Construction method for supporting deep foundation pit through grouting after pile arrangement and anchor cable mounting

A technology of deep foundation pit support and construction method, applied in the field of foundation pit support construction, can solve the problems of high input cost, low construction efficiency, complicated construction process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

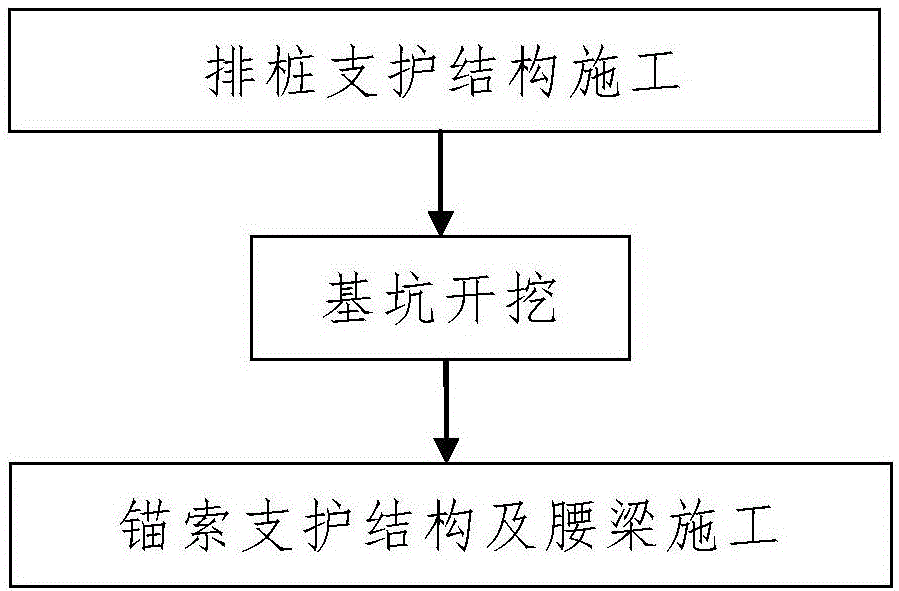

[0071] Such as figure 1 A construction method for deep foundation pit support with grouting after the row of piles and anchor cables is shown, comprising the following steps:

