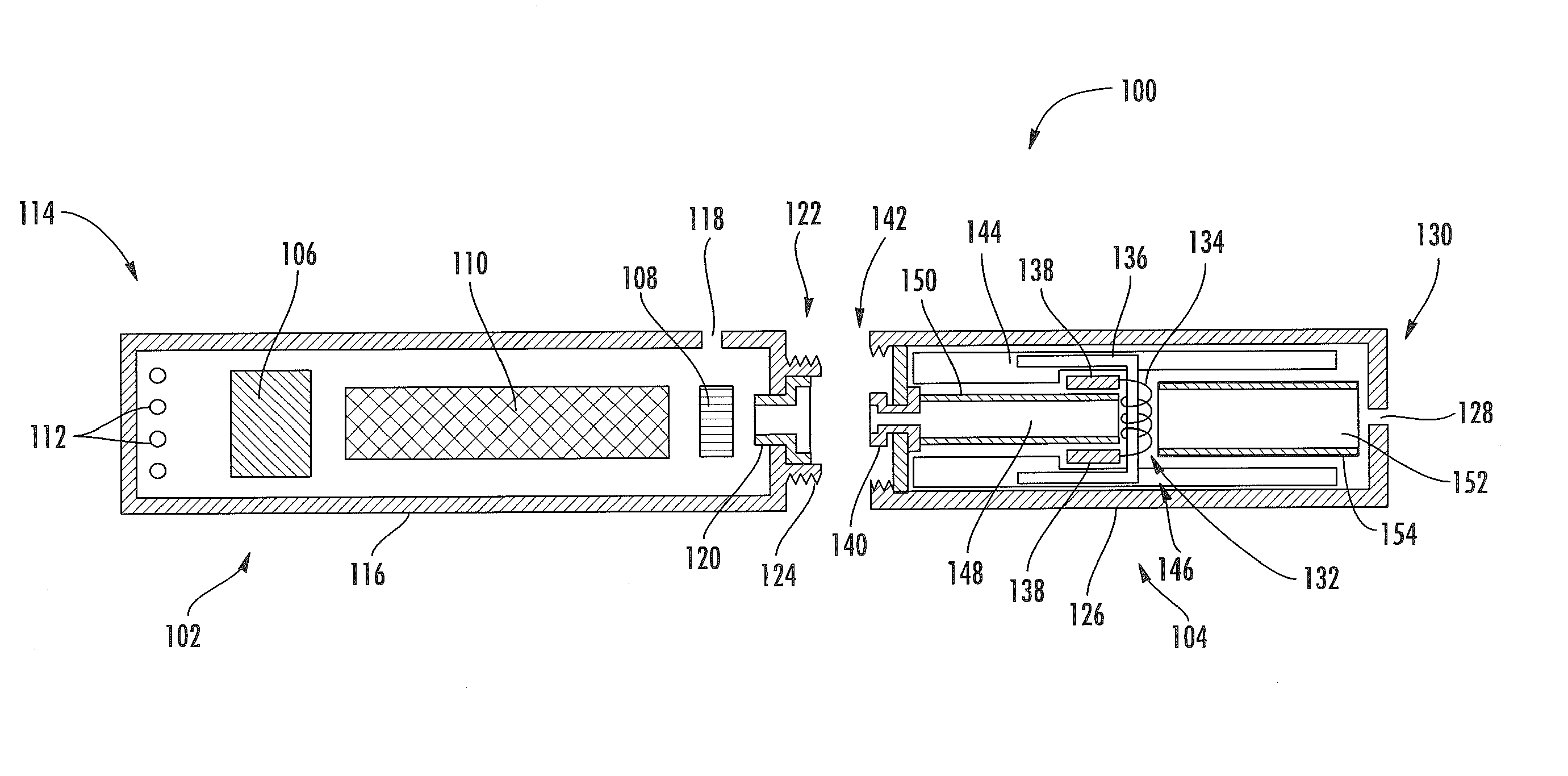

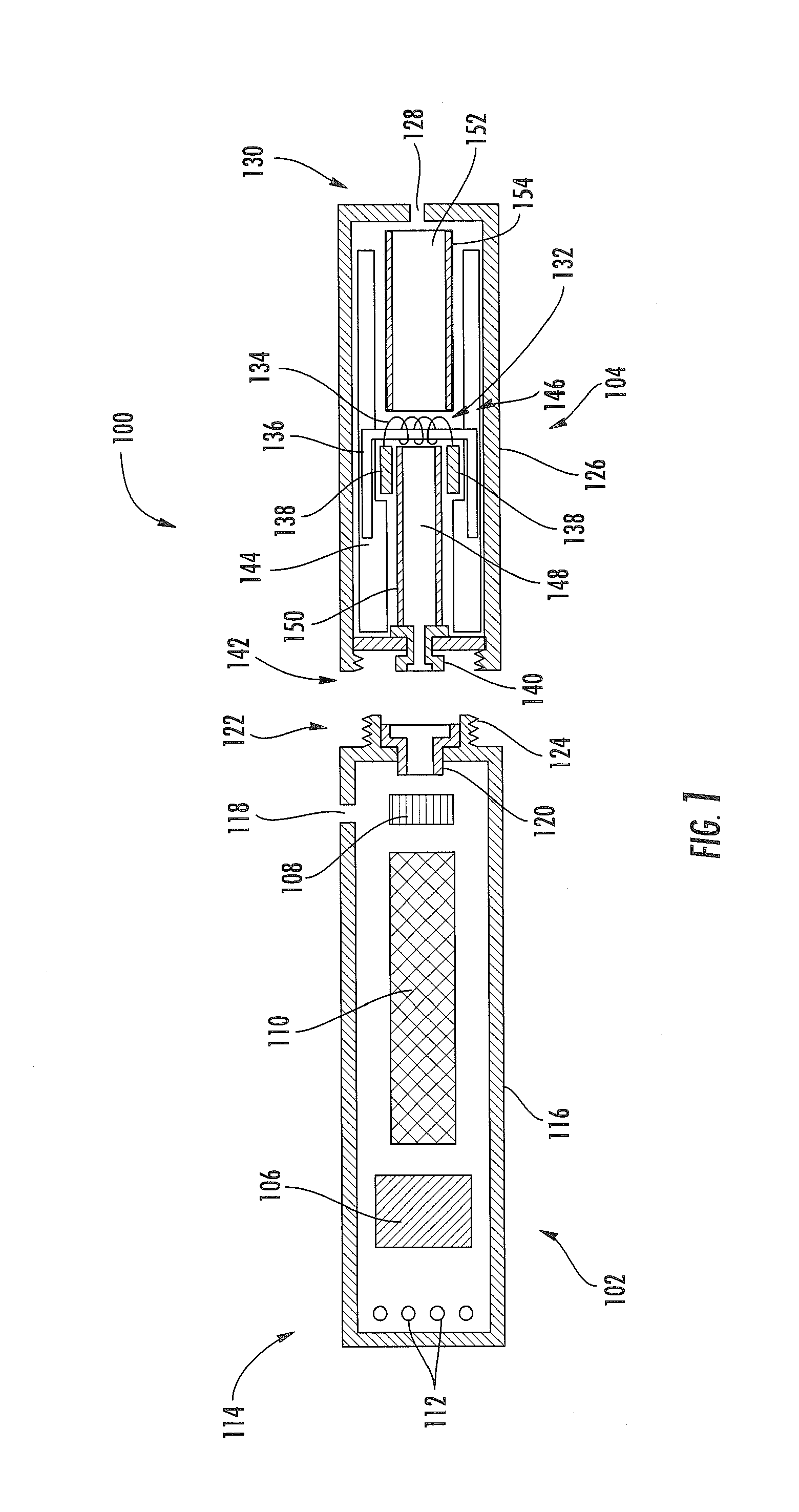

Heating control for vaporizing device

ActiveUS20160053988A1Machines/enginesGaseous substancesElectrical resistance and conductanceElectronic communication

The temperature of a vaporizing device, e.g., the temperature of a heating element of the vaporizing device, may be controlled according to various aspects of the present disclosure. The vaporizing device may comprise a heating element, a power source, at least one sensor in electronic communication with the heating element and the power source, and a processor configured to control the temperature of the heating element. The method of controlling the temperature may comprise receiving a resistance measurement of the heating element from the at least one sensor, determining the temperature of the heating element based on the resistance measurement, and adjusting the amount of power supplied to the heating element based on the determined temperature of the heating element.

Owner:NJOY LLC

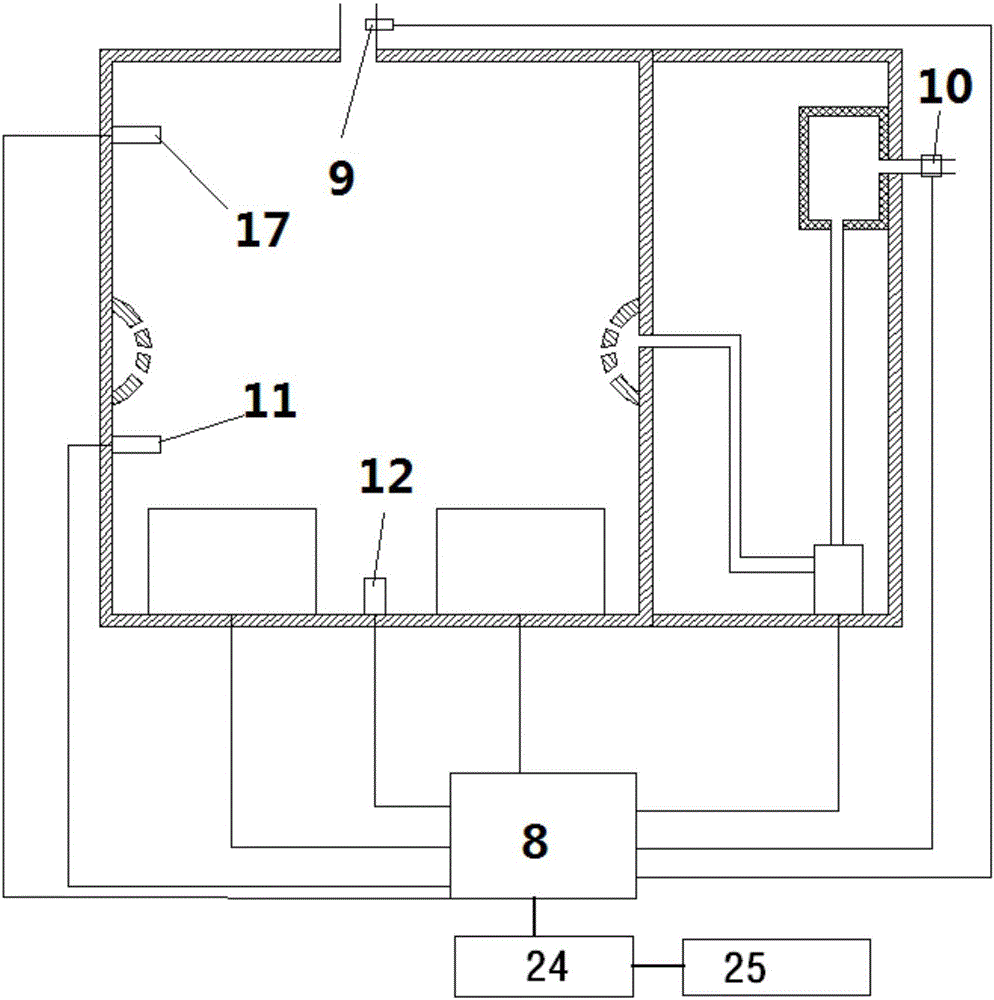

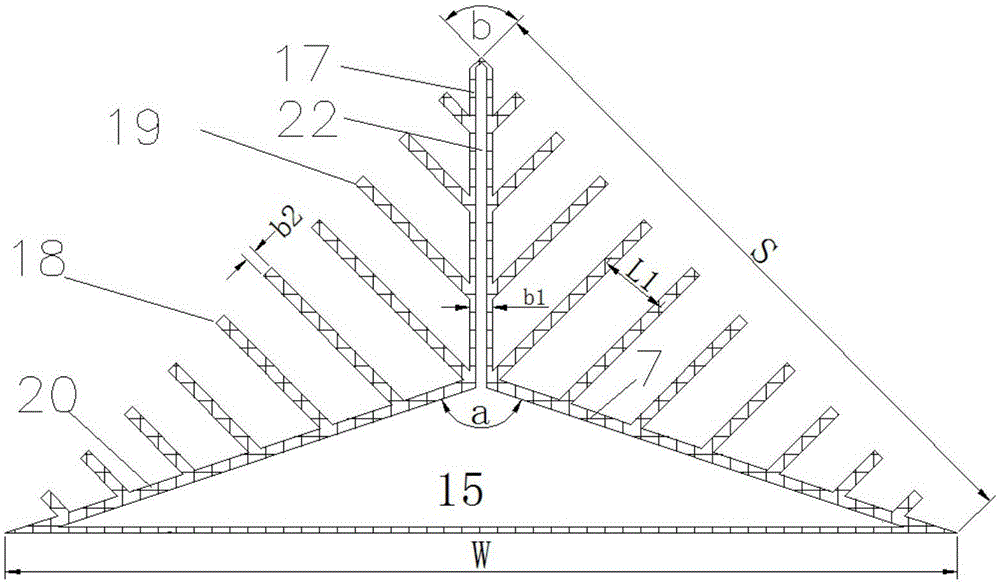

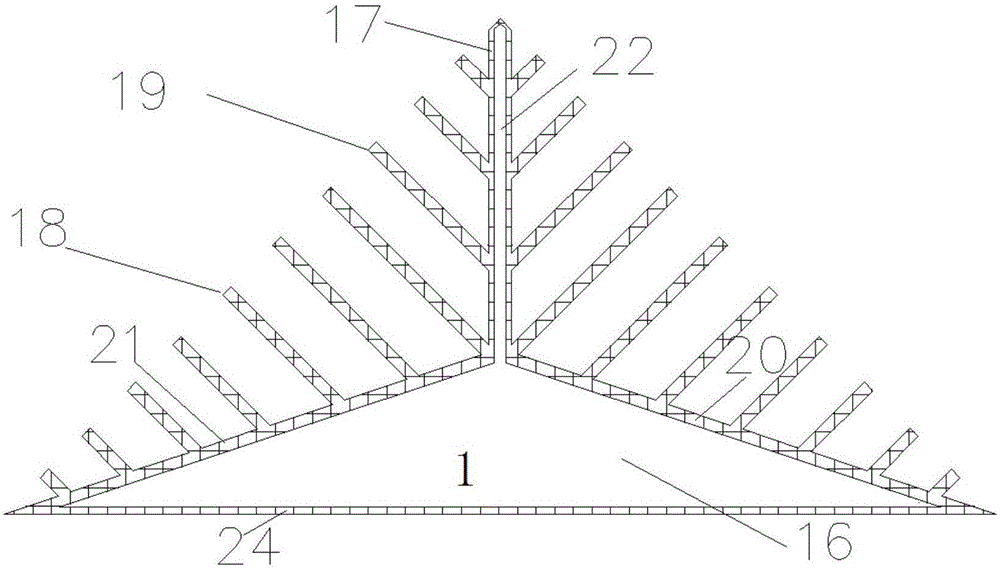

Steam generator with heating power intelligently distributed through mobile phone APP

InactiveCN106402824ARealize automatic allocationImprove intelligenceSteam generation heating methodsBoiler controlData connectionAutomatic control

The invention provides a steam generator which comprises a furnace body, a water tank and a water pump. An electric heating device is arranged in the furnace body. A steam outlet pipeline is arranged on the upper portion of the furnace body. The water tank is provided with an inlet pipe. The electric heating device comprises a left pipe box, a right pipe box and a floating coiled pipe. A first electric heater is arranged in the left pipe box, a second electric heater is arranged in the right pipe box, the first electric heater and the second electric heater are in data connection with a controller, the controller is connected with a cloud server, and the cloud server is connected with a client side. The measured heating power of the first electric heater and that of the second electric heater are transmitted to the cloud server through the controller and then transmitted to the client side through the cloud server, the client side is a mobile phone, an APP is installed in the mobile phone, and a user can select a working mode of automatic control or manual control at the client side. Operation of the steam generator is monitored through the mobile phone APP, and the intelligent control that the steam generator is remotely monitored is achieved.

