Patents

Literature

5364results about "Surface mining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

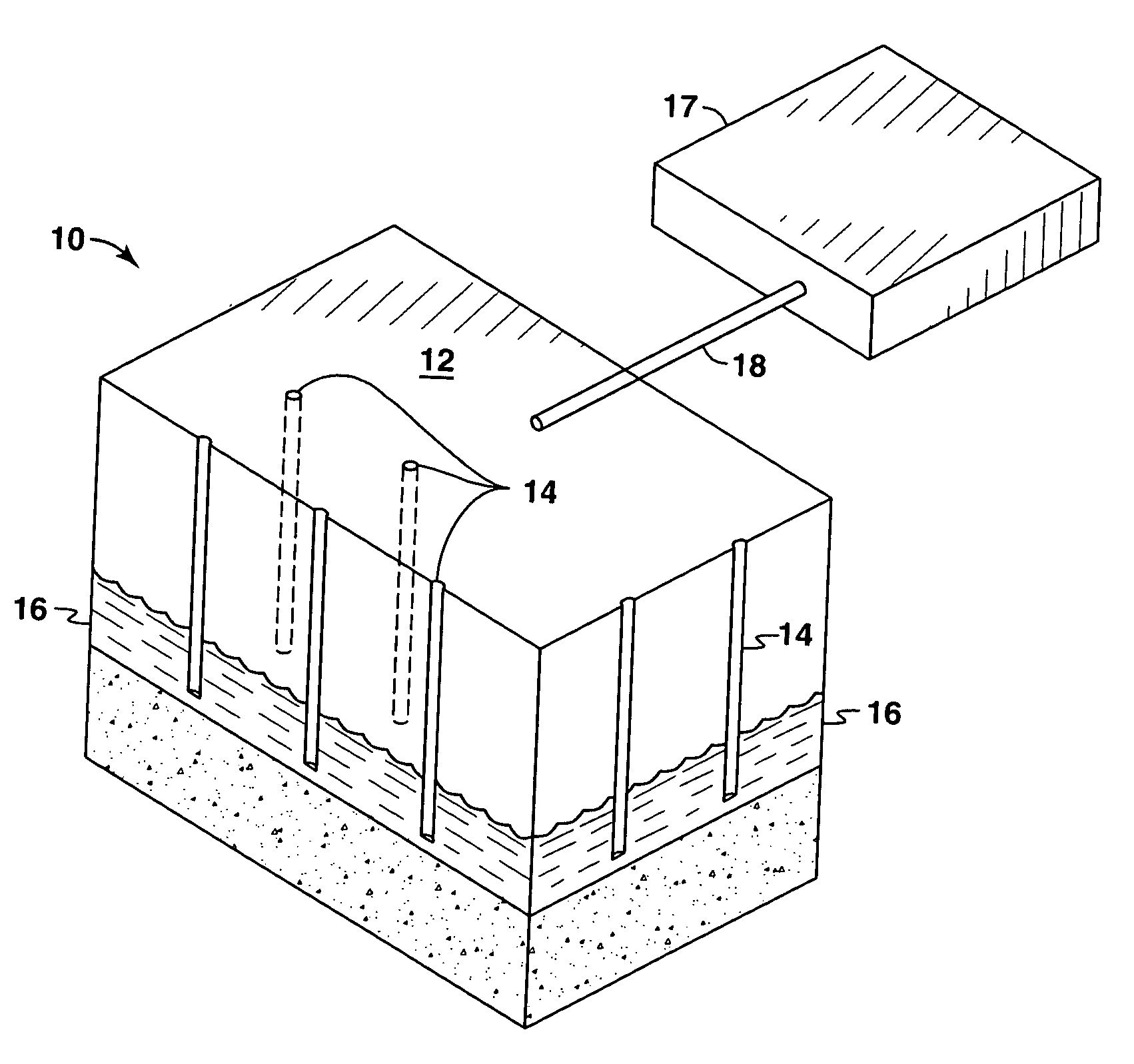

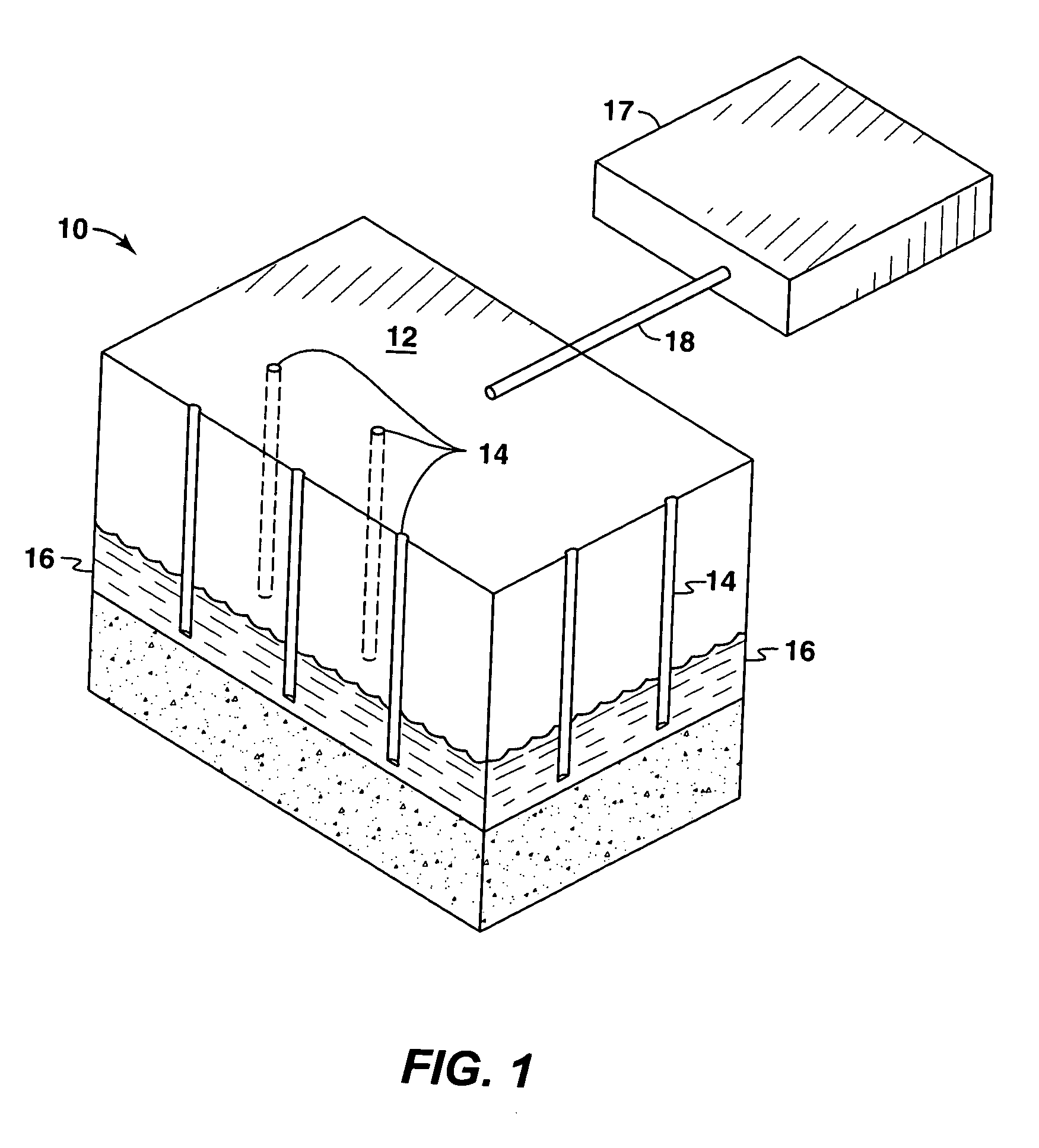

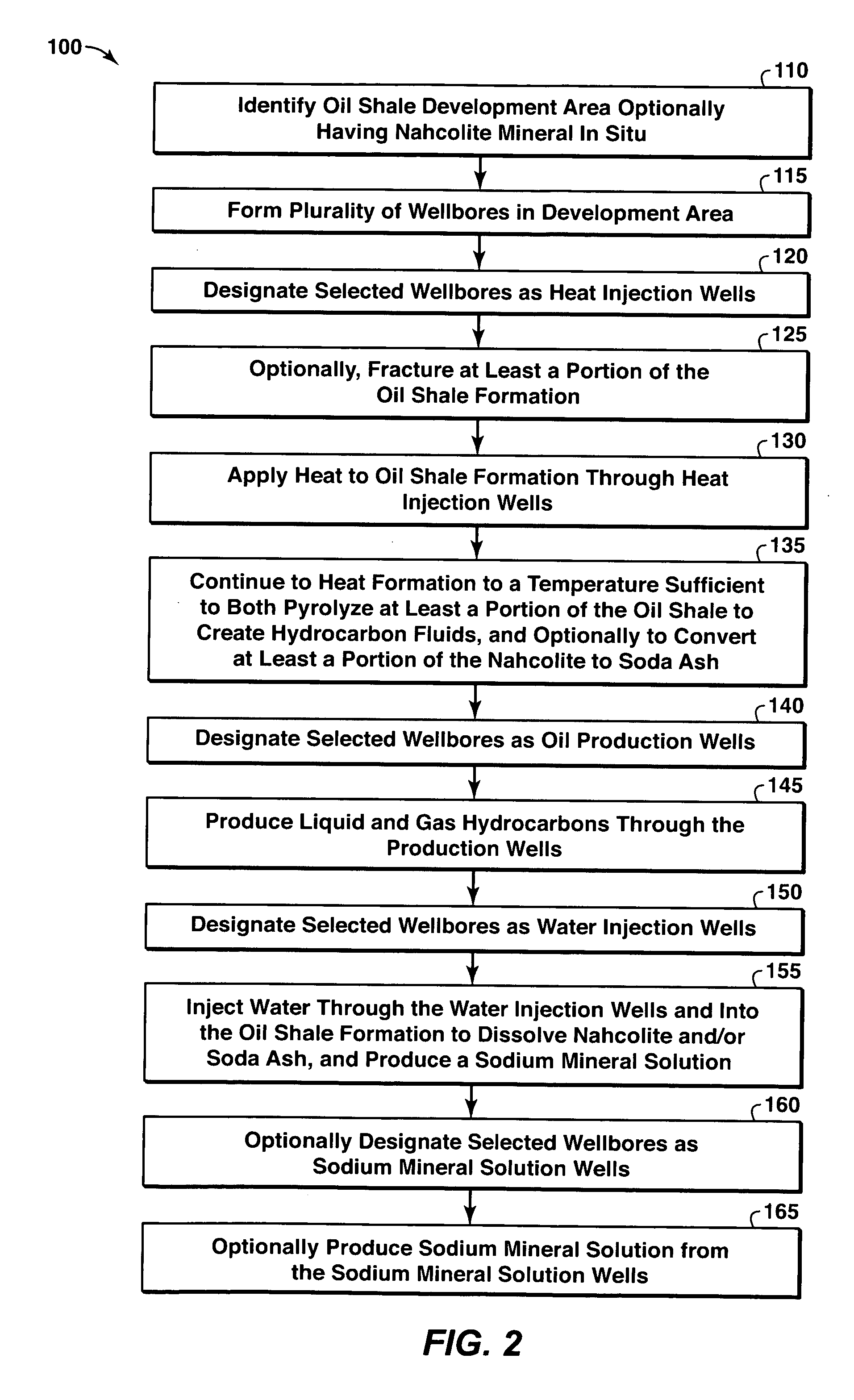

Process for producing Hydrocarbon fluids combining in situ heating, a power plant and a gas plant

An in situ method of producing hydrocarbon fluids from an organic-rich rock formation is provided. The method may include heating an organic-rich rock formation, for example an oil shale formation, in situ to pyrolyze formation hydrocarbons, for example kerogen, to form a production fluid containing hydrocarbon fluids. The method may include separating the production fluid into at least a gas stream and a liquid stream, where the gas stream is a low BTU gas stream. The low BTU gas stream is then fed to a gas turbine where it is combusted and is used to generate electricity.

Owner:KAMINSKY ROBERT D +4

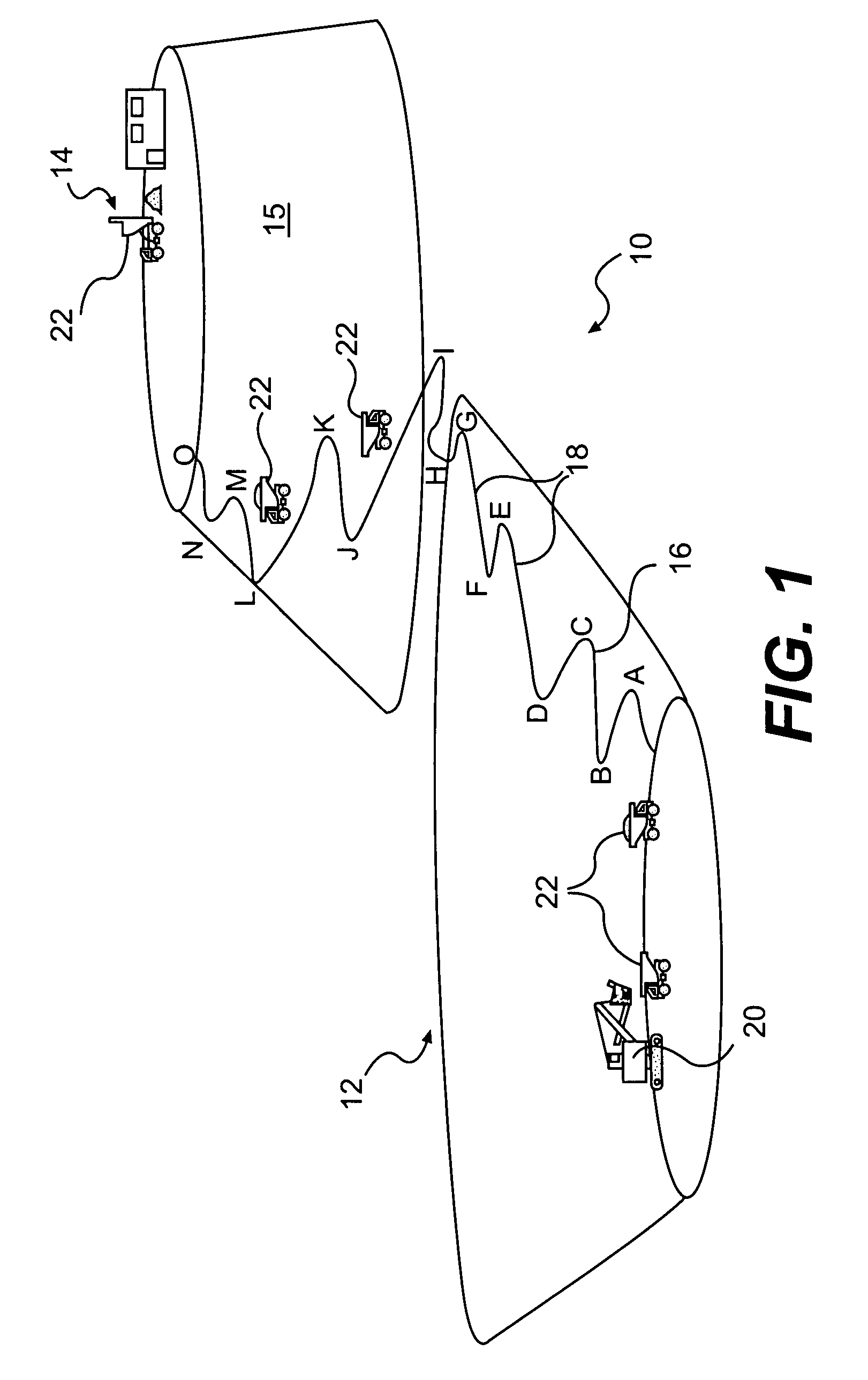

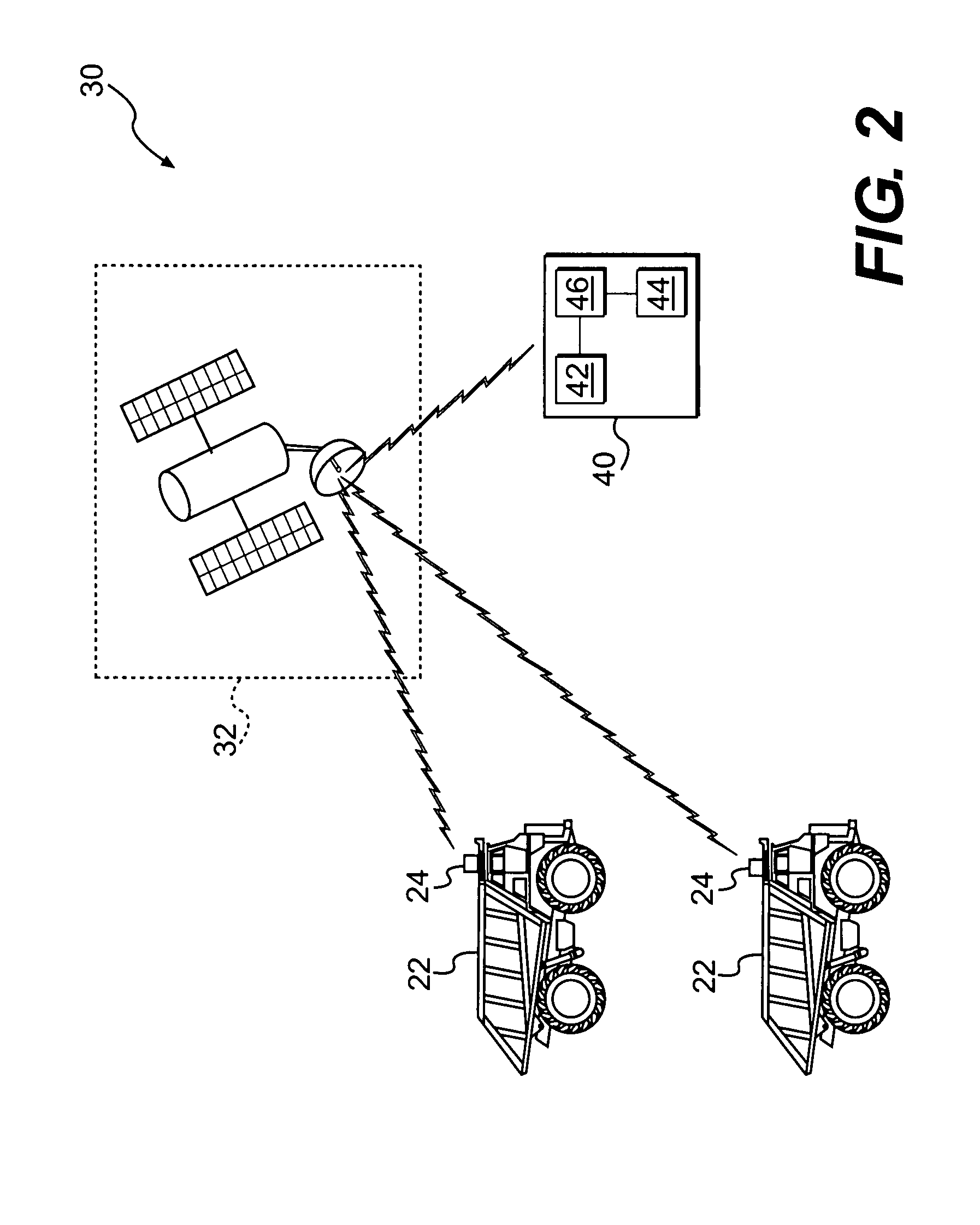

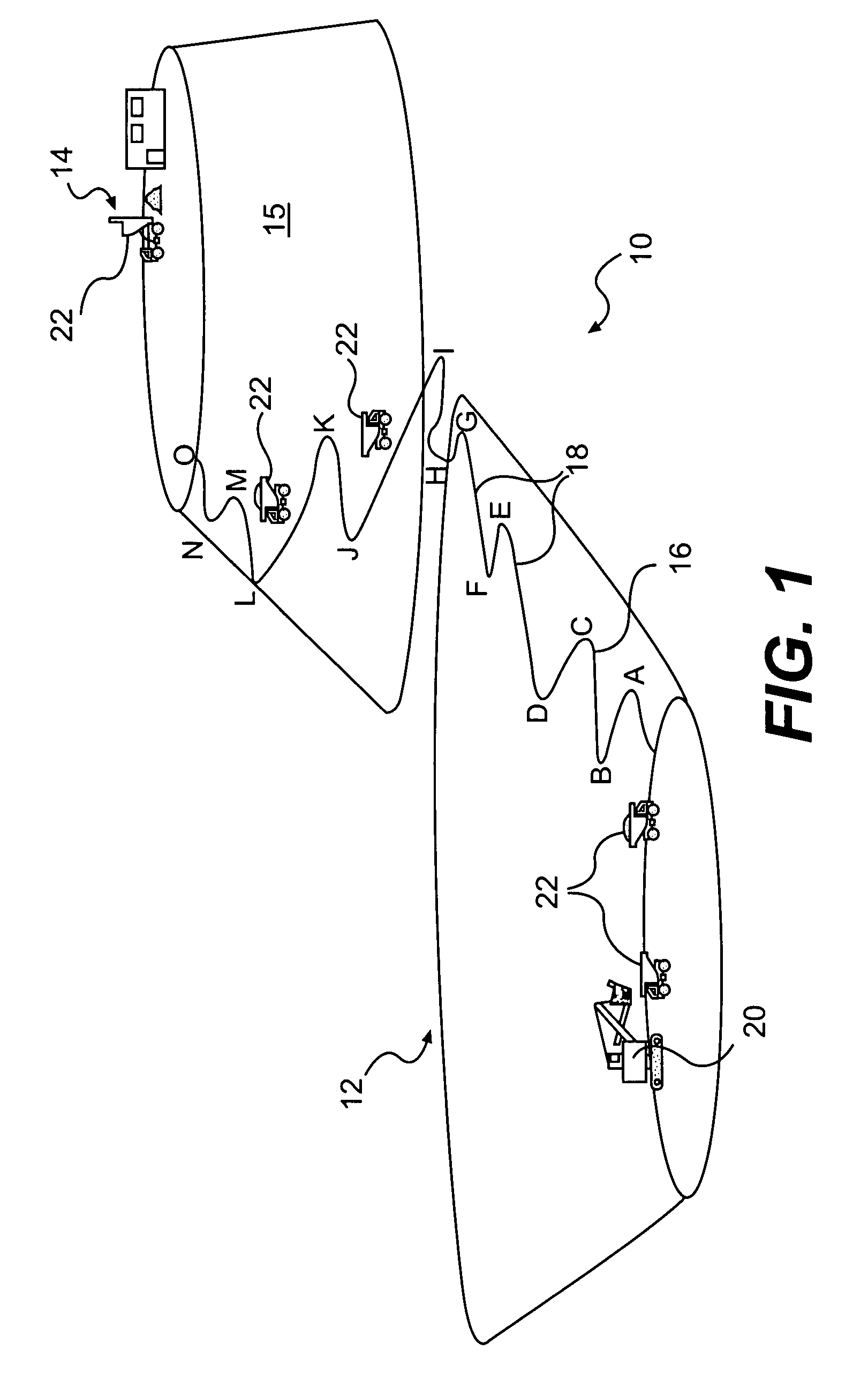

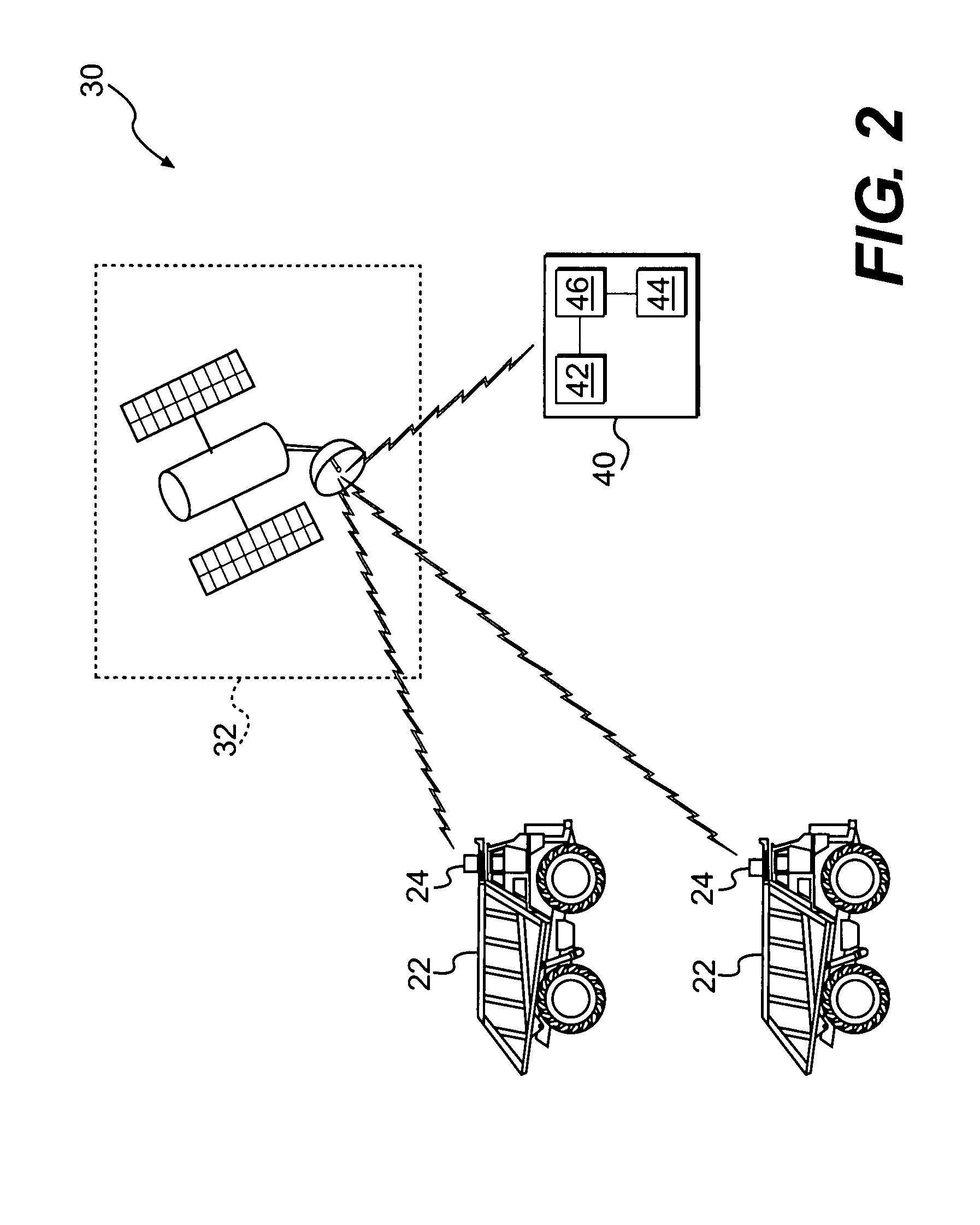

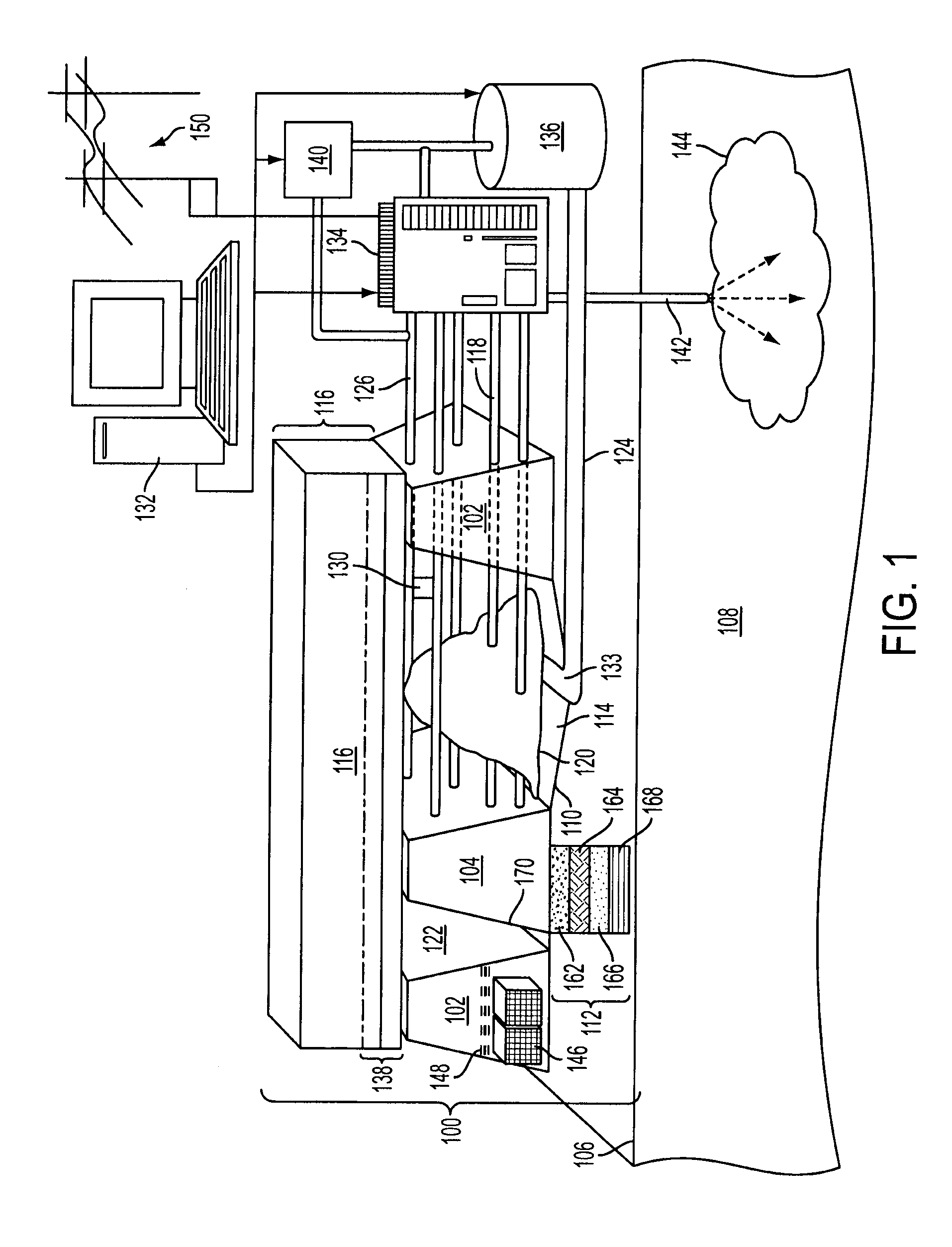

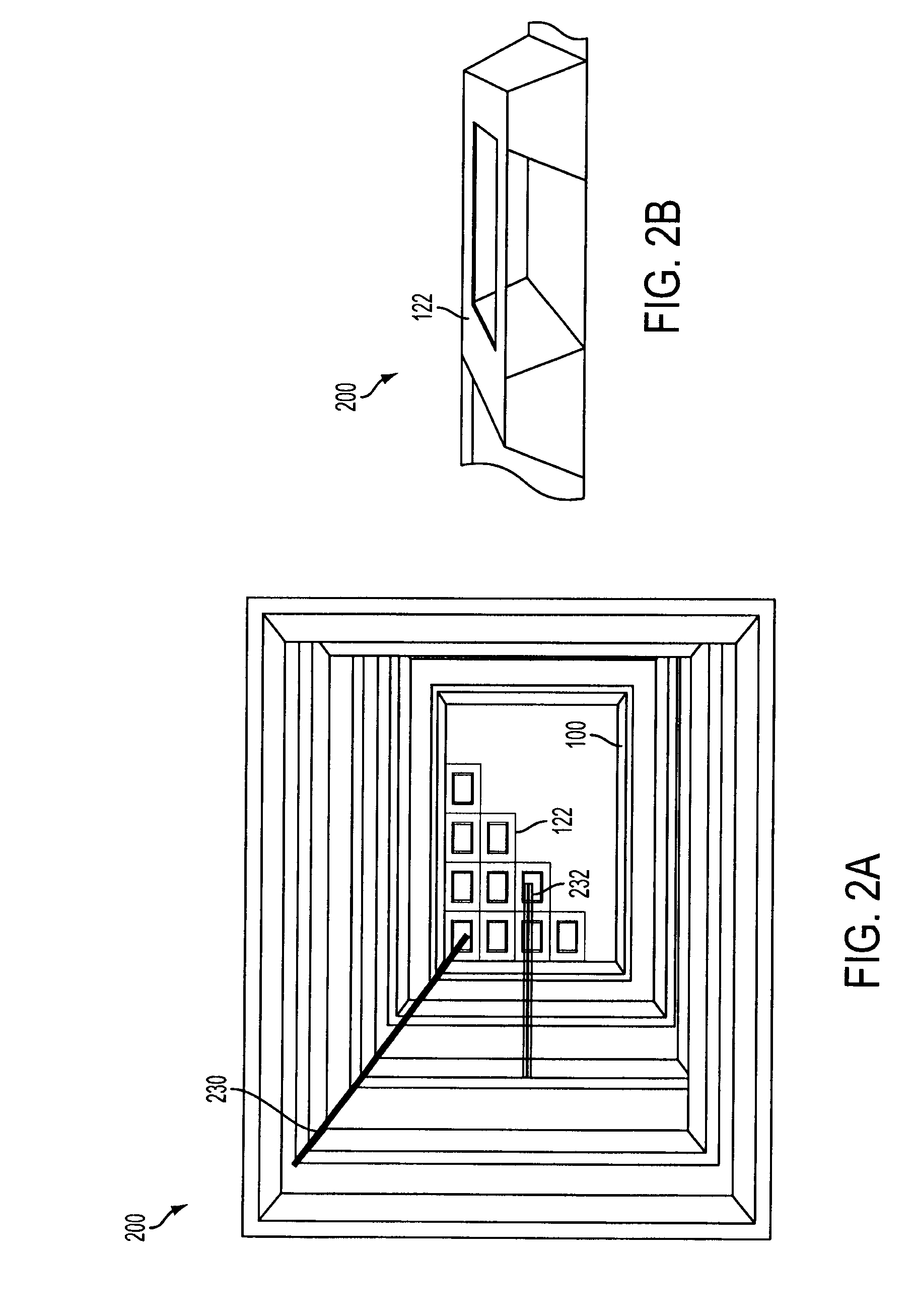

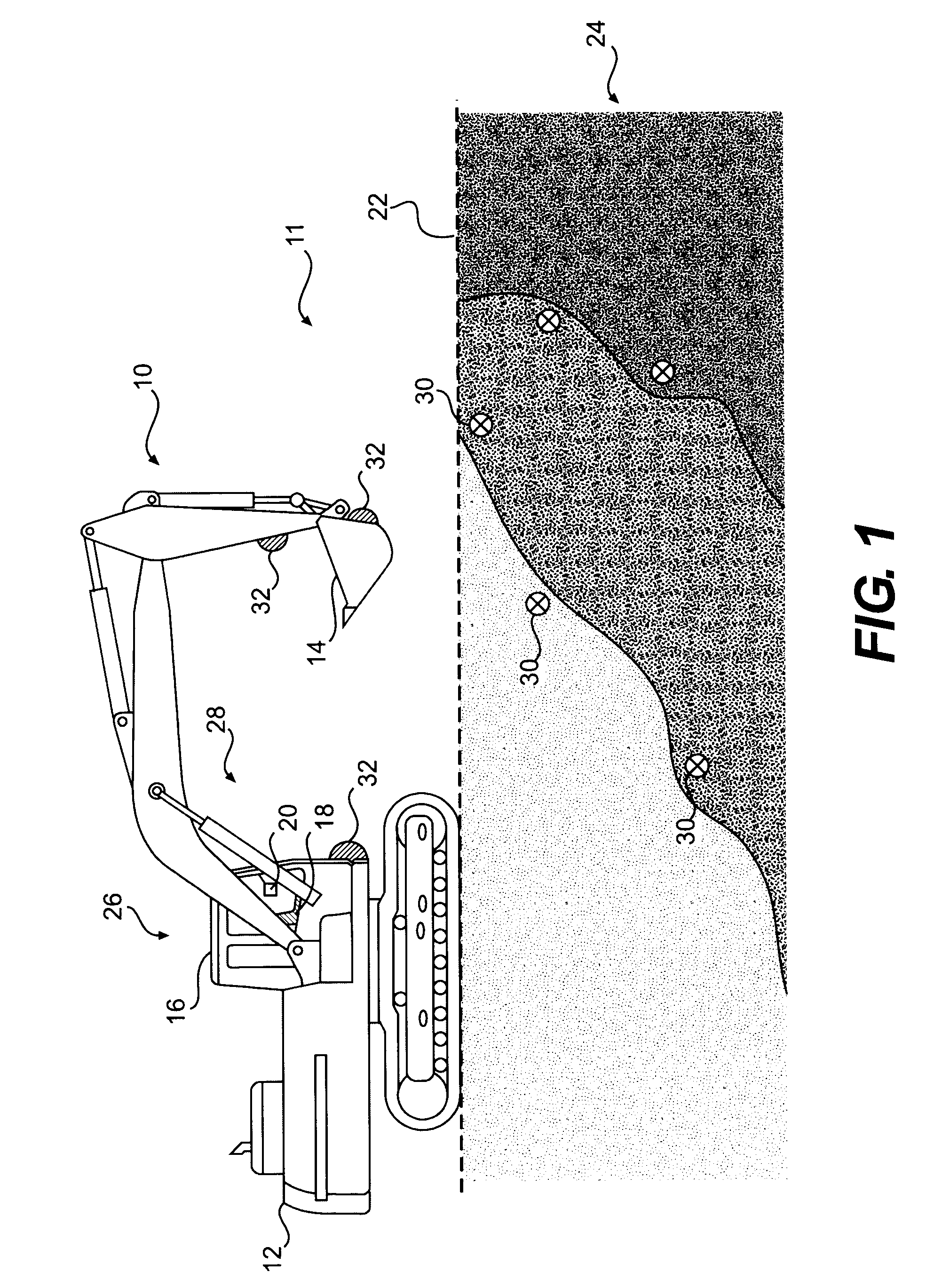

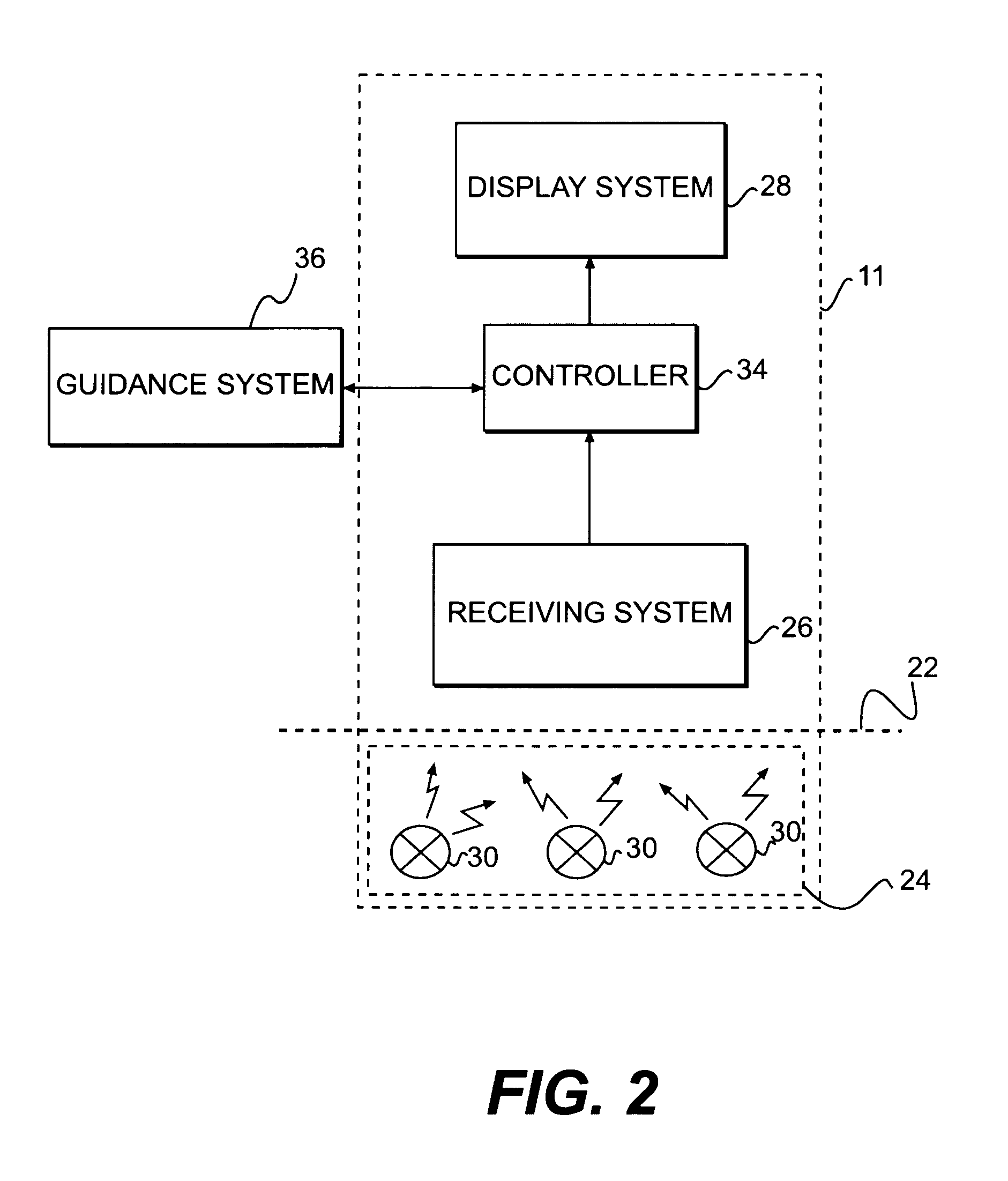

Method of determining a machine operation using virtual imaging

ActiveUS20080208415A1Instruments for road network navigationAnalogue computers for trafficPredicting performanceComputer science

A method of determining a machine for operating at an actual site includes establishing a three-dimensional geographical model representing the actual site, determining at least one operation characteristic relating to the operation of each of a set of machines in relation to the model, and predicting at least one performance characteristic for each machine based on the at least one operation characteristic and at least one respective characteristic of the different machines. The method further includes comparing the predicted performance characteristics for the different machines, and determining a target machine based on the comparison.

