Patents

Literature

64results about "Drilling using explosives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

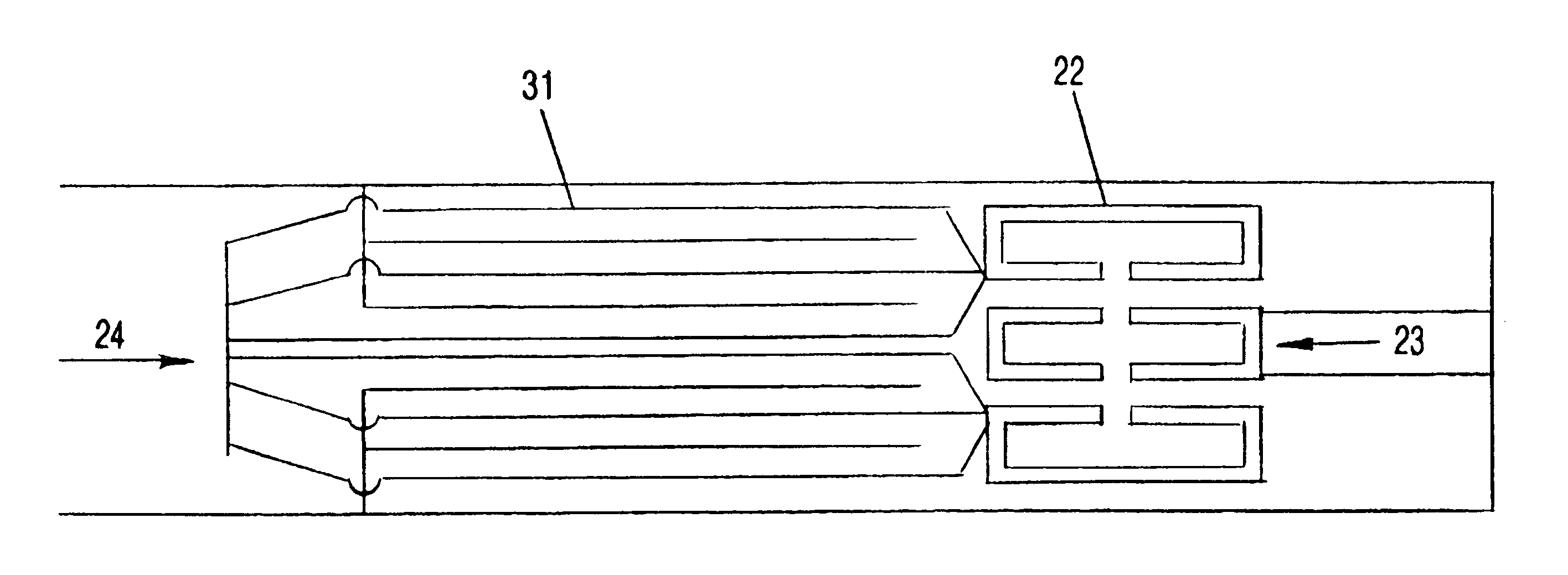

Electrohydraulic pressure wave projectors

A projector (10) for creating electrohydraulic acoustic and pressure waves comprising an energy source (21) (such as a capacitor) within approximately one meter of an electrode array (23). Larger projectors may be formed by arraying the projectors, and still larger projectors by arraying them.

Owner:SDG LLC

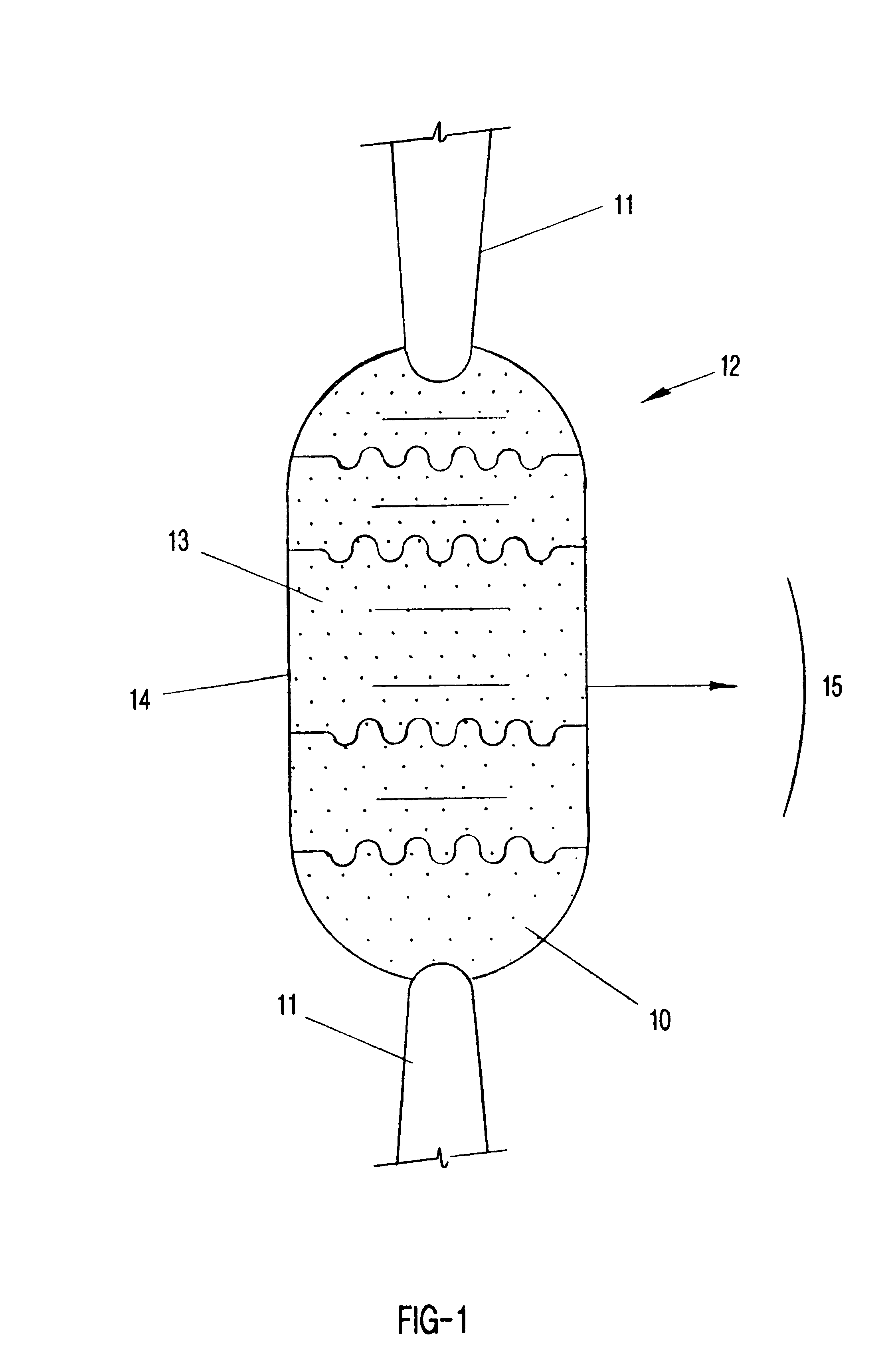

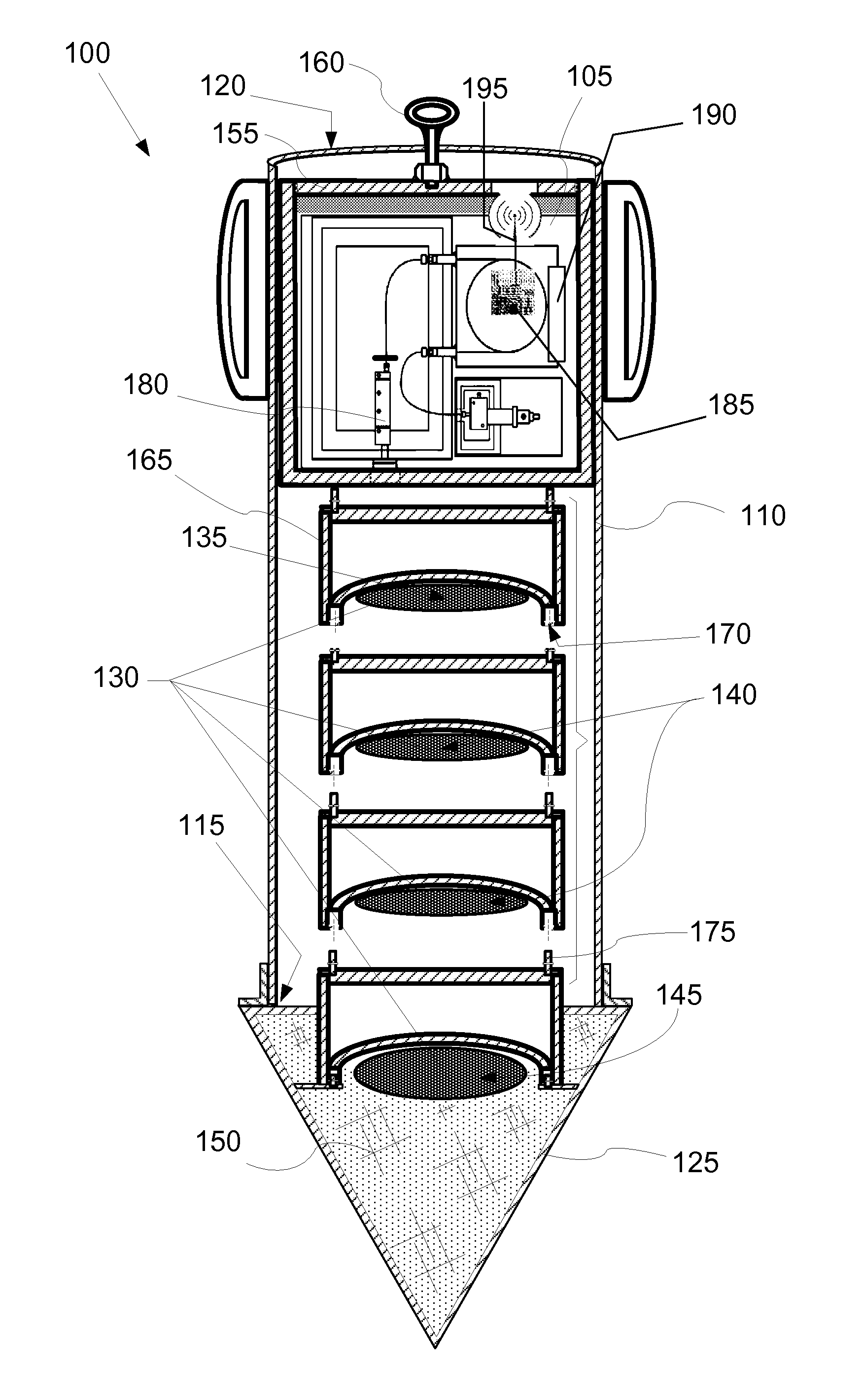

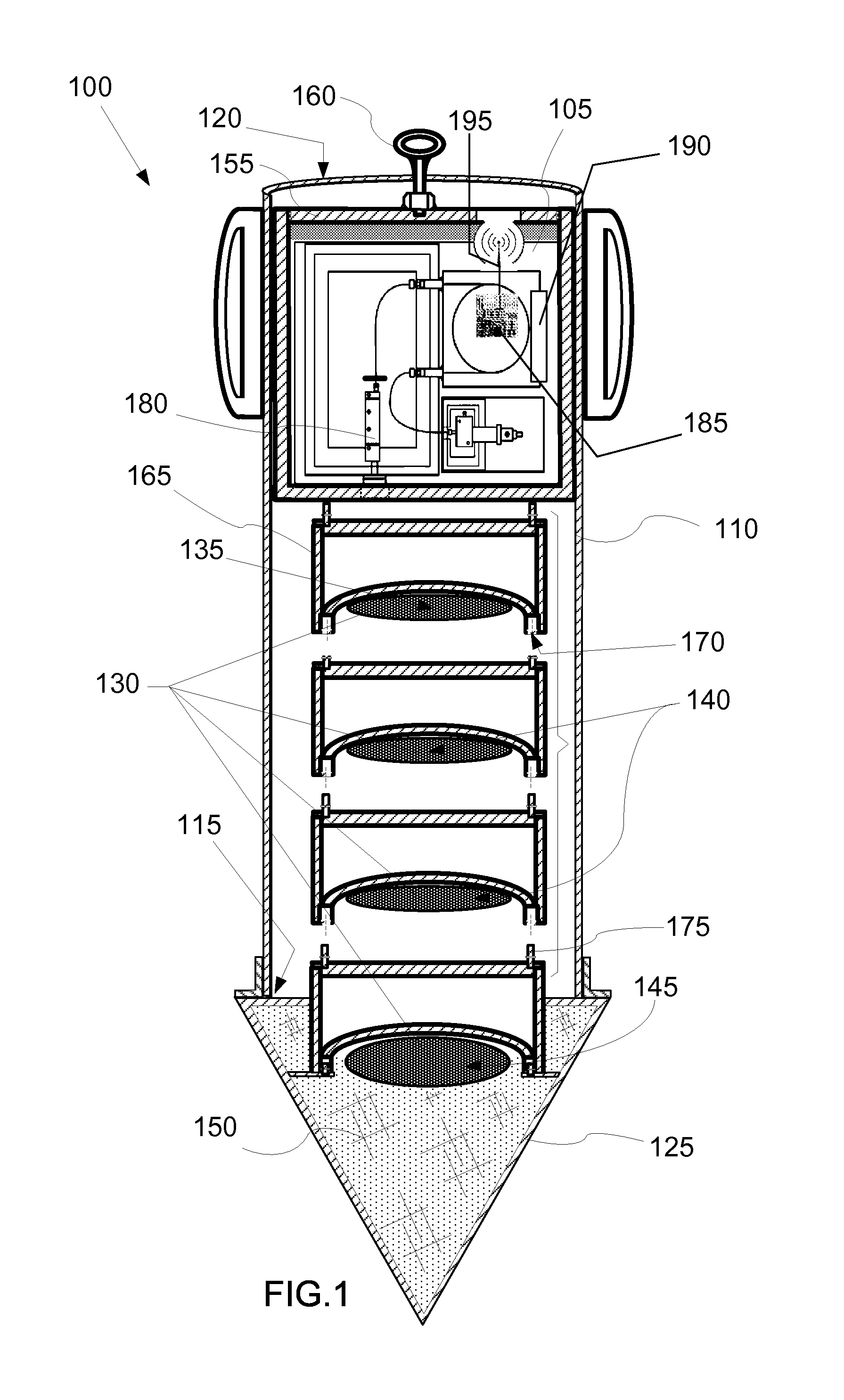

Oil exploration probe

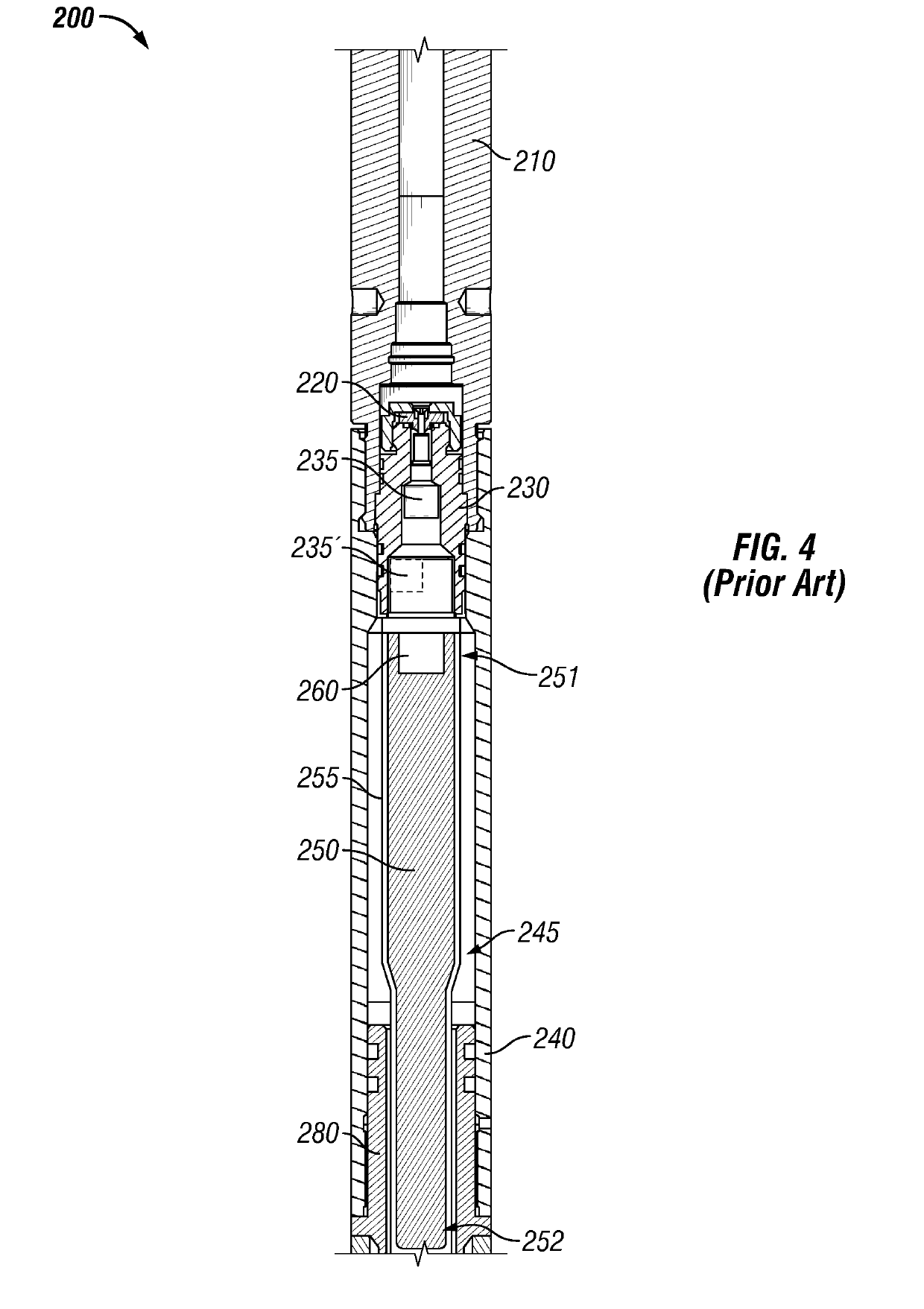

ActiveUS9169695B1Lowered into the ground inexpensivelyStrengthen and boost economyDrilling using explosivesFluid removalDetonationShaped charge

An exploratory shaft-making apparatus creates a vertical hole down into a geological formation while sending a payload into the vertical hole. The apparatus includes a metallic cylindrical casing; a hollow, conical head section; a payload body; and shaped charges of high explosive below the payload body. The shaped charges are adapted to sequentially detonate starting with the bottom-most shaped charge. The detonation of each shaped charge is configured to create a void space in the geological formation below the casing. The void space permits gravity to move the remaining shaped charges and the payload body atop them to slide downward so that the next shaped charge to detonate is positioned below the bottom end of the metallic cylindrical casing. A shock absorbing material may be included in the head section. The payload body optionally has a removable cap. A lift fitting may be attached to the payload body.

Owner:OEP ASSOC TRUSTEE FOR OIL EXPLORATION PROBE CRT TRUST

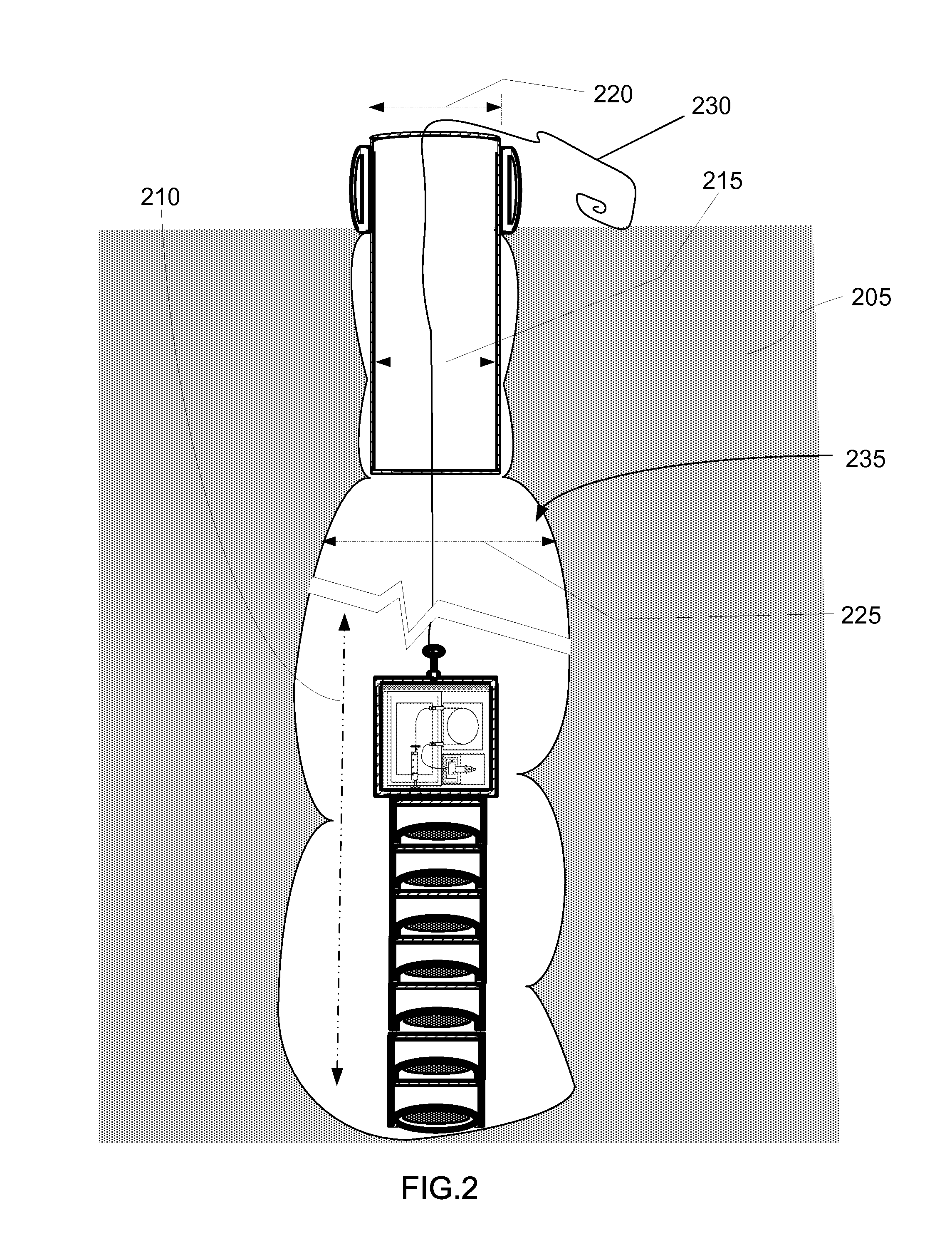

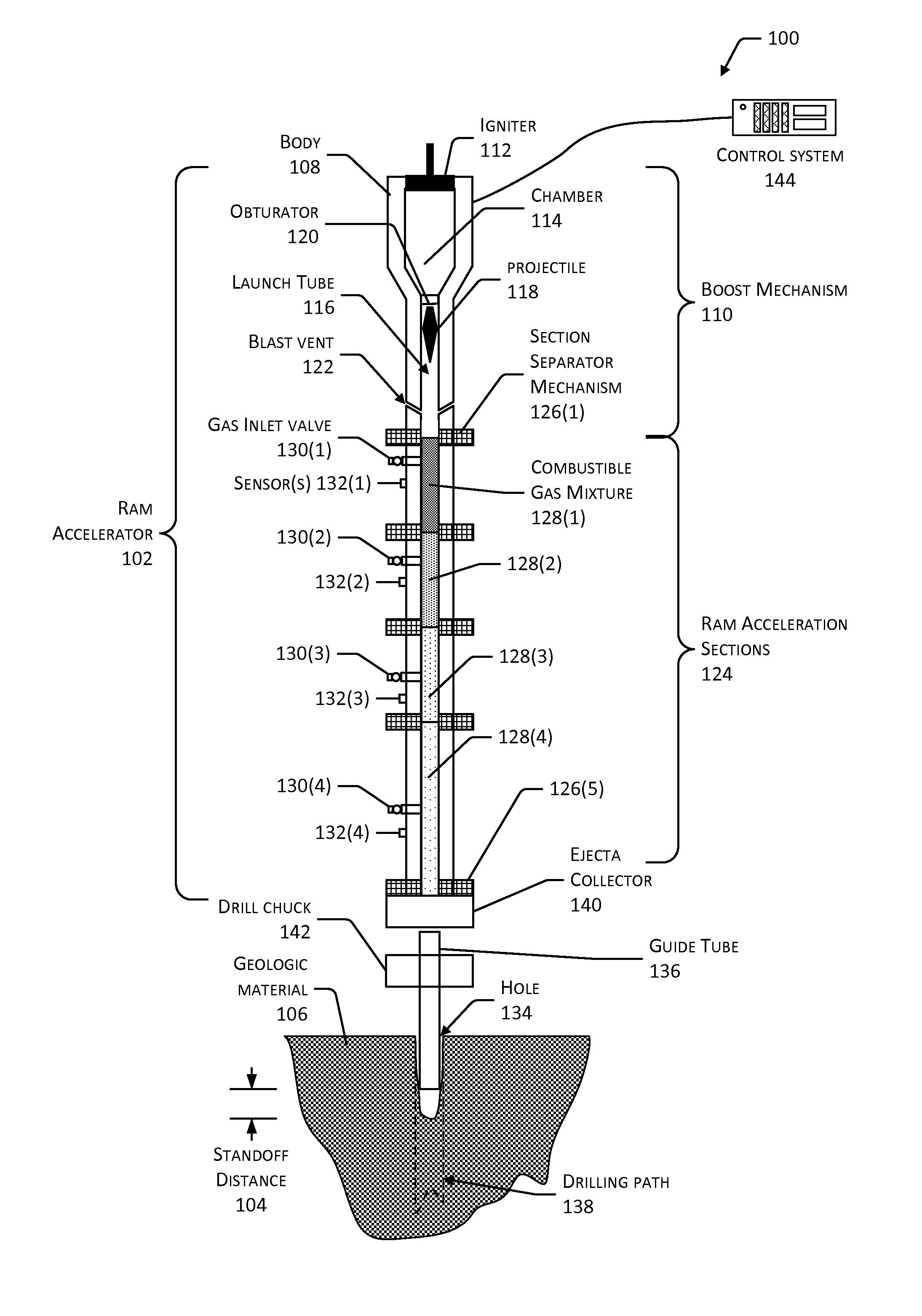

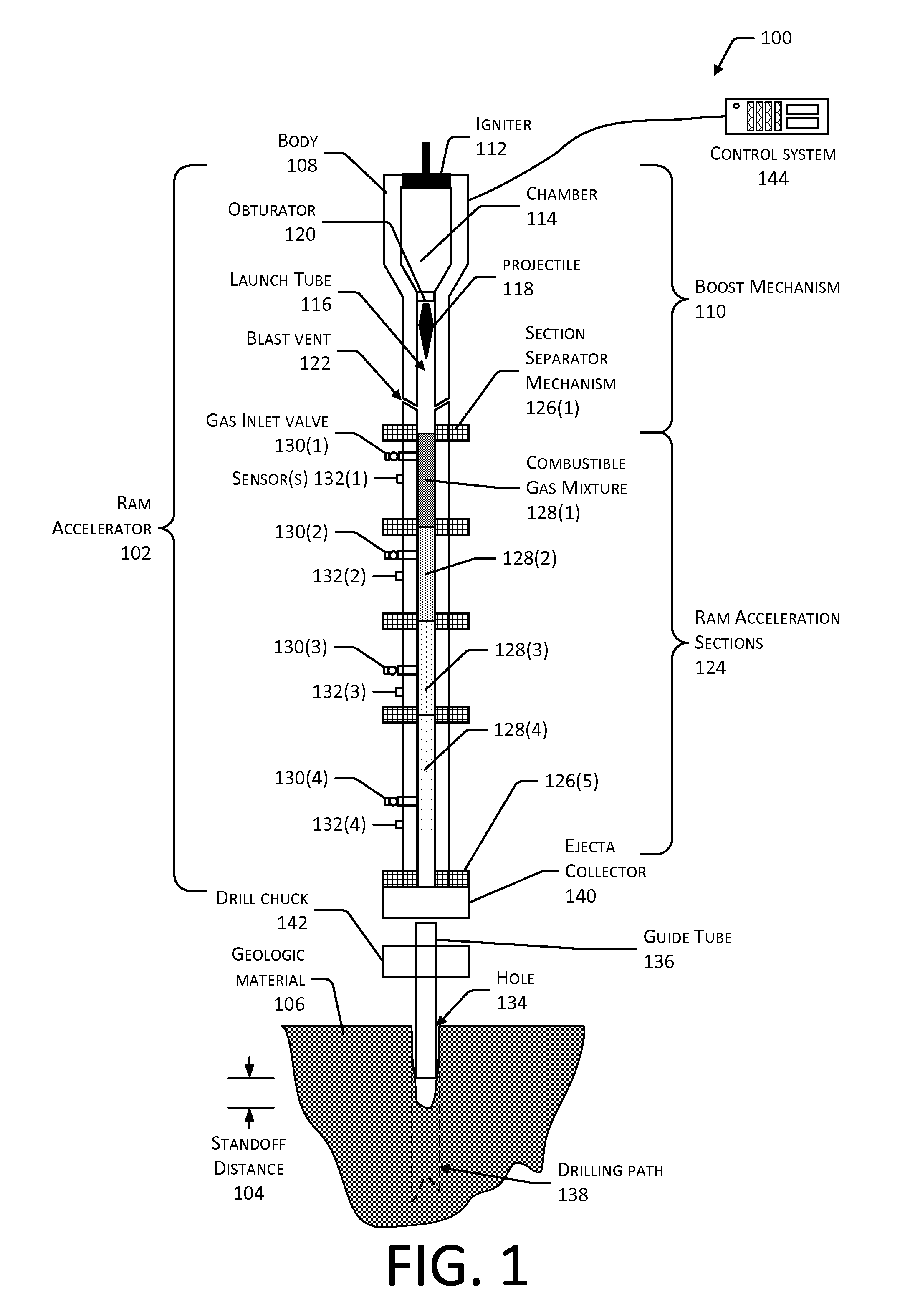

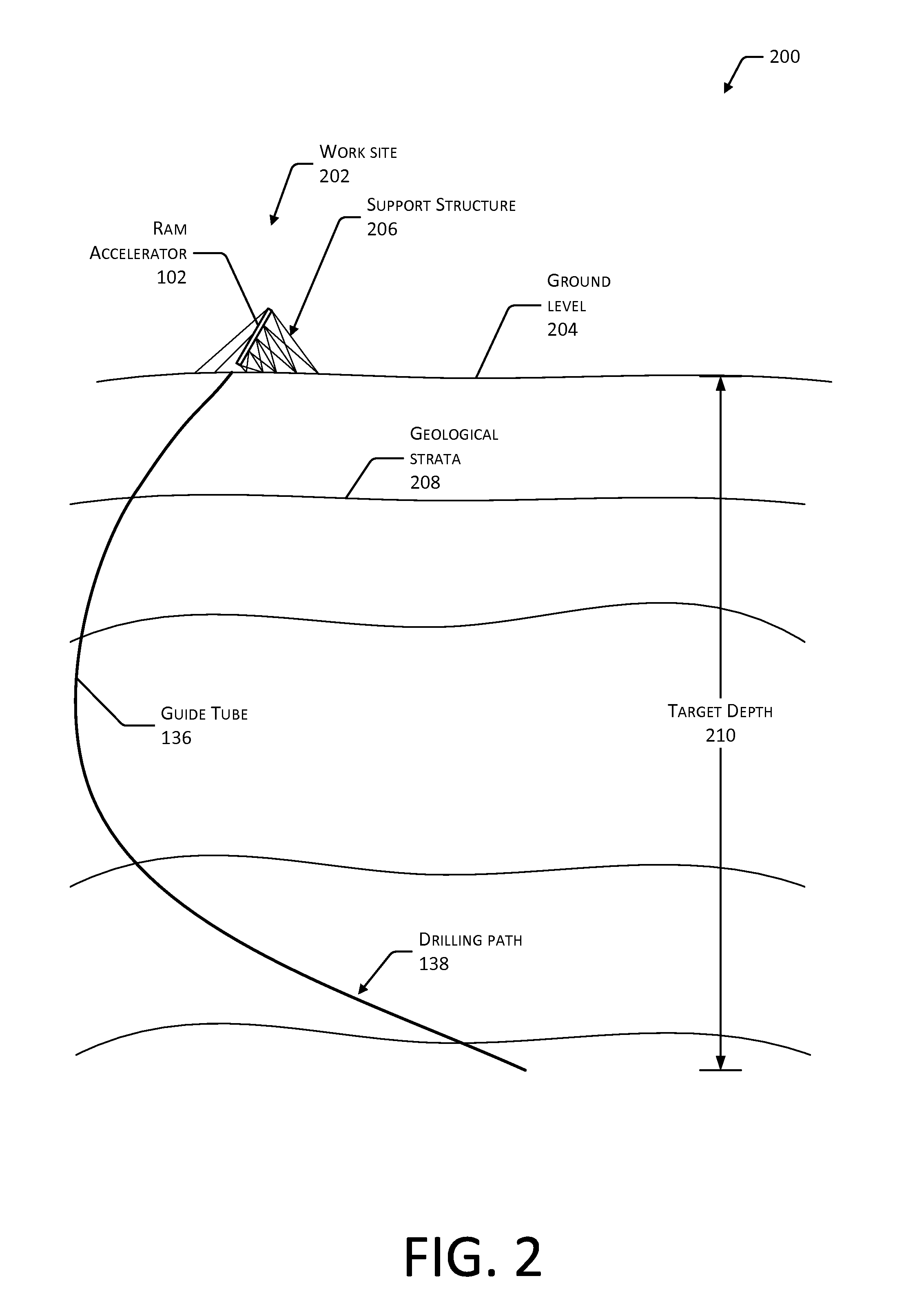

Ram accelerator system with endcap

One or more ram accelerator devices may be used to form one or more holes in geologic or other material. These holes may be used for drilling, tunnel boring, excavation, and so forth. The ram accelerator devices propel projectiles which are accelerated by combustion of one or more combustible gasses in a ram effect to reach velocities exceeding 500 meters per second. An endcap may be deployed within a tube of the ram accelerator device to prevent incursion of formation pressure products such as oil, water, mud, gas, and so forth into a guide tube of the ram accelerator. During operation the projectile penetrates the endcap and at least a portion thereof impact a working face. In some implementations a purge gas may be used to form a ullage between the endcap and the working face.