Owner:QINGDAO UNIV OF SCI & TECH

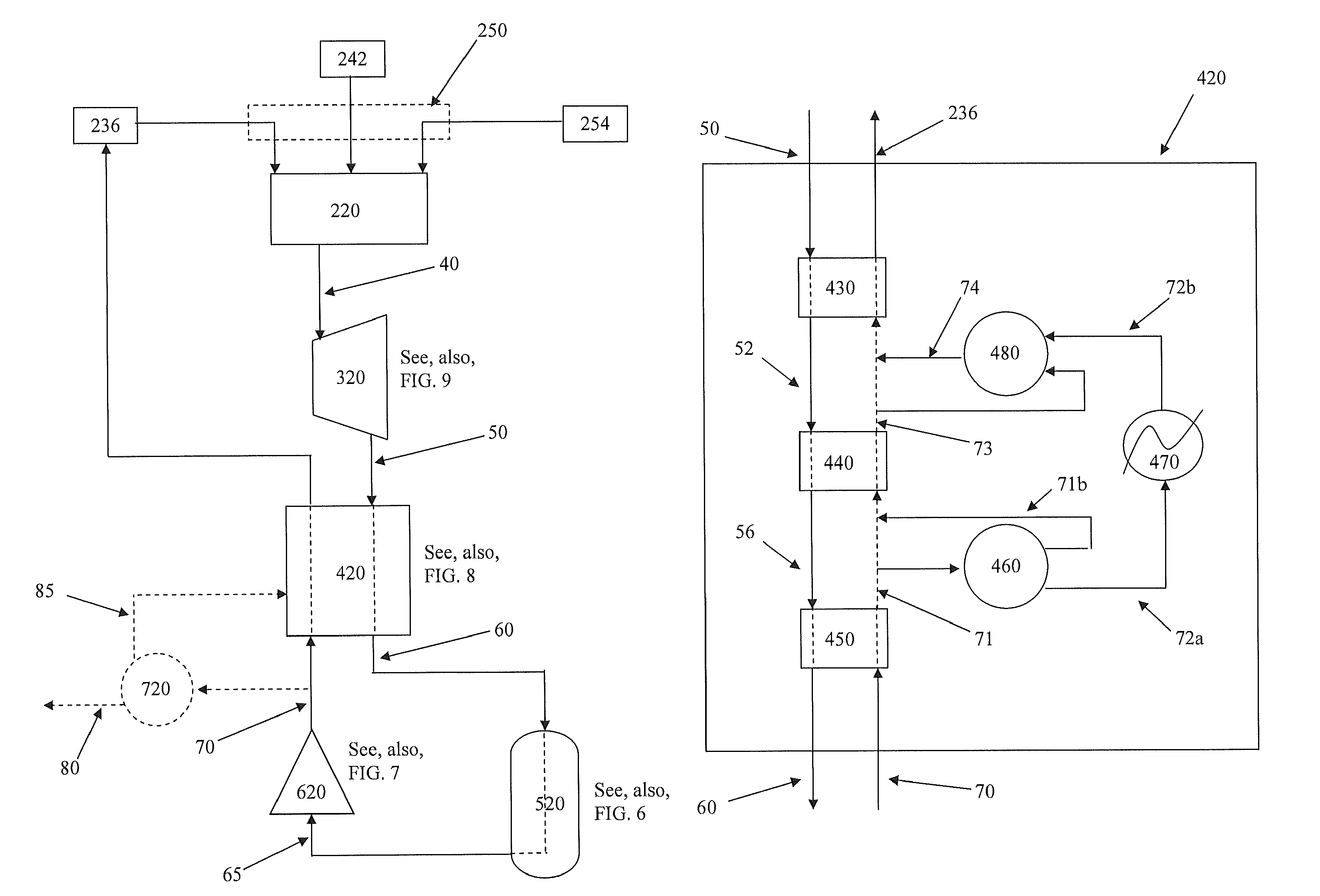

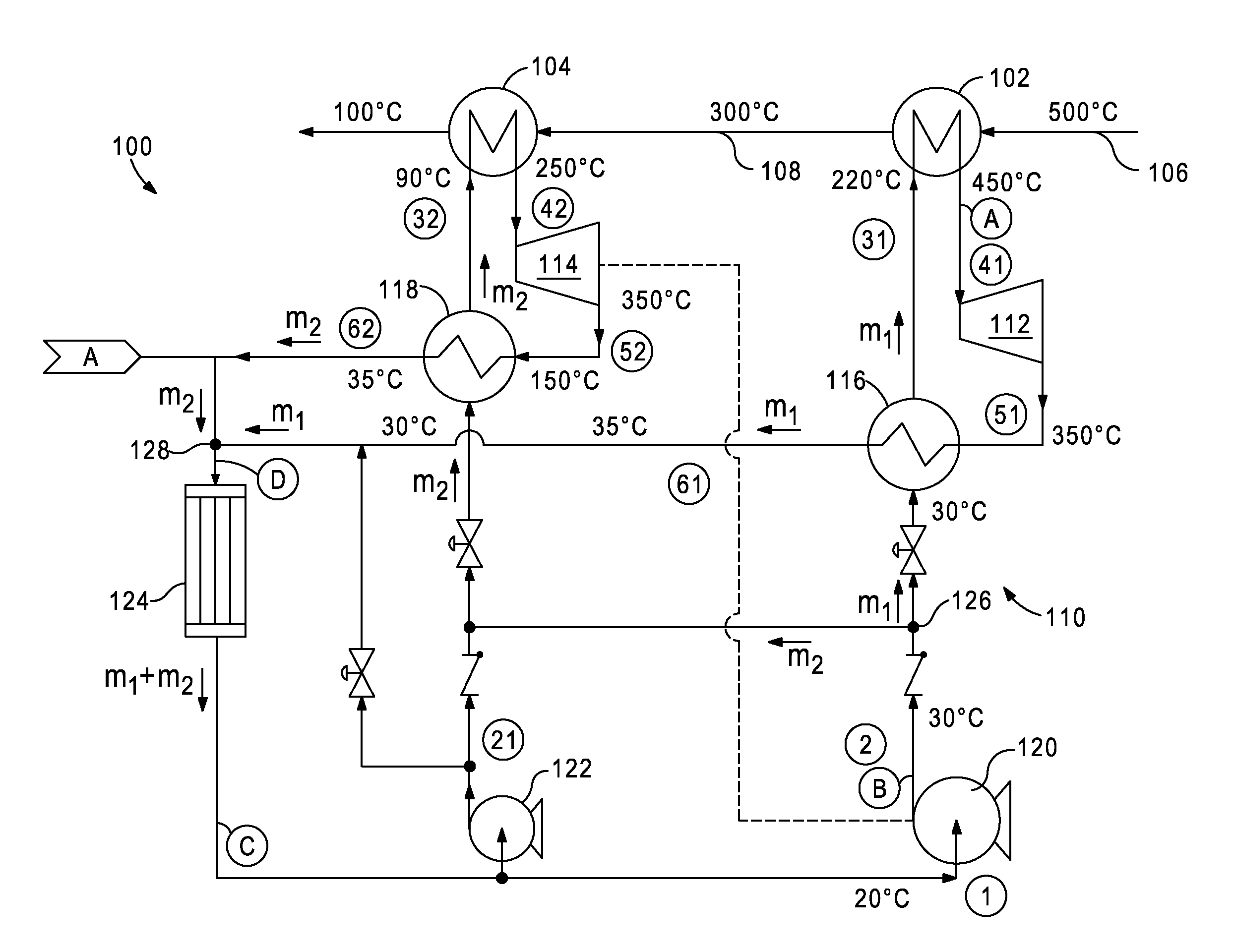

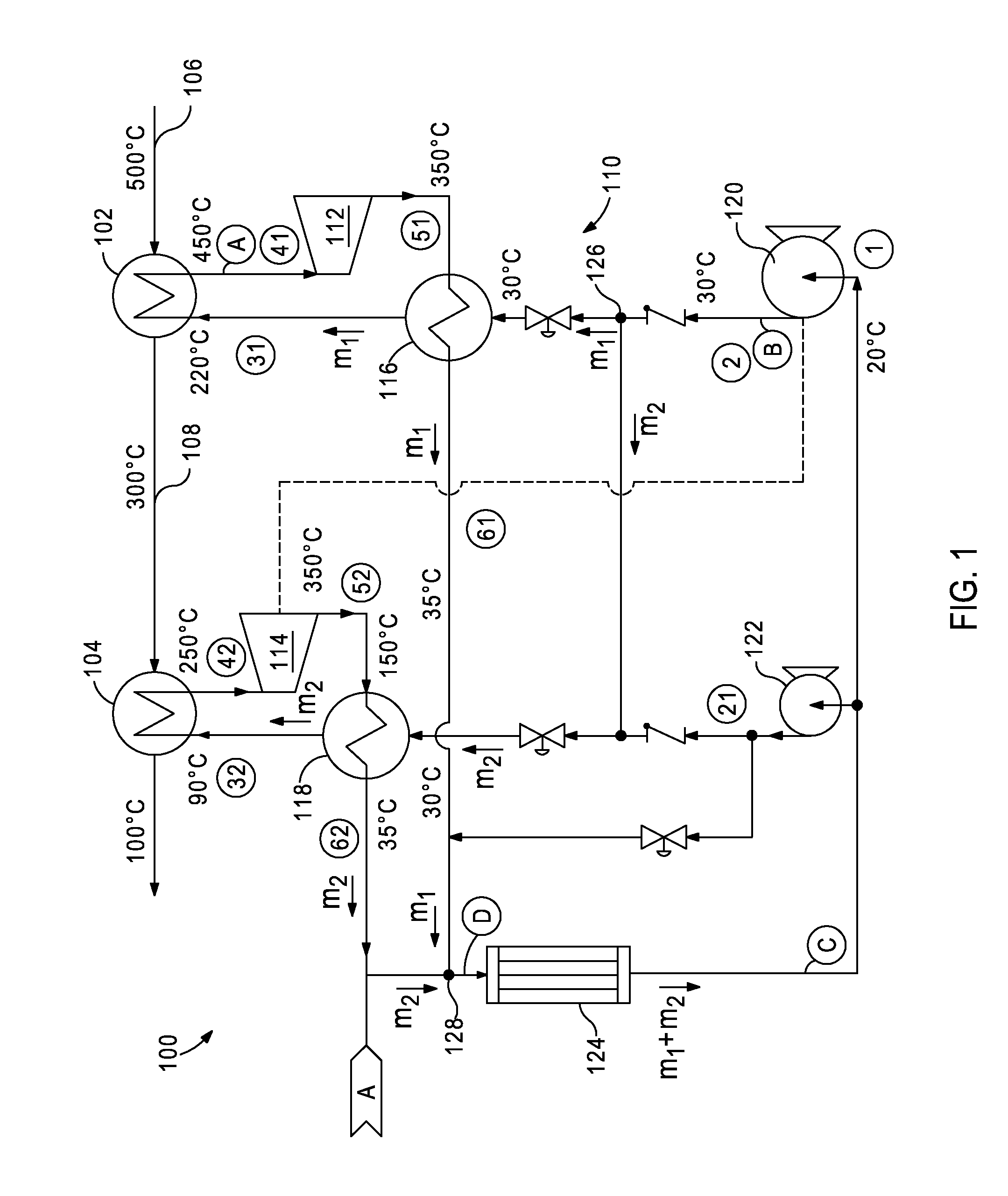

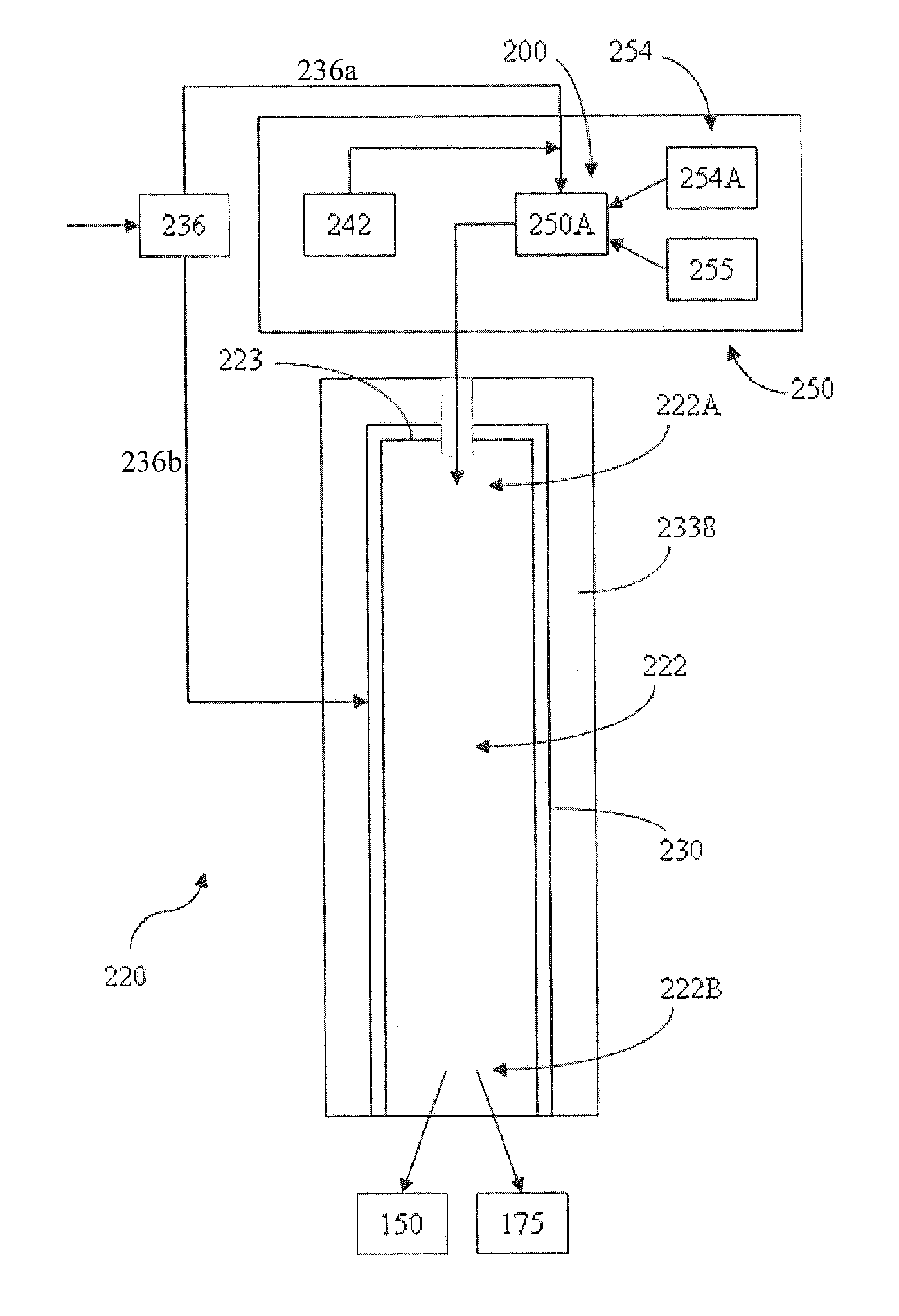

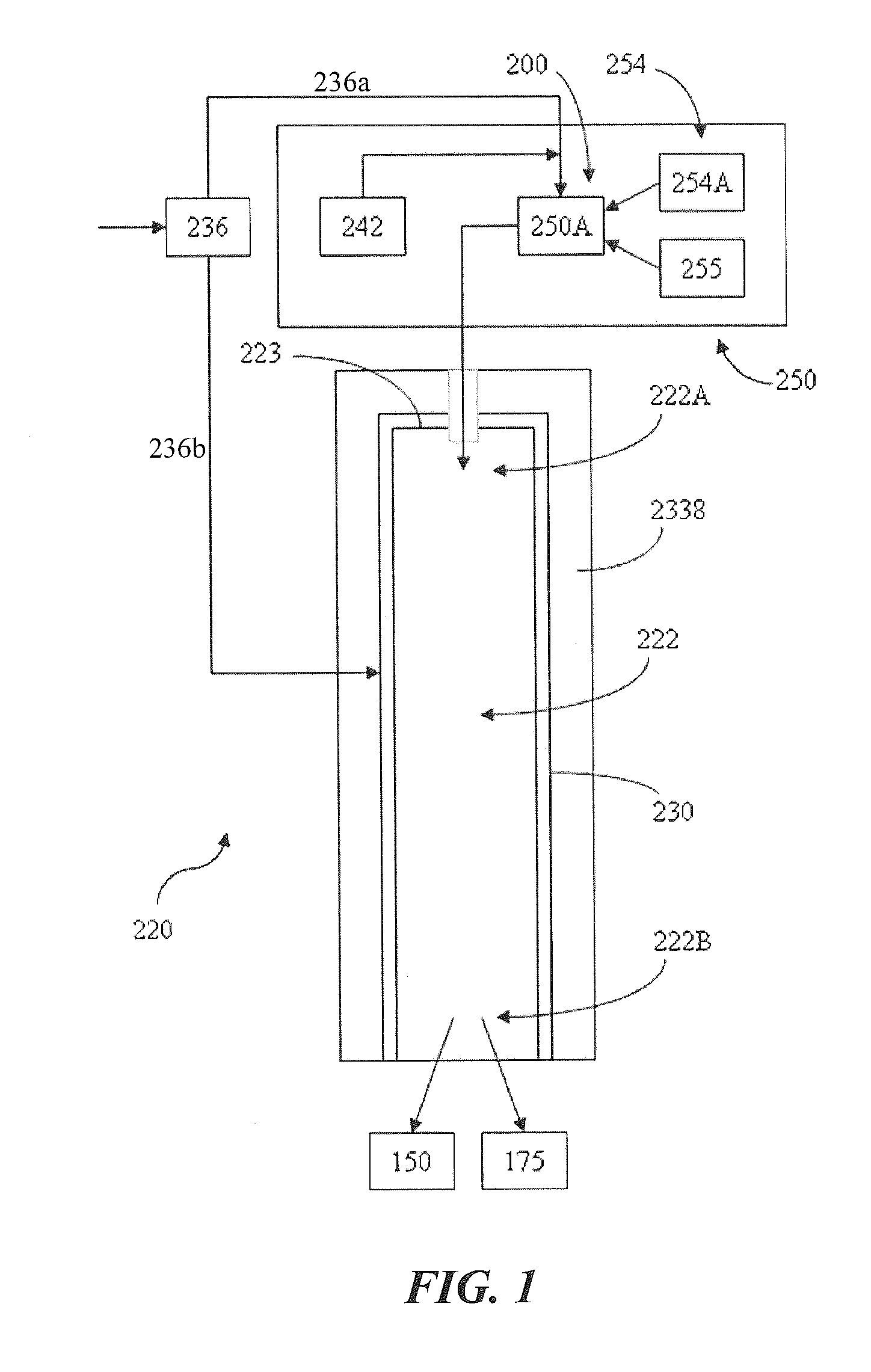

Parallel cycle heat engines

Waste heat energy conversion cycles, systems and devices use multiple waste heat exchangers arranged in series in a waste heat stream, and multiple thermodynamic cycles run in parallel with the waste heat exchangers in order to maximize thermal energy extraction from the waste heat stream by a working fluid. The parallel cycles operate in different temperature ranges with a lower temperature work output used to drive a working fluid pump. A working fluid mass management system is integrated into or connected to the cycles.

