Patents

Literature

3605results about "Fuel supply regulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

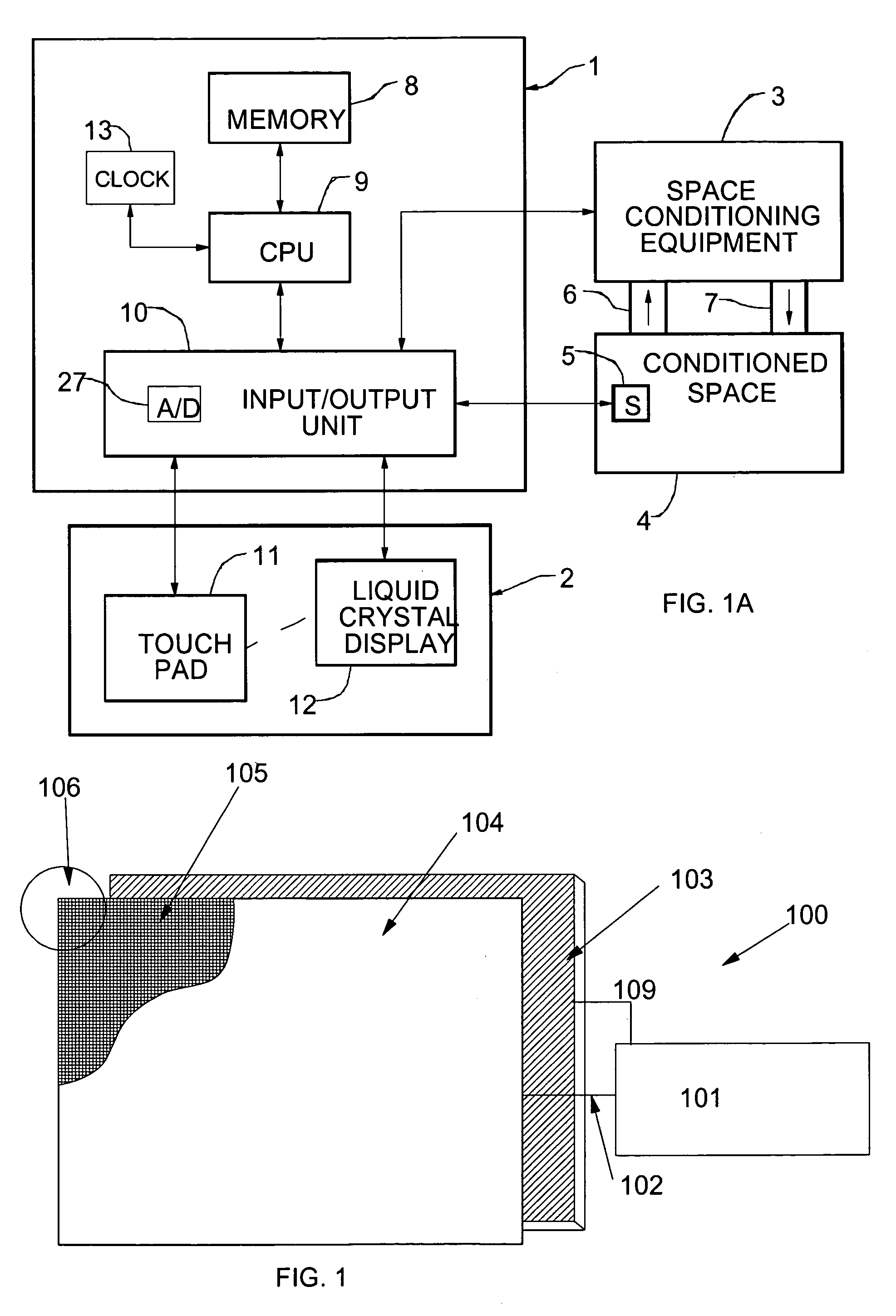

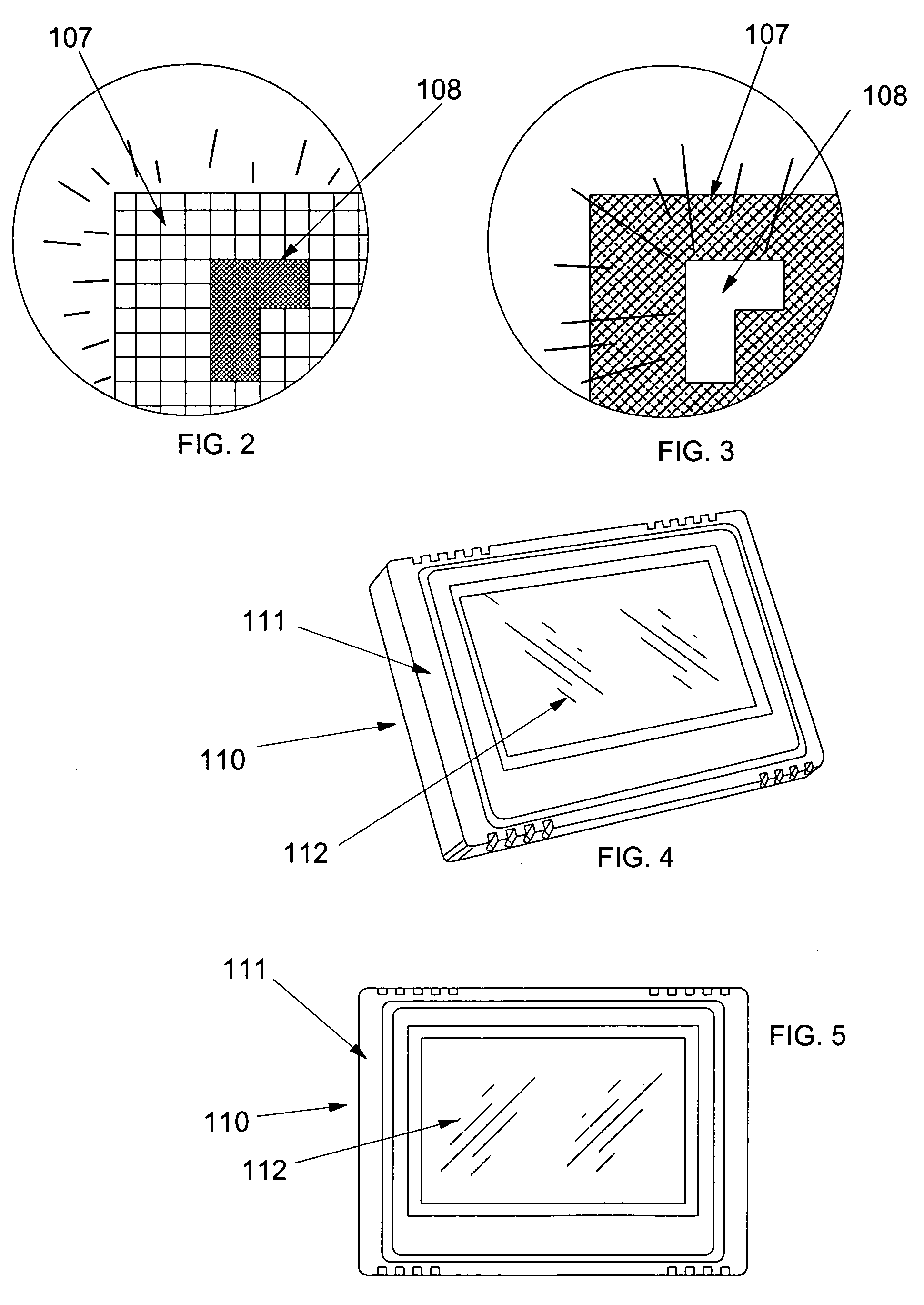

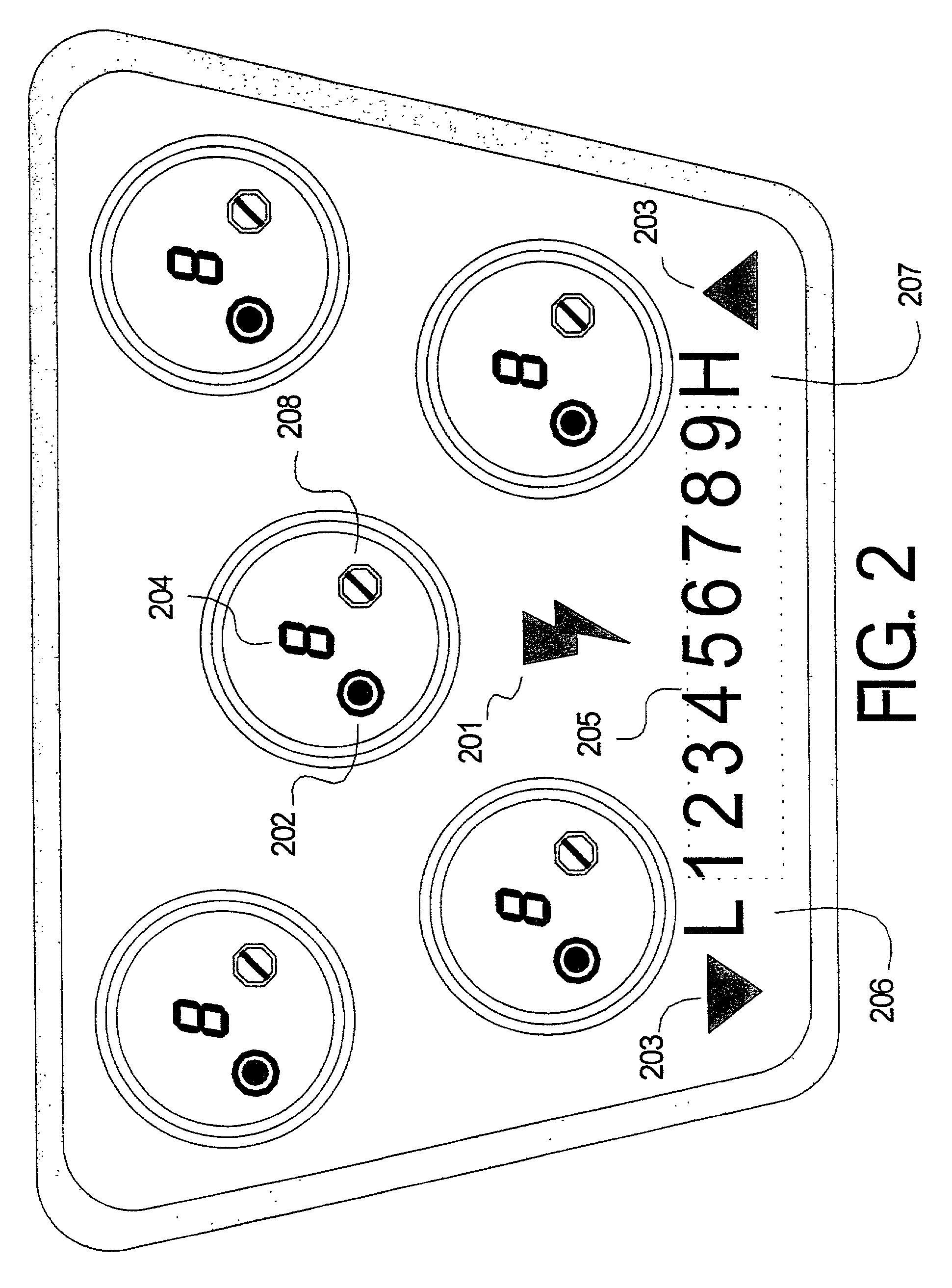

Programmable thermostat incorporating a liquid crystal display and having a feature for mounting horizontally, vertically and any intermediate orientation

ActiveUS7152806B1Facilitate intuitive programmingSampled-variable control systemsFuel supply regulationGraphicsDot matrix

A programmable thermostat having a touch screen dot matrix LCD in which the pictorial presenting information and virtual buttons on the touch screen is user configurable to be correctly oriented whether the thermostat is mounted horizontally or vertically.

Owner:ROSEN TECH LLC

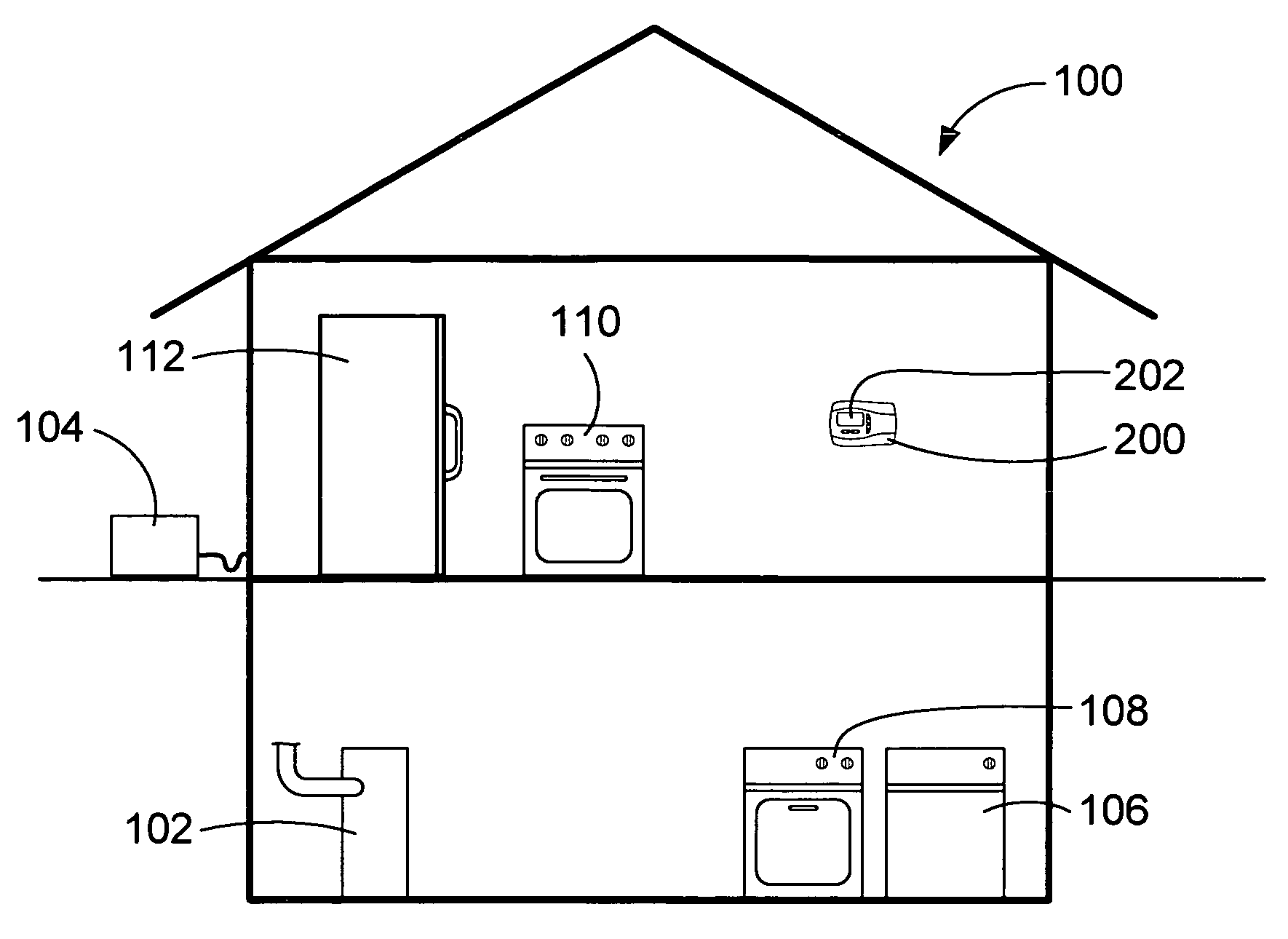

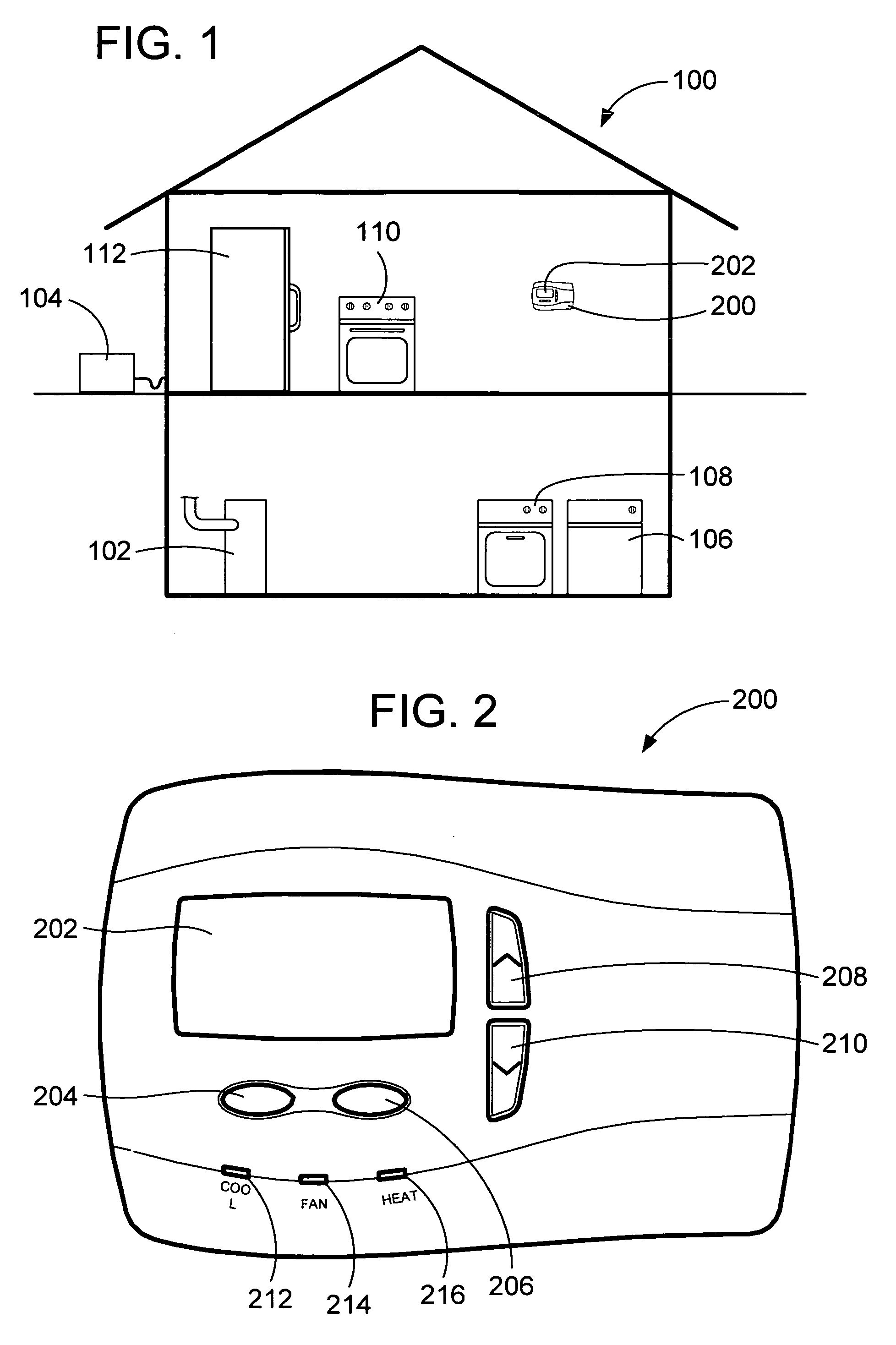

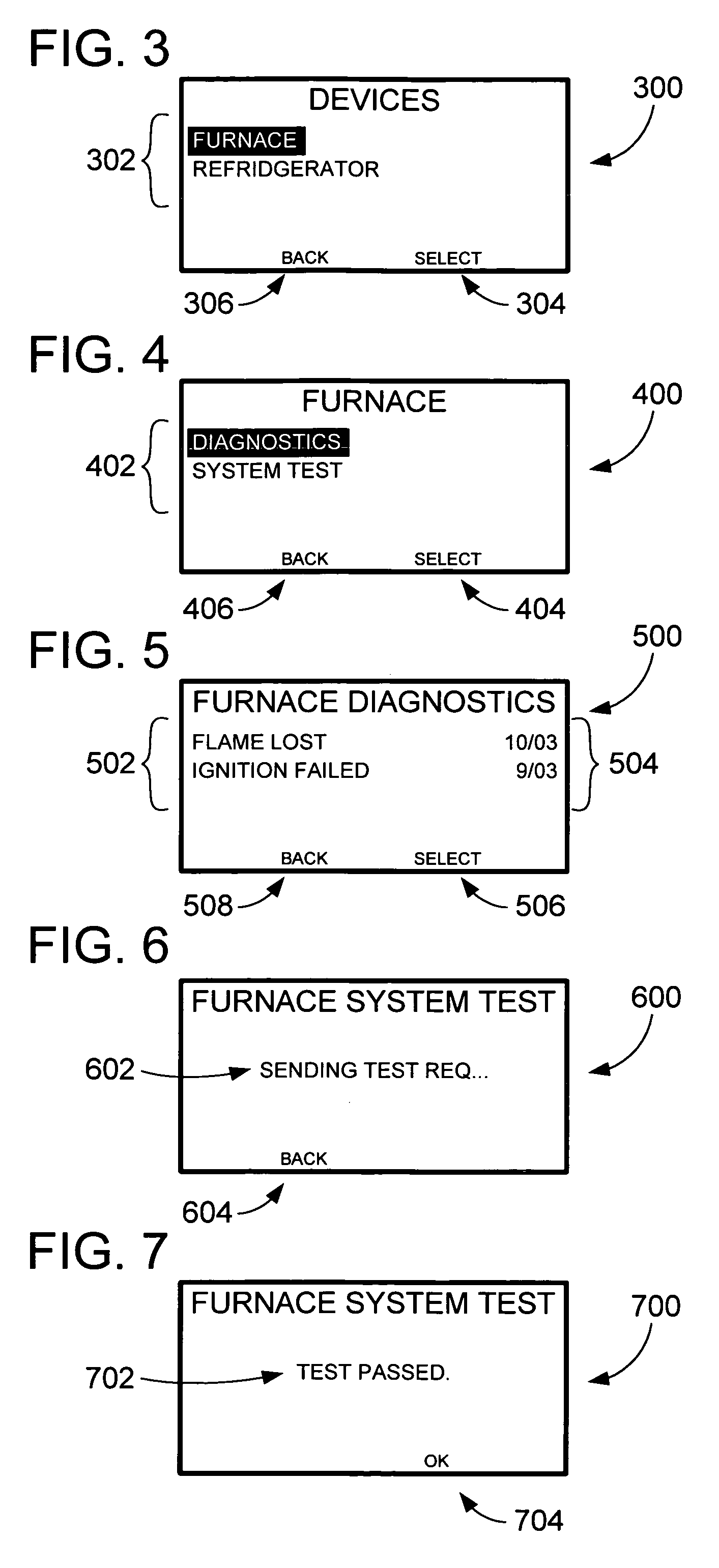

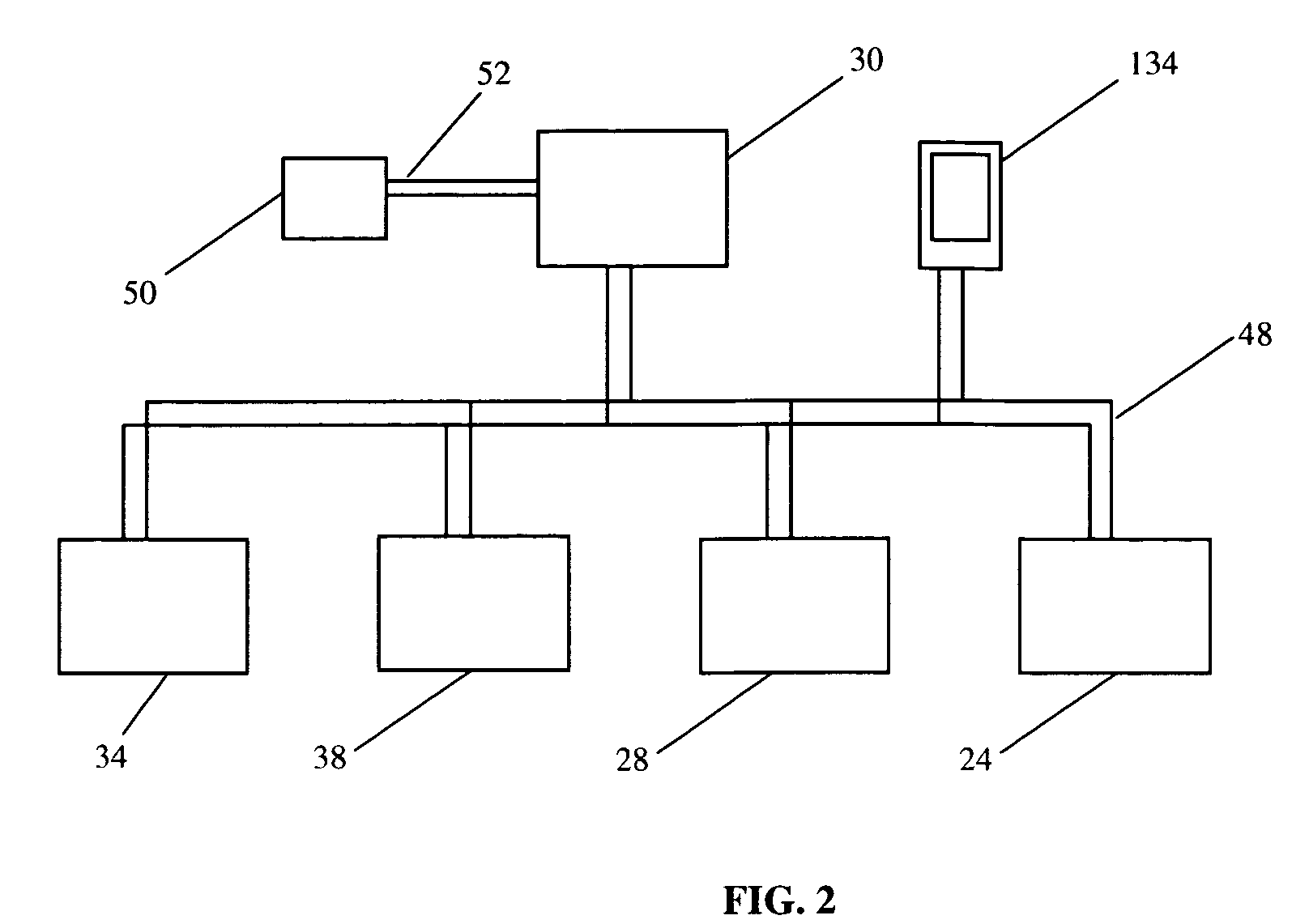

Appliance diagnostic display apparatus and network incorporating same

InactiveUS7188002B2Easy to testSpace heating and ventilationTemperatue controlWired communicationSystem testing

An appliance diagnostic display and interface system providing a centralized user interface for appliance diagnostic information and control of system self-tests is provided. This centralized user interface is provided via an intelligent thermostat that includes an LCD display. The intelligent thermostat interfaces, via wireless or wired communications, with the appliances installed in the home. The intelligent thermostat then generates and displays various user interface screens that allow particular appliances to be selected. Separate appliance specific screens are then generated that allow the user to access the diagnostic information in system test functionality provided by the individual appliance. Soft function keys provided on the intelligent thermostat allow multi-functional access to the features of the invention depending on which screen is currently being displayed.

Owner:INVENSYS SYST INC

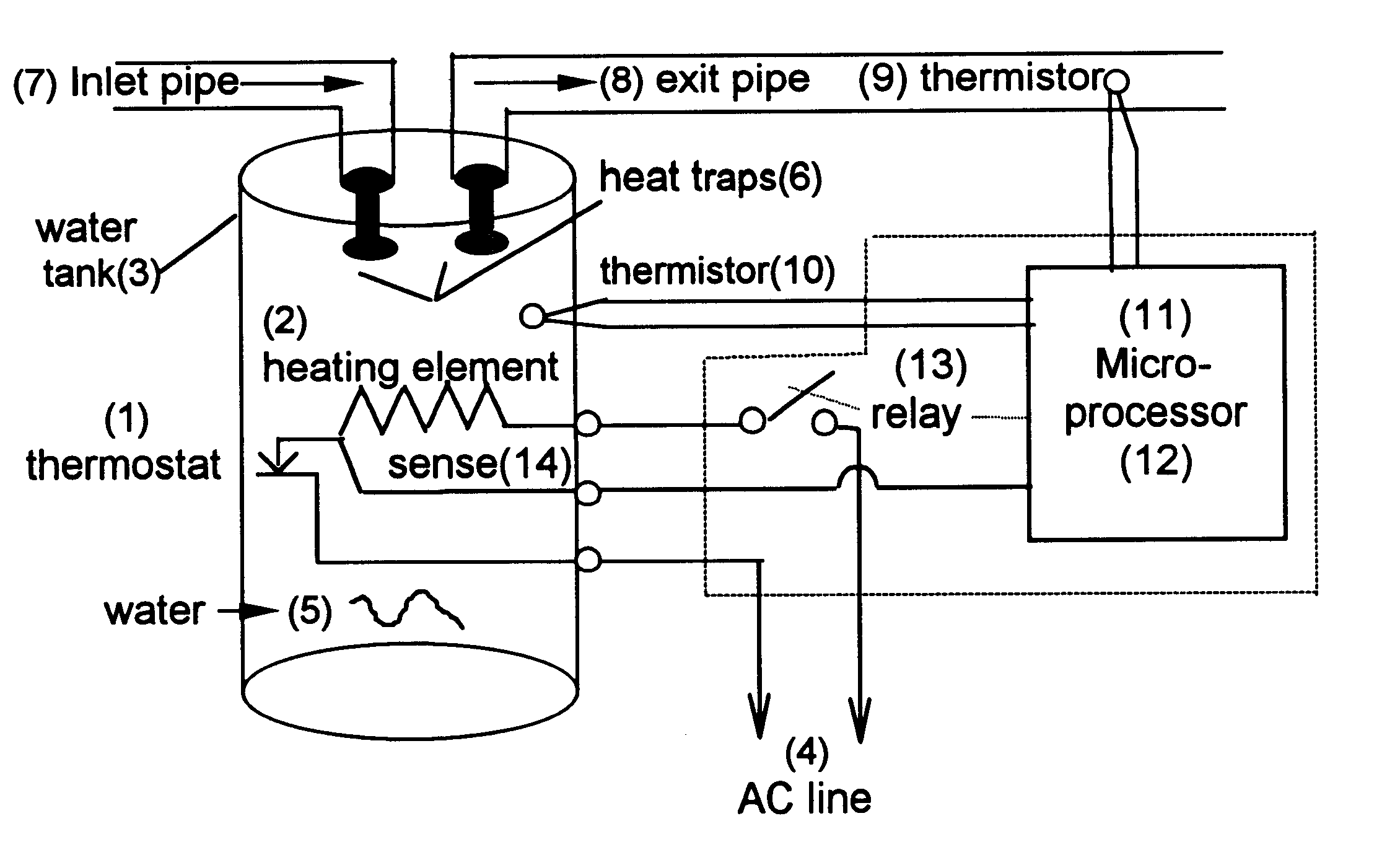

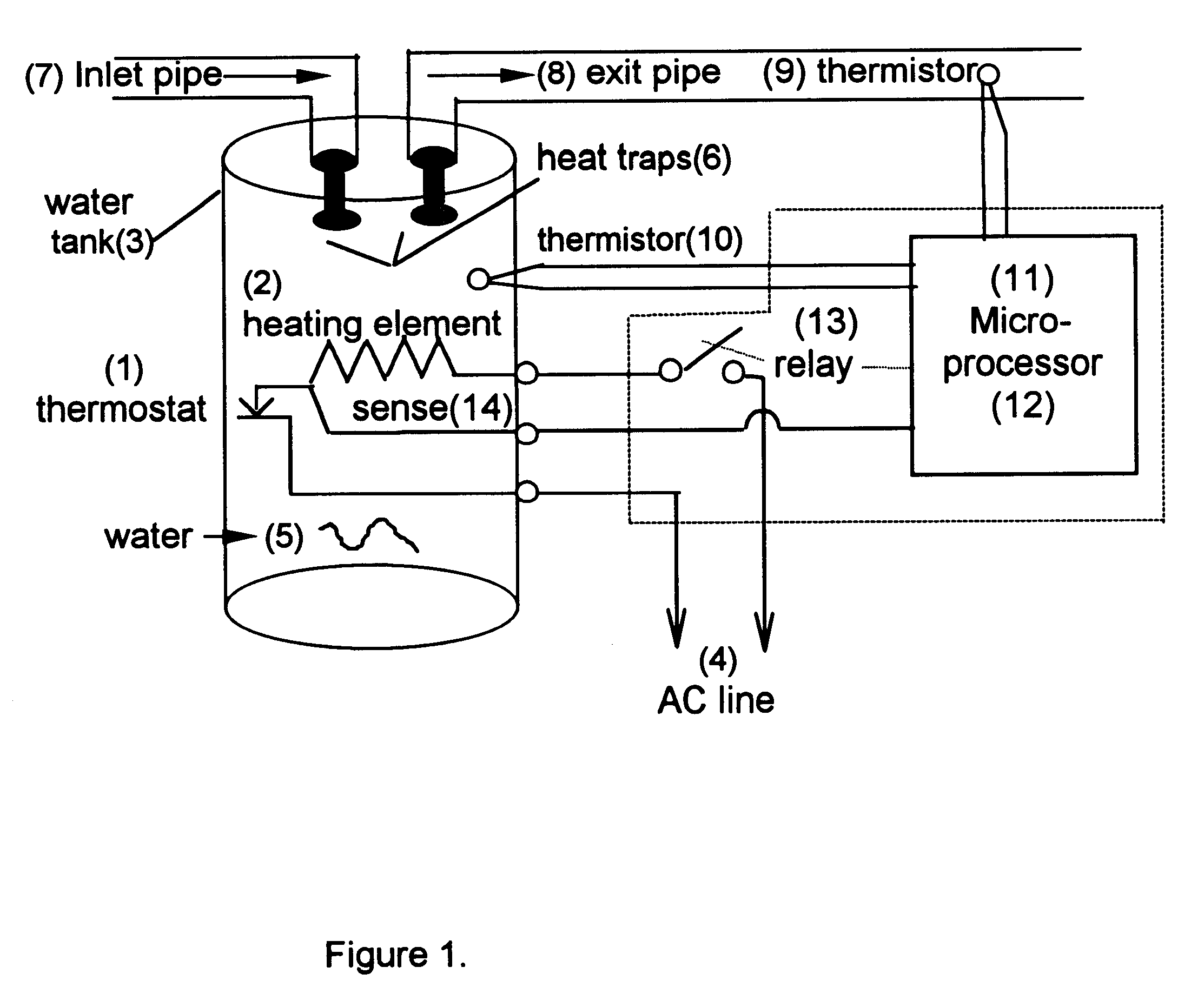

Heater control device and method to save energy

InactiveUS6293471B1Fuel supply regulationTemperature control using digital meansWater basedAutomatic control

A device and method is provided for automatically controlling the heating element(s) of an electric hot water heater to minimize electric energy consumption over a prolonged time period by projecting the future need for hot water based on it's use in prior time periods as well as by monitoring the use of hot water during current periods. The device saves energy by switching the heater "off" during times when the projected and current need for hot water is low or nonexistent thereby reducing the tank temperature and therefore energy losses to the ambient, while detecting the instantaneous requirement for hot water through utilization of a flow sensor arrangement, one of which is the utilization of thermistors on the exit pipe and on the tank or body of the heater. The device leaves all existing controls intact and may be adapted by end users to existing heaters or by manufacturers of original equipment (OEMs).