Owner:HYPERSCI

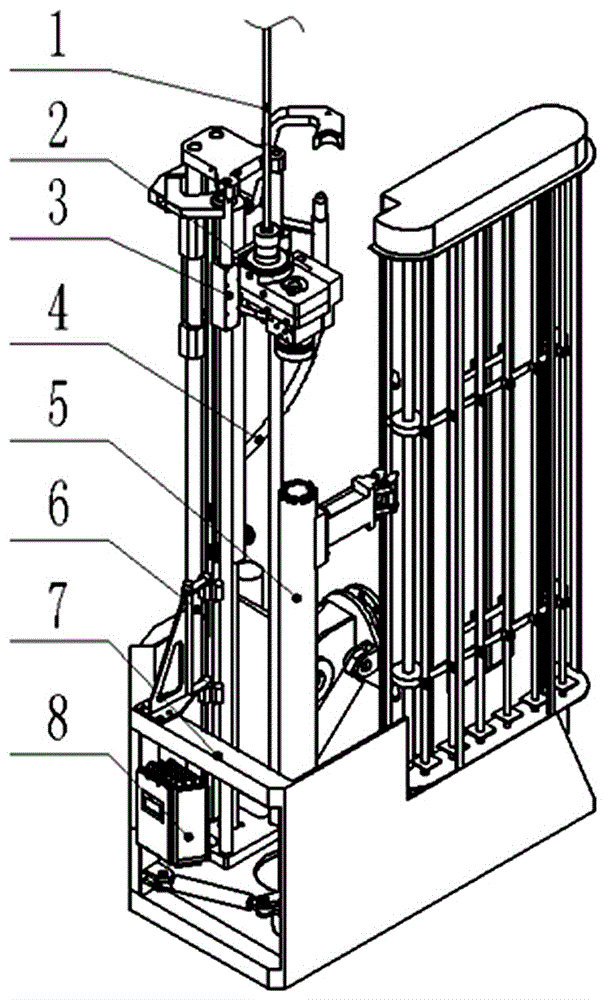

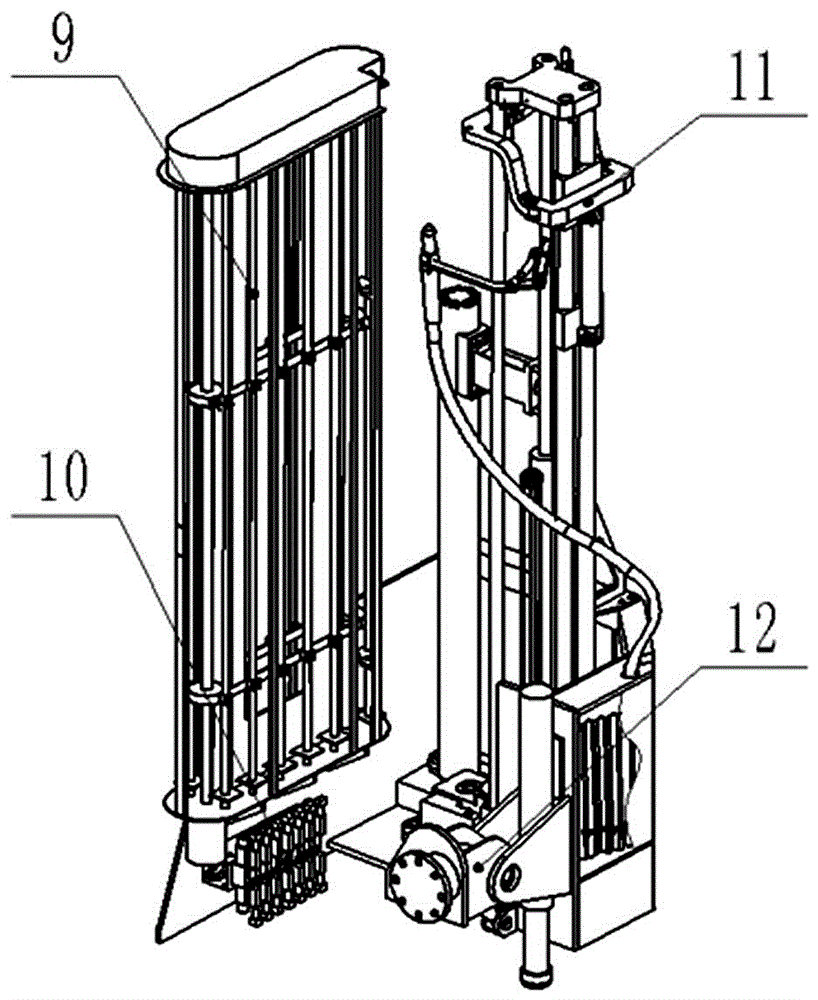

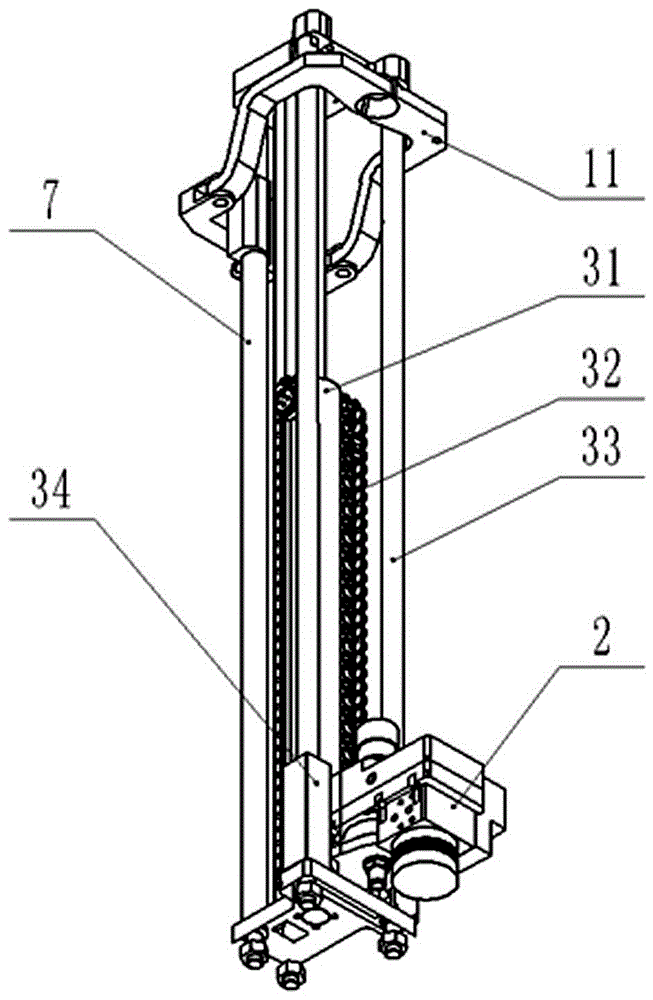

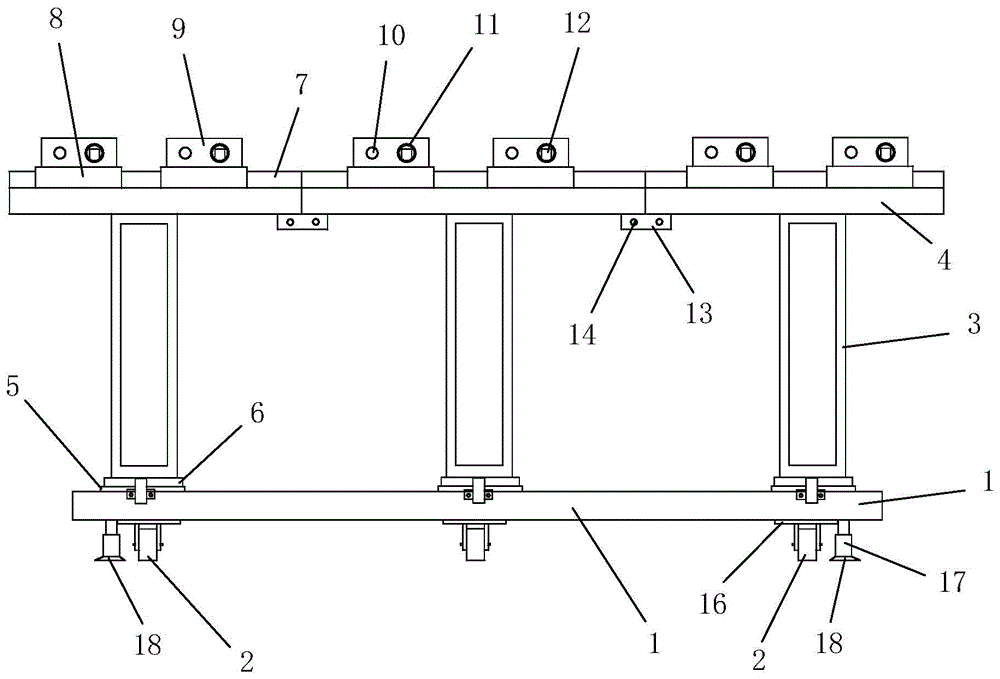

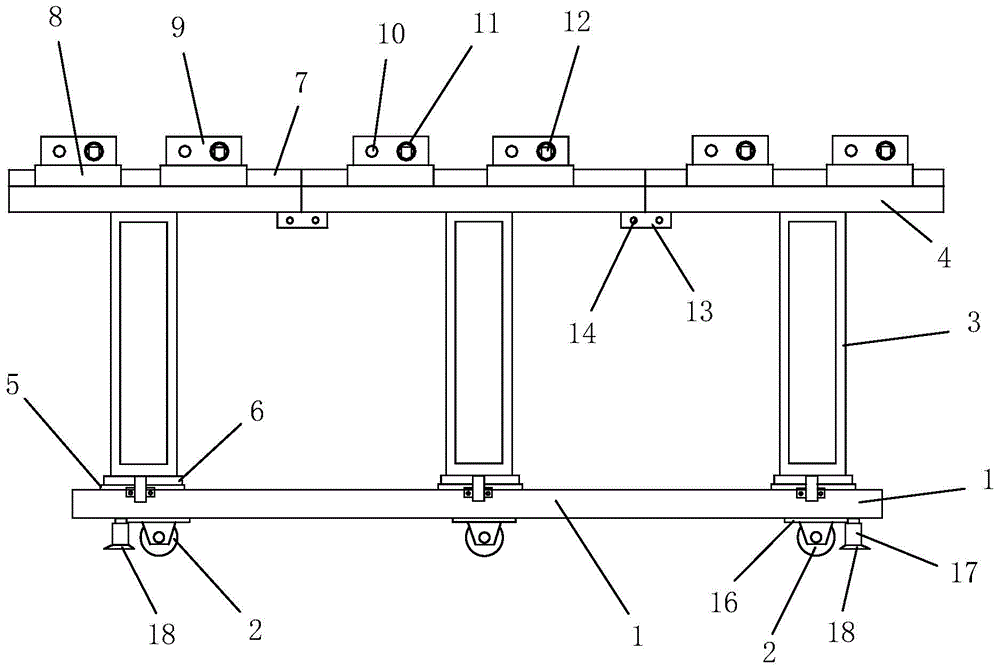

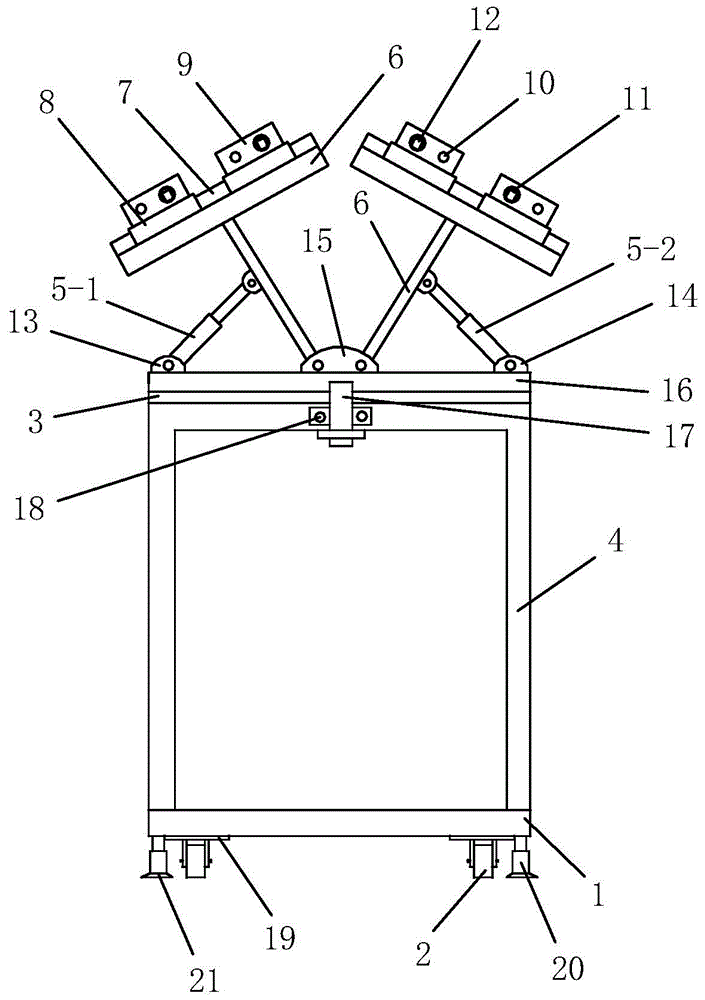

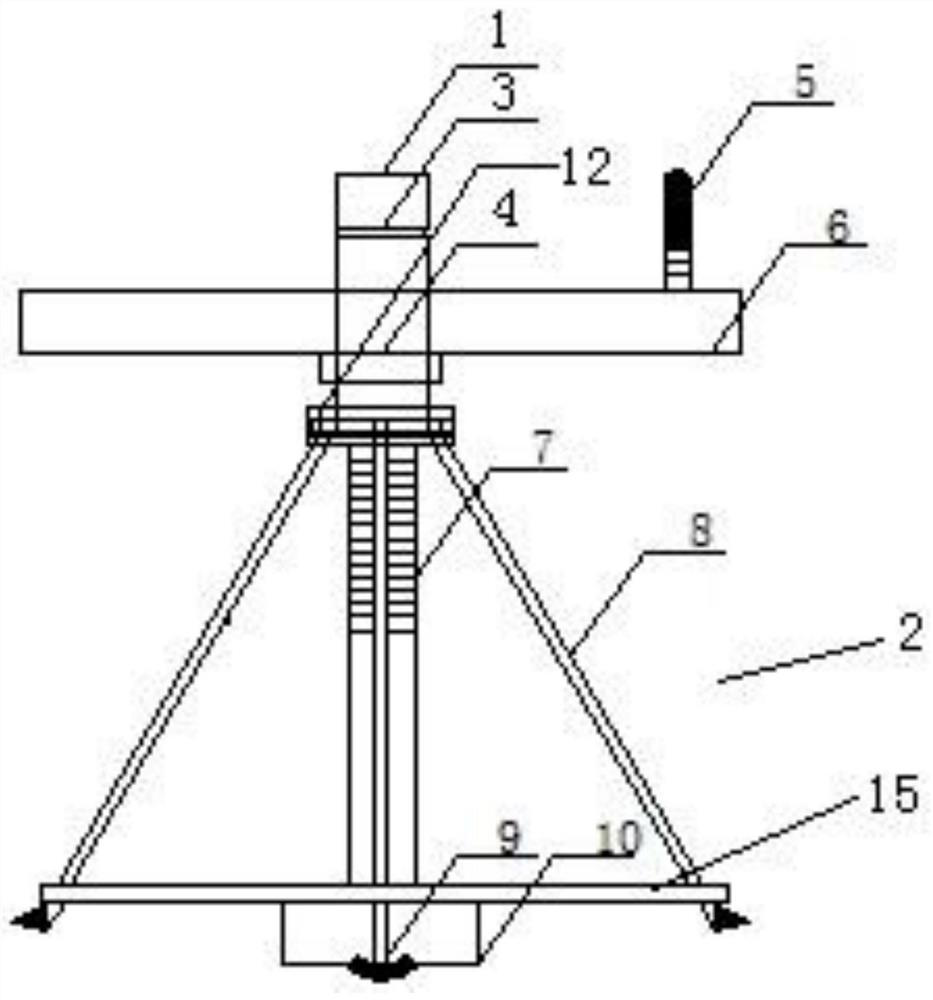

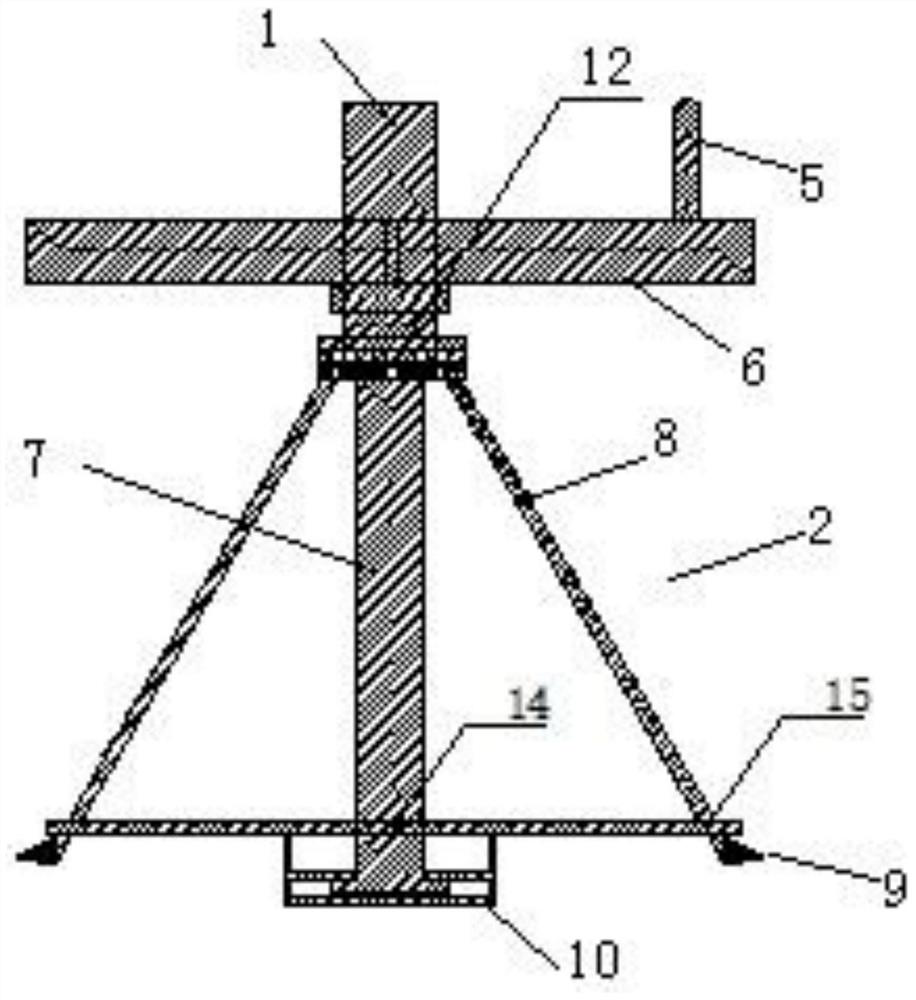

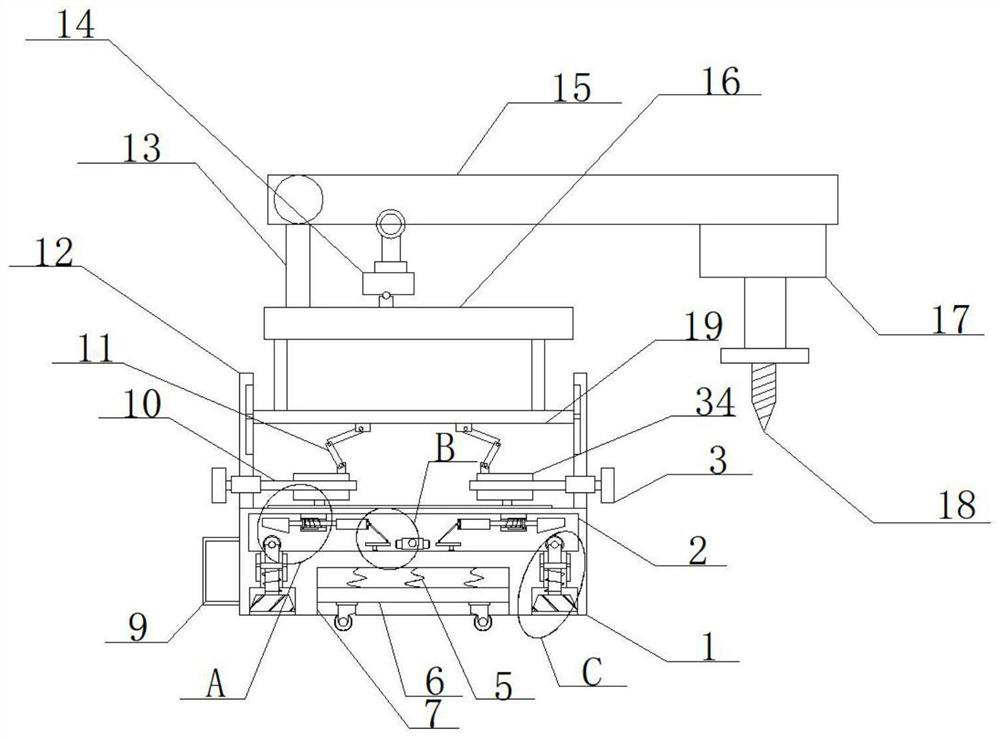

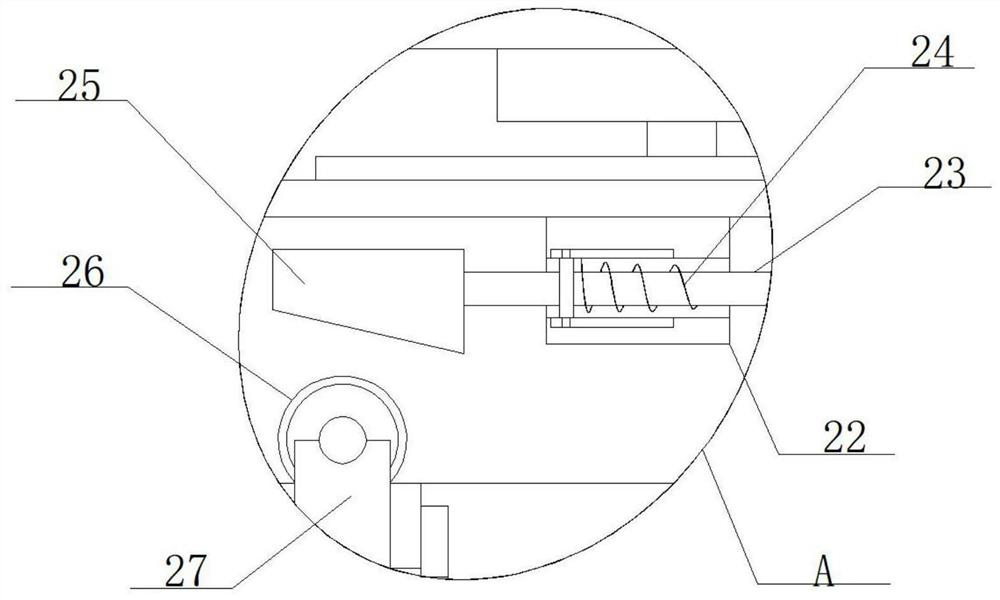

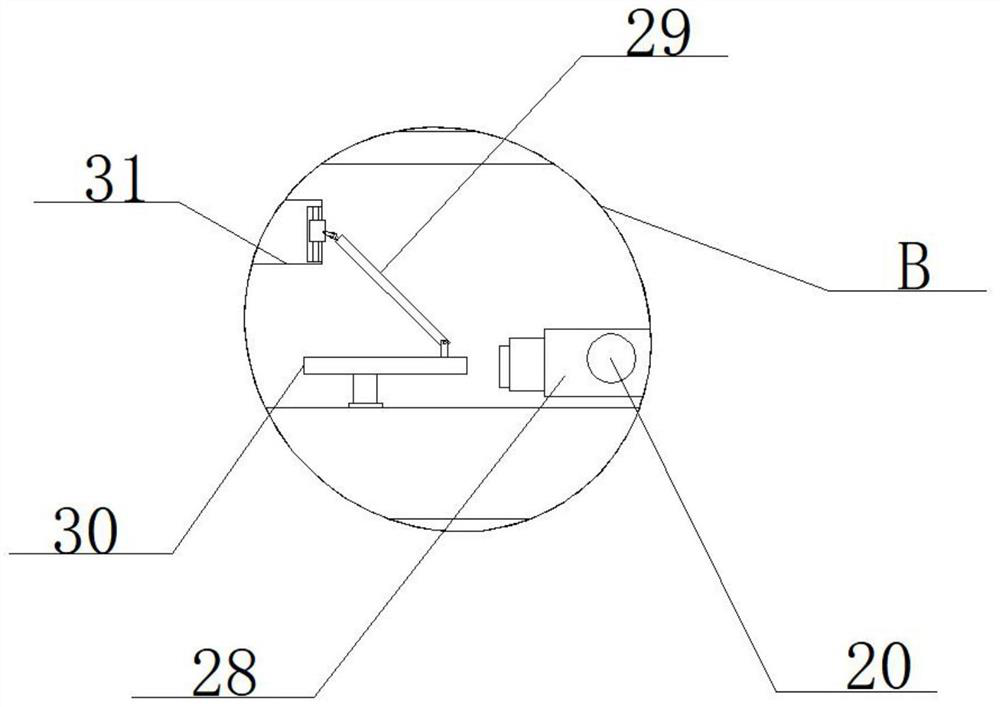

Intelligent drilling frame

PendingCN107178317AEnable remote boltingReduce workloadDrilling using explosivesDrilling rodsElectrical controlManipulator

The invention provides an intelligent drilling frame and belongs to the technical field of mine roof and side wall maintenance devices. The technical problems that when mine roof and side wall maintenance is conducted through manual construction, the dust content is high in an operating environment, working is dangerous and maintenance efficiency is low are solved. The intelligent drilling frame comprises a drilling rod, a drilling box, a lifting mechanism, a cartridge injection system, a manipulator, a drilling rod clamping mechanism, a frame body, an electrical control system, an anchor rod bin, a hydraulic system, a borer clamping mechanism and a connecting swinging mechanism; the drilling rod is fixed into the drilling rod clamping mechanism; the anchor rod bin is internally provided with a plurality of anchor rods; the manipulator is arranged between the drilling rod clamping mechanism and the anchor rod bin; the manipulator is rotatably used for grabbing the drilling rod or the anchor rods; the drilling box is connected with the lifting mechanism connected with the electrical control system; and the lifting mechanism drives the drilling box to move up and down. According to the intelligent drilling frame, automation and intellectualization of the anchor rod operation working procedure are achieved, and the safety factor of roof and side wall maintenance is increased, and roof and side wall maintenance efficiency is improved.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