Owner:CATERPILLAR INC

Electrohydraulic pressure wave projectors

A projector (10) for creating electrohydraulic acoustic and pressure waves comprising an energy source (21) (such as a capacitor) within approximately one meter of an electrode array (23). Larger projectors may be formed by arraying the projectors, and still larger projectors by arraying them.

Owner:SDG LLC

Artificial soil and method for land reclamation by aid of gold mine tailing slag backfill exploitation regions

InactiveCN109429610AHigh organic contentImprove breathabilityUnderground miningGrowth substratesResource utilizationCircular economy

The invention provides artificial soil and a method for land reclamation by the aid of gold mine tailing slag backfill exploitation regions. The method includes carrying out filling and compaction onthe tailing waste slag backfill exploitation regions; uniformly mixing various components of the optimally designed artificial soil with one another and ultimately covering tailing waste slag backfillsurfaces with the novel artificial soil with a certain thickness so as to effectively treat mine tailing. The artificial soil and the method have the advantages that the prepared artificial soil contains abundant nutrient components, the contents of organic matters can be increased, the gas permeability of the soil can be improved, and the artificial soil is excellent in water retention capacityand fertilizer preservation capability and suitable for growth of plants; organic thoroughly decomposed substances come from agricultural and forestry waste, are extensive in source and are easily available, accordingly, solid waste can be comprehensively utilized in a 'reduction, resource utilization and harmlessness' manner, and the artificial soil and the method conform to principles of circular economy; the land occupation problems of tailing ponds and the problems in the aspect of tasks of land reclamation of mined-out regions can be simultaneously solved by the aid of the artificial soiland the method, and the artificial soil and the method have large market spaces.

Owner:杰瑞(莱州)矿山治理有限公司

Sublevel shrinkage caving stage open stope afterwards filling mining method

InactiveCN101881169ALarge amount of filling at one timeIncrease production capacityUnderground miningSurface miningEarth surfaceComputer science

The invention discloses a sublevel shrinkage caving stage open afterwards filling mining method. In the earlier stage of stoping, caved ores are utilized to support surrounding rocks on a top tray, and in the later stage of stoping, a goaf area is filled with fillers to control ground pressure so as to achieve safe and efficient mining. Ore blocks are mined in two steps, mining blocks in step two are stoped after the mining blocks in step one are stoped and filled. After the ores are completely let out, the goaf area is filled with the fillers to control the ground pressure. Because the stoping modes of sublevel ore caving, sublevel shrinkage, final ore drawing and empty area afterwards filling are adopted, the mining method has large one-time filling amount and low cost; the method adopts middle-deep hole drilling and blasting and carry scraper ore removal, and the device has high level and large production capacity; the method has the advantages of large production capacity of the sublevel caving method and the stage open stope method, high recovery rate of the filling method, and earth surface protection; the safety is good, and drilling, ore removal and other operations are all carried out in a sublevel drilling and ore removal approach roadway; and the ores can be removed in advance, and the ores can be removed partially after the first sublevel is ready.

Owner:NORTHEASTERN UNIV +1

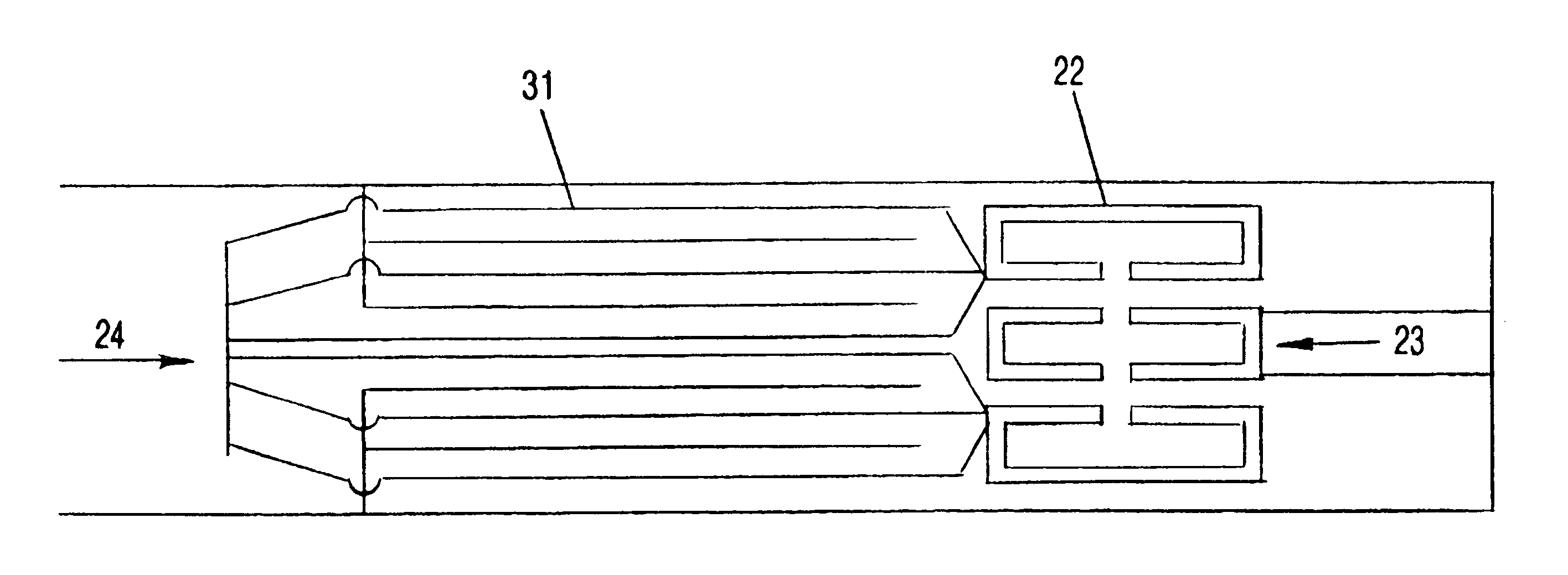

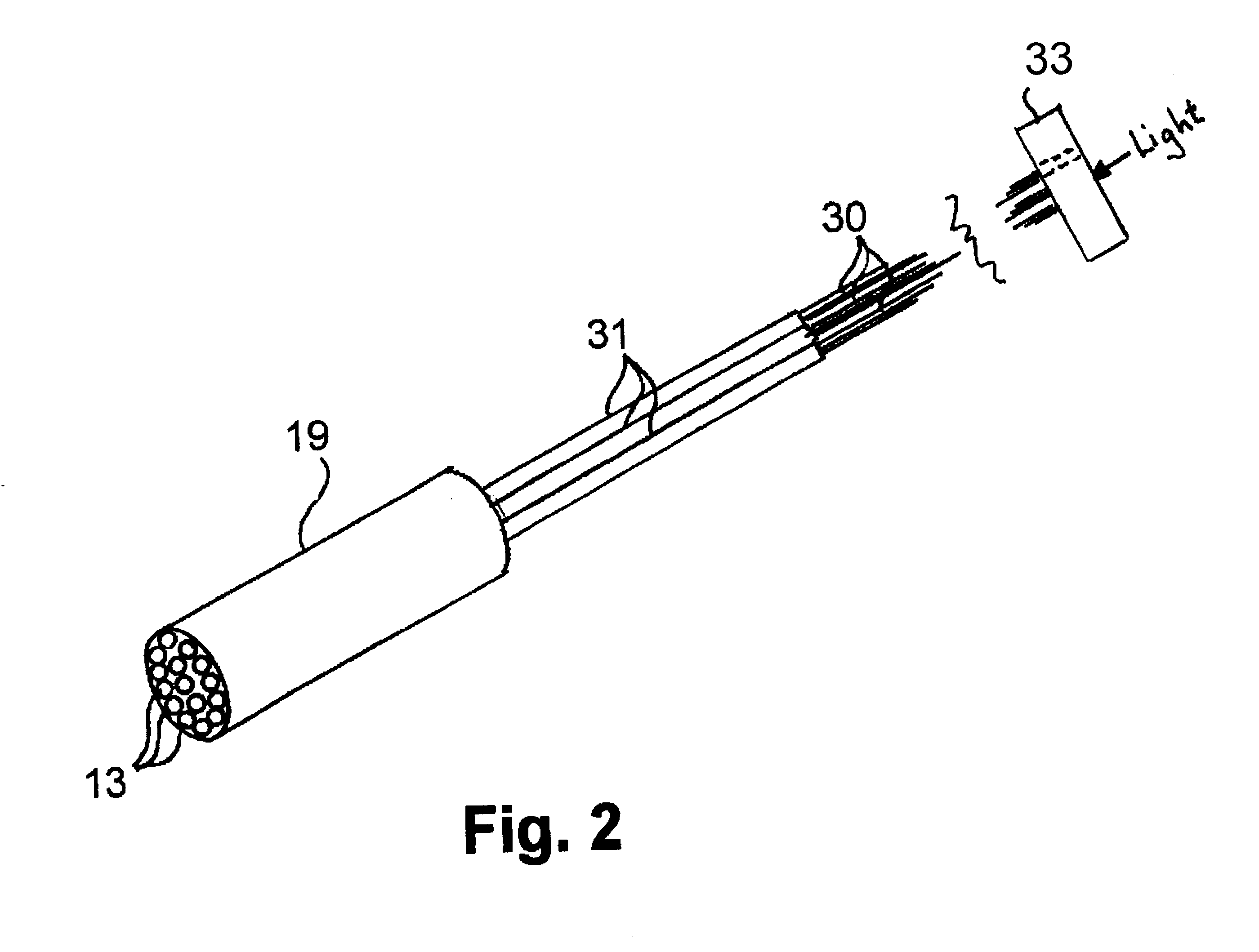

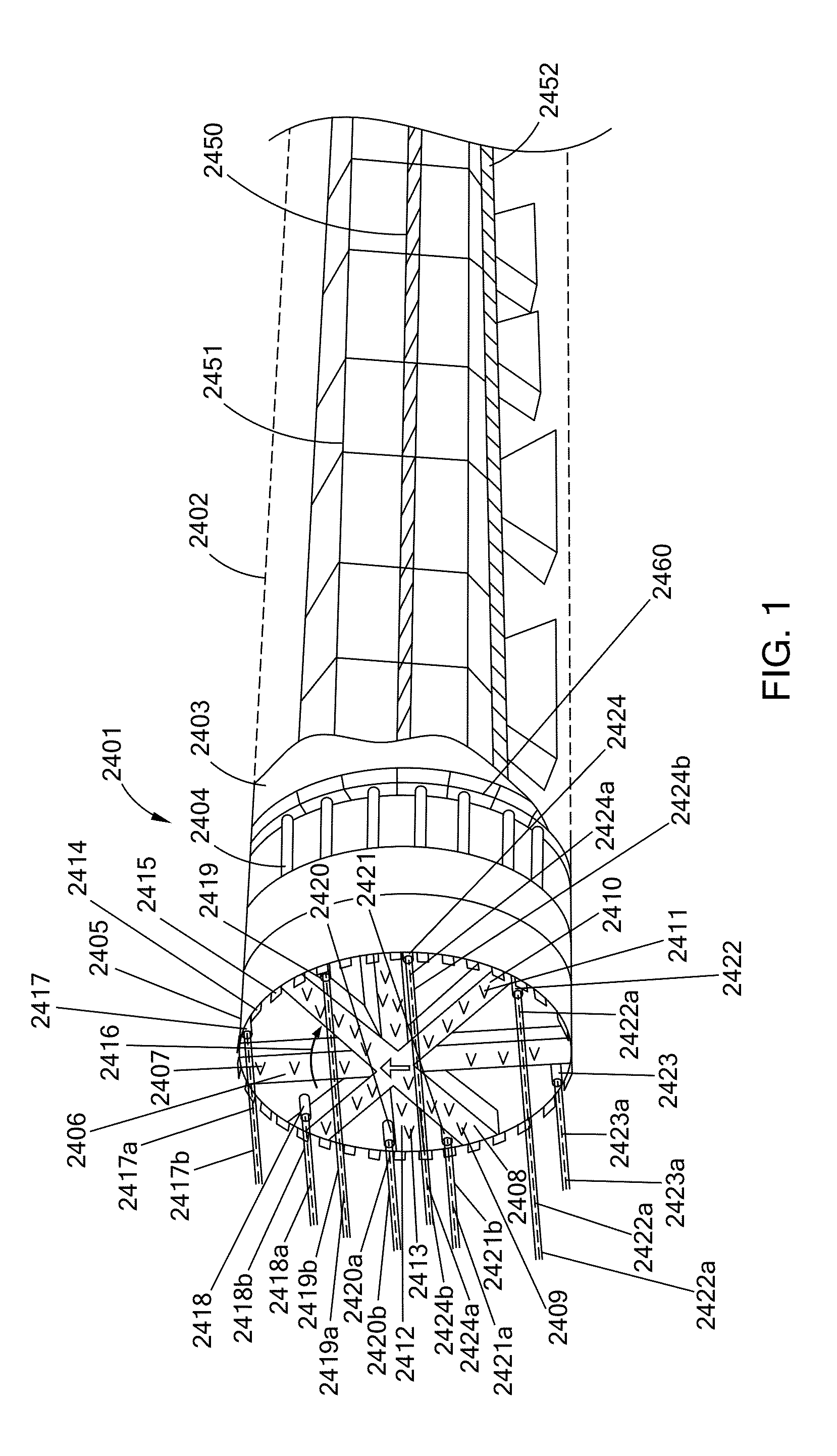

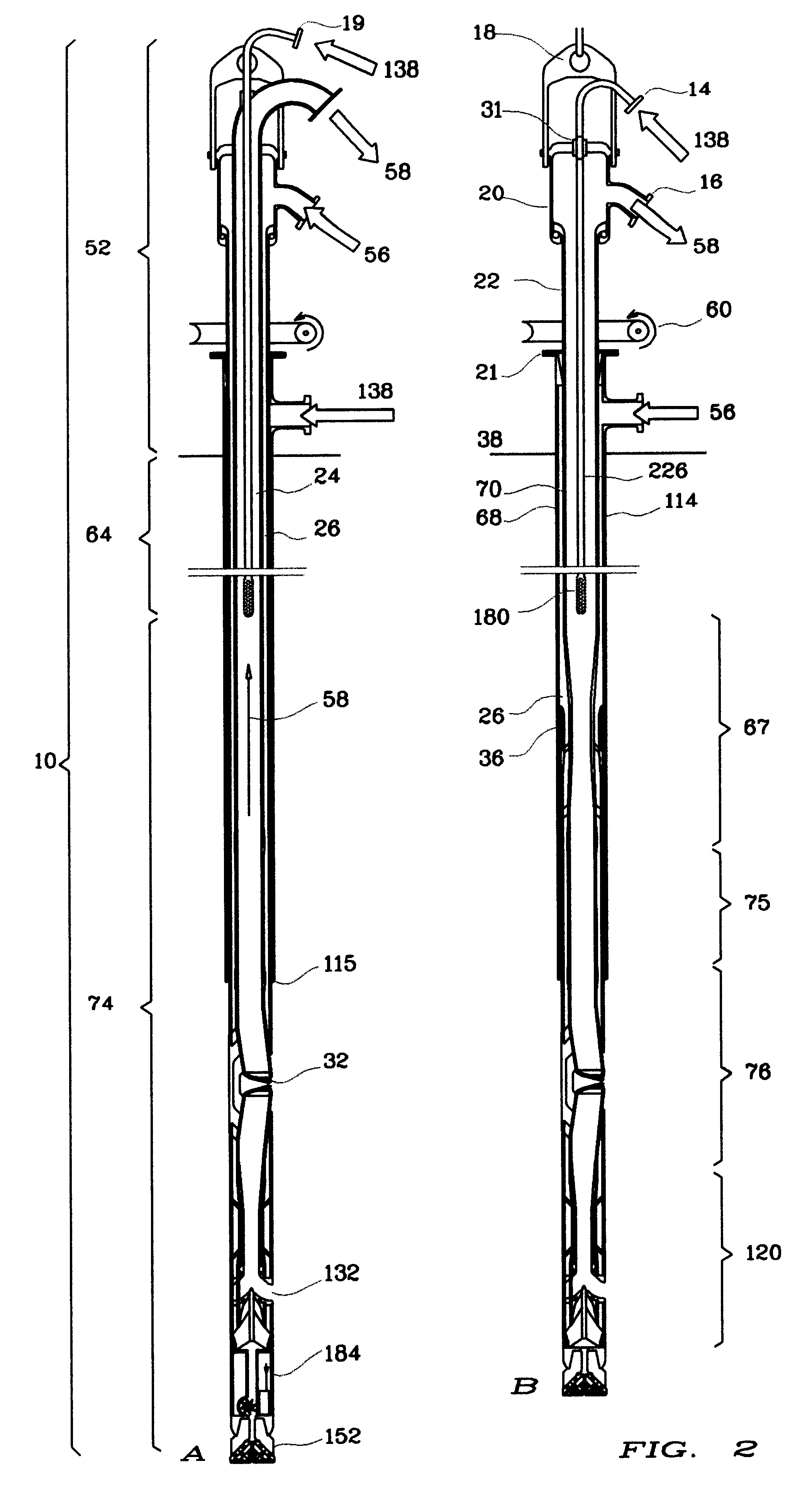

Downhole lens assembly for use with high power lasers for earth boring

InactiveUS6755262B2Difficult to controlRelative position is not easyEarth drilling toolsDisloding machinesFiberHigh power lasers

An earth boring apparatus at least partially locatable within a borehole. The apparatus includes a plurality of optical fibers, each of which has a proximal fiber light energy input end and a distal fiber light energy output end. At least one focal lens is disposed at the distal fiber light energy output end. The focal lens is made up of a plurality of focal elements, each of which corresponds to the distal fiber light energy output end of at least one optical fiber. The focal lens is arranged to receive light energy from the corresponding distal fiber light energy output end of the at least one optical fiber and focus it outwardly from the distal fiber light energy output end.

Owner:GAS TECH INST

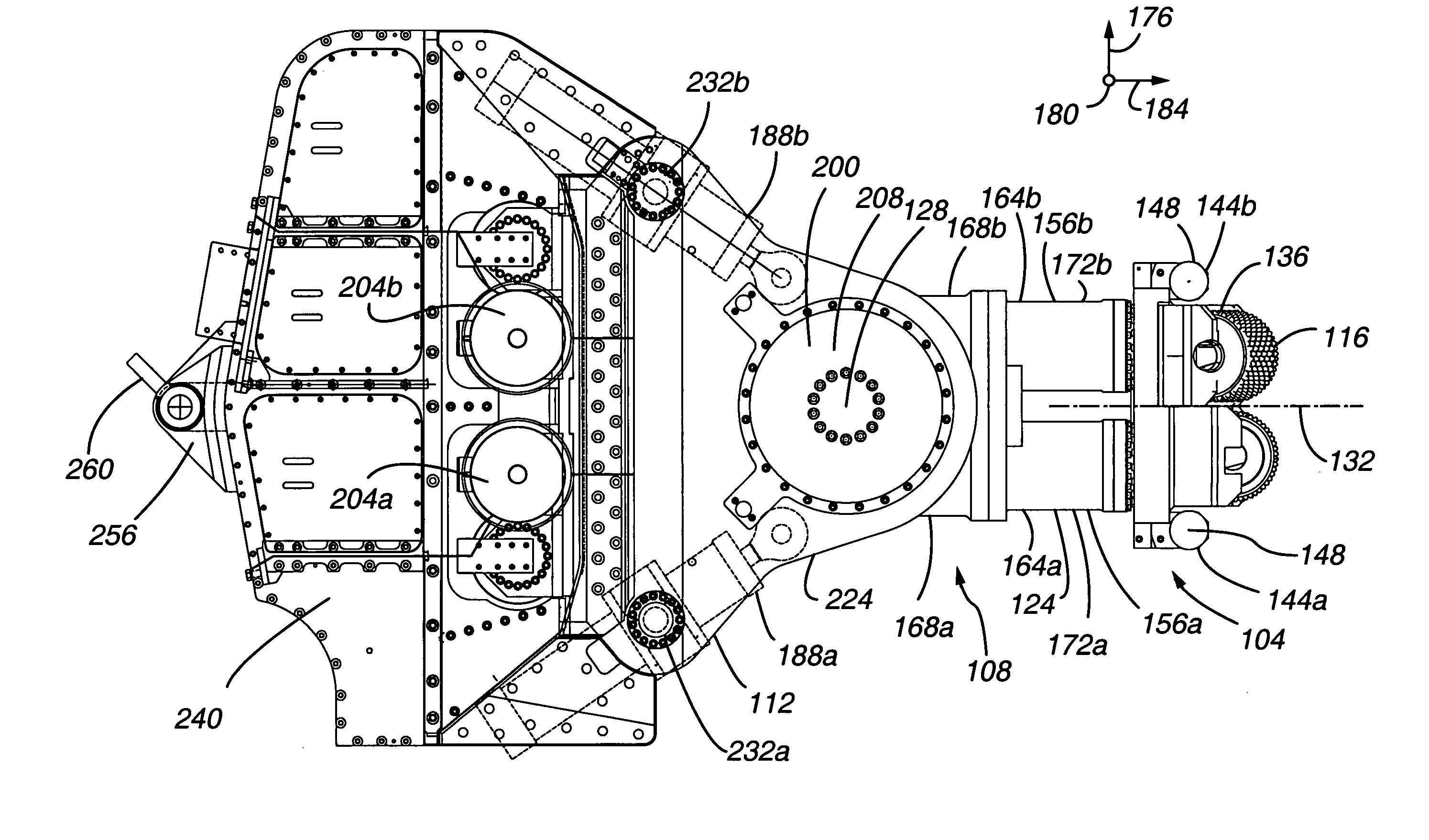

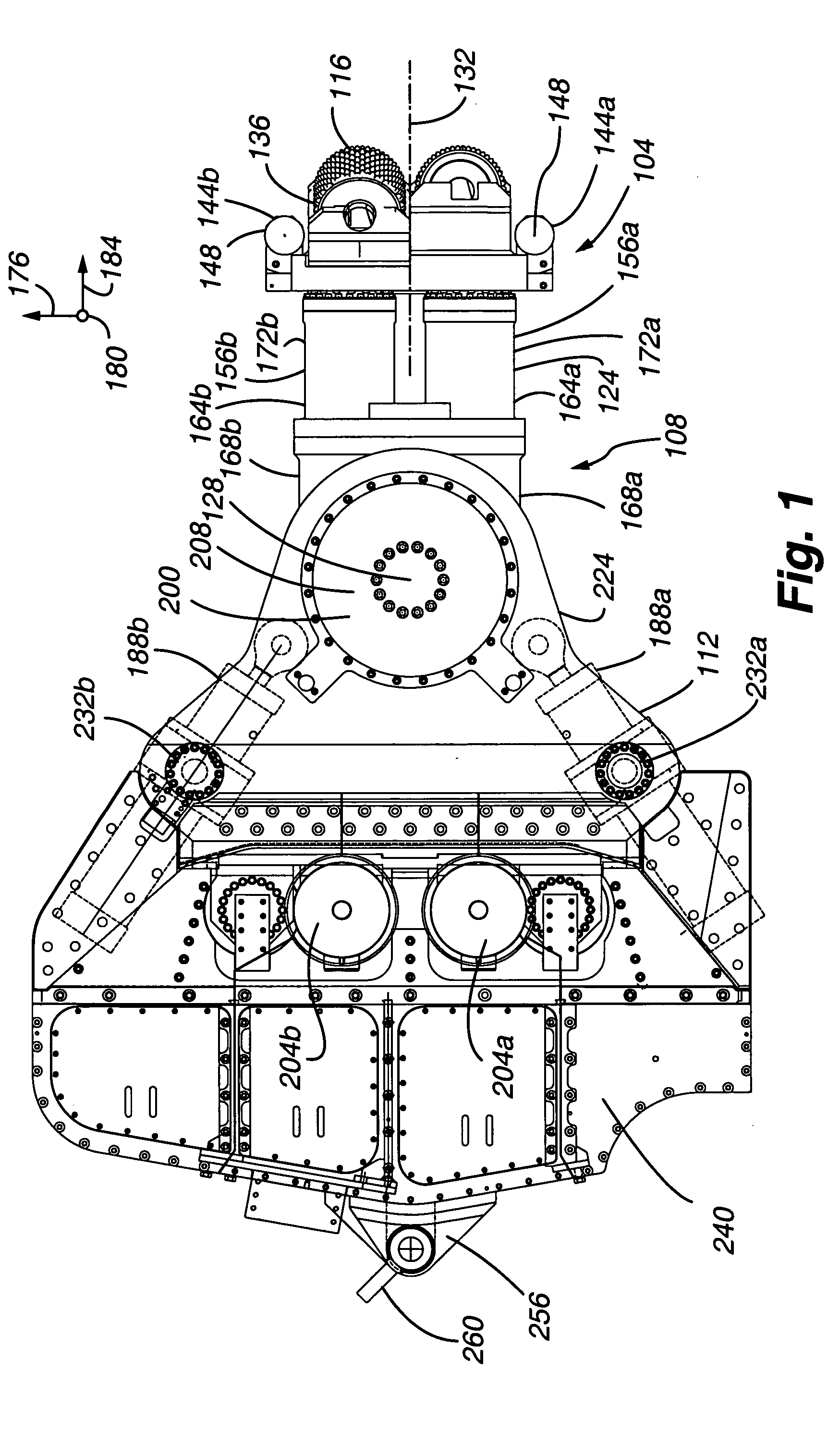

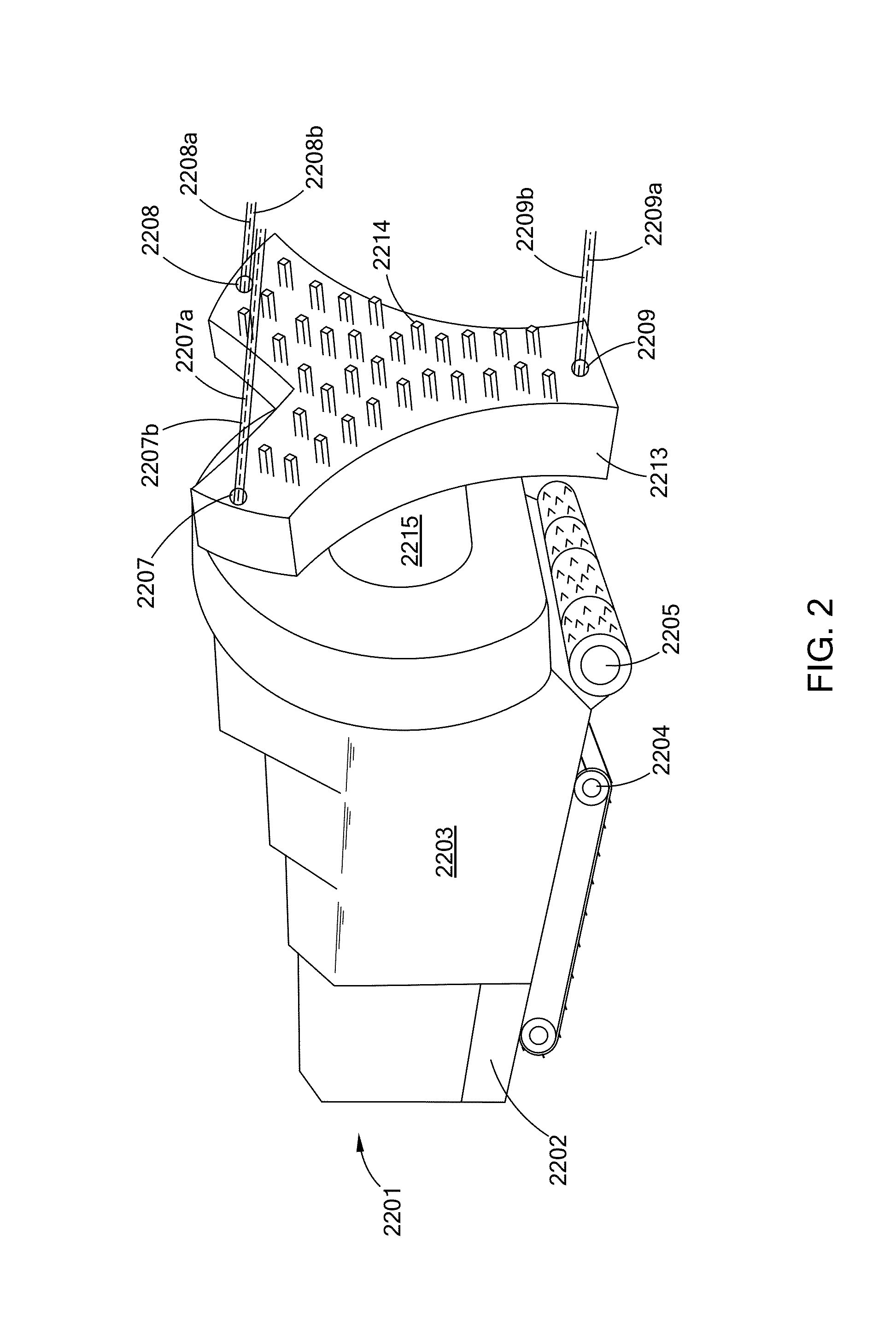

Automated excavation machine

InactiveUS7695071B2Efficiently and effectively excavatingUnderground miningSlitting machinesActuatorExcavator

The present invention is directed to an excavator that is operable in manual and automatic modes and uses state machines to effect unit operations, rotationally offset swing actuators to rotate boom and cutter head, a fail safe hydraulic system to maintain gripper pressure in the event of a malfunction of the hydraulic system, differing position and pressure control functions in the hydraulic actuators, a kinematic module to effect pitch and roll adjustments, a cutting face profile generator to generate a profile of the excavation face, and an optimization module to realize a high degree of optimization of excavator operation.

Owner:MIN OF NATURAL RESOURCES CANADA

Plasma channel drilling process

Material is removed from a body of material, e.g. to create a bore hole, by plasma channel drilling. High voltage, high energy, rapid rise time electrical pulses are delivered many times per second to an electrode assembly in contact with the material body to generate therein elongate plasma channels which expand rapidly following electrical breakdown of the material causing the material to fracture and fragment.