Owner:STETTIN DANIEL R +1

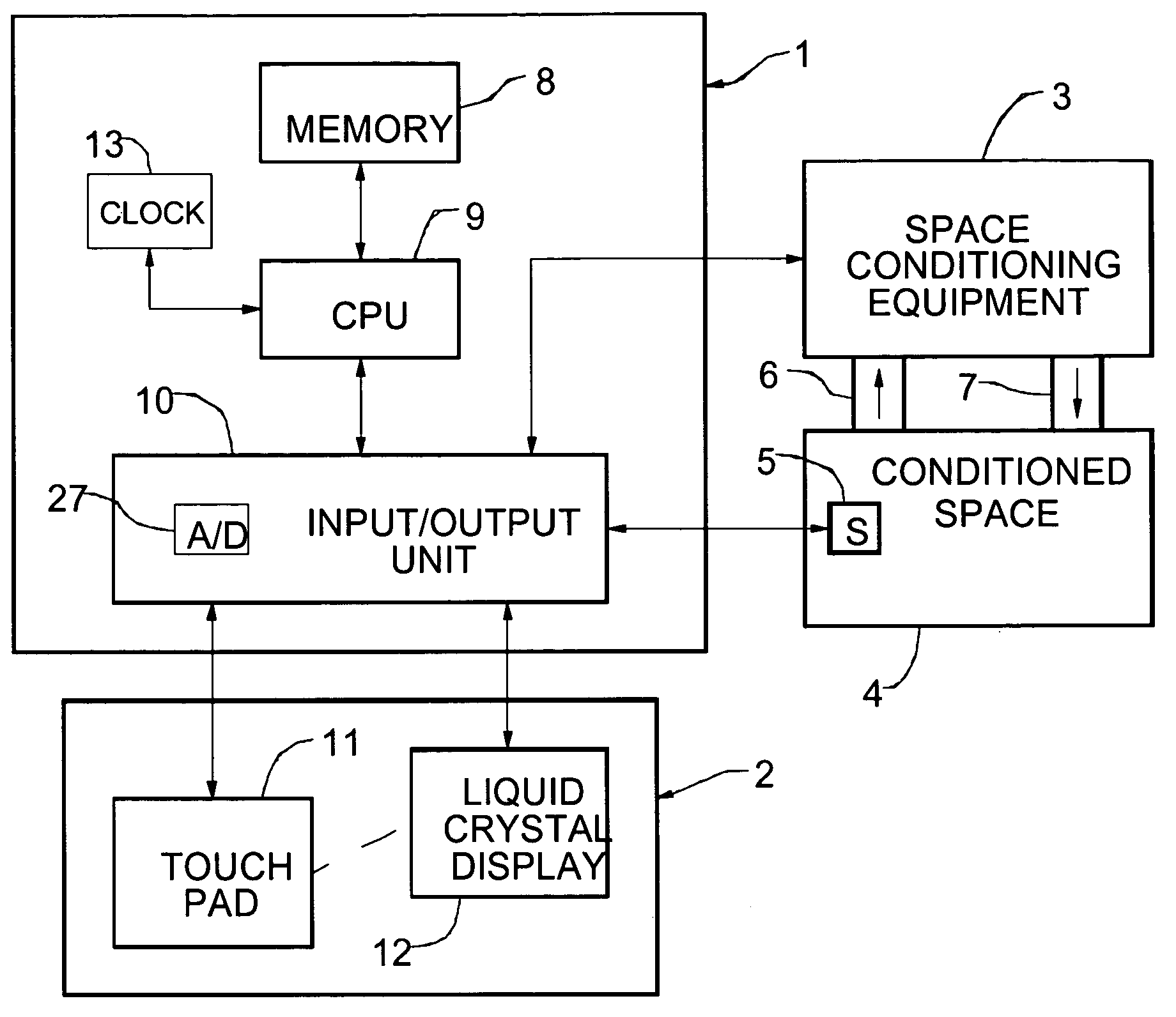

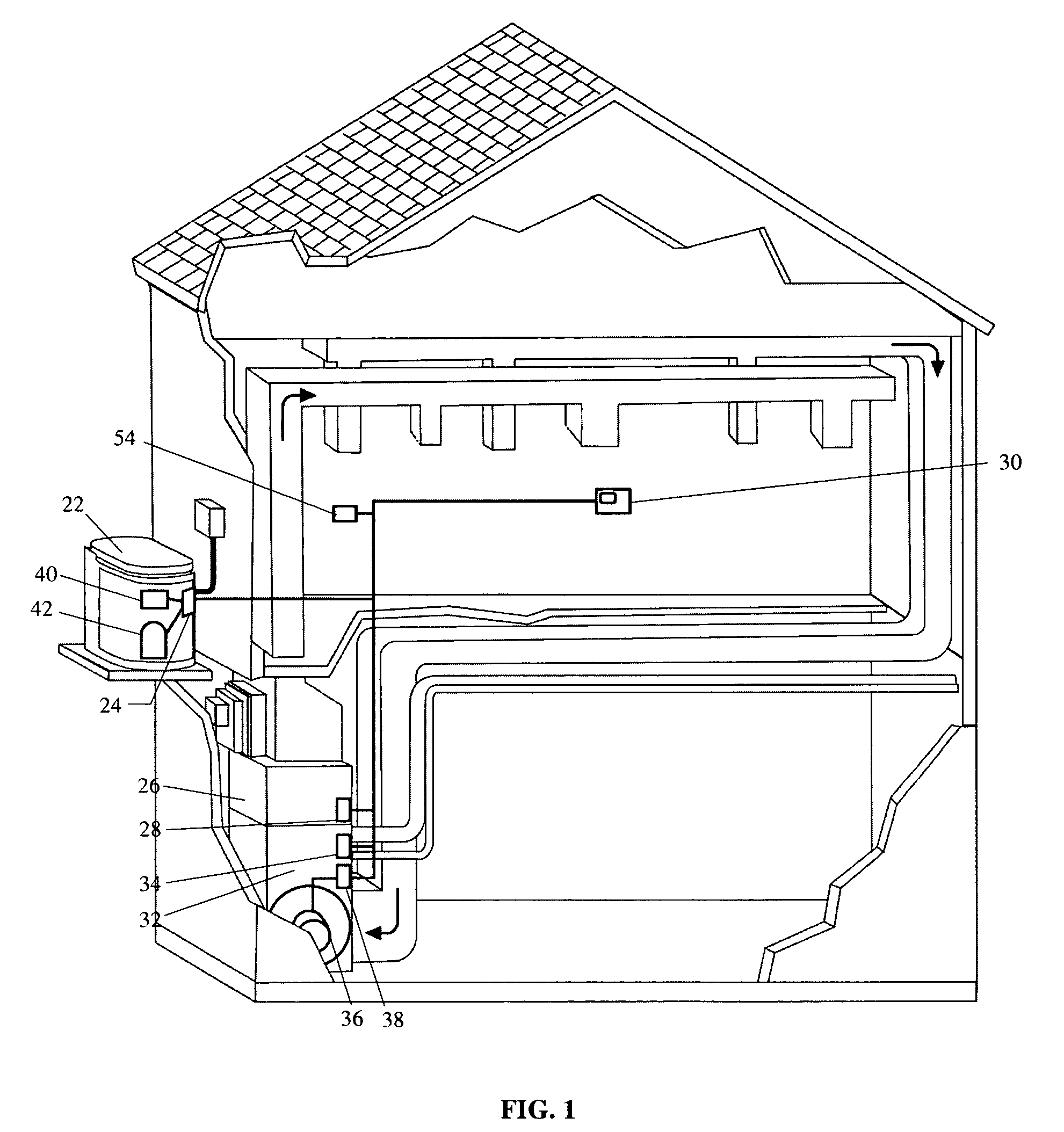

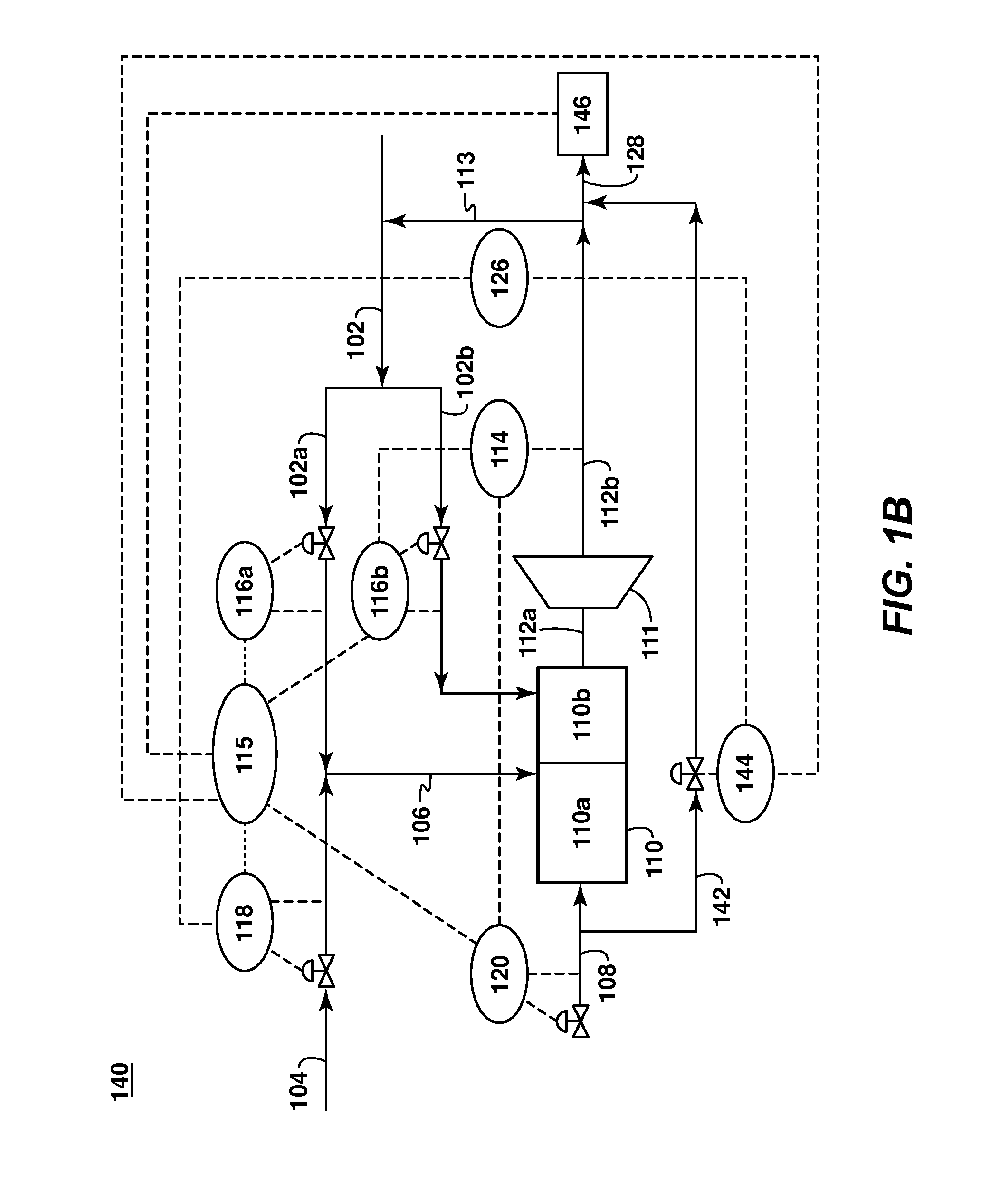

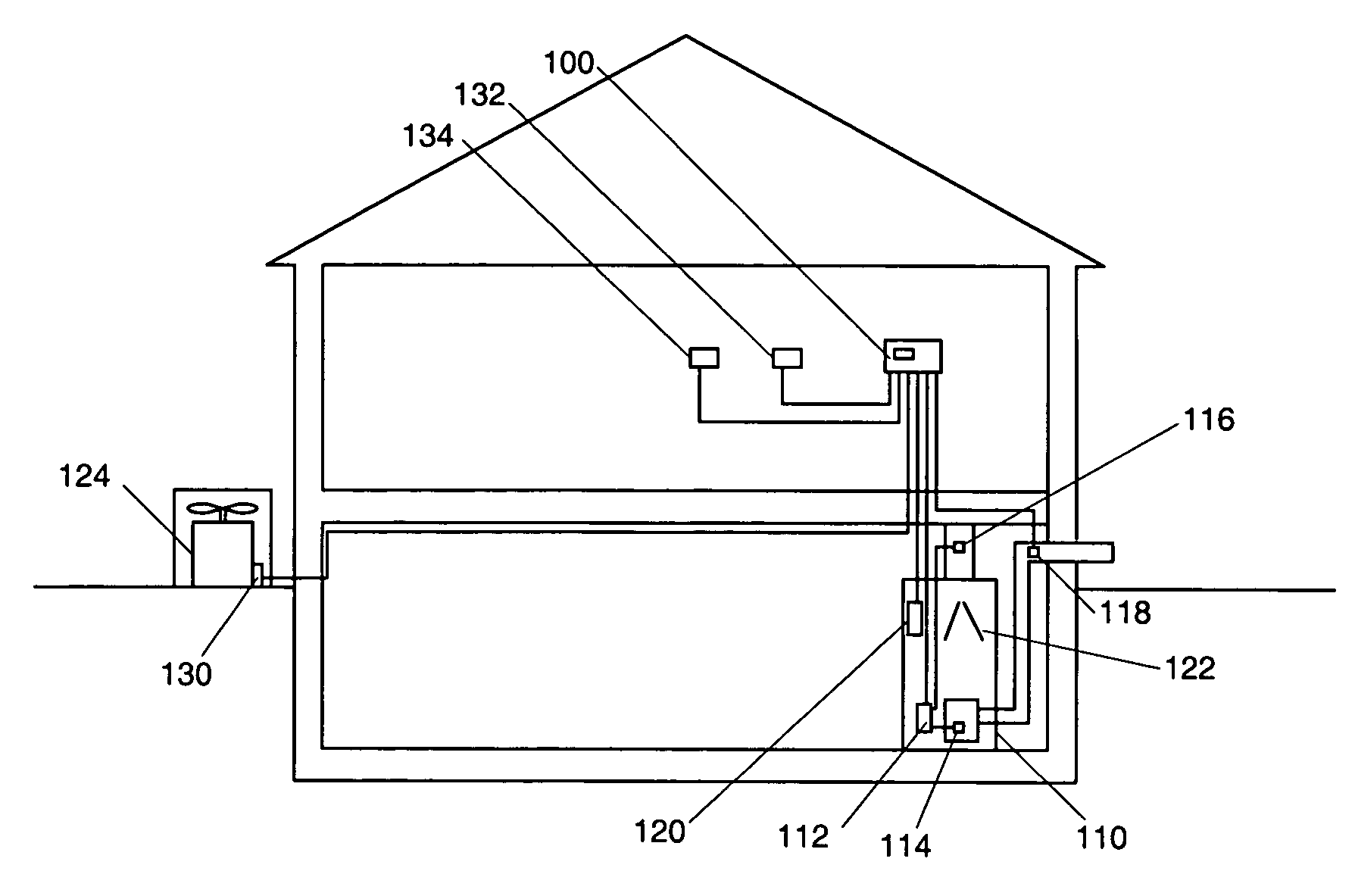

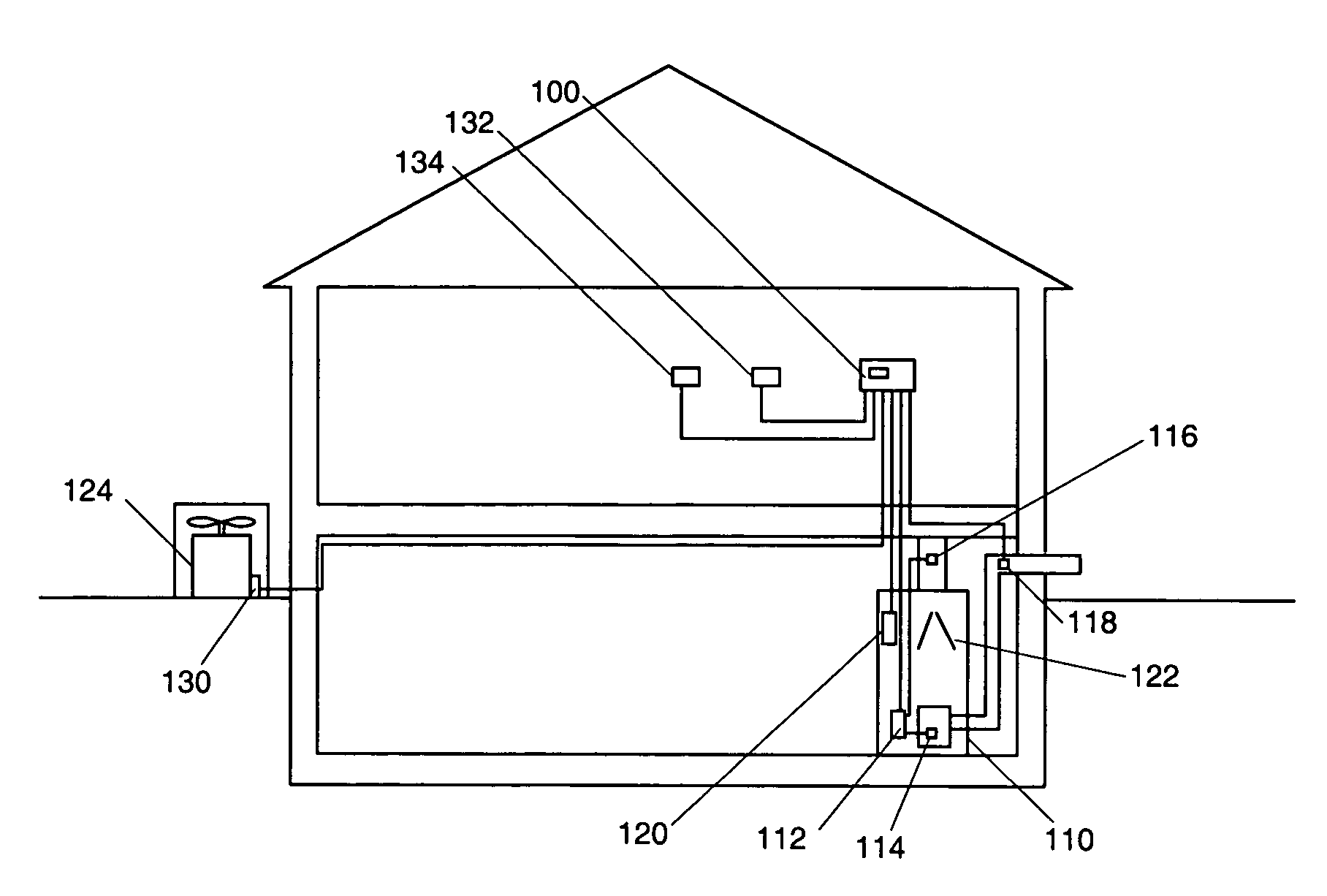

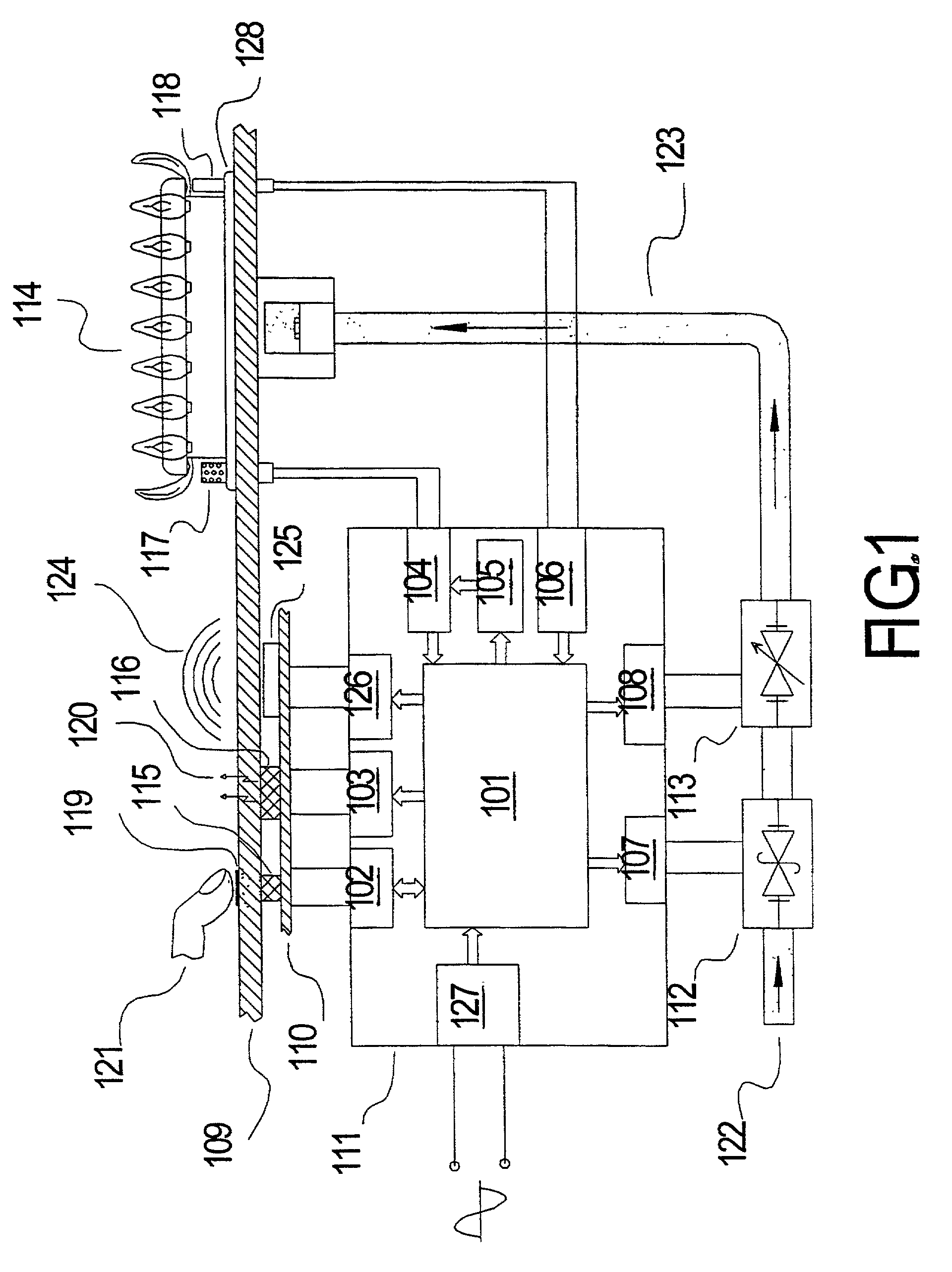

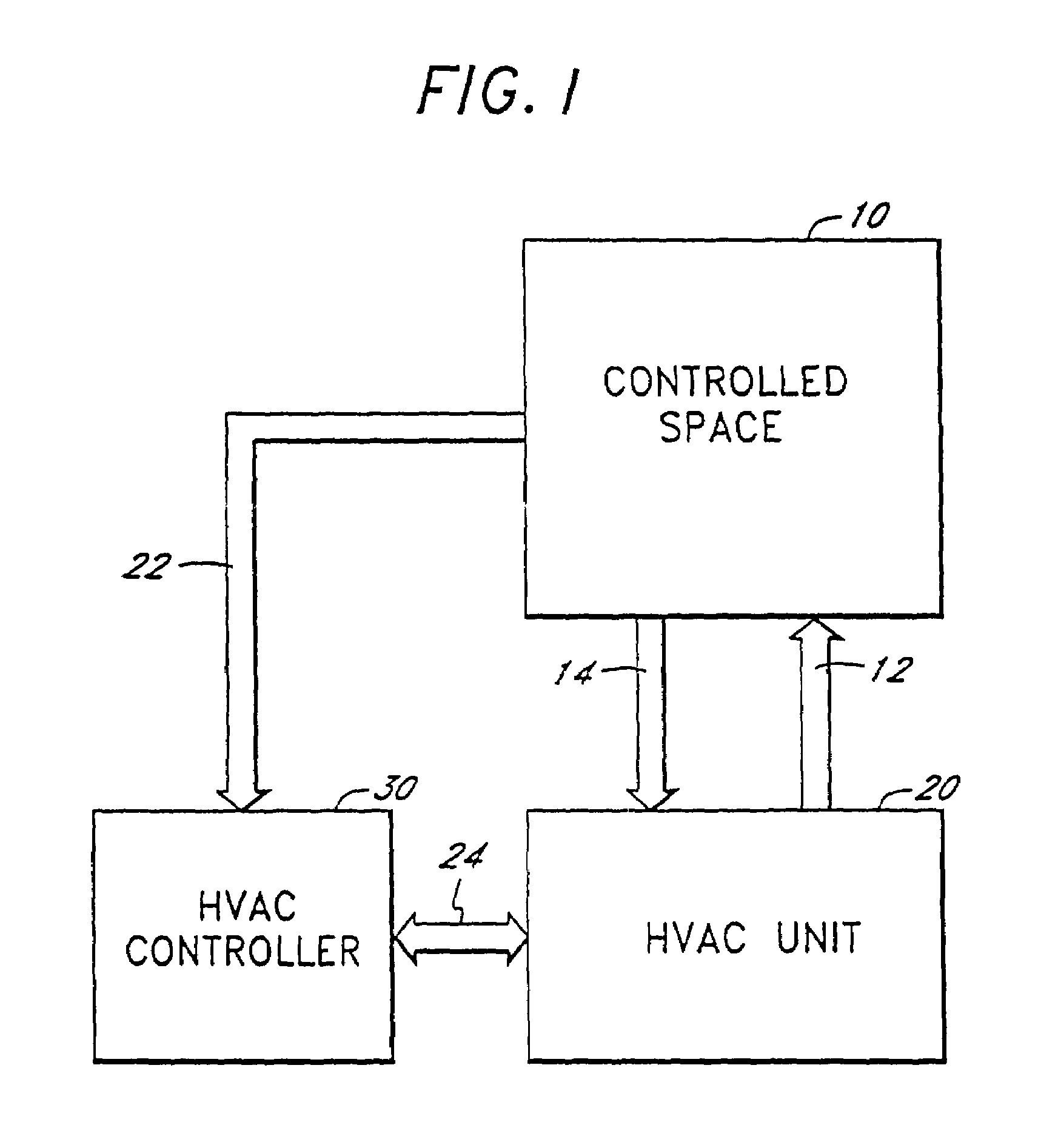

Interactive control system for an HVAC system

An interactive system for controlling the operation of an HVAC system is provide that comprises a thermostat for initiating the operation of the HVAC system in either a full capacity mode of operation or at least one reduced capacity mode of operation, and a controller for an outside condenser unit having a condenser fan motor and a compressor motor, the controller being capable of operating the compressor in a full capacity mode and at least one reduced capacity mode. The system also comprises a controller for an indoor blower unit having a blower fan motor, the controller being capable of operating the blower fan motor in a full capacity mode an at least one reduced capacity mode. The system further includes a communication means for transmitting information between the outside condenser unit controller and at least the indoor blower controller, where the information relates to the operation of the indoor blower and the outdoor condenser unit. The indoor blower controller responsively controls the operation of the blower fan motor in a full capacity mode or a reduced capacity mode based on the information received from the outdoor unit controller, and the outdoor unit controller responsively controls the operation of the compressor in a full capacity mode or a reduced capacity mode based on the information received from the indoor blower controller.

Owner:COPELAND COMFORT CONTROL LP

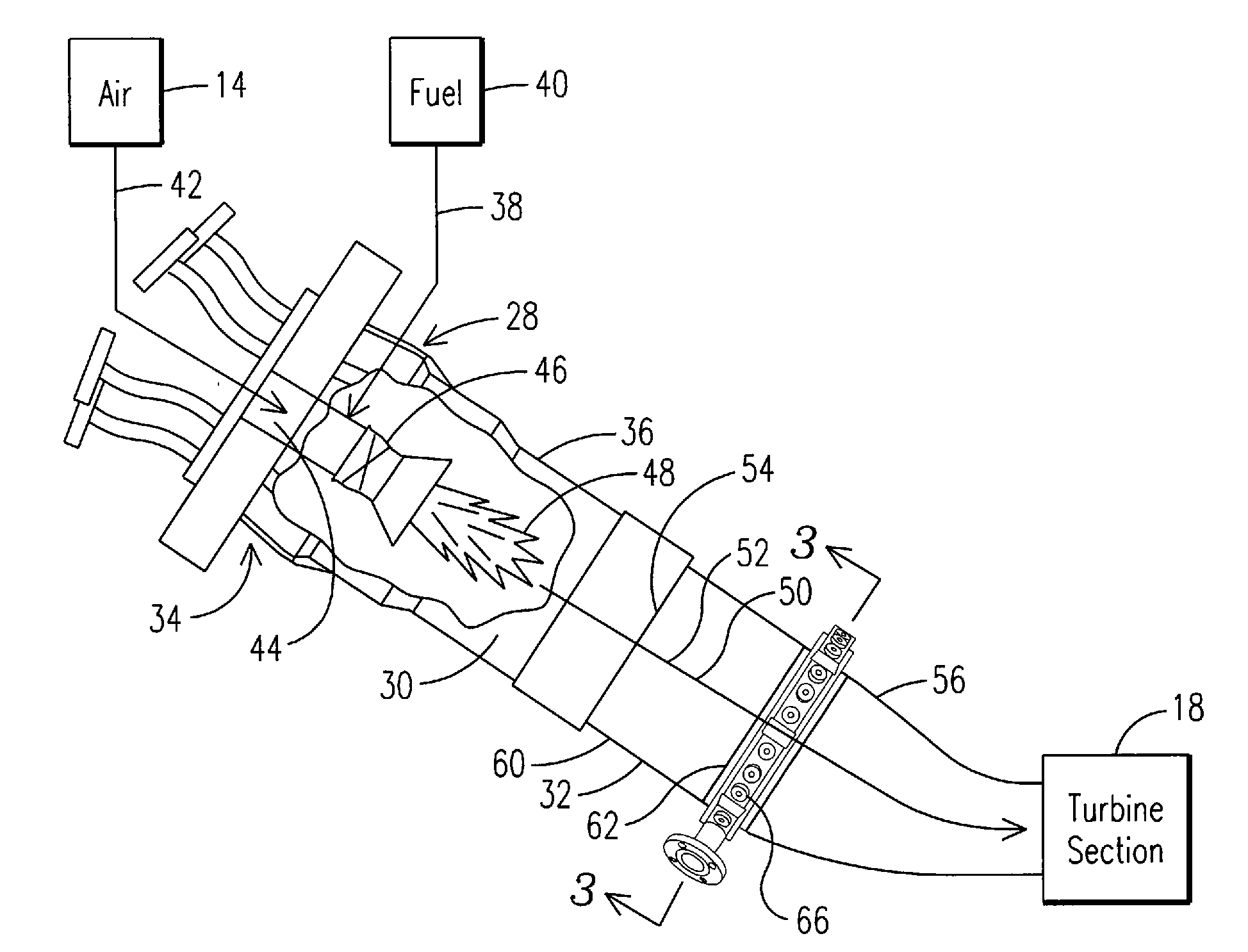

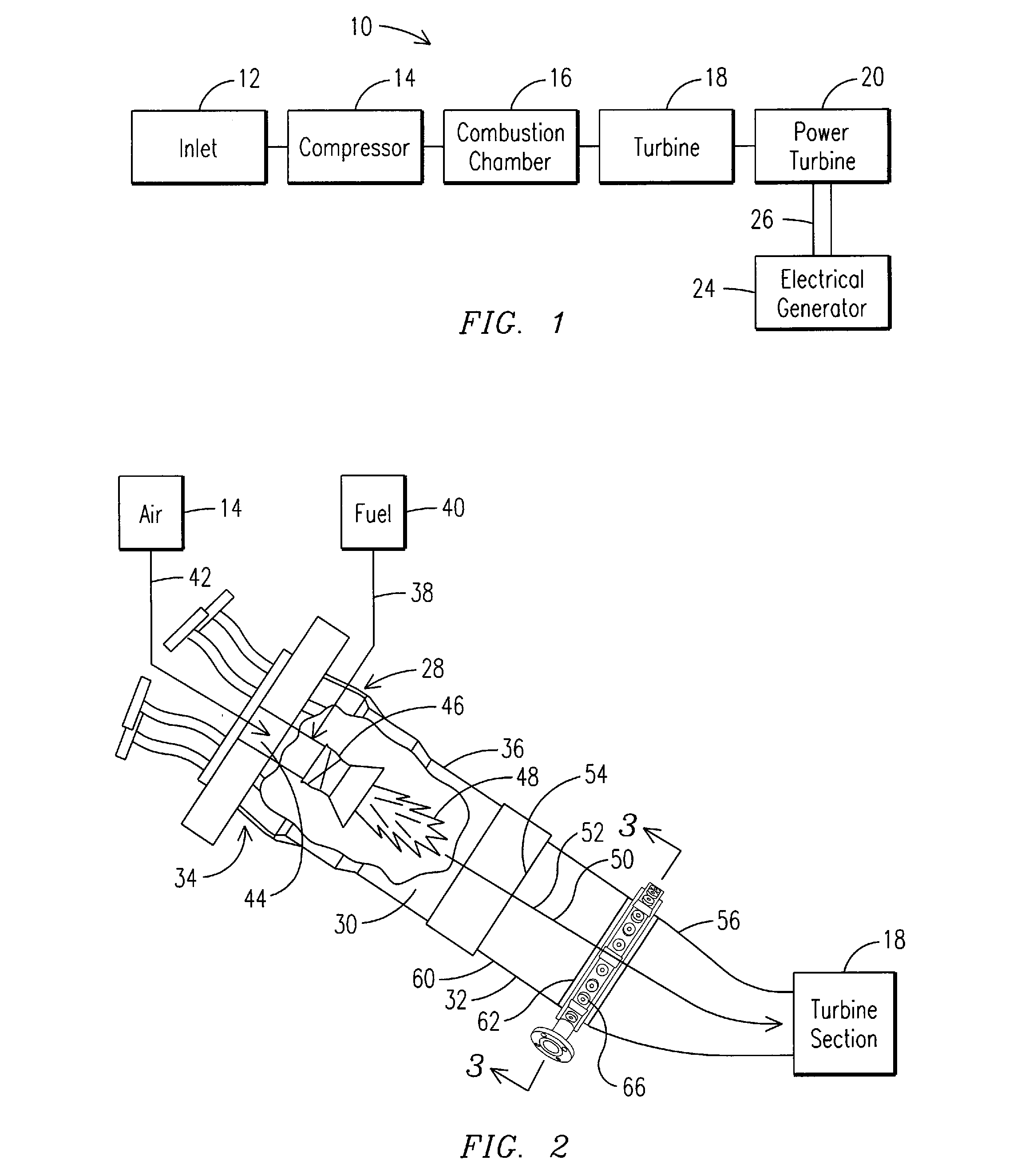

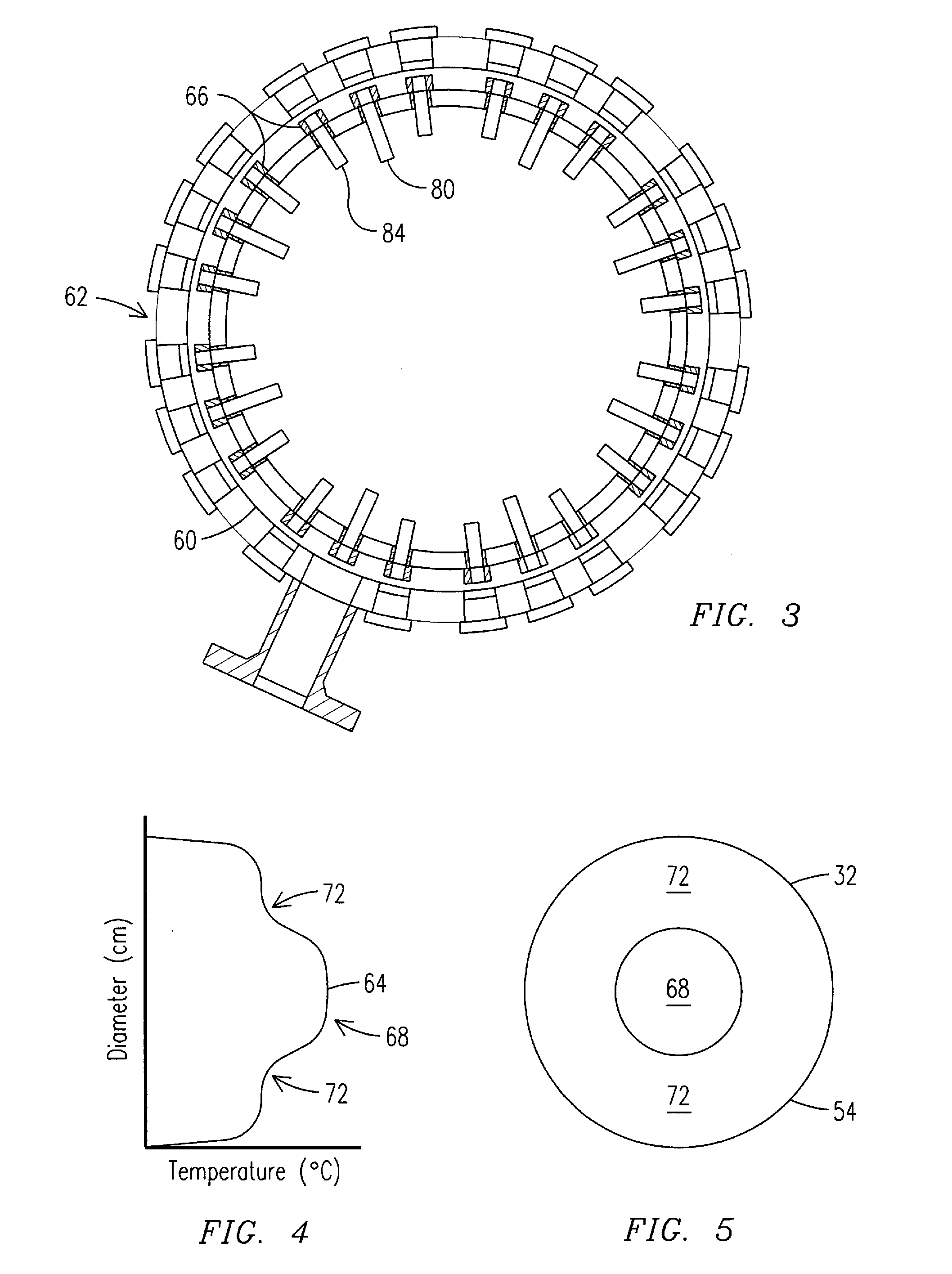

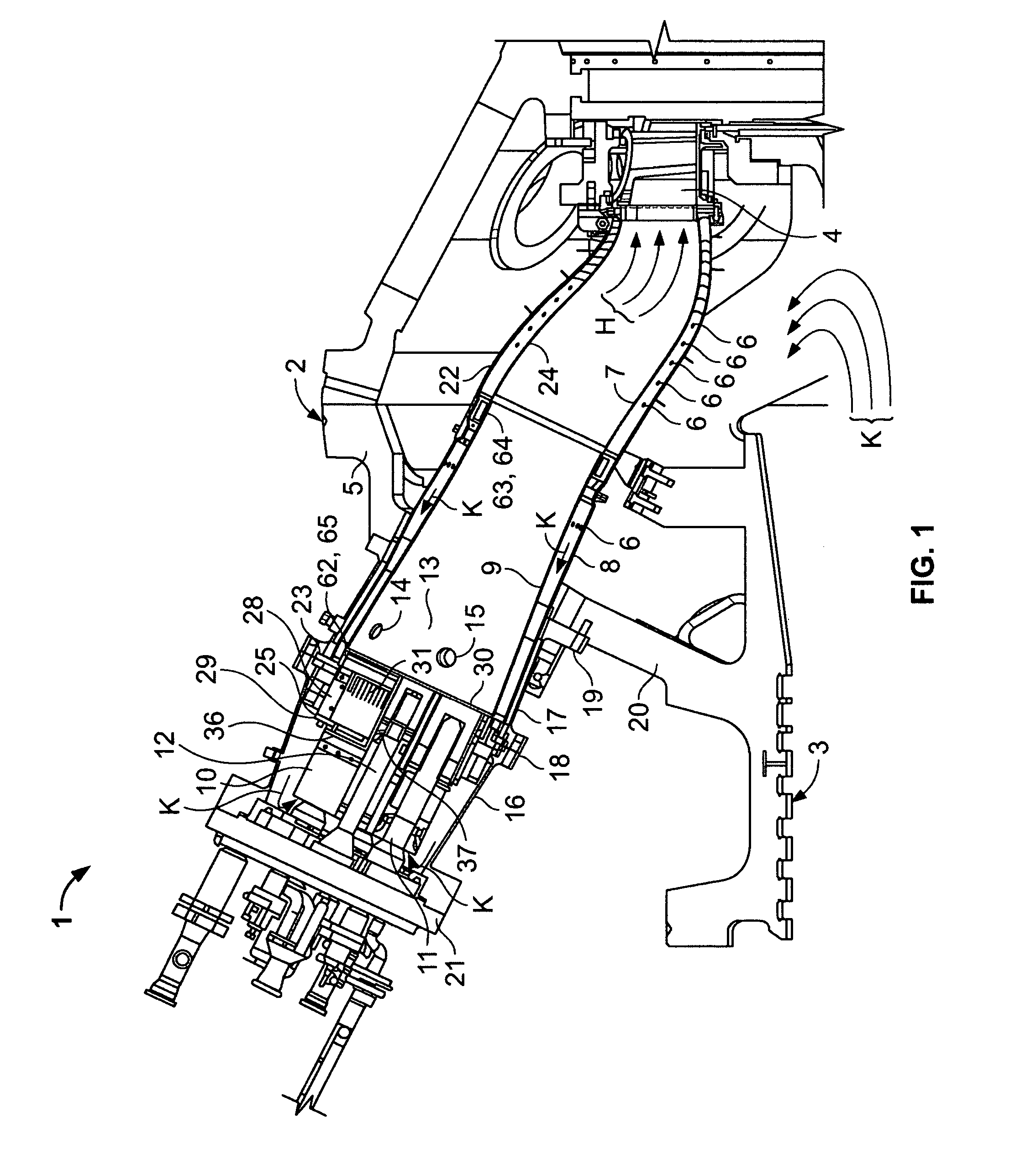

Apparatus and Method for Controlling the Secondary Injection of Fuel

In one embodiment, a combustor (28) for a gas turbine engine is provided comprising a primary combustion chamber (30) for combusting a first fuel to form a combustion flow stream (50) and a transition piece (32) located downstream from the primary combustion chamber (30). The transition piece (32) comprises a plurality of injectors (66) located around a circumference of the transition piece (32) for injecting a second fuel into the combustion flow stream (50). The injectors (66) are effective to create a radial temperature profile (74) at an exit (58) of the transition piece (32) having a reduced coefficient of variation relative to a radial temperature profile (64) at an inlet (54) of the transition piece (32). Methods for controlling the temperature profile of a secondary injection are also provided.

Owner:SIEMENS ENERGY INC

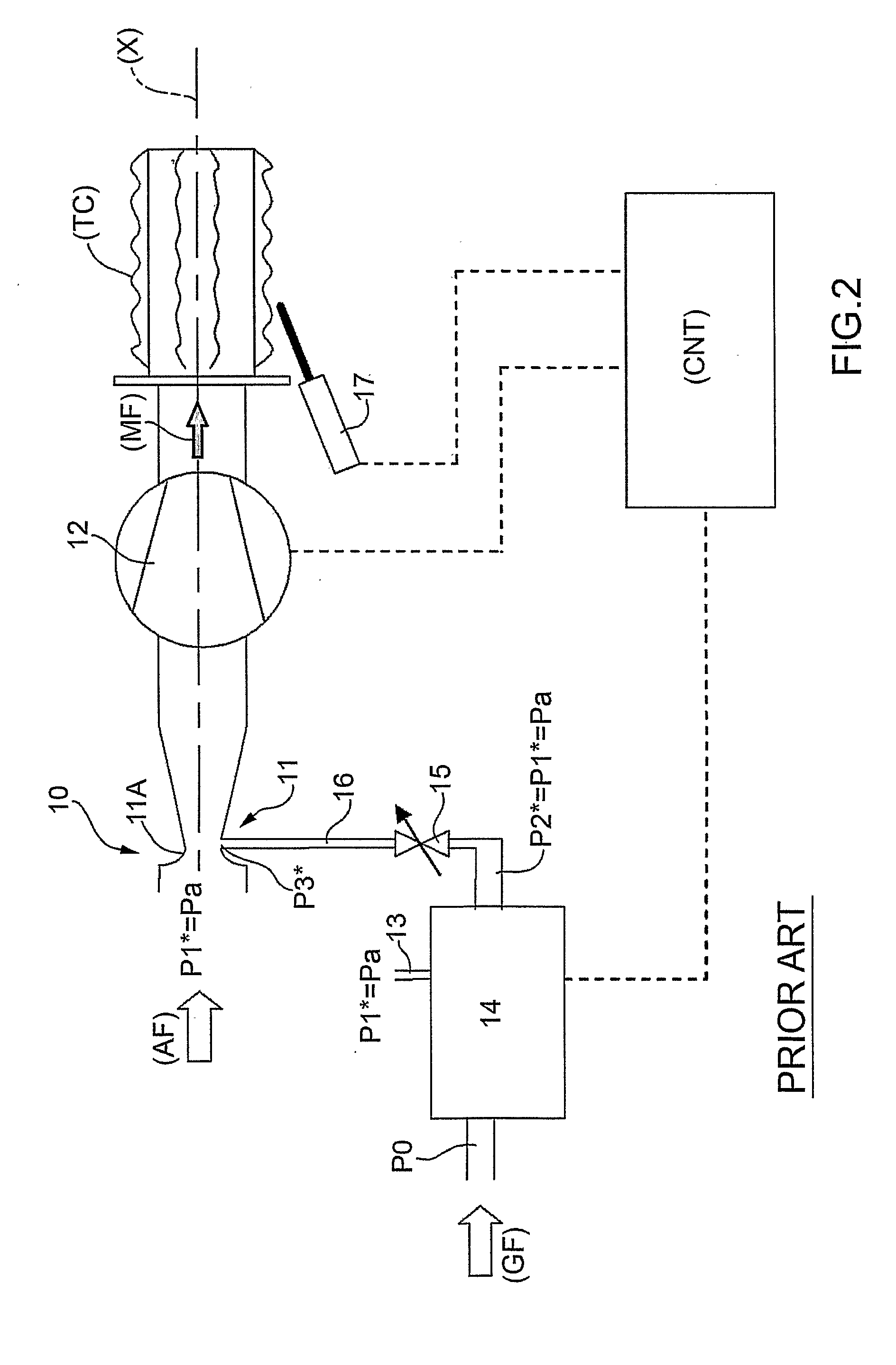

Premix gas burner

ActiveUS20110139045A1Easy and inexpensive to produceFuel supply regulationGaseous fuel burnerCombustible gasEngineering

An air / gas premix burner, comprising:a fan for sending the air / gas mixture to a combustion head;a gas valve for regulating admission of the combustible gas;an air / gas mixer, which comprises a device for localized loss of pressure; anda combustion head.The premix burner is characterized in that the air / gas mixer comprises at least two channels for mixing the air with the gas; in addition, a channel is provided with an open / close element designed to regulate the flow rate of the mixture.

