Process for producing Czochralski silicon single crystal

A production process, Czochralski silicon technology, applied in single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of poor slag extraction effect, difficult to grasp the time of slag removal, low purity of silicon single crystal, etc., to achieve easy control , Reduce the probability of silicon leakage accidents, and the effect of simple processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

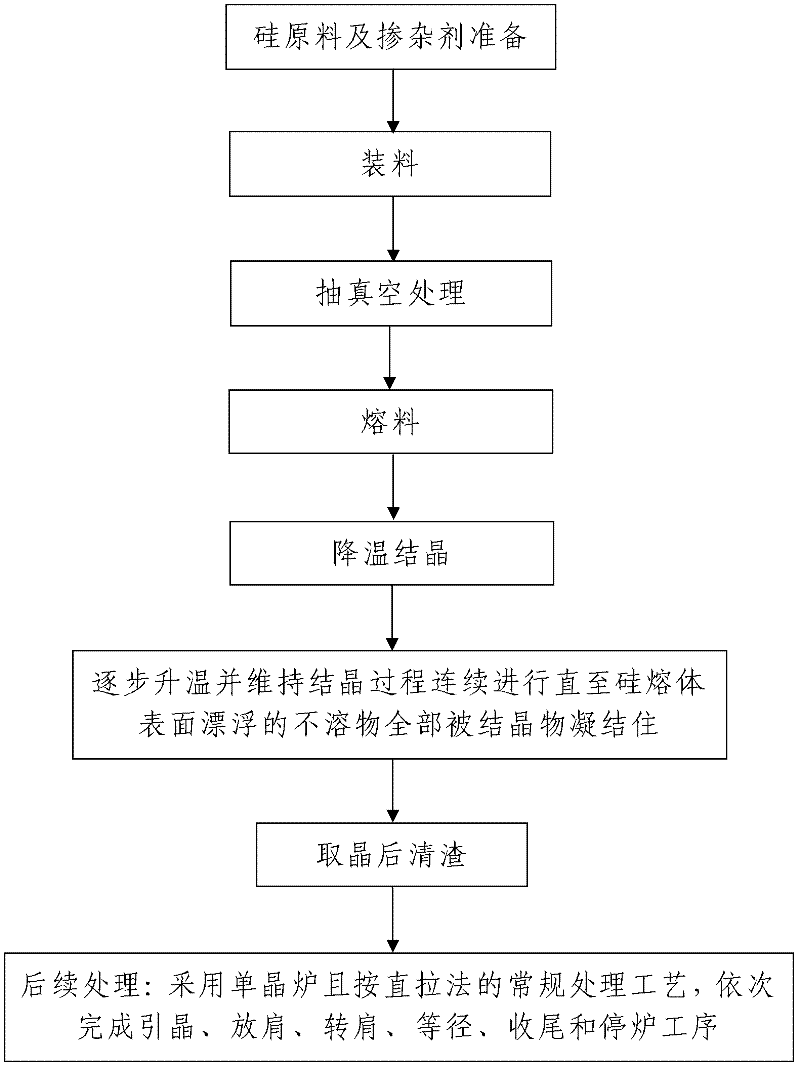

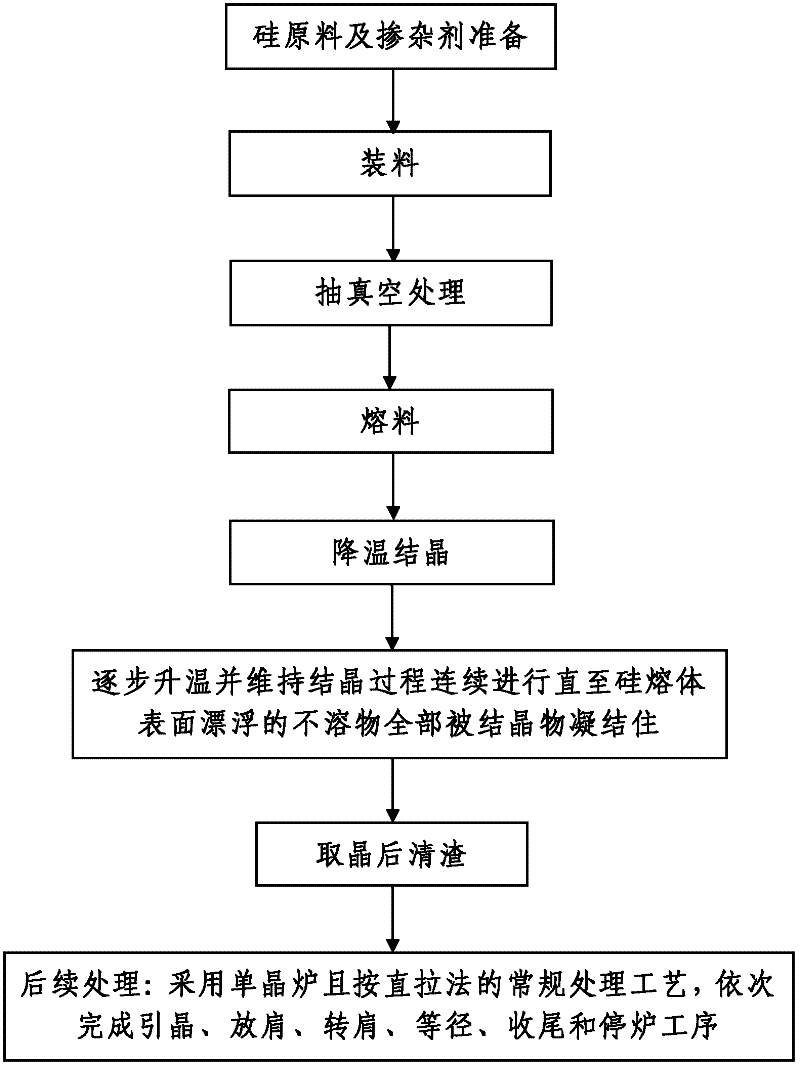

[0043] like figure 1 A production process for a Czochralski silicon single crystal shown, comprising the following steps:

[0044] Step 1. Preparation of silicon raw material and dopant: According to the conventional preparation method of silicon raw material for single crystal furnace, the silicon raw material for growing Czochralski single crystal silicon is prepared, and according to the conventional cleaning treatment method of silicon raw material for single crystal furnace, Clean the prepared silicon raw material; at the same time, according to the type and resistivity of the silicon single crystal to be produced, determine the type and doping amount of the dopant to be added, and determine the dopant used for growing Czochralski single crystal silicon Get ready.

[0045] In this embodiment, the same as the conventional method of preparing silicon raw materials for growing Czochralski silicon single crystals, first determine the silicon single crystal production accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com