Owner:ECHOGEN POWER SYST

System and method for high efficiency power generation using a carbon dioxide circulating working fluid

ActiveUS20130213049A1Improve efficiencyIncrease pressure ratioSolidificationLiquefactionWorking fluidCombustor

The present invention provides methods and system for power generation using a high efficiency combustor in combination with a CO2 circulating fluid. The methods and systems advantageously can make use of a low pressure ratio power turbine and an economizer heat exchanger in specific embodiments. Additional low grade heat from an external source can be used to provide part of an amount of heat needed for heating the recycle CO2 circulating fluid. Fuel derived CO2 can be captured and delivered at pipeline pressure. Other impurities can be captured.

Owner:8 RIVERS CAPTTAL LLC

Aerosol generator having heater arranged to vaporize fluid in fluid passage between bonded layers of laminate

An aerosol generator includes a fluid supply which supplies fluid to a fluid passage and a heater which heats the fluid into a gaseous state, the fluid passage being located between opposed layers of a laminate. The fluid passage can be a capillary sized passage formed by locating a mandrel between opposed layers of the laminate, bonding the layers together and removing the mandrel such that the space previously occupied by the mandrel forms the fluid passage. The opposed layers of the laminate can be copper sheets and ceramic layers can be provided on the outside of the copper layers. The aerosol generator can be used to generate aerosols containing medicated materials.

Owner:PHILIP MORRIS USA INC

Humidification control unit and method of manufacturing same

A humidity regulating unit including a heating element housed inside a covering that has a porous retaining wall through which water does not pass but steam or gas passes. In one embodiment, the covering has several bulges along the circumference of the heating element that protrudes outward from the outer surface of heating element to form several water routes along the outer surface of heating element. The covering and the outer surface of heating element are bonded between adjacent water routes so that the outer surface of heating element is used as part of the wall of the water routes. As a result, the size of heating element does not restrict making the cross section of each water route as small as possible, and even if the covering breaks, the amount of water leaking from the humidity regulating unit is minimized.

Owner:KK METRAN

Process temperature control in oxy/fuel combustion system

An oxy / fuel combustion system having a furnace arranged and disposed to combust a fuel to form a combustion fluid. The system further includes a convective section having at least one heat exchanger arranged and disposed to exchange heat between the combustion fluid and steam for use in a steam turbine. A flue gas recycle is arranged and disposed to recycle at least a portion of the combustion fluid as a recycled flue gas, the flue gas recycle having at least two expellant locations downstream of a primary combustion zone. The system includes a flow control mechanism that provides controlled amounts of the recycled flue gas to the at least two expellant locations to control temperature of the steam.