Owner:GAS POINT

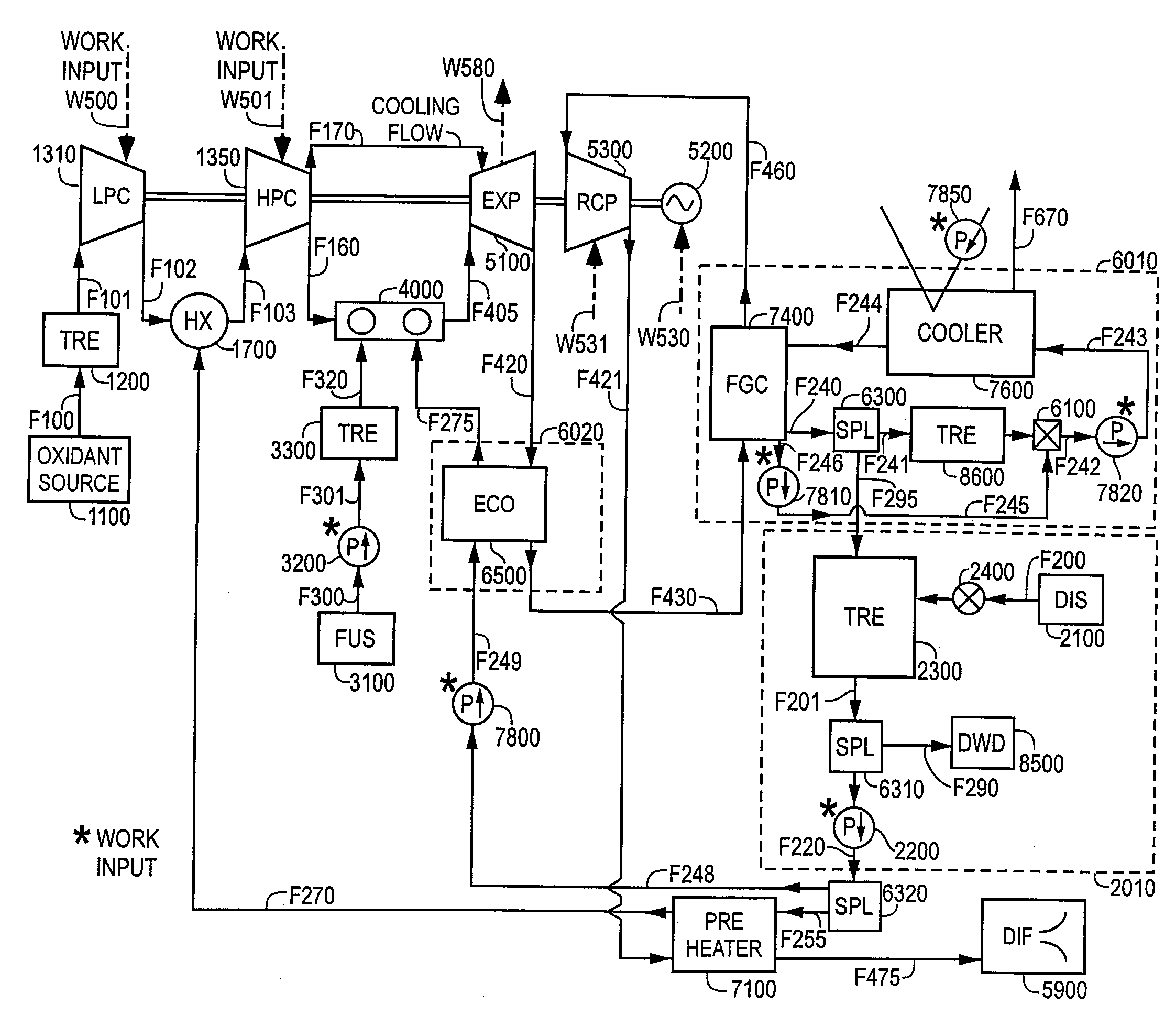

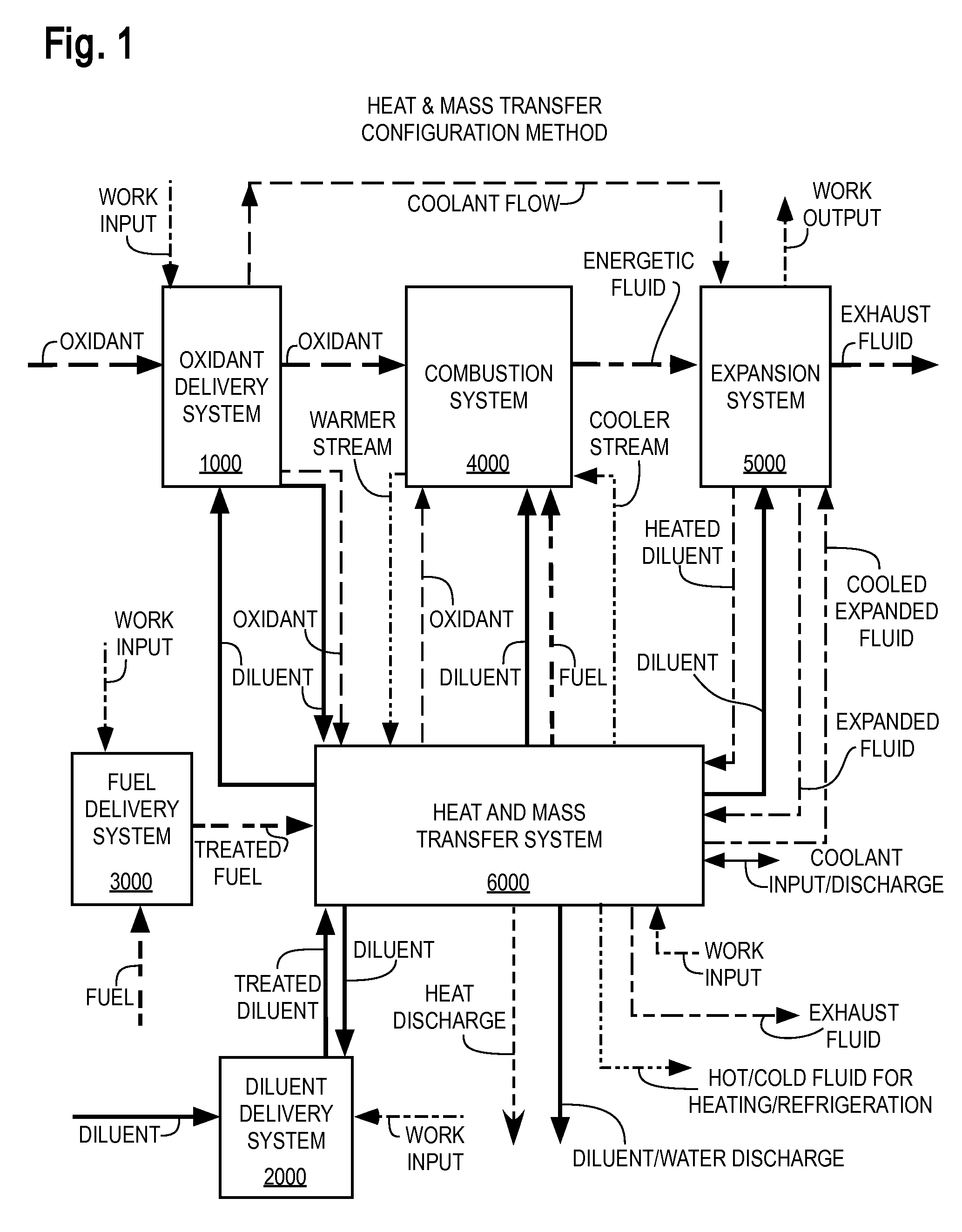

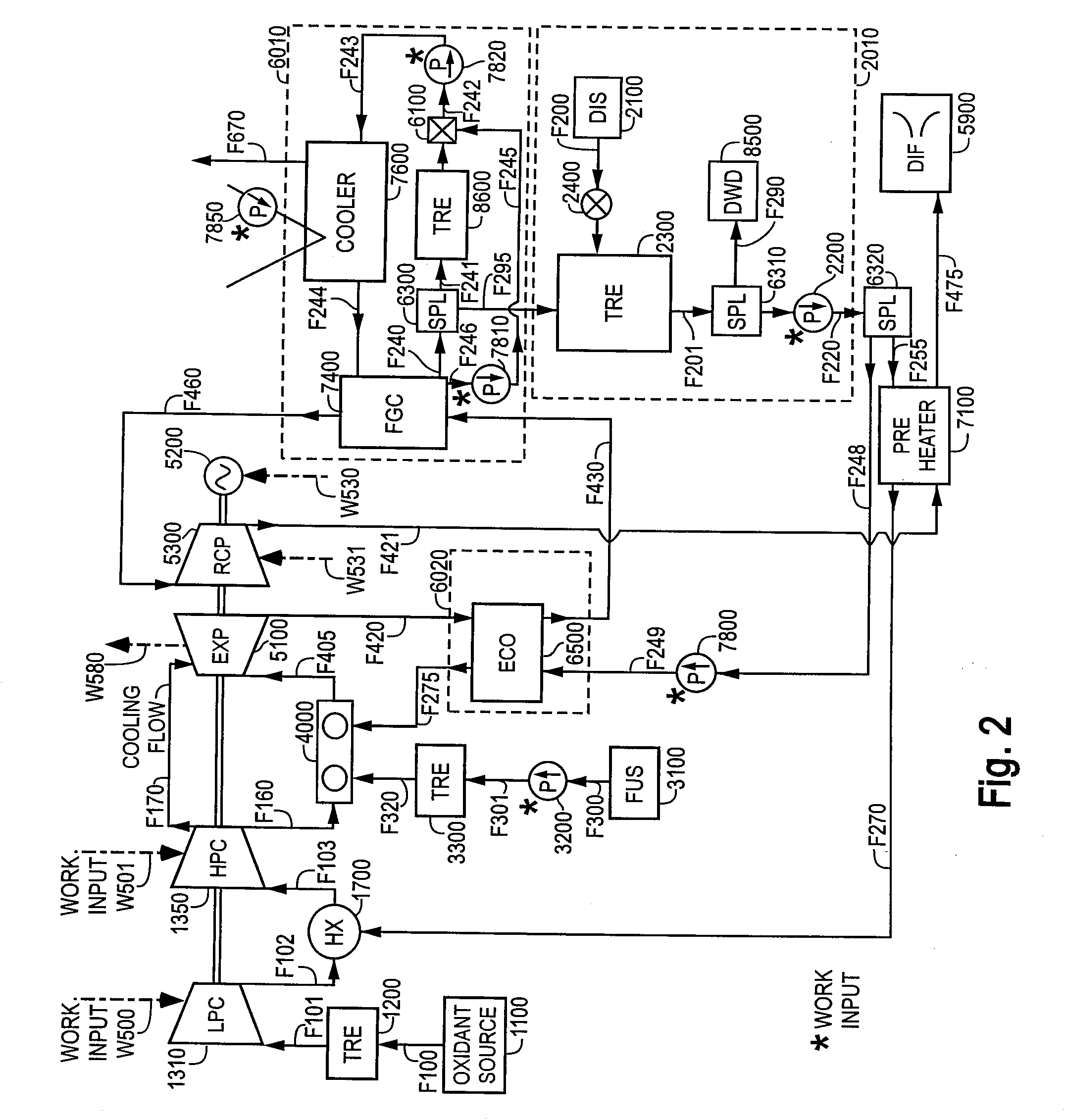

Thermodynamic cycles using thermal diluent

ActiveUS20090071166A1Low costEmission reductionSpace heating and ventilationSulfur compoundsCombustion systemCombustion

A thermodynamic system that produces mechanical, electrical power, and / or fluid streams for heating or cooling. The cycle contains a combustion system that produces an energetic fluid by combustion of a fuel with an oxidant. A thermal diluent may be used in the cycle to improve performance, including but not limited to power, efficiency, economics, emissions, dynamic and off-peak load performance, and / or turbine inlet temperature (TIT) regulation and cooling heated components. The cycle preferably includes a heat recovery system and a condenser or other means to recover and recycle heat and the thermal diluent from the energetic fluid to improve the cycle thermodynamic efficiency and reduce energy conversion costs. The cycle may also include controls for temperatures, pressures, and flow rates throughout the cycle, and controls power output, efficiency, and energetic fluid composition.

Owner:VAST HLDG LLC

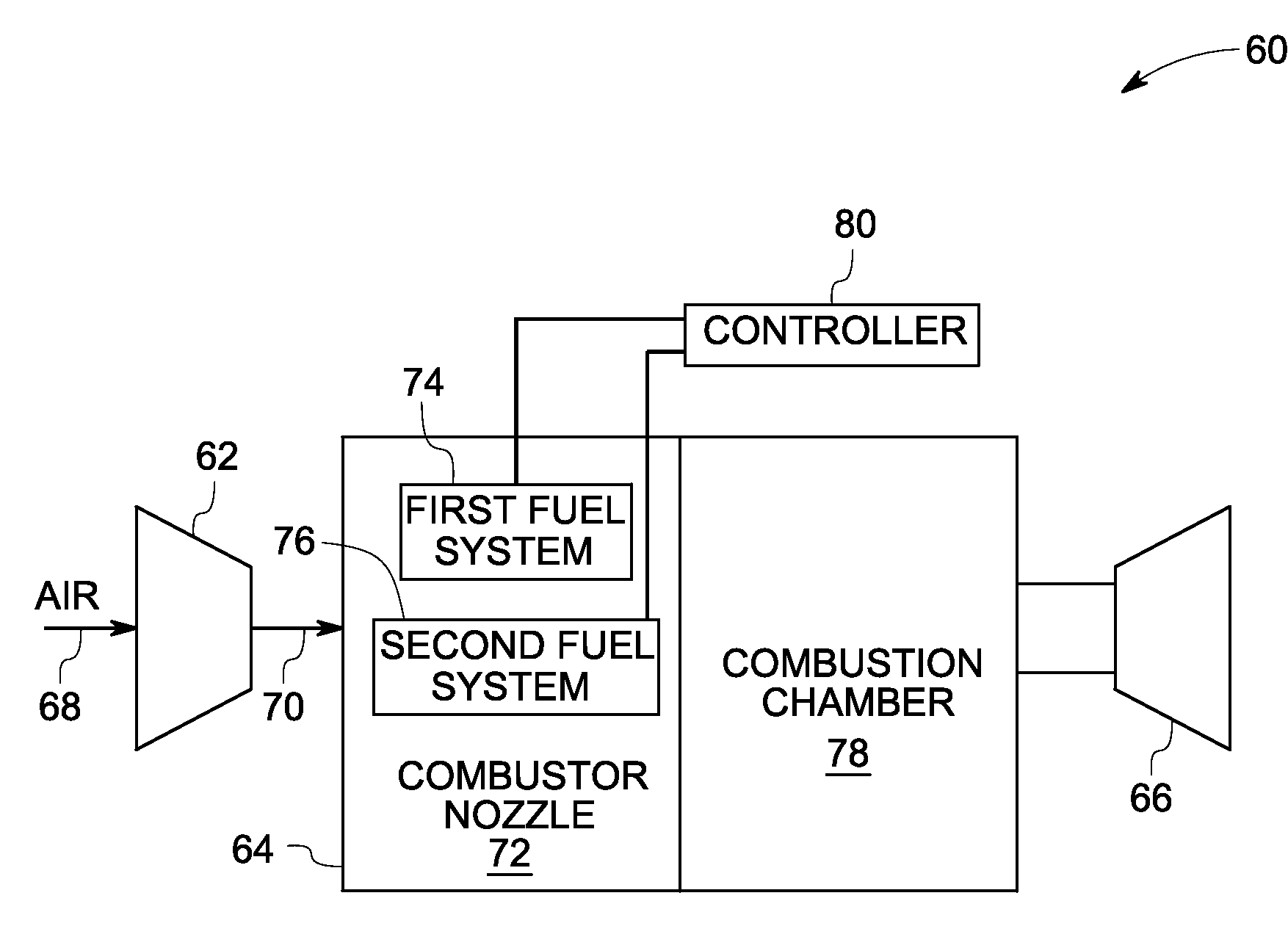

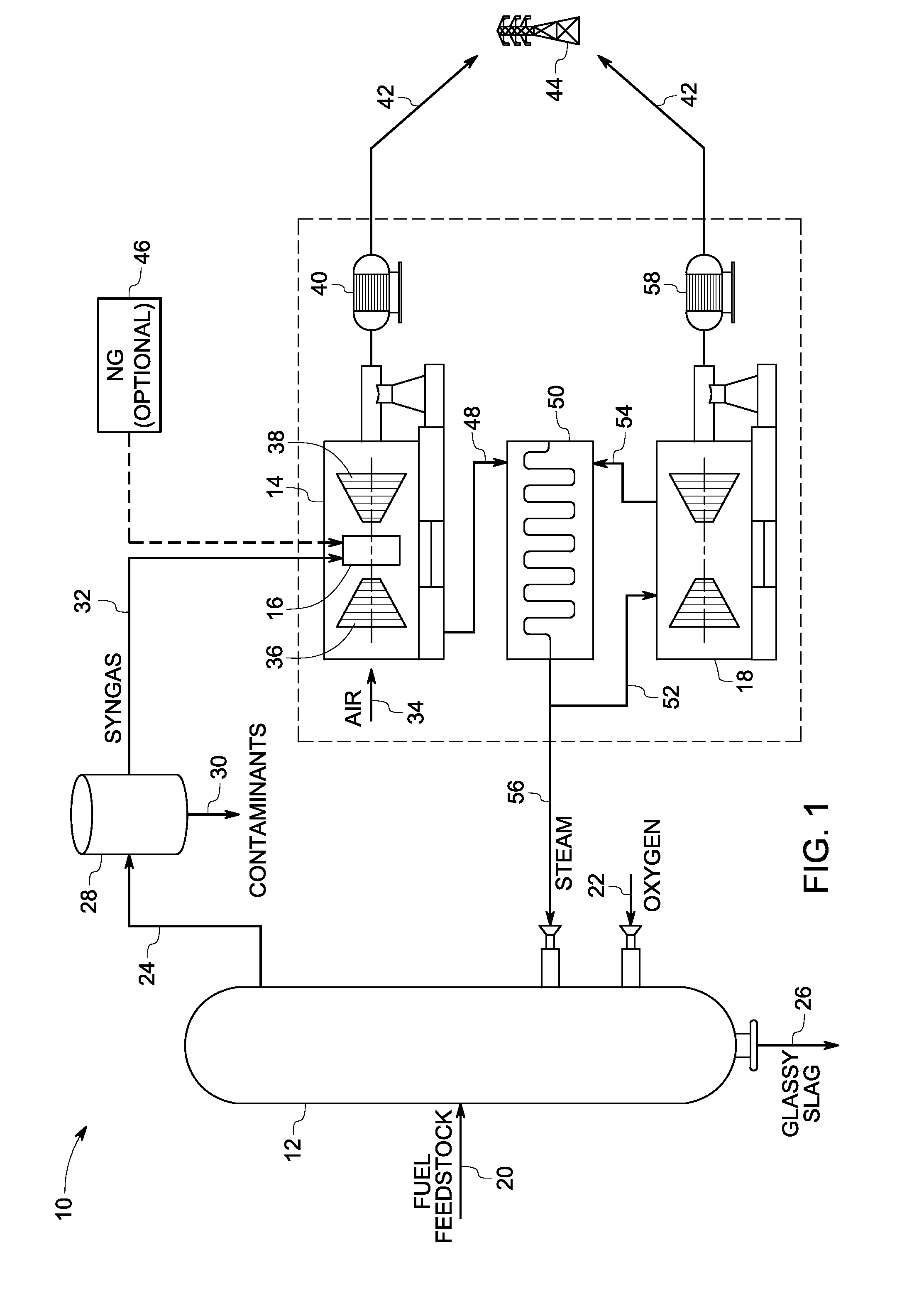

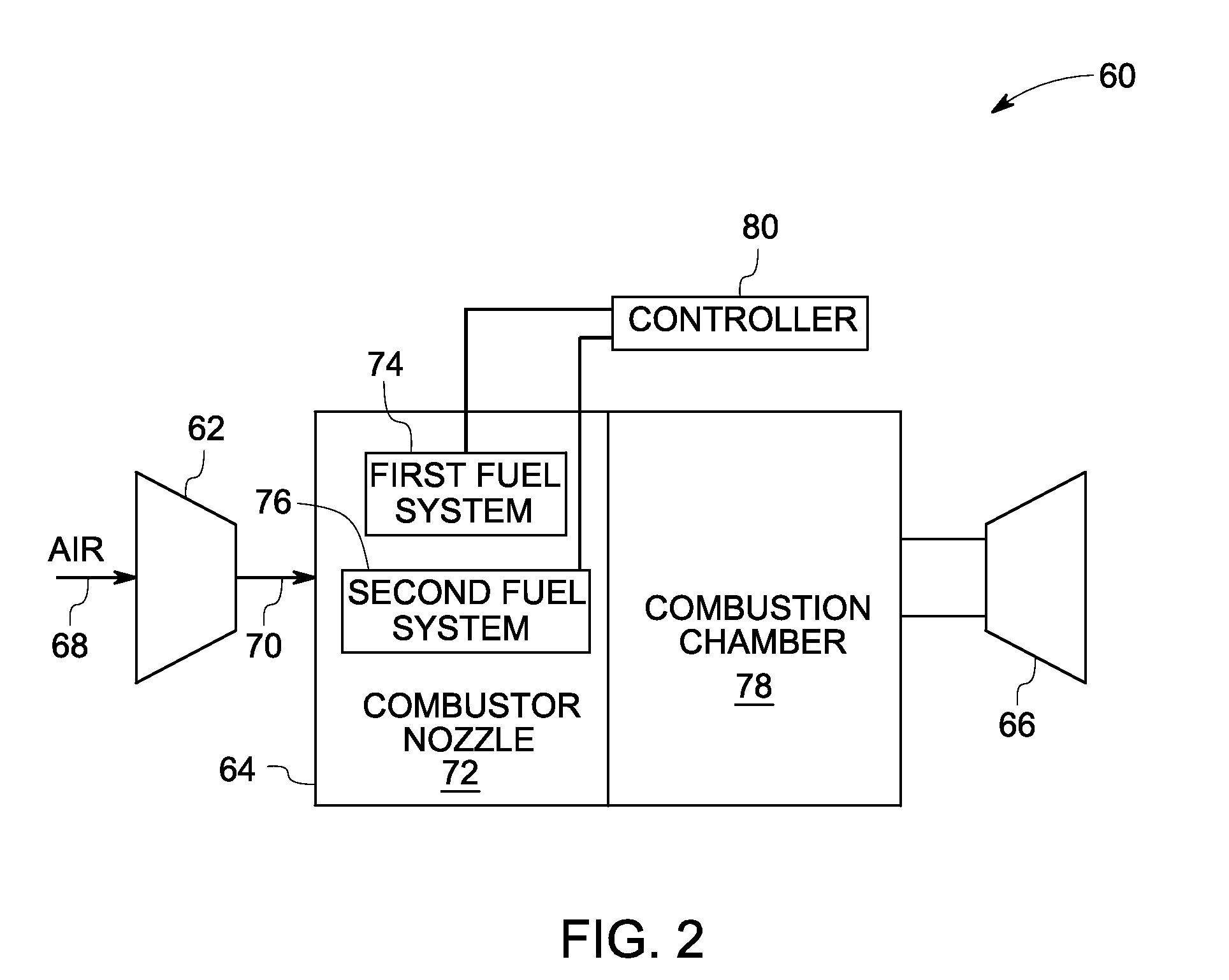

Combustor nozzle for a fuel-flexible combustion system

A combustor nozzle is provided. The combustor nozzle includes a first fuel system configured to introduce a syngas fuel into a combustion chamber to enable lean premixed combustion within the combustion chamber and a second fuel system configured to introduce the syngas fuel, or a hydrocarbon fuel, or diluents, or combinations thereof into the combustion chamber to enable diffusion combustion within the combustion chamber.

Owner:NUOVO PIGNONE TECH SRL

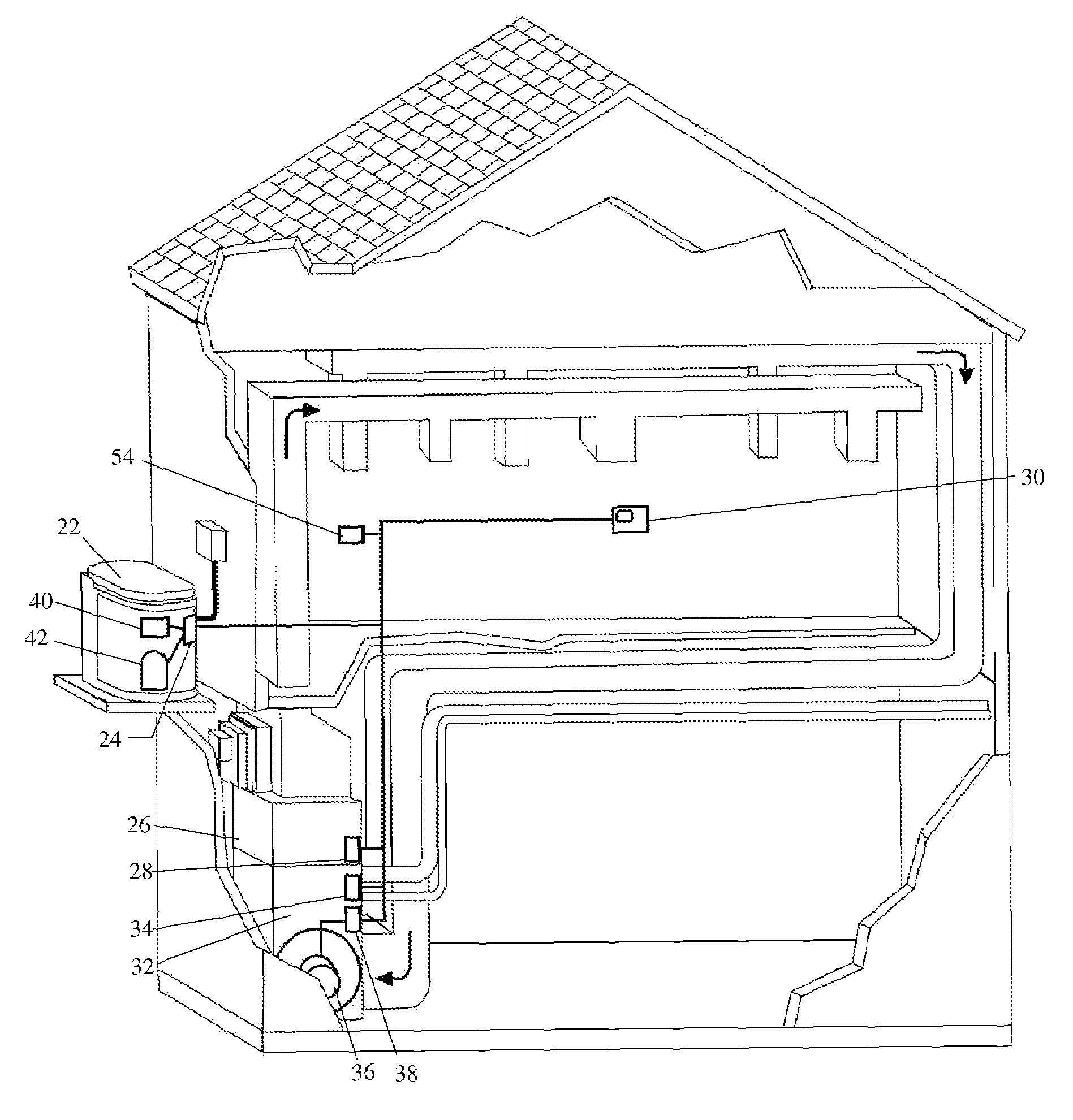

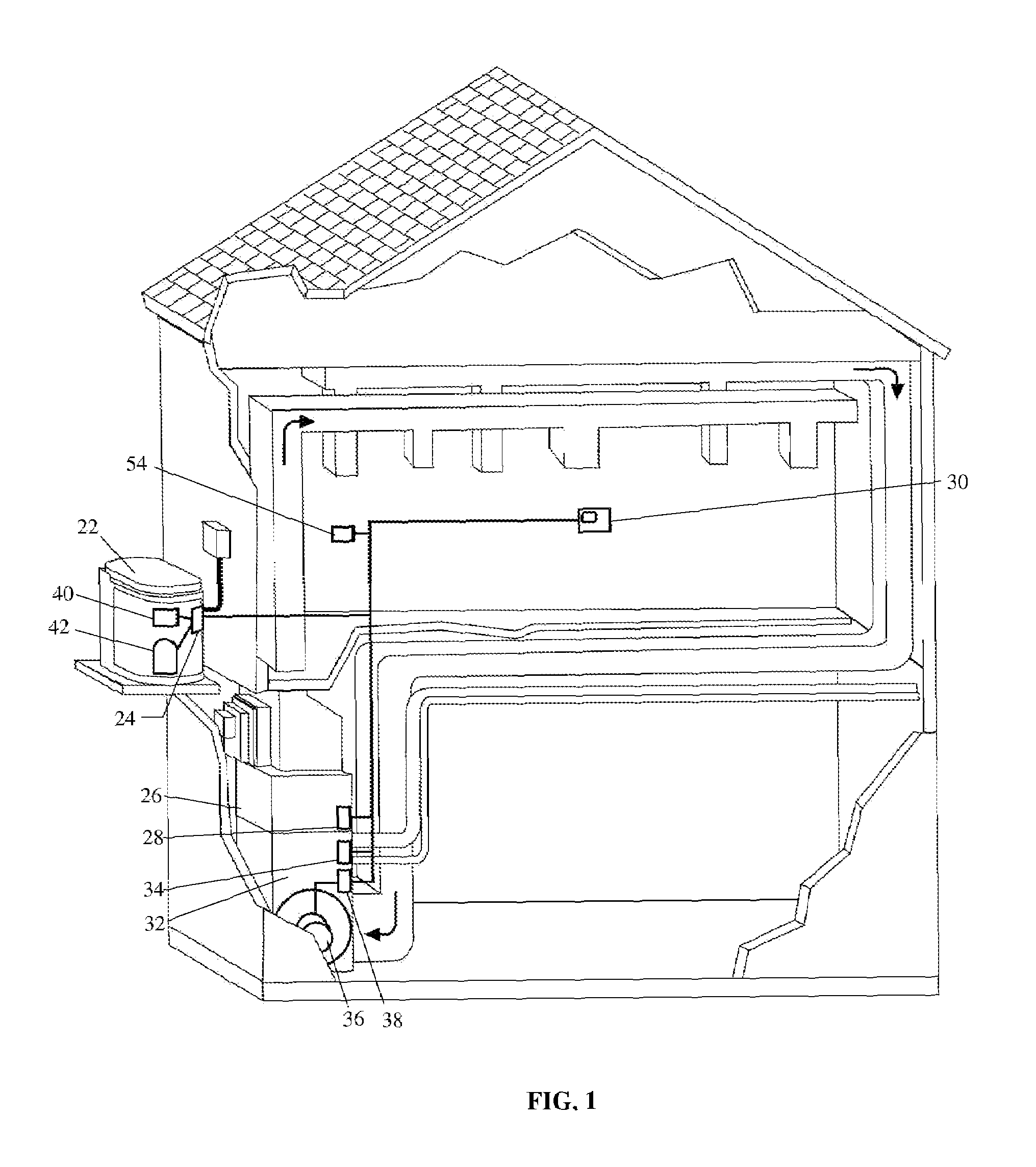

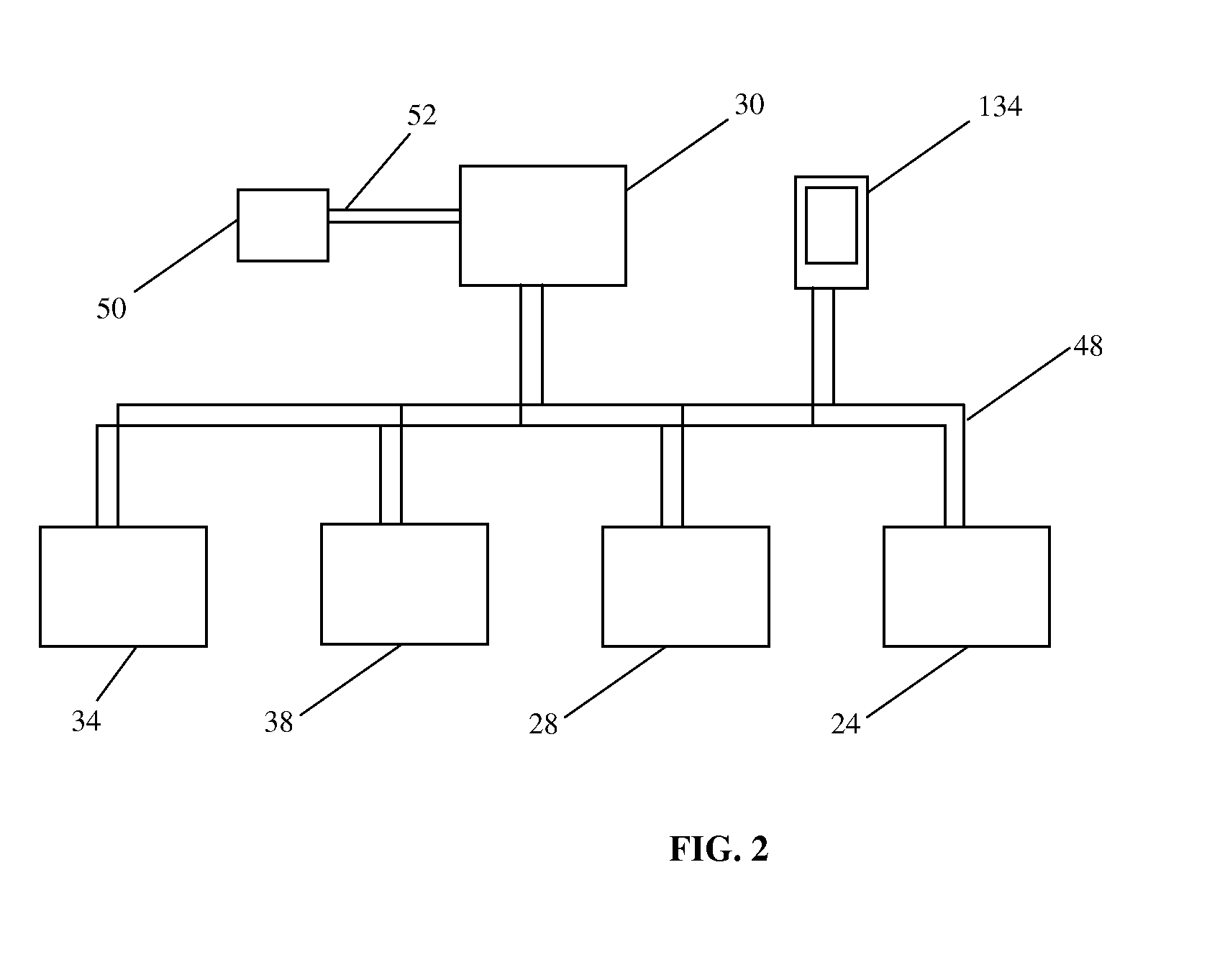

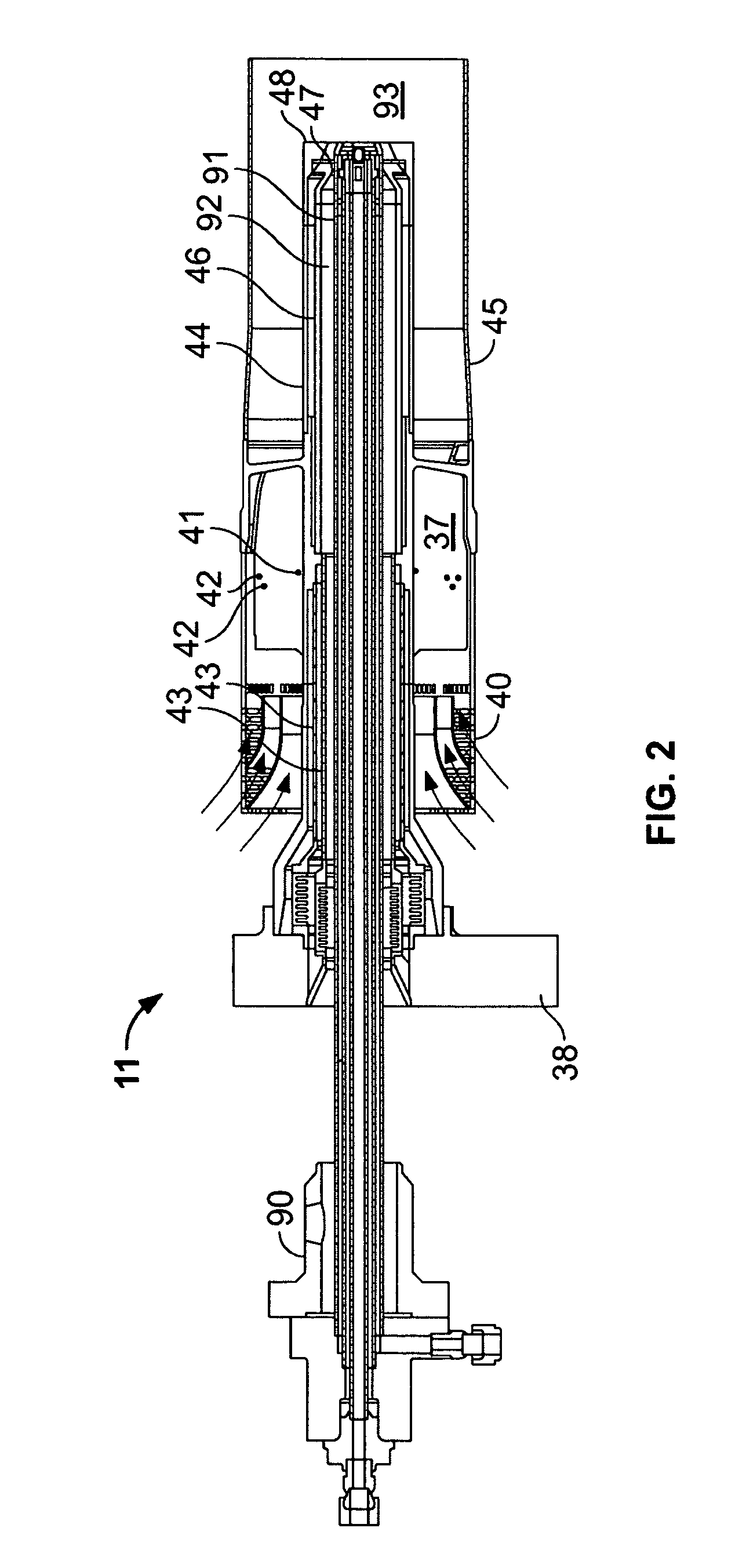

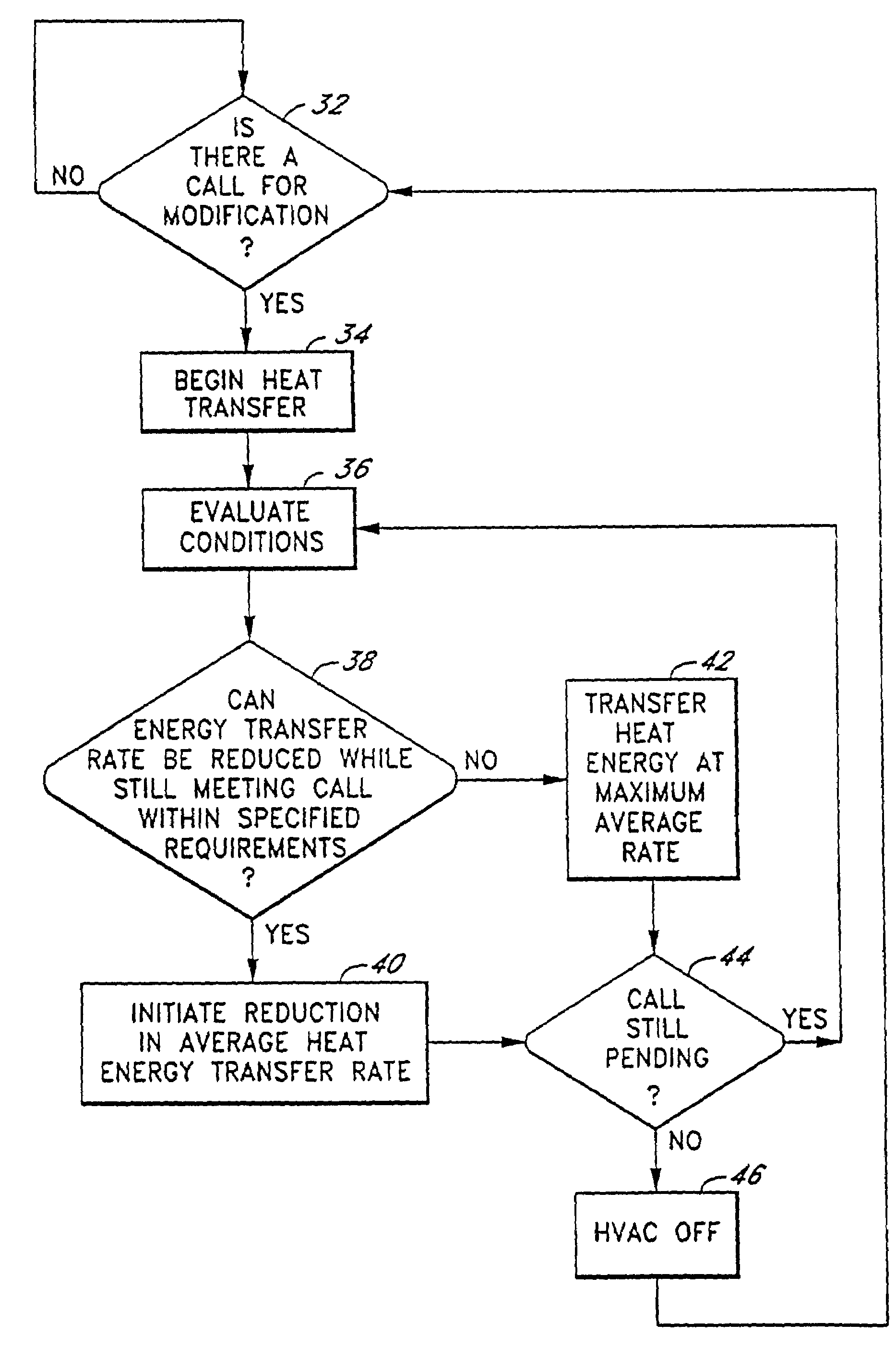

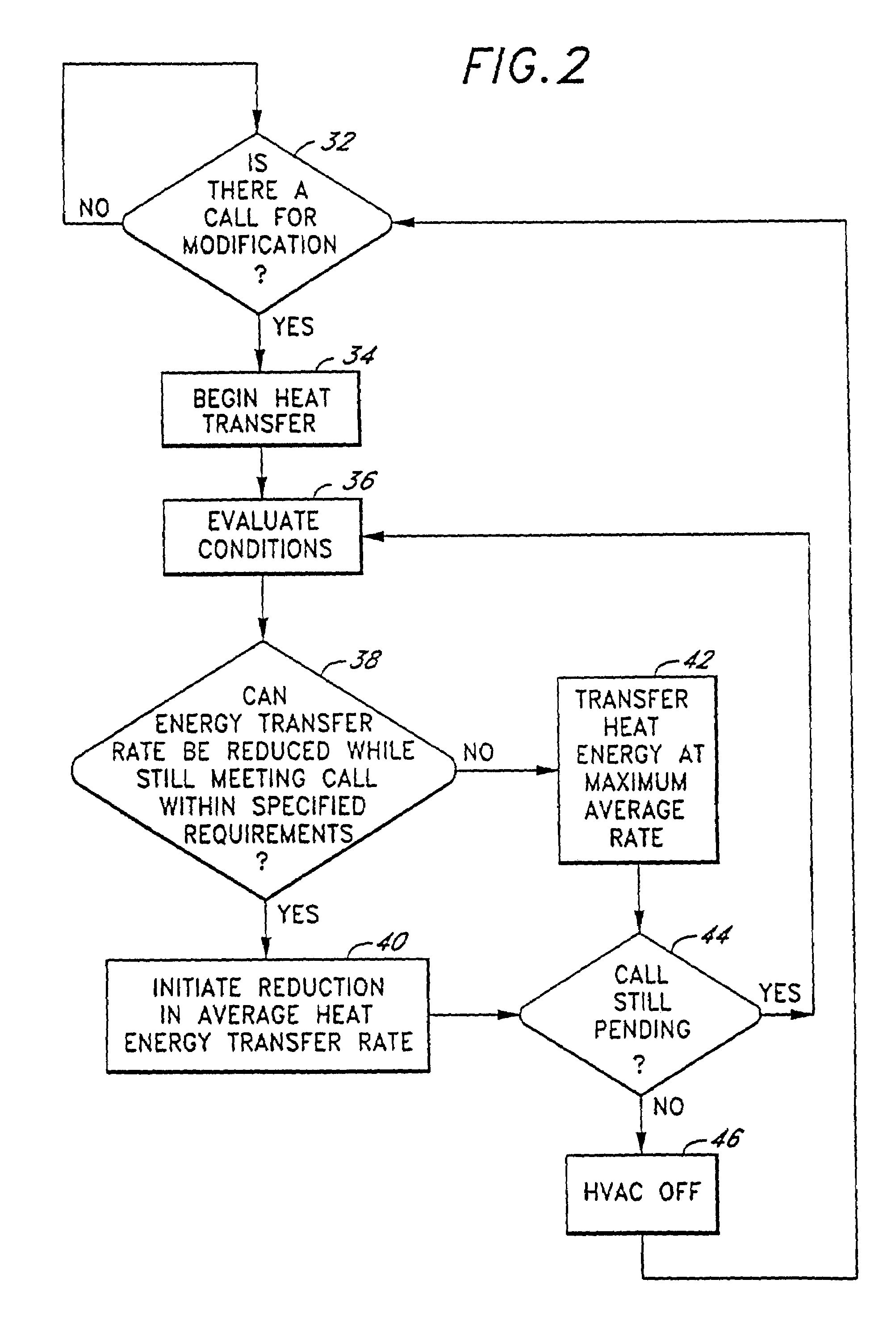

Interactive control system for an HVAC system

ActiveUS8550368B2Temperature control without auxillary powerMechanical apparatusControl systemOperation mode

An interactive system for controlling the operation of an HVAC system is provide that comprises a thermostat for initiating the operation of the HVAC system in either a full capacity mode of operation or at least one reduced capacity mode of operation, and a controller for an outside condenser unit having a condenser fan motor and a compressor motor, the controller being capable of operating the compressor in a full capacity mode and at least one reduced capacity mode. The system also comprises a controller for an indoor blower unit having a blower fan motor, the controller being capable of operating the blower fan motor in a full capacity mode an at least one reduced capacity mode. The system further includes a communication means for transmitting information between the outside condenser unit controller and at least the indoor blower controller, where the information relates to the operation of the indoor blower and the outdoor condenser unit. The indoor blower controller responsively controls the operation of the blower fan motor in a full capacity mode or a reduced capacity mode based on the information received from the outdoor unit controller, and the outdoor unit controller responsively controls the operation of the compressor in a full capacity mode or a reduced capacity mode based on the information received from the indoor blower controller.

