Patents

Literature

44results about How to "Realize precise positioning function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

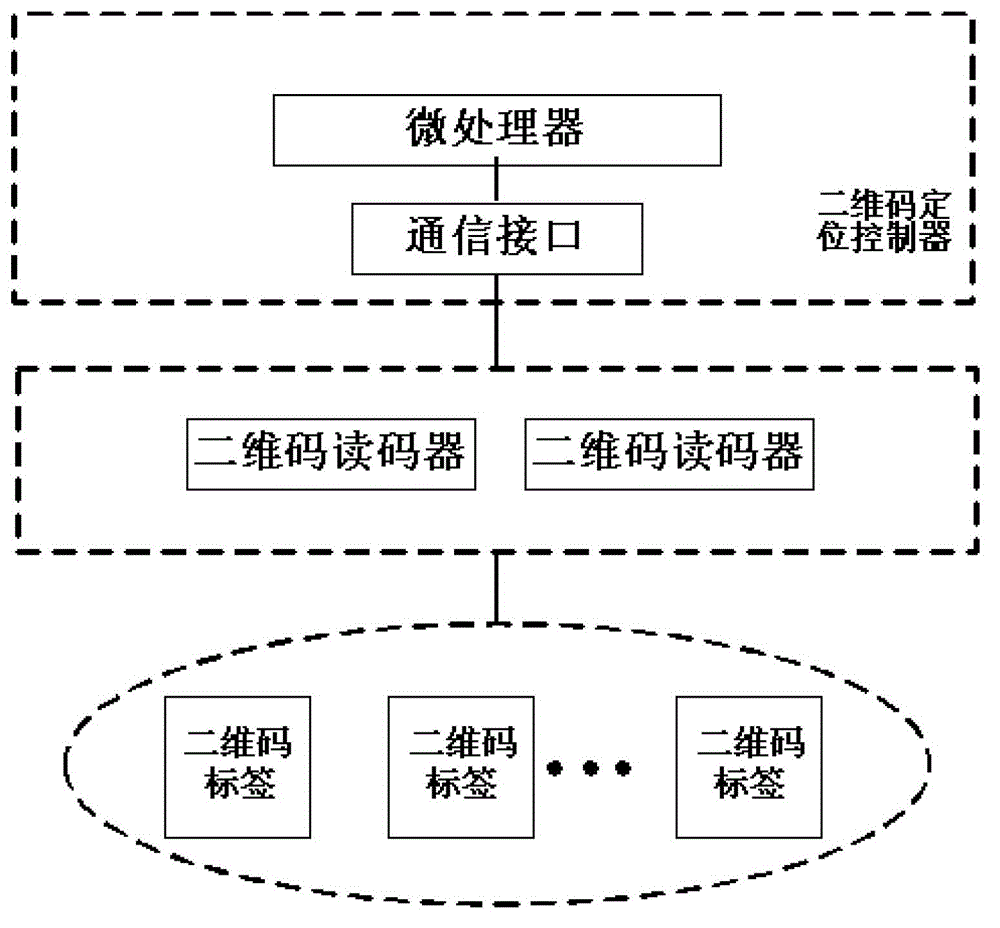

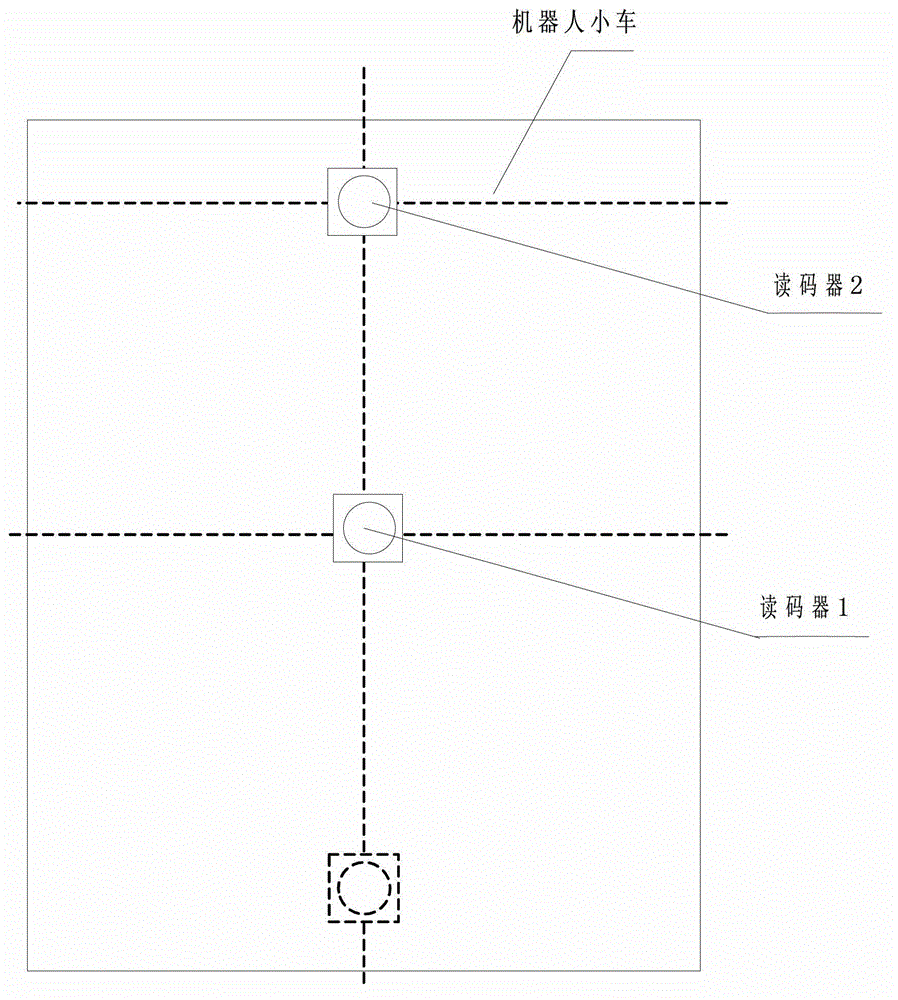

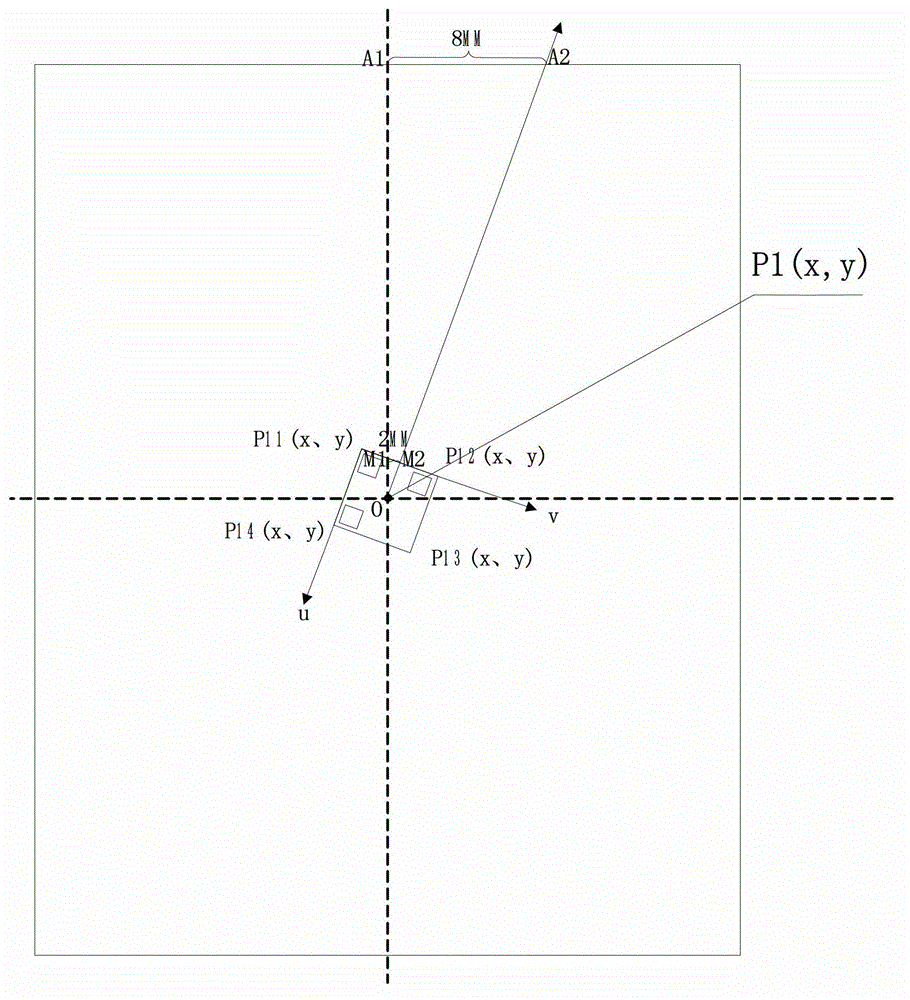

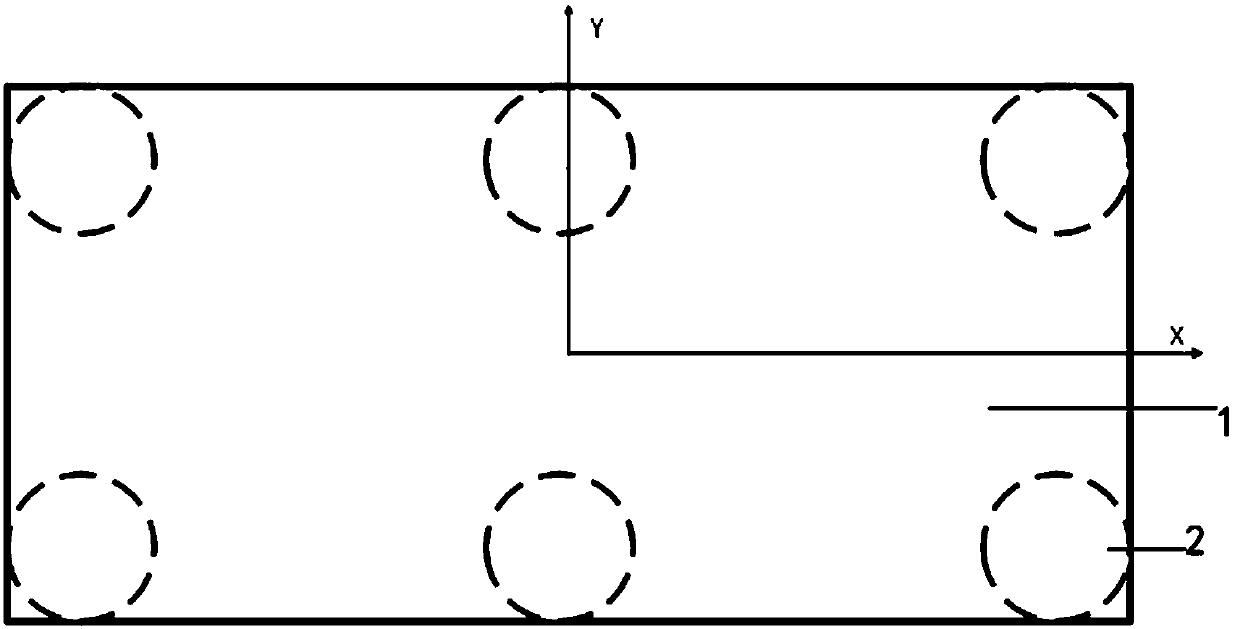

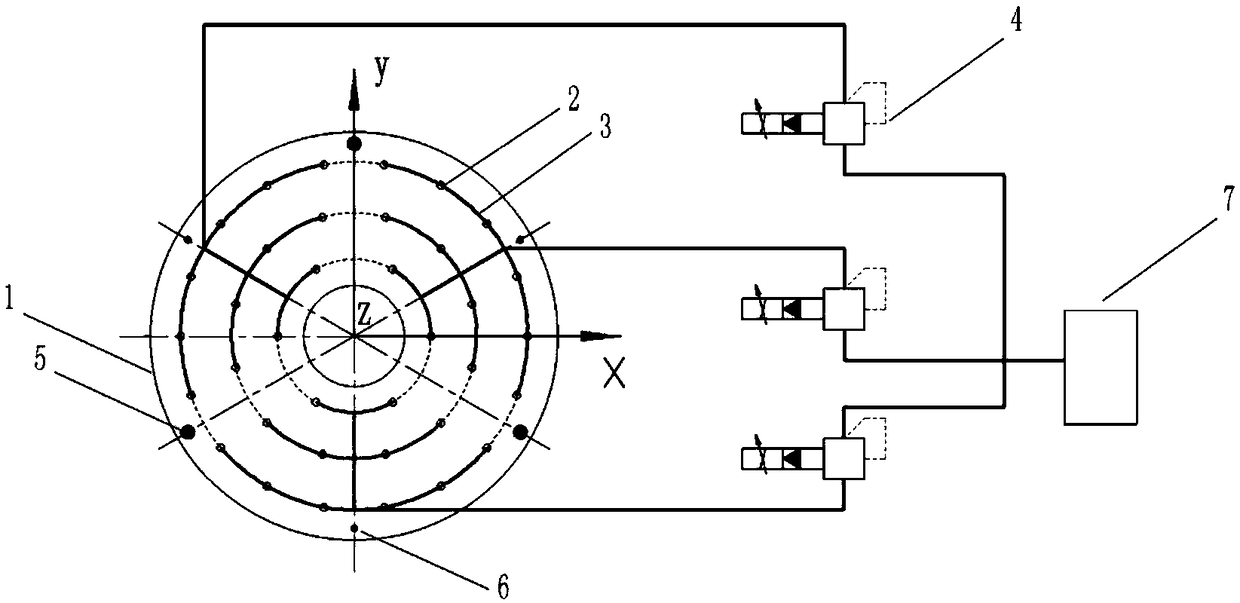

Mobile robot positioning system and method based on a plurality of two-dimensional code readers

InactiveCN102944236ARealize precise positioning functionSmall margin of errorNavigation instrumentsCommunication interfaceComputer vision

The invention relates to a mobile robot positioning system and a method based on the plurality of the two-dimensional code readers. The mobile robot positioning system and the method are characterized in that the positioning system comprises a two-dimensional code positioning controller mounted on a mobile robot trolley, at least two two-dimensional code readers and two-dimensional code tags which are distributed on the ground, the two-dimensional code positioning controller is composed of a microprocessor and a communication interface which is connected with the at least two two-dimensional code readers; and the positioning method includes building three coordinate systems, calculating a deviation angle of the mobile robot trolley in a trolley coordinate system relative to a central point connection line of two two-dimensional codes, calculating a deviation angle of the central point connection line of two two-dimensional codes relative to a world coordinate system and calculating a deviation angle of the mobile robot trolley relative to the world coordinate system to obtain an accurate position of the mobile robot. According to the mobile robot positioning system and the method, the design is reasonable, an accurate positioning function for the mobile robot is achieved, and advantages of high accuracy and stability, implement convenience and the like are provided.

Owner:SHENZHEN PUZHILIANKE ROBOT TECH CO LTD

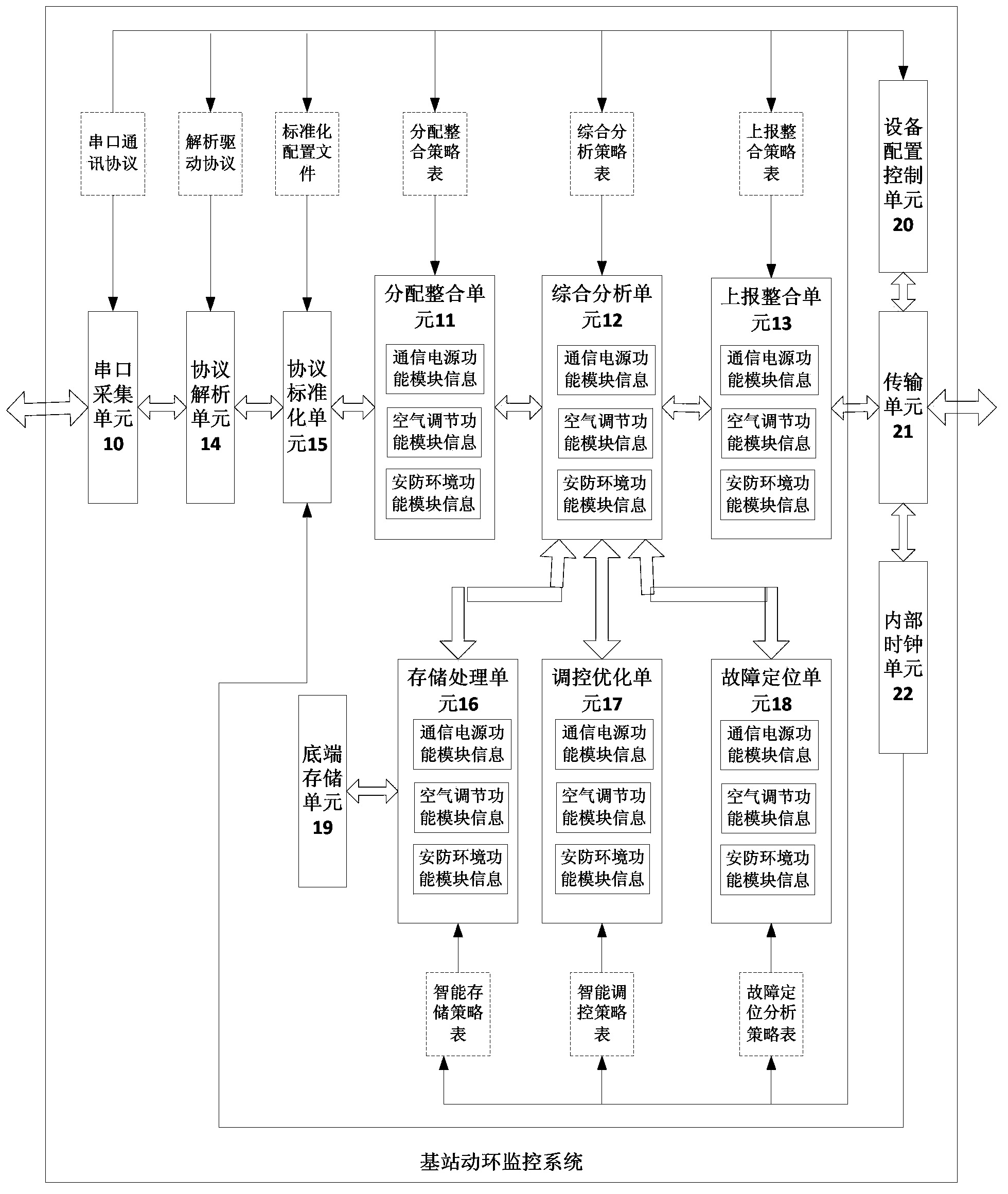

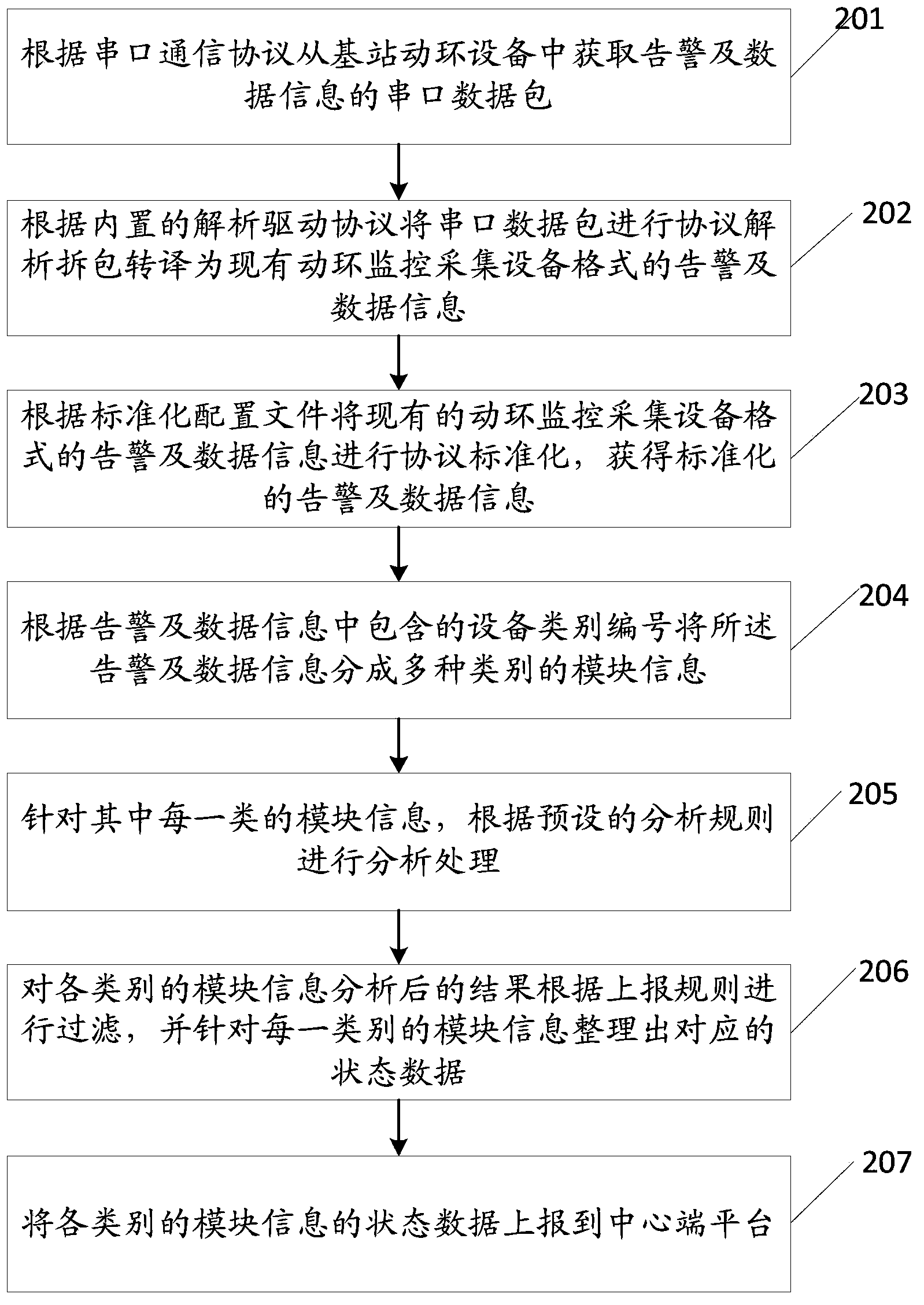

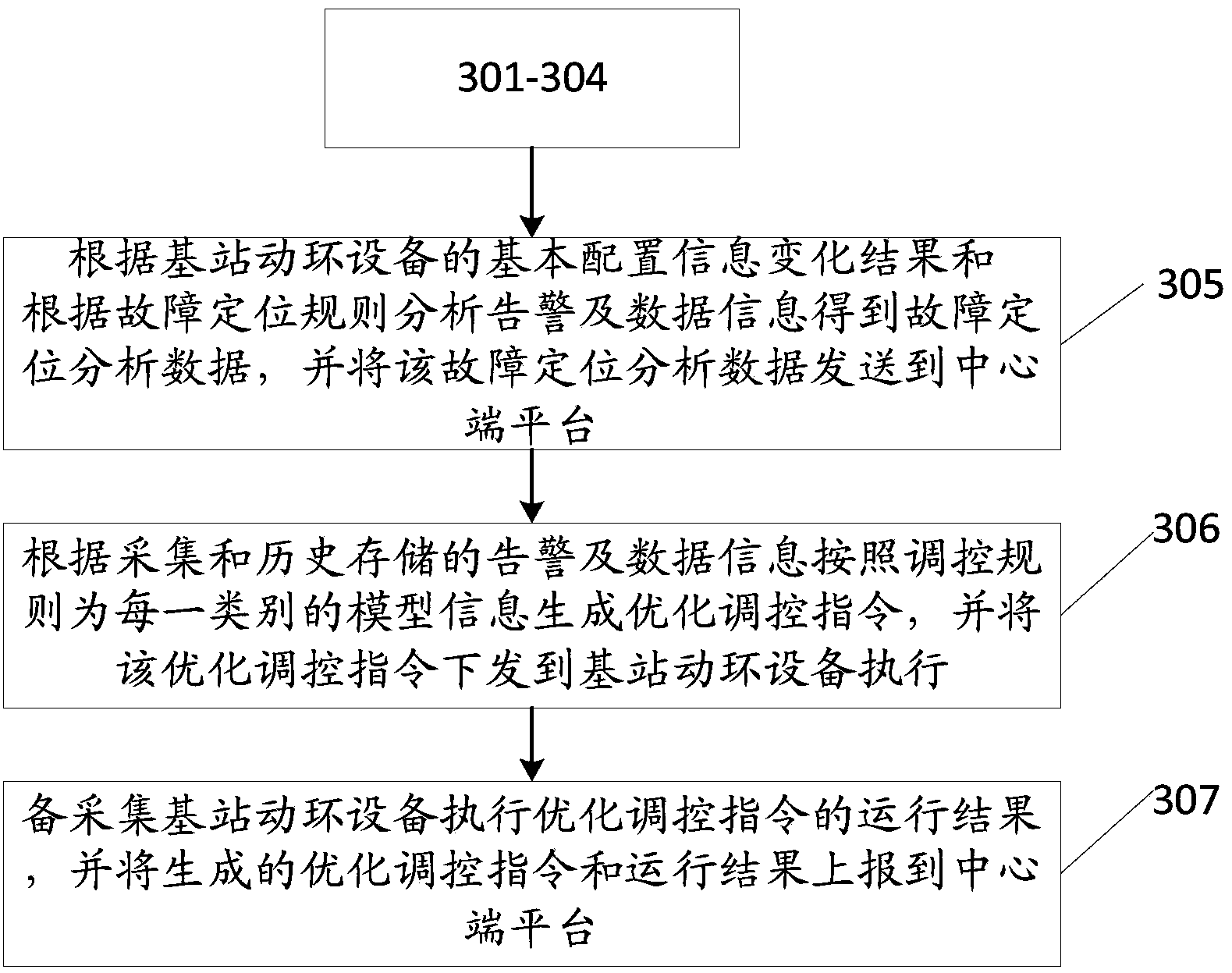

Method and system for achieving base station dynamic environment monitoring

ActiveCN104244300AImprove effectivenessRealize precise positioning functionWireless communicationData informationSerial port

The invention discloses a method and system for achieving base station dynamic environment monitoring and relates to the technical field of communication. The method and system solve the technical problems that in the prior art, the information transmission efficiency of a base station dynamic environment monitoring device is quite low and fault location is inaccurate. The system comprises a serial port acquisition unit used for acquiring alarm and data information from a base station dynamic environment device, an allocation integration unit used for classifying the alarm and data information into multiple categories of module information according to the device category number contained in the alarm and data information, a comprehensive analysis unit used for analyzing and processing each category of module information according to a preset analysis rule, and a reporting integration unit used for reporting results obtained after analysis of each category of module information to a center-side platform. The system is mainly used for managing and controlling the base station dynamic environment device.