Owner:STRATHCLYDE UNIV OF

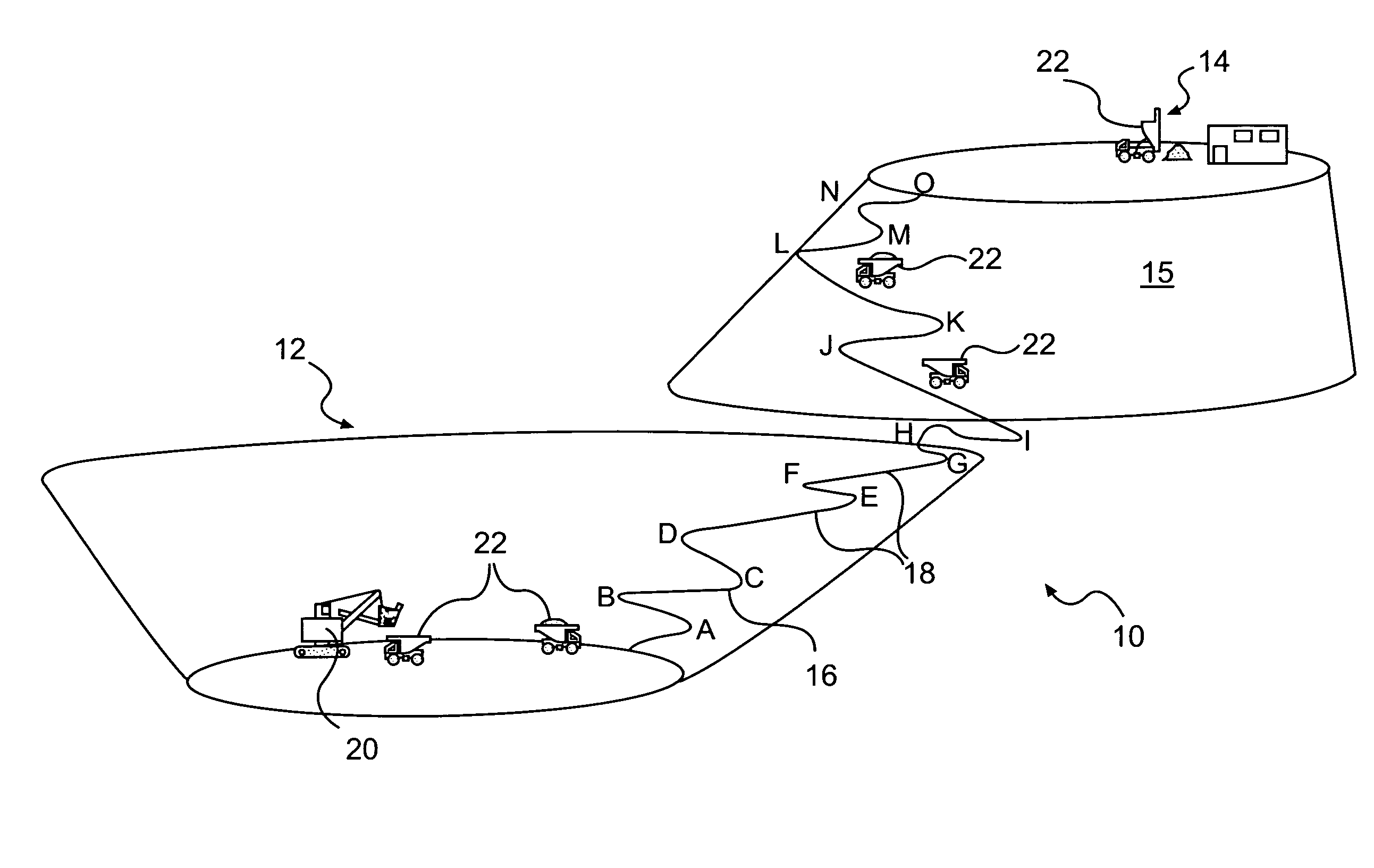

Method of determining a machine operation using virtual imaging

ActiveUS8144245B2Color television with pulse code modulationColor television with bandwidth reductionPredicting performanceComputer science

A method of determining a machine for operating at an actual site includes establishing a three-dimensional geographical model representing the actual site, determining at least one operation characteristic relating to the operation of each of a set of machines in relation to the model, and predicting at least one performance characteristic for each machine based on the at least one operation characteristic and at least one respective characteristic of the different machines. The method further includes comparing the predicted performance characteristics for the different machines, and determining a target machine based on the comparison.

Owner:CATERPILLAR INC

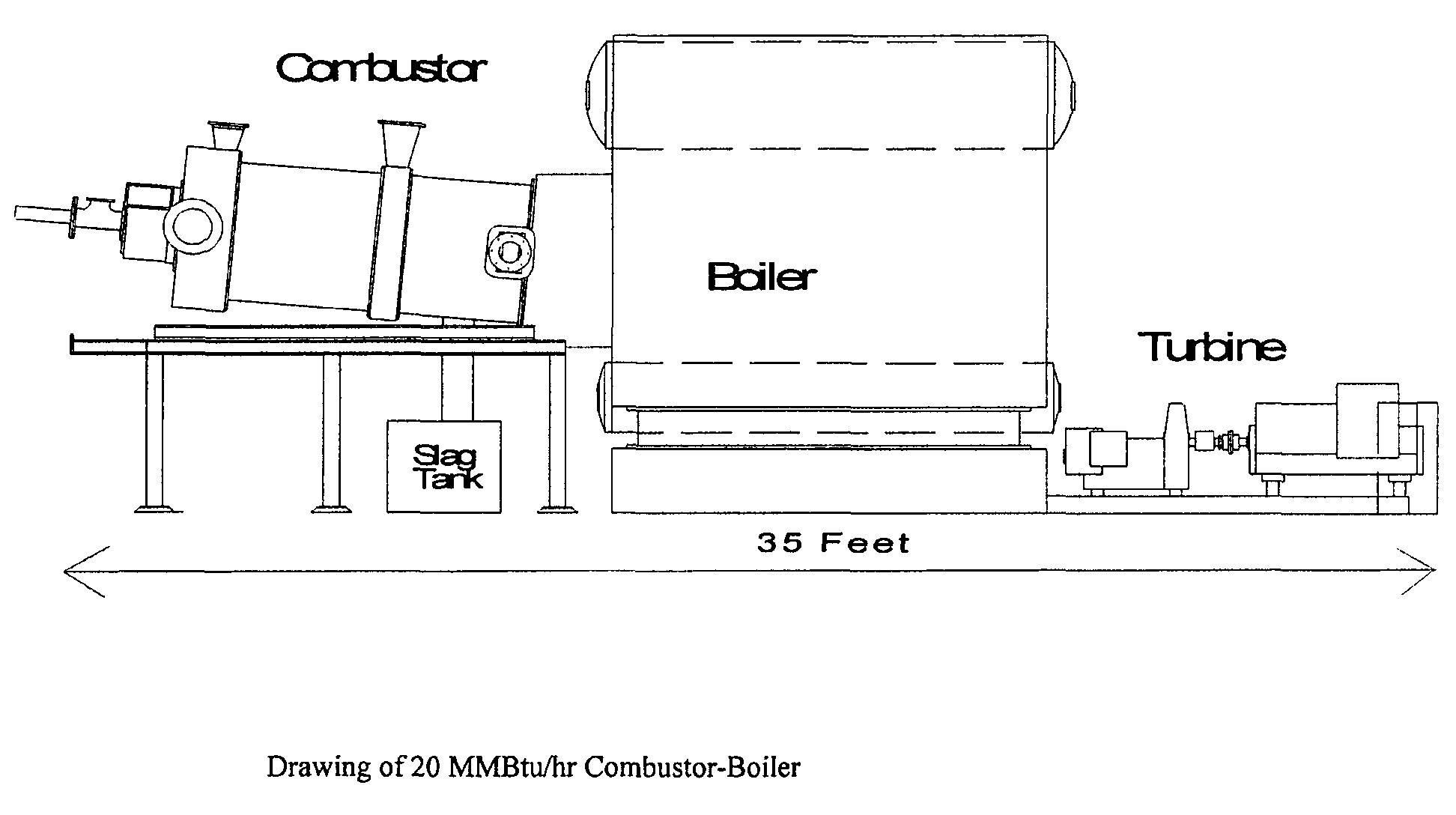

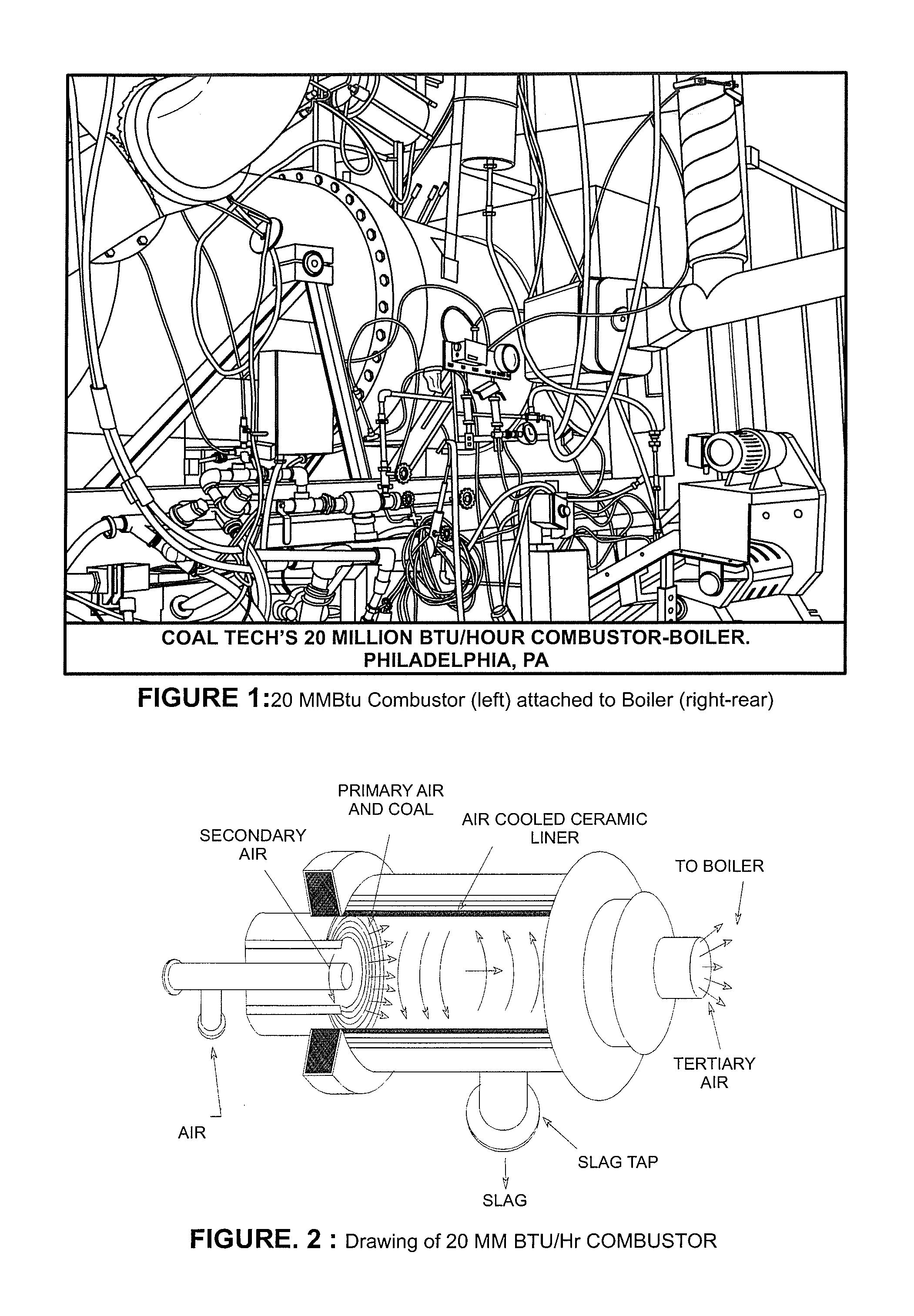

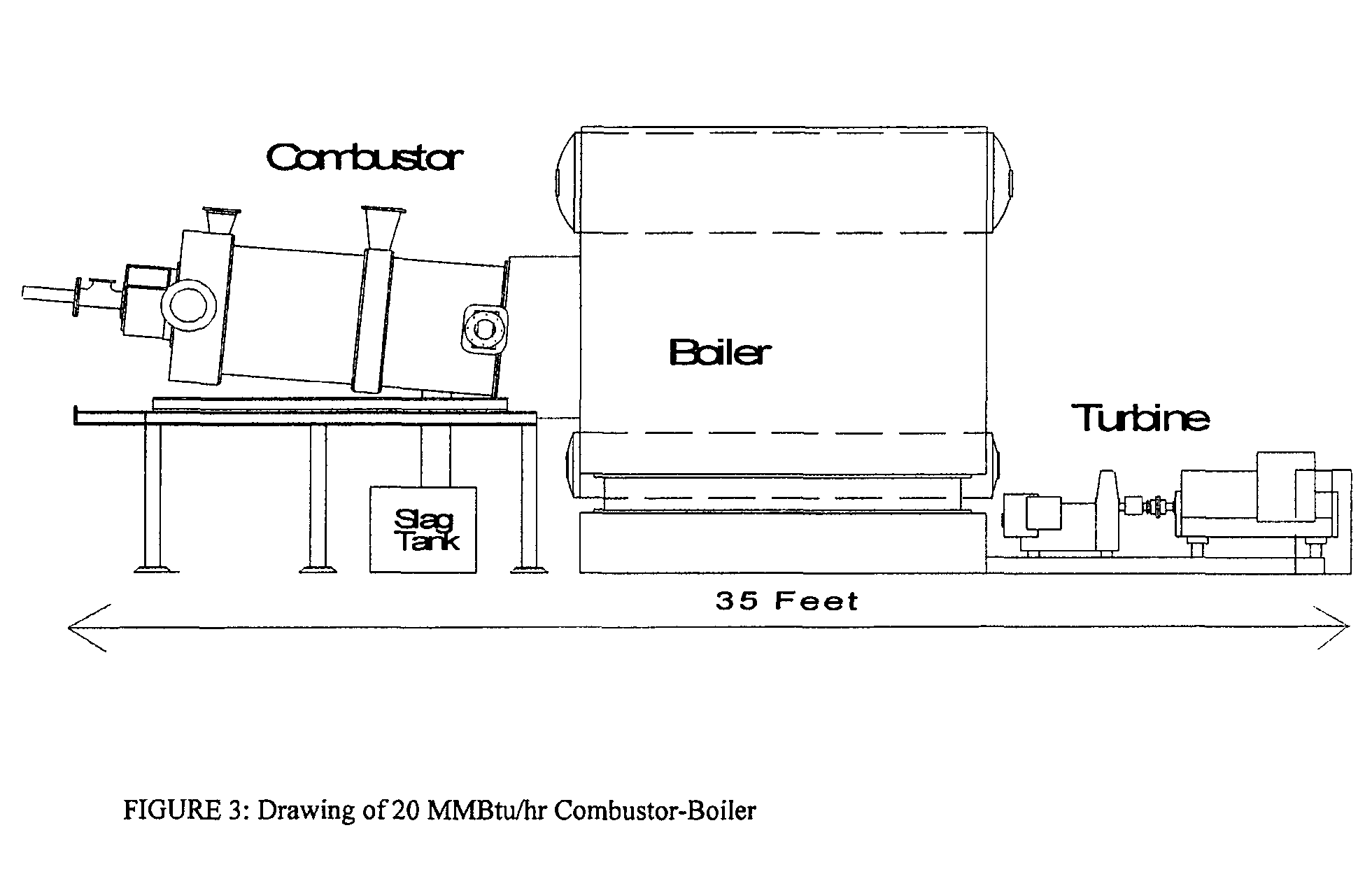

Slagging coal combustor for cementitious slag production, metal oxide reduction, shale gas and oil recovery, enviromental remediation, emission control and CO2 sequestration

InactiveUS8337613B2Reduce transportationMinimize disfiguringNitrogen compoundsSulfur compoundsCombustorEnvironmental remediation

Systems, methods and processes teach by specific examples how the cost of sequestering carbon dioxide (CO2) can be totally offset and turned into profits during coal powered electricity generation from revenue and co-benefits. The process is provided whereby fly ash-carbon mixtures, or de-volatilized coal char, or anthracite coal culm is co-fired in an air-cooled, slagging combustor with limestone or similar slag fluxing materials converts the ash into cementitious slag with properties similar to ground granulated blast furnace slag.