Owner:COPELAND COMFORT CONTROL LP

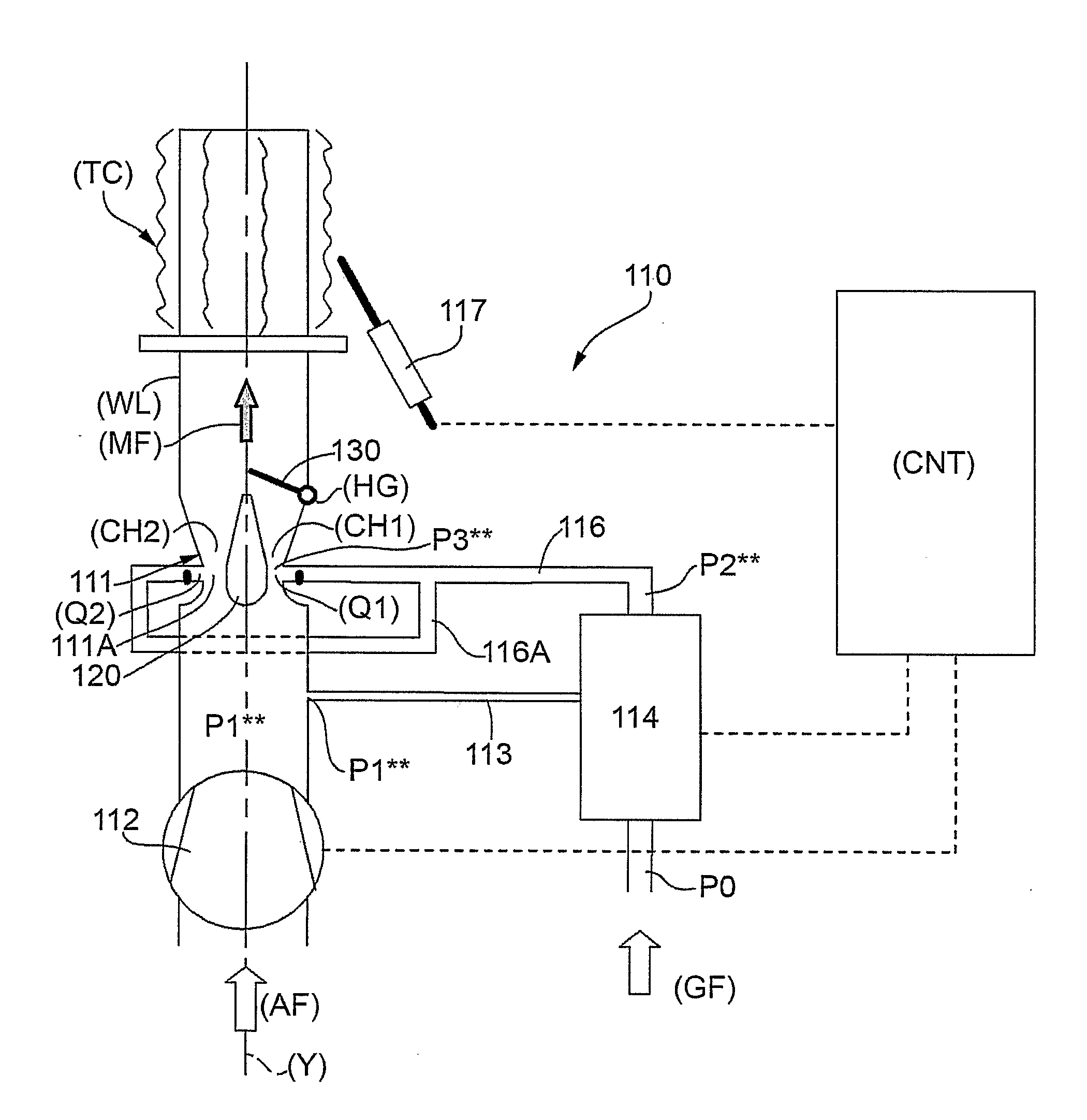

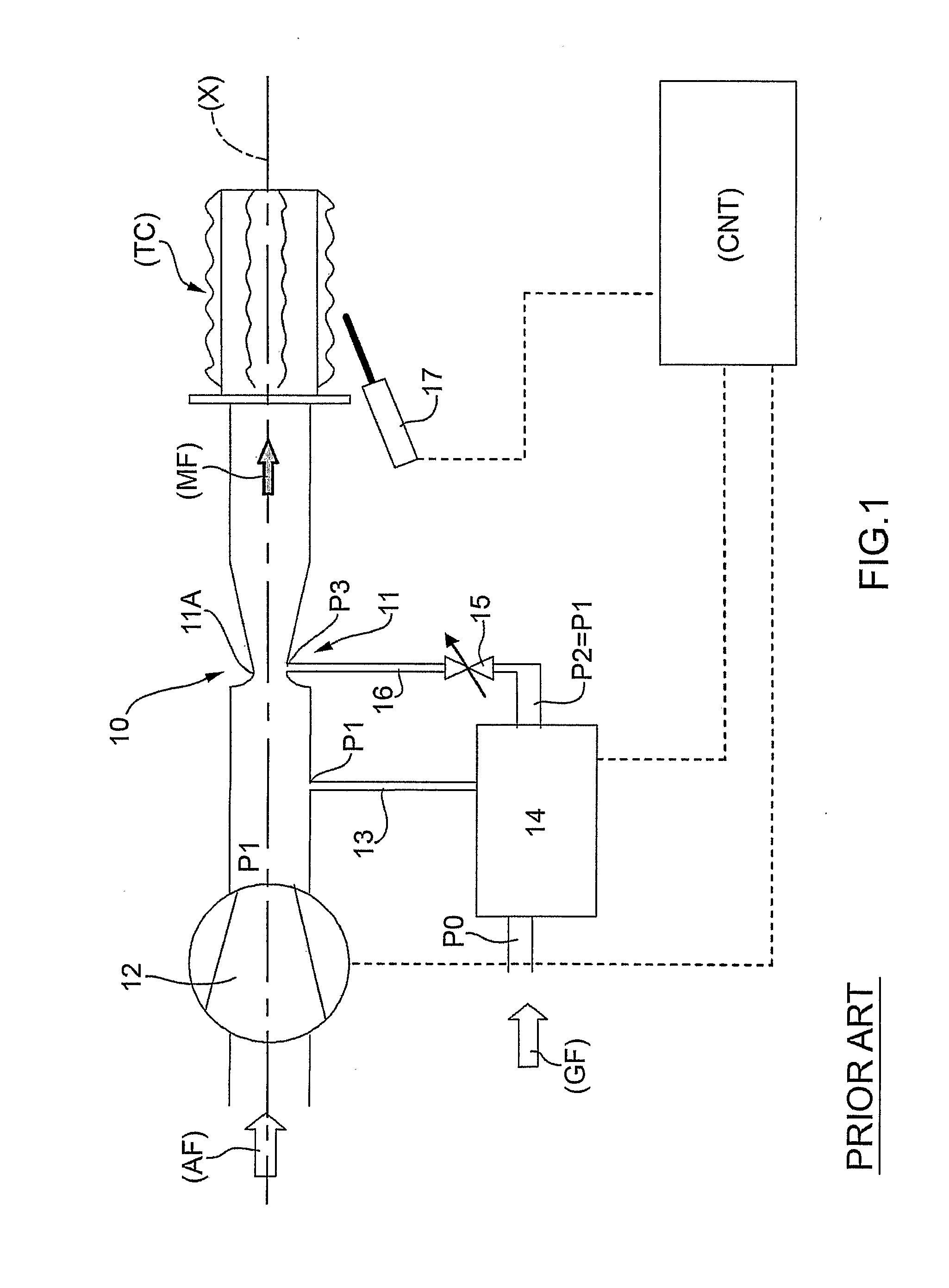

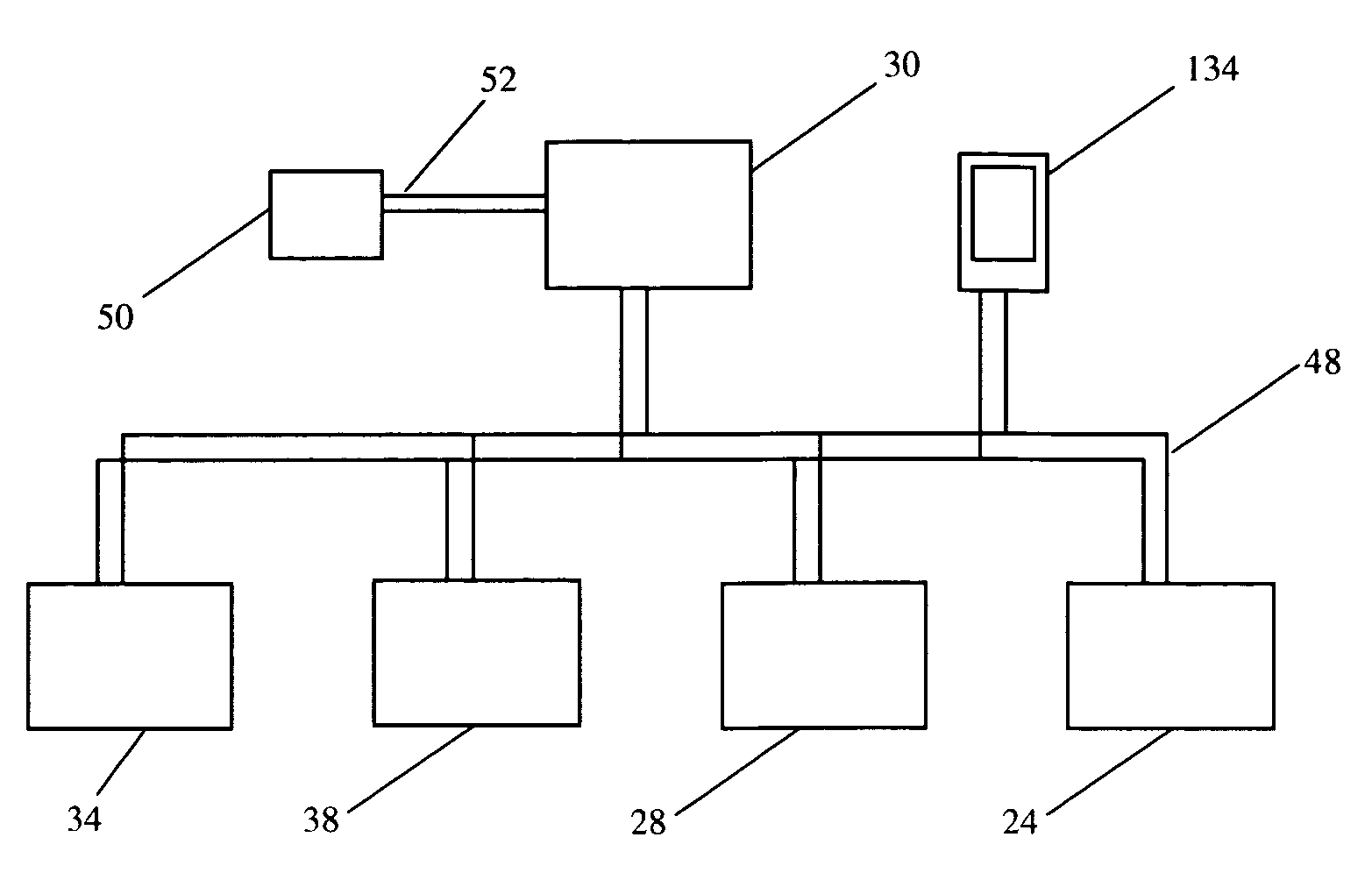

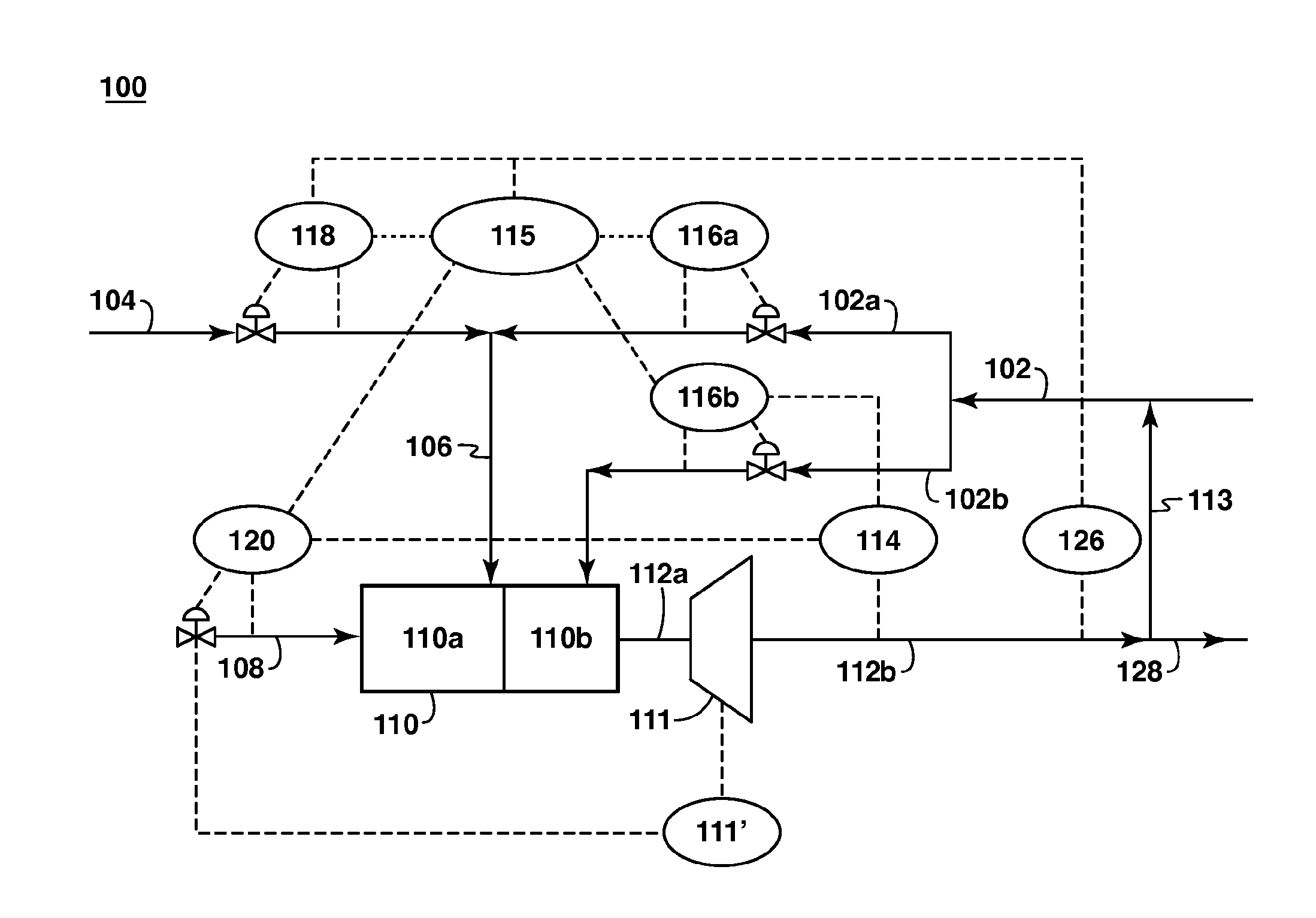

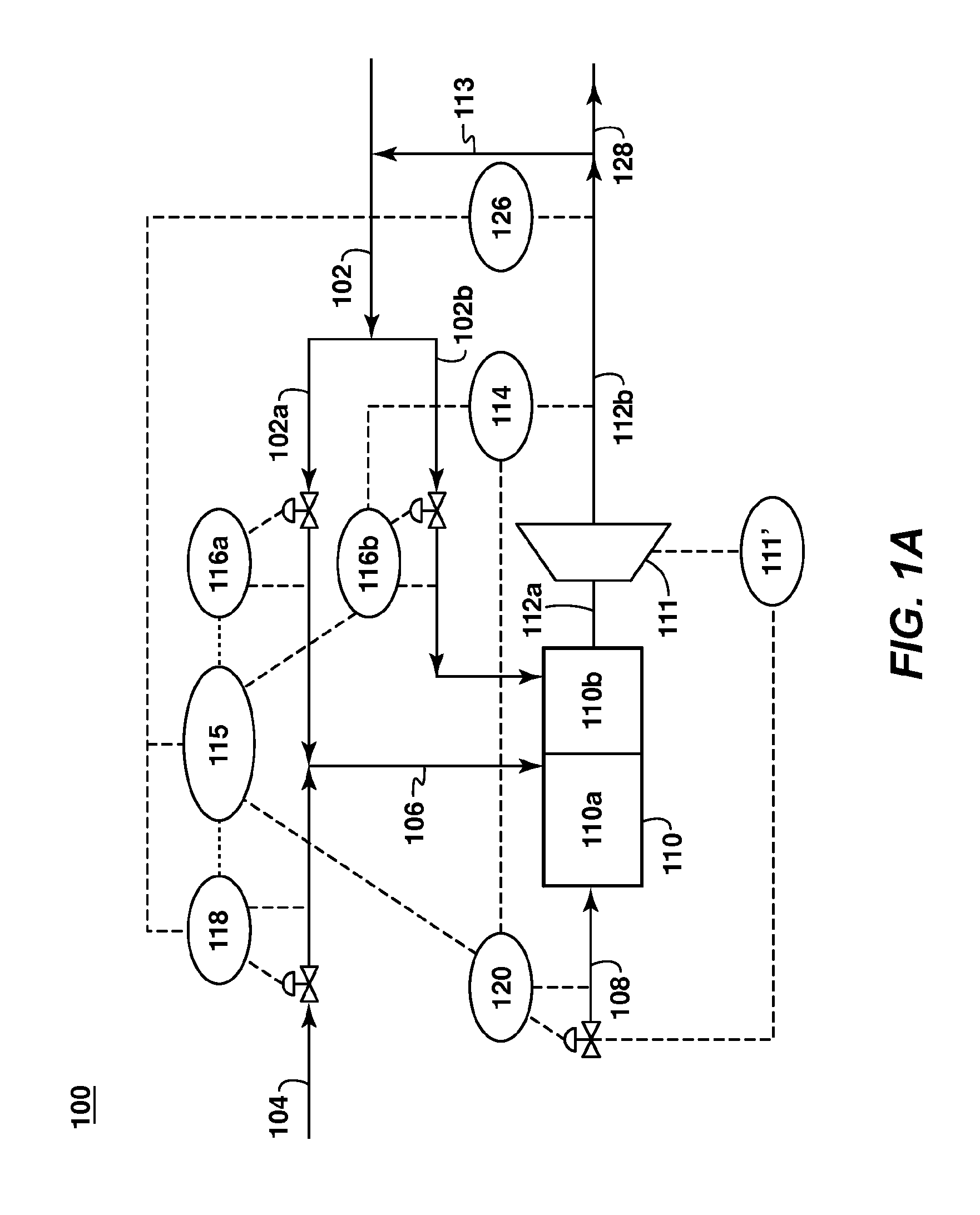

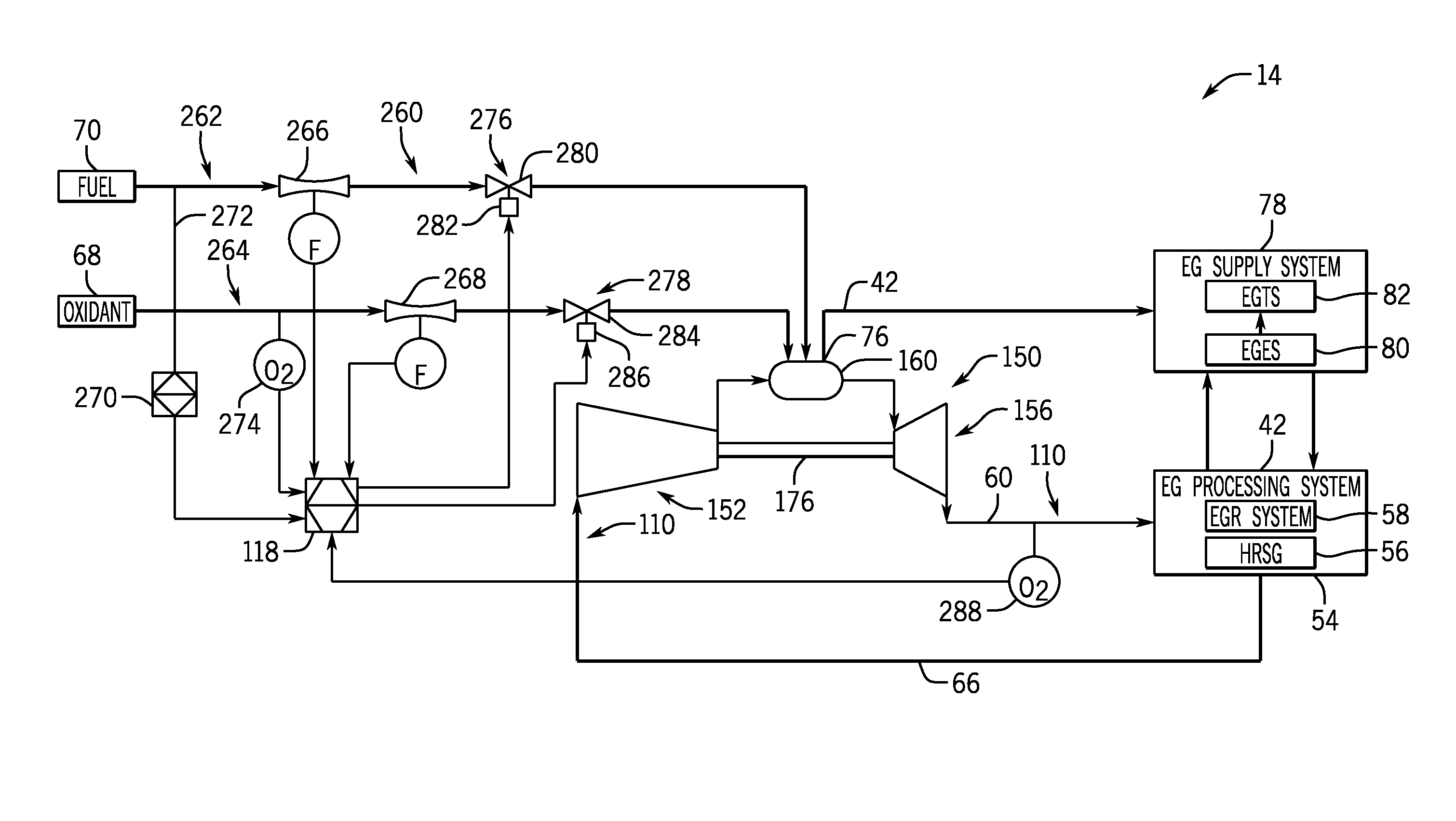

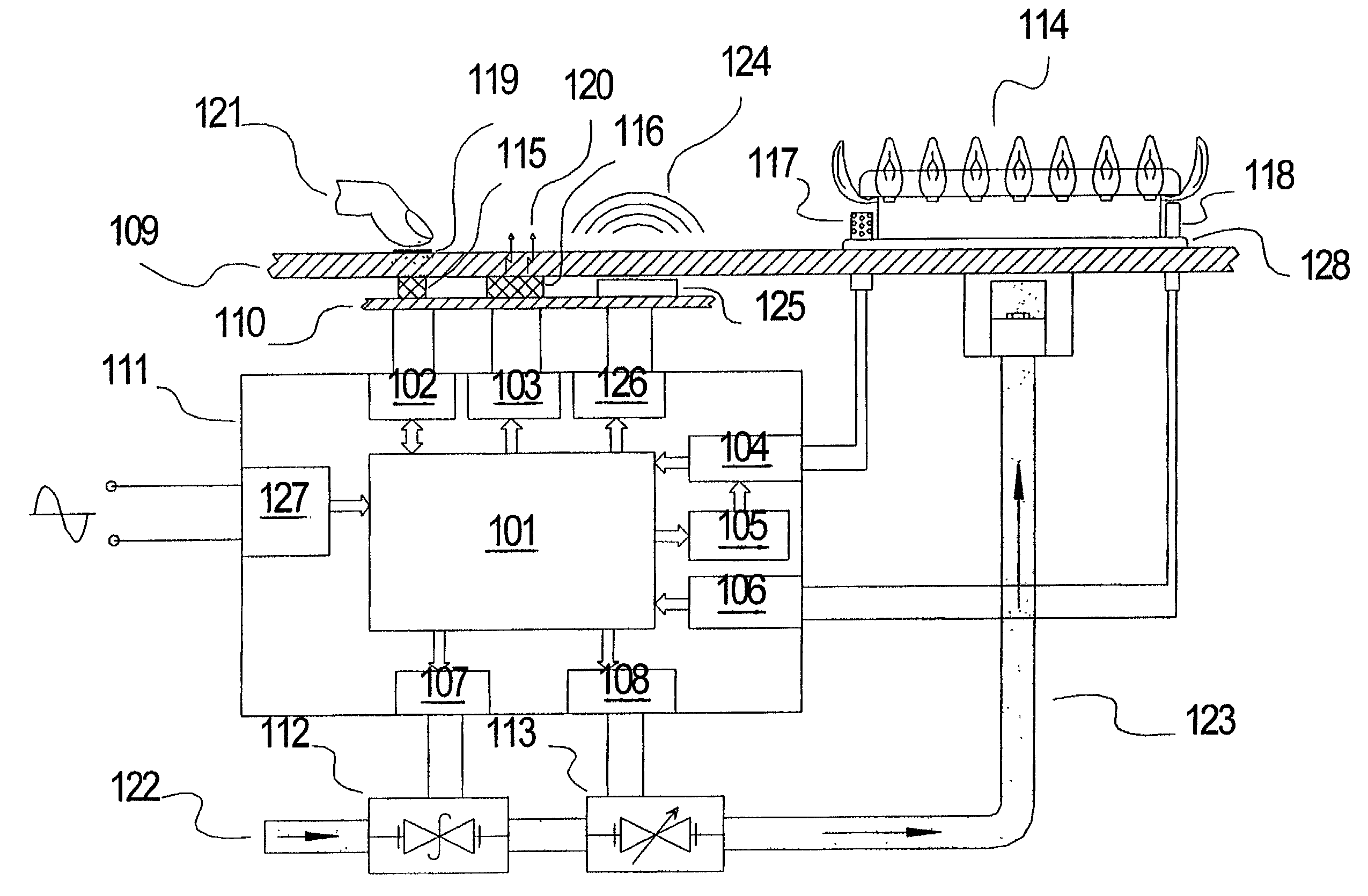

Methods and Systems For Controlling The Products of Combustion

ActiveUS20110300493A1Avoid flame burnoutTemperature regulationGas turbine plantsFluegas recirculationCombustorControl system

The present invention relates to methods and systems for controlling a combustion reaction and the products thereof. One embodiment includes a combustion control system having an oxygenation stream substantially comprising oxygen and CO2 and having an oxygen to CO2 ratio, then mixing the oxygenation stream with a combustion fuel stream and combusting in a combustor to generate a combustion products stream having a temperature and a composition detected by a temperature sensor and an oxygen analyzer, respectively, the data from which are used to control the flow and composition of the oxygenation and combustion fuel streams. The system may also include a gas turbine with an expander and having a load and a load controller in a feedback arrangement.