Owner:CHINA MOBILE GROUP ZHEJIANG +1

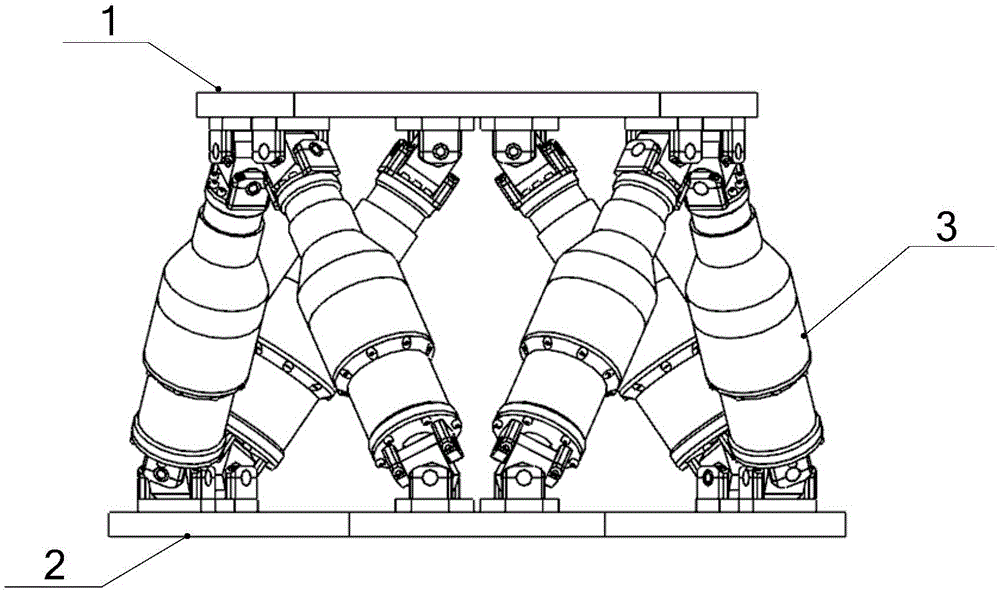

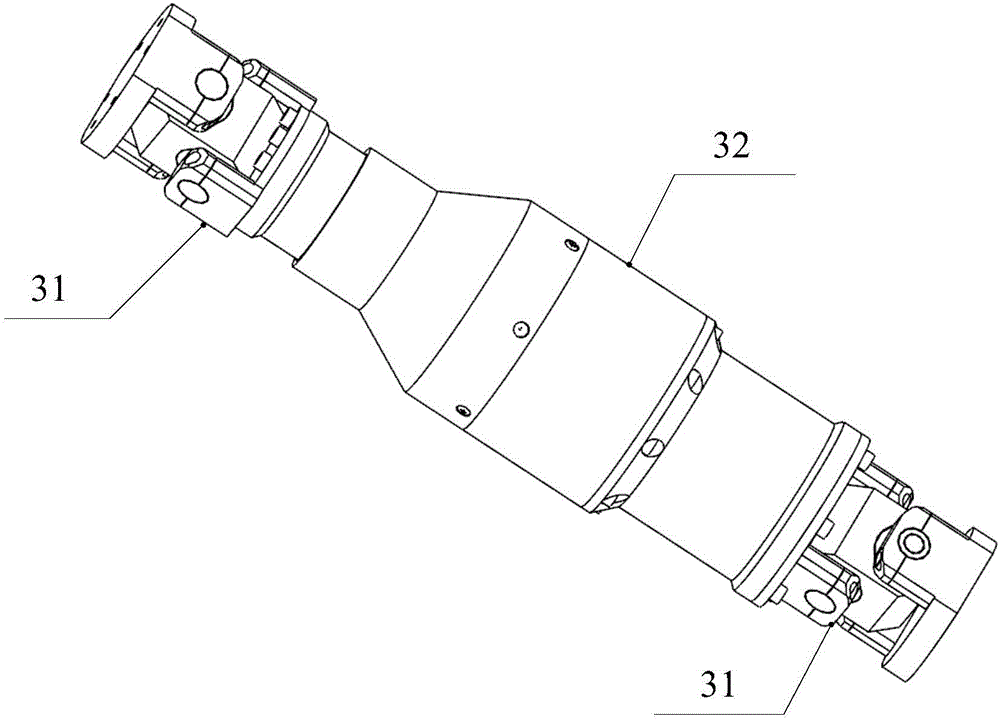

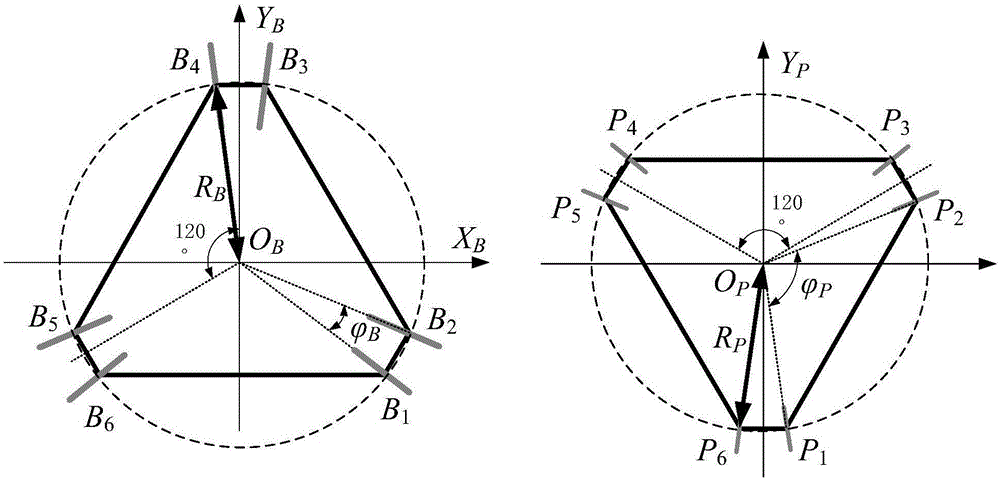

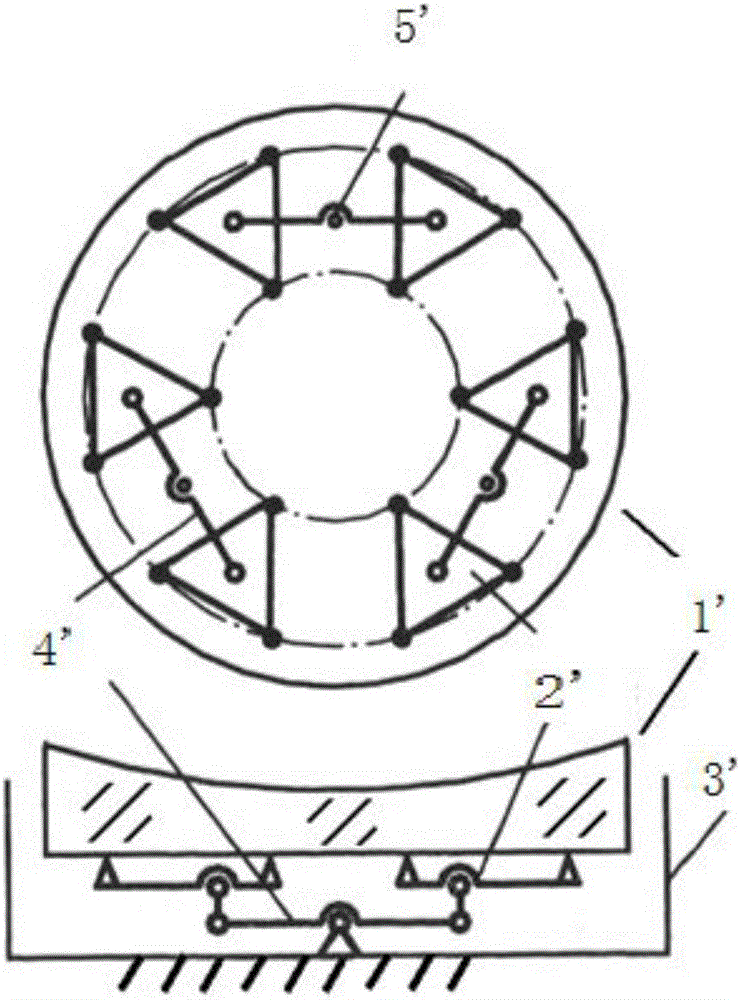

6RRRPRR-based six-degree-of-freedom high-precision adjusting and positioning system

InactiveCN106886227AEasy to process and manufactureLarge working spaceControl using feedbackSix degrees of freedomLinear actuator

The invention relates to a 6RRRPRR-based six-degree-of-freedom high-precision adjusting and positioning system the mechanical structure of which is composed of a stationary fixed platform, a movable moving platform and six supporting rods in linear motion. Each support rod is composed of rotary hinges for connecting the moving platform with the fixed platform and a linear actuator. The rotary hinges are offset universal hinges and are connected with the moving and fixed platforms through flanges. The linear actuators achieve linear motion by using ball screw pairs. Such design can provide axial rotational freedom by using the relative rotation between screws and nuts so as to meet a degree of freedom distribution relation, prevent a guide mechanism, simplify structural design and improve the motion accuracy of the support rods. The stretch and retraction of the six linear support rods and the rotation of the offset universal hinges achieve the six-degree-of-freedom high-precision adjustment and positioning of the moving platform.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

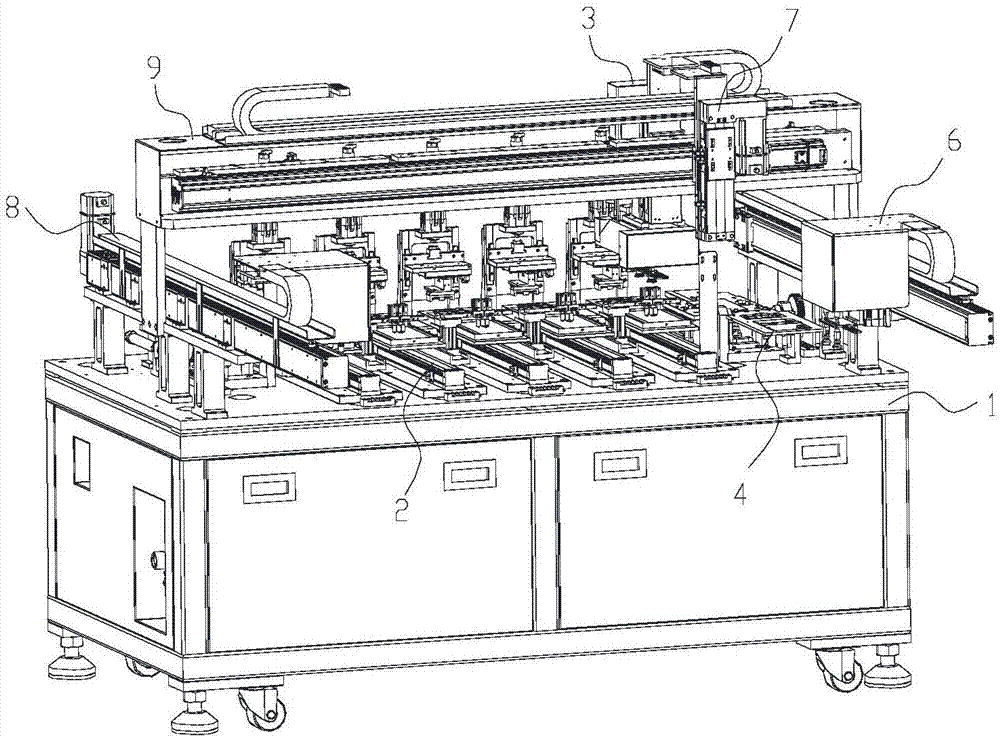

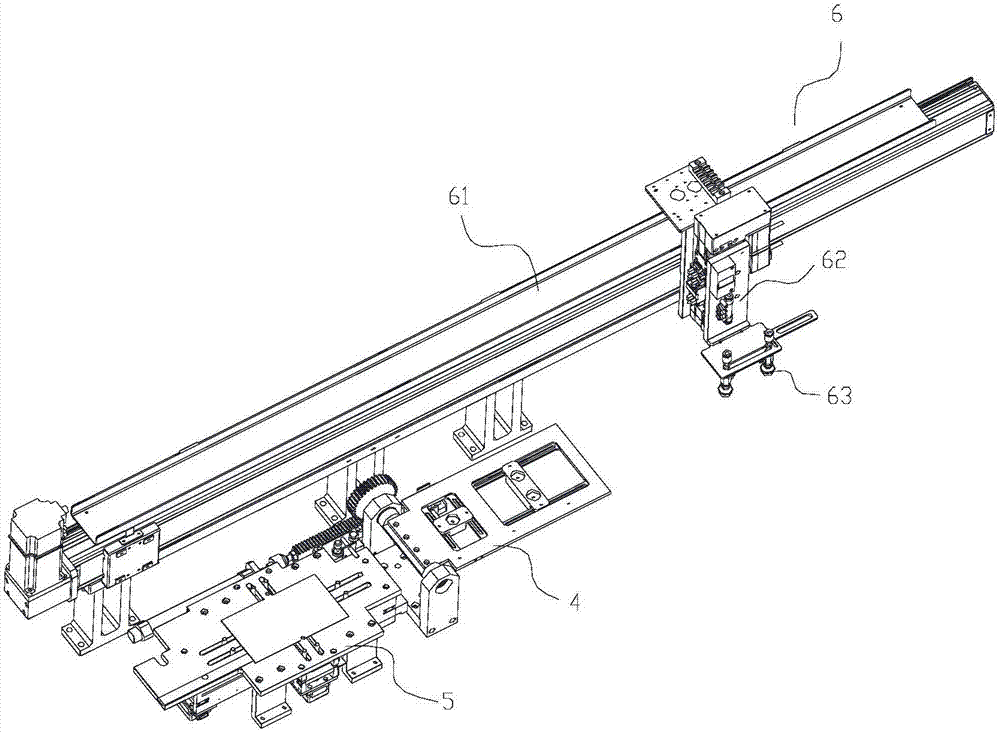

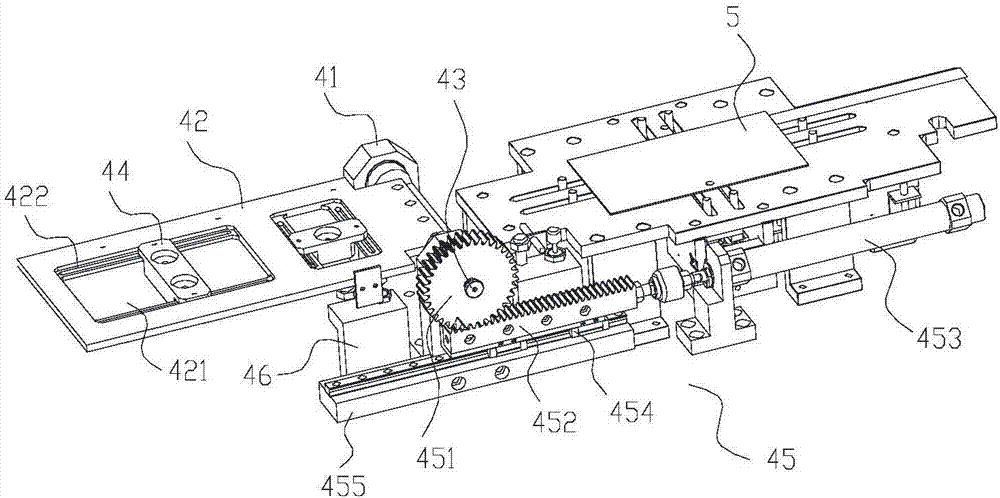

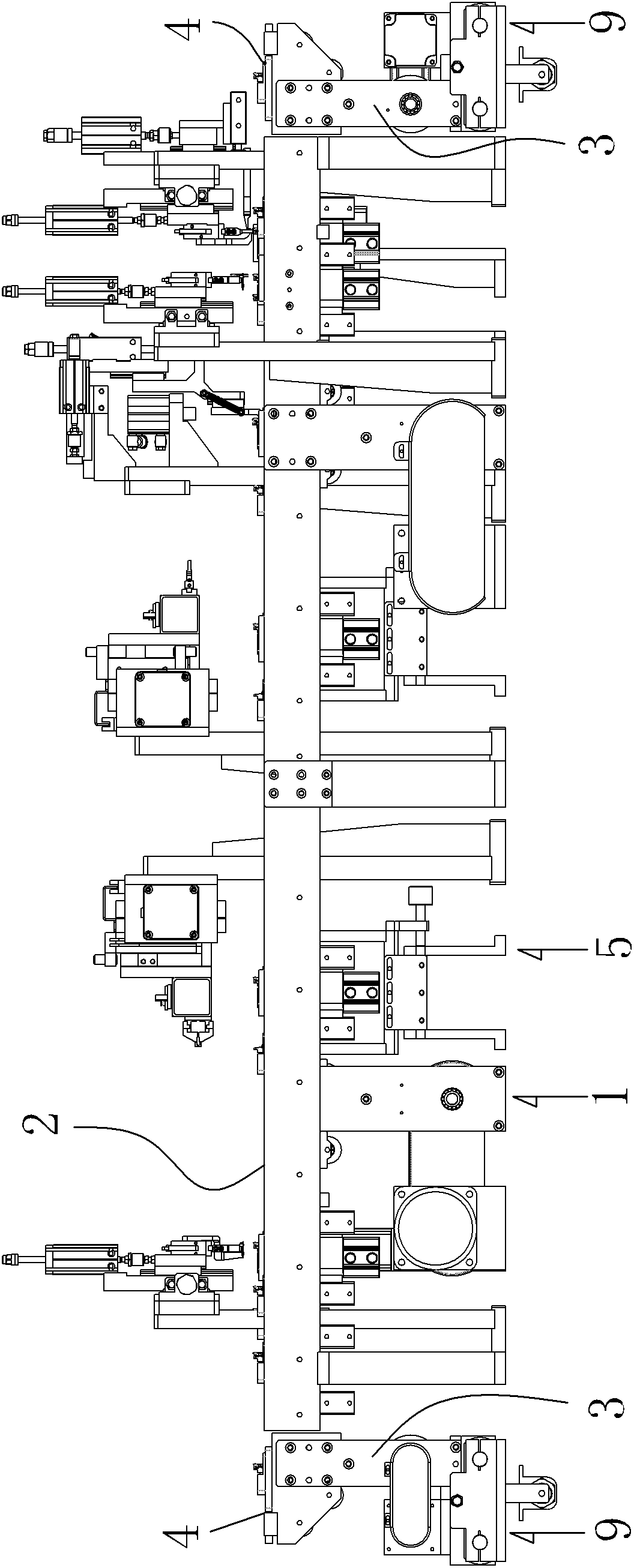

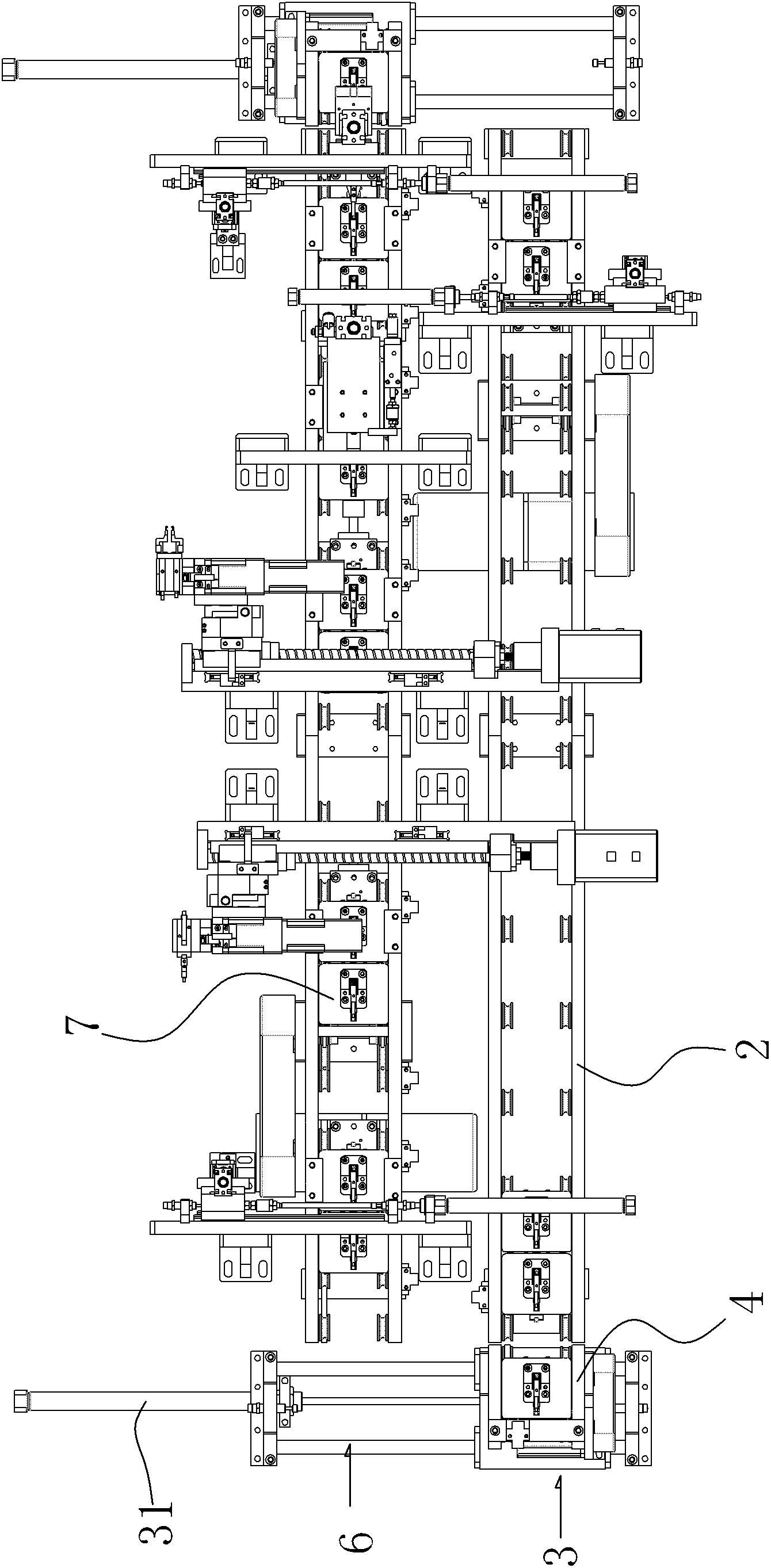

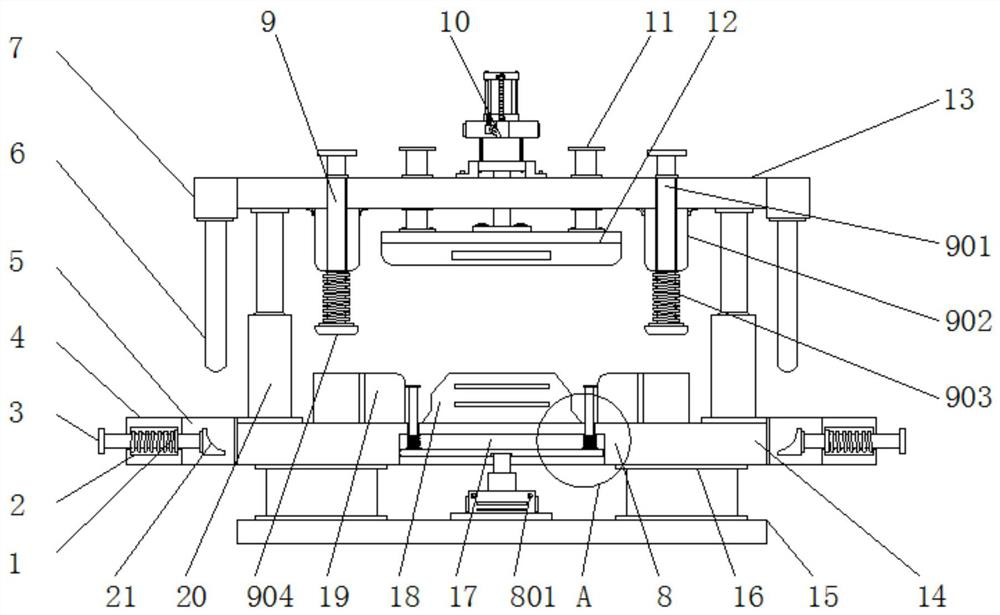

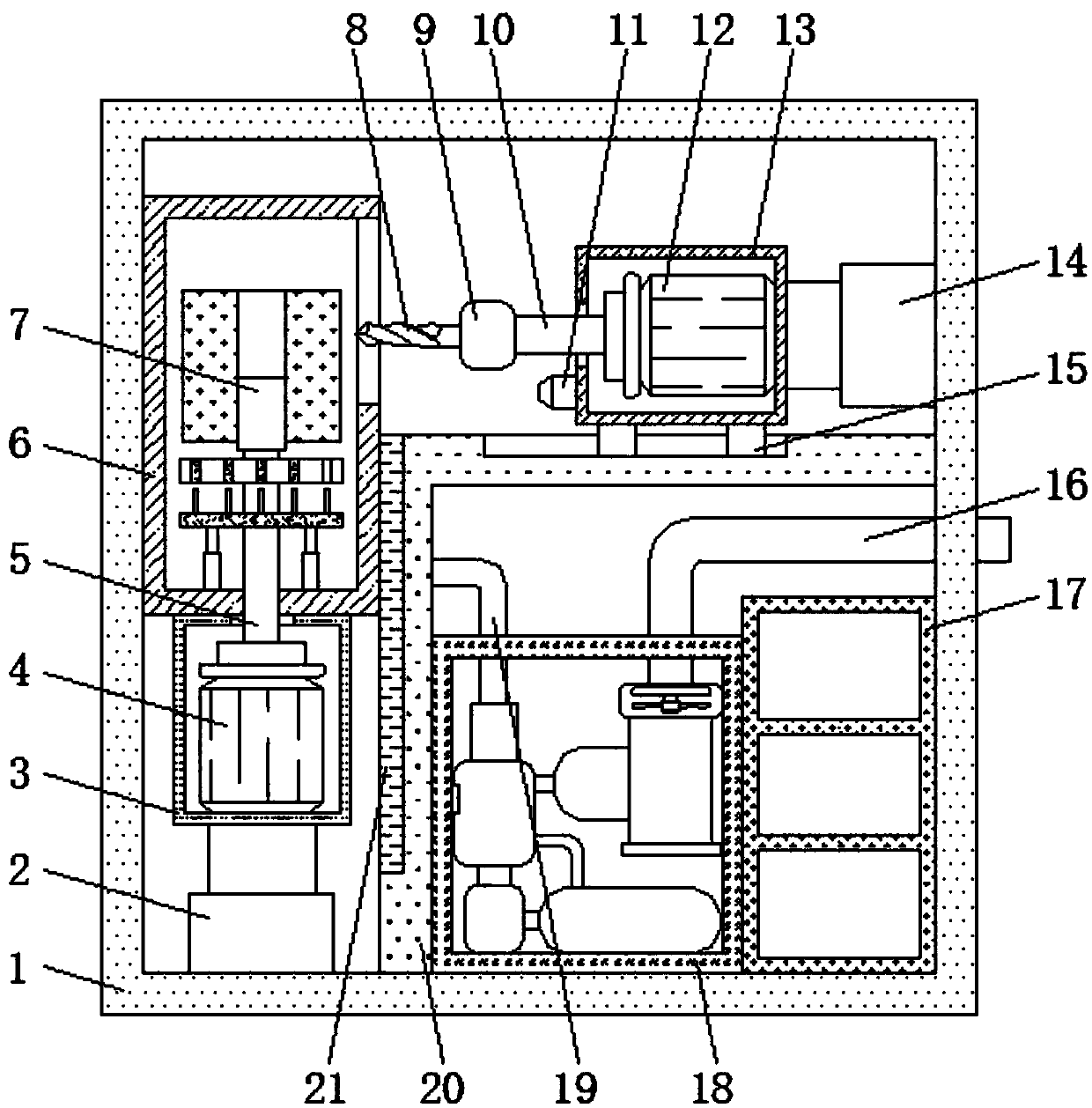

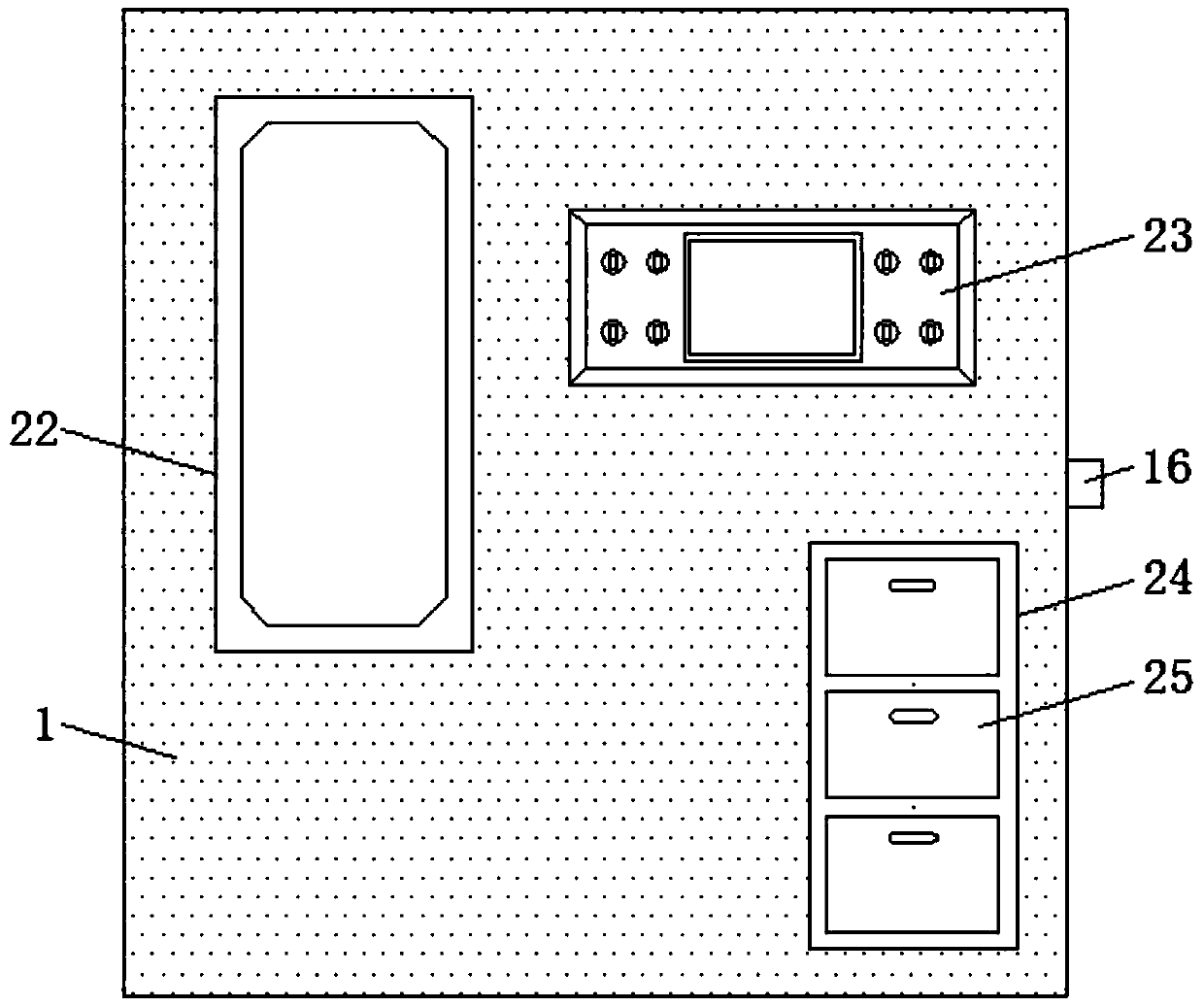

Test device and method for computer function of mobile phone screen connector

The invention discloses a test device and method for the computer function of a mobile phone screen connector. The test device comprises a machine body, a test tool, a positioning mechanism, a transfer mechanism and a discharging mechanism, wherein the test tool, the positioning mechanism, the transfer mechanism and the discharging mechanism are installed on the machine body. The test tool is provided with a detection station. A mobile phone screen connector of a to-be-tested mobile phone screen is subjected to adjustment and angle positioning to a required angle through the positioning mechanism so as to adapt to the detection station position, so that the crimping detection of the mobile phone screen connector is enabled to achieve precise positioning, the detection process is fast, the degree of automation is high, and the detection efficiency is high. The test device is simple and reasonable in structure, the usage is convenient, the space is saved, the application is stable, the cost performance is high, and the accurate positioning is achieved.

