Patents

Literature

1059results about How to "Improve the support effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

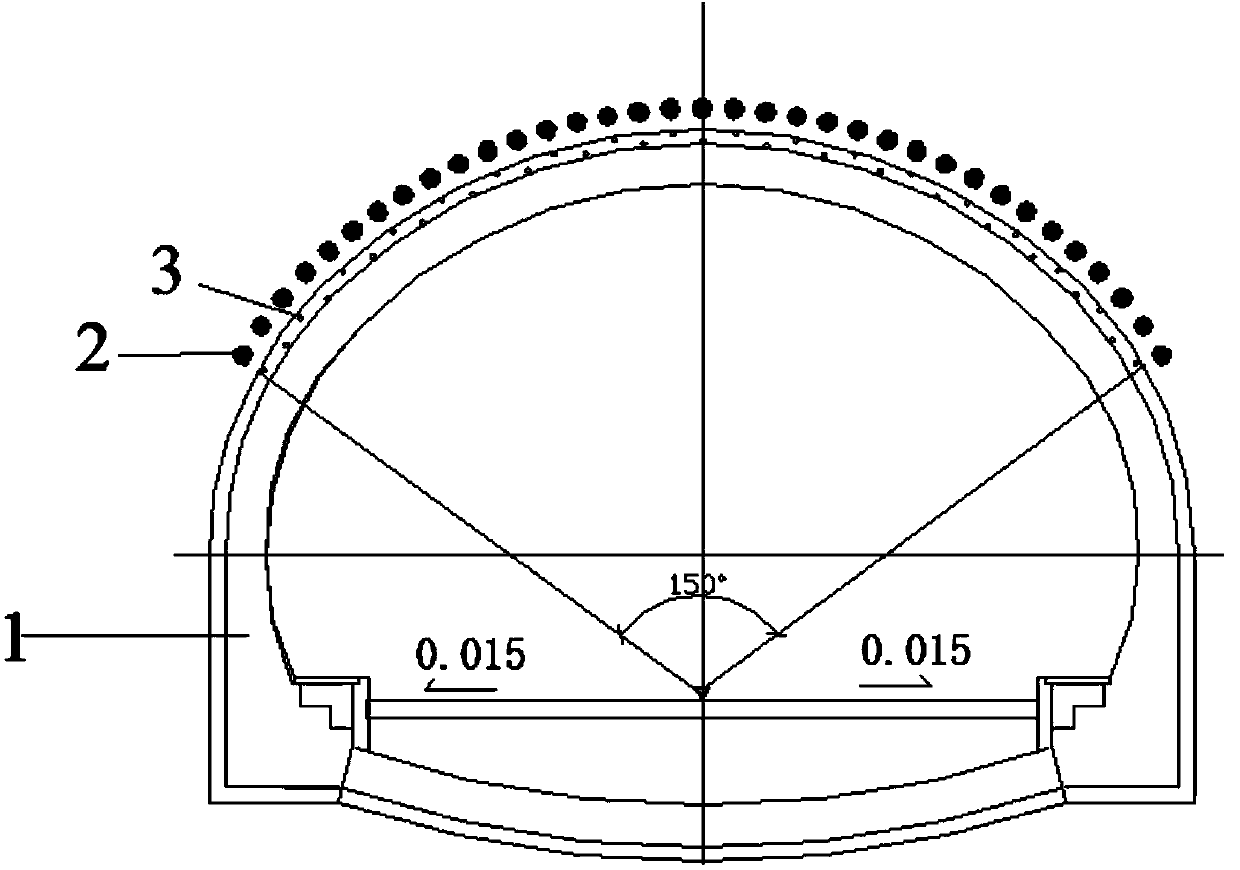

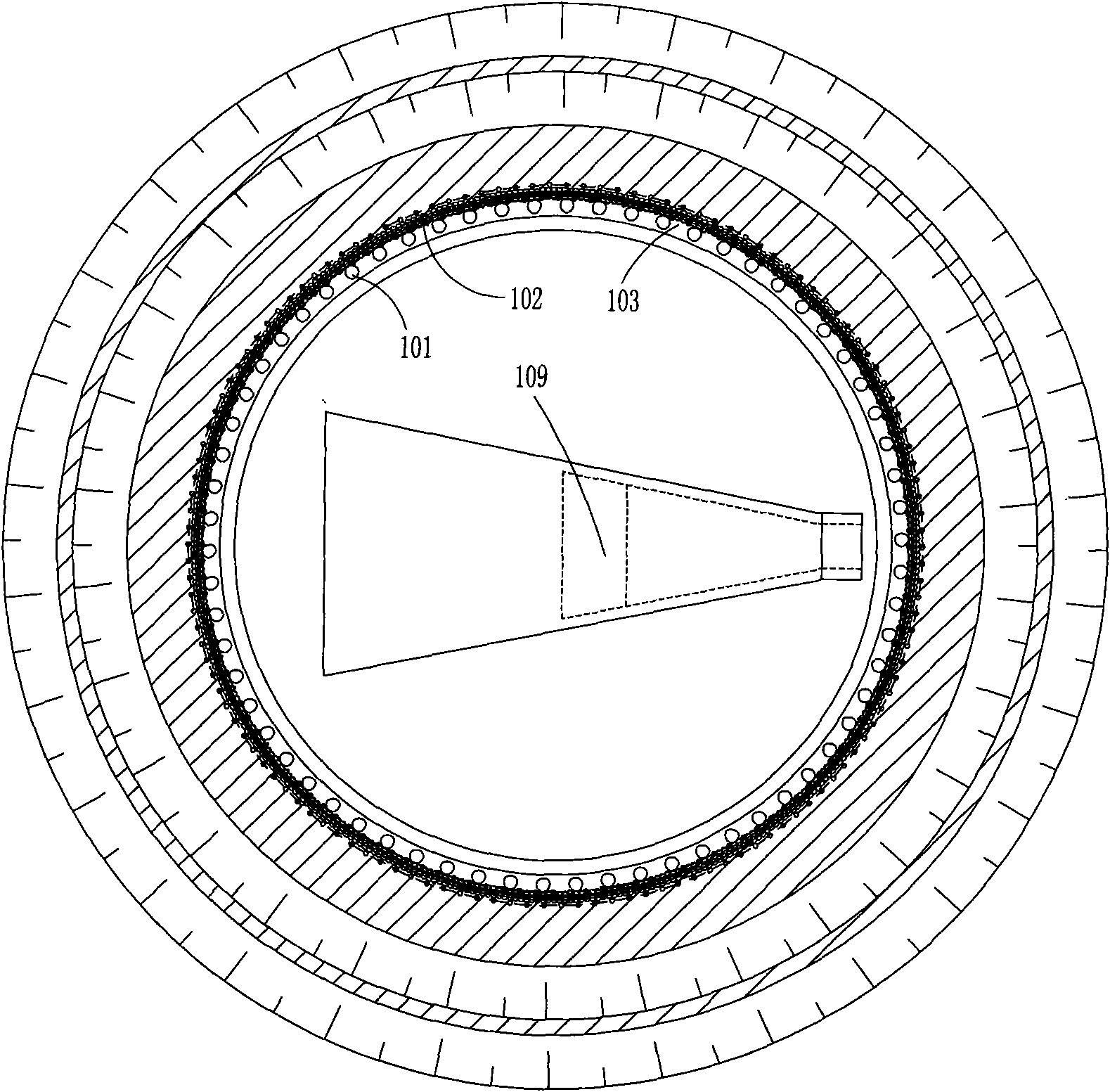

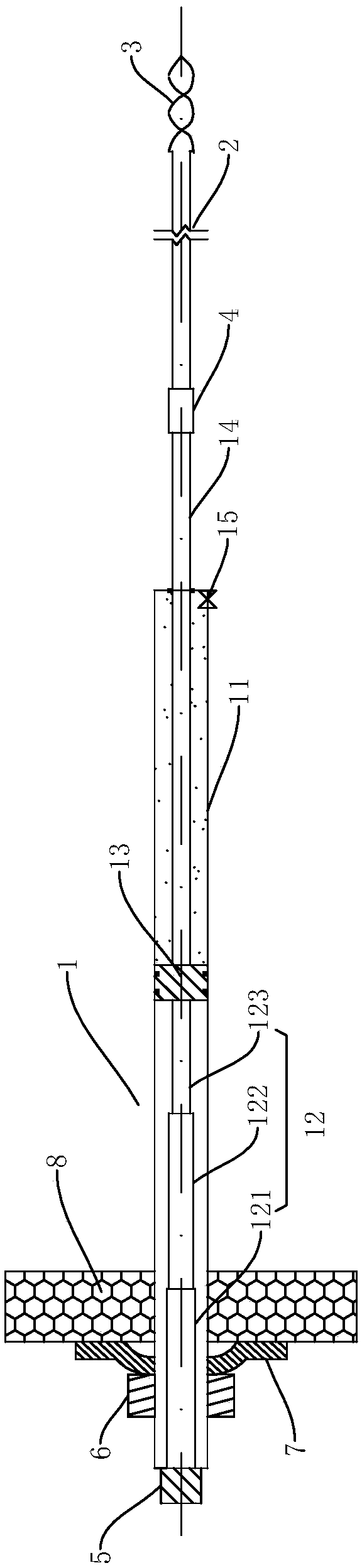

High-strength three-dimensional support system of yielding type restriction concrete lagging jack

InactiveCN102852533AImprove carrying capacityIncrease surface areaUnderground chambersTunnel liningSupporting systemPre stress

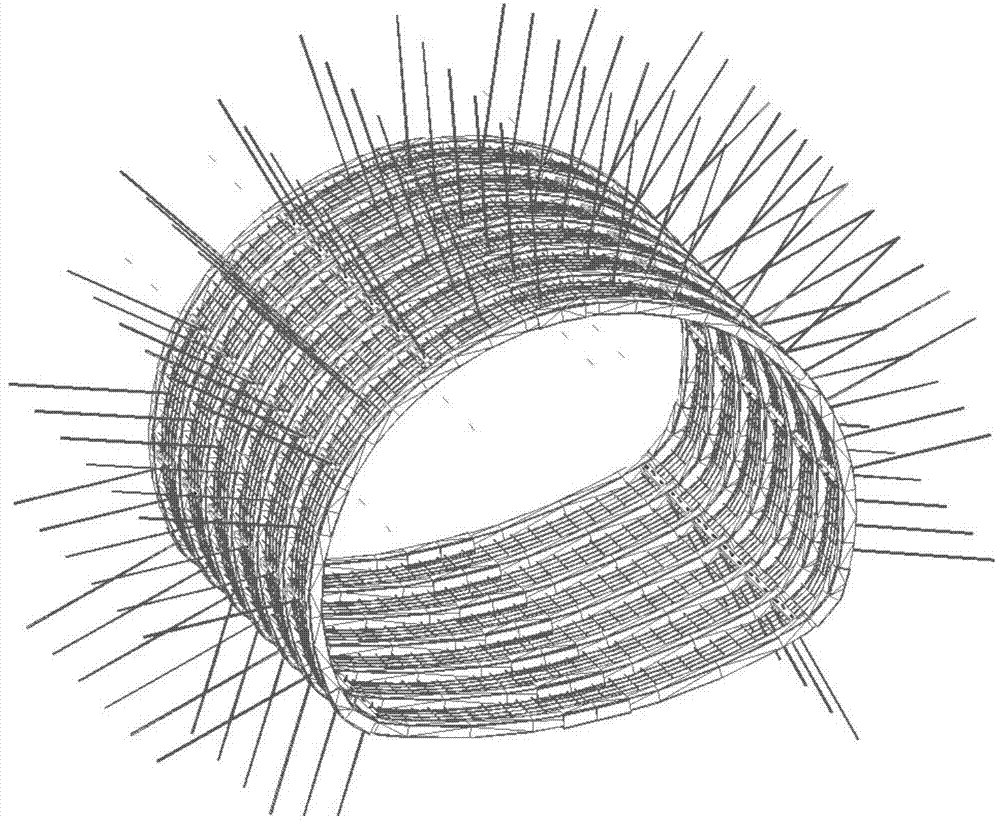

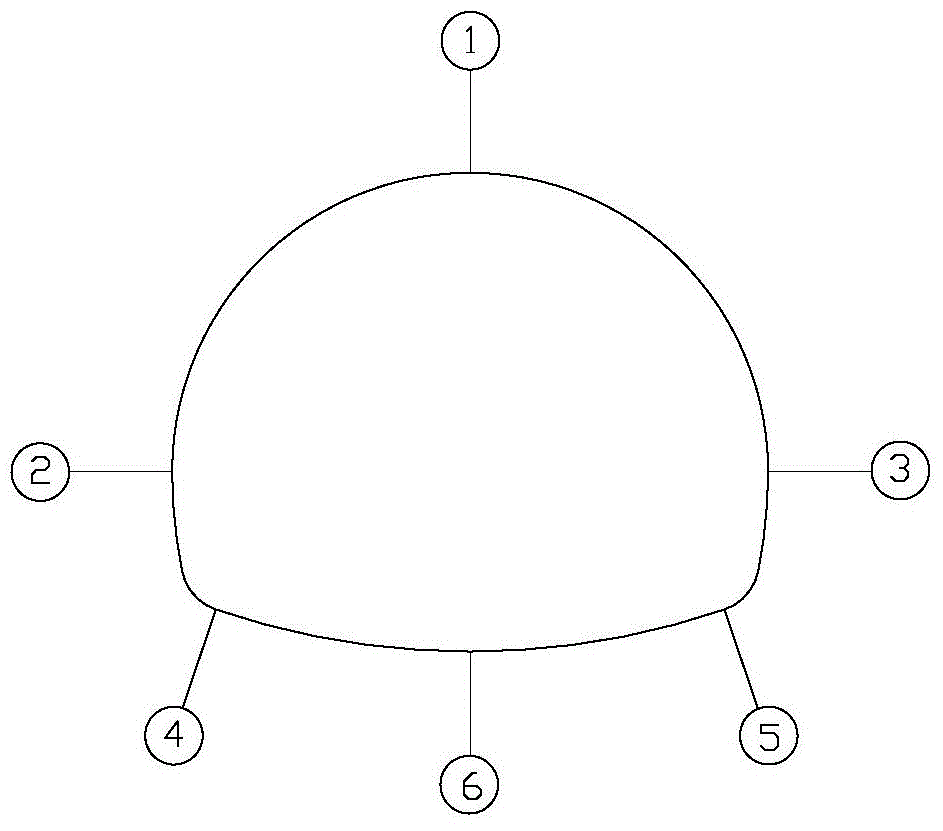

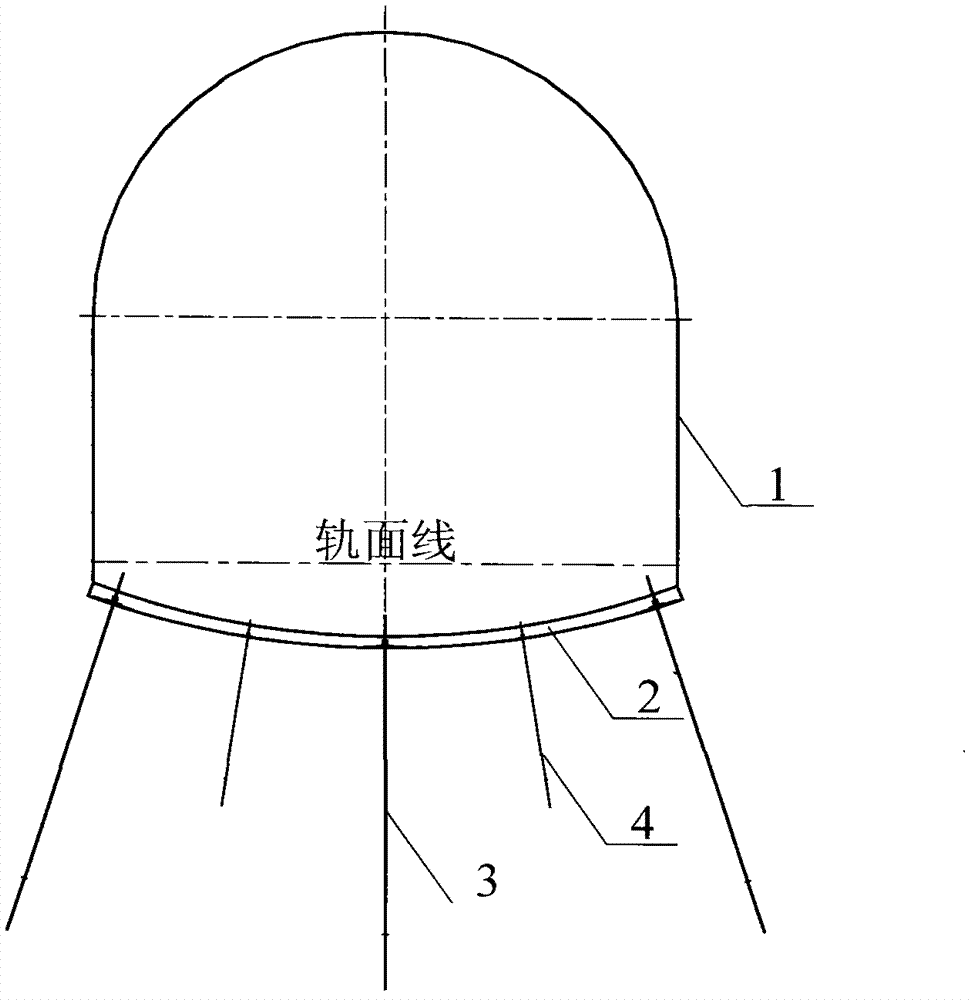

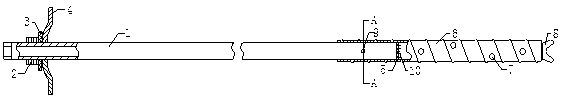

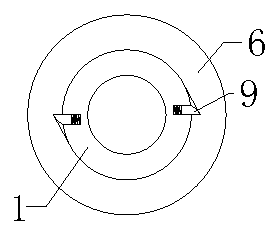

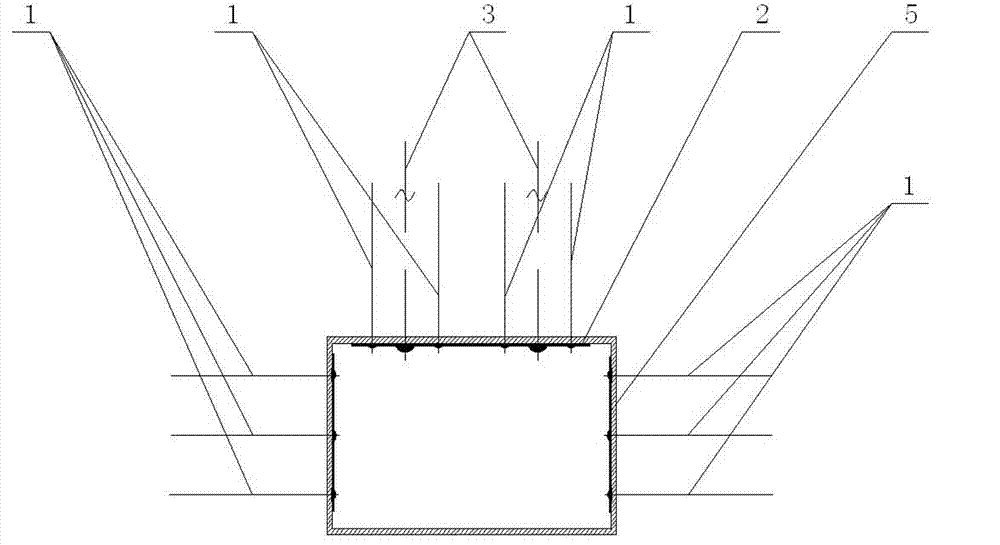

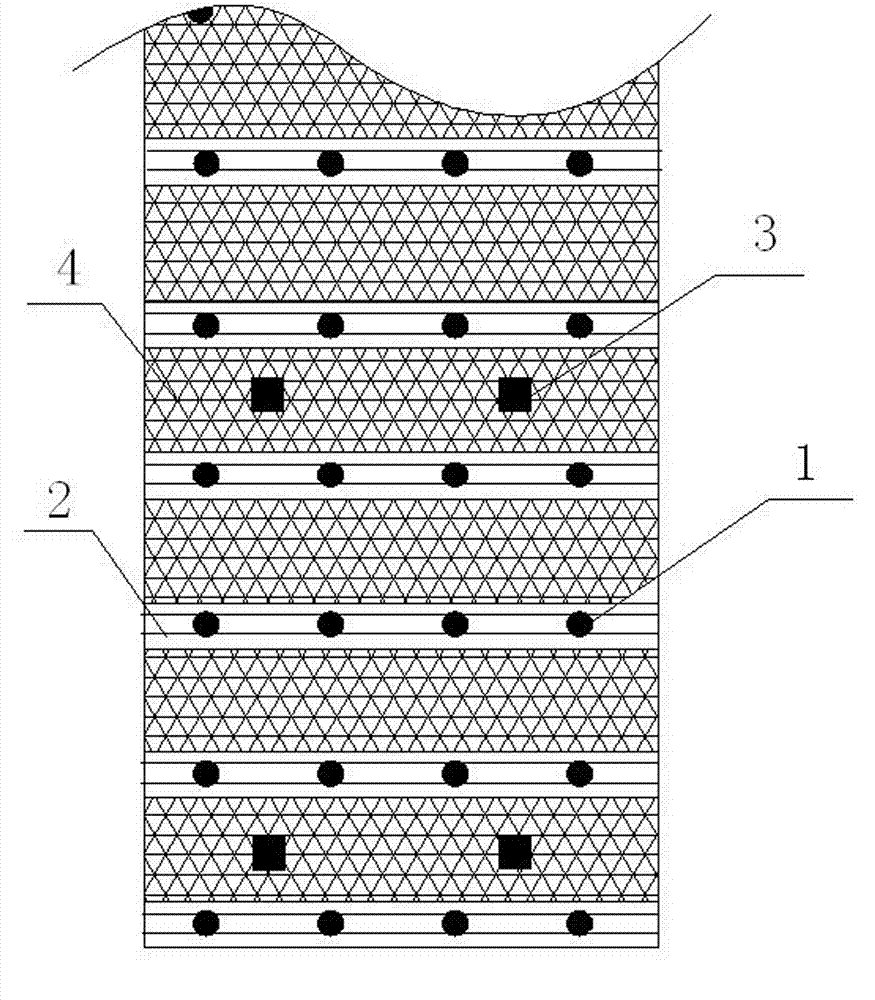

The invention discloses a high-strength three-dimensional support system of a yielding type restriction concrete lagging jack, which is mainly formed by a restriction concrete lagging jack, a yielding node, a vertical beam, an anchor rod or an anchor cable, wherein the restriction concrete lagging jack is in a closed structure which is the same as the shape of a roadway and is formed by connecting and combining restriction concrete through a sleeve and the yielding node; the restriction concrete is distributed at an interval and is connected through the vertical beam; the anchor rod or the anchor cable passes through the vertical beam to be anchored into a rock layer; pre-stress is applied so as to form extrusion effect on a surrounding rock; and the lagging jack forms an integral structure with the anchor rod or the anchor cable through the vertical beam, and a space three-dimensional support system is formed by combined action. The high-strength three-dimensional support system is applicable to an underground engineering support including a deep soft rock underground roadway and the like, and has the advantages of high supporting strength, good stability, reasonable stress and the like; and the high-strength three-dimensional support system has a yielding function and can effectively control the stability of a roadway surrounding rock.