Owner:EXXONMOBIL UPSTREAM RES CO

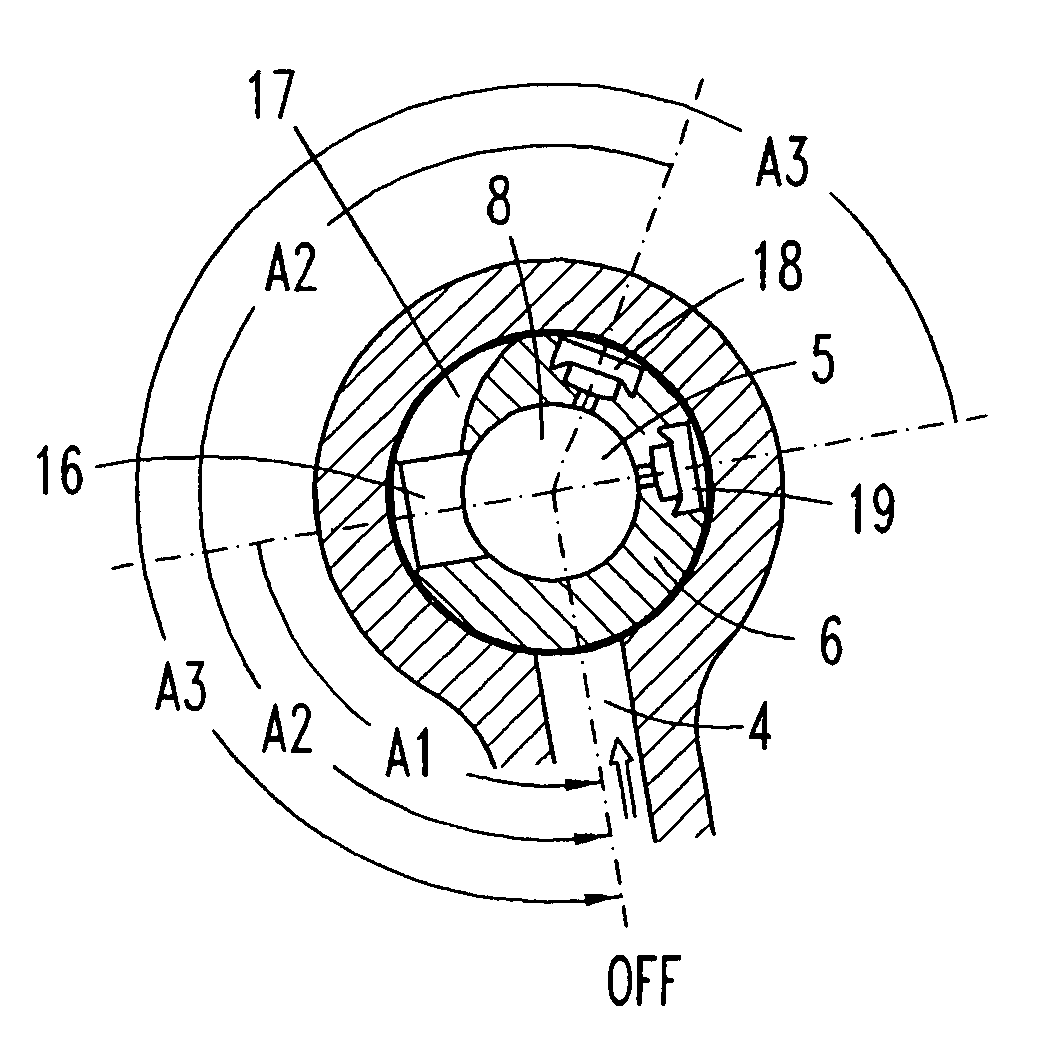

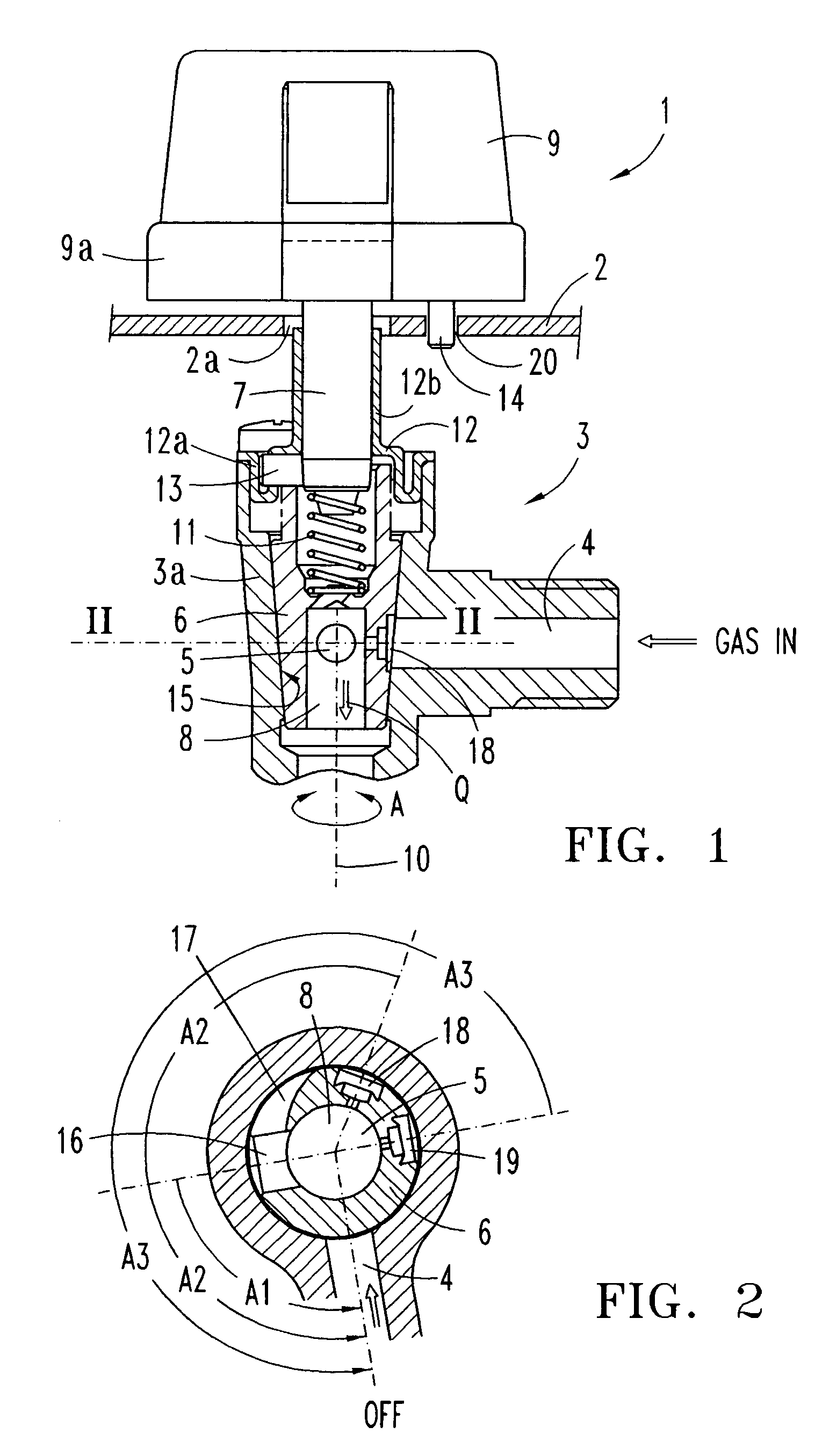

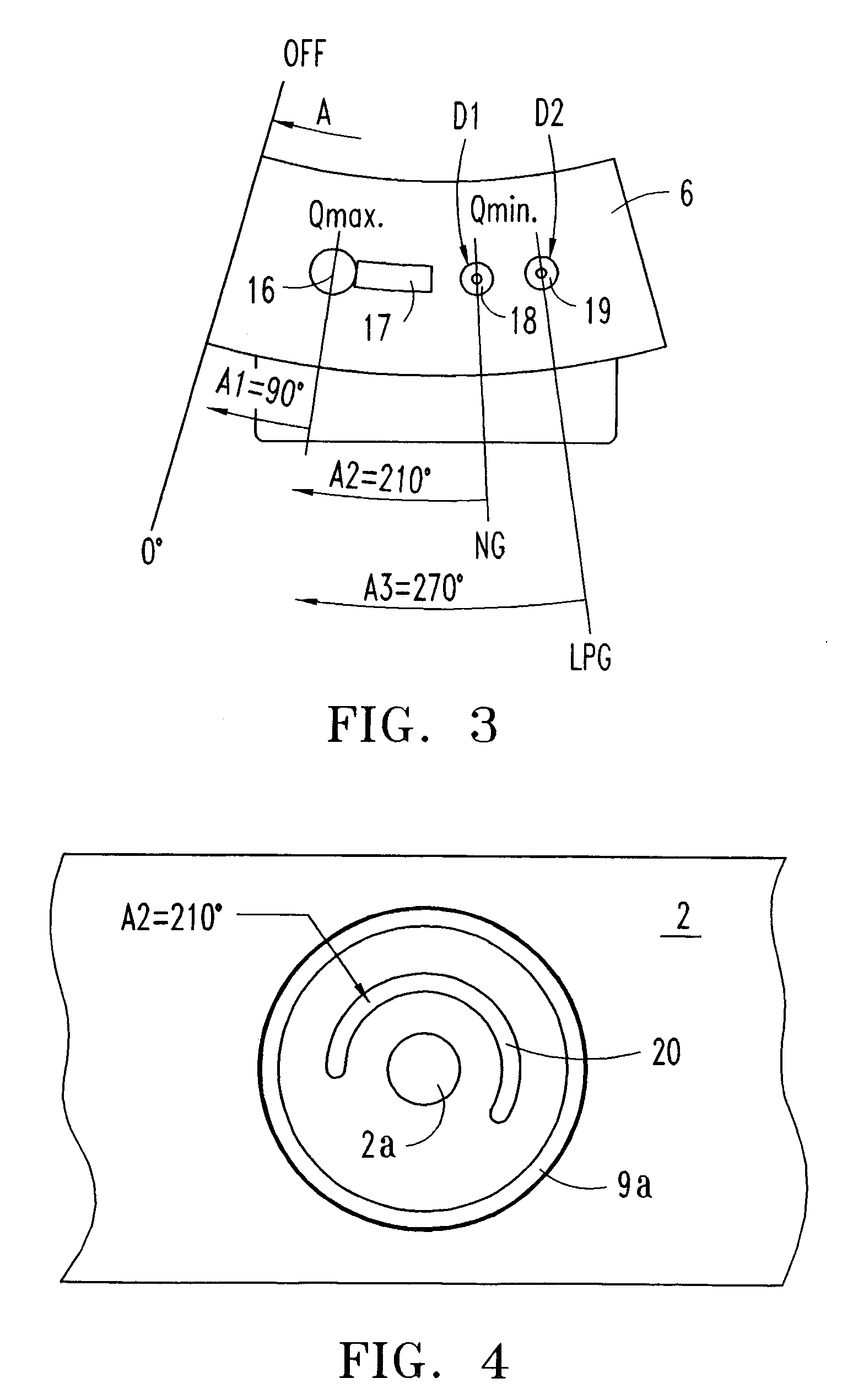

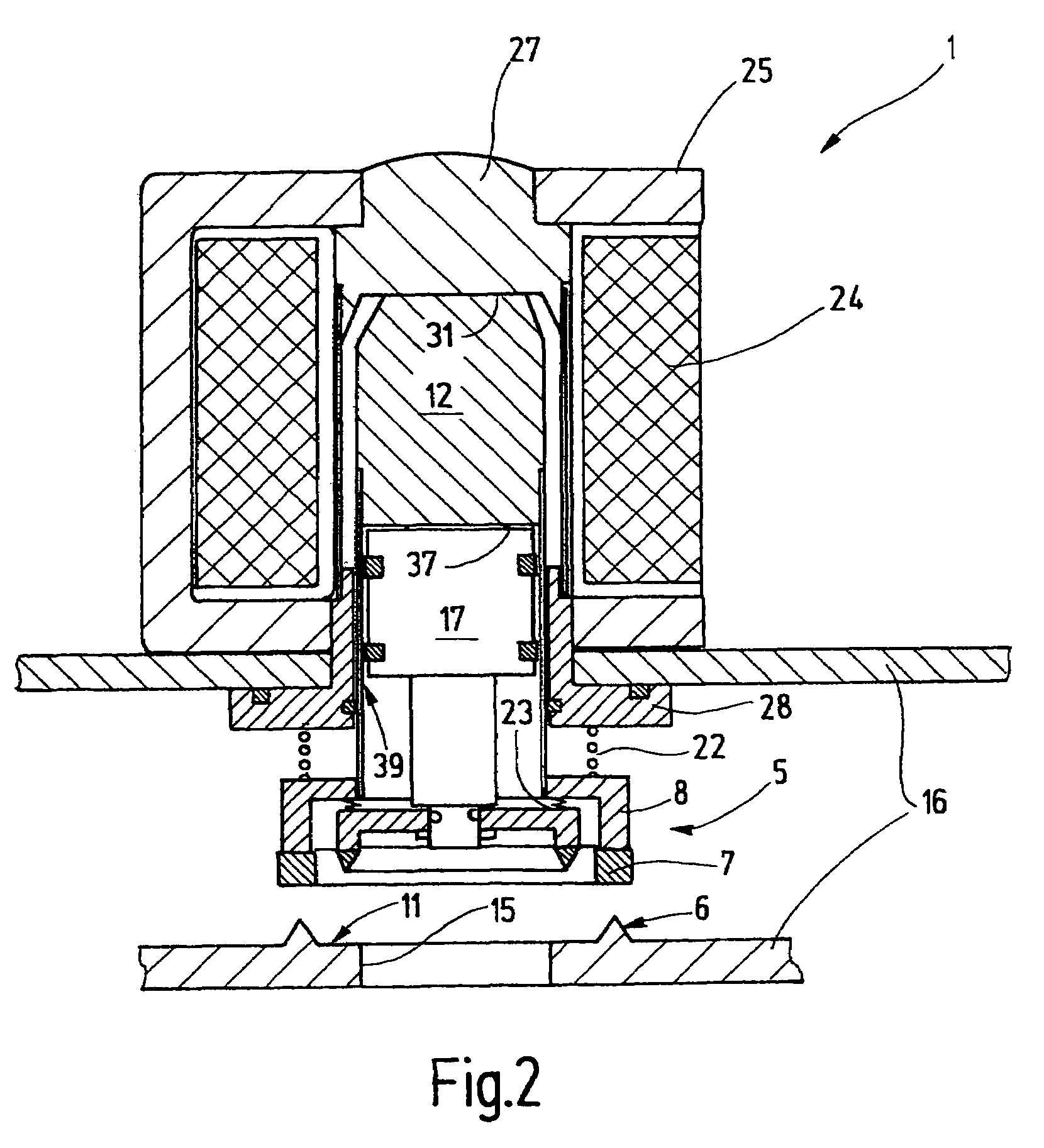

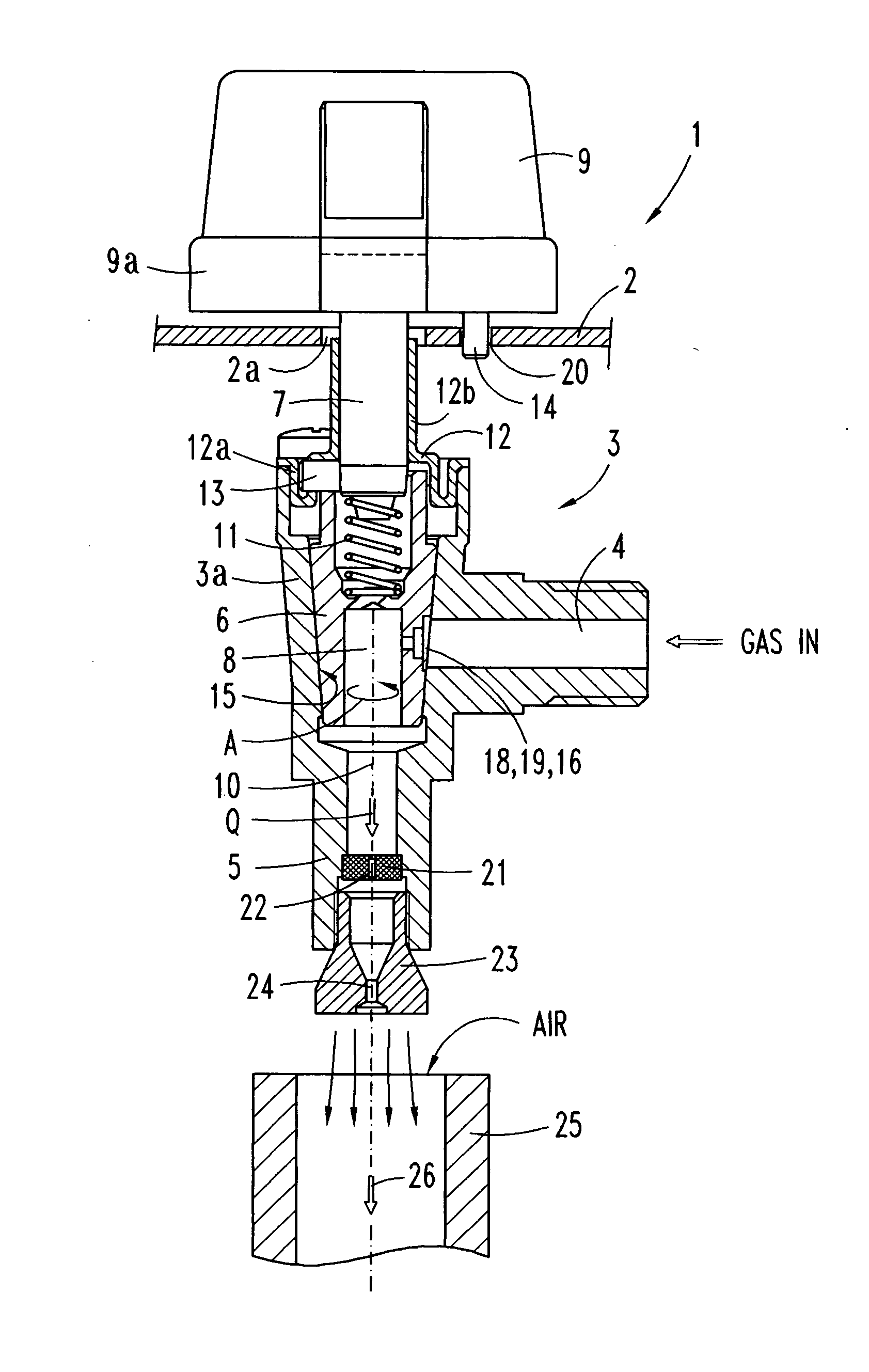

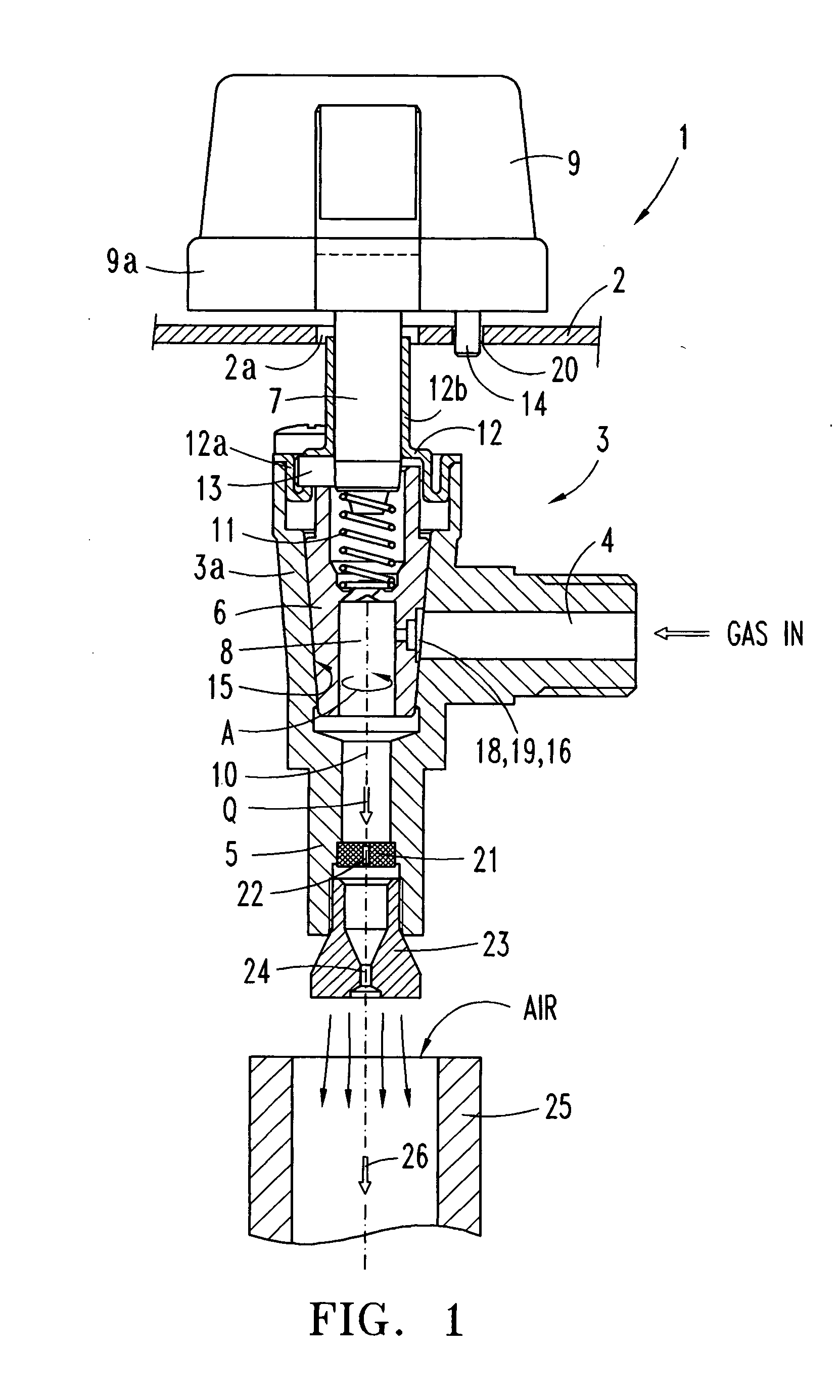

Rotary valve in a multi-gas cooker

The cooking appliance (1) having a control panel (2) is equipped with one or more gas flow (Q) regulating valves, wherein the rotary regulator organ (6) is provided with various peripheral through holes (16–19). The control knob (9) being interchangeable for fitting to the actuating shaft (7), is chosen from the two units available, one and the other permitting different angular limit positions (A2, A3) for the supply of a constant minimum gas flow Qmin, through one of two successive holes (18, 19) calibrated each one for a different type of gas NG or LPG, one or the other hole being superimposed to a valve inlet duct (4) at a different angular position A2, A3. An integral lug (14) on the control knob (9) running into a slide groove (20) in the control panel (2), establishes a first rotation stop A2.

Owner:ALBIZURI INIGO

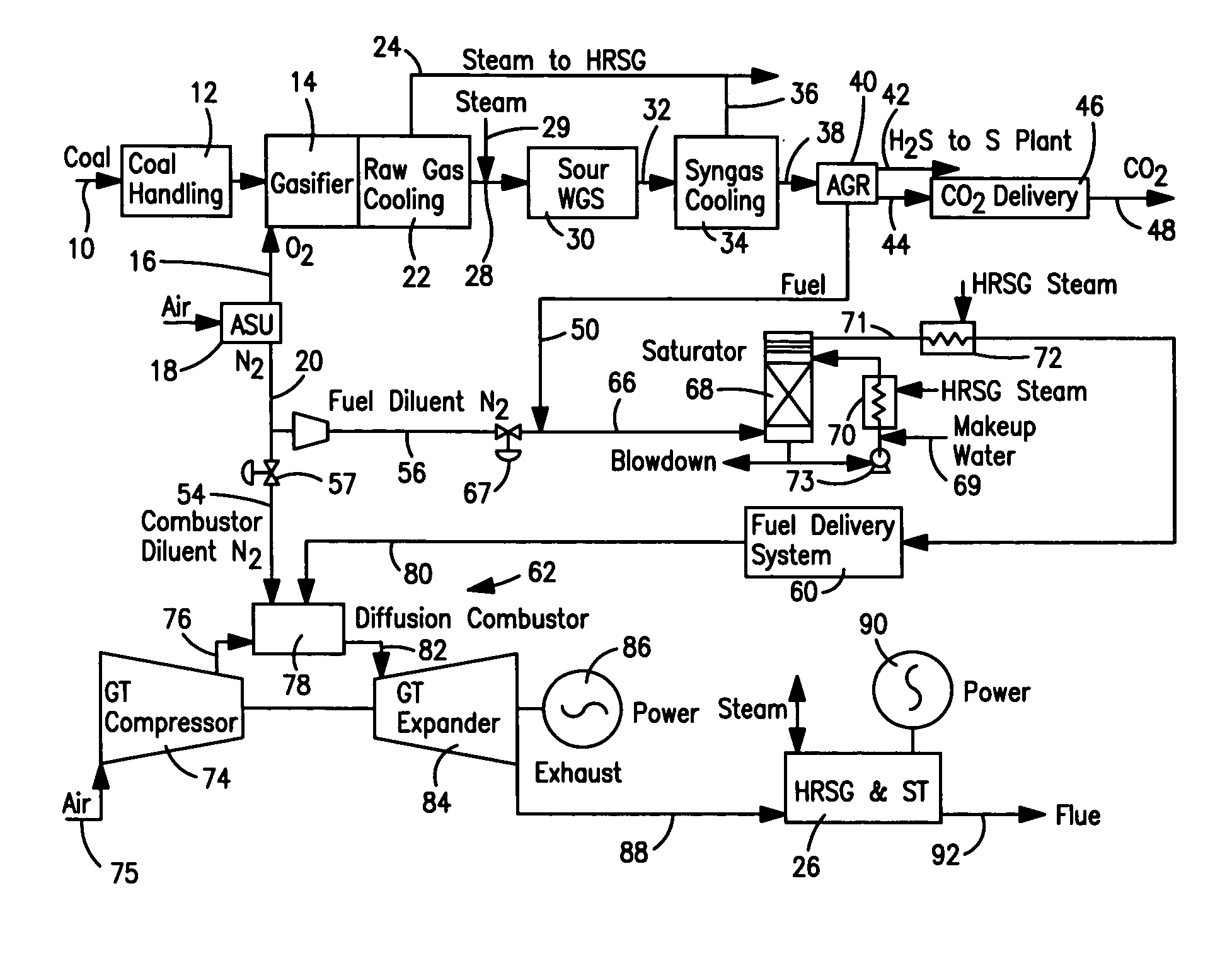

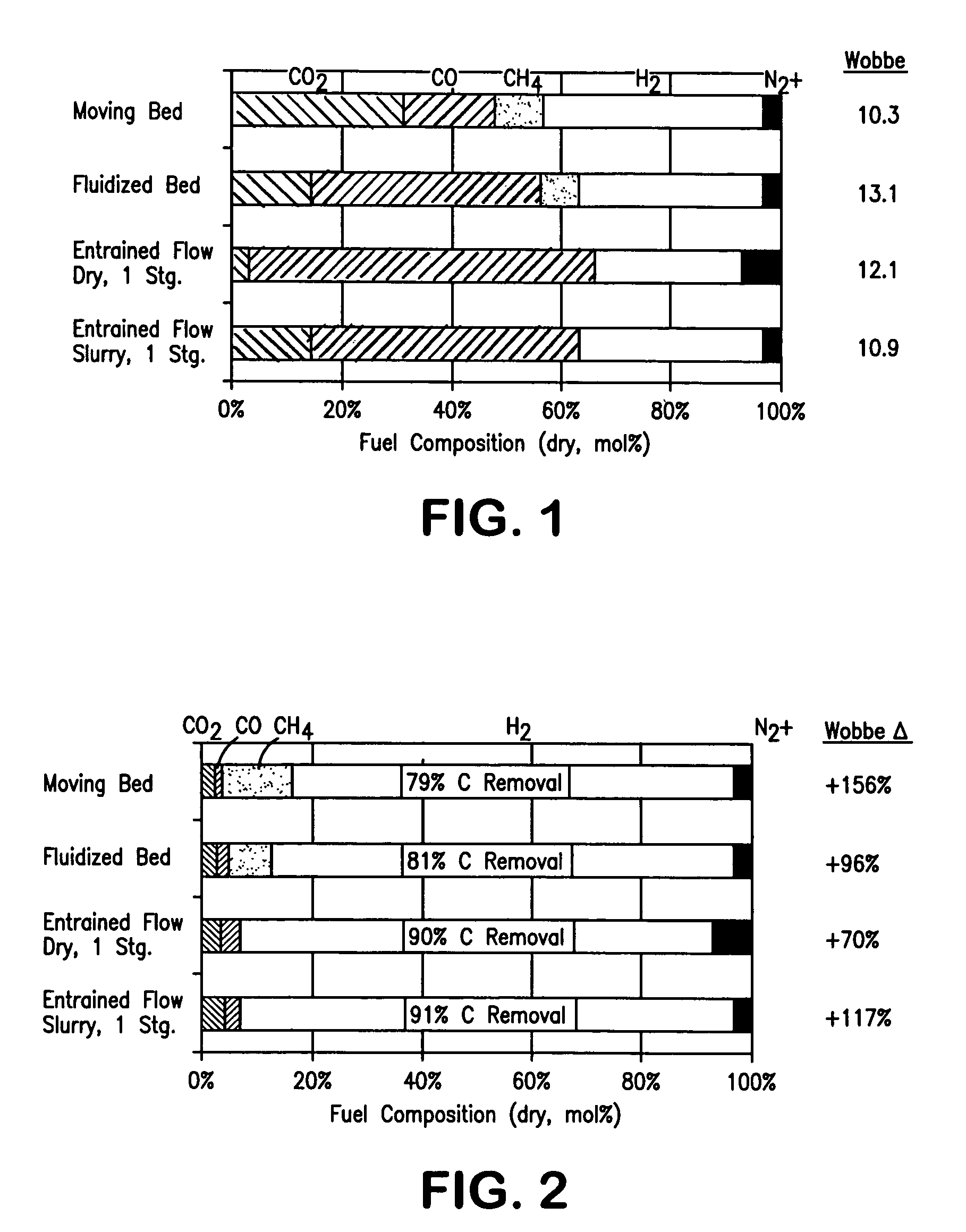

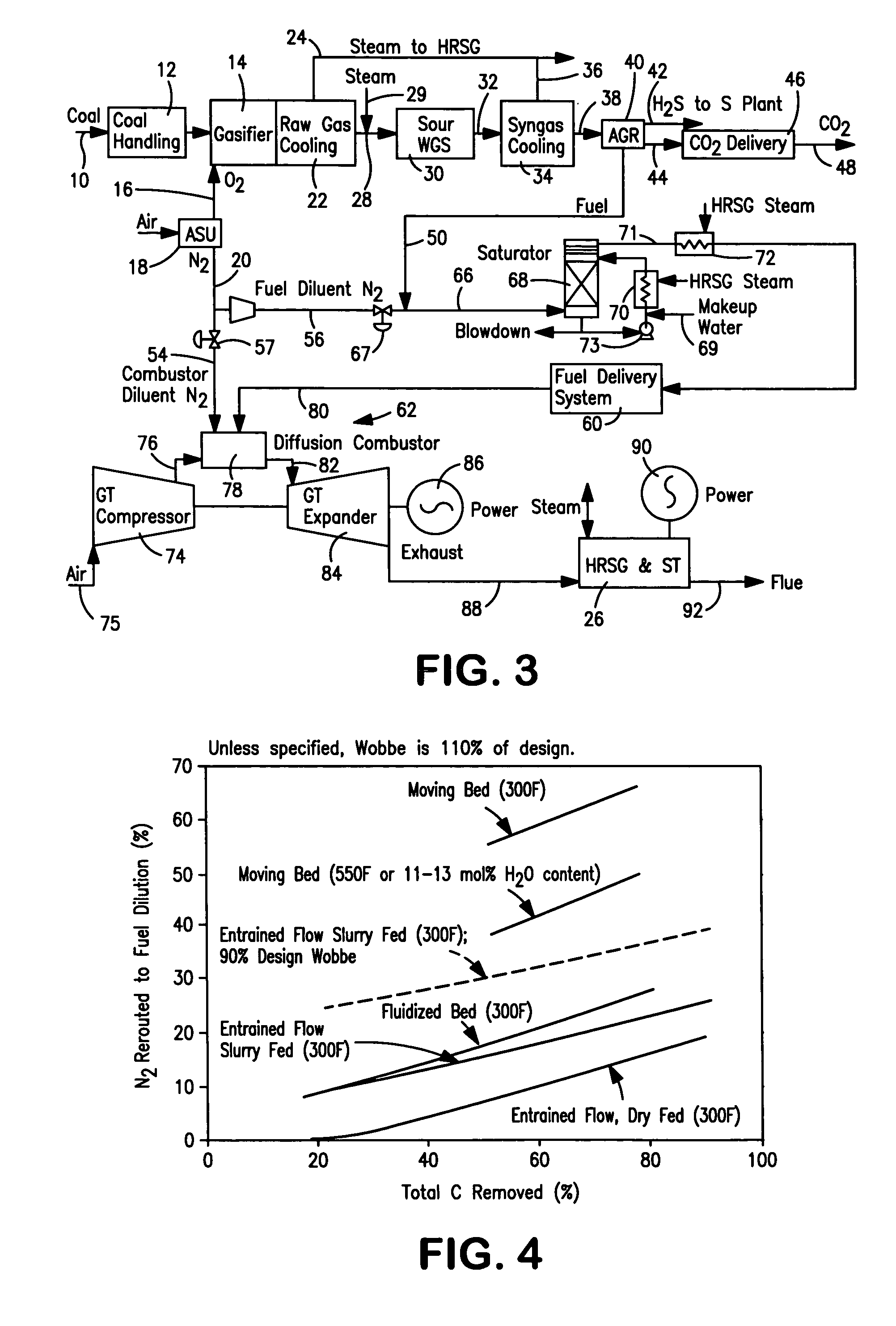

Method of maintaining a fuel Wobbe index in an IGCC installation

InactiveUS7690204B2Low indexFuel supply regulationGaseous fuel feeder/distributionWater-gas shift reactionNitrogen

A method of reducing a modified Wobbe index of a fuel stream fed to diffusion combustors of a gas turbine that is used in connection with an IGCC installation in which a nitrogen stream is fed into the head ends of the combustor of NOx control and the modified Wobbe index of the fuel stream has been increased in an amount that is greater than at least about 10 percent of a design Wobbe index for the fuel to be fed to the gas turbine. The reason for the increase is the conversion of the carbon monoxide within the fuel stream to hydrogen and carbon dioxide by a water gas shift reaction and subsequent removal of the carbon dioxide. The nitrogen stream is maintained at the same level both with and without conversion and subsequent removal of carbon atoms. The nitrogen stream is divided to subsidiary streams that are respectively fed into the head end of the combustors and that are mixed with a fuel to lower the modified Wobbe index to acceptable levels for the gas turbine.

Owner:PRAXAIR TECH INC

Thermostat responsive to inputs from external devices

ActiveUS7261243B2Temperature control without auxillary powerMechanical apparatusControl systemThermostat

Owner:COPELAND COMFORT CONTROL LP

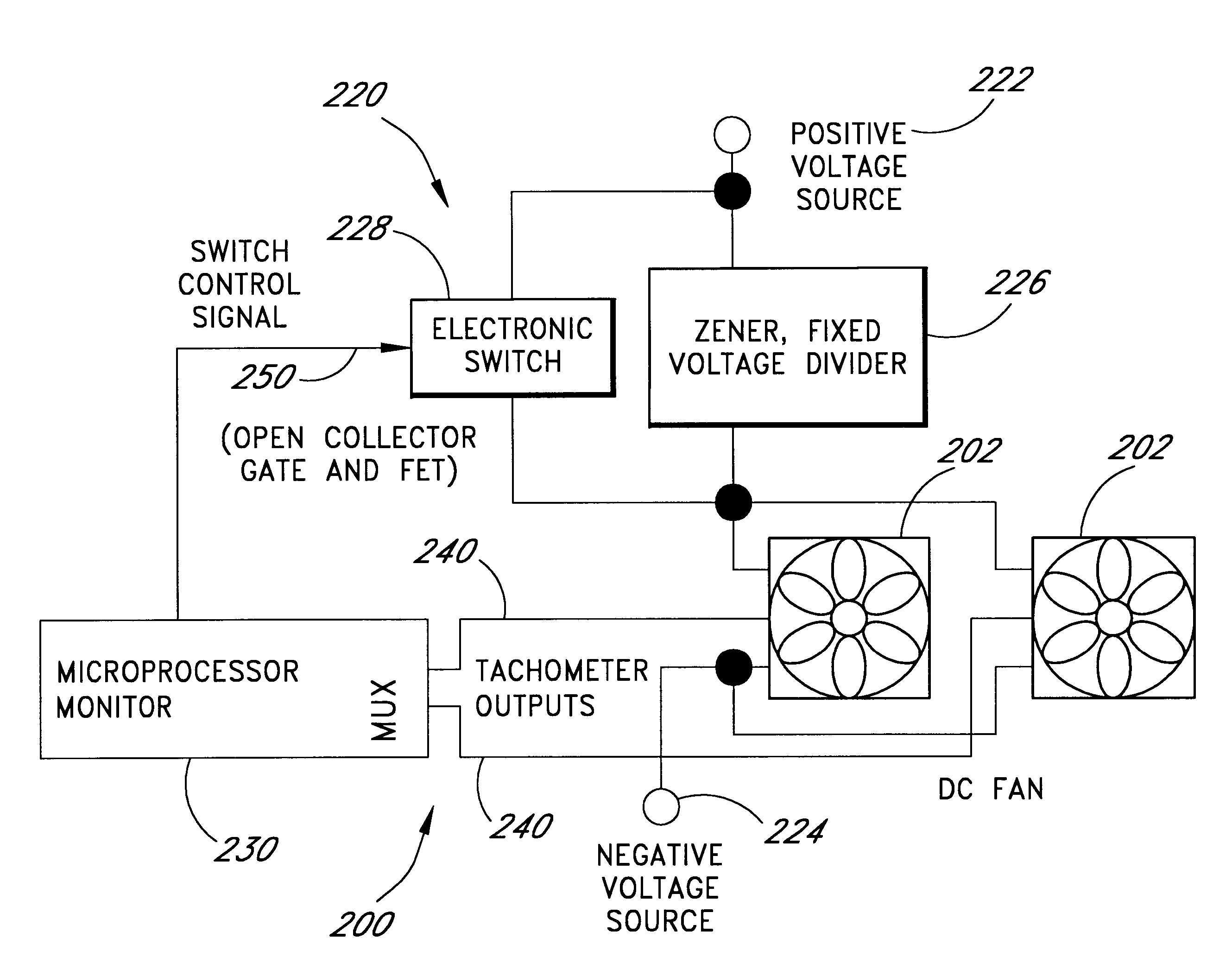

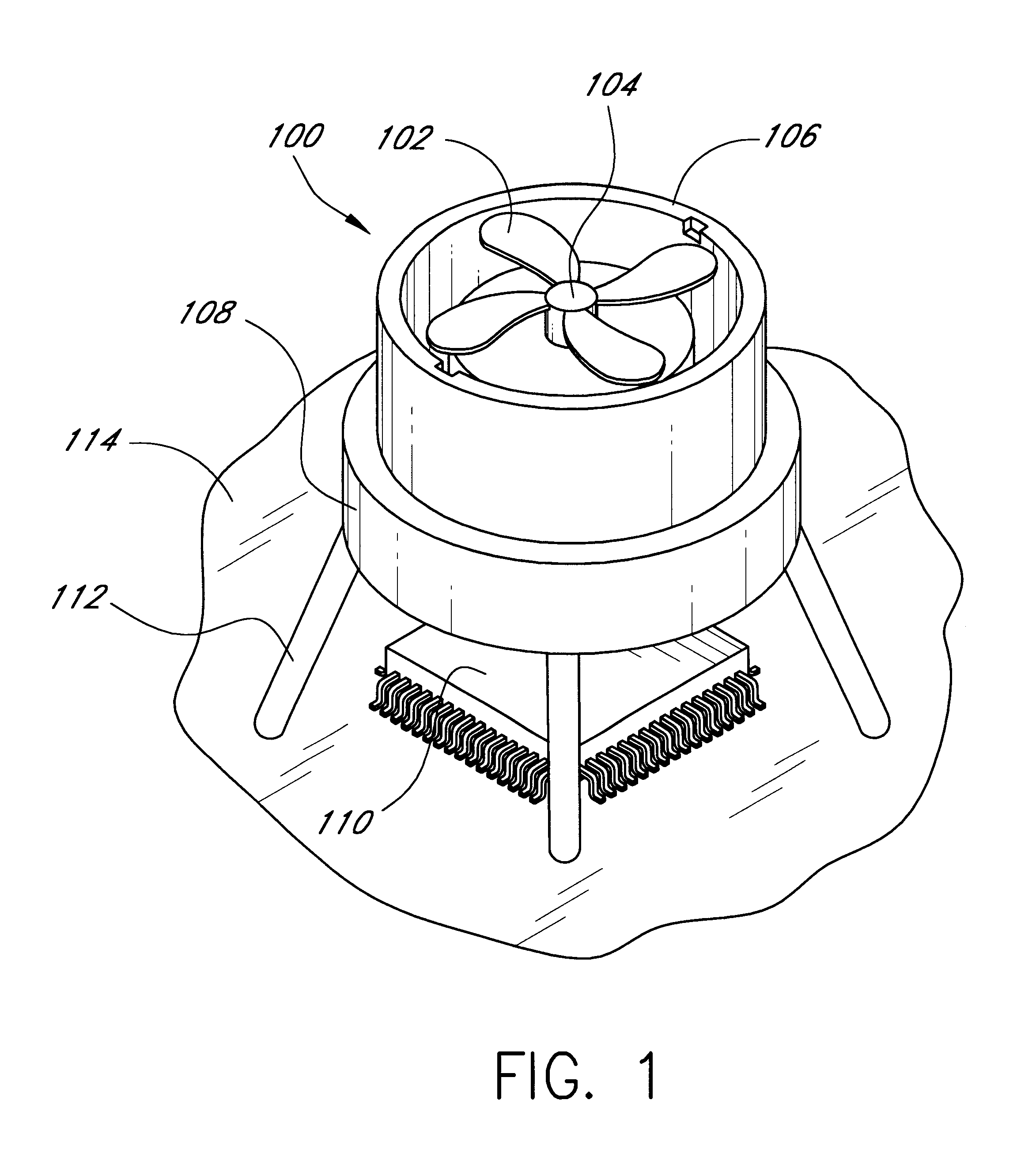

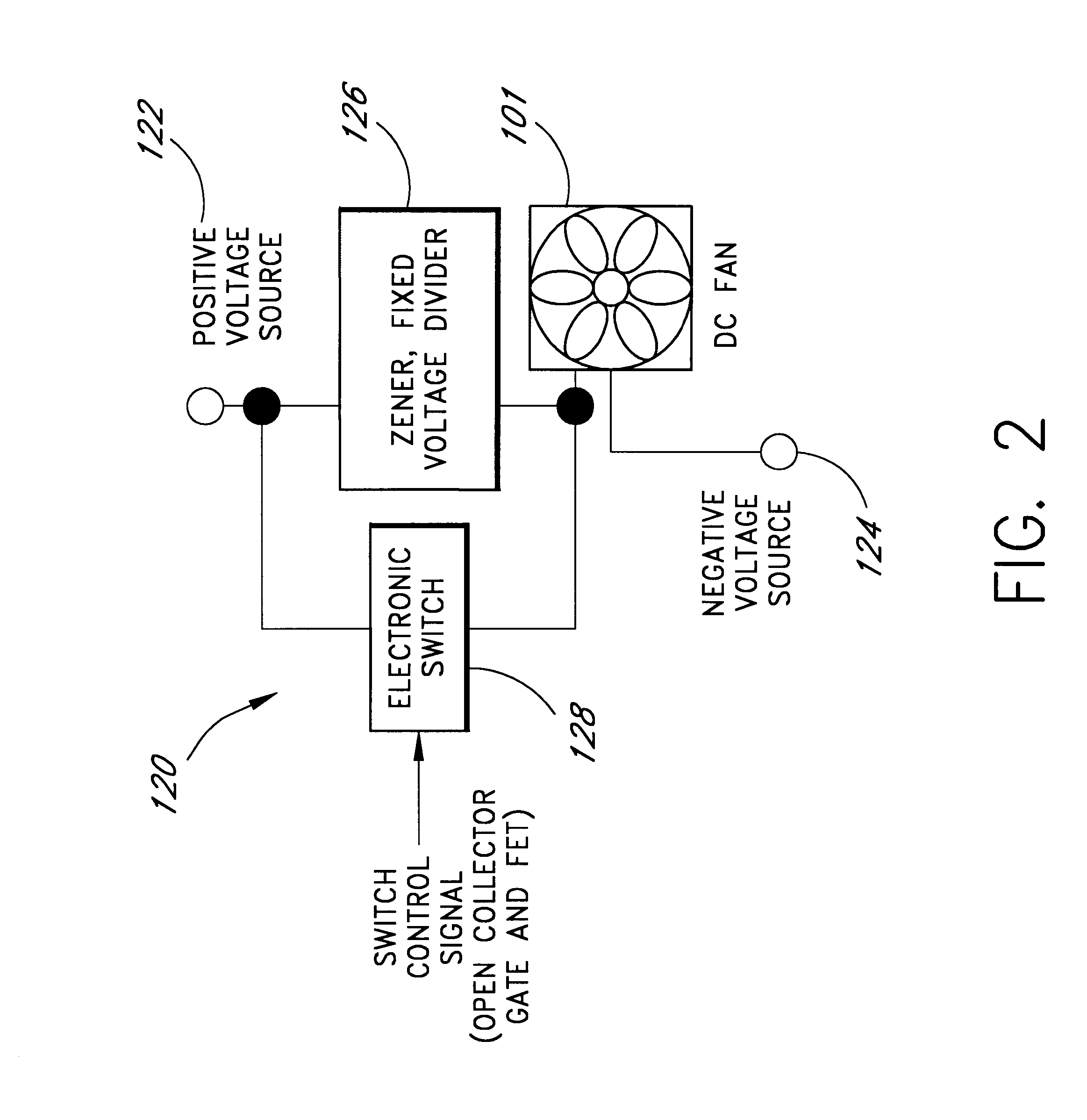

Computer fan speed control system

InactiveUS6247898B1Reduce stepsReduce voltageDigital data processing detailsTemperatue controlSpeed control systemZener diode

A cooling system for cooling components of a computer is provided. The cooling system includes a DC fan which operates at a speed which is substantially proportional to the voltage that is applied to the fan. A zener diode voltage divider is connected in series between a voltage source and a first input of the fan. The second input of the fan is connected to a reference voltage source. A switch is also connected in series between the voltage source and the first voltage input of the fan so as to be connected in parallel with the zener diode voltage divider. When the switch is in a first position, the voltage produced by the voltage source is applied directly to the fan allowing the fan to operate at a first speed. When the switch is in a second position, the voltage from the voltage source is applied to the first input of the fan through the zener diode such that the first input of the fan receives a second voltage that is less than the first voltage thereby causing the fan to operate at a second speed. The zener diode voltage divider is substantially current independent such that the voltage drop across the zener diode is substantially independent of the current that is drawn by the fan.

Owner:ROUND ROCK RES LLC

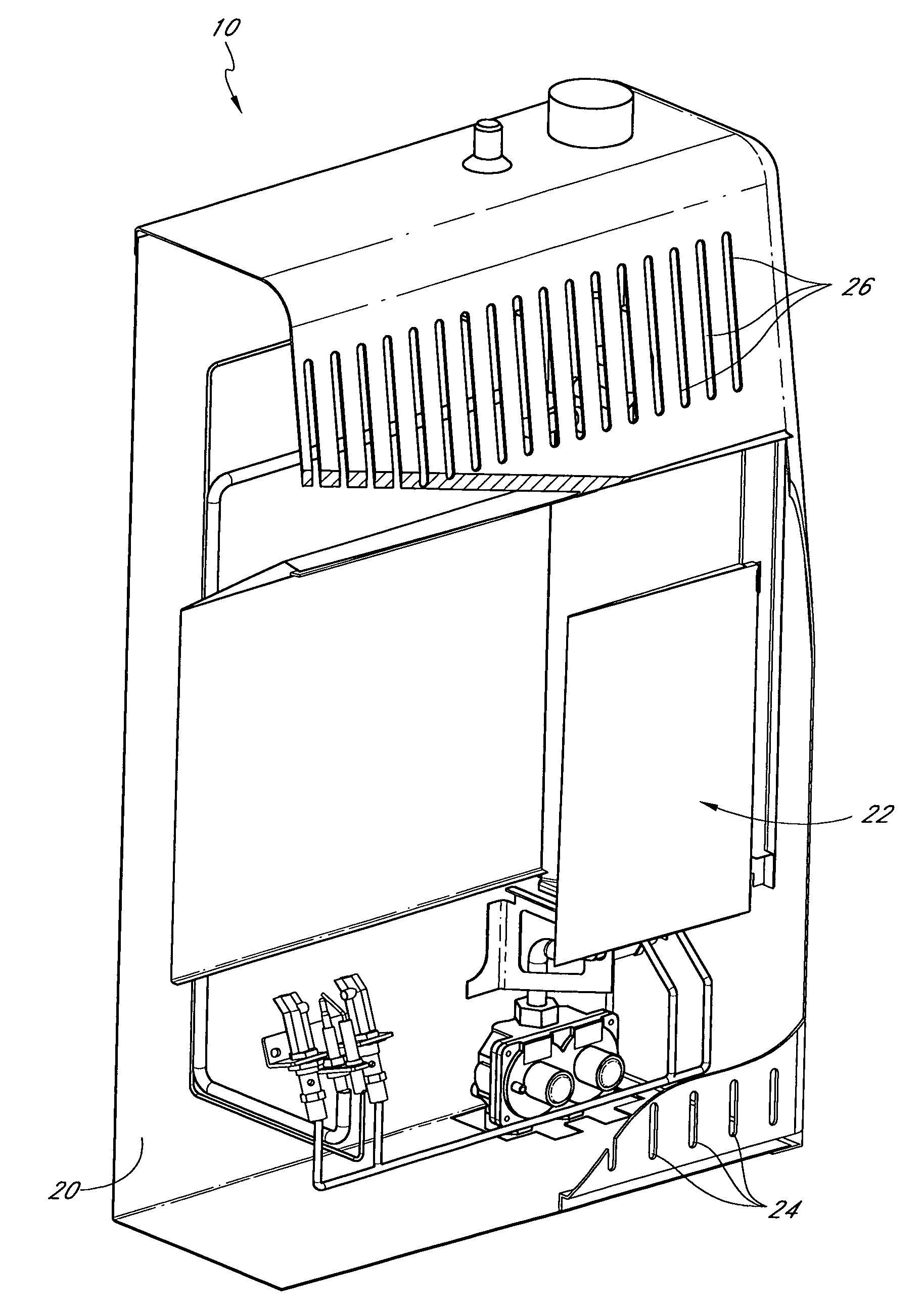

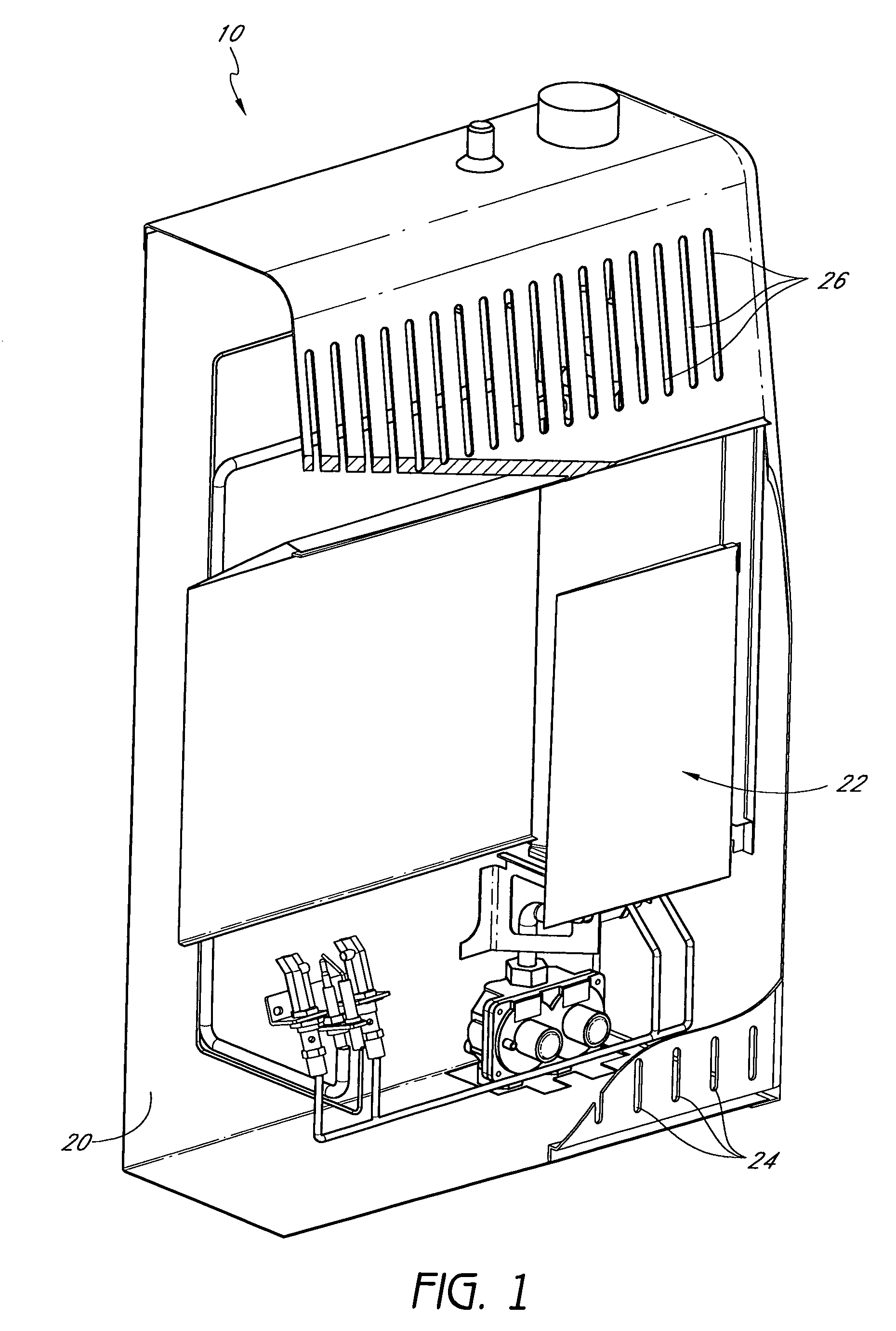

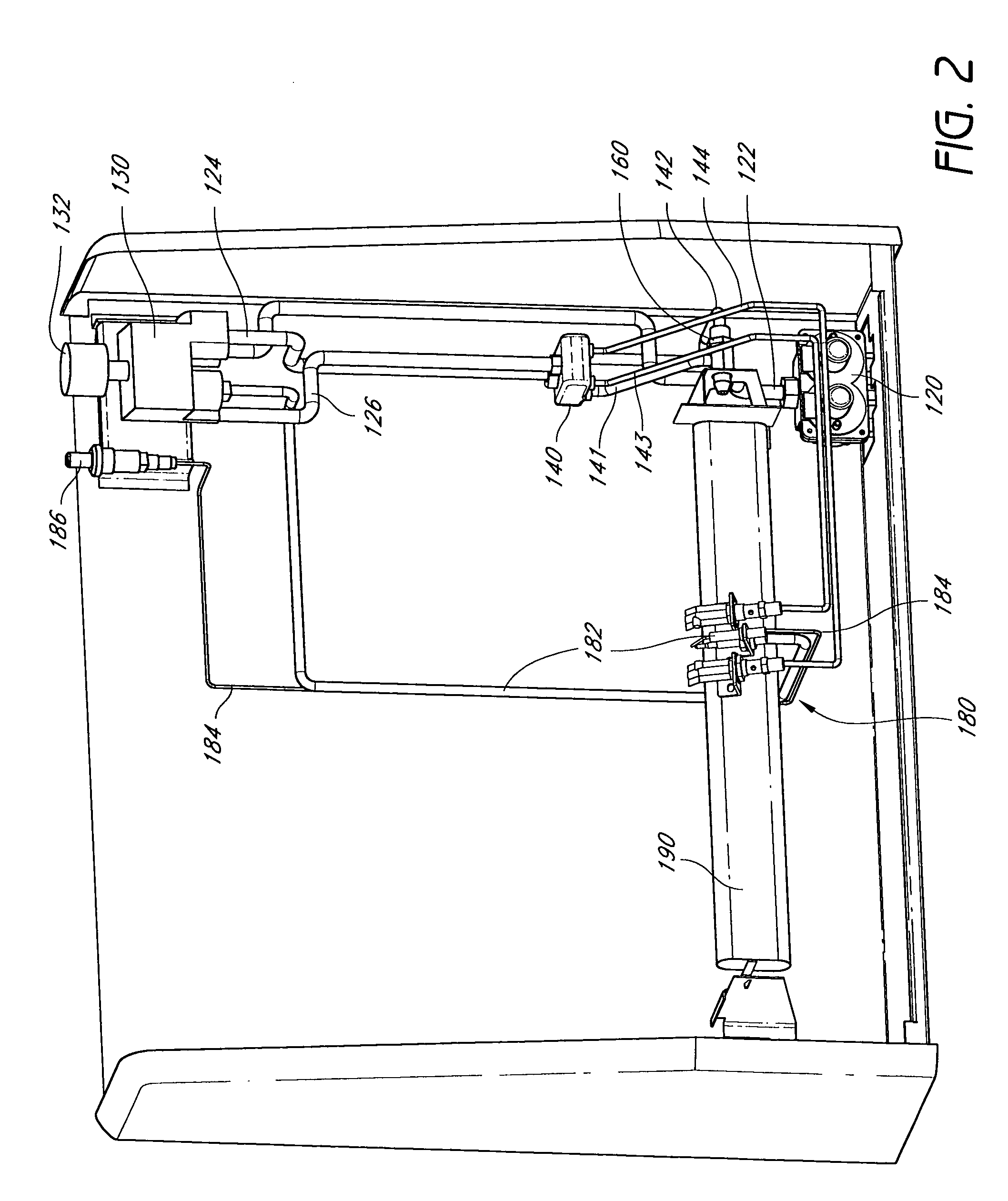

Dual fuel heater

ActiveUS7607426B2Fuel supply regulationDomestic stoves or rangesCombustion chamberNuclear engineering

In certain embodiments, a dual fuel heater has a pressure regulating device for selectively coupling with a first source or a second source operating at different pressures. The dual fuel heater can also include first and second fuel lines, a fluid flow controller, a combustion chamber and first and second oxygen depletion sensor nozzles. The fluid flow controller is configured to selectively permit flow of fuel to either the first fuel line or to the second fuel line. In some embodiments, the first fuel line is connected to the first oxygen depletion sensor nozzle and the second fuel line is connected to the second oxygen depletion nozzle.

