Patents

Literature

577results about How to "Reduce heating power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

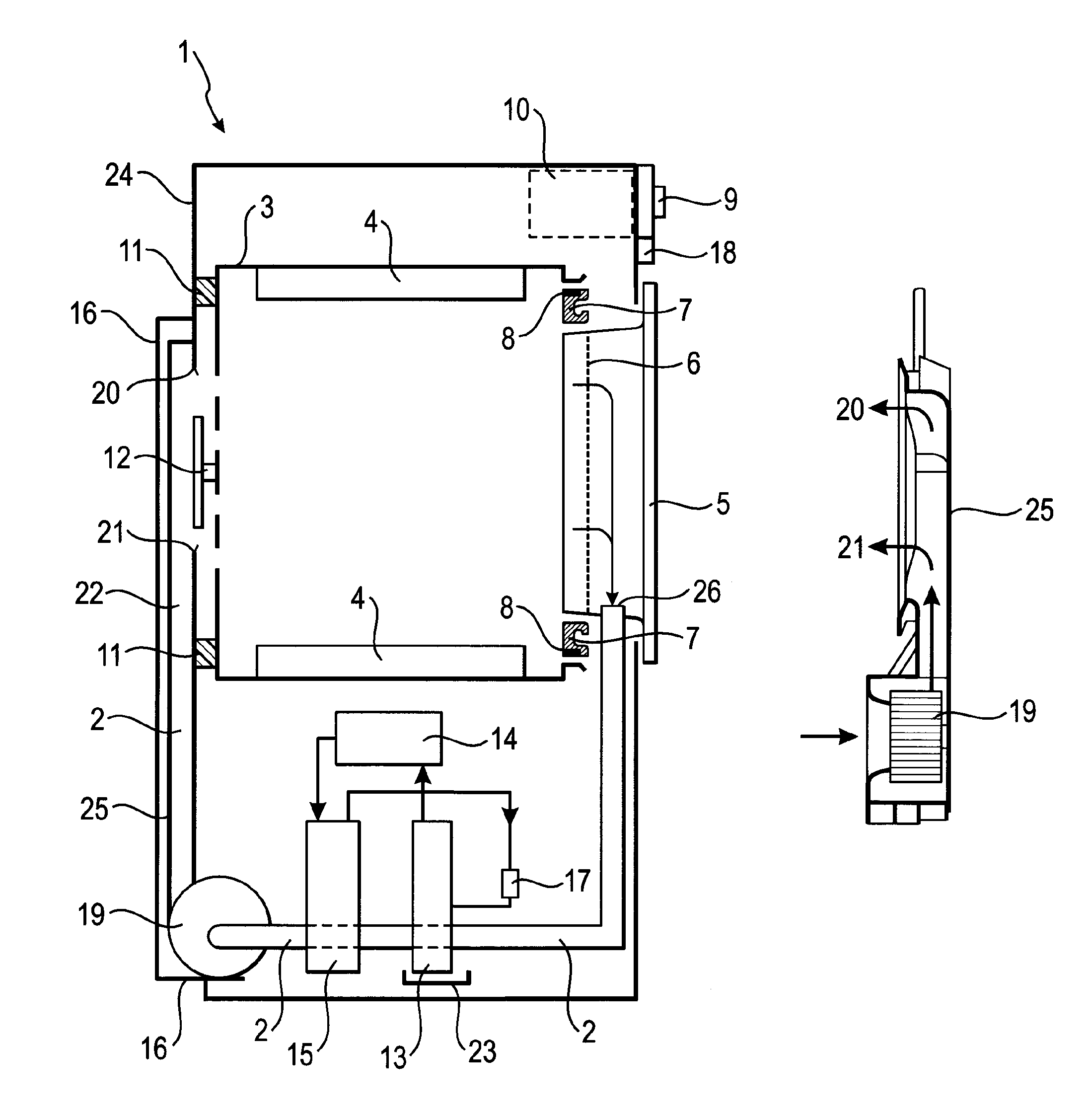

Heating system comprising semiconductor light sources

ActiveUS20160381732A1Improve homogeneityHeating system be improvedSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor structureEngineering

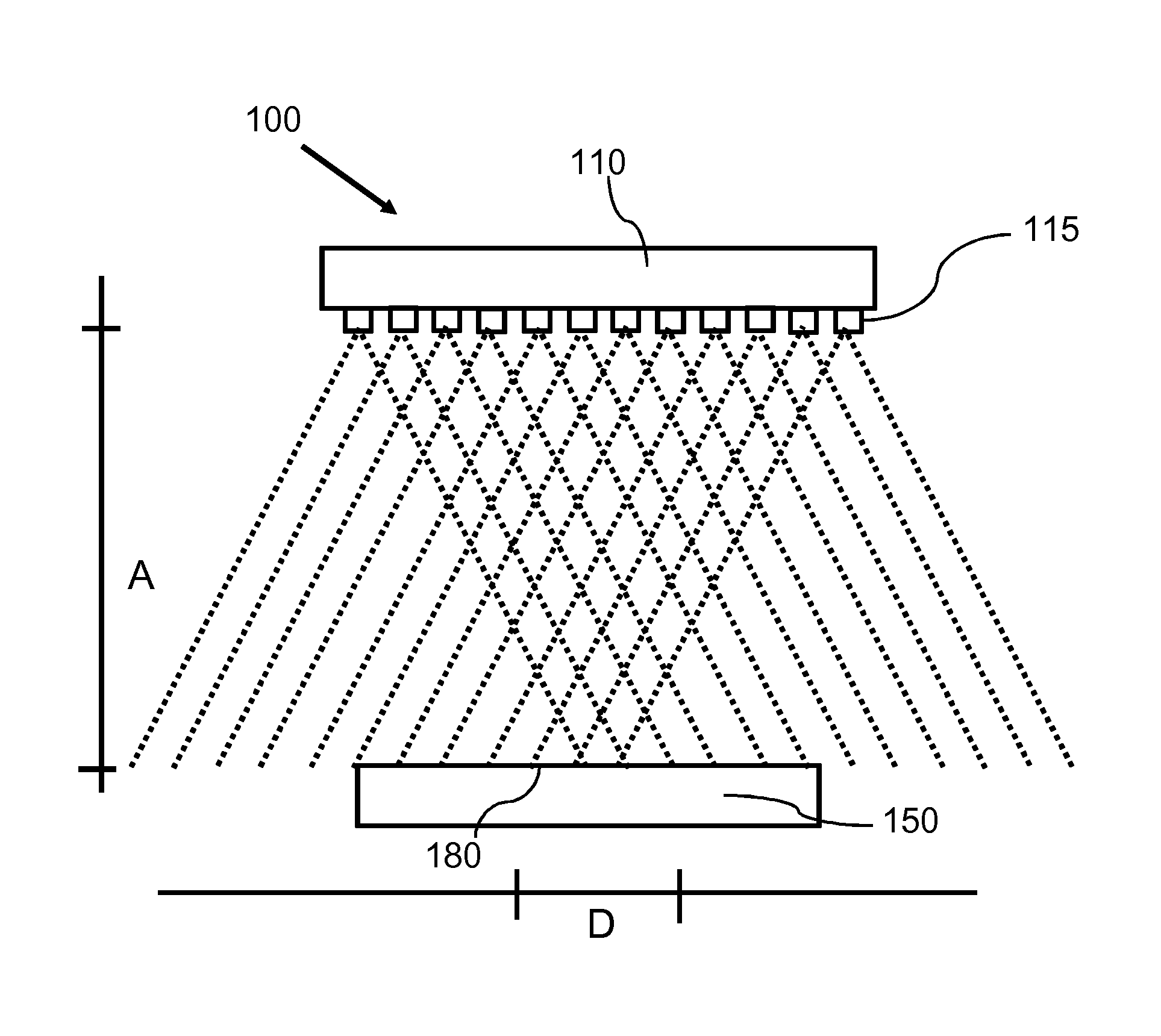

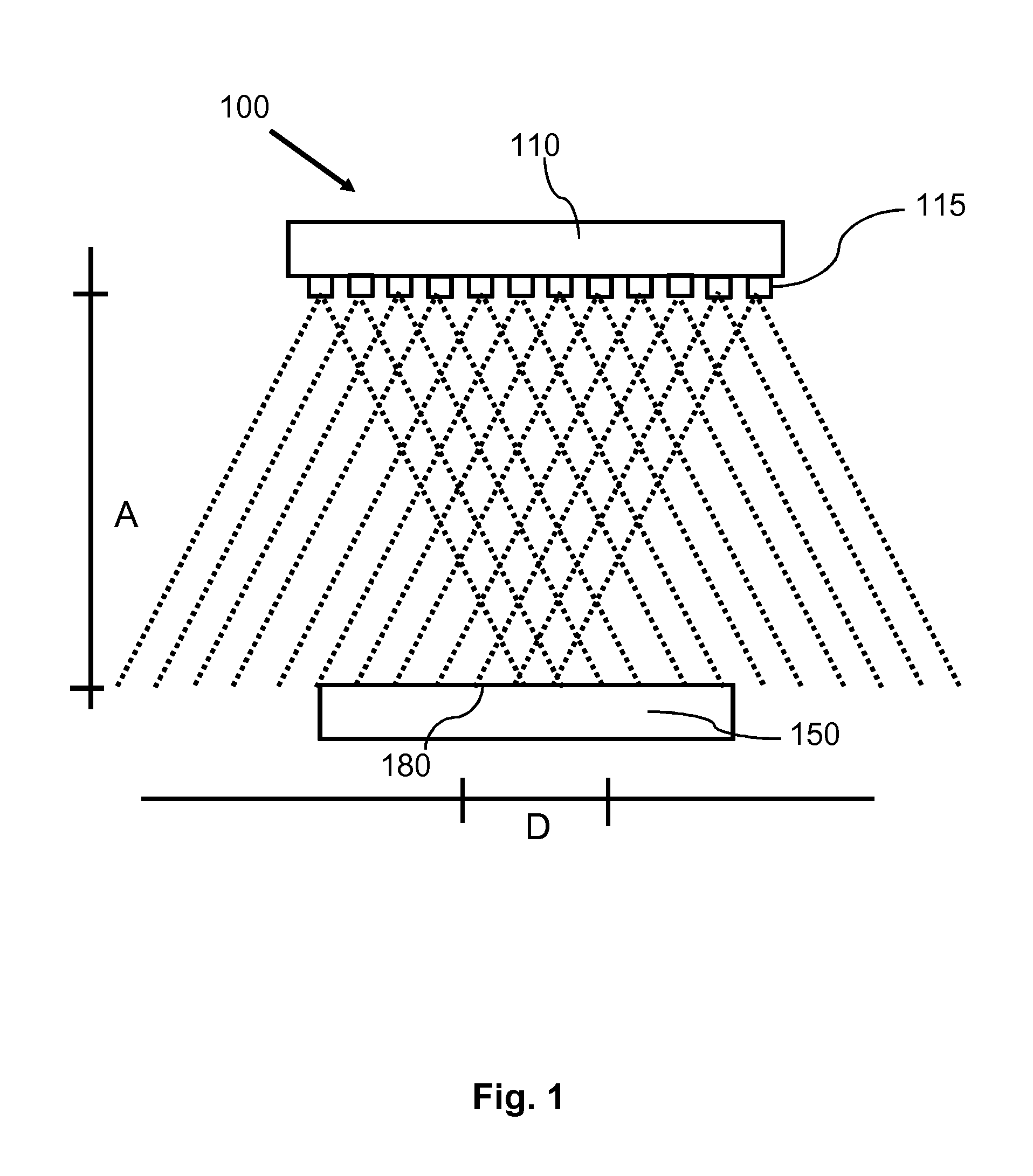

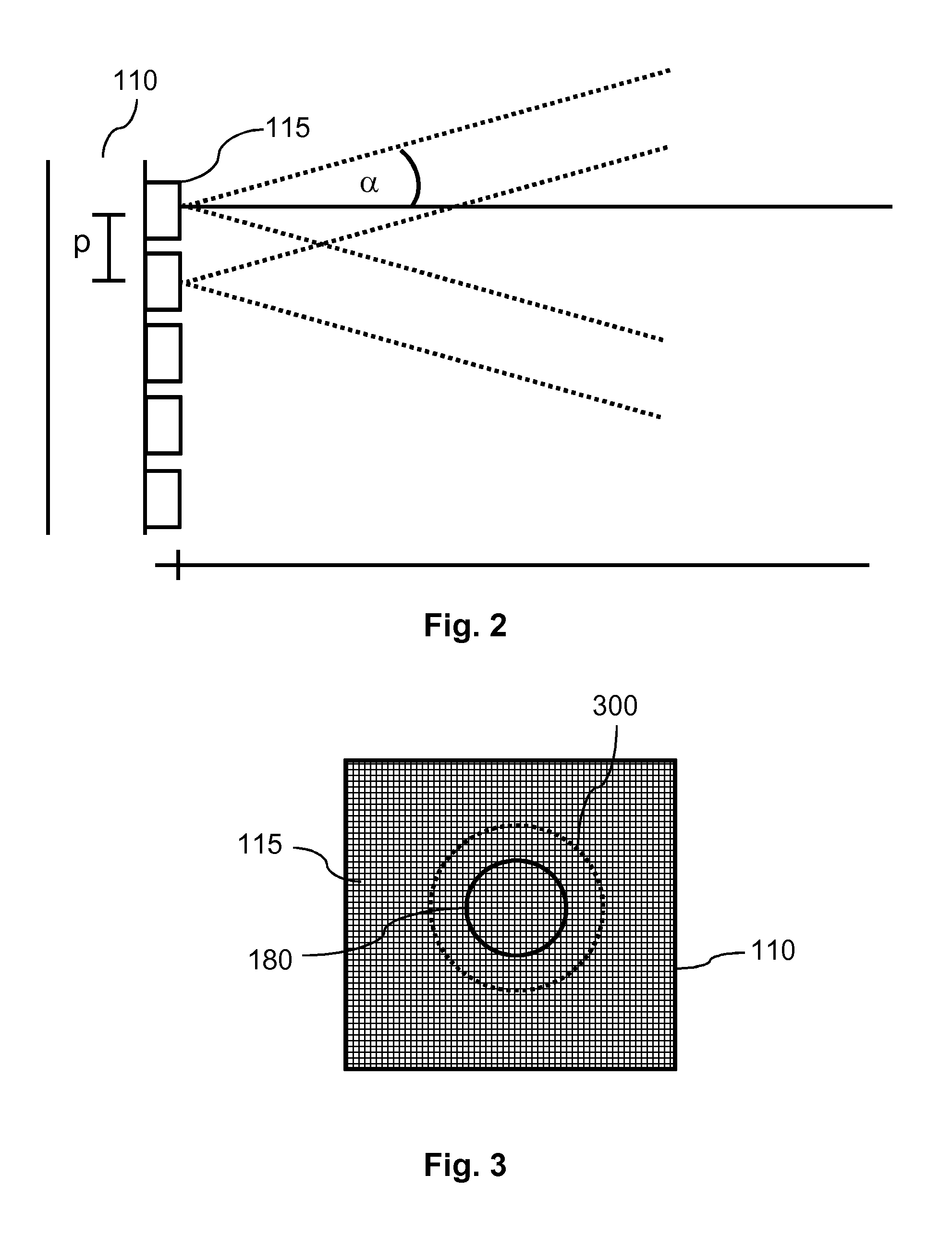

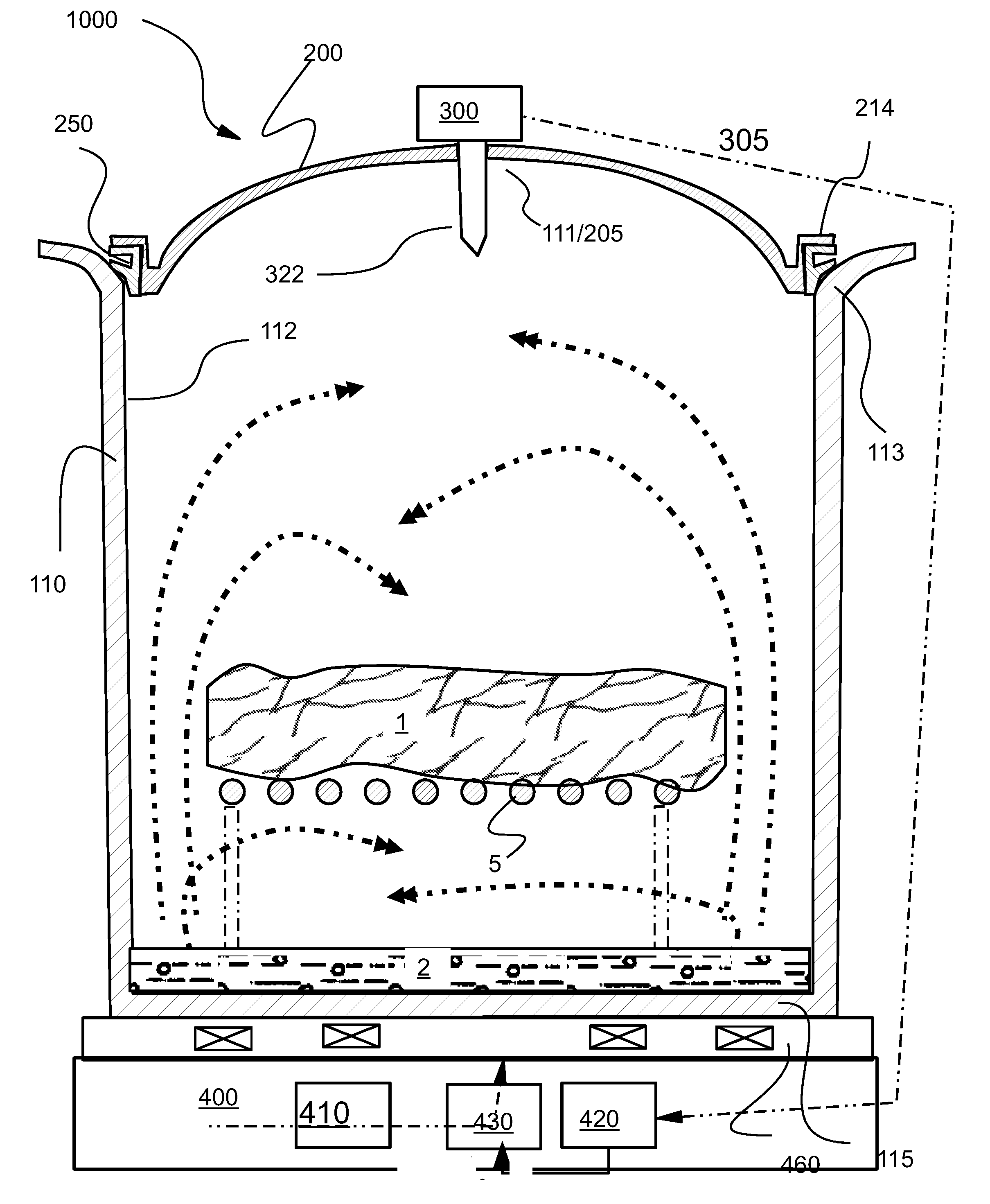

The invention describes a heating system (100) and a corresponding method of heating a heating surface (180) of an object (150, 950) to a processing temperature of at least 100° C., wherein the heating system (100) comprises semiconductor light sources (115), and wherein the heating system (100) is adapted to heat an area element of the heating surface (180) with at least 50 semiconductor light sources (115) at the same time. The heating system (100) may be part of a reactor for processing semiconductor structures. The light emitted by means of the semiconductor light sources (115) overlaps at the heating surface (180). Differences of the characteristic of one single semiconductor light source (115) may be blurred at the heating surface (180) such that a homogeneous temperature distribution across a processing surface of a, for example, wafer may be enabled.

Owner:TRUMPF PHOTONIC COMPONENTS GMBH

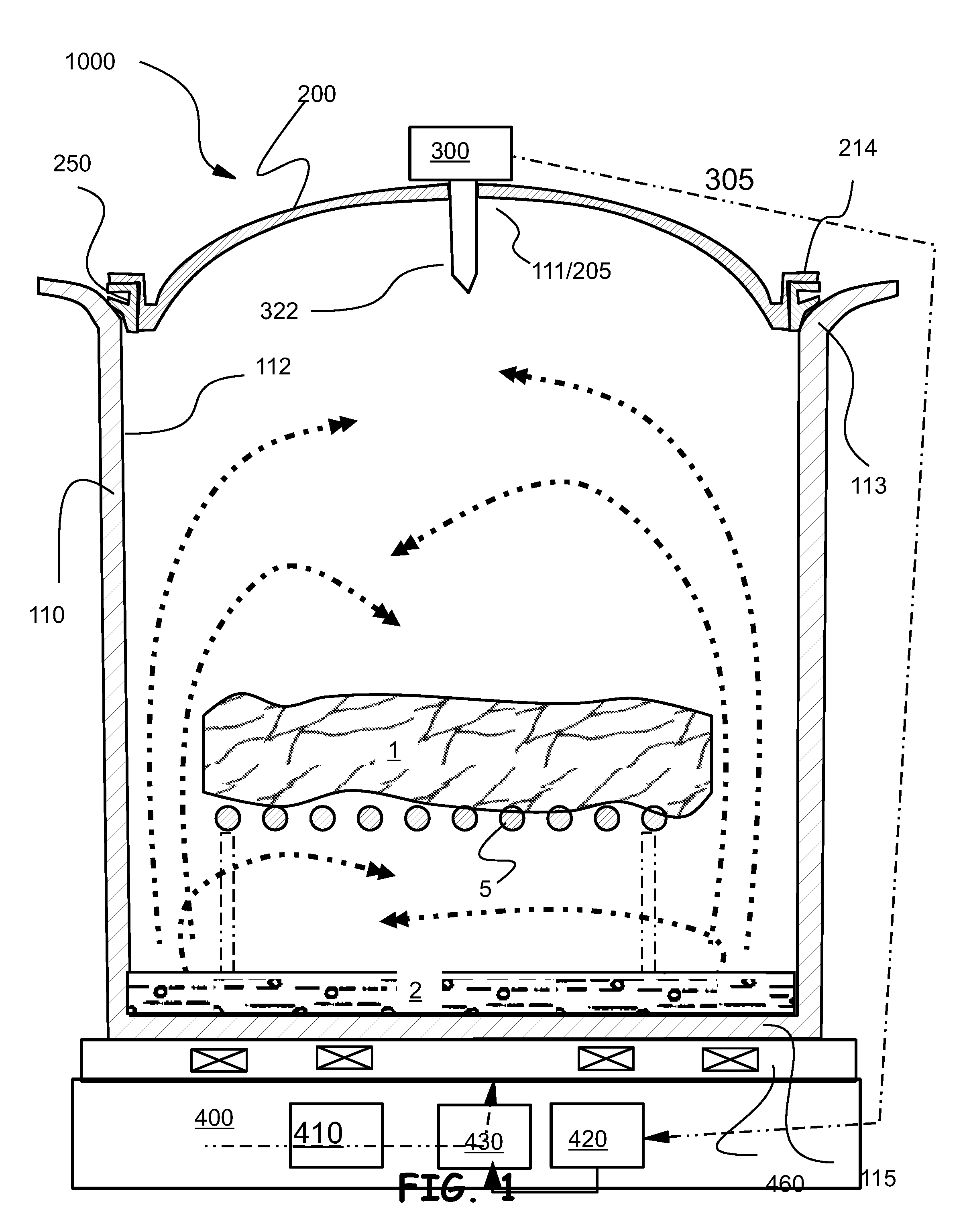

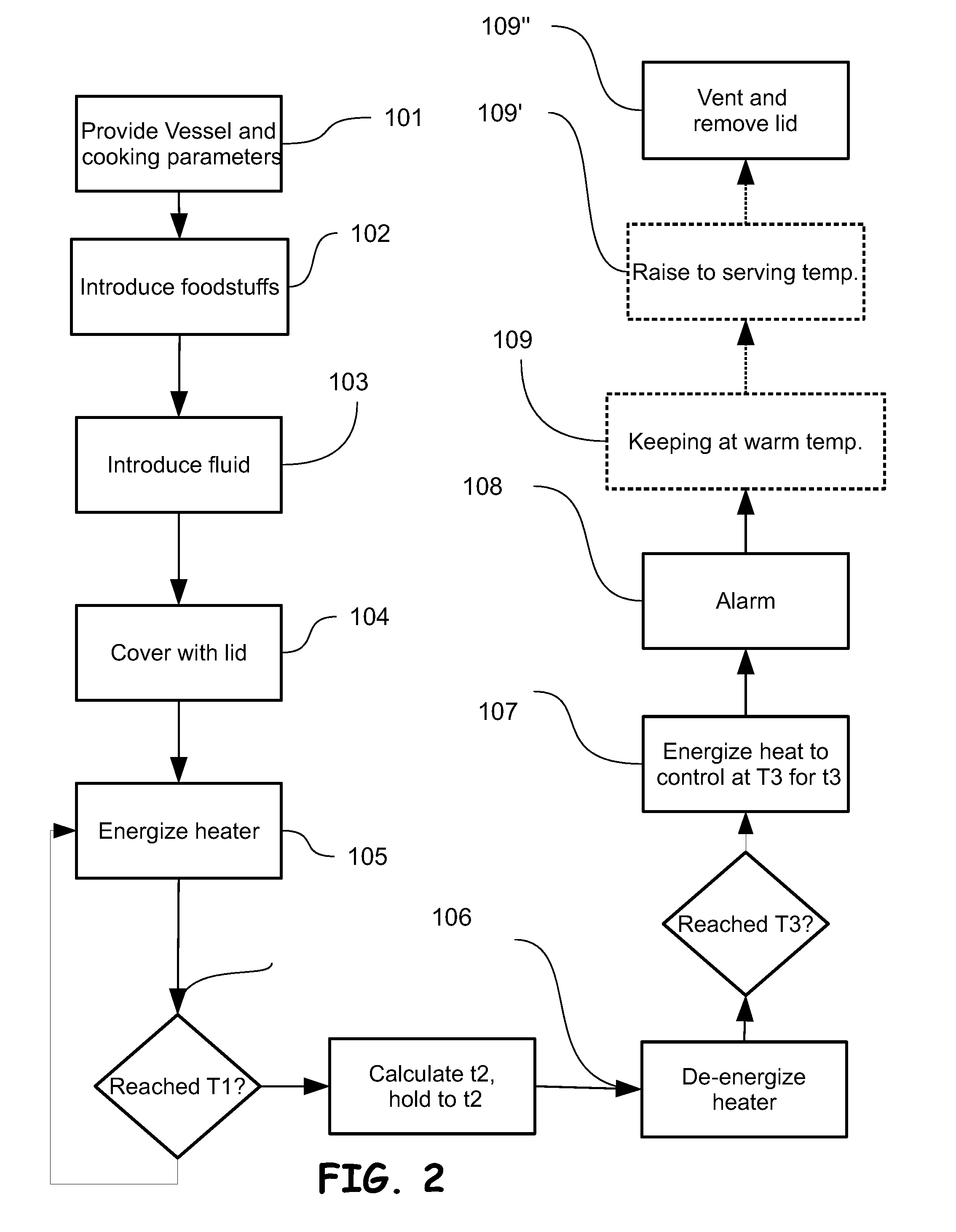

Low-pressure cooking method and cookware vessel adapted for the same

ActiveUS20140348987A1Long cooking timeReduce heating powerBoiling over preventionSteam cooking vesselsTemperature controlWater vapor

Food stuffs are cooked at precise temperatures, which are optionally below 100° C., in a vessel that is evacuated to exclude air, in which low pressure steam replaces the air. When a sufficient quantity of air is excluded and replaced with water vapor, the temperature of vapor is accurately measured inside the vessel below the lid to control the temperatures within about 1° C. Air is preferably excluded via a controlled heated process for a relatively short period of time at high temperature to generate steam, the temperature is lowered to condense water vapor upon which the lid will sealingly engage the rim of the vessel, forming a partial vacuum in the cooking vessel.

Owner:MEYER INTPROP

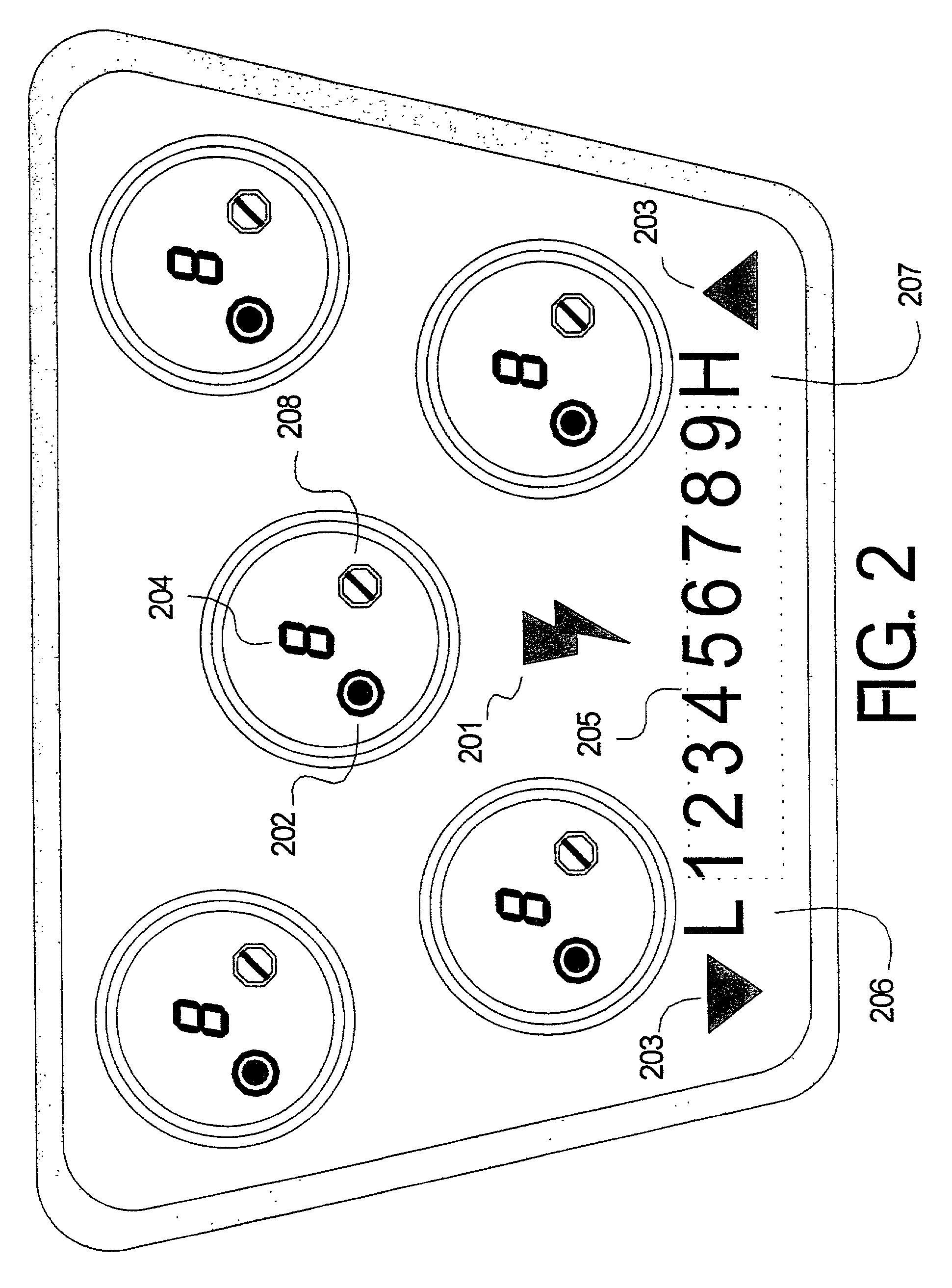

Electronic gas cooktop control with simmer system and method thereof

InactiveUS7255100B2Reduce heating powerHigh outputFuel supply regulationDomestic stoves or rangesControl systemElectromagnetic interference

An electronically activated gas cooktop control system, responsive to a touch-sensitive user interface, and capable of providing a predetermined range of cooking and simmer levels of BTU output, has two complementary heating modes of operation A first heating mode of operation is provided to produce a wide selection of simmer levels of BTU output, by electronically sequencing a solenoid-operated modulating gas valve “on” and “off”, at a predetermined level of flame. A second cooking mode of operation is provided by electronically modulating the level of flame, through use of a pulse-width-modulation (PWM) output signal to produce a wide selection of cooking levels of BTU output. An igniter system capable of insuring proper ignition of gas without generating harmful electromagnetic interference is also provided.