Owner:ZAUDERER BERT

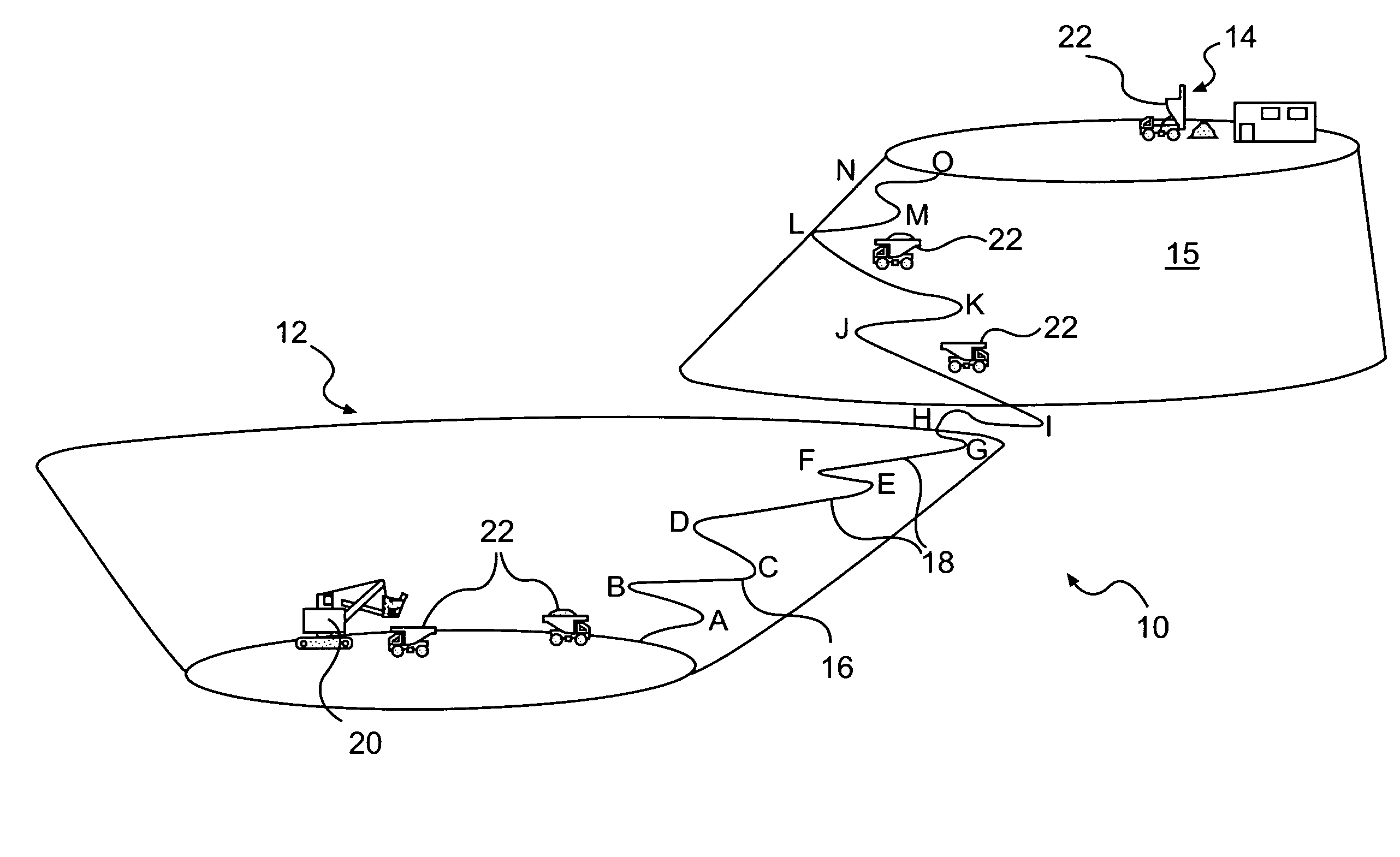

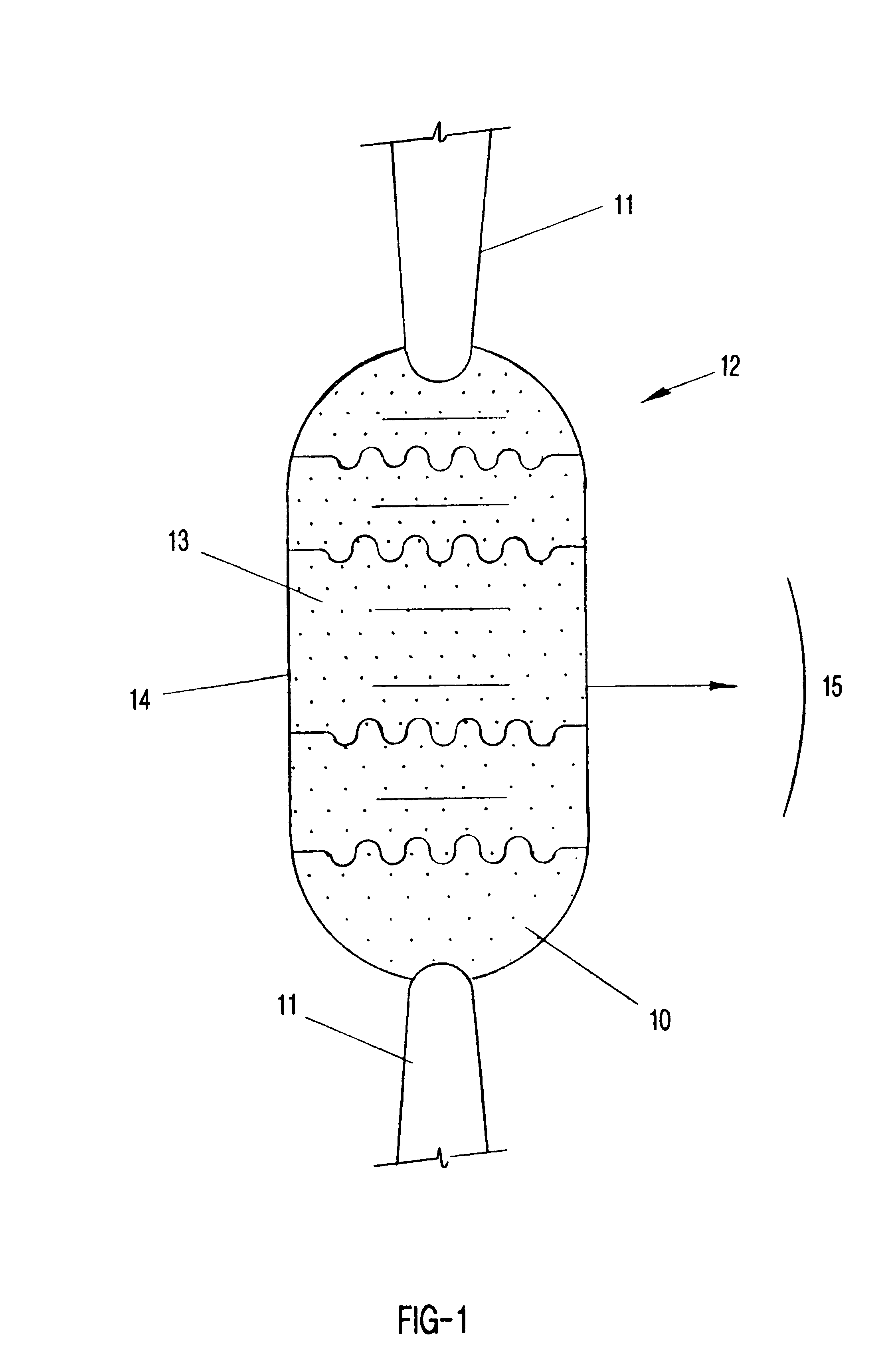

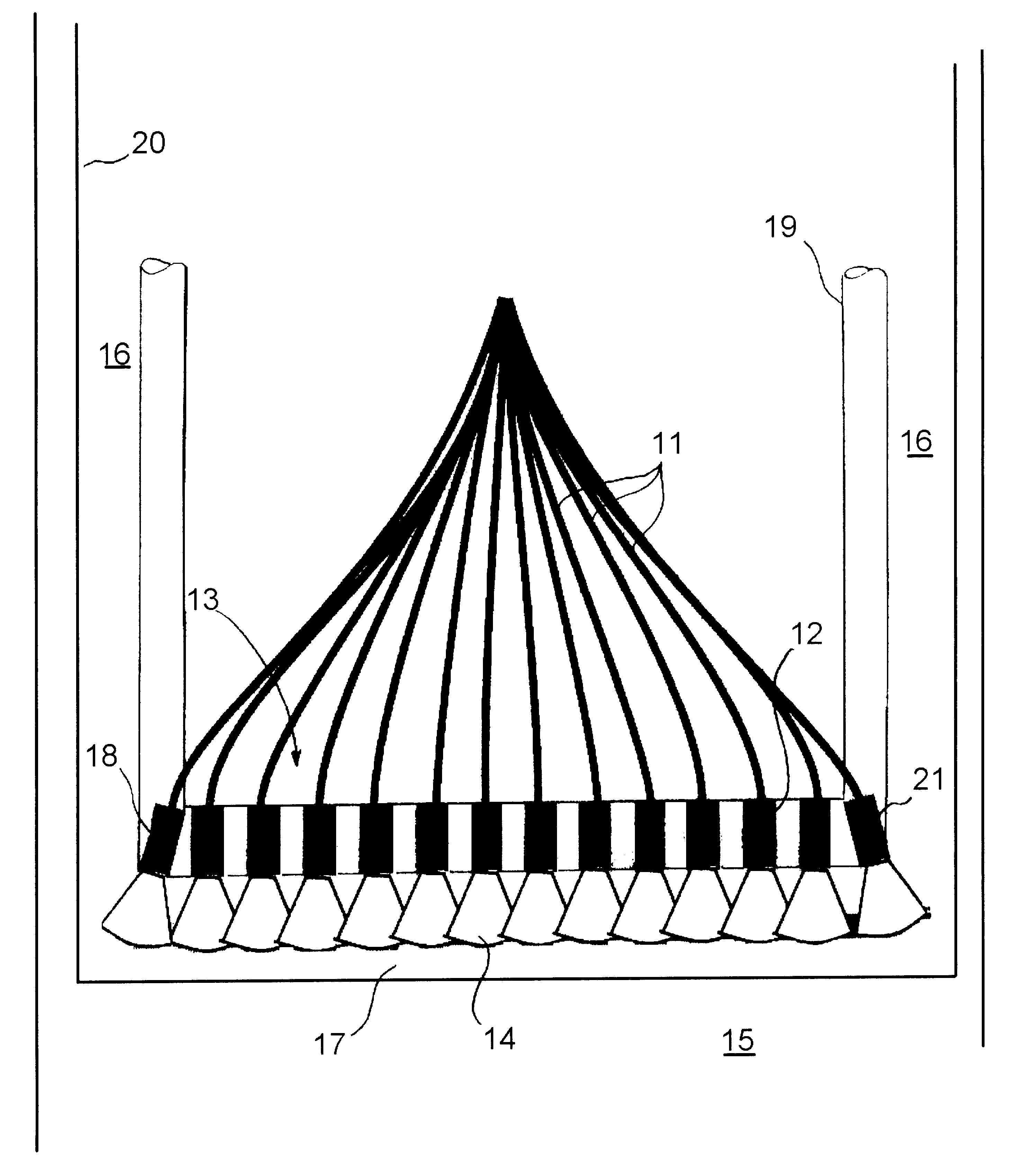

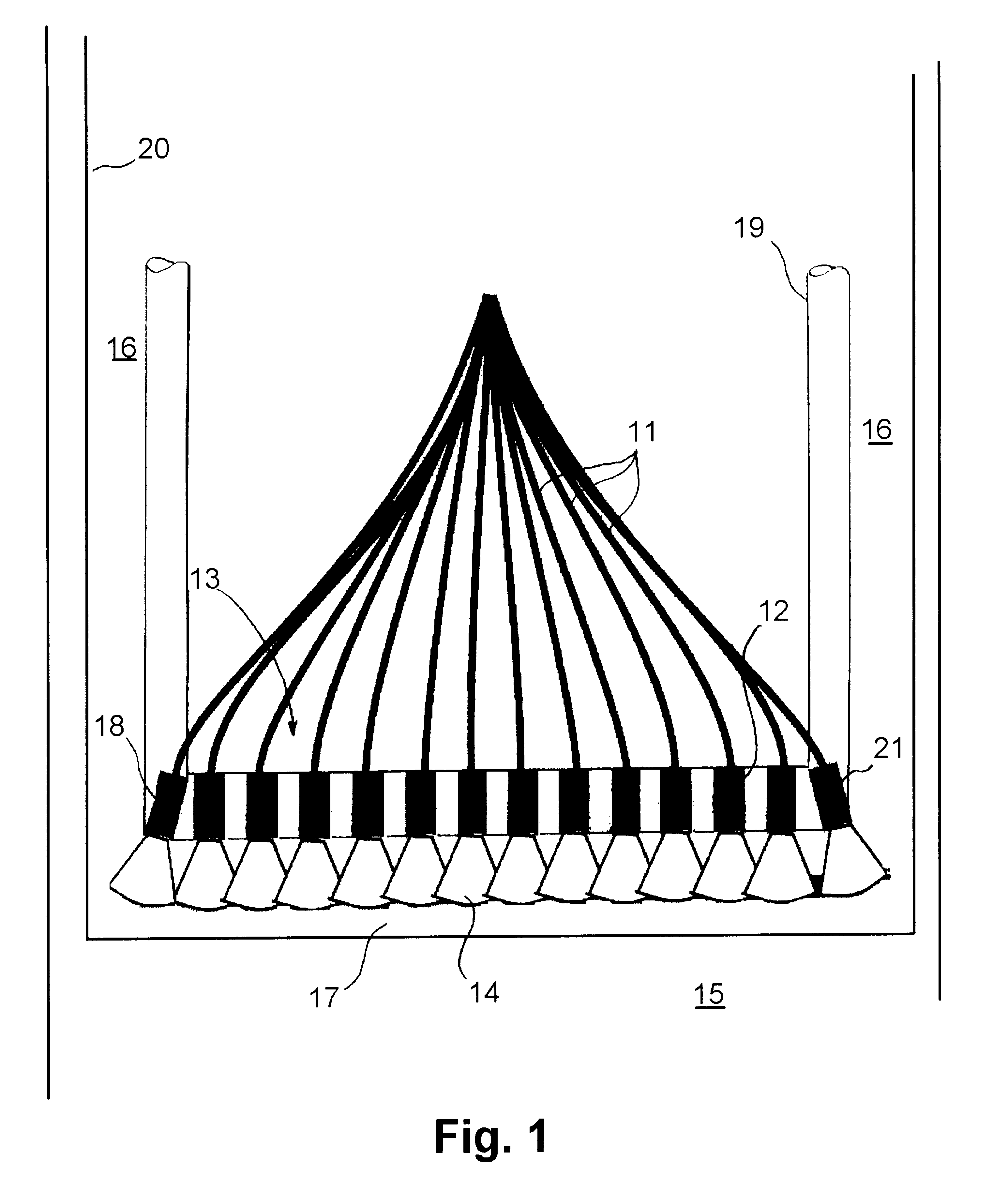

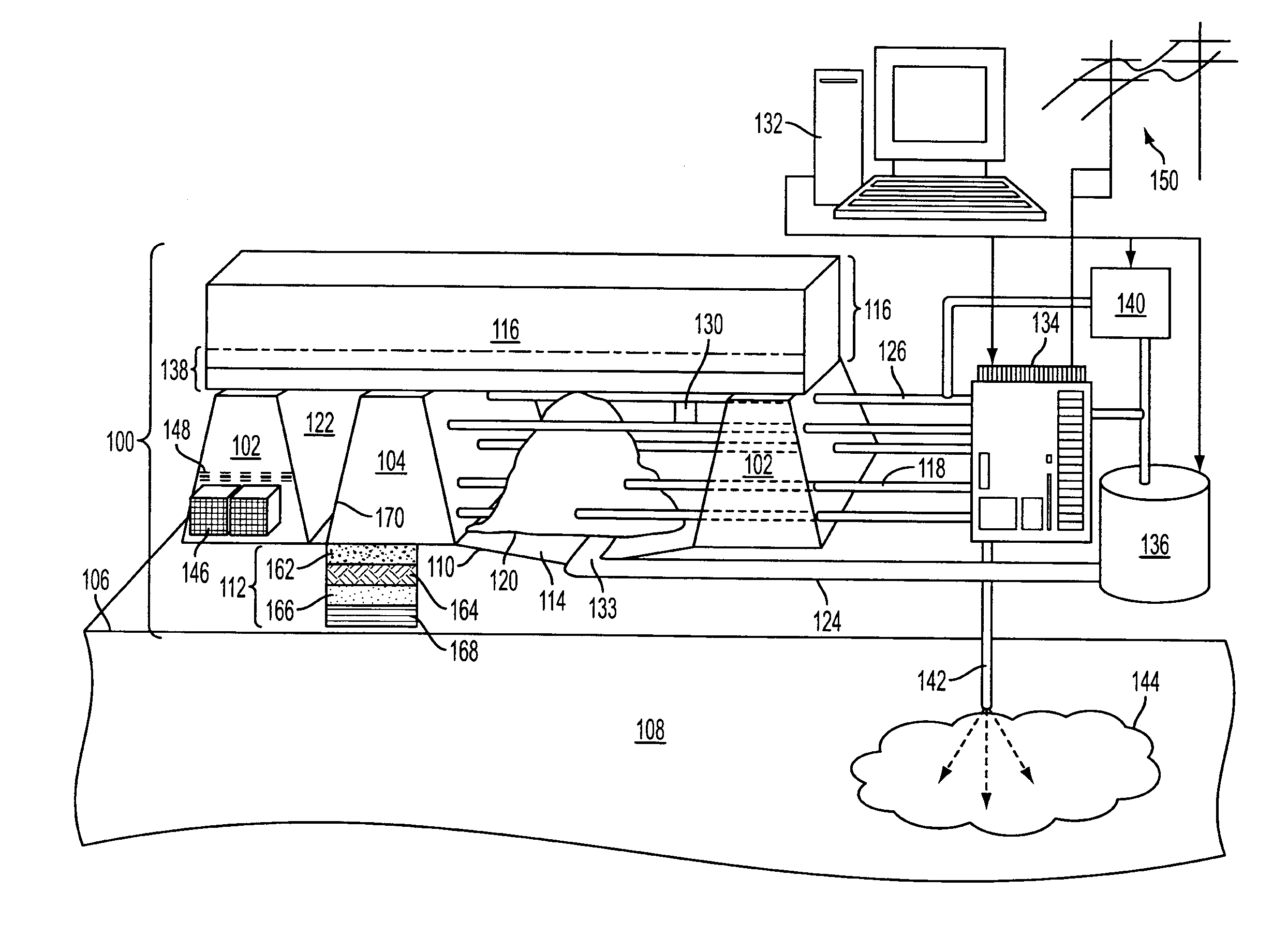

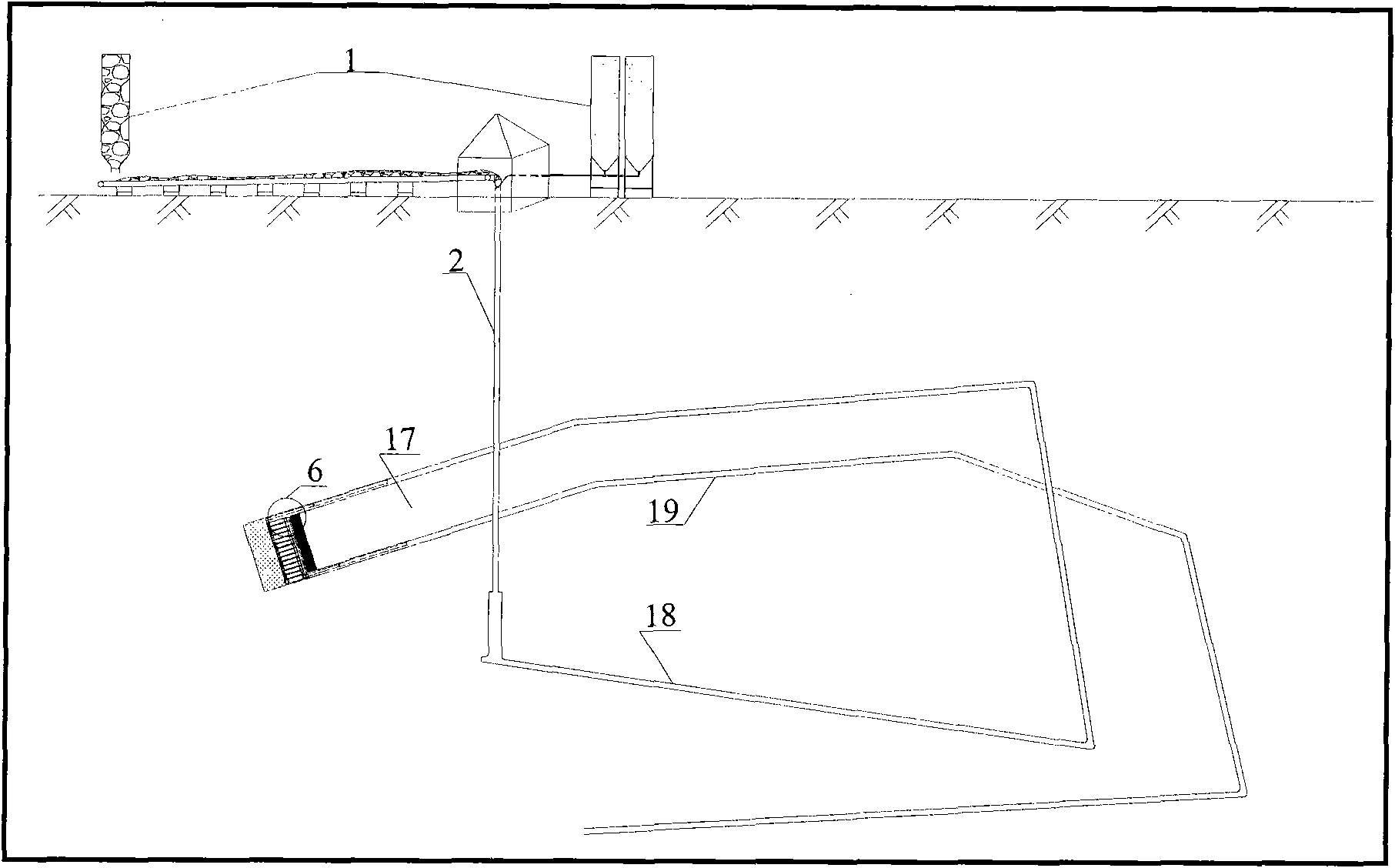

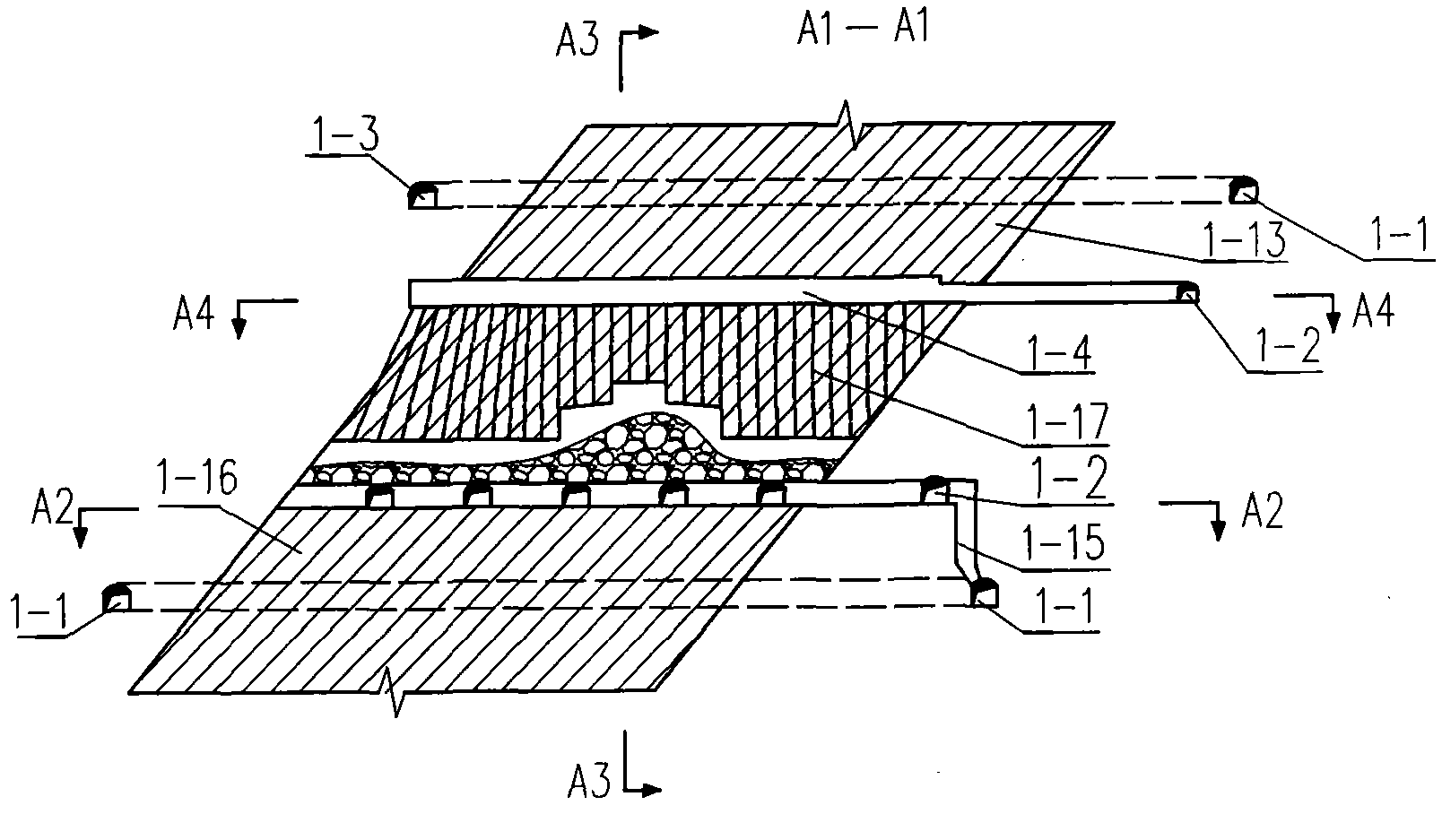

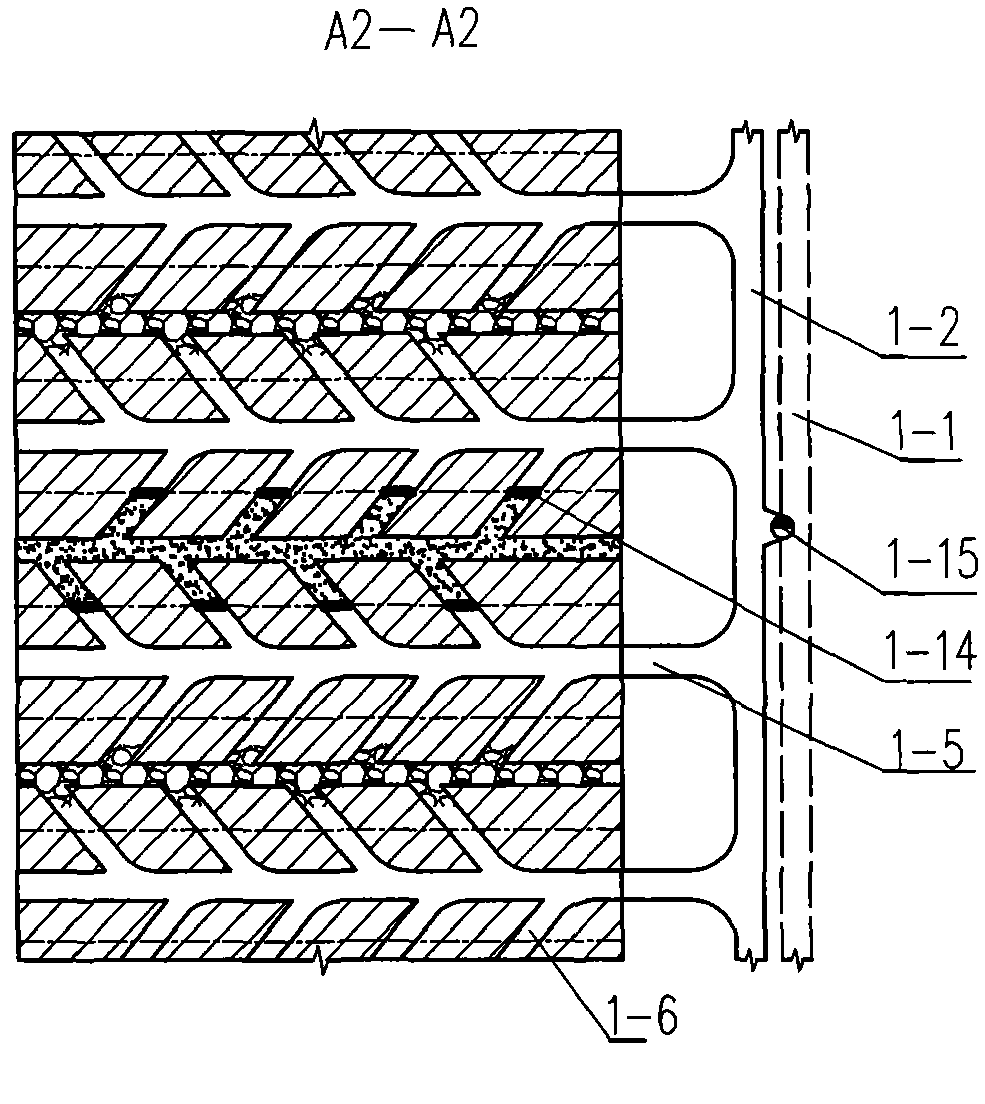

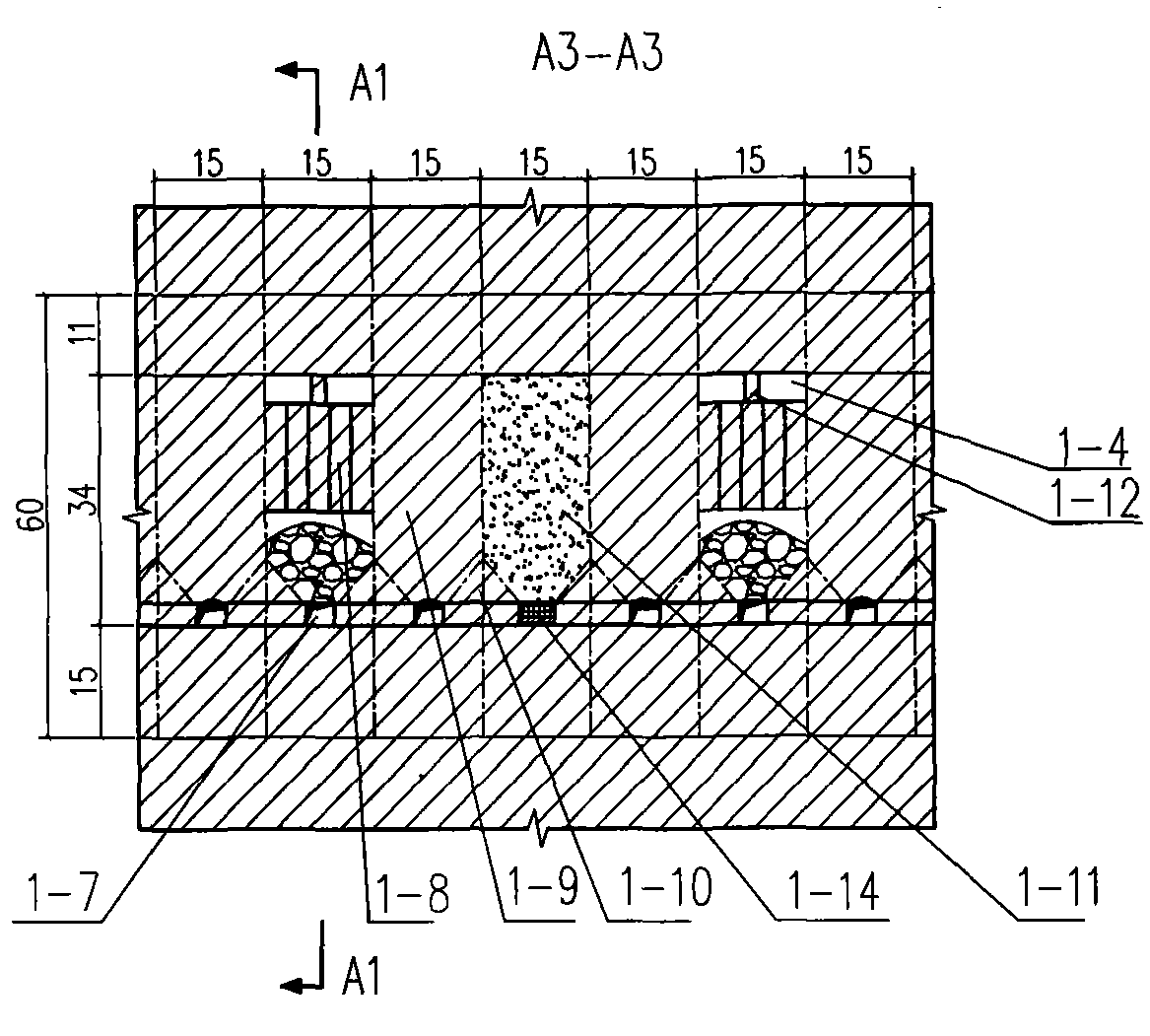

Methods of recovering hydrocarbons from hydrocarbonaceous material using a constructed infrastructure and associated systems

ActiveUS20080190818A1Reduce processing costsIncrease volume outputThermal non-catalytic crackingSolid waste disposalEngineeringHydrocarbon

A method of recovering hydrocarbons from hydrocarbonaceous materials can include forming a constructed permeability control infrastructure. This constructed infrastructure defines a substantially encapsulated volume. A comminuted hydrocarbonaceous material can be introduced into the control infrastructure to form a permeable body of hydrocarbonaceous material. The permeable body can be heated sufficient to remove hydrocarbons therefrom. During heating the hydrocarbonaceous material is substantially stationary as the constructed infrastructure is a fixed structure. Removed hydrocarbons can be collected for further processing, use in the process, and / or use as recovered.