Owner:SHANDONG UNIV

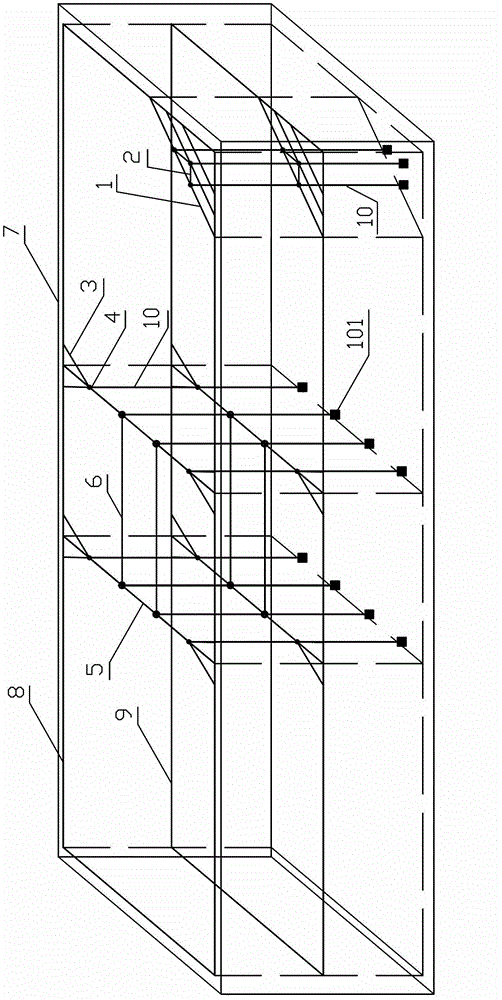

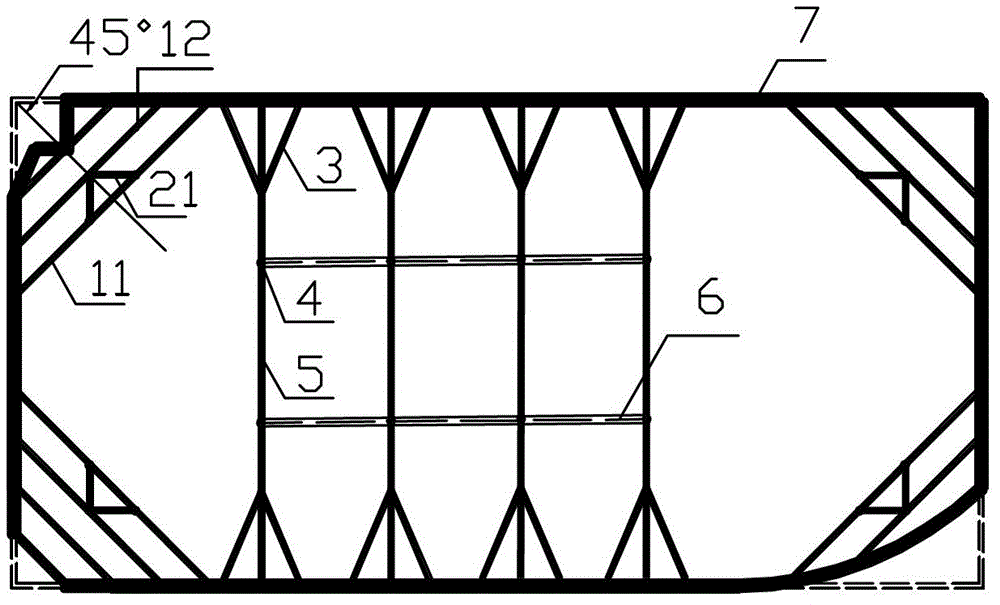

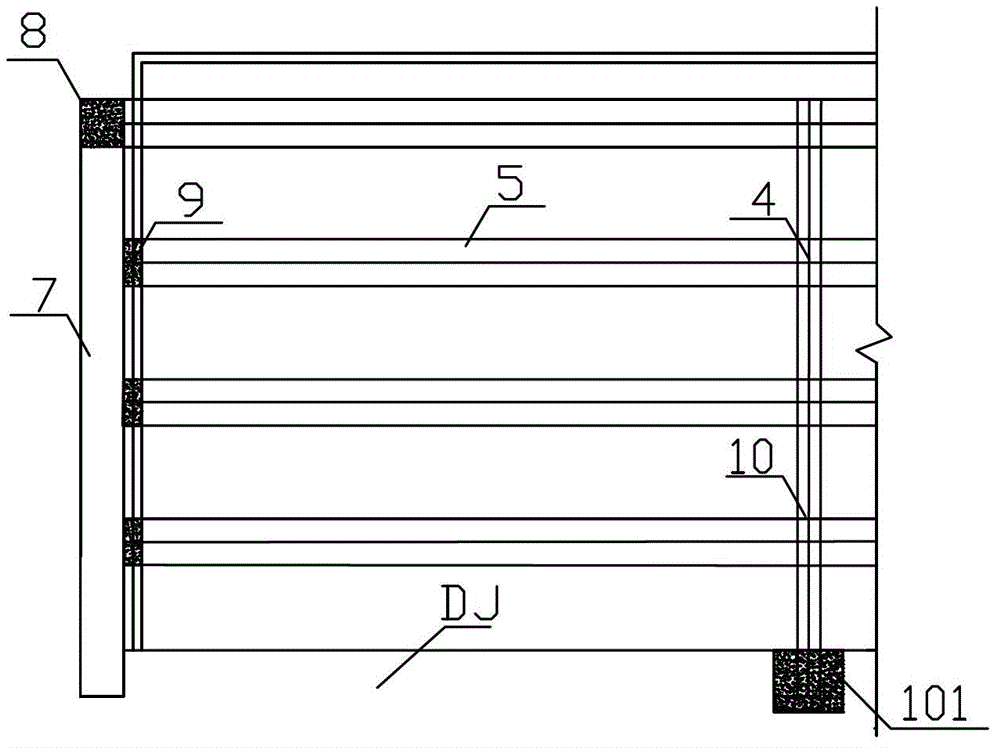

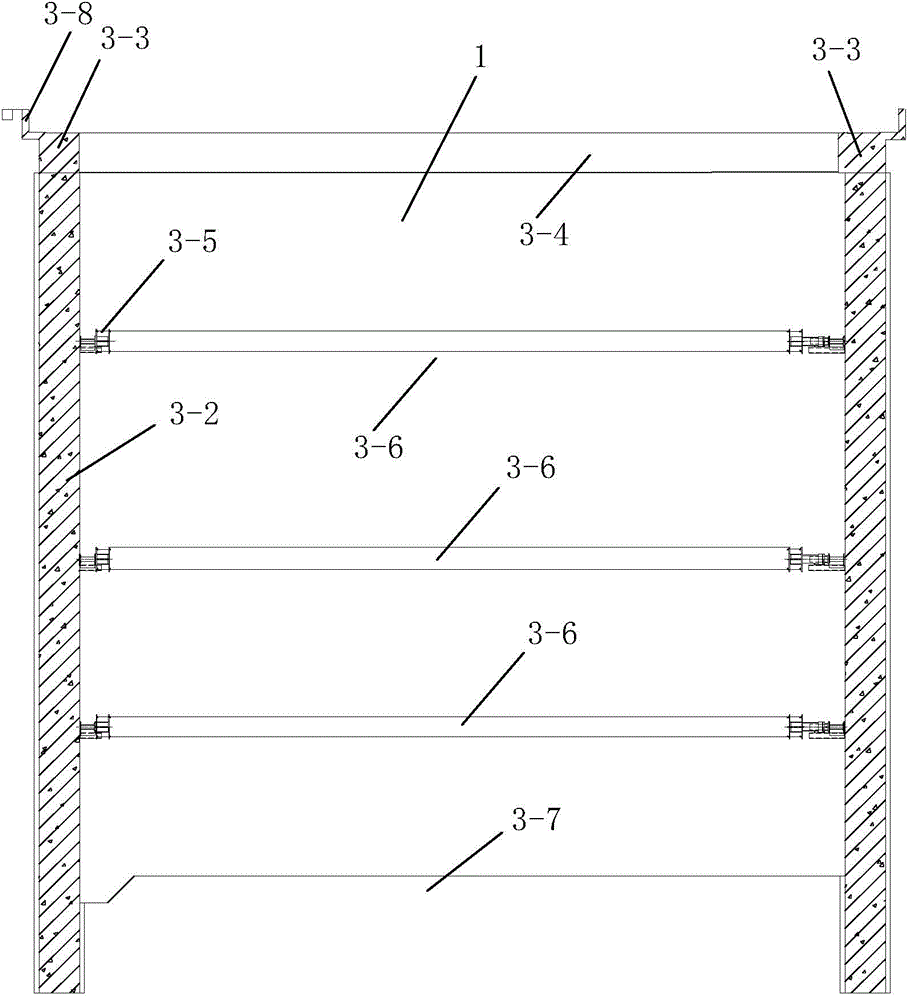

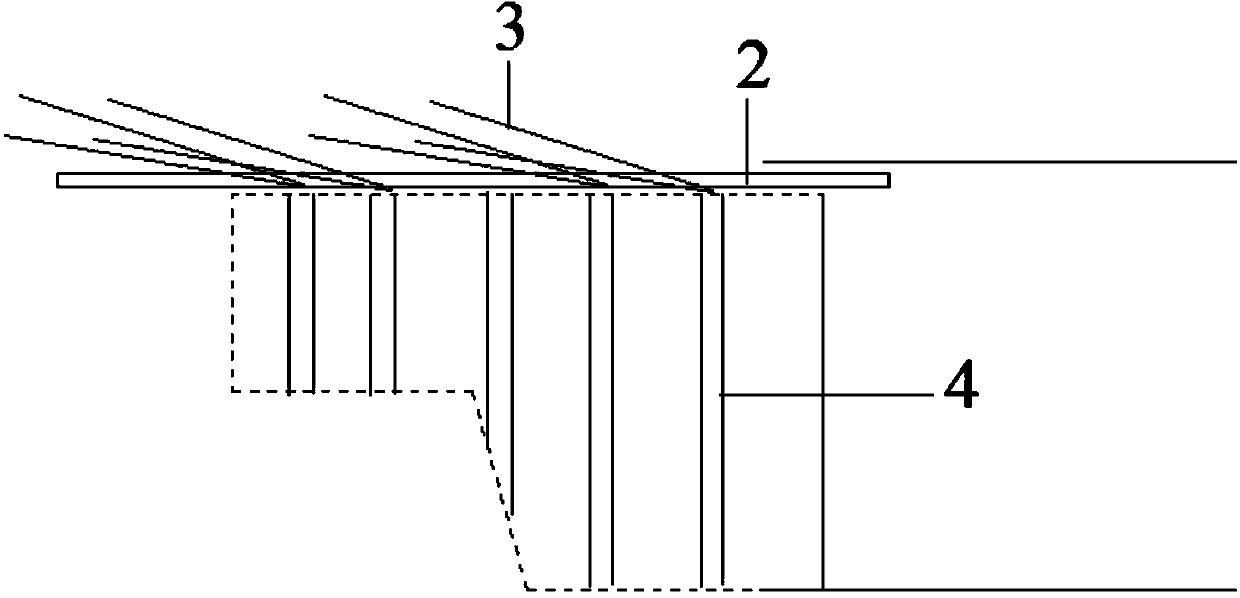

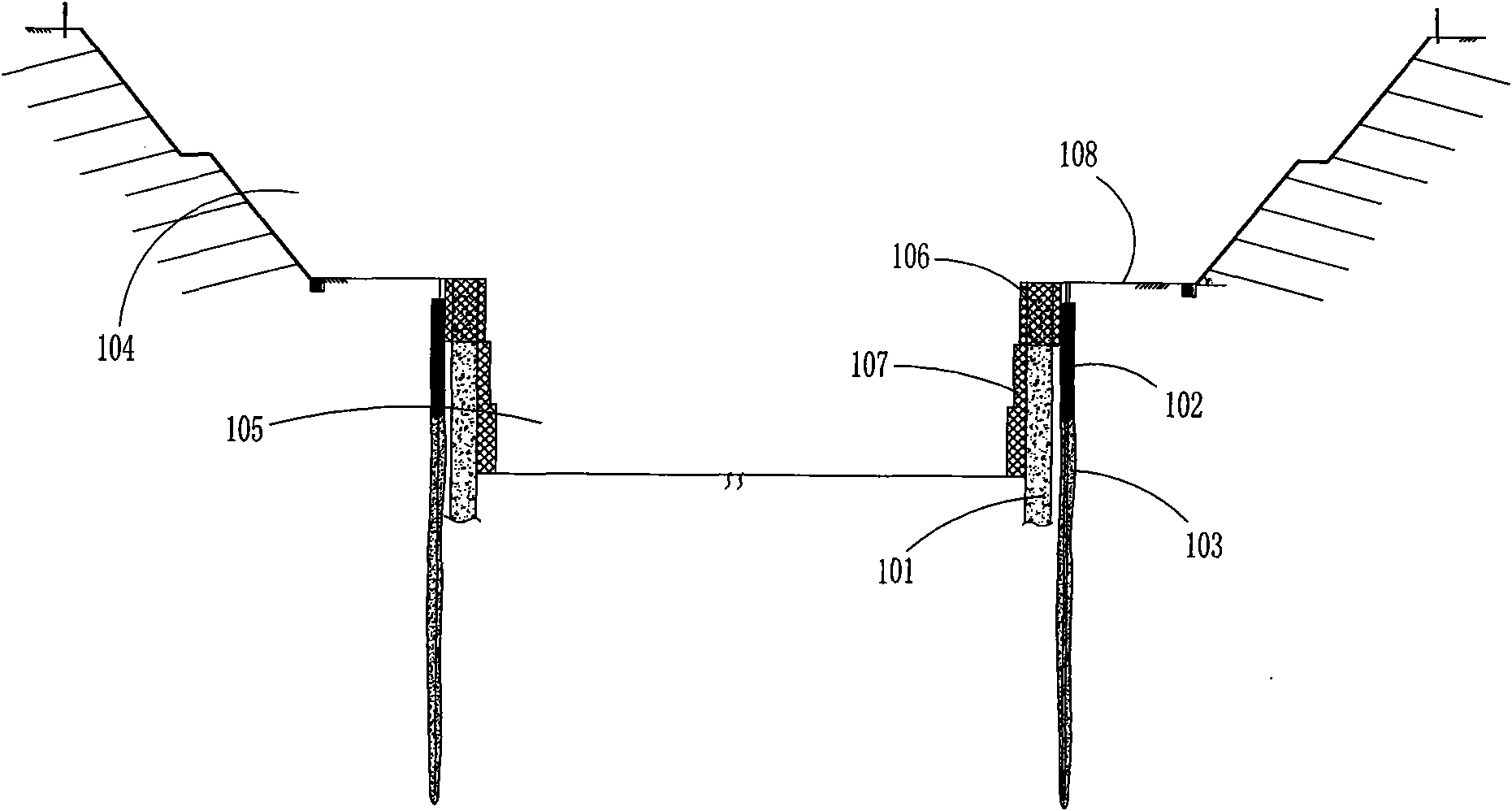

Long-span reinforced concrete inner support structure of rectangular deep foundation pit and construction method of structure

The invention discloses a long-span reinforced concrete inner support structure of a rectangular deep foundation pit, which comprises a foundation pit edge breast wall retaining structure, a plurality of layers of inner support three-dimensional timbering structures with steel structure support columns, and a top beam, wherein each inner support three-dimensional timbering structure comprises a foundation pit corner part structure, a foundation pit middle part symmetrical and opposite support structure, and longitudinal beams; each foundation pit middle part symmetrical and opposite support structure comprises a cross beam and two small inclined struts positioned at the two ends of the cross beam; the longitudinal beams are beams which are parallel to long edges of the foundation pit and are positioned at the middle part of the foundation pit; the steel support columns directly reach below the bottom of the foundation pit; the bottoms of the steel structure support columns are anchored by placed concrete; ring beams are arranged at parts where the cross beams, the longitudinal beams and the steel structure support columns at the middle part of the foundation pit are intersected; a support waist beam is arranged at a connection part between the inner support three-dimensional timbering structure and the middle part of the foundation pit edge breast wall retaining structure; and the cross beams, longitudinal beams, the ring beams and the waist beam of the inner support three-dimensional timbering structure are reinforced concrete or combined type large steel frame structures. The inner support structure is simple and visual in design, convenient to construct, large in support span, and significant in timbering effect.