Owner:PROCOM HEATING

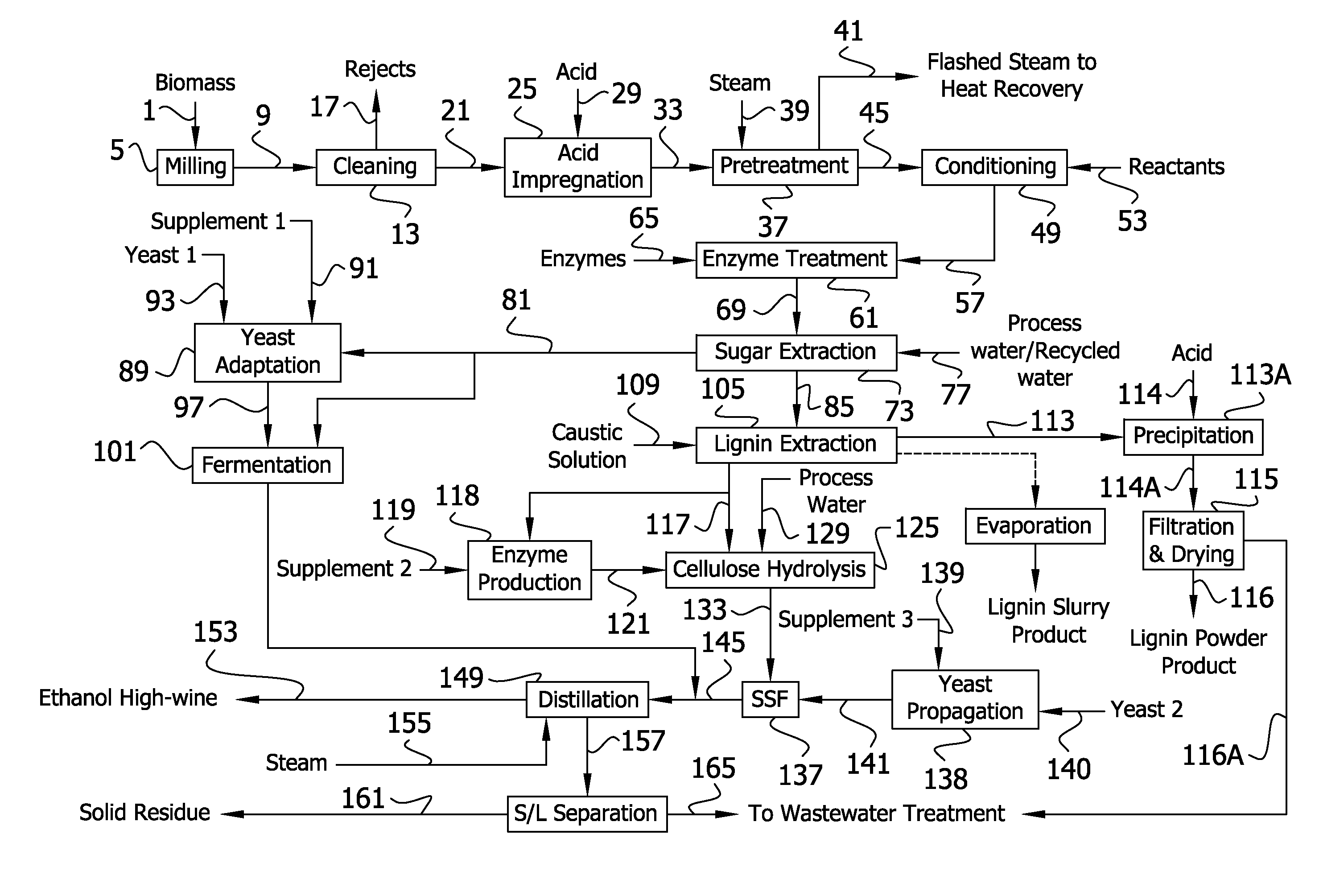

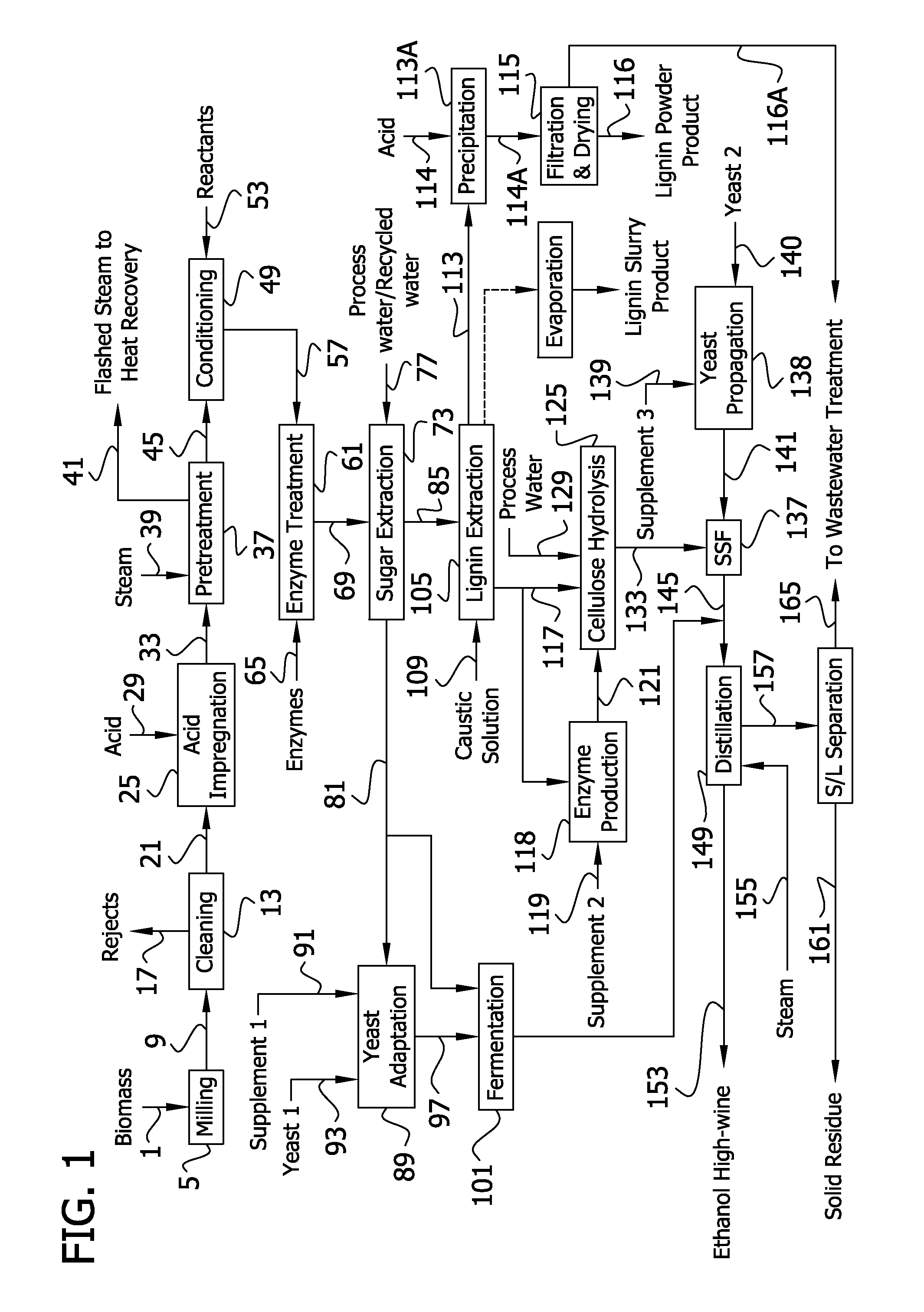

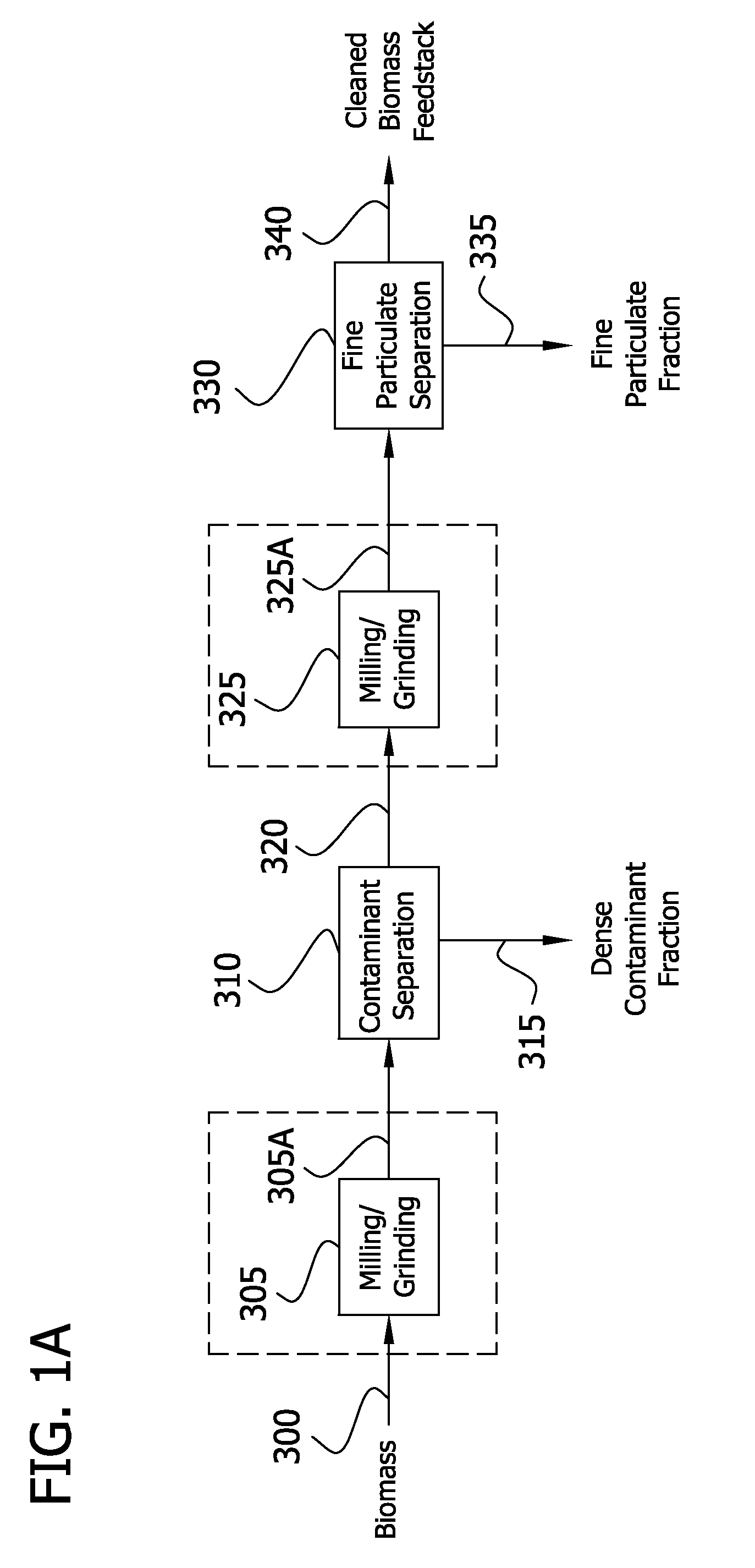

Method for producing ethanol and co-products from cellulosic biomass

InactiveUS20120006320A1Increased ethanol productionImproved co-productsFuel supply regulationPretreatment with acid reacting compoundsCelluloseLignocellulosic biomass

The present invention generally relates to processes for production of ethanol from cellulosic biomass. The present invention also relates to production of various co-products of preparation of ethanol from cellulosic biomass. The present invention further relates to improvements in one or more aspects of preparation of ethanol from cellulosic biomass including, for example, improved methods for cleaning biomass feedstocks, improved acid impregnation, and improved steam treatment, or “steam explosion.”

Owner:ABENGOA BIOENERGY NEW TECH

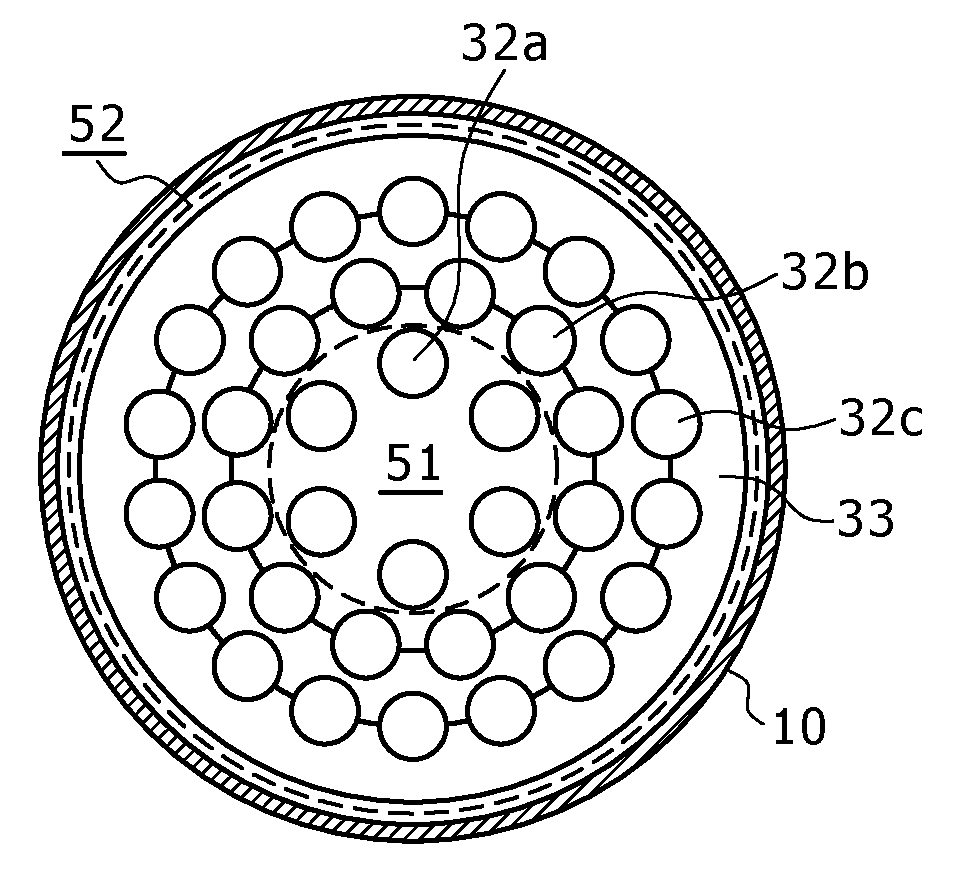

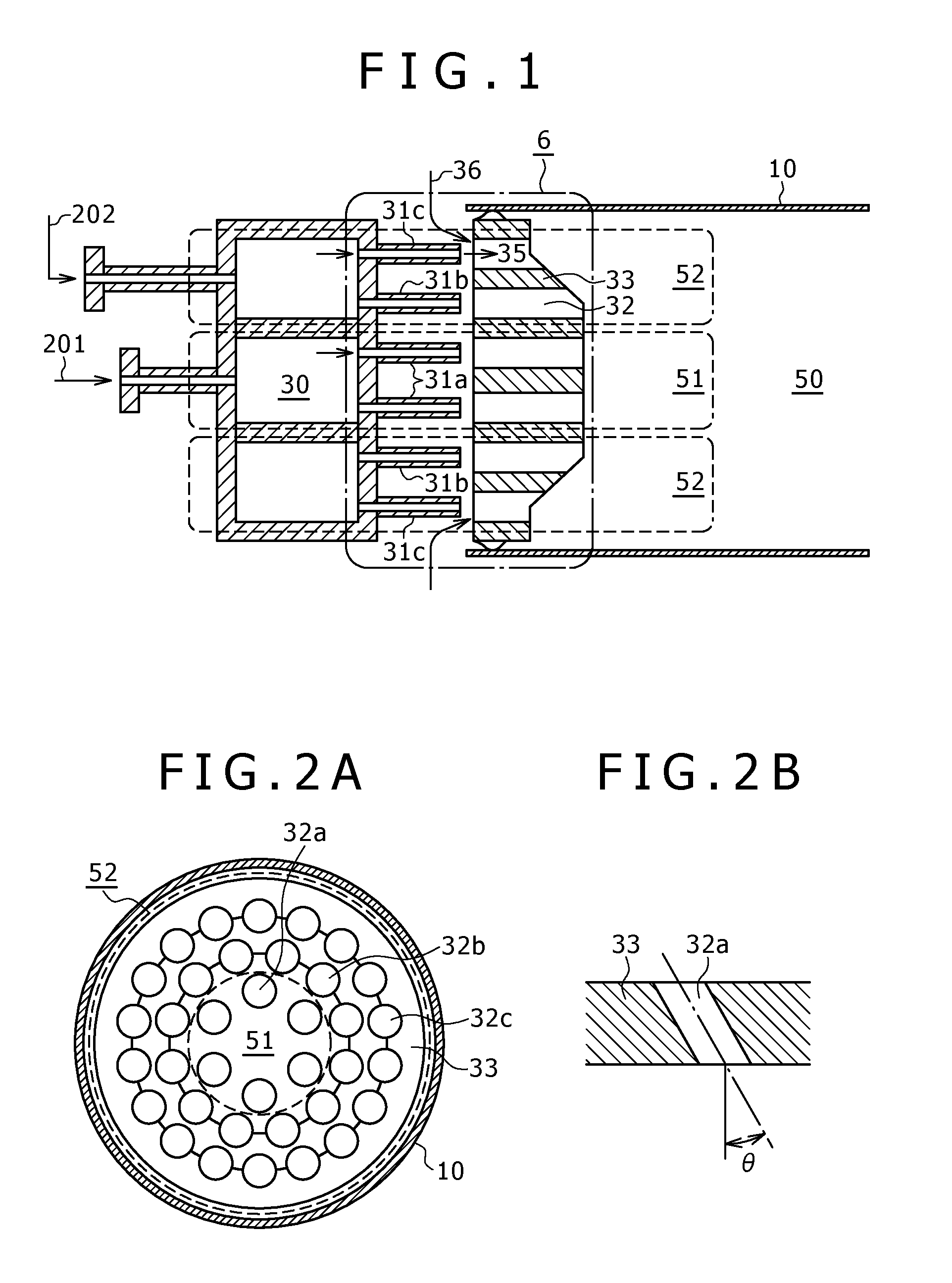

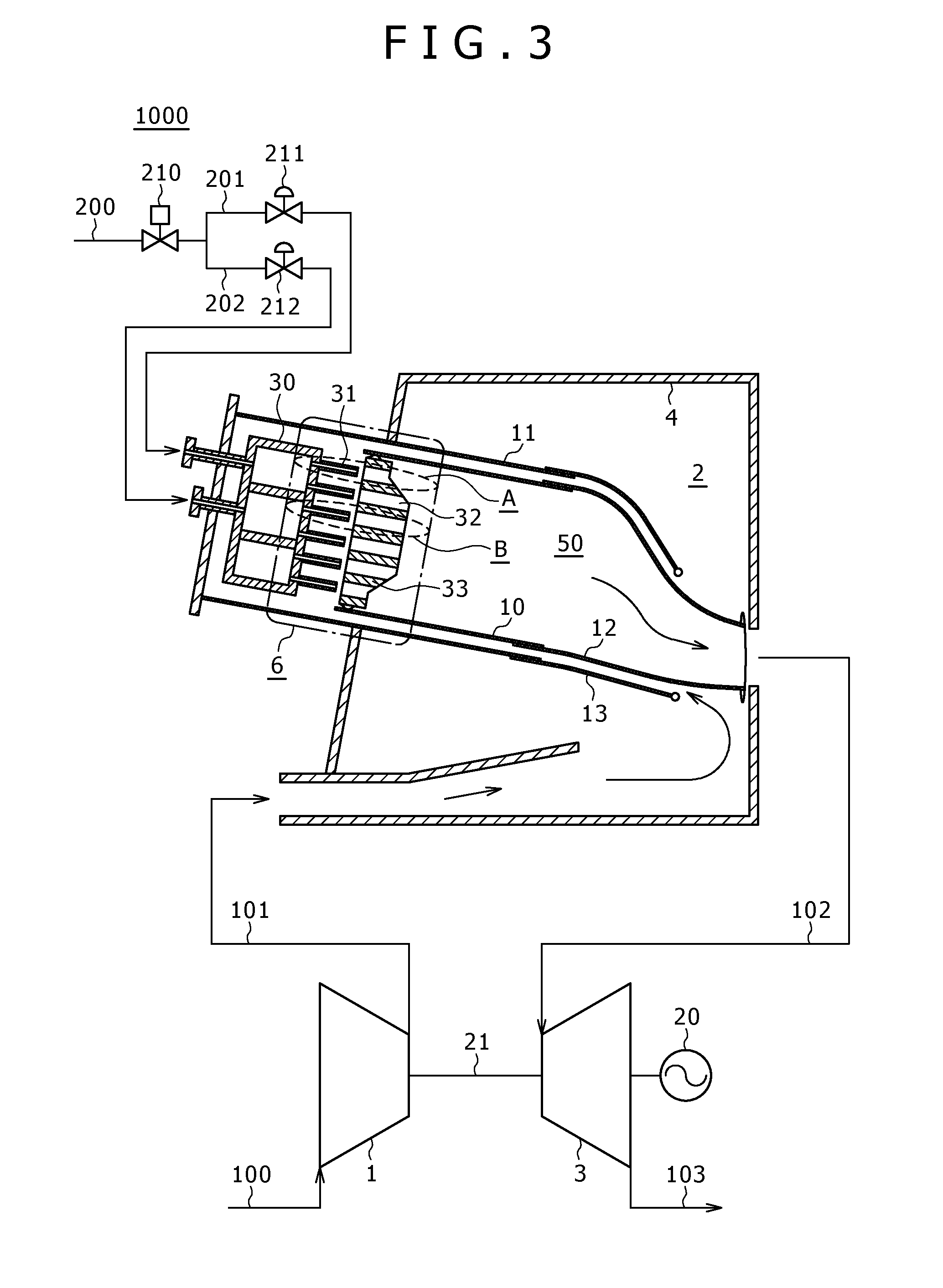

Combustor

ActiveUS20110076628A1Reduce nitrogen oxide emissionsMaintains combustion stabilityFuel supply regulationContinuous combustion chamberCombustorCombustion chamber

This invention is directed to supply a combustor having a structure that reduces NOx emissions while maintaining combustion stability. The combustor has a chamber into which fuel and air are supplied. An air hole plate having a plurality of air holes upstream of the chamber is also disclosed, and fuel nozzles supplying fuel to the air holes of the air hole plate are further disclosed. In the combustor, a center of a chamber-side of the air hole plate is closer to the chamber than exits of outermost peripheral air holes.

Owner:MITSUBISHI POWER LTD

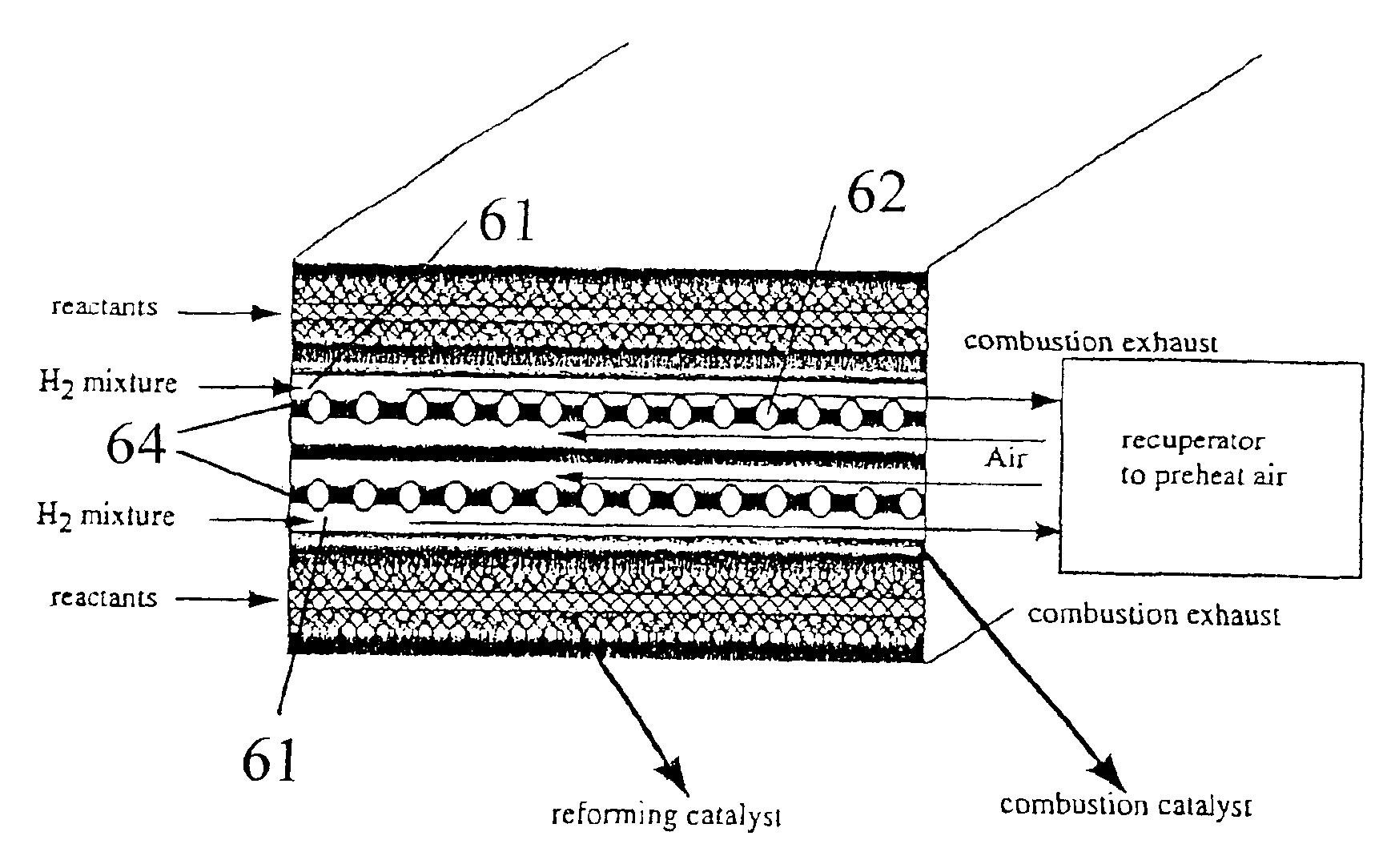

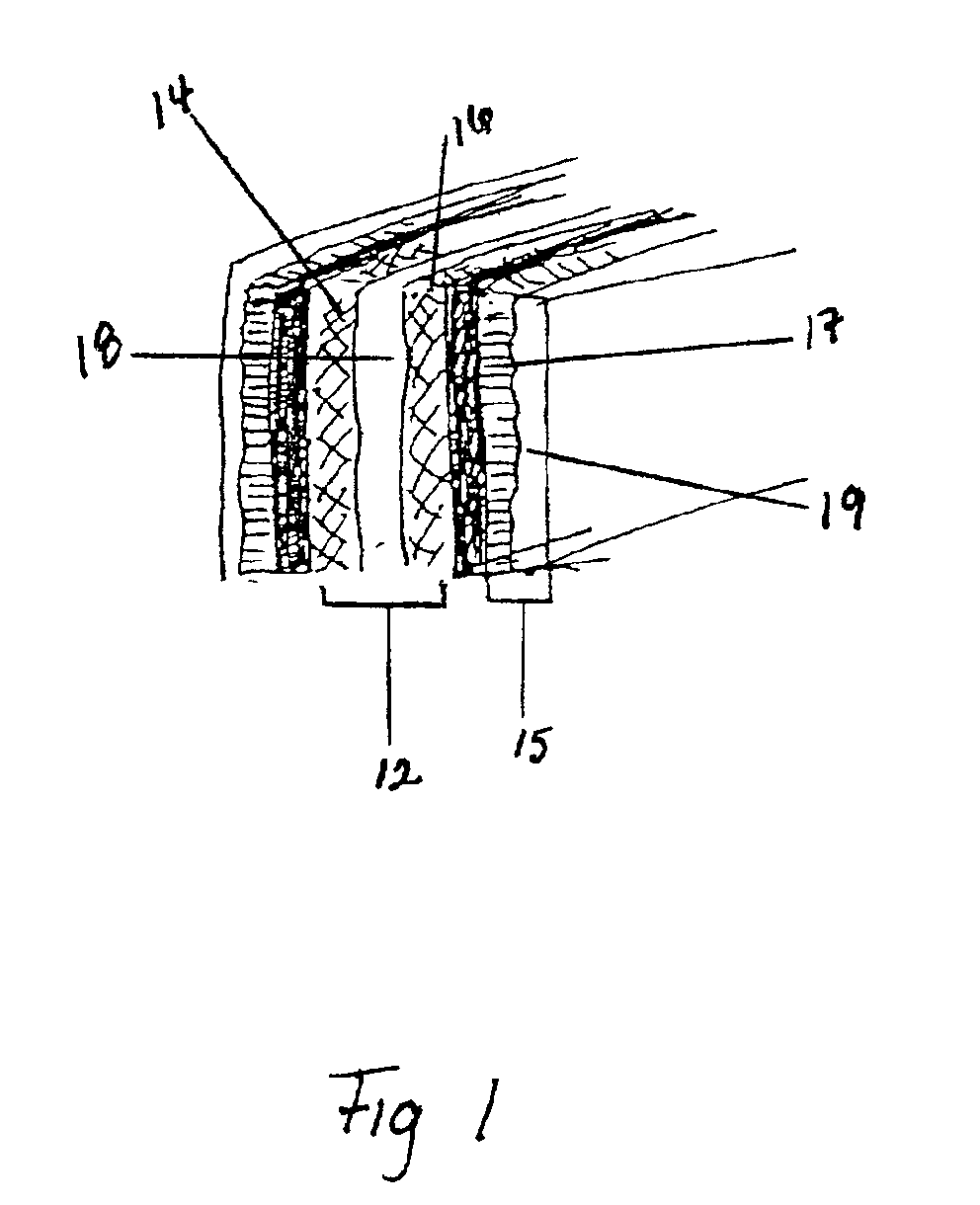

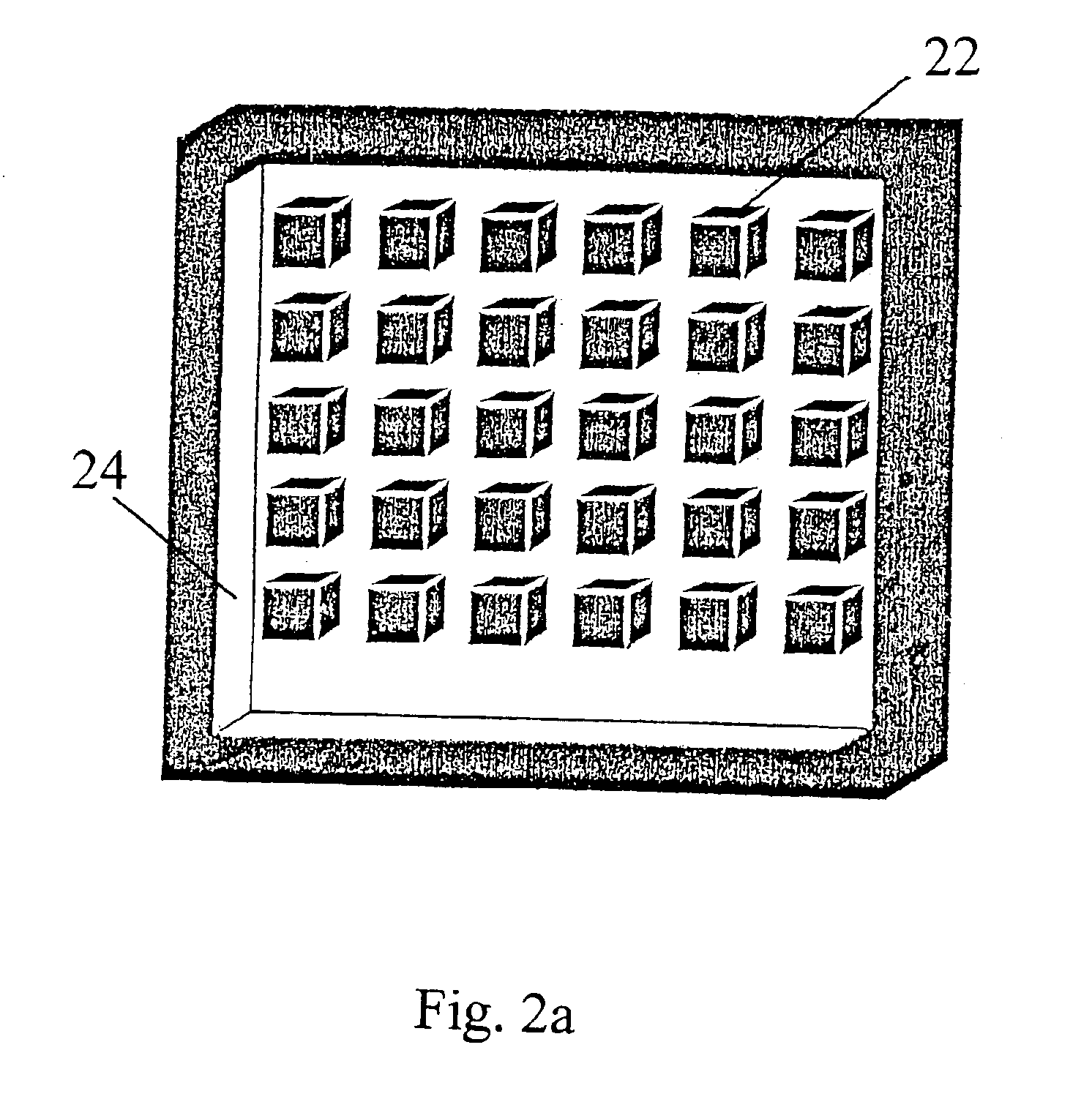

Methods of conducting simultaneous exothermic and endothermic reactions

InactiveUS6969506B2High yieldImprove performanceFinal product manufactureChemical/physical/physico-chemical microreactorsCombustion chamberEngineering

Integrated Combustion Reactors (ICRs) and methods of making ICRs are described in which combustion chambers (or channels) are in direct thermal contact to reaction chambers for an endothermic reaction. Superior results were achieved for combustion chambers which contained a gap for free flow through the chamber. Particular reactor designs are also described. Processes of conducting reactions in integrated combustion reactors are described and results presented. Some of these processes are characterized by unexpected and superior results.