Owner:深圳眼千里科技有限公司

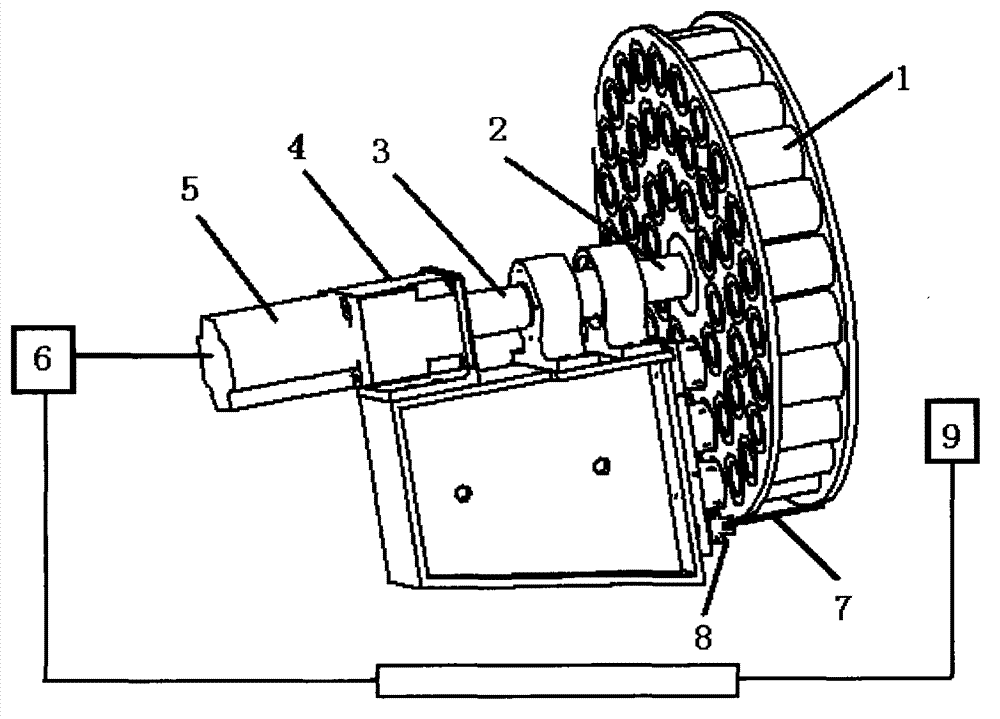

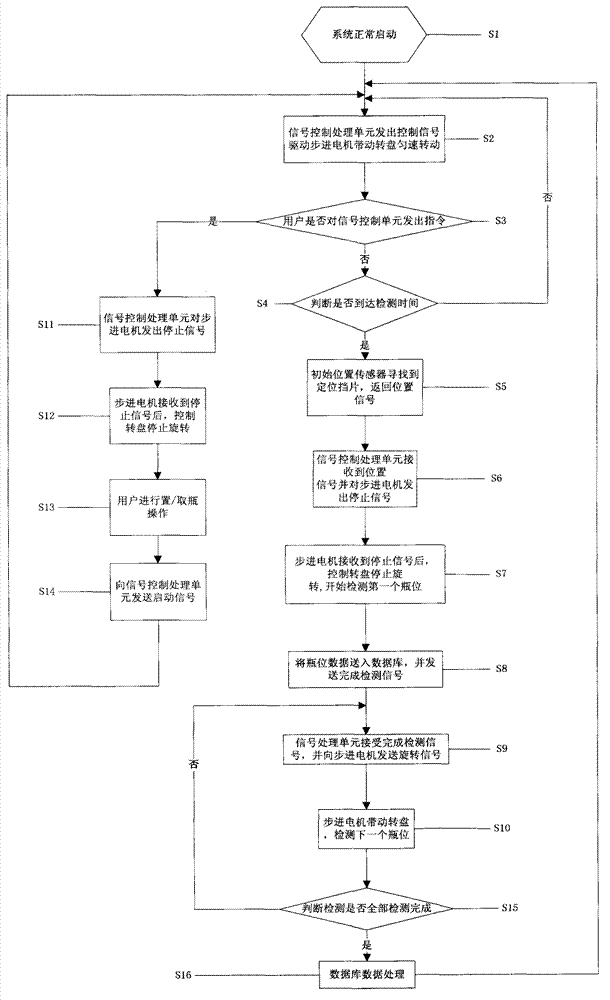

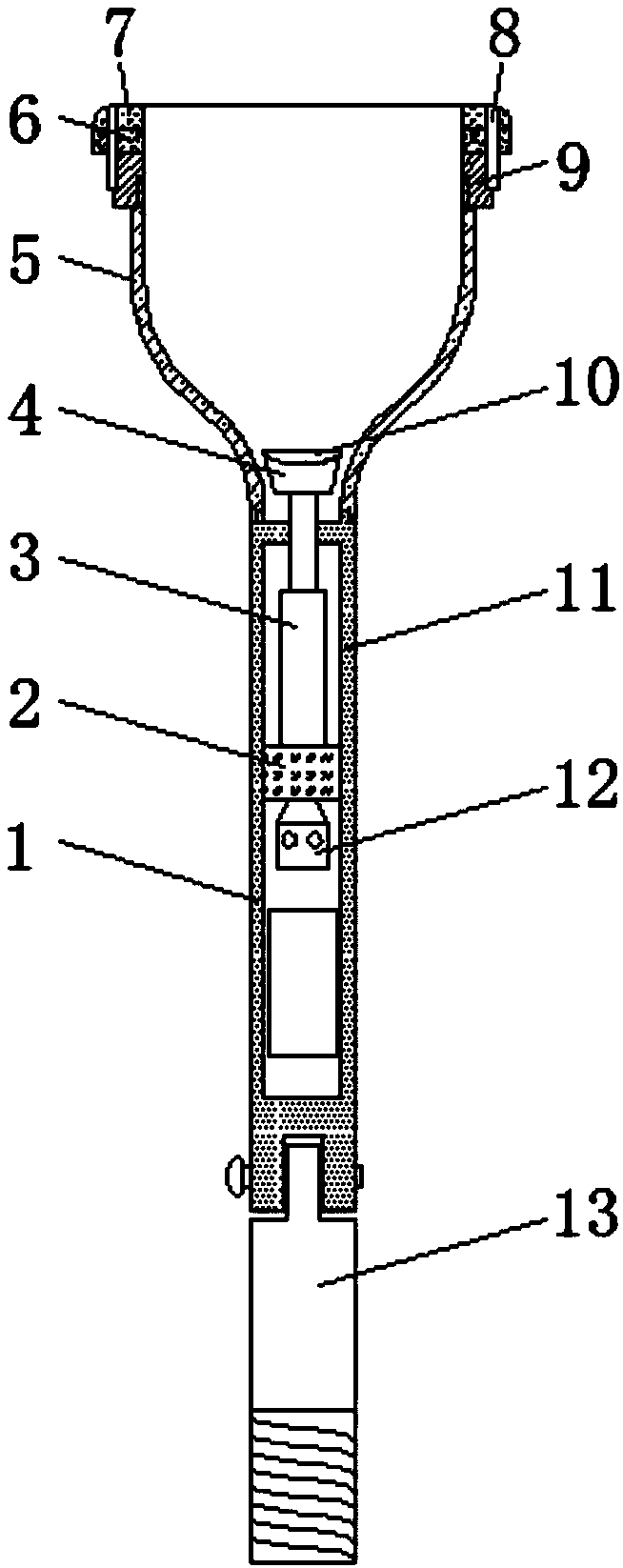

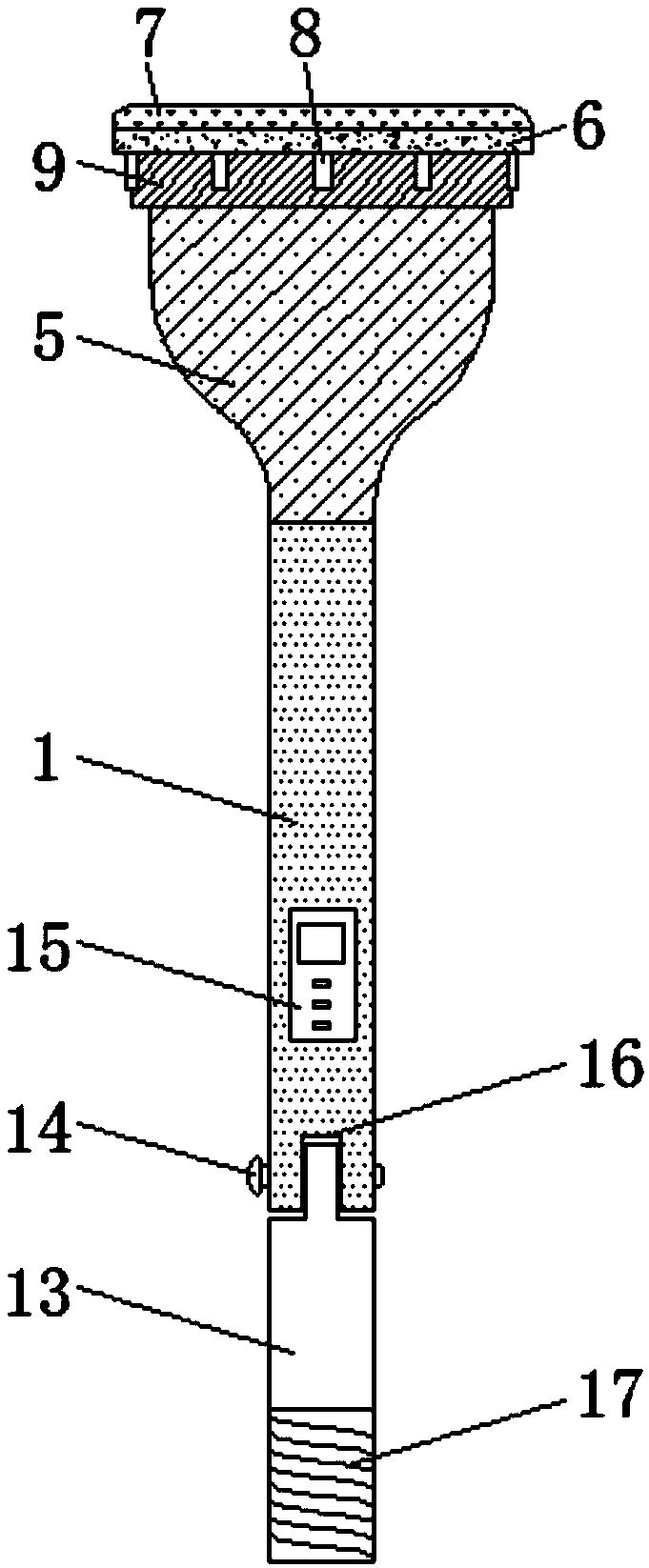

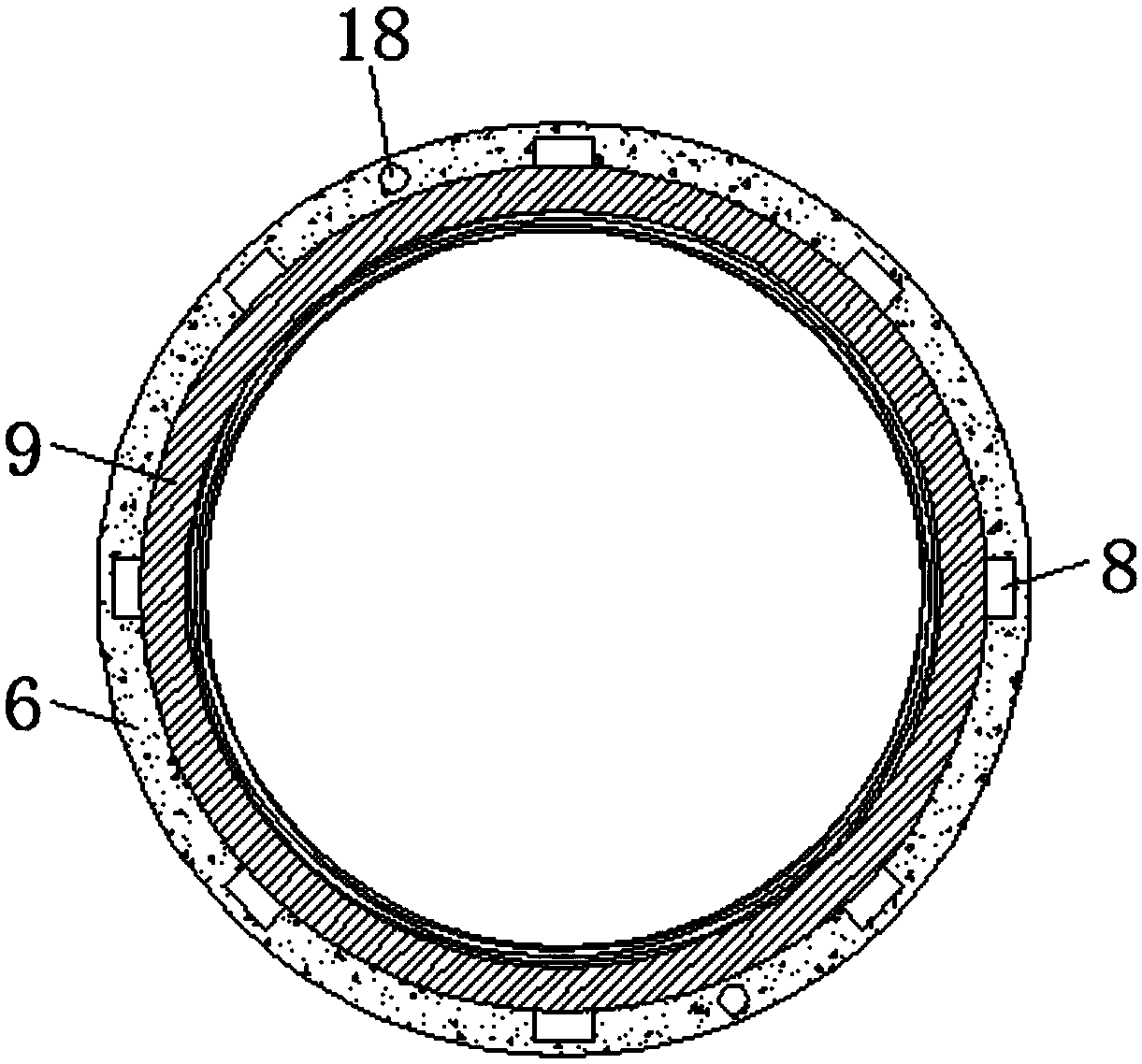

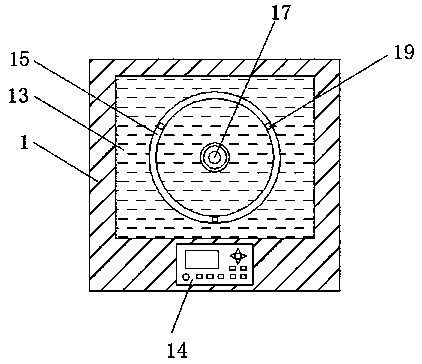

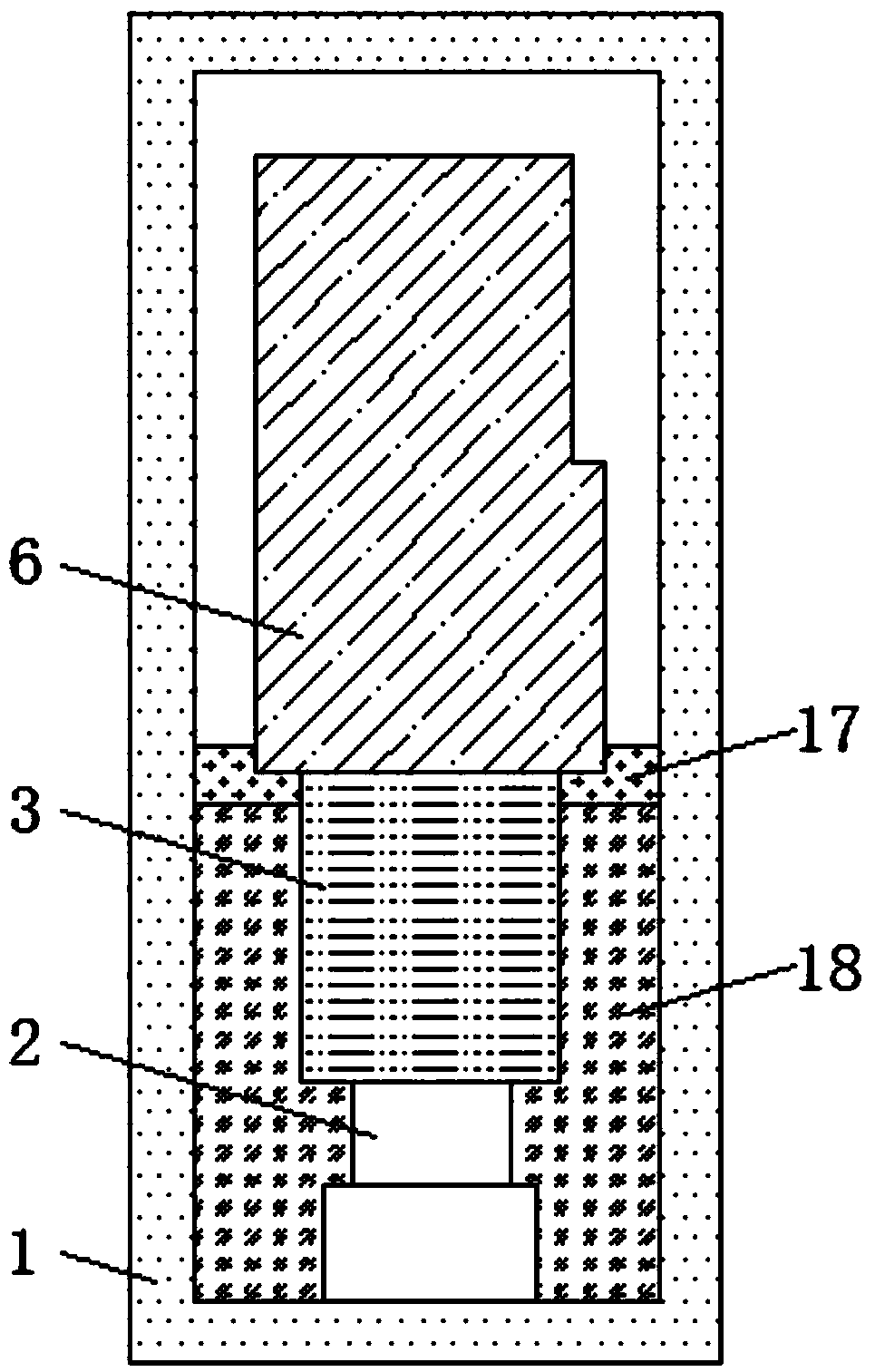

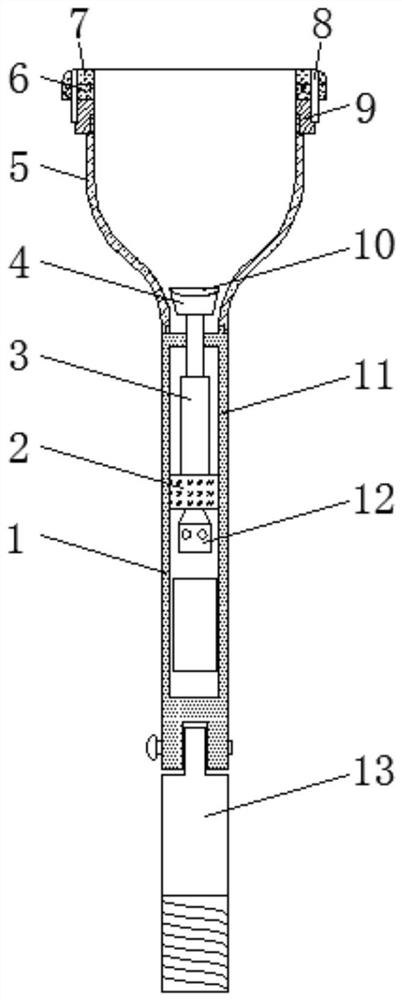

Rotary motion control device of full-automatic blood bacterial culture device

InactiveCN103045471AImprove one-to-one correspondence detection methodImplement automatic detectionBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringData lines

The invention relates to a rotary motion control device of a full-automatic blood bacterial culture device, which includes a turnplate (1), a stepping motor (5), a signal control processing unit (6), a positioning catch (7) and a start bit position sensor (8), wherein the turnplate (1) is a culture device for specimens and provided with a plurality of specimen positions distributed for placing blood culture flasks; the positioning catch (7) is fixed at a start bit of the edge of the turnplate (1); the start bit position sensor (8) is fixed under the turnplate (1), and is used for detecting the positioning catch (7); the turnplate (1) is connected with the stepping motor (5); and both the stepping motor (5) and the start bit position sensor (8) are connected with the signal control processing unit (6) through a data line.