Owner:广西建工第五建筑工程集团有限公司

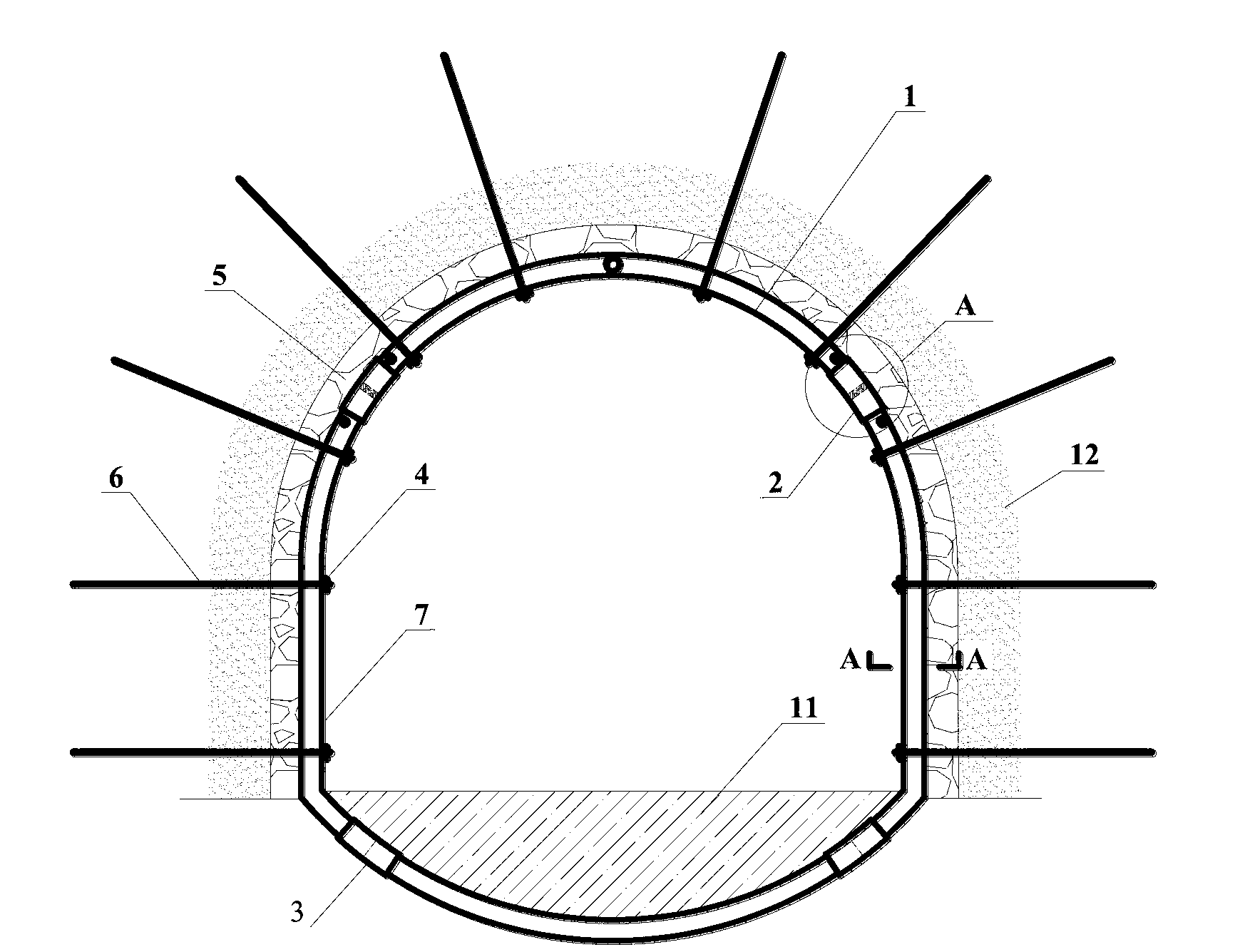

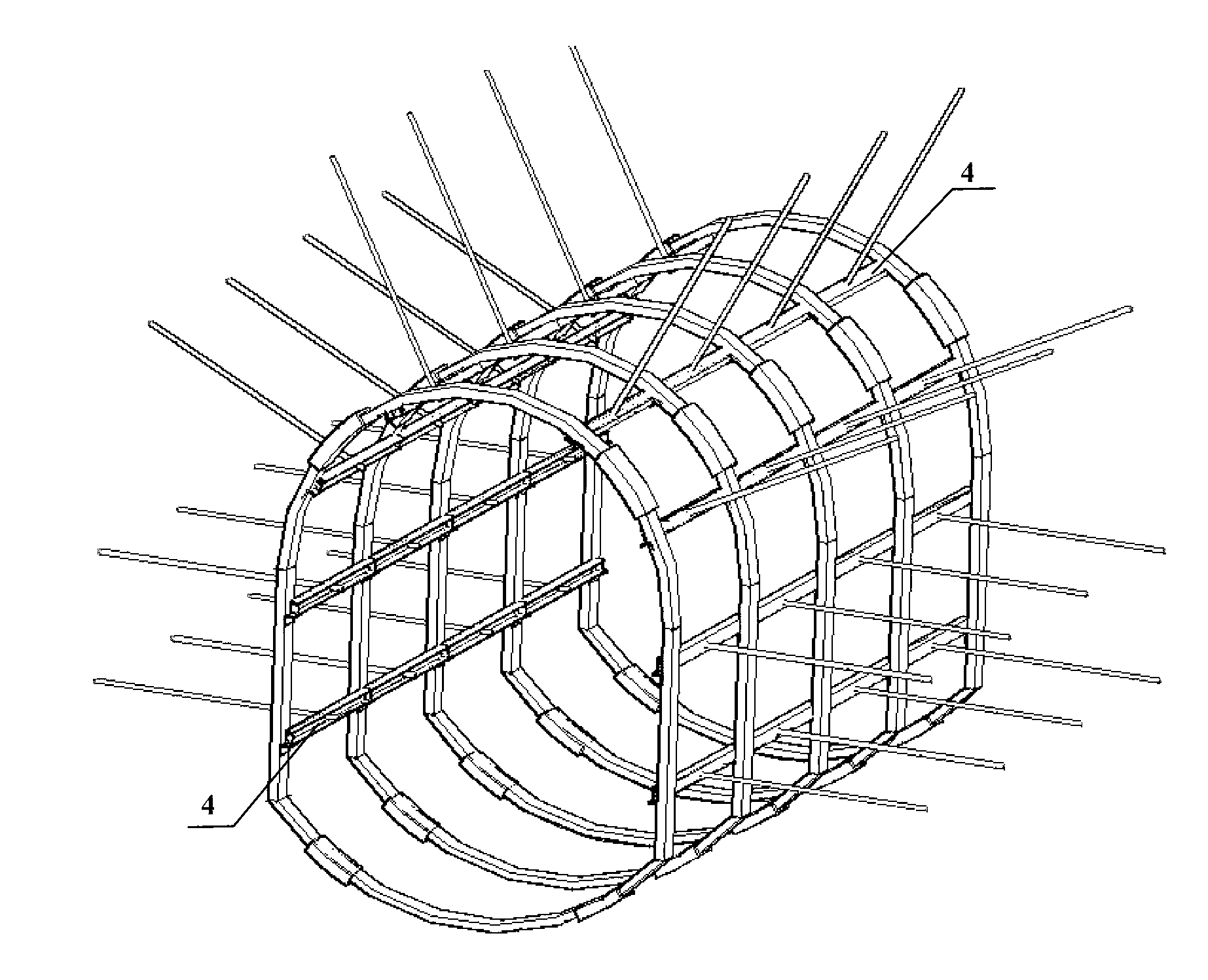

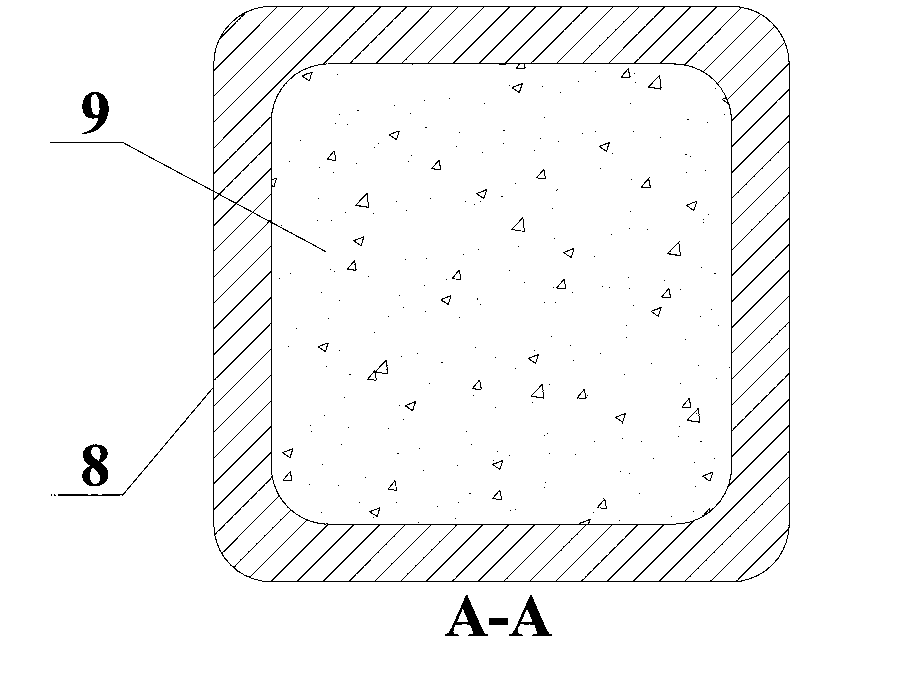

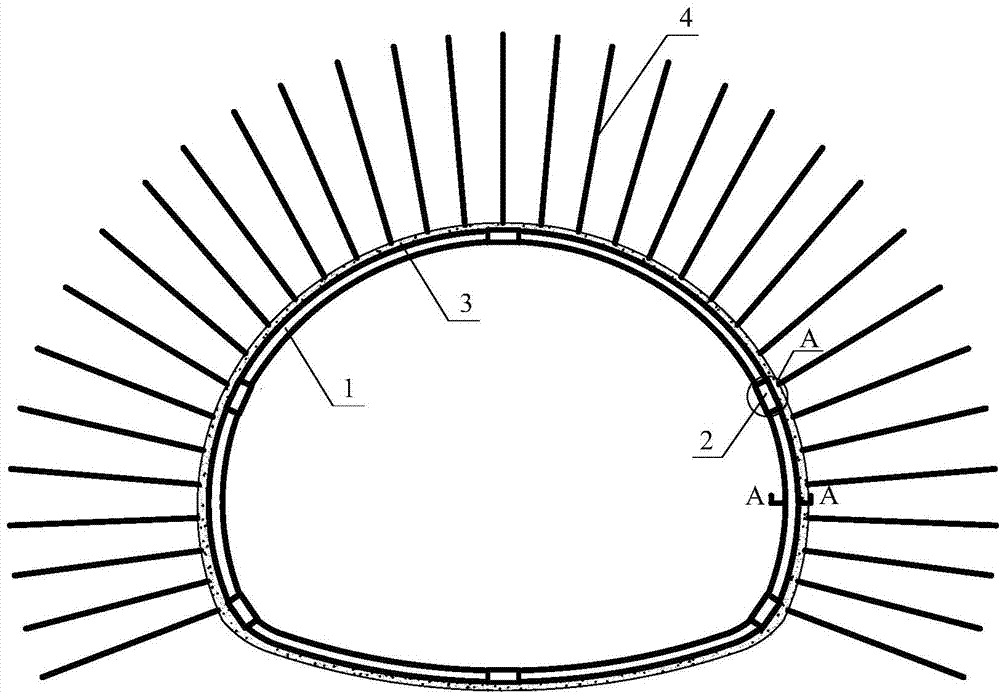

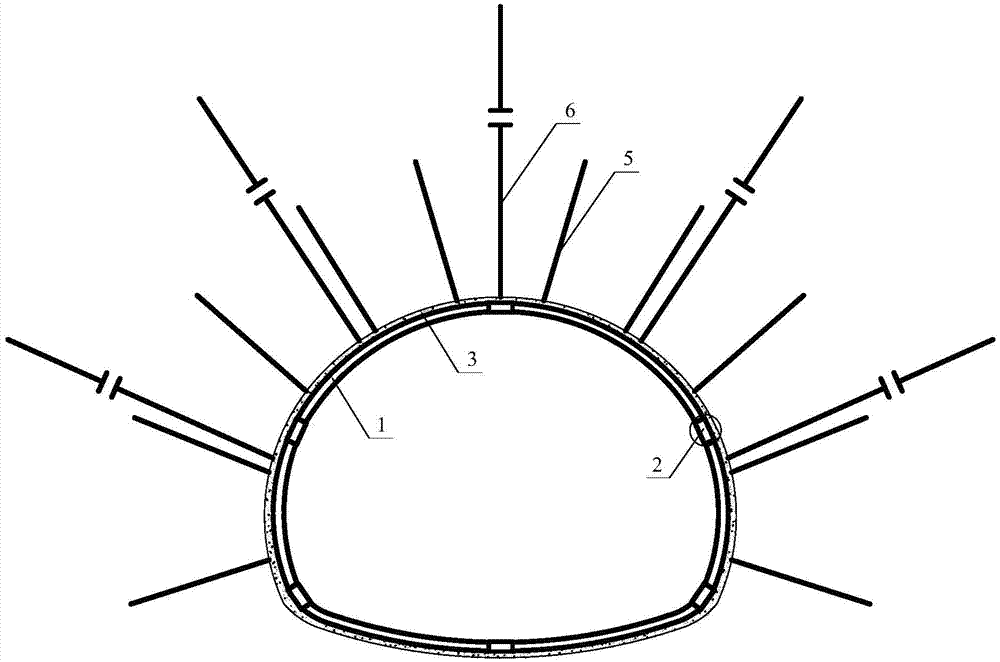

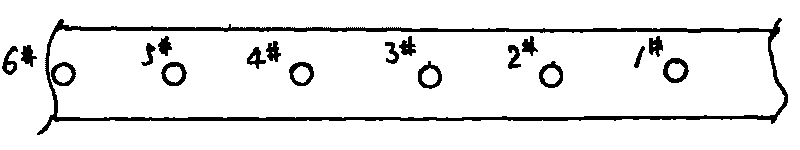

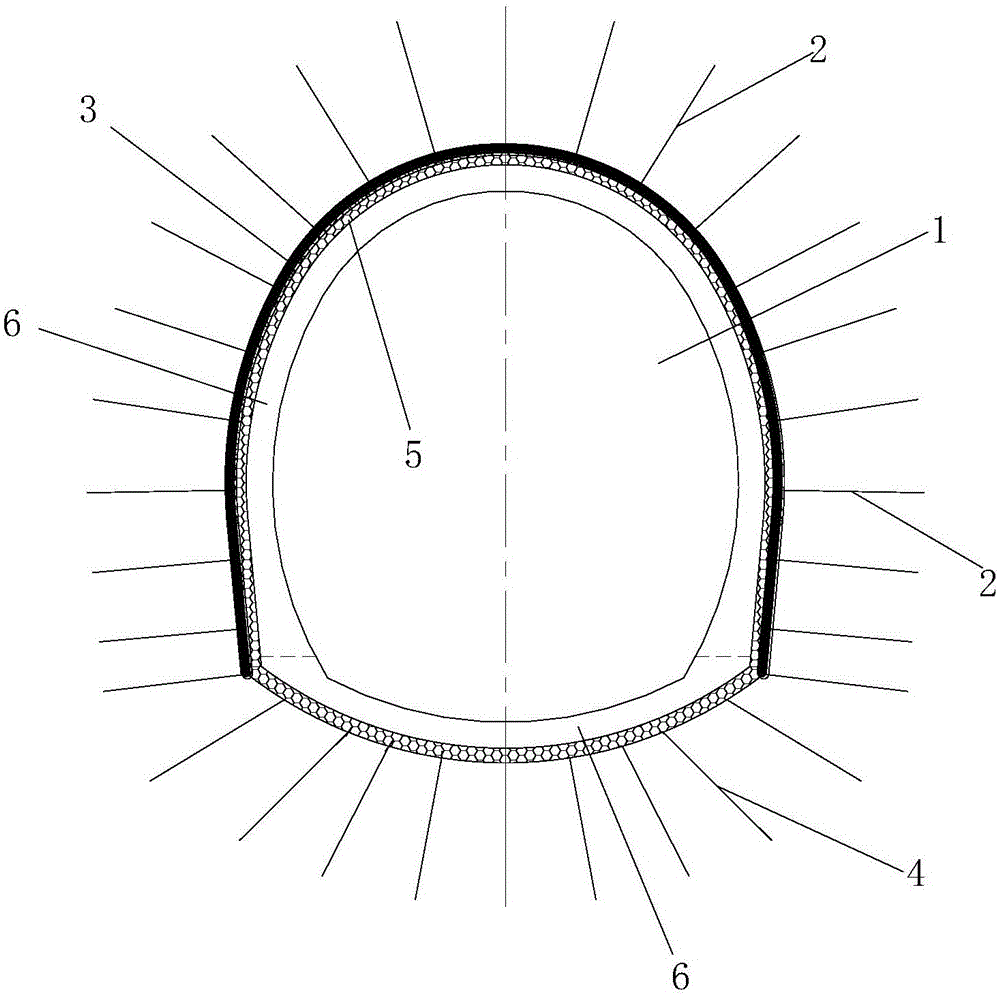

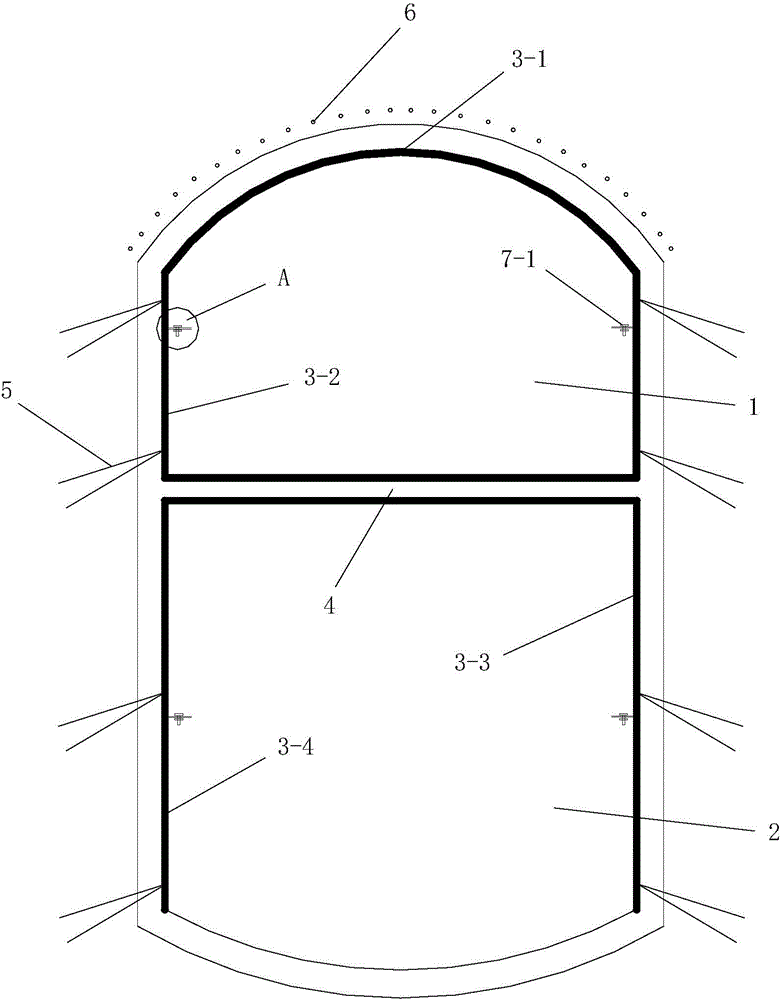

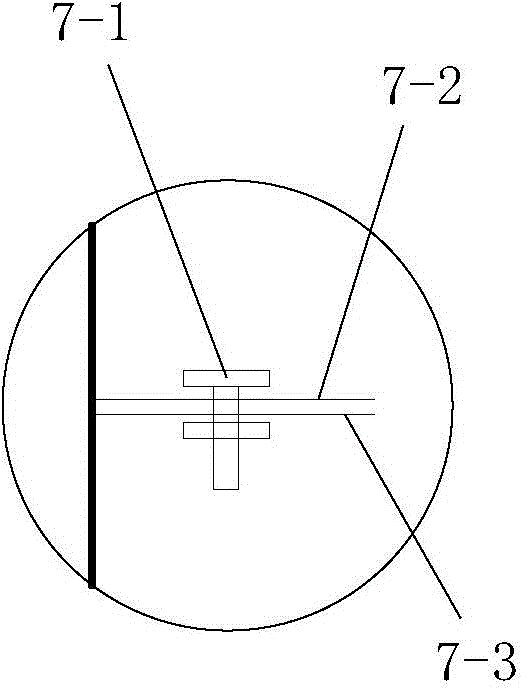

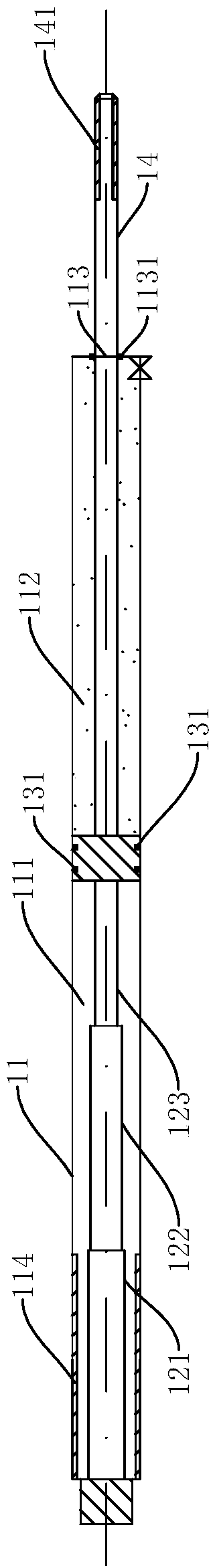

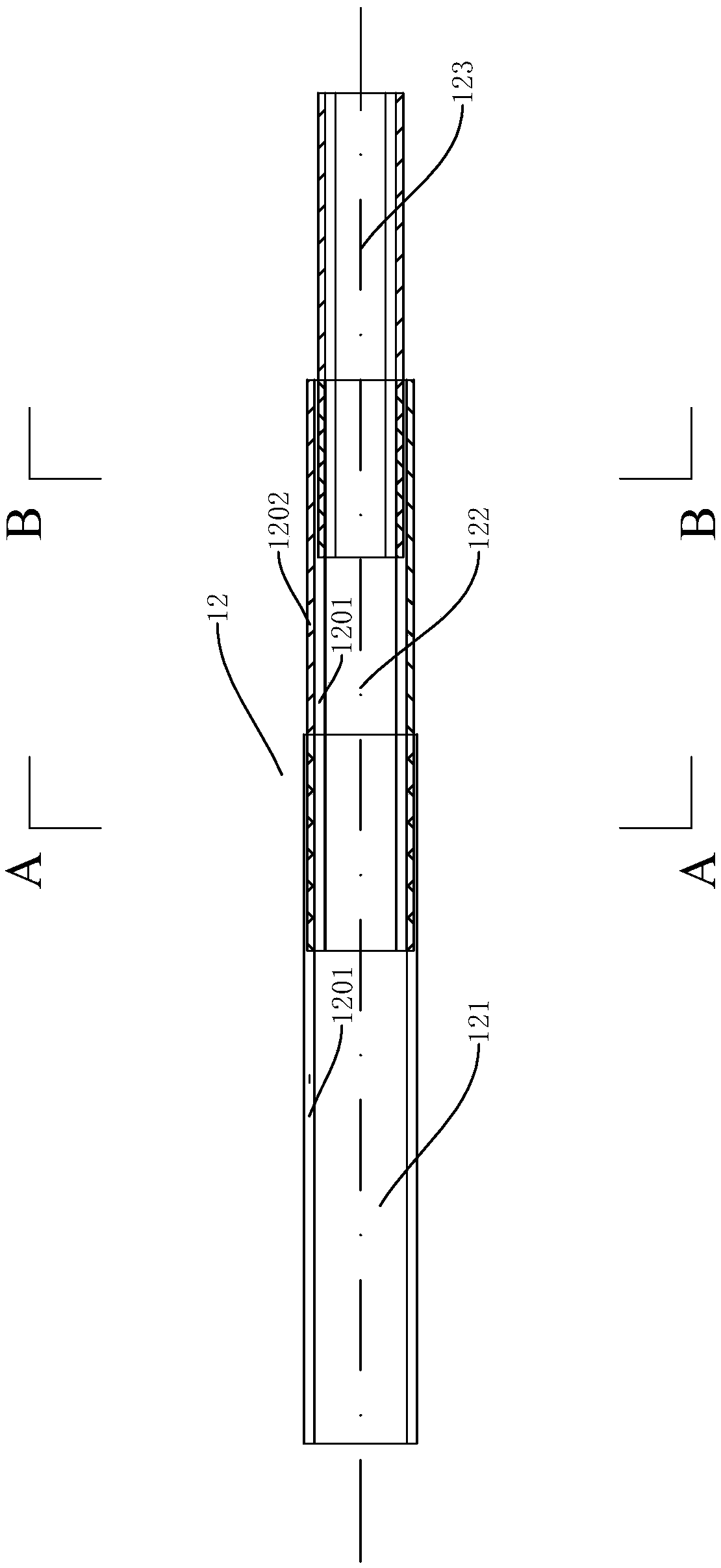

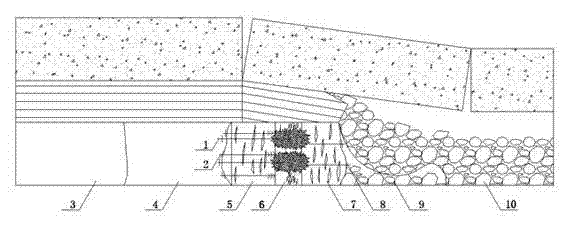

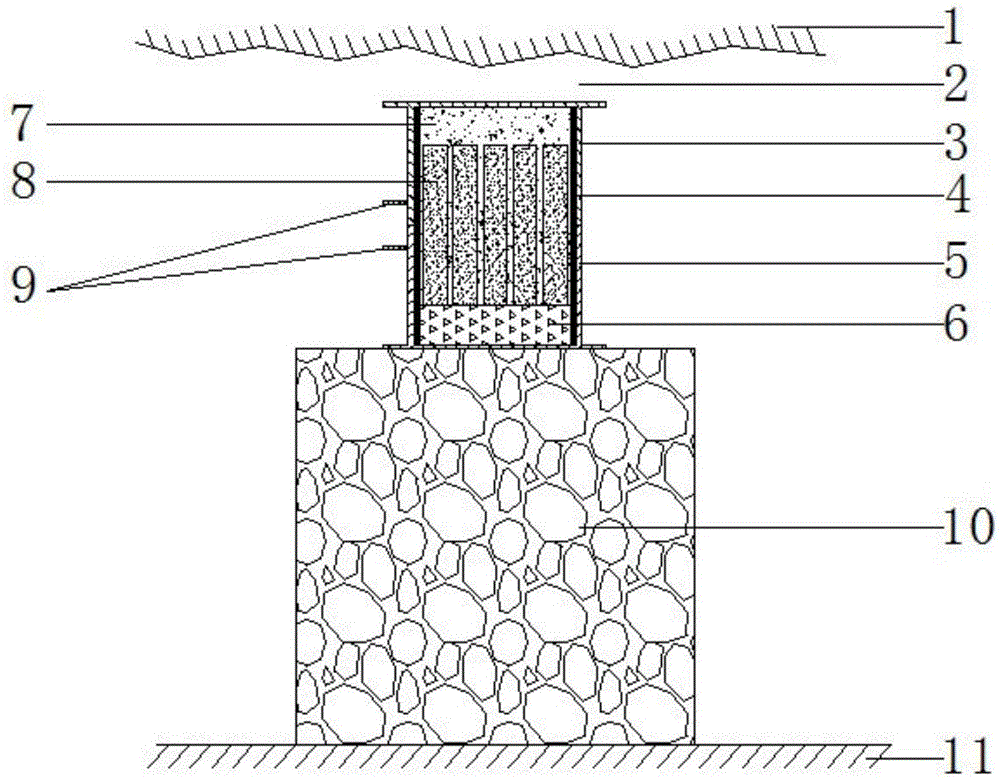

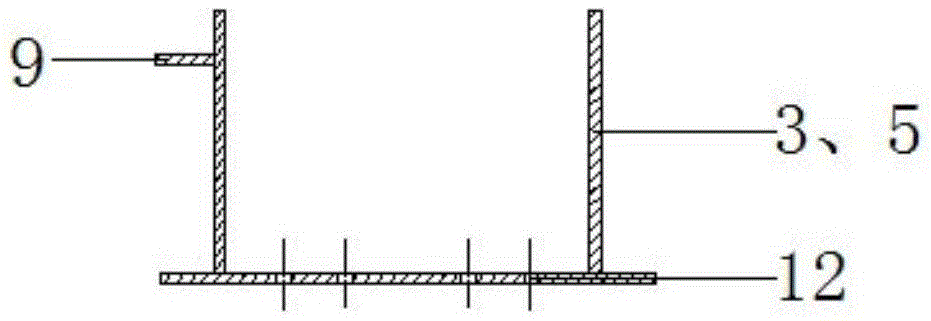

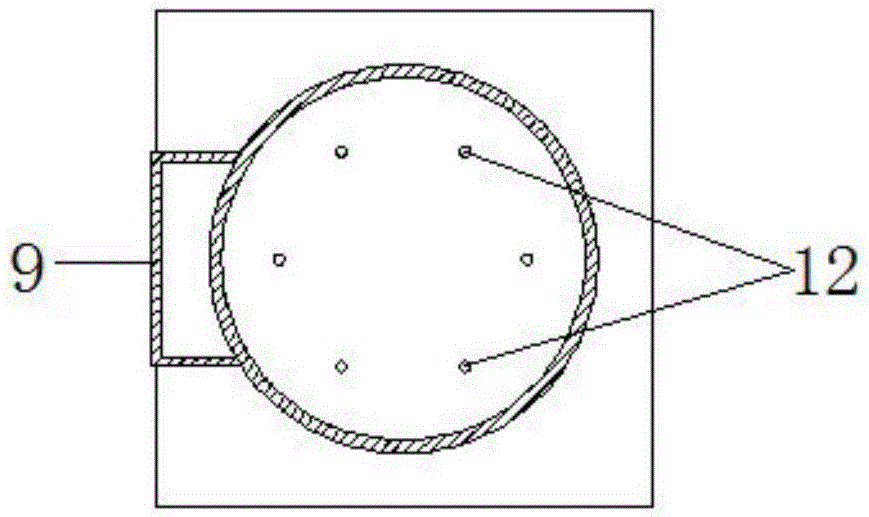

Square steel confined concrete arch center wall back filling bolting-grouting support system and construction method

InactiveCN103615273AImprove self-supporting capacityFill in timeAnchoring boltsSupporting systemRock tunnel