Owner:RED LEAF RESOURCES

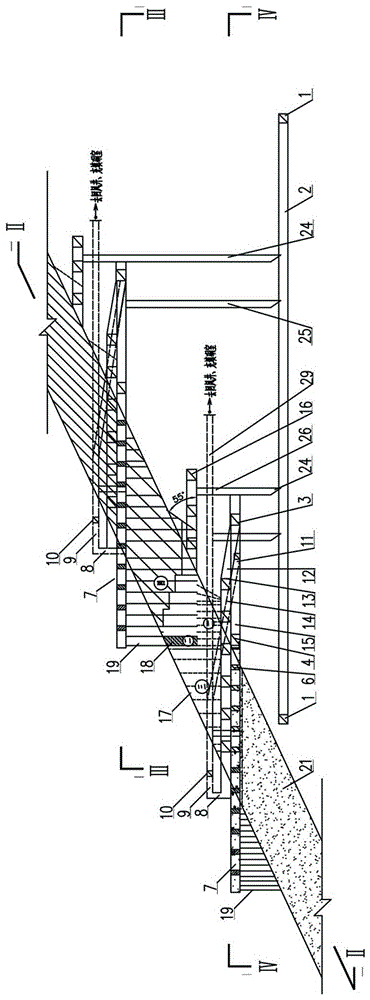

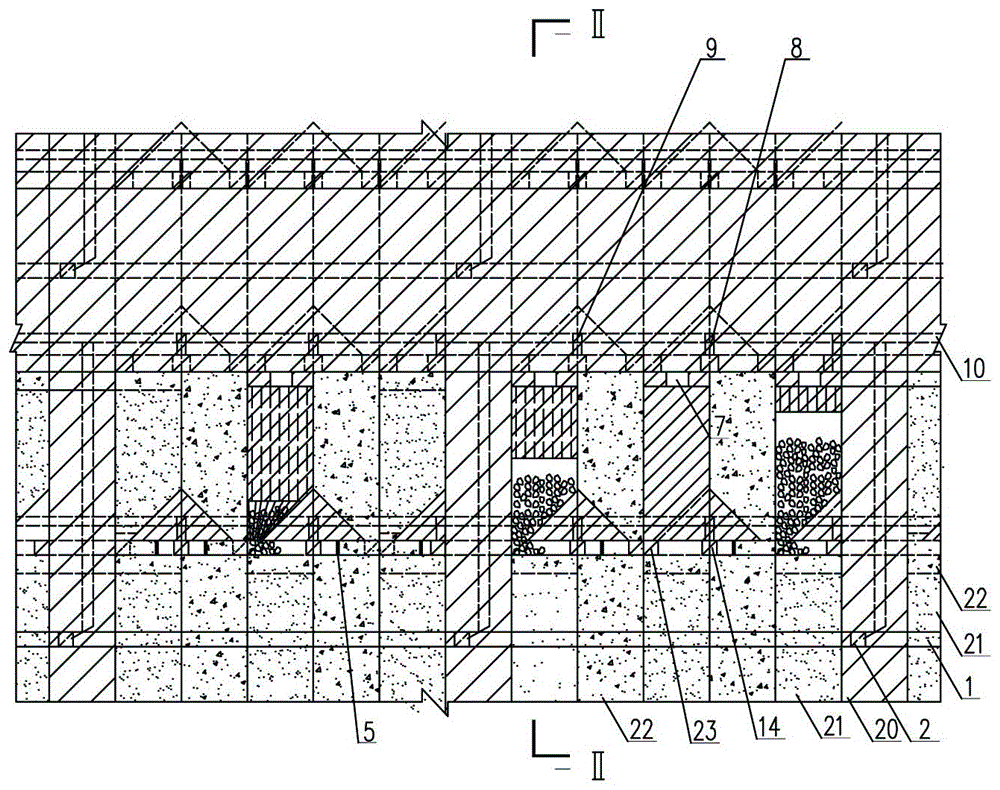

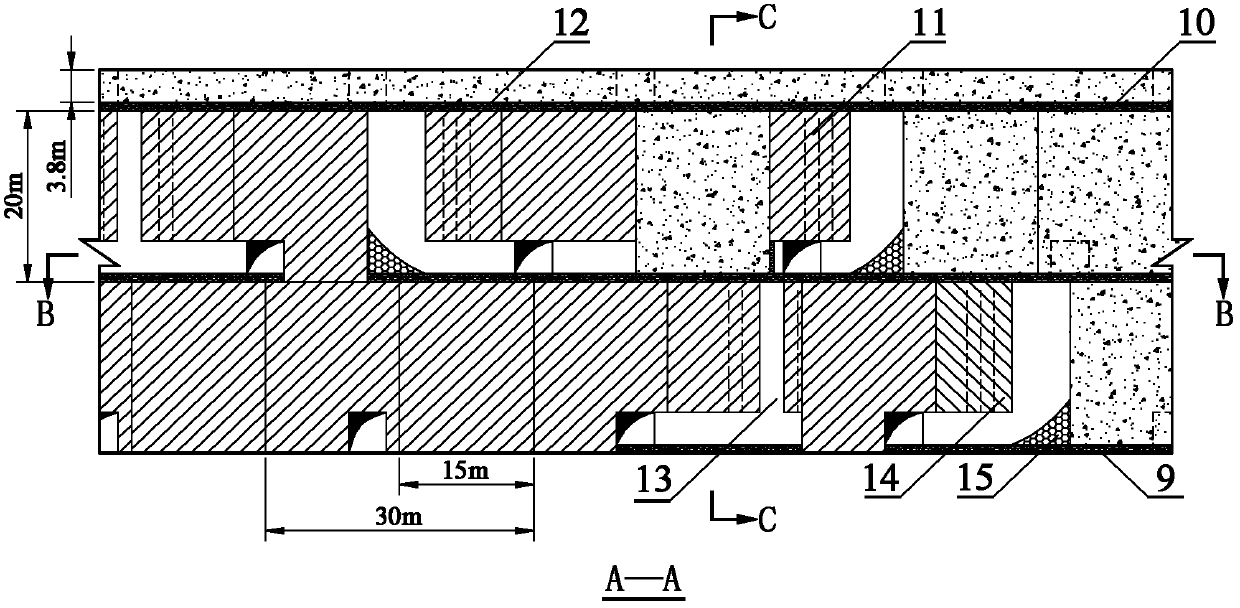

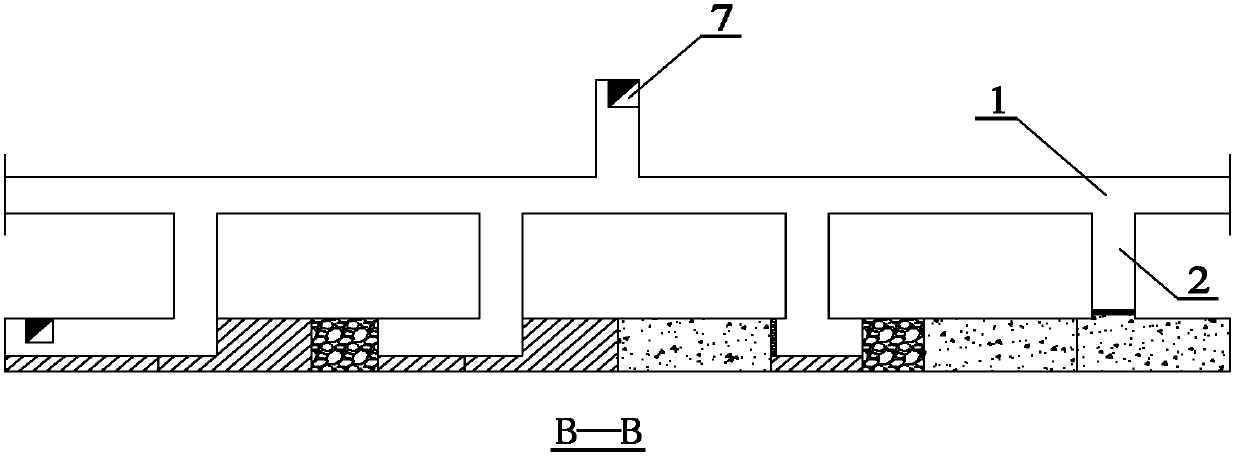

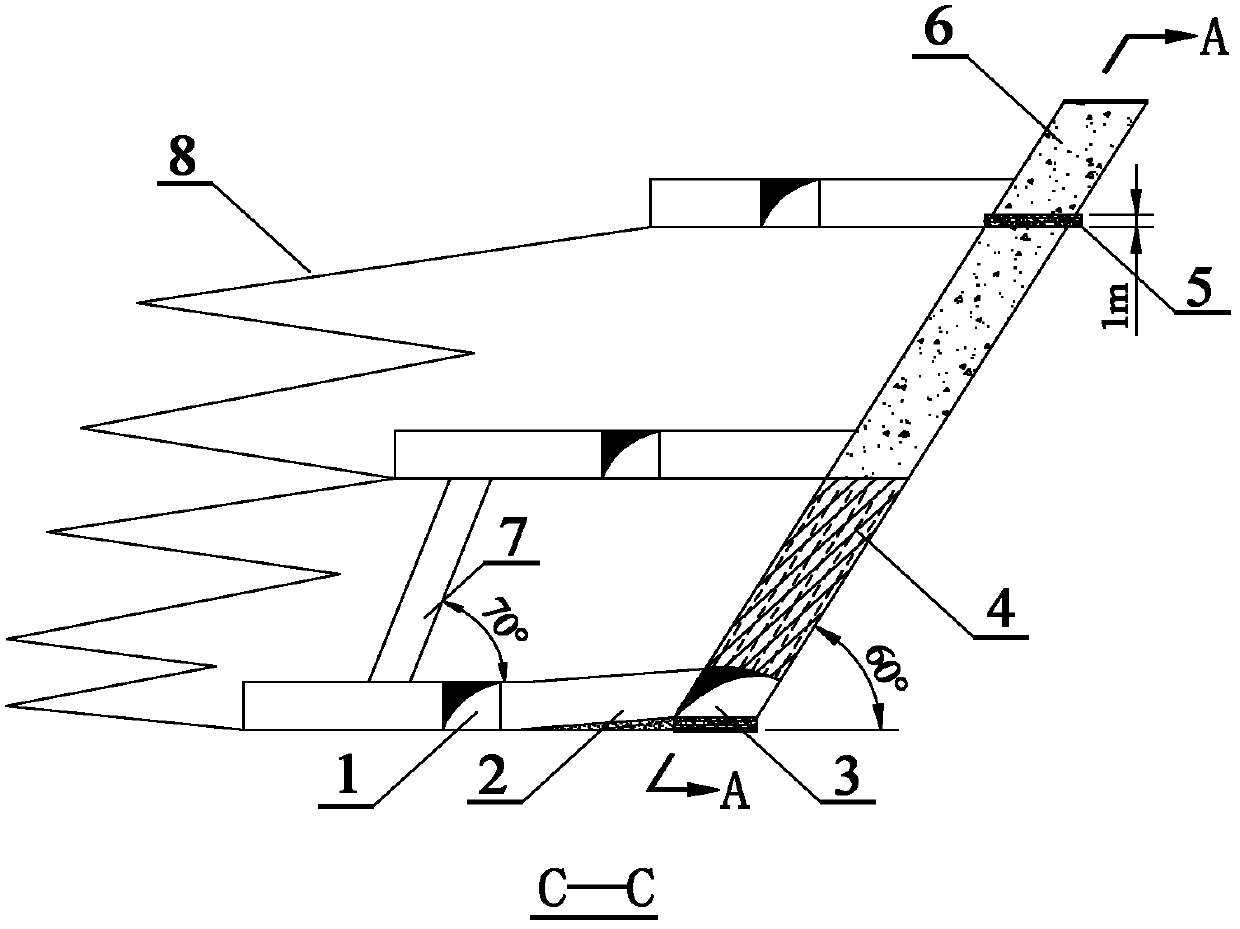

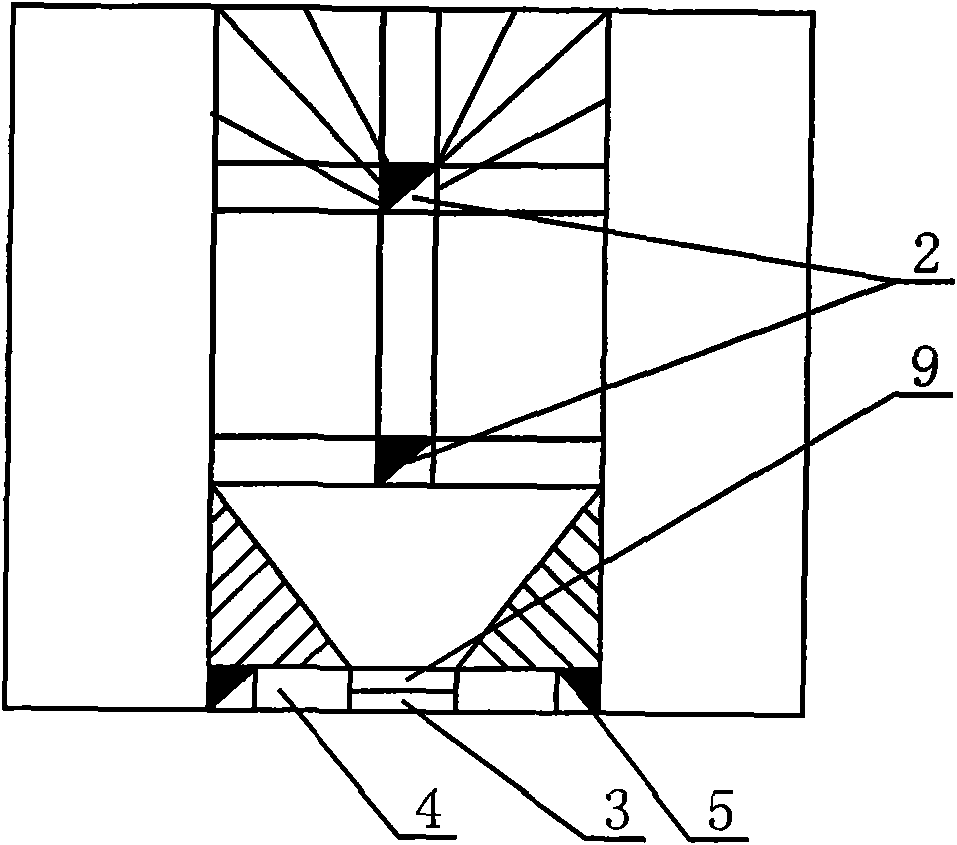

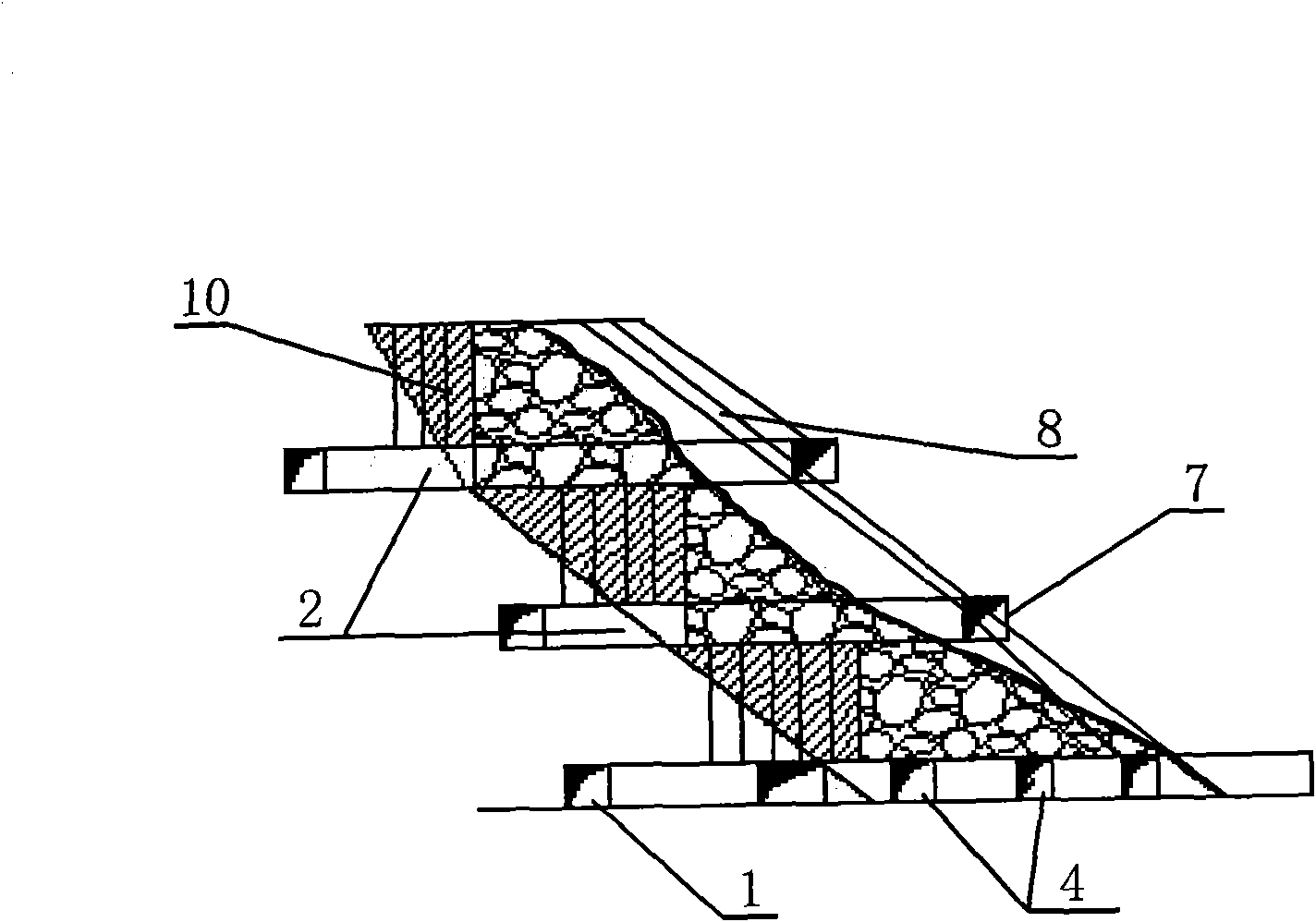

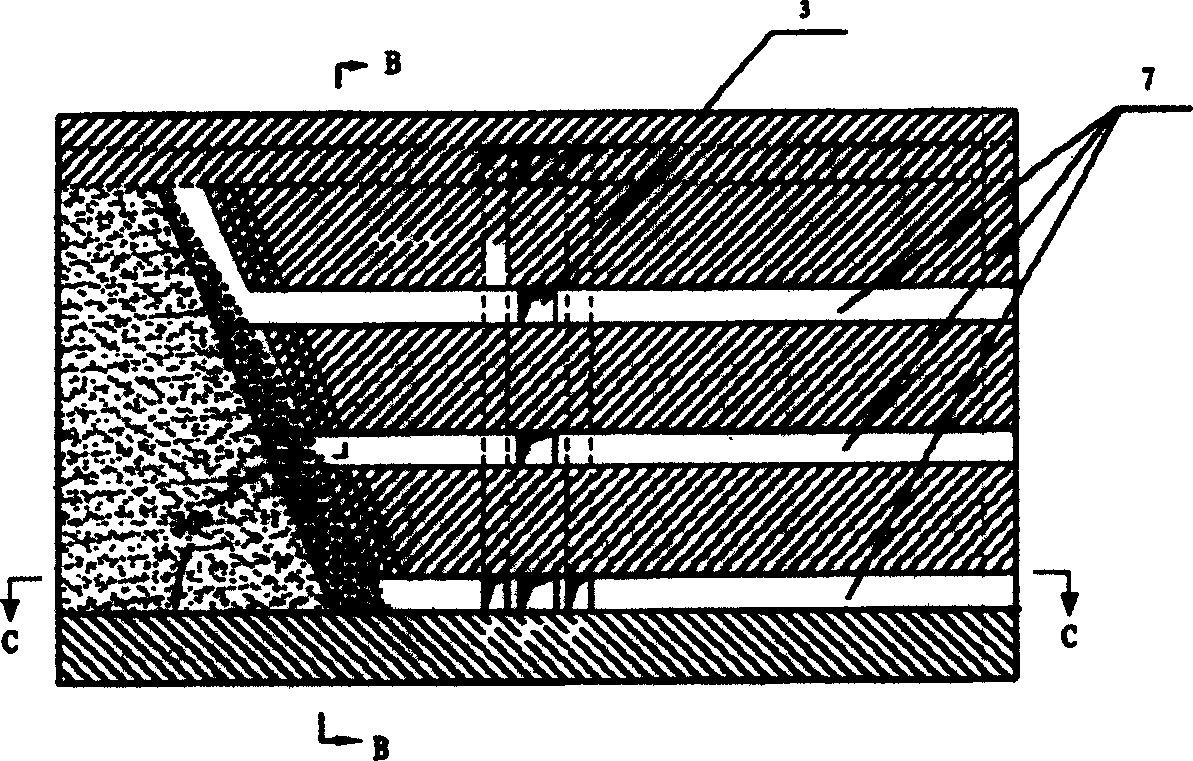

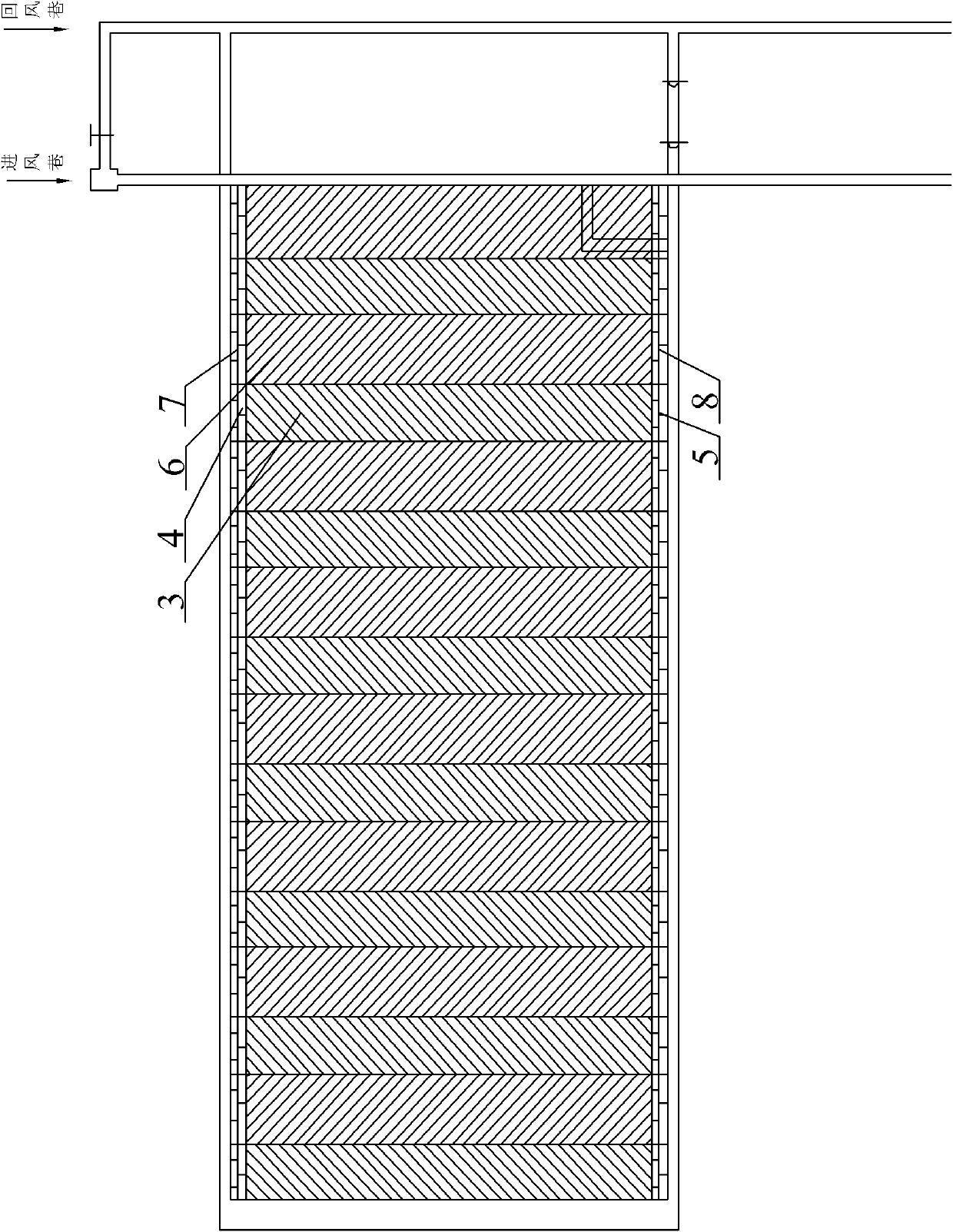

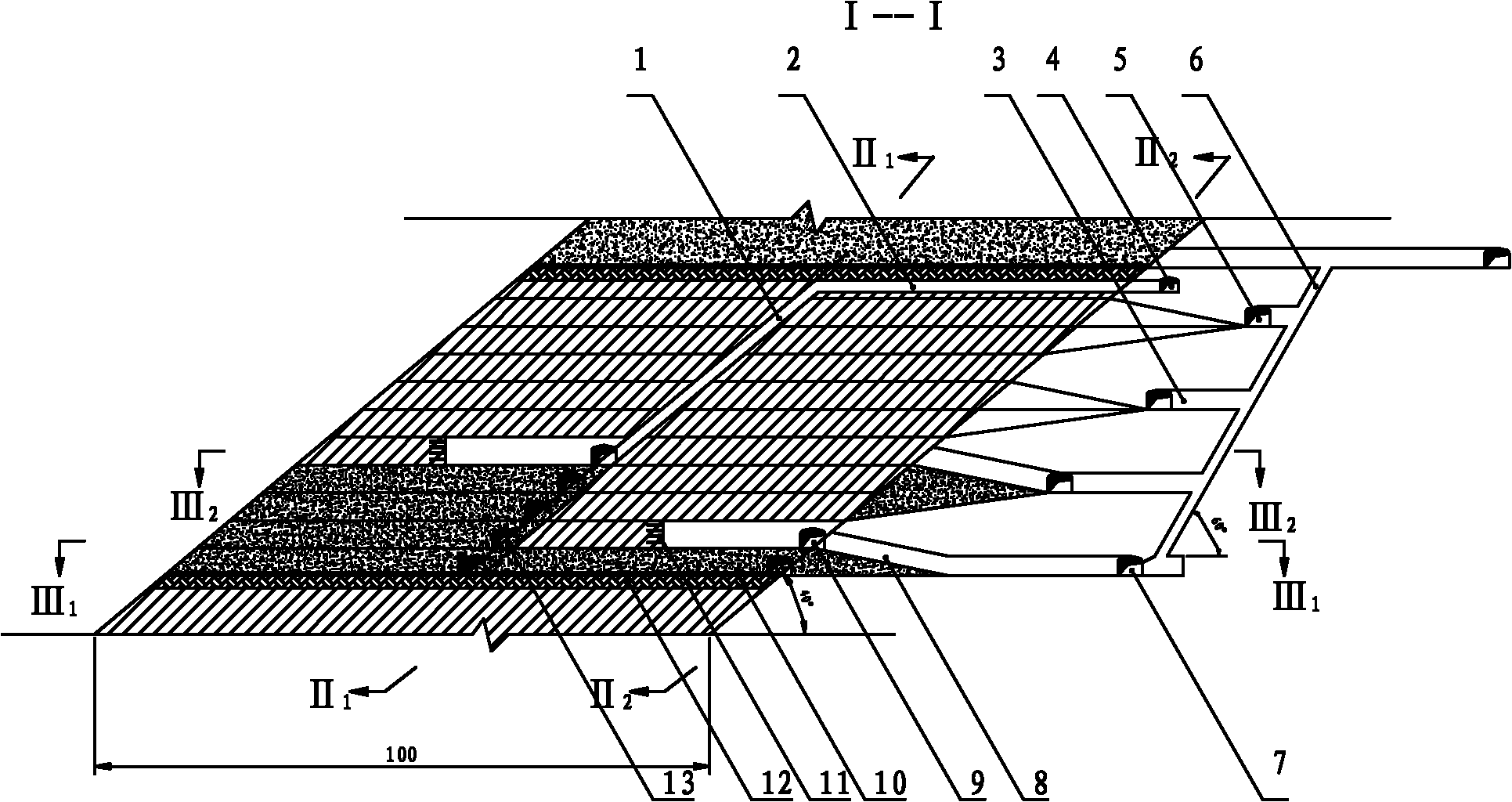

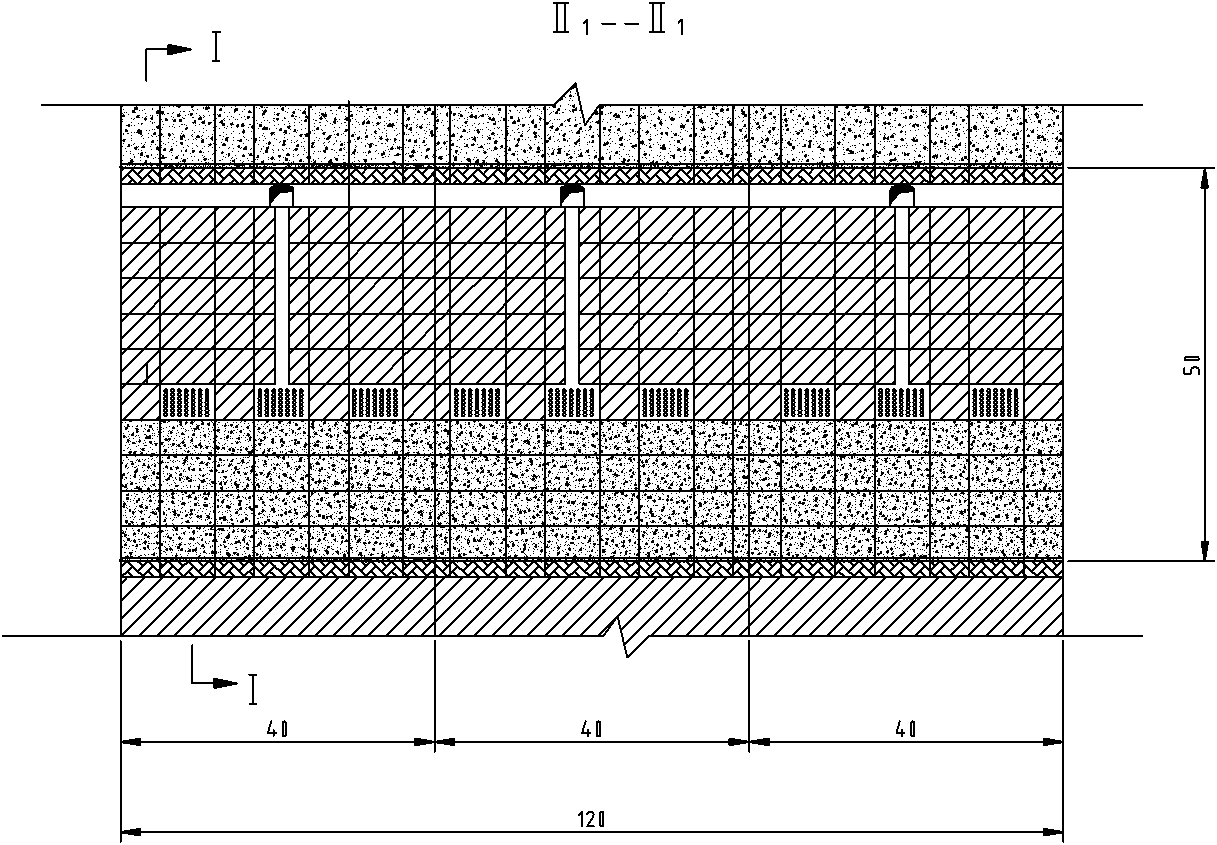

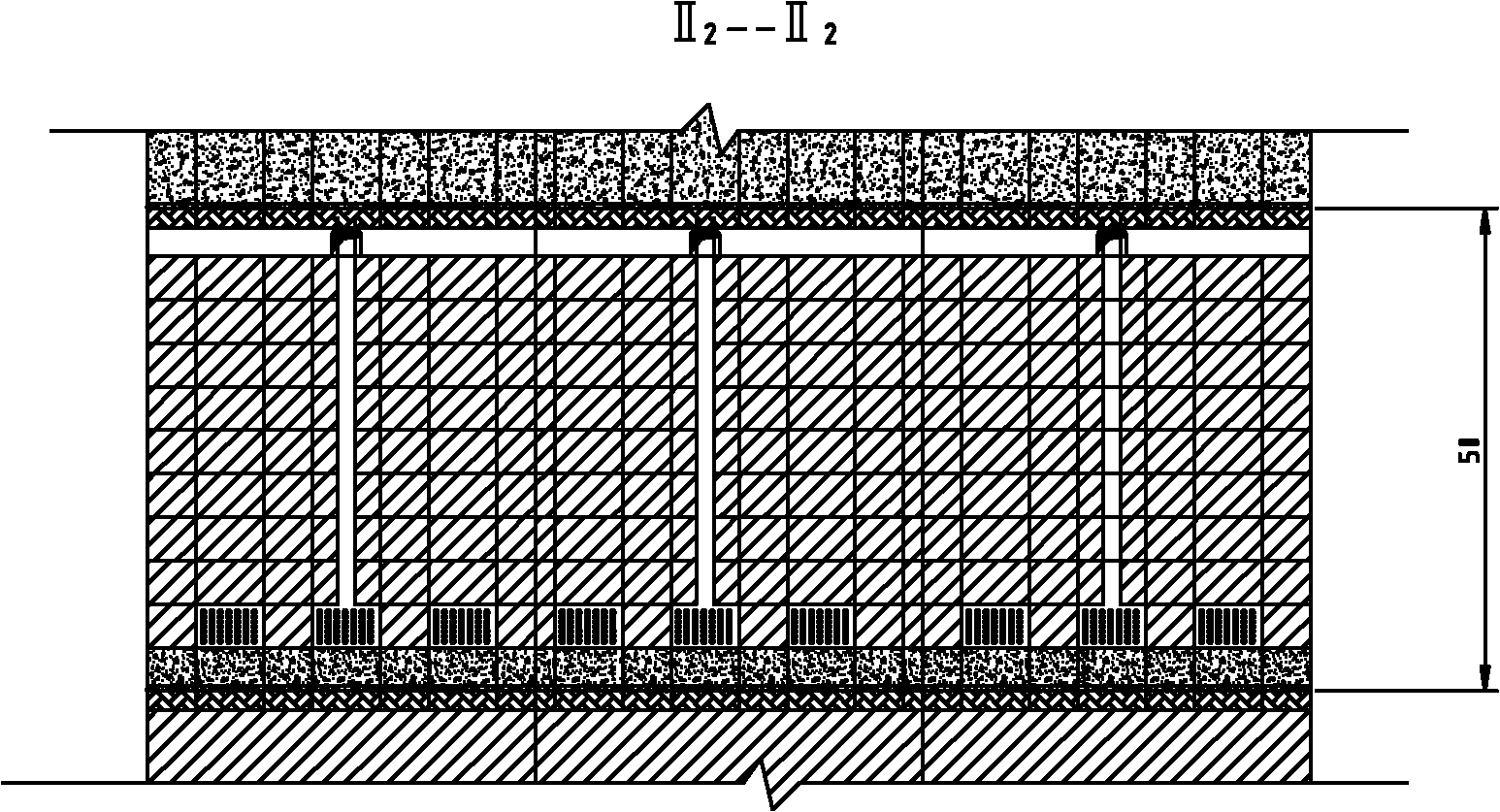

Upward and downward staged rock drilling, sublevel bottom cutting and ore removal subsequent backfilling mining method

ActiveCN106677780AImprove securityEnsure safetyUnderground miningTunnel/mines ventillationDetonationEngineering

The invention provides an upward and downward staged rock drilling, sublevel bottom cutting and ore removal subsequent backfilling mining method. The method includes the following steps that panels are divided in the ore direction, a stope preparation system is arranged, upward fan-shaped medium-depth blast holes are drilled from one side to the other side of a chamber, the blast holes are filled with explosives for detonation, and an undercut space is formed after detonation; cut grooves are formed through a VCR method, and as for ore above the undercut space, downward vertical deep holes are drilled in a drilling chamber at the top of the chamber, and the holes are filled with explosives for detonation with the cut grooves as a compensation space; the chamber in each panel is subjected to two-step backstoping, after ore removal of a first-step chamber is finished, the first-step chamber is filled with cementing materials, after the first-step chamber is filled and cured, a second-step chamber is subjected to backstoping, the backstoping steps of the second-step chamber are the same as those of the first-step chamber, and the second-step chamber is filled with cemented filling bodies and non-cemented filling bodies; and the steps are repeated in this way till backstoping of all chambers are completed. The upward and downward staged rock drilling, sublevel bottom cutting and ore removal subsequent backfilling mining method has the advantages that the rock drilling efficiency of the upward fan-shaped medium-depth blast holes is improved, the waste hole rate is lowered, efficient and safe bottom ore removal is achieved, and the mechanization level is high.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

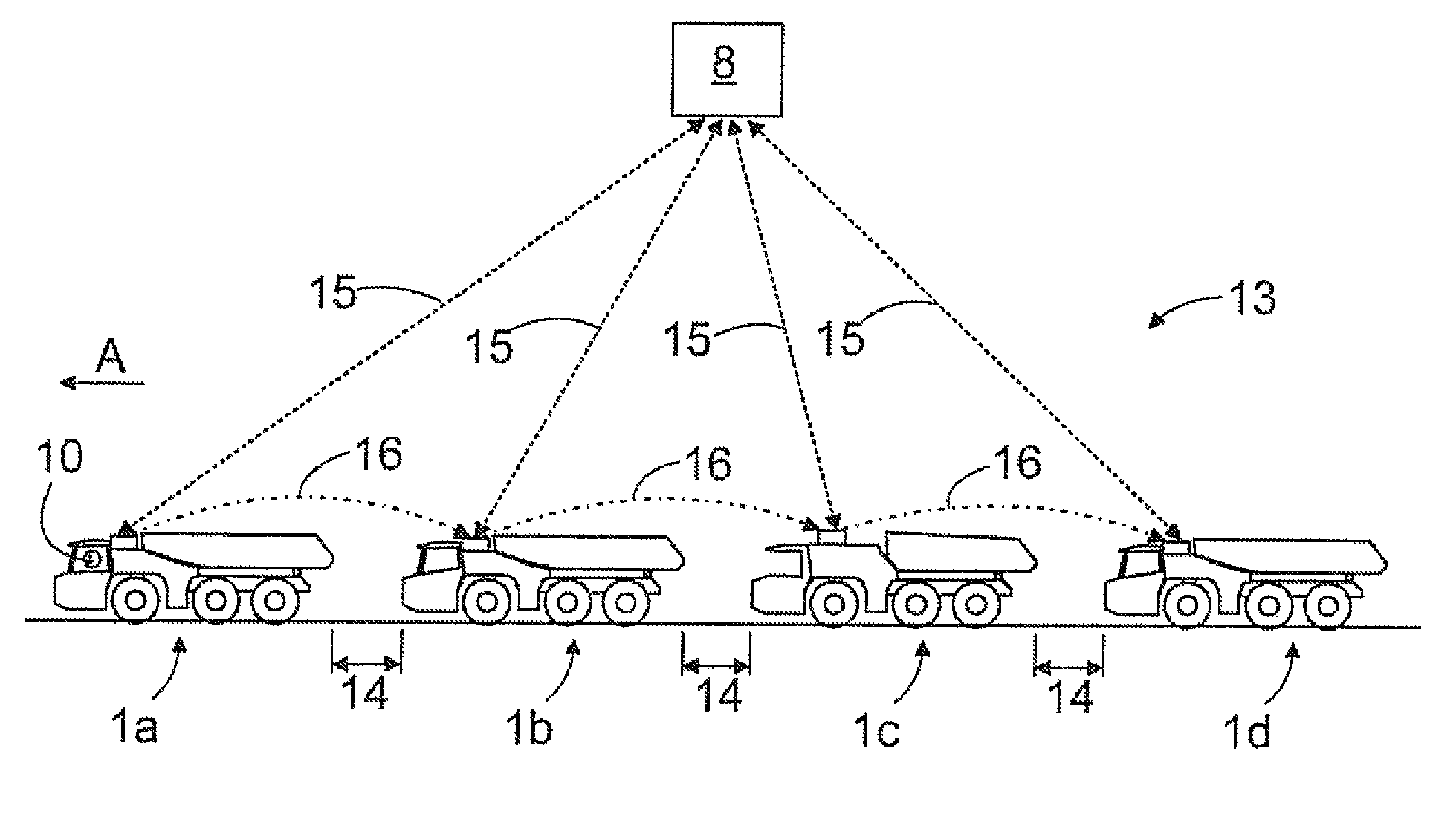

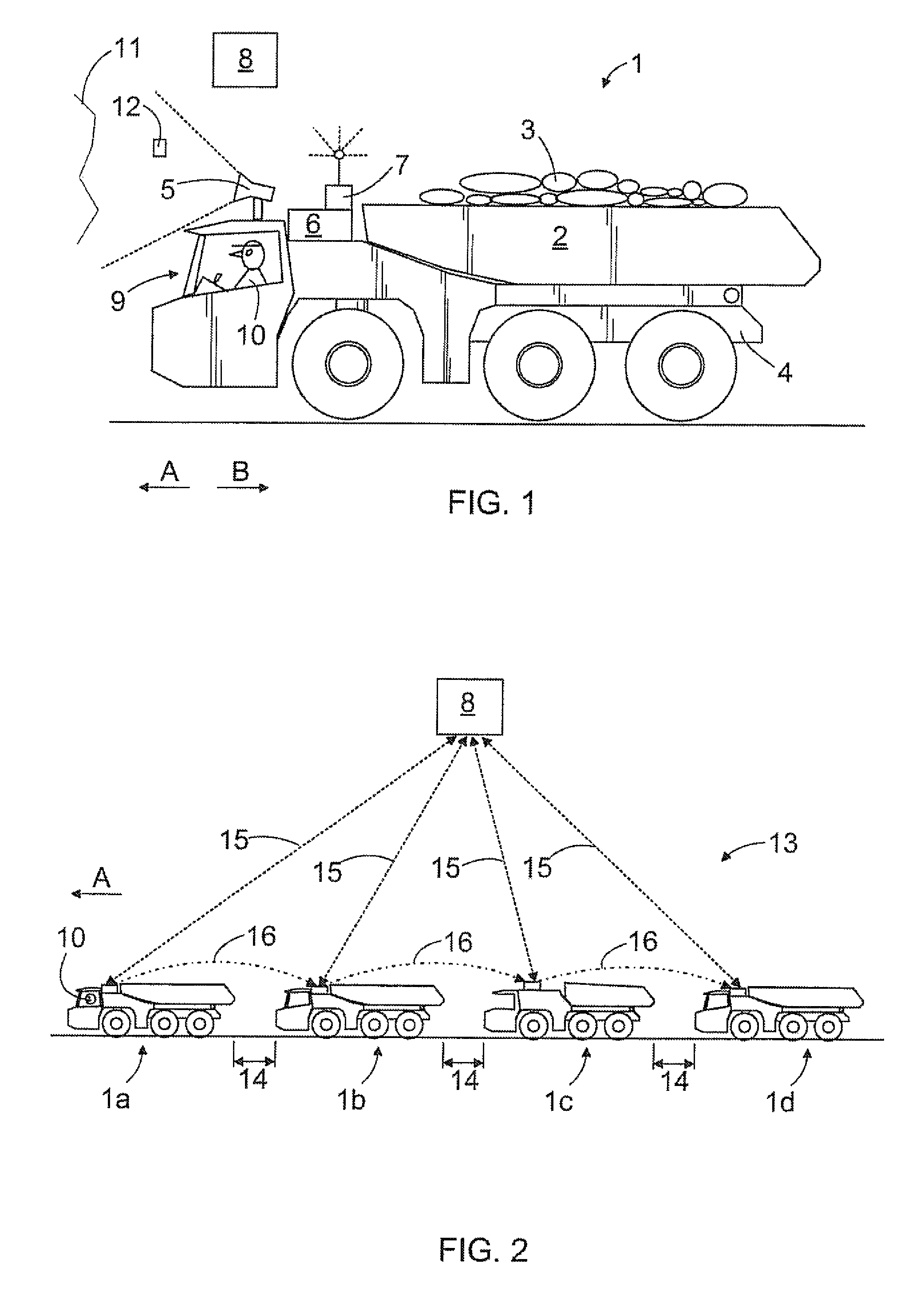

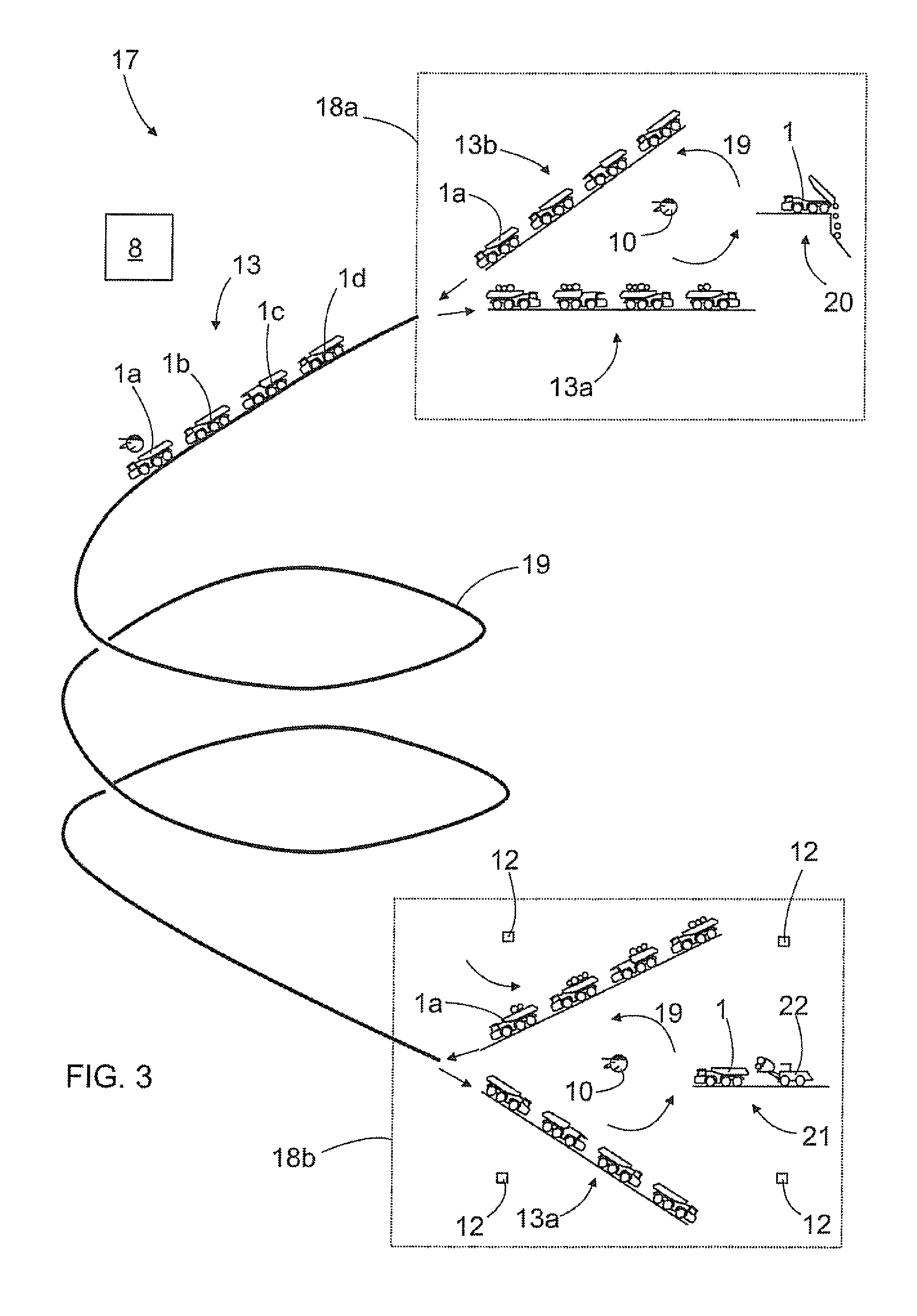

Method of driving plurality of mine vehicles in mine, and transport system

ActiveUS7831345B2Convenient ArrangementSimple and quick to useDigital data processing detailsControl initiation meansTransport systemSingle vehicle

A method of driving mine vehicles in a mine, and a transport system. A plurality of mine vehicles is arranged in succession and driven in convoy between working areas. A master vehicle in the convoy is driven manually, and slave vehicles follow the master, provided with no mechanical connection. In the working areas, the convoy is disassembled, since single vehicles are each driven separately. When assigned tasks in the working areas have been completed, the vehicles are reassembled into a convoy so as to be driven to a next working area.

Owner:SANDVIK MINING & CONSTR OY

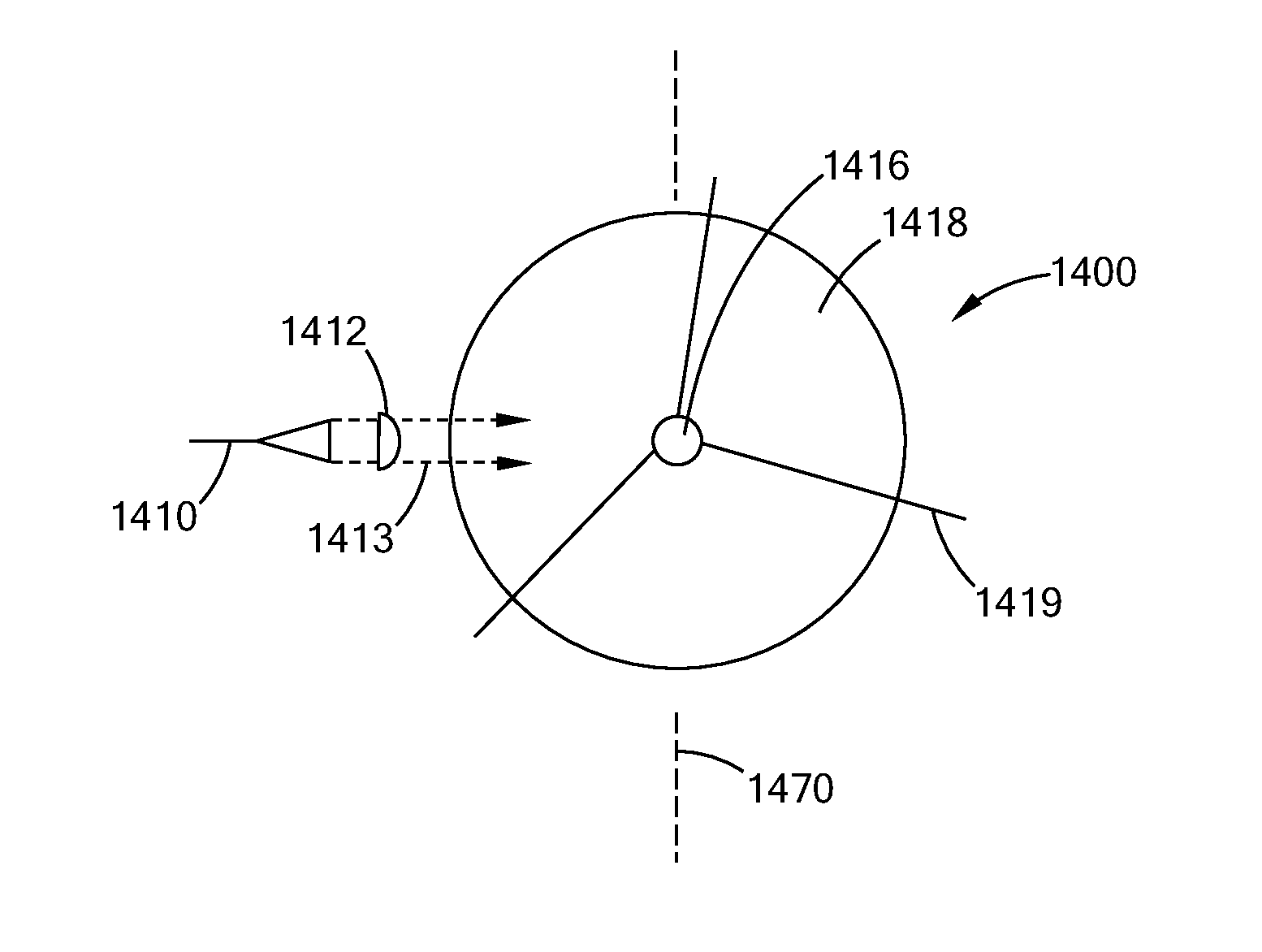

High power laser tunneling mining and construction equipment and methods of use

ActiveUS20140231398A1Underground miningWelding/cutting auxillary devicesHigh power lasersEngineering

There are provided high power laser and laser mechanical earth removing equipment, and operations using laser cutting tools having stand off distances. These equipment provide high power laser beams, greater than 1 kW to cut and volumetrically remove targeted materials and to remove laser affected material with gravity assistance, mechanical cutters, fluid jets, scrapers and wheels. There is also provided a method of using this equipment in mining, road resurfacing and other earth removing or working activities.