Owner:SHANDONG XINKE BIOLOGICAL TECH

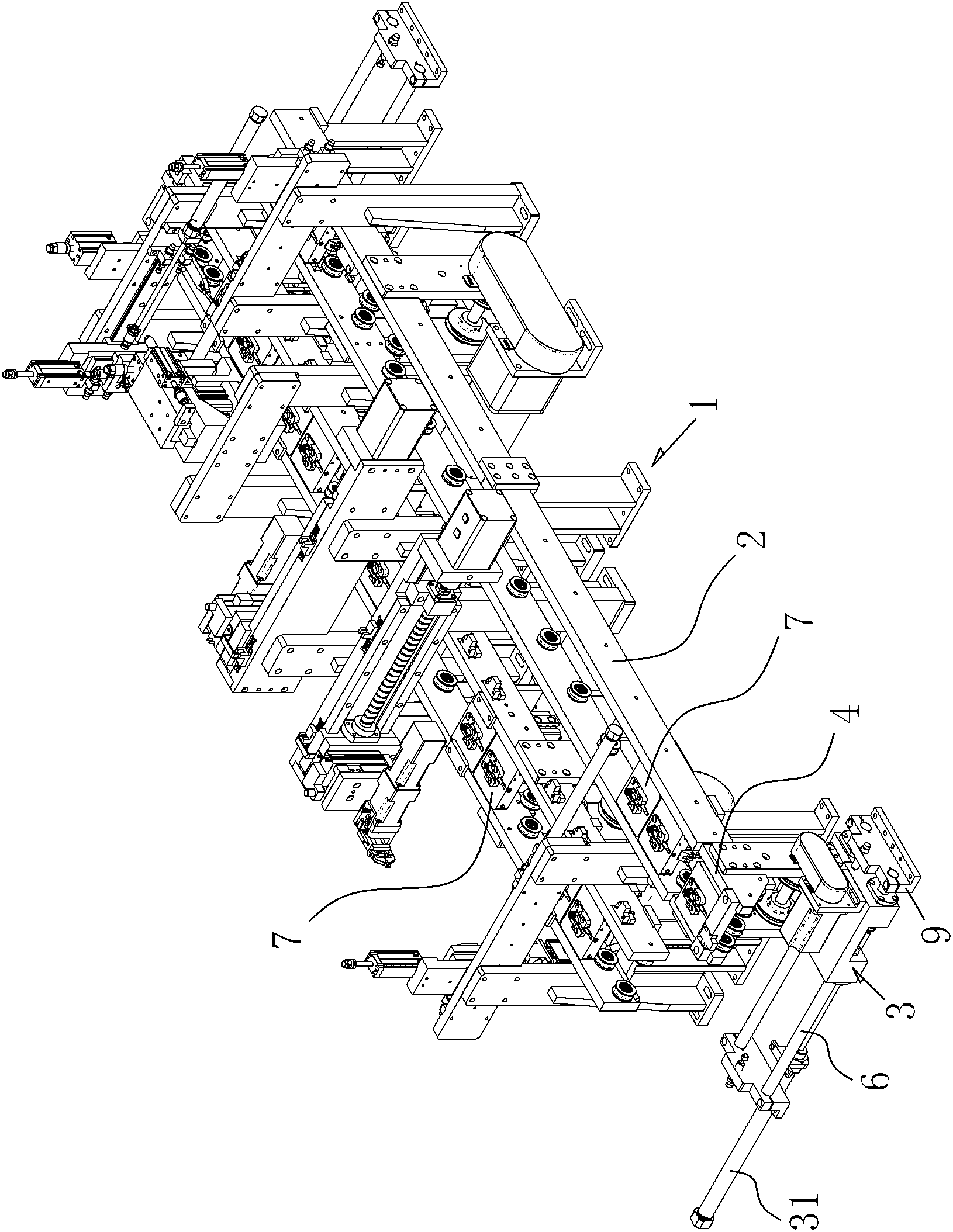

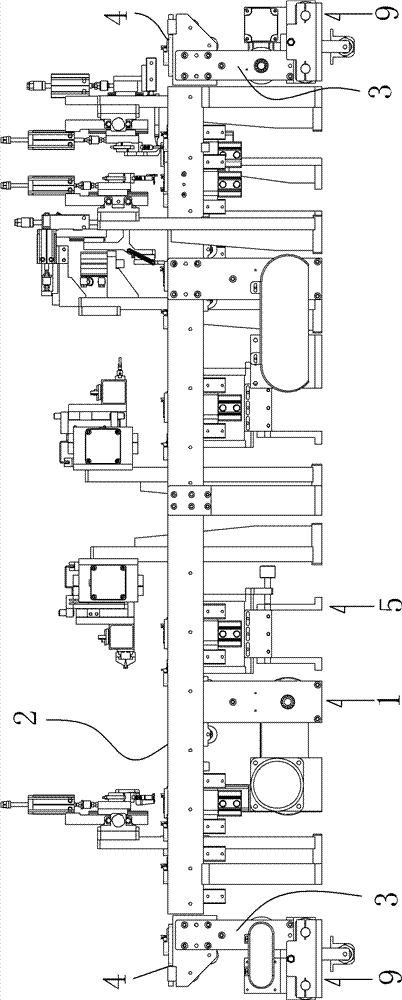

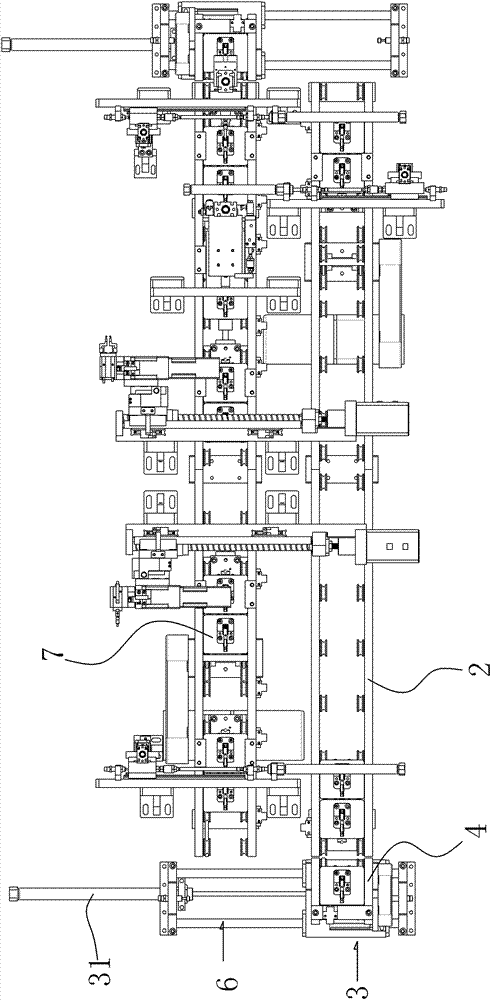

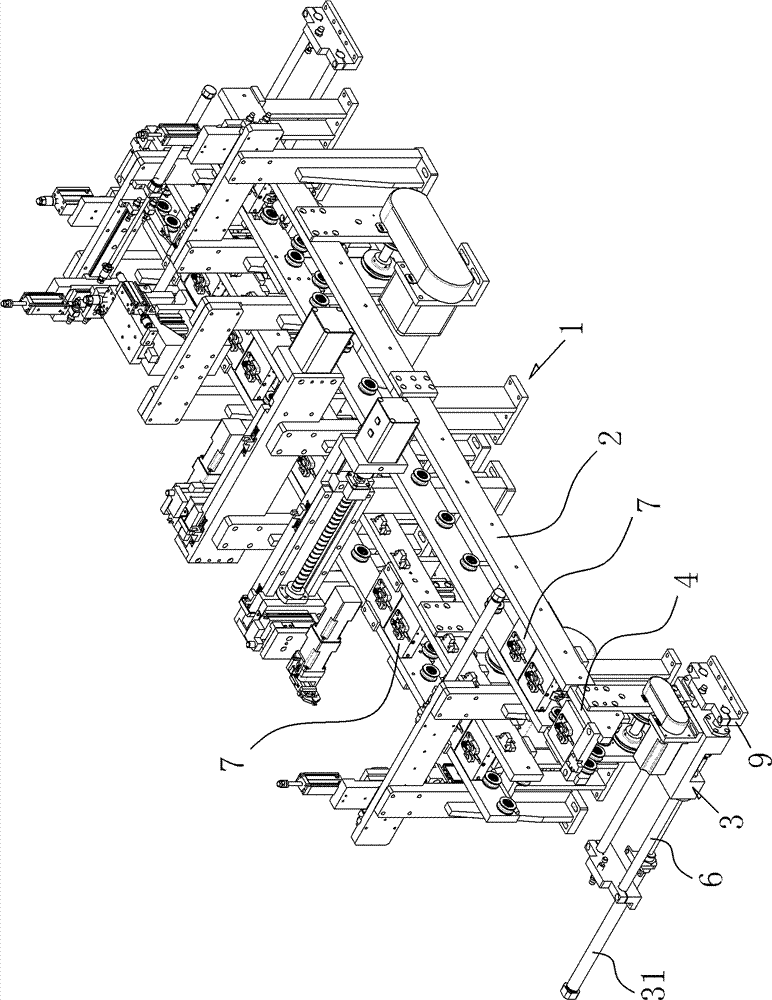

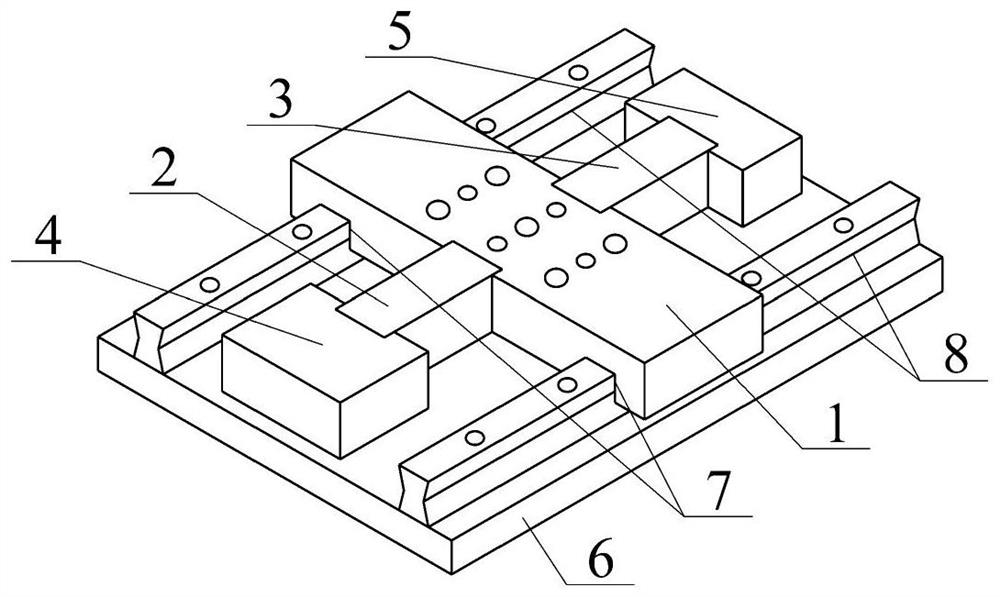

Transport mechanism

ActiveCN102431763APrecise positioningShorten the lengthConveyorsConveyor partsEngineeringMechanical engineering

The invention discloses a transport mechanism which comprises a base frame, two parallel transporting rails and a die holder, wherein the two parallel transporting rails are installed on the base frame, and the die holder is placed on the transporting rails and is driven by the transporting rails. The transport mechanism also comprises joining mechanisms arranged on two ends of the transporting rails; the die holder on one transporting rail is transferred to the other transporting rail by the joining mechanisms; and the two transporting rails form a circulating transmission rail. The transport mechanism can be suitable for automatically machining on multiple stations, can accurately position and can circularly convey devices.

Owner:DONGGUAN DUOHE AUTOMATION TECH

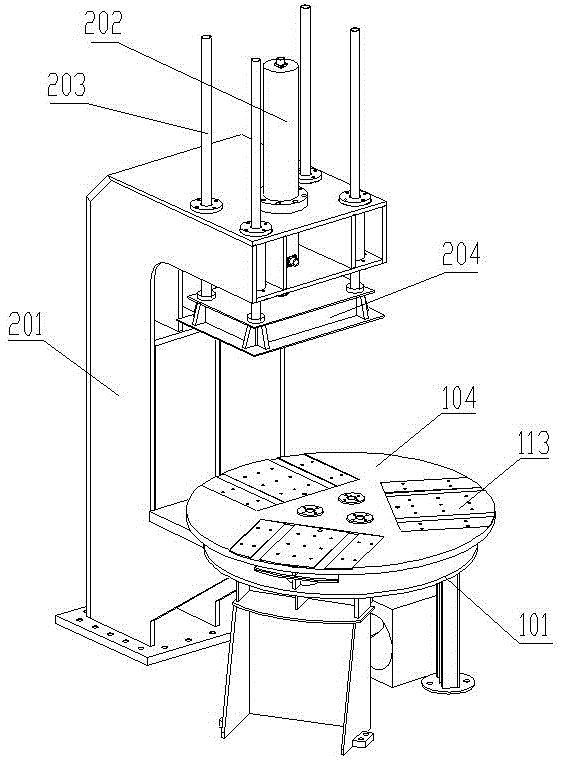

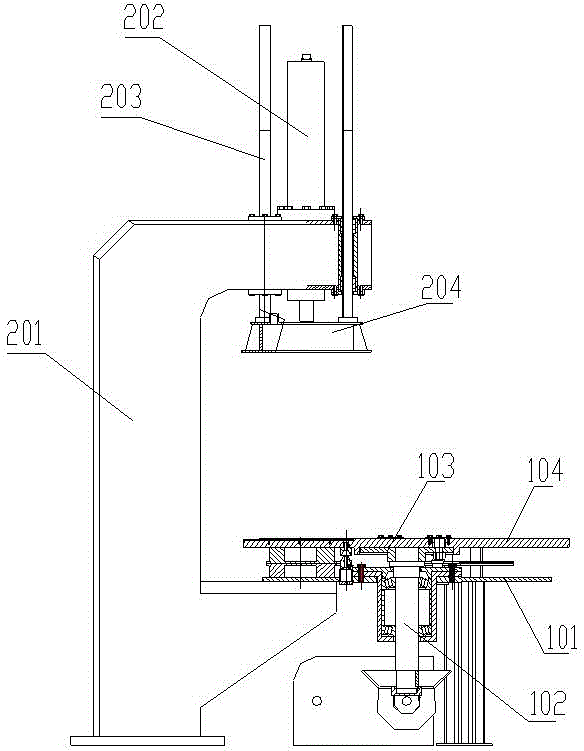

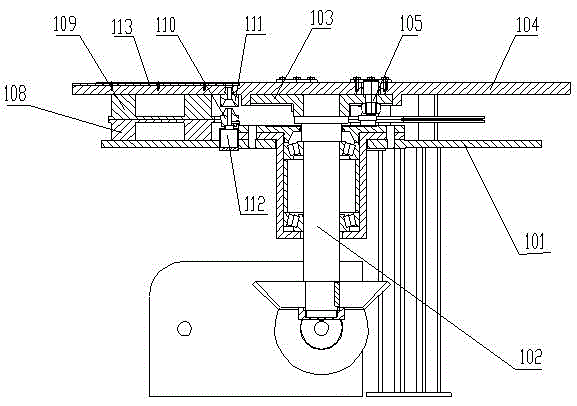

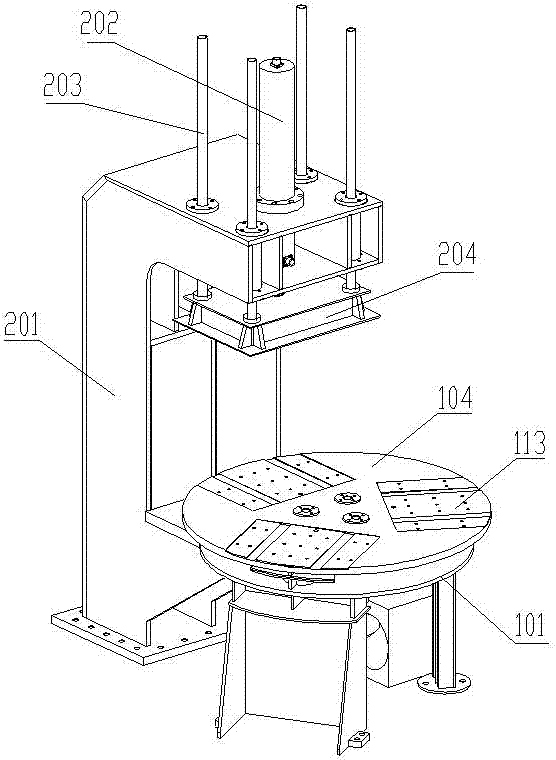

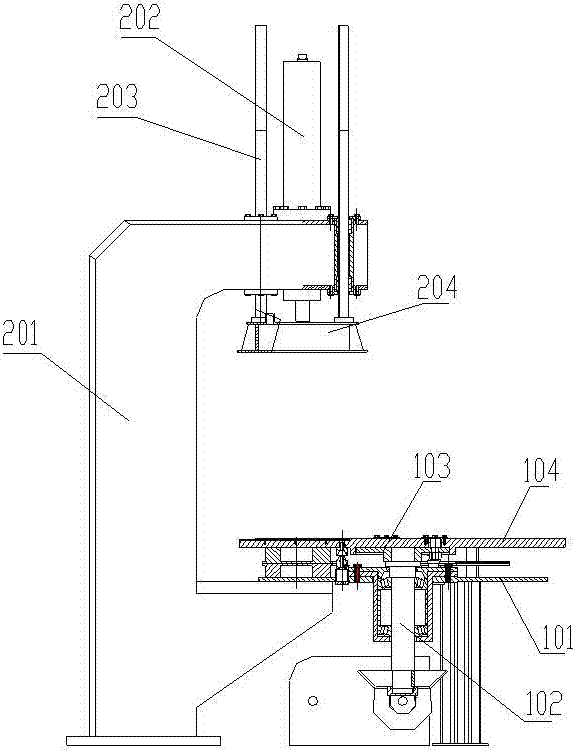

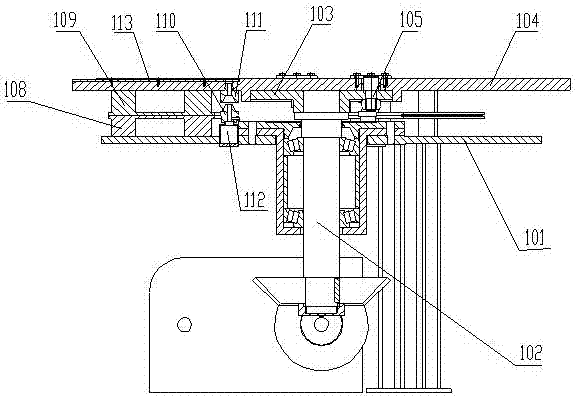

Paper-plastic shaper and shaping technology thereof

InactiveCN105544309AWith up and down slip compensation abilityNo radial forceTextiles and paperEngineeringMechanical engineering

The invention relates to a paper-plastic shaper and a shaping technology thereof. The paper-plastic shaper comprises an upper mould assembly provided with an upper mould, and a lower mould assembly provided with a lower mould. The lower mould assembly comprises a rotary table rack (101). A rotating shaft (102) is vertically installed on the rotary table rack (101). A rotary connecting disc (103) is installed at the top of the rotating shaft (102) in a sleeving mode by means of key joint. Multiple guide columns (105) are installed on the rotary connecting disc (103) in the vertical direction. A rotary table (104) is arranged on the rotary connecting disc (103) in a shelved mode and provided with connecting holes for the guide columns (105) to be inserted. Each guide column (105) is sleeved with a lubricating sleeve (106). The lubricating sleeves (106) are located between the guide columns (105) and the inner walls of the connecting holes. The paper-plastic shaper and the shaping technology thereof effectively stop stress transmission and can ensure transposition precision.

Owner:JIANGYIN POLYTECHNIC COLLEGE

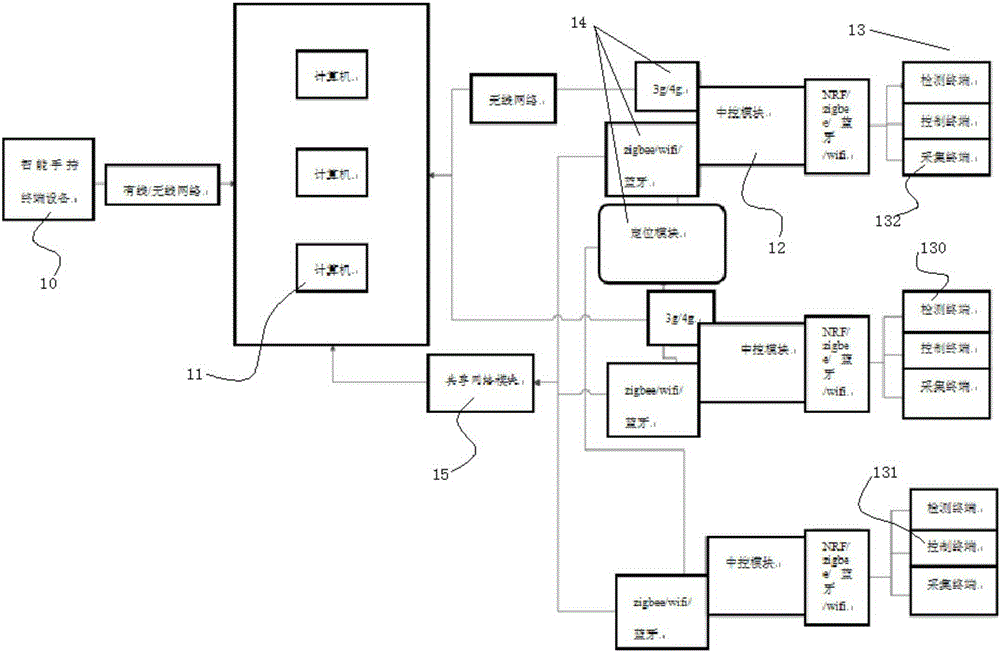

Greenhouse intelligent control system

InactiveCN105242722AEasy to operateEasy to controlTotal factory controlSimultaneous control of multiple variablesEconomic benefitsComputer science

The invention provides a greenhouse intelligent control system comprising an intelligent control module, a computing service cluster module, a central control module, a terminal monitoring module and a communication module. The terminal monitoring module comprises a detection terminal, a control terminal and a collection terminal; the intelligent control module is in a first communication connection with the computing service cluster module, the computing service cluster module is in a second communication connection with the central control module, and the central control module is in a third communication connection with the terminal monitoring module. The greenhouse intelligent control system has advantages of convenient operation, high management efficiency, low labor cost, and good economic benefit, and can monitor and effectively control the ecological environment of greenhouses in real time.

Owner:费帆

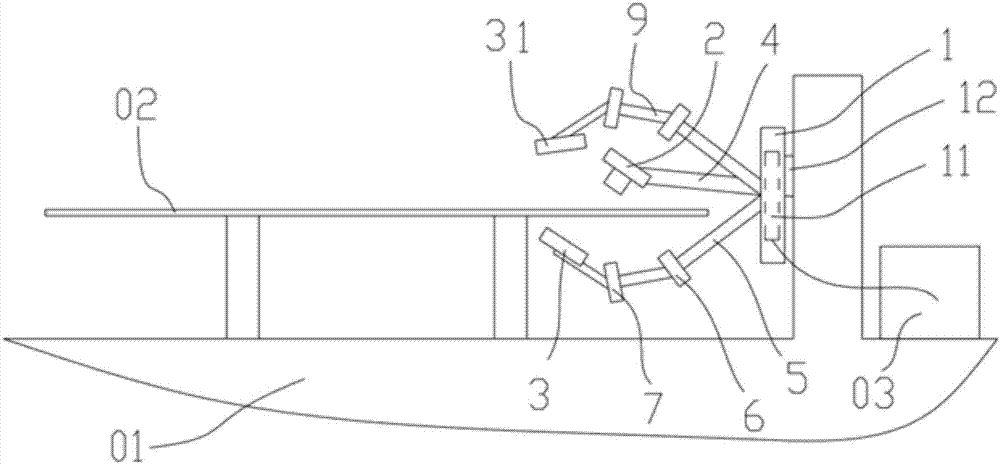

Portable defect detector

InactiveCN107479226APrecise positioningExpand the detection rangeNon-linear opticsProduction lineLiquid-crystal display

The invention relates to a detector of a glass substrate in the manufacture procedure of a liquid crystal displayer. The detector comprises a base, a detection device, a light projector, a first support, a second support and a processing terminal. A positioning unit which can be quickly connected or disconnected with a machine table is arranged on the base so that the installation position of the detector can be freely selected on the machine table. The detection device is cooperated with the light projector in use, and especially, the light penetration irradiation or reflective irradiation can be achieved by the light projector so that the detectable range of the detector can be extended, and the requirements of any detection position and environment on a production line can be met. The portable defect detector is simple in structure and convenient to position so that the detector can work at any position on the machine table, and the function that the defect detection of substrates on the production line are positioned precisely is achieved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