Owner:COMPUVALVE +1

Dispensing device and method for rapidly heating and delivering a flowable product

InactiveUS6419121B1Improved heating/cooling outputShorten the timeLiquid flow controllersLiquid transferring devicesBiomedical engineeringFood products

Owner:NESTEC SA

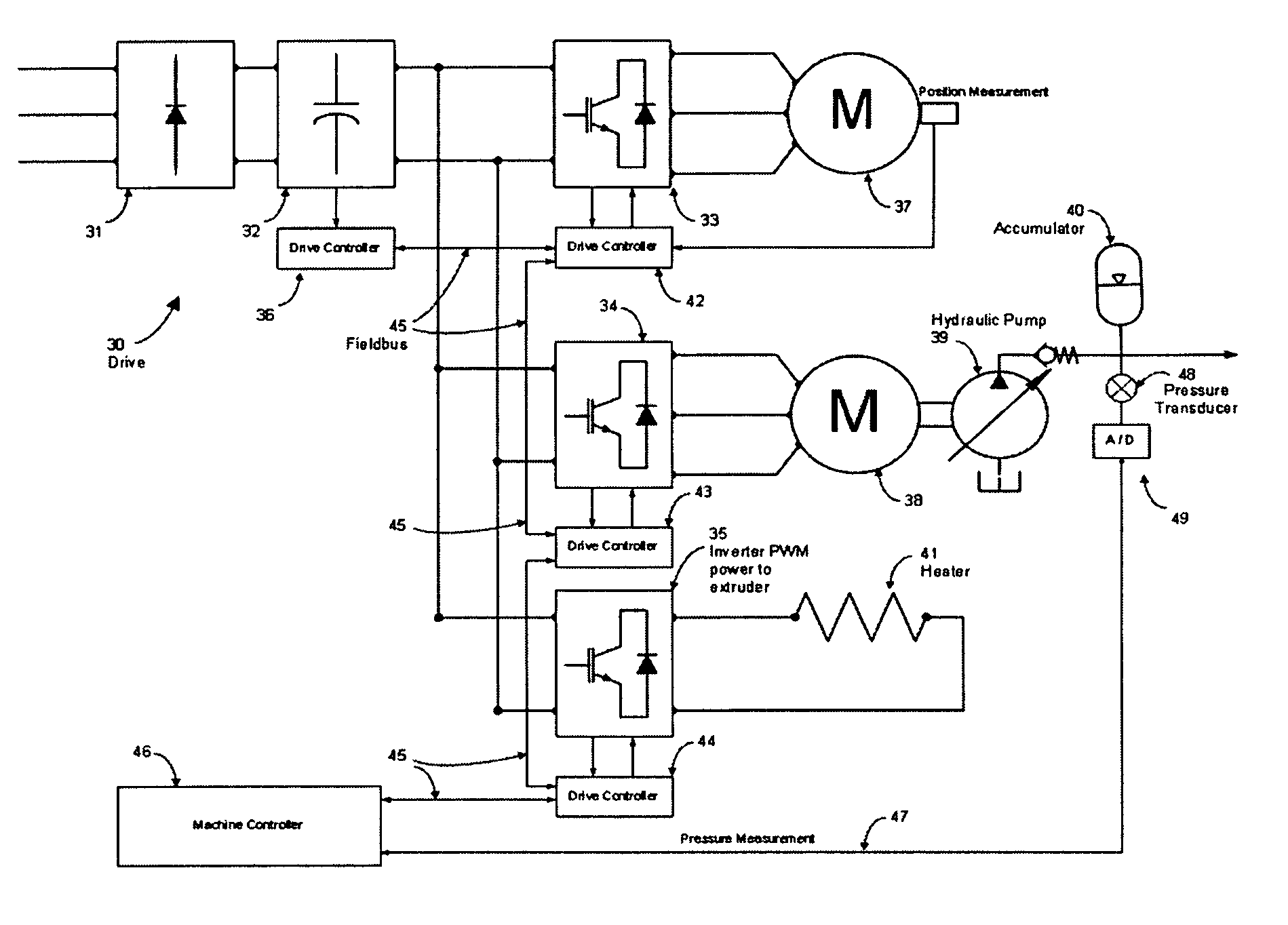

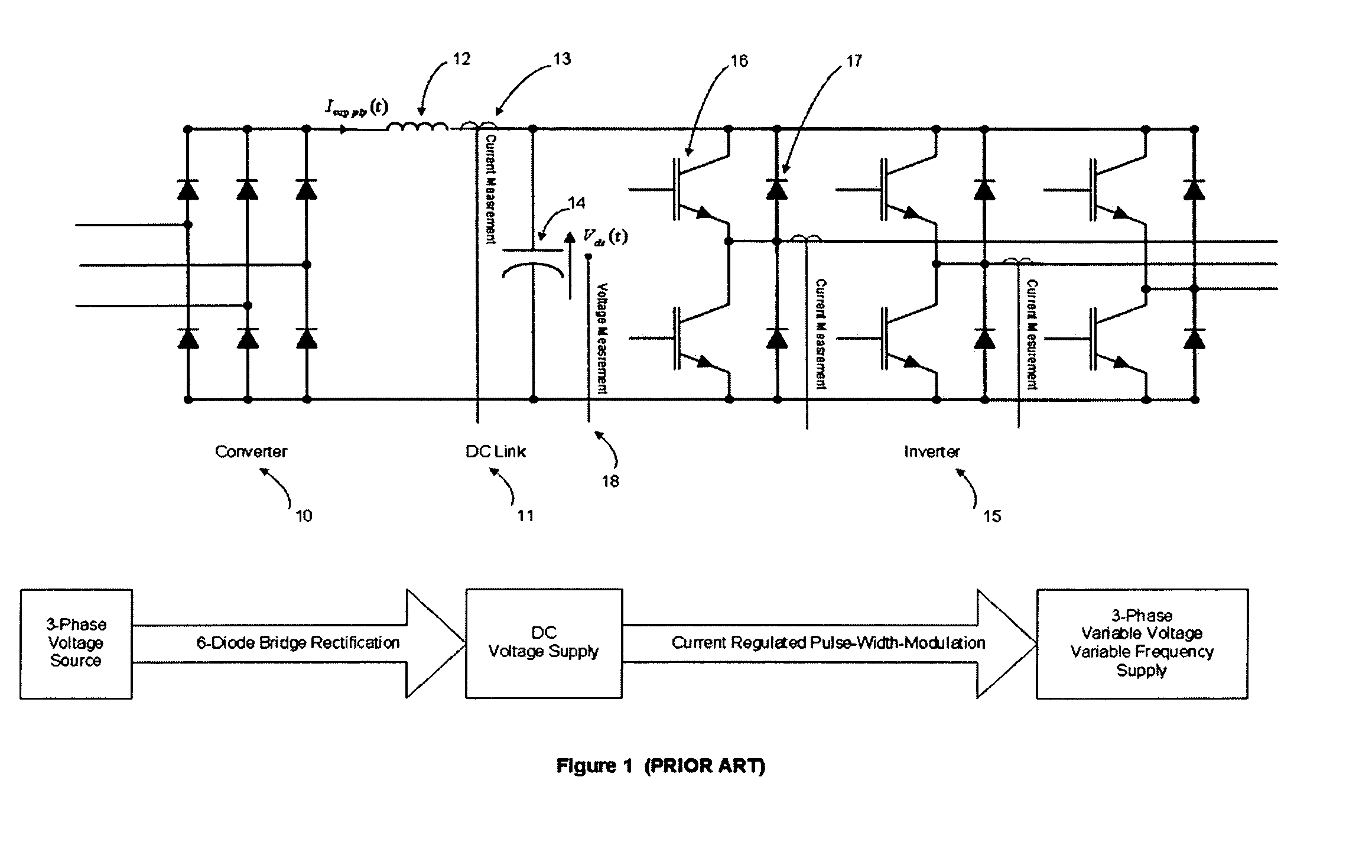

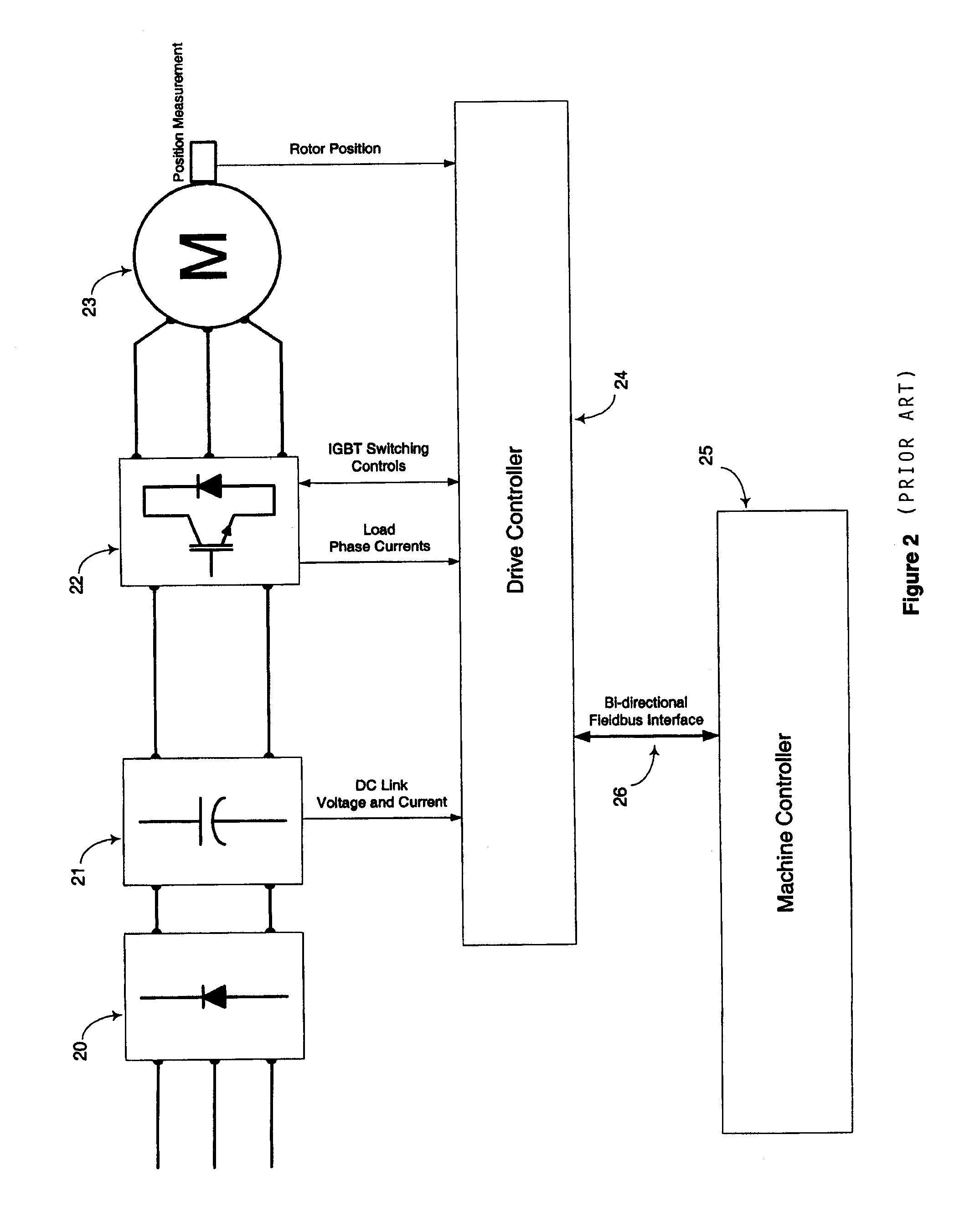

Energy management apparatus and method for injection molding systems

ActiveUS7176648B2Uniform heating powerReduce processing needsSynchronous motors startersAC motor controlElectricityMolding machine

Owner:HUSKY INJECTION MOLDING SYST LTD

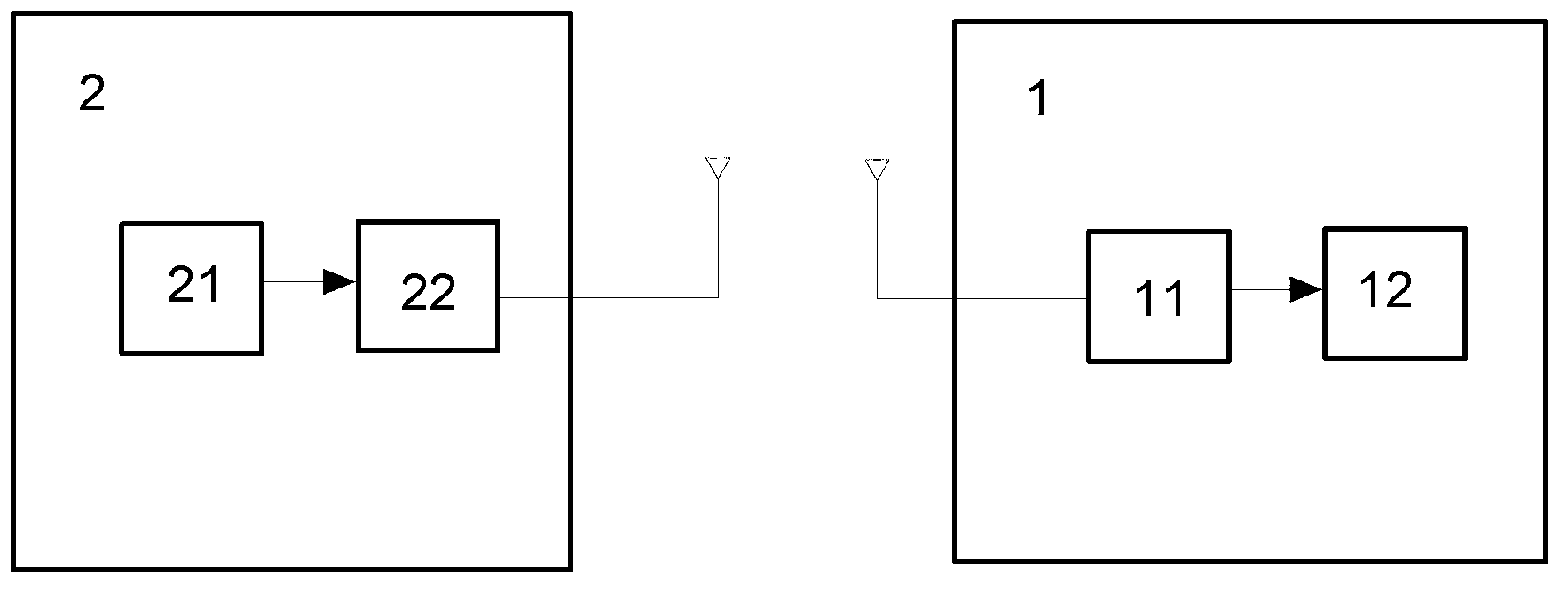

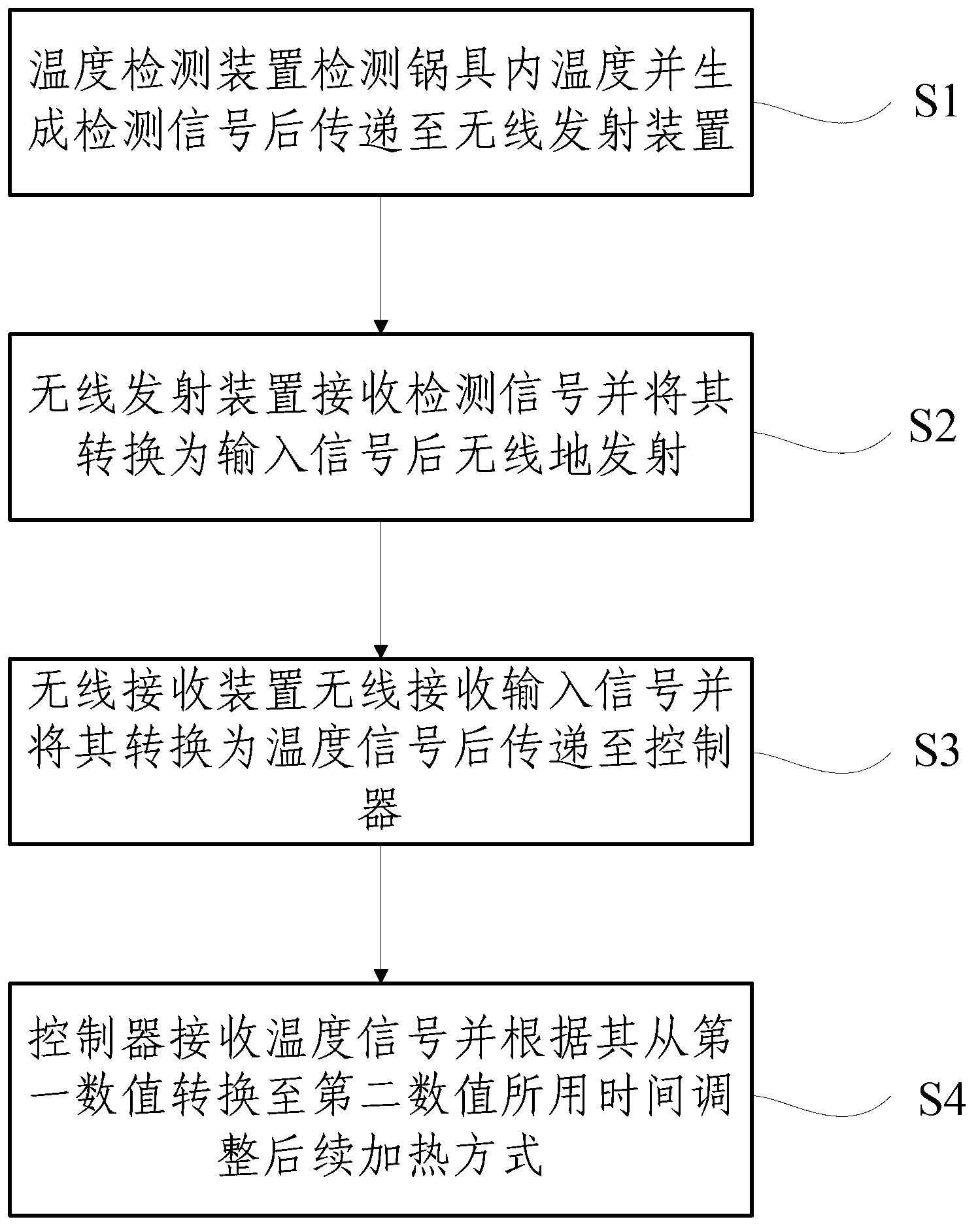

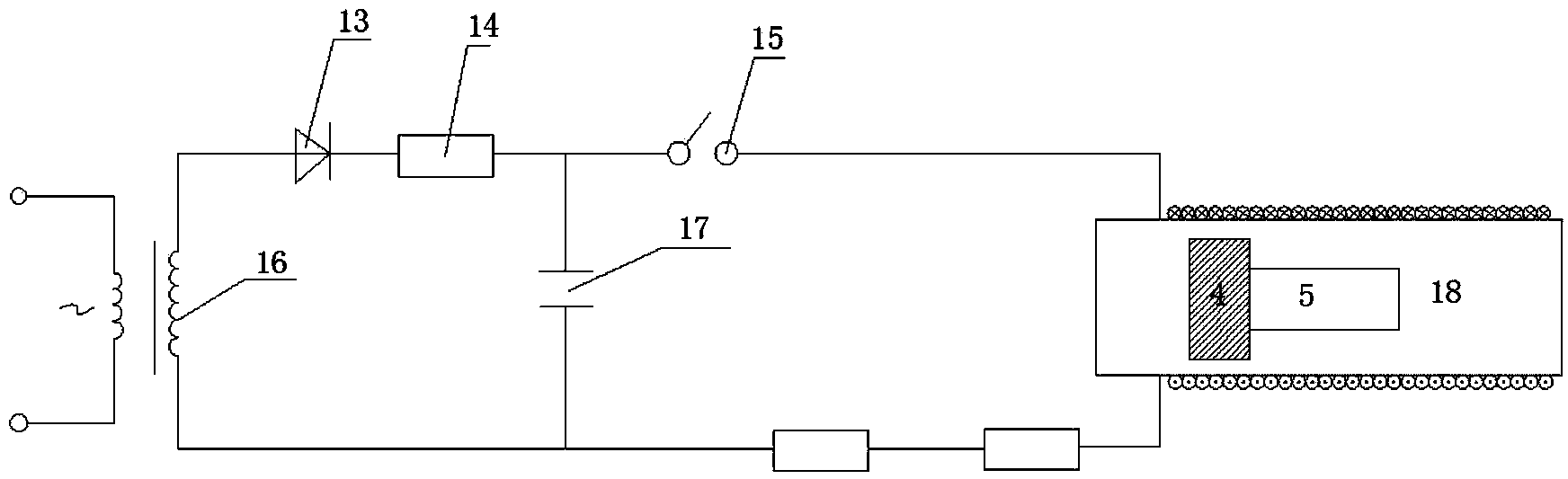

Electric heating device, electric cooking device and wireless temperature control method

ActiveCN103263224AThe temperature is more accurate and timelyAvoid drying outDomestic stoves or rangesLighting and heating apparatusElectric heatingCooker

The invention provides an electric heating device, an electric cooking device and a wireless temperature control method. The electric heating device can be used for heating cookware and comprises a wireless receiving device and a controller which are electrically connected and arranged in the electric heating device. The wireless receiving device is used for receiving an input signal corresponding to the temperature in the cookware in a wireless mode, converting the input signal into a temperature signal and transferring the temperature signal to the controller. The controller is used for receiving a temperature signal in the process that the controller controls the electric heating device to conduct heating and adjusting the following heating mode according to actually measured temperature rise time of the temperature signal from a first value to a second value showed , wherein the first value corresponds to first temperature in the cookware, the second value corresponds to second temperature in the cookware, and the second temperature is higher than the first temperature. The electric heating device can achieve the effect that the heating process is accurately controlled according to food quantity, and the problems of dryout and overflowing in the heating process are solved effectively.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

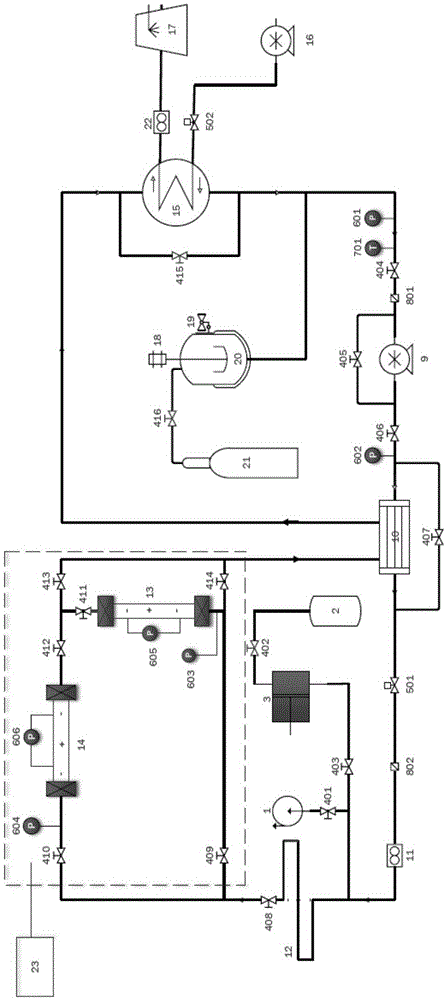

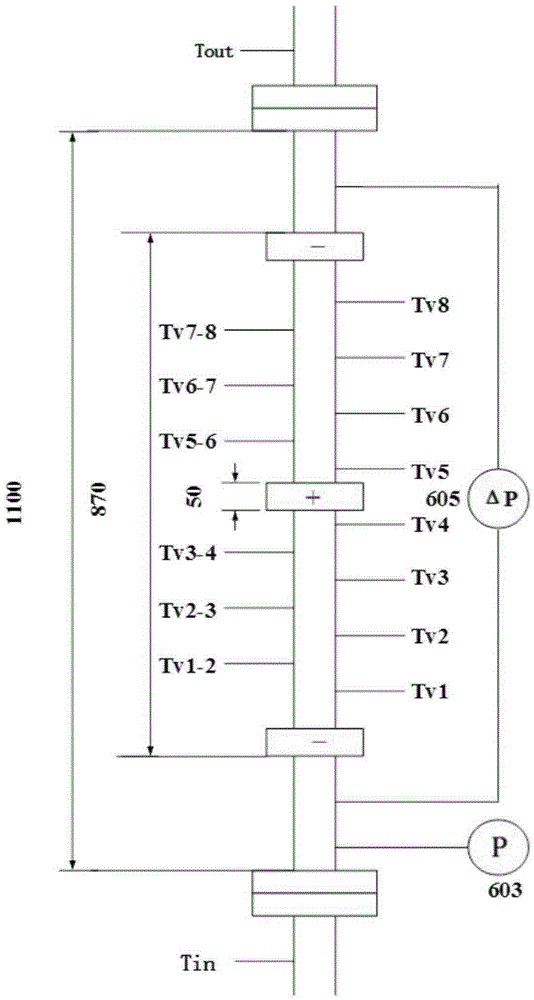

Supercritical Freon heat exchange experiment system and experiment method thereof

ActiveCN105301047AVersatileSimple and reliable structureMaterial heat developmentEngineeringHigh pressure

The invention discloses a supercritical Freon heat exchange experiment system and an experiment method thereof. The system comprises a vacuum and Freon injection module consisting of a vacuum pump, a coolant tank, a coolant recycling and injection machine, a valve and a pipeline connected to a main loop, a circulating module consisting of a shield pump and a closed type loop pipeline, a heat return module consisting of a heat regenerator and a bypass pipeline, a preheating module consisting of a snake-shaped preheating section and a direct current power supply, an experiment module consisting of an experiment section and a relevant valve, and a pressure adjustment module consisting of a high-pressure nitrogen bottle, a pressure stabilizer, a safety valve and a pressure reduction valve, wherein Freon flows into the experiment section after being subjected to heat regeneration and preheated from the outlet of the shield pump, and then finally returns to the inlet of the shield pump after being cooled by a condenser, thus forming a closed circulation. The invention further provides an experiment method of the system. The system can bear a higher-temperature working condition and a higher-pressure working condition, ensure that the Freon can run cyclically under a supercritical state, and also easily, conveniently and quickly adjust system parameters.

Owner:XI AN JIAOTONG UNIV

Electronic gas cooktop control with simmer system and method thereof

InactiveUS20050089809A9Facilitate maintenanceEliminate needFuel supply regulationDomestic stoves or rangesProcess engineeringElectromagnetic interference

An electronically activated gas cooktop control system, responsive to a touch-sensitive user interface, and capable of providing a predetermined range of cooking and simmer levels of BTU output, has two complementary heating modes of operation A first heating mode of operation is provided to produce a wide selection of simmer levels of BTU output, by electronically sequencing a solenoid-operated modulating gas valve “on” and “off”, at a predetermined level of flame. A second cooking mode of operation is provided by electronically modulating the level of flame, through use of a pulse-width-modulation (PWM) output signal to produce a wide selection of cooking levels of BTU output. An igniter system capable of insuring proper ignition of gas without generating harmful electromagnetic interference is also provided.