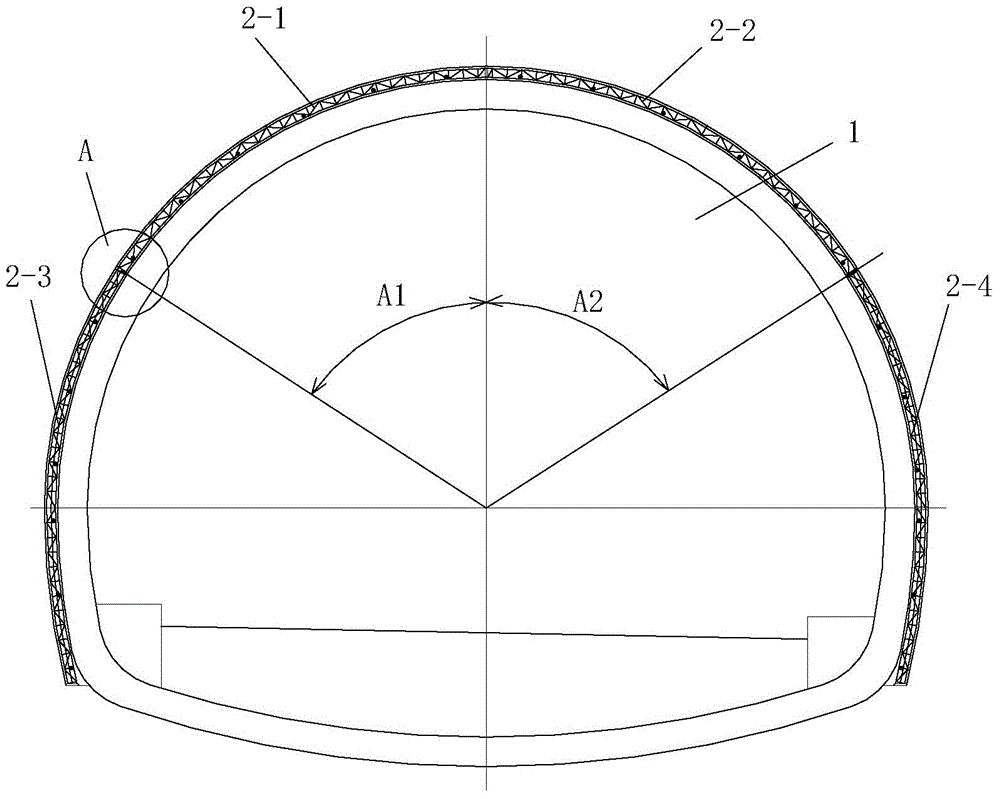

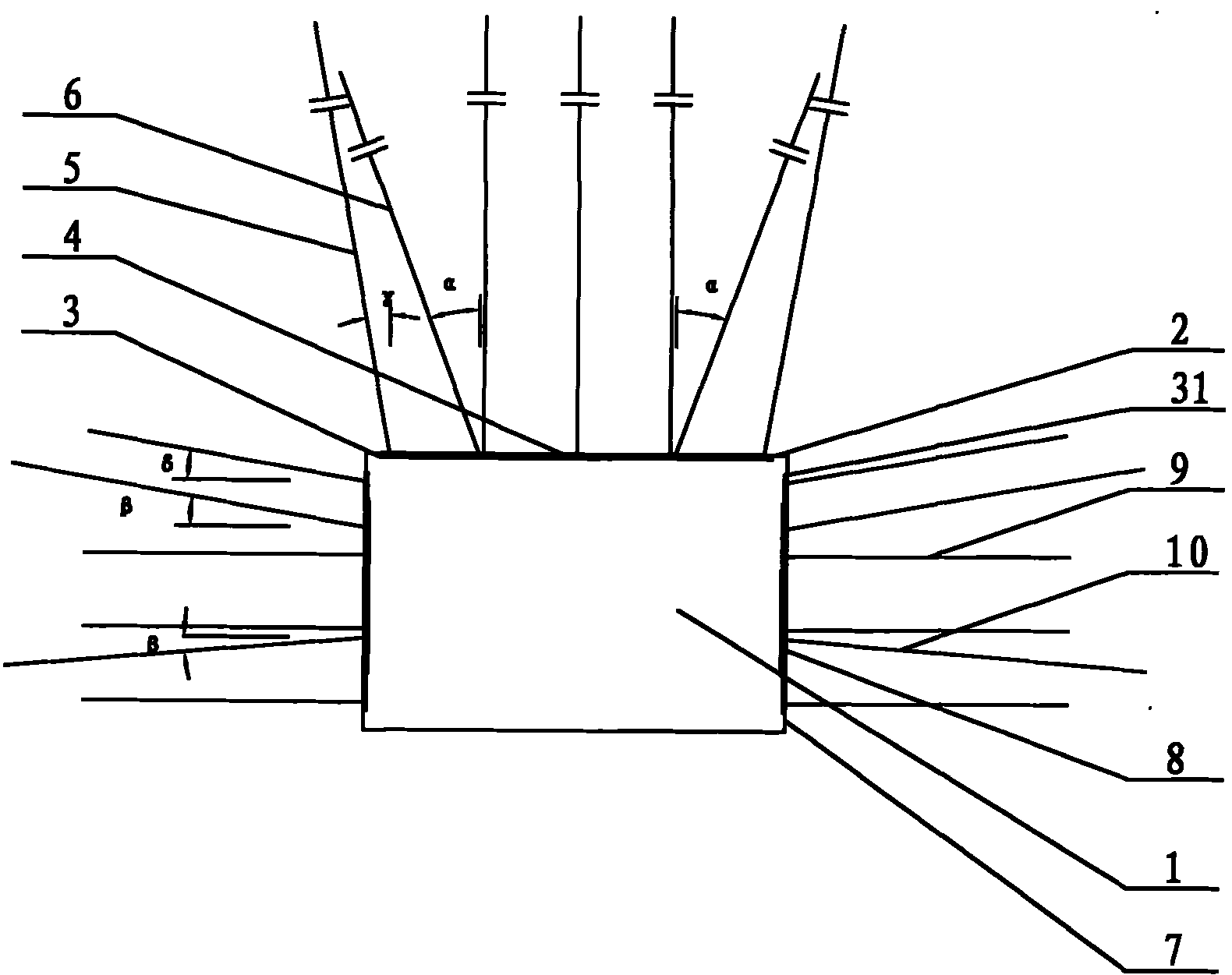

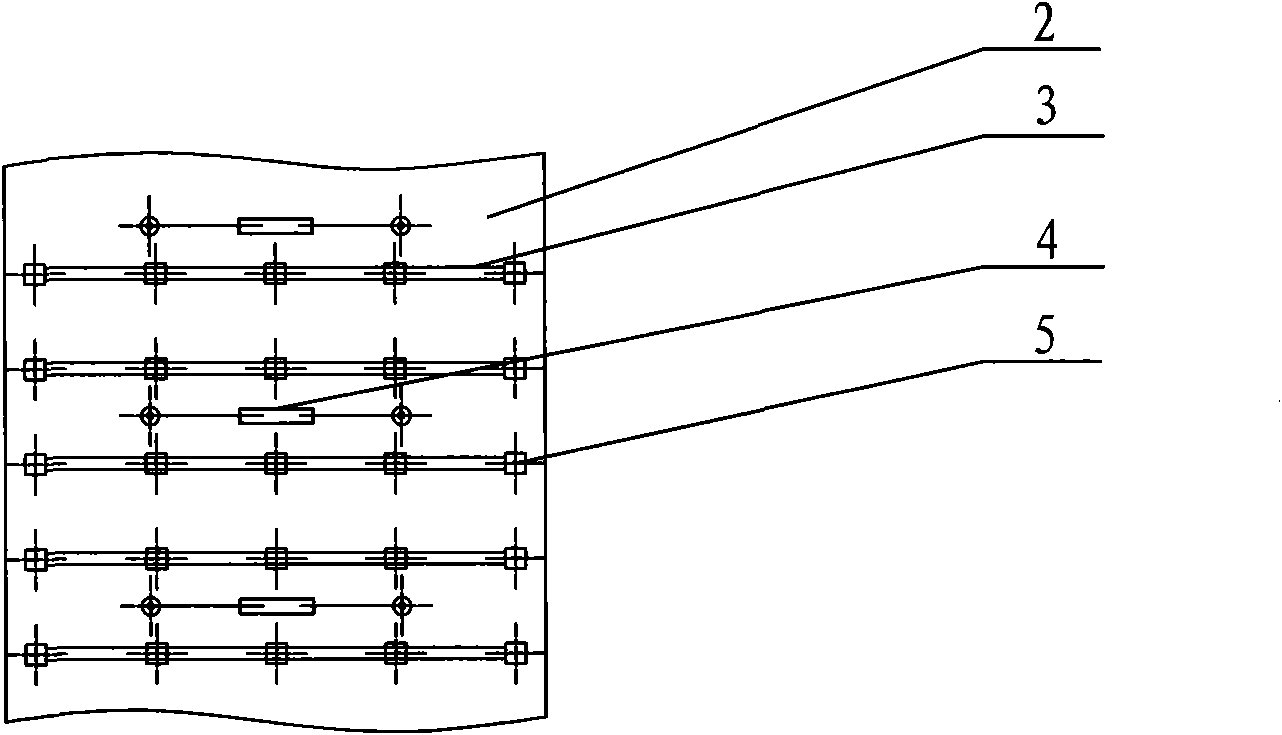

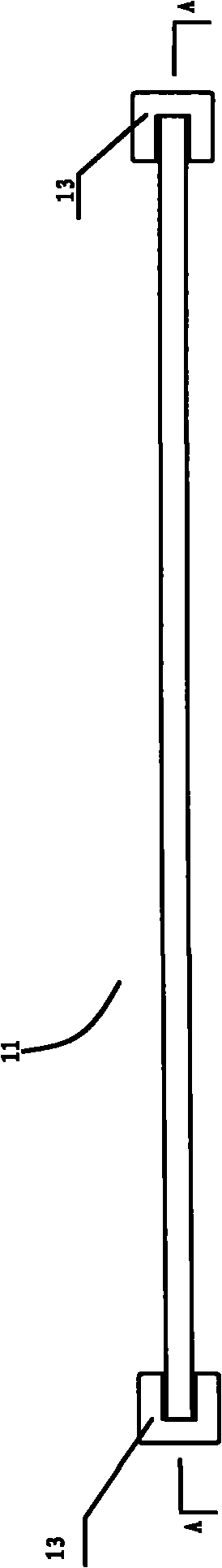

The invention discloses a square steel confined concrete arch center wall back filling bolting-grouting support system and a construction method. The square steel confined concrete arch center wall back filling bolting-grouting support system comprises high-strength anchor rods, grouting anchor rods, grouting anchor cables and multiple square steel confined concrete arch centers, wherein adjacent square steel confined concrete arch centers are connected through longitudinal beams, anchor rod holes are formed in the longitudinal beams, longitudinal beam anchor rods penetrate the longitudinal beams through the anchor rod holes to be anchored into a surrounding rock, a wall back filling layer is arranged between the square steel confined concrete arch centers and the surrounding rock, and the square steel confined concrete arch centers, the wall back filling layer and the tunnel surrounding rock are connected through the longitudinal beam anchor rods. The high-strength anchor rods, the grouting anchor rods and the grouting anchor cables are constructed before the square steel confined concrete arch centers are erected. The square steel confined concrete arch center wall back filling bolting-grouting support system and the construction method are applicable to supporting of underground projects including weak broken surrounding rock tunnels and the like, the square steel confined concrete arch center wall back filling bolting-grouting support system has the advantages of being high in strength, good in stability, reasonable in stress and the like, and the square steel confined concrete arch center wall back filling bolting-grouting support system and the construction method can effectively improve the primary supporting strength after tunnel excavation and ensure the stability of the tunnel surrounding rock.

Owner:SHANDONG UNIV

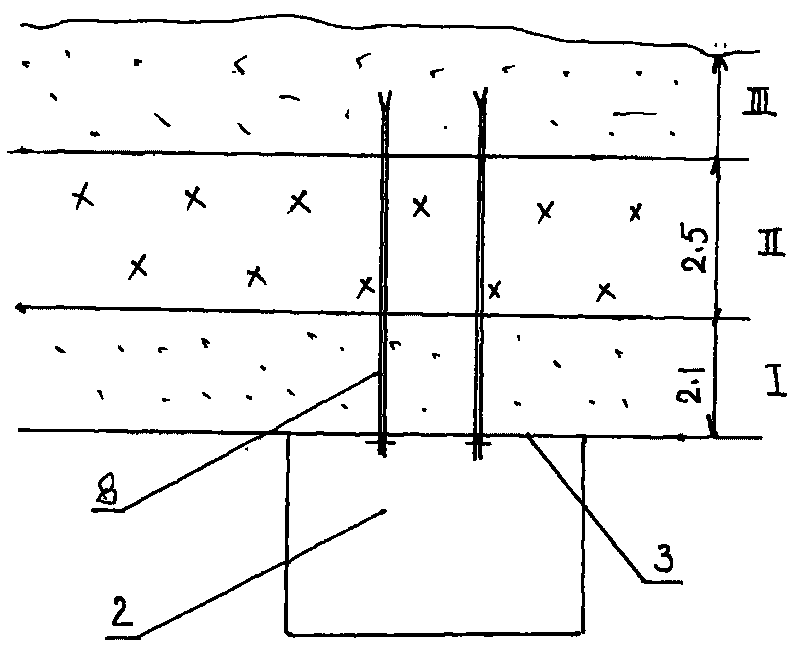

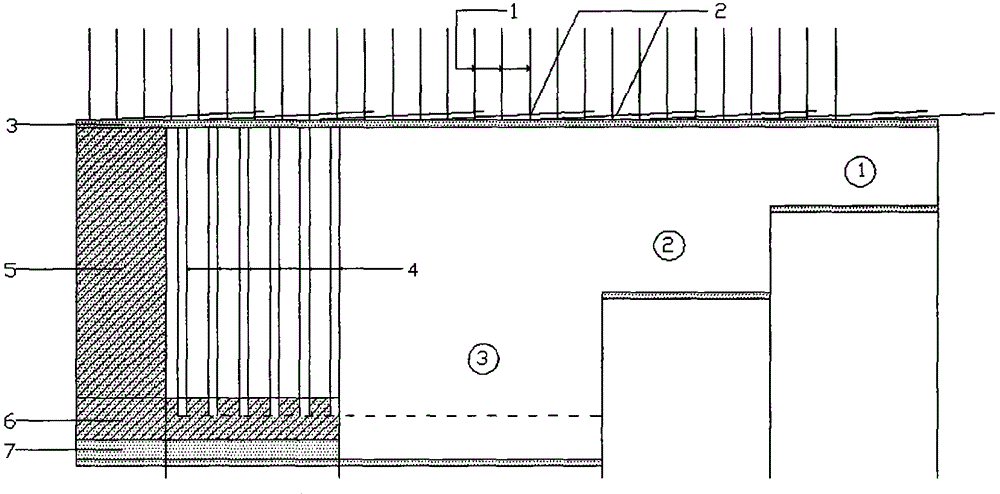

Subway station deep foundation pit excavation construction method

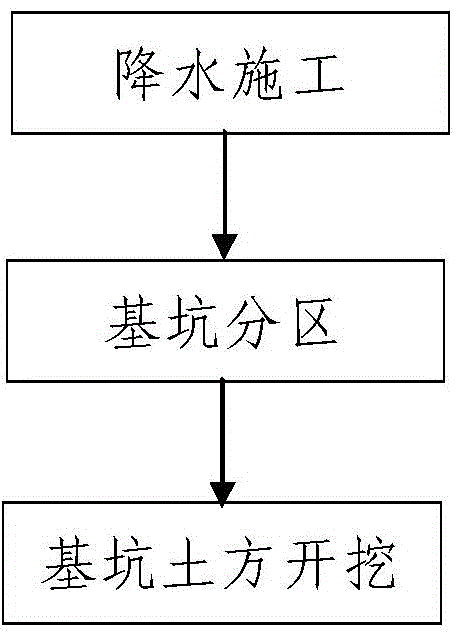

ActiveCN104612162AThe method steps are simpleReasonable designExcavationsReinforced concreteSubway station

The invention discloses a subway station deep foundation pit excavation construction method, wherein the upper portion of an excavated foundation pit is a sandy gravel stratum, and the lower portion of the excavated foundation pit is a mud rock stratum. The method includes the steps of 1, precipitation construction, wherein precipitation construction is conducted on the sandy gravel stratum through a precipitation well and 2, foundation pit excavation, wherein the foundation pit excavation includes the following steps of foundation pit partition and foundation pit earthwork excavation; the excavated foundation pit is divided into a plurality of small foundation pit bodies to conduct excavation respectively; the small foundation pits comprise first foundation pit bodies and second foundation pit bodies; excavation is conducted on the divided small foundation pit bodies; an open-cut method is adopted for the first foundation pit bodies and the second foundation pit bodies; the first foundation pit bodies are supported by fender posts, reinforced concrete supports and steel pipe inner supports; the second foundation pit bodies are supported by the fender posts, pre-stressed anchor cables and the steel pipe inner supports. The subway station deep foundation pit excavation construction method is simple in step, reasonable in design, convenient to construct, faster in construction process, good in construction effect and capable of easily conveniently and fast to finish deep foundation pit excavation construction process, and the influences on the surrounding environment by the excavation construction process are smaller.

Owner:中铁二十局集团第三工程有限公司

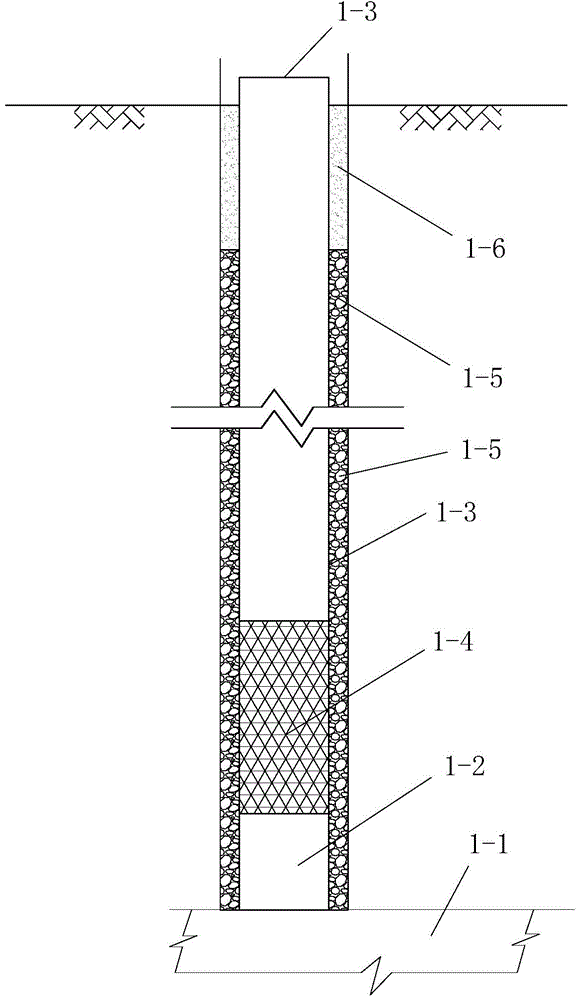

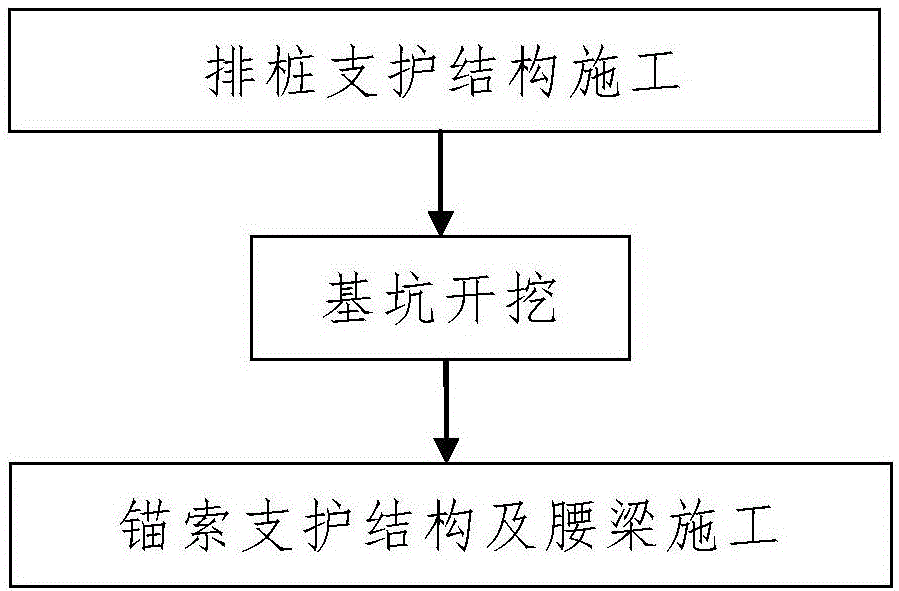

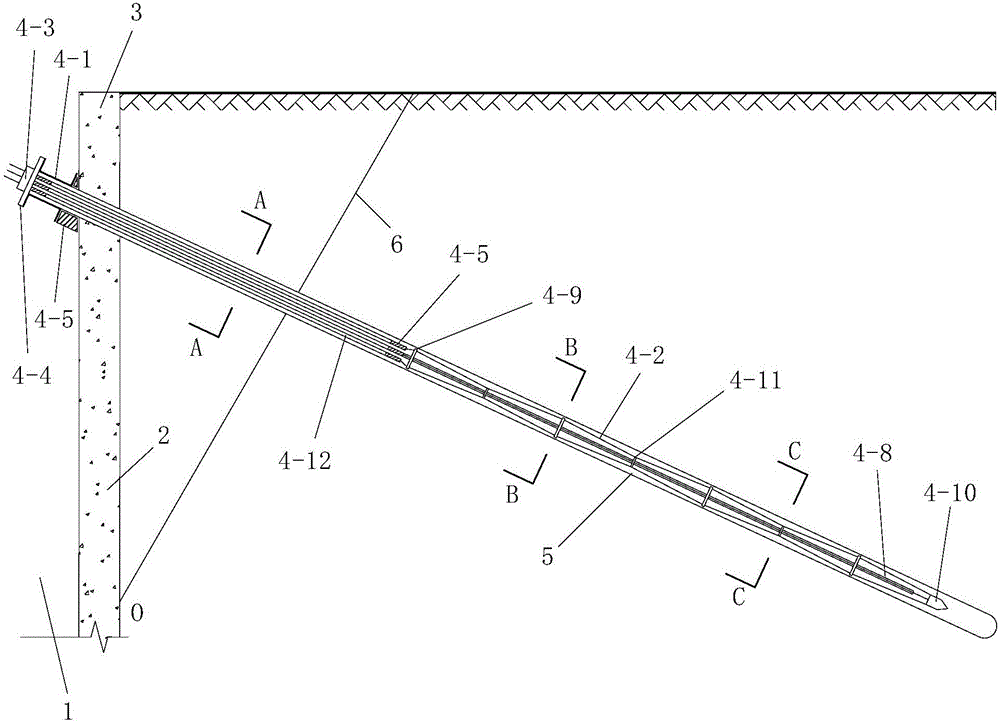

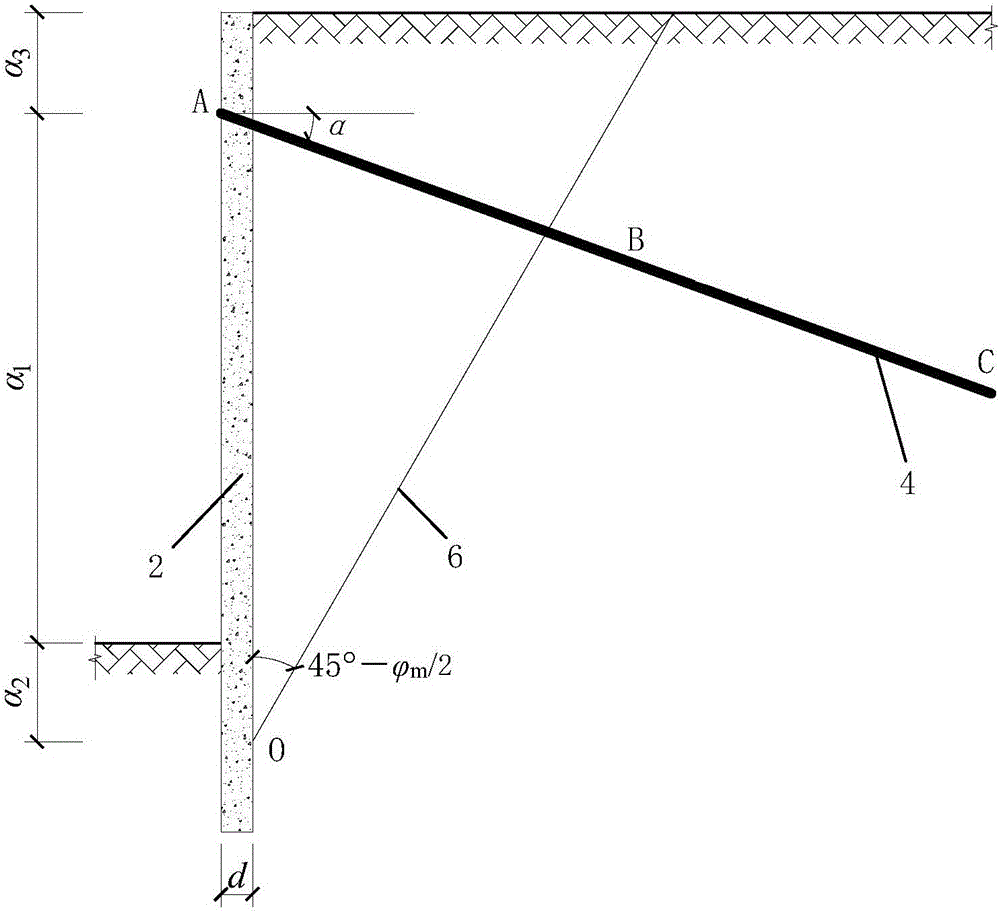

Construction method for supporting deep foundation pit through grouting after pile arrangement and anchor cable mounting

ActiveCN106320346AThe method steps are simpleReasonable designExcavationsBulkheads/pilesPre stressEngineering

The invention discloses a construction method for supporting a deep foundation pit through grouting after pile arrangement and anchor cable mounting. The construction method comprises the steps that firstly, pile arrangement supporting structure construction is performed, wherein a pile arrangement supporting structure comprises multiple slope protection piles which are arranged along the peripheral edge line of the constructed foundation pit from front to rear and a crown beam connected to the upper portions of the slope protection piles; secondly, foundation pit excavation is performed, wherein the constructed foundation pit is excavated from top to bottom; and thirdly, anchor cable supporting structure and waist beam construction is performed, wherein during excavation of the constructed foundation pit, the constructed foundation pit is excavated to the anchoring position of an anchor cable supporting structure, and the anchor cable supporting structure is constructed; and the anchor cable supporting structure comprises multiple prestress anchor cables, each prestress anchor cable comprises an anchor cable body, a primary grouting pipe and a secondary grouting pipe, and each anchor cable body comprises multiple steel strands. The method has the beneficial effects that the steps are simple, the design is reasonable, construction is easy and convenient, the use effect is good, the deep foundation pit supporting construction process can be completely easily, conveniently and quickly, the cost of the adopted prestress anchor cables is low, the anchoring force is high, and the deep foundation pit can be supported effectively.