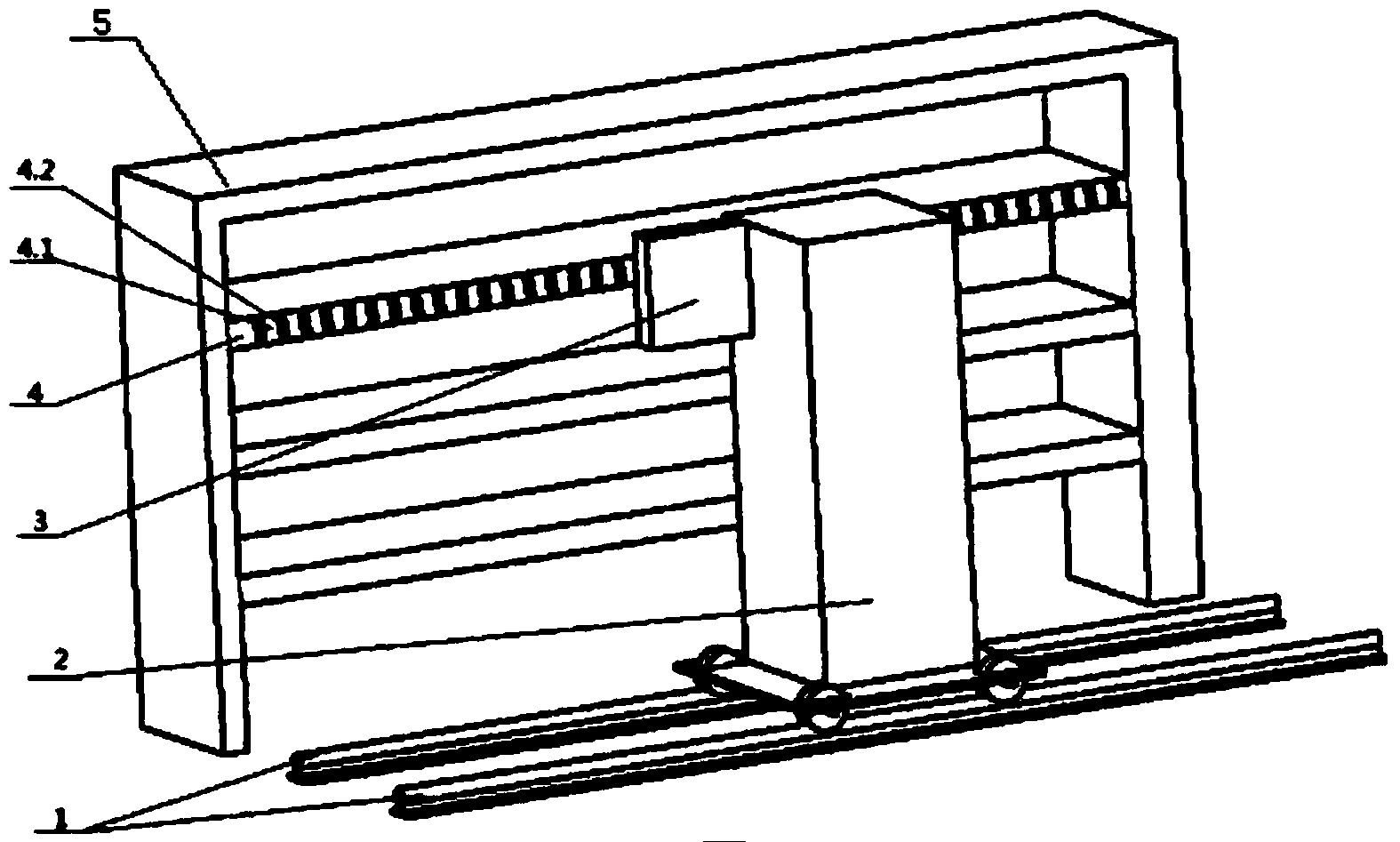

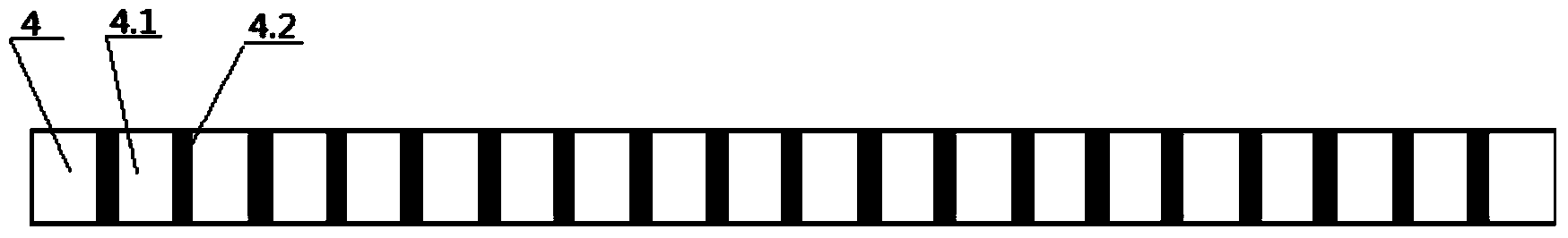

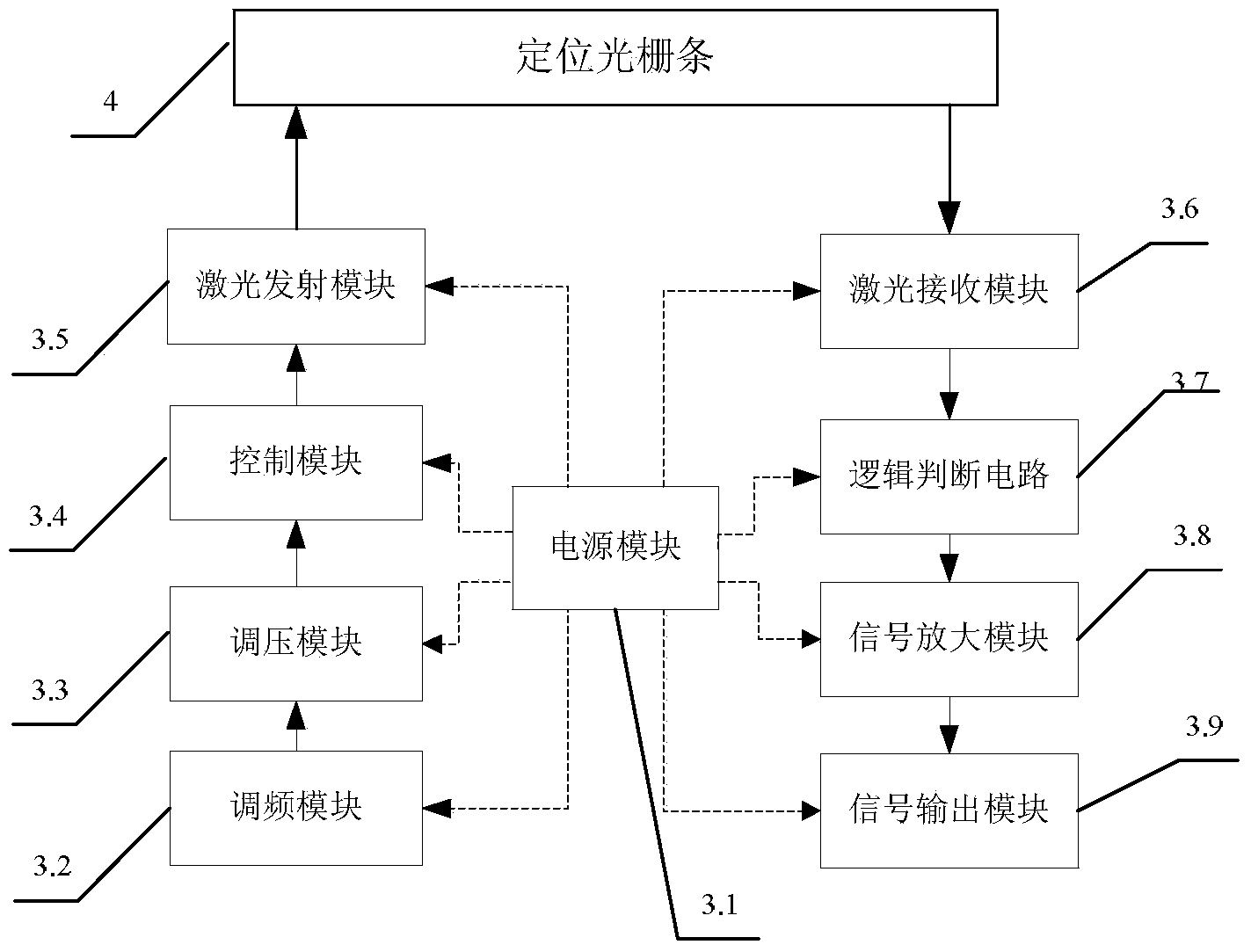

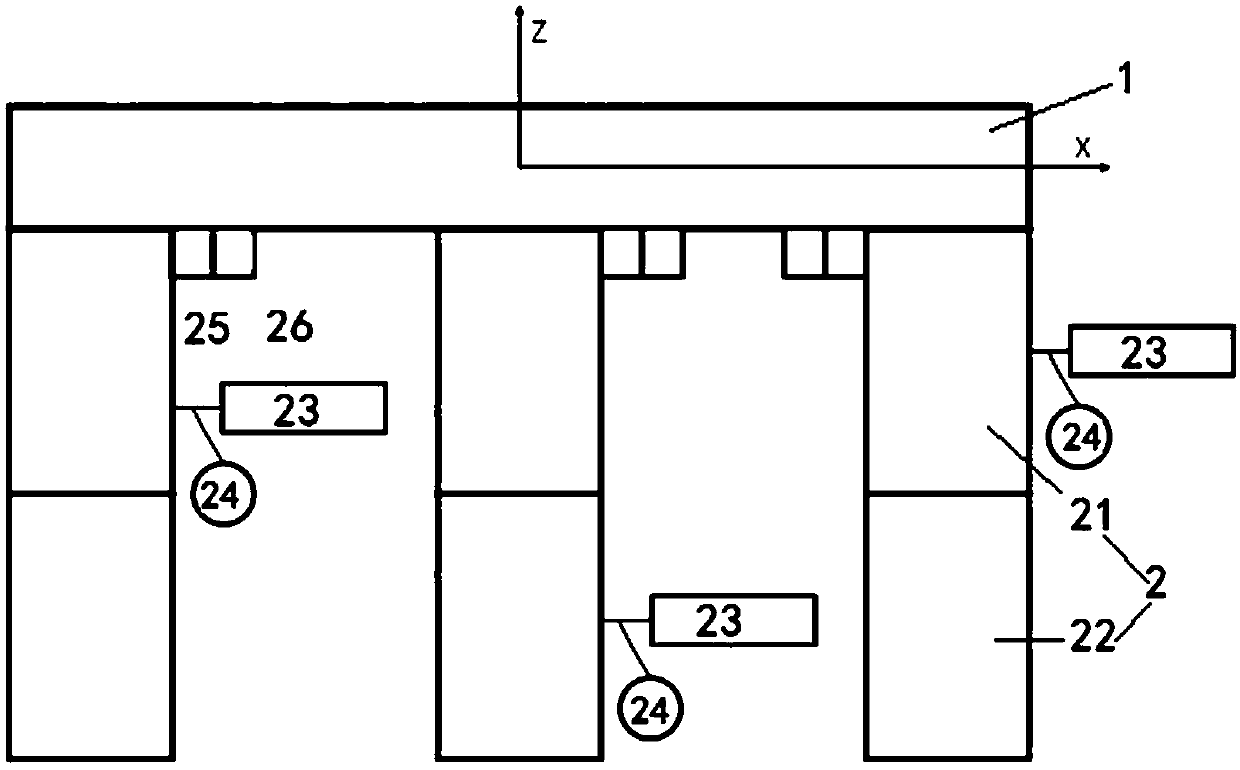

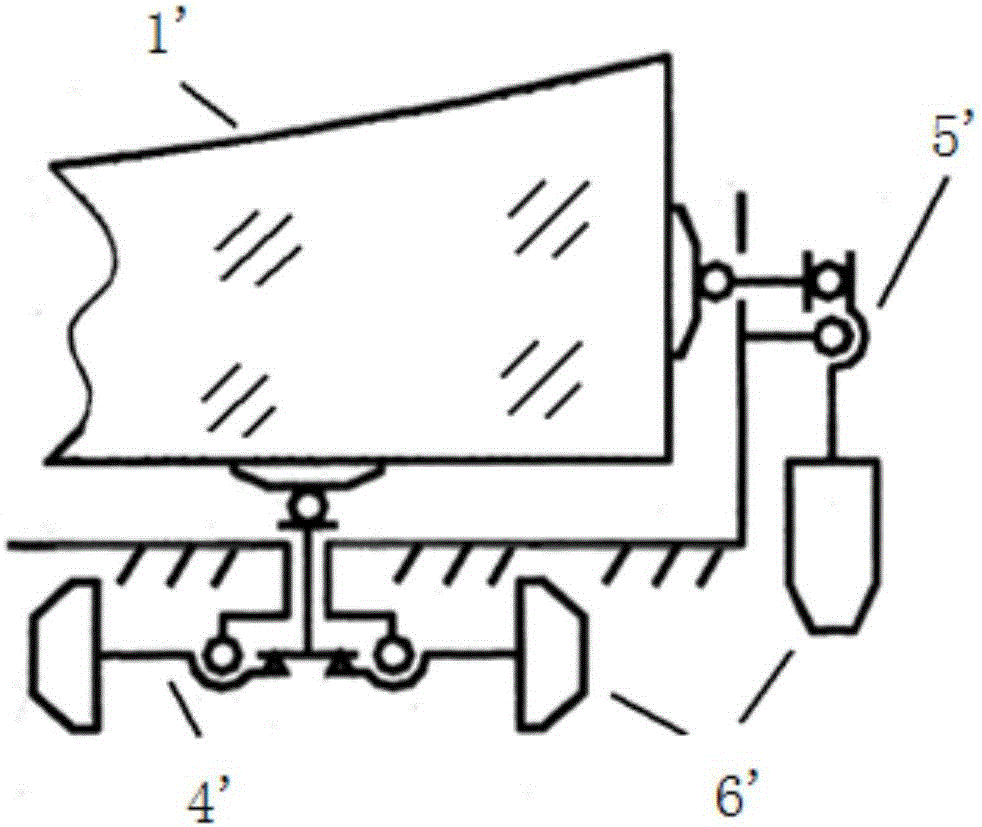

Laser raster locating system for rail mobile device

ActiveCN103439980AHigh positioning accuracyRealize precise positioning functionControl using feedbackGratingEngineering

The invention provides a laser raster locating system for a rail mobile device and relates to a laser locating system. The laser raster locating system for the rail mobile device comprises a movement guide rail (1), the mobile device (2), a laser emitting and receiving module (3) and a locating raster bar (4). The movement guide rail (1) is used for offering movement restraint and a movement trail of the mobile device; the bottom of the mobile device (2) is installed on the movement guide rail and the mobile device (2) moves laterally along the movement guide rail; the laser emitting and receiving module (3) is fixed to the mobile device (2) and used for emitting lasers and receiving reflected laser signals; the locating raster bar (4) is installed on a fixed rack (5) and used for providing the reflected laser signals with different intensities and modes, wherein the fixed rack (5) is used for containing an object to be located. According to the laser raster locating system for the rail mobile device, the locating error is smaller than 2mm, the locating accuracy and the locating reliability are high, the manufacturing cost is low, and the laser raster locating system for the rail mobile device is particularly suitable for the accurate location of the rail mobile device.

Owner:广西恒帆智能科技有限公司

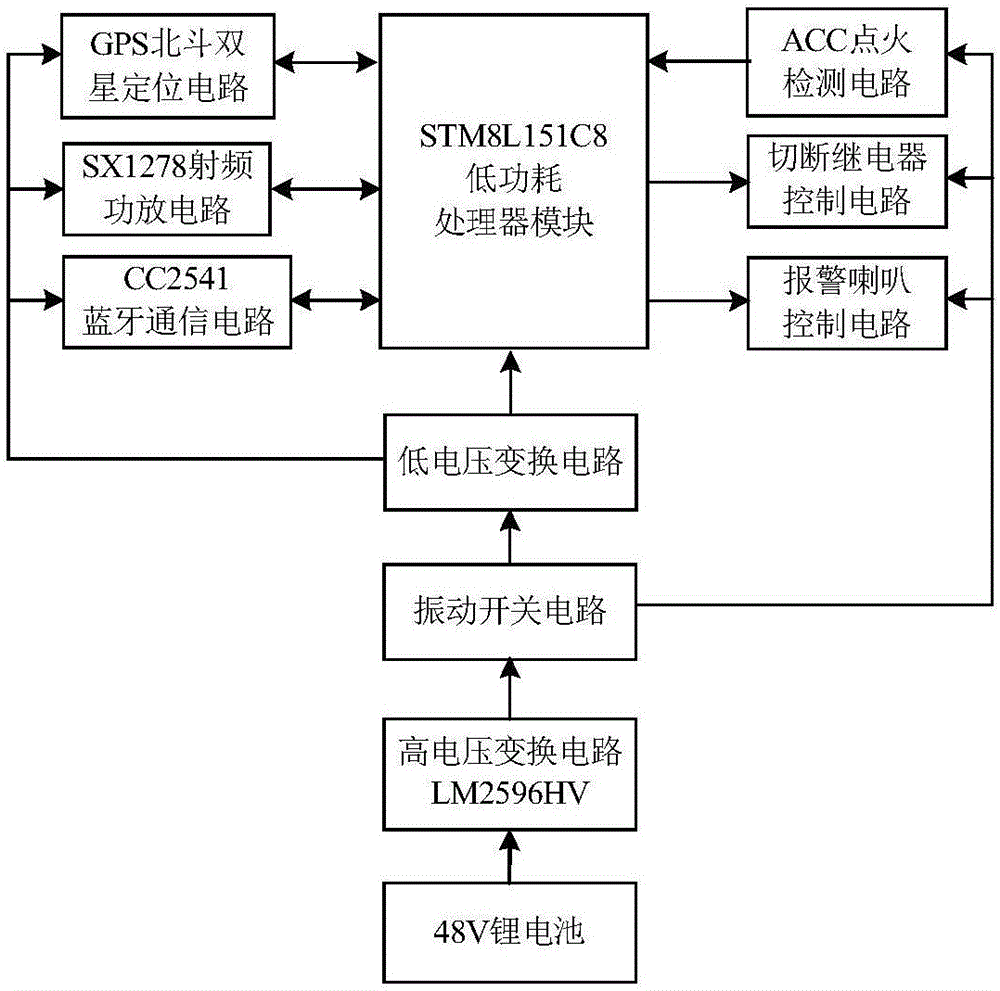

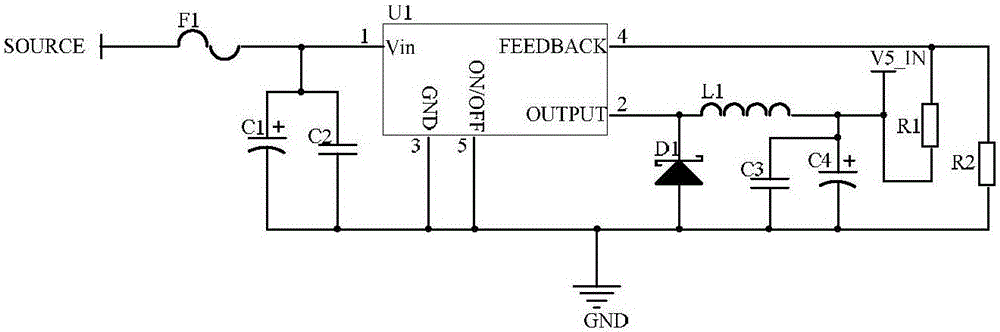

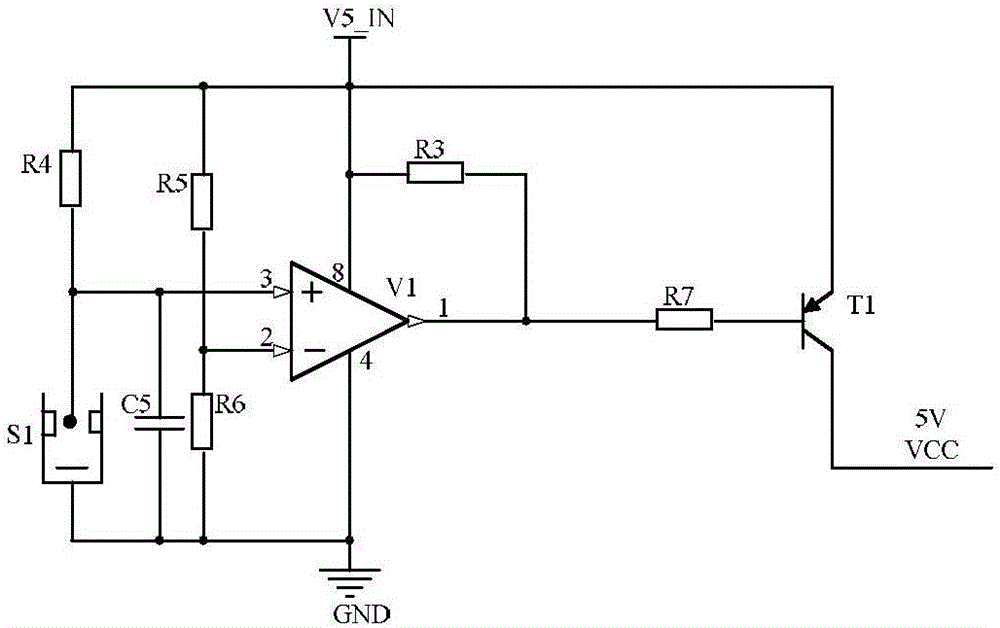

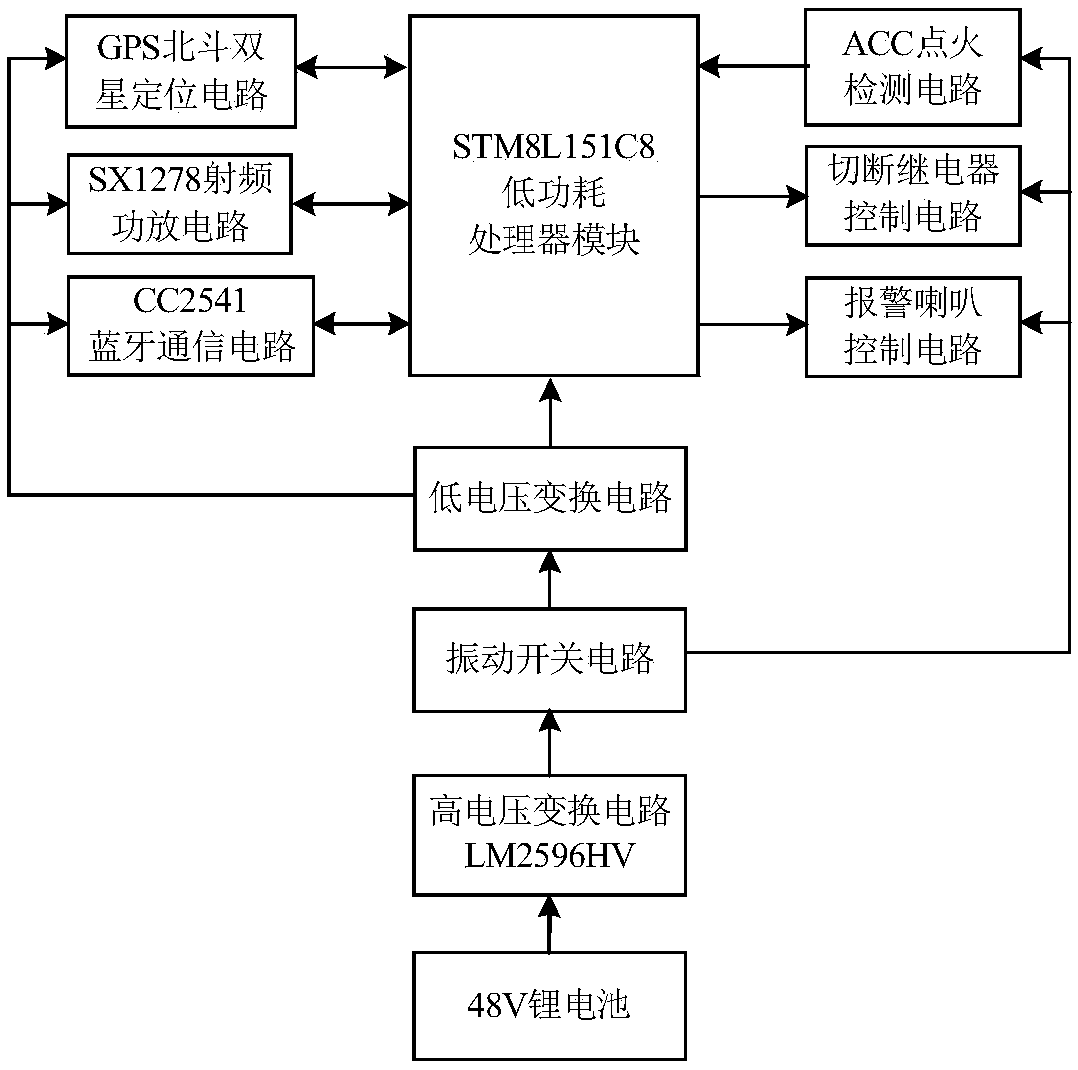

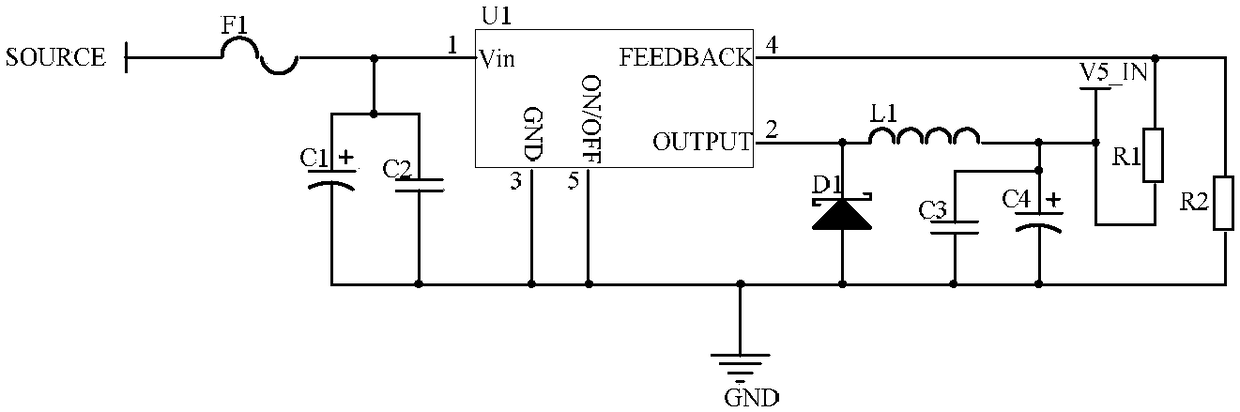

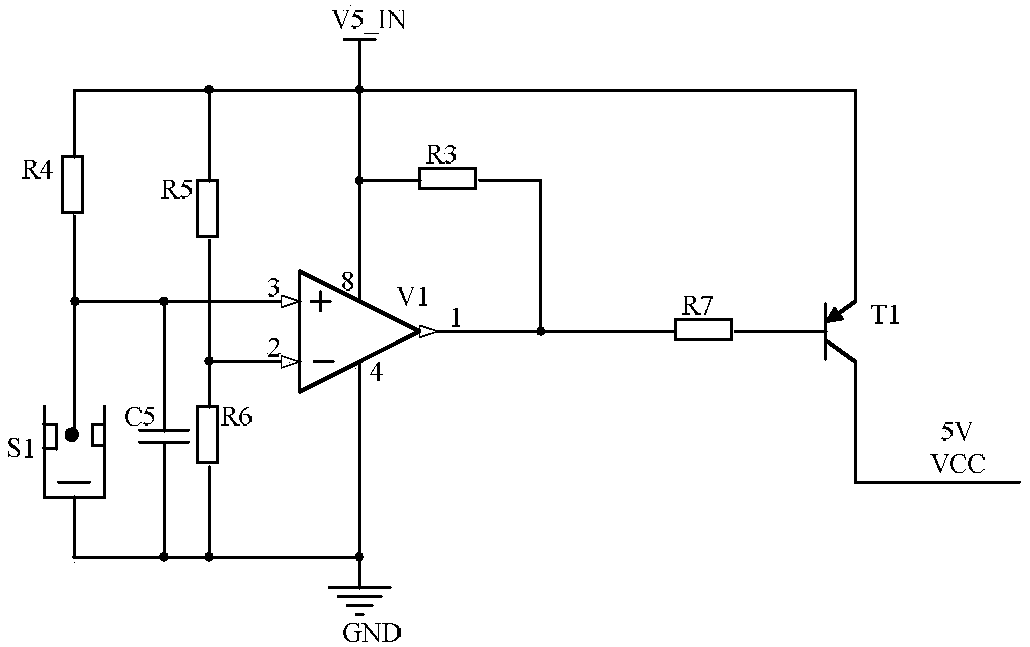

Vehicle anti-theft tracking circuit based on LoRa (long range) radio frequency technology

The invention relates to a vehicle anti-theft tracking circuit based on a LoRa (long range) radio frequency technology. A power supply part of the vehicle anti-theft tracking circuit is divided into a high voltage transformation circuit and a low voltage transformation circuit, and after a vibration switch detects vibration, the low voltage transformation circuit is switched on to provide low-voltage power supply for a system. STM8L151C8 microcontroller is taken as the core to perform information interaction with a GPS / beidou double-star positioning circuit through a UART serial port and communicates with an SX1278 radio frequency circuit through an SPI, status information of the system is sent to a LoRa base station, and long-distance transmission with low power consumption is realized. An alarm interface is used for accessing a vehicle control terminal, and the terminal initiatively uploads alarm data once a vehicle is stolen. The latest vehicle position and alarm lamp status data are sent with a LoRa wireless transmission technology, so that the effects of real-time vehicle tracking, theft alarm and the like are realized, and vehicle losing is prevented.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

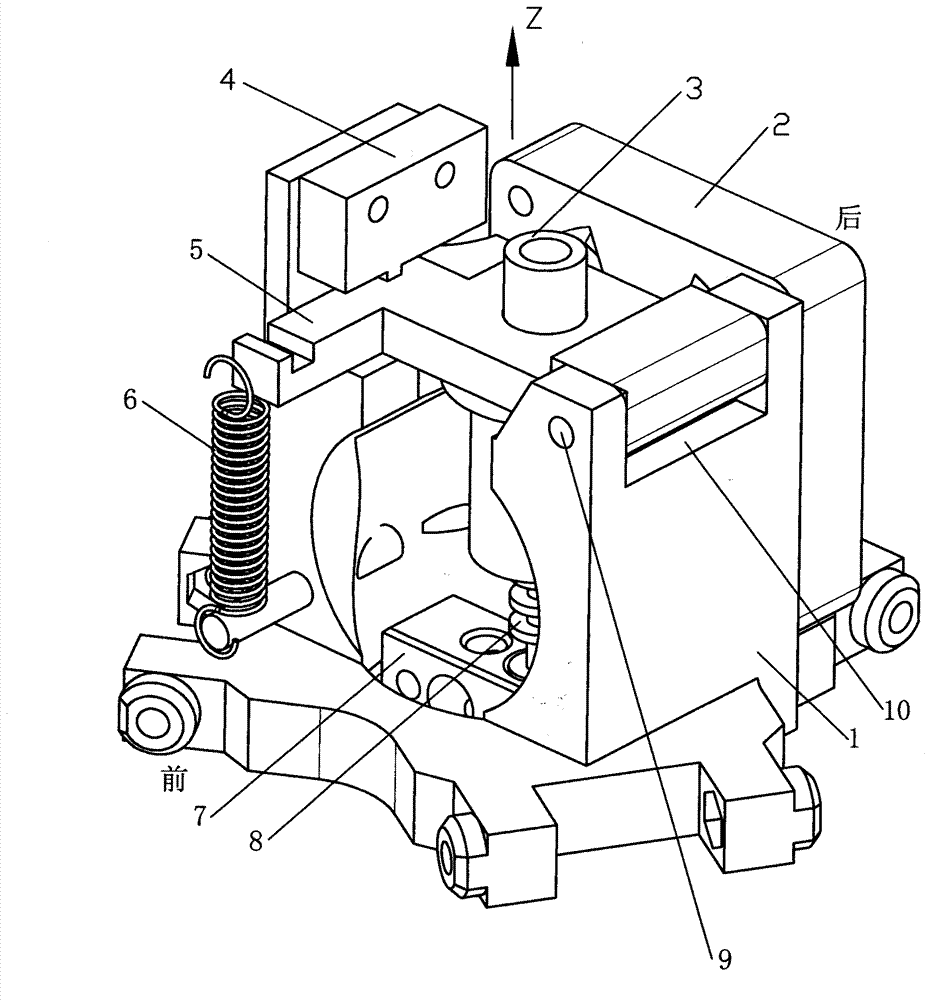

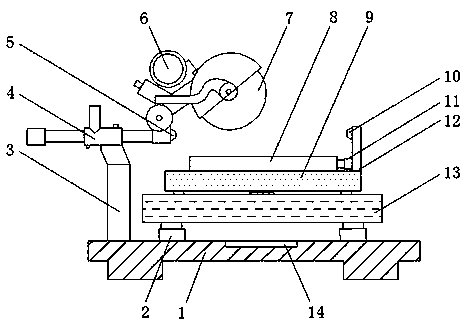

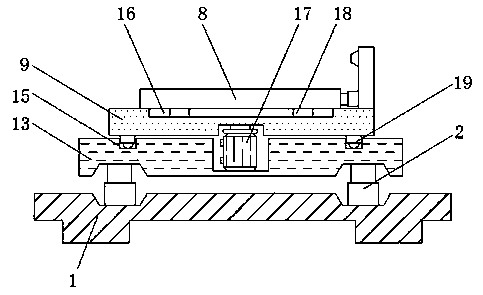

Automatic leveling mechanism for parallel transmission structure

ActiveCN104267740ARealize precise positioning functionSimple structurePosition/direction controlNumerical controlLeveling mechanism

The invention provides an automatic leveling mechanism for a parallel transmission structure and belongs to the technical field of automatic precision adjustment. The automatic leveling mechanism aims to solve the problems that when a numerically-controlled machine tool, a numerically-controlled carving machine, a 3D printer and other devices are positioned accurately in the Z-axis direction through manual adjustment, consumed time is long, the labor intensity is high and the error of a measuring result is large in the adjusting process. A heating block is arranged in a parallel connection support. The lower end of a spray head stretches out of a spray head mounting hole in the heating block. The upper end of the spray head is fixedly connected with a spray head fixing base. The upper end of the spray head fixing base fixedly penetrates out of a through hole of a hot end assembly fixing frame. One end of the hot end assembly fixing frame is hinged to the parallel connection support. A microswitch is fixedly connected with the parallel connection support. The microswitch is located over the other end of the hot end assembly fixing frame. A gap is formed between the microswitch and the hot end assembly fixing frame. The hot end assembly fixing frame is connected with the bottom of the parallel connection support through an elastic extension mechanism. The automatic leveling mechanism is mainly applied to the numerically-controlled machine tool, the numerically-controlled carving machine, the 3D printer, a sorting system and the like.