Owner:AIR PROD & CHEM INC

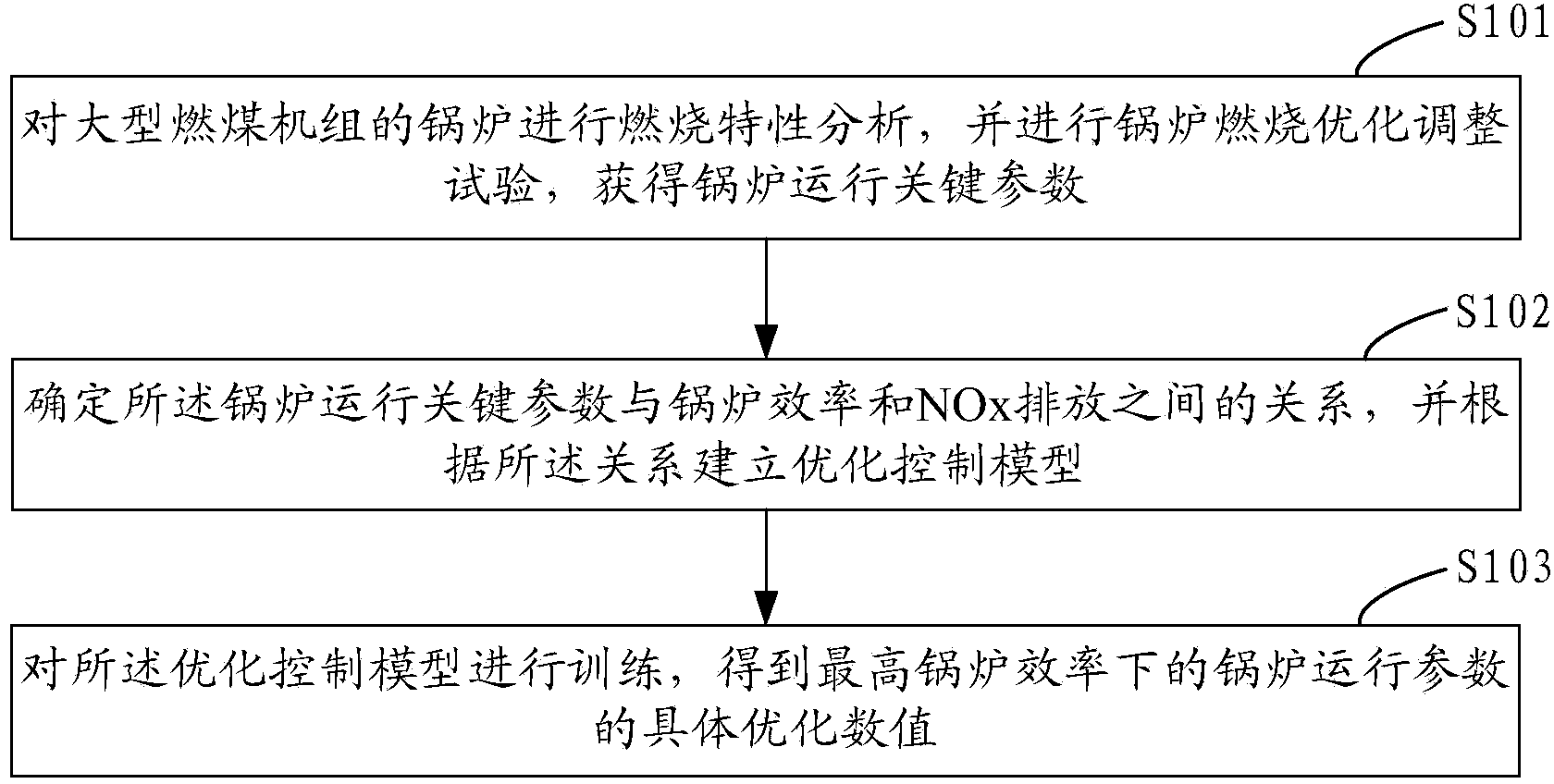

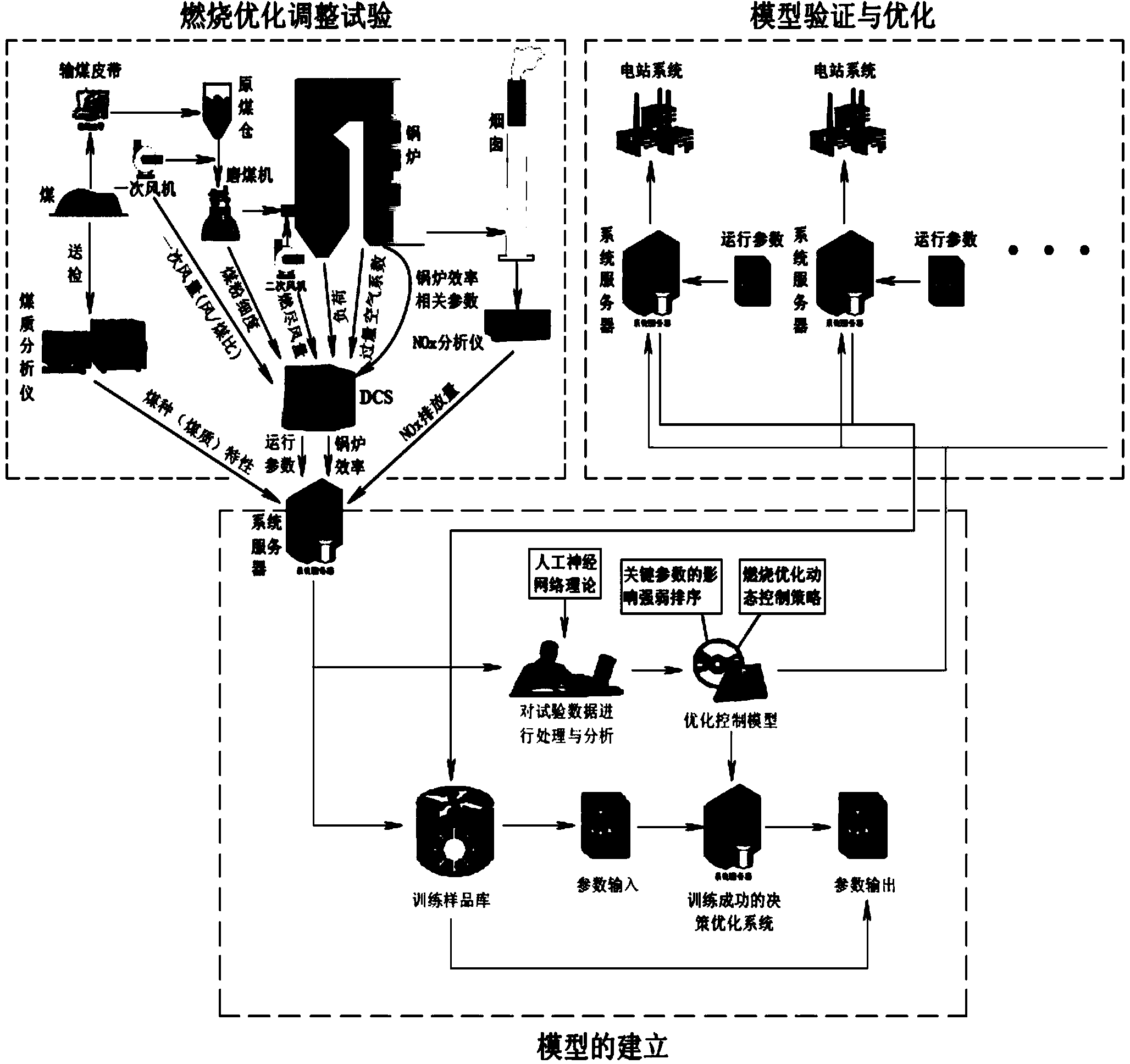

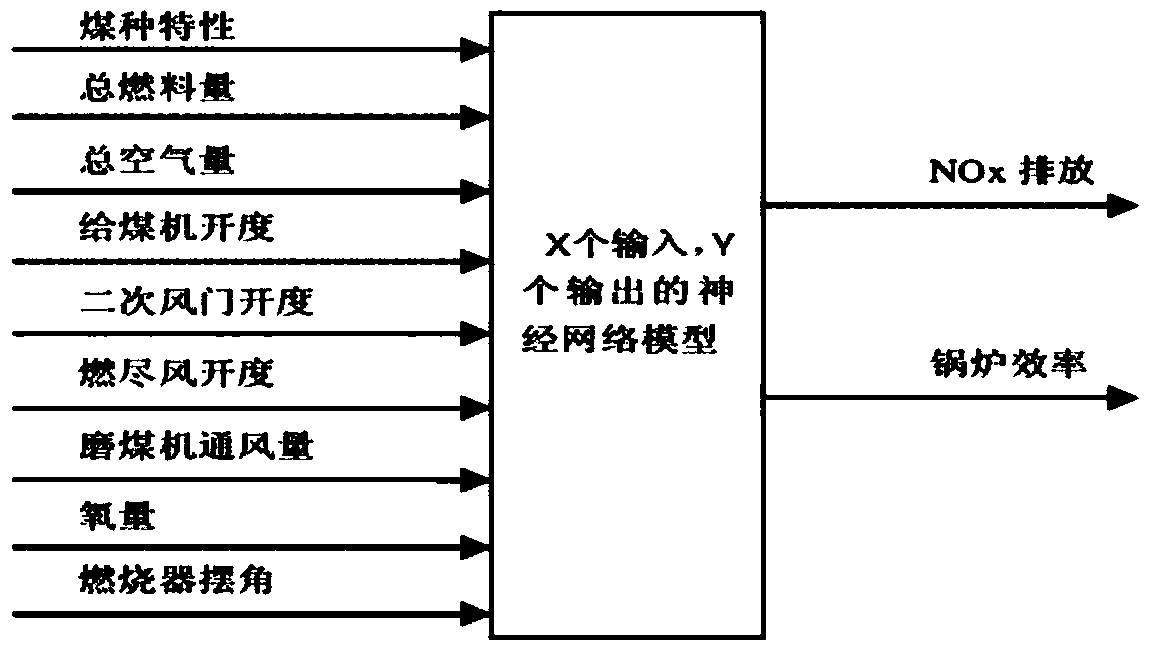

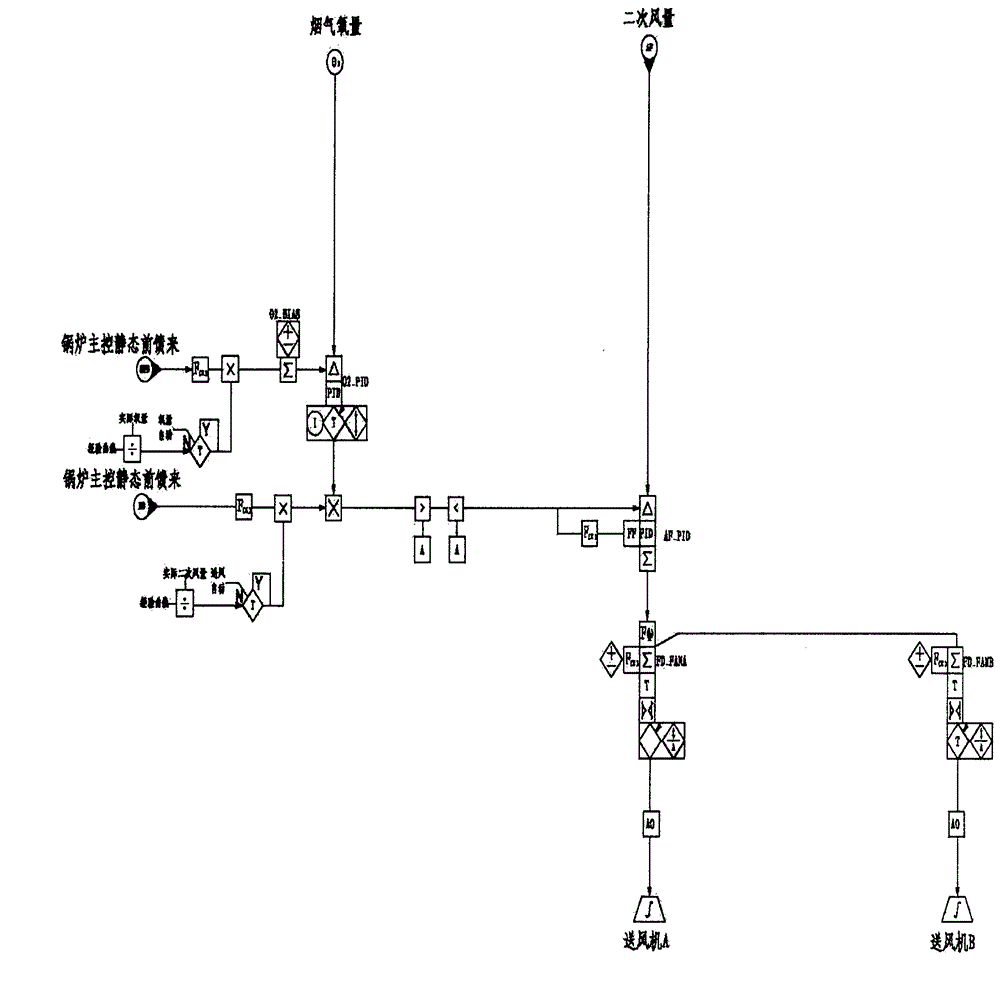

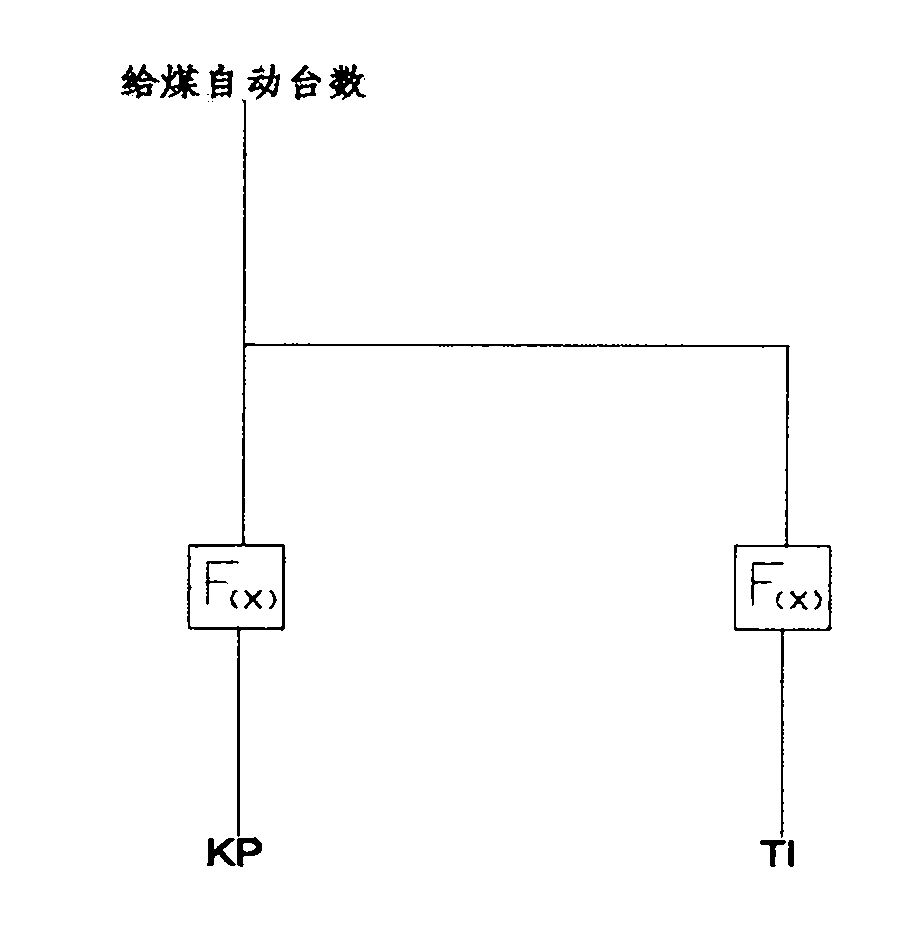

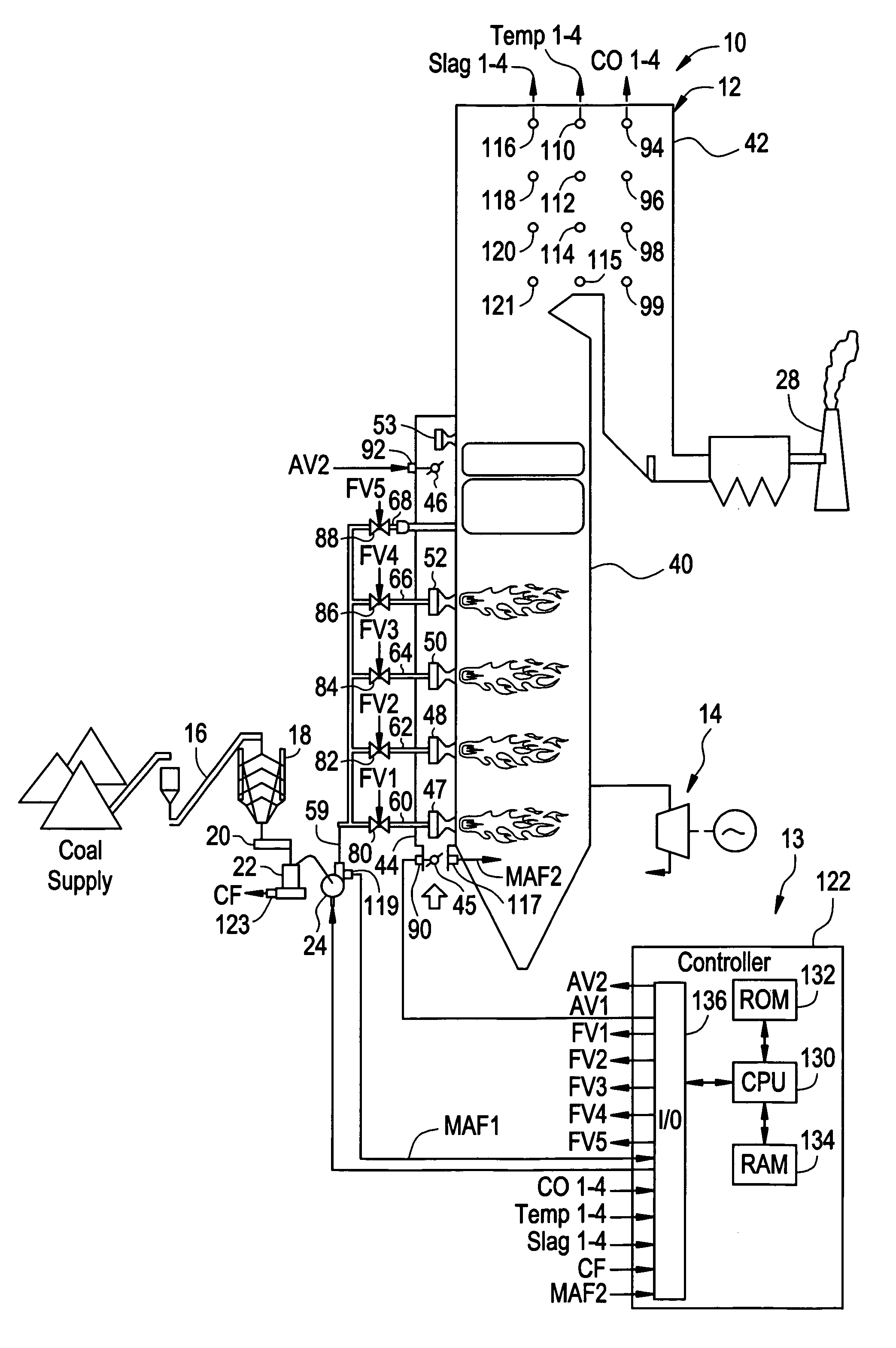

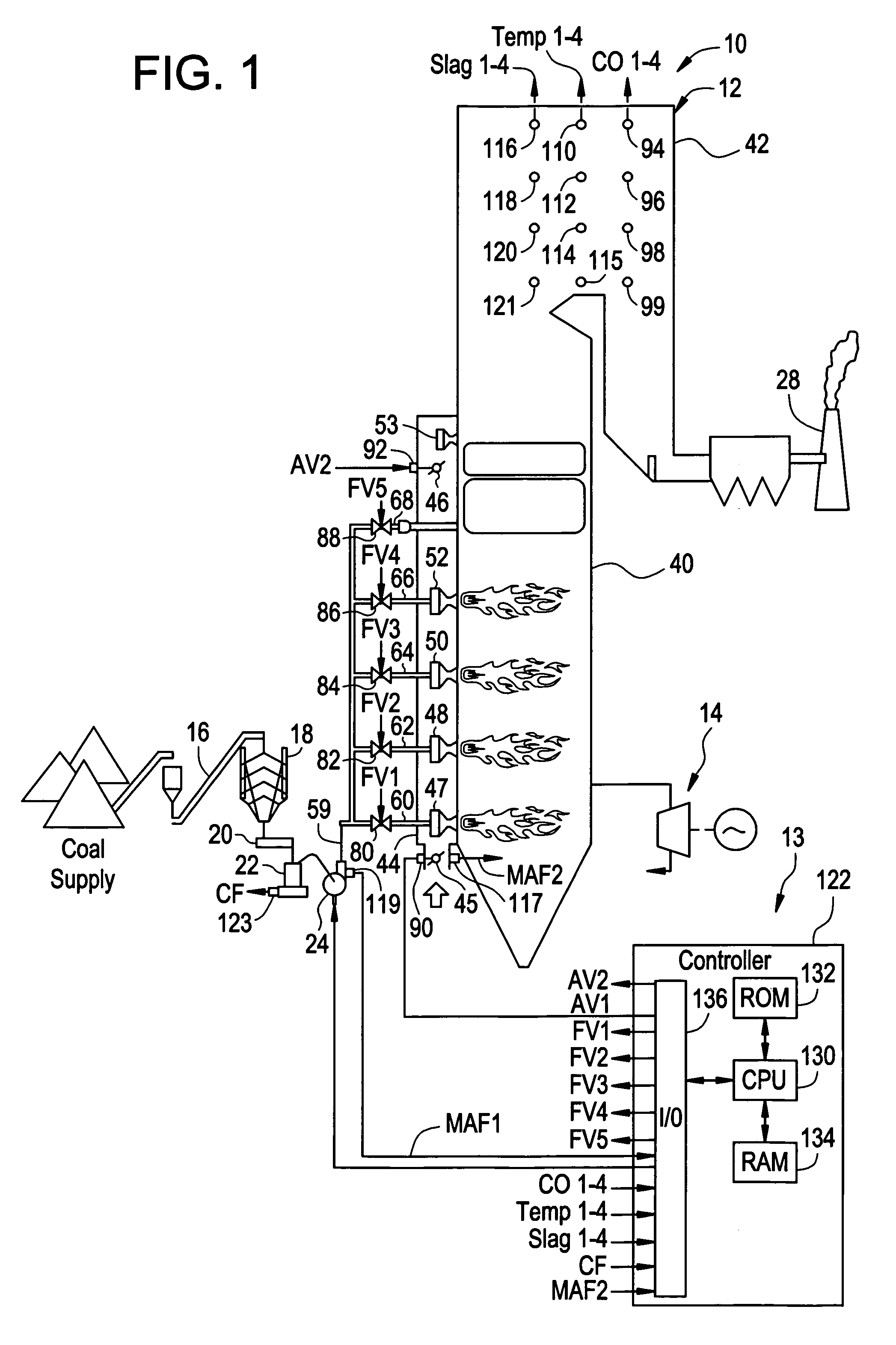

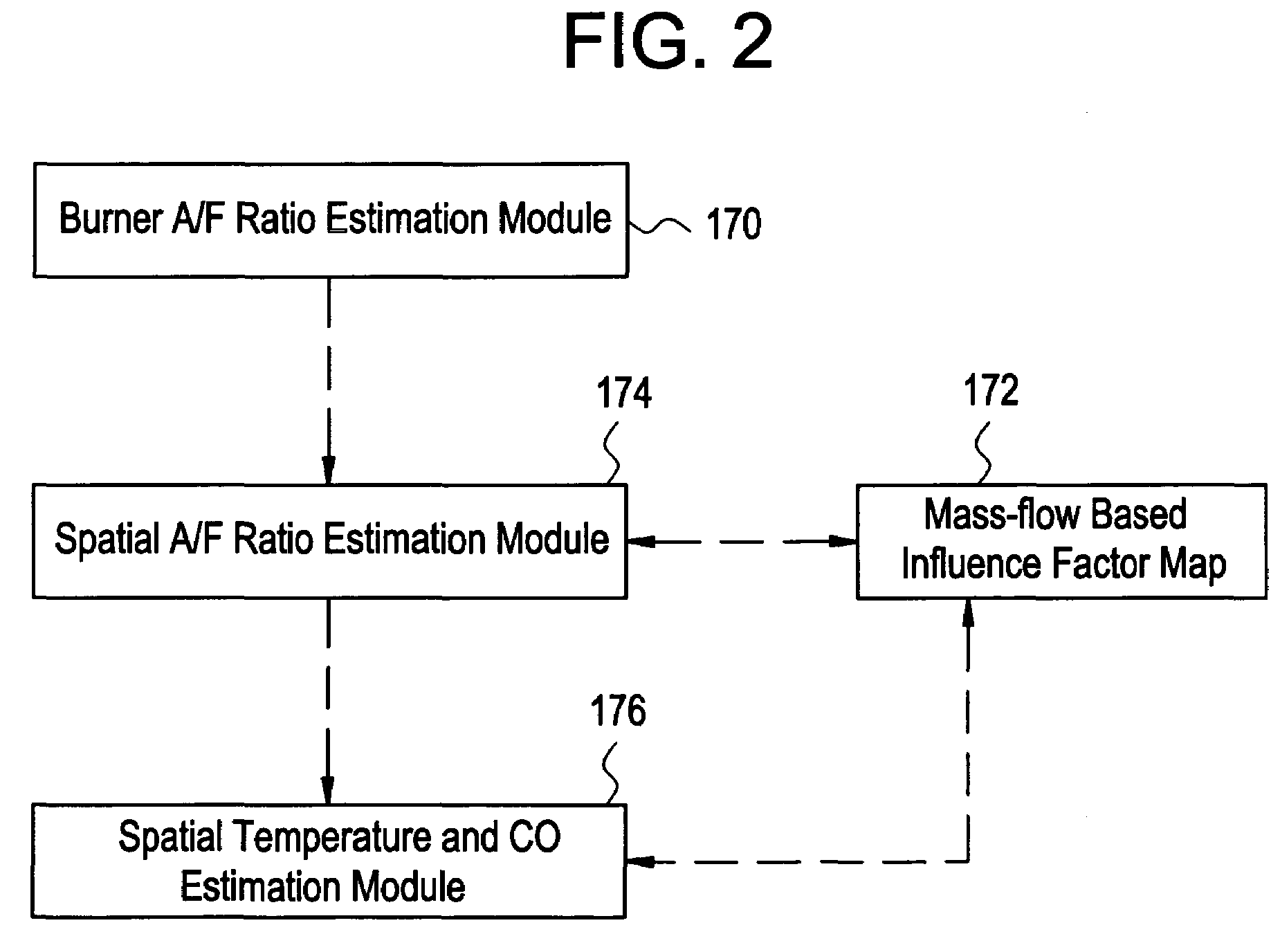

Large coal-fired unit online monitoring and optimal control system and implementation method thereof

InactiveCN103759290AImprove efficiencyHigh power consumptionBoiler controlCombustion regulationOptimal control systemProcess engineering

The invention provides a large coal-fired unit online monitoring and optimal control system and an implementation method thereof. The method includes the steps of analyzing combustion characteristics of a boiler of a large coal-fired unit, and performing boiler combustion optimization and adjustment test to acquire boiler operation key parameters; determining a relation of the boiler operation key parameters to boiler efficiency and NOx emission, and establishing an optimal control model according to the relation; training the optimal control model to obtain specific optimal values of boiler operation parameters under highest boiler efficiency. The large coal-fired unit online monitoring and optimal control system and the implementation method thereof have the advantages that boiler efficiency is improved on the premise of guaranteeing low NOx emission and operational economy of power plants is effectively improved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