Owner:BATTELLE MEMORIAL INST

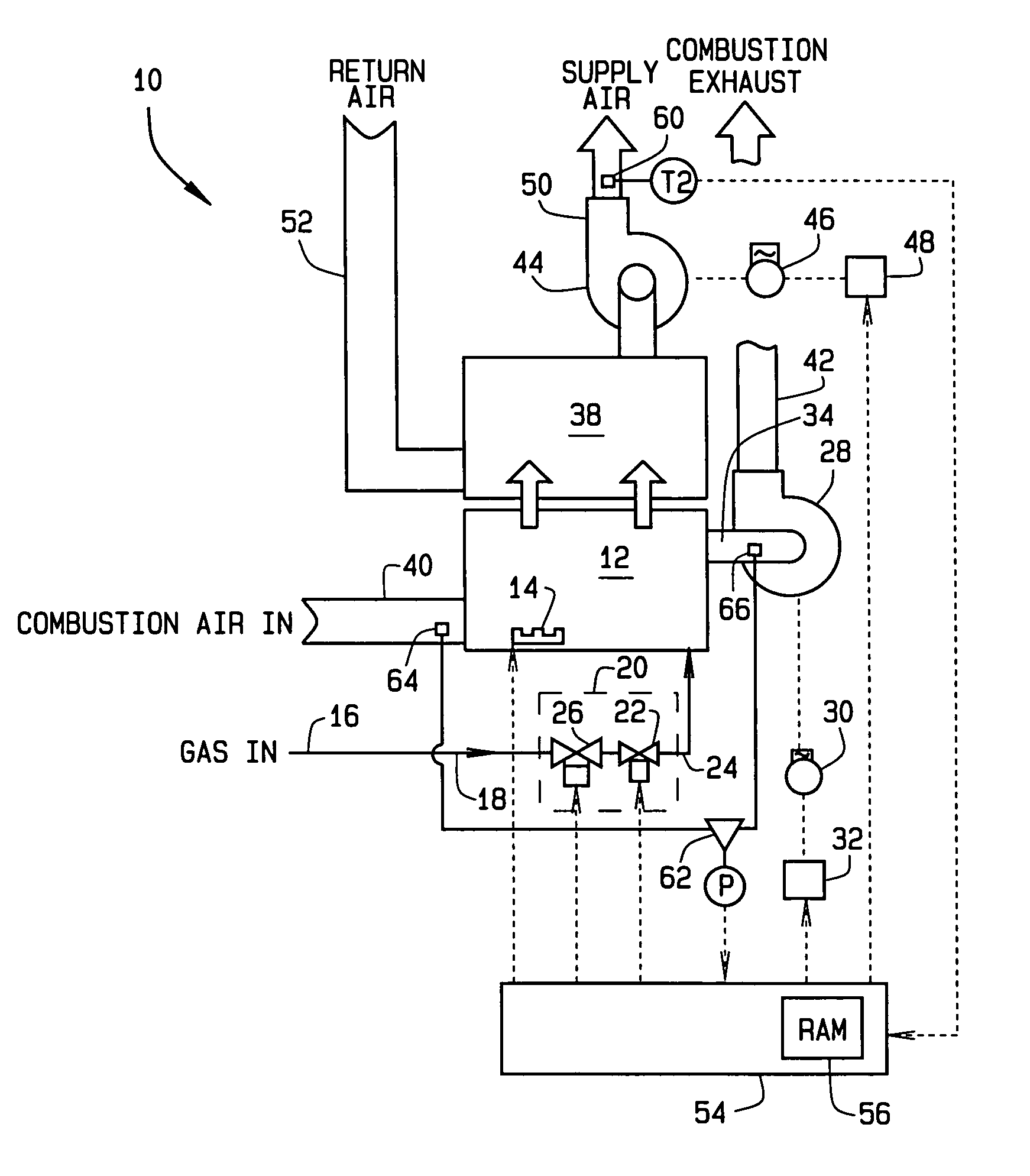

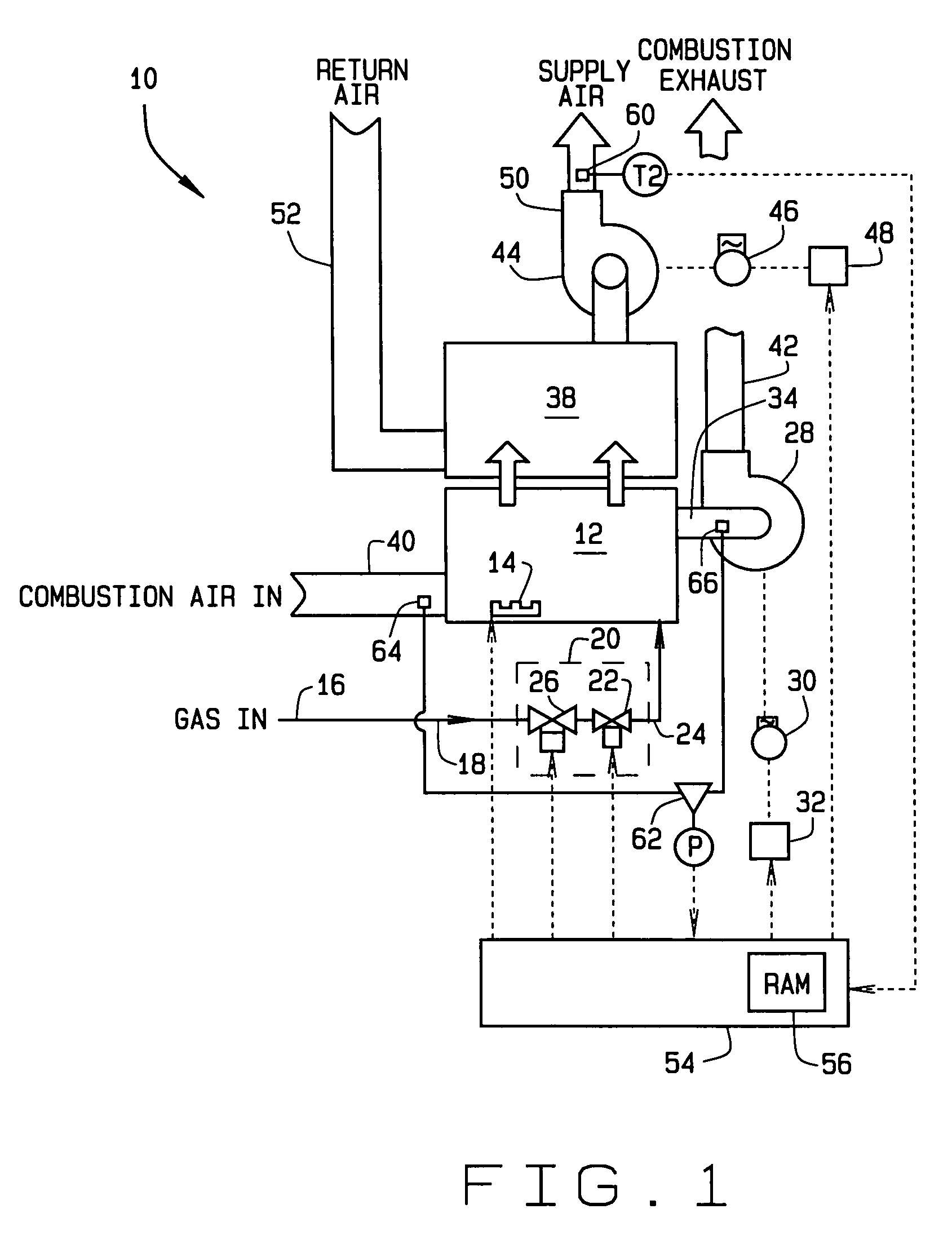

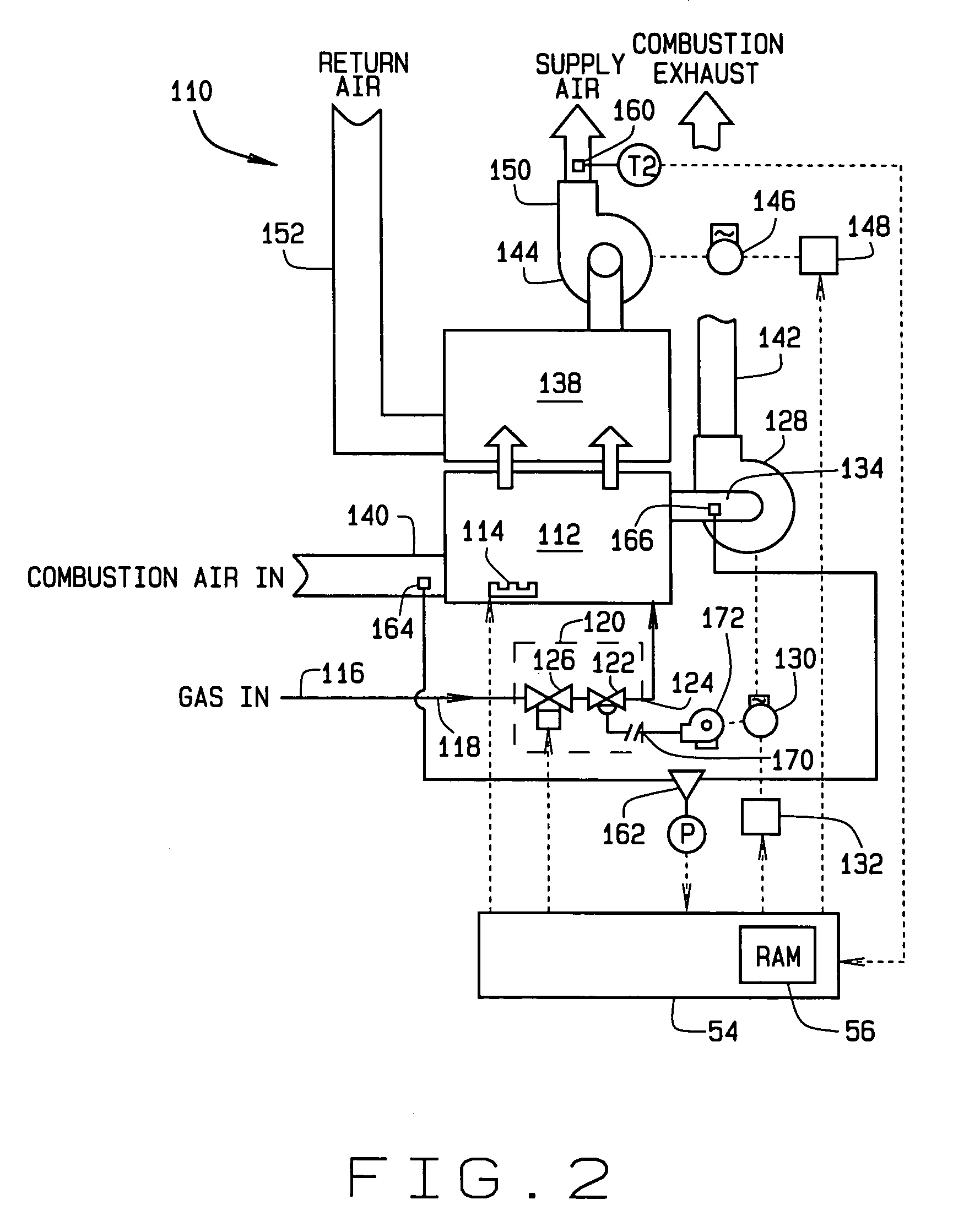

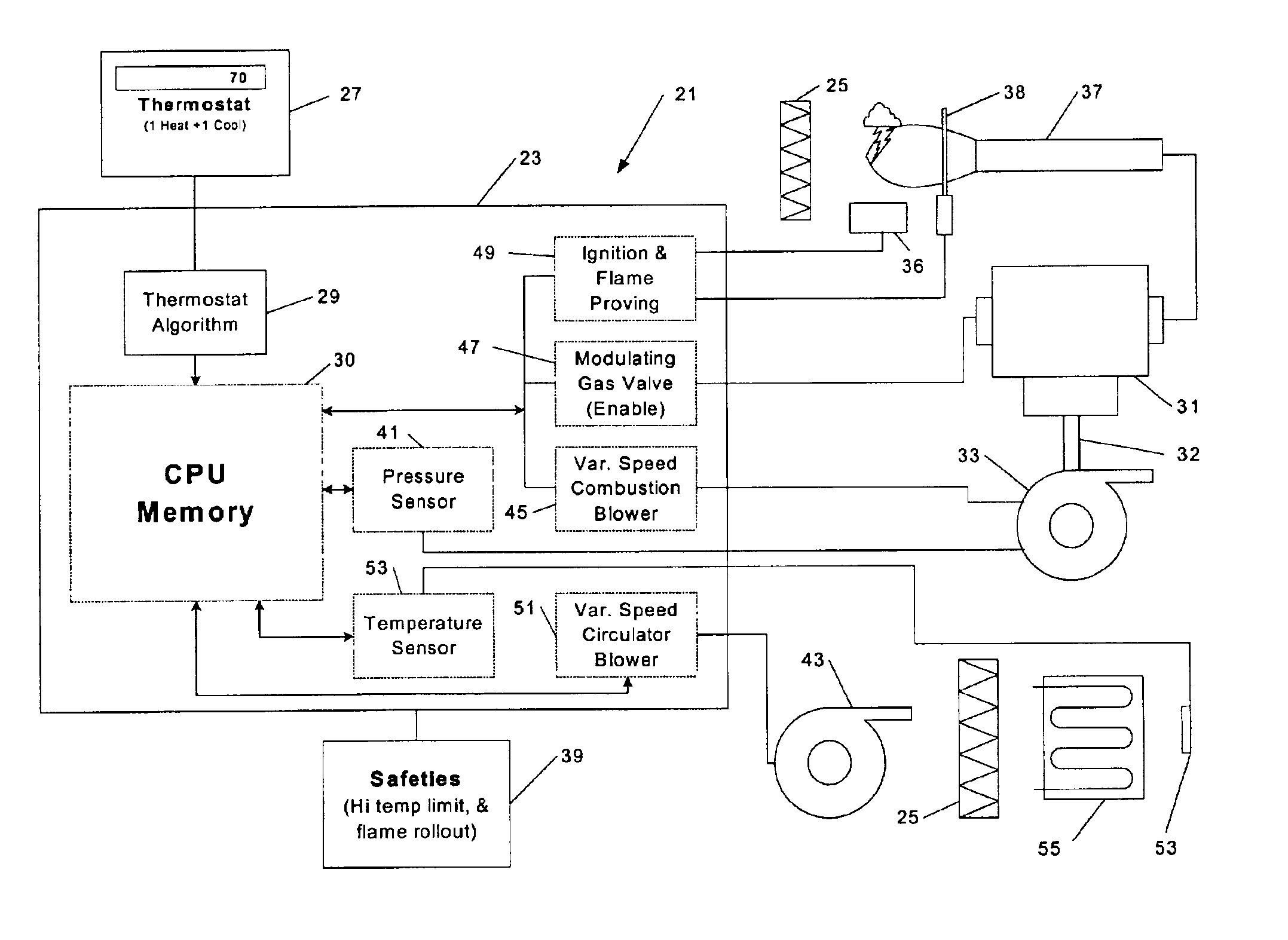

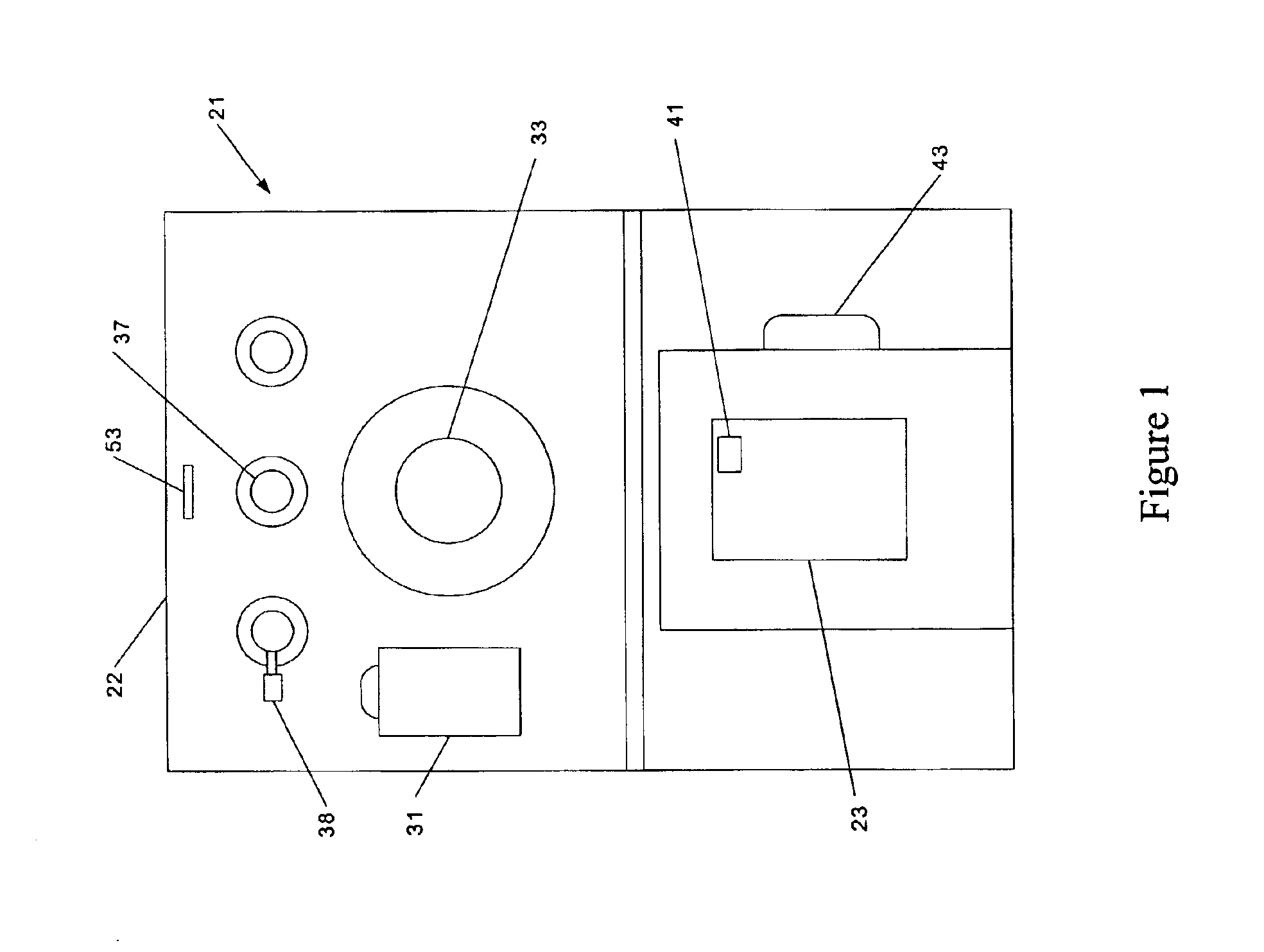

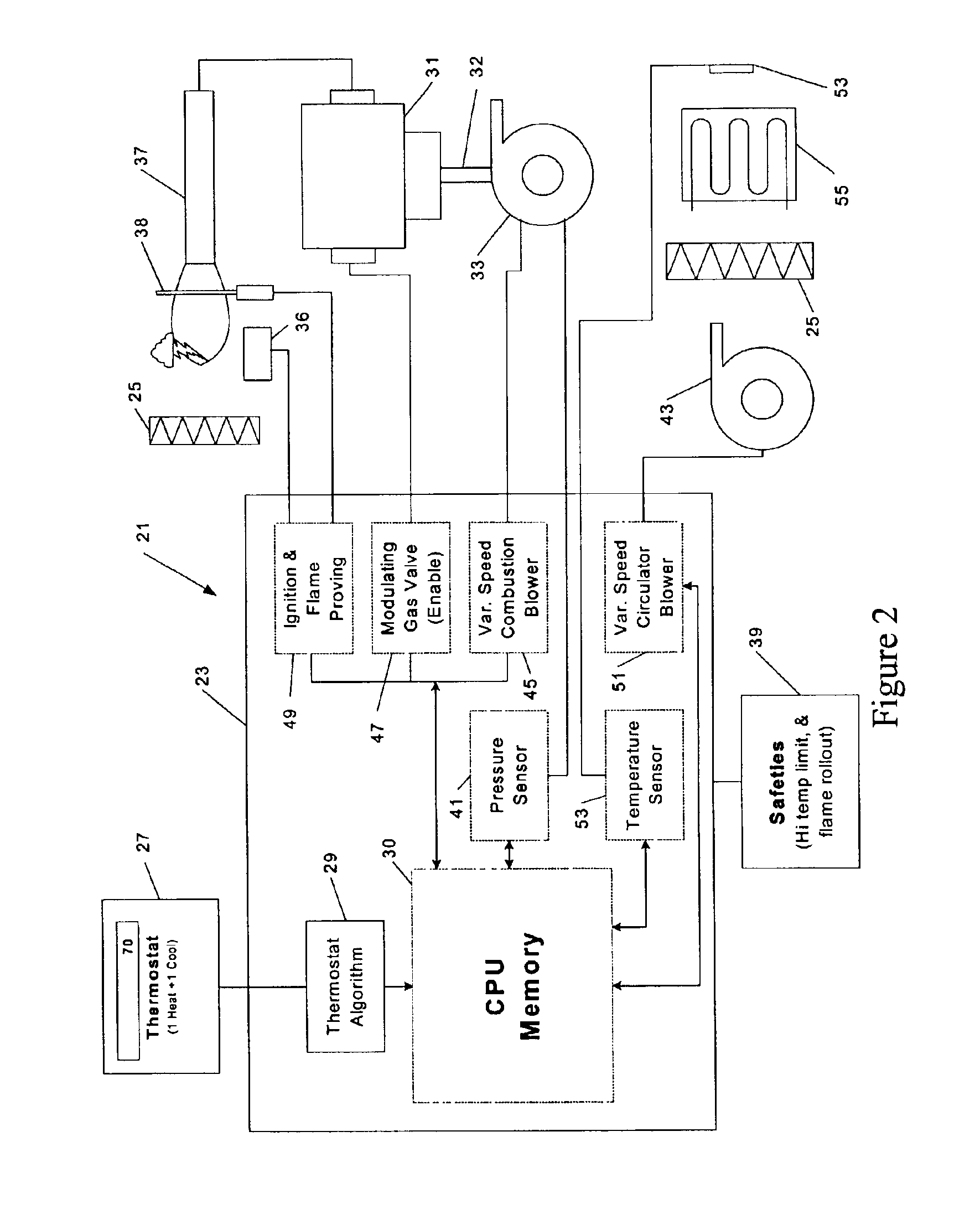

Apparatus and methods for variable furnace control

InactiveUS7101172B2Speed of can varyGreat pressure dropFuel supply regulationAir supply regulationMotor speedCombustion chamber

A furnace control system for controlling a gas-fired induced-draft furnace having a variable speed inducer blower. A control apparatus, responsive to a signal corresponding to the magnitude of a pressure difference between an inlet and outlet of the combustion chamber, controls blower motor speed to maintain the pressure difference at a predetermined magnitude corresponding to a selected gas flow rate. Inducer blower motor speed is varied directly and precisely to maintain an optimal pressure drop across the combustion chamber. The control system can be used in multi-stage and modulating furnace systems and in furnace systems utilizing pressure-assist modulating gas valves.

Owner:COPELAND COMFORT CONTROL LP

Variable output heating and cooling control

A heating or cooling system, such as an HVAC system, of variable output has a number of control elements and may include a variable speed compressor, a variable speed combustion (induced or forced draft) blower motor; a variable speed circulator blower motor; a variable output gas valve or gas / air premix unit; and a controller specifically developed for variable output applications. The system may utilize a pressure sensor to determine the actual flow of combustion airflow in response to actual space conditions, vary the speed of the inducer blower, and subsequently vary the gas valve output to supply the correct amount of gas to the burner system. A temperature sensor may be located in the discharge air stream of the conditioned air to provide an input signal for the circulator blower.

Owner:HVAC MODULATION TECH

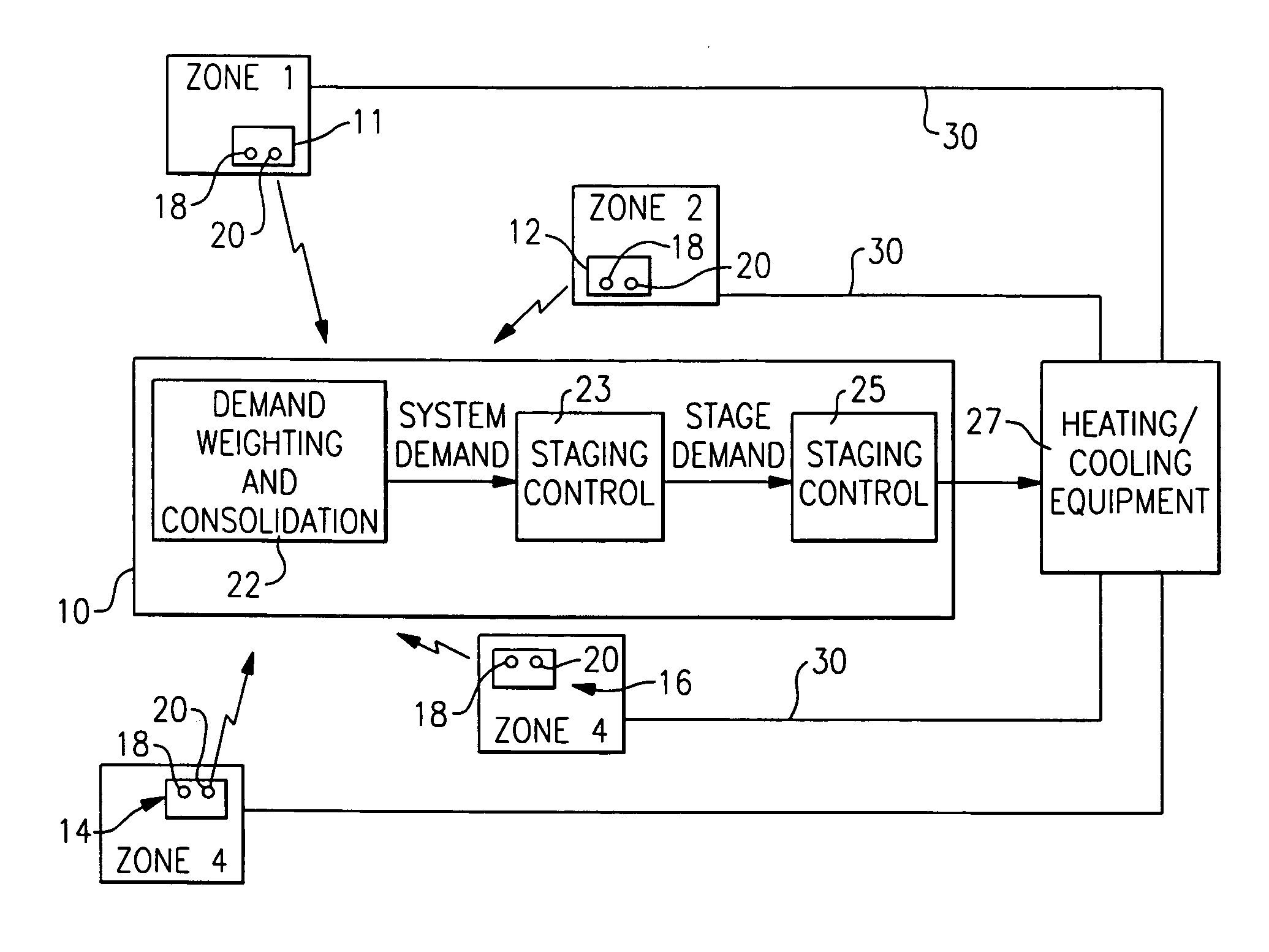

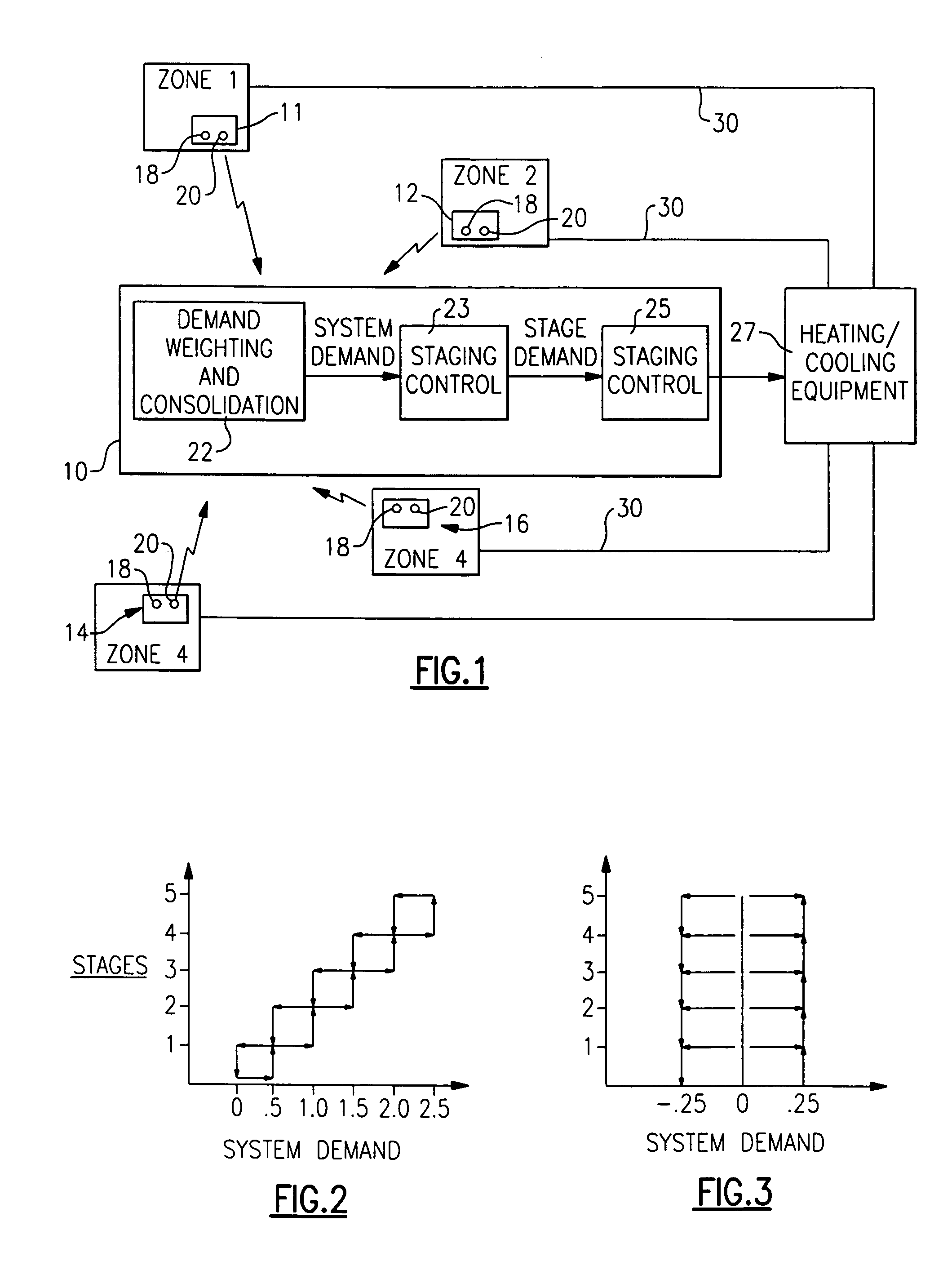

Control of multi-zone and multi-stage HVAC system

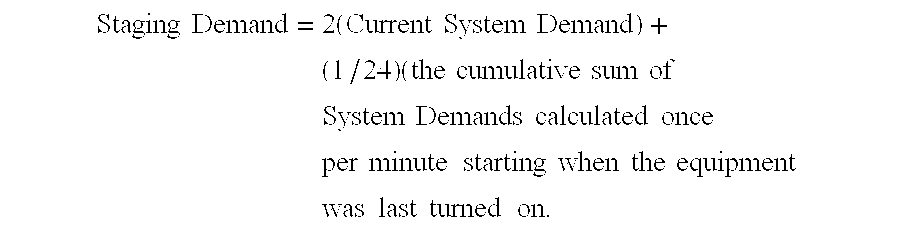

A control for controlling a multi-zone HVAC system, wherein the heating or cooling equipment is operable in multiple stages, takes the demand on the system over time into account when determining an appropriate stage. In particular, a time integral of the system demands is utilized along with a current system demand to determine an appropriate stage. In this manner, a weakness in the prior art of allowing a long-term, small difference between the desired set point and the actual temperature in the various zones is addressed.

Owner:CARRIER CORP

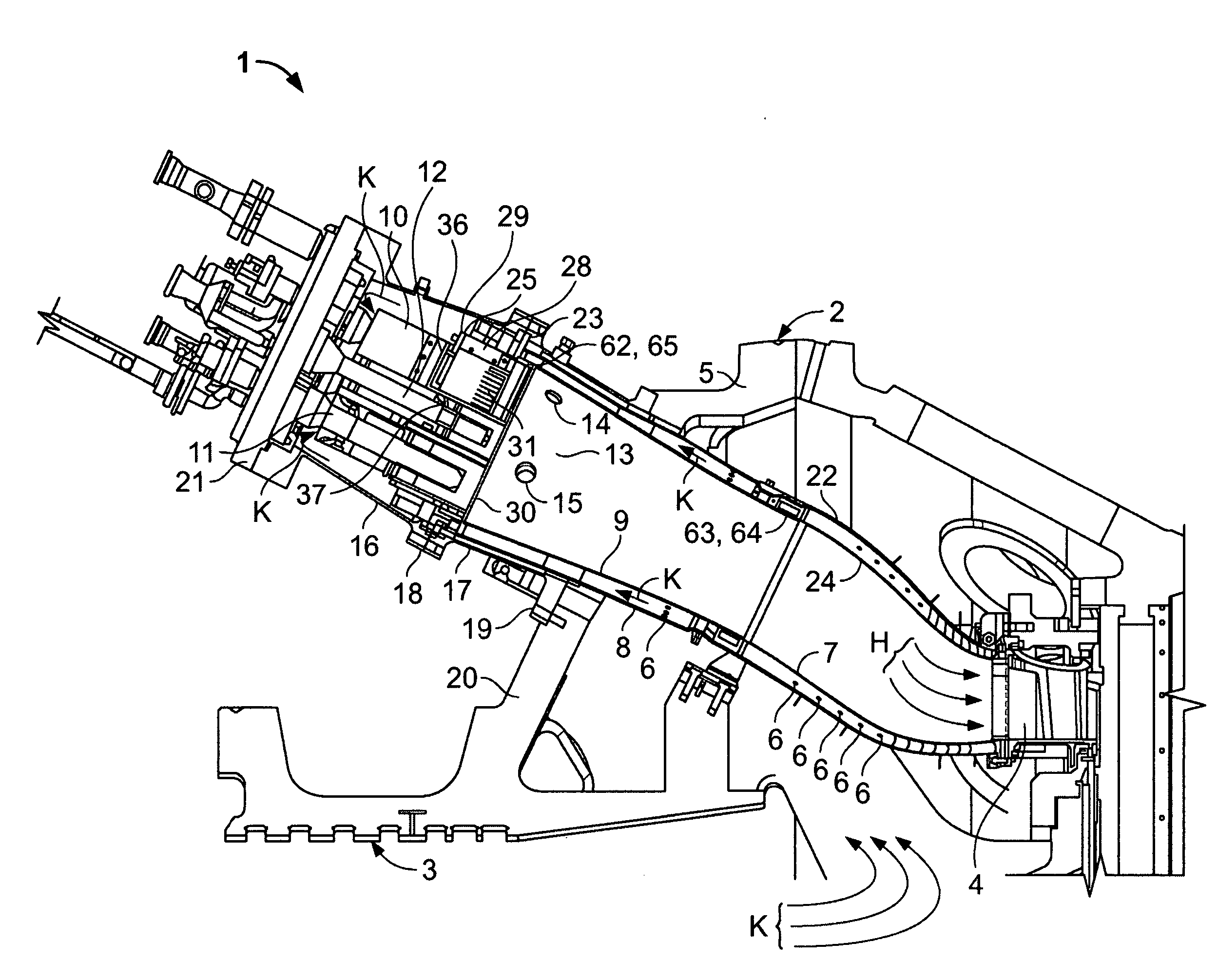

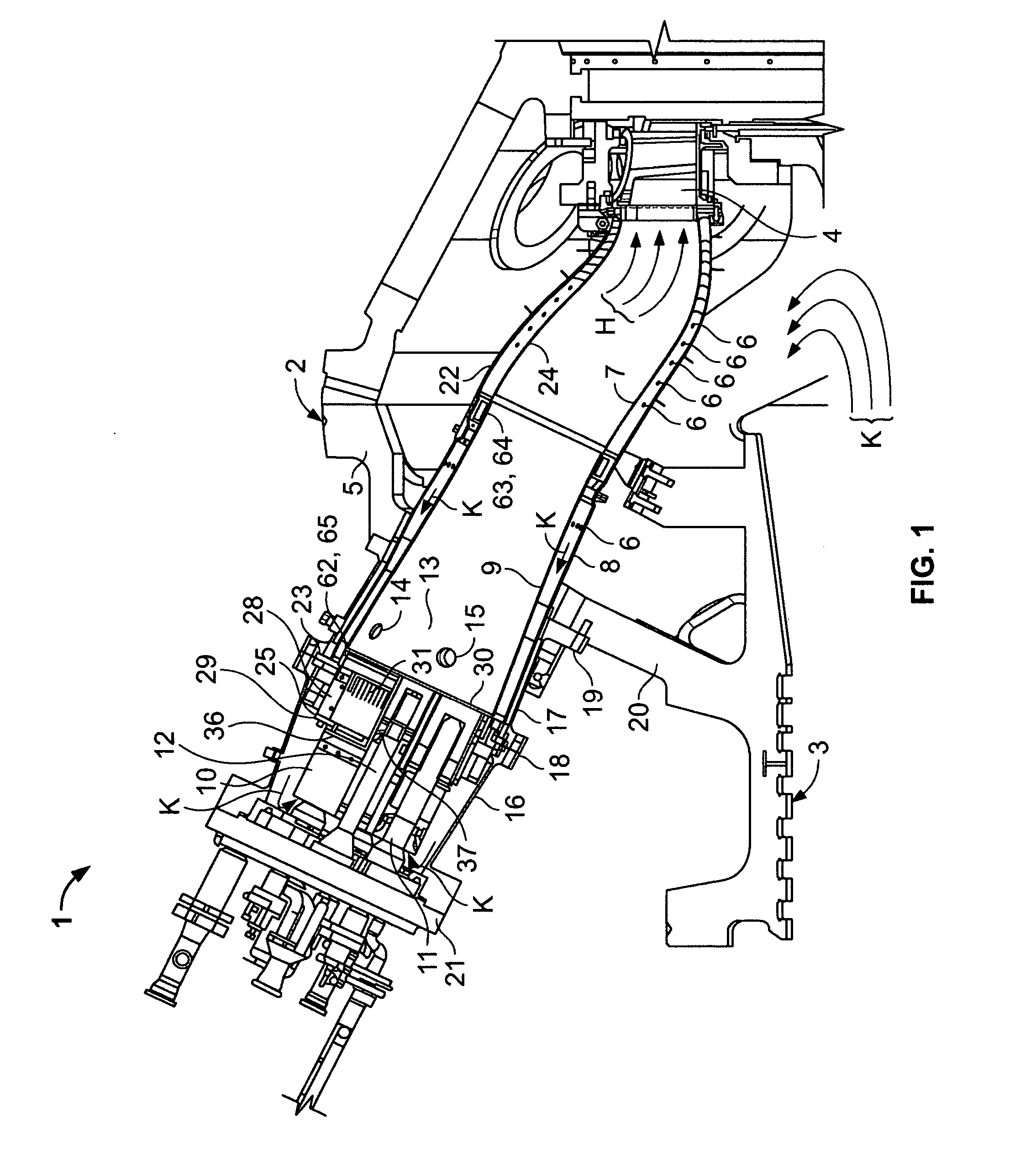

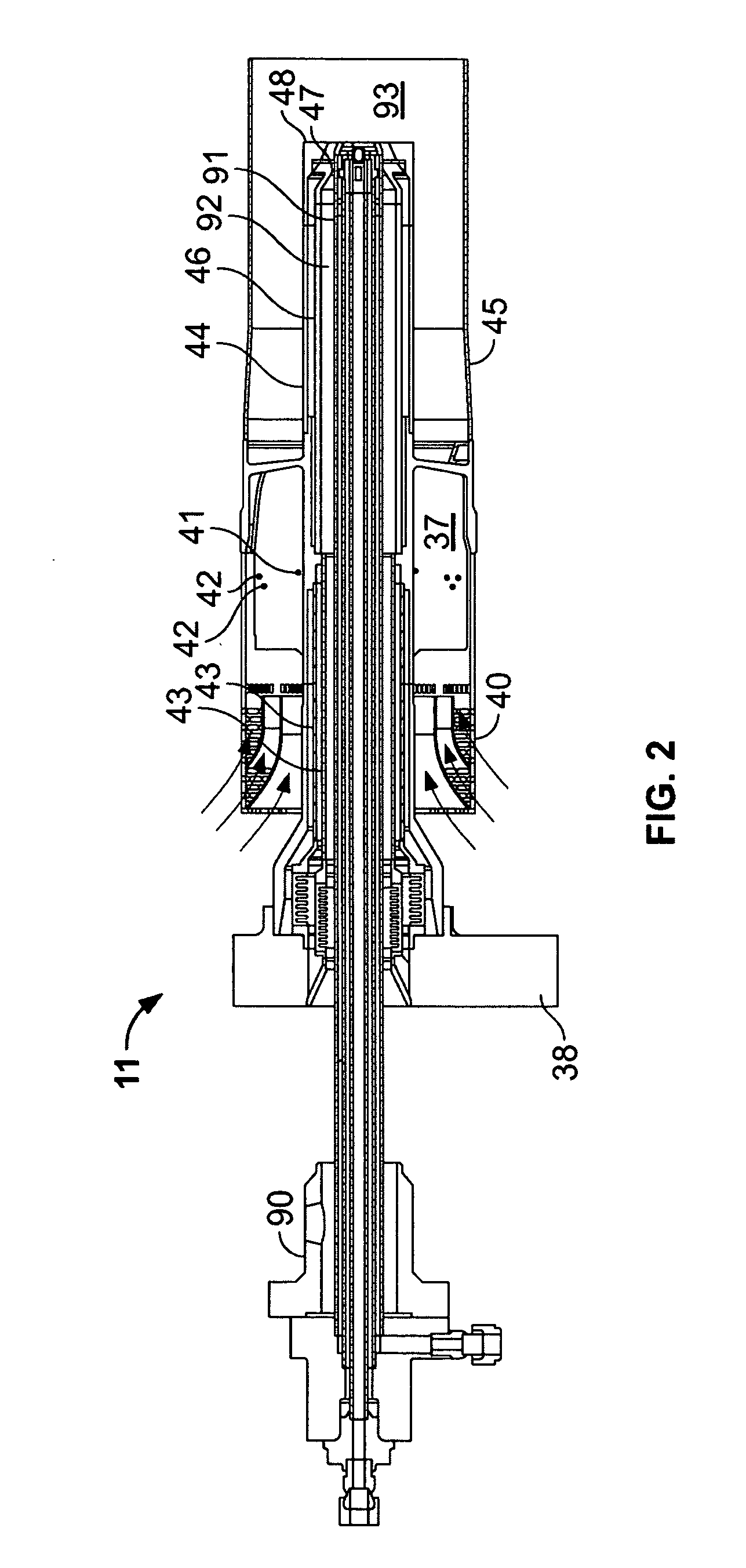

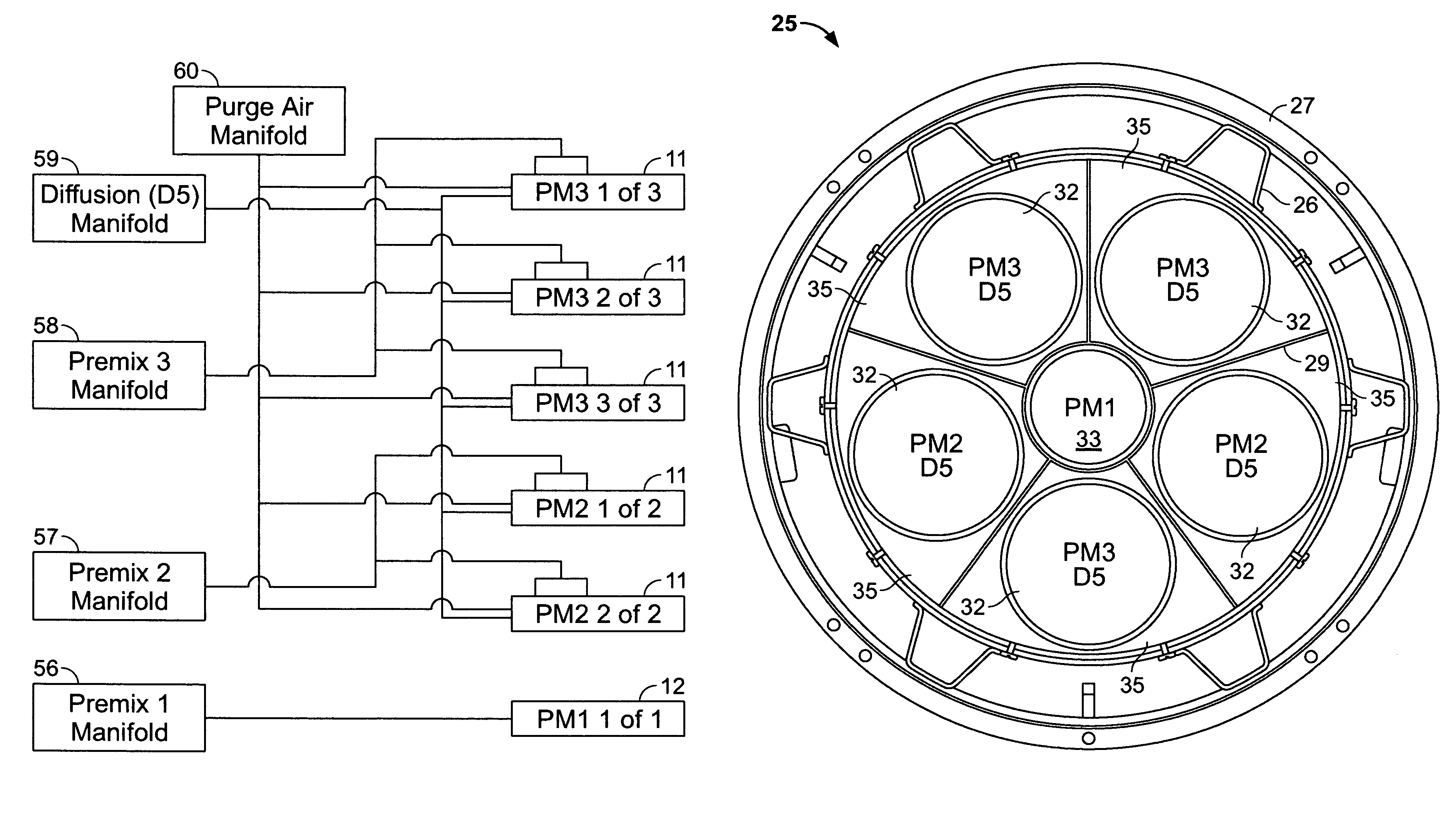

Methods and apparatus for low emission gas turbine energy generation

ActiveUS20050268617A1Reduce nitrogen oxide emissionsFuel supply regulationContinuous combustion chamberEngineeringLow emission

A low-emission method for producing power using a gas turbine includes premixing a plurality of fuel and air mixtures, injecting the fuel and air mixtures into a combustion chamber using a plurality of fuel nozzles, and adjusting a ratio of fuel and air injected by at least one of the nozzles to control a fuel / air concentration distribution within the combustion chamber.