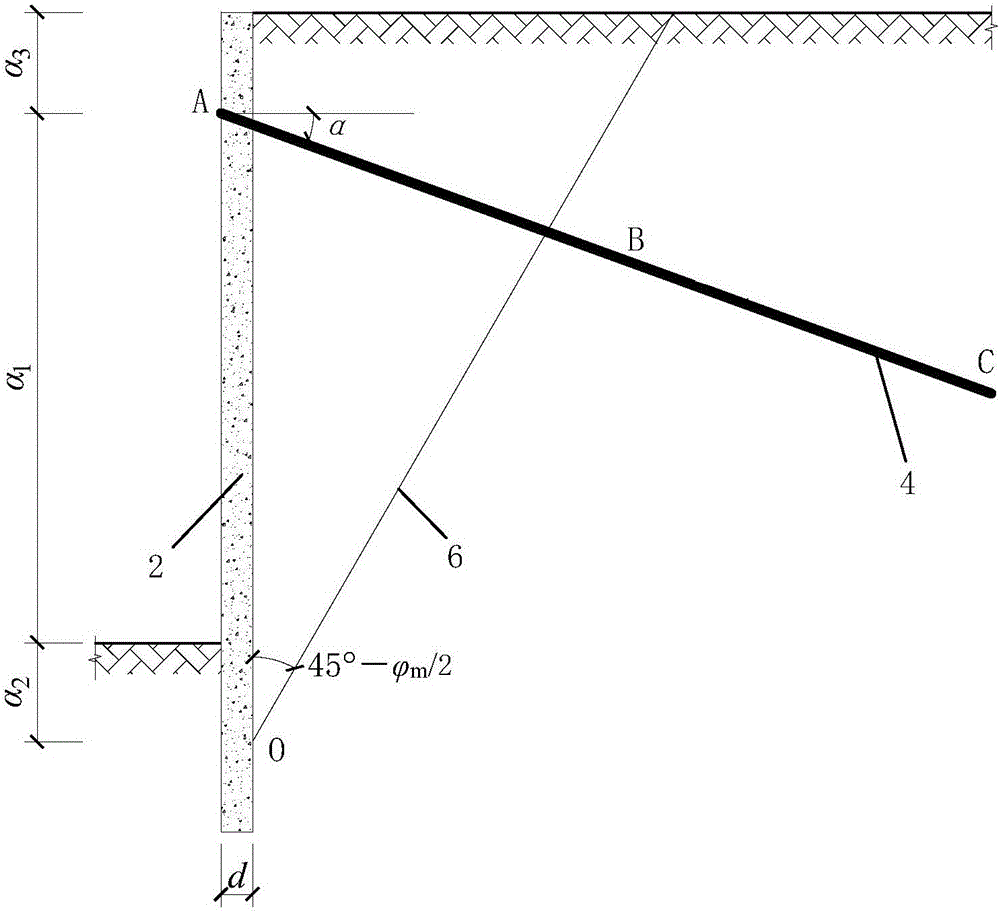

[0072] Step 1, construction of the pile row support structure: before excavating the foundation pit 1 to be constructed, first construct the row pile support structure;

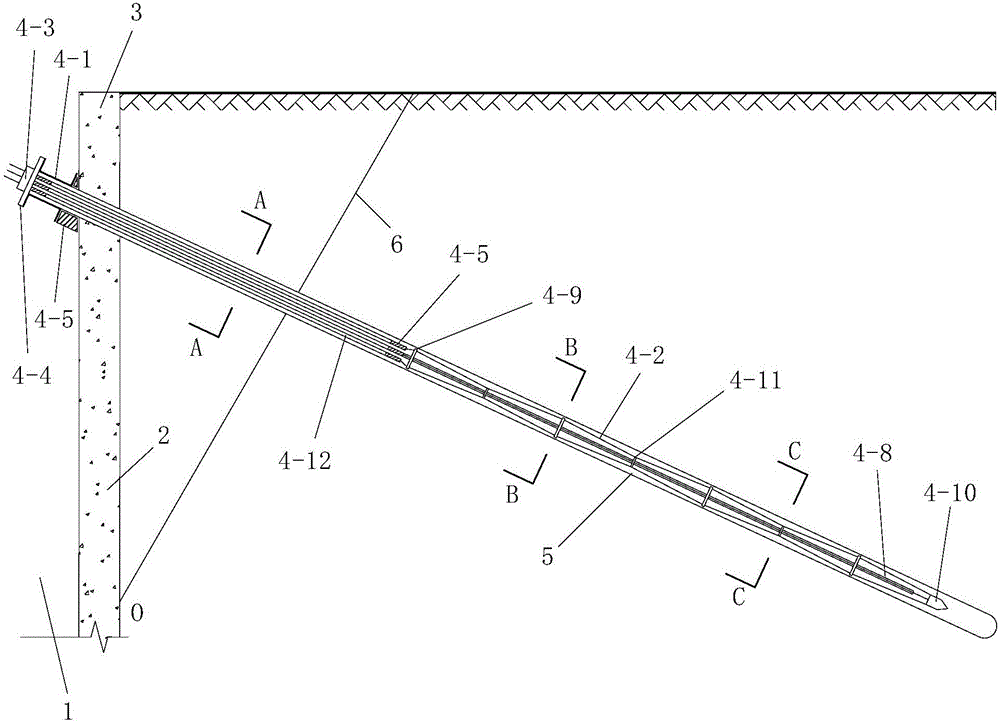

[0073] The pile row support structure includes a plurality of slope protection piles 2 arranged from front to back along the four peripheral lines of the constructed foundation pit 1 and crown beams 3 connected to the upper parts of the plurality of slope protection piles 2. The slope protection piles 2 It is arranged vertically and it is a reinforced concrete pile. The crown beam 3 is a reinforced concrete beam arranged horizontally. The top of each slope protection pile 2 is fastened and connected with the crown beam 3 as a whole. See Picture 1-1 ;

[0074] When carrying out construction to described pile row support structure, fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com