Owner:COMPUVALVE +1

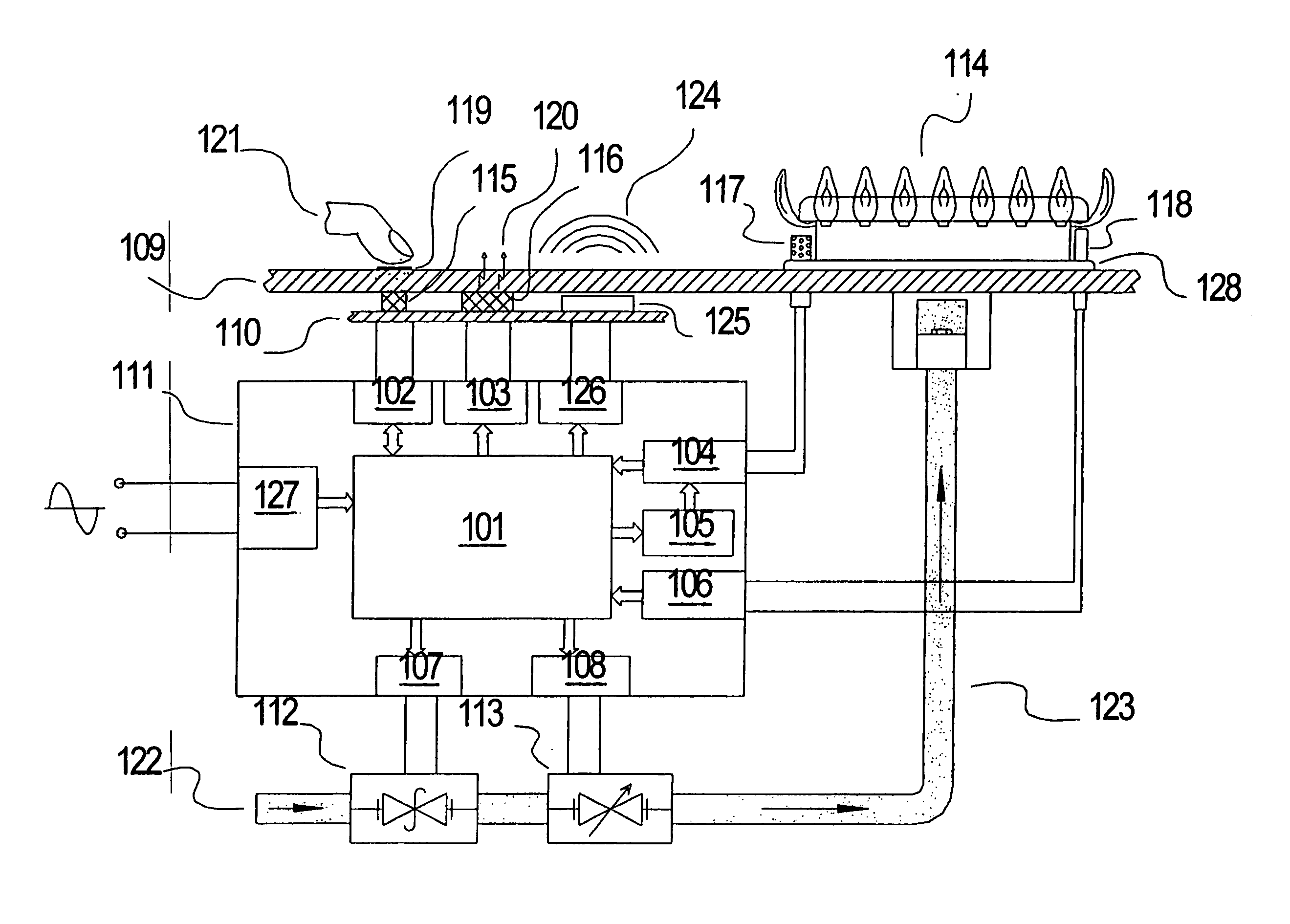

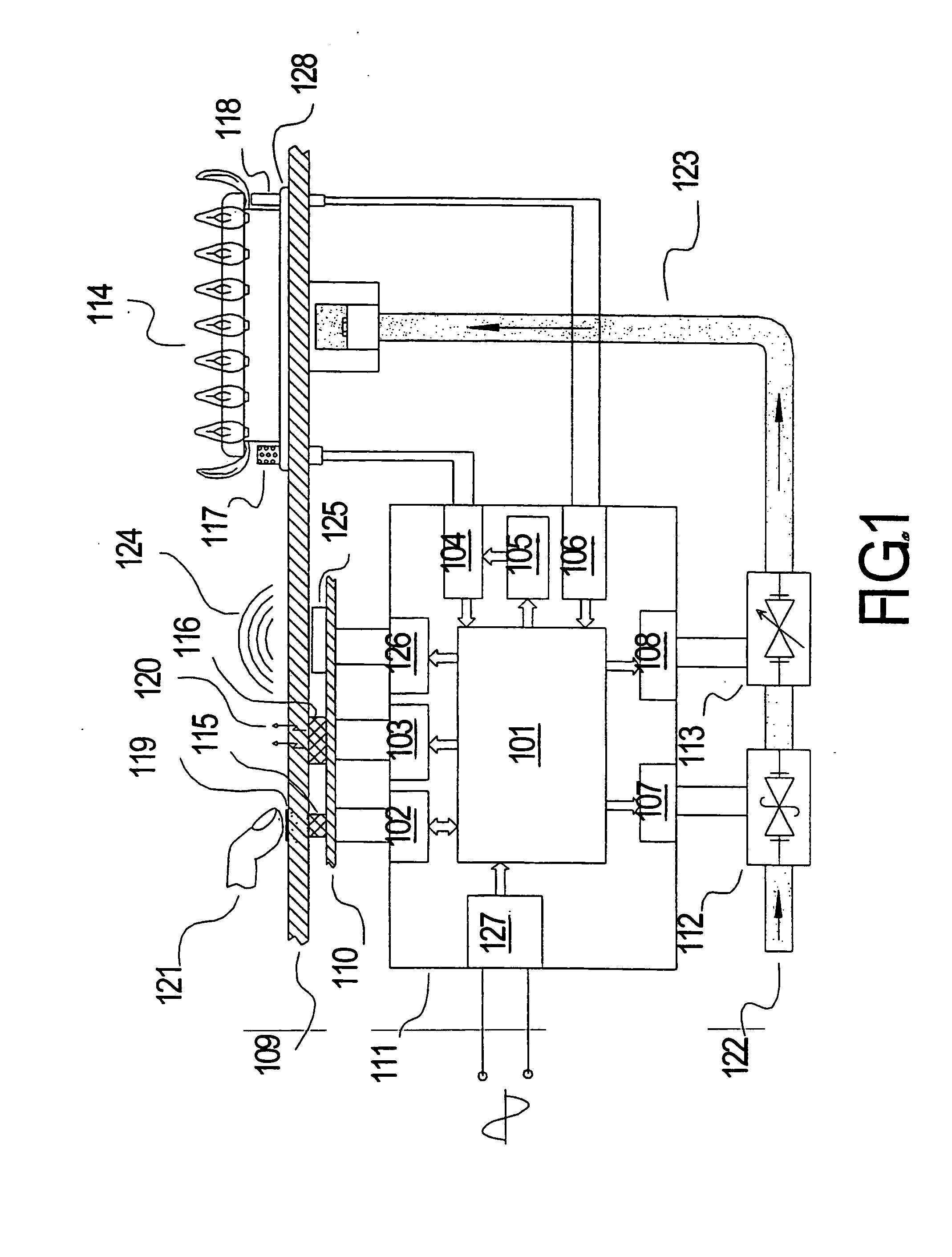

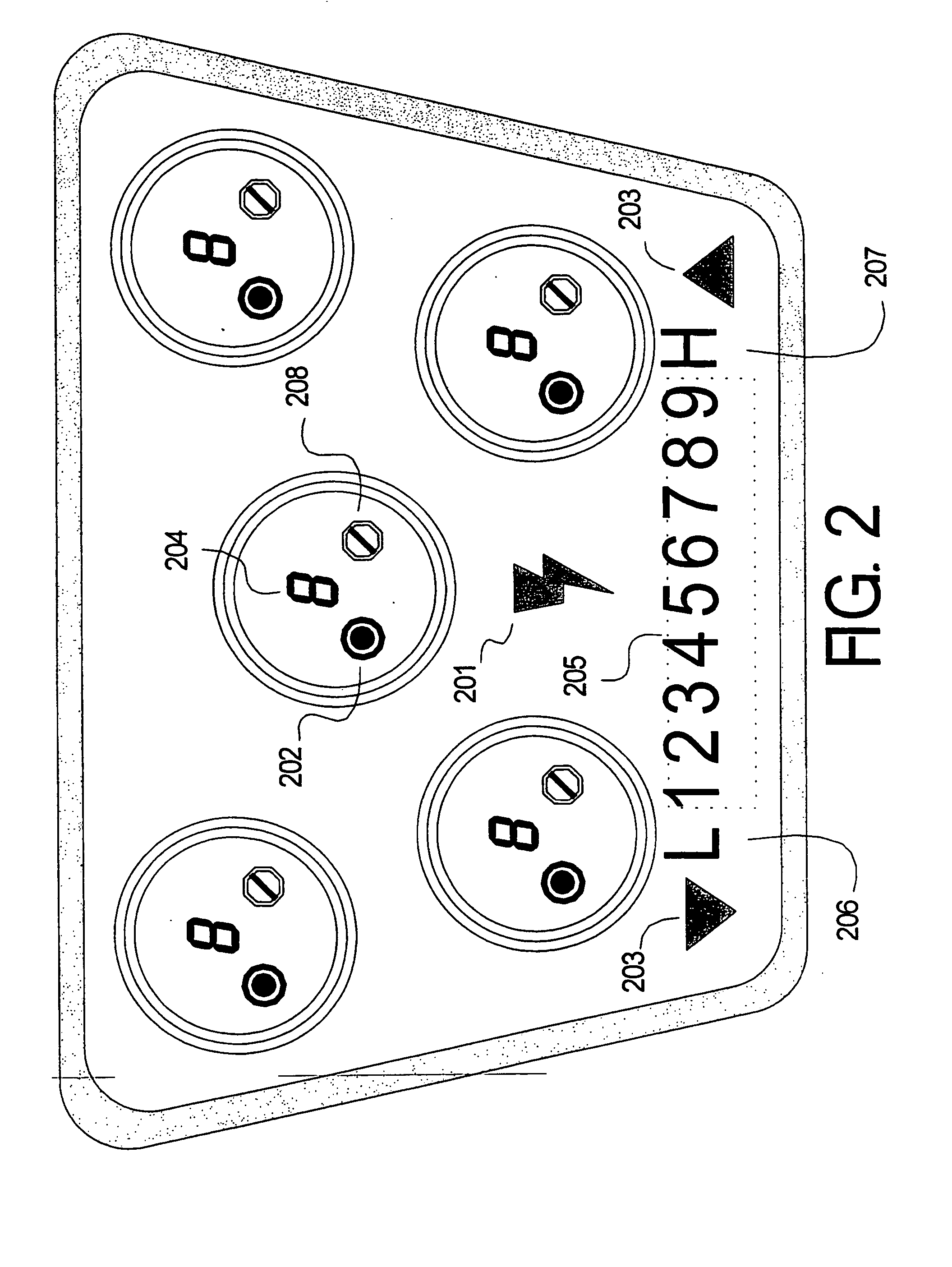

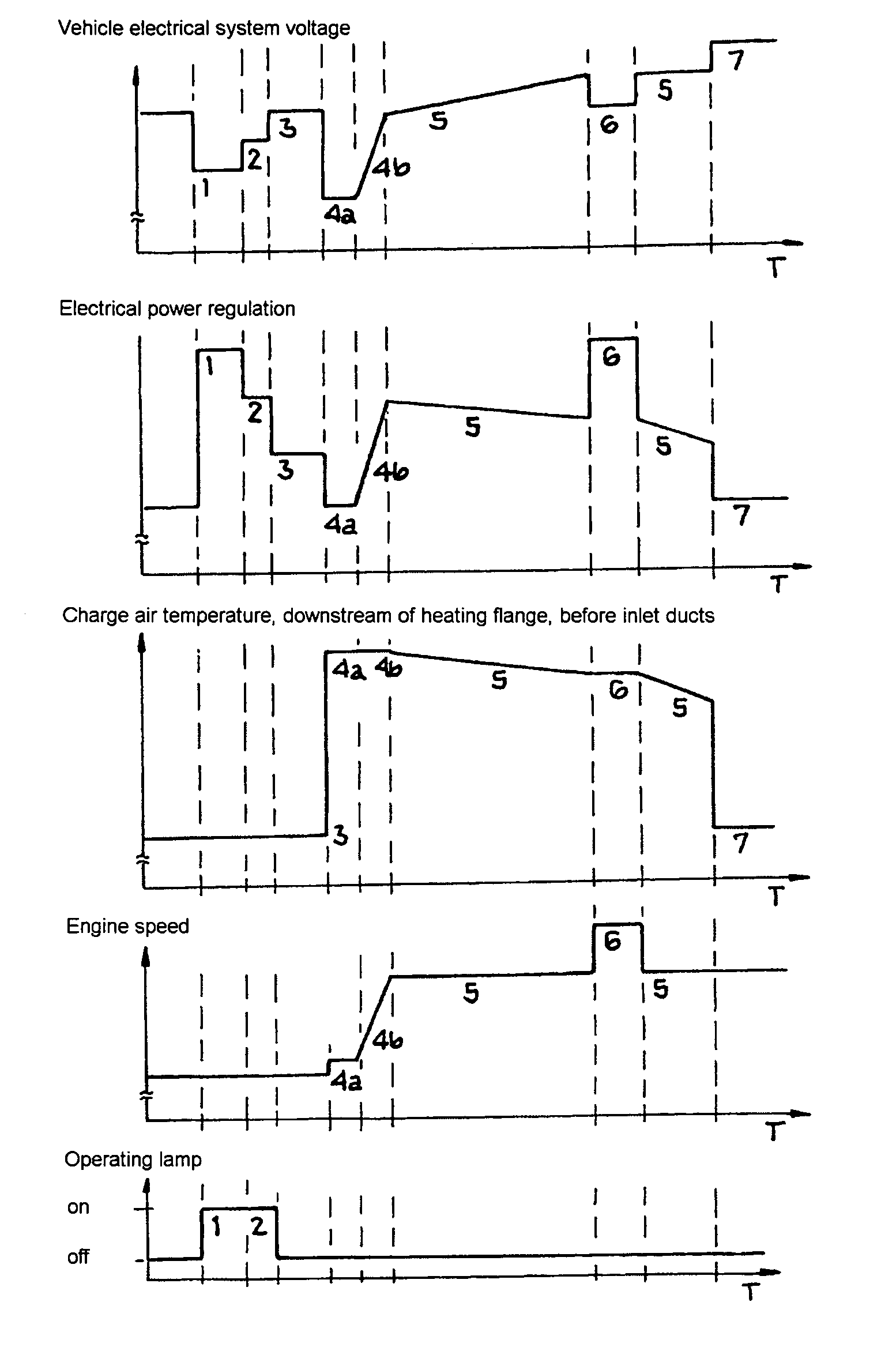

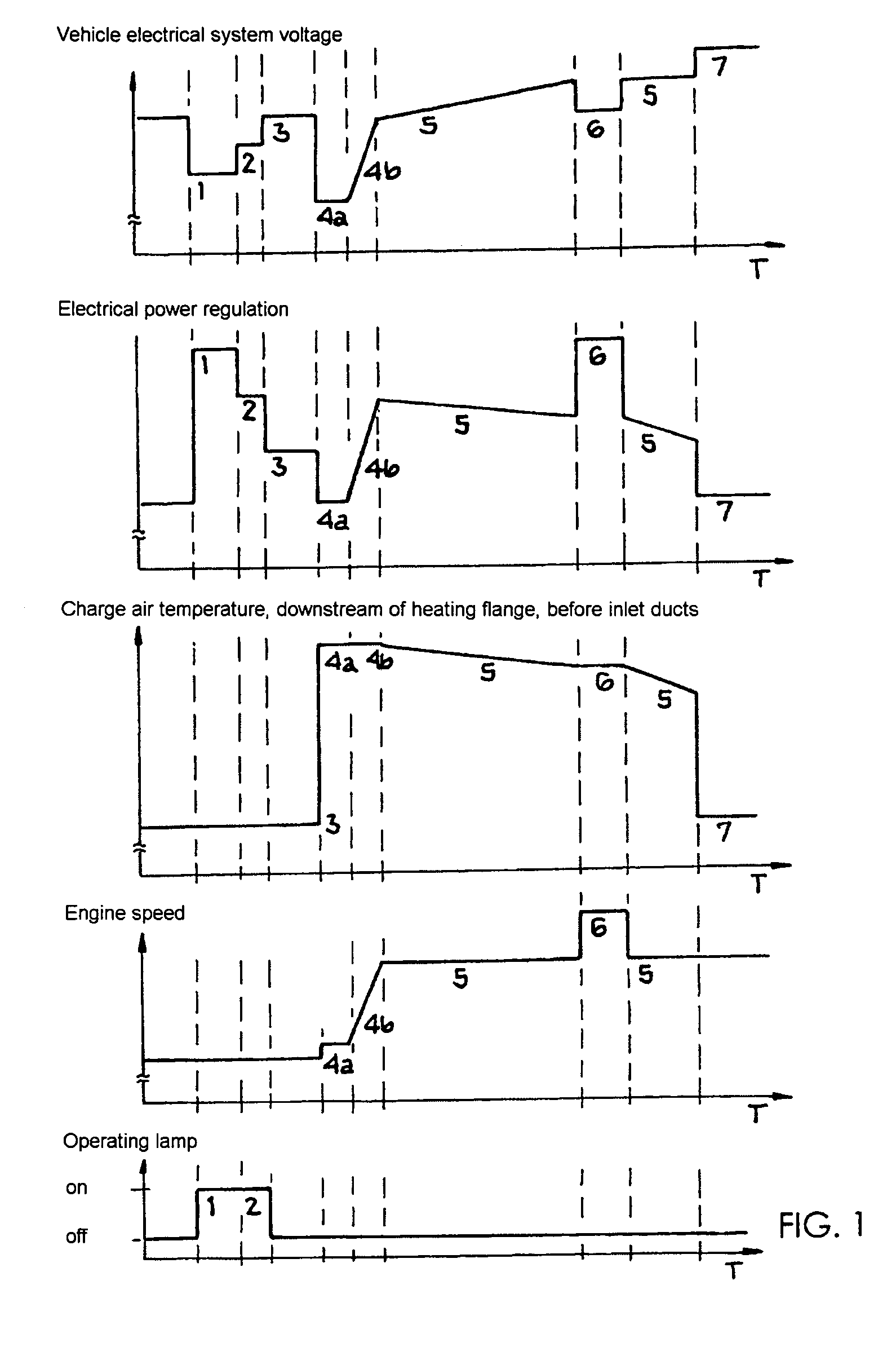

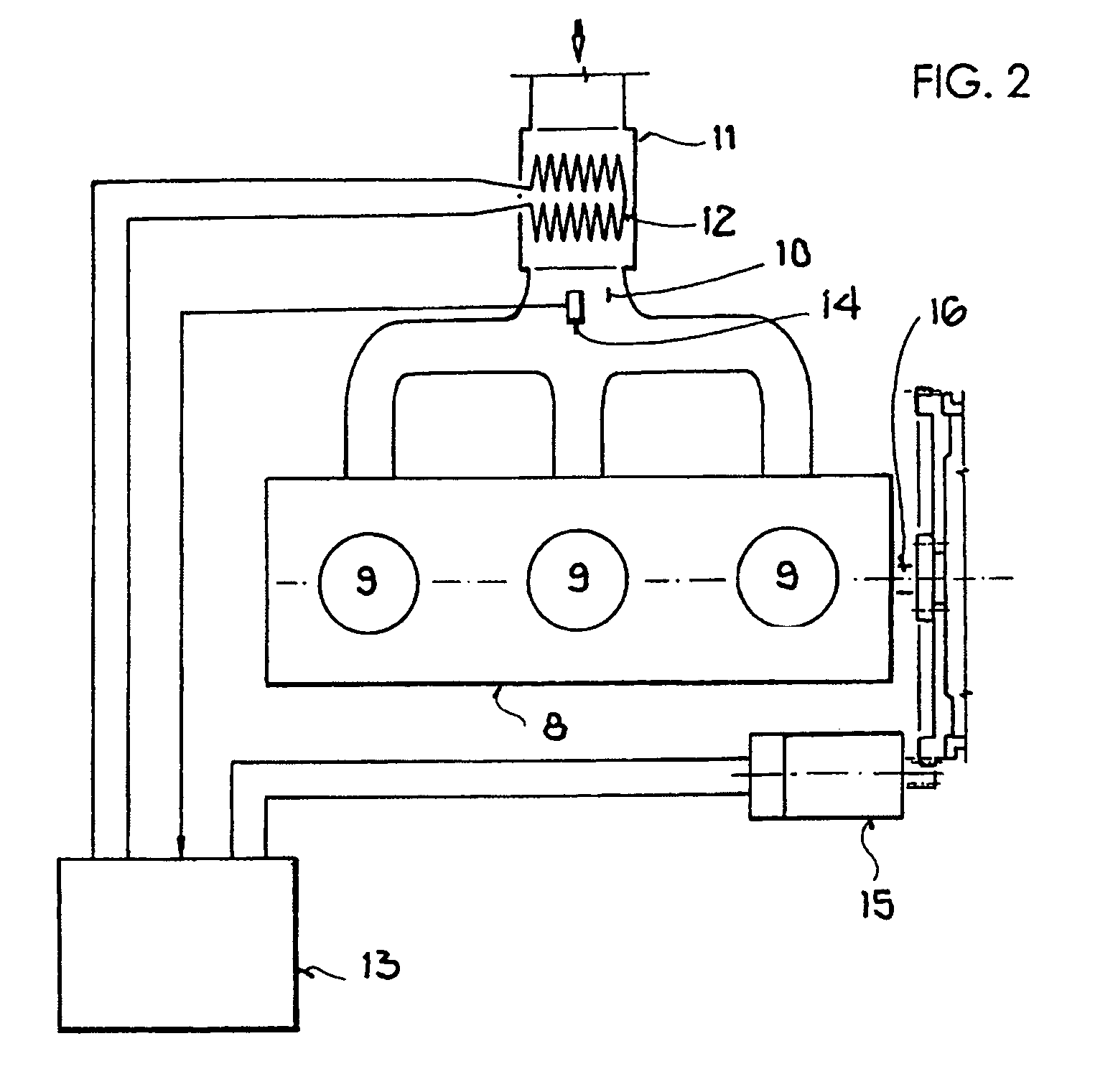

Control of an electrically heated pre-heating device for cold-starting internal combustion engines

InactiveUS7464699B2Good effectAccelerate emissionsInternal combustion piston enginesEngine controllersCombustionExternal combustion engine

In a method for heating up the intake air of an internal combustion engine during the preglow phase or start-up phase, the heating power is controlled by a control unit of the engine electronics as a function of the operating data of the internal combustion engine. During the preglow phase, the heating element is initially supplied with full current until the heating element reaches its reference temperature. After the reference temperature has been reached and until the start-up phase, a post-heating phase begins in which the heating element is kept at a constant temperature by way of a relatively low power. During the start-up phase, in a first time period, the heating element is switched off, and in a second time period in which the speed of the internal combustion engine is raised to the starting speed, the heating element is switched on again.

Owner:DAIMLER AG

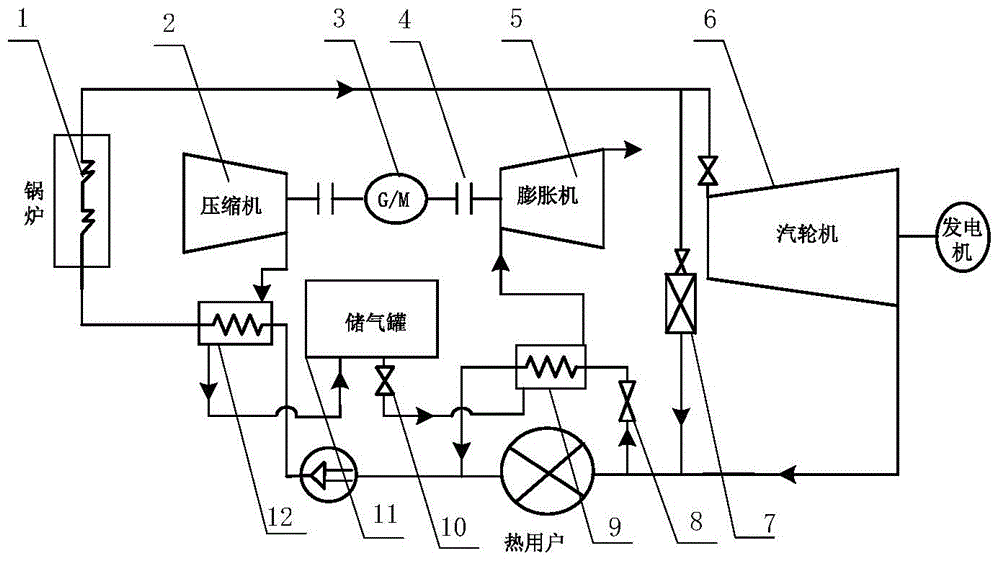

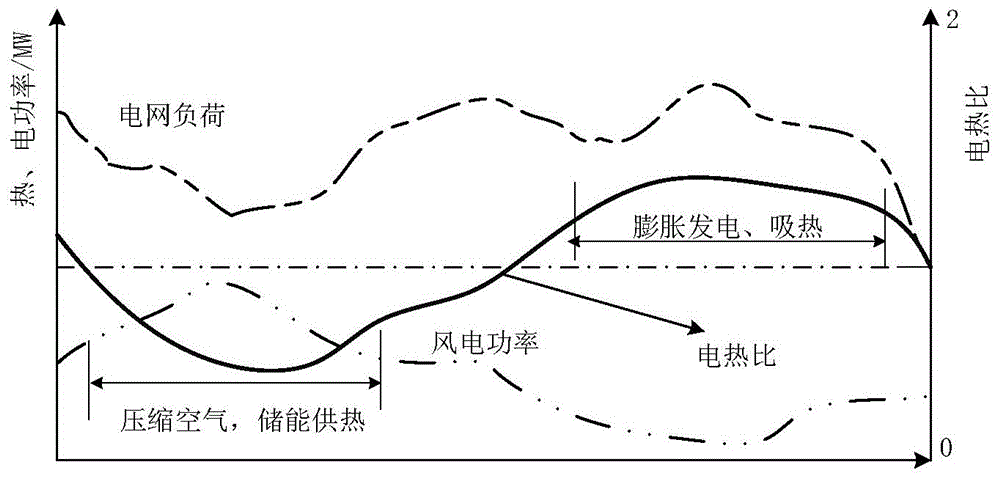

Thermoelectricity combined supply type compressed air energy storage system and method for back pressure type thermoelectric unit

ActiveCN104675458AReduce heating powerMultiple peak shaving spaceHot-air central heatingLighting and heating apparatusThermal energy storageCogeneration

The invention discloses a thermoelectricity combined supply type compressed air energy storage system and a thermoelectricity combined supply type compressed air energy storage method for a back pressure type thermoelectric unit. The system comprises the back pressure type thermoelectricity cogeneration unit and a heat insulation compressed air energy storage system. During the electricity consumption valley time period at night, a compressed air energy storage device is used for storing redundant electric energy by compression, and heat generated in an air compression process is supplied to the thermoelectricity cogeneration unit through a heat exchange device; during the electricity consumption peak time period in the day, compressed air is expanded to generate power and absorbs the redundant heat generated by the thermoelectricity cogeneration unit. According to the system and the method, the electric energy is stored by the compressed air, and the heat-to-electricity ratio of the back pressure type thermoelectric unit can be regulated in the air compression and release processes, so that the peak load regulation capacity of the thermoelectricity cogeneration unit is improved; compared with the existing single-electric-energy storage system, the system disclosed by the invention has the advantage that under the same energy storage capacity, the system can provide a larger wind-power consumption space.

Owner:SHANDONG UNIV

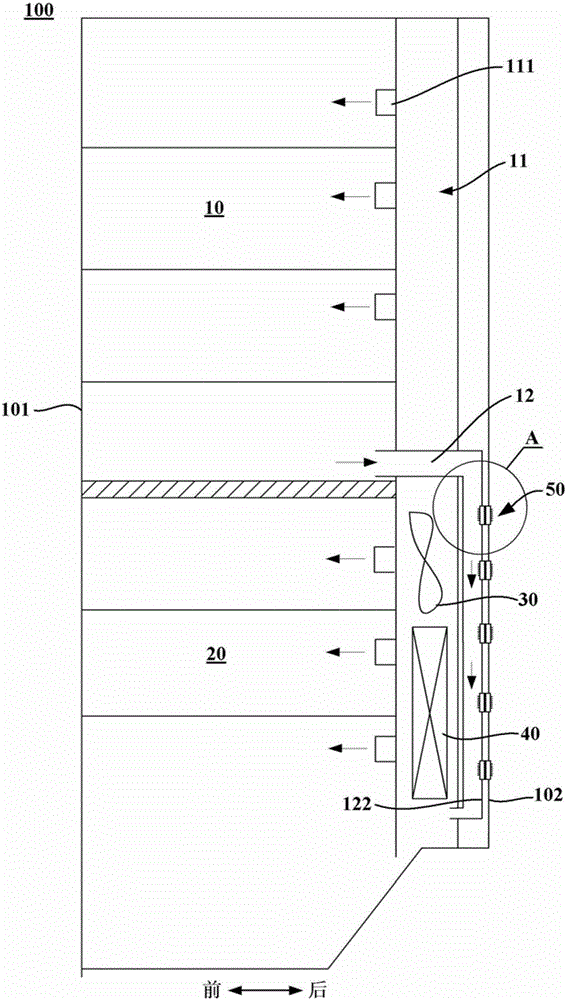

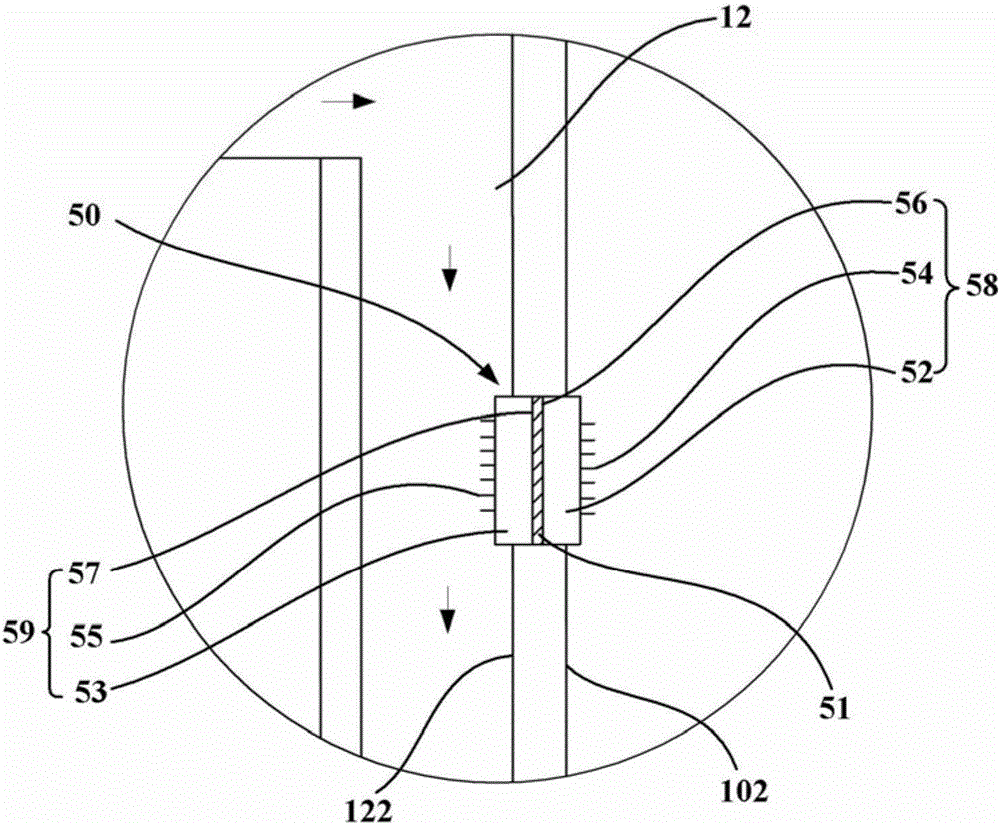

Air cooling refrigerator and dehumidifying method thereof

ActiveCN106196826AReduce the amount of frostingReduce power consumptionDomestic refrigeratorsMachines using electric/magnetic effectsHigh humidityEngineering

The invention provides an air cooling refrigerator and a dehumidifying method thereof. The air cooling refrigerator comprises a refrigerator body; a refrigeration chamber which is limited in the refrigerator body; an evaporator which cools flowing air; an air supply flue which is configured to supply the air cooled by the evaporator to the refrigeration chamber; an air return flue which is configured to convey the air from the refrigeration chamber to the evaporator for cooling; and at least one semiconductor refrigeration module which has a first temperature change end and a second temperature change end. The first temperature change end of each semiconductor refrigeration module is arranged in the air return flue; and each semiconductor refrigeration module is configured to allow the first temperature change end and the second temperature change end to serve as a refrigeration end for reducing temperature and a heating end for raising the temperature under control, so that the air entering the air return flue flows through the first temperature change end and the evaporator in sequence, and water therein is condensed at the first temperature change end. Before the air with higher humidity in the refrigeration chamber is returned to the evaporator, the water is condensed and removed at the first temperature change end, so that the frosting quantity of the evaporator is largely reduced.