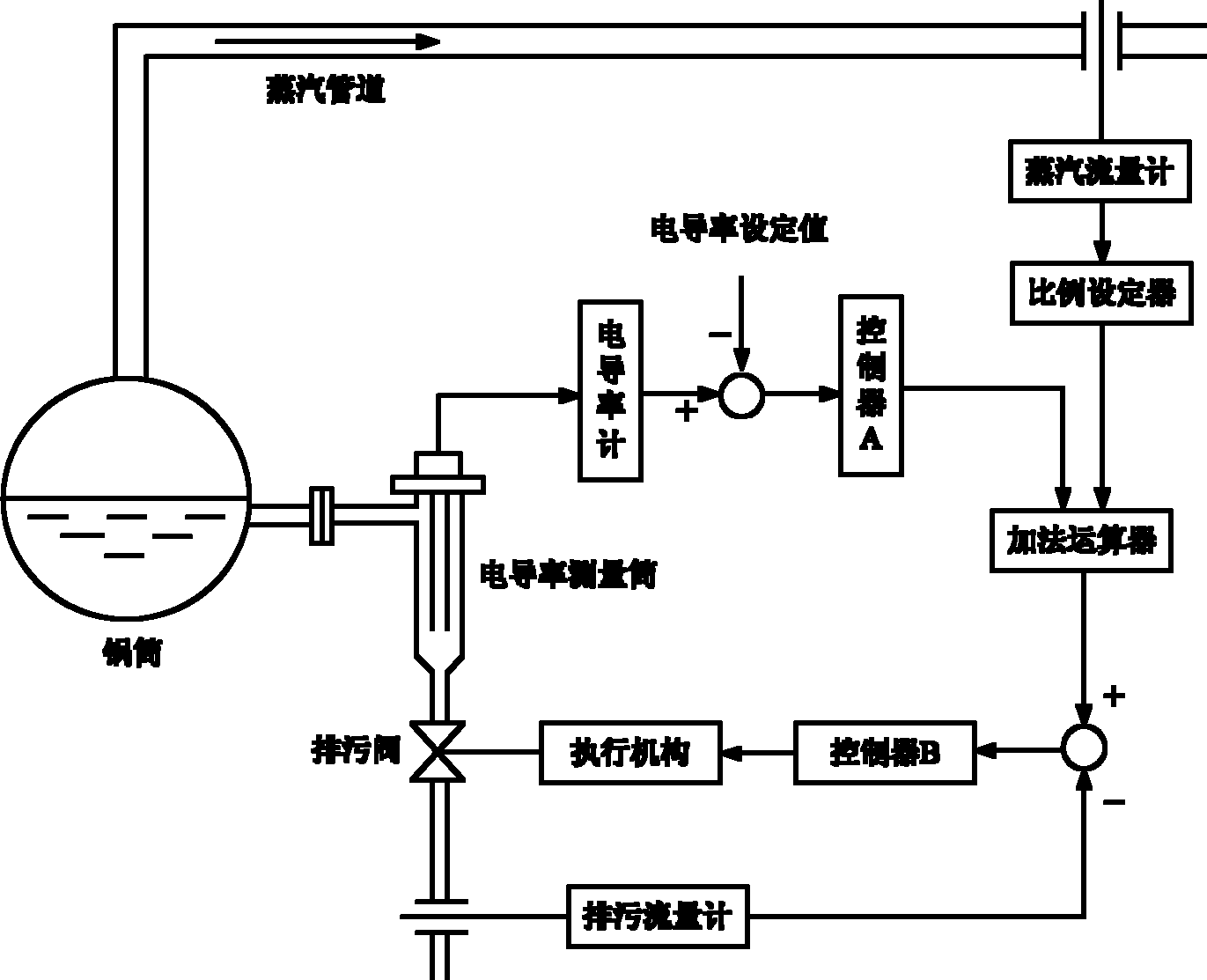

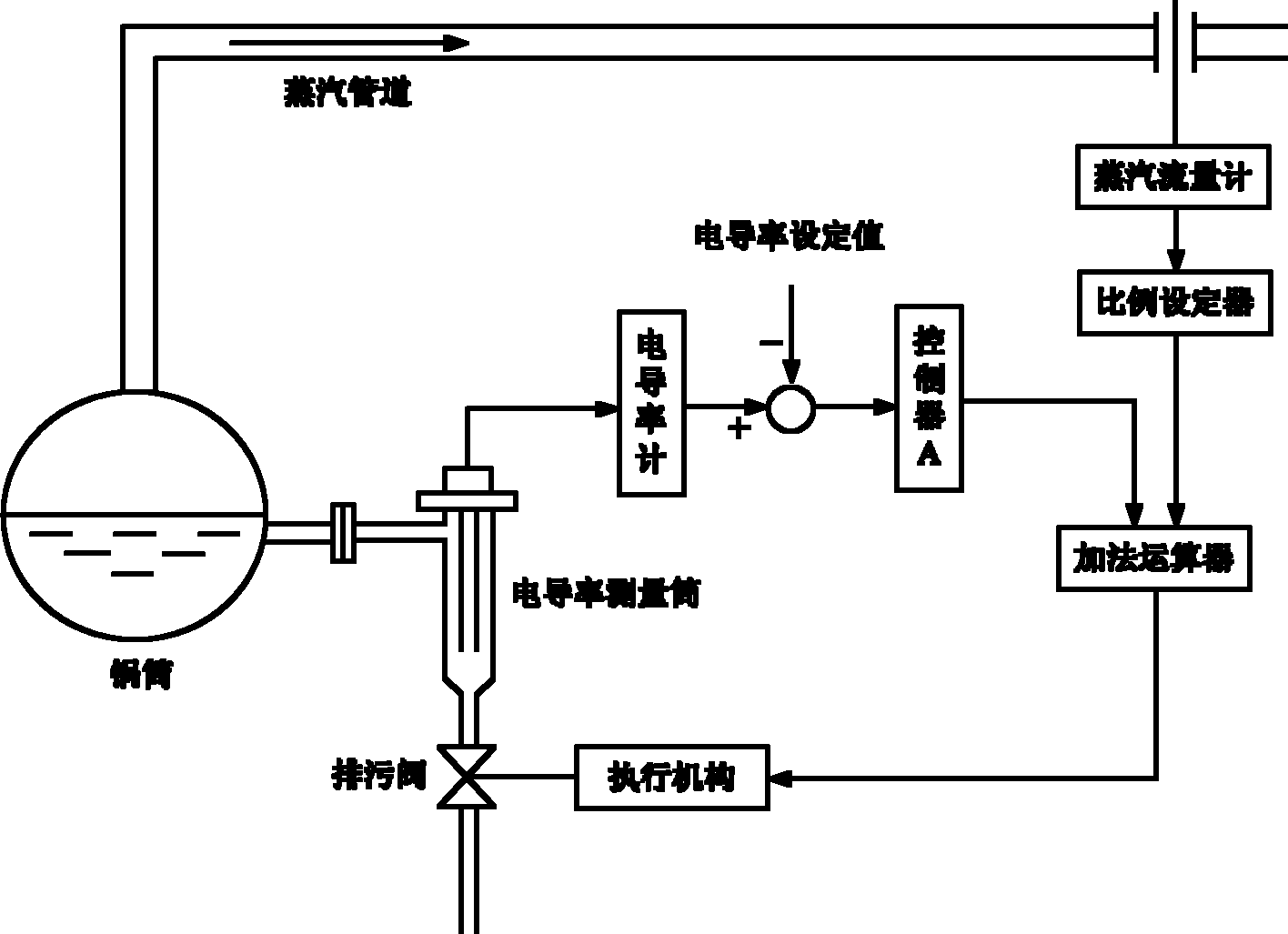

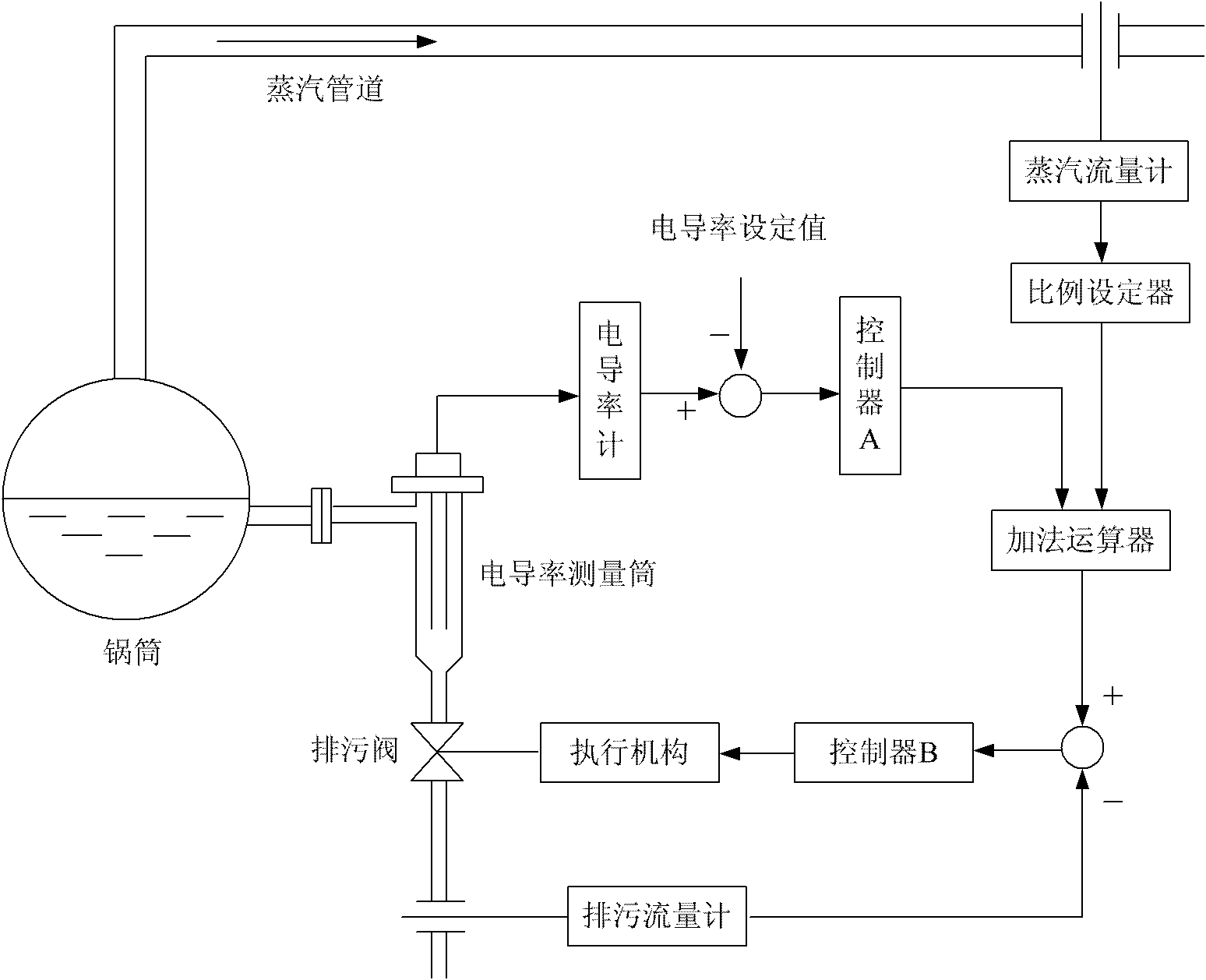

Optimal energy-saving method for controlling surface pollutant discharge of steam boiler

The invention discloses an optimal energy-saving method for controlling the surface pollutant discharge of a steam boiler. The method comprises the steps of firstly controlling the flow of pollutant discharge according to the steam flow proportionally, and continuously diluting water in the steam boiler as required; on this basis, configuring a conductivity close loop control circuit to prevent the influences, such as water supply salinity fluctuation, flow rate measurement error, boiler bottom periodic pollutant discharge and the like, and coupling the both by an addition logic unit so as to form a feedforward-feedback complex control system. The invention can prevent various interferences, stably keep the salinity of the water in the steam boiler above the desired level, and realize the optimal energy-saving and emission-reducing effects by the least pollutant discharge amount.

Owner:西安交大思源科技股份有限公司 +2

Electromagnetically responsive heating apparatus for vaporizer

InactiveUS6906296B2Increase productionReduced resistive electrical power loadSteam generation heating methodsGrinding feed controlParticulatesMicrowave

A vaporizer heating apparatus is comprised of electromagnetically responsive material and electrically non-conductive material. A antimicrobial fluid to be vaporized, such as water or hydrogen peroxide solution, is supplied to the heating apparatus where it is converted to a vapor. In one embodiment of the present invention, electromagnetically responsive material particulate is embedded into the electrically non-conductive material. In another embodiment of the present invention, a microwave generator is used to produce heat.

Owner:AMERICAN STERILIZER CO

Capillary force vaporizers

ActiveUS20090220222A1Easy to assembleEliminate needSpace heating and ventilationMedical devicesCapillary networkEngineering

The present invention concerns capillary force vaporizers for use in vaporizing liquids and emitting pressurized vapors. In one embodiment, the inventive capillary force vaporizer includes a porous member, a heater component to convey heat to the porous member, and a vapor containment region. The porous member further includes a capillary network, a surface for receiving liquid and a vaporization area in which vapor is produced from the liquid. The vapor is collected and pressurized within the vapor containment region, which includes one or more openings for the release of vapor at a velocity greater than zero. Several different embodiments for capillary force vaporizers and systems comprising capillary force vaporizers are disclosed along with methods for their use.