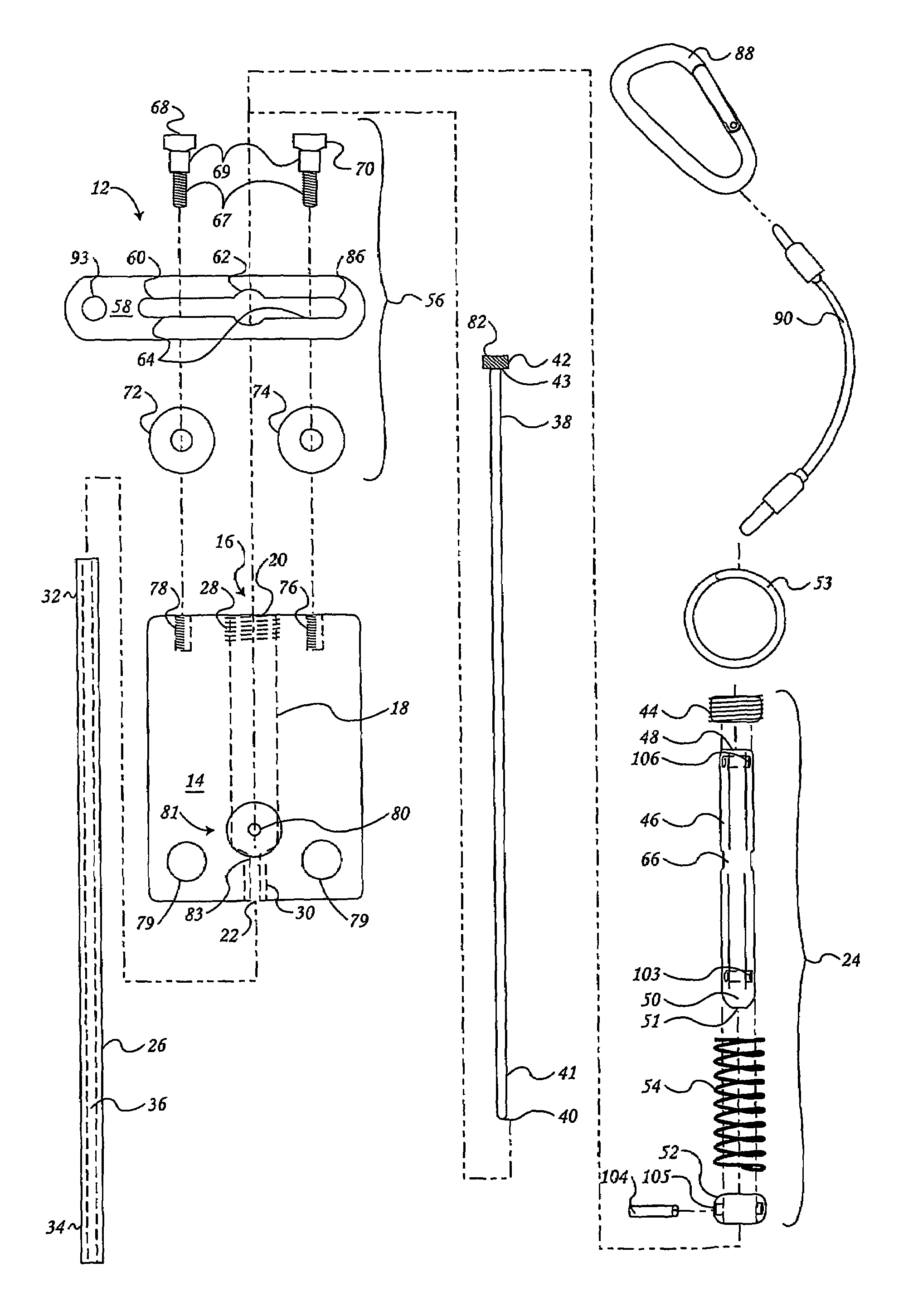

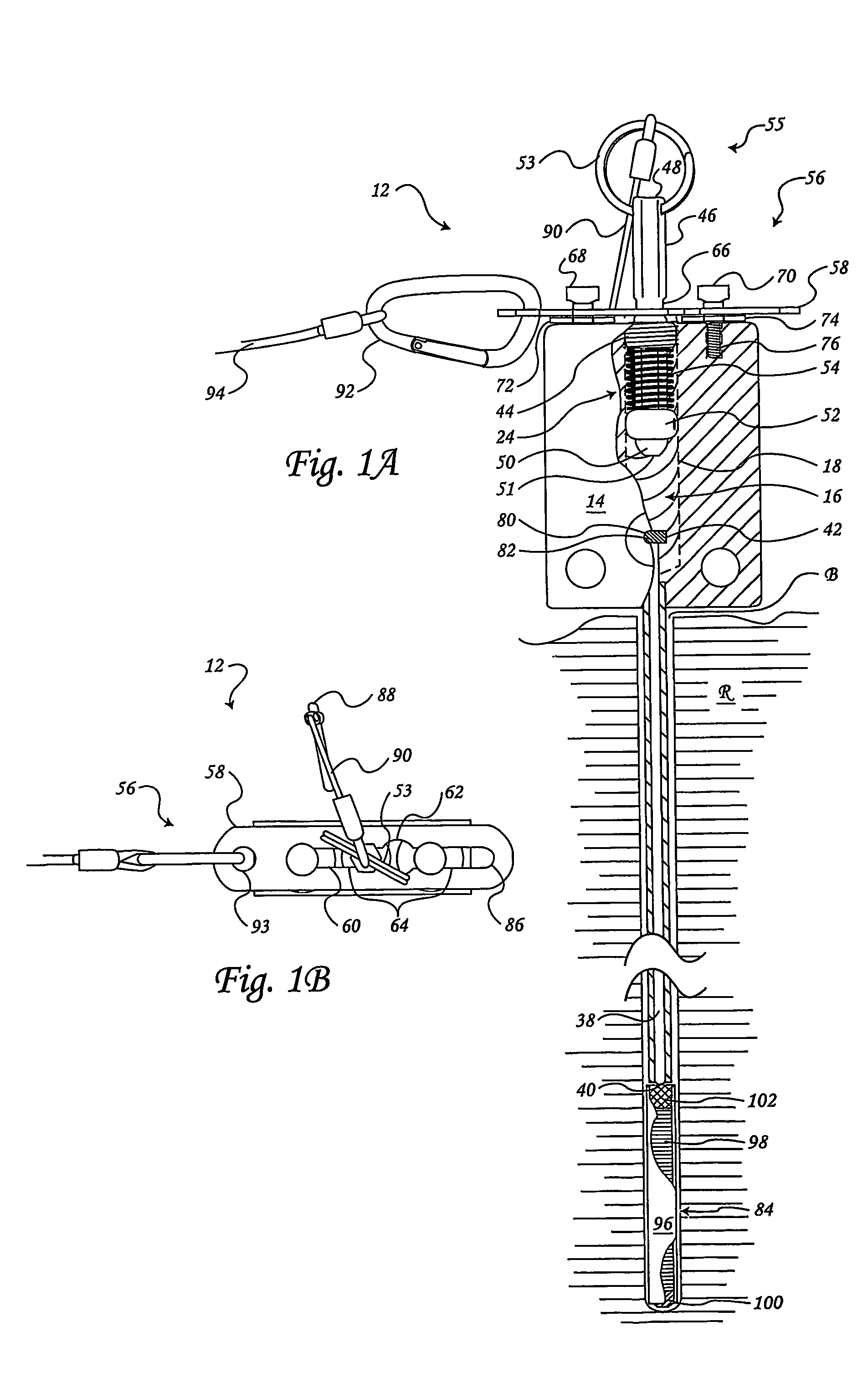

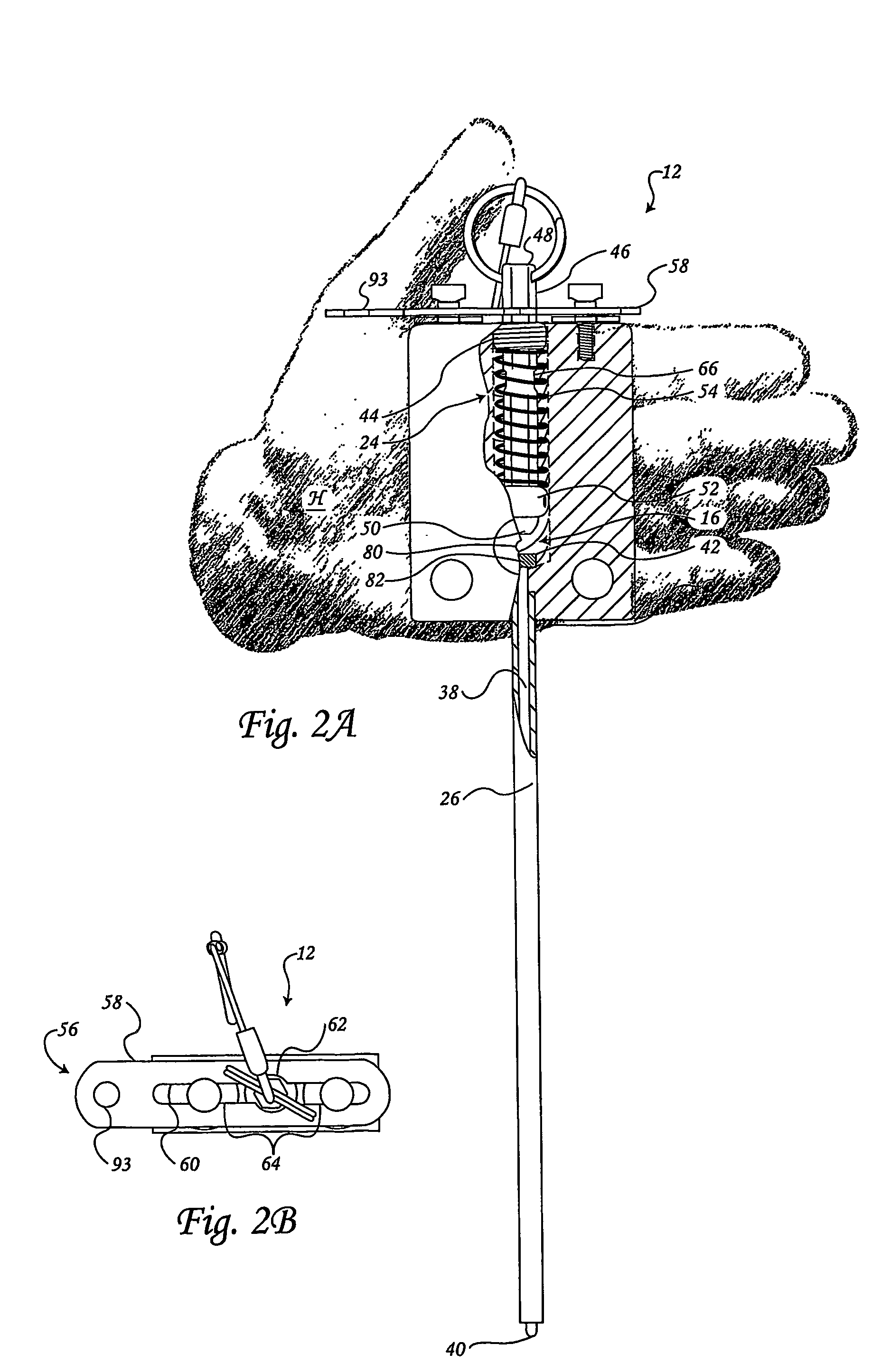

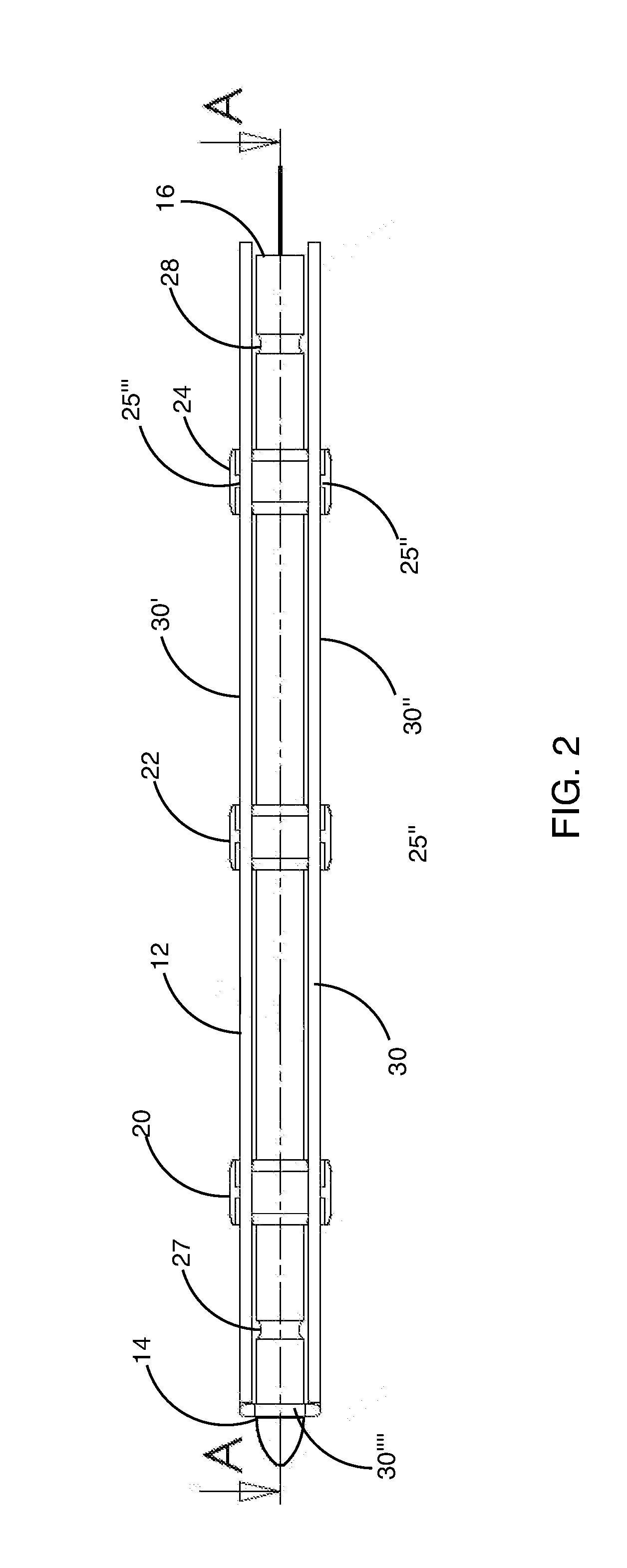

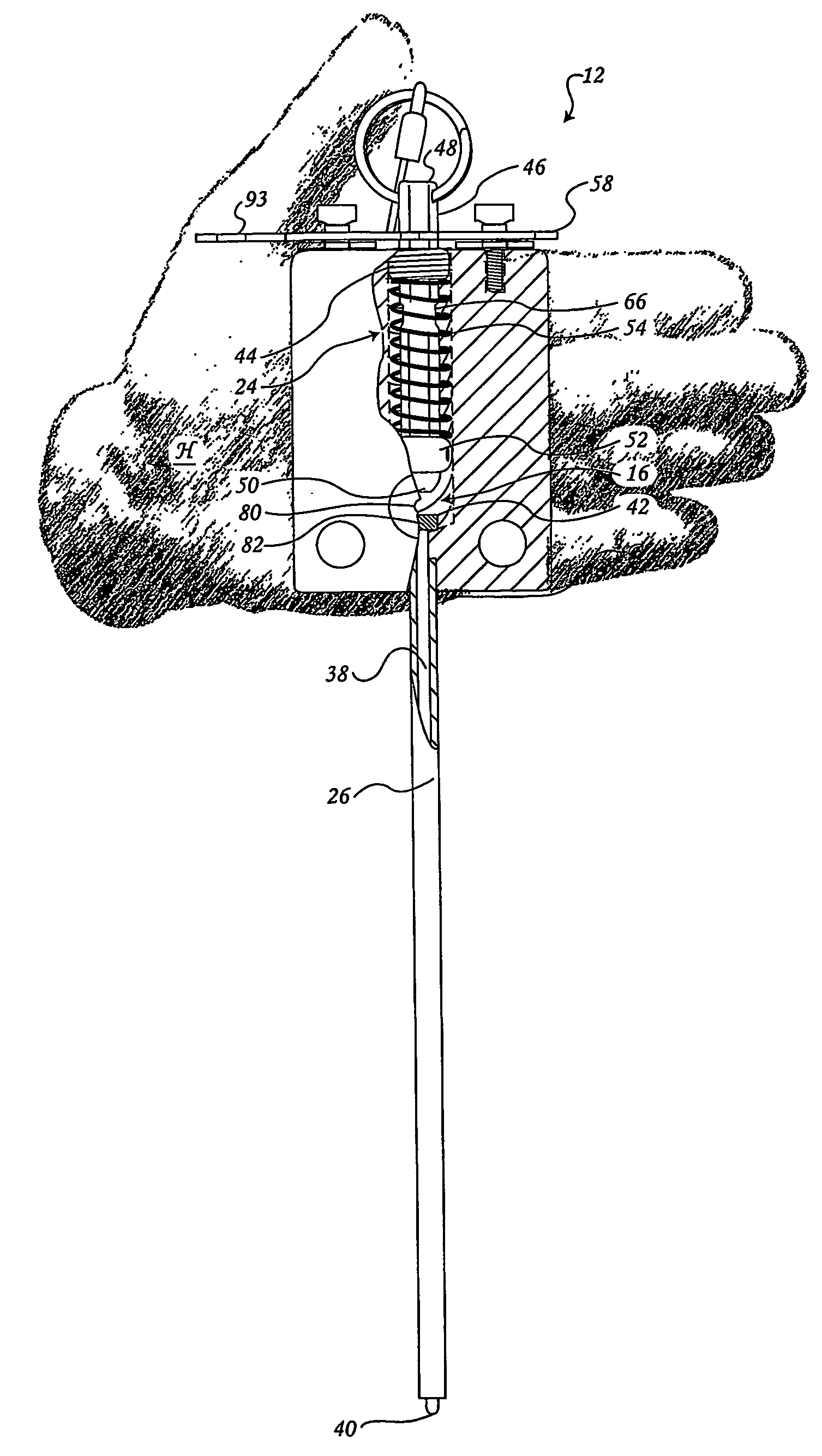

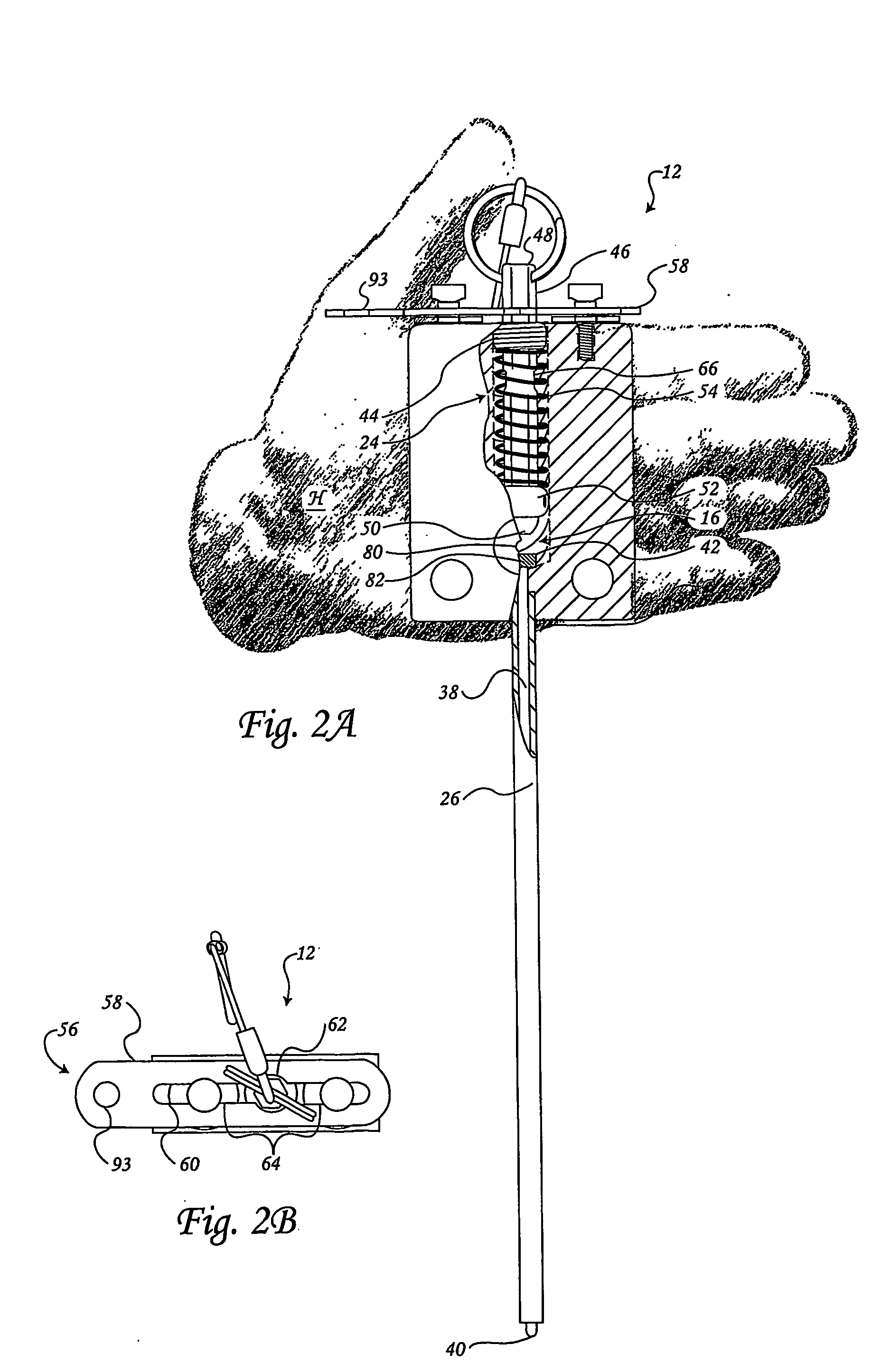

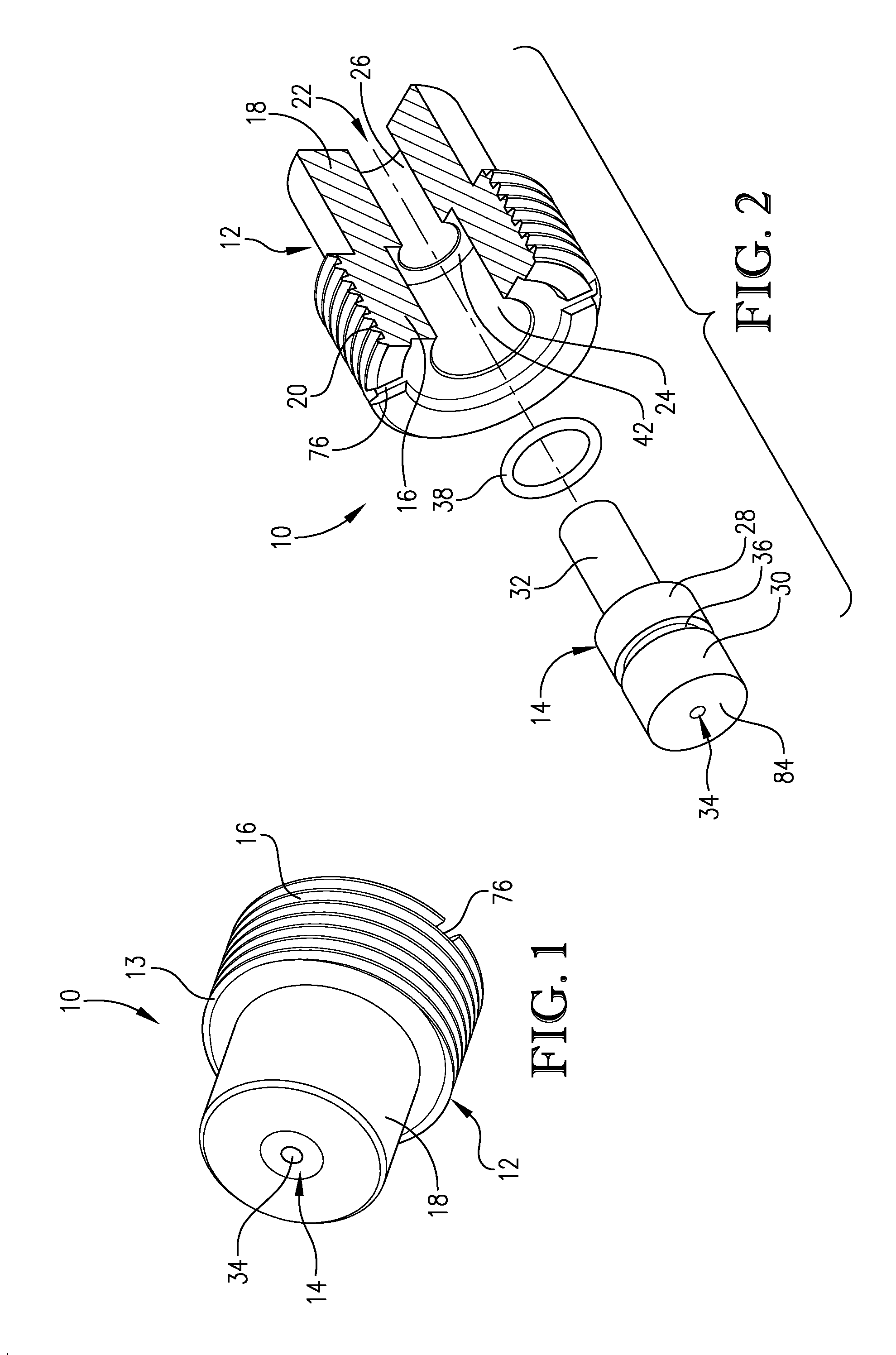

Handheld tool for breaking up rock

InactiveUS7069862B2Easy to drillHigh levelDrilling using explosivesDisloding machinesEngineeringActuator

A tool (12) has a body (14) with a barrel (18) having opposing threaded and fitted openings (30 and 28). An actuator pin tube (26), for slidably engaging an actuator pin (38) having a tip (40) opposing a retention head (42), extending from the fitted opening (30). A spring assembly (24), disposed in the barrel (18), has a hammer guide (44) engaged in the threaded opening (28) with a hammer (46) slidably engaged therein, a handle mechanism (55) disposed at one end and a spring retainer (52) disposed adjacent the other end of the hammer (46) before a hammerhead (51), and a spring (54) engaged between the hammer guide (44) and the spring retainer (52). A release mechanism (56) engages the hammer (46). A kit (108) containing the tool (12) and a method of operating the tool (12) involving drilling and cleaning a borehole, inserting a cartridge and tool therein, and detonating the load remotely using a pull cord.