Owner:HAIER SMART HOME CO LTD

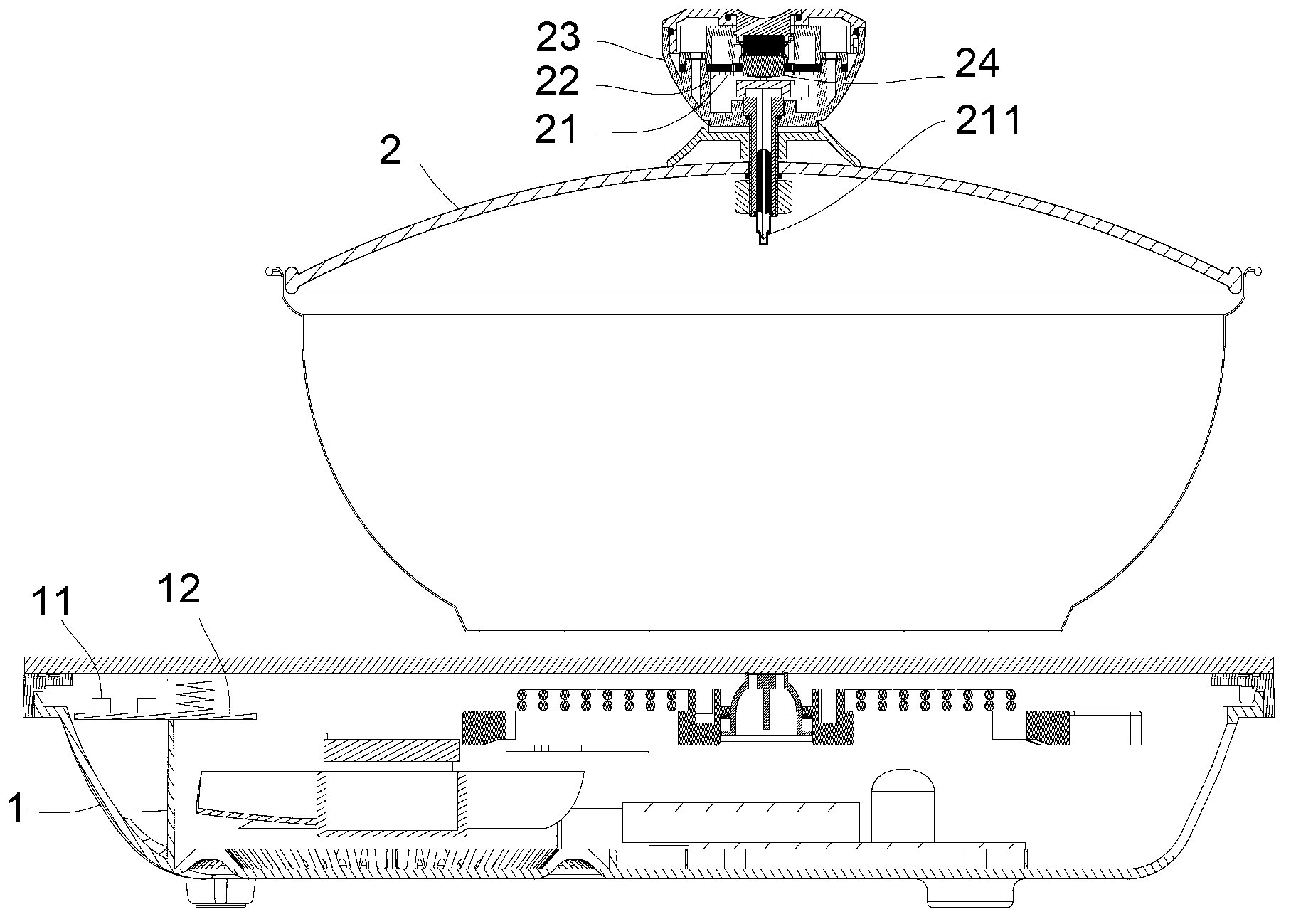

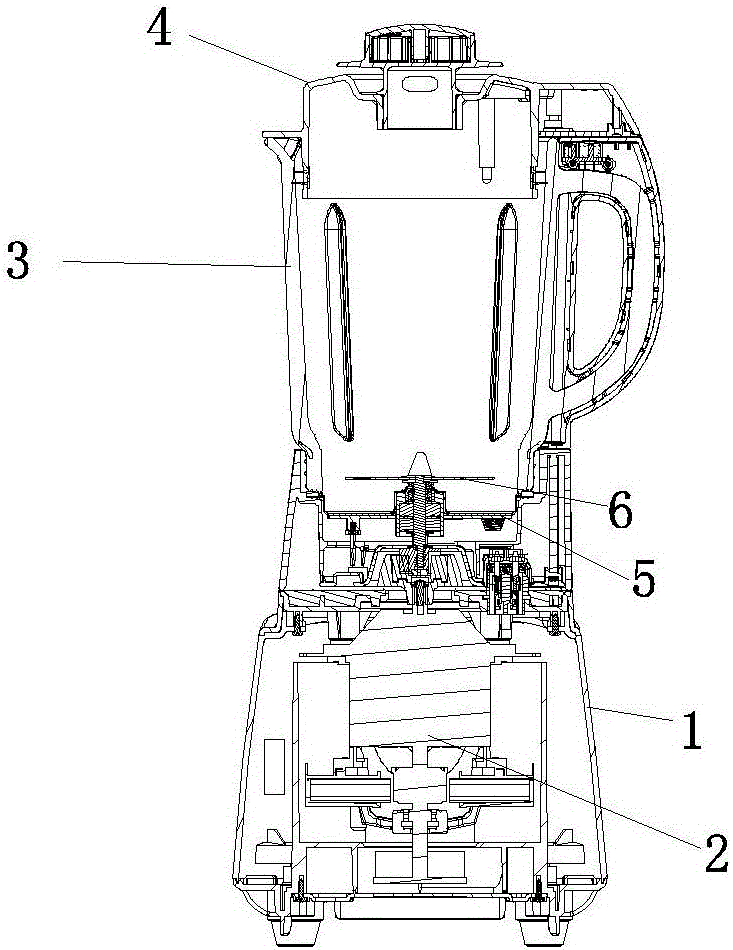

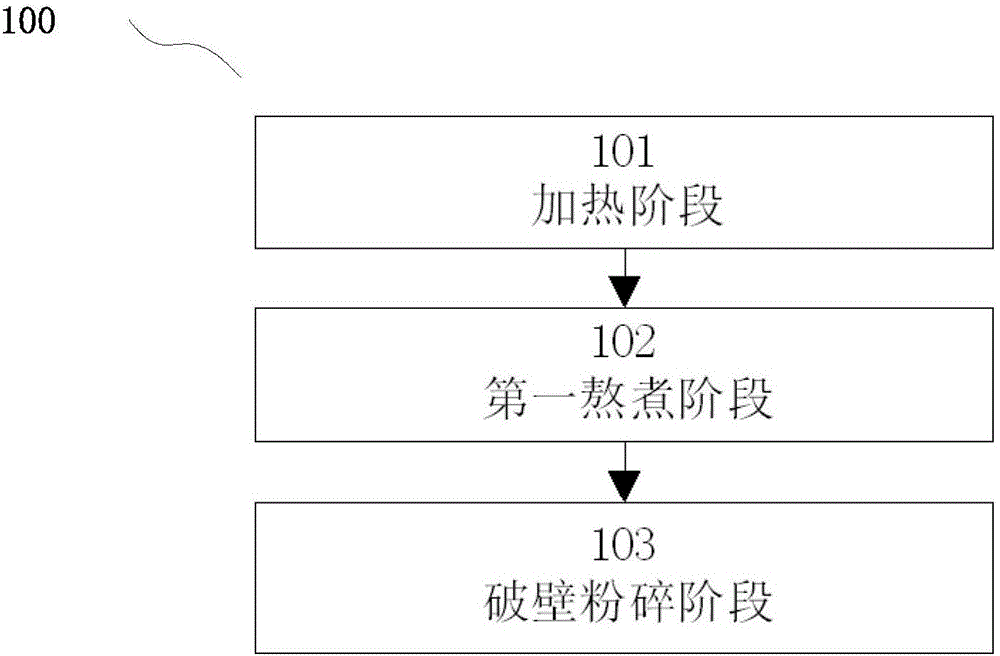

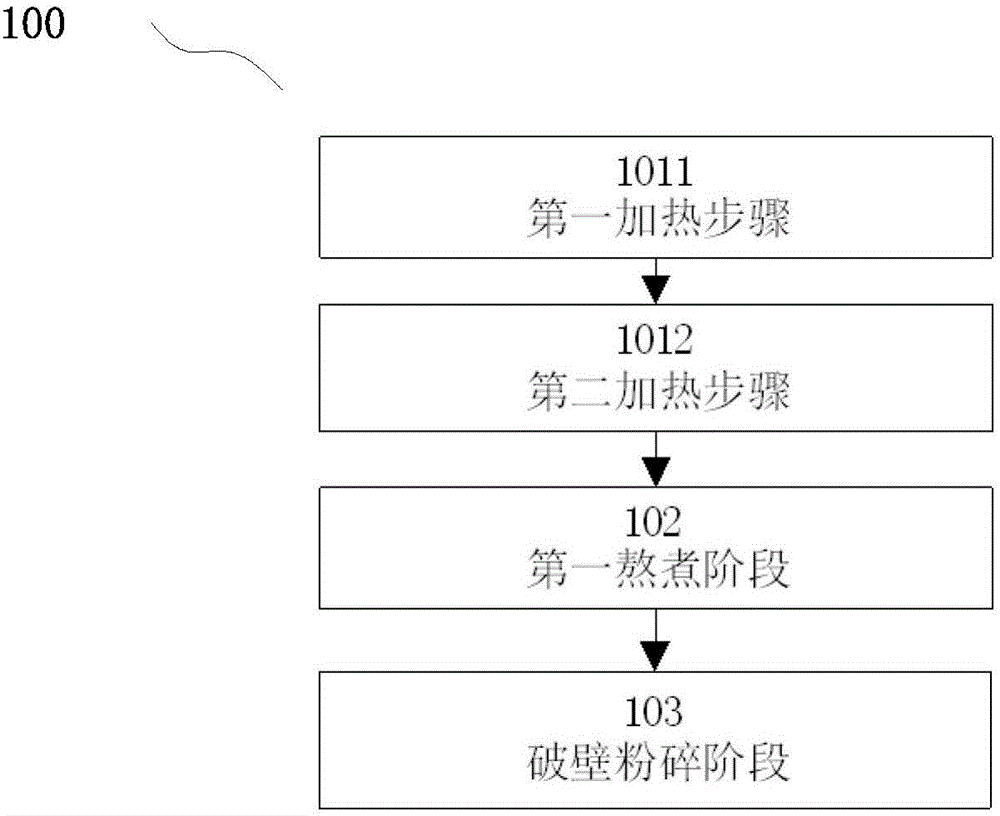

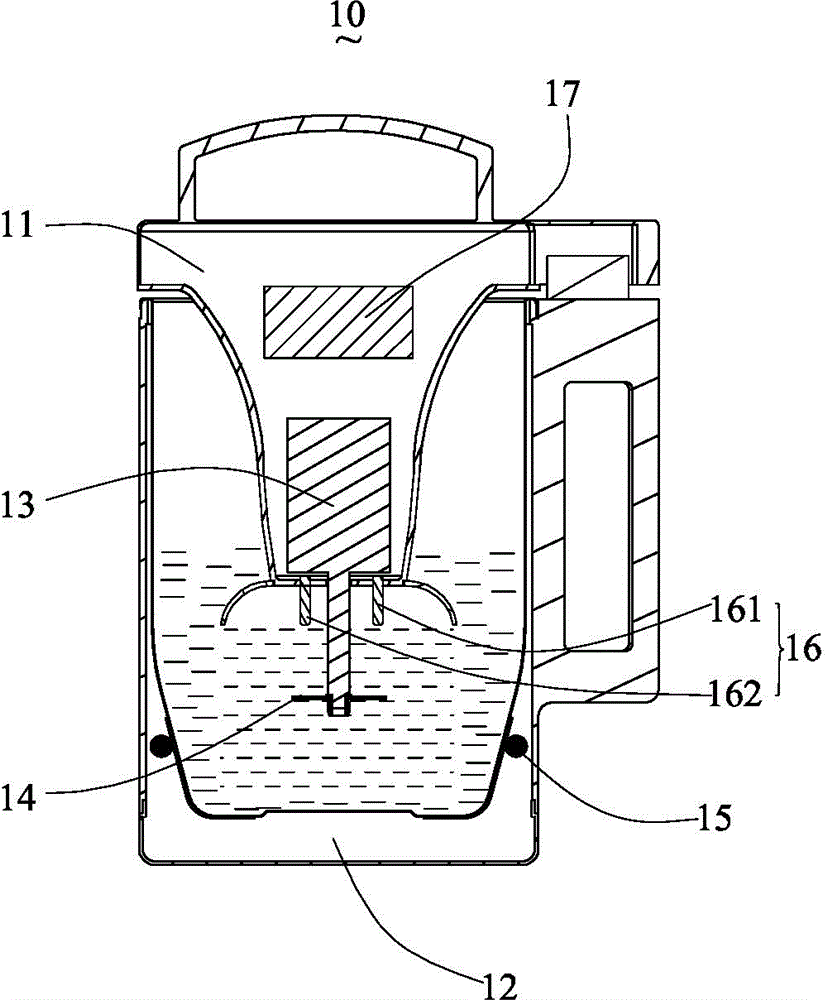

Food processing method of motor under-set-type food processing machine and food processing machine

The invention relates to a food processing method of a motor under-set-type food processing machine and the food processing machine, and belongs to the field of food processing. The food processing method at least comprises a heating stage, a first cooking stage and a wall-breaking and grinding stage, wherein in the heating stage, food in a stirring cup is heated to be boiling by virtue of a heating device; in the first cooking stage, the food in the stirring cup is cooked for a duration of t1 by virtue of the heating device until the food is completely cooked, and during cooking, a grinding cutter is driven to do intermittent rotation at a first rotating speed by virtue of a motor; and in the wall-breaking and grinding stage, the grinding cutter is driven to rotate at a second rotating speed by virtue of the motor so as to grind the cooked food in the stirring cup, and the second rotating speed, which ranges from 20000r / min to 40000r / min, is greater than the first rotating speed, wherein the power of the heating device in the first cooking stage is less than that in the heating stage. The food processing machine using the food processing method provided by the invention can uniformly heat the food, and the phenomenon of over-burnt bottom and spillover cannot occur easily.

Owner:JOYOUNG CO LTD

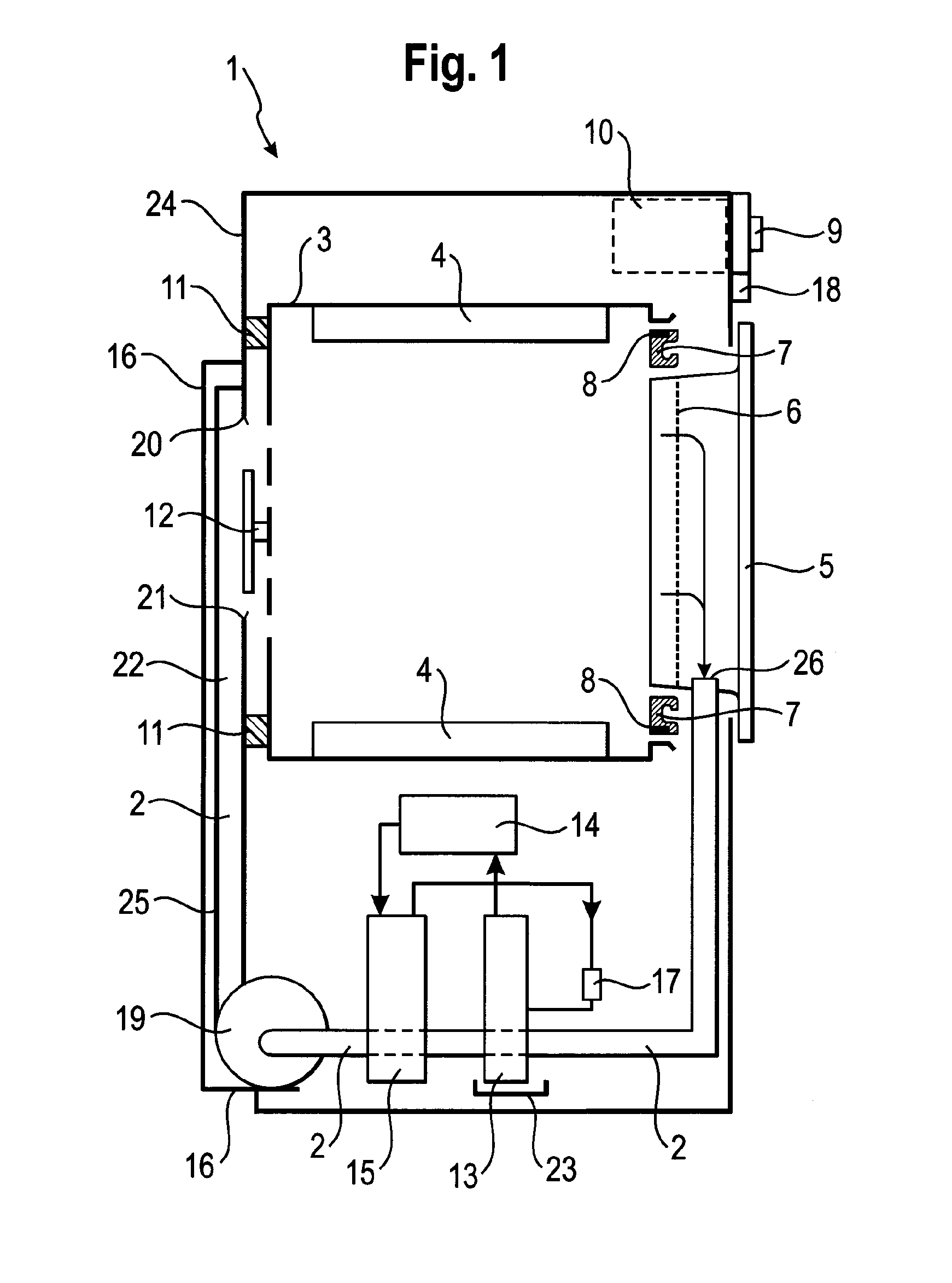

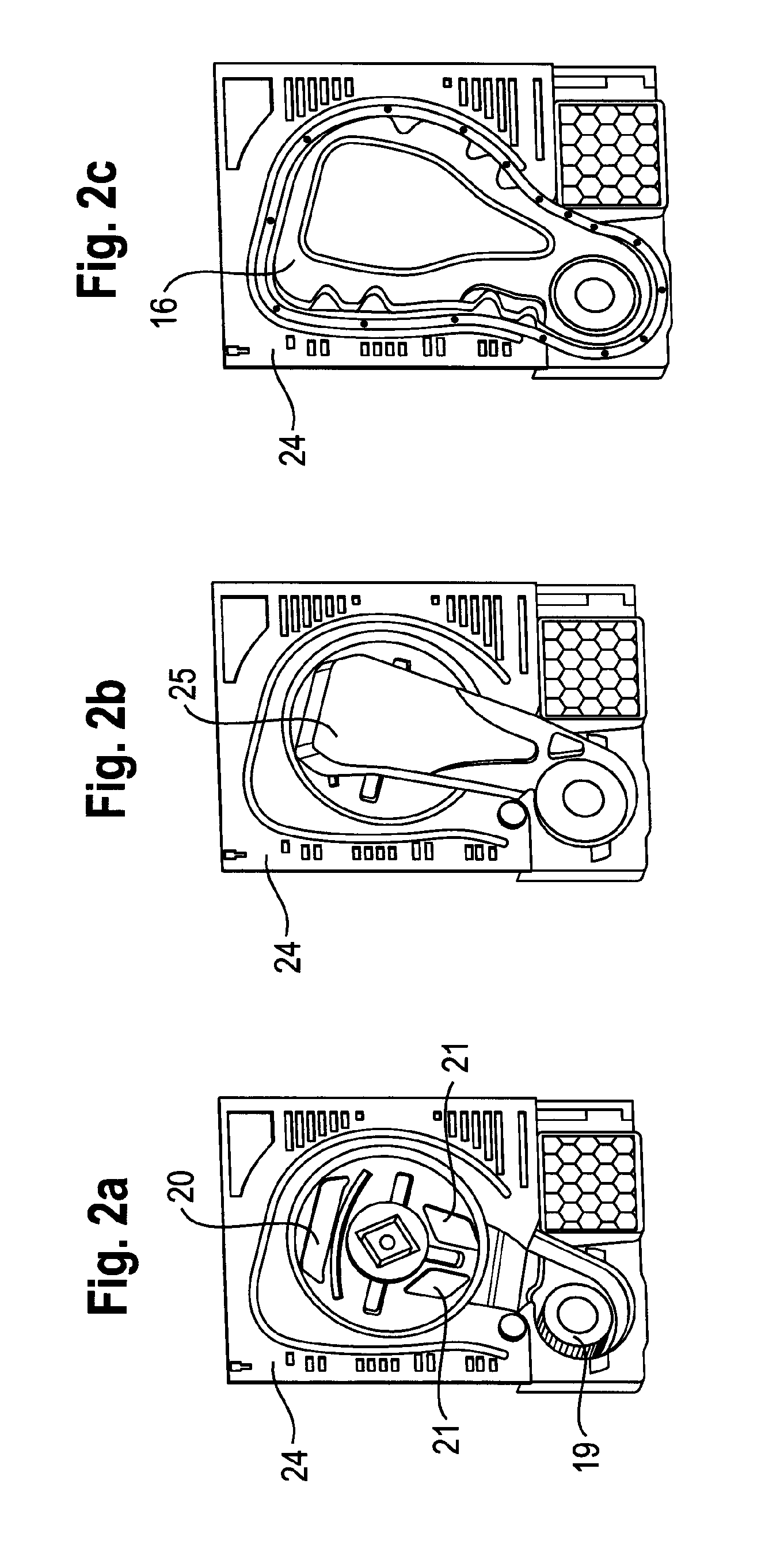

Condensation dryer with a housing

InactiveUS8656604B2Simple processReduce total pressure lossContainer filling methodsOther washing machinesHeat pumpHeat spreader

A condensation dryer includes a housing having a wall area which forms a rear side, and a process air circuit for circulating process air. The process air circuit has a first section outside the housing and running along the wall area and a remaining second section inside the housing. The first section which is located at the wall area is formed by a profile part placed on the wall area and is covered by a hood placed in sealing fashion on the wall area. A fan is arranged in the process air circuit for circulating the process air, and a drying chamber is arranged in the process air circuit for holding objects to be dried. A heat pump is disposed in the housing and includes a heat sink which is thermally coupled to the process air circuit, and a heat source, which is thermally coupled to the process air circuit.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