Owner:VAPORE

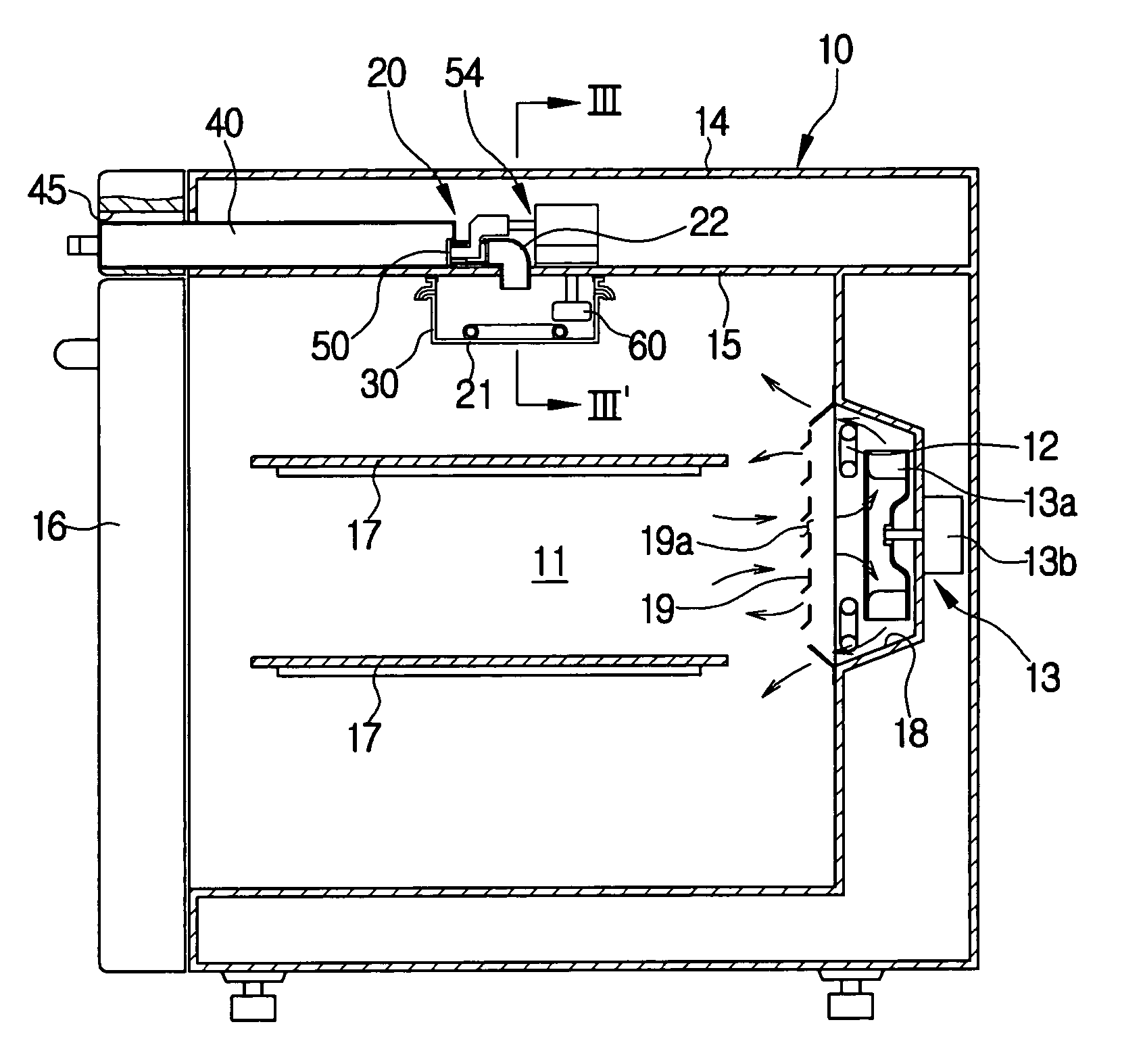

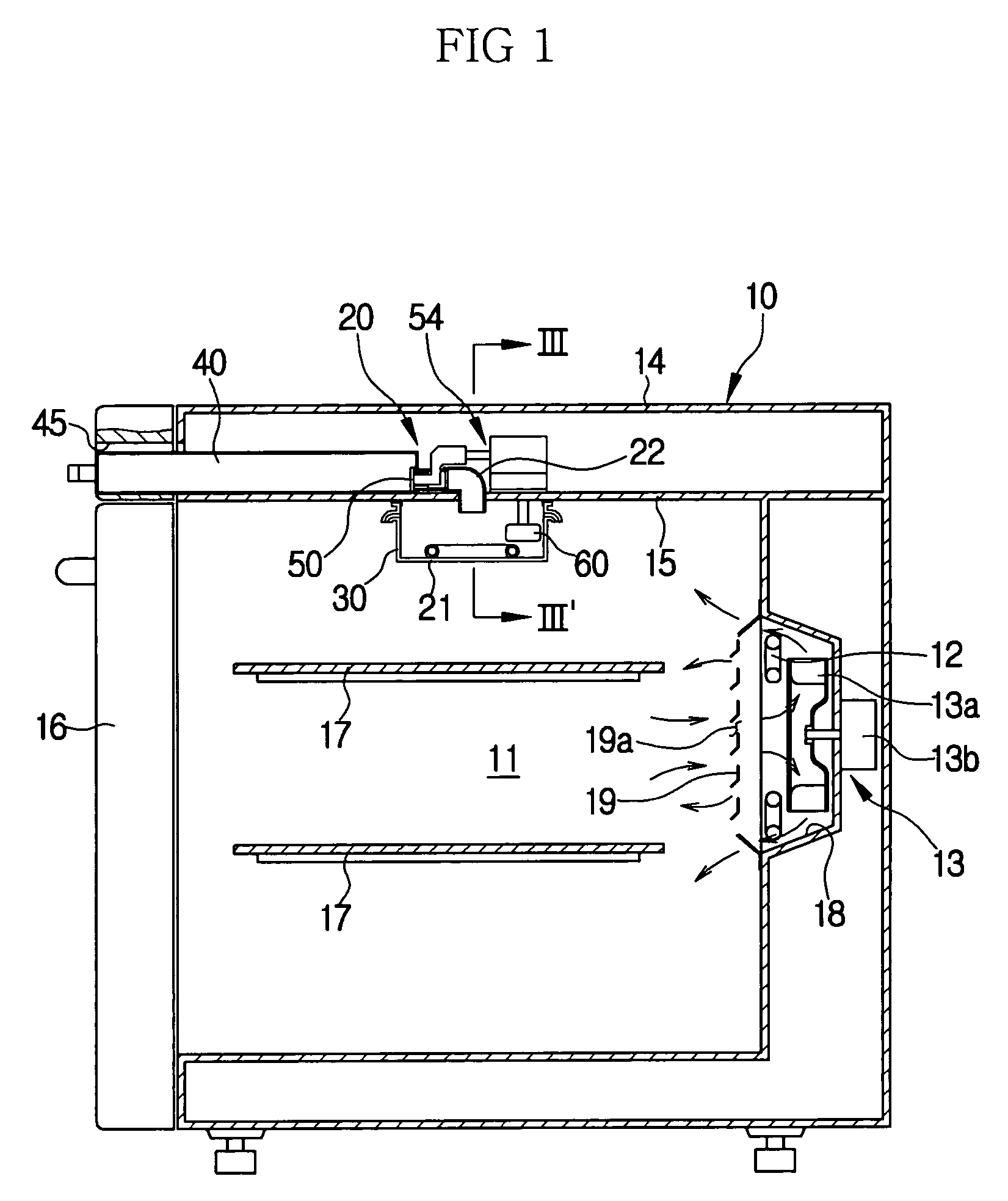

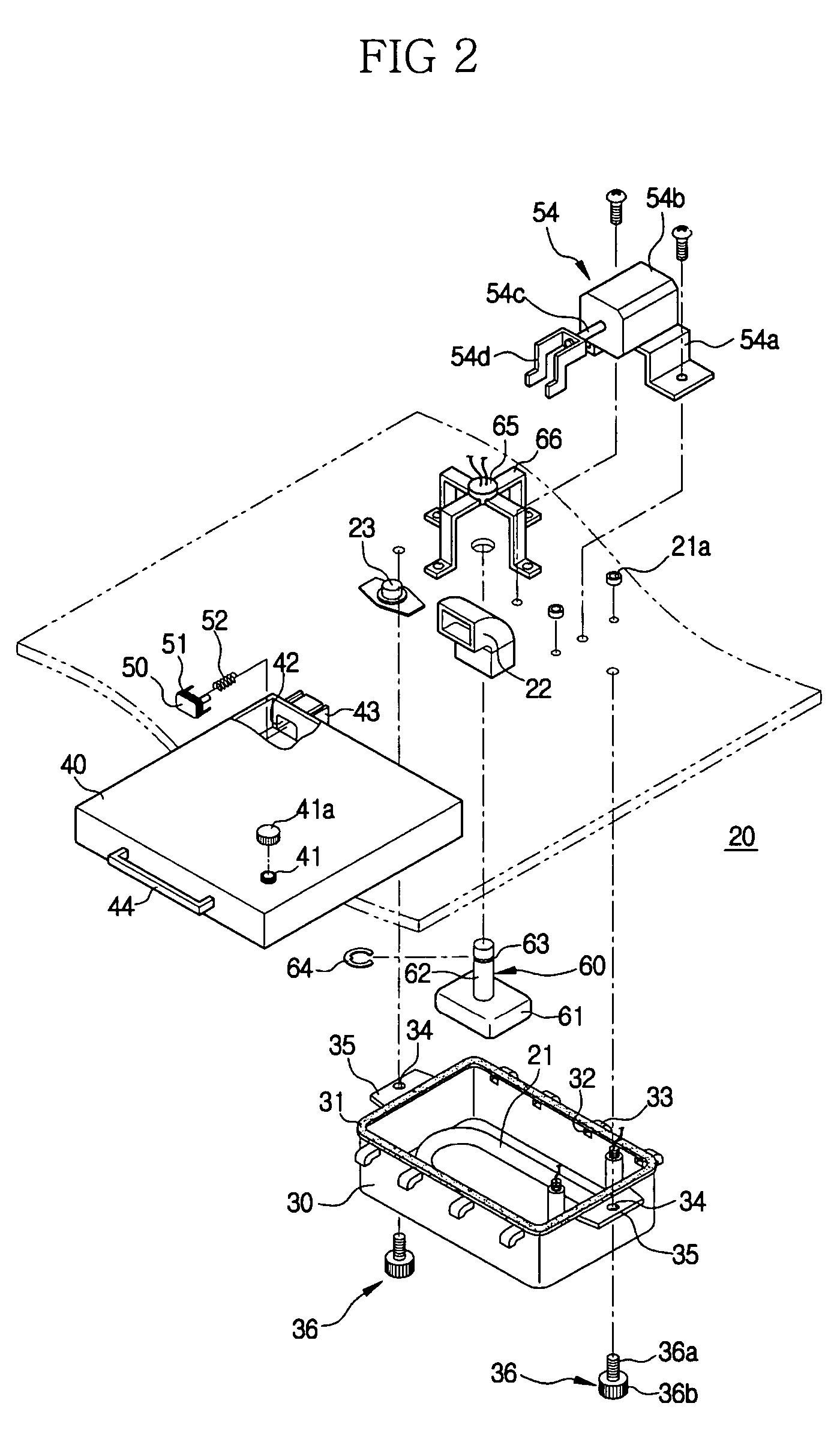

Heating cooker having a steam generating unit

Owner:SAMSUNG ELECTRONICS CO LTD

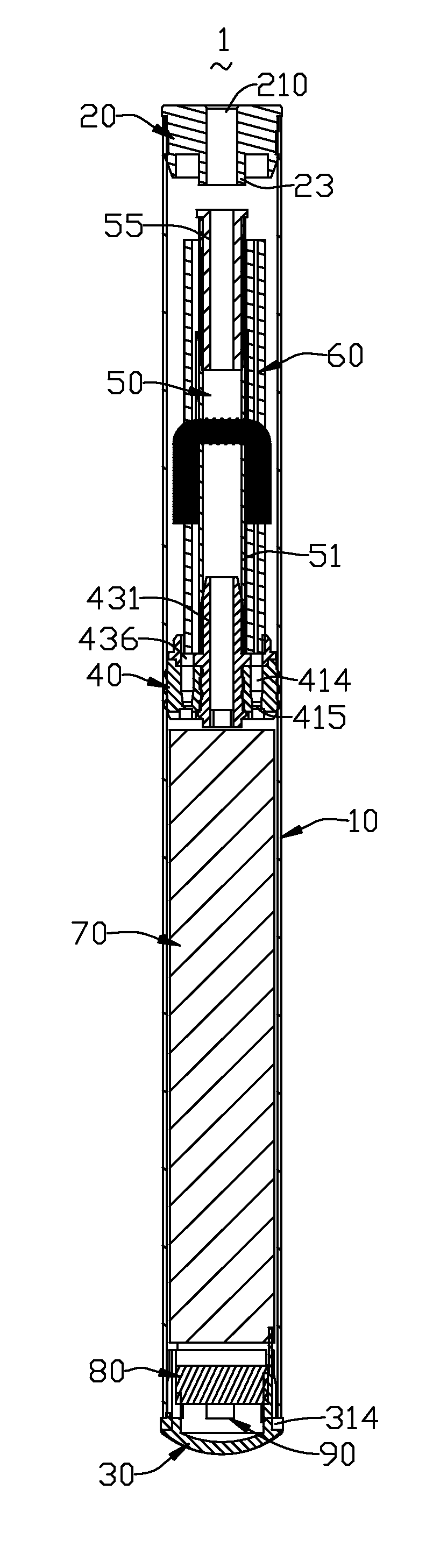

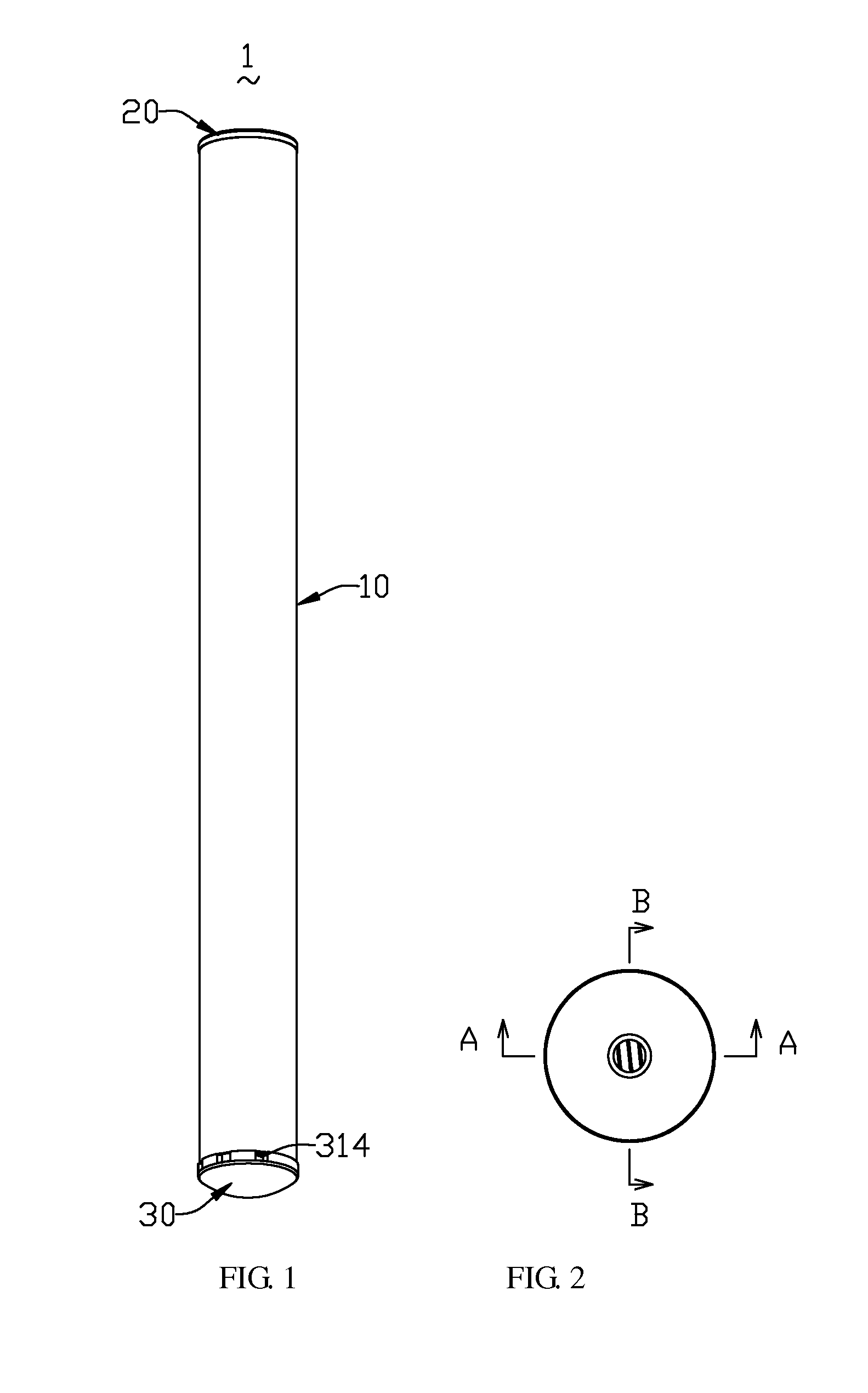

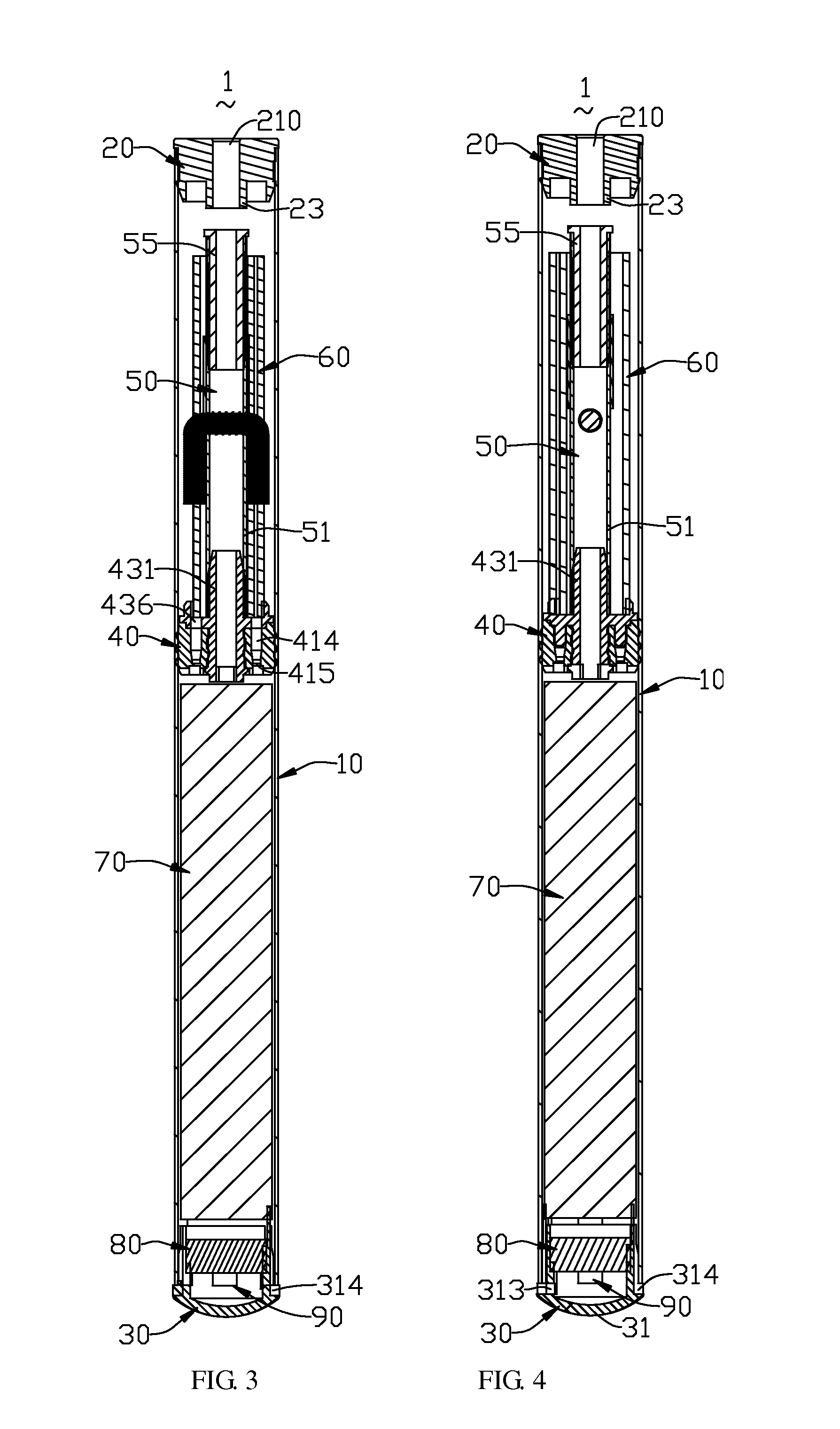

Electronic Cigarette and Atomizer Assembly Thereof

ActiveUS20160058073A1Easy to installSteam generation heating methodsTobacco pipesElectronic cigaretteEngineering

The present invention provides an electronic cigarette and an atomizer assembly thereof. The atomizer assembly includes an air flowing pipe, a wick extending laterally through a sidewall of the air flowing pipe, and a heating member disposed within the air flowing pipe and engaging with the wick. The air flowing pipe defines opposite holes. The wick extends through the holes with opposite ends extending out of the air flowing pipe. The sidewall of the air flowing pipe further defines a cut communicating with the holes, to enable the wick being placed laterally into the holes. By virtue of the cut, two parts of the air flowing pipe divided by the cut are split off to form an open communicating with the closed holes, and the wick can be placed laterally into the holes via the open. Thus, the wick is easily installed without aligning and extending through the holes.