Owner:SCEGC NO 6 CONSTR ENG GRP CO LTD

Supporting method for soft broken nonuniform stratum tunnel construction

InactiveCN103993892AImprove self-stabilityReduce construction difficultyUnderground chambersMine roof capsEngineeringSelf-stabilization

The invention discloses a supporting method for soft broken nonuniform stratum tunnel construction. The supporting method includes the steps that firstly, an arch support is erected in a bottom layer tunnel through steel pipes, and the portion, on the top of the arch support, of the bottom layer tunnel is drilled; secondly, a small pipe roof is constructed on the drilled portion of the arch crown of the arch support; thirdly, during construction of the small pipe roof for supporting, advanced reinforcement treatment is conducted on a top arch of the tunnel through advanced small pipes in a floor staggered mode; fourthly, the tunnel is excavated; fifthly, after the tunnel is excavated, preliminary supporting construction is conducted in time each cycle; sixthly, after excavation and supporting of a tunnel trunk of the tunnel, an inverted arch is constructed and sealed into a loop; and then secondary lining following operation is conducted. The method has the advantages that deformation of tunnel surrounding rocks can be effectively reduced, self-stabilization and seepage prevention capacity of the tunnel is permanently improved, a multifunctional surrounding rock reinforcement region is formed, and safety of tunnel constructors and equipment is guaranteed.

Owner:SHANDONG UNIV

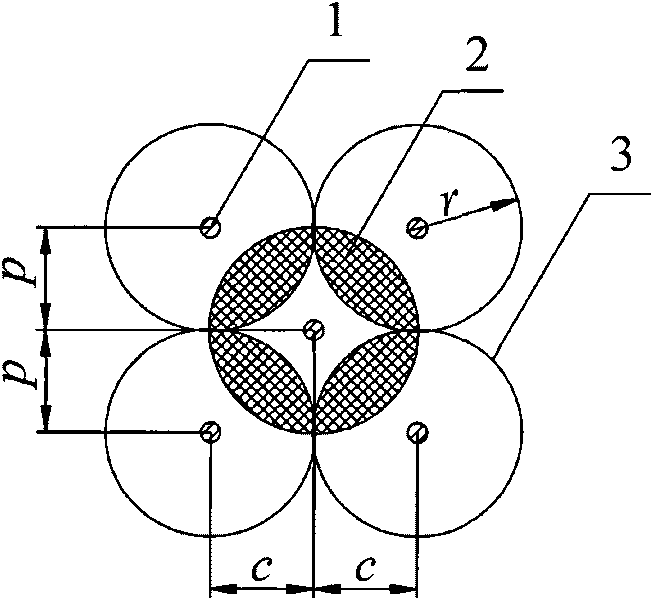

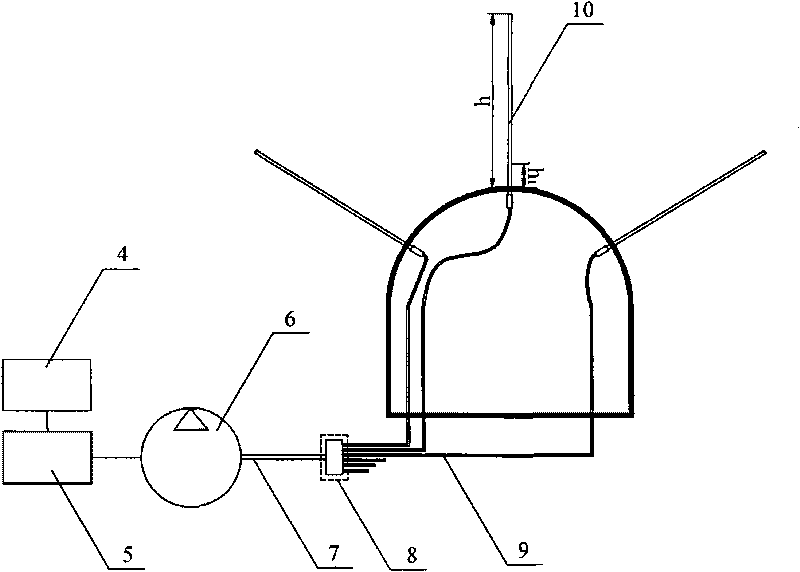

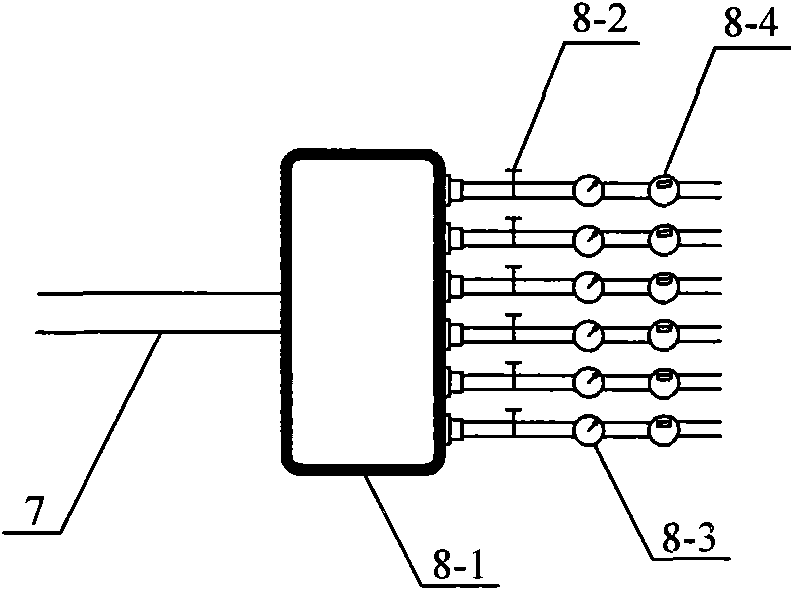

Porous parallel-connected grouting method and device for reinforcing roadway weak surrounding rock

InactiveCN101749030ANo deformationChanges can only spread in the direction of the advantageUnderground chambersTunnel liningSlurryEngineering

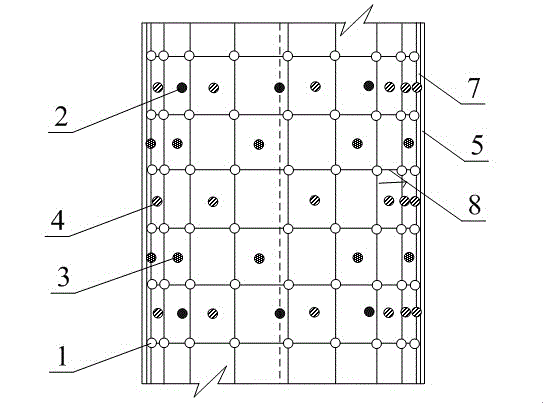

The invention provides a porous parallel-connected grouting method and a device for reinforcing a roadway weak surrounding rock. Hole sites of grouting hole are arranged in a plum flower shape, and an electric grouting pump with a large flow (no less than 52L / min) and a grouting pipe with a large diameter are adopted to be connected with 3-9 grouting pipelines through a multi-level shunt controller; a pressure gauge, a control valve and a flowmeter are all installed on each grouting pipeline so as to be used for controlling the pressure and the flow of the grouting holes in real time; the same position with similar development degree of damage and a crack on a bottom plate, a side part or a top plate in a certain region of a roadway is selected to punch with a plurality of grouting holes,and grouting anchors are installed; and a plurality of grouting anchors are connected through a plurality of grouting pipelines so as to realize simultaneously grouting on the plurality of grouting holes. When slurry in one hole does not flow any longer, and the grouting pressure achieves above 2MPa, grouting of the grouting hole is stopped, the grouting pipeline is connected to the next groutinganchor so as to implement grouting of the next grouting hole until the grouting holes in the region are all grouted. The grouting speed is enhanced by above 3-9 times, thereby greatly enhancing the self bearing ability of the surrounding rock.

Owner:CHINA UNIV OF MINING & TECH

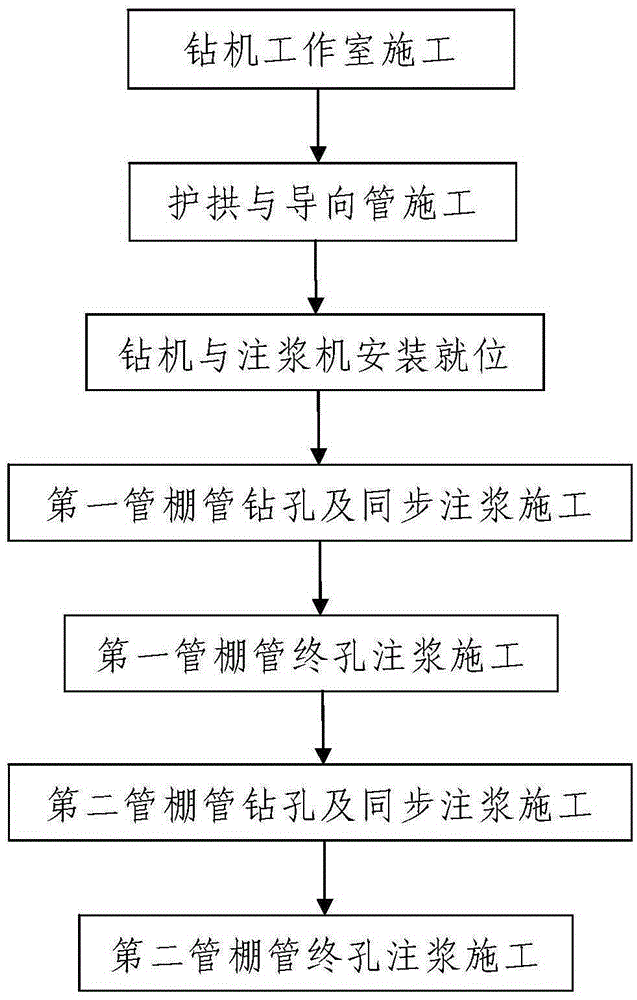

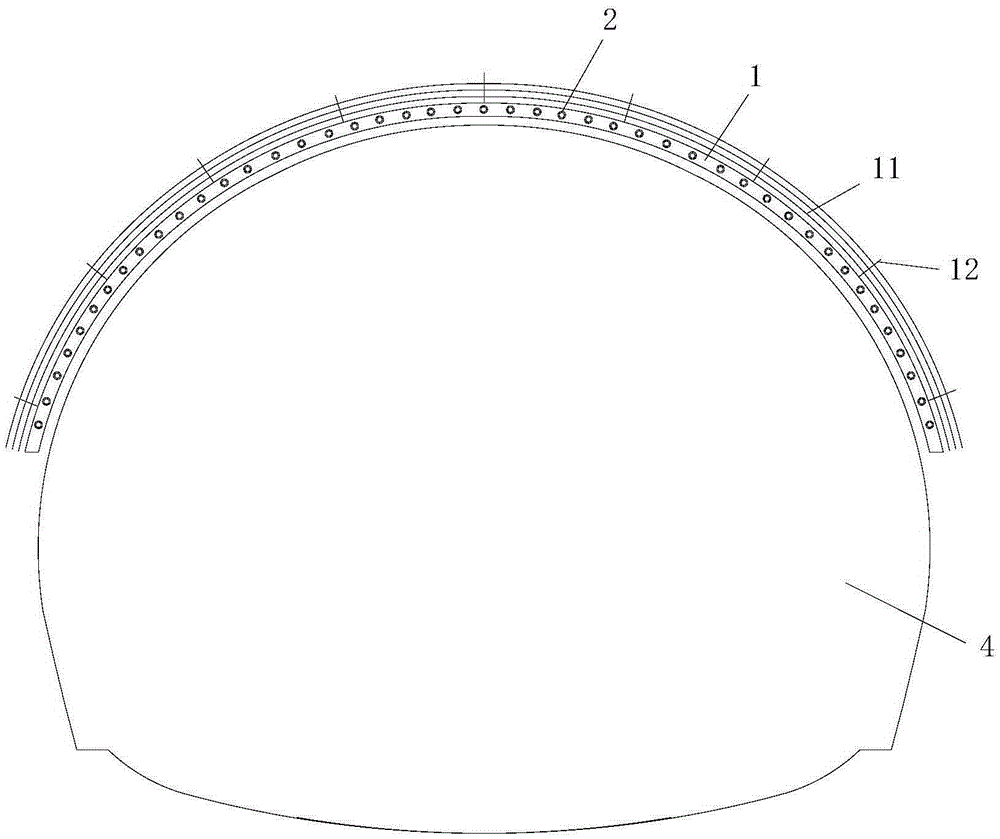

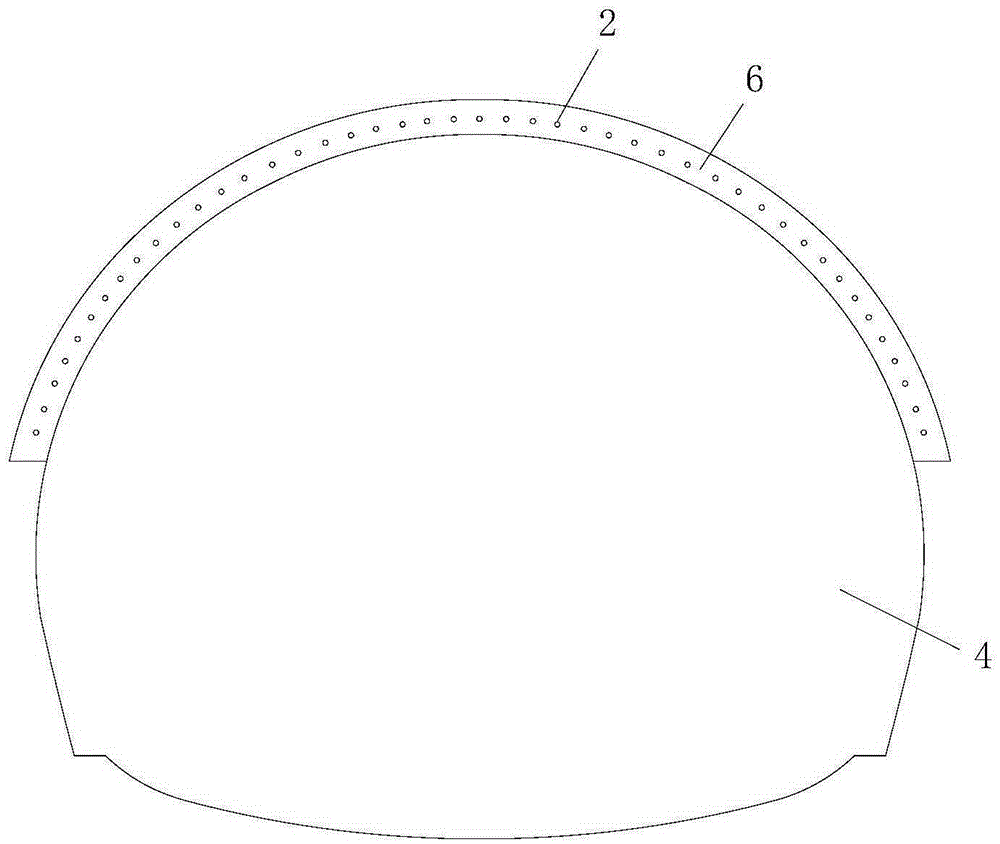

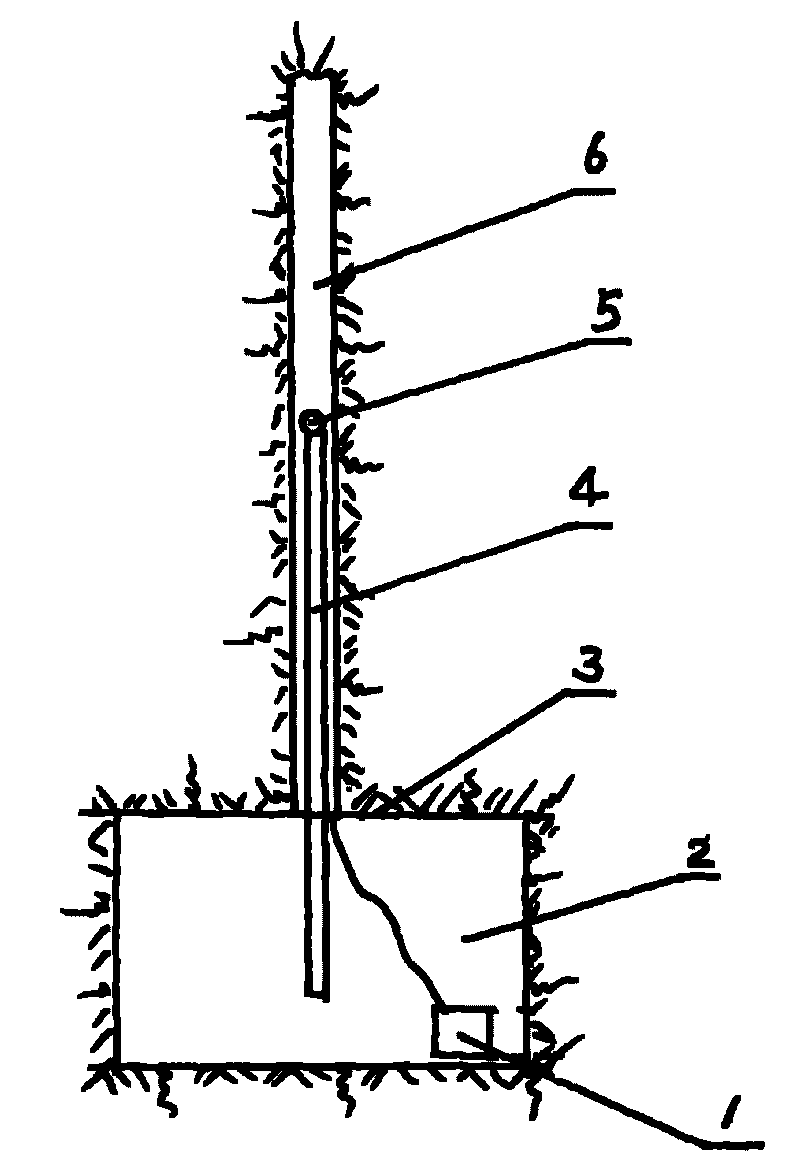

Soft and weak wall rock tunnel advance reinforced support construction method

InactiveCN105298517AThe method steps are simpleEasy to implementUnderground chambersTunnel liningGuide tubeDrilling machines

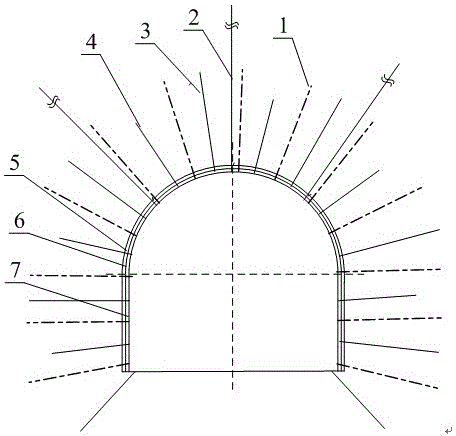

The invention discloses a soft and weak wall rock tunnel advance reinforced support construction method. When a pipe roof advance support construction is carried out on one segment of the constructed tunnel, the construction method comprises the following steps: (1) support arch and guide pipe construction, wherein a plurality of guide tubes for carrying out guiding on a plurality of pipe roof pipes are arranged on a support arch; each pipe roof pipe comprises a pipe body and a drill bit; each pipe body is formed by splicing a plurality of pipe joints; each drill bit is coaxially arranged at the front end of the pipe body; the pipe joints are spiral steel pipes; the pipe roof pipes are first pipe roof pipes or second pipe roof pipes; and the first pipe roof pipes and the second pipe roof pipes are staggered; (2) drilling machine and slip casting machine installation and emplacement; (3) pipe roof advance support construction, which comprises the following processes: first pipe roof pipe drilling and synchronous grouting construction, final hole grouting construction of the first pipe roof pipes, second pipe roof pipe drilling and synchronous grouting construction and final hole grouting construction of the second pipe roof pipes. The method disclosed by the invention is simple in steps, reasonable in design, simple and convenient to construct and good in support effect; and the soft and weak wall rock tunnel advance reinforced support process can be simply, conveniently and quickly finished.

Owner:中铁二十局集团第二工程有限公司

Determination method of deep tunnel roof support forms and support depth

InactiveCN101694163ASupport parameters are economical and reasonableGood support effectSurveyConstructionsLithologyGeomorphology

The invention discloses a determination method of deep tunnel roof support forms and support depth, which comprises the steps of using an intelligent drill imager to measure inner wall lithology of different depth drill holes, fracture distribution and images and data of abscission layer consitions, treating data and image edit, achieving the alternate interval attitudes and space distribution conditions of wall rock inner fracture zones and intact zones of each drill hole, and adopting anchor rods, anchor ropes or unite support forms and depth of anchor rods and anchor ropes under the conditions of construction zones with different thickness. When the support depth of anchor rods and anchor cables is designed in the invention, completely scientific bases are achieved to support parameters to be more economic and rational, and the best support effect can be achieved under the most economic conditions. The invention can scientifically and quantitatively determine anchoring forms of deep tunnels and length of top plate anchor rods and anchor cables, can achieve the deep high-stress tunnel anchoring support quantitative design, and guarantee the top plate safety of deep tunnels to be provided with important promotion value.

Owner:SHANDONG UNIV OF SCI & TECH

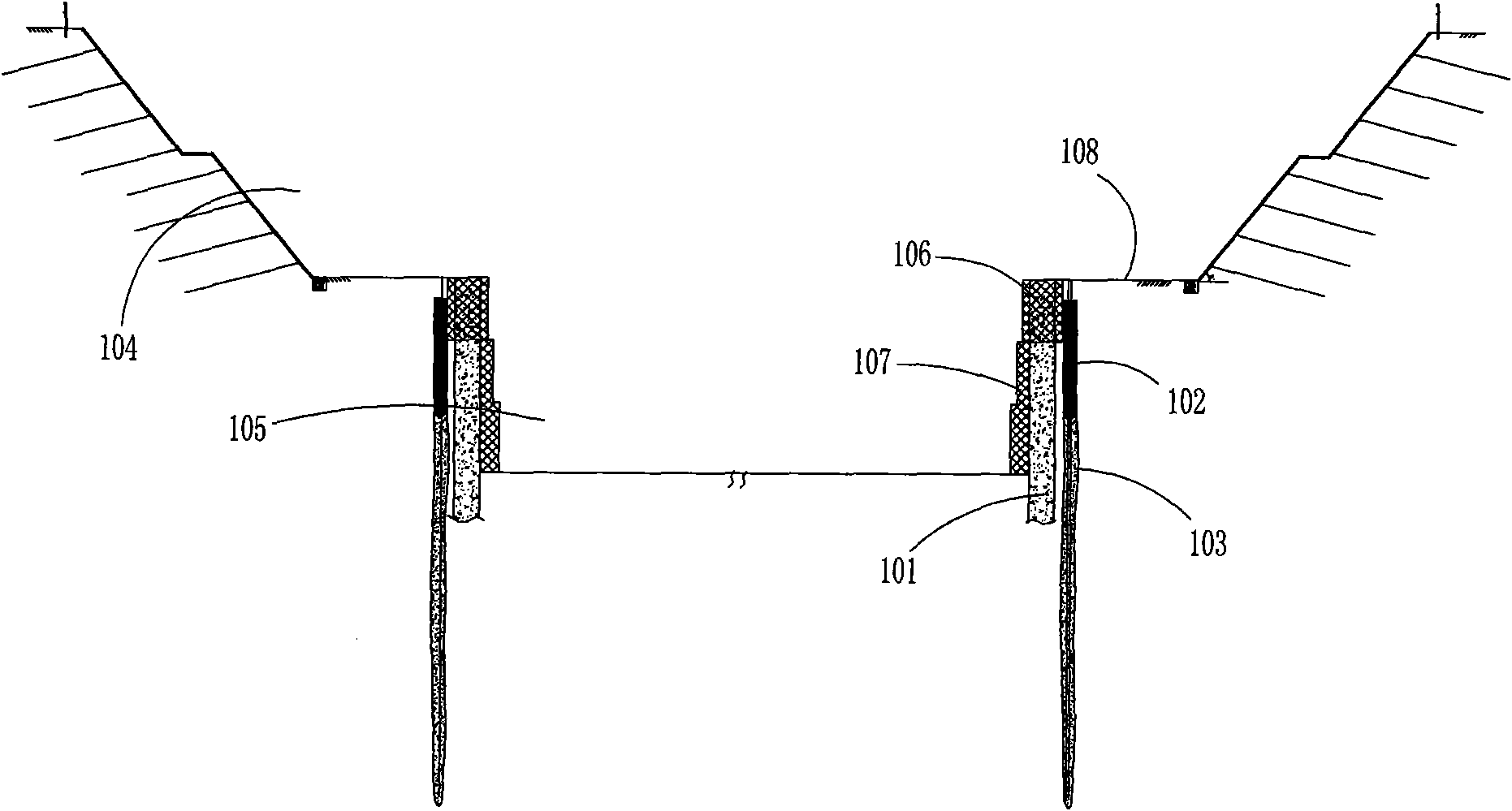

Combined support-excavated geologically solutional deep foundation pit and construction method thereof

ActiveCN101892668APrevent landslidesImprove the support effectExcavationsSoil massReinforced concrete

The invention discloses a combined support-excavated geologically solutional deep foundation pit and a construction method thereof. The deep foundation pit is characterized by consisting of an upper slope foundation pit and a lower vertical foundation pit; the construction method thereof comprises the steps that: in case of vertical excavation of the deep foundation pit, the periphery of the foundation pit is supported and reinforced by reinforced concrete support piles to prevent the foundation pit from collapse owing to lateral pressure of soil mass; then a high pressure jet grouting pile waterproof curtain is adopted for performing water sealing on soil mass outside the support piles and a bedrock internal grouting curtain is adopted for performing water sealing on geological situations in rocks, such as solution cavity, solution, crack and the like; and in the process of layered excavation, an annular continuous concrete slab wall is adopted for the soil mass and the rocks at the periphery of the foundation pit to form a continuous arch ring lagging. The construction method according to the invention can effectively guarantee the safe, stable, fast and effective excavation of the geologically solutional deep foundation pit.