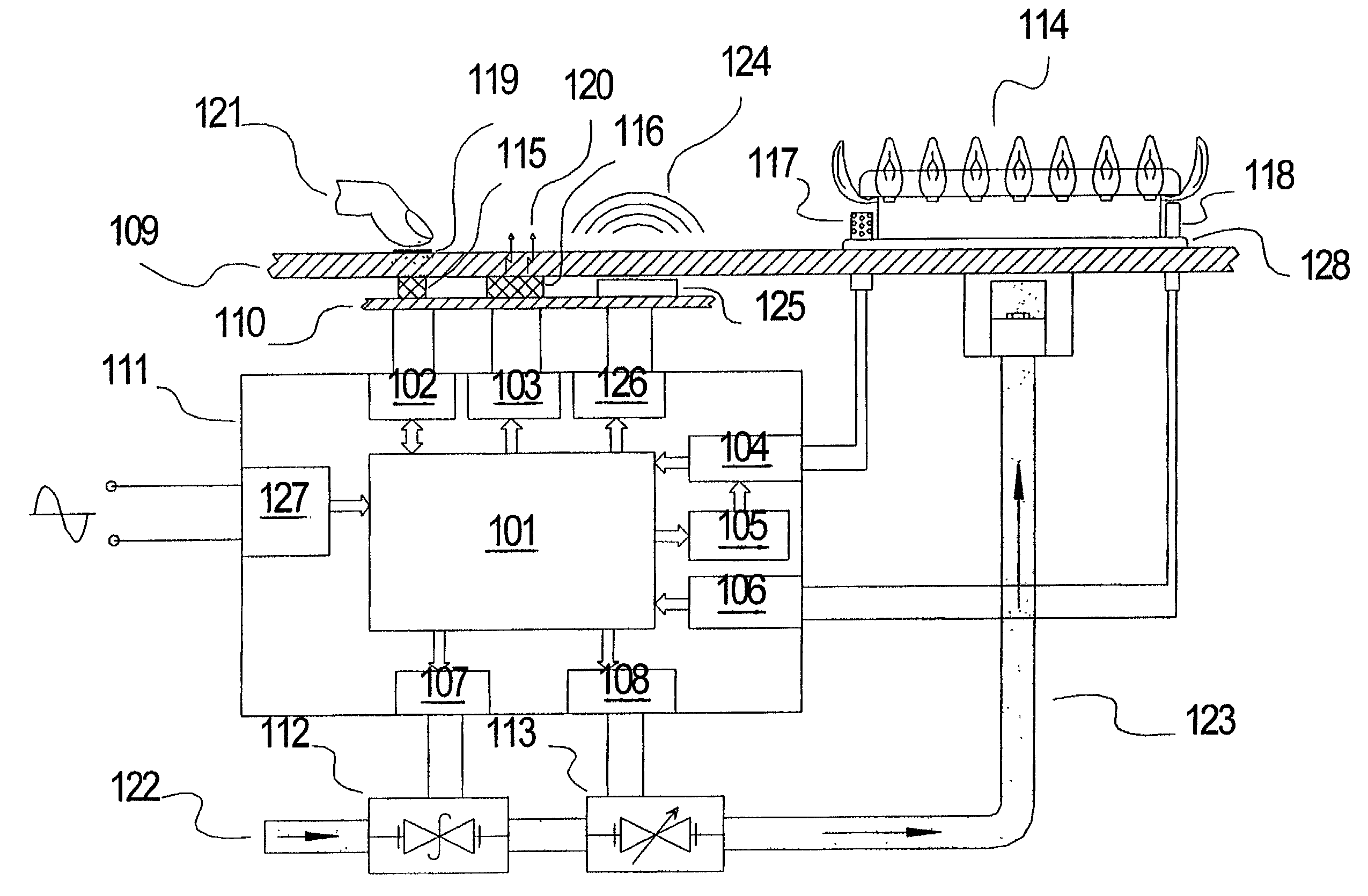

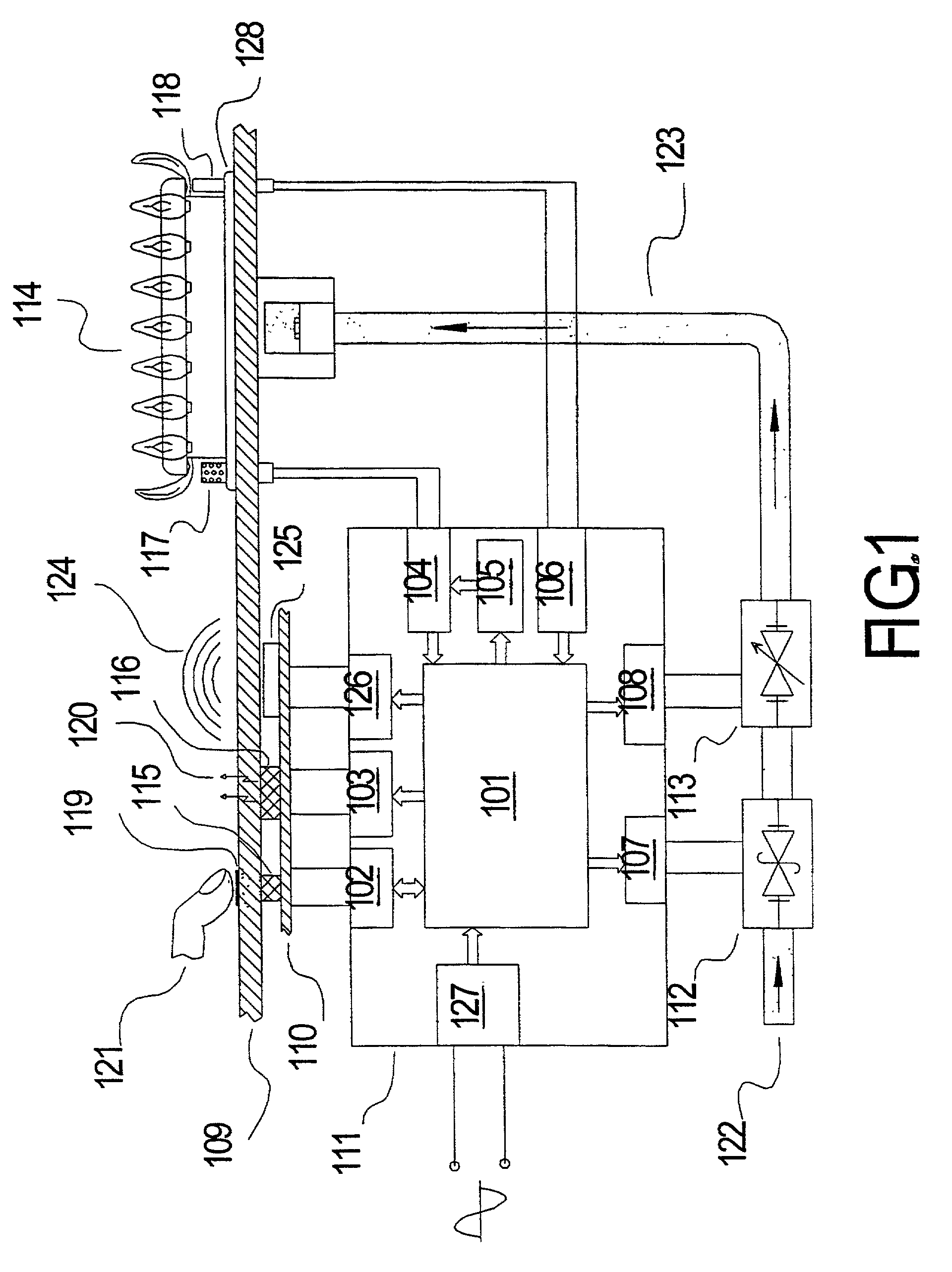

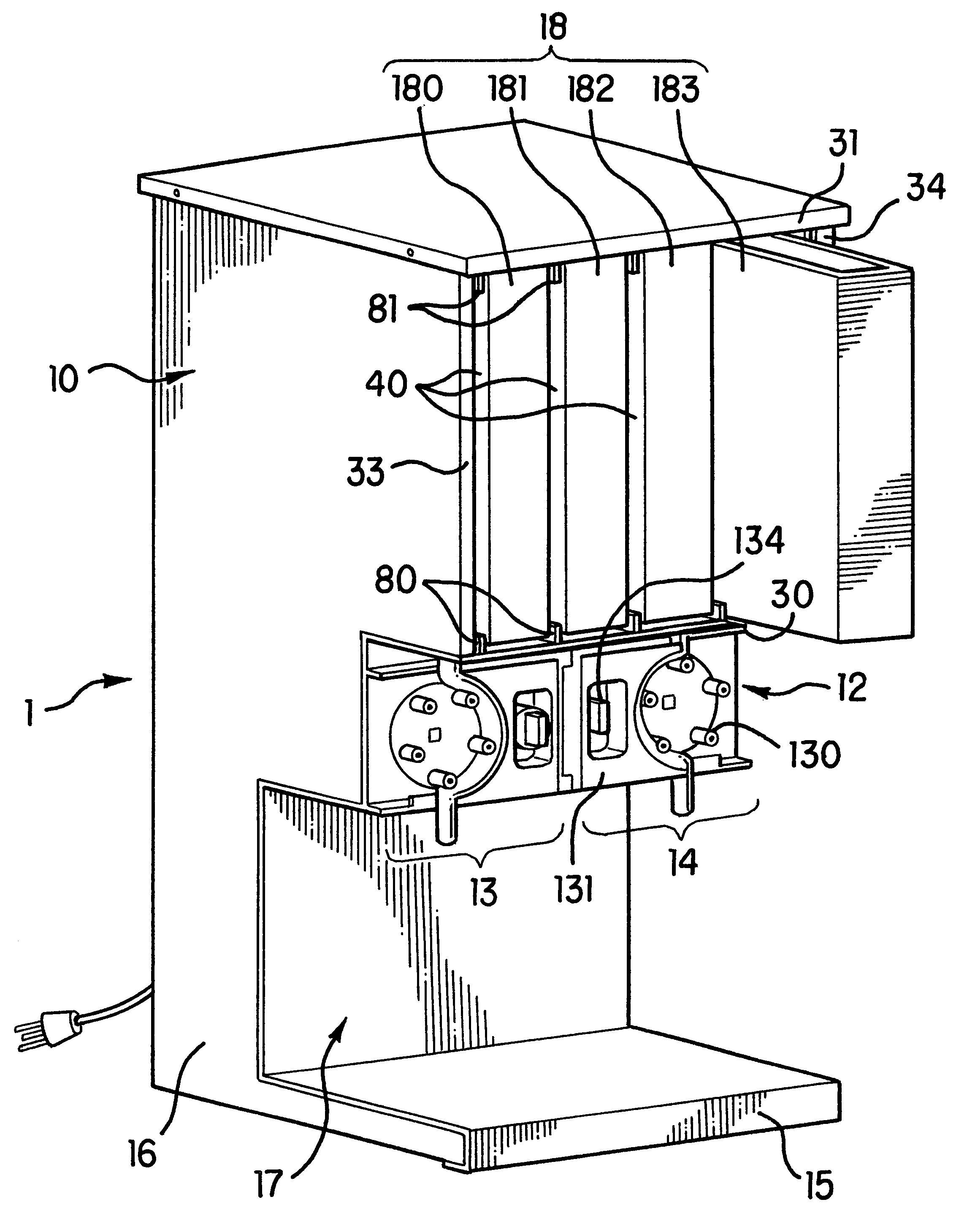

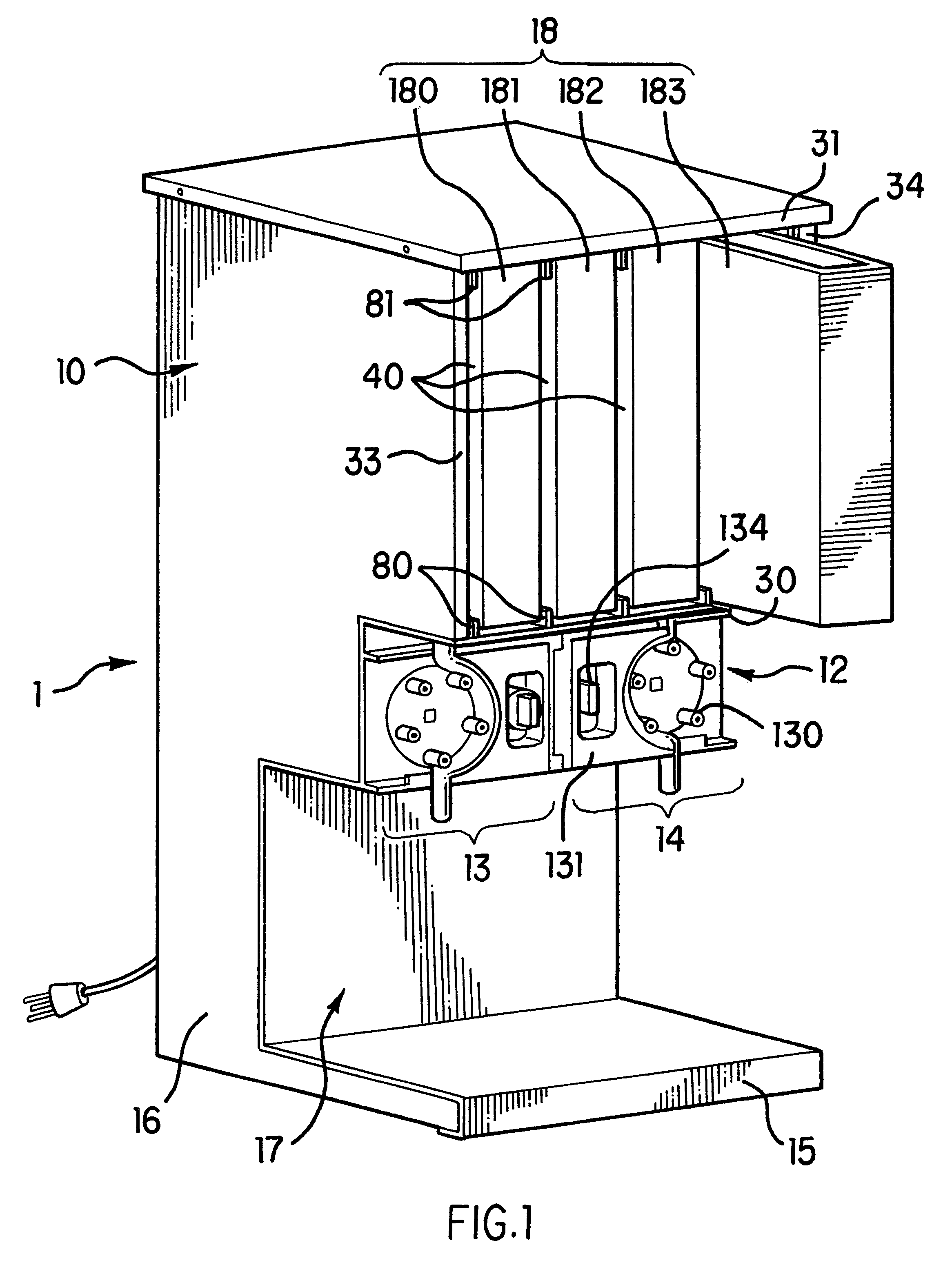

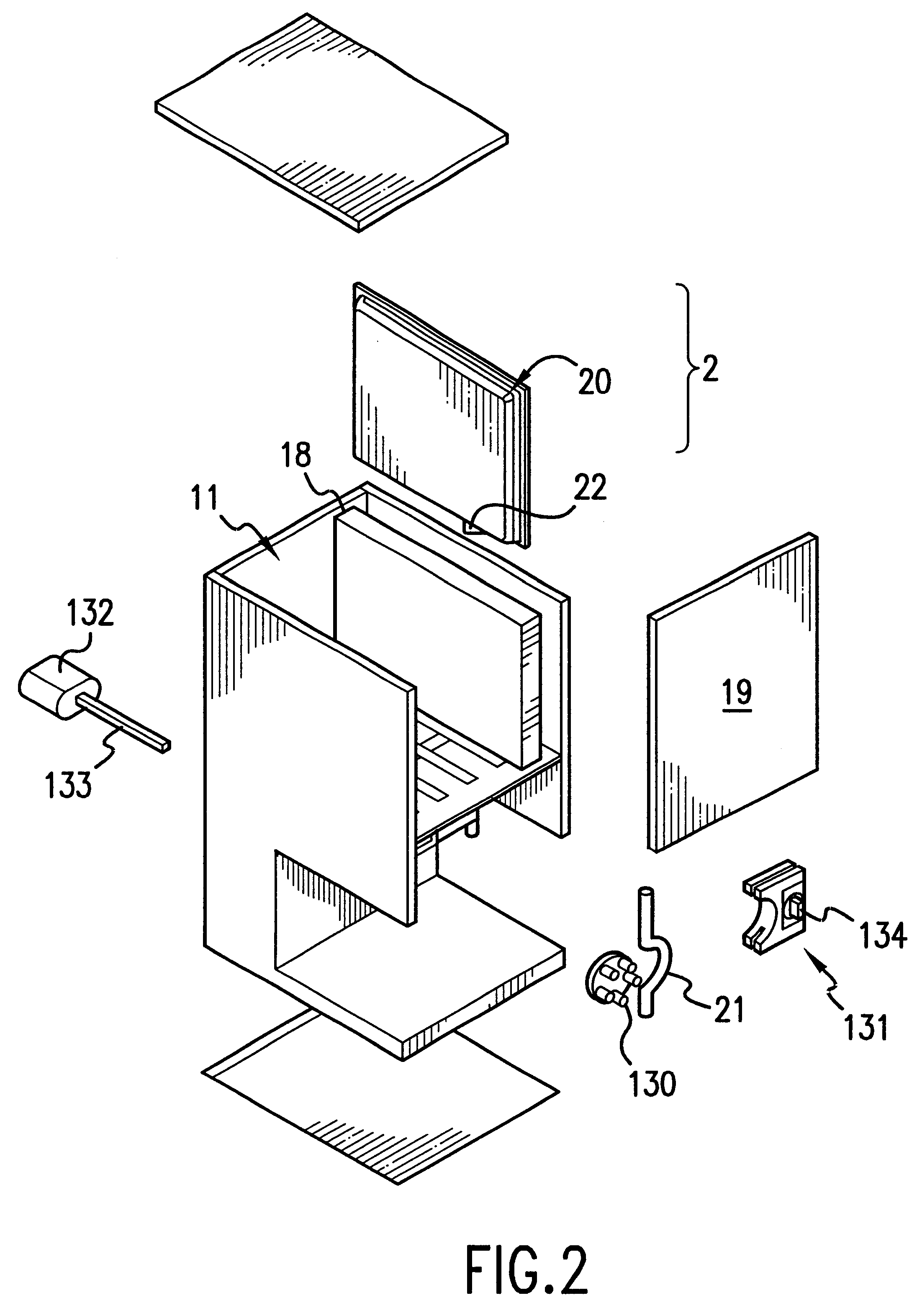

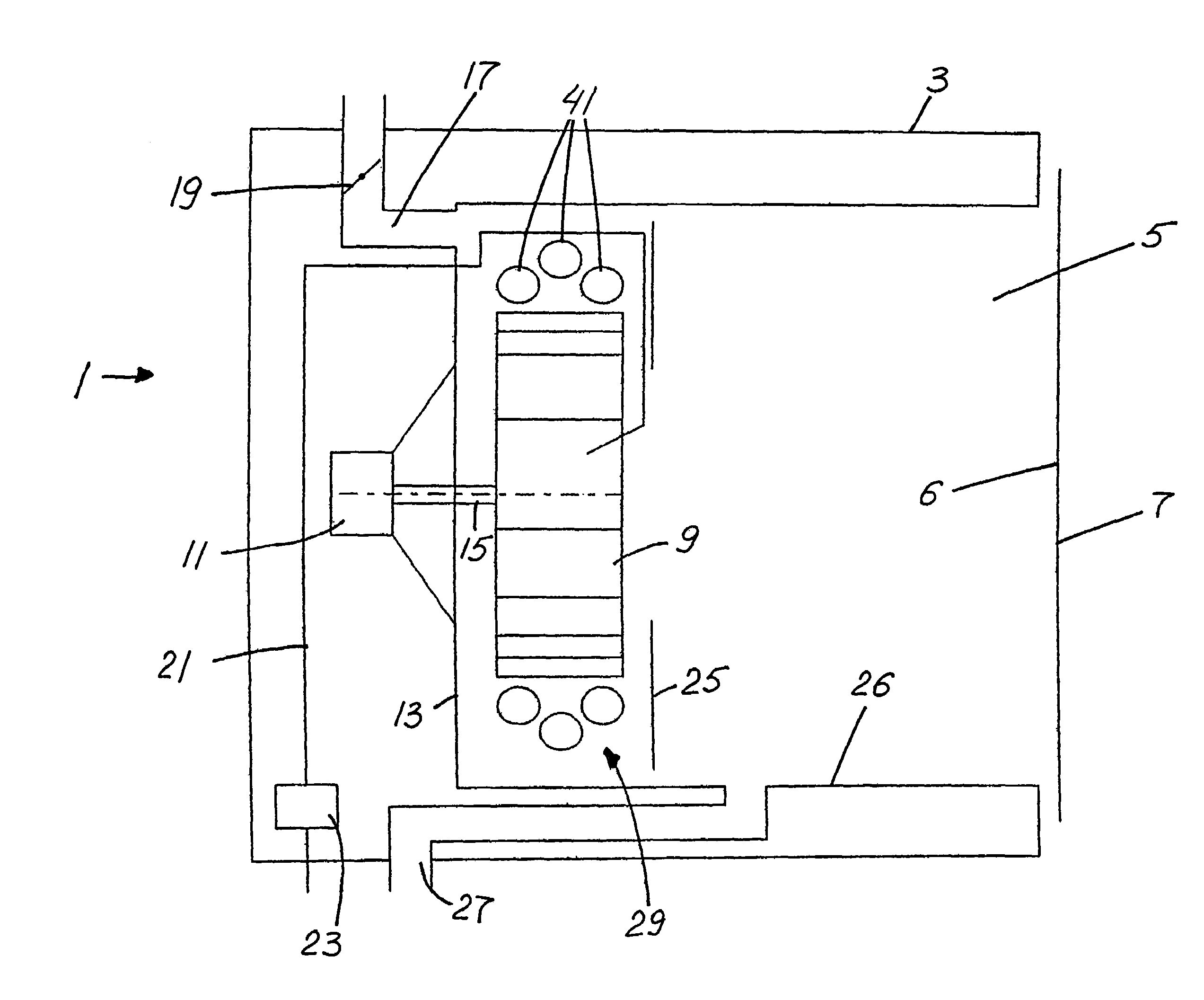

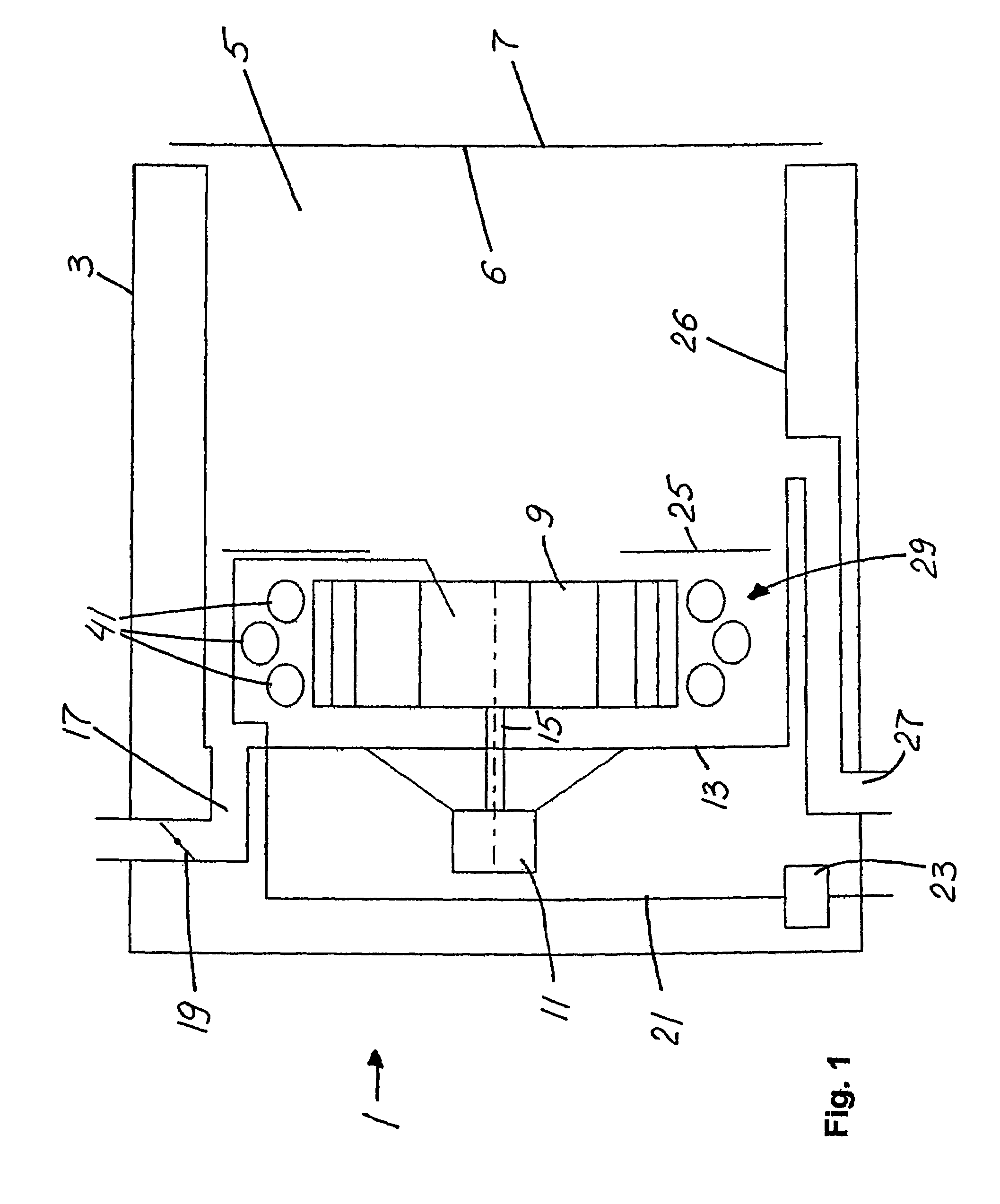

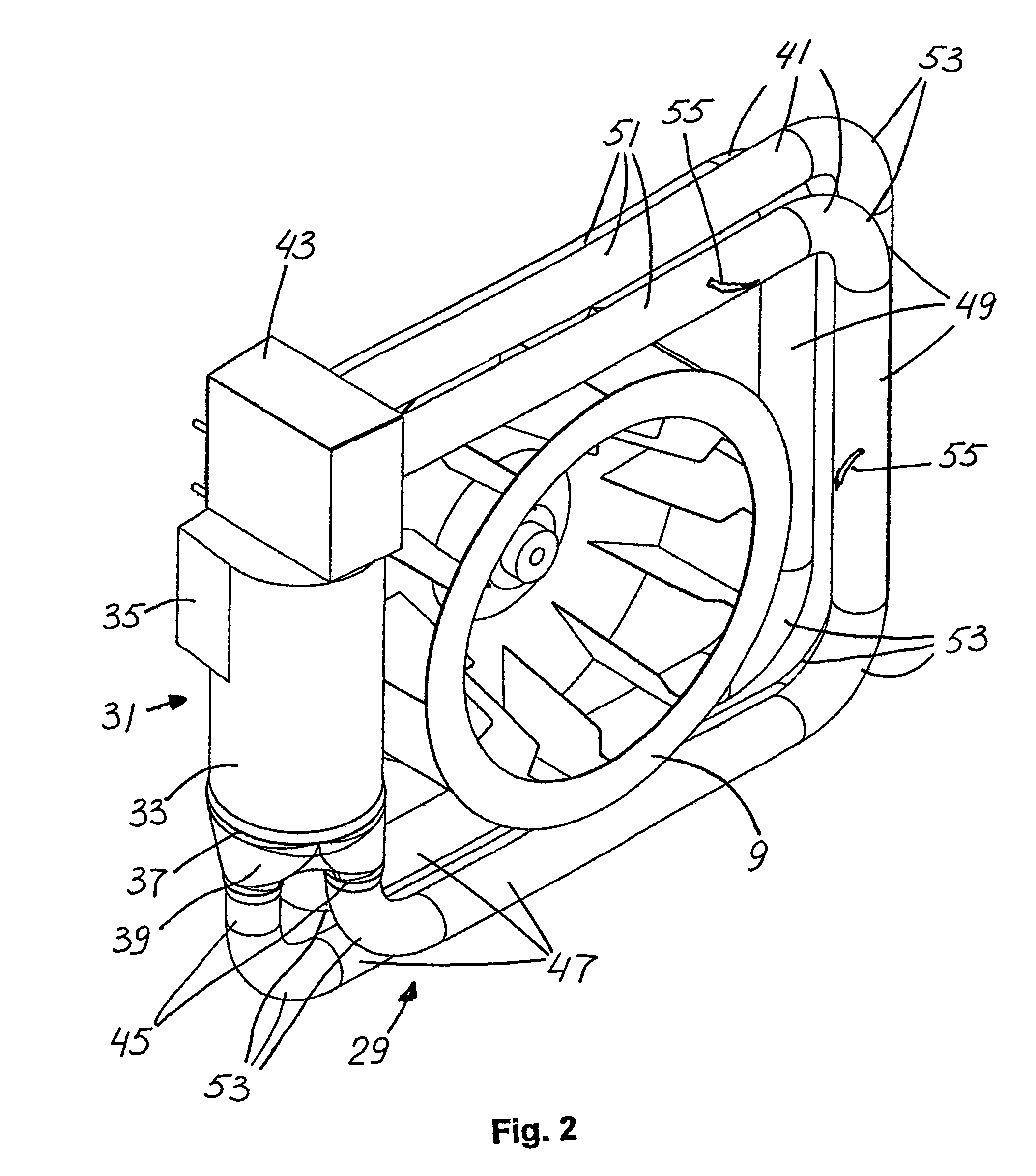

Apparatus for treating and preparing food by gas-fired heating and a heat exchange device for such an apparatus

InactiveUS7325480B2Increase heat transferLow heating powerAir-treating devicesDomestic stoves or rangesProcess engineeringGas burner

The present invention refers to an apparatus for treating and preparing food having a cooking chamber in which the food is treated and cooked. The apparatus further includes a motor-driven ventilation fan which serves to circulate the cooking chamber atmosphere, and a gas burner which serves for combusting the gas-air mixture. The cooking chamber is heated by use of a heat exchange device which includes a heat exchange pipe assembly. The heat exchange device surrounds the ventilation fan. The heat exchange pipe assembly is characterized in that at least two pipe strands are provided which extend substantially around the ventilation wheel in a continuous bordering or loop of the ventilation wheel. The subject matter of the present invention is also a heat exchange device for an apparatus of this type.

Owner:ELOMA GROSSKUCHENTECHN

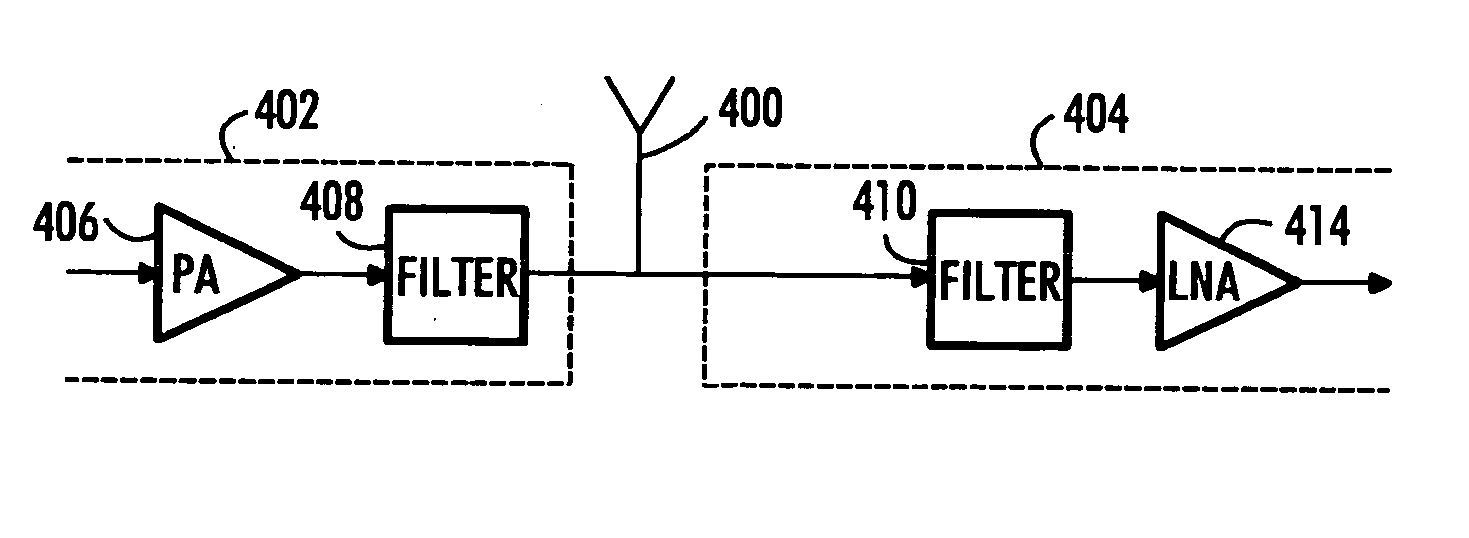

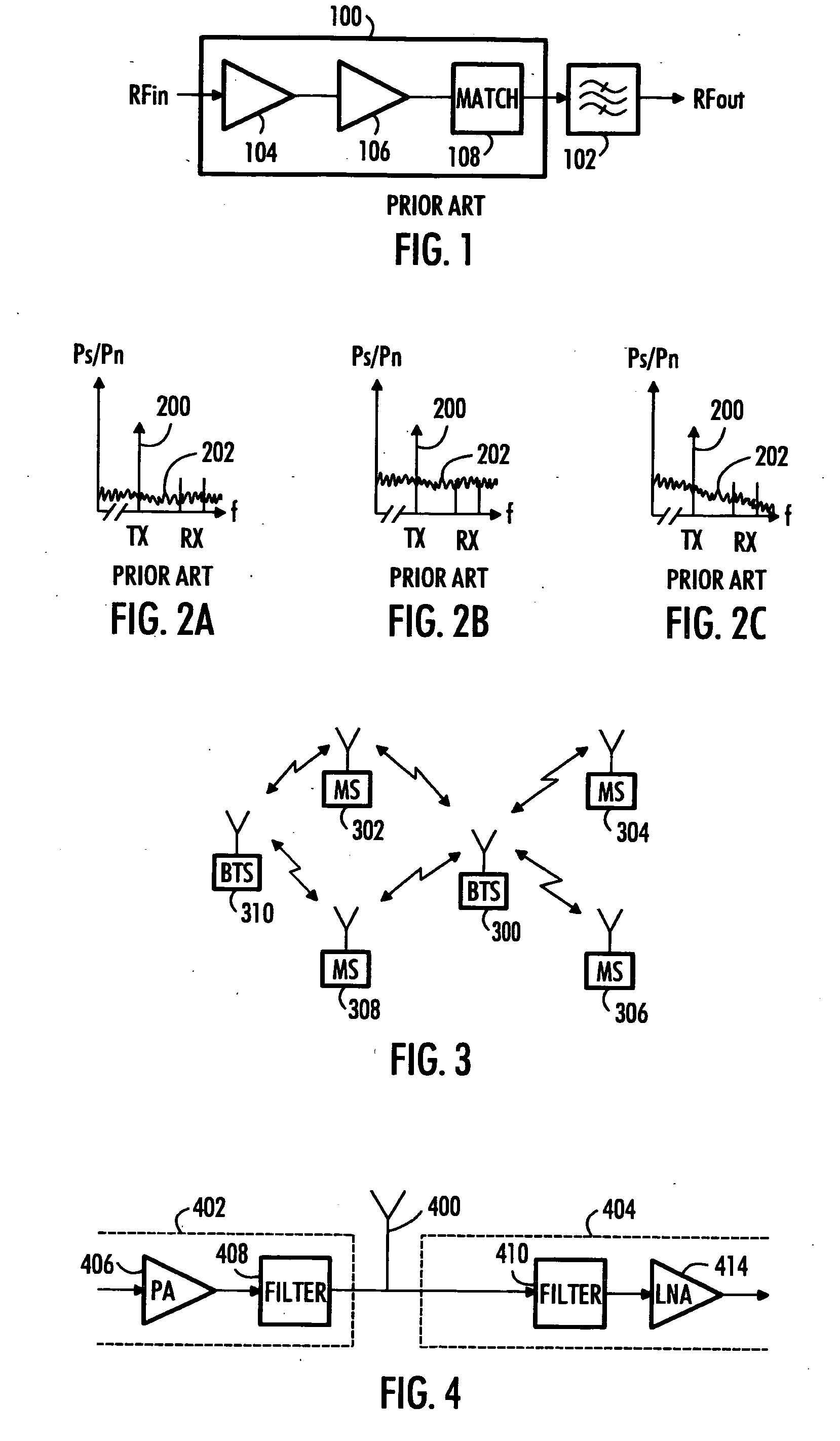

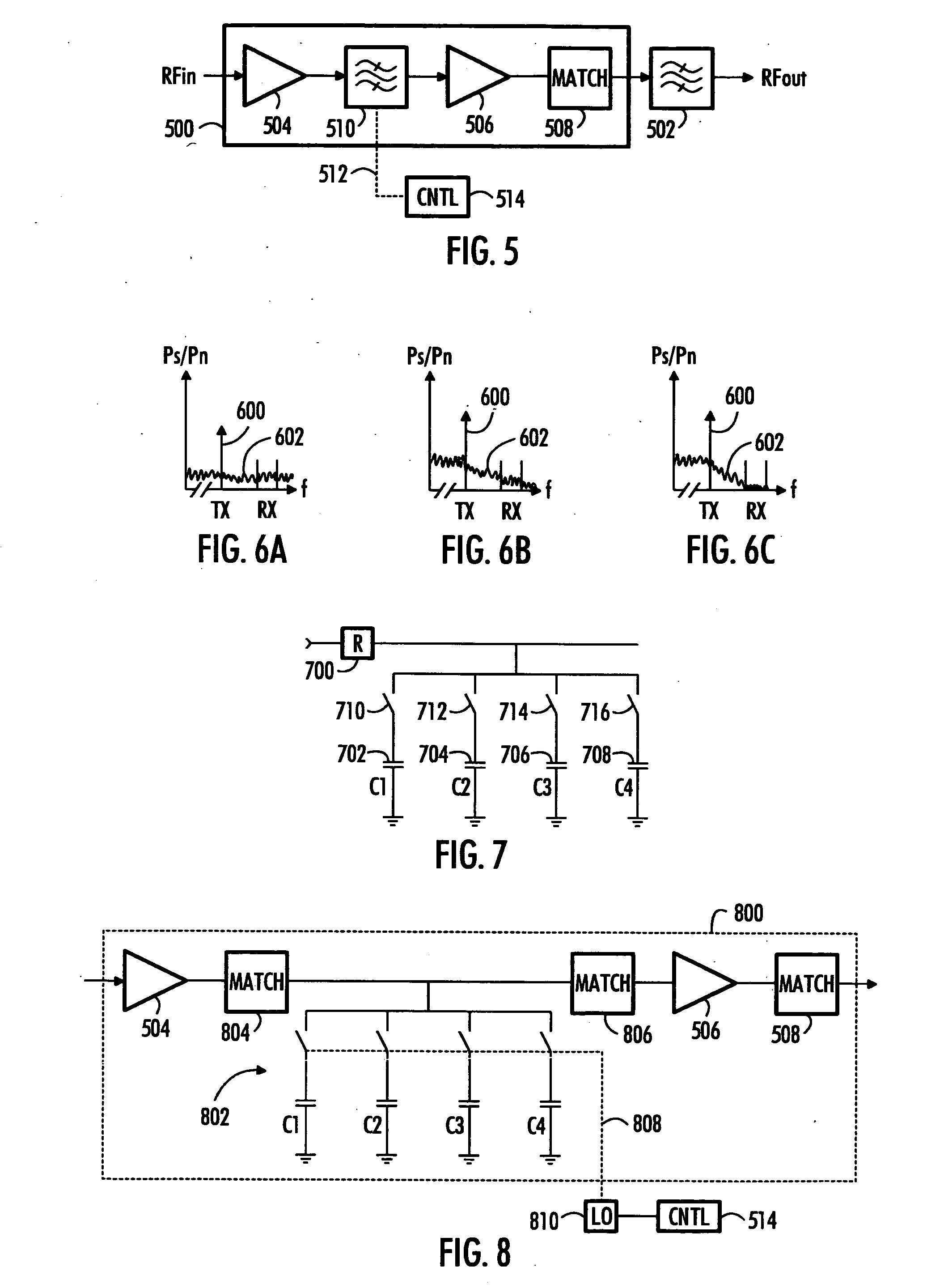

Transmitter, power amplifier and filtering method

ActiveUS20070218844A1Increases total transmitter chain efficiencyImprove power amplifier efficiencyResonant long antennasModulation with suppressed carrierAudio power amplifierTransceiver

A filtering method, a transceiver and a transmitter are provided. The transmitter comprises a power amplifier amplifying an RF signal and having multiple stages, and a local oscillator, the power amplifier comprising between at least two stages of the power amplifier an impedance circuitry for forming an impedance at a frequency related to the frequency of the local oscillator, and a switch for switching the impedance of the impedance circuitry means to RF frequency.

Owner:NOKIA TECHNOLOGLES OY

Sheetlike products and works

InactiveUS20090321028A1Good hygroscopicityGuaranteed specific surface areaNon-fibrous pulp additionSpecial paperMoisture absorptionMetal

This invention is to provide a sheet product that is excellent in moisture absorption amount, moisture absorption speed and moisture release speed and is capable of keeping a powder from falling off and that can have a large content of a moisture adsorbent, and the sheet product of this invention contains (a) a moisture adsorbent formed of a tubular or fibrous metal oxide, (b) a cellulosic fibrillated fiber, and (c) an organic fiber having a fineness of 0.01 dtex to 0.45 dtex and is characteristically produced by a paper-making method.