Owner:FORO ENERGY

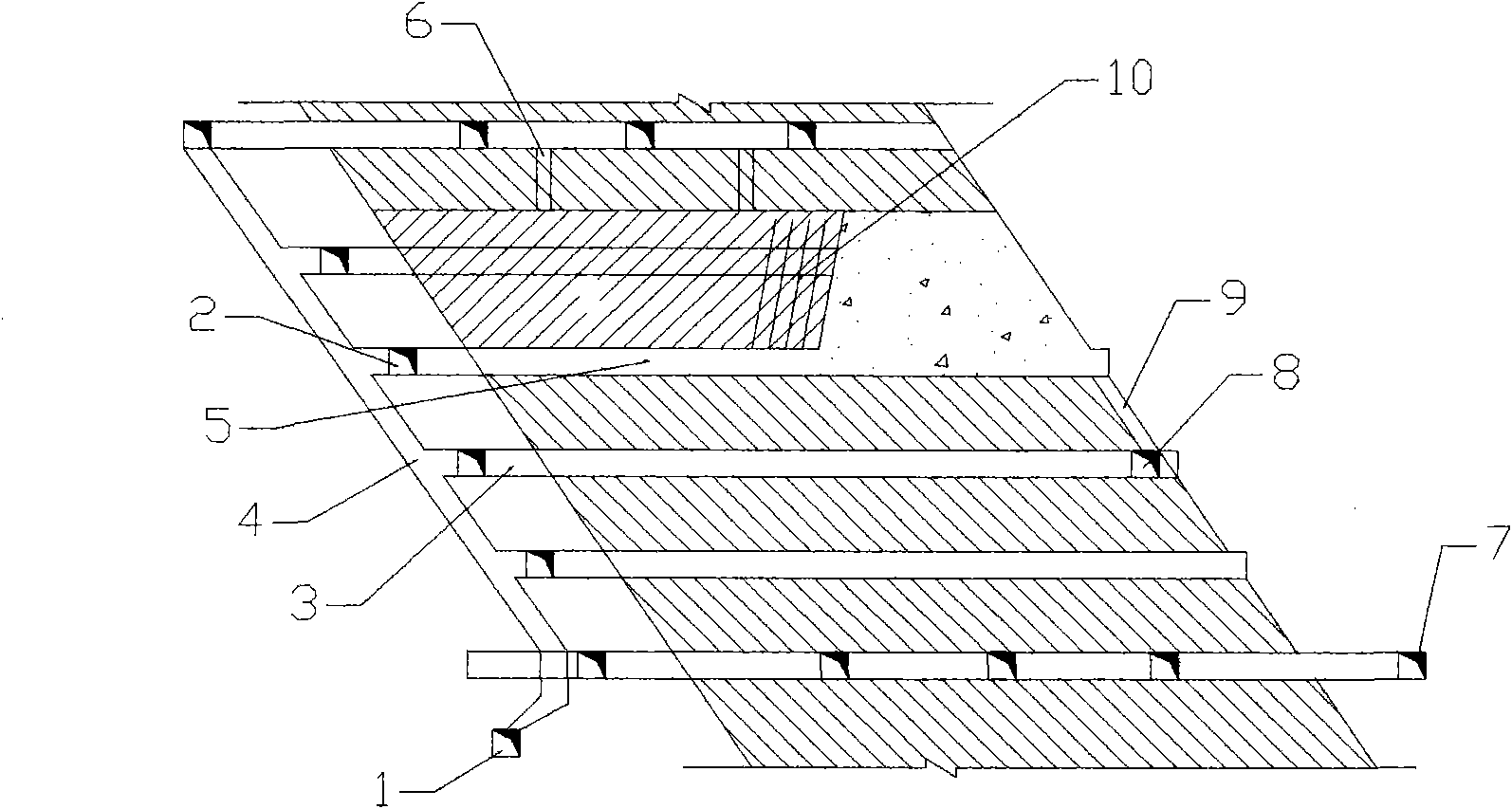

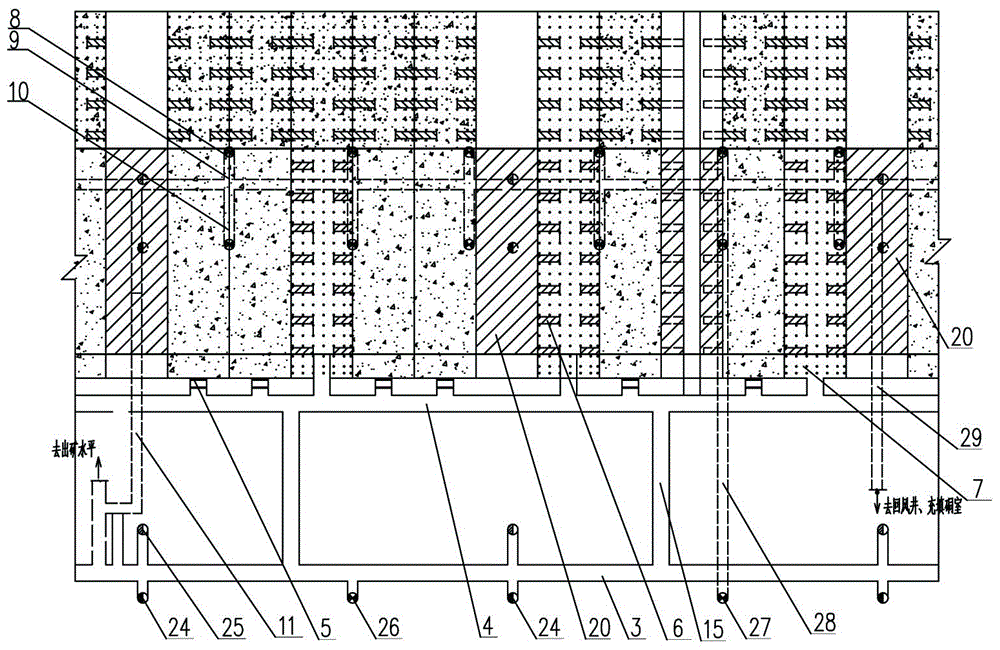

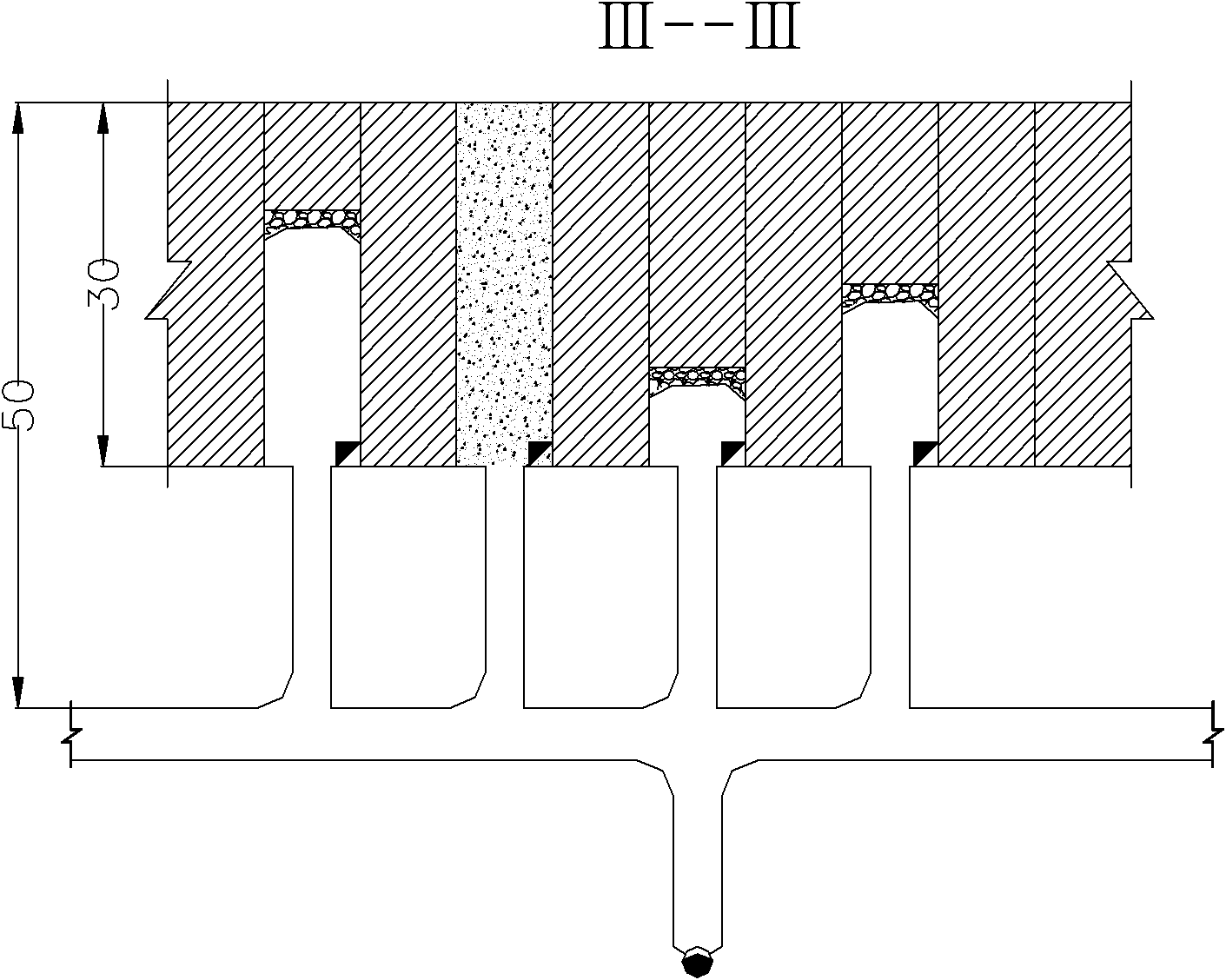

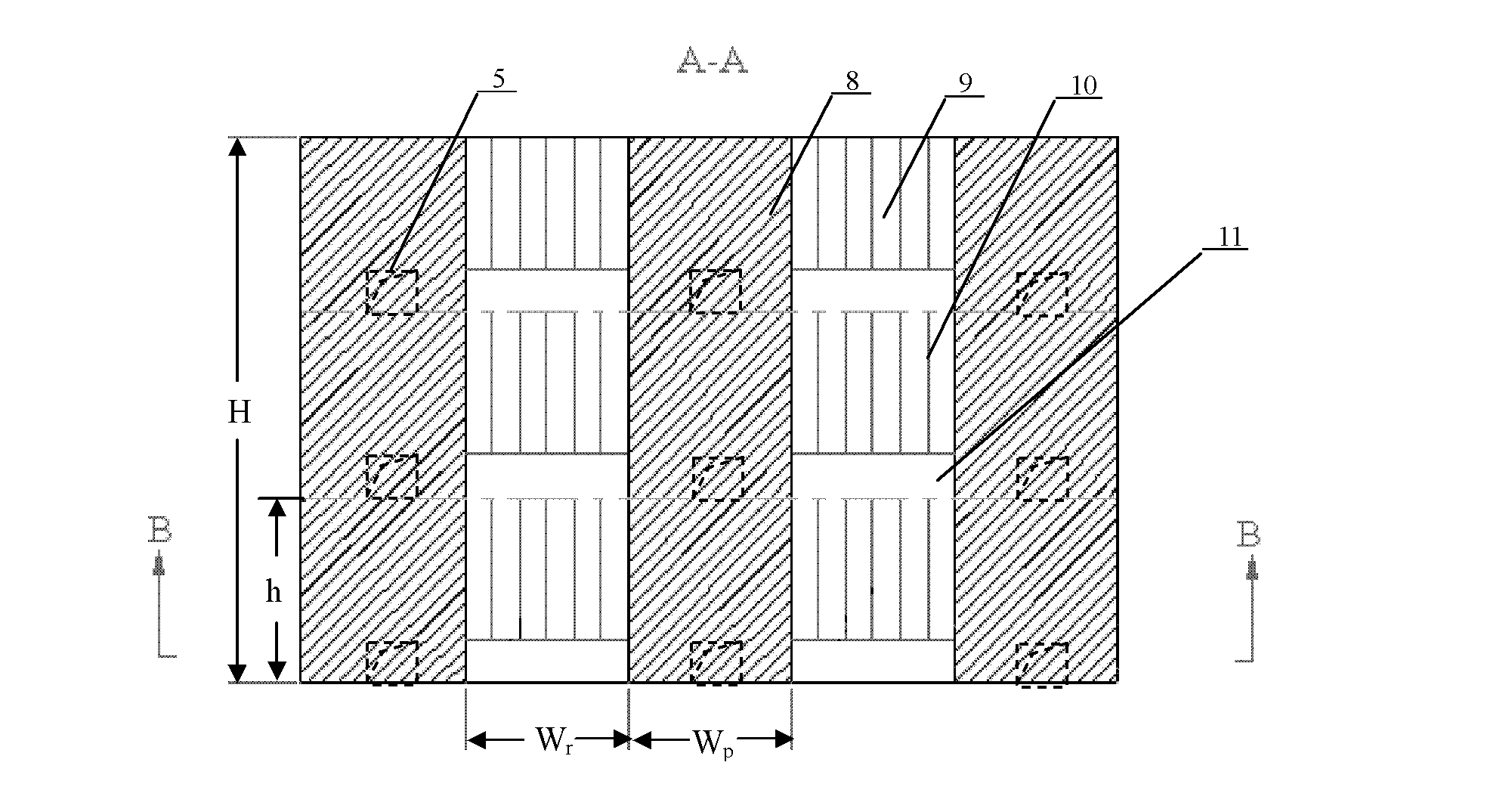

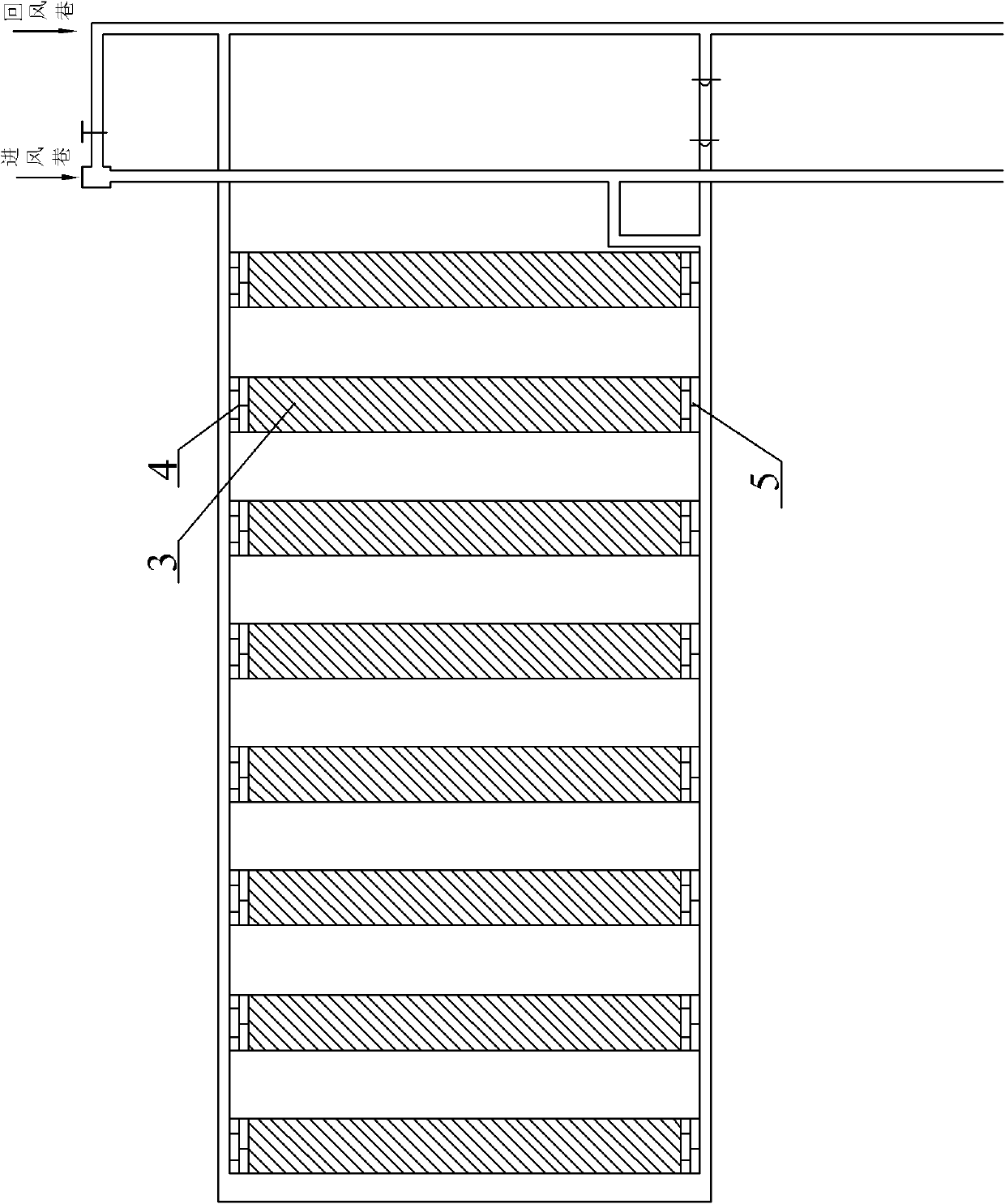

Medium thick heavy-pitch crushed ore body frame type artificial top downward segmenting cemented filling method

InactiveCN102606159AImprove efficiencyImprove securityUnderground miningTunnel/mines ventillationRoom and pillar miningReinforced concrete

The invention discloses a medium thick heavy-pitch crushed ore body frame type artificial top downward segmenting cemented filling method which comprises the following steps: dividing chamber jambs along the trend of an ore body; adopting a rail-less mining aligning system; pre-constructing a high-strength reinforced concrete artificial top in a segmented drilling lane; adopting a stoping sequence from up to down; performing drilling and blasting ore removal on the ore body through the segmented drilling lane at bottom; adopting medium-length hole drilling and remotely controlling a scraper to discharge ore; after finishing the mining of the chamber, utilizing concrete tailings to perform cemented filling; after finishing the mining of the jambs, utilizing concrete tailings or pure tailings to perform cemented filling; after completely stoping the mine chamber in the frame under the protection of the concrete artificial top, starting to stope the jamb adjacent to the segment, and meanwhile stoping the corresponding mine chamber in the frame of the next segment, and then stoping the corresponding jamb of the next segment; and after completely mining the chamber jamb in the middle segment, immediately turning towards the lower middle segment for stoping. The method provided by the invention has the advantages that the safety for mining the heavy-pitch medium thick crushed or ultra-crushed ore body is high, the resource depletion loss rate is low, the mechanical degree is high, the production capacity is high, and the like.

Owner:CENT SOUTH UNIV +1

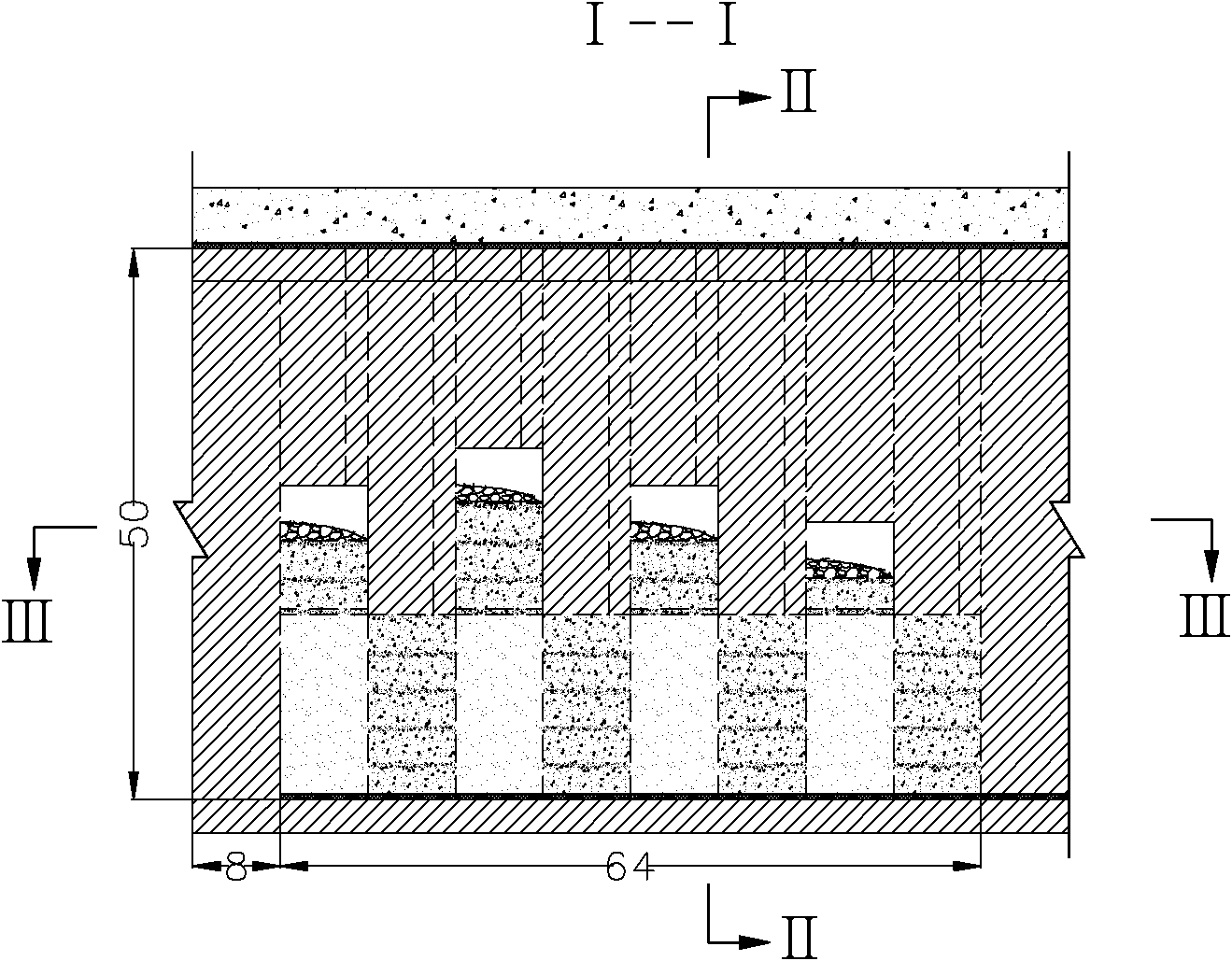

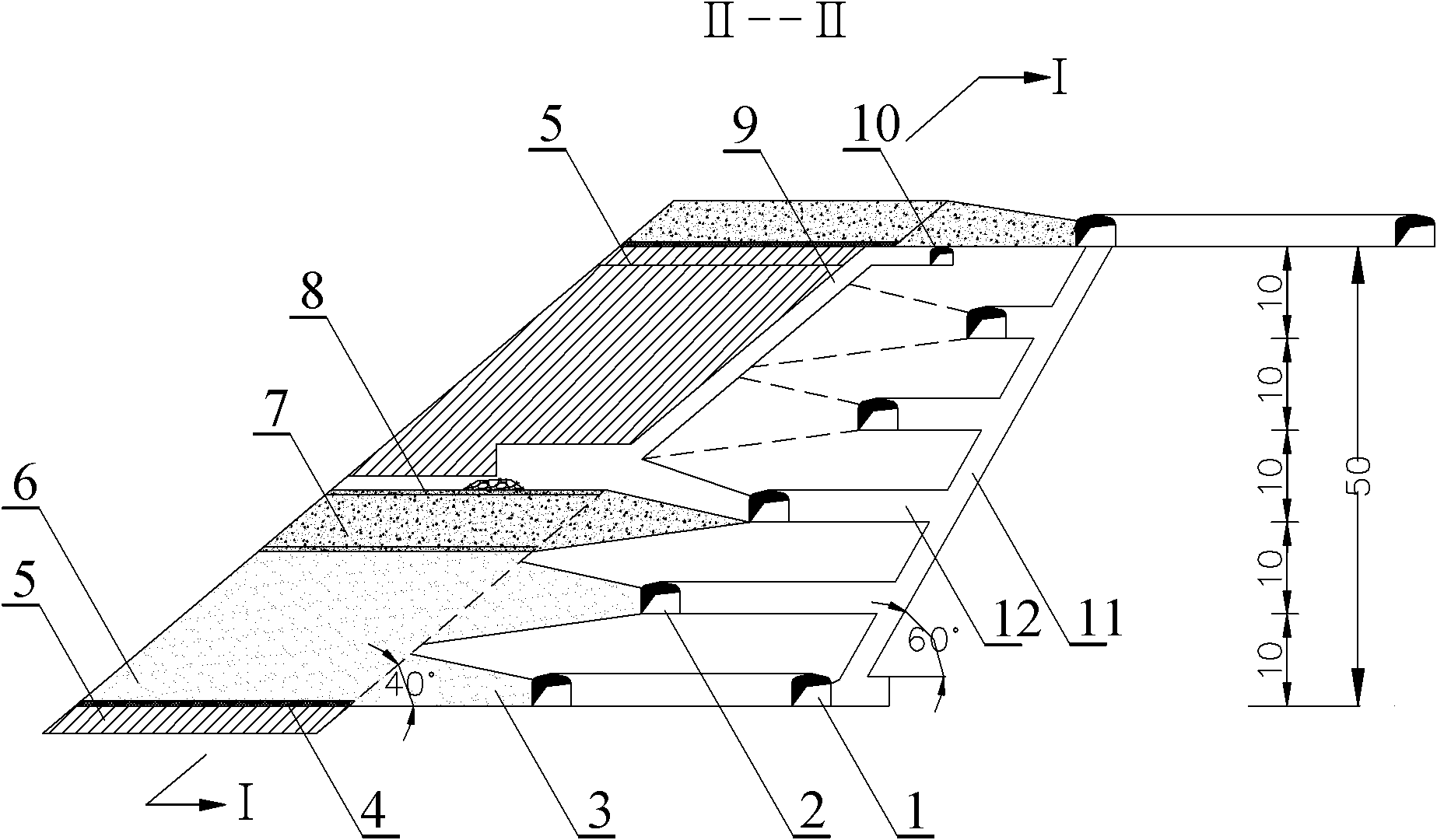

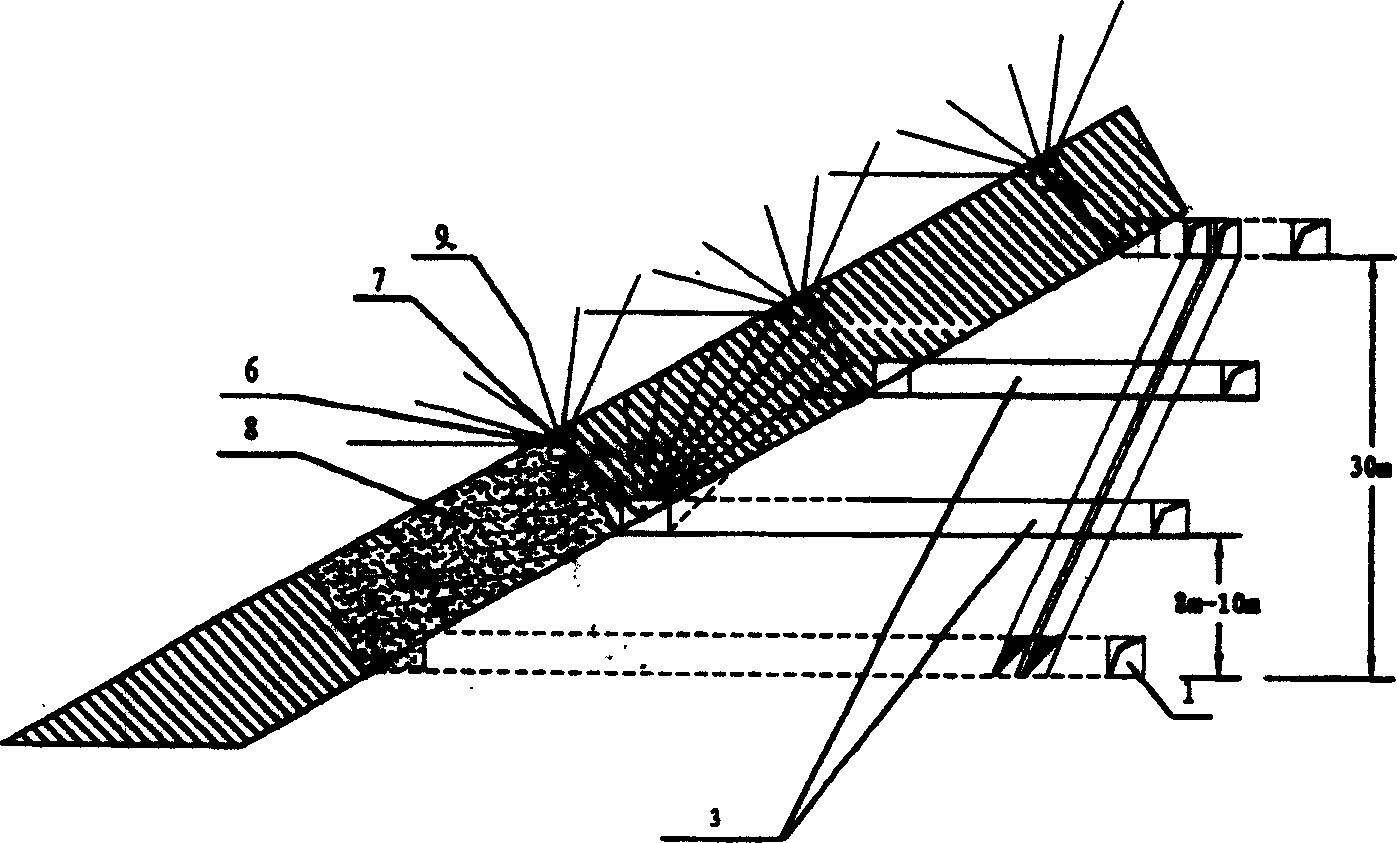

Efficient mining method for thick metal ore body in slanting

InactiveCN102182461ARealize continuous productionImprove mining efficiencyUnderground miningSurface miningEngineeringMetal

The invention relates to an efficient mining method for a thick metal ore body in slanting, comprising the following mining steps: constructing a transportation roadway outside a dike, constructing flat roadways for rock drilling by sections, constructing a cutting roadway, constructing a cutting well, constructing a cutting groove and reserving a temporary triangular ore pillar, constructing a trench, constructing a sector medium-deep hole and implementing blasting and ore removal, and recovering residual ore. The method realizes safe and efficient recovering of metal ore bodies with the inclination of 30 to 55 degrees and the average thickness of 4 to 15m by adopting a medium-deep hole blasting ore dropping valve under the circumstance without a filling condition, thereby further improving the mining recovery rate and the mining efficiency.

Owner:SHANDONG GOLD MINING LINGLONG

House pillar changeable panel upward demix filling mining method

InactiveCN101858217AReduced suspension heightImprove integrityUnderground miningSurface miningRoom and pillar miningMineralogy

The invention discloses a house pillar changeable panel upward demix filling mining method. An ore body is divided into an ore house and an ore pillar arranged at intervals along the strike direction; a plurality of house pillars form a panel; a rock trackless preparation system is adopted and comprises a ramp, a rock slice drift, a demix ventilation connection and a rock concentrated ore removal winze; the mechanical upward demix filling mining method is adopted for mining, which mines a slice and fills the slice until the position required by the lower slice blasting compensation is reached. The backstopping order of the house pillars in the panel is the ore house first and then the ore pillar; all ore houses are subjected to upward backstopping at the same time; after a backstopping unit of the ore house is finished, the roof-contacted filling is carried out, and the mining of the ore house is temporarily stopped and the mining of the ore pillar is started; after two backstopping units of the ore pillar are finished, the roof-contacted filling is carried out, and the mining of the ore house is resumed; the abovementioned steps are repeated until the backstopping of the ore block is completed. The invention has the remarkable characteristics of improving the backstopping safety, reducing the resource dilution rate, lowering the support cost, increasing the enterprise profit, and the like.

Owner:CENT SOUTH UNIV +1

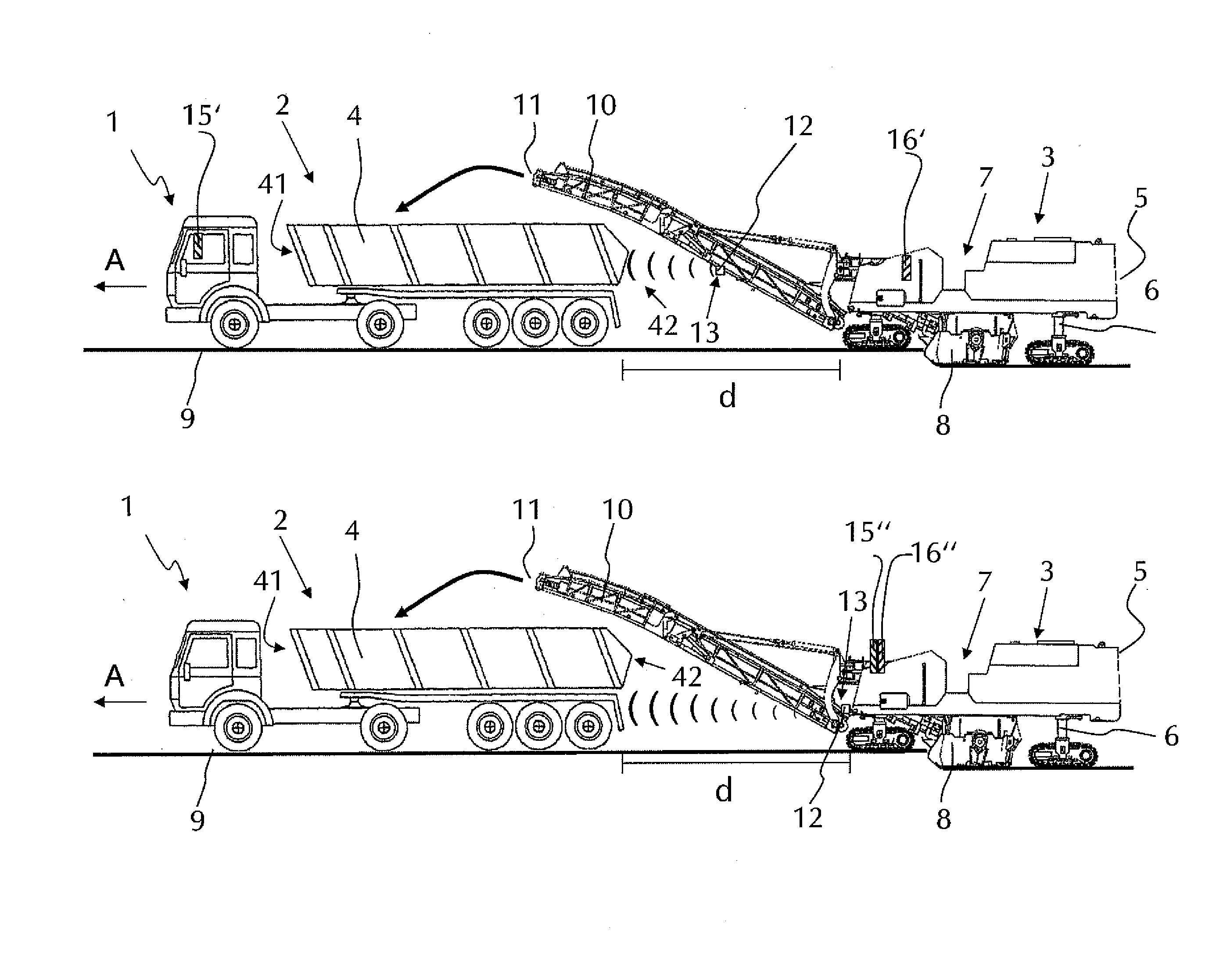

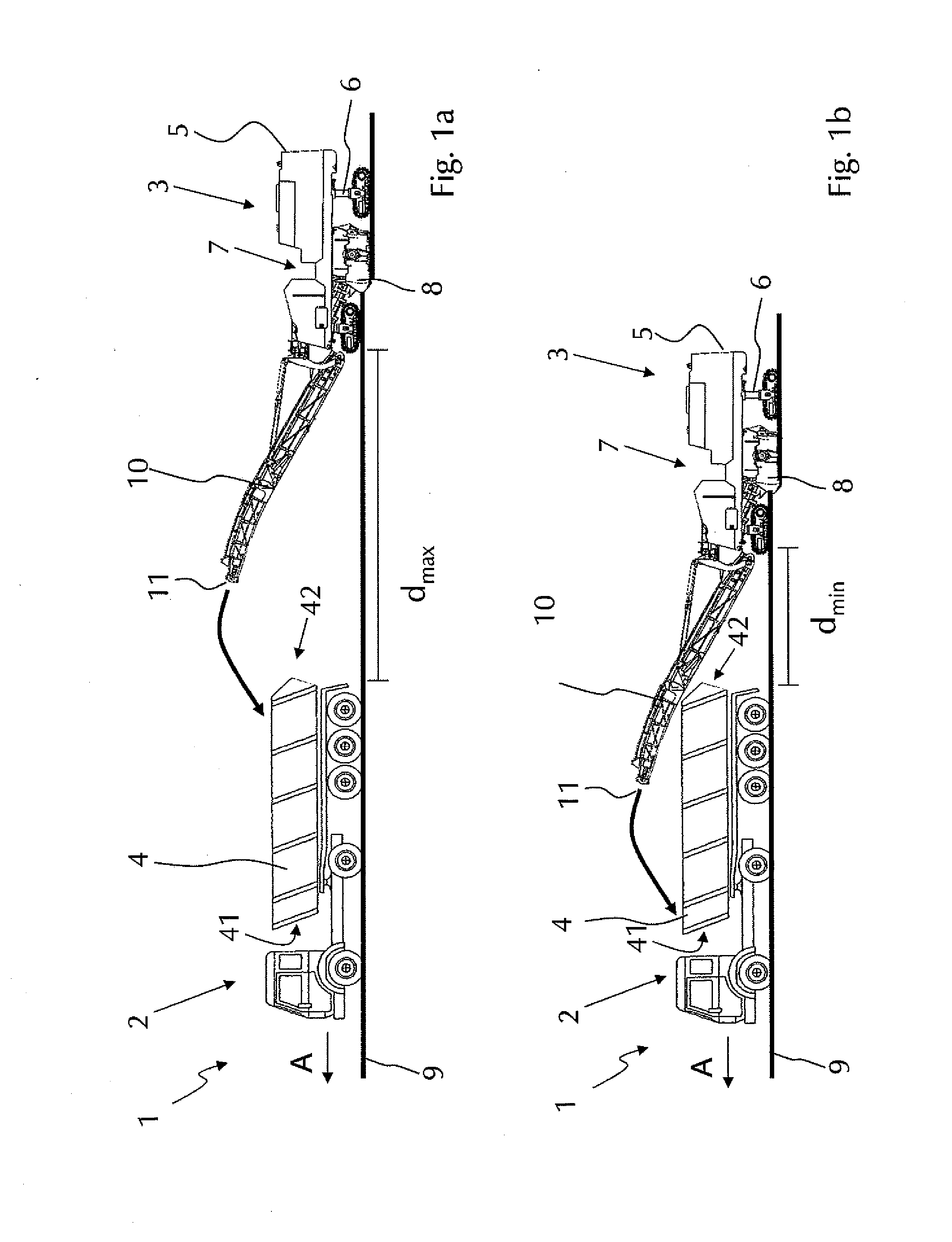

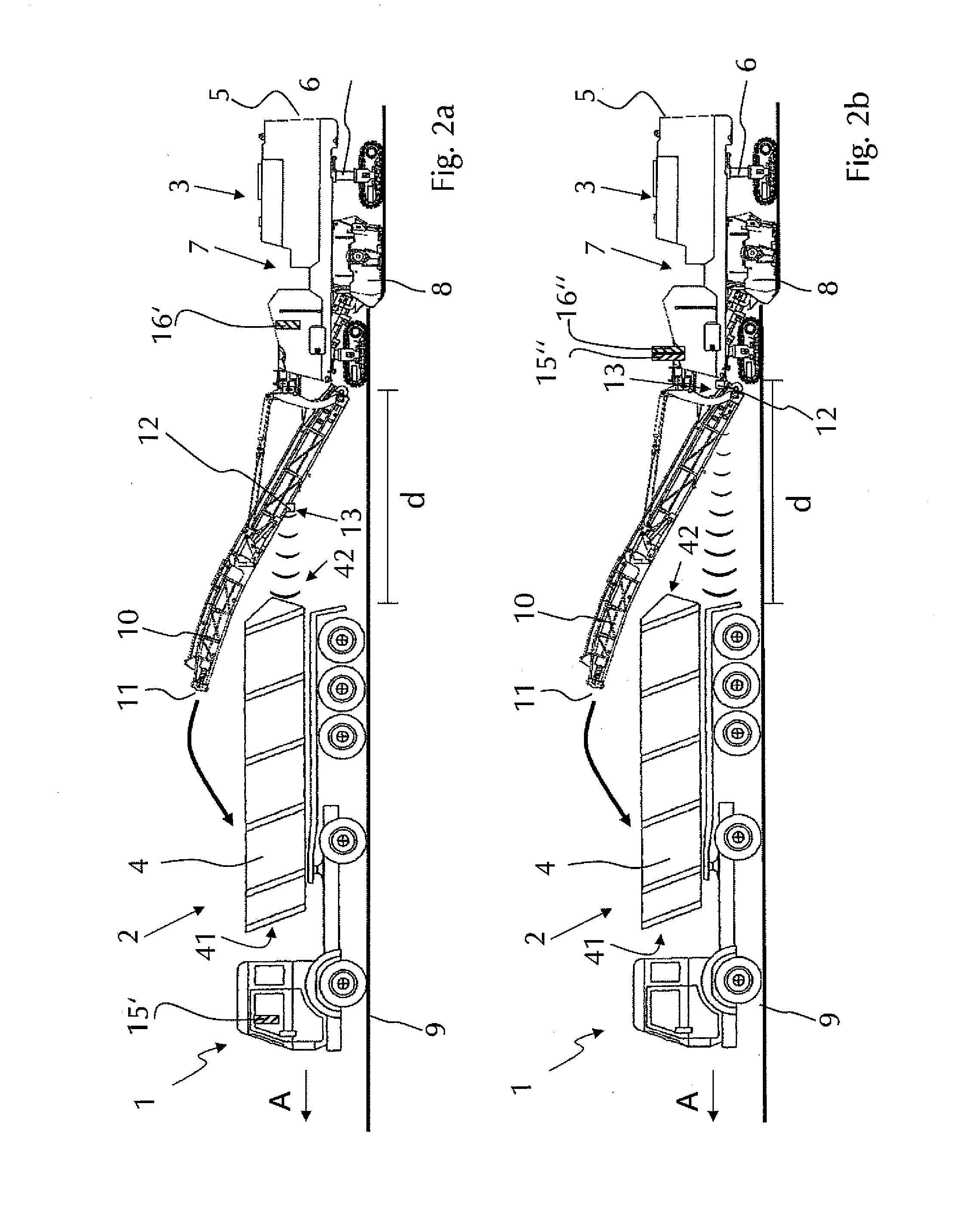

Work Train With A Milling Device And A Transport Device With A Sensor Device For Distance Monitoring, Milling Device With A Sensor Device And Method For Distance Monitoring With A Work Train

ActiveUS20130076101A1Relieve pressureMinimize disruptionVehicle testingRegistering/indicating working of vehiclesDisplay deviceEngineering

The present invention relates to a work train, a device and a method for distance measurement between a transport device and a milling device. During the loading of a transport device with milled material from the milling device, the operator of the milling device normally transmits control commands to the transport device driver for coordination of the loading process. Through the automated distance measuring between the transport device and the milling device and control of a display device according to the present invention, this task is taken over from the operator of the milling device, who can concentrate on the actual milling process.