Owner:BASSETT CARROLL

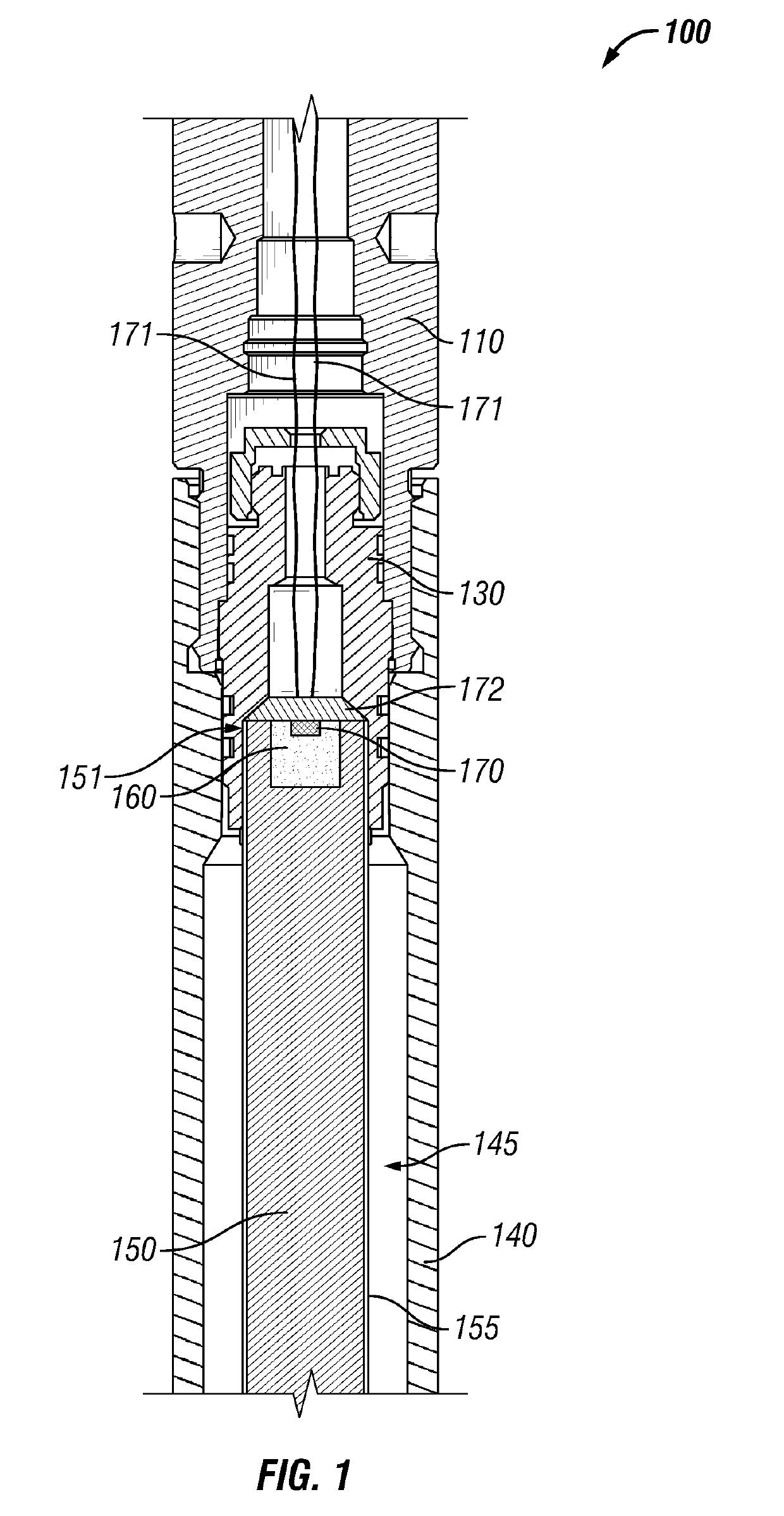

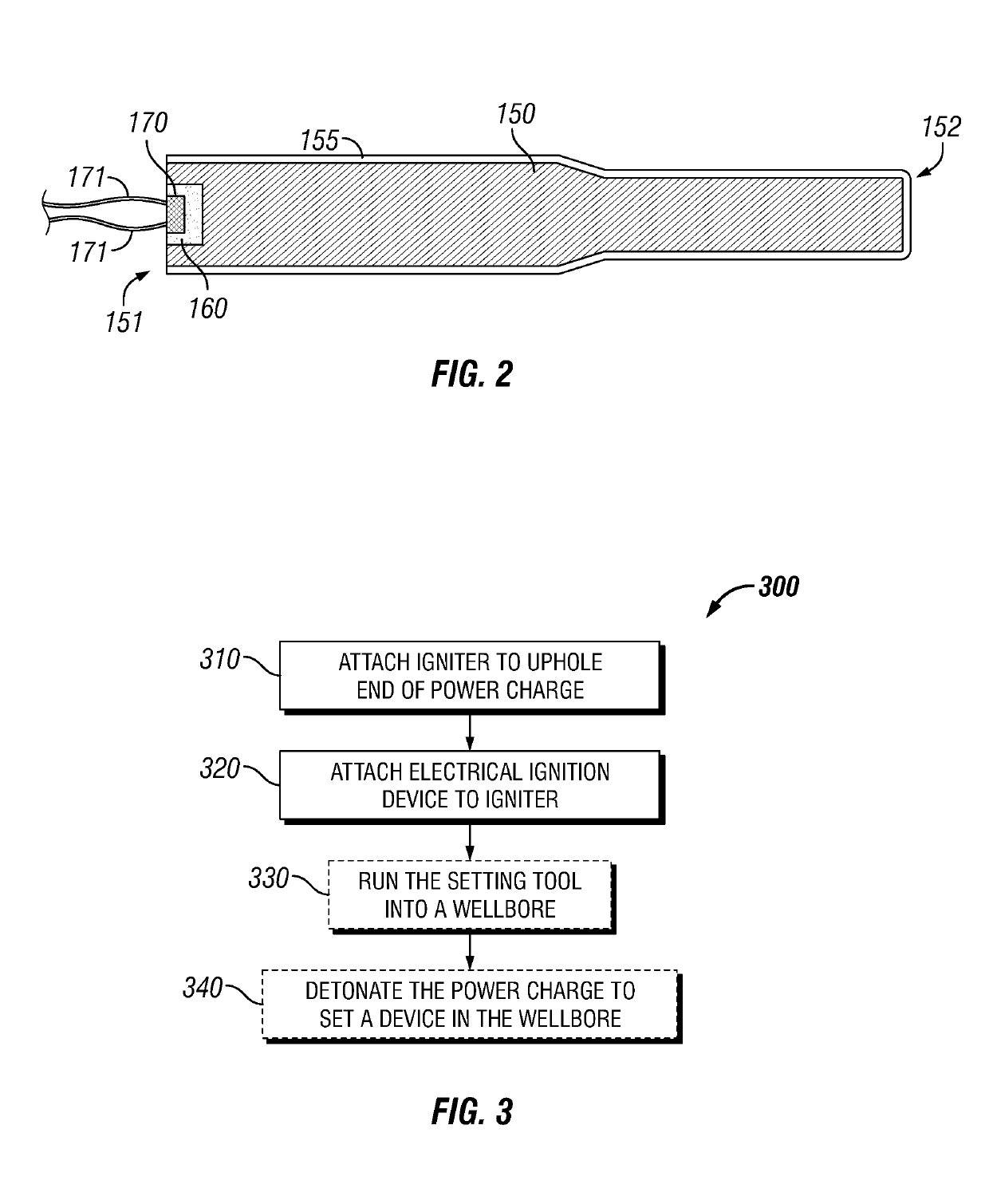

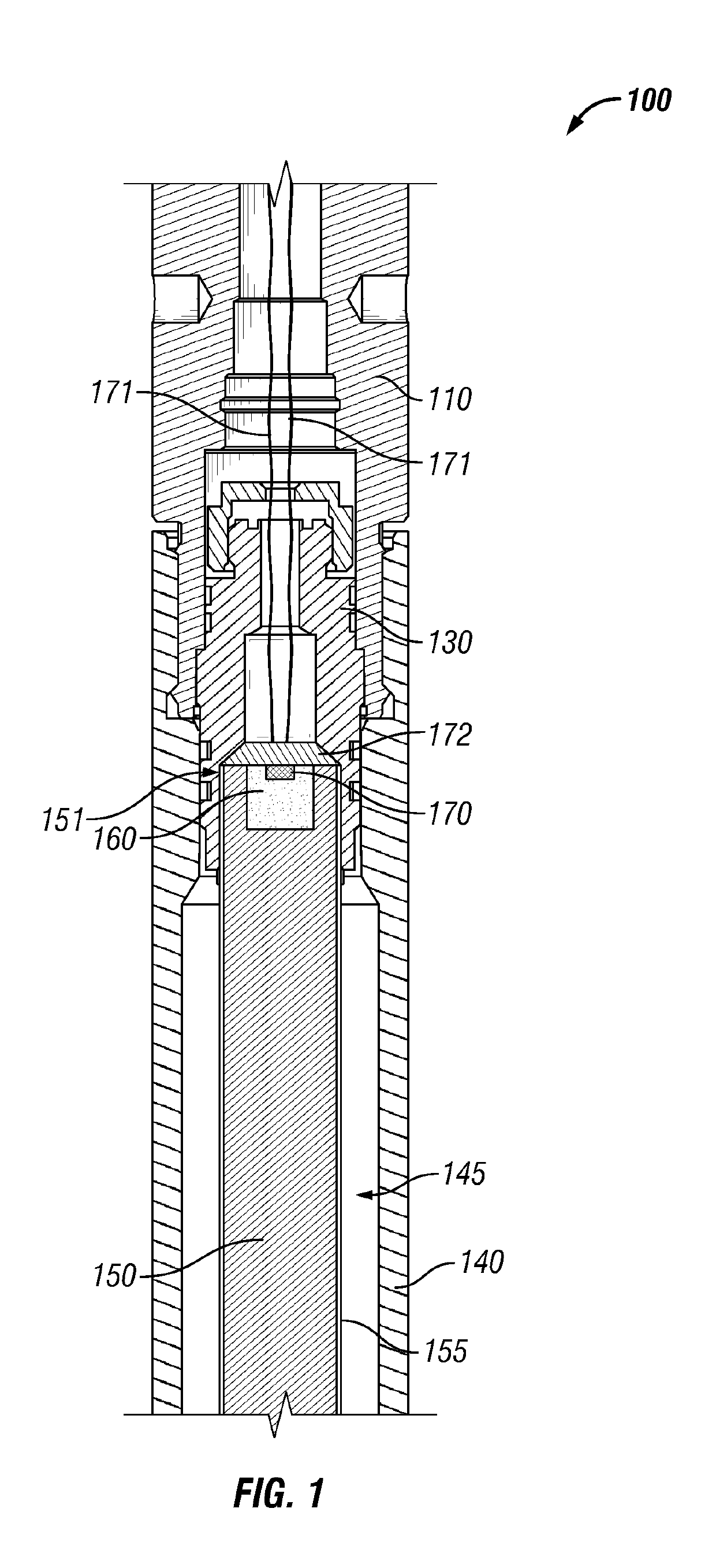

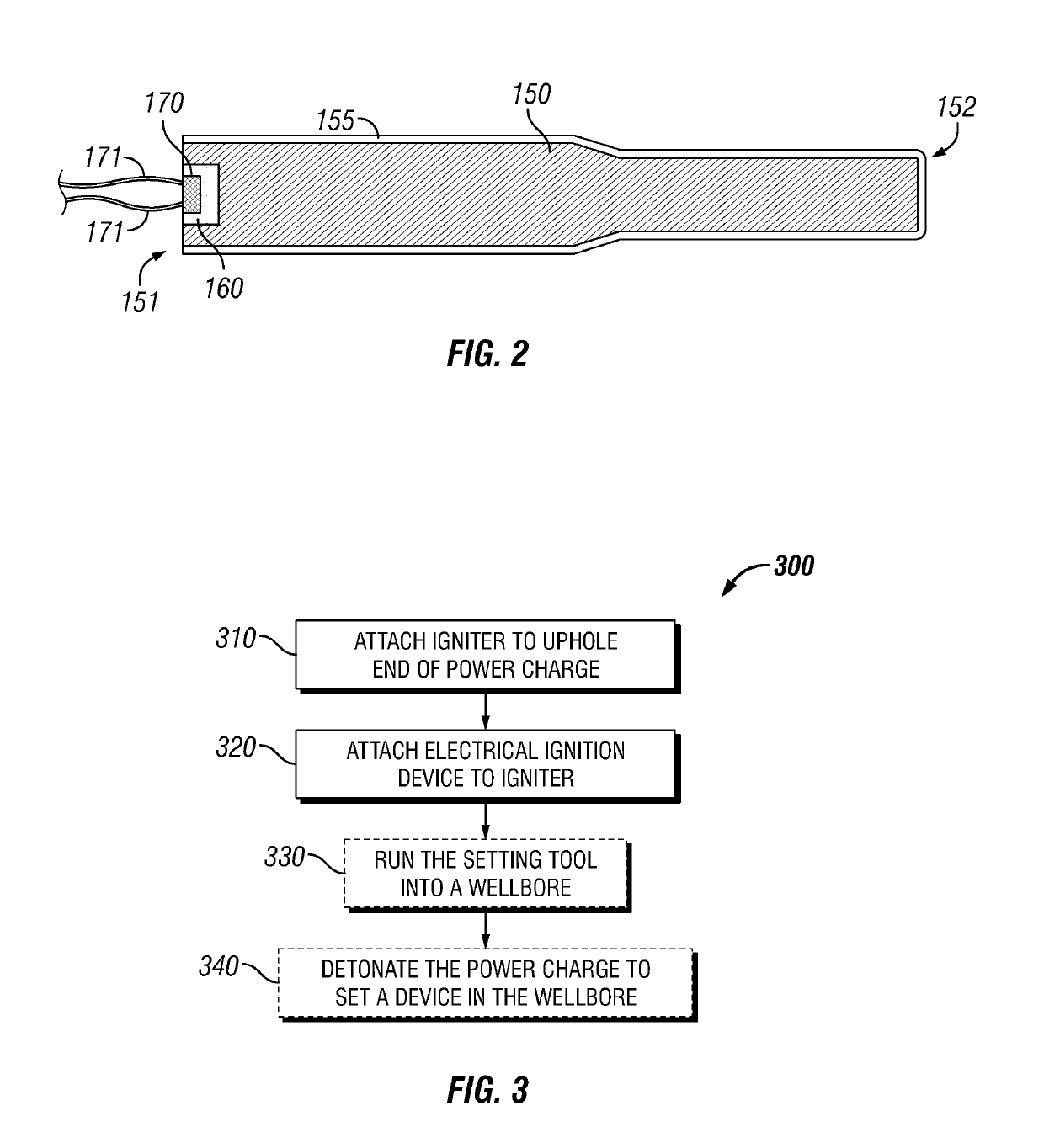

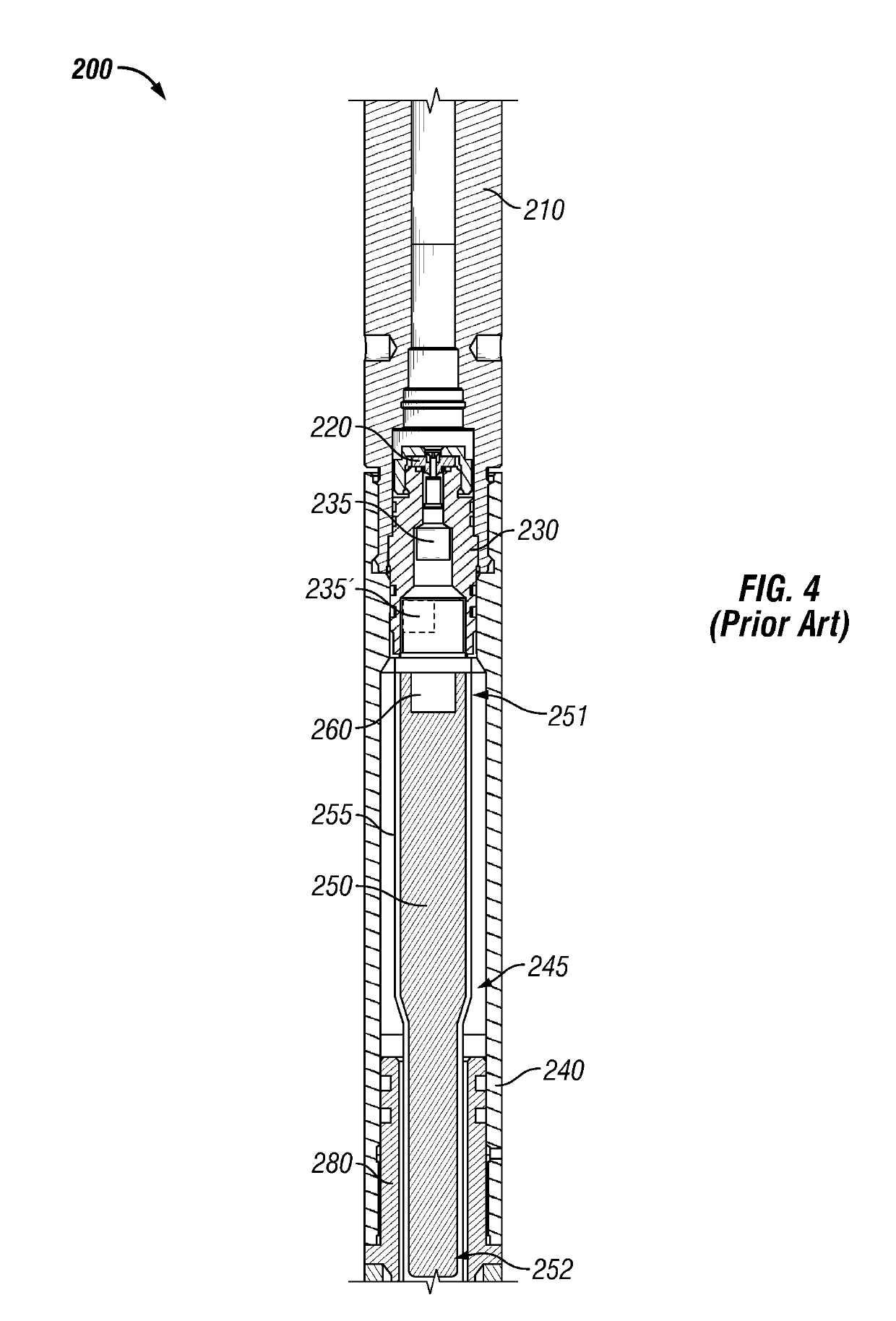

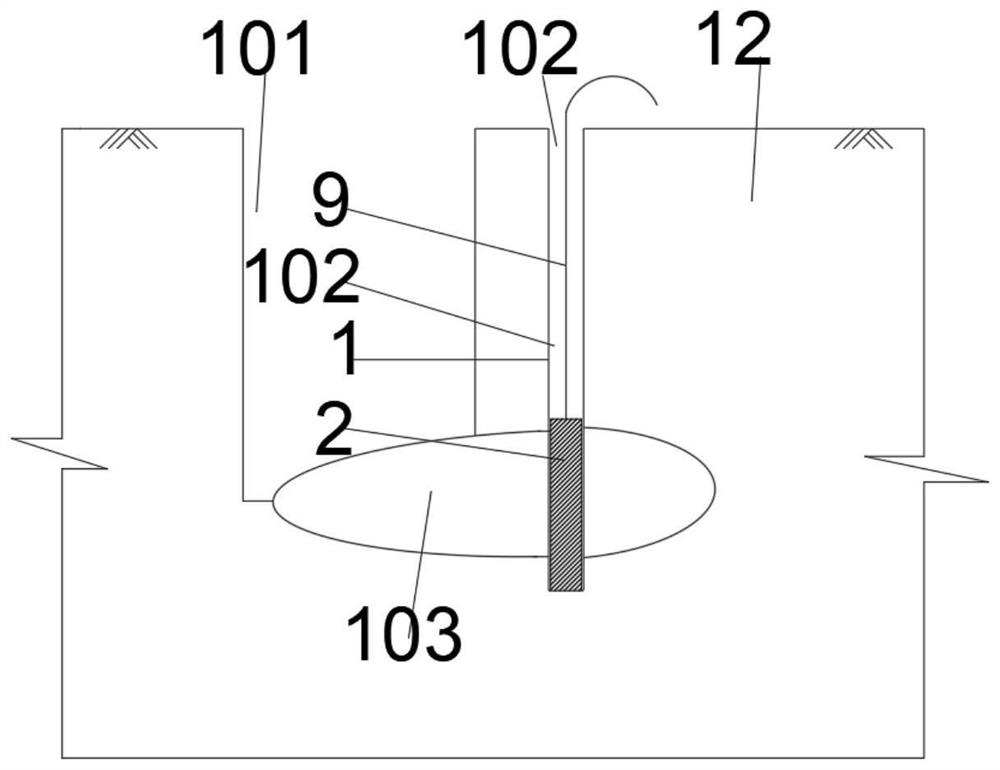

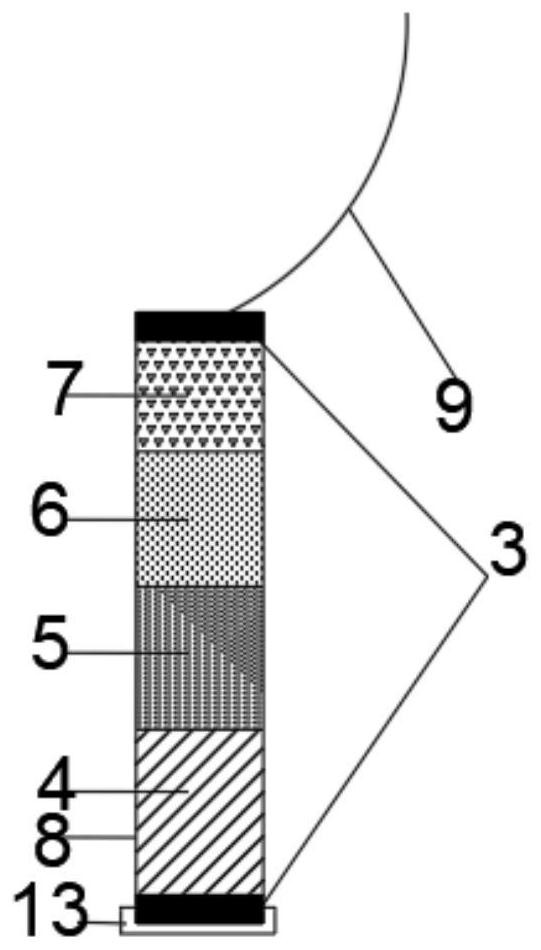

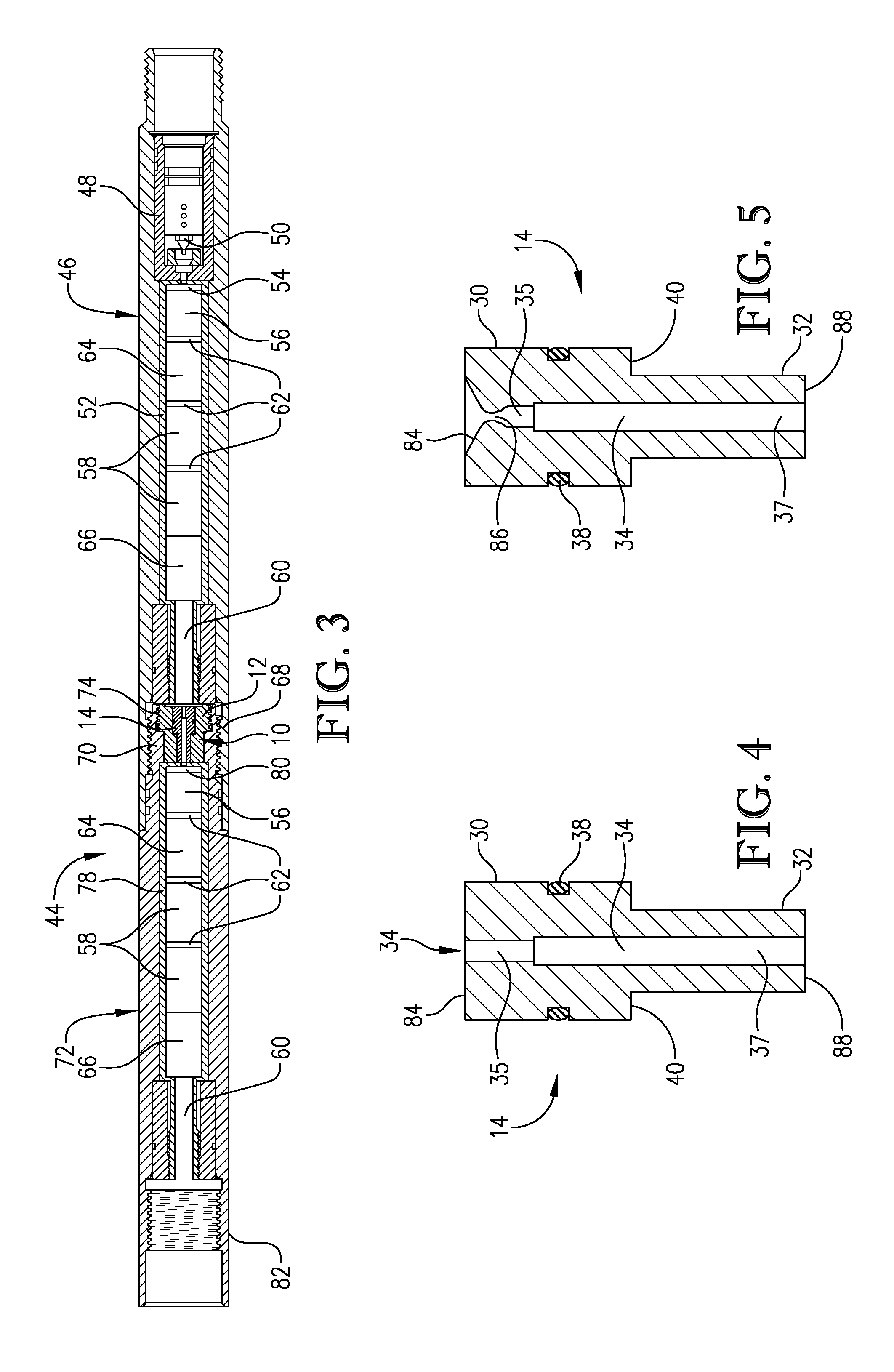

Igniter and Ignition Device for Downhole Setting Tool Power Charge

A downhole setting tool having a first housing, a second housing having a chamber connected to the first housing, a power charge positioned within the chamber, an igniter connected to a portion of the power charge, and an ignition device connected to the igniter. The ignition device is configured to actuate upon receipt of an electrical signal. The ignition device is configured to ignite the igniter. The ignition device may rapidly heat up or apply a voltage or current to the igniter. The igniter is configured to cause the detonation of the power charge to set a device within a wellbore. The igniter may be embedded into the power charge with the ignition device positioned within a cavity in the igniter. The igniter may be a pyrotechnic material or may release high energy heat upon application of voltage or current.

Owner:BAKER HUGHES INC

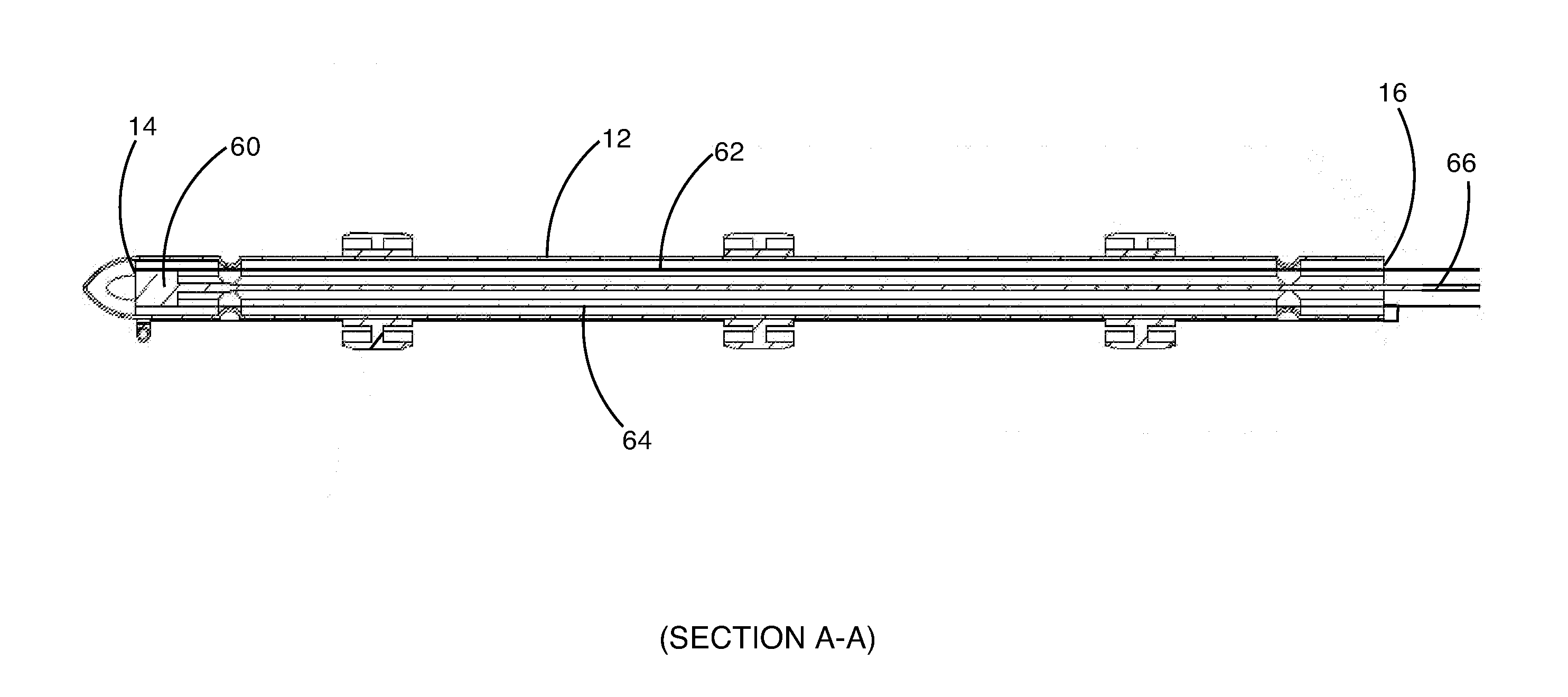

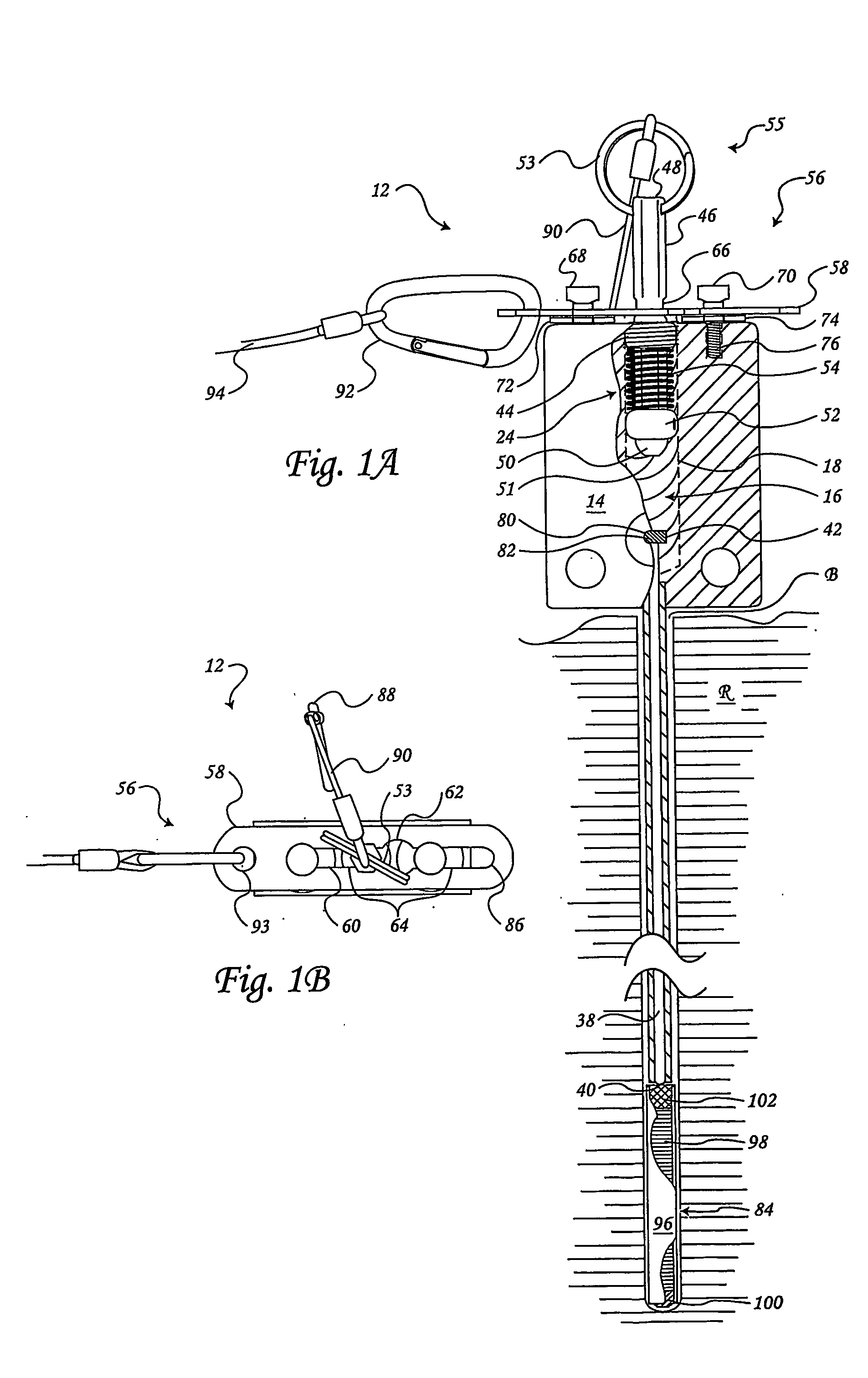

Energy transfer device

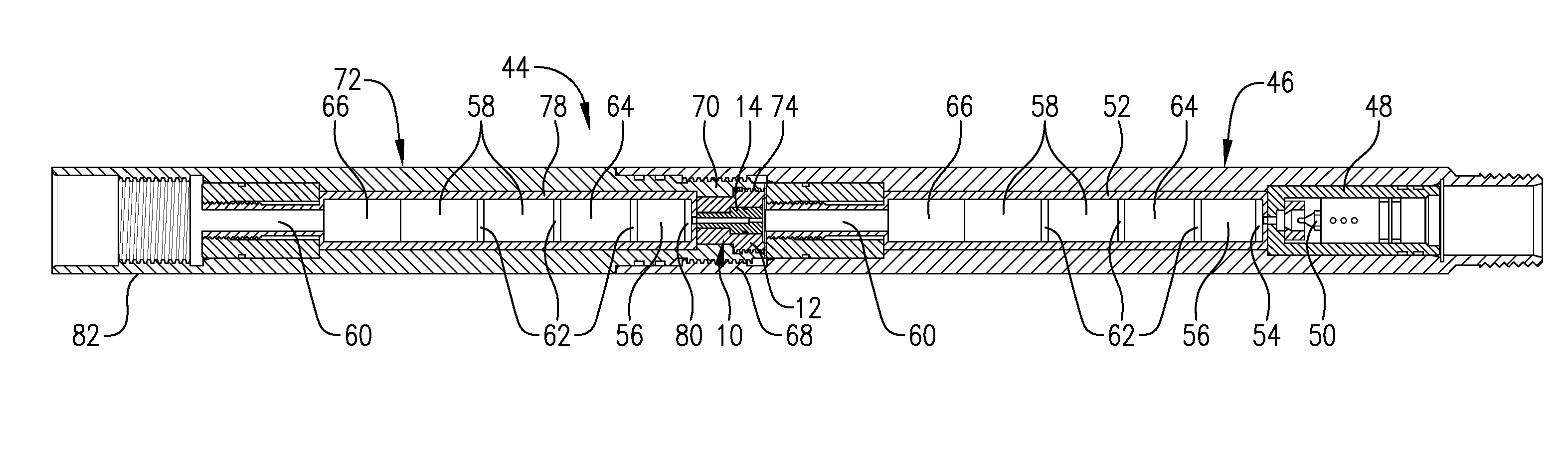

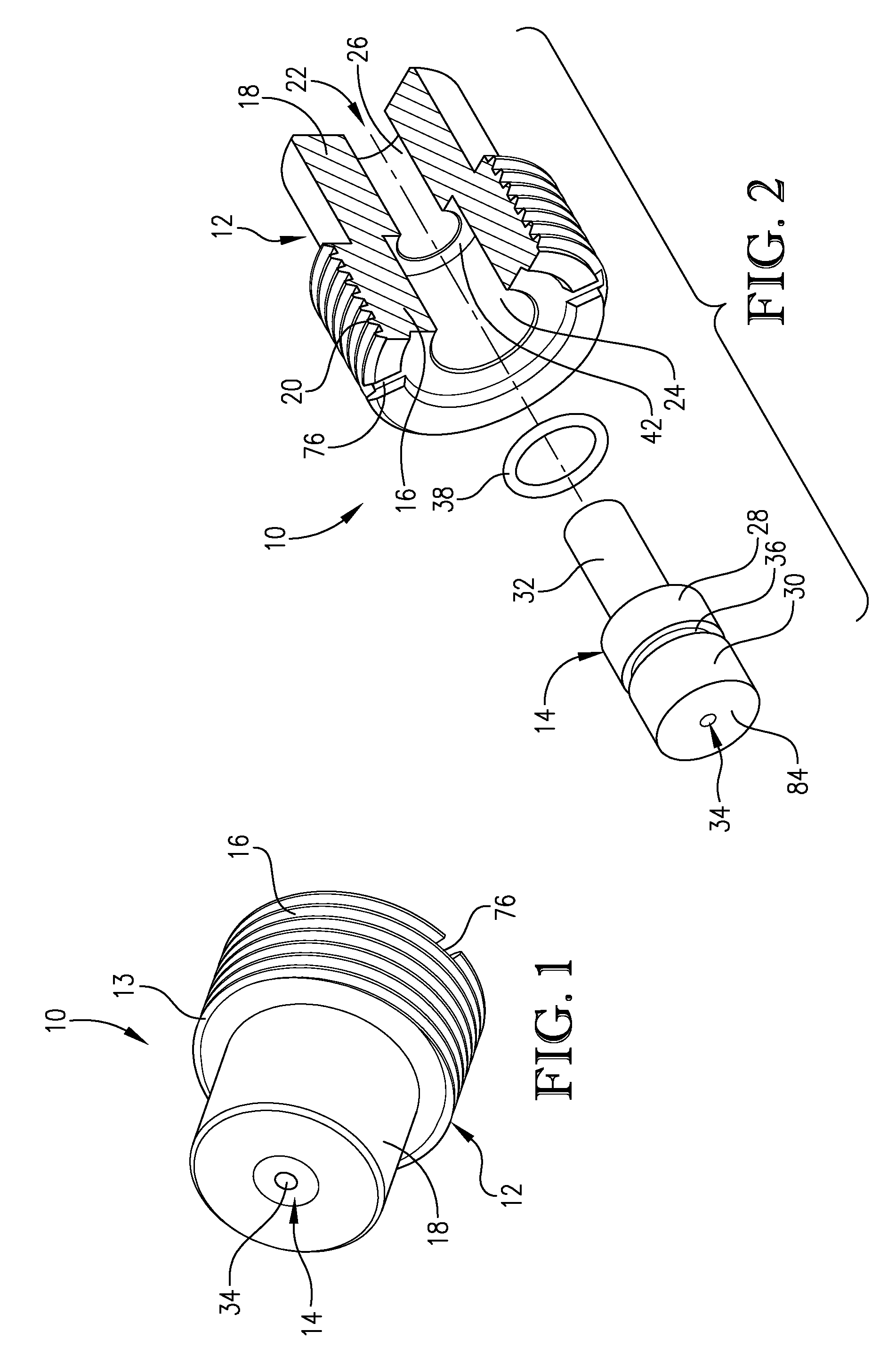

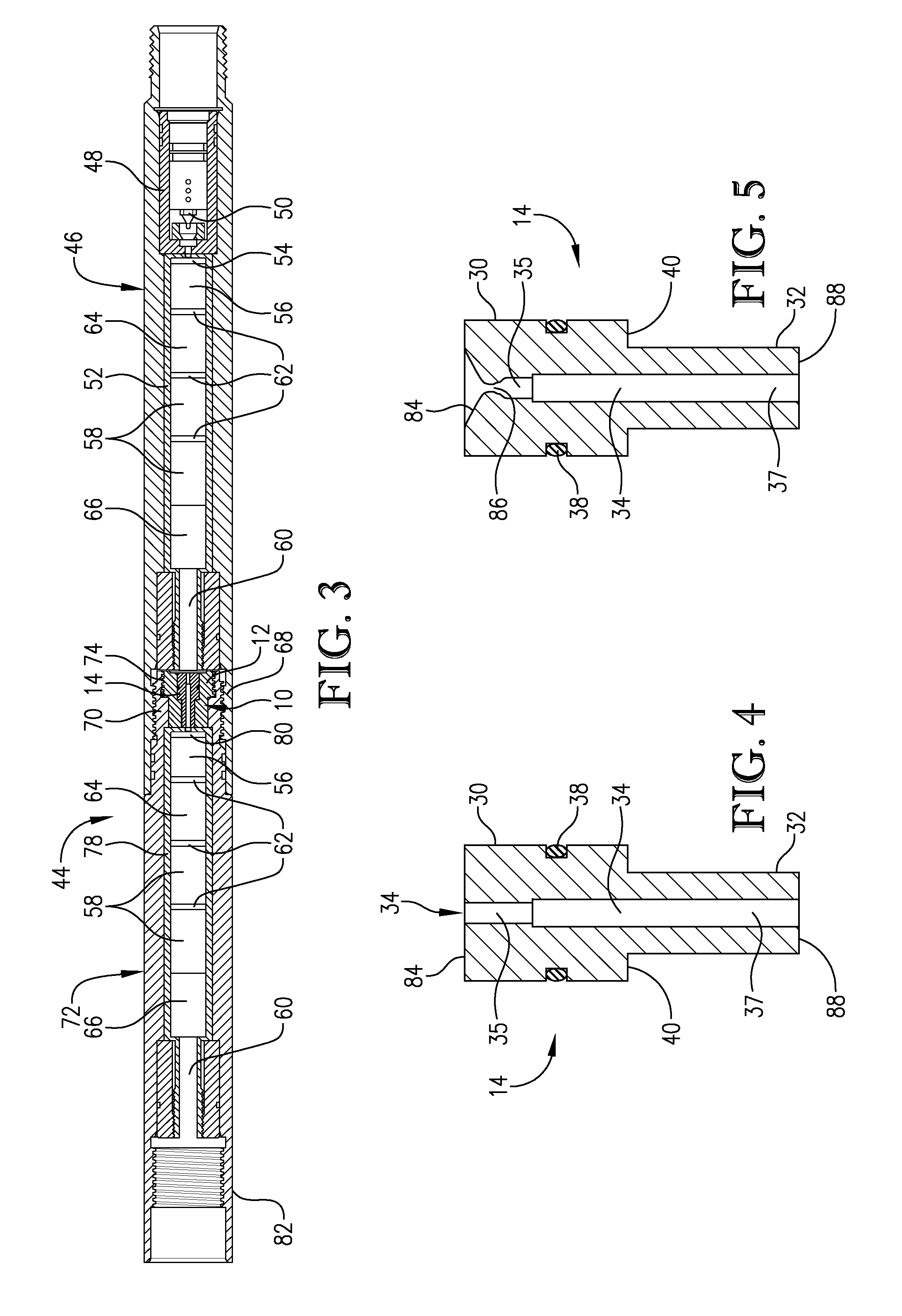

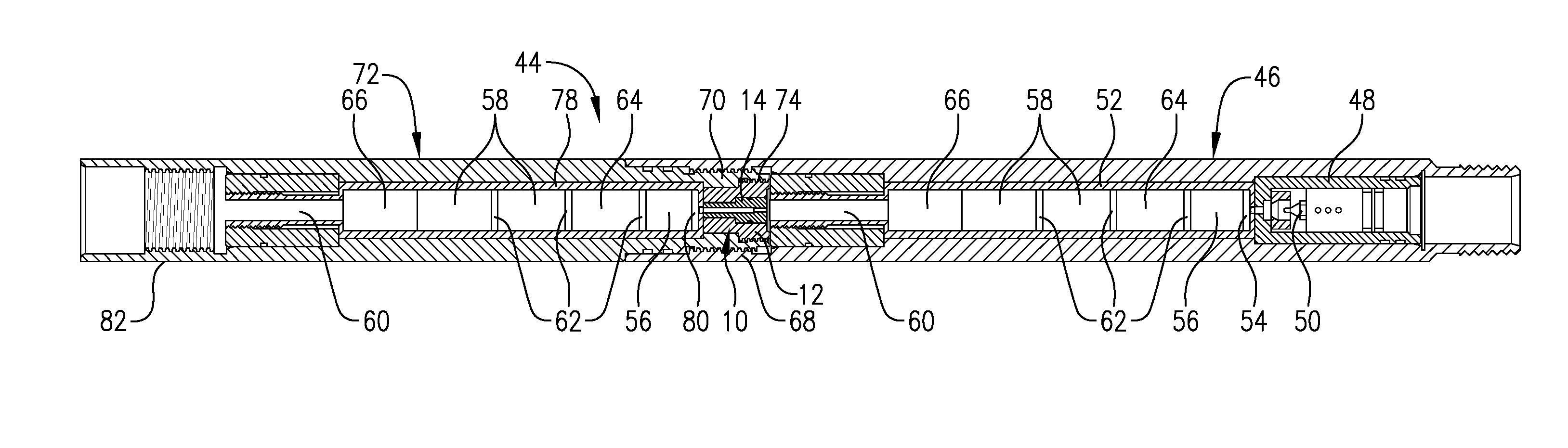

InactiveUS8943970B2Drilling using explosivesIncandescent ignitionEnergy transferBiomedical engineering