Owner:黑龙江科大科技开发有限公司

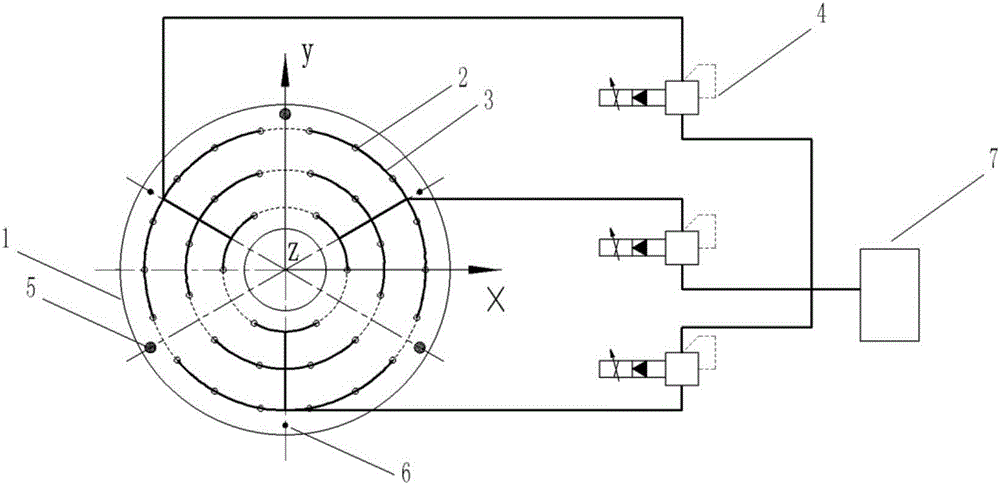

Multi-degree-of-freedom active vibration isolation device and method

ActiveCN108679141AReduce stiffnessLower resonance frequencySpringsSprings/dampers functional characteristicsElectricityResonance

The invention discloses a multi-degree-of-freedom active vibration isolation device and method. The device includes a platform and six support legs arranged on the lower edge of a support platform. The six support legs are evenly arranged in two rows, wherein each support leg includes a double chamber vertical air spring and a horizontal air spring disposed at a lower end of the double chamber vertical air spring. Each support leg is provided with a pneumatic proportional valve, a pressure sensor for detecting gas pressure, a displacement sensor and a speed sensor, which are respectively electrically connected by a controller. Each pneumatic proportional valve is in communication with the double chamber vertical air spring and the horizontal air spring of the corresponding support leg. Theinvention has advantages of suppressing the resonance peak and effectively isolating the vibration exceeding the natural frequency.

Owner:浙江埃特斯力试验设备有限公司

Transport mechanism

ActiveCN102431763BPrecise positioningRealize precise positioning functionConveyorsConveyor partsMechanical engineeringEngineering

Owner:DONGGUAN DUOHE AUTOMATION TECH

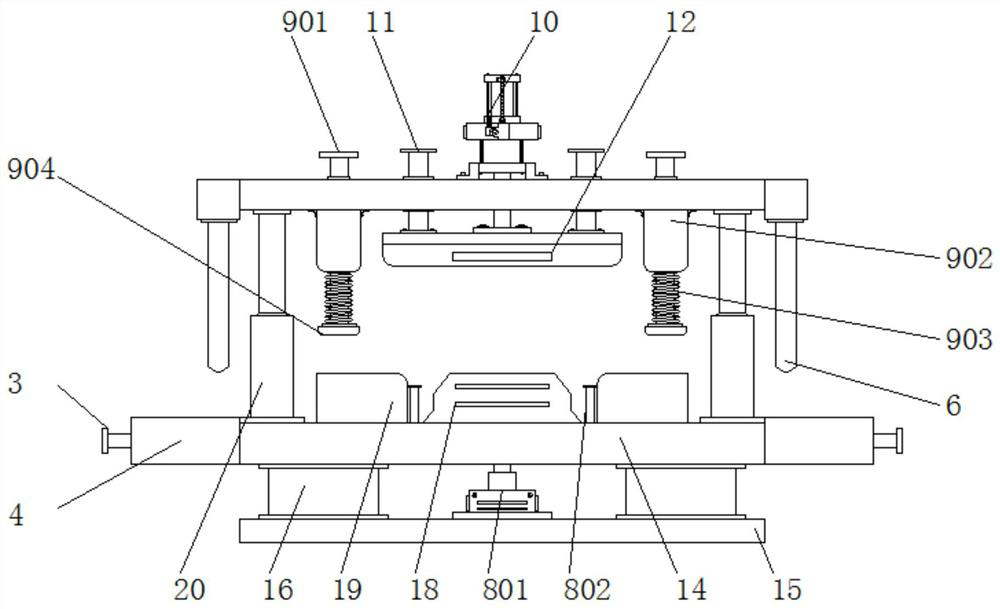

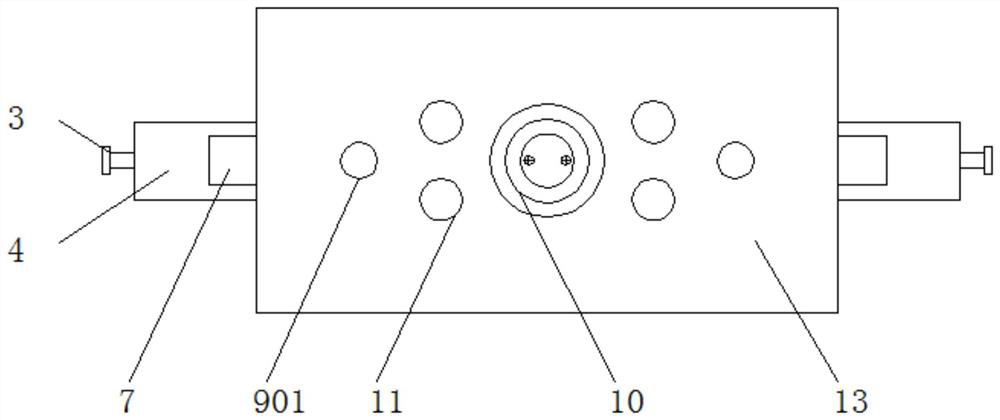

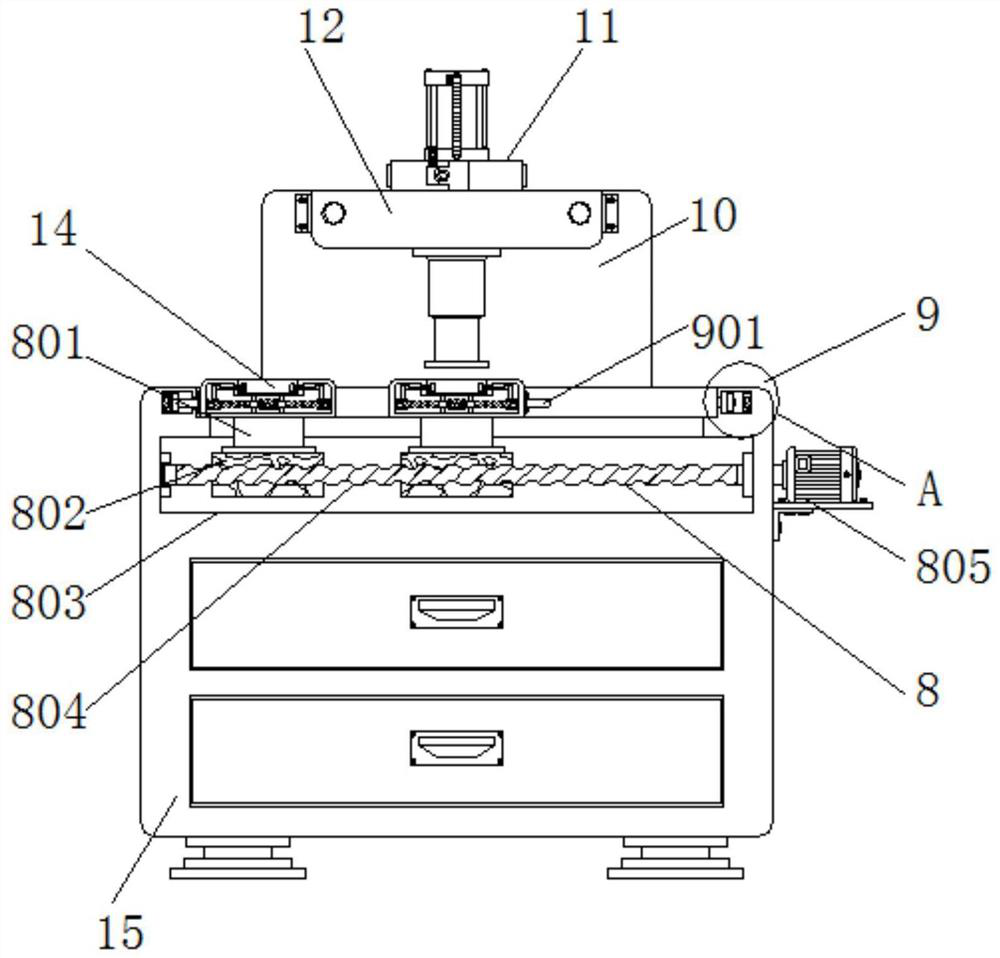

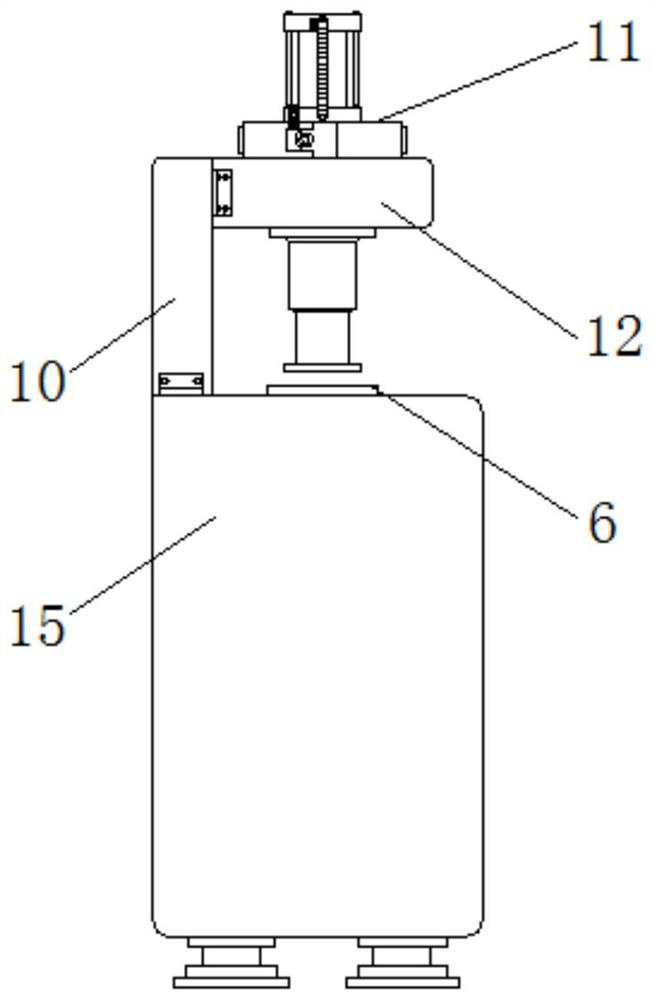

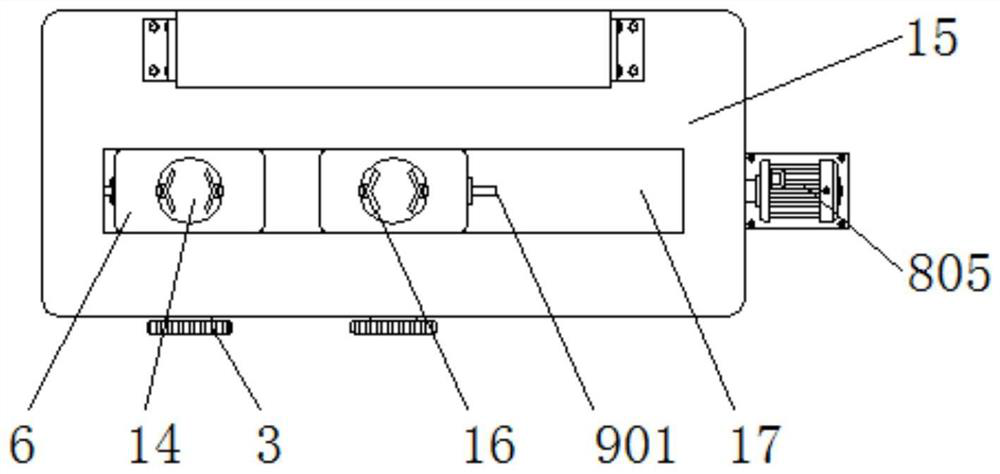

High-precision punch forming die for ceiling crossbeam in bullet train carriage

PendingCN112547938AAvoid offsetEasy to fixShaping toolsMetal-working feeding devicesMachine partsCarriage

The invention discloses a high-precision punch forming die for a ceiling crossbeam in a bullet train carriage. The high-precision punch forming die comprises a bottom plate and further comprises an ejection structure facilitating part taking, a fixing structure preventing a workpiece from deviating and a positioning structure guaranteeing normal work of a device, two supporting legs are arranged on each of the two sides of the top end of the bottom plate, and a supporting plate is arranged at the top ends of the supporting legs. A lower die base is installed in the middle of the top end of thesupporting plate, side plates are installed in the positions, on the two sides of the lower die base, of the top end of the supporting plate, an empty groove is formed in the center of the bottom endof the supporting plate, the ejection structure is arranged in the empty groove, two third air cylinders are arranged in the position, on one side of each side plate, of the top end of the supportingplate, and top plates are mounted at the top ends of the third air cylinders. A first air cylinder is started to work, thus a transverse plate can be pushed to move, an ejector rod moves upwards, anauxiliary spring deforms till the ejector rod ejects out a machined part, and the structure is beneficial to relieving the burden of workers.

Owner:盐城市富源引擎科技有限公司

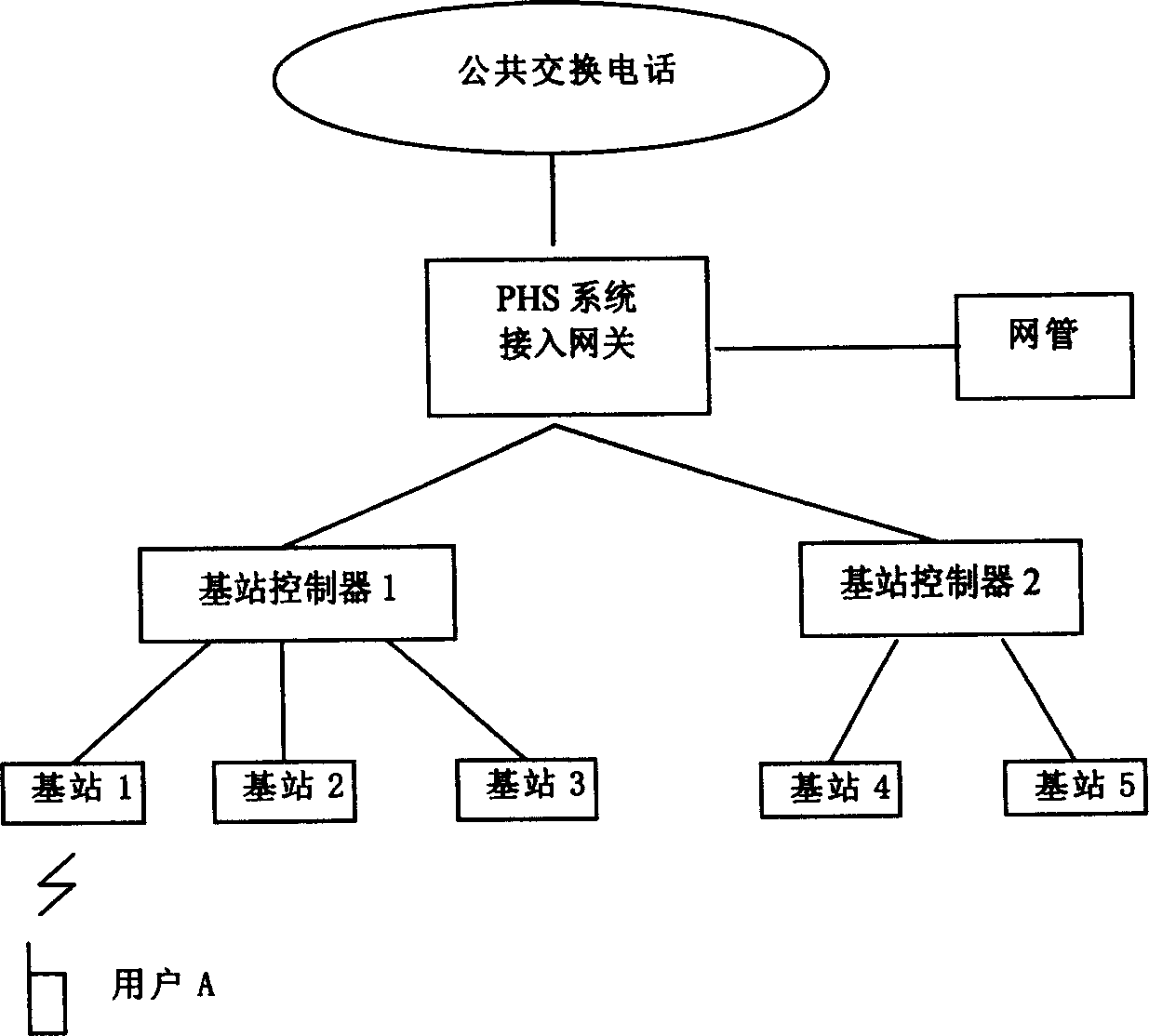

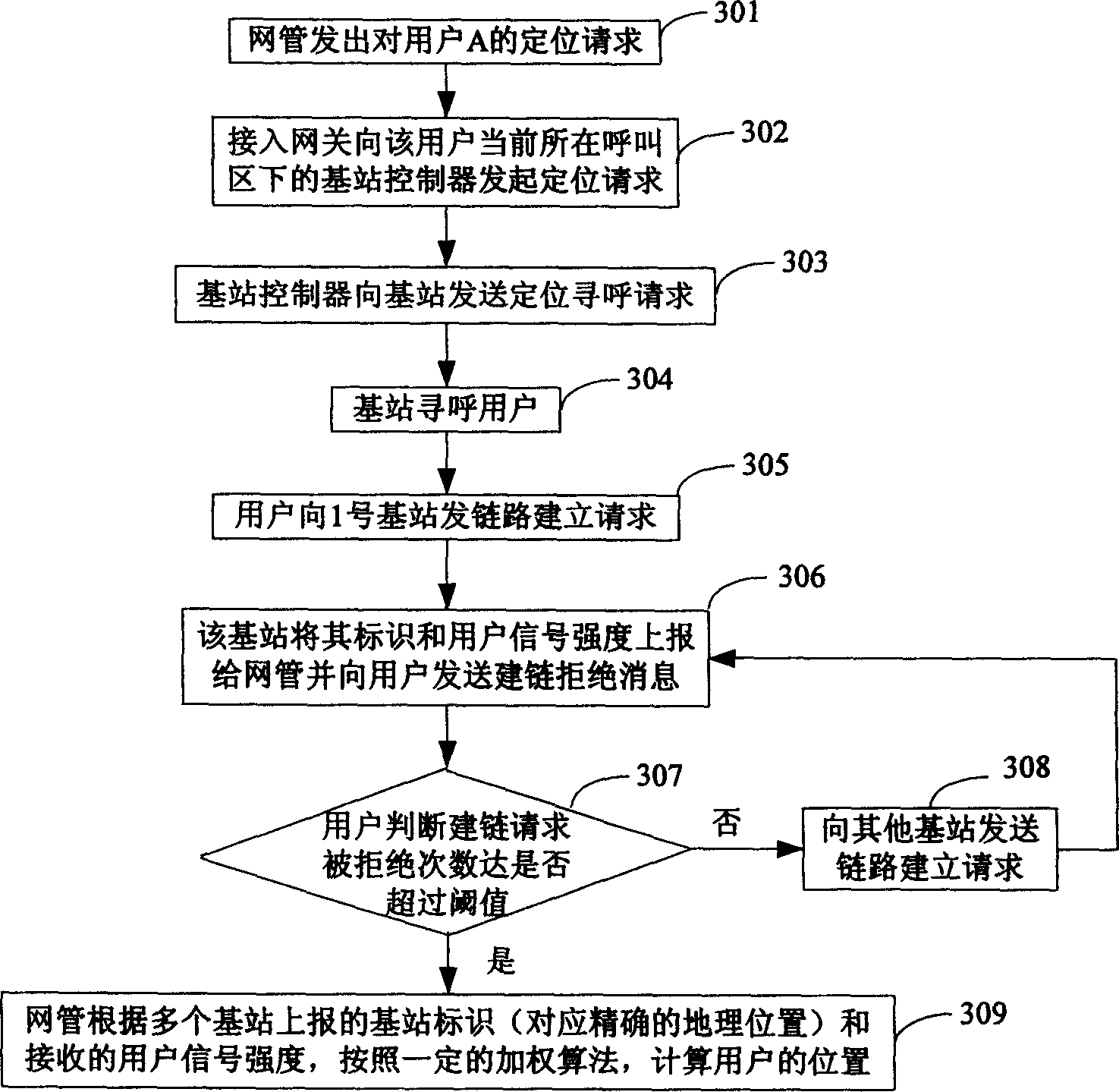

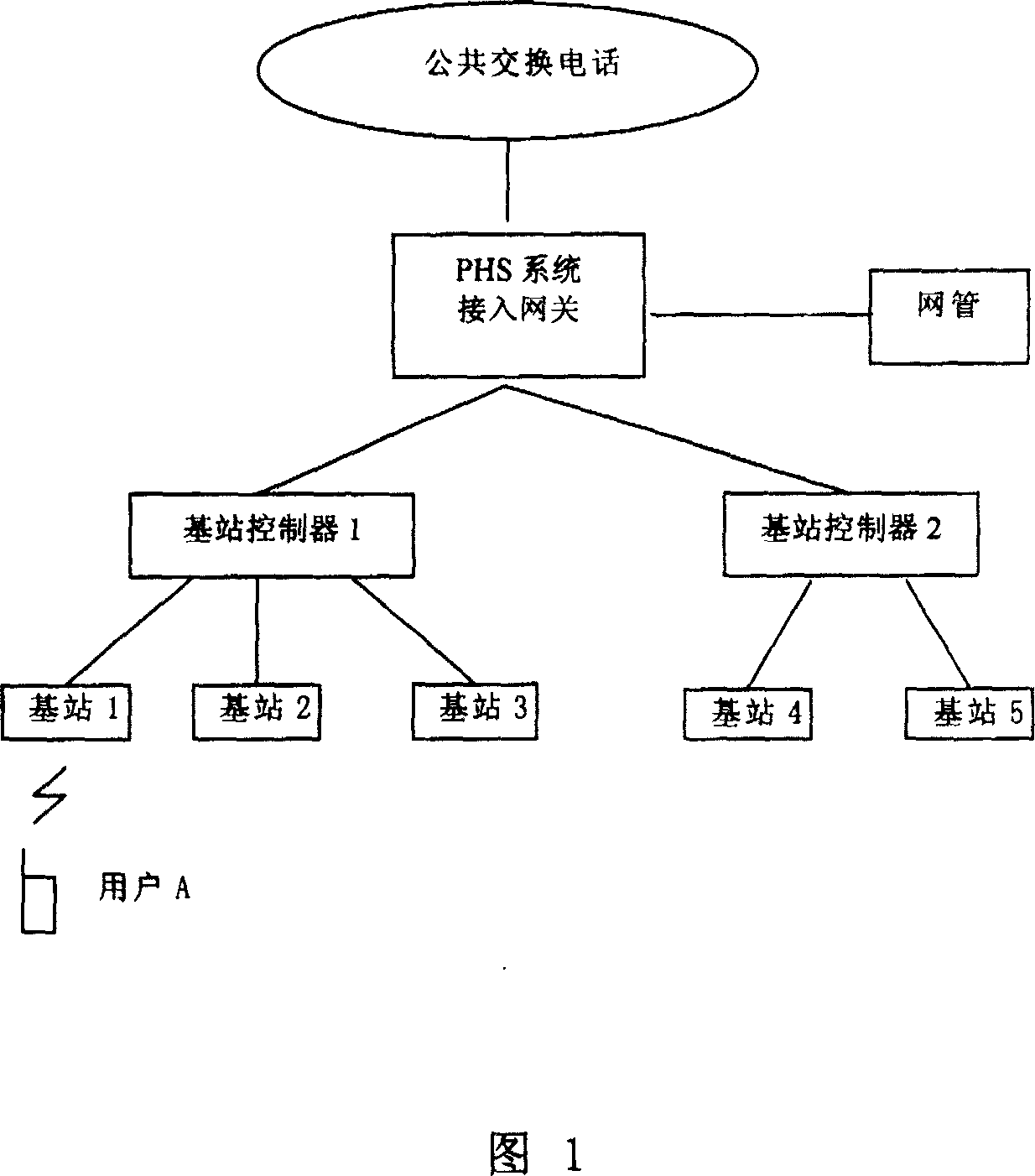

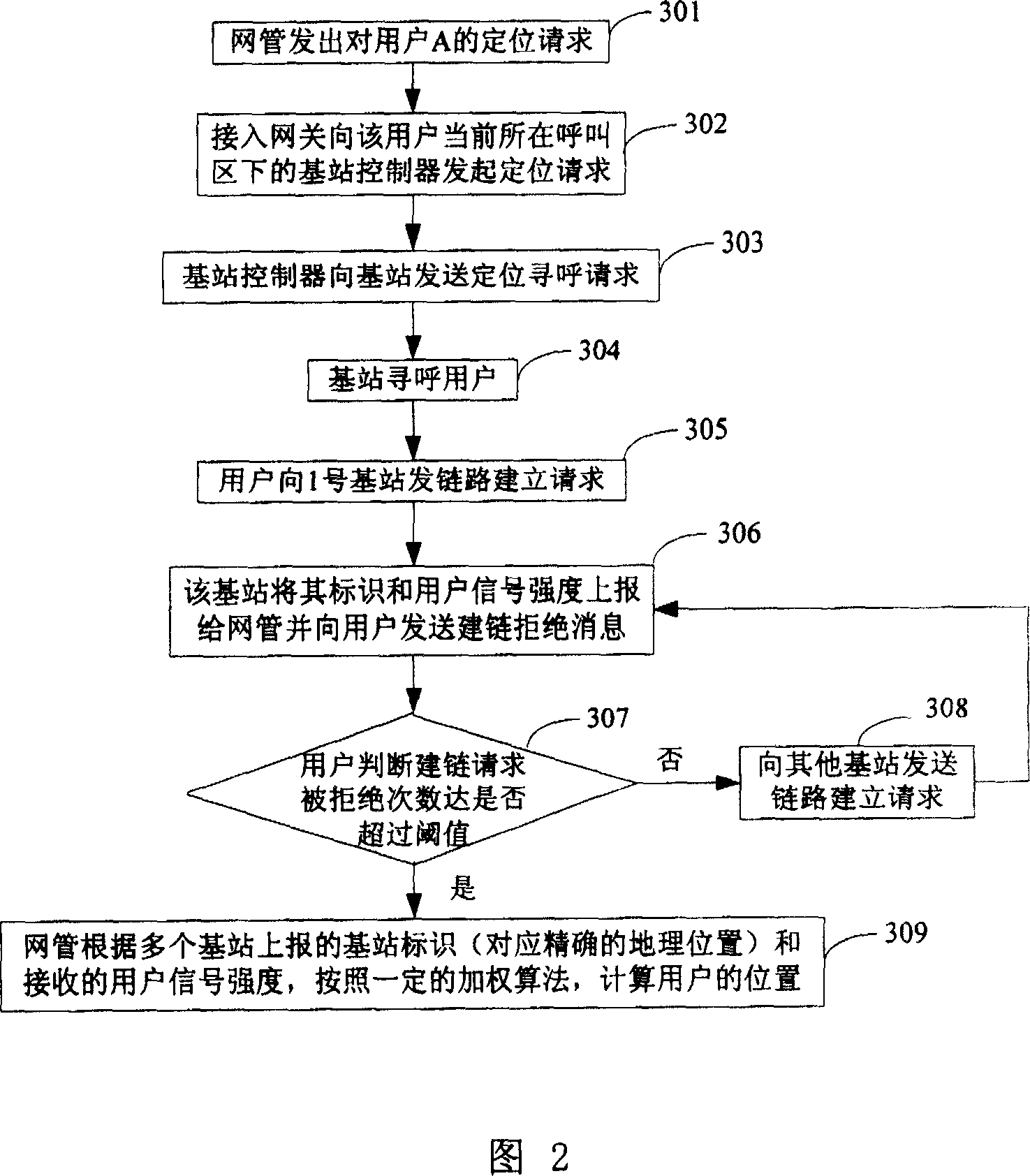

Accurately positioning method for personal hand-held telephone system user

InactiveCN1582052ALow costRealize precise positioning functionRadio/inductive link selection arrangementsLocation information based serviceNetwork managementBase station

The method for accurate positioning users in PHS system includes steps: network management through access gateway sends request for positioning user to base station controller under call region where the user current belongs to; the controller sends seeking positioning request to own base stations; base stations seek the user; the user sends request for building link to a base station; the base station reports associated position information and signal intensity of the user to network supervisor, and sends message of refusing building link to the user; the user determines whether number of refusing the said request reaches to threshold; if yes, based on information received from multiple base stations, the network supervisor calculates out user's position; otherwise, seeking other base stations to carry out steps of request for building link again. The invention realizes positioning users in PHS system in low cost and high precision.