Owner:BOMAG

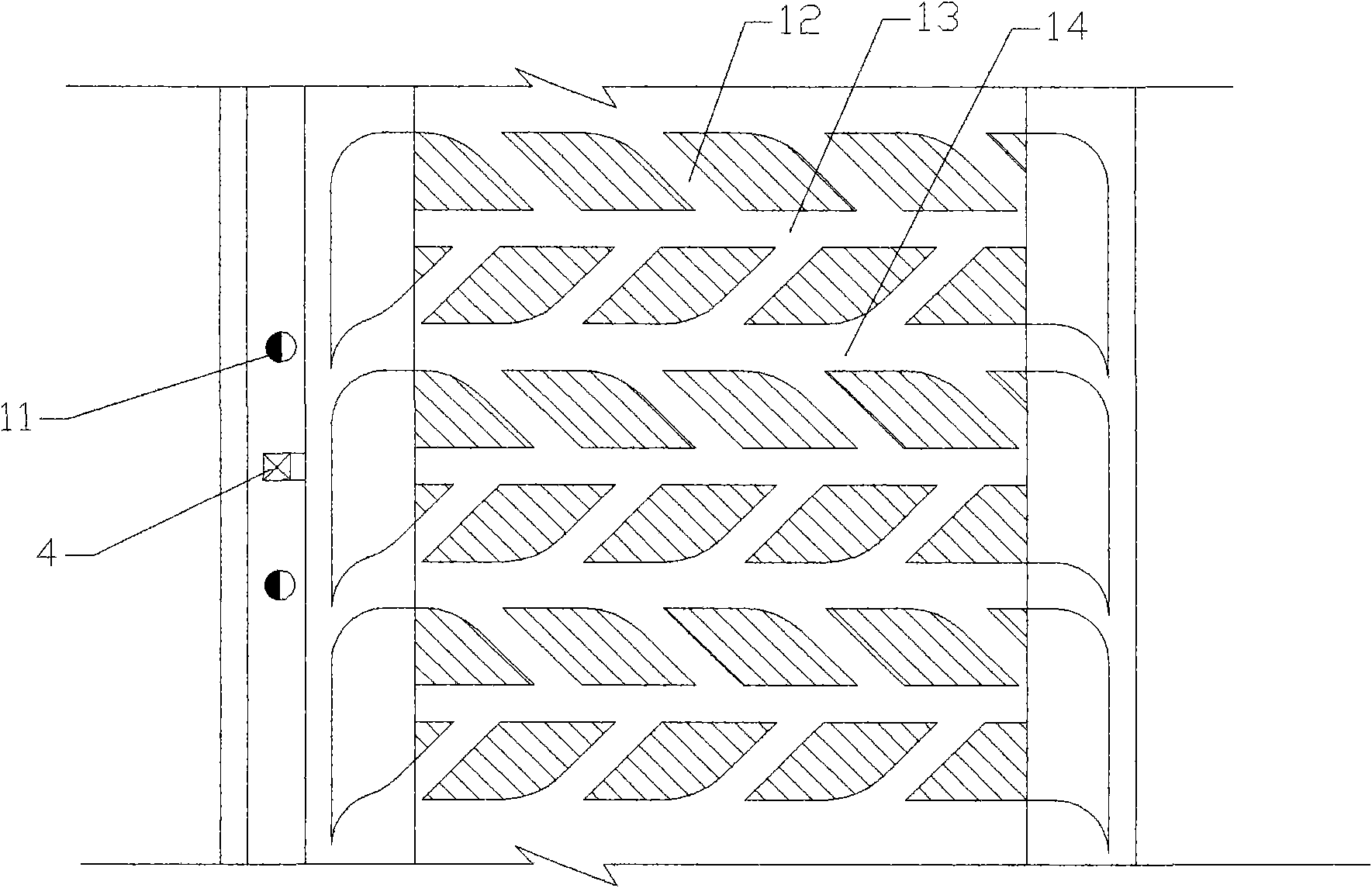

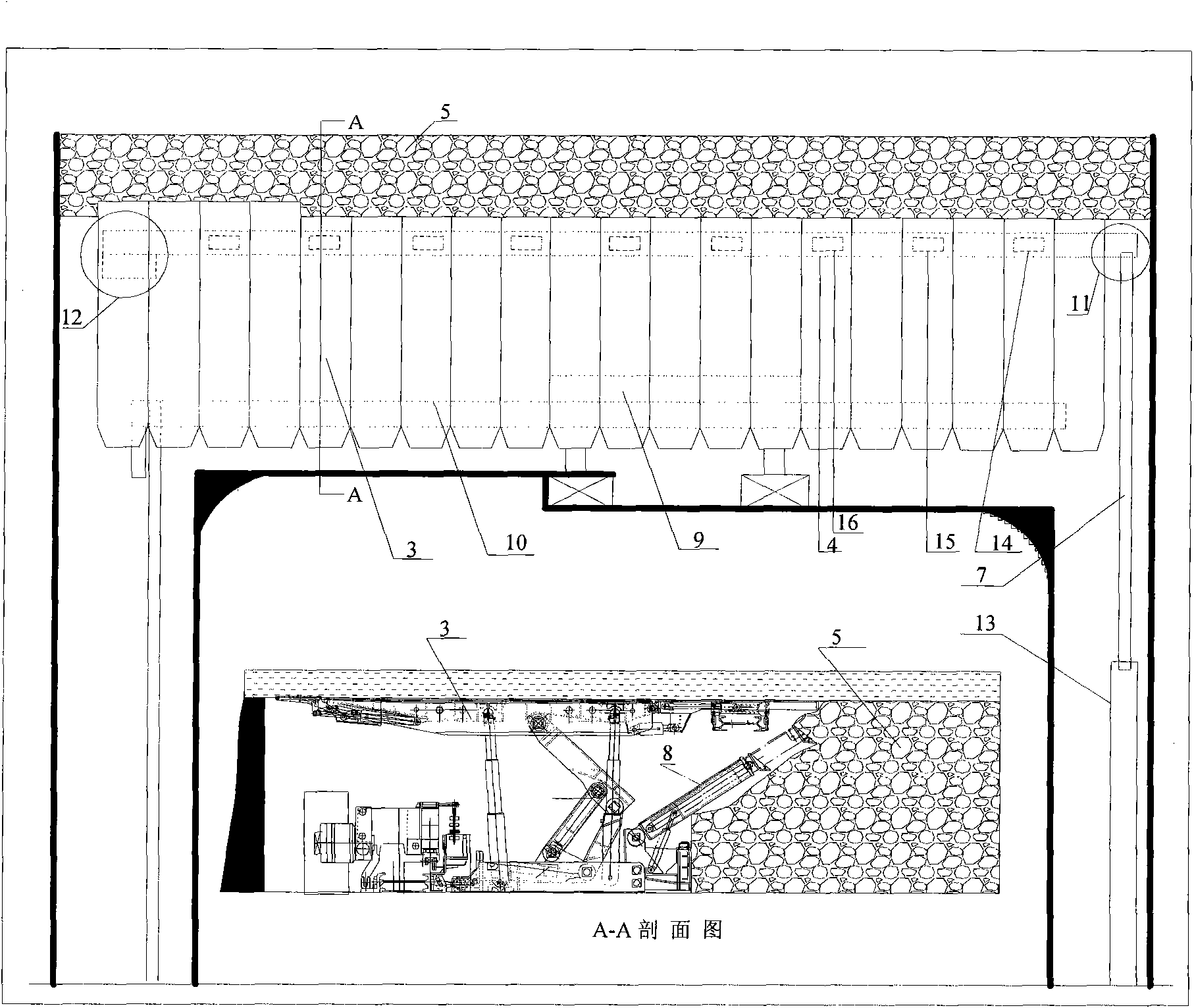

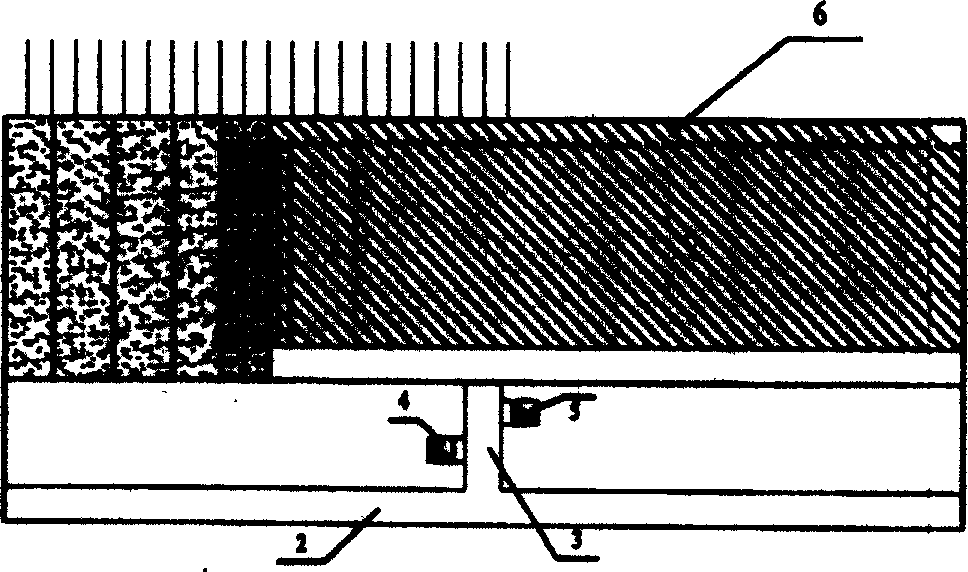

Coal mining solid filling method

InactiveCN101586460AHelps control sinkingEasy to useUnderground miningSurface miningSolid massFilling materials

A coal mining solid filling method comprises following steps: using the stacked solids on the ground as the filling materials for the working surface goaf, directly putting the solid filling materials from the ground to a belt conveyor in the underworkings by a perpendicular feeding well, transporting to the end of a coal face through the underground belt conveyor, reloading the solid filling materials to a solid filling mining conveyor hung under a back tail beam of a self-impacting type filling hydraulic support by a self-moving type filling material reloading machine. In the process of mining work, the coal is mined and the filling materials are filled on the bottom; and the solid filling materials are compacted by means of a compactor of the self-impacting type filling hydraulic support. The method solves the problem of coal compaction under the building and low coal recovery.

Owner:CHINA UNIV OF MINING & TECH +1

Method for extracting gas from high gas low permeability coal seam by punching, slotting, pressure releasing, and permeability increasing

InactiveCN101644166AImprove flow statusEasy to extractUnderground miningSurface miningHigh pressure waterHigh pressure

The invention discloses a method for extracting gas from high gas low permeability coal seam by punching, slotting, pressure releasing and permeability increasing, comprising the following steps: whena drill is drilled into a predetermined position of the coal seam, coal bodies at both sides of a drill hole are cut in the drill hole by high pressure water jet with a certain pressure and flow; a flat slot is formed at both sides of the drill hole; the cut coal bodies is led out the hole by the high pressure water jet. The exposed area of the coal body at the slotted part in the drill hole aregreatly increased, namely that an extremely thin protective layer is exploited with local scope of the flat slot, which enlarges effective influential range of pressure releasing, permeability increasing and gas discharging of the coal bodies in the drill hole, thus the air permeability of the coal bodies is increased about 200-300 times, the average amount of single-hole gas extraction reaches 0.3m<3> / min, the concentration of the gas extraction is 30-60%, gas drainage rate of working face of coal extraction is more than 50%, the number of drill holes for gas drainage is reduced by 10-20% after slotting, pressure releasing and permeability increasing. The method realizes the safety, high efficiency and uniform extraction of the gas from the high gas low permeability outburst coal seam, and changes high gas coal seam with outburst danger into low gas coal seam without outburst danger.

Owner:CHINA UNIV OF MINING & TECH

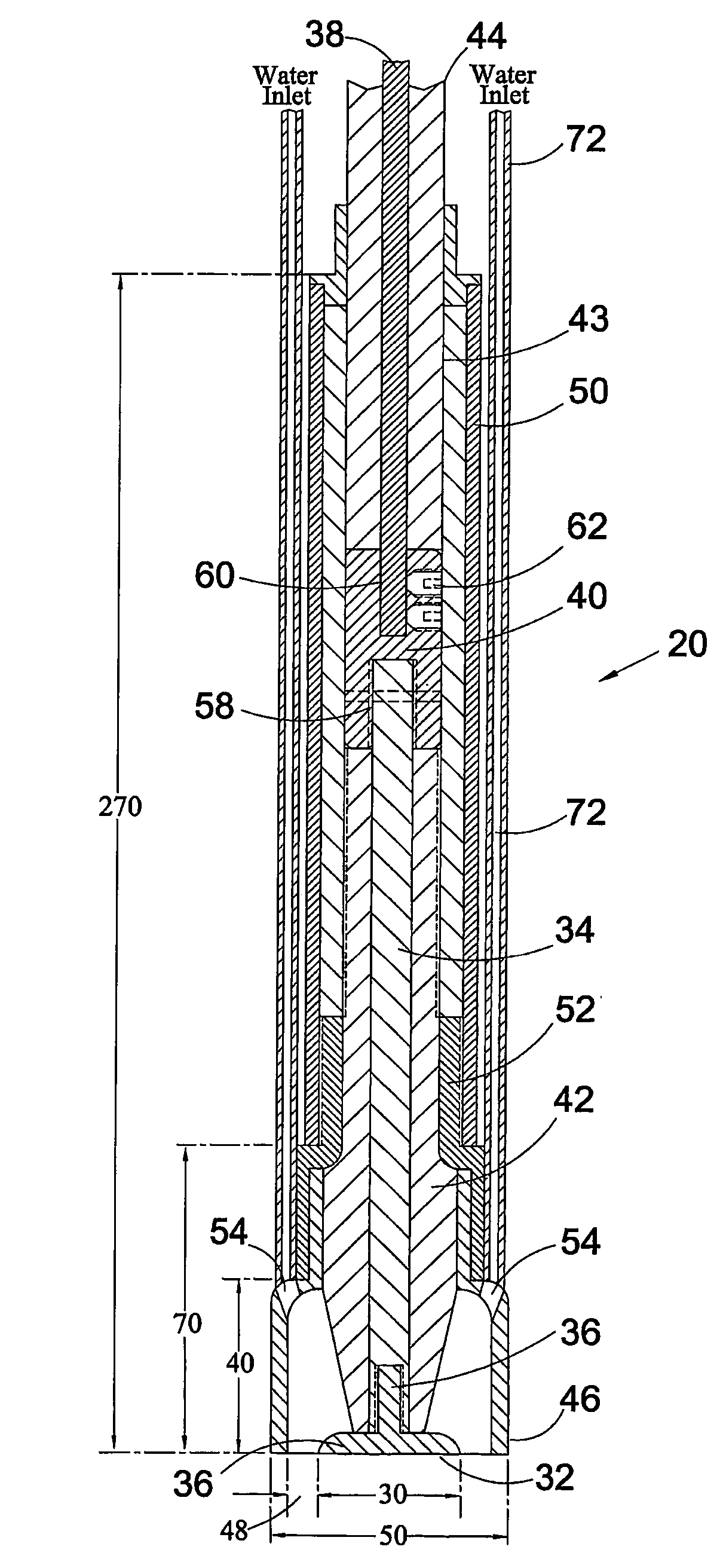

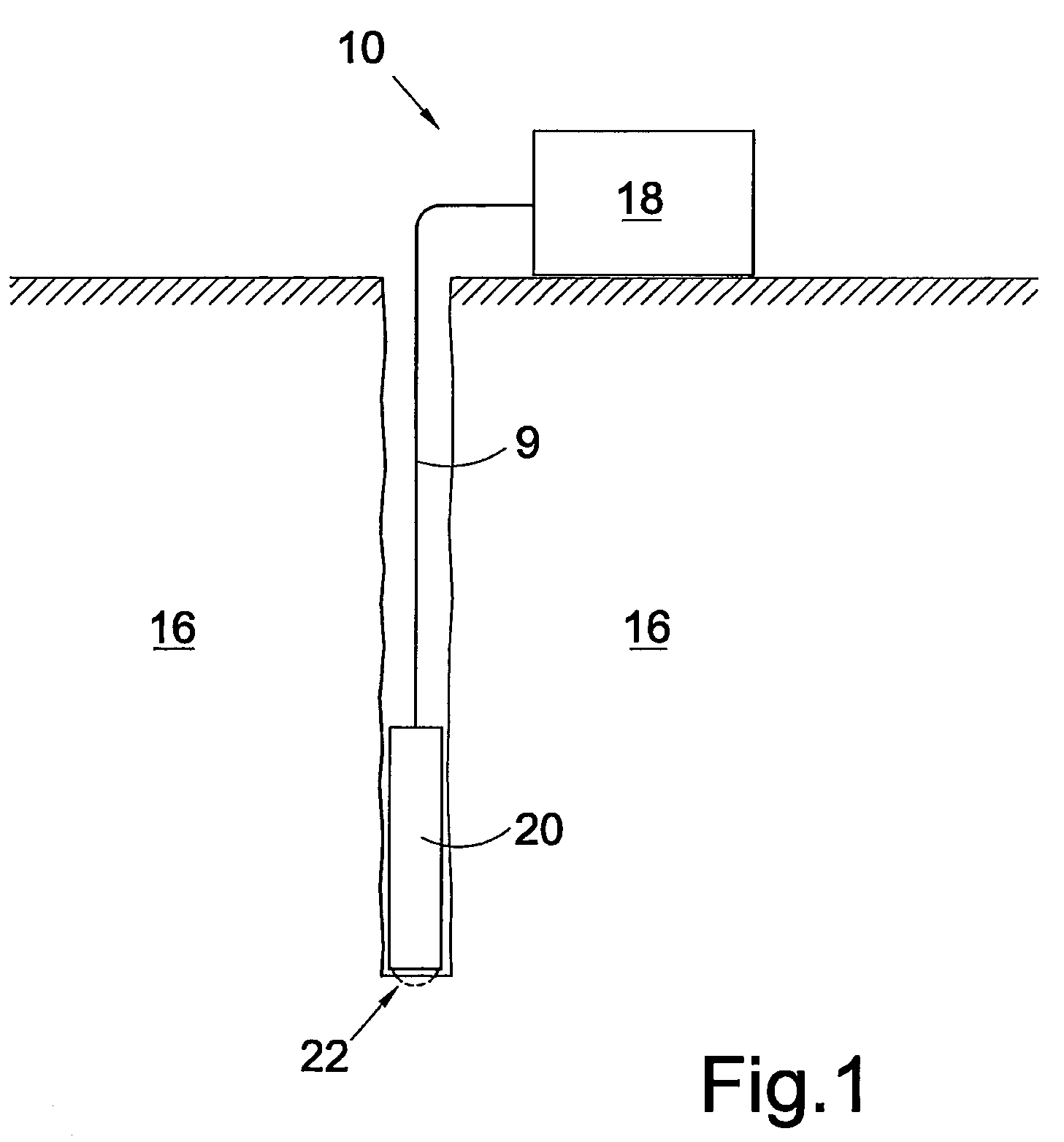

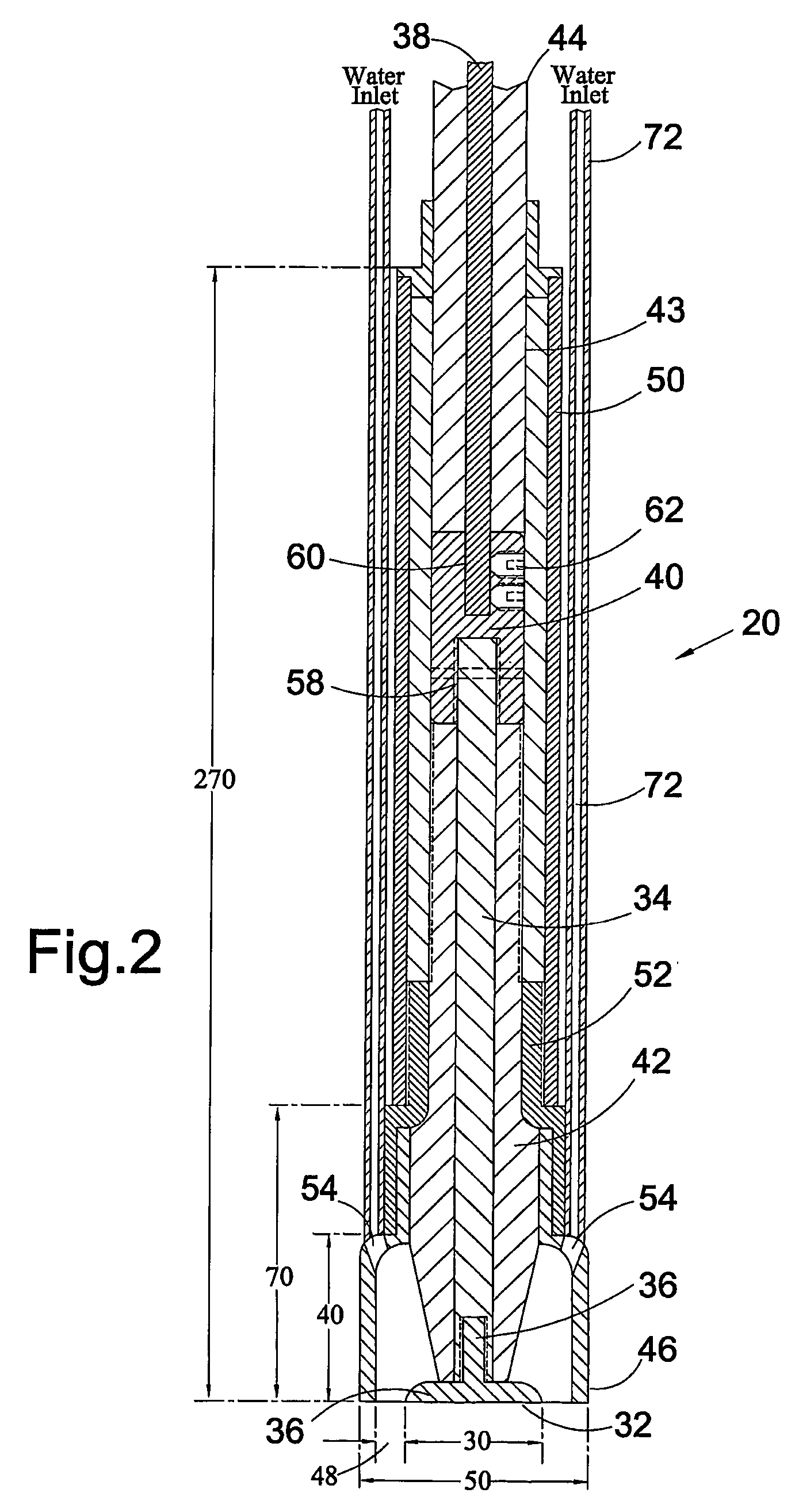

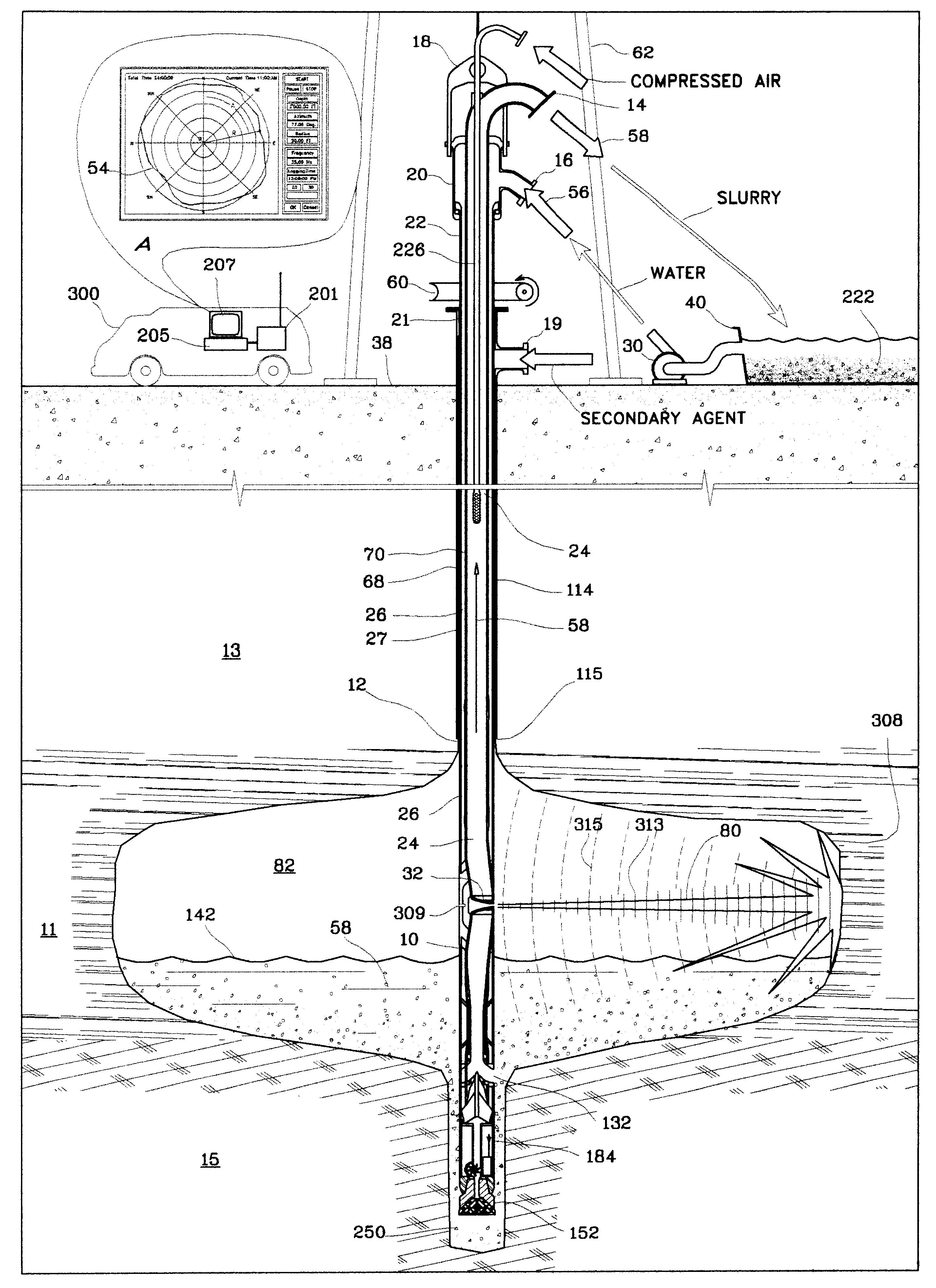

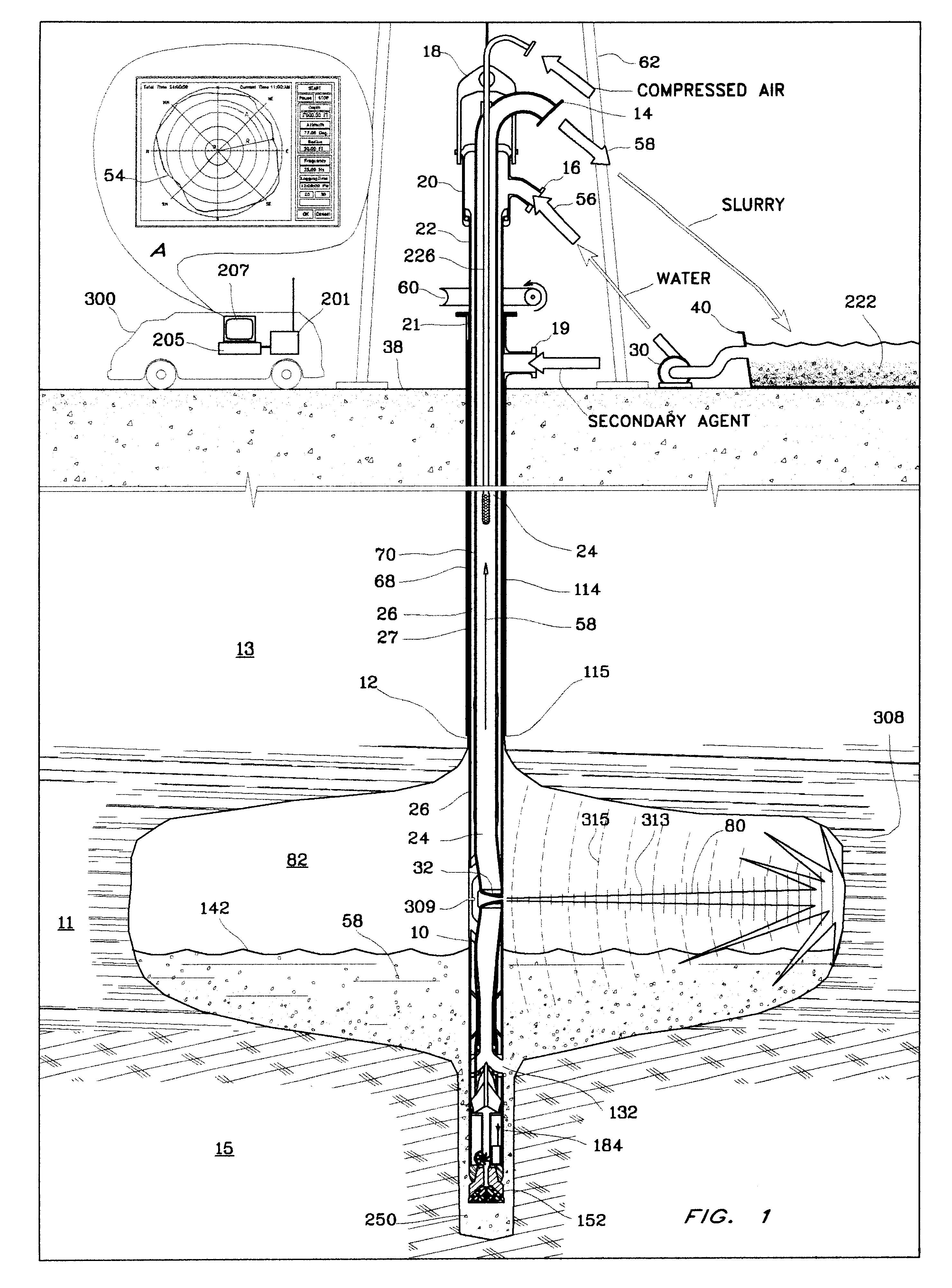

Borehole mining tool

A borehole mining tool comprising a drill string having an inner pipe column and an outer pipe column. Water is forced under high pressure down an annulus between the outer pipe and inner pipe. A hydromonitor is attached to the end of the drill string. A nozzle in the hydromonitor directs the pressurized water into a stope or work area, thereby loosening the material to be mined. The slurry is educted from the mined area by the action of a venturi attached downstream of the hydromonitor. Water flow through the venturi creates a vacuum which draws the pregnant slurry from the work area up through the inner pipe to the surface. A plurality of tools may be attached to the hydromonitor by a connection comprising a gasket having an interference fit. The gasket allows quick connection and removal of a plurality of tools from the hydromonitor. A radar is include to provide an image of the stope being worked.

Owner:BOREHOLE MINING INT

Method for filling and mining after ore caving

ActiveCN102587916AReduce impact damageImprove work efficiencyUnderground miningSurface miningSpelunkingMineral Sources

The invention discloses a method for filling and mining after ore caving, which includes the following steps: exploiting; mining quasi work; cutting work: including excavation of mine collection trench and patio cutting, cutting a patio at one end portion of a rock drilling chamber, cutting the patio by using a vertical deep hole ore falling stage chamber method, and enabling patio cutting to provide sufficient compensation space for actual mining; chamber extraction work: constructing a downward blasthole in the rock drilling chamber, filling and blasting, one-time blasting charging at the entire middle section height of the blasthole, and enabling blasting to adopt one-time lateral blasting and ore removal; filling and maintaining: closing all outlets communicated with a lower mine of the empty area, burying strainer pipes, leading in filling pipelines from the upper portion of the chamber, and filling and maintaining the chamber; and pillar recovery: recovering pillars after filling and maintaining the chamber, and the pillar recovery is the same as the chamber extraction work. The method for filling and mining after ore caving is high in recovery rate of mineral resources, small in blasting impact effect, low in cost and high in production efficiency.

Owner:金建工程设计有限公司

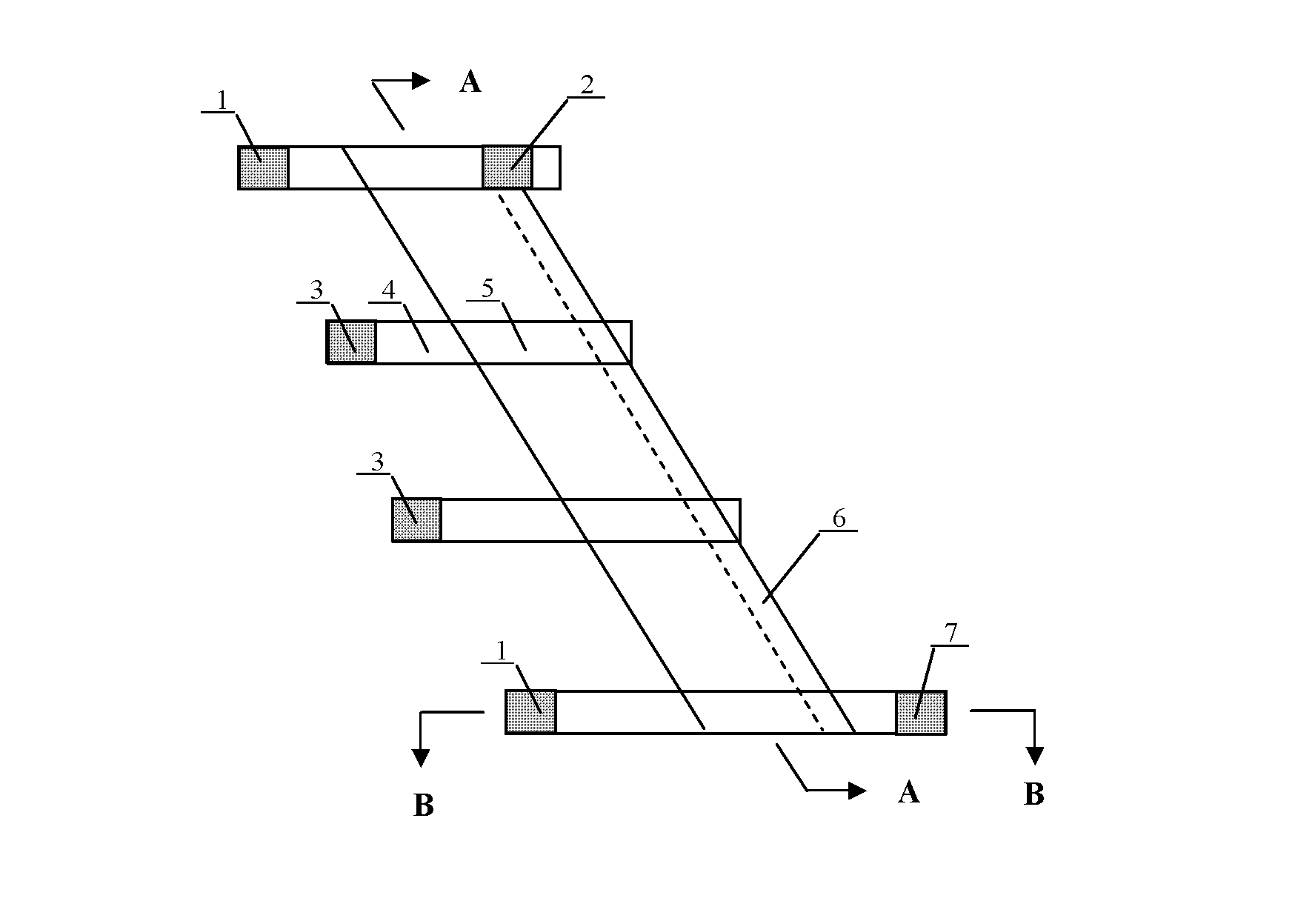

Continuous mining method of stepped sectional extruding and ore caving followed by filling

In the continuous mining method, ore body are divided into sections, subsections and mini-sections stepwisely along the ore vein; arranging mini-section drilling mine tunnels along the ore vein in the ore body bottom wall and connecting the mini-section tunnels with the main ramp way via linking tunnel; arranging support and filling tunnel along ore vein in the upper wall in the ore section; stoping from two ends to the central part of the bordroom via stepped continuous advance; drilling fanned holes with rock drill machine, breaking ore with rock explosive, charging with charging machine and combined elementary error detonation; filling finished stope via filling tunnel and filling dewatering device; and supporting crushed upper wall roof with deep anchor rod and steel fiber concrete. The present invention has high production capacity, high safety, less ore loss and low mining cost.

Owner:CENT SOUTH UNIV

Sublevel open-stop and delayed filling mining method

InactiveCN102562065AImprove drilling positioning accuracyNo lossUnderground miningSurface miningTailings damFilling materials

The invention relates to a sublevel open-stop and delayed filling mining method. According to the method, cutting crosscuts are wholly undercut along the width of chambers and pillars so that the space of scope rock drilling is shared with ore drawing, drilling operations of vertical parallel blast holes are achieved in undercutting space, positioning accuracy of drilling the vertical parallel blast holes is high, the intervals among the blast holes are even, and the defect of high blasting boulder yield caused by drilling sector blast holes in traditional rock drilling cross cuts is avoided; during chamber (or pillar) scoping, driving of ore drawing gateways and ore drawing admission passages in fill materials of adjacent pillars (or chambers) isn't needed, and accordingly the safety is improved; simultaneously, ores are directly drawn from the undercutting space of the chambers and the pillars, the space of ore drawing is large, mutual interference is small, ore drawing efficiency is high, and ores are drawn completely without any dead space and secondary ore loss; artificial sill pillars are constructed, ore sill plates aren't needed to be reserved, the ores are free of primary loss, and the rate of resource recycling is high. Barren rocks and ore beneficiation tailings are used for filling gobs, the barren rocks are not taken out of pits, constructions of tailing dams and barren rock yards are reduced, and land occupation is small.