A energy transfer device (10) is provided that is capable of transferring the energy output from one pyrotechnic device (52) to another device (78) for initiating firing thereof. Device (10) comprises a device housing (12) in which a deformable device insert (14) is received. Device insert (14) comprises a central passageway (34) for transmitting the output from a pyrotechnic device (52), including energy, gasses, and / or solids, to another pyrotechnic device (78). The passageway (34) conducts the pyrotechnic device output to a precise location on the second pyrotechnic device (78) where firing is most effectively initiated. The energy transfer device (10) may be employed as a part of a tool (44) used in well completion operations.

Owner:CARTRIDGE ACTUATED DEVICES

Hot hole charge system

InactiveUS8820242B2Maximize the effectSimple and safe to useDrilling using explosivesThermal insulationDetonatorHot holes

An apparatus, method and insulation medium for inserting and insulating a charge medium within a borehole includes a charge tube comprised of an elongate tube having a length and diameter sufficient for containing a desired quantity of a charge medium. A charge medium in a pumpable form is provided for substantially filling the charge tube. An insulation medium in a pumpable form is provided for substantially encapsulating the charge tube and substantially filling an annular space between the charge tube and the borehole for insulating the charge tube from a downhole environment in which the charge tube is to be inserted. A detonator is inserted within the charge medium proximate a distal end of the charge tube and a charge cable extends from the detonator through the charge tube and exits from the charge tube.

Owner:ALEXANDER BRENT DEE

Igniter and ignition device for downhole setting tool power charge

A downhole setting tool having a first housing, a second housing having a chamber connected to the first housing, a power charge positioned within the chamber, an igniter connected to a portion of the power charge, and an ignition device connected to the igniter. The ignition device is configured to actuate upon receipt of an electrical signal. The ignition device is configured to ignite the igniter. The ignition device may rapidly heat up or apply a voltage or current to the igniter. The igniter is configured to cause the detonation of the power charge to set a device within a wellbore. The igniter may be embedded into the power charge with the ignition device positioned within a cavity in the igniter. The igniter may be a pyrotechnic material or may release high energy heat upon application of voltage or current.

Owner:BAKER HUGHES INC

Construction method of complex inclined rock and boulder geological bored pile

ActiveCN111720051AAvoid severe reamingImprove crushing effectDrilling using explosivesGeotextilesRebarGeotextile

The invention relates to a construction method of a complex inclined rock and boulder geological bored pile. The construction method comprises the following steps of: S1, drilling first drill holes ina foundation and boulders on the pile side by using a coring machine; S2, manufacturing an explosive tube; S3, burying wall protecting tubes in the first drill holes every other first drill hole; S4,mounting a lifting rope at the top of a limiting rod; S5, sleeving the outer side of the limiting rod with a steel casing to the highest point of the rock surface; S6, pre-cracking and loosening rocks by using a static crushing agent; S7, lifting the lifting rope to recover the limiting rod and a PVC tube for secondary utilization; S8, arranging a geotextile bag at the position, corresponding toa boulder hole, of a reinforcement cage; S9, arranging water-swellable rubber between a first iron sheet and a second iron sheet; and S10, sinking the assembled reinforcement cage to a designated position, and pouring concrete. The construction method has the advantages that the limiting rod is arranged on the inclined rock and boulders, so that the casing can be prevented from deflecting; and when a drill bit is ejected and deflects to affect the casing, the drill bit can be limited by the limiting rod, so that the perpendicularity of a pile hole is improved.

Owner:ZHEJIANG UNIV CITY COLLEGE

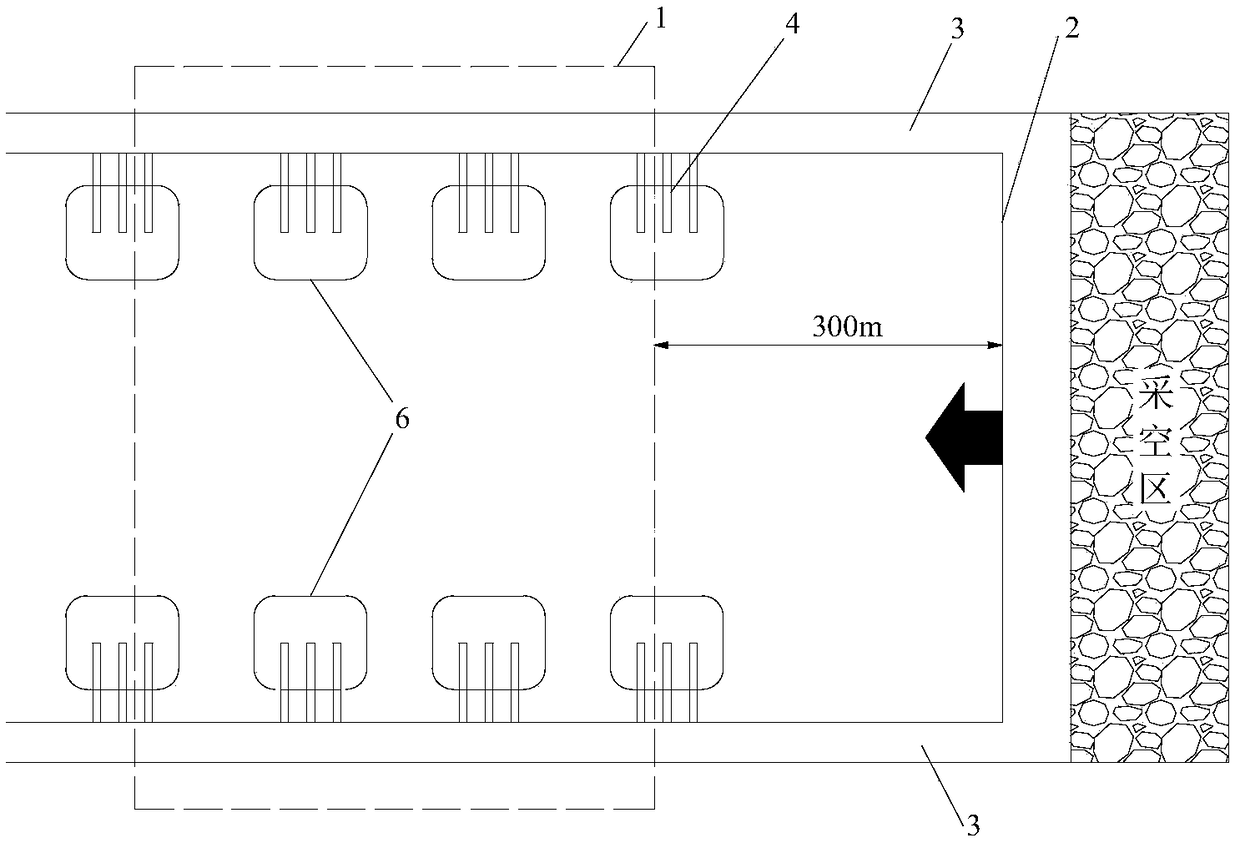

Rock burst prevention and control method of three-dimensional coal pillar coal compressing area

InactiveCN108756881AReduced impact riskPlay a blocking roleDrilling using explosivesUnderground miningHigh energyEngineering

The invention discloses a rock burst prevention and control method of a three-dimensional coal pillar coal compressing area, and relates to the technical filed of coal mining. A plurality of blastingdrilling groups are formed in a coal wall of a working face, and the high energy level impact energy formed by three-dimensional coal pillars can be blasted by high-strength to form a plurality of low-energy block regions, and the accumulated elastic energy is released to a large extent. The energy block area blocks and eliminates high stress and high energy, reduces the impact risk of a three-dimensional coal pillar area, and realizes the control of high energy level impact energy.

Owner:HUAIHAI INST OF TECH

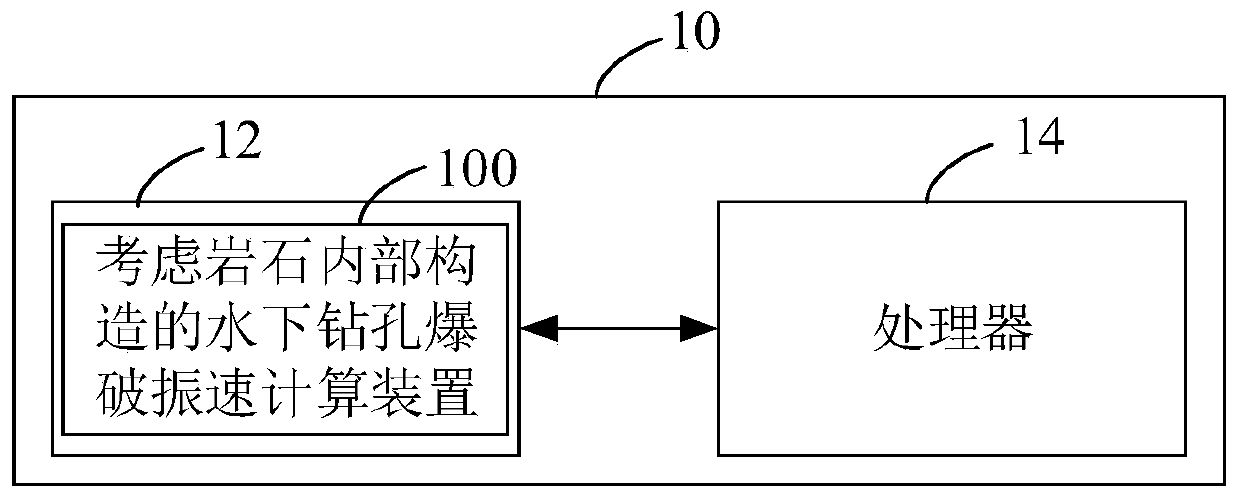

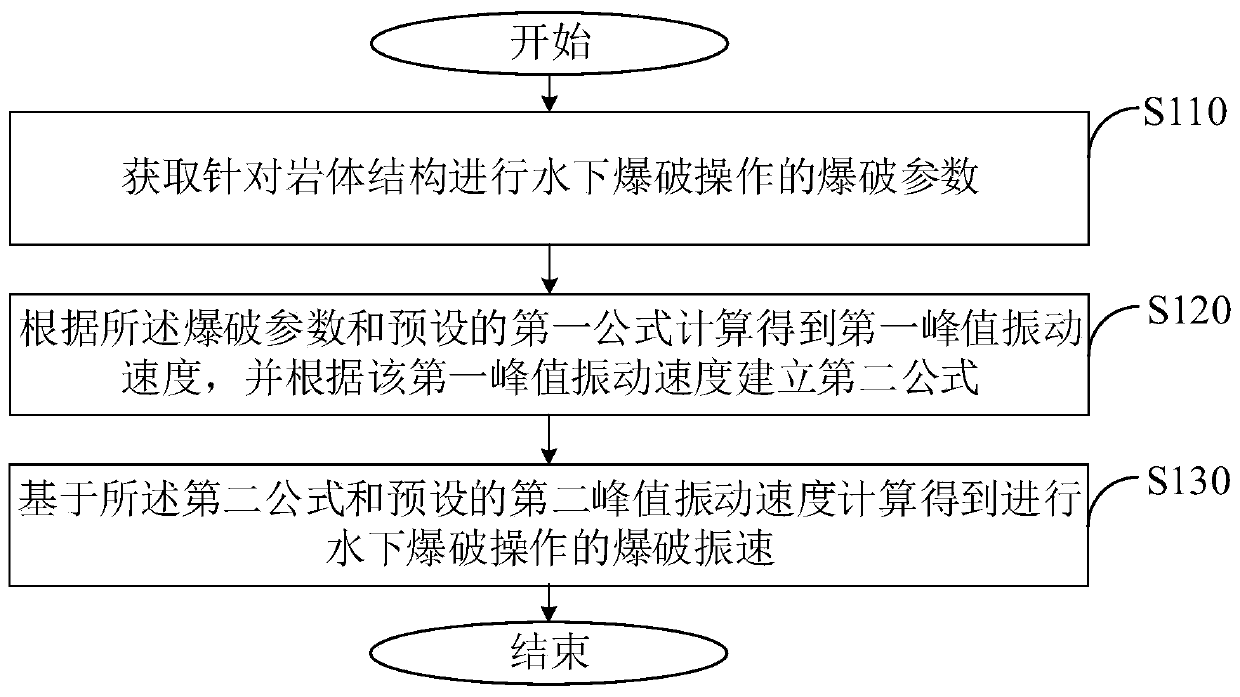

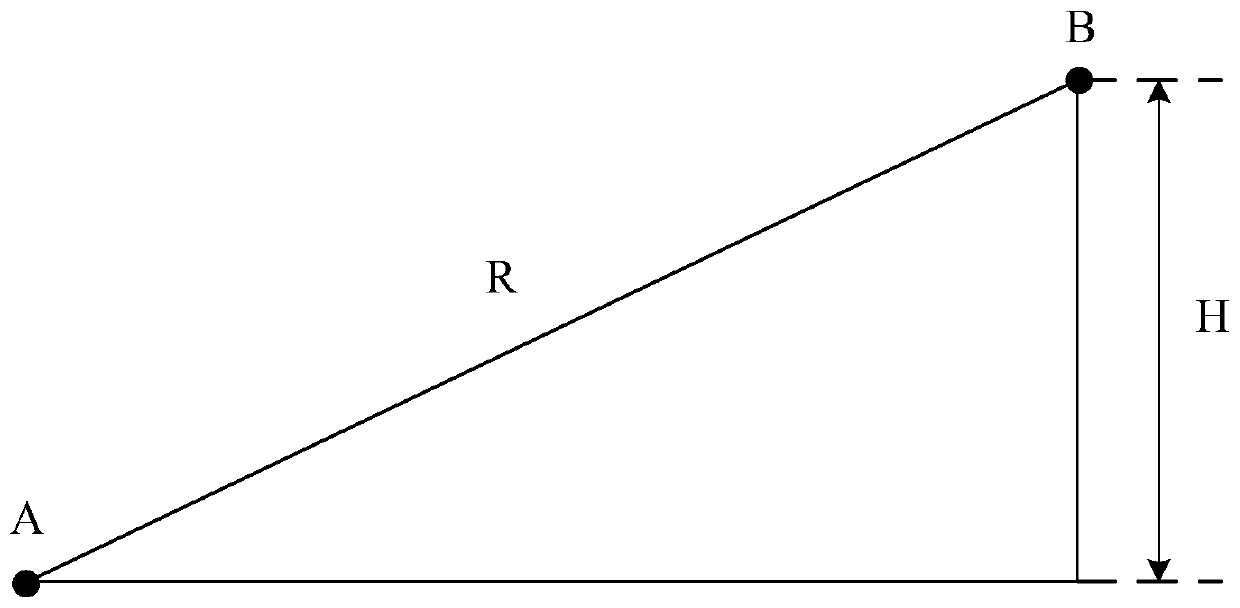

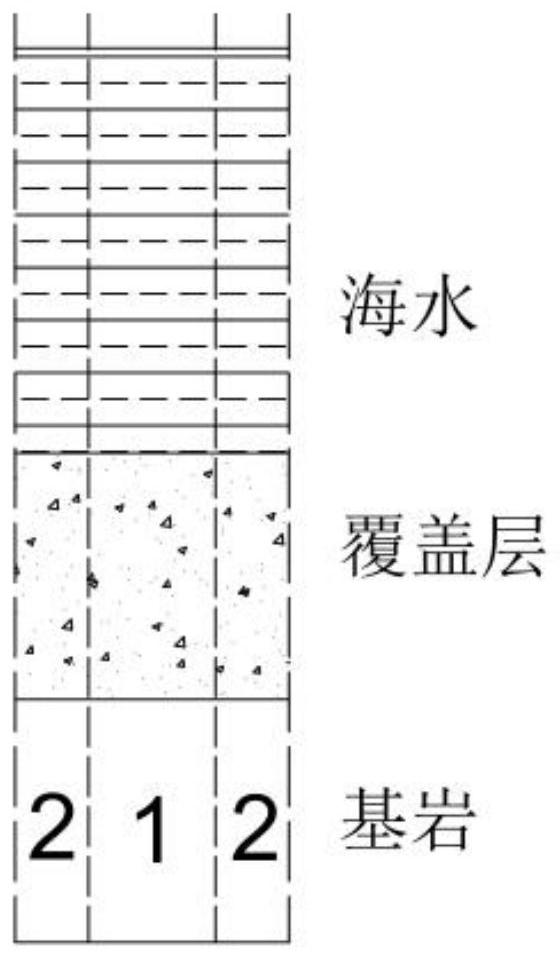

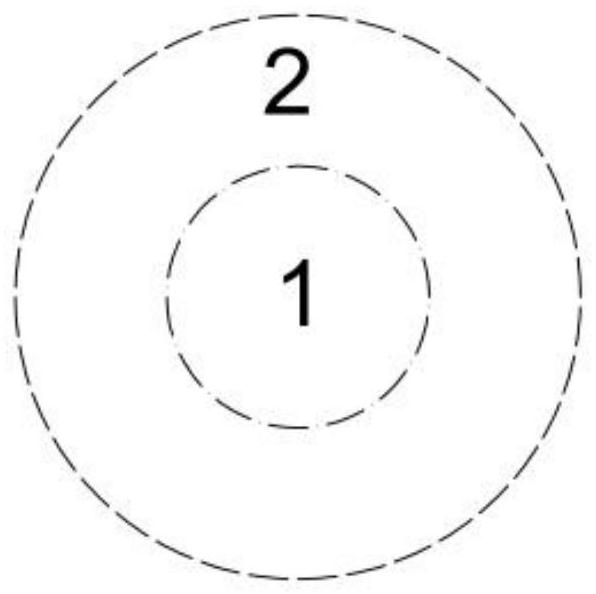

Method for calculating vibration velocity of underwater drilling and blasting considering internal structure of rock

ActiveCN110736400ASolve the problem that the accuracy of blasting vibration velocity calculation is not highImprove accuracyDrilling using explosivesBlastingUnderwaterClassical mechanics

The embodiment of the invention provides a method and device for calculating the vibration velocity of underwater drilling and blasting considering the internal structure of rock, an electronic deviceand a computer-readable storage medium, and relates to the technical field of vibration velocity calculation of underwater drilling and blasting. In the embodiment of the invention, the method includes the steps that firstly, blasting parameters for underwater blasting operation for the rock mass structure are obtained, wherein the blasting parameters include the maximum charge amount of a singlesection, a distance between blasting centers and an elevation difference; secondly, the first peak vibration velocity is calculated according to the blasting parameters and a preset first formula, and a second formula is established according to the first peak vibration velocity, wherein the second formula satisfies the normal distribution; and then, the blasting vibration speed for the underwater blasting operation is calculated based on the second formula and the preset second peak vibration speed. Through the method, the accuracy of blasting vibration velocity calculation can be improved.

Owner:长江重庆航道工程局

Hot hole charge system

InactiveUS20130247789A1Easy to useMaximize the effectDrilling using explosivesThermal insulationDetonatorEngineering

An apparatus, method and insulation medium for inserting and insulating a charge medium within a borehole includes a charge tube comprised of an elongate tube having a length and diameter sufficient for containing a desired quantity of a charge medium. A charge medium in a pumpable form is provided for substantially filling the charge tube. An insulation medium in a pumpable form is provided for substantially encapsulating the charge tube and substantially filling an annular space between the charge tube and the borehole for insulating the charge tube from a downhole environment in which the charge tube is to be inserted. A detonator is inserted within the charge medium proximate a distal end of the charge tube and a charge cable extends from the detonator through the charge tube and exits from the charge tube.

Owner:ALEXANDER BRENT DEE

Handheld tool for breaking up rock

InactiveUS20050257675A1Easy to drillHigh level of skillCartridge extractorsUnderground miningClassical mechanicsRetainer

A tool (12) has a body (14) with a barrel (18) having opposing threaded and fitted openings (30 and 28). An actuator pin tube (26), for slidably engaging an actuator pin (38) having a tip (40) opposing a retention head (42), extending from the fitted opening (30). A spring assembly (24), disposed in the barrel (18), has a hammer guide (44) engaged in the threaded opening (28) with a hammer (46) slidably engaged therein, a handle mechanism (55) disposed at one end and a spring retainer (52) disposed adjacent the other end of the hammer (46) before a hammerhead (51), and a spring (54) engaged between the hammer guide (44) and the spring retainer (52). A release mechanism (56) engages the hammer (46). A kit (108) containing the tool (12) and a method of operating the tool (12) involving drilling and cleaning a borehole, inserting a cartridge and tool therein, and detonating the load remotely using a pull cord.

Owner:BASSETT CARROLL

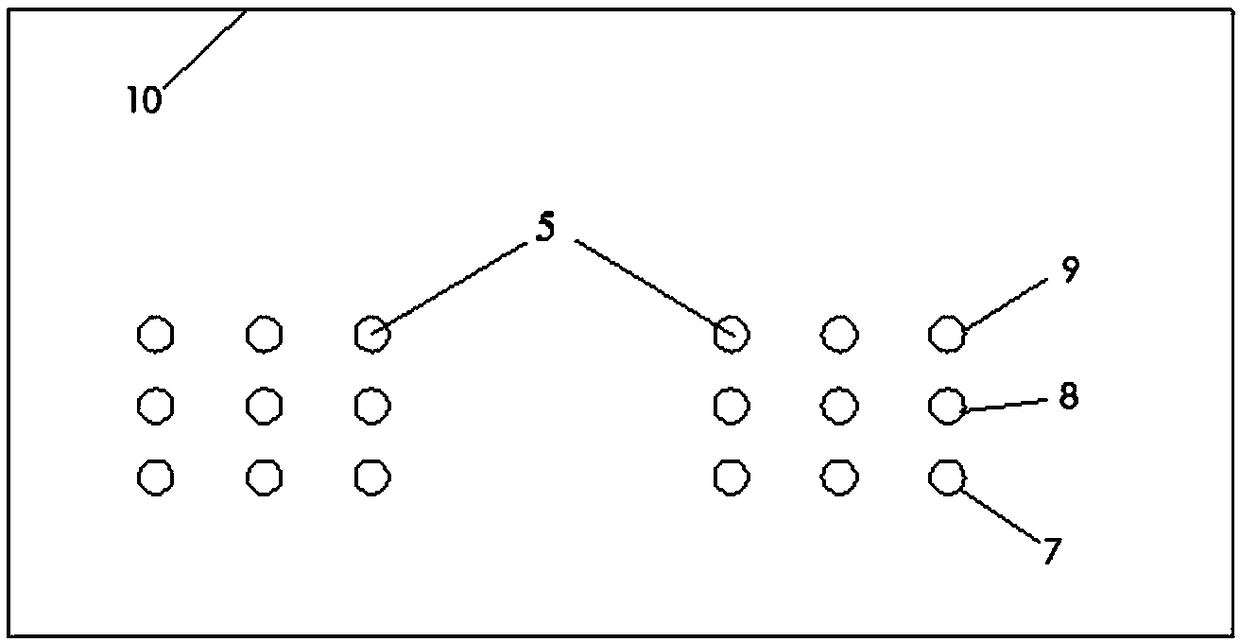

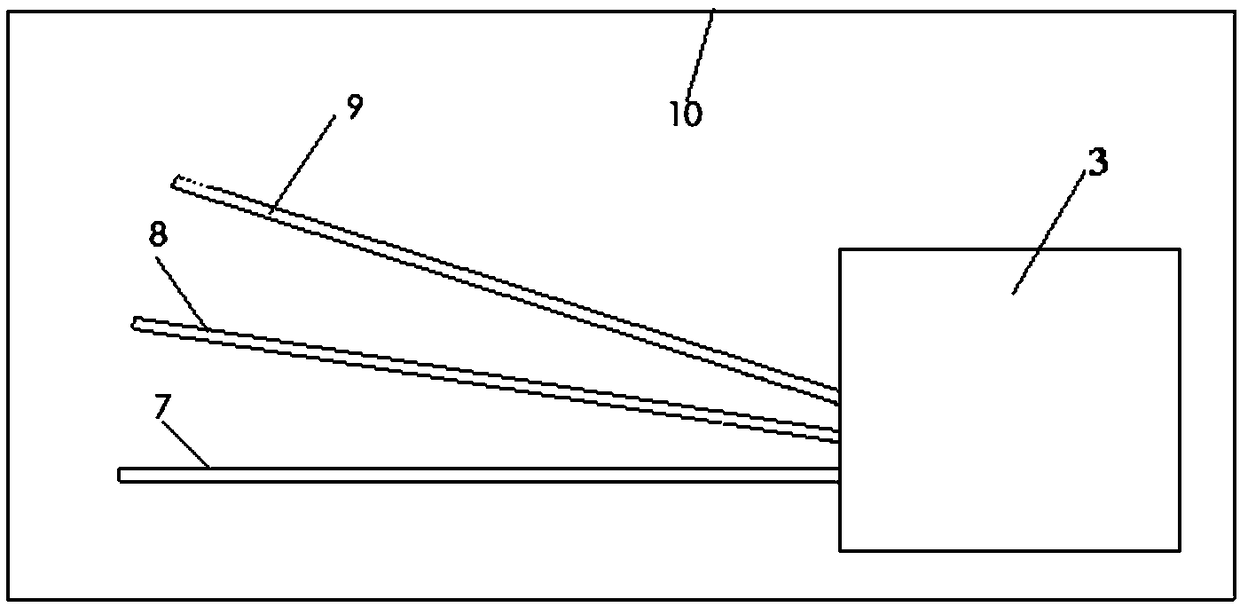

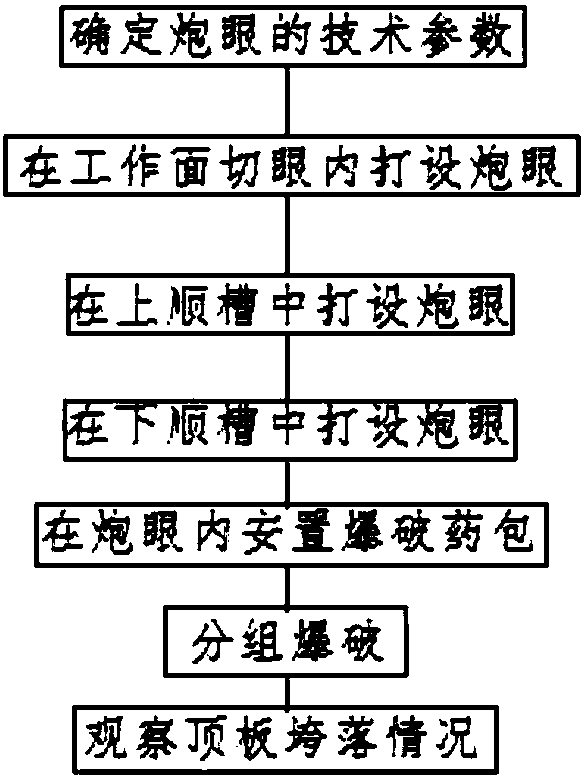

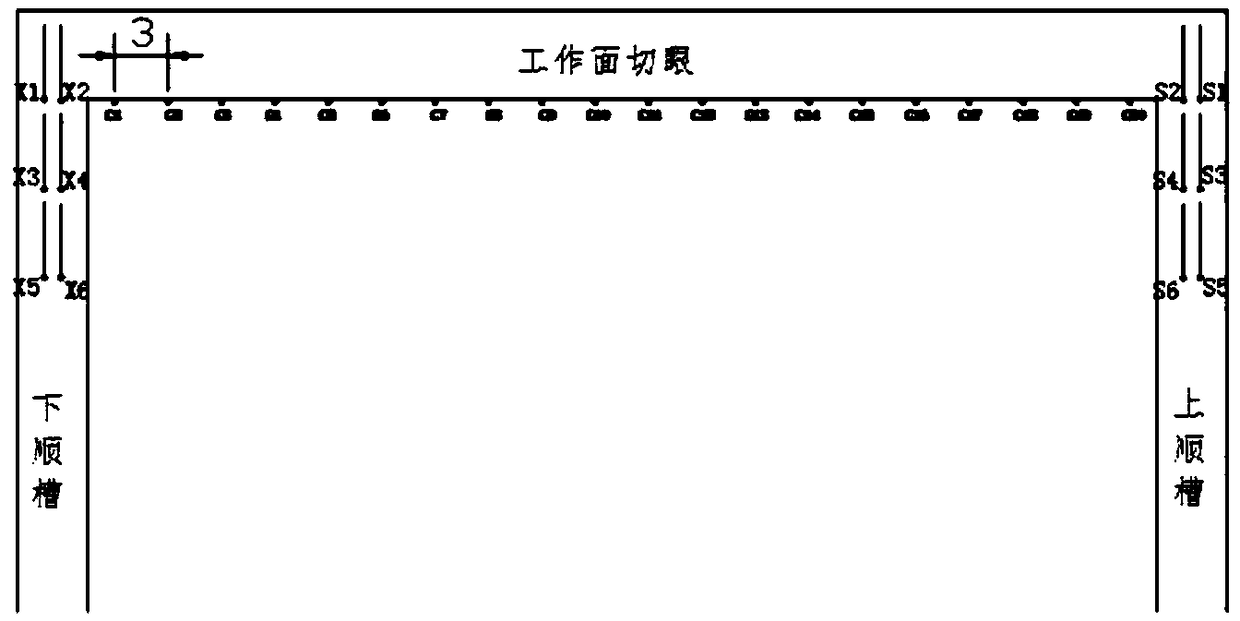

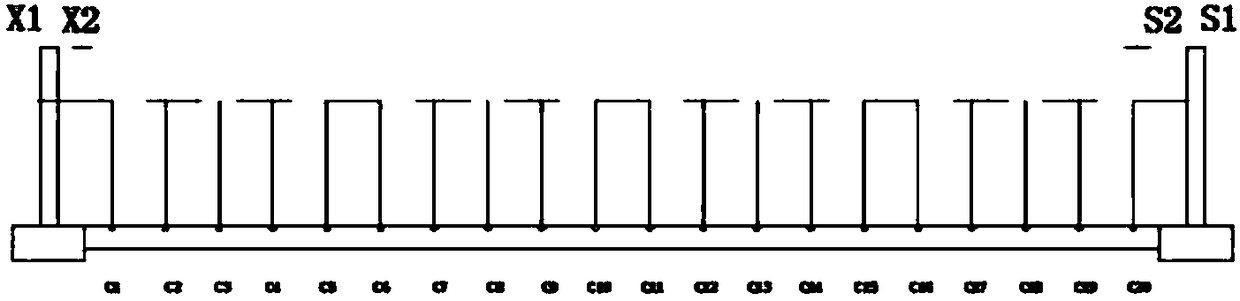

Method for pre-splitting of roof through multipoint dispersed parallel-type blastholes in fully mechanized mining face

ActiveCN108252651AGood for complete collapseImprove caving efficiencyDrilling using explosivesDrill bitsEngineeringDrilling machines

The invention discloses a method for pre-splitting of a roof through multipoint dispersed parallel-type blastholes in a fully mechanized mining face. The supporting angle of a drilling machine is determined on site according to the maximum mining height and the minimum mining height of a support mounted in a cutting hole, and the final hole depths and angles of the blastholes, the interval of theblastholes and the number of the blastholes are determined according to lithological characters of the roof; and the blastholes are drilled in an upper gate road and a lower gate road, and the roof ispre-split through the dispersed parallel-type blastholes. According to the method for advance pre-splitting of the mining face roof through the multipoint dispersed parallel-type blastholes in the fully mechanized mining face, complete caving of the roof is facilitated, the caving impact range of the suspended roof is shortened to the maximum extent, and the roof caving efficiency is improved.