Owner:SHENZHEN SMOORE TECH LTD

Intelligent measurement and control boiler system dynamically calculating water loss according to drum water level

InactiveCN105135406AKeep abreast of the operation status in timeAvoid wastingBoiler indication operationsBoiler cleaning apparatusData connectionEngineering

The invention provides a boiler system. A monitoring diagnosis controller calculates water loss of a boiler by calculating the ratio of the sum of the steam mass, the change mass of drum water and the sewage discharge mass to the mass of water input into the boiler. The monitoring diagnosis controller is in data connection with a cloud server, so that monitored data are transmitted to a cloud server; the cloud server is connected with a client side, and the client side can obtain the monitored data by means of the cloud server. By means of the client side, the operation condition of water loss of the boiler can be mastered in time, and by means of the client side, the situation that due to water loss of the boiler, a large amount of heat is wasted can be avoided in time.

Owner:SHANDONG UNIV OF TECH

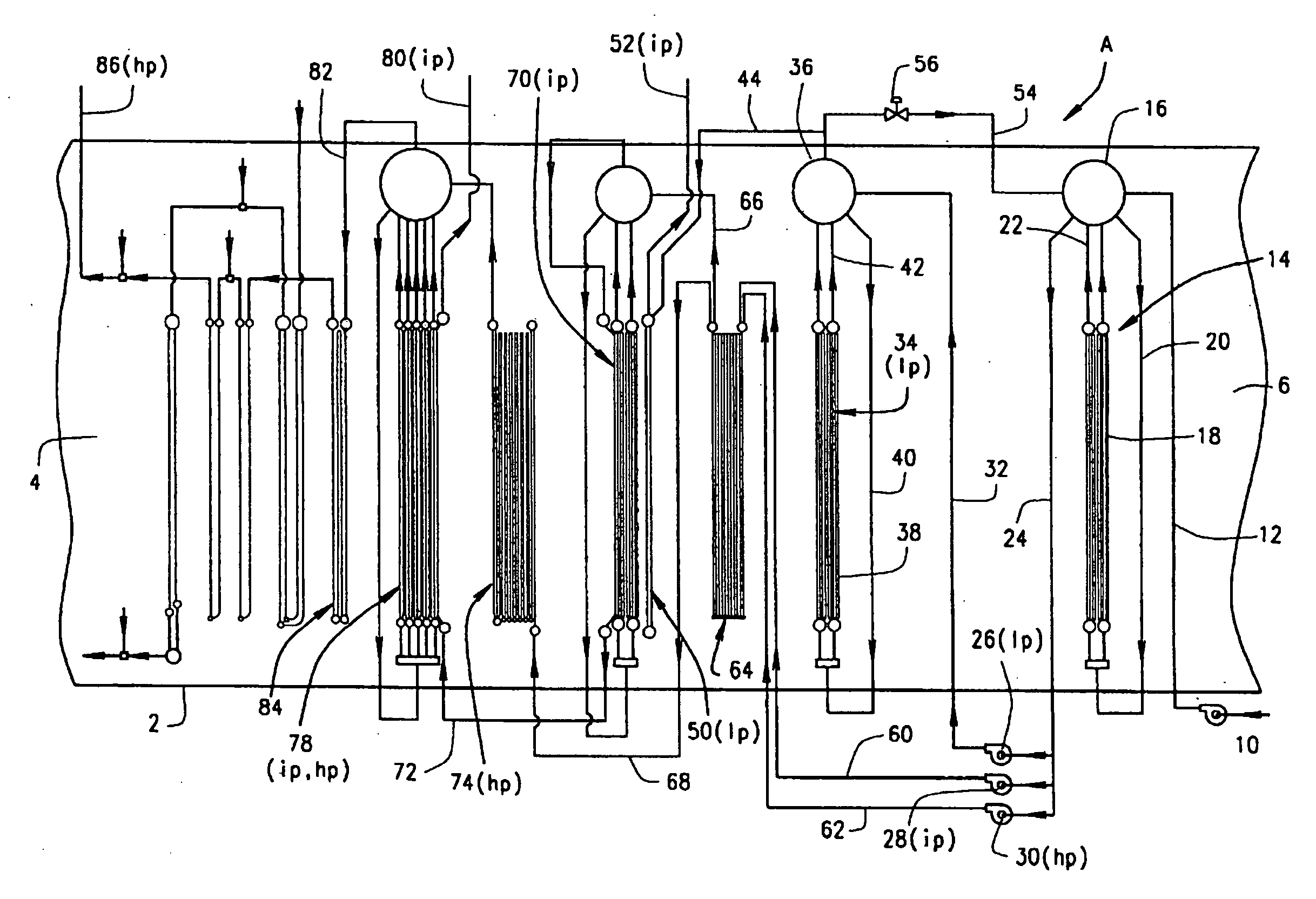

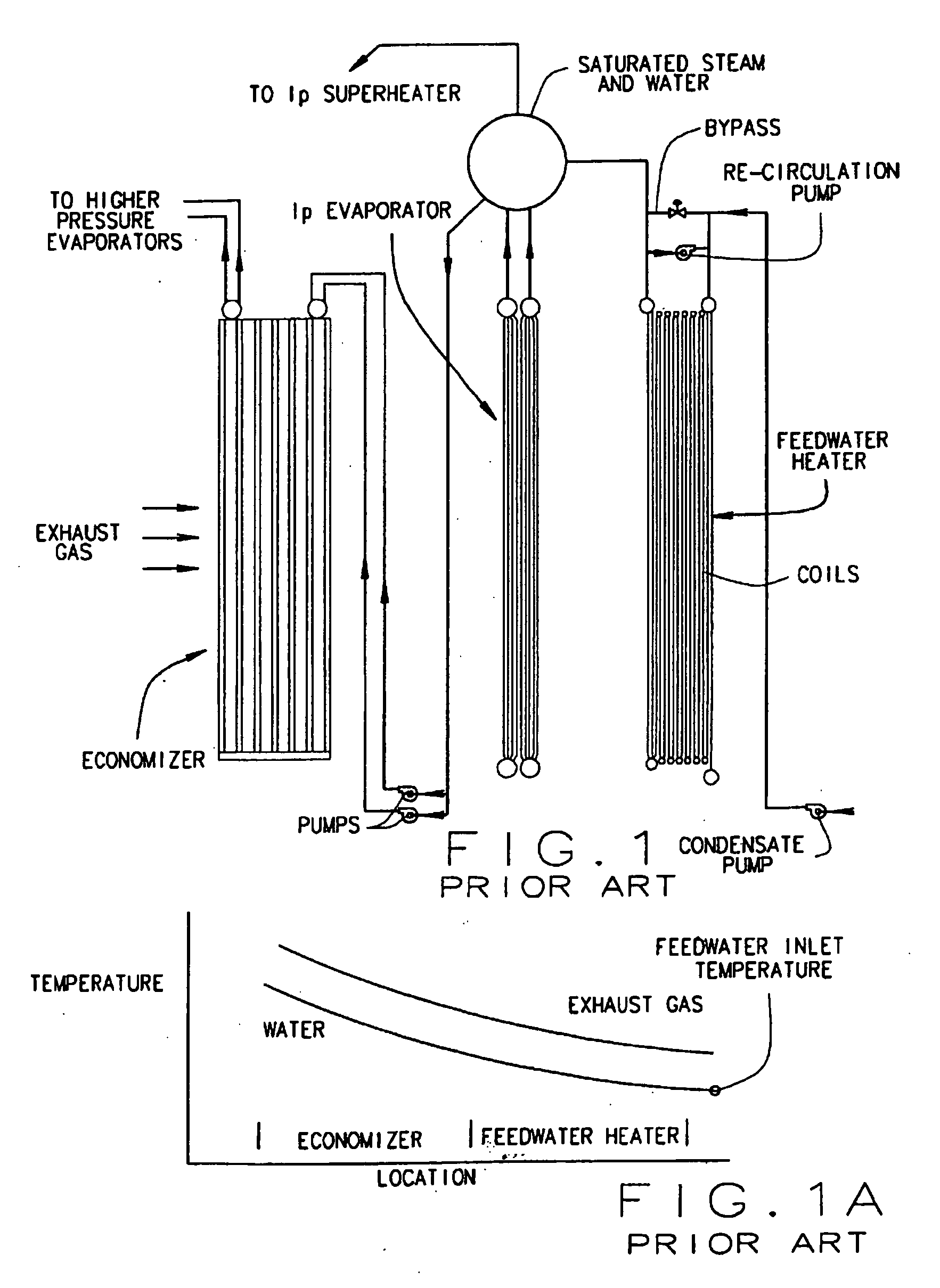

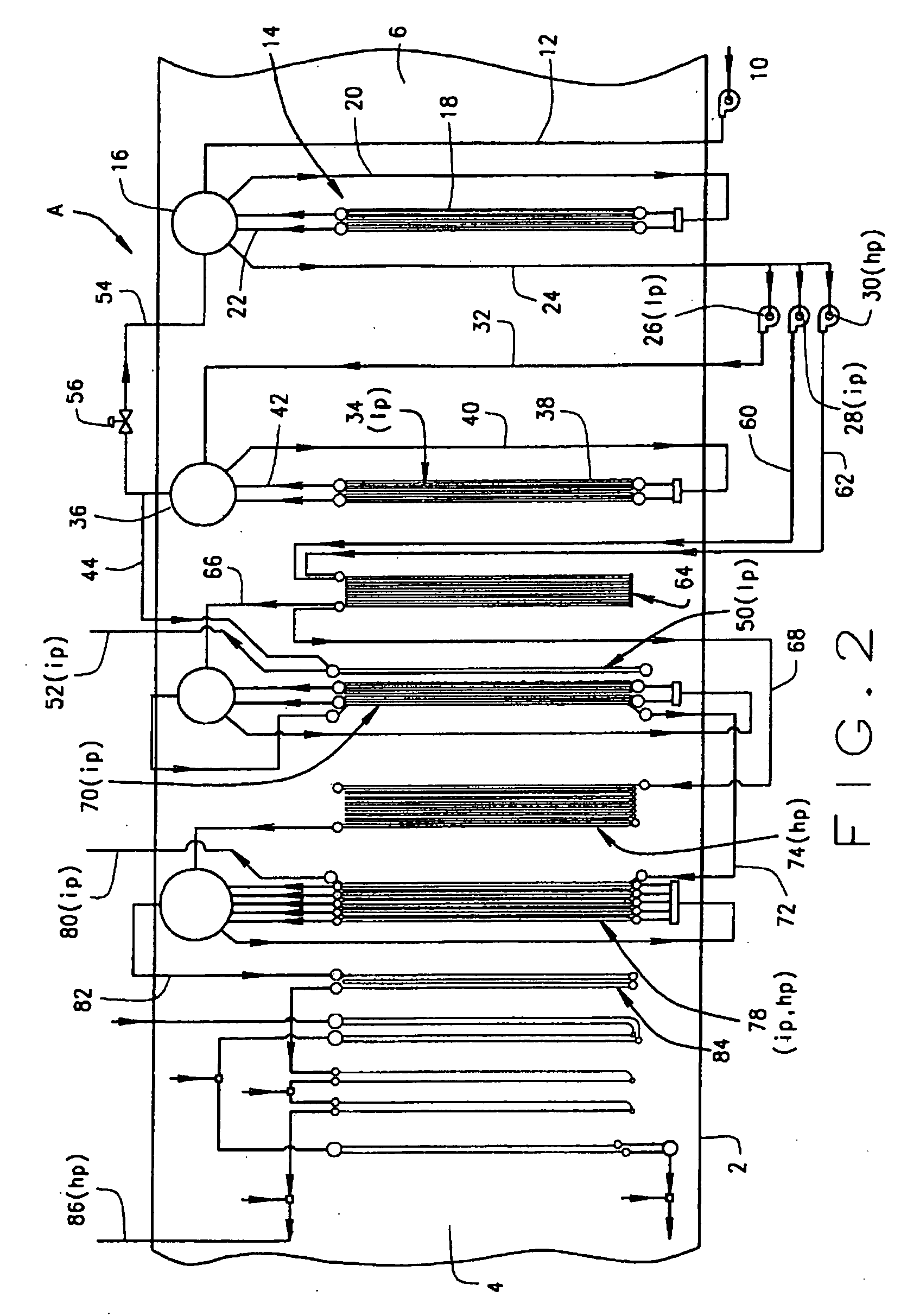

Process and apparatus for heating feedwater in a heat recovery steam generator

InactiveUS20120312019A1Steam generation heating methodsSteam accumulatorsCorrosive acidExhaust fumes

A feedwater heater (14) in a heat recovery steam generator (A,B) lies within a flow of hot exhaust gas. The feedwater heater (14) converts subcooled feedwater into saturated feedwater water, the temperature of which is only lightly above the acid dew point temperature of the exhaust gas so that corrosive acids do not condense on coils (18) of the feedwater heater (14). Yet the temperature of the saturated feedwater lies significantly below the temperature of the exhaust gas at the coils (18), so that the coils (18) operate efficiently and require minimal surface area. Pumps (26, 28, 30) elevate the pressure of the saturated feedwater and direct it into an economizer (64, 90) where, owing to the increase in pressure, the water is again subcooled. The economizer (64, 90) elevates the temperature still further and delivers the higher pressure feedwater to evaporators (34, 70, 78) that convert it into saturated steam that flows on to the superheaters (50, 78, 84). Higher pressure pegging stem admitted to the feedwater heater (14) controls the pressure—and temperature—of saturated steam and water in the feedwater heater (14).

Owner:NOOTER ERIKSEN INC

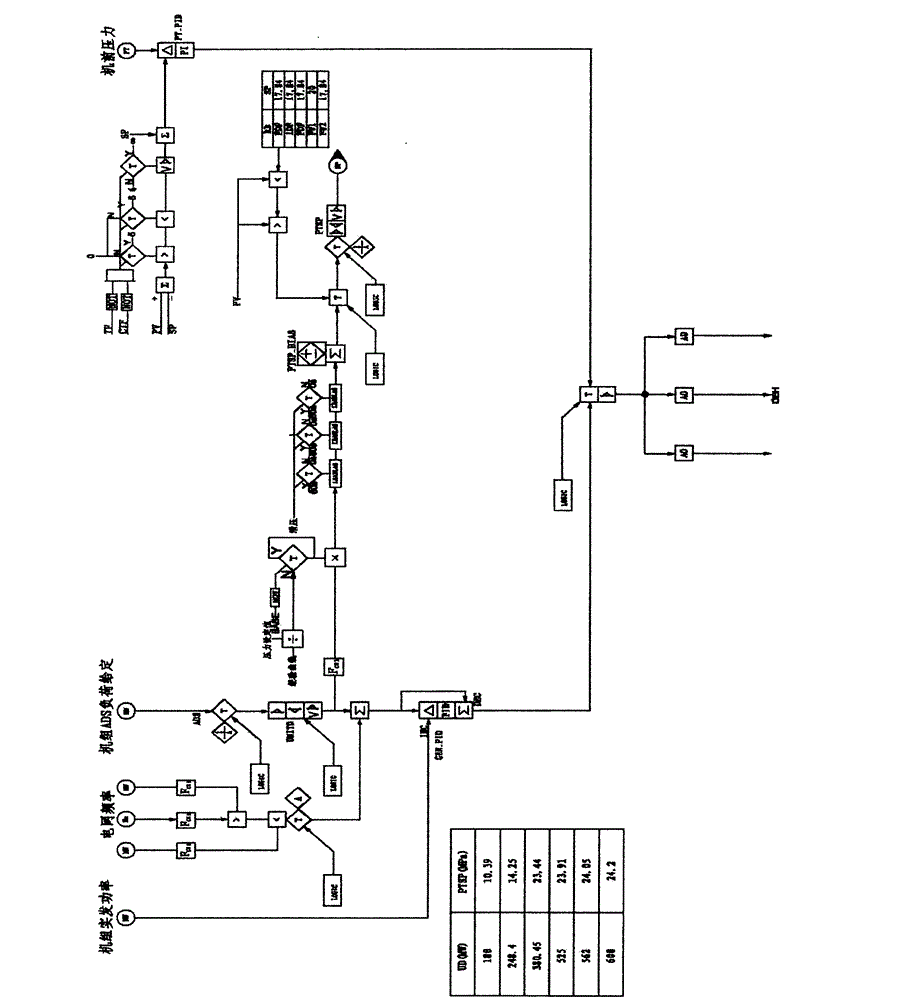

Method for coordinating and controlling quality change of coal in supercritical once-through boiler unit