Owner:GENERAL ELECTRIC CO

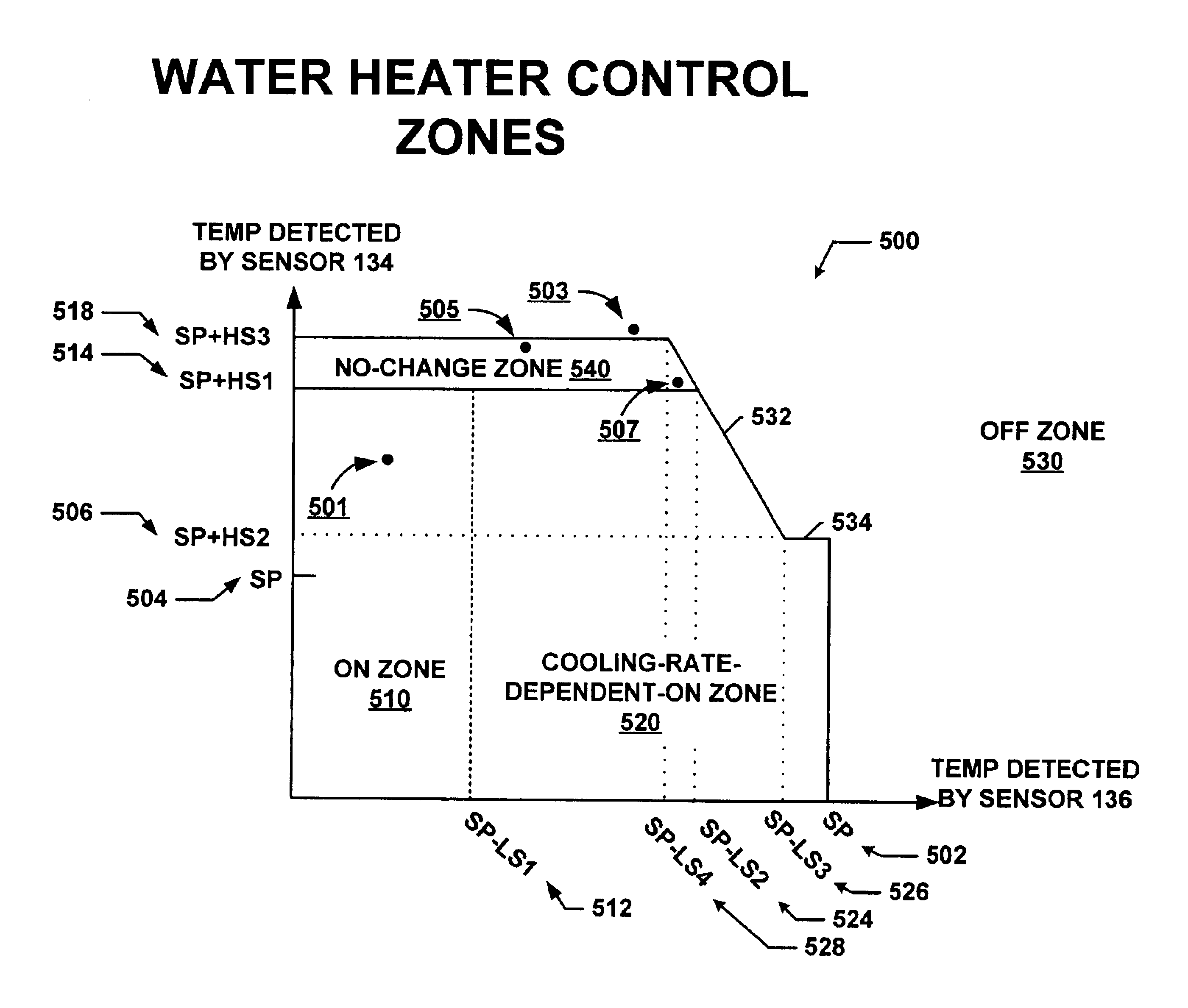

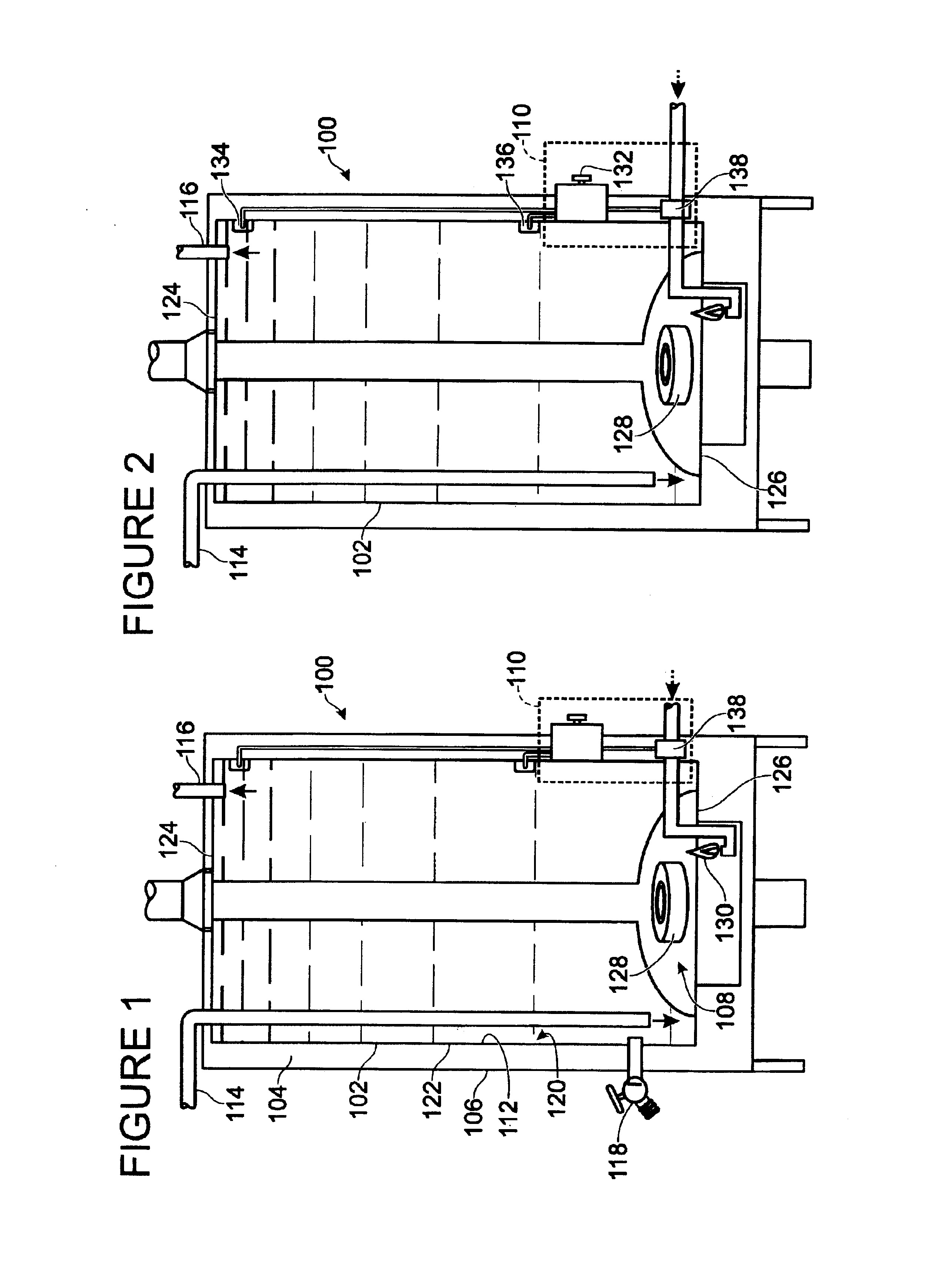

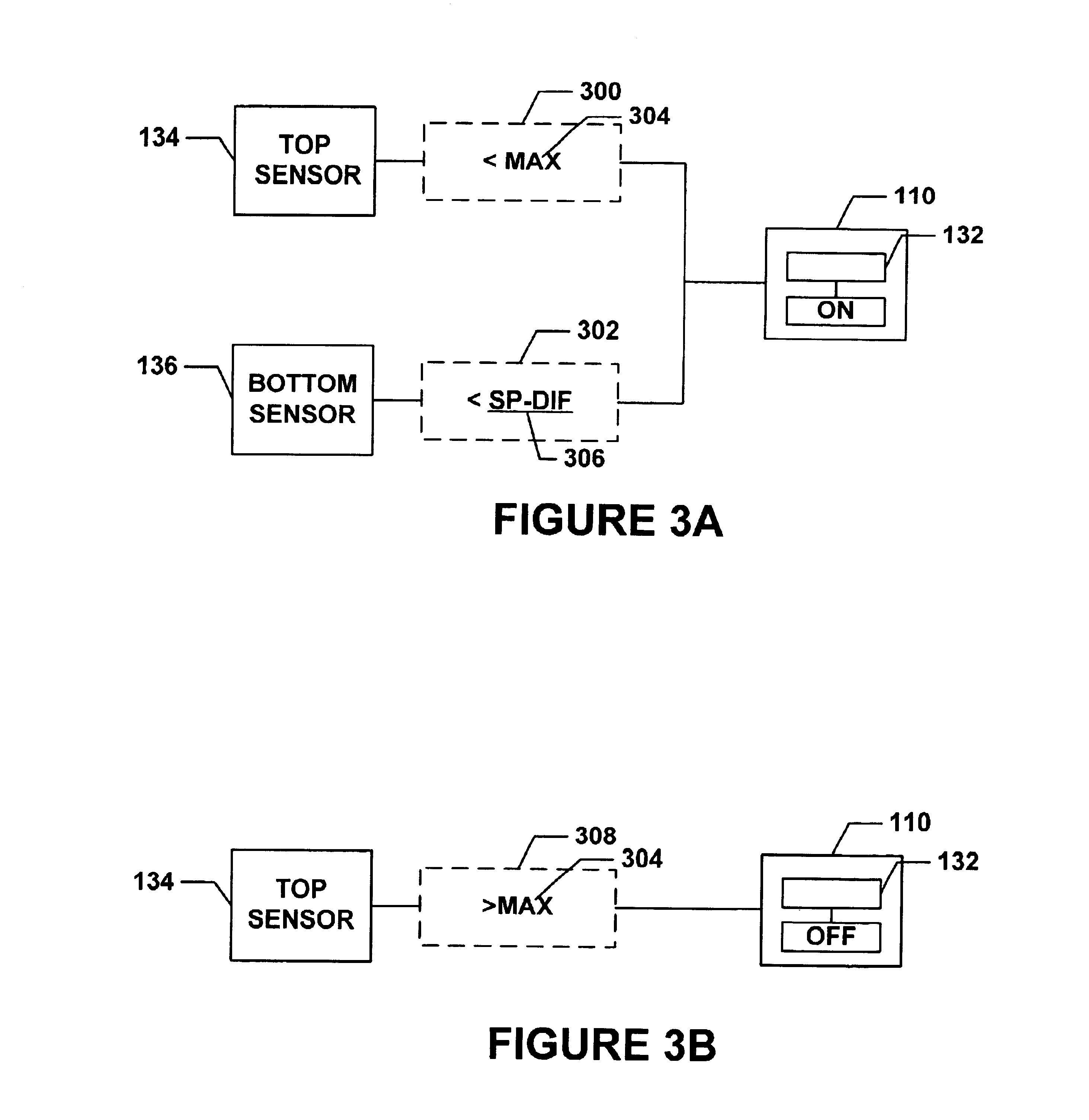

Water heater and control

An improved heater and method of controlling the same is provided. The water heater has the combination of a tank for holding water, a heater for heating the water, a controller having logic to regulate the heater, and first and second sensors. Each of the sensors detects the water temperature at different areas within the water heater. The sensors also provide the controller with signals corresponding to the detected water temperature. In response to these signals, the controller regulates the heater when at least one of the signals of the first and second sensors satisfies at least one predetermined state condition.

Owner:ADEMCO INC

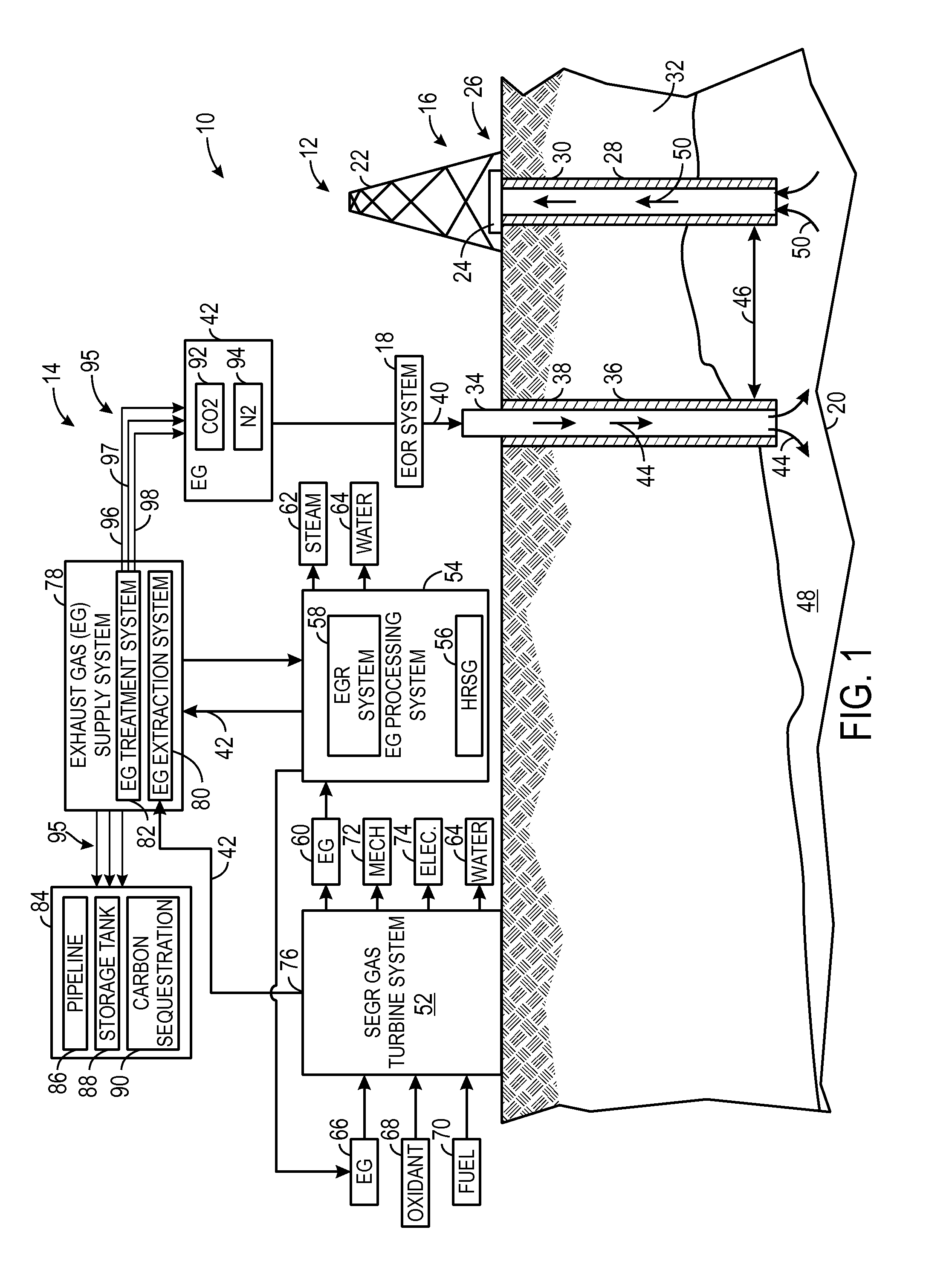

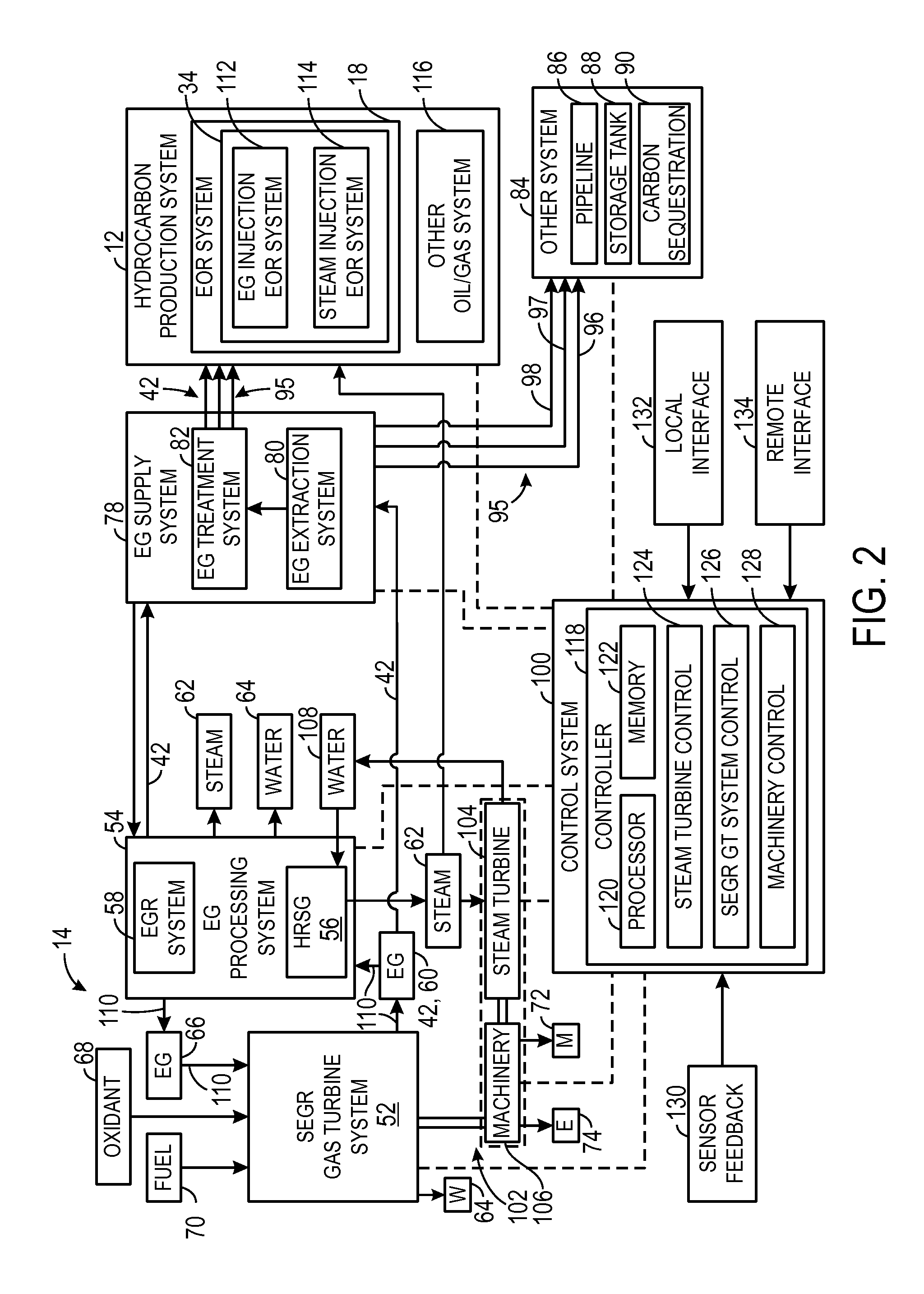

Gas turbine combustor control system

ActiveUS20140123624A1Fuel supply regulationEfficient propulsion technologiesCombustion chamberCombustor

In one embodiment, a gas turbine system includes a controller configured to receive fuel composition information related to a fuel used for combustion in a turbine combustor; receive oxidant composition information related to an oxidant used for combustion in the turbine combustor; receive oxidant flow information related to a flow of the oxidant to the turbine combustor; determine a stoichiometric fuel-to-oxidant ratio based at least on the fuel composition information and the oxidant composition information; and generate a control signal for input to a fuel flow control system configured to control a flow of the fuel to the turbine combustor based on the oxidant flow information, a target equivalence ratio, and the stoichiometric fuel-to-oxidant ratio to enable combustion at the target equivalence ratio in the presence of an exhaust diluent within the turbine combustor.

Owner:GENERAL ELECTRIC CO +1

Methods and apparatus for low emission gas turbine energy generation

ActiveUS7284378B2Reduce nitrogen oxide emissionsFuel supply regulationContinuous combustion chamberCombustion chamberLow emission

A low-emission method for producing power using a gas turbine includes premixing a plurality of fuel and air mixtures, injecting the fuel and air mixtures into a combustion chamber using a plurality of fuel nozzles, and adjusting a ratio of fuel and air injected by at least one of the nozzles to control a fuel / air concentration distribution within the combustion chamber.

Owner:GENERAL ELECTRIC CO

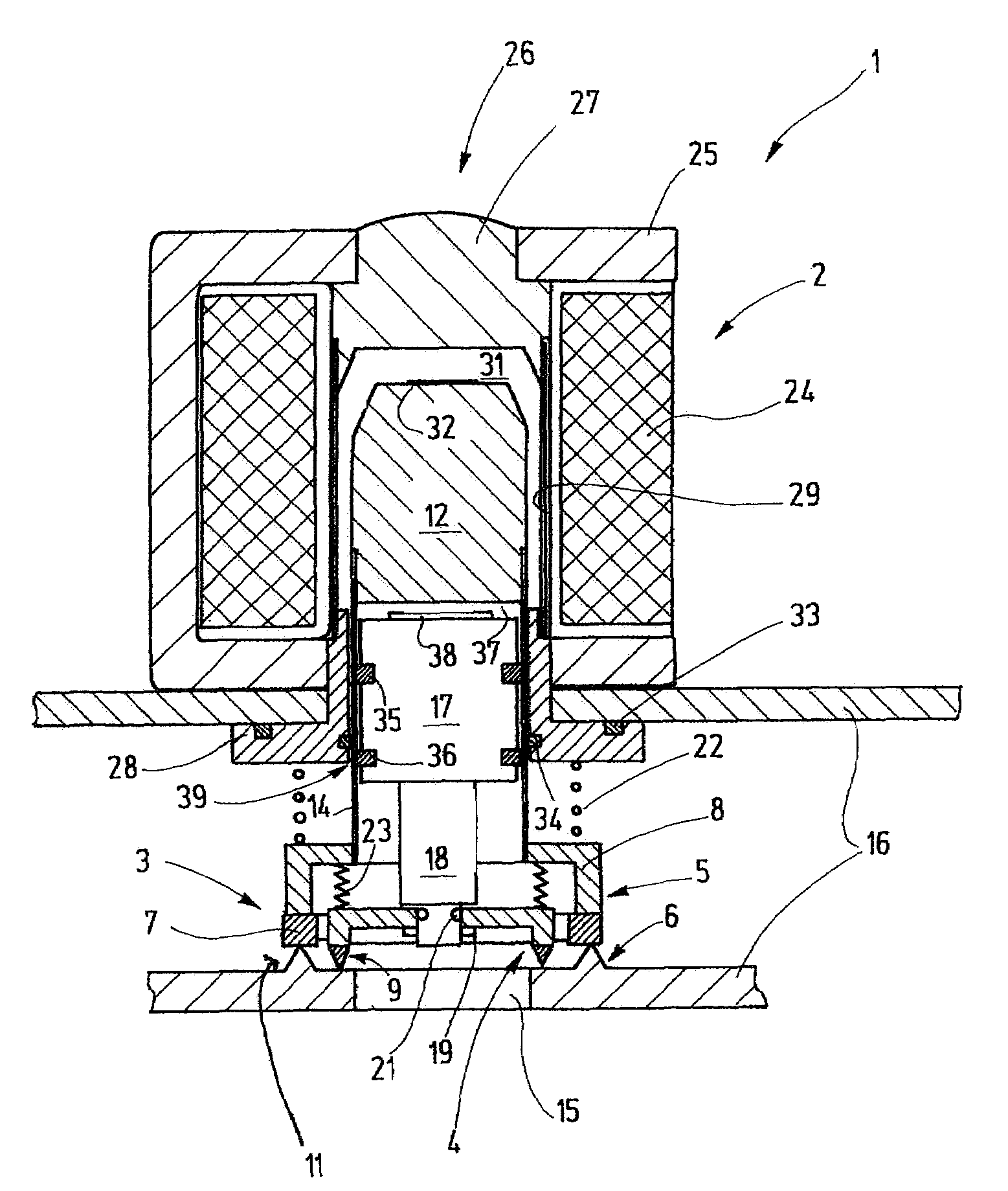

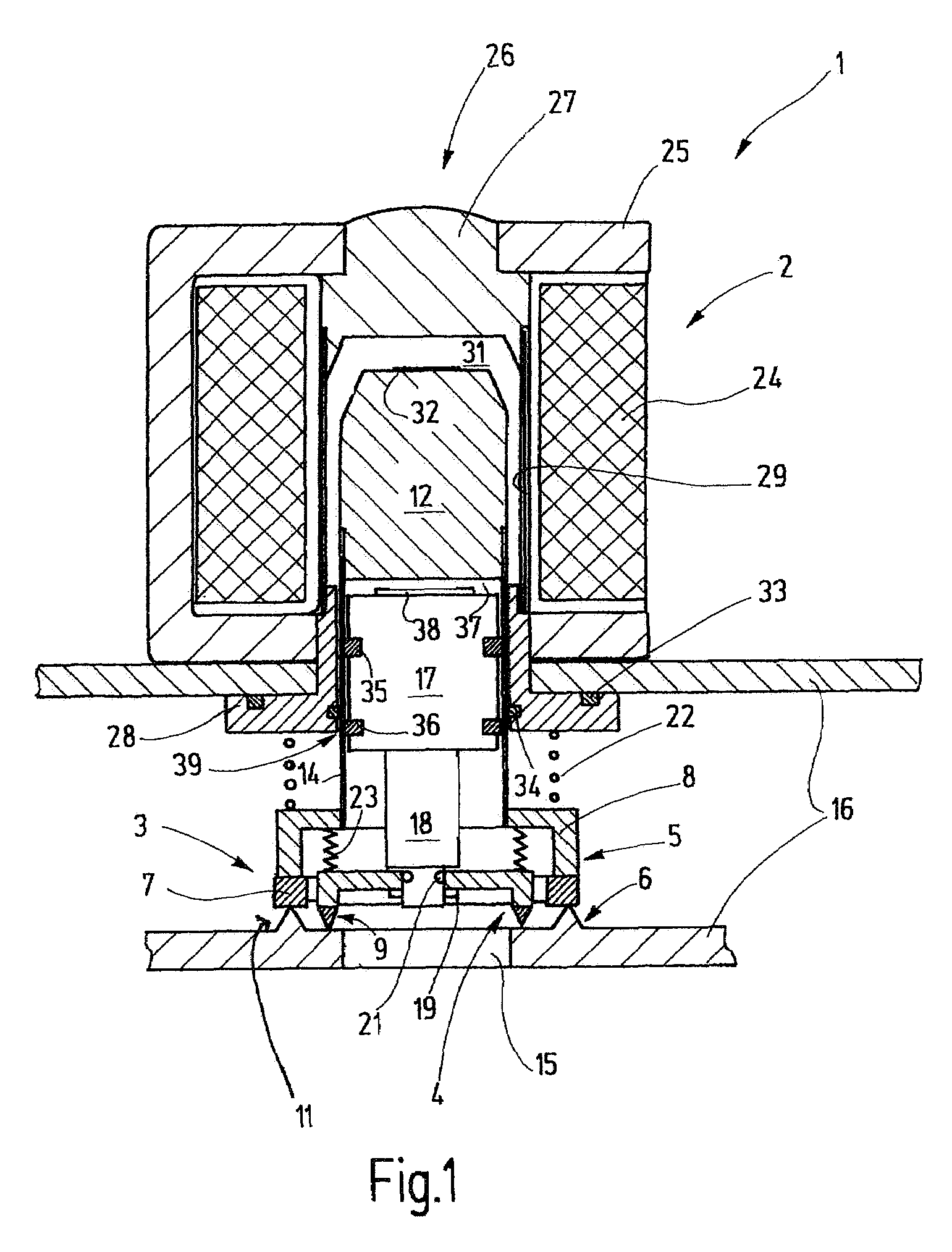

Solenoid valve

ActiveUS7347221B2Easy to moveMinimal gap widthFuel supply regulationGaseous fuel feeder/distributionPower flowSolenoid valve

A valve assembly comprises two valves and a single solenoid actuator with only one magnetizing coil that controls both valves. The corresponding magnetic circuit comprises a yoke with only two pole pieces. The valves are arranged concentric to one another. The valve closing element of the outer valve is connected to an armature by means of a sleeve. The cup thus formed receives the armature that is connected to the valve closing element of the inner valve. The pole piece and the armature form a transmission air gap through which the sleeve extends. A coupling air gap is formed between the armatures. The armature and the pole piece form a working air gap. The valves are opened collectively and are able to close independently of one another when the coil is rendered currentless.

Owner:KARL DUNGS

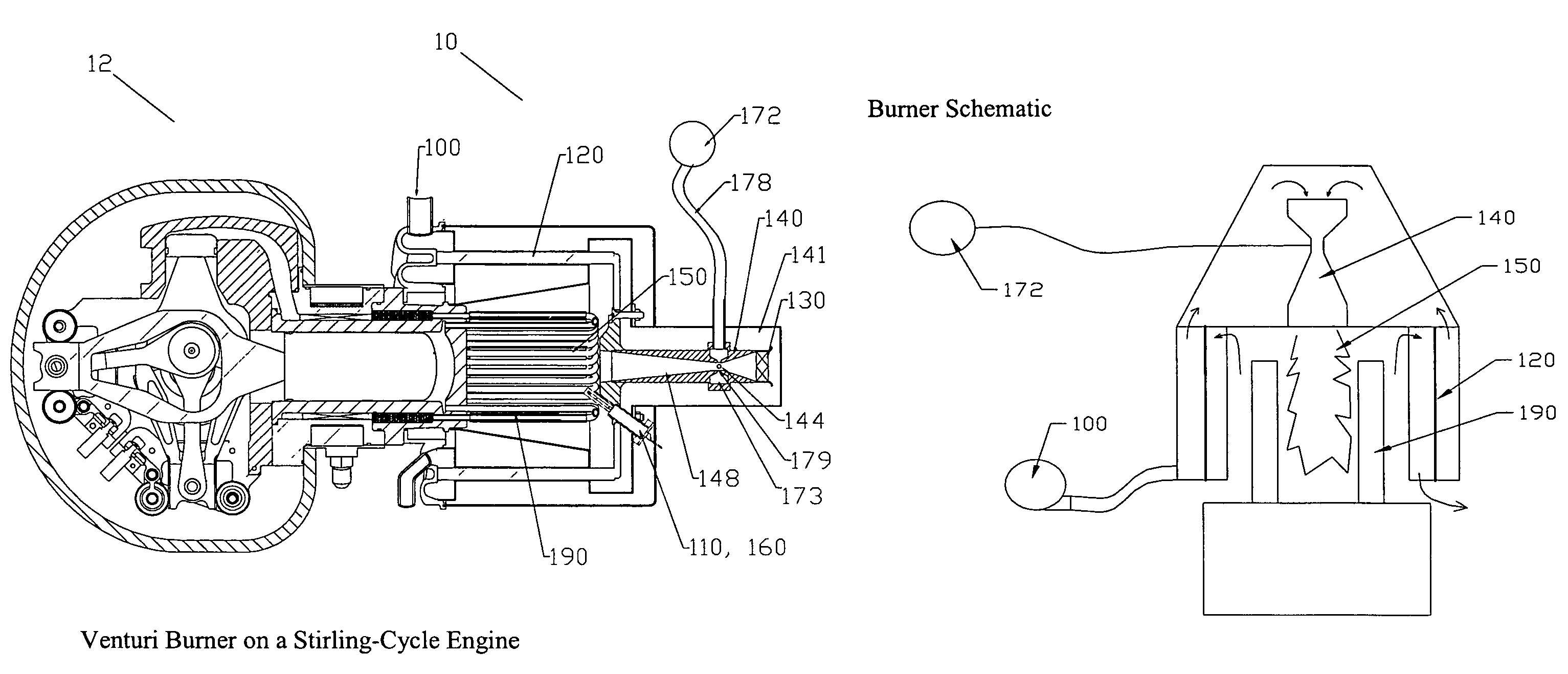

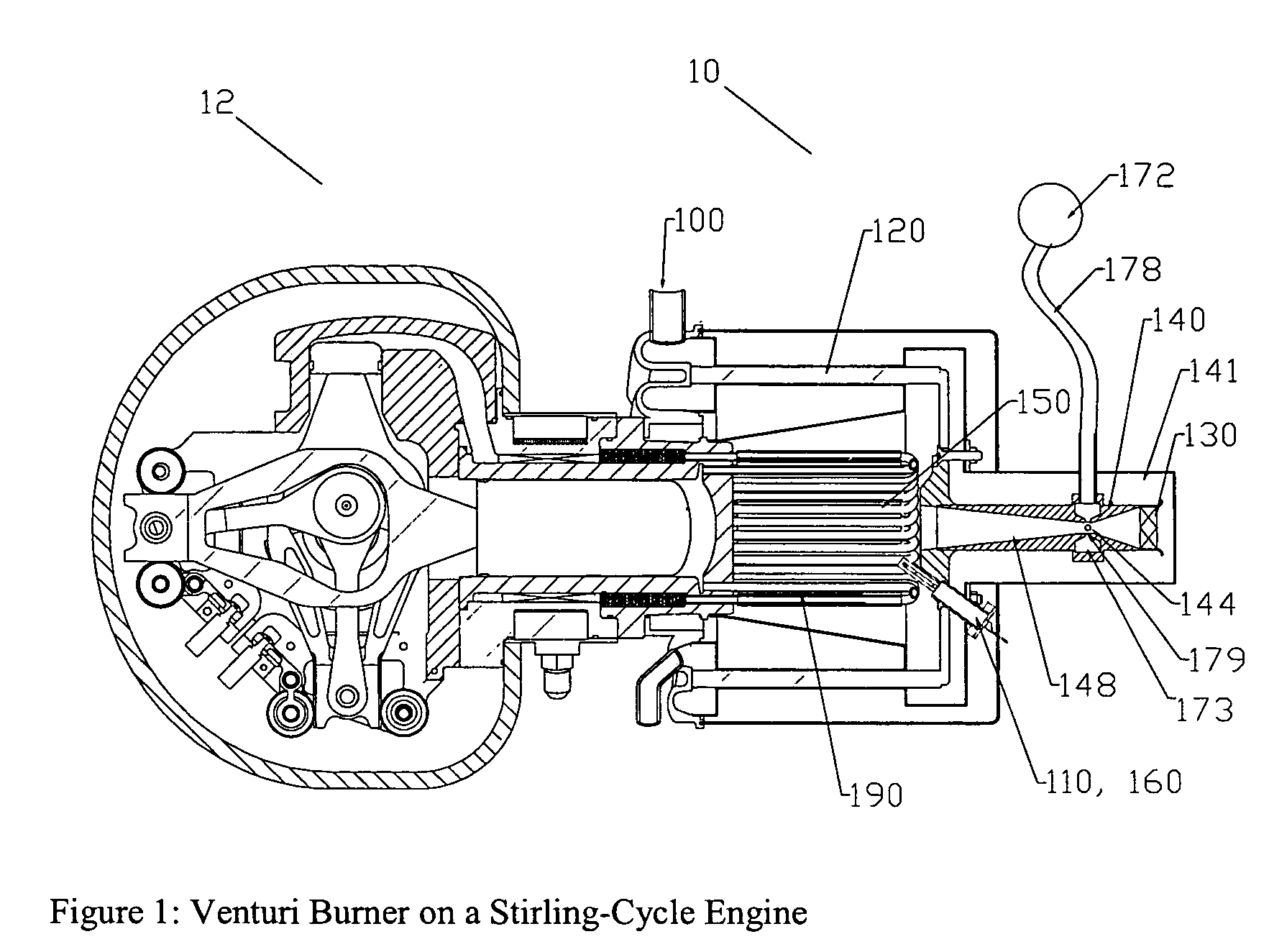

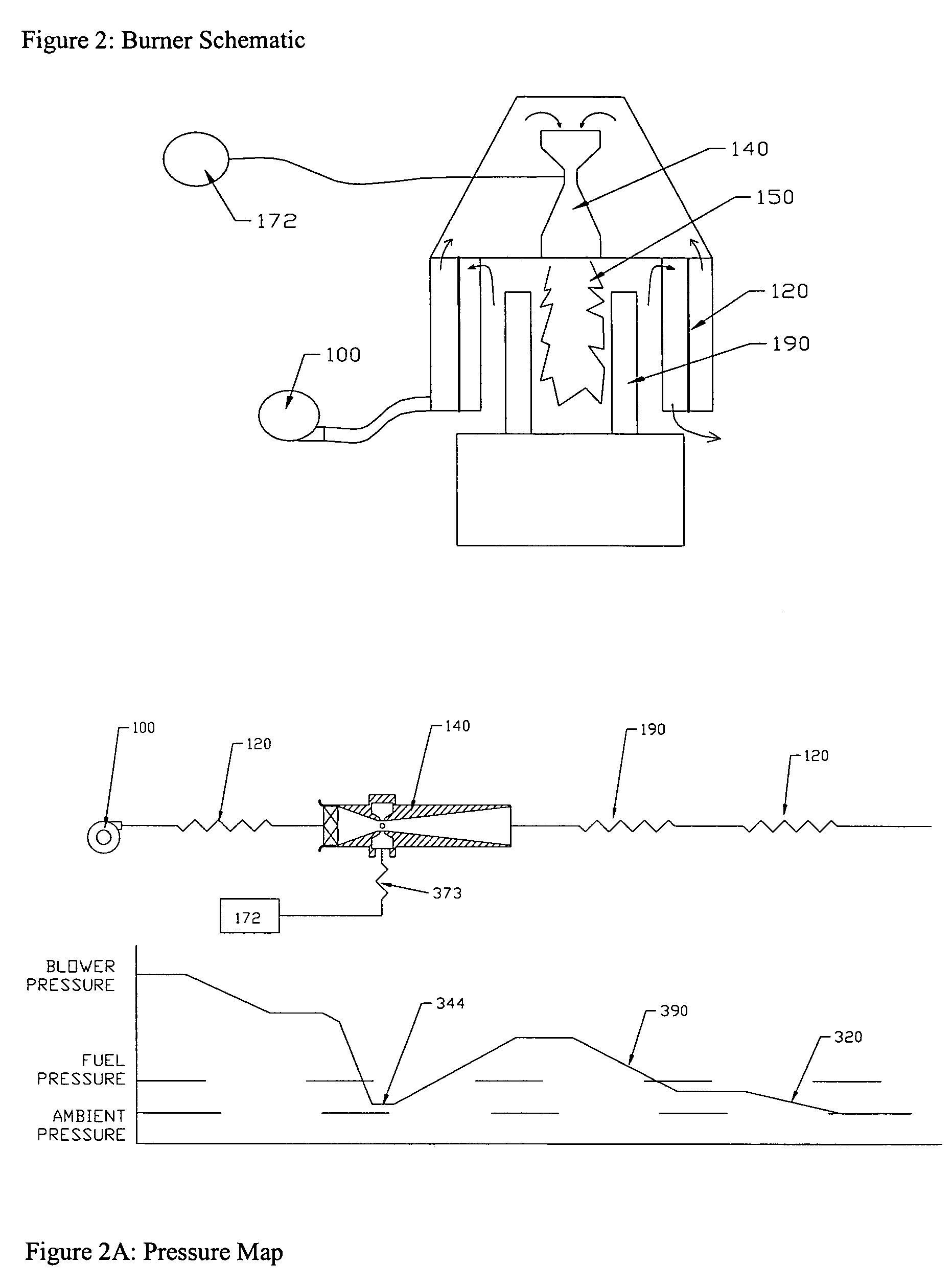

Gaseous fuel burner

ActiveUS7934926B2Address is challengeEliminate needFuel supply regulationAir supply regulationAir velocityAutomatic control

Owner:NEW POWER CONCEPTS

Electronic gas cooktop control with simmer system and method thereof

InactiveUS7255100B2Reduce heating powerHigh outputFuel supply regulationDomestic stoves or rangesControl systemElectromagnetic interference

An electronically activated gas cooktop control system, responsive to a touch-sensitive user interface, and capable of providing a predetermined range of cooking and simmer levels of BTU output, has two complementary heating modes of operation A first heating mode of operation is provided to produce a wide selection of simmer levels of BTU output, by electronically sequencing a solenoid-operated modulating gas valve “on” and “off”, at a predetermined level of flame. A second cooking mode of operation is provided by electronically modulating the level of flame, through use of a pulse-width-modulation (PWM) output signal to produce a wide selection of cooking levels of BTU output. An igniter system capable of insuring proper ignition of gas without generating harmful electromagnetic interference is also provided.

Owner:COMPUVALVE +1

Multi-gas cooker, with a rotary valve provided with interchangeable regulating means

The cooking appliance (1) having a control panel (2) is equipped with one or more gas flow (Q) regulating valves, wherein the rotary regulating plug (6) is provided with various peripheral through holes (16-19). The control knob (9) being interchangeable for fitting to the actuating shaft (7), is chosen from the two units available, one and the other permitting different angular limit positions of the regulating plug (6) for the supply of a constant minimum gas flow Qmin, adjusted each one for a different type of gas N gas or LP gas. The outlet conduit (5) of the valve is equipped with a further injector nozzle (21,23) for adjusting a constant gas flow Qmax to be fed into the conduit (25) of the correspondent burner, when the cooking appliance is supplied with a LP gas.

Owner:COPRECITEC

Method and apparatus for energy recovery in an environmental control system

Control apparatus for an environmental control system comprises input circuitry receiving environmental information and output circuitry for controlling an HVAC system. Processing circuitry in the controller configures the output circuitry based at least in part on the signals received on the input circuitry. Information about the status of the HVAC system may be transferred to system administrators using a wireless link.

Owner:ELUTIONS

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com