Owner:MITSUBISHI PAPER MILLS LTD

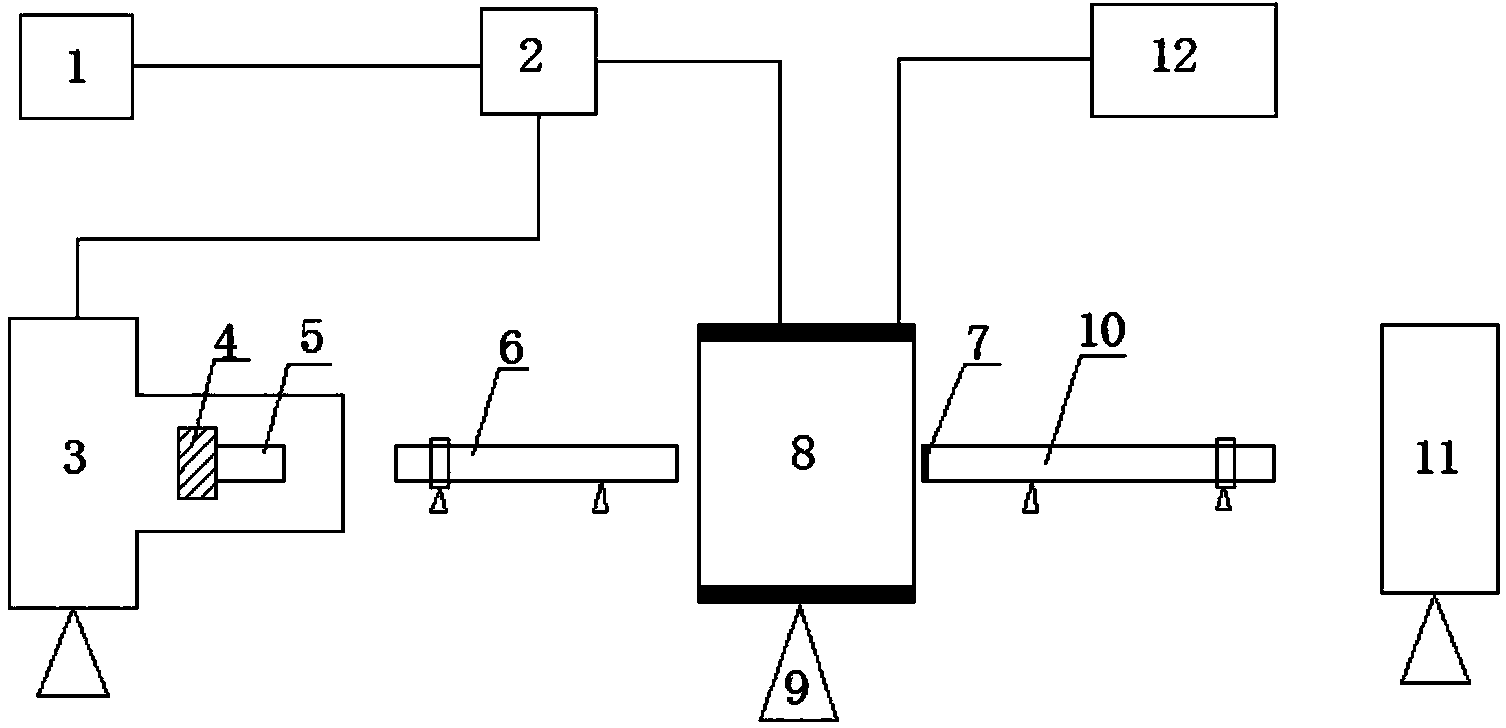

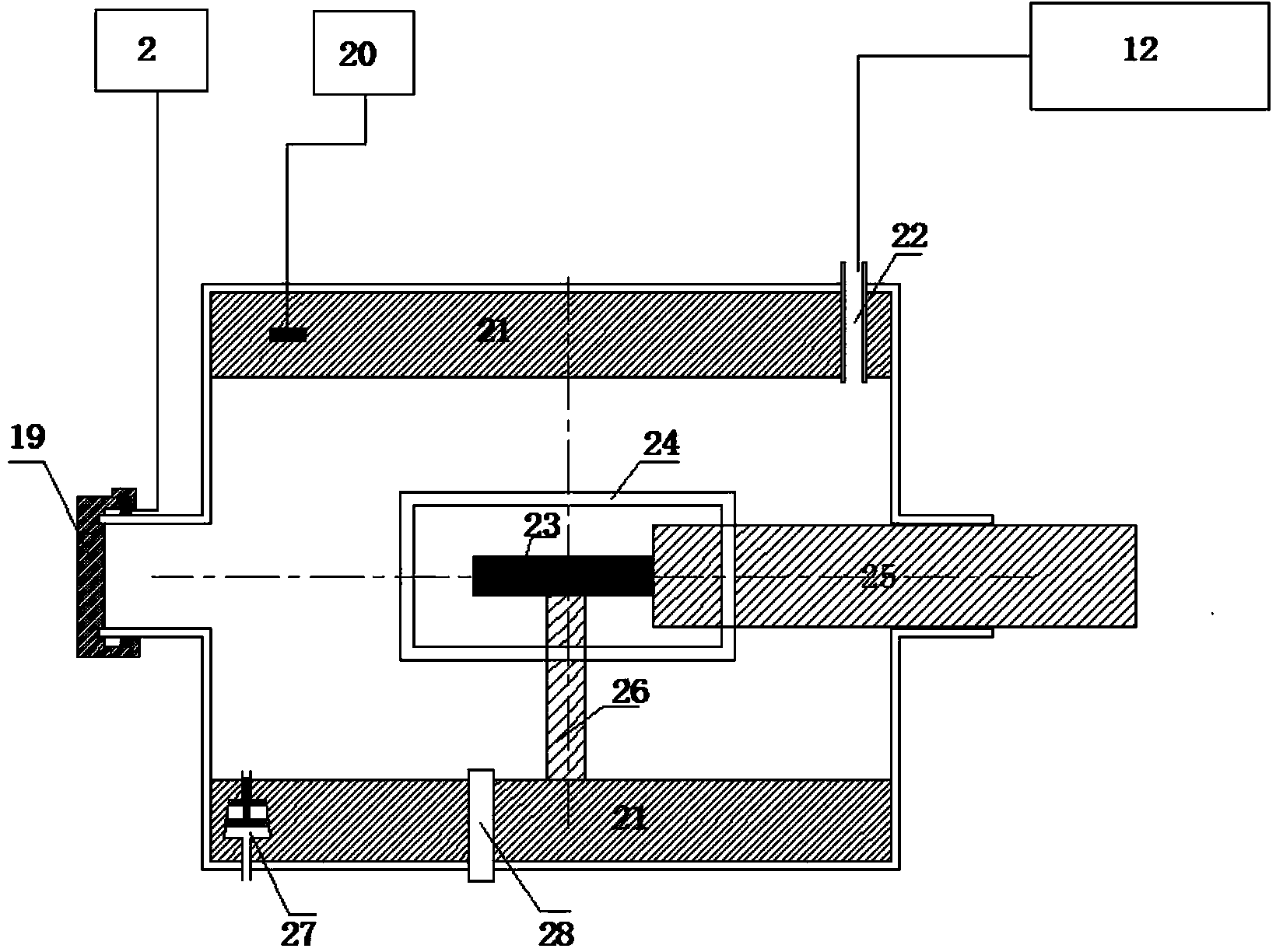

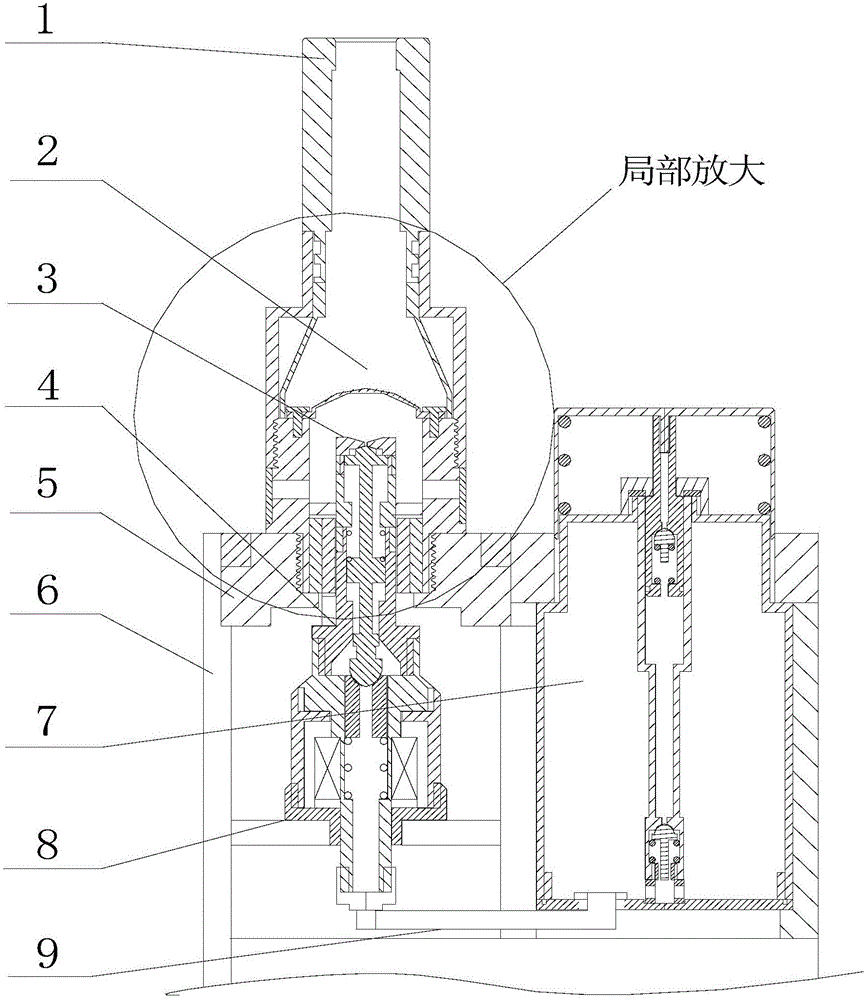

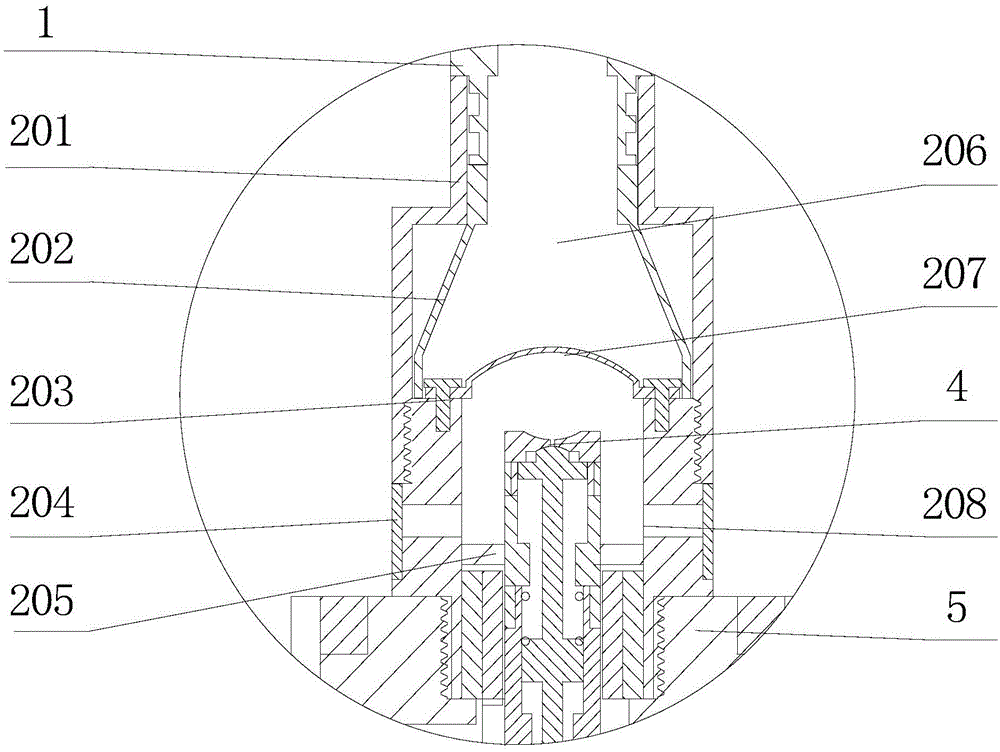

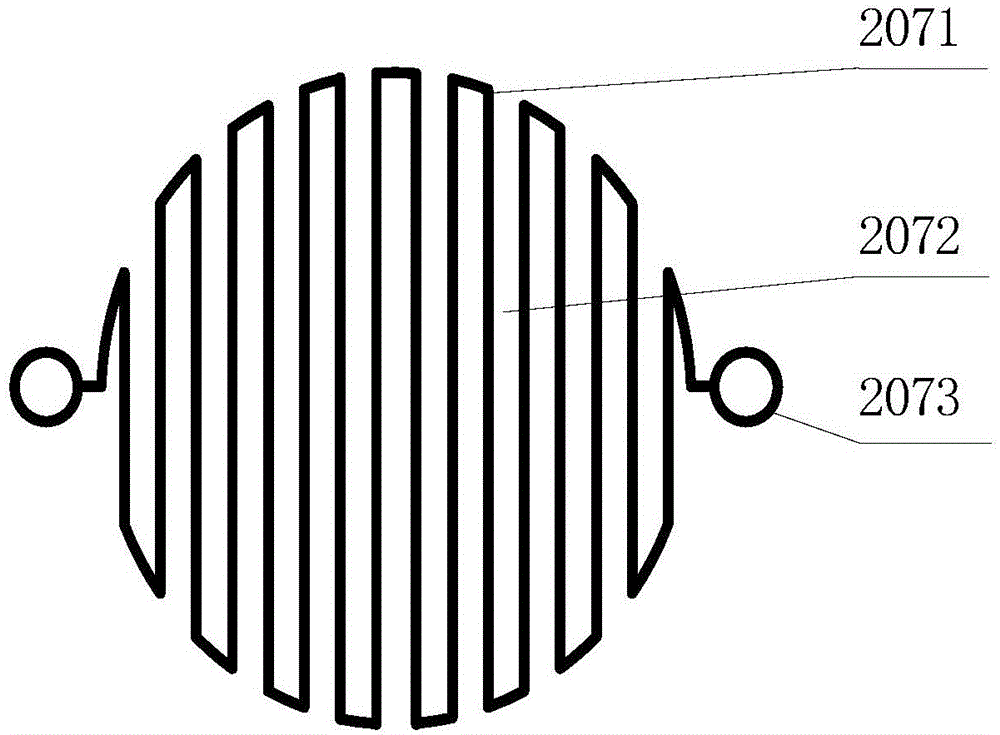

Hopkinson pressure bar experimental apparatus

InactiveCN103868806AAvoid Complexity and UncertaintyHigh repeatabilityStrength propertiesStress waveEngineering

The invention discloses a Hopkinson pressure bar experimental apparatus. The Hopkinson pressure bar experimental apparatus is characterized by comprising an electromagnetic trigger switch (1), a heating furnace door automatic opening switch (2), an electromagnetic driving device (3), a driving panel (4), a bullet (5), an incident pole (6), a force sensor (7), a heating furnace (8), a heating furnace supporting device (9), a transmitting pole (10), a buffer device (11) and an air compressing and filtering device (12); and the heating furnace is designed for preventing a test piece from being oxidized at a high temperature while heating the test piece and keeping the temperature of the test piece; as high temperature can influence the conduction of stress wave, the digital image correlation (DIC) technology is used for obtaining the change images of the test piece and analyzing the strain, the force sensor is used for analyzing stress, so as to obtain a stress strain curve. The Hopkinson pressure bar is combined with the electromagnetic driving technology and the DIC technology, and therefore the application range of the Hopkinson pressure bar experiment is expanded and a new method for acquiring dynamic parameters of high temperature materials is provided.

Owner:HUNAN UNIV

Electronic cigarette device

ActiveCN105011379ANo leakageNo more problems with changing coilsTobacco devicesSpray nozzleEngineering

The invention discloses an electronic cigarette device. The electronic cigarette device comprises a cigarette liquid supplying device, a cigarette liquid atomizing device and an atomized cigarette mist sucking-out device. The cigarette liquid supplying device is a cigarette liquid pressurizing supplying device. The cigarette liquid atomizing device further comprises a cigarette liquid spraying atomization device body and a cigarette liquid heating atomization device body. The cigarette liquid pressurizing supplying device is communicated with the cigarette liquid spraying atomization device body. The cigarette liquid spraying atomization device body is provided with a spraying nozzle, and the spraying nozzle is arranged to face and be close to the cigarette liquid heating atomization device body. The cigarette liquid heating atomization device body is an electric heating plate. The atomized cigarette mist sucking-out device comprises a sucking-out channel and a sucking-out nozzle. According to the electronic cigarette device, due to the assisting effect of spraying atomization, the heating atomization temperature can be reduced in cooperation with the heating atomization effect, and the stability of an electronic cigarette can be kept to the maximum degree; meanwhile, liquid leakage can be prevented, and no atomization core is needed. The electronic cigarette device is an electronic cigarette product of a brand new structure.

Owner:INNOKIN TECH

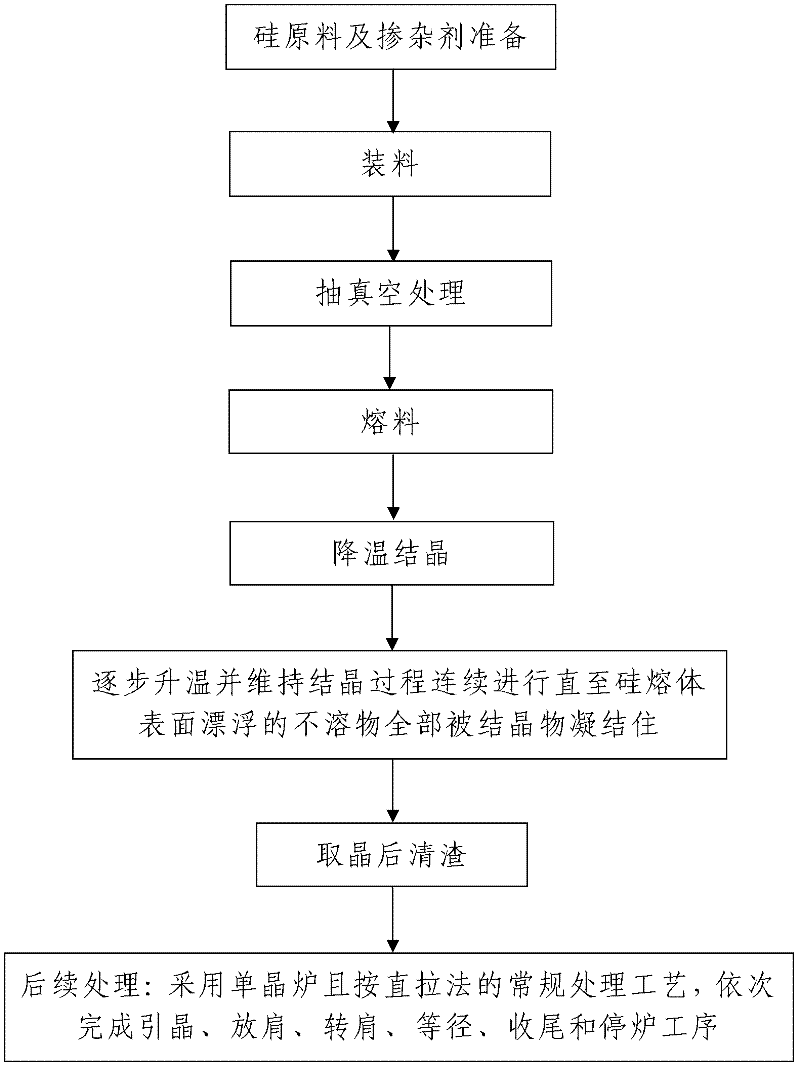

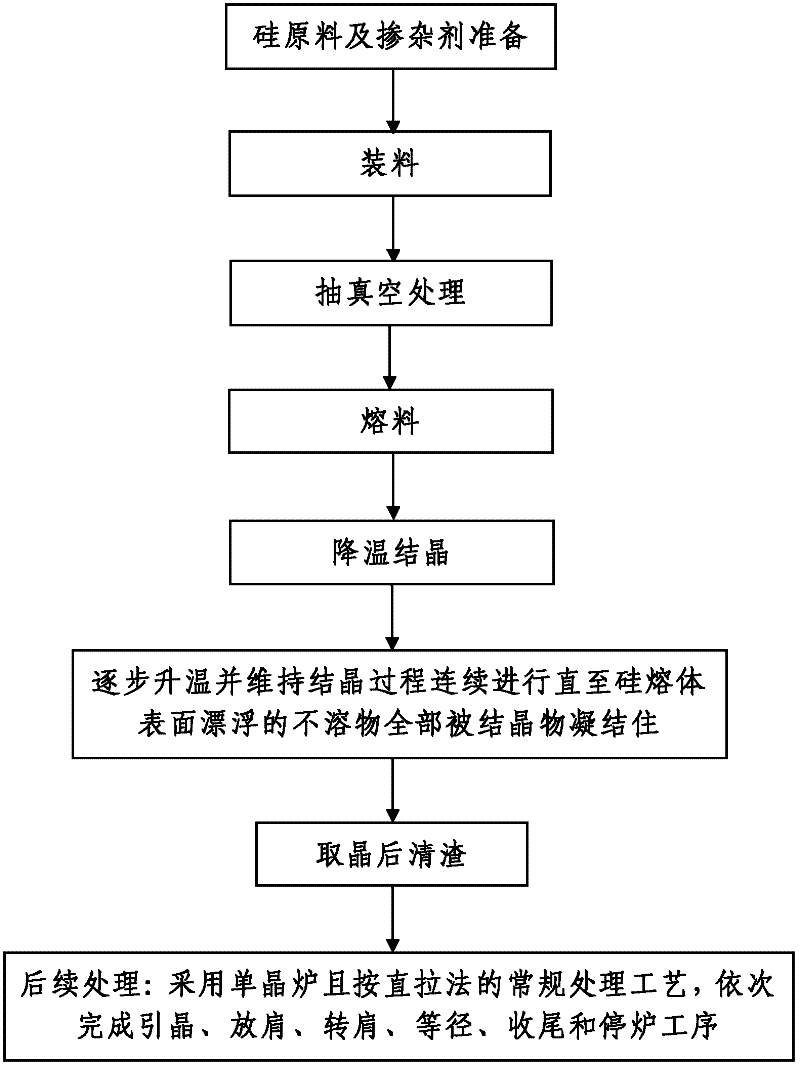

Process for producing Czochralski silicon single crystal

InactiveCN102242397AReasonable designThe process steps are simplePolycrystalline material growthBy pulling from meltDopantSlag

The invention discloses a process for producing a Czochralski silicon single crystal, which comprises the following steps of: 1, preparing a silicon raw material and a doping agent; 2, charging; 3, vacuumizing; 4, melting; 5, extracting slag, namely 501, performing cooling crystallization, 502, gradually heating, and keeping the crystallization process continuously performed until insoluble substances floating on the surface of a silicon melt are completely condensed by the crystal, and 503, taking the crystal out, and removing the slag; and 6, performing subsequent treatment, namely finishing crystal leading, shoulder expanding, shoulder rotating, diameter equalizing, ending and blowing down processes in turn by using a single crystal furnace according to the conventional treatment process of a Czochralski method to obtain the finished silicon single crystal formed by pulling. The process is reasonable in design, simple in steps, convenient to implement, easy to master and good in using effect, can effectively ensure the quality of the produced silicon single crystal, and can solve the practical problems that slag removing time is difficult to master, the slag extracting effect is poor, the produced silicon single crystal has low purity, and the like.

Owner:XIAN HUAJING ELECTRONICS TECH

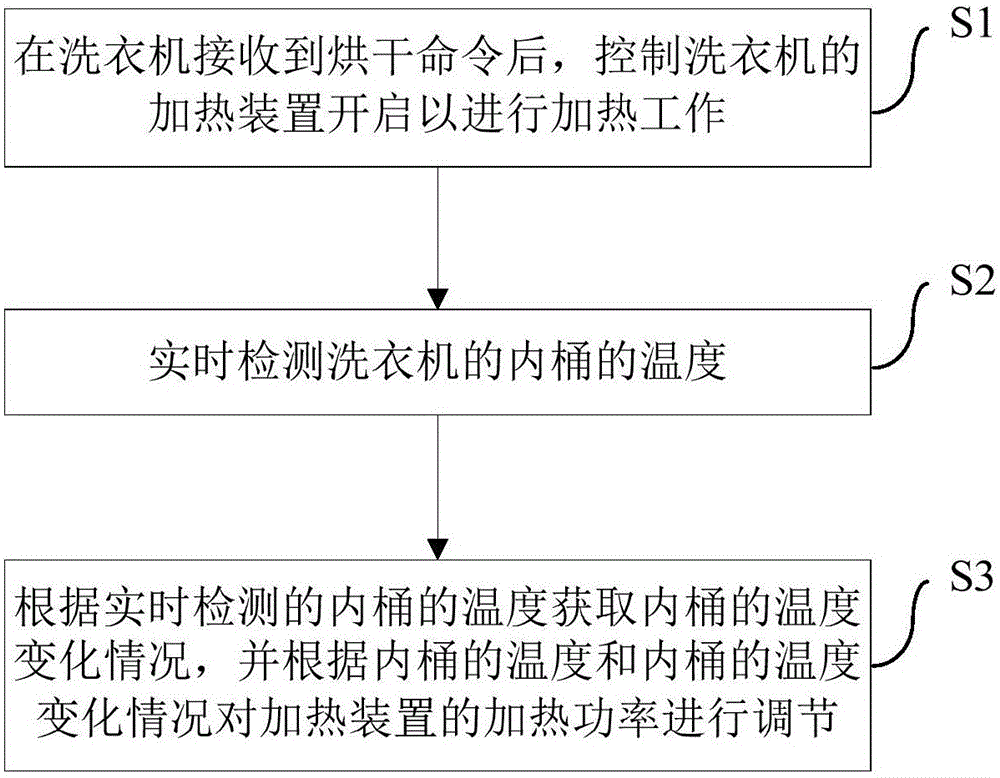

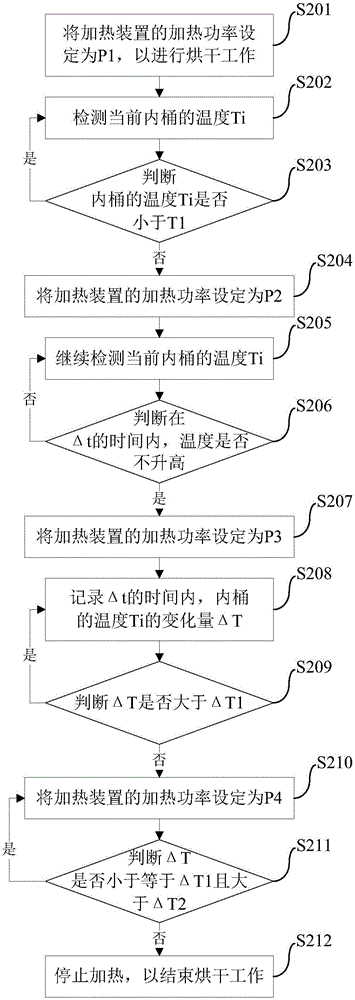

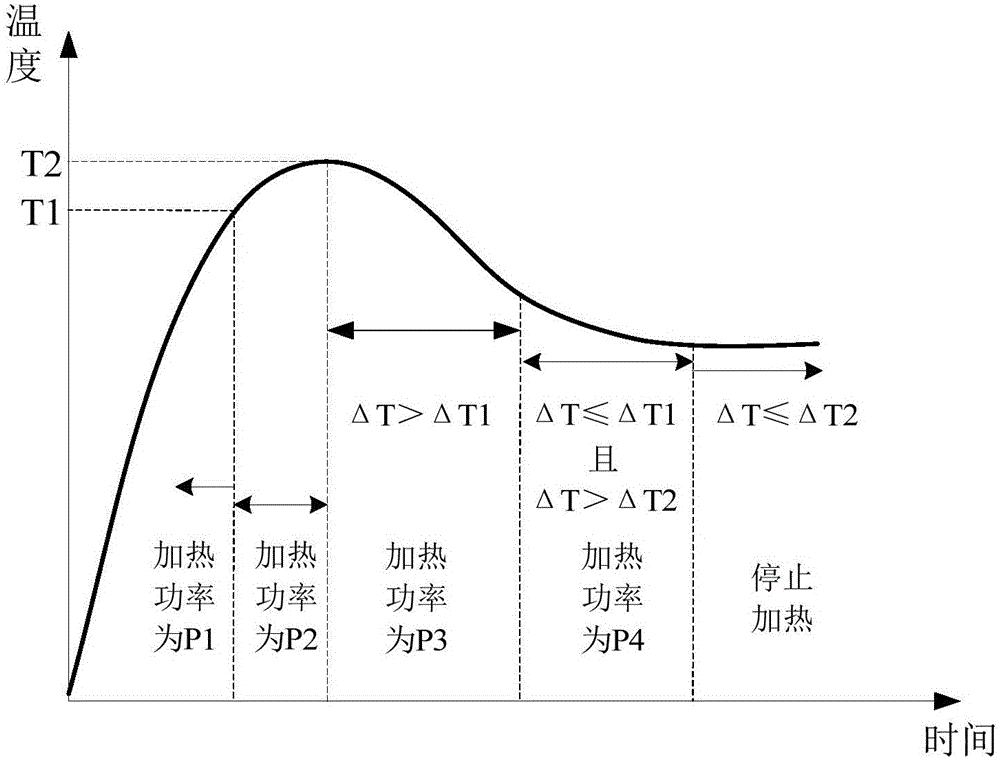

Drying control method of washing machine and washing machine

ActiveCN106012411AImprove drying efficiencyHeating power regulationOther washing machinesWashing machine with receptaclesProcess engineeringHeating power

The invention discloses a drying control method of a washing machine and the washing machine. The drying control method comprises the following steps: controlling a heating device of the washing machine to start so as to carry out heating work after a drying command is received by the washing machine; detecting the temperature of an inner barrel of the washing machine in real time; obtaining the temperature variation situation of the inner barrel according to the temperature, which is detected in real time, of the inner barrel, and regulating the heating power of the heating device according to the temperature of the inner barrel and the temperature variation situation of the inner barrel. According to the method disclosed by the invention, not only can the drying efficiency of the washing machine be increased, but also the consumption of electric energy can be reduced, and energy conservation and environment protection are realized.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

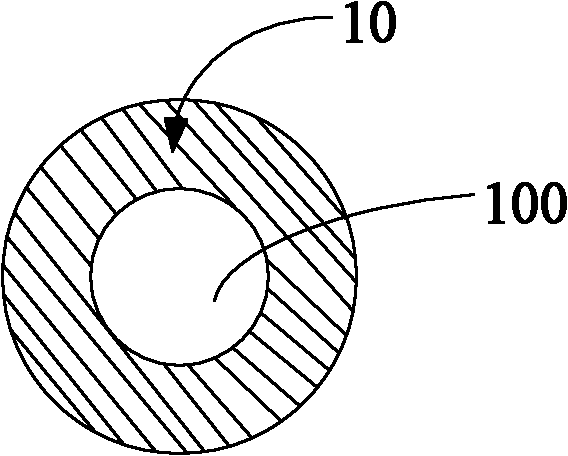

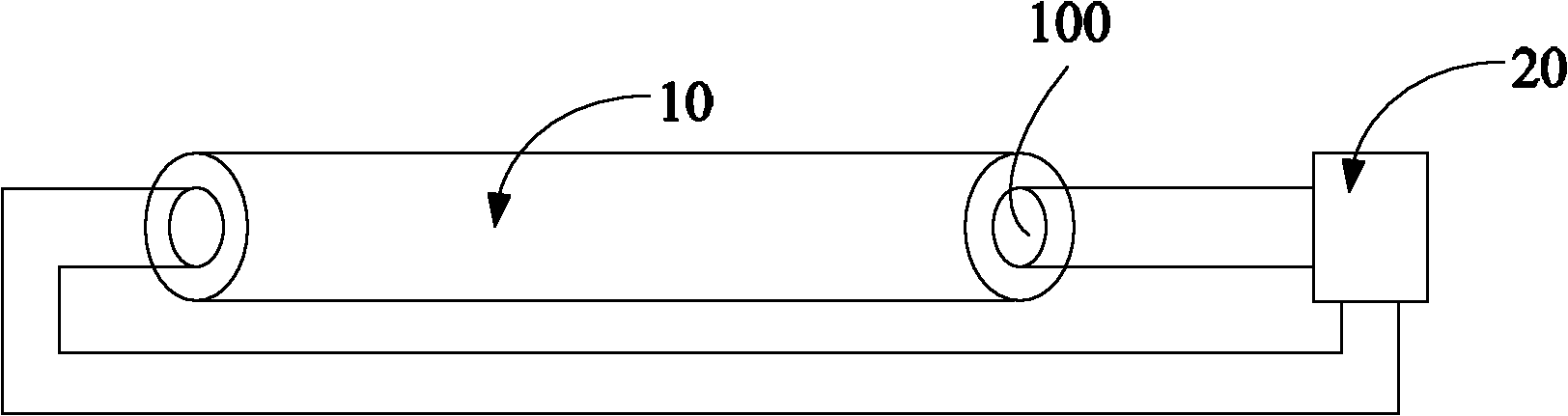

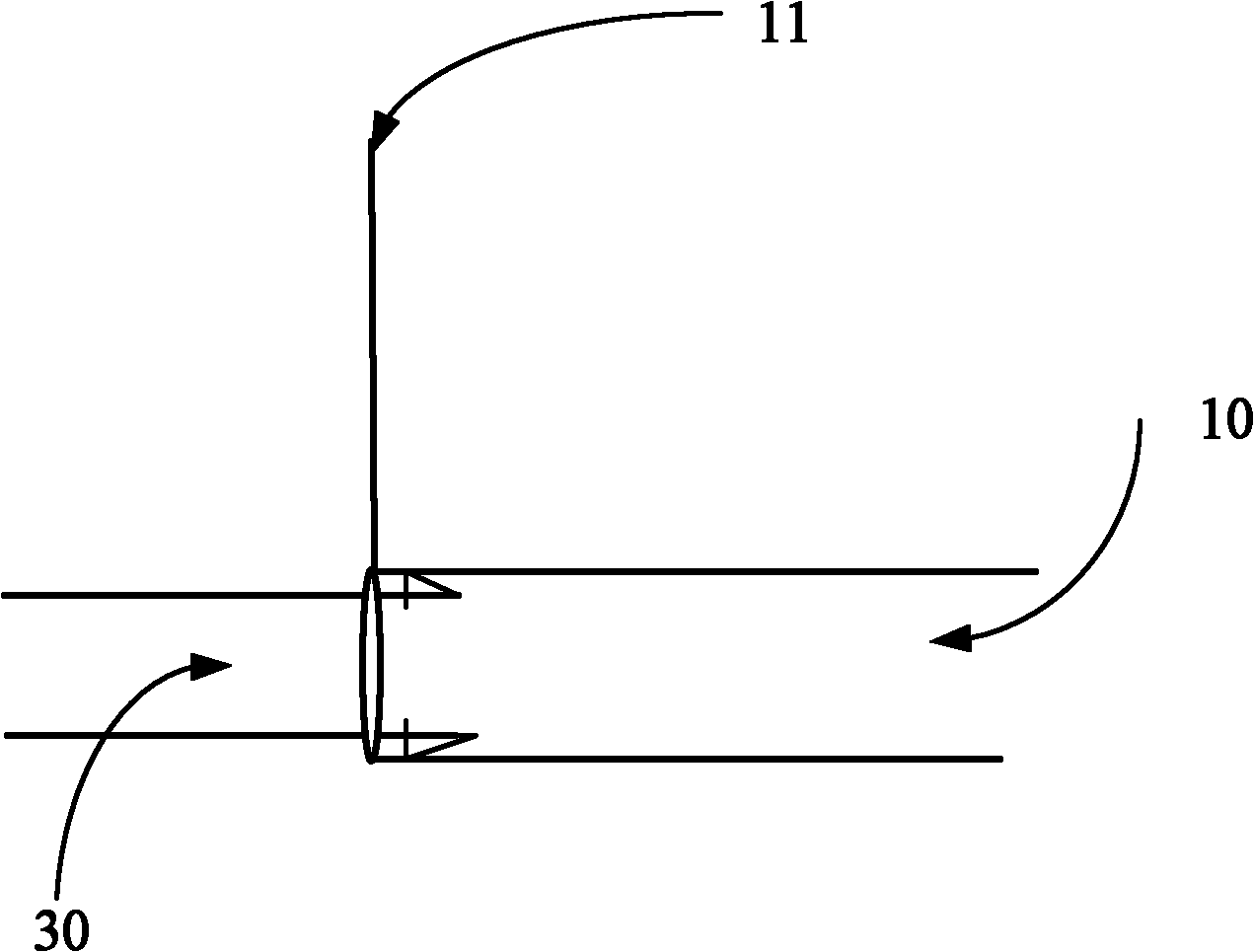

Coil of magnetic resonance imaging system, and cooling device and method thereof

ActiveCN102110510AReduce heating powerIncrease the cross-sectional areaDiagnostic recording/measuringSensorsSkin effectConductive materials

The invention relates to a coil of a magnetic resonance imaging system, and a cooling device and a cooling method thereof. The coil of the magnetic resonance imaging system is formed by winding a hollow wire which is made of a magnetic compatible conducting material. In the coil of the magnetic resonance imaging system, and the cooling device and the cooling method thereof, the coil is formed by winding the hollow wire, and the cross sectional area of a cylindrical coil is increased; a conductor skin effect is reduced due to the increase of the cross sectional area, so that the radiating power of the coil is reduced, and the effect of generating less heat is achieved; and the hollow wire is made of the magnetic compatible conducting material, so that the influence on a magnetic field is reduced and the performance of a gradient coil is improved.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Capacity-self-adaptive pulping method

ActiveCN104872292AAccurate measurementPrecise pulping capacityMilk substitutesThermal energyElectricity

The invention relates to a capacity-self-adaptive pulping method which comprises the following stages: (1), a preheating stage, to be specific, starting a heating device for heating to T1, continuously heating to T2, wherein delta T is equal to T2 minus T1, calculating out electric energy consumed when the temperature is increased to T2 from T1 by a control device, wherein a preset heat efficiency coefficient eta and a specific heat capacity c are stored in the control device, m represents the pulping capacity, and W<electricity> represents electric energy, and calculating out the pulping capacity by the control device according to the law of conservation of energy, namely heating electric energy*eta is equal to thermal energy absorbed during temperature increase and the formula is that (eta)W<electricity> is equal to cm(delta)T; (2), a smashing stage, to be specific, adjusting smashing frequency, smashing time and / or smashing power by the control device according to the pulping capacity; (3), a decocting stage, to be specific, adjusting the heating time and / or heating power by the control device according to the pulping capacity. Therefore, intelligent optimization of pulping parameters is realized and an optimum pulping effect is realized.