Owner:XINJIANG GUICI MINING IND CO LTD

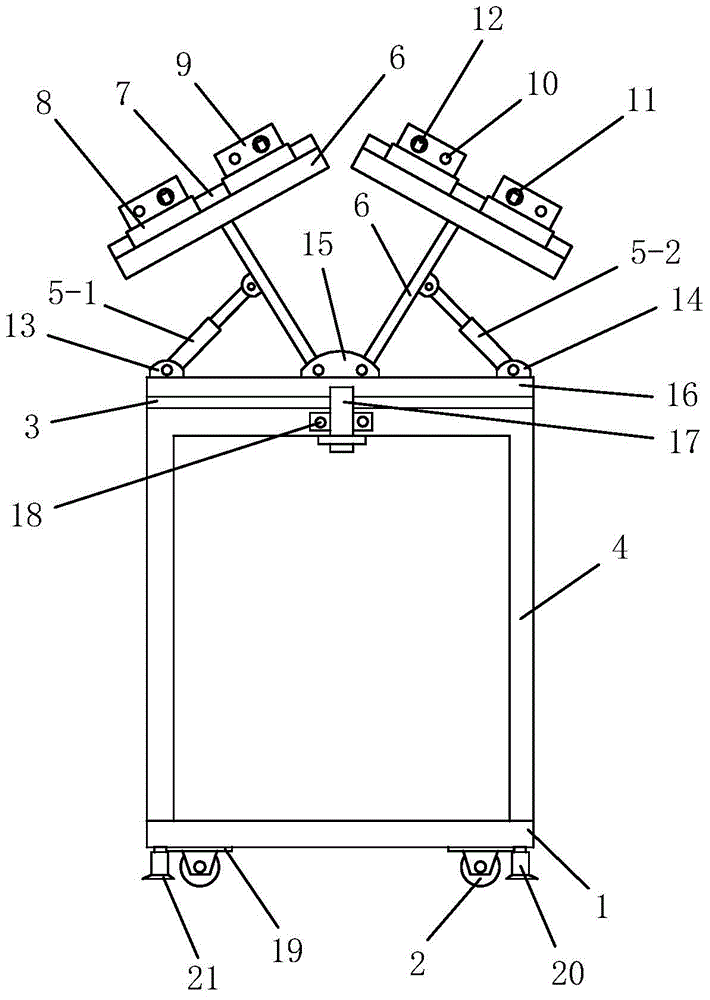

Tunnel blasting excavation construction multi-functional drilling and blasting trolley

InactiveCN104675326ASimple structureEasy to moveDrilling using explosivesTunnelsHydraulic cylinderSlide plate

The invention discloses a tunnel blasting excavation construction multi-functional drilling and blasting trolley. The tunnel blasting excavation construction multi-functional drilling and blasting trolley comprises a horizontal chassis, a plurality of round horizontal sliding boards mounted on the horizontal chassis from left to right, a plurality of round horizontal rotating plates respectively mounted on the plurality of round horizontal sliding boards, and a plurality of electric lifting support frames fixedly mounted on the plurality of round horizontal rotating plates respectively. The round horizontal rotating plates are mounted on the horizontal chassis through rotating shafts. The plurality of electric lifting support frames are arranged from left to right and respectively mounted with a drilling and blasting mechanism. A plurality of moving wheels and a support hydraulic cylinder for supporting and ejecting the horizontal chassis during the rotation to the left and the right are mounted at the bottom of the horizontal chassis. The tunnel blasting excavation construction multi-functional drilling and blasting trolley is simple in structure, reasonable in design, easy to use and operate, good in use effect, flexible in assembly mode and capable of easily and quickly completing a process of drilling of multiple blast holes and explosive feeding.

Owner:XIAN ZHONGZHI HUIZE PHOTOELECTRIC TECH

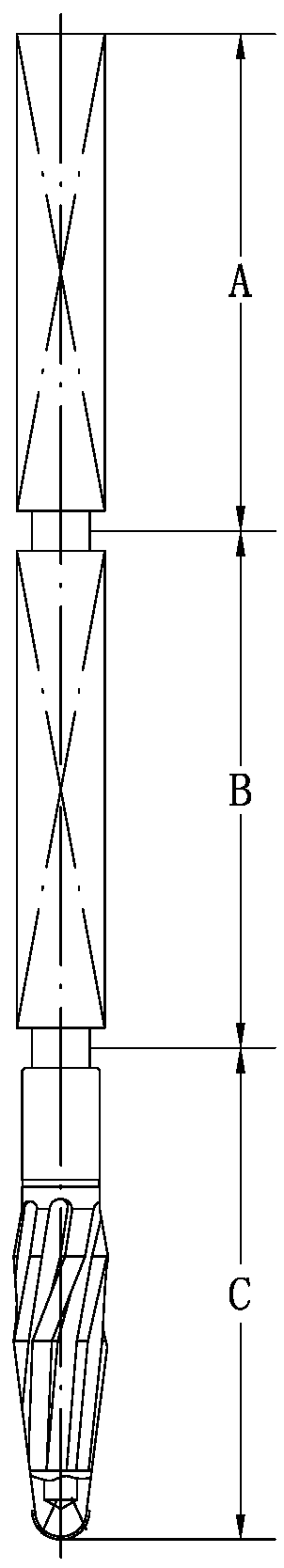

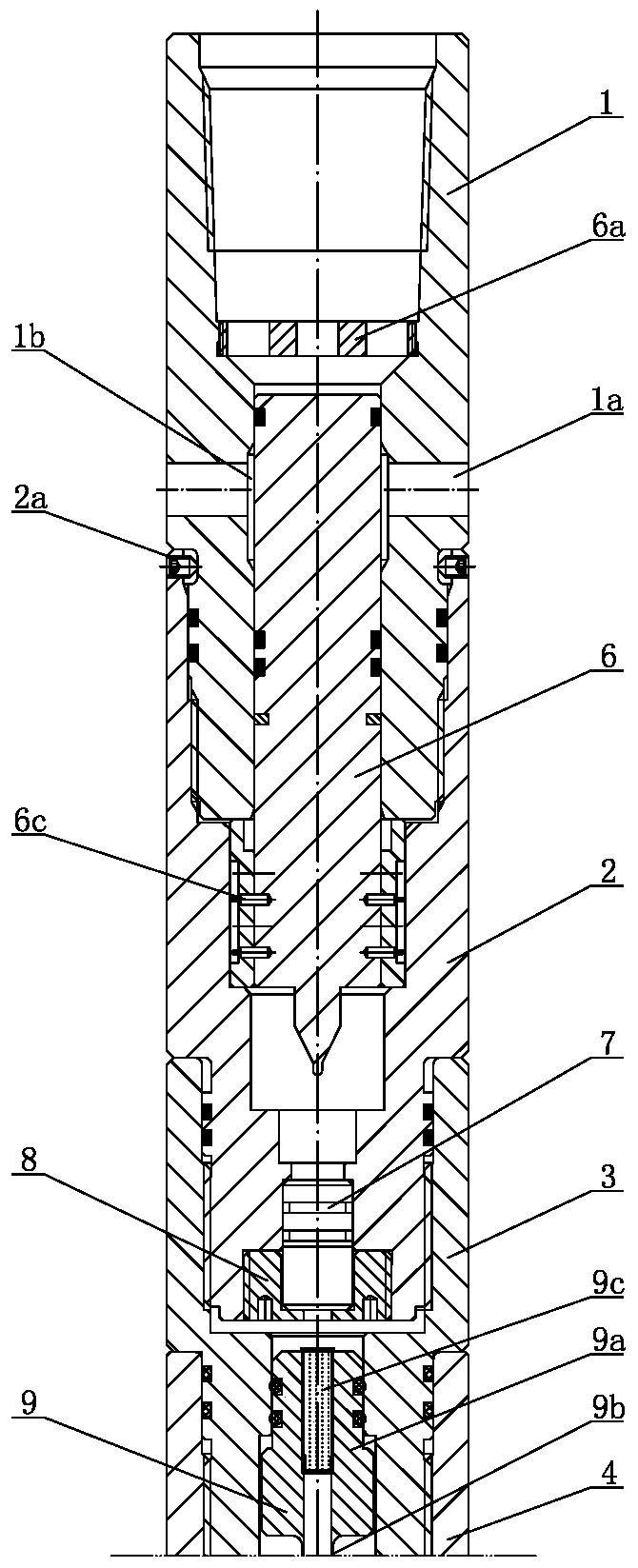

Well-drilling redressing and reaming device

PendingCN108505943AIncrease productivityAvoid eatingDrilling using explosivesDrill bitsPilot holeWell drilling

The invention relates to a well-drilling redressing and reaming device. The well-drilling redressing and reaming device comprises a pilot hole redressing device located at the lowermost end of a drillstring, an explosive reaming device is connected to the upper portion of the pilot hole redressing device, and a variable-diameter hole grinding device is connected to the upper portion of the explosive reaming device; the pilot hole redressing device comprises a redressing drill string, and the redressing drill string comprises a redressing device female connector, a redressing upper cone, a redressing cylinder and a redressing lower cone which are sequentially connected into a whole from top to bottom and are coaxial; the lower end of a female thread of the redressing device female connector is provided with a redressing device liquid flowing channel extending downwards; a plurality of redressing spiral bands are evenly distributed on the outer circumferences of the redressing upper cone, the redressing cylinder and the redressing lower cone; and redressing scrapers are embedded in all the redressing spiral bands; the bottom of the redressing lower cone is connected with a pilot hole spherical head, a plurality of redressing device water holes are formed in the bottom of the pilot hole spherical head, and all the redressing device water holes communicate with the redressing device liquid flowing channel through redressing water-hole hole channels correspondingly. The well-drilling redressing and reaming device is high in reaming speed and low in downhole risk, repeated tripping operation is avoided, and the well-drilling efficiency is greatly improved.

Owner:SINOPEC SSC +1

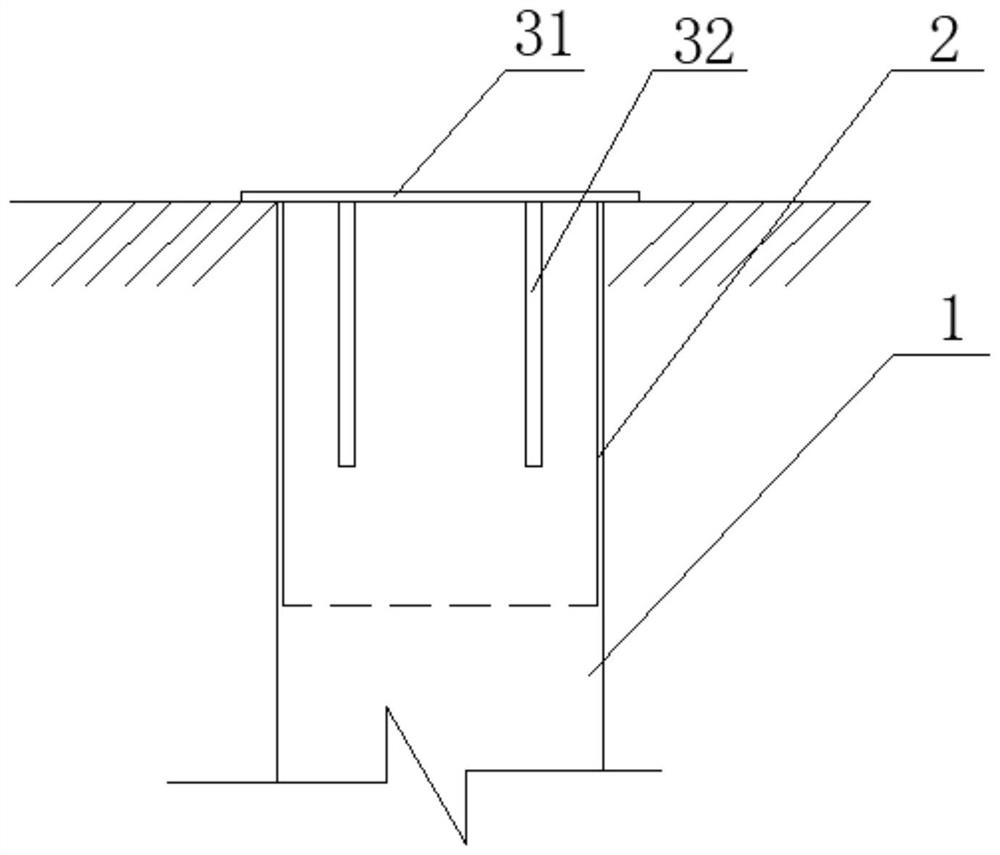

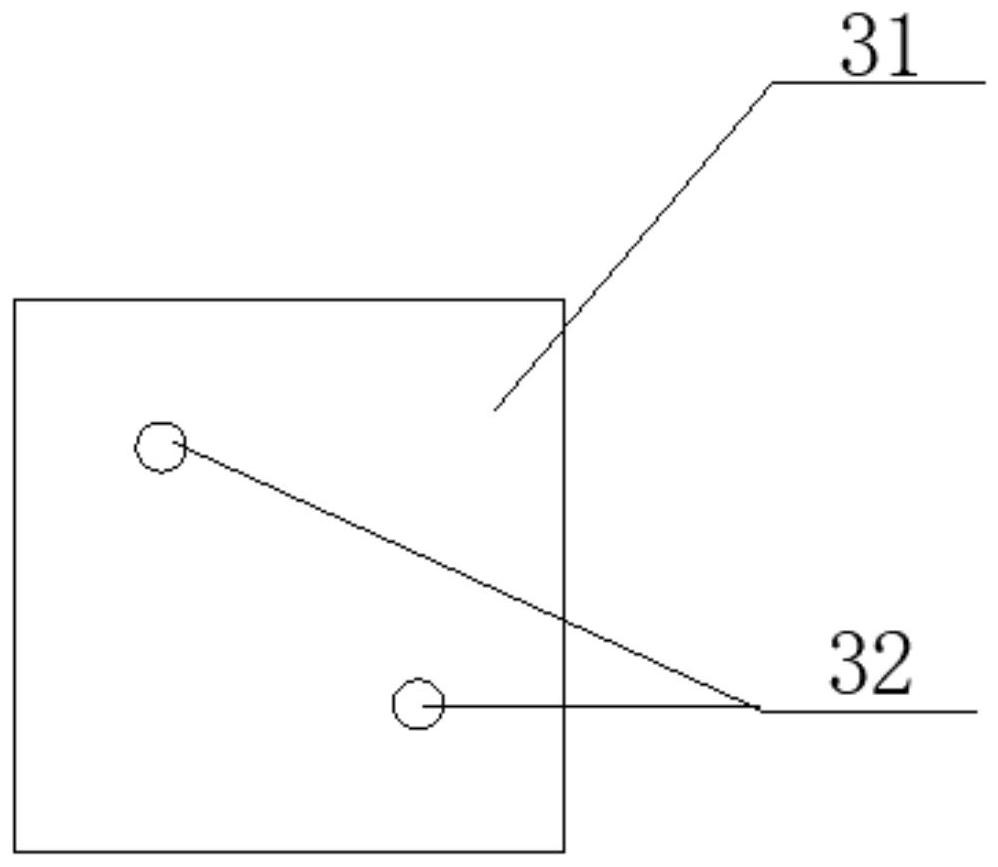

Mine downward deep hole protection device and protection method

InactiveCN112796697APrevent collapseAvoid misalignmentDrilling using explosivesDrilling rodsStructural engineeringRock flour

The invention provides a mine downward deep hole protection device and method. The mine downward deep hole protection device comprises an in-hole protection wall structure, a covering structure and a blocking structure. The in-hole retaining wall structure comprises a sleeve arranged along the inner side wall of the deep hole, and an upper port of the sleeve is flush with the ballast surface of an orifice of the deep hole. The covering structure comprises an insertion fixing structure arranged in the sleeve and a cover body arranged at the top of the sleeve. The insertion fixing structure comprises at least two rod-shaped structures which are vertically arranged on the bottom surface of the cover body, and the distance between the adjacent rod-shaped structures is smaller than the internal diameter of the sleeve. The plugging structure comprises a powder structure arranged on the periphery of the top of the cover body. By means of the method, the problems that in the prior art, when a traditional woven bag is adopted for filling rock powder to cover and protect a deep hole opening, the woven bag is prone to damage, the rock powder is prone to scattering to block a blast hole, and the protection effect is poor can be solved.

Owner:CHINA HUAYE GROUP

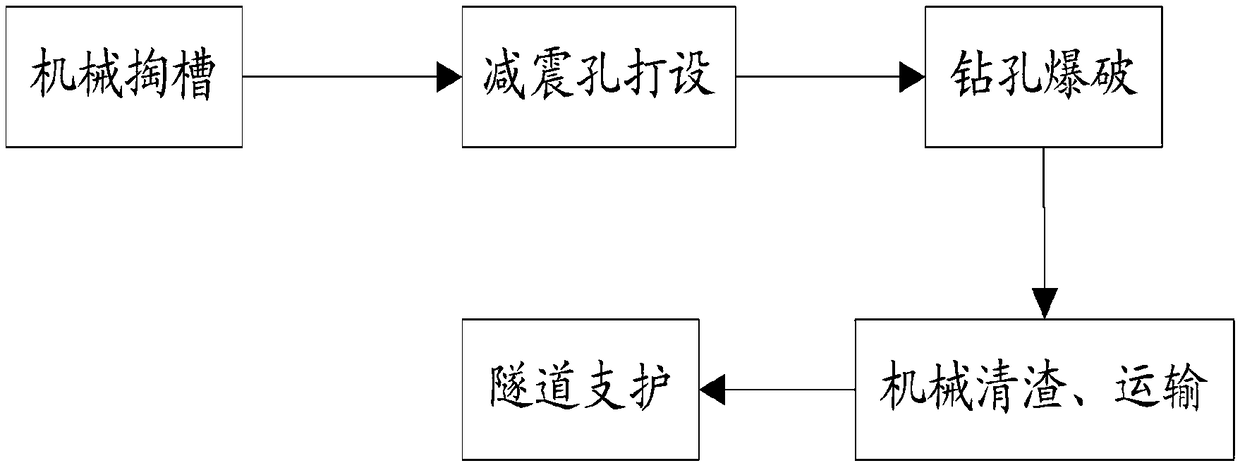

Construction method for shallowly buried tunnel segment passing through intensive residence area from below

InactiveCN109025806APrevent subsidenceGuaranteed uptimeDrilling using explosivesMining devicesResidenceDynamic monitoring

The invention discloses a construction method for a shallowly buried tunnel segment passing through an intensive residence area from the below. The method includes mechanical underholing, damping holedrilling, drill hole blasting, mechanical slug removal, and tunnel support. According to the invention, the construction safety of the tunnel itself and the safety of the residential communities above the tunnel are taken into comprehensive comprehension in the construction method for the shallowly buried tunnel segment passing through roads and also the residential communities from the below comprehensively. Effective measures are taken during the construction process for preventing inner-tunnel structure settlement and settlement of building above, and dynamic monitoring is performed. The construction method is safe, reasonable, economical efficiency and quick. The safety of the construction process is ensured and normal operation of the intensive residence area in a city is also ensured.