Owner:ELECTRIC POWER RES INST OF STATE GRID ANHUI ELECTRIC POWER

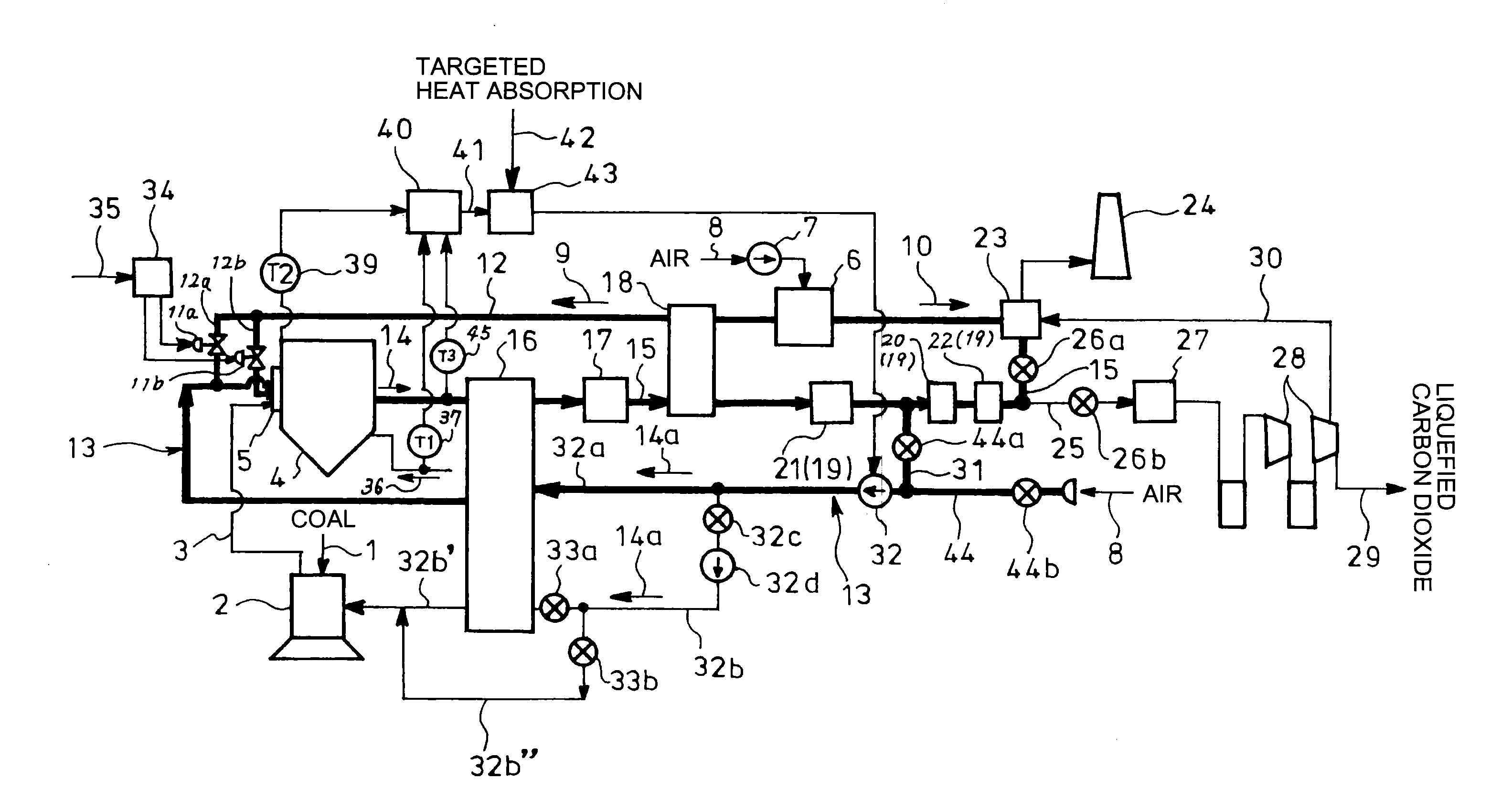

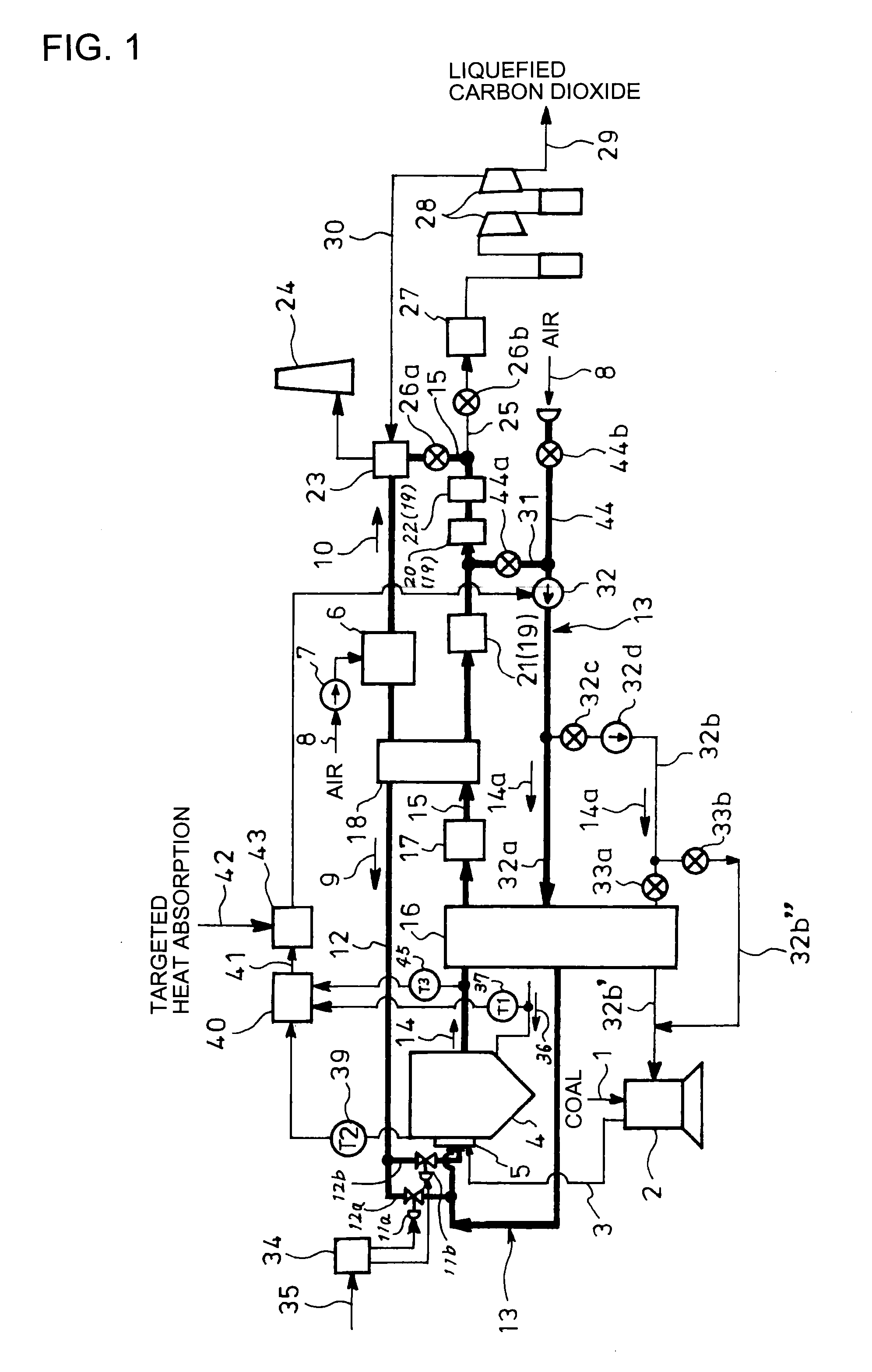

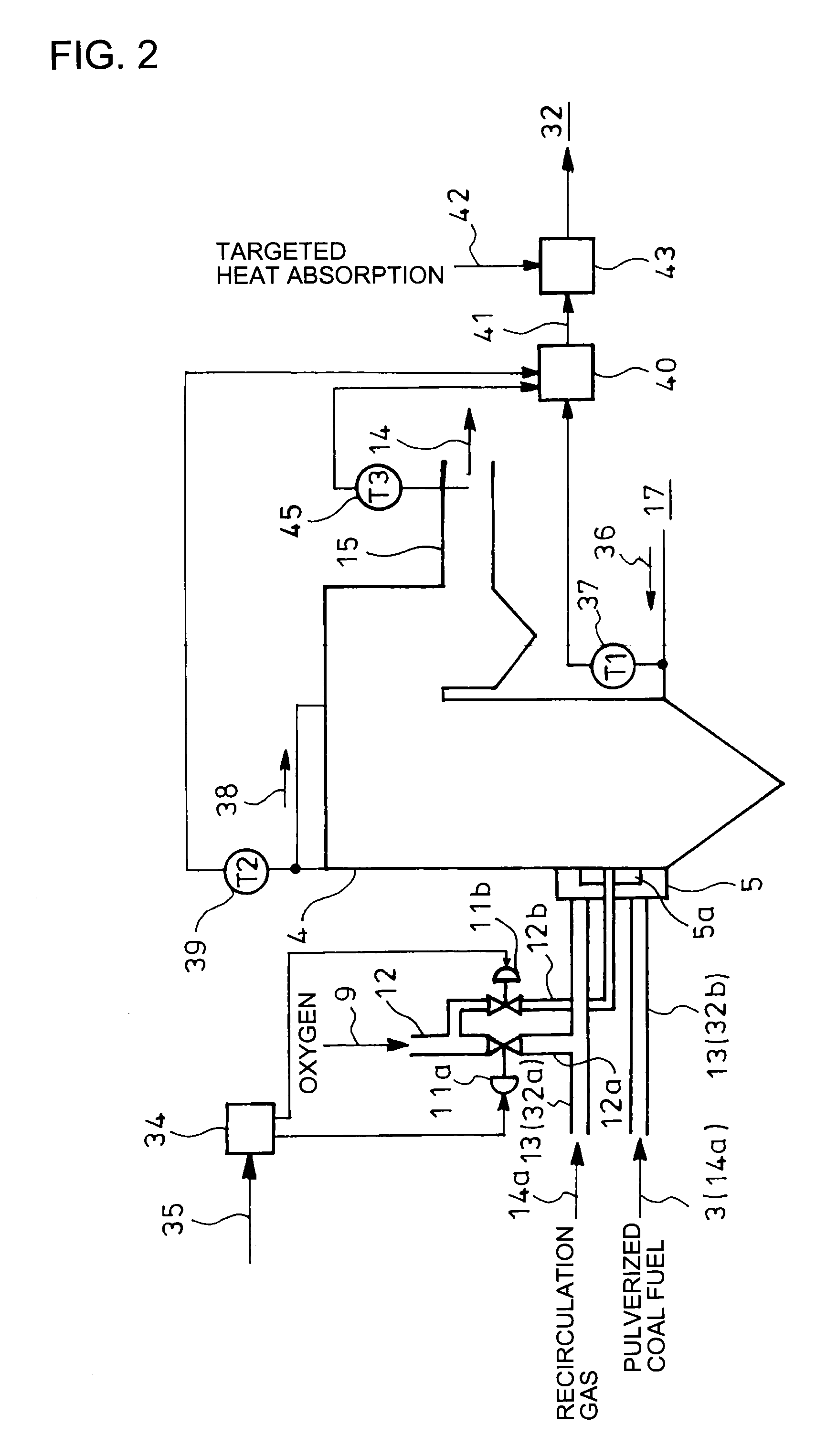

Method and apparatus for controlling combustion in oxygen fired boiler

ActiveUS20090272300A1Great advantageGood effectMechanical apparatusFluegas recirculationCombustionEngineering

Provided are a method and an apparatus for controlling combustion in an oxygen fired boiler which are easily applicable to an existing air fired boiler for easy and stable control of the combustion.Oxygen with a setting amount in accordance with a boiler load demand 35 is supplied to a boiler body 4. Heat absorption amount of the boiler is measured from inlet temperature of feedwater supplied to the boiler body 4 and outlet temperature of steam. Recirculation flow rate of combustion exhaust gas 14a is controlled such that heat absorption amount 41 of the boiler body 4 becomes equal to a targeted heat absorption amount 42 to thereby control oxygen concentration in all gas guided to the boiler body 4.

Owner:ELECTRIC POWER DEVELOPMENT COMPANY +1

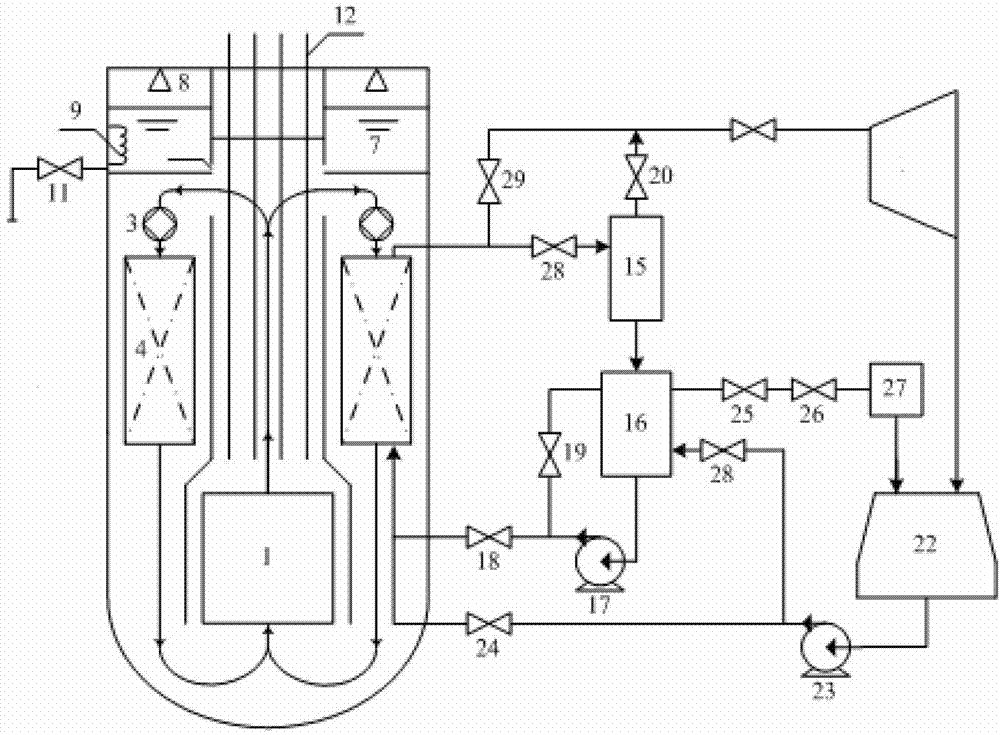

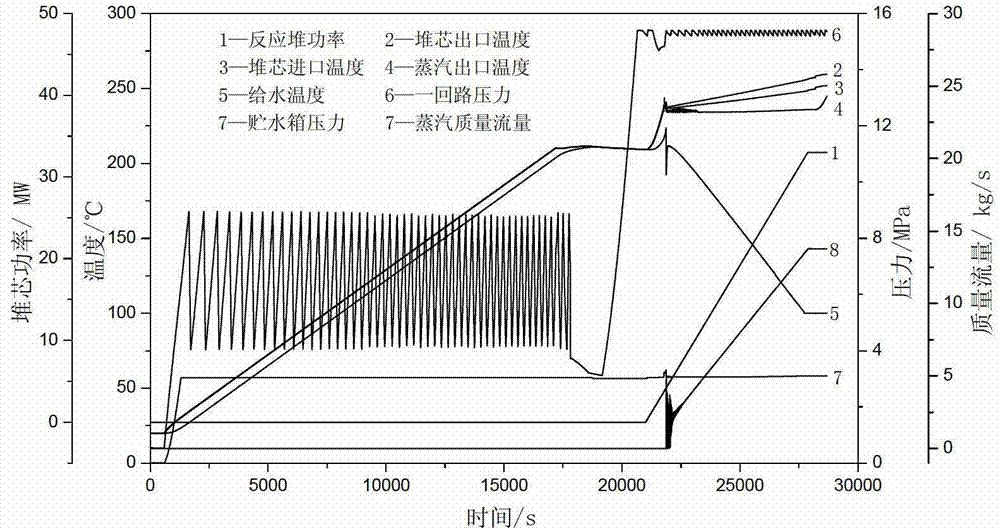

Start-stop auxiliary device used in integral reactor and cold starting method of integral reactor

ActiveCN103117101AShorten the timeSafe and stable operationPlant parameters regulationNuclear energy generationStart timeWater storage tank

The invention provides a start-stop auxiliary device used in an integral reactor and a cold starting method of the integral reactor. An inlet of a starting separator is connected with an outlet conduit of a once-through steam generator, an outlet of the starting separator is connected with a main steam pipe through a steam valve, and a drain outlet is connected with a water storage tank. An outlet at the bottom of the water storage tank is connected with a circulating water pump, and one conduit at the outlet of the water storage tank is connected with a condenser through an outlet stop valve of the water storage tank, a water storage tank water level control valve and a thermoreduction and dropping device. The circulating water pump is connected with a water supply conduit at the inlet of the once-through steam generator through a circulating water-carrying control valve. A water feed pump is connected with the condenser, the water feed pump is further connected with the inlet conduit of the once-through steam generator through a main water feed valve and with the water storage tank through a cold water valve. The start-stop auxiliary device is capable of increasing the temperature and pressure of refrigerant in a first circuit when the reactor starts, starting pressure and starting flow of a second circuit are established effectively, phenomenon of unstable flow is avoided, working media and heat energy are recycled effectively, and starting time is shortened.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com