Owner:HONGYANG HOME APPLIANCES

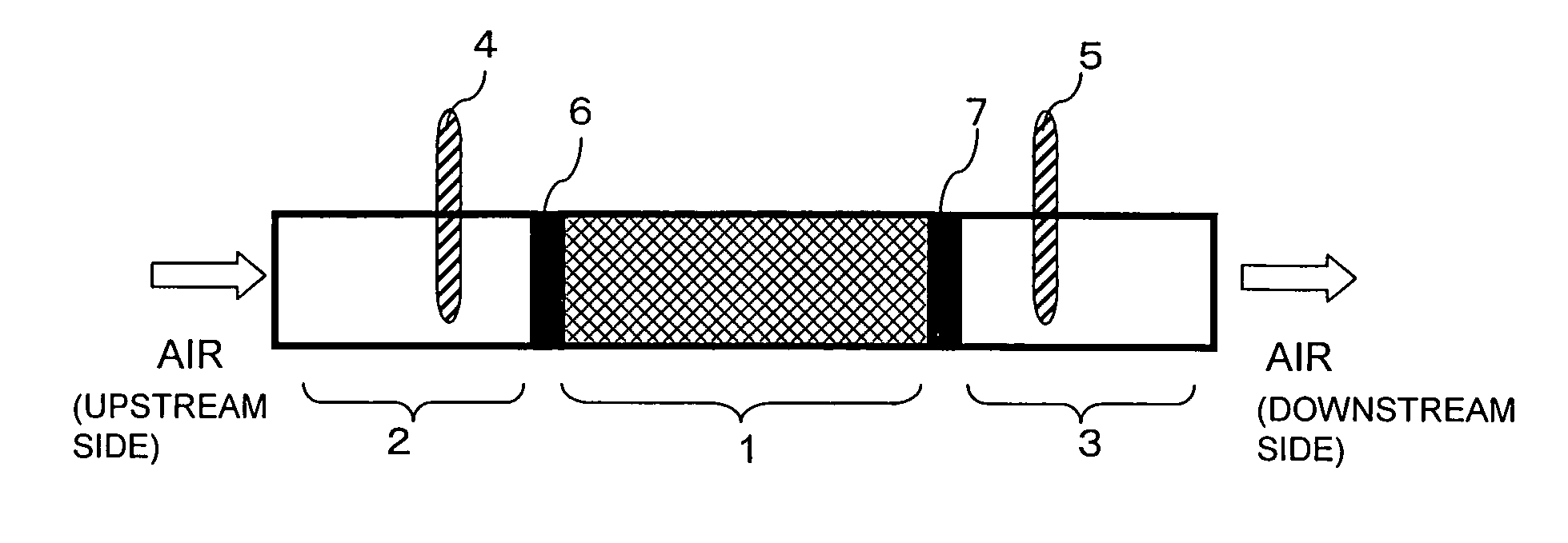

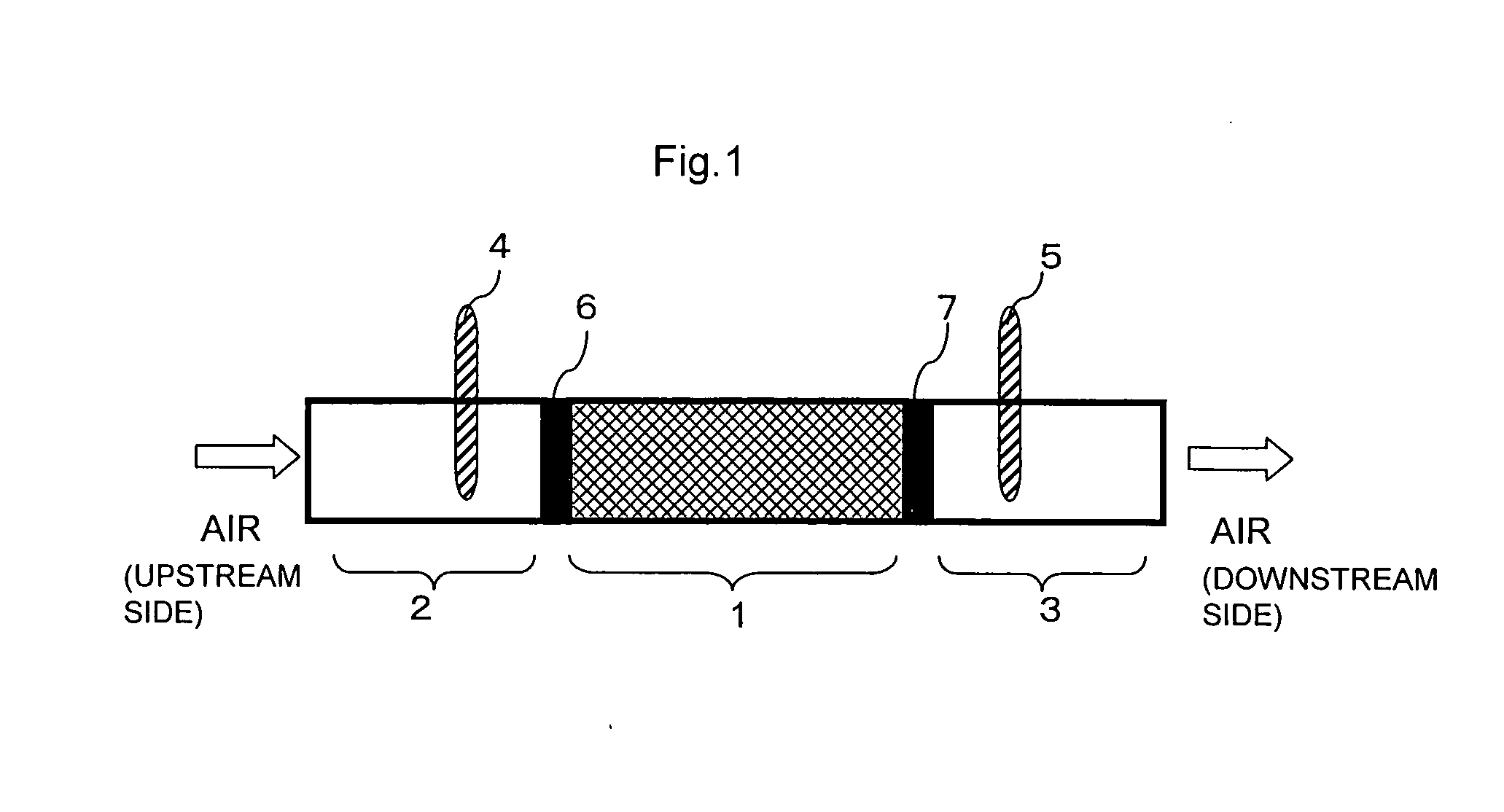

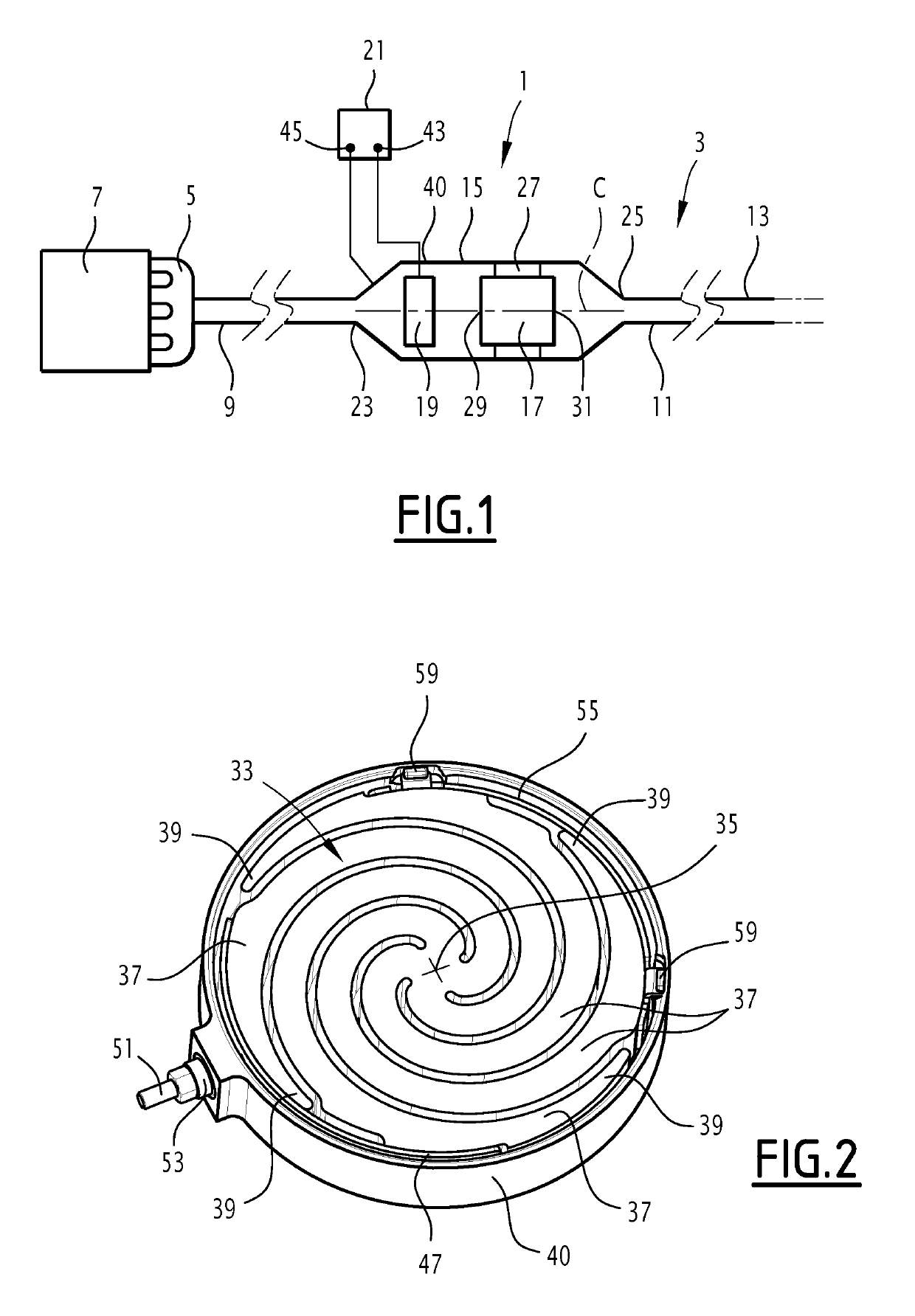

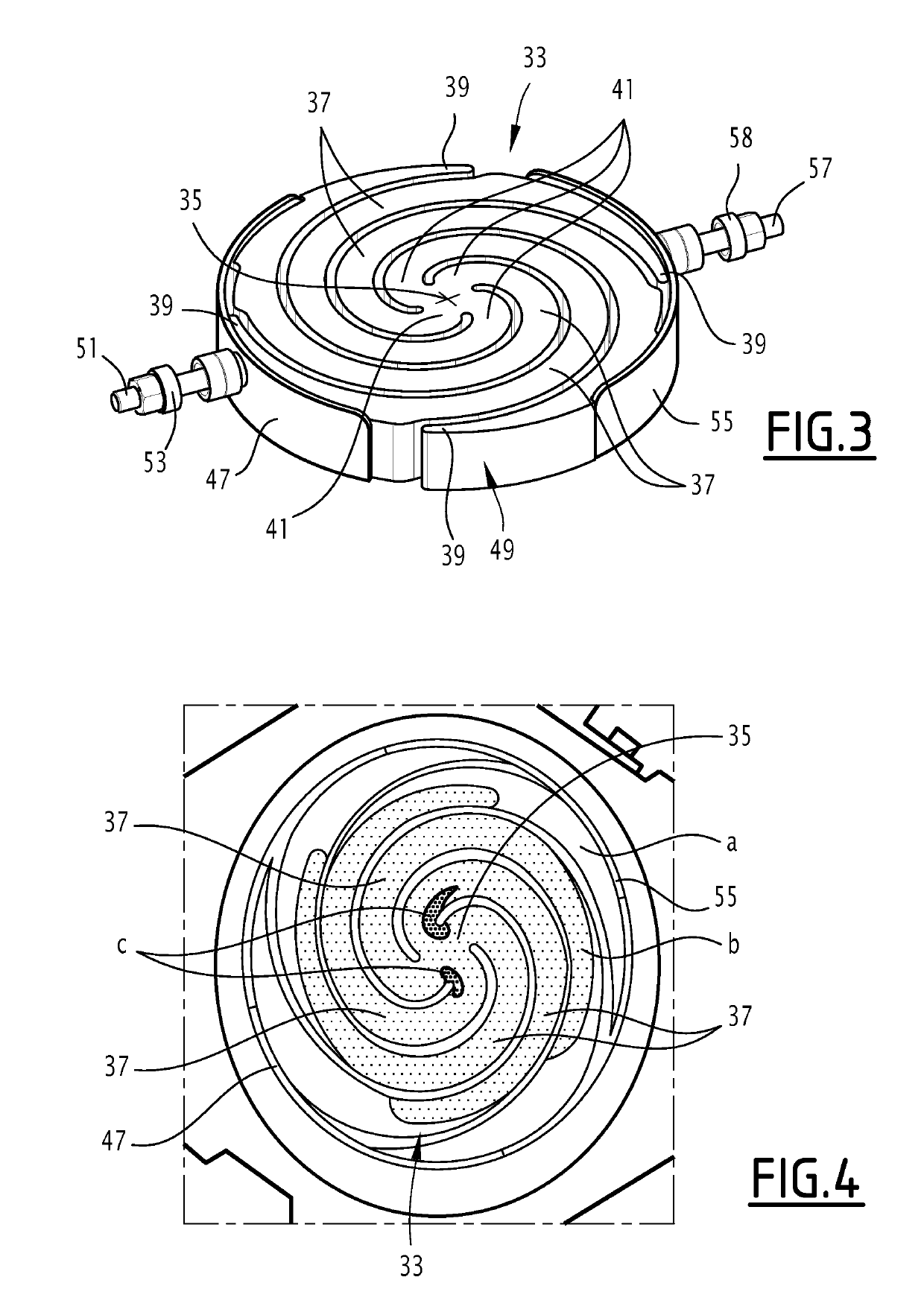

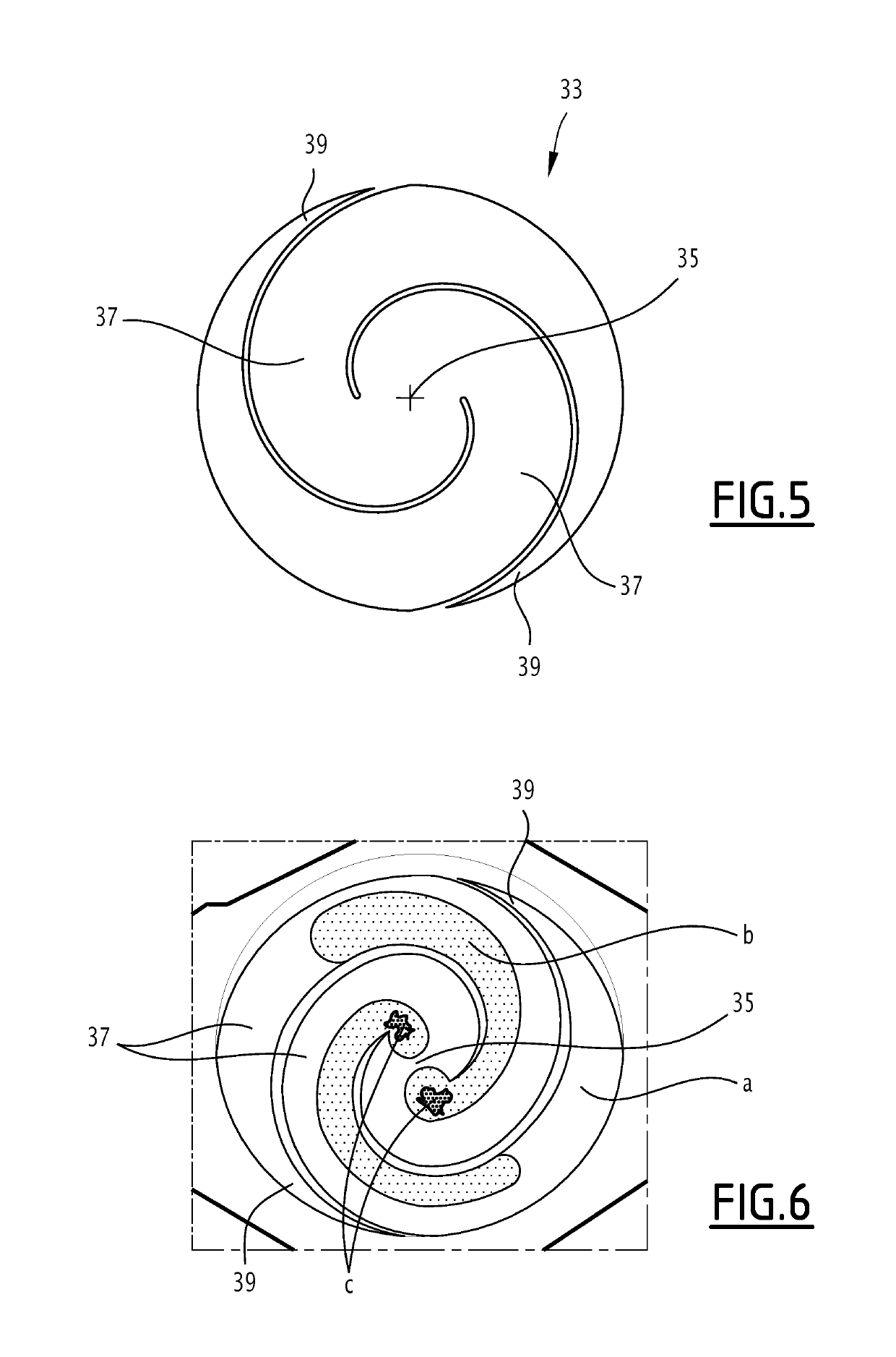

Exhaust line, exhaust gas purification device, and purification device manufacturing process

ActiveUS20190316507A1Improve heat transfer performanceReduce heating powerInternal combustion piston enginesDispersed particle filtrationExhaust gasElectrically conductive

An exhaust gas purification device for a vehicle includes a tubular enclosure having a central axis, a purification member for exhaust gases housed in the tubular enclosure, an electric heating member housed in the tubular enclosure, and a power source electrically powering the electric heating member. The electric heating member comprises a heating plate made from an electrically conductive material extending in a plane substantially perpendicular to the central axis. The heating plate has a solid center and at least two branches, each branch extending in a spiral from the solid center to a free end located near the tubular enclosure. The heating plate is permeable to the exhaust gases and comprises a network of passages for the exhaust gas generating a turbulent flow of the exhaust gases through the heating plate.

Owner:FAURECIA SYST DECHAPPEMENT

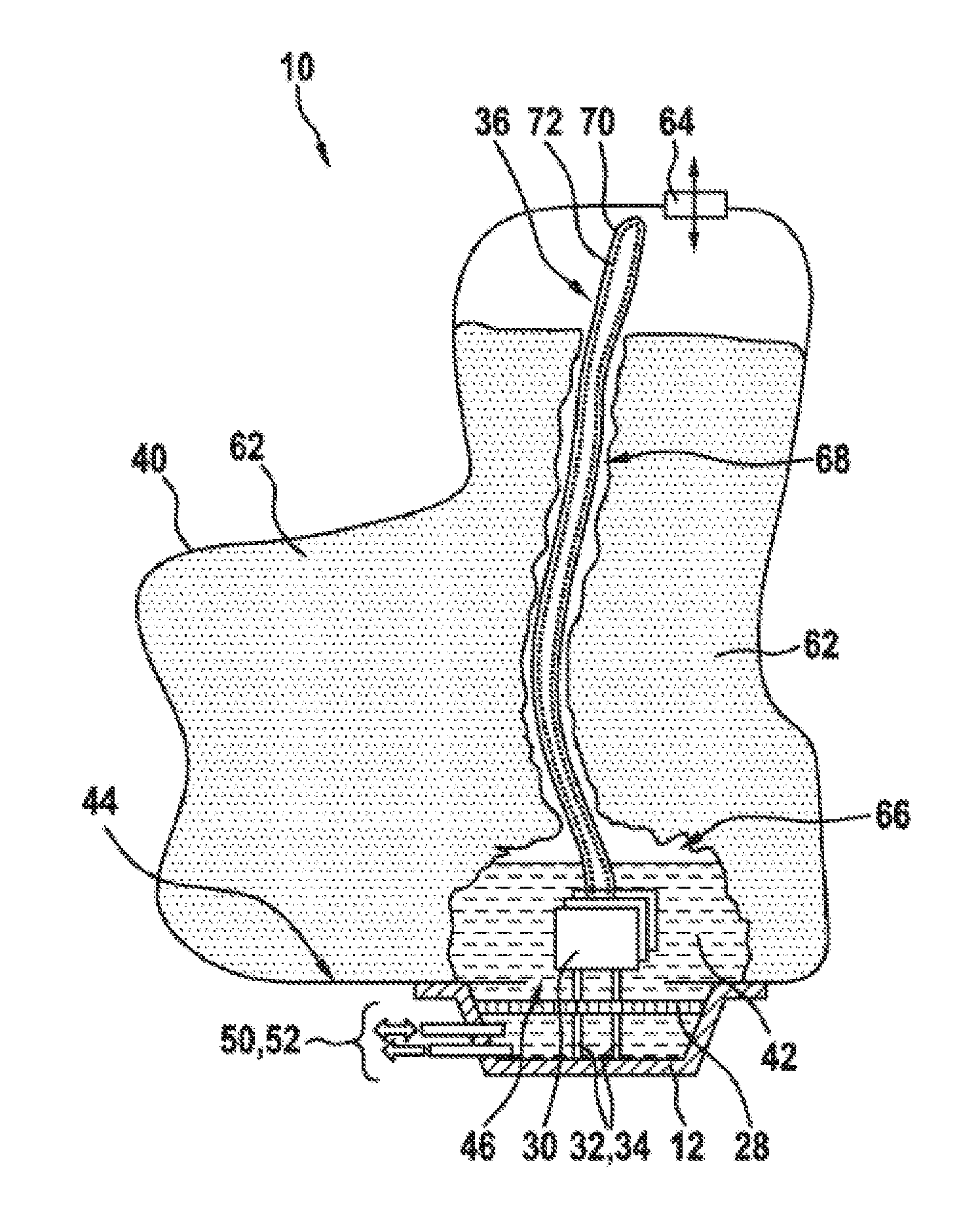

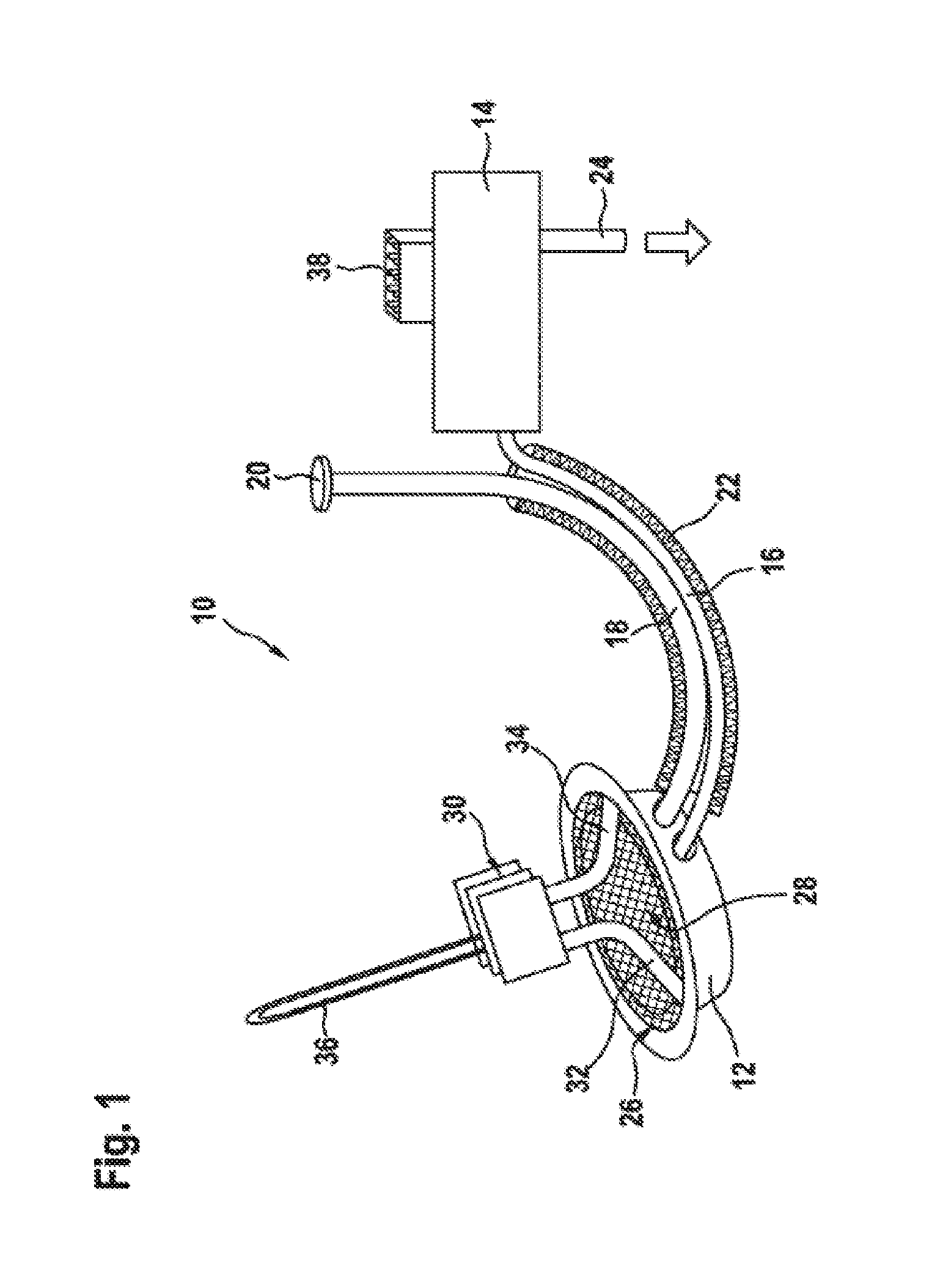

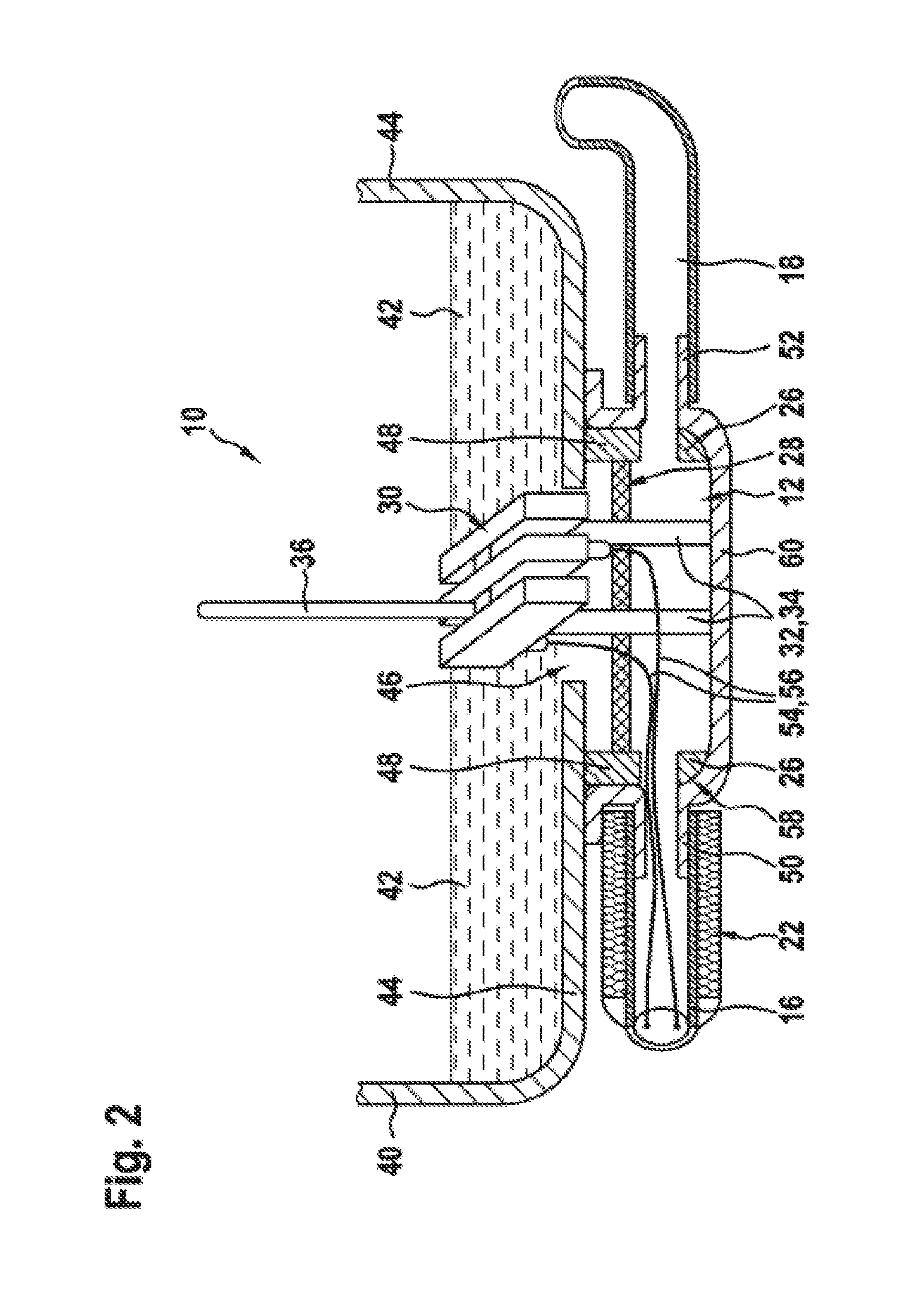

Device for supplying a reducing agent to an exhaust-gas aftertreatment system

InactiveUS20130318950A1Simple structural designAvoid measurement errorsInternal combustion piston enginesExhaust apparatusElectricityNitrogen oxides

The invention relates to a device (10) for supplying to an exhaust-gas aftertreatment system a reducing agent (42), in particular a urea-water solution for the reduction of nitrogen oxides in the exhaust-gas flow of a diesel engine, having a tank (40) for the reducing agent (42) and having a delivery module (14) for delivering the reducing agent (42) out of the tank (40) via an in particular electrically heatable suction line (16). According to the invention, a) the suction line (16) which runs outside the tank (40) is connected to a pump sump (12) situated in the region of the tank base (44), b) an in particular electrically operated pump sump heater (30) is arranged in the region of the pump sump (12), c) at least one in particular electrically operated heating rod (36) extends into the tank (40), and d) at least one fill level sensor (18) runs outside the tank (40). The pump sump heater (30), the heated suction line (16), the heating rod (36) and an optional elastic compensating element (26) in the region of the pump sump (12) permit a substantially temperature-independent supply of the reducing agent (42) to an exhaust-gas aftertreatment system of a diesel engine. The pump sump (12) which is mounted on the bottom of the tank (40) furthermore makes it possible for the reducing agent (42), which must be available in the exact dose for correct execution of the SCR method, to be supplied virtually completely independent of position, and nevertheless uniformly, to the exhaust-gas aftertreatment system.