Owner:CHONGQING COMM CONSTR GRP +1

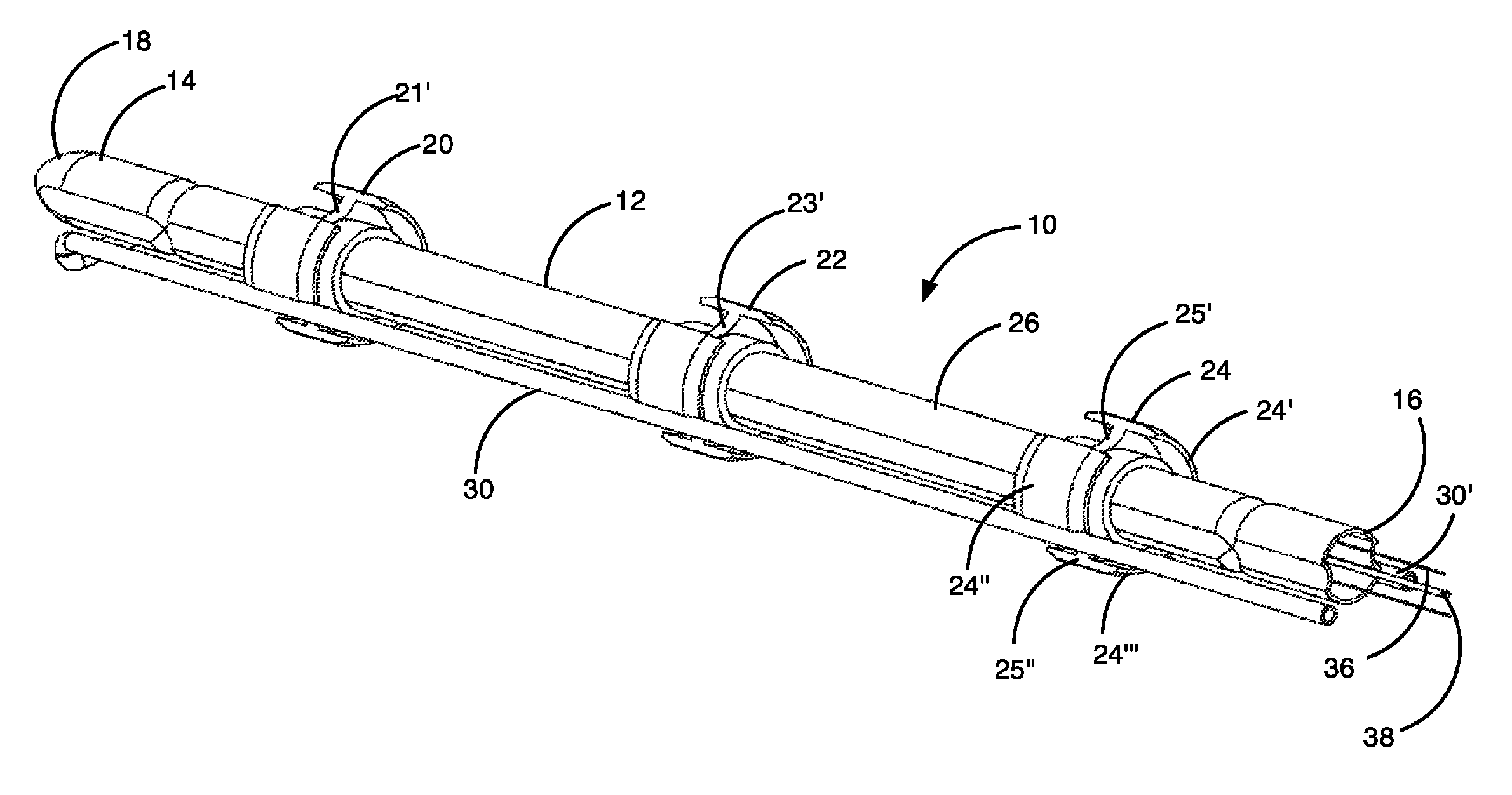

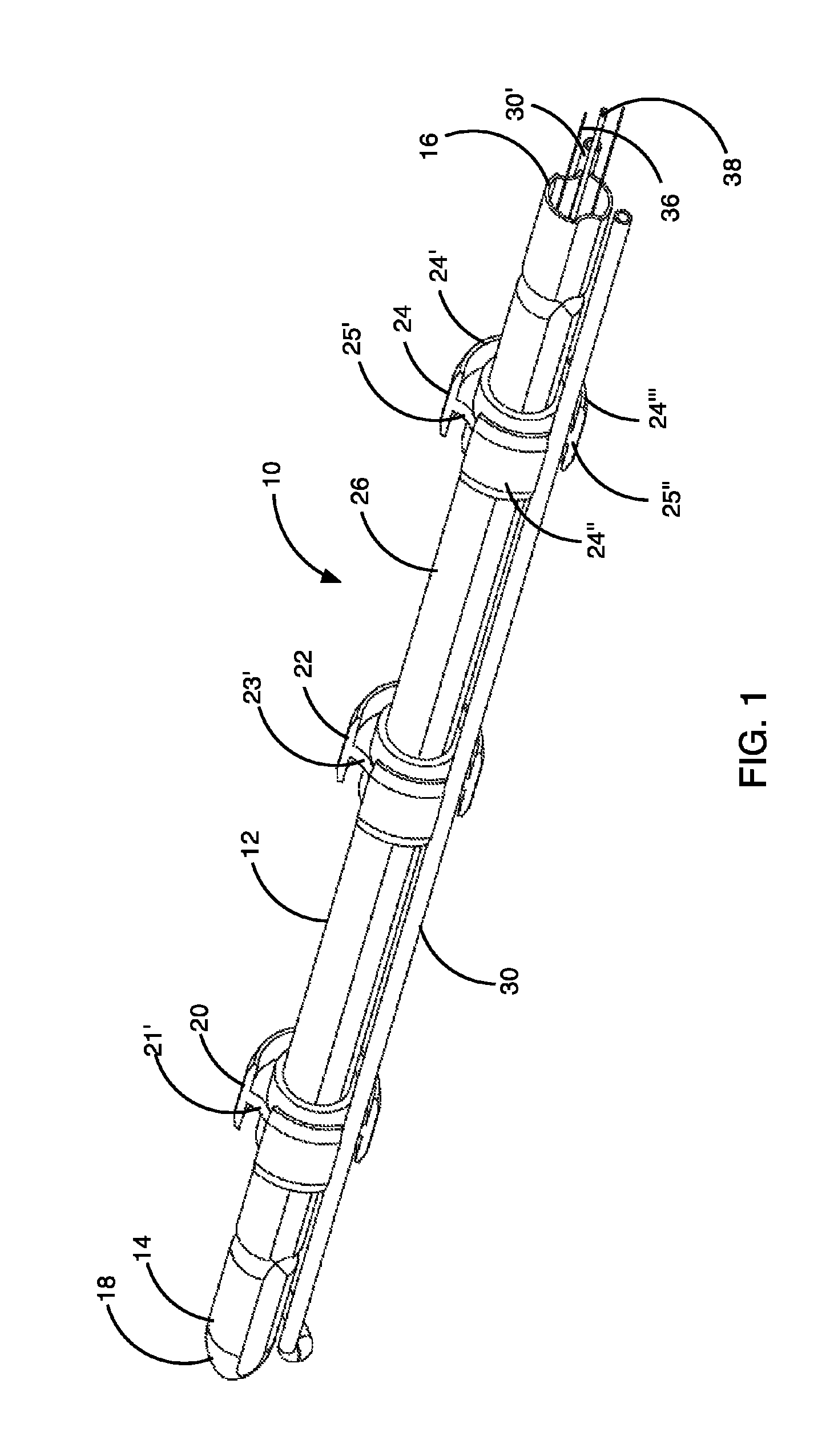

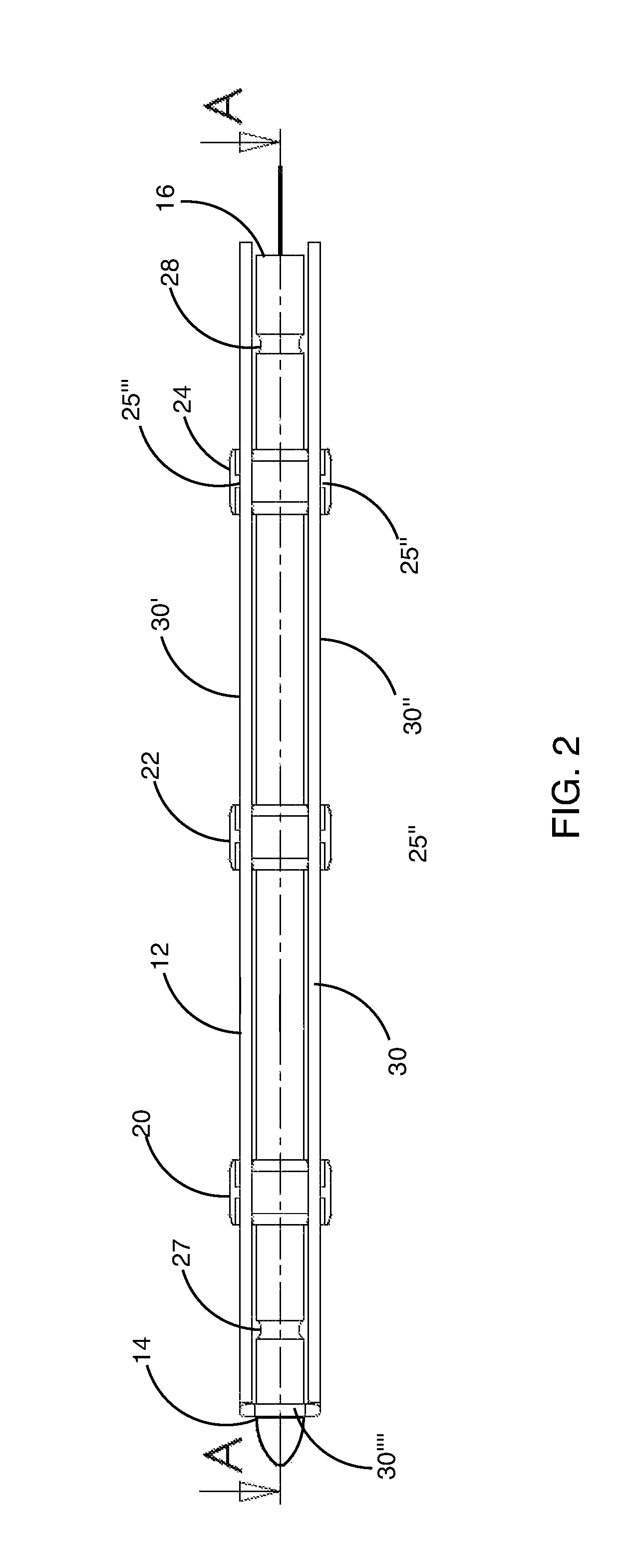

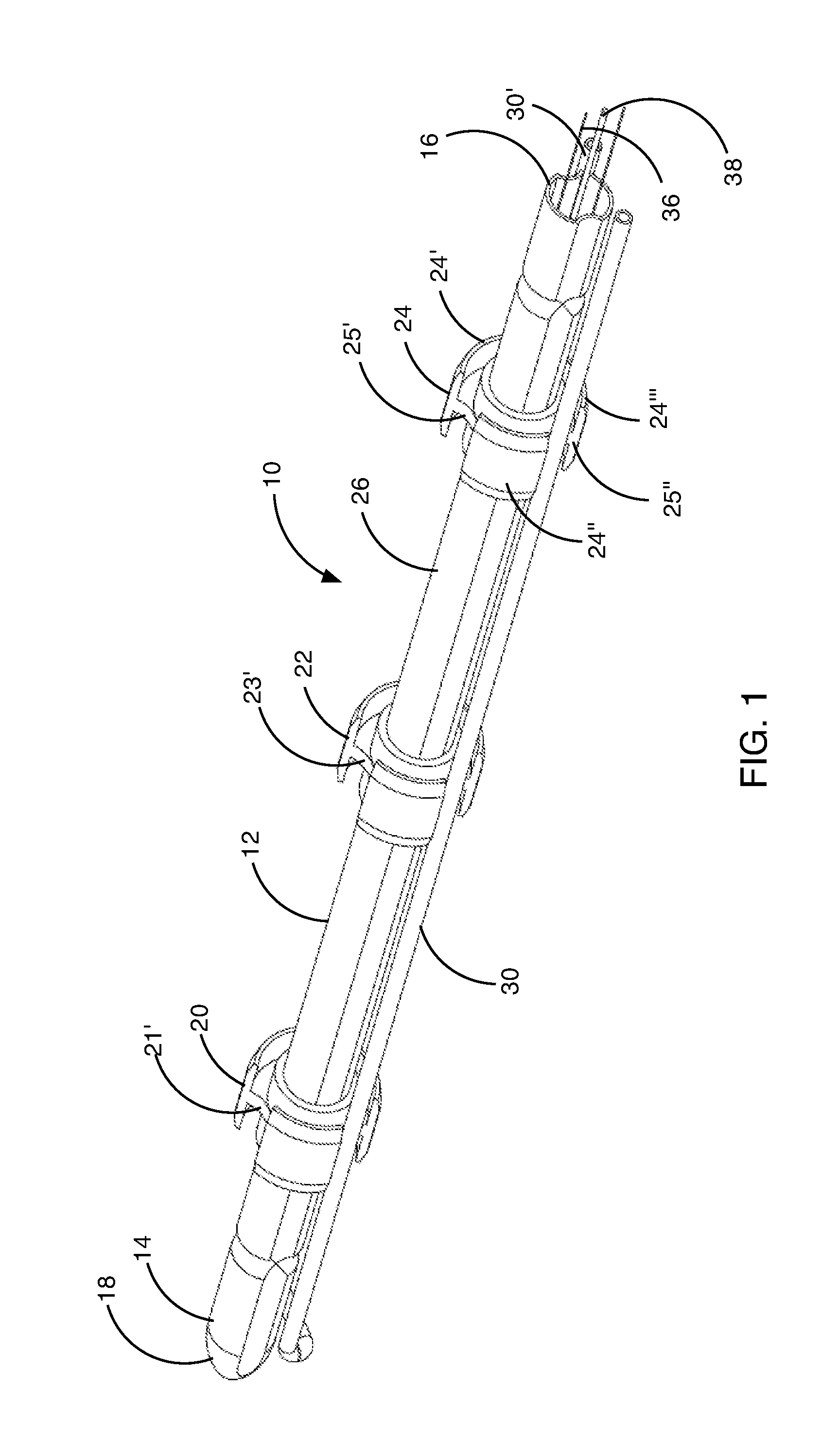

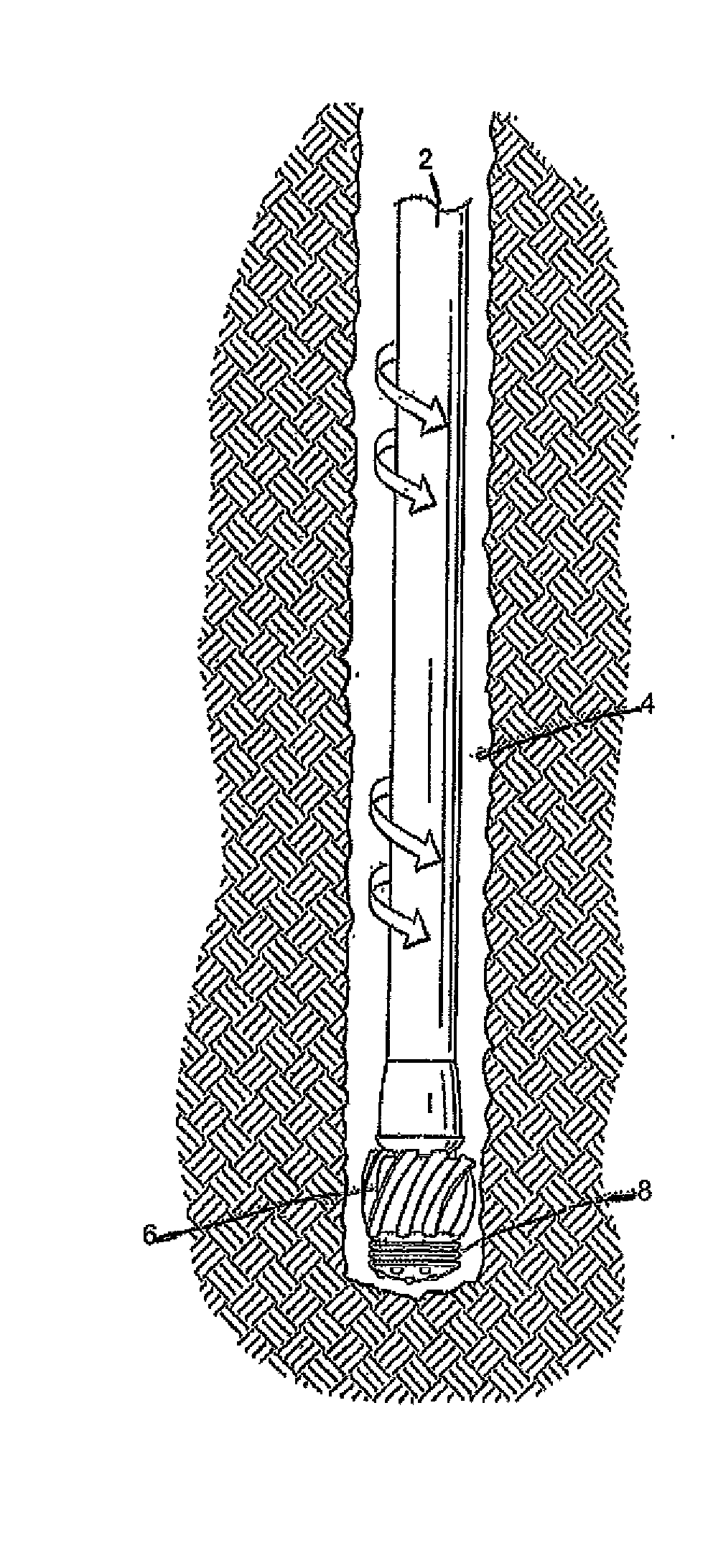

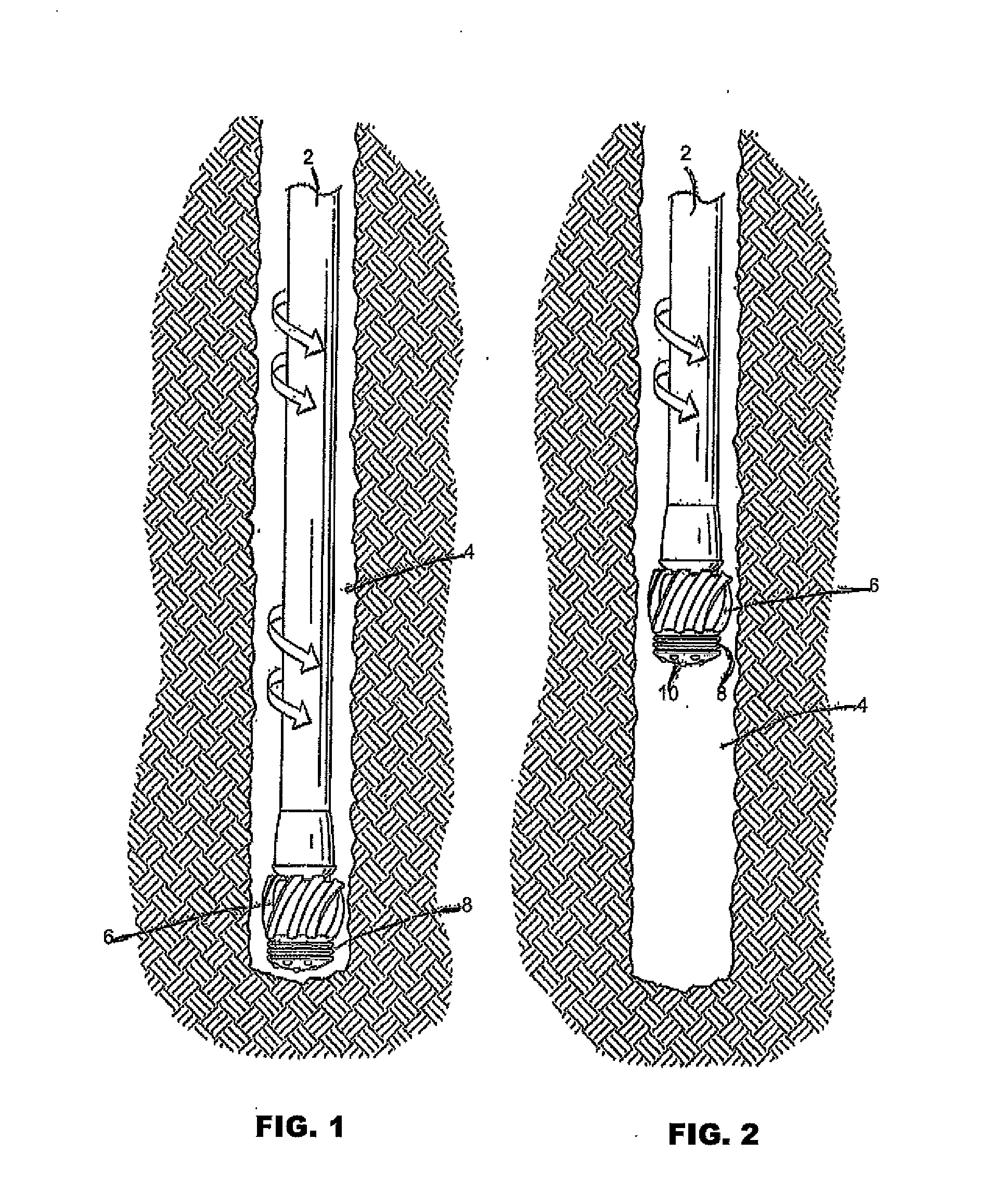

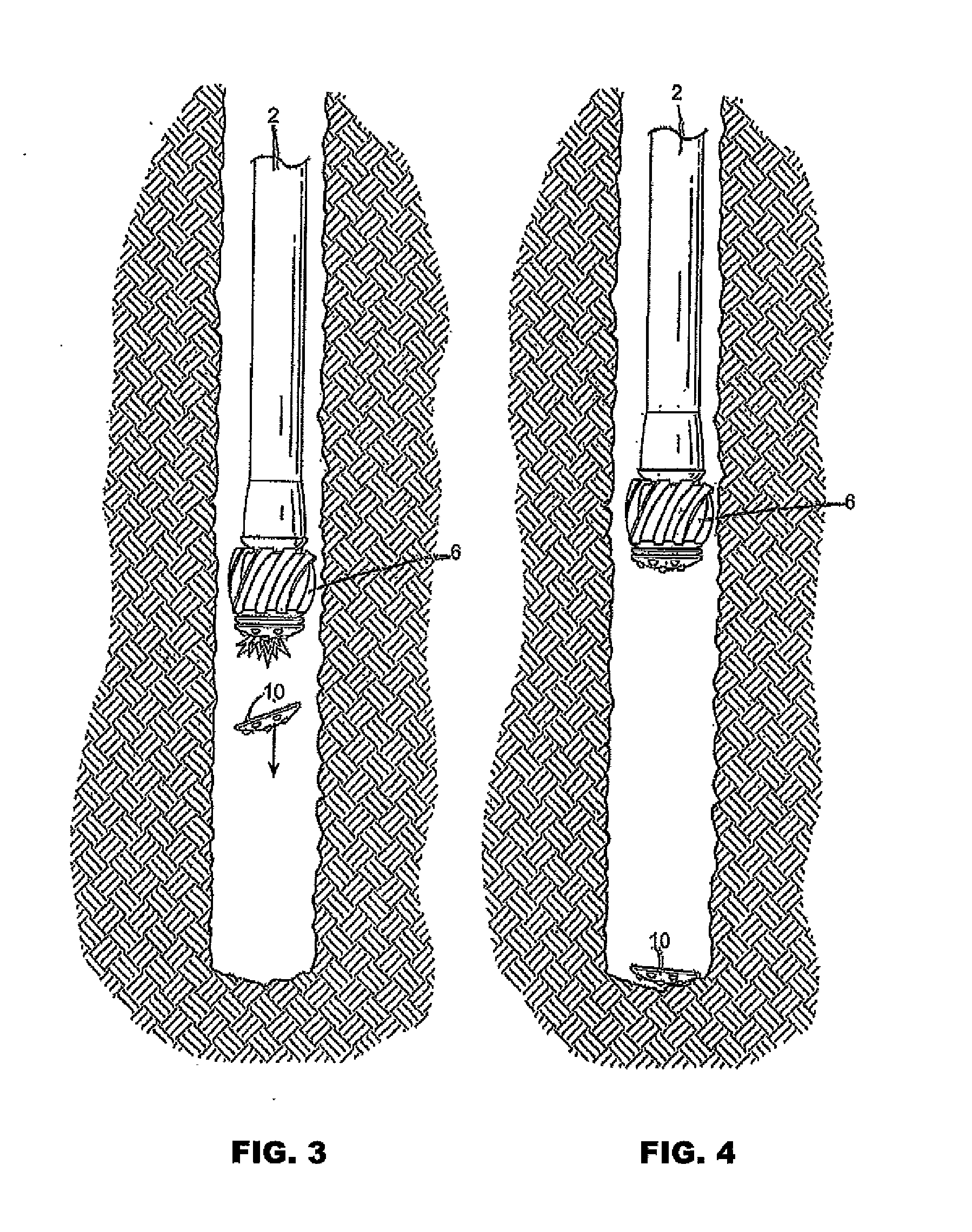

Drilling device and process

A plurality of cutting faces is attached sequentially at a distal end of a drill string. The forward most cutting face that is distal to the top of the hole is exposed and used for drilling until worn to a point of inefficiency. The forward most or distal cutting face is then detached, exposing the next cutting face in the sequence. Detachment of the forward most cutting face is performed by remote actuation at the top of the drill string and / or outside the hole. A new cutting face is provided without the necessity of removing the drill string. The detachment process is repeated as long as drilling is continued and cutting faces remain.

Owner:BLOOMFIELD JOHN

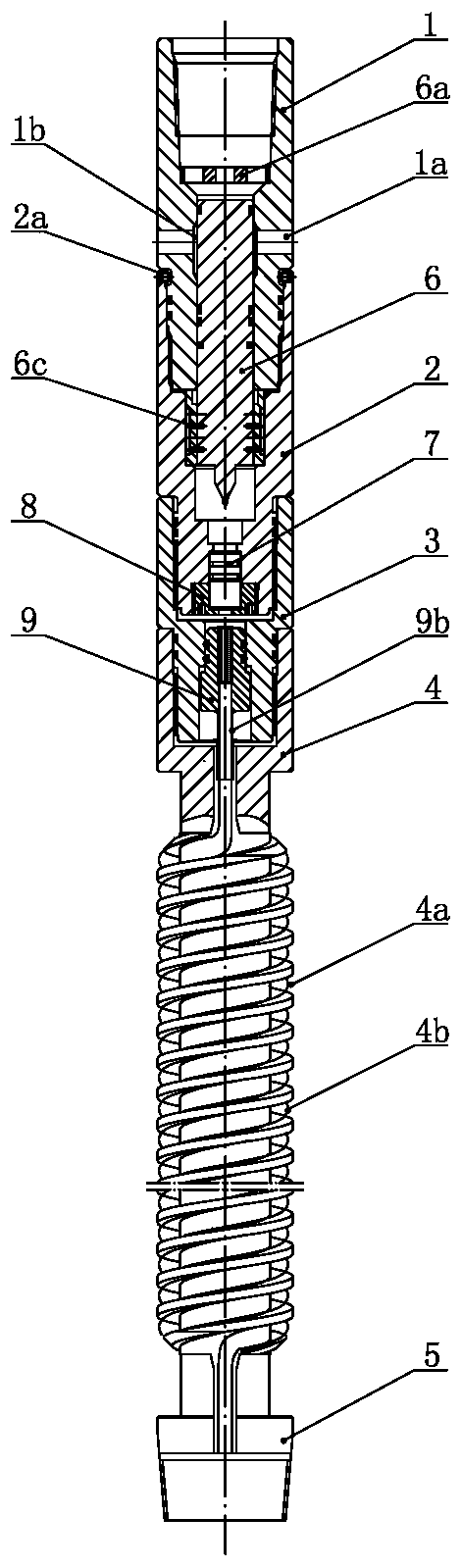

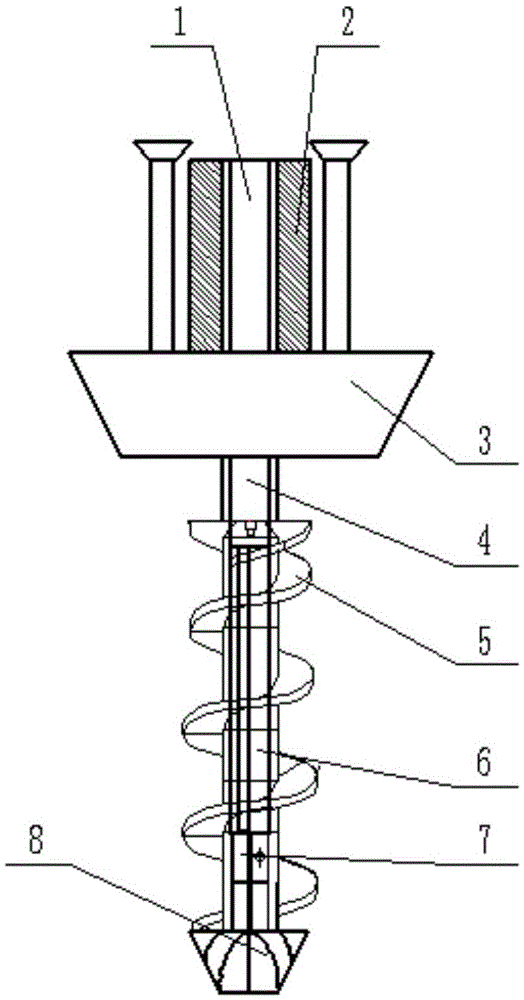

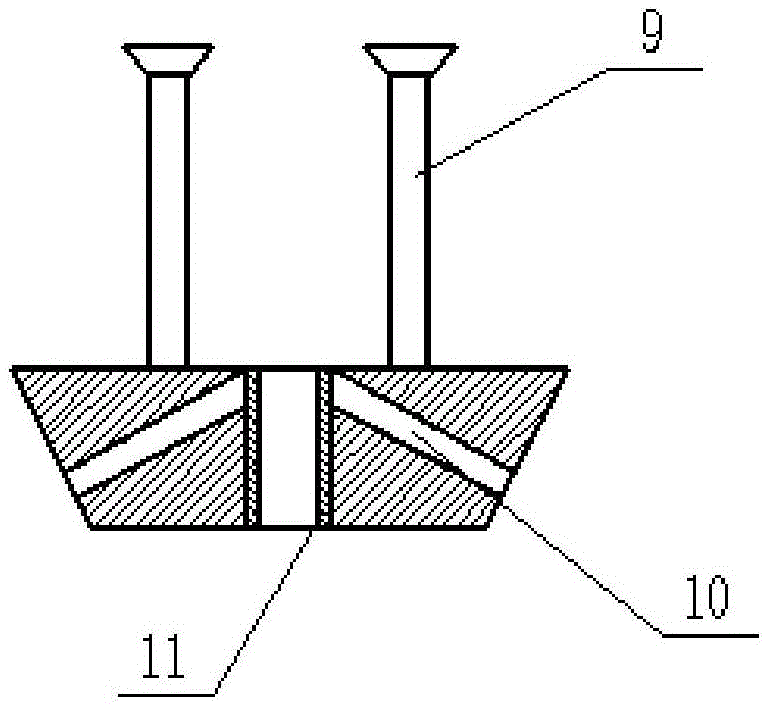

Novel drilling rig used for oil exploration

The invention discloses a new type of drilling rig for oil exploration, which comprises a main drilling shaft, a sliding main body, a dragon body and a main drill bit. The end of the main drilling shaft is connected with the sliding main body, and the bottom of the sliding main body is An intermediate connecting shaft is installed at the end of the intermediate connecting shaft, and the end of the intermediate connecting shaft is provided with an auger shaft. The bottom end of the auger shaft is equipped with the main drill bit. A drill shaft sleeve is installed on the end face of the main drill shaft, explosive tubes are installed at both ends of the sliding main body, a lubricating sleeve is installed in the middle hole groove, a drainage channel is arranged inside the sliding main body, and the auger shaft The end face is equipped with the dragon body through the dragon connecting bearing bush. The beneficial effect is that: the use of the Jiaolong body and the main drill bit to detect oil in the rock has higher detection efficiency, and the cooperation of the explosive tube makes the rock crushing more thorough.

Owner:TIANJIN DAGANG OILFIELD SHENGDA TECH

Energy transfer device

ActiveUS20150144399A1Drilling using explosivesFuse ignition meansEnergy transferBiomedical engineering

An energy transfer device (10) is provided that is capable of transferring the energy output from one pyrotechnic device (52) to another device (78) for initiating firing thereof. Device (10) comprises a device housing (12) in which a deformable device insert (14) is received. Device insert (14) comprises a central passageway (34) for transmitting the output from a pyrotechnic device (52), including energy, gasses, and / or solids, to another pyrotechnic device (78). The passageway (34) conducts the pyrotechnic device output to a precise location on the second pyrotechnic device (78) where firing is most effectively initiated. The energy transfer device (10) may be employed as a part of a tool (44) used in well completion operations.

Owner:CARTRIDGE ACTUATED DEVICES

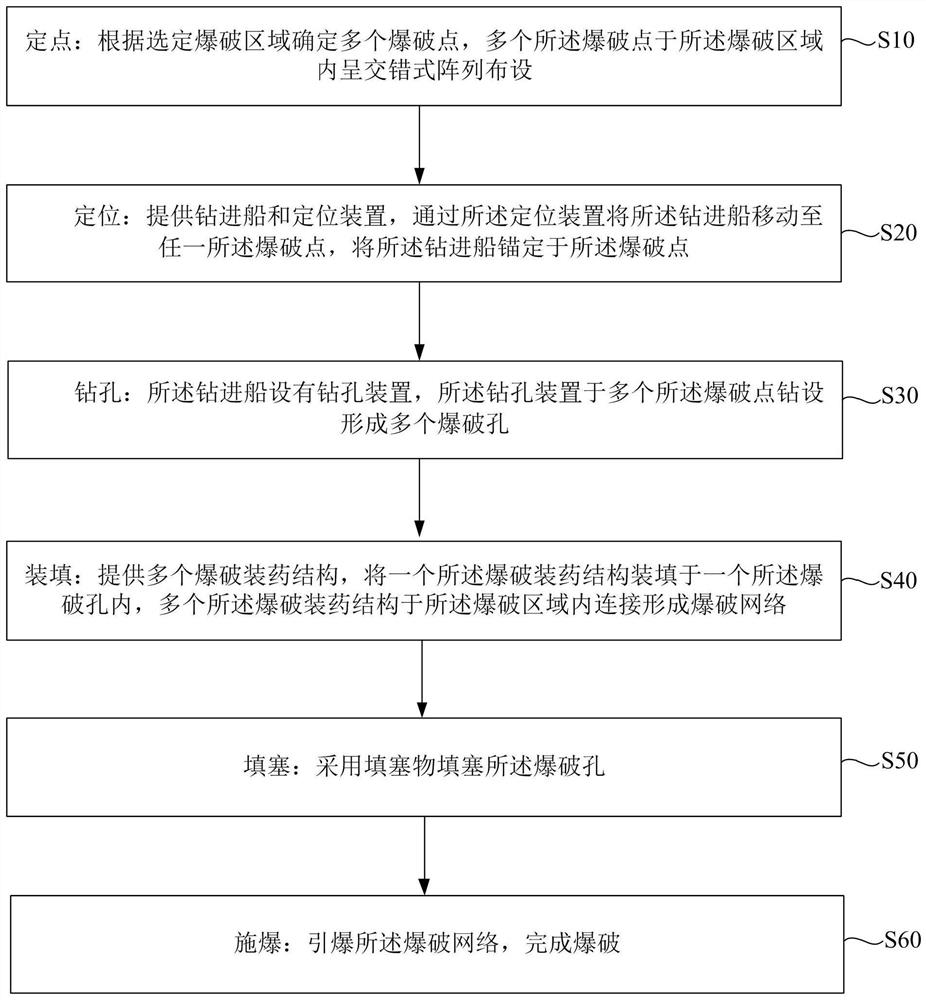

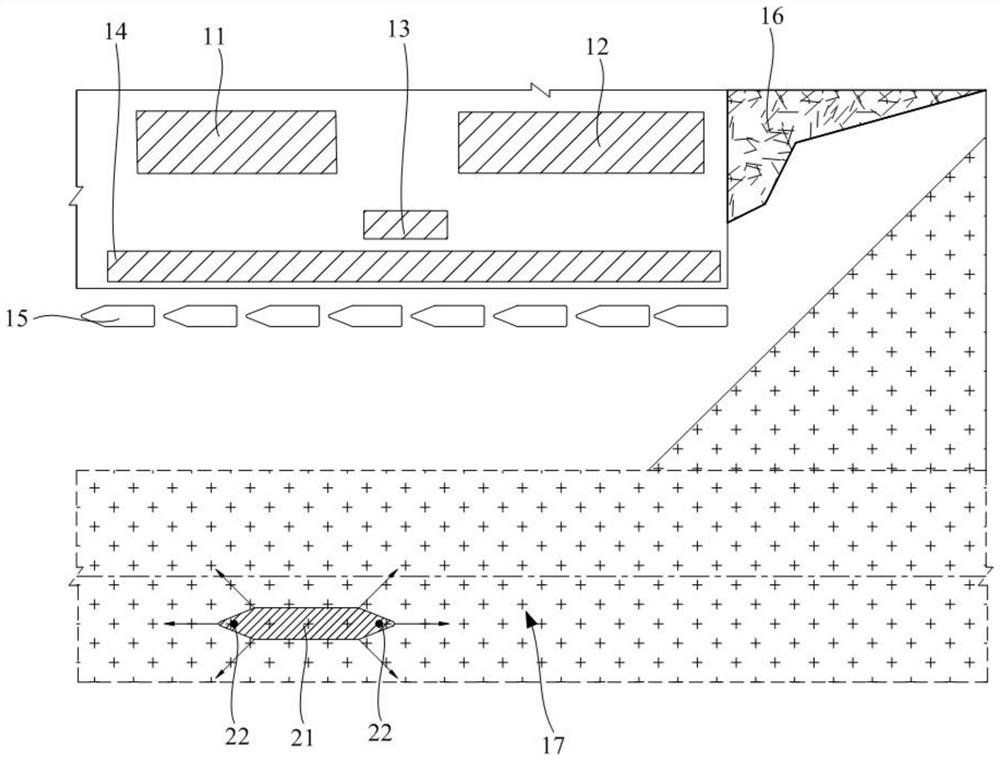

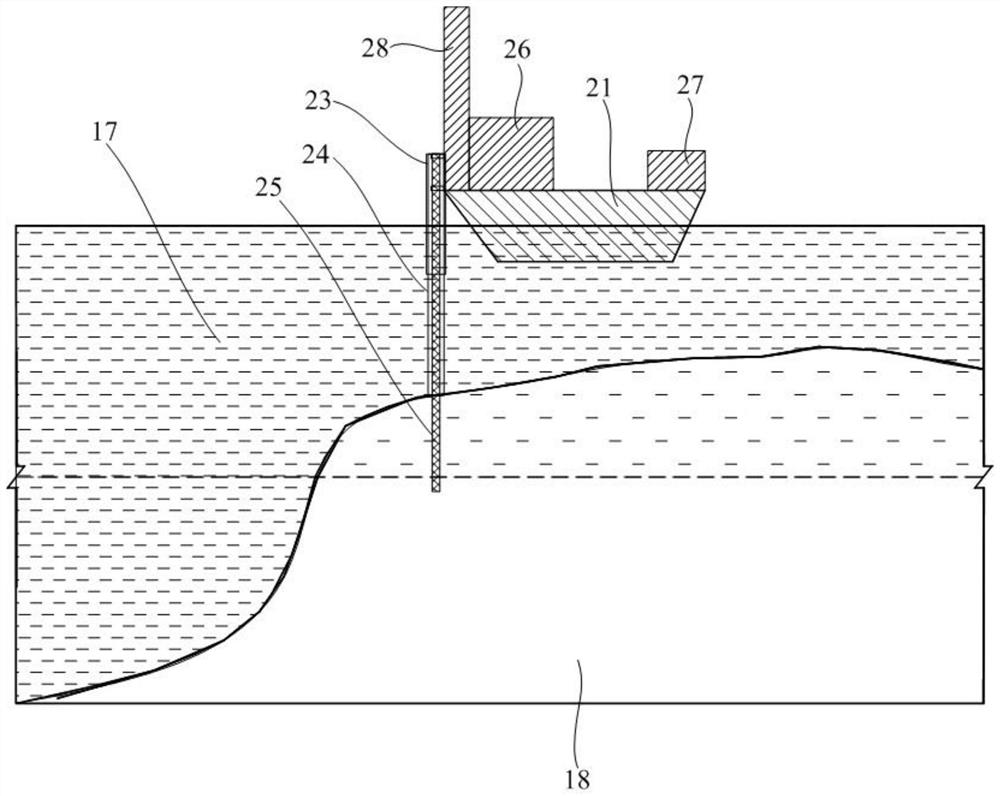

Inshore underwater slope bedrock blasting excavation construction method and blasting charging structure

PendingCN114877769AUniform impact loadReduce unit consumptionDrilling using explosivesBlastingExplosive AgentsStructural engineering

The invention discloses an offshore underwater slope bed rock blasting excavation construction method and a blasting charging structure applied to the method, and the offshore underwater slope bed rock blasting excavation construction method sequentially comprises the steps of point fixing, positioning, drilling, filling and blasting. Specifically, a plurality of blasting points are determined according to a selected blasting area, the blasting points are distributed in the blasting area in a staggered array mode, a drilling ship is moved to the blasting points through a positioning device, the drilling ship is anchored to the blasting points, and a plurality of blasting holes are formed in the blasting points through drilling accurately determined by a drilling device. And the multiple blasting holes are sequentially filled with the multiple blasting charging structures, a blasting network is completed according to design connection, the blasting network is set to be in a millisecond delay blasting mode, the blasting network is excited and detonated, and blasting is completed. According to the offshore underwater slope bedrock blasting excavation construction method, the blasting effect is good, the unit consumption of blasting explosives is low, and the blasting construction cost is low.