Owner:THE FIRST CIVIL ENG CO LTD OF CREC SHANGHAI GRP

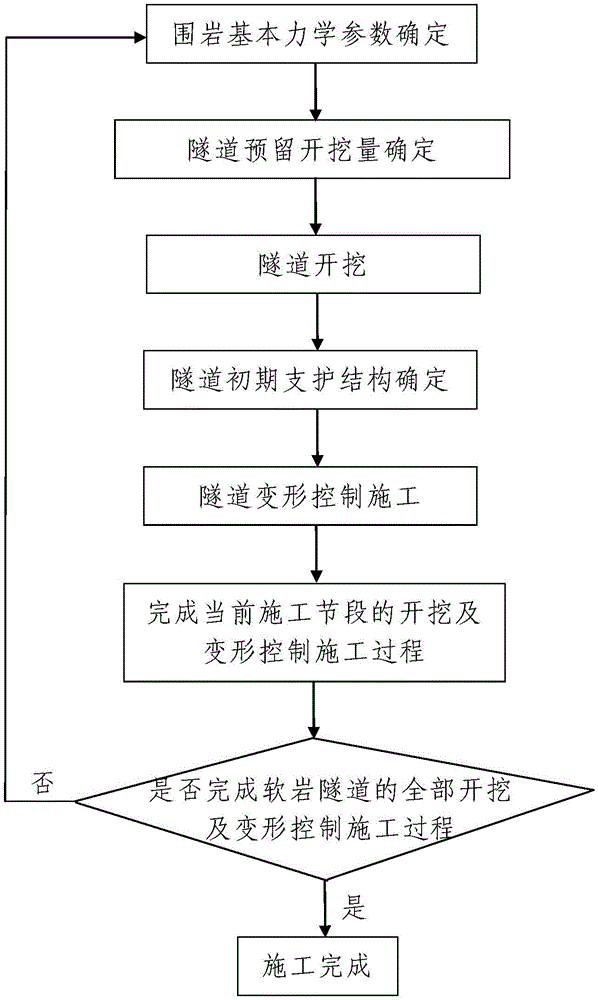

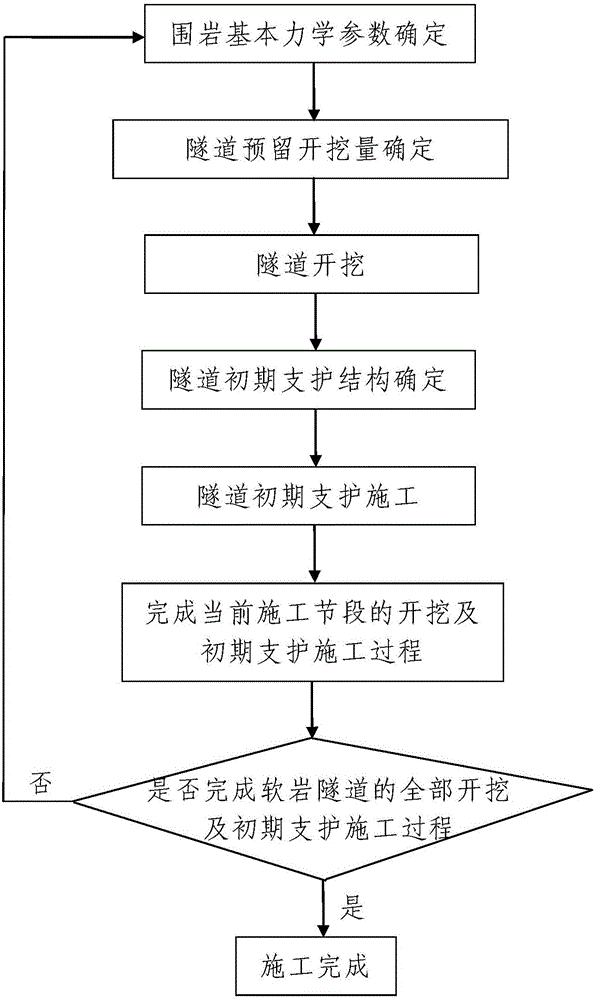

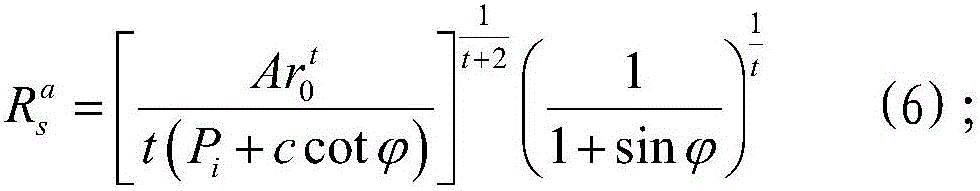

Soft rock tunnel deformation control method based on anchor rod force analysis

InactiveCN106499397AThe method steps are simpleEasy to implementUnderground chambersTunnel liningStructure of the EarthForce analysis

The invention discloses a soft rock tunnel deformation control method based on anchor rod force analysis. A soft rock tunnel is excavated and subjected to deformation control construction from back to front according to multiple segments, and when any segment is excavated and subjected to deformation control construction, the method includes the steps that 1, surrounding rock basic mechanical parameters are determined; 2, the tunnel reserved excavated volume is determined; 3, the tunnel is excavated; 4, a tunnel preliminary bracing structure is determined; 5, tunnel deformation control construction is carried out, wherein in the tunnel preliminary bracing construction process, a flexible mold bracing structure is constructed from back to front; 6, a next segment is excavated and subjected to deformation control construction; 7, the step 6 is repeated multiple times till the full excavation and deformation control construction process of the soft rock tunnel is completed. The soft rock tunnel deformation control method is reasonable in design, convenient to achieve and good in use effect, the reserved excavated volume is determined according to the surrounding rock deformation condition of the soft rock tunnel, the flexible mold bracing structure is adopted for carrying out full-section bracing on the tunnel, the flexible mold bracing structure and the tunnel preliminary bracing structure are in coordination deformation, and deformation of the soft rock tunnel can be effectively controlled.

Owner:XIAN UNIV OF SCI & TECH

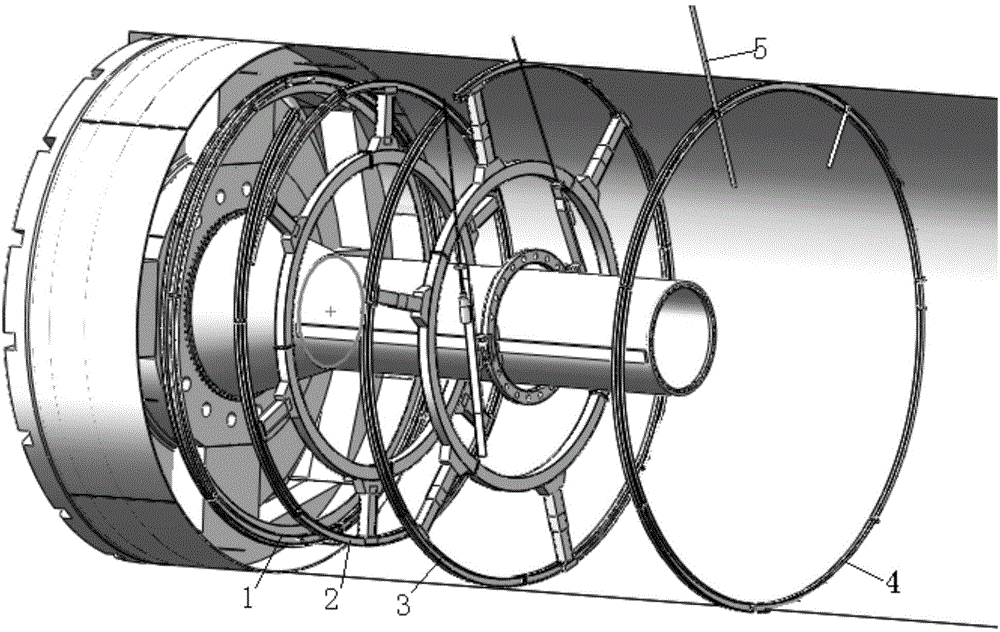

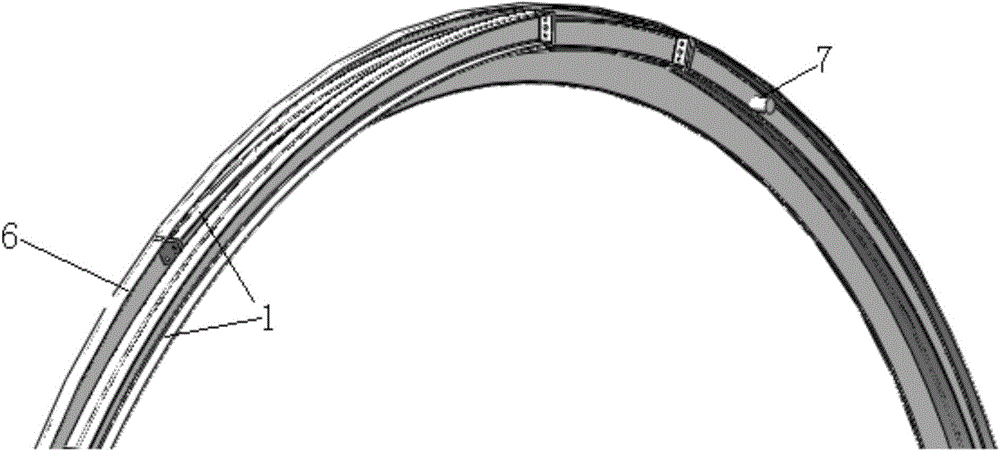

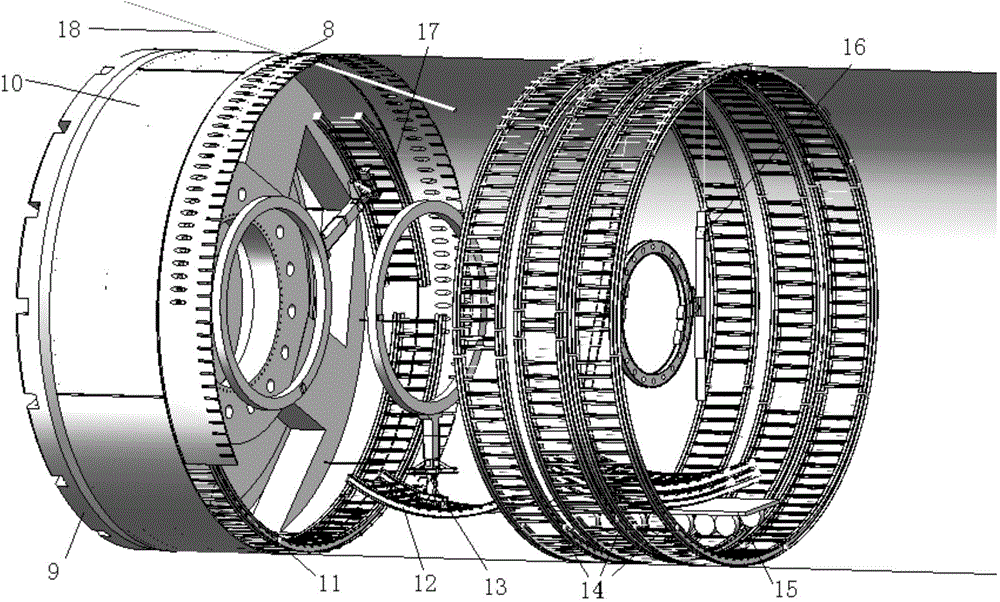

Annular steel structure supporting construction method with open type TBM (tunnel boring machine)

InactiveCN103557013AAvoid manual cleaningReduce dependenceUnderground chambersTunnel liningGratingSlag

An open state is formed behind a shield of an open type TBM (tunnel boring machine), so that bolting and shotcreting with wire mesh and the like can be realized, when unfavorable geological conditions such as crushed zones are encountered, broken surrounding rock collapses and falls, which not only threatens the safety of operating personnel and equipment, but also greatly lowers the construction efficiency. The invention discloses an annular steel structure supporting construction method with the open type TBM. The supporting TBM is provided with a shield which has an annular steel structure installation space. When the unfavorable geological conditions are encountered, the annular steel structure can be fast erected in an assembly line mode under the protection of the shield, the shield is replaced with the annular steel structure for supporting the surrounding rock as the TBM tunnels; under the protection of the annular steel structure, an annular steel grating and a steel mesh hollow structure are used for carrying out the bolting and shotcreting supporting and the like, the previous extensive construction is changed to controllable standardized operation, the original open type unsafe environment is changed to a closed protected operation zone; the construction method disclosed by the invention is different from the passive supporting which is carried out after the surrounding rock collapses and falls; the annular steel structure actively close off the broken surrounding rock, then the surrounding rock becomes a part of the supporting structure, the work amount for backfilling concrete and removing slag is greatly reduced, and thus the method is more efficient and safer, the cost is reduced and the operation is easy to realize.

Owner:王静

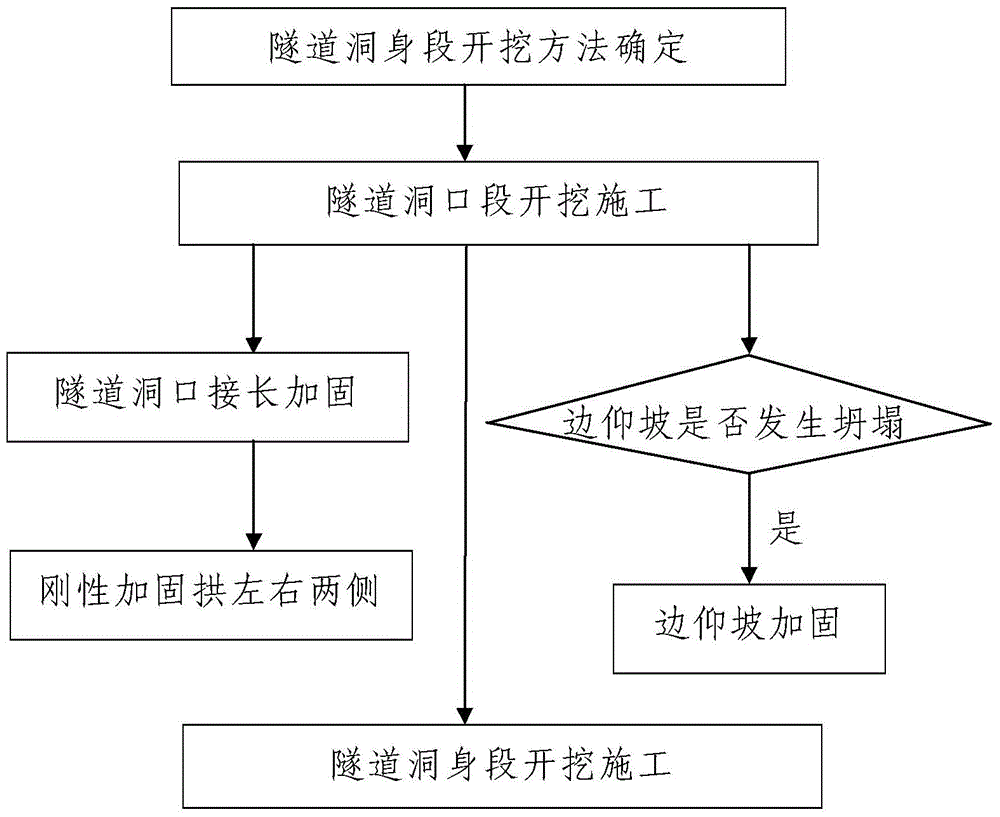

Process for excavating and constructing soft rock tunnels

ActiveCN104453921AThe process steps are simpleReasonable designTunnel liningStructural engineeringRock tunnel

The invention discloses a process for excavating and constructing soft rock tunnels. Each constructed soft rock tunnel comprises two tunnel portal sections and a tunnel trunk section. Each tunnel trunk section is arranged between the two corresponding tunnel portal sections in a connected manner, surrounding rock level of two tunnel portals of each constructed soft rock tunnel is V level, surrounding rock level of each tunnel trunk section is IV level, and entrances and exits of the constructed soft rock tunnels simultaneously start to be constructed and are constructed in opposite directions. The process includes constructing procedures of firstly, determining methods for excavating the tunnel trunk sections, to be more specific, simulating excavating and constructing procedures by the aid of tunnel excavating and constructing simulation software, and determining the methods for excavating and constructing the tunnel trunk sections according to simulation results; secondly, excavating and constructing the tunnels, to be more specific, dividing each soft rock tunnel to be constructed into a plurality of sections from the rear of the corresponding tunnel portal to the front and starting to excavate and construct the multiple sections. The tunnel trunk sections are excavated in the excavating and constructing procedures by the aid of full-section techniques. The process has the advantages of simple steps, reasonable design, convenience in construction, good service effects, safe constructing procedures and capabilities of easily and conveniently completing the soft rock tunnel excavating and constructing procedures and guaranteeing the construction periods.

Owner:CHINA RAILWAY 20 BUREAU GRP

Supporting method of permeable soft broken rock stratum roadway

InactiveCN103603675AEffective deformationEffectively closedUnderground chambersTunnel liningSteel barCement slurry

The invention relates to a supporting method of a roadway in a coal mime, particularly to a supporting method of a permeable soft broken rock stratum roadway. The supporting method aims at solving the problems that soft broken rock stratum roadways especially permeable soft broken rock stratum roadways are poor in supporting effect, high in cost and the like. The supporting method comprises the steps of first concrete spraying; combined support through high strength deformed steel bar anchor rods and diamond metal nets; anchor cable installation; secondary concrete spraying; installation of chemical pulp grouting anchor rods; installation of cement slurry grouting anchor rods.

Owner:张瀚

Construction method for enabling shallowly buried and darkly excavated tunnel to pass through cottage area

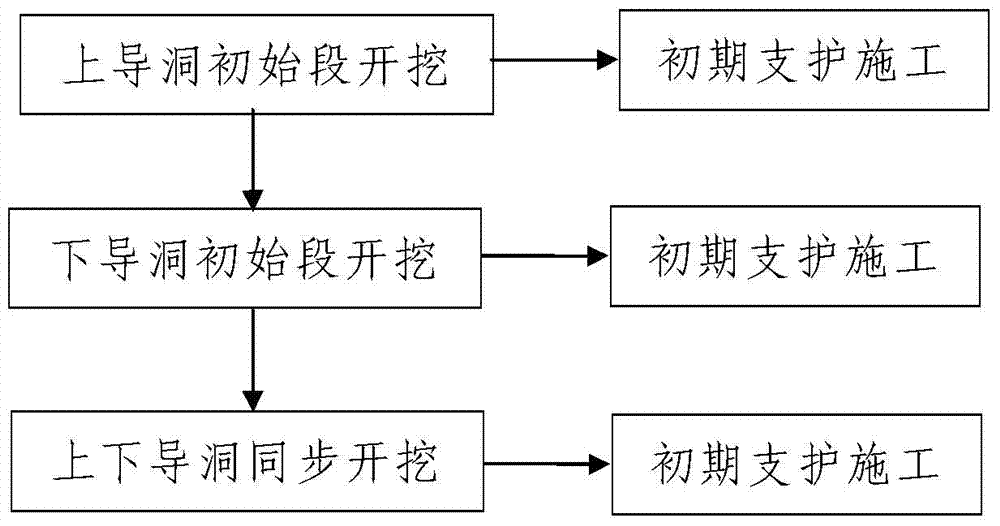

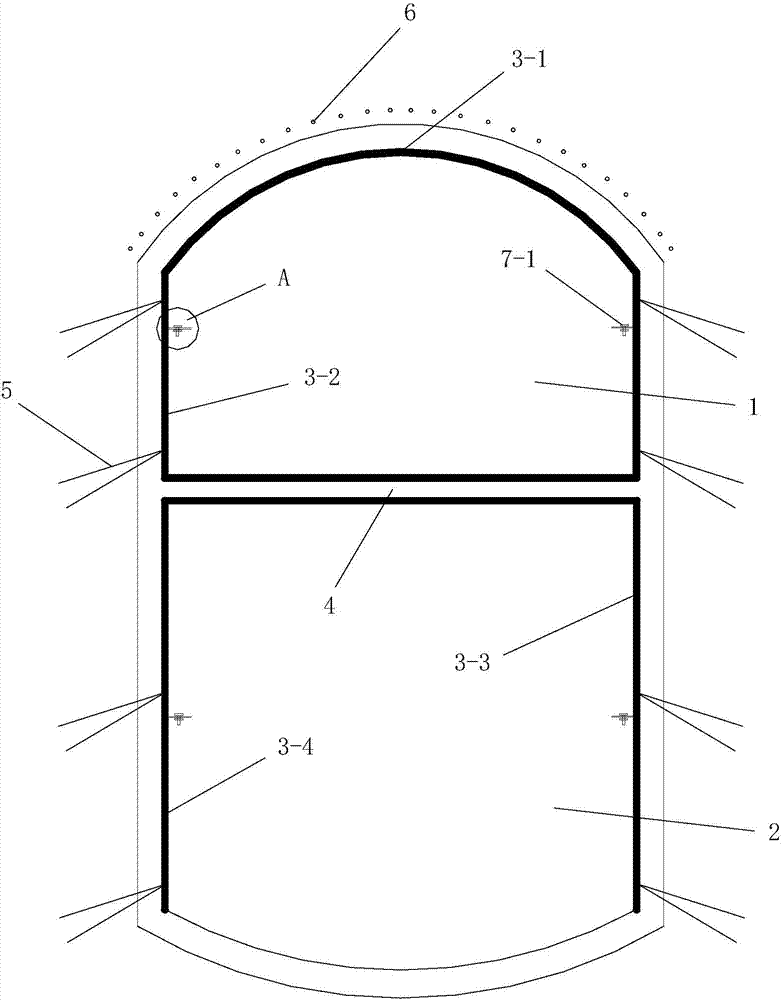

ActiveCN104500077AThe method steps are simpleReasonable designUnderground chambersTunnel liningRebarInitial segment

The invention discloses a construction method for enabling a shallowly buried and darkly excavated tunnel to pass through a cottage area. The construction method comprises the following steps: excavating a tunnel hole of the constructed shallowly buried and darkly excavated tunnel from back to front through a step excavation process, and performing preliminary bracing on the tunnel hole formed by excavating from back to front in an excavating process, wherein the tunnel hole consists of an upper guide hole and a lower guide hole positioned right below the upper guide hole, the rear part of the tunnel hole is connected with a vertical well, the preliminary bracing structure of the tunnel hole comprises a plurality of grating steel frameworks for supporting the tunnel hole from back to front, a layer of bar-mat reinforcement suspended on the inner wall of the tunnel hole and a concrete layer jetted on the inner wall of the tunnel hole. The process for excavating the tunnel hole of the shallowly buried and darkly excavated tunnel comprises the following steps: I, excavating the initial segment of the upper guide hole; II, excavating the initial segment of the lower guide hole; III, synchronously excavating the upper and the lower guide holes. The construction method disclosed by the invention is simple in step, reasonable in design, convenient in construction, good in construction effect, capable of simply completing the construction process of the shallowly buried and darkly excavated tunnel that passes through the cottage area, and safe and reliable in a construction process.

