Advanced pre-splitting method for lump coal mining

A pre-splitting and advanced technology, applied in the fields of fluid extraction, ground mining, earth-moving drilling, etc., can solve the problems of poor use effect, high input cost, unsafety, etc., and achieve better effect, low input cost, and safe mining process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

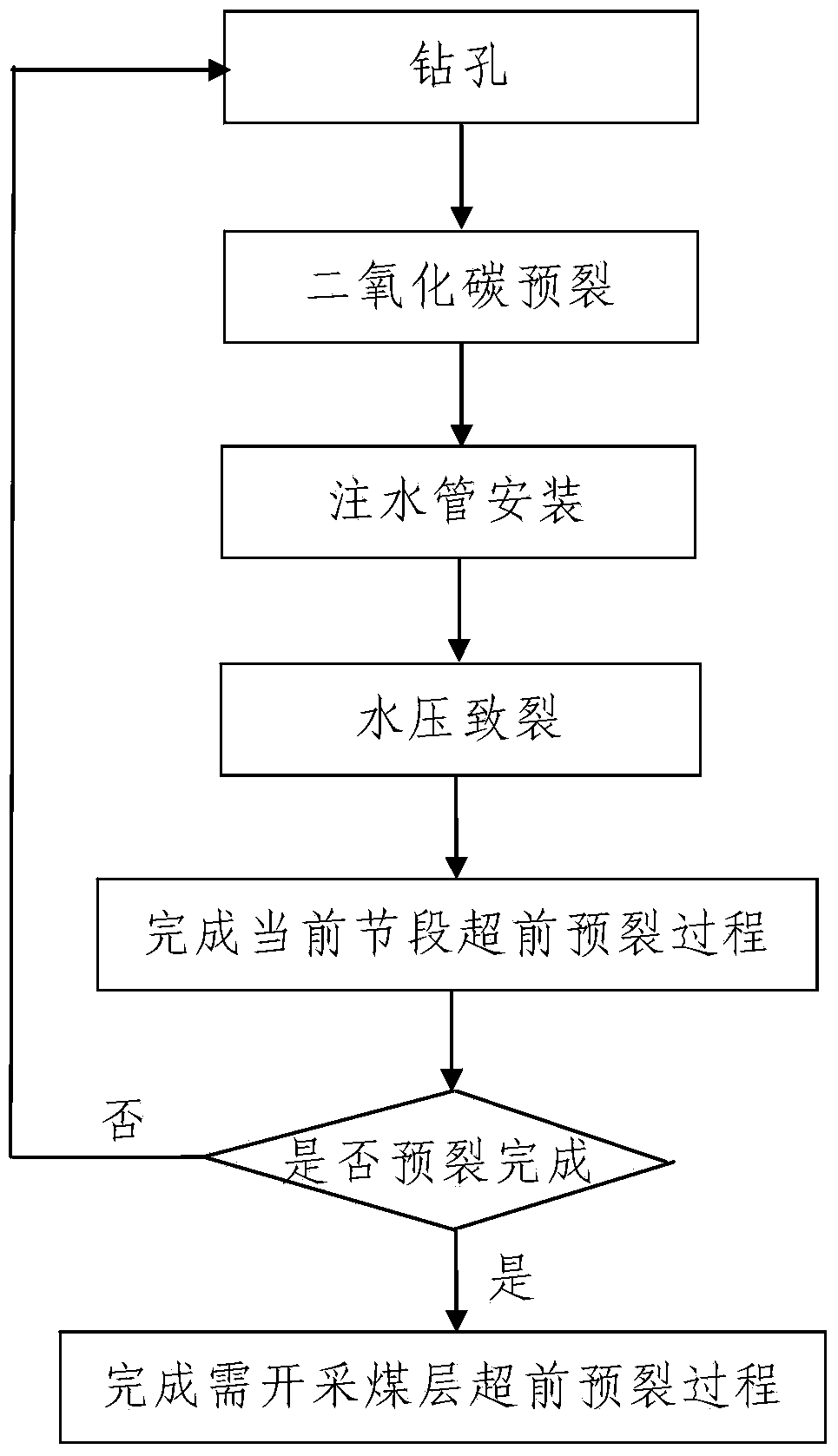

[0034] Such as figure 1 The block coal mining shown adopts the advanced pre-cracking method, and adopts the method of combining carbon dioxide pre-cracking and hydraulic fracturing to work on the coal seam to be mined in multiple segments along the advancing direction of the coal seam working face. The advanced pre-splitting of the surface; the advanced pre-splitting methods of a plurality of the segments are all the same; wherein, when any segment is carried out to the advanced pre-splitting, the process is as follows:

[0035] Step 1, drilling: drill a pre-splitting borehole on the current pre-splitting section, the number of the pre-splitting boreholes is one or more; the drilling direction of the pre-splitting borehole is consistent with the current coal mining face Arranged in parallel and / or vertically; the length of the pre-splitting borehole is 50m-150m. The current pre-splitting segment is located 50m to 150m in front of the current coal mining face.

[0036] Wherei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com