Owner:UNIV OF SCI & TECH BEIJING

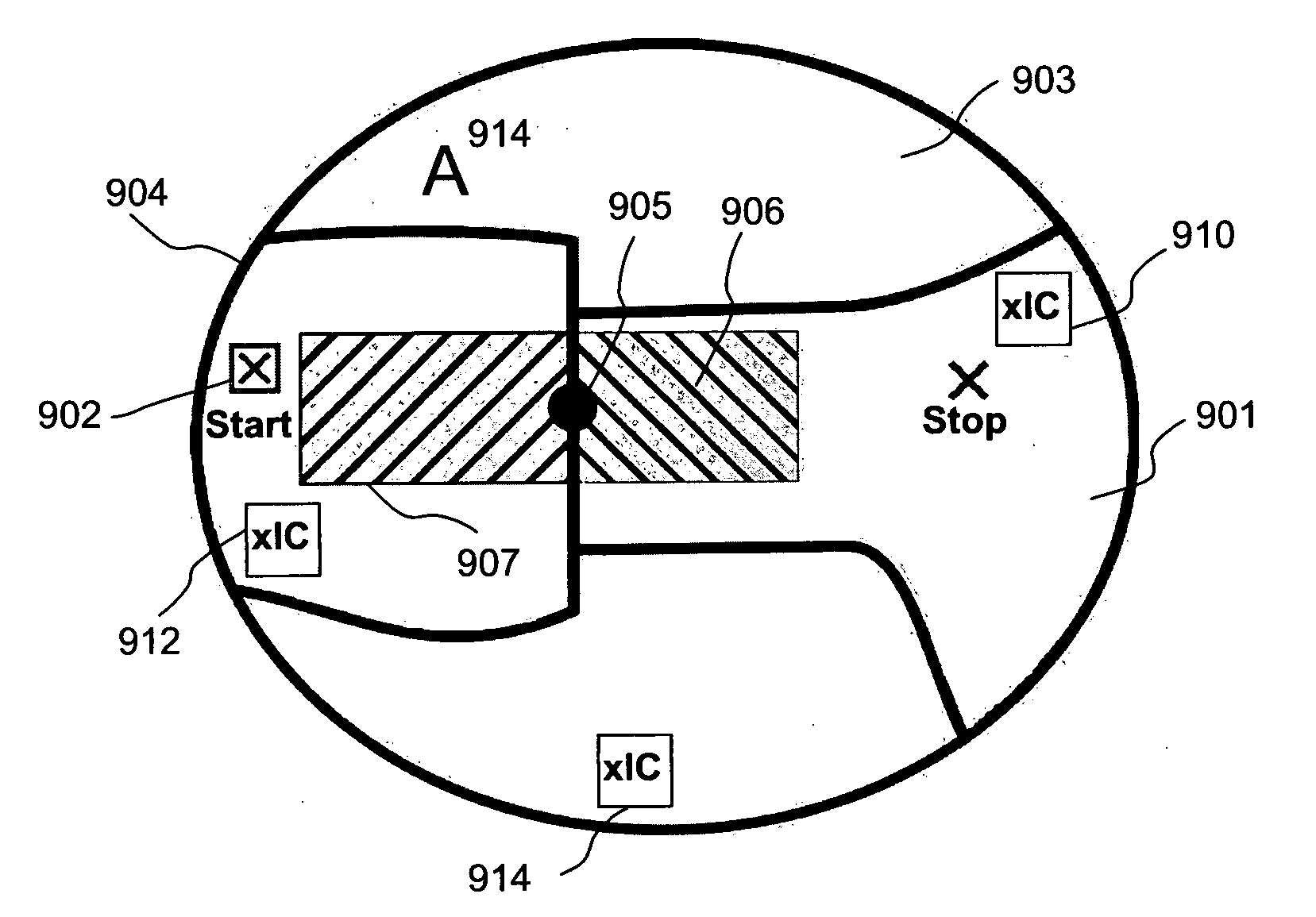

Method and system for regulating movemnet of an autonomous entity between zones

ActiveUS20120053775A1Extensive automationUnderground miningSurface miningOperational definitionComputer science

A method is described of regulating movement of an autonomous entity between a first zone (904) and a second zone (901), wherein the first and second zones each have an operation-defined geographical boundary within a defined geographical region. The autonomous entity is instructed to move into a transition zone (906, 907) that spans the first zone and the second zone, wherein the autonomous entity while located in the first zone is responsive to supervisory control of a first controller (912) associated with the first zone. The autonomous entity is registered with a second controller (910) associated with the second zone to enable the autonomous entity to respond to supervisory control of the second controller as the autonomous entity enters the second zone through the transition zone. The autonomous entity is de-registered from the first controller.

Owner:TECHNOLOGICAL RESOURCES +1

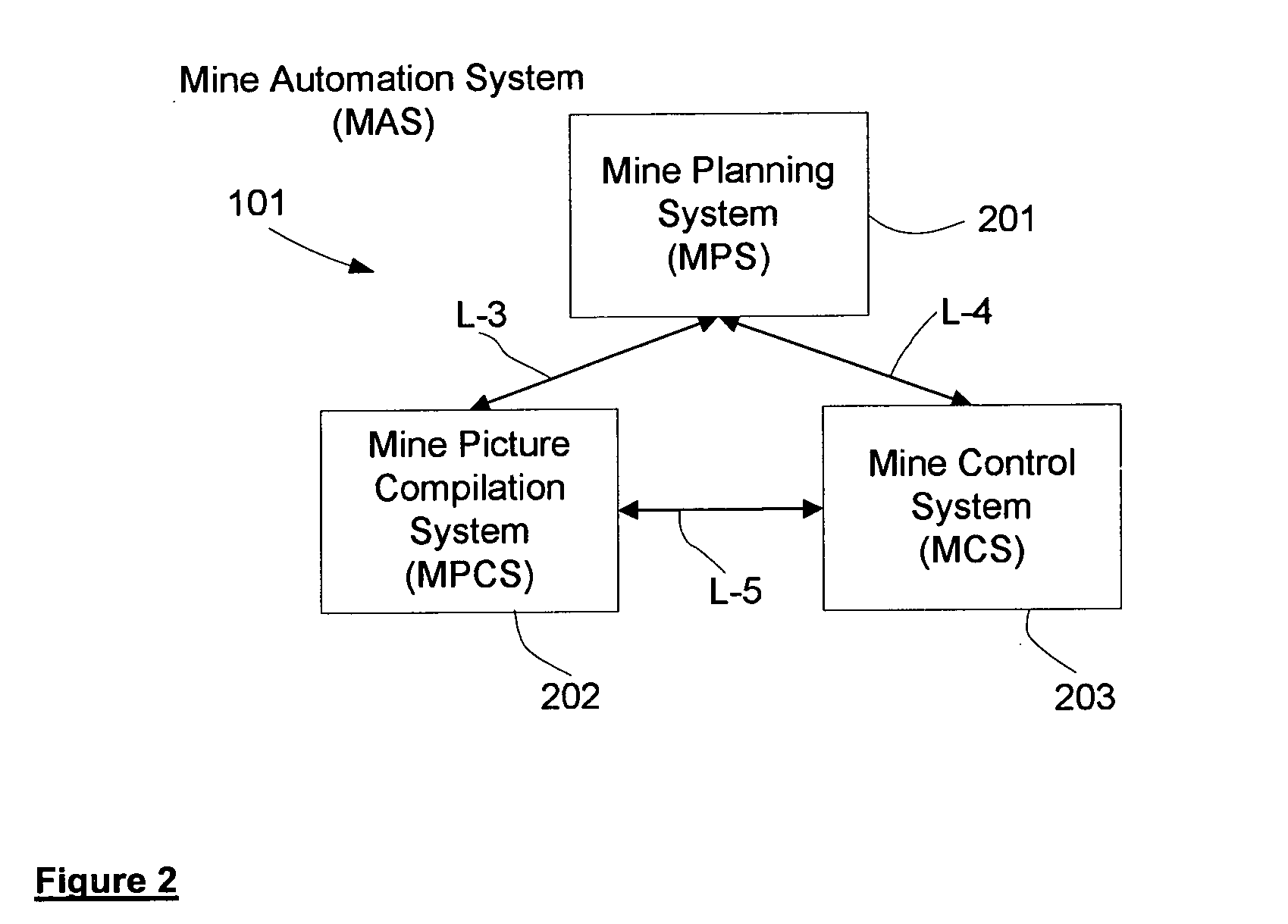

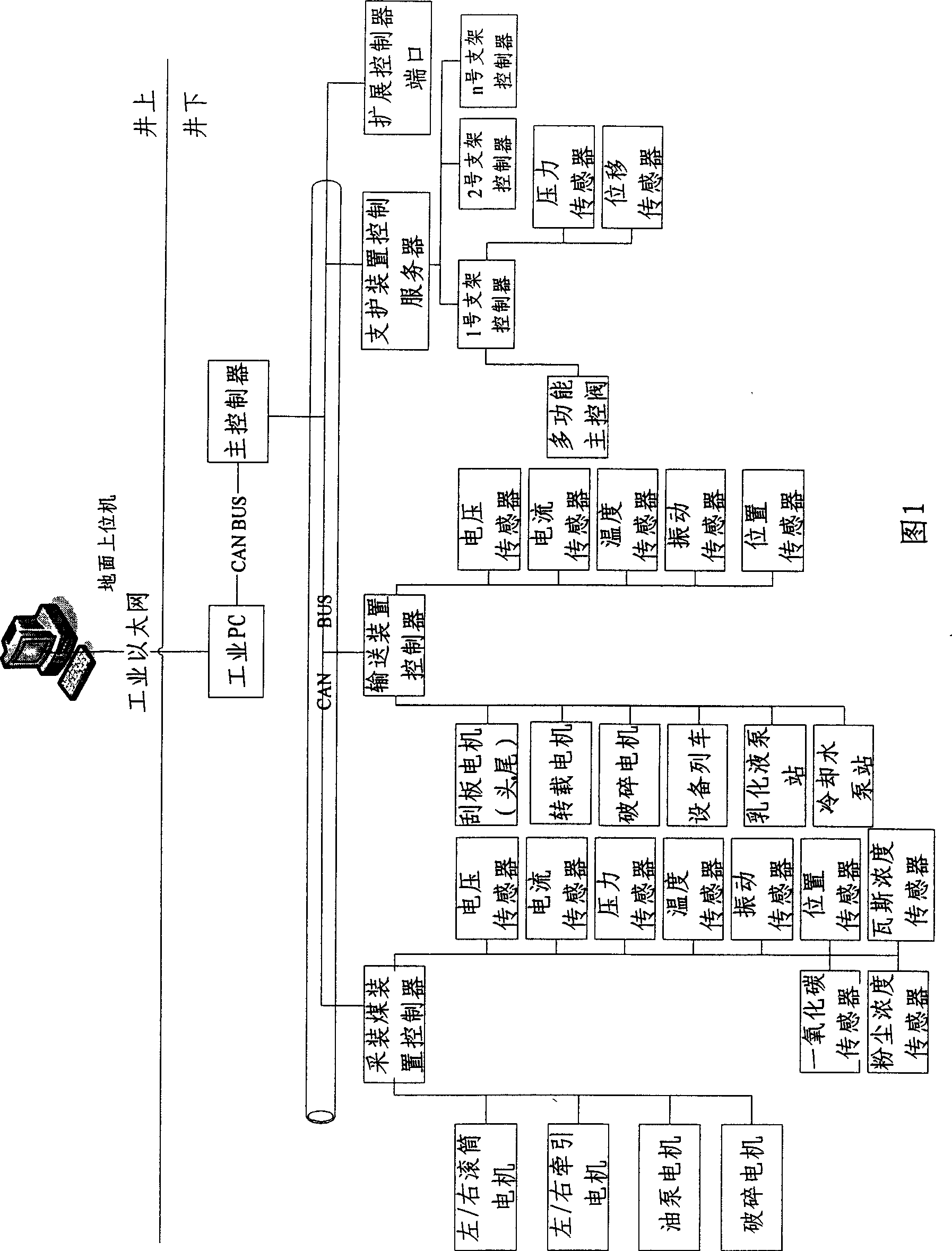

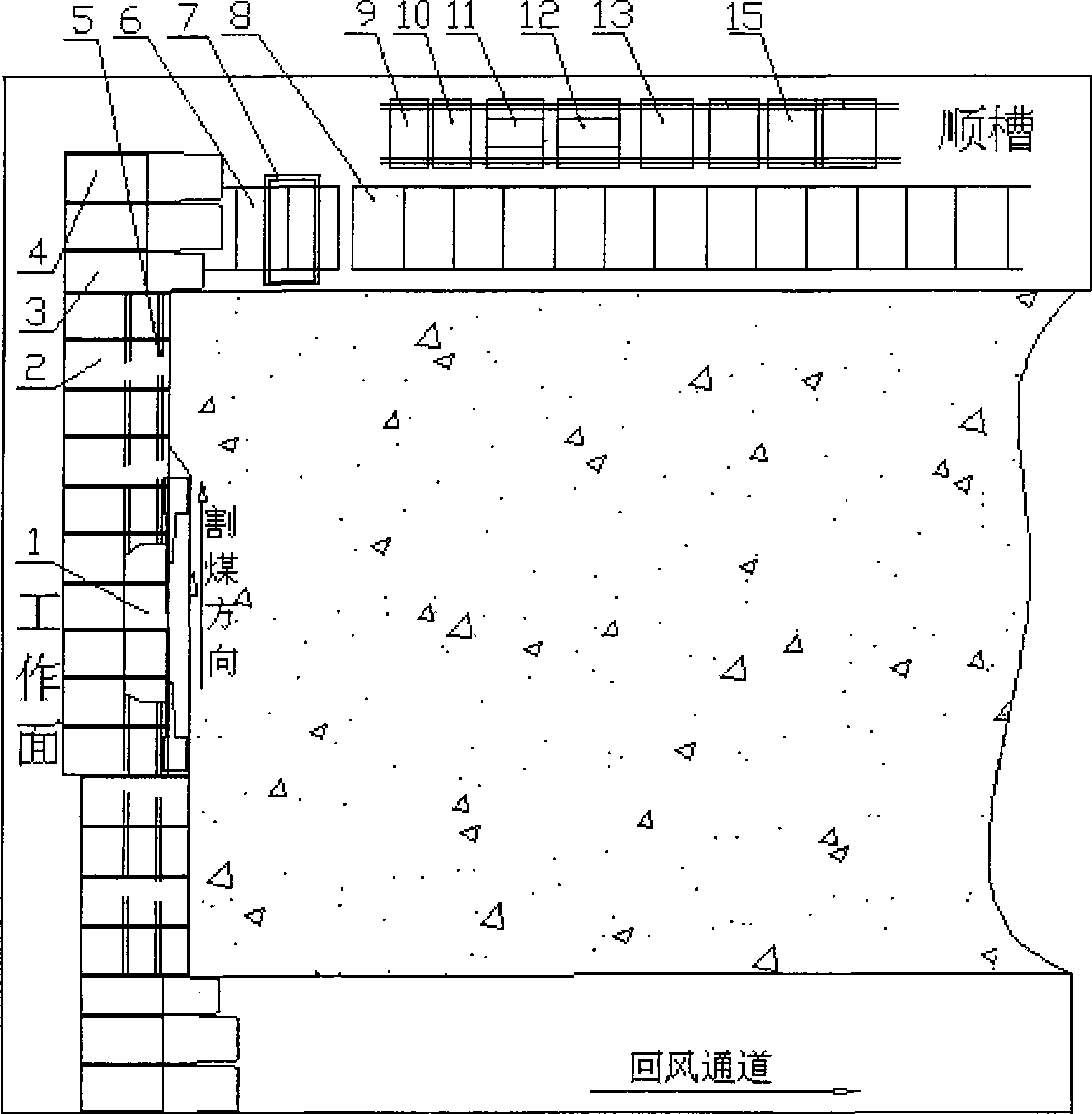

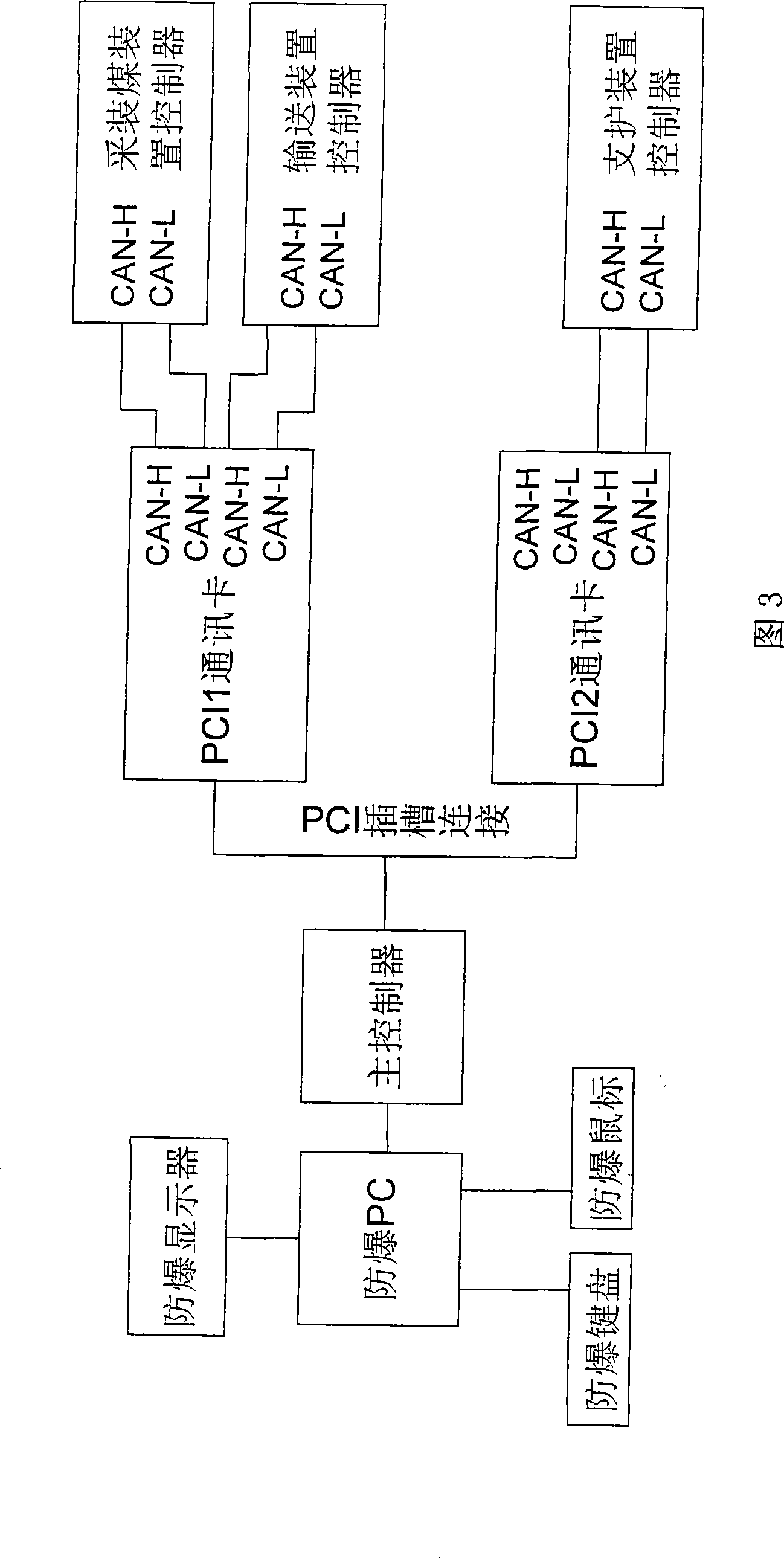

Intelligent full automatic combine coal mining system

ActiveCN101418688ARealize comprehensive applicationImprove completenessMining devicesUnderground miningProcess engineeringControl equipment

The invention relates to an intelligent type full-automatic combined coal mining system, which comprises a coal mining and loading device, a conveying device, a supporting device, and an equipment train, and is mounted in the working face and crossheading in the coal mine well. The coal mining and loading device is mounted on the conveying device, the coal conveying port of the conveying device is conveyed to the outside of the well or the coal bunker through a belt type conveyor in the crossheading, the supporting device is arranged behind the conveying device for supporting the top plate of the coal seam and linking with the conveying device, the equipment train comprises a central control chamber of a central control equipment, a starter, a power device, and a lifesaving cabin, the central control equipment monitors and controls the coordination operation of the devices, the equipment train, and the power device of the equipment train, the power device provide power source for the devices and the equipment train, and the equipment train moves freely in the crossheading with the feeding of the working faces. The invention improves system complete ability and execution efficiency, and has strong function, high intelligent degree, high safety, high production efficiency, and the like.

Owner:SANY HEAVY EQUIP

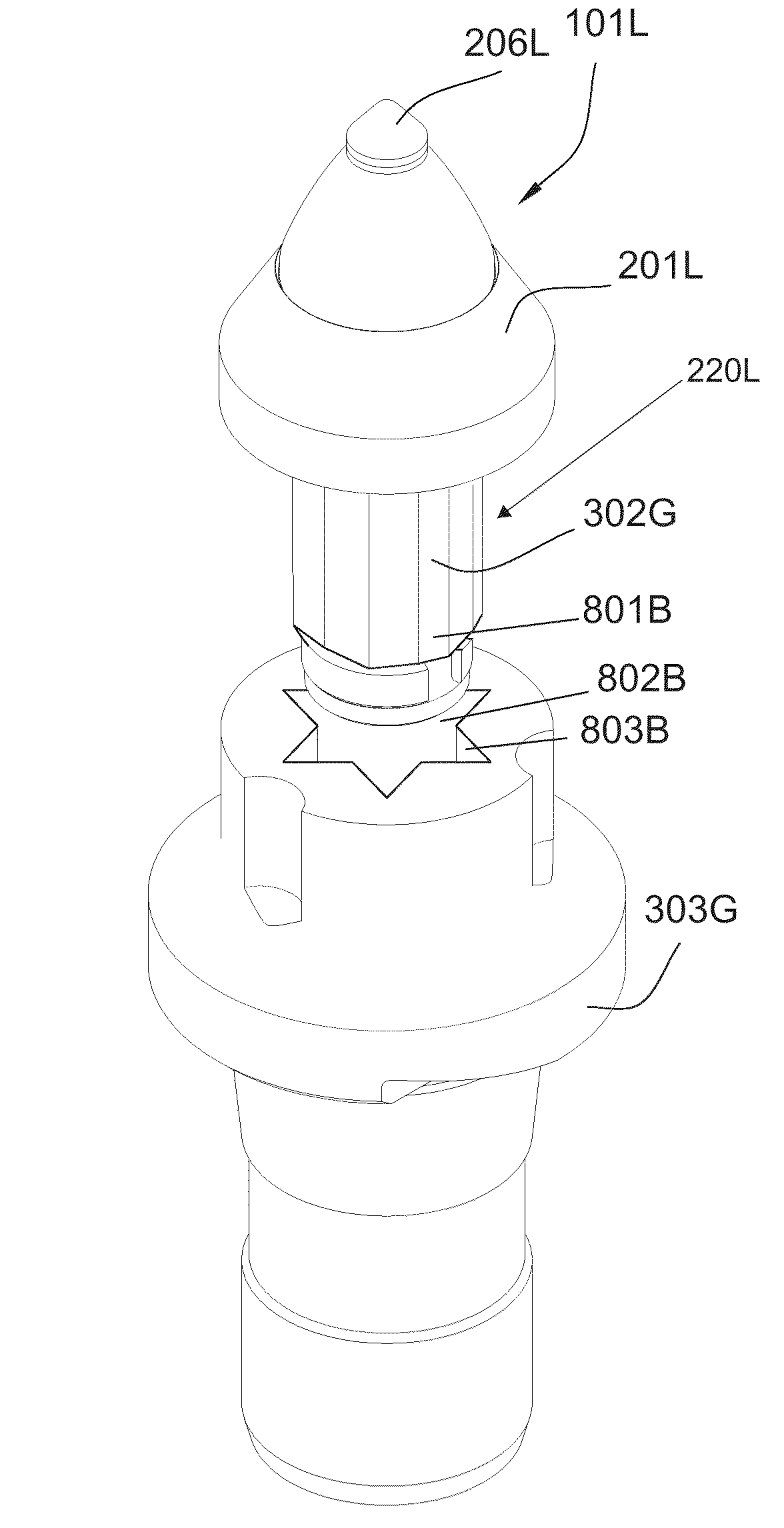

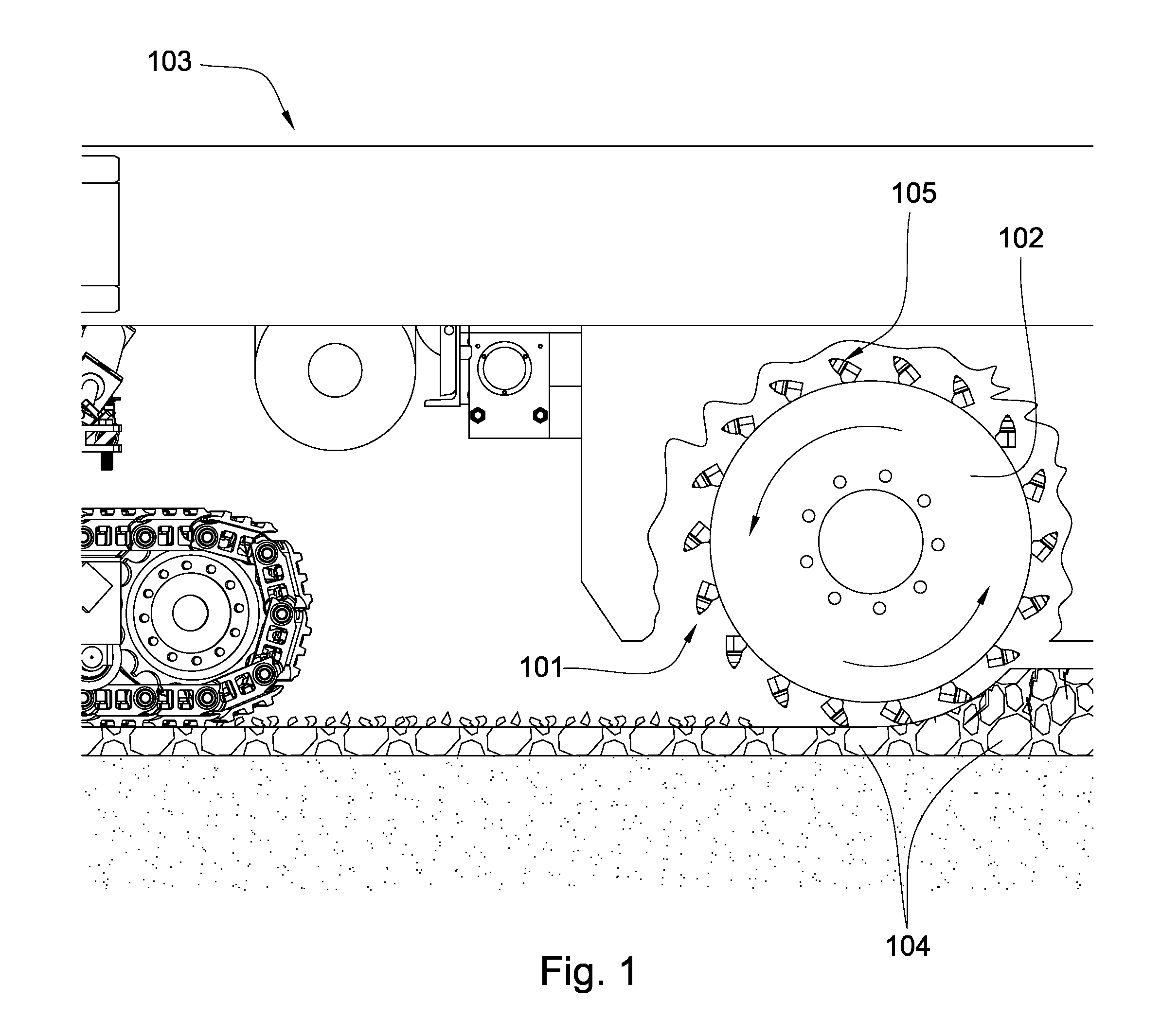

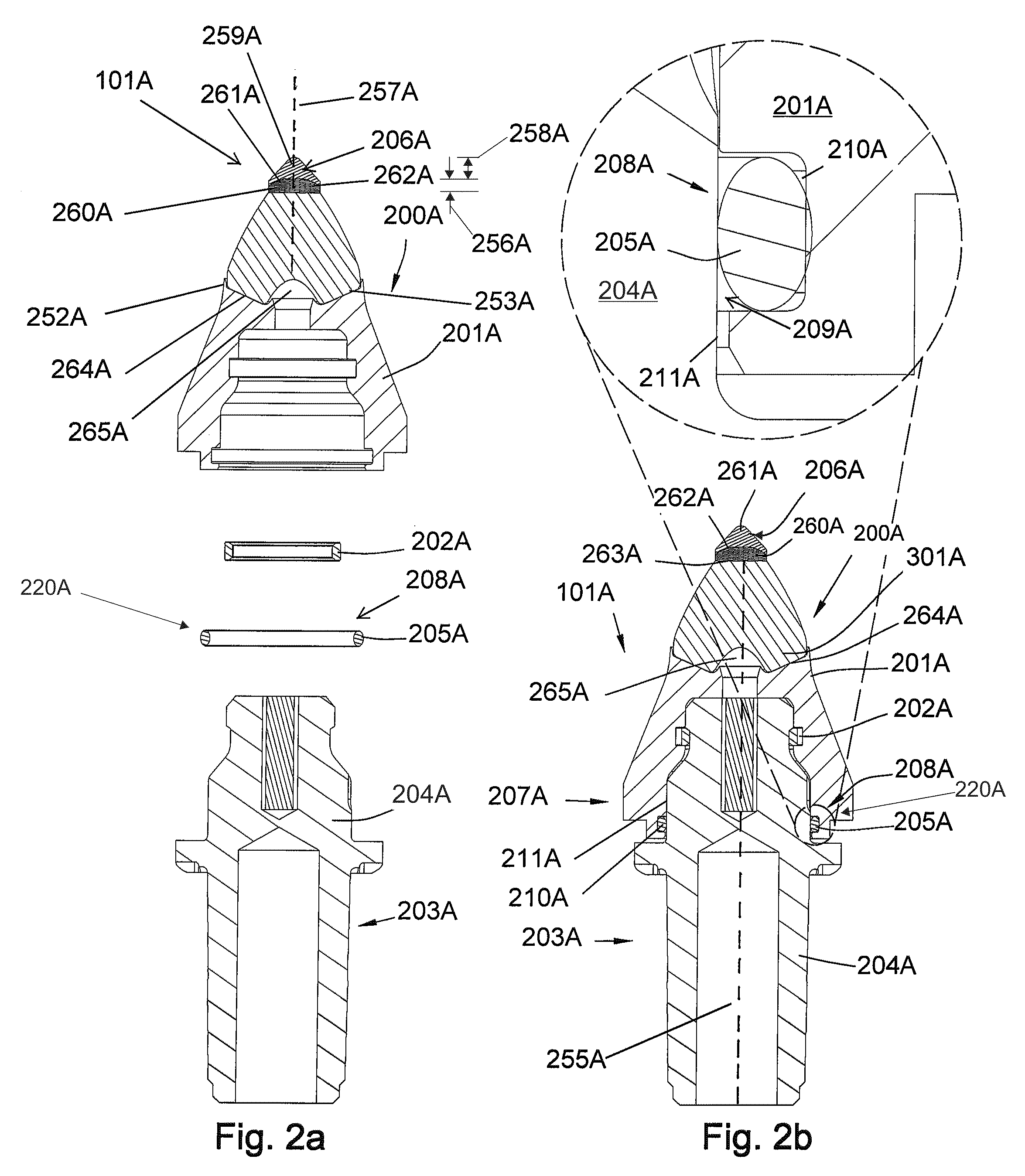

Manually rotatable tool

A degradation assembly comprises a rotary portion and a stationary portion. The rotary portion includes a cemented metal bolster bonded to a tip. The tip comprises a asymmetric, substantially conically shaped tip formed of diamond and a cemented metal carbide substrate. The stationary portion comprises a holder configured to be coupled to a block mounted to a driving mechanism. A compressible element is disposed between and in mechanical contact with both the rotary portion and the stationary portion.

Owner:SCHLUMBERGER TECH CORP

House pillar type cutting and filling method of medium coal seam for controlling movement deformation of overlying rock

InactiveCN102011588AImprove securityIncrease productivityUnderground miningSurface miningEngineeringCoal pillar

The invention belongs to the field of coal cutting and filling, in particular to a house pillar type cutting and filling method of the medium coal seam for controlling the movement deformation of the overlying rock, which is suitable for the coal face with the coal seam thickness more than 2 meters. The method comprises the following steps: determining the initial weighting interval L and the periodic weighting interval M of the main roof according to the main roof initial weighting interval theory; arranging the rooms and the coal pillars at intervals; and using the material with high expansibility in water during the filling according to the method comprising the following steps of mining the rooms, filling the empty rooms, mining the coal pillars and filling the empty zones of the coal pillars. The method provided by the invention can determine the most economical filling ratio through controlling the key layer to maximize the benefits; the method provided by the invention can control the movement deformation of the overlying rock absolutely within the allowed range when realizing the pulling without pillars, and realize the extremely small gentle uniform sinking of the ground; and the method provided by the invention can realize the mining of the coal resource with high recovery rate under any condition by using the material with high expansibility in water, and greatly enhance the security of coal face. When the rooms are mined, a plurality of coal face of rooms can be arranged at intervals to enhance the working efficiency.

Owner:ZIBO WANGZHUANG COAL MINE

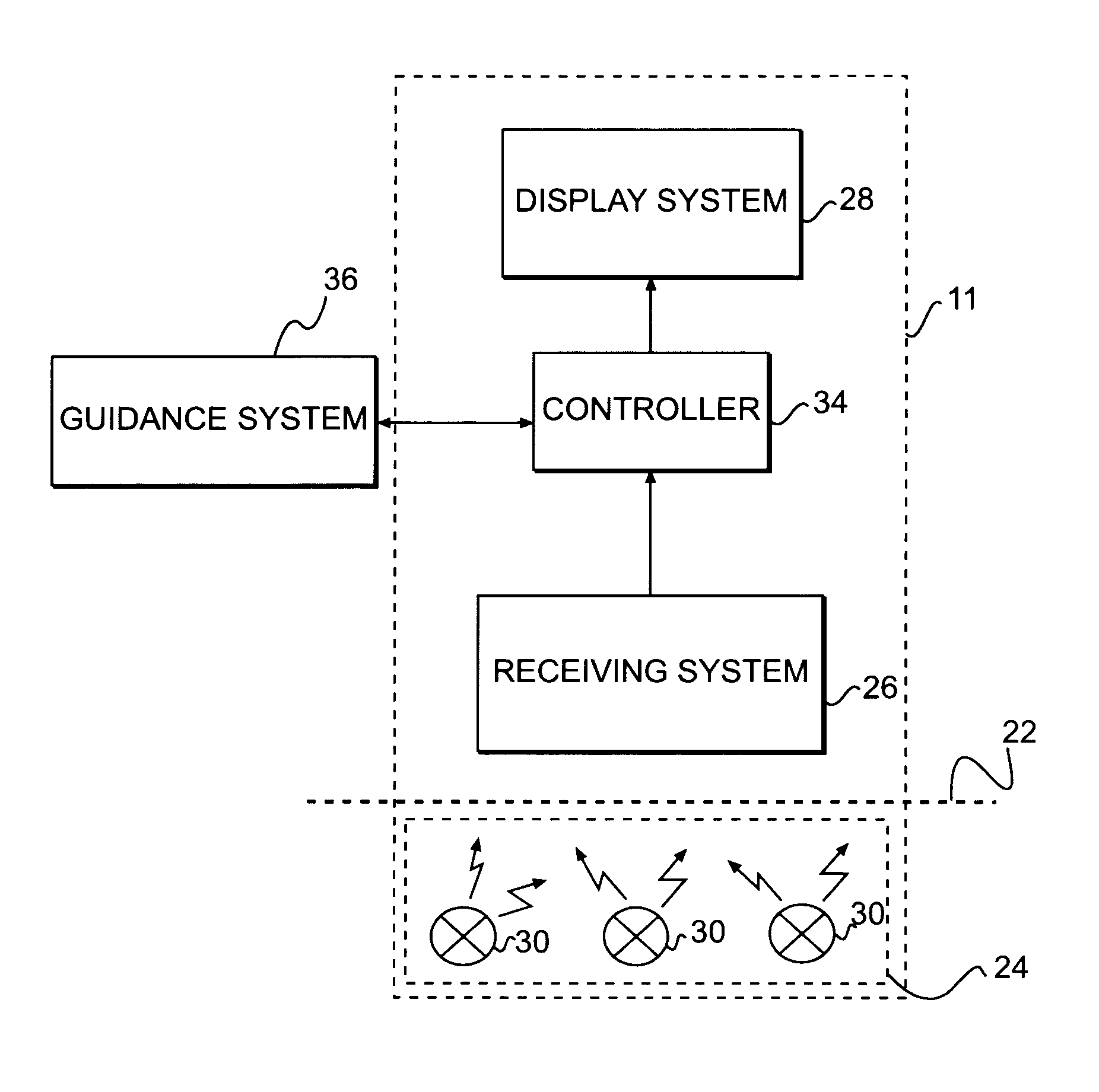

Work machine having boundary tracking system

The boundary tracking system has a plurality of signal transmitting devices located to represent at least one boundary of a work site. The boundary tracking system also has a receiving device configured to receive signals transmitted from one or more of the plurality of transmitting devices and to generate an output based on the received signals. The boundary tracking system also has a controller configured to determine a location of at least one of the plurality of transmitting devices based on the output from the receiving device.

Owner:CATERPILLAR INC

Stepped non-pillar continuous filling mining method for deep well super high large breaking ore body panel

InactiveCN101818643ASafe miningMining guaranteeUnderground miningSurface miningEngineeringCompressive strength

The invention discloses a stepped on-pillar continuous filling mining method for deep well super high large breaking ore body panel. An ore body is divided into a front part and a rear part in a super high large breaking ore body center by an transportation roadway, then the front part and the rear part are respectively divided into a plurality of panels, no pillar exists between pillars, each panel is partitioned into a primary extracting drift and a second extracting drift, the panels in the front part are extracted at first and then the panels in the rear part are extracted, the front and rear panels are extracted in a stepped manner, each production technology is carried out in the same level, and procedures can not influence each other; after the stop back production is finished, the primary extracting drift is filled with cement and the secondary extracting drift is filled by classifying tailings while roof-contacted filling is ensured; and the primary extraction drift and the secondary extraction drift adopt high strength filling topping, and binding materials are added in the filling tailings so as to improve the compression strength of a topping layer. The invention has the characteristics of high extraction safety, small loss and dilution, high mechanical degree, large stope amount, large back production strength, high production capability, short back production time and the like.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com