Owner:CHINA RAILWAY 20 BUREAU GRP

Method for preventing and treating roof falling and side collapsing of coal roadway surrounding rock by anchor rope truss

InactiveCN102121389AFlexible constructionImprove the support effectAnchoring boltsShear stressPre stress

The invention provides a method for preventing and treating roof falling and side collapsing of coal roadway surrounding rock by an anchor rope truss, which belongs to the field of mineral engineering or civil engineering, and mainly solves the problem of roof falling and side collapsing accidents of the coal roadway surrounding rock. In the method, a plurality of groups of top late monomer anchor ropes and top plate truss anchor ropes are arranged on the top plate of the coal roadway at intervals so as to support and protect the top plate of the coal roadway; and a plurality of groups of side monomer anchor ropes and side truss anchor ropes are arranged on the roadway side so as to support and protect the roadway side; the whole design takes full advantage of being flexible construction, occupying less sections, costing short construction time, having excellent safety and reliability, saving money, applying strong pre-stress and the like of the anchor ropes, the top plate truss anchor ropes can penetrate into a maximum shear stress region at the top of the coal roadway to form very strong pre-stress, and the side truss anchor ropes can penetrate into the deep part of the roadway side and can be fixed by a channel steel to form very strong pre-stress, so that the method is more advantageous, particularly, in strengthening the damaged coal roadway in comparison with other methods.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Method for controlling floor heave through inverted arch anchoring beam

InactiveCN102852528AImprove supportImprove the support effectUnderground chambersTunnel liningEngineeringRock bolt

The invention discloses a method for controlling a floor heave through an inverted arch anchoring beam. The method comprises the following steps of: constructing a grouting pipe, an anchor cable or a high-strength anchor rod and other prestressed anchorage systems on an inverted arch of a constructed tunnel, forming a bottom beam and an anchoring beam coupled through the prestressed anchoring function, cooperatively exerting the active and passive supporting functions, and fulfilling the aim of controlling the bottom plate for a long time. In addition, longitudinal reinforcing ribs are connected between the inverted arch beams, and concrete is poured, so that the whole control system can exert greater supporting functions. The floor heave can be effectively controlled in a developing entry with high dynamic pressure or a developing tunnel with long service time and heading engineering, and the application prospect is wide.

Owner:CHINA UNIV OF MINING & TECH

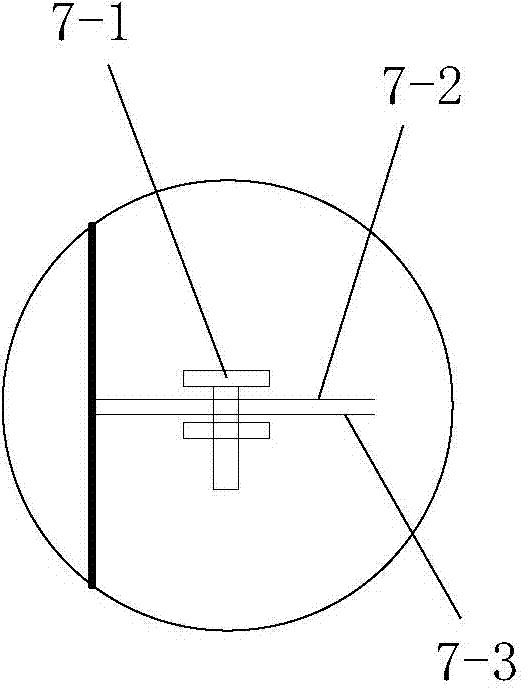

Deformation monitoring method for shallow-buried excavation tunnel construction

ActiveCN104564128AThe method steps are simpleReasonable designMining devicesUnderground chambersTunnel constructionCondition monitoring

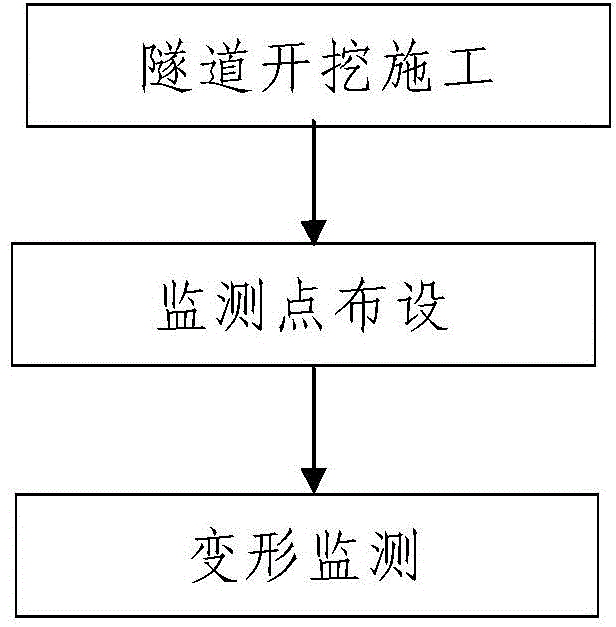

The invention discloses a deformation monitoring method for shallow-buried excavation tunnel construction. The deformation monitoring method comprises the following steps: 1) digging a tunnel: digging a tunnel cavity for a constructed shallow-buried excavation tunnel from back to front, primarily supporting the dug tunnel cavity from back to front during the digging process, and forming a primary supporting structure, wherein the primary supporting structure comprises a plurality of grating steel frames for supporting the tunnel cavity from back to front, and each grating steel frame is composed of an arch supporting steel frame and left and right vertical supporting steel frames; 2) arranging monitoring points: arranging multiple sets of supporting state monitoring points on the primary supporting structure of the constructed tunnel cavity from back to front during the digging process, and meanwhile, arranging a plurality of ground surface settlement monitoring points in a construction area of the constructed shallow-buried excavation tunnel from back to front; 3) monitoring the deformation. The method provided by the invention has the advantages of simple steps, reasonable design, convenience in construction, good use effect and capability of effectively monitoring the stability of the constructed shallow-buried excavation tunnel and the ground surface settlement.

Owner:CHINA RAILWAY 20 BUREAU GRP

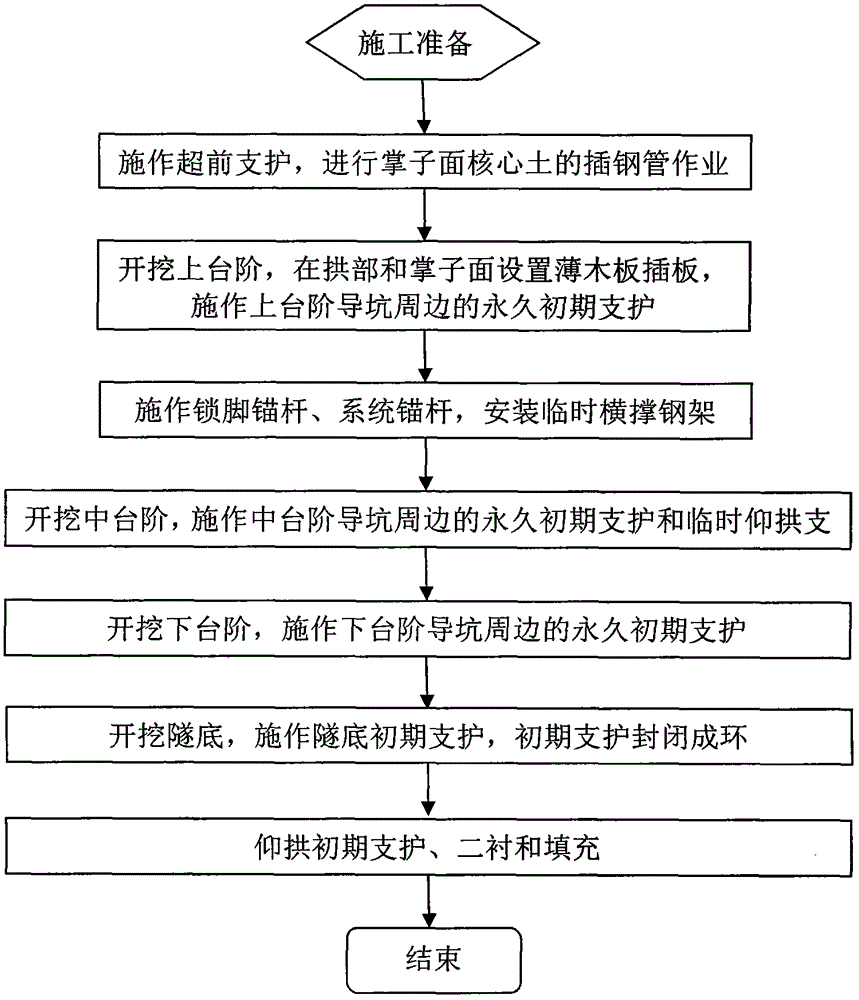

Construction method for excavating support body in tunnel by crossing quicksand stratum

InactiveCN104405399AImprove the support effectIncrease job securityUnderground chambersTunnel liningSupporting systemSteel frame

The invention relates to a construction method for excavating a support body in a tunnel by crossing a quicksand stratum. The construction method comprises the following steps of arranging veneer plugboards on the outer side and the face of a steel frame of an arch, using advanced small guide pipes on the arch, and plugging boards on the outer sides of the small guide pipes; plugging boards on the face, arranging guide pipes at the periphery of core soil, welding steel bars, close to the face, on the advanced small guide pipes of the arch and the guide pipes of the core soil, ensuring that intervals of the steel bars are suitable to blocking of veneers, paving the plugboards on the surrounding rock face, preserving the core soil and taking other related measures; in the excavation engineering, dividing the tunnel face into an upper step, a middle step and a lower step, ensuring that the excavation and support of each part are staggered along the longitudinal direction of the tunnel and are carried out in parallel, and quickly constructing a support system structure. The construction method can effectively prevent the risk of quicksand in a sand layer, and the construction safety is high.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP 2ND ENG CO LTD

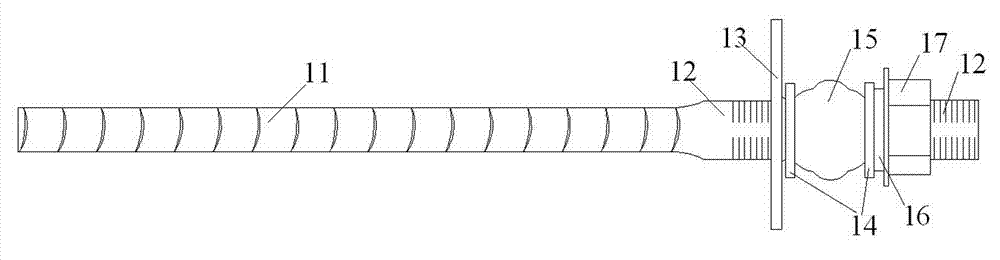

Recoverable anchor rod for drilling, anchoring and grouting and supporting method thereof

The invention relates to a recoverable anchor rod for drilling, anchoring and grouting and a supporting method thereof. The anchor rod comprises a hollow grouting rod body, a nut, a gasket, a tray and a hollow threaded rod body. A drill bit is arranged at the front end of the hollow threaded rod body, and the hollow threaded rod body is provided with multi-purpose holes; the hollow grouting rod body advances inwards through threads, metal nails welded to the internal surface of the front end of the hollow grouting rod body pierce an anchoring agent package inside the hollow threaded rod body, and then, an anchoring agent is mixed and is then discharged through the holes, so as to play an anchoring role; the hollow grouting rod body is used for grouting, and slurry is exported through the multi-purpose holes, so as to cement and solidify loose coal rock bodies; and the hollow threaded rod body is snapped with the wall of a drilled hole through threads on the external surface of the hollow threaded rod body, so as to strengthen an anchoring role in end parts. The one-time drilling, anchoring and grouting supporting of loose coal rocks is realized through tightening and tensioning the tail of the hollow anchor rod, so that the difficult problem that the anchor rod dose not easily enter the loose coal and rocks caused by the fact that the loose coal rocks are subjected to hole collapsing after the loose coal and rocks are subjected to drilling is solved, the load capacity of a coal body is increased, and the supporting strength for surrounding rock of a roadway is enhanced. The recoverable anchor rod for drilling, anchoring and grouting and the supporting method thereof have the advantages of simple structure, low cost, little waste, easiness in construction, and good supporting effect.

Owner:CHINA UNIV OF MINING & TECH

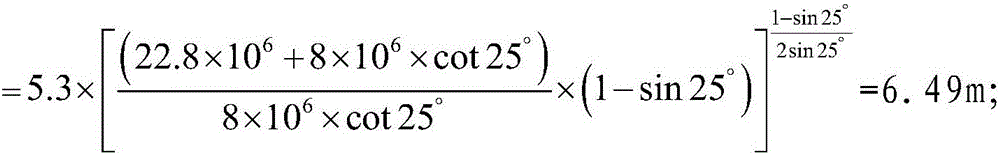

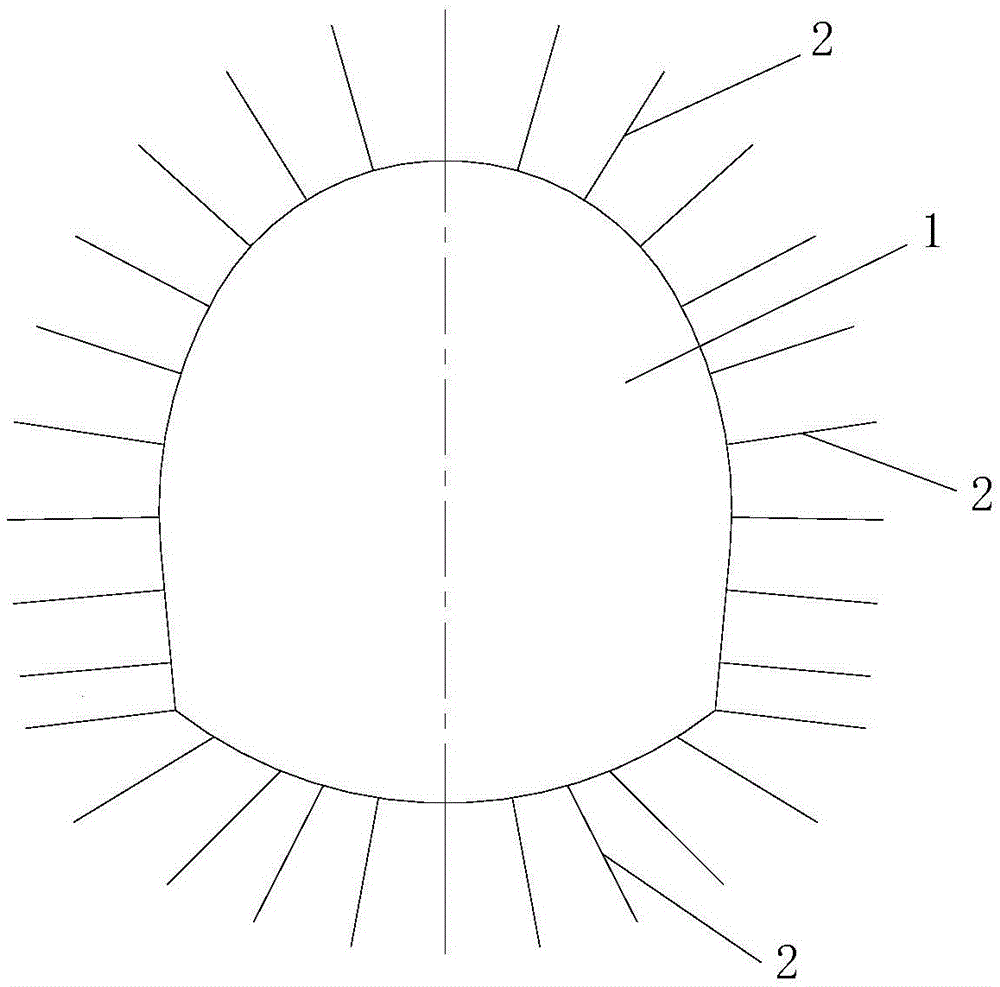

Excavation and preliminary bracing method for soft rock tunnel

InactiveCN106481343AThe method steps are simpleEasy to implementUnderground chambersTunnel liningRock tunnelWall rock

The invention discloses an excavation and preliminary bracing method for a soft rock tunnel. The excavation and preliminary bracing construction for the soft rock tunnel are performed in sections from back to front. When any section is subjected to excavation and preliminary bracing construction, the method comprises the following steps: 1) confirming basic mechanical parameters of the surrounding rock; 2) confirming the reserved excavated volume of the tunnel: confirming the reserved excavated volume of the currently constructed section according to a theoretical value of inward displacement of the surrounding rock of the soft rock tunnel after being braced; 3) excavating the tunnel; 4) confirming a preliminary bracing structure of the tunnel; 5) constructing the preliminary bracing of the tunnel; 6) performing the excavation and preliminary bracing construction of the next section; and 7) repeating the step 6) till all the processes of the excavation and preliminary bracing construction of the soft rock tunnel are completed. The method disclosed by the invention has the advantages of simple steps, reasonable design, convenience in realization and good use effect; the reserved excavated volume is confirmed according to the surrounding rock deformation condition of the soft rock tunnel; and the steel bracket and the anchoring net sprayed preliminary bracing structure are coordinated for performing all-section preliminary bracing on the tunnel.

Owner:XIAN UNIV OF SCI & TECH

Mining high durability light sprayed concrete

The invention relates to a concrete, in particular to a mining high durability light sprayed concrete, aiming at solving the problems of dust pollution caused by improper mixture ratio of raw materials, high resilience rate and the like in the prior art of the sprayed concrete. The sprayed concrete comprises the raw materials based on the parts by weight: 320-350 parts of cement, 710-750 parts of furnace slag, 550-590 parts of sand, 40-50 parts of pulverized fuel ash, 40-50 parts of mineral waste residue micro powder, 20-25 parts of siliceous dust, 10-15 parts of accelerating agent and 160-200 parts of water. Compared with the common sprayed concrete, the sprayed concrete using light aggregate has the self weight to be reduced by 25-35%, has the mechanical property meeting the tunnel supporting protection need under a certain density grade, and is beneficial to the protection of a whole supporting protection system.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

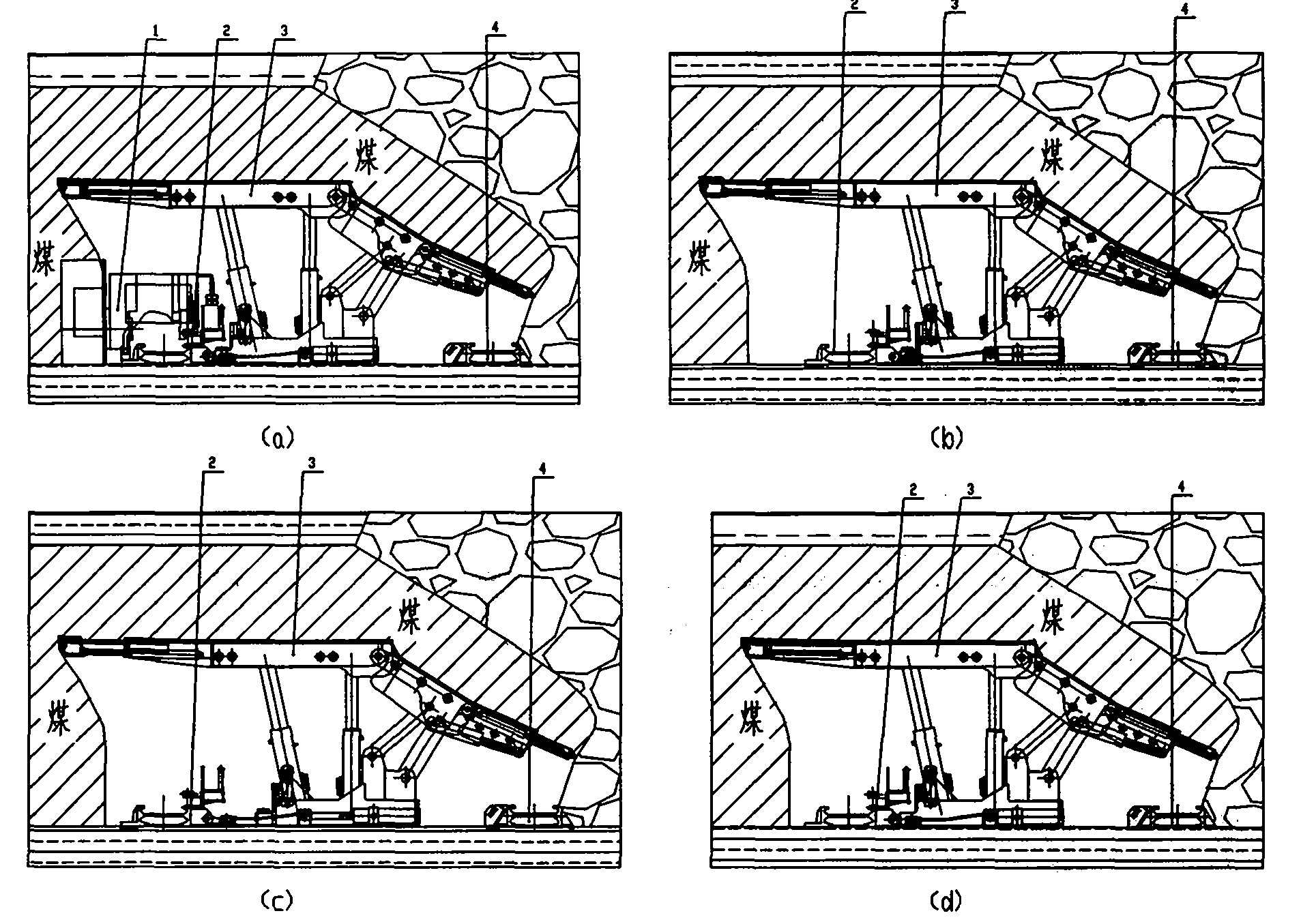

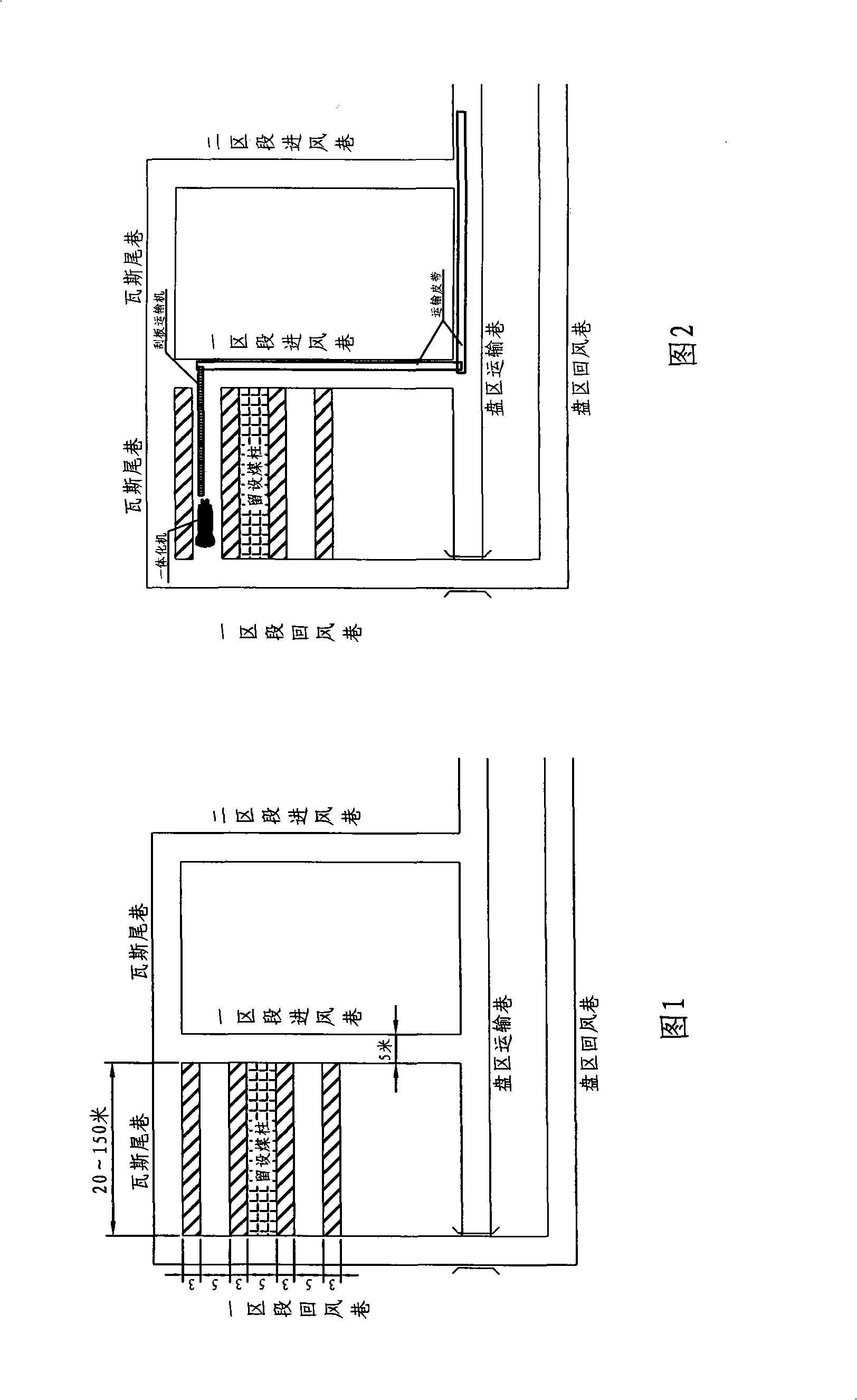

Very soft thick coal seam forepoling hold top coal caving mining method and hydraulic support structure

InactiveCN101936164ARealize fully enclosed miningImprove the support effectUnderground miningSurface miningEngineeringFall accident

The invention discloses a very soft thick coal seam hold and full-mechanized top coal caving mining method and a top coal caving hydraulic support structure which is applicable to the process requirements of very soft coal seam hold and full-mechanized top coal caving, and the method can form the hold mining process features by using a roller of a coal mining machine to cut and load coal under a top beam of the support, realize the full-closed mining of a working face, and lead the beam end distance of the top beam (the distance between the front end of the top beam and the coal wall when using the coal mining machine to cut and mine) to be close to zero or be a negative value, and a coal shoveling plate is arranged at the front end of a shovel type telescopic beam, thereby being capable of shoveling off top coal under the situation that the coal wall spalling is insufficient, protecting an exposed top plate under the situation that the coal wall is sufficiently spalled and further avoiding the large-area roof-fall accidents, wherein the telescopic stroke of a jack of the telescopic beam is larger than a web of the coal mining machine. The method can realize the full-mechanized mining of a very soft coal seam and has the advantages of low cost, simple process, safety, high efficiency and the like.