Owner:ROBERT BOSCH GMBH

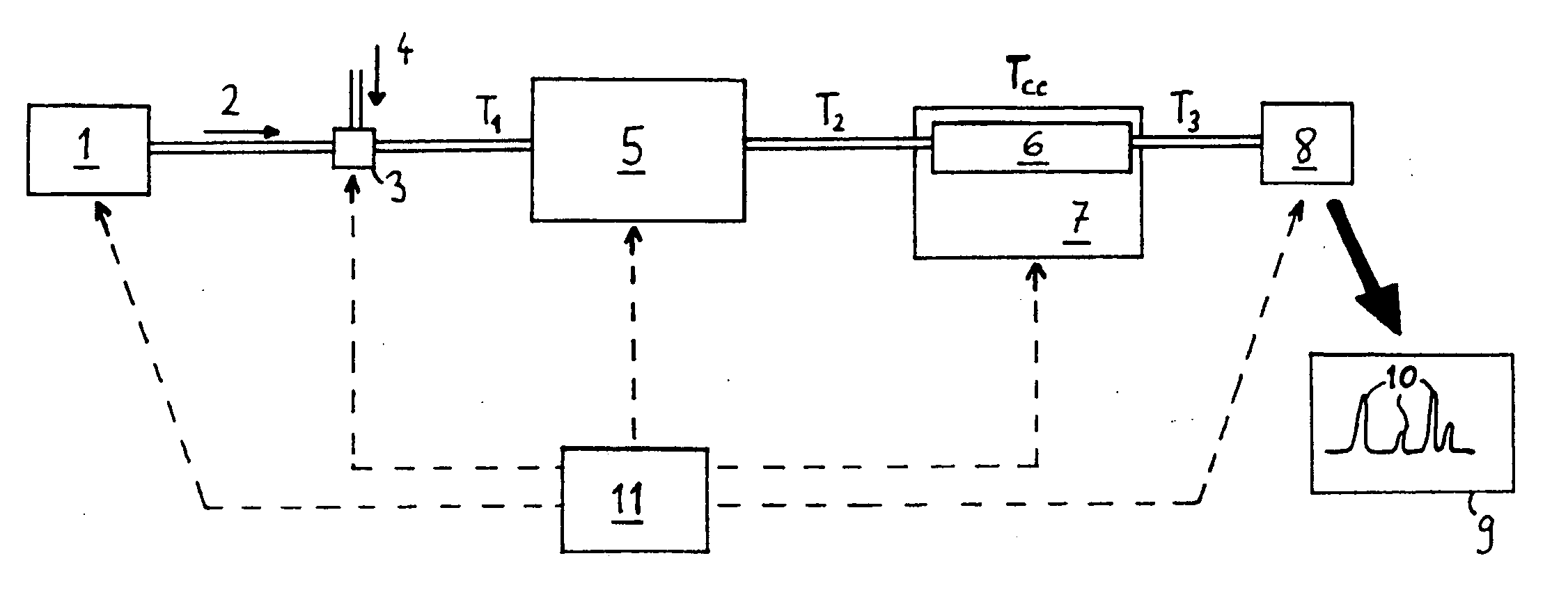

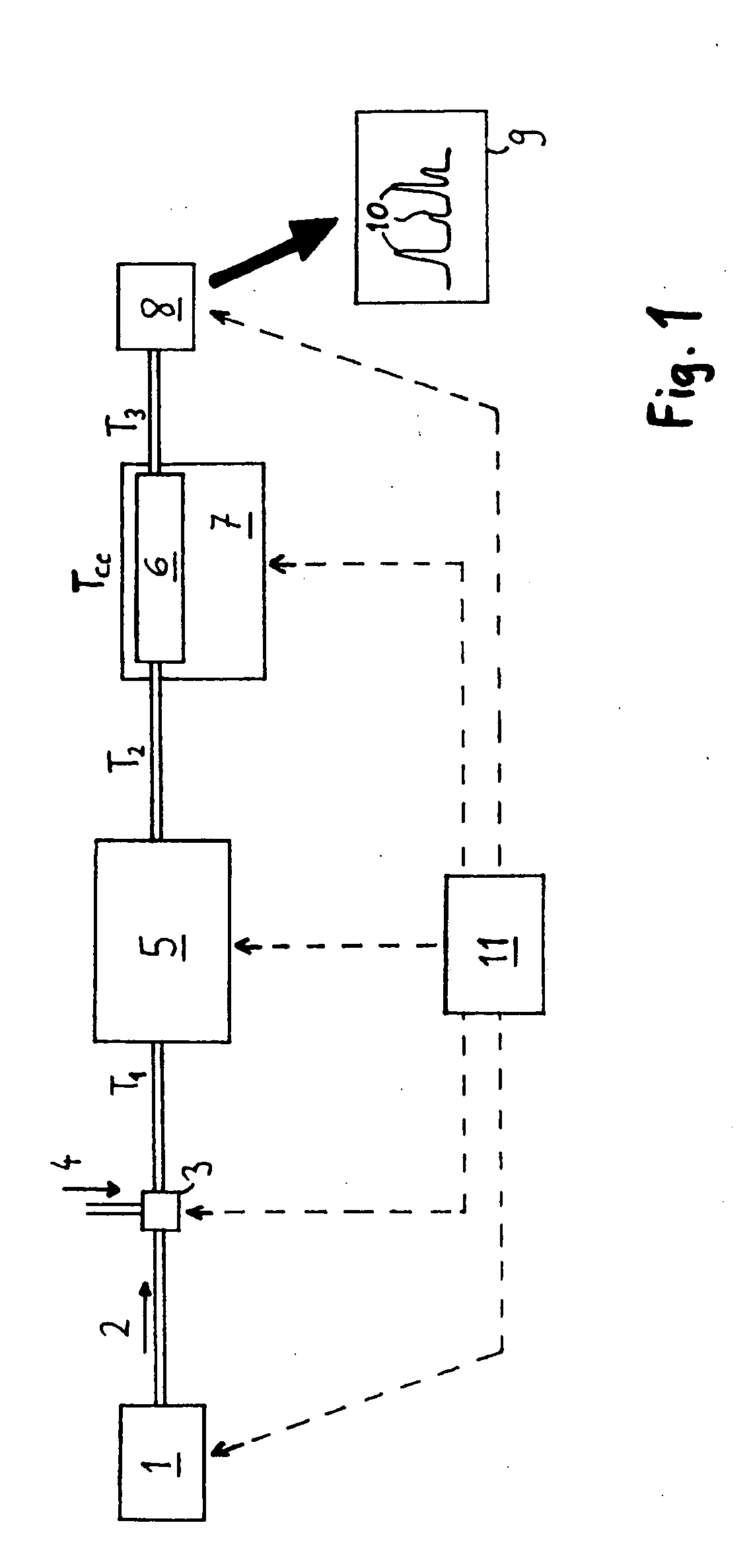

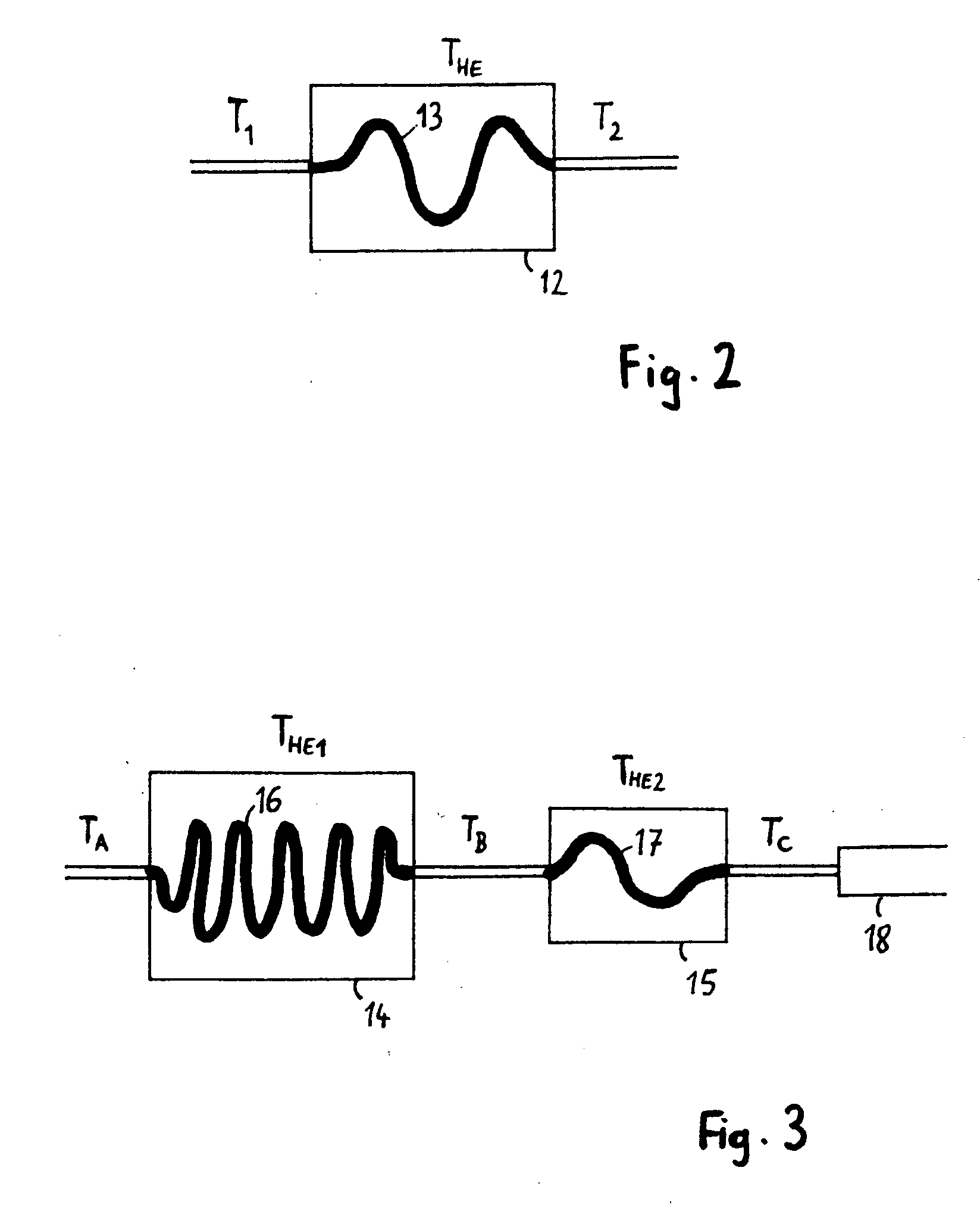

Fluid preheating

InactiveUS20070181702A1Reduction of half widthImprove resolutionComponent separationWater heatersHeating systemEngineering

A heating system for preheating a fluid. The heating system comprises a heating unit with a heating flow path; wherein the heating unit is adapted to be operated at a first temperature and to provide a heat transfer between the heating unit and the fluid passing through the heating flow path, with the heat transfer not being sufficient for heating up the fluid passing through the heating flow path to the first temperature.

Owner:AGILENT TECH INC

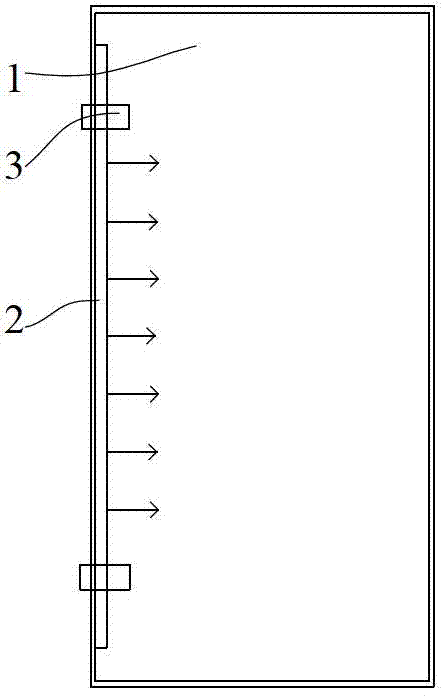

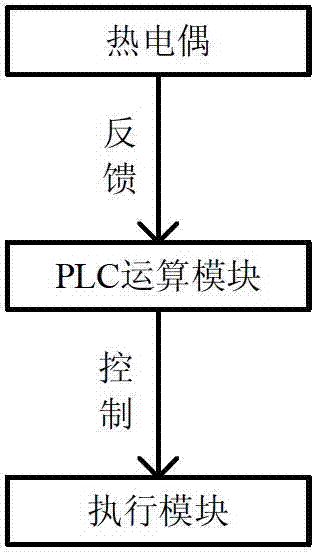

High-temperature solidifying furnace

InactiveCN102784747ATemperature monitoringImprove monitoring accuracyThermometer detailsMuffle furnacesMonitoring temperatureTemperature monitoring

The invention discloses a high-temperature solidifying furnace. The high-temperature solidifying furnace comprises a heating cavity, a heater and a temperature monitoring system, wherein the heater comprises a plurality of heating modules which can be controlled independently; and the temperature monitoring system comprises a thermocouple for monitoring the internal ambient temperature information of the heating cavity, an infrared monitoring device for monitoring temperature information on the surface of each layer of substrate inside the heating cavity and generating a temperature signal, a signal processing module for performing signal connection of the thermocouple and the infrared monitoring device and generating a corresponding execution command when a substrate with temperature abnormality is judged according to the temperature information fed back by the thermocouple and the temperature signal fed back by the infrared monitoring device, and an executing module in signal connection with the signal processing module and regulating the heating power of a heating module corresponding to the substrate with the temperature abnormality according to the execution command generated by the signal processing module. The high-temperature solidifying furnace monitors the ambient temperature of the heating cavity and the temperature on the surface of the substrate through the thermocouple and the infrared monitoring device, so that the solidifying temperature monitoring precision is improved.

Owner:BOE TECH GRP CO LTD +1

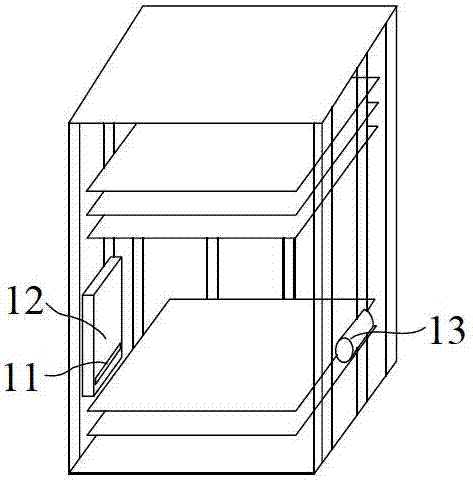

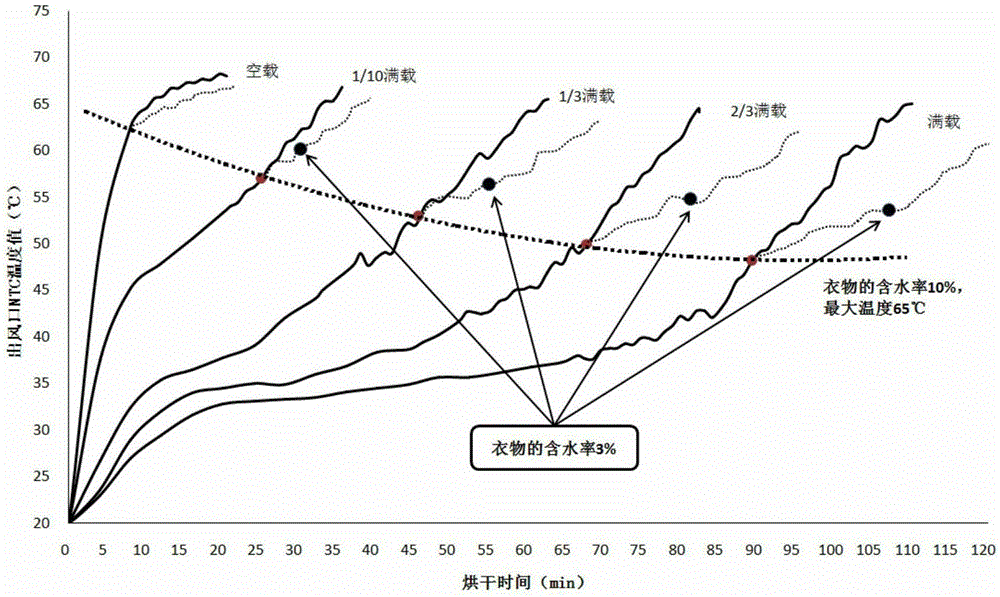

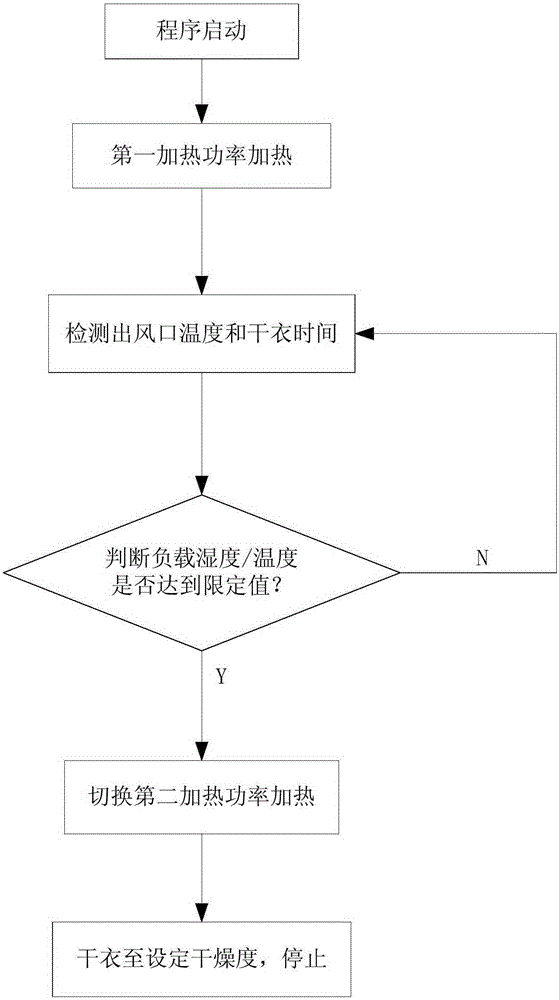

Clothes dryer control method

ActiveCN106498678AAvoid high temperature burnsPrevent shrinkage and even high temperature damageTextiles and paperLaundry driersProcess engineeringLimit value

The invention discloses a clothes dryer control method. A clothes dryer heating device is provided with at least two heating powers; At the beginning of clothes drying, the heating device is controlled to heat at a first heating power; the air outlet temperature and the drying time are detected in real time; whether the load water content and / or load temperature reach to preset limit values is determined according to the detected air outlet temperature and the drying time; when the load water content and / or load temperature reach to the preset limit values, the heating device is controlled to heat at a second heating power for a set time period, then clothes drying is completed. The method is simple and reliable, which can meet the needs of users and reduce cost. At the beginning of a clothes drying process, the heating device heats at a higher heating power; and under the condition that the dryness of clothes reaches to a preset value, the heating device is controlled to heat at a lower heating power for a set time period. By means of the method, burn of clothes due to high temperature can be avoided; the final water content of clothes can be accurately controlled, which effectively increase drying effect.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

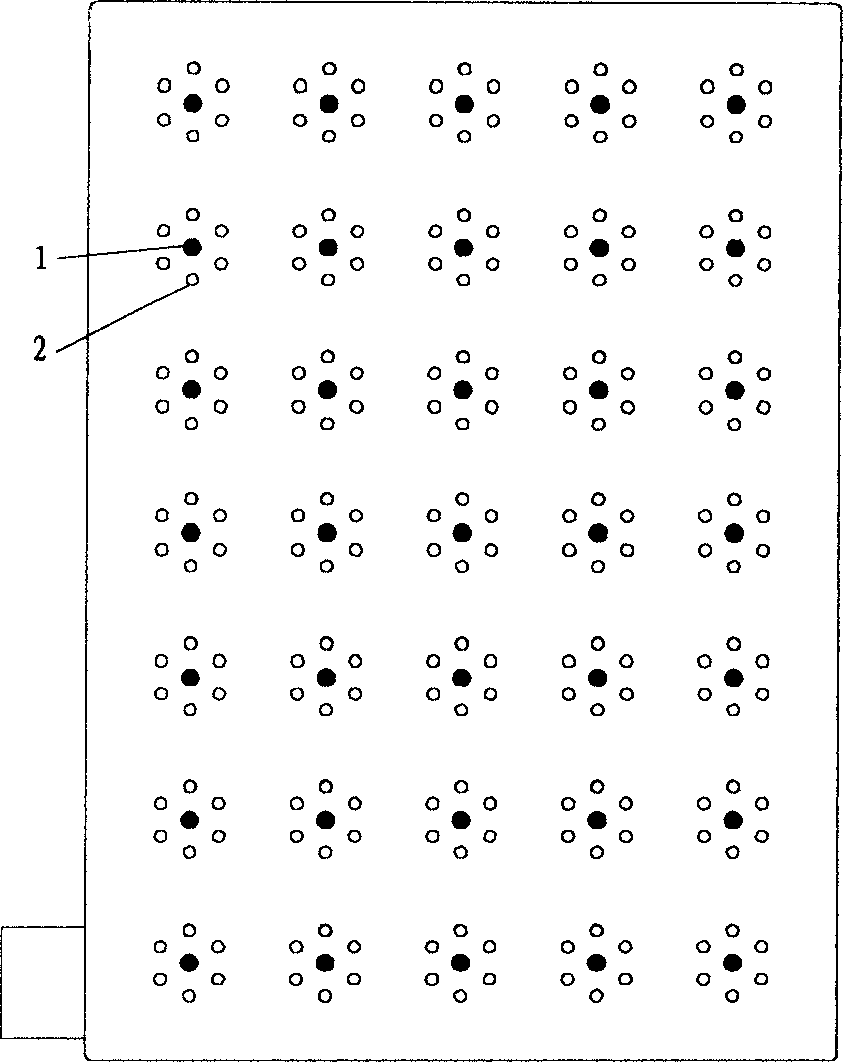

Warm air cushion

ActiveCN1600198AEasy to useAvoid radiationStuffed mattressesSpring mattressesTemperature differenceEngineering

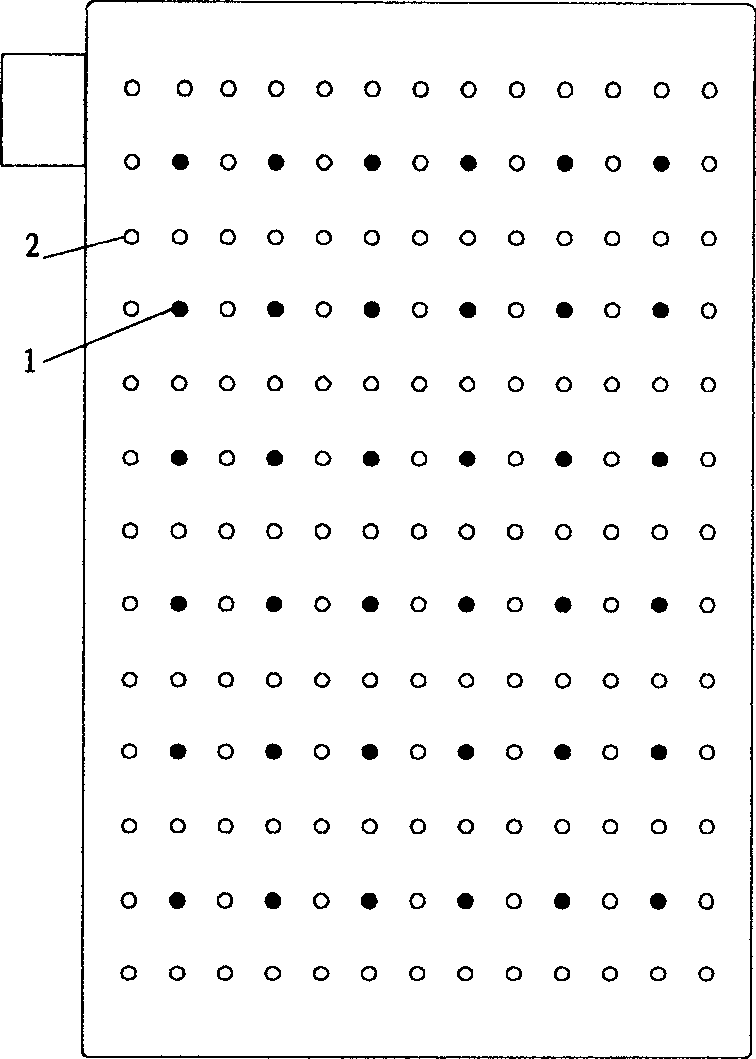

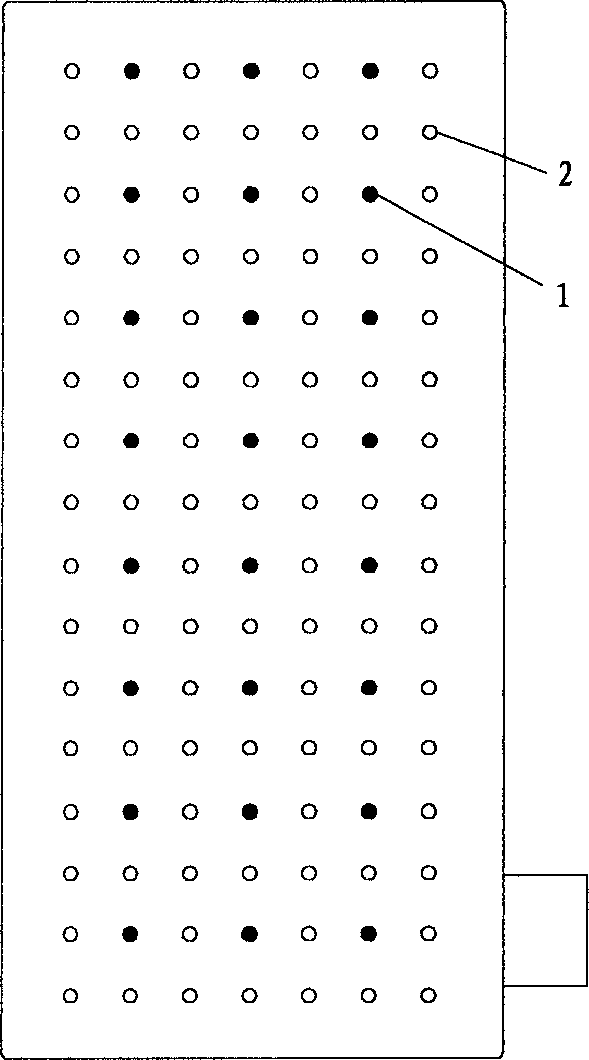

A warm air pad for heat dissipation in a quick drying device for quilts. After a large number of experiments on different perforation parameter combinations on the warm air pad, the present invention finds that the area and number of air holes and the number of adjacent riveted holes on the same layer The spacing is the most important factor in determining the performance of the heater pad. According to the present invention, through the control of the related parameters of the later punching of the pad body, the warm air pad manufactured has smooth air exhaust and uniform heat dissipation. The warm air pad is used to heat the bedding, with fast temperature rise, large temperature rise, and small temperature difference between the front and the rear. It can be used for bedding preheating and heat preservation, dehumidification, moisture-proof, disinfection and sterilization.

Owner:丛德奎

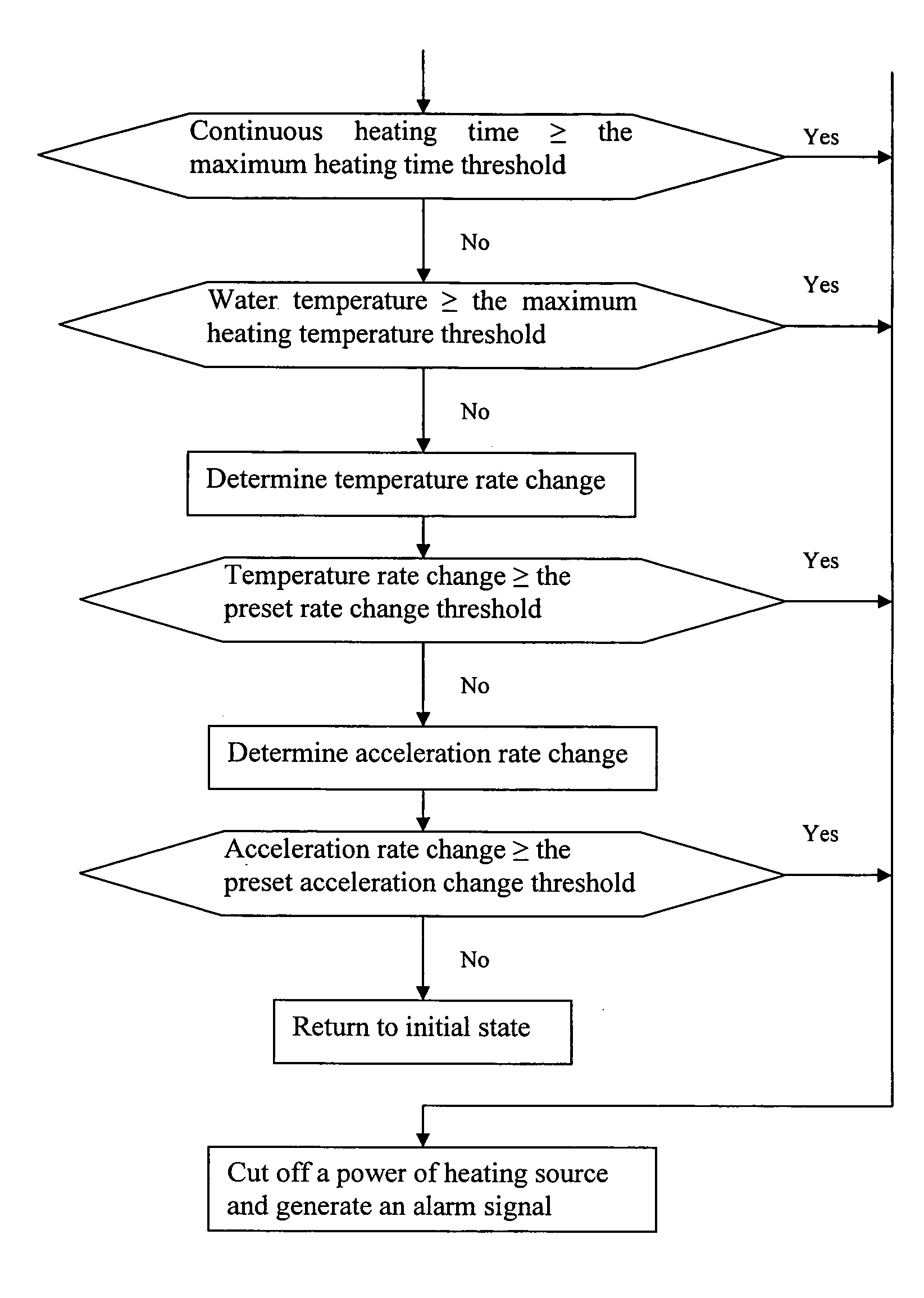

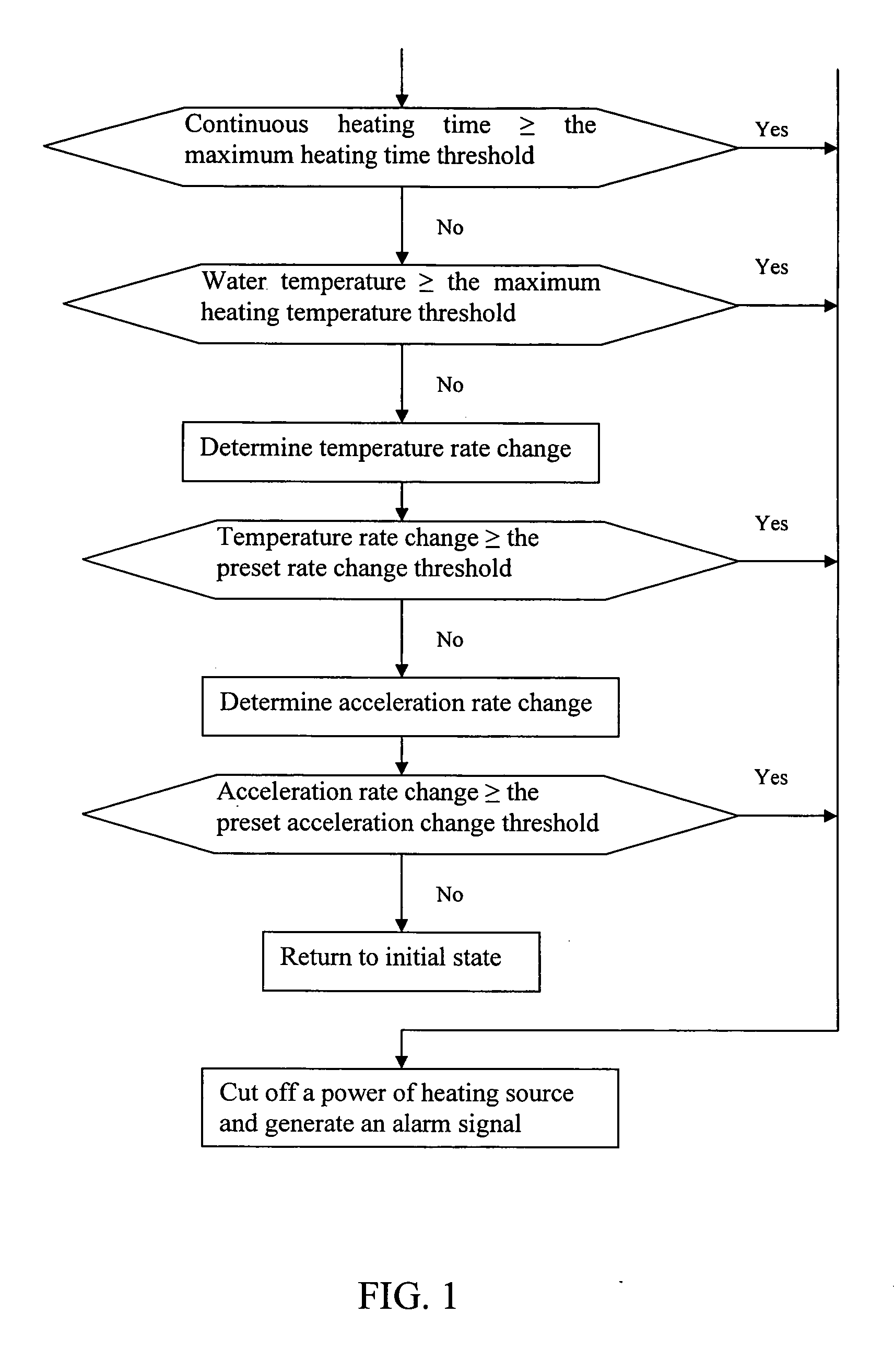

Method of Controlling Electric Kettle for "Dry" Burn Prevention

ActiveUS20080308547A1Accurately determineReduce heating powerBoiling over preventionElectric heatingControl signalEngineering

A method of controlling an electric kettle for “dry” burn prevention during heating process, including the steps of: providing a temperature sensor, a microprocessor, and a control circuit; detecting the water temperature; determining the temperature rate change and comparing the temperature rate change with the rate change threshold; and when the temperature rate change is larger than the preset rate change threshold, sending a control signal to the control circuit. The microprocessor determines the temperature rate change and the acceleration rate change that when the temperature rate change and acceleration rate change are larger than the corresponding thresholds respectively, the microprocessor sends the control signal to the control circuit to stop the heating process. Therefore, the present invention accurately determines the increasing temperature of the water and simultaneously cuts off the heating power to prevent the electric kettle from being burnt.

Owner:SHENZHEN CRASTAL TECH CO LTD

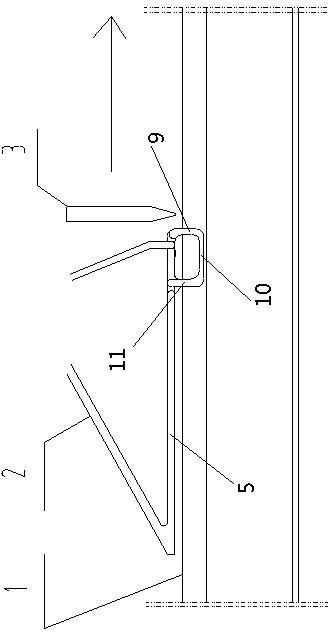

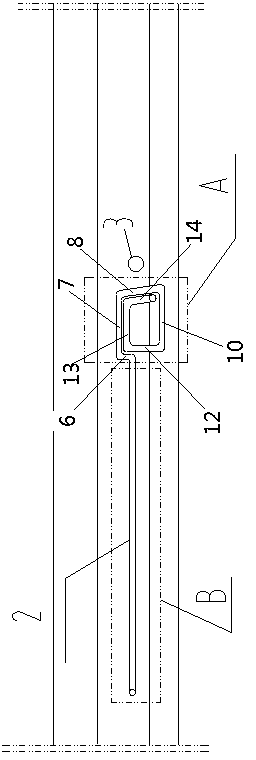

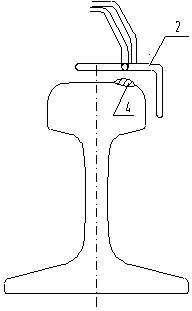

Induction heater and method for realizing non-preheating cladding of alloy on steel rail by using same

InactiveCN103132008ASave energyExtended heating rangeMolten spray coatingHeat transmissionMiniaturization

The invention discloses an induction heater which comprises a heating zone 1 and a heating zone 2, wherein the heating zone 1 is divided into two heating surfaces; a first heating surface is shaped like a trapezoid without the bottom; a second heating surface is a U-shaped one; the two lateral sides of the trapezoid-shaped heating surface are connected with the U-shaped heating surface; and an included angle is formed between the first heating surface and the second heating surface. When the induction heater is used to perform alloy cladding on a steel rail, preheating does not need to be performed in advance, so that on the premise of the same steel rail cladding speed, heat energy required by the method is only one third or less of the prior art; and meanwhile, the method lays a foundation for miniaturization of a generator or even construction without the aid of a rail car. By performing detailed analysis on structure phase change and heat transmission of a steel rail in the cladding process, the invention breaks through the theory that the steel rail must be preheated prior to welding for the first time, and presents that the steel rail can be directly subjected to alloy cladding without being preheated while generation of martensite can be avoided. The technology disclosed by the invention is put forward for the first time at home and abroad.

Owner:CHENGDU ZHONGGUI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com