Owner:ZTE CORP

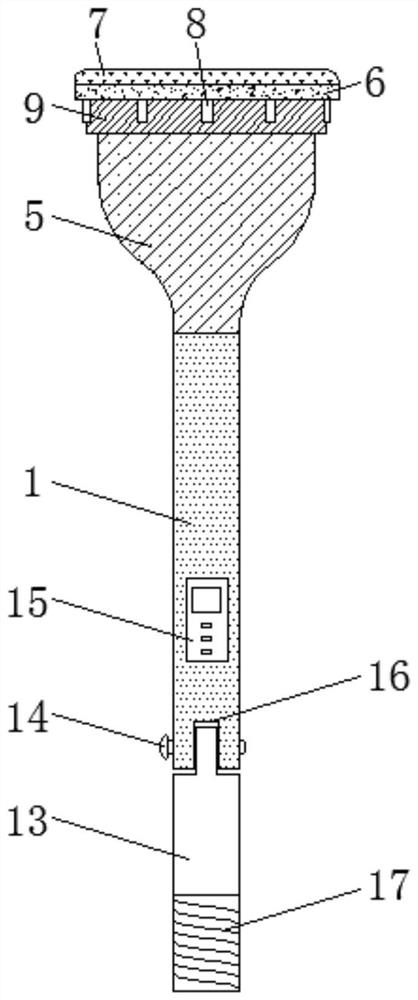

Glans penis cover for circumcision

ActiveCN109091206ARealize precise positioning functionAchieve securitySurgeryForeskinPressure sensor

The invention discloses a glans penis cover for circumcision, comprising a connection bridge, a partition, a one-way telescopic rod, a cavity and a pressure sensor. The cavity is arranged in the connection bridge; the partition is fixed in the center of the cavity; one end of the partition is fitted with the pressure sensor; the end of the partition, far away from the pressure sensor is fixedly provided with the one-way telescopic rod; the end of the connection bridge close to the one-way telescopic rod is in threaded connection with a cover body; the inside part of the cover body close to theconnection bridge is provided with a positioning block; the end of the cover body far away from the connection bridge is in threaded connection with a circular support; the end of a nail plate far away from the circular support is fixedly provided with an anastomotic plate; the edge of the anastomotic plate is provided with nail storage holes; the outer wall of the end, far away from the cover body, of the connection bridge is fitted with a controller. The glans penis cover for circumcision has the advantages that application safety of the glans penis cover is guaranteed, the glans penis is more convenient to use, and practicality of the glans penis cover is improved.

Owner:嘉兴星创科技有限公司

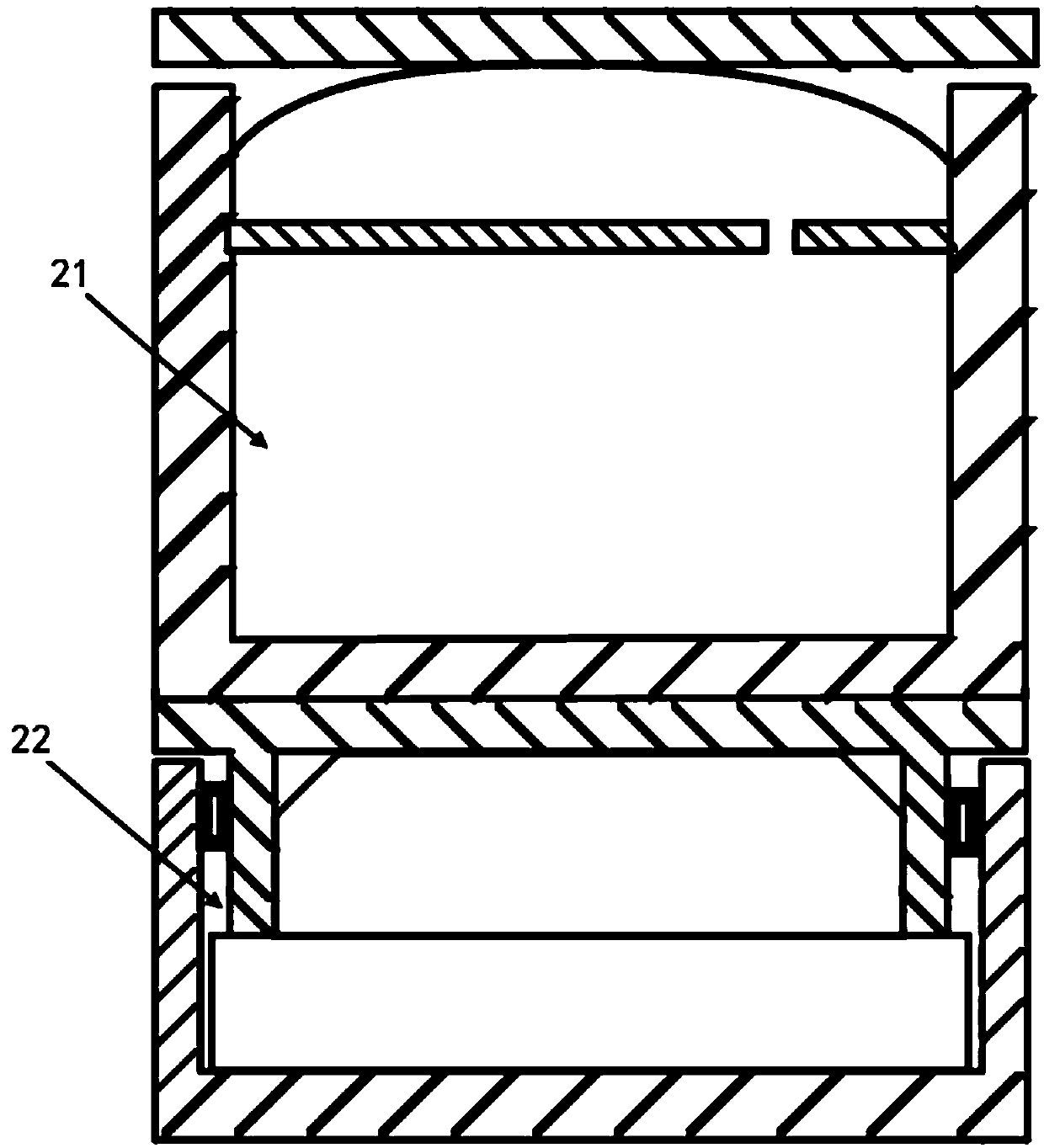

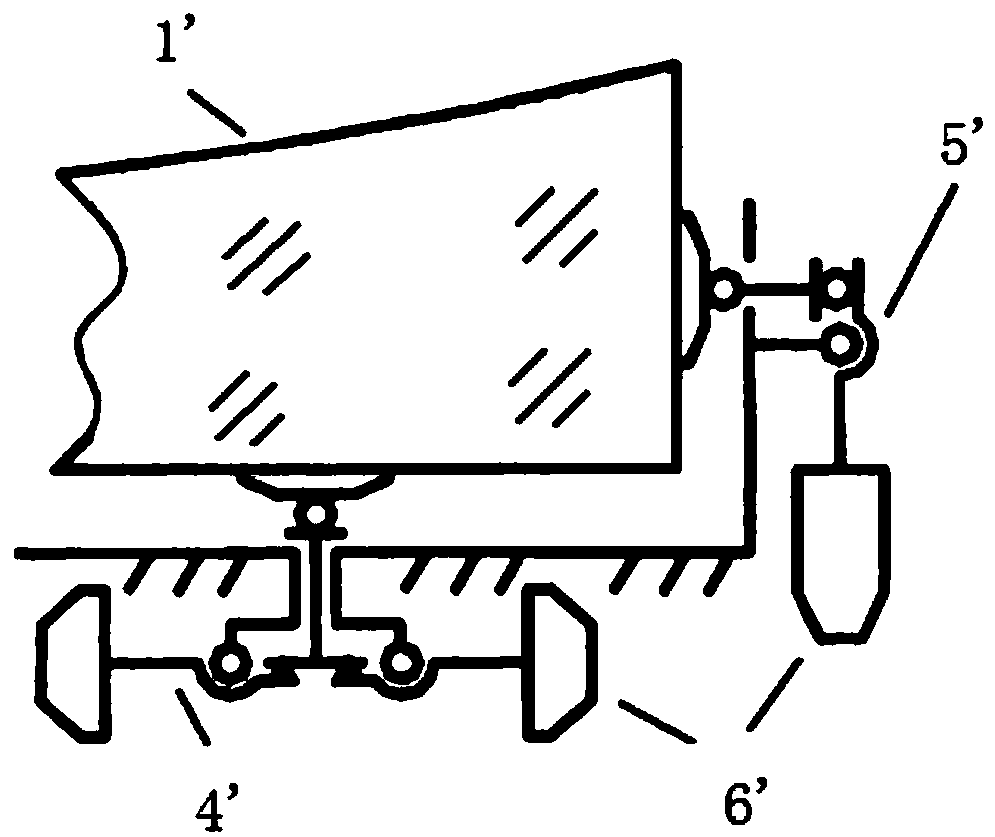

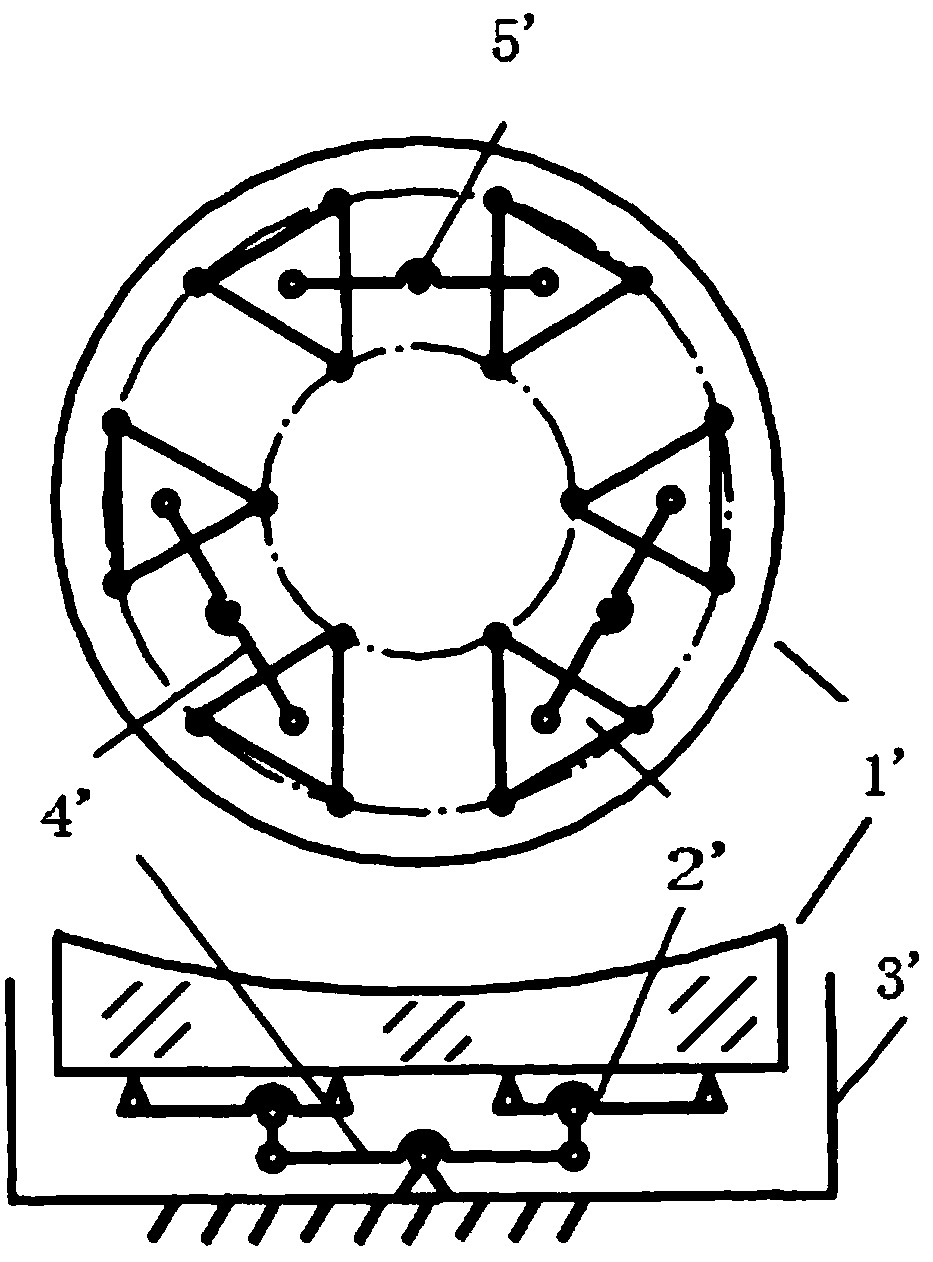

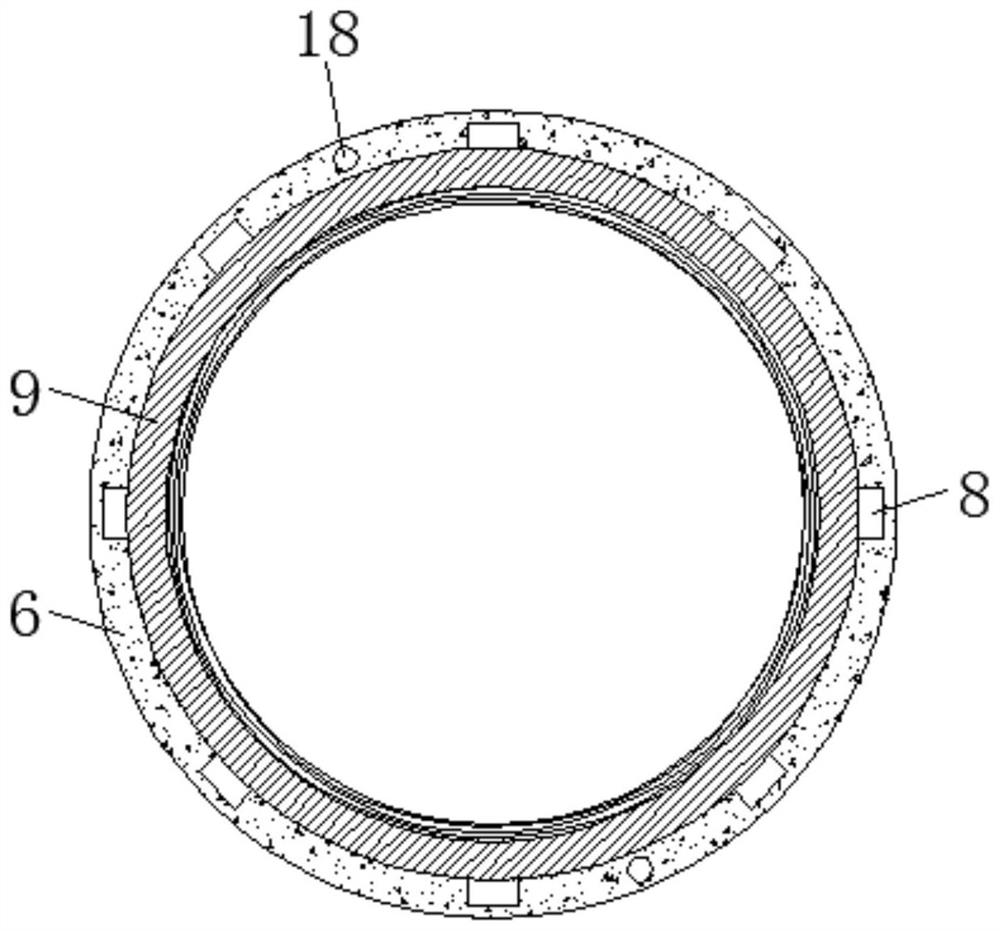

Semi-active reflecting mirror surface supporting and positioning system

InactiveCN106646818AImprove the support effectRealize precise positioning functionMountingsAxial displacementSupporting system

The invention discloses a semi-active reflecting mirror surface supporting and positioning system. The system is used for supporting and positioning a reflecting mirror surface and comprises a mirror surface supporting system and a mirror surface pose adjusting system; the mirror surface supporting system comprises an axial supporting system and a lateral supporting system, and the mirror surface pose adjusting system comprises an axial mirror surface pose adjusting system and a lateral mirror surface pose adjusting system; the axial mirror surface pose adjusting system is used for adjusting three freedom degrees, namely translation along the Z axis, rotation along the X axis and rotation along the Y axis, of the reflecting mirror surface and comprises a displacement actuator used for adjusting axial pose and an axial displacement sensor; and the axial supporting system is used for bearing component of gravity of the reflecting mirror surface in the axial direction, namely W*sintheta and comprises an axial fluid force actuator. Therefore, axial supporting and positioning of the reflecting mirror surface are based on fluid pressure control and drive, and axial precision positioning function of the mirror surface can be realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Cutting workbench convenient to adjust

InactiveCN111215693ARealize automatic lifting functionImprove convenienceMetal sawing devicesElectric machineStructural engineering

The invention discloses a cutting workbench convenient to adjust. The cutting workbench comprises a workbench base, vertical telescopic rods, a vertical frame, a baffle and a lifting table, wherein the four vertical telescopic rods are arranged at the top end of the workbench base; the lifting table is arranged above the vertical telescopic rods; the bottom end of the lifting table is fixedly connected with the output ends of the vertical telescopic rods; a main motor is arranged at the center position in the lifting table; the output end of the main motor is provided with a rotation shaft through a coupler; a rotation table is arranged above the lifting table; the bottom end of the rotation table is fixedly connected with the top end of the rotation shaft; an infrared receiver is arrangedon one side of the top end of the baffle; and the side, close to the lifting table, of a cross beam is provided with an infrared emitter, and the output end of the infrared emitter is electrically connected with the input end of the infrared receiver. According to the cutting workbench, the convenience degree during cutting platform adjusting usage is improved, the adjusting range of the workbench is enlarged, and the work efficiency of the workbench is greatly improved.

Owner:新沂经济开发区建设发展有限公司

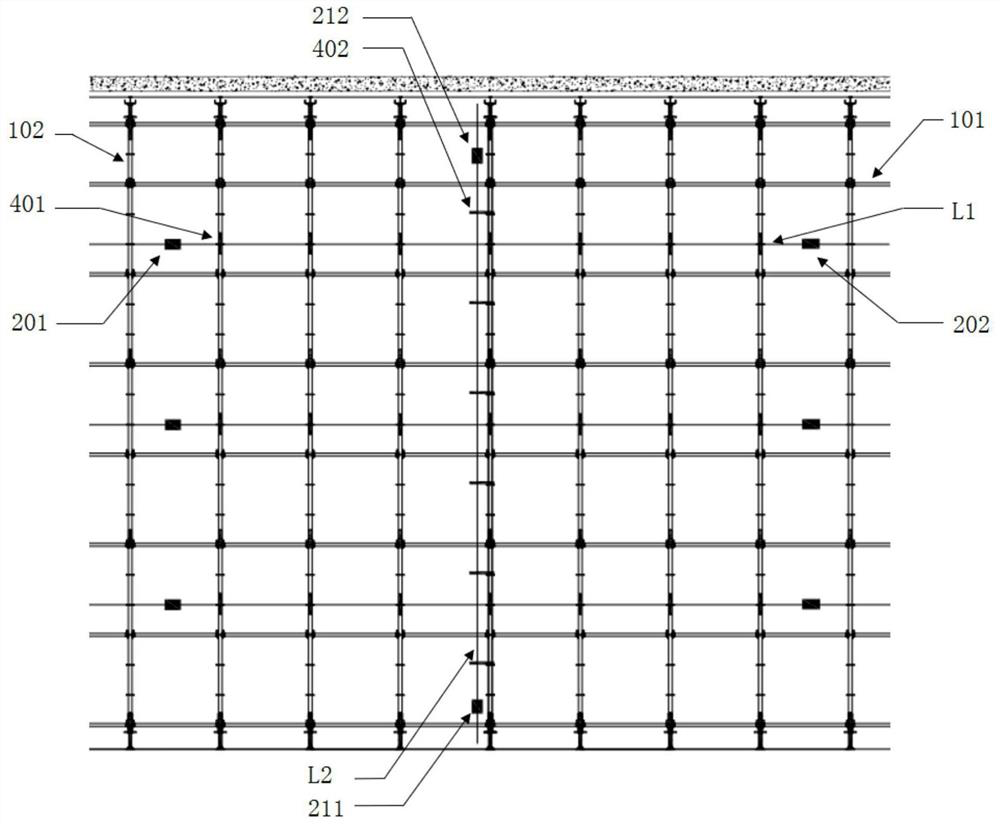

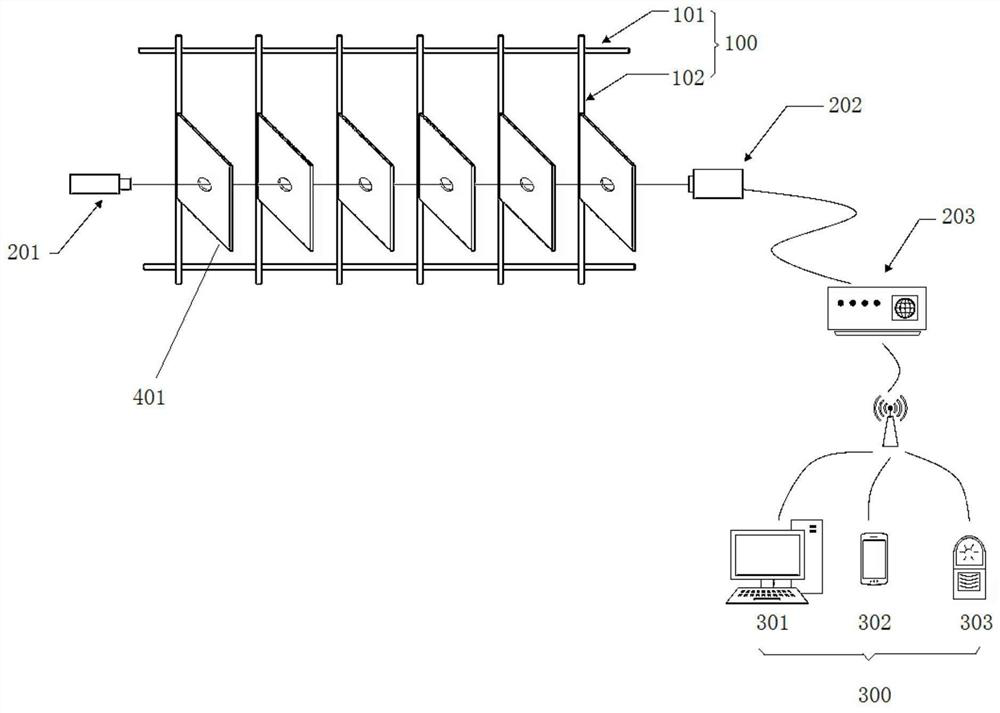

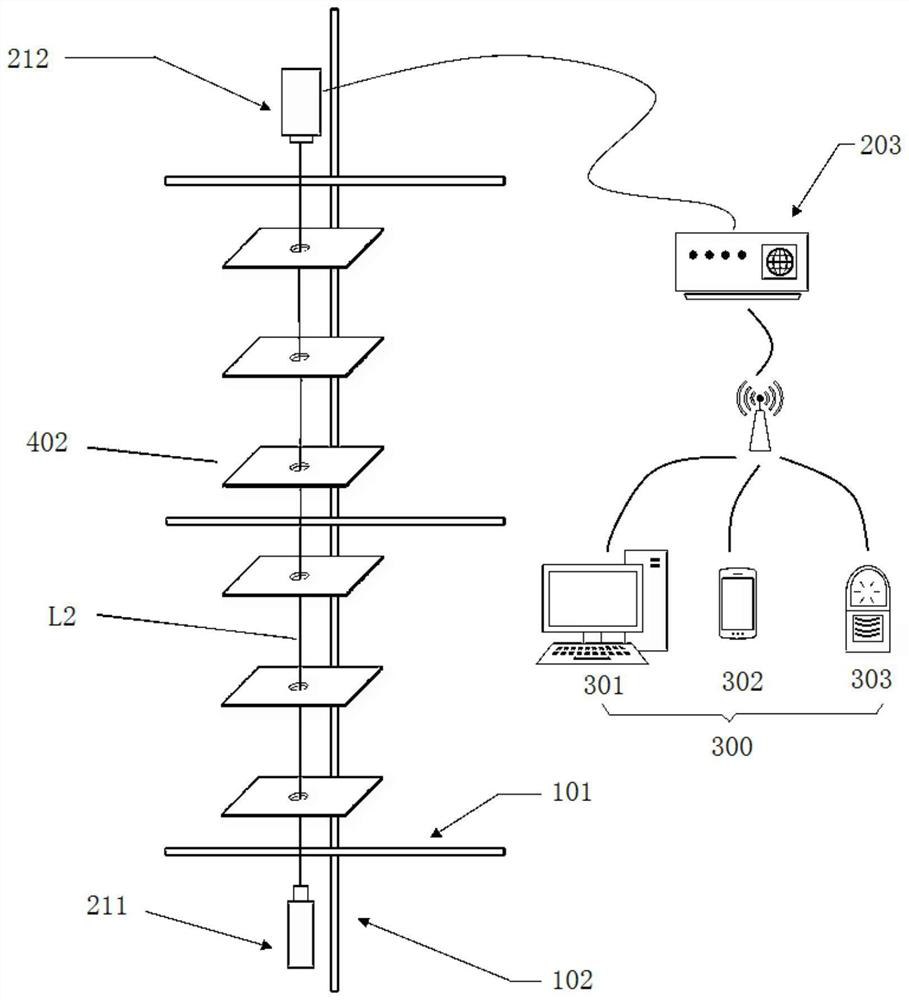

Laser-based high-formwork vertical rod displacement monitoring device and early warning method

PendingCN113865489AMulti-point displacement synchronous real-time monitoringReal-time monitoring of multi-point displacementUsing optical meansLaser transmitterLight beam

The invention relates to the technical field of building construction monitoring, in particular to a laser-based high-formwork vertical rod displacement monitoring device and an early warning method.The laser-based high-formwork vertical rod displacement monitoring device comprises a monitoring module, and the monitoring module comprises laser emitters, laser receivers, an analyzer and displacement follow-up parts; the plurality of laser emitters and the plurality of laser receivers are respectively arranged on the side of a high-formwork transverse rod and the side of a high-formwork vertical rod in pairs, laser beams between each pair of laser emitter and laser receiver are vertical or parallel to the ground, and the plurality of displacement follow-up parts are arranged on the high-formwork vertical rod. Any one displacement follow-up part is subjected to displacement change along with the high-formwork vertical rod where the displacement follow-up part is located, the analyzer is connected with the laser transmitter and the laser receiver, and multi-point monitoring of the high-formwork vertical rod and accurate positioning of the position where the displacement of the high-formwork vertical rod exceeds a preset value can be achieved.