Owner:TIANDI SCI & TECH CO LTD

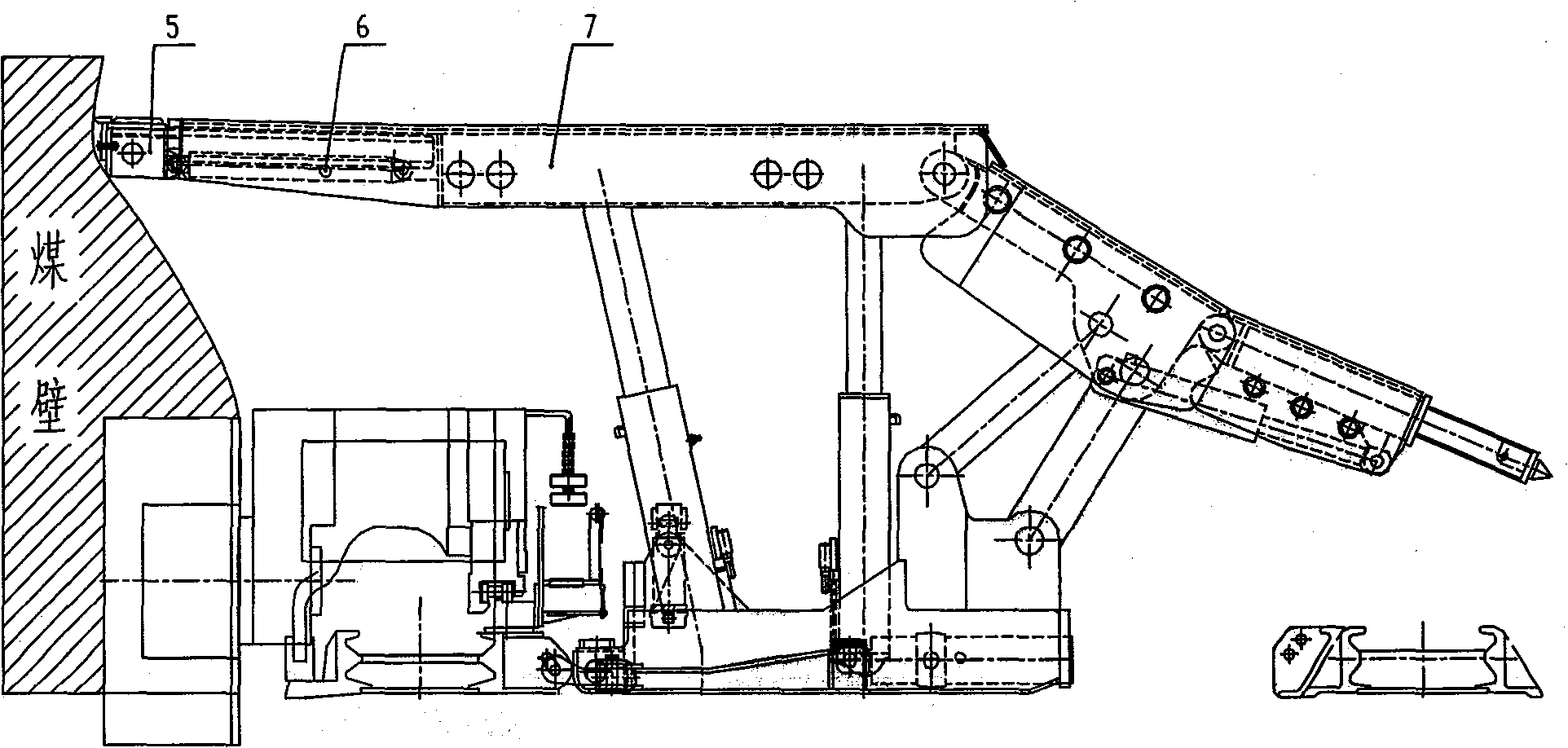

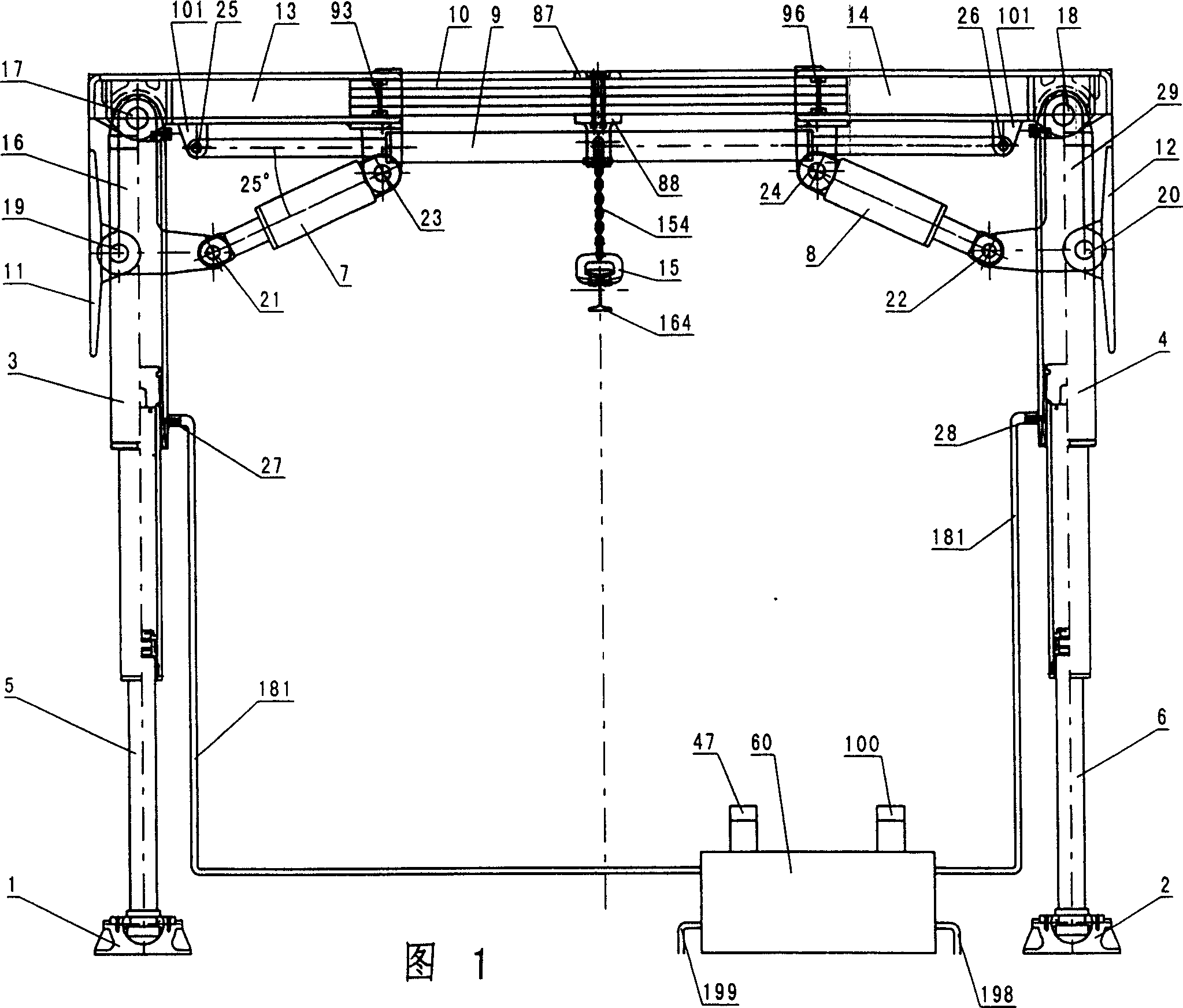

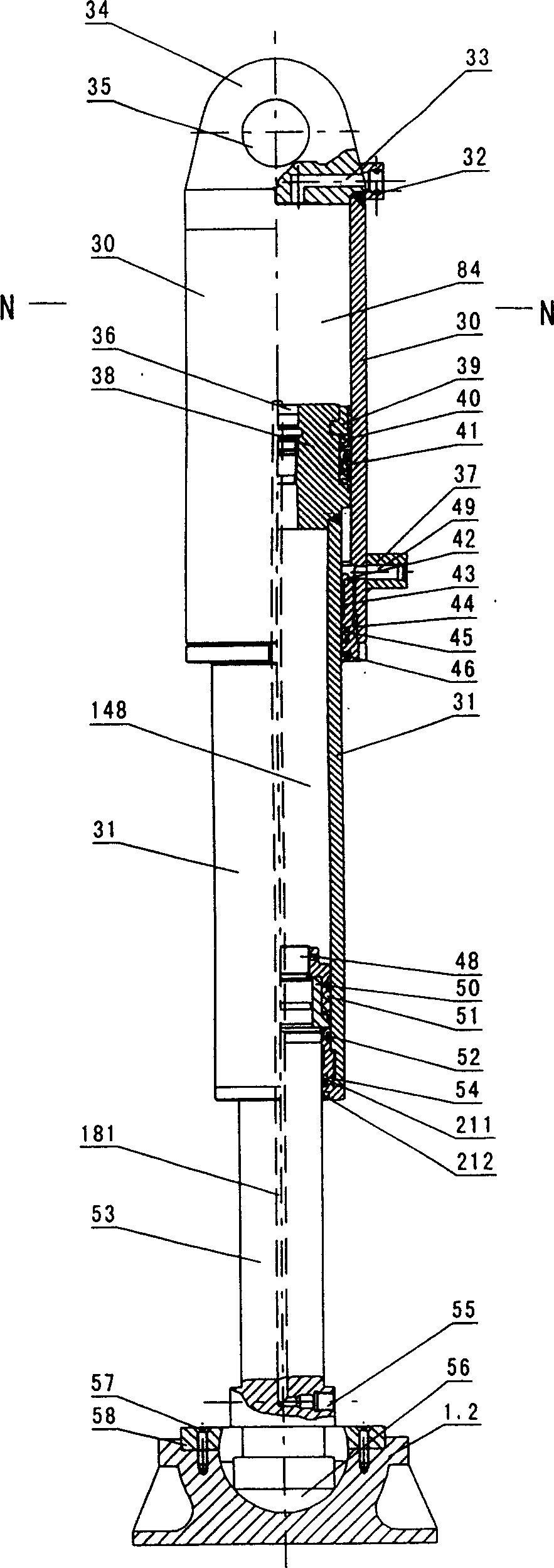

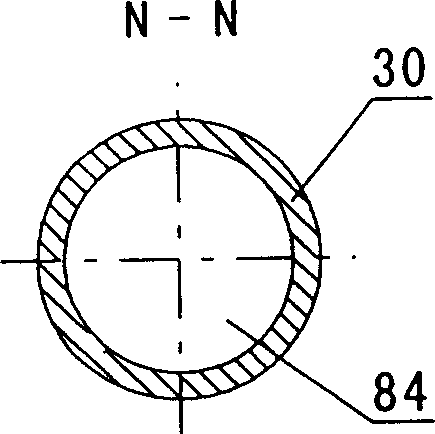

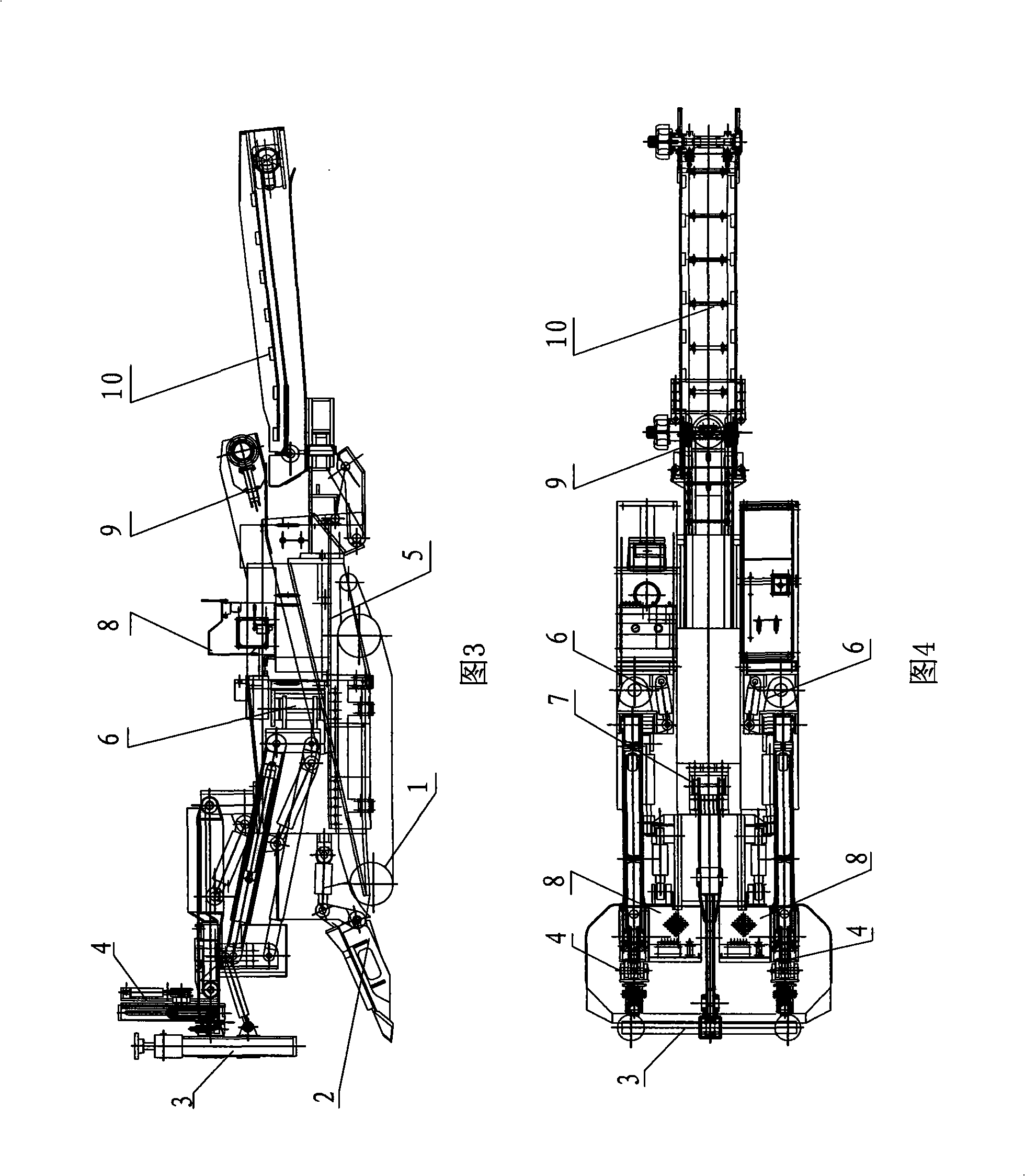

Suspending movable hydraulic support rack for advanced support in coal cutting roadway

The suspending movable hydraulic support rack for advanced support in coal cutting roadway has the structure comprising mainly upright, side protecting beam, shoulder beam, telescopic beam, link rod, bottom shoe, upright cylinder, telescopic beam cylinder, inclined drawing cylinder, suspended hoisting mechanism and hydraulic operating mechanism, and is in portal structure. It has double upright and two-stage telescopic cylinder support, side protecting beam to protect wall, shoulder beam and telescopic beam to support roof, bi-directional telescopic beam cylinder for transverse extending, inclined drawing cylinder for contracting location, integral suspended hoisting moving, and ring I-steel beam for suspending, moving and turning. The present invention has excellent support effect, and may be used also in other kinds of mines as ideal advanced support apparatus.

Owner:TAIYUAN BRANCH ACAD OF COAL SCI

Roadway support method for fully mechanized caving mining of weak extra-thick coal seam

Owner:DATONG COAL MINE GRP

Method for extracting rim angle coal and re-extracting after warehouse coal extracting

InactiveCN101302931ASave resourcesImprove resource recoveryUnderground miningBlastingResource depletionCoal pillar

The invention relates to a method for re-mining after the coal mining in a barn and the stoping of irregular coal. The method of the invention includes the arrangement of roadways and the technologies of mining, coal blasting, coal loading, coal transporting, supporting and dual-wing recovery and is characterized in that as for the arrangement of the roadways, a plurality of sections are divided in a panel and two preparation roadways are arranged in the sections, with one preparation roadway serving as an air intake way and the other one as an air return way; after the coal mining is finished in the previous section, the air intake way of the previous section can be taken as the air return way of the next section; only one air return way needs excavating in the next section; a long strip-shaped room pillar is arranged between the two preparation roadways, which ensures that the stopping of the next room pillar can be carried out under the less pressure of a top plate; as for the technology of mining, room mining is first carried out in the strip-shaped room pillar by adopting anchor net support; the coal at two wings are recovered by bidirectional retreating after the air return way is communicated, which causes small and medium-sized coal mines with 'resource depletion' to realize the re-mining and large and medium-sized coal mines to achieve the stopping of coal pillars and the irregular coal, thus improving recovery ratio and conserving resources.

Owner:闫振东

Detachable hydraulic anchor rod with steady yielding and energy release and supporting method thereof

ActiveCN109184765AAchieve constant resistance and large deformationImprove scalabilityAnchoring boltsHydraulic cylinderDrive shaft

The invention discloses a detachable hydraulic anchor rod with steady yielding and energy release and a supporting method thereof. The anchor rod comprises an anchor rod body and a hydraulic constantresistance device. The hydraulic constant resistance device comprises a hydraulic cylinder column and a piston. The piston divides the hydraulic cylinder column into a cavity and a hydraulic oil cavity, a telescopic transmission shaft is axially arranged along hydraulic cylinder column in the cavity, a connecting rod is fixedly arranged along the opposite extension direction of the telescopic transmission shaft in the hydraulic oil cavity, the distal end of the connecting rod passes through a hydraulic cylinder opening to be threadingly connected to the front end of the anchor body, the connecting rod is sealingly sleeved in the hydraulic cylinder opening, an automatic liquid discharging device is installed near the hydraulic cylinder opening, the hydraulic cylinder column is also providedwith a liquid injection device, the back end of the anchor rod body is fixedly provided with a stirring head, and the front end of the hydraulic cylinder column is fixedly provided with a tighteningend, a nut and a tray. The piston is driven by the connecting rod to slide to the hydraulic oil cavity such that the telescopic transmission shaft extends with the movement of the piston, the constantresistance large deformation yielding and energy release is achieved, the anchor rod can be disassembled after use and is convenient to use repeatedly.

Owner:CENT SOUTH UNIV

Trinity coupling support stability control method for gob-side entry-driving coal pillar

InactiveCN103244122AMaintain stabilityStability replayUnderground miningSurface miningPre stressInstability

The invention provides a trinity coupling support stability control method for a gob-side entry-driving coal pillar, which is particularly suitable for a large-deformation gob-side roadway with an unstable overlying rock. A pre-stress threaded steel anchor rod is used on the gob-side entry-driving coal pillar on an upper zone roadway coal pillar side to tension a coal pillar goaf-side coal body; a short anchor rod on a lower zone gob-side entry-driving coal pillar side is used for controlling the integrity of a whole displacement region of a coal pillar roadway side; and meanwhile, a long grouting anchor cable is matched to reinforce an anchoring point so as to limit the development of an inner separation layer in the whole displacement region. A range of generating a crushed region of the coal pillar under the effect of lateral supporting pressure can be relieved under the expression of a haling effect of the pre-stress threaded steel anchor rod, so as to prevent an instability state of the coal pillar from worsening; and 'controlling by the short rod and grouting by the long rod' of the short anchor rod and the long grouting anchor cable are given into fully play so as to prevent a coal pillar support structure from losing effect and re-achieve the supporting capability of a remained anchoring structure in the coal pillar, so that coupling support with alternative anchor net support and anchor grouting support is formed between the gob-side entry-driving coal pillar side and a goaf side.

Owner:CHINA UNIV OF MINING & TECH +1

Underground stope artificial pillar expansion jacking device and construction method

The invention discloses an underground stope artificial pillar expansion jacking device mounted between an artificial pillar foundation and a stope top plate. The underground stope artificial pillar expansion jacking device comprises an upper cover barrel, an inner sleeve and a lower cover barrel; the inner sleeve is positioned between the upper cover barrel and the lower cover barrel; the upper cover barrel has a barrel bottom I and a barrel wall I; the lower cover barrel has a barrel bottom II and a barrel wall II; the upper cover barrel is arranged above the inner sleeve; the outer wall of the inner sleeve is in clearance fit with the inner wall of the barrel wall I; the lower cover barrel covers the lower side of the inner sleeve; the outer wall of the inner sleeve is in clearance fit with the inner wall of the barrel wall II; a gravel cushion layer and an expansion agent cartridge are arranged in the inner sleeve from bottom to top in sequence; and gravels fill the expansion agent cartridge; and water drainage exhaust holes are respectively formed in the barrel bottom I and the barrel bottom II. The underground stope artificial pillar expansion jacking device has such advantages as simple structure, low production cost, convenience for use, capability of quickly and actively jacking, good jacking effect and high support force.

Owner:NORTHEASTERN UNIV

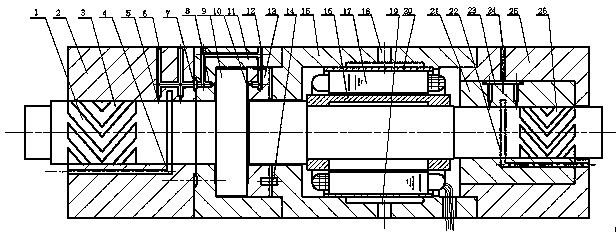

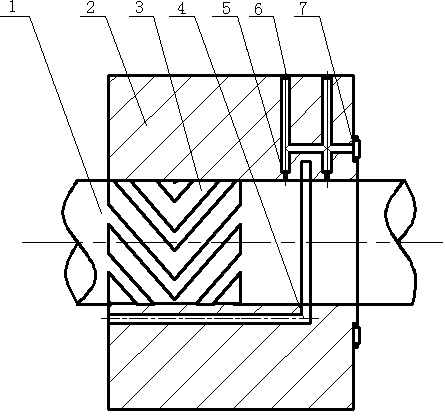

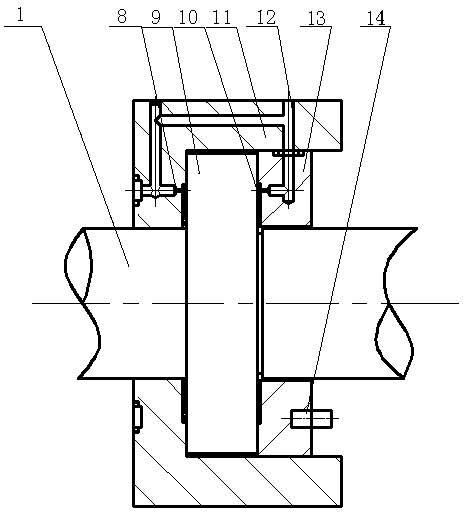

Electric main shaft supported by hydrostatic integrated gas bearing

InactiveCN103846459AHighlight substantiveReduce supplyLarge fixed membersMaintainance and safety accessoriesElectric machineEngineering

The invention discloses an electric main shaft supported by a hydrostatic integrated gas bearing. The electric main shaft comprises a revolving shaft, a front radial hydrostatic integrated gas bearing, a front thrust gas bearing, a thrust color, a back thrust gas bearing, a fastening bolt, a shell, a motor rotor, a motor stator, a back radial hydrostatic integrated gas bearing and a back end cover. The electric main shaft is supported by the hydrostatic integrated gas bearing, the hydrostatic gas bearing of the bearing is supplied with air for a certain period of time till the rotor can float, the hydrodynamic effect of a dynamic pressure gas bearing is utilized by increasing the rotating speed to support a load, so that the air supply time of a static pressure gas is shortened on the basis of not changing the bearing structure, the cost is lowered, the hydrodynamic effect of the hydrodynamic gas bearing is used fully for supporting the load, the carrying force and the stability are improved, and the electric main shaft can keep working normally.

Owner:SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com