Owner:广西桂物爆破工程有限公司 +1

Drilling and blasting vehicle for tunnel excavation construction integrated with rotating and translation functions

InactiveCN104675328ASimple structureEasy to moveDrilling using explosivesTunnelsHydraulic cylinderVehicle frame

The invention discloses a drilling and blasting vehicle for tunnel excavation construction integrated with rotating and translation functions. The drilling and blasting vehicle comprises a steel section chassis, a vertical frame, a horizontal sliding plate, a horizontal rotary table, two hydraulic cylinders and two oscillating drilling and blasting mechanisms, wherein the two hydraulic cylinders are respectively a left hydraulic cylinder and a right hydraulic cylinder, the two oscillating drilling and blasting mechanisms are respectively a first oscillating drilling and blasting mechanism and a second oscillating drilling and blasting mechanism, the first oscillating drilling and blasting mechanism is driven to swing leftwards and rightwards by the left hydraulic cylinder and the second oscillating drilling and blasting mechanism is driven to swing leftwards and rightwards by the right hydraulic cylinder; the bottom of the steel section chassis is provided with a plurality of rotary chassis and a plurality of support hydraulic cylinders, travelling wheels are arranged on the rotary chassis and the rotary chassis can drive the travelling wheels to rotate leftwards and rightwards on a horizontal plane, and the support hydraulic cylinders are used for supporting the vertical frame in the process of rotating the plurality of travelling wheels leftwards and rightwards. The drilling and blasting vehicle provided by the invention is simple in structure, reasonable in design, convenient to use and operate and good in using effect, and the process of forming a plurality of blast-holes and feeding explosives can be completed conveniently and quickly; furthermore, the vehicle body has the functions of rotating and translating longitudinally and transversely.

Owner:XIAN ZHONGZHI HUIZE PHOTOELECTRIC TECH

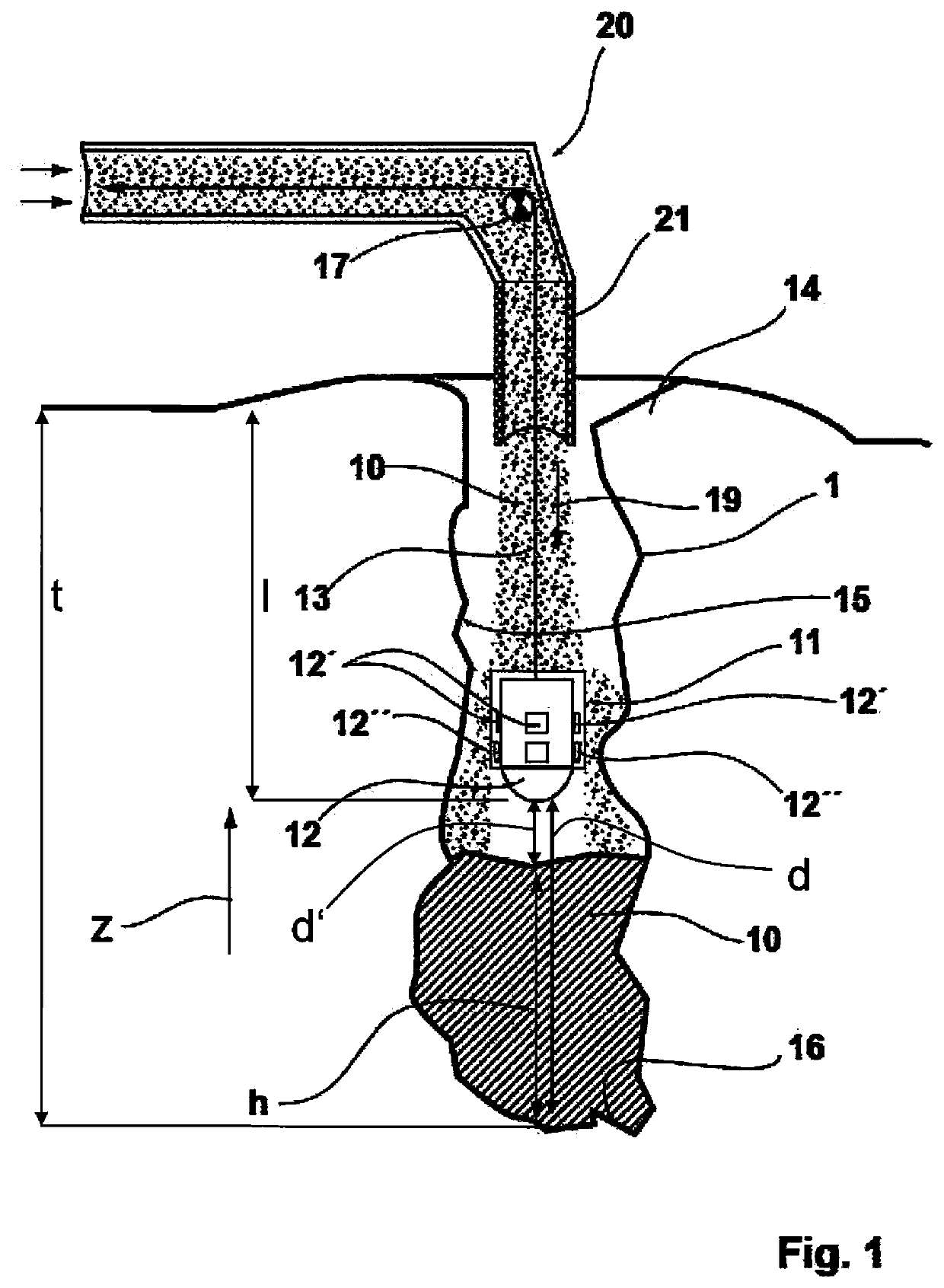

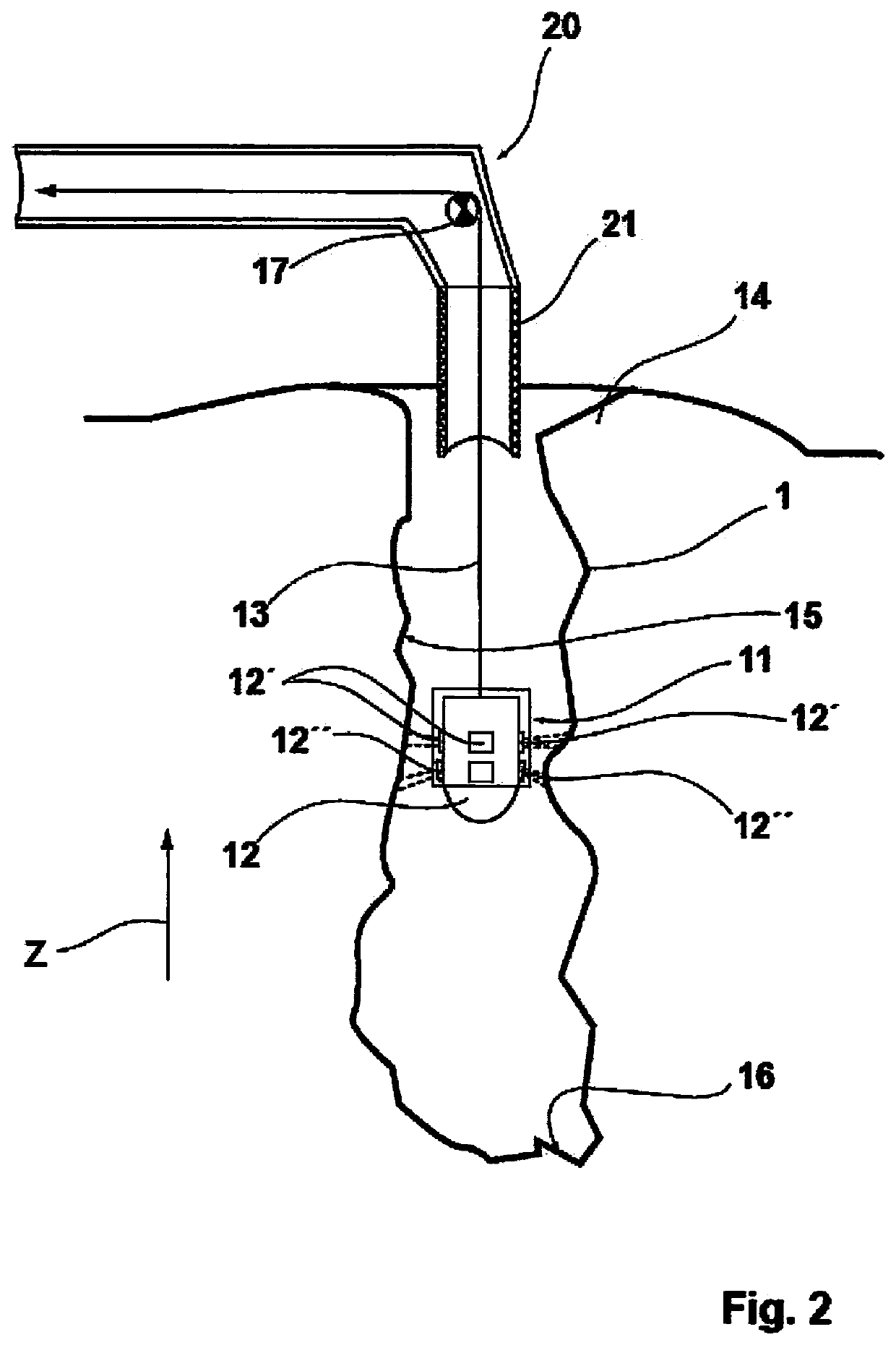

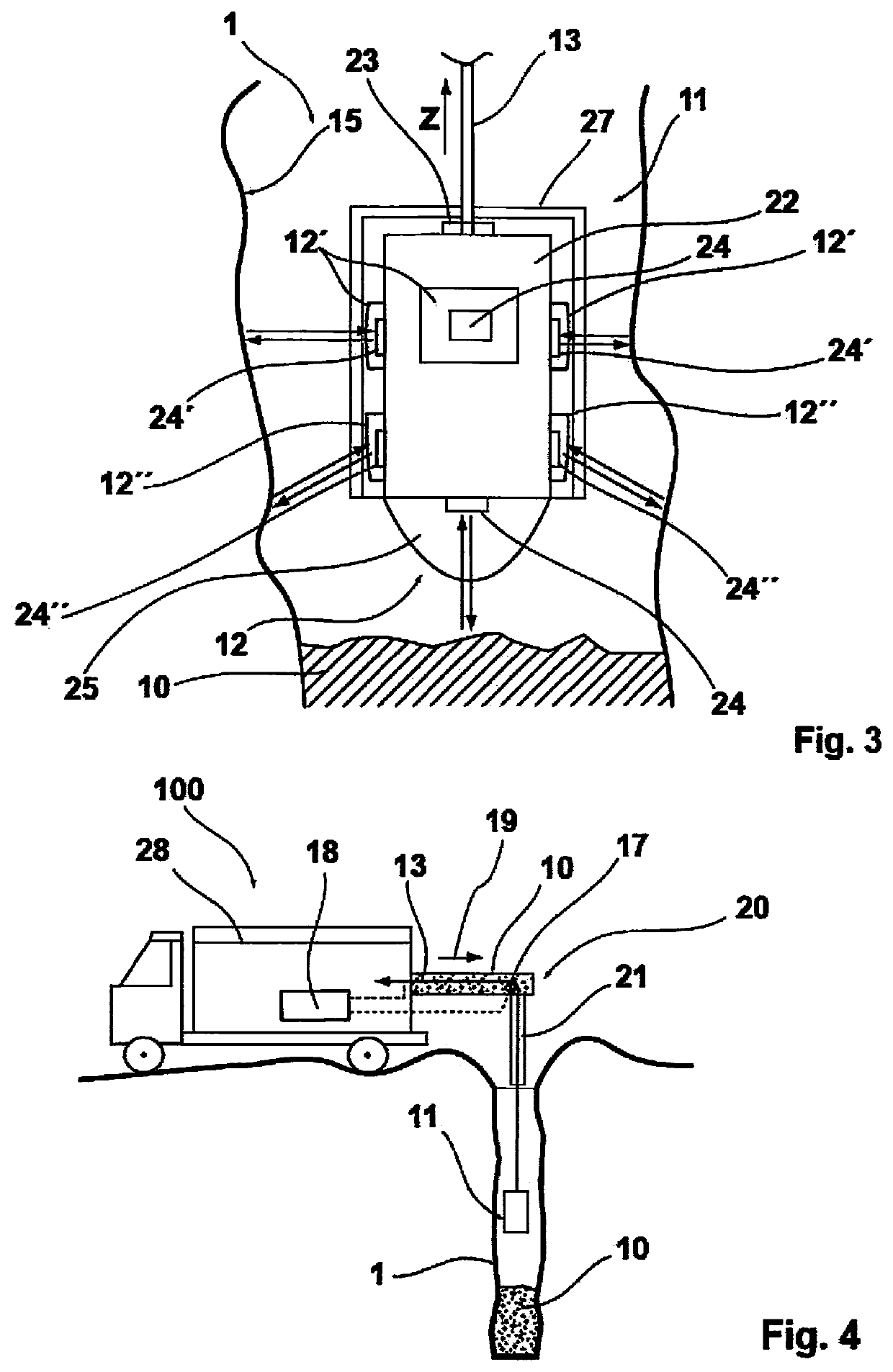

Method and device for controlled filling and inspection of blast holes

PendingUS20210310780A1High frequencySmall dimensionDrilling using explosivesSurveyAbrasive blastingTEX-explosive

A method and apparatus for controlled charging of blasting boreholes with a flowable / pourable explosive, in particular in open-cast mining, includes: providing a radar head with at least one radar unit operated in a non-rock penetrating frequency range; arranging the radar head on a pulling element; introducing the radar head into the borehole in that the radar head is lowered into the blasting borehole in an arrangement at the pulling means from an upper aperture opening of the blasting borehole; and detecting at least one measurement value comprising a base distance of the radar head from the blasting borehole base and / or a charge level distance to determine the charge level of the explosive in the blasting borehole; and / or comprising the shape of the jacket section over at least a portion of the depth of the blasting borehole by means of the operation of at least one of the radar units.

Owner:INDURAD

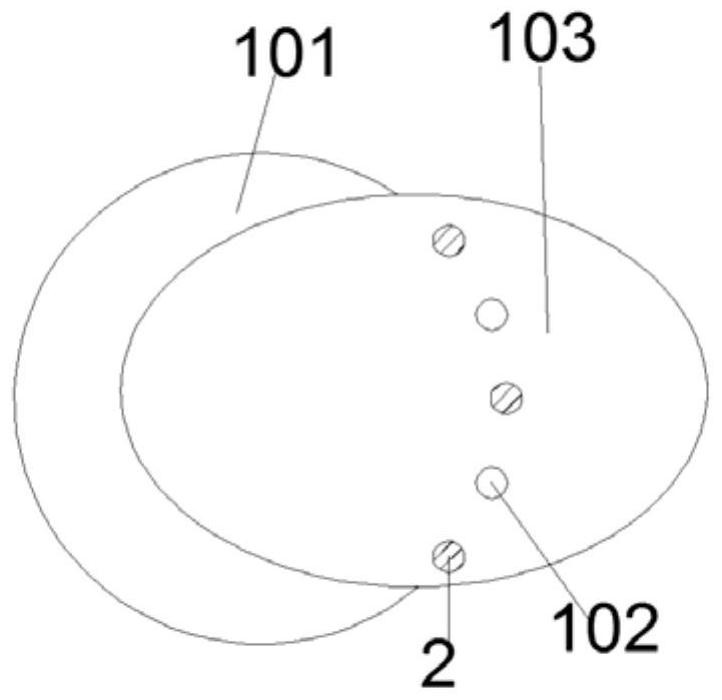

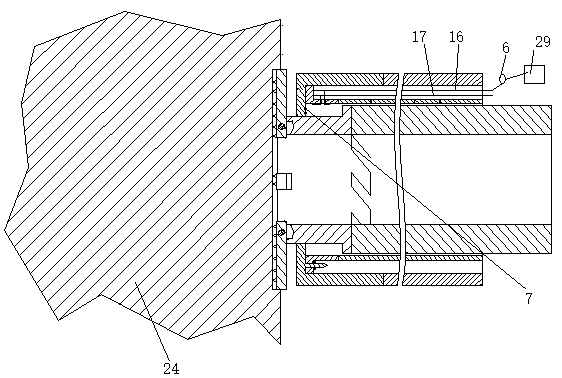

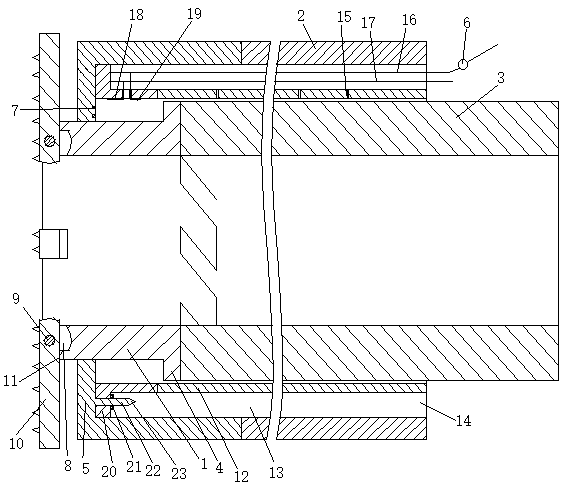

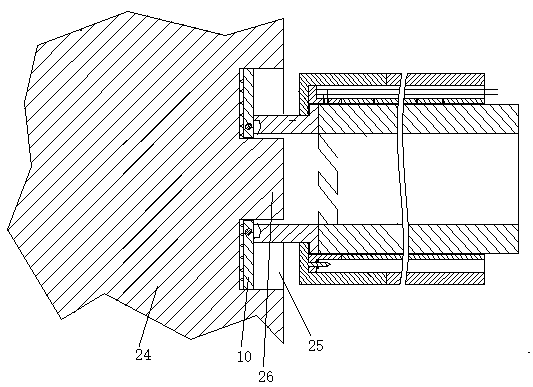

Repeated dry ice cracking rock breaking orifice clamping device and using method thereof

PendingCN111964541AReduce usageImprove securityDrilling using explosivesBlastingCircular discDry ice

The invention discloses a repeated dry ice cracking rock breaking orifice clamping device. The repeated dry ice cracking rock breaking orifice clamping device comprises a clamping device body (2), wherein the clamping device body (2) comprises a semi-threaded column (7) with threads on the upper half section; an upper end head (1) is arranged at the top end of the semi-threaded column (7), and anannular groove (3) is formed in the side wall of the upper end head (1); a lower movable end head (10) is arranged at the bottom end of the semi-threaded column (7); the lower movable end head (10) isa box body with an opening in the top end; the opening in the top end of the lower movable end head (10) is fixedly connected with the lower surface of a limiting disc (15); and the semi-threaded column (7) penetrates through the limiting disc (15) and then is movably connected to the interior of the lower movable end head (10). The invention further discloses a using method of the repeated dry ice cracking rock breaking orifice clamping device. According to the repeated dry ice cracking rock breaking orifice clamping device and the using method thereof, the punching phenomenon can be effectively reduced, and the operation safety is improved.

Owner:江苏中控能源科技有限公司

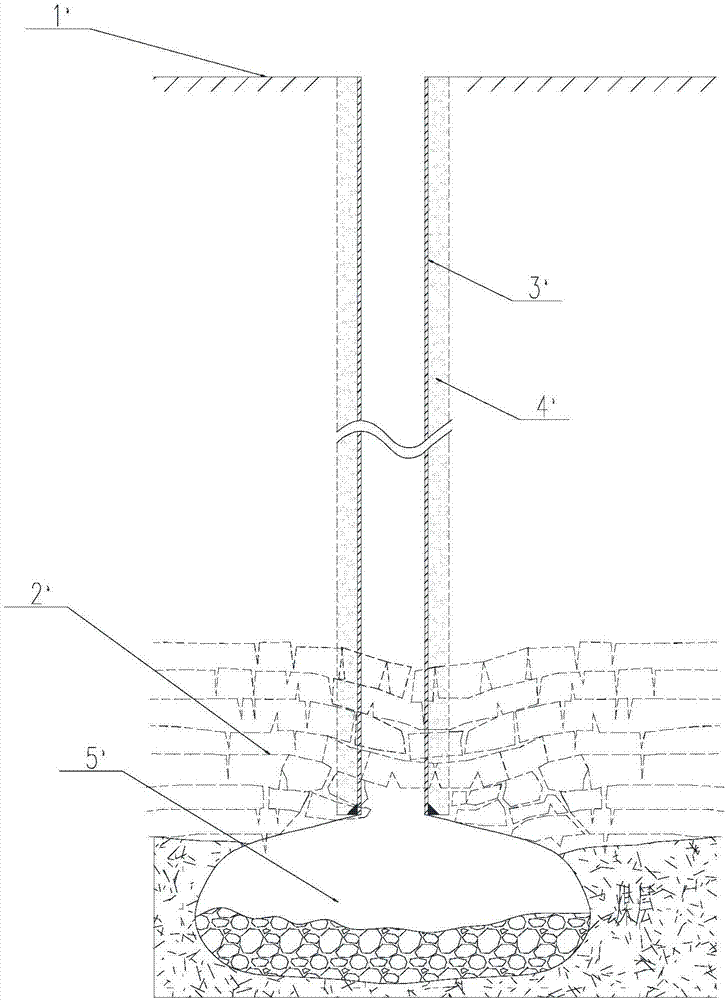

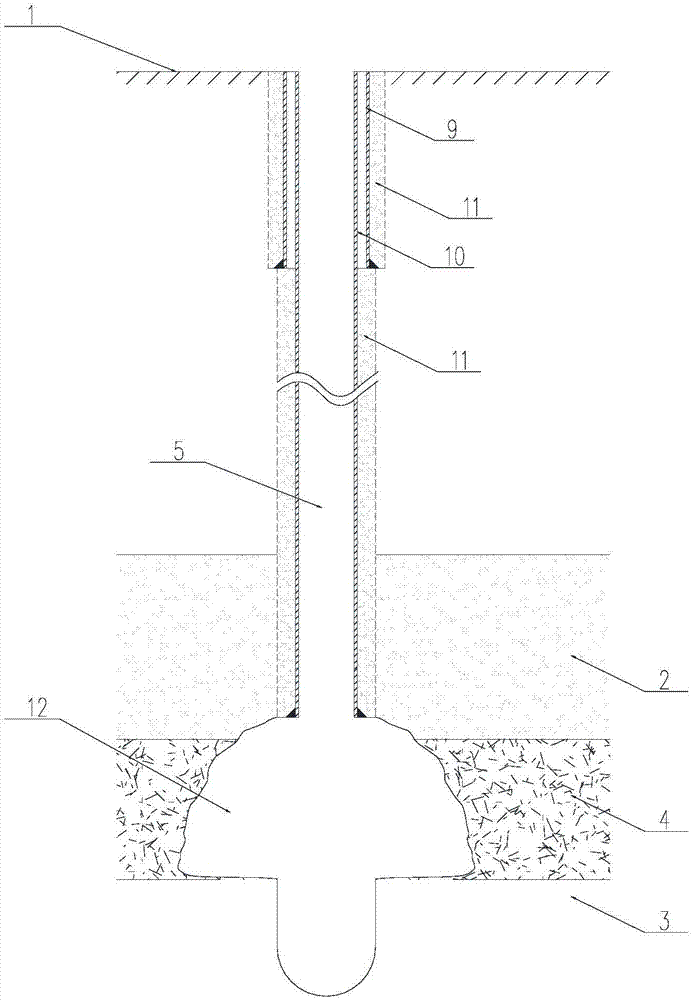

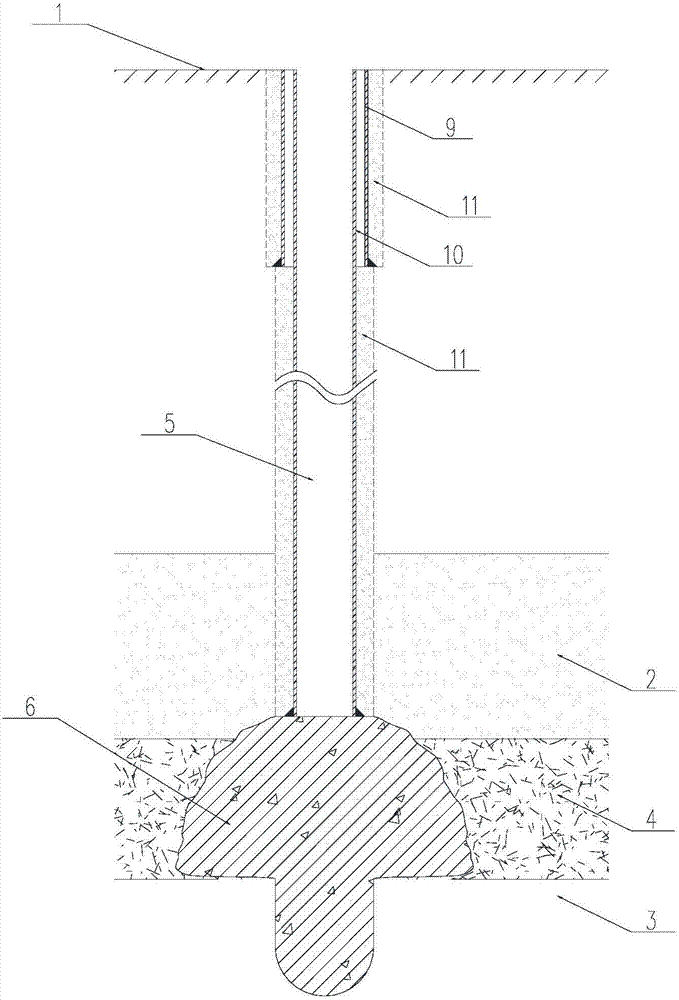

Coal underground gasified drill hole and constructing method of drill hole

PendingCN107191174AAvoid deformationPrevent collapseDrilling using explosivesConstructionsEngineeringEarth surface

The invention discloses a coal underground gasified drill hole and a constructing method of the coal underground gasified drill hole. The drill hole comprises a first hole which extends to a top plate of a coal layer from the earth surface, and further comprises a support body and a second hole which penetrates through the support body, the top of the support body is located in the top plate of the coal layer, the bottom of the support body is located on the bottom plate, one end of the second hole is communicated with the first hole, and the other end of the second hole is located in the coal layer. According to the coal underground gasified drill hole and the constructing method of the coal underground gasified drill hole, one support body is arranged in the coal layer, the support body supports the top plate from the bottom plate of the coal layer, in this way, the top plate is prevented from deformation and caving, and therefore the drill hole located in the top plate is protected.

Owner:XINJIANG GUOLIHENG CLEAN ENERGY TECH CO LTD

Method for punching transverse blind hole

The invention relates to a method for punching a transverse blind hole. The blind hole is punched through a punching mechanism. The punching mechanism comprises an annular blade seat, a cast iron outer sleeve arranged at the tail end of the annular blade seat in a sleeve mode and a drill rod which penetrates in the cast iron outer sleeve, is connected with the tail end of the blade seat and is ofa pipe body structure. The outer peripheral surface of the tail end of the annular blade seat is provided with a protective ring, the front end of the cast iron outer sleeve is provided with an end ring capable of being in butt joint with the protective ring, the projection of the inner peripheral surface of the end ring in the axial direction of the drill rod is all located on the protective ring, the inner end of the end ring is provided with an induction switch matched with the protective ring and connected in series with a warning lamp located at the rear end of the cast iron outer sleevethrough a wire, and the front end surface of the annular blade seat is provided with a plurality of blades capable of being folded together and penetrating through the end ring. The method for punching the transverse blind hole has the advantage of good safety, and solves the problem of poor safety in the existing blind hole construction process.

Owner:JIANGSHAN XIANJIN ELECTRICAL & MECHANICAL TECH SERVICES CO LTD

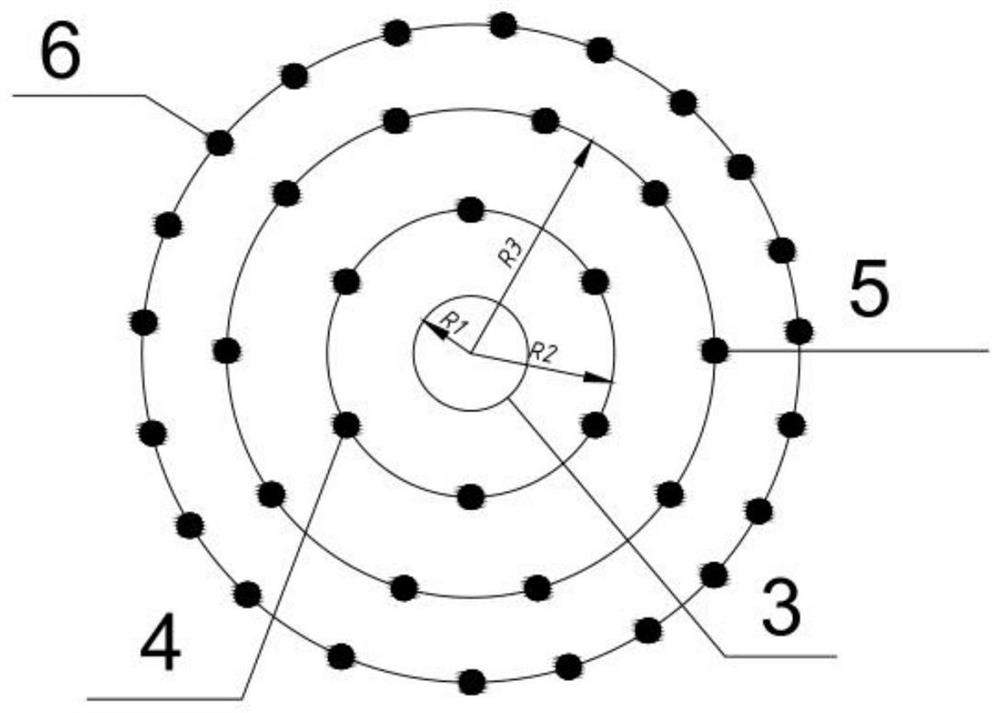

Large-diameter offshore rock-socketed pile foundation pit excavation method

ActiveCN111749612AImprove excavation efficiencyReduce excavation costsDrilling using explosivesUnderwater drillingSlagStructural engineering

The invention discloses a large-diameter offshore rock-socketed pile foundation pit excavation method. The method comprises the following processes of putting a guide well protection barrel in, mechanically drilling and digging a guide well, drilling and lowering a casing pipe to protect a hole, charging in the casing pipe and blasting, lowering a rock-socketed pile steel protection barrel, sucking silt, pulling out the guide well protection barrel and the drilling casing pipe, and grabbing slag. The method adopts the combination of mechanical excavation of the guide well and blasting and expanding excavation; main blast holes are strengthened and broken by high specific consumption, and the impact of a shock wave and blasting vibration is controlled by adopting an electronic detonating technology; profile blasting adopts smooth blasting; and the depth of the guide well is 0.1-0.15 times the depth of a pile well, and the well completion design depth is guaranteed. Main blast hole continuous charging and profile hole interval charging are adopted; and blast holes on the inner ring and the outer ring are detonated in sections, a main blast hole inner ring is detonated before a main blast hole outer ring, and the bottom section of the inner ring is simultaneously detonated. The method can effectively solve the problem that an offshore rock-socketed pile foundation with the diameter of 8-10m or more is excavated by using a 2-4m diameter petroleum drilling machine and a common geological drilling machine, and has the advantages of high speed, low cost and the like.

Owner:WUHAN UNIV

Drilling device for mine engineering blasting

InactiveCN114033305APlay the brakesPlay a bufferDrilling using explosivesConstructionsMining engineeringGear wheel

The invention belongs to the technical field of drilling devices, and particularly relates to a drilling device for mine engineering blasting, which comprises a base, two grooves and a mounting groove are formed in the bottom of the base, a square cavity is formed in the base, the mounting groove is positioned between the two grooves, and a connecting plate is slidably mounted in the mounting groove along the vertical direction; universal wheels are rotatably installed at the four corners of the bottom of the connecting plate, two through holes are formed between the two grooves and the square cavity, vertical rods are movably installed in the two through holes, rolling wheels are rotatably installed at the top ends of the two vertical rods, and buffer blocks are fixedly installed at the bottom ends of the two vertical rods; and two plastic blocks are fixedly mounted on the inner wall of the top of the square cavity, and two sector gears are rotationally mounted on the inner wall of the bottom of the square cavity. The drilling device for mine engineering blasting is simple in structure and convenient to use, the drilling device for mine engineering blasting is convenient to move, buffering and damping are facilitated, and the drilling angle and height can be adjusted.

Owner:刘建法

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com