Owner:JILIN UNIV

Grinding device for metal products

ActiveCN109955149ARealize precise positioning functionImprove convenienceGrinding carriagesGrinding feed controlFixed frameEngineering

The invention discloses a grinding device for metal products. The grinding device comprises an outer box body, a heat discharging pipe, a cabinet body, an air cooler and an L-shaped plate; the air cooler is arranged at the central position of the bottom of the outer box body; the L-shaped plate is arranged in the outer box body on the side of the air cooler far away from the cabinet body; a secondtelescopic rod is fixed at the bottom of the outer box body on the side of the L-shaped plate far away from the air cooler; a second motor is fixed in a second fixing frame; a working bin is fixed atthe top end of the second fixing frame; a supporting plate is fixed to the surface of a second rotating shaft above the bottom plate; a first telescopic rod is fixed to the inner side wall of the outer box body far away from the working bin above the L-shaped plate; a first motor is fixed in the first fixing frame; and a distance detector is arranged at the bottom of the first fixing frame closeto one side of the working bin. The convenience and the safety when the grinding device is used are improved, and the service life of the grinding device is prolonged.

Owner:深圳市建福科技有限公司

Accurately positioning method for personal hand-held telephone system user

InactiveCN1305347CRealize precise positioning functionAchieve precise positioningRadio/inductive link selection arrangementsLocation information based serviceHand heldNetwork management

The method for accurate positioning users in PHS system includes steps: network management through access gateway sends request for positioning user to base station controller under call region where the user current belongs to; the controller sends seeking positioning request to own base stations; base stations seek the user; the user sends request for building link to a base station; the base station reports associated position information and signal intensity of the user to network supervisor, and sends message of refusing building link to the user; the user determines whether number of refusing the said request reaches to threshold; if yes, based on information received from multiple base stations, the network supervisor calculates out user's position; otherwise, seeking other base stations to carry out steps of request for building link again. The invention realizes positioning users in PHS system in low cost and high precision.

Owner:ZTE CORP

Vehicle anti-theft tracking circuit based on lora radio frequency technology

ActiveCN106740691BRealize precise positioning functionAnti-theft devicesMicrocontrollerWireless transmission

The invention relates to a vehicle anti-theft tracking circuit based on a LoRa (long range) radio frequency technology. A power supply part of the vehicle anti-theft tracking circuit is divided into a high voltage transformation circuit and a low voltage transformation circuit, and after a vibration switch detects vibration, the low voltage transformation circuit is switched on to provide low-voltage power supply for a system. STM8L151C8 microcontroller is taken as the core to perform information interaction with a GPS / beidou double-star positioning circuit through a UART serial port and communicates with an SX1278 radio frequency circuit through an SPI, status information of the system is sent to a LoRa base station, and long-distance transmission with low power consumption is realized. An alarm interface is used for accessing a vehicle control terminal, and the terminal initiatively uploads alarm data once a vehicle is stolen. The latest vehicle position and alarm lamp status data are sent with a LoRa wireless transmission technology, so that the effects of real-time vehicle tracking, theft alarm and the like are realized, and vehicle losing is prevented.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

Paper Plastic Shaping Machine and Its Shaping Process

InactiveCN105544309BWith up and down slip compensation abilityNo radial forceTextiles and paperMolded pulpEngineering

The invention relates to a paper-plastic shaper and a shaping technology thereof. The paper-plastic shaper comprises an upper mould assembly provided with an upper mould, and a lower mould assembly provided with a lower mould. The lower mould assembly comprises a rotary table rack (101). A rotating shaft (102) is vertically installed on the rotary table rack (101). A rotary connecting disc (103) is installed at the top of the rotating shaft (102) in a sleeving mode by means of key joint. Multiple guide columns (105) are installed on the rotary connecting disc (103) in the vertical direction. A rotary table (104) is arranged on the rotary connecting disc (103) in a shelved mode and provided with connecting holes for the guide columns (105) to be inserted. Each guide column (105) is sleeved with a lubricating sleeve (106). The lubricating sleeves (106) are located between the guide columns (105) and the inner walls of the connecting holes. The paper-plastic shaper and the shaping technology thereof effectively stop stress transmission and can ensure transposition precision.

Owner:JIANGYIN POLYTECHNIC COLLEGE

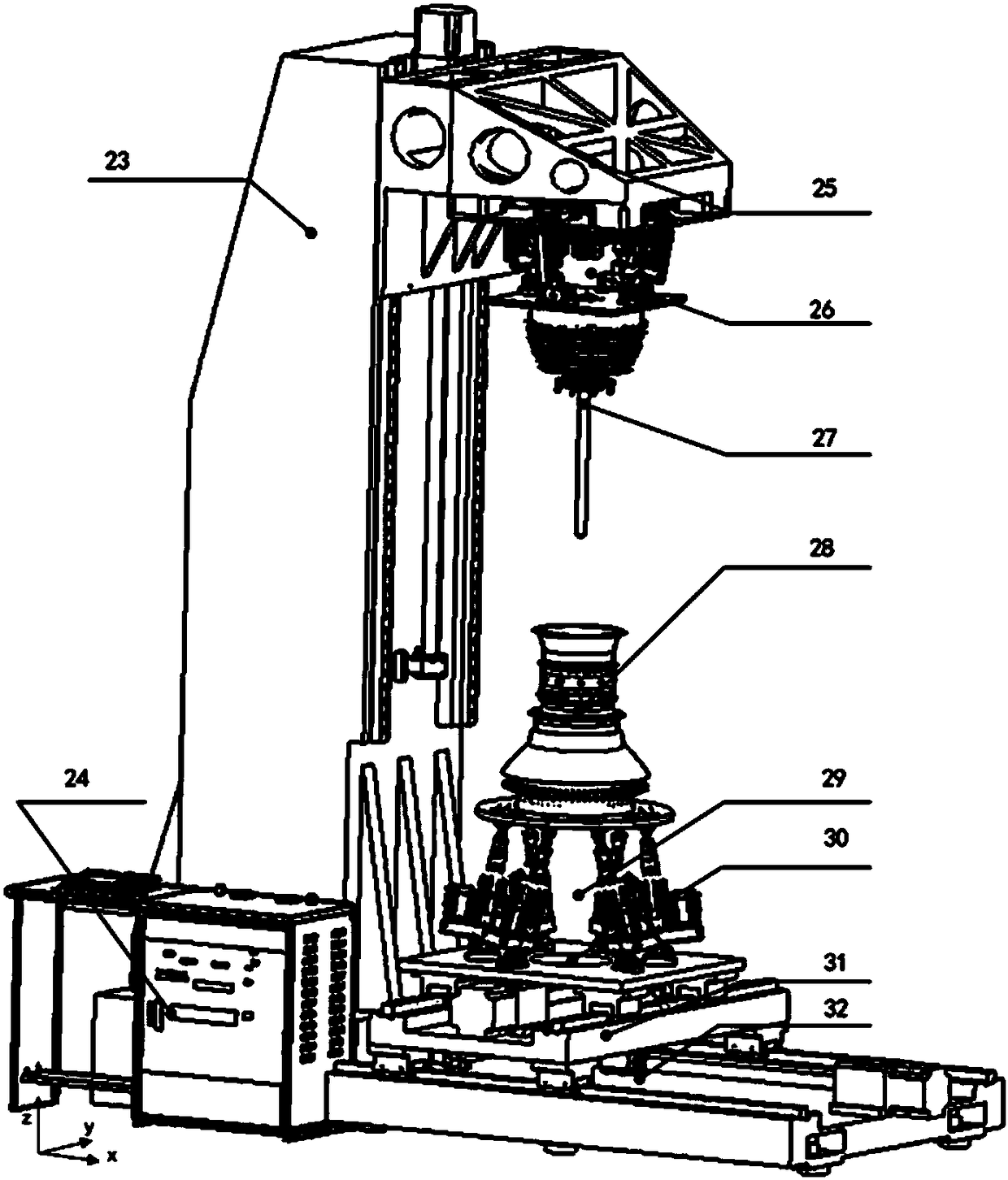

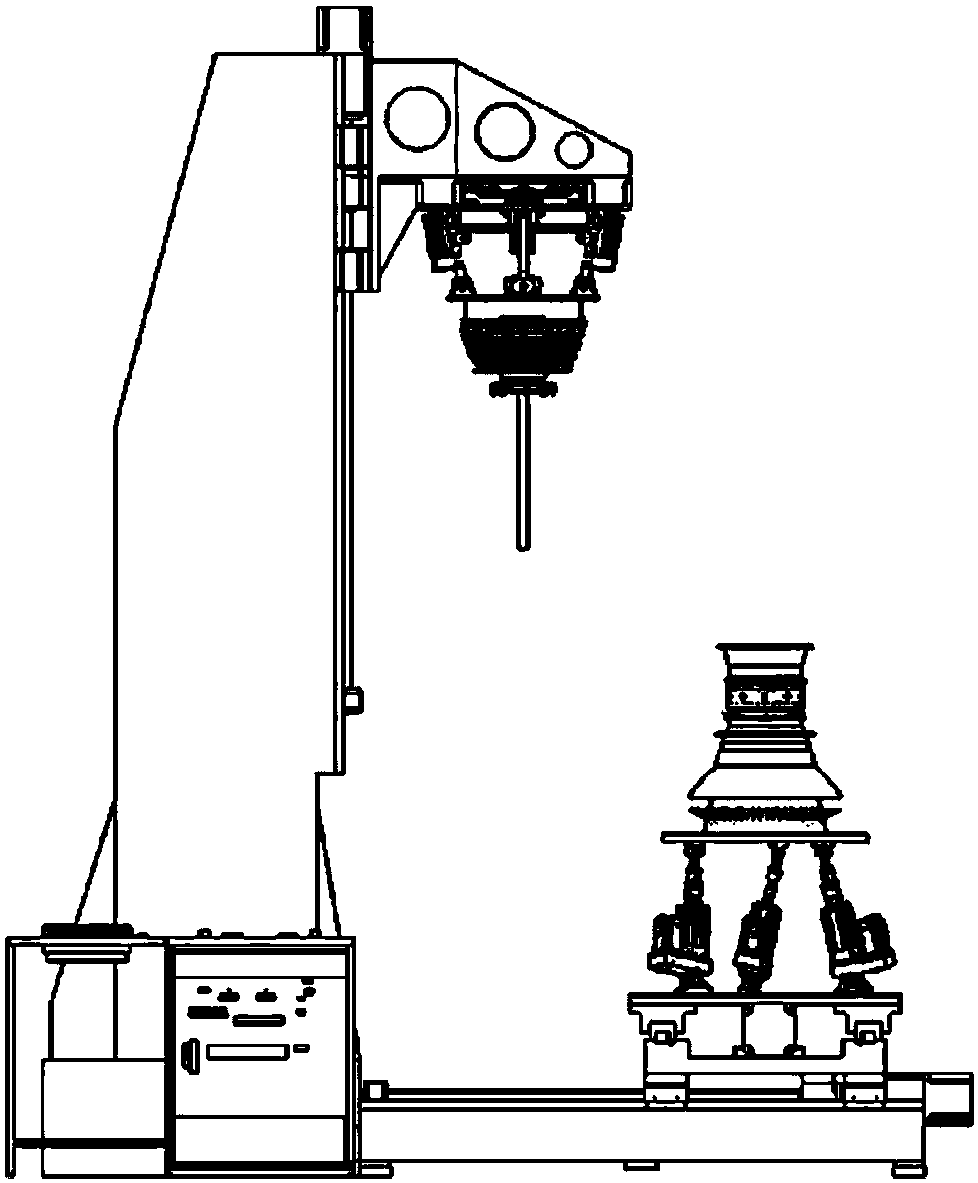

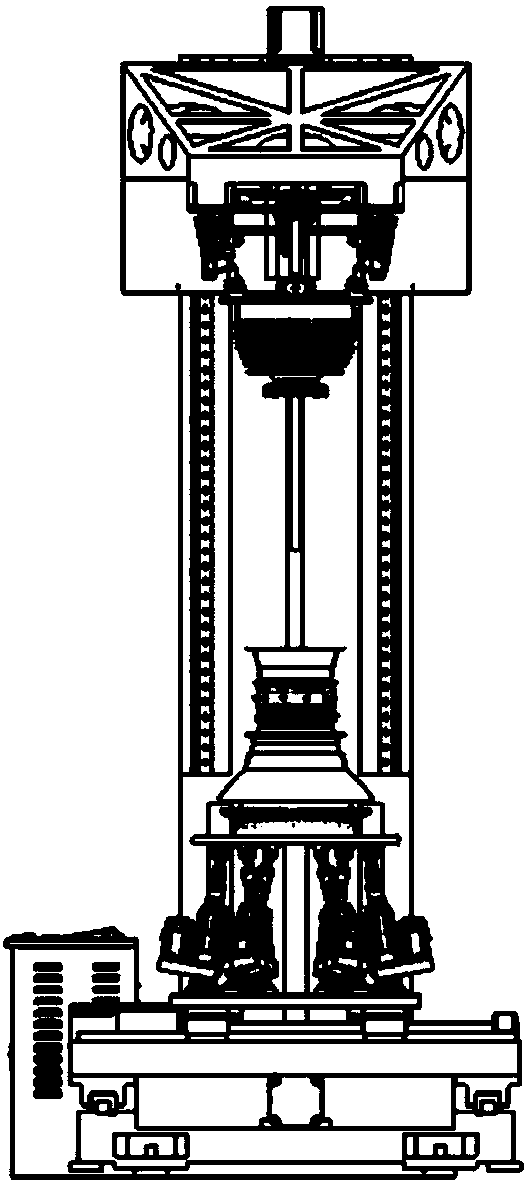

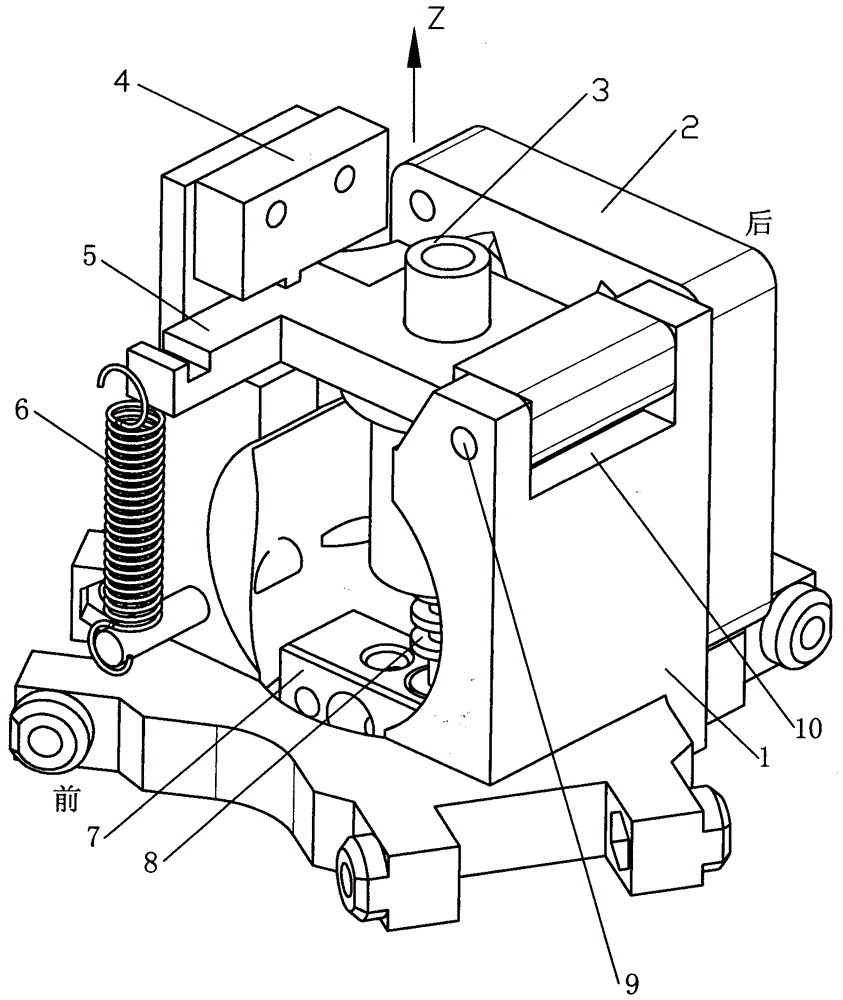

Vertical assembly equipment for shaft assembly of components

ActiveCN106563941BRealize precise positioning functionReduce positioning errorsMetal working apparatusAviationSix degrees of freedom

The invention discloses vertical-type assembling equipment for part hole and shaft assembling. The vertical-type assembling equipment comprises a passive compliance device which is arranged on a vertical wide-range feeding mechanism and used for guaranteeing passive safety, and a six-degrees-of-freedom precision posture-adjusting mechanism which is arranged on a horizontal wide-range feeding mechanism and used for achieving the precision posture-adjusting function. A to-be-assembled hole part is arranged on the passive compliance device and directly faces a to-be-assembled shaft part arranged on the six-degrees-of-freedom precision posture-adjusting mechanism. The vertical-type assembling equipment is used for completing aero-engine assembly. The device is compact in structure, capable of achieving stepped control, high in operation precision, high in assembling efficiency, and capable of achieving six-degrees-of-freedom posture adjustment and guaranteeing the passive safety of the to-be-assembled parts.

Owner:SHANGHAI JIAO TONG UNIV

Semi-active mirror support and positioning system

InactiveCN106646818BImprove the support effectRealize precise positioning functionMountingsAxial displacementActuator

The invention discloses a semi-active mirror support and positioning system for supporting and positioning the mirror, including a mirror support system and a mirror pose adjustment system; the mirror support system includes an axial support system and a lateral support system, and The mirror pose adjustment system includes an axial mirror pose adjustment system and a lateral mirror pose adjustment system; the axial mirror pose adjustment system is used to adjust the translation of the mirror surface along the Z axis, around the X axis, and the Y axis Three degrees of freedom of rotation, including displacement actuators for axial pose adjustment, axial displacement sensors; axial support system, used to bear the axial component W*sinθ of gravity of the mirror surface, including axial fluid force actuator. Therefore, the axial support and positioning of the reflective mirror surface of the present invention are controlled and driven based on fluid pressure, which can realize the precise axial positioning function of the mirror surface.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A kind of glans mask for circumcision

The invention discloses a glans penis cover for circumcision, comprising a connection bridge, a partition, a one-way telescopic rod, a cavity and a pressure sensor. The cavity is arranged in the connection bridge; the partition is fixed in the center of the cavity; one end of the partition is fitted with the pressure sensor; the end of the partition, far away from the pressure sensor is fixedly provided with the one-way telescopic rod; the end of the connection bridge close to the one-way telescopic rod is in threaded connection with a cover body; the inside part of the cover body close to theconnection bridge is provided with a positioning block; the end of the cover body far away from the connection bridge is in threaded connection with a circular support; the end of a nail plate far away from the circular support is fixedly provided with an anastomotic plate; the edge of the anastomotic plate is provided with nail storage holes; the outer wall of the end, far away from the cover body, of the connection bridge is fitted with a controller. The glans penis cover for circumcision has the advantages that application safety of the glans penis cover is guaranteed, the glans penis is more convenient to use, and practicality of the glans penis cover is improved.

Owner:嘉兴星创科技有限公司

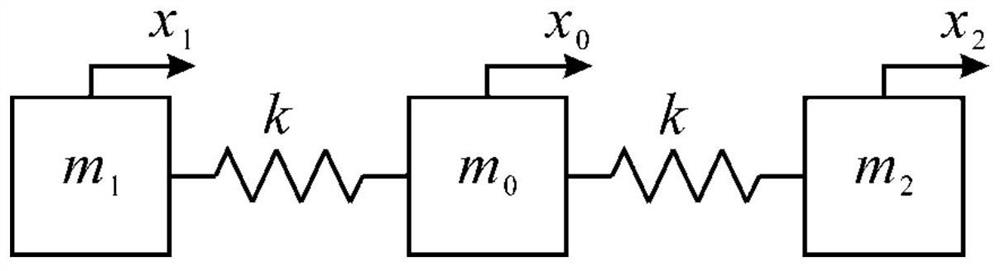

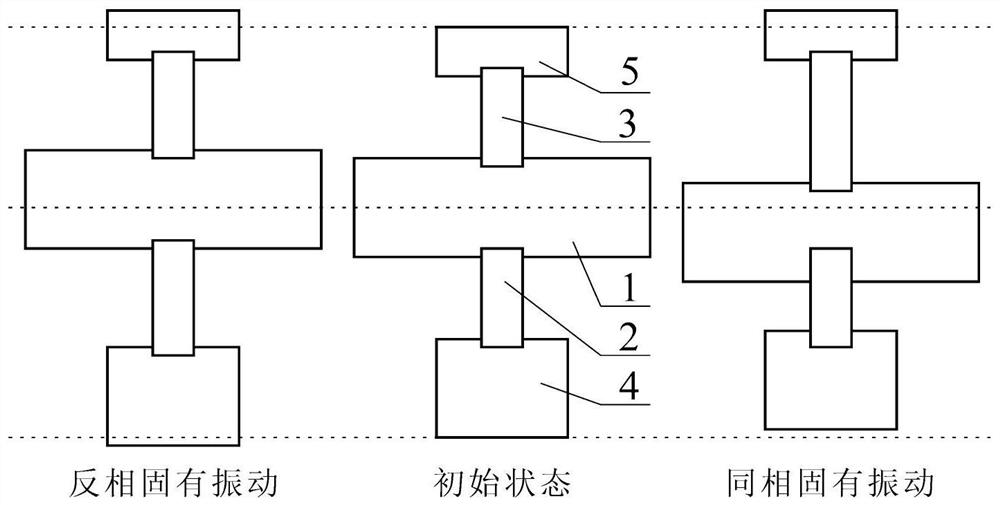

A High Frequency Resonant Piezoelectric Inertial Drive Linear Displacement Platform

ActiveCN109378995BLarge longitudinal vibration amplitudeImprove structural rigidityPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsResonance

The present invention discloses a high-frequency resonance piezoelectric inertial drive linear displacement platform. An unsymmetrical inertial promoter formed by a base body, a first piezoelectric driver, a second piezoelectric driver, a main inertial body, an assistant inertial body obtains two effective natural vibrations consisting of reversed natural vibration and in-phase natural vibration to change the quality ratio of the base body, the main inertial body and the assistant inertial body to regulate the ratio of the reversed natural vibration frequency and the in-phase natural vibrationfrequency of the inertial promoter to be 1:2, two multi-layer stackable piezoelectric ceramics are employed as piezoelectric actuators to respectively excite simple harmonic vibrations in two inherent frequencies to allow the base body to combine an unsymmetrical vibration waveform in a resonance state, and the asymmetric sliding friction between the slide ports at two sides of the base body andguide rails at two side of a pedestal is employed to drive the inertial promoter to perform continuous linear displacement in a one-way direction along the guide rails. The high-frequency resonance piezoelectric inertial drive linear displacement platform is simple in structure and convenient to excite to further improve the integrated drive performances of a traditional inertial drive mechanism.

Owner:HEFEI UNIV OF TECH

Parallel transmission structure automatic leveling mechanism

ActiveCN104267740BRealize precise positioning functionSimple structurePosition/direction controlNumerical controlLeveling mechanism

The invention provides an automatic leveling mechanism for a parallel transmission structure and belongs to the technical field of automatic precision adjustment. The automatic leveling mechanism aims to solve the problems that when a numerically-controlled machine tool, a numerically-controlled carving machine, a 3D printer and other devices are positioned accurately in the Z-axis direction through manual adjustment, consumed time is long, the labor intensity is high and the error of a measuring result is large in the adjusting process. A heating block is arranged in a parallel connection support. The lower end of a spray head stretches out of a spray head mounting hole in the heating block. The upper end of the spray head is fixedly connected with a spray head fixing base. The upper end of the spray head fixing base fixedly penetrates out of a through hole of a hot end assembly fixing frame. One end of the hot end assembly fixing frame is hinged to the parallel connection support. A microswitch is fixedly connected with the parallel connection support. The microswitch is located over the other end of the hot end assembly fixing frame. A gap is formed between the microswitch and the hot end assembly fixing frame. The hot end assembly fixing frame is connected with the bottom of the parallel connection support through an elastic extension mechanism. The automatic leveling mechanism is mainly applied to the numerically-controlled machine tool, the numerically-controlled carving machine, the 3D printer, a sorting system and the like.

Owner:黑龙江科大科技开发有限公司

Two-end press-fit equipment for nut special for automobile fastener

PendingCN113070668ARealize the clamping functionImprove work efficiencyMetal working apparatusPositioning apparatusMotor vehicle partGear wheel

The invention discloses two-end press-fit equipment for a nut special for an automobile fastener, and relates to the technical field of automobile part machining. The two-end press-fit equipment comprises a main box, and further comprises a moving structure for improving the working efficiency, a positioning structure for precise machining and a clamping structure convenient to operate, and a sliding groove is formed at the top end of the main box; and two placing plates are slidably connected into the sliding groove, a vertical plate is installed at one end of the top end of the sliding groove, a top plate is installed at the top end of one end of the vertical plate, an air cylinder is installed at the center of the top end of the top plate, and the bottom end of the air cylinder penetrates to the position below the top plate. A rotating rod is rotated, a driving gear rotates, a driven gear is driven to rotate, so that a first lead screw rotates, under cooperation of threads of a first sleeve, the first sleeve can move, and therefore clamping plates are driven to move until the two clamping plates fix a part, and the structure is beneficial for improving the convenience of the device.

Owner:上海东